Patents

Literature

37results about How to "Fully dipped" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

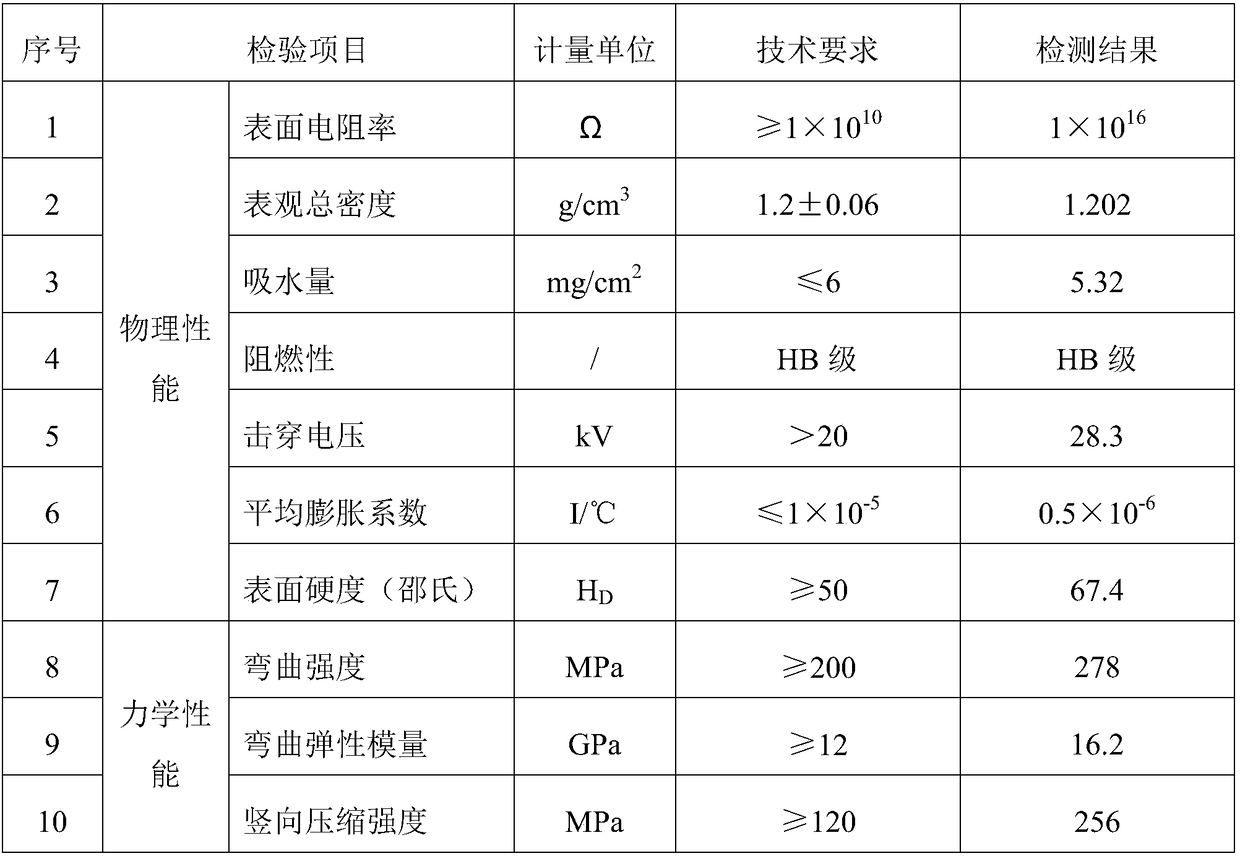

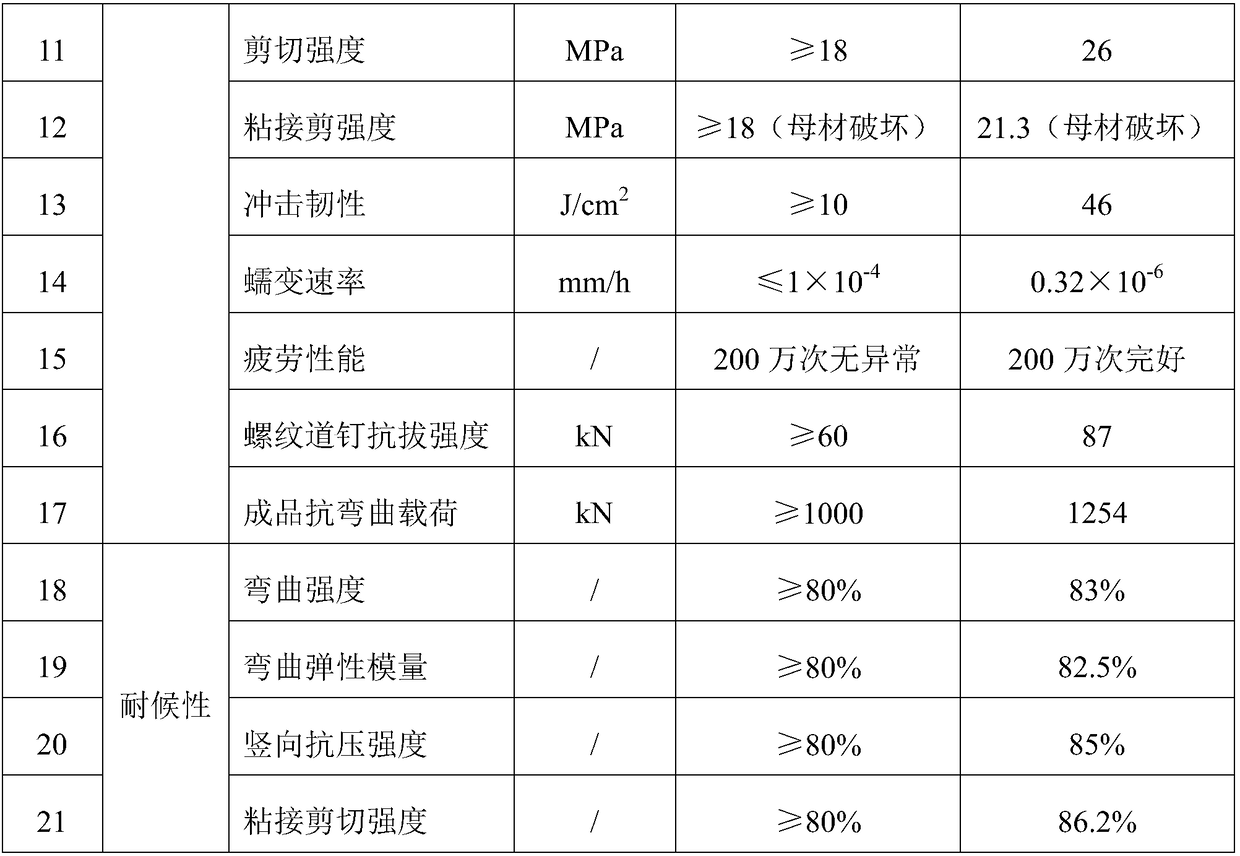

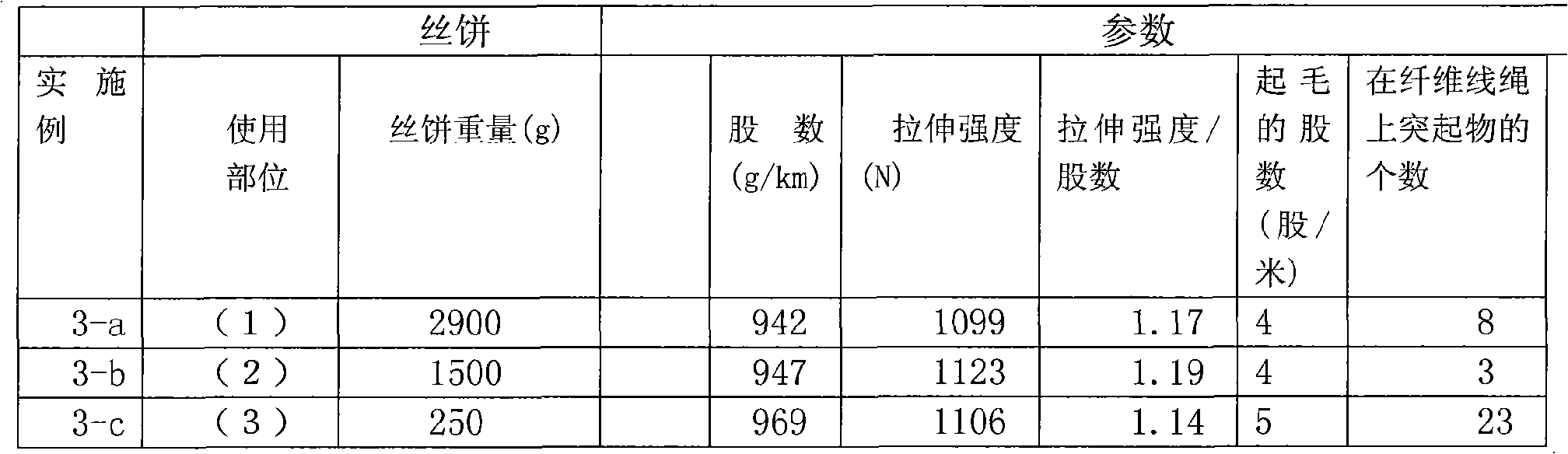

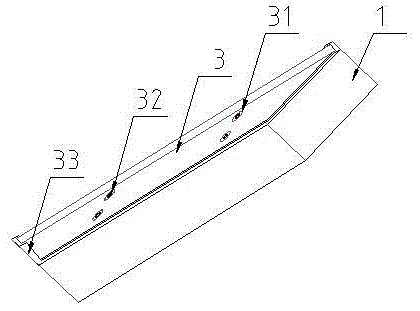

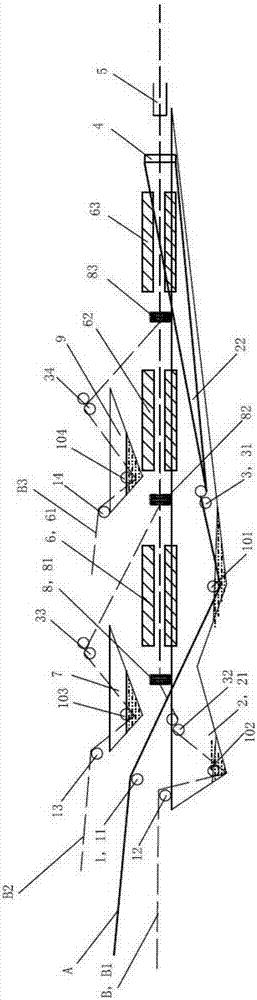

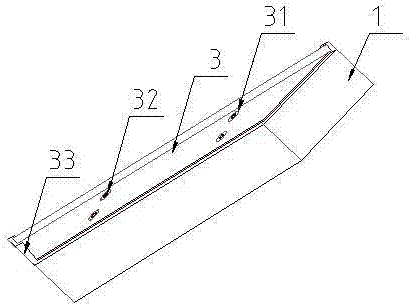

Fiber-reinforced polyurethane foamed and synthesized sleeper and preparation method thereof

The invention discloses a fiber-reinforced polyurethane foamed and synthesized sleeper and a preparation method thereof. The sleeper comprises a body formed by polyurethane resin in a one-time lamination manner, wherein multiple layers of composite felts with a transverse reinforcing effect are transversely arranged in the body, and a fiber yarn layer with a longitudinal reinforcing effect penetrates into the polyurethane resin between two adjacent composite felts; the fiber yarn layer and the composite felts account for 65%-75% of the total weight of the sleeper; the polyurethane resin accounts for 25%-35% of the total weight of the sleeper, and the density of the sleeper is 0.6g / cm<3>-1.6g / cm<3>; and the sleeper is prepared through combination of a double-steel belt laminating machine and a multilayer synchronous glue injection primary formation. According to the fiber-reinforced polyurethane foamed and synthesized sleeper, gum dipping is relatively adequate and uniform, so that thetransverse strength of the sleeper is enhanced, and the cracking phenomenon of a product during punching and indenting can be avoided; and the production process is simple, the equipment input is reduced, the production cost is lowered, and the production efficiency is improved.

