Patents

Literature

15399 results about "Diesel engine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The diesel engine (also known as a compression-ignition or CI engine), named after Rudolf Diesel, is an internal combustion engine in which ignition of the fuel is caused by the elevated temperature of the air in the cylinder due to the mechanical compression (adiabatic compression). This contrasts with spark-ignition engines such as a petrol engine (gasoline engine) or gas engine (using a gaseous fuel as opposed to petrol), which use a spark plug to ignite an air-fuel mixture.

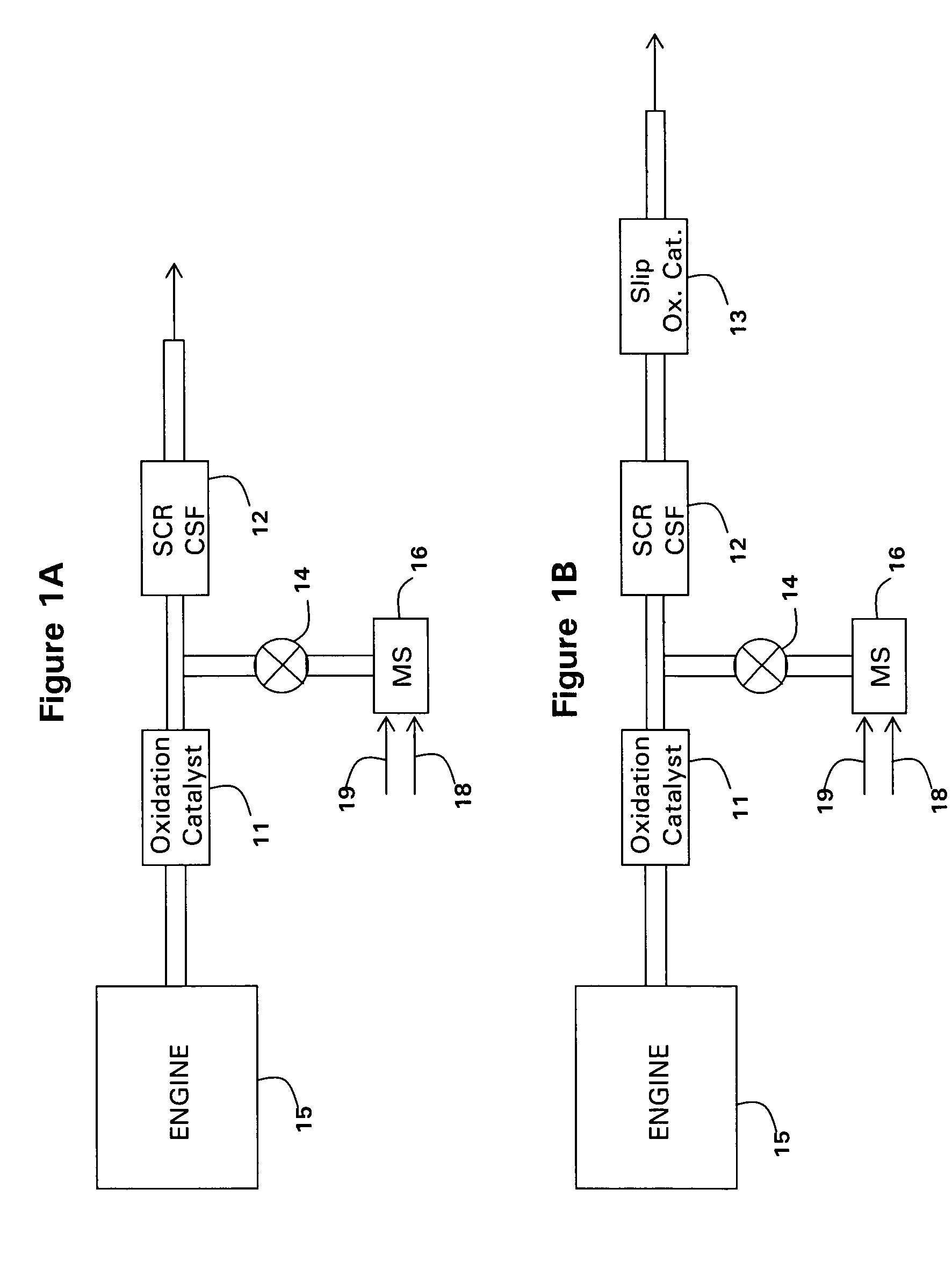

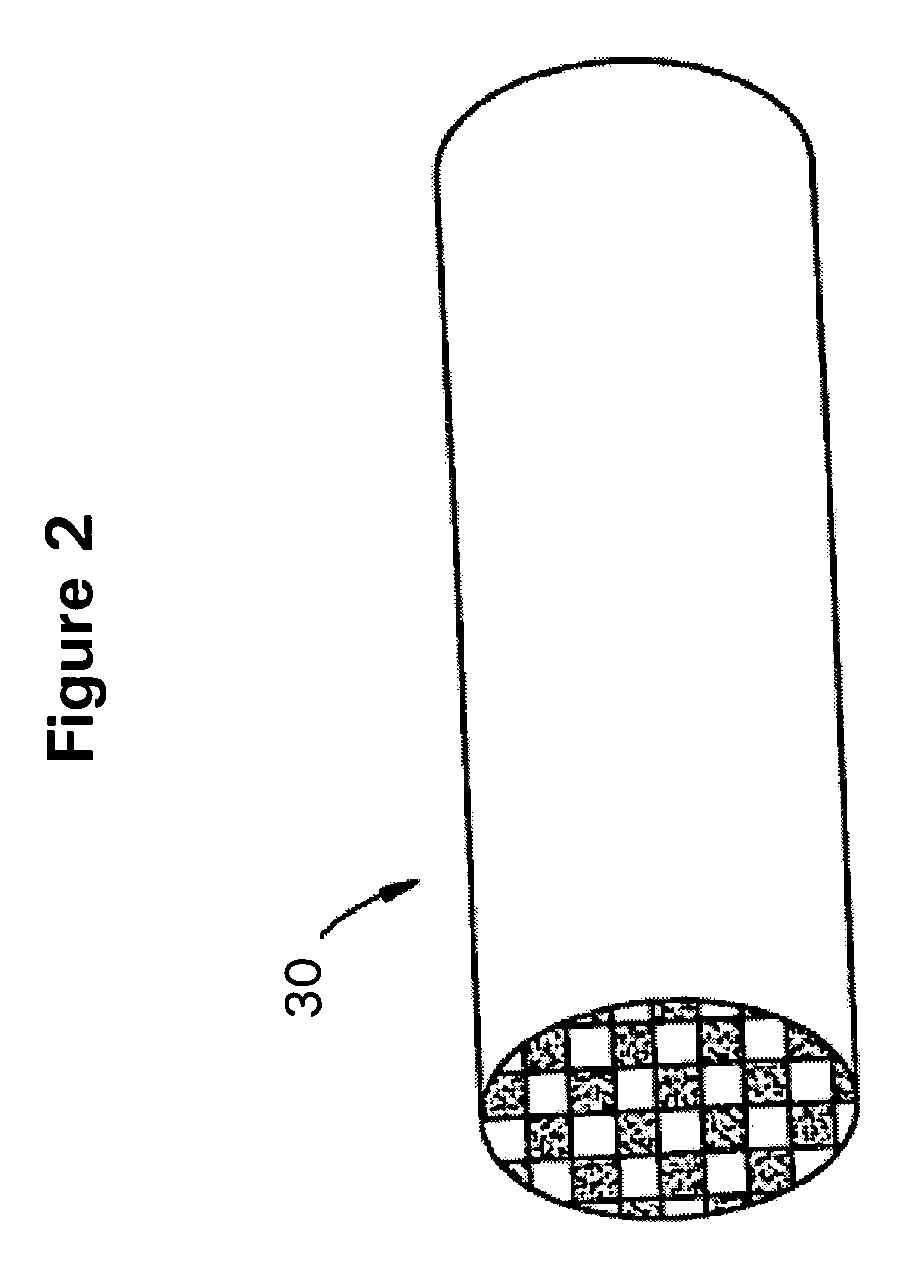

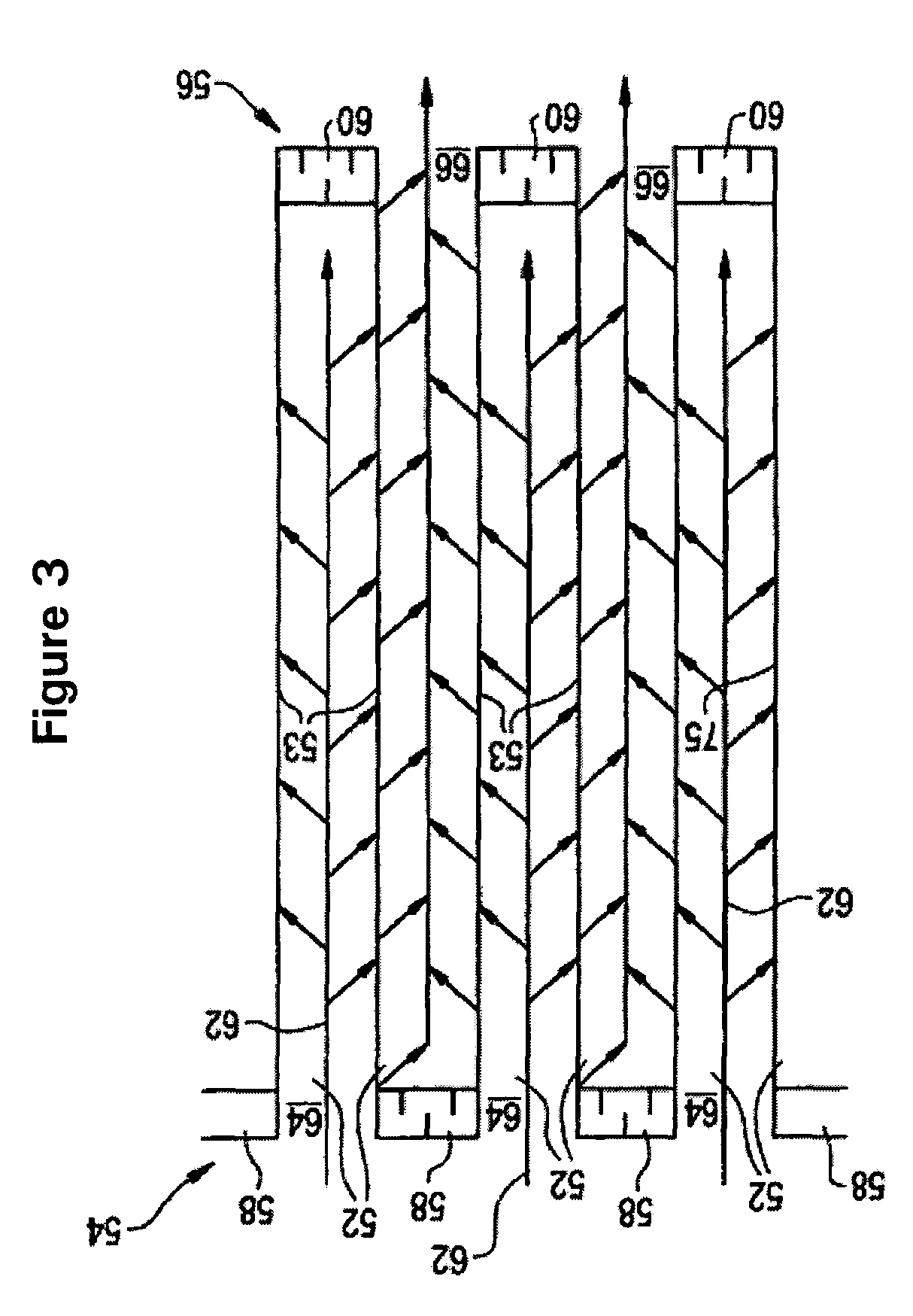

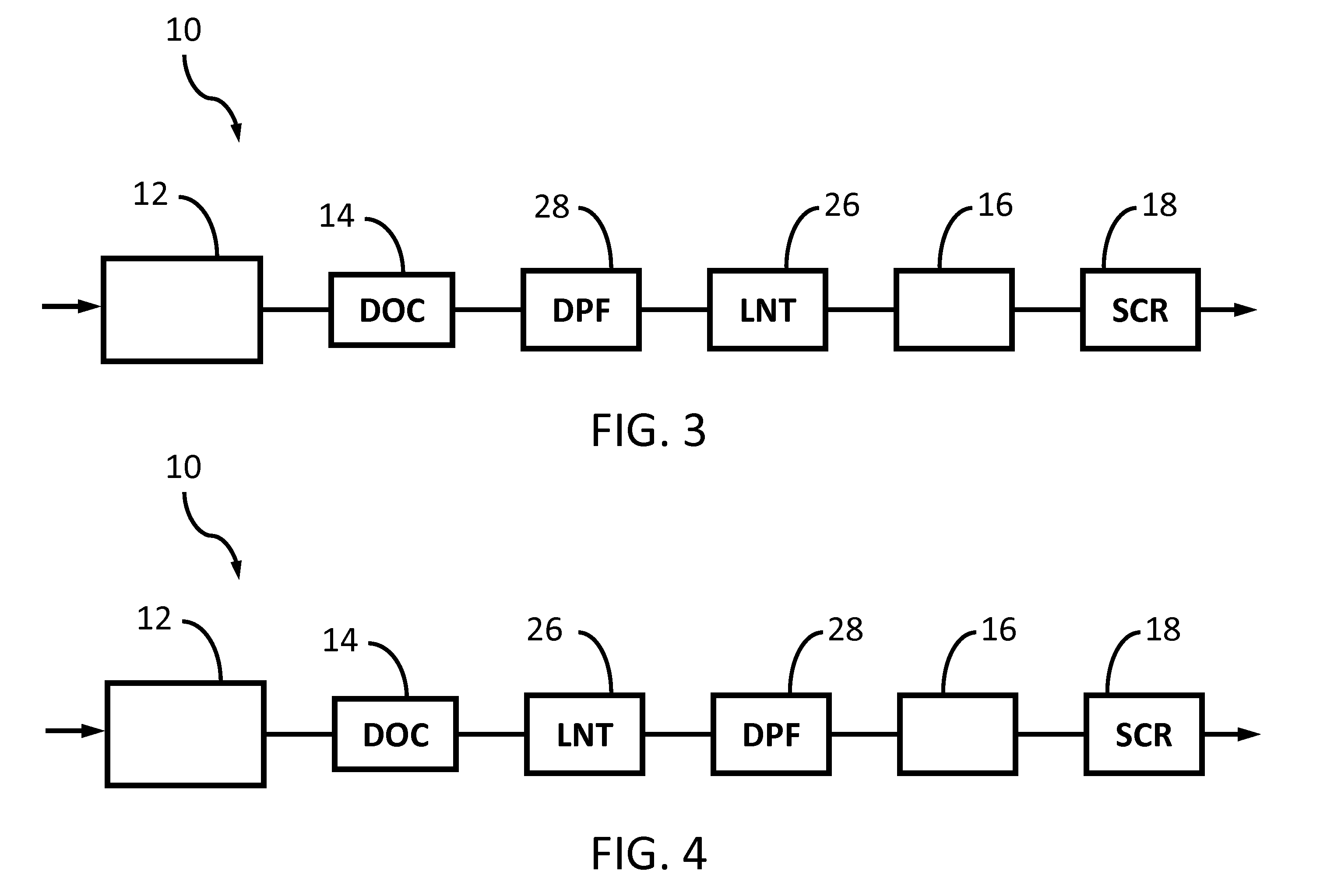

Catalyzed SCR filter and emission treatment system

ActiveUS7229597B2Reduce the temperaturePromote regenerationCombination devicesLiquid degasification with auxillary substancesNitrogen oxideSoot

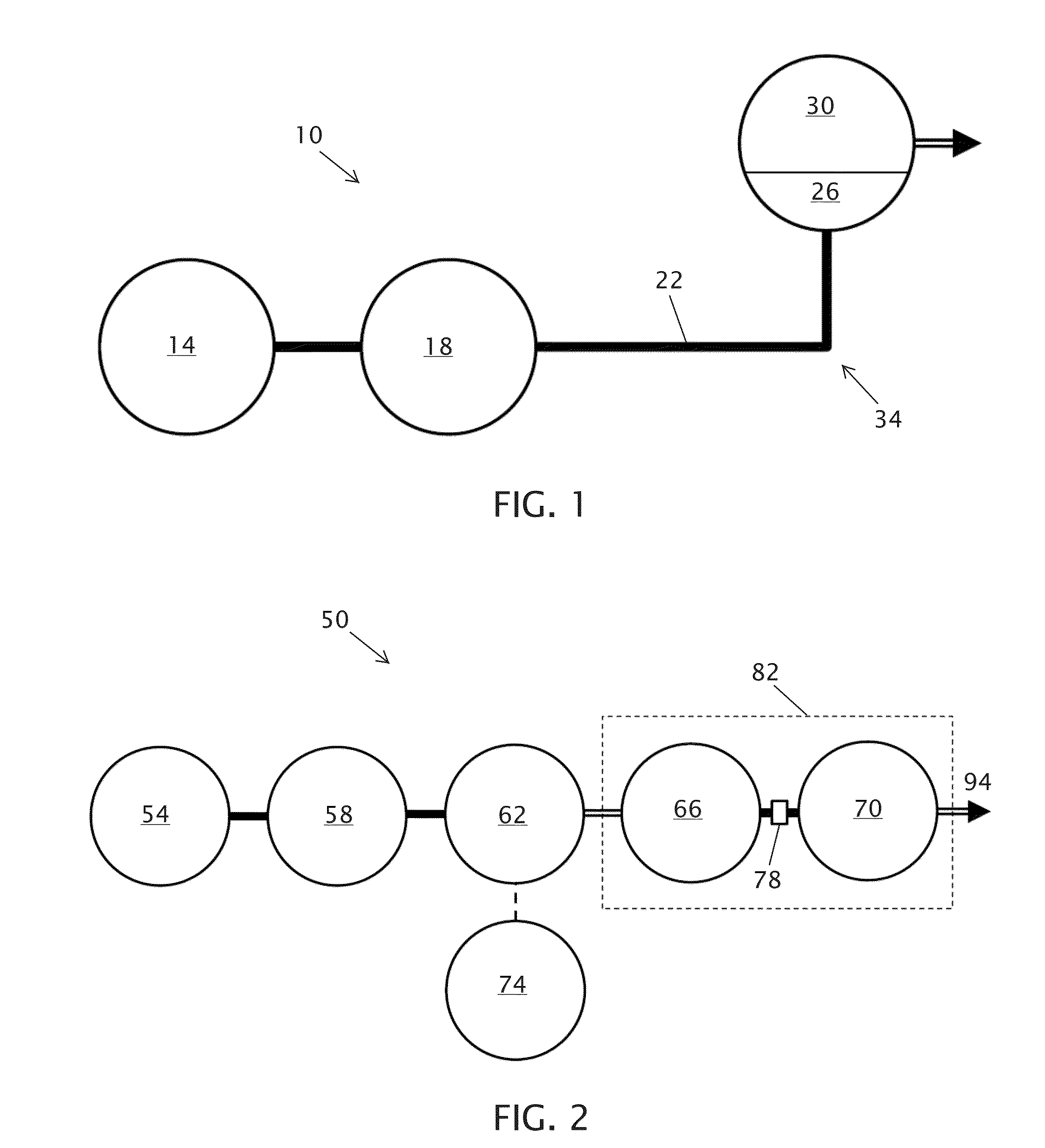

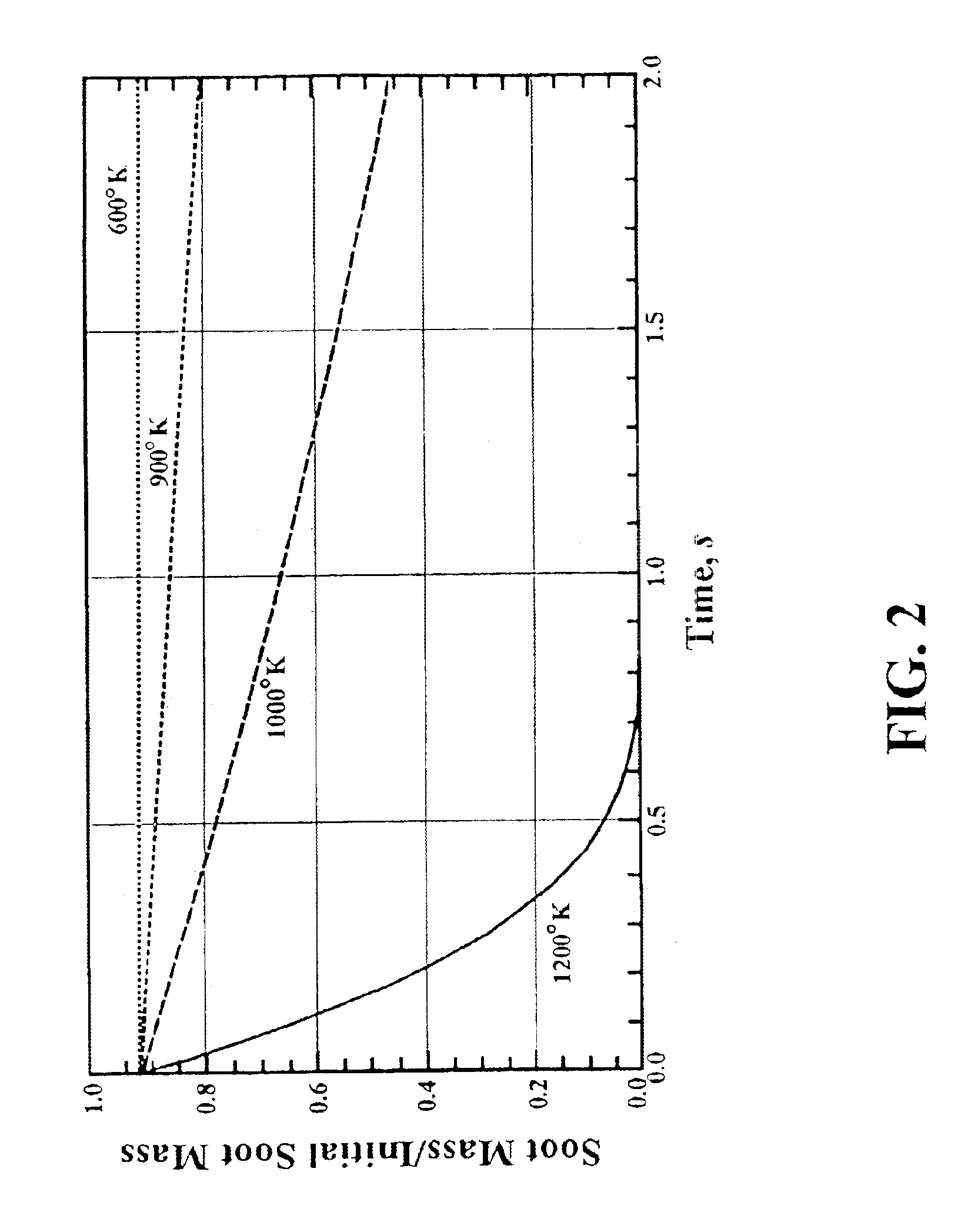

Provided is an emission treatment system and method for simultaneously remediating the nitrogen oxides (NOx), particulate matter, and gaseous hydrocarbons present in diesel engine exhaust streams. The emission treatment system has an oxidation catalyst upstream of a soot filter coated with a material effective in the Selective Catalytic Reduction (SCR) of NOx by a reductant, e.g., ammonia. Also provided is a method for disposing an SCR catalyst composition on a wall flow monolith that provides adequate catalyst loading, but does not result in unsuitable back pressures in the exhaust.

