Patents

Literature

3431 results about "Nickel salt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composition, method of making, and treatment of wood with an injectable wood preservative slurry having biocidal particles

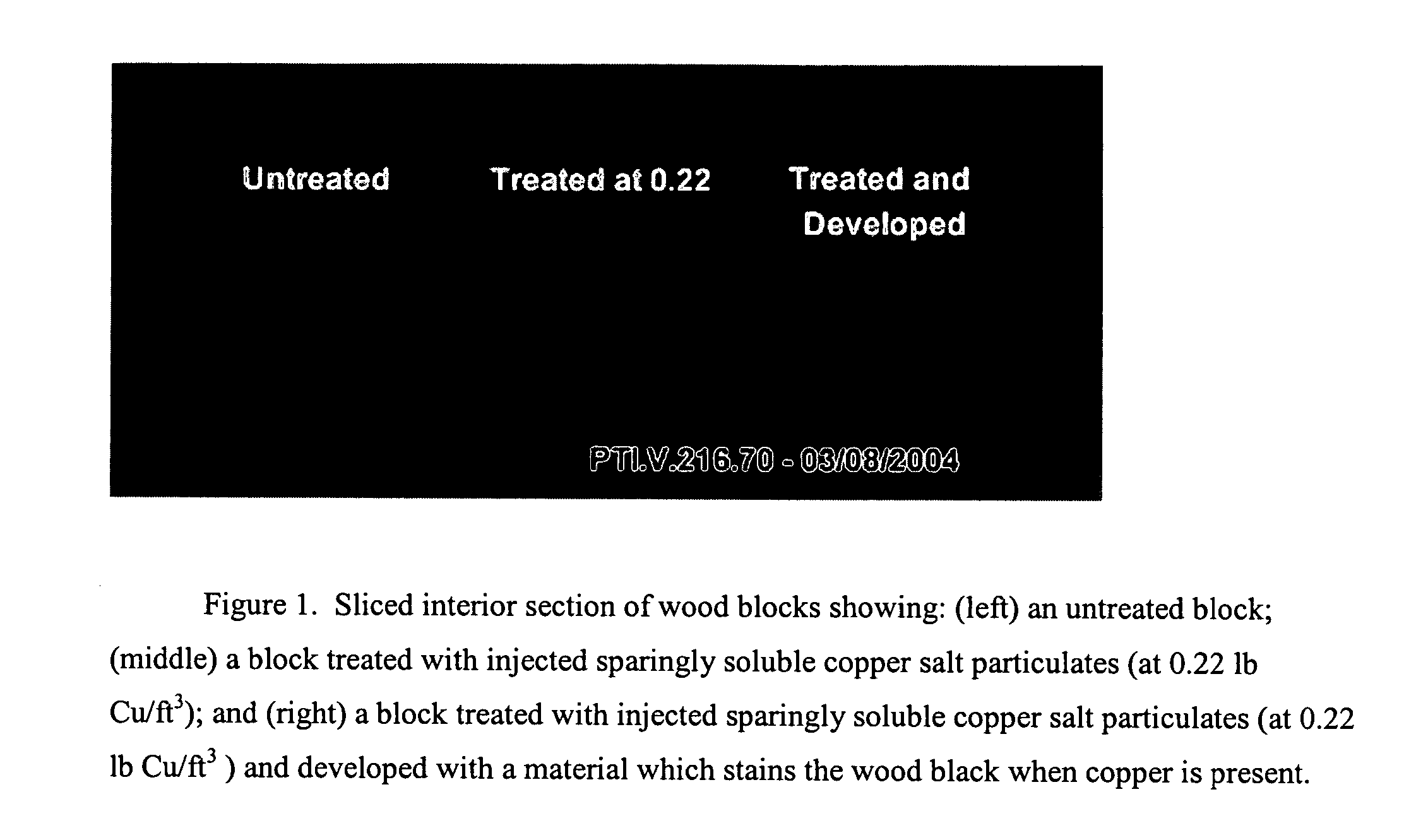

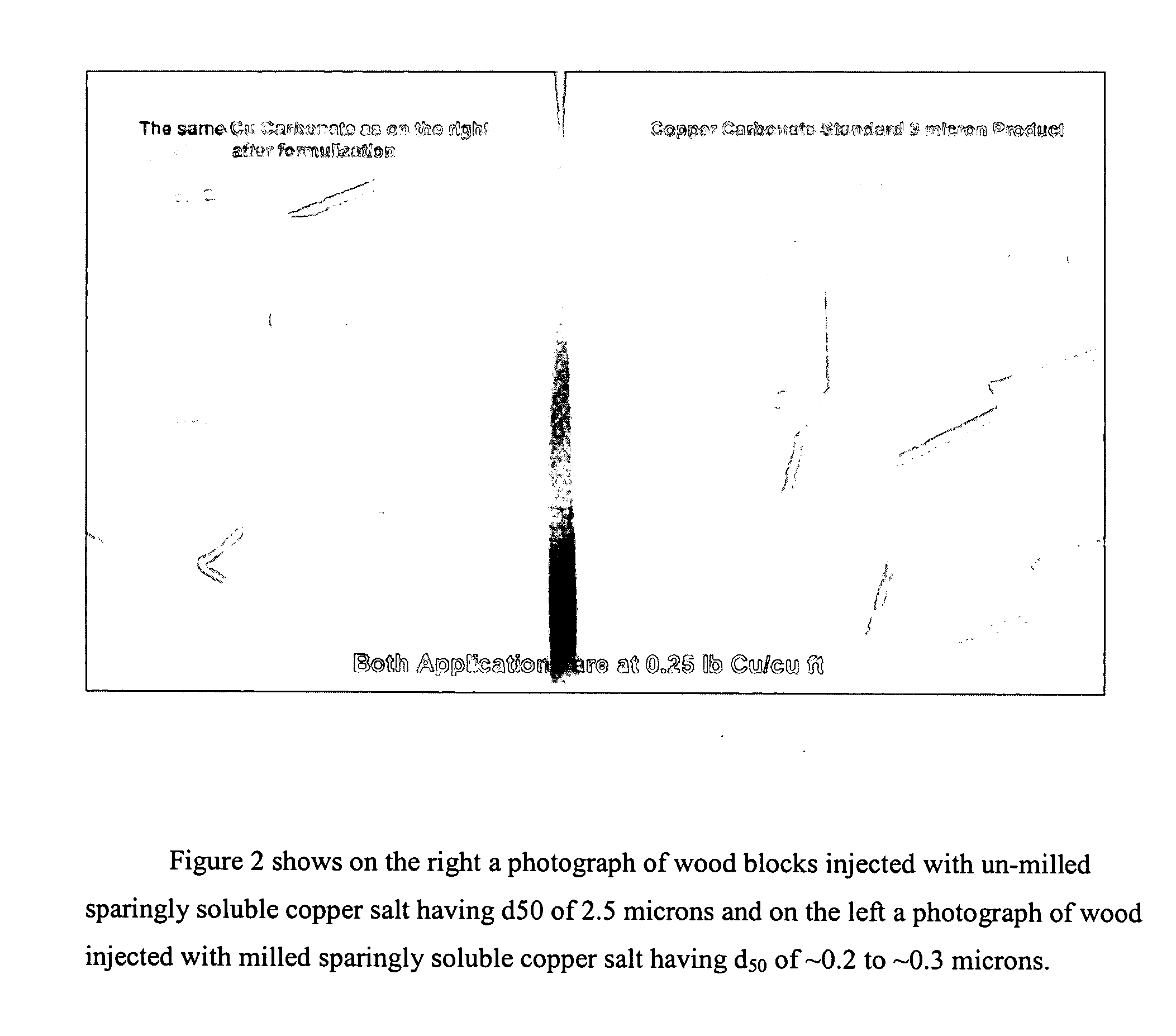

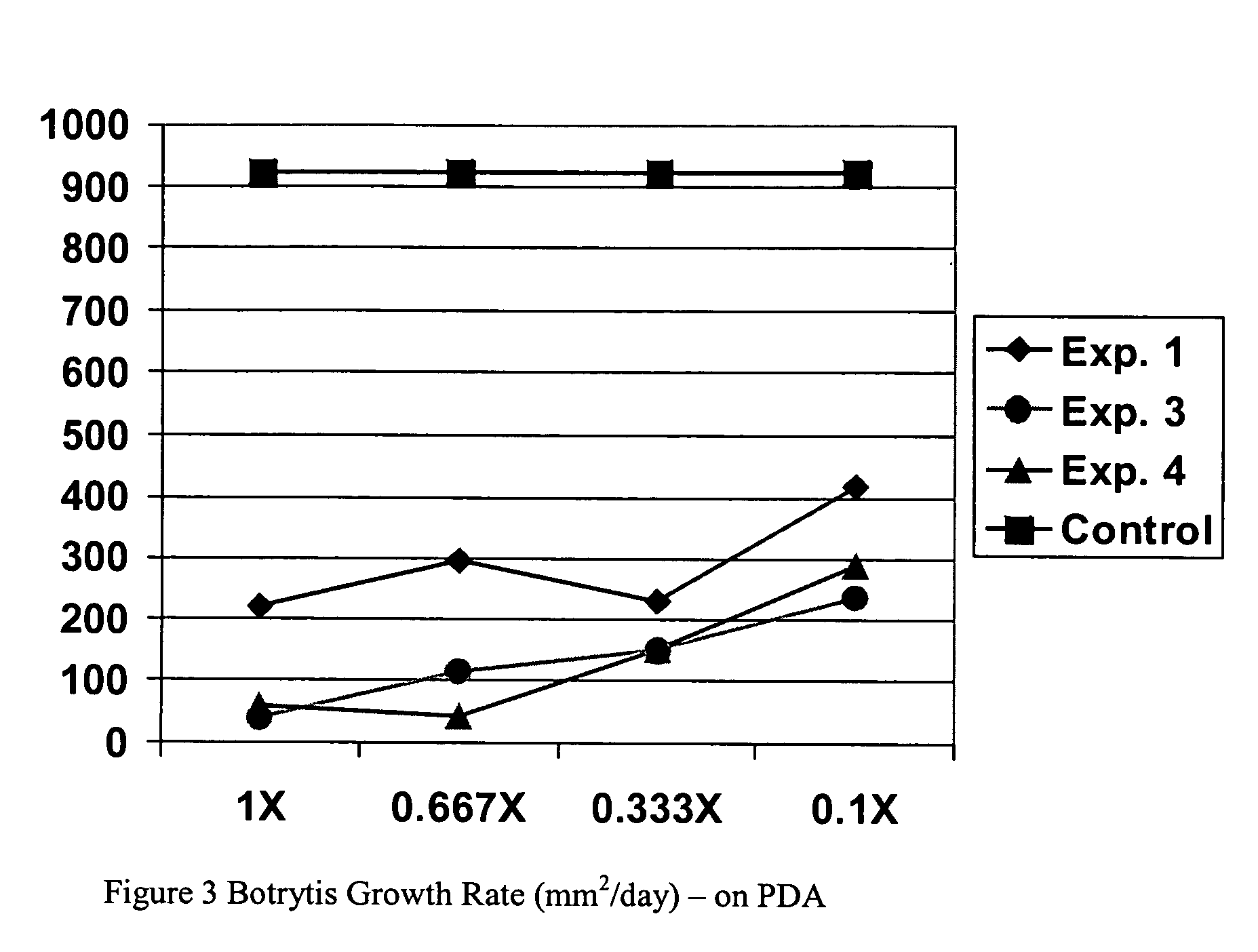

A method of preserving wood includes injecting into the wood an effective amount of a aqueous wood-injectable biocidal slurry, said a wood-injectable biocidal slurry containing dispersants and sub-micron biocidal particles selected from at least one of the following classes: 1) a plurality of particles containing at least 25% by weight of a solid phase of sparingly soluble salts selected from copper salts, nickel salts, tin salts, and / or zinc salts; 2) a plurality of particles containing at least 25% by weight of a solid phase of sparingly soluble metal hydroxides selected from copper hydroxide, nickel hydroxide, tin hydroxide, and / or zinc hydroxide; 3) a plurality of particles containing at least 25% by weight of a solid phase comprising a substantially-insoluble organic biocide selected from triazoles, chlorothalonil, iodo-propynyl butyl carbamate, copper-8-quinolate, fipronil, imidacloprid, bifenthrin, carbaryl, strobulurins, and indoxacarb; 4) a plurality of particles containing on the outer surface thereof a substantially-insoluble organic biocide; 5) a plurality of particles containing a solid phase of a biocidal, partially or fully glassified composition comprising at least one of Zn, B, Cu, and P. The particles may advantageously contain metallic copper, a leachability barrier, pigments, dyes, or other adjuvants disposed on the outer surface thereof.