Owner:铁科腾跃科技有限公司

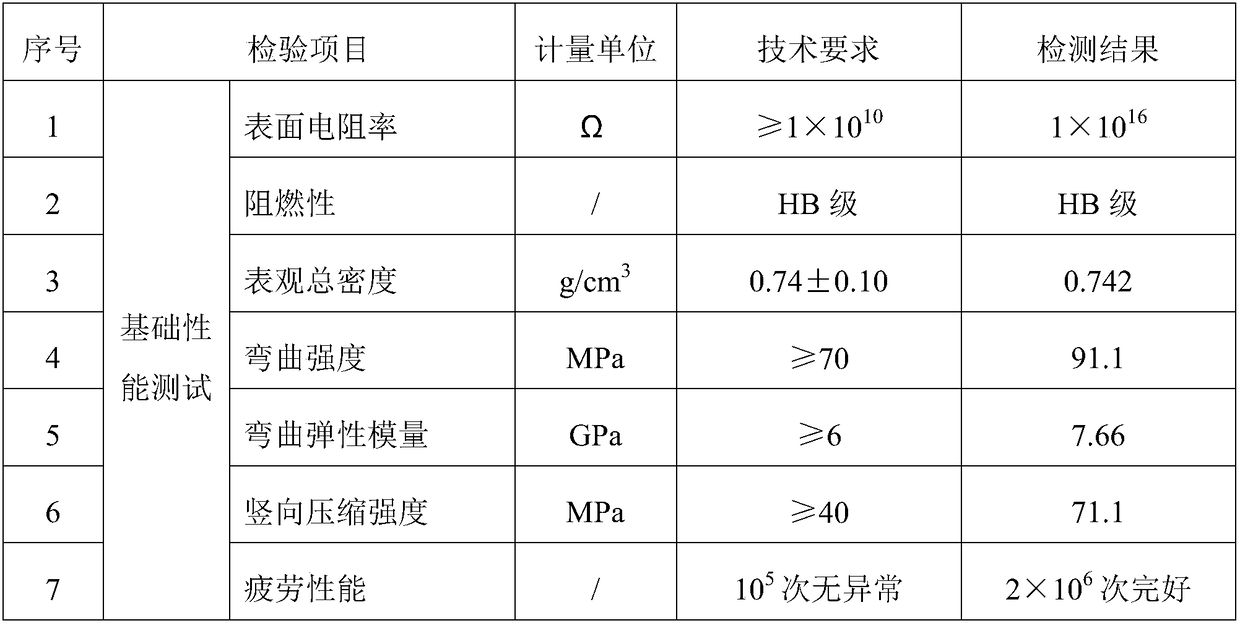

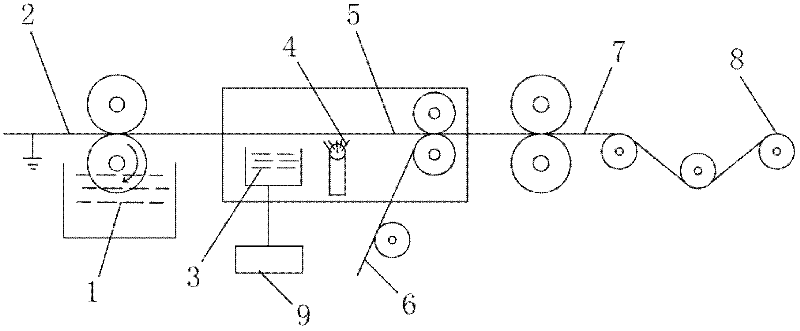

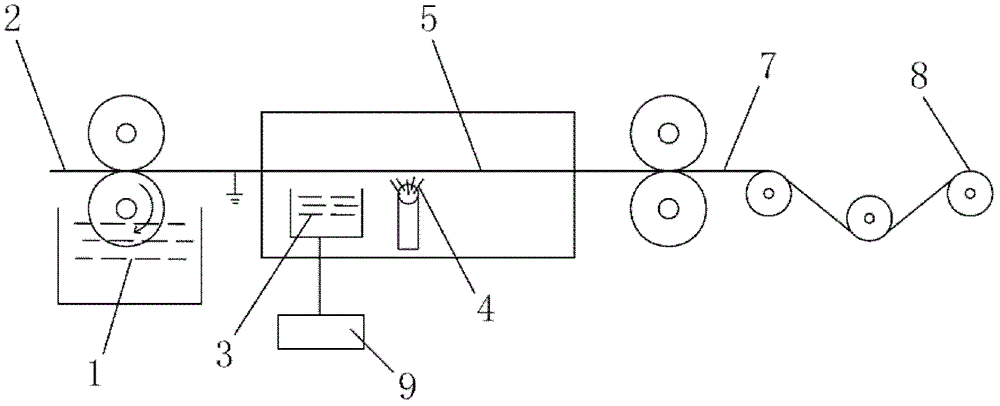

Production process of fiberglass threads used for rubber reinforcement

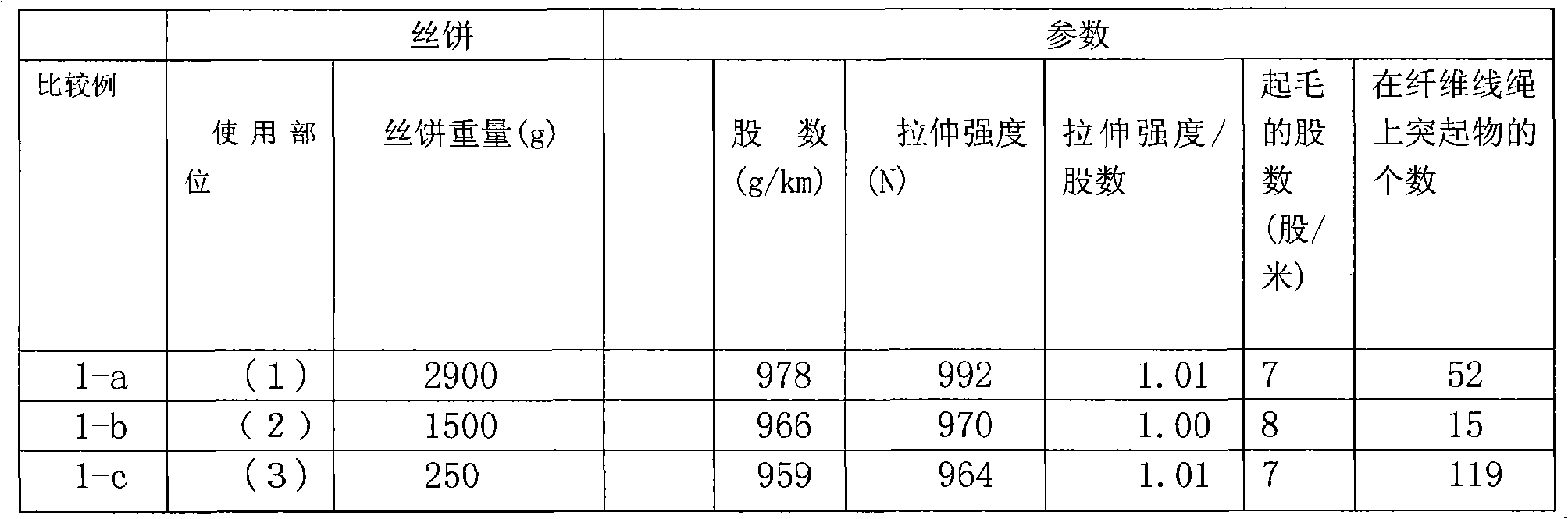

InactiveCN101654527AFully dippedThere is no uneven application of forceFibre treatmentTextile cablesGlass fiberYarn

The invention discloses a production process of fiberglass threads used for rubber reinforcement. The production process comprises the following steps: carrying out gum dipping of fiberglass bundles in turn by using RFL treating agent which uses rubber latex and the water-soluble condensation compound of resorcinol formaldehyde as main components; then, solidifying the fiberglass bundles to form fiberglass folded yarns containing inner gum dipped layers; carrying out primary twist of one or more than two fiberglass folded yarns containing the inner gum dipped layers; and finally, taking more than two fiberglass folded yarns after first twist to carry out stranding secondary twist, and the fiberglass folded yarns obtained after secondary twist are the fiberglass threads used for rubber reinforcement. The production process not only realizes effective gum dipping of fiberglass bundles, but also ensures the tensile strength of the fiberglass bundles, thereby increasing the eligible rate of the finished products of the fiberglass bundles.

Owner:ZHEJIANG LONGSHENG CHEM RES

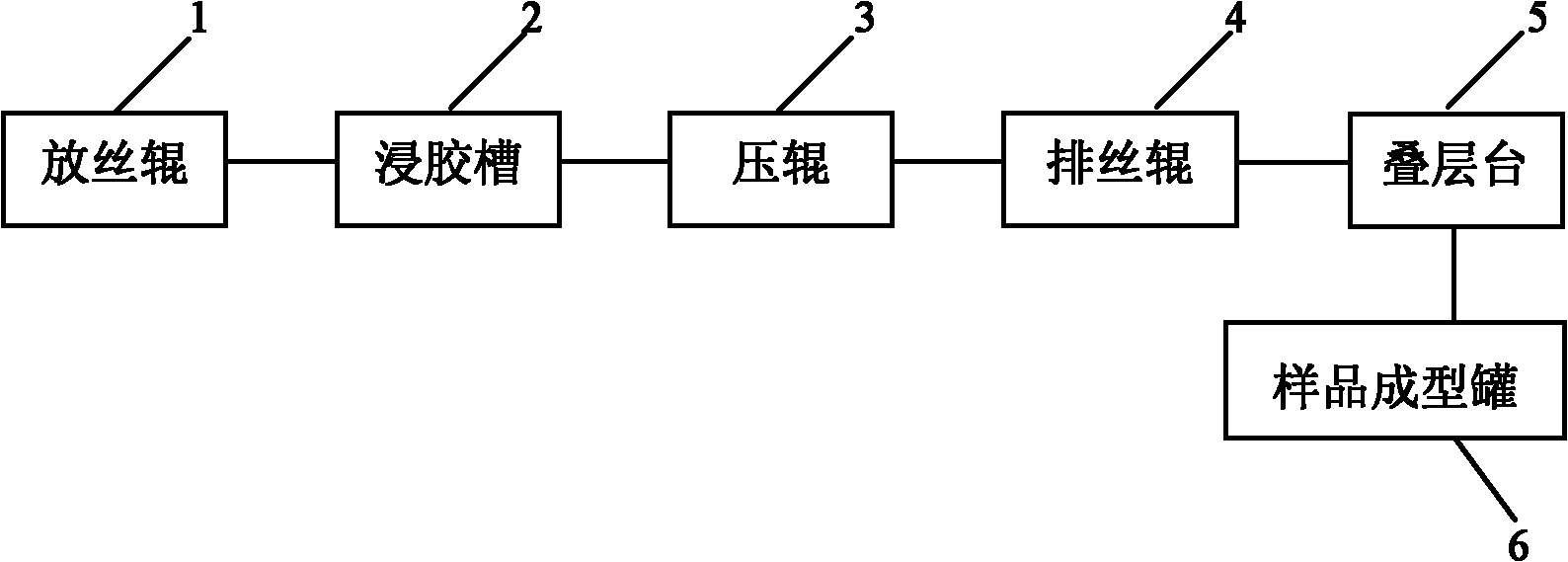

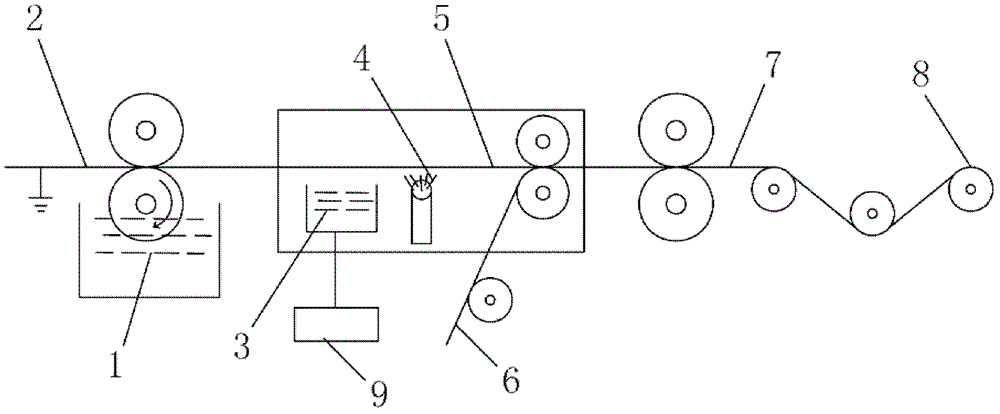

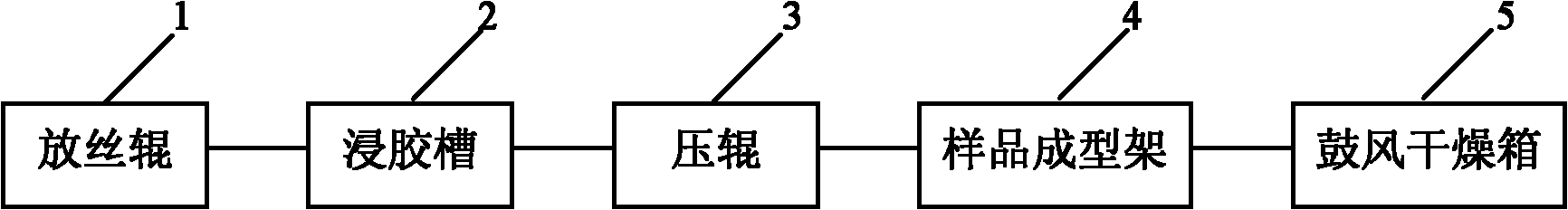

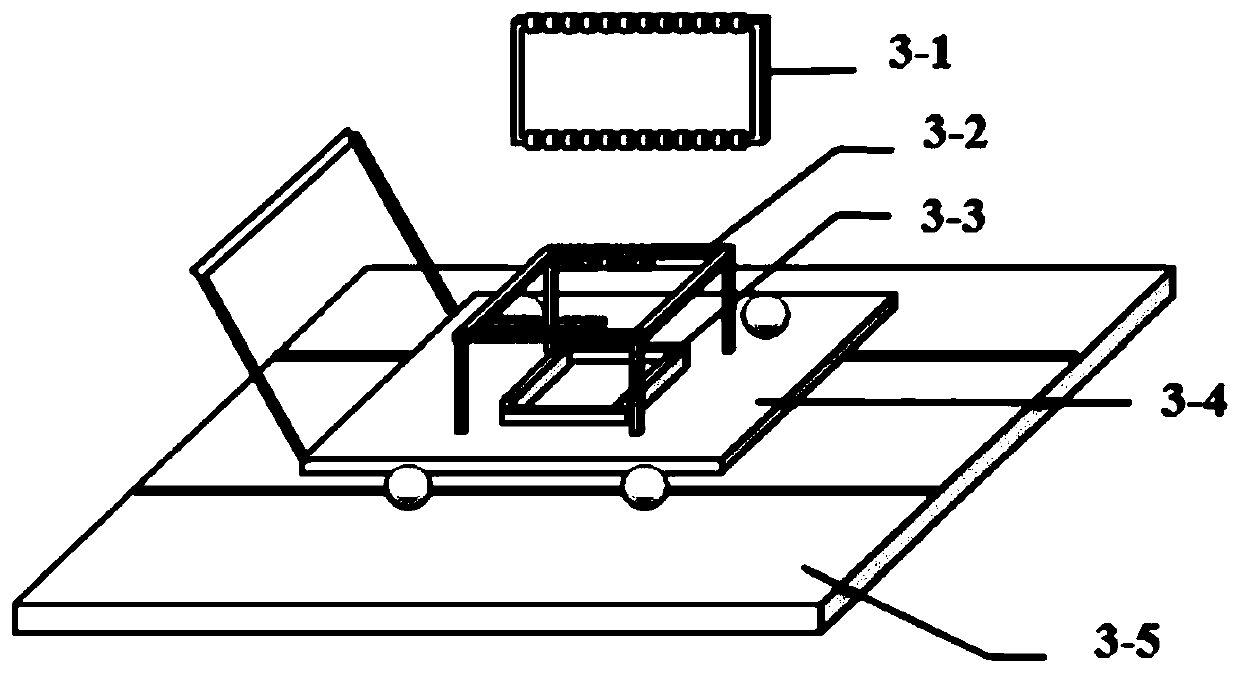

Sample preparation method for testing inter-laminar shear performance of carbon fiber composite material

InactiveCN101968409AAdd steps for extrusion removalFully dippedPreparing sample for investigationFiberTest sample

The invention relates to a sample preparation method for testing the inter-laminar shear performance of a carbon fiber composite material. The method comprises the following steps of; 1) putting samples to be tested on a fiber releasing roller; 2) performing gum dipping on the samples which pass through the fiber releasing roller by using a gum dipping groove; 3) allowing the gum-dipped samples to pass through a compression roller; 4) uniformly arranging the samples which pass through the compression roller on a fiber arrangement roller; 5) putting the samples arranged on the fiber arrangement roller at a ventilation position and drying for 10 to 14 hours; 6) shearing and laminating for 15 to 20 layers on a laminating platform; and 7) putting laminated sheets into a mold, putting the mold into a sample molding tank, vacuumizing and raising the temperature for molding. The technical problem that non-uniform gum content phenomenon easily occurs in a sample prepared by the conventional sample preparation method is solved. The test sample is dipped in gum more sufficiently and the gum content is more uniform.

