Patents

Literature

30396 results about "Distilled water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Distilled water is water that has been boiled into vapor and condensed back into liquid in a separate container. Impurities in the original water that do not boil below or near the boiling point of water remain in the original container. Thus, distilled water is one type of purified water.

Cleaning solution for photoresist and method for forming pattern using the same

ActiveUS7238653B2Use cleanOrganic detergent compounding agentsTransportation and packagingResistAlcohol

Cleaning solutions for photoresist are disclosed which are useful for cleaning a semiconductor substrate in the last step of development when photoresist patterns are formed. Also, methods for forming photoresist patterns using the same are disclosed. The disclosed cleaning solution comprises H2O as a solution, a surfactant which is phosphate-alcoholamine salt represented by Formula 1, and an alcohol compound. The disclosed cleaning solution has lower surface tension than that of distilled water which has been used for conventional cleaning solutions, thereby improving resistance to photoresist pattern collapse and stabilizing the photoresist pattern formation.wherein R, x, y, z, a and b are as defined in the specification.

Owner:SK HYNIX INC

Inorganic/organic nano composite antibacterial agent and its fabric product application

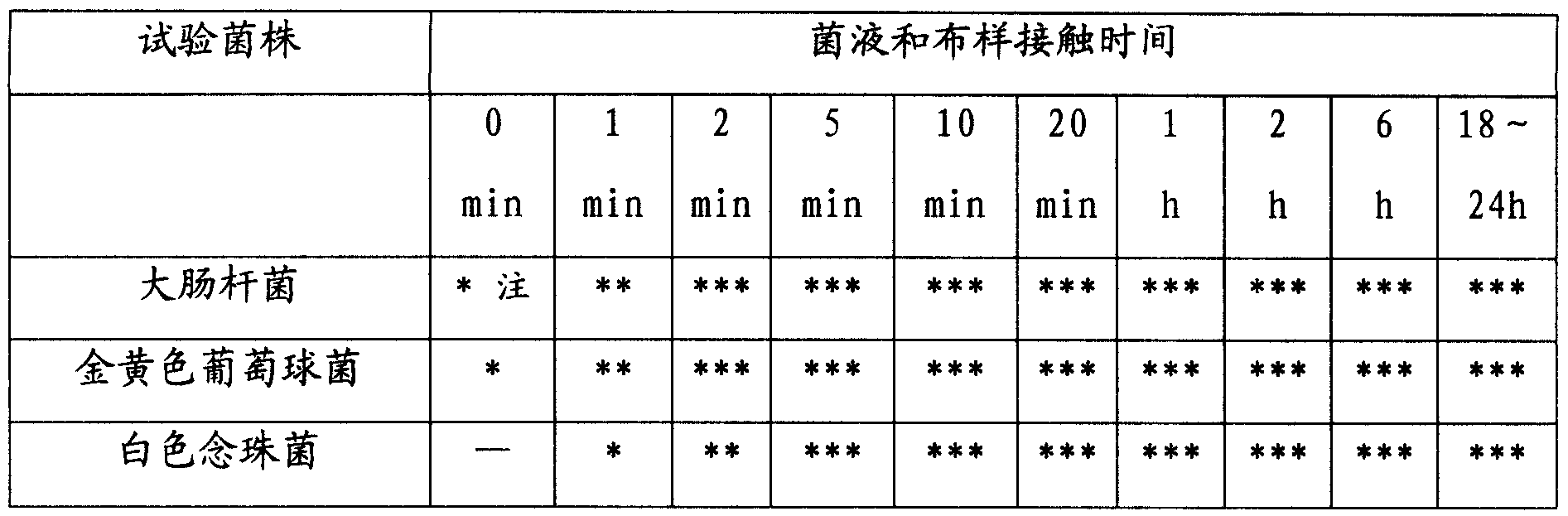

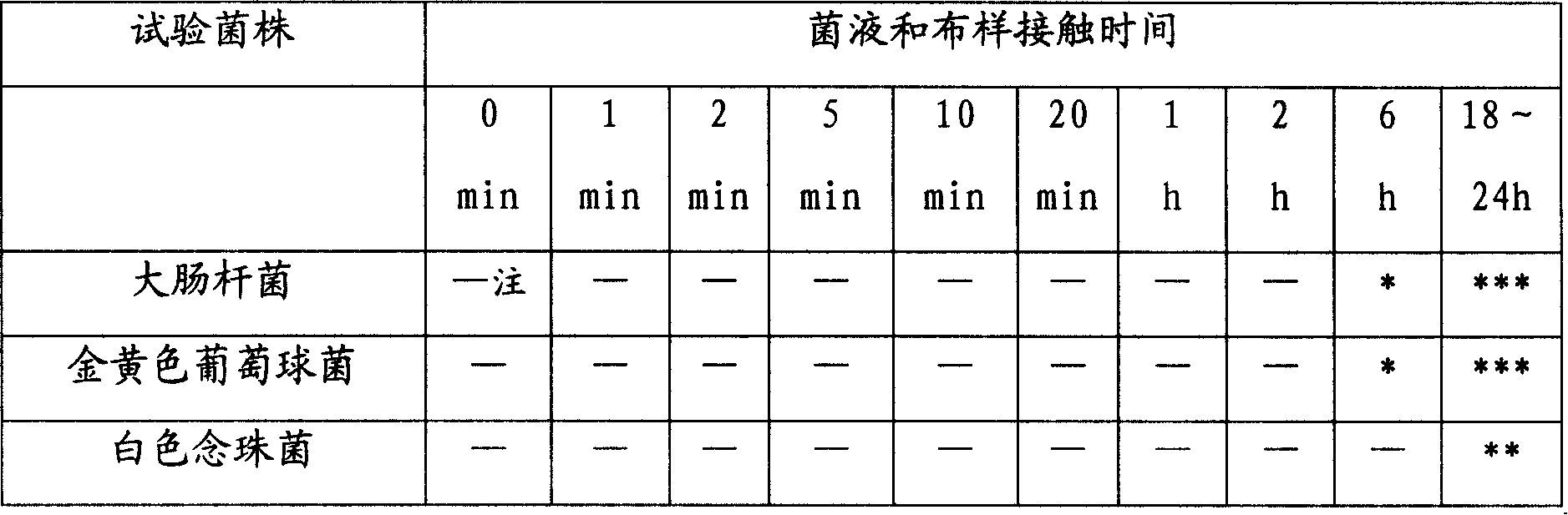

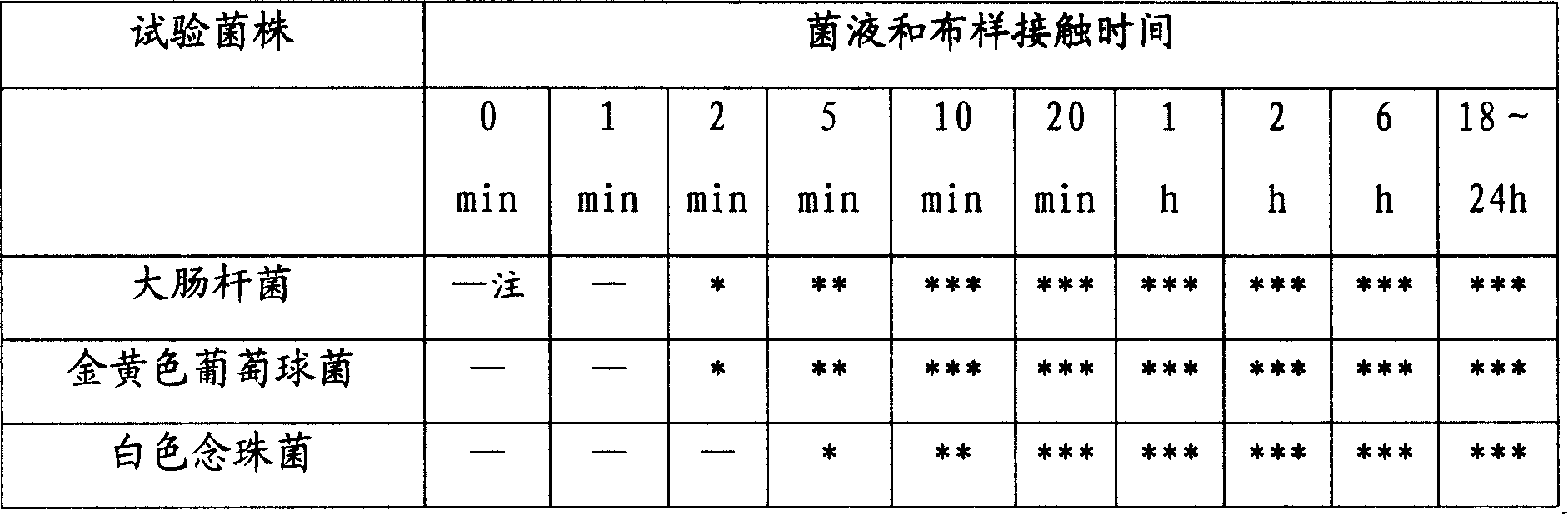

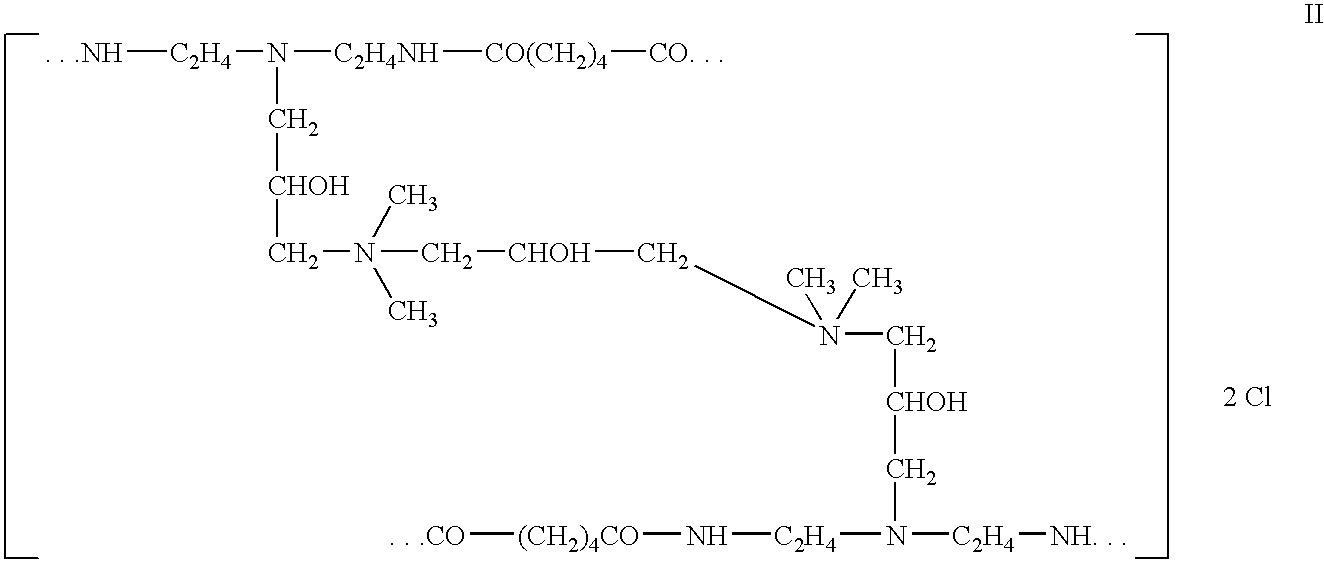

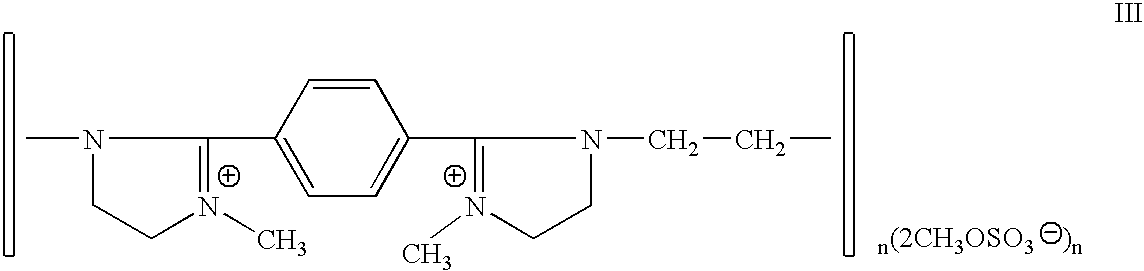

The invention relates to an inorganic / organic nano-composite antibacterial and application of fiber product thereof. 0.01-20 proportions of inorganic antibacterial, 0.01-35 proportions of organic antibacterial, 0.0001-0.4 proportion of inorganic / organic antibacterial compatibility finishing agent, 0.05-40 proportions of macromolecule bond, 0.0001-0.4 proportion of stabilizer that prevents color change of the inorganic antibacterial, 0.1-30 proportions of high efficiency emulsifying agent and 100 proportions of distilled water are added in sequence by weight proportion, wetted, dispersed, ground, dispersed at high-speed, stirred, etc., so as to acquire the nano-composite antibacterial. The antibacterial can process the fiber product by a dip-dye method, a roll-dye method, a spray method, etc. Dresses, socks and socks, blankets, beddings, gowns, patient wears, masks, medicinal gauzes, air filtering nettings, etc., made from the inorganic / organic nano-composite antibacterial of the invention are characterized by high antibacterial efficiency, rapid antibacterial function, long lasting antibacterial performance, laundering durability, etc., and the inorganic / organic nano-composite antibacterial of the invention is applicable to life, medical care, etc., and has the functions of preventing the occurrence and transmission of diseases, protecting the health of people and improving life quality.

Owner:BEIJING CHAMGO NANO TECH

Method for preparing loading functional oxide porous carbon

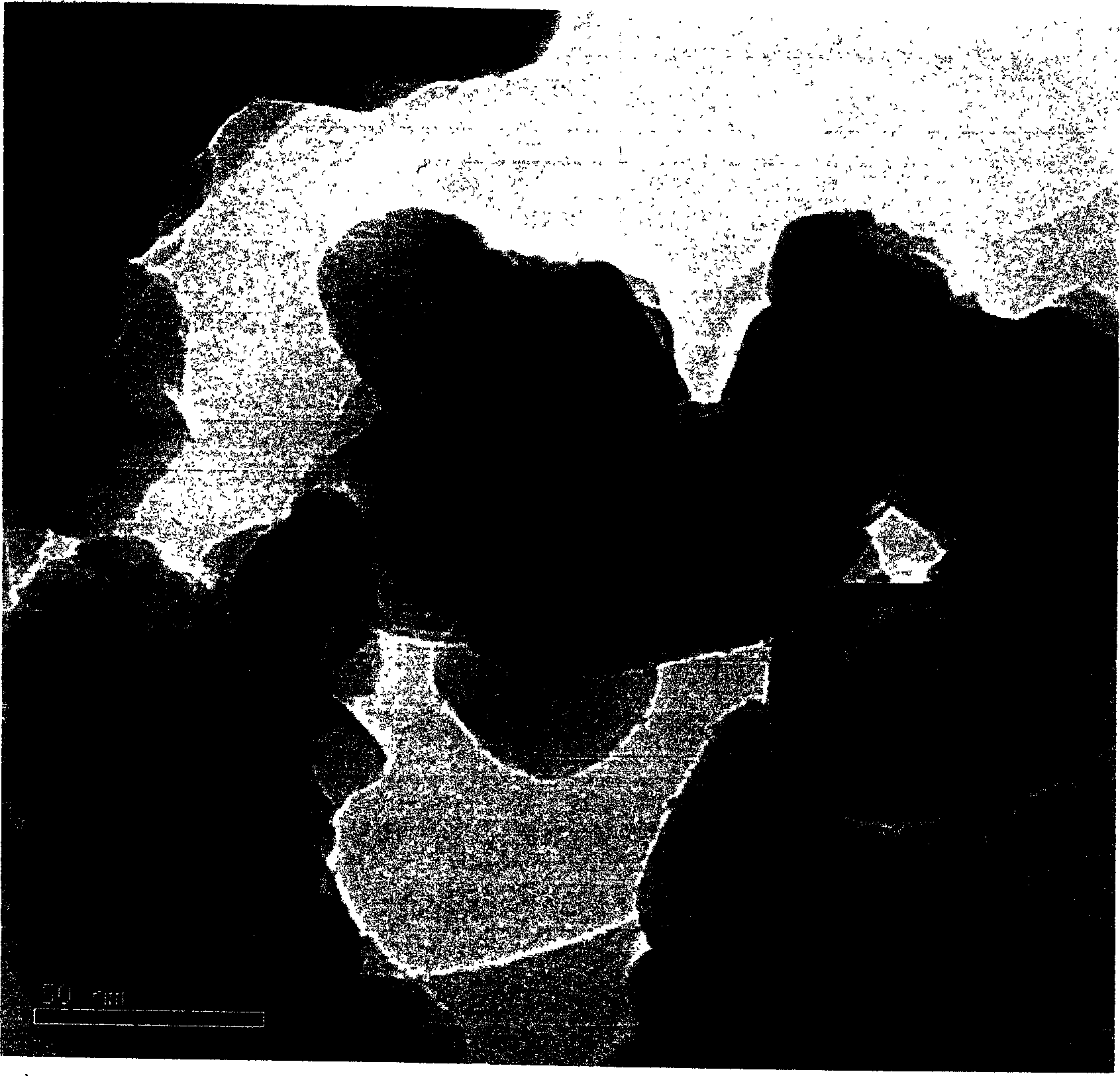

InactiveCN101780952AThe shape is fine and differentFine and varied structureOther chemical processesBy adsorptionPorous carbonMaterials science

The invention relates to a method for preparing a loading functional oxide porous carbon, which belongs to the technical field of carbon material. The method comprises the following steps of: selecting biomass material, and carbonizing at the temperature of 400-1000 DEG C in vacuum or on inert condition; preparing porous carbon by a physical activating or chemical activating process according to the requirement on the pore structure by the carbonized porous carbon; immersing the porous carbon into a precursor solution of an element M, cleaning many times with distilled water, and drying; roasting on the porous carbon at the temperature of 300-1000 DEG C in vacuum or on inert atmosphere, and then the active carbon of the loading functional oxide MxOy is prepared. The active carbon of the loading functional oxide MxOy prepared by the invention has the special pore structure of the biomass, also has the functions performed by the oxides, and has important application value in water treatment, hydrogen storage, photocatalysis, fuel cells and relevant fields.

Owner:SHANGHAI JIAO TONG UNIV

Beverage system, including bubble beverage, instant beverage, beverage with dissolved gas, and beverage with ingredient

InactiveUS20140234488A1Modest expenseTea substituesAlcoholic beverage preparationAdditive ingredientLoment

A beverage system is created having beverage, with at least one liquid. The beverage is created in a variety, including tea drink, coffee drink, milk drink, yogurt drink, malted drink, roasted cereal grain beverage, roasted nut and seed beverage, roasted bean beverage, distilled water, mineral water, sports drink, fruit juice, vegetable juice, fruit drink, vegetable drink, fruit skin drink, vegetable skin drink, plant drink, soft drink, alcoholic drink, and soup drink. The beverage is also created with or without addition of ingredient, including flavoring ingredient, nutritional ingredient, health ingredient, and other ingredient. The beverage can be served as hot drink, cold drink, cold drink with ice, and warm drink. The beverage can be caffeinated, or non caffeinated; and diet or non diet. The liquid includes water, oil, and alcohol. The beverage system is created in various form, including bubble beverage, instant beverage, and beverage with dissolved gas.

Owner:CHANG ALICE

Laundry cleansing and conditioning compositions

InactiveUS6949498B2Effective conditioningCationic surface-active compoundsOrganic detergent compounding agentsPolymer scienceCationic polymerization

Fabric and textile conditioning compositions containing particular combinations of cationic polymers and anionic surfactants are disclosed. The polymers are soluble or dispersible to at least 0.01% by weight in distilled water at 25° C., are preferably below a particular molecular weight to afford optimal cleaning and conditioning, and must be present in an effective amount to yield a substantial conditioning benefit. A method of conditioning articles using the polymer / surfactant combinations is also disclosed.

