Patents

Literature

347 results about "Fluorinated ethylene propylene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

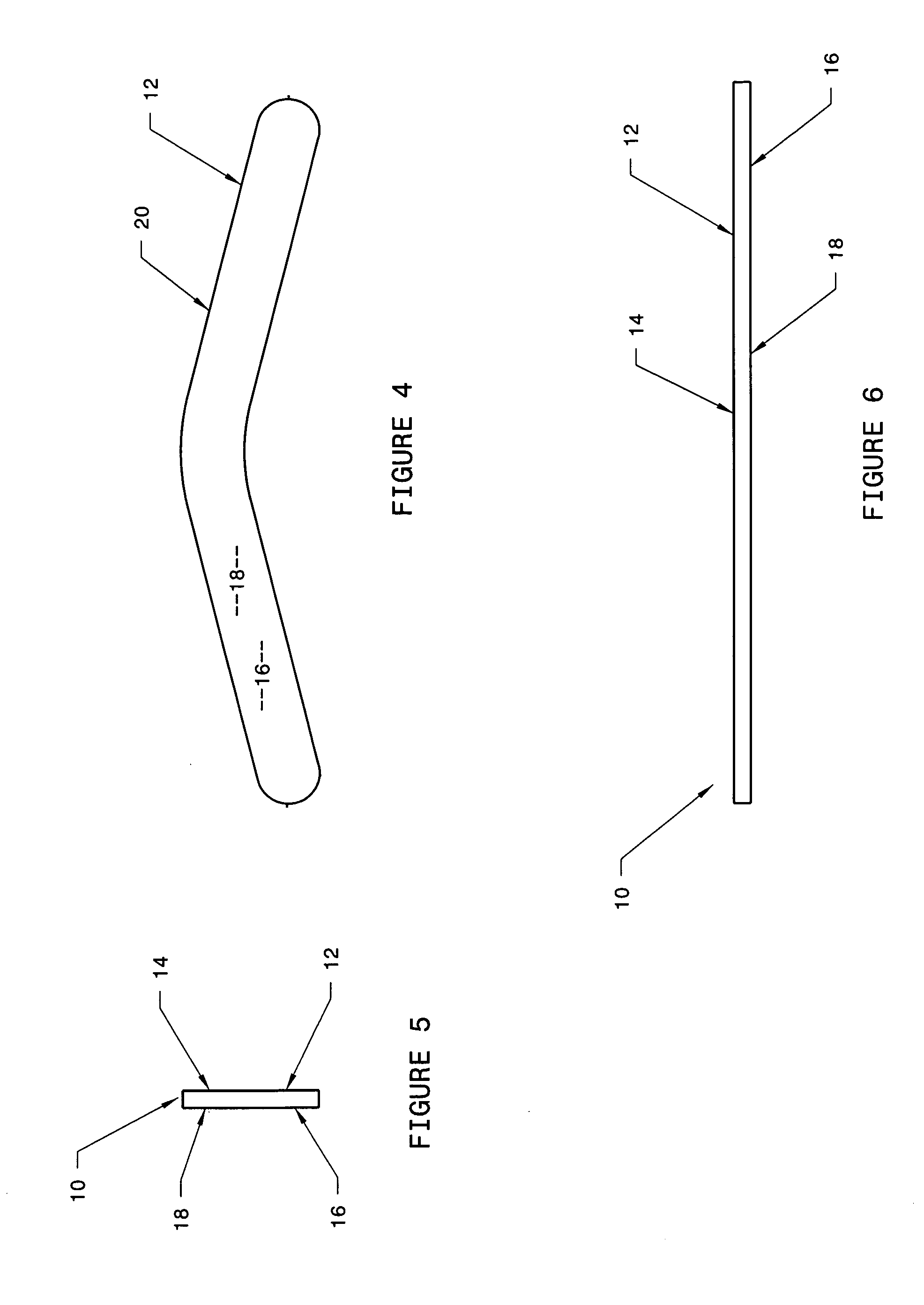

Fluorinated ethylene propylene (FEP) is a copolymer of hexafluoropropylene and tetrafluoroethylene. It differs from the polytetrafluoroethylene (PTFE) resins in that it is melt-processable using conventional injection molding and screw extrusion techniques. Fluorinated ethylene propylene was invented by DuPont and is sold under the brandname Teflon FEP. Other brandnames are Neoflon FEP from Daikin or Dyneon FEP from Dyneon/3M.

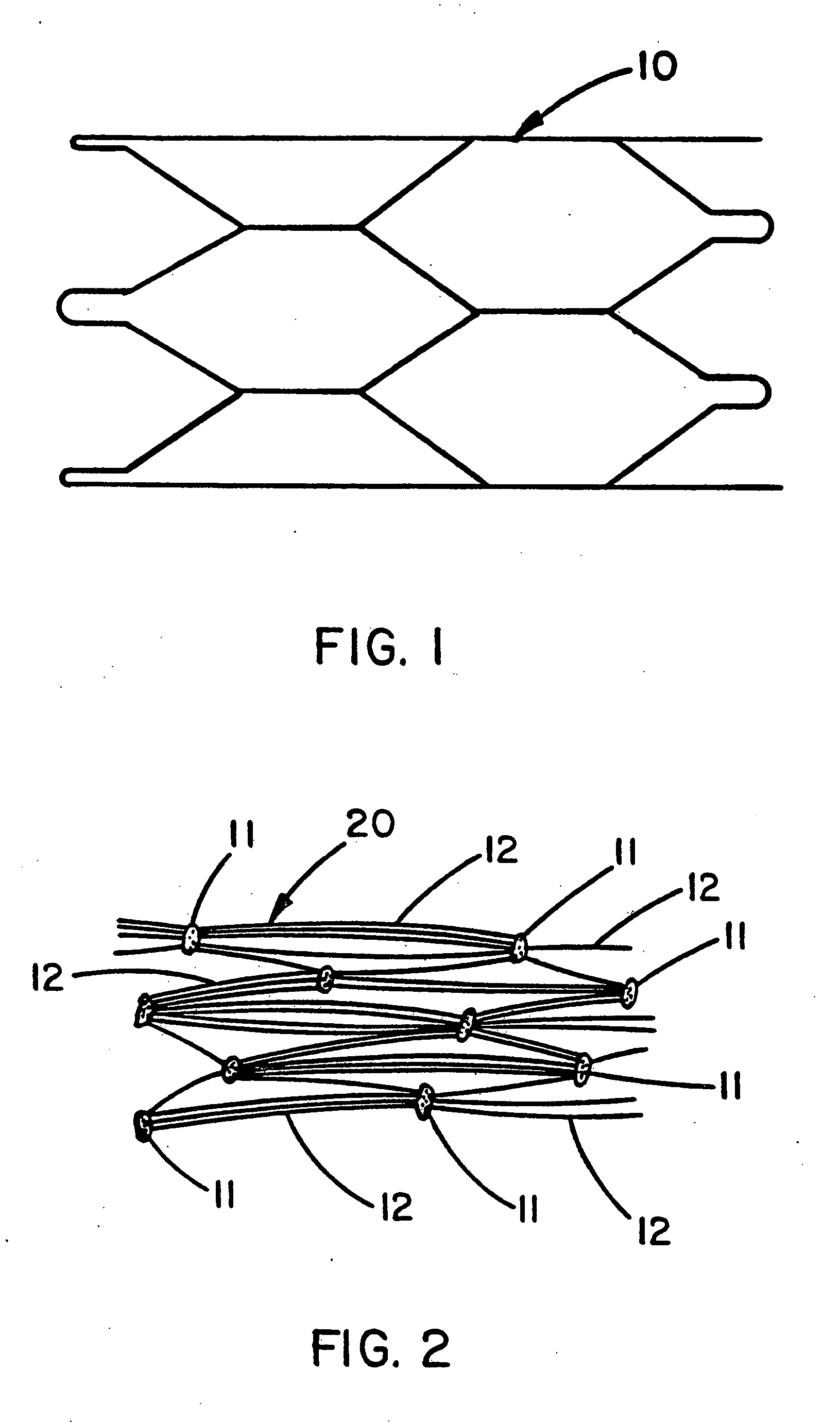

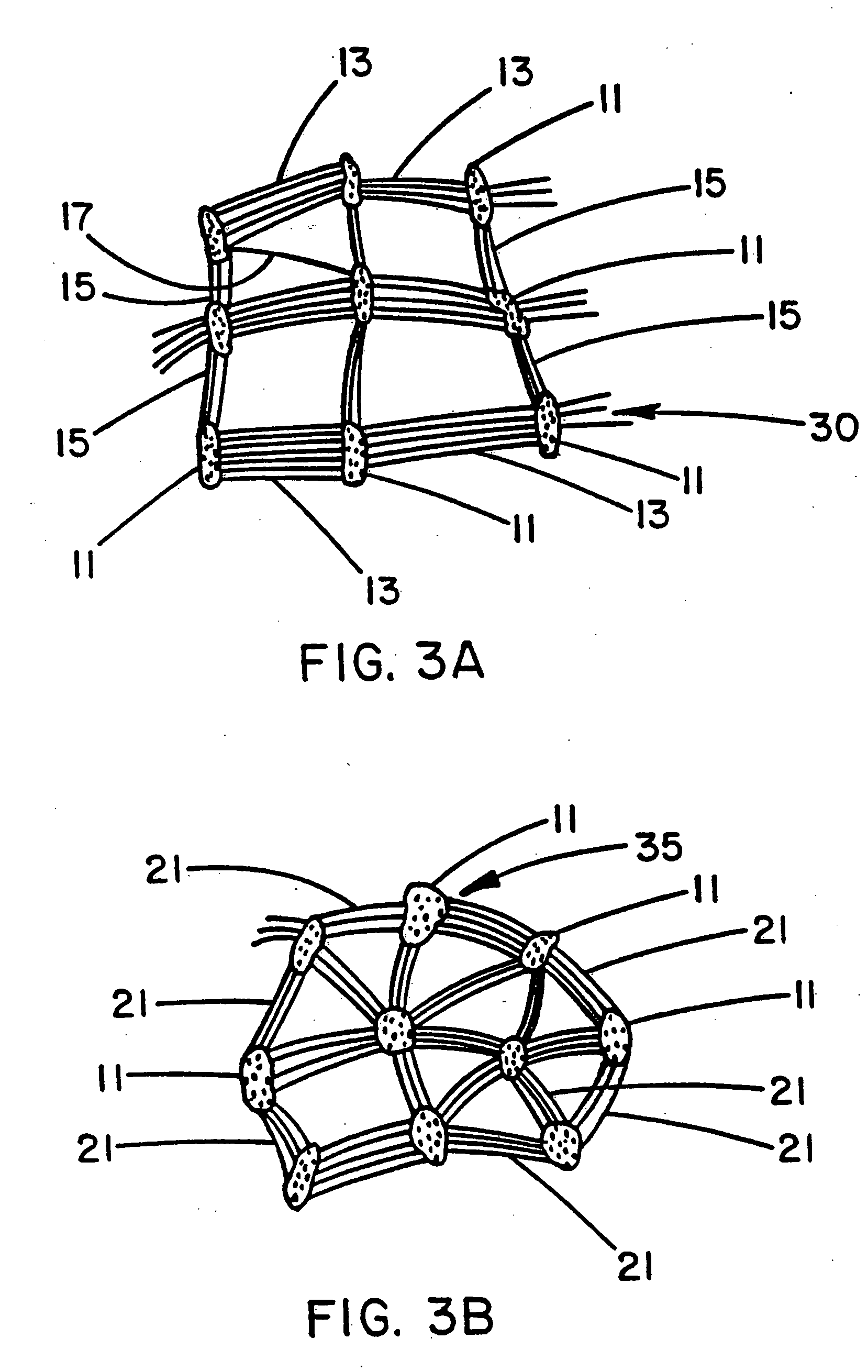

Thin-wall polytetrafluoroethylene tube

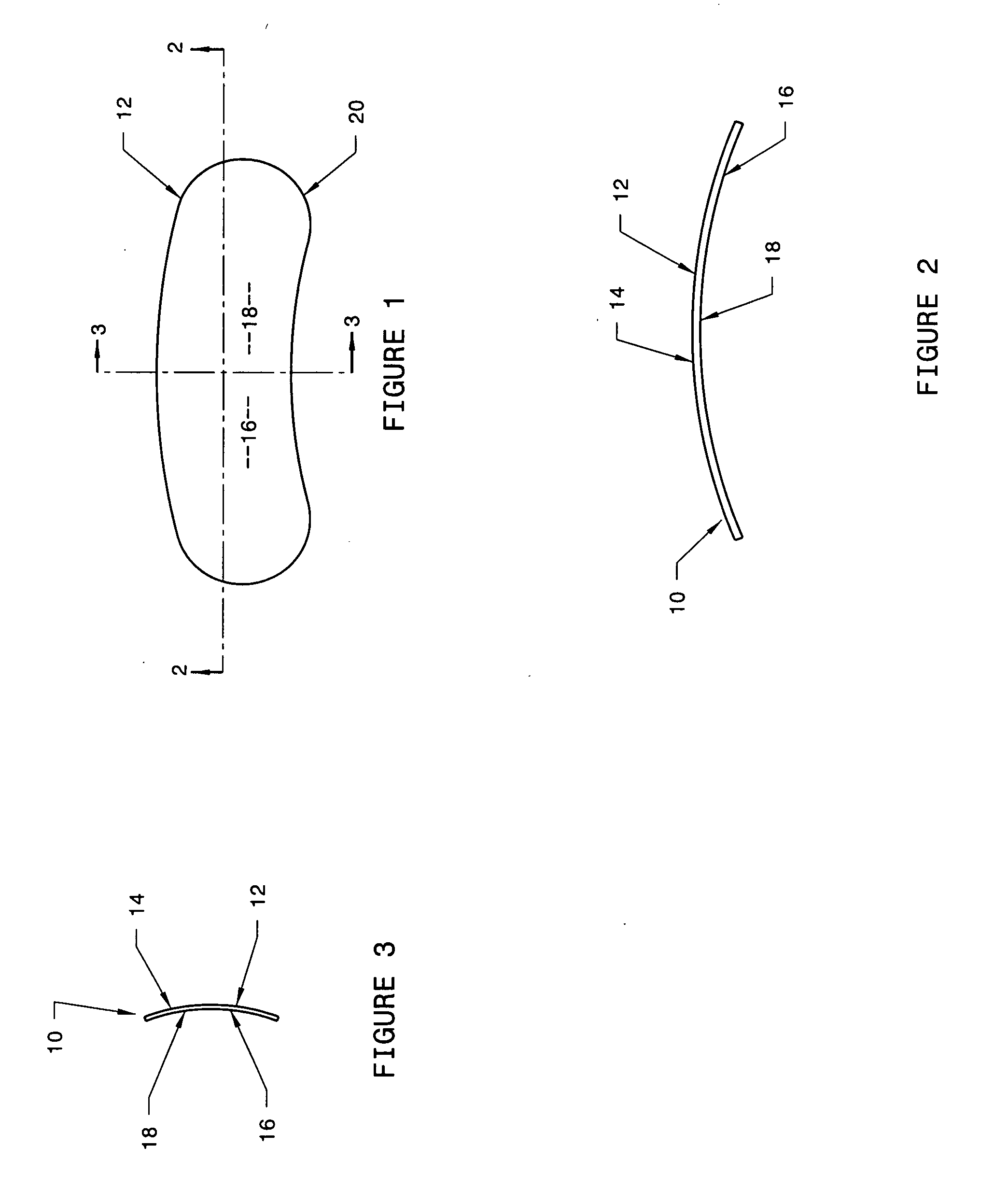

A thin-wall PTFE (polytetrafluoroethylene) tube in the form of a tube of porous expanded PTFE film wherein the porous PTFE film has a microstructure containing a multiplicity of fibrils. The thin-wall tube is used in a non-porous embodiment as the balloon portion of a balloon catheter. The thin-wall tube is not elastomeric; however, because of the thinness, strength and flexibility of the tube, it may be inserted into a body conduit in a collapsed state and then deployed from a catheter and inflated up to the maximum diameter of the thin-wall tube. The porous PTFE film is provided with a continuous layer of adhesive to provide the non-porous tube; the adhesive is preferably a thermoplastic and more preferably a thermoplastic fluoropolymer such as fluorinated ethylene propylene.