Owner:JIANGSU HANGKE COMPOSITE MATERIALS TECH

Manufacturing method of mica tape

ActiveCN102514345AReduce consumptionReduce manufacturing costLaminationLamination apparatusSolventElectric energy

The invention relates to a mica tape manufacturing method with low production cost. With the method, environment pollution is reduced. The method is suitable for energy saving and emission reduction. The method comprises the steps that: a nano-grade material processed through a surface activation treatment is added to mica powder; the nano-grade material and the mica powder are subject to high-speed stirring dispersion, and an obtained uniformly-mixed material is preserved for later use; a first adhesive is coated on a reinforcing material by using a roller; with an electrostatic field, the mica raw material is absorbed onto the reinforcing material; a second adhesive is sprayed onto the mica raw material of the reinforcing material; the one-side reinforced mica tape half-finished product is delivered through a baking oven, such that an organic solvent is removed by baking; the product is cooled, and is rolled and coiled by using a roller, such that a one-side reinforced mica tape finished product is obtained. The invention relates to a novel production technology designed according to natural characteristics of electric charges. Only a small amount of the solvent is required, such that the production cost of the mica tape is reduced, and environment pollution caused by the organic solvent is greatly reduced. Also, production speed can be improved, and baking temperature can be reduced, such that electric energy consumption can be reduced by approximately 1 / 3.

Owner:江苏冰城氢能科技有限公司

3D science paper as well as production method and production equipment thereof

ActiveCN104562848AHigh hardnessImprove wear resistanceNon-fibrous pulp additionPaper/cardboardCross-linkEnvironmental resistance

The invention provides 3D science paper as well as a production method and production equipment thereof. The 3D science paper is prepared by soaking printing decorative paper serving as a raw material into glue with high transparency, wherein the glue comprises the following components in percentage by weight: 20-30% of polyurethane, 30-50% of acrylic resin, 1-3% of a cross-linking agent, 1-3% of a curing agent, 3-5% of a permeating agent, 1% of a flatting agent and the balance of water. The 3D science paper has an extremely good homochromatic effect, does not have chromatic aberration, is high in hardness, scratch-resistant, wear-proof and good in toughness, can be bent for 180 degrees without cracking, and is favorable for packaging. Moreover, the raw materials, aids, resin and the like in the production process of the product are water-soluble, so the 3D science paper is nontoxic and environmentally friendly.