Owner:HENKEL KGAA

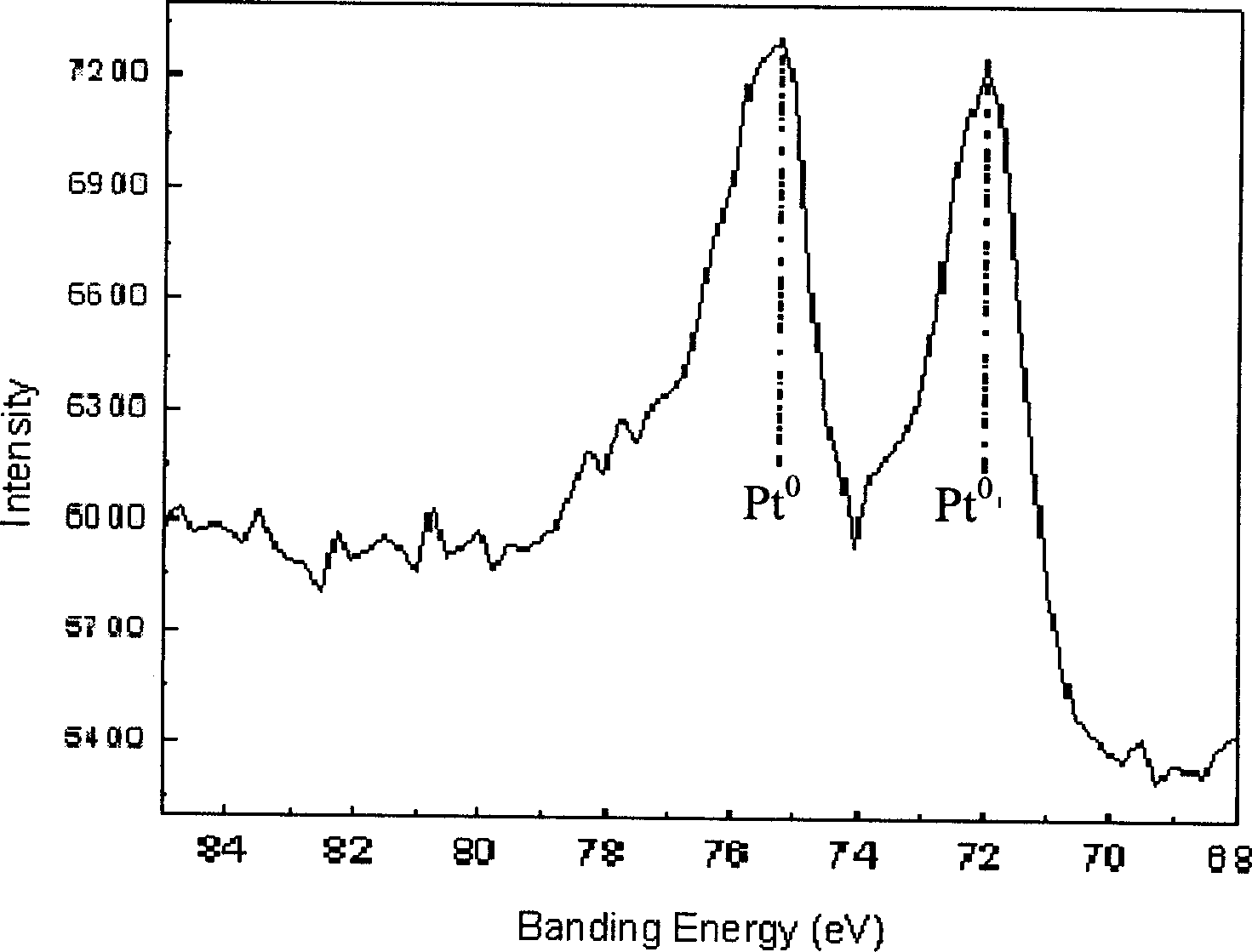

Method for improving catalyst reacting activity in the propylene producing through propane dehydrogenation

InactiveCN101138734AHigh reactivityHigh mechanical strengthMolecular sieve catalystsHydrocarbonsRare earthDehydrogenation

A method to promote the activity of a catalyst for dehydrogenation of propane to propylene is as follows: (1) an inorganic oxide bonding agent, a promoter and an acid solvent are added into a heat-resistant oxide; then after the oxide bonding agent, the promoter, the acid solvent and the oxide are kneaded evenly, the oxide is molded by rolling or band-extruding; (2) the catalyst carrier prepared is dried for 2 to 10 hours under the temperature of 60 centigrade degrees, and calcined under the temperature of 400 to 800 degrees; (3) the calcined carrier is immersed in a rare earth metal water solution under the temperature of 60 to 100 centigrade degrees for 2 to 10 hours; (4) the catalyst carrier modified by the rare earth is immersed in a water solution comprising platinum metal elementsand the fourteenth metal elements under the temperature of 400 to 600 centigrade degrees for 2 to 10 hours, and then the carrier is filtered, washed with distilled water, dried under the temperature of 60 to 180 centigrade degrees for 2 to 10 hours, and calcined under the temperature of 400 to 600 centigrade degrees for 2 to 10 hours; (5) the catalyst prepared is activated in the air under the temperature of 400 to 600 centigrade degrees for 3 to 10 hours, and reduced in a hydrogen flow under the temperature of 400 to 600 centigrade degrees for 2 to 10 hours; the reduced catalyst is used for catalytic reaction for dehydrogenation of propane to propylene.

Owner:SOUTHEAST UNIV

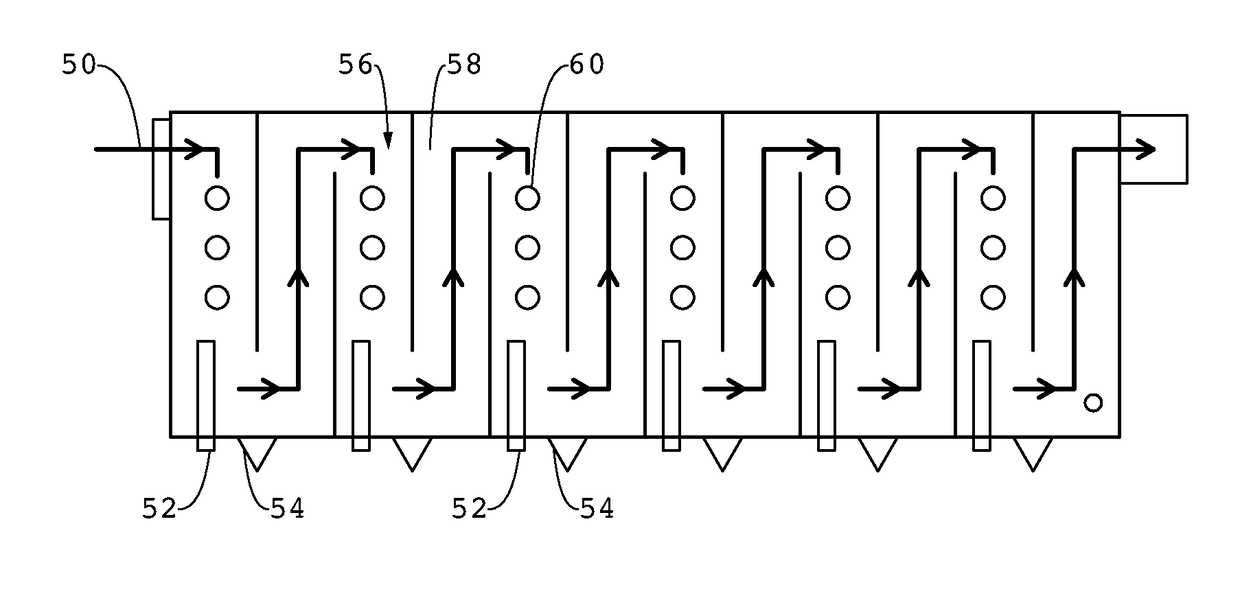

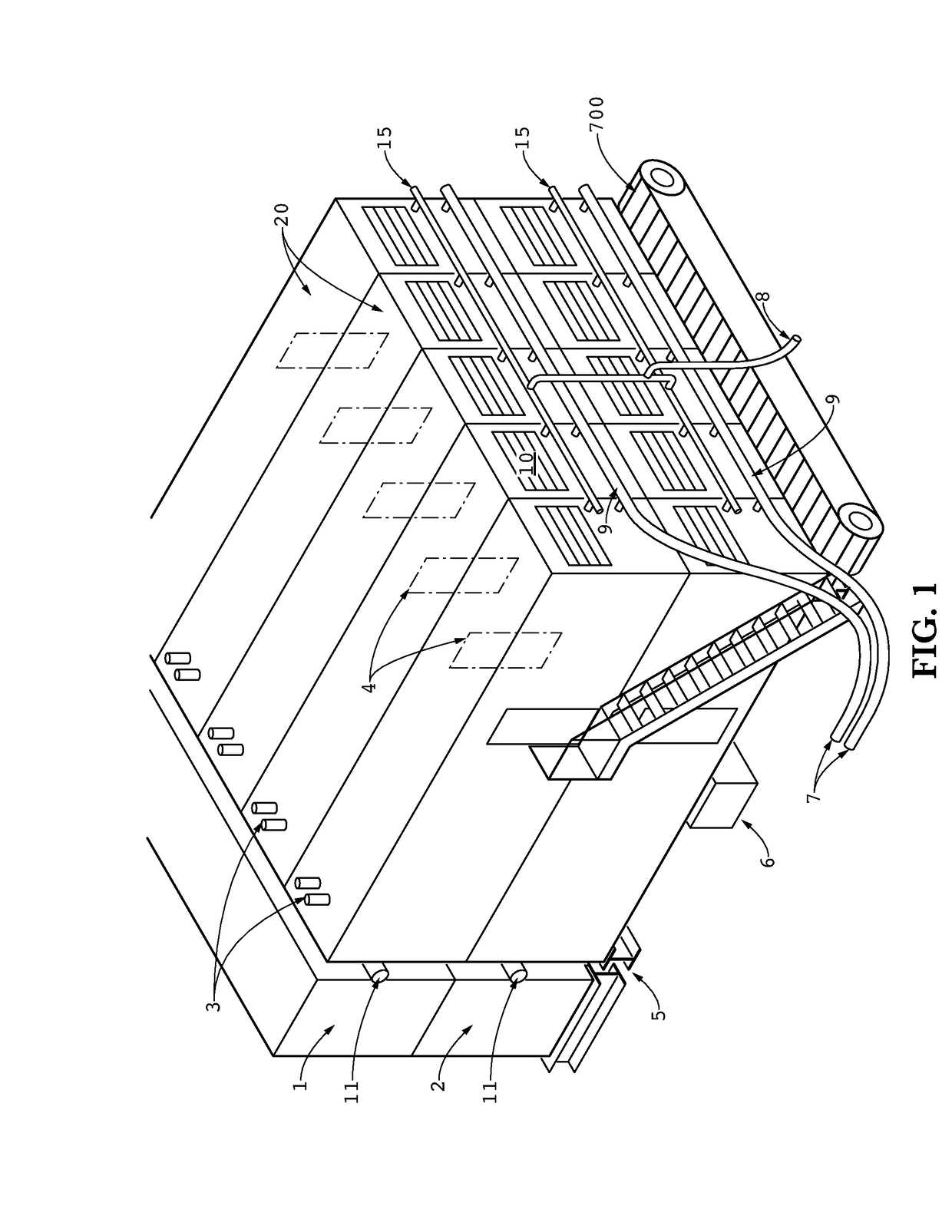

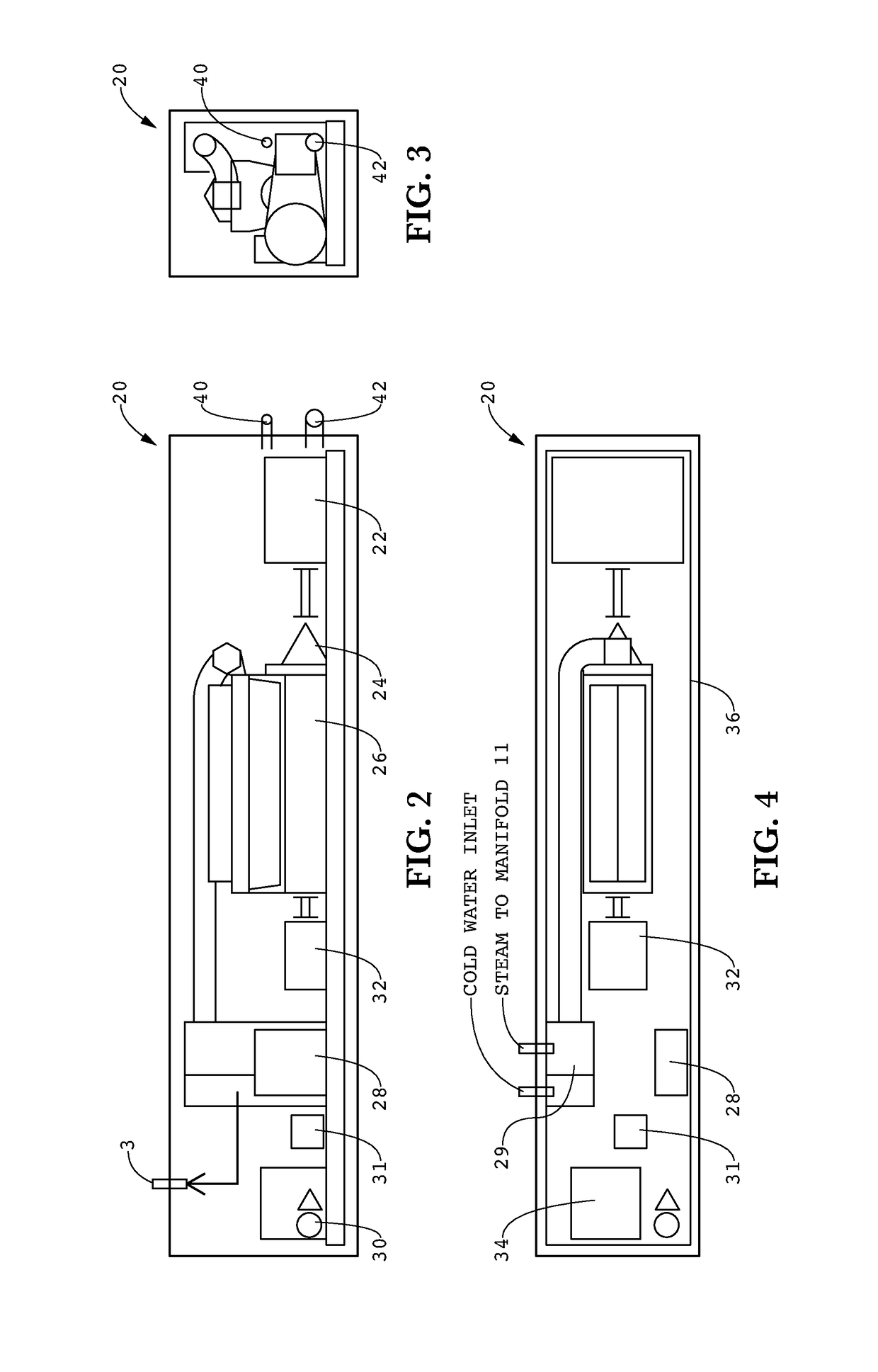

Hydraulic fracturing system and method

ActiveUS9840897B2Multiple-effect/fractional condensationSteam/vapor condensersDistilled waterHydraulic fracturing

Disclosed herein is a fracturing unit for hydraulic fracturing having an engine and a fracturing pump connected to the engine through a variable speed torque converter. Also disclosed is a hydraulic fracturing system using multiple fracturing units which are sized similar to ISO containers. A hydraulic fracturing system may also force flow back water, produced water, or fresh water through a heat exchanger so that heat from the fracturing engines can be transferred to these liquids in order to vaporize them. A force cooled fractioning unit then can accept the vapor / steam in order to condense the various components and produce distilled water for re-use in the fracturing process or for release into the environment.

Owner:LARSON KEVIN

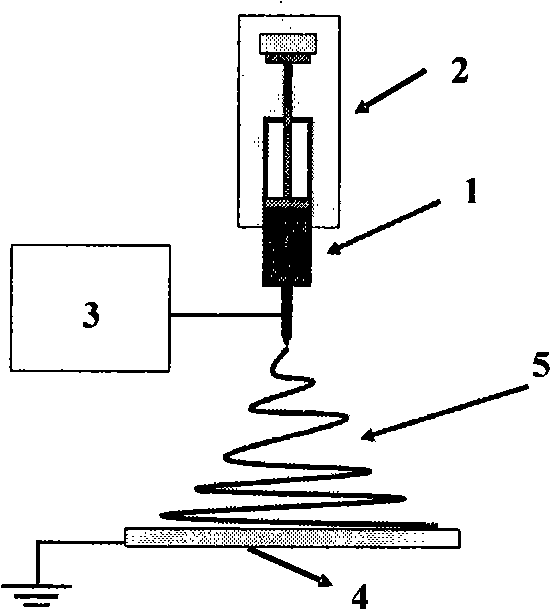

Antibacterial nano fiber material and preparation method thereof

InactiveCN101358382ANo side effects on the human bodyContinuous and stable releaseFilament/thread formingMacromolecular non-active ingredientsFiberSide effect

The invention relates to an antibacterium nano fiber material and a preparation method thereof; the material comprises polymer superfine fiber and antibacterial agent, and the weight ratio is 60 to 98: 2 to 40; the preparation method comprises the following steps: (1) the antibacterial agent is dissolved in distilled water to prepare solution; the polymer superfine fiber is dissolved in methylene dichloride or chloroform organic solvent, emulsifier is added to be mixed evenly, to obtain solution which is dispersed evenly; (2) the two types of solution are mixed to obtain even water-in-oil W / O latex, and then electrostatic spinning is conducted to the latex, to obtain the antibacterium nano fiber material. The nano fiber material has good ventilation property and filterability, still has bacteriostasis and sterilization functions for a long time after stably releasing the antibacterial agent, has simple preparation method, adopts the biodegradable and bioabsorbable polymer as carrier materials, can be absorbed by the human body after fully releasing, is not left, does not need secondary operation and has no side effect.

Owner:DONGHUA UNIV

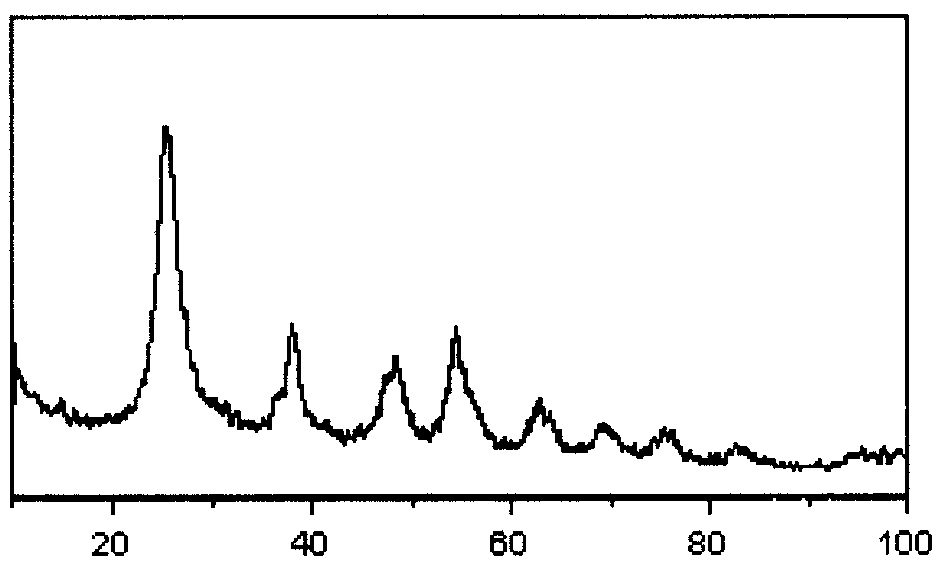

Low-temperature smoke denitration SCR (silicon controlled rectifier) catalyst and preparation method

ActiveCN102114424ARich pore structureLarge specific surface areaDispersed particle separationCatalyst activation/preparationSilicon-controlled rectifierManganese oxide

The invention relates to a low-temperature smoke denitration SCR (silicon controlled rectifier) catalyst, which comprises a carrier, a manganese oxide, and composite oxide of one or more of Ce, Zr, Ti, Co, Fe and Cu, the mass content of manganese is 0.1-66 percent, and the total mass content of the Ce, Zr, Ti, Co, Fe or / and Cu is 0-50 percent; and glass fiber and / or kieselguhr is used as the carrier, wherein the glass fiber of the carrier is calcined for 2-4 hours at temperature of 400-600 DEG C, then placed in a nitric acid, sulfuric acid or hydrochloric acid solution with mass concentration of 5-40 percent for acidizing for 1-8 hours, washed by distilled water to be neutered, dried at temperature of 80-120 DEG C, and crushed to have the fineness of 20-325 meshes. The catalyst uses the glass fiber and the kieselguhr as the carriers, so that the dispersion effect of nanoparticles and specific surface area of the catalyst are increased, the high adsorptive capacity and strong heat resistance and corrosion resistance capacity are achieved, stronger toxic resistance capacity to sulfur dioxide and stream contained in the smoke is realized, the invention can be used for 10-200 DEG C of low temperature smoke denitration, and has strong water resisting and sulphur toxic resisting capacities.

