Patents

Literature

554results about How to "Superhydrophobic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of silicon-carbide-fibrofelt-enhanced silica aerogel composite material

The invention relates to a preparation method of a silicon-carbide-fibrofelt-enhanced silica aerogel composite material, and relates to an aerogel composite material. According to the invention, a carbon-rich silicon carbide micro-nano ceramic fibrofelt with small fiber diameter, high porosity, communicating pores, fast impregnation speed, and good compatibility with a substrate is prepared with a static electro-spinning technology combined with a precursor conversion method; a silica sol is prepared with an acid-alkali two-step method; with an infiltration technology, the electro-spun silicon carbide ceramic fibrofelt or precast is soaked into the sol; and through processes such as gel process, aging, curing, solvent exchange, supercritical drying, and the like, the silicon-carbide-fibrofelt-enhanced silica aerogel composite material is obtained. The prepared composite material has the characteristics of low density, large specific surface area, super-hydrophobicity, low thermal conductivity, and the like. The strength and toughness of the material are also greatly improved. The carbon-rich silicon carbide fiber has an infrared shielding effect, such that composite material thermal insulation effect and ultra-high-temperature stability can be improved.

Owner:ZHONGKE RUNZI (CHONGQING) ENERGY SAVING TECH CO LTD

Processing method of aluminum and aluminum alloy super hydrophobic surface

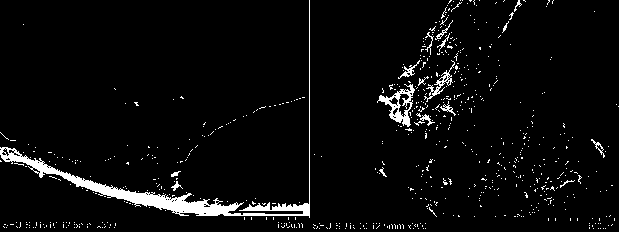

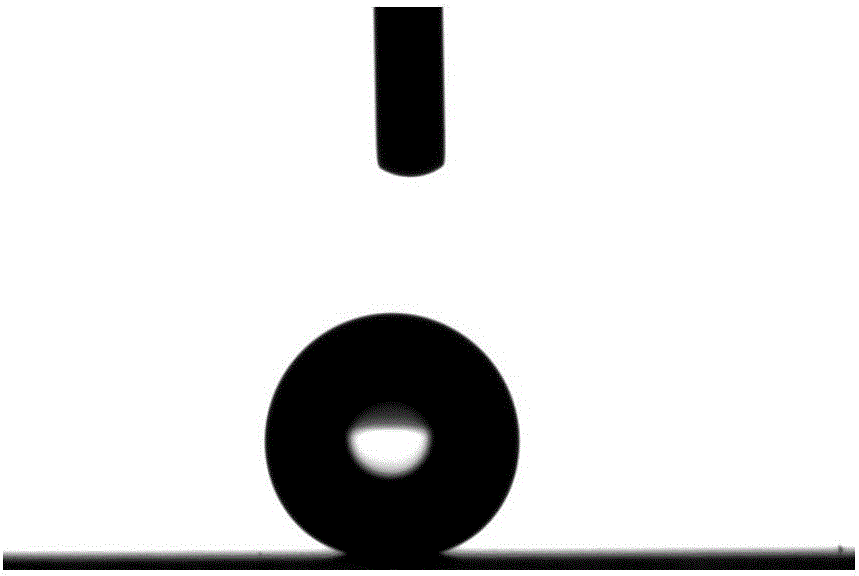

InactiveCN101007304ASuperhydrophobicEasy to rollAntifouling/underwater paintsPretreated surfacesNickel saltCopper

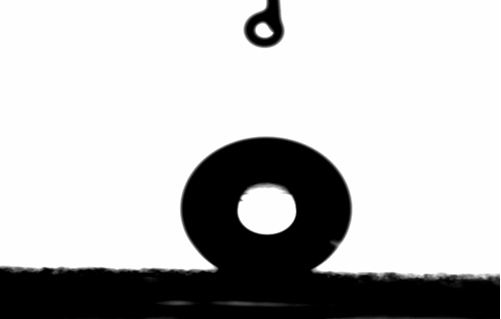

The invention involves an aluminum or aluminum alloy super-hydrophobic surface preparation method. The method is: polishing the surface of aluminum or aluminum alloy using metallographic sandpaper or polishing paste, pure water washing, acetone ultrasonic cleaning, pure water washing and other clean treatment, handing it with chemical etching solution containing nitric acid and metal salts (copper or nickel salt) 30s-20min under 90 ~ 100 degree C, then coating low surface energy material on its surface to get super-hydrophobic property. The aluminum or aluminum alloy surface treated by the invention has excellent hydrophobicity, the contact angle of water and surface can be as high as 150-165 degree, droplets are easy to roll on the surface. The method of the invention need not complex equipment, cost is low, technology is simple and repeatability is good.

Owner:SOUTH CHINA UNIV OF TECH

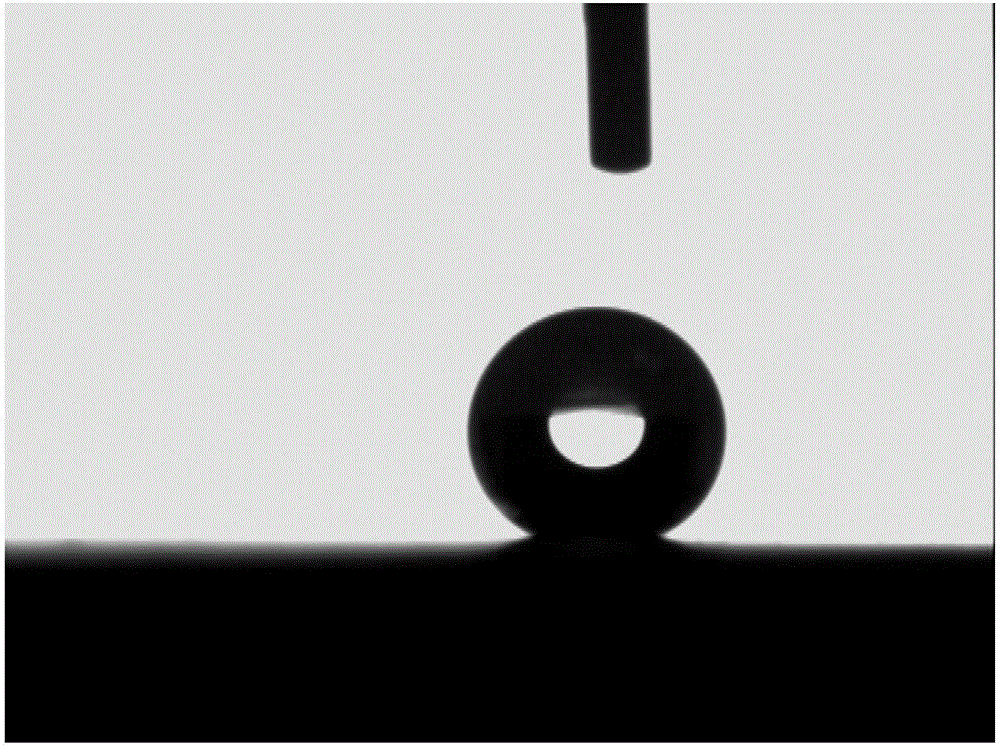

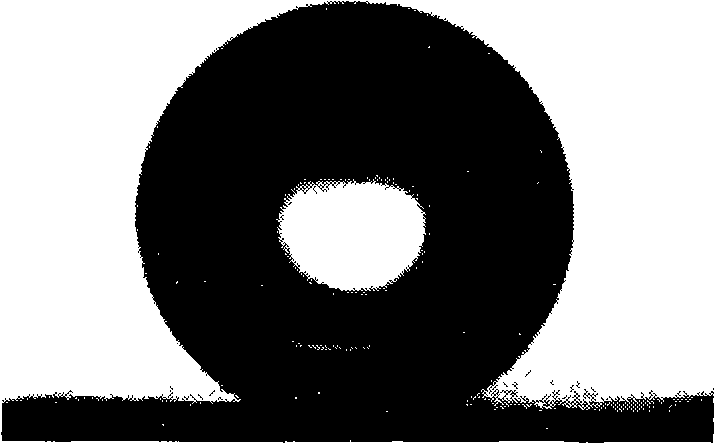

Modified graphene-loaded polyurethane sponge and preparation method thereof

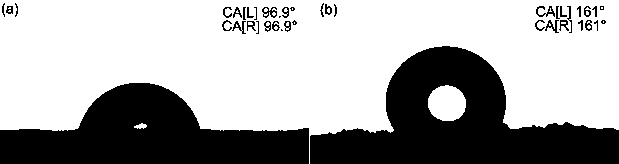

InactiveCN104338519AHydrophobicImprove hydrophobicityOther chemical processesCvd grapheneGraphene coating

The invention relates to modified graphene-loaded polyurethane sponge which is characterized in that a modified graphene coating is loaded on the surface of the polyurethane sponge, and is 0.5mm-1.0mm thick, a silane coupling agent is coated on the surface of the modified graphene, wherein the mass ratio of the silane coupling agent to the graphene is 1 to 100. Experiments prove that by measuring the dewatering effect and the oil absorption capability of the loaded sponge, the sponge is super-hydrophobic from hydrophilic (a contact angle is 161 degrees), the oil absorption capability is remarkably enhanced, and the saturation adsorption amount for diesel reaches 37.89g. According to the modified graphene-loaded polyurethane sponge, the modified graphene is loaded on the sponge by using the silane coupling agent, so that the sponge has super-hydrophobic and super-oleophylic performances, and has a potential application value in a process of remediating a petroleum pollution water body.