Owner:GORE ENTERPRISE HLDG INC

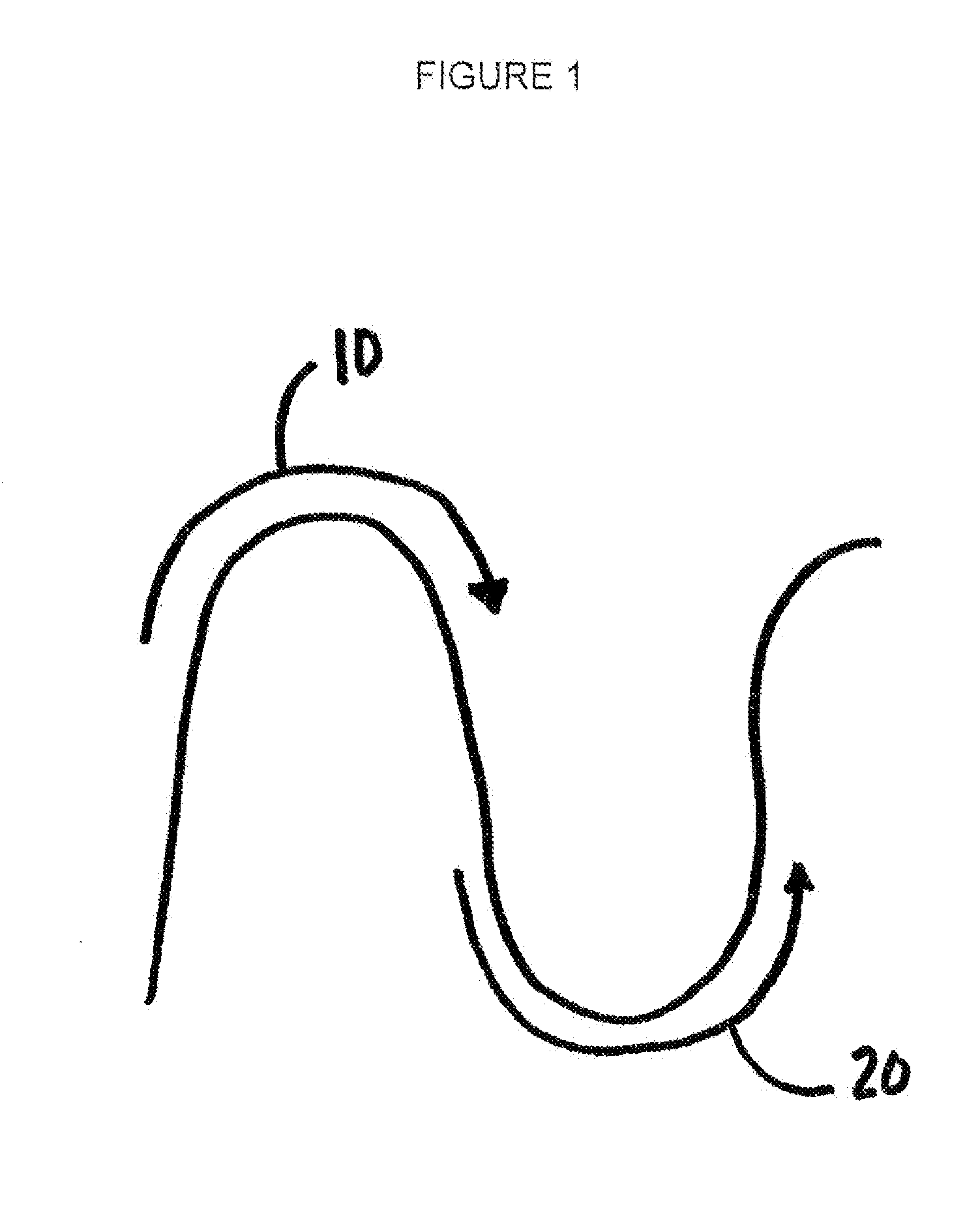

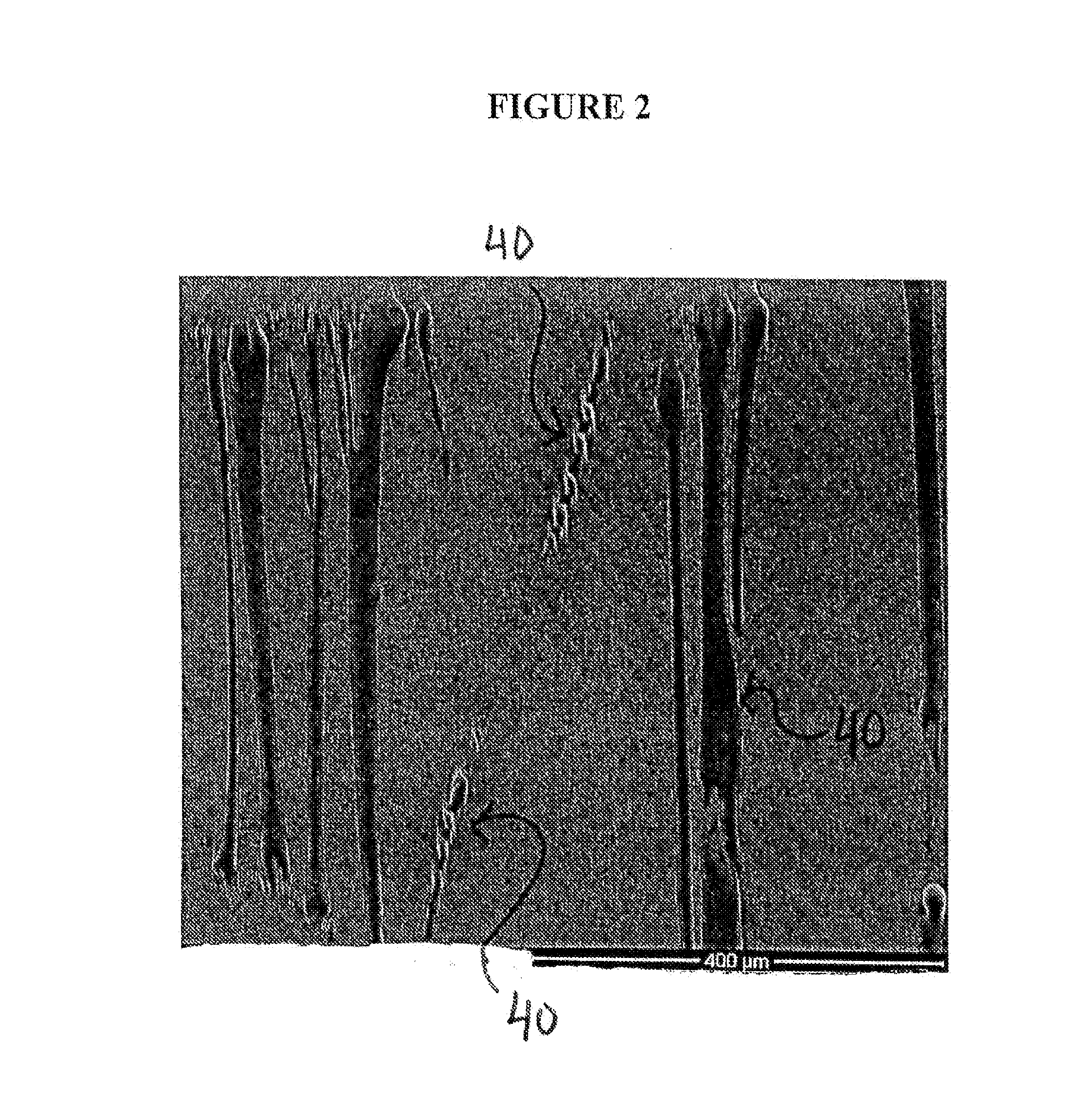

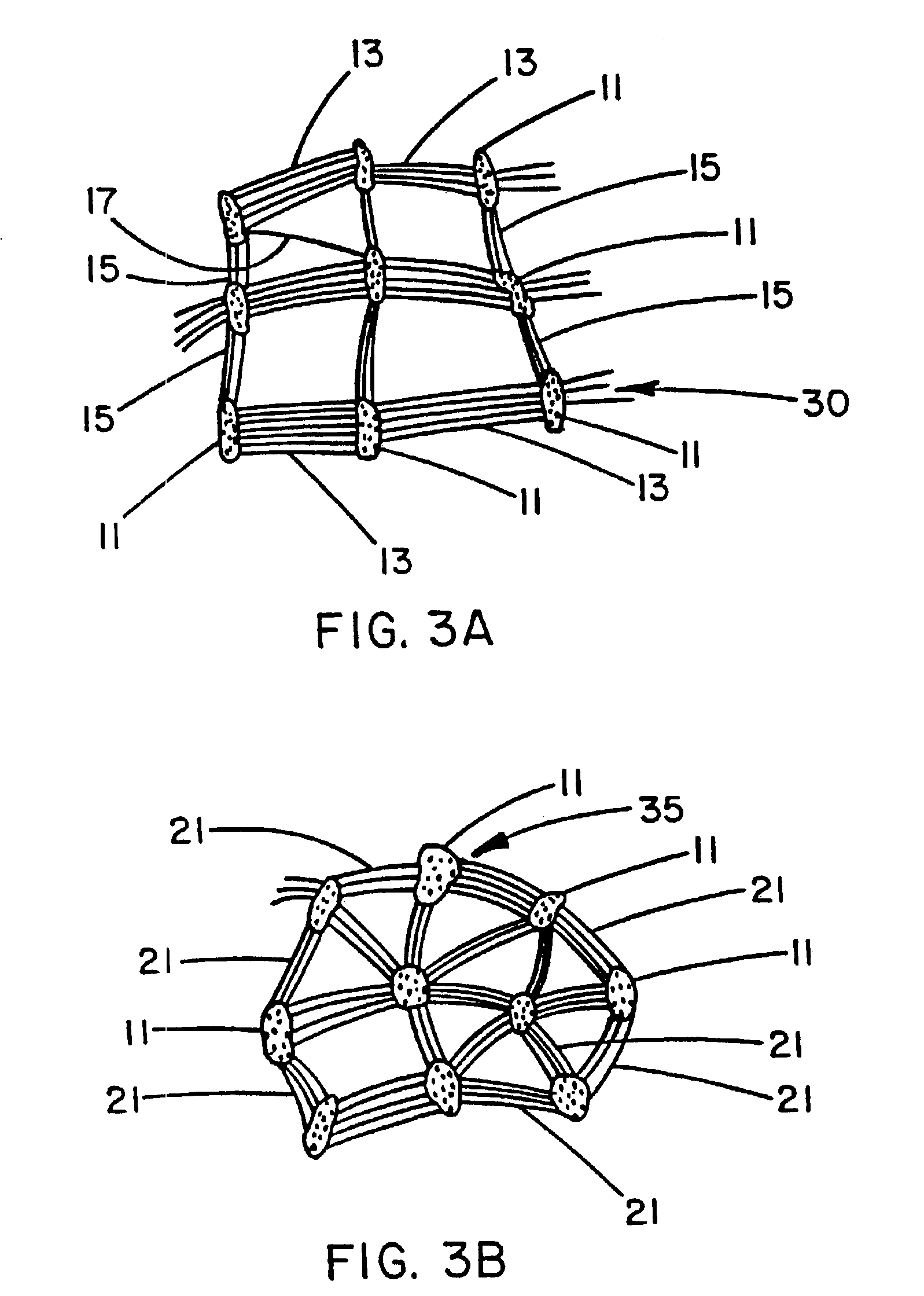

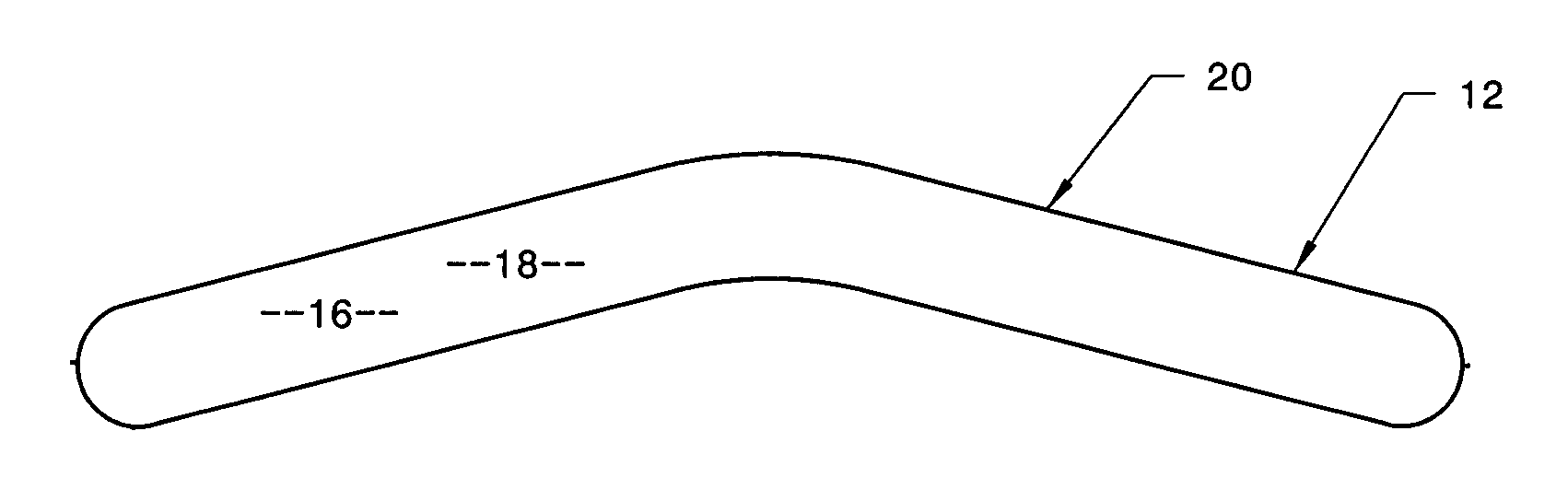

Articles Including Expanded Polytetrafluoroethylene Membranes with Serpentine Fibrils and Having a Discontinuous Fluoropolymer Layer Thereon

ActiveUS20130184807A1High elongationIncrease stiffnessDecorative surface effectsLighting elementsFiberTetrafluoroethylene

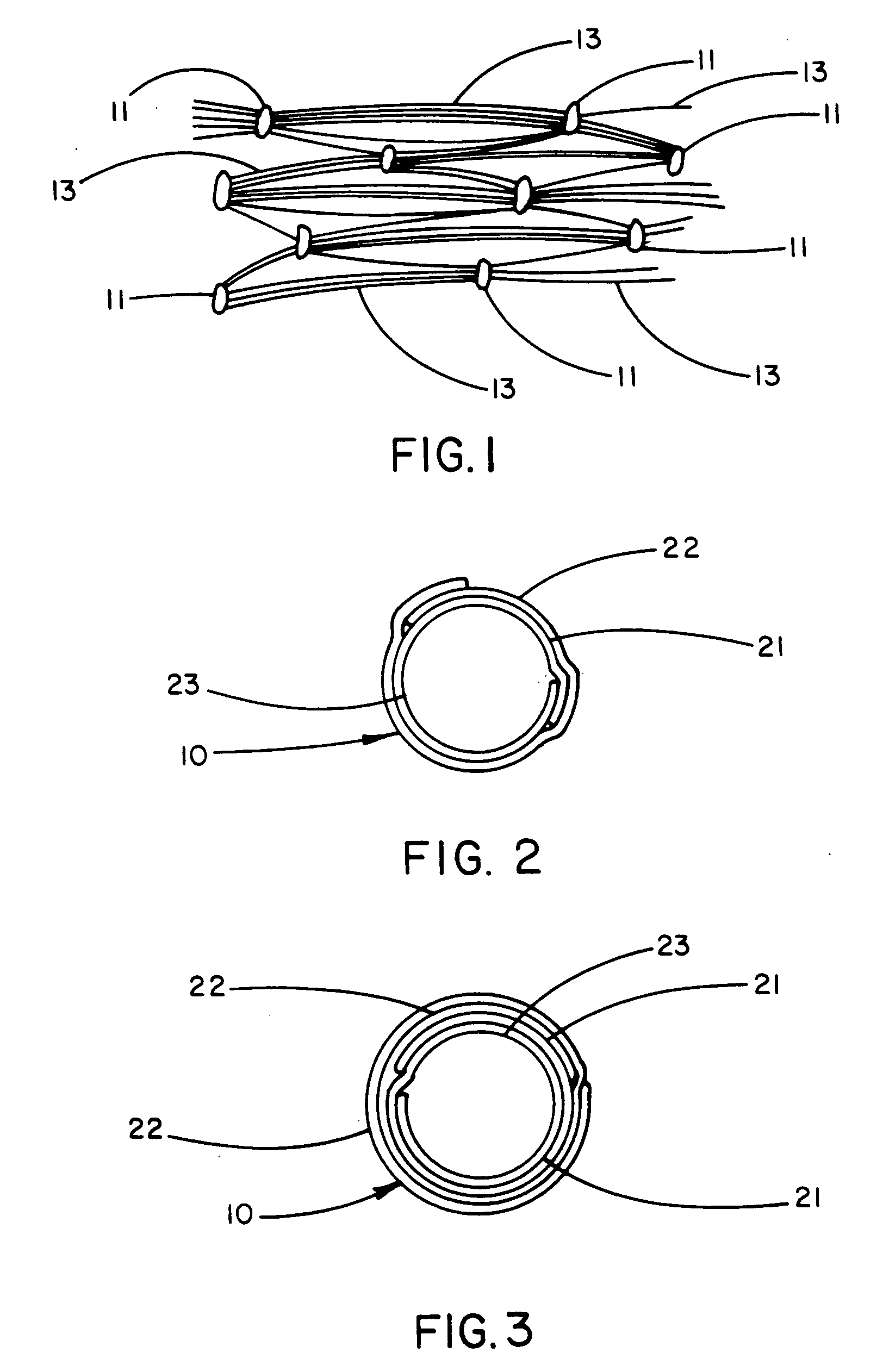

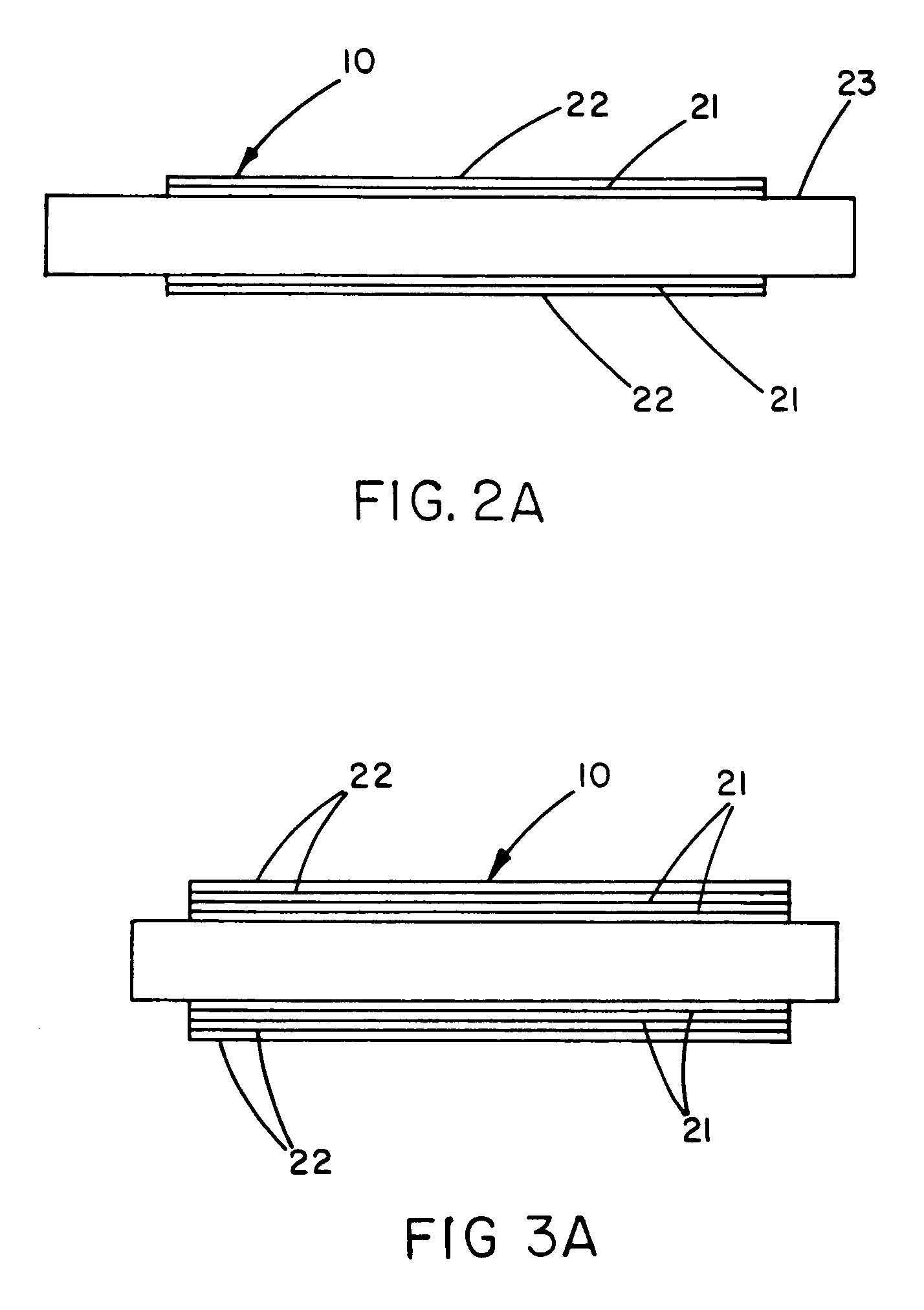

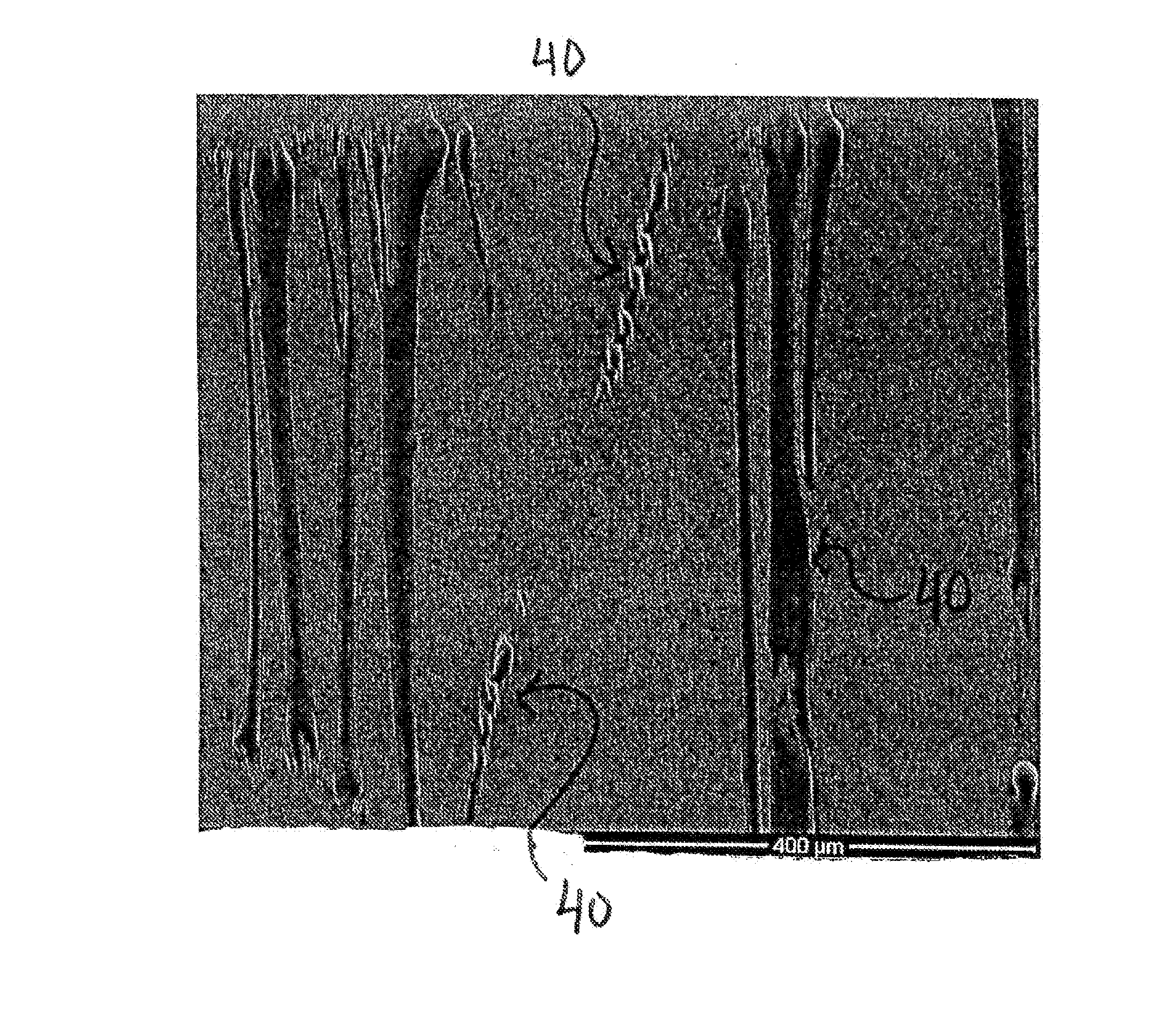

Articles comprising an expanded polytetrafluoroethylene membrane having serpentine fibrils and having a discontinuous coating of a fluoropolymer thereon are provided. The fluoropolymer may be located at least partially in the pores of the expanded fluoropolymer membrane. In exemplary embodiments, the fluoropolymer is fluorinated ethylene propylene. The application of a tensile force at least partially straightens the serpentine fibrils, thereby elongating the article. The expanded polytetrafluoroethylene membrane may include a microstructure of substantially only fibrils. The articles can be elongated to a predetermined point at which further elongation is inhibited by a dramatic increase in stiffness. In one embodiment, the articles are used to form a covered stent device that requires little force to distend in the radial direction to a first diameter but is highly resistant to further distension to a second diameter (stop point). A large increase in diameter can advantageously be achieved prior to reaching the stop point.