Owner:GUODIAN SCI & TECH RES INST +1

Vegetable capsule of starch composition and preparation method

InactiveCN1687203AWide variety of sourcesNo pollution in the processPharmaceutical delivery mechanismFood preparationPreservativePlasticizer

The present invention relates to a starch composite plant capsule and its preparation method. Said method includes the following steps: uniformly mixing starch or starch composite, dispersing it in distilled water, heating for 15-60 min, at 60-95 deg.c to make starch be fully gelatinated, then adding plasticizer, gel, surfactant, opacifier, edible color matter, preservative, ant-oxidant and enhancer, fully and uniformly mixing them, then decompressing and defoaming, and adopting conventional capsule-forming process to make the obtained colloid liquid into the invented starch composite plant hollow capsule, and its capsule-forming temperature is 40-95 deg.C.

Owner:TIANJIN UNIV

Dressing material containing medicine chitoholosida and its preparation method

InactiveCN1579559AHas therapeutic effectSustained releaseAbsorbent padsBandagesSolid componentPhosphate

The invention produces polyethylene alcohol hydrogel dressing containing medicine and chitosan with 60Co gamma-radial or high energy electron beam radial cross linking. Additional, adds in some humectant, plasticizer, medicine, the solvent is the secondary distilled water, physiological saline or phosphate neutral buffer liquid. The product can release medicine slowly and has natural amylose chitosan with biology sterilization activity, it has active sterilization function, at the same time, it has high water quantity, and good water reserving performance, the mechanical intensity is moderate, and the light penetration and air penetration are excellent. It can accord the demands for curing each kind of wound. It can used as the permanent dressing for light skin injuries, and it also can be applied to the temporally close of severe skin organization wound or burn wound.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

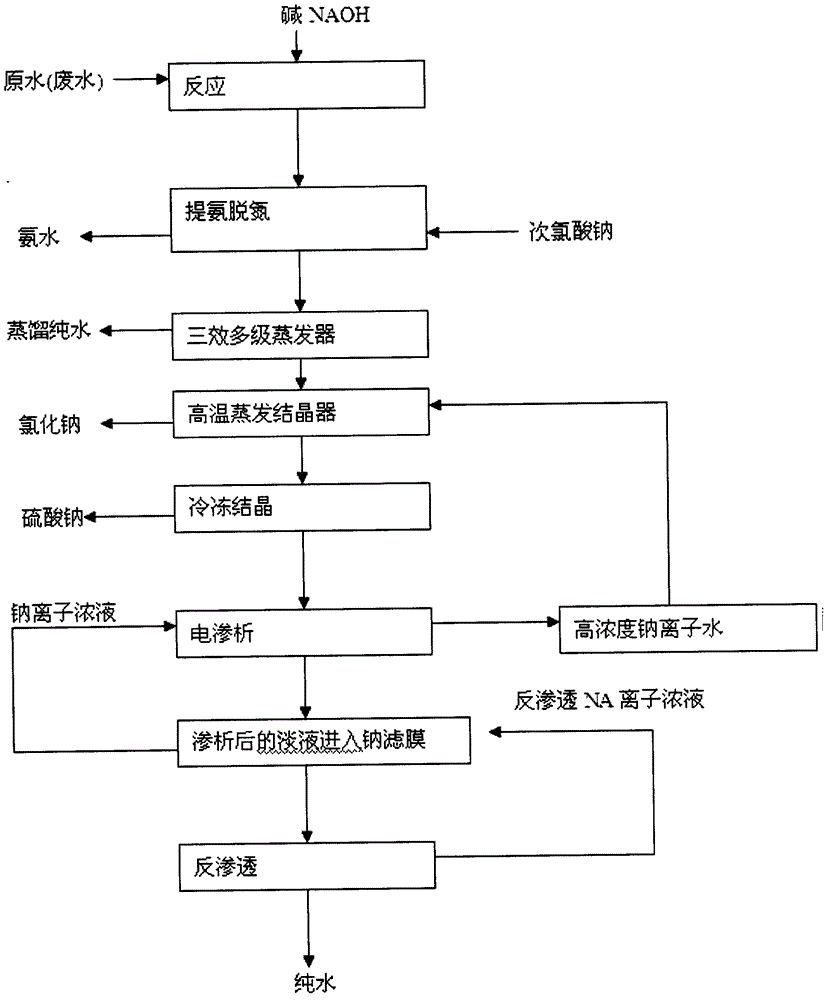

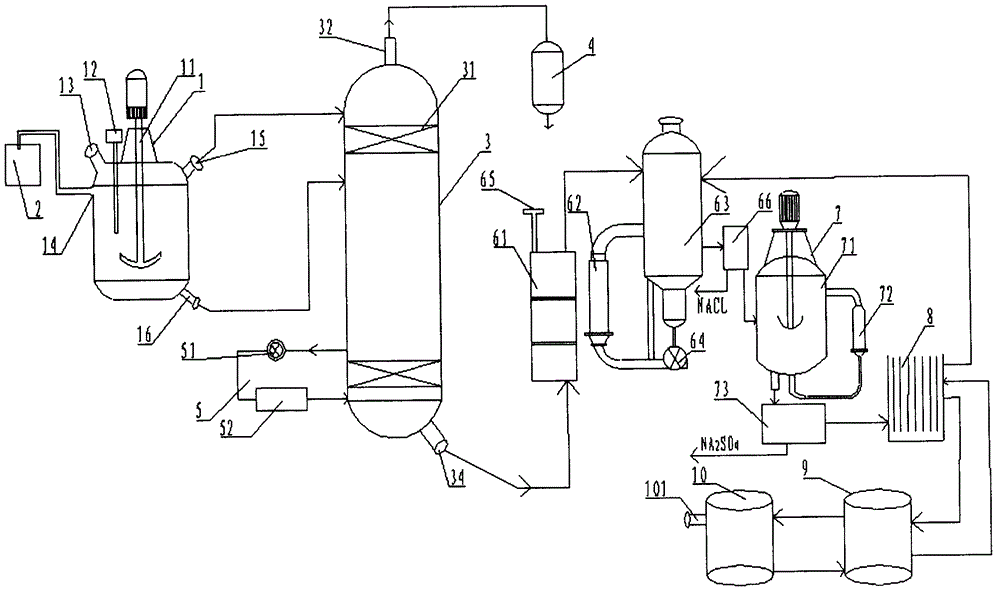

Method and device for utilizing sewage containing ammonia and sodium

ActiveCN104609633AReduce energy consumptionSave energyWater contaminantsMultistage water/sewage treatmentResource utilizationReverse osmosis

The invention discloses a method and device for utilizing sewage containing ammonia and sodium. The method comprises the steps of deamination reaction, denitrification reaction, gas-liquid separation, triple-effect multistage evaporation, evaprative crystallization and freezing crystallization, electrodialysis and sodium filteration membrane, and concentration of reverse osmosis membrane, so that distilled water and membrane deion pure water are recovered, and the resource utilization of sole sodium chloride and sodium sulfate is realized.

Owner:RUANSHI CHEM CHANGSHU

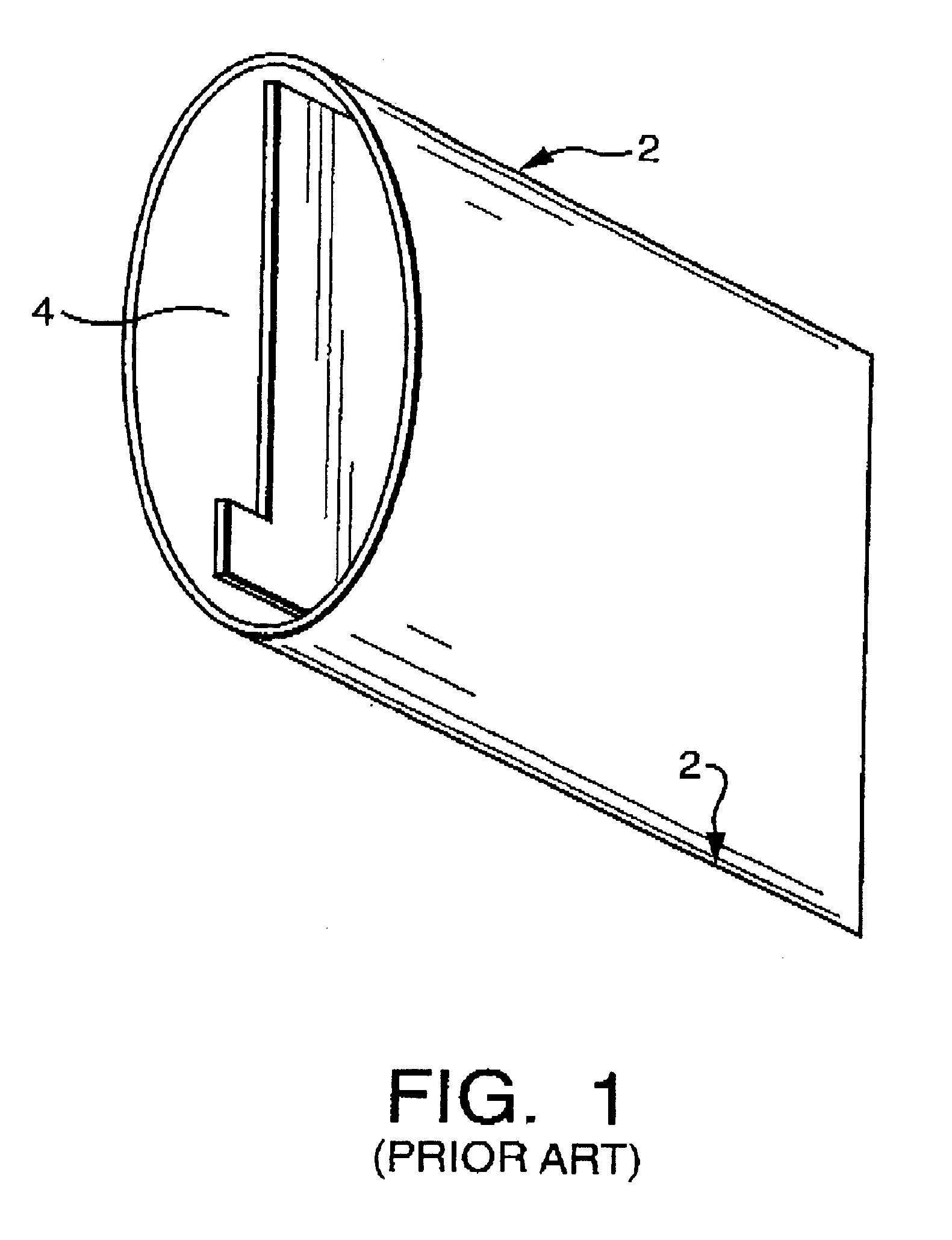

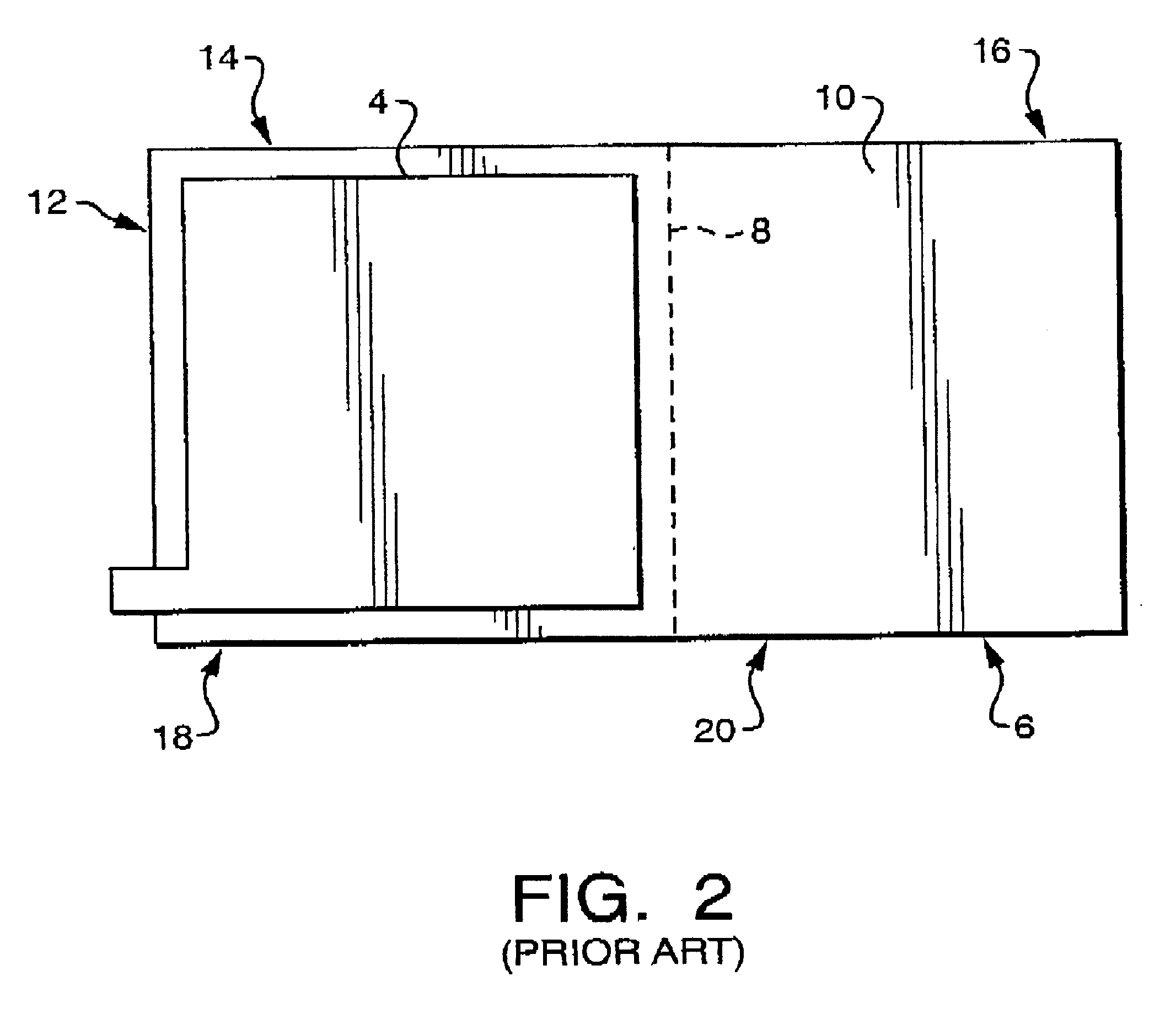

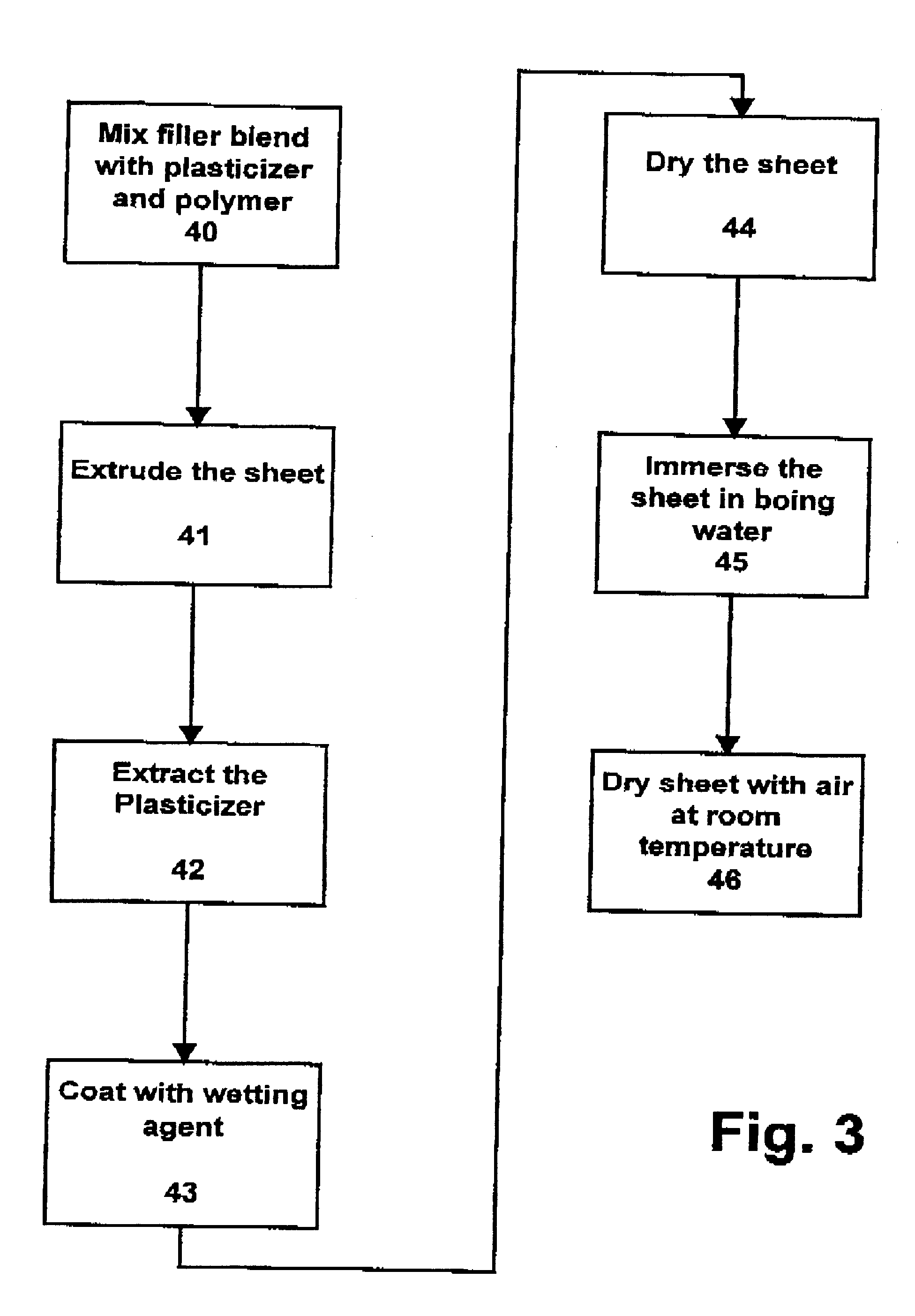

Microporous membrane battery separator for silver zinc batteries

InactiveUS6372379B1Improve cycle lifeExtended calendar lifeSilver accumulatorsCell component detailsPolyolefinFuel oil

A separator membrane for use in silver-zinc batteries is produced by extruding a blend of two fillers with the same chemical formula but different particle size. A polyolefine polymer and a plasticizer are blended and extruded to form a thin sheet of 1 to 10 mil thickness. The plasticizer is then extracted to leave submicron voids in the membrane. Plasticizers are added as processing aids, and can be either soluble or insoluble in water, and include petroleum oils, lubricating oils, fuel oils, and natural oils such as tall oils and linseed oils. The oil are then extracted from the membrane by conventional procedures such as single stage extraction using a suitable solvent. Commercially available wetting agents known to the art such as dodecylphenoxy polyethoxy ethanol and isooctyl phenyl polyethoxy ethanol are coated onto the sheet to improve wettability. The sheet is then dried, and boiled in distilled water for one minute or more, before being finally dried.