Owner:OSMOSE

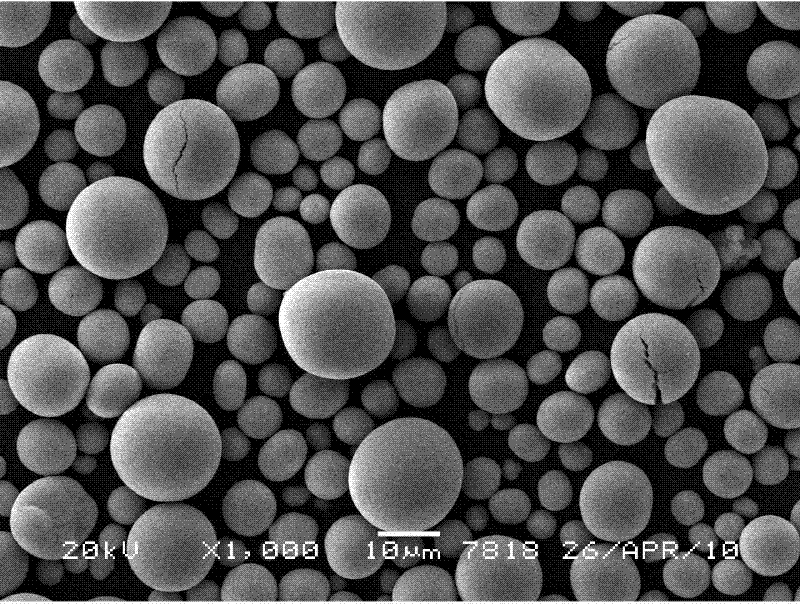

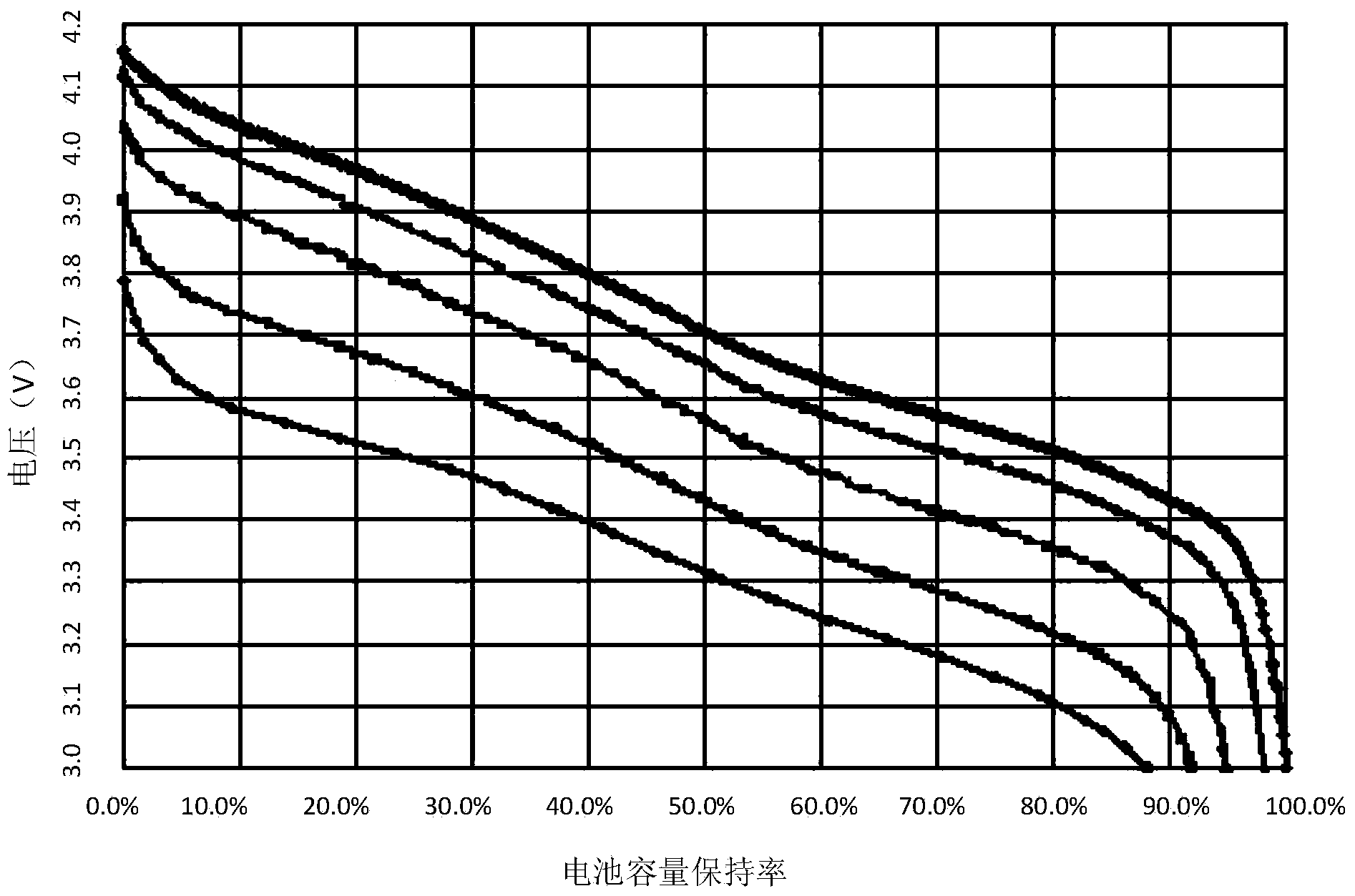

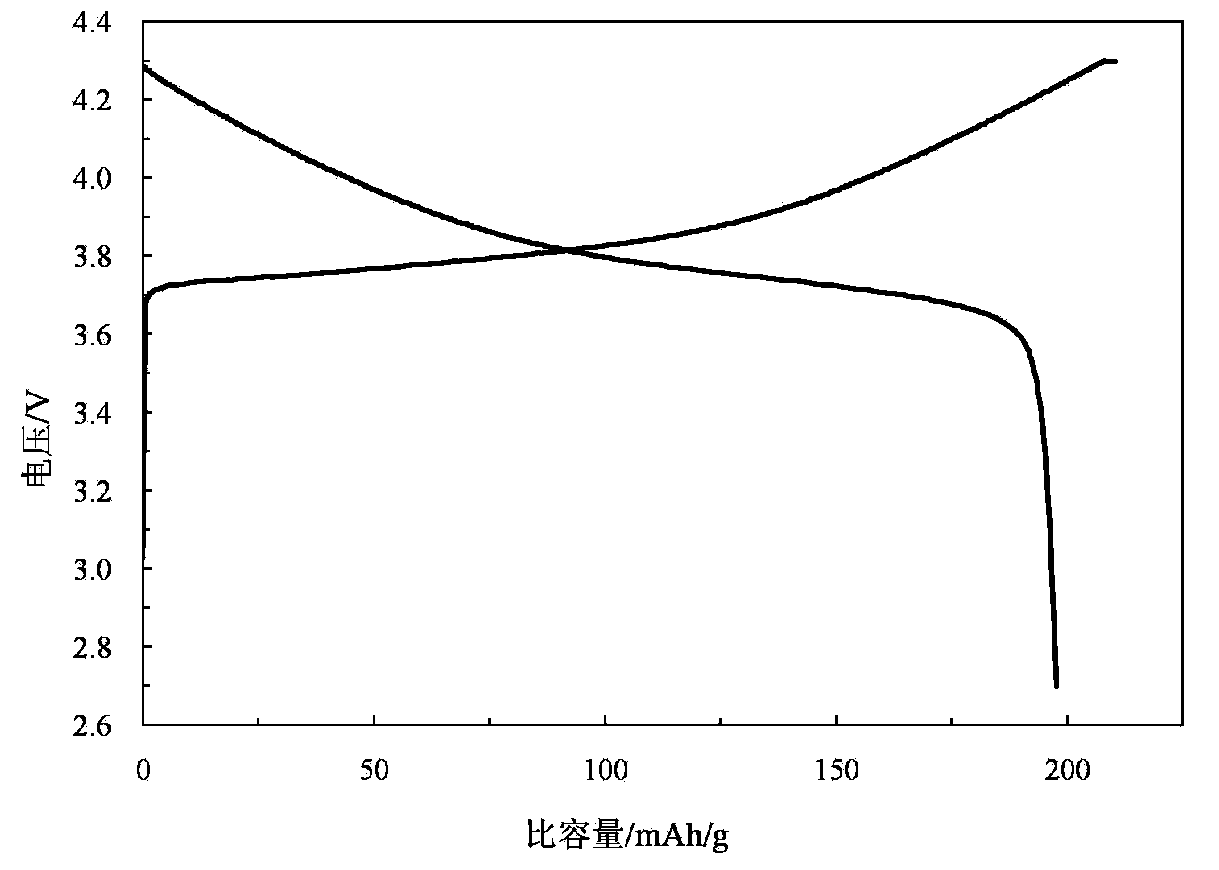

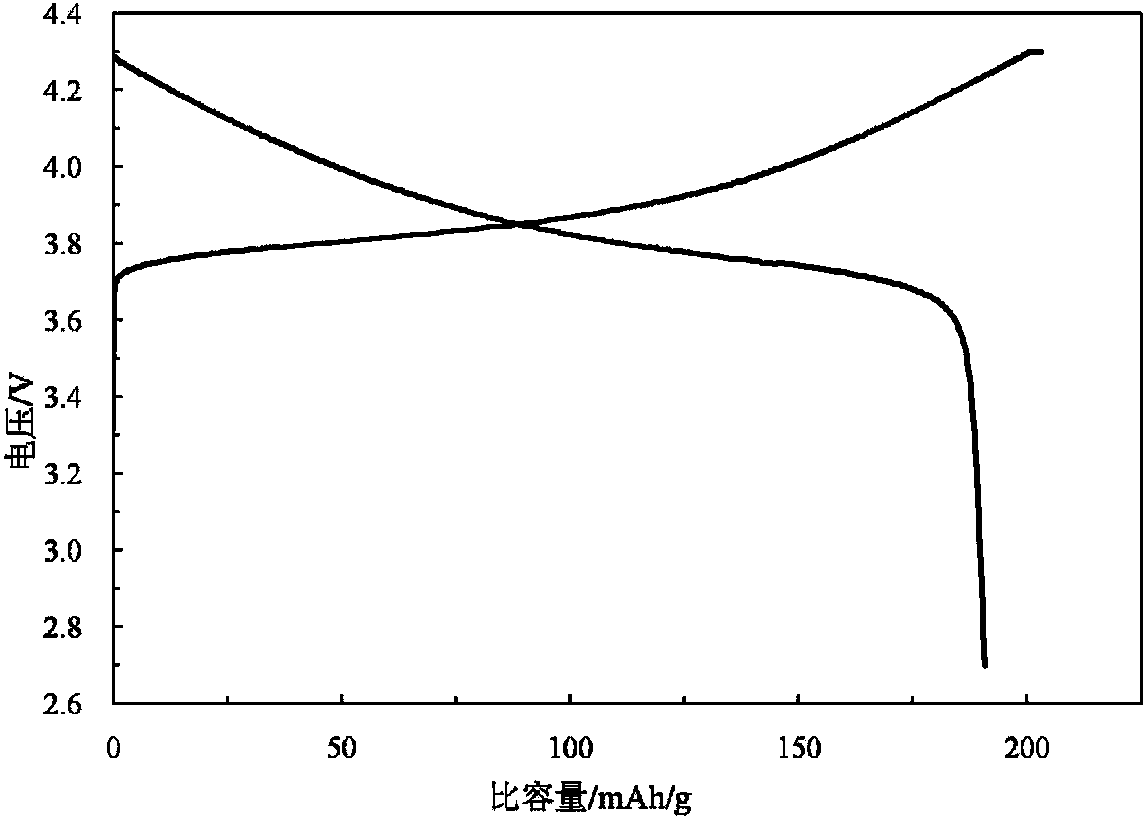

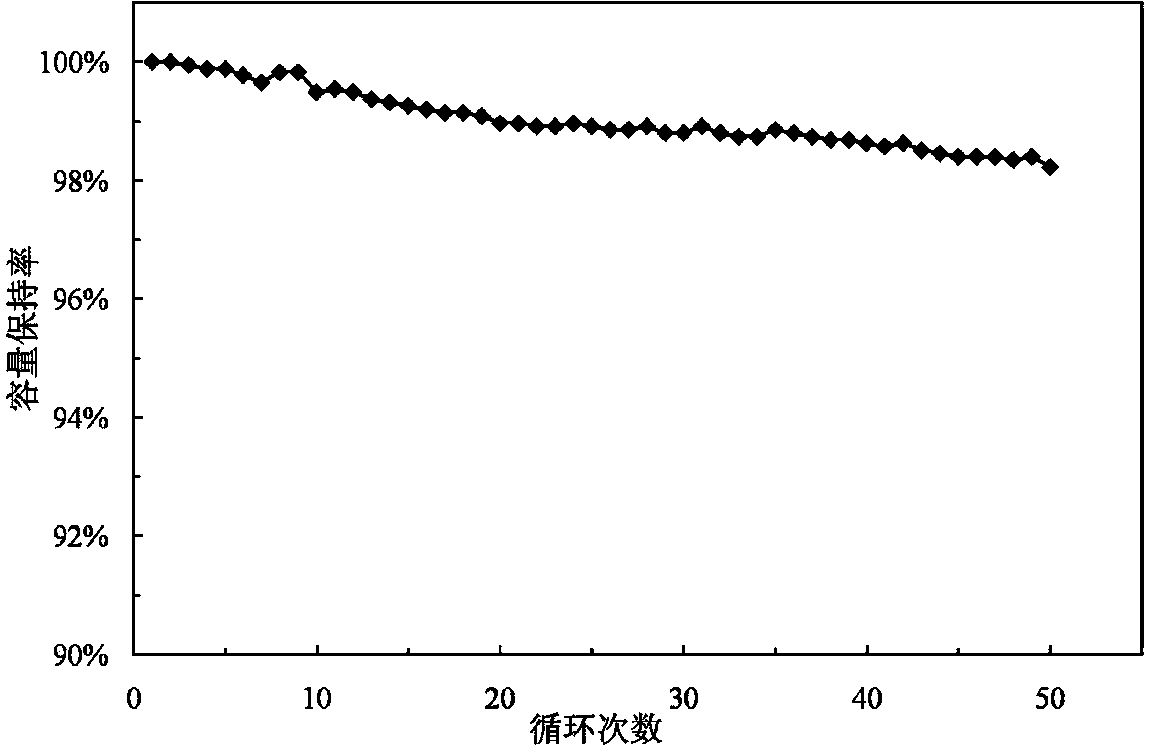

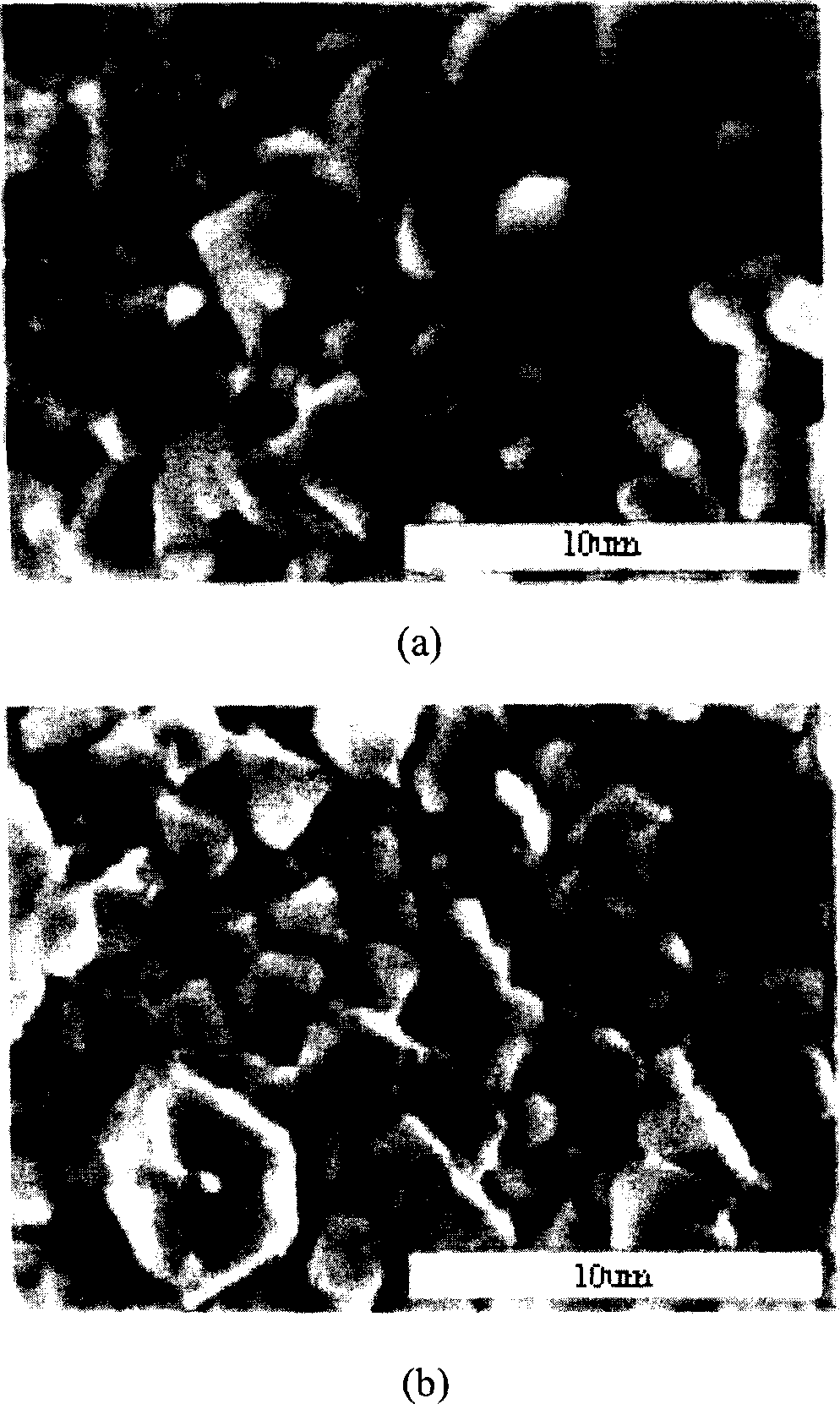

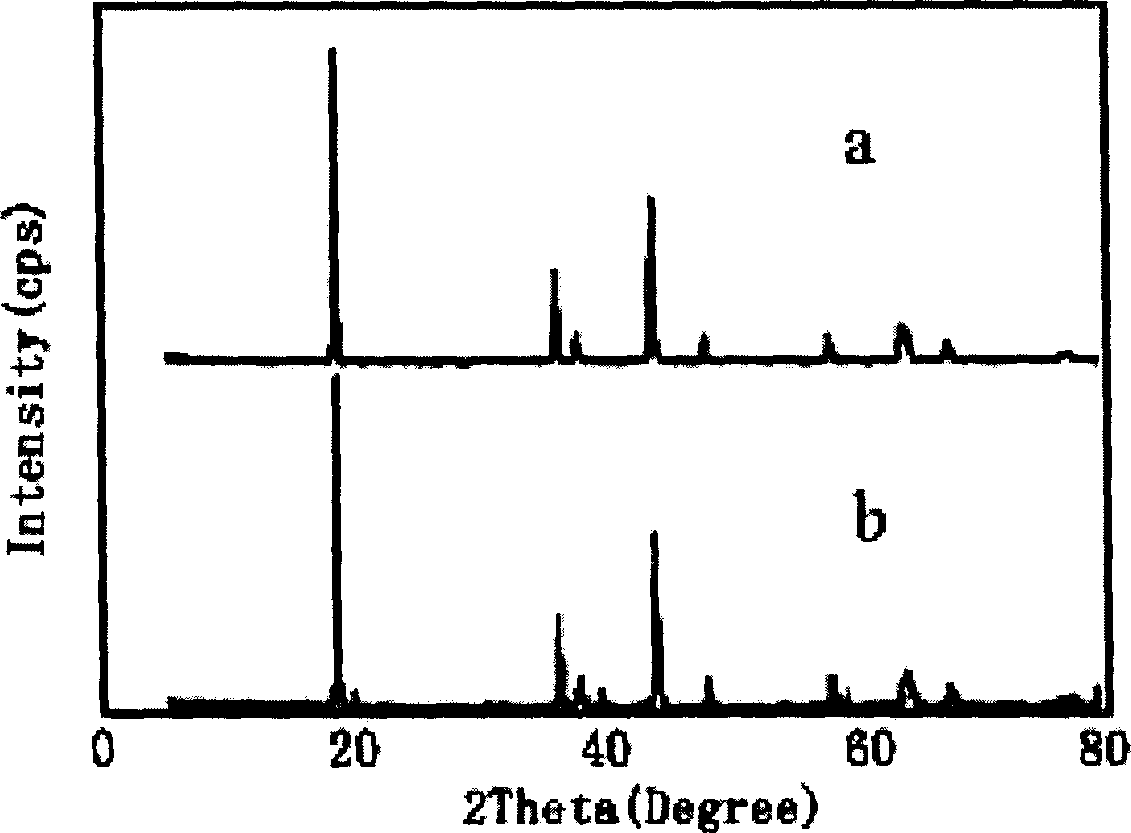

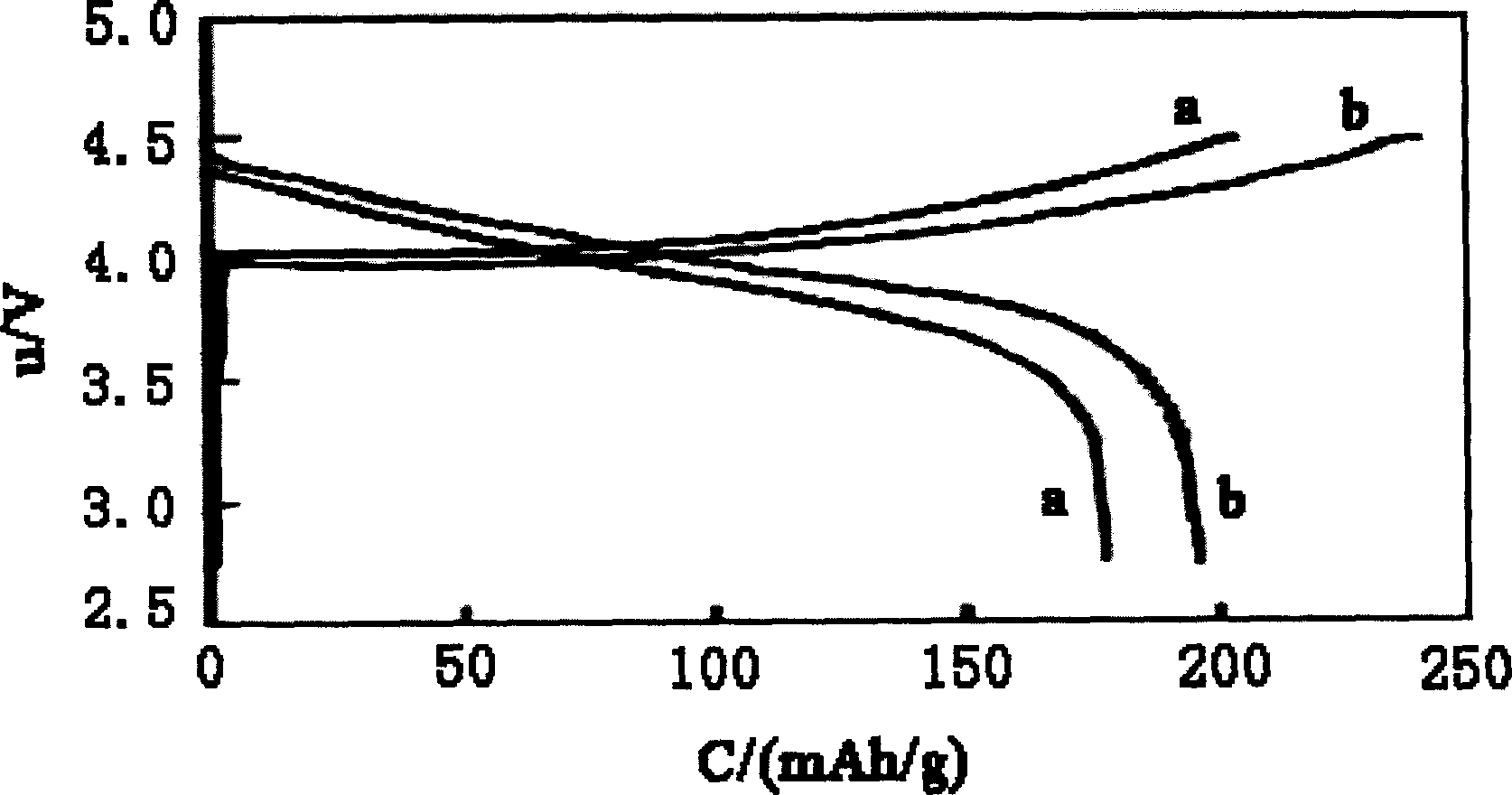

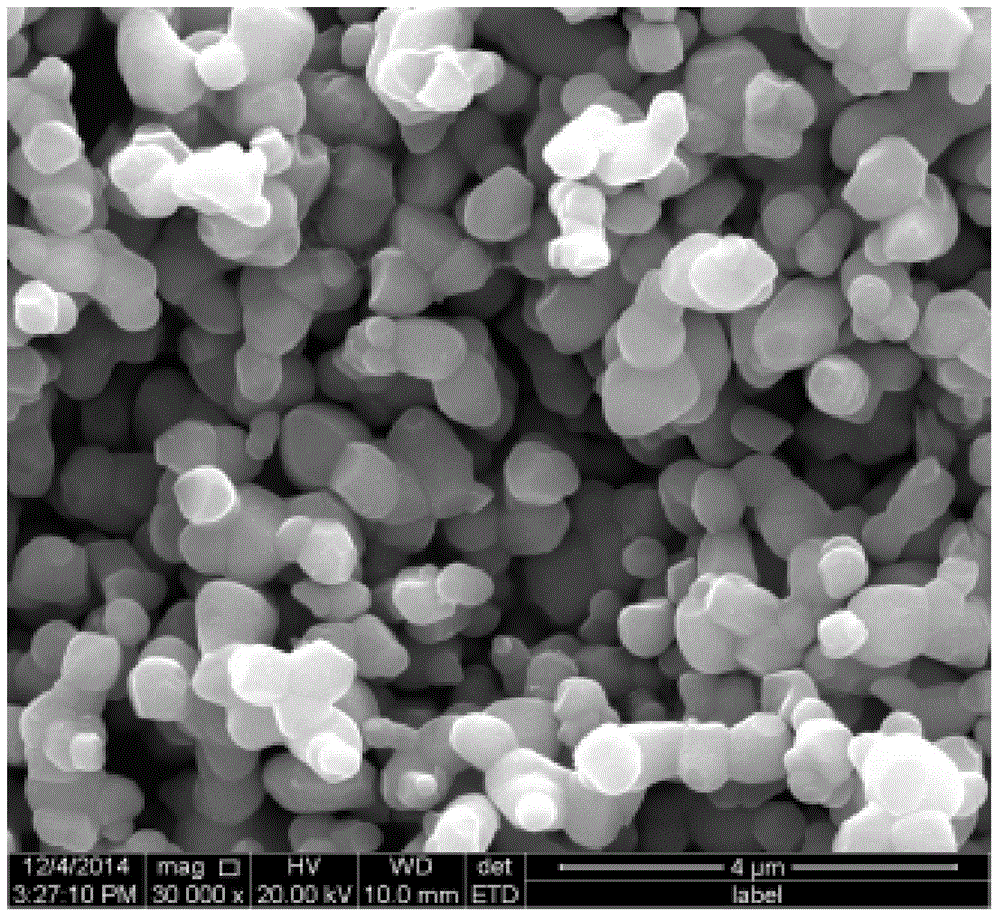

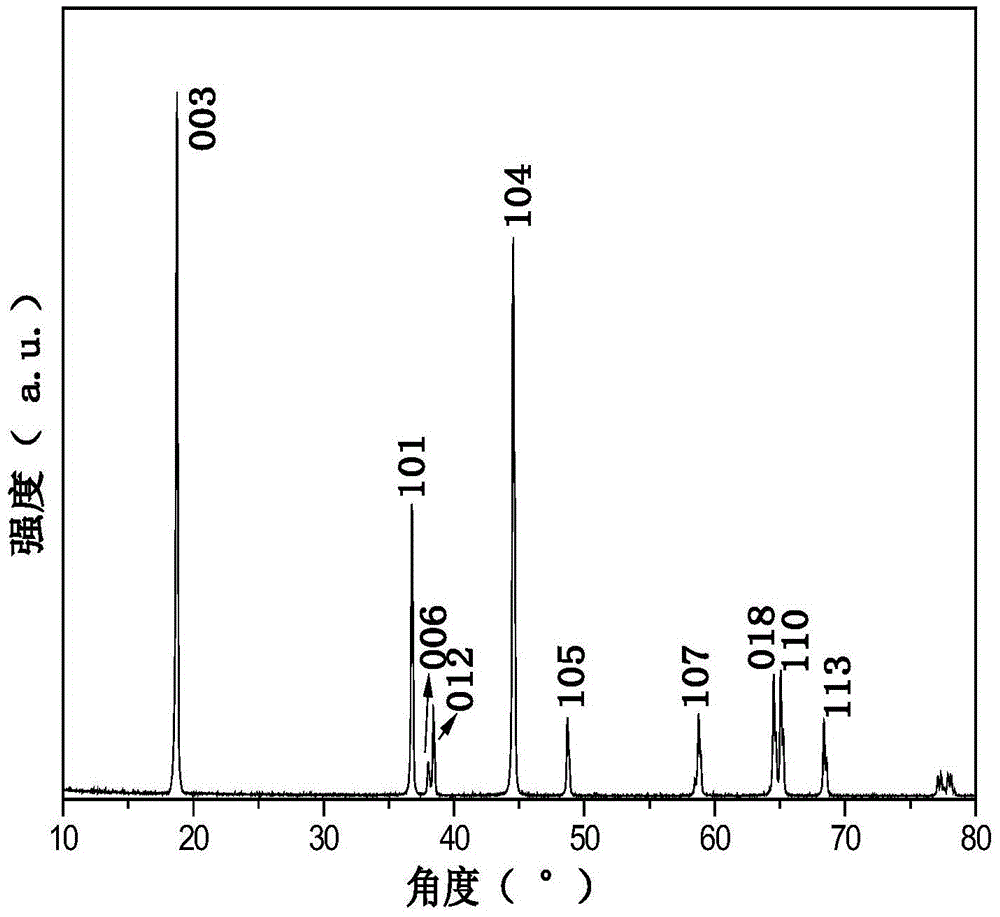

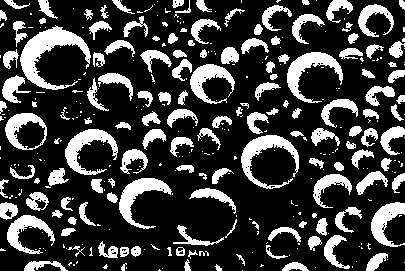

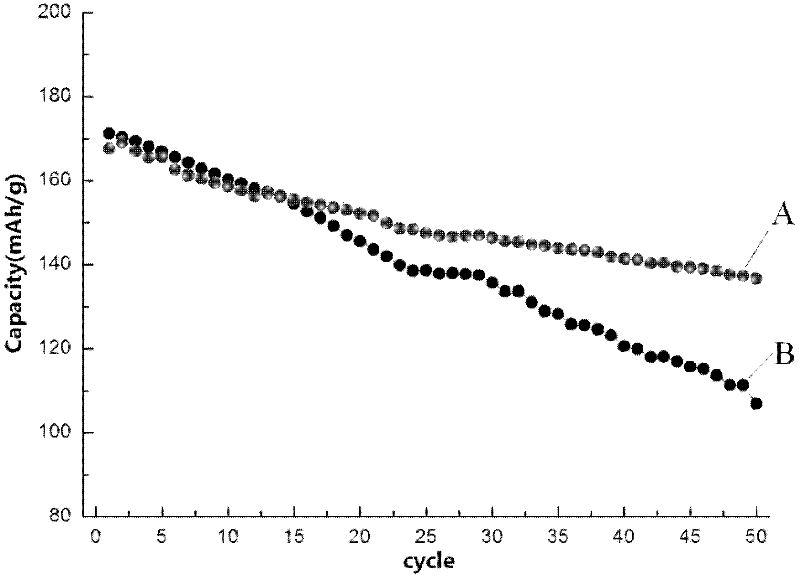

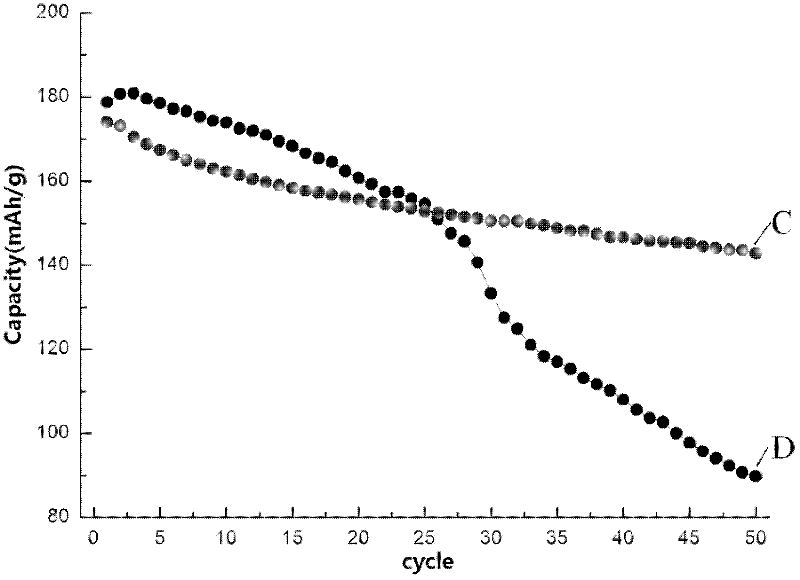

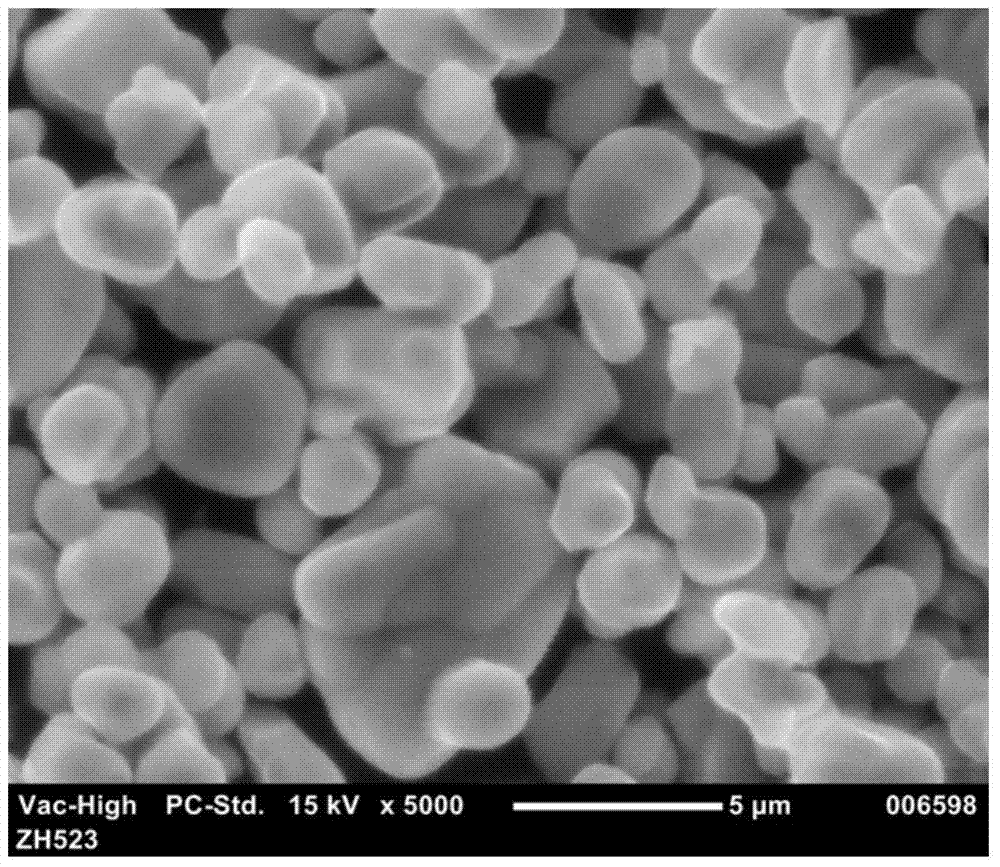

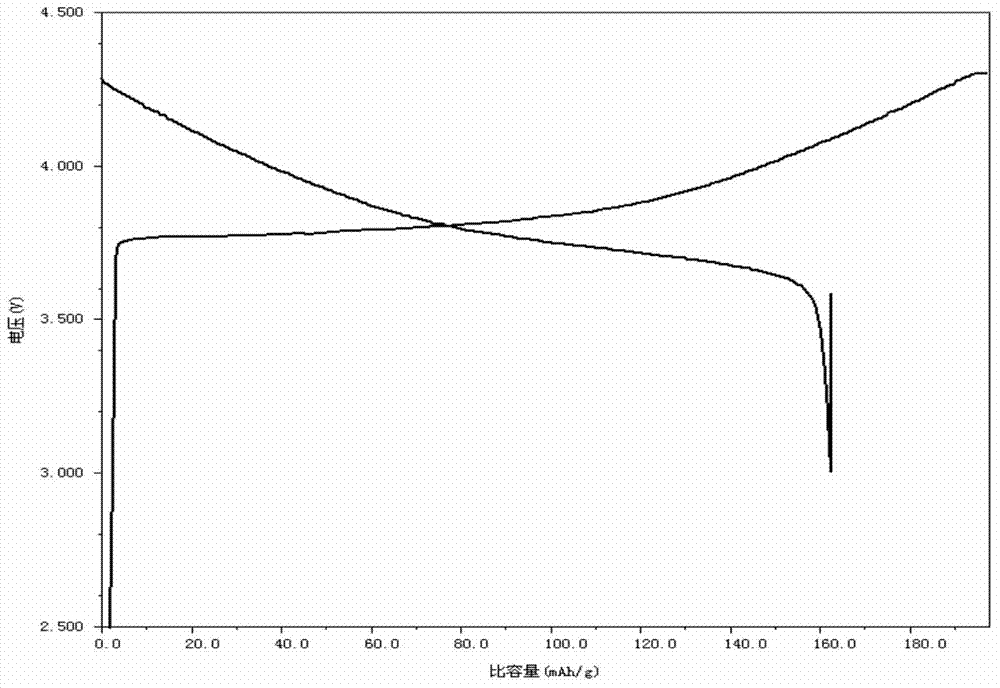

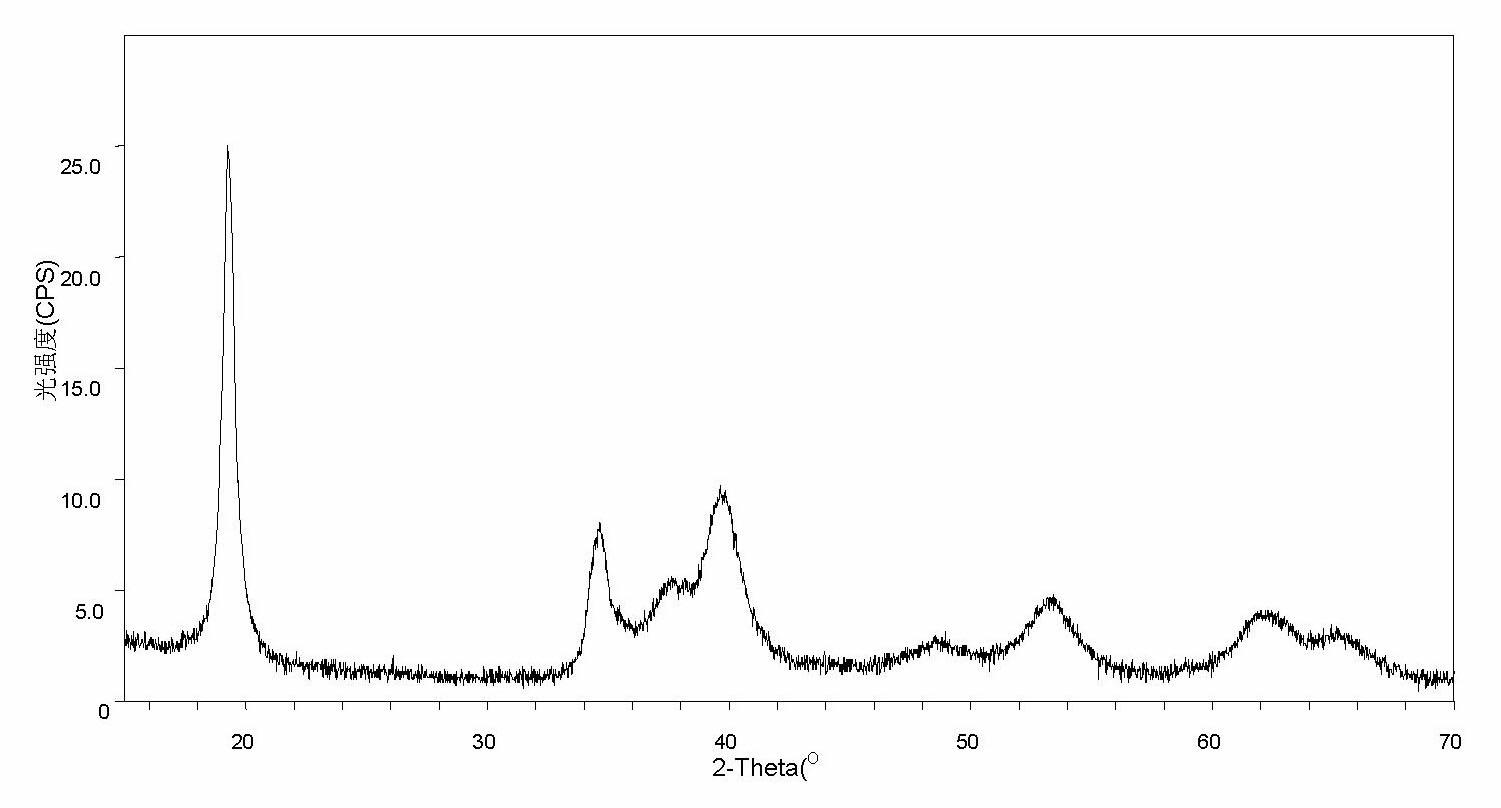

Process for preparing high density spherical nickel-cobalt lithium manganate as anode material of lithium ion cell

InactiveCN1622371AWell mixedImprove performanceElectrode manufacturing processesLithium compoundsNickel saltManganate

The present invention relates to energy source material technology, and is preparation process of high density spherical lithium nickel-cobalt-manganate as positive electrode material for lithium ion cell. The preparation process includes the reaction of nickel salt, cobalt salt, manganese salt, ammonium hydroxide and ammonian in water solution to synthesize spherical or spheroid precursor Ni1 / 3Co1 / 3Mn1 / 3 (OTHER)2, washing, drying and mixing with lithium carbonate; and high temperature treatment in the air at 750-950 deg.c for 8-48 hr to obtain spherical lithium nickel-cobalt-manganate. The spherical lithium nickel-cobalt-manganate has great bulk density reaching 2.25-2.50 g / cu cm after vibration densifying, average grain size of 3-7 microns, and reversible specific capacity up to 172-185 mA.hr / g.

Owner:TSINGHUA UNIV

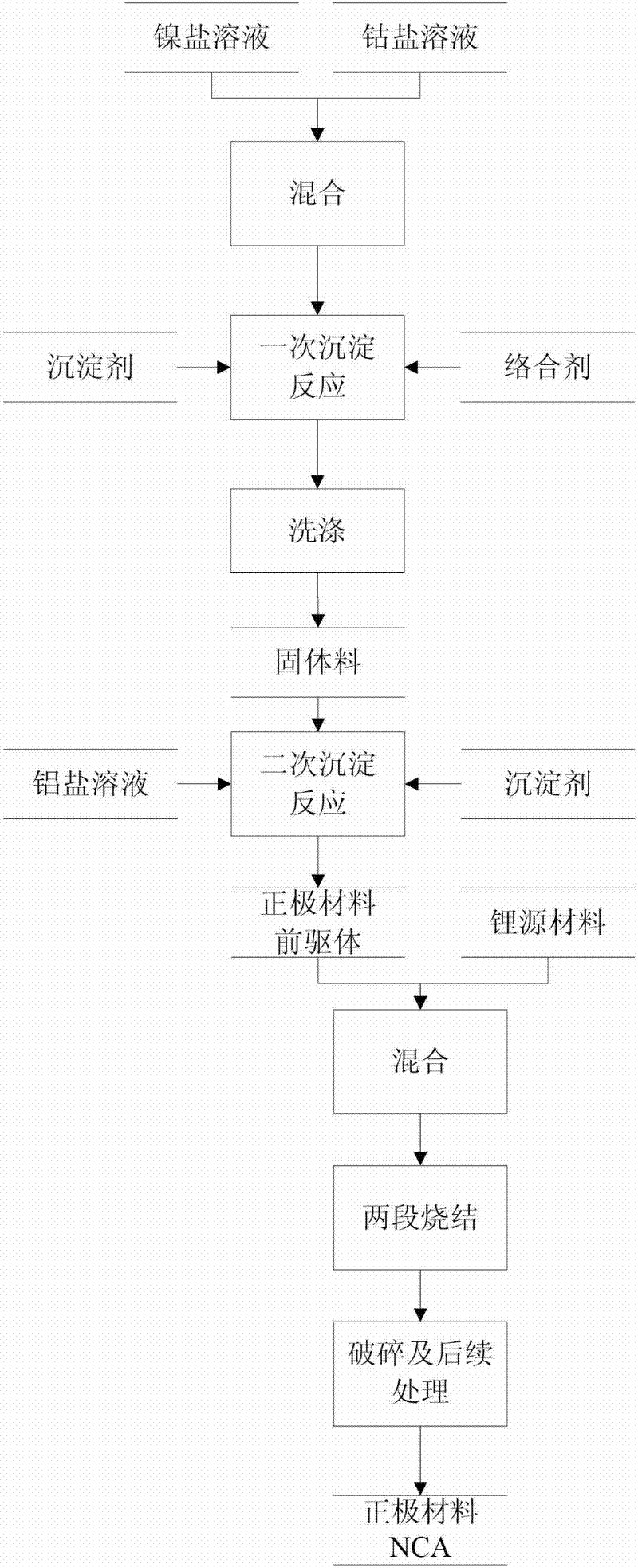

Method for preparing nickel cobalt aluminum serving as cathodic material of lithium ion battery

ActiveCN102244239AIncrease capacityImprove cycle performanceCell electrodesNickel saltElectrical battery

The invention discloses a method for preparing nickel cobalt aluminum serving as a cathodic material of a lithium ion battery, which comprises the following steps of: mixing nickel salt solution and cobalt salt solution uniformly, adding complexing agent solution, precipitant solution and the mixed solution into a reaction kettle with base solution in a parallel flow mode to perform precipitation reaction, performing solid-liquid separation after the reaction is performed fully, and washing; adding the washed solid material into the reaction kettle, dripping aluminum