Owner:HANGZHOU TALENT DECORATION PAPER

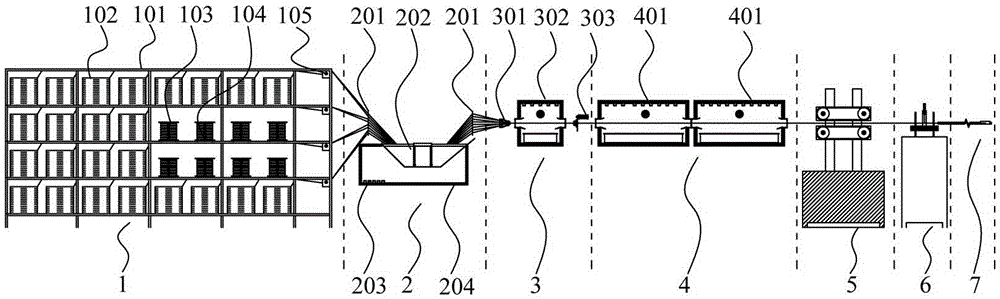

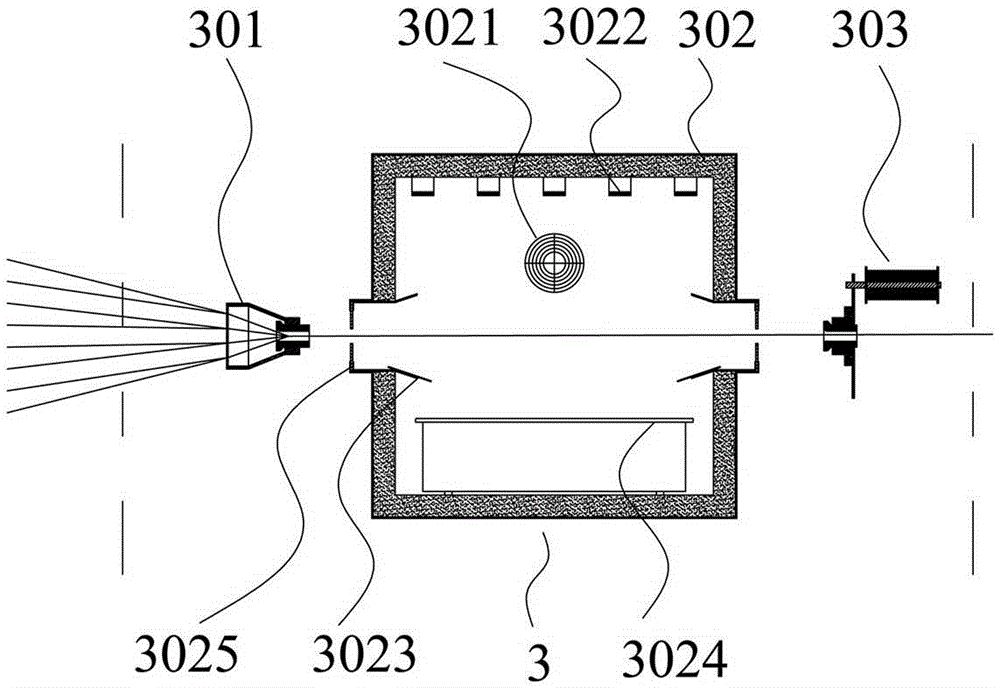

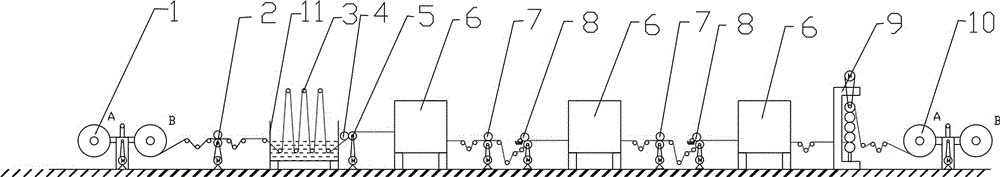

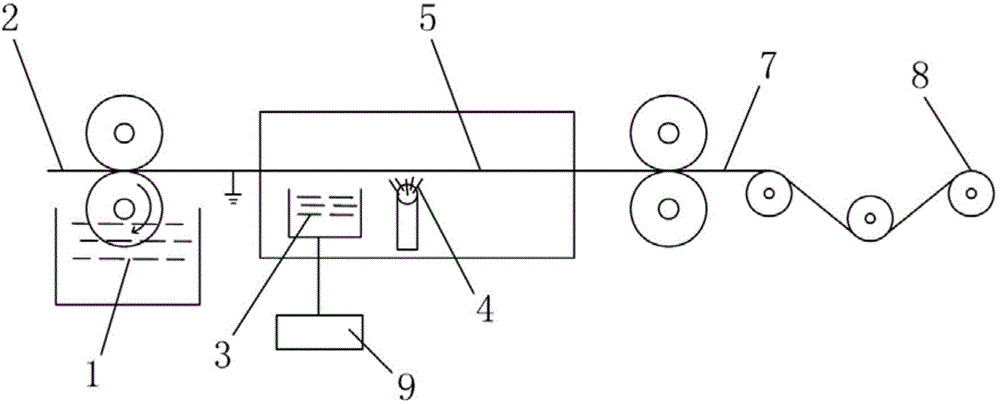

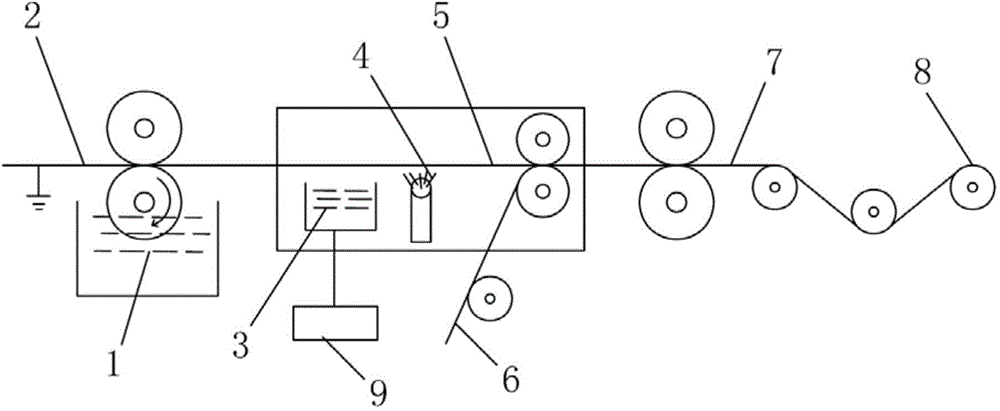

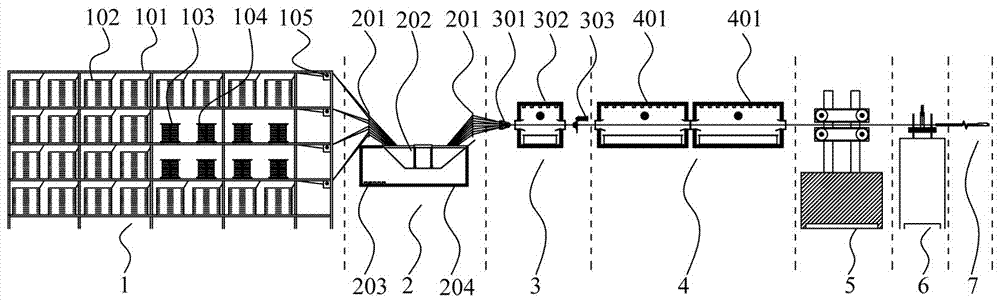

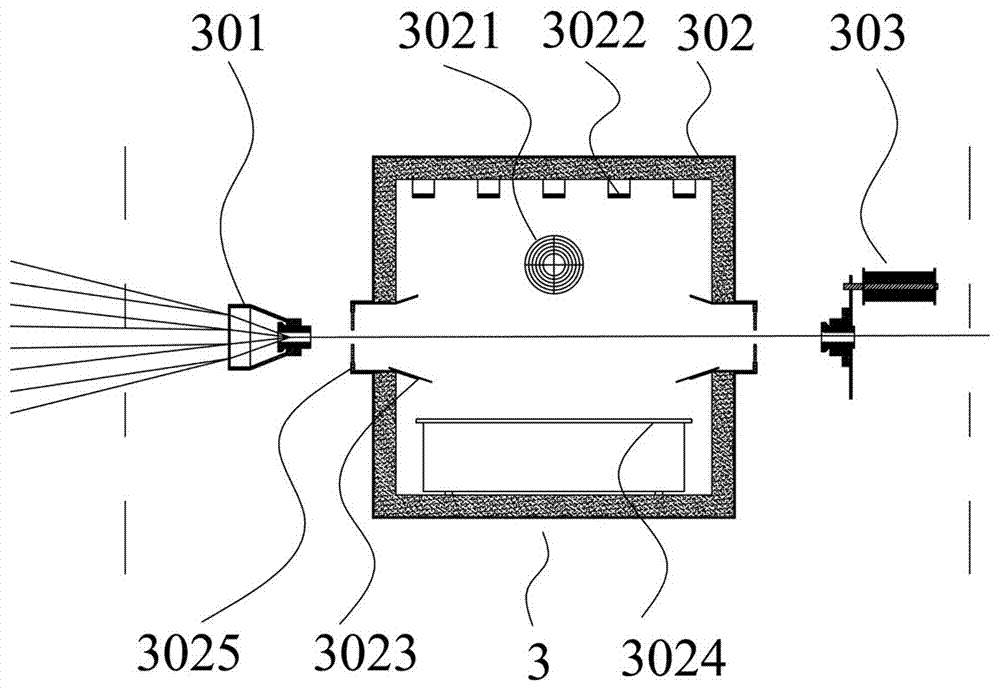

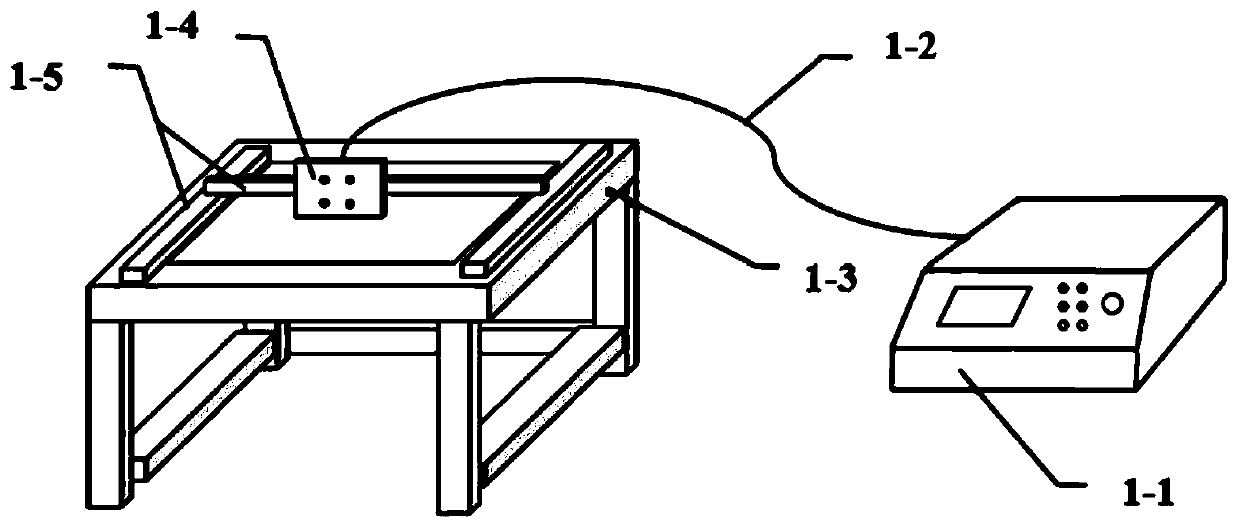

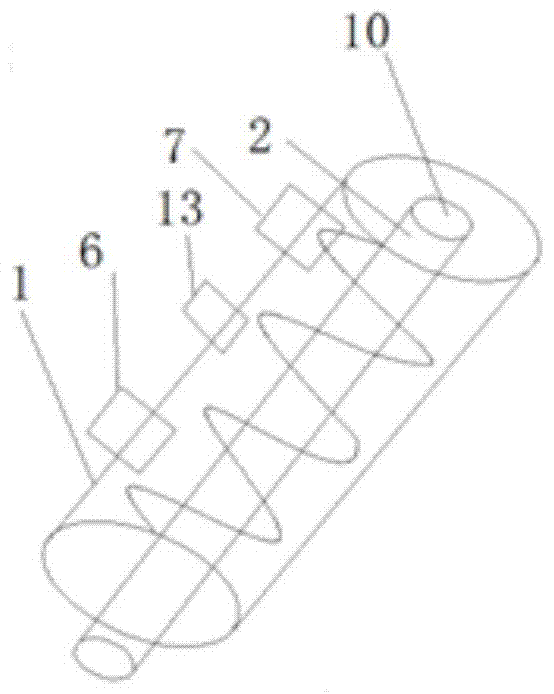

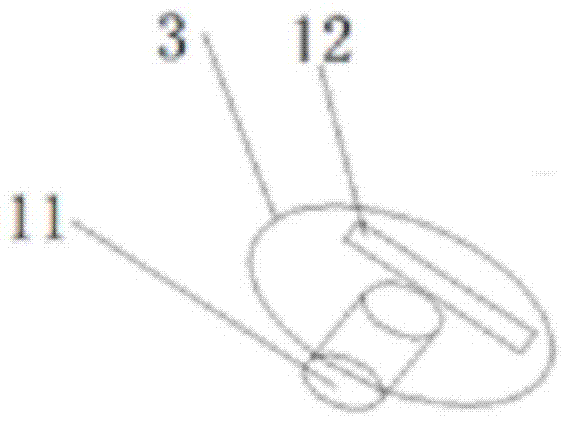

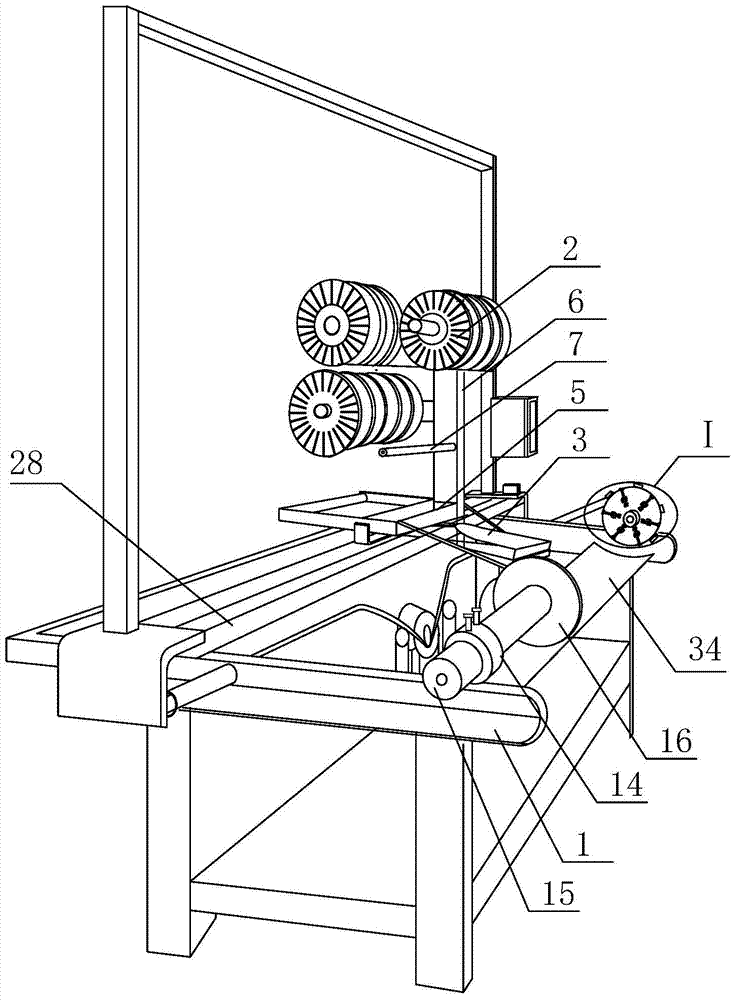

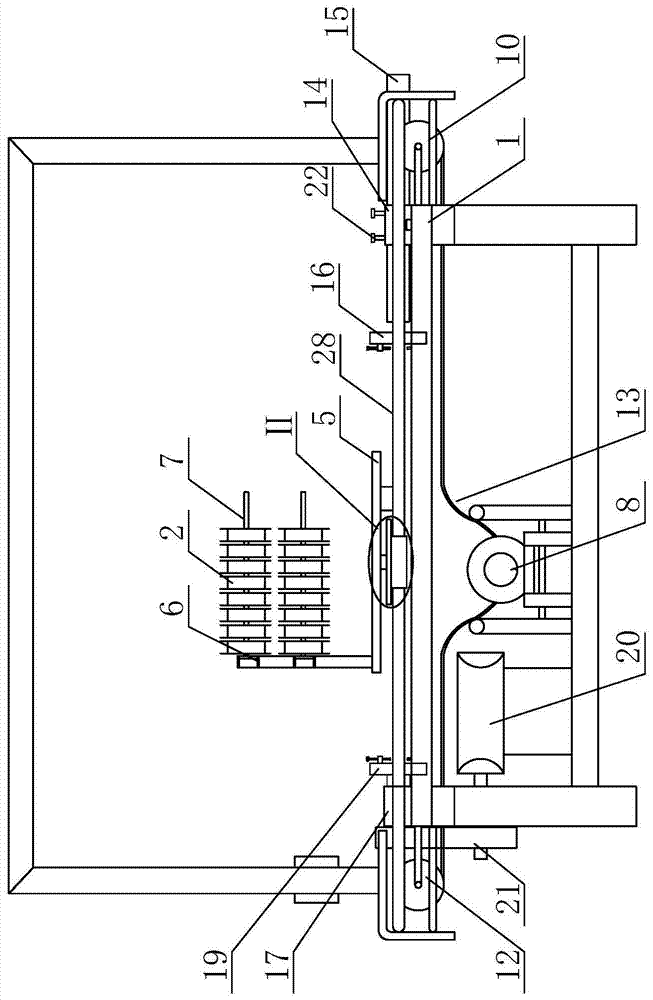

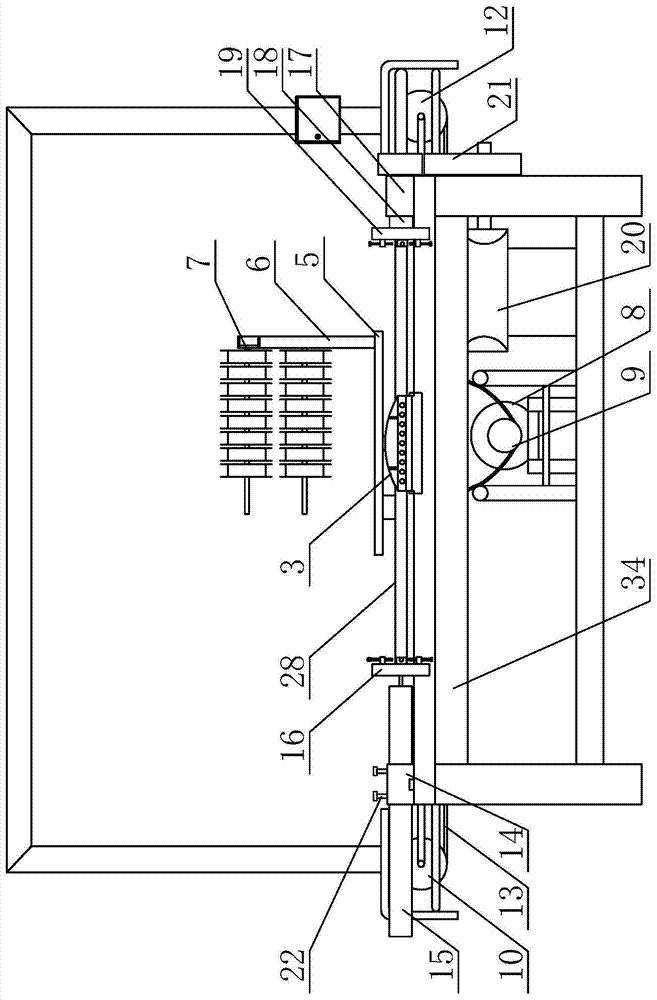

Composite fiber reinforced polymer (FRP) rebar preparation device

The invention provides a composite fiber reinforced polymer (FRP) rebar preparation device which comprises a yarn feeding device, an impregnation device, a forming device, a heating curing device, a traction device, a cutting device and a length control device. Relative to the prior art, the preparation device has substantive characteristics and progress, particularly, yarn pressing rolling shafts and yarn threading holes are arranged in the yarn feeding device of the composite FRP rebar preparation device, so that fiber bundles are enabled to be in a tension state, and different fiber bundles are prevented from knotting and rubbing; through the adoption of the impregnation device, the fiber bundles are fully and uniformly impregnated, the coating amount is small, the fiber content of a composite FRP rebar is increased, and the standard deviation of the mechanical performance of the composite FRP rebar is reduced; through the adoption of the forming device, the distribution uniformity of the fiber bundles in thermosetting resin is greatly improved; through the adoption of the heating curing device, the curing temperature is enabled to be stable, and the production is facilitated; and through the adoption of a buzzer of the length control device, operators can be reminded to carry out cutting, the FRP rebar is prevented from being over-roasted, and the continuity and safety of production are improved.

Owner:ZHENGZHOU UNIV

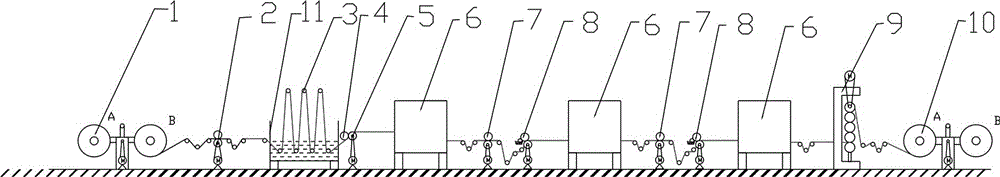

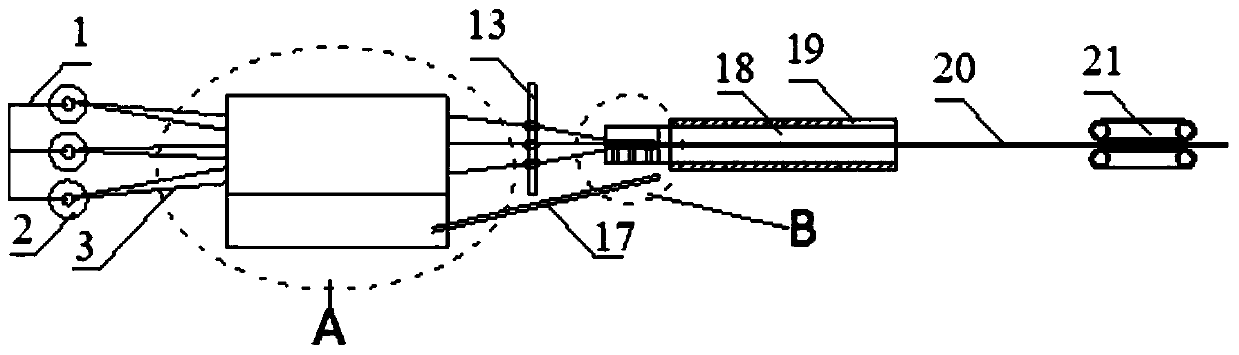

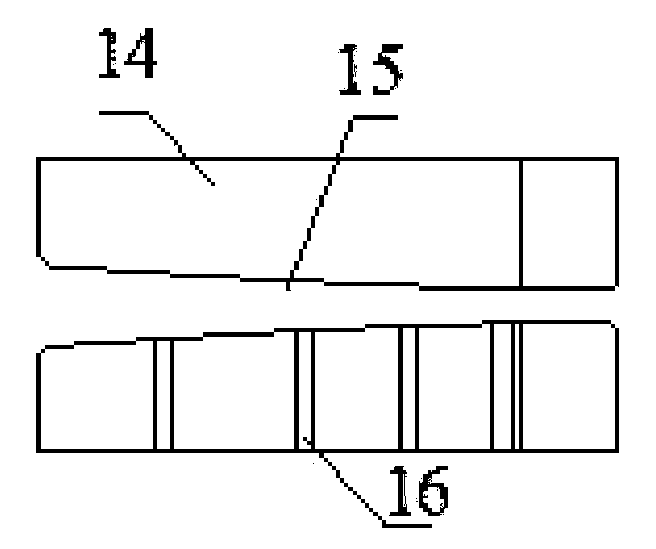

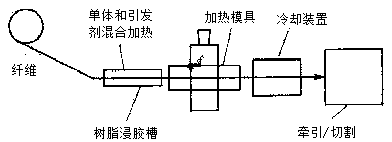

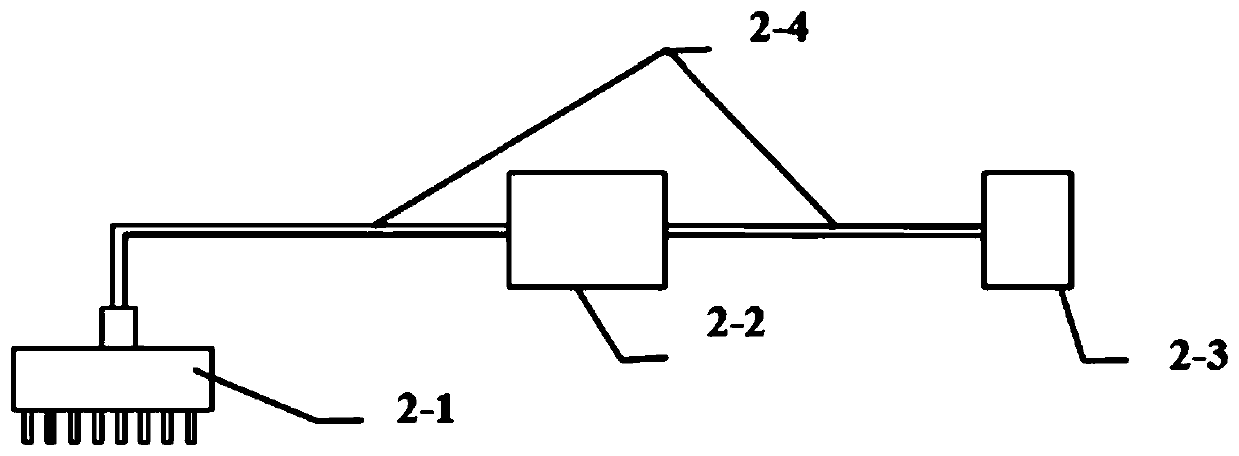

Pultrusion device and preparation process for high-strength FRP materials

The invention discloses a pultrusion device for high-strength FRP materials. The pultrusion device for the high-strength FRP materials is characterized by comprising a yarn collecting part, a glue solution steeping part, a glue squeezing part, a thermal forming part and a traction part. The yarn collecting part comprises a creel, a first yarn collecting plate, a second yarn collecting plate and athird yarn collecting plate. The glue solution steeping part comprises a glue steeping groove, a first heating device, a first yarn pressing cylinder, a second yarn pressing cylinder and a third yarnpressing cylinder. The glue squeezing part comprises a pre-forming mold and a glue collection plate. The thermal forming part comprises a pultrusion mold and a second heating device. A preparation process for the high-strength FRP materials has the advantages that it is ensured that internal fiber of an FRP pultrusion product is not uncrossed, fiber rough yarn is sufficiently steeped with glue andsurplus glue soluting can be sufficiently extruded out, and accordingly preparation of the high-strength FRP materials is achieved.