Owner:WL GORE & ASSOC INC

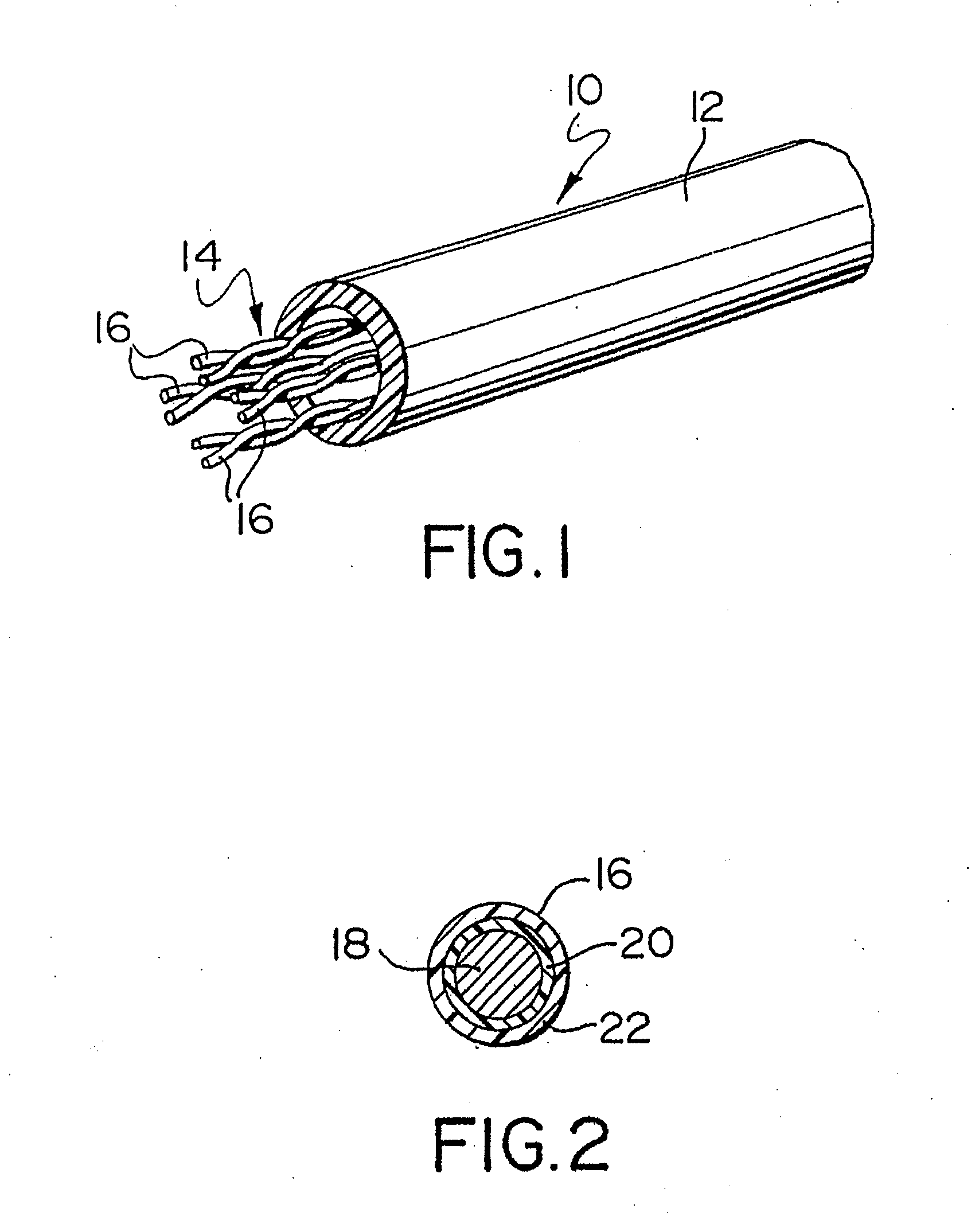

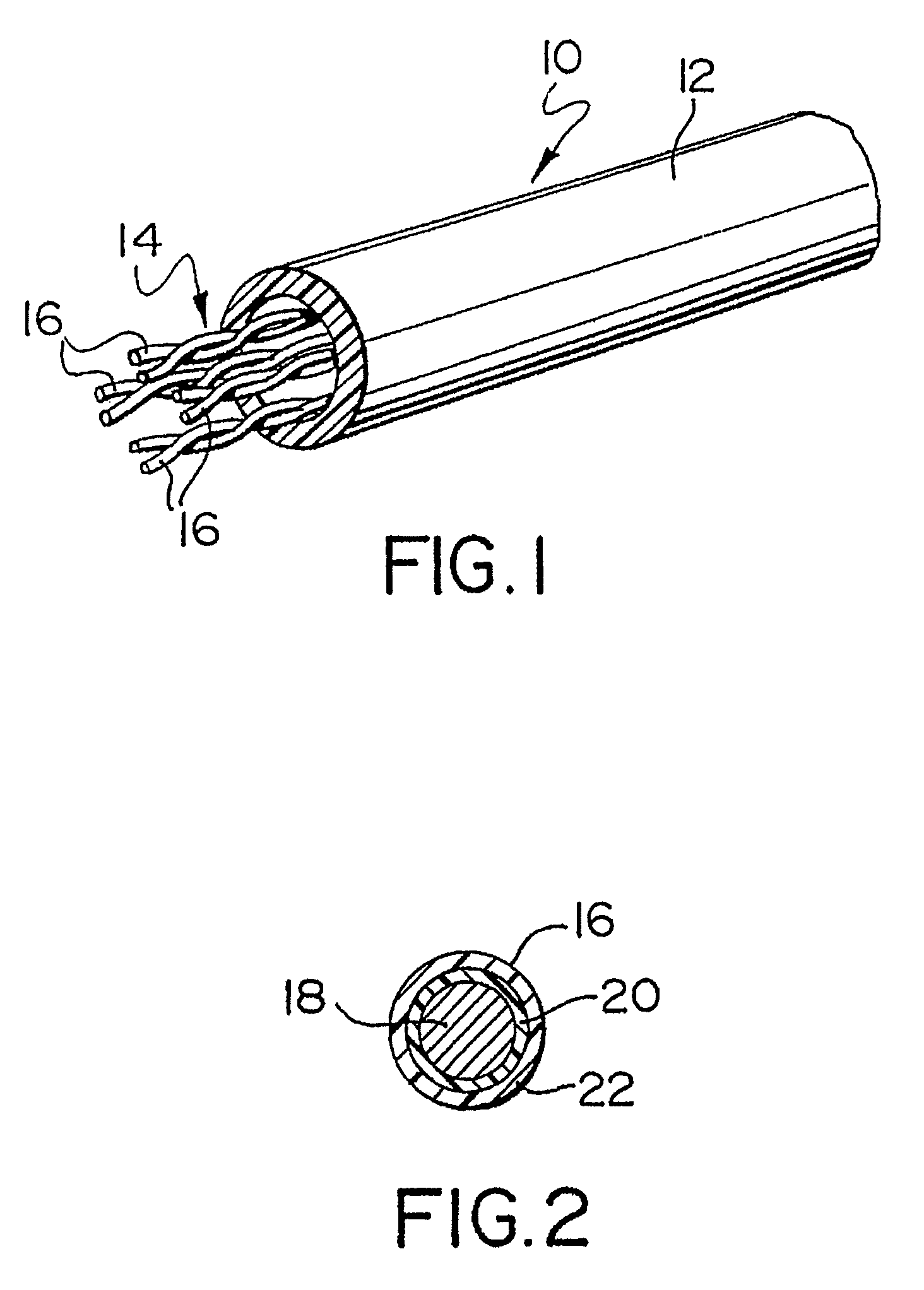

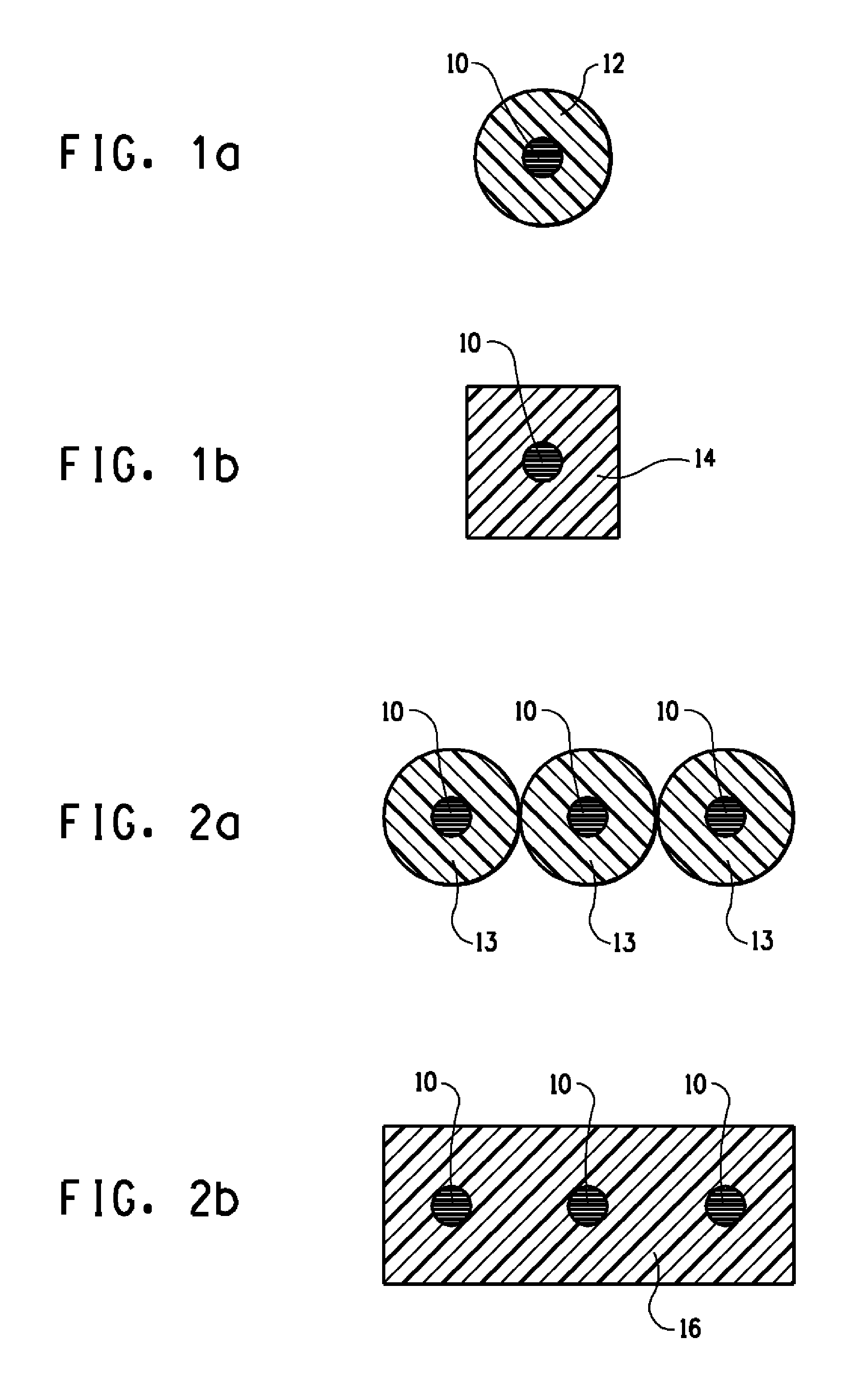

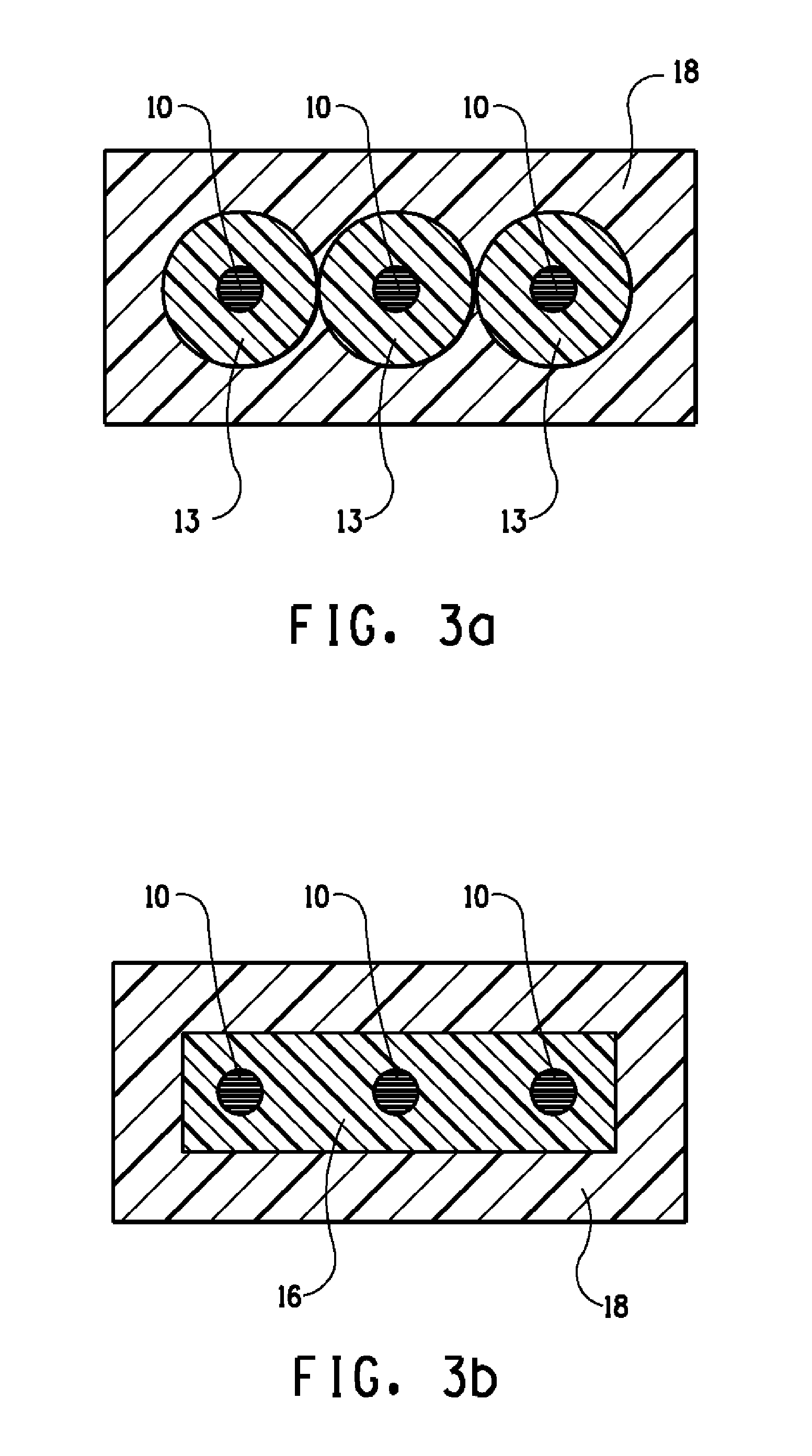

Telecommunications cable

ActiveUS20080073105A1Suppress generationDampens spreadEmergency protective circuit arrangementsInsulated cablesElectrical conductorPolyolefin

A telecommunications cable having a cable core in which each conductor is surrounded by an individual dual layer insulation of an inner layer of flame retardant polyolefin and an outer layer of fluorinated ethylene propylene. The cable is for plenum chamber usage in which smoke is to be minimized. Although the flame retardant polyolefin is a known smoke generating substance which does not satisfy plenum test smoke requirements, its use in this structure is entirely suitable for plenum chamber use because little or no smoke is actually generated as the outer layer protects the inner layer from combustion.

Owner:BELDEN TECHNOLOGY INC

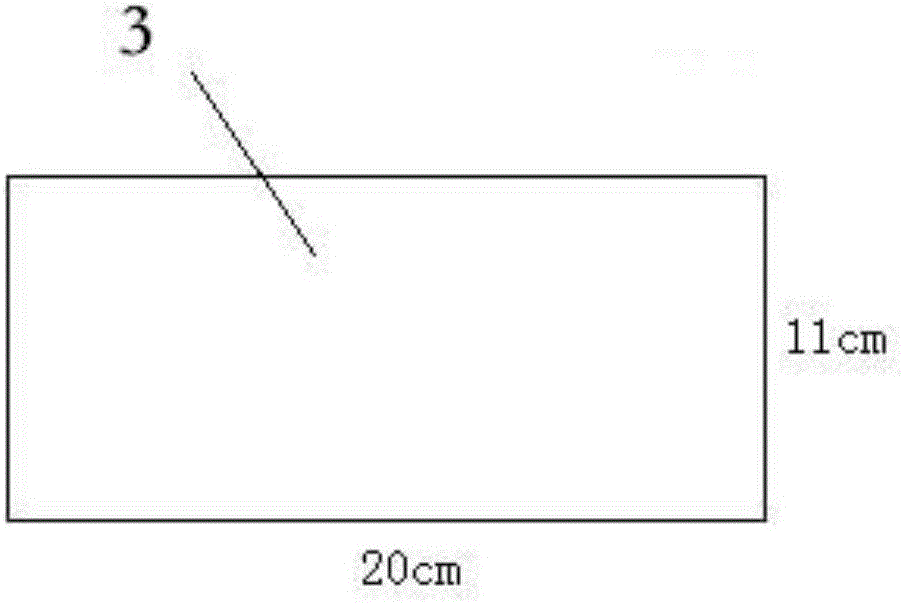

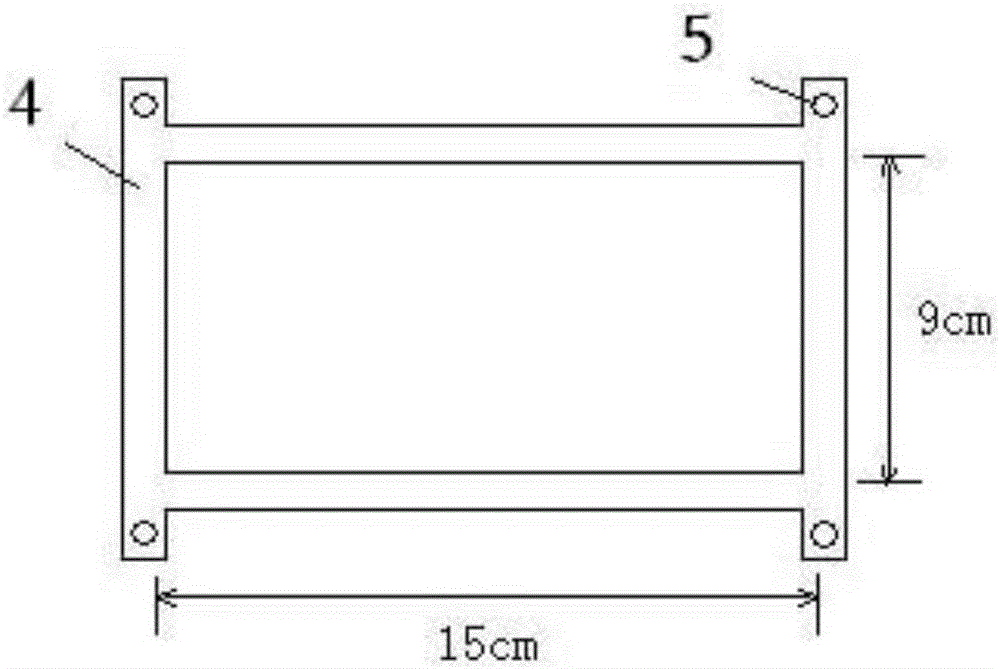

Fluoro-resin mixture, copper-clad plate made of same and making method thereof

ActiveCN101857708AImprove dipping qualityUniform glue contentFibre treatmentLaminationGlass fiberPolymer science

The invention relates to a fluoro-resin mixture, a copper-clad plate made of the same and a making method thereof. The fluoro-resin mixture comprises the following two substances as necessary components: 90-99 parts by weight of polytetrafluoroethylene (PTFE) emulsion and 1-10 parts by weight of fluorinated ethylene propylene (FEP) based on 100 parts by weight of an organic solid matter. The copper-clad plate made of the fluoro-resin mixture comprises a plurality of pieces of superimposed varnished cloth and copper foils covering one side or two sides of the varnished cloth, wherein each piece of varnished cloth comprises glass fiber cloth and a fluoro-resin mixture adhered thereon through dipping drying. The fluoro-resin mixture is prepared by taking the PEFE emulsion as base resins, the glass fiber cloth can be dipped for many times in the mixture under the condition of below PTFE sintering temperature (330 DEG C) to obtain the varnished cloth. The varnished cloth made from the fluoro-resin mixture has favorable gum dipping quality, uniform gum content, smooth surface, softness and easy operation. The copper-clad plate made from the fluoro-resin mixture has favorable comprehensive properties, excellent dielectric properties, simple making method and process, satisfies the dielectric property requirements on substrate materials in the field of high frequency communication and is beneficial to industrial continuous production.

Owner:GUANGDONG SHENGYI SCI TECH

Telecommunications cable

ActiveUS7696437B2Suppress generationDampens spreadPlastic/resin/waxes insulatorsEmergency protective circuit arrangementsElectrical conductorPolyolefin

A telecommunications cable having a cable core in which each conductor is surrounded by an individual dual layer insulation of an inner layer of flame retardant polyolefin and an outer layer of another material, for example, fluorinated ethylene propylene, MFA, PVDF, ECTFE, PTFE, or foamed PFA.