salt solution and the precipitant solution slowly to perform secondary precipitation reaction, so that an aluminum element is precipitated on the surface of the solid material gradually, stirring continuously in the integral process, performing solid-liquid separation after the reaction is finished, and washing and drying the solid material to a precursor of the cathodic material of the lithium ion battery; and mixing the precursor and a lithium source, performing two-section sintering under the condition of introducing oxygen, and crushing the calcined material which is subjected to the two-section sintering and performing subsequent processing to obtain the nickel cobalt aluminum serving as the cathodic material of the lithium ion battery. The method has the advantages of low requirement on equipment, high automation degree, environment friendliness, few wastes, high quality of products and the like and is easy to operate.

Owner:HUNAN CHANGYUAN LICO CO LTD

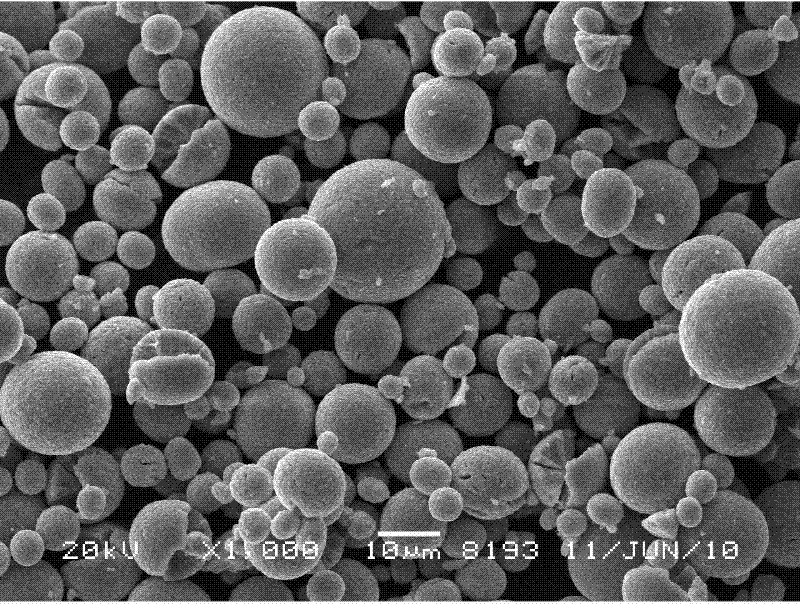

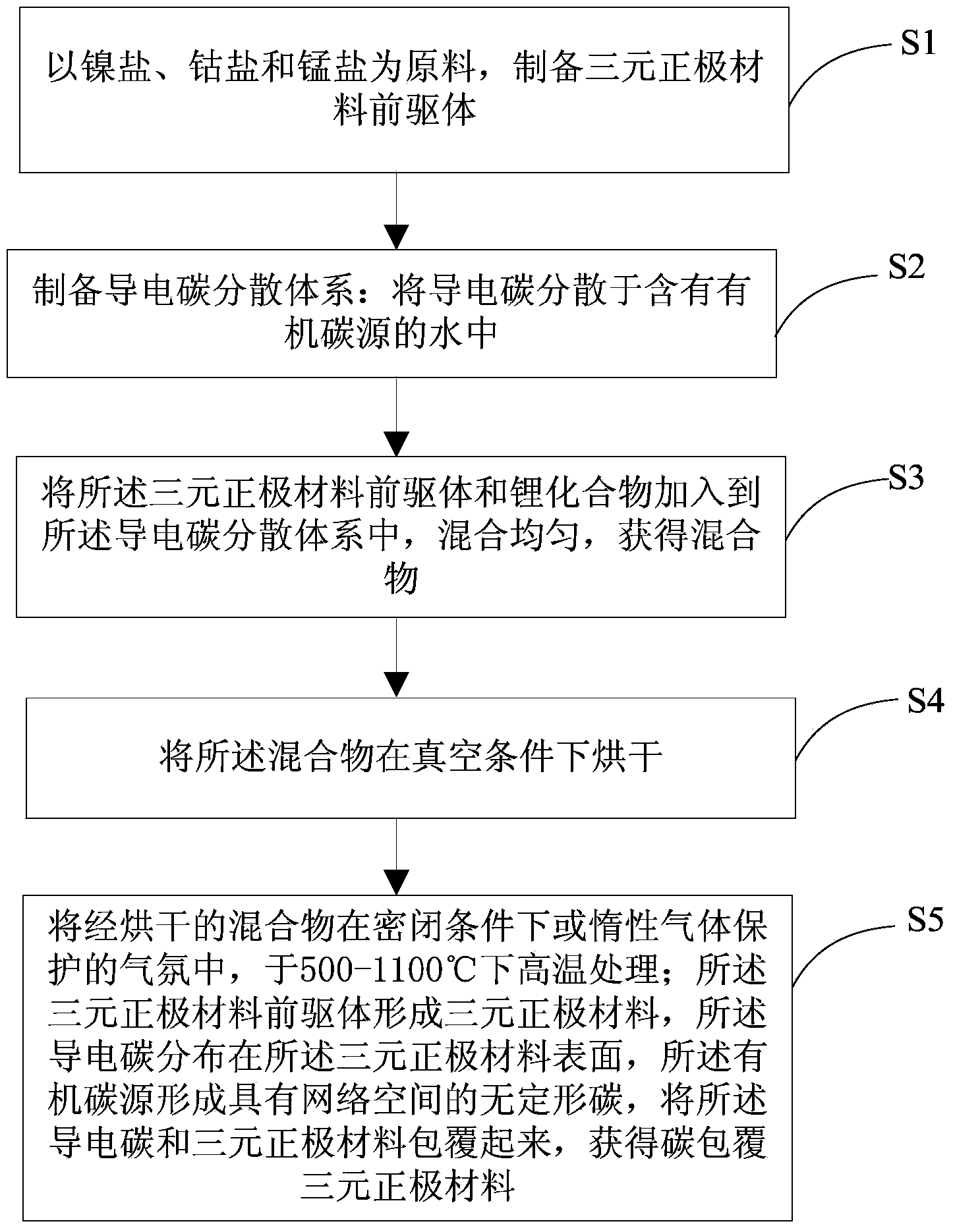

Carbon-coated ternary positive electrode material and preparation method thereof

ActiveCN103474628AImproved magnification performanceImprove conductivityCell electrodesNickel saltManganese

The invention discloses a carbon-coated ternary positive electrode material and a preparation method thereof. The preparation method comprises the following steps: S1, preparing a ternary positive electrode material precursor by taking nickel salt, cobalt salt and manganese salt as raw materials; S2, preparing a conductive carbon dispersion system, wherein conductive carbon is dispersed in water containing an organic carbon source; S3, adding the ternary positive electrode material precursor and a lithium compound into the conductive carbon dispersion system, and mixing uniformly to obtain a mixture; S4, drying the mixture under a vacuum condition; S5, carrying out high temperature treatment on the dried mixture under a closed condition or in an inert gas protection atmosphere so as to obtain the carbon-coated ternary positive electrode material. The carbon-coated ternary positive electrode material is uniform in coating, simple to operate, low in cost and high in efficiency; the conductive carbon and the ternary positive electrode material are simultaneously coated with network-shaped amorphous carbon which serves as a conductive medium or a channel of the conductive carbon and the ternary positive electrode material, thereby greatly improving the rate performance of the ternary positive electrode material.

