Patents

Literature

1505results about "Fatty oils/acids recovery from waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for the manufacture of diesel range hydrocarbons

ActiveUS20070010682A1Fatty oils/acids recovery from wasteHydrocarbon by isomerisationIsomerizationReaction temperature

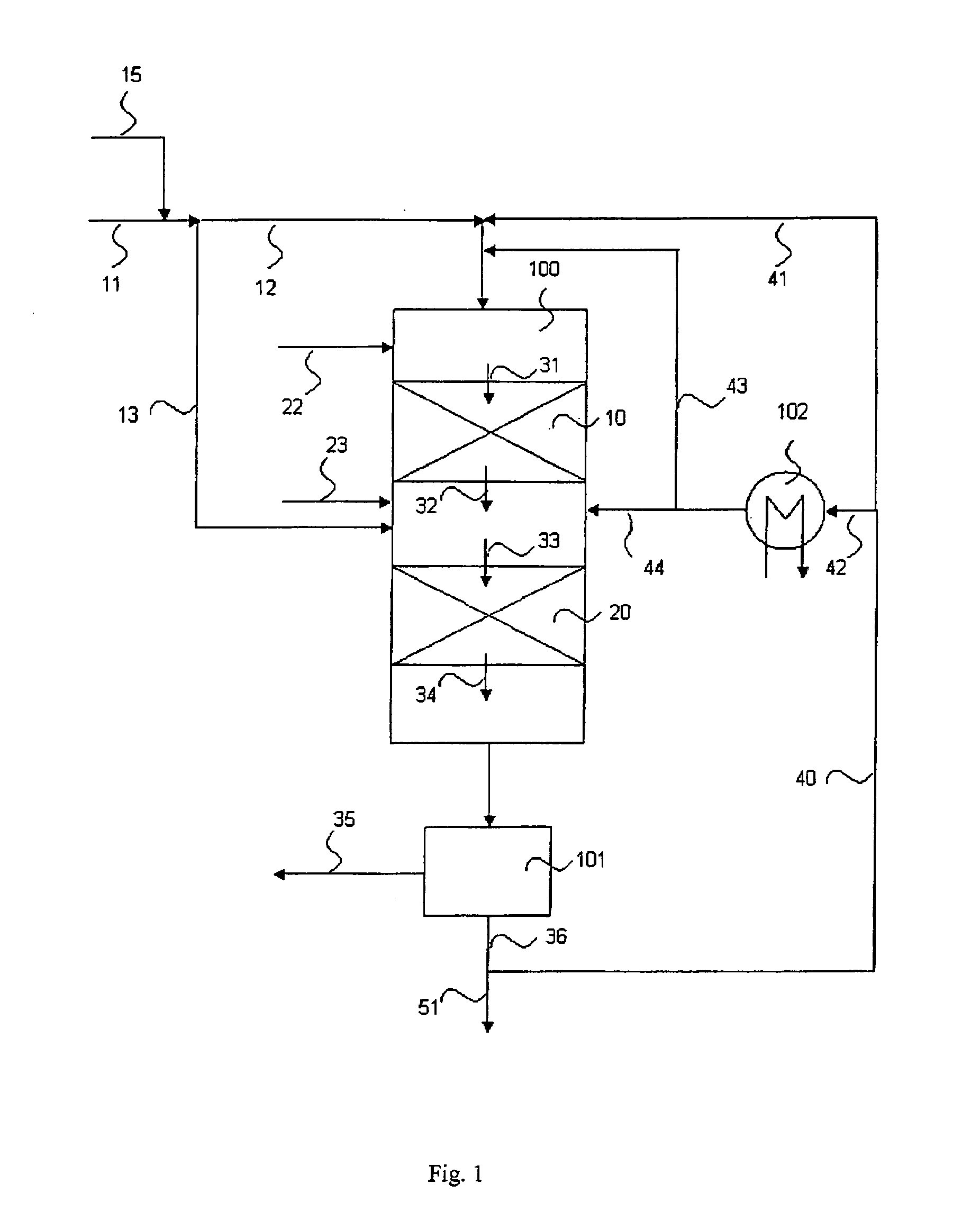

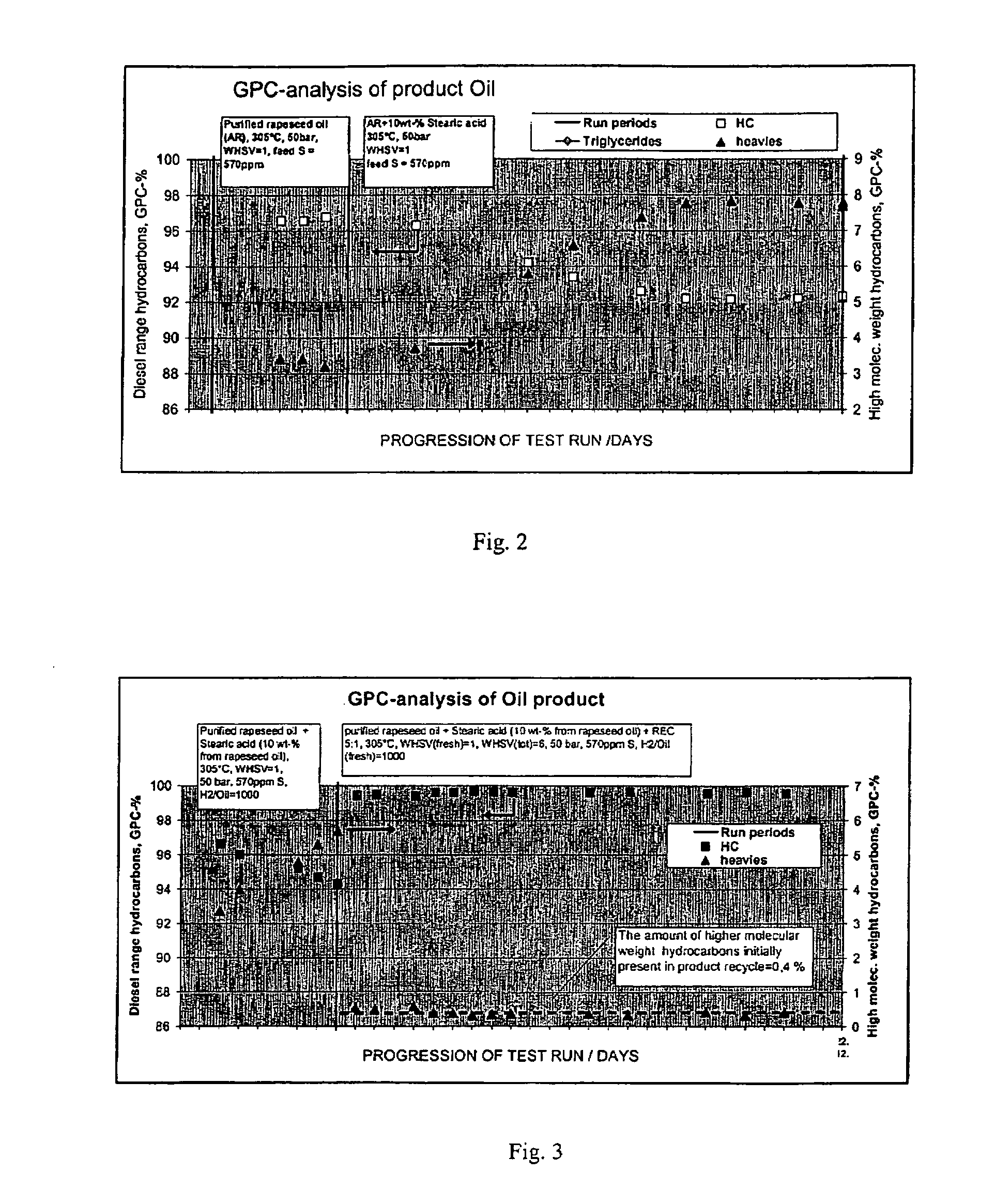

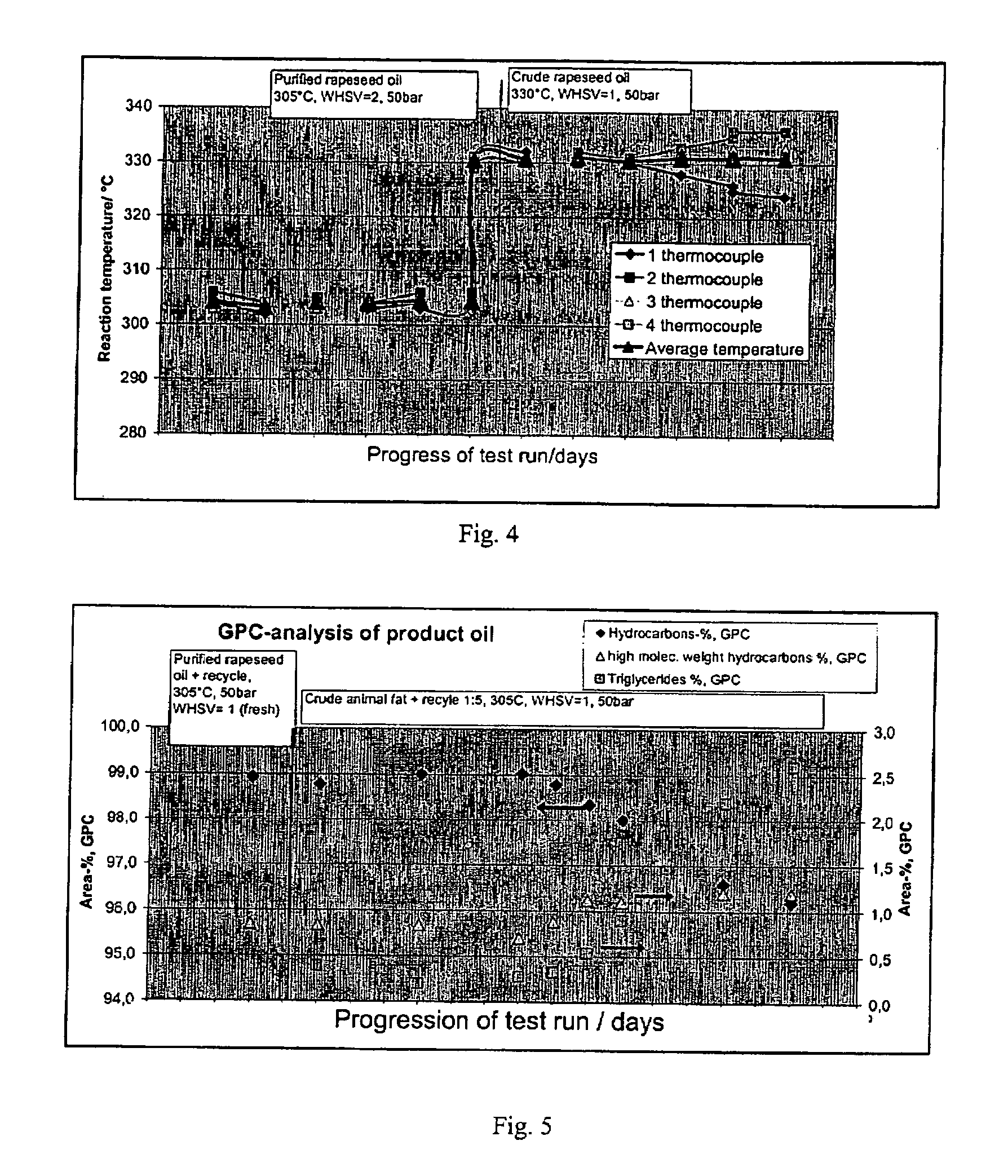

The invention relates to a process for the manufacture of diesel range hydrocarbons wherein a feed is hydrotreated in a hydrotreating step and isomerised in an isomerisation step, and a feed comprising fresh feed containing more than 5 wt % of free fatty acids and at least one diluting agent is hydrotreated at a reaction temperature of 200-400° C., in a hydrotreating reactor in the presence of catalyst, and the ratio of the diluting agent / fresh feed is 5-30:1.