Owner:BASF CORP

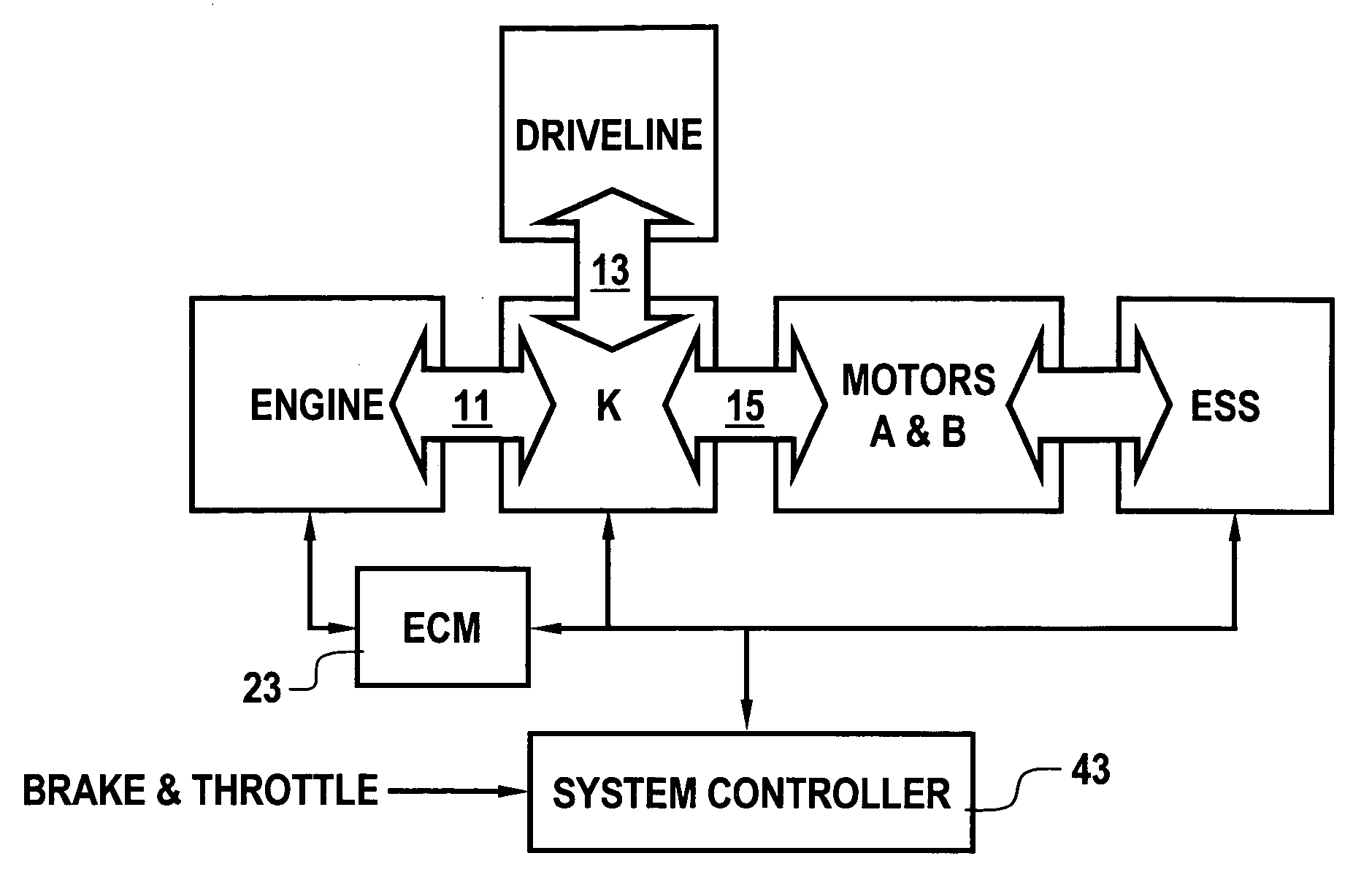

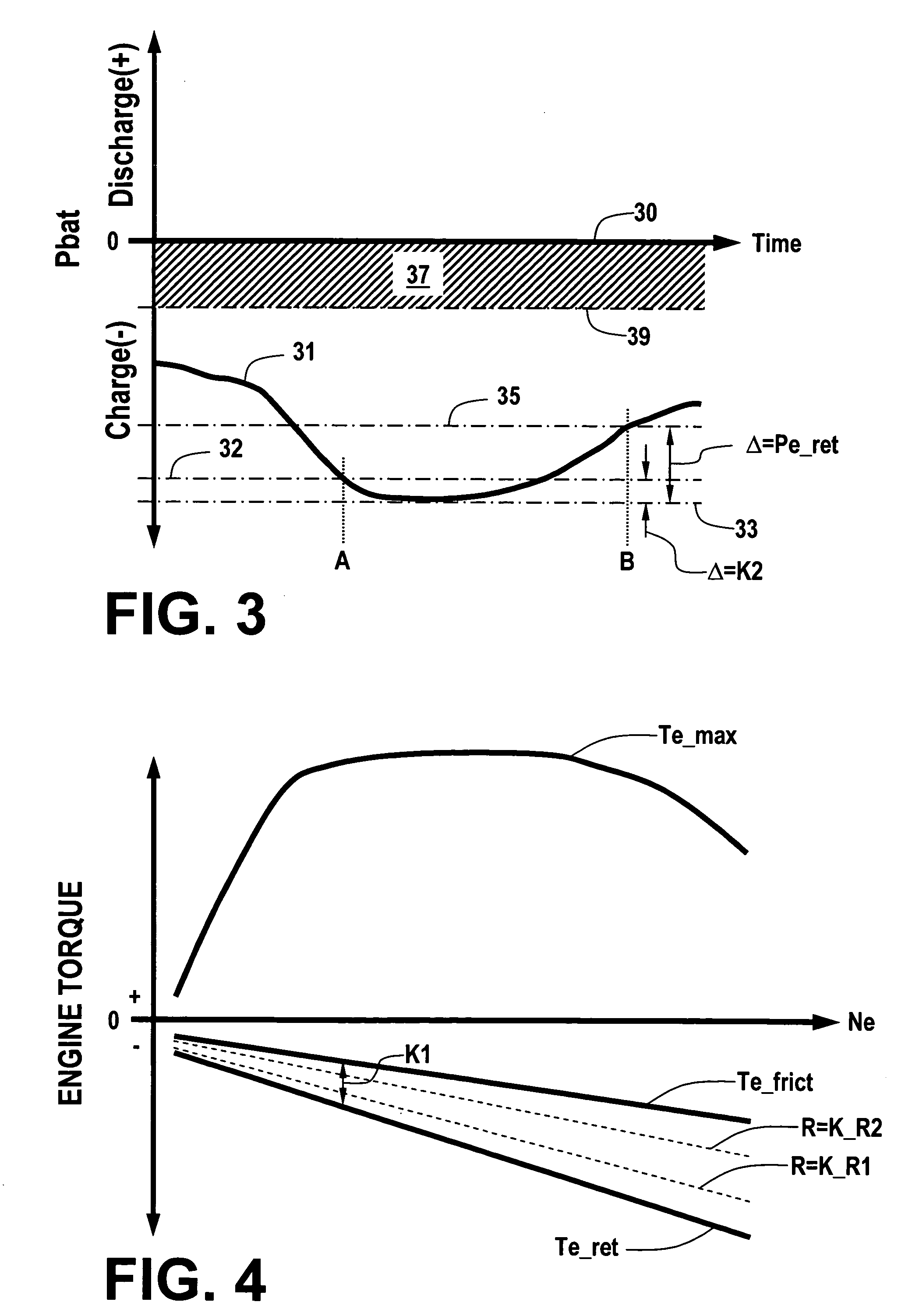

Coordinated regenerative and engine retard braking for a hybrid vehicle

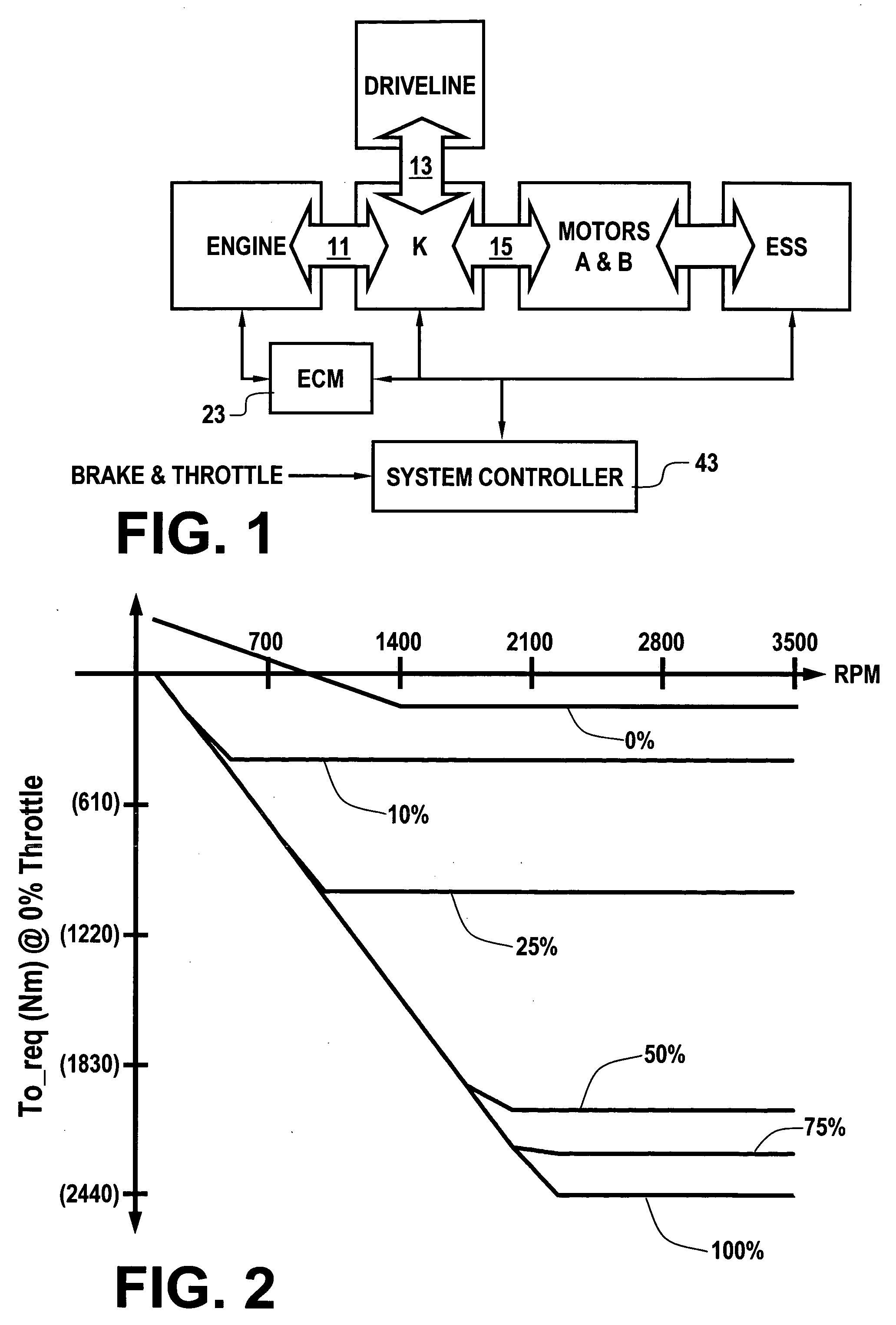

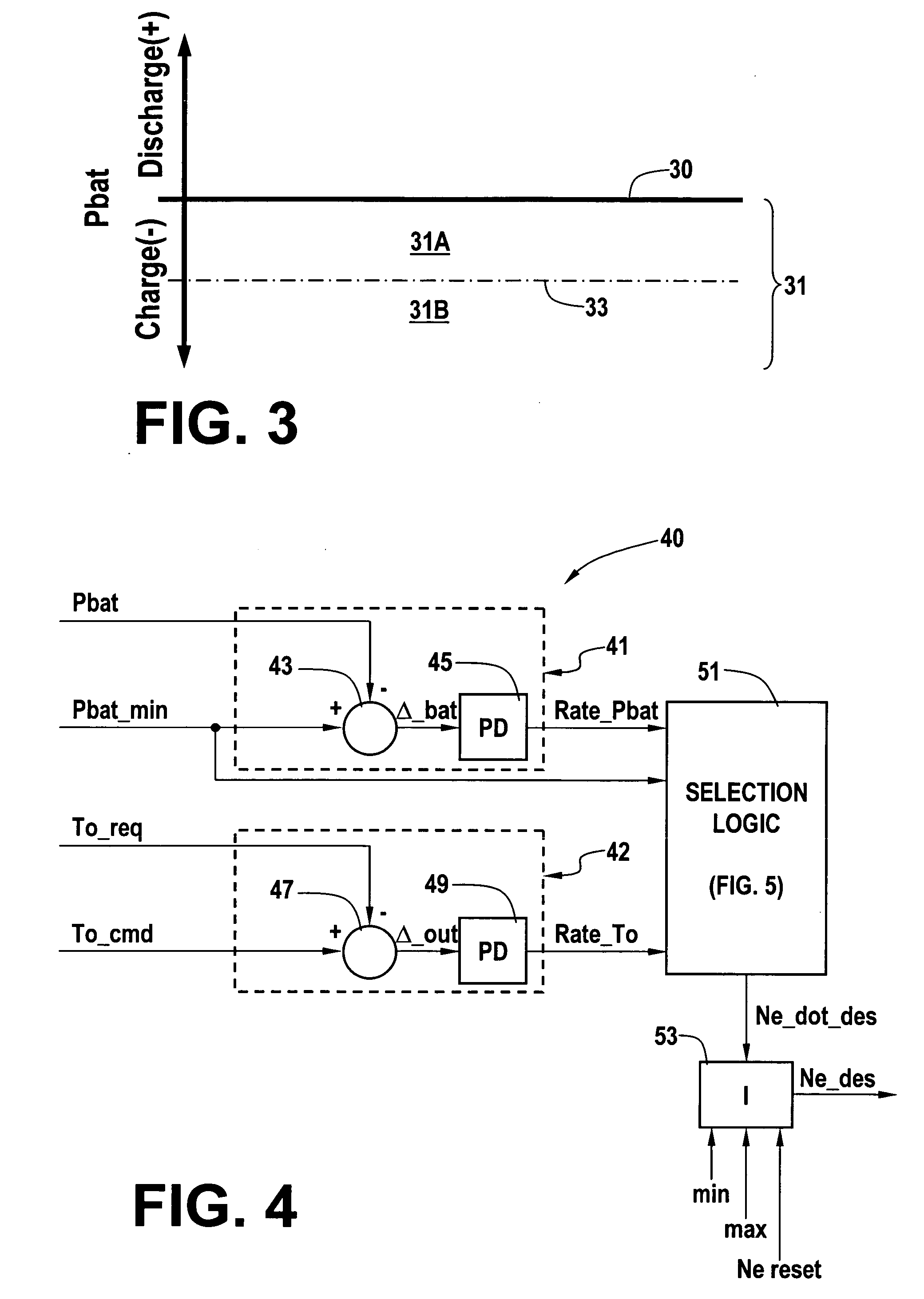

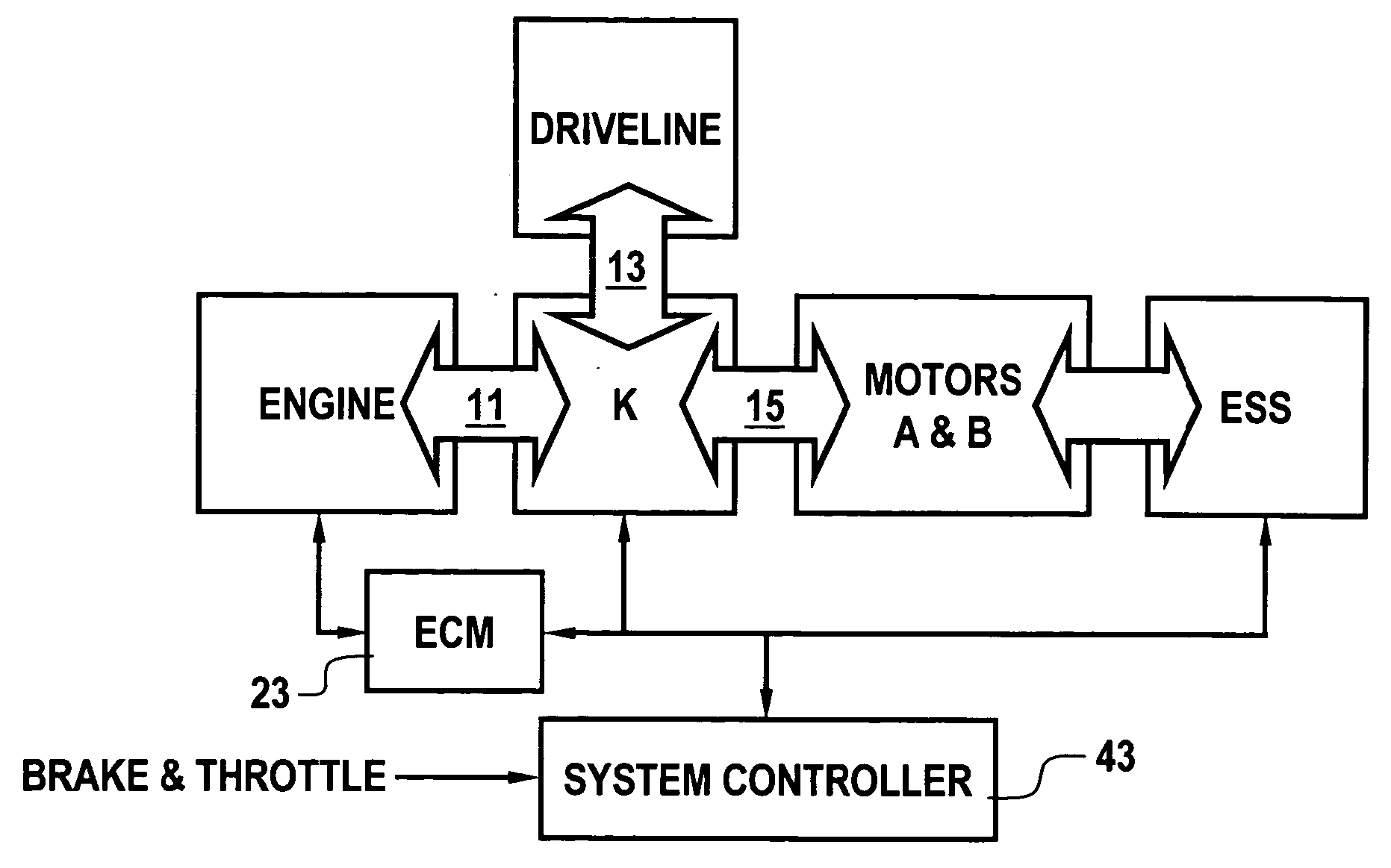

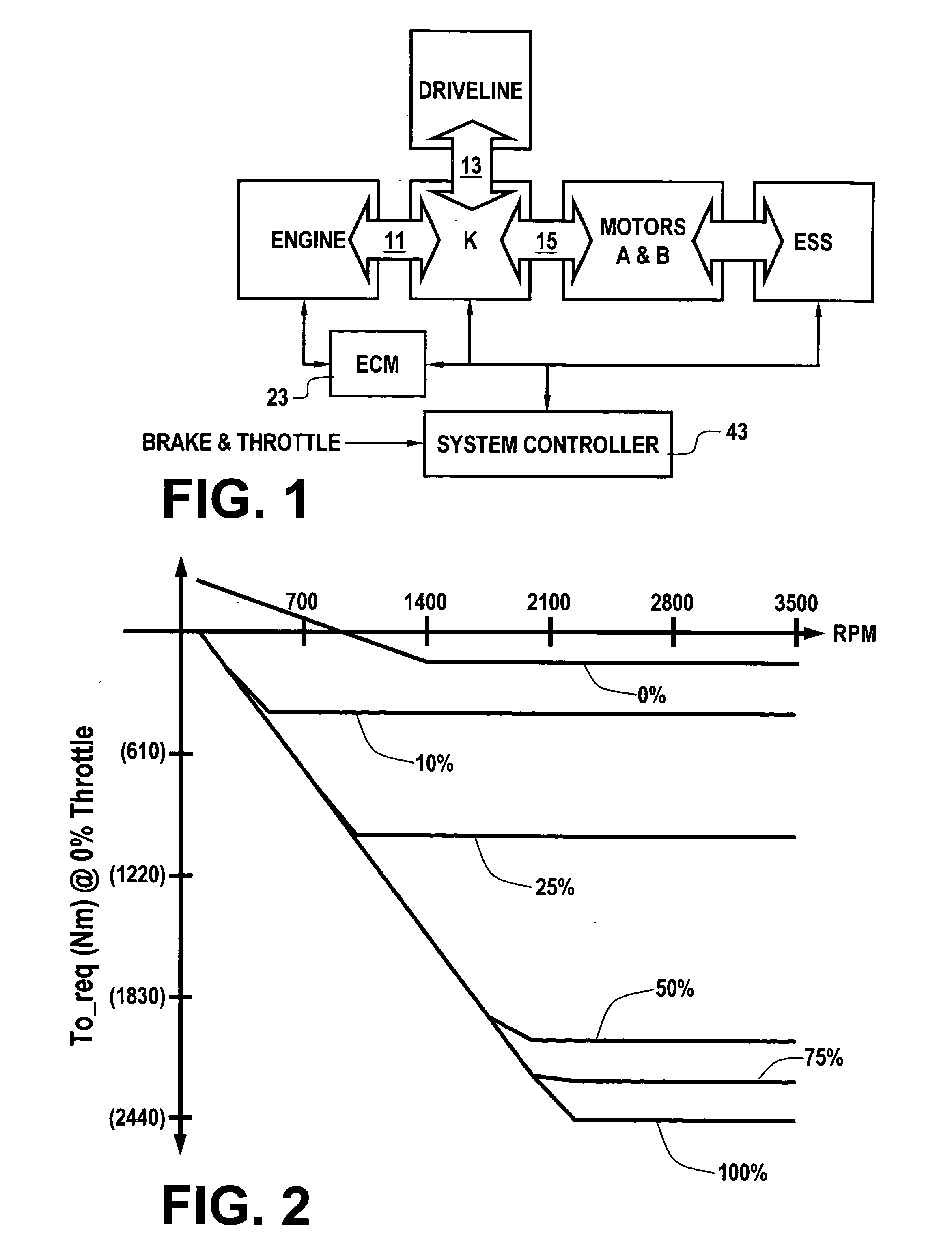

ActiveUS20050255965A1Increases the engine retard braking contributionReduce contributionHybrid vehiclesBraking element arrangementsPower flowGear wheel

A hybrid vehicle includes a powertrain having a retarded diesel engine, an electric machine and energy storage system. The engine and motor are operatively coupled through one or more planetary gearsets and selective coupling paths in accordance with application and release of various torque transfer devices to a drivetrain via an output. Regenerative and retarded engine braking are coordinated to provide priority to energy return to an energy storage system in accordance with predetermined power flow limits. Power flow in excess of the limits are handled by increased engine retard braking contributions via engine speed increases.

Owner:ALLISON TRANSMISSION INC

Engine retard operation scheduling and management in a hybrid vehicle

ActiveUS20050255966A1Hybrid vehiclesBraking element arrangementsOperation schedulingElectric machine

A hybrid vehicle includes a powertrain having a retarded diesel engine, an electric machine and energy storage system. The engine and motor are operatively coupled through one or more planetary gearsets and selective coupling paths in accordance with application and release of various torque transfer devices to a drivetrain via an output. Regenerative and retarded engine braking are coordinated to provide priority to energy return to an energy storage system in accordance with predetermined power flow limits.

Owner:GM GLOBAL TECH OPERATIONS LLC

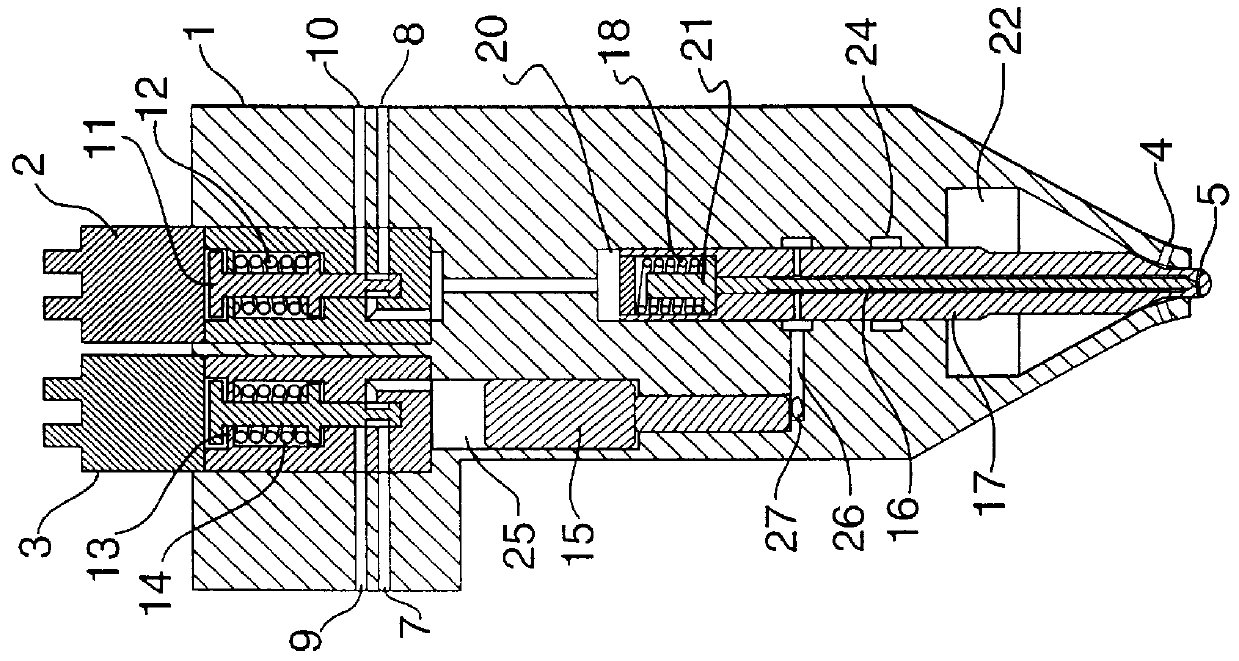

Gaseous and liquid fuel injector

A hydraulically actuated dual fuel injector for an internal combustion engine. More particularly, the application pertains to a hydraulically actuated injector for injecting controlled quantities of a first fuel and of a second fuel into an internal combustion diesel engine at different times. A dual fuel injector comprising: (a) an injector body; (b) an inlet port in the injector body for enabling pressurized hydraulic fluid from a hydraulic fluid source to be introduced into the interior of the injector body, the hydraulic fluid being of sufficient pressure to maintain injection valves in the injector body in a closed position until actuated; (c) a first inlet port in the injector body for enabling a first fuel to be introduced into the interior of the injector body; (d) a first injection valve in the injector body connected to the second inlet port for controlling injection of the first fuel from the injector through a first fuel ejection port; (e) a second inlet port in the injector body for enabling a second fuel to be introduced into the interior of the injector body; (f) a second injection valve in the injector body connected to the second inlet port for controlling injection of the second fuel from the injector through a second fuel ejection port; (g) a first control valve which causes the hydraulic fluid to actuate the first injection valve; (h) a second control valve which causes the hydraulic fluid to actuate the second injection valve; (i) a metering device in the injector body for metering the amount of first fuel injected by the first injection valve; and (j) a seal in the injector body which prevents leakage of the second fuel into the first fuel.

Owner:WESTPORT POWER

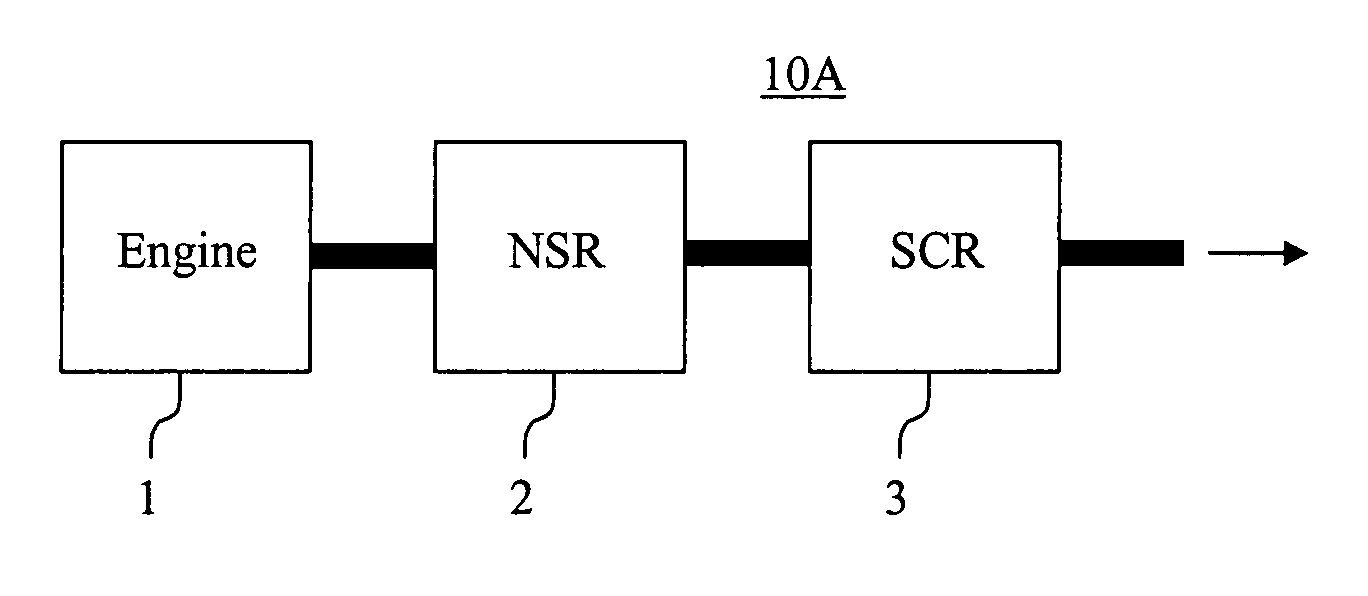

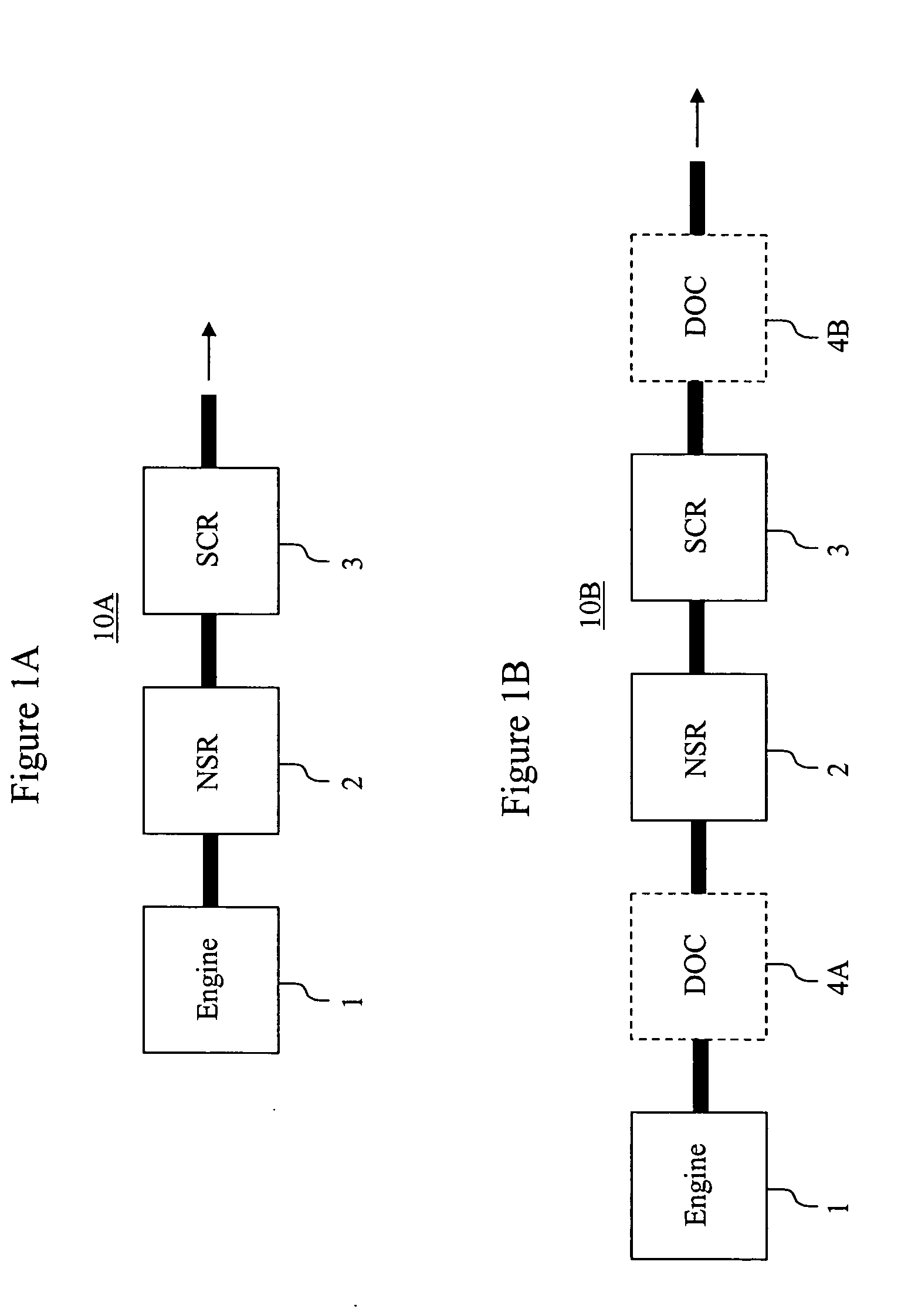

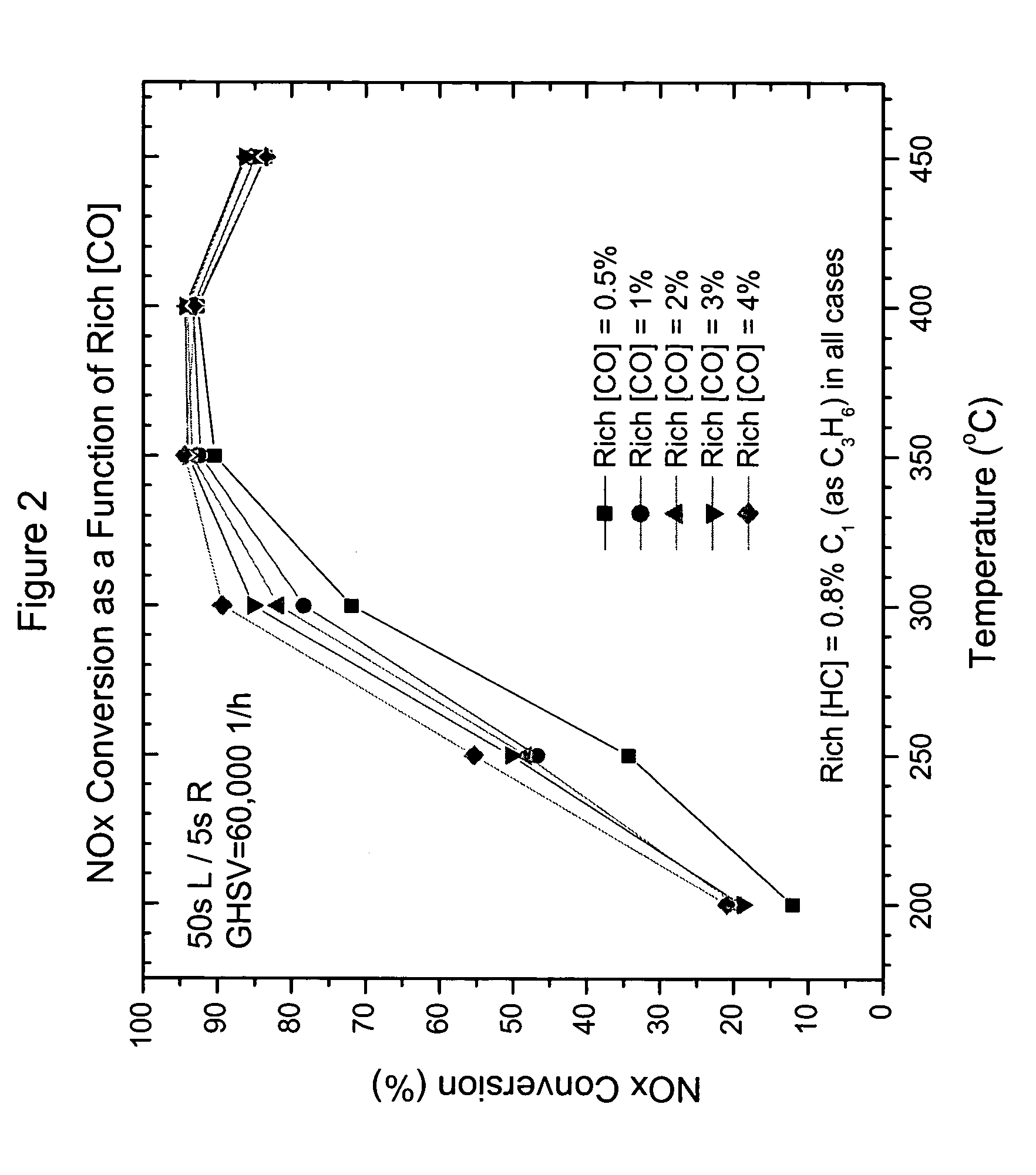

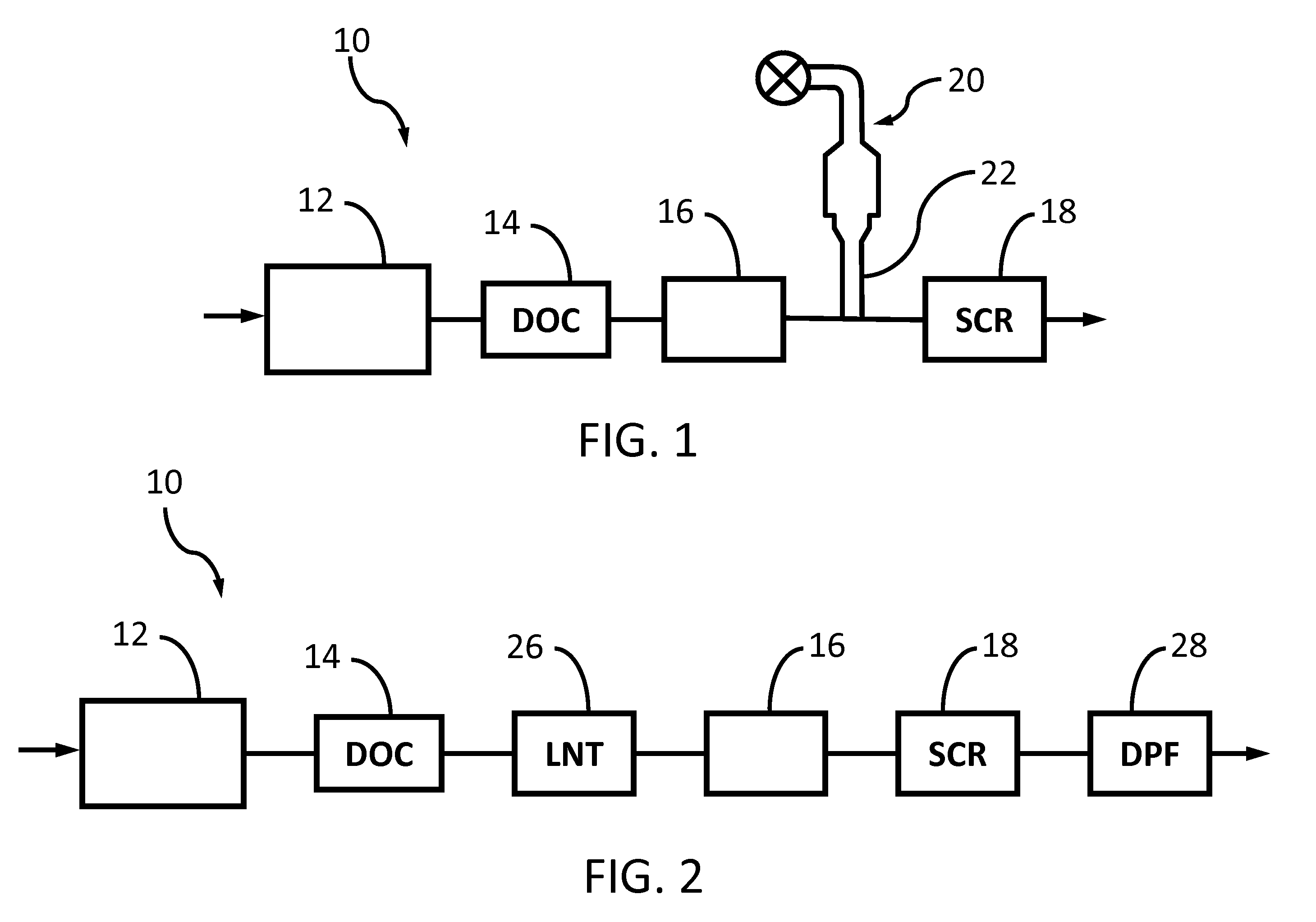

Emissions treatment system with NSR and SCR catalysts

ActiveUS20050129601A1Small sizeReduce amount particulate matterGas treatmentNitrogen compoundsSorbentGasoline

Provided is an emissions treatment system for an exhaust stream, having a NOx storage reduction (NSR) catalyst with a NOx sorbent at a concentration of at least 0.1 g / in3 and a platinum group metal component dispersed on a refractory metal oxide support; and, an SCR catalyst disposed downstream of the NSR catalyst. The emissions treatment system is advantageously used for the treatment of exhaust streams from diesel engines and lean burn gasoline engines.

Owner:BASF CATALYSTS LLC

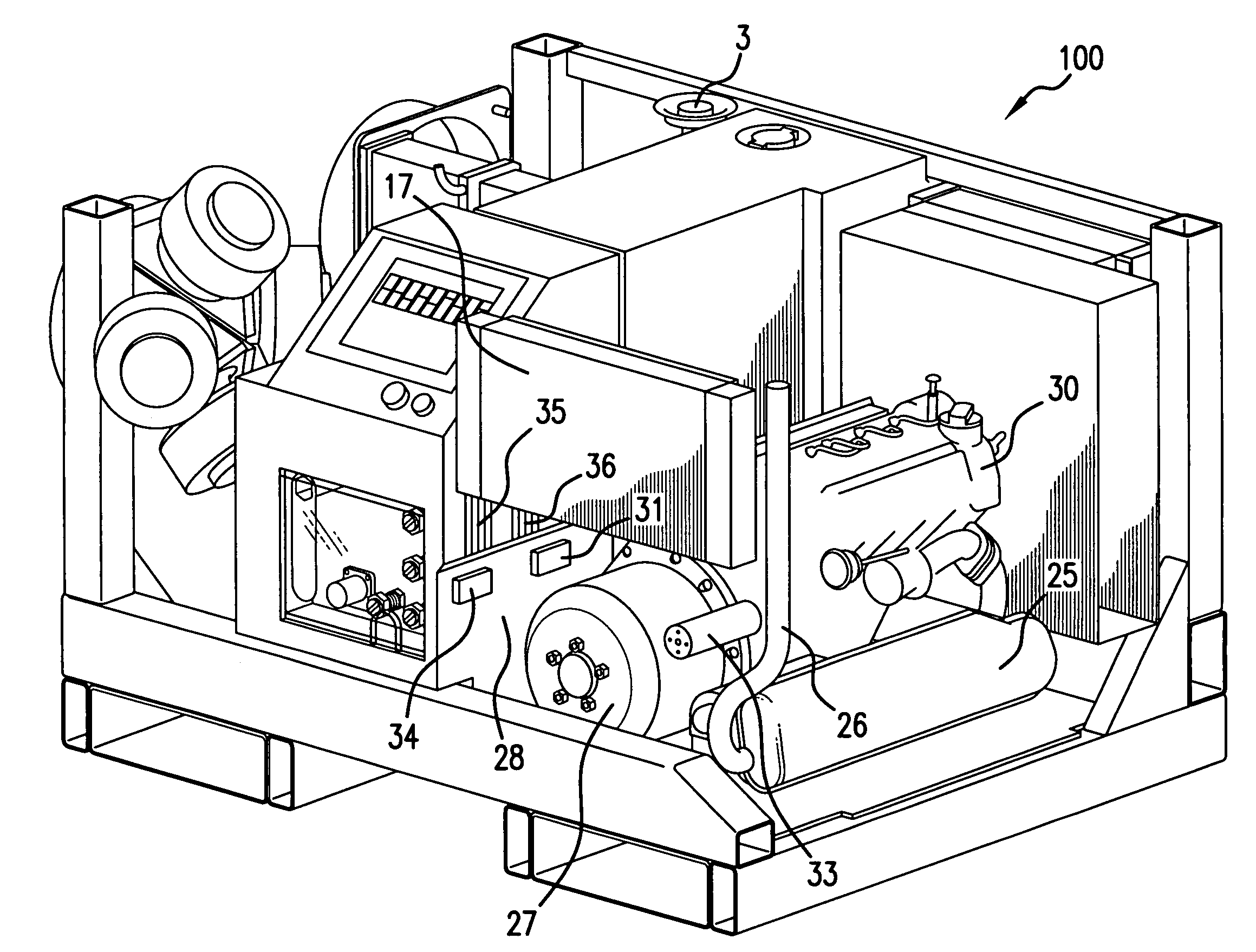

Well Service Pump System

A well service pump system supplies high pressure working fluid to a well. The pump system is a linear design which incorporates a diesel engine, a hydraulic drive gear box, open loop hydraulic Pumps, hydraulic ram cylinders, controls for the hydraulic system hydraulic cylinders, working fluid end cylinders and a coupling to connect the hydraulic cylinders and the working fluid ends. The engine powers the hydraulic system which, in turn, provides hydraulic fluid to operate the hydraulic ram cylinders. Each of the polished rods of the hydraulic ram cylinders is connected axially to a plunger rod end of a working fluid end cylinder. There is no crankshaft or automatic transmission required. The linear design allows for a longer plunger stroke length while still allowing highway transport on a truck or skid.