Owner:SHENZHEN BETTERPOWER BATTERY

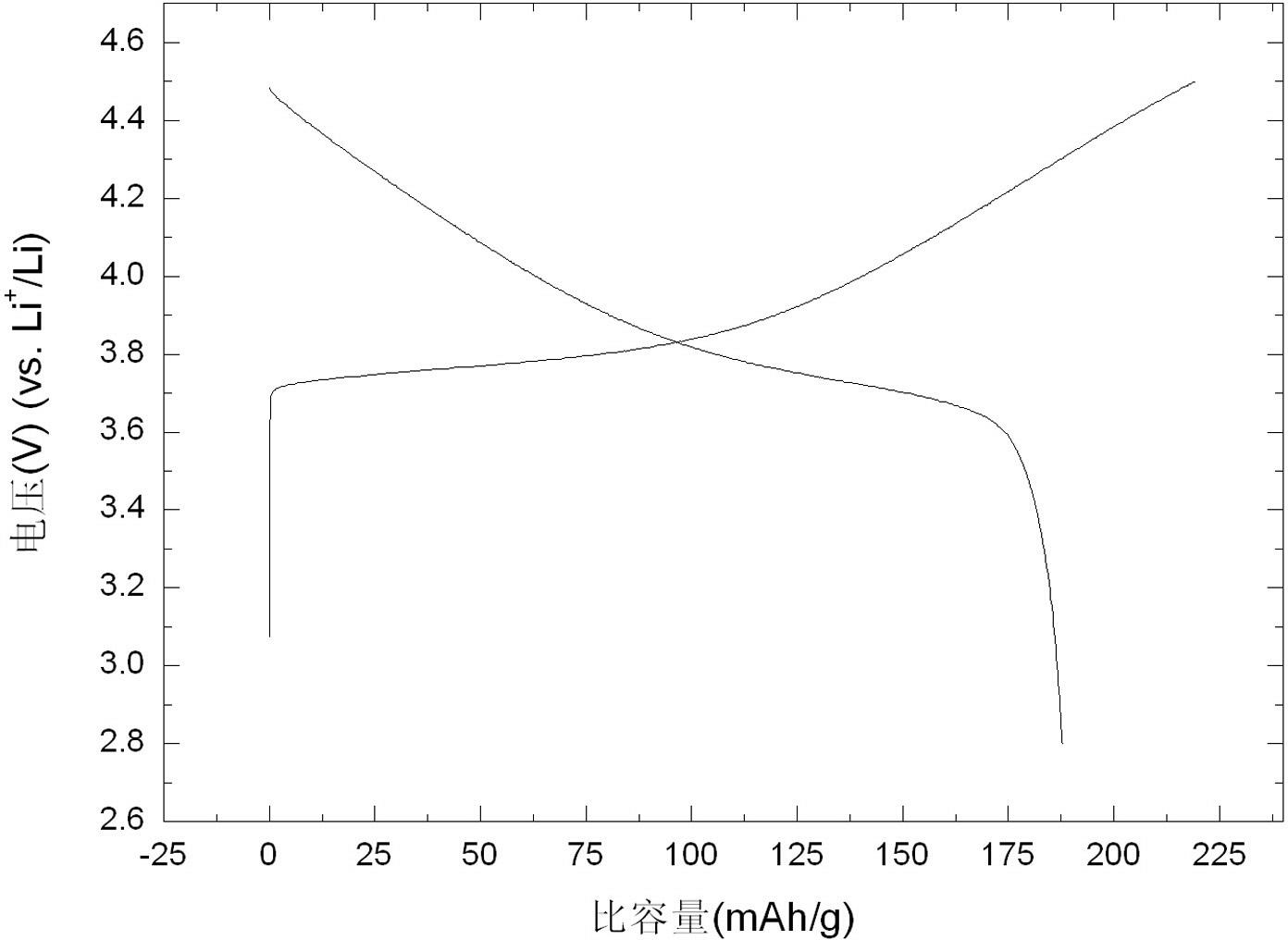

Preparation method of nano positive material for lithium ion battery

InactiveCN102386381AShort heat treatment timeReduce energy consumptionNanostructure manufactureCell electrodesNickel saltElectrical battery

The invention belongs to the field of preparation techniques of nanophase materials and green energy resources, and relates to a preparation method of a nano positive material LiNi1 / 3Mn1 / 3Co1 / 3O2 applied to a lithium ion battery. By using the method, the defects that the calcining temperature needed by a current synthetic material is high, the calcining time is long, the particle sizes of a product are not uniform, and the like, are mainly solved. The preparation method comprises the following steps: adding a certain amount of template agent in a mixed aqueous solution of a nickel salt, a manganese salt and a cobalt salt, and then, dripping a precipitant and a complexing agent into the obtained mixture to form a precipitate; subjecting the precipitate and the mixed aqueous solution to a high-pressure thermal reaction in a hydrothermal kettle, cleaning and baking the obtained product to be dry, so as to obtain a nickel manganese cobalt oxide; and finally, uniformly mixing the nickel manganese cobalt oxide with the lithium salt to prepare a final product by calcining and cooling. By using the preparation method, the product with favorable electrochemical performance can be obtained within a shorter calcining time; the energy consumption is decreased; and the preparation method has obvious economic benefit in the large-scale application of industrial synthesis.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +2

Method for preparing nickel-coated alumina powder

The invention relates to a preparation method of nickel-coated alumina oxide powder, in particular to the preparation method of nickel-coated aluminum oxide powder for thermal spraying in aviation, aerospace and military fields. The invention is characterized in that: a suspension is made from a mixing liquid of nano-aluminum oxide and dispersant, stirred and added with nickel salt solution at the same time, and the obtained mixture liquid is dropped with ammonium water after being fully stirred, added with distilled water, when dark blue mixing solution C of nickel ammonia complex ([Ni (NH3)) 2+and alumina oxide is obtained; the mixing solution C is aged by water, filtered, washed and dried, and a green middle coated product is obtained; the green middle coated product is further reduced and roasted, finally, black nickel-coated aluminum oxide powder is prepared. The nickel-coated aluminum oxide powder prepared through the invention has uniform granularity, with average size less than or equal to 1.0Mum, and can enhance the application performance of nano-alumina and expand the application of nano-aluminum oxide; the product is mainly used for aviation, aerospace and military materials and other high-tech fields. The method of the invention is simple, reproducible and easy to be industrialized.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Rare-earth doping modified lithium ion battery ternary positive electrode material and preparation method thereof

ActiveCN103855384AEase of industrial productionImprove charge and discharge efficiencyCell electrodesSecondary cellsCarbon compositesNickel salt

The invention relates to a rare-earth doping modified lithium ion battery ternary positive electrode material and a preparation method of the rare-earth doping modified lithium ion battery ternary positive electrode material. The chemical general formula of the material is as follows: LiNiaCo<1-a-b>MnbRxO2 / M, wherein a is more than 0 and less than 1, b is more than 0 and less than 1, (1-a-b) is more than 0 and less than 1, x is more than 0.005 and less than 0.1, R is one or more of rare-earth lanthanum, cerium, praseodymium and samarium, and M is a composite cladding layer of oxide of aluminum, titanium or magnesium and carbon. The soluble metal nickel salt, cobalt salt, manganese salt and rare-earth compound are mixed to prepare a mixed salt solution, the mixed salt solution is reacted with a mixed alkaline solution prepared by mixing NaOH and ammonium hydroxide, after the reaction solution is filtered, washed and dried, the obtained product is uniformly mixed with lithium salt powder to be ball milled, then the mixture is calcined at the high temperature and coated with the composite cladding layer of the aluminum, titanium or magnesium oxide and carbon, and finally the calcined mixture is calcined at a constant temperature to obtain the rare-earth doping modified lithium ion battery ternary positive electrode material. After doping the rare earth, the metal oxide and carbon composite cladding layer, which are cheap and easy to obtain, are adopted, so that the cycling performance and the rate performance can be improved, and the charging-discharging efficiency of the material also can be improved.

Owner:ZHEJIANG MEIDARUI NEW MATERIAL TECH CO LTD

Processing method of aluminum and aluminum alloy super hydrophobic surface

InactiveCN101007304ASuperhydrophobicEasy to rollAntifouling/underwater paintsPretreated surfacesNickel saltCopper

The invention involves an aluminum or aluminum alloy super-hydrophobic surface preparation method. The method is: polishing the surface of aluminum or aluminum alloy using metallographic sandpaper or polishing paste, pure water washing, acetone ultrasonic cleaning, pure water washing and other clean treatment, handing it with chemical etching solution containing nitric acid and metal salts (copper or nickel salt) 30s-20min under 90 ~ 100 degree C, then coating low surface energy material on its surface to get super-hydrophobic property. The aluminum or aluminum alloy surface treated by the invention has excellent hydrophobicity, the contact angle of water and surface can be as high as 150-165 degree, droplets are easy to roll on the surface. The method of the invention need not complex equipment, cost is low, technology is simple and repeatability is good.

Owner:SOUTH CHINA UNIV OF TECH

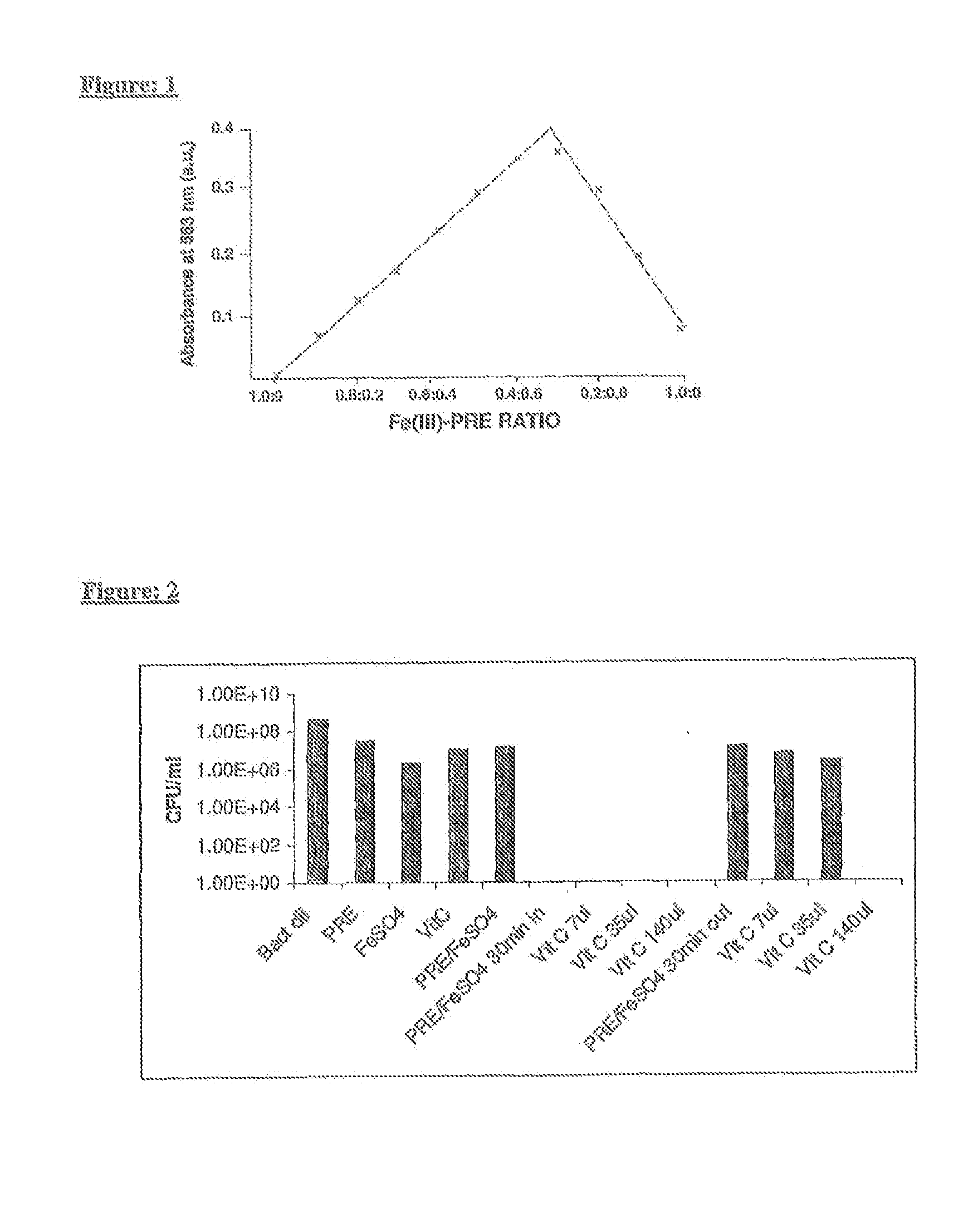

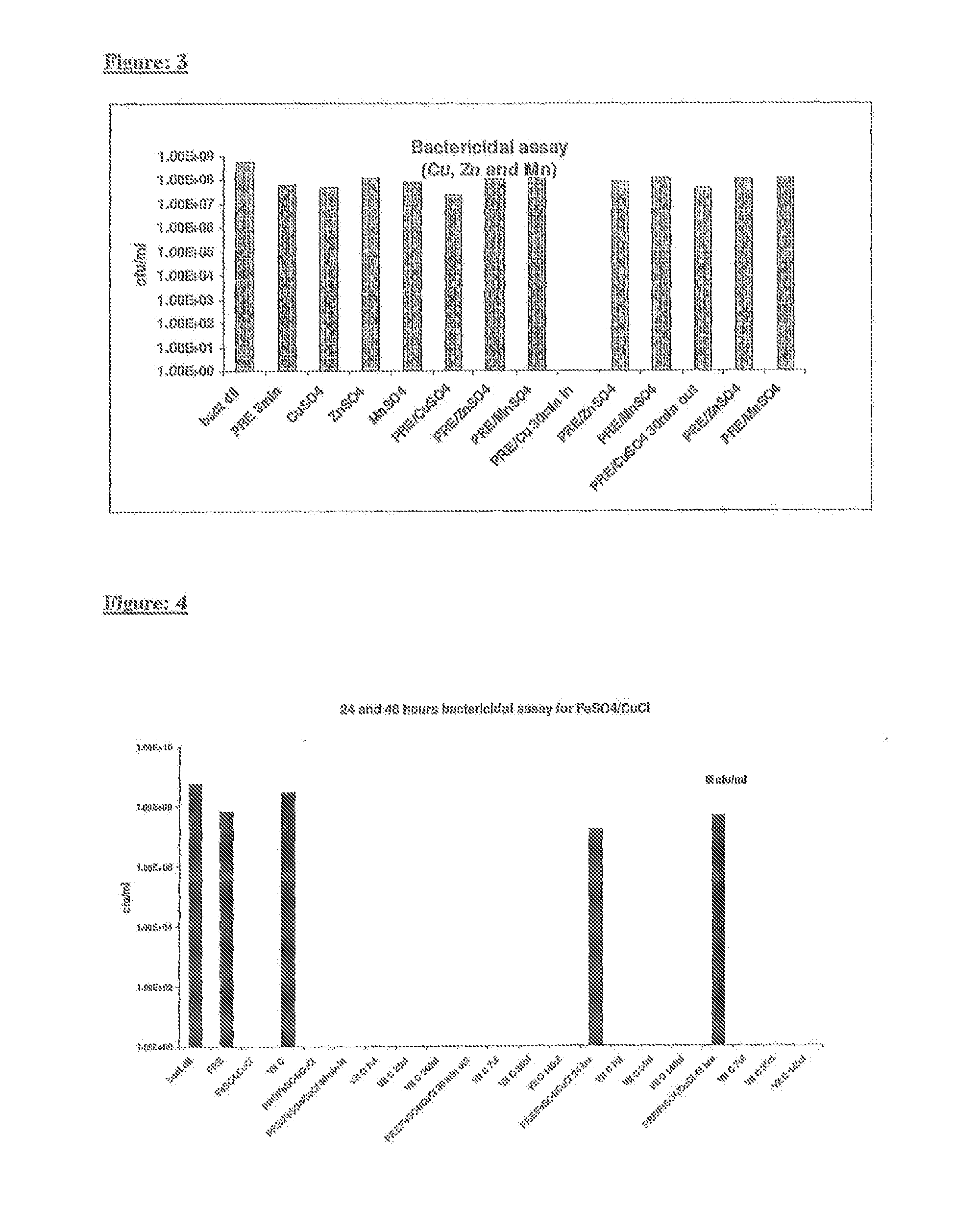

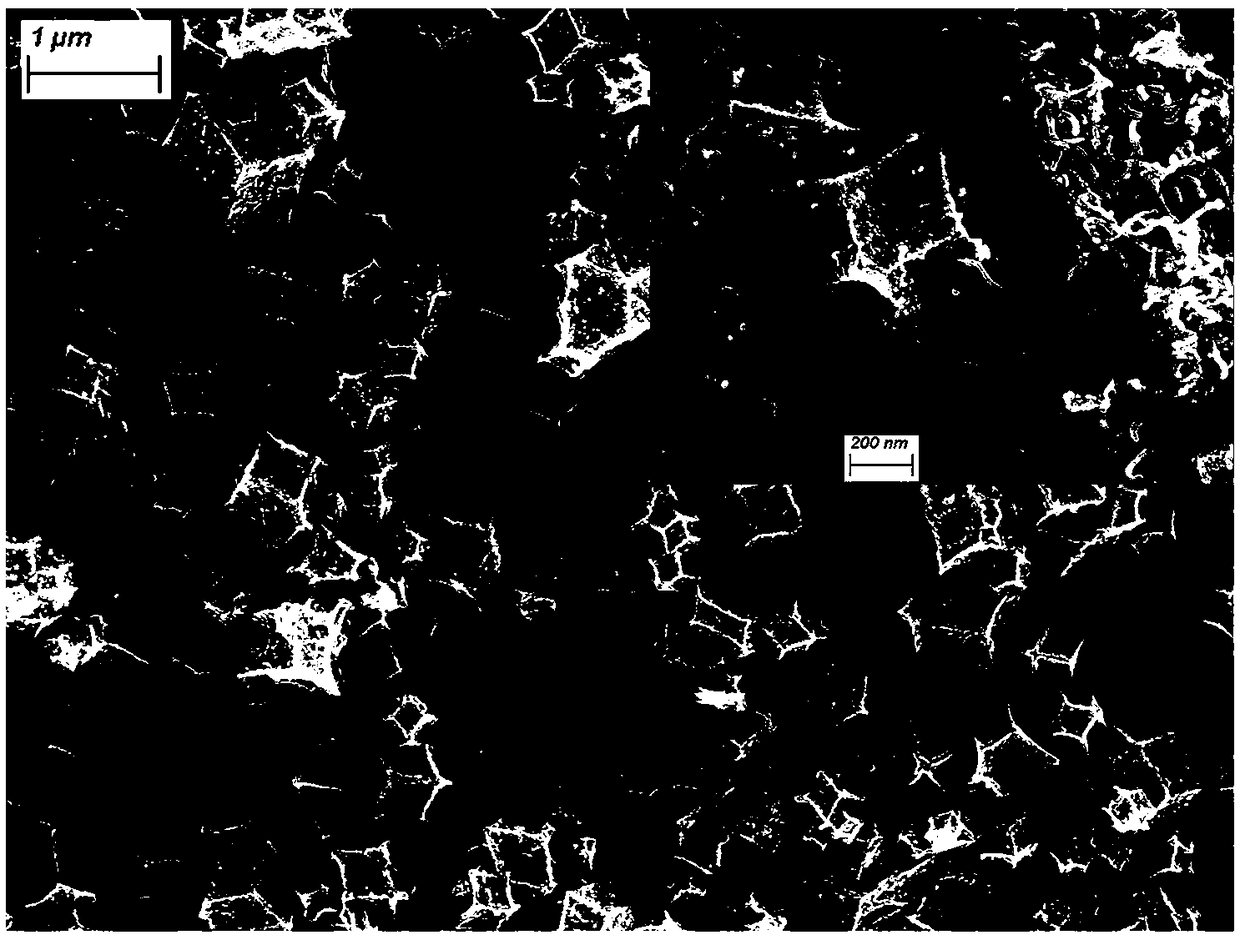

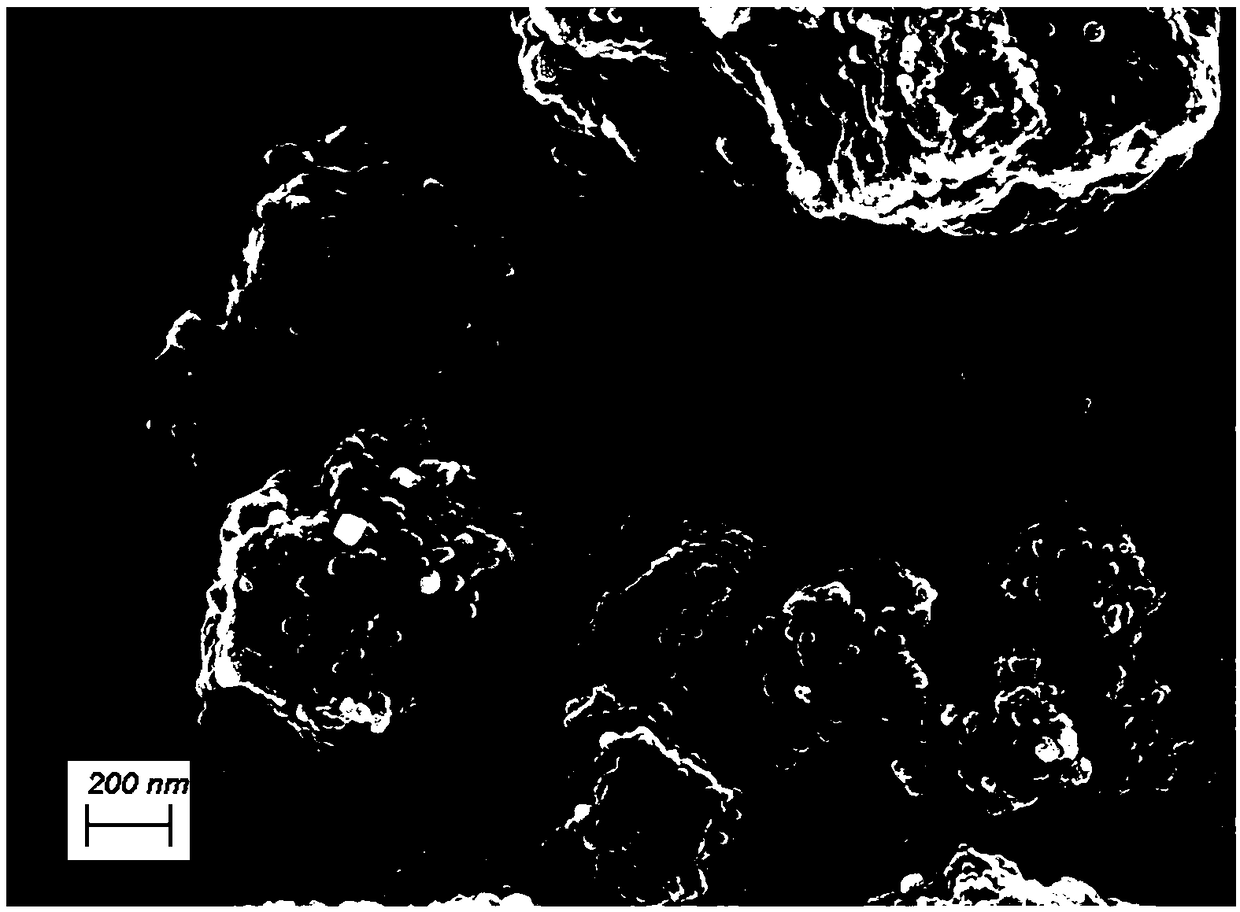

Antimicrobial Composition

Disclosed herein are antimicrobial compositions comprising an effective concentration of a metal salt combined with a plant extract. In some embodiments the composition comprises a copper salt and / or an iron salt and / or a nickel salt and / or a cobalt salt; and an extract of a plant selected from a group consisting of Punka granatum, Viburnum plicatum, Camellia sinensis, and Acer spp. The invention extends to uses of such compositions as medicaments, and to methods of treating microbial infections. The invention extends to methods for preventing microbial infections by coating objects and surfaces with the compositions.

