Patents

Literature

779 results about "Initiation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chain Initiation Reaction : A free radical reaction mechanism step that has no radical reactant (s) and give radical product (s). In chemistry, initiation is a chemical reaction that triggers one or more secondary reactions. Often the initiation reaction generates a reactive intermediate from a stable molecule which is then involved in secondary reactions. In polymerisation, initiation is followed by a chain reaction and termination.

Preparation method of star branched polyisobutylene or butyl rubber

The invention relates to a preparation method of star-shaped branched polyisobutylene or butyl rubber, which uses polystyrene / isoprene block copolymers containing silicon chloride groups at the end or polystyrene / isoprene block copolymers containing silicon chloride groups at the end. As the initiator-grafting agent of cationic polymerization, the diene block copolymer directly participates in cationic polymerisation; through the initiation of cationic polymerisation by silicon chloride group, the star-branched polymer is prepared by participating in the grafting reaction through unsaturated bonds. Isobutylene and butyl rubber products; the advantages of the present invention are: the synthesized branched polymer exhibits different processing properties from the original linear branched polymer molecule in terms of colloidal strength and stress relaxation balance, and has excellent performance, involving thermoplastic elasticity body more.

Owner:CHINA PETROLEUM & CHEM CORP +1

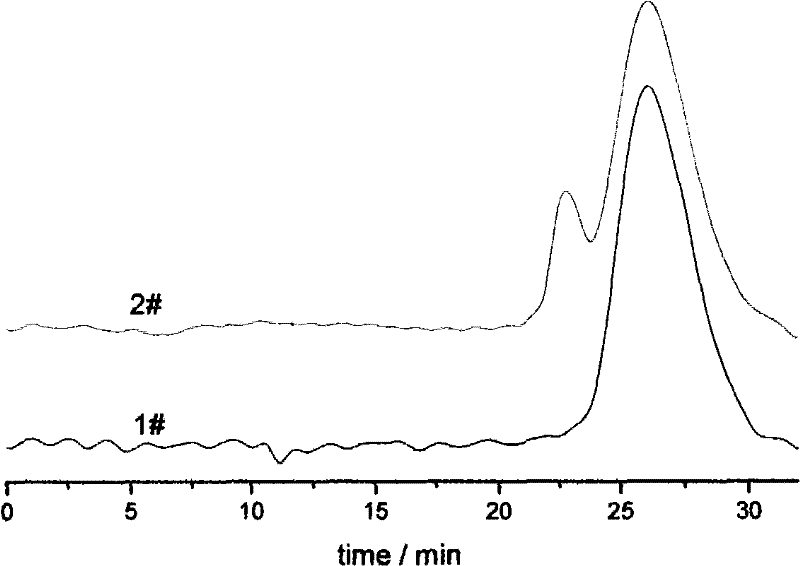

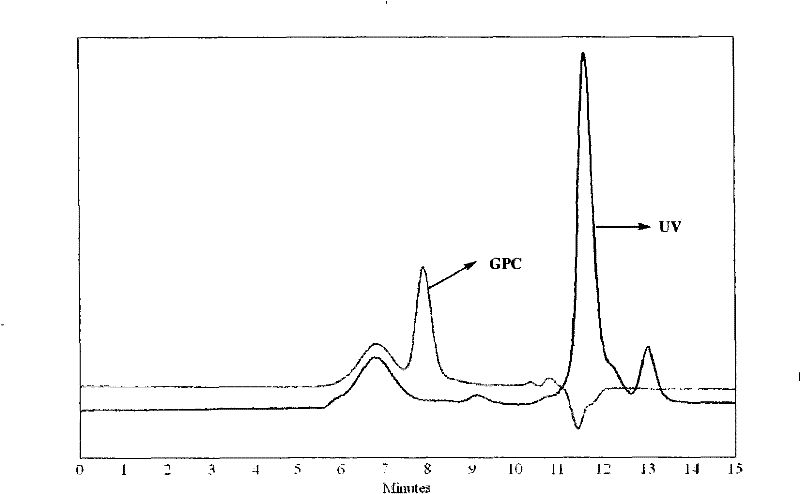

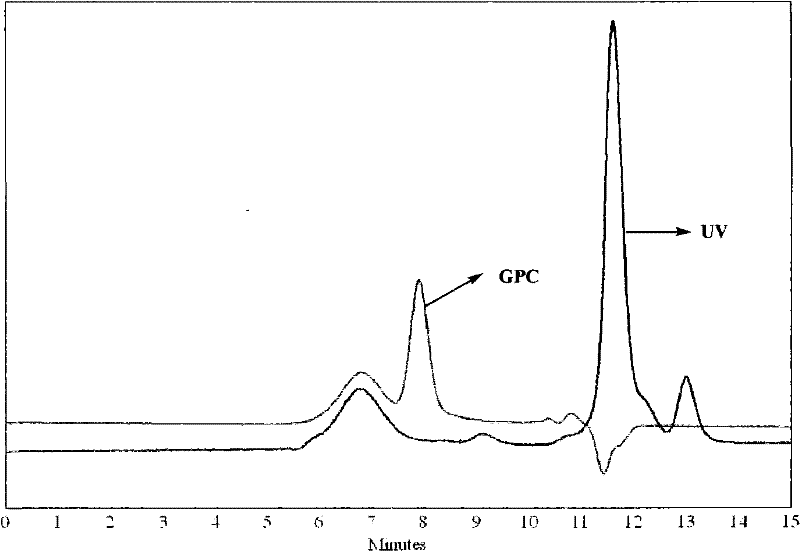

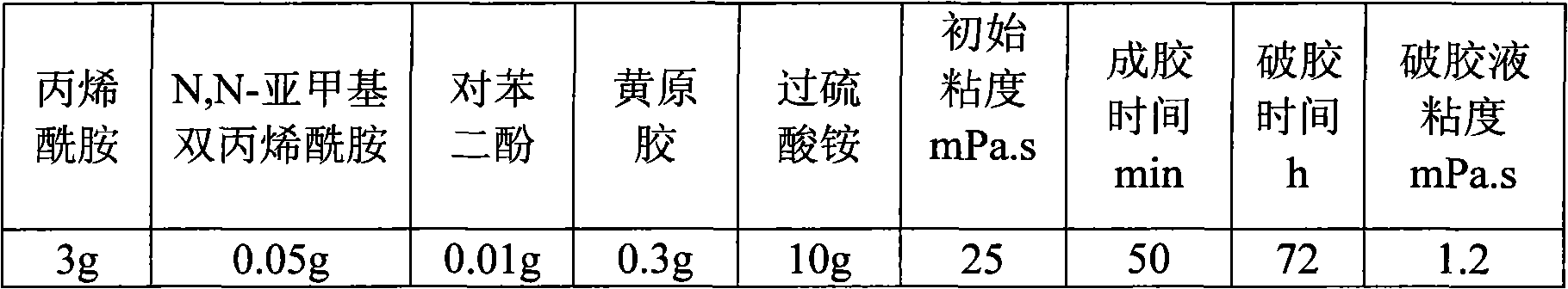

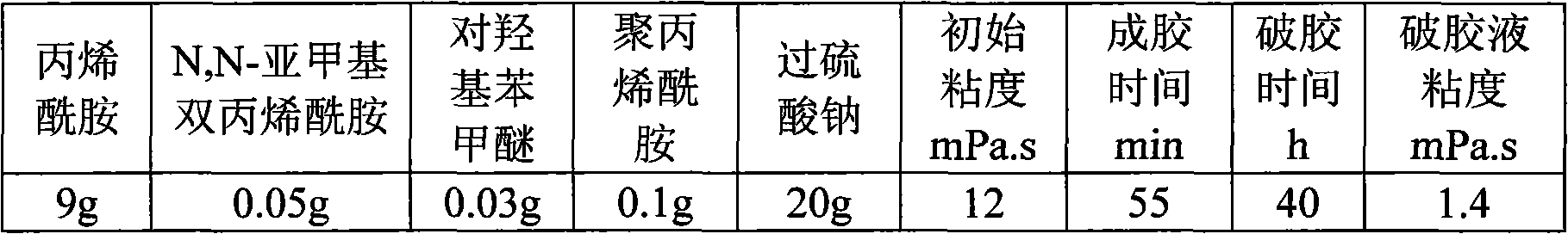

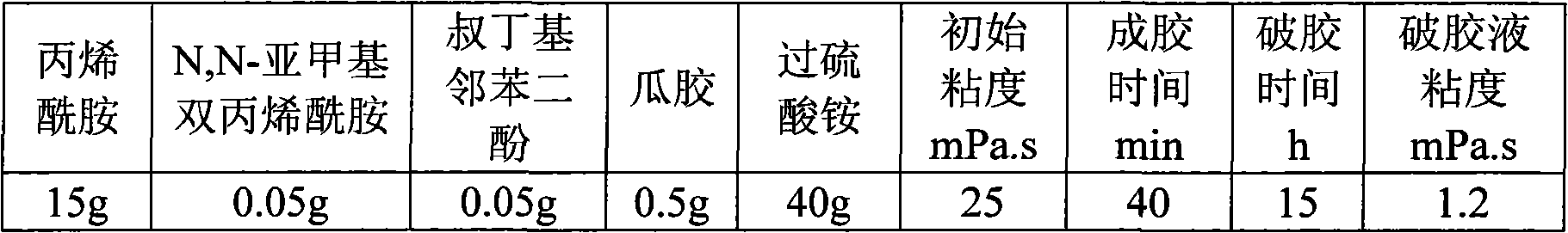

High-strength temporary blocking agent and preparation method thereof

ActiveCN101906292AGood sealingMeet the needs of on-site constructionDrilling compositionHigh intensityMethylene bisacrylamide

The invention relates to a high-strength temporary blocking agent and a preparation method thereof. The temporary blocking agent consists of the following components in percentage by mass: 2 to 20 percent of acrylamide, 0.02 to 0.1 percent of N,N-methylene-bisacrylamide, 0.001 to 0.1 percent of polymerization inhibitor, 0 to 1.0 percent of thickening agent, 2 to 50 percent of initiation gel breaker and the balance of water. The high-strength temporary blocking agent can form high-strength gel under intermediate / low-temperature reservoir conditions, can realize gel-formation and complete gel breaking in a given time, has no damage to the reservoir after the gel breaking and can be adapted to the temporary blocking operation of intermediate / low temperature oil-gas reservoirs.

Owner:PETROCHINA CO LTD

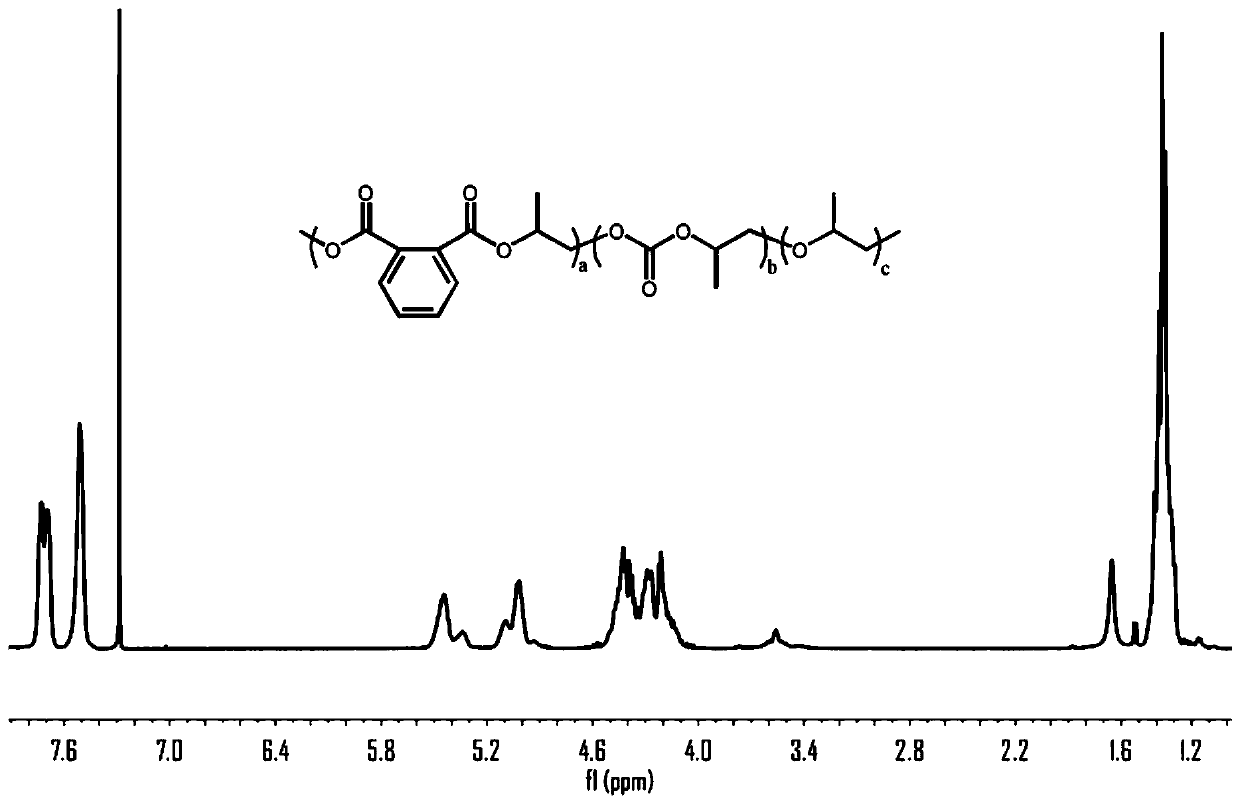

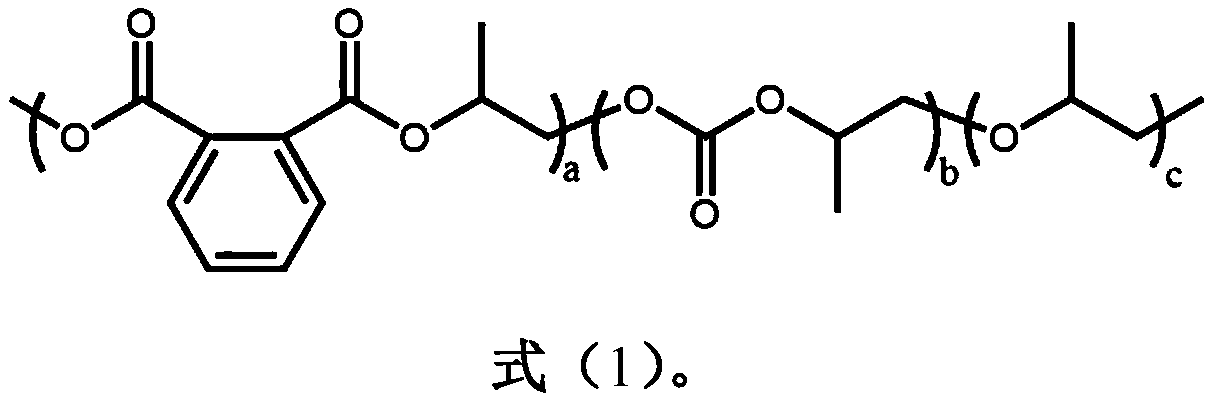

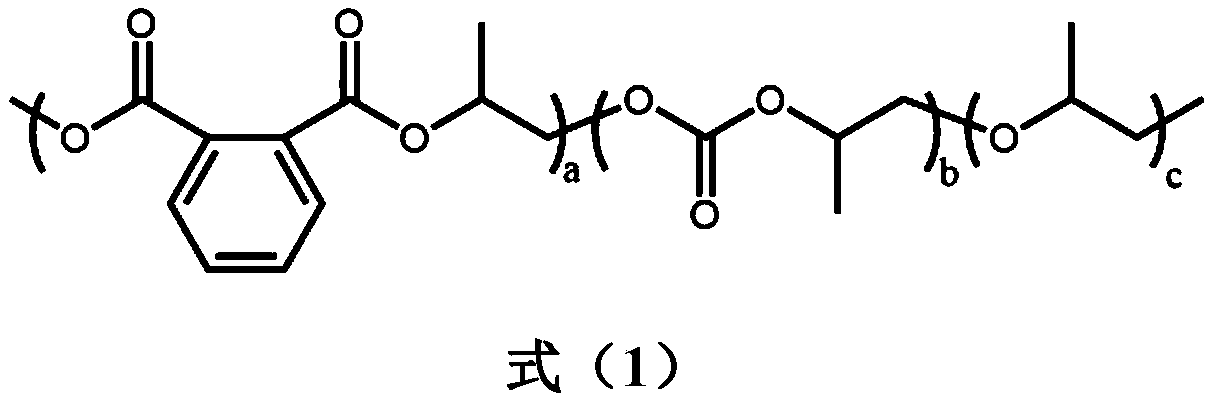

Preparation method of biodegradable carbon dioxide-based polyester-polycarbonate terpolymer

The invention discloses a preparation method of a biodegradable carbon dioxide-based polyester-polycarbonate terpolymer. A commercialized, simple and efficient nonmetal triethyl boron / tetra-n-butyl ammonium chloride catalytic initiation system is used for catalyzing and initiating epoxypropane, carbon dioxide and phthalic anhydride to be subjected to a ternary polymerization reaction, and an aromatic polyester structure with the content of 10%-40% is successfully introduced into a main chain of polymethyl ethylene carbonate (PPC). The terpolymer can have different sequence structures; and haverandom and block structures and the like, the glass transition temperature and the thermal stability of PPC are improved, and a catalytic system does not contain metal components, so that the phthalic anhydride modified PPC has extremely high light transmittance, very high melt viscosity and good foaming performance on the premise of keeping the biodegradability of a PPC material. The method canbe used for synthesizing the modified PPC biodegradable material, and widens the application range of the PPC material.

Owner:SUN YAT SEN UNIV

Microemulsion of fluorin containing crylic acid of self-crosslink in normal temperature and its production method

The invention discloses a normal temperature self-crosslinked fluoro-containing polyacrylic acid microemulsion and its preparing process, wherein the microemulsion comprises the constituents of (methyl) acrylic ester, alkenyl carboxylic acid, alkenyl linking agent, ethenyl aromatic compound, alkenyl fluoro-containing alkyl ester, other olefins unsaturated monomer, initiating agent, buffering agent, emulsifying agent, neutralization agent and water. The preparation process comprises making seed emulsion under oxidation and reduction initiation system, then employing semi-continuous polymerization process to prepare the fluoro-containing polyacrylic acid microemulsion with good polymerization stability, small particle size, low film coating surface tension, and strong adhesion.

