Patents

Literature

977results about How to "Reduced insulation performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

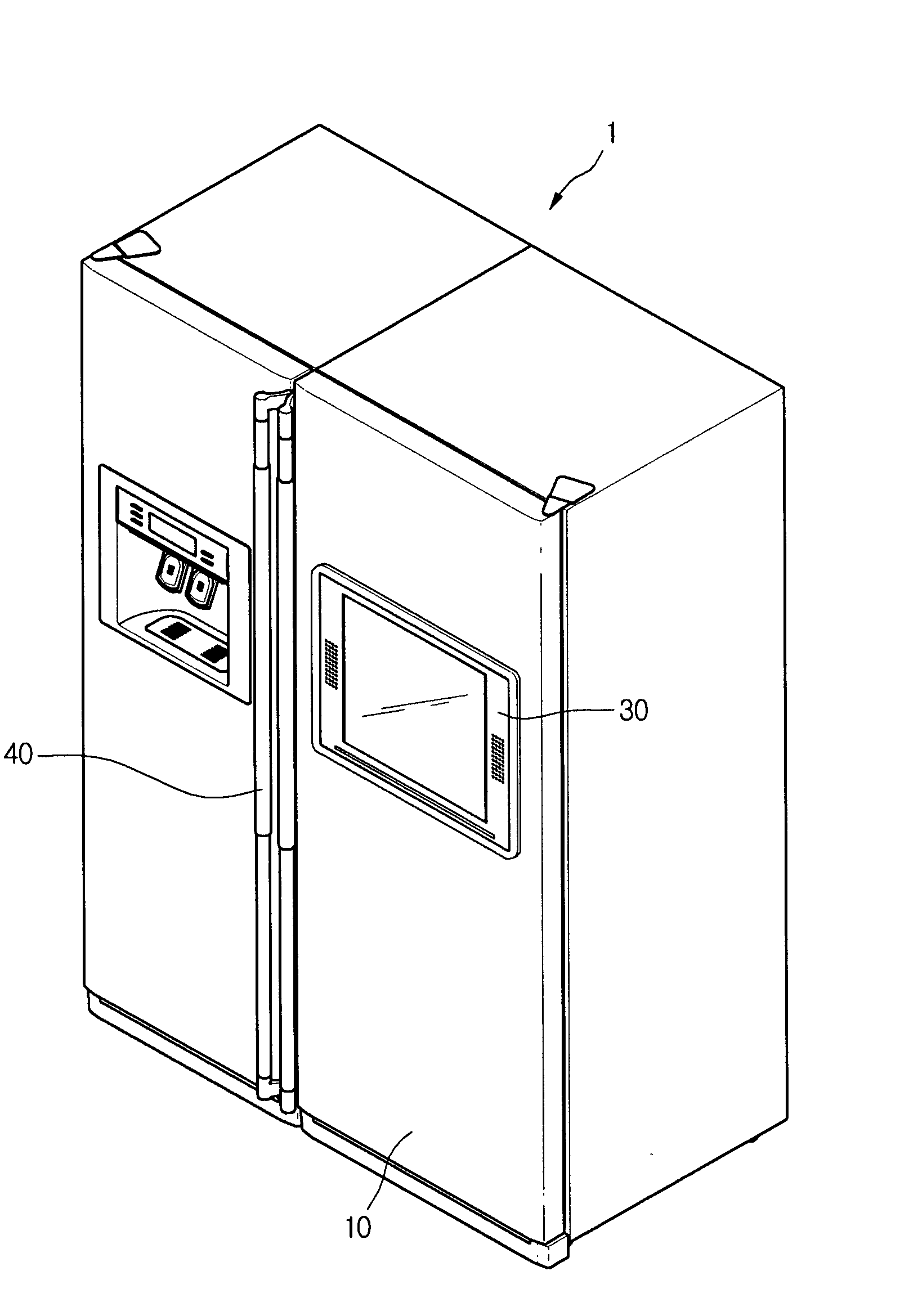

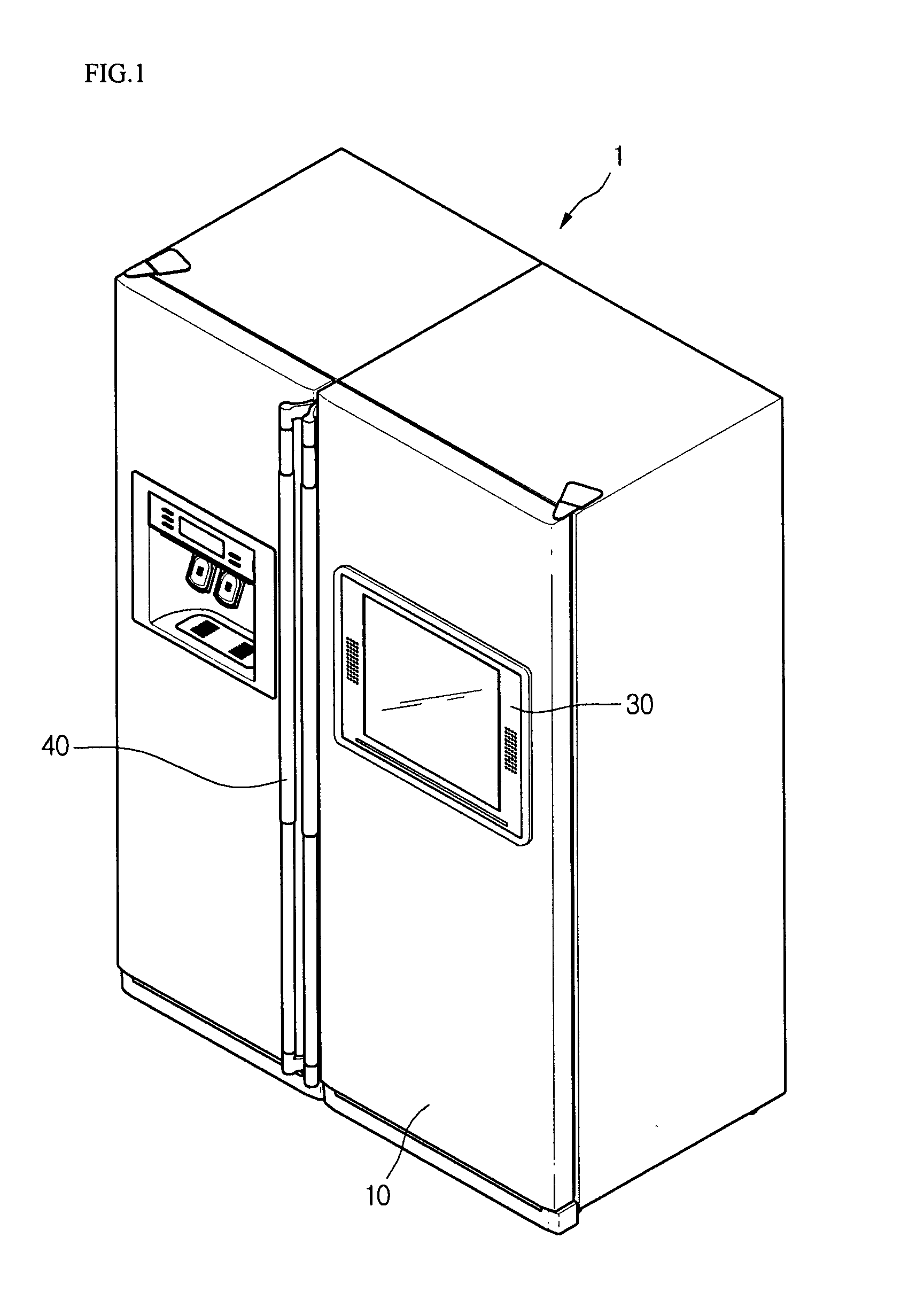

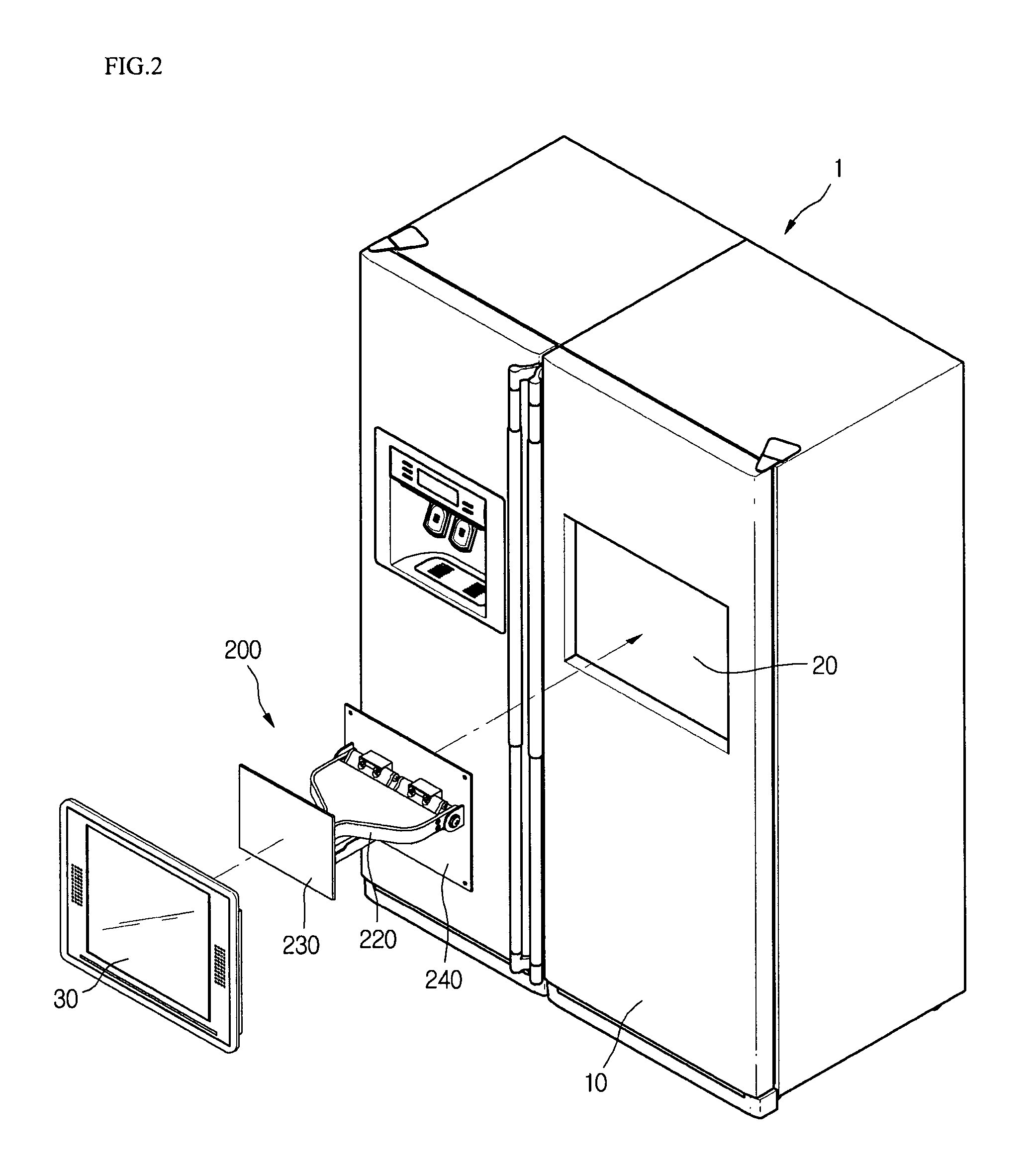

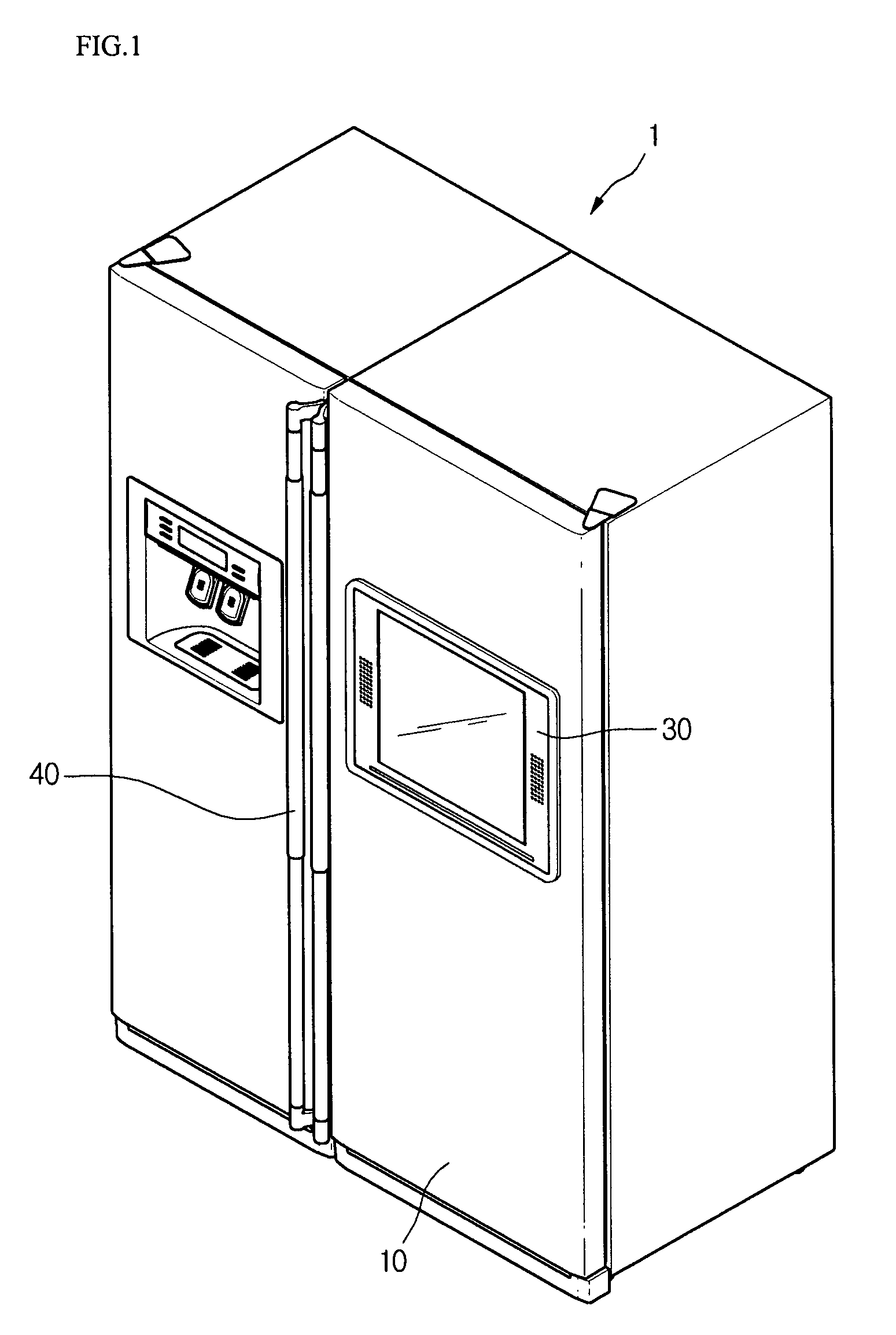

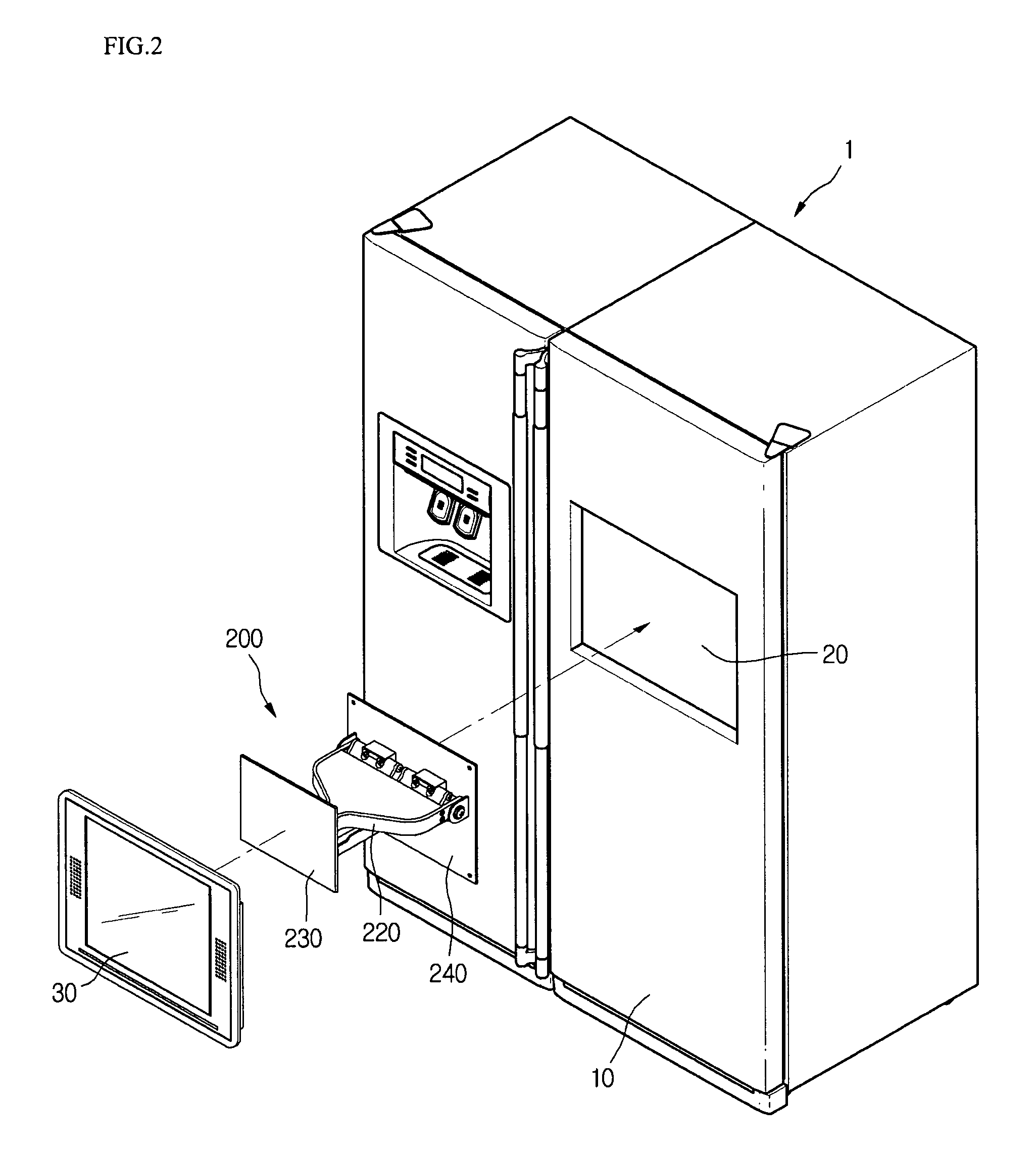

Refrigerator and display device guiding apparatus of the same

InactiveUS20060118694A1Depth is minimizedReduced insulation performancePicture framesDoors/windowsDisplay deviceEngineering

A display device guiding apparatus includes a receiving portion in which a display device can be received and a guide unit provided between the display device and the receiving portion. The guide unit includes a hinge assembly for pivoting the display at a predetermined angle, an arm assembly having first and second ends respectively connected to the hinge assembly and the receiving portion, and a pivot control unit providing a pivotal force of the arm assembly with respect to the receiving portion.