Owner:NATURE THERAPEUTICS

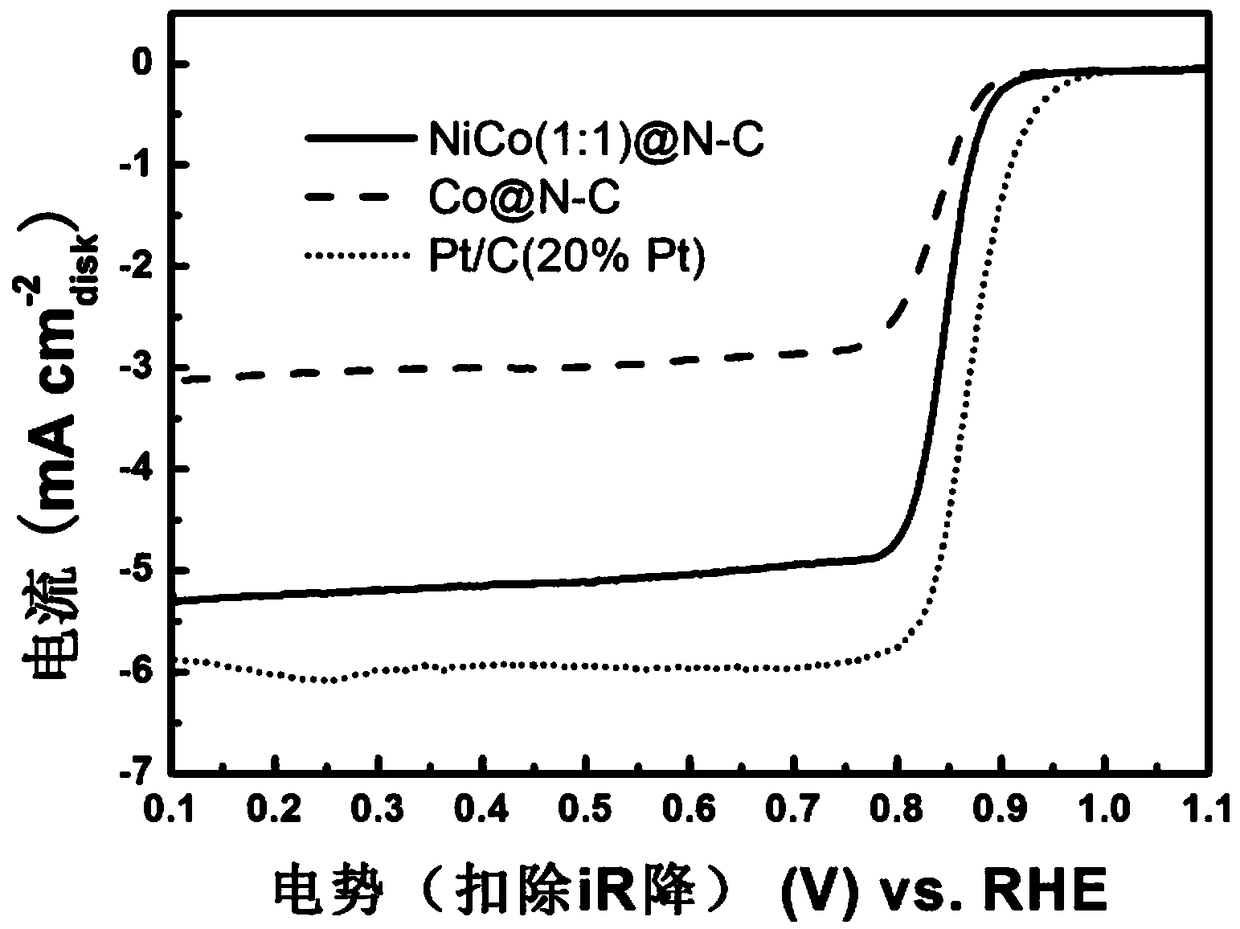

MOFs (Metal Organic Frameworks)-based NiCo@N-C dual-function oxygen electrode catalyst and preparation method thereof

InactiveCN108722460AImprove conductivityImprove stabilityCatalyst activation/preparationNickel saltCarbonization

The invention discloses an MOFs (Metal Organic Frameworks)-based NiCo@N-C dual-function oxygen electrode catalyst and a preparation method thereof. The NiCo@N-C dual-function oxygen electrode catalystis a rhombic polyhedral having a carbon nano tube structure on the surface. The NiCo@N-C dual-function oxygen electrode catalyst has the BET superficial area of 169.9-268.7m<2> / g and the total pore volume of 0.26-0.20cm<3> / g, and is of an N-doped C cage coated NiCo alloy structure. The preparation method disclosed by the invention comprises the following steps: performing coordination on a cobaltsalt and a nickel salt with dimethylimidazole in an organic reagent so as to obtain NiCo bimetallic MOFs of different atomic ratios, performing high-temperature pyrolysis under inert gas shielding bytaking the bimetallic MOFs as a template, performing one-step carbonization on N-containing organic ligands to produce an N-doped coating structure coated with the NiCo alloy. Therefore, electronic structure control of metal catalytic activity is realized, highly regular porous structure and high specific surface area are remained, and the high N doping amount and conductivity of the obtained N-Cmaterial are improved.

Owner:HUBEI UNIV

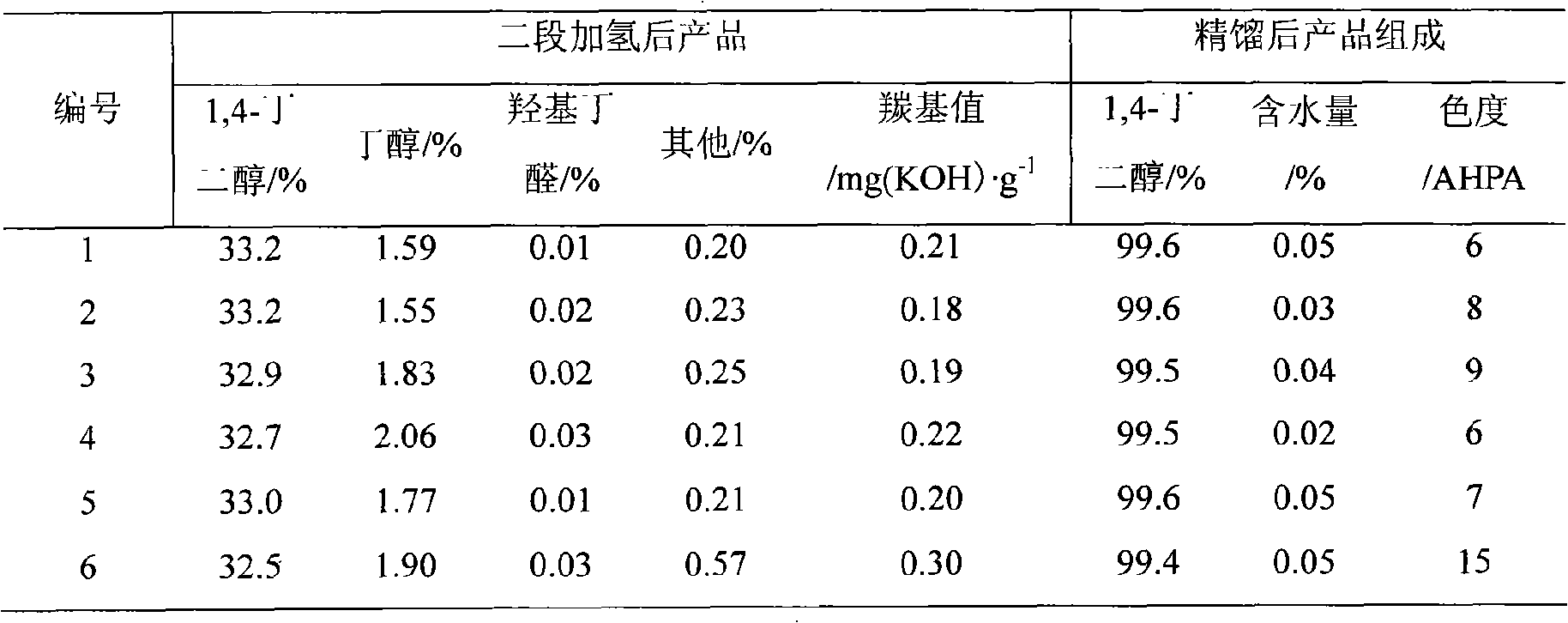

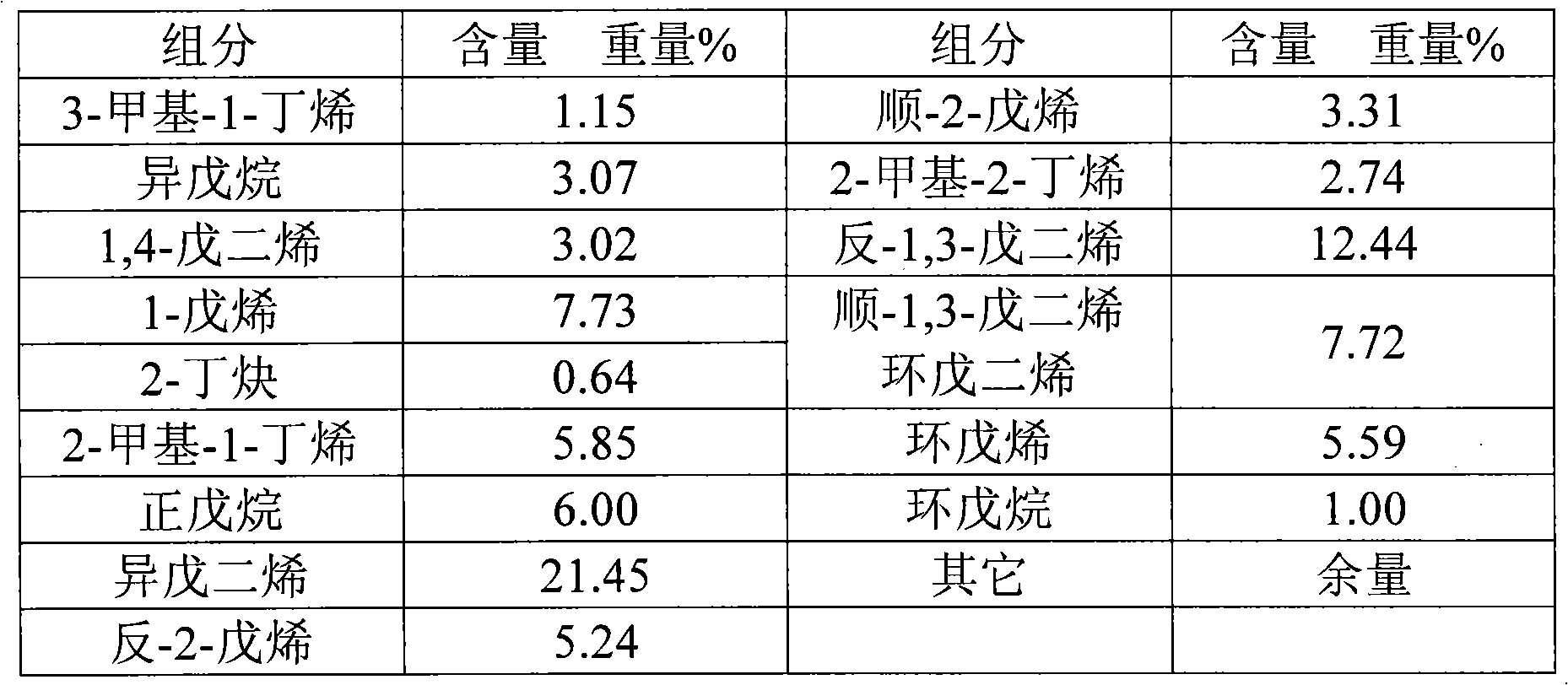

Preparation method of butanediol secondary hydrogenation catalyst by butynediol two-step hydrogenation

ActiveCN101306368AUniform depositionGood dispersionPreparation by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsNickel saltSURFACTANT BLEND

The invention provides a method for preparing a butanediol secondary hydrogenation catalyst through adopting the butynediol two-step hydrotreation, and the method comprises the following steps: an accelerant is introduced into an alumina carrier; the carrier is heated; mixed nickel complex solution containing organic nickel salt, inorganic nickel salt and surfactant is prepared; the mixed nickel salt solution is dipped on the heated carrier, and the catalyst product with the nickel content of 5-25 w% and the accelerant content of 0.001-6 w% can be obtained by drying, baking, deoxidizing and passivating. The catalyst can be used in the process of preparing the butanediol secondary hydrogenation by adopting the butynediol two-step hydrotreation, the carbonyl can be reduced to be lower than 0.2 mg (KOH)*g<-1>, and the contents of acetal and butylene glycol are enabled to be reduced to the lowest level. Through the subsequent rectification, the butylene glycol product with the purity more than or equal to 99.5 percent and the chromaticity lower than or equal to 10 AHPA can be produced.

Owner:SHANXI UNIV

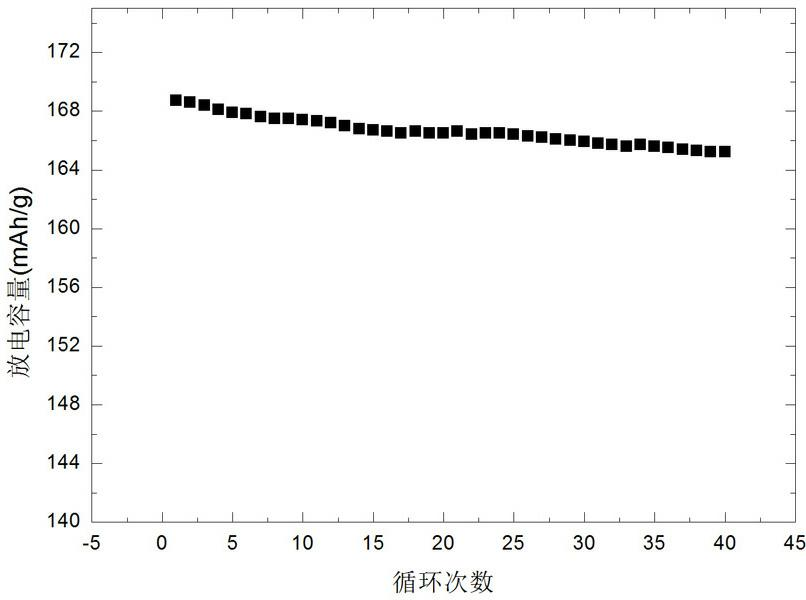

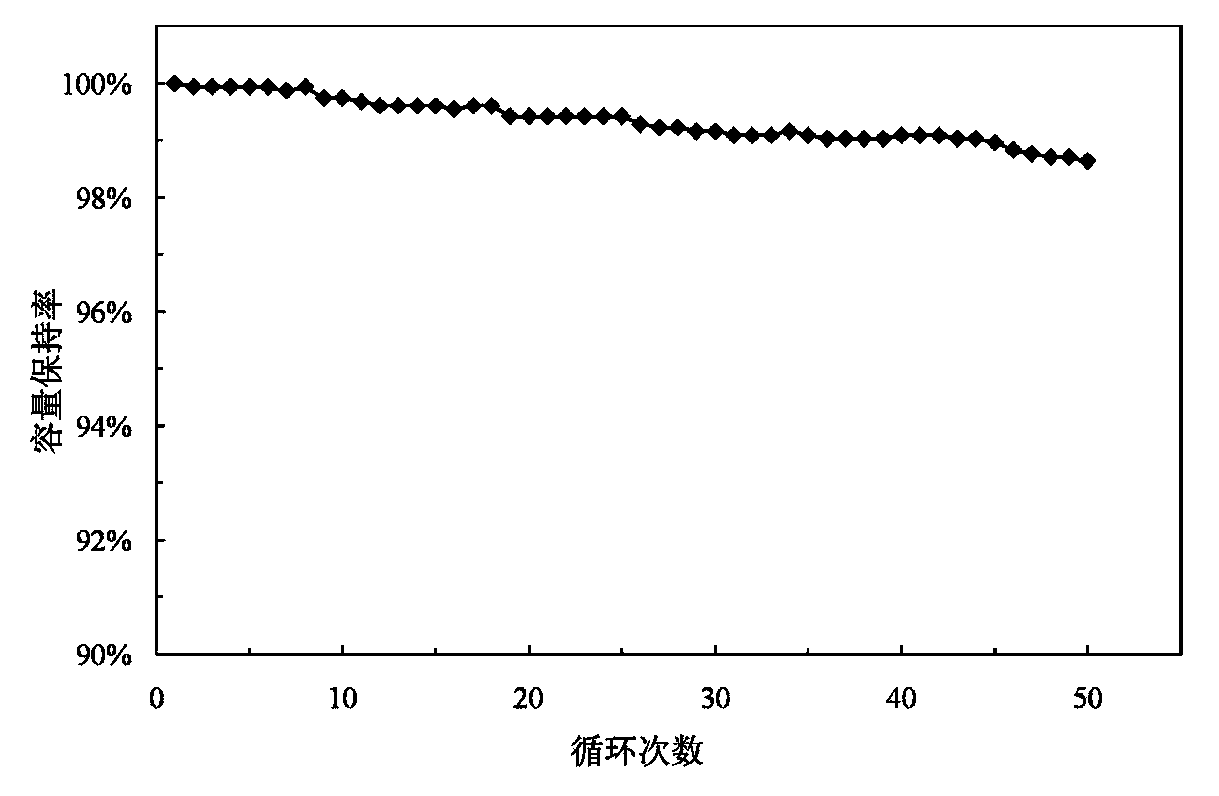

Modified lithium ion battery ternary positive electrode material and preparation method thereof

InactiveCN103855387ALower sintering temperatureHigh tap densityCell electrodesSecondary cellsAir atmosphereNickel salt

The invention relates to a modified lithium ion battery ternary positive electrode material and a preparation method of the modified lithium ion battery ternary positive electrode material. The chemical generation formula of the material is as follows: LiNiaCo<1-a-b>MnbBxO2 / TiO2, wherein a is more than 0 and less than 1, b is more than 0 and less than 1, (1-a-b) is more than 0 and less than 1, x is more than 0.005 and less than 0.1, and the TiO2 is a cladding layer. The soluble nickel salt, cobalt salt and manganese salt are prepared into a mixed salt solution, the mixed salt solution is reacted with a mixed alkaline solution prepared by mixing the NaOH and ammonium hydroxide, after being filtered, washed and dried, the reaction product is mixed with a boronic compound and roasted for 4h to 12h at the temperature of 300 to 800 DEG C under an air atmosphere, then the roasted product is ball milled with the lithium salt to be uniformly mixed together, the mixture is coated with titanium dioxide after being calcined at the high temperature to obtain the modified lithium ion battery ternary positive electrode material. The prepared boron doping modified ternary positive electrode material is high in specific capacity and good in cycling performance.