Owner:江苏绿材谷新材料科技发展有限公司

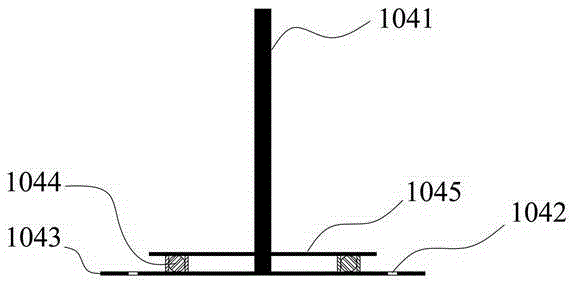

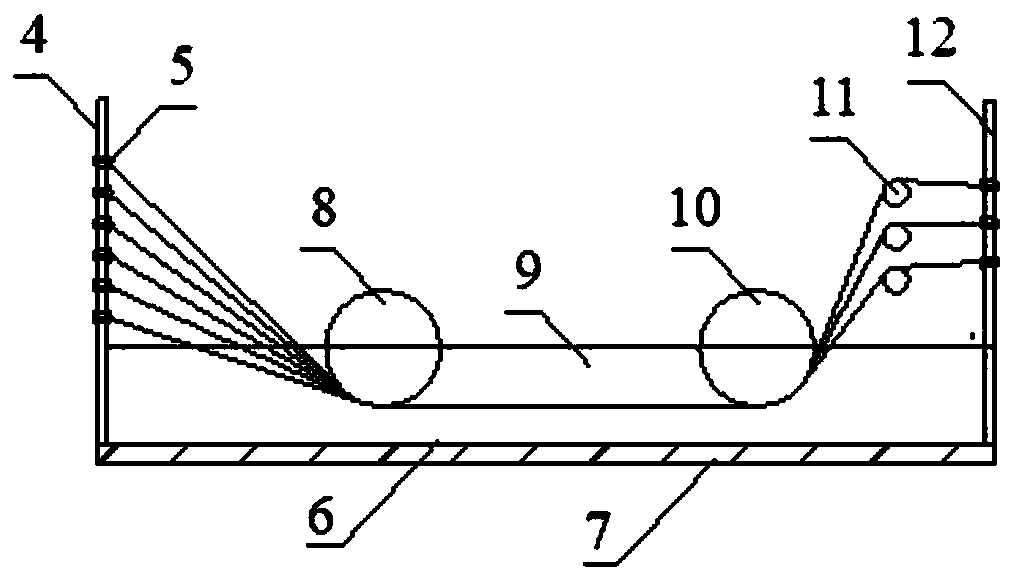

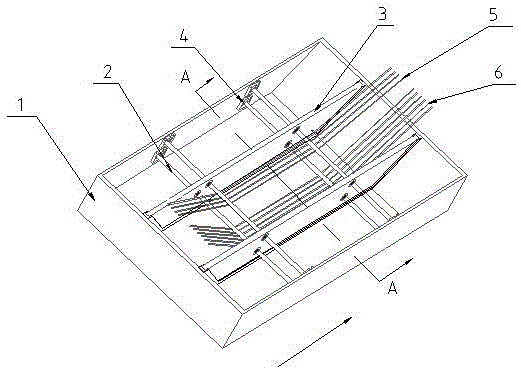

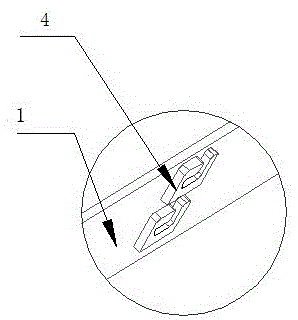

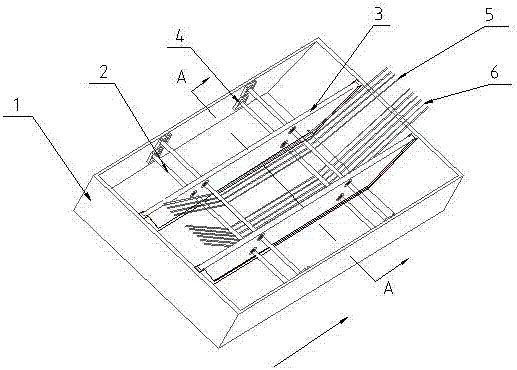

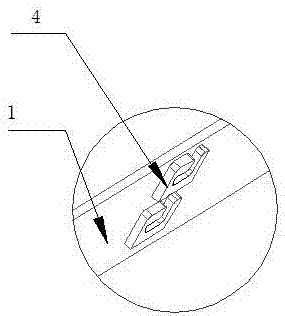

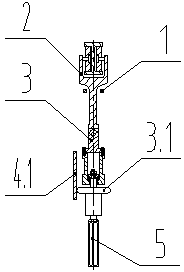

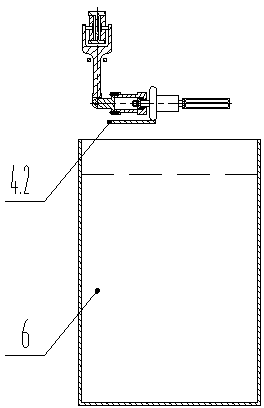

Gum dipping device and method

The invention discloses a gum dipping device and a method. The gum dipping device comprises an inverted gum dipping tank taking the shape of an isosceles trapezoid; a pair of longitudinal and opposite limiting baffle plates is arranged in the gum dipping tank; the bottom end and two ends of each limiting baffle plate are slidingly contacted with the inner surface of the gum dipping tank; at least two sets of transverse yarn pressing rods, penetrating through the limiting baffle plates, are arranged in the gum dipping tank side by side; and the yarn pressing rods are perpendicular to the limiting baffle plates. The gum dipping device can perform the layered gum dipping for a reinforcing material to guarantee full gum dipping and uniform tension, can adjust the volume of the gum tank to adapt to different reinforcing material quantities so as to adjust the gum volume in an optimal range, improves the gum utilization rate, and is simple in structure and convenient for installation, disassembly and control.

Owner:HENGSHEN

A kind of 3D technology paper and its production method and production equipment

ActiveCN104562848BHigh hardnessImprove wear resistanceNon-fibrous pulp additionPaper/cardboardCross-linkAcrylic resin

The invention provides 3D science paper as well as a production method and production equipment thereof. The 3D science paper is prepared by soaking printing decorative paper serving as a raw material into glue with high transparency, wherein the glue comprises the following components in percentage by weight: 20-30% of polyurethane, 30-50% of acrylic resin, 1-3% of a cross-linking agent, 1-3% of a curing agent, 3-5% of a permeating agent, 1% of a flatting agent and the balance of water. The 3D science paper has an extremely good homochromatic effect, does not have chromatic aberration, is high in hardness, scratch-resistant, wear-proof and good in toughness, can be bent for 180 degrees without cracking, and is favorable for packaging. Moreover, the raw materials, aids, resin and the like in the production process of the product are water-soluble, so the 3D science paper is nontoxic and environmentally friendly.

Owner:HANGZHOU TALENT DECORATION PAPER

Mica tape manufacturing method suitable for energy conservation, emission reduction and reduction of environmental pollution

InactiveCN104409187AReduced insulation performanceReduce manufacturing costLaminationLamination apparatusOrganic solventAdhesive

The invention relates to a mica tape manufacturing method suitable for energy conservation, emission reduction and reduction of environmental pollution. The mica tape manufacturing method includes adding nanometer materials subjected to surface activation into mica powder; uniformly stirring and dispersing the nanometer materials and the mica powder at high speed for standby application; coating first adhesive on a reinforced material through a drum, and adsorbing mica raw materials onto the reinforced material by means of an electrostatic field; spraying second adhesive onto the mica raw materials on the reinforced material, compositing the second layer of a reinforced material to obtain a semi-finished double-side reinforced mica tape; drying the semi-finished double-side reinforced mica tape to remove organic solvent through a drying oven, cooling and rolling the semi-finished double-side reinforced mica tape to obtain a mica roll, namely a finished double-side reinforced mica tape. The mica tape manufacturing method is a new production process utilizing natural characteristics of charge. Only by little solvent, production cost of the mica tape is reduced, and the environmental pollution of the organic solvent is greatly reduced.

Owner:JIANGSU ICE CITY INSULATION MATERIALS STOCK

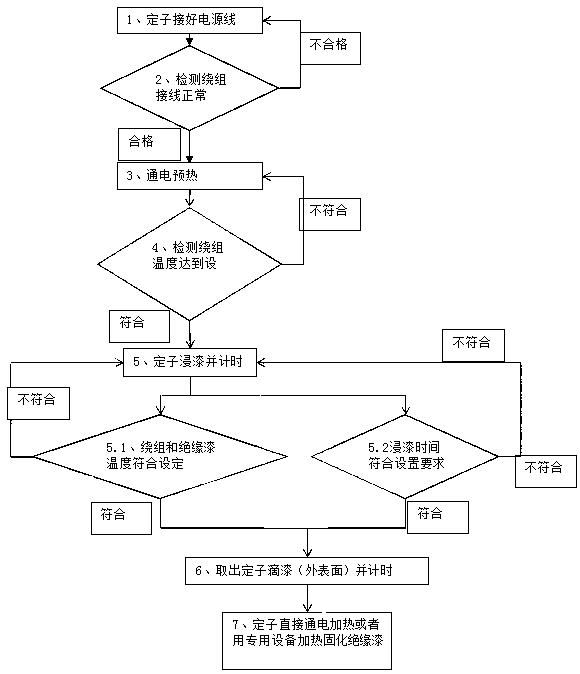

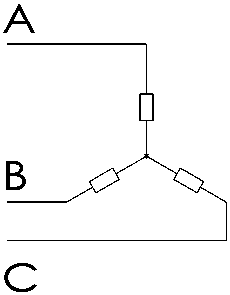

A method for paint dipping and curing of motor stator

InactiveCN109038985AHigh dielectric strengthFully dippedManufacturing dynamo-electric machinesAlternating currentUltimate tensile strength

The invention relates to the technical field of motor manufacturing, in particular to a method for paint dipping and curing of a motor stator, which comprises the following steps: preheating the stator winding with alternating current, and detecting whether the winding temperature reaches the temperature set by the stator winding; heating the insulating paint and detecting whether the temperatureof the insulating paint reaches the temperature set by the insulating paint; When the stator winding and the insulating varnish reach the set temperature, the stator is immersed in the insulating varnish, and the insulating varnish is kept constant temperature; The stator winding is continuously energized and heated to the temperature of insulating paint gelatinization, and the stator winding is kept constant temperature for a certain time; Remove the stator to drip paint and solidify the insulating paint. As that stator and the insulate paint are respectively heated to a certain temperature,the stator is put into the insulate paint, the stator is continuously heated and the insulating paint is subjected to constant temperature, so that the stator dip paint is more sufficient, the insulation strength of the motor stator is improved, and the curing hardness and the thermal conductivity of the winding are increased.

Owner:东莞市博瓦特动力科技有限公司

Cold press molding production process of heavy bamboo blank plate

ActiveCN106607975AHigh surface hardnessTo achieve the purpose of carbonizationWood treatment detailsCane mechanical workingCarbonizationEngineering

The invention belongs to the technical field of production of heavy bamboo floors, and discloses a cold press molding production process of a heavy bamboo blank plate. The technical problem to be solved by the invention is to provide the cold press molding production process capable of guaranteeing the machining uniformity of the heavy bamboo blank plate in the machining process to prevent edge paralysis so as to reduce such bad phenomenon as cracking, wire jumping and deformation. The process presses the heavy bamboo blank plate through steps a-f by such procedures as hacking, rough planing, carbonization and gum dipping. The cold press molding production process overcomes such bad phenomenon as cracking, wire jumping and deformation caused by easy edge paralysis in a traditional cold press molding production process of the heavy bamboo blank plate, solves the problems to the greatest extent through scientific and reasonable procedures, guarantees the produced blank plate to be not easy to generate mould and worm damage, increases the surface hardness of the blank plate, and guarantees quick and effective implementations of the machining procedures and the blank plate pressing quality when not wasting raw materials.

Owner:江西米来竹业有限公司

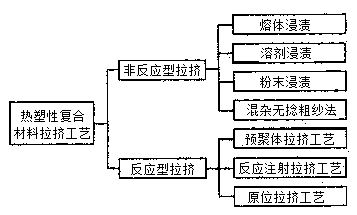

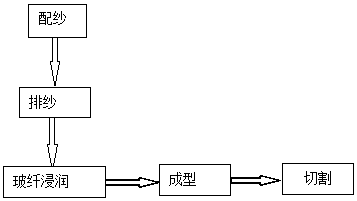

Thermoplastic pultrusion once-forming process

The invention relates to a thermoplastic pultrusion once-forming process and belongs to the field of thermoplastic composite material production and processing. The thermoplastic pultrusion once-forming process sequentially comprises the following steps of yarn distribution, wherein yarn is placed on a yarn rack; yarn arranging, wherein the yarn on the yarn rack is subjected to threading, arranging and carding; glass fiber infiltration, wherein the arranged and carded yarn is injected into a gum dipping area by means of extrusion by screw rod extrusion equipment and high temperature, and resinmelts at high temperature to realize glass fiber infiltration; forming traction, wherein resin obtained after gum dipping passes through a preforming mold and is directly formed after heat preservation and cooling, and then a product is pulled out through traction; and cutting. The thermoplastic pultrusion once-forming is simple and reasonable in process design, stable, reliable and quick in forming, realizes continuous pultrusion once-forming, and meets use requirements.

Owner:ZHENSHI GRP HUAMEI NEW MATERIALS

Production process of melamine glue dipped veneer

ActiveCN111993509AAvoid breakingImprove wear resistanceWood treatment detailsPretreatment apparatusPolymer scienceAdhesive glue

The invention discloses a production process of a melamine glue dipped veneer, which comprises the following steps of: A, cutting and trimming purchased veneers to obtain a veneer raw material; B, splicing the veneer raw material into a roll to obtain a spliced veneer; C, carrying out dipping treatment, namely carrying out gum dipping treatment on the spliced veneer twice to obtain a melamine gumdipped veneer, wherein the total gluing amount of the spliced veneer is 120-180% of the weight of the spliced veneer. According to the invention, the veneer is subjected to gum dipping treatment twice, the components and the use amount of glue in a glue dipping pool during each glue dipping, the gluing amount and the total gluing amount of each time, and two drying processes are controlled, so that the melamine glue can be well attached to the surface of the veneer, the cured veneer has good wear resistance and waterproof and flame-retardant properties and also has a good pressing and pastingeffect, the requirement of subsequent pressing and pasting can be met, and the glue cost can also be reduced. The production process has the characteristics that the production efficiency can be improved, the product quality is improved and the subsequent pressing process is simplified.