Owner:广东鸿昌化工有限公司

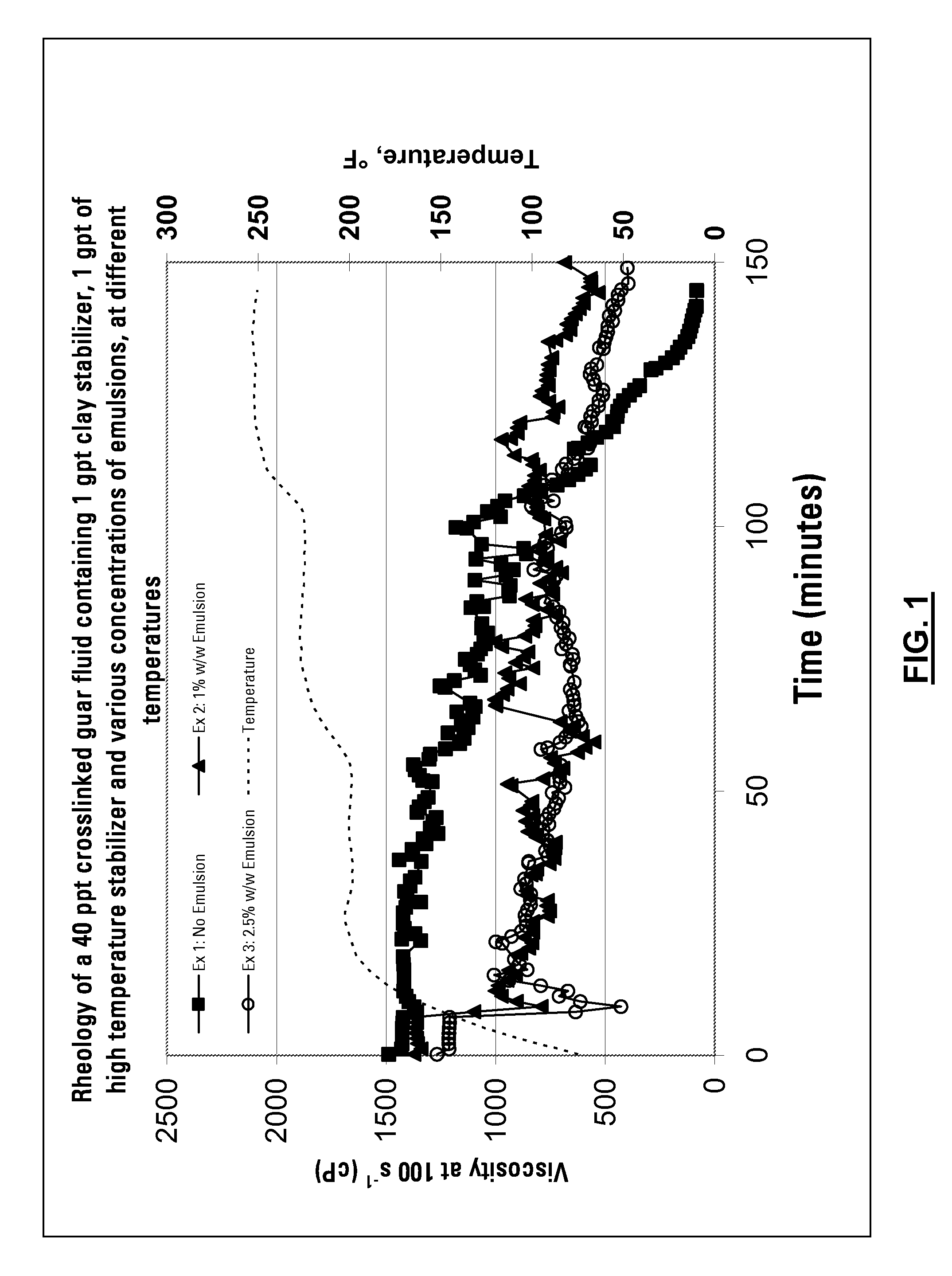

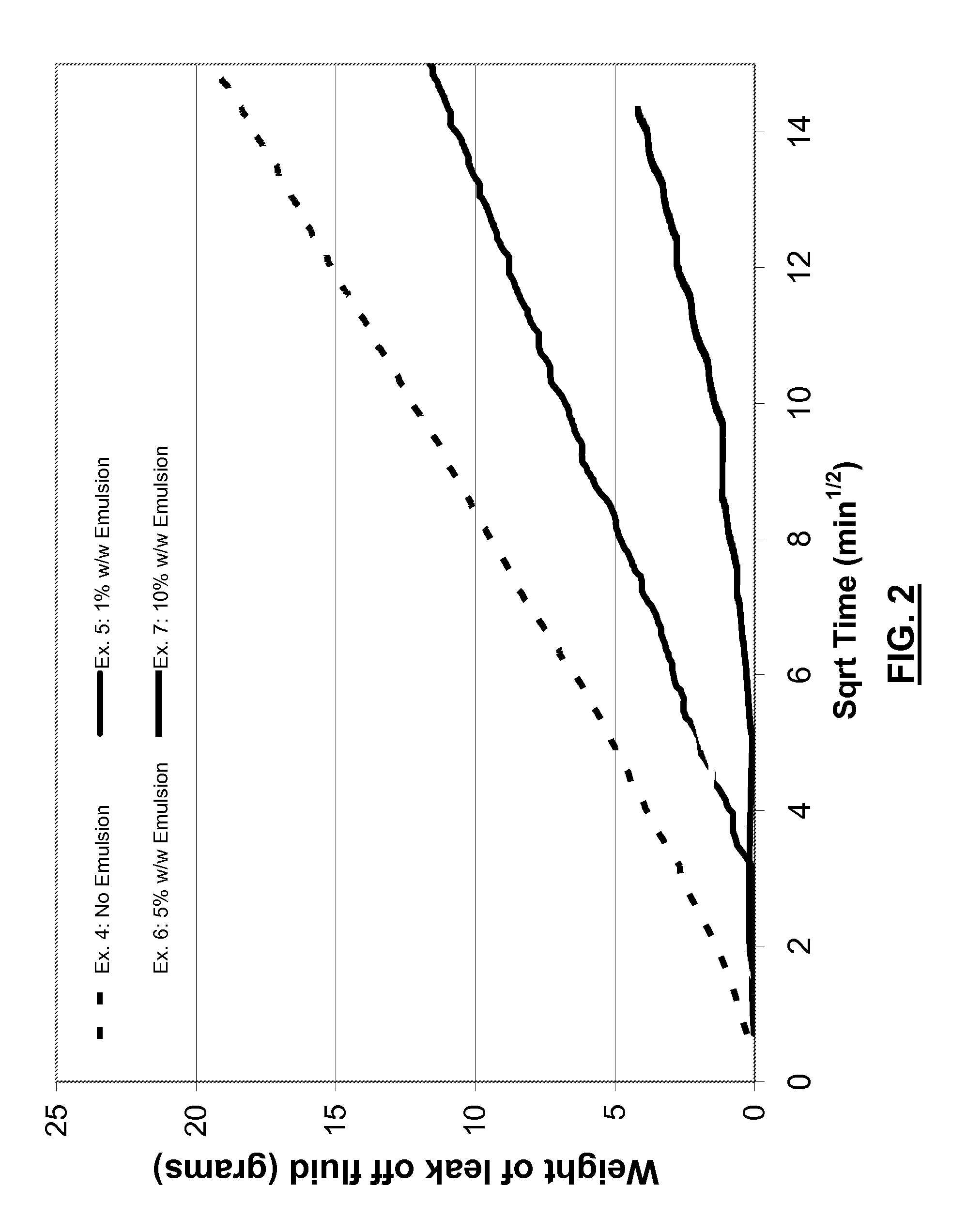

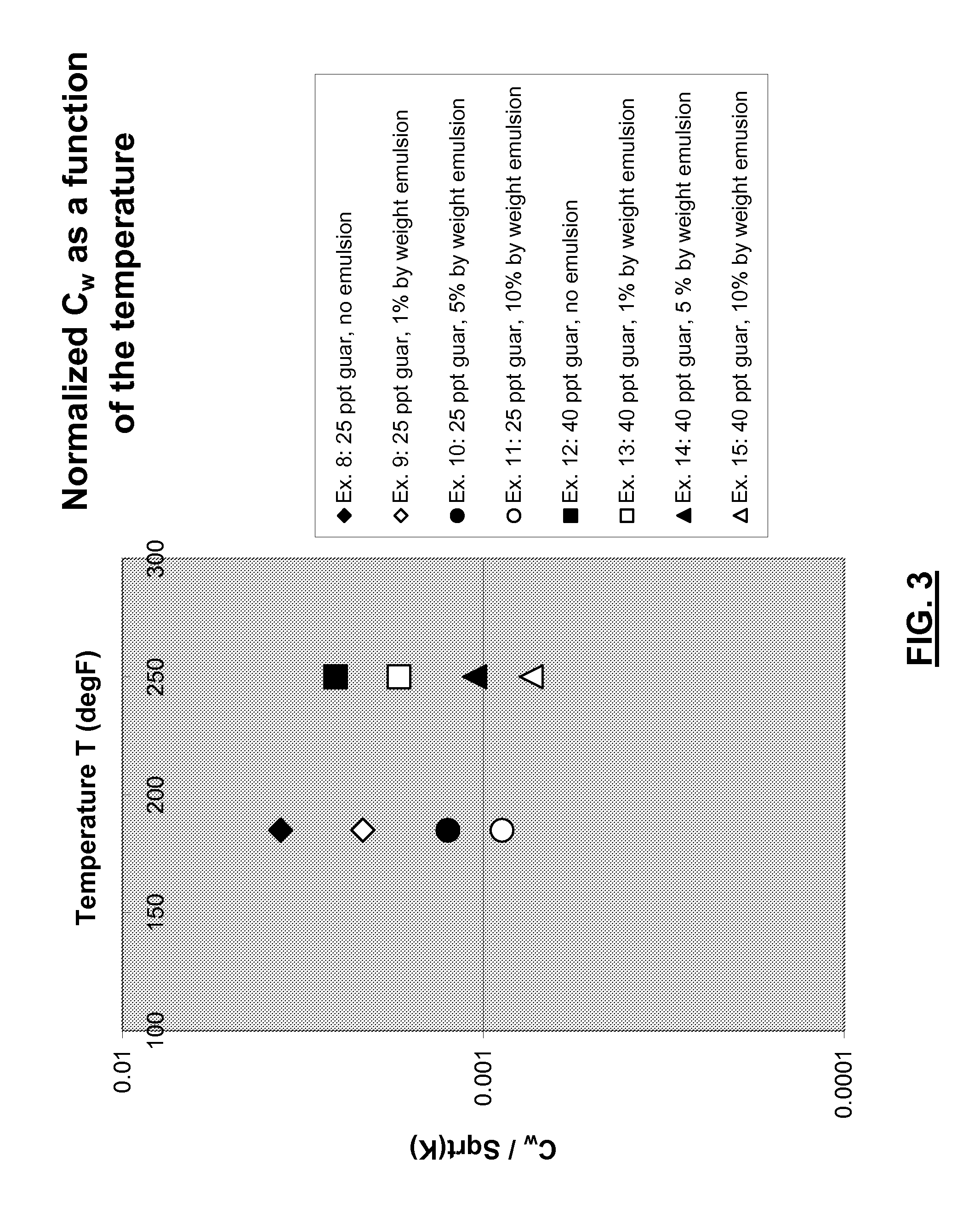

Methods of limiting leak off and damage in hydraulic fractures

Methods for treating a formation penetrated by a wellbore which improves fluid loss control during treatment. In some aspects, the treatments include preparing an aqueous fluid including one or more water inert polymers and an optional viscosifier, injecting the aqueous fluid into the wellbore at a pressure equal to or greater than the formation's fracture initiation pressure, and thereafter injecting into the wellbore a proppant laden fluid at a pressure equal to or greater than the formation's fracture initiation pressure. The water inert polymer may be a polymer such as an emulsion polymer or a latex polymer. Some methods of the invention use a fluid which may have a normalized leak off coefficient (Cw / sqrt(K)) equal to or less than about 0.0022, 0.0014, or 0.0010. A conventional fluid loss additive may or may not be used in conjunction with the treatment fluid and / or the proppant laden fluid. The water inert polymer may or may not substantially enter formation pores. In another aspect, methods for reducing matrix damage to a formation during a treatment operation include preparing an aqueous treatment fluid formed of at least one water inert polymer, and injecting the fluid at a pressure equal or greater than the formation's fracture initiation pressure.

Owner:SCHLUMBERGER TECH CORP

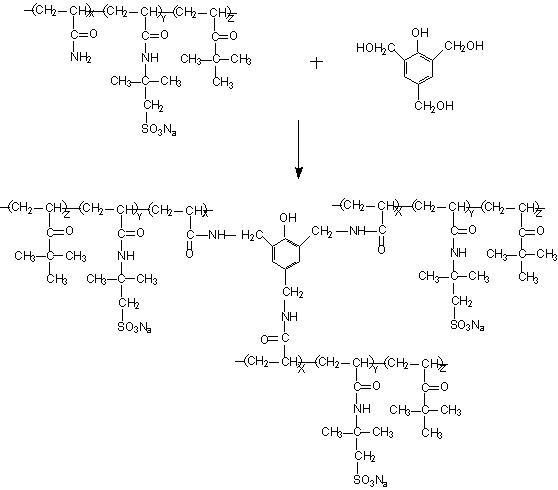

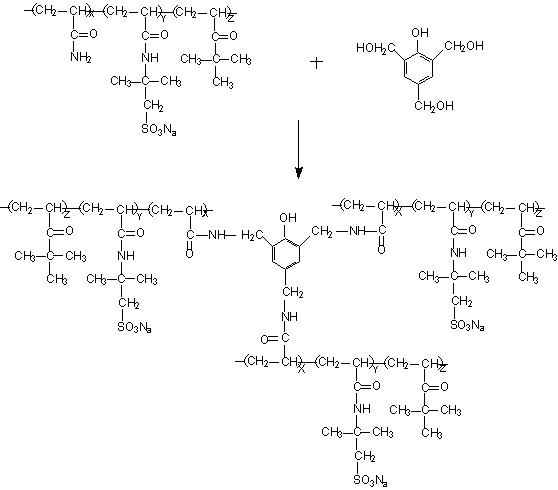

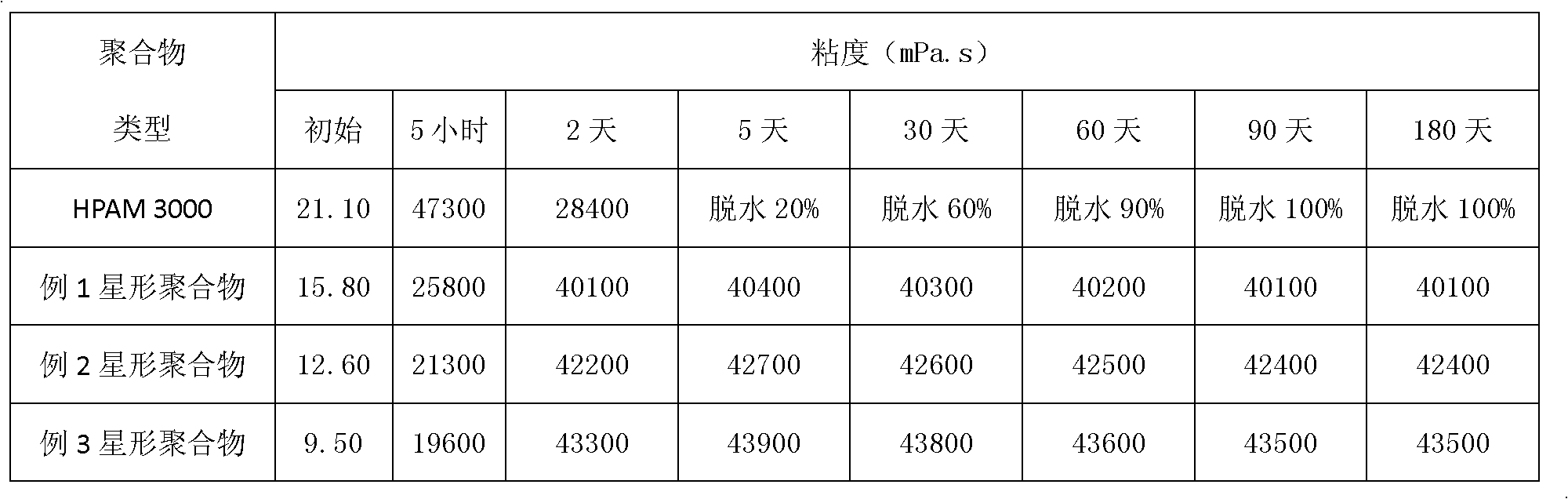

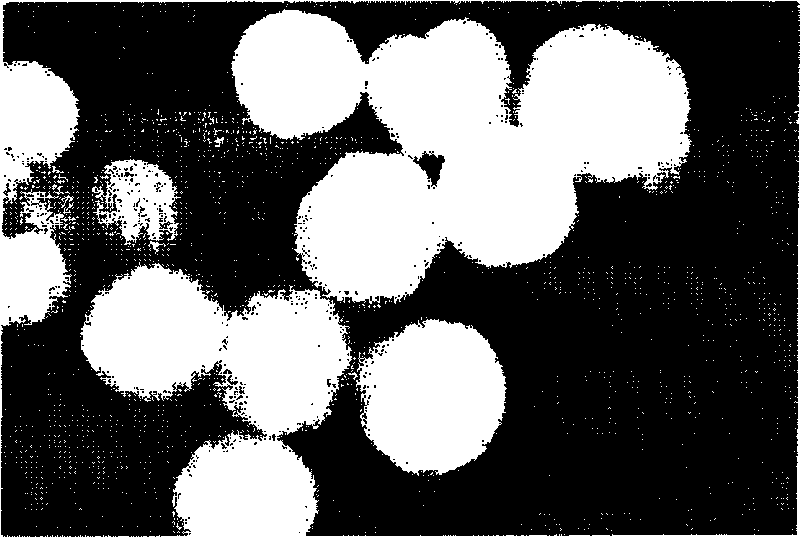

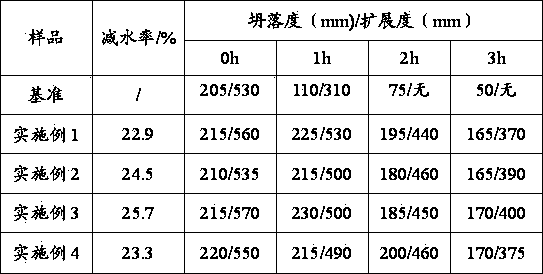

Preparation method of star polymer

ActiveCN102093505AHigh molecular weightLower the polymerization initiation temperaturePolymer scienceMeth-

The invention discloses a preparation method of a star polymer, belonging to the technical field of petroleum extraction. The method adopts a redox initiation system, and carries out water solution radical copolymerization on three water-soluble monomers, including tert-butyl acrylate, 2-acrylamido-2-methylpropane sulfonic acid and acrylamide. The redox initiation system comprises trihydroxymethyl phenol, persulfate, hydrogen peroxide, urea, sodium formaldehyde bisulfite, azoisobutyronitrile, chain transfer agent and surfactant. The molecular weight of the star polymer prepared by the method is 8-15 million; the star polymer is water-soluble; the content of the residual monomers in the product is less than or equal to 0.1 wt%; and the star polymer and a crosslinking system, which is composed of water-soluble phenolic resin and polyethylene imine, can form a movable gel system for carrying out deep profile control on a high-temperature high-salt oil reservoir of which the salinity is 117000 mg / L and the temperature is 140 DEG C.