Owner:NESTE OIL OY

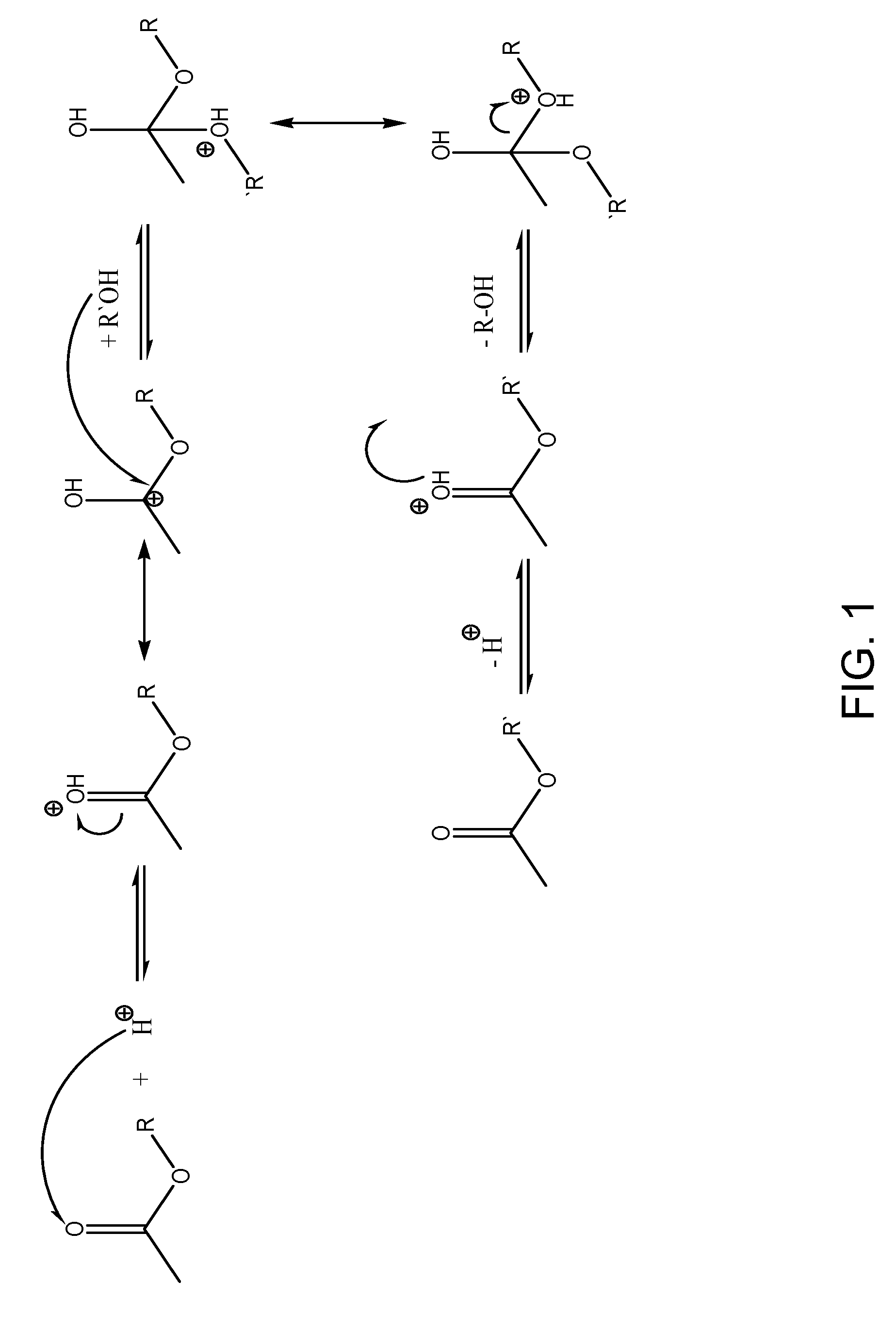

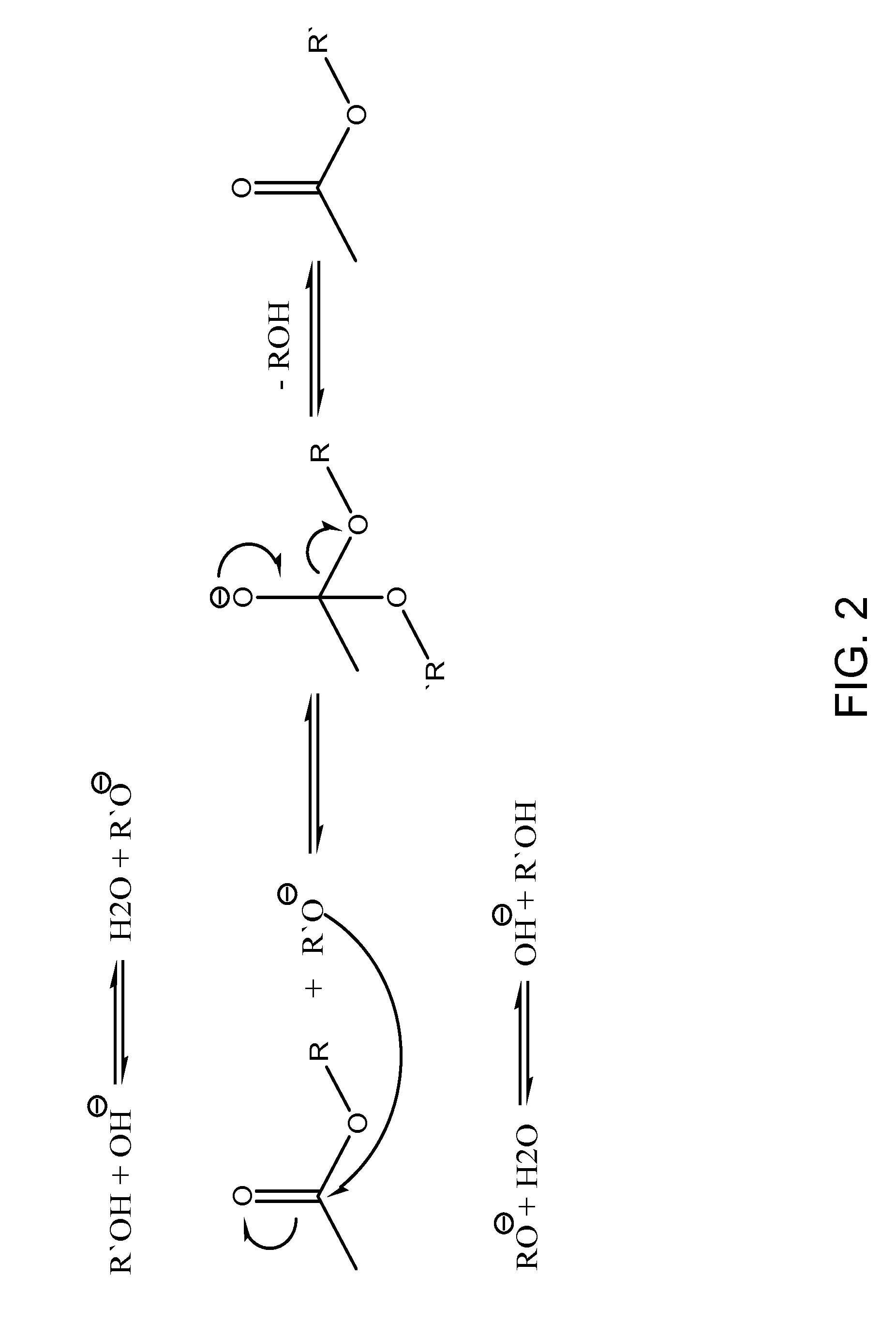

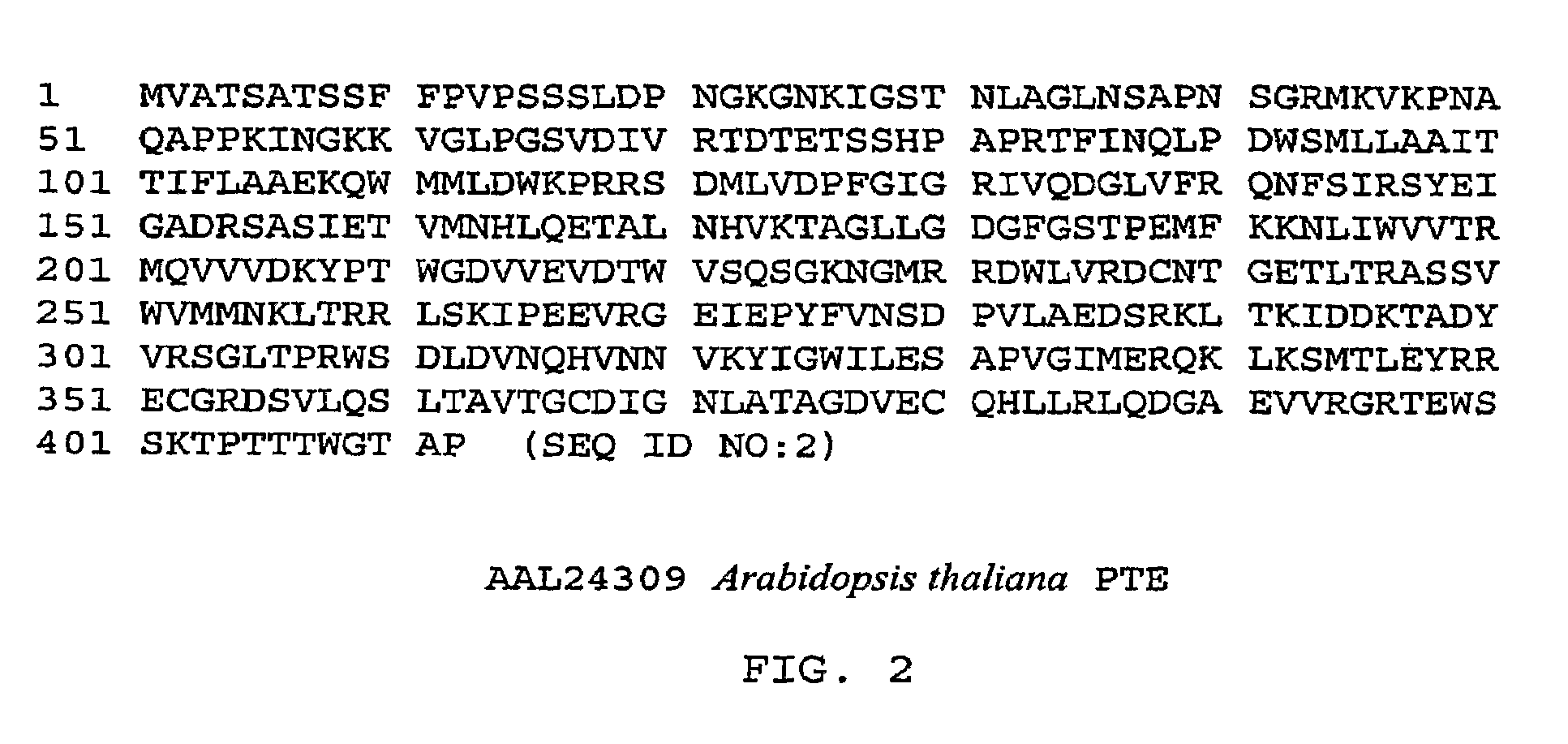

Methods and compositions for extraction and transesterification of biomass components

InactiveUS20090234146A1Fatty oils/acids recovery from wasteFatty acid esterificationTransesterificationBiofuel

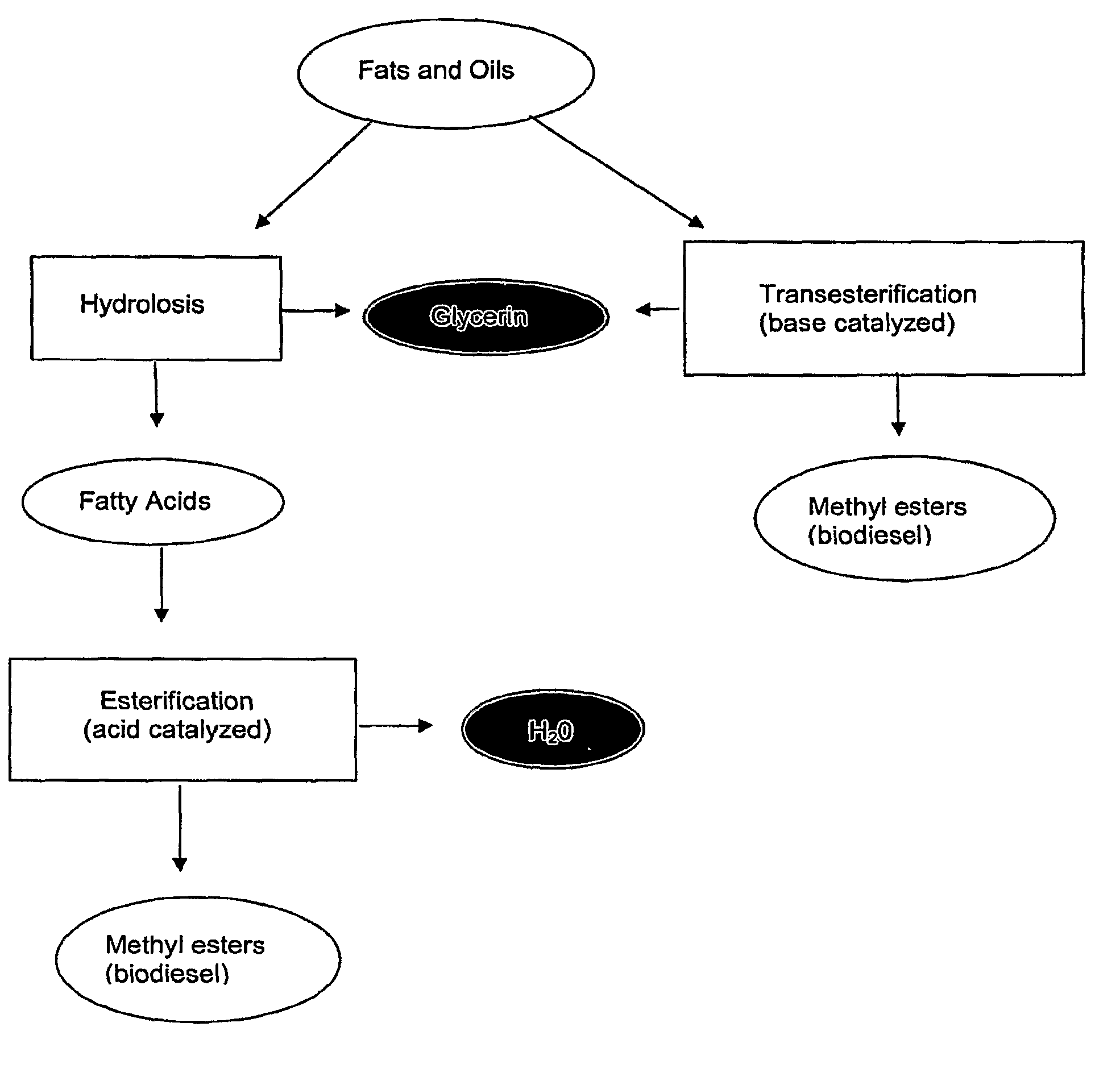

Methods and compositions are disclosed for the direct transesterification and extraction of bio-lipids and bio-oils in the production of biofuel, particularly fatty acid methyl ester products.

Owner:UNIV OF HAWAII

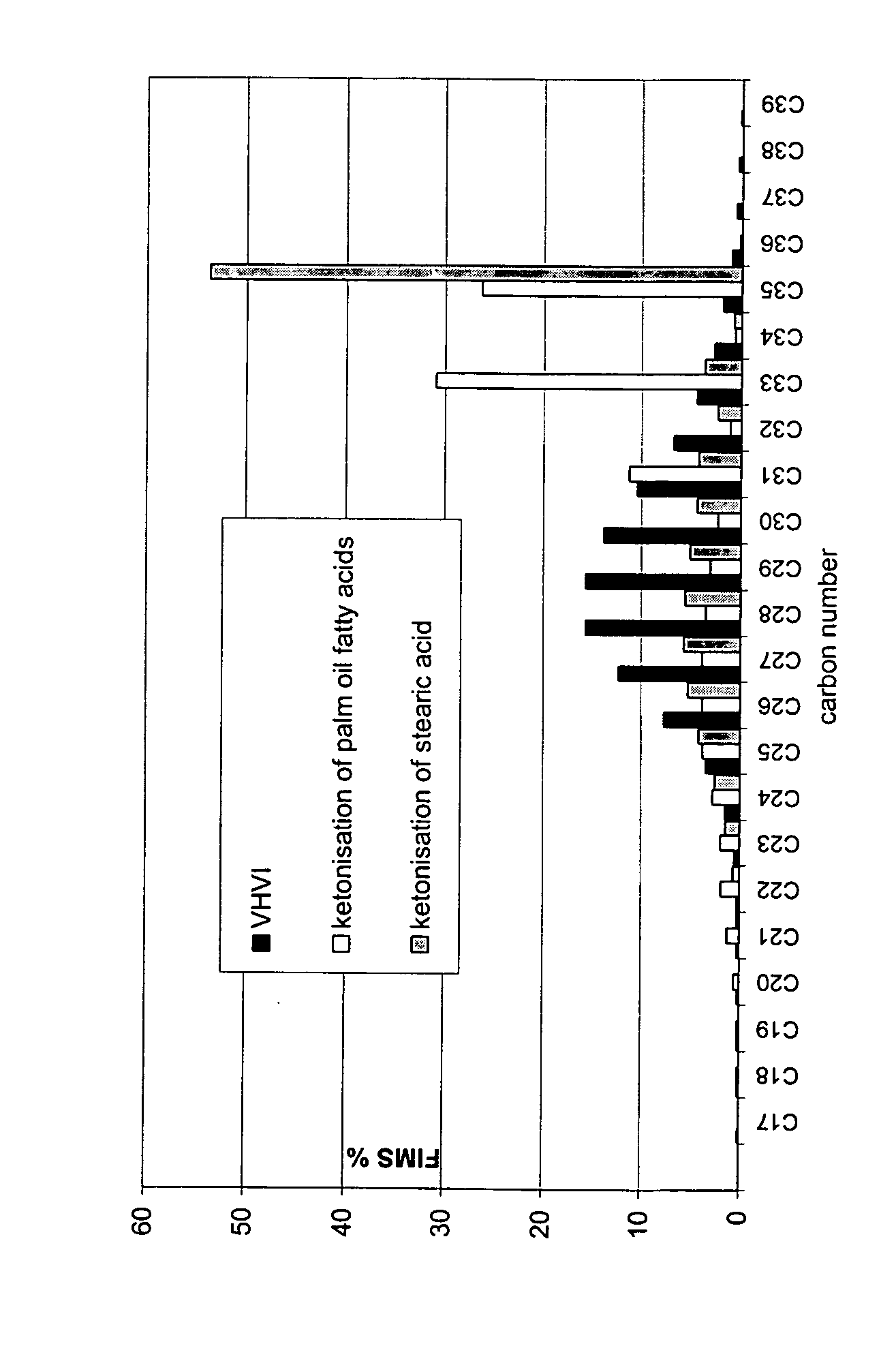

Process for producing a hydrocarbon component

ActiveUS20070161832A1Reduce carbon dioxide emissionsImprove low temperature performanceFatty oils/acids recovery from wasteFatty acid hydrogenationIsomerizationHydrodeoxygenation

The invention relates to a process for producing a new type of high-quality hydrocarbon base oil of biological origin. The process of the invention comprises ketonisation, hydrodeoxygenation, and isomerization steps. Fatty acids and / or fatty acid esters based on a biological raw material are preferably used as the feedstock.