Owner:BELDEN TECHNOLOGY INC

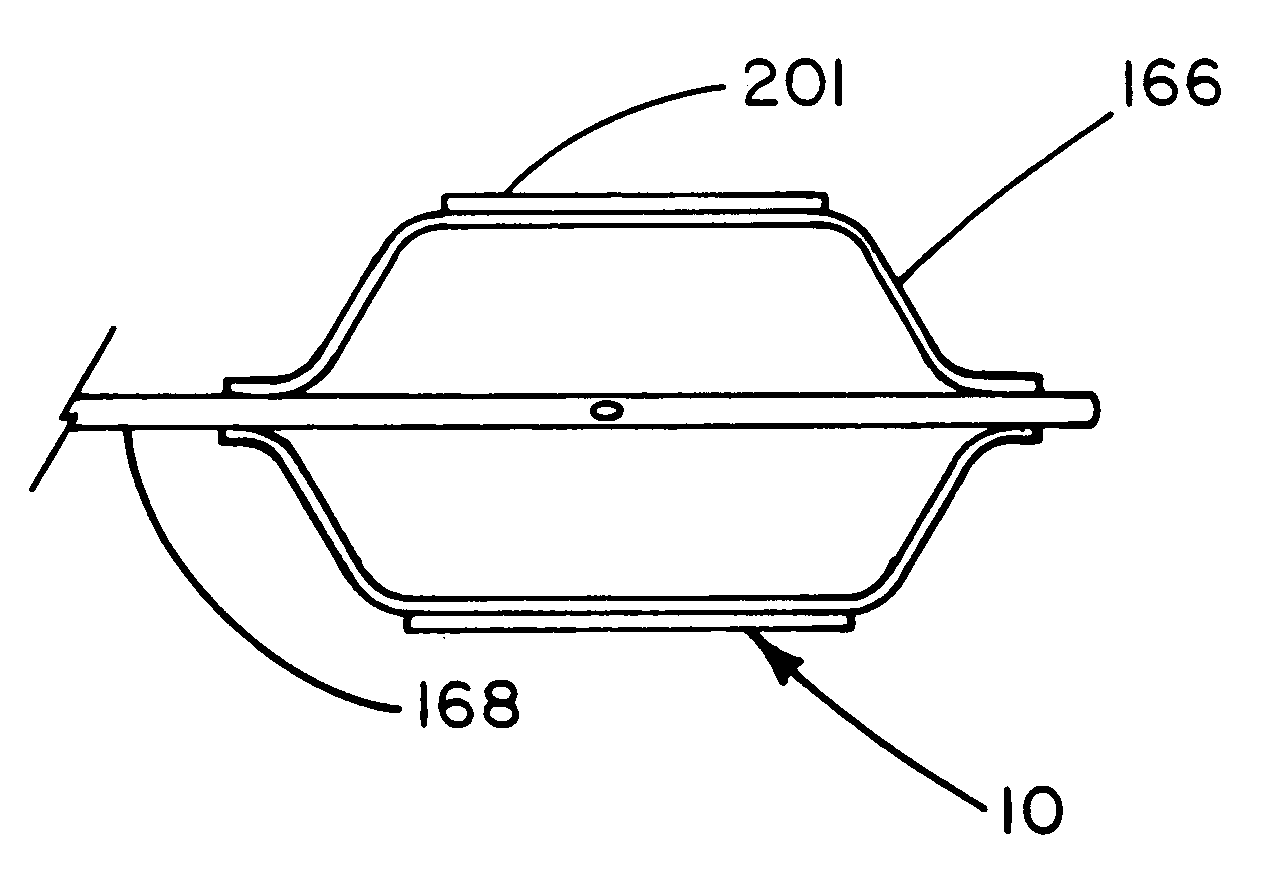

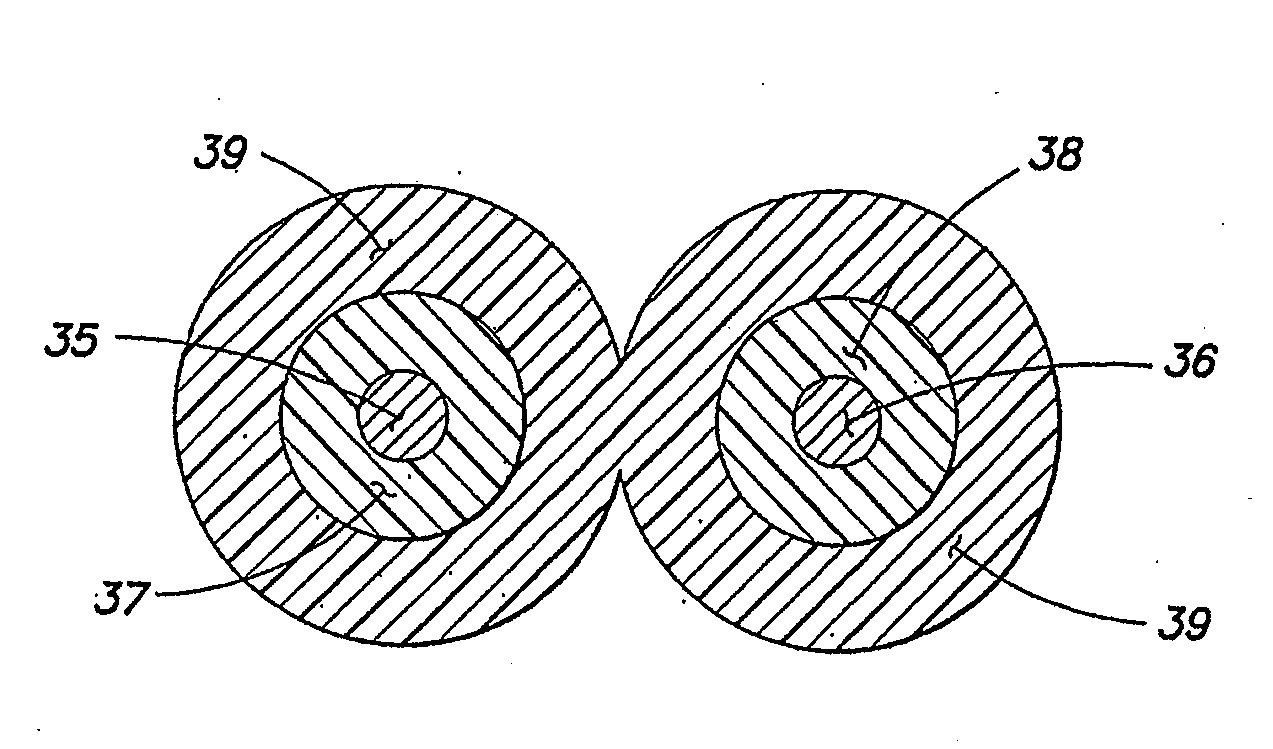

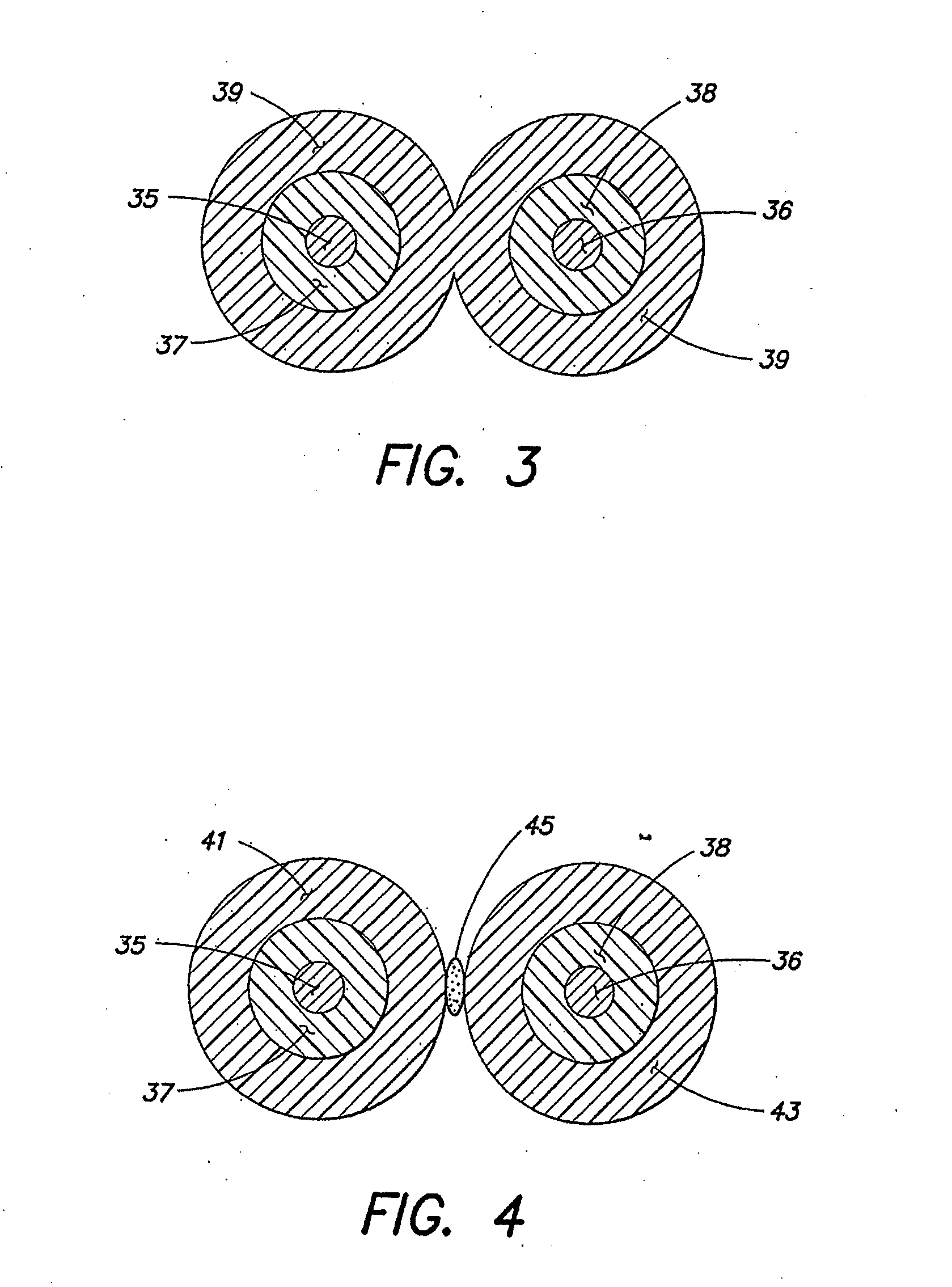

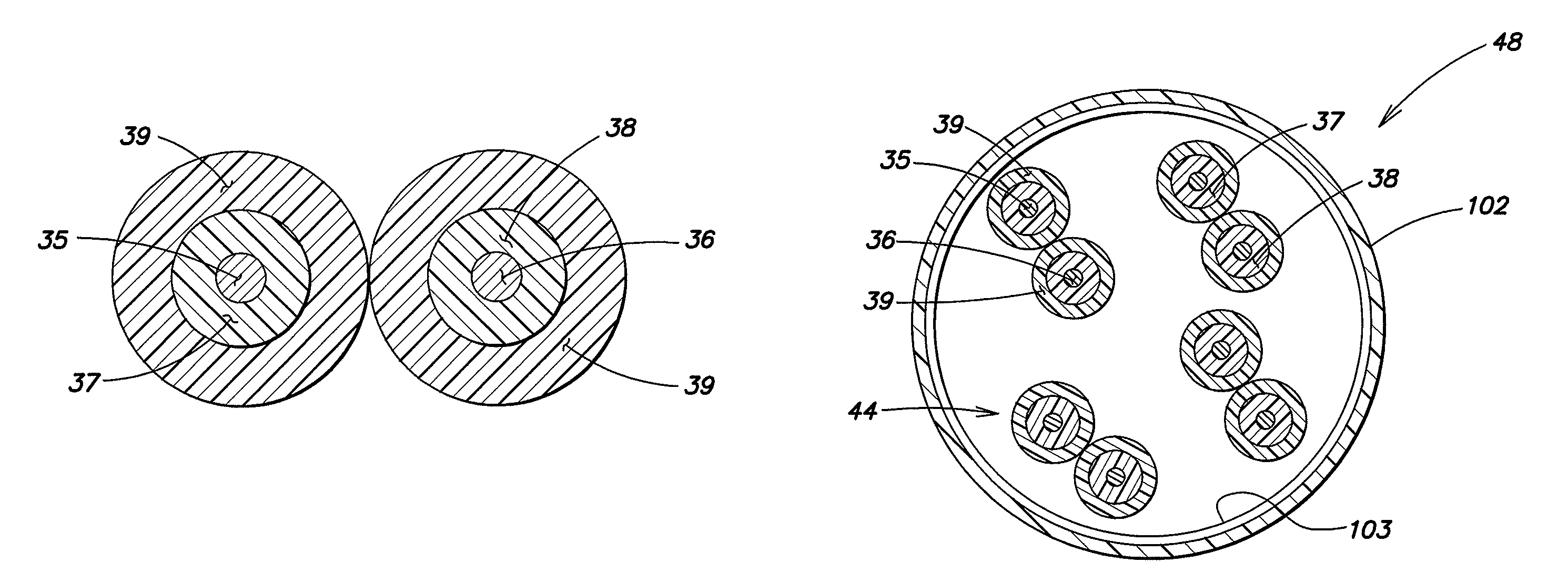

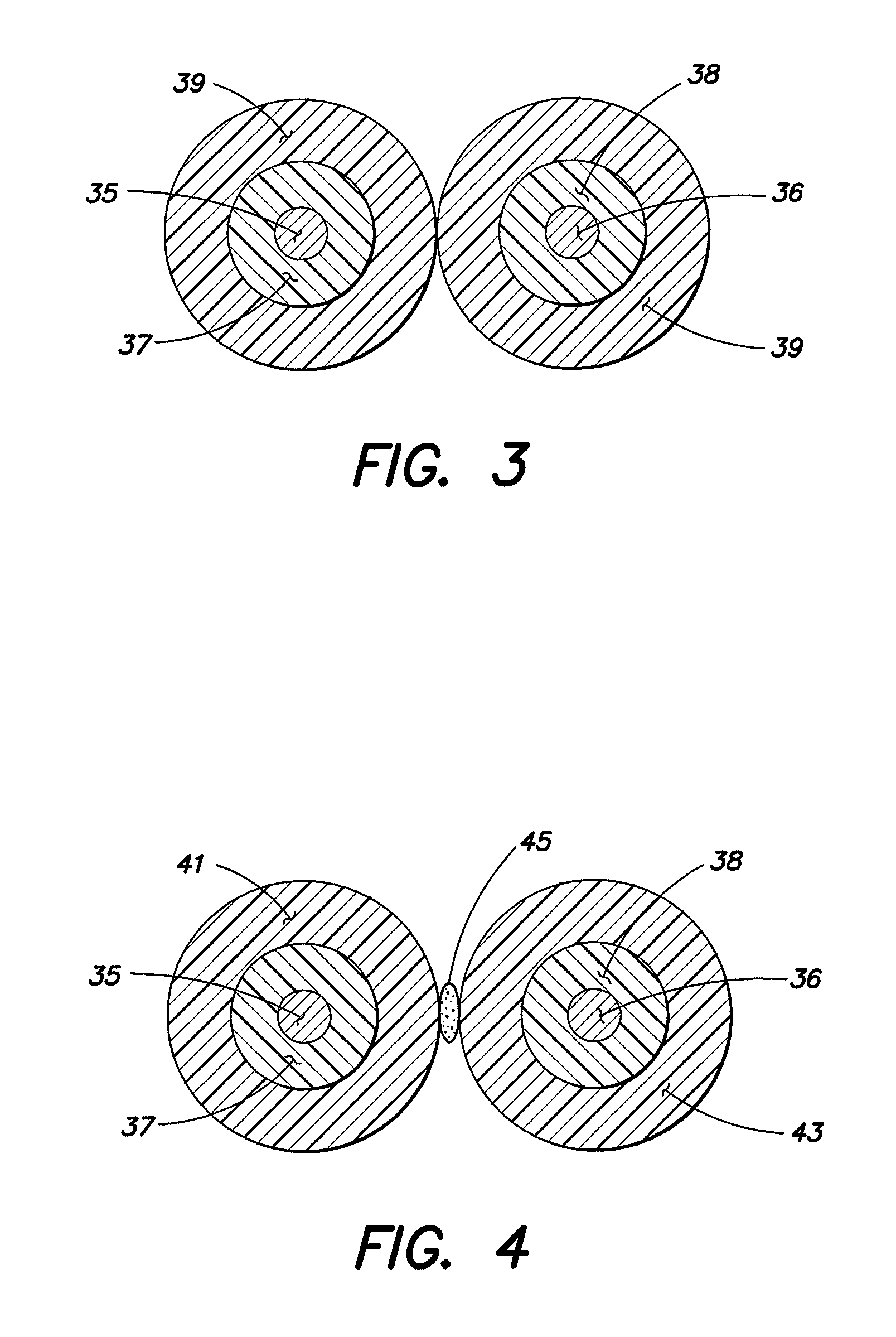

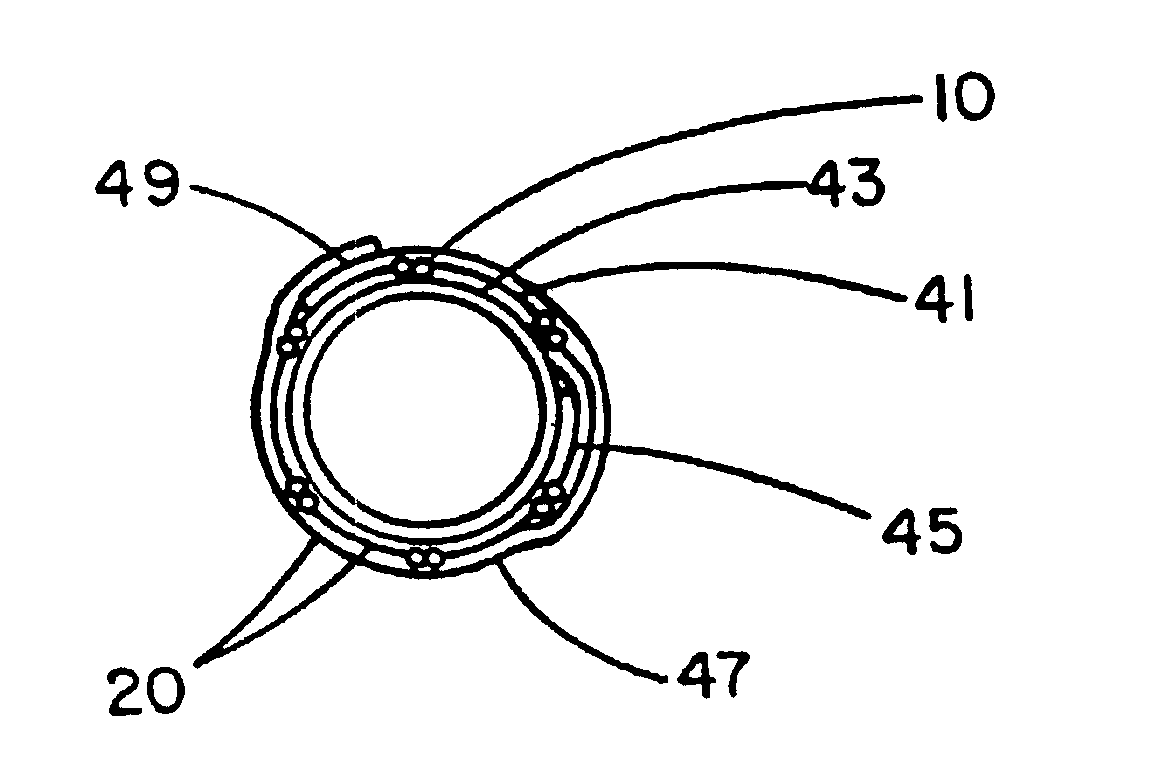

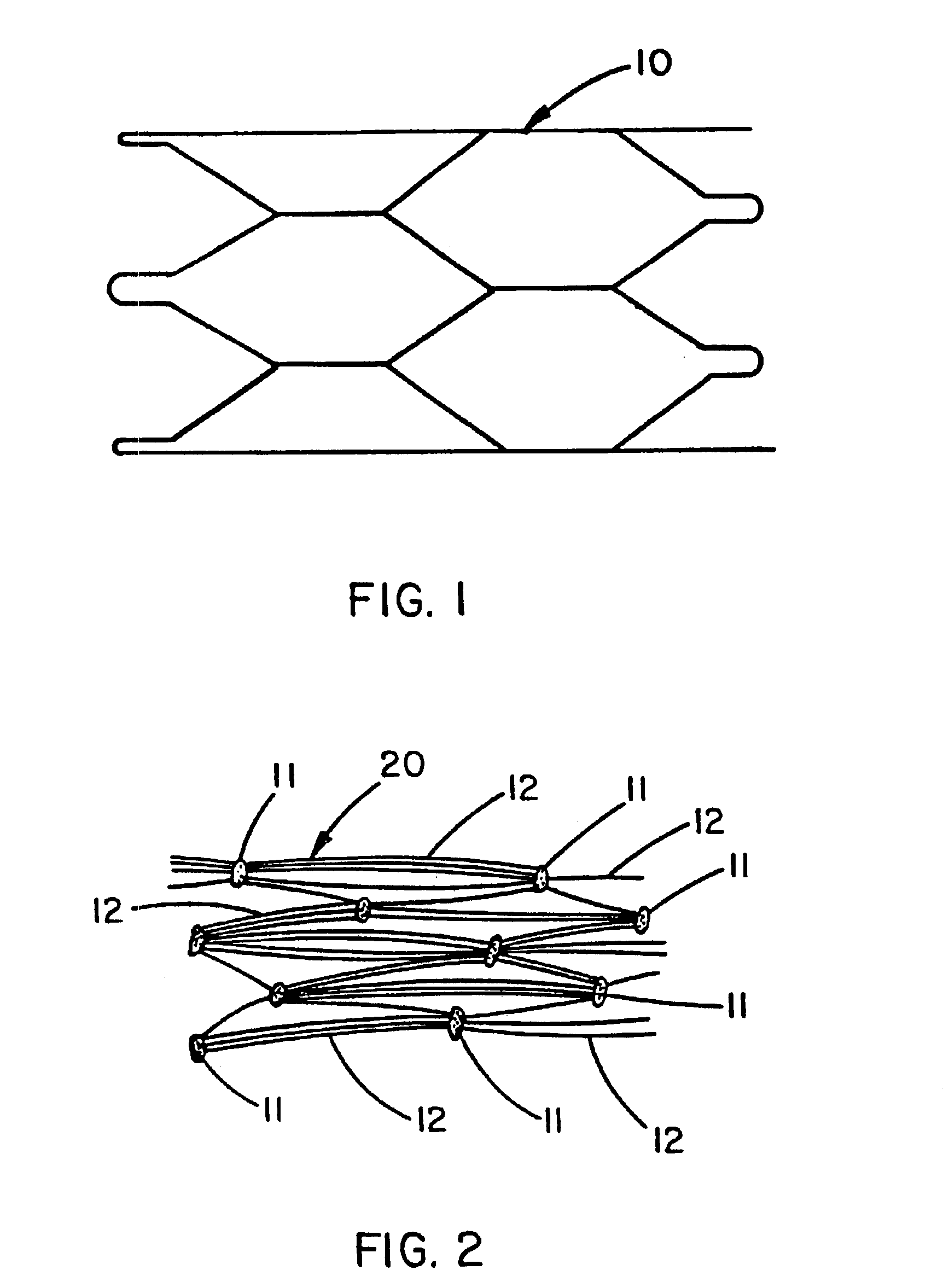

Method of making an intraluminal stent graft

A method of making an tubular intraluminal graft in the form of a tubular diametrically adjustable stent having a tubular covering of porous expanded polytetrafluoroethylene which is less than 0.10 mm thick. The covering may be on the exterior surface of the stent, or on the interior surface of the stent, or both. The covering may be affixed to the stent by an adhesive which is preferably fluorinated ethylene propylene.

Owner:GORE ENTERPRISE HLDG INC

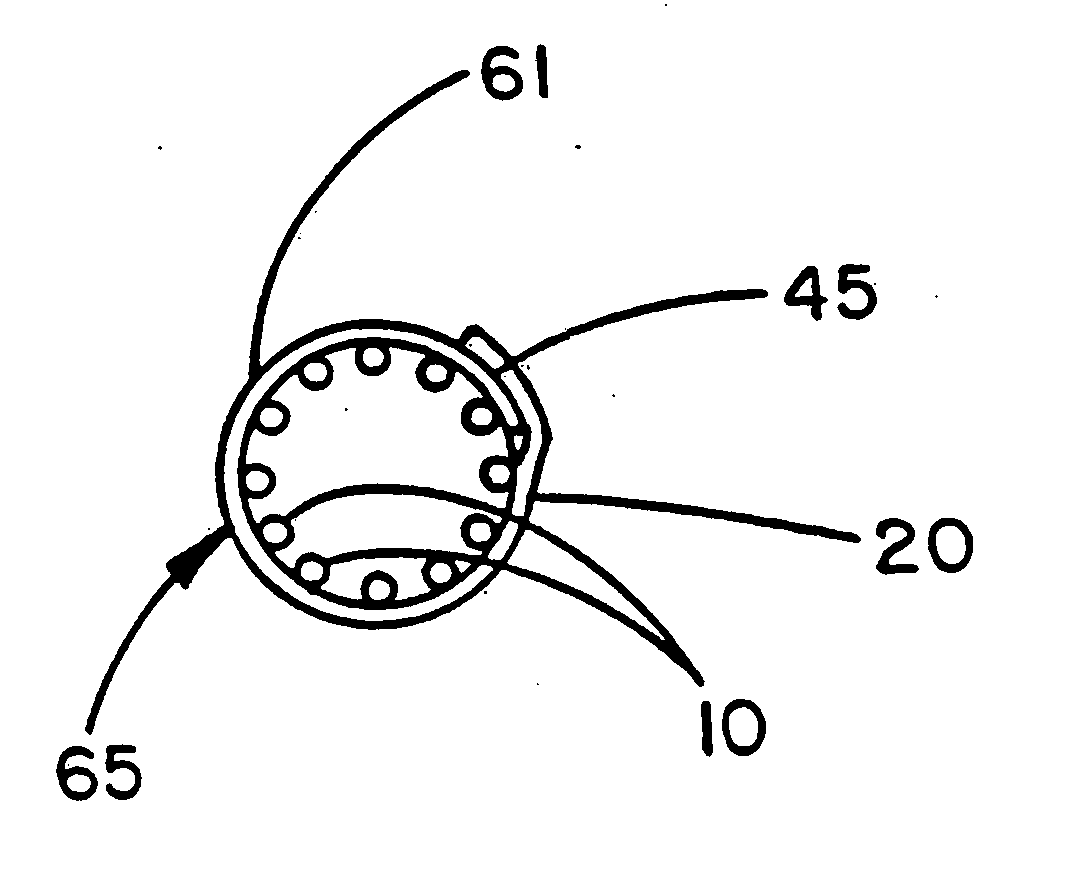

Matrix band for dental applications

A matrix band for dental applications comprising a base material and a coating. The base material has an outer surface and a tooth contact surface as well as a perimeter. The coating is applied to the tooth contact surface and extends to the perimeter of the tooth contact surface. The coating is a fluorinated ethylene propylene, polytetrafluoroethylene and polyether sulfone.

Owner:GARRISON DENTAL SOLUTIONS

Condensation washing method for fluorinated ethylene-propylene resin

The invention relates to a condensation washing method for fluorinated ethylene-propylene resin. An emulsion polymerization method is adopted for preparing luorinated ethylene-propylene resin polymerization emulsion, then, the fluorinated ethylene-propylene resin is obtained through still standing, dilution, stirring condensation and washing, and a chemical condensation mode can also be used as an auxiliary mode in the stirring condensation process. The mechanical condensation and the chemical condensation are combined in the condensation washing method provided by the invention, the condensation effect is excellent and is obviously superior to that of the traditional condensation method, the obtained fluorinated ethylene-propylene resin has large grain diameter and high volume density, fluorinated ethylene propylene (FEP) plastics can be favorably and further processed, and in addition, the method has the advantages that the operation is simple and convenient, the condition is mild, and the method is suitable for industrial large-scale application.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Stable pressurised aerosol solution composition of glycopyrronium bromide and formoterol combination

Aerosol solution compositions intended for use with a pressurized metered dose inhaler, comprising glycopyrronium bromide and formoterol, or a salt thereof or a solvate of said salt, optionally in combination with one or more additional active ingredients, and stabilized by a selected amount of a mineral acid, exhibit improved stability when contained in a can internally coated by a resin comprising a fluorinated ethylene propylene (FEP) polymer.

Owner:CHIESI FARM SPA

Fluorinated ethylene-propylene polymeric membranes for gas separations

A fluorinated ethylene-propylene polymeric membrane comprising a copolymer comprising 2,3,3,3-tetrafluoropropene and vinylidene fluoride is disclosed. The fluorinated ethylene-propylene polymeric membranes of the invention are especially useful in gas separation processes in air purification, petrochemical, refinery, and natural gas industries.