Owner:AMERIFORGE GRP

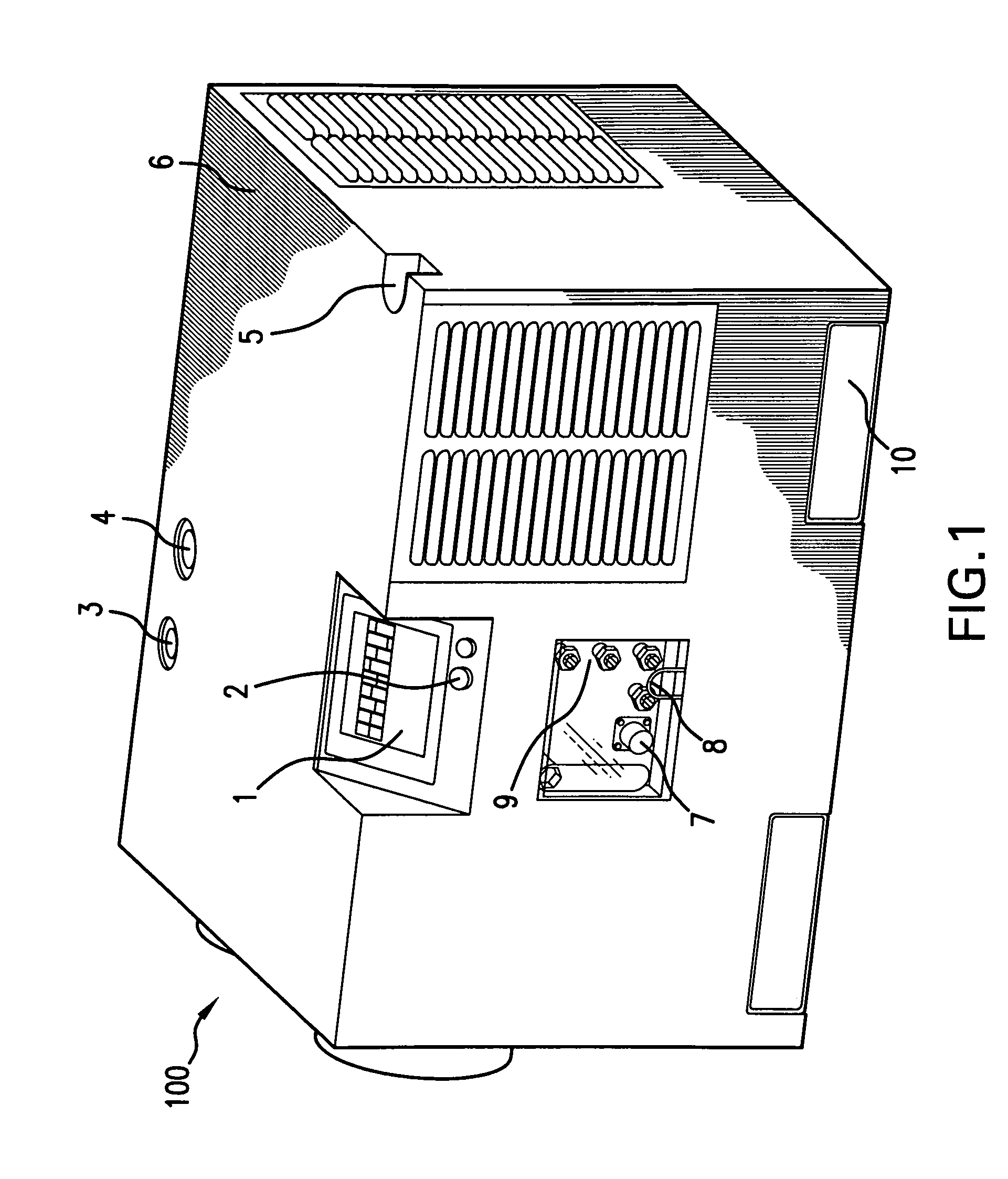

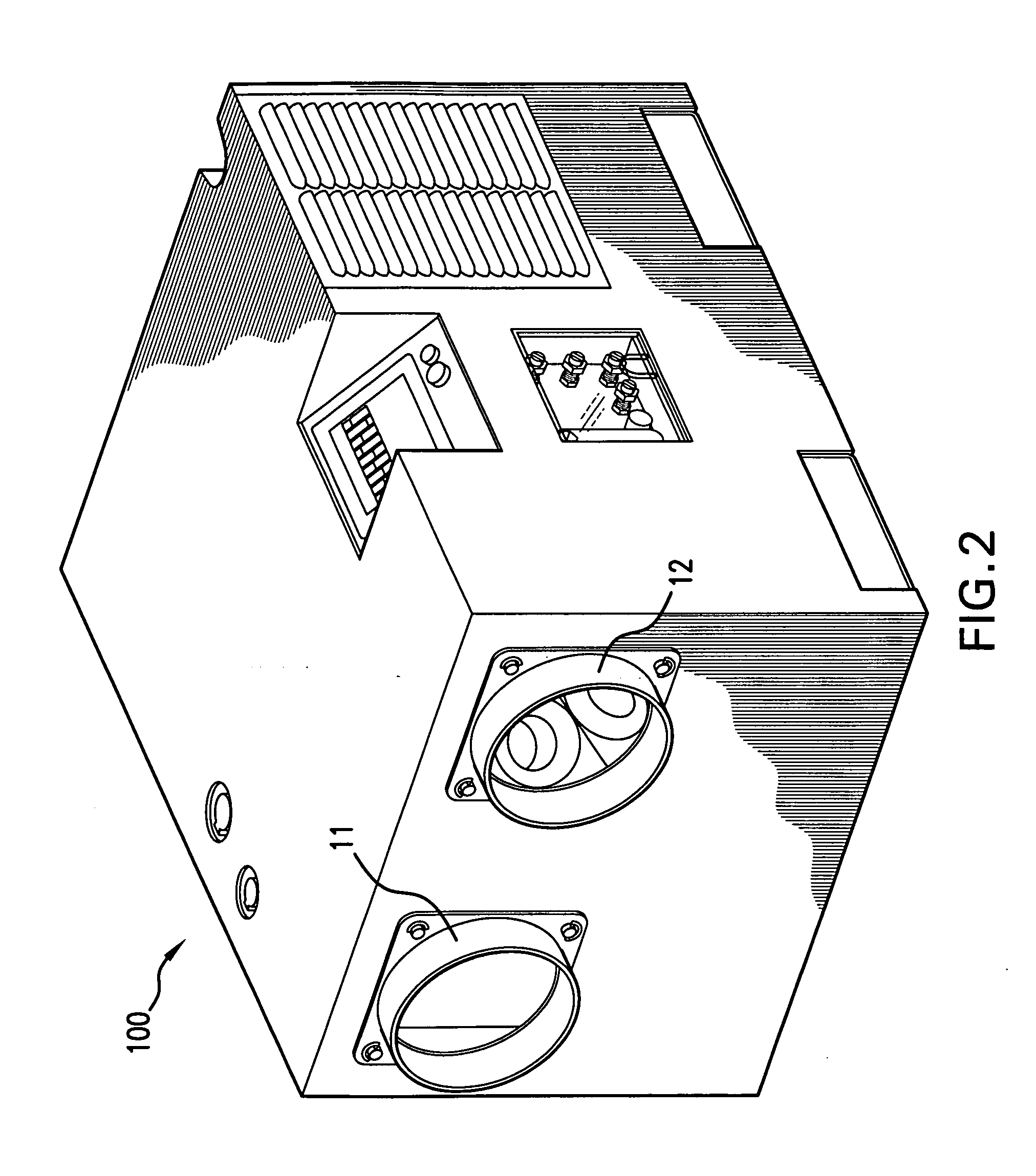

Environmental control and power system

InactiveUS20080161974A1Decrease external thermal signatureHeat dissipationStatic/dynamic balance measurementSpeed sensing governorsControl mannerElectric power system

A self-contained environmental control and power system (ECAPS) unit including an HVAC system with at least one variable-speed compressor driven by a DC motor, wherein the HVAC system is adapted to condition air and output the conditioned air and a variable-speed diesel engine connected to a generator. The generator is configured to vary in speed so as to output AC power at a variable frequency. The unit includes a rectification assembly which transforms the AC power from the generator and / or external AC power to DC power, and an inverter assembly which transforms the DC power to an export AC power. The ECAPS unit directs the DC power to the DC motor to drive the variable speed compressor and varies, in a controlled manner, at least one parameter of the outputted conditioned air from the HVAC system.

Owner:GLACIER BAY

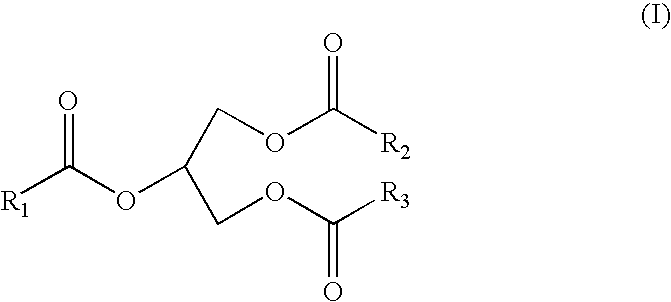

Fuel composition for a diesel engine

InactiveUS20040055209A1Meet quality requirementsImprove low temperature performanceSolid fuelsLiquid carbonaceous fuelsProcess engineeringDiesel engine

The invention is directed to a fuel composition for diesel engines. The fuel composition comprises 0.1-99% by weight of a component or a mixture of components produced from biological raw material originating from plants and / or animals and / or fish. The fuel composition comprises 0-20% of components containing oxygen. Both components are mixed with diesel components based on crude oil and / or fractions from Fischer-Tropsch process.

Owner:NESTE OIL OY

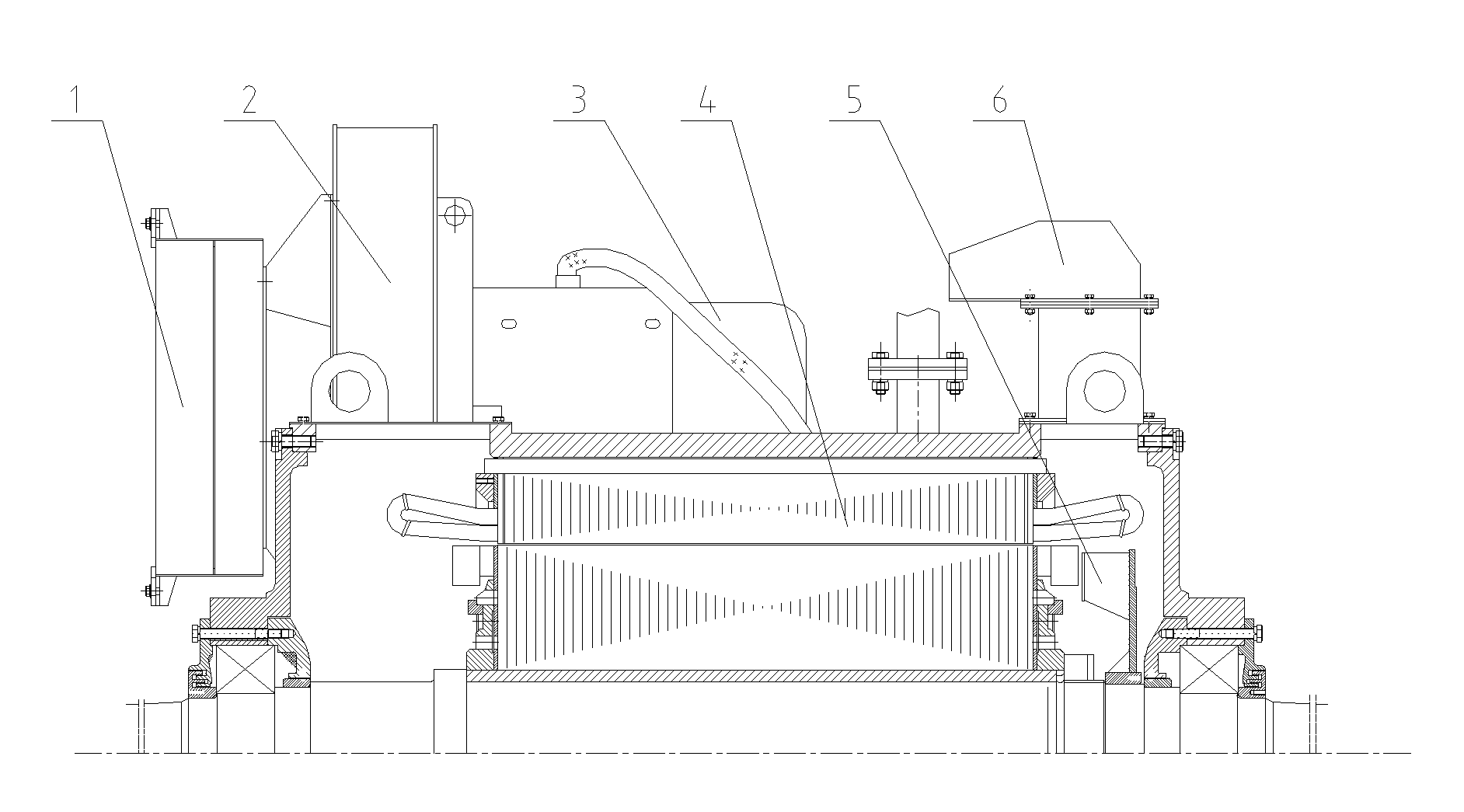

Fracturing Pump

InactiveUS20150078924A1Large single-machine powerWork at highPositive displacement pump componentsFlexible member pumpsEngineeringDiesel engine

The invention discloses a fracturing pump, comprising a cooling device and a control device, wherein a motor is connected on an shaft of the fracturing pump, the cooling device comprises an air-cooled device for cooling a rotor of the motor and a water-cooled device for cooling a stator of the motor, and the control device is connected with the motor and the cooling device, respectively. The fracturing pump in the invention adopts a structure directly driven by the motor, thus breaking the form of a transmission structure of a diesel engine of the conventional fracturing pump added with a transmission tank, simplifying the structure of the entire fracturing pump, reducing the apparatus mounted on a fracturing car, decreasing failure rate of the apparatus, and becoming more safe and reliable.

Owner:SICHUAN HONGHUA PETROLEUM EQUIP

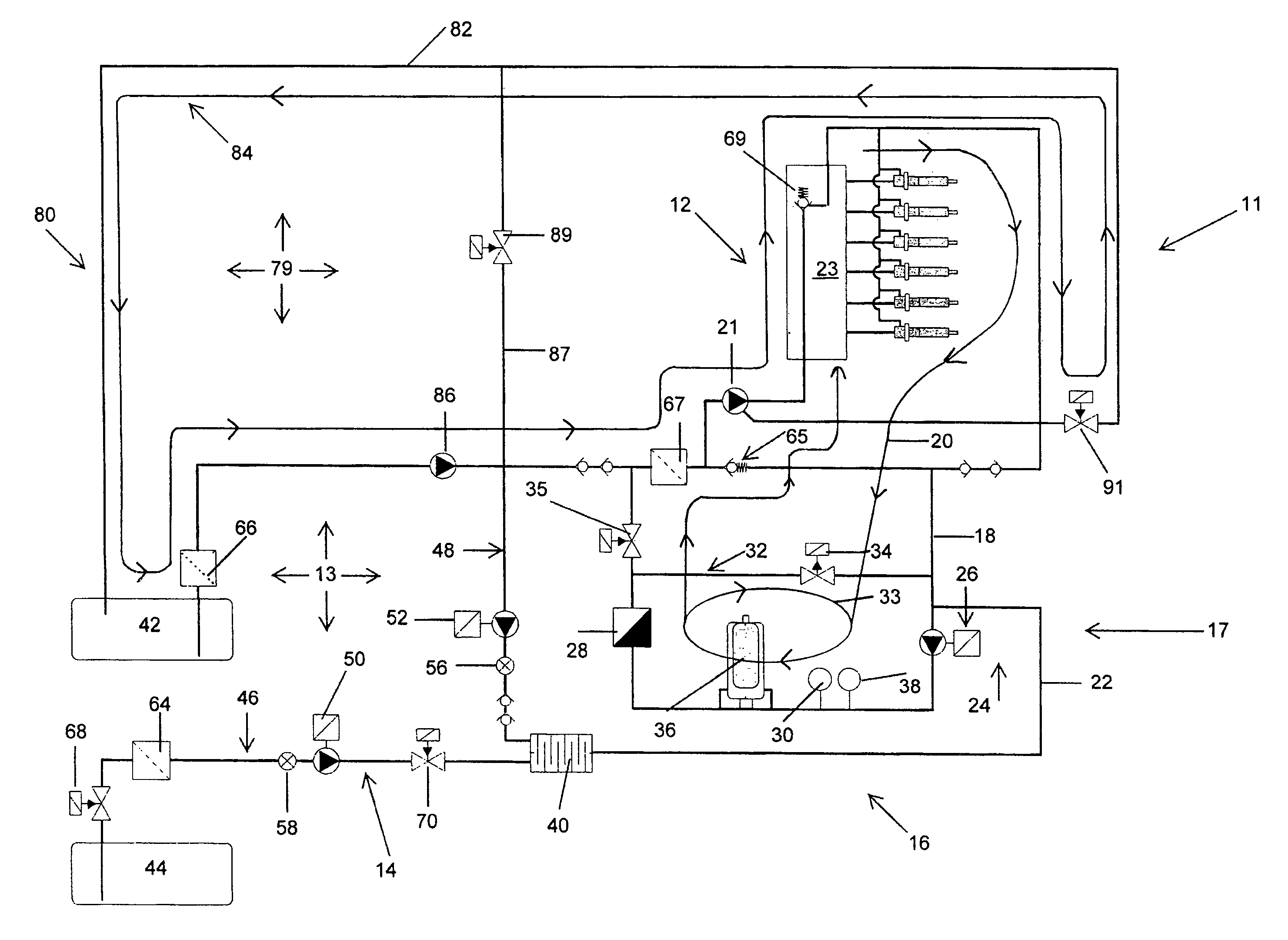

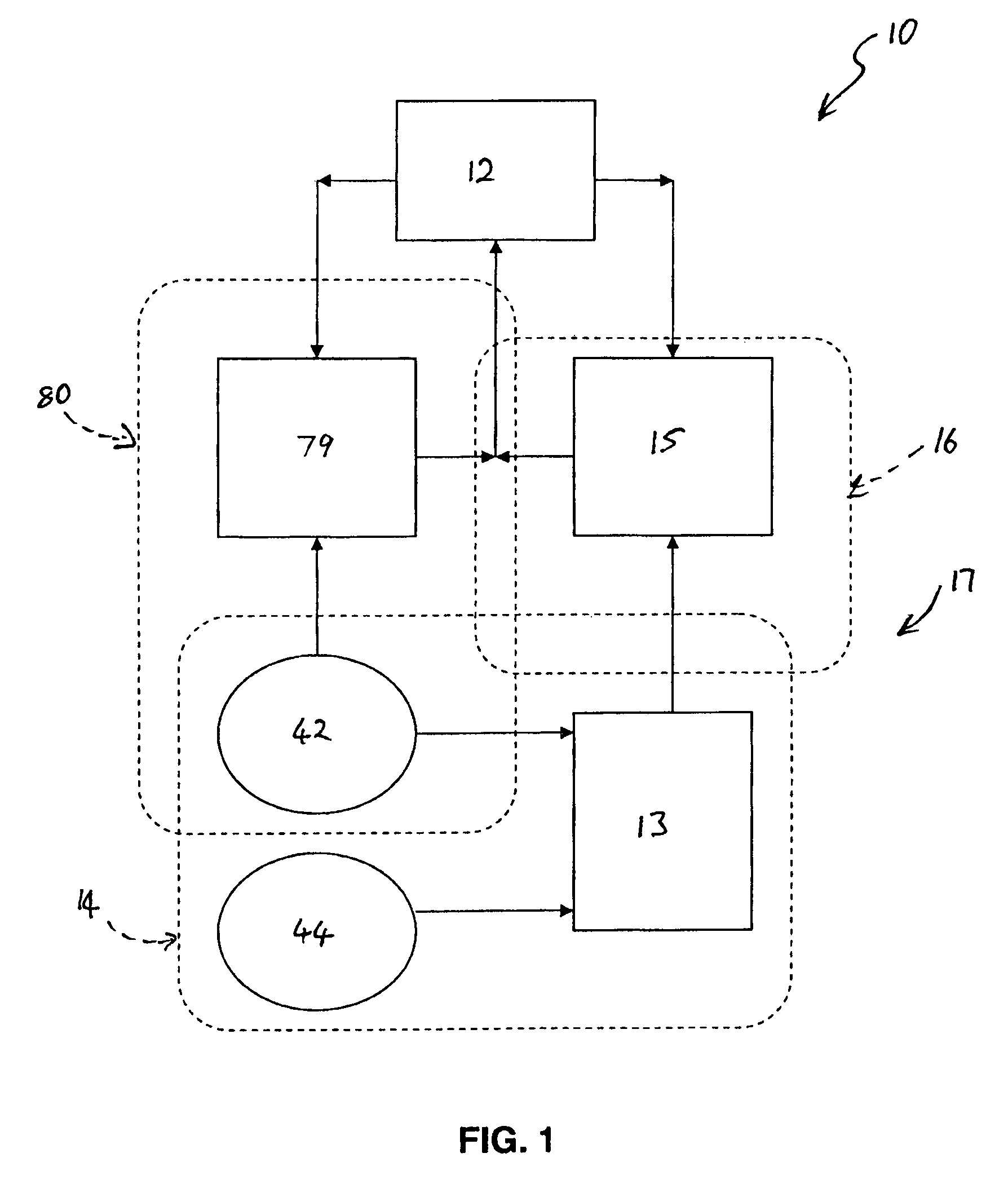

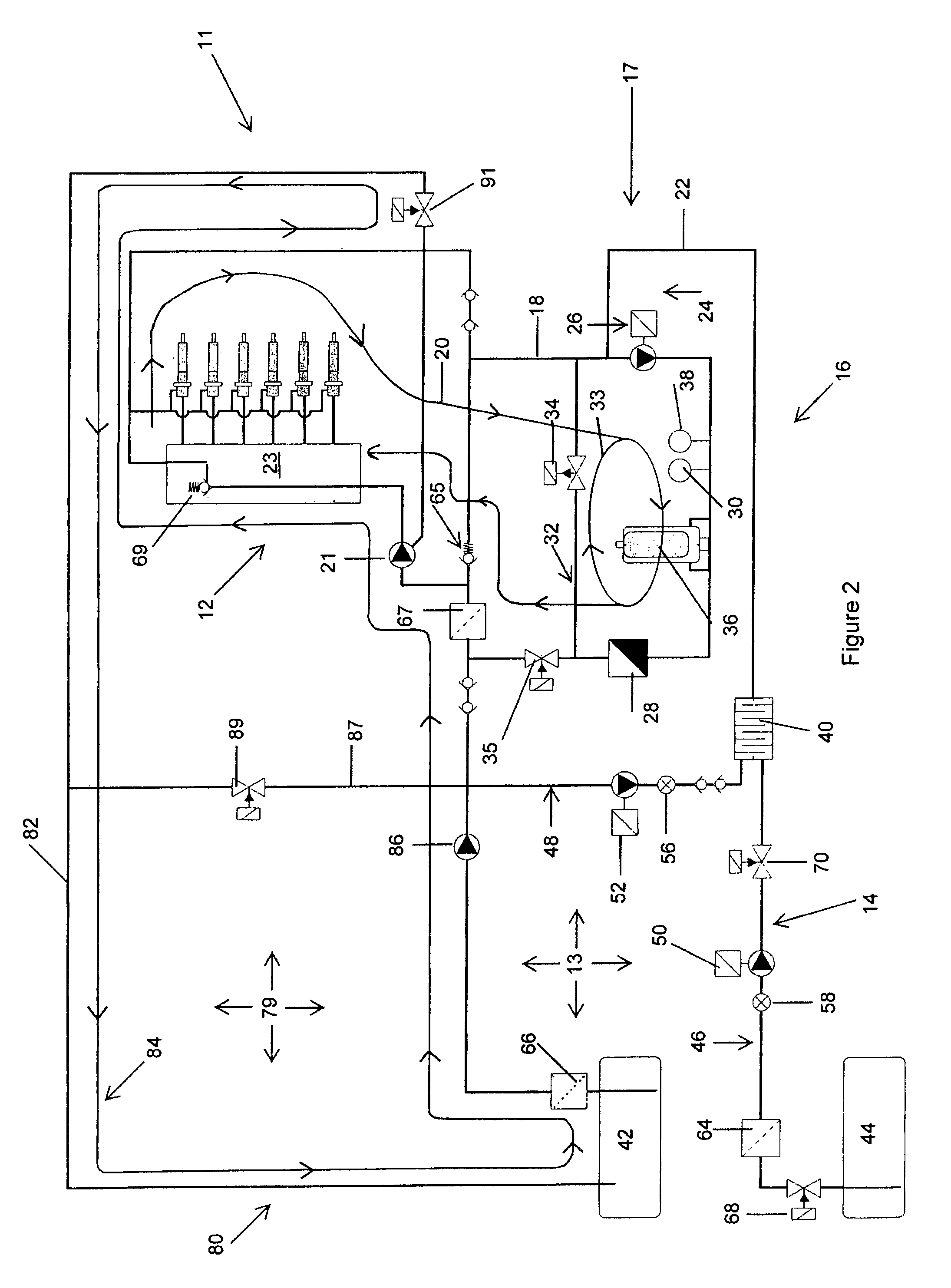

Dual fuel supply system for a direct-injection system of a diesel engine with on-board mixing

InactiveUS8973560B2Non-fuel substance addition to fuelInternal combustion piston enginesOn boardEngineering

The present invention is directed to a dual fuel supply system for supplying fuel to a direct-injection system of a diesel engine. The dual fuel supply system includes a diesel supply system to supply diesel to the direct-injection system; and a mixed fuel supply system that is operatively able to supply a liquid fuel premixture of diesel and liquefied gaseous fuel to the direct-injection system at a supply pressure within a fuel demand pressure range of the direct-injection system and at a corresponding temperature range that retains the fuel premixture below its vapor temperature as it flows through the fuel path of the direct-injection system and the diesel engine. The dual fuel supply system is configured to permit selective change over between the diesel supply system and the mixed fuel system to supply the direct-injection system selectively with either diesel or liquid fuel premixture respectively.

