Active type direct-current system insulation resistor detection method

A technology of insulation resistance and DC system, which is applied in the direction of measuring resistance/reactance/impedance, measuring devices, measuring electrical variables, etc. It can solve the problems of inability to realize real-time monitoring of insulation resistance status, reduce the insulation performance of equipment, and reduce the safety of personnel and equipment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Hereinafter, the present invention will be further described in detail with reference to the accompanying drawings and specific embodiments, and the specific flow of the method implementation will be described:

[0053] Circuit design:

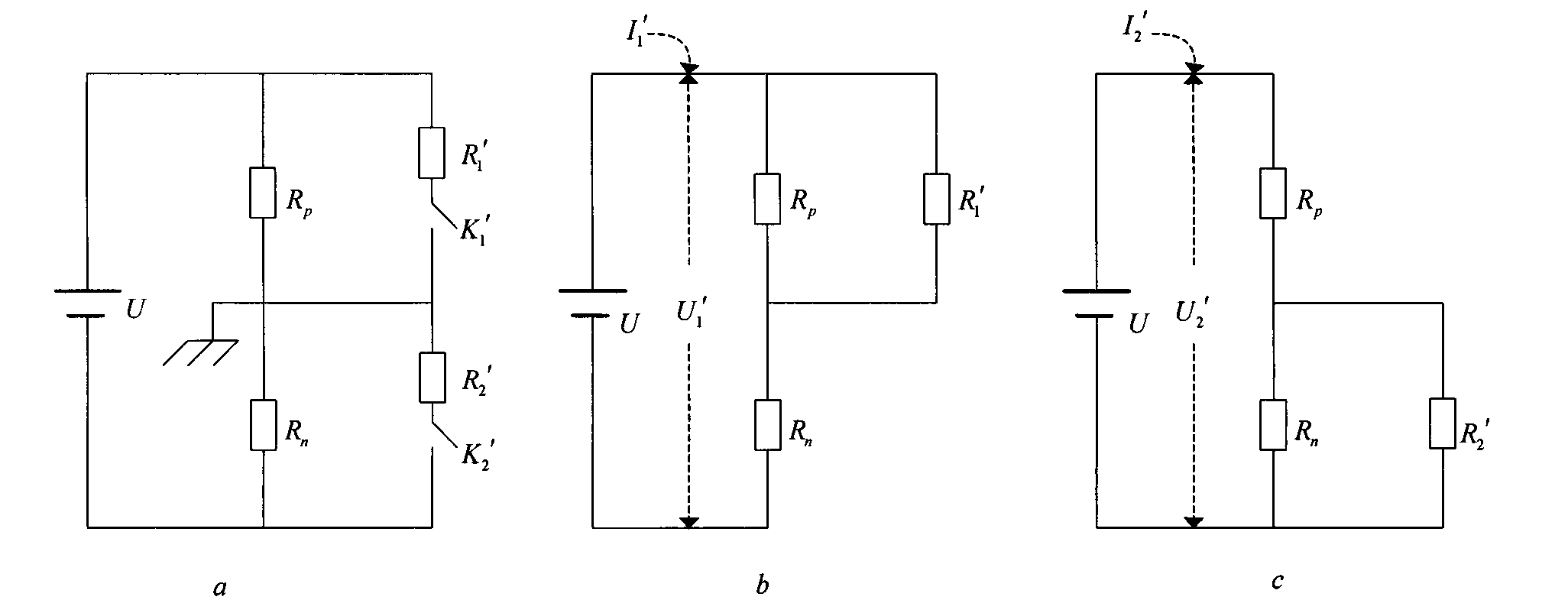

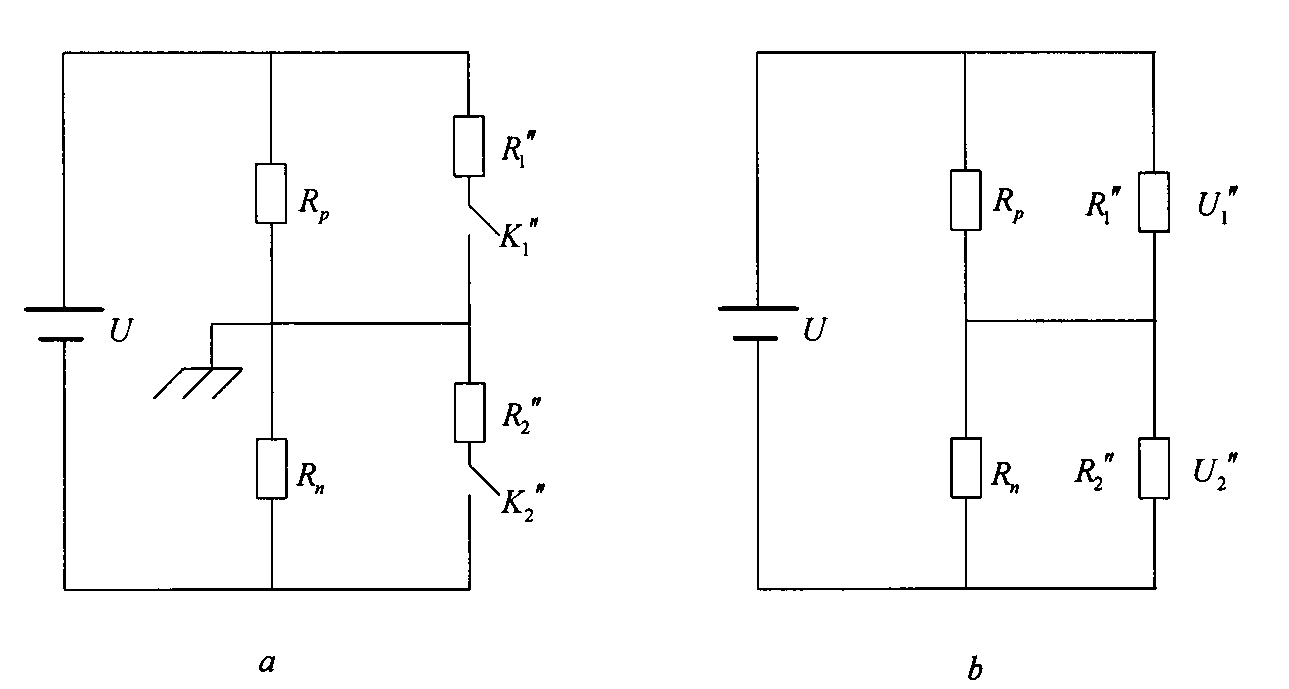