Owner:SHANGHAI UNIV

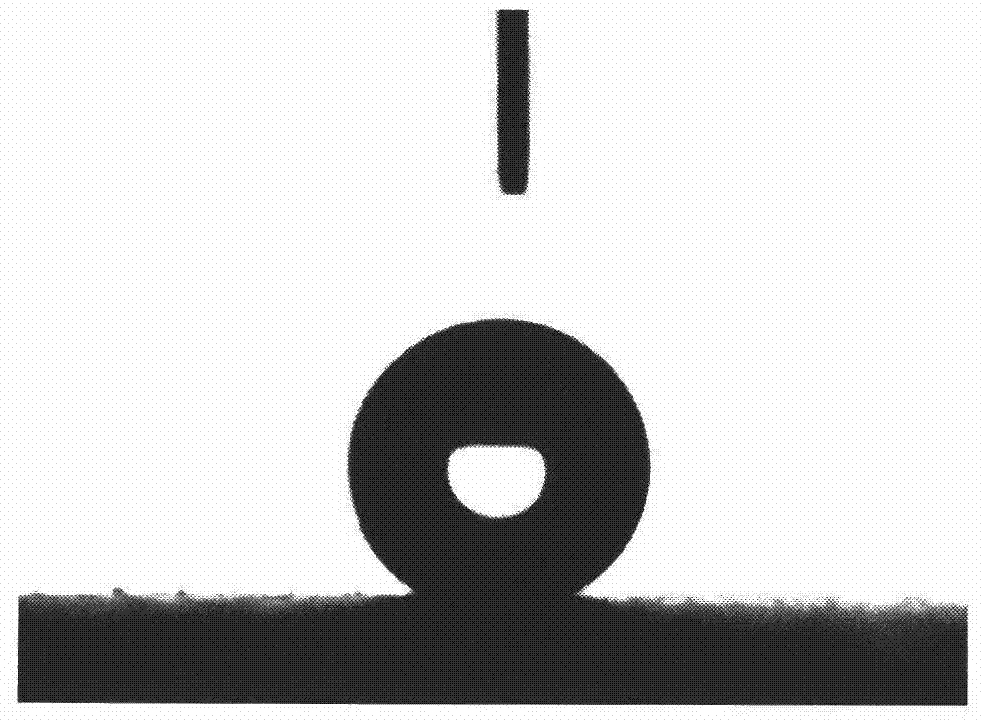

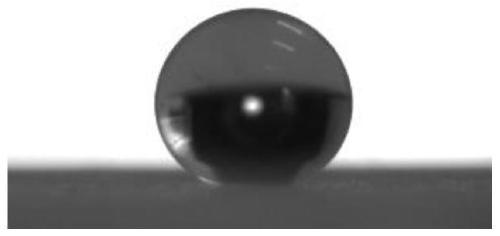

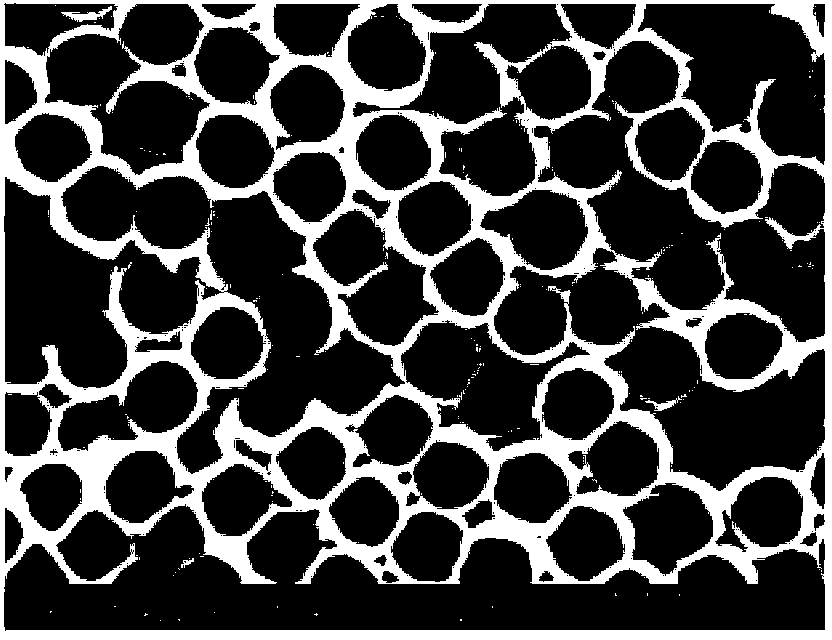

Super-hydrophobic porous polyvinyl chloride film and its preparing process

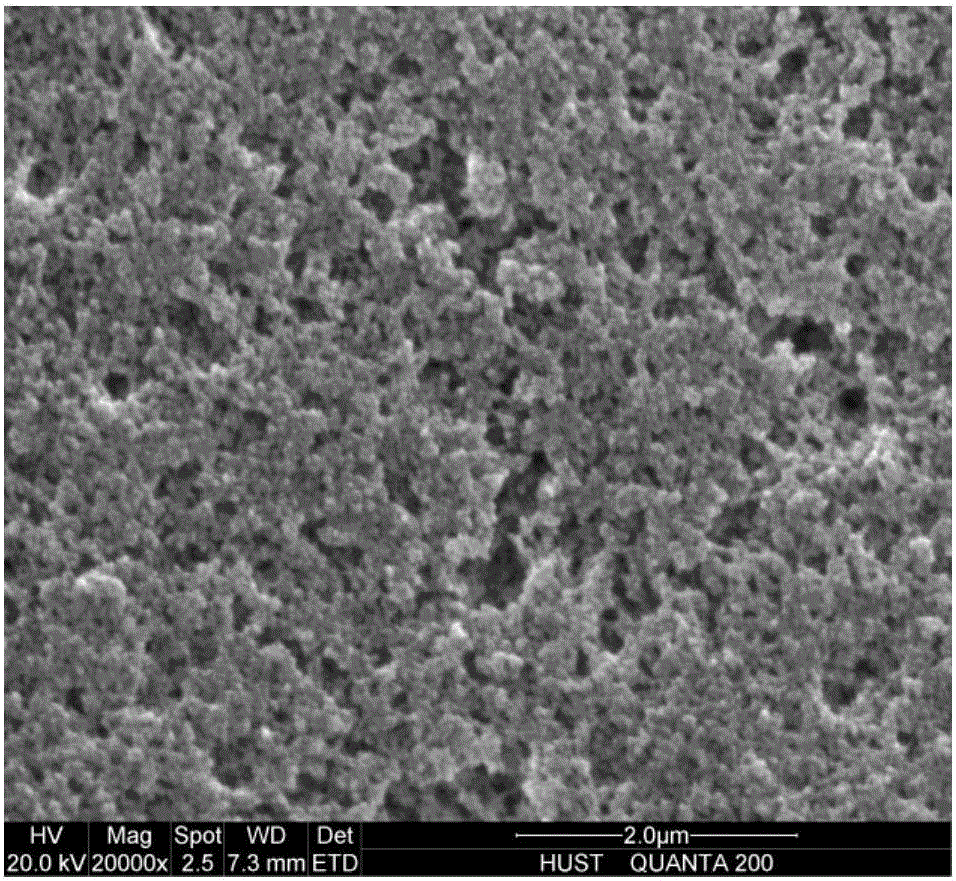

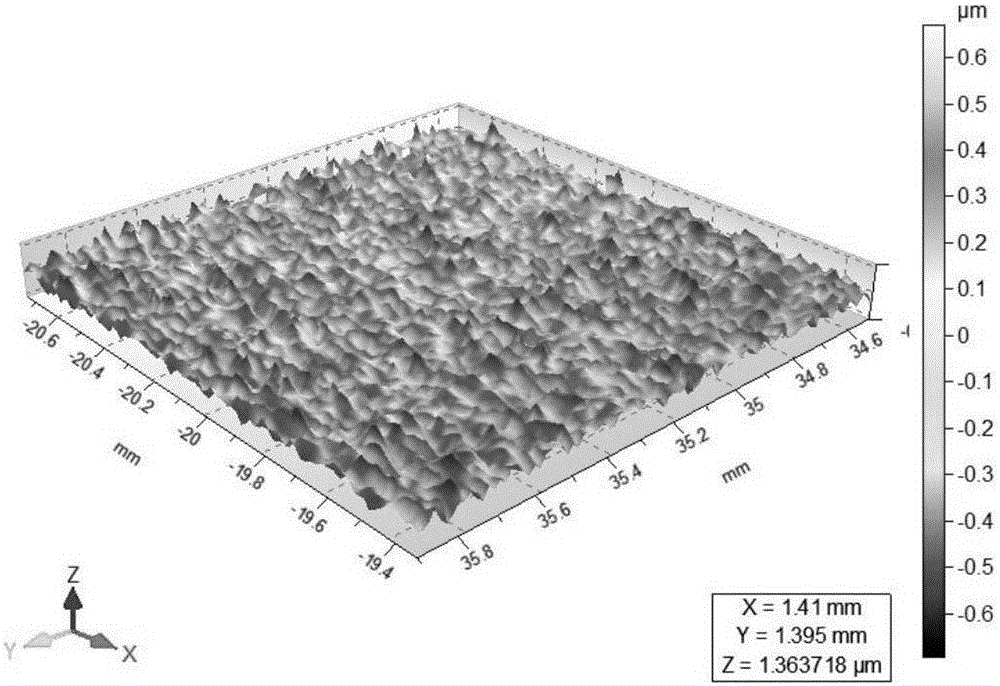

InactiveCN1621434AStable superhydrophobic propertiesSimple and fast operationCoatingsMicro structurePhase conversion

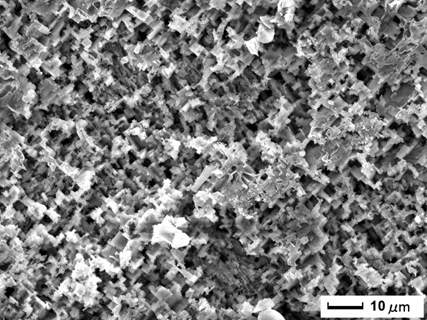

The present invention belongs to the field of porous polyvinyl chloride film material, and is especially super-hydrophobic porous polyvinyl chloride film and its preparation process. By means of solvent-precipitant phase conversion process, porous loose polyvinyl chloride film with surface micro structure of piled micron and nanometer level grains is prepared, and the film has water contact angle greater than 150 deg, water drop rolling angle smaller than 15 deg and extremely high super-hydrophobic property. The present invention provides new method of realizing super-hydrophobic characteristic of polymer film without modification of low surface energy matter and opens one new way of expanding the application fields of common plastics.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Method for performing anticorrosive hydrophobic modification on surface of aluminum alloy

InactiveCN101885934ACoating thickness is thinImprove adhesionAnti-corrosive paintsMetallic material coating processesSpray coatingLayer thickness

The invention discloses a method for performing anticorrosive hydrophobic modification on the surface of an aluminum alloy, which belongs to the technical field of corrosion prevention. The method specifically comprises the following steps of: (1) performing surface degreasing and oil removing on an aluminum alloy material by using conventional alkaline degreasing solution first, performing surface activation treatment by using reductive acidic cleaning solution, and then performing inactivation and sealing treatments on the activated surface; (2) preparing a composition with a hydrophobic effect, wherein the composition consists of a first component and a second component in a weight ratio of 9-16:1, the first component is prepared from the following materials in percentage by weight: 35 to 60 percent of fluorocarbon resin, 10 to 40 percent of anticorrosive pigment, 1 to 8 percent of organosilicon compound, 0.5 to 5 percent of dispersing agent, 0.5 to 3 percent of anti-settle agent and 10 to 40 percent of organic solvent, and the second component is a fatty series / aromatic series curing agent; and (3) performing anticorrosive hydrophobic modification on the surface of the aluminum alloy, namely coating the composition with the hydrophobic effect in the step (2) on the surface of the aluminum alloy after treatment in a brush coating, spray coating or dip coating mode, and curing the surface for about 12 hours. The anticorrosive hydrophobic coating layer obtained on the surface of the aluminum alloy by using the technique of the invention has the advantages of thin coating layer thickness, high adhesive force, sea water corrosion resistance, surface super-hydrophobic property and the like.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of super hydrophobic coating based on super hydrophobic silica and resin

InactiveCN103587185ASuperhydrophobicRestoring the superhydrophobic functionSynthetic resin layered productsSurface layerHydrophobic silica

The invention discloses a preparation method of a super hydrophobic coating based on super hydrophobic silica and resin. The resin as a substrate is coated on a glass slide; the super hydrophobic silica is bonded to the resin; and the resin is cured to prepare the super hydrophobic coating. The super hydrophobic coating prepared by the invention is composed of a base resin and a super hydrophobic silica surface layer. The body of the super hydrophobic silica layer is a super hydrophobic material, and if the surface is worn, the coating still has the same super hydrophobic property. When the super hydrophobic coating is polluted, the super hydrophobic function can be recovered by scraping off the surface layer. The super hydrophobic coating provided by the invention also can achieve waterproof effect due to the base resin.

Owner:WUXI SHUNYE TECH

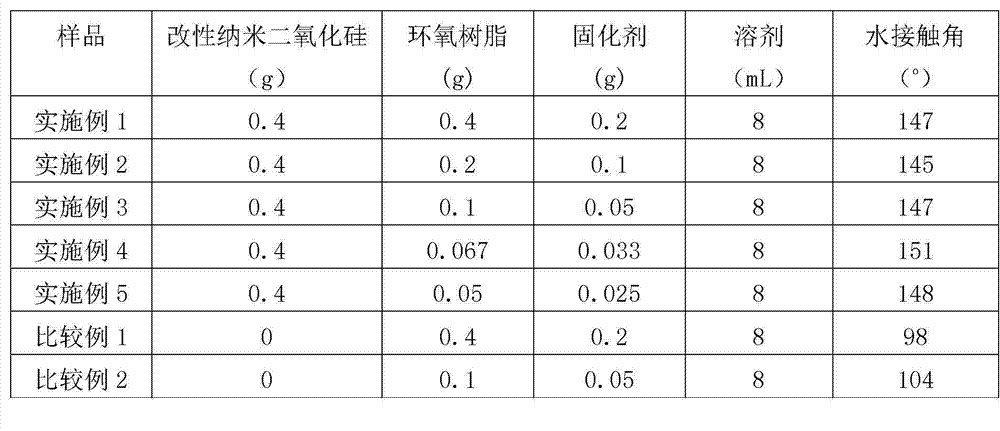

Method for preparing organic and inorganic composite super-hydrophobic coatings

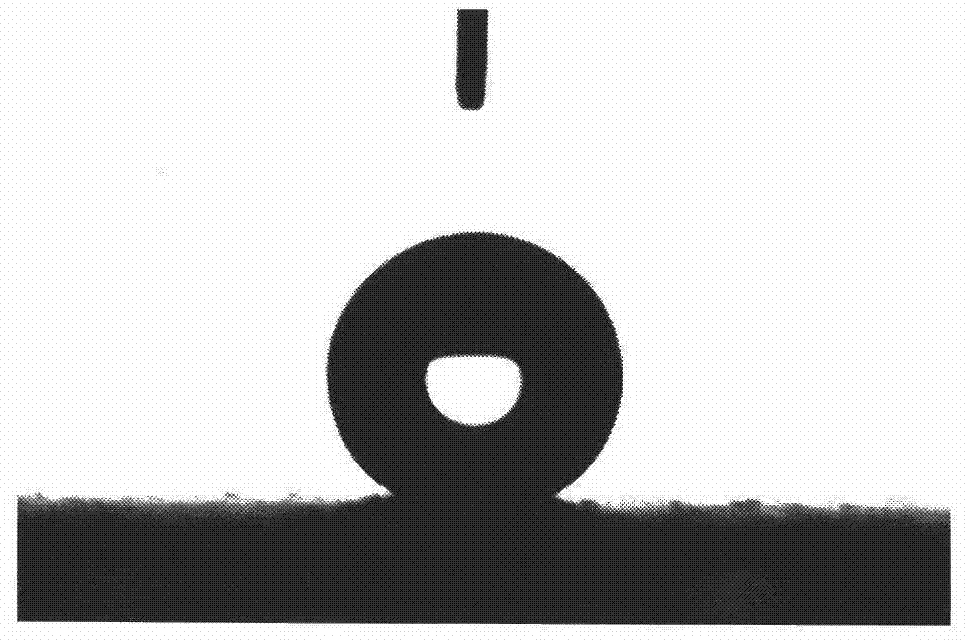

ActiveCN102807803AEasy to prepareLow costSpecial surfacesEpoxy resin coatingsNanometreOrganic inorganic

The invention discloses a method for preparing organic and inorganic composite super-hydrophobic coatings. The method comprises the following steps of: preparing modified silicon dioxide nano particles, preparing coating sol and coating the surface of a substrate material. The method is simple in process, readily available in raw materials and low in cost and is suitable for large-scale production and application; and the prepared coatings have high super-hydrophobic property, self-cleaning performance and freezing resistance.