Owner:DGC IND

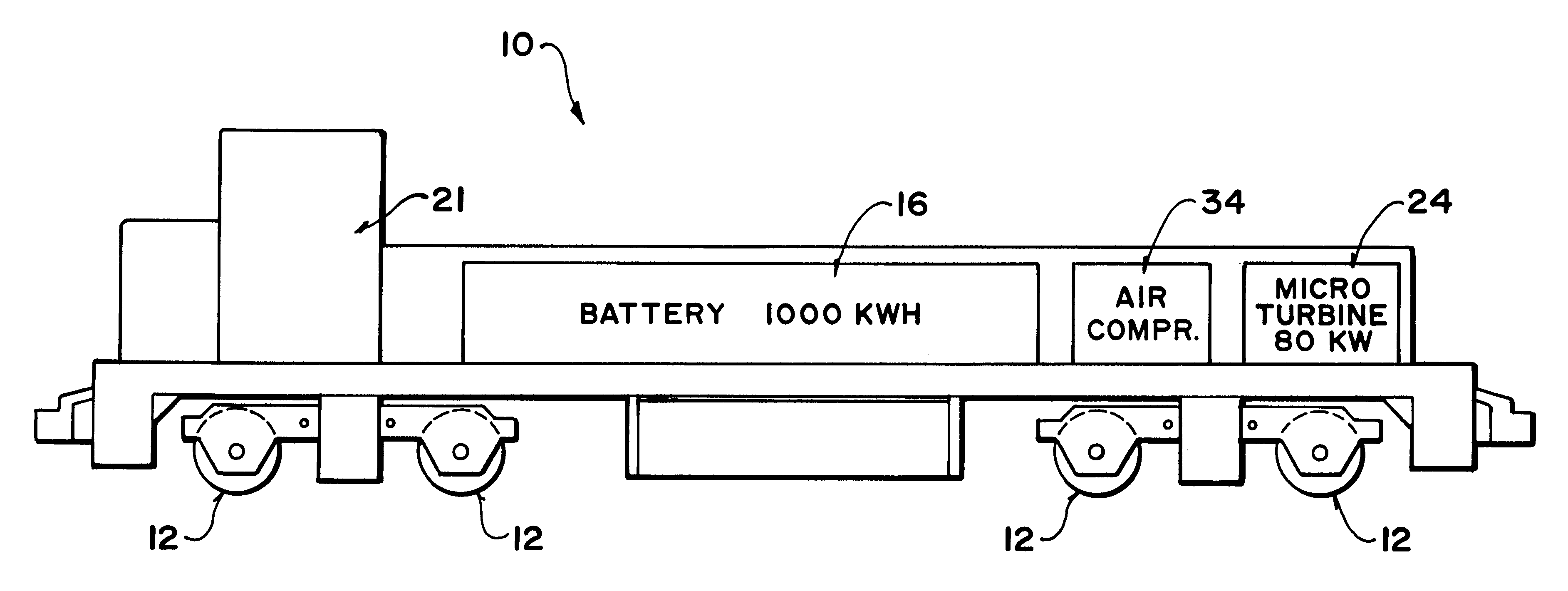

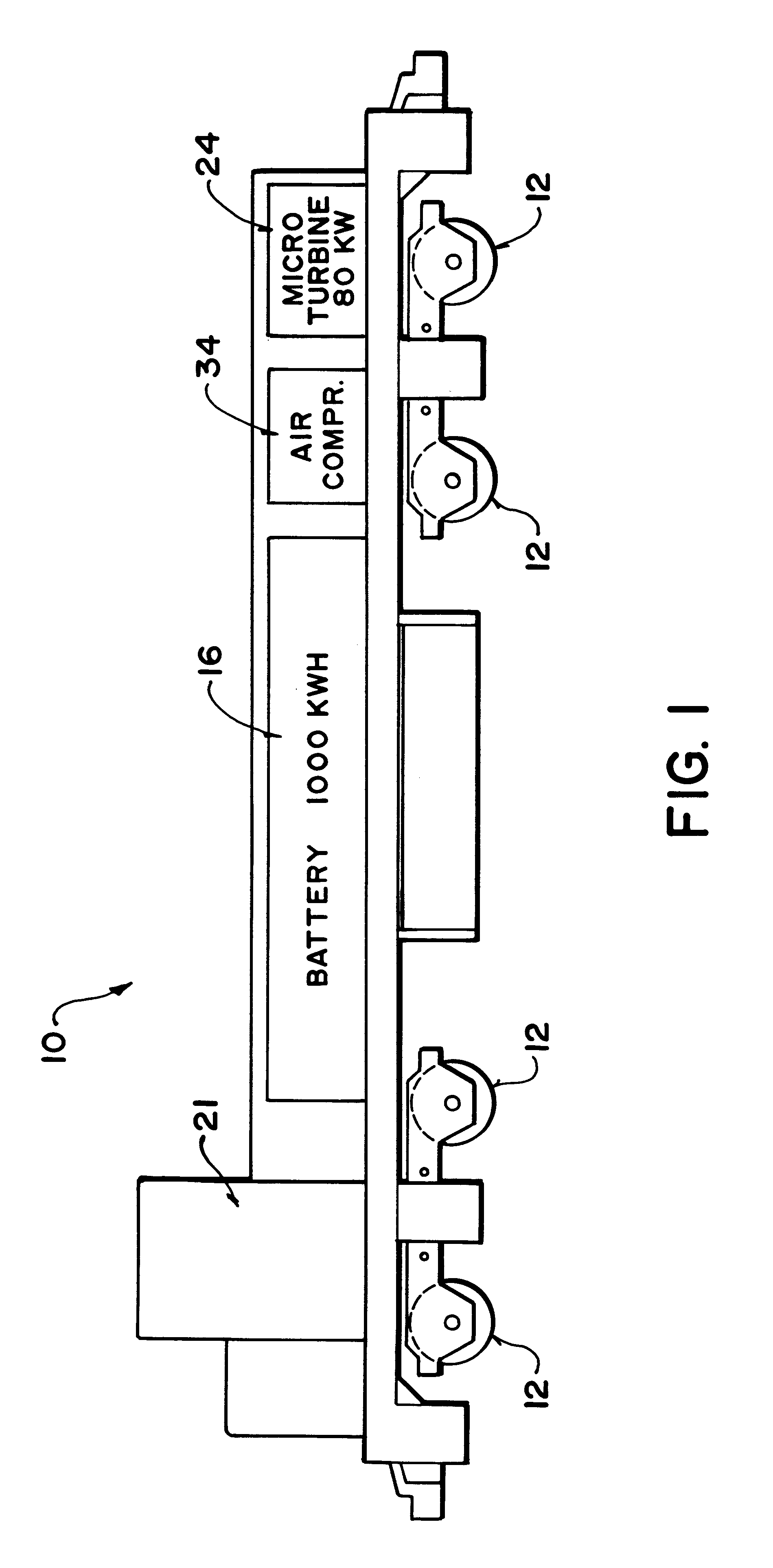

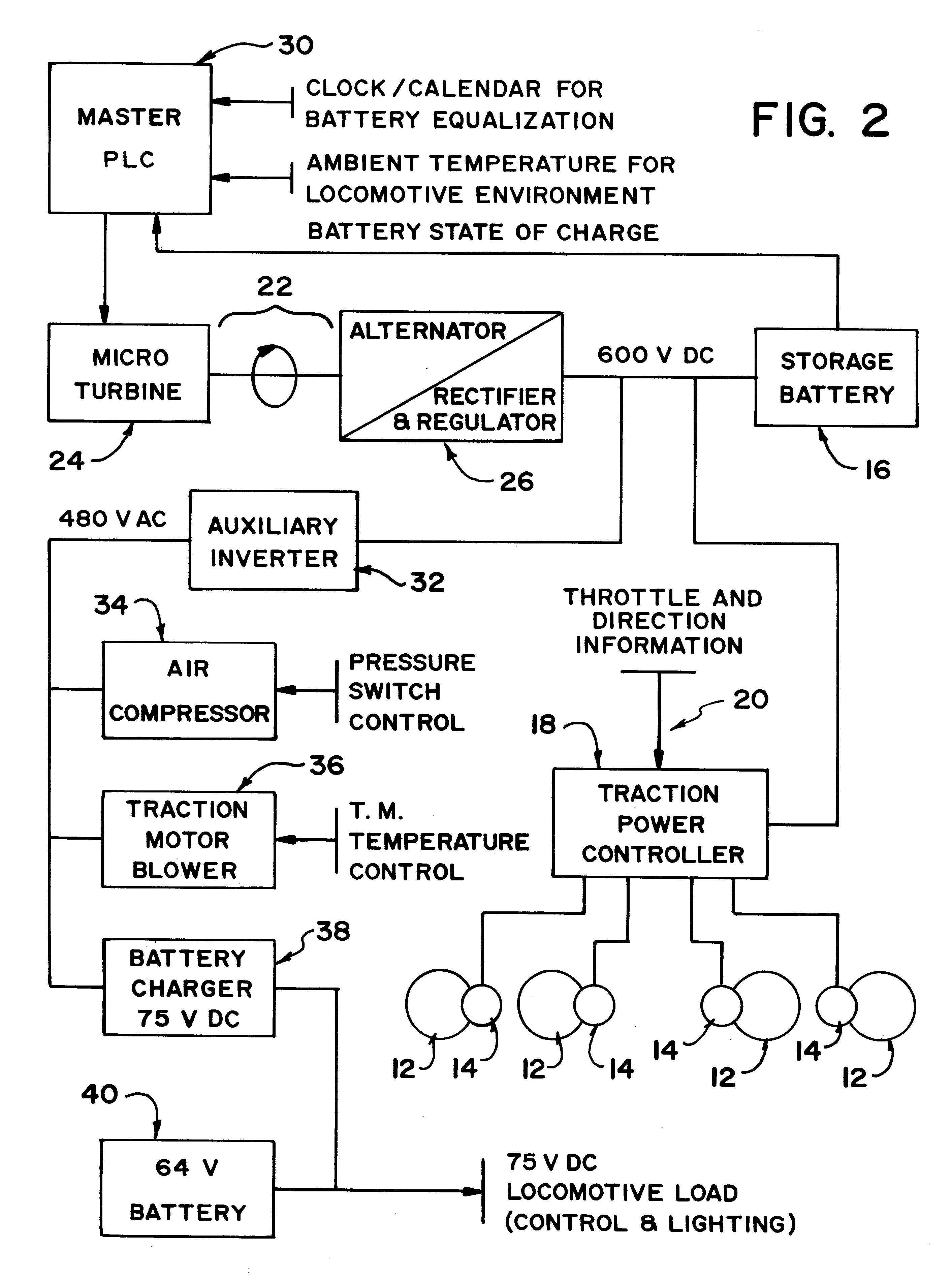

Hybrid battery/gas turbine locomotive

Prior battery-powered electric locomotives have used multiple diesel engines to charge the batteries and have not been commercially accepted. The present invention provides a yard switcher which combines battery storage with a gas microturbine generator to provide an effective fuel-efficient and environmentally friendly locomotive. locomotive.

Owner:RAILPOWER LLC

Fuel composition for a diesel engine

Owner:NESTE OIL OY

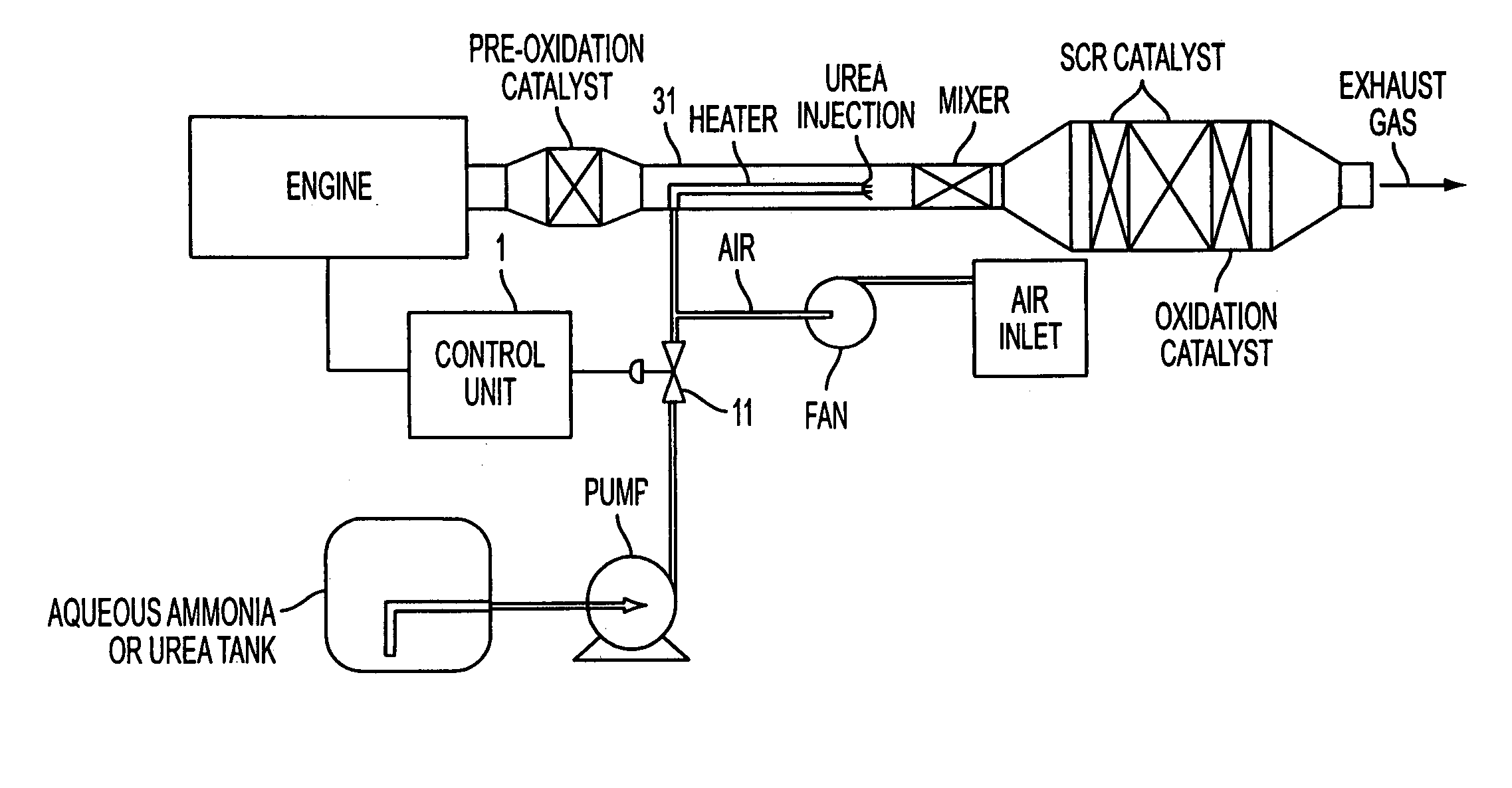

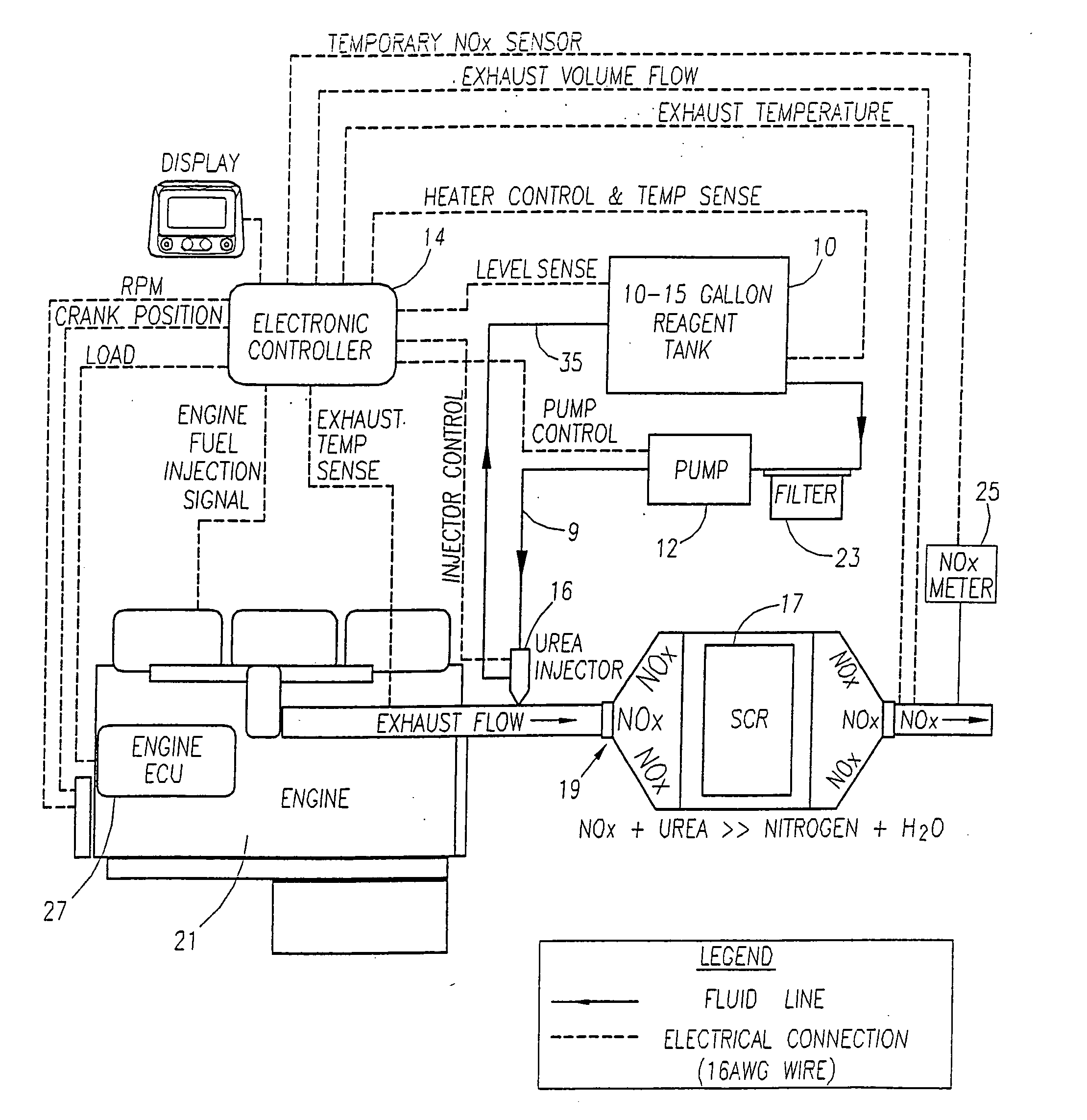

Emission control system

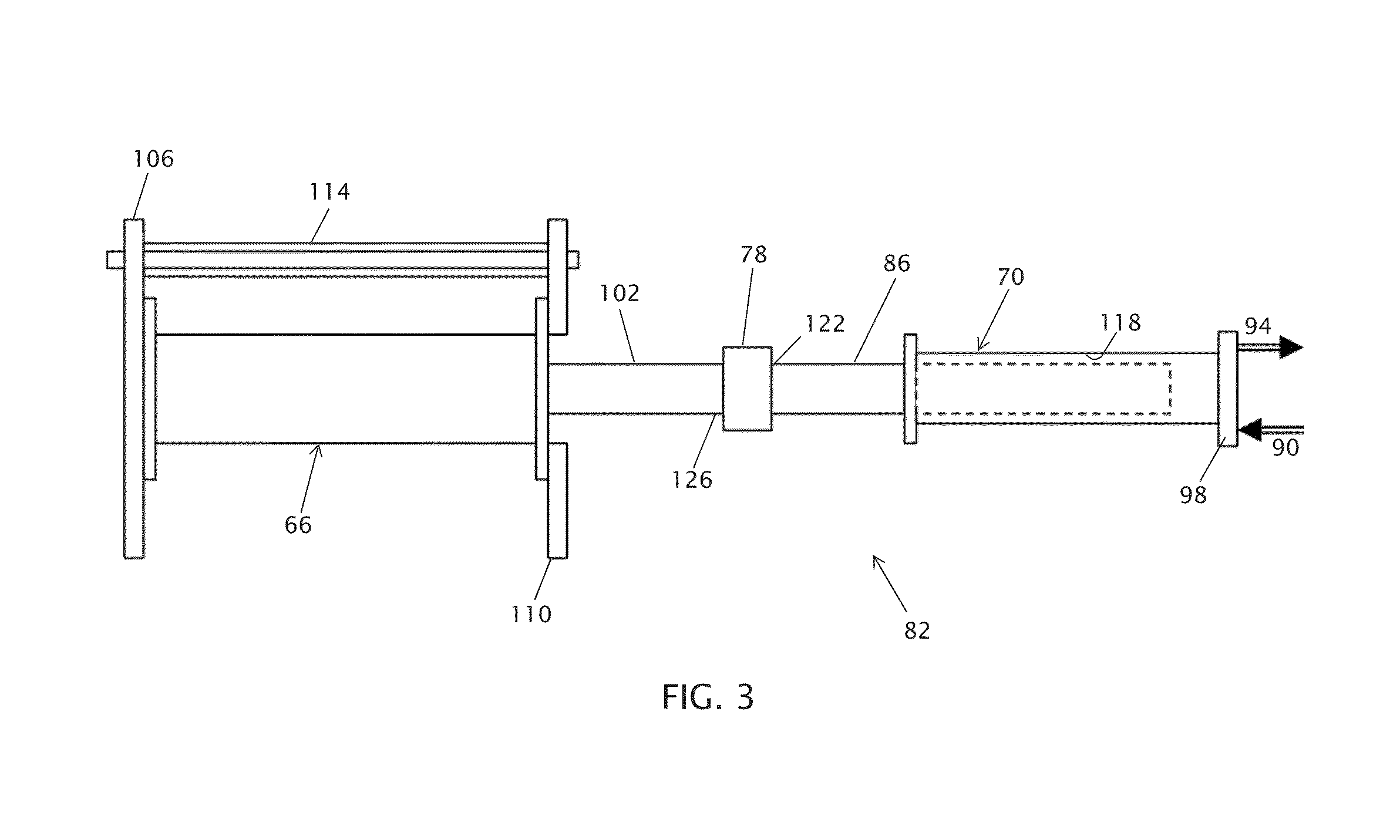

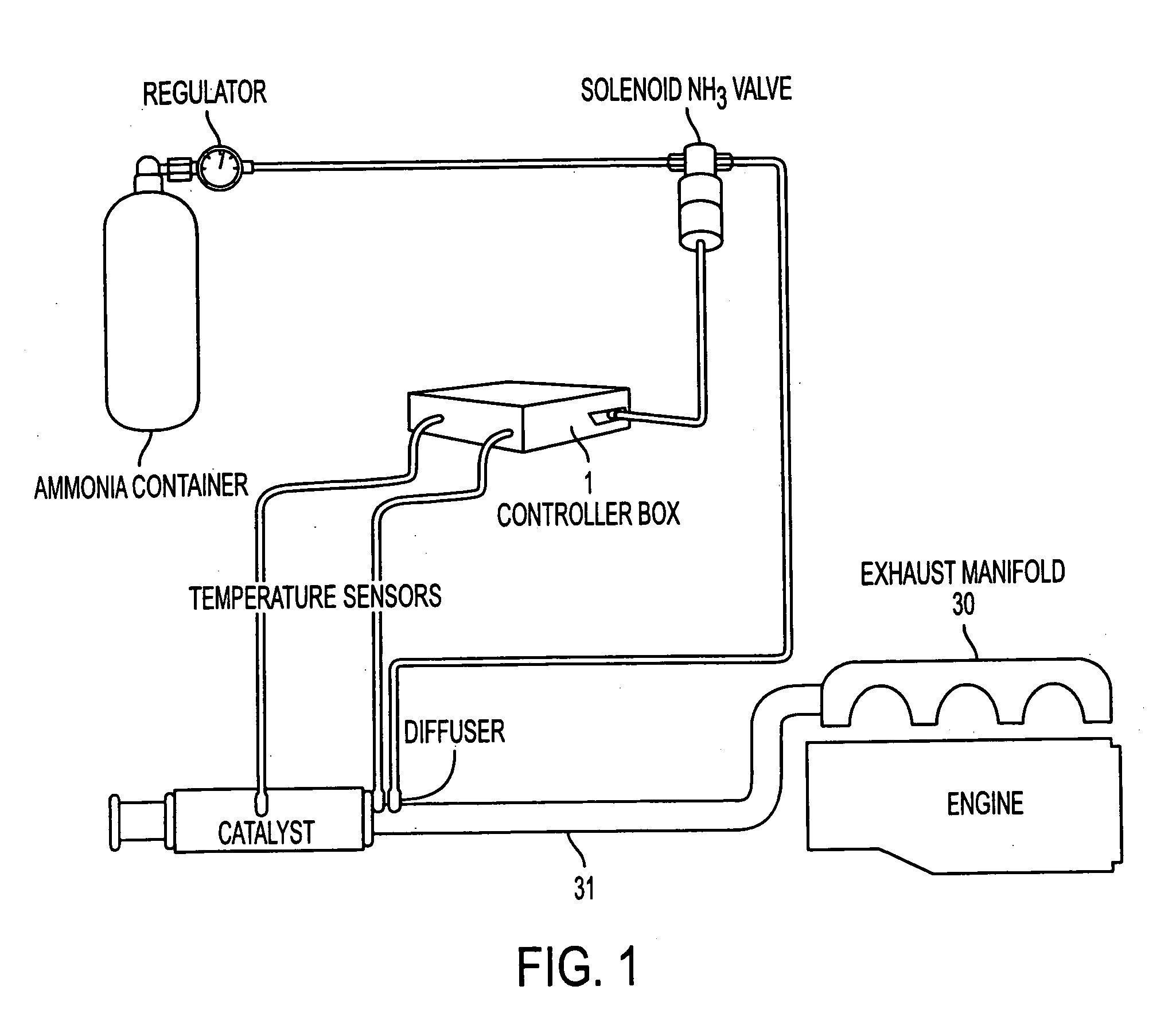

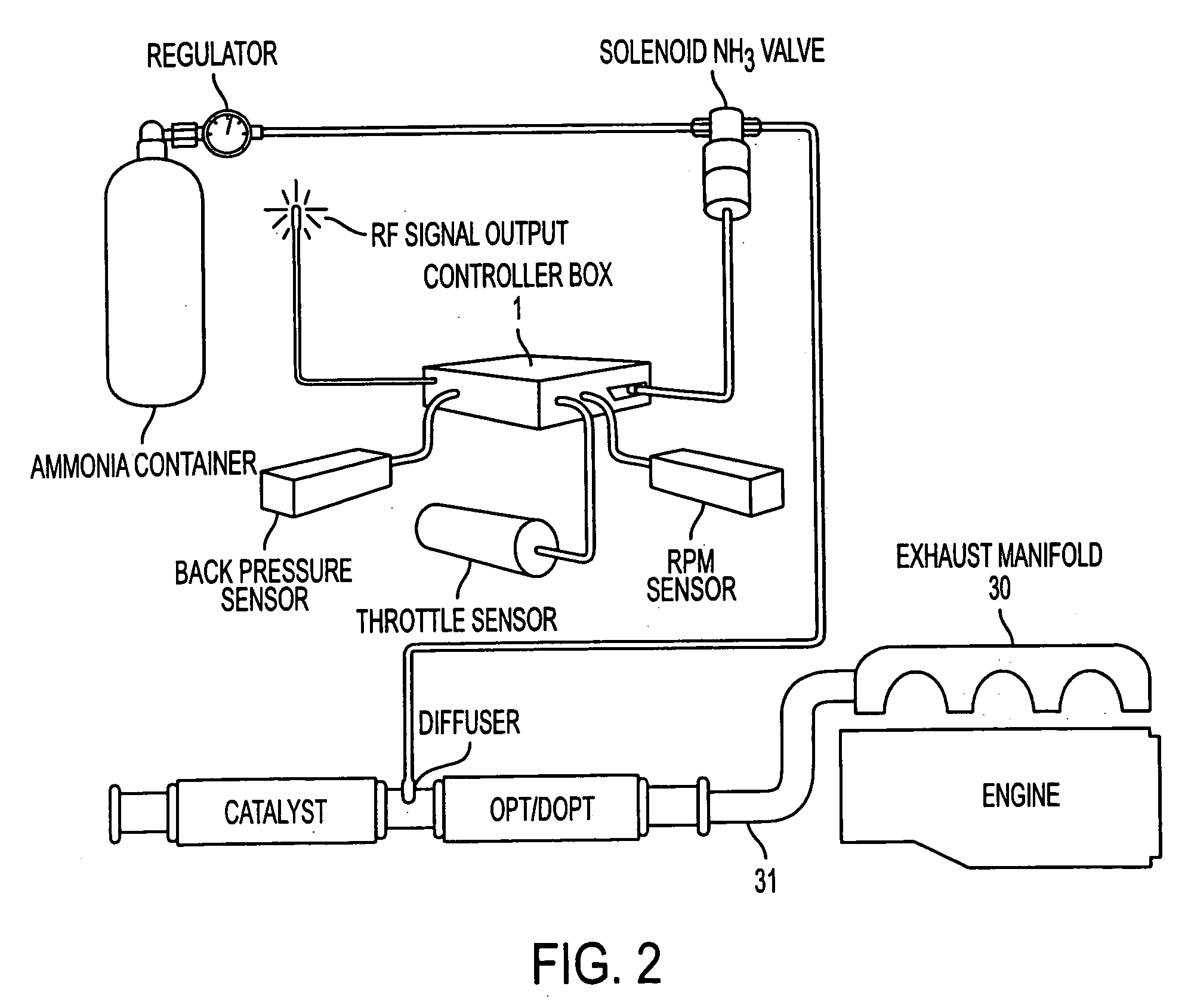

InactiveUS7065958B2Emission reductionEfficientlyInternal combustion piston enginesFlow mixersNitrogen oxidesControl system

A method and apparatus to reduce the emissions of an exhaust stream is provided. One feature of the present invention includes a control unit for metering a reagent into the exhaust stream. The control unit adjusts a quantity of the reagent to be metered into the exhaust stream. One embodiment of the present invention concerns a method of removing nitrogen oxides in exhaust gases from a diesel engine by introducing ammonia into the exhaust stream. This Abstract is provided for the sole purpose of complying with the Abstract requirement rules that allow a reader to quickly ascertain the subject matter of the disclosure contained herein. This Abstract is submitted with the explicit understanding that it will not be used to interpret or to limit the scope or the meaning of the claims.

Owner:EXTENGINE TRANSPORT SYST

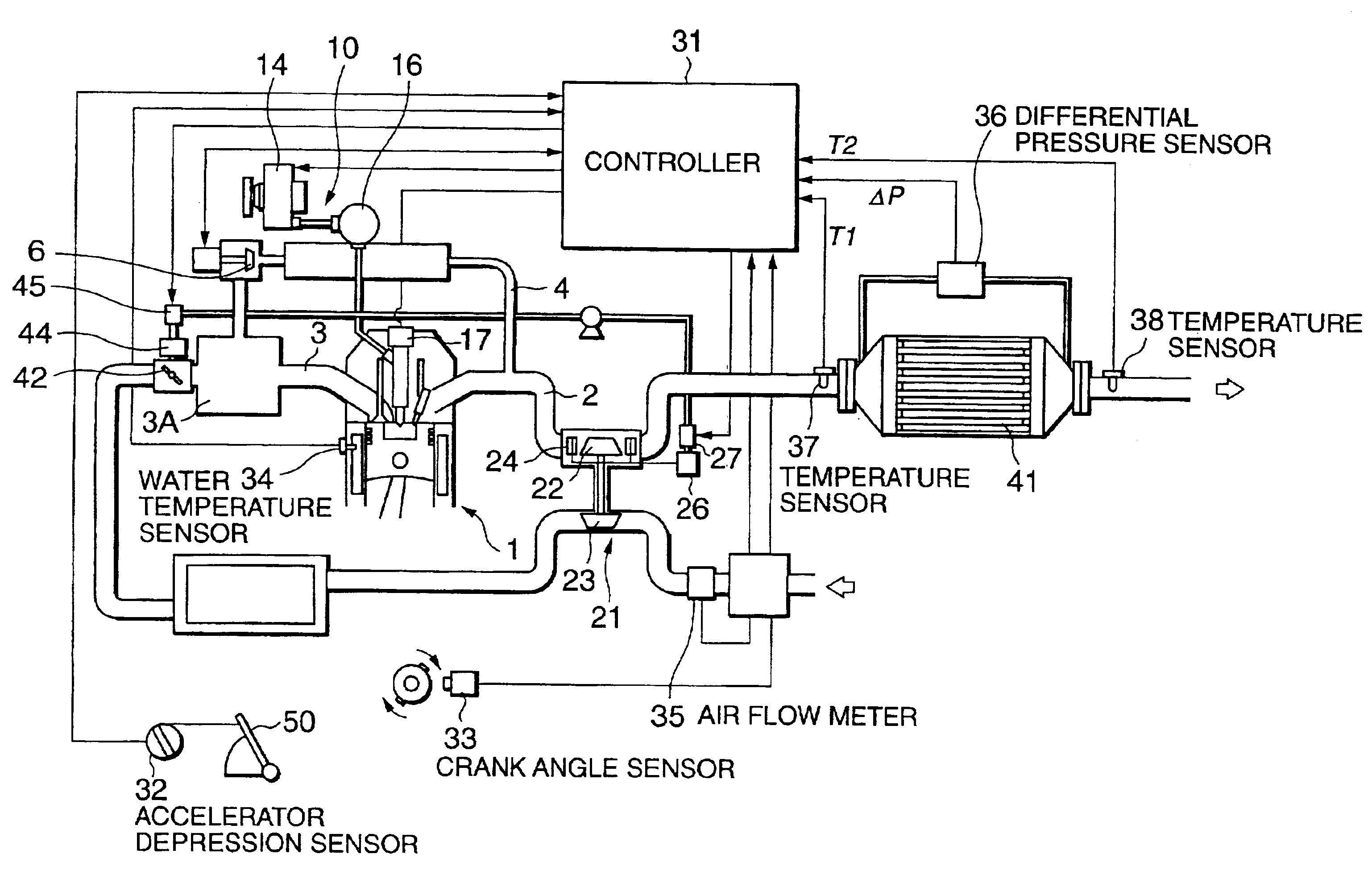

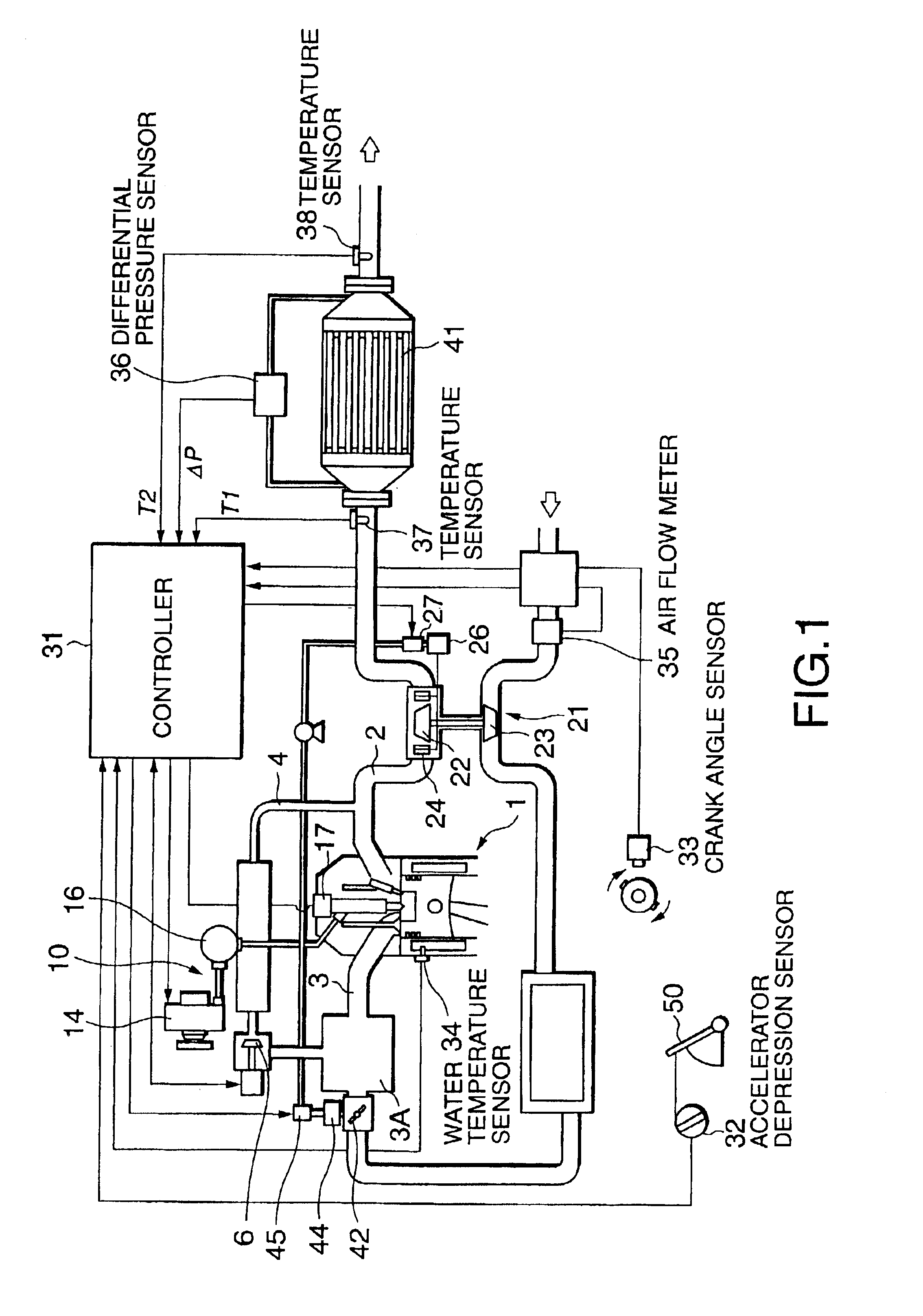

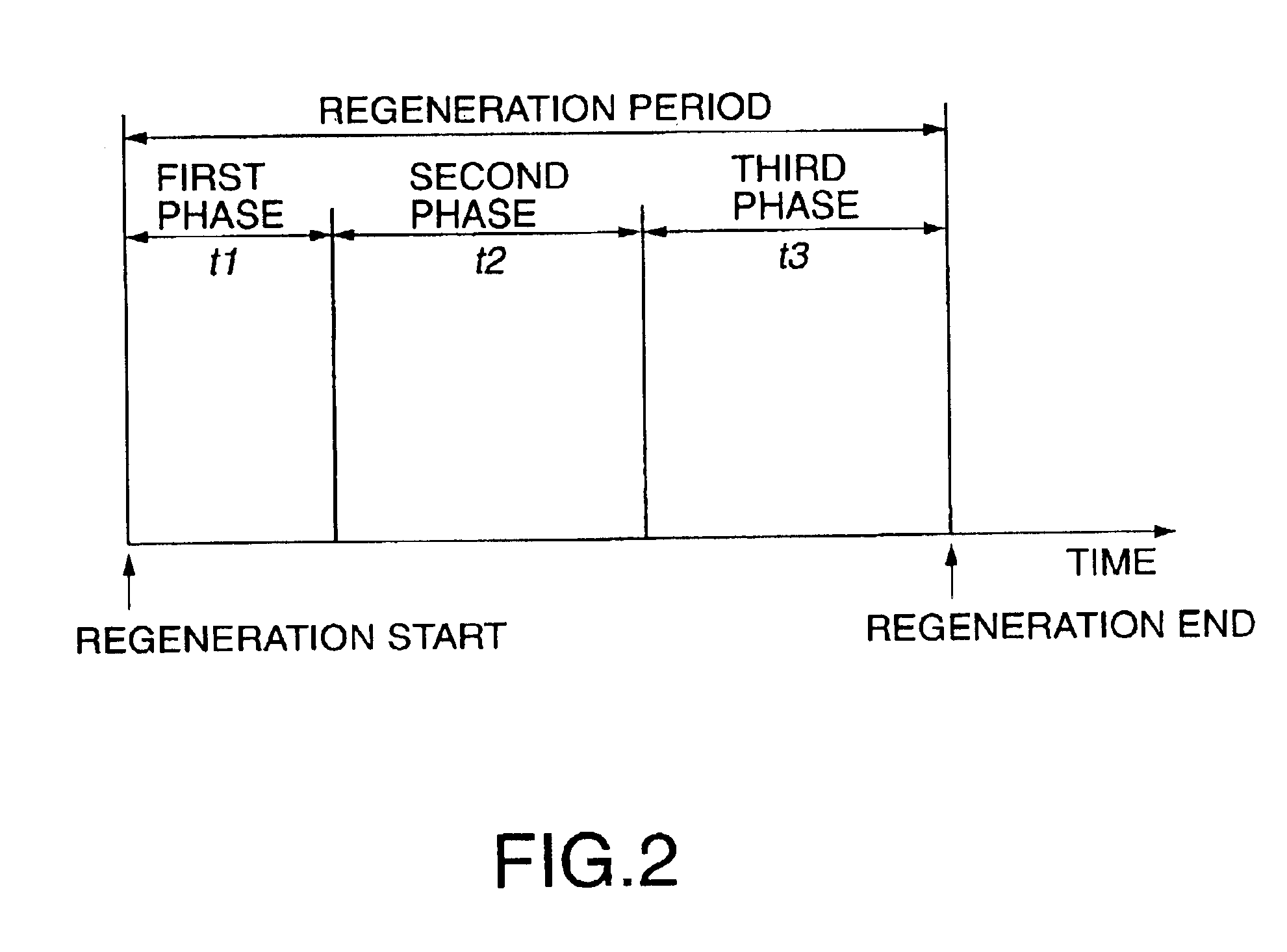

Regeneration of particulate filter

InactiveUS6851258B2Inhibit deteriorationShorten the overall cycleElectrical controlNon-fuel substance addition to fuelParticulatesCombustion

An exhaust passage (2) of a diesel engine (1) is provided with a filter (41) for trapping particulate matter. Regeneration of the filter (41) is divided into first to third phases. In the first phase the filter temperature is raised to the combustion temperature of the particulate matter in a short period of time through control of the exhaust gas temperature. In the second phase, the oxygen concentration of the exhaust gas is held at a predetermined low level while the filter temperature is maintained so as to prevent excessive combustion of particulate matter. In the third phase, wherein the amount of trapped particulate matter has been reduced, the oxygen concentration of the exhaust gas is held at a predetermined high level while the filter temperature is maintained so as to complete the combustion of the trapped particulate matter.