Owner:ZHEJIANG MEIDARUI NEW MATERIAL TECH CO LTD

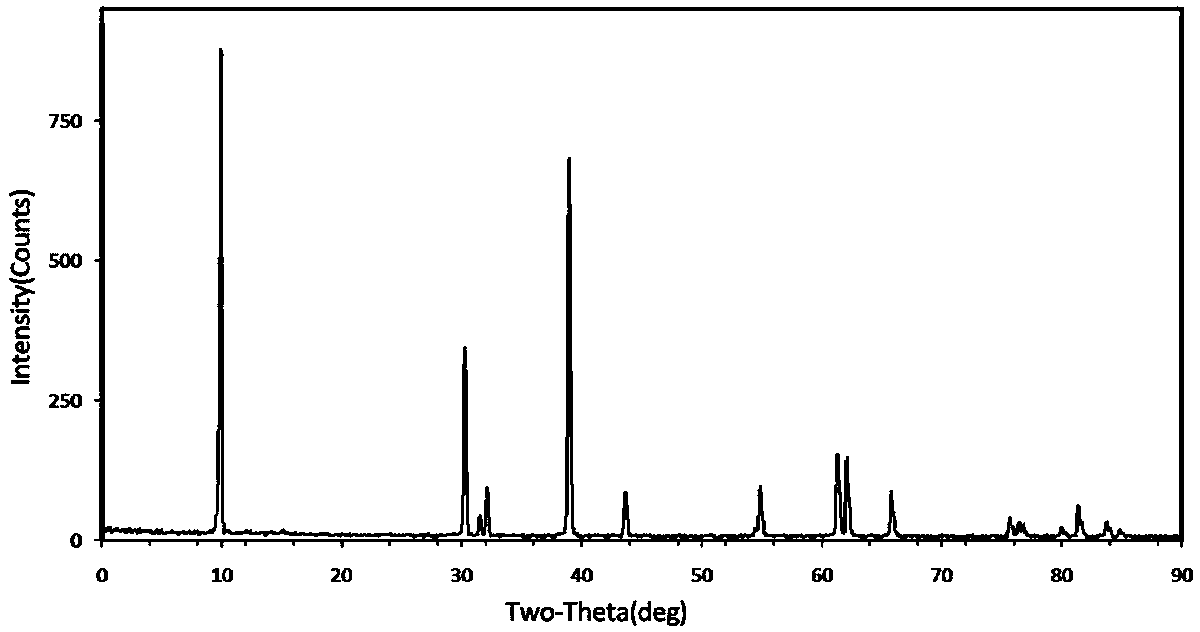

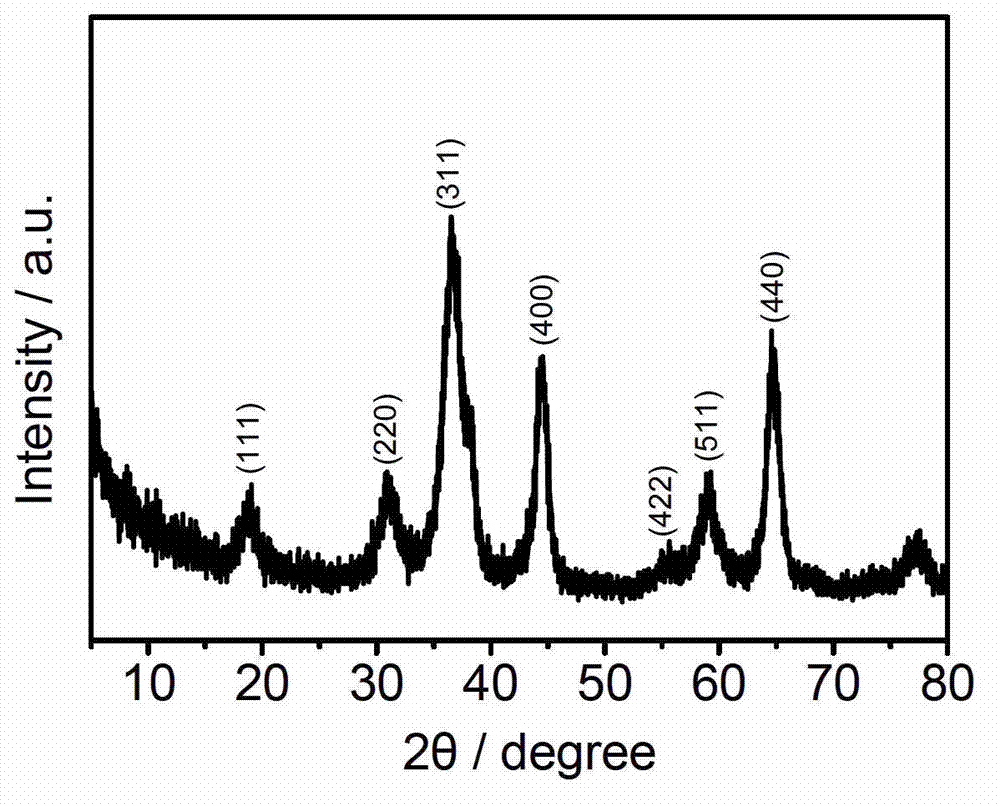

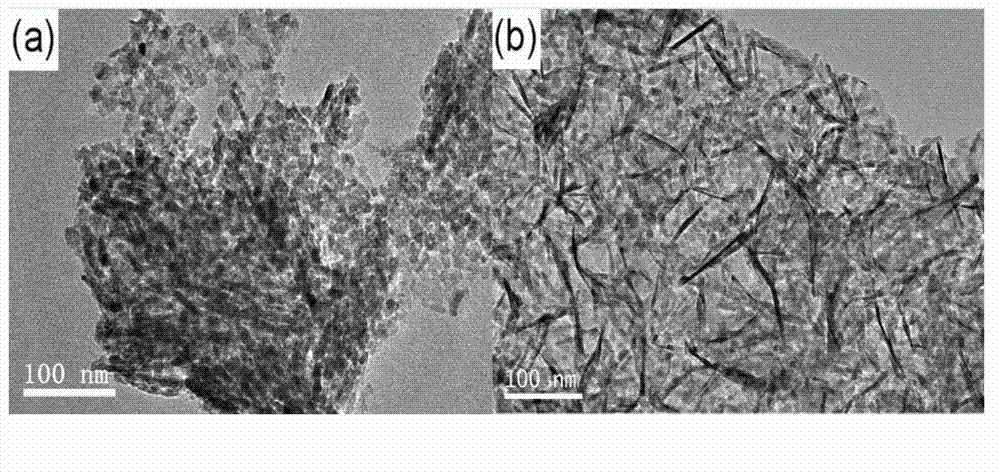

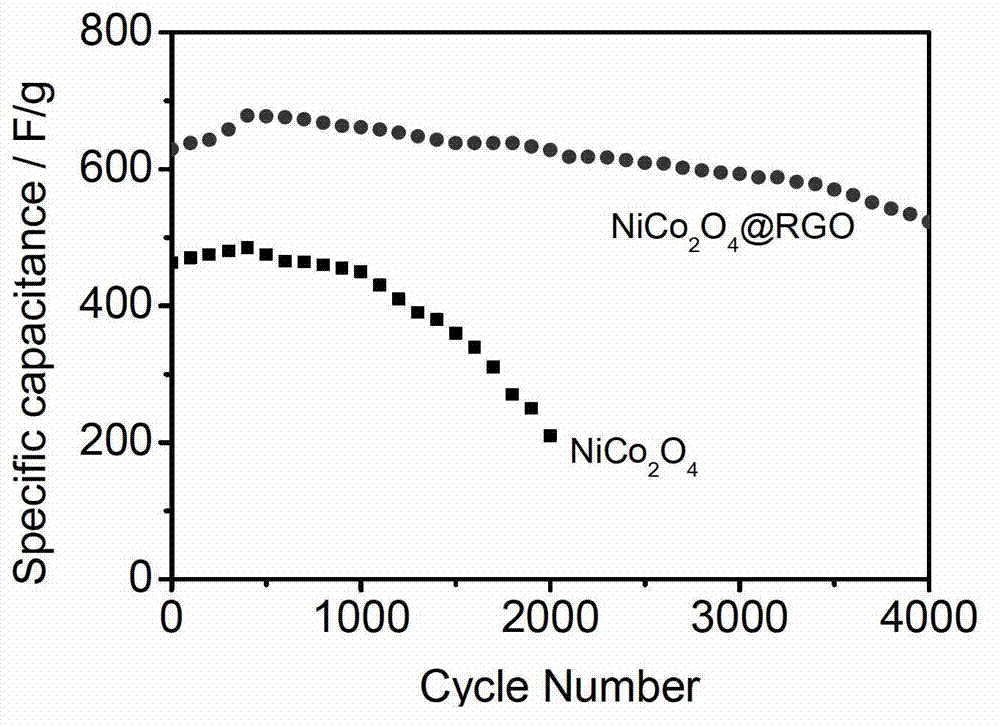

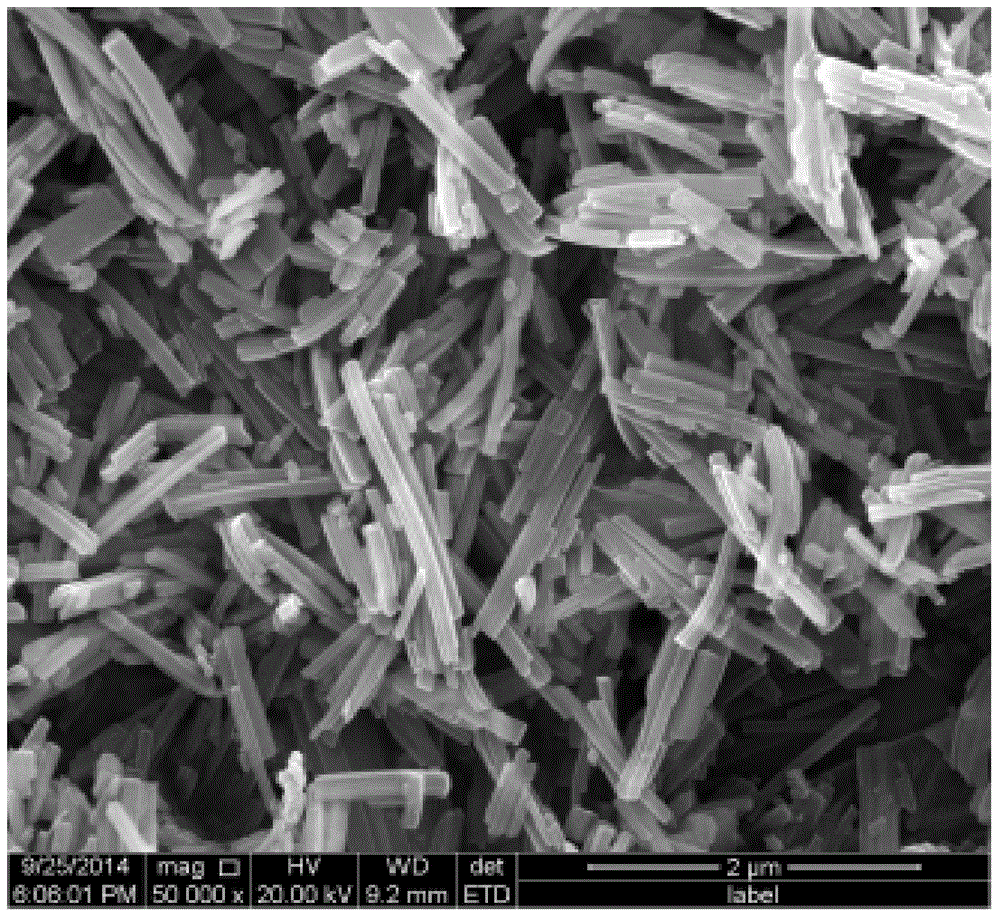

Nickel cobaltate-graphene composite material and application and preparation method thereof

InactiveCN102891016ASmall sizeLarge specific surface areaElectrolytic capacitorsCapacitanceNickel salt

The invention relates to a nickel cobaltate-graphene composite material and a preparation method thereof. The composite material comprises graphene and nickel cobaltate, wherein nickel cobaltate nanowires are uniformly grown on a graphene sheet, the wire length of the nickel cobaltate nanowires is 50-300nm, and the wire width is 5-30nm. The preparation method comprises the following steps of: taking a graphene oxide water solution and a cobalt salt and nickel salt water solution which are dispersed in an ultrasonic manner, mixing, further adding a precipitator, uniformly stirring and mixing, transferring into a high-temperature reaction kettle, performing hydro-thermal reaction for a certain period of time, filtering, washing and drying an obtained product, and further performing thermal treatment so as to obtain the nickel cobaltate nanowire-graphene composite material. The nickel cobaltate nanowire-graphene composite material prepared by the method disclosed by the invention has the advantages of high single-electrode capacitance and good cycle performance, and is suitable for being used as an electrode material of a super-capacitor.

Owner:CHANGZHOU UNIV

Manganese-included multi-element metal oxide, lithium ion secondary battery anode material and its preparing method

ActiveCN1770513AImprove cycle performanceUniform particle sizeCell electrodesSecondary cellsNickel saltLithium hydroxide

This invention relates to one multi-element metal oxidation and discloses The process method, which comprises the following steps: a, in nitrogen or inertance gas depositing the mixture of cobalt salt, nickel salt and maganism salt to generate Ni-Co-Mn compound hydrogen oxidation to process front drive after drying and grinding; b, adding lithium hydrate into the front drive grinding and processing mixture to remove absorbed water and structure water; c, processing products under degrees of 650 to 850 degrees; d, using high polymer as assistant agent to process surface covering on product; e, processing the product to remove solvent to process multi-metal oxidation.

Owner:TIANJIN GUOAN MGL NEW MATERIALS TECH CO LTD

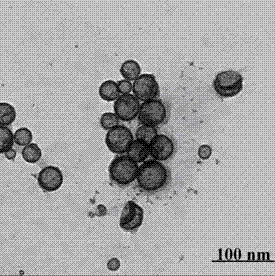

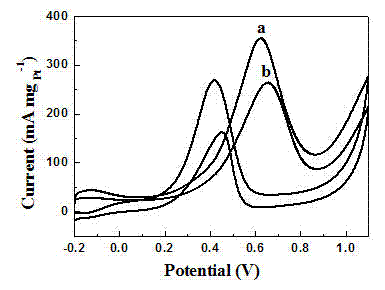

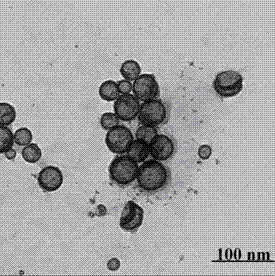

PtNi alloy/graphene combined nanometer catalyst with hollow structure and preparation method thereof

InactiveCN102430413AUnique hollow structureReduce dosageCell electrodesMetal/metal-oxides/metal-hydroxide catalystsNano catalystPlatinum salts

A PtNi alloy / graphene combined nanometer catalyst with a hollow structure adopts the graphene as a carrier and loads the PtNi alloy nanometer particles of which the grain diameter is 10-50 nm on the surface of the graphene, wherein the PtNi alloy nanometer particles are hollow spherical structures. The method for preparing the combined catalyst comprises the following steps: dispersing the graphene oxide in water liquor to which surfactant is added through ultrasound; uniformly mixing with soluble nickel salt (II); adding the reducing agent in inert gas atmosphere; adding soluble platinum salt (IV); stirring at 0-50 DEG C to execute the reduction reaction; centrifuging, washing and drying the reaction product to obtain the PtNi alloy / graphene combined nanometer catalyst with the hollow structure. The PtNi alloy / graphene combined nanometer catalyst with the hollow structure in the invention has good electro-catalytic property on electrochemical oxidation of methyl alcohol, and can be widely applied in methyl alcohol fuel cells.

Owner:NANJING NORMAL UNIVERSITY

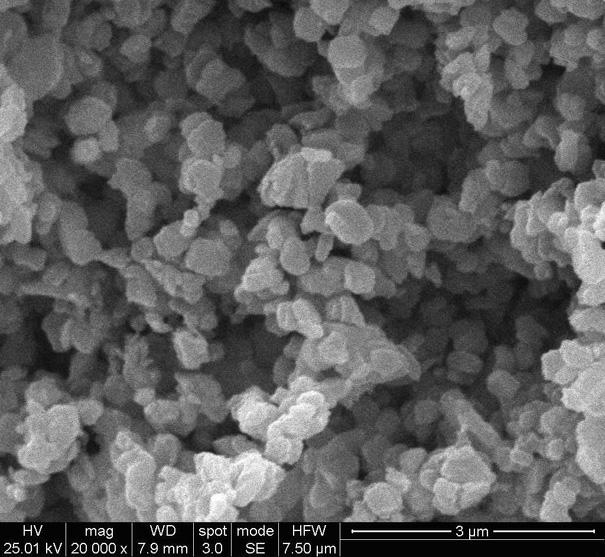

Preparation method of single-crystal Li(NiCoMn)O2 ternary cathode material

InactiveCN104868122AUniversalSimple preparation processCell electrodesNickel compoundsNickel saltHigh rate

The invention relates to a preparation method of a single-crystal Li(NiCoMn)O2 ternary cathode material, and belongs to the technical field of a manufacturing process for chemical electrode materials. The preparation method comprises the following steps: firstly, nickel salt, cobalt salt and manganese salt are dissolved in a deionized water and ethylene glycol mixed solution, the mixture is uniformly stirred, a surfactant is added, the mixed solution is clarified, a precipitant is added, the mixture is uniformly stirred and poured into a reactor, the reactor is arranged in a drying oven for a reaction, and then an obtained precursor and lithium salt are mixed, presintered and calcined to obtain a target product. The preparation method is simple and convenient to operate, the controllability of preparation parameters is high, the prepared ternary cathode material is a single-crystal material, particle sizes are concentrated at the submicron dimension, a fast conveying channel with the short path is provided for lithium ions, and contact of the material with an electrolyte is increased. The ternary cathode material has high specific capacity, high rate capability and high cycling stability, and meets the requirements of electronic products with high volume energy density.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

High-density spherical nickel-cobalt-aluminum precursor material and preparation method thereof

ActiveCN103553152AEffective control of coprecipitation reaction processControl the Co-precipitation Reaction ProcessCell electrodesNickel oxides/hydroxidesNickel saltHigh density

The invention discloses a high-density spherical nickel-cobalt-aluminum precursor material. The chemical molecular formula of the nickel-cobalt-aluminum precursor material is Ni(1-x-y)CoxAly(OH)(2+y); the tap density of the nickel-cobalt-aluminum precursor material is 1.8-2.4 g / cm3; the material is spherically granular; the average particle size of the material ranges from 6 to 17 microns. The invention also discloses a preparation method of the precursor material. The preparation method comprises the following steps of: firstly, evenly mixing an aluminum salt with a complexing agent; secondly, evenly mixing a nickel salt with a cobalt salt solution; adding the mixed solution, the complexing agent and a precipitator solution to a reactor in parallel for continuous coprecipitation reaction, controlling the pH value in the reaction process within the range from 11 to 12, keeping the materials stay in the reactor not more than 20 h, performing solid-liquid separation after stable reaction, and finally, aging, washing and drying the solid material to obtain the high-density spherical nickel-cobalt-aluminum precursor material. The aluminum element in the high-density spherical nickel-cobalt-aluminum precursor material provided by the invention can be combined with nickel and cobalt elements evenly; and the tap density of the high-density spherical nickel-cobalt-aluminum precursor material is higher.

Owner:JINCHI ENERGY MATERIALS CO LTD

Method for preparing catalyst for preparing synthesis gas by reforming methane and carbon dioxide

InactiveCN101637726ALow costHigh catalytic activityHydrogenMetal/metal-oxides/metal-hydroxide catalystsNickel saltCerium

The invention relates to a method for preparing a catalyst for preparing synthesis gas by reforming methane and carbon dioxide, which comprises the following steps: soaking a carrier into a mixed solution of cerium(III) nitrate and lanthanum nitrate, and drying and roasting the soaked carrier for 2 to 10 hours to obtain a modified carrier (A); soaking the (A) into a soluble nickel salt solution orsoaking the (A) into a chloroplatinic acid solution, and drying and roasting the soaked carrier to obtain (B) or (C); soaking the (B) into the chloroplatinic acid solution or soaking the (C) into thesoluble nickel salt solution, and drying and roasting the soaked carrier to obtain a catalyst precursor, or soaking the modified carrier into a mixed solution of the soluble nickel salt solution andthe chloroplatinic acid, and drying and roasting the soaked carrier to obtain a catalyst precursor; and reducing the precursor in hydrogen and nitrogen mixed gas to obtain the catalyst. The catalyst has the advantages of low cost, good catalytic activity under the reaction condition of large space velocity, high selectivity for H2 and CO, and good sintering resistance and carbon deposition resistance.

Owner:PETROCHINA CO LTD

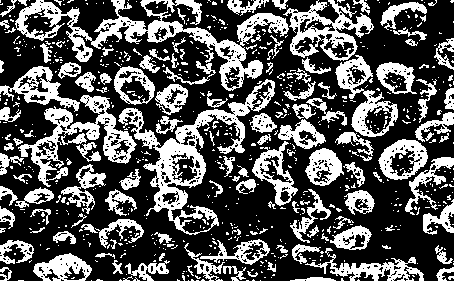

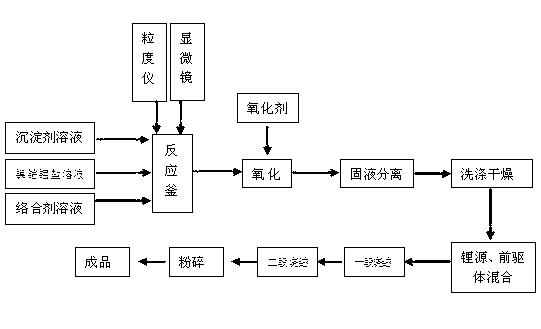

Method for preparing nickel cobalt lithium aluminate cathode material

The invention discloses a method for preparing a nickel cobalt lithium aluminate cathode material. The method comprises the following steps of: uniformly mixing a nickel salt solution, a cobalt salt solution and an aluminum salt solution in a certain mole ratio of metal ions; adding a complexing agent solution, a precipitator solution and a metal salt solution together into a high-speed stirring reaction kettle with a base solution, and performing precipitation reaction; after complete reaction, performing oxidizing reaction on discharged slurry and an oxidizing agent with certain concentration in an alkaline environment; after the oxidizing reaction is finished, performing solid liquid separation on the slurry, washing in pure water, and drying to obtain a nickel cobalt aluminum hydroxyl oxide precursor of a lithium ion battery cathode material; fully mixing the precursor with a lithium source, and performing multi-step sintering in an oxygen atmosphere; and performing crushing and subsequent treatment on a material obtained by sintering, and thus obtaining the nickel cobalt lithium aluminate cathode material. The method is low in equipment requirement, simple in flow, low in energy consumption and low in waste. The produced material is high in tap density and high in capacity.