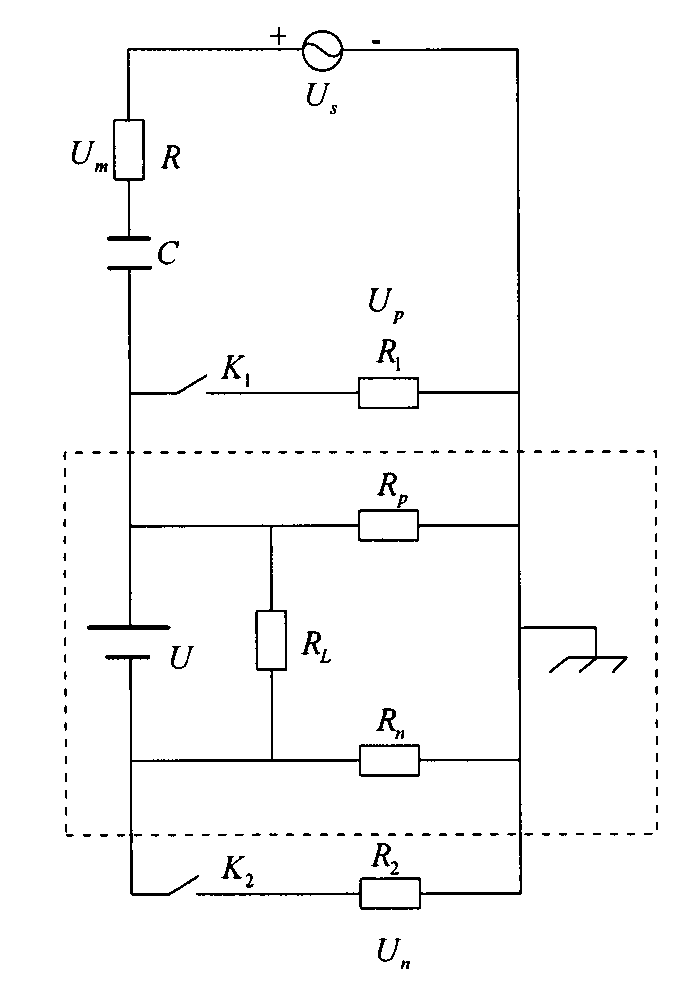

[0054] The insulation resistance detection of this method belongs to the insulation resistance detection of active DC system, image 3 It is the equivalent circuit of the active insulation resistance detection principle. The virtual box in the figure is the actual operating circuit part, U is a high-voltage DC voltage source, R L Is the load, R p , R n They are the insulation resistance of the positive pole and negative pole of the DC voltage source to the ground. In the actual circuit system, the insulation resistance of the positive pole and the negative pole to the ground are floating, and the equivalent resistance R is used here. p , R n Said. The part outside the dashed box in the figure is the auxiliary measurement circuit added, U s It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com