Owner:PETROCHINA CO LTD

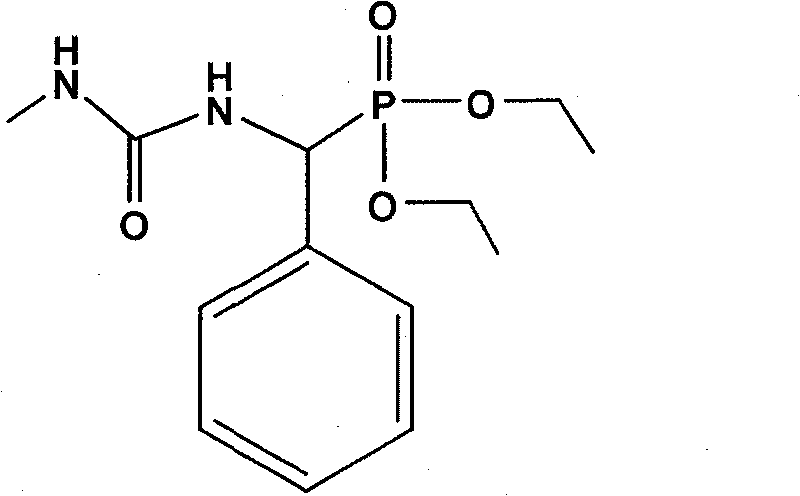

Molecular imprinting polymer as well as preparation method and application thereof

InactiveCN101721981ASelectiveExpand the scope of detectionOther chemical processesCross-linkOrganic solvent

The invention discloses molecular imprinting polymer which belongs to the technical field of pesticide molecular imprinting and preparation method thereof. The molecular imprinting polymer is prepared by the following steps of: mixing a polymerization reaction monomer, a cross-linking agent, a hole inducing agent, an initiating agent and an imprinting molecule diethyl(3-methyluren)(phenyl)methyl phosphonate, carrying out in-situ polymerization reaction under the condition of thermal initiation and / or photo-initiation to obtain a polymer containing diethyl(3-methyluren)(phenyl)methyl phosphonate; washing the polymer till an imprinting molecule is not detected; and then washing by an organic solvent to neutrality and drying in vacuum to obtain the molecular imprinting polymer. The invention also discloses applications of the molecular imprinting polymer in aspects of separating, purifying and detecting organophosphorus pesticide in a sample. The applications of the polymer prevent the influence of target analyte template leakage on a following adsorption experiment, can simultaneously detect various target molecules and widen the detecting range of the target molecules.

Owner:CHINA AGRI UNIV

Dipping copolymer latex

InactiveUS20060235158A1Improve the immunityHigh tensile strengthCoatingsVulcanizationOrganic solvent

There are provided a dip-molded product that has good resistance to organic solvents, good feeling, sufficient tensile strength, and high contact-state-sustaining performance, a dip-molding composition for forming the dip-molded product, and a dip-molding copolymer latex that can suitably be used for the dip-molding composition. The copolymer latex is a carboxylated acrylonitrile-butadiene copolymer latex that is produced by copolymerization of a monomer mixture of a specific composition comprising 1,3-butadiene, acrylonitrile and methacrylic acid, in which a part of the total amount of the acrylonitrile and a part of the total amount of the methacrylic acid are added to the polymerization reaction system at a specific time after the initiation of the polymerization, and the content of methyl ethyl ketone-insoluble components in the resulting polymer is in a specific range. The dip-molding composition comprises the latex, a vulcanizing agent and a vulcanization accelerator.

Owner:ZEON CORP

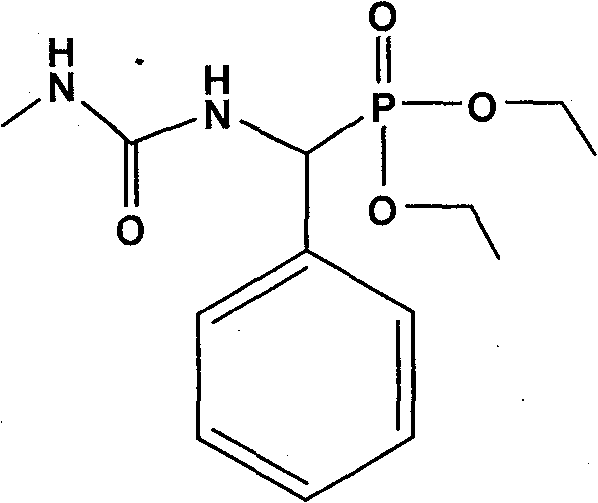

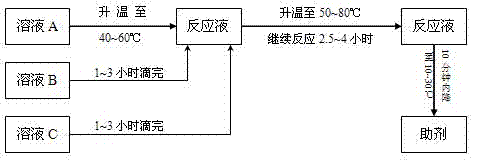

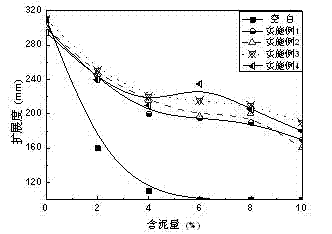

Preparation method for high-slump-retention polycarboxylate water reducer

InactiveCN103450411AIncreased steric hindranceSolve problems such as difficult pumpingMeth-Ptru catalyst

The invention discloses a preparation method for a high-slump-retention polycarboxylate water reducer. The preparation method comprises the following steps of: esterifying methoxylpolyethylene glycol monomethyl ethers with different molecular weights with methacrylic acid and a mixed polymerization inhibitor for a period of time under the action of a catalyst and at a certain temperature, then adding allyl alcohol in one time, further esterifying in the same conditions to obtain an esterified macromonomer MP containing crosslinking monomer allyl methacrylate; then performing aqueous solution polymerization on the MP, unsaturated sulfonate, (meth)acrylate unsaturated monomers and a chain transfer agent in a low-temperature condition and within a redox initiation system; and finally adding caustic soda liquid to neutralize, so as to obtain the polycarboxylate water reducer with a certain concentration. The high-slump-retention polycarboxylate water reducer prepared by the preparation method disclosed by the invention is a high-performance water reducer which is prepared at a low temperature by virtue of a molecular structure design, as well as is high in slump retention, excellent in dispersing performance, good in adaptability, simple in process, pollution-free, low in energy consumption, and easy to realize industrialized production.

Owner:KZJ NEW MATERIALS GROUP CO LTD

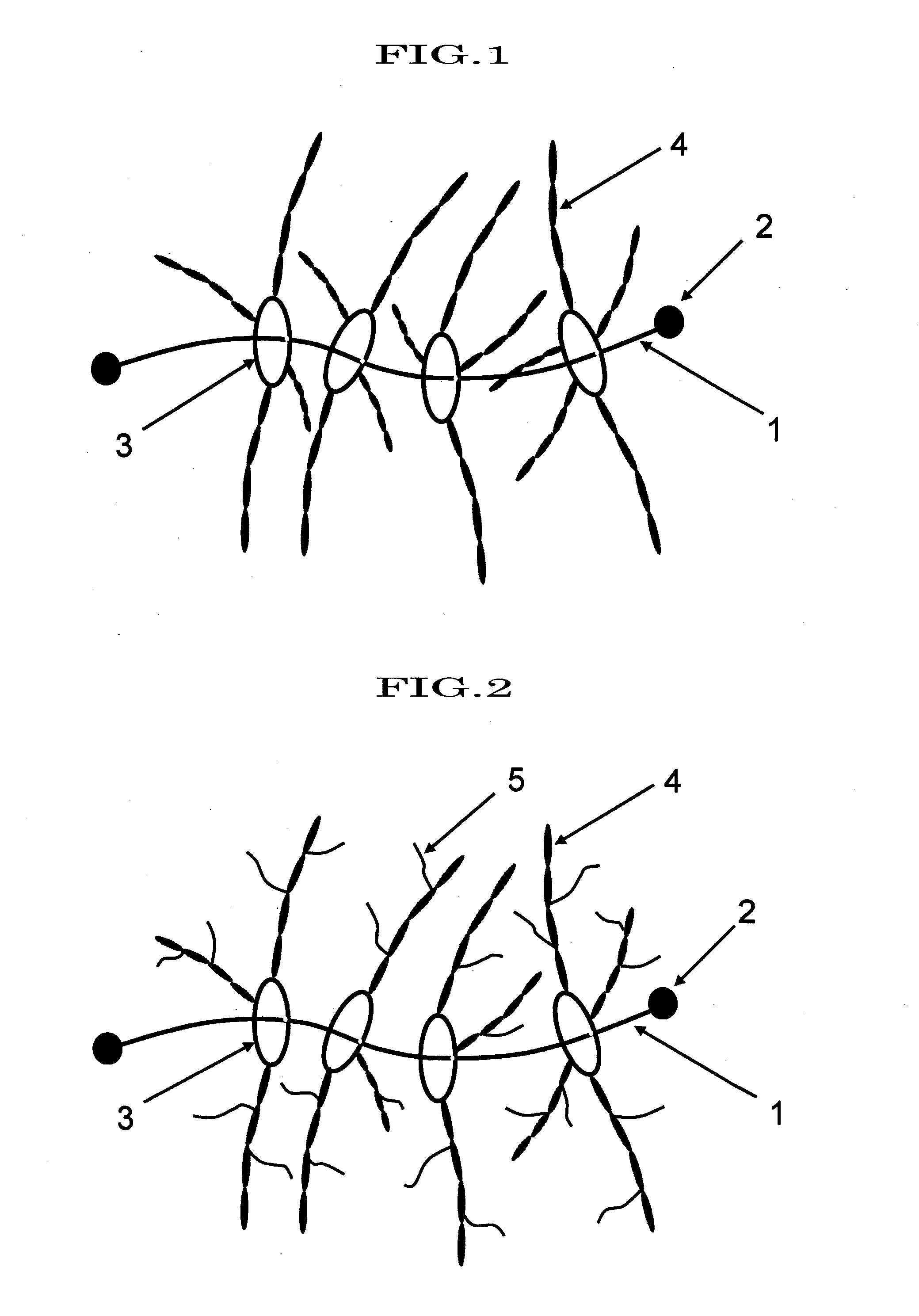

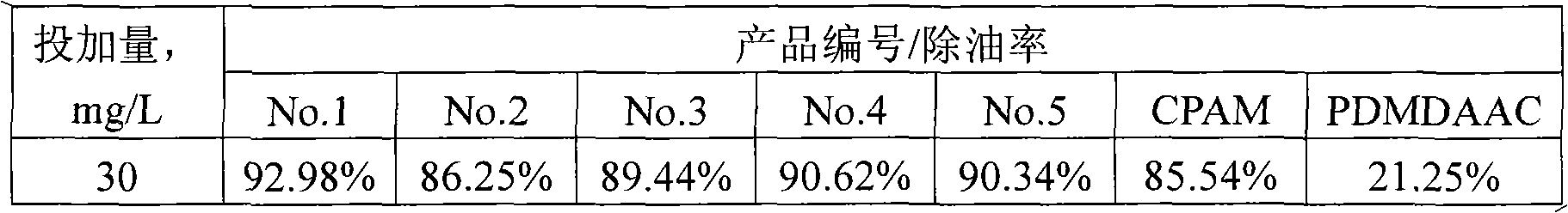

Polyrotaxane, crosslinked structure comprising polyrotaxane and polymer, and processes for producing these

A process is provided by which a polyrotaxane including cyclic molecules having a relatively long graft chain is easily obtained. Also provided is a polyrotaxane which includes cyclic molecules having a radical polymerization initiation site and is for use as a raw material in the process. The polyrotaxane comprises: a pseudo-polyrotaxane comprising cyclic molecules clathrated with a linear molecule, the cavities of the cyclic molecules having been pierced by the linear molecule; and blocking groups disposed respectively at both ends of the pseudo-polyrotaxane so as not to release the cyclic molecules. The cyclic molecules in the polyrotaxane have a radical polymerization initiation site.

Owner:ADVANCED SOFTMATERIALS INC

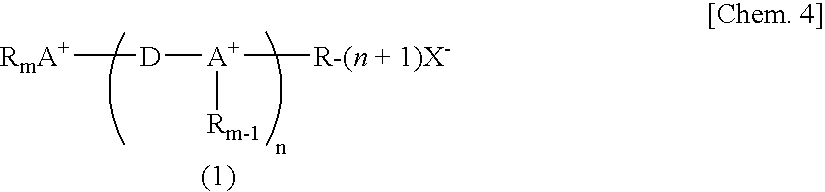

Cation-type hydrophobic association polymer and its preparation method and application

InactiveCN101260174AHigh molecular weightGood product stabilityWaste water treatment from quariesWater/sewage treatment by flocculation/precipitationButyl acrylateUrea

The invention discloses a cation type hydrophobic association polymer and a preparation method and application thereof. Through adopting acrylamide, dimethyl diallyl ammonium chloride and butyl acrylate as synthesis monomer, the cation type hydrophobic association polymer is made through a common free radical micelle polymerization method and making use of a composite initiation system and additive auxiliary agent urea. Moreover, the cation type hydrophobic association polymer, which has the characteristics of high molecular weight, excellent product stability, strong adsorption bridging capacity of colloid matter, good flocculation effect, wide application scope, less generated sludge and hydrophobic association function, etc., can be widely used in the treatment of oil field oily wastewater.

Owner:SHANDONG UNIV

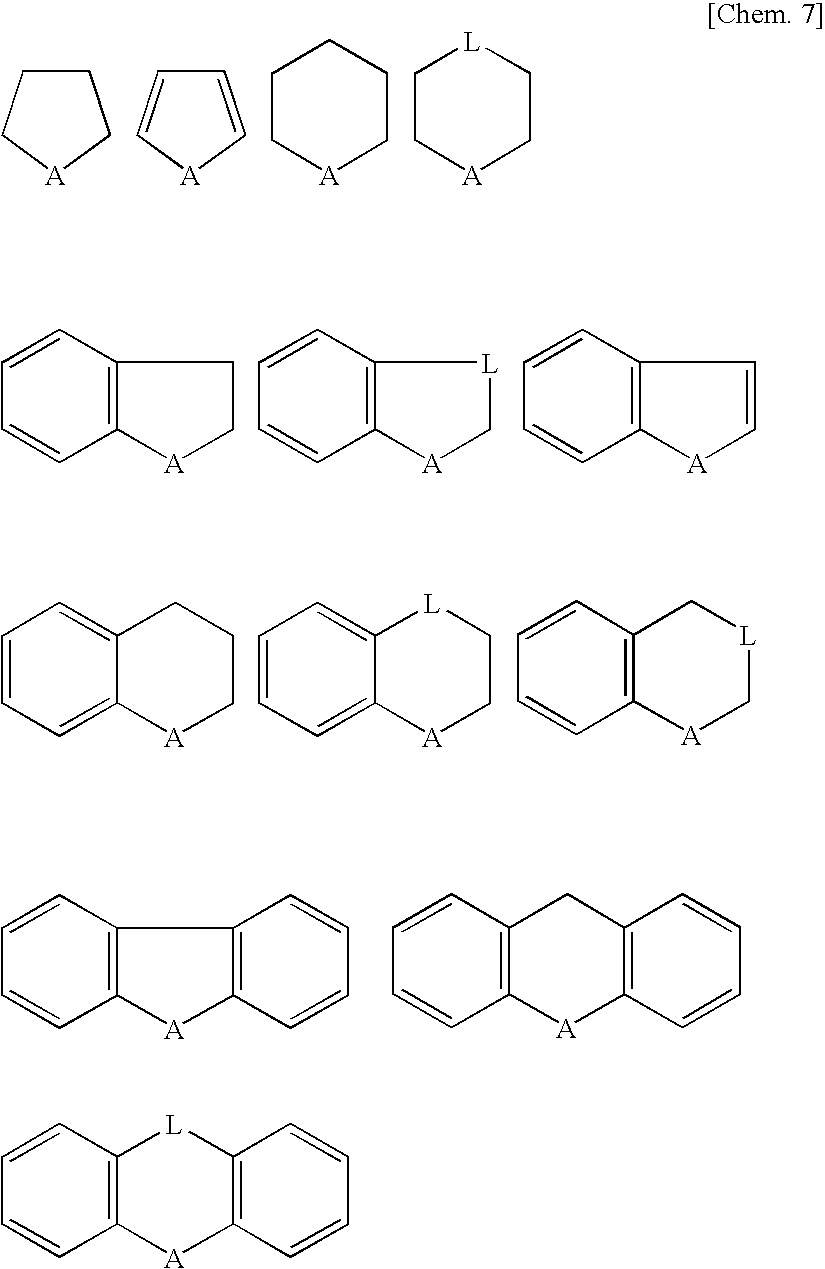

Novel Fluorinated Alkyl Fluorophosphoric Acid Salts of Onium and Ttransition Metal Complex

ActiveUS20070225458A1Excel pointImprove solubilityIron group organic compounds without C-metal linkagesPhosphorus organic compoundsCationic polymerizationPhosphate

To obtain a polymerization initiator (acid generating agent) having excellent power for initiation of cationic polymerization without containing arsenic or antimony. [Means for solution] Provided is a specific onium salt or transition metal complex salt of a fluorinated alkyl fluorophosphoric acid.