Owner:LG ELECTRONICS INC

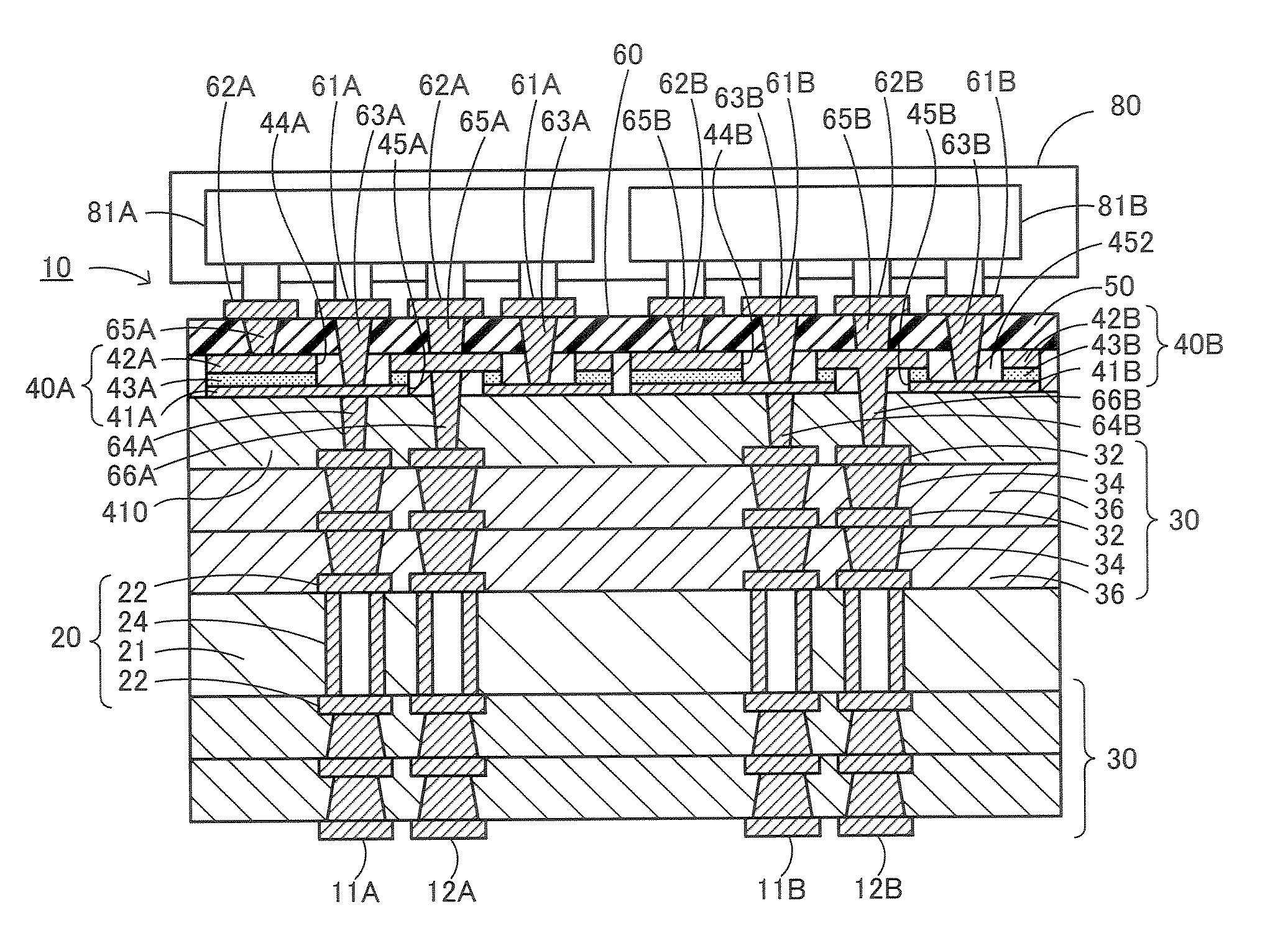

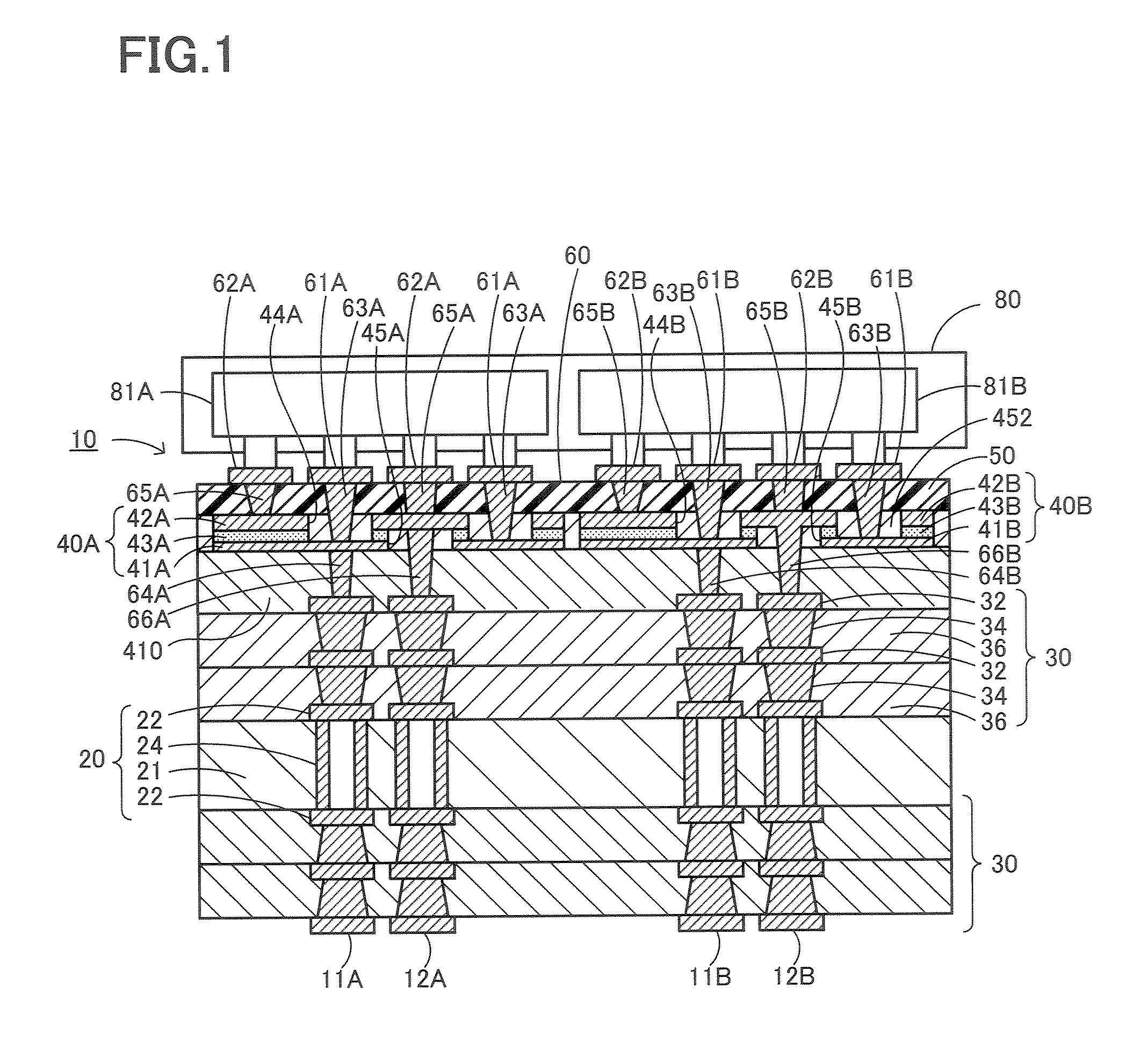

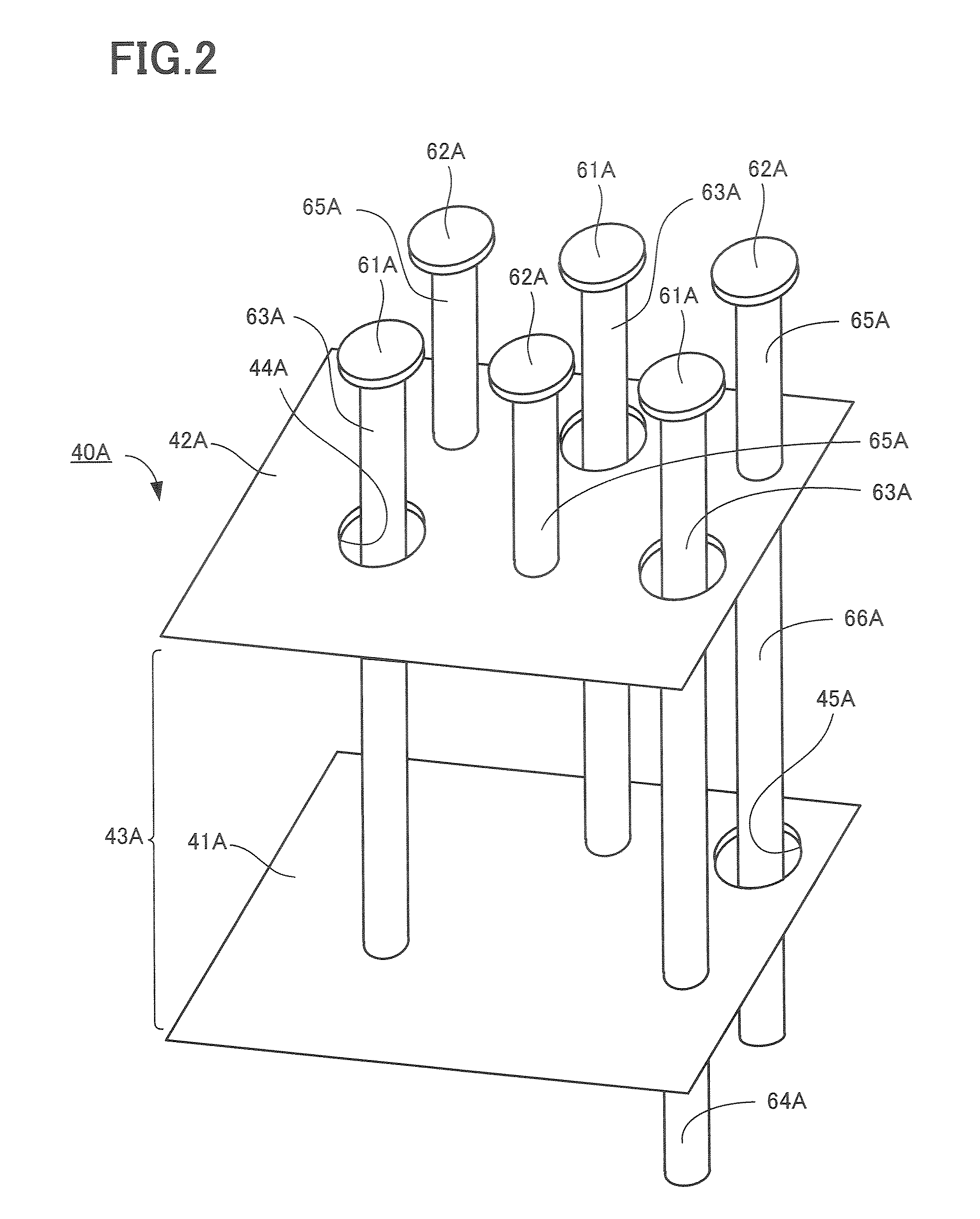

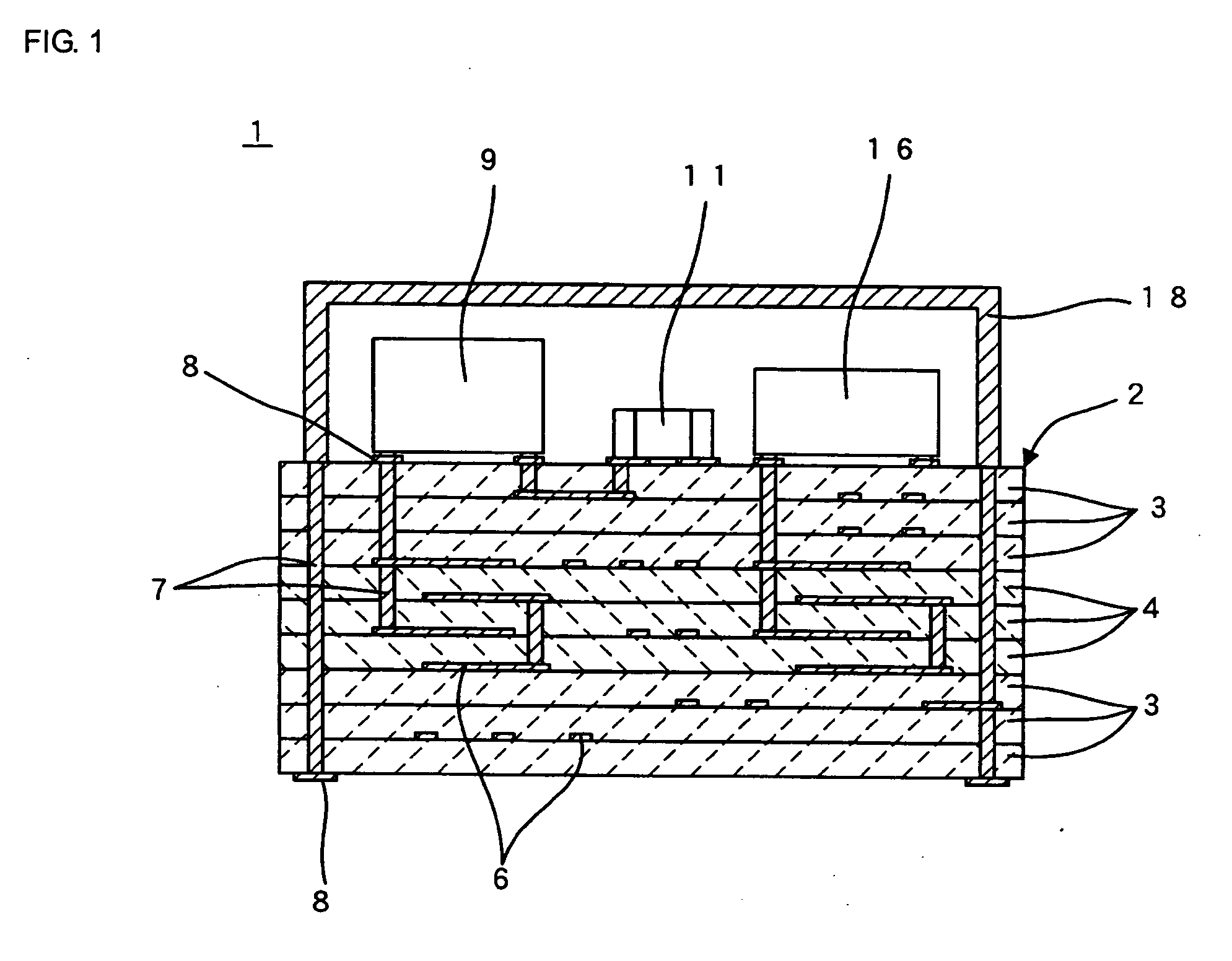

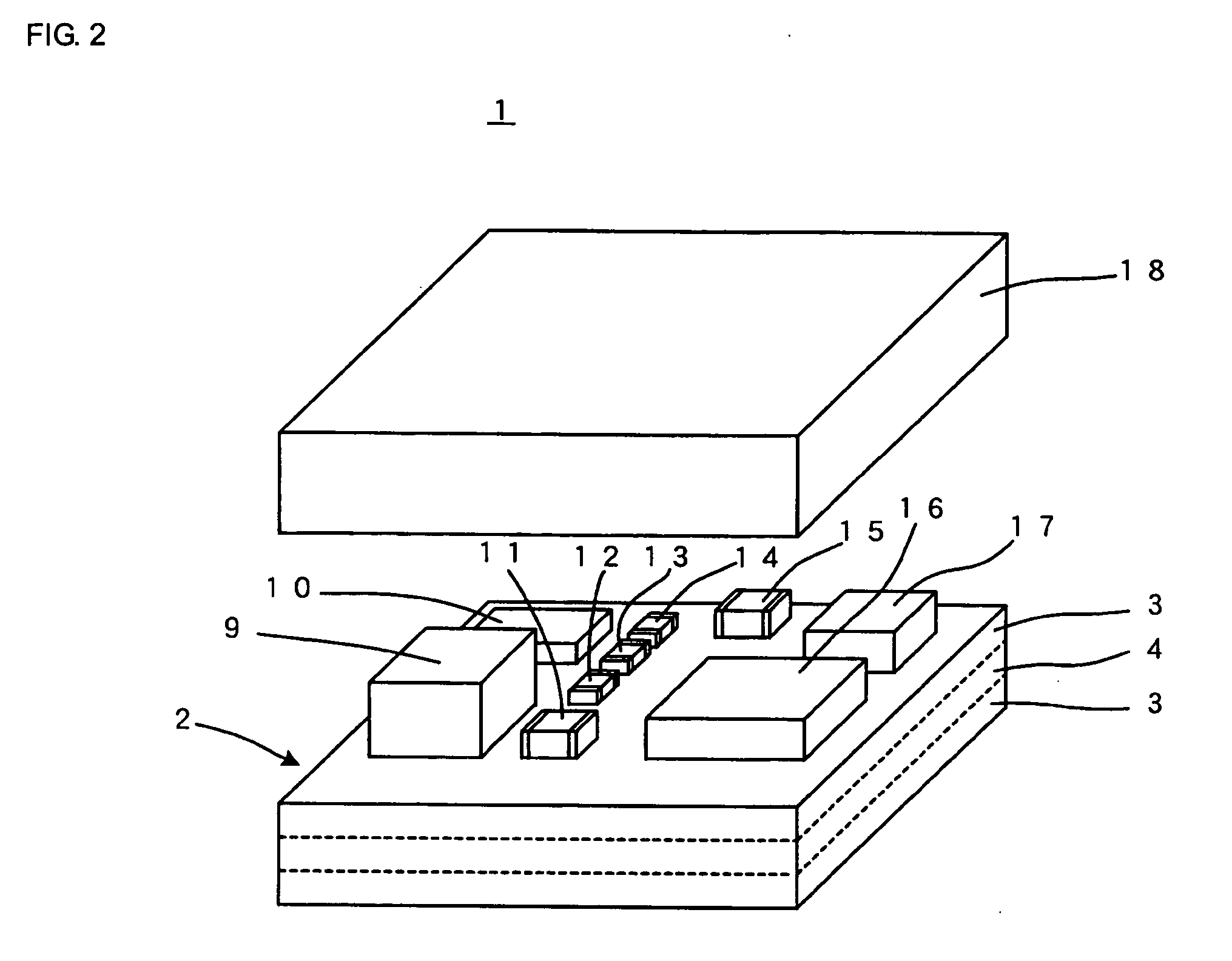

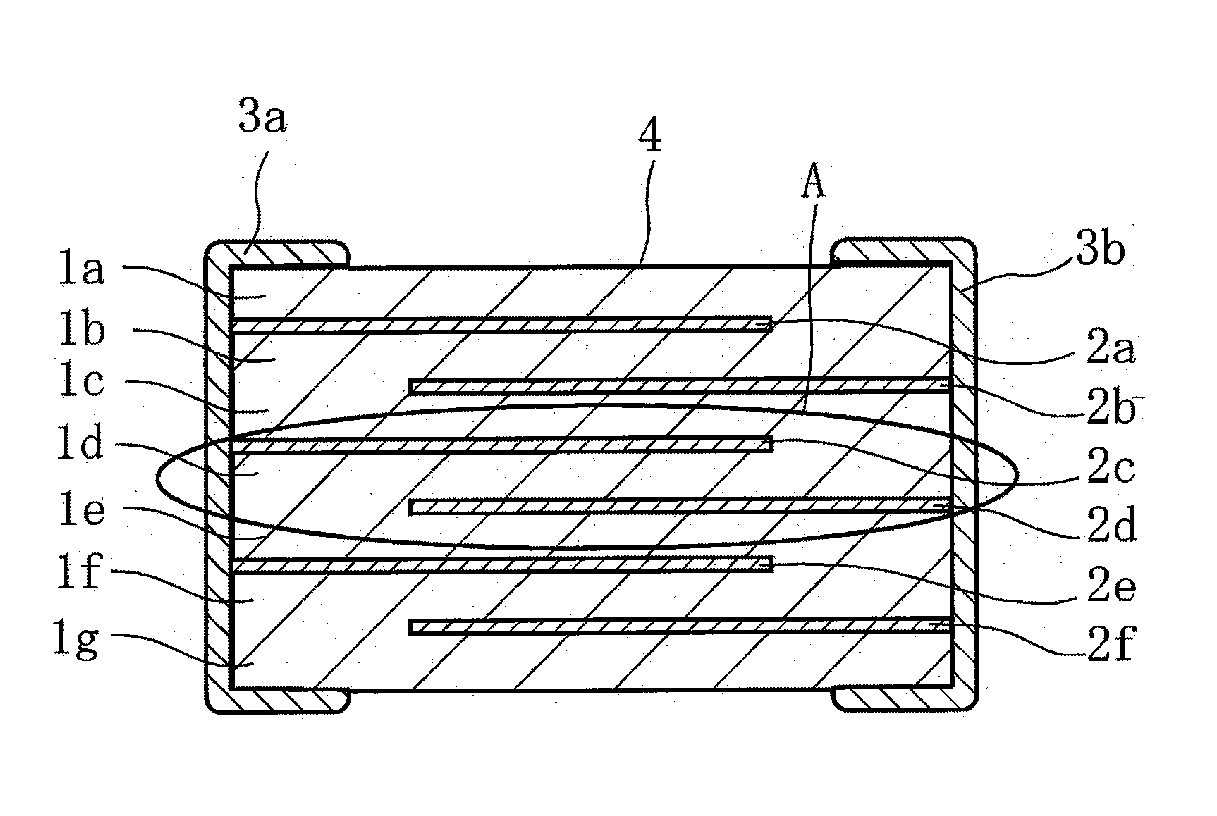

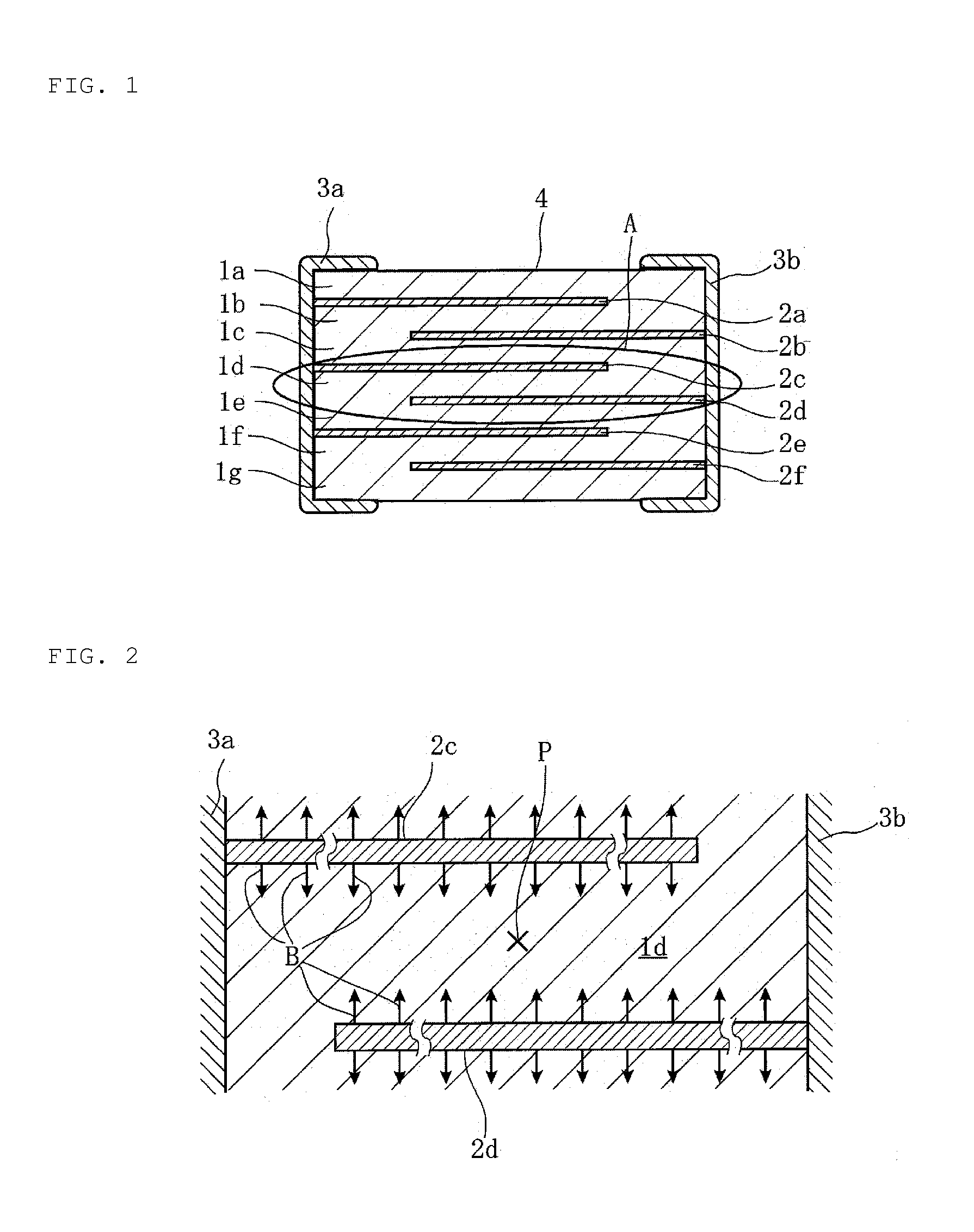

Printed wiring board

ActiveUS20090290316A1Decoupling effect decreaseGood decoupling effectSemiconductor/solid-state device detailsPrinted circuit aspectsDual coreVoltage variation

A printed wiring board includes a mounting portion on which a dual core processor including two processor cores in a single chip can be mounted, power supply lines, ground lines, and a first layered capacitor and a second layered capacitor that are independently provided for each of the processor cores, respectively. Accordingly, even when the electric potentials of the processor cores instantaneously drop, an instantaneous drop of the electric potential can be suppressed by action of the layered capacitors corresponding to the processor cores, respectively. In addition, even when the voltage of one of the processor cores varies, the variation in the voltage does not affect the other processor core, and thus malfunctioning does not occur.

Owner:IBIDEN CO LTD

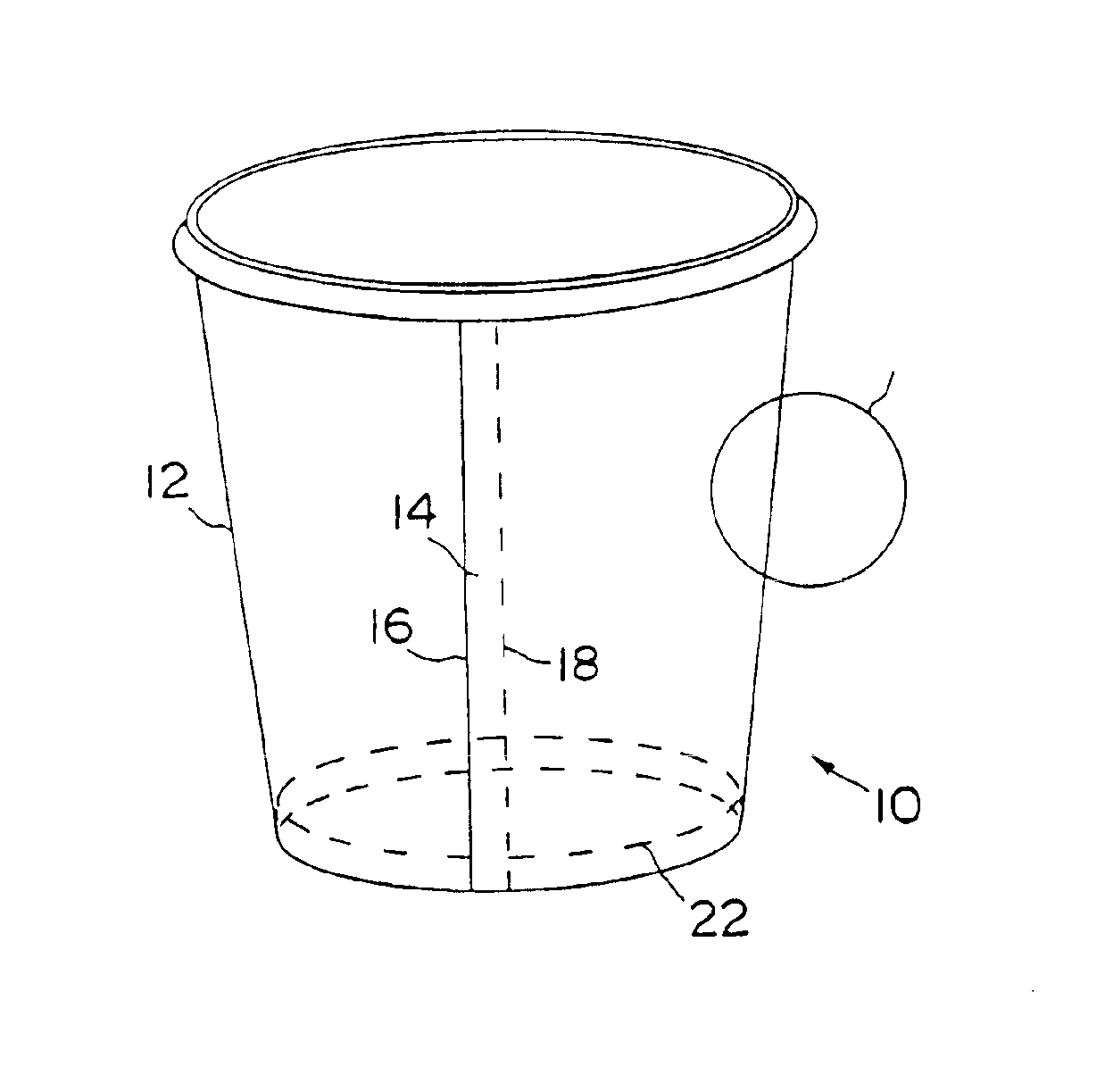

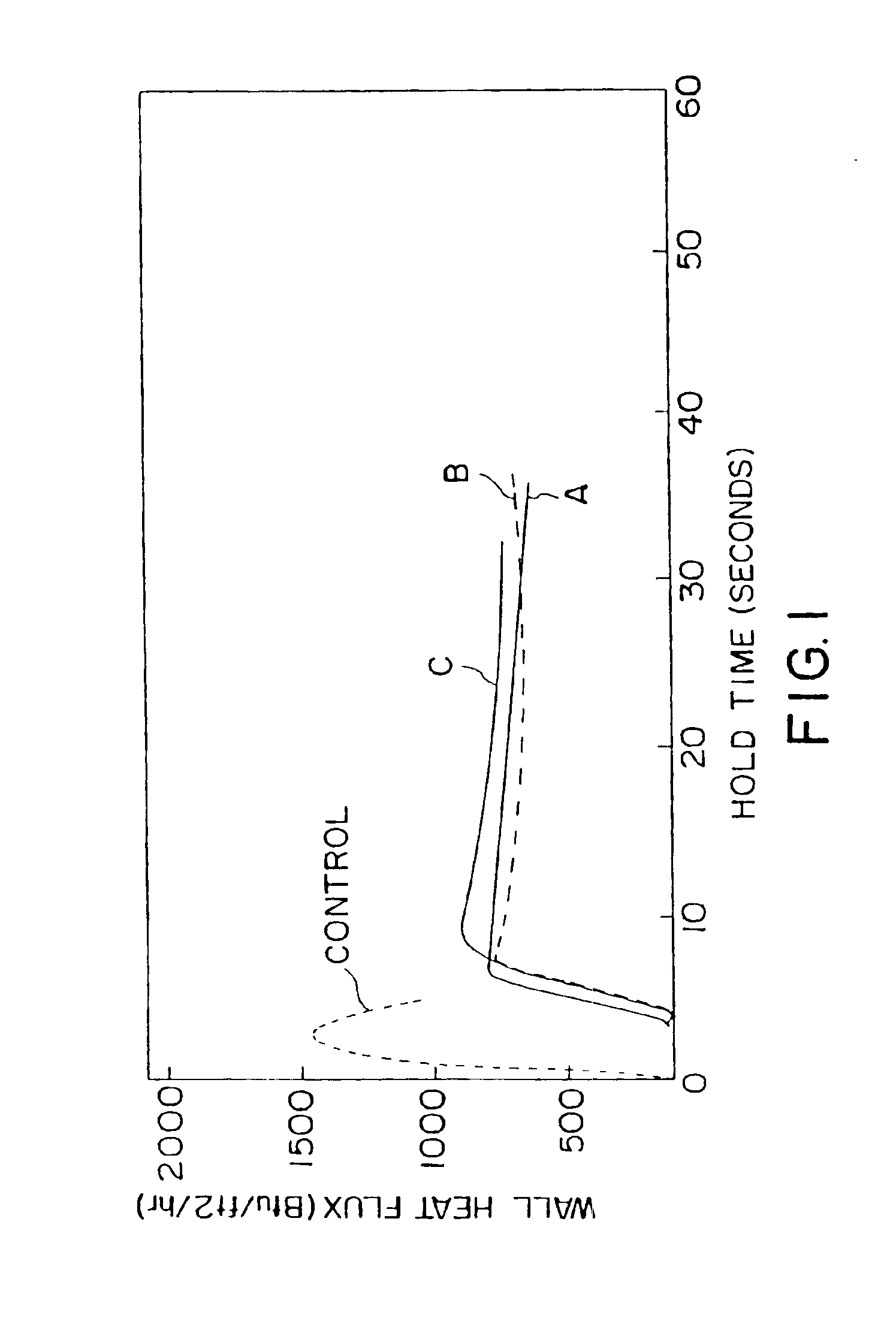

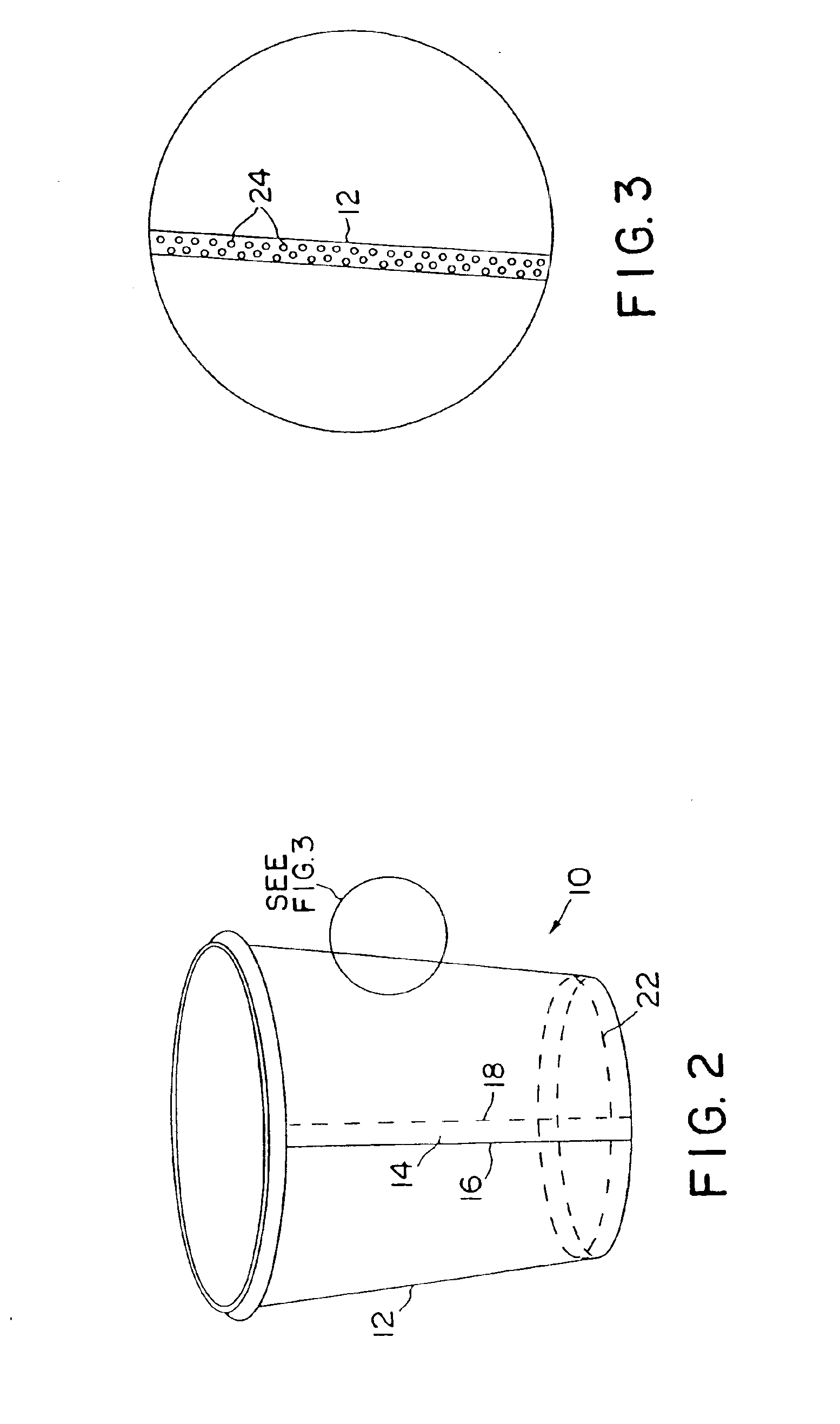

Low density paperboard articles

InactiveUS6846529B2Improve insulation performanceLess-expensive to produceNon-fibrous pulp additionNatural cellulose pulp/paperLow-density polyethyleneLinear low-density polyethylene

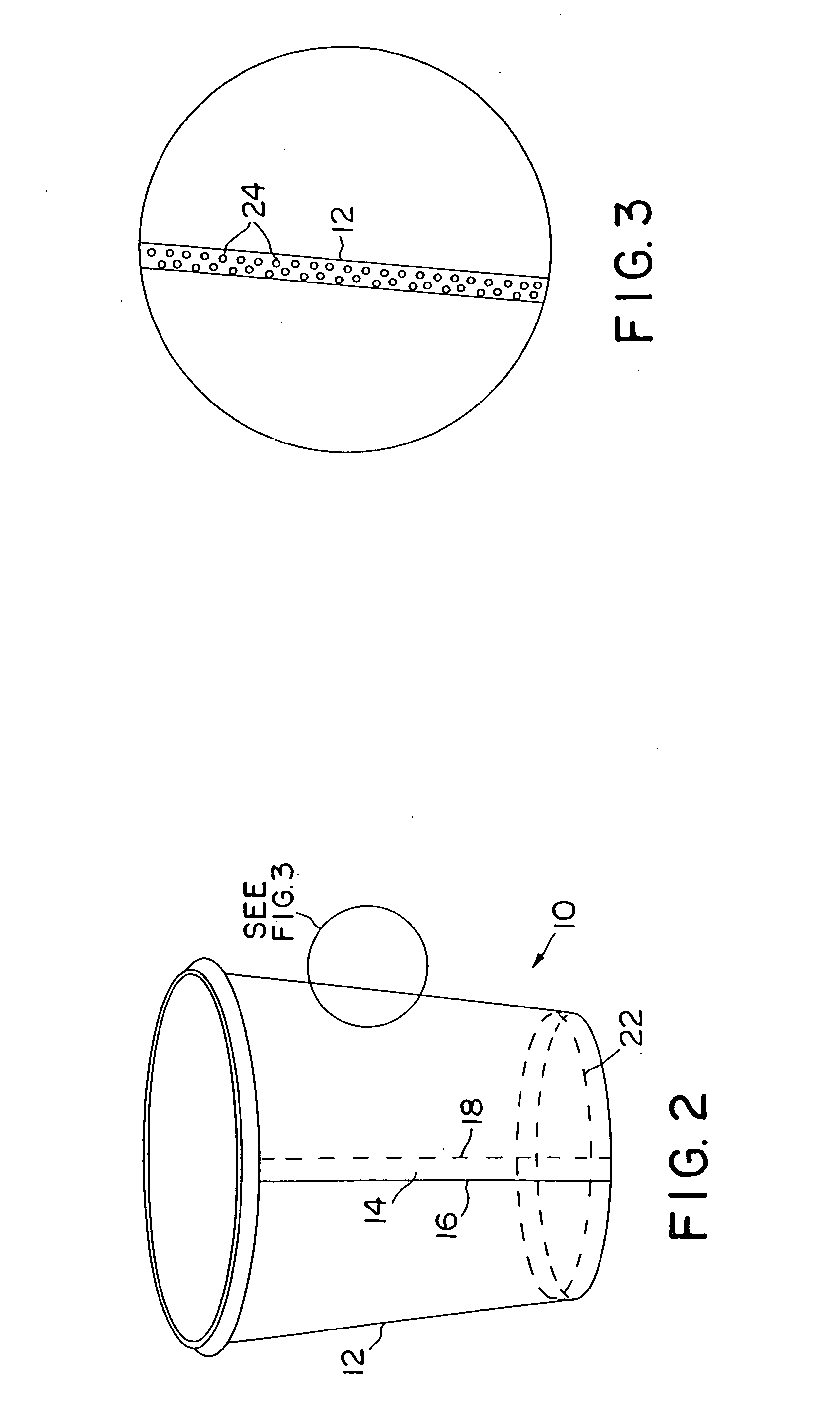

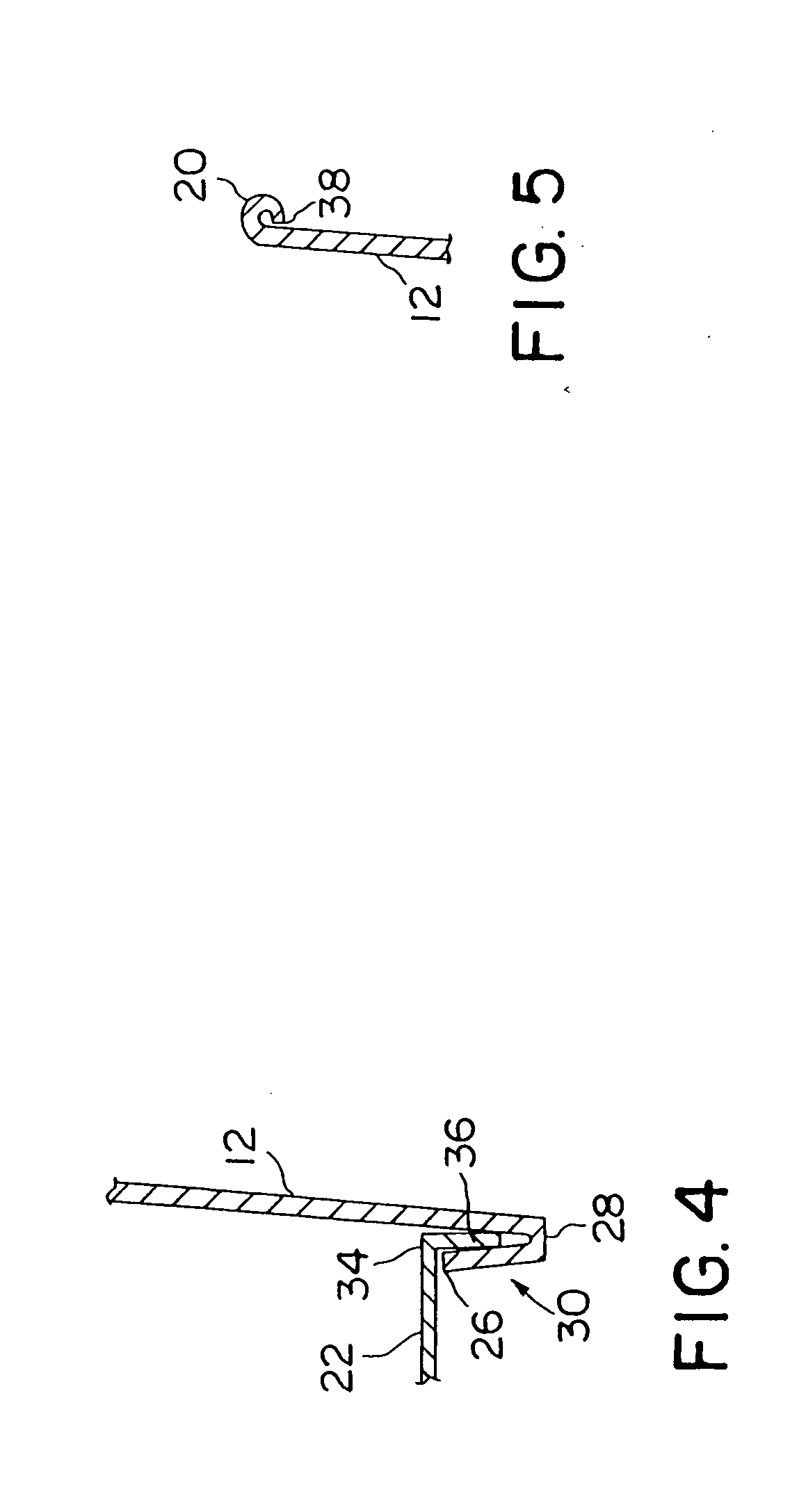

The invention provides a low density paperboard material for use in producing an insulated container, and is especially well-suited for making cups. The paperboard material comprises a paperboard web including wood fibers and expanded microspheres, and has a relatively low density ranging from about 6 to about 10 lb / 3MSF / mil, a relatively high caliper ranging from about 24 to about 35 mil, and an internal bond strength of at least about 80×10−3 ft-lbf preferably at least 100×10−3 ft-lbf. For applications such as cups the material is also coated on one or both sides with a barrier coating, preferably low density polyethylene, to limit liquid penetration into the web. The low density paperboard material of the invention is convertible for manufacture of containers, particularly cups, and the surface of the low density board may have a Sheffield smoothness of 300 SU or greater.