Owner:李公浩

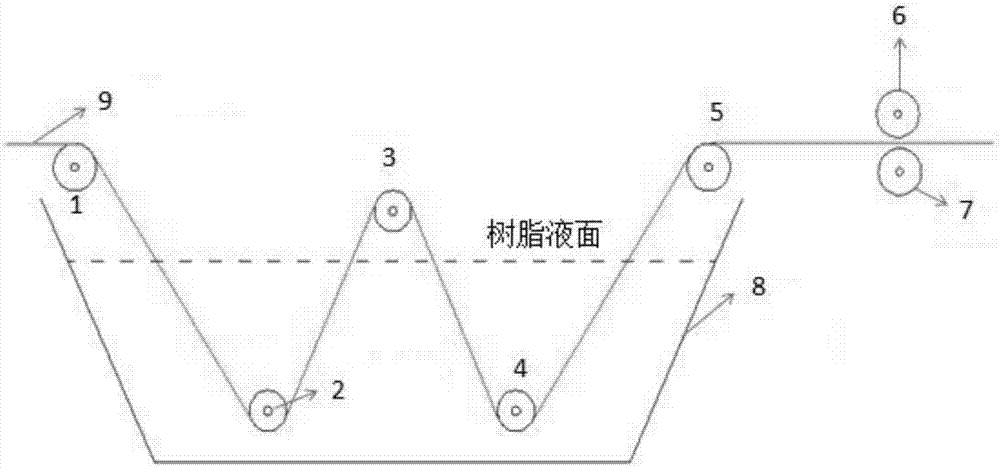

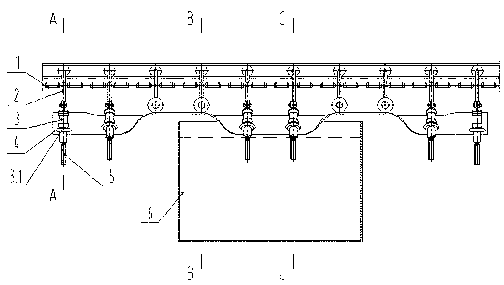

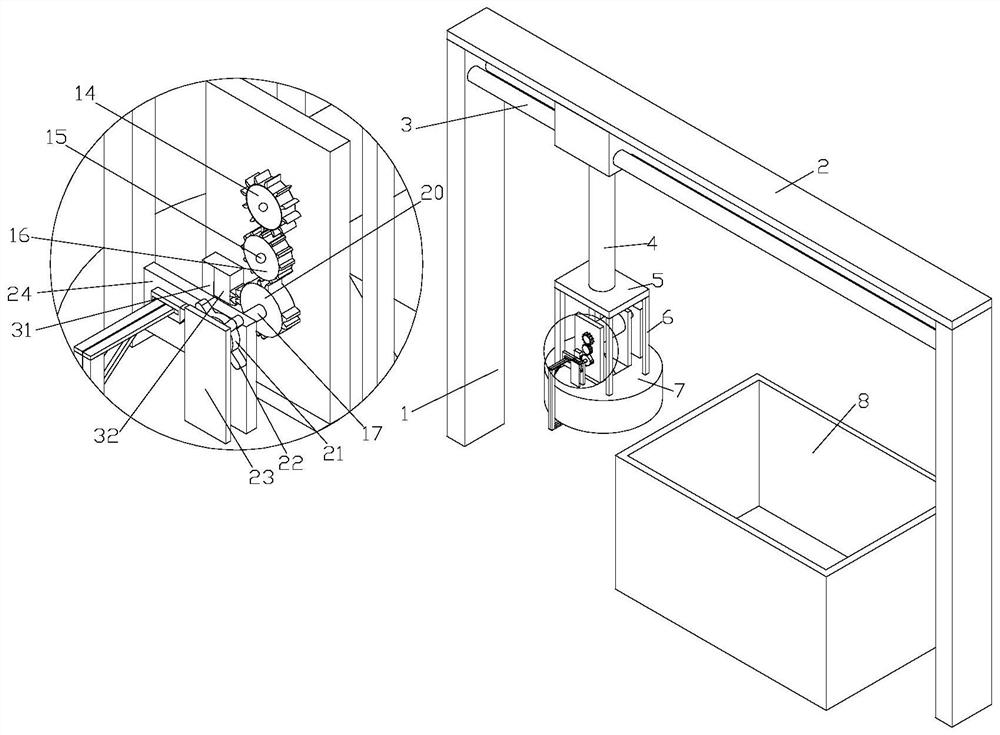

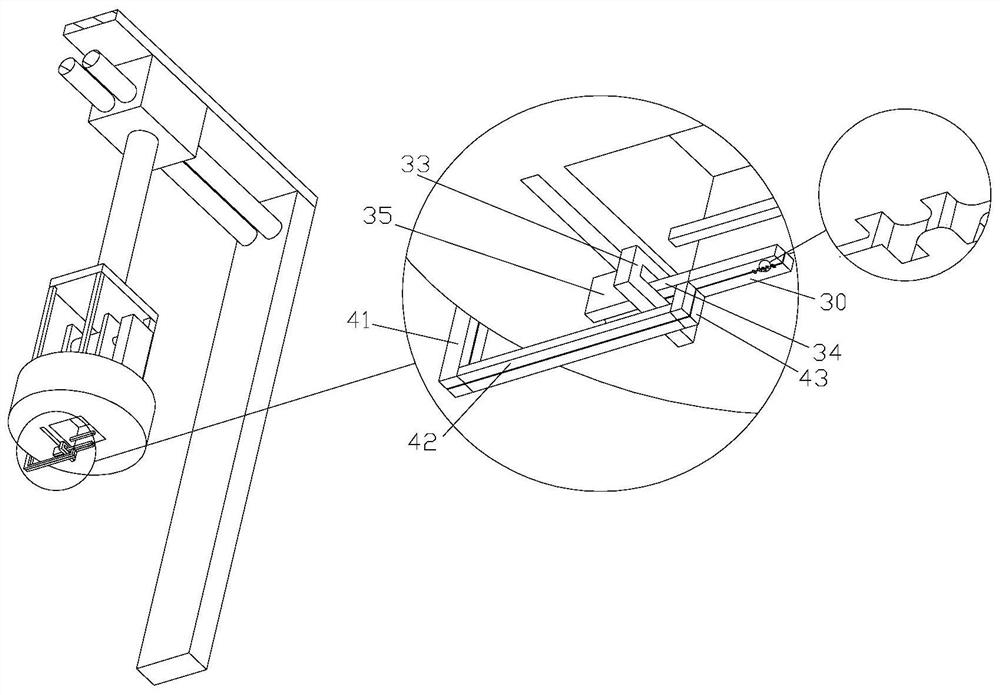

Even gluing device for composite material electric pole winding machine

The invention relates to an even gluing device for a composite material electric pole winding machine. The device is used for performing even gluing on a fiber cloth (9) and comprises a glue dipping tank (8) containing colloid resin, at least two glue dipping rollers arranged inside the glue dipping tank (8), driving rollers arranged above the glue dipping tank (8), and a pneumatic roller. The driving rollers are used for feeding the fiber cloth (9) into the glue dipping tank (8) through the glue dipping rollers, and then the fiber cloth (9) is fed into the pneumatic roller after being fully dipped with glue by means of the colloid resin. The pneumatic roller comprises a controllable roller (6) and a fixed roller (7) which are spaced by a certain clearance up and down. By the adoption of the even gluing device, the fiber cloth can be fully dipped with the glue, the gluing amount of the fiber cloth can be controlled to be within a reasonable range, and a prepared composite material electric pole is made uniform in structure and good in performance; and moreover the using amount of the colloid resin can be reduced, the conditions of fiber fuzzing, cracking and winding procedure interruption are avoided, and production efficiency is improved.

Owner:WUHAN NANRUI ELECTRIC POWER ENG TECH EQUIP

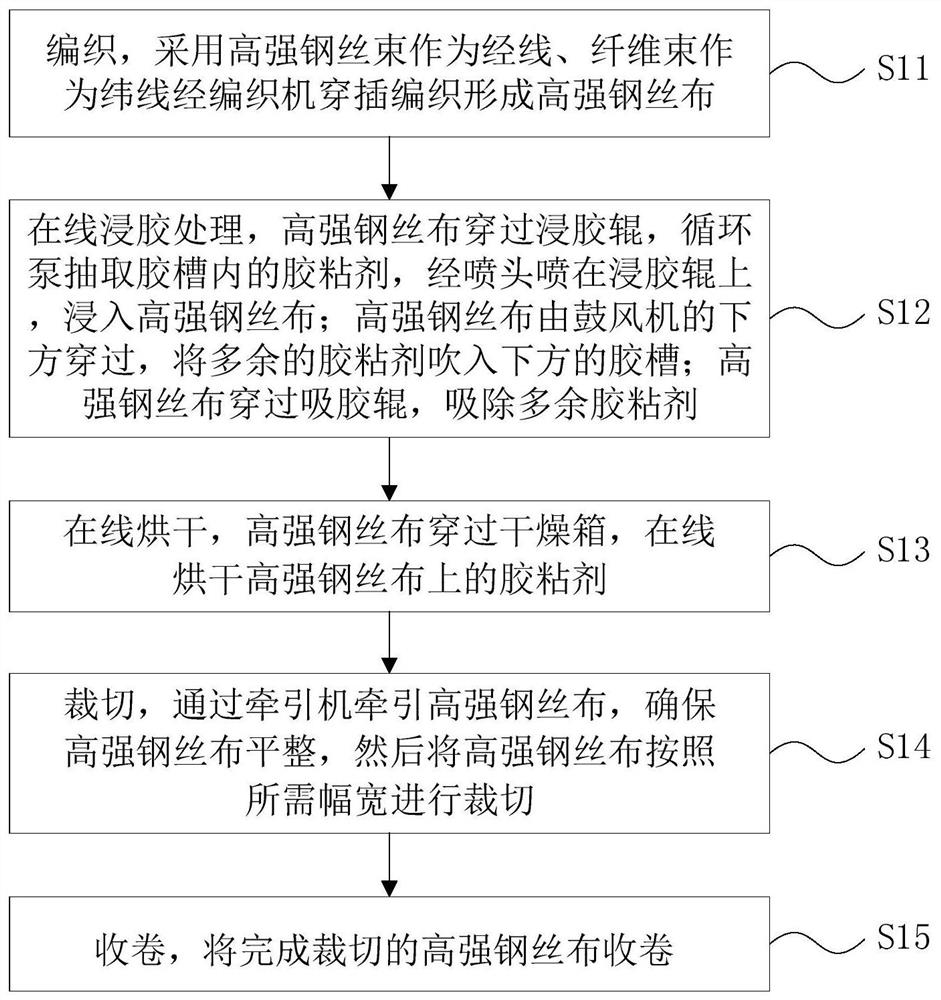

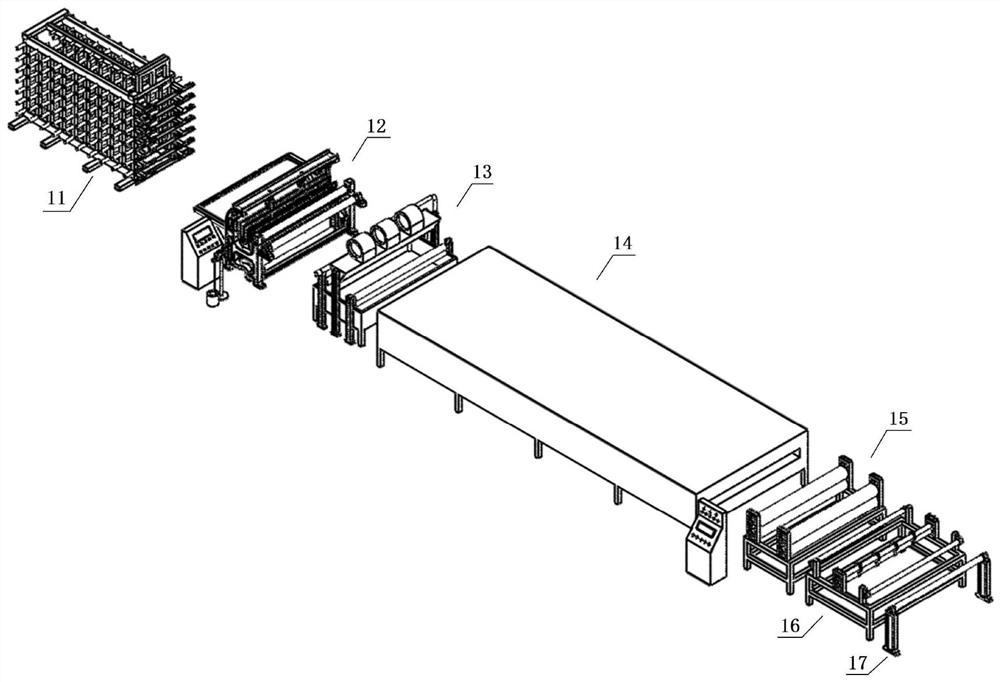

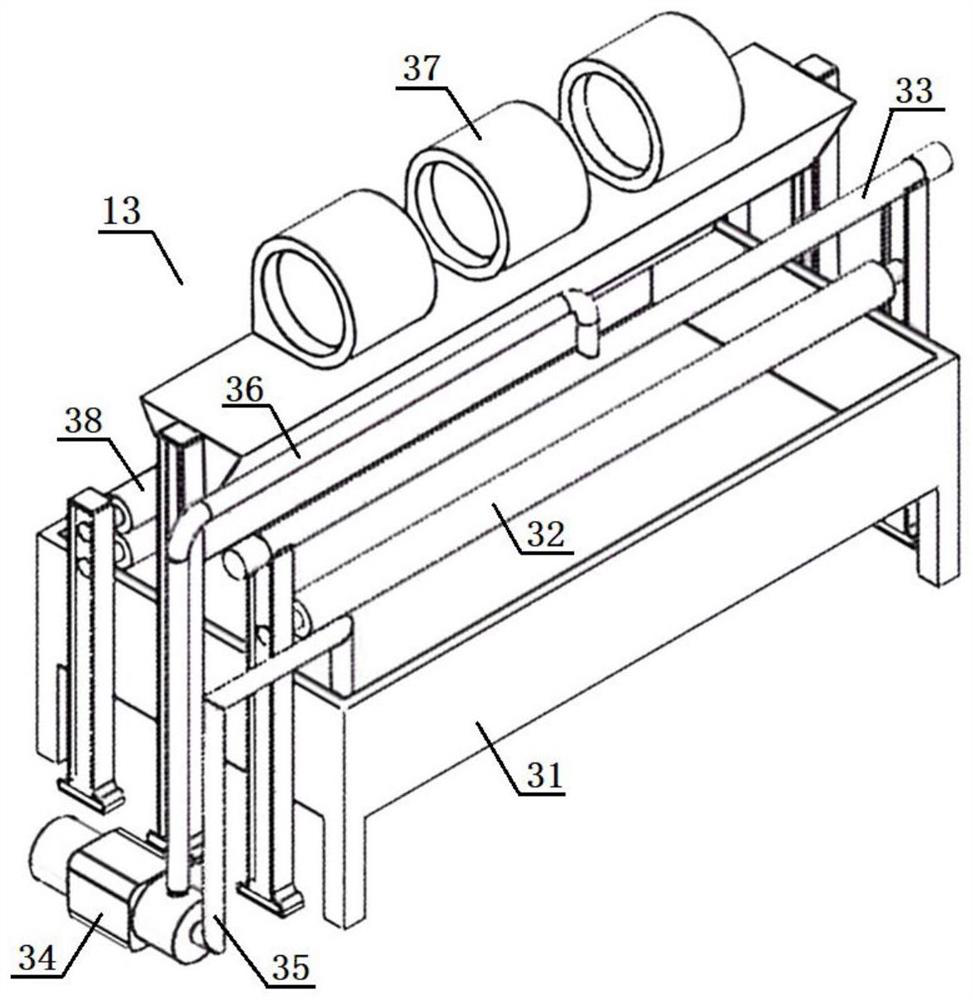

Production process and equipment of high-strength steel wire cloth

ActiveCN112981668ARealize the processing effectIncrease productivityLiquid surface applicatorsTextile/flexible product manufactureProcess engineeringComposite material

The invention discloses a production process and equipment of high-strength steel wire cloth. The production process includes the following step: carrying out online gum dipping treatment; and the online gum dipping treatment includes: gum dipping, blowing to remove gum, and absorbing and removing the gum. According to the production process and equipment, the high-strength steel wire cloth can be subjected to online gum dipping curing, and one-time processing molding can be achieved, so that the production efficiency is greatly improved.