Owner:SAN APRO

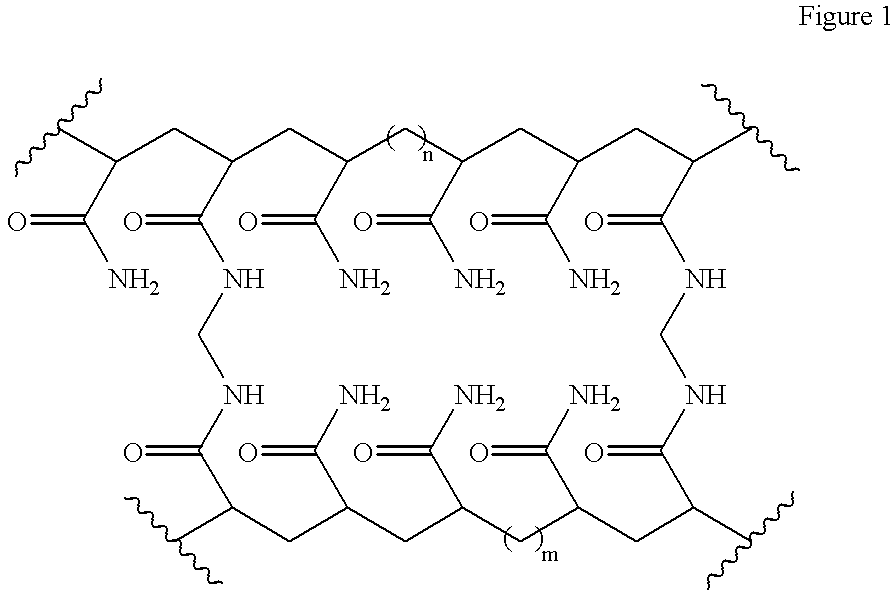

Polyacrylamide hydrogel as a soft tissue filler endoprosthesis

InactiveUS20020150550A1Excellent templateExcellent matrixSurgical adhesivesPharmaceutical delivery mechanismProsthesisSaline solutions

A hydrogel is obtained by combining acrylamide and methylene based-acrylamide, radical initiation and washing with pyrogen-free water or saline solution to give less than 3.5% by weight polyacrylamide, based on the total weight of the hydrogel. The hydrogel may be used as a soft tissue filler endoprosthesis. Also disclosed is a method of filling a soft tissue in a mammal using the endoprosthesis, and a prosthetic device comprising the polyacrylamide hydrogel.

Owner:AXONICS WOMENS HEALTH LTD

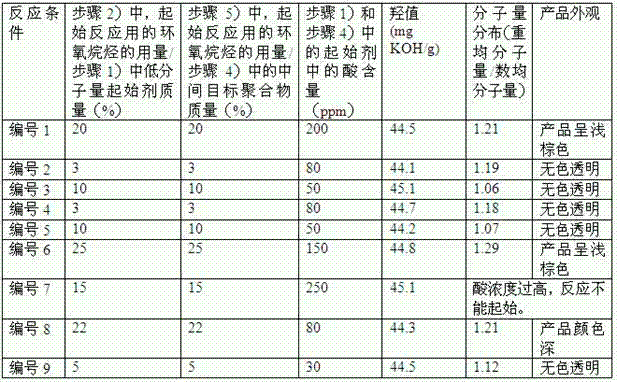

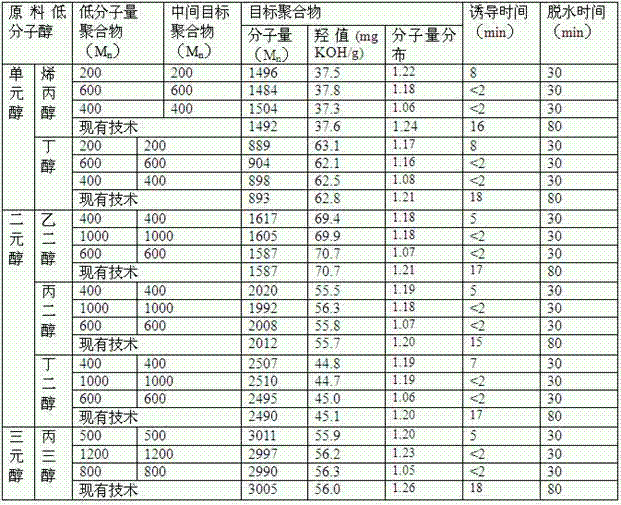

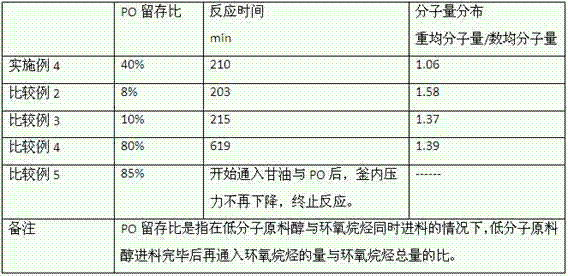

Method for preparing polyether polyol in recycling manner by aid of DMC (double metal cyanide) catalyst

The invention discloses a method for preparing polyether polyol in a recycling manner by the aid of a DMC (double metal cyanide) catalyst. The method includes carrying out polymerization reaction on first low-molecule alcohol and alkylene oxide to obtain polymers with low molecular weights; carrying out reaction on the polymers with the low molecular weights, DMC, acid and alkylene oxide, simultaneously filling the polymers with the low molecular weights with a certain quantity of second low-molecule alcohol used as a raw material to obtain intermediate target polymers; preparing target polymers from a part of the obtained intermediate target polymers and preparing other intermediate target polymers from another part of the obtained intermediate target polymers in a recycling manner. The first low-molecule alcohol is used as a raw material. The polymers with the low molecular weights are used as initiators, the DMC is used as the catalyst, and the acid is used as an auxiliary. The average molecular weight of the intermediate target polymers is identical to the average molecular weight of the polymers with the low molecular weights. The method has the advantages that the polyether polyol can be prepared by the aid of the method in the recycling manner without alkali manufacturing initiators, and accordingly loss of materials and discharge of filter residues and wastewater can be reduced; the DMC catalyst in reaction systems for initial reaction is already activated under the condition that the concentration of the DMC in the target polymers keeps identical, accordingly, the dehydration time and the initiation time can be shortened to a great extent in production procedures, and the utilization efficiency of devices can be improved.

Owner:HUAIAN BUD POLYURETHANE SCI & TECH CO LTD

Diene rubber, process for production thereof, rubber compositions, process for producing the same, and crosslinked rubbers

InactiveUS6984706B2Easy to processHigh tensile strengthSpecial tyresHydrocarbon solventsPolymer science

A diene rubber (A) having a weight average molecular weight (Mw) of 100,000 to 3,000,000, an Mw / number average molecular weight (Mn) ratio of 1.30 to 2.50, and an Mw / peak top molecular weight (Mp) ratio 0.70 to 1.30. A rubber composition comprising the diene rubber (A) and a diene rubber (B) having an Mw of 2,000 to 90,0000 and / or an oil extender for rubber has good processability and can give a rubber vulcanizate having high tensile strength and good abrasion resistance. The diene rubber (A) is produced by conducting a living polymerization of diene monomer in a hydrocarbon solvent; adding a polymerization stopper to a polymerization mixture at a conversion of 5 to 98% to deactivate 10 to 90% by mole of active terminals present as of the initiation of polymerization; and finally adding a polymerization stopper to completely terminate the polymerization reaction.

Owner:ZEON CORP

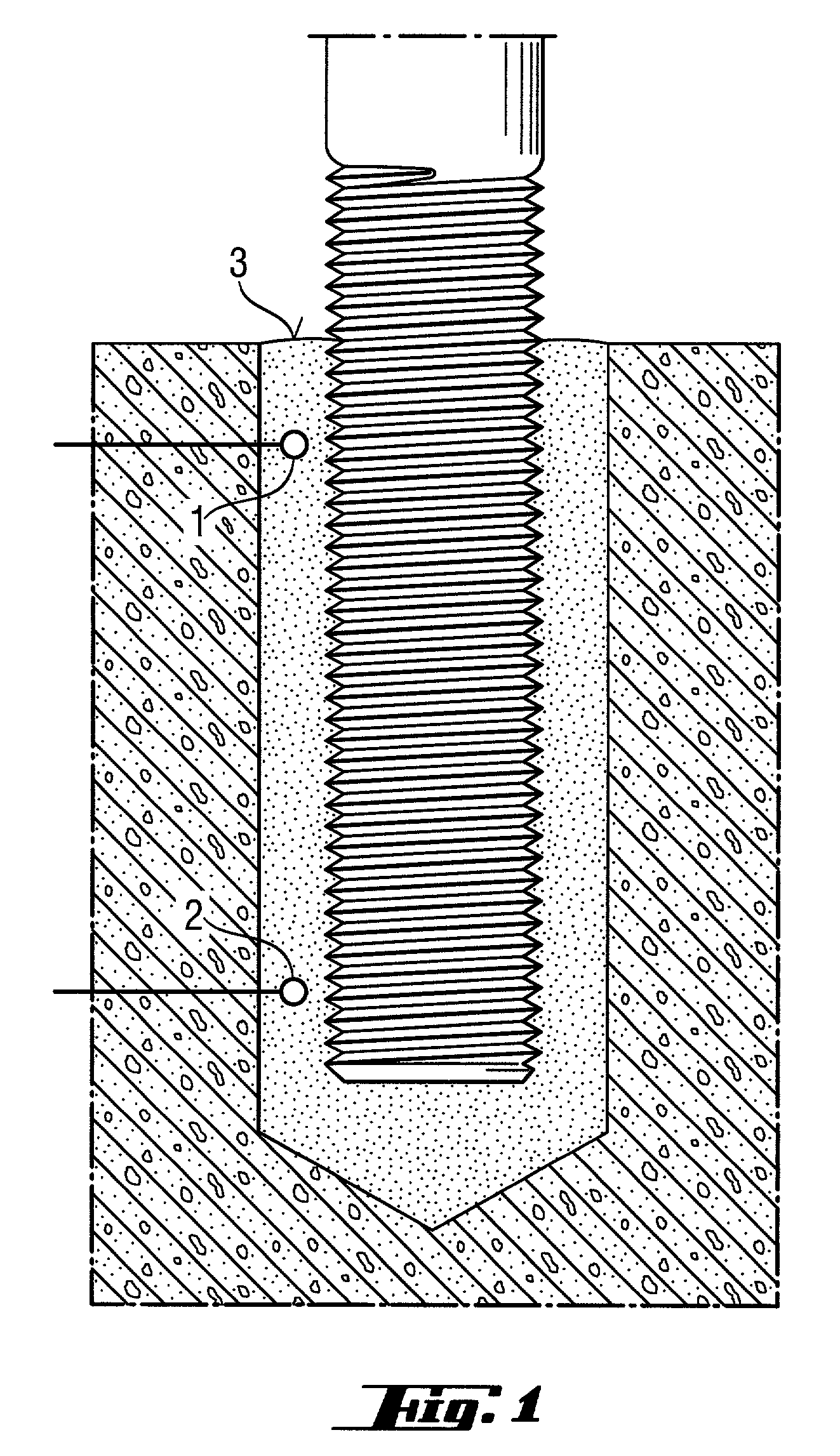

Mortar composition, curable by frontal polymerization, and a method for fastening tie bars

InactiveUS20010018880A1Selective curingFoundation engineeringBuilding constructionsChemistryRadical polymerization

A mortar composition, curable by frontal polymerization after heat initiation, is described, wherein are contained a) at least one polymerizable monomer and / or at least one curable resin, b) at least one polymerization initiator, which can be activated and / or released thermally at a temperature above 30° C., for the polymerizable monomers and / or curing accelerator for the curable resin and c) optionally at least one filler, the nature and amount of polymerizable monomer or curable resin and polymerization initiator or curing accelerator being selected so that a polymerization front velocity of at least 10 cm / min results after the polymerization is initiated, as well as a method for fastening tie bars, reinforcing steel or the like in solid substrates.

Owner:HILTI AG

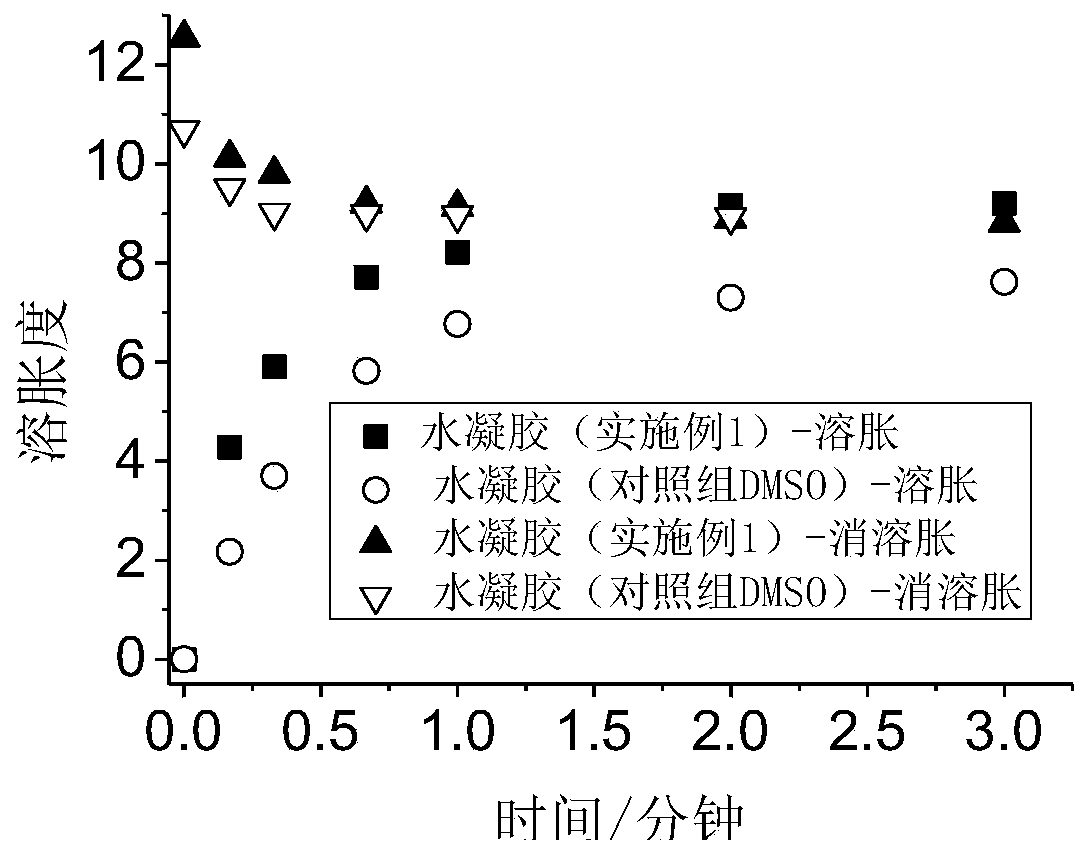

Preparation method of high-strength nano-composite hydrogel with rapid dual responses of pH and temperature

The invention relates to a preparation method of high-strength nano-composite hydrogel capable of rapidly responding to pH and temperature. The preparation method taking dimethylaminoethyl methacrylate as a monomer, inorganic nanometer clay and N,N'-methylenebisacrylamide as co-crosslinking agents, and a nanometer cellulose whisker as a gel composite reinforcer comprises the following steps of: stirring the components, carrying out uniform ultrasonic oscillation, carrying out photo-initiation free radical polymerization in 0 DEG C ice-bath, then reacting at -18 DEG C for 24 hours to obtain the final gel product. The hydrogel prepared by the method has the dual responses of temperature and pH and excellent mechanical performance and can rapidly swell and deswell; and the lowest transformation temperature of the hydrogel is close to temperature of human bodies; raw materials are cheap; the preparation method is simple; and the high-strength nano-composite hydrogel has the potential of application in fields such as sustained release of medicines and tissue engineering.

