Sampling method for mechanics performance testing of preoxidized fibers

A pre-oxidized fiber and performance technology, which is applied in the field of sample preparation for testing the mechanical properties of pre-oxidized fibers, can solve problems such as the inability to guarantee the glue content of the pre-oxidized fibers to be tested and affect the mechanical properties of the fibers, and achieves no hanging glue beads, surface Smooth, even dipping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

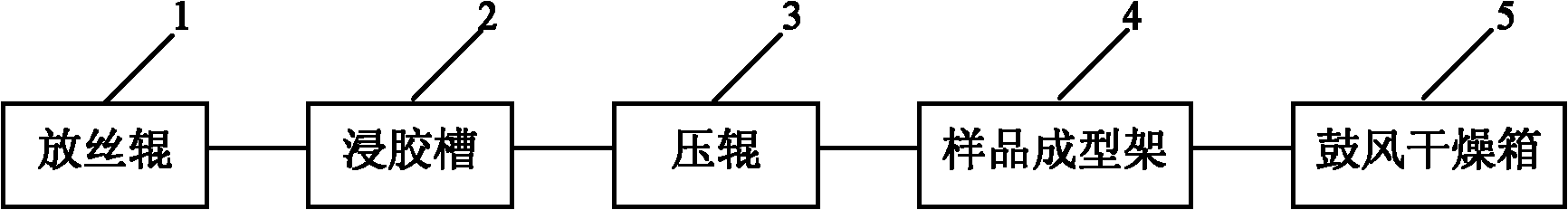

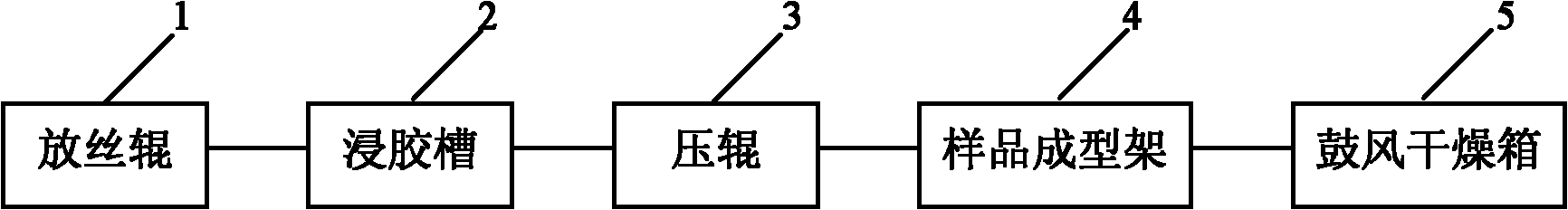

[0027] exist figure 1 Among them, the equipment arrangement of the technological process of the present invention is as follows: spinning roller 1 - dipping tank 2 - pressing roller 3 - sample forming frame 4 - blast drying box 5 .

[0028] The specific process is as follows:

[0029] 1) Put the pre-oxidized fiber to be tested on the vertical spinning roll 1 at a uniform speed. Compared with the previous horizontal laying structure, the spinning spinning roll 1 is a vertical structure, which can reduce the swing of the wire; oscillating, the spinning tension is more uniform;

[0030] 2) Pass the pre-oxidized fibers passing through the spinning roll 1 through the dipping tank 2, and the dipping time is 3 to 10 minutes; the dipping tank 2 is a structure with a movable cover that can be easily removed, and the length of the dipping tank 2 is 20 to 10 minutes. 40cm, preferably 30cm; the dipping tank can completely soak the pre-oxidized fibers when passing through the dipping tan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com