Owner:CARBON TECH CO LTD

A smart energy large-scale composite core pultrusion process and device

The invention discloses a smart energy large-size composite core pultrusion process and device. The device comprises yarn dividing devices, a main resin dipping groove, resin extruding rollers, a yarn collecting device, a curing die, pre-curing dies, a first auxiliary resin dipping groove, resin scraping devices and a second auxiliary resin dipping groove. The main resin dipping groove comprises a first main resin dipping groove position and a second main resin dipping groove position; the pre-curing dies are arranged above the main resin dipping groove and comprise the first pre-curing die, the second pre-curing die and the third pre-curing die which are sequentially arranged; the resin scraping devices comprise the first resin scraping device, the second resin scraping device and the third resin scraping device and provided with inlets of the three pre-curing dies; and the smart energy large-size composite core pultrusion device comprises the main resin dipping groove with two groove positions and two auxiliary resin dipping grooves, most carbon fibers and all glass fibers are subject to resin dipping through the main resin dipping groove, a small part of carbon fibers are subject to resin dipping through the auxiliary resin dipping grooves, rein in the groove is not heated and is not prone to aging, and quality stability of a core stick is improved.

Owner:FAR EAST CABLE +2

A kind of dipping device and method

The invention discloses a gum dipping device and a method. The gum dipping device comprises an inverted gum dipping tank taking the shape of an isosceles trapezoid; a pair of longitudinal and opposite limiting baffle plates is arranged in the gum dipping tank; the bottom end and two ends of each limiting baffle plate are slidingly contacted with the inner surface of the gum dipping tank; at least two sets of transverse yarn pressing rods, penetrating through the limiting baffle plates, are arranged in the gum dipping tank side by side; and the yarn pressing rods are perpendicular to the limiting baffle plates. The gum dipping device can perform the layered gum dipping for a reinforcing material to guarantee full gum dipping and uniform tension, can adjust the volume of the gum tank to adapt to different reinforcing material quantities so as to adjust the gum volume in an optimal range, improves the gum utilization rate, and is simple in structure and convenient for installation, disassembly and control.

Owner:HENGSHEN

Manufacturing method of mica tape

ActiveCN102514345BReduced insulation performanceReduce manufacturing costLaminationLamination apparatusOrganic solventAdhesive

Owner:JIANGSU BINGCHENG HYDROGEN ENERGY TECH CO LTD

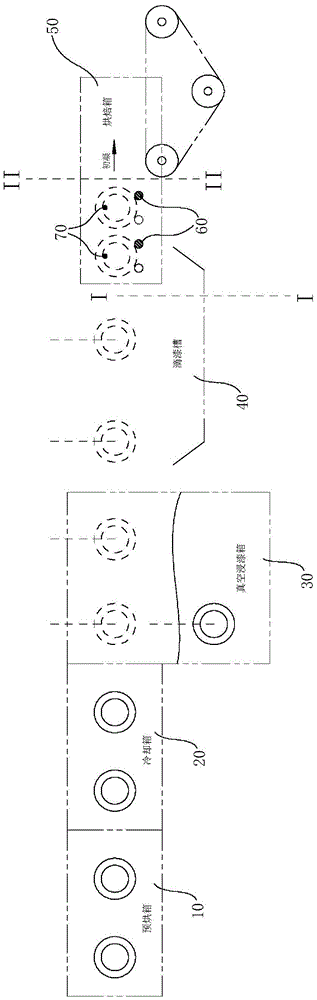

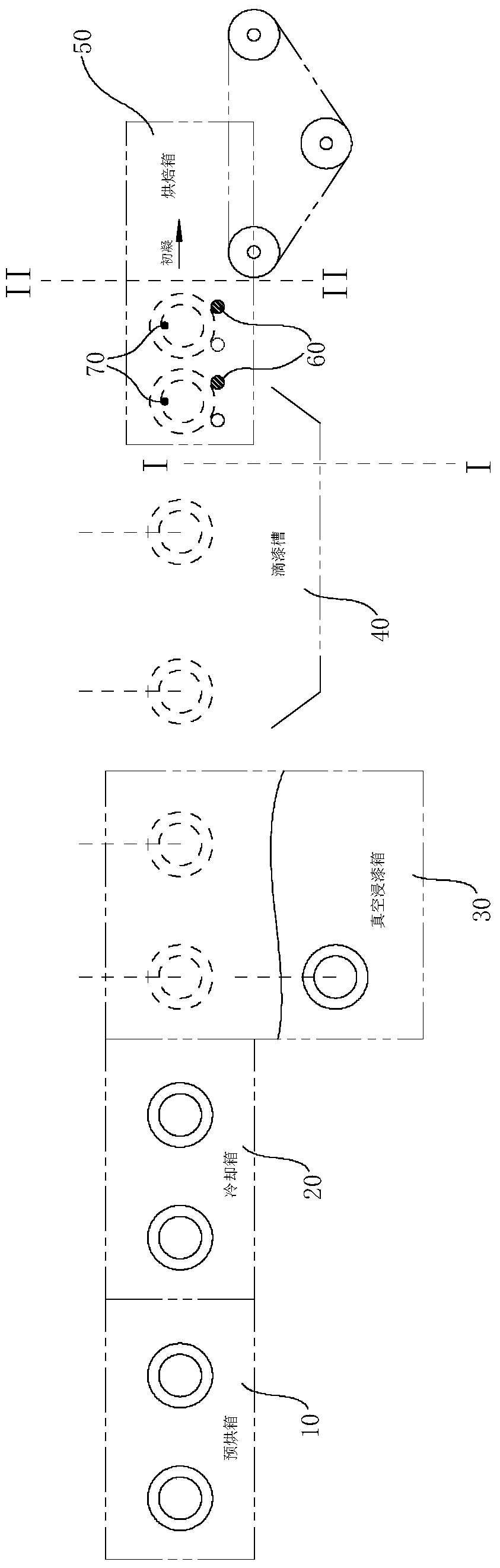

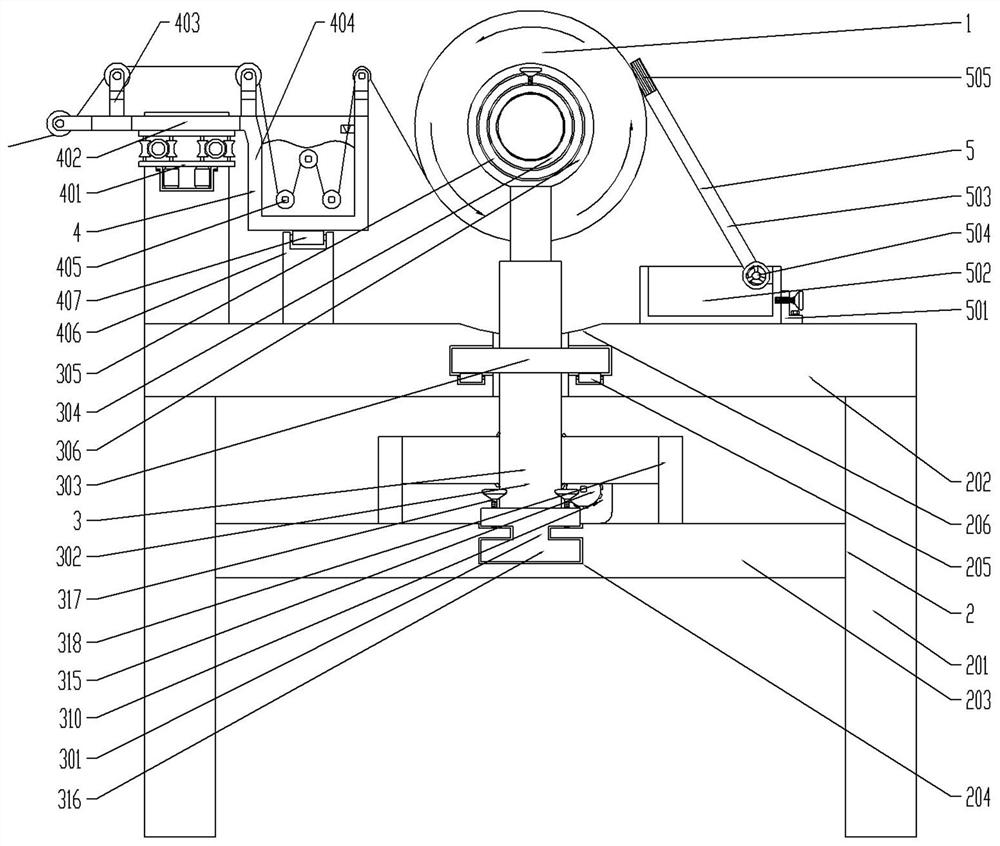

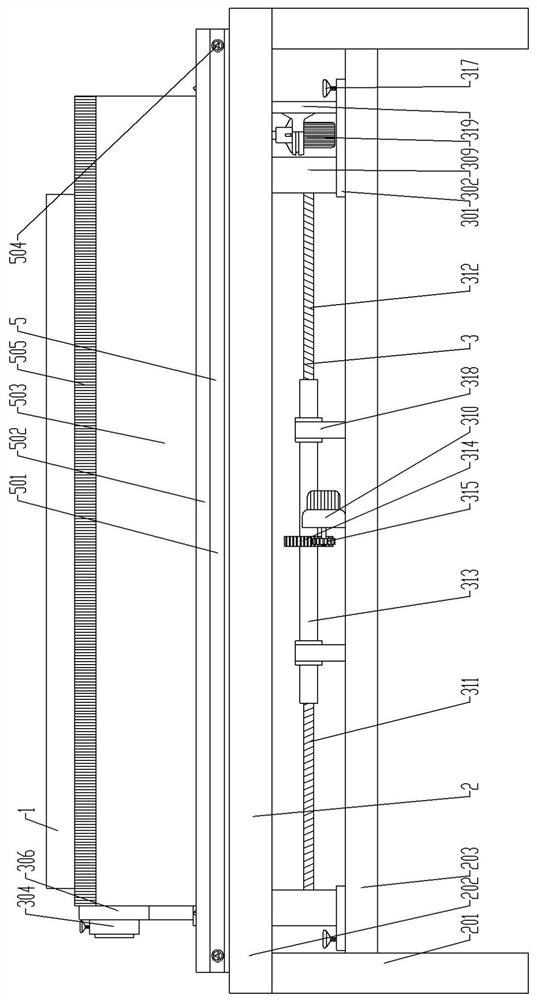

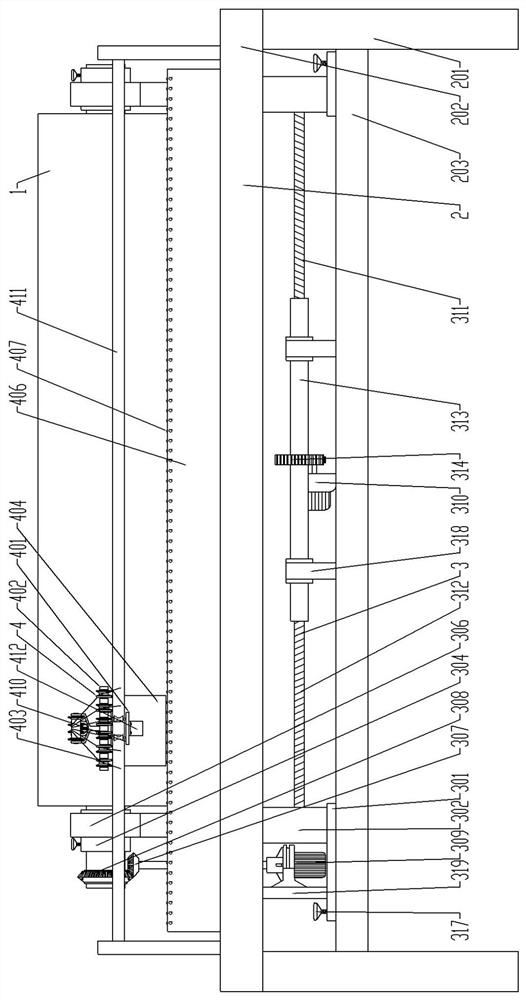

Paint dipping method and system for winding stator of motor

ActiveCN105471206AFully dippedDip paint evenlyManufacturing dynamo-electric machinesEngineeringMechanical engineering

The invention relates to a paint dipping method and system for a winding stator of a motor. The method comprises the processes of pre-drying, cooling, vacuum paint dipping, paint dripping and baking. The winding stator keeps running in a horizontal rotary state at at least the front section of the baking process until an initial solidification state of paint dipping is reached. The system comprises a pre-drying box, a cooling box, a vacuum paint dipping box, a paint dripping box and a baking box. A rotary bearing mechanism is arranged at at least the front section of the baking box and drives the winding stator to run in the horizontal rotary state until the initial solidification state of paint dipping is reached; the winding stator keeps running in the horizontal rotary state and is baked after pre-drying, cooling and vacuum paint dipping operations, so that the phenomenon of winding paint shortage caused by dripping of paint in the winding stator can be avoided; and the winding stator in the horizontal rotary state enables the paint dipping to be complete and uniform, thereby ensuring the paint dipping quality.