Owner:UOP LLC

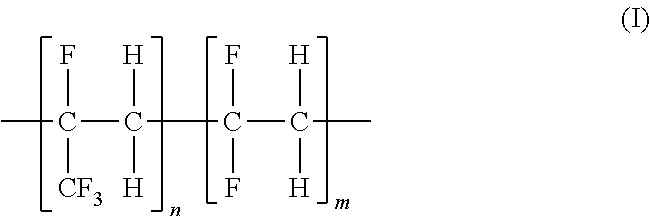

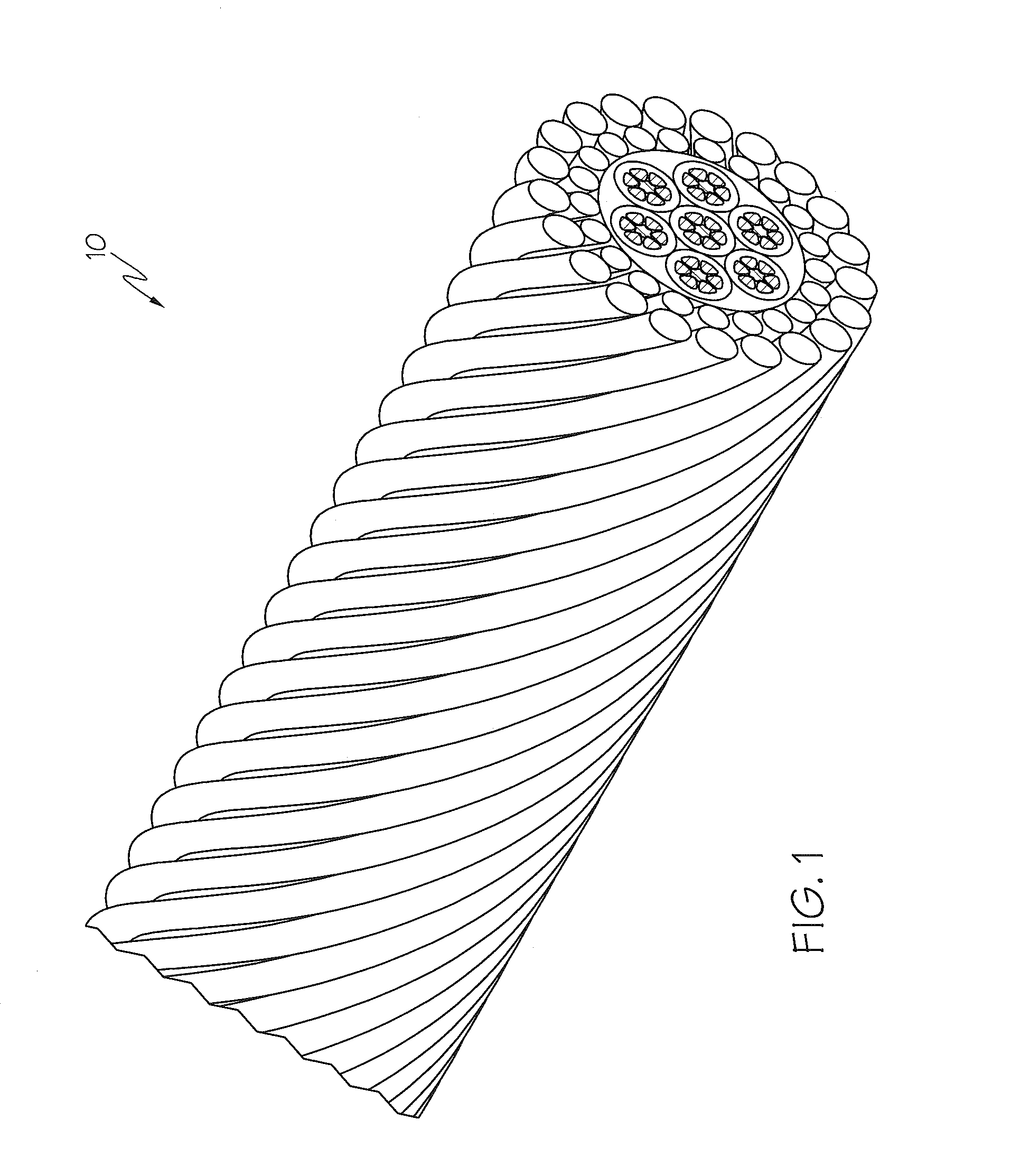

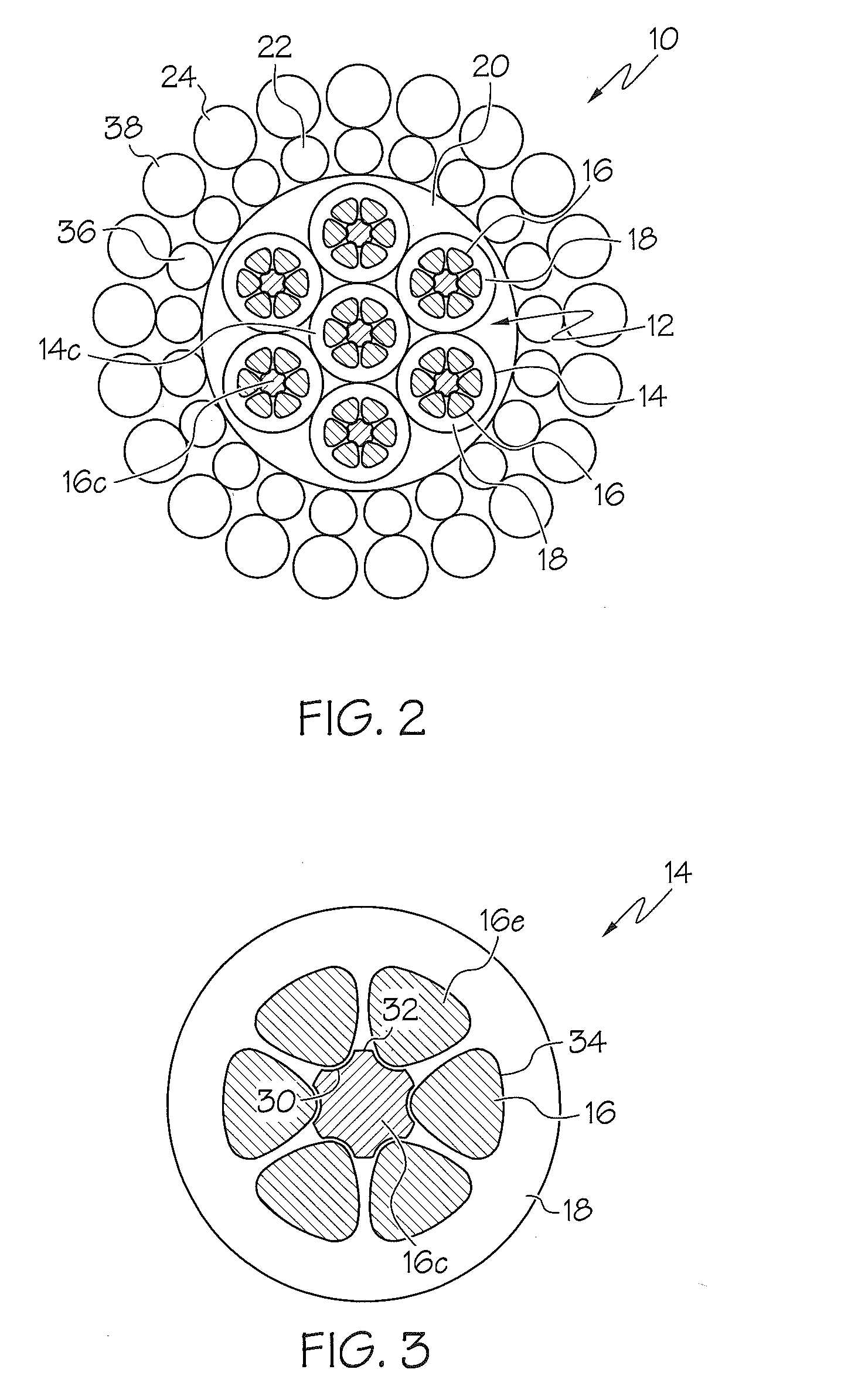

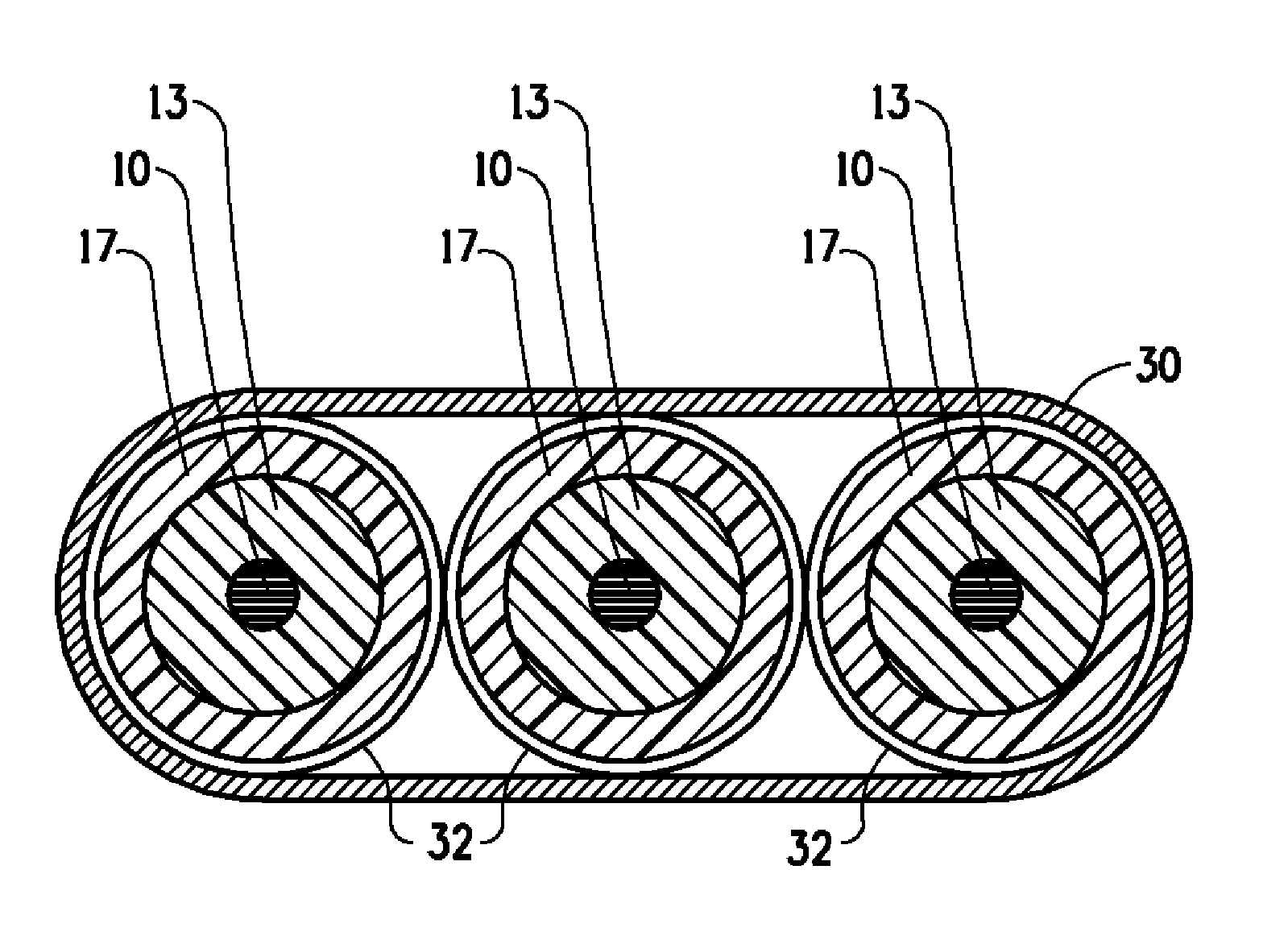

High-power low-resistance electromechanical cable

ActiveUS20140318858A1Power cables with screens/conductive layersInsulated cablesTetrafluoroethyleneElectrical conductor

A high-power low-resistance electromechanical cable constructed of a conductor core comprising a plurality of conductors surrounded by an outer insulating jacket and with each conductor having a plurality of wires that are surrounded by an insulating jacket. The wires can be copper or other conductive wires. The insulating jacket surrounding each set of wires or each conductor can be comprised of ethylene tetrafluoroethylene, polytetrafluoroethylene, polytetrafluoroethylene tape, perfluoroalkoxyalkane, fluorinated ethylene propylene or a combination of materials. A first layer of a plurality of strength members is wrapped around the outer insulating jacket. A second layer of a plurality of strength members may be wrapped around the first layer of a plurality of strength members. The first and / or second layer of strength members can be made of single wires, synthetic fiber strands multi-wire strands, or rope. If either or both layers are made up of synthetic fiber, then the synthetic fibers may be surrounding and encapsulated by an additional insulating and protective layer.

Owner:WIRECO WORLDGROUP INC

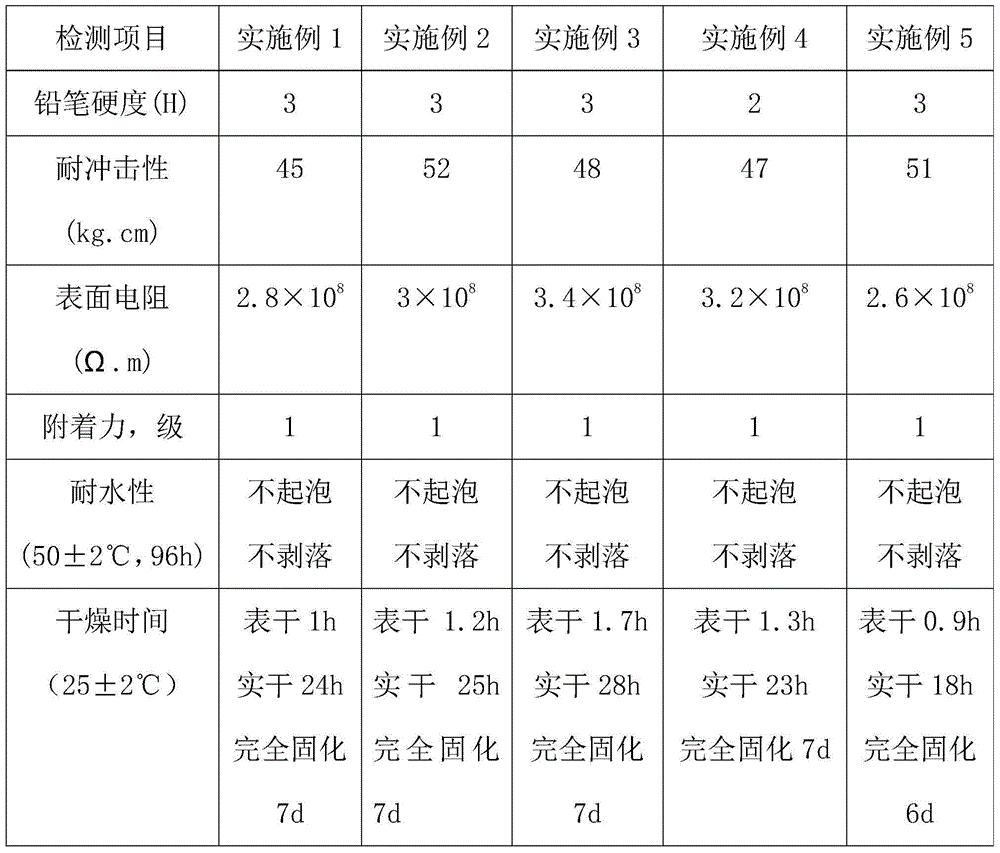

High temperature wear resistance antistatic coating

InactiveCN104946124AHigh hardnessImprove adhesionEpoxy resin coatingsElectrically-conductive paintsEpoxyConductive polymer

The invention discloses a high temperature wear resistance antistatic coating. Raw materials of the coating comprise polyphenylene sulfide resin, polyester resin, epoxy resin, teflon, fluorinated ethylene-propylene resin, carboxyl powdered nitrile rubber, amino resin, carbon nanotube, nano-zinc oxide, carbon black, polyethylene glycol, sorbitan fatty acid ester, a conducting polymer 3,4-ethylenedioxythiophene dispersion, methyl ethyl ketoxime, water, a silane coupling agent containing an amino-group, an antifoaming agent, a thickening agent, a leveling agent and a coalescing agent. The high temperature wear resistance antistatic coating has excellent antistatic property and shock resistance and good high temperature wear resistance.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

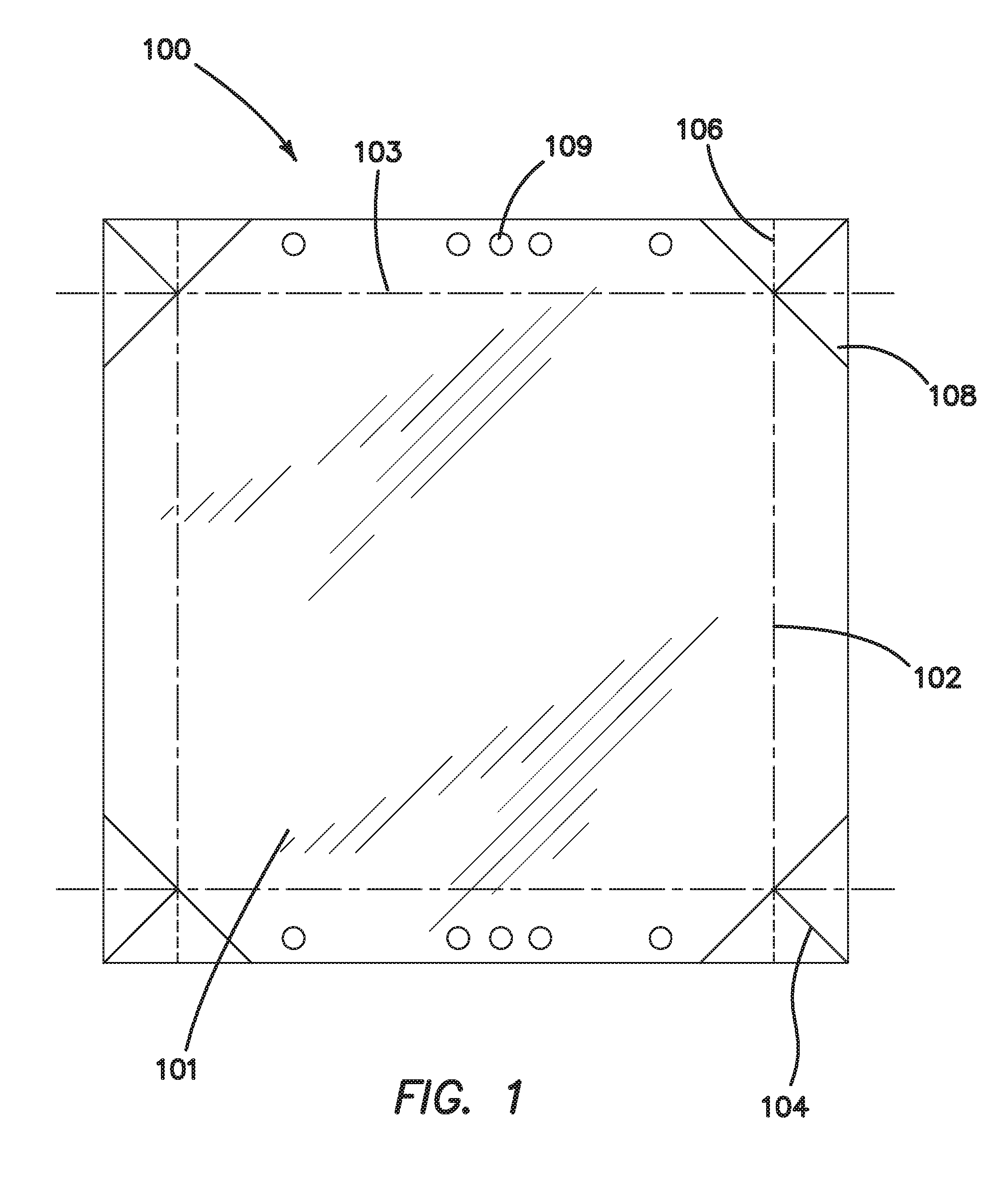

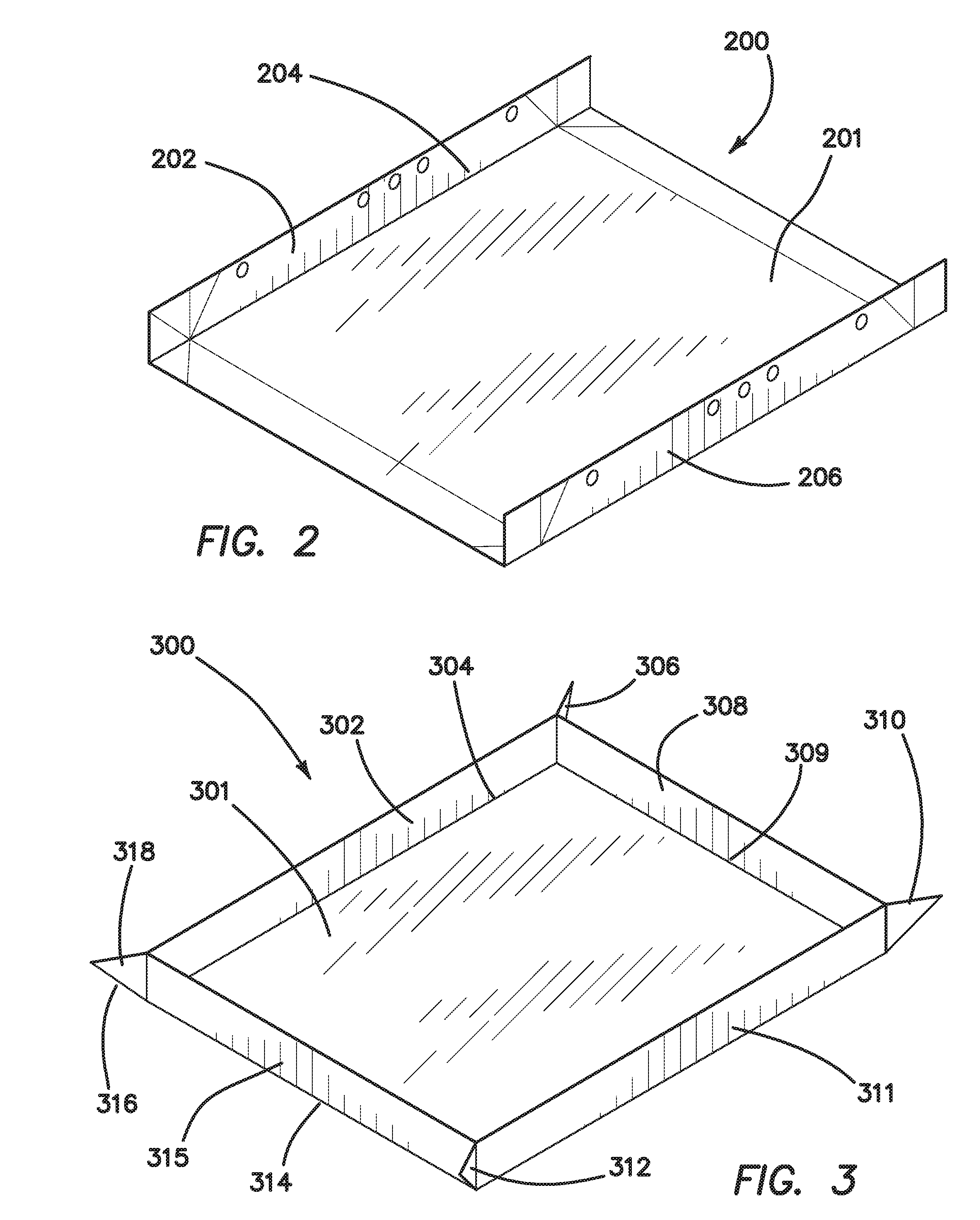

Release liner/layer, system and method of using the same with additive manufacturing

InactiveUS20160176112A1Easy to removeEasy to replaceManufacturing platforms/substratesLayered productsPolyolefinThermoforming

Release liner forming structures and methods of making and using the same. The methods of making the release liner include thermoforming and sheet bending. The flexible release liner may be used in conjunction with a rigid, transparent supporting surface. The release liner may be developed from a flexible sheet formed into a deformable resin fluid vat. A release layer, and additional structure if desired, can be formed of or include plastic, such as polyolefin or fluoropolymer. In some instances, the polyolefin is, or includes, polymethylpentene or a fluropolymer is fluorinated ethylene propylene. The optical and other properties of the release layer can be altered with treatments and other materials to, for example, reduce over-penetration of a light beam or deform a release layer.

Owner:FULL SPECTRUM LASER

Coating composition, preparation method and application thereof

InactiveCN101531853AImprove wear resistanceImprove anti-corrosion performancePretreated surfacesCoatingsVinyl etherImide

The invention relates to a coating composition, a preparation method and an application thereof. The coating composition comprises (a) priming paint which consists of (i) fluor resin, (ii) inorganic filler and (iii) bonding resin, and (b) surface layer coating. The fluor resin is selected from polytetrafluoroe thylene resin, tetrafluoroethylene-perfluorinated alkey vinye copolymer, fluorinated ethylene propylene copolymer and combinations thereof, with a content of 30 to 70 parts by weight, calculated by the total solid weight of the priming paint; the inorganic filler has a grain size of 0.1 to 50 microns and a content of 5 to 30 parts by weight, calculated by the total solid weight of the priming paint; the bonding resin is selected from daiamid-imide copolymer, polyimide, polyphenylene sulfide, polyethersulfone and combinations thereof, with a content of 10-40 parts by weight, calculated by the total solid weight of the priming paint; the surface layer coating comprises (i') tetrafluoroethylene-perfluorinated alkey vinye copolymer with a content of 80-100 parts by weight, calculated by the total solid weight of the surface layer coating; (ii') assisted film forming organic resin with a content of 0-20 parts by weight, calculated by the total solid weight of the surface layer coating; and (iii') mica flashlight powder with a content of 0-3 parts by weight, calculated by the total solid weight of the surface layer coating.

Owner:科慕有限公司

ESP Power Cables

InactiveUS20130153260A1Small sectionReduce spacingPower cables with screens/conductive layersInsulated cablesTetrafluoroethyleneElectrical conductor

An electrical submersible pump (ESP) power cable for use in oil wells is provided, comprising at least two electrical conductors, a first fluoropolymer layer surrounding each of the at least two electrical conductors, an outer metal armouring, wherein the first fluoropolymer layer surrounding each of the at least two electrical conductors is composed of at least one fluoropolymer chosen among ETFE (ethylene tetrafluoroethylene copolymer), PFA (perfluoroalkoxy copolymer), FEP (fluorinated ethylene propylene copolymer) and / or mixtures thereof.