Owner:NESTE OIL OY

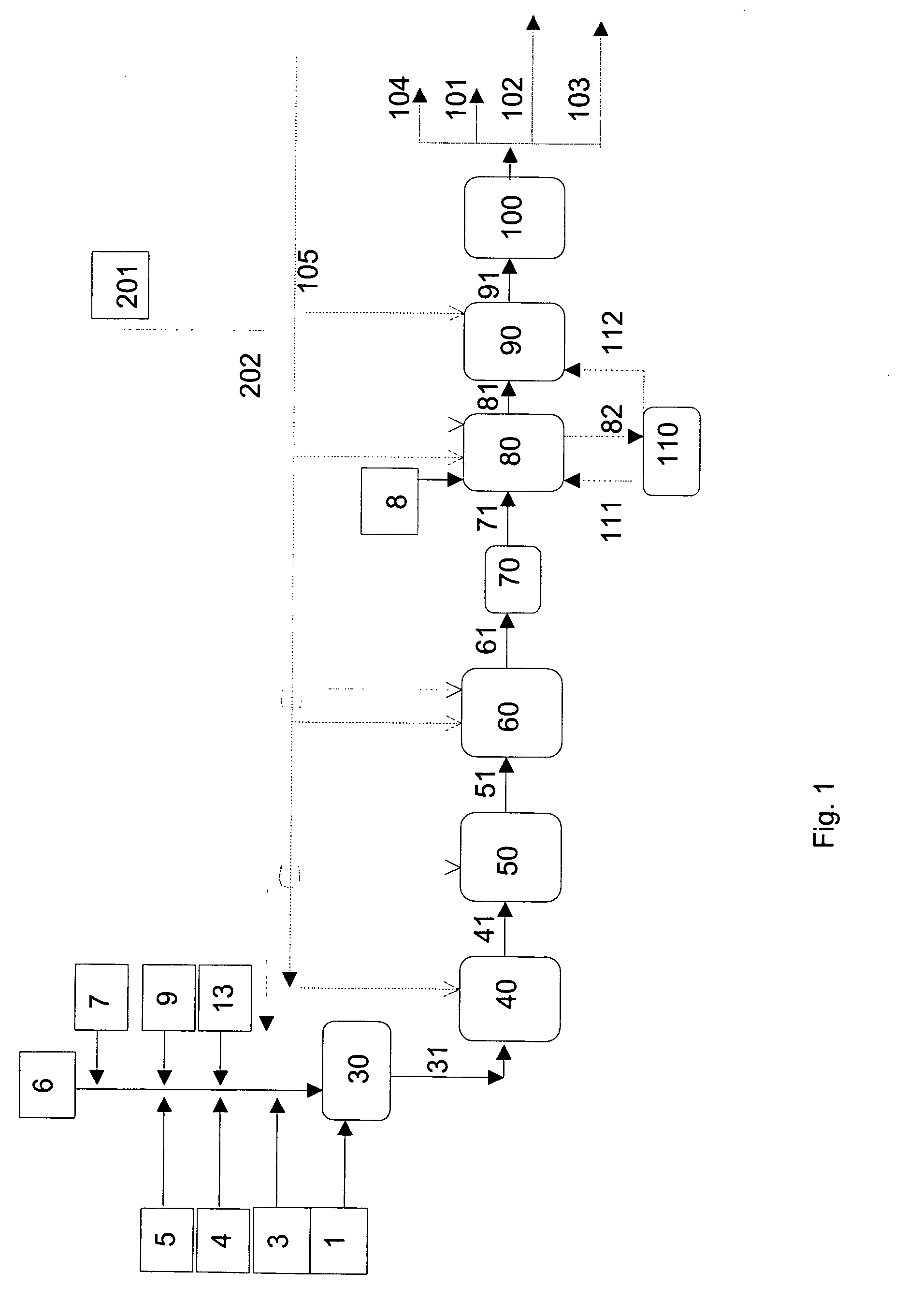

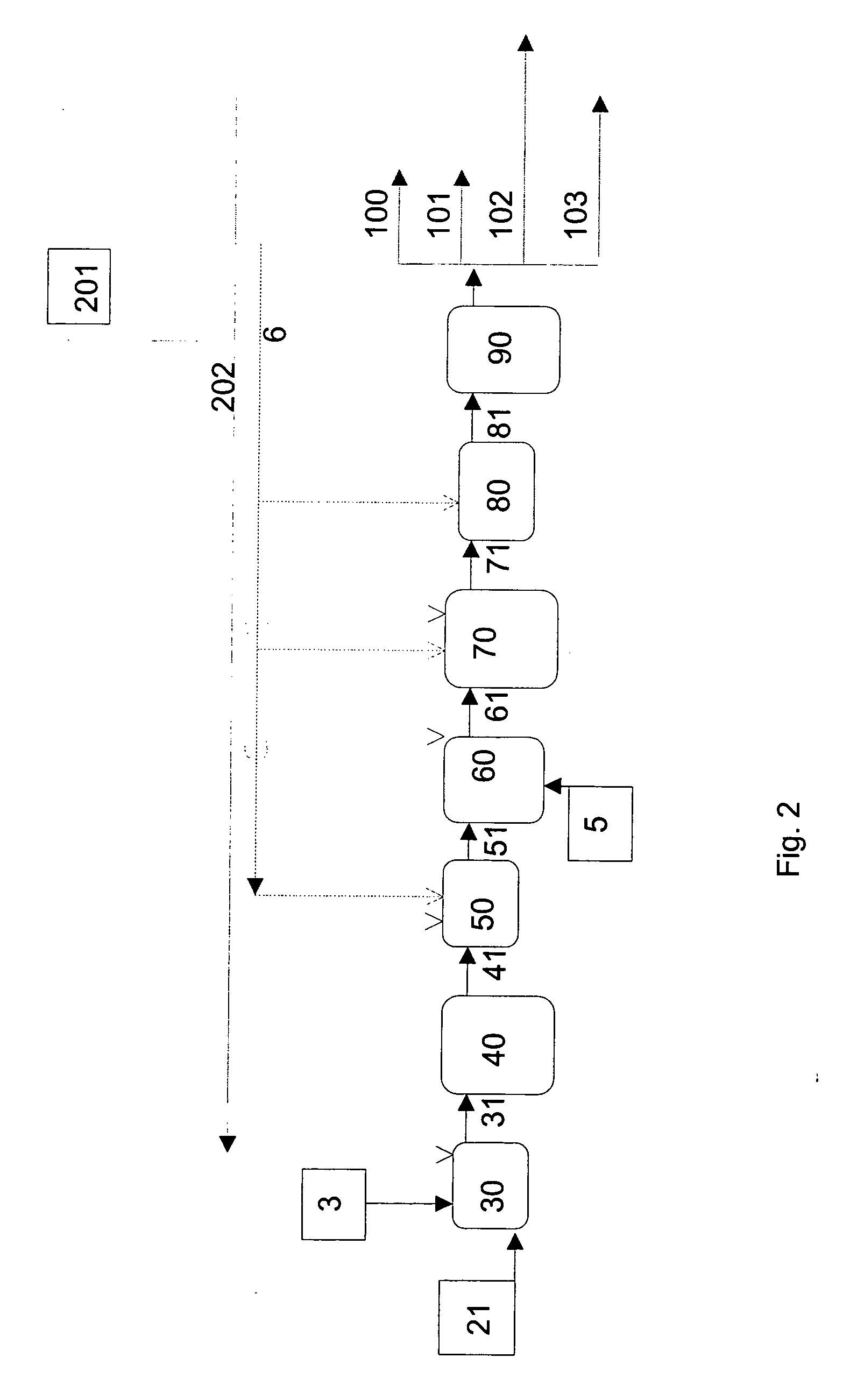

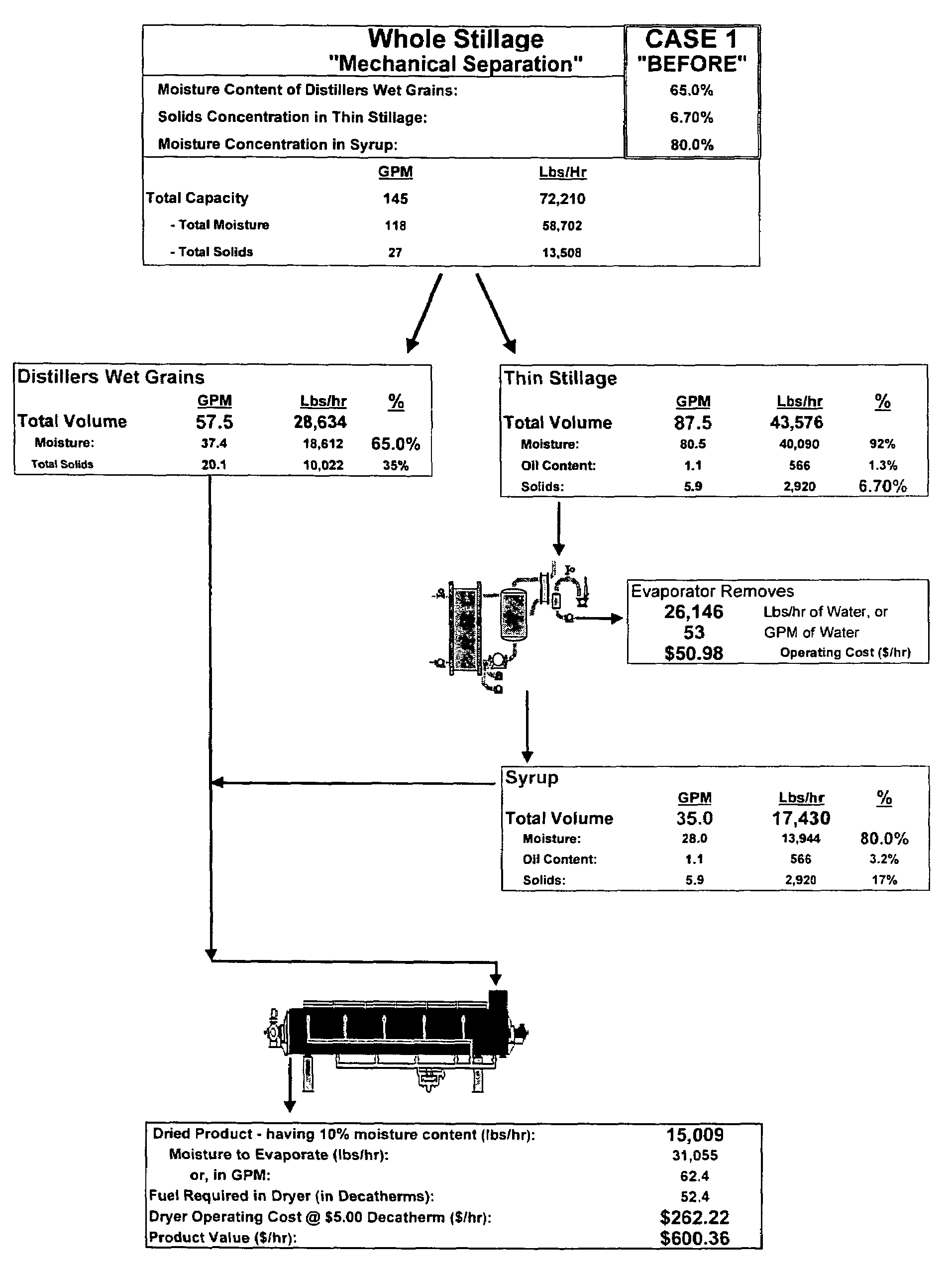

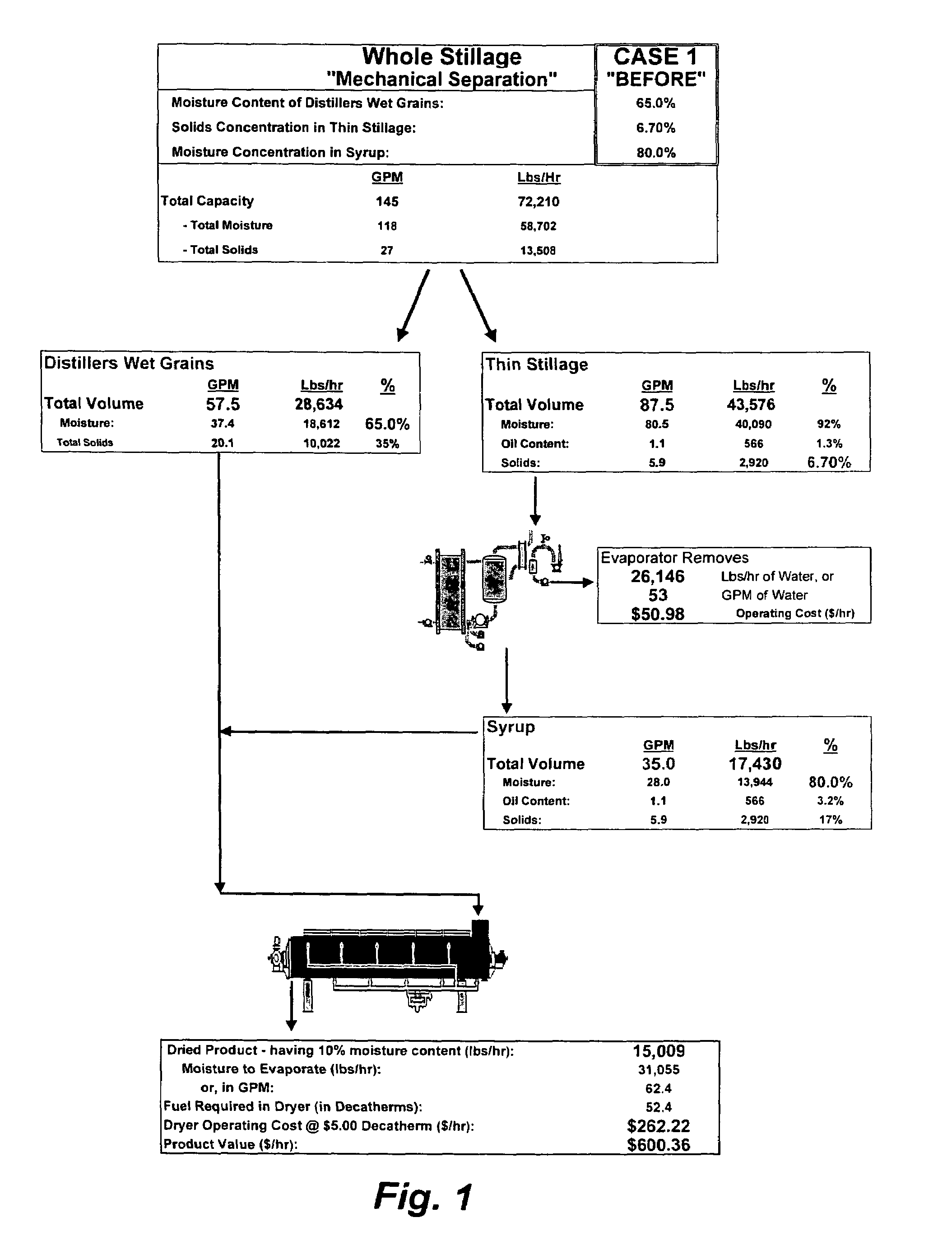

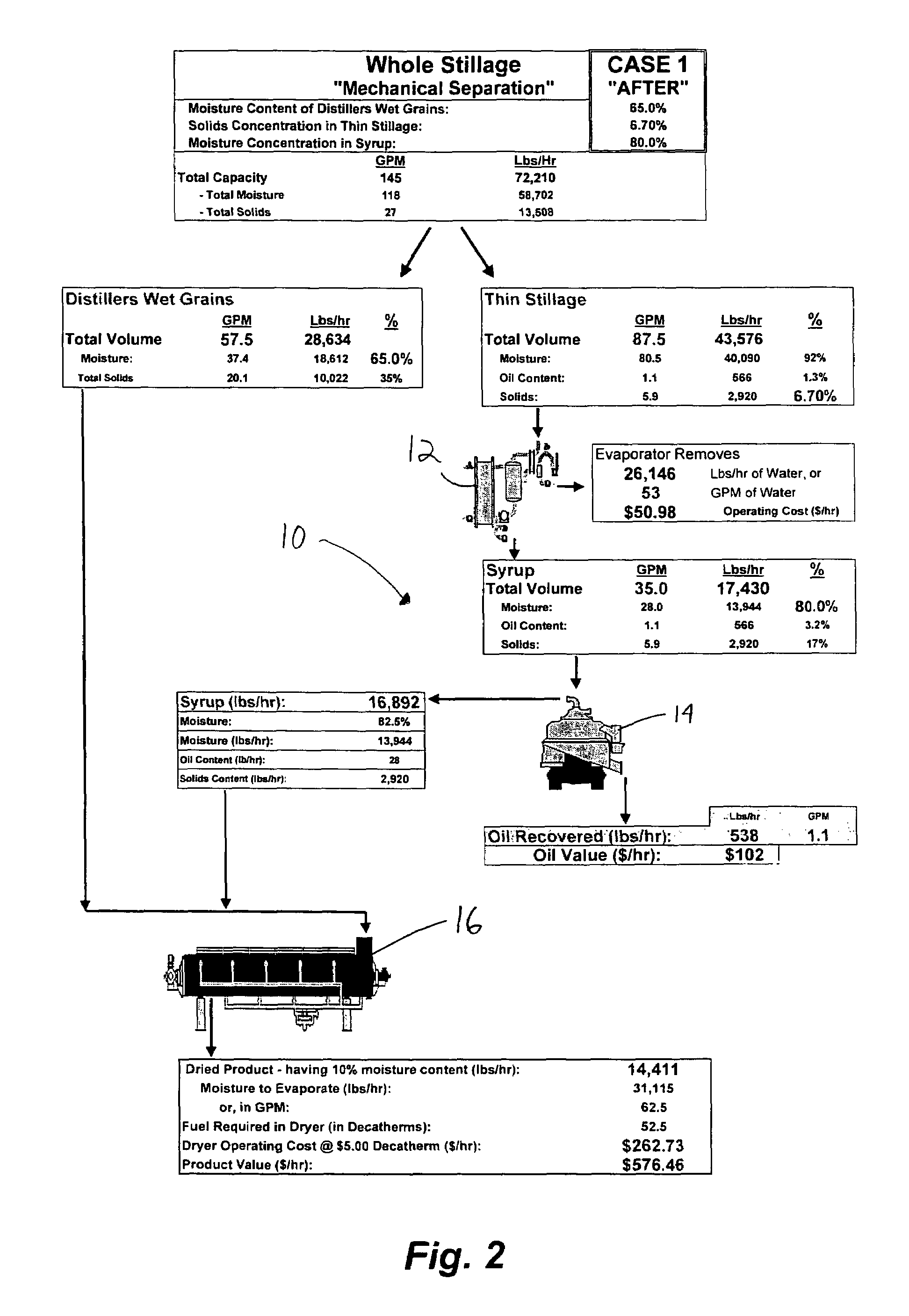

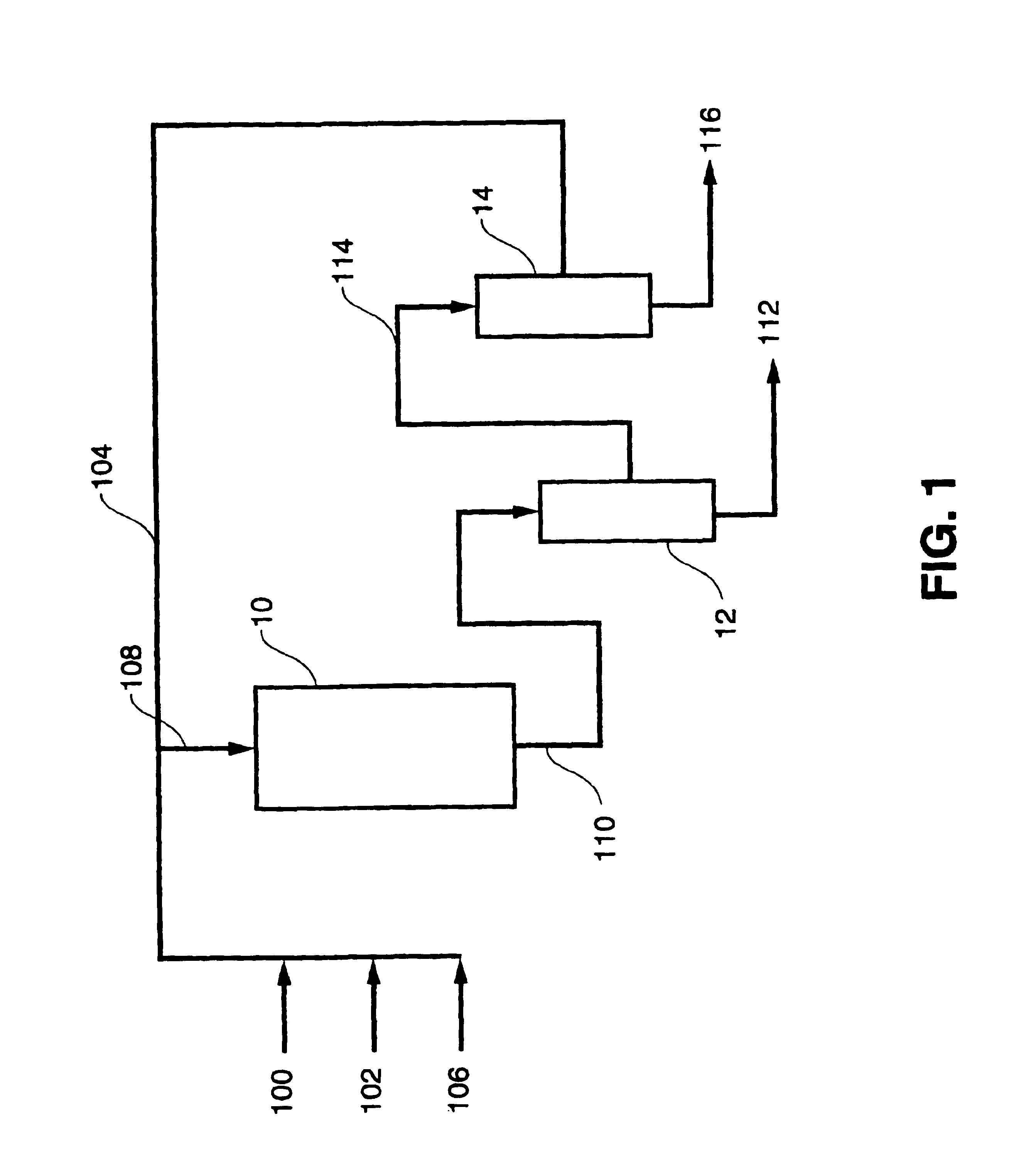

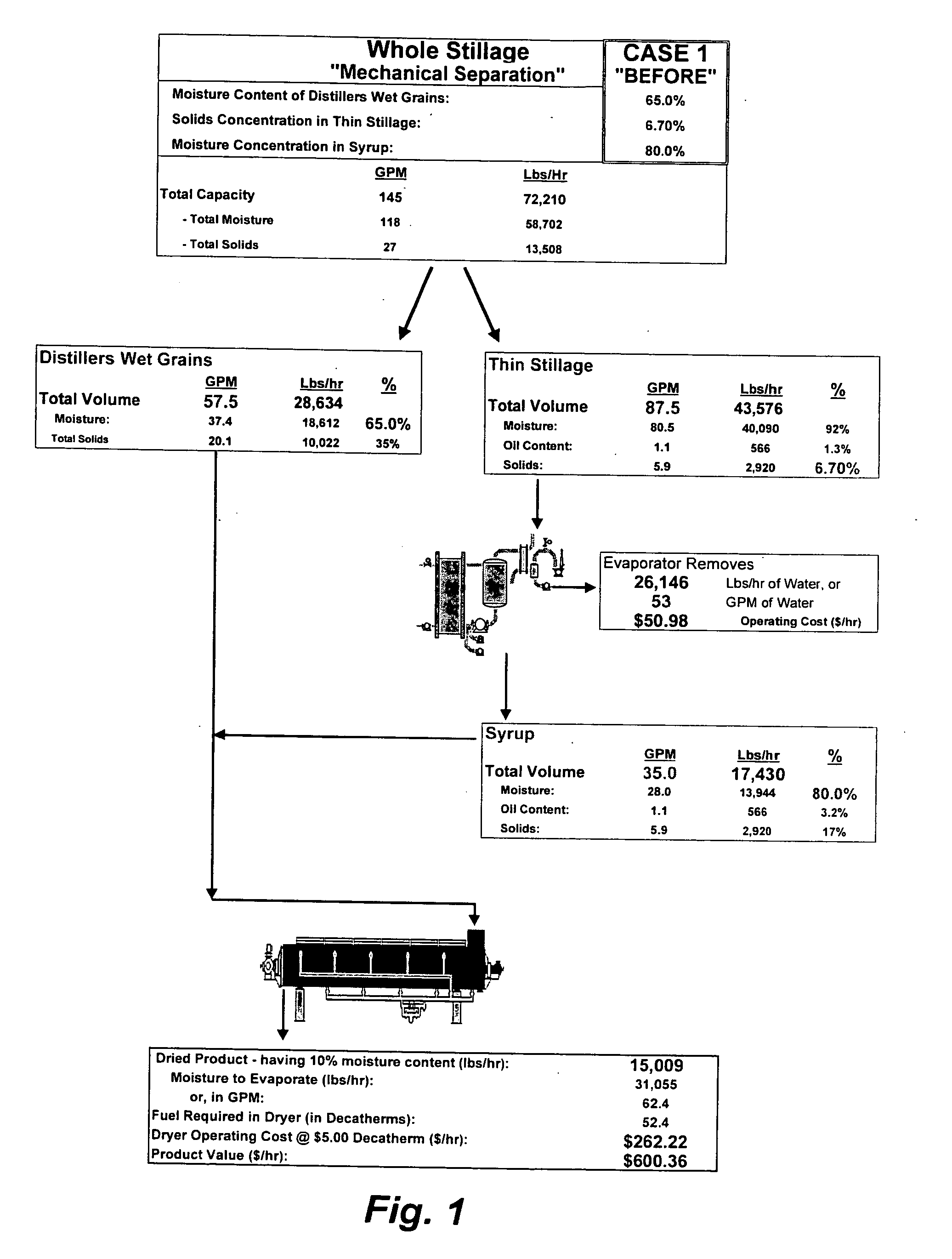

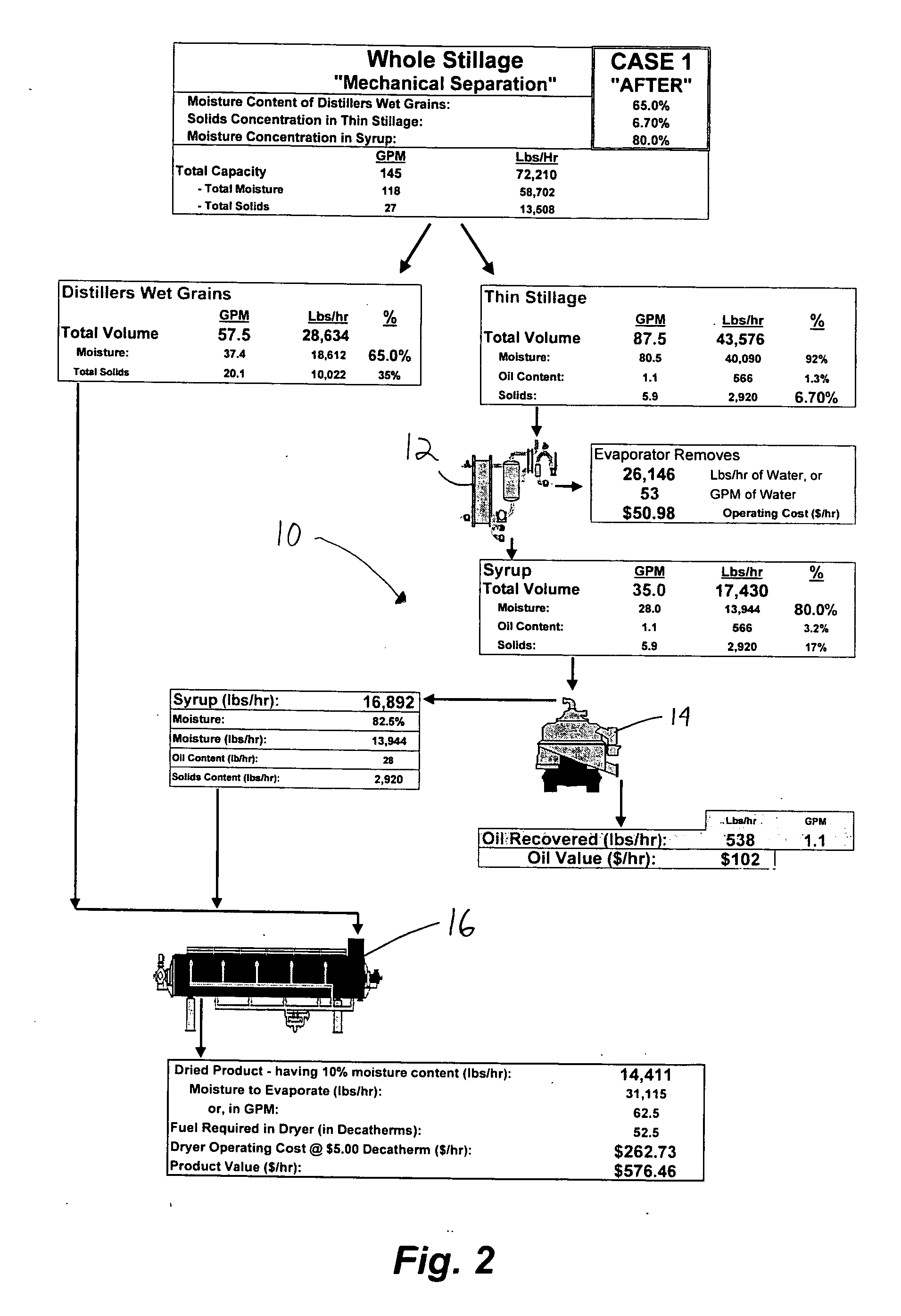

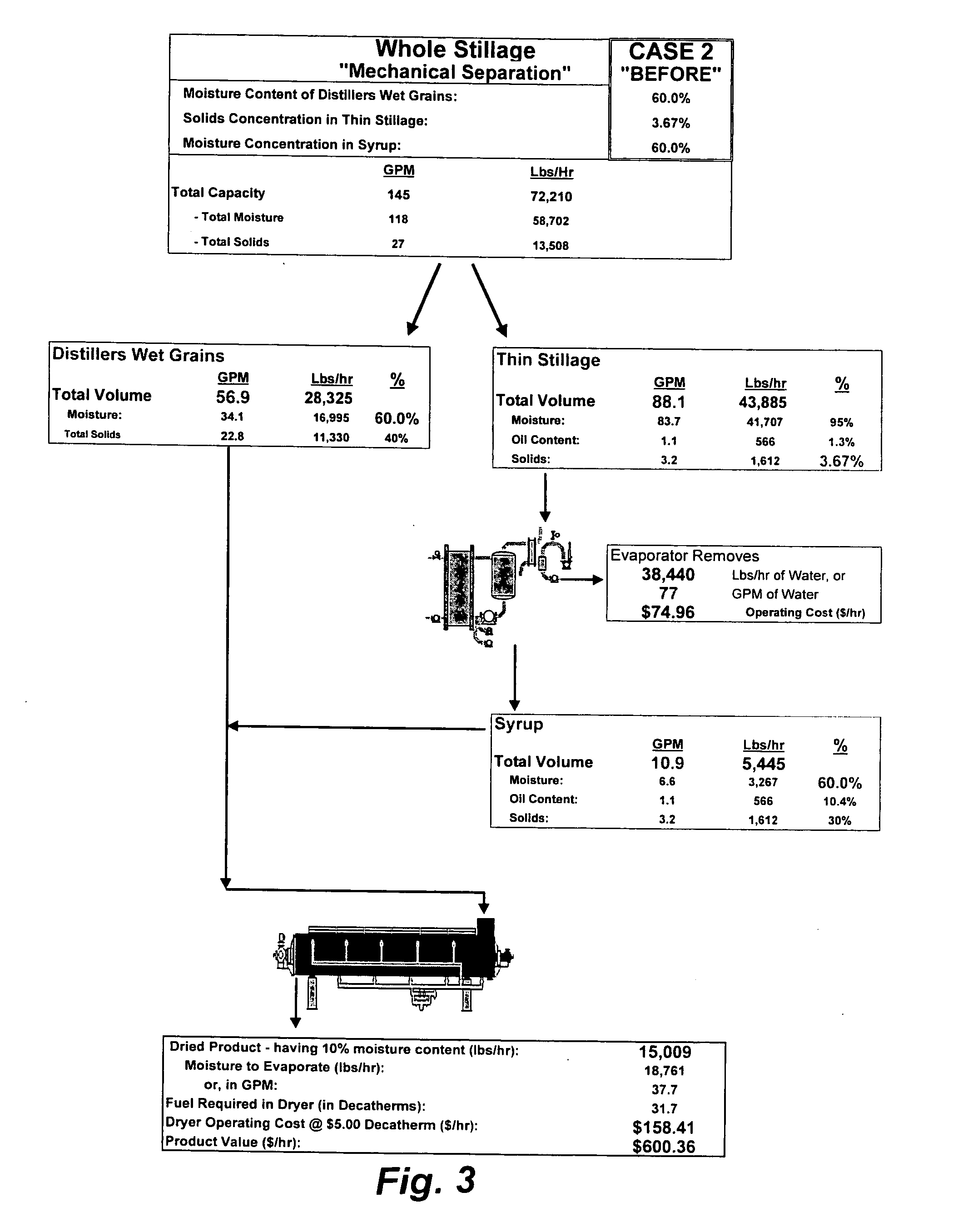

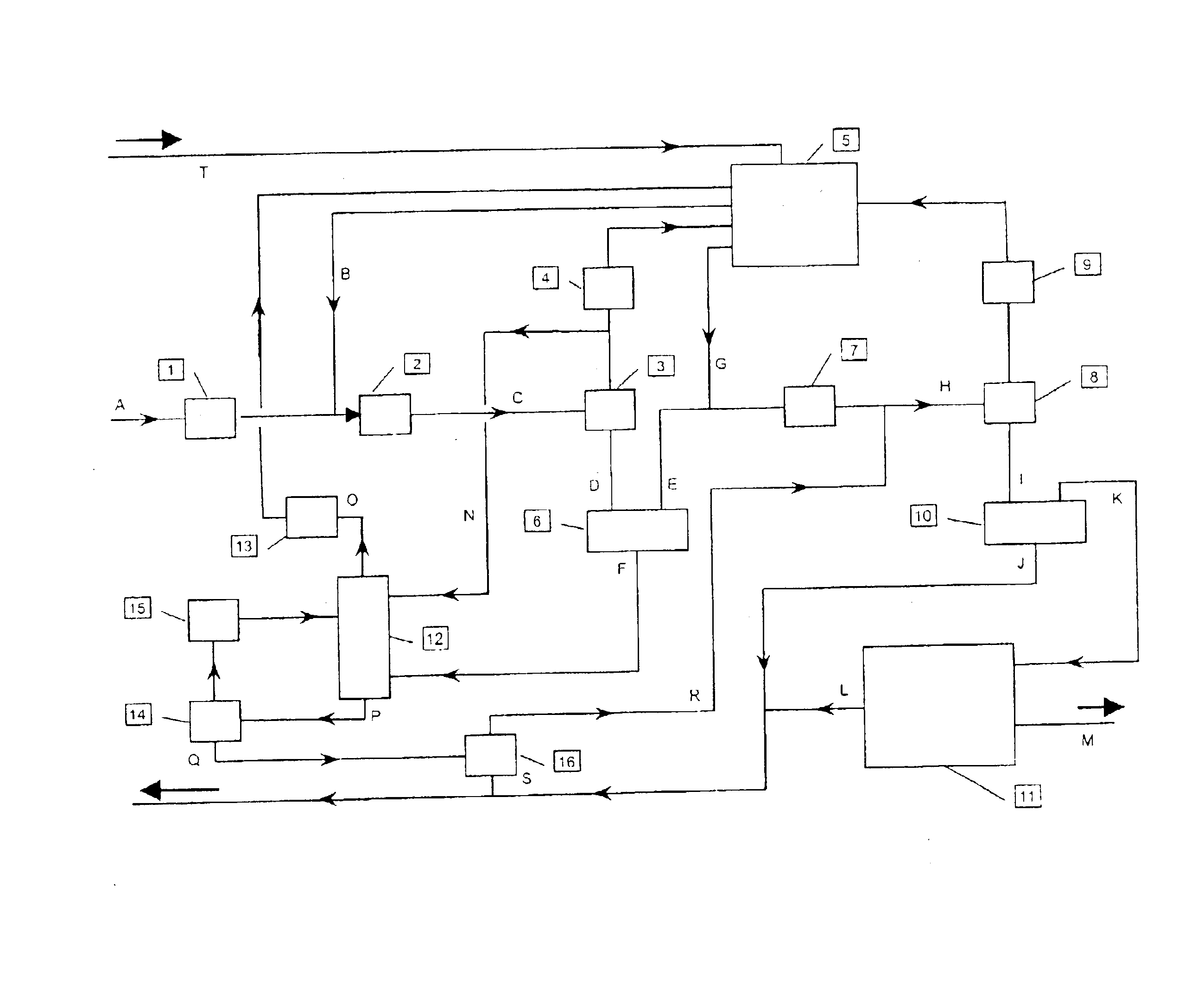

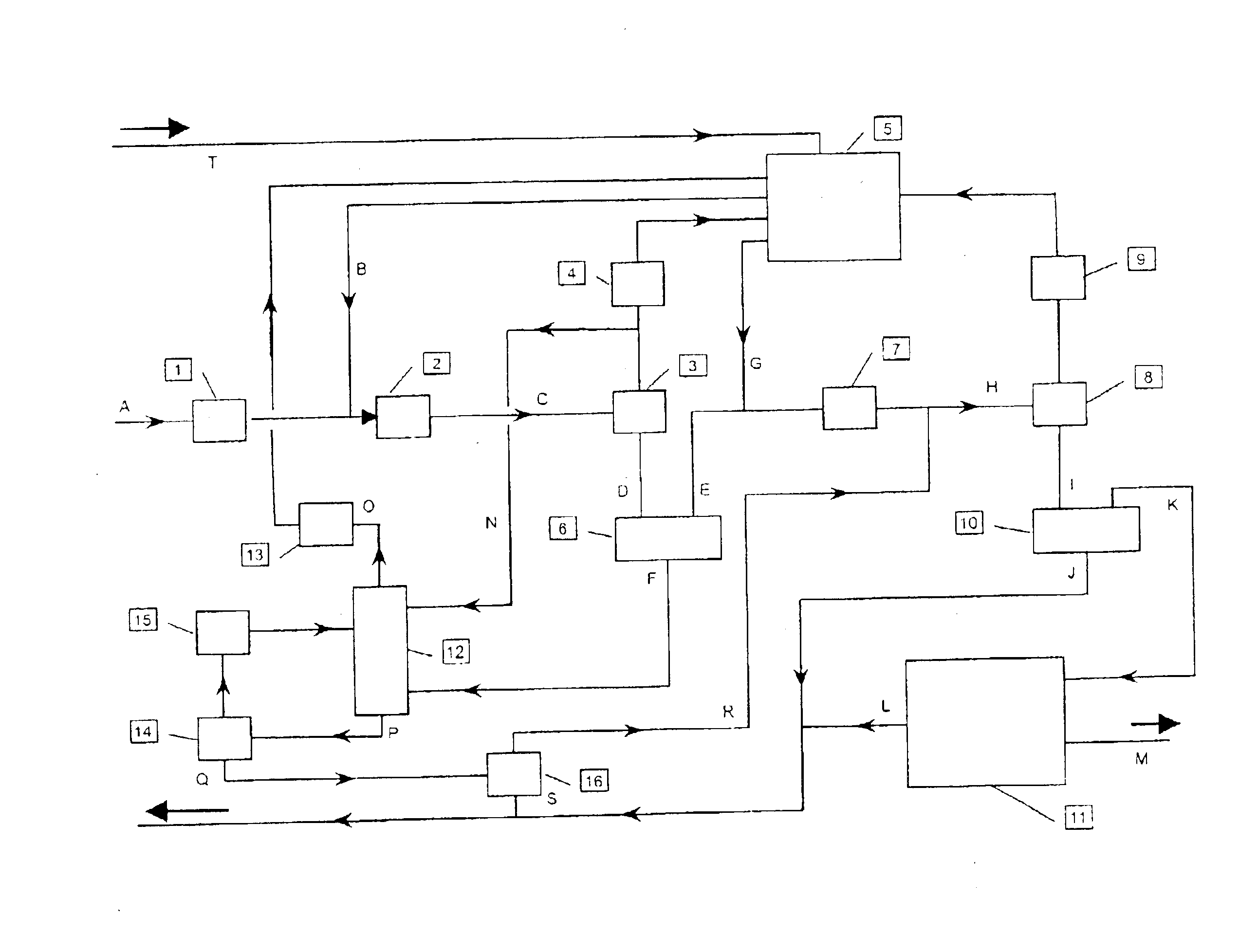

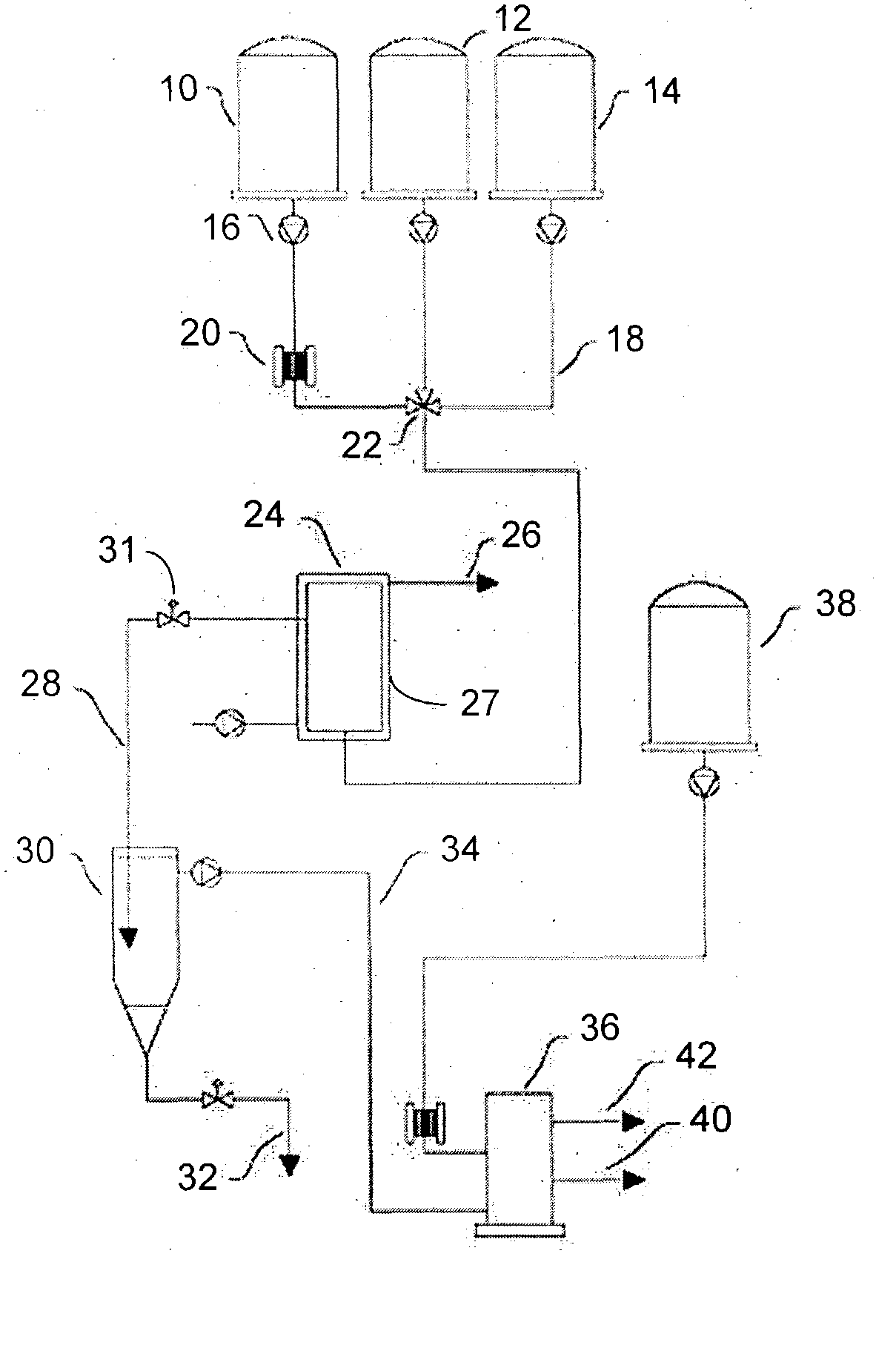

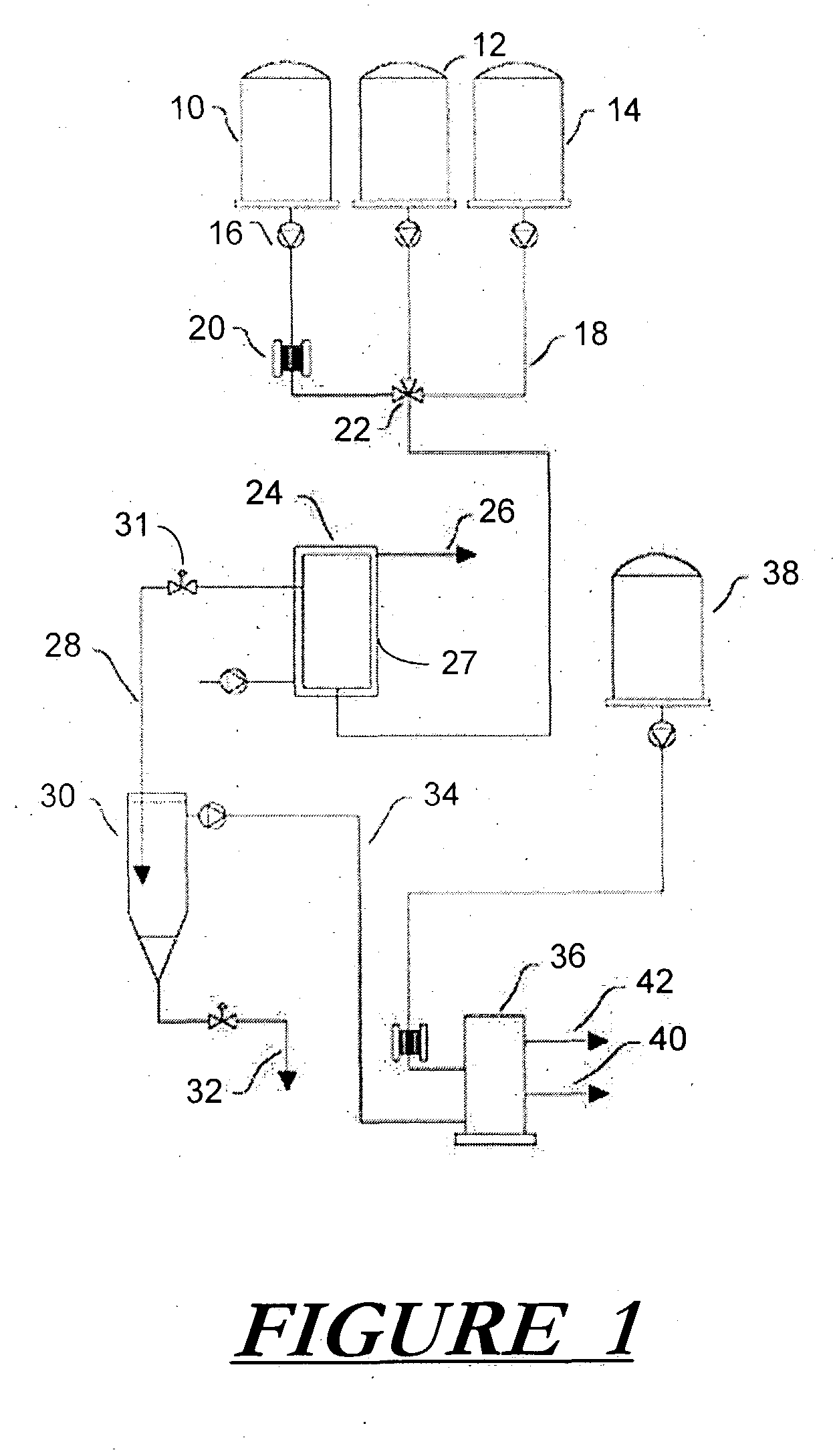

Method of processing ethanol byproducts and related subsystems

In one aspect of the invention, a method recovers oil from a concentrated byproduct, such as evaporated thin stillage formed during a dry milling process used for producing ethanol. The method includes forming a concentrate from the byproduct and recovering oil from the concentrate. The step of forming the concentrate may comprise evaporating the byproduct. Further, the step of separating the oil from the concentrate may comprise using a centrifuge and, in particular, a disk stack centrifuge. Other aspects of the invention include related methods and subsystems for recovering oil from thin stillage.