Owner:ANHUI WANNAN ELECTRIC MACHINE

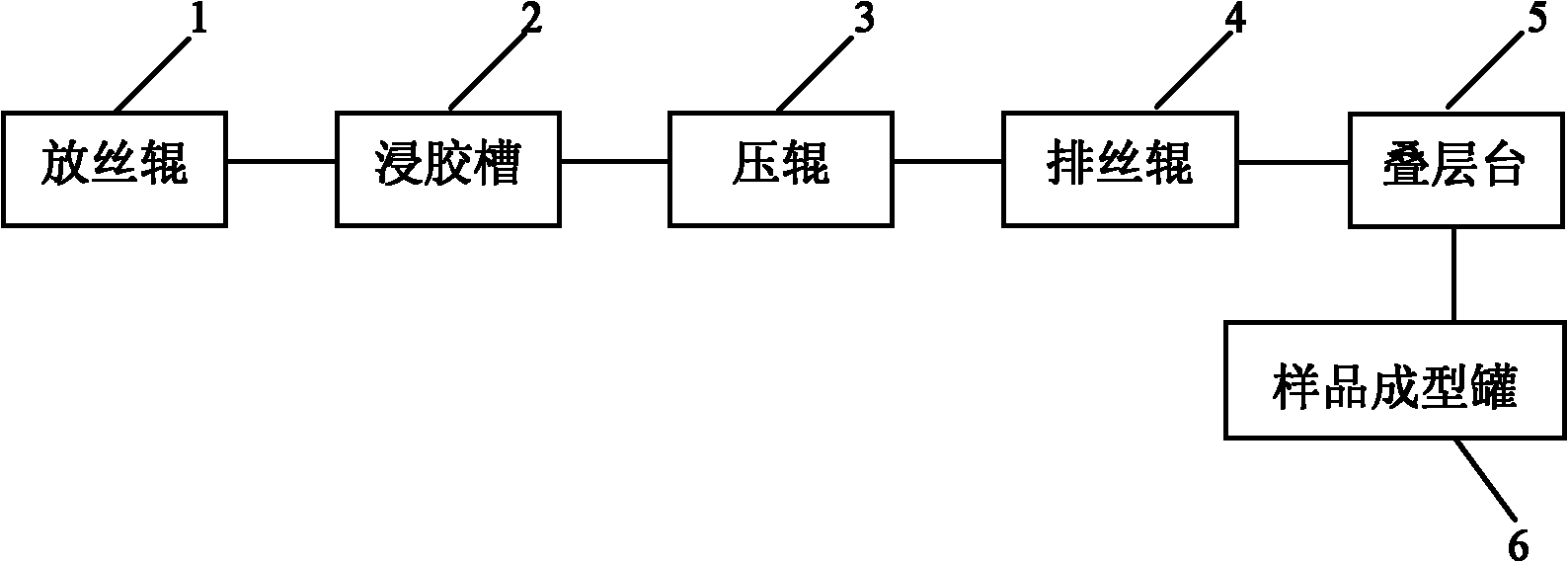

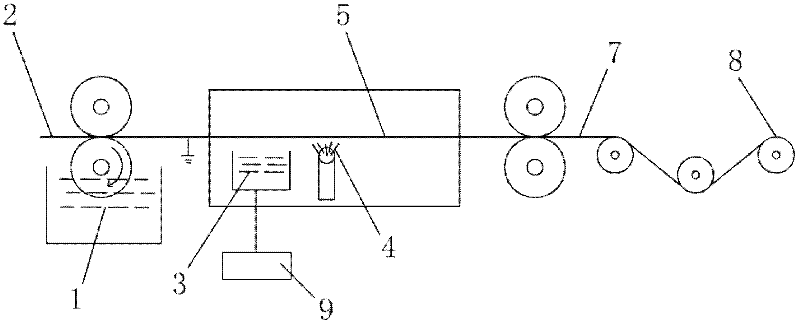

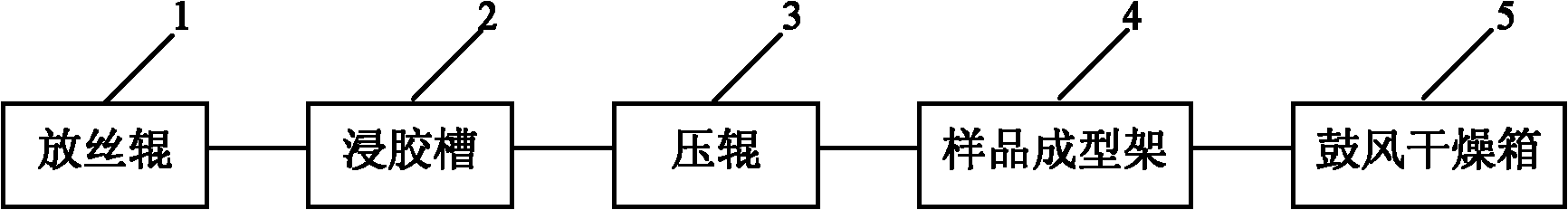

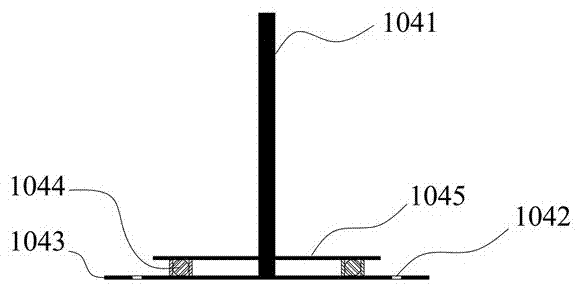

Sampling method for mechanics performance testing of preoxidized fibers

InactiveCN101968410AFully dippedUniform glue contentPreparing sample for investigationMechanical properties of carbon nanotubesFiber

The invention relates to a sampling method for mechanics performance testing of preoxidized fibers, which comprises the following steps of: 1) putting the preoxidized fibers to be tested on a releasing roller; 2) performing gum dipping on the preoxidized fibers passing through the releasing roller in a gum dipping tank; 3) allowing the preoxidized fibers subjected to gum dipping to pass through a compression roller; 4) fixing the preoxidized fibers passing through the compression roller and subjected to uniform gum dipping to a sample forming frame, wherein the sample forming frame can rotate at a uniform speed and is used for fixing the preoxidized fibers; and 5) drying the preoxidized fibers fixed to the sample forming frame. The method solves the technical problem that the conventional sampling method for mechanics performance testing of the preoxidized fibers cannot ensure the gum content of the preoxidized fibers to be tested so as to influence the mechanics performance of the fibers, and makes a tested sample dip gum more fully have the gum content more uniform; and gum beads influencing test results cannot be left on the sample.

Owner:JIANGSU HANGKE COMPOSITE MATERIALS TECH

Composite frp bar preparation equipment

Owner:ZHENGZHOU UNIV

Tensile property sample preparation device of ultra-high modulus carbon fiber multifilament and sample preparation method

The invention relates to a tensile property sample preparation device of an ultra-high modulus carbon fiber multifilament and a sample preparation method, and belongs to the technical field of material property testing. The tensile property sample preparation device of the ultra-high modulus carbon fiber multifilament includes a precision control system, an automatic glue dispensing system and anauxiliary positioning system. The sample preparation method comprises the following steps of: placing a pre-wound ultra-high modulus carbon fiber multifilament frame on a sample preparation glue dispensing device, and automatically adding a glue solution through the precision control system; then placing the glue-dipped carbon fiber multifilament in an oven for curing; and pasting a reinforcing sheet for tensile testing. The invention solves the problem of high damage and brittle fracture of fibers encountered during a manual glue-dipping process of ultra-high modulus carbon fibers, and prepares multifilament tensile sample strips with smooth appearance. The tensile property sample preparation device of the ultra-high modulus carbon fiber multifilament and the sample preparation method disclosed by the invention have important popularization and application prospects in the engineering development and production of the ultra-high modulus carbon fibers and composite materials thereof, and high thermal conductivity mesophase pitch-based carbon fibers and composite materials thereof.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Automatic dipping system for silica sol shell molding

InactiveCN102950262AReduce labor intensityImprove productivityMoulding toolsFoundry mouldsWaxShell molding

The invention belongs to the field of precision casting and discloses an automatic dipping system for silica sol shell molding. The automatic dipping system for silica sol shell molding comprises a horizontal catenary conveying line, hooks, hangers, wax molds and a dipping tank. The dipping tank is disposed below the catenary conveying line. A roller is disposed on the outer wall of each hanger and capable of driving the corresponding wax mold to synchronously rotate. A roller guide board is disposed on one sides of the hangers and between the catenary conveying line and the dipping tank. The roller guide board is an elongated board component parallel with the catenary conveying line and crossing over the dipping tank. Along with the hangers, the wax molds are guided by the roller guide board to cross the side wall of the dipping tank and enter and immerge under the liquid level of the dipping tank. During slurry dipping, the wax molds synchronously rotate with the rollers to allow all parts of each wax mold to be fully dipped. Slurry dipping for silica sol shell molding by the automatic dipping system is high in production efficiency and low in labor intensity of workers, dipping uniformity can be guaranteed, manufacturing cost is low, and use cost is low.

Owner:TAIZHOU JINDING PRECISION CASTING

A screw type dipping equipment

The invention relates to a screw type dipping equipment, comprising a dipping sleeve, a dipping shaft fitted inside the dipping sleeve, a glue injection port, a tow inlet and a tow outlet arranged on the same side of the dipping sleeve , the tow inlet and tow outlet are respectively located at the left and right ends of the dipping sleeve. The dipping shaft is a screw type dipping shaft, and the thread length of the dipping shaft is less than the length of the dipping sleeve. The glue is poured from the glue injection port, and the size of the tow inlet and tow outlet can be adjusted by adjusting the block and fastening bolts. By adjusting the size of the tow inlet to ensure that the tow entering the dipping sleeve is neat Generally, the glue content of the fibers coming out of the dipping sleeve after dipping is controlled by adjusting the size of the tow outlet. The invention is a closed glue dipping device, the glue liquid does not contact with the outside atmosphere, and has no pollution; the screw type glue dipping is adopted, all tows enter the glue liquid, the contact time with the glue liquid is long, the glue dipping is sufficient, and the effect of the glue dipping is good.

Owner:SHANDONG UNIV

A chain dipping equipment

ActiveCN110841866BFully dippedSimple structureLiquid surface applicatorsCoatingsCircular discDrive shaft

Owner:QUANZHOU HENGLIDA ENG MACHINERY

Method and system for varnish dipping of motor with winding stator

ActiveCN105471206BFully dippedDip paint evenlyManufacturing dynamo-electric machinesElectric machineEngineering

The invention relates to a paint dipping method and system for a winding stator of a motor. The method comprises the processes of pre-drying, cooling, vacuum paint dipping, paint dripping and baking. The winding stator keeps running in a horizontal rotary state at at least the front section of the baking process until an initial solidification state of paint dipping is reached. The system comprises a pre-drying box, a cooling box, a vacuum paint dipping box, a paint dripping box and a baking box. A rotary bearing mechanism is arranged at at least the front section of the baking box and drives the winding stator to run in the horizontal rotary state until the initial solidification state of paint dipping is reached; the winding stator keeps running in the horizontal rotary state and is baked after pre-drying, cooling and vacuum paint dipping operations, so that the phenomenon of winding paint shortage caused by dripping of paint in the winding stator can be avoided; and the winding stator in the horizontal rotary state enables the paint dipping to be complete and uniform, thereby ensuring the paint dipping quality.

Owner:ANHUI WANNAN ELECTRIC MACHINE

A kind of cold pressing forming production process of heavy bamboo blank board

ActiveCN106607975BHigh surface hardnessTo achieve the purpose of carbonizationWood treatment detailsCane mechanical workingCarbonizationHardness

The invention belongs to the technical field of production of heavy bamboo floors, and discloses a cold press molding production process of a heavy bamboo blank plate. The technical problem to be solved by the invention is to provide the cold press molding production process capable of guaranteeing the machining uniformity of the heavy bamboo blank plate in the machining process to prevent edge paralysis so as to reduce such bad phenomenon as cracking, wire jumping and deformation. The process presses the heavy bamboo blank plate through steps a-f by such procedures as hacking, rough planing, carbonization and gum dipping. The cold press molding production process overcomes such bad phenomenon as cracking, wire jumping and deformation caused by easy edge paralysis in a traditional cold press molding production process of the heavy bamboo blank plate, solves the problems to the greatest extent through scientific and reasonable procedures, guarantees the produced blank plate to be not easy to generate mould and worm damage, increases the surface hardness of the blank plate, and guarantees quick and effective implementations of the machining procedures and the blank plate pressing quality when not wasting raw materials.

Owner:江西米来竹业有限公司

A glass fiber reinforced plastic winding pipe processing equipment

The present invention relates to a glass fiber reinforced plastic winding pipe processing equipment, which includes a winding pipe mold, and also includes a supporting assembly, a retaining assembly and a wire feeding dipping assembly, the retaining assembly is slidably arranged in the middle of the supporting assembly, and the The wire feeding and dipping assembly is set on the support assembly. The FRP winding pipe processing equipment of the present invention can be adjusted in a wide range according to the length of the winding pipe mold when fixing the winding pipe mold through the retaining assembly. The adjustment of this equipment It has a wide range and can be applied to winding pipe molds of various lengths. It has strong applicability and practicability. This equipment also has a wire feeding and dipping mechanism. The wire can be fully dipped in glue when dipping, and the cable board can arrange the wires neatly when winding, making the internal structure of the finished product more compact, thereby improving the processing quality of the winding pipe.

Owner:许绝电工股份有限公司

Glass filament winding machine

The invention discloses a glass fiber winding machine which comprises a machine frame, wherein a pipeline fixing mechanism is mounted on the machine frame, can be used for clamping two ends of a pipeline, and can rotate around a shaft; a guide rail mechanism is arranged on one longitudinal side surface of the pipeline fixing mechanism; a wire coil rack is mounted on the guide rail mechanism; a transversal moving mechanism is mounted below the wire coil rack, and can drive the wire coil rack to slide along the guide rail mechanism; a gum dipping mechanism capable of moving along with thesubtype wire coil rack is arranged between the wire coil rack and the pipeline fixing mechanism, and comprises a groove-shaped gum hopper; a first cross rod is arranged in the gum hopper; the wire coil rack comprises a bracket base and a vertical plate; a second cross rod is arranged on the vertical plate; the transversal motion mechanism comprises a first motor and a first gear; a second gear and a third gear are arranged at two sides of the first gear; a chain is arranged on the first gear, the second gear and the third gear, and is fixed with the bracket base. The glass fiber winding machine is convenient and efficient, and has the advantages that cross winding can be realized, so that a flue pipe made with the glass fiber winding machine is high in quality; the thickness of a wound layer is controllable and adjustable.

Owner:青岛昊运船艇制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com