Owner:GRAPHIC PACKAGING INT

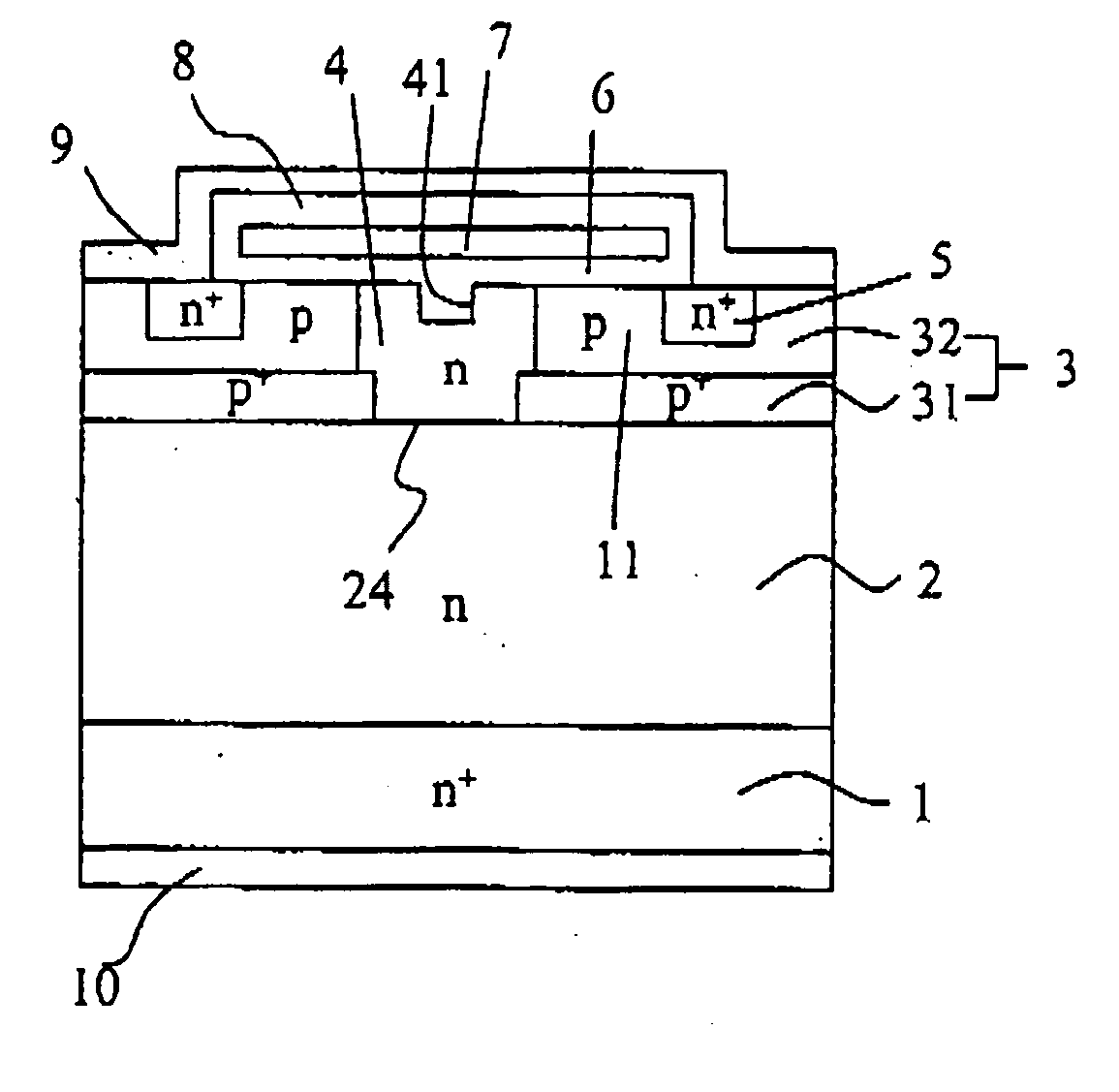

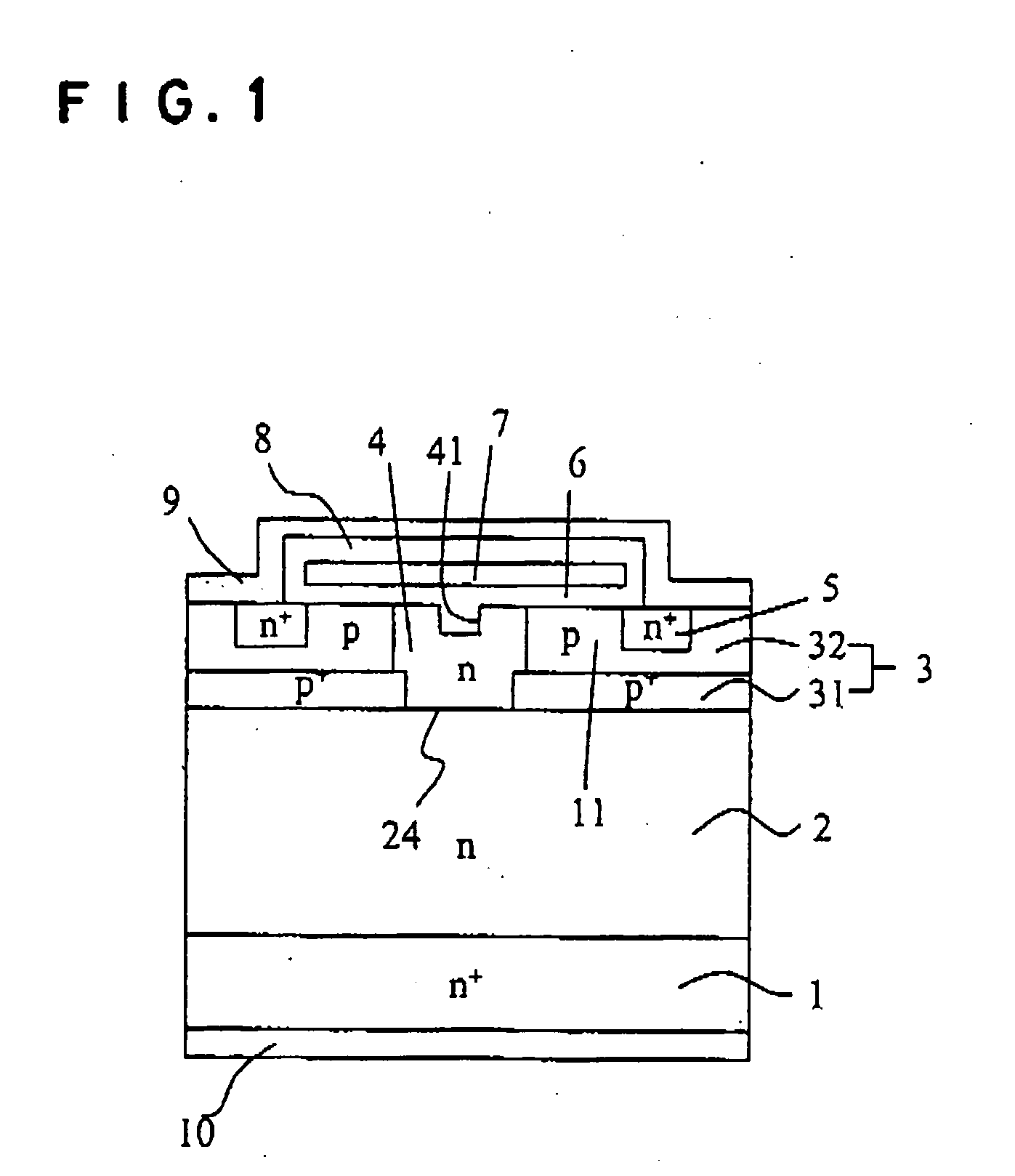

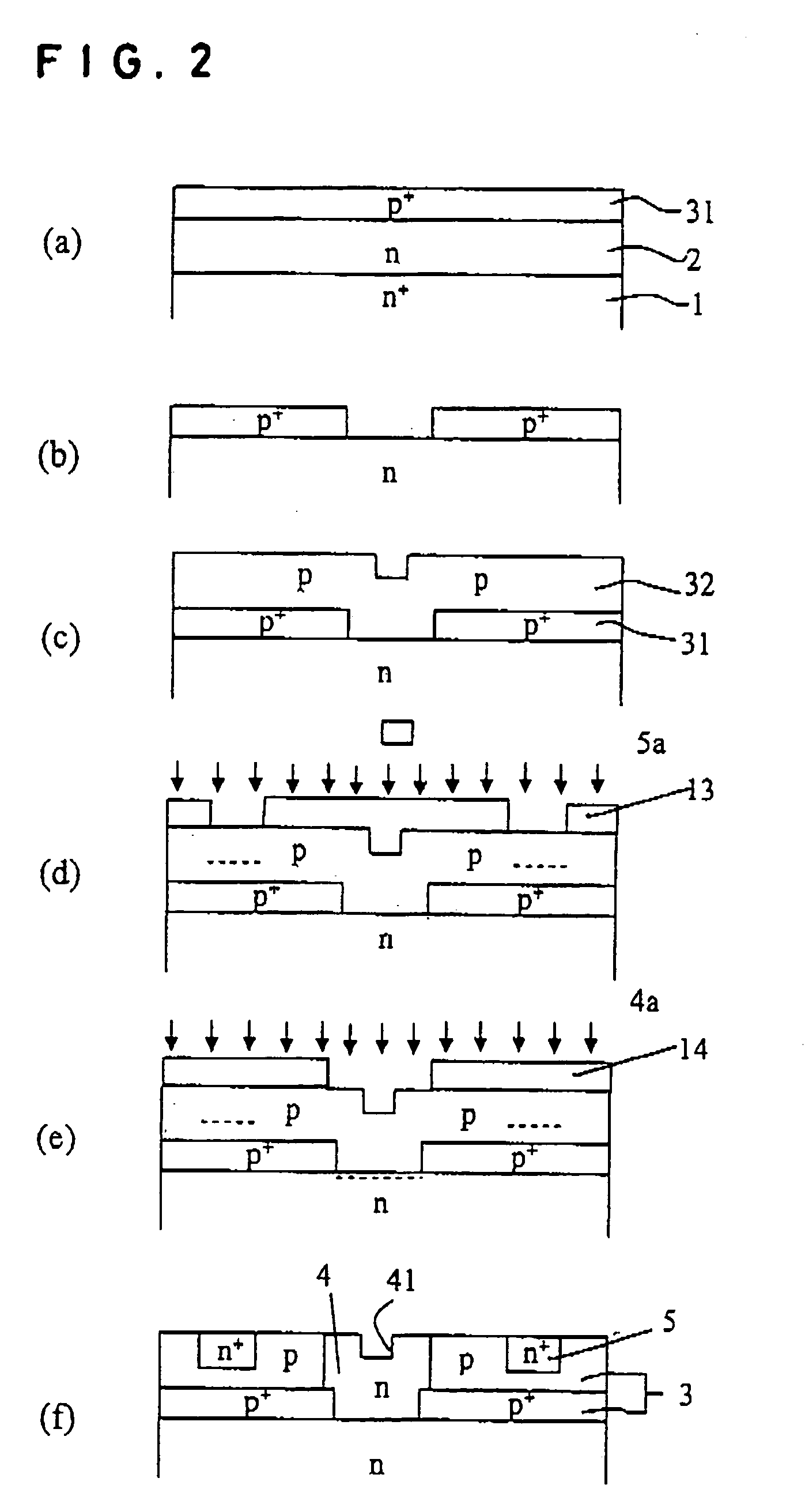

Silicon carbide semiconductor device and its method of manufacturing method

InactiveUS20060057796A1Resistance component be reduceDecrease in numberSemiconductor/solid-state device manufacturingSemiconductor devicesMOSFETHigh concentration

A silicon carbide vertical MOSFET having low ON-resistance and high blocking voltage. A first deposition film of low concentration silicon carbide of a first conductivity type is formed on the surface of a high concentration silicon carbide substrate of a first conductivity type. Formed on the first deposition film is a second deposition film that includes a high concentration gate region of a second conductivity type, with a first region removed selectively. A third deposition film is formed on the second deposition film, which includes a second region that is wider than the selectively removed first region, a high concentration source region of a first conductivity type, and a low concentration gate region of a second conductivity type. A low concentration base region of a first conductivity type is formed in contact with the first deposition film in the first and second regions.

Owner:SANYO ELECTRIC CO LTD SHARE 20 +1

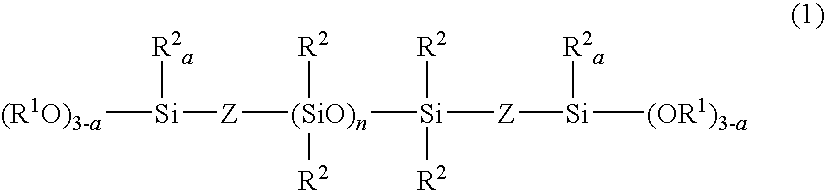

RTV silicone rubber composition for electric and electronic part protection, circuit boards, silver electrodes, and silver chip resistors

InactiveUS7553901B2Prevent and retard partPrevent short-circuitingLayered productsSemiconductor/solid-state device detailsSulfur containingElectron

RTV silicone rubber compositions are provided comprising (A) an organopolysiloxane, (B) an organosilicon compound or partial hydrolytic condensate thereof, and (C) a non-aromatic amino-bearing compound. The compositions, when electric and electronic parts having a copper, silver or other metal portion on their surface are encapsulated or sealed therewith, can prevent or retard the parts from corrosion with sulfur-containing gas.

Owner:SHIN ETSU CHEM IND CO LTD

SiO2 enriched nano composite heat preserving and thermal insulating paste and preparing process thereof

The invention relates to SiO2 nano composite thermal insulation paste, which is characterized in that the form of the SiO2 nano composite thermal insulation paste is a paste mixture, and the dried paste mixture becomes micro pores, nano holes and a fiber structure compound. The paste comprises the following components by weight percentage: 20 to 50 percent of SiO2 nano aerogel, 0 to 30 percent of inorganic closed-hole micro-bead material, 7 to 15 percent of expanded pearlite, 0 to 1 percent of bentonite, 2 to 6 percent of penetrating agent, 10 to 20 percent of adhesive, 3 to 6 percent of calcium silicate fiber, 0 to 5 percent of magnesium aluminum silicate fiber, 0 to 5 percent of aluminum silicate fiber, 0 to 40 percent of water, 0.1 to 2 percent of flame retardant, and 3 to 7 percent of pigment. A preparation device is a vacuum intake and stirring device.