Owner:HUNAN UNIV OF TECH

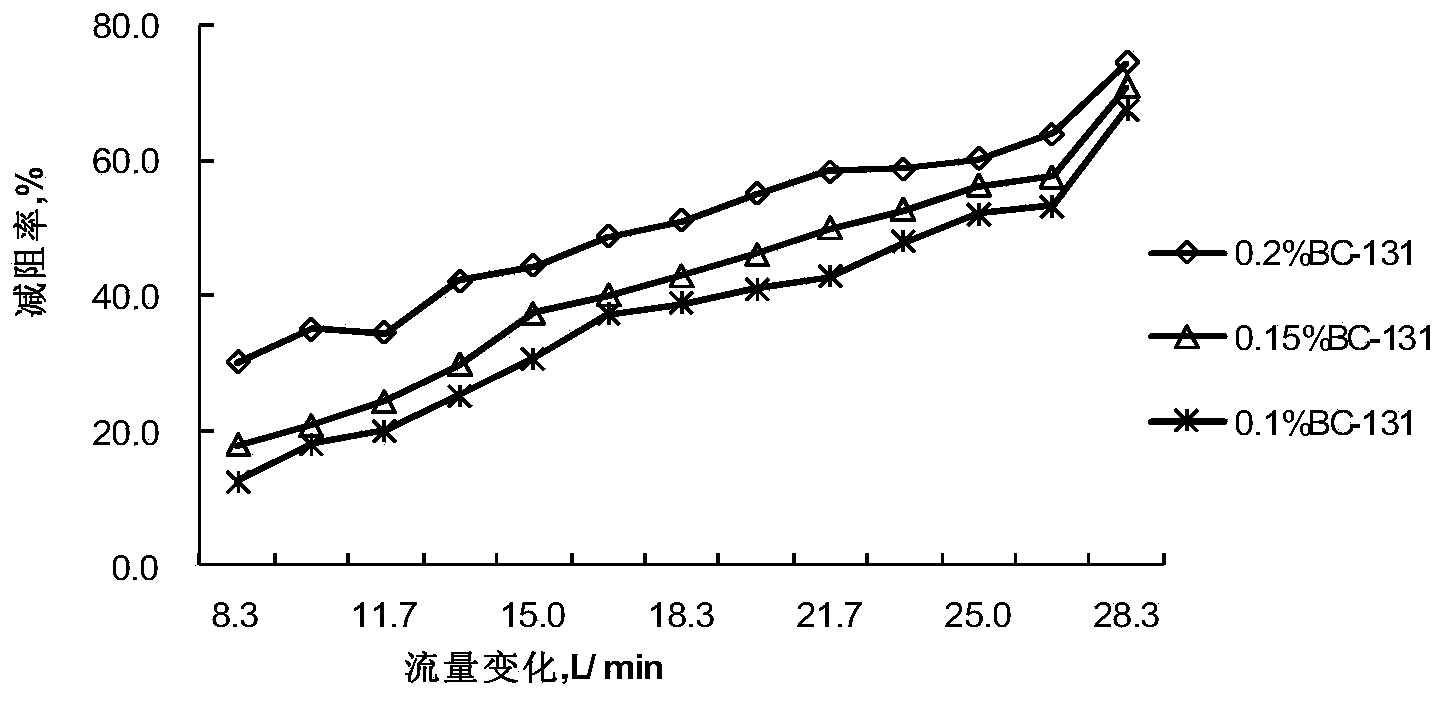

Acid liquor friction reducer and preparation method thereof

InactiveCN103820099AHigh resistance reduction rateImprove temperature resistanceDrilling compositionMeth-Pump pressure

The invention discloses an acid liquor friction reducer and a preparation method thereof. According to the invention, the preparation method comprises the following steps: weighing monomer 2-acrylamide-2-methylpro panesulfonic acid; placing into a beaker; adding deionized water for dissolution; adding caustic soda flakes to adjust to the pH value of the system to be 8-10; adding monomer acrylamide and long-chain cation monomer; mixing under the condition of supplying an inert gas; adjusting the water bath temperature to be the initiation reaction temperature and adding an initiator; reacting to obtain transparent gelatin blocks; manually cutting the transparent gelatin blocks; drying, smashing, and screening with 100 mesh to obtain powdered acid liquor friction reducer. According to the invention, the synthesis method is simple, the raw materials are easy to obtain, and the cost is lowered; the acid liquor friction reducer prepared by the invention has a friction reducing rate as high as 65%, the pump pressure is reduced, the pipe line loss is reduced, and the service life of equipment is prolonged; the acid liquor friction reducer is good in temperature tolerance and compatibility, and has a certain speed reducing effect.

Owner:CHENGDU BAICHUN PETROLEUM TECH

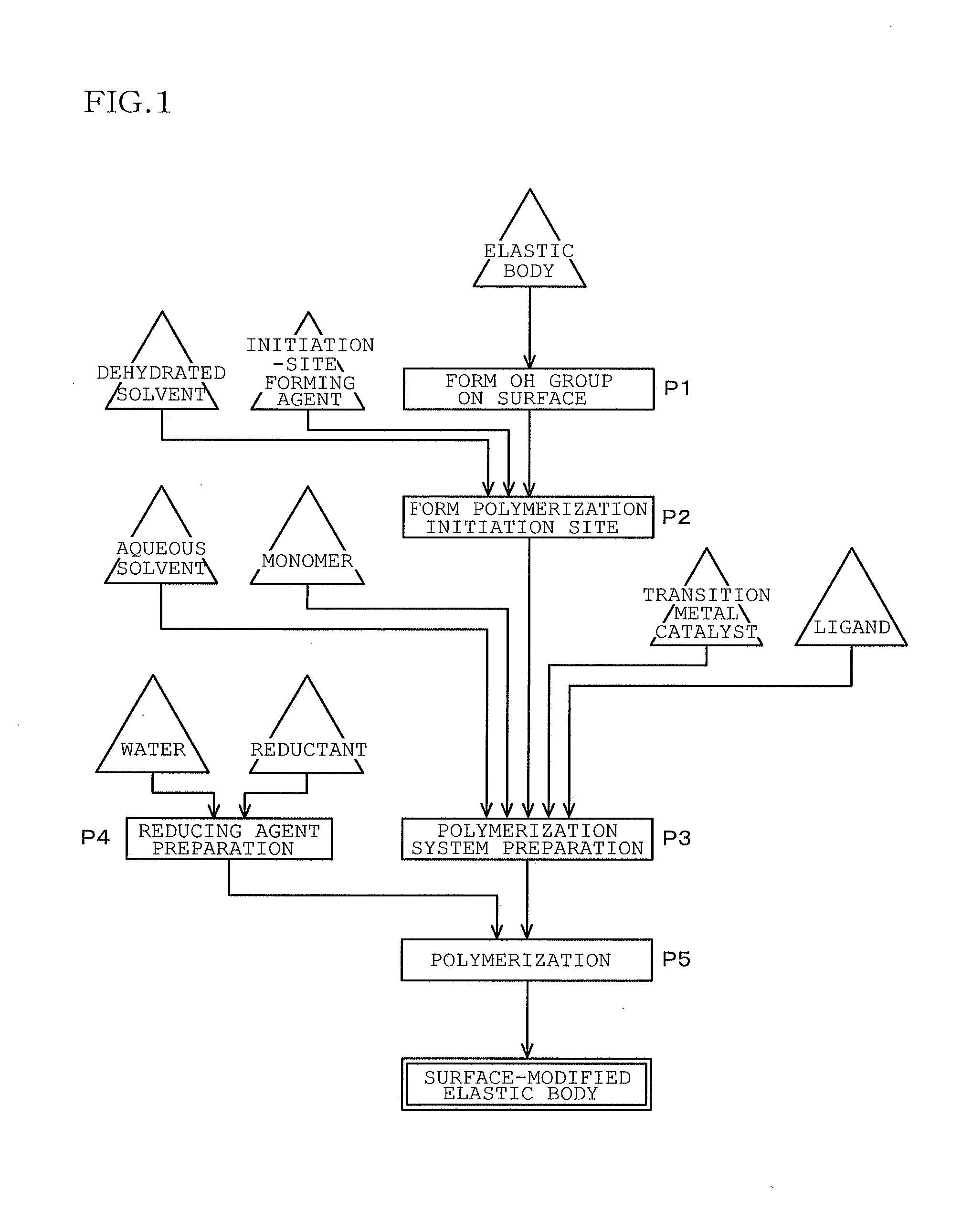

Surface modification method, surface-modified elastic body, gasket for injector, injector, and tire

ActiveUS20130274367A1Imparting slidabilityPiston ringsBraking action transmissionElastomerPolymer science

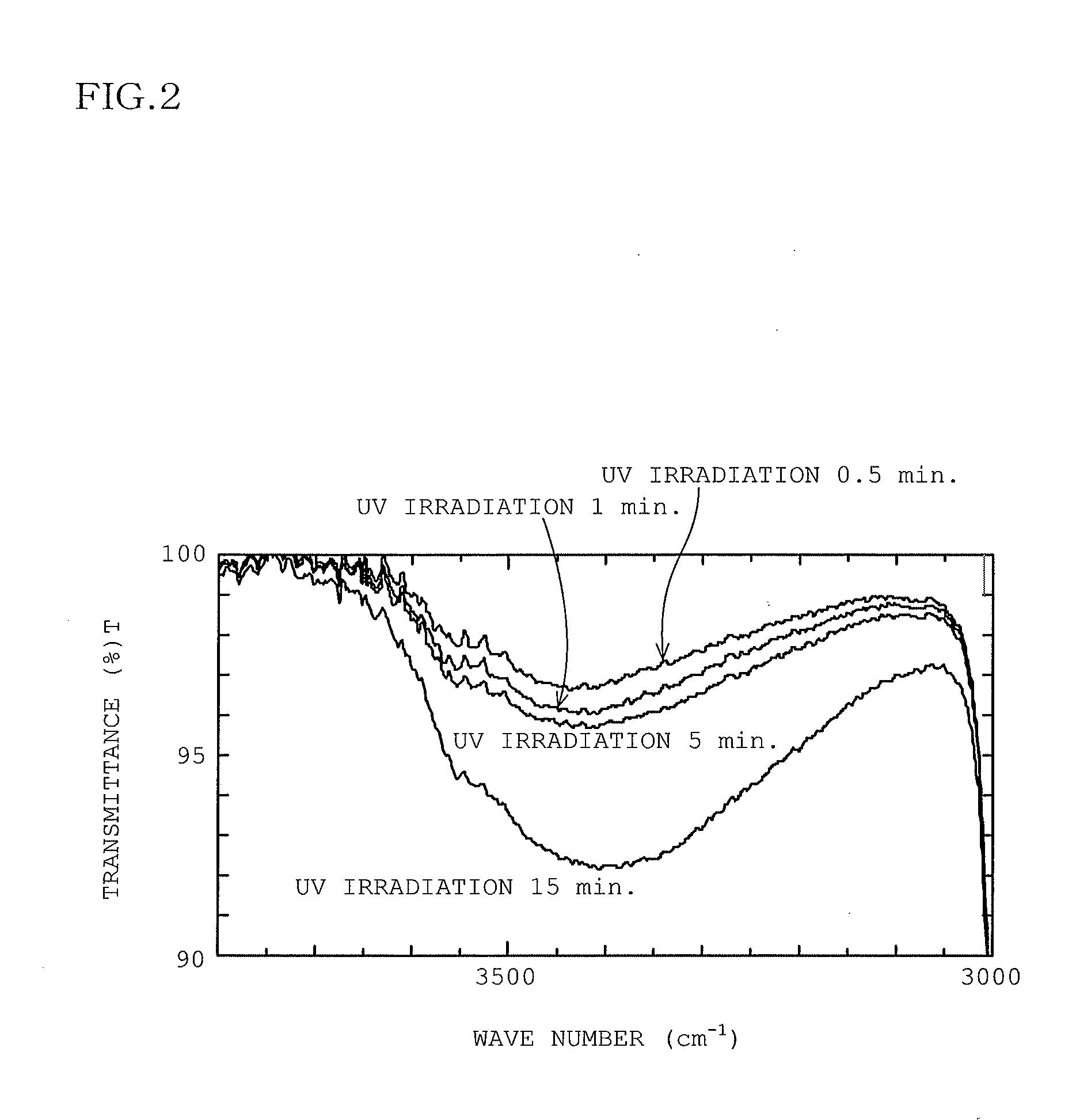

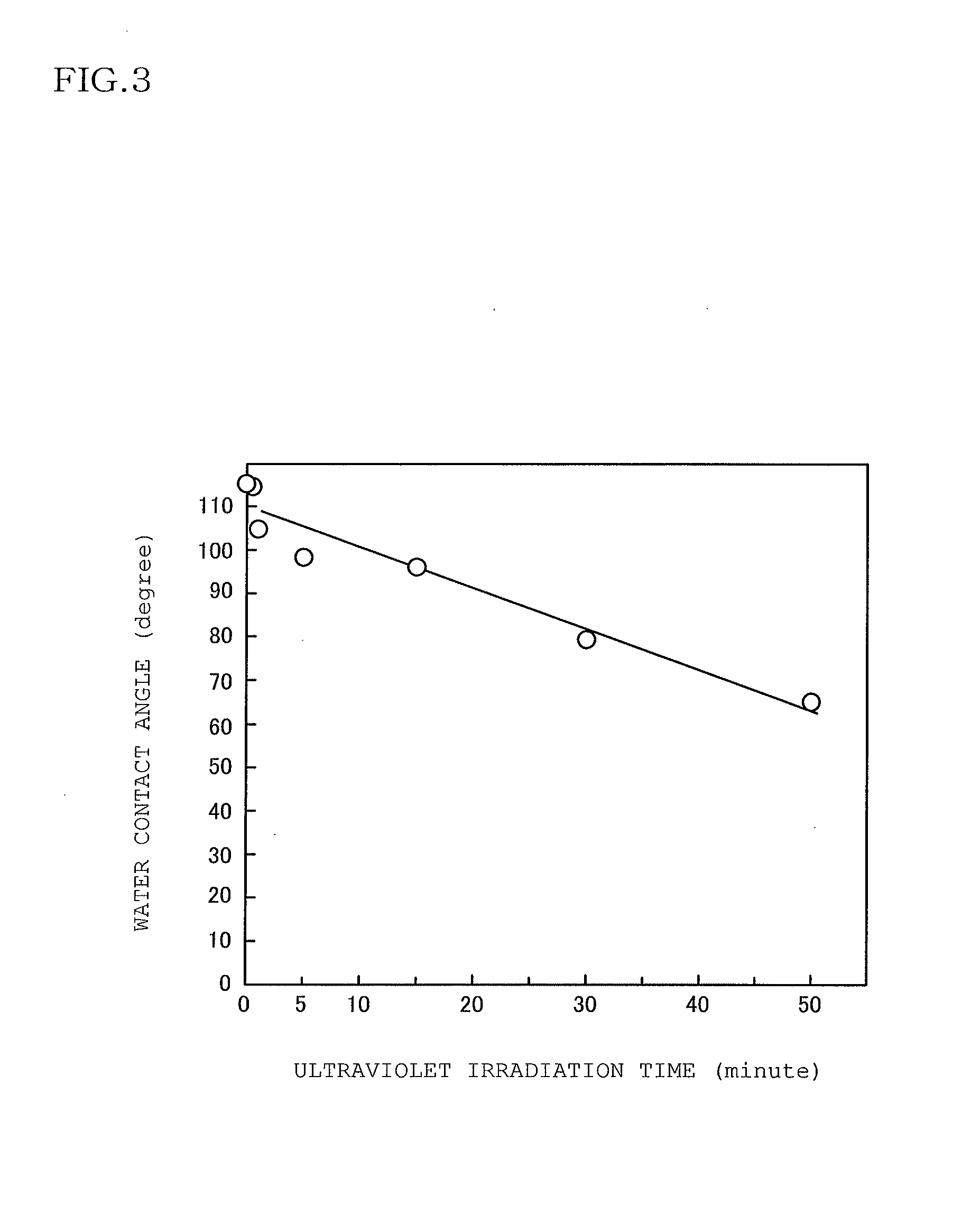

Provided are: surface modification method for imparting slidability to surface of elastic body such as vulcanized rubber or thermoplastic elastomer without using expensive self-lubricating resin; surface-modified elastic body with polymer brush formed on its surface; and gasket for injector and injector formed of surface-modified elastic body. The surface modification method applies to surface of thermoplastic elastomer or vulcanized rubber. The surface modification method comprises the step of forming hydroxyl group on surface of to-be-modified object such as rubber so that water contact angle of the surface becomes 8 to 50 degrees smaller than original water contact angle in unmodified condition, the step of forming polymerization initiation site by subjecting the hydroxyl group to action of secondary or tertiary organic halide, and the step of growing polymer brush on the surface of to-be-modified object by subjecting monomer to radical polymerization at the polymerization initiation site acting as a point of initiation.

Owner:SUMITOMO RUBBER IND LTD +1

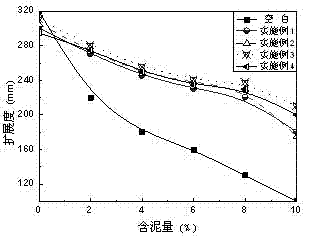

Assistant for polycarboxylic acid water reducing agent and preparation method thereof

In order to overcome the phenomenon that the existing polycarboxylic acid water reducing agent is hypersensitive to slime contained in aggregate, the invention provides an assistant which can effectively inhibit the influence of the slime on the polycarboxylic acid water reducing agent and a preparation method thereof. The assistant for the polycarboxylic acid water reducing agent is a product obtained by the polymerization of an acrylamide monomer and an amine-alkene-containing monomer under the initiation effect of an initiator, wherein the amine-alkene-containing monomer specifically refers to one of dimethylallyl amine, diallyl amine, dimethylaminoethyl methacrylate or dimethylaminoethyl acrylate. The assistant provided by the invention can well inhibit the influence of the slime contained in aggregate on the polycarboxylic acid water reducing agent and keep a favorable working state. Besides, the preparation method provided by the invention has simple reaction conditions and is applicable to industrial production; and the obtained product contains no chloride ion.