Owner:EI DU PONT DE NEMOURS & CO

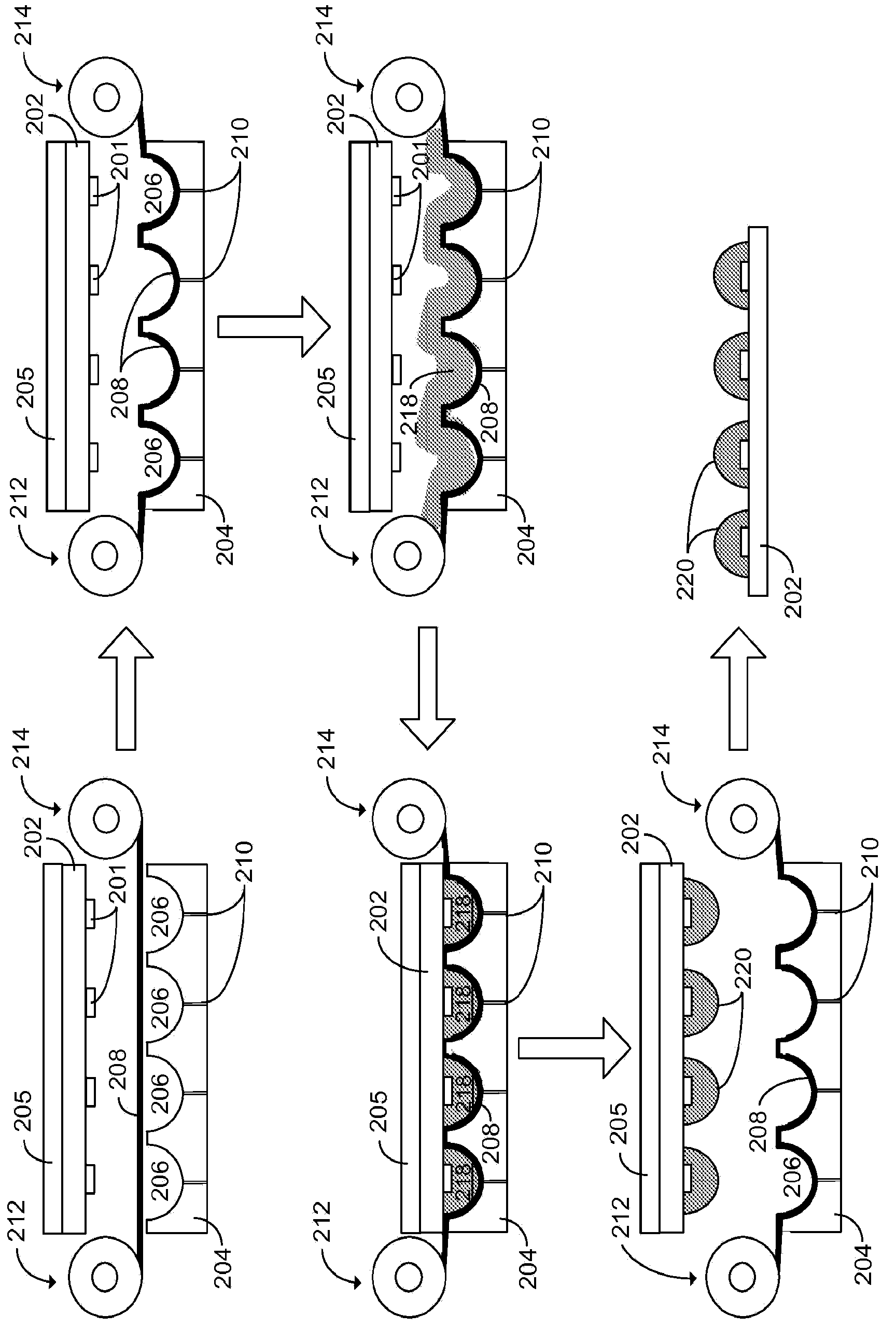

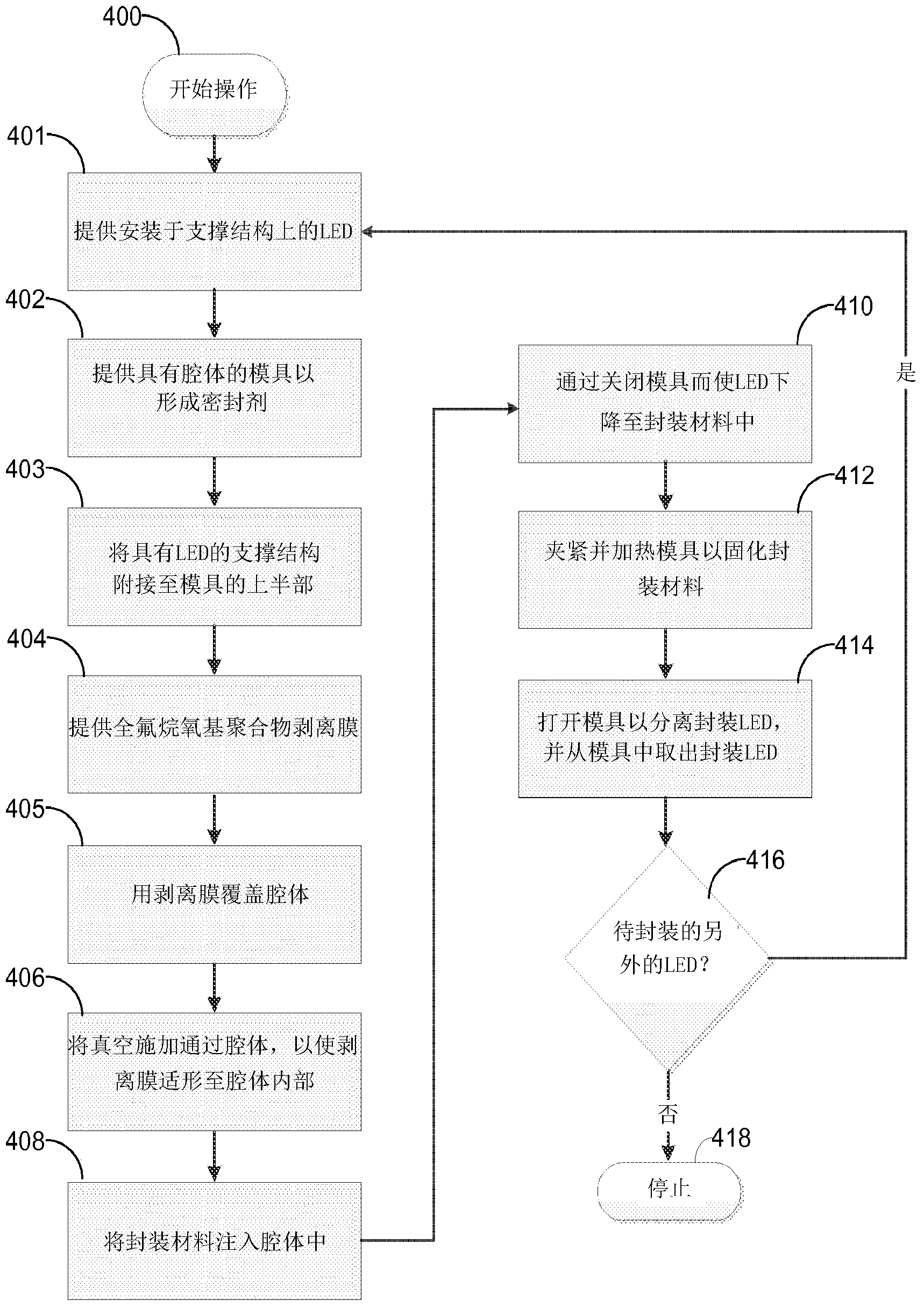

Method of manufacturing light emitting device

InactiveCN104170101AEasy to modifySimple designSynthetic resin layered productsSolid-state devicesGlass transitionFluorinated ethylene propylene

A novel method of producing an encapsulated light emitting device. A preferred mold release film that can be used during the encapsulation of a LED chip has an elastic modulus and a glass transition temperature that are low enough as compared to the desired molding temperature that the release film will closely conform to the interior of the molding cavities used to form a protective lens surrounding an LED chip. A preferred release film according to embodiments of the present invention comprises a fully fluorinated polymer, such as a perfluoroalkoxy polymer, including MFA, or fluorinated ethylene propylene.

Owner:SAINT GOBAIN PERFORMANCE PLASTICS CORP

Intraluminal stent graft

Owner:GORE ENTERPRISE HLDG INC

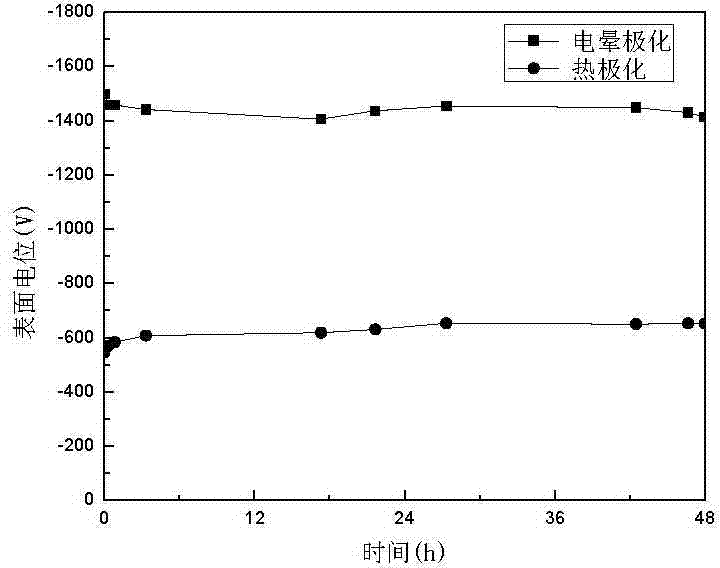

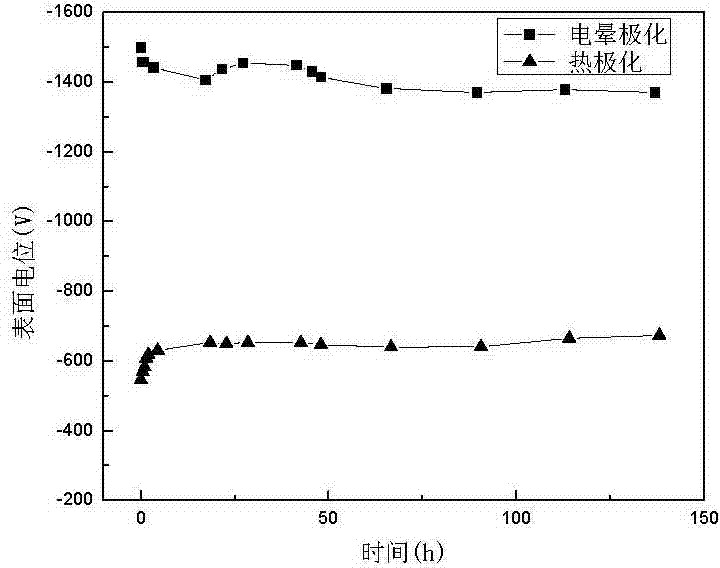

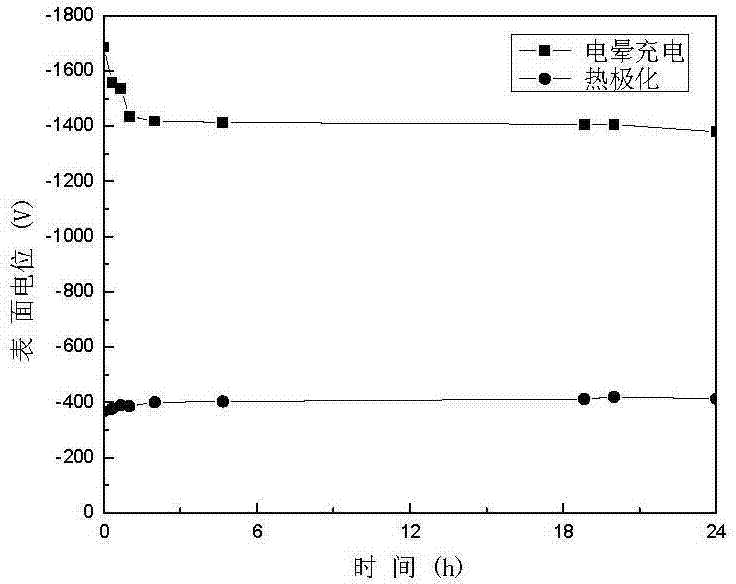

Method for preparing composite polymer electret

ActiveCN103240945AGood surface potential stabilityReduce chargeLaminationLamination apparatusTetrafluoroethylenePolymer science

The invention relates to a method for preparing a composite polymer electret. The method for preparing the composite polymer electret comprises the following steps: (1) preparation of a composite membrane: based on a functional polymer layer as an intermediate layer, covering a teflon or fluorinated ethylene propylene copolymer membrane at one side of the intermediate layer, and covering a teflon or fluorinated ethylene propylene copolymer membrane at the other side of the intermediate layer, thereby obtaining the composite membrane through suppressing and bonding; and (2) formation of the electret: injecting the composite membrane prepared from the step (1) by adopting a corona polarization or hot polarization method. The composite polymer electret prepared by the method has favorable surface potential stability; the polymer composite membrane is stored at normal temperature for a long time after being injected, and the potential is unchanged basically; meanwhile, the composite polymer electret also has favorable alcohol-resistant cleaning performance; and the composite membrane wiped by alcohol cotton is stored at normal temperature for a long time, and the potential is also unchanged basically, which shows that in a damp environment, or even in an organic solvent environment, the electret charge also cannot be attenuated easily.