Owner:ZPOWER LLC

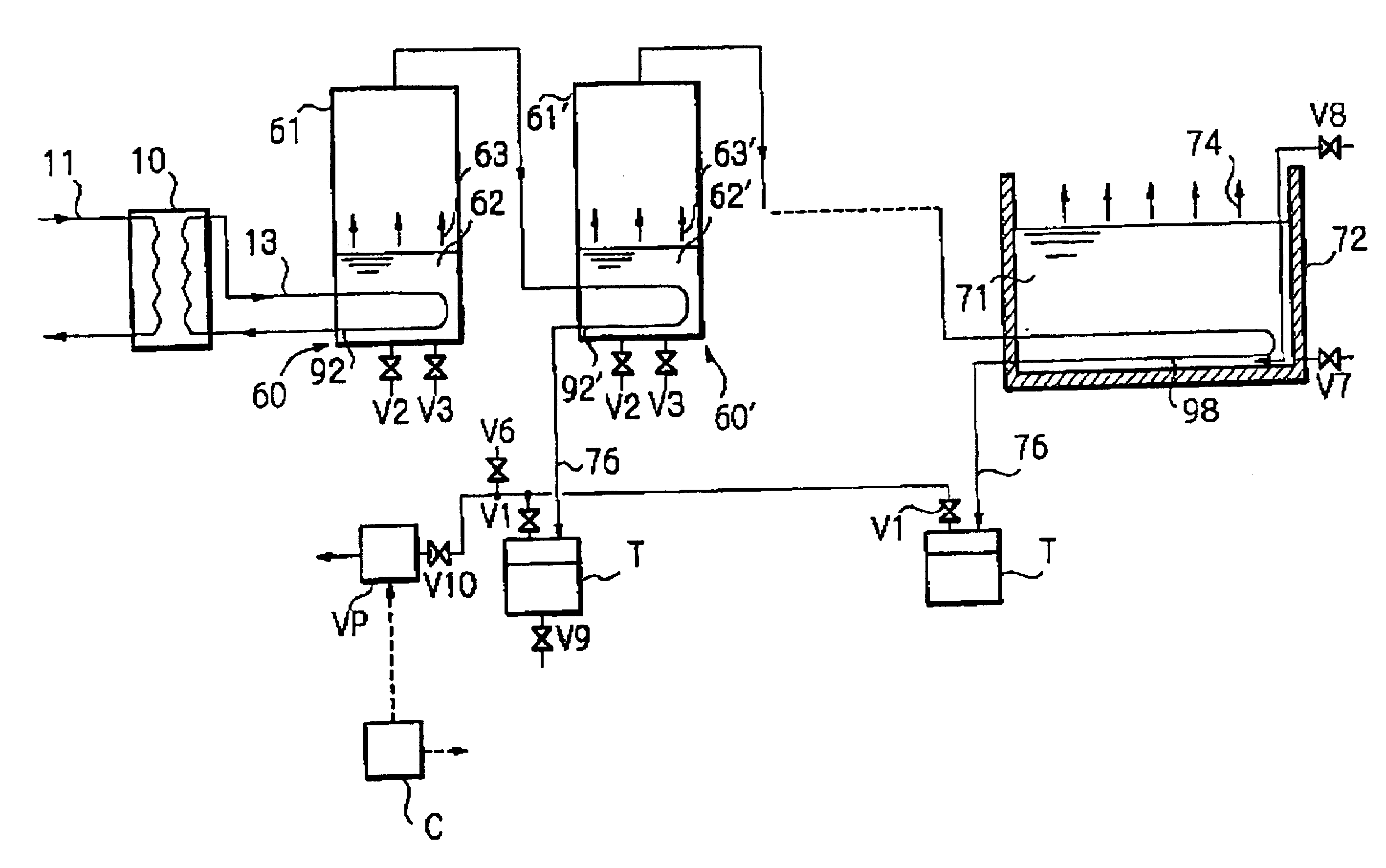

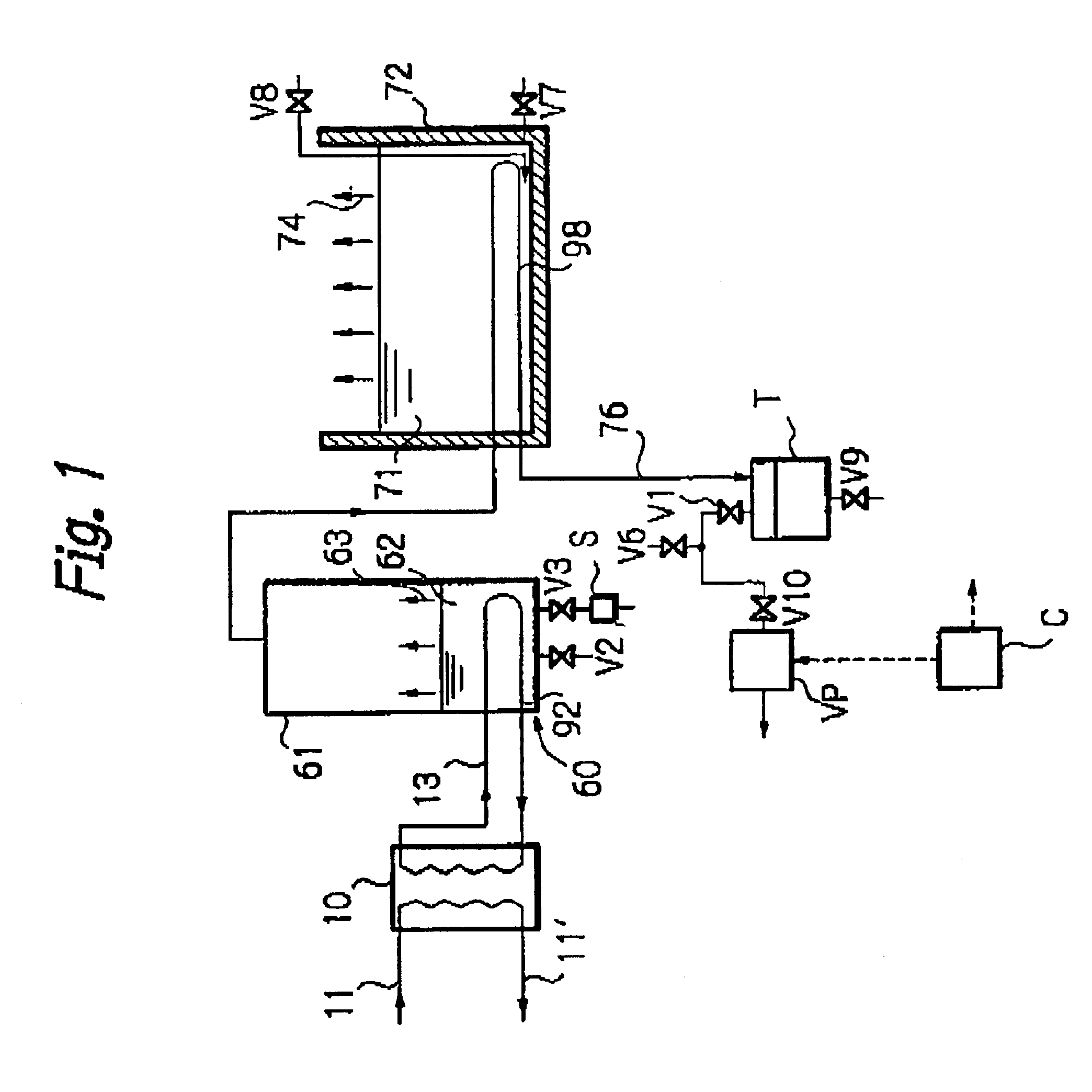

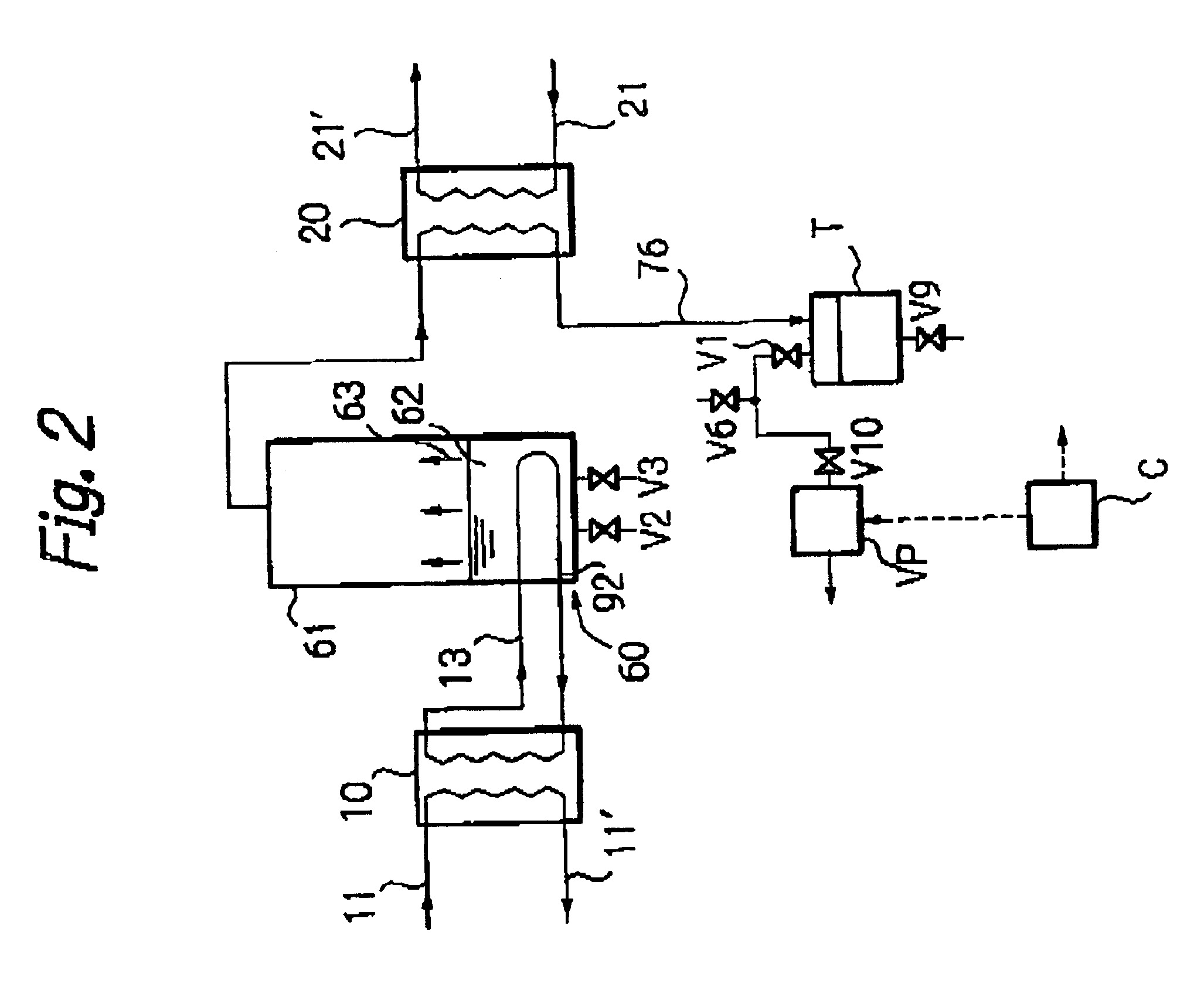

Desalination method and desalination apparatus

InactiveUS6833056B1Number of stage increasingIncrease the number ofAuxillariesGeneral water supply conservationDesalinationDistilled water

A desalination apparatus capable of obtaining fresh water stably at low cost by utilizing low-temperature waste, wherein the desalination apparatus including a heat exchanger 92 cooperating with an evaporation can 60 so as to subject a low-temperature waste heat 11 and raw water 62 in the evaporation can 60 to heat exchange and generate water vapor 63 in the evaporation can 60; a condenser 98 cooperating with a raw water tank 72 so as to receive the water vapor 63 from the evaporation can 60, cool the water vapor 63 by subjecting the water vapor 63 and raw water 71 in the raw water tank 72 to heat exchange and obtain distilled water 76; a distilled water tank for storing the distilled water 76; vacuum means for evacuating the evaporation can 60 and depressurizing the inside thereof so as to promote generation of water vapor 63 in the evaporation can 60; and raw water supply means for supplying raw water to the evaporation can.

Owner:EBARA CORP

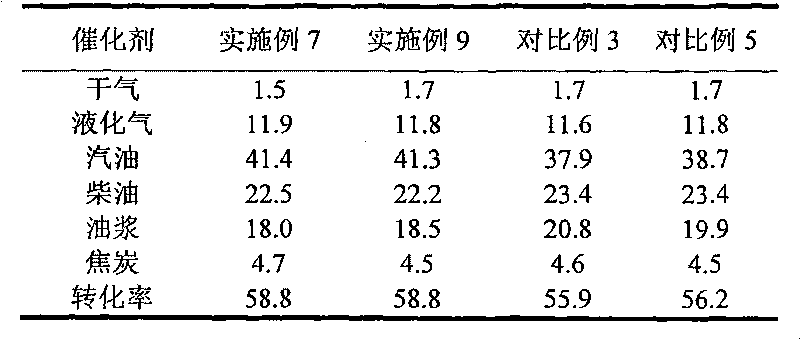

Alkali treatment modifying method of Y-shaped molecular sieve

ActiveCN101722022ALarge adsorption capacityImprove ion exchange efficiencyMolecular sieve catalystsMolecular sieveMass ratio

The invention provides an alkali treatment modifying method of a Y-shaped molecular sieve, which comprises the following steps of: beating and uniformly mixing the Y-shaped molecular sieve and a strong alkali aqueous solution according to the mass ratio of the molecular sieve, a strong alkali and distilled water as (0.1-2): (0.05-2): (4-15), and carrying out alkali treatment for 0.1-24 hours at the temperature of 0-120 DEG C; compared with a parent Y-shaped molecular sieve, the obtained molecular sieve has the advanced performance of higher N2 adsorptive capacity, larger water absorbing capacity and the like. On the basis of modified treatment, the invention also provides a preparation method of an NH4 molecular sieve and an ultrastable Y-shaped molecular sieve, which comprises ammonium exchange treatment and hydrothermal ultrastable treatment implemented for a modified NaY molecular sieve after alkali treatment, and the obtained NH4 molecular sieve has lower metallic ion residues; an obtained USY molecular sieve has more abundant secondary holes while keeping high degree of crystallinity, thereby improving the catalytic activity of the USY molecular sieve.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

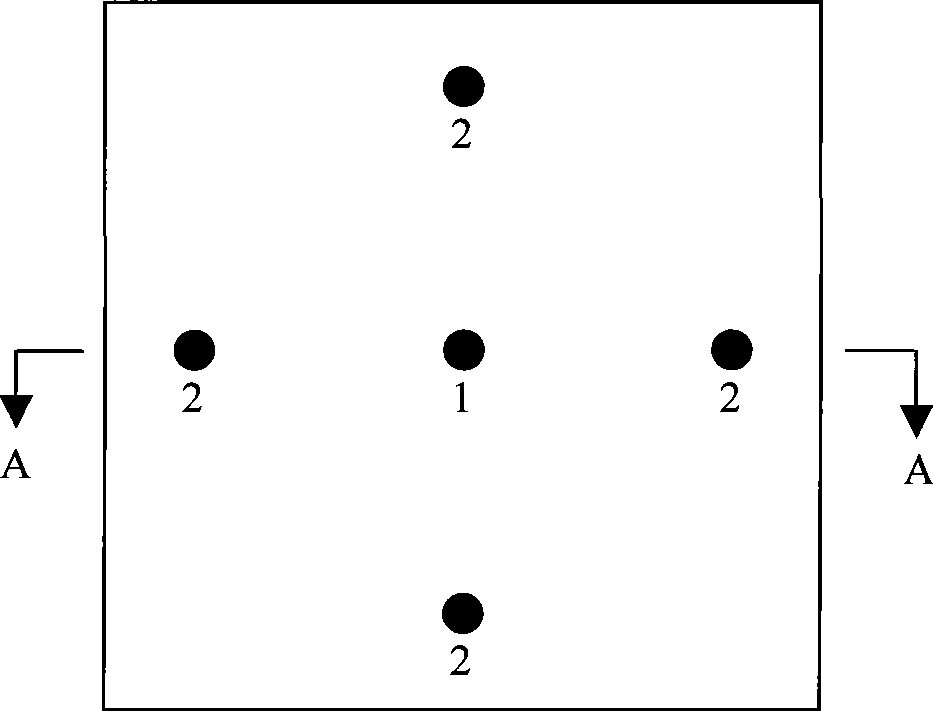

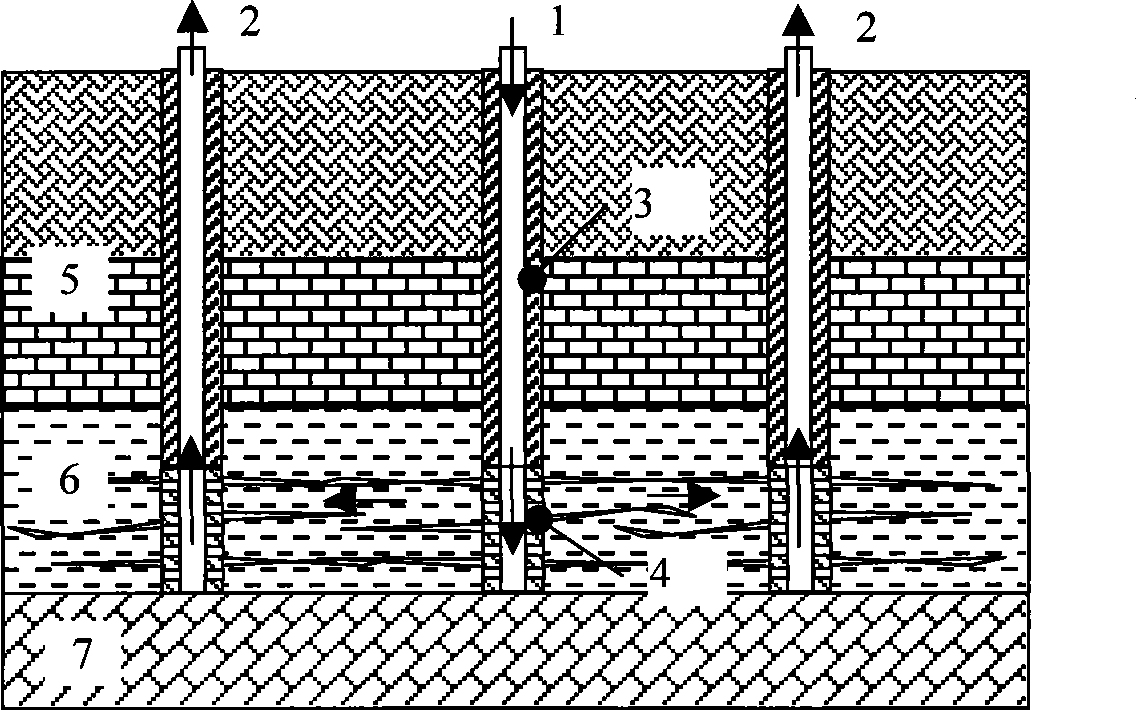

Method for pumping coalbed gas by heating coal bed

ActiveCN101418679AAchieve separationEfficient extractionFluid removalGas removalWater vaporDistilled water

Provided is a method for heating coal seam and extracting coal seam gas. Firstly, a plurality of vertical wells are drilled from the ground to the coal seam, after the drilled well reached to the coal seam, the coal seam is inserted with a screen tube casing (4), the section above the coal seam is inserted with a heat insulation casing (31) and the well is correspondingly fixed. At least one well of the wells is selected to be a heat source injection well (1) and other wells are gas production wells (2), steam with high temperature and high pressure is injected into the heat source injection well (1) to perform fracturing to communicate all the wells in the network. Drainage and pressure reduction are performed to the gas production wells (2) to extract the mixed gas of the coal seam gas and steam. The mixed gas of the coal seam gas and steam is cooled by known cooling method so as to obtain gaseous coal seam gas and liquid distilled water to realize the separation of the mixed gas. According to the change of the coal seam temperature, the heat source injection well (1) and the gas production wells (2) are allocated to control the heated coal seam and extract coal seam gas. The method of he invention can effectively perform the extraction of the coal seam gas, accelerate the coal seam extraction speed, and improve the extraction rate.