Owner:SHANDONG PROVINCIAL ACAD OF BUILDING RES

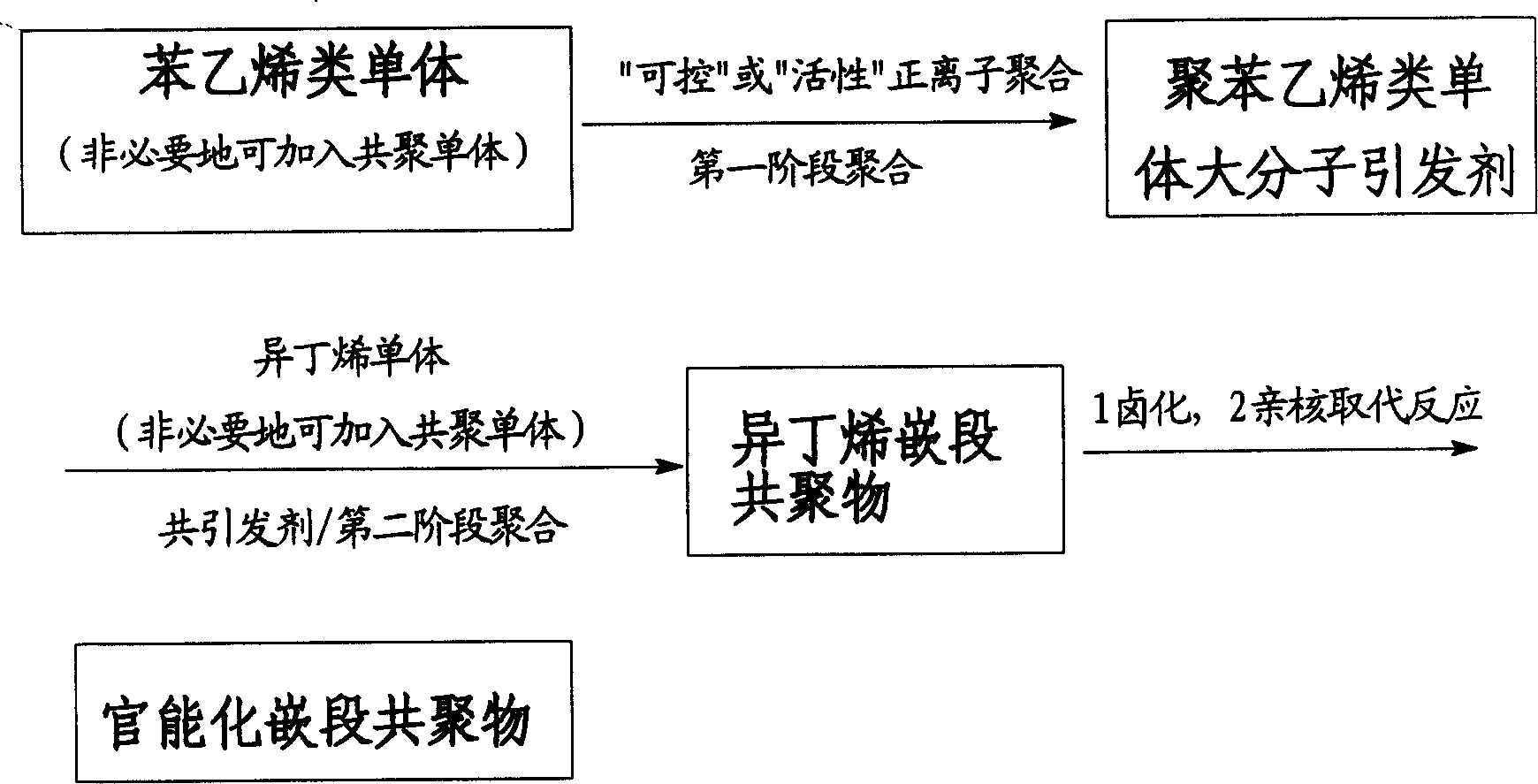

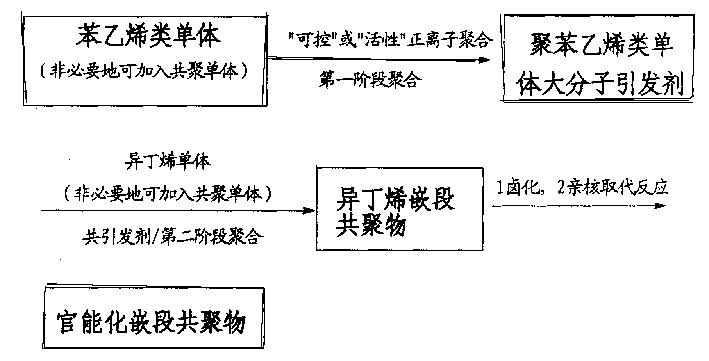

Method for preparing isobutylene block copolymer by sequential initiation

The present invention provides a method for preparing isobutene block copolymer by adopting sequence initiation. Said method successively includes the following steps: (1) first-stage polymerization: making styrene monomer (monomer A) implement 'controllable' or 'active' cationic homopolymerization or copolymerization; and (2) second-stage polymerization: using isobutene as monomer, using polymerization product of first-stage as macromolecular initiator, adding a novel Lewis acid as coinitiator and making homopolymerization of isobutene; or using isobutene as monomer, using polymerization product of first stage as macromolecular initiator, adding a novel Lewis acid as coinitiator and making copolymerization of copolymerization monomer of isobutene so as to obtain the invented block copolymer.

Owner:CHINA PETROLEUM & CHEM CORP +1

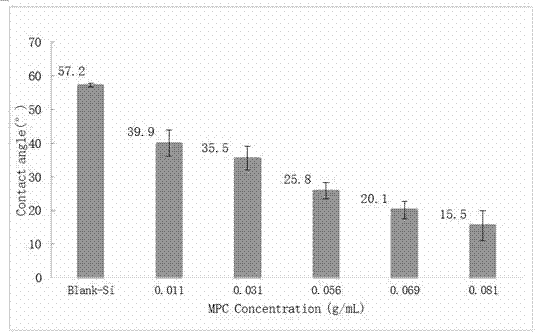

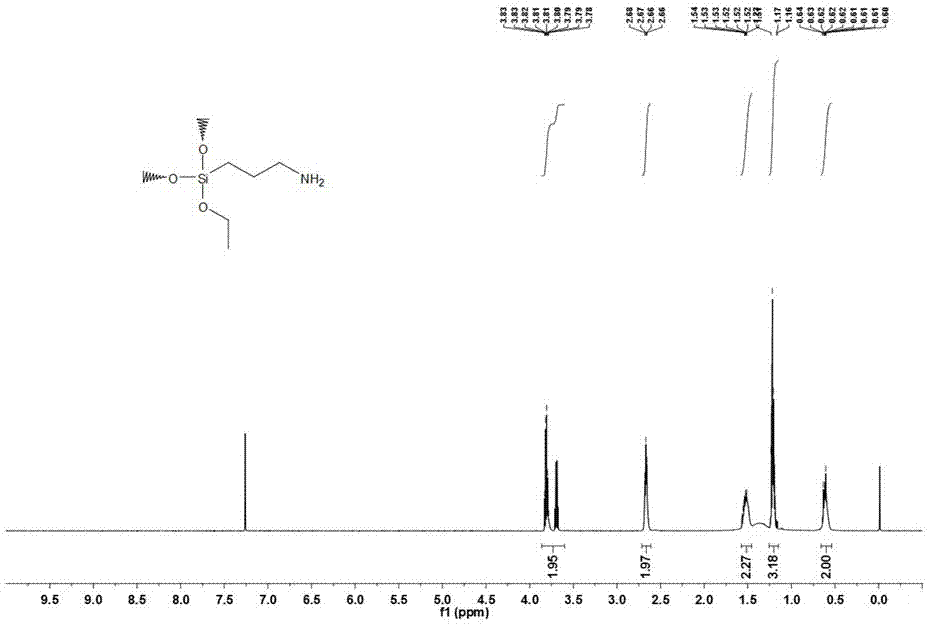

Universal and efficient material surface modification method

InactiveCN106967228AOptimize experimental conditionsAdhesion is gentleCoatingsSurface modificationSubstrate surface

The invention discloses a universal and efficient material surface modification method which comprises the following steps: 1) preparing a dopamine solution; 2) treating a substrate surface, washing, and preserving for later use; drying a substrate material in a blowing manner before being used; putting a substrate into the dopamine solution, and drying in the blowing manner for later use; 3) grafting a PEI (Polyethyleneimine) layer on the basis of a dopamine coating, preparing a Tris*HCl solution, and sealing for preservation; preparing a polyethyleneimine (PEI) solution for later use; putting the substrate coated by a PDA layer into the polyethyleneimine (PEI) solution, sealing the opening with a preservative film, stirring at room temperature for reaction, grafting the polyethyleneimine (PEI) layer, performing reaction, taking out by using tweezers, and blowing for later use; 4) inoculating an activated initiator; 5) performing surface initiation polymerization, immobilizing the initiator on surfaces of different substrates, and preparing different types of polymer brushes on the surfaces of different substrates by using a surface initiation polymerization method. The method has the advantages of being gentle and universal.

Owner:NORTHWEST UNIV

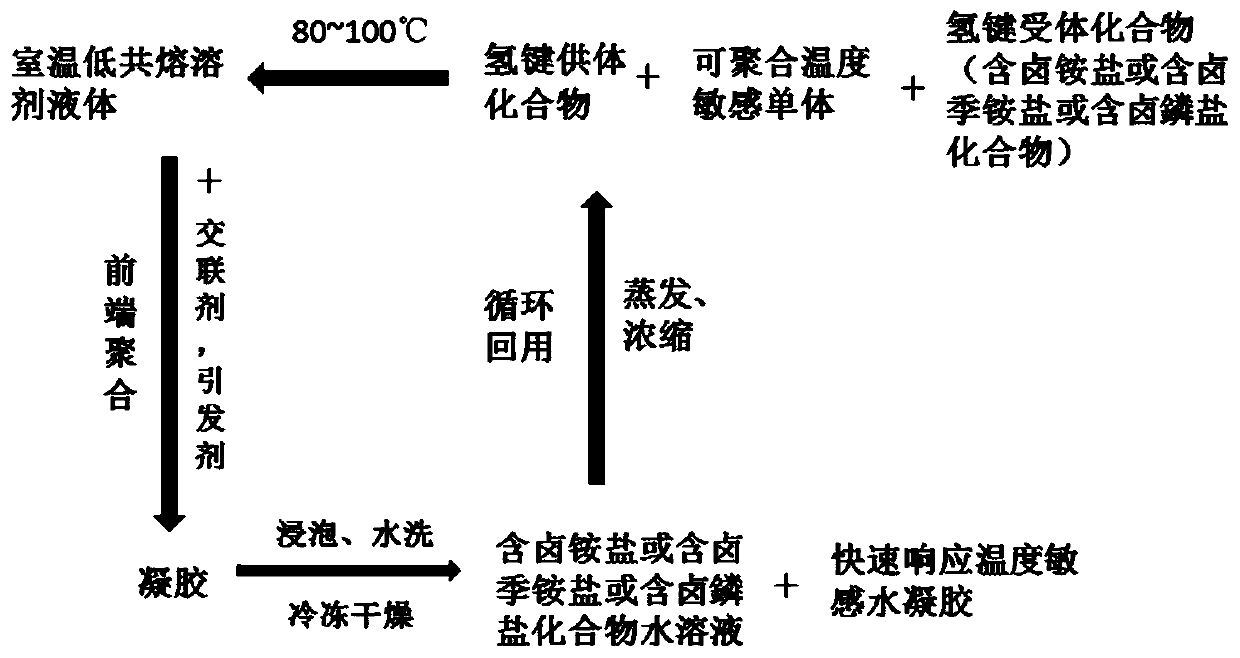

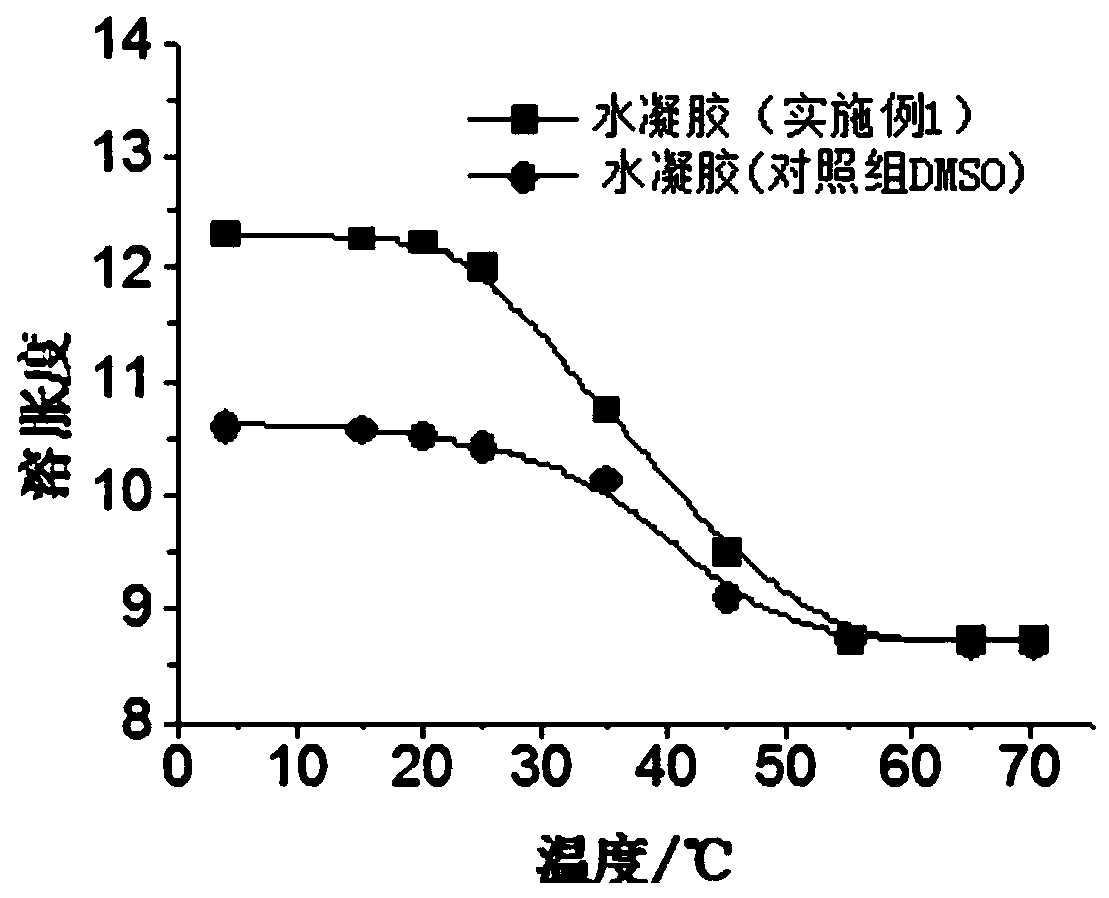

Method for preparing quick-response temperature-sensitive hydrogel by adopting room-temperature eutectic solvent liquid frontal polymerization

The invention discloses a method for preparing a quick-response temperature-sensitive hydrogel by adopting room-temperature eutectic solvent liquid frontal polymerization, and belongs to the technicalfield of preparation of functional polymer materials. The method comprises the following steps: mixing a polymerizable temperature-sensitive monomer, a hydrogen bond donor compound and a hydrogen bond acceptor compound, stirring at 80-100 DEG C until a transparent and clear liquid is formed, and cooling to room temperature to obtain a room-temperature eutectic solvent liquid; adding a cross-linking agent and an initiator into the room-temperature eutectic solvent liquid to form a mixture solution; transferring the formed mixture solution into a tubular reactor, initiating a reaction at the upper end or the lower end of the reactor by adopting a heat source or ultraviolet light, and removing the heat source or the ultraviolet light after the thermal initiation reaction is started until allthe raw materials in the whole reactor are converted into a polymer gel; and soaking and washing the obtained polymer gel with distilled water, and freeze-drying to obtain the target hydrogel. No extra liquid solvent is needed, the polymerization speed is high, the reaction time is short, and the energy consumption is low.