Owner:上海暄洋化工材料科技有限公司

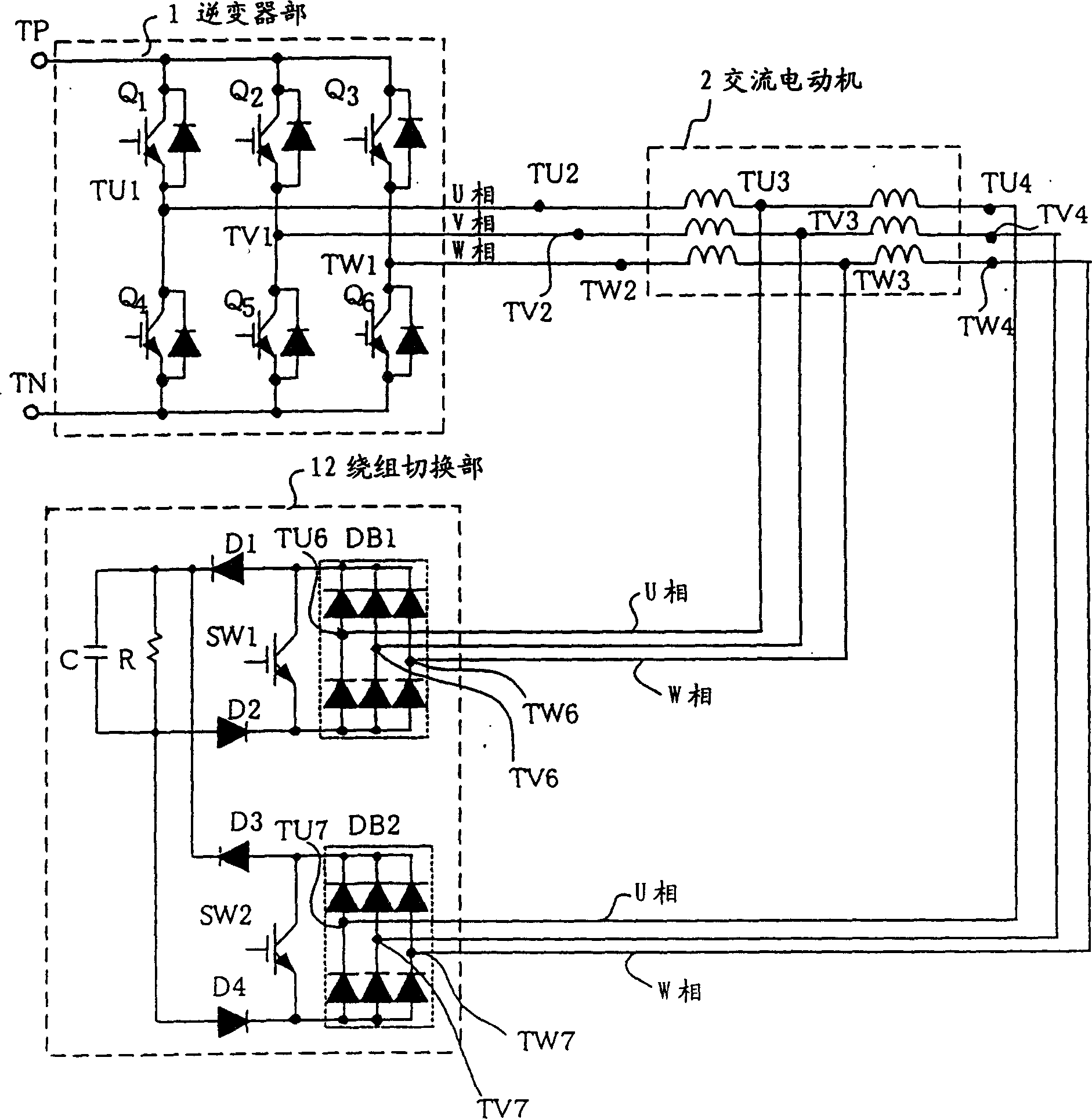

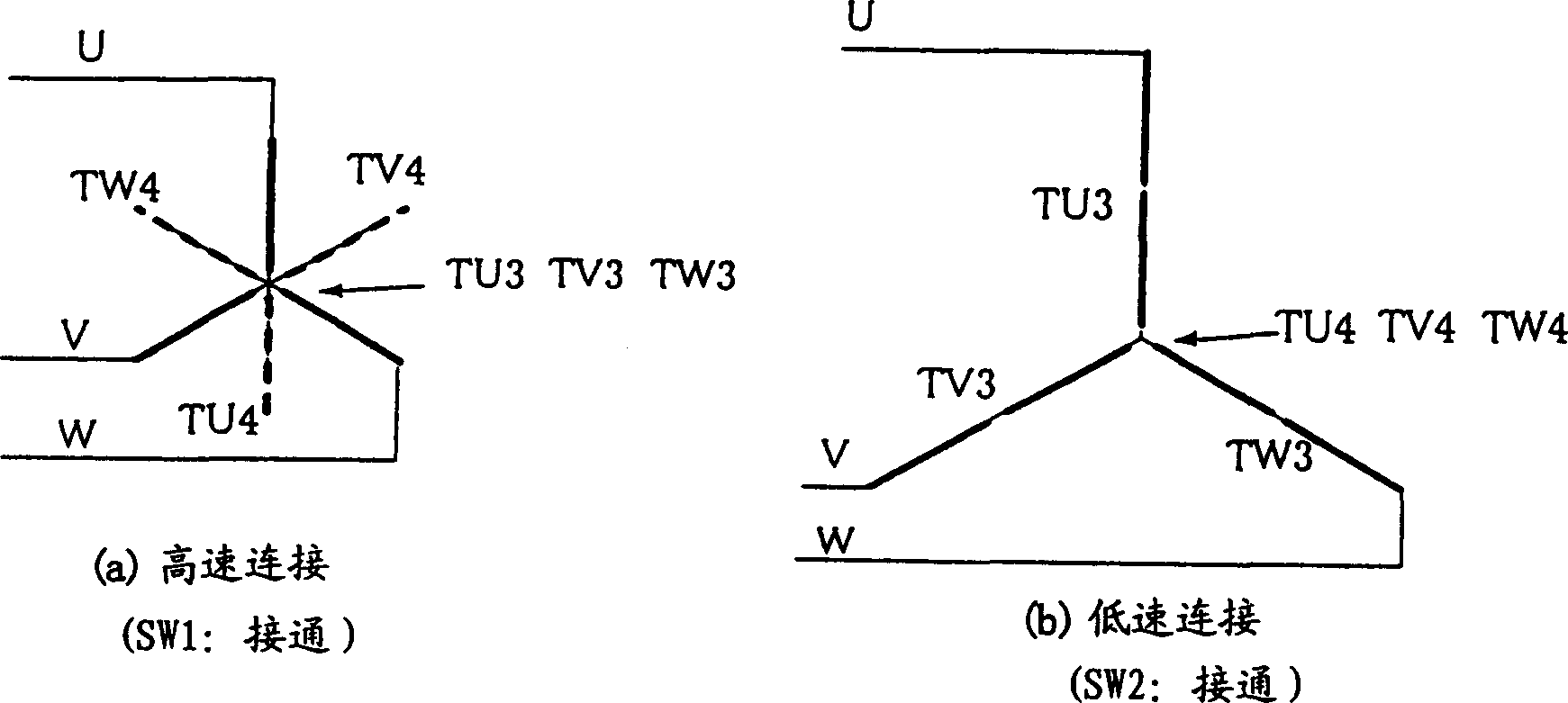

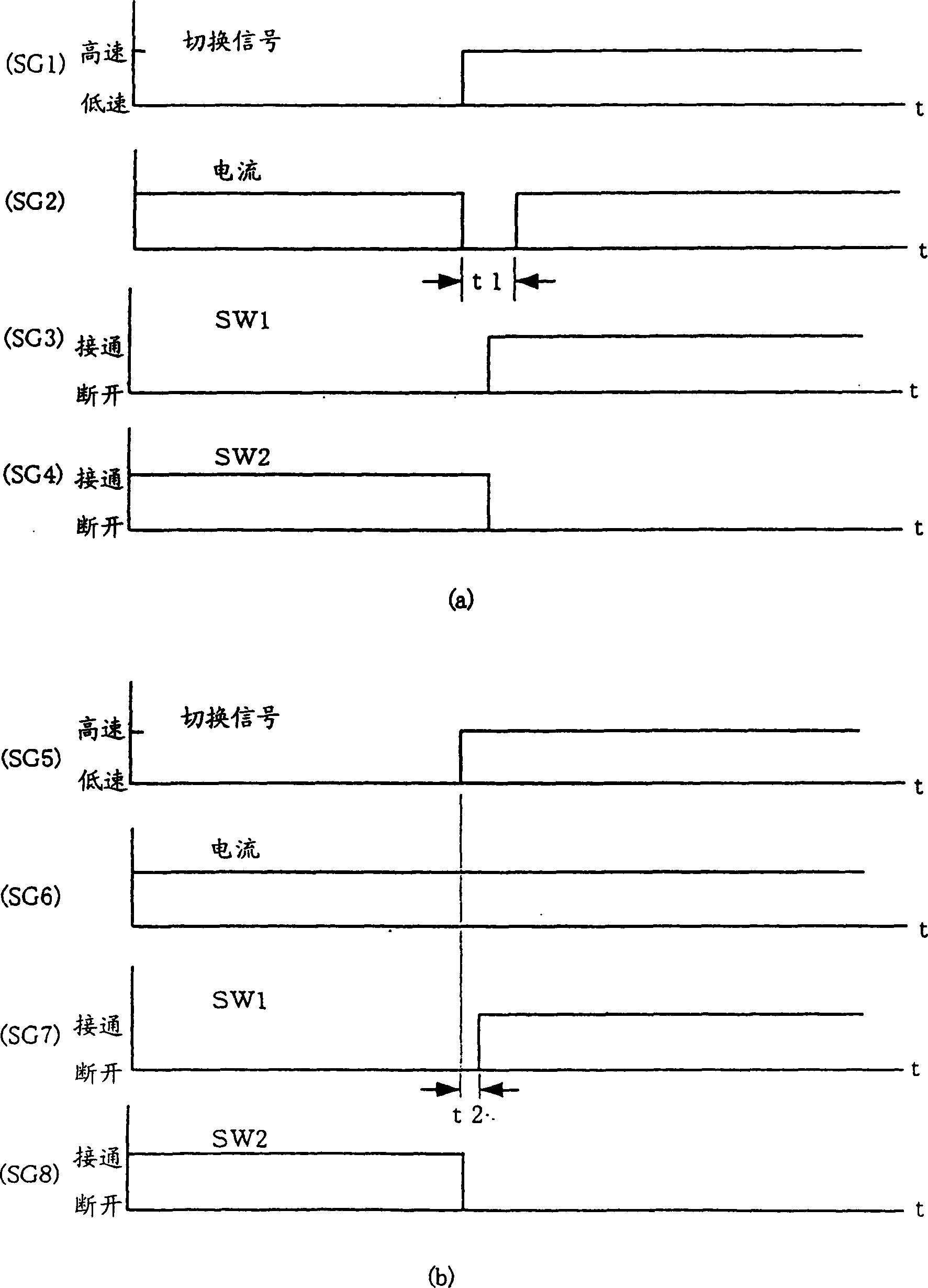

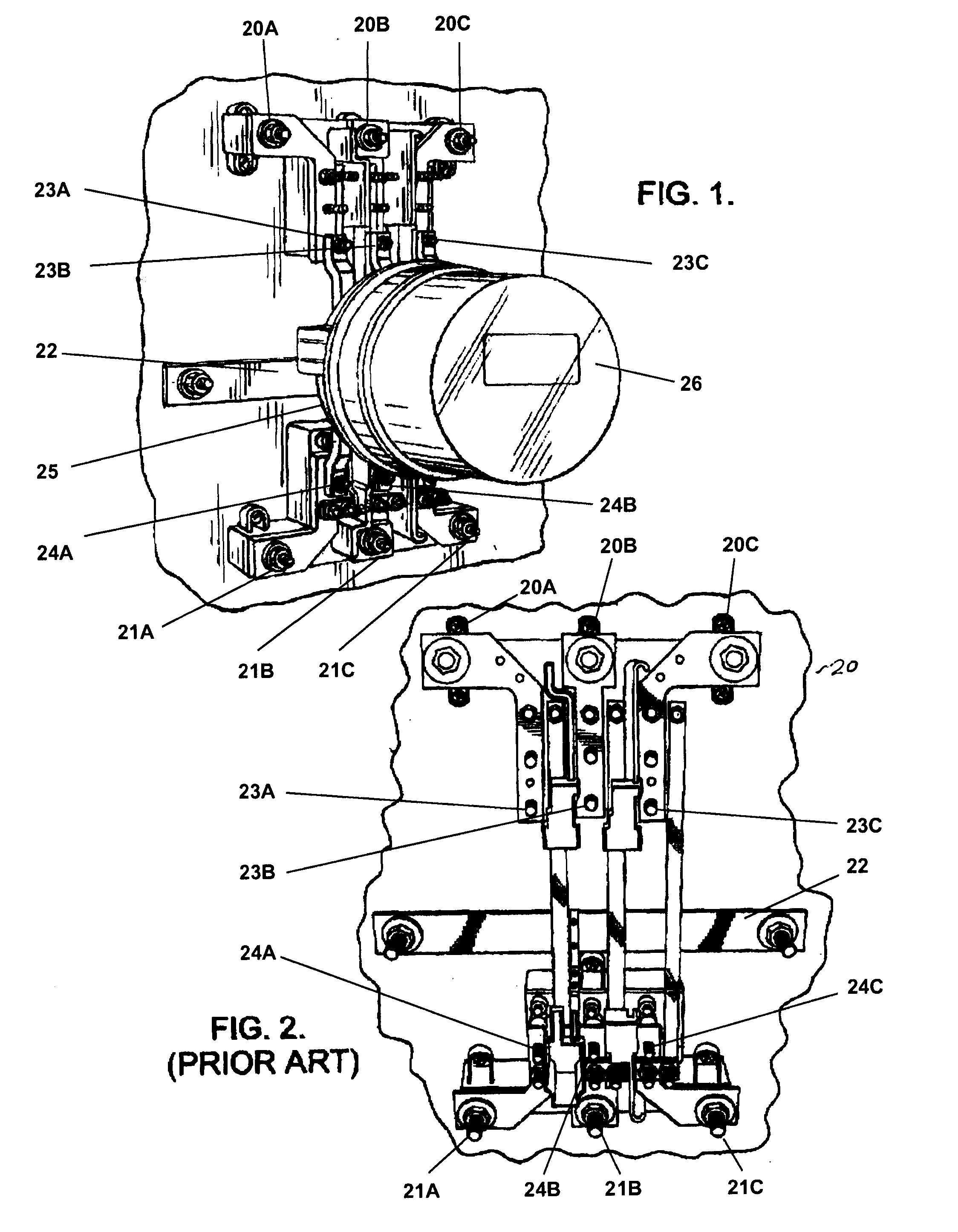

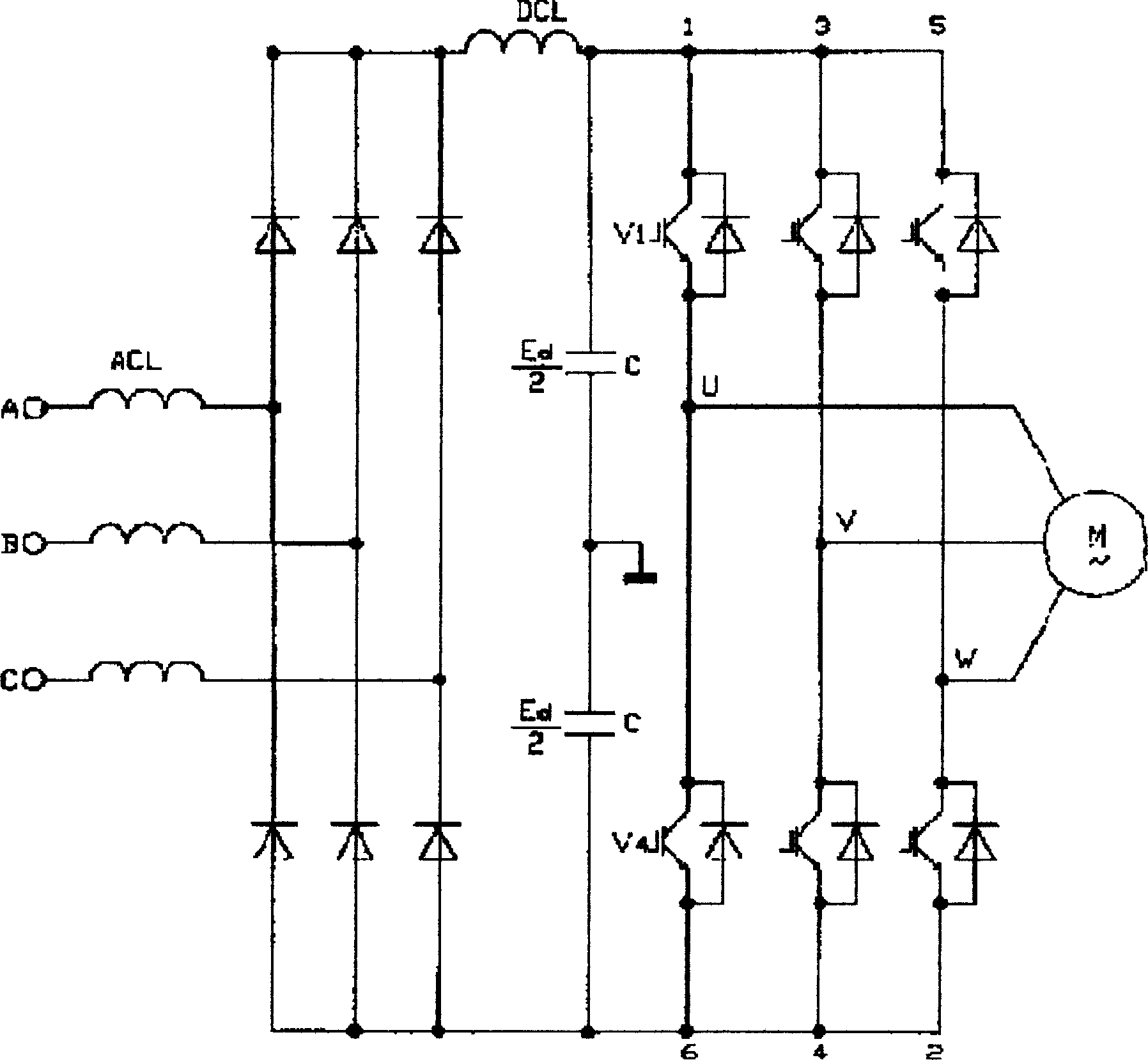

Apparatus for switching windings of AC three-phase motor

InactiveCN1565075AShorten the timeReduce usageDC motor speed/torque controlMotor control in four quadrantsThree-phaseEngineering

It is an object to provide a winding switching device of a three-phase AC motor having a small size at a low cost in which a time required for switching a winding is shortened and the number of semiconductor switch units is decreased as much as possible. In a winding switching device of a three-phase AC motor including an AC motor in which a winding having each phase is formed by a plurality of windings and a connecting terminal connecting the windings to each other and both terminals of the winding having the phase are provided on an outside of a motor, winding switching means for properly switching the connecting terminal, and a variable frequency power source for supplying a variable voltage having a variable frequency to the AC motor, the winding switching means is constituted by a plurality of three-phase rectifying means connecting one of ends of the winding having the phase to the variable frequency power source and connecting the other end and the connecting terminal to an input terminal on an AC side of the three-phase rectifying means for each phase, and a semiconductor switch provided to open and close both ends on a DC output side of the three-phase rectifying means.

Owner:YASKAWA DENKI KK

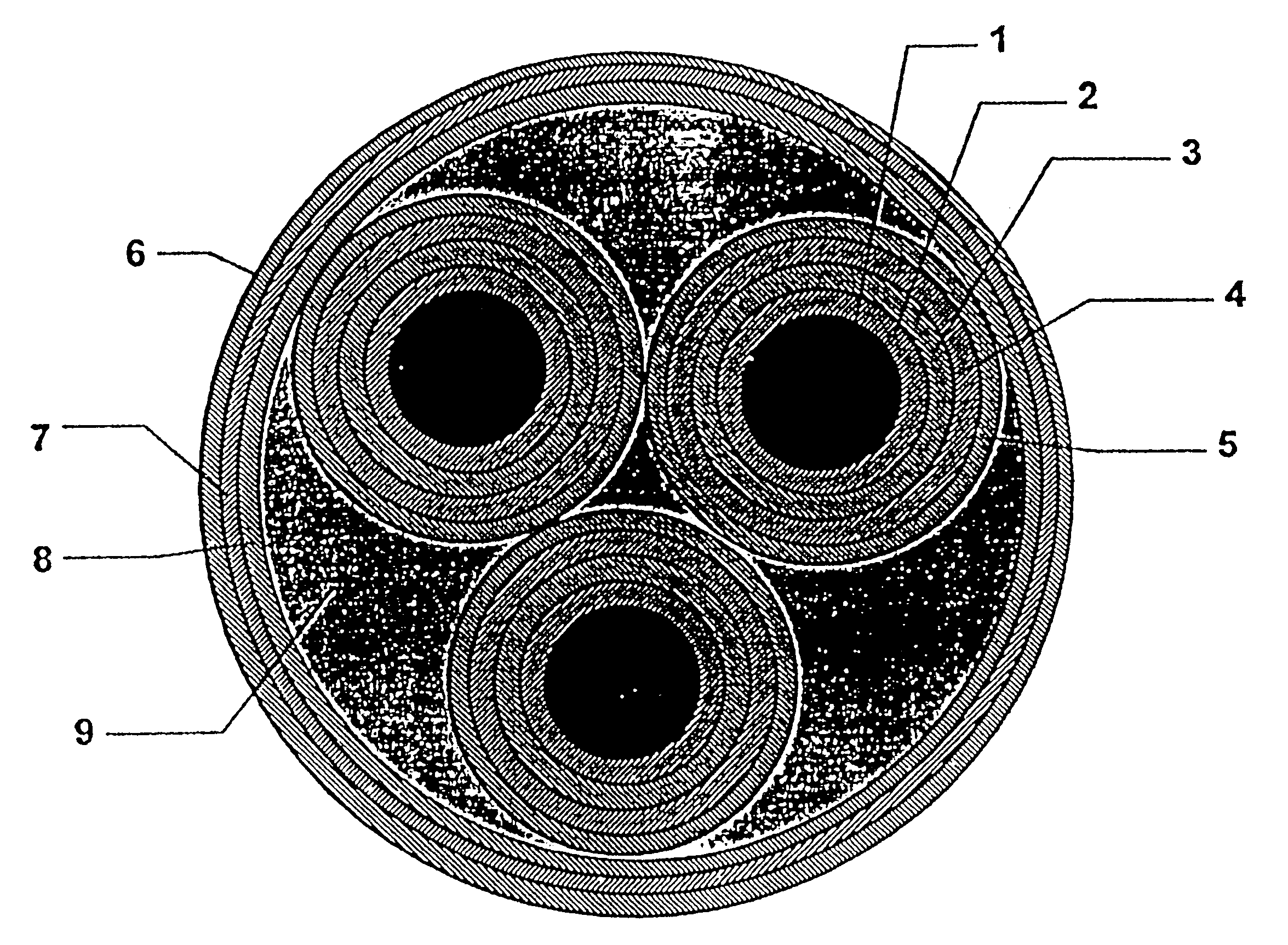

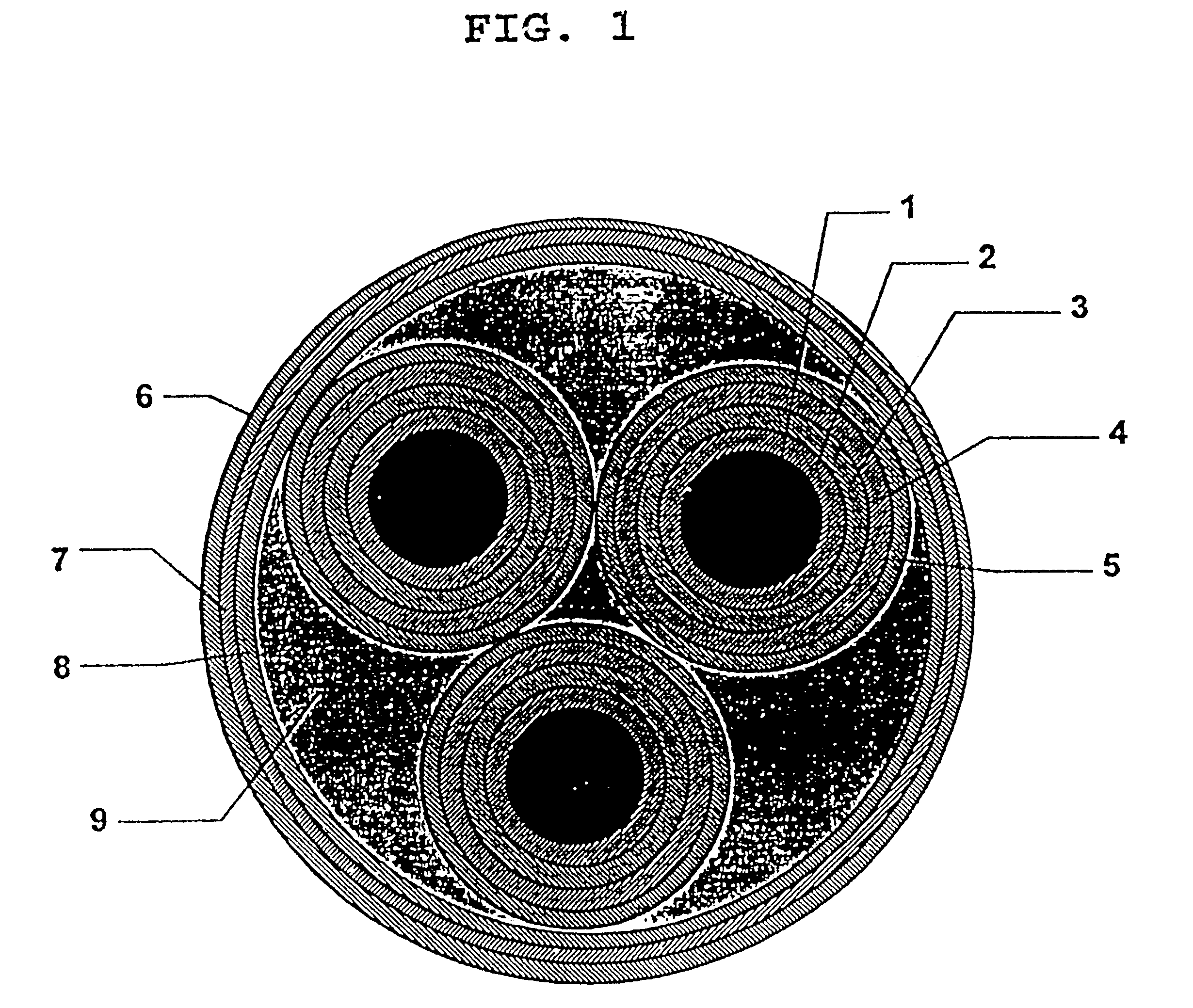

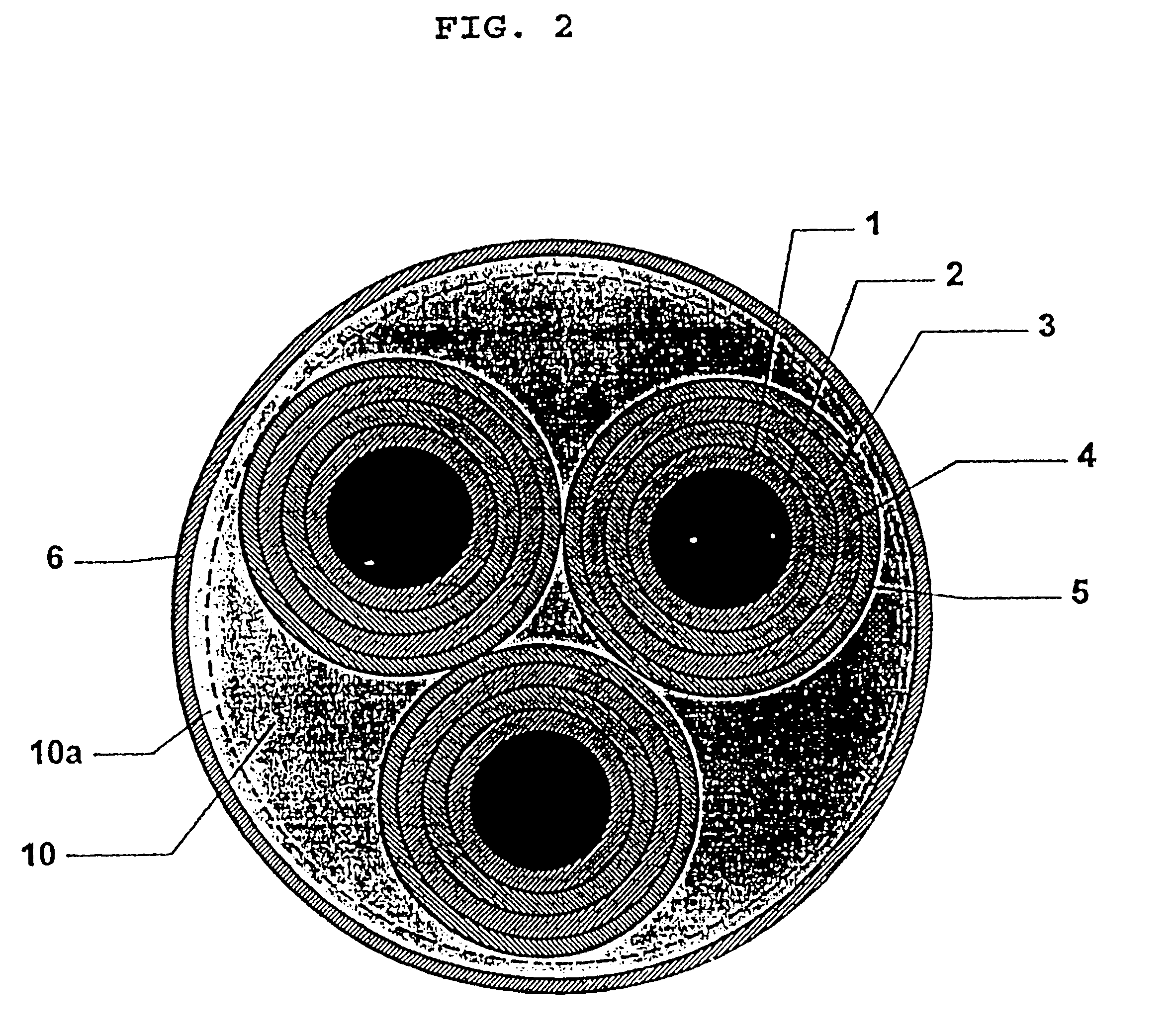

Cable with impact-resistant coating

InactiveUS6501027B1Easy to processReduce environmental impactPlastic/resin/waxes insulatorsInsulated cablesPolymer coatingsEngineering

The invention relates to a coating for cable which is capable of protecting the cable against accidental impacts. By inserting into the structure of a power transmission cable a suitable coating of expanded polymer material of adequate thickness, preferably in contact with the sheath of outer polymer coating to obtain a cable which has a high impact strength.

Owner:PIRELLI CAVI E SISTEMI SPA +1

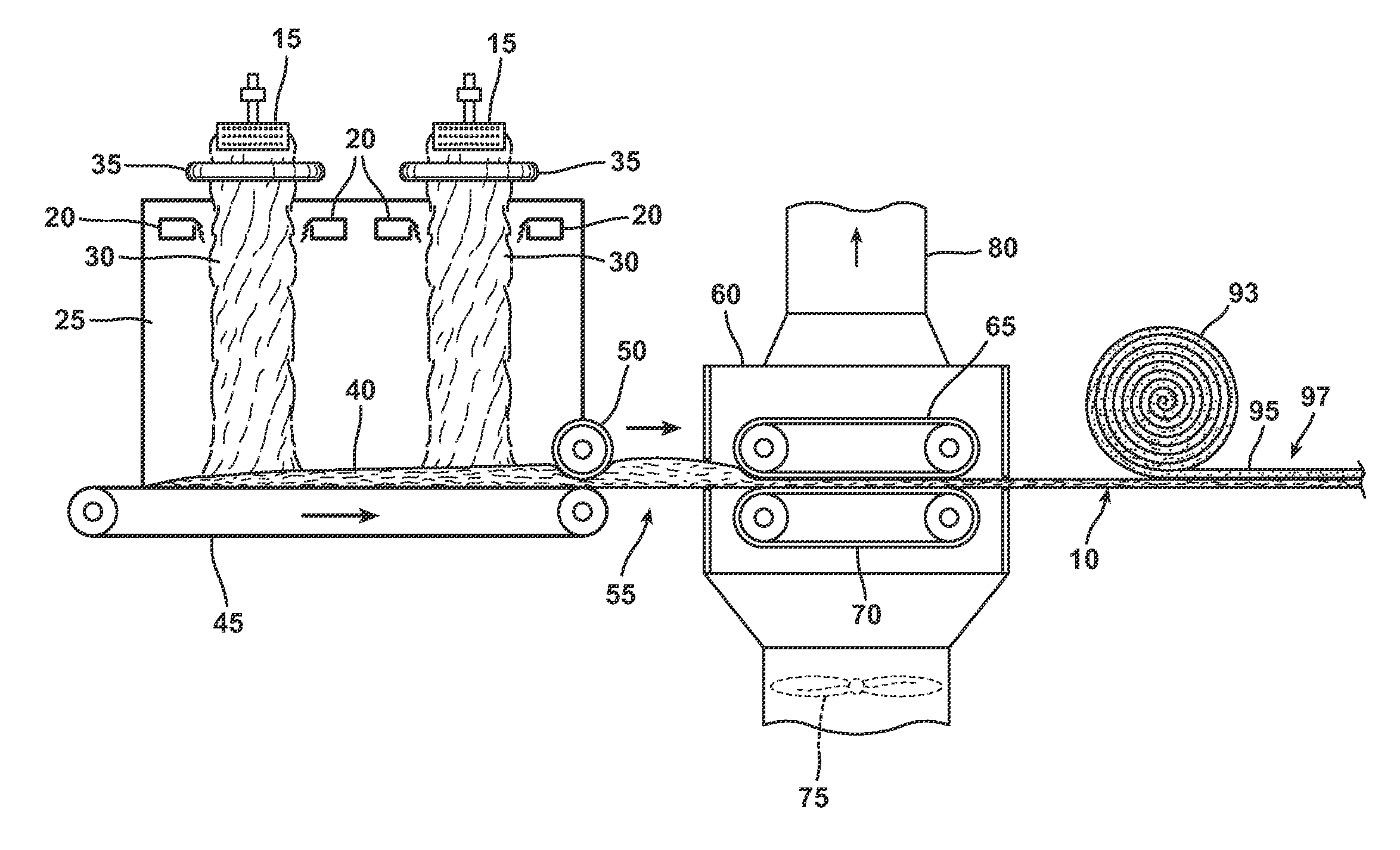

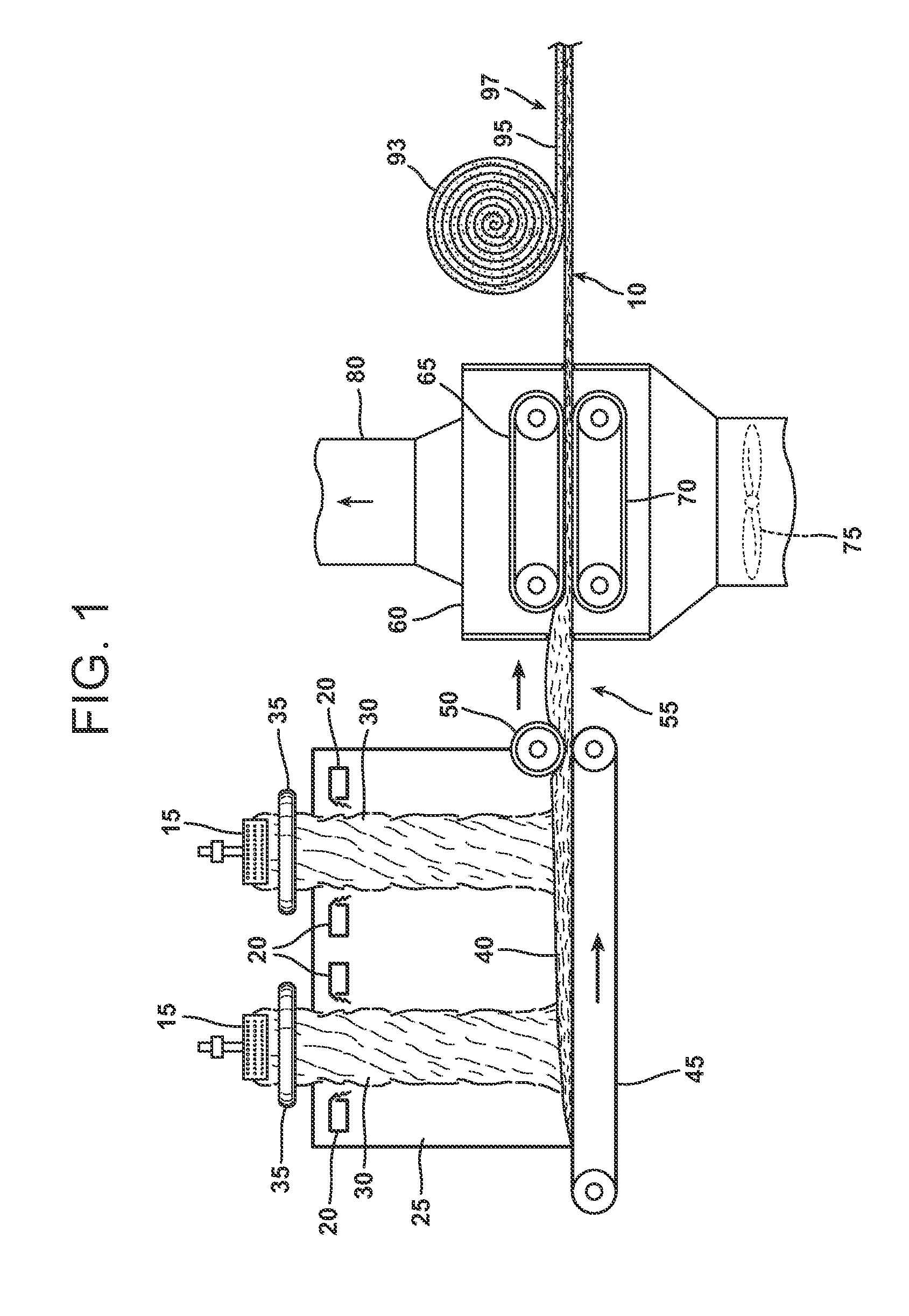

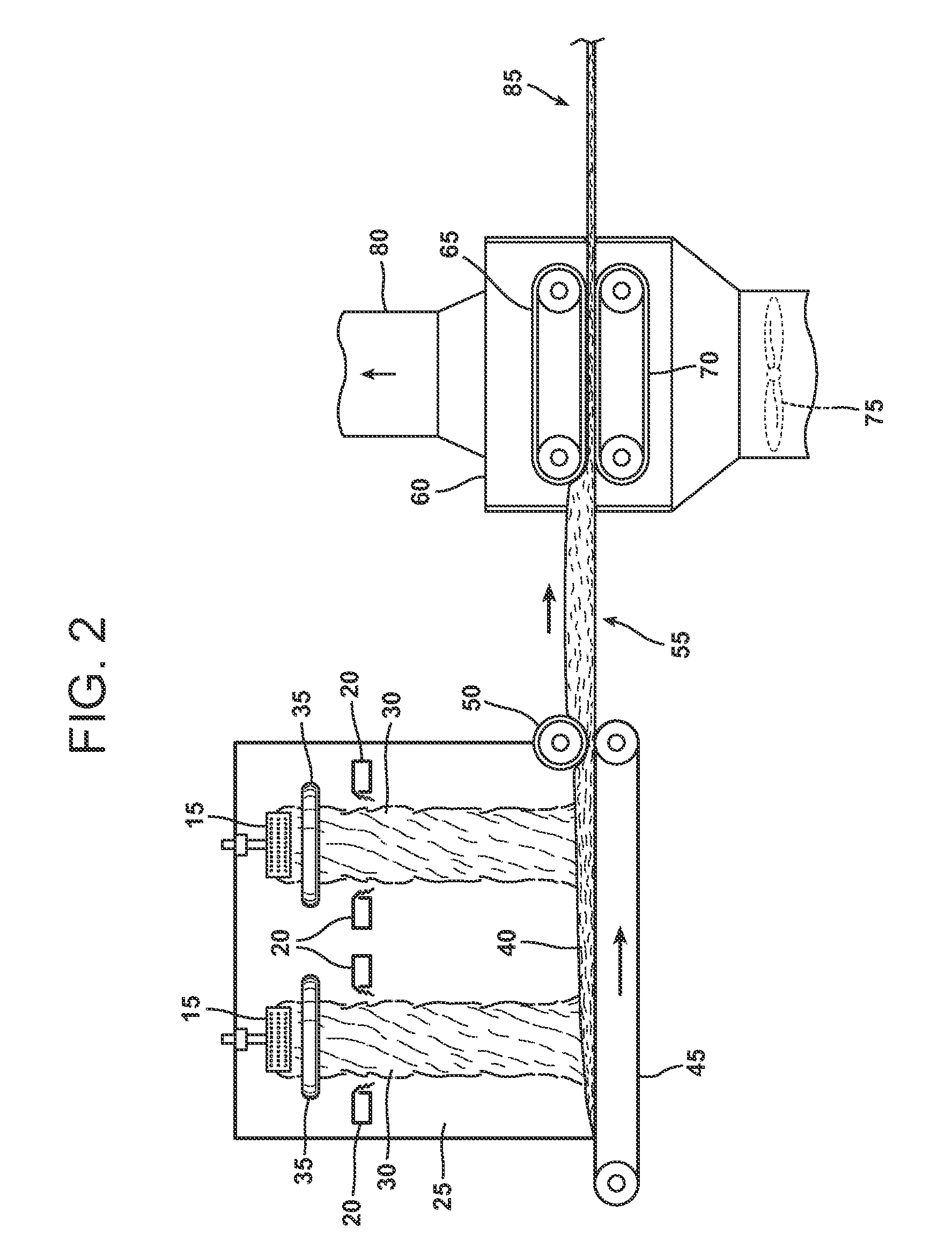

Bio-based aqueous binder for fiberglass insulation materials and non-woven mats

InactiveUS20110003522A1Reduced insulation performanceImprove worker safetyOther chemical processesProtein adhesivesGlass fiberAnimal Sources

An aqueous binder composition is provided that includes a protein-containing biomass and a pH adjuster. Optionally, a crosslinking agent and / or a moisture resistant agent may be included in the binder composition. The protein-containing biomass is natural in origin and may be derived from plant or animal sources. The pH adjuster is used to adjust the pH of the binder to a desired pH and lower the viscosity of the protein-based biomass. In addition, the pH adjuster may act as a crosslinking agent. The crosslinking agent may be any compound suitable for crosslinking the protein-containing biomass and reacting with the moisture resistant agent, when the moisture resistant agent is present in the binder. In addition, the binder has a light color after it has been cured. The environmentally friendly, formaldehyde-free binder may be used in the formation of insulation materials and non-woven chopped strand mats.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

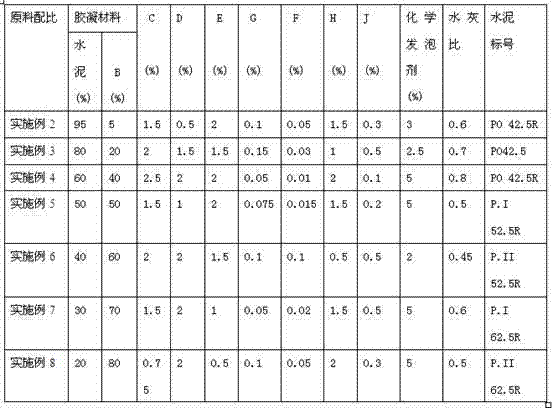

Inorganic foaming thermal-insulation mortar and preparation method thereof

The present invention provides an inorganic foaming thermal-insulation mortar and a preparation method thereof, and belongs to the technical field of building material preparation. The thermal-insulation mortar comprises a cementing material, expanded perlite particles, a macromolecule polymer, a coagulant, an early strength agent, a physical foaming agent, a chemical foaming agent hydrogen peroxide, a chemical foaming agent foaming catalyst, a hydrophobic agent, reinforced short fibers and water. According to the present invention, the inorganic foaming thermal-insulation mortar can be directly coated on the wall and the roof requiring the thermal-insulation treatment, the thickness of the inorganic thermal-insulation mortar layer can be adjusted within 10-100 mm, screeding finishing construction is performed before the cementing material is subjected to final setting, and hardening is performed to obtain the inorganic thermal-insulation mortar layer with characteristics of good durability, good water resistance and good heat insulation, wherein the inorganic thermal-insulation mortar layer never sheds, and has the same service life as the building being subjected to thermal-insulation by the inorganic thermal-insulation mortar layer; and the raw material cost is low, and significant economic benefits and environmental benefits are provided.