Owner:SHANDONG JIAOTONG UNIV

Super-hydrophobic self-cleaning paint

InactiveCN101205439ASuperhydrophobicSelf-cleaningPolyurea/polyurethane coatingsPolyether coatingsEngineeringSolvent

The invention relates to super-hydrophobic self-cleaning paint suitable to be used in various surfaces. The paint comprises the following components: 100 portions of filler, 30 to 50 portions of polyurethane, 300 to 500 portions of mixed solvent and 1 to 5 portions of Gamma-aminopropyltrimethoxysilane. The invented paint has the advantages of super-hydrophoby, self cleaning, antifouling, antisticking, denoise and drag reduction, etc.; meanwhile, the paint has low price cost, convenient construction and less environmental pollution.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

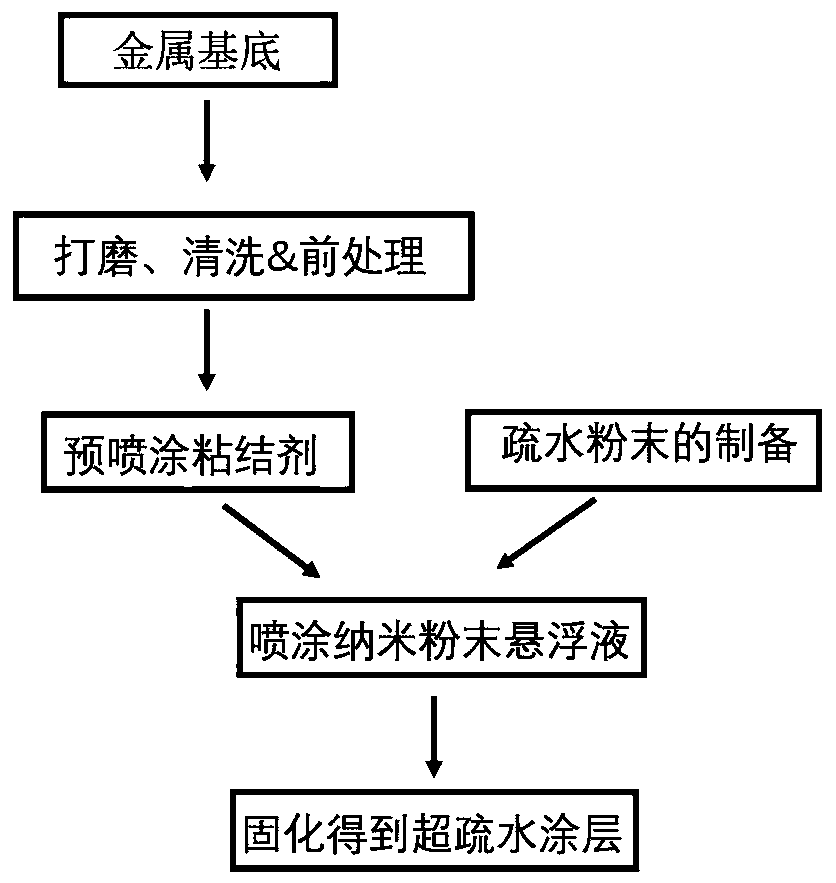

Preparation method of icing-resistant/ corrosion-resistant integrated functional super-hydrophobic coating for aviation

InactiveCN109746172AGood low temperature water repellencyLong freeze delay timeAnti-corrosive paintsSpecial surfacesAviationMicro nano

The invention discloses a preparation method of an icing-resistant / corrosion-resistant integrated functional super-hydrophobic coating for aviation. The method comprises the following steps: preprocessing titanium alloy, aluminum alloy and stainless steel to build a micro-nano structure; pre-spraying an adhering agent; continuously spraying a low-surface-energy nanometer powder coating; and curing to obtain the super-hydrophobic coating with outstanding icing resistance and corrosion resistance. According to the method, the prepared icing-resistant / corrosion-resistant integrated functional super-hydrophobic coating for aviation is good in protection effect. The preparation method is simple in processes, and suitable for massive production; ideas are supplied to solve the problems that anair craft is easily iced and low in corrosion resistance; and the method has a wide application prospect.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

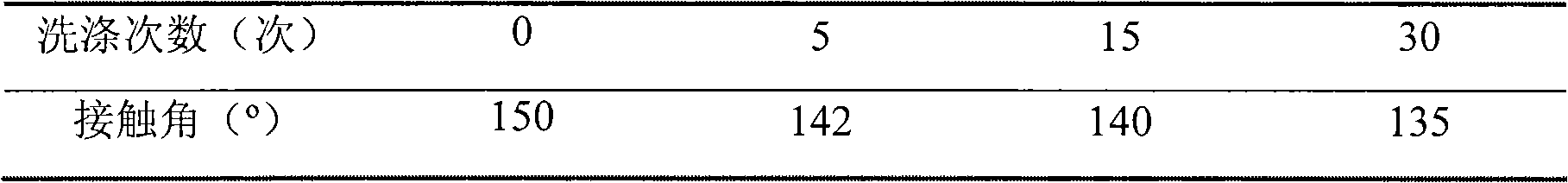

Fluorine-free nano durable super hydrophobicity finishing method for cellulose fabric

InactiveCN101591853AEasy to prepareThe preparation method is safeVegetal fibresCelluloseOrganic acid

The invention relates to a fluorine-free nano durable super hydrophobicity finishing method for cellulose fabric, which comprises the following steps: (1) preparing hydrous medium solution containing tetra-alkyl ester silicate, polycarboxylic acid and a crosslinked catalyst, oscillating and stirring the hydrous medium solution to obtain SiO2 sol, soaking and rolling the cellulose fabric twice respectively, and curing the cellulose fabric; and (2) preparing non-aqueous solvent solution of alkyl siloxane catalyzed and hydrolyzed by using inorganic acid or organic acid water solution, soaking the cellulose fabric in the solution, and curing the cellulose fabric. The method is simple and safe, has low performance requirement on equipment, is easy for industrialization, and is particularly applicable to the hydrophobicity finishing of the cellulose fabric.

Owner:DONGHUA UNIV

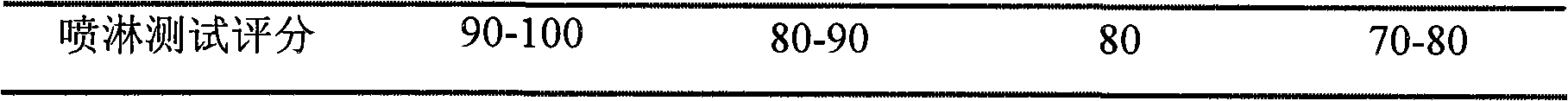

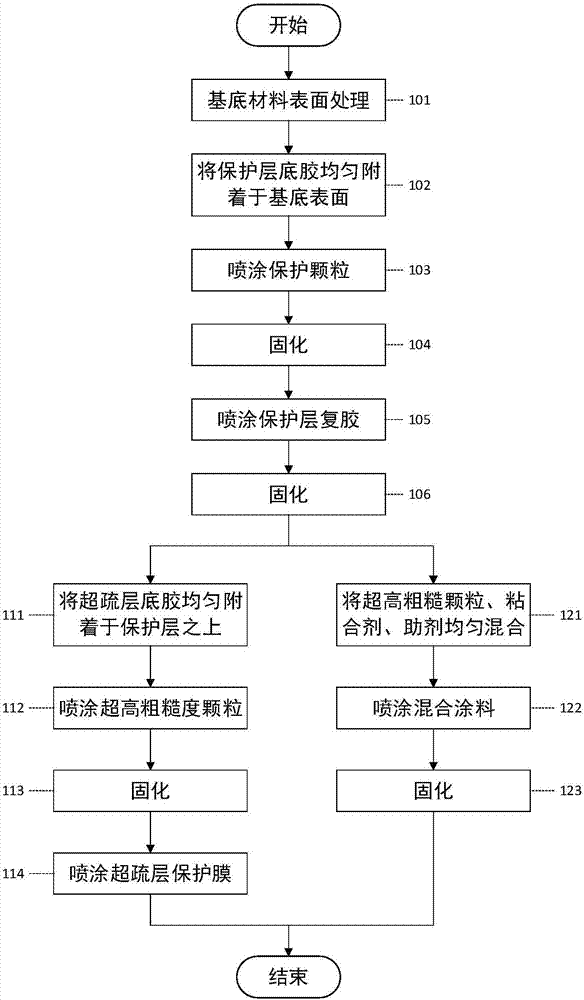

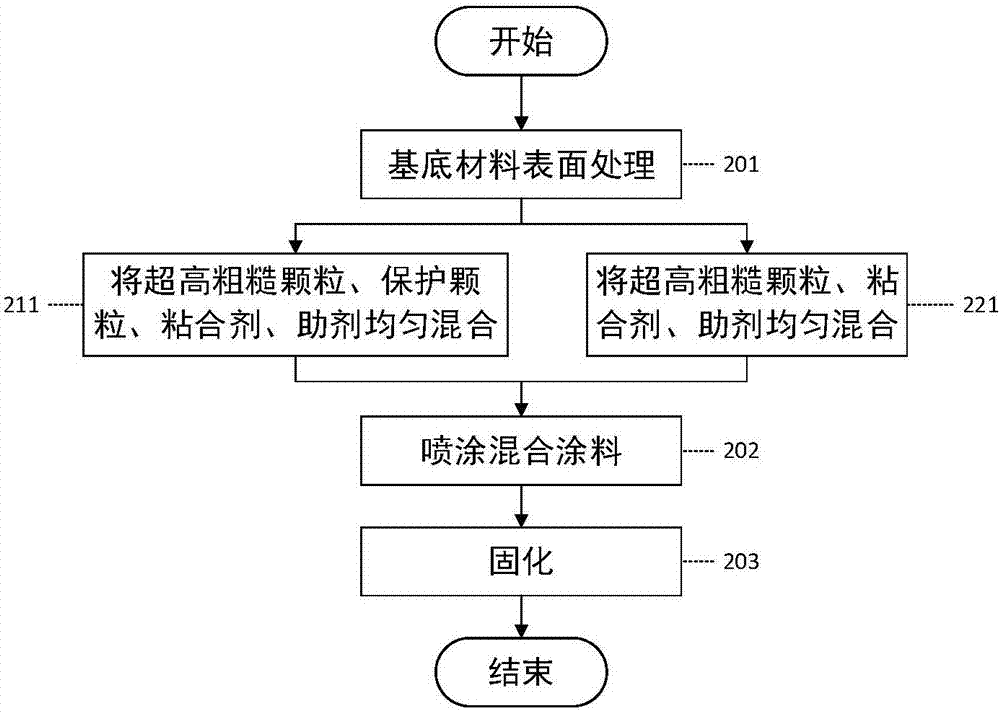

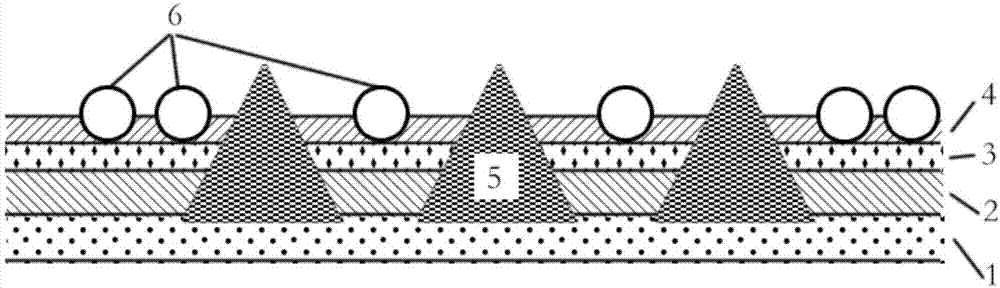

Coating prepared from particles with ultrahigh roughness

ActiveCN107254237AImprove performanceOvercome structurePretreated surfacesPolyurea/polyurethane coatingsSuperhydrophobic coatingLotus effect

The invention provides a superhydrophobic coating prepared from particles with ultrahigh roughness. The superhydrophobic coating is prepared from the following components: particles with protrusions or holes and unsmooth structures, protective particles, a bonding agent and an assistant, wherein the volume ratio of the particles with the protrusions or the holes and the unsmooth structures to the protective particles to the bonding agent is (0.1-7):(1-7):(1-10). A lotus effect technical theory is applied to obtain a super-hydrophobic, underwater superhydrophobic oil or super-amphiphobic surface coating, further the performance of the coating is improved, and the defects of the conventional superhydrophobic coating that the structure is easy to damage, the service life is short and the like are overcome. The prepared coating has super hydrophobic properties (super-hydrophobic, underwater superhydrophobic oil or super-amphiphobic properties), self-cleanness and excellent wear resistance; substrate materials suitable for the coating are glass, plastic, rubber, textiles, paper, metal, cement, ceramic materials or the materials covering other coatings.