Owner:NISSAN MOTOR CO LTD

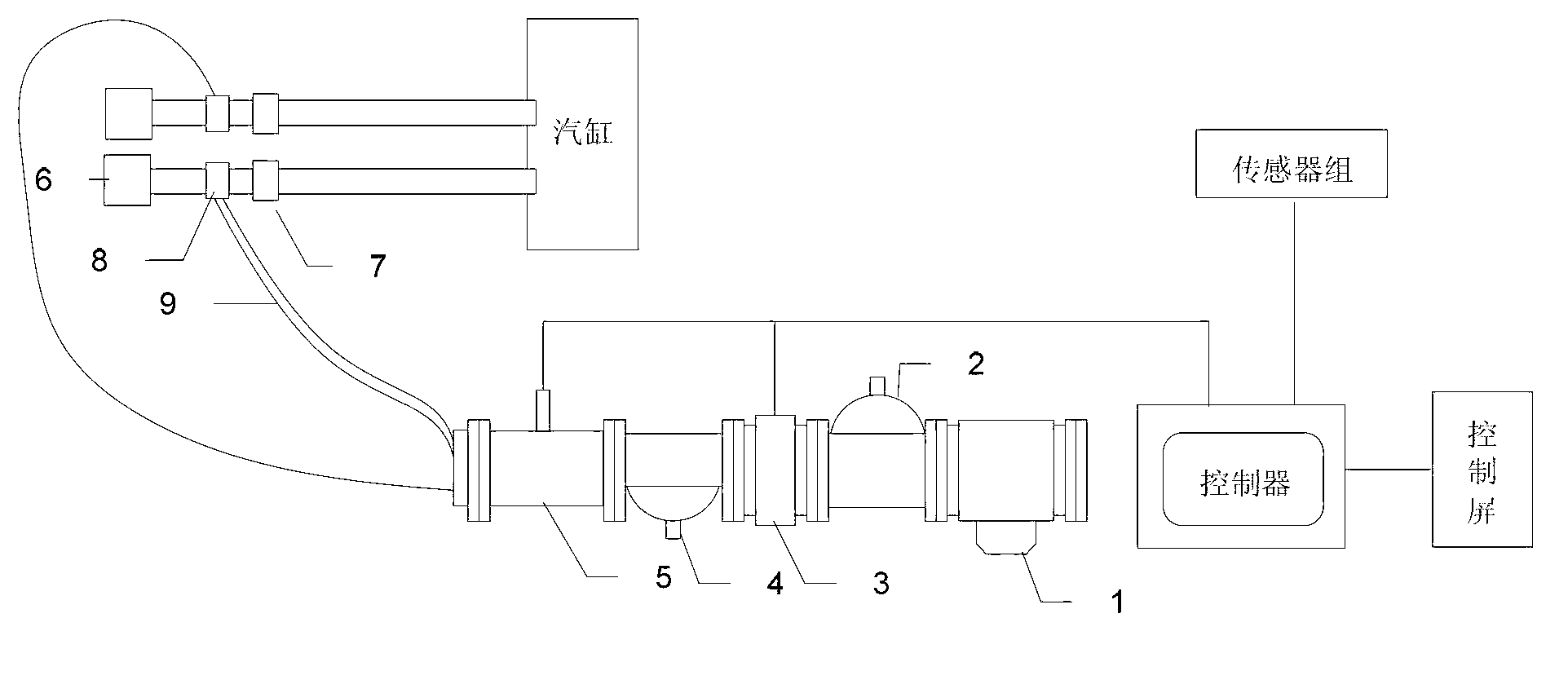

Dual-fuel modified system

ActiveCN103321782ACut off the supplyAchieve combustionInternal combustion piston enginesFuel supply apparatusControl systemEngineering

The invention discloses a dual-fuel modified system. A natural gas supply system comprises a natural gas main pipeline, a mixer, a sensor set and a control system. The control system is in communication connection with the sensor set and an electromagnetic switch valve in the natural gas main pipeline. The dual-fuel modified system is started under the mode of diesel oil. When operation signals transmitted by the sensor set are within a preset range, the control system controls the electromagnetic switch valve to be opened, and when the operation signals transmitted by the sensor set are beyond the preset range, the control system controls the electromagnetic switch valve to be closed. According to the dual-fuel modified system, the natural gas main pipeline, the mixer, the sensor set and the control system are arranged on the basis of an original diesel engine, the original diesel engine and an ECU of the original diesel engine are not modified largely, the modifying process is simple, the modifying cost is low, and therefore the feasibility for modifying the large-scale diesel engine to the dual-fuel modified system is improved.

Owner:YANTAI JEREH OILFIELD SERVICES GROUP

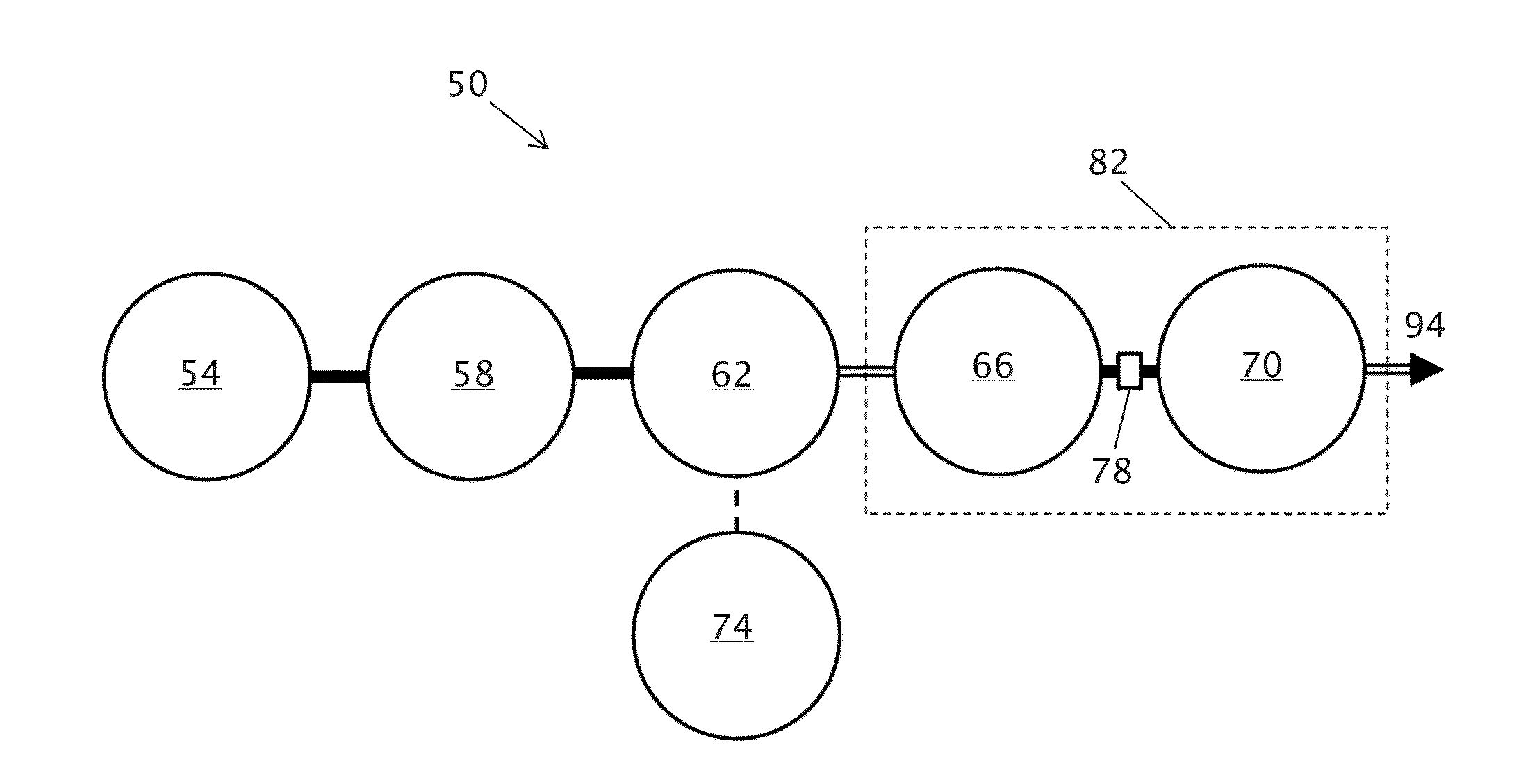

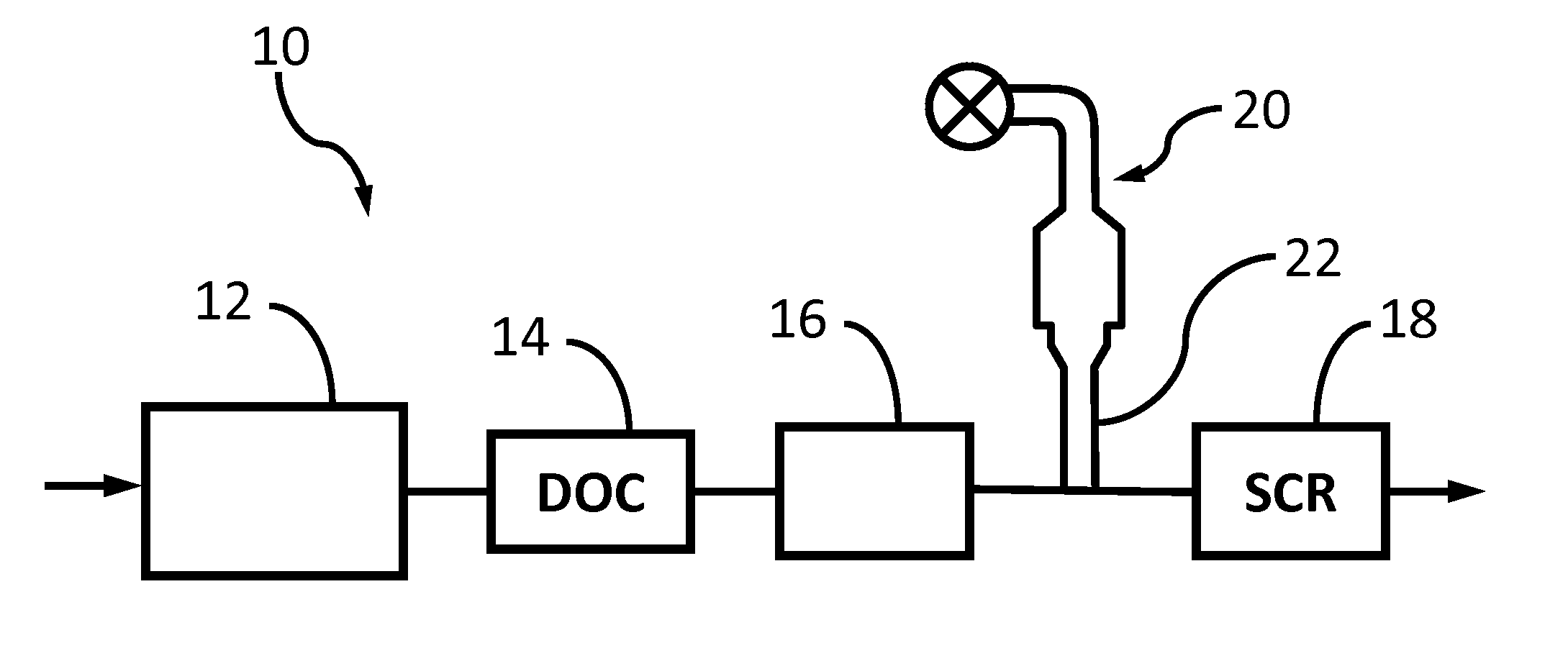

Diesel engine exhaust treatment system and method including a platinum group metal trapping device

ActiveUS20110138777A1Avoid depositionReduces platinum group metal contaminationCombination devicesNitrogen compoundsExhaust fumesEnvironmental engineering

A diesel engine exhaust treatment system and method is provided which includes a platinum group metal trapping device positioned between a diesel oxidation catalyst and an SCR catalyst. The platinum group metal trapping device traps trace amounts of platinum group metals which may be released from the diesel oxidation catalyst during engine operation and prevents them from accumulating on the SCR catalyst, preventing potential contamination of the SCR catalyst as well as ensuring that the performance of the SCR catalyst is uninhibited.

Owner:FORD GLOBAL TECH LLC

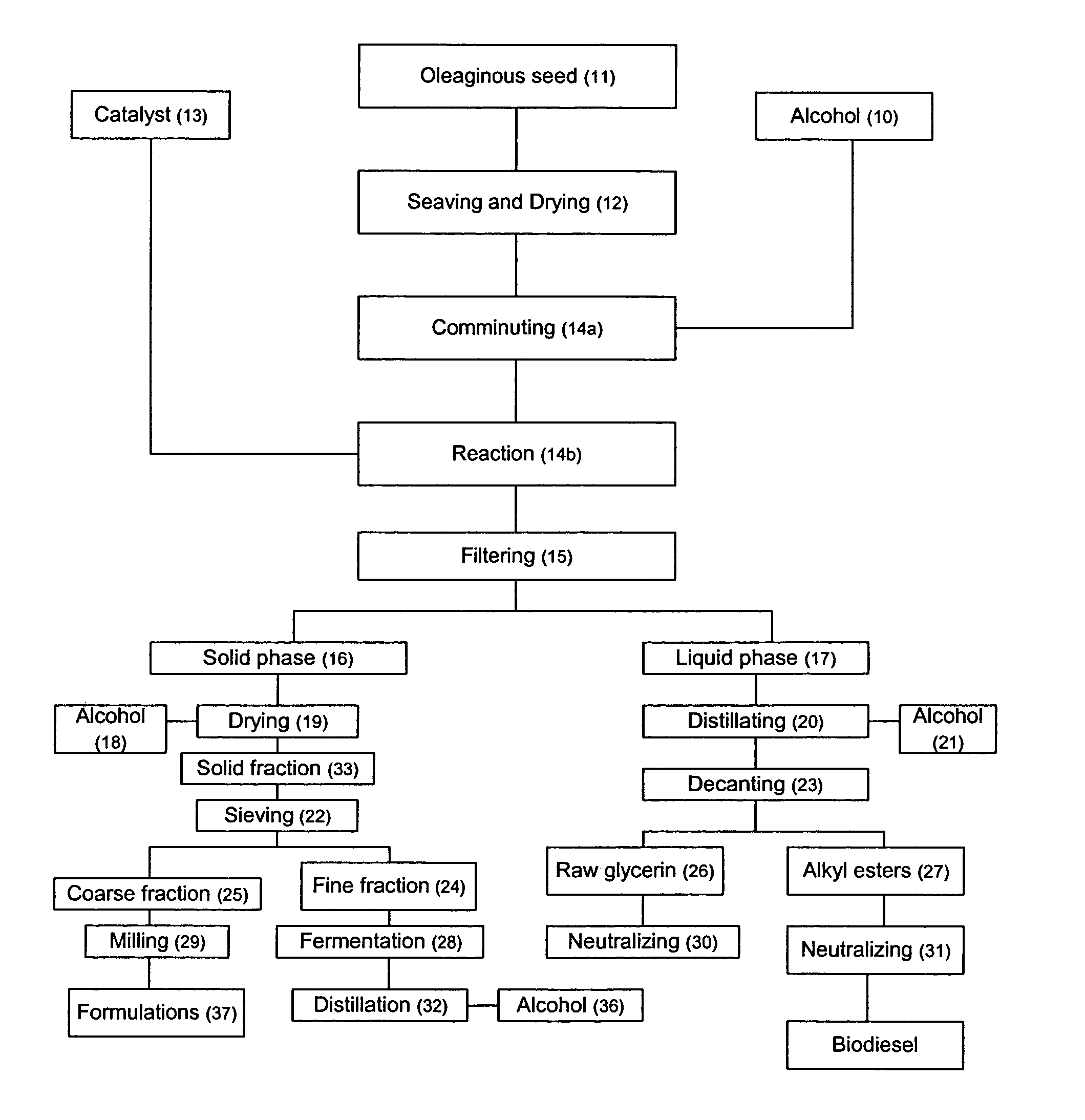

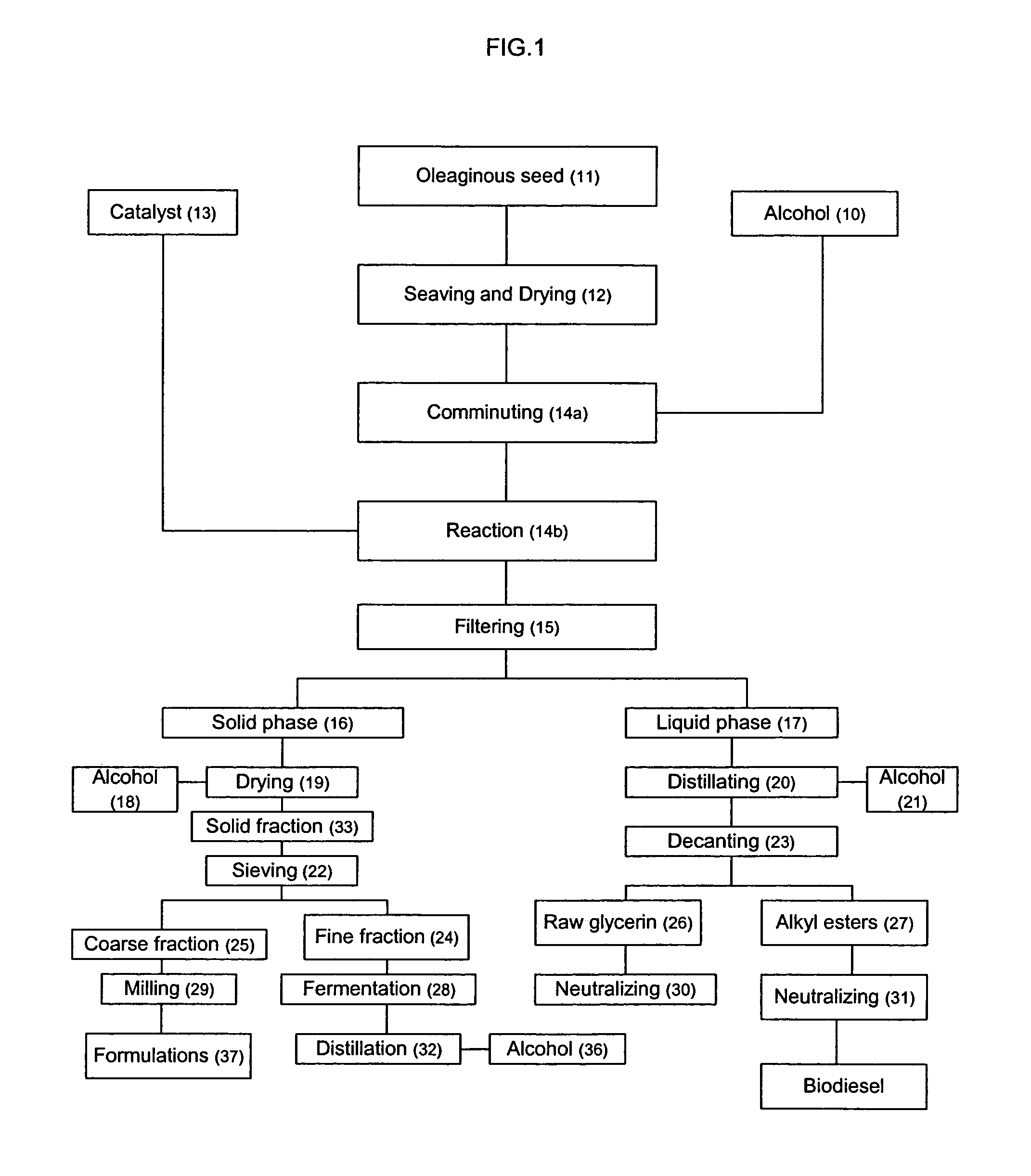

Process for producing biodiesel fuel using triglyceride-rich oleagineous seed directly in a transesterification reaction in the presence of an alkaline alkoxide catalyst

InactiveUS7112229B2Fatty oils/acids recovery from wasteFatty acid esterificationOil and greaseBiodiesel

An integrated process is described for producing biodiesel from oleaginous seeds, preferably castor bean seeds. The inventive process includes a transesterification reaction where the seeds themselves react with anhydrous ethyl alcohol in the presence of an alkaline catalyst. The resulting ethyl esters are then separated by decantation and neutralized and used as fuel for diesel engines, co-solvents for diesel and gasoline mixtures with anhydrous or hydrated ethyl alcohol. The solid fractions may be used as fertilizers, for feeding cattle and as a raw material for producing ethyl alcohol.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

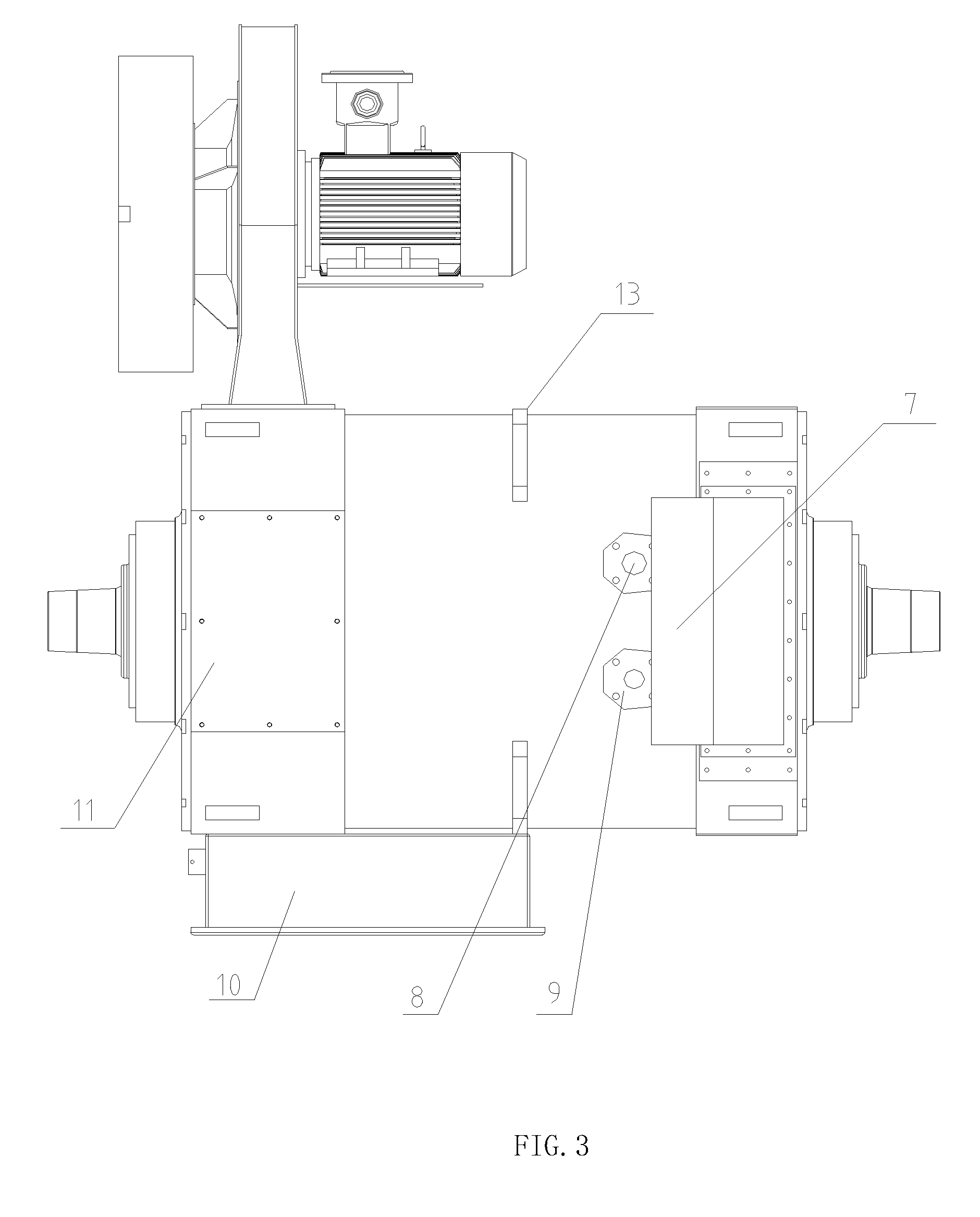

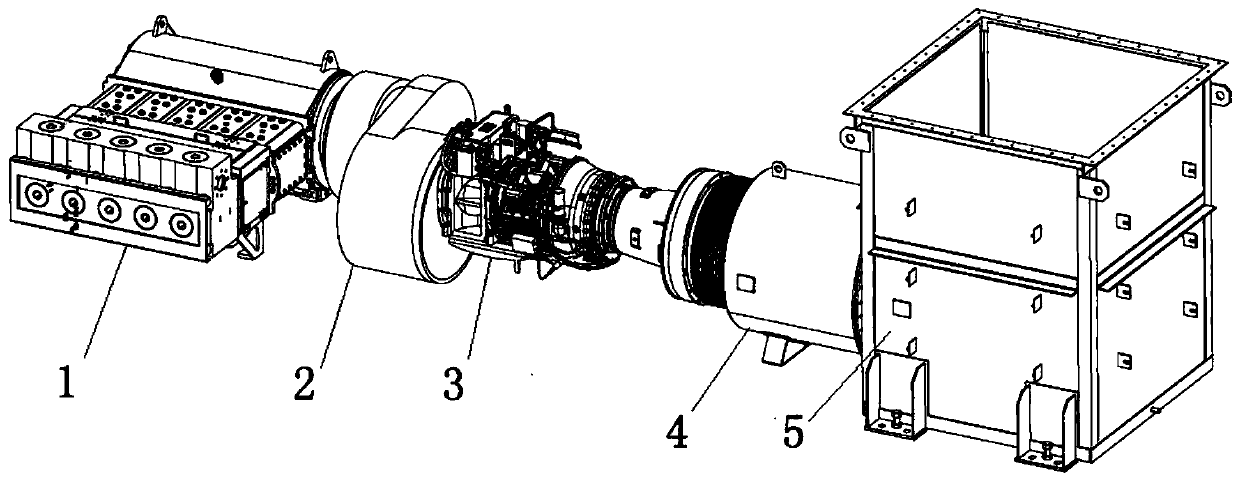

Fracturing pump power driving system

The invention discloses a fracturing pump power driving system. The fracturing pump power driving system adopts a turbine engine for driving, the turbine engine can take natural gas as fuel 100%, andcan replace diesel consumption in diesel engine drive, the fuel cost of a customer is reduced, the turbine engine has the advantages of being small in size and small in weight, the size, the weight and the like of the fracturing pump power driving system are greatly reduced, the turbine engine is directly connected with the input end of a reducer casing of a fracturing pump, a transmission devicebetween the fracturing pump and the turbine engine is simplified, a transmission shaft or coupler is omitted, the whole length of the fracturing pump power driving system is greatly shortened, according to the technical scheme, a power source is the turbine engine, the transmission device is the reducer casing of the fracturing pump, an execution element is the fracturing pump, the structure is simple, and maintaining is convenient.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH

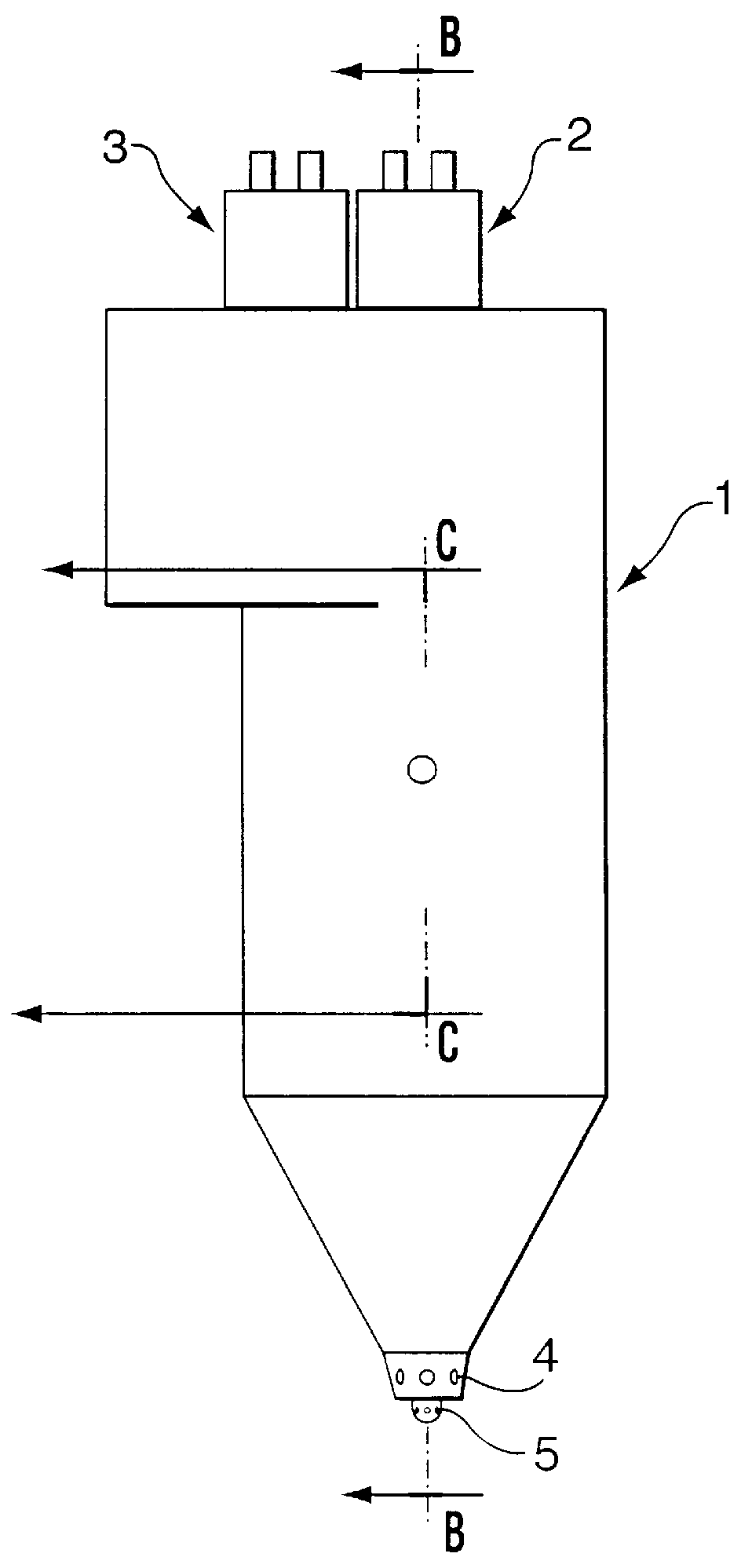

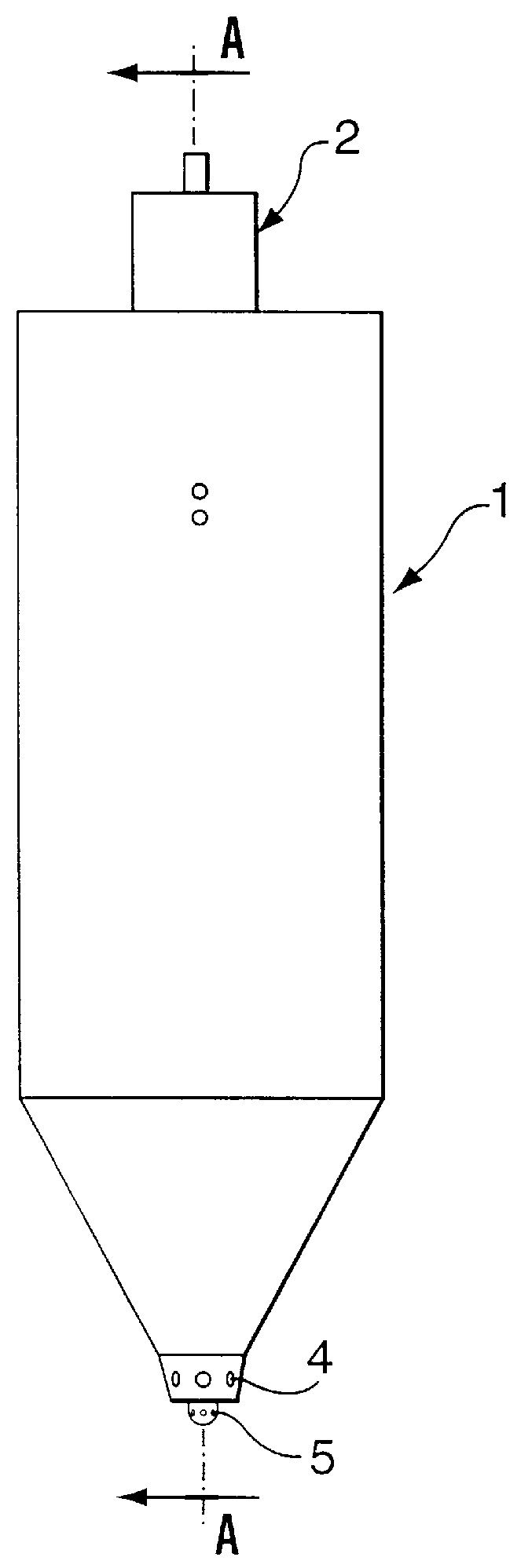

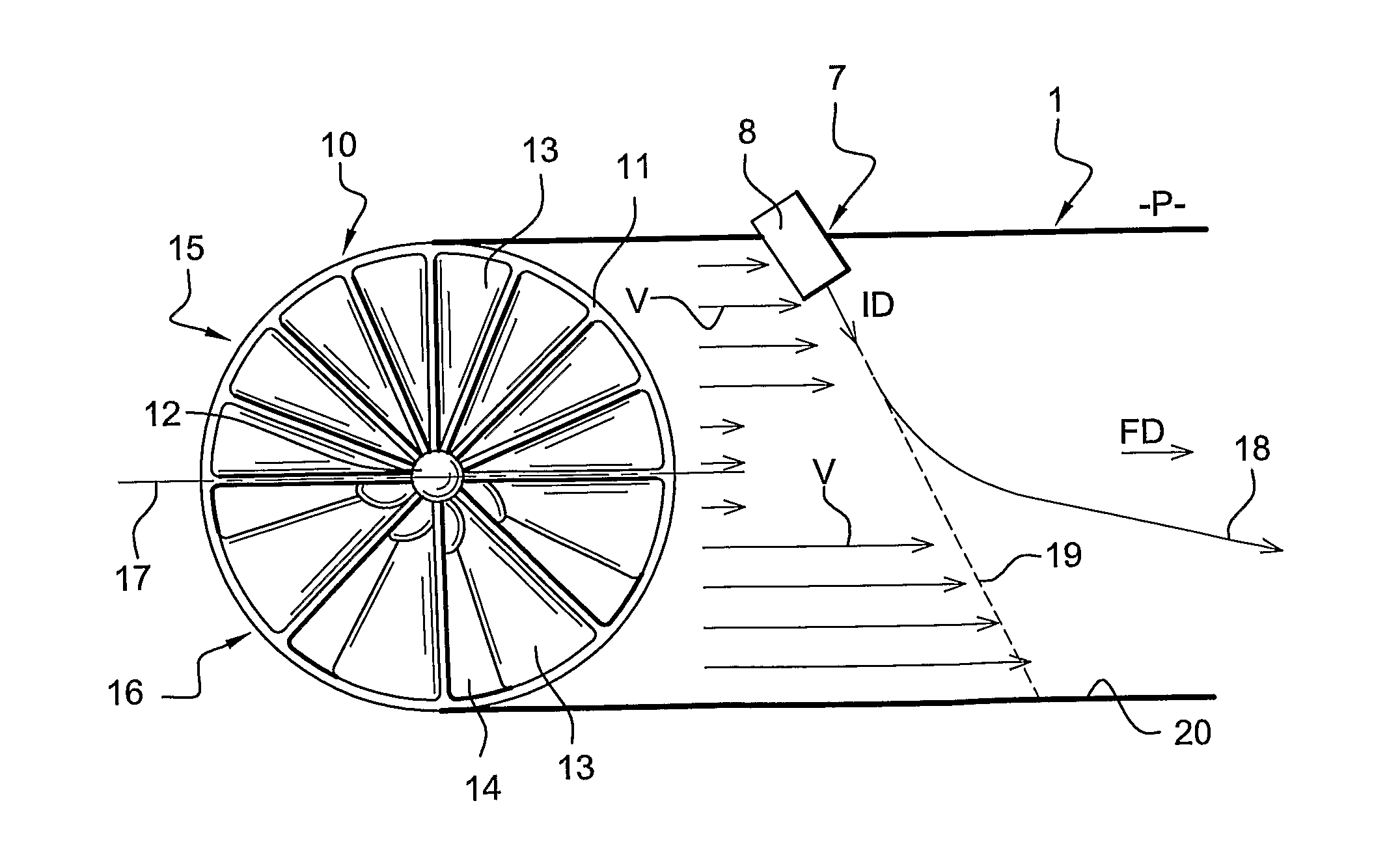

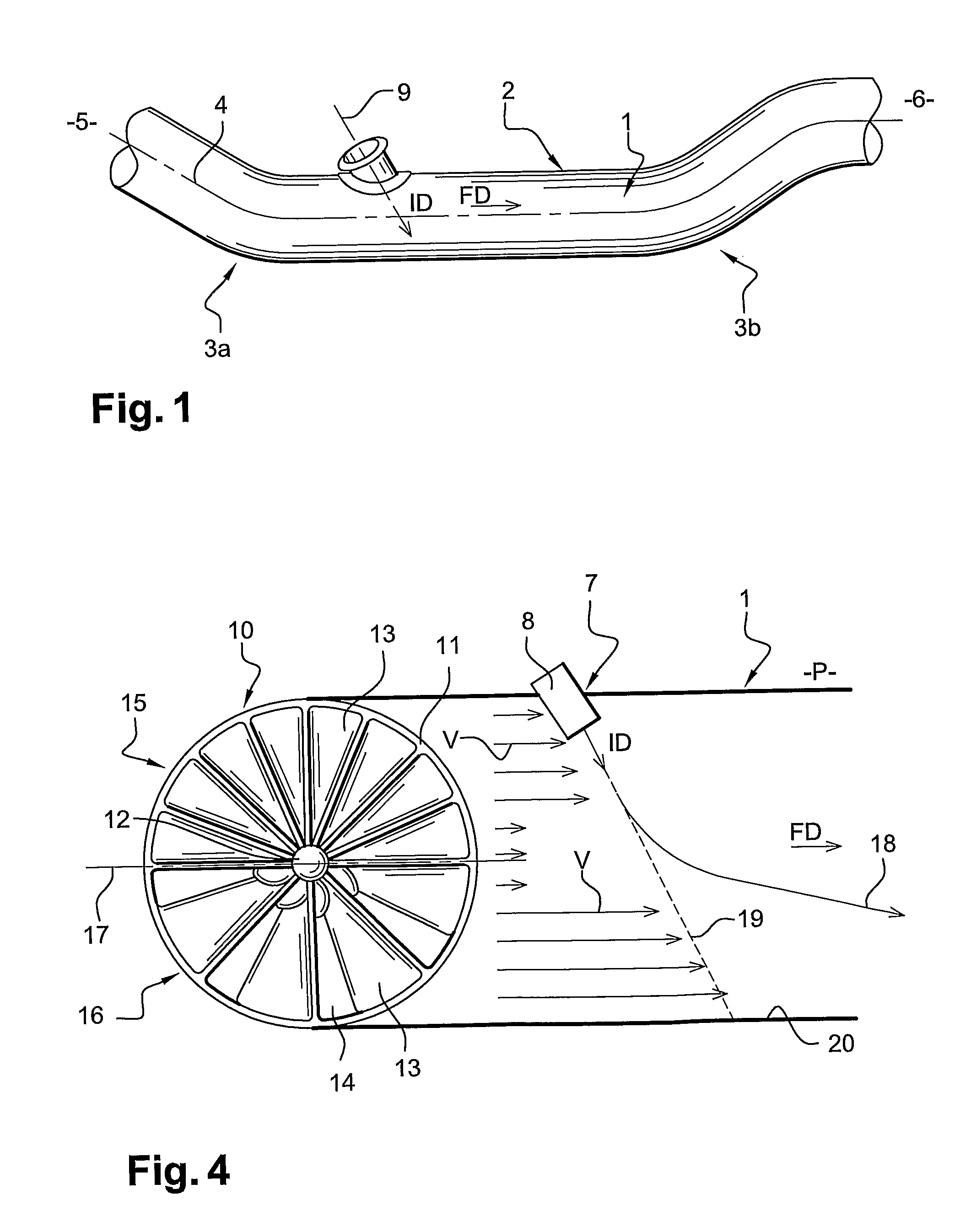

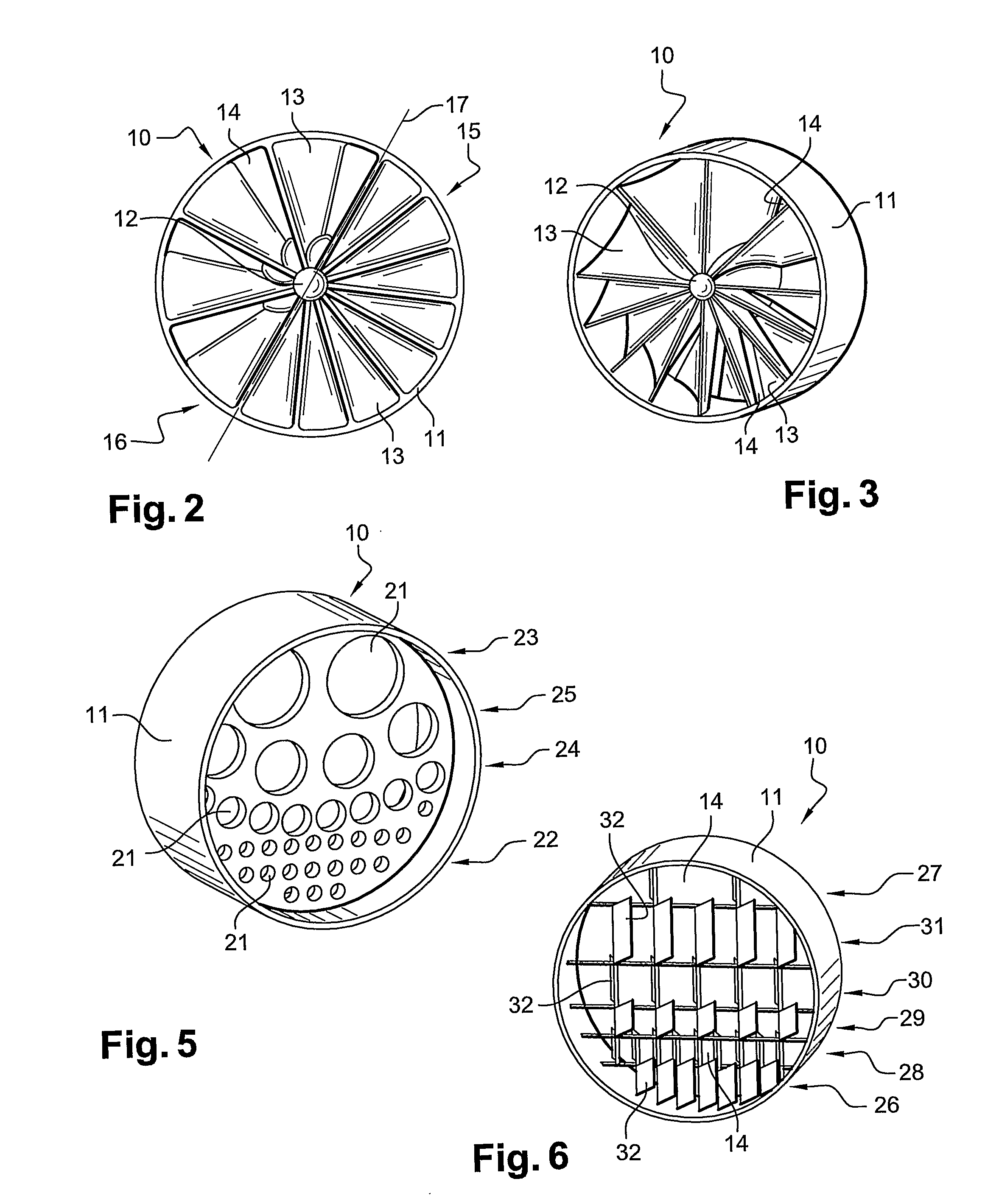

Mixing device in an exhaust gas pipe

ActiveUS20110162353A1Flow fastBetter mixing of fluidGas treatmentInternal combustion piston enginesExhaust fumesEngineering

In an exhaust gas pipe, a first fluid flows in a flow direction in the pipe, and a second fluid is injected inside the pipe by a nozzle, from an injection inlet arranged in the pipe wall, according to an injection direction. A mixing device fastened inside the pipe upstream from the injection inlet creates turbulence that helps the mixing of the fluids. The mixing device has a first portion located on the injection inlet side of the pipe and a second portion located opposite the injection inlet side of the pipe, the portions being designed so that the fluid velocity is higher downstream from the mixing device second portion than downstream from the mixing device first portion. An aqueous solution of urea can be injected inside an exhaust pipe of a diesel engine.

Owner:VOLVO LASTVAGNAR AB

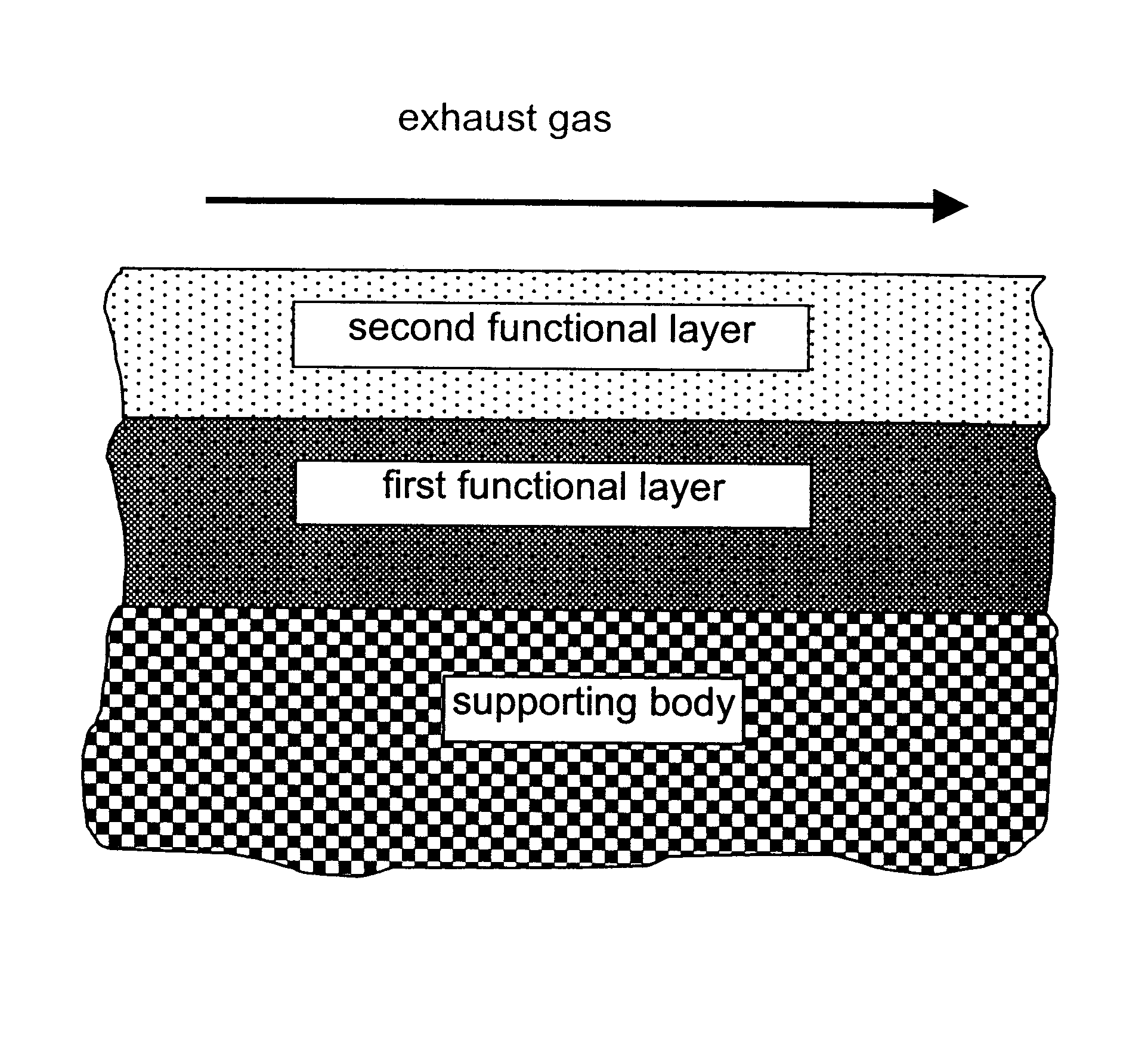

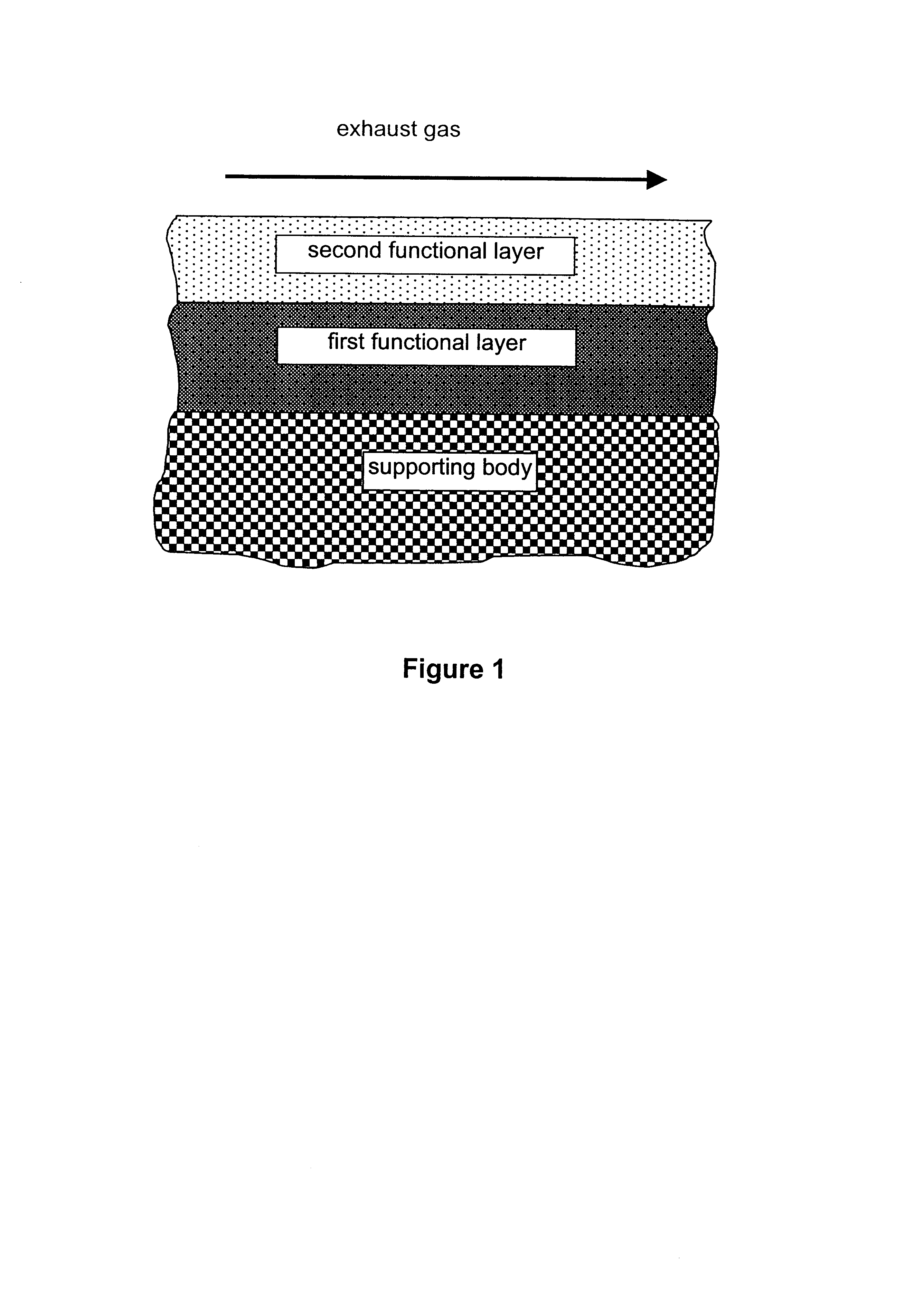

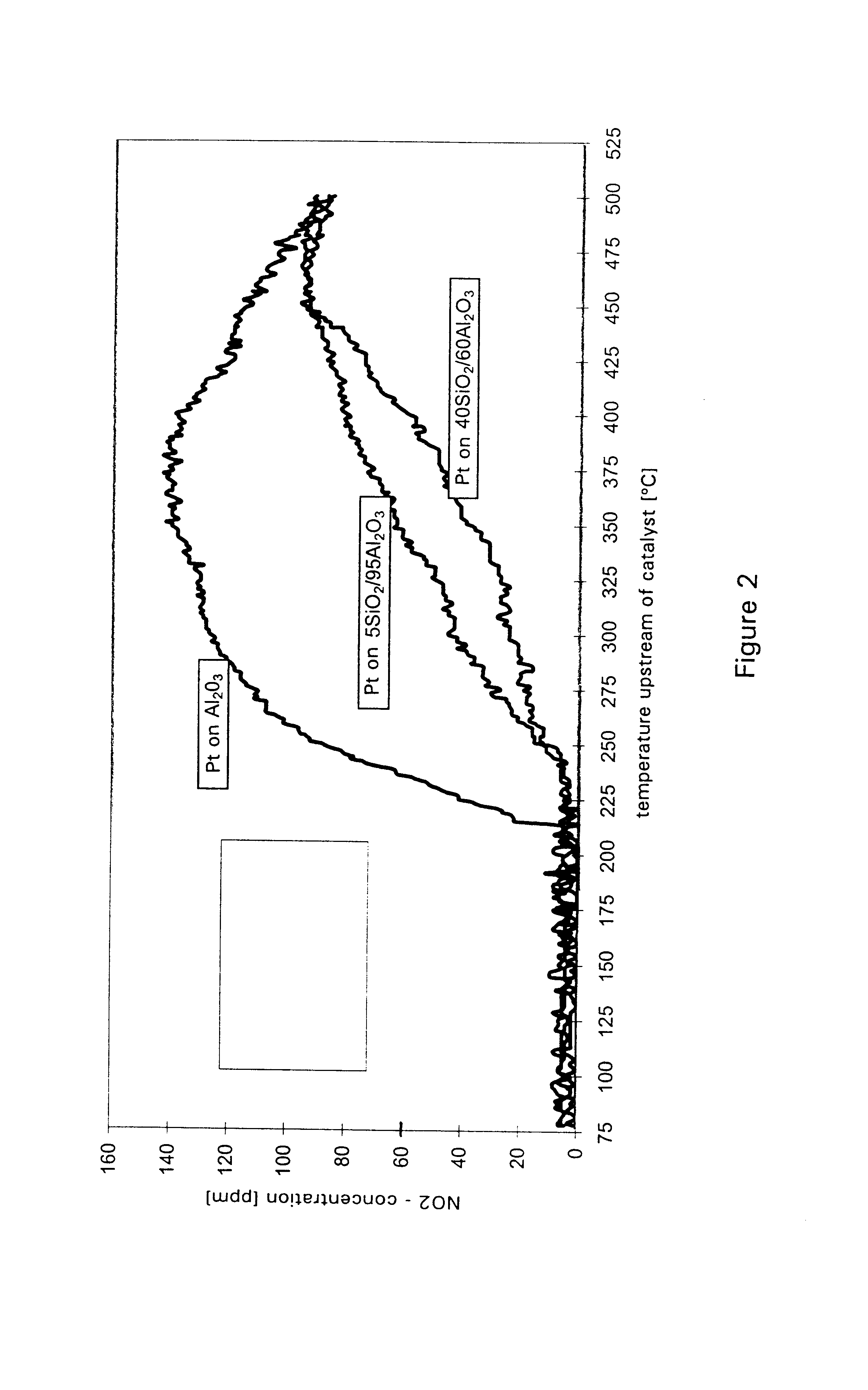

Catalyst for cleaning up the exhaust gases of a diesel engine

InactiveUS6677264B1Reduced activityReduce componentsMolecular sieve catalystsInternal combustion piston enginesCatalytic functionComponents of crude oil

A catalyst for purifying exhaust gases of a diesel engine. The catalyst contains two functional layers superimposed on an inert supporting body, whereby the first layer, which is situated directly on the supporting body, has a nitrogen oxide storage function and the second layer, which is in direct contact with the exhaust gas, has a catalytic function. The second functional layer additionally has a hydrocarbon-storage function and its catalytic function is provided by catalytically active noble metals of the platinum group which are deposited in highly dispersed form on finely divided, acidic carrier materials. Nitrogen oxides in the oxygen-rich exhaust gas of a diesel engine can be converted with optimal utilization of the reductive constituents contained in the exhaust gas. For this purpose, no reducing agents going beyond the reductive components (carbon monoxide and hydrocarbons) which are contained as a consequence of incomplete combustion need to be added to the exhaust gas. Nevertheless, rates of conversion in respect of the nitrogen oxides are obtained, averaged over practical driving cycles, which lie distinctly above the rates of conversion of conventional reduction catalysts.

Owner:UMICORE AG & CO KG +1

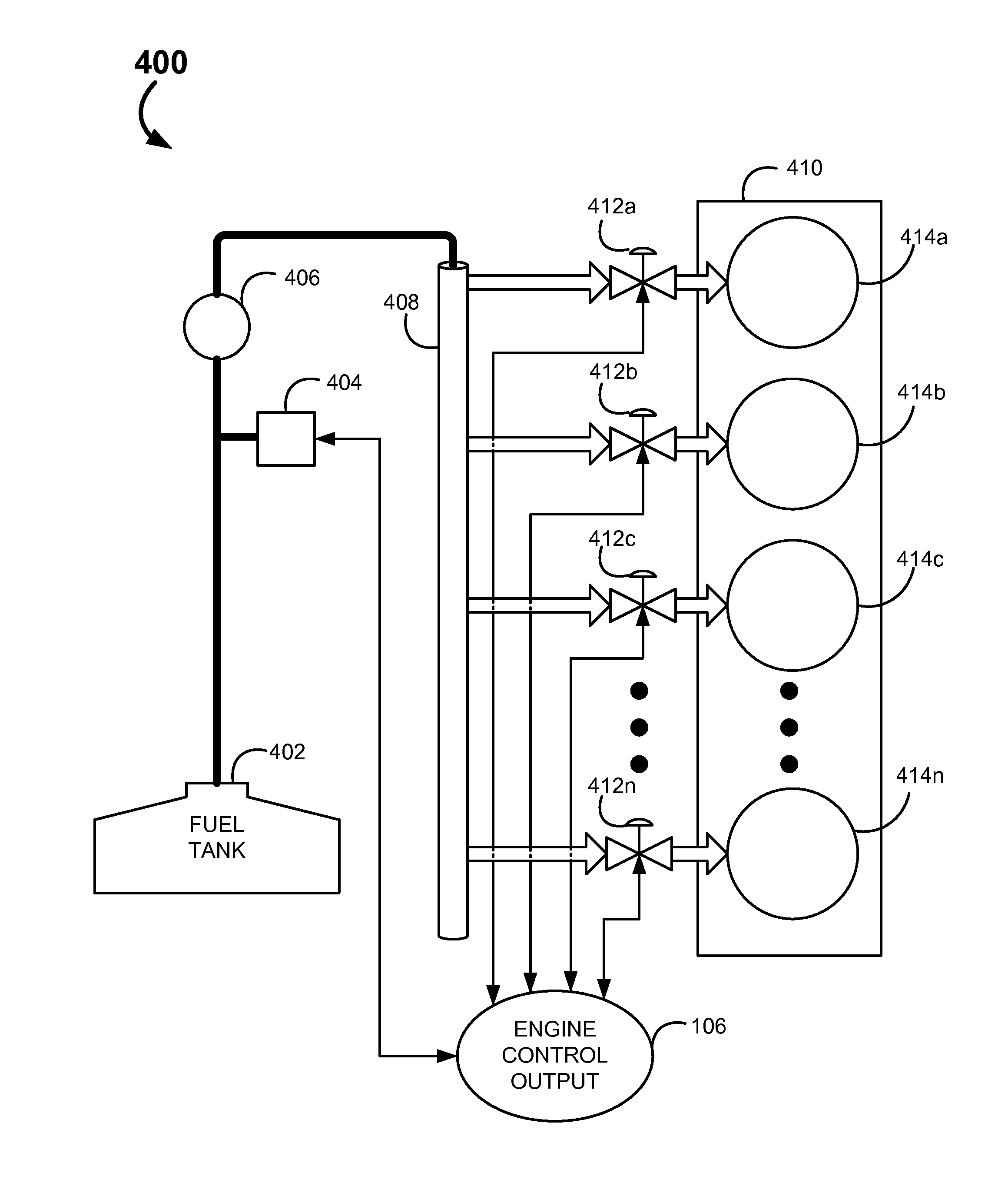

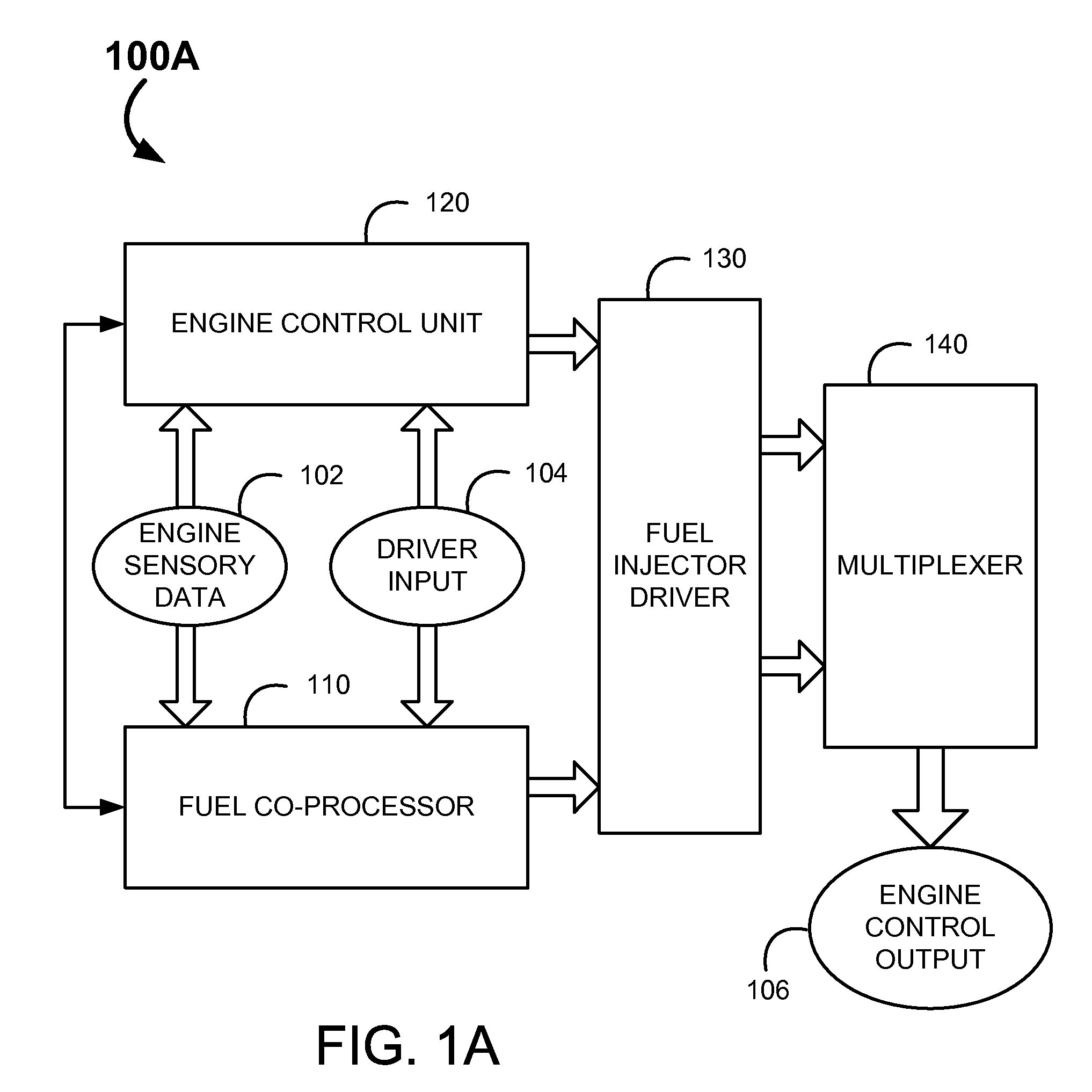

System and Methods for Stoichiometric Compression Ignition Engine Control

ActiveUS20110048372A1Enhanced skip fire operationEasy to controlElectrical controlInternal combustion piston enginesCombustionControl system

The present invention relates to a diesel engine control system and methods for substantially operating a diesel engine at stoichiometric fuel to air ratios. The system may include a fuel processor which receives instructions for a desired engine output and current operating conditions. The fuel processor may also generate fueling instructions for the cylinders, including: substantially regulating fuel delivery into to a first group of cylinders at or near stoichiometric fuel levels, and substantially disabling fuel injection into to a second grouping of cylinders. The number of cylinders being fueled, and therefore undergoing a combustion event corresponds to the desired engine output. This may be calculated by dividing the desired output by the power provided by one cylinder operating at substantially stoichiometric fuel levels. The number of cylinders receiving fuel may be varied over a succession of engine revolutions such that the actual average engine power output conforms to the desired output.