Owner:HUNAN SOUNDDON NEW ENERGY

Method of electroplating zinc, nickel, molybdenum and their alloys by using ionic liquid

The invention discloses a novel cleaning plating technology by using an ionic liquid which is a non-aqueous media as an electroplate liquid. Through using the technology, problems of bad environment and unstable qualities of electroplates existing in the condition of electroplating zinc, nickel, molybdenum and their alloys in an aqueous system can be solved. Qualities of coatings generated by using the technology are better than the qualities of coatings generated in the traditional system. The technology comprises the following steps: dissolving zinc salts, nickel salts and molybdate salt into the ionic liquid which is regarded as an electrolyte to prepare the electroplate liquid; electroplating at a current density of 1-30mA / cm2, wherein metallic zinc, nickel, molybdenum and their alloys are taken as soluble anode or graphite, complex carbon, glassy carbon, metal tungsten and titanium base plating platinum are taken as insoluble anode, and components which are needed to be electroplated are taken as cathode. Needed depth of coating can be obtained through controlling the current density and electroplating time.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Eggshell type nickel-based catalyst

ActiveCN101890351AHigh activityHigh selectivityMolecular sieve catalystsCatalyst activation/preparationSal ammoniacNickel salt

The invention discloses an eggshell type nickel-based catalyst and a preparation method and application thereof, belonging to the technical field of nickel-based catalysts and aiming at developing the eggshell type nickel-based catalyst for meeting the demand. The research shows that the eggshell type nickel-based catalyst can be prepared by dissolving nickel salt into ammonia water solution, loading the mixed solution on a catalyst carrier by adopting a spraying or immersing mode, drying, roasting and reducing. The active component of nickel is mostly centralized in an area from the surface of the carrier to the part of 0.7mm below the surface and can remarkably improve the conversion rate and the selectivity of the catalyst. The invention can be applied to the technical fields of hydrogen addition and trace amount of carbon monoxide removal from hydrogen and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of lithium-ion battery cathode material coated aluminum

InactiveCN102299299ACoating process conditions are easy to controlImprove high temperature stabilityCell electrodesNickel saltElectrical battery

The invention relates to a method for preparing aluminum-coated anode materials of lithium-ion batteries, which is characterized in that: firstly, soluble nickel salts, cobalt salts, and manganese salts are formulated into salt solutions, and then mixed with ammonia-water-mixed sodium hydroxide or potassium hydroxide solutions React to form precursor particles, wash and dry; add water to the dried precursor particles to prepare a flowable slurry, stir, and add trivalent aluminum salt solution and sodium hydroxide or potassium hydroxide solution dropwise to the slurry at the same time , to obtain the precursor of nickel hydroxide cobalt manganese coated with aluminum; then mix the precursor with lithium source, and then sinter to obtain the positive electrode material of lithium ion battery coated with aluminum. The present invention has the following obvious advantages: raw materials are easy to obtain; coated The process conditions are easy to control, and it is easy to obtain a relatively uniform coating body; the prepared positive electrode material can make the lithium ion battery have superior high temperature stability and better cycle characteristics.

Owner:深圳市天骄科技开发有限公司

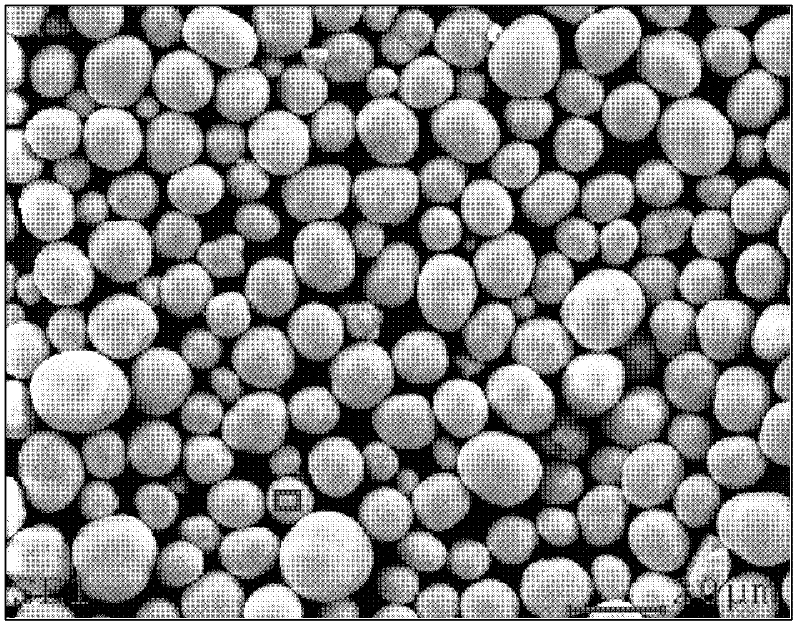

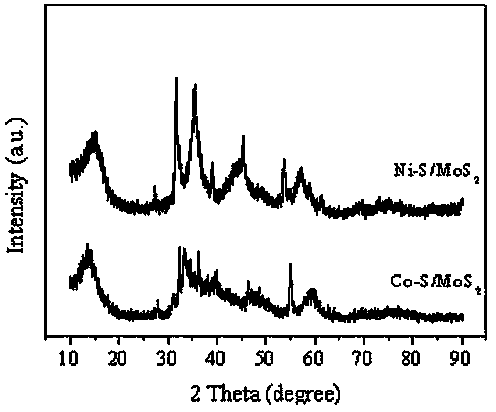

Double-metal-sulfide catalyst with high hydrodeoxygenation activity and preparation method thereof

InactiveCN103920506ALarge specific surface areaHigh catalytic activityPhysical/chemical process catalystsRefining to eliminate hetero atomsNickel saltVulcanization

The invention relates to a preparation method for a double-metal-sulfide catalyst. Soluble molybdate and nickel salt or cobalt salt serves as a raw material, thiourea or thioacetamide serves as a sulfur source, and a Ni(Co)-S / MoS2 catalyst is prepared through a two-step hydrothermal method. The method particularly comprises the following steps: MoS2 is prepared in a high pressure reactor through the hydrothermal method first, then the nickel salt or cobalt salt and the sulfur source are added into the reactor of the obtained MoS2 to be evenly mixed, the reactor is sealed and heated, a reaction is conducted for a certain period of time, and Ni-S or Co-S is deposited on the MoS2, so that the Ni(Co)-S / MoS2 catalyst is prepared. The preparation method is characterized in that the specific area of the Ni(Co)-S / MoS2 catalyst prepared through the two-step hydrothermal method is large, high temperature vulcanization is not required in the preparation process, the preparation condition is mild, the catalyst is used for hydrodeoxygenation, a target product has high yield and good repeatability, and hydrodeoxygenation activity of the catalyst is high.

Owner:XIANGTAN UNIV

Preparation method of high density nickel cobalt lithium manganate positive electrode material

The invention discloses a preparation method of a high density nickel cobalt lithium manganate positive electrode material, LiNixCoyMnzO2. The preparation method comprises the following steps: firstly, mixing a nickel salt solution, a cobalt salt solution and a manganese salt solution according to a certain mol ratio, adding the mixed solution, a complexing agent solution and a precipitant solution together to a stirring reaction kettle with a base solution, fully reacting, carrying out solid-liquid separation, and washing and drying to obtain a globular nickel cobalt manganese oxyhydroxide precursor; calcining the precursor at the temperature of 350-900 DEG C for 2-20 hours to obtain a globular nickel cobalt manganese oxide precursor, and smashing the globular nickel cobalt manganese oxide precursor at high speed to obtain a mono-crystalline nickel cobalt manganese oxide precursor; mixing a lithium source and the mono-crystalline precursor according to a certain mol ratio, calcining at the temperature of 700-980 DEG C for 2-20 hours, and smashing and classing to obtain the mono-crystalline nickel cobalt lithium manganate positive electrode material. The preparation method provided by the invention has the advantages that the compacted density of the prepared nickel cobalt lithium manganate material is large, the specific capacity is high, the rate property and consistency are good, the preparation method is simple, and the preparation process is easy to control and operate.

Owner:HUNAN SOUNDDON NEW ENERGY

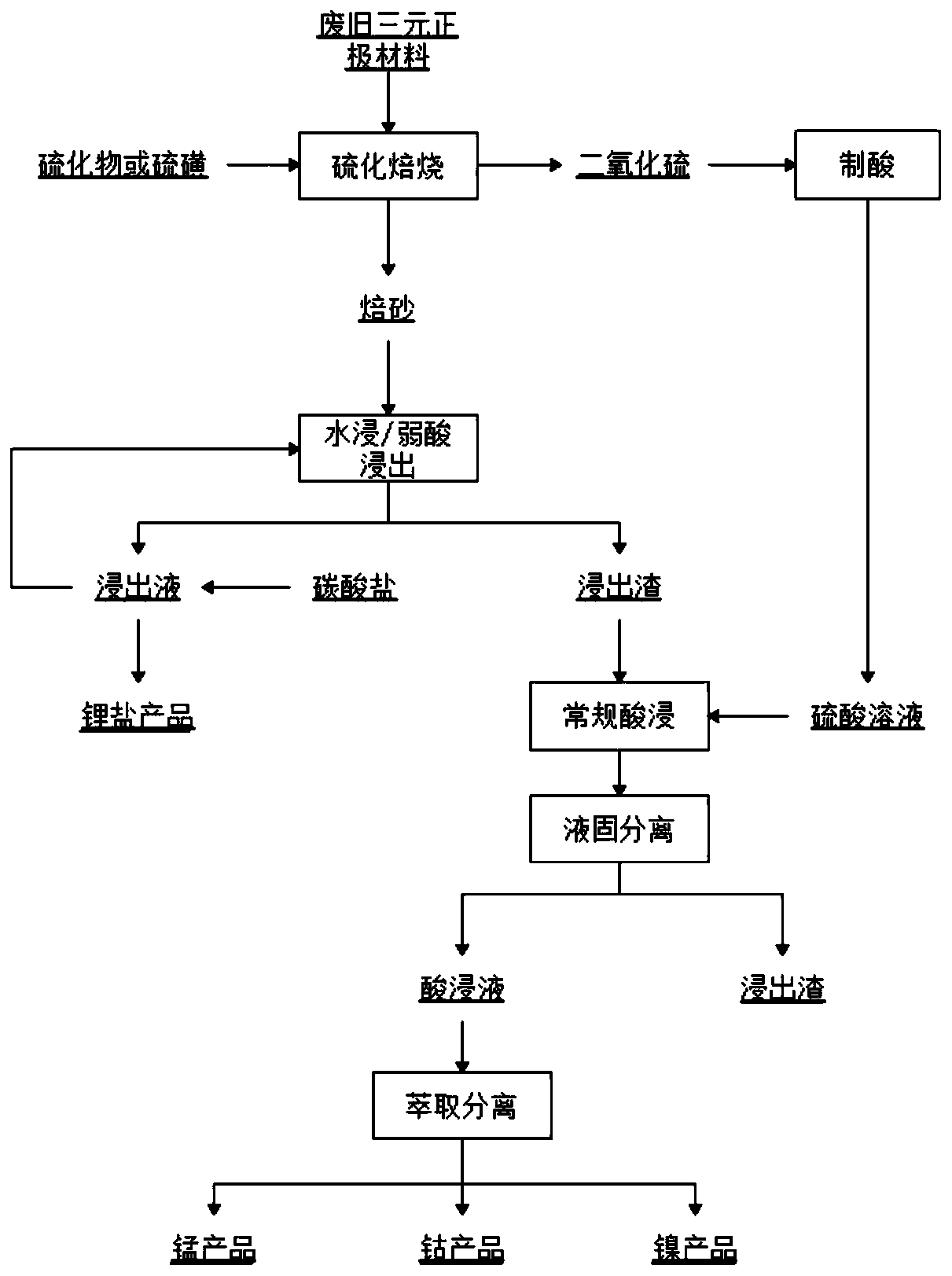

Method for recovering valuable metal from waste lithium ion battery material

ActiveCN109935922AAchieve separationReduce consumptionWaste accumulators reclaimingProcess efficiency improvementNickel saltManganese

The invention discloses a method for recovering valuable metal from a waste lithium ion battery material, and belongs to the technical field of comprehensive recycling and resource recycling of electronic wastes. The method comprises steps of mixing the cathode material of the waste lithium ion battery with low-valence sulfate such as sulfur or sulfide; subjecting the mixture to a sulfuration calcination treatment at a temperature of 300 to 900 degrees centigrade; immersing a calcined product in water to obtain a lithium salt aqueous solution which can be further used for preparing a lithium carbonate product; subjecting to water leaching residues to oxidation acid leaching or direct acid leaching to extract valuable elements such as nickel, cobalt and manganese; and purifying and extracting the leaching solution to obtain the corresponding cobalt salt and nickel salt products. The method of the invention has a simple process and a short process flow. The sulfur dioxide gas generated by calcining the sulfide can be used for preparing sulfuric acid used for subsequent nickel-cobalt leaching, thereby achieving zero pollution discharge and finally achieving a purpose of comprehensively recovering the valuable metal in the lithium ion battery cathode material at high efficiency and low cost.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

Method for preparing lithium-enriched lithium manganese oxide solid solution cathode material

ActiveCN102544475AFlexible adjustment ratioHomogeneous coprecipitationCell electrodesOXALIC ACID DIHYDRATENickel salt

The invention relates to a method for preparing a lithium-enriched lithium manganese oxide solid solution cathode material. The method comprises the following steps of: adding a mixed aqueous solution of nickel salt, cobalt salt and manganese salt into an oxalic acid or oxalate aqueous solution by an oxalate coprecipitation high-temperature solid state method, and stirring and reacting to generate nickel, cobalt and manganese oxalate coprecipitation; performing solid and liquid separation, washing and drying to obtain a nickel, cobalt and manganese oxalate precursor; and mixing and grinding the precursor and lithium salt, drying, baking at high temperature in an air atmosphere, and thus obtaining the lithium-enriched lithium manganese oxide solid solution cathode material. During preparation of the precursor, the proportion of the nickel salt, the cobalt salt and the manganese salt is adjusted, so that the constituents of the lithium-enriched lithium manganese oxide solid solution cathode material can be adjusted flexibly. The preparation method is suitable for large-scale, economic, stable and reliable production of the lithium-enriched lithium manganese oxide solid solution cathode material, has obvious advantages, and is high in practical value.