Owner:HONGDA TECH BEIJING CO LTD

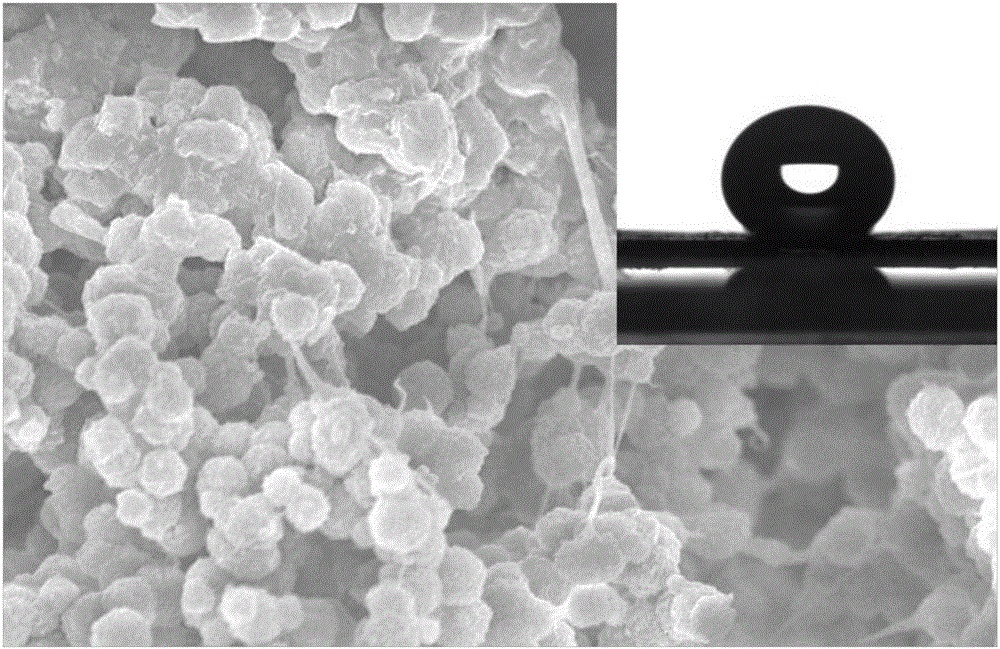

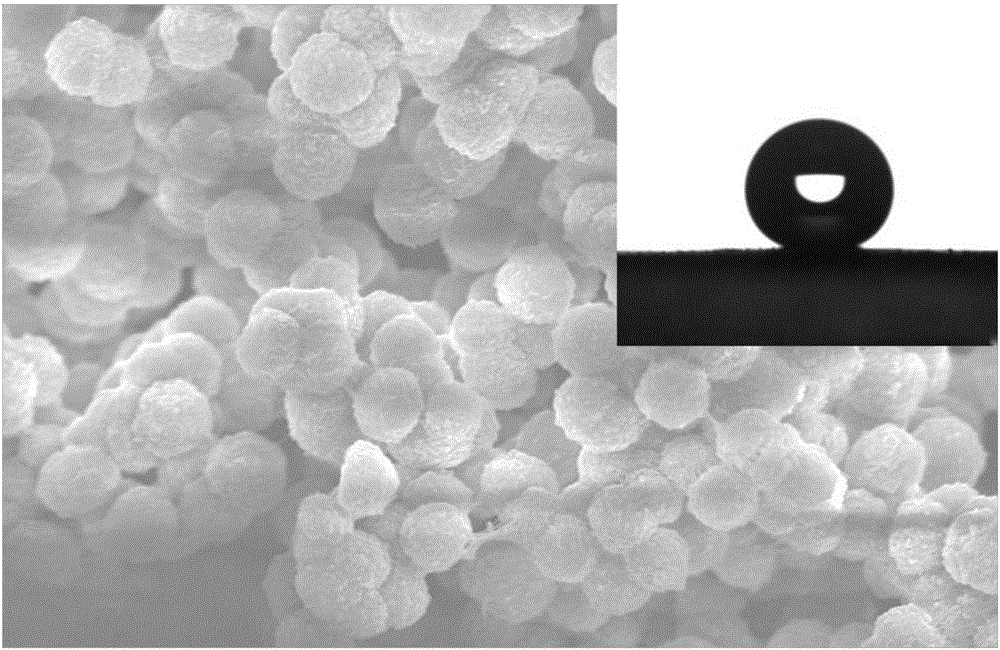

Preparation method of super-hydrophobic PVDF (polyvinylidene fluoride) membrane

ActiveCN106823829AImproves anti-wetting propertiesEase membrane wettingSemi-permeable membranesMembranesPolyvinylidene fluorideChemistry

The invention discloses a preparation method of a super-hydrophobic PVDF (polyvinylidene fluoride) membrane. The method mainly comprises the following steps: preparing a PVDF membrane casting solution and preparing a mixed coagulating bath; preparing a primary flat-sheet membrane or spinning a hollow fiber membrane by a hollow spinneret; leaving the primary membrane to stand in air, placing the primary membrane in the coagulating bath, and soaking a product in deionized water after complete curing to remove residual organic matter to obtain the super-hydrophobic PVDF composite membrane. The super-hydrophobic PVDF membrane prepared with the method shows a spherically stacked zero-defect cascade porous structure, surfaces of PVDF microspheres separated out of the surface layer and the inside of the membrane show a micro-nano-binary microstructure like a lotus leaf surface, so that the membrane surface and membrane pores all show the super-hydrophobic characteristic, and the wetting resistance of the membrane is improved fundamentally. The preparation method of the super-hydrophobic PVDF membrane has the advantages that the preparation process is simple, the operability is high and the like. The defect that the wetting resistance effect of super-hydrophobic modification of single membrane surface is not lasting is overcome, and the method is applicable to membrane processes such as membrane distillation, membrane absorption and the like.

Owner:TIANJIN POLYTECHNIC UNIV +1

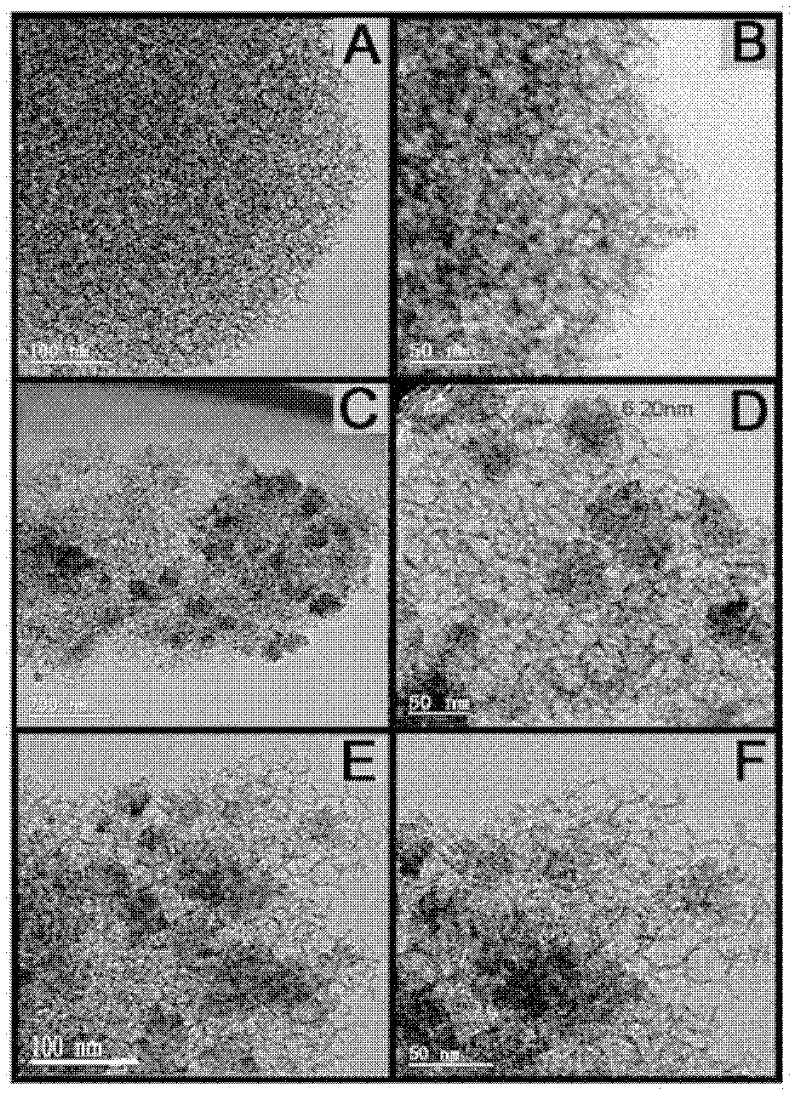

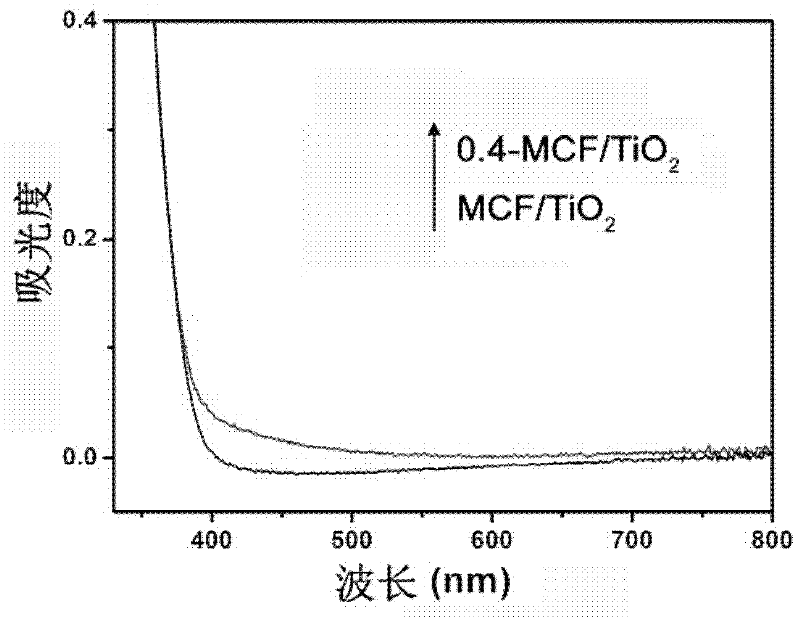

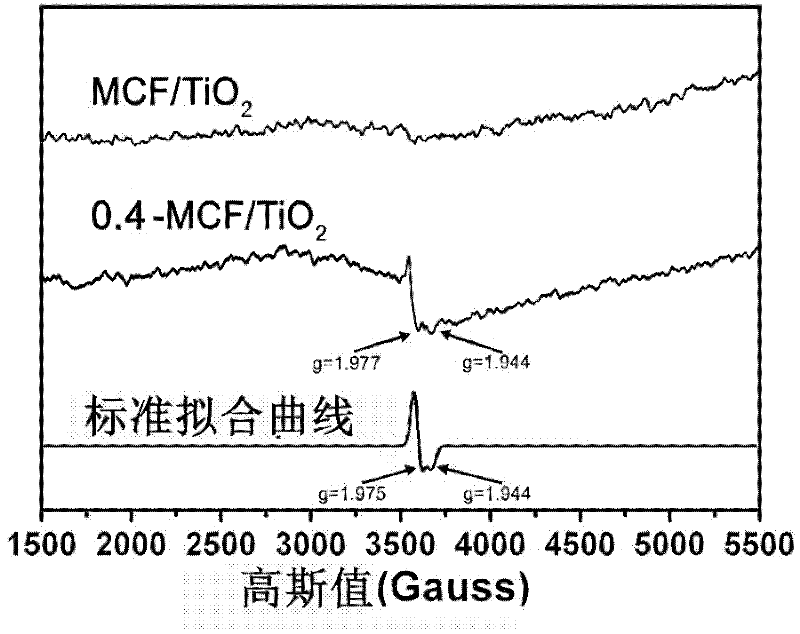

A kind of synthetic method of ammonium fluoride modified titanium dioxide visible light catalyst

InactiveCN102266792ASynthetic operation is simpleLow toxicityMolecular sieve catalystsWater/sewage treatment by irradiationHigh concentrationActivation method

The invention relates to a synthesis method for a visible photocatalyst by modifying titanium dioxide (TiO2) by using ammonium fluoride (NH4F). The synthesis method comprises three steps of: preparing a mesocellular foam silica (MCF) molecular sieve, preparing an MCF carrying TiO2 catalyst and modifying MCF / TiO2 by using the NH4F. Compared with the prior art, the carrying catalyst MCF / TiO2 is subjected to NH4F hydrophobic modification through a hydrothermal process and a low-temperature vacuum activation method; as a mesoporous material has extremely high absorption capability, the visible photocatalyst has outstanding absorption performance and catalyzing and degrading performance on ultraviolet and visible light of high-concentration organic pollutants during degrading of organic compounds, such as rhodamine B and the like; furthermore, during hydrophobic modification, if isopropyl alcohol is found to be a solvent, the NH4F hydrophobic modification effect of the prepared catalyst isthe optimal and the hydrophobic stability is quite good; moreover, the synthesis method is simple in operation and low in cost, and the raw materials are easily obtainable.