Owner:安徽融博科技有限公司

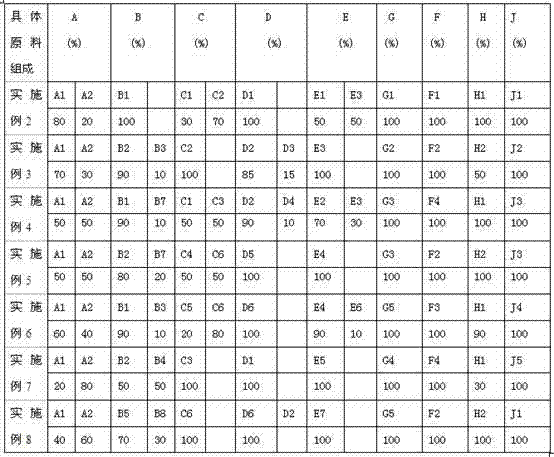

Polymer modified expanded perlite and method for making same

The present invention discloses a polymer modification expansion perlite and the preparation method. The polymer modification expansion perlite is a polymer modification expansion perlite particle used to carry out the surface coating modification by adopting the polymer modifiers. The preparation method is that the expansion perlite is delivered into a rotary drum, and the polymer modifiers are delivered into the rotary drum from the other inlet of the rotary drum in the form of sprayer together with the hot air, the temperature of which ranges from 30 to 150 Celsius system. A polymer film with a certain strength is formed on the surface of the expansion perlite, and the materials are outputted from a discharge hole so as to obtain the polymer modification expansion perlite particle. The present invention has the following advantages: the polymer modifiers completely coat the expansion perlite particle, thus lowering the water absorption and eliminating the defect that the expansion perlite easily absorbs the water with the thermal insulation performance lowered; the polymer film with a certain strength and toughness is formed on the surface of the expansion perlite, thus solving the problem that the expansion perlite is easy to be broken up with lowering the quality of the products in the process of transportation and use; the preparation technique is simple and is easy to be carried out and controlled, thus being beneficial to the industrialized popularization and application.

Owner:宁波荣山新型材料有限公司

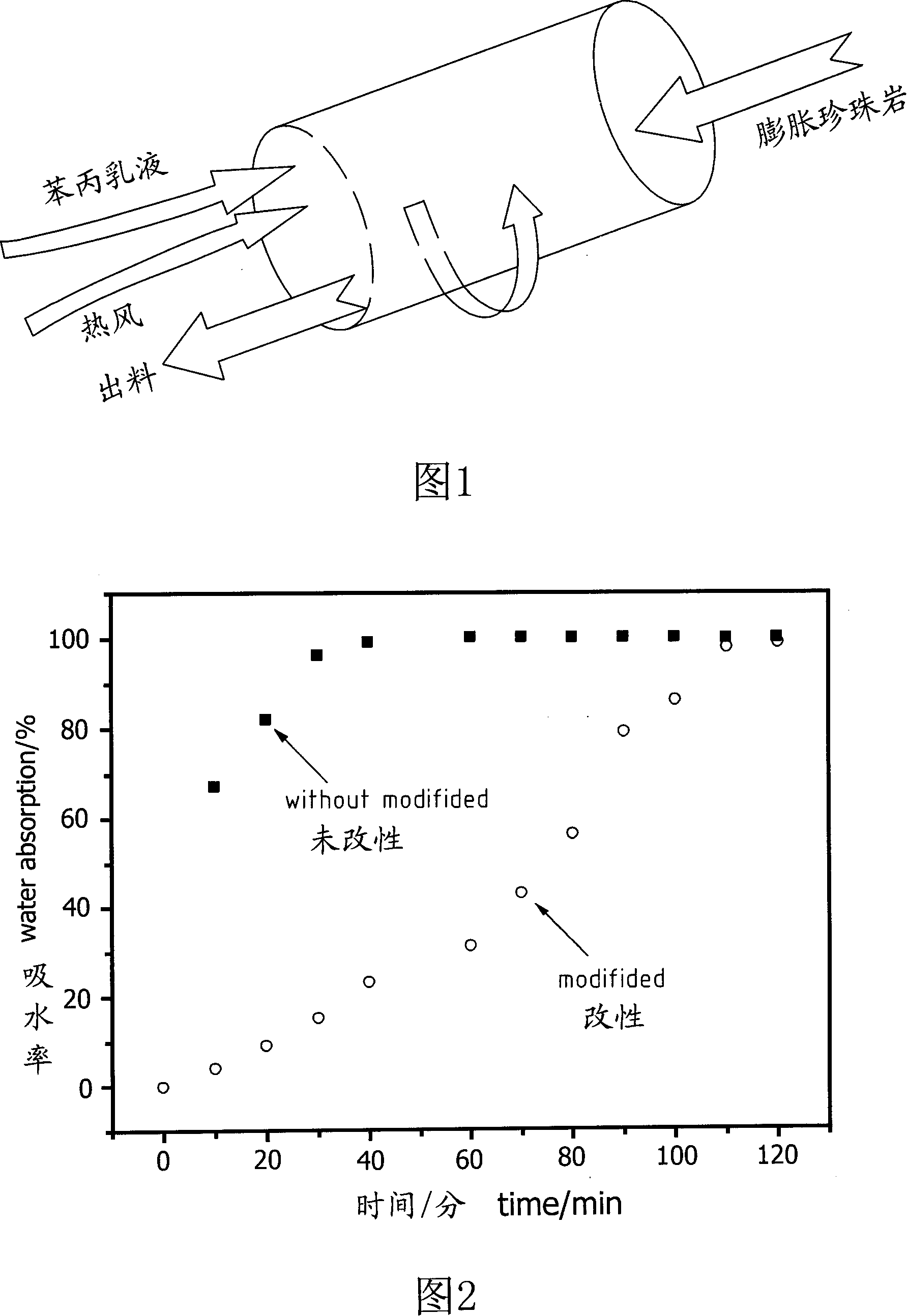

Refrigerator and display device guiding apparatus of the same

InactiveUS7546745B2Depth is minimizedReduced insulation performancePicture framesDoors/windowsDisplay deviceEngineering

A display device guiding apparatus includes a receiving portion in which a display device can be received and a guide unit provided between the display device and the receiving portion. The guide unit includes a hinge assembly for pivoting the display at a predetermined angle, an arm assembly having first and second ends respectively connected to the hinge assembly and the receiving portion, and a pivot control unit providing a pivotal force of the arm assembly with respect to the receiving portion.

Owner:LG ELECTRONICS INC

Heat insulating reflecting anticorrosive paint

InactiveCN101585992AAdd supportImprove performanceAnti-corrosive paintsPolyurea/polyurethane coatingsSurface oceanWeather resistance

A heat insulating reflecting anticorrosive paint, in a coordinated system composed of bottom, surface and middle layer paints coated on surface of concrete or metal, is suitable for sea climate and chemical engineering air severe atmosphere, which breaks convention of making the heat reflecting surface paint in white in prior market. Surface paints in present coordinated system is added with dye infrared transparent block powder with special function or gray, yellow and brown series made of titanium yellow powder so that the color of paints is versatile, which enlarges use scale. The whole paint system has excellent heat insulating, solar heat reflecting property by rational match and good heavy-duty anticorrosive property as well as excellent weather resistance. Thickness of total dry film does not exceed 250microns. Heat reflecting effect of surface paint in various colors is similar to that of white paint which has greater reflectivity and insulating effect. Compared with a tank coating aluminum powder chlorinated rubber solvent, the tank coating the paint has inner temperature 15 DEG.. C lower, surface temperature 23 DEG.. C.

Owner:袁泉利

Preparation method of fused silica refractory casting material unwetted by aluminum liquid

The invention belongs to the field of refractory materials and discloses a preparation method of a fused silica refractory casting material unwetted by an aluminum liquid, which comprises the following step of: enhancing a ground substance by adopting 10-20wt% of white alundum powder, 4-8wt% of calcium aluminate cement, 3-5wt% of hydrated alumina compound binding agent, 4-10wt% of silicon oxide micropowder and 3-6wt% of alumina micropowder, wherein 60-70wt% of fused silica is used as a main material, BaSO4 and Na3AlF6 is adopted as a compound aluminum liquid anti-wetting agent with the addition of 1-6wt%, and additional 0.12wt% of trimeric sodium phosphate and additional 0.03wt% of sodium hexametahposphate are adopted as dispensing agents. The casting material prepared by using the method has high strength, is unwetted by the aluminum liquid, has the highest use temperature of 1000 DEG C and can be used as the refractory materials, such as an aluminum flowing groove of an aluminum smelting furnace and the like.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Glass fiber reinforced modified polypropylene material and preparation method thereof

The present invention discloses a glass fiber reinforced modified polypropylene material and a preparation method thereof, the glass fiber reinforced modified polypropylene material comprises the following components: 20 to 80 parts of glass fiber reinforced polypropylene masterbatch and 20 to 80 parts of glass bead masterbatch; wherein the glass bead masterbatch comprises the following components: 40-70 parts of polypropylene, 20-50 parts of glass beads and 1-10 parts of a grafting compatibility agent. The preparation method is as follows: firstly weighing the polypropylene, the glass beads and the grafting compatibility agent in proportion and mixing evenly for extruding, pulling and pelletizing to obtain the glass bead masterbatch by a twin-screw extruder; mixing the glass bead masterbatch and the glass fiber reinforced polypropylene masterbatch in proportion, using a single-screw injection molding machine for injection to obtain the glass fiber reinforced modified polypropylene material. The glass fiber reinforced modified polypropylene material has the characteristics of high strength, low density, low dielectric constant, low buckling deformation and thermal insulation and the like, and can meet the people requirements of lightweight plastic products; by use of the masterbatch production way, the operation is simple, the complex proportion can be changed according to the performance requirements of the final products, and the glass fiber reinforced modified polypropylene material has high application value and broad application prospects.

Owner:KINGFA SCI & TECH CO LTD

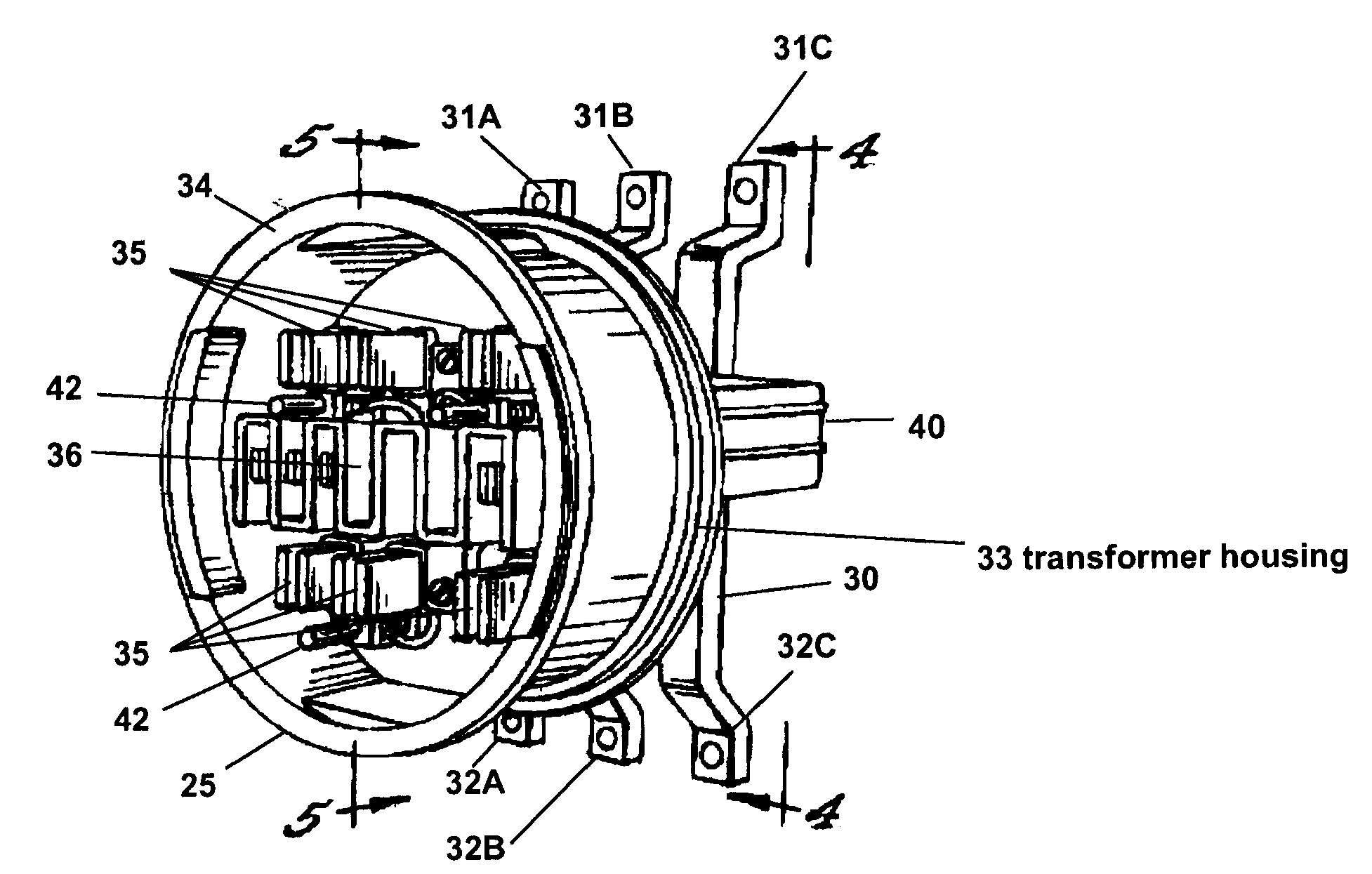

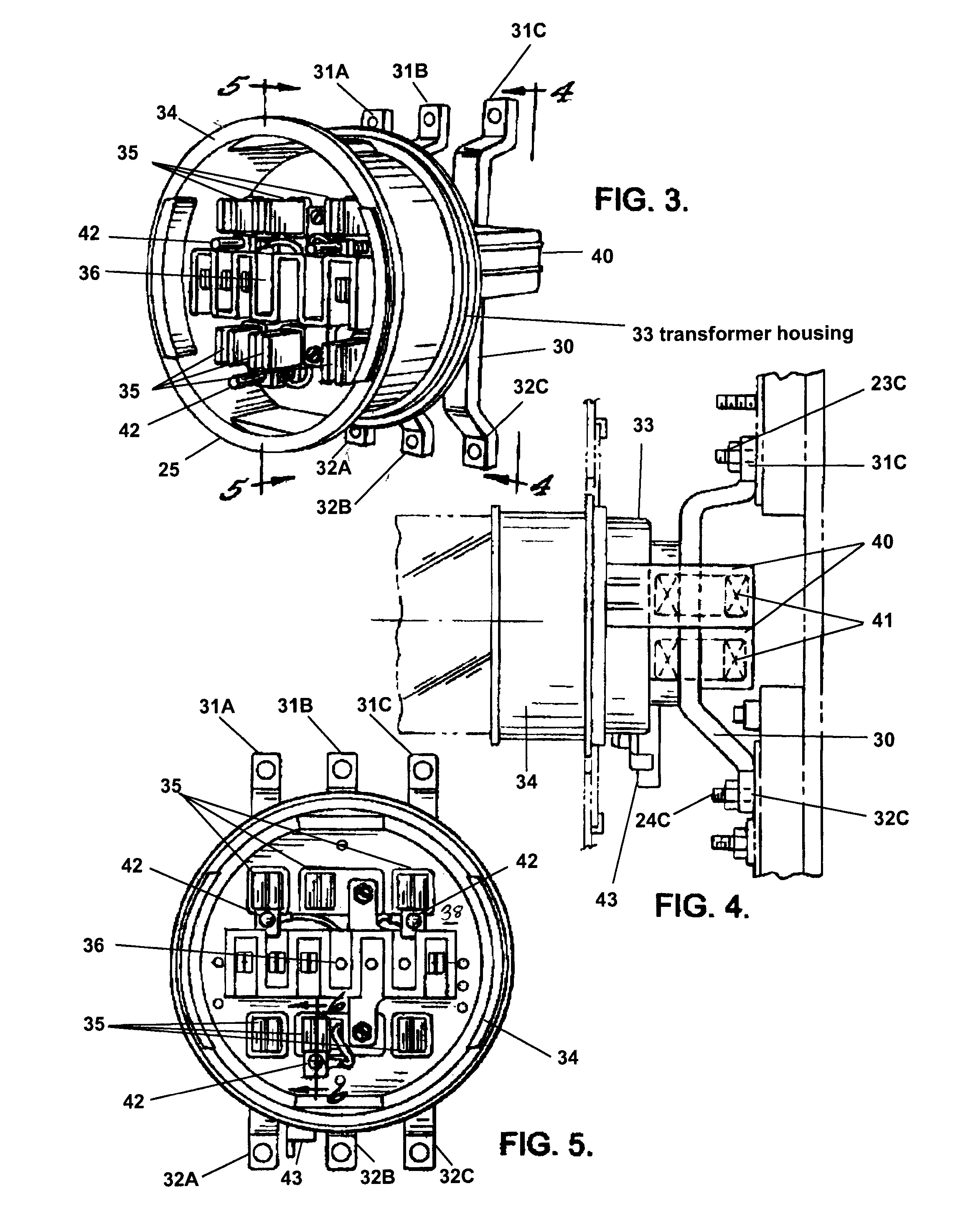

Watt Hour Meter Socket Adapter with Current Transformer Housing Structure

InactiveUS20090124119A1Improve fitReduced insulation performanceCoupling device connectionsElectric discharge tubesSocket AdapterDielectric plate

A meter socket adapter includes an insulating housing that is connected to a power circuit on one side by bus bars and connected to a watt-hour meter on the other side by jaw contacts. The housing includes insulating compartments for current transformers through which the bus bars extend. Current transformers extend around the bus bars and are housed in individual compartments in the current transformer housing. Transformed current is directed to the jaw contacts for metering with the watt-hour meter. The bus bars include an insulating layer there on, reducing the need for insulation around the secondary of the current transformers. The current transformers are then significantly smaller and fit within a K-Base meter socket. The adapter housings define a cavity with separate dielectric plates between the bus bars and the jaw contacts. The adapter conveniently allows for self-contained meters to be used in high current installations.

Owner:AUSTIN RANDY

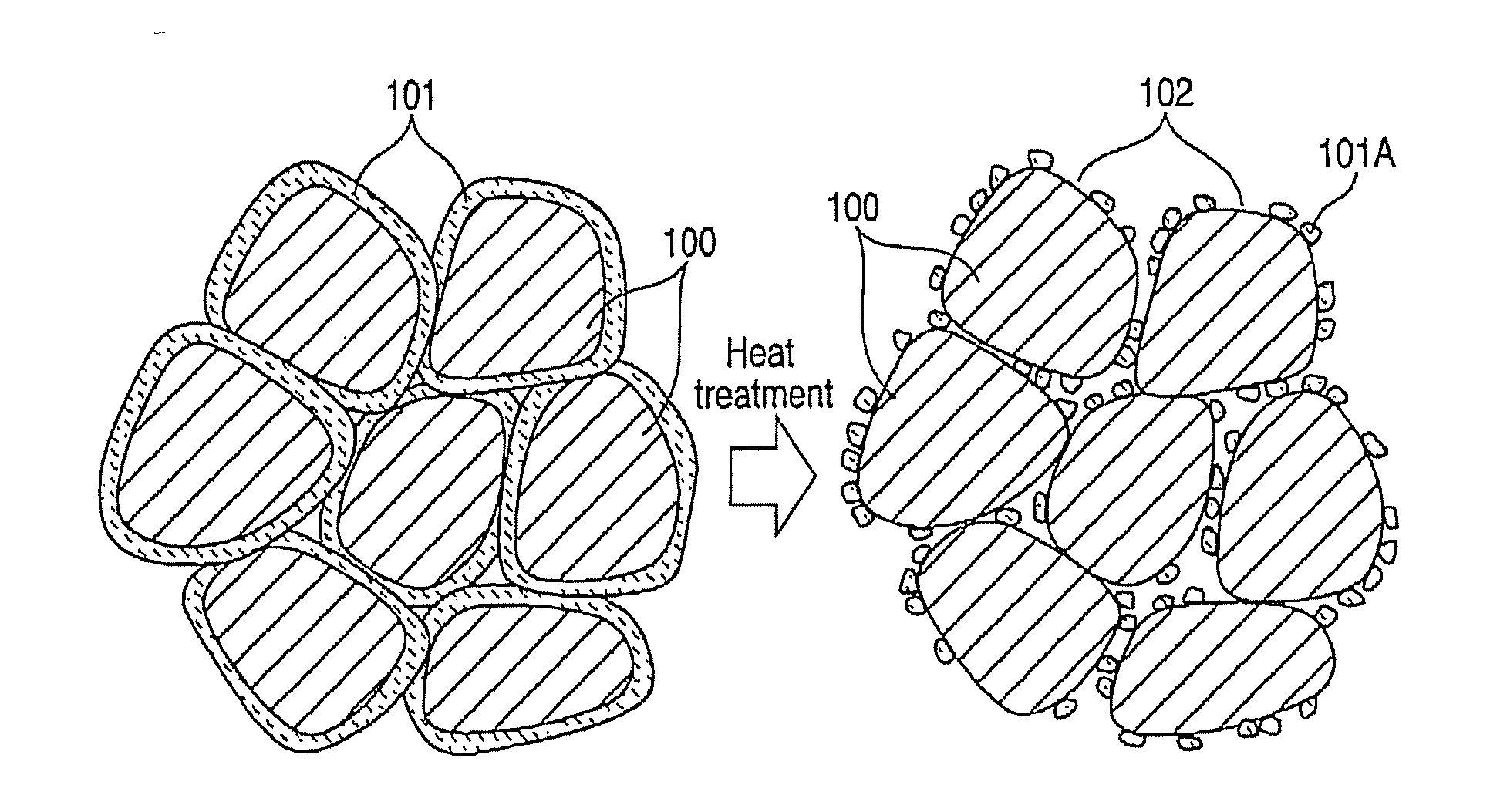

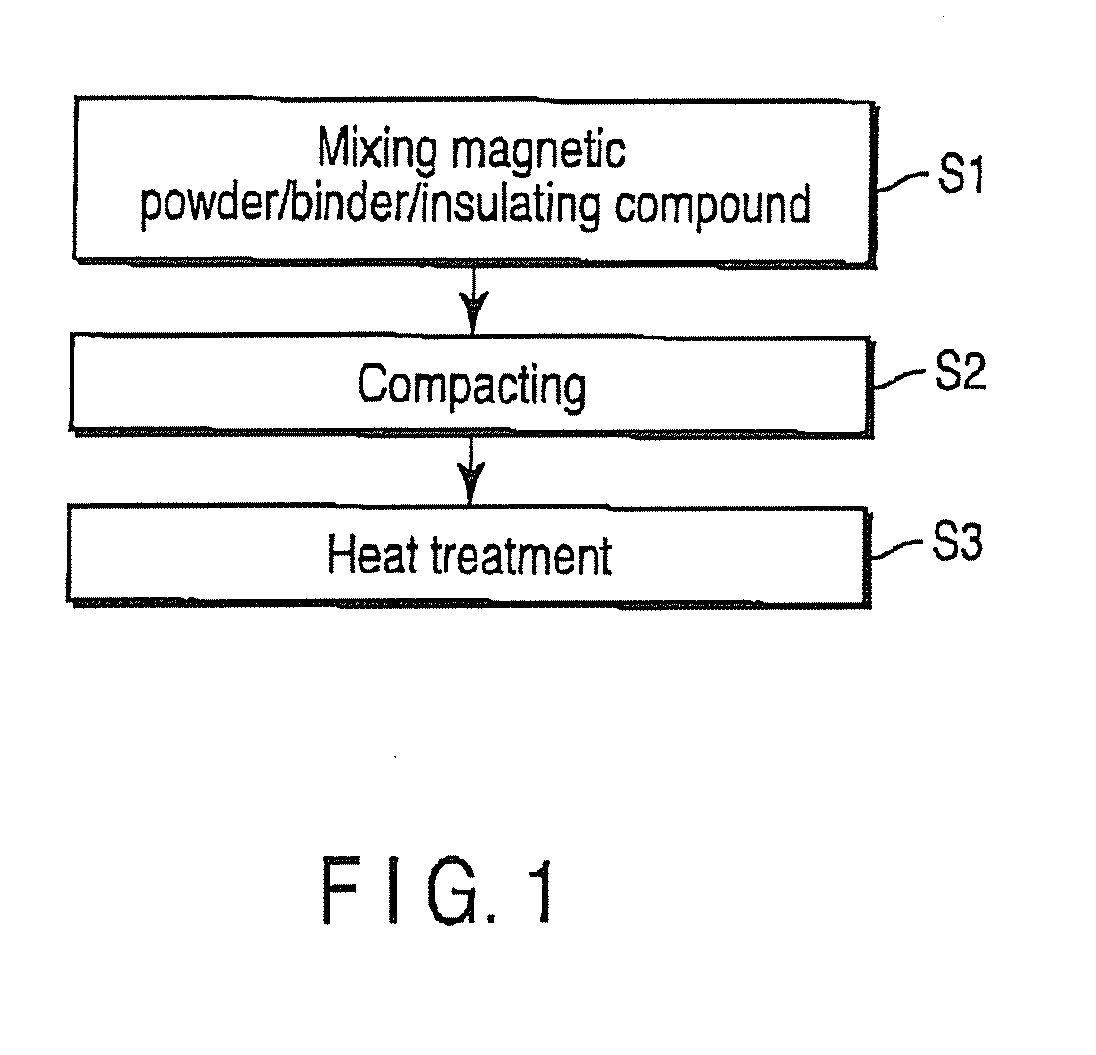

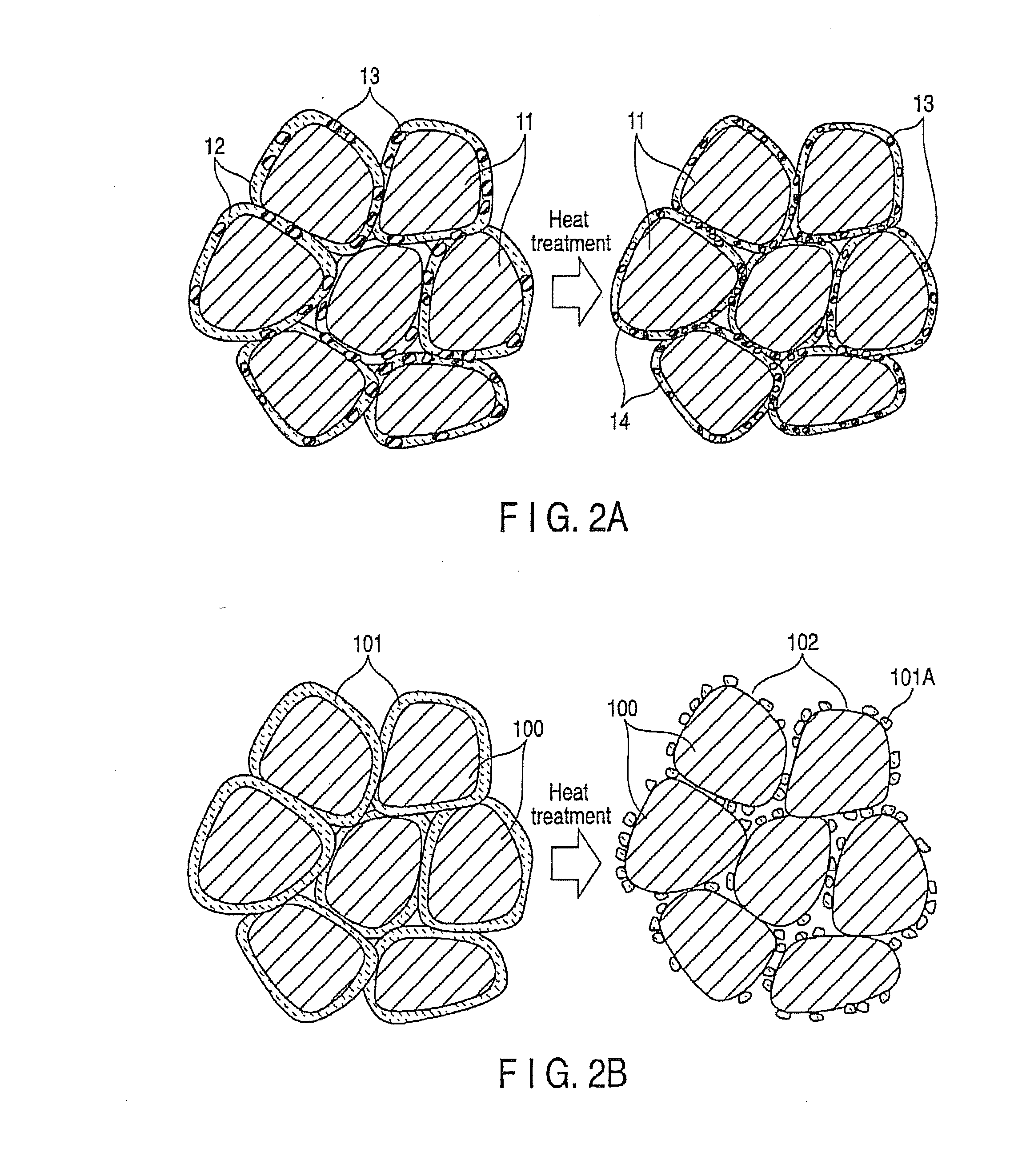

Method of producing composite magnetic material and composite magnetic material

InactiveUS20110024671A1Improve insulation performanceImprove pressure resistanceTransportation and packagingMetal-working apparatusNon magneticMetal powder

In one embodiment, a method is disclosed for producing a composite magnetic material, wherein the non-magnetic binder comprises a layered compound having an insulation property and the non-magnetic binder and soft magnetic metal powder is admixed with each other, the admixture is compacted to a desired shape, and the compact is heat-treated under predetermined condition to form a thin insulating layer made of the insulating layered compound on the surface of the soft magnetic metal powder, thereby producing the composite magnetic material having a withstand voltage of 20 V or more.