Owner:HANGZHOU DIANZI UNIV

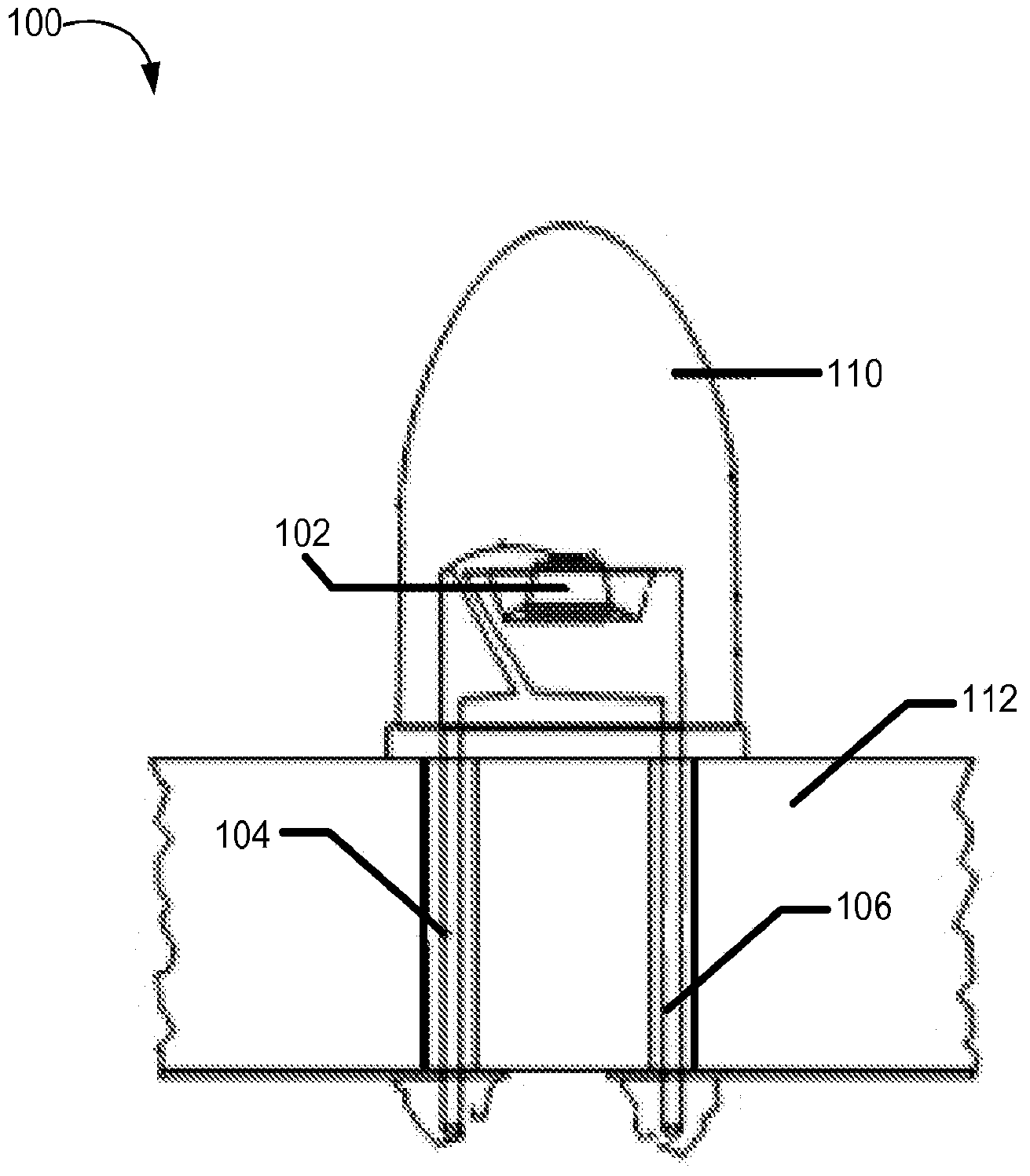

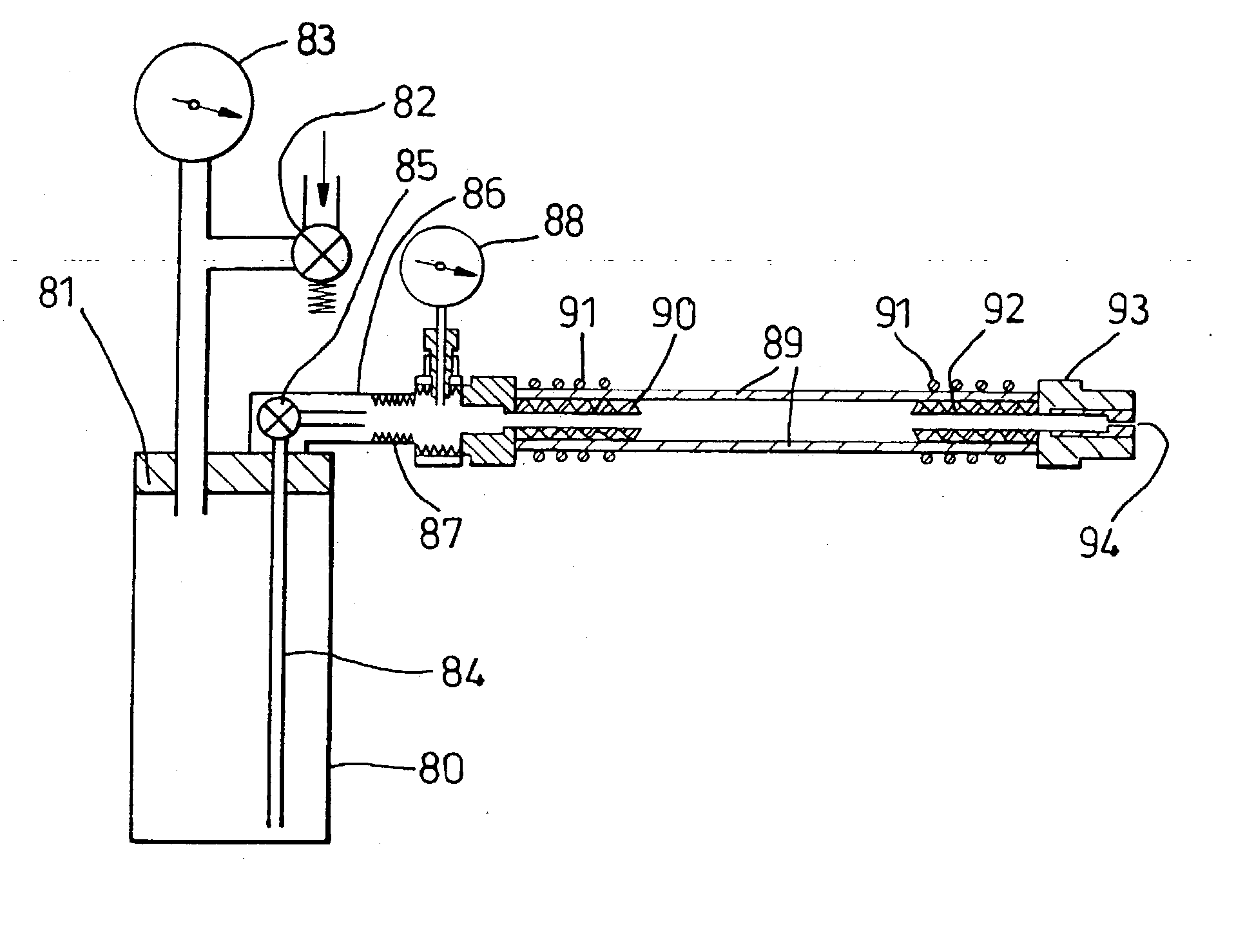

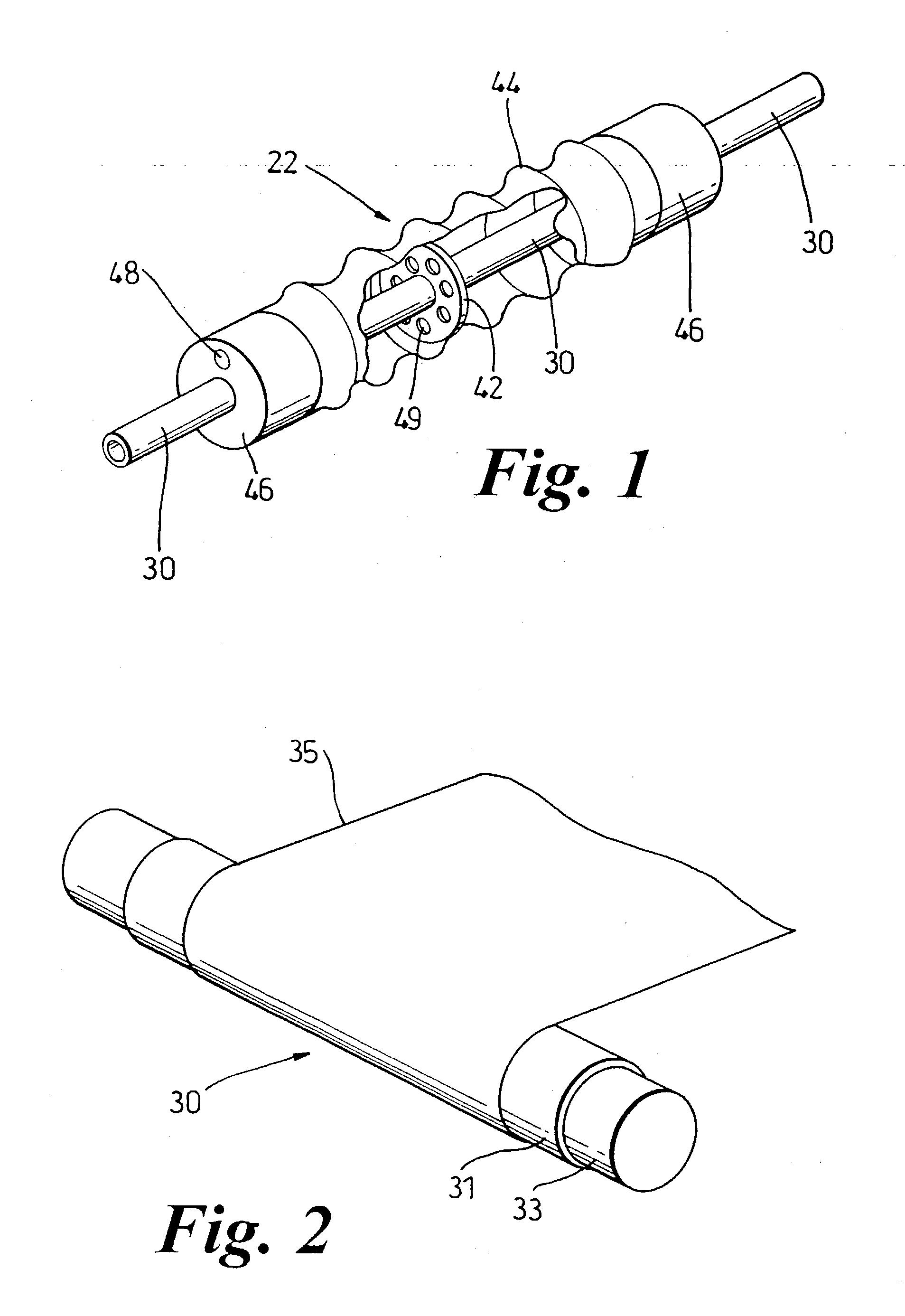

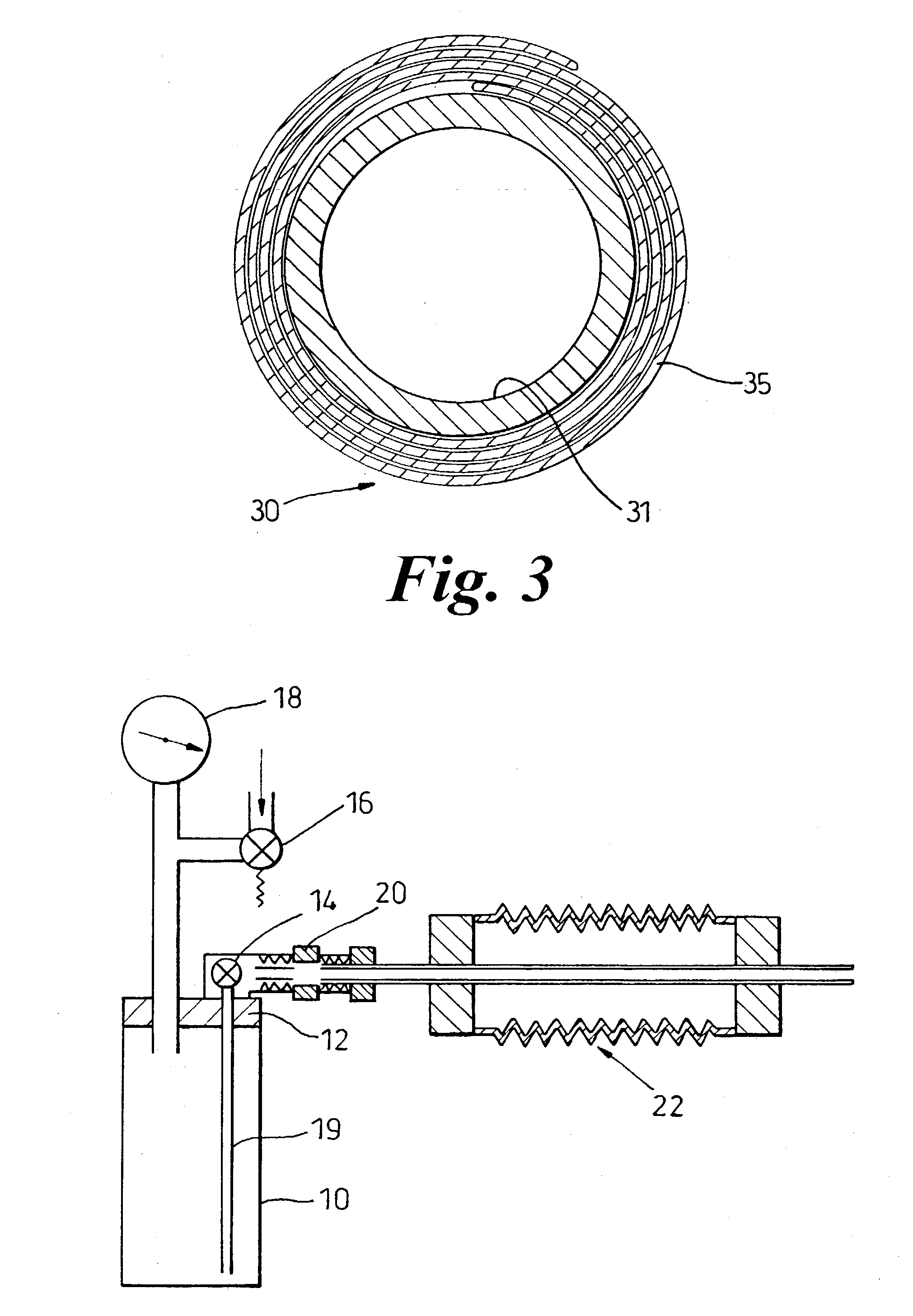

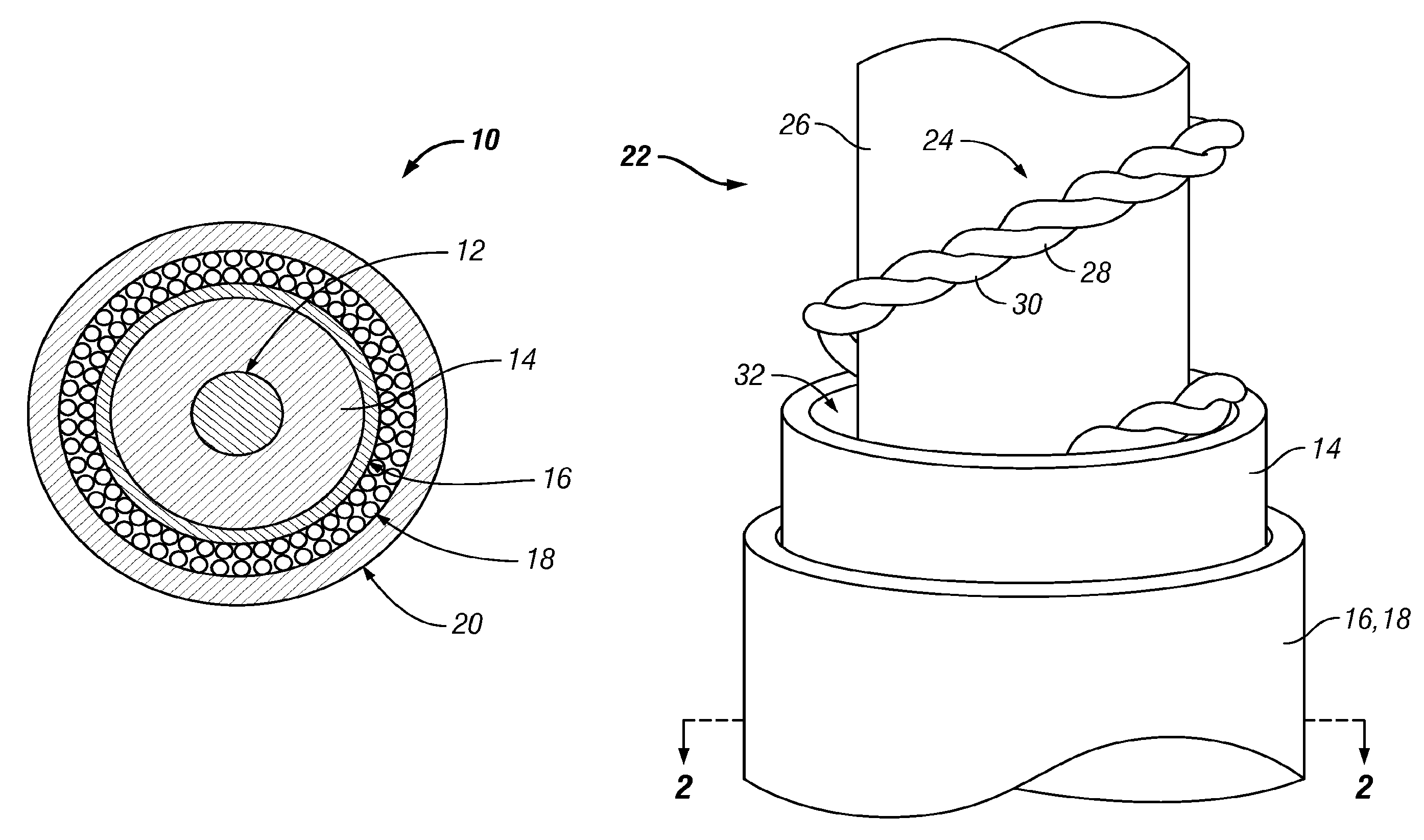

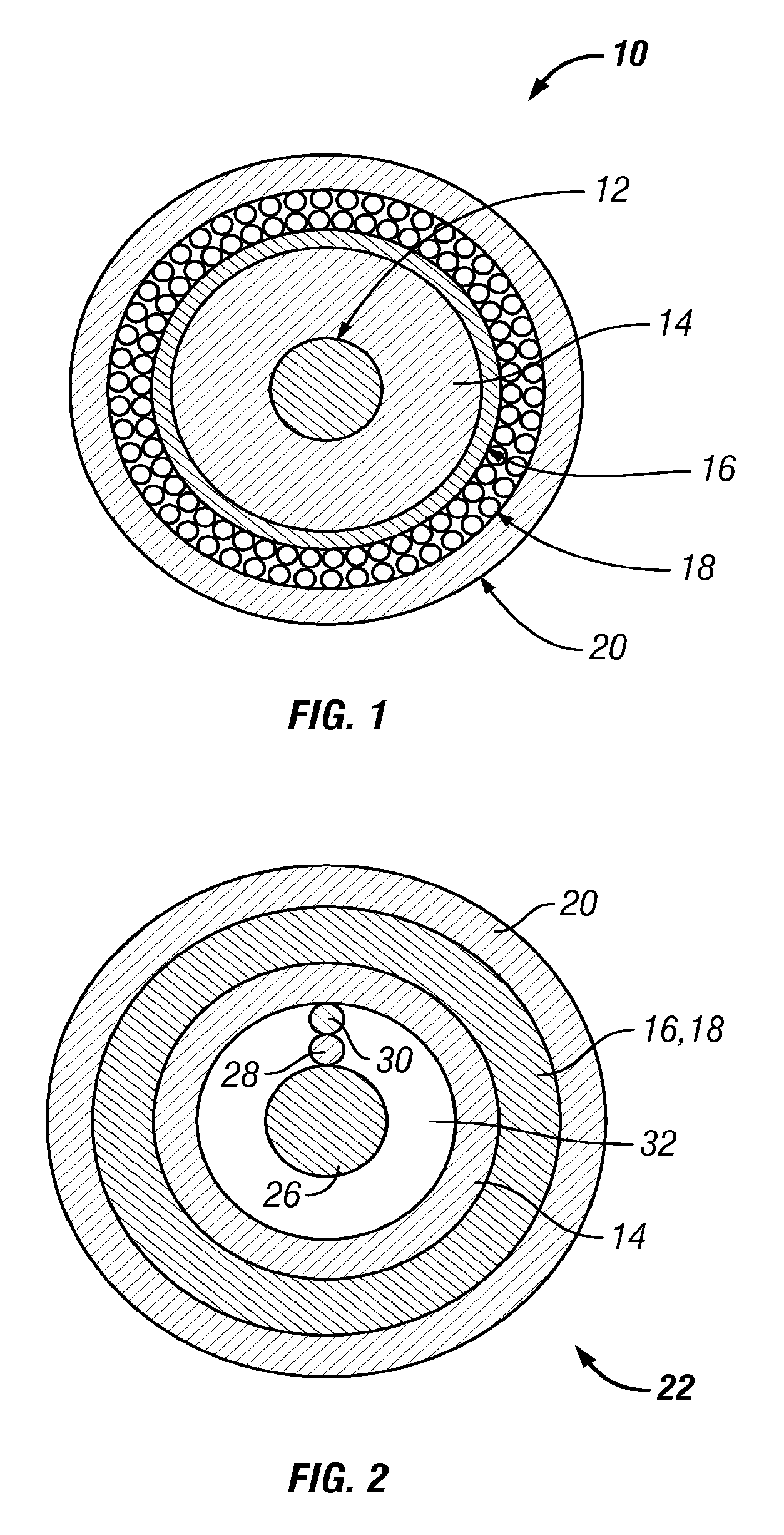

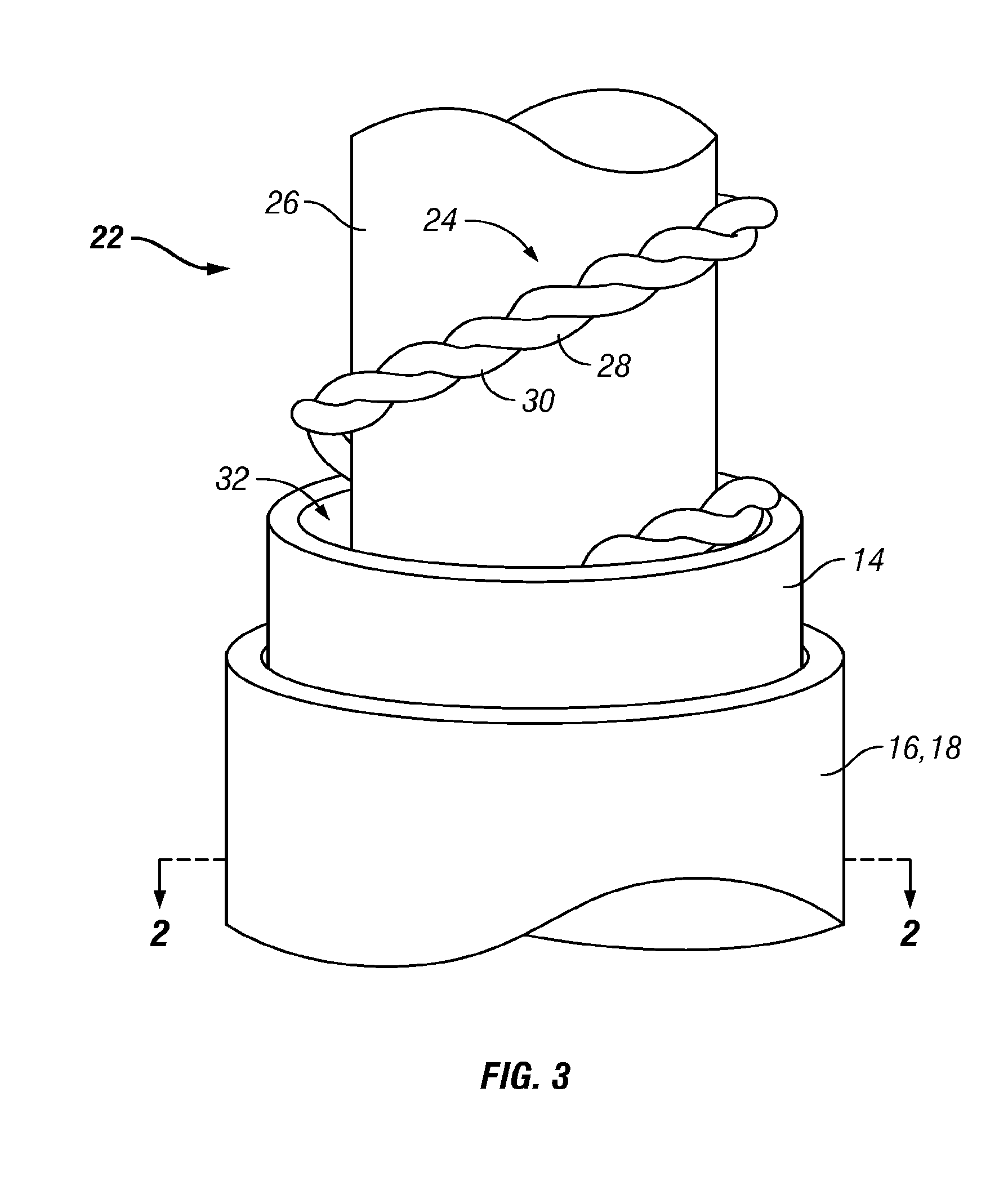

Cryogenic fluid transfer tube

InactiveUS20030106325A1Maximise fluid deliveryFast deliveryThermal insulationContainer filling methodsTetrafluoroethyleneFluoropolymer

The present invention is an improved tube for the effective transfer of cryogenic fluids and the like. The transfer tube (22) comprises at least two tubes, an inner tube (30) coaxially housed within an outer tube (44) with a defined gap therebetween. The inner tube is sufficiently permeable to gaseous cryogenic fluid that it allows release of limited amounts of gaseous fluid into the defined gap. The outer tube is essentially impermeable so as to contain the gaseous fluid within the gap. Preferably both tubes are constructed from flexible and cold temperature resistant polymer materials, such as fluoropolymer materials and especially expanded polytetrafluoroethylene (PTFE) and / or fluorinated ethylene propylene (FEP). The transfer tube of the present invention is highly effective at cryogenic fluid transfer while being lighter, more flexible, and more efficient than currently available transfer tubes.

Owner:W L GORE & ASSOCS UK

Cross-linked fluoroplastic heat-shrinkable tube and preparation method thereof

ActiveCN106317598AImprove temperature resistanceMedium resistance (good oil resistanceCross-linkFire retardant

The invention discloses a cross-linked fluoroplastic heat-shrinkable tube and a preparation method thereof and relates to a plastic heat-shrinkable tube. The cross-linked fluoroplastic heat-shrinkable tube is made of cross-linked fluoroplastic, and the cross-linked fluoroplastic is prepared from components of raw materials in parts by weight as follows: 50-95 parts of thermoplastic fluoroplastic, 1-8 parts of an assistant crosslinker, 1-5 parts of pigments, 1-10 parts of a fire retardant and 1-20 parts of other aids. Compared with heat-shrinkage tubes made of thermoplastic materials such as FEP (fluorinated ethylene propylene), PFA (polytetrafluoroethylene) and the like, the cross-linked fluoroplastic heat-shrinkable tube has higher expansion rate and is wider in use range, better in radiation resistance and capable of bearing 50 or more Mrad of radiation.

Owner:SHANGHAI KAIBO SPECIAL CABLE FACTORY

Electric cable insulation material and production method thereof

The present invention discloses an electric cable insulation material, which comprises, by weight, 60-80% of fluorinated ethylene propylene, 10-12% of a butyl rubber, 10-12% of an ethylene propylene diene monomer, 1-2% of a self-adhesive butyl semi-conductive tape, 5-10% of an organic solvent, 2-3% of a fluorine-containing diacyl peroxide, 2-3% of polyphenylene sulfide, 2-3% of polytetrafluoroethylene powder, and 1-2% of alkali-free glass fiber. The prepared electric cable insulation material provides more excellent temperature tolerance, insulation property and flame resistance compared with other existing electric wire and electric cable materials, and can be widely used in petroleum, chemical engineering, medicine and other corrosive chemical industries.

Owner:KUNSHAN FENFA INSULATING MATERIALS

Antibacterial PTCA dilatation catheter

InactiveCN101843949AAntibacterialSimple processStentsBalloon catheterPolyvinyl chlorideFluorinated ethylene propylene

The invention relates to a dilatation catheter used for treatment, in particular to an antibacterial PTCA dilatation catheter which comprises a sacculus, a far-end tube body part, a near-end tube body part that are sequentially connected and communicated with each other. The antibacterial PTCA dilatation catheter is prepared by the steps of: mixing one, two or three in ciprofloxacin powder, rifampicin powder and metal tungsten powder according to a certain proportion; fully mixing the prepared antibacterial powder with plastic master batch for milling; and finally, precisely extruding and blow molding for shaping, wherein the antibacterial powder accounts for 1-50% of the total weight ratio of the dilatation catheter, and the plastic master batch is prepared by one in poly-fluorinated ethylene propylene, polyfluortetraethylene, polyvinyl chloride, polyethylene, polyurethane, fluoro-polymer and thermoplastic elastomer. The antibacterial PTCA dilatation catheter has simple production technique, realizes long-acting antibacterial function, and greatly improves the safety factor of operation.

Owner:DONGGUAN DIKAI MEDICAL

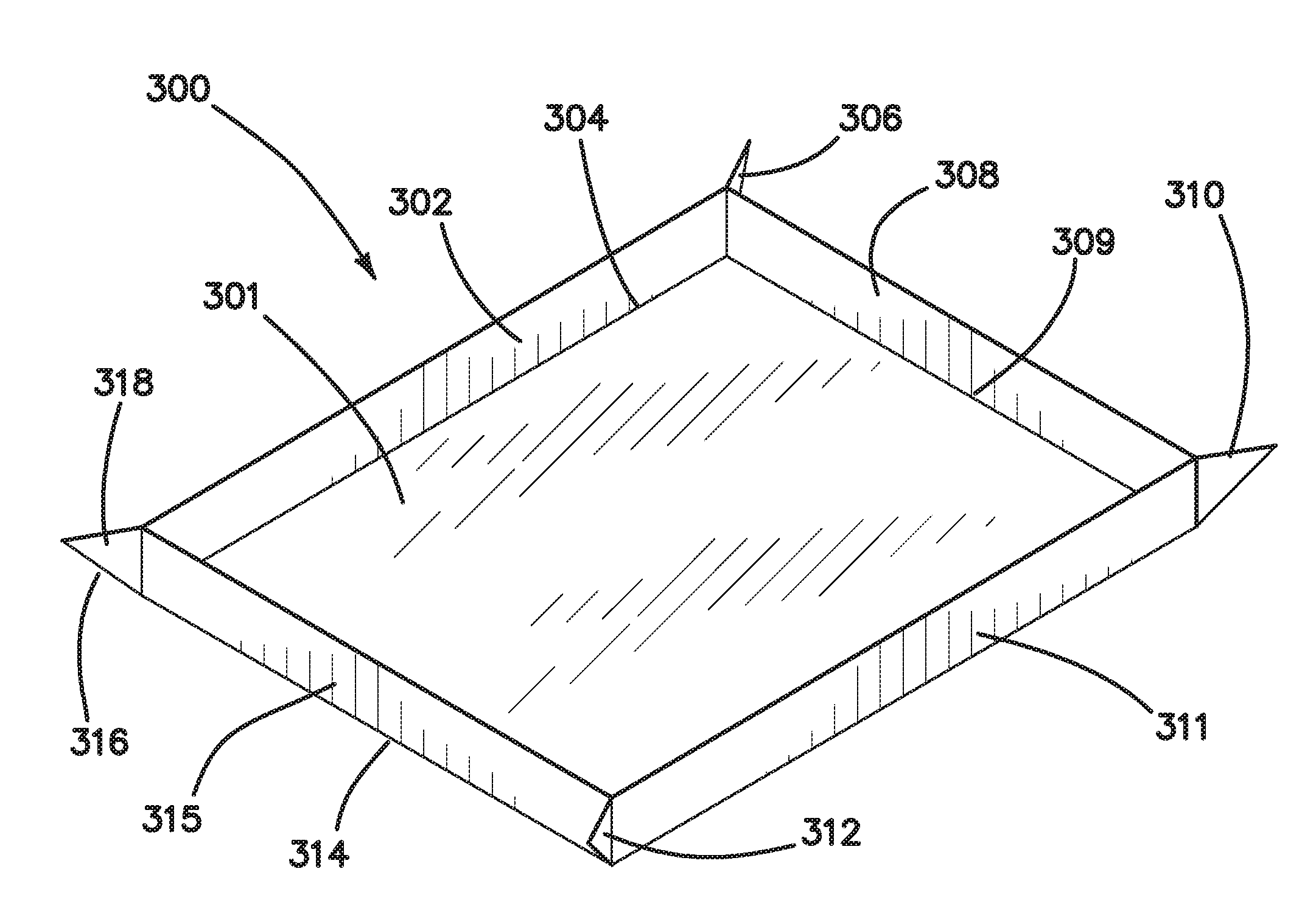

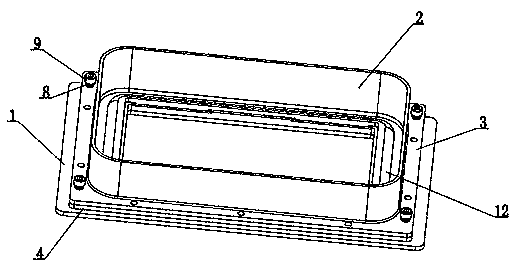

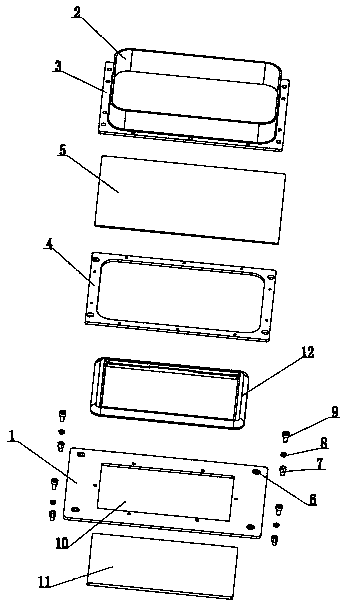

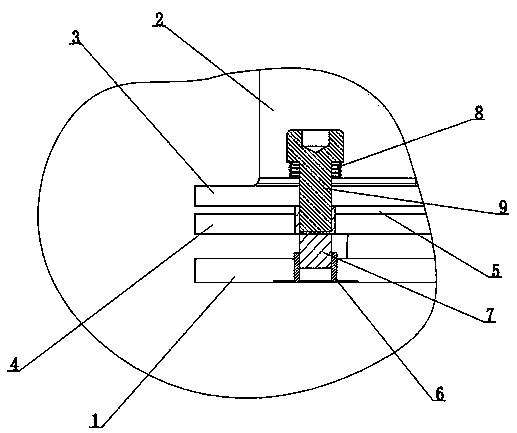

Resin tank for digital light processing (DLP) photocuring 3D printer

ActiveCN105365218AEnergy savingHigh surface finishAdditive manufacturing apparatusDigital signal processingCoil spring

The invention discloses a resin tank for a digital light processing (DLP) photocuring 3D printer. A periphery mounting face is formed at the bottom of a box frame, a soft cushion plate is arranged under the periphery mounting face and fixedly attached to the periphery mounting face, and a fluorinated ethylene propylene copolymer thin film or a teflon thin film is clamped between the periphery mounting face and the cushion plate. The box frame can be lifted relative to a bottom plate through external force and can be reset in time after the external force is gone, an opening is formed in the bottom plate and located in the box frame, and a transparent sealing plate covers the opening and is fixed through a cambered pressing frame. When the box frame is kept in a downward-pressing state through the acting force of spiral springs, part of the cambered pressing frame extends into the box frame, and the fluorinated ethylene propylene copolymer thin film or the teflon thin film is tensioned. The technical purpose that the bottom of the resin tank can be conveniently stripped from cured resin in the working process of the DLP photocuring 3D printer is achieved, and the printing effect is improved.