Owner:HUBEI POLYTECHNIC UNIV

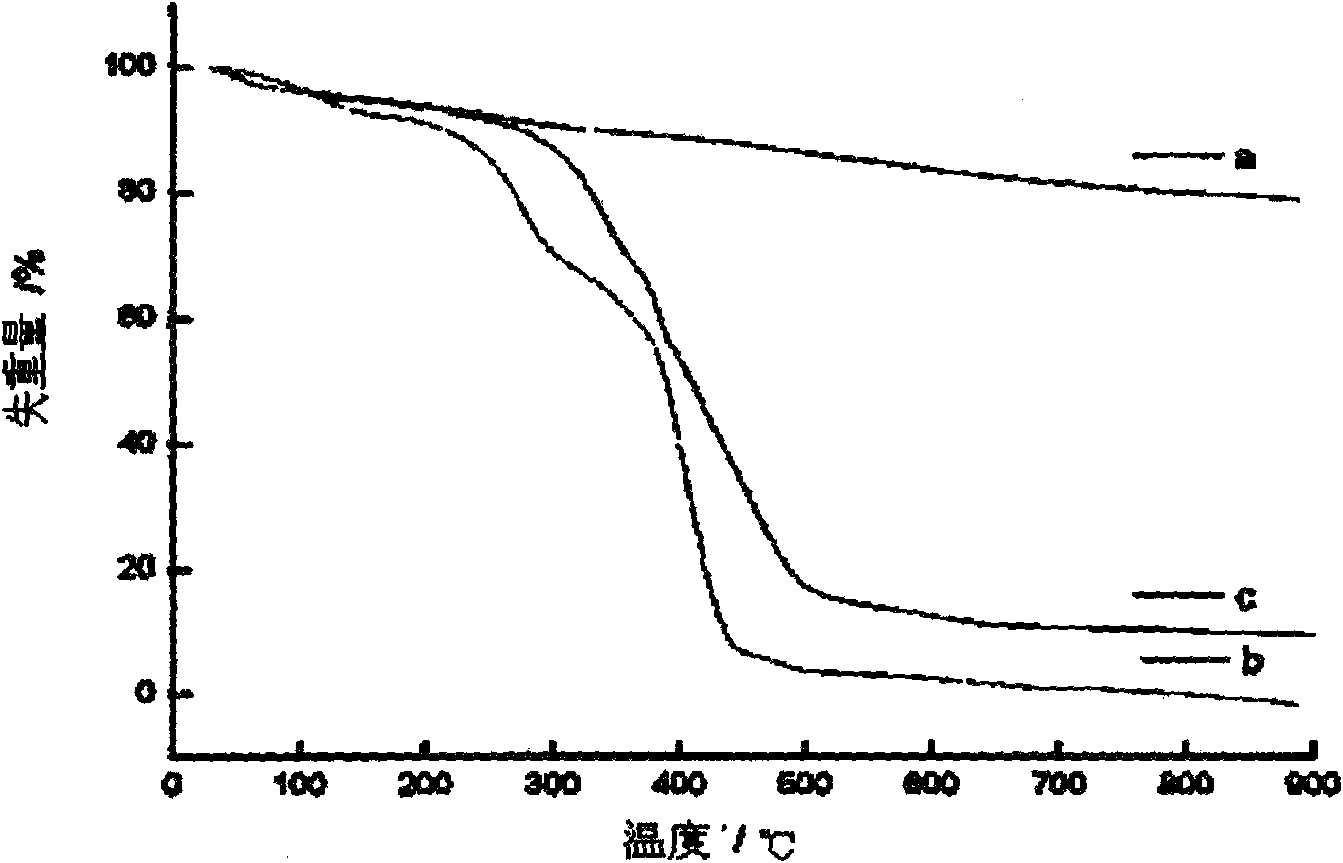

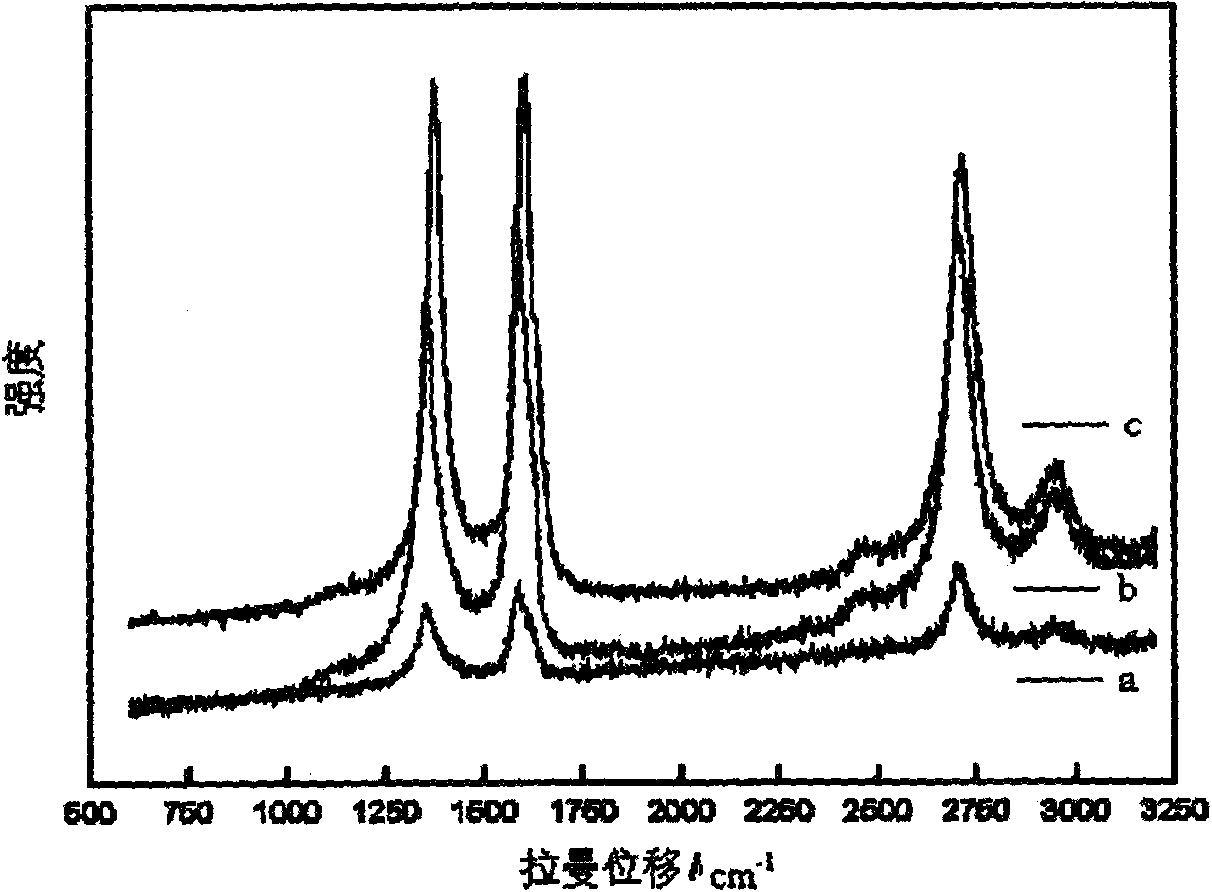

Carbon nano-tube modified by in-situ polymerization based on plasma initiation and preparation method thereof

InactiveCN101559936AGood dispersionEasy to manufactureNanostructure manufactureSolubilityIn situ polymerization

The invention provides a method for preparing a carbon nano-tube modified in-situ polymerization based on plasma initiation. The method takes a carbon nano-tube and acrylic acid, styrene or acrylamide monomers as raw materials for functional polymerization reaction preparation, and functional groups grafted to the surface of the carbon nano-tube accounts for 12 to 72 percent of the total amount. The obtained carbon nano-tube subjected to in-situ polymerization has good solubility and compatibility, can conveniently react with other compounds, and can be conveniently combined with other high polymers to prepare nano composite materials so as to have wide application prospect. The method is simple and practical, has high efficiency and mild reaction conditions, and does not need complex testing apparatuses.

Owner:TIANJIN UNIV

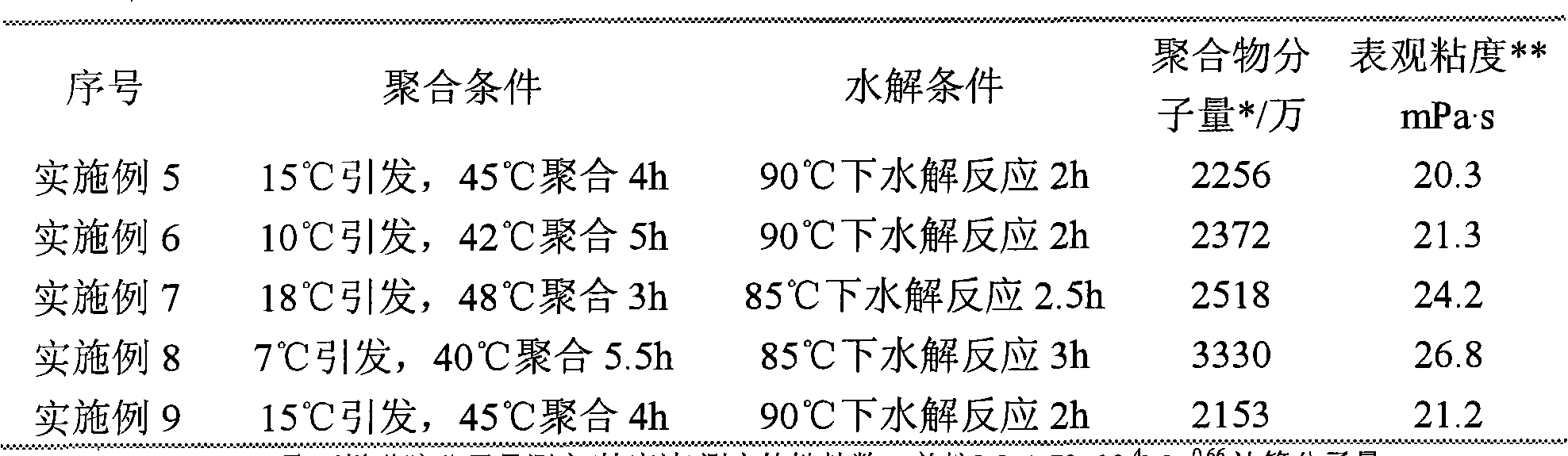

Preparation method of heat-resistance and salt-tolerance anionic polyacrylamide for oil displacement

ActiveCN102372807AHigh molecular weightSmooth responseDrilling compositionHeat resistanceAqueous solution

The invention relates to a preparation method of heat-resistance and salt-tolerance anionic polyacrylamide for oil displacement and mainly solves the problems of low molecular weight and poor heat resistance as well as salt tolerance of polymers in the prior art. With the combination of a complex initiation system composition and a post-hydrolysis technology, the method provided by the invention comprises the following steps of: carrying out aqueous solution polymerization on acrylamide, crushing gel slug, mixing with a certain concentration of alkali lye for hydrolysis reaction, drying and crushing to obtain fine granular anionic polyacrylamide. The technical scheme greatly solves the problems and can be used in the industrial production of heat-resistance and salt-tolerance anionic polyacrylamide for oil displacement.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrophylic phenylboric acid functional porous integral material, preparation method and application thereof

InactiveCN102059103AReduce hydrophobicityReduce manufacturing costIon-exchange process apparatusOther chemical processesBoronic acidEngineering

The invention provides a hydrophilic phenylboric acid functional porous integral material, which is a cross-linked framework structured hydrophilic phenylboric acid functional porous integral material with penetrated transparent ducts, is formed by 4-(-3-butenyl sulfone) phenylboric acid and crosslinker N,N-bisacrylamide under initiation of a free radical reaction initiator, and can perform a covalent interaction with dihydroxyl compound under a neutral pH condition. The hydrophilic phenylboric acid functional porous integral material can be used for specifically identifying, separating, enriching or immobilizing the dihydroxyl compounds. The invention also discloses a method for preparing the hydrophilic phenylboric acid functional porous integral material.

Owner:NANJING UNIV

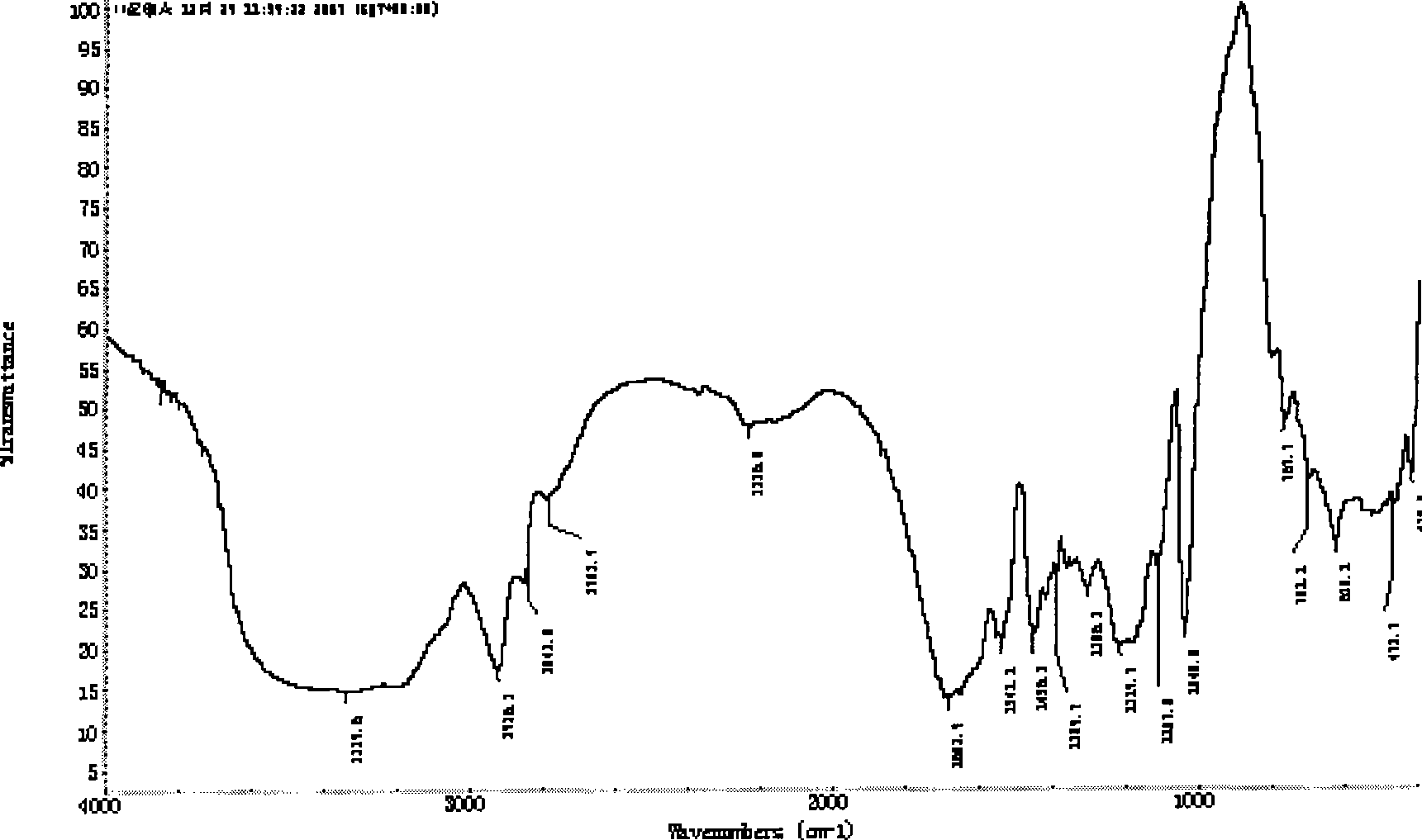

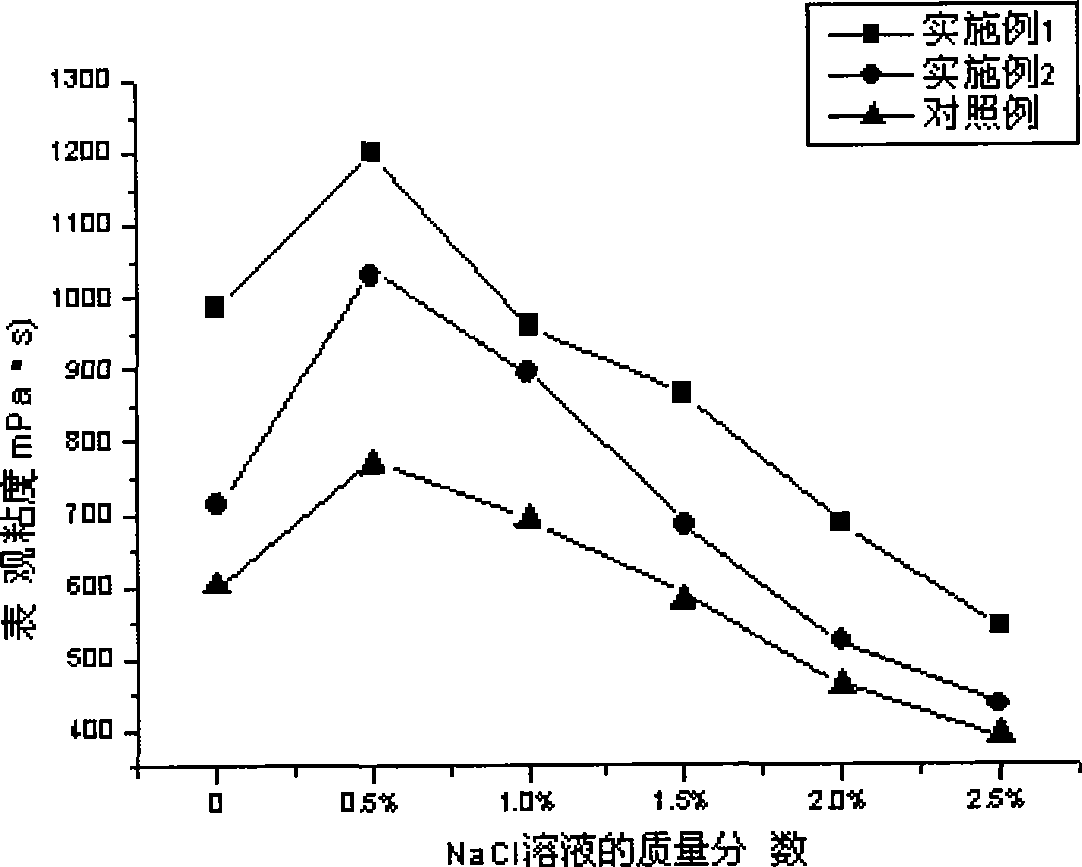

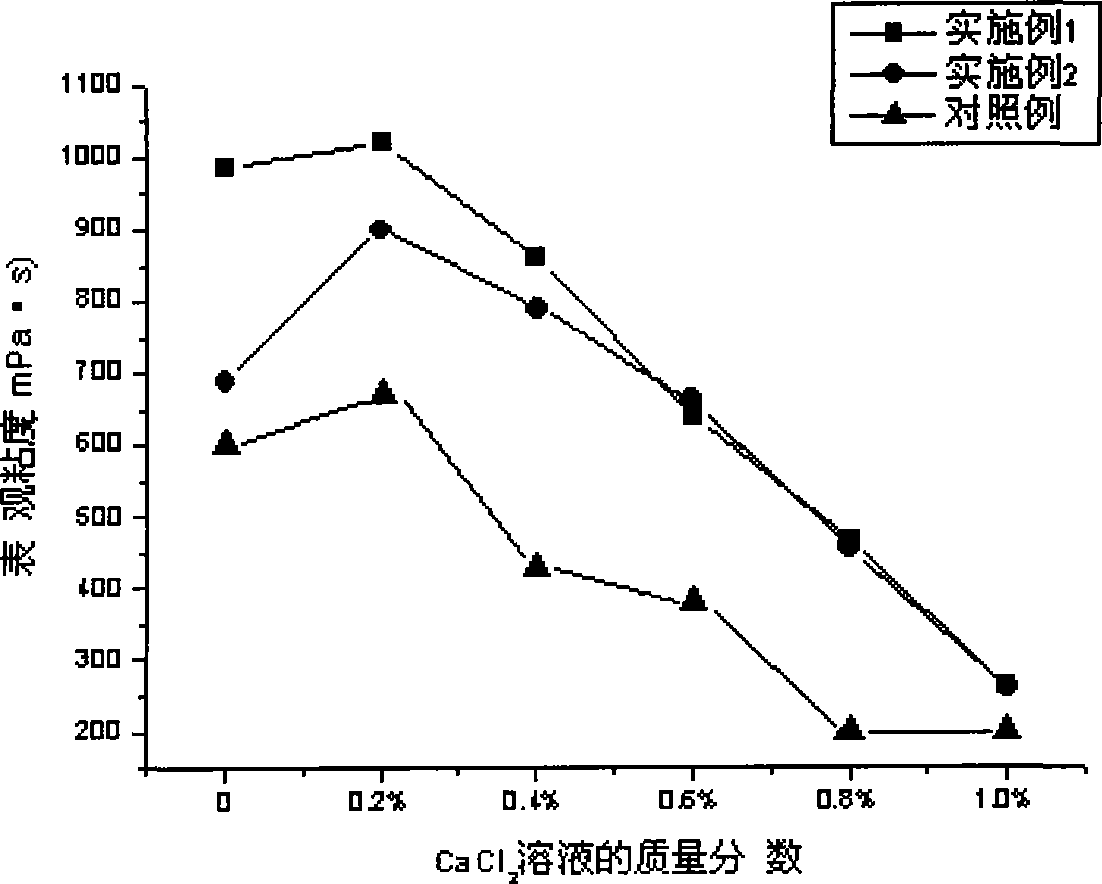

Hydrophobic associating polymer containing capsaicine and sulfonic group and preparation method thereof

InactiveCN101392041AIncrease viscosityImprove salt toleranceDrilling compositionPolymer scienceFatty alcohol

The invention discloses a hydrophobic association polymer containing capsaicine and sulfonyl, and a preparation method thereof. During the preparation, compounds containing capsaicine functional groups, acrylamide, 2-acrylamide-2-methylpropanesulfonic acid and (methyl) acrylic acid long-chain fatty alcohol ester are polymerized under the initiation of a a redox initiator; the mole percentage ratio of the compounds containing the capsaicine functional groups, the acrylamide, the 2-acrylamide-2-methylpropanesulfonic acid and the (methyl) acrylic acid long-chain fatty alcohol ester is 0.5-5 to 65-92.5 to 6.5-20 to 0.5-10; the reaction temperature is 30 DEG C to 120 DEG C; and the reaction time is 1h to 20h. The preparation method simultaneously introduces sulfonyl that is insensitive to salt and capsaicine functional group units with rigidity into the large molecules of the hydrophobic association polymer, thereby obtaining the water soluble hydrophobic association polymer which has high tackification and the properties of anti-salt and high temperature resistance, and can be applied to the tertiary oil recovery in oil fields as a novel oil-displacing agent.