Owner:EAST CHINA UNIV OF SCI & TECH

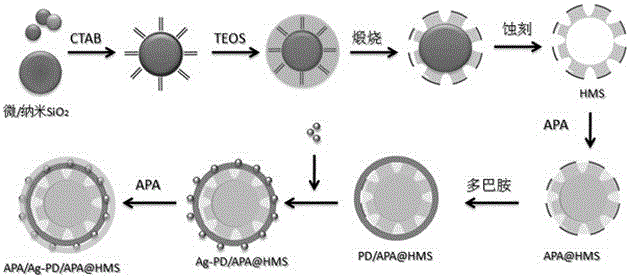

Self-repairing super-hydrophobic composite material, preparation method and application thereof

ActiveCN105949861ASuperhydrophobicAntifoulingAntifouling/underwater paintsPaints with biocidesMicrosphereCarbon chain

The invention discloses a self-repairing super-hydrophobic composite material, a preparation method and application thereof. The composite material has a structural general formula of: APA / M-PD / APA@HMS, wherein, APA is alkyl primary amine having a long carbon chain with C greater than or equal to 12, PD is polydopamine, HMS is hollow mesoporous SiO2 microsphere, APA@HMS refers to HMS loaded with APA, and the M refers to an antifouling able to stick on PD. The preparation method provided by the invention has the advantages of simple operation, and rich raw material sources, and is suitable for mass production. The prepared APA / M-PD / APA@HMS can be used as a paint additive, can endow a coating with super-hydrophobicity, antifouling property, self-repairability, and durability, and can be used for protective coatings of marine materials.

Owner:SHANGHAI MARITIME UNIVERSITY

Anti-corrosion super-hydrophobic heat reflecting paint and preparation method thereof

ActiveCN105925073AImprove lotus leaf effectImprove hydrophobicityAnti-corrosive paintsReflecting/signal paintsNano sio2Water contact

The invention discloses an anti-corrosion super-hydrophobic heat reflecting paint and a preparation method thereof. The anti-corrosion super-hydrophobic heat reflecting paint is prepared from the following raw materials: modified nano TiO2, modified nano SiO2, micron TiO2 and / or SiO2, fluorocarbon resin, a solvent, a curing agent, a defoaming agent, a wetting dispersant and a flatting agent. After experiments, the heat reflecting rate of the obtained product reaches 90 percent or more, the water contact angle reaches 145 degrees or more, and the product can meet the requirements on a coating under outdoor severe environments.

Owner:SHANDONG UNIV OF SCI & TECH

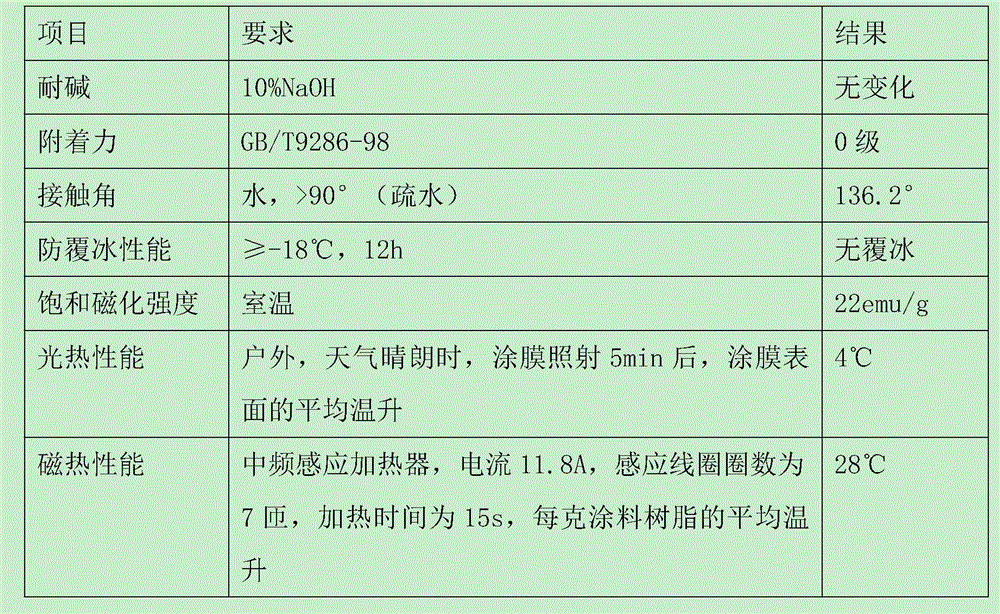

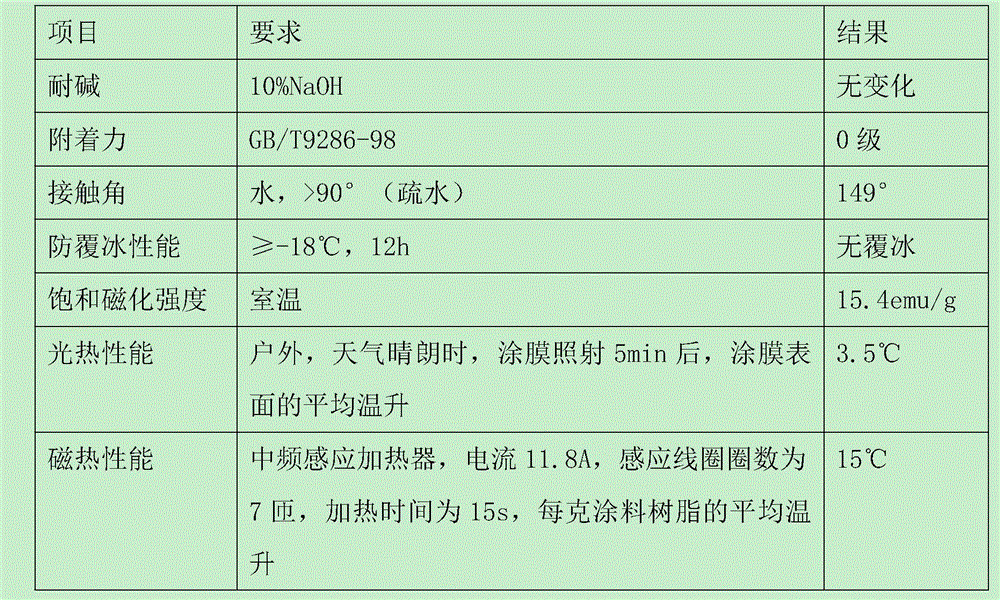

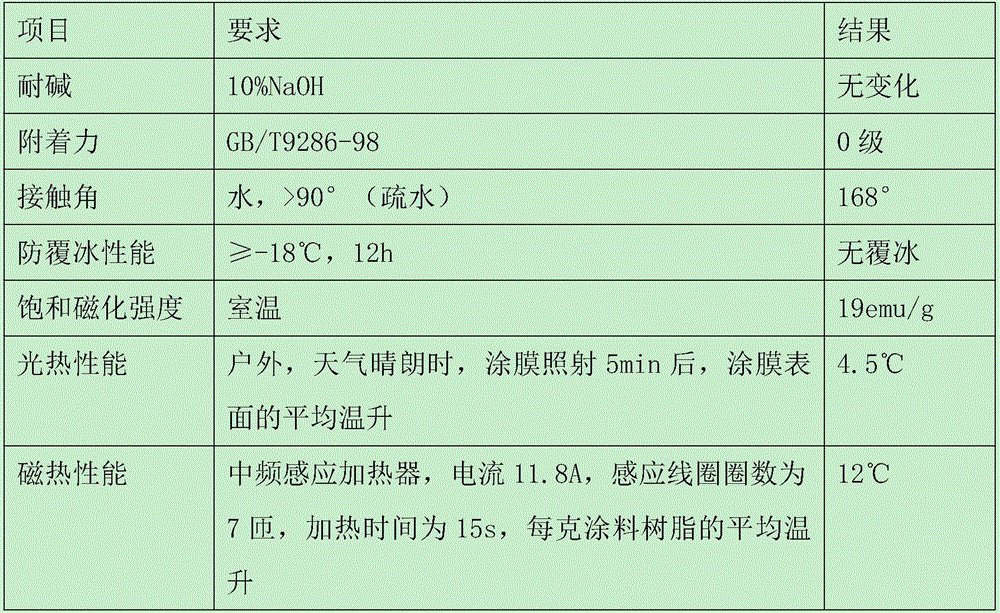

Super-hydrophobic ice-over resistant coating with thermomagnetic property and preparation method of super-hydrophobic ice-over resistant coating

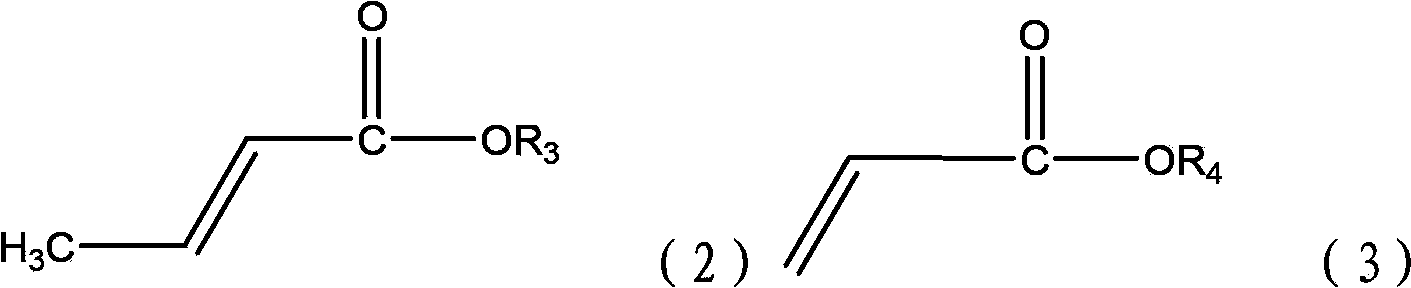

ActiveCN104804603AExcellent magnetocaloric performanceDelayed icingCoatingsWeather resistanceHydrocarbon

The invention discloses a super-hydrophobic ice-over resistant coating with a thermomagnetic property and a preparation method of the super-hydrophobic ice-over resistant coating. The super-hydrophobic ice-over resistant coating comprises the following components by mass percent: 20-68% of fluorine-containing acrylic acid epoxy resin, 19-69% of an organic solvent, and 10-50% of inorganic particles which are magnetic particles or mixture of magnetic particles and nonmagnetic particles, wherein the fluorine-containing acrylic acid epoxy resin is obtained through reaction of two components; one component is obtained through free radical polymerization of a fluorine-containing acrylate monomer, a hydrocarbon chain acrylate monomer and an expoxy group-containing acrylic acid ester monomer; the other component belongs to polyamines or acid anhydrides. The coating provided by the invention is environmentally friendly, and excellent in weather resistance and chemical resistance, has excellent adhesion with a base material, can be heated in the external alternating magnetic field or light condition, and can be used for preventing and controlling icing on the surfaces of telecommunication lines and the like; the preparation method is simple in process and convenient to operate.