Owner:TOHO ZINC

Low density paperboard articles

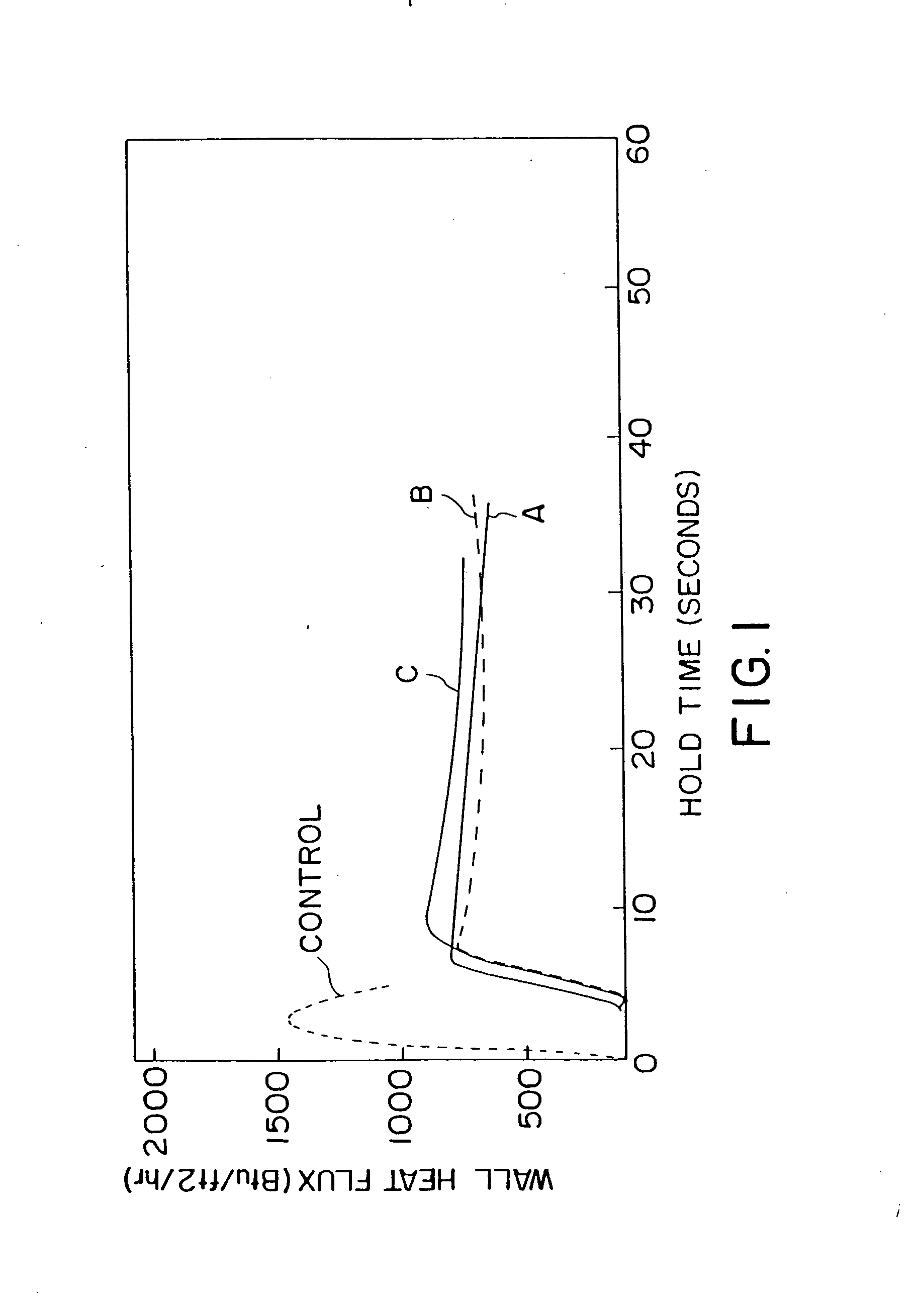

InactiveUS20050133183A1Improve thermal conductivityHigh densityDomestic cooling apparatusLighting and heating apparatusCardboardLow-density polyethylene

The invention provides a low density paperboard material and associated method for use in producing an insulated container, and is especially well-suited for making cups. The paperboard material comprises a paperboard web including wood fibers and expanded microspheres, and has a relatively low density ranging from about 6 to about 10 lb / 3MSF / mil, a relatively high caliper ranging from about 24 to about 35 mil, and an internal bond strength of at least about 80×10−3 ft−lbf., preferably at least 100×10−3 lft−lbf. For applications such as cups the material is also coated on one or both sides with a barrier coating, preferably low density polyethylene, to limit liquid penetration into the web. The low density paperboard material of the invention is convertible for manufacture of containers, particularly cups, and exhibits insulative properties comparable to higher cost materials conventionally used to make cups. Also, the surface of the low density board may have a Sheffield smoothness of 300 SU or greater compared with the surface smoothness of 160 to 200 SU for conventional cupstock, the latter having been thought necessary for adequate print quality. However, it has been found that the low density board exhibits good printability on flexo printing machines despite its relatively rough surface, which is surprising and bonus effect realized along with the insulative and other properties of the board.

Owner:MOHAN KOSARAJU KRISHNA +3

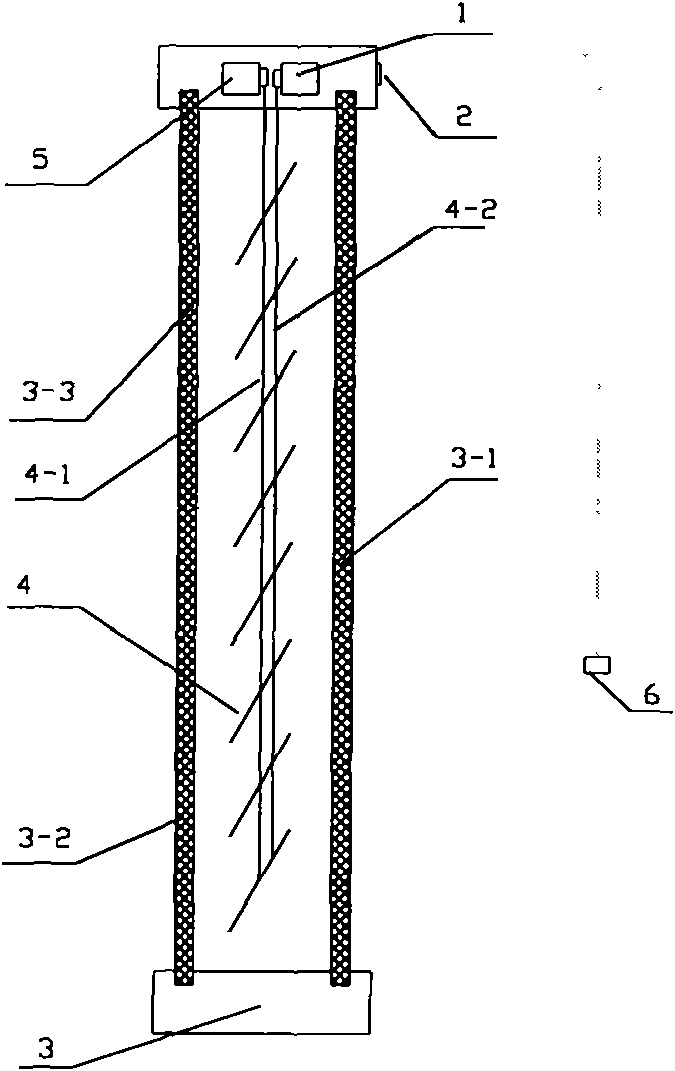

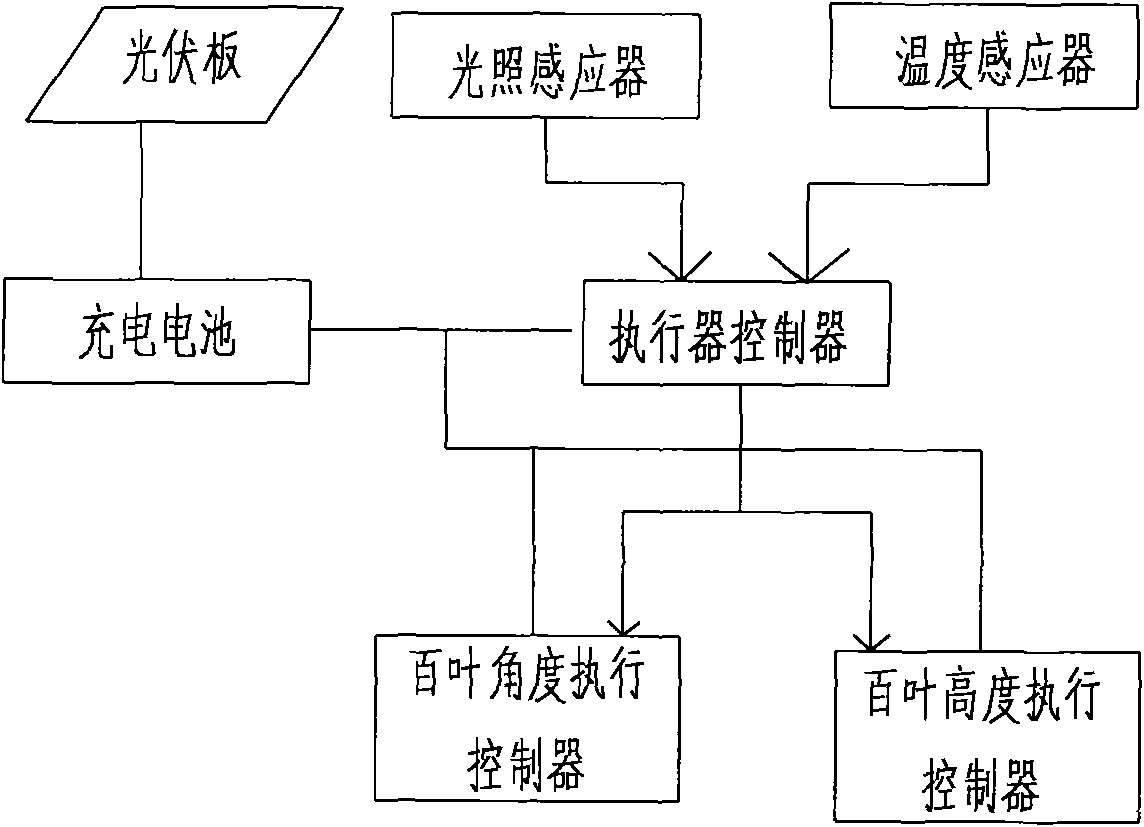

Method and device for controlling built-in automatic control shading double-layer glass window

InactiveCN101638971AReduced insulation performanceFully automatic sunshade controlLight dependant control systemsDoor/window protective devicesMicrocomputerAutomatic control

The invention discloses a method and a device for controlling a built-in automatic control shading double-layer glass window. The device comprises a window body and a shading automatic control circuit, wherein the window body comprises a window body with double-layer glasses and a built-in shading shutter window body mounted between the double-layer glasses; the shading automatic control circuit comprises a shutter height control actuator, a shutter angle control actuator, an actuator controller, a light sensor, a temperature sensor and a direct-current power source; the output ends of the shutter height control actuator and the shutter angle control actuator are respectively connected with a shutter angle and lifting control stay guy rotating shaft of the shutter; the actuator controlleris a microcomputer circuit; and the input end of the actuator controller is connected with the light sensor and the temperature sensor. The invention can solve the technical problems that the traditional active-mode shading system is possible to have a fault, is not suitable to be mounted on prior buildings, difficult to clean and unattractive in appearance.

Owner:许鹏

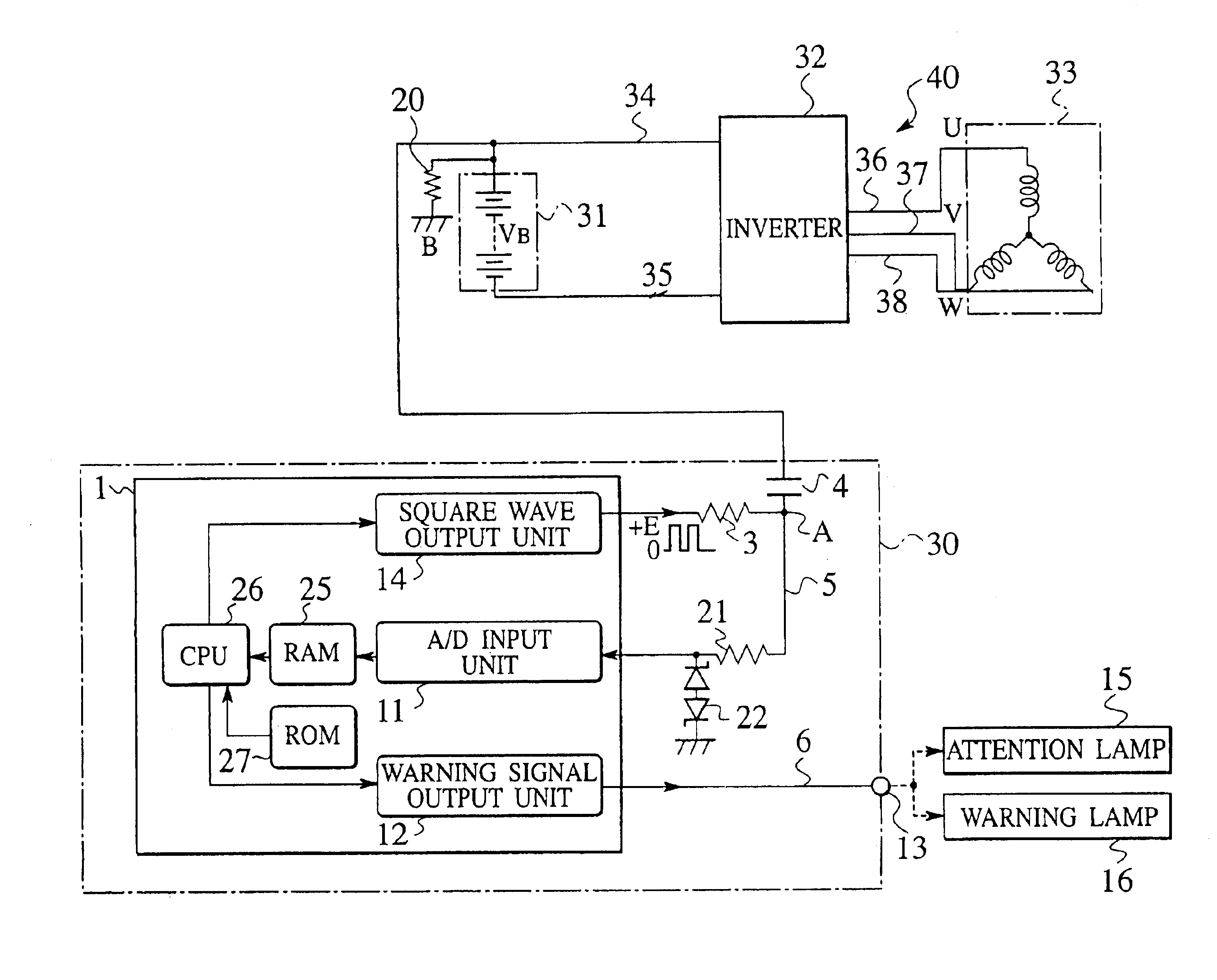

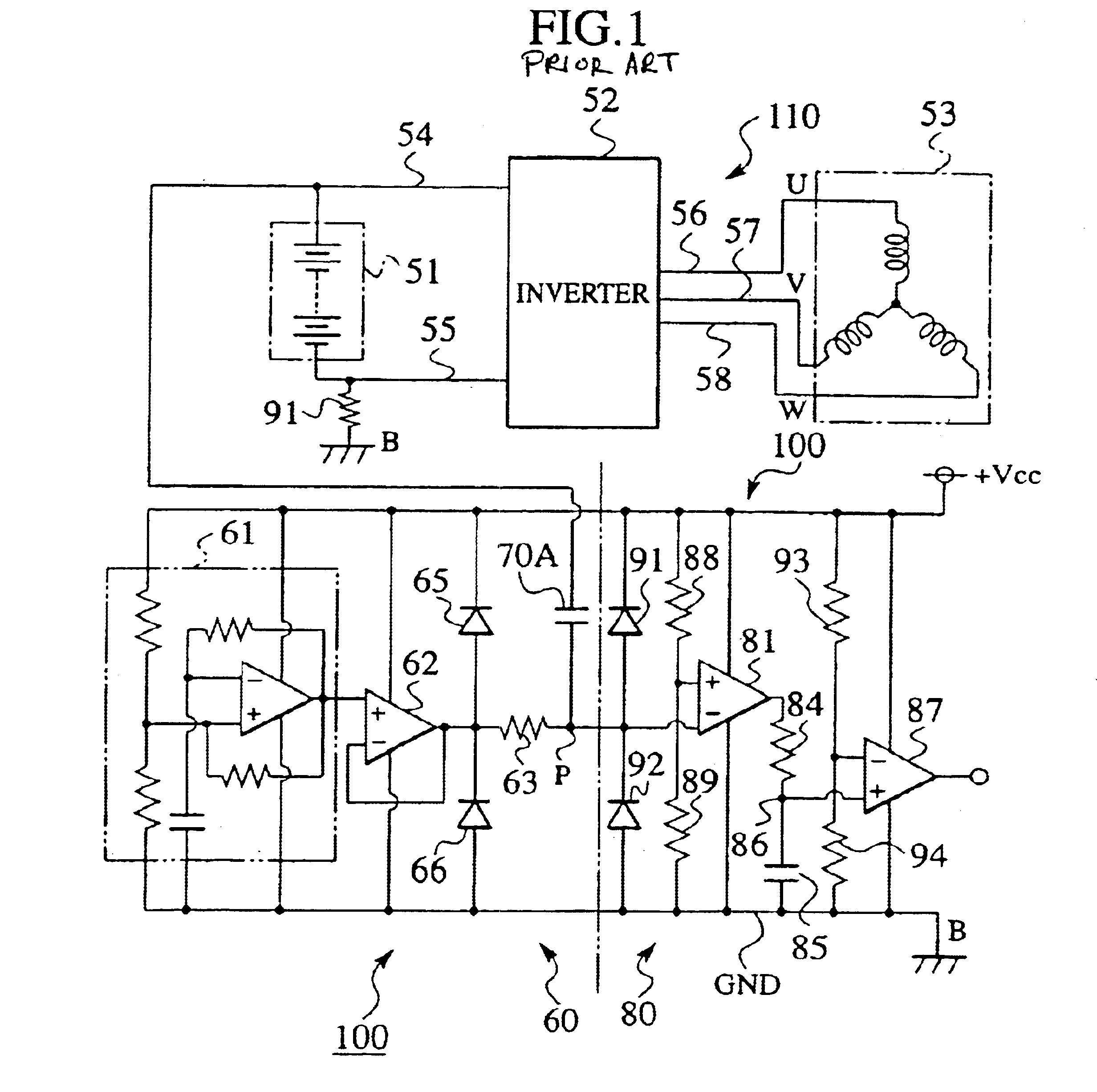

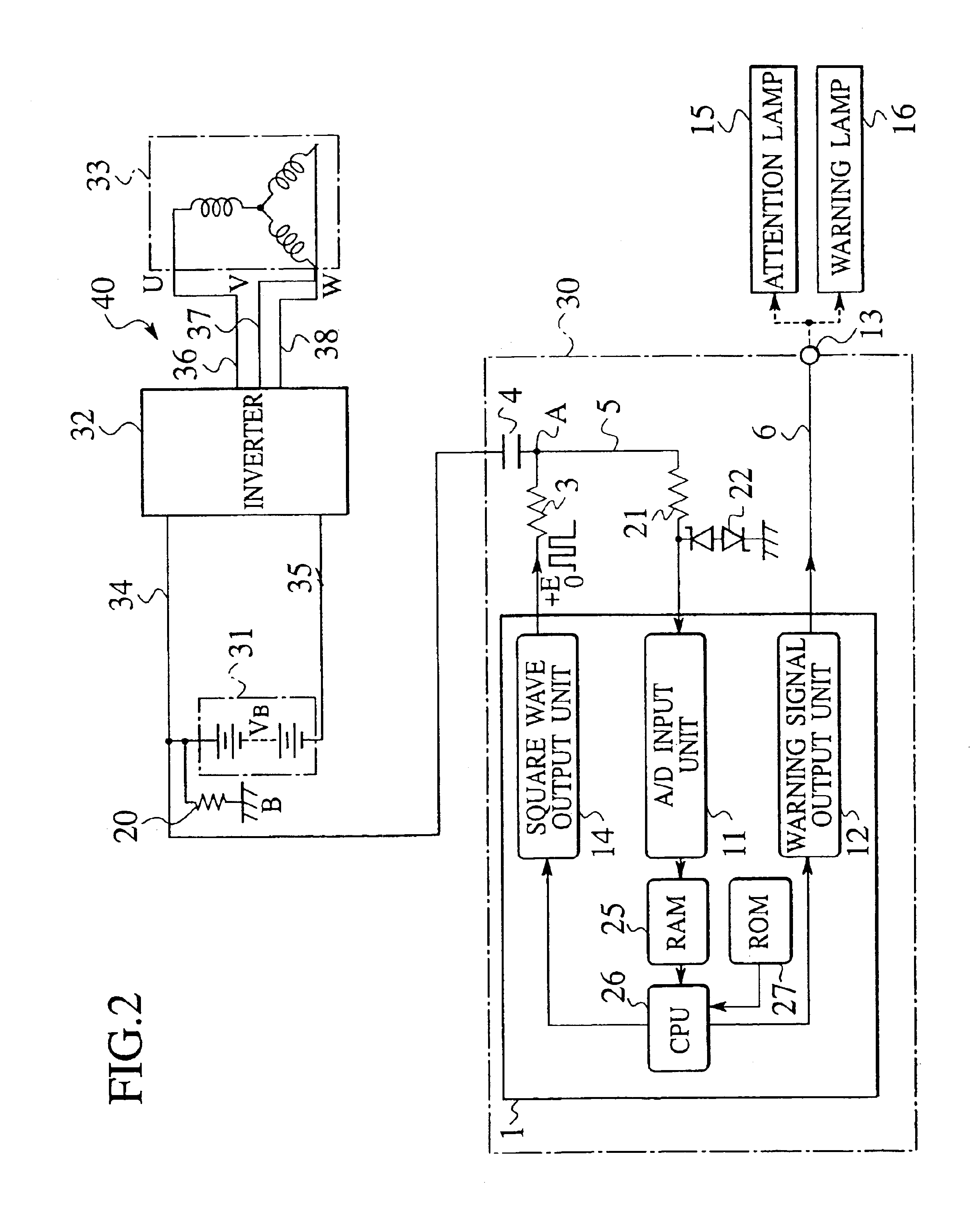

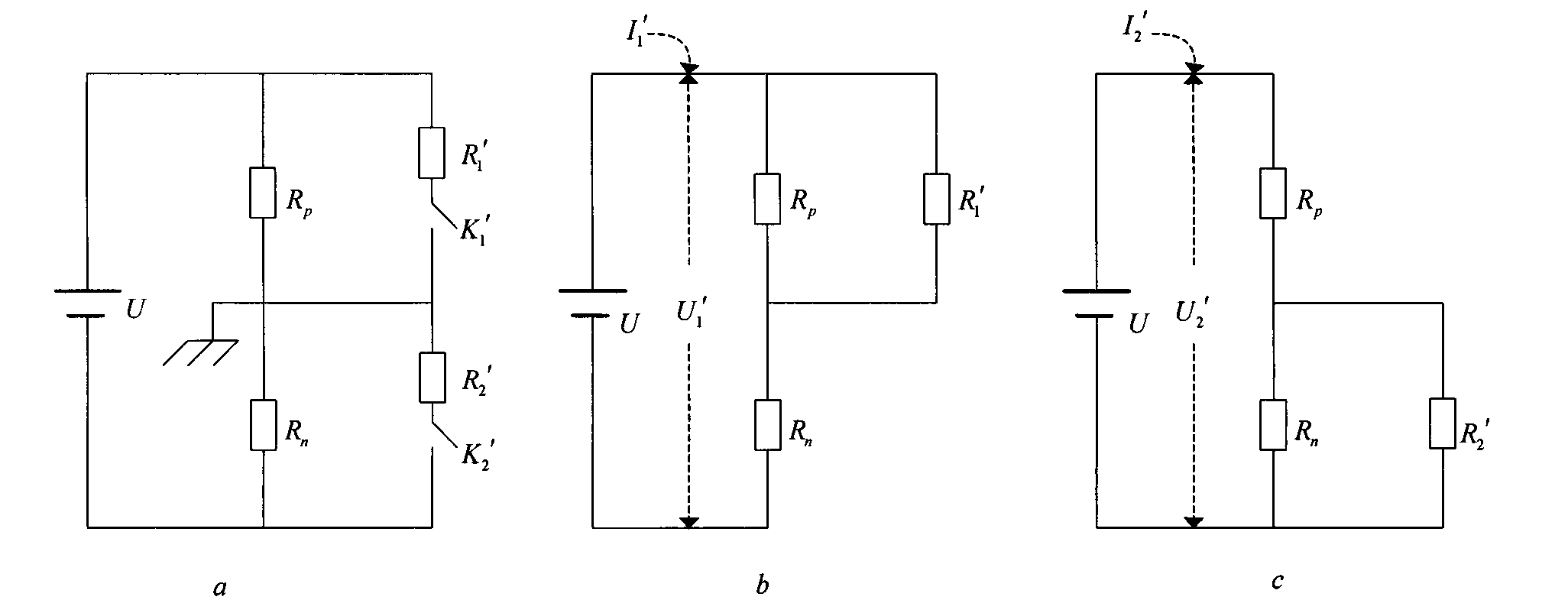

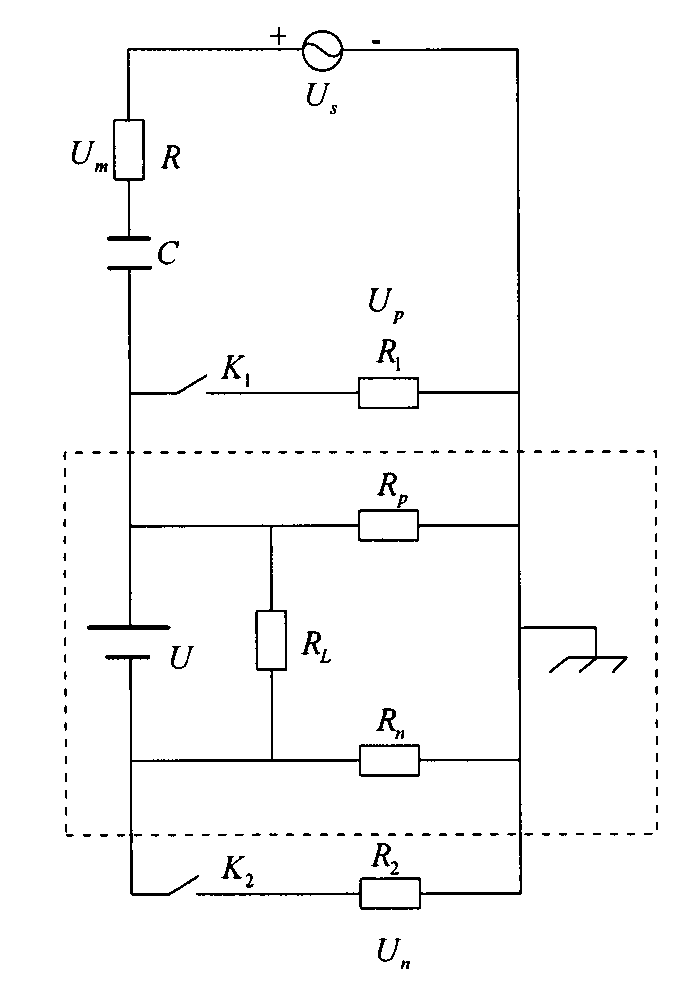

Ground detection apparatus for electric vehicle

InactiveUS6906525B2Simple circuit configurationHigh-precision detectionElectric devicesRailway vehiclesVoltage amplitudeHigh-voltage direct current

A ground detection apparatus for electric automobile having a high-voltage DC power supply (31) which is electrically insulated from a body and a three-phase AC motor (33) which is driven by a DC voltage from the high-voltage DC power supply. A ground detection signal consisting of a square waveform is supplied to the DC power supply circuit through a detection resistor and a coupling capacitor, a voltage amplitude of a ground detection point serving as a connection point between the detection resistor (3) and the coupling capacitor (4) is detected, the detected voltage amplitude is converted into an insulation resistance on the basis of the relationship between a preset voltage amplitude and a preset insulation resistance, and levels of insulation resistance deterioration of the high-voltage DC power supply are detected by comparing the converted insulation resistance with a preset ground decision threshold value.