Owner:TAIYUAN UNIV OF TECH

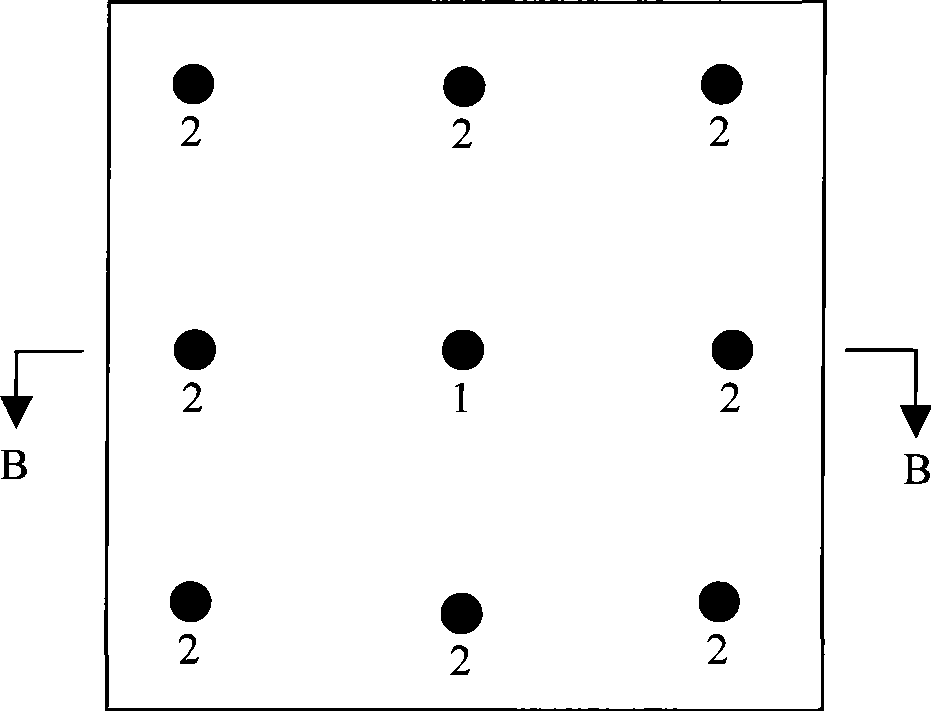

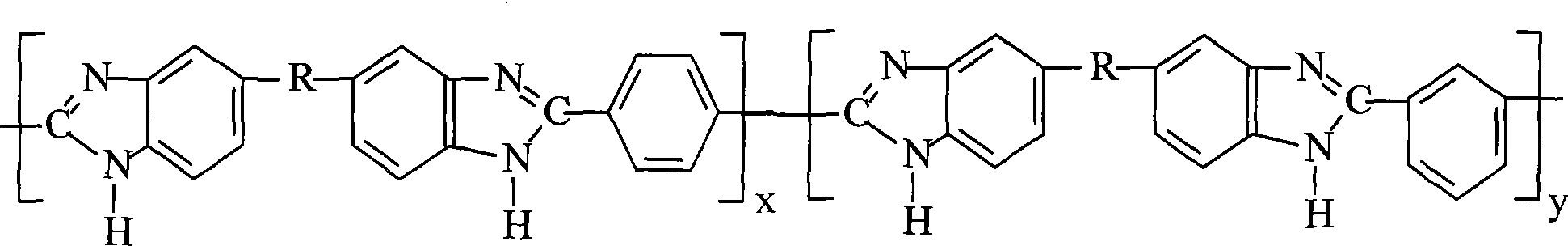

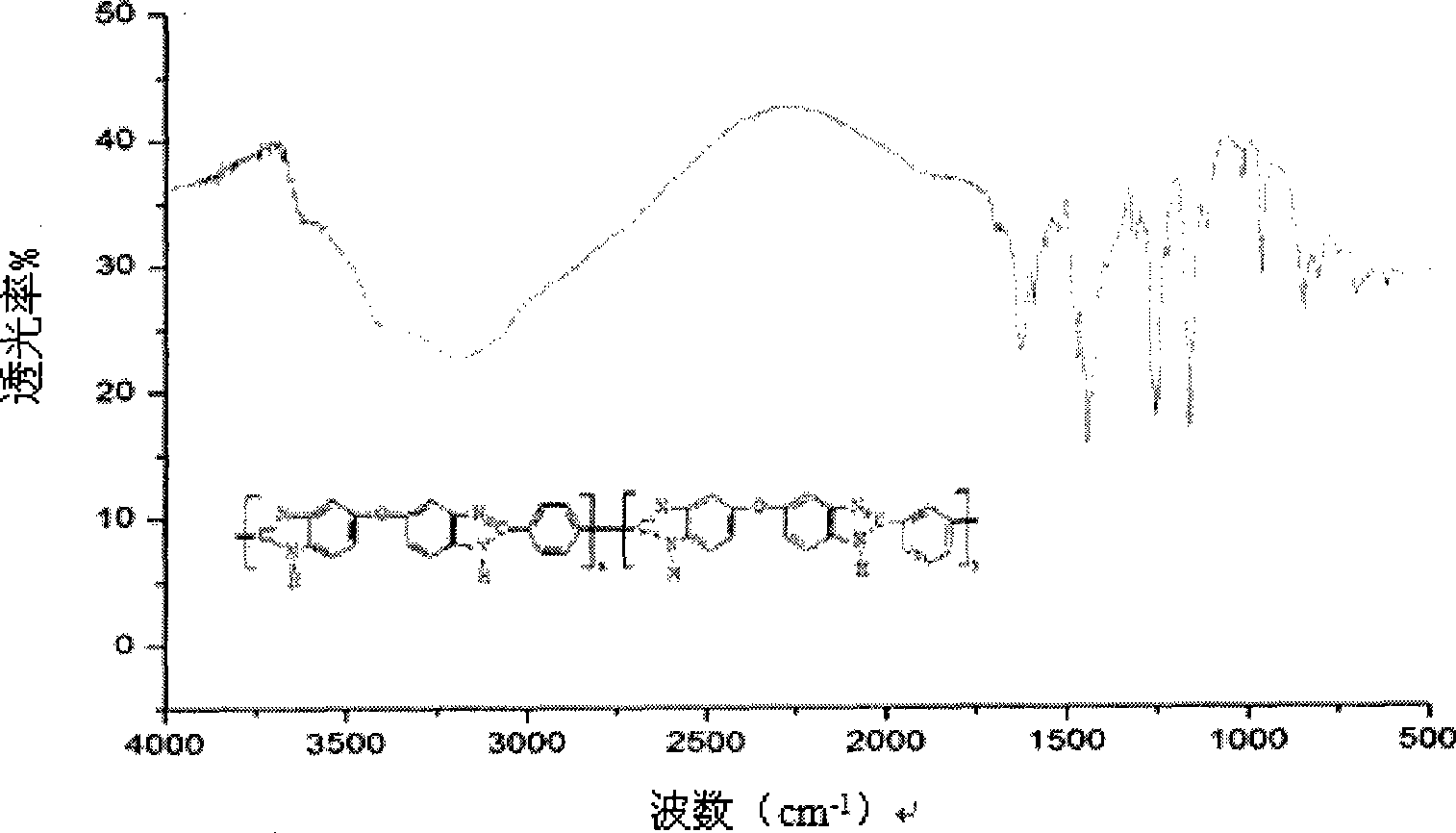

Method for preparing aromatic polybenzimidazole resin film

InactiveCN101456964AHigh molecular weightImprove thermal stabilitySemi-permeable membranesCell component detailsSolubilityNitrogen gas

The invention relates to a preparation method for aromatic series polybenzimidazole resin film, comprising: (1) under function of polyphosphoric acid / phosphorus pentoxide system, condensation polymerization reaction is carried out to aromatic series amine and aromatic series dicarboxylic acids mixed according to mol ratio of 1:1 in nitrogen atmosphere; (2) after cooling, polymer is poured into water and broken down into powder in a resin pulper and washed over and over again by distilled water and soaked for 48 hours in NaHCO3 solution and washed till pH value shows neutral and drawn and filtered for drying in vacuum; (3) the polymer dried is dissolved in even solution prepared by organic solvent with mass percent of 5 percent, and then is dried at temperature of 130 DEG C for 12 hours, and is soaked in hot water for boiling and striping, and is dried in vacuum at temperature of 100 DEG C for 5 hours and then is obtained. The polybenzimidazole prepared by the invention has the advantages of big molecule weight, stable thermal stability, fine solubility and film forming performance, etc. The preparation has simple technology, low cost, convenient operation and can be finished in common equipments through preparation procedure.

Owner:DONGHUA UNIV

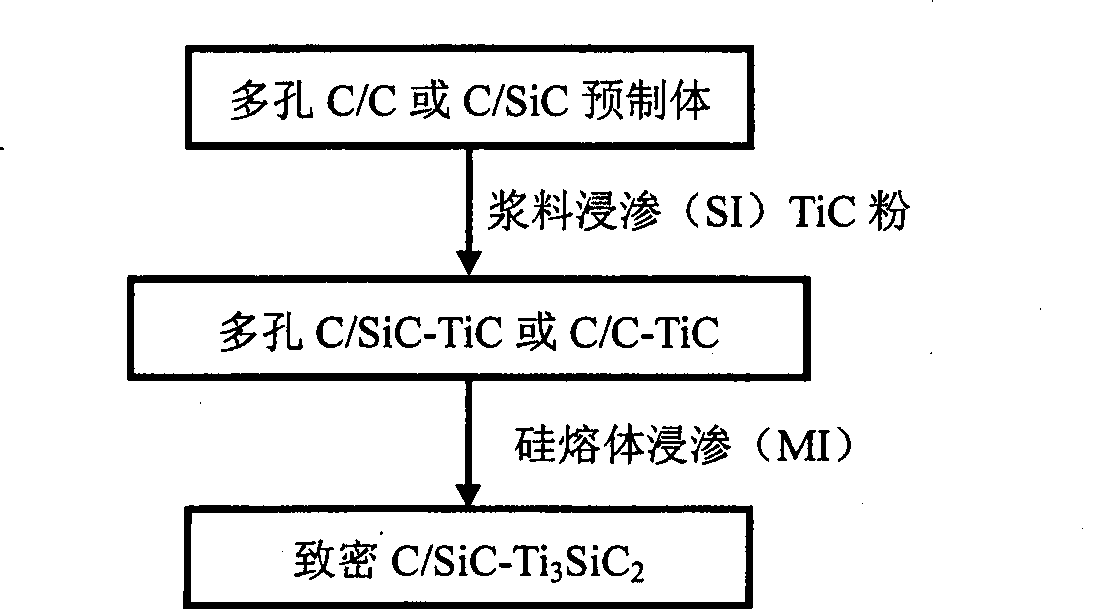

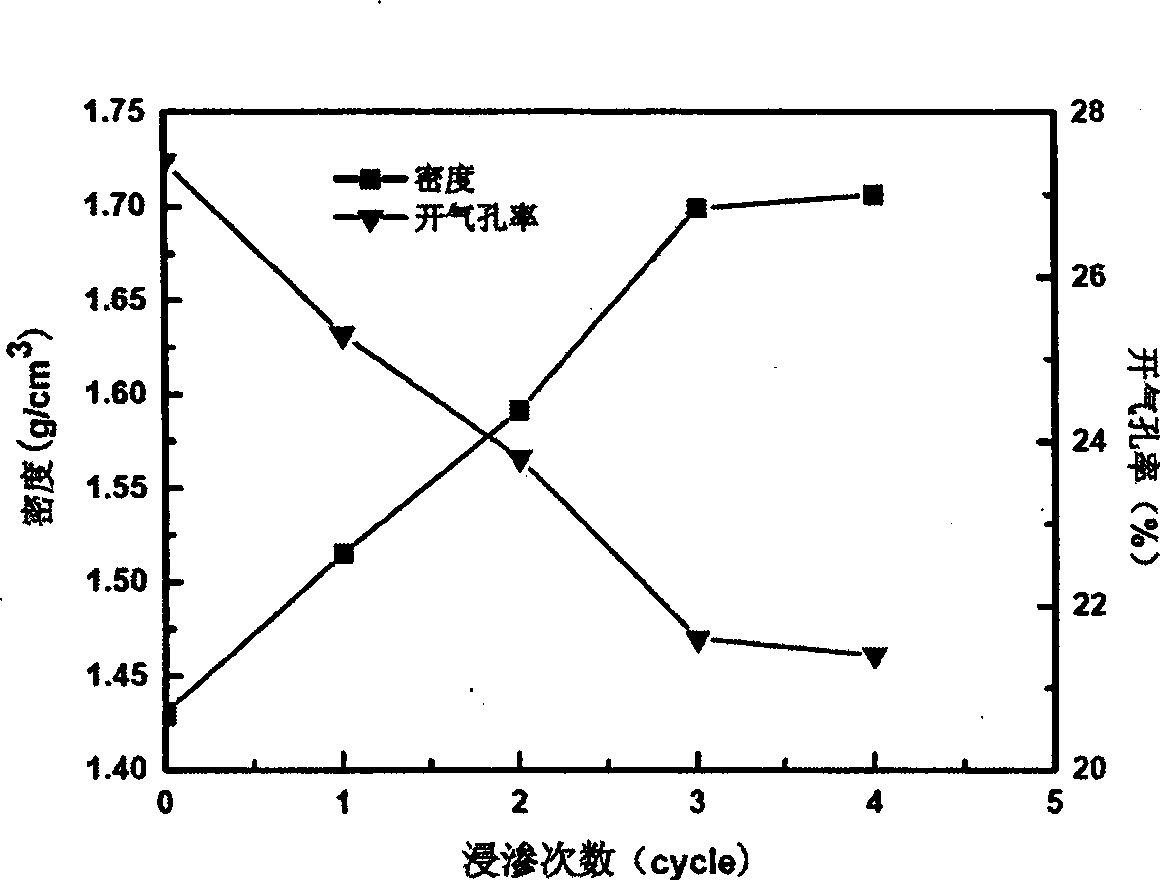

Process for producing composite material of Ti3SiC2 modified C/SiC

The invention discloses a method for preparing Ti3SiC2 modified C / SiC composite material, comprising the following steps: firstly, carrying out ultrasonic cleaning and drying on the pre-prepared body to be modified; compounding the size with distilled water, cellulose sodium carboxy methyl and TiC powder; then carrying out vacuum infiltration combined with pressure infiltration on the pre-prepared body and refrigeration and drying in vacuum; coating industrial silicon powder on the surface of the pre-prepared body; calcining the pre-prepared body in a vacuum furnace to lead the silicon to fuse to penetrate into the pre-prepared body; and cooling the pre-prepared body gradually to room temperature after full reaction in the vacuum furnace. As SI method is adopted to lead C / C or C / SiC composite material to be firstly internally filled with TiC granules, then MI method is adopted to penetrate silicon fusant, and TiC reacts with Si to generate Ti3SiC2 and SiC, the content of residue Si in the composite material is reduced, and the Ti3SiC2 phase in-situ generated in the C / SiC composite material causes the use temperature of the modified C / SiC composite material to rise from 1420 DEG C in the prior art to 1500-2300 DEG C and the fracture toughness property to rise from 8MPa.m in the prior art to 9-16 MPa.m.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