Owner:ZHEJIANG UNIV

Method for enabling PTFE (Polytetrafluoroethylene) or FEP (Fluorinated Ethylene Propylene) surface to have super-hydrophobic and underwater high reflective properties simultaneously

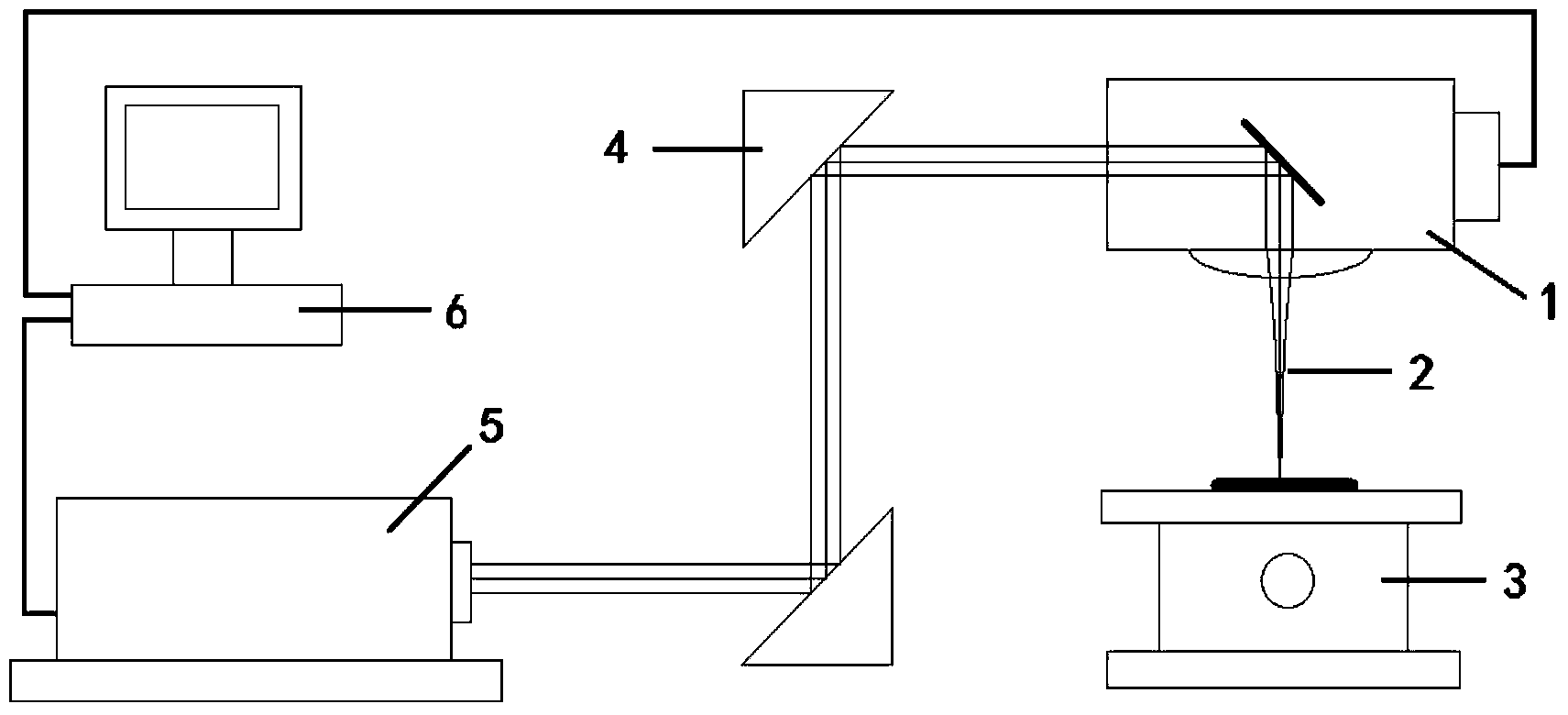

ActiveCN103551734AGood surface stabilityInternal nature influenceWelding/soldering/cutting articlesLaser beam welding apparatusOptical pathFluorinated ethylene propylene

A method for enabling a PTFE (Polytetrafluoroethylene) or FEP (Fluorinated Ethylene Propylene) surface to have super-hydrophobic and underwater high reflective properties simultaneously belongs to the laser machining field. According to the method, a 1064 nm picosecond laser micro-machining system is utilized to machine a one-dimensional or a dimensional trench array with a 25 mum seam width in PTFE and FEP surfaces so as to enable the surfaces to have super-hydrophobicity; if a prepared super-hydrophobic sample is completely immersed in water, a super-hydrophobic surface may take on a metallic luster high reflective surface. The method comprises the operating steps of: adjusting a picosecond laser light path, drawing a machining path by utilizing professional software, adjusting a picosecond laser output power based on a machining requirement, outputting picosecond pulse laser for machining when the laser power meets the requirement, achieving a super-hydrophobic requirement without subsequent cleaning after the machining is finished, and immersing the finished product in water to make a metal-like high reflective surface appear directly.

Owner:BEIJING UNIV OF TECH

Method used for preparing TiO2/Cu2O nano heterojunction by composite mask method

ActiveCN103409778AFlat surfaceHighly orderedSurface reaction electrolytic coatingNanotechnologyHeterojunctionTio2 nanotube

The invention belongs to the field of photoelectric nano-material technologies, and more specifically relates to a method used for preparing TiO2 / Cu2O nano heterojunction by composite mask method. The method comprises following steps: titanium sheets are subjected to secondary anodic oxidation so as to obtain TiO2 nanotube array thin films; the TiO2 nanotube array thin films are immersed in a compound solution of phenyltriethoxysilane and methanol, and the TiO2 nanotube array thin films with super-hydrophobicity are prepared by mask method and ultraviolet light treatment; and then Cu2O nanocrystals produced by the high-frequency impulse electrodeposition method are uniformly distributed on the surface and inner wall of the TiO2 nanotube array thin films to obtain the TiO2 / Cu2O nano heterojunction. The photoelectric property of the TiO2 / Cu2O nano heterojunction is higher than 6 to 14 times of the photoelectric property of the TiO2 nanotube array; the photoelectric property is excellent; and the TiO2 / Cu2O nano heterojunction can be used as ideal materials for solar energy photoelectric conversion and solar energy efficient utilization.

Owner:HEFEI UNIV OF TECH

Superhydrophobic silicon-aluminum-zirconium composite material and preparation method thereof

InactiveCN106830878ALow vibration mass loss rateStable structureAluminium silicatesAerogel preparationFiberSupercritical drying

The invention provides a superhydrophobic silicon-aluminum-zirconium composite material and a preparation method thereof. The superhydrophobic silicon-aluminum-zirconium composite material comprises a silicon-aluminum-zirconium aerogel and a fiber material. The silicon-aluminum-zirconium aerogel is composed of the following components in percentage by mass: 30-95% of SiO2, 5-70% of Al2O3 and 0-10% of ZrO2. The method comprises the following steps: impregnating the fiber material into the silicon-aluminum-zirconium aerogel, and carrying out gel and supercritical drying treatment to obtain the superhydrophobic silicon-aluminum-zirconium composite material. According to the technical scheme, the obtained silicon-aluminum-zirconium composite material has the advantages of low vibration mass loss rate and stable structure at high temperature. The method has the advantages of simple technique, high controllability and low cost.

Owner:CANEW TECH SHENZHEN CO LTD

Method for acquiring super-double-thinning property on metallic copper or copper alloy backing material surface

InactiveCN101492815AAvoid corrosionTo achieve the purpose of anticorrosionMetallic material coating processesSurface finishingWork in process

The invention relates to corrosion resistance and self cleaning of a metal surface, in particular to the corrosion resistance and self cleaning realized by obtaining super-amphiphobic property on the surface of copper metal and copper alloy. The method is to clean the copper metal, a copper alloy base material or a base material coated by the copper metal on the surface to be immersed in a perfluorinated aliphatic acid organic solvent with concentration of 0.005-0.05mol / L, thereby obtaining a self-cleaning surface with super-dual hydrophobic property on the surface of the copper metal, the copper alloy base material or the base material coated by the metal copper on the surface. The method has simple operation and low requirement on equipment, is not restricted by the shape of the base material, is also applicable to surface treatment of a finished product and a semi-finished product workpiece, and is easy to realize industrialization. The method can be widely applied to each department of national production and living, such as machinery, shipbuilding, electric power, military, building, kitchenware and the like, and has wide practical value.

Owner:INST OF CHEM CHINESE ACAD OF SCI

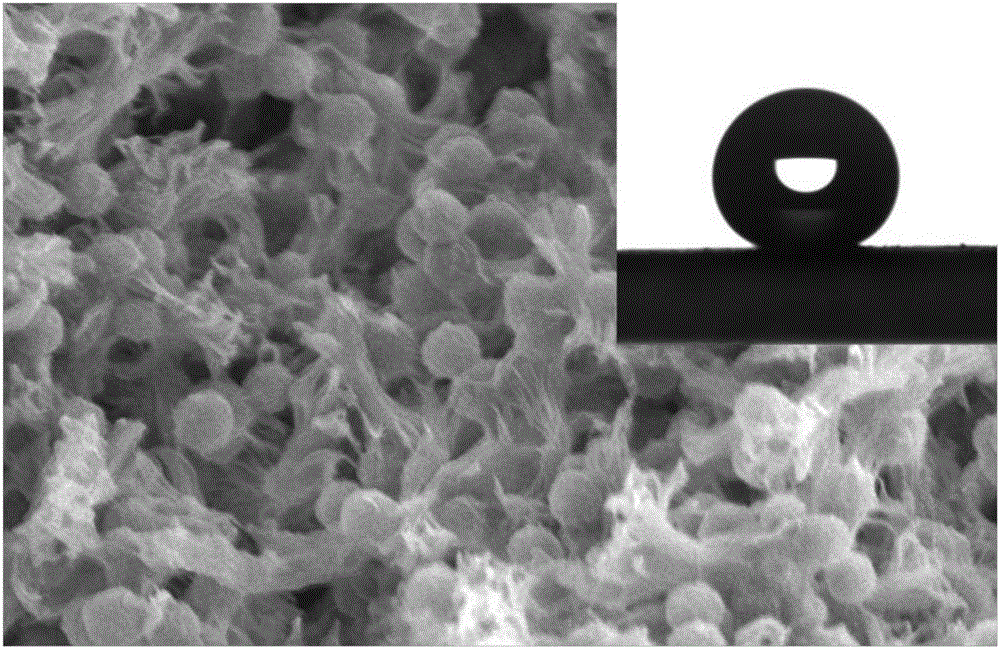

Method for preparing superhydrophobic composite microporous membrane

ActiveCN106582332ASuperhydrophobicLower free energySemi-permeable membranesPolyvinylidene fluorideChemistry