Owner:TULA TECH INC

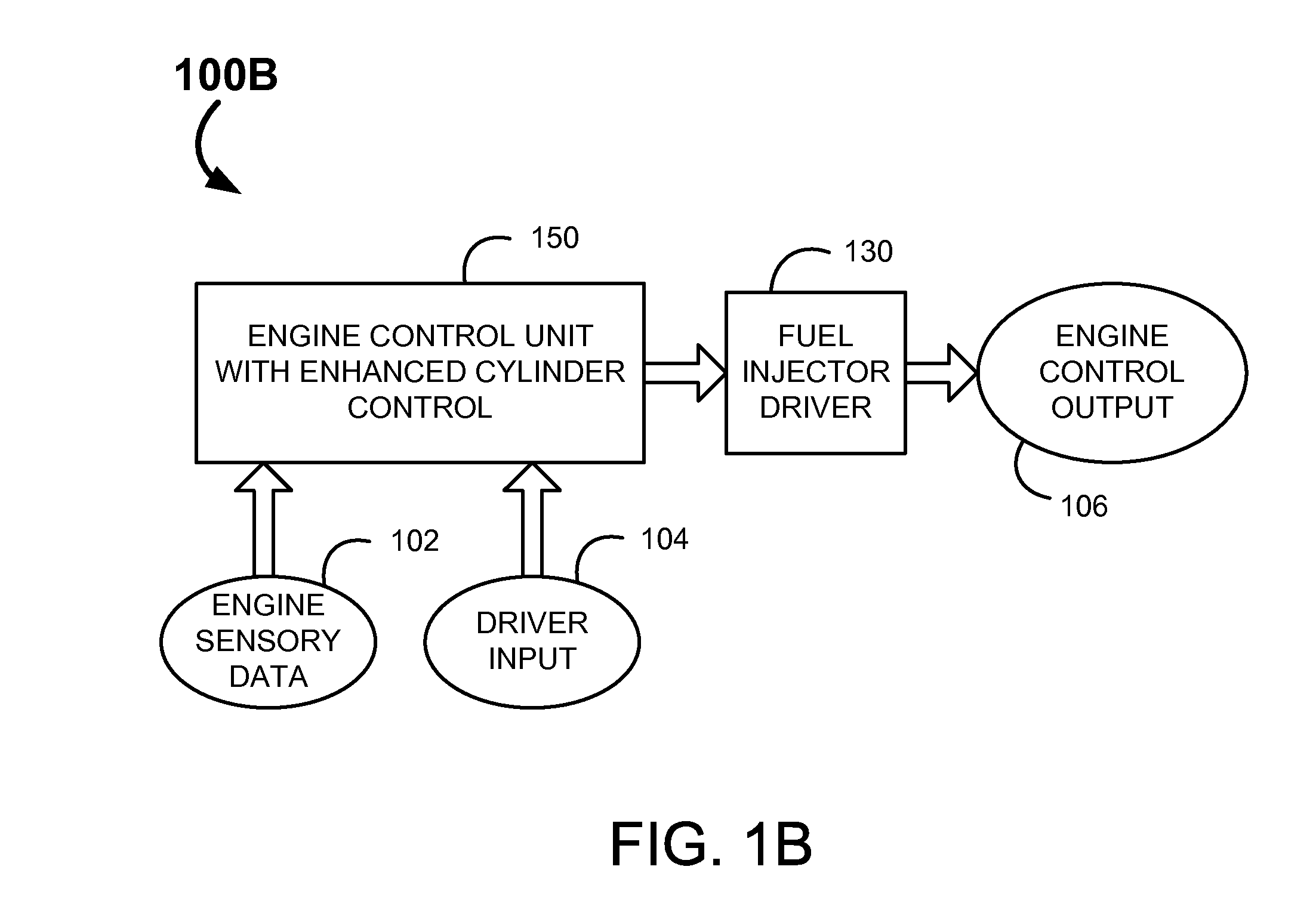

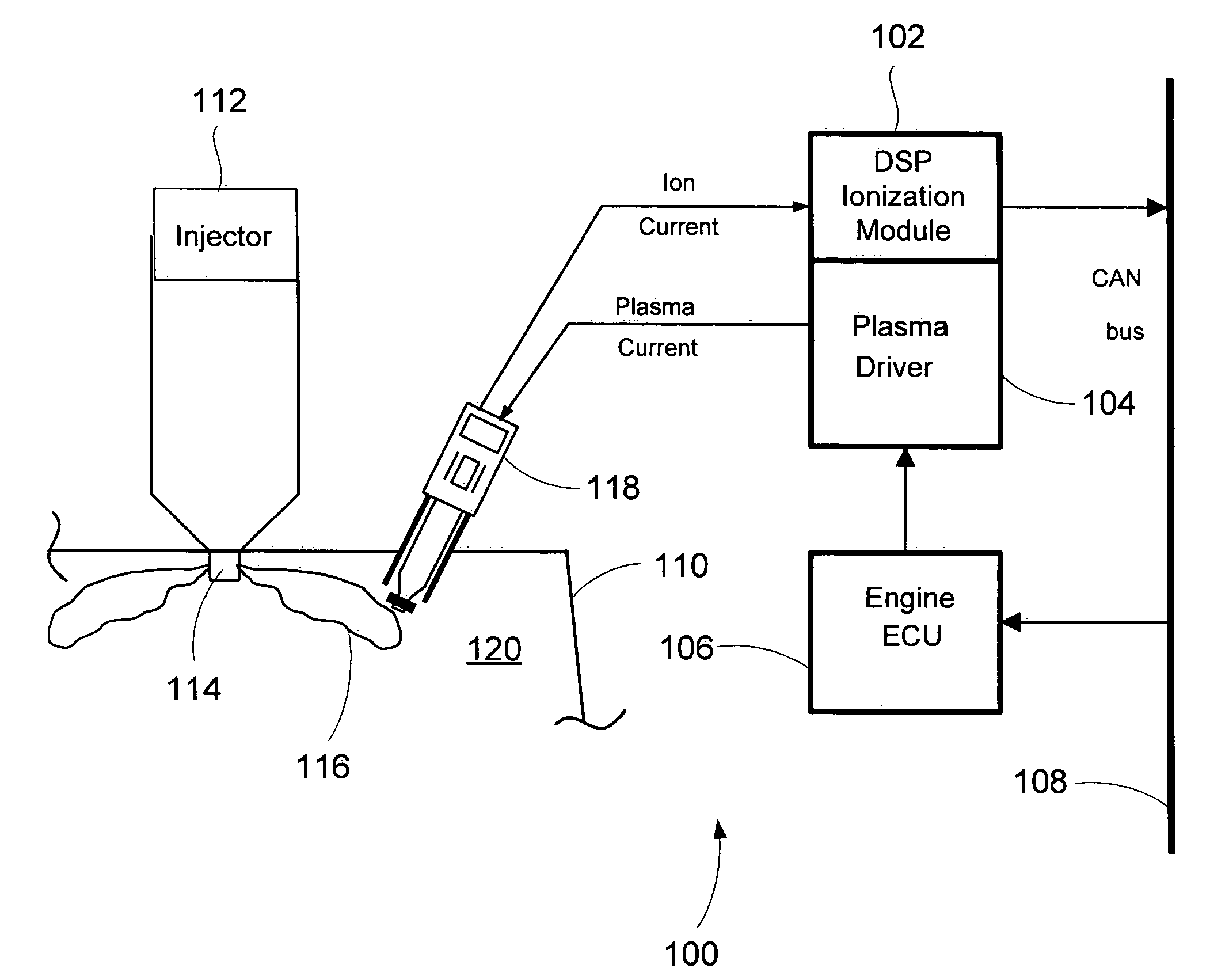

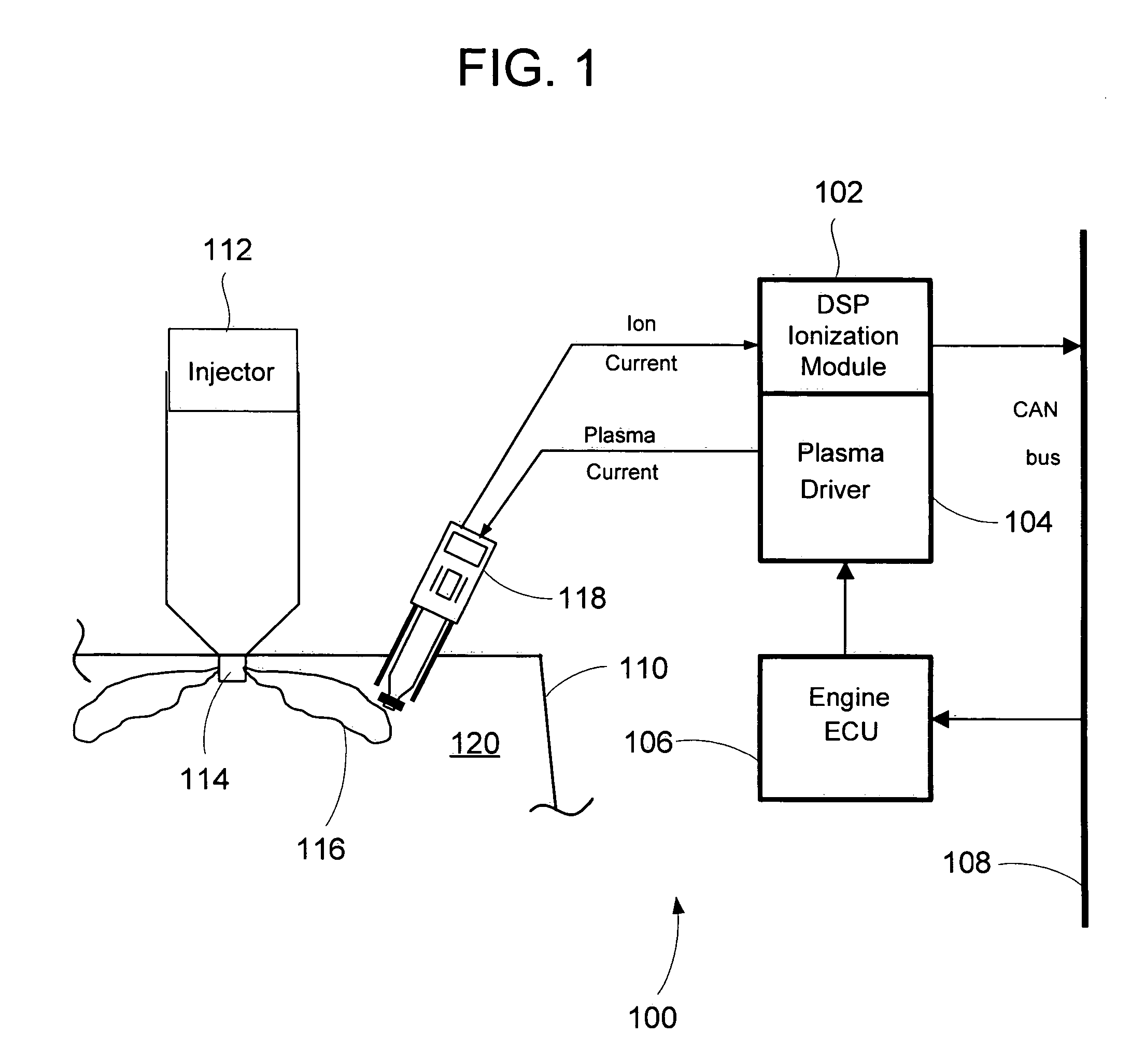

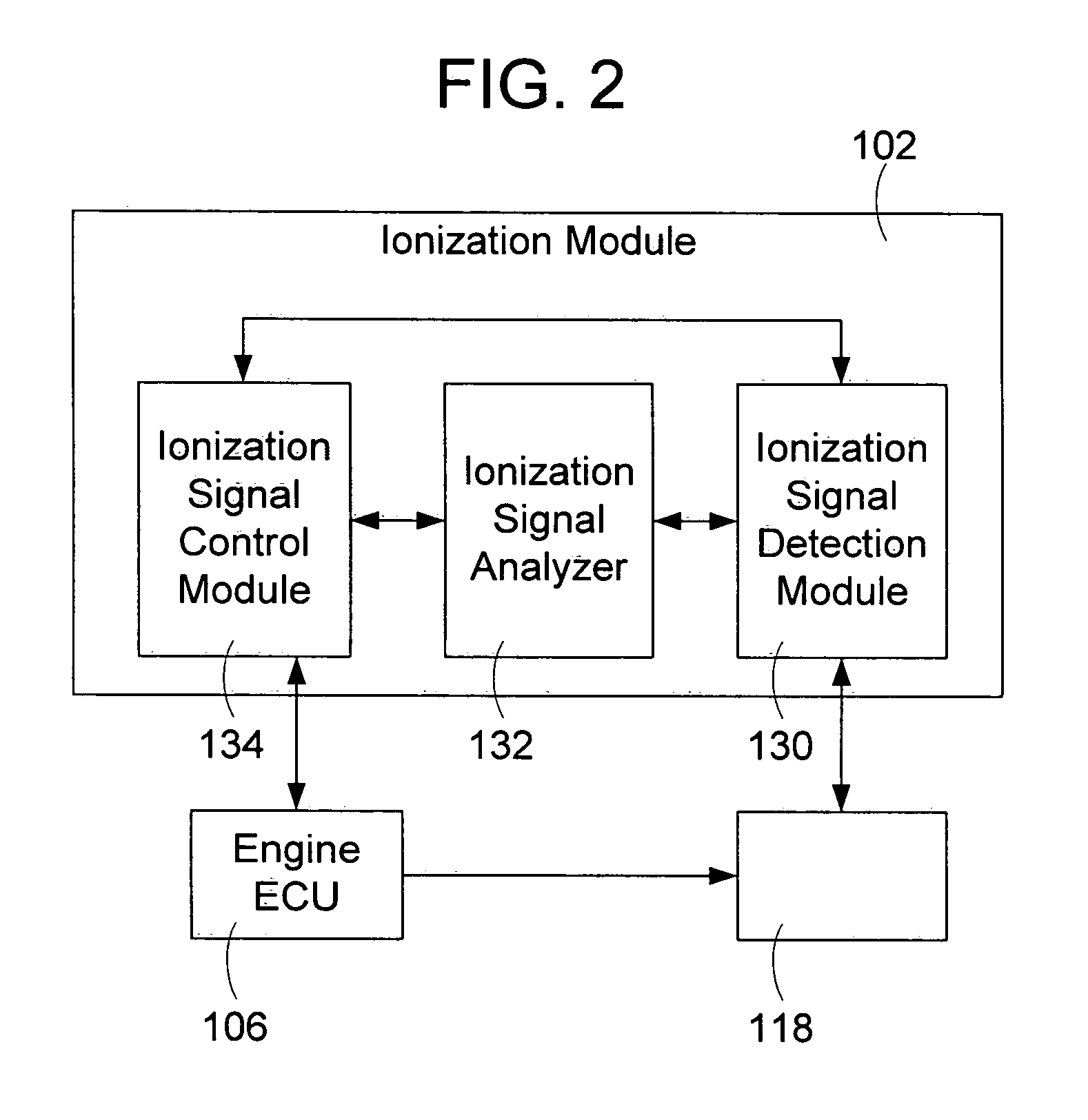

Method and apparatus for detecting ionization signal in diesel and dual mode engines with plasma discharge system

Owner:WOODWARD GOVERNOR CO

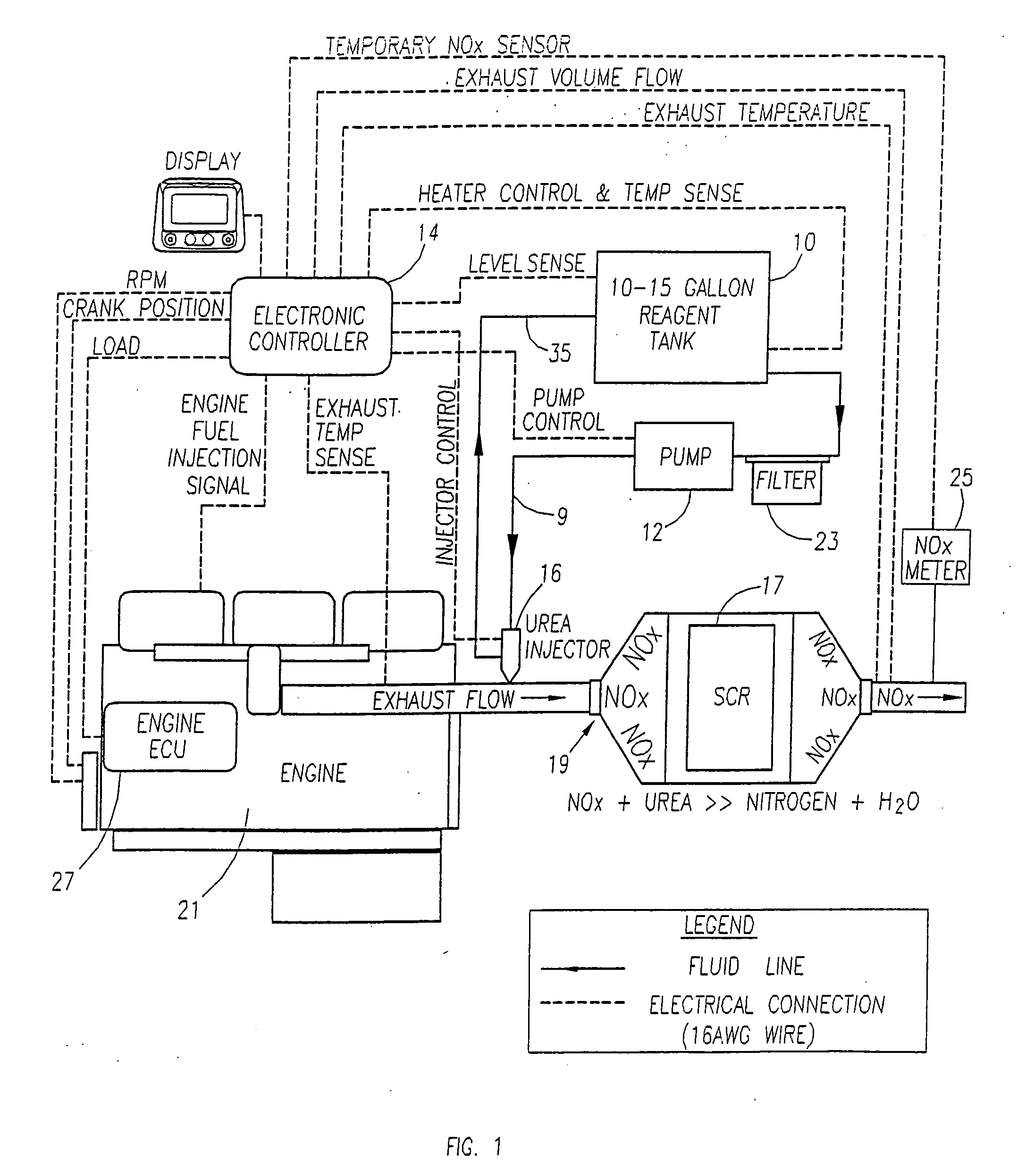

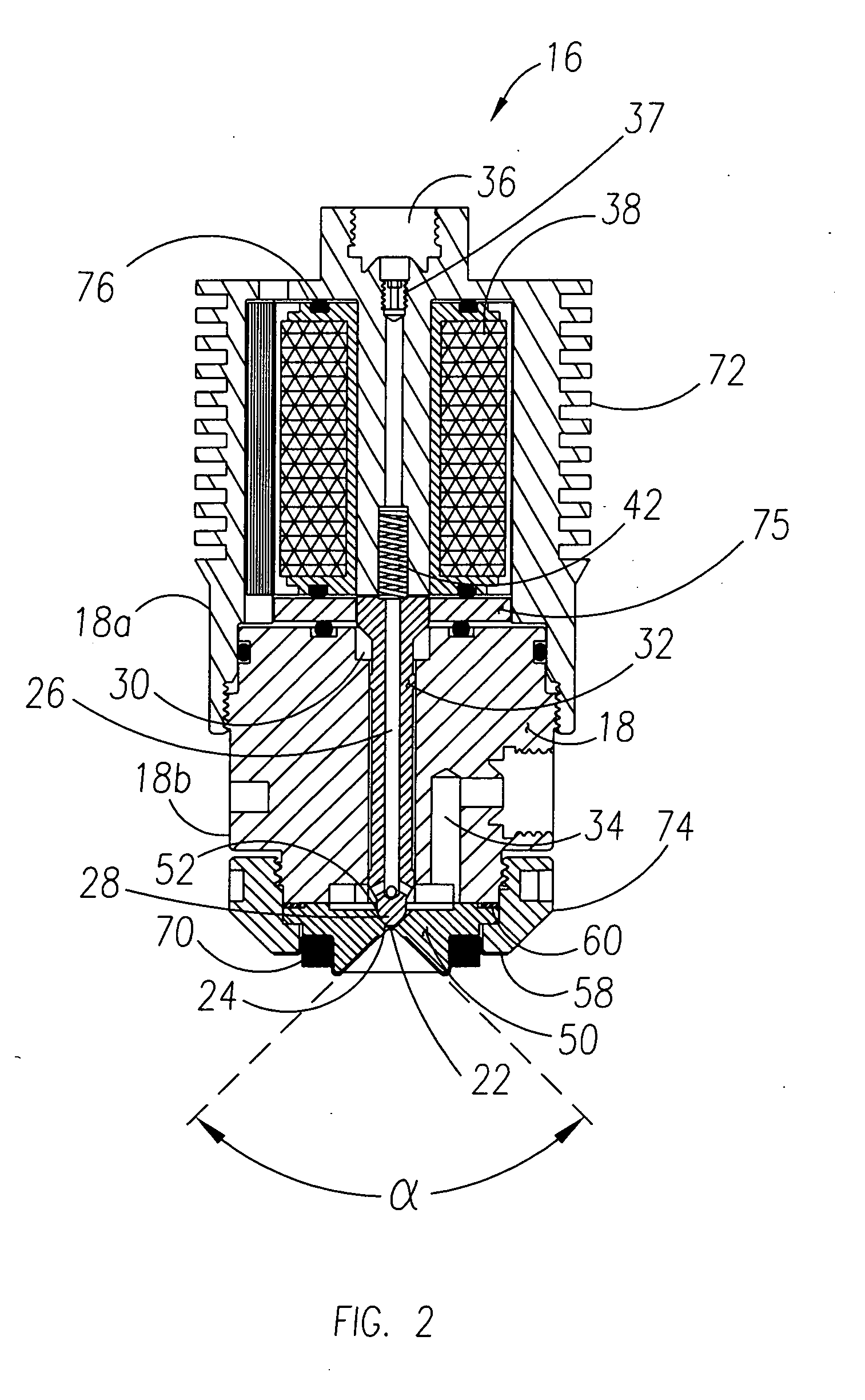

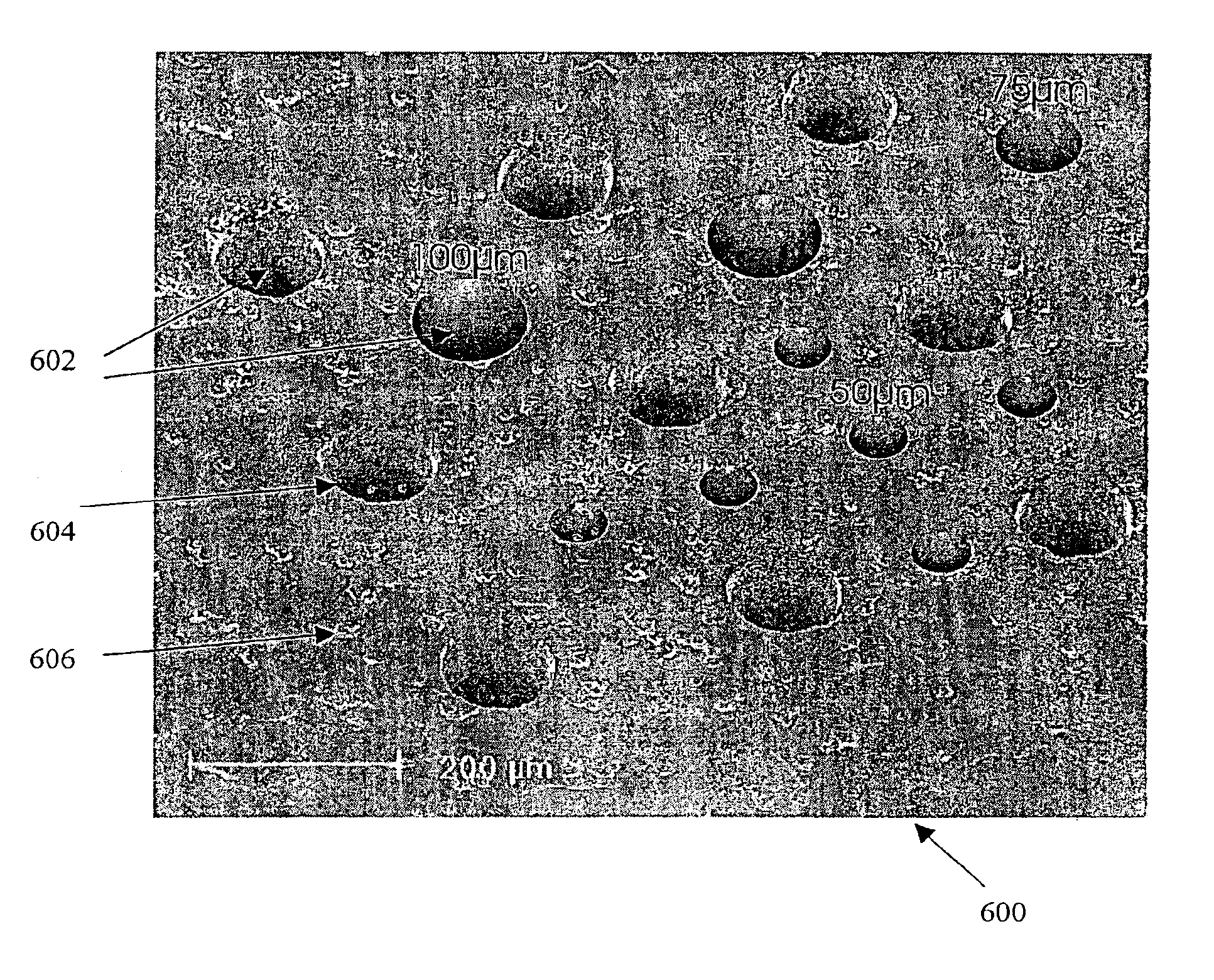

Methods and apparatus for injecting atomized fluid

ActiveUS20050235632A1Reduce oxide of nitrogen (NOx) emissionImprove performanceInternal combustion piston enginesExhaust apparatusDiesel engineNOx

The present invention provides methods and apparatus for injecting fluid, such as an aqueous urea solution, into an exhaust stream in order to reduce oxides of nitrogen (NOx) emissions from diesel engine exhaust The present invention uses mechanical spill return atomization techniques to produce droplets approximately 50 μm SMD (Sauter mean diameter) or smaller. This size range is appropriate to allow urea to react into ammonia within the residence time associated with an on-road diesel engine. This effect is achieved through the use of a whirl plate having a plurality of whirl slots surrounding an exit orifice of the injector, which produce a high velocity rotating flow in the whirl chamber. When the rotating flow of fluid is passed through the exit orifice into an exhaust stream, atomization occurs from a combination of centrifugal force and shearing of the fluid by air as it jets into the exhaust stream.

Owner:TENNECO AUTOMOTIVE OPERATING CO INC

Ceramic exhaust filter

InactiveUS6946013B2Low thermal expansionLarge specific surface areaMaterial nanotechnologyCombination devicesFiberParticulates

An improved, efficient, and regenerable exhaust emission filter and filter system are provided which incorporate the use of an inorganic, non-woven fiber filter element. The filter is able to capture exhaust pollutants and particulates through the interwoven nature of the filter element and due to area enhancements applied to the filter element including microscopic enhancements. The filter has an improved life and is able to combust a greater percentage of trapped particulates due to the high temperatures the filter element can withstand. The filter element if formed from a non-woven fiber block which is machined or shaped into a filter foundation. The filter element can have a multitude of coatings and catalysts applied and can be wrapped in insulation and a casing. The improved exhaust emission filter is particularly useful for diesel engine exhausts.

Owner:GE02 TECH INC

Monolithic honeycomb structure made of porous ceramic and use as a particle filter

InactiveUS6582796B1Prevent the evaporation of the waterEasy curingInternal combustion piston enginesSilencing apparatusSodium BentoniteOxygen

A monolithic honeycomb-type structure useful in particular as a particle filter for exhaust gases from diesel engines has a number of passages that empty into the end faces of said monolith, but are alternately open and sealed. The monolith consists of a porous refractory material that comprises: 70 to 97% by mass of alpha and / or beta crystallographic-type silicon carbide that has at least one particle size and preferably at least two particle sizes, and 3 to 30% by mass of at least one bonding ceramic phase in the form of a micronic powder or particles that are obtained by atomization, comprising at least one simple oxide, for example, B2O3, Al2O3, SiO2, MgO, K2O, Li2O, Na2O, CaO, BaO, TiO, ZrO2 and Fe2O3 and / or at least one mixed oxide, for example, the alkaline aluminosilicates (of Li, Na, or K) or alkaline-earth aluminosilicates (of Mg, Ca, Sr or Ba), clays, bentonite, feldspars or other natural silico-aluminous materials. The production of the monolith comprises a calcination stage under an oxygen-containing atmosphere at a temperature up to 1650° C., but less than 1550° C.

Owner:INST FR DU PETROLE

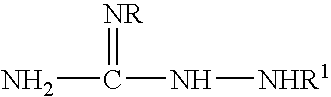

Fuel additives to maintain optimum injector performance

ActiveUS20090282731A1Maximize driveabilityMaximize fuel economyLiquid carbonaceous fuelsFuel additivesHydrogenCarboxylic acid

A diesel fuel, diesel fuel additive concentrate and method for improving the performance of fuel injectors for a diesel engine are provided. The diesel fuel includes a major amount of middle distillate fuel; and a reaction product of a hydrocarbyl substituted dicarboxylic acid or anhydride and an amine compound or salt. The amine compound has the formulawherein R is selected from the group consisting of a hydrogen and a hydrocarbyl group containing from about 1 to about 15 carbon atoms, and R1 is selected from the group consisting of hydrogen and a hydrocarbyl group containing from about 1 to about 20 carbon atoms. The reaction product contains at least one amino triazole group and is present in the fuel in an amount sufficient to improve the performance of diesel fuel injectors.