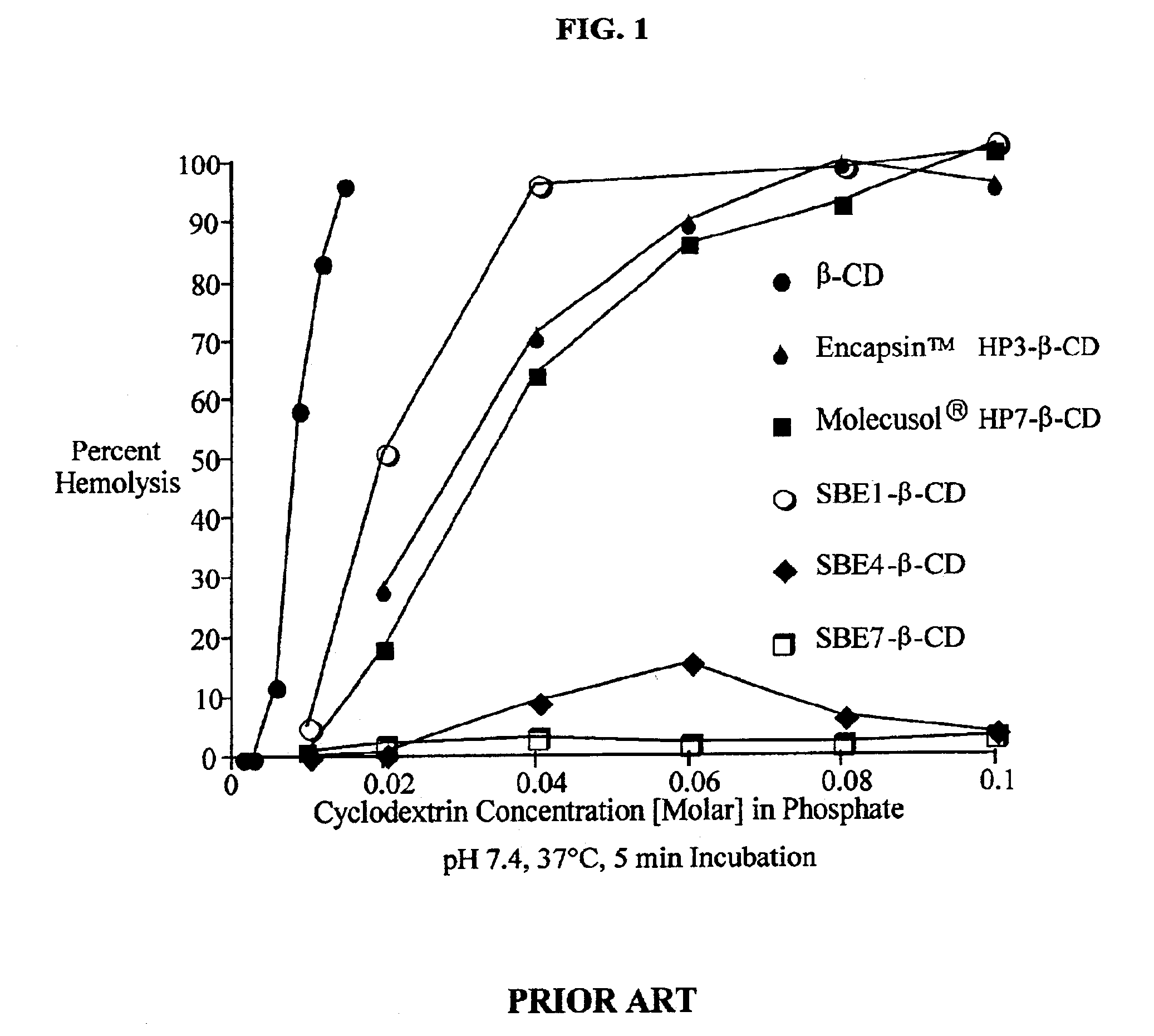

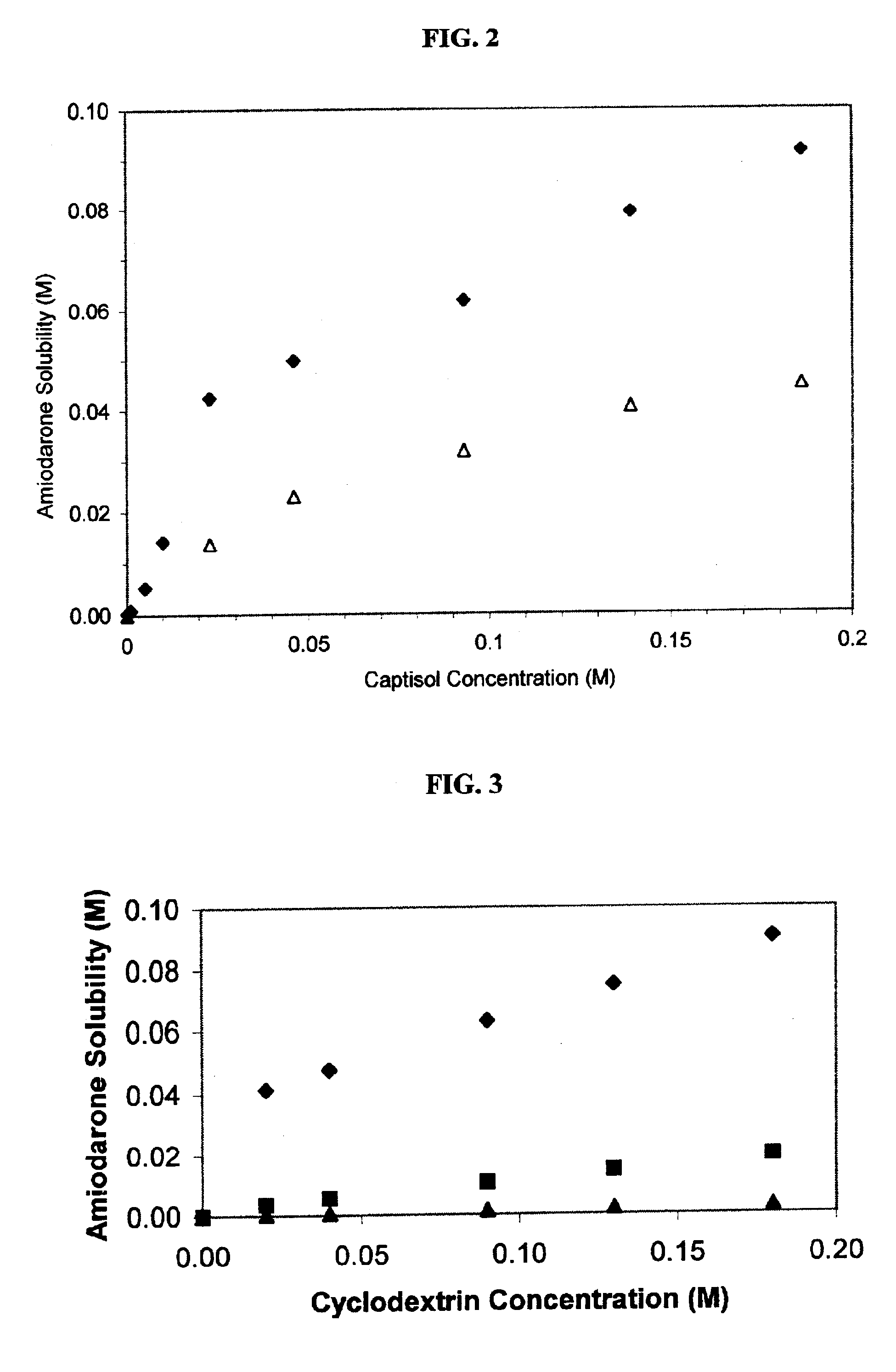

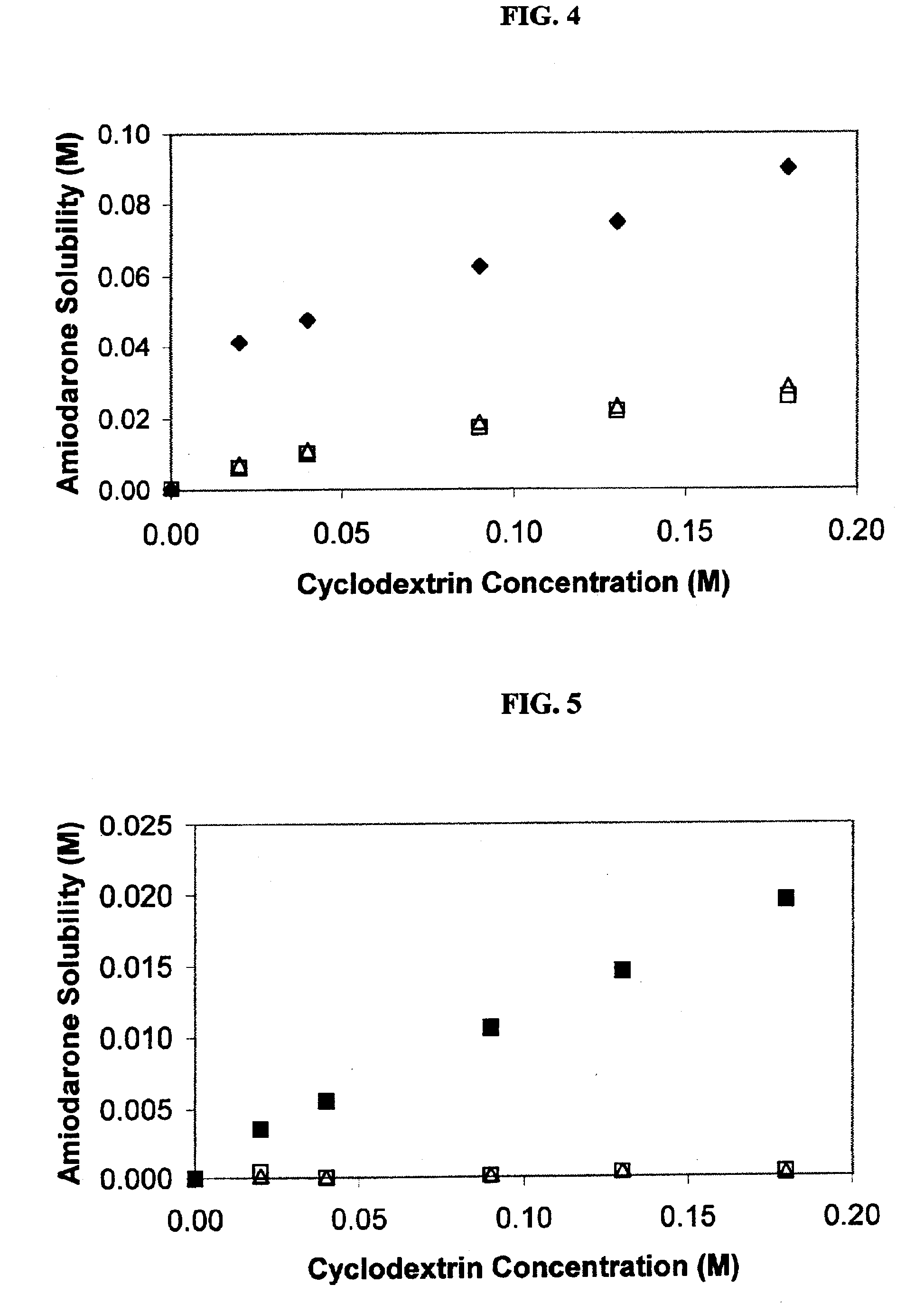

Formulations containing amiodarone and sulfoalkyl ether cyclodextrin

InactiveUS6869939B2Increase surface tensionAccurate doseCompounds screening/testingPowder deliveryCyclodextrinRoom temperature

The present invention provides aqueous parenteral formulations containing an antiarrhythmic agent, such as amiodarone, and a sulfoalkyl ether cyclodextrin. The liquid formulations are clear, sterilizable, and chemically and physically stable. The liquid formulations do not require a surfactant and do not precipitate upon dilution with distilled water or other pharmaceutically acceptable liquid carrier. The sulfoalkyl ether cyclodextrin-containing formulation provides significant advantages over other cyclodextrin-containing formulations of amiodarone. The formulation can be prepared in acidic, neutral and slightly basic medium while providing acceptable concentrations of amiodarone suitable for parenteral administration. An SAE-CD-containing formulation of amiodarone can be provided in liquid form or as a reconstitutable powder. Moreover, highly concentrated solutions exceeding 200 mg of amiodarone per mL can be prepared. Solutions can be made either dilutable or non-dilutable with water at room temperature or under conditions typically encountered in the clinic.

Owner:CYDEX PHARMACEUTICALS INC

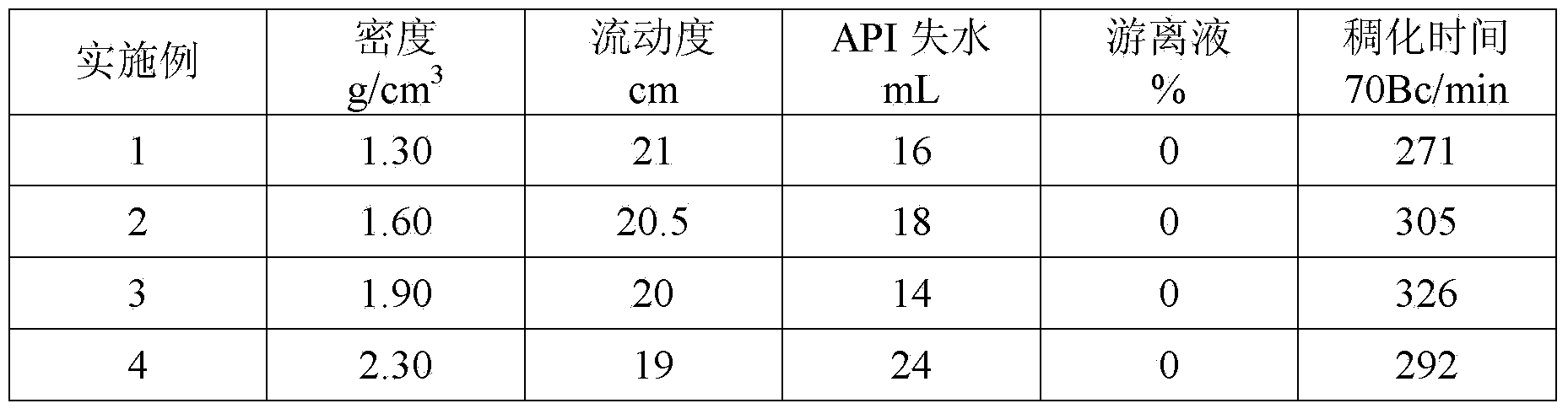

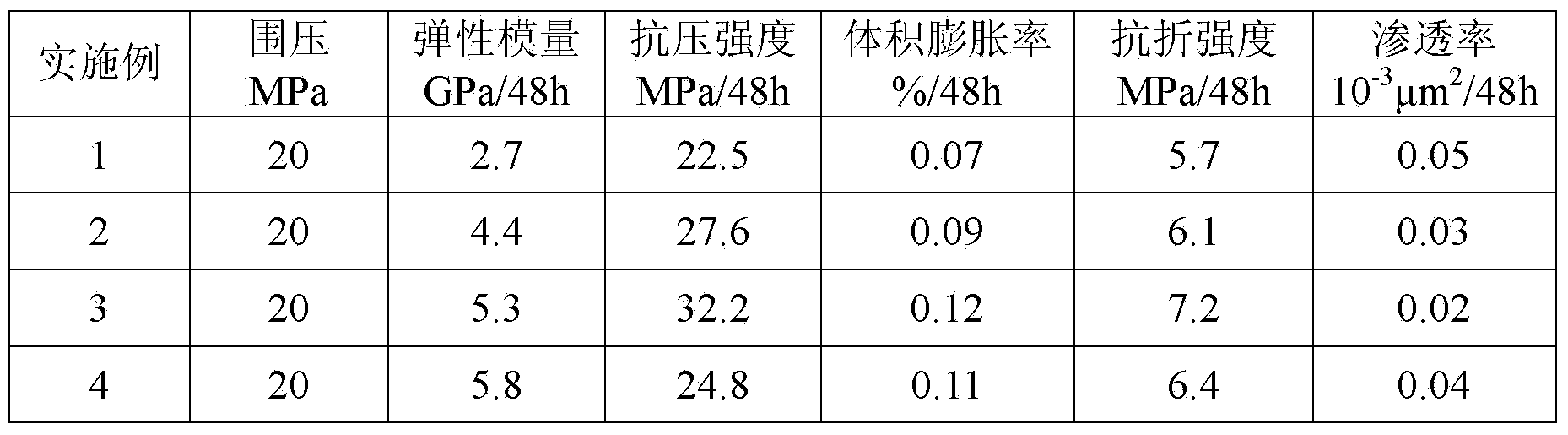

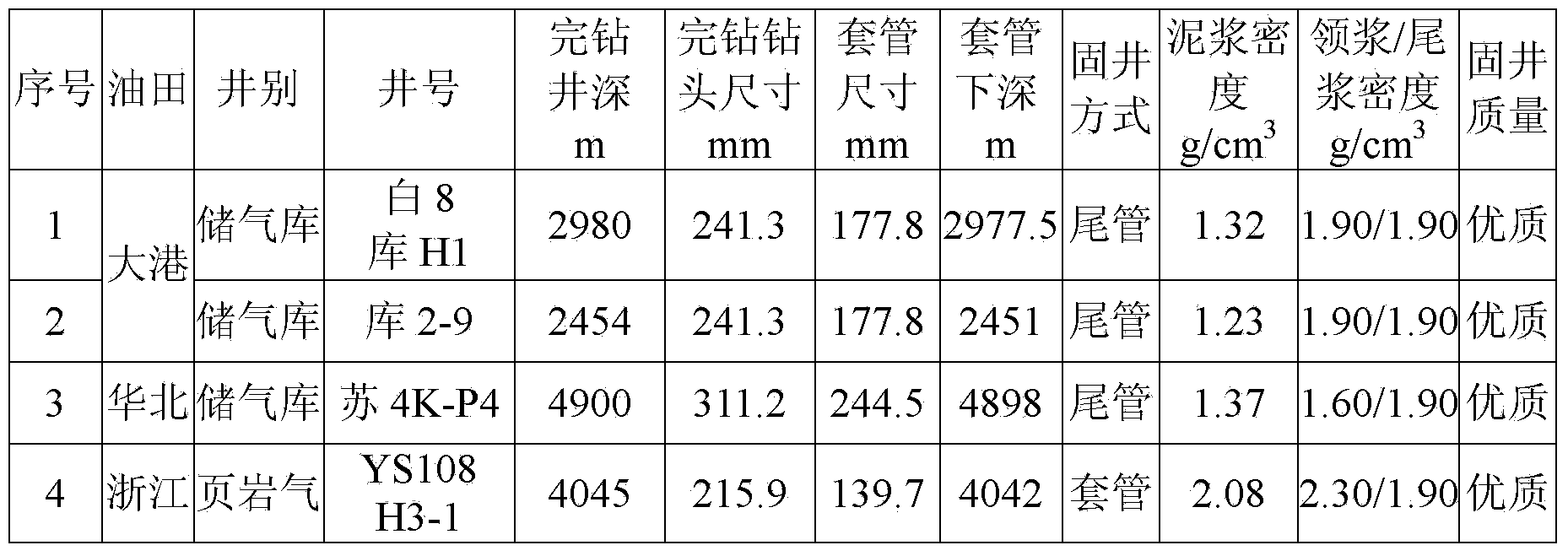

Expanded flexible well cementing grout and preparation method thereof

ActiveCN104371678ALow elastic modulusLower transfer coefficientDrilling compositionHorizontal wellsVolumetric Mass Density

The invention provides an expanded flexible well cementing grout and a preparation method thereof. The grout comprises the following components in parts by weight: 100 parts of cement, 6-14 parts of toughening material, 3-80 parts of reinforcing material, 8-120 parts of density modifier, 0.5-2.5 parts of suspension stabilizer, 20-40 parts of high-temperature stabilizer, 35-100 parts of distilled water, 0.5-2 parts of dispersant, 0.5-4 parts of fluid loss agent, 0.3-4 parts of retarder, 0.1-2 parts of foam inhibitor and 0.1-2 parts of defoamer. The invention further provides a preparation method of the expanded flexible well cementing grout. The grout has good sedimentation stability; and the set cement has the characteristics of micro expansion, high strength and low elasticity modulus, and can avoid the phenomena of micro cracks, micro annuluses, even fracture and the like caused by cement sheaths in subsequent operation of gas storage wells, shale gas wells, dense oil-gas horizontal wells and the like, thus realizing good zonal isolation and providing a technical support for long-term, safe and effective operation of oil-gas wells.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

