Patents

Literature

31results about How to "Uniform glue content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

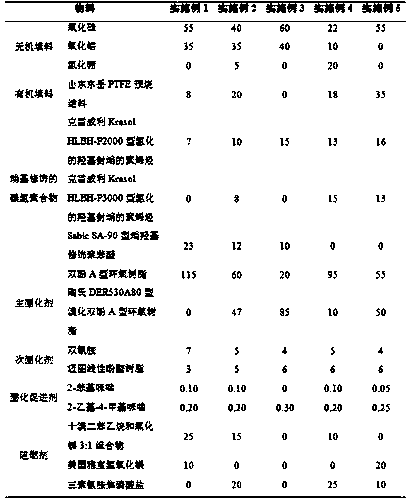

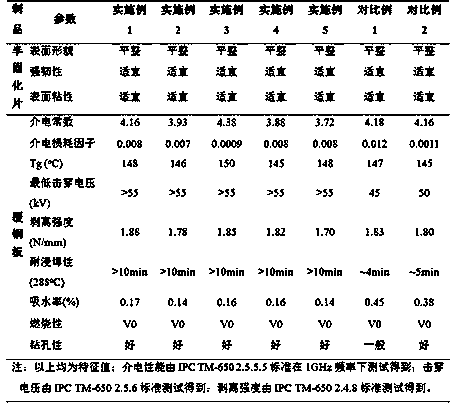

Fluororesin mixture, copper-clad plate prepared therefrom and manufacturing method thereof

ActiveCN101838431AImprove dipping qualityUniform glue contentGlass/slag layered productsMetal layered productsVinyl etherGlass fiber

The invention relates to a fluororesin mixture, a copper-clad plate prepared therefrom and a manufacturing method thereof. The fluororesin mixture contains the following two substances as necessary components in 100 parts by weight of an organic solid substance: 90-99 parts of polytetrafluoroethylene (PTFE) emulsions and 1-10 parts of polytetrafluoroethylene perfluoroalkyl vinyl ether (PFA) emulsions. The copper-clad plate prepared from the fluororesin mixture comprises a plurality of superimposed varnished cloths and copper foil coating one or two surfaces of the varnished cloths, and each varnished cloth comprises a glass fiber cloth and the fluororesin mixture attached to the dipped and dried glass fiber cloth. The fluororesin mixture is prepared by using the PTFE emulsions as main resins and can dip the glass fiber cloths many times under the condition that the PTFE sintering temperature is330 DEG C to prepare the vanished cloths, and the vanished cloths prepared from the fluororesin mixture has the advantages of good gum dipping quality, level surface, flexibility and easy operation; and besides, the copper-clad plate made from the fluororesin mixture has excellent dielectric performance which meets the dielectric performance requirement of the high-frequency communication field for a base plate material, and has simple making method and process and is beneficial to industrial continuous production.

Owner:GUANGDONG SHENGYI SCI TECH

Fluoro-resin mixture, copper-clad plate made of same and making method thereof

ActiveCN101857708AImprove dipping qualityUniform glue contentFibre treatmentLaminationGlass fiberPolymer science

The invention relates to a fluoro-resin mixture, a copper-clad plate made of the same and a making method thereof. The fluoro-resin mixture comprises the following two substances as necessary components: 90-99 parts by weight of polytetrafluoroethylene (PTFE) emulsion and 1-10 parts by weight of fluorinated ethylene propylene (FEP) based on 100 parts by weight of an organic solid matter. The copper-clad plate made of the fluoro-resin mixture comprises a plurality of pieces of superimposed varnished cloth and copper foils covering one side or two sides of the varnished cloth, wherein each piece of varnished cloth comprises glass fiber cloth and a fluoro-resin mixture adhered thereon through dipping drying. The fluoro-resin mixture is prepared by taking the PEFE emulsion as base resins, the glass fiber cloth can be dipped for many times in the mixture under the condition of below PTFE sintering temperature (330 DEG C) to obtain the varnished cloth. The varnished cloth made from the fluoro-resin mixture has favorable gum dipping quality, uniform gum content, smooth surface, softness and easy operation. The copper-clad plate made from the fluoro-resin mixture has favorable comprehensive properties, excellent dielectric properties, simple making method and process, satisfies the dielectric property requirements on substrate materials in the field of high frequency communication and is beneficial to industrial continuous production.