Owner:OCEAN UNIV OF CHINA

Reversible self-repair antibacterial acrylic coating and preparation and self-repair methods

ActiveCN106928797AReversible self-healingAntibacterialAntifouling/underwater paintsPaints with biocidesMethacrylateBetaine

The invention discloses a reversible self-repair antibacterial acrylic coating and preparation and self-repair methods. The preparation method comprises the steps of adding methyl methacrylate, butyl acrylate, sulfonyl betaine methacrylate and acetoacetoxy methacrylate gylcol ester into an alcohol solvent, and performing free radical polymerization under the initiation of azodiisobutyronitrile to obtain linear acrylic resin; and dissolving the linear acrylic resin and amino-containing hyperbranched polysiloxane into the alcohol solvent, coating the surface of a base material, and drying, thus obtaining the reversible self-repair antibacterial acrylic coating. Efficient and mild repair of the coating is realized by using the characteristic of reversible reaction of vinylogous urethane bonds at room temperature and amino rich at the terminal of the hyperbranched polysiloxane, and the acrylic coating is endowed with excellent antibacterial property by the safe, nontoxic and non-specific sulfonyl betaine. The product has good applicability and strong practicability; the preparation method has the characteristics of wide raw material source, simple process and environment friendliness.

Owner:SUZHOU UNIV

Preparation method of hyperbranched multifunctional dispersant

ActiveCN104211849AComposition is easy to controlOptimal Control StructurePigment pastesFreeze thawingHydrophilic monomer

The invention discloses a preparation method of a hyperbranched multifunctional dispersant, and belongs to the field of fine chemical engineering. The preparation method comprises the following steps: by taking p-vinyl benzyl mercaptan as a branching monomer and chain transfer agent, carrying out free radical polymerization reaction on polymerizable double-bond hydrophobic monomers and a hydrophilic monomer maleic anhydride in a certain proportion in a solvent under initiation of an initiator; and then, esterifying and modifying polymerization products under action of an esterification catalyst to obtain the hyperbranched multifunctional dispersant. The hyperbranched multifunctional dispersant is suitable for dispersing a plurality of inorganic and organic pigments; and moreover, the prepared pigment is low in paste viscosity, and good in storage stability and freeze-thaw stability. The hyperbranched multifunctional dispersant can be applied to the industries such as paint, textiles and chemical engineering.

Owner:JIANGNAN UNIV

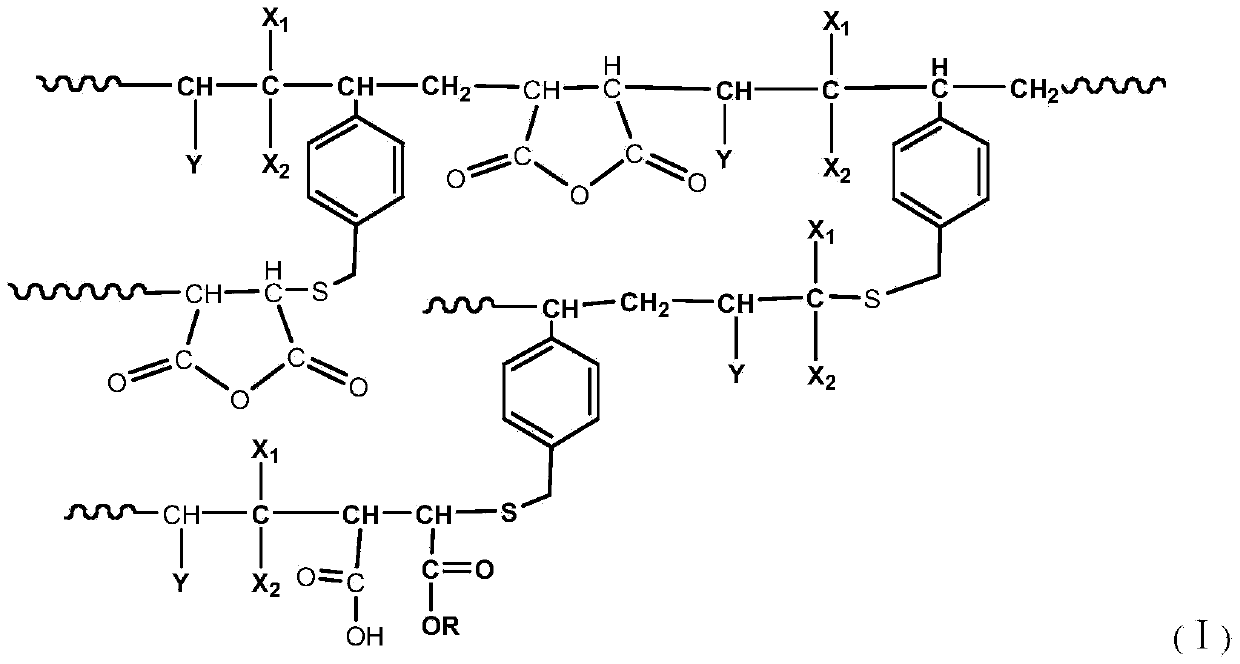

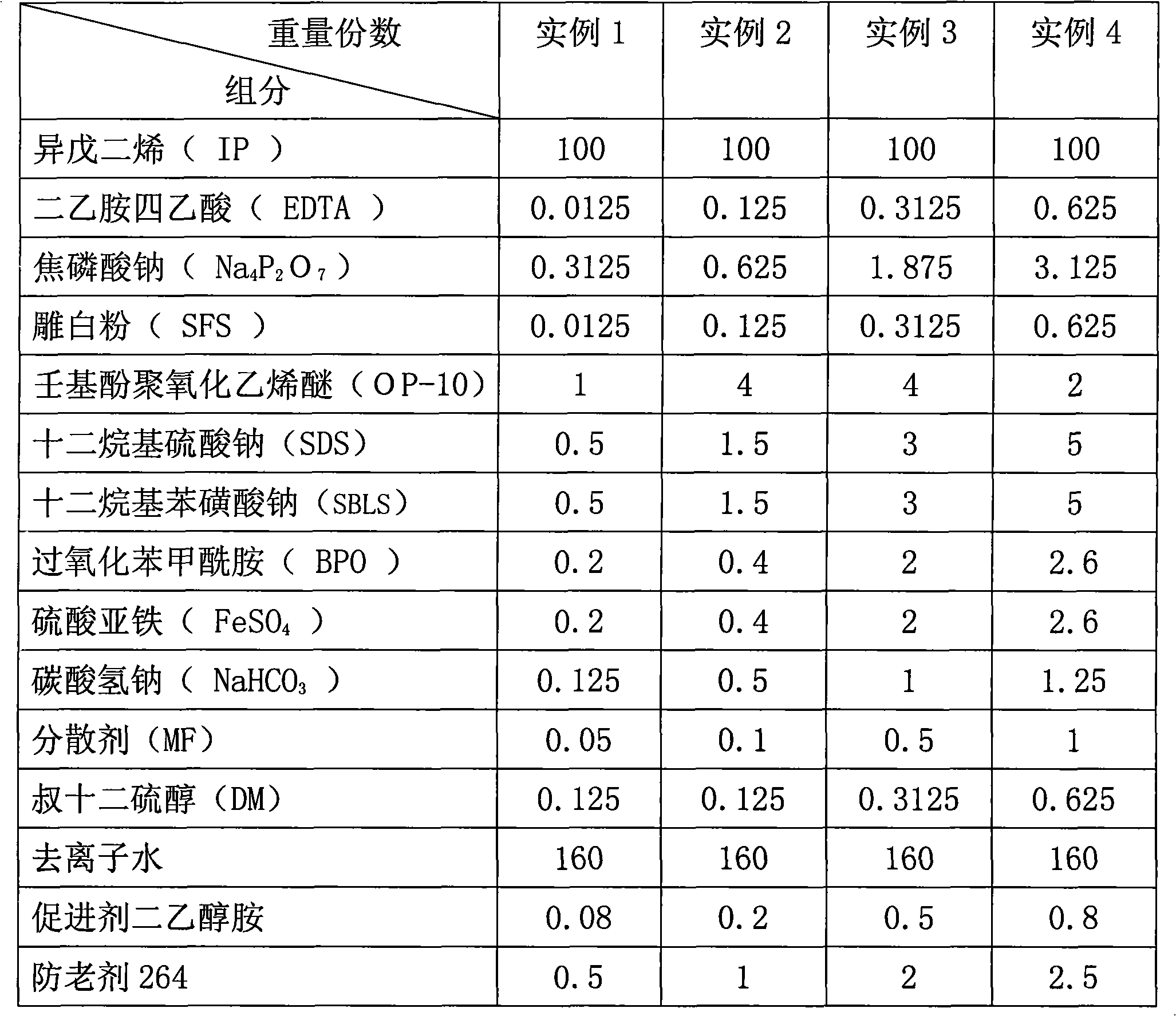

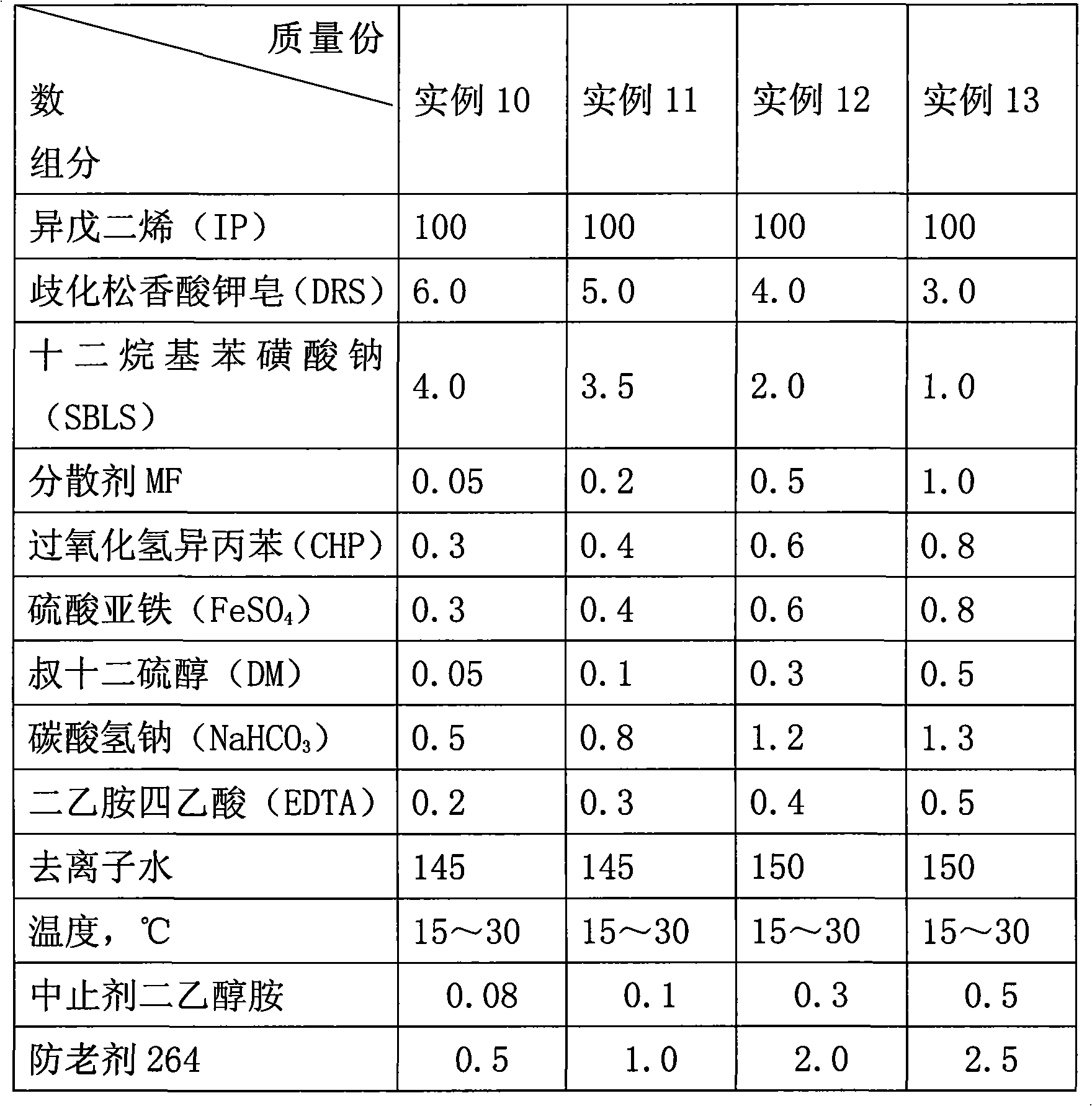

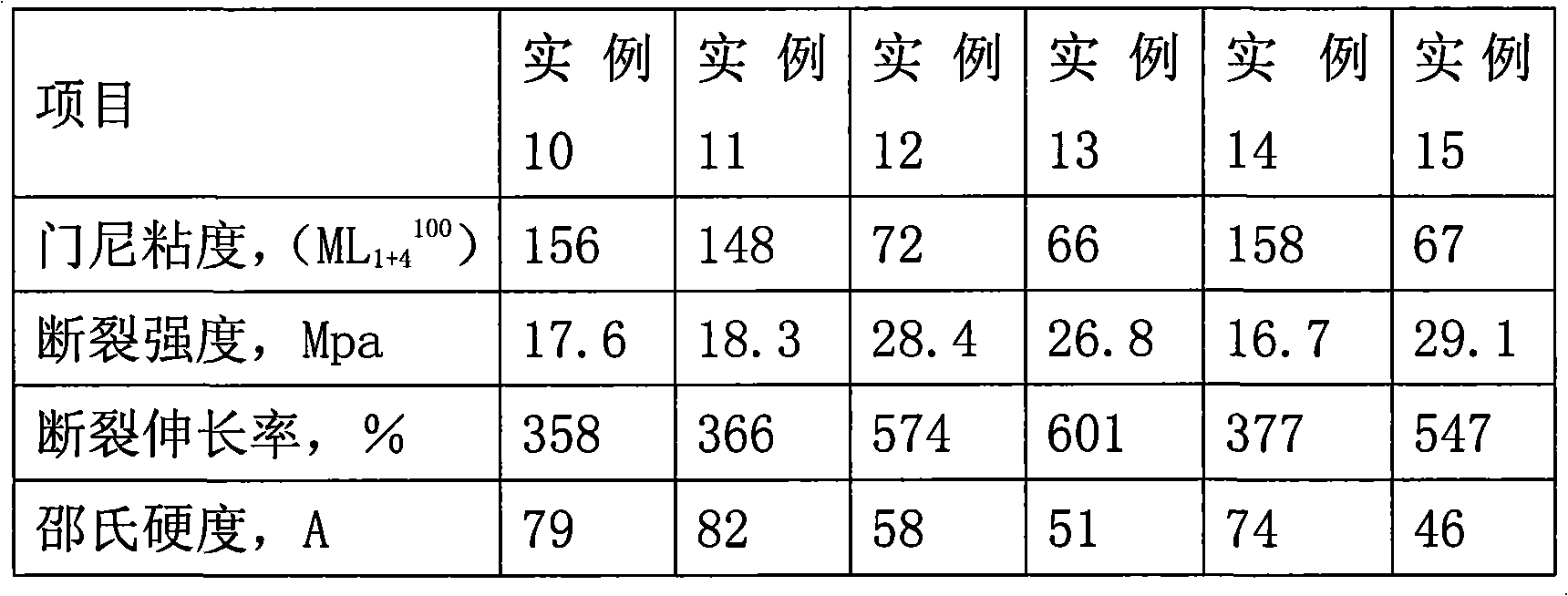

Polyisoprene aqueous emulsion and method for preparing glove and related products

InactiveCN101838360AThe polymerization process is stableEmulsion stabilizationGlovesCoatingsIsopreneRadical polymerization

The invention relates to a polyisoprene aqueous emulsion and a method for preparing a glove and related products thereof. The polyisoprene aqueous emulsion is a stable polyisoprene rubber emulsion which is obtained by performing radical emulsion polymerization under normal pressure and the initiation of an initiator by taking isoprene as a monomer, taking an emulsifying agent and a dispersant as an emulsification system and adopting a redox initiation system, wherein an oil phase obtained after the isoprene and the initiator are mixed and a reducing agent are added dropwise together in a sectional dropwise adding way. The polymerization conversion rate of the polyisoprene aqueous emulsion of the invention is increased to be over 97.5 percent from original 78 percent; and a prepared polyisoprene glove and related thin emulsion products have the characteristics of high strength, high extensibility, good handfeel and no anaphylaxis to human bodies, and can meet the requirements of different purposes.

Owner:SHANGHAI SHENGDA MEDICAL HEALTH STOCK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com