Owner:GS CLEANTECH CORP

Integrate chemical processes for industrial utilization of seed oils

ActiveUS20050154221A1Easy to operateHigh olefin conversionFatty oils/acids recovery from wasteOxygen-containing compound preparationPolyesterAmino esters

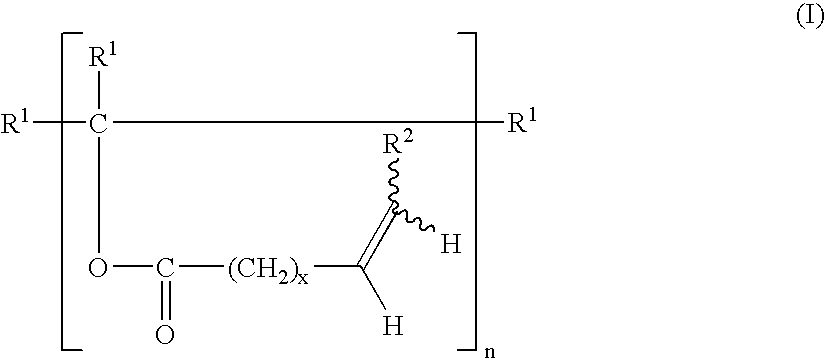

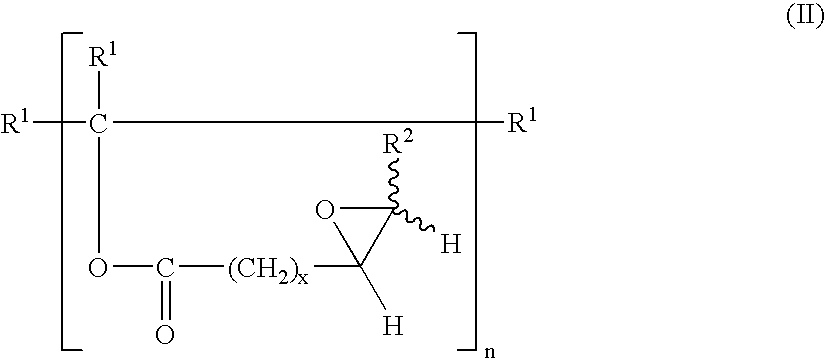

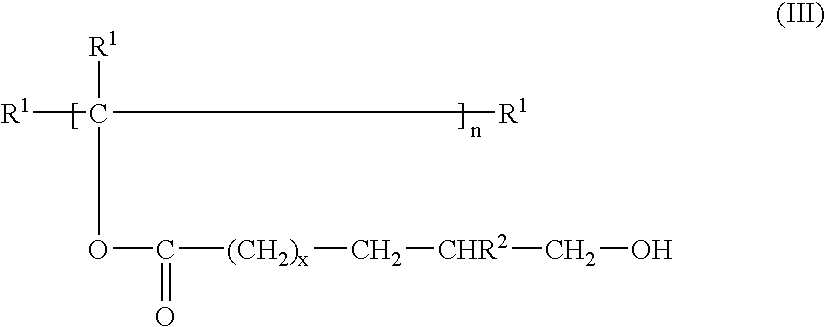

Integrated processes of preparing industrial chemicals starting from seed oil feedstock compositions containing one or more unsaturated fatty acids or unsaturated fatty acid esters, which are essentially free of metathesis catalyst poisons, particularly hydroperoxides; metathesis of the feedstock composition with a lower olefin, such as ethylene, to form a reduced chain olefin, preferably, a reduced chain α-olefin, and a reduced chain unsaturated acid or ester, preferably, a reduced chain α,Ω-unsaturated acid or ester. The reduced chain unsaturated acid or ester may be (trans)esterified to form a polyester polyolefin, which may be epoxidized to form a polyester polyepoxide. The reduced chain unsaturated acid or ester may be hydroformylated with reduction to produce an α,Ω-hydroxy acid or α,Ω-hydroxy ester, which may be (trans)esterified with a polyol to form an α,Ωpolyester polyol. Alternatively, the reduced chain unsaturated acid or ester may be hydroformylated with reductive amination to produce an α,Ω-amino acid or α,Ω-amino ester, which may be (trans)esterified to form an α,Ωpolyester polyamine.

Owner:DOW GLOBAL TECH LLC

Method for preparing pure EPA and pure DHA

InactiveUS6846942B2Easy to disassembleSimple procedureFatty oils/acids recovery from wasteFatty acids production/refiningSolubilitySolvent

Pure DHA and pure EPA can be obtained from a mixture of EPA and DHA in a solution by forming salts of DHA and EPA which have different solubilities in the solvent, cooling the solution until the salt of EPA is formed, filtering the solution to recover the salt of EPA, and acidifying the EPA salt and the DHA salt to obtain pure EPA and pure DHA.