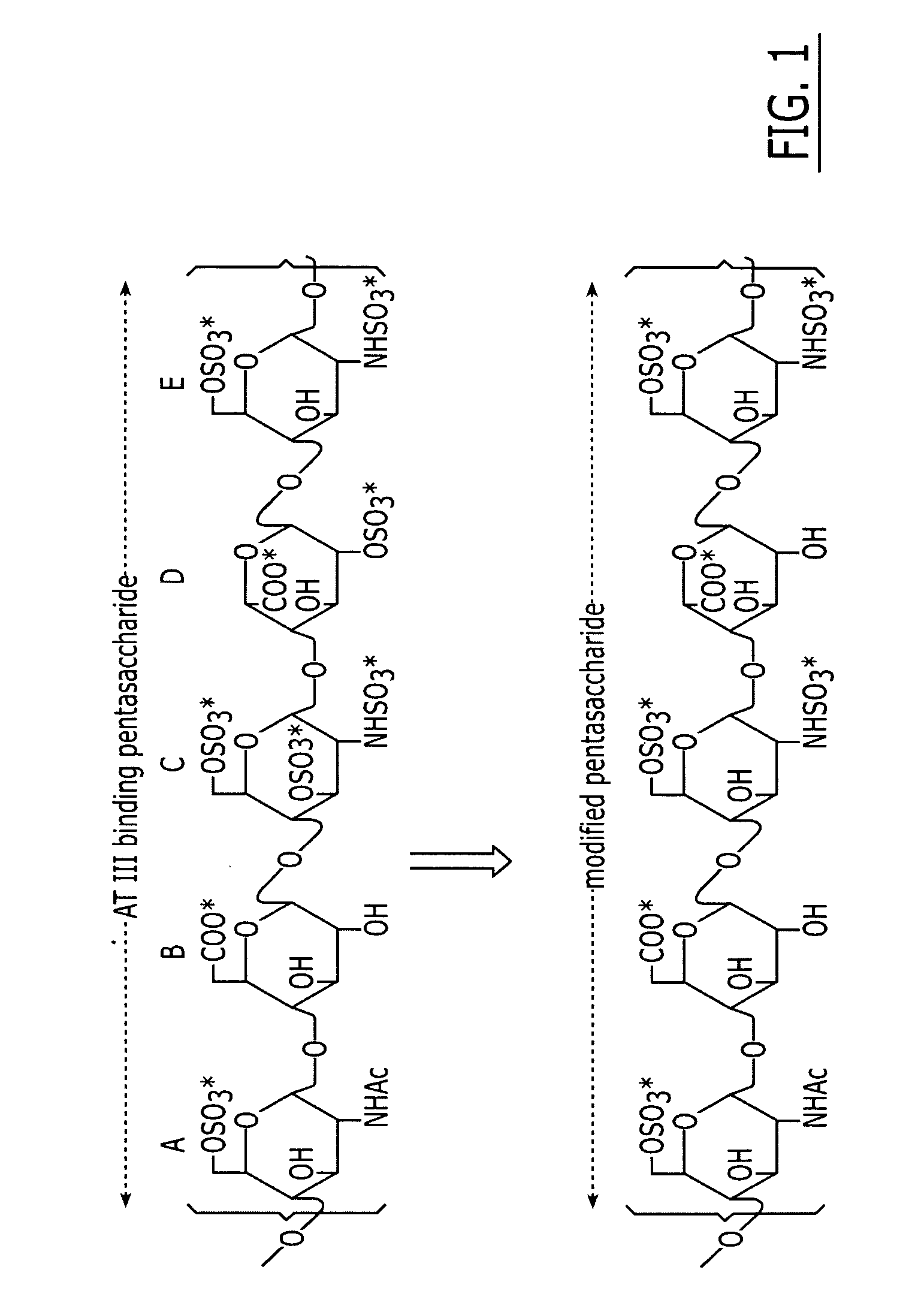

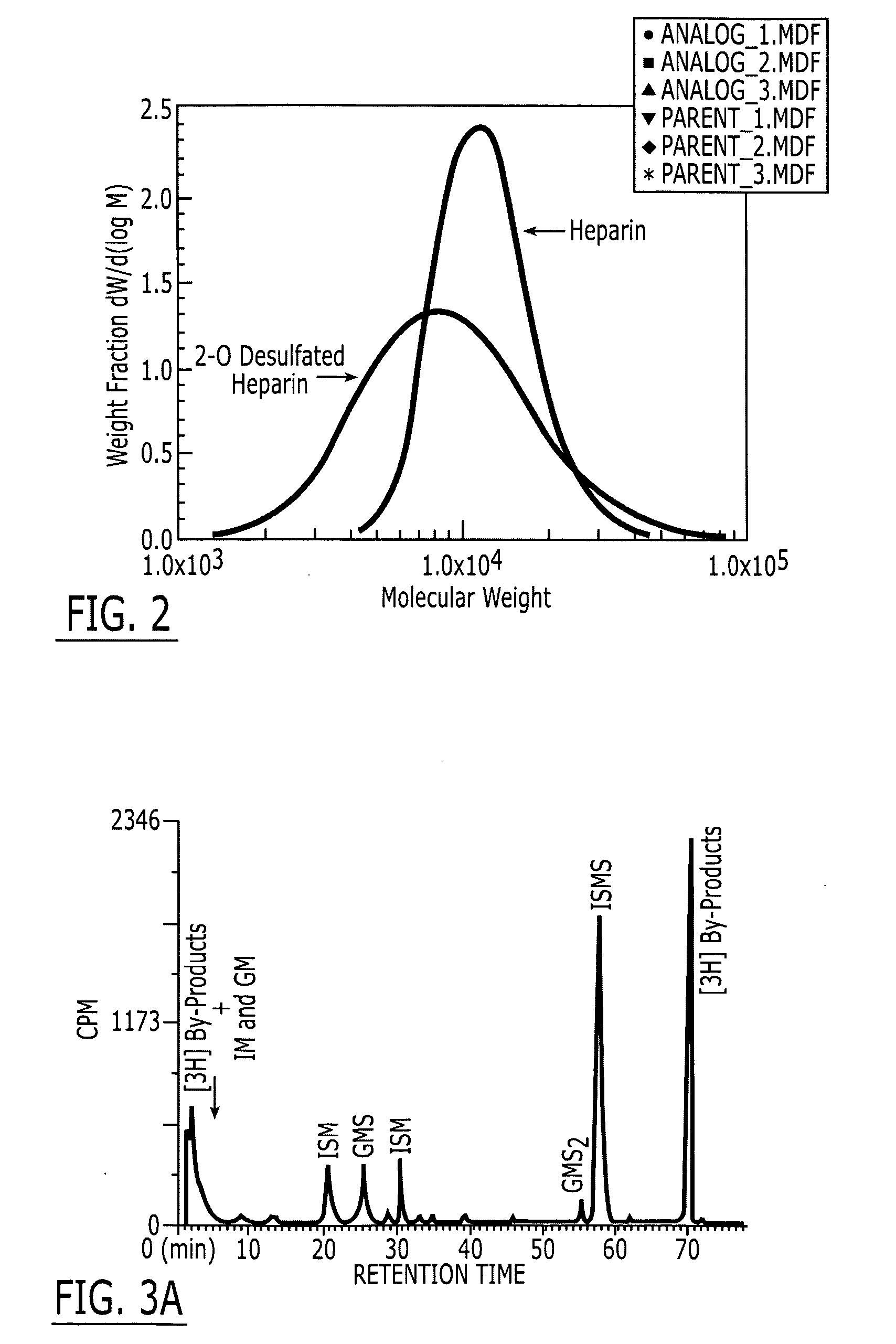

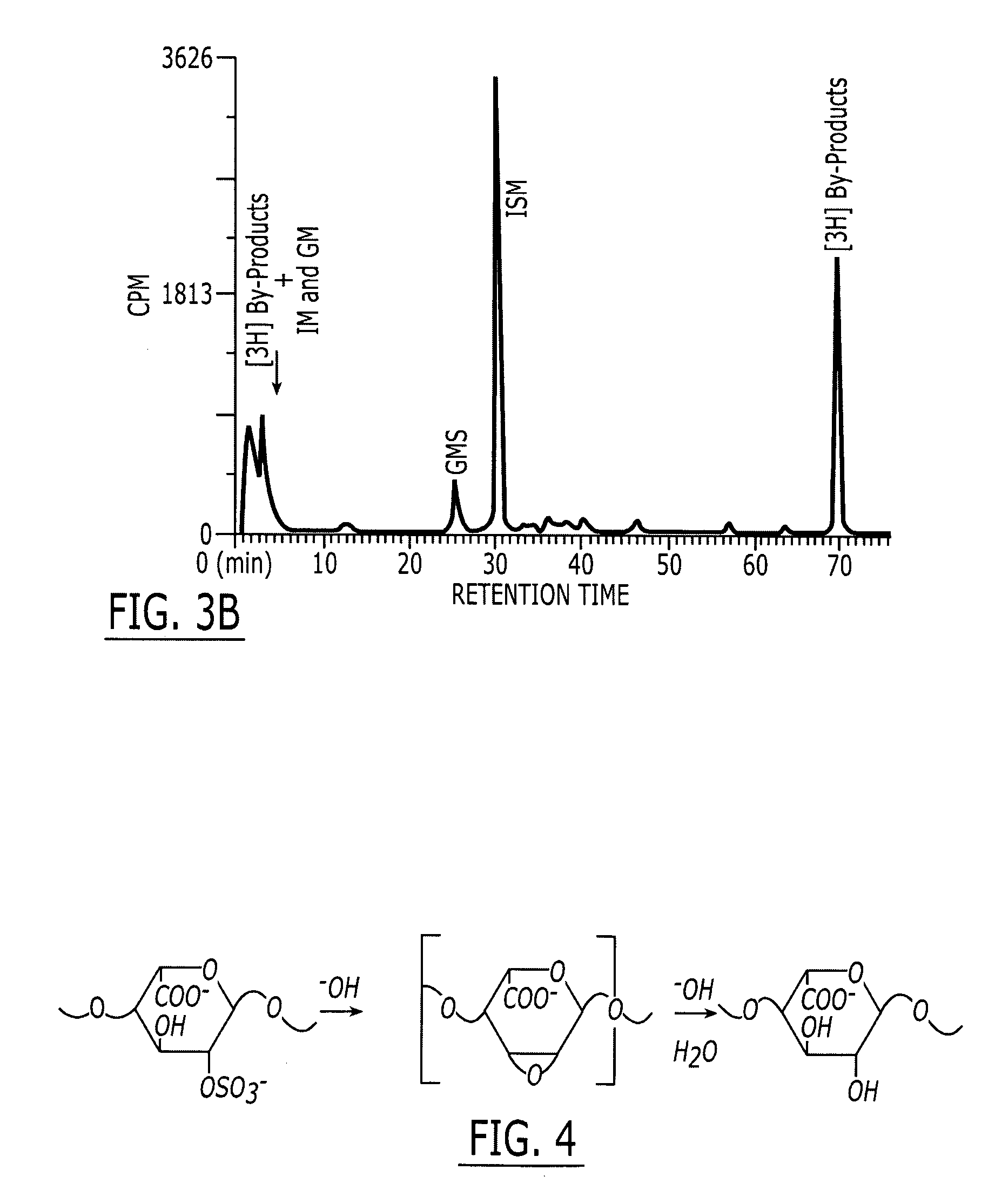

Method and medicament for anticoagulation using a sulfated polysaccharide with enhanced anti-inflammatory activity

InactiveUS20060040896A1Sufficient degreeGood anti-inflammatory activityOrganic active ingredientsBlood disorderSulfated polysaccharidesMedicine

A method and medicament for anticoagulating a patient with a sulfated polysaccharide mixture that demonstrates enhanced anti-inflammatory activity compared to anticoagulation with unfractionated heparin comprising various combinations of fully anticoagulant unfractionated heparin with 2-O desulfated heparin demonstrating reduced anticoagulant activity but enhanced anti-inflammatory actions. The medicament preferably is administered intravenously, by aerosolization or orally. Preferably, the 2-O desulfated heparin medicament includes a physiologically acceptable carrier which may be selected from the group consisting of physiologically buffered saline, normal saline and distilled water. Additionally provided is a method of synthesizing 2-O desulfated heparin in commercially practical quantities for the formulation of an anticoagulant 2-O desulfated heparin and heparin mixture.

Owner:CANTEX PHARMA

Watery zinc-aluminium heavy-duty coating in compounding squama shape and preparation method thereof

InactiveCN101525505AAchieve complete chrome-freeImprove bindingAnti-corrosive paintsPotassium hydroxideHeavy duty

The invention relates to a watery zinc-aluminium heavy-duty coating in a compounding squama shape and a preparation method thereof. The watery zinc-aluminium heavy-duty coating belongs to a bi-component coating and is prepared from organic-inorganic modified base stock and pigment according to a certain proportion by weight, wherein the organic-inorganic modified base stock contains silica sol, potassium hydroxide, silicone-acrylate emulsion, a pigment dispersing agent, a film forming addition agent and an antifoaming agent, and the balance is deionized water or distilled water; the pigment comprises squama-shaped zinc powder and squama-shaped aluminium powder; and the weight ratio of the organic-inorganic modified base stock to the pigment is 5: 1-2. The watery zinc-aluminium heavy-duty coating contains no chrome, can be solidified at the normal temperature, has environmental protection and low energy consumption and can be used for preparing thin coatings with high corrosion resistance, and the like.

Owner:HOHAI UNIV +1

Method for preparing biomedical material of static self-assembly modified nano fiber

InactiveCN101798756AStable structureDoes not destroy activityFilament/thread formingFiberElectrolysis

The invention relates to a method for preparing a biomedical material of a static self-assembly modified nano fiber, which is characterized by comprising the following concrete steps of: stirring and dissolving a water-insoluble macromolecular polymer for spinning in a solvent in a stirring kettle at room temperature to obtain an electric spinning raw material with the weight percentage of 5-30 percent; adding the electric spinning raw material into a static spinning device and statically spinning to obtain a nano fiber template material; soaking the nano fiber template material into a weak polymerized electrolyte aqueous solution which has the concentration of 0.01-10g / ml and an opposite charge, adsorbing for balance and drying; soaking the dried material into the weak polymerized electrolyte aqueous solution which has the concentration of 0.01-10g / ml and the opposite charge, adsorbing for balance, washing by distilled water for 5-30 minutes and drying; and obtaining the biomedical material of the static self-assembly modified nano fiber. The invention has simple molding and high bioactivity.

Owner:DONGHUA UNIV

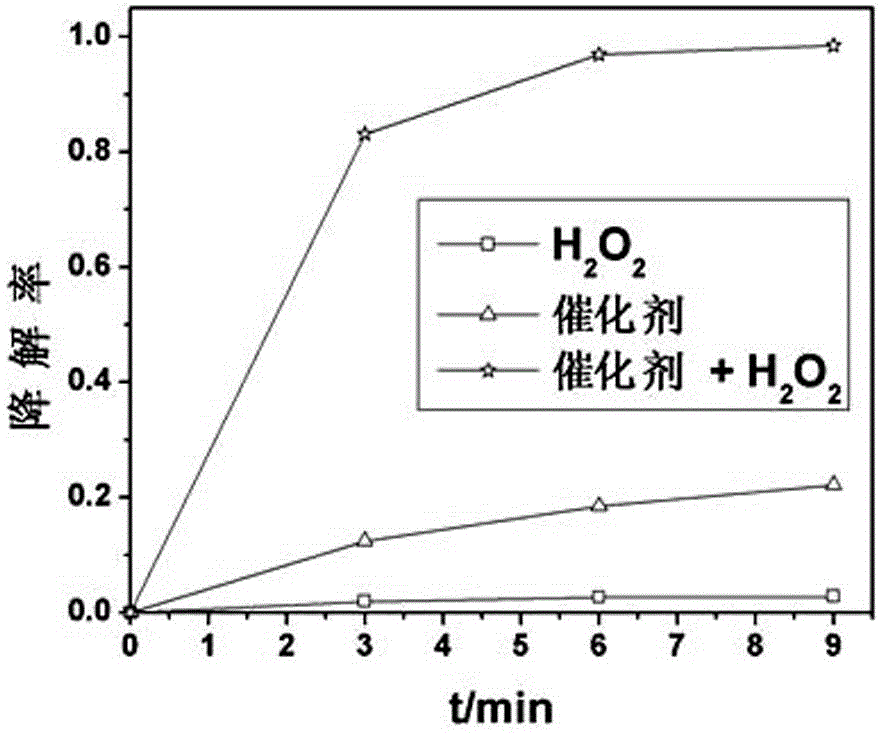

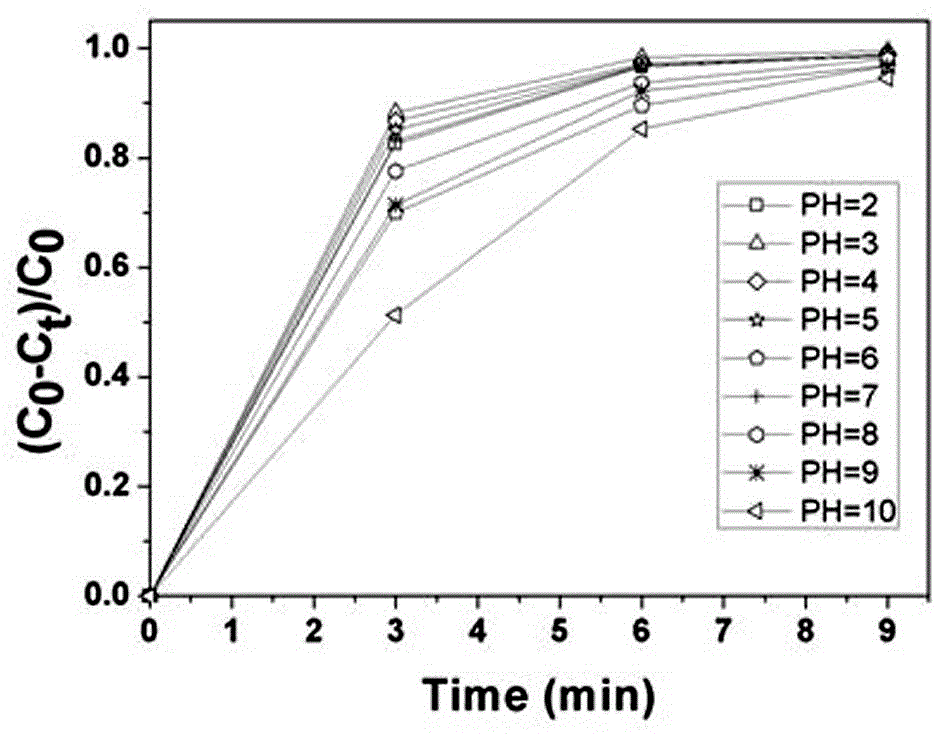

Preparation method and application of heterogeneous Fenton-like catalyst

InactiveCN102909073ALow costEfficient degradationOrganic-compounds/hydrides/coordination-complexes catalystsWaste water treatment from textile industryFiberCarbon fibers

Disclosed are a preparation method and application of heterogeneous Fenton-like catalyst. The preparation method includes the steps of firstly, dissolving complexing agent and metal salt in distilled water to respectively prepare complexing agent and metal salt solutions; secondly dropwise adding the metal salt solution into the complexing agent solution under the action of a magnetic mixer, and mixing for 20-60 after dropwise addition to obtain metal complex solution; and thirdly, impregnating activated carbon fiber in the metal complex solution for 1-24h, and subjecting taken-out activated carbon fiber to distilled water washing and drying to obtain the heterogeneous Fenton-like catalyst. The preparation method is simple, and conditions are mild. Environment-friendly hydrogen peroxide is used as oxidant, no extra ultraviolet light or even visible light is needed, and the heterogeneous Fenton-like catalyst is capable of efficiently degrading organic pollutants such as dye within a wide pH range of 2-10. The heterogeneous Fenton-like catalyst is well repeatable, and secondary pollution of the homogeneous Fenton reagent caused by iron ions is avoided.

Owner:ZHEJIANG SCI-TECH UNIV

Method for preparing nickel-coated alumina powder

The invention relates to a preparation method of nickel-coated alumina oxide powder, in particular to the preparation method of nickel-coated aluminum oxide powder for thermal spraying in aviation, aerospace and military fields. The invention is characterized in that: a suspension is made from a mixing liquid of nano-aluminum oxide and dispersant, stirred and added with nickel salt solution at the same time, and the obtained mixture liquid is dropped with ammonium water after being fully stirred, added with distilled water, when dark blue mixing solution C of nickel ammonia complex ([Ni (NH3)) 2+and alumina oxide is obtained; the mixing solution C is aged by water, filtered, washed and dried, and a green middle coated product is obtained; the green middle coated product is further reduced and roasted, finally, black nickel-coated aluminum oxide powder is prepared. The nickel-coated aluminum oxide powder prepared through the invention has uniform granularity, with average size less than or equal to 1.0Mum, and can enhance the application performance of nano-alumina and expand the application of nano-aluminum oxide; the product is mainly used for aviation, aerospace and military materials and other high-tech fields. The method of the invention is simple, reproducible and easy to be industrialized.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Detergent tablet

InactiveUS7153817B2Improve production stabilityDifficult to bindInorganic/elemental detergent compounding agentsTableware washing/rinsing machine detailsDistilled waterNon ionic

A machine cleaner tablet comprising from about 10 to about 75% of a limescale remover acid, from about 1 to about 20% of low foaming non-ionic surfactant, from about 0.5 to about 5% of a detergency enzyme and wherein the tablet has a pH measured as a 1% solution in distilled water at 20° C. in the range from about 1 to about 5. The tablet is used for cleaning the interior of automatic dishwashers, food processing machines and the like.

Owner:THE PROCTER & GAMBLE COMPANY

Method for reducing loaded metal catalyst using low temperature plasma

InactiveCN1647858ARestore quickly and efficientlyGood dispersionCatalyst activation/preparationOxygenLow temperature plasma

The method of reducing loaded metal catalyst with low temperature plasma includes the steps of: 1) dissolving active metal salt component in deionized water or distilled water to form solution with metal component content of 0.01-20 wt%, filling solution into catalyst carrier, letting stand at room temperature for 8-24 hr and drying at 40-110 deg.c for 2-10 hr; and 2) setting the catalyst between two electrodes of plasma apparatus, introducing inert gas, air or oxygen as plasma discharge gas into discharge tube of pressure of 50-10000 Pa, and applying DC or AC voltage of 100-20000 V across the electrodes to process for 5-200 min. The low temperature plasma contains great amount of electrons, has powerful reducing capacity to reduce metal ion into metal simple substance and has no negative reaction appearing at high temperature. The process is simple, short in reduction time, without need of chemical reductant and environment friendly.

Owner:TIANJIN UNIV

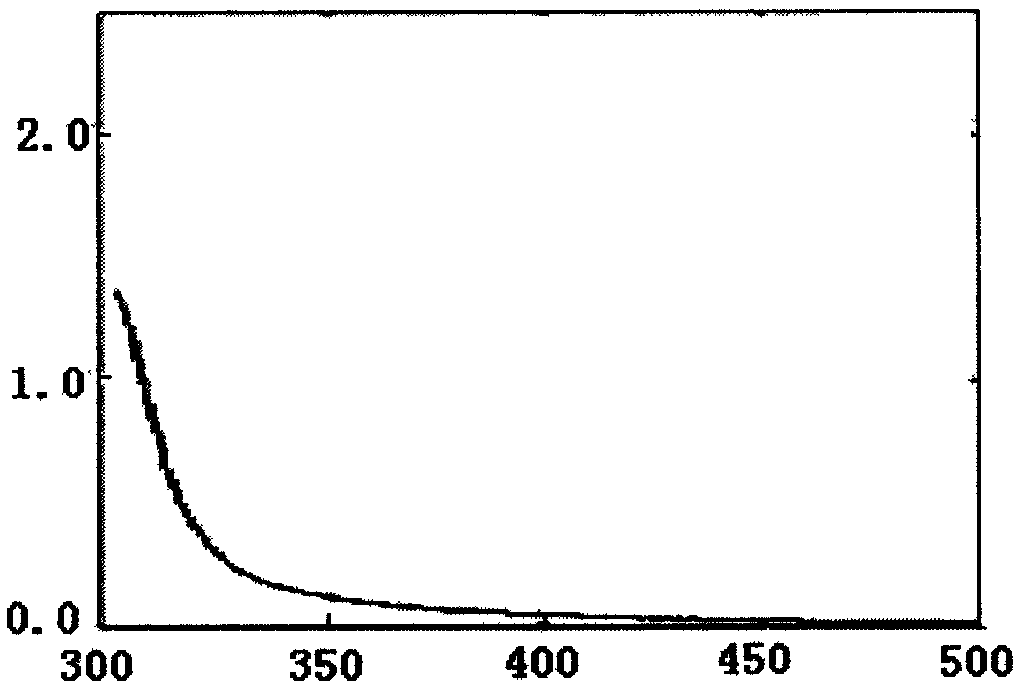

Method for producing nano-anatase mine-titanium oxide water sol

InactiveCN101028937AEasy-to-implement generationEase of mass production: no production involved in the preparation processTitanium dioxideDistilled waterTitanium

A process for preparing the hydrosol of nano-class anatase-type TiO2 features that reaction between Ti-contained organic substance, distilled water or deionized water, chelating agent and hydrodecomposing inhibitor at 30-120 deg.C for 3-12 hr while stirring and controlling pH=1-5.