Owner:NISSAN MOTOR CO LTD

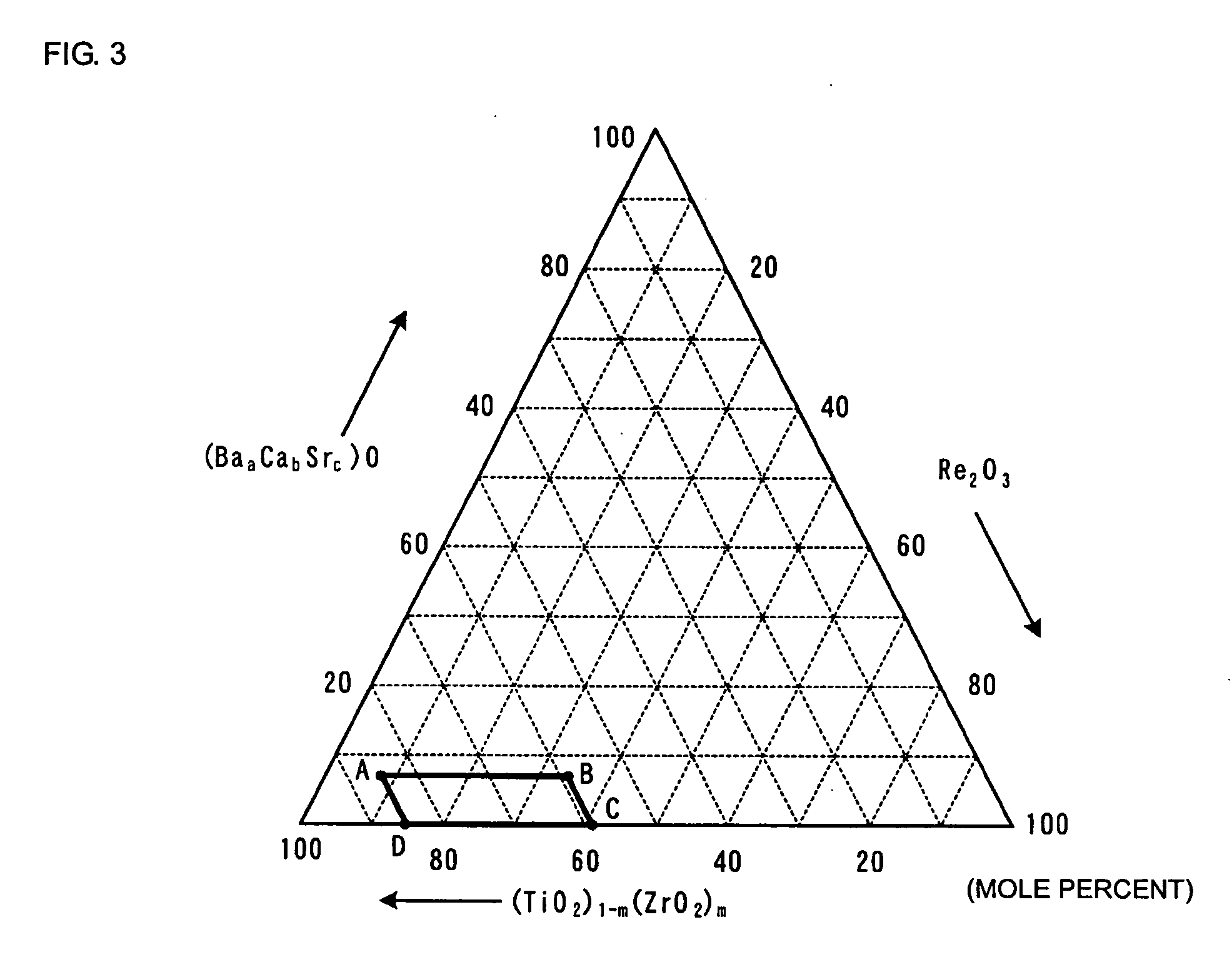

Glass-ceramic composition, glass-ceramic sintered body, and monolithic ceramic electronic component

InactiveUS20060287184A1Improve electrical insulation reliabilityReduced insulation performanceCeramic layered productsPrinted circuit manufactureStrontium titanateLithium oxide

A glass-ceramic composition contains first ceramic particles principally containing forsterite; second ceramic particles principally containing at least one selected from the group consisting of calcium titanate, strontium titanate, and titanium oxide; and borosilicate glass particles containing about 3% to 15% lithium oxide, about 20% to 50% magnesium oxide, about 15% to 30% boron oxide, about 10% to 45% silicon oxide, about 6% to 20% zinc oxide, 0% to about 15% aluminum oxide, and at least one additive selected from the group consisting of calcium oxide, barium oxide, and strontium oxide on a weight basis. The content of the borosilicate glass particles is about 3% or more; the lower limit of the content of the additive is about 2%; and the upper limit of the additive content is about 15%, about 25%, or about 25% when the additive is calcium oxide, barium oxide, or strontium oxide, respectively, on a weight basis.

Owner:MURATA MFG CO LTD

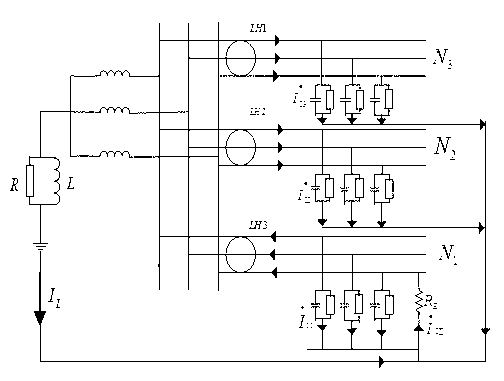

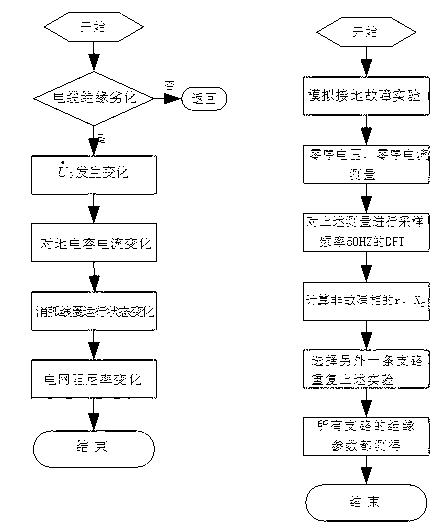

Coal mine grid system insulation state monitoring method

ActiveCN103135031AAccurate measurementEliminate measurement errorsImpedence measurementsShort-circuit testingCapacitanceElectric power system

The invention provides a coal mine grid system insulation state monitoring method and belongs to an electrical power system feed line insulation state monitoring method. A feed line branch circuit is selected for doing single-phase longitude metal grounding experiment, zero sequence voltage of a bus and zero sequence current of a non-malfunction branch circuit are tested, zero sequence impedance of the non-malfunction branch circuit is obtained, namely, insulation resistance and ground capacitance, for obtaining insulation parameters of all circuits, another branch circuit is reselected to do a single-phase connection low resistance ground experiment or the next circuit with the non-branch-circuit number 1 is waited for generating single-phase ground malfunction, the experiment is repeated, insulation parameters of a first experiment malfunction circuit are obtained, and the insulation parameters of all feed line branch circuits are obtained by synthesizing results of the two experiments. The coal mine grid system insulation state monitoring method has the advantages that insulation degradation degree of the circuits is analyzed from state change of the bus zero sequence voltage and an arc suppression coil, the zero sequence voltage changes to a certain extent, switching-in situations of damping resistance change, and the degradation degree of circuit insulation is forecasted by monitoring change of transient states of a plurality of feature quantities.

Owner:CHINA UNIV OF MINING & TECH

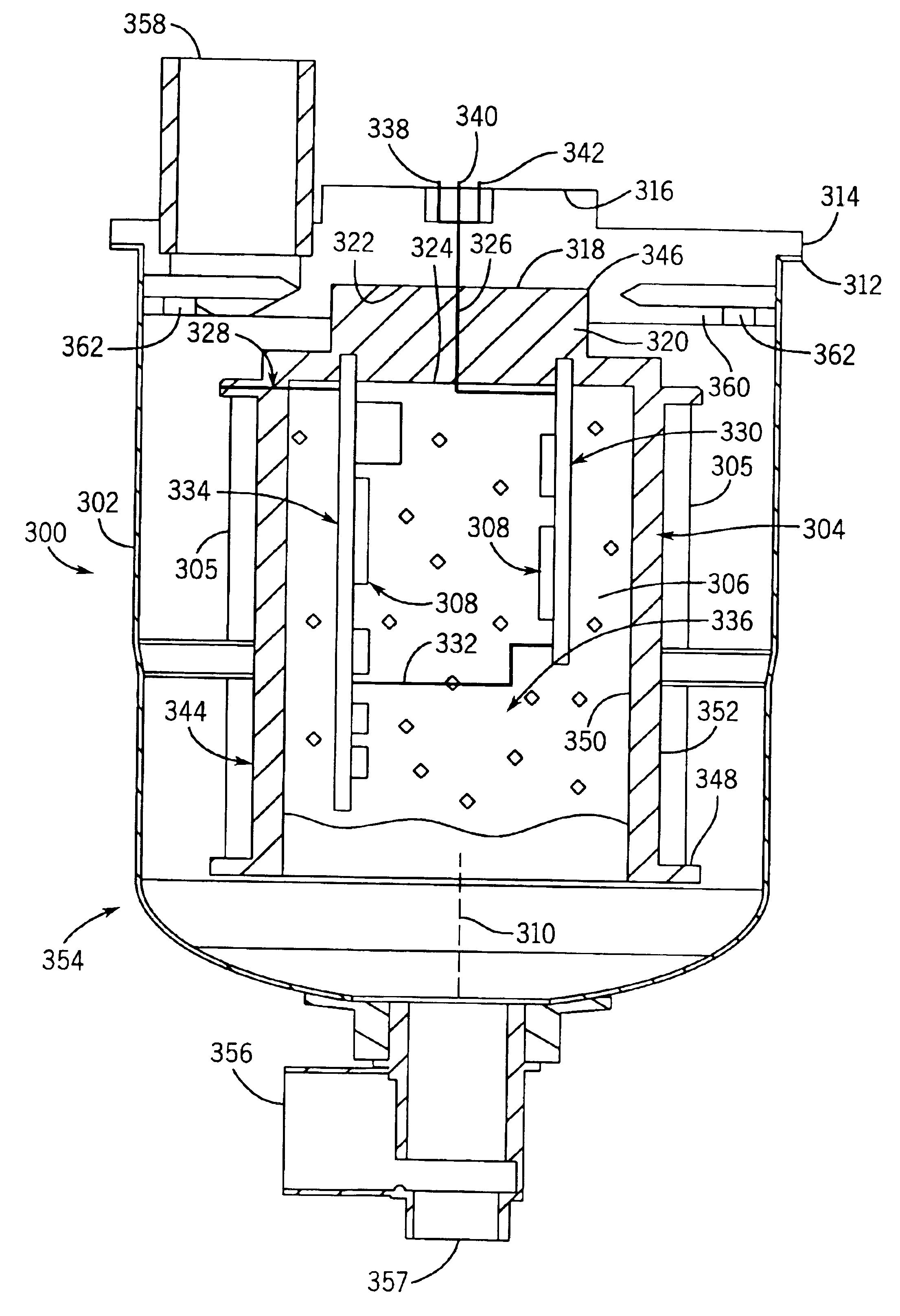

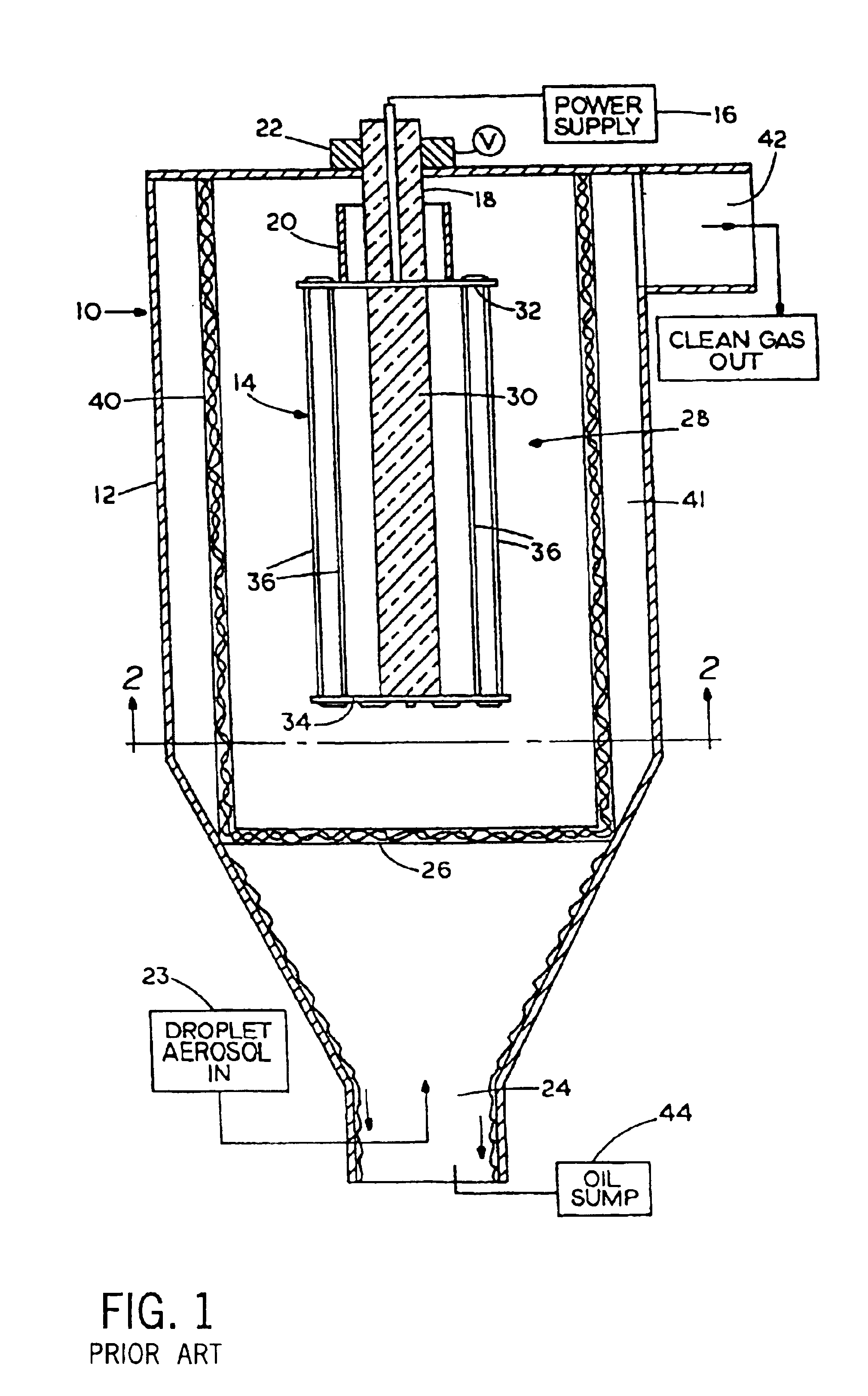

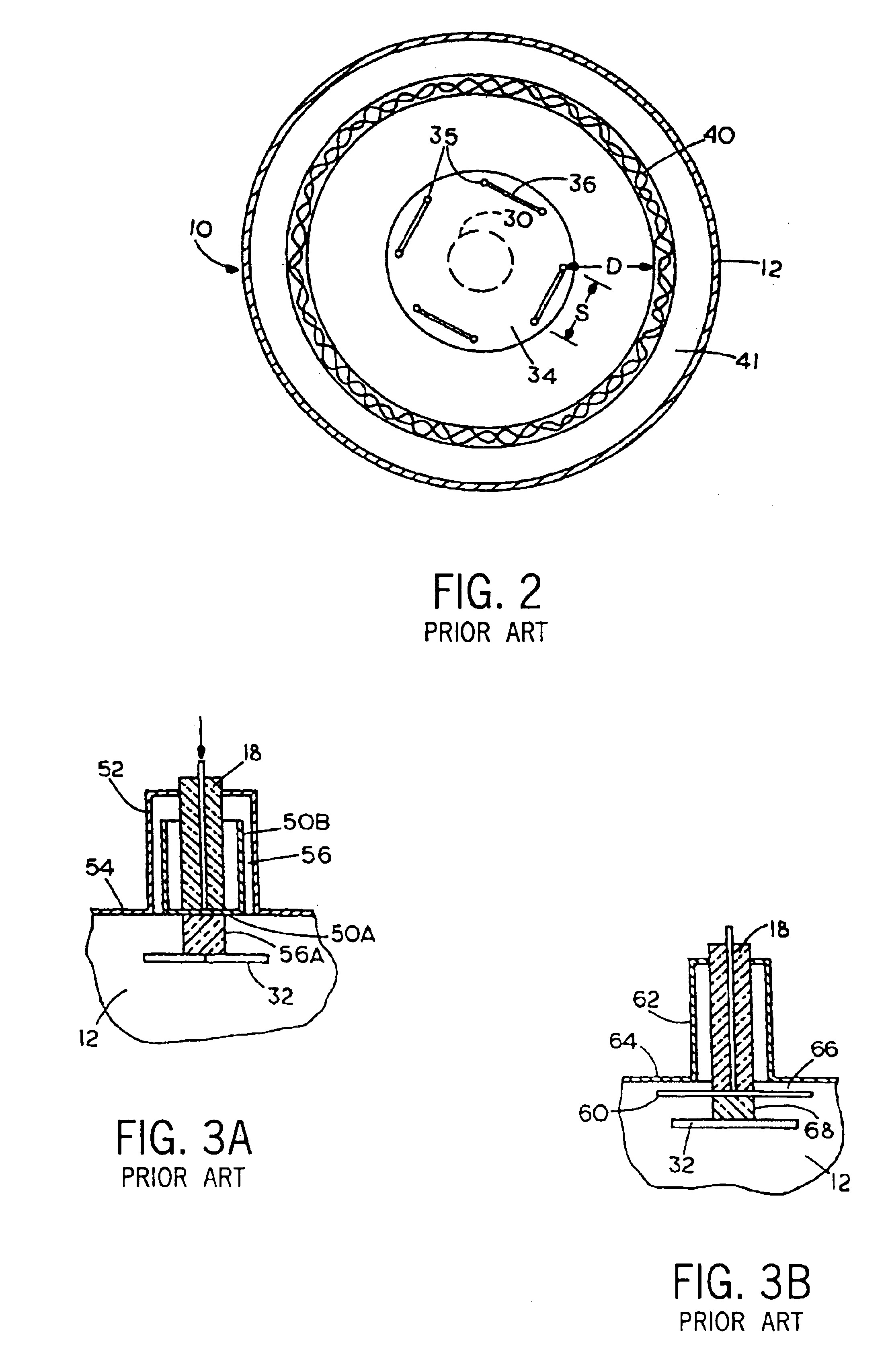

Electrostatic precipitator with internal power supply

InactiveUS6902604B2Prevent moisturePrevent contaminant accumulationCombination devicesIsotope separationElectricityLow voltage

An electrostatic precipitator, including for a diesel engine electrostatic crankcase ventilation system for blowby gas, includes a corona discharge electrode assembly in a housing, an insulator extending along an internal surface of a wall of the housing, a power supply in the housing on the opposite side of the insulator from the housing wall such that the insulator is between the housing wall and the power supply, and a low voltage lead extending through the housing wall and through the insulator to the power supply, eliminating pass-through of a high voltage lead through the housing wall and through the insulator. The power supply is preferably provided in the hollow interior of the corona discharge electrode assembly.

Owner:CUMMINS FILTRATION INC +1

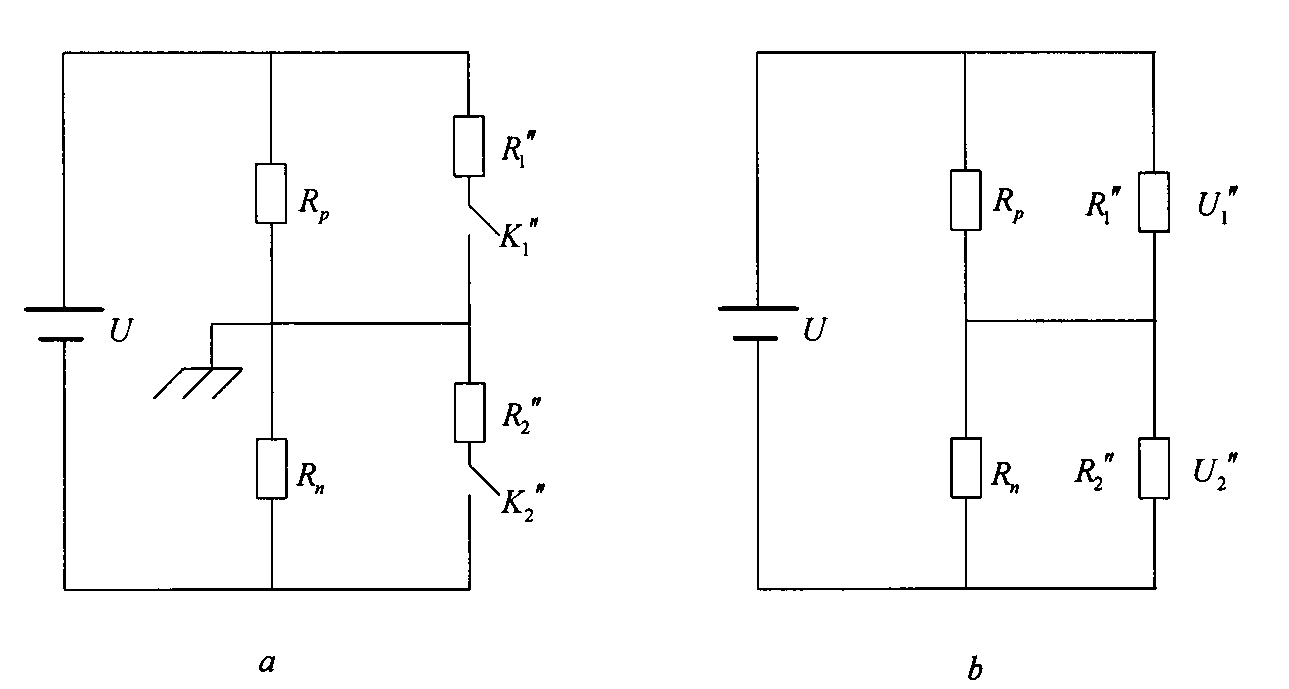

Active type direct-current system insulation resistor detection method

InactiveCN104142433AImprove securityReduced insulation performanceTesting dielectric strengthResistance/reactance/impedenceElectrical resistance and conductanceEngineering

The invention discloses an active type direct-current system insulation resistor detection method. The active type direct-current system insulation resistor detection method is applicable to real-time detection of insulation resistors of a direct-current high-voltage source electrical equipment system. The insulation resistor detection method comprises the two stages of fault detection and insulation resistor calculation. According to the fault detection, a parallel-connection resistance value of the positive and the negative insulation resistors can be calculated by measuring voltage values at the two ends of a measurement resistor, and whether the positive and negative insulation resistors break down or not is judged according to the parallel-connection resistance value. According to the insulation resistor calculation, the resistance values of the positive and negative insulation resistors can be calculated by measuring voltage values at the two ends of an access resistor. The active type direct-current system insulation resistor detection method has the advantages that the fault conditions of the positive and negative insulation resistors can be monitored in real time, the whole load is not affected, and the basis is provided for fault diagnosis of the whole system by calculating the resistance values of the positive and negative insulation resistors.

Owner:CENT SOUTH UNIV

Artificial stone with irregular pore and preparation method thereof

The invention provides an artificial stone with irregular pores and a preparation method thereof. The artificial stone composed of a cementitious material, a pore forming agent and a thickener is prepared by the following method: preparing a slurry; casting the prepared slurry in a mould; and vibrating for molding in a vibration table. Compared with the natural stone, the artificial stone with irregular pores provided by the invention has the advantages of low cost, multiple effect changes, environment-friendliness, no radiation, low density, excellent thermal insulation, sound insulation and refractory properties, and good mechanical property; and the artificial stone with irregular pores has strong durability and color stability in all kinds of weather conditions, and is an ideal decorative material.

Owner:SHANGHAI APE STONE

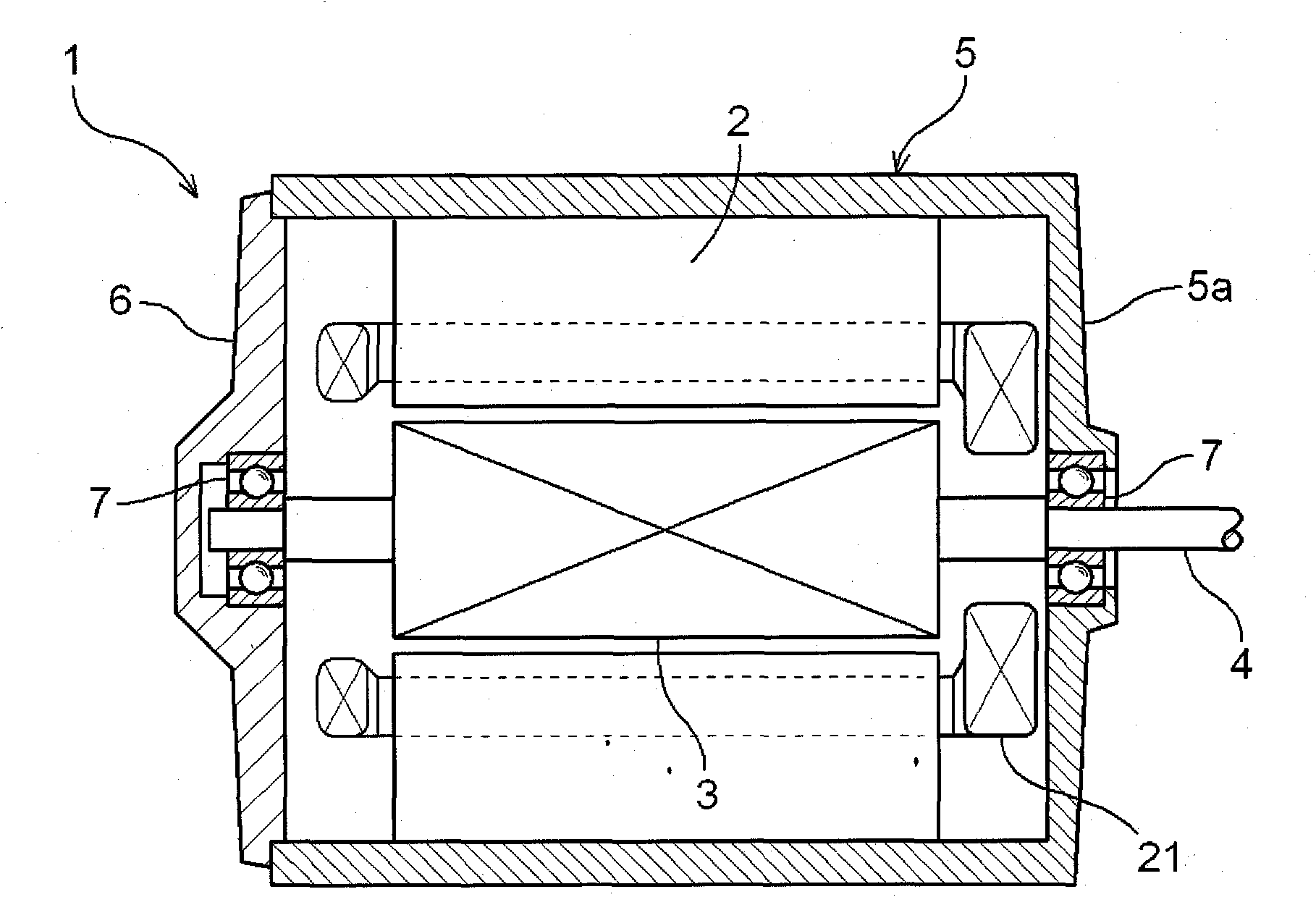

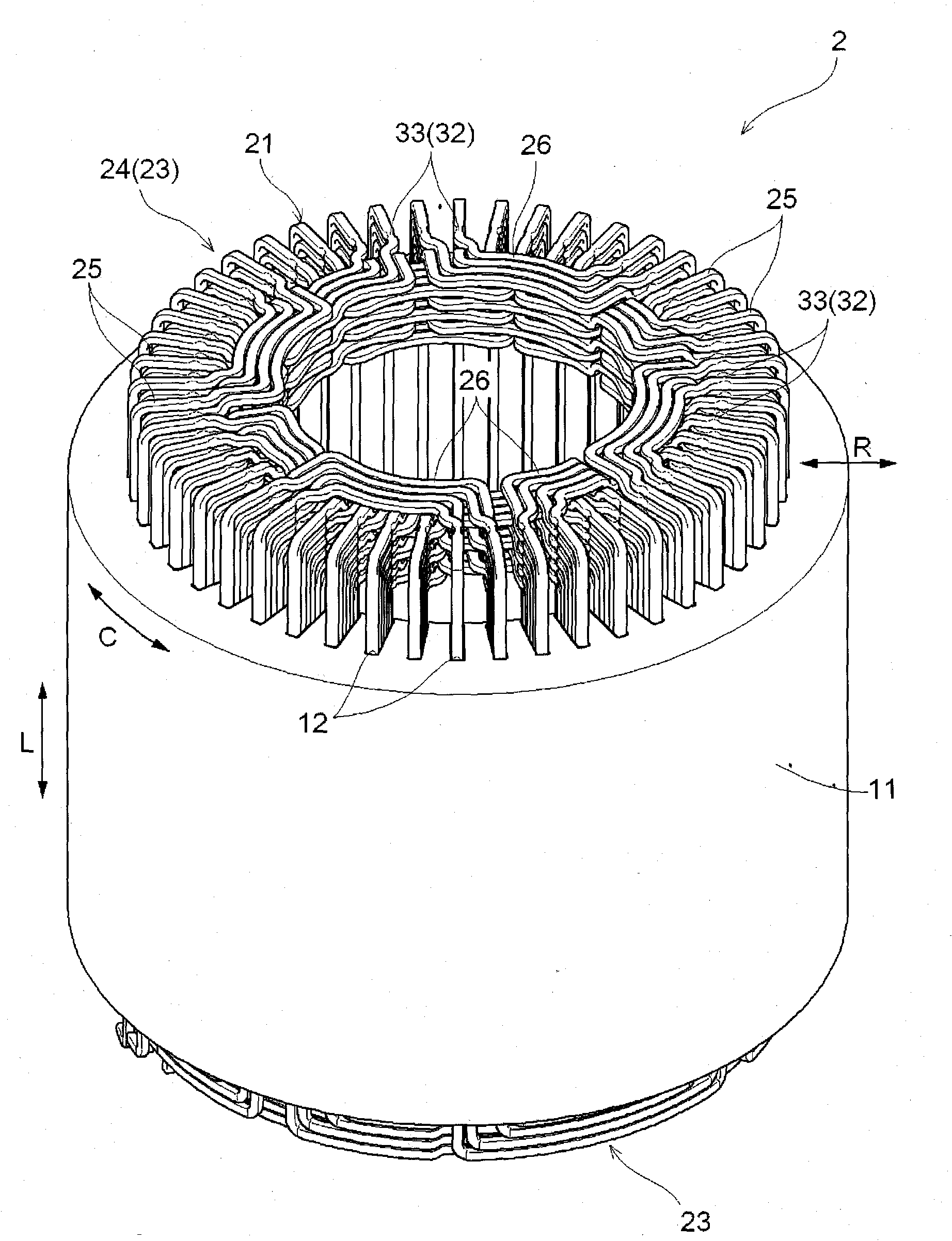

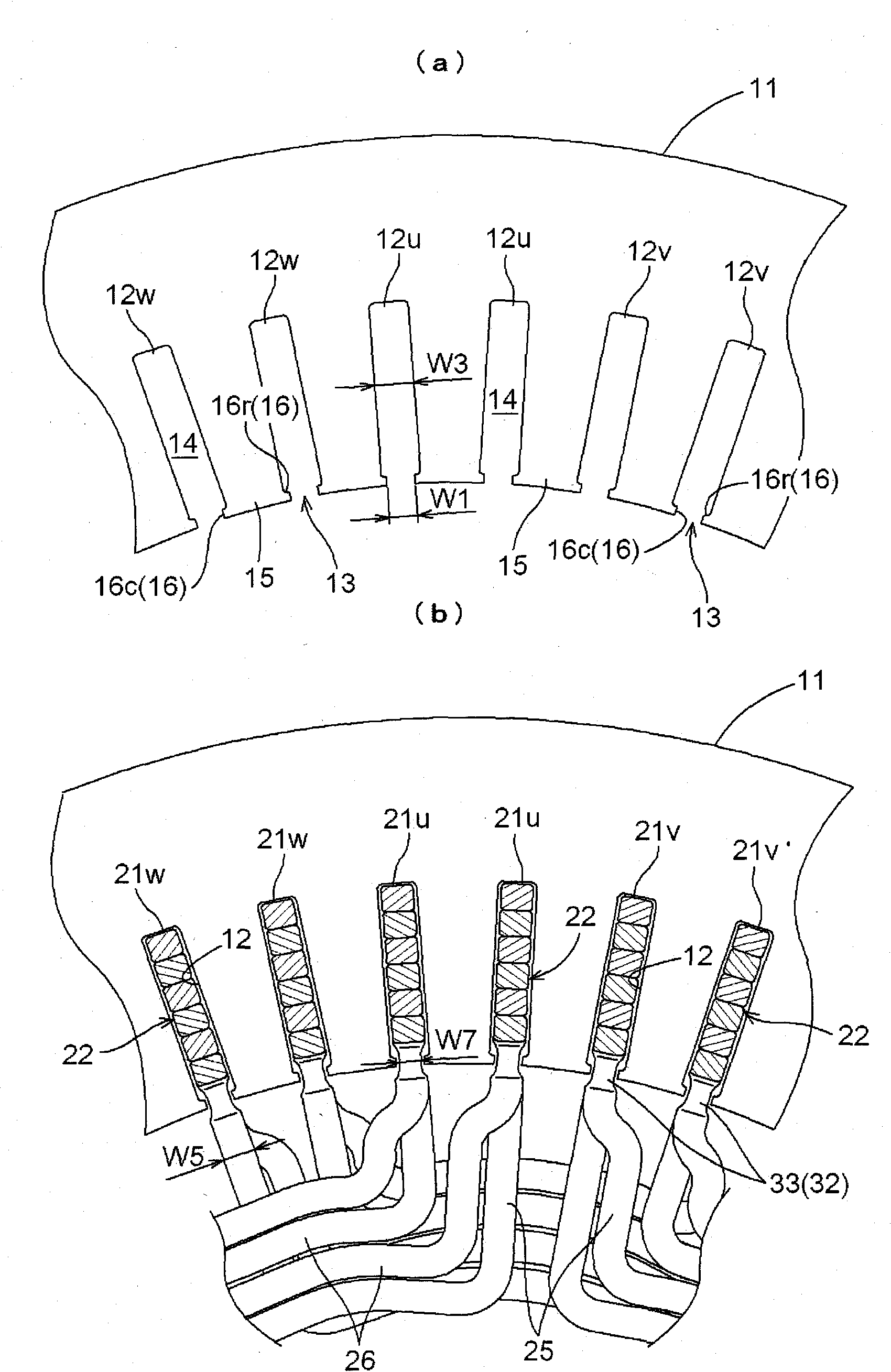

Armature for electric rotating machine and method of manufacturing same

InactiveCN102160266AReduced insulation performanceReduce stressWindings insulation shape/form/constructionEmbedding prefabricated windingsElectrical conductorElectric machine