Owner:RUBIN DAVID

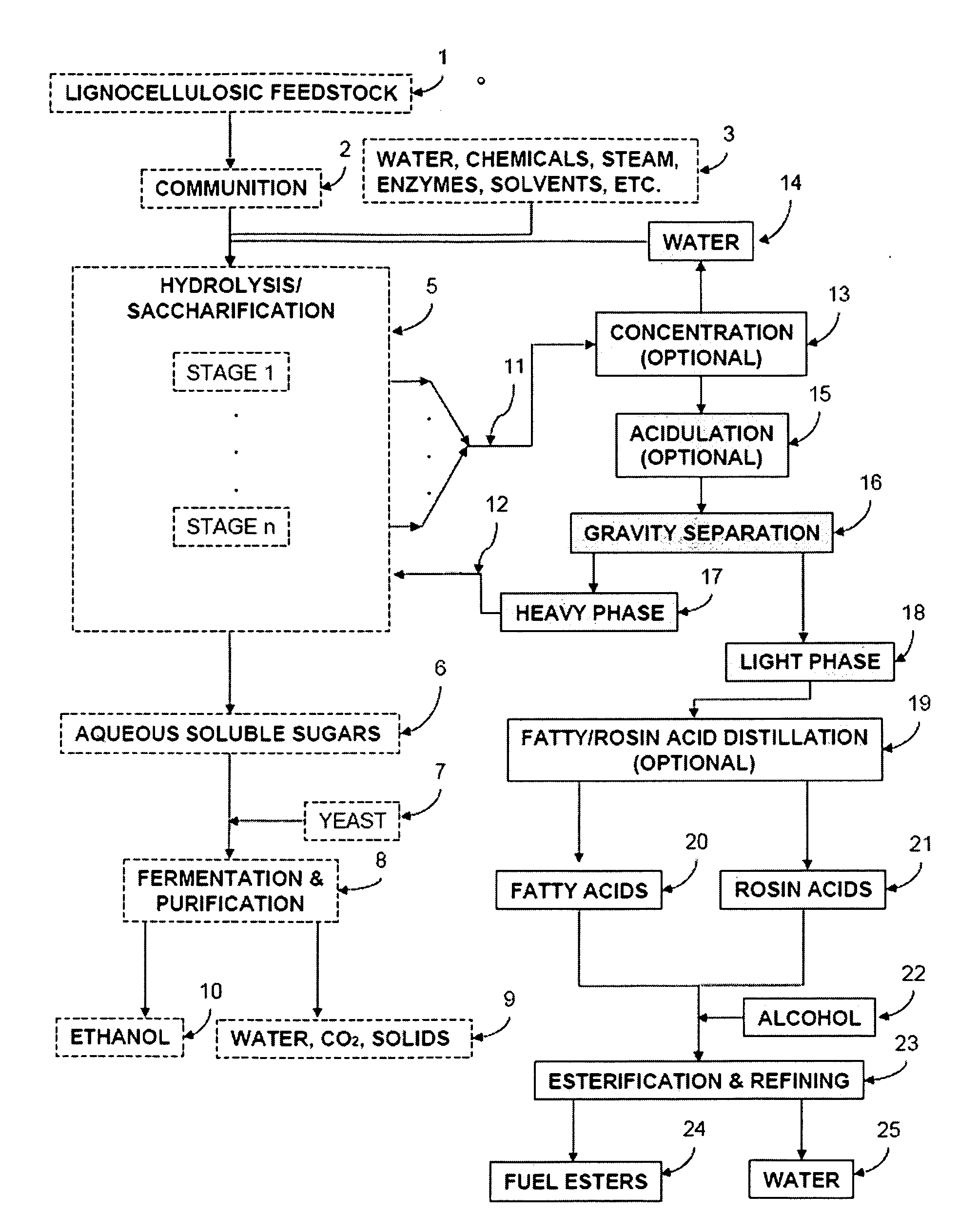

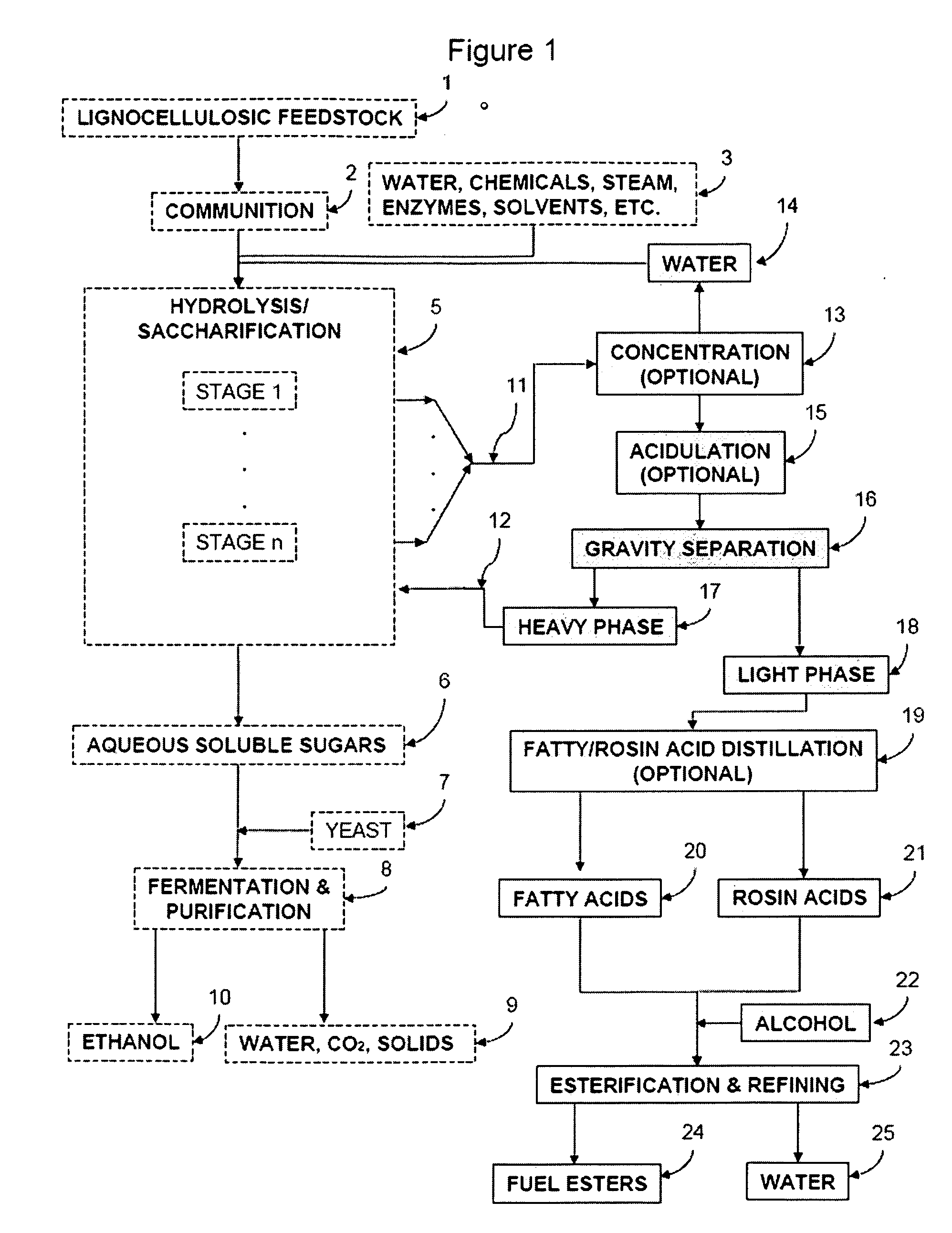

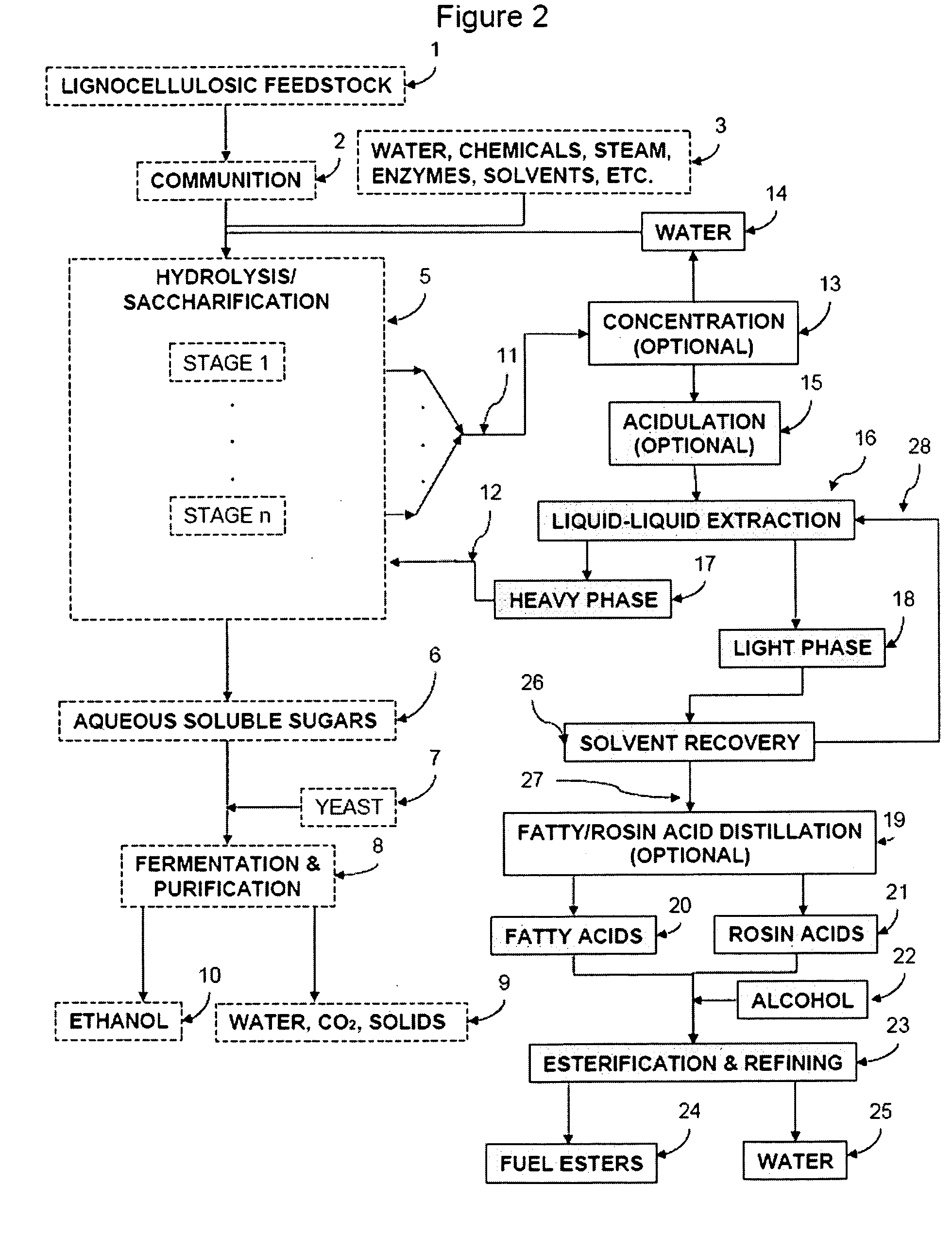

Production of Ester-based Fuels Such As Biodiesel From Renewable Starting Materials

ActiveUS20090056201A1Fatty oils/acids recovery from wasteFatty acid esterificationCelluloseBiodiesel

Production of ester-based fuels such as biodiesel or jet fuel from renewable starting materials such as lignocellulosic material or algae is disclosed. Pulping and saccharification of the renewable starting materials produces carboxylic acids such as fatty acids or rosin acids, which are esterified via a gas sparged, slurry form of heterogeneous reactive distillation to yield ester-based fuels.

Owner:ENDICOTT BIOFUELS II

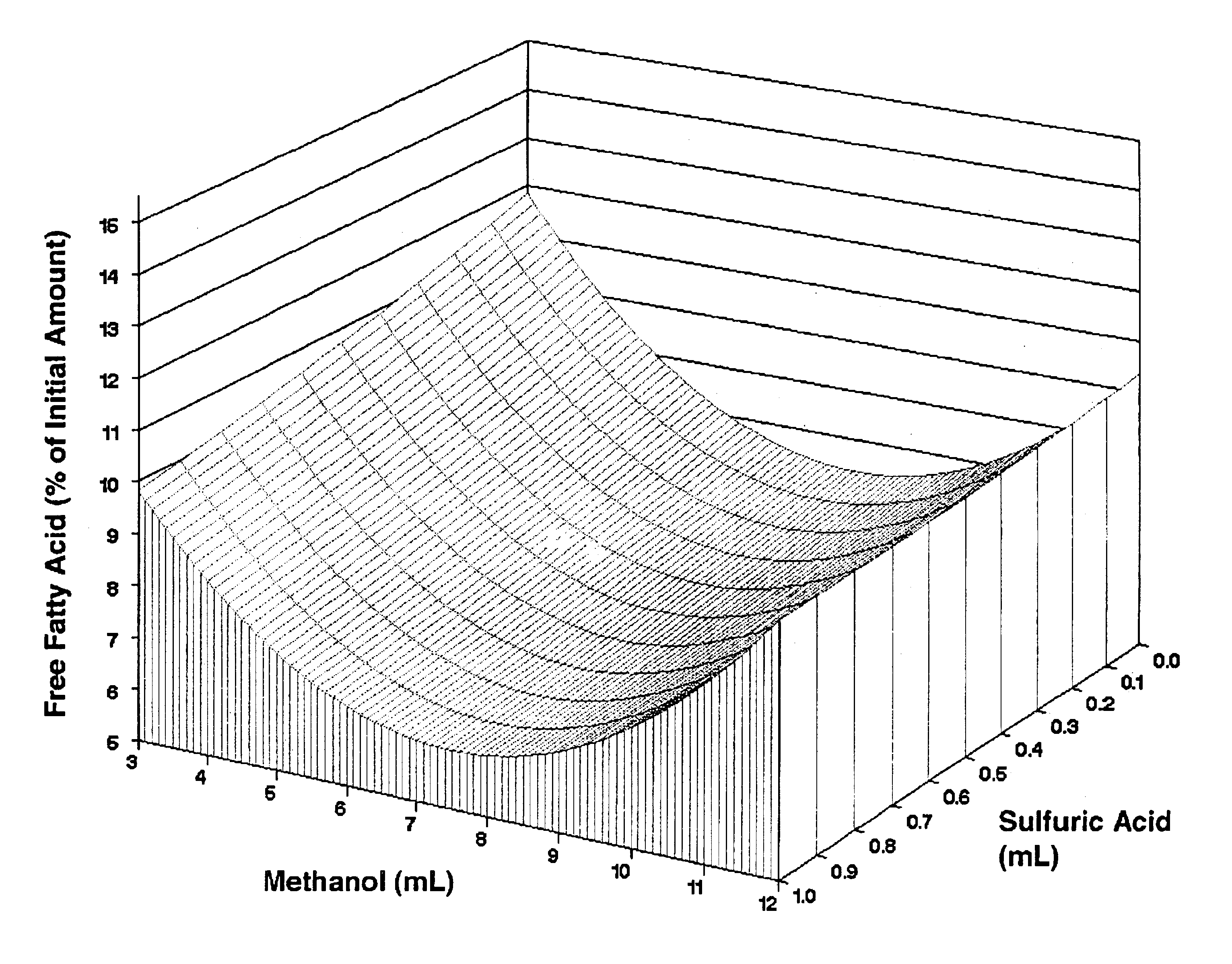

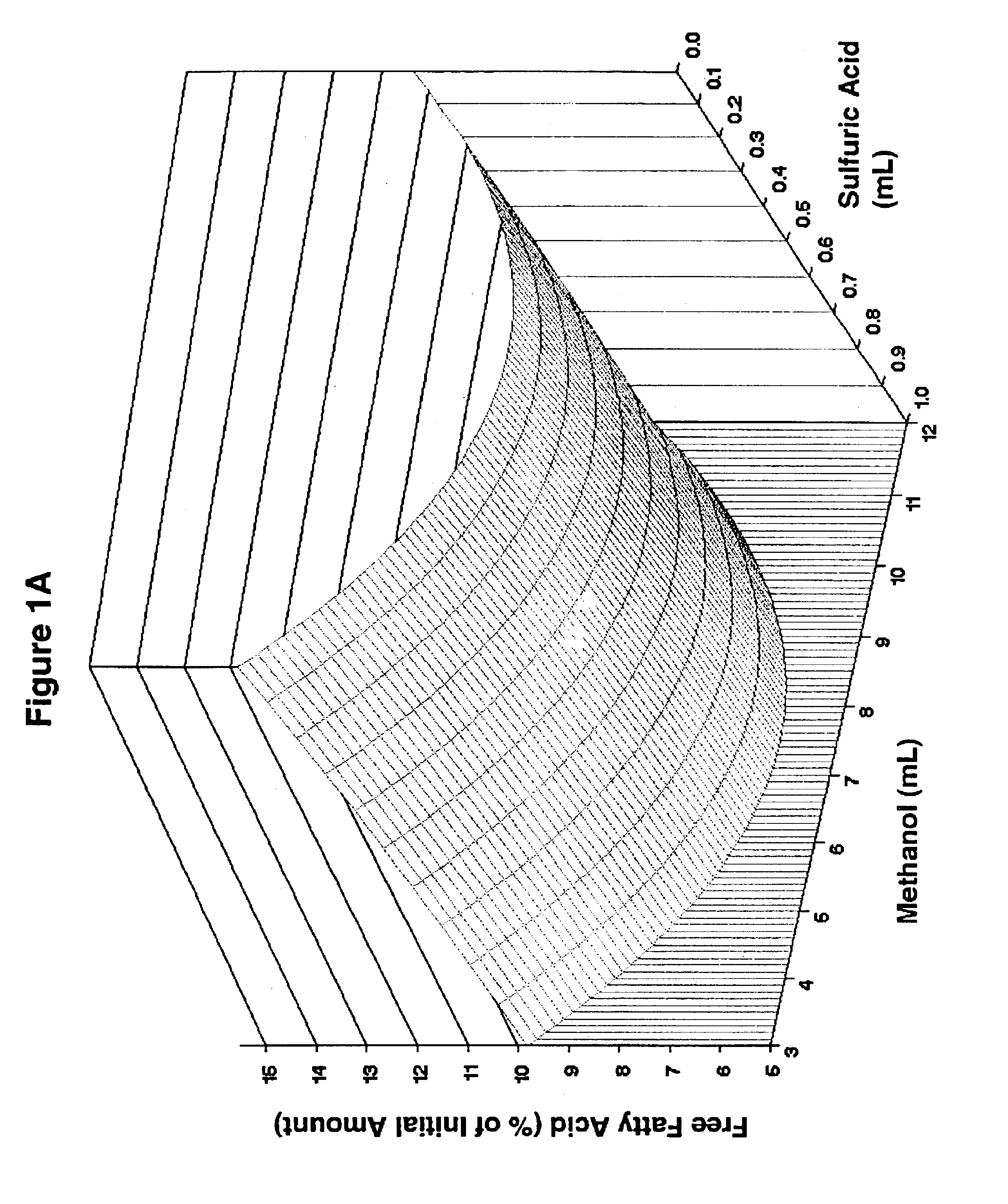

Lipid rich compositions, production of lipid rich compositions, production of fatty acid alkyl esters from heterogeneous lipid mixtures

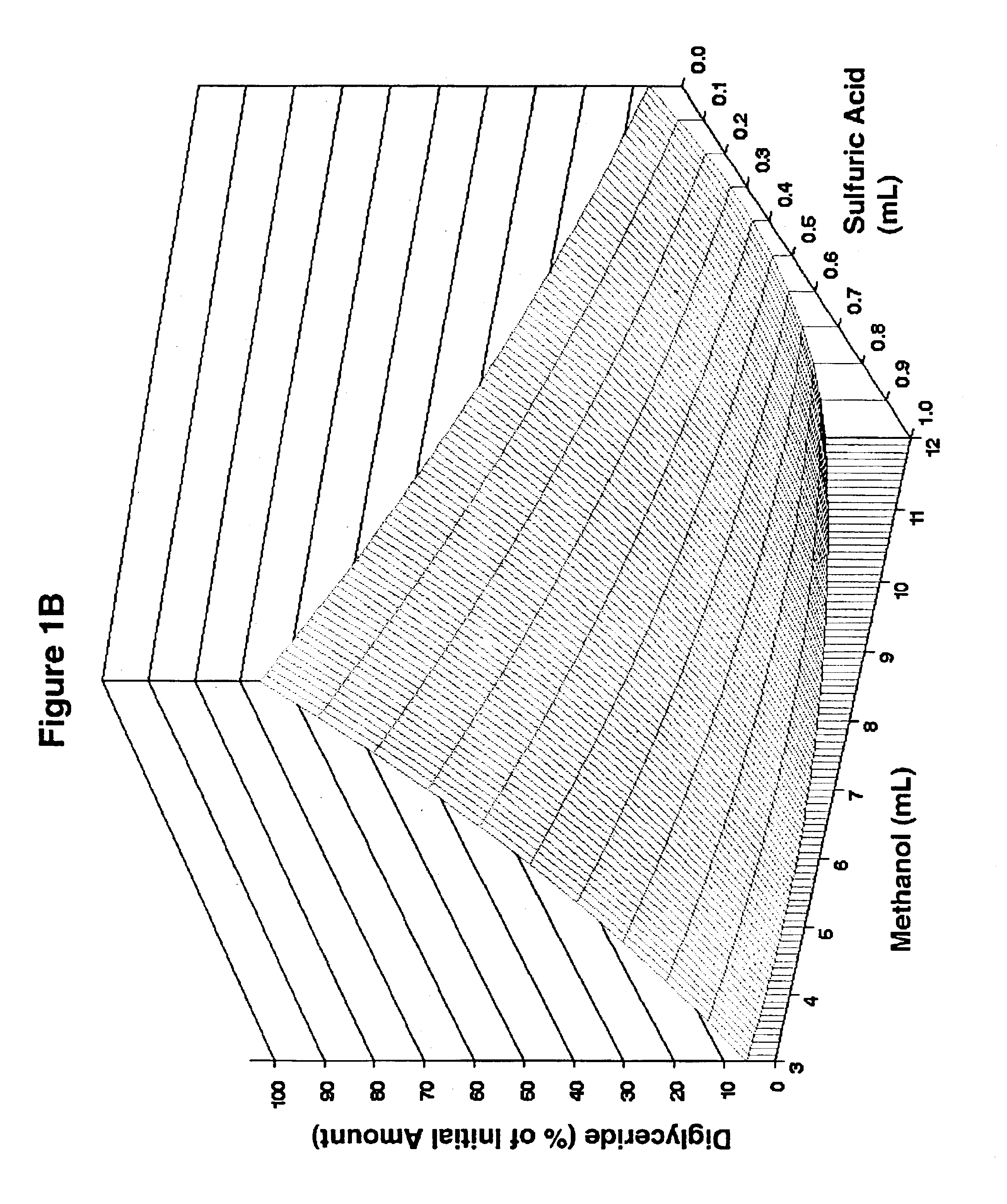

InactiveUS6855838B2Fatty oils/acids recovery from wasteFatty acid esterificationFatty acid esterSulfuric acid

The present invention relates to a method for producing fatty acid alkyl esters, involving esterifying a material containing free fatty acids (FFA) with an alcohol and an inorganic acid catalyst to form a product containing fatty acid alkyl esters, wherein (i) the material contains at least about 40% FFA