Owner:AFTON CHEMICAL

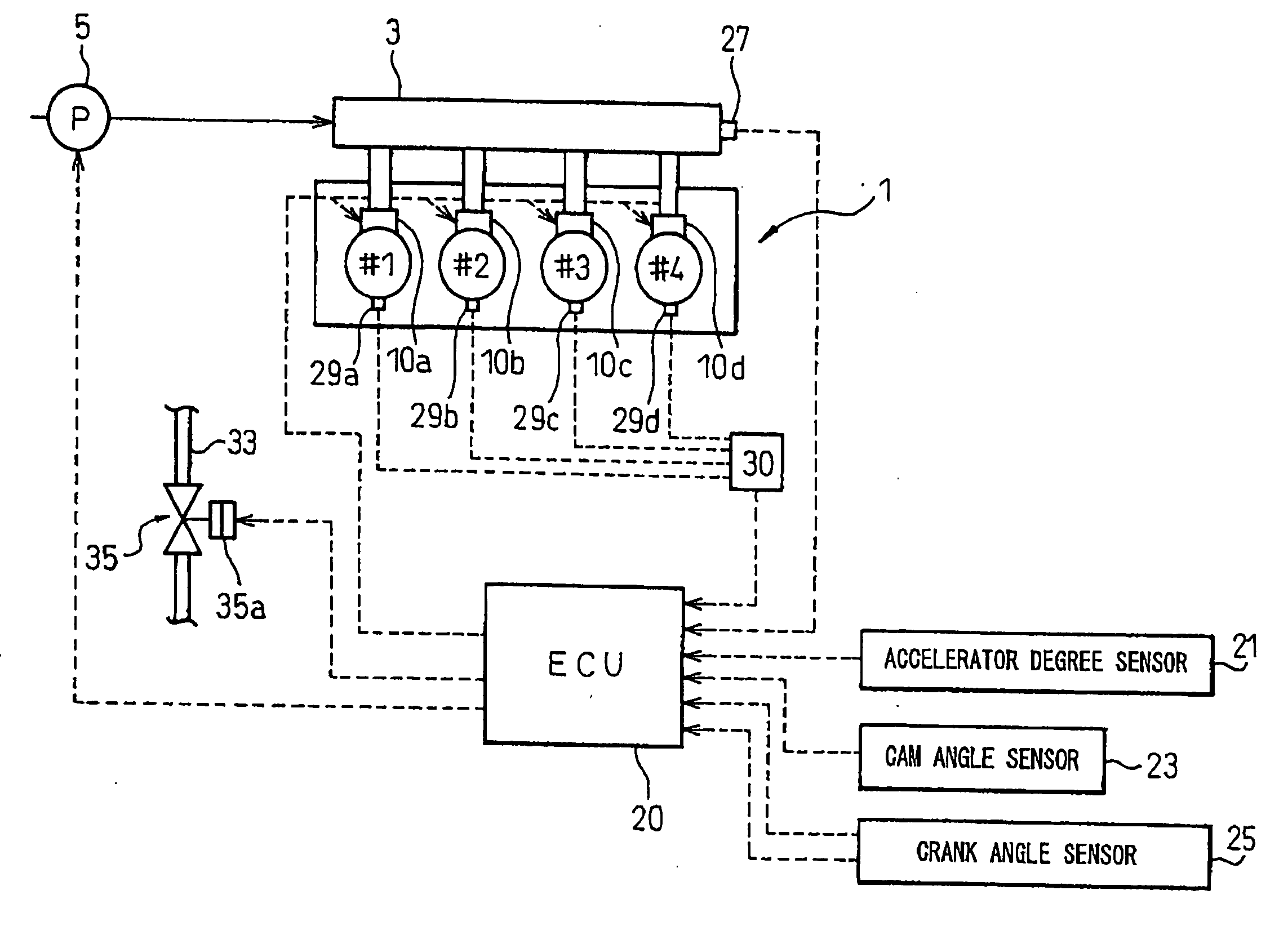

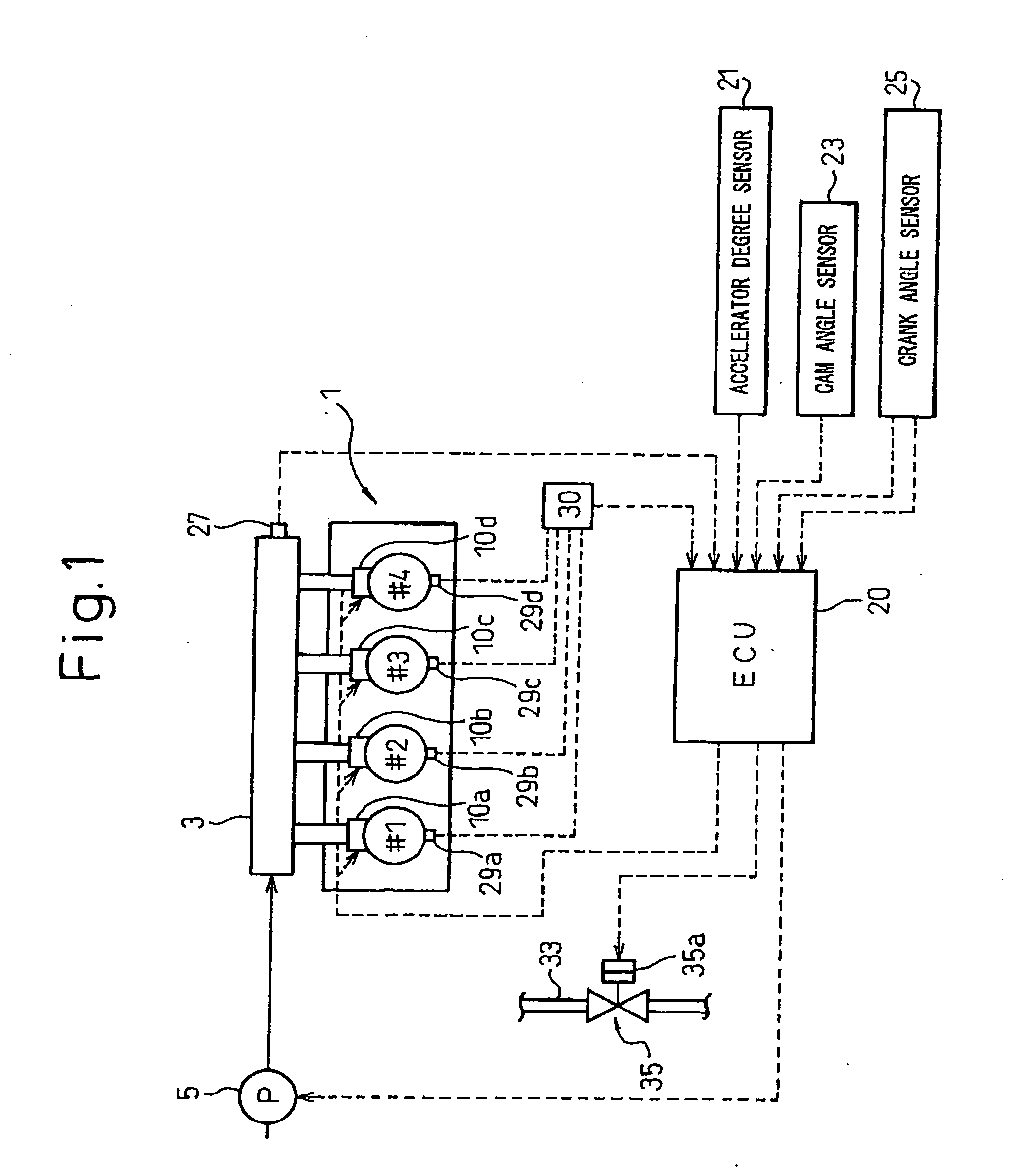

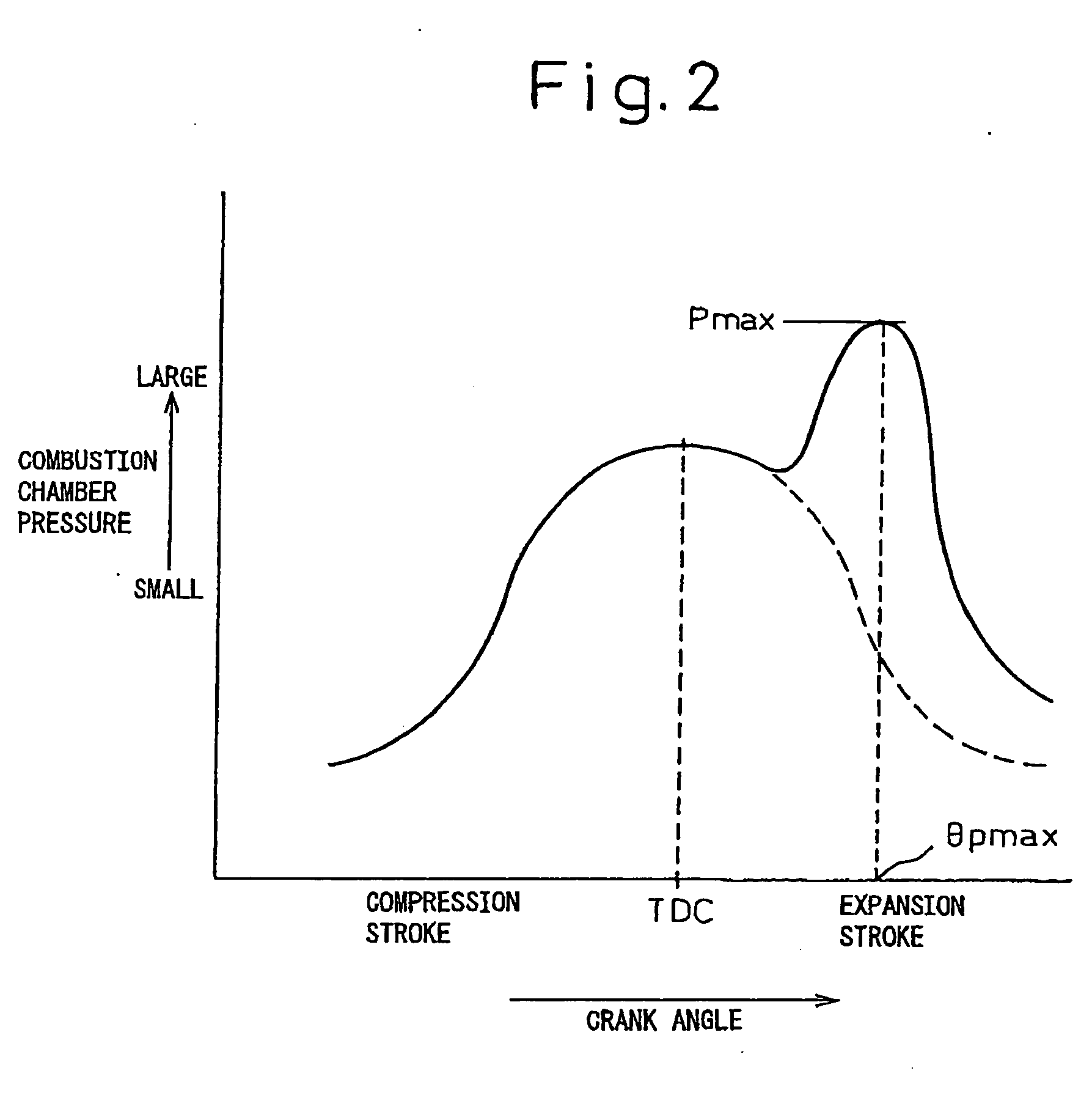

Control device of internal combustion engine

InactiveUS20050229903A1Good precision EGR controlEasy to controlElectrical controlNon-fuel substance addition to fuelCombustion chamberInternal combustion engine

Cylinders of a diesel engine 1 are provided with cylinder pressure sensors 29a to 29d for detecting combustion chamber pressures. An electronic control unit (ECU) 20 of the engine selects optimum combustion parameters in accordance with a fuel injection mode of fuel injectors 10a to 10d of the engine and a combustion mode determined by the amount of EGR gas supplied from the EGR valve 35 from among a plurality of types of combustion parameters expressing the combustion state of the engine calculated based on the cylinder pressure sensor output and feedback controls the fuel injection amount and fuel injection timing so that the values of the combustion parameters match target values determined in accordance with the engine operating conditions. Due to this, the engine combustion state is controlled to the optimum state at all times regardless of the fuel injection mode or combustion mode.

Owner:TOYOTA JIDOSHA KK

Blended compression-ignition fuel containing light synthetic crude and blending stock

InactiveUS6056793AImprove performanceEmission reductionLiquid carbonaceous fuelsFuel additivesAlcoholIgnition delay

This invention is a composition of matter useful as a compression-ignition fuel. The composition has from about 30 to about 95 mass % of a light synthetic crude or syncrude, preferably from Fischer-Tropsch synthesis or related processes, and from about 5 to about 70 mass % of a blending stock that improves one or more desirable fuel property(s) including but not limited to pour point temperature, viscosity and emissions generated during combustion in a diesel engine. The blend stock preferably has an average molecular weight less than the average molecular weight of the light syncrude. Preferred blending stocks include hydrocarbons and oxygenates, such as alcohols, and ethers, having average molecular weights less than 200, preferably less than 160. The composition may optionally also contain pour point depressants, cetane improvers, carbon-containing compounds which react with water, and / or emulsifiers.

Owner:REG SYNTHETIC FUELS LLC +1

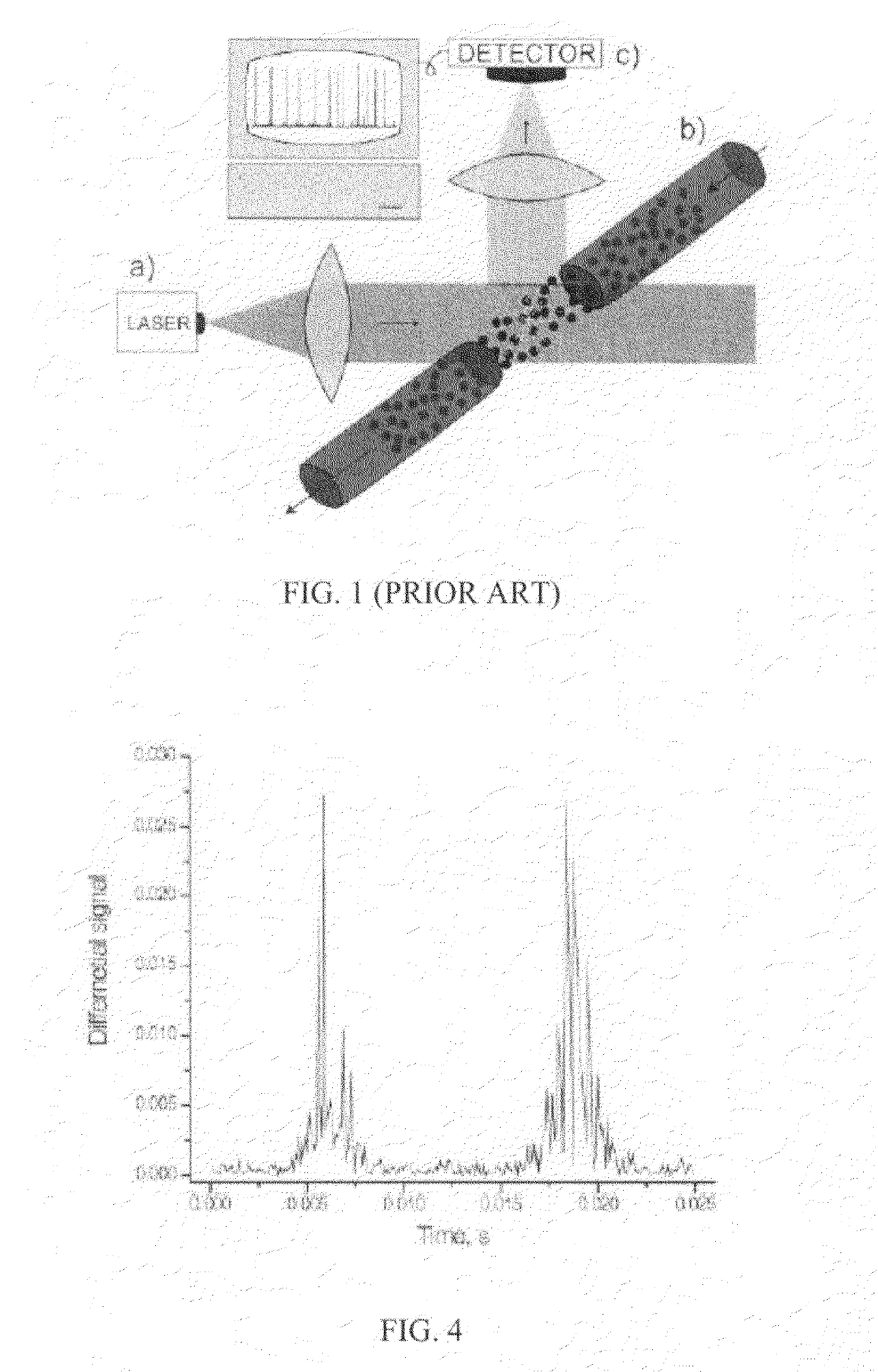

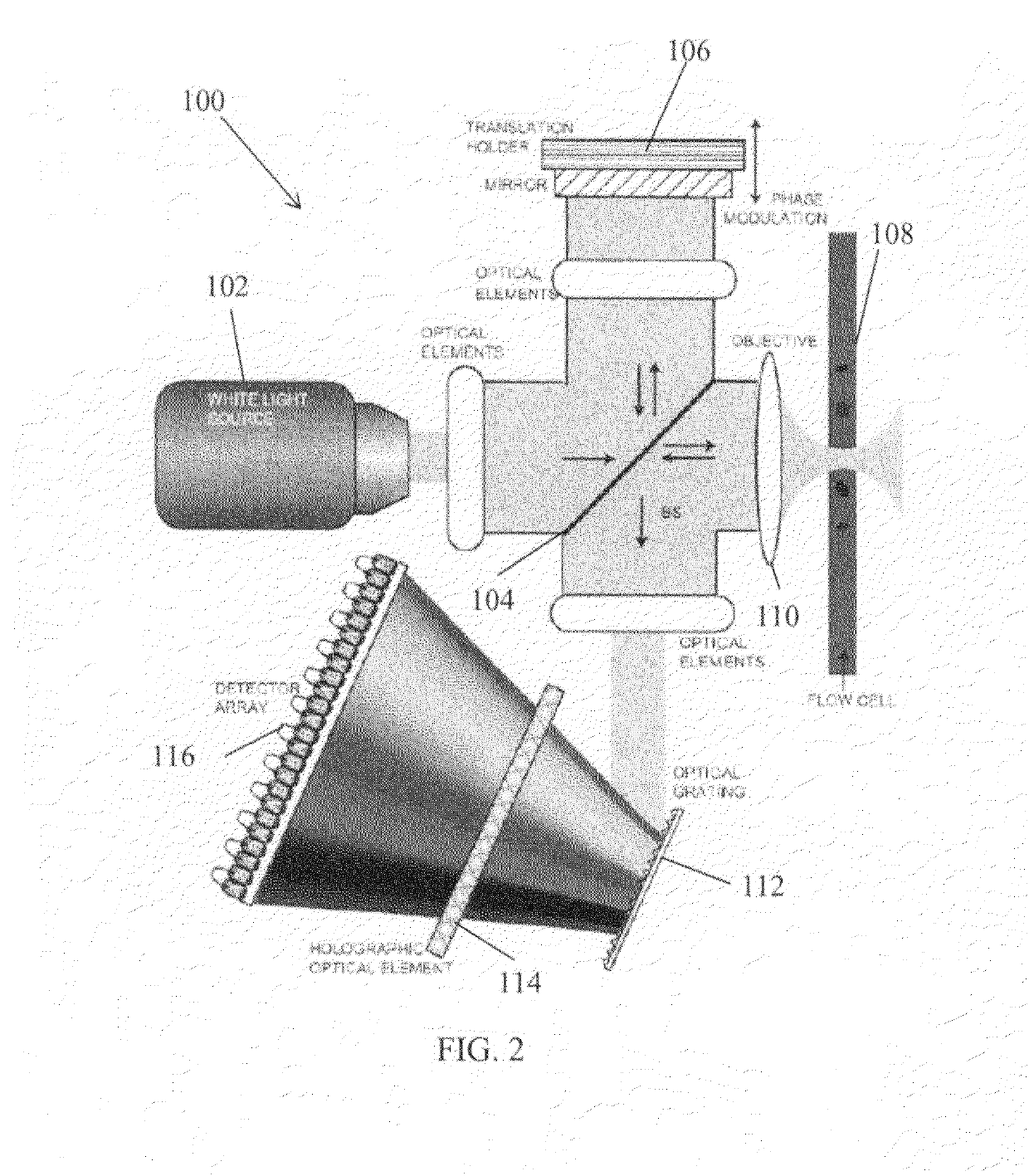

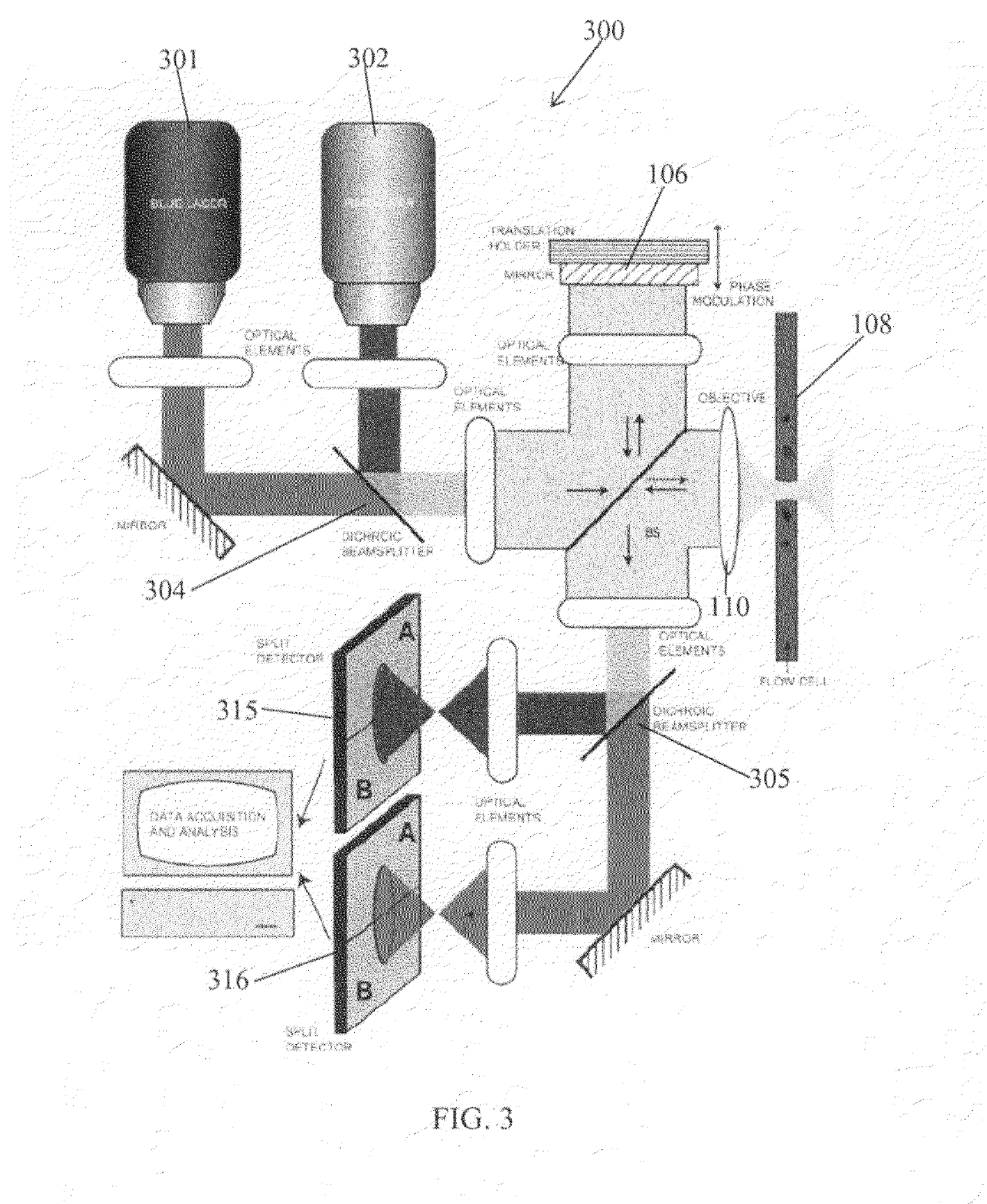

Multi-color hetereodyne interferometric apparatus and method for sizing nanoparticles

A nanoparticle sensor is capable of detecting and recognizing single nanoparticles in an aqueous environment. Such sensor may find applications in broad areas of science and technology, from the analysis of diesel engine emissions to the detection of biological warfare agents. Particle detection is based on interferometric detection of multi-color light, scattered by the particle. On the fundamental level, the detected signal has a weaker dependence on particle size (ÿ R3), compared to standard detection methods (ÿ R6). This leads to a significantly larger signal-to-noise ratio for smaller particles. By using a multi-color or white excitation light, particle dielectric properties are probed at different frequencies. This scheme samples the frequency dependence of the particle's polarizability thereby making it possible to predict the composition of the particle material. The detection scheme also employs a heterodyne or pseudoheterodyne detection configuration, which allows it to reduce or eliminate noise contribution from phase variations, which appear in any interferometric measurements.

Owner:UNIVERSITY OF ROCHESTER

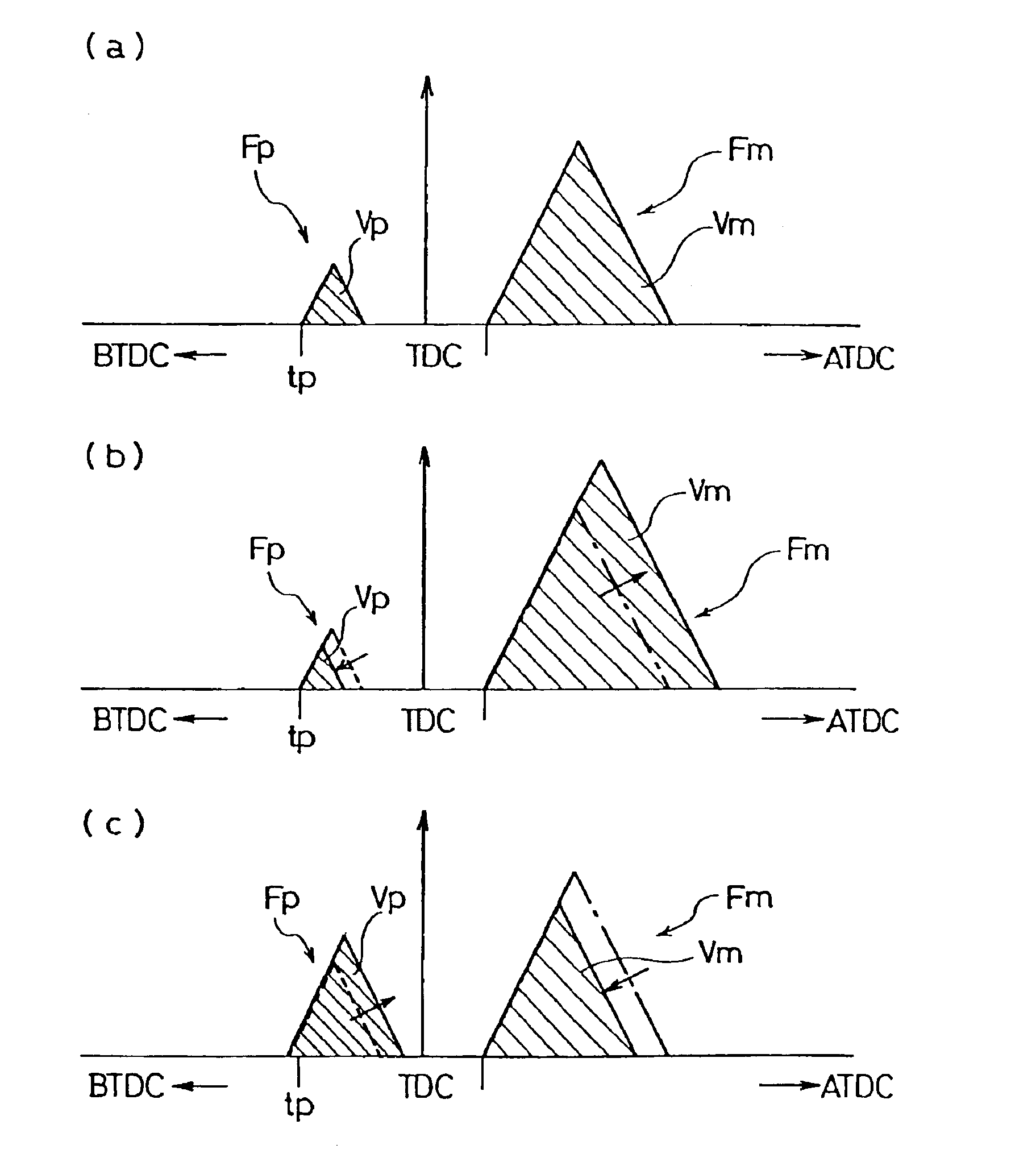

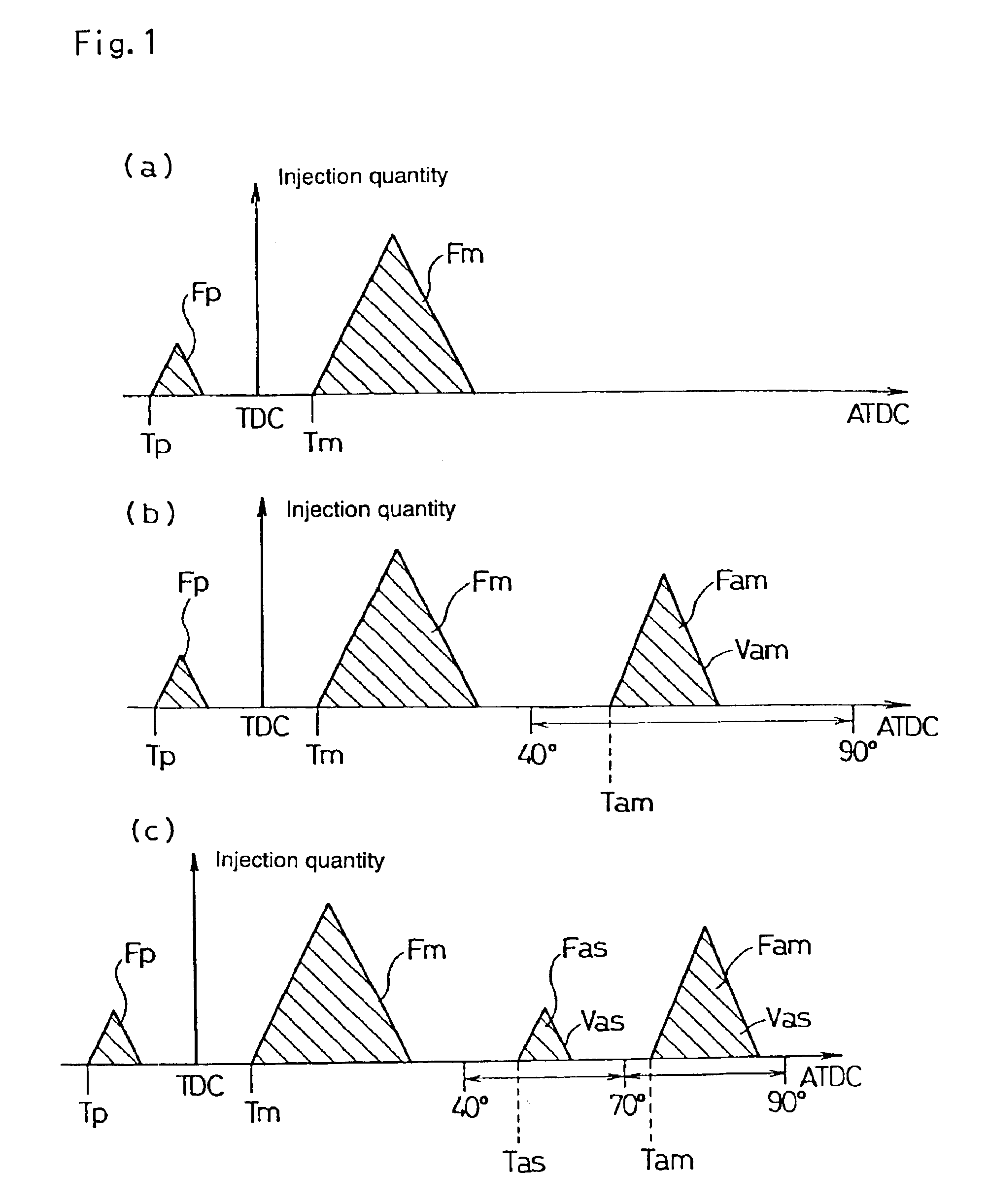

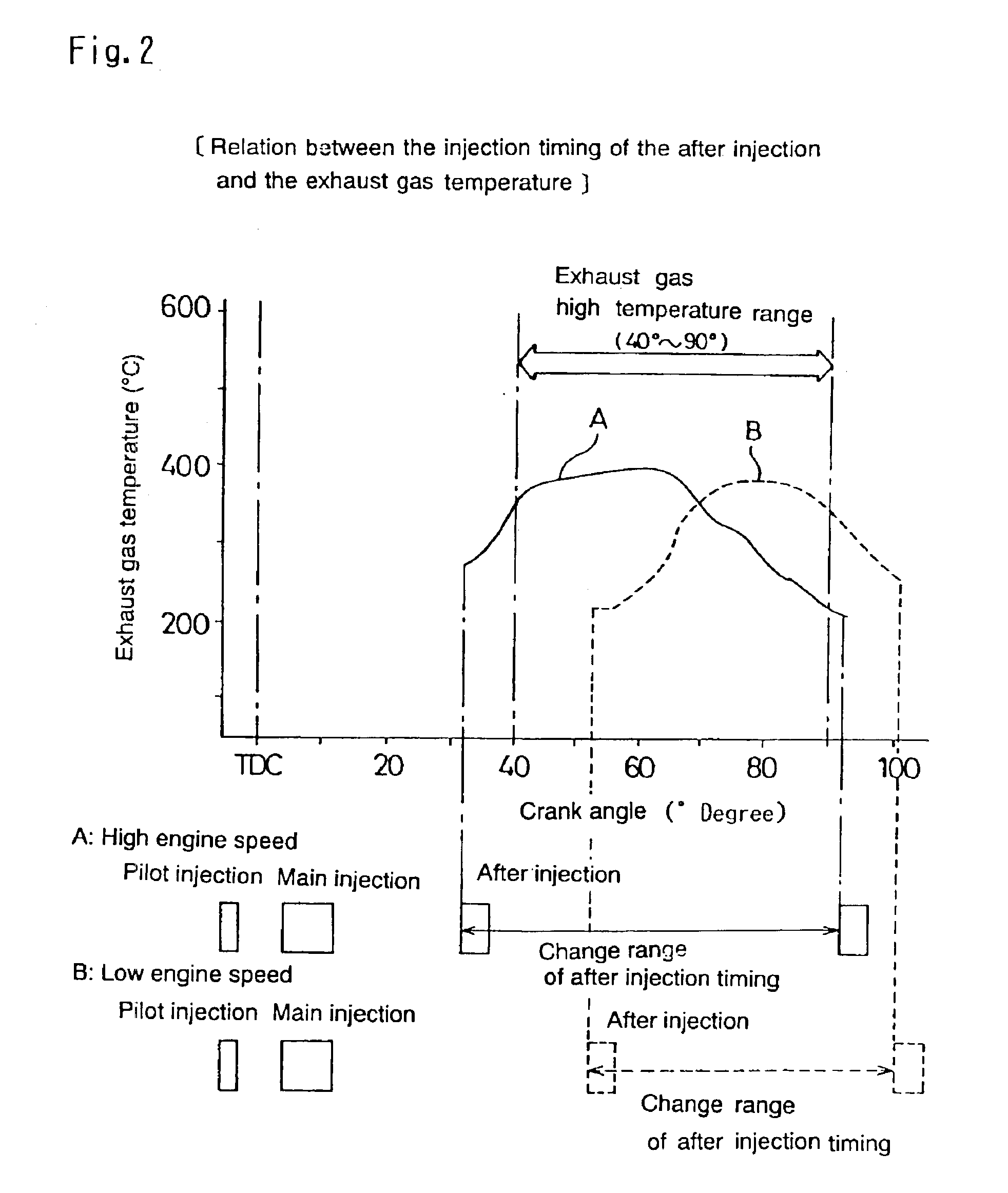

Fuel injection control method for diesel engine and regenerative control method for exhaust gas after treatment device

InactiveUS6901747B2Accumulate moreFilter meltingElectrical controlInternal combustion piston enginesAfter treatmentCombustion

Owner:ISUZU MOTORS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com