Provided is an armature for an electric rotating machine wherein the eddy current loss can be reduced while enhancing the space factor of coil. The present invention relates to an armature (2) for an electric rotating machine including a cylindrical core (11) where a plurality of slots (12) extending in the axial direction are positioned in a dispersion manner in the circumferential direction, and a coil (21) wound in the slots (12) each of which is formed in such a manner that the circumferential width of the inner circumferential opening of the slot (12) is narrower than the inner circumferential width of the slot, the circumferential width of a linear conductor constituting the coil is wider than the circumferential width of the inner circumferential opening, the coil end (23) of the coil (21) on one side in the axial direction thereof is a bent coil end (24); which is bent radially inward and provided with a radial conductor (25), and at a radial position in the radial conductor (25) corresponding to the inner circumferential opening, a narrow recess (32) which is recessed for other portion of the radial conductor (25) is provided so that the circumferential width becomes narrower than that of the inner circumferential opening.

Owner:AISIN AW CO LTD

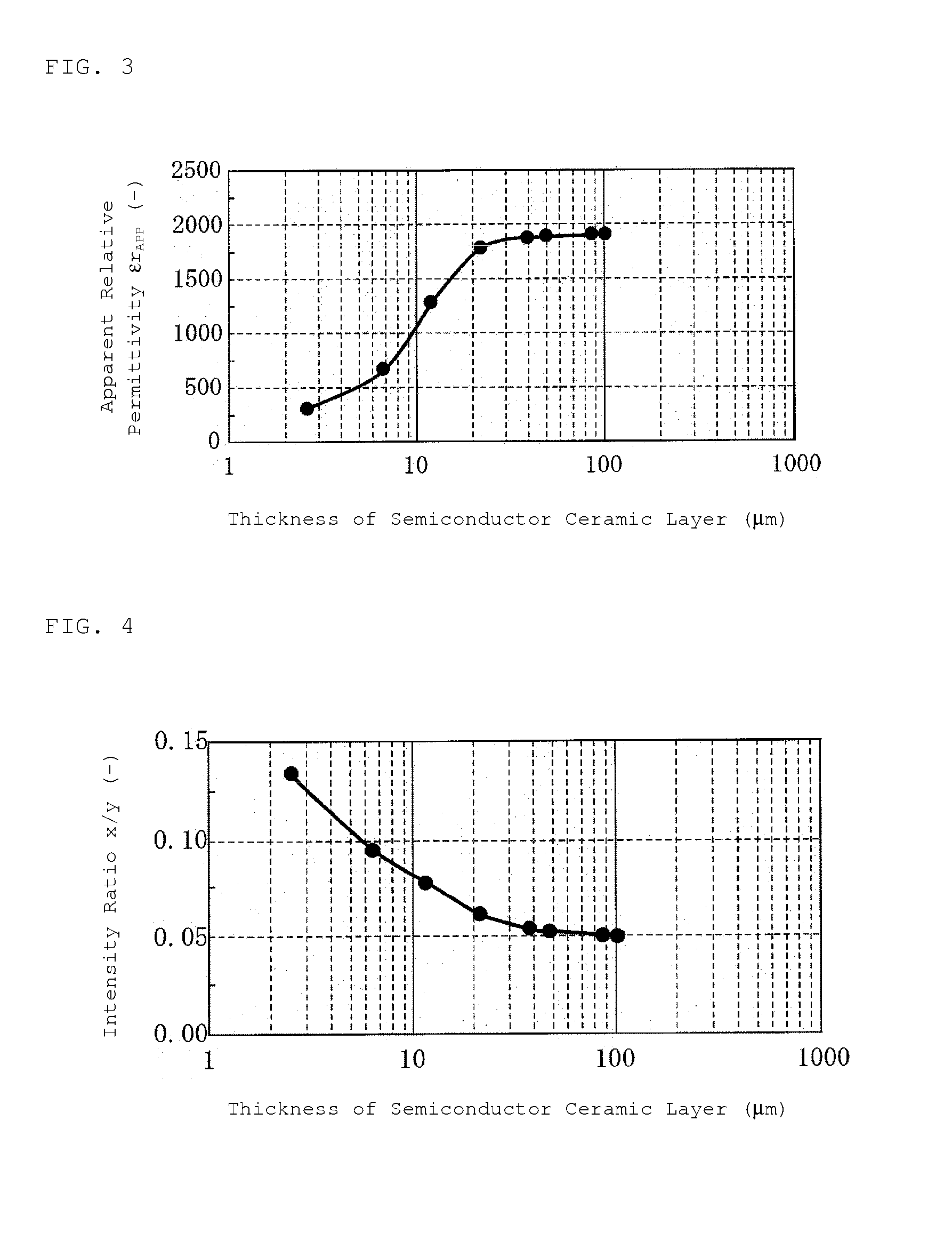

Laminated semiconductor ceramic capacitor with varistor function and method for manufacturing the same

InactiveUS20130286541A1Reduced insulation performanceFacilitated DiffusionFixed capacitor dielectricStacked capacitorsCeramic capacitorNi element

A laminated semiconductor ceramic capacitor with a varistor function includes a component body having a plurality of semiconductor ceramic layers formed of a SrTiO3-based grain boundary insulated semiconductor ceramic and a plurality of internal electrode layers predominantly composed of Ni, and external electrodes on both ends of the component body. The external electrodes are electrically connected to the internal electrode layers. A thickness of each of the semiconductor ceramic layers, excluding the outermost semiconductor ceramic layers, is 20 μm or more, and an average grain diameter of crystal grains in the semiconductor ceramic layers is 1.5 μm or less. When a central part or the vicinity of the central part in a laminating direction of the semiconductor ceramic layer is analyzed by a WDX method, a ratio x / y of the intensity x of the Ni element to the intensity y of the Ti element is 0.06 or less.

Owner:MURATA MFG CO LTD

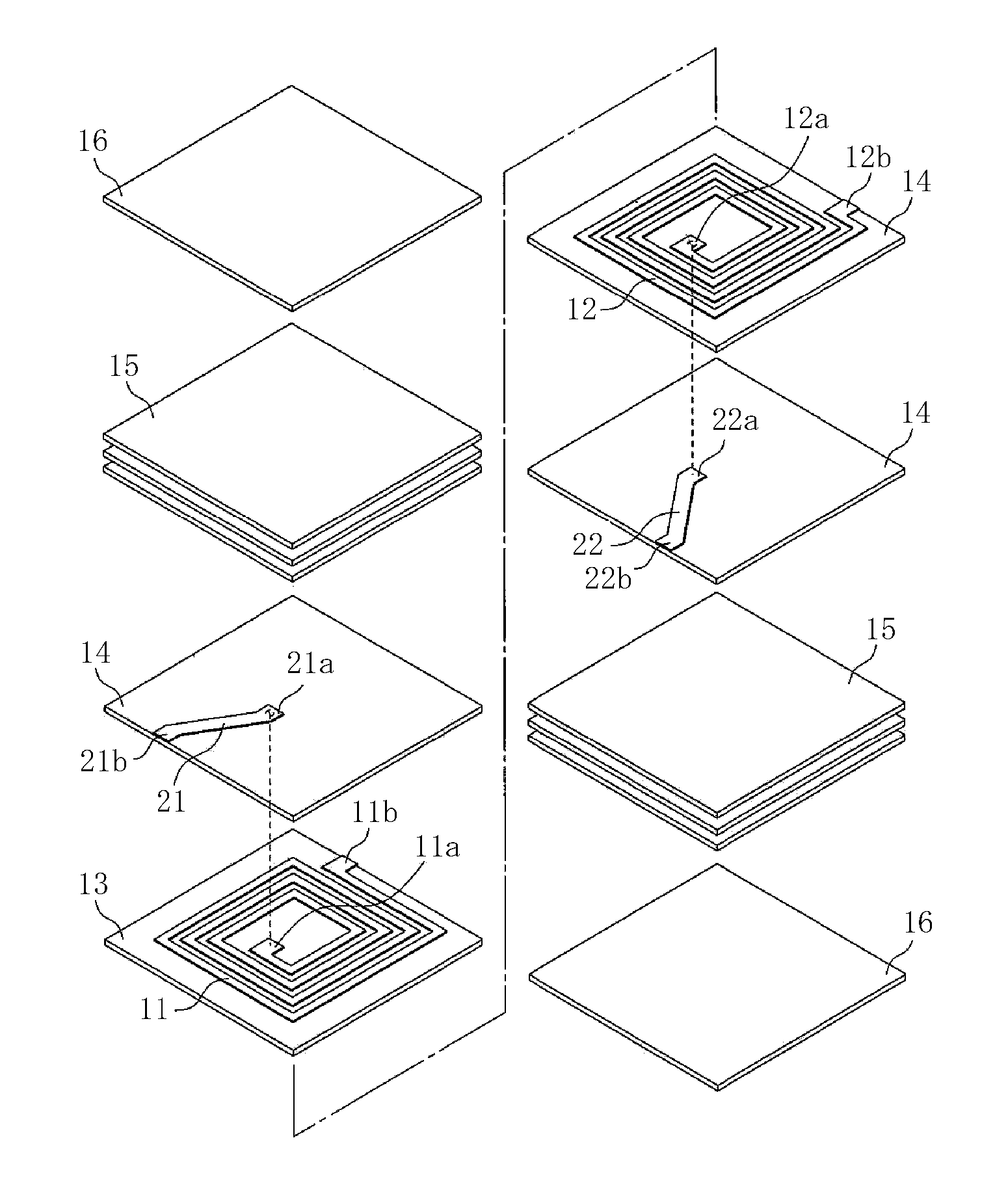

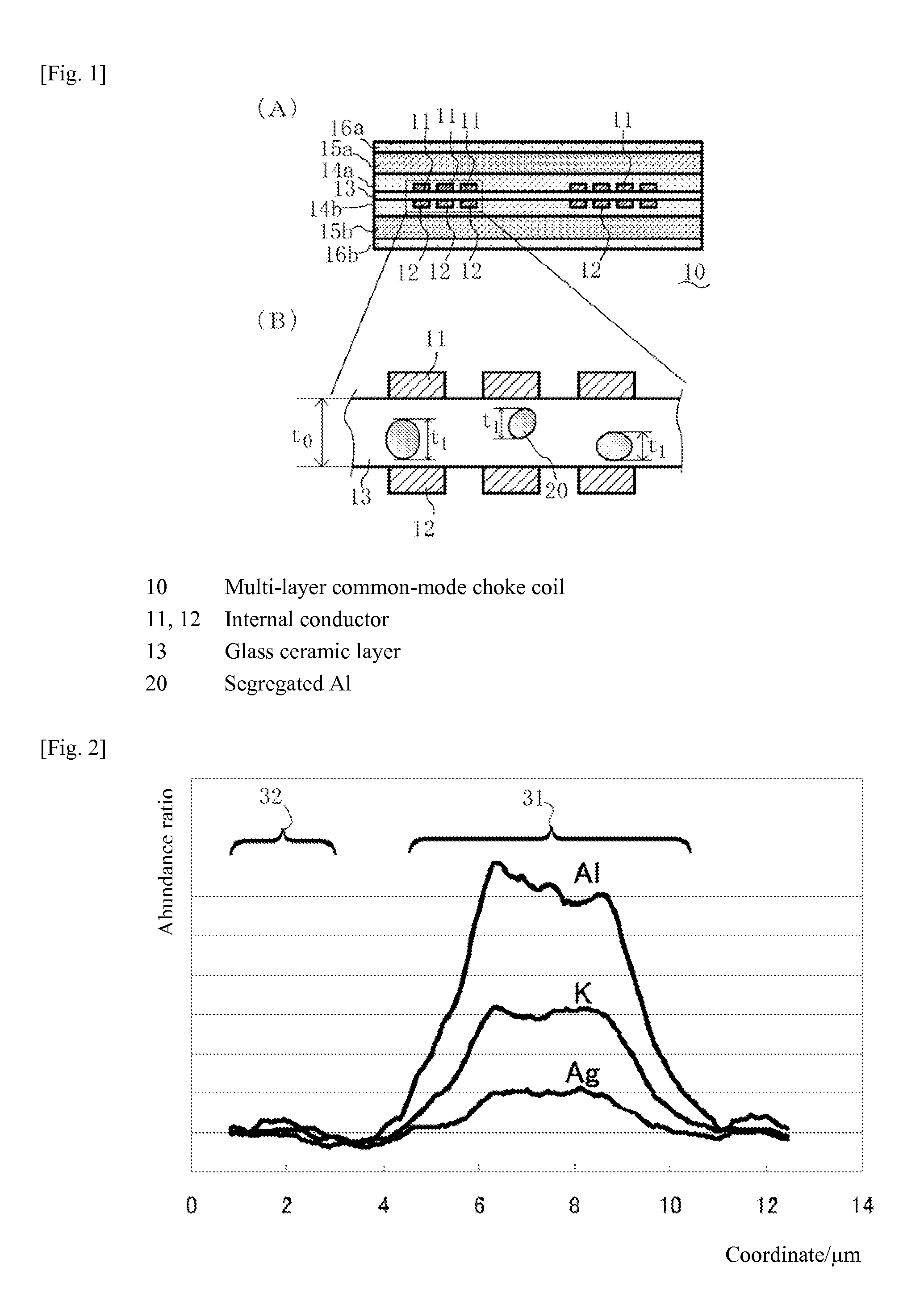

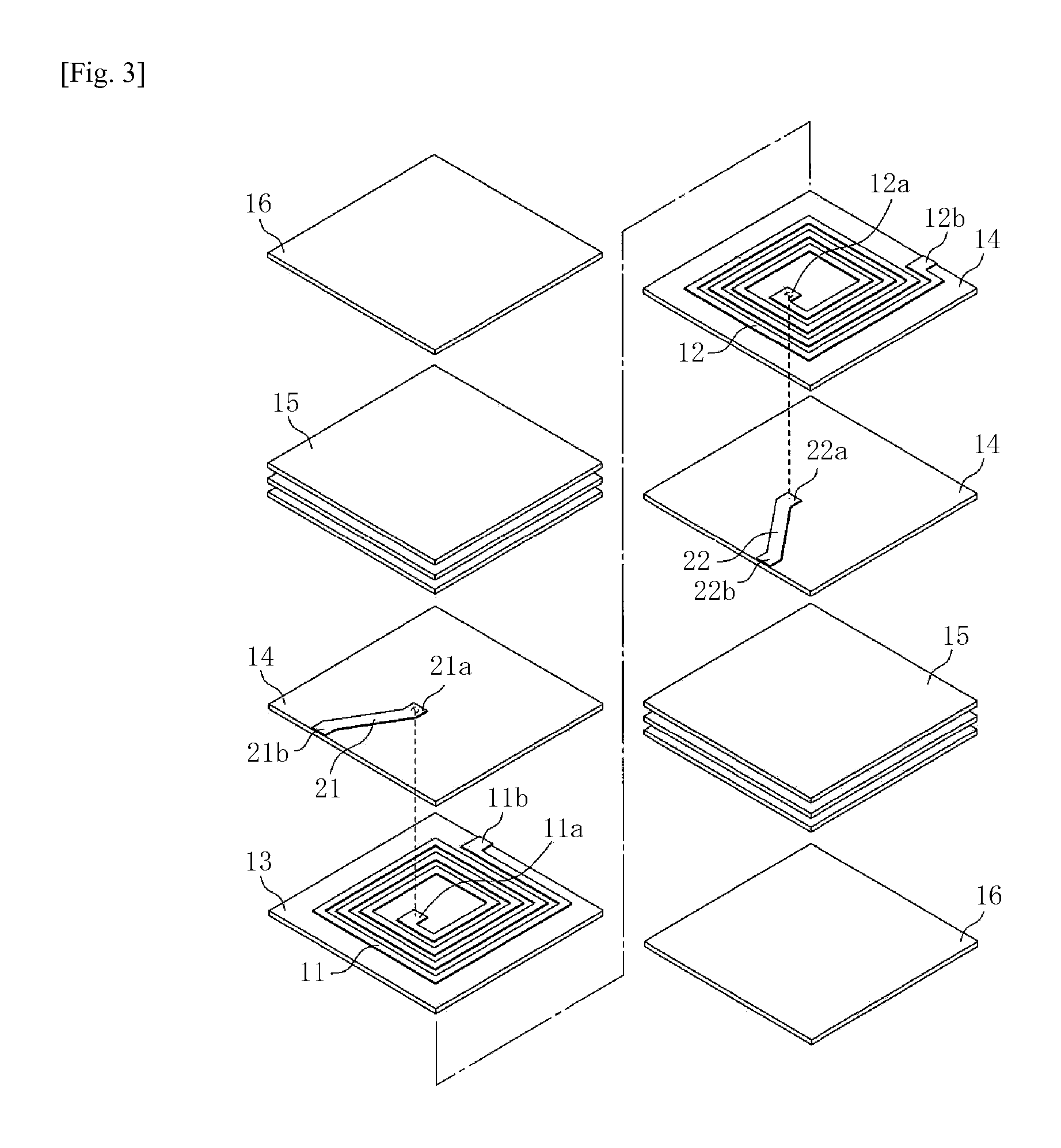

Laminated common-mode choke coil

ActiveUS20130154786A1Insulation property be lowerHigh insulation reliabilityCoilsFixed signal inductancesManufacturing engineeringElectrical conductor

A laminated common-mode choke coil offering higher insulation reliability has a glass ceramic layer, two spiral internal conductors facing each other and sandwiching the glass ceramic layer in between, and insulation layers sandwiching the two internal conductors, wherein the glass ceramic layer contains segregated Al regions and the maximum dimension t1 of each segregated Al region in the glass ceramic layer, in the layer-thickness direction, is no more than 80% of the distance t0 between the two internal conductors.

Owner:TAIYO YUDEN KK

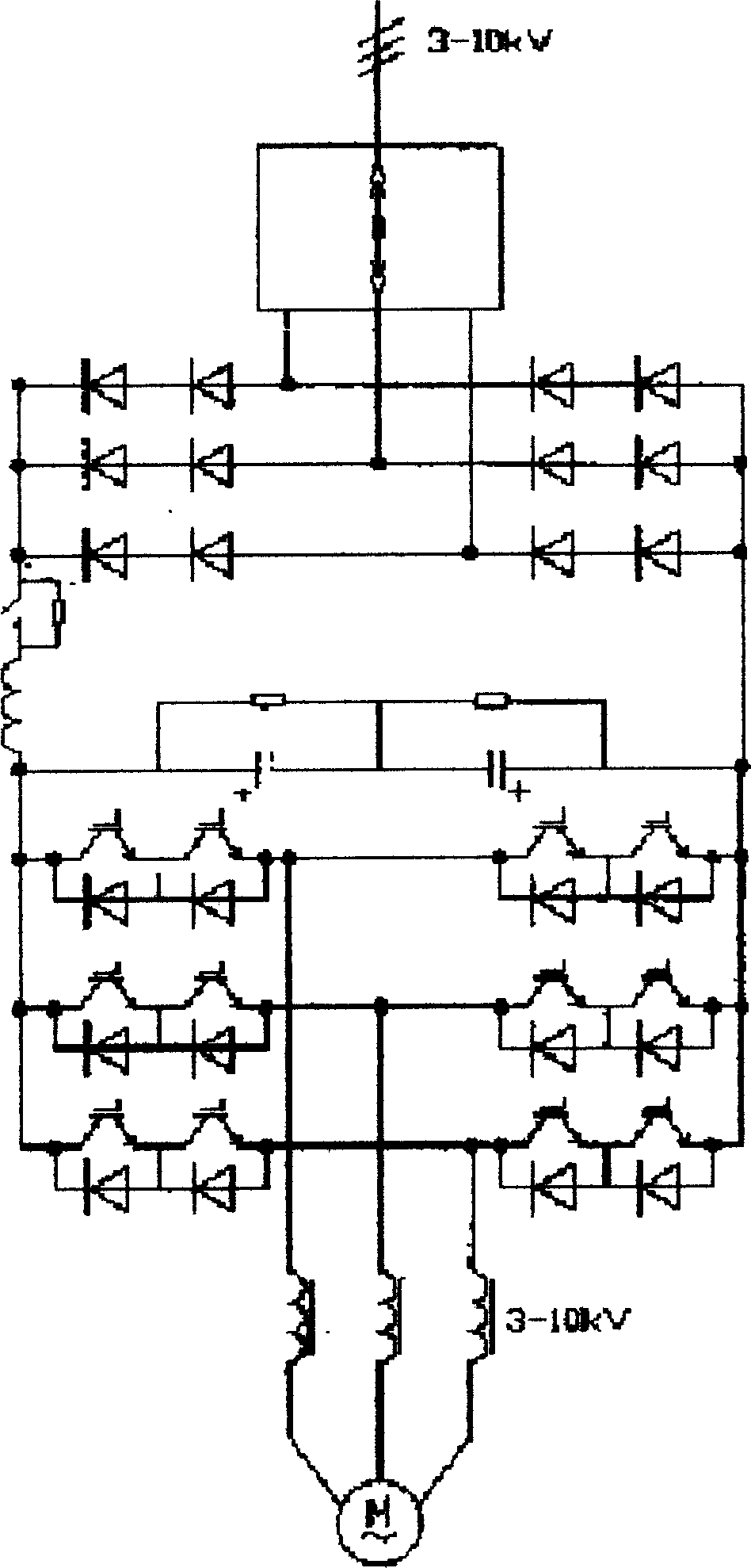

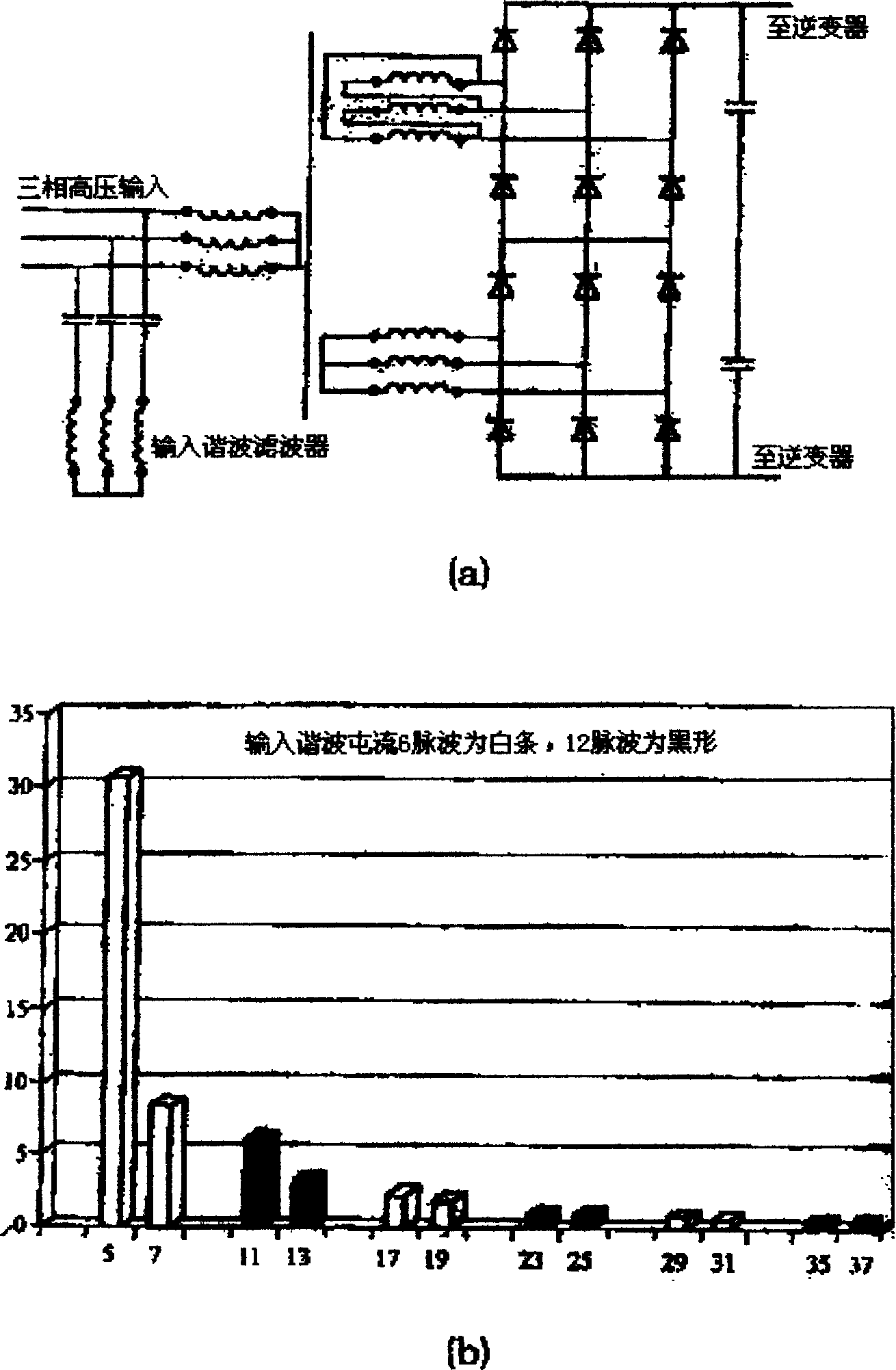

Three-phase split phase-shifting transformer for high-voltage frequency conversion and its use

InactiveCN1529404AReduce feverAvoid feverDC motor speed/torque controlTransformersLow noiseTransformer

In the transformer, line side windings connected in star type continuous form is adopted in inner side. Structure of outer side is three groups divided, N groups phase shifted cake typed line side windings. The invented transformer solves issues of harmonic polluting on power grid and harmonic wastage, possessing advantages: reliable operation, simple maintenance, small harmonic current at power grid side, low noise, low heat generated, high power factor. When being applied to high voltage frequency control, the invention solves issues: heating of motor, torque ripple, influence of dv / dr and common mode voltage on insulation of motor. The invention can reaches ideal effect of harmonic elimination even if out of balanced currents occurred, providing advantages of approximate to sinusoidal waveform output, high conversion efficiency etc.

Owner:谭勇

Foaming composition for water tank of solar water heater

InactiveCN102516494APrevent severe shrinkageNo significant deformationSodium bicarbonateFoaming agent

The invention discloses a foaming composition for a water tank of a solar water heater, which is characterized by comprising the following main raw materials: a polyether foaming agent, sodium bicarbonate, chitosan and hollow glass beads. The improved polyether rigid foam composition can be used for reducing the phenomena that after being sprayed from a glossy jar and formed, a polyurethane material has high contractibility, the heat preservation effect of the water tank of the solar water heater is influenced and the water tank is deformed, bulged and barred, or even cracked.

Owner:杜立立

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com