Owner:GUANGDONG SHENGYI SCI TECH

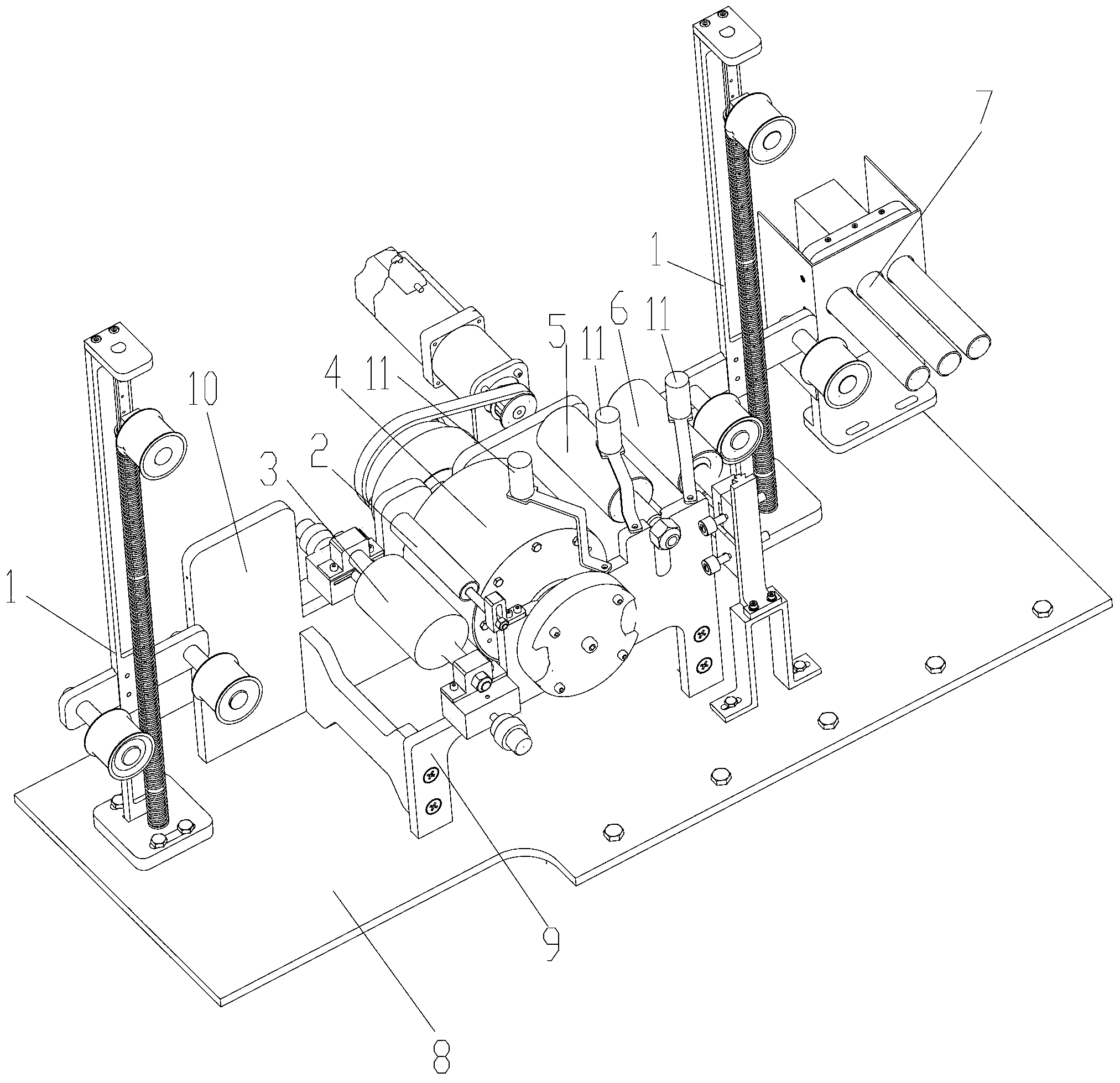

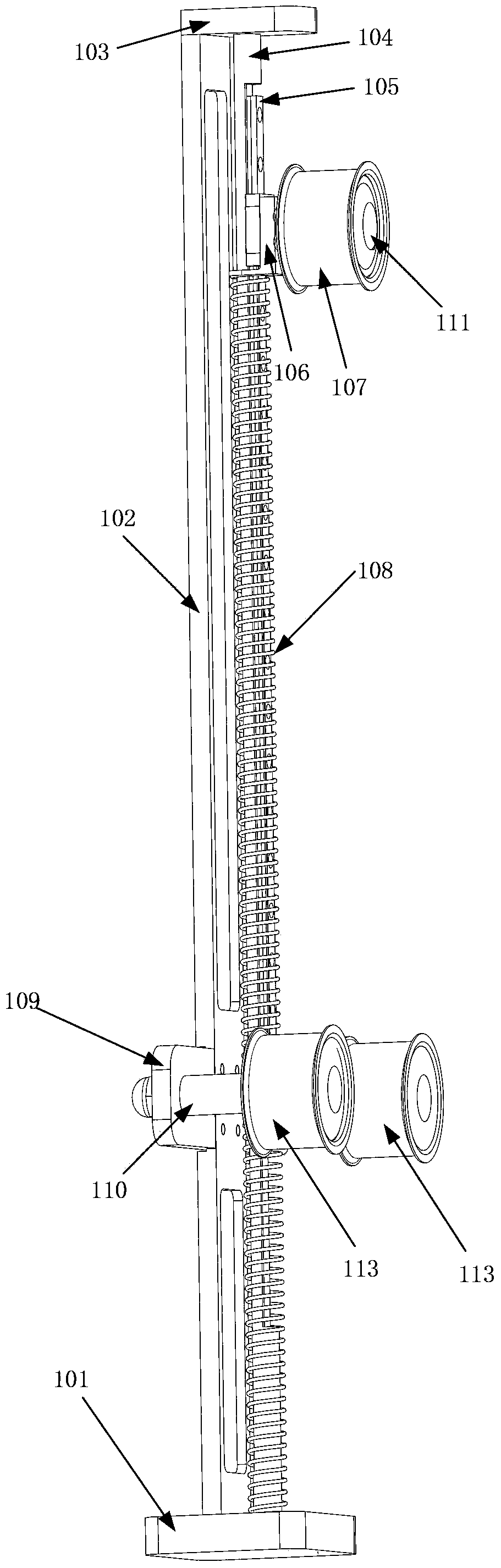

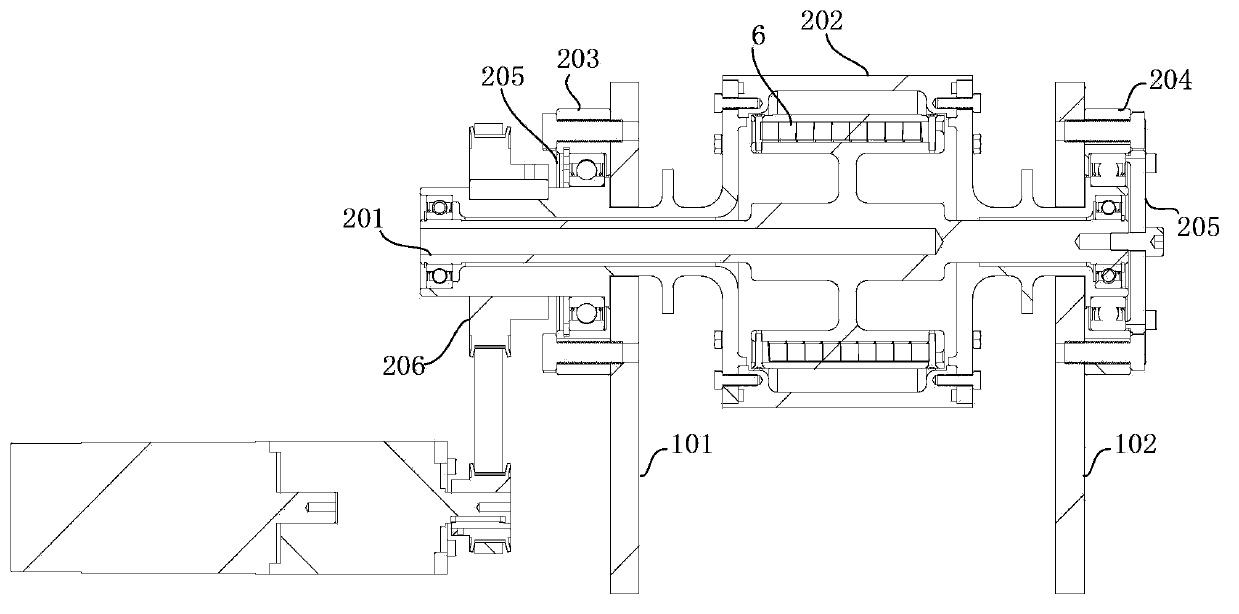

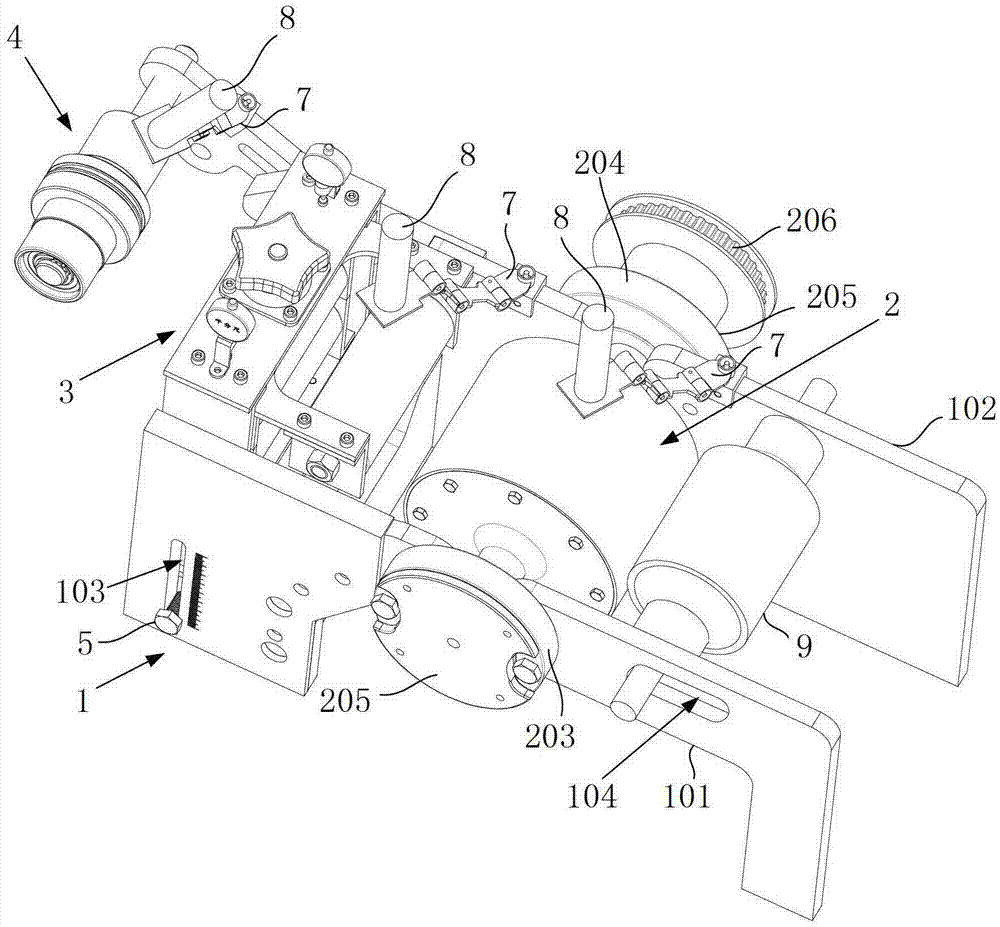

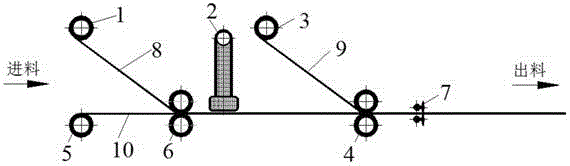

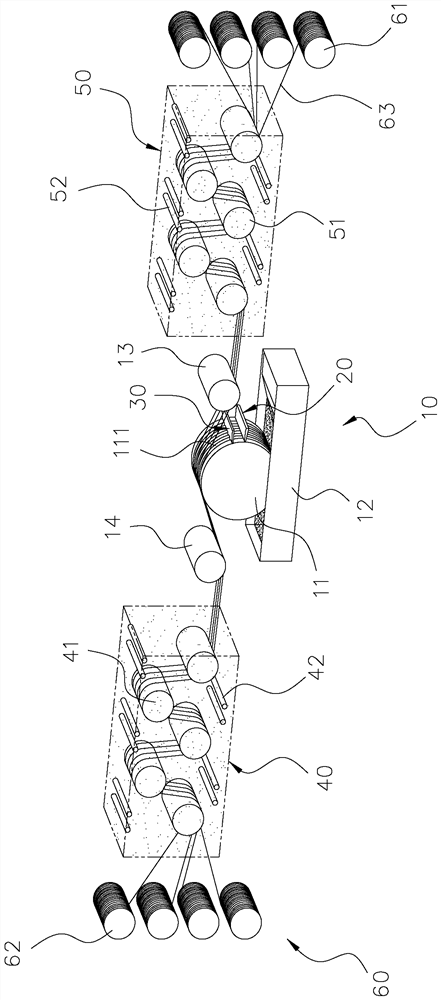

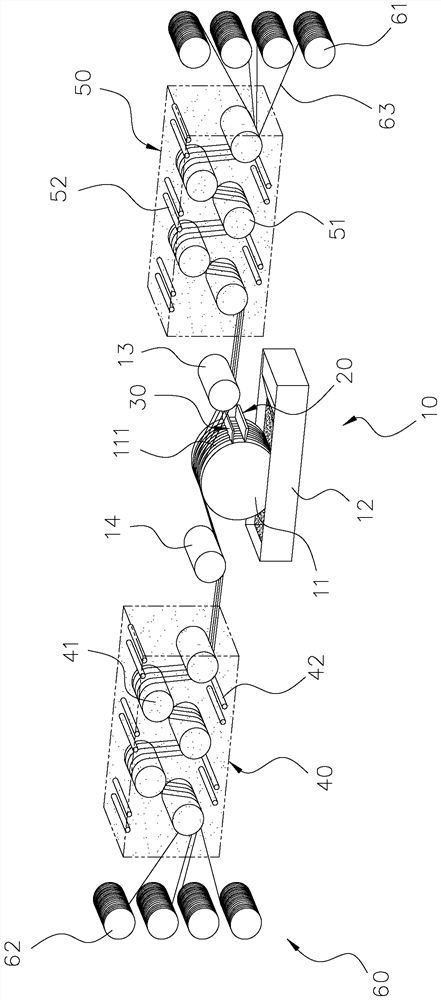

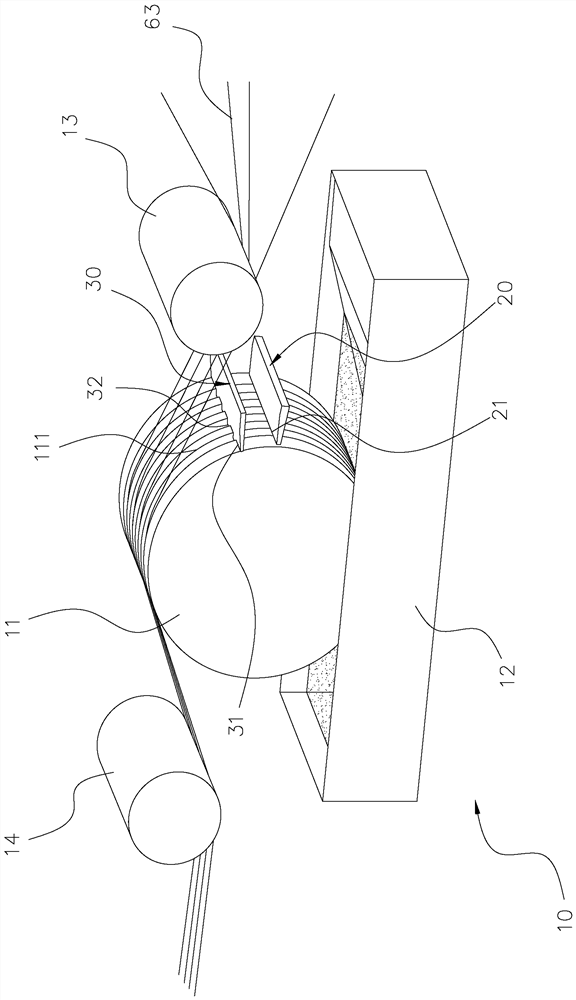

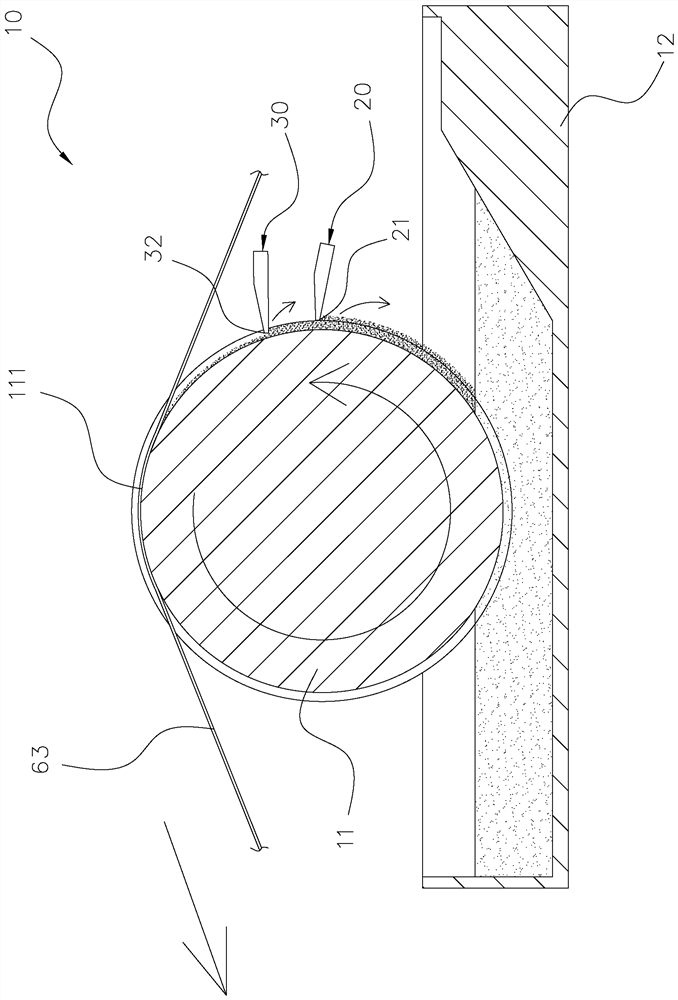

Fiber conduction device for carbon fiber winding machine

The invention discloses a fiber conduction device for a carbon fiber winding machine. The fiber conduction device comprises a tension adjustment device, a front wrap angle adjusting roller, a frictioning device, a driving impregnation roller, a rear wrap angle adjusting roller, a glue extrusion device, a tension measurement device, a frame bottom plate, a left frame and a right frame. Fibers pass though the middle part of each conduction roller; the driving impregnation roller is driven by a servo motor and is arranged on the frame through a bearing block; a gap between a frictioning roller and glue extrusion rollers can be adjusted through a sliding table by the frictioning roller; the positions of the front wrap angle adjusting roller and the rear wrap angle adjusting roller are adjustable; the gap between the glue extrusion rollers can be adjusted through the sliding table by the glue extrusion device; a tension measurement guide roller is arranged on a tension sensor. According to the fiber conduction device, damage in the fiber conduction device can be effectively reduced, problems of fuzziness, line breakage and the like in the processes of winding and molding fibers are reduced, and the glue content and glue uniformity of the fibers are guaranteed, so that the quality of the fiber-wound product is improved.