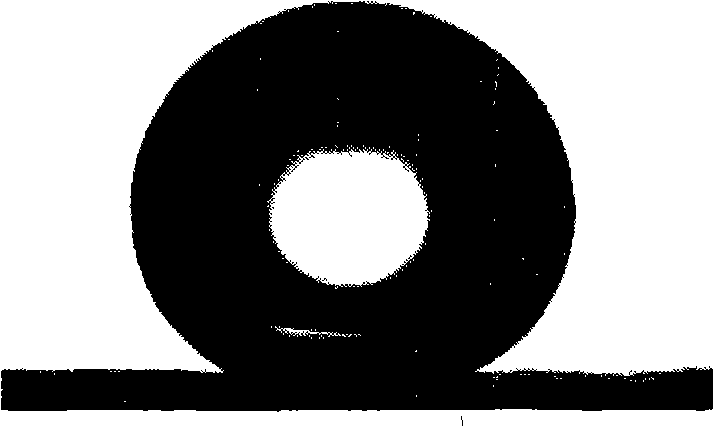

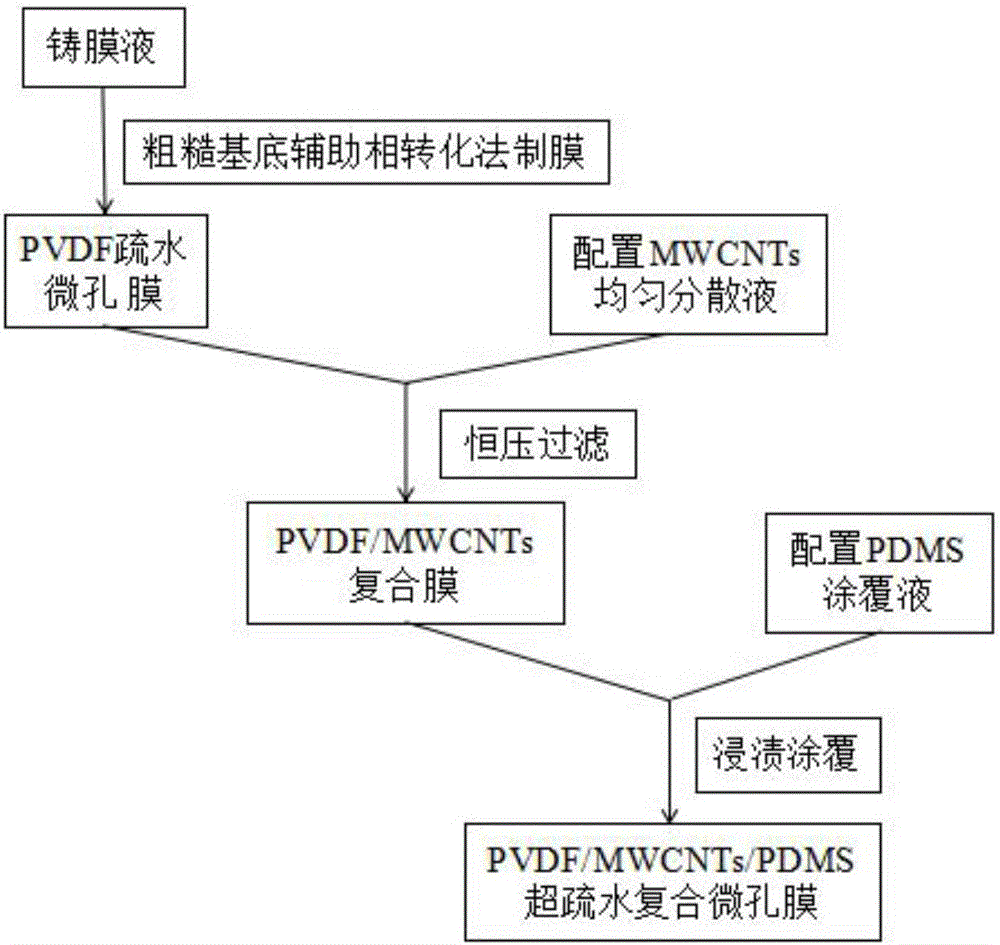

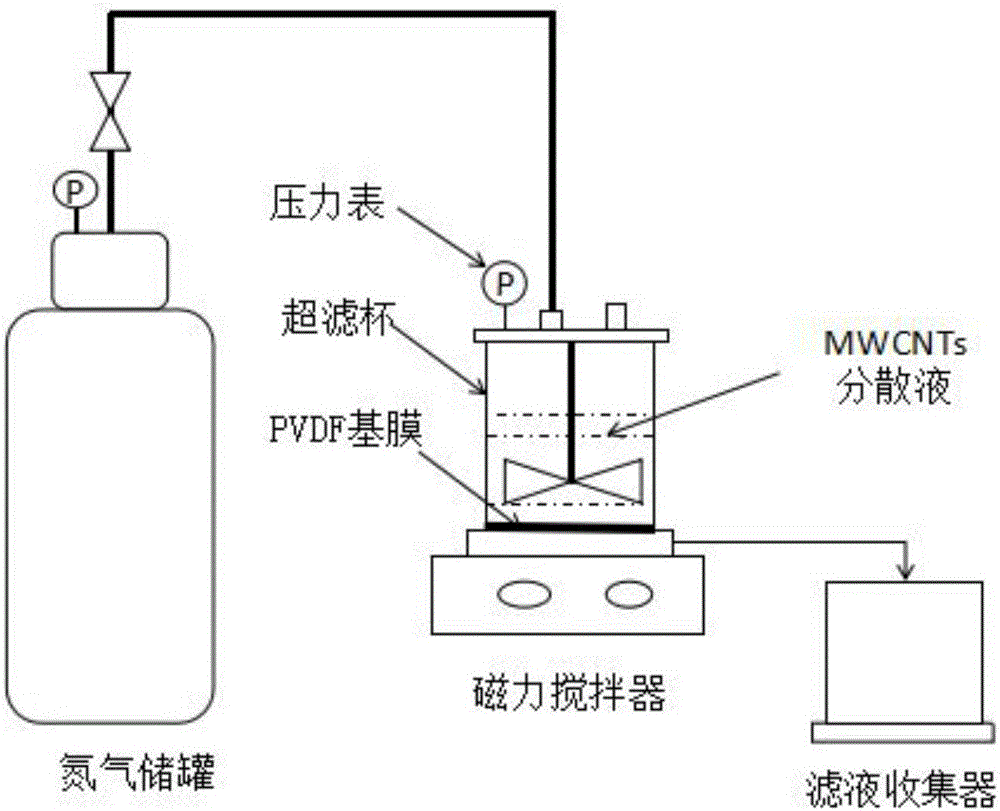

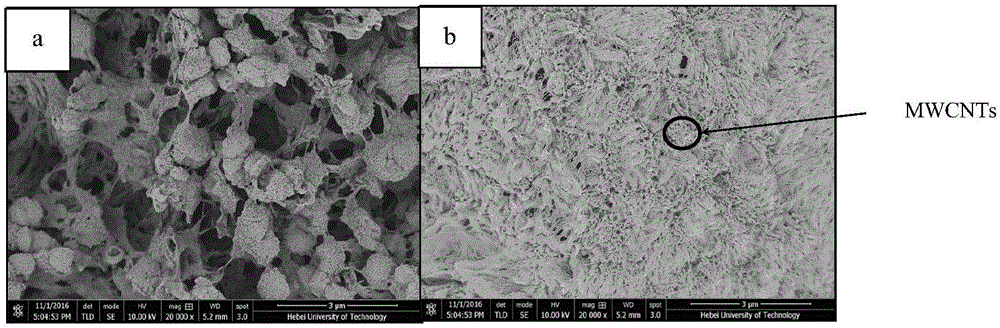

The invention relates to a method for preparing a superhydrophobic composite microporous membrane. The method comprises the following steps: firstly, preparing a polyvinylidene fluoride (PVDF) high-hydrophobic microporous membrane as a basal membrane by a coarse substrate assisted phase inversion method, then, preparing a multi-walled carbon nanotube (MWCNTs) uniform dispersion solution, filtering the MWCNTs dispersion solution with the prepared PVDF basal membrane at constant pressure by adopting a constant-pressure filtering method so as to prepare a PVDF / MWCNTs composite membrane, and carrying out coating with an n-hexane solution of polydimethylsiloxane (PDMS), thereby preparing the PVDF / MWCNTs / PDMS superhydrophobic composite microporous membrane. According to the composite microporous membrane obtained by the method, the static water contact angle can reach 162 degrees, the angle of roll is 10 to 20 degrees, the nitrogen gas flux at the pressure of 100kPa is greater than 0.3m<3> / (m<2>.s), the tensile strength is higher than 2.6MPa, and the elongation at break is higher than 96%, so that the superhydrophobic composite microporous membrane can be applied to membrane contact procedures such as membrane distillation and membrane absorption.

Owner:HEBEI UNIV OF TECH

Preparation of super-hydrophobic transparent silicon dioxide film

InactiveCN101407648ASuperhydrophobicThickness is easy to controlElectrophoretic coatingsPaints for electrolytic applicationsTransmittanceFilm material

The invention discloses a preparation method of a super-hydrophobic transparent silica thin film, the method mixes and stirs silica particles with alcohol solution, carries out the ultrasonic dispersion and regulates the pH value to obtain a silica colloid electrophoresis buffer; the silica colloid electrophoresis buffer is electrophoretically deposited on a clean conductive substrate, the drying is carried out after the leaching by anhydrous ethanol, thereby obtaining a silica thin film conductive substrate; the thermal treatment is carried out on the silica thin film conductive substrate at 120 to 400 DEG C for 30-60 minutes; the silica thin film conductive substrate after the thermal treatment is arranged in hydrophobic treatment liquid for immersion for 12 to 24 hours and then taken out, the drying is carried out after the leaching by the ethanol, and the super-hydrophobic transparent silica thin film is obtained. The prepared thin film material has excellent hydrophobic property and transmittance, the contact angle between water and the surface is 153 degrees to 162 degrees, and the transmittance under the wavelength of 500nm can reach 90.2 to 95.5 percent.

Owner:SOUTH CHINA UNIV OF TECH

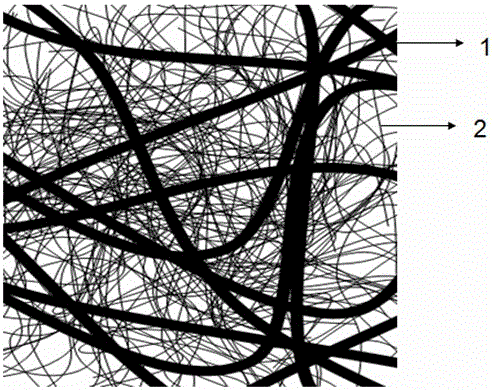

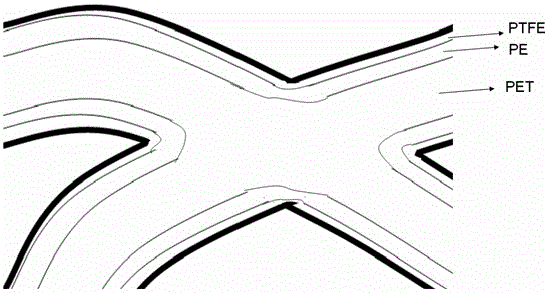

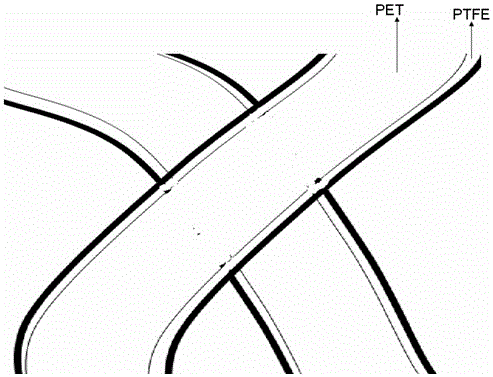

Electret non-woven filter material for air filtering

ActiveCN105771427AHigh strengthDimensionally stableFilament/thread formingHeating/cooling textile fabricsFiberPorosity

The invention discloses an electret non-woven filter material for air filtering.An evenly-distributed three-dimensional spatial network structure is formed by 0.06D PET superfine fibers and 30D PE / PET skin core complex fibers, linkage joints are formed by the skin core complex fibers and the fibers in contact with the skin core complex fibers, and PTFE coatings are arranged on the surfaces of the superfine fibers and the skin core complex fibers.A preparation method of the electret non-woven filter material comprises the steps that the PET / PET figured sea-island staple fibers and the PE / PET skin core complex short fibers are mixed according to a certain mass ratio and carded, and the electret non-woven filter material is formed through needling net forming, alkali liquor melting, roll compacting and washing, PTFE emulsion dipping, tentering heat shaping and cooling curing.The electret non-woven filter material has the advantages of being high in strength, stable in size and small in resistance.The filter material is high in porosity, small and even in aperture and good in breathability.The electron work function is high, the dielectric constant is small, and the static adsorption effect on PM2.5 dust is good.Super-hydrophobic performance is achieved, and the static adsorption function of the filter material cannot be weakened by damp air.

Owner:QINGDAO JINMEISHENG NON WOVEN CO LTD

Preparation method of porous hydrophobic oleophylic sponge

The invention provides a preparation method of a porous hydrophobic oleophylic sponge. The method comprises the steps: taking polymer foams, placing in a heating furnace, under the protection of inert gas, heating up to 150-1000 DEG C, calcining for 0.2-10 h, and thus obtaining the porous hydrophobic oleophylic sponge. The porous hydrophobic oleophylic sponge obtained by the method adsorbs oil, does not adsorb water, can adsorb the oil or organic matters which are hundreds of times heavier than the sponge, and has good toughness; and after the oil or organic matters are adsorbed, the adsorbed oil or organic matters can be removed through extrusion, distillation, burning and other methods, and thus the porous hydrophobic oleophylic sponge can be used repeatedly. The preparation method is simple, needs no complicated chemical reactions or material preparation processes, and has the advantages of convenient operation, good repeatability and easily industrialized implementation. The porous oil-adsorption sponge has the characteristics of large specific surface area, low density, good flexibility, hydrophobic oleophylic performance and the like, can be used for oil-water separation, and has good application prospects in the fields of wastewater treatment, adsorption of leaking crude oil or organic matters and the like.