Owner:HUBEI WANRUN NEW ENERGY TECH DEV

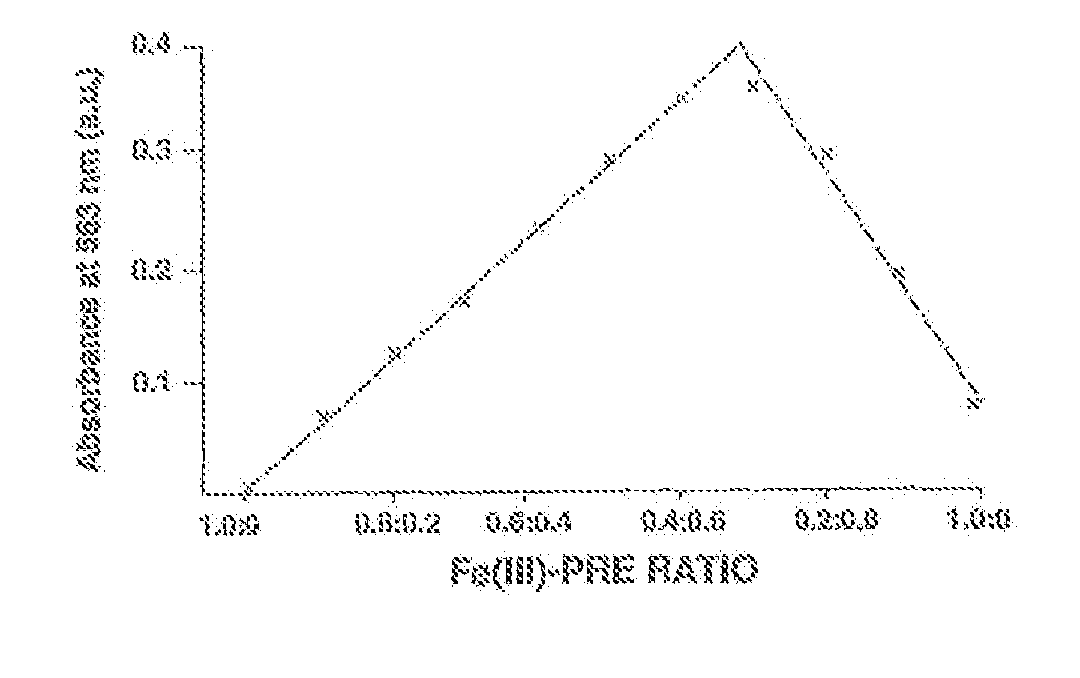

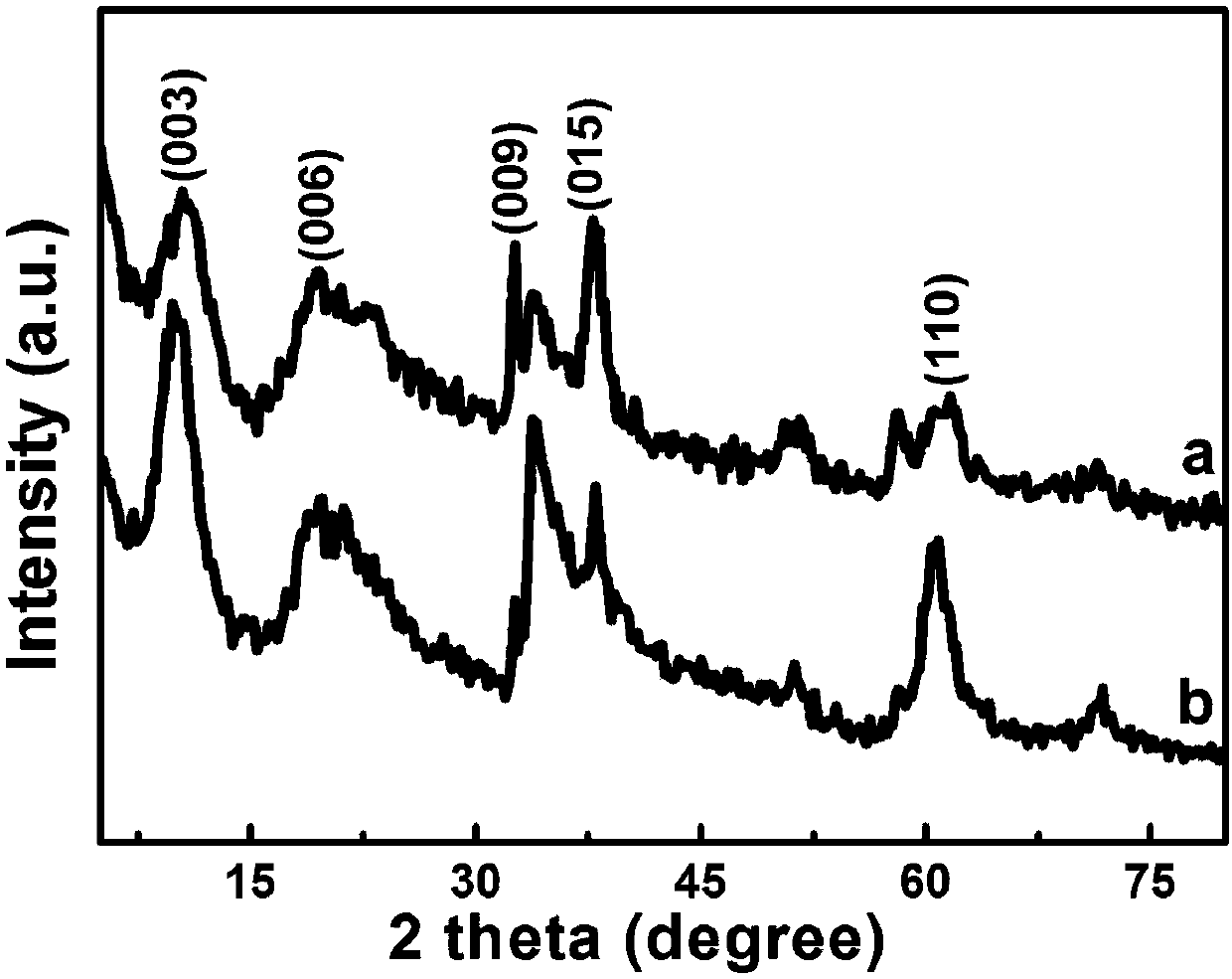

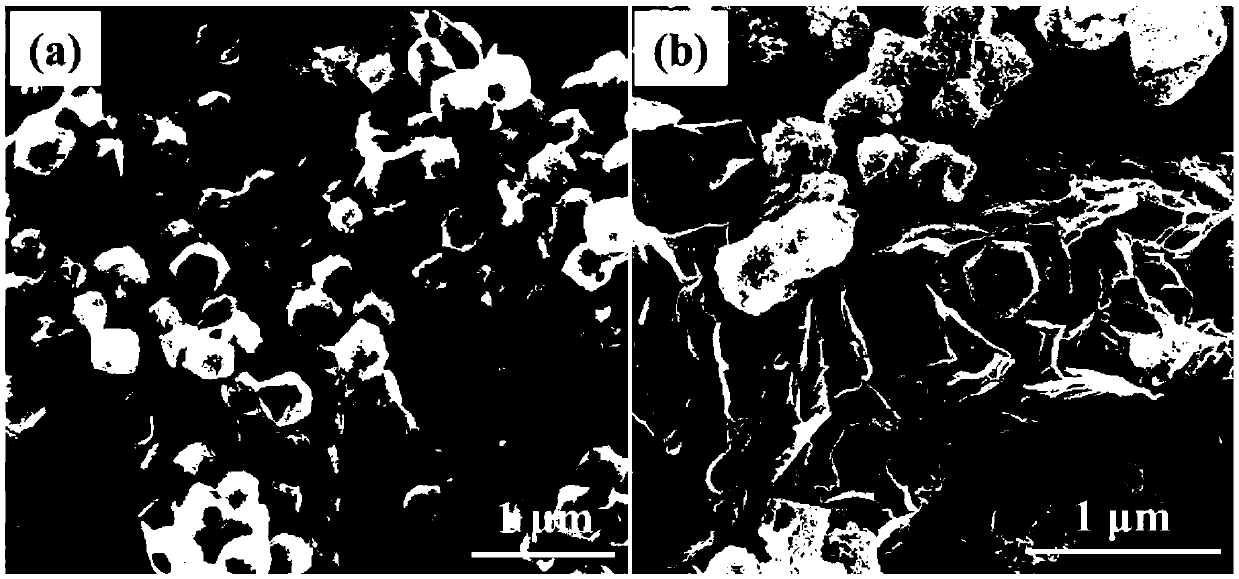

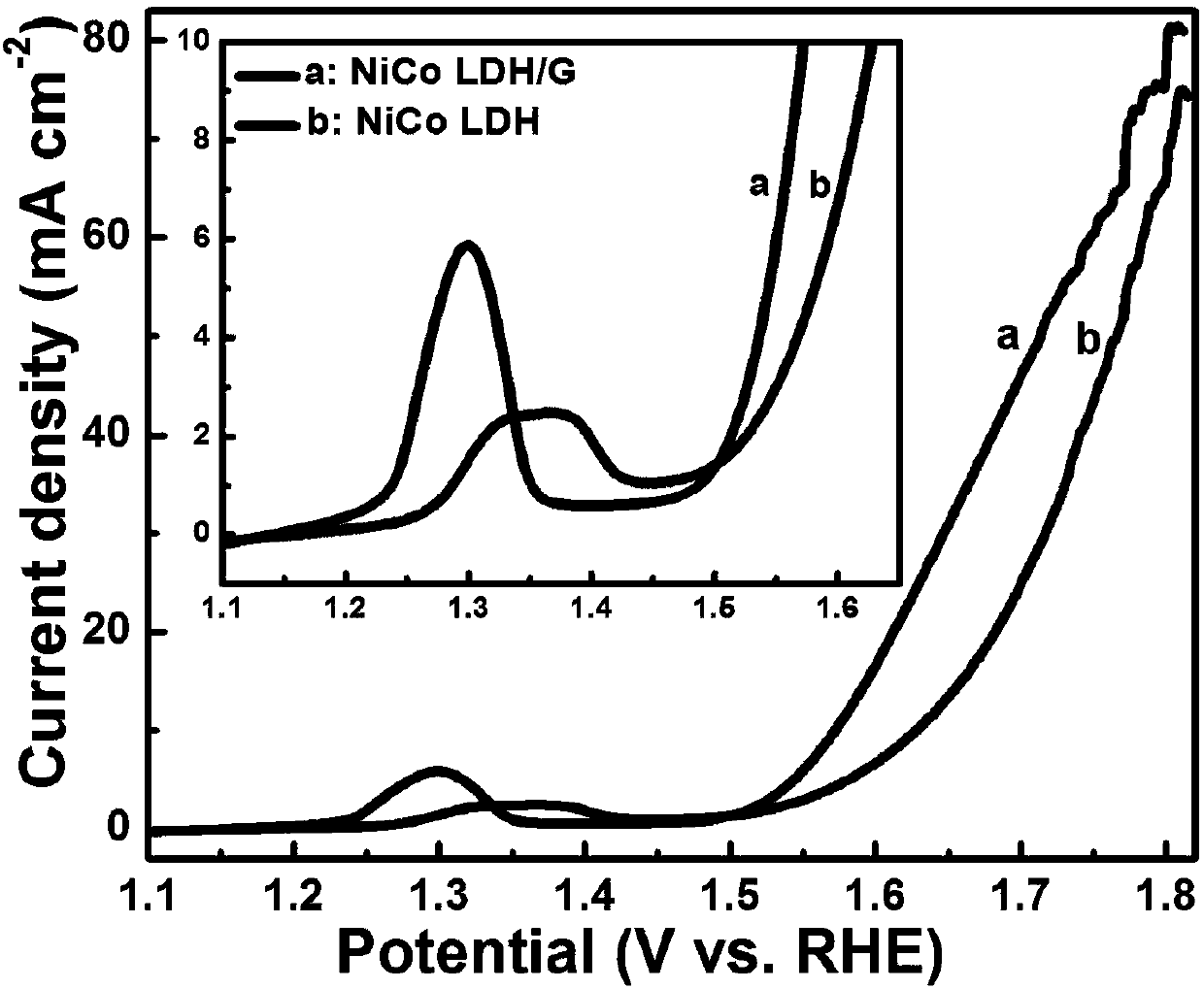

Preparation method of nickel-cobalt layered bimetallic hydroxide/graphene electrocatalyst

ActiveCN107824188ASimple processOvercoming demandsCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsNickel saltSynthesis methods

The invention provides a preparation method of a nickel-cobalt layered bimetallic hydroxide / graphene electrocatalyst, which belongs to the technical field of electrocatalysts. The method disclosed bythe invention comprises the following steps: graphene and cobalt nitrate are uniformly dispersed in a methanol solvent by ultrasonic waves, so that an ultrasonic solution is obtained; the ultrasonic solution is added into a methanol solution of dimethylimidazole, is uniformly mixed and then is enabled to stand, and centrifuging, washing and drying are then carried out, so that a ZIF-67 / graphene composite material is obtained; the ZIF-67 / graphene composite material and nickel salt are mixed and dissolved in a solvent, refluxing is carried out for reaction, centrifugal separation is then carriedout, obtained precipitate is washed with absolute ethyl alcohol, and drying is carried out to obtain a NiCo LDH / G composite material with a nanoscale morphology. The method disclosed by the inventionovercomes the defects of high requirement on equipment, need for high temperature and high pressure and need for an expensive surfactant existing in conventional synthesis methods, and compared withthe prior art, the preparation method has the advantages of simple process, low cost, easy reaction process control and the like, and is suitable for industrial mass production.

Owner:GUANGXI NORMAL UNIV

Preparation method of high-tap spherical ternary cathode material precursor

InactiveCN102280619AImprove physicsImprove electrochemical performanceCell electrodesNickel saltManganese

The present invention discloses a high -vibration -shaped triggea orthopedic material preparation method. Put nickel salt, cobalt salt, manganese salt and alkaline aquatic solution, complexing agent in the reactor.Synthetic spherical or spherical ternary orthopedic material front -drive body, chemical formula is NIXCOYMNZ (OH) 2,0.5 ≤ x ≤1,0≤y ≤ 0.5, 0 ≤Z ≤ 0.5, x+y+z = 1, add alkaline pH pHSurface treatment, washing dry and drying the three -yuan positive electrode material front drive body.The present invention improves the processing performance of ternary positive electrode materials, vibrating density, overcoming material capacity and stability defects. By controlling the appearance and particle size of the front -drive body, the materialization performance of the three yuan positive pole material is achieved, and the stability of the material is improved.

Owner:XIAMEN TUNGSTEN

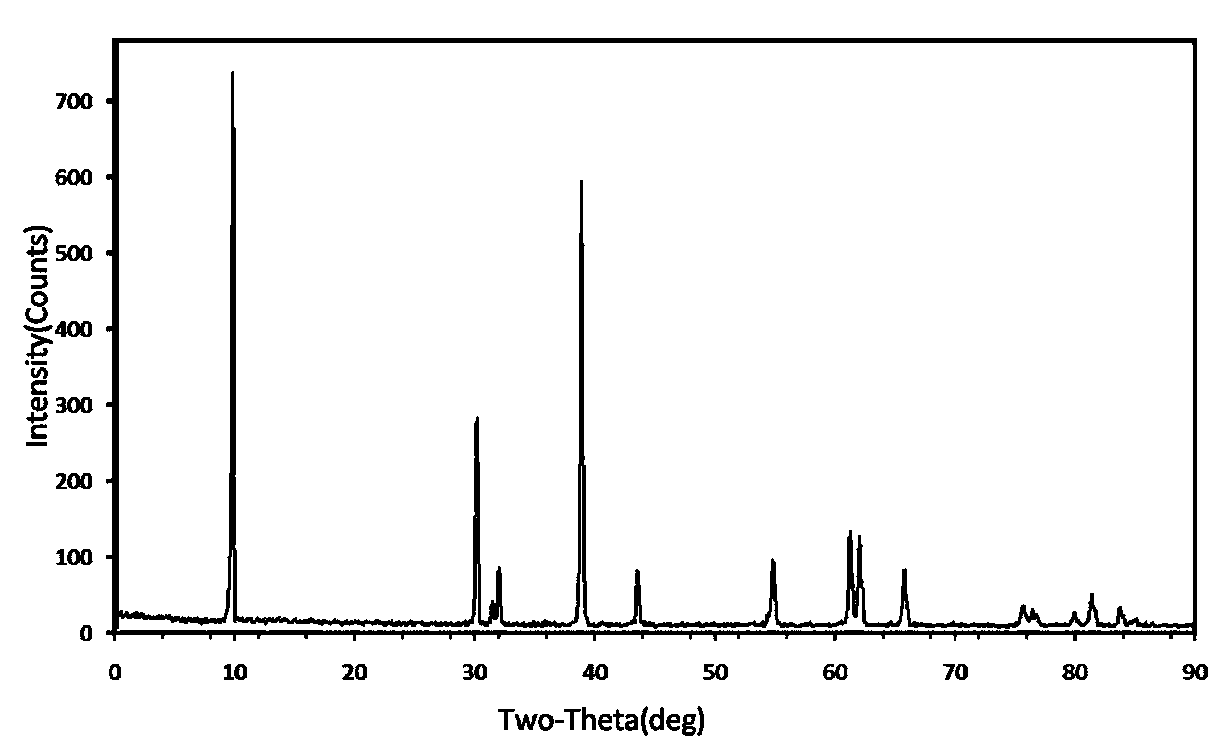

Preparing method of lithium ionic cell 5V anode material spherical LiNi*Mn*O*

InactiveCN101335348AImprove electrochemical performanceSimple processElectrode manufacturing processesLithium compoundsNickel saltHigh energy

The invention relates to a preparation method of 5V level anode material of a lithium ion battery, namely, ball LiNi0.5Mn1.5O4, and pertains to the energy material and novel material preparation technology field. The method includes the steps that: a liquid mixture of manganese salt and nickel salt which is prepared according to a molar ration of 3:1, reacts with dissoluble carbonate or bicarbonate water solution and ammonia or ethylene diamine water solution to obtain ball MnCO3-NiCO3, processes of centrifugal separation, washing and drying are carried out, ball Mn2O3-Ni2O3 powder is obtained by heat treatment at 400 DEG C to 600 DEG C, the ball Mn2O3-Ni2O3 powder is mixed with lithium salt compound, ball LiNi0.5Mn1.5O4 is obtained by heat treatment at 700 DEG C to 900 DEG C. The LiNi0.5Mn1.5O4 anode material obtained by the method has high purity and relatively high specific capacity; the product grain is a ball shape, with high tap density which can reach 2.2 to 2.5 g question mark cm <-3>; the ball grain can provide a beneficial condition to the further carrying out of surface coating and to the improvement of the cycle stability of the material, and has great practical value in the field of high energy density and high power lithium ion battery.

Owner:TSINGHUA UNIV

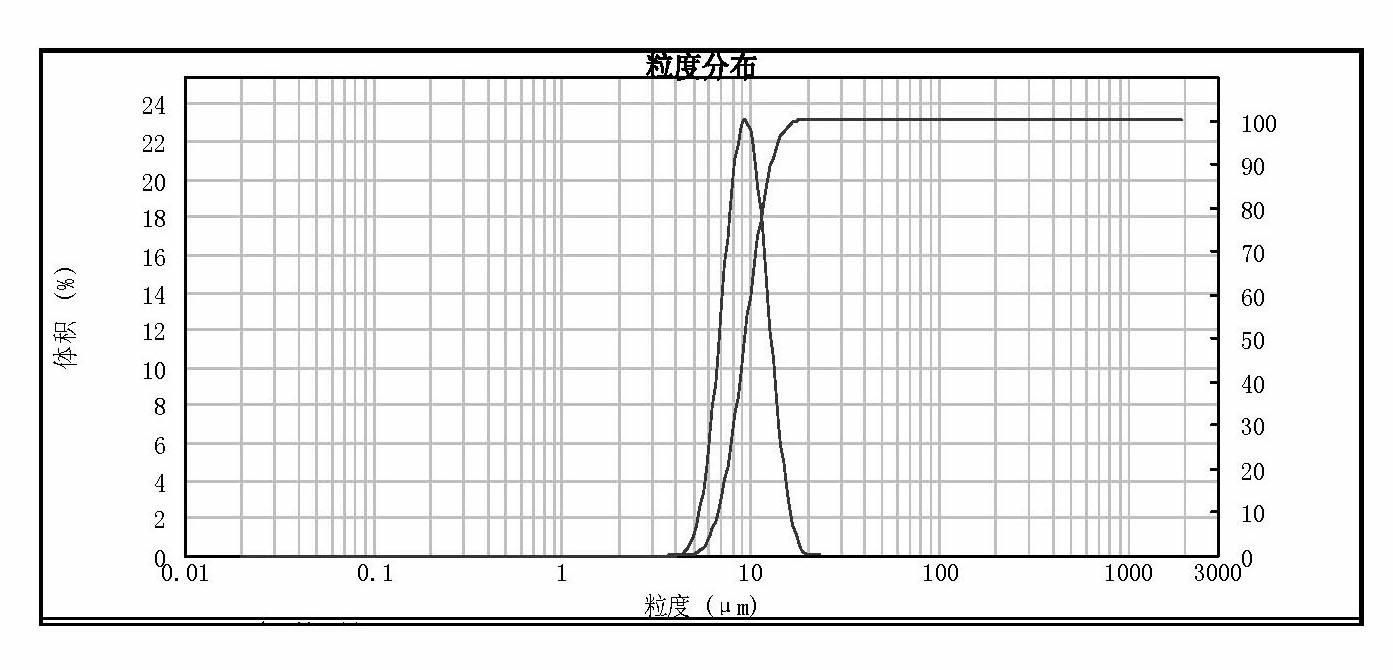

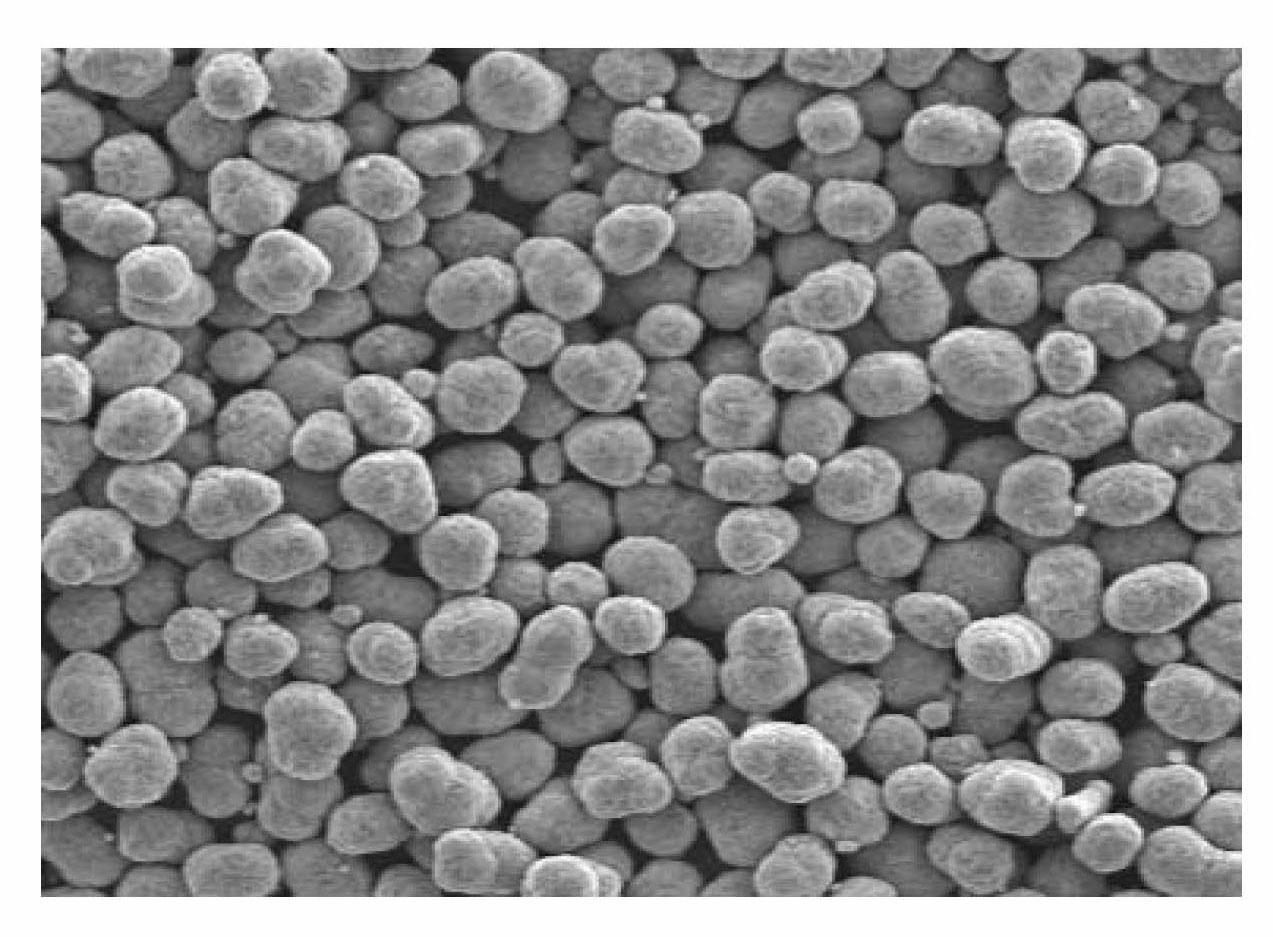

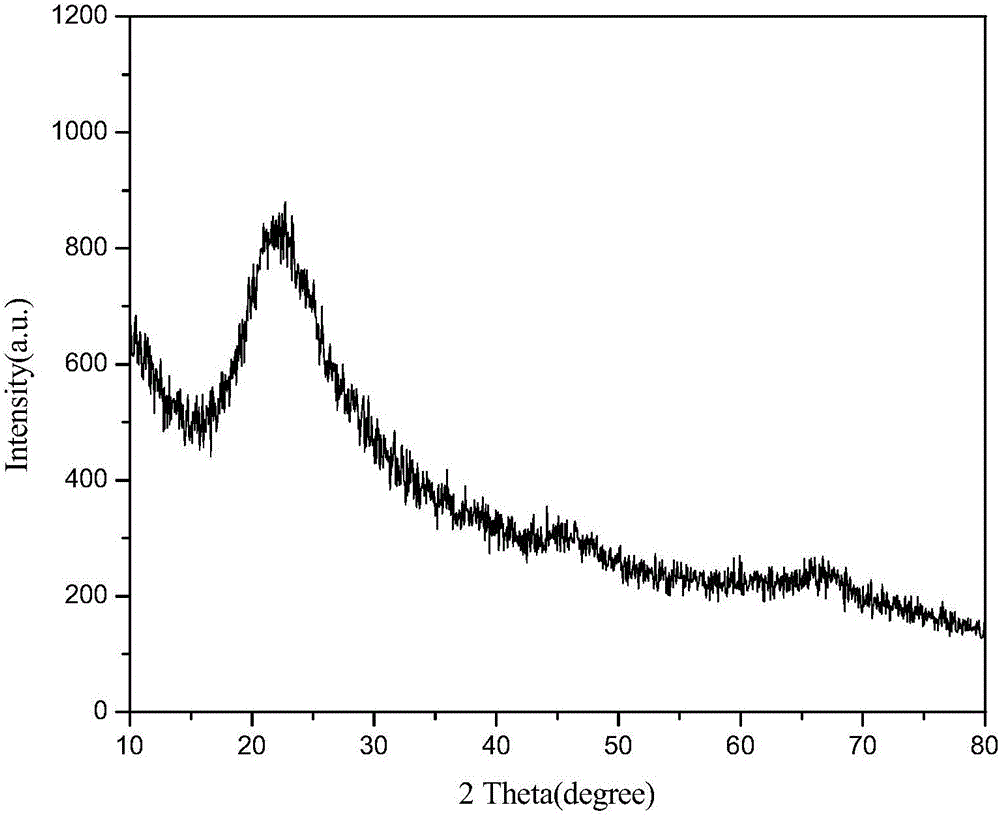

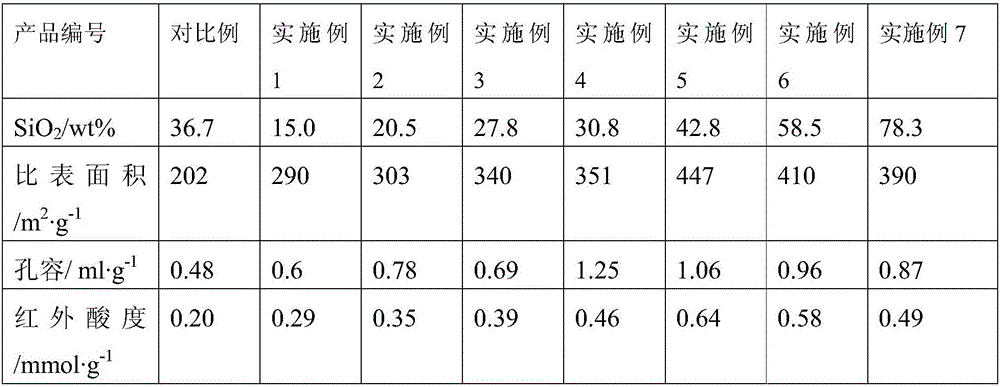

High-activity amorphous silica-alumina, hydrocracking catalyst supported by amorphous silica-alumina, and preparation methods thereof

The invention discloses a high-activity amorphous silica-alumina, a hydrocracking catalyst supported by amorphous silica-alumina, and preparation methods thereof. The preparation method of the amorphous silica-alumina supporter comprises the following steps: preparing a silicon source-aluminum source mixed water solution, mixing the mixed water solution with a precipitant solution, carrying out cocurrent flow coprecipitation to obtain a precipitated slurry, transferring the slurry into a closed vessel, aging, molding, and roasting. The invention also provides a preparation method of a hydrocracking catalyst by using the amorphous silica-alumina as the supporter. The preparation method of the hydrocracking catalyst is as follows: in the preparation method of the amorphous silica-alumina supporter, a nickel salt or nickel salt and metal aid M salt is / are added into the silicon source-aluminum source mixed water solution in the step (1), and the rest steps are the same as those in the preparation method of the amorphous silica-alumina supporter. The coprecipitation process is adopted in the preparation process, and the silicon source and aluminum source finally exist in the catalyst in the form of the amorphous silica-alumina, but the catalyst has much higher activity than the common amorphous silica-alumina catalyst.

Owner:SYNFUELS CHINA TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com