Owner:NINGBO YINZHOU INTELLIGENT MFG DIGITAL TECH

Method for preparing microemulsion of fluorinated ethylene propylene powder

The invention discloses a microemulsion polymerization method of perfluoroethylene and hexafluoropropene copolymer, which uses monomer medium liquefied hexafluoropropene as organic phase, adds monomer medium liquefied hexafluoropropene, emulsifier and co-emulsifier into water, to form O / W type microemulsion, feeds perfluoroethylene and hexafluoropropylene initial mixture gas and complement mixture gas, uses oil-soluble free radical initiator to initialize reaction, after the reaction, heats to separate and recover liquefied hexafluoropropene, discharges water, heats obtained polymer powder, to remove non-decomposed initiator, decomposition product, and residual water and foreign materials. The product powder of the invention has uniform and small size, non block. And the invention uses liquefied hexafluoropropene as organic phase to avoid organic solvent pollution on product and environment.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

Agglomeration washing method of fluorinated ethylene propylene

This invention discloses a method for condensing and washing perfluoroethylene-perfluoropropylene copolymer prepared by emulsion polymerization. The method comprises: (1) adding 1-10 deg.C deionized water to perfluoroethylene-perfluoropropylene copolymer emulsion, stirring, demulsifying, and washing the precipitate with 40-80 deg.C deionized water for 2-6 times (1-5 min for each time). The method can largely increase the equipment productivity, lower the consumption of pure water, save the raw materials, and shorten the treatment period.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

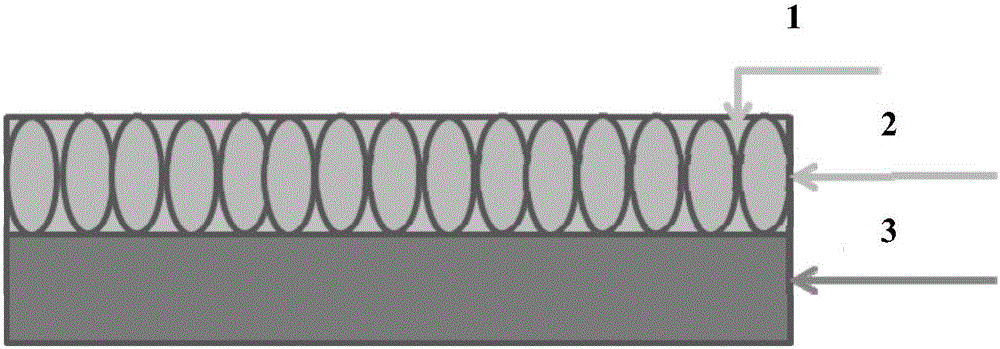

Bonding and curing process of expanded polytetrafluoroethylene membrane

ActiveCN105751668ASolve the problem of extremely difficult bondingSolve the problem that micropores will disappear when shrinking backLamination ancillary operationsSynthetic resin layered productsEmulsionPorous membrane

The invention discloses a bonding and curing process of an expanded polytetrafluoroethylene membrane, comprising: using FEP (fluorinated ethylene propylene) emulsion as a binder, brushing the FEP emulsion among a plurality of stacked e-PTFE (expanded polytetrafluoroethylene) porous membrane, and bonding the plurality of porous membranes into a sheet of certain thickness to obtain a membrane composite; fixing the membrane composite between two plate-frame fixing clamps; placing the membrane composite along with the clamps in an oven, and heating at 65-250 DEG C in a segmental gradient manner; curing at high temperature and then cooling.By using the FEP emulsion as the binder, the problem of bonding difficulty is solved; by using segmental gradient heating, the problem of removing an emulsifier in the binder is effectively solved; by designing the plate-frame fixing clamps, fixing the membrane composite between the two plate-frame fixing clamps and carrying out segmental gradient heating and high-temperature curing, the problem that the e-PTFE porous membranes experience micropore loss after being heated is solved effectively.

Owner:SHANGHAI KANGNING MEDICAL DEVICE

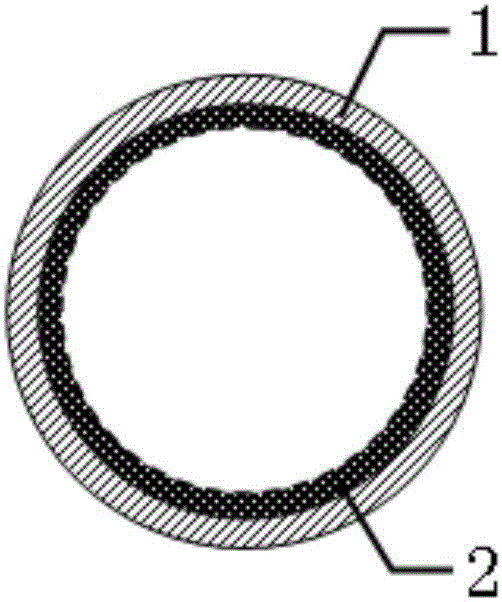

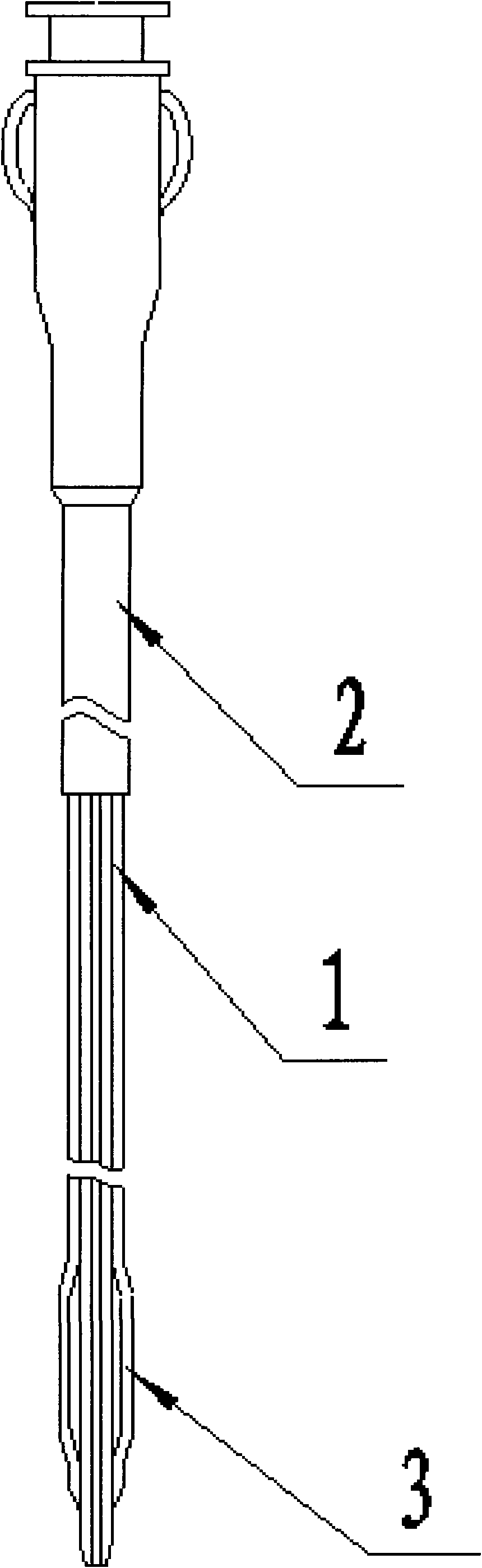

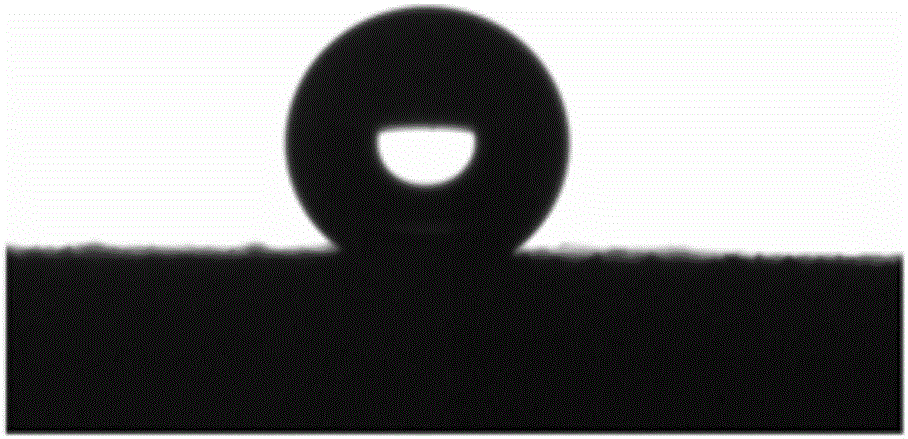

Cored wire with super-hydrophobic function and application of cored wire with super-hydrophobic function to preparation of coating with super-hydrophobic function

ActiveCN106676451AImprove self-cleaning effectImprove corrosion resistanceMolten spray coatingThermal sprayingAlloy

The invention provides a cored wire with a super-hydrophobic function. The cored wire with the super-hydrophobic function comprises a cored material and a metal wire coat, wherein the metal wire coat is used for coating the cored material. The cored material is formed by a metal cored material and a high molecular cored material through mixing. The metal cored material is selected from metal aluminum, copper, nickel and chromium or is any one kind of alloy formed by two kinds of the metal. The high molecular cored material is at least one of teflon, fluorinated ethylene-propylene, polytrifluorochloroethylene, polyvinylidene fluoride, ethylene-tetrafluoroethylene copolymer, ethylene-chlorotrifluoroethylene copolymer, polyvinyl fluoride, fluorocarbon resin and polyurethane. The invention further provides a coating with a super-hydrophobic function. The coating with the super-hydrophobic function is made of cored wires with the super-hydrophobic function and prepared through a thermal spraying technology. The coating has excellent super-hydrophobic performance and corrosion resistance, and has the good application prospect in the fields of self-cleaning, marine pollutant prevention, contamination resistance and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Corrosion-resistant inflaming retarding heat-proof cable sheath material

InactiveCN104098899AImprove high temperature resistanceImprove corrosion resistancePlastic/resin/waxes insulatorsBoron fiberFluorinated ethylene propylene

The invention discloses a corrosion-resistant inflaming retarding heat-proof cable sheath material which comprises the following raw materials in parts by weight: 19-21 parts of fluorinated ethylene propylene copolymer (FEP), 4-6 parts of polytetrafluoroethylene, 20-23 parts of polyphenylene sulfide (PPS), 7-9 parts of boron fiber, 4-6 parts of nylon fiber, 10-13 parts of short glass fiber, 0.5-1.2 parts of dimethyl phthalate (DMP), 9-11 parts of kaolin, 4-6 parts of mica, 3-5 parts of quartz, 10-12 parts of nano-montmorillonite, 3-4 parts of ammonium phosphate, 1-2 parts of hydrated zinc borate, 0.5-1.5 parts of bis stearamide, 4-6 parts of silicone oil, 1-2 parts of a titanate coupling agent NDZ-101 and 2-3 parts of castor acid barium. The corrosion-resistant inflaming retarding heat-proof cable sheath material has excellent corrosion-resistant performance and inflaming retarding heatproof performance, and is good in processability and excellent in impact strength.

Owner:安徽宁国市高新管业有限公司

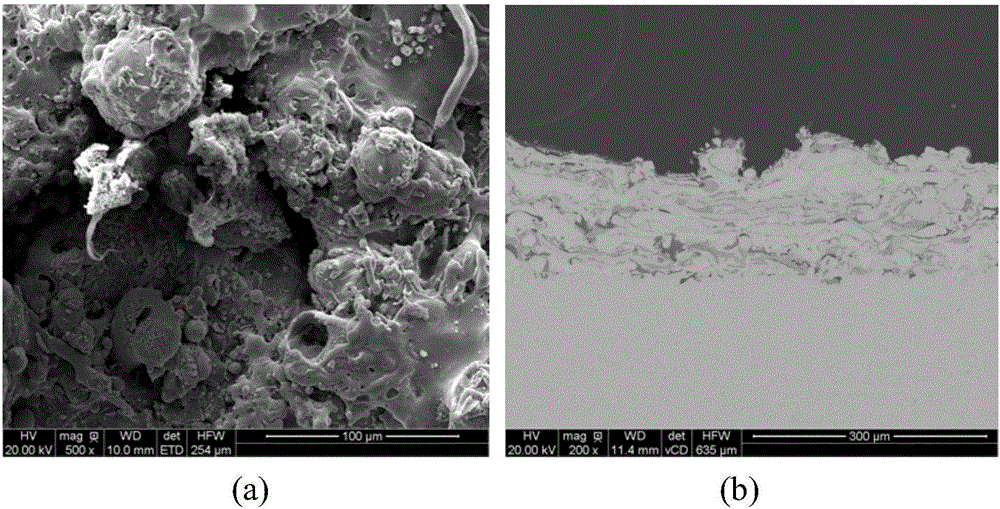

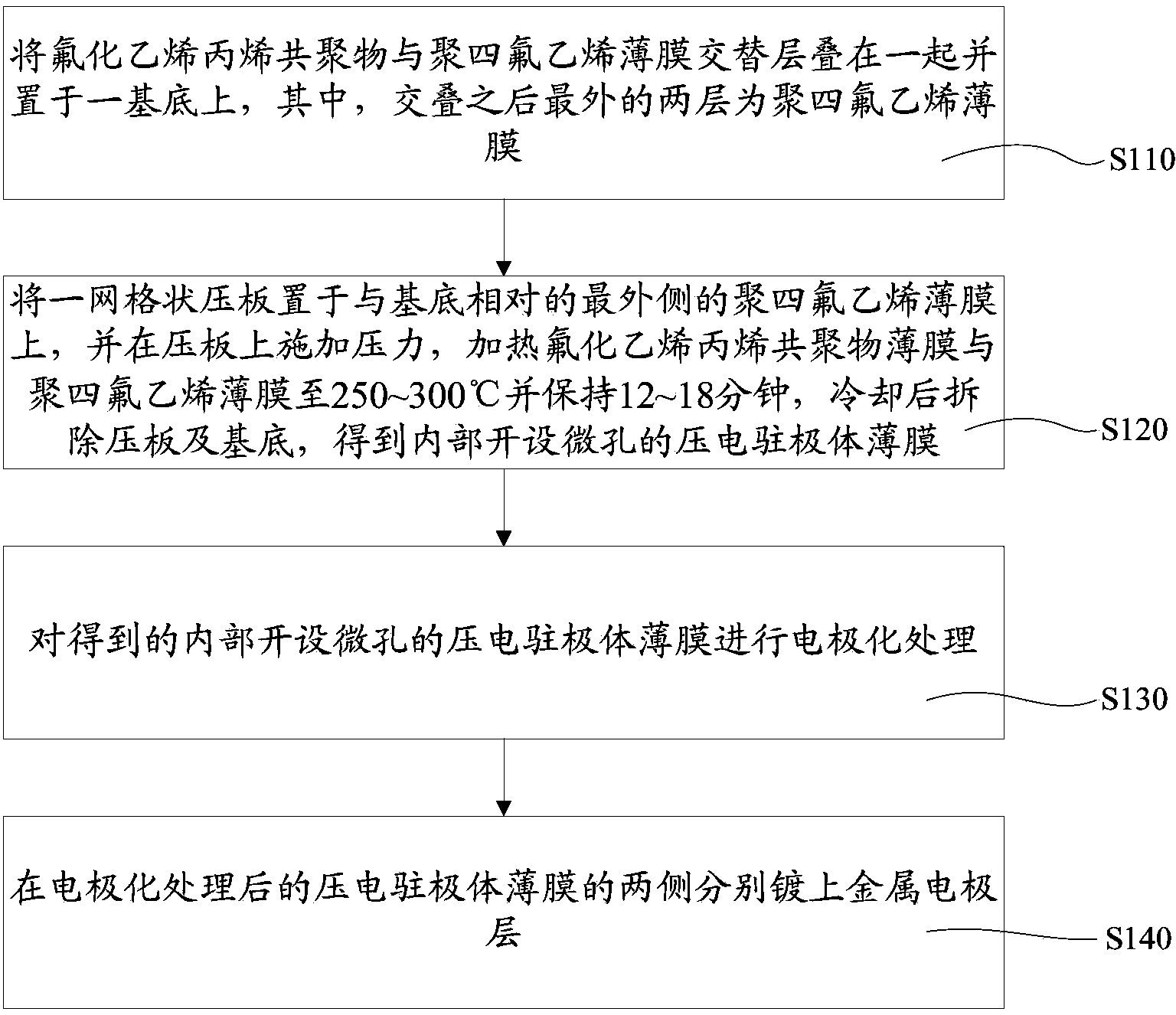

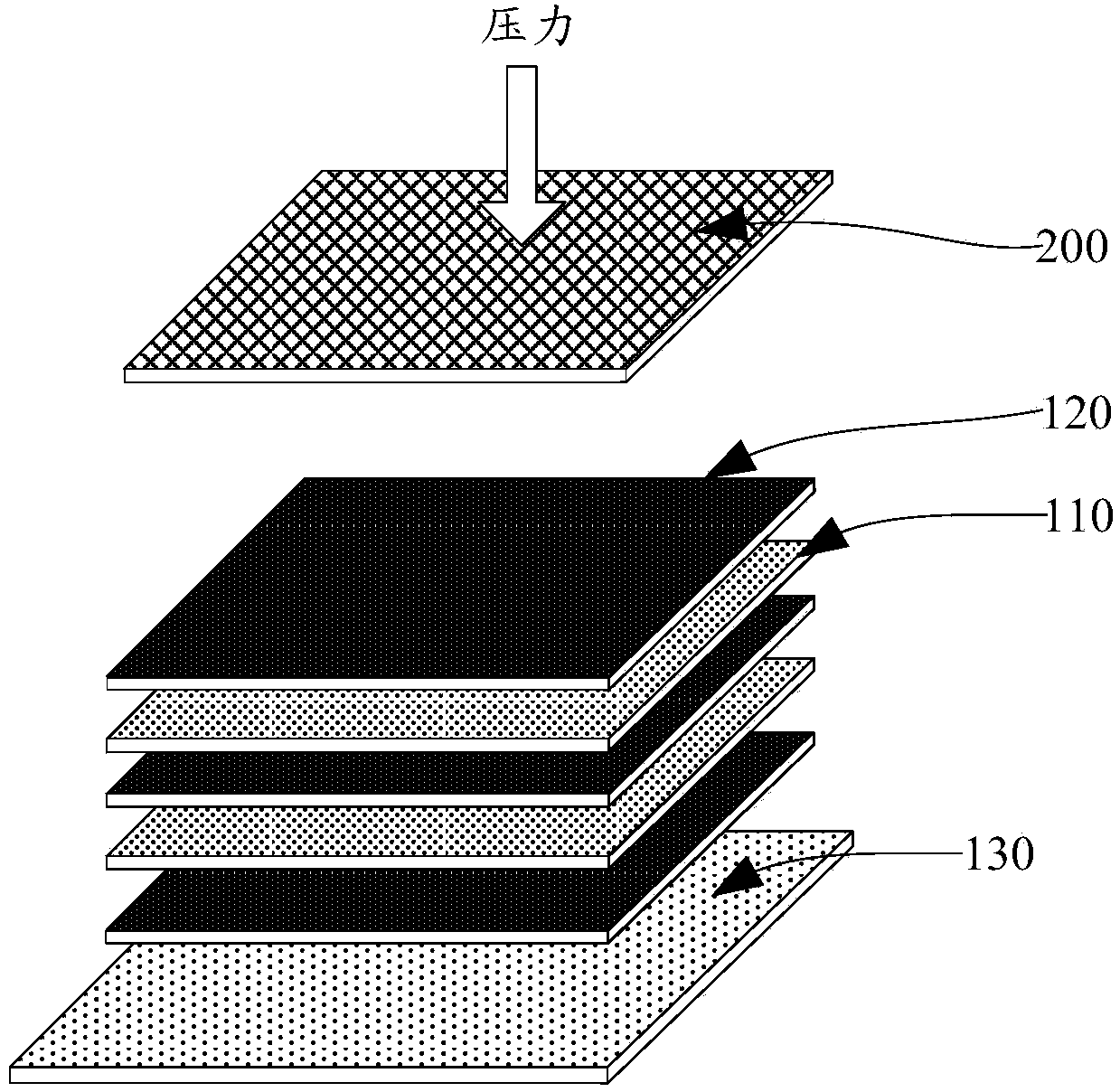

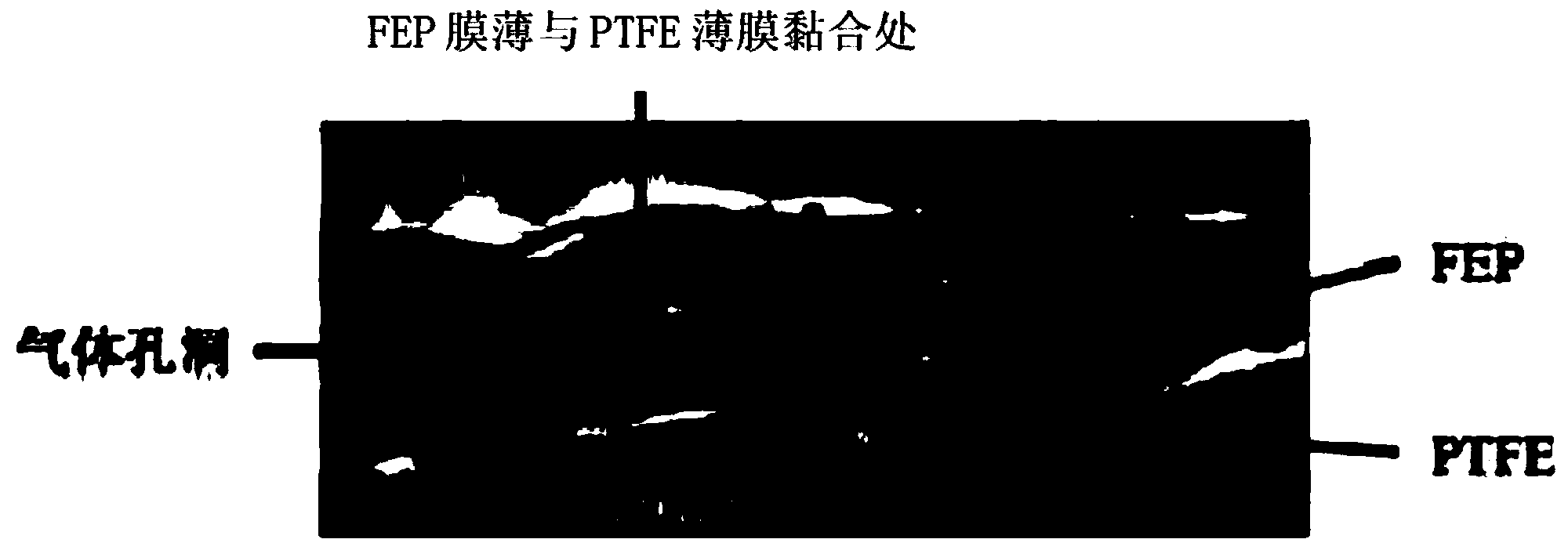

Piezoelectric electret film and producing method thereof

InactiveCN104044327ARealize fine controlPracticalSynthetic resin layered productsLaminationFerroelectretFluorinated ethylene propylene

The invention relates to a producing method of a piezoelectric electret film, and the producing method is as follows: fluorinated ethylene propylene copolymer films and polytetrafluoroethylene films are alternately laminated together, and then placed on a substrate, after the alternate lamination, two outermost layers are the polytetrafluoroethylene films; a latticed pressing plate is arranged on an outermost layer t polytetrafluoroethylene film opposite the substrate, pressure is applied to the pressing plate, the alternately laminated structure of the fluorinated ethylene propylene copolymer films and the polytetrafluoroethylene films is heated, after cooling, the pressing plate and the substrate are removed to obtain the piezoelectric electret film provided with micropores in the middle. In the production process of the piezoelectric electret film, through selection of latticed pressing plates with different specifications, such as regulation of mesh net opening mesh number, wire diameter, shape and other parameters and thermal bonding process parameter of the pressing plates, the fine adjustment of microporous structure of the piezoelectric electret film can be realized, and the producing method is strong in practicability, and can be widely popularized and applied. In addition, the invention also relates to the piezoelectric electret film produced by the producing method.

Owner:深圳市明鑫高分子技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com