Owner:JIANGSU UNIV

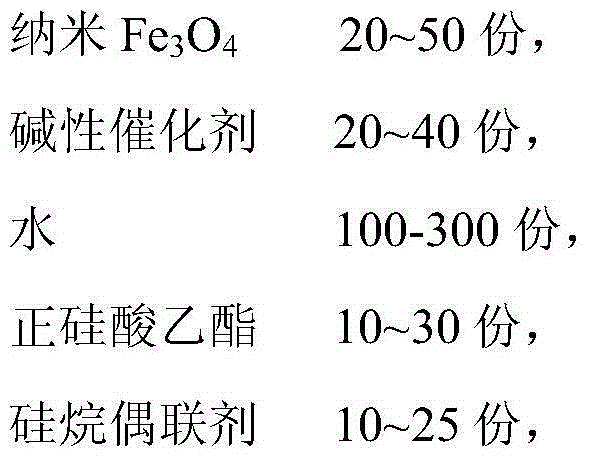

Preparation method of superhydrophobic superparamagnetic silicone resin composite coating

ActiveCN104694001AStrong interfacial adhesionSuperhydrophobicMagnetic paintsPolymer scienceElectromagnetic shielding

Owner:HANGZHOU NORMAL UNIVERSITY

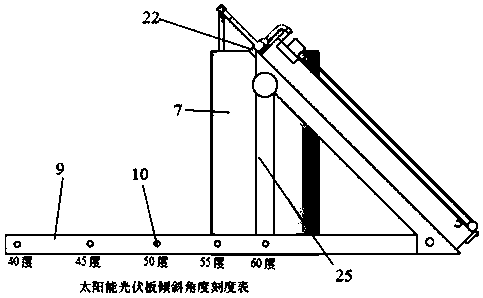

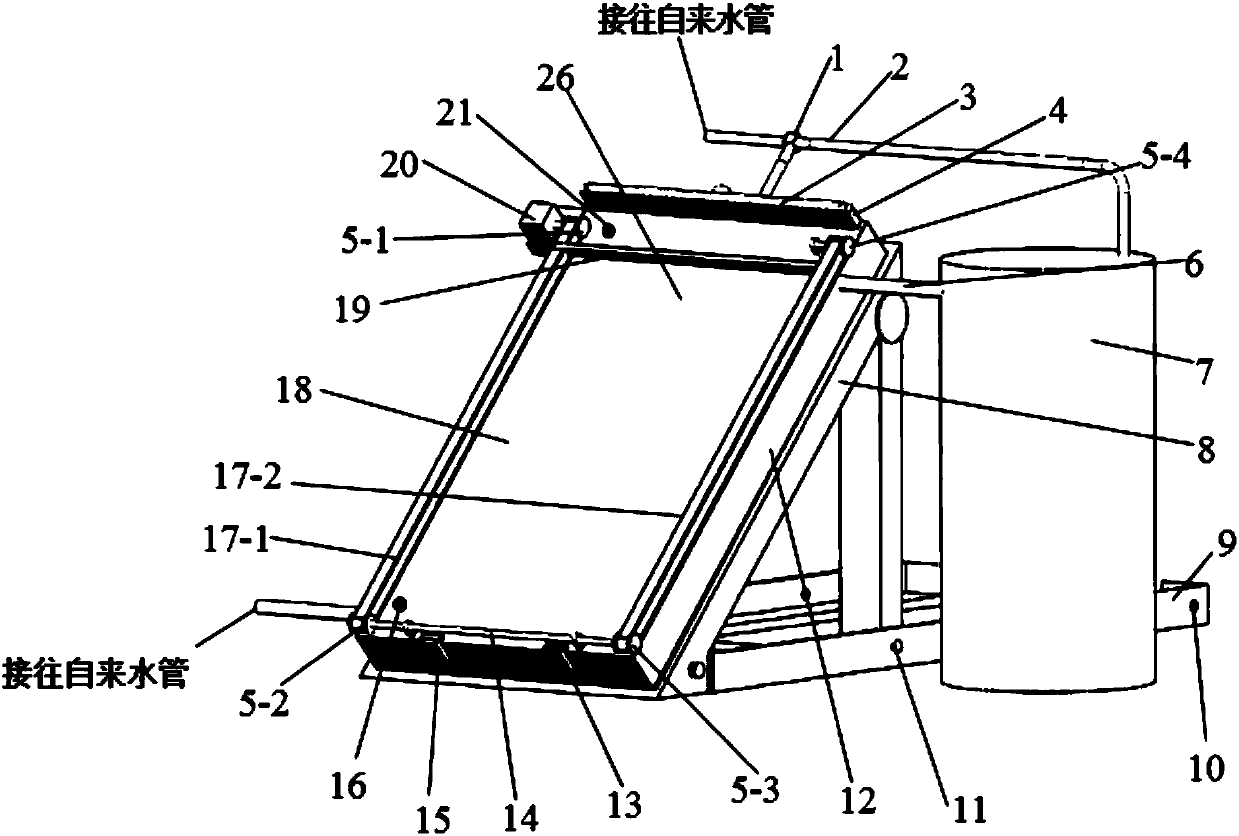

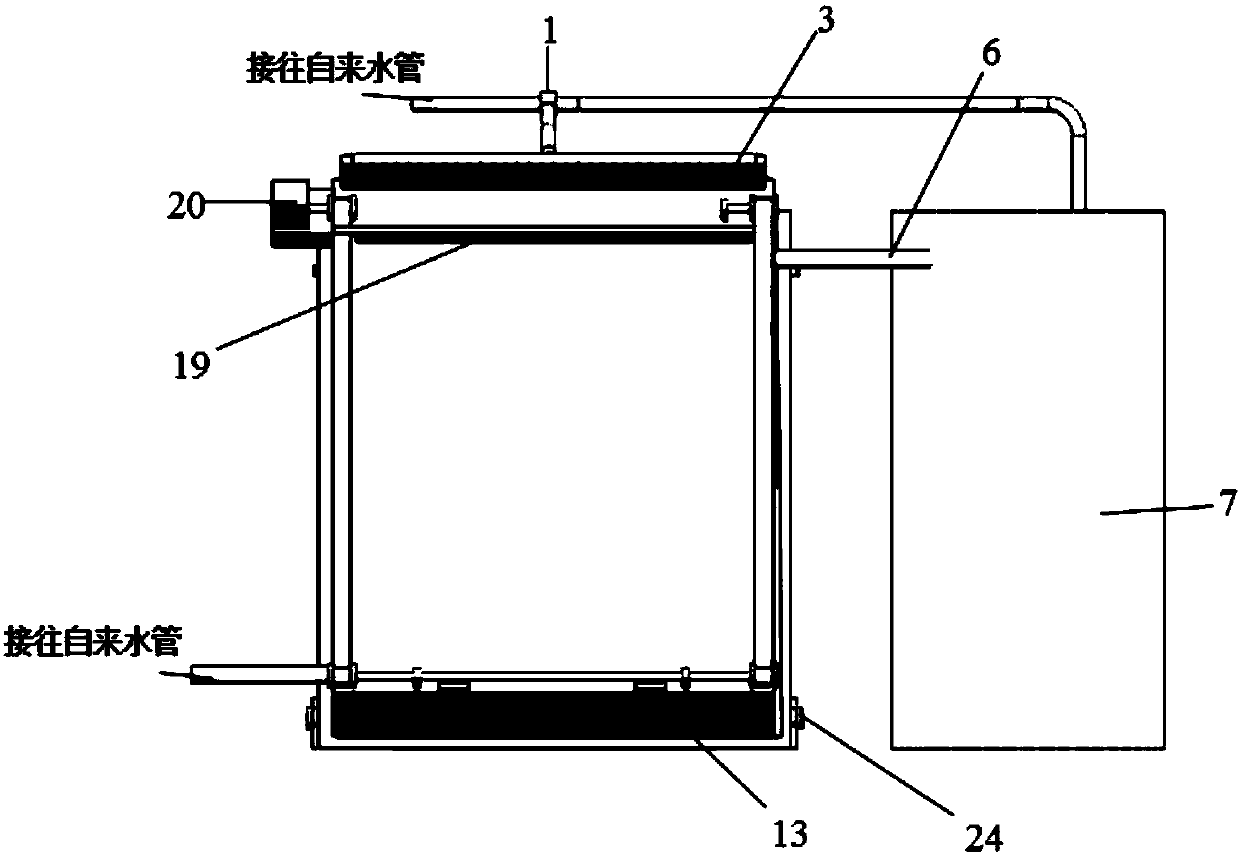

Self-cleaning solar photovoltaic heat collection system based on hydrophobicity of lotus leaves

InactiveCN107671050ASuperhydrophobicIncrease profitSolar heating energyBatteries circuit arrangementsElectricityCollection system

The invention provides a self-cleaning solar photovoltaic heat collection system based on the hydrophobicity of lotus leaves. The self-cleaning solar photovoltaic heat collection system based on the hydrophobicity of lotus leaves comprises a solar photovoltaic heat collection system body and an automatic cleaning system. The self-cleaning solar photovoltaic heat collection system based on the hydrophobicity of lotus leaves has the effects that the functions of power generation, heat collection, automatic cleaning and the like are achieved, automatic cleaning can be achieved through devices such as a pulley assembly and a spraying pipe according to the hydrophobicity principle of lotus leaves, and the utilization rate of solar energy is increased. Power stored in a solar photovoltaic panelis supplied to electric equipment such as a driving motor, a water pump and a controller, and thus no extra power supply is needed. A control hub is mounted in the system, and thus manual control canbe achieved in certain emergencies. Hot water and electricity used in the cleaning process are all supplied by the system, and thus the self-cleaning solar photovoltaic heat collection system based onthe hydrophobicity of lotus leaves accords with the concept of environmental friendliness, energy saving and sustainability.

Owner:TIANJIN CHENGJIAN UNIV

Functional gradient composite structure wear-resistant transparent super-hydrophobic coating and preparation method thereof

InactiveCN106085173ANo shape requirementSimple processLiquid surface applicatorsPolyurea/polyurethane coatingsMicro nanoWear resistant

The invention discloses a functional gradient composite structure wear-resistant transparent super-hydrophobic coating and a preparation method thereof. Specifically, the method consists of: firstly coating a substrate with a polyurethane modified reinforced bonding layer, then conducting coating of a polyurethane and super-hydrophobic compound transition layer to obtain a polyurethane / polyurethane and silicon dioxide transition layer compound coating, and finally performing coating of a micro-nano super-hydrophobic layer, thus forming a polyurethane / polyurethane-silicon dioxide / silicon dioxide functional gradient composite structure wear-resistant transparent super-hydrophobic coating. The preparation method provided by the invention has the characteristics of simple process, easy operation, normal pressure and low cost, the prepared functional gradient composite structure wear-resistant transparent super-hydrophobic coating can be used for water and fouling prevention on ship surface coatings, automotive glass surfaces, mobile phone screen surfaces and other transparent materials.

Owner:WUHAN UNIV OF TECH

Preparation method of super-hydrophobic coating with phase change function

ActiveCN103666159AMaintain phase change abilityEasy to use in large areaCoatingsMicroballoon preparationMicro nanoWater based

The invention discloses a preparation method of a super-hydrophobic coating with a phase change function applied to the fields of a building exterior wall and a thermal insulation pipeline, and relates to the technical fields of coatings and general heat insulation. The super-hydrophobic phase-change coating with a micro-nano secondary structure is built by a composite water-based fluorine silicone acrylic emulsion, an organic phase-change microcapsule and nano particles. The fluorine silicone acrylic emulsion, the organic phase-change microcapsule, the nano particles, a defoamer and water are evenly mixed, and then dispersed by adopting a high-speed disperser or an ultrasonic crusher for 0.3-2 hours, so as to obtain the super-hydrophobic coating. The preparation method disclosed by the invention is simple, the prepared super-hydrophobic coating has heat-insulating and self-cleaning properties, and large-area construction is facilitated.

Owner:PIPECHINA SOUTH CHINA CO

Preparation method of gecko structure simulating adhesive

InactiveCN103274354AGood removal effectLow costNon-macromolecular adhesive additivesDecorative surface effectsAdhesiveElectrochemistry

The invention discloses a preparation method of a gecko structure simulating adhesive and relates to a preparation method of a gecko foot simulating microarray. The preparation method of the gecko structure simulating adhesive, disclosed by the invention comprises the following steps of: (1) preparing a porous metal film by using a hydrogen bubble template method; (2) mixing a high polymer with a cross-linking agent, vacuumizing, pouring the mixed liquor on a template of the porous metal plate for curing; and (3) removing a base and the porous metal template by using chemical and electrochemical methods. The preparation method disclosed by the invention is easy to operate and needs no complex instruments; experiment parameters are controllable; and a prepared gecko foot simulating microarray structure has very high adsorption capacity, also can be easily separated from the absorptive surface and simultaneously has super-hydrophobicity and self-cleaning capability. For the gecko foot simulating microarray prepared by using the hydrogen bubble template method and taking porous metal as a template, the area is 0.1-5 square centimeters, the diameter is 0.5-100 micrometers, the height is 0.5-20 micrometers, the elasticity modulus of a material is 1-15GPa, and the shear strength is 1-150kPa.

Owner:HARBIN INST OF TECH

Super-hydrophobic aluminium and preparation method thereof

InactiveCN102677059ASuperhydrophobicMetallic material coating processesSpecial surfacesMicro nanoPhysical chemistry

The invention relates to the technical field of super-hydrophobic materials, in particular to super-hydrophobic aluminium and a preparation method thereof. The preparation method comprises the following steps of: taking aluminium as a base material; soaking an aluminum sheet into hydrochloric acid solution so as to carry out chemical reaction; boiling through boiled water; forming a micro-nano composite structure with micron-sized bulges, holes and a nano-scale scaly shape on the surface of the aluminium; and modifying through perfluoro caprylic acid to obtain the surface of the aluminium sheet with a super-hydrophobic performance.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com