and is produced by reacting a feedstock with steam and sulfuric acid at a pH of about 1-about 2 or (ii) the material contains at least about 80% FFA and is produced by reacting a feedstock with steam and alkali at a pH of about 11-about 13 and further reacting the feedstock with steam and sulfuric acid at a pH of about 1-about 2. The feedstock may be selected from the oils or soapstocks of soy, coconut, corn, cotton, flax, palm, rapeseed / canola, safflower, sunflower; animal fats; waste greases; and mixtures thereof; or other fully or partially hydrolyzed preparations of such feedstocks. The present invention also relates to a method for producing a lipid rich composition containing at least about 80% FFA, the method involving reacting a feedstock with steam and alkali at a pH of about 11-about 13 and further reacting the feedstock with steam and sulfuric acid at a pH of about 1-about 2. The feedstock may be selected from soy, coconut, corn, cotton, flax, palm, rapeseed / canola, safflower, sunflower, animal fats, waste greases, and mixtures thereof. The feedstock may be selected from the oils or soapstocks of soy, coconut, corn, cotton, flax, palm, rapeseed / canola, safflower, sunflower; animal fats; waste greases; and mixtures thereof; or other fully or partially hydrolyzed preparations of such feedstocks. Furthermore, the present invention concerns a lipid rich composition containing at least about 80% FFA.

Owner:RUNYON IND +1

Process for producing biodiesel, lubricants, and fuel and lubricant additives in a critical fluid medium

InactiveUS6887283B1Limited mass transferImprove reaction speedFatty oils/acids recovery from wasteFatty acid esterificationBiodieselVegetable oil

A process for producing alkyl esters useful in biofuels and lubricants by transesterifying glyceride- or esterifying free fatty acid-containing substances in a single critical phase medium is disclosed. The critical phase medium provides increased reaction rates, decreases the loss of catalyst or catalyst activity and improves the overall yield of desired product. The process involves the steps of dissolving an input glyceride- or free fatty acid-containing substance with an alcohol or water into a critical fluid medium; reacting the glyceride- or free fatty acid-containing substance with the alcohol or water input over either a solid or liquid acidic or basic catalyst and sequentially separating the products from each other and from the critical fluid medium, which critical fluid medium can then be recycled back in the process. The process significantly reduces the cost of producing additives or alternatives to automotive fuels and lubricants utilizing inexpensive glyceride- or free fatty acid-containing substances, such as animal fats, vegetable oils, rendered fats, and restaurant grease.

Owner:BATTELLE ENERGY ALLIANCE LLC

Method of processing ethanol byproducts and related subsystems

In one aspect of the invention, a method recovers oil from a concentrated byproduct, such as evaporated thin stillage formed during a dry milling process used for producing ethanol. The method includes forming a concentrate from the byproduct and recovering oil from the concentrate. The step of forming the concentrate may comprise evaporating the byproduct. Further, the step of separating the oil from the concentrate may comprise using a centrifuge and, in particular, a disk stack centrifuge. Other aspects of the invention include related methods and subsystems for recovering oil from thin stillage.

Owner:GS CLEANTECH CORP

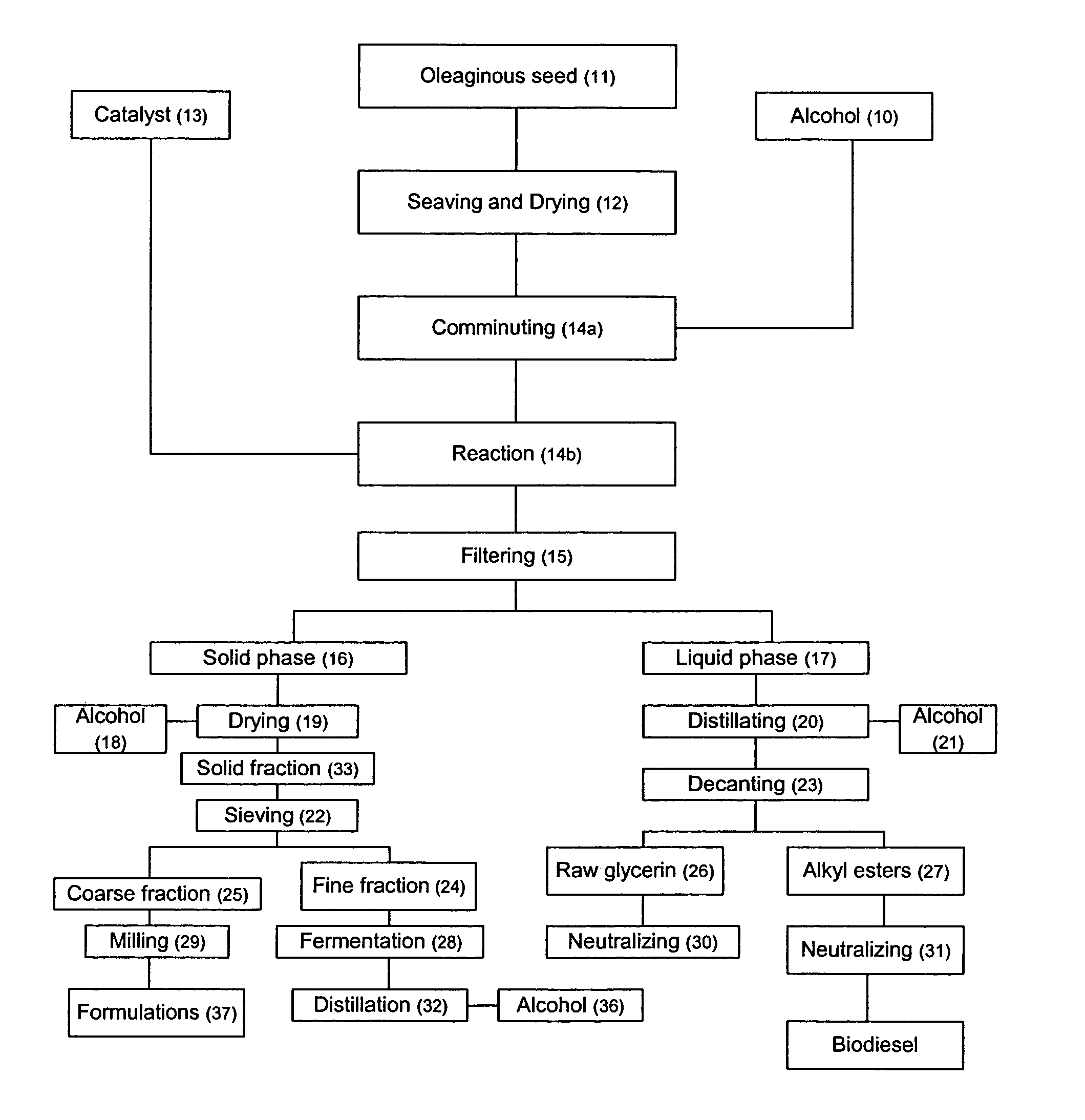

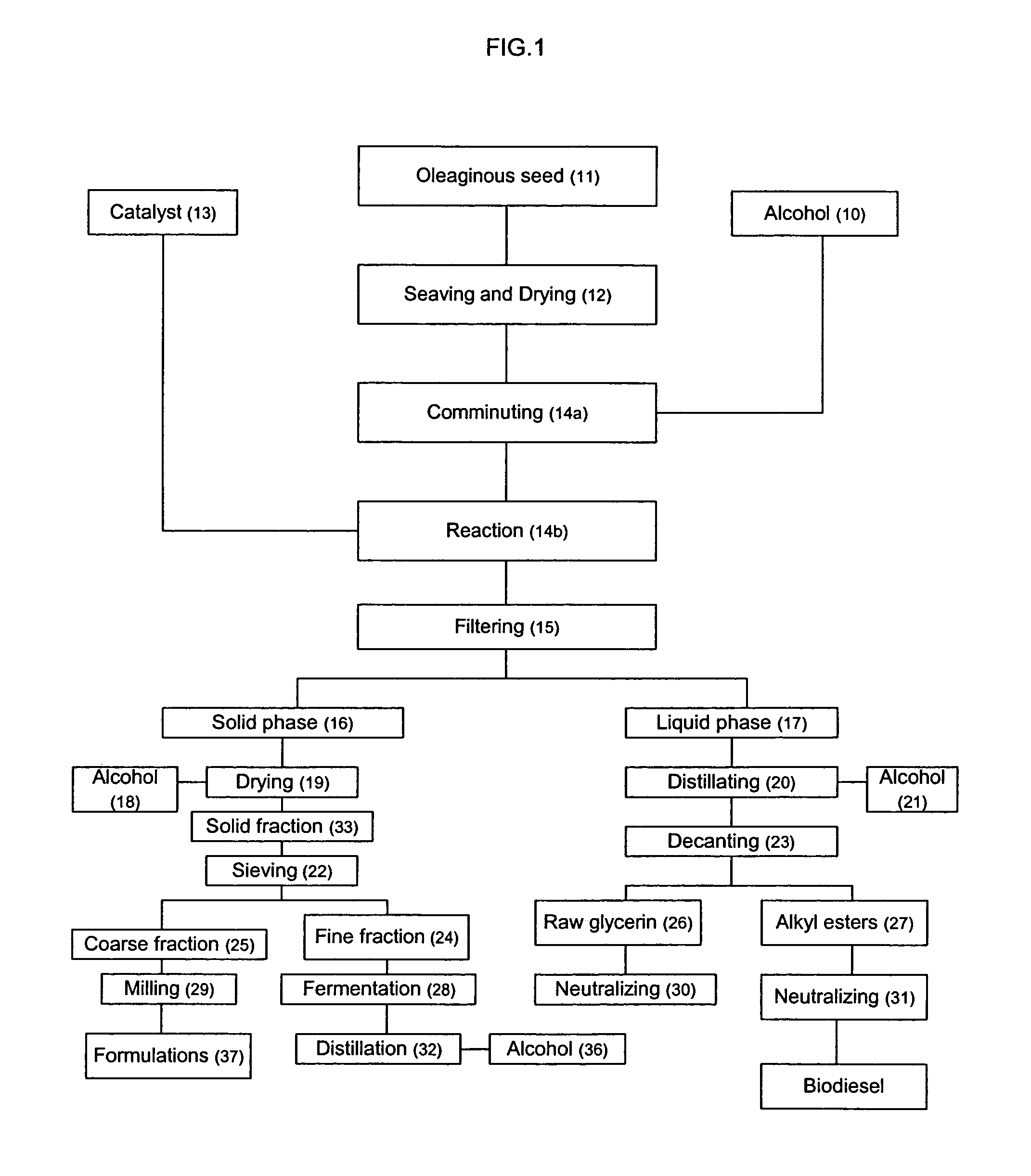

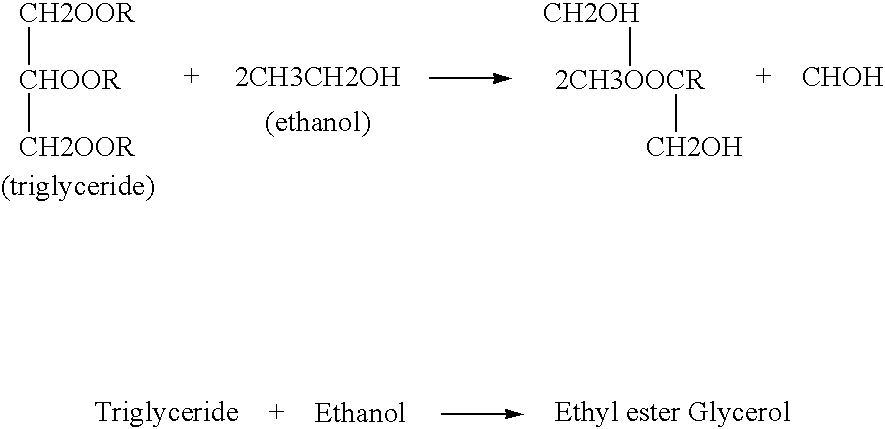

Process for producing biodiesel fuel using triglyceride-rich oleagineous seed directly in a transesterification reaction in the presence of an alkaline alkoxide catalyst

InactiveUS7112229B2Fatty oils/acids recovery from wasteFatty acid esterificationOil and greaseBiodiesel

An integrated process is described for producing biodiesel from oleaginous seeds, preferably castor bean seeds. The inventive process includes a transesterification reaction where the seeds themselves react with anhydrous ethyl alcohol in the presence of an alkaline catalyst. The resulting ethyl esters are then separated by decantation and neutralized and used as fuel for diesel engines, co-solvents for diesel and gasoline mixtures with anhydrous or hydrated ethyl alcohol. The solid fractions may be used as fertilizers, for feeding cattle and as a raw material for producing ethyl alcohol.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

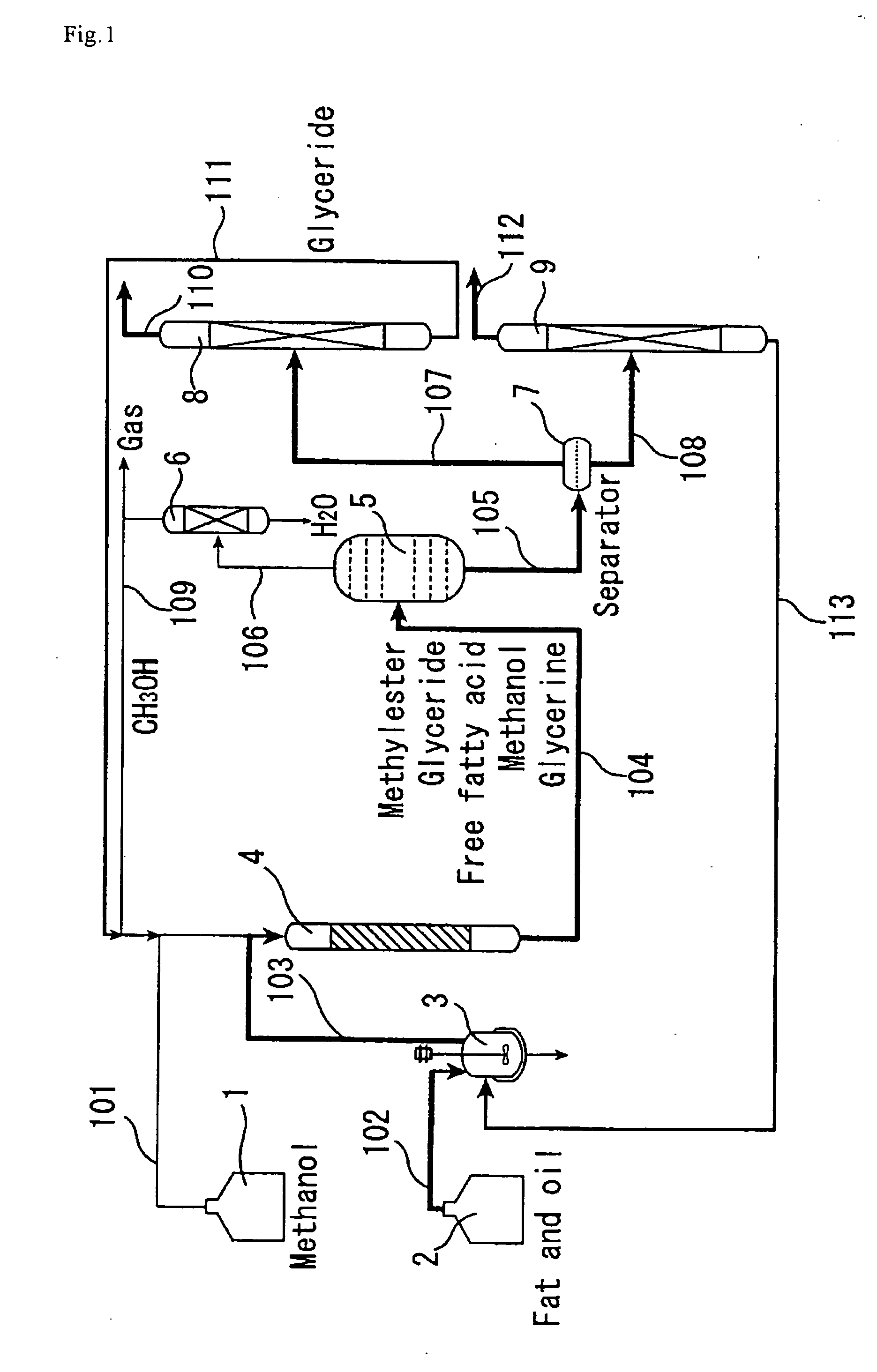