Owner:YUNNAN UNIV

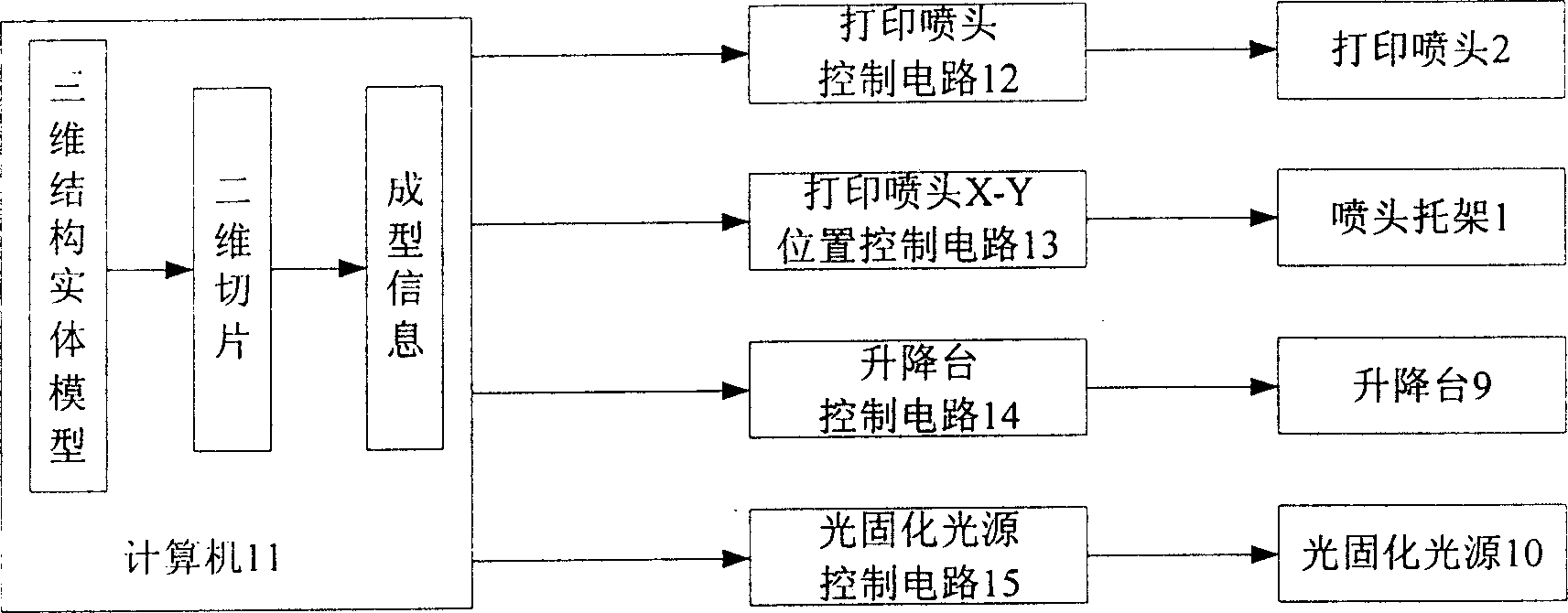

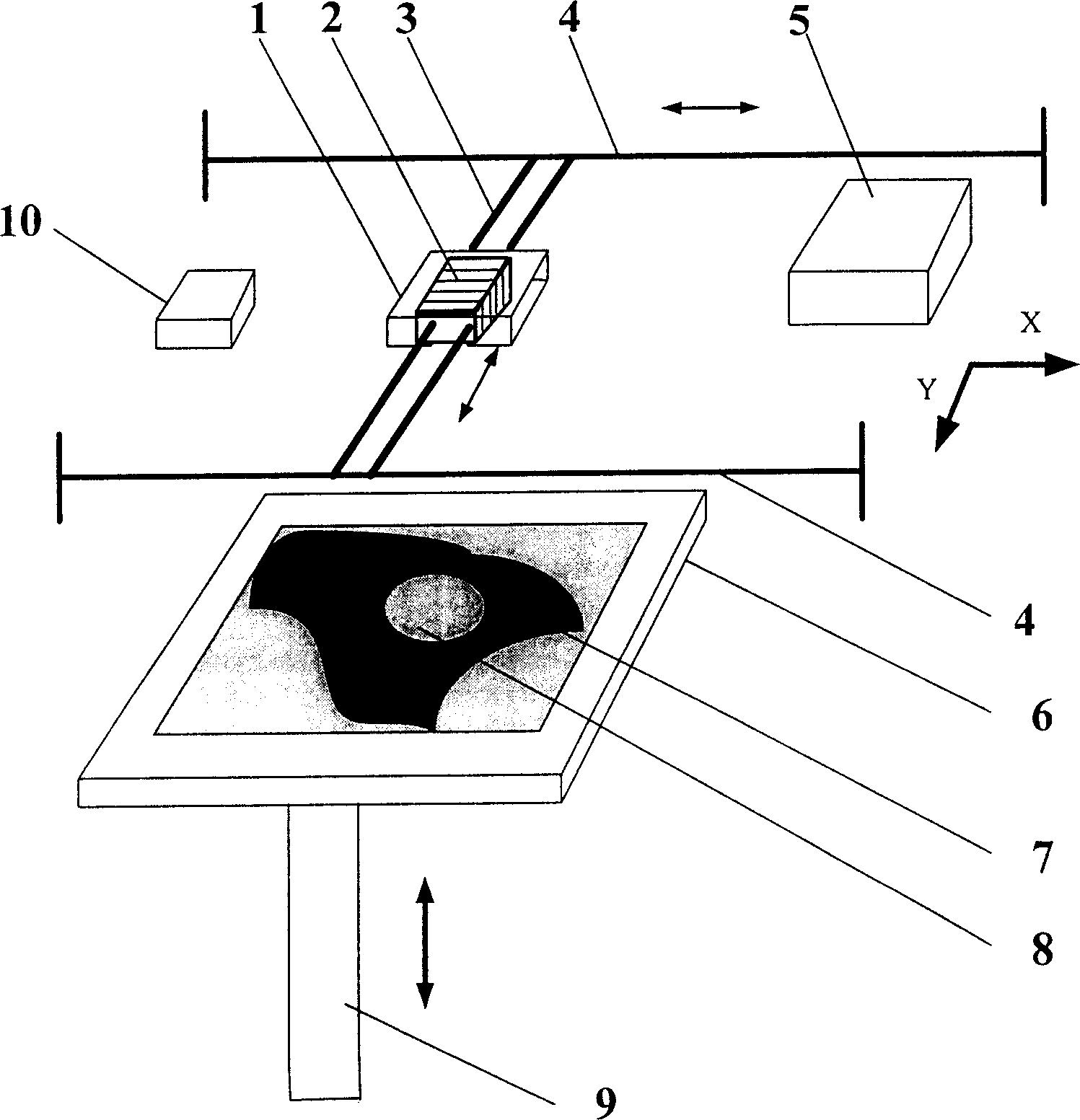

Printing shaping method for making three-dimensional object and support

InactiveCN1814431AHigh speedHigh precisionOrnamental structuresCeramic shaping apparatusDistilled waterEngineering

The invention discloses a print molding method for 3D object and support that the process includes the following steps: building up computer solid model, taking slicing and delaminating, the printing nozzle spraying UV liquid material and moving according the information set according to the layers, solidifying to form slice sheet; spraying supporting material to fill the blank area, concreting to solid state to be used for the support for the next layer; superposing to form 3D object and support. The support material could be one from distilled water, watercraft liquid, solvent-liquid, and dyestuff type liquid that would form support after concreting. After making the 3D object, heating until melting, the 3D object would be gained. The invention would be fast, reliable, safe and low cost to make a complex 3D object. It is asepsis, either.

Owner:NANJING NORMAL UNIVERSITY

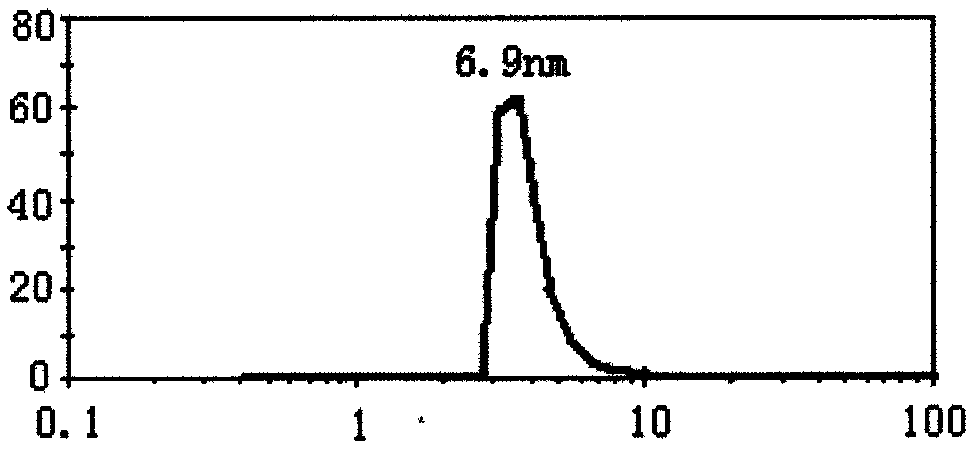

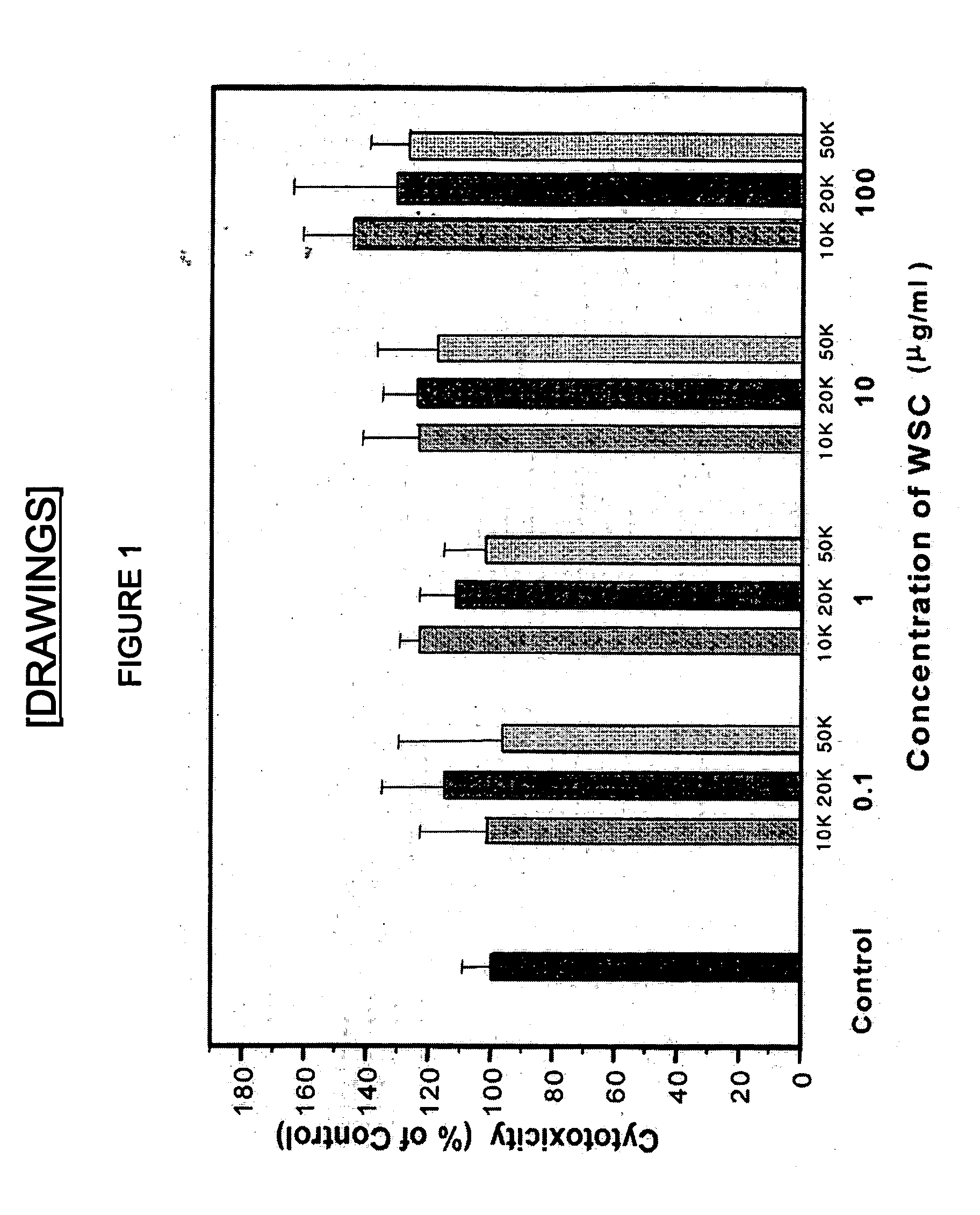

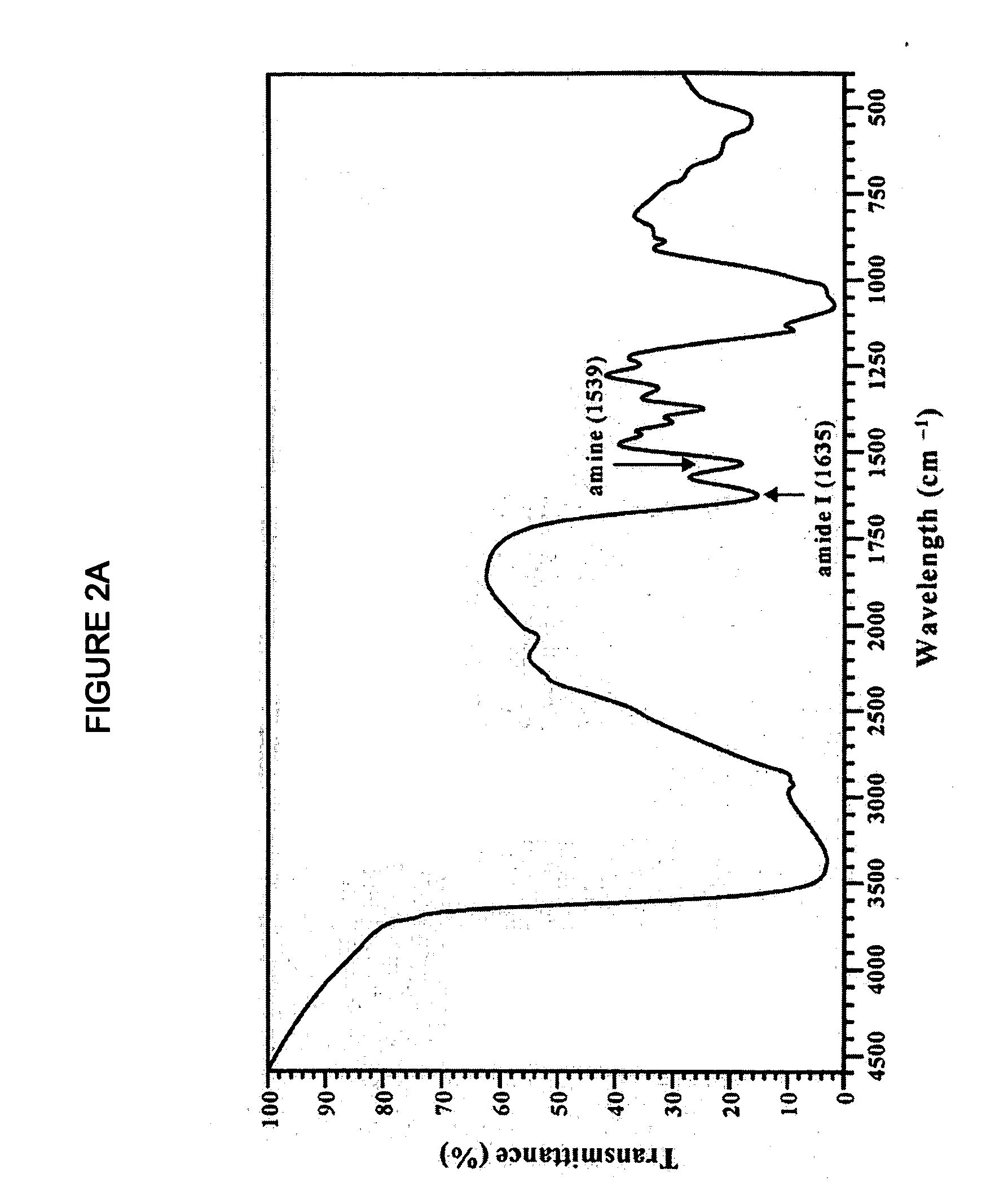

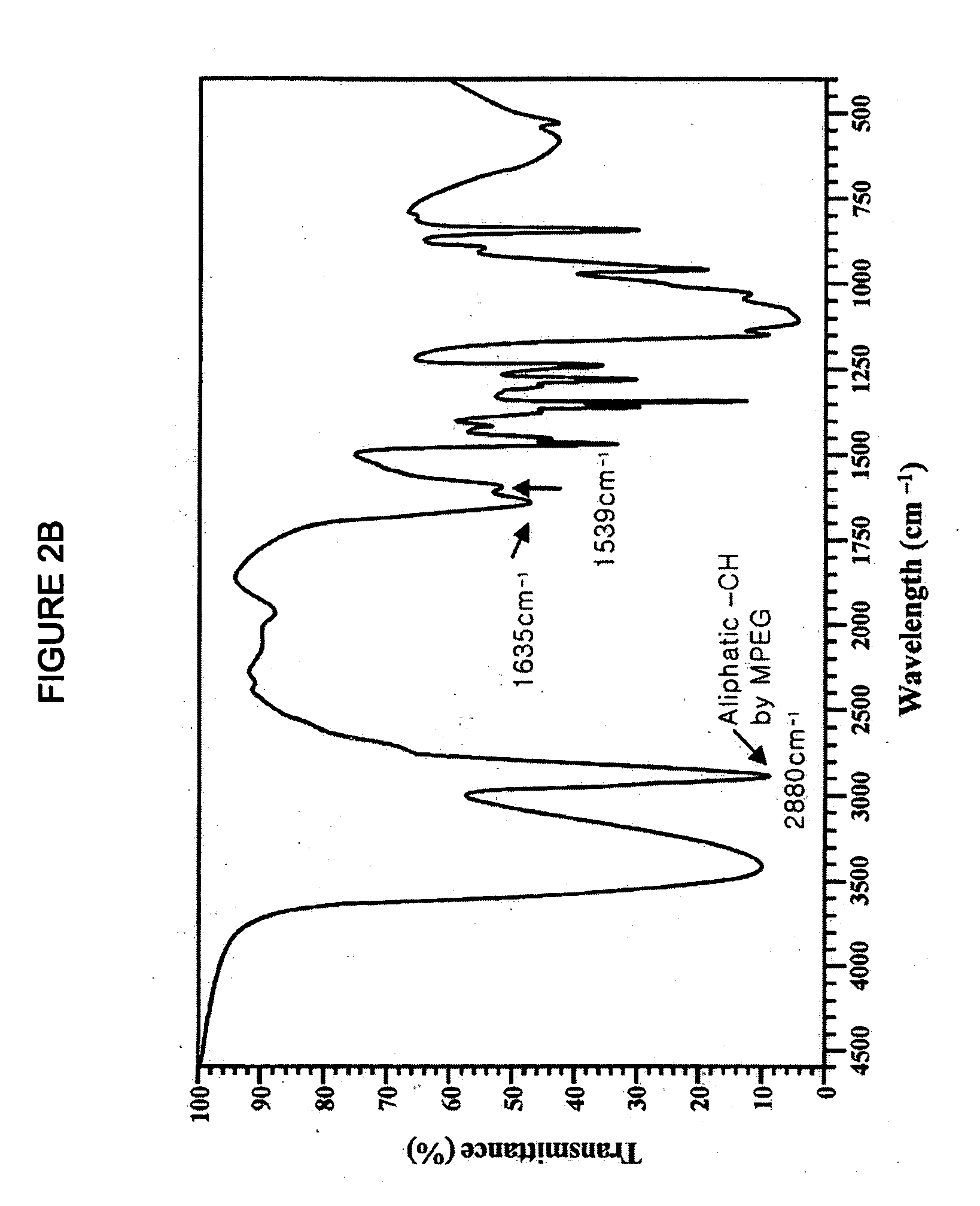

Water soluble chitosan nanoparticle for delivering an anticancer agent and preparing method thereof

The present invention relates to a water soluble chitosan nanoparticle (WSC-NP) for delivering an anticancer agent and a preparing method thereof, more precisely, a water soluble chitosan nanoparticle for delivering an anticancer agent which has function of targeting on a wanted area by introducing a functional group in the location of highly reactive amine group and becomes an excellent gene carrier with the use of water soluble chitosan since the water soluble chitosan itself can combined with DNA having a negative electric charge(−) owing to the very strong positive electric charge(+) of its amine group, and a preparing method thereof. Therefore, a water-soluble chitosan nanoparticle for delivering an anticancer agent of the present invention can effectively envelope paclitaxel by introducing hydrophilic and hydrophobic groups in the position of highly reactive amine group of the water-soluble chitosan. A water soluble chitosan nanopaclitaxel prepared as the above has an excellent re-dispersion force, after freeze-drying, in distilled water and has an outstanding anticancer effect with its accumulation in tumor cells greater than that of the other anticancer agent carriers.

Owner:JEONG TUK RAI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com