Owner:BEIHANG UNIV

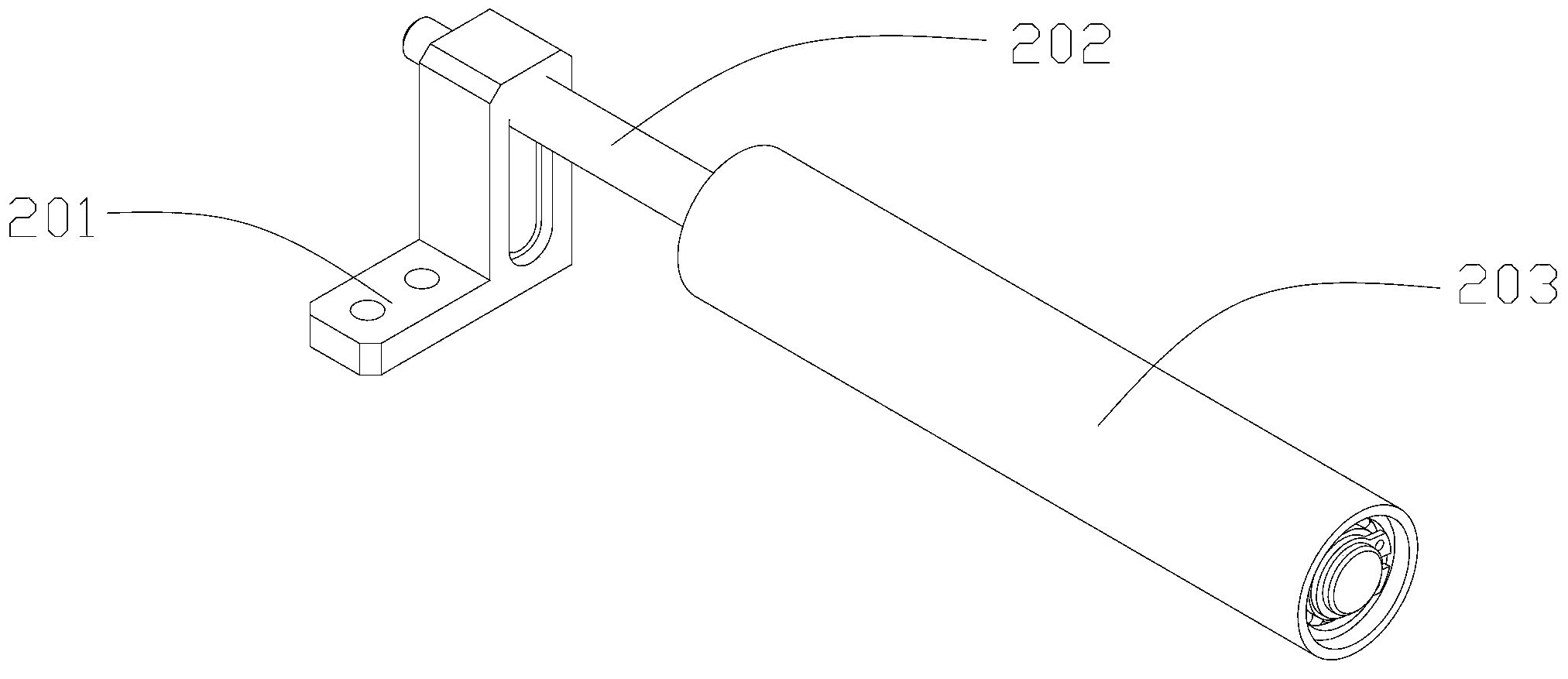

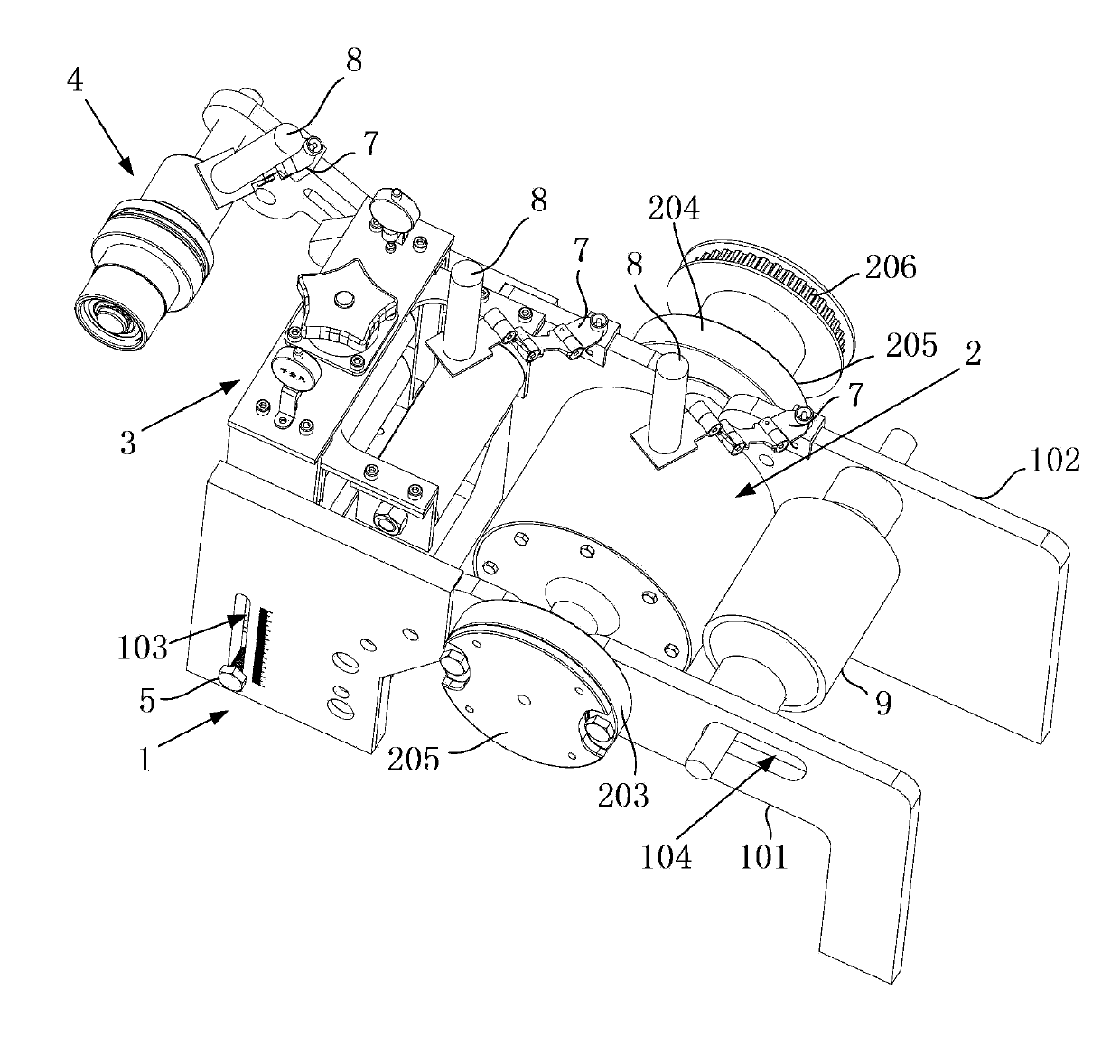

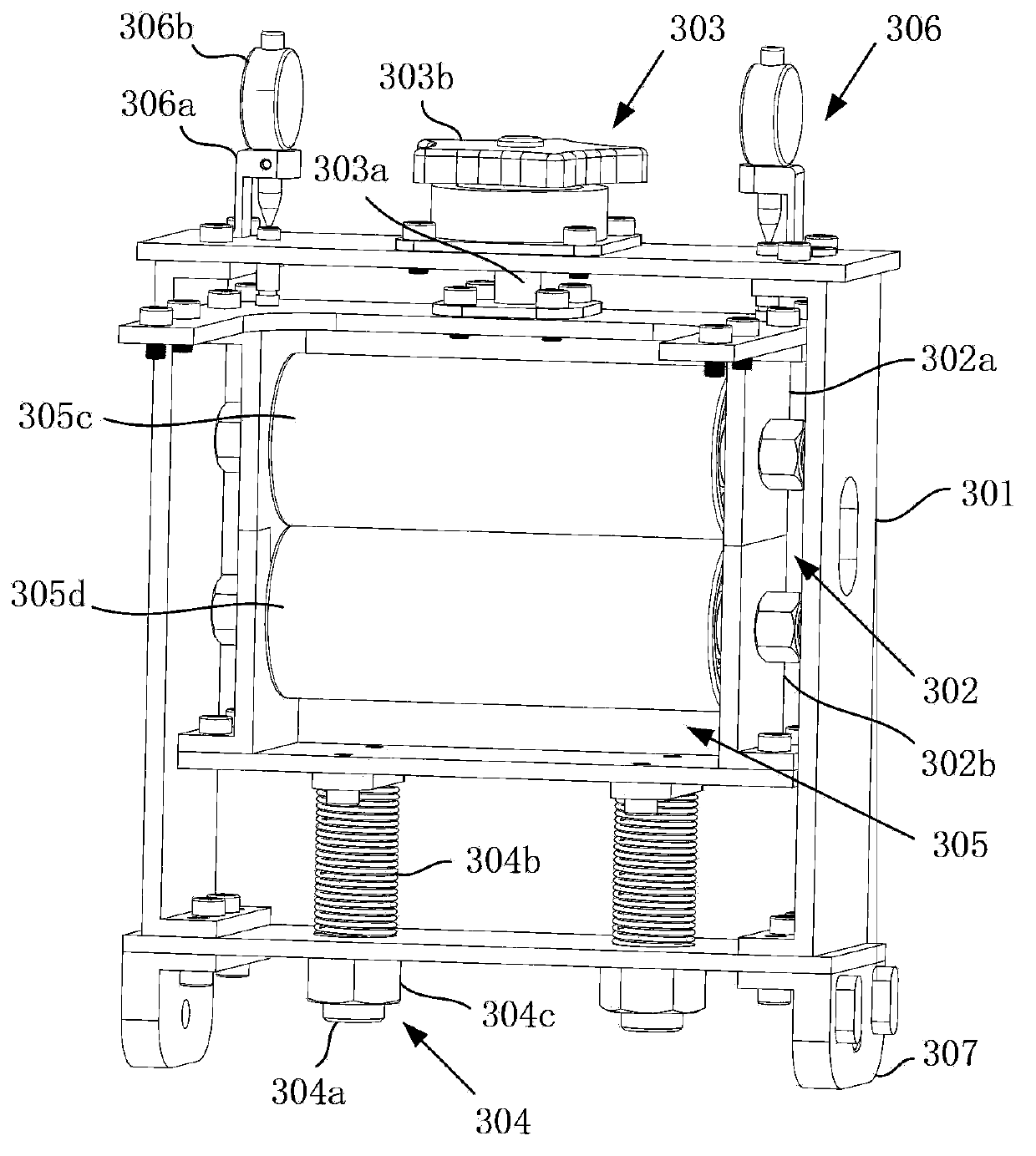

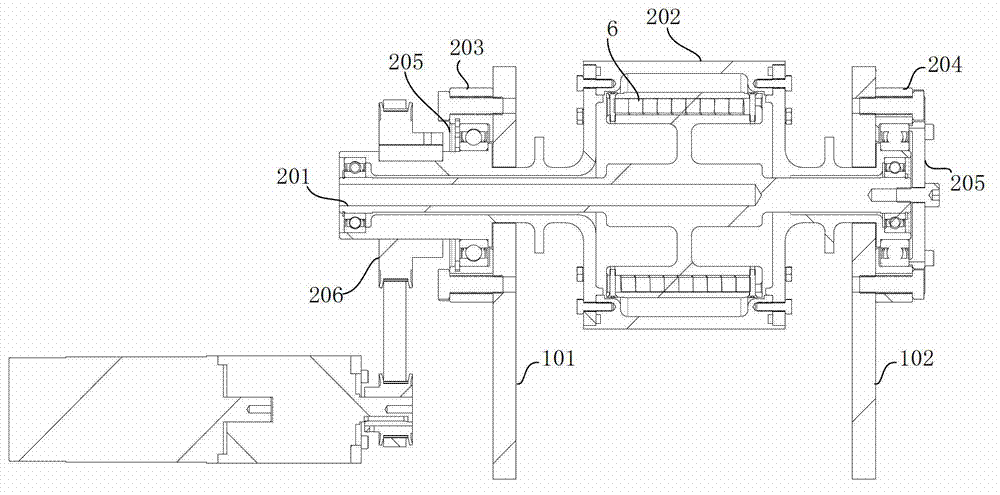

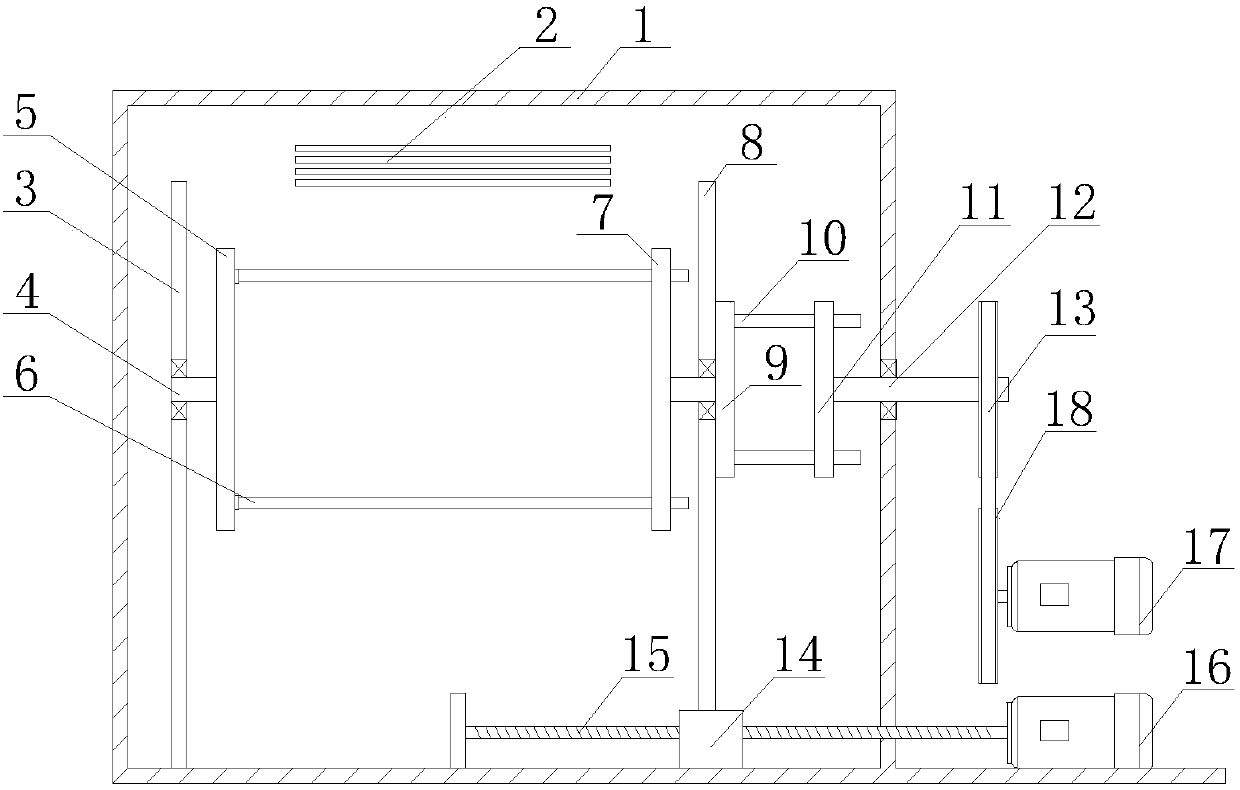

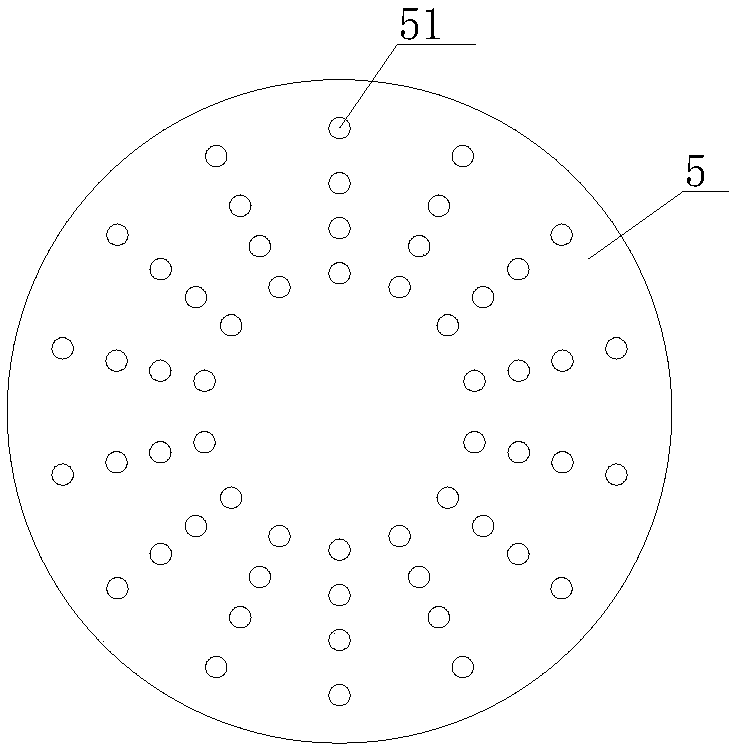

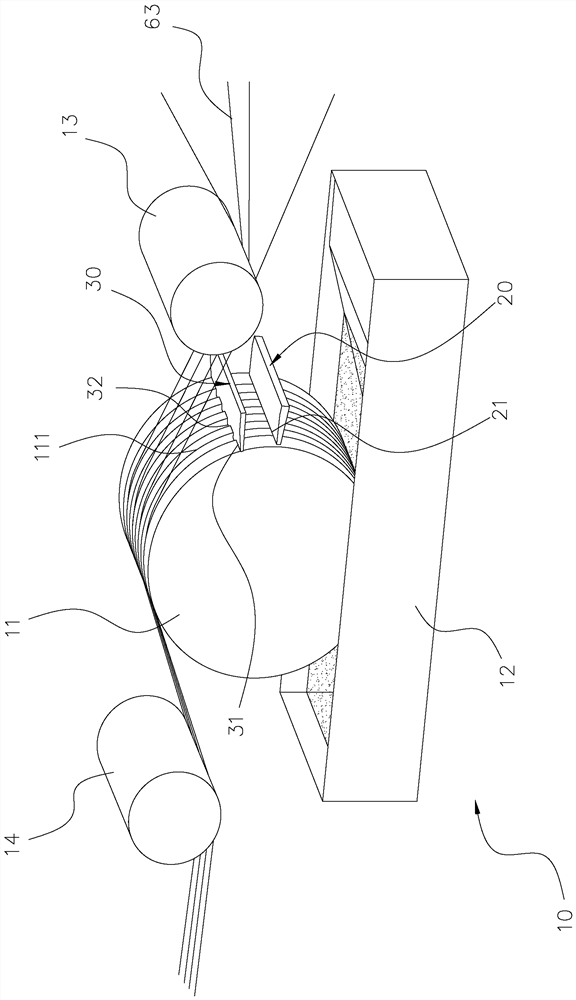

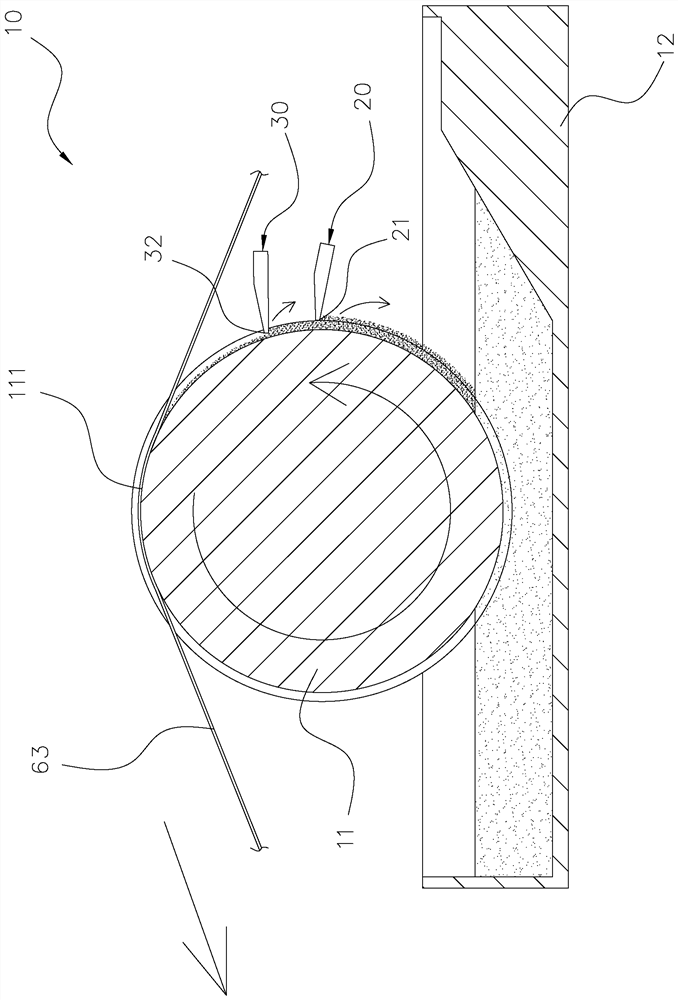

Fiber spreading device

ActiveCN103397490ASpread evenlyReduce flash seamTextile treatment machine arrangementsLiquid/gas/vapor yarns/filaments treatmentYarnFiber bundle

The invention discloses a fiber spreading device which comprises a machine frame, a gum dipping roller, a gum extruding device and a yarn evening mechanism. The gum dipping roller is connected with a machine frame bearing and driven by a motor to rotate. The gum extruding device is composed of three gum extruding rollers, the front gum extruding roller can achieve wrap angle adjustment of fiber bundles on the gum dipping roller by adjusting the vertical position of the gum extruding device, the two rear gum extruding rollers can adjust the thickness of gum on the fiber bundles and can meanwhile provide pressing force for evenly spreading the fiber bundles, a gap between the two rear gum extruding rollers can be adjusted through a gap adjusting mechanism, and the size of the gap can be read through a gap measuring mechanism. A spring adjusting portion can automatically adjust the gap between the two rear gum extruding rollers. The yarn evening mechanism comprises a yarn evening roller and a yarn evening sleeve, wherein the yarn evening sleeve sleeves a yarn evening barrel, and a groove is formed in the yarn evening sleeve. When fibers pass through the groove, the tension of the fibers can force the fibers to evenly spread to the two sides of the groove. The fiber spreading device has the advantages of effectively controlling the spreading width of the prepreg fibers and controlling the thickness of the fibers dipped in gum.

Owner:BEIHANG UNIV

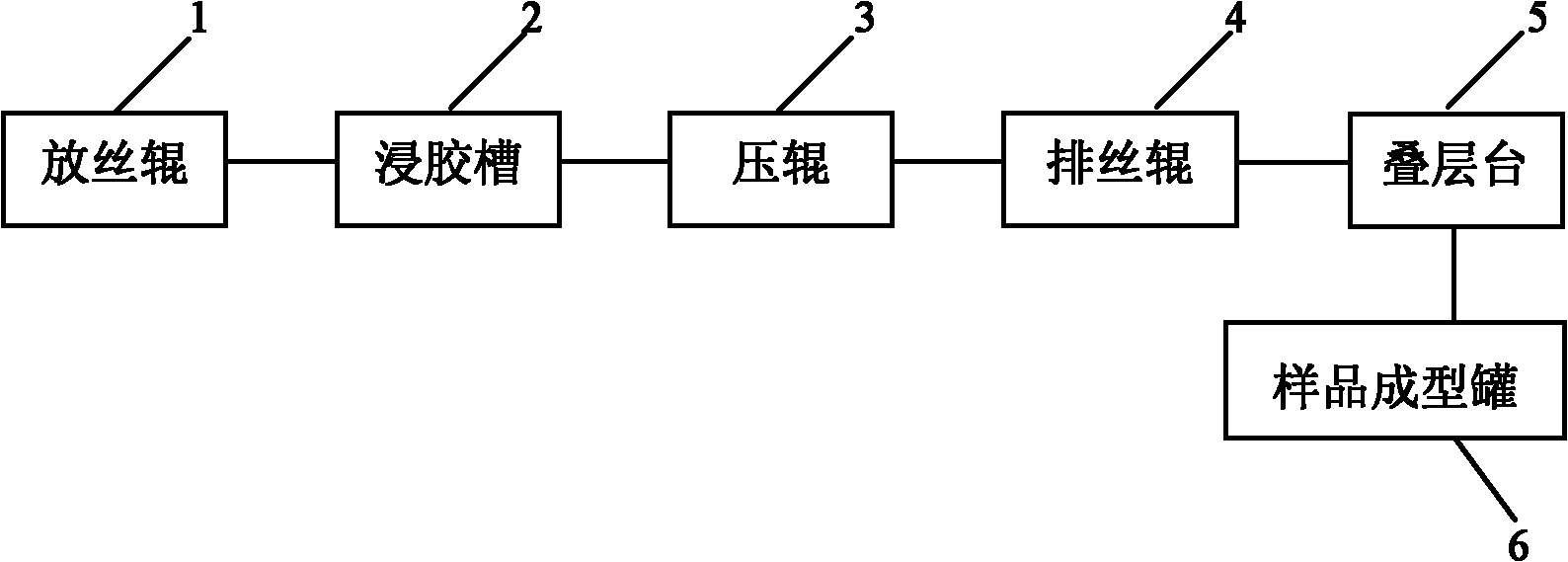

Sample preparation method for testing inter-laminar shear performance of carbon fiber composite material

InactiveCN101968409AAdd steps for extrusion removalFully dippedPreparing sample for investigationFiberTest sample

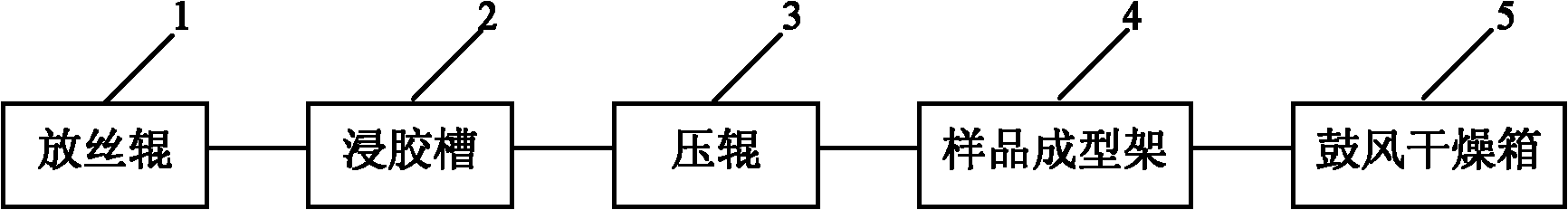

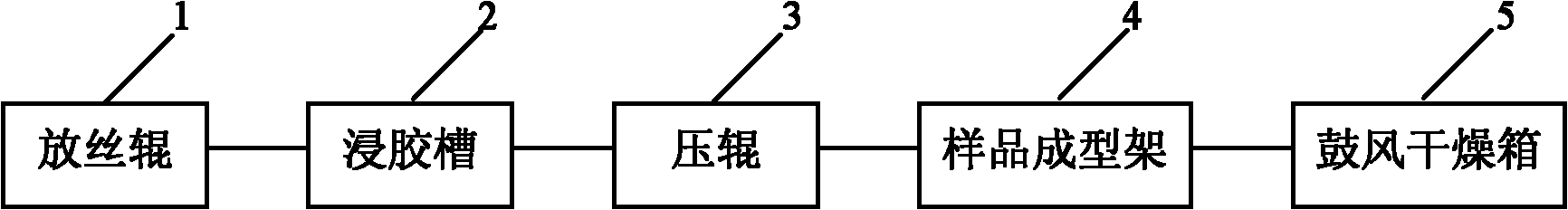

The invention relates to a sample preparation method for testing the inter-laminar shear performance of a carbon fiber composite material. The method comprises the following steps of; 1) putting samples to be tested on a fiber releasing roller; 2) performing gum dipping on the samples which pass through the fiber releasing roller by using a gum dipping groove; 3) allowing the gum-dipped samples to pass through a compression roller; 4) uniformly arranging the samples which pass through the compression roller on a fiber arrangement roller; 5) putting the samples arranged on the fiber arrangement roller at a ventilation position and drying for 10 to 14 hours; 6) shearing and laminating for 15 to 20 layers on a laminating platform; and 7) putting laminated sheets into a mold, putting the mold into a sample molding tank, vacuumizing and raising the temperature for molding. The technical problem that non-uniform gum content phenomenon easily occurs in a sample prepared by the conventional sample preparation method is solved. The test sample is dipped in gum more sufficiently and the gum content is more uniform.

Owner:JIANGSU HANGKE COMPOSITE MATERIALS TECH

Fluororesin mixture, copper-clad plate prepared therefrom and manufacturing method thereof

ActiveCN101838431BImprove dipping qualityUniform glue contentGlass/slag layered productsMetal layered productsTetrafluoroethyleneVinyl ether

Owner:GUANGDONG SHENGYI SCI TECH

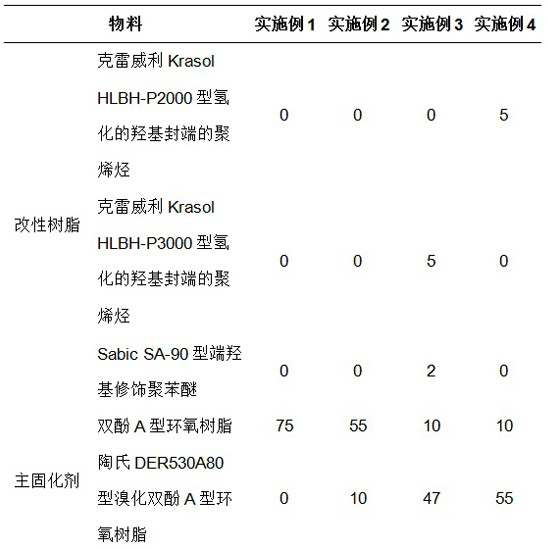

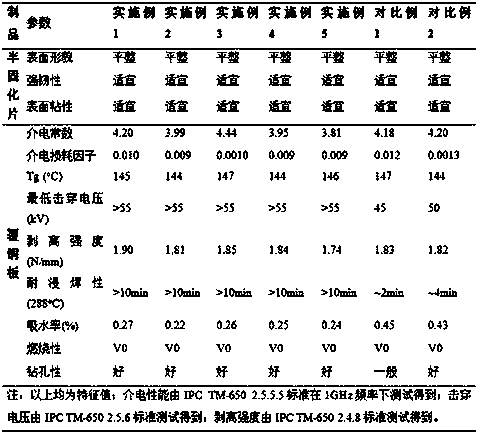

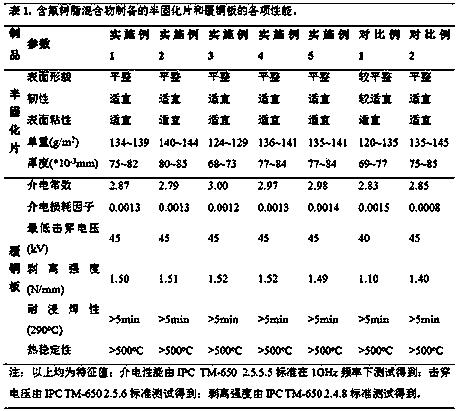

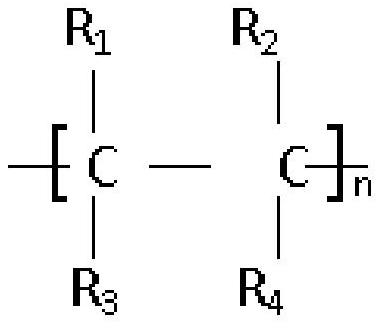

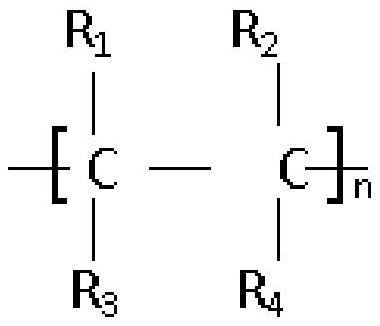

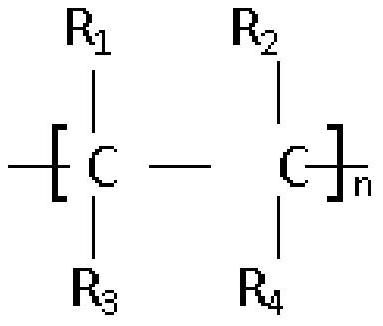

Fluoro-substituted vinyl polymer resin composition, prepreg and laminated board

ActiveCN106751711AFast transmissionHigh glass transition temperatureDielectric materialsFilm/foil adhesivesHeat resistancePolymer chemistry

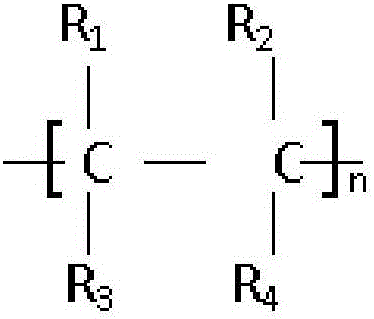

The invention discloses a fluoro-substituted vinyl polymer resin composition, and a prepreg and a laminated board prepared therefrom. The fluoro-substituted vinyl polymer resin composition contains fluoro-substituted vinyl polymer resin and a functionalized high-molecular polymer, wherein the fluoro-substituted vinyl polymer resin is expressed by the following formula, and the maximum grain size of the fluoro-substituted vinyl polymer resin does not exceed 100um. FORMULA. At least one of substituent groups R1, R2, R3 and R4 is a fluorine atom, and the number of repetitive units is not smaller than 100. A preparation method of the composition in the invention is simple, the composition can be applied to electronic equipment, the signal transmission speed is greatly increased, and the signal loss is reduced; the prepreg is uniform in gel content, smooth in surface and stable in performance; a manufacturing process of the laminated board is simple, and has excellent mechanical performance, heat resistance and dielectric property.

Owner:VENTEC ELECTRONICS SUZHOU

Flame-retardant polyarylether-based composition

The invention belongs to the technical field of communication materials, and particularly relates to a flame-retardant polyarylether-based composition. Any one or both of a double-terminal hydroxyl type phosphorus-bromine-containing polyarylether oligomer and a multi-terminal hydroxyl type phosphorus-bromine-containing polyarylether oligomer are used as matrix resin, so that when only a small amount of flame retardant is used or even no flame retardant is used in the flame-retardant polyarylether composition, the prepared prepreg and copper-clad plate can also ensure the effects of sufficient overall performance and better flame retardant property.

Owner:CHANGZHOU ZHONGYING SCI & TECH CO LTD

Polytetrafluoroethylene glass fiber breathable varnished cloth and formula

The invention discloses a formula of polytetrafluoroethylene glass fiber breathable varnished cloth. The formula is characterized by consisting of the following components in percentage by mass: 30 to 40 percent of polytetrafluoroethylene, 0.5 to 0.8 percent of a surfactant and the balance of non-ionic water and alkali-free glass cloth of which the warp density and the weft density are 200 pieces per 10 centimeters (+ / -10 percent), the thickness is 0.04 to 0.06mm and the breadth is 900 to 1,000mm. The polytetrafluoroethylene glass fiber breathable varnished cloth has the beneficial effects that by customization of a piece of glass fiber base cloth, the formula and the production technology are improved, so that the alkali-free glass cloth is uniformly coated with and immersed by polytetrafluoroethylene emulsion, and the formula is more reasonable; no bubbles are produced on the surface of the prepared polytetrafluoroethylene glass fiber breathable varnished cloth, and the glue content is uniform; the breathability is high, and the production cost is low; the polytetrafluoroethylene glass fiber breathable varnished cloth has high-temperature resistance and high intensity of a glass fiber fabric and also has a series of properties of high insulation performance, high viscosity prevention and the like of polytetrafluoroethylene.

Owner:赵国平

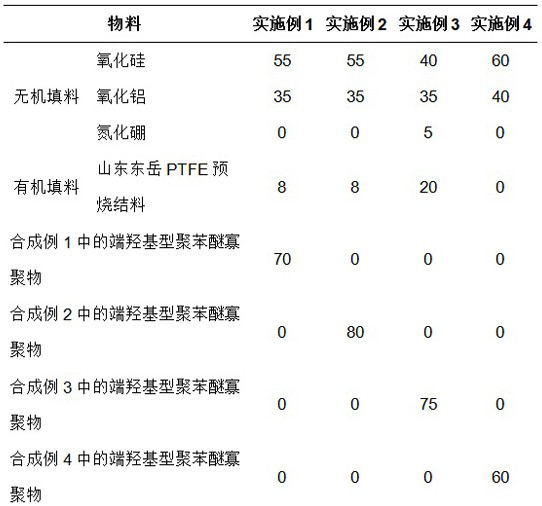

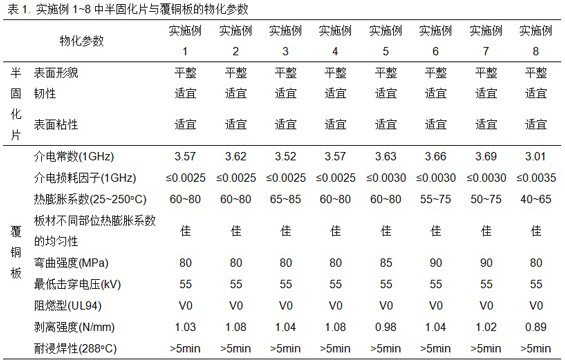

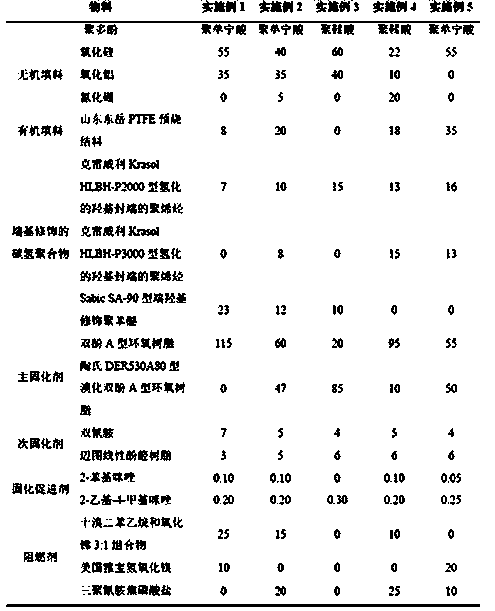

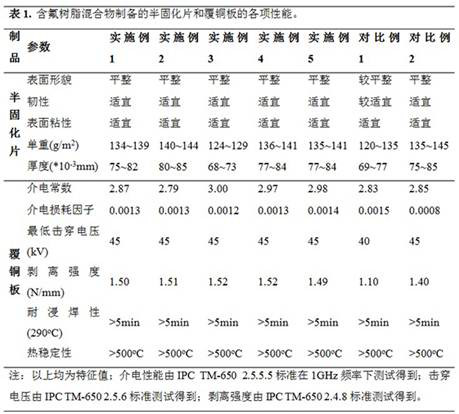

Flame-retardant polyarylether-based composition as well as prepreg and thermosetting high-frequency copper-clad plate prepared from flame-retardant polyarylether-based composition

ActiveCN113214630AFlat surfaceAppropriate toughnessLaminationLamination apparatusPolymer scienceOligomer

The invention belongs to the technical field of communication materials, and particularly relates to a flame-retardant polyarylether-based composition and a prepreg and a thermosetting high-frequency copper-clad plate prepared from the flame-retardant polyarylether-based composition. The flame-retardant polyarylether composition is prepared by combining a necessary vinyl-terminated polyarylether oligomer, a cross-linking agent, modified resin, a filler, an initiator and an unnecessary flame retardant; and the prepreg and the copper-clad plate which are finally prepared have the advantages of outstanding flame retardance, excellent dielectric property, and overall performance meeting high-frequency communication requirements.

Owner:CHANGZHOU ZHONGYING SCI & TECH CO LTD

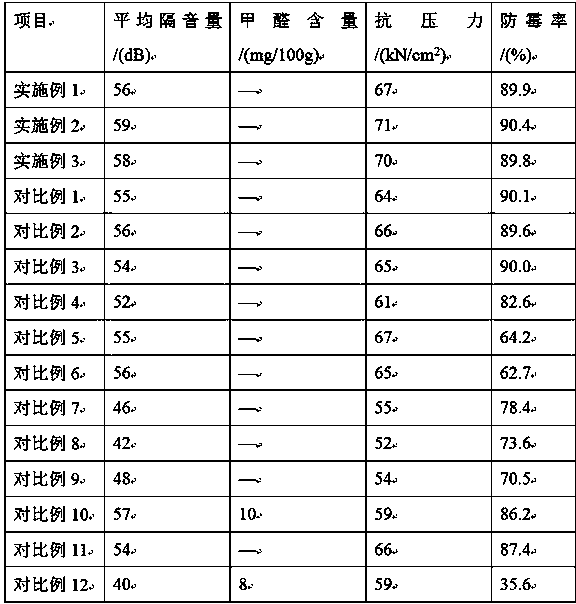

Natural mildew-proof sound-insulation density board

InactiveCN110480789AHigh strengthAvoid uneven structureWood treatment detailsFlat articlesFiberACETIC ACID LIQUID

The invention mainly relates to the technical field of artificial board machining, and discloses a preparation method of a natural mildew-proof sound-insulation density board. The preparation method comprises the steps of wood crushing, drying, raw material mixing, glue applying and hot pressing. The preparation method of the natural mildew-proof sound-insulation density board has a natural mildew-proof function, the mildew-proof rate reaches 90.4%, and sound insulation can be effectively performed; the wood is cut into long sections, the sections are soaked in an acetic acid liquid, the length of wood fibers can be prolonged, the problems that the strength of a density board is low due to short fibers and the structure of the density board is uneven due to long fibers can be avoided, andthe strength and practicability of the density board are improved; and the wood sections are subjected to freezing and drying after being soaked, so that the porosity of the sections is increased, breaking of the fibers is reduced during longitudinal rolling, and the strength of the density board is improved.

Owner:含山县金中环装饰材料有限公司

Production process of high-frequency circuit board glass fiber substrate

ActiveCN113402738AImprove wettabilityImprove permeabilityLaminationLamination apparatusPhysical chemistryCopper foil

The invention relates to the technical field of production of high-frequency circuit board glass fiber substrates, in particular to a production process of a high-frequency circuit board glass fiber substrate. The comprises the following steps: preparing a gum dipping solution; manufacturing the glass fiber bonding cloth, namely drying the glass fiber cloth raw material for at least two times, and carrying out gum dipping treatment for a plurality of times before each drying treatment; and cutting the glass fiber bonding cloth according to the required shape and size to obtain a prepreg, covering the prepreg with a copper foil, and pressing to obtain the glass fiber substrate. The process is simple, production and manufacturing are convenient, the glass fiber bonding cloth is good in wettability and permeability, soaking leakage can be avoided, the overall glue content is uniform, and it can be guaranteed that the overall dielectric constant is uniform; and the high-frequency circuit board glass fiber substrate has the excellent characteristics of high bonding force, high toughness, high hardness, abrasion resistance, cold and hot impact resistance, high temperature aging resistance and the like, and can be suitable for harsh use environments such as high-temperature environments.

Owner:DONGGUAN XIANGSI ELECTRONICS TECH CO LTD

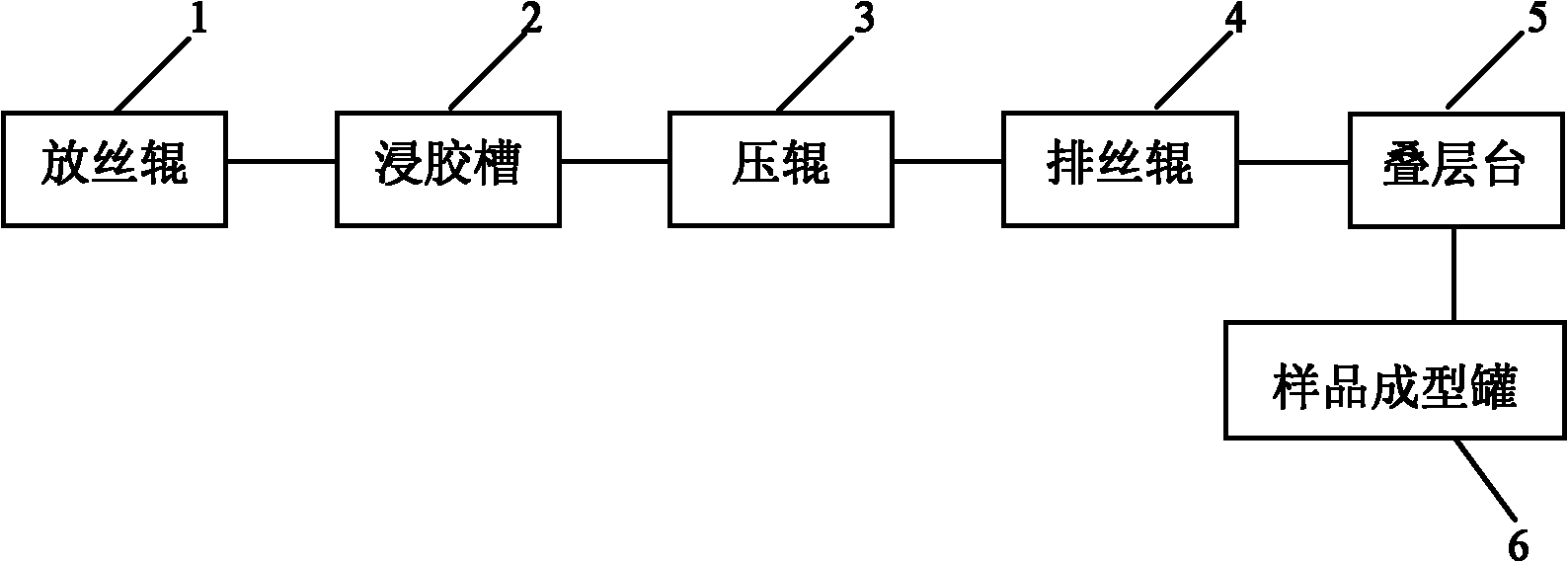

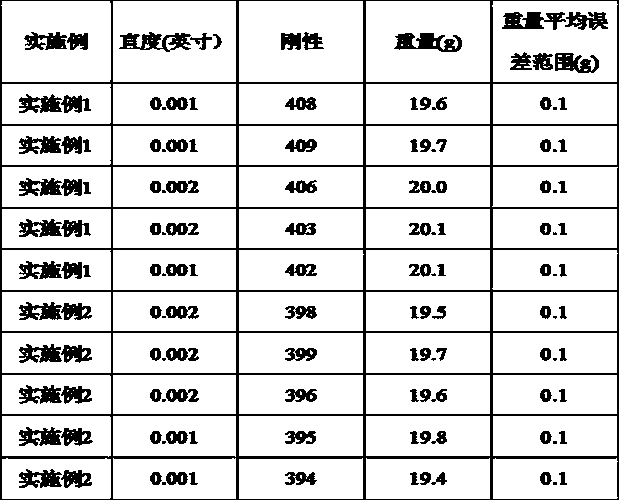

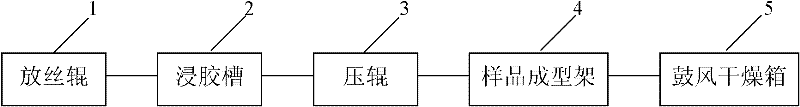

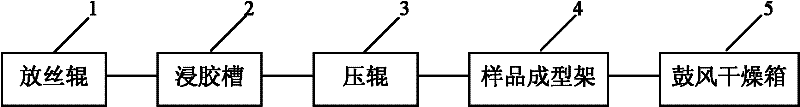

Sampling method for mechanics performance testing of preoxidized fibers

InactiveCN101968410AFully dippedUniform glue contentPreparing sample for investigationMechanical properties of carbon nanotubesFiber

The invention relates to a sampling method for mechanics performance testing of preoxidized fibers, which comprises the following steps of: 1) putting the preoxidized fibers to be tested on a releasing roller; 2) performing gum dipping on the preoxidized fibers passing through the releasing roller in a gum dipping tank; 3) allowing the preoxidized fibers subjected to gum dipping to pass through a compression roller; 4) fixing the preoxidized fibers passing through the compression roller and subjected to uniform gum dipping to a sample forming frame, wherein the sample forming frame can rotate at a uniform speed and is used for fixing the preoxidized fibers; and 5) drying the preoxidized fibers fixed to the sample forming frame. The method solves the technical problem that the conventional sampling method for mechanics performance testing of the preoxidized fibers cannot ensure the gum content of the preoxidized fibers to be tested so as to influence the mechanics performance of the fibers, and makes a tested sample dip gum more fully have the gum content more uniform; and gum beads influencing test results cannot be left on the sample.

Owner:JIANGSU HANGKE COMPOSITE MATERIALS TECH

Dry winding based production process for carbon fiber arrow shaft

The invention discloses a dry winding based production process for a carbon fiber arrow shaft. The process comprises the following steps: a, combining carbon fibers with epoxy resin in proportion andperforming rolling-up quickly; b, performing sealed packaging and freezing a product in a warehouse; c, unfreezing the product in advance and directly placing the product on processing equipment for winding processing to obtain the arrow shaft. The arrow shaft is prepared directly with a dry method, so that limitation that raw materials in a workshop have to be prepared for use is omitted, pollution of volatile molecules in the workshop is reduced, the workshop is more environmentally friendly, quality of the arrow shaft is improved, and material loss is reduced.

Owner:东莞市嘉信复合材料有限公司

Fluoro-resin mixture, copper-clad plate made of same and making method thereof

ActiveCN101857708BImprove dipping qualityUniform glue contentFibre treatmentLaminationFiberGlass fiber

The invention relates to a fluoro-resin mixture, a copper-clad plate made of the same and a making method thereof. The fluoro-resin mixture comprises the following two substances as necessary components: 90-99 parts by weight of polytetrafluoroethylene (PTFE) emulsion and 1-10 parts by weight of fluorinated ethylene propylene (FEP) based on 100 parts by weight of an organic solid matter. The copper-clad plate made of the fluoro-resin mixture comprises a plurality of pieces of superimposed varnished cloth and copper foils covering one side or two sides of the varnished cloth, wherein each piece of varnished cloth comprises glass fiber cloth and a fluoro-resin mixture adhered thereon through dipping drying. The fluoro-resin mixture is prepared by taking the PEFE emulsion as base resins, theglass fiber cloth can be dipped for many times in the mixture under the condition of below PTFE sintering temperature (330 DEG C) to obtain the varnished cloth. The varnished cloth made from the fluoro-resin mixture has favorable gum dipping quality, uniform gum content, smooth surface, softness and easy operation. The copper-clad plate made from the fluoro-resin mixture has favorable comprehensive properties, excellent dielectric properties, simple making method and process, satisfies the dielectric property requirements on substrate materials in the field of high frequency communication andis beneficial to industrial continuous production.

Owner:GUANGDONG SHENGYI SCI TECH

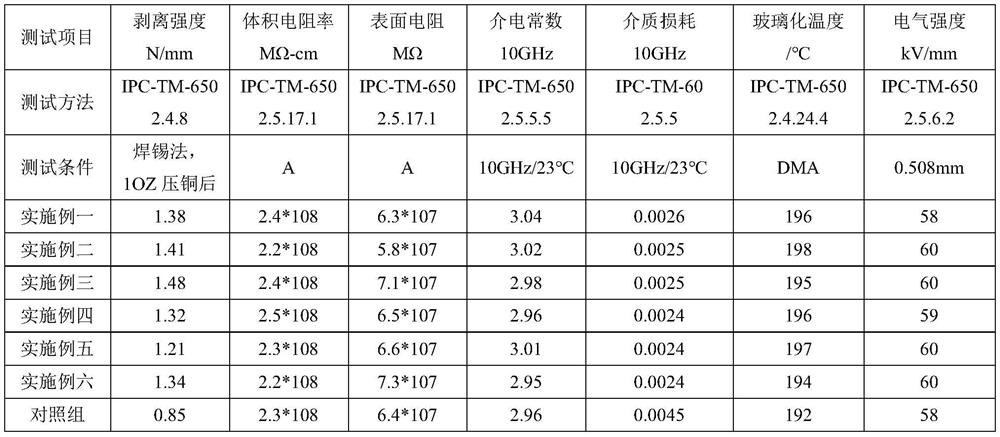

A polyphenol-modified hydrocarbon composition-based prepreg and its prepared copper-clad laminate

ActiveCN109796728BStrong adhesionAppropriate viscosityLaminationLamination apparatusPolymer sciencePolyolefin

The invention relates to a hydrocarbon composition-based prepreg modified by polyphenol and a copper-clad laminate prepared therefrom. The invention selects polyarylether or polyolefin resin modified by hydroxyl-terminated, amino-terminated or mercapto-terminated as matrix resin, and epoxy resin as main curing agent to construct a hydrocarbon composition with excellent dielectric properties. At the same time, the present invention also modifies polypolyphenols on the surface of reinforcing materials and fillers, because polypolyphenols are rich in hydroxyl functional groups, and can participate in the cross-linking and curing reaction of terminal-modified polyarylethers or polyolefins with epoxy resins In this way, the matrix resin is directly bonded to the surface of the reinforcement and filler, enhancing their compatibility and adhesion. Further, the high-frequency copper-clad laminate made of the prepreg and copper foil has good thermal-mechanical properties, excellent dielectric properties, good overall performance stability, good uniformity, high copper foil peel strength, and can meet high-frequency, high-speed Various comprehensive performance requirements for substrate materials in the communication field.

Owner:CHANGZHOU ZHONGYING SCI & TECH CO LTD

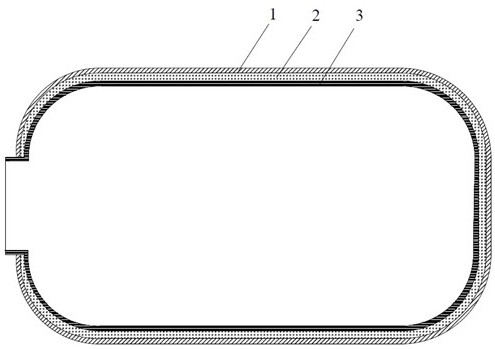

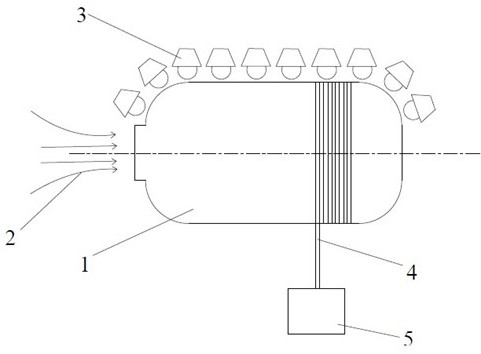

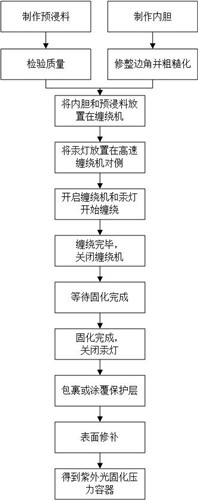

Ultraviolet curing composite material pressure container and forming method

InactiveCN113290887ASimple molding processShorten the timeDomestic articlesHollow articlesWinding machineUltraviolet lights

The invention relates to an ultraviolet curing composite material pressure container and a forming method, and mainly solves the problems of low curing speed, low efficiency, uncontrollable quality, high energy consumption and the like in the traditional curing of a composite material pressure container. The ultraviolet curing composite material pressure container comprises a protective layer, a composite material winding layer and an inner container. The forming method comprises the steps that prepreg is wound on the surface of the inner container through a winding machine according to a track planned in advance, ultraviolet light is irradiated outside so as to complete winding and curing in one step, and the inside of the inner container needs to be inflated and pressurized during winding. According to the ultraviolet light curing forming method, a curing oven with a large size is not needed, the energy is clean, the manufacturing cost is low, the manufacturing process is simple and environmentally friendly, and the resin viscosity is controllable.

Owner:HARBIN UNIV OF SCI & TECH

Aerogel thermal insulation material and preparation method thereof

InactiveCN113714031AIncreased ability to block heatEasy to processPretreated surfacesCoatingsAir velocityThermal insulation

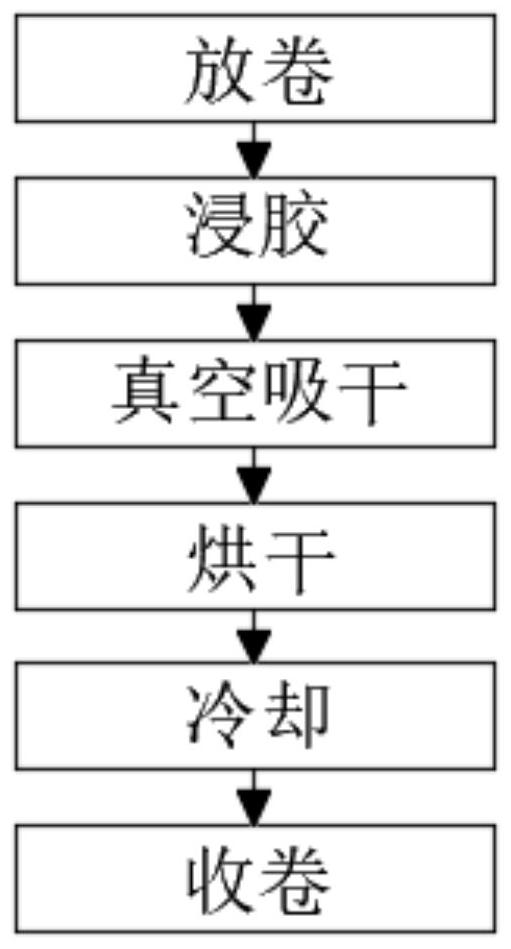

The invention discloses an aerogel thermal insulation material and a preparation method thereof. The preparation method comprises the following steps that unwinding is conducted, specifically, a non-woven fabric is unwound and unfolded through an unwinding machine, and surface dust is removed; glue dipping is conducted, a glue solution is injected into a glue dipping pool of a glue dipping machine, the temperature of the glue solution is controlled to be 32-40 DEG C, the unfolded non-woven fabric is fed into the glue dipping machine, and the glue solution permeates into the non-woven fabric; vacuum suction drying is conducted, the non-woven fabric obtained after glue dipping is fed into a vacuum suction dryer, and redundant glue liquid in the non-woven fabric is sucked out in a negative pressure mode; rolling is conducted, and the non-woven fabric subjected to vacuum suction drying is extruded through opposite roll shafts of double-roll extrusion equipment; drying is conducted, and the rolled non-woven fabric is fed into a drying machine for drying; cooling is conducted, the dried non-woven fabric is guided into an air cooling machine to cool the two sides of the non-woven fabric, the aerogel thermal insulation material is formed, and the air speed of the air cooling machine is controlled to range from 1.2 m / s to 1.8 m / s. According to the aerogel thermal insulation material and the preparation method thereof, the process is simple, and the thermal insulation effect of the prepared thermal insulation material is improved.

Owner:常熟市常盛无纺制品有限公司

Fiber spreading device

ActiveCN103397490BSpread evenlyReduce flash seamTextile treatment machine arrangementsLiquid/gas/vapor yarns/filaments treatmentYarnFiber bundle

Owner:BEIHANG UNIV

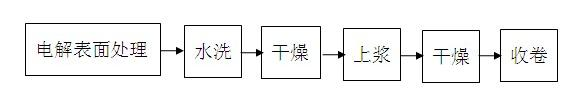

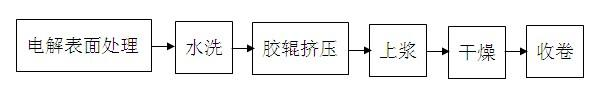

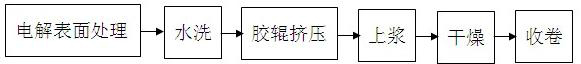

Novel process flow for carrying out surface treatment on carbon fiber

InactiveCN102465444AOil content is easy to controlUniform moisture contentCarbon fibresTextile shapingCarbon fibersFiber bundle

The invention relates to a novel process flow for carrying out surface treatment on carbon fiber, aiming at realizing the purposes that burrs on the surface of produced carbon fiber are remarkably reduced, the mechanical property of the carbon fiber is enhanced and the energy source consumption is reduced. The technical scheme for realizing the purposes is as follows: the novel process flow for carrying out surface treatment on the carbon fiber comprises the following steps: surface electrolysis treatment; water washing; extrusion with a rubber roller; starching; drying; and rolling. The surface of the carbon fiber is treated by adopting a surface electrolysis treatment method; the treated carbon fiber is subjected to starching treatment to form a carbon fiber bundle; the starched carbon fiber bundle is subjected to drying treatment so as to size the carbon fiber bundle; and the dried carbon fiber is wounded into a bobbin shape by a fiber rolling machine and is then packaged for marketing and sales after rolling treatment. Compared with the carbon fiber produced by adopting the traditional surface treatment process, the carbon fiber produced by using the novel process flow disclosed by the invention has the advantages of short process flow, high production efficiency, remarkably-reduced burrs on the appearance, slightly-increased mechanical property index and reduced energy source consumption, and thereby the novel process flow for carrying out surface treatment on the carbon fiber is worthy of application and popularization.

Owner:XIAOJIAN TECH DALIAN

Poly-polyphenyl modified fluorine-containing resin mixture and prepreg and copper-clad plate prepared therefrom

ActiveCN109825011AGood dispersionImprove adhesionSynthetic resin layered productsLaminationDispersityGlass fiber

The invention relates to a poly-polyphenyl modified fluorine-containing resin mixture and prepreg and a copper-clad plate prepared therefrom. Poly-polyphenyl is modified on the surfaces of inorganic filler and glass fiber fabric, so that dispersity of the inorganic filler in a fluorine-containing resin matrix, compatibility among the inorganic filler, the glass fiber cloth and fluorine-containingresin is improved, and interaction force among the inorganic filler, the fluorine-retaining resin, the glass fiber cloth and a copper foil is enhanced. Further, a high-frequency copper-clad plate madeby using the prepreg, a film and the copper foil is good in thermal-mechanical performance, excellent in dielectric performance, high in comprehensive performance stability, excellent in uniformity,especially high in striping strength of the copper foil and capable of meeting various comprehensive performance requirements of the high-frequency communication field on a substrate material.

Owner:CHANGZHOU ZHONGYING SCI & TECH CO LTD

A preparation process of room temperature curing wet prepreg

ActiveCN103921529BUniform glue contentReduce labor costsLamination ancillary operationsLaminationRoom temperatureEngineering

The invention discloses a process for preparing room temperature curing wet-process prepreg. The process comprises the following steps: emptying, glue spraying, laminating and cutting, wherein the laminating step comprises the substep of laminating a first isolating membrane and a second isolating membrane on two surfaces of a base material through a first extrusion roller arranged on a base material advancing path after glue spraying. According to the process for preparing wet-process prepreg, the continuous production can be realized, the labor cost is lowered, and the production efficiency is high. Meanwhile, according to the extrusion of the extrusion roller, the glue content of the prepreg can be uniform, and a local poor / rich glue phenomenon is avoided.

Owner:CETC WUHU DIAMOND AIRCRAFT MFG

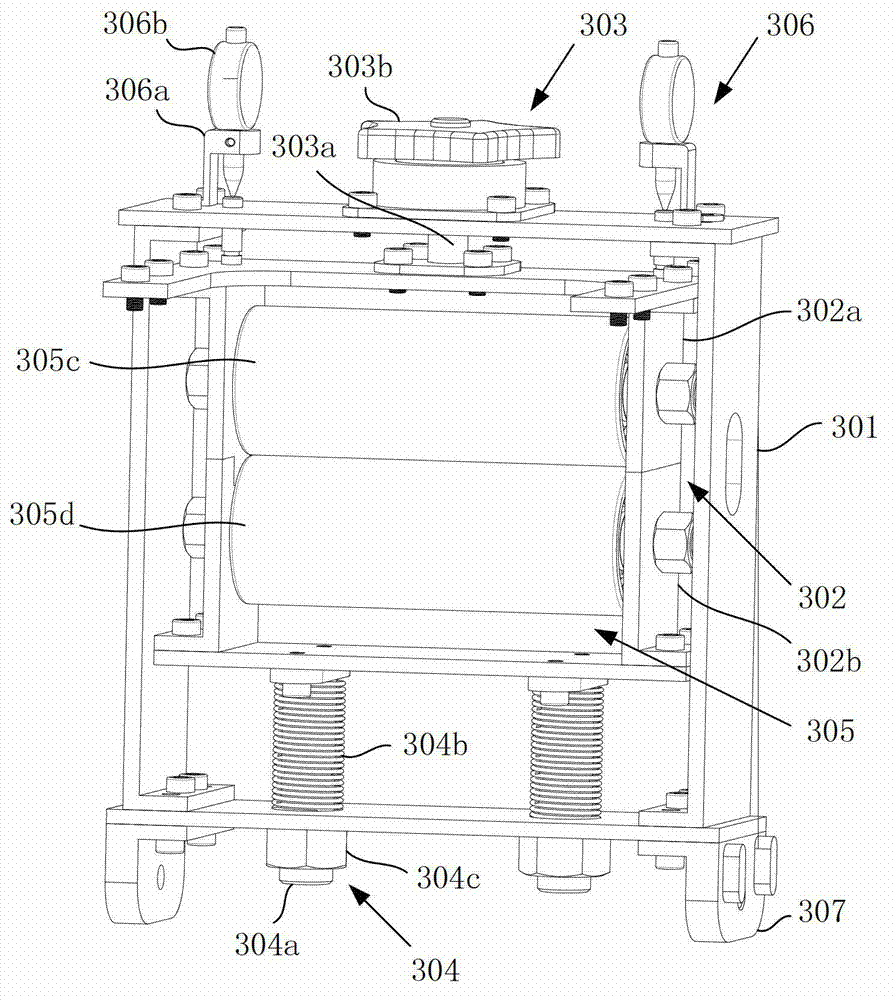

Hollow reactor coil curing device

InactiveCN107863248AEasy loadingEasy to unloadFixed inductances without magnetic coreCoils manufactureDrive shaftEngineering

The invention relates to a coil curing device for an air-core reactor. The overall glue content of the cured coil winding is uniform and stable, the insulation level of each part can reach the design value, and the mechanical strength of the dry-type reactor after encapsulation and curing is improved. and electrical strength. Wherein, a heating pipe is arranged in the curing chamber, and the first vertical plate is connected with the first insulating disc through the rotation of the first rotating shaft, and a plurality of supporting rods arranged in a ring shape along the axis of the first insulating disc are installed on the first vertical plate; the second vertical plate and the The lower driving unit is driven and connected. The second vertical plate is connected to the second insulating disk and the first rotating disk through the second rotating shaft. A plurality of first through holes matching the shape of the support rod are opened on the second insulating disk. A plurality of insertion rods are installed; a drive shaft is rotatably connected to the third vertical plate, and one end of the drive shaft is located in the curing chamber, and a second turntable is set on the second turntable, and a plurality of second through holes matching the shape of the insertion rods are opened on the second turntable; The drive shaft is drivingly connected to the upper drive unit.

Owner:天津市纳斯特科技有限公司

A polyphenol-modified fluorine-containing resin mixture and prepreg and copper-clad laminate prepared therefrom

ActiveCN109825011BGood dispersionImprove adhesionSynthetic resin layered productsLaminationGlass fiberPolymer science

The invention relates to a polyphenol-modified fluorine-containing resin mixture and a prepreg and a copper-clad laminate prepared therefrom. The present invention modifies the surface of the inorganic filler and the glass fiber cloth with polyphenol, so as to promote the dispersion of the inorganic filler in the fluorine-containing resin matrix, improve the compatibility between the inorganic filler, the glass fiber cloth and the fluorine-containing resin, and further Enhance the interaction between inorganic filler, fluorine-containing resin, glass fiber cloth and copper foil. Further, the high-frequency copper-clad laminate made of the prepreg, film and copper foil has good thermal-mechanical properties, excellent dielectric properties, good overall performance stability, and good uniformity, especially the peel strength of the copper foil is very high, It can meet the comprehensive performance requirements of substrate materials in the high-frequency communication field.

Owner:CHANGZHOU ZHONGYING SCI & TECH CO LTD

A polydopamine-modified hydrocarbon composition-based prepreg and its prepared copper-clad laminate

ActiveCN109867914BAppropriate viscosityUniform glue contentLamination ancillary operationsLaminationPolymer sciencePolyolefin

Owner:CHANGZHOU ZHONGYING SCI & TECH CO LTD

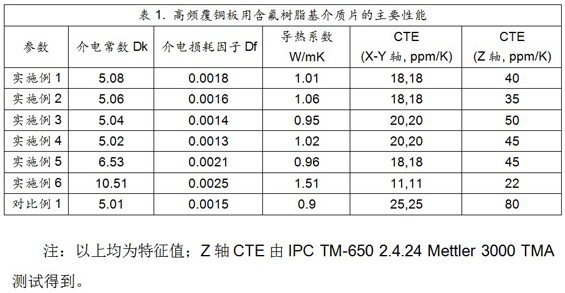

Fluorine-containing resin-based high-thermal-conductivity high-frequency copper-clad plate with high dielectric constant

PendingCN114536923ASmall coefficient of thermal expansionImprove bending strengthChemical industrySynthetic resin layered productsDielectricPhysical chemistry

The invention belongs to the technical field of communication materials, and particularly relates to a fluorine-containing resin-based high-thermal-conductivity high-frequency copper-clad plate with a high dielectric constant. The fluorine-containing resin-based high-thermal-conductivity high-frequency copper-clad plate is prepared in the mode that fluorine-containing resin mixture uniform dispersion liquid is prepared at first, then fluorine-containing resin-based composite paste is prepared, then a fluorine-containing resin-based dielectric sheet is prepared through blade coating, drying and sintering, and finally the fluorine-containing resin-based dielectric sheet and a copper foil are overlapped to prepare the final fluorine-containing resin-based high-thermal-conductivity high-frequency copper-clad plate.

Owner:CHANGZHOU ZHONGYING SCI & TECH CO LTD

High-speed and high-precision single-bundle fiber impregnation machine

ActiveCN112295852BReduce the amount of adhesionGlue volume controlLiquid surface applicatorsFilament handlingYarnFiber

The invention provides a high-speed and high-precision single-bundle fiber impregnation machine, which includes: an impregnation wheel set is concavely provided with a plurality of yarn guide grooves on the surface of the impregnation roller, and the yarn guide grooves at the lower edge of the impregnation roller are soaked in the resin tank In the resin liquid, a first scraper is arranged between the impregnation roller and the front guide wheel, and the first scraper is formed with a scraper plane, and the scraper plane is used to scrape off a large amount of resin adhering to the surface of the impregnation roller liquid, a second scraper is arranged between the impregnation roller and the front guide wheel, and the second scraper is farther away from the resin tank than the first scraper, and the second scraper is formed with a scraper edge, and the scraper edge A plurality of convex parts are protruded, and the second scraper is inserted into the yarn guide groove of the impregnating roller with the convex part, and the convex part is used to control the resin amount of the yarn guide groove with high precision.

Owner:浙江抟原复合材料有限公司

Sample preparation method for testing mechanical property of carbon fiber

InactiveCN101949792BAdd steps for extrusion removalFully dippedPreparing sample for investigationStrength propertiesFiberCarbon fibers

Owner:JIANGSU HANGKE COMPOSITE MATERIALS TECH

Fluorine-substituted vinyl polymer resin composition, prepreg and laminate

ActiveCN106751711BFast transmissionHigh glass transition temperatureDielectric materialsFilm/foil adhesivesPolymer sciencePolymer chemistry

Owner:VENTEC ELECTRONICS SUZHOU

High-speed and high-precision single-bundle fiber impregnation machine

ActiveCN112295852AReduce the amount of adhesionGlue volume controlLiquid surface applicatorsFilament handlingYarnFiber

The invention provides a high-speed and high-precision single-bundle fiber impregnation machine which comprises an impregnation wheel set, a first scraper and a second scraper. A plurality of yarn guide grooves are concavely formed in the surface of an impregnation idler wheel, the yarn guide grooves in the lower edge of the impregnation idler wheel are soaked in resin liquid of a resin tank, thefirst scraper is arranged between the impregnation roller and a front guide wheel, the first scraper is provided with a scraper plane, the scraper plane is used for scraping a large amount of resin liquid adhered to the surface of the impregnation idler wheel, the second scraper is arranged between the impregnation idler wheel and the front guide wheel, the second scraper is far away from the resin tank relative to the first scraper, the second scraper is provided with a scraper edge, a plurality of convex parts are convexly arranged on the edge of the scraper, the second scraper is inserted into the yarn guide grooves of the impregnation idler wheel through the convex parts, and the convex parts are used for controlling the resin amounts of the yarn guide grooves with high precision.

Owner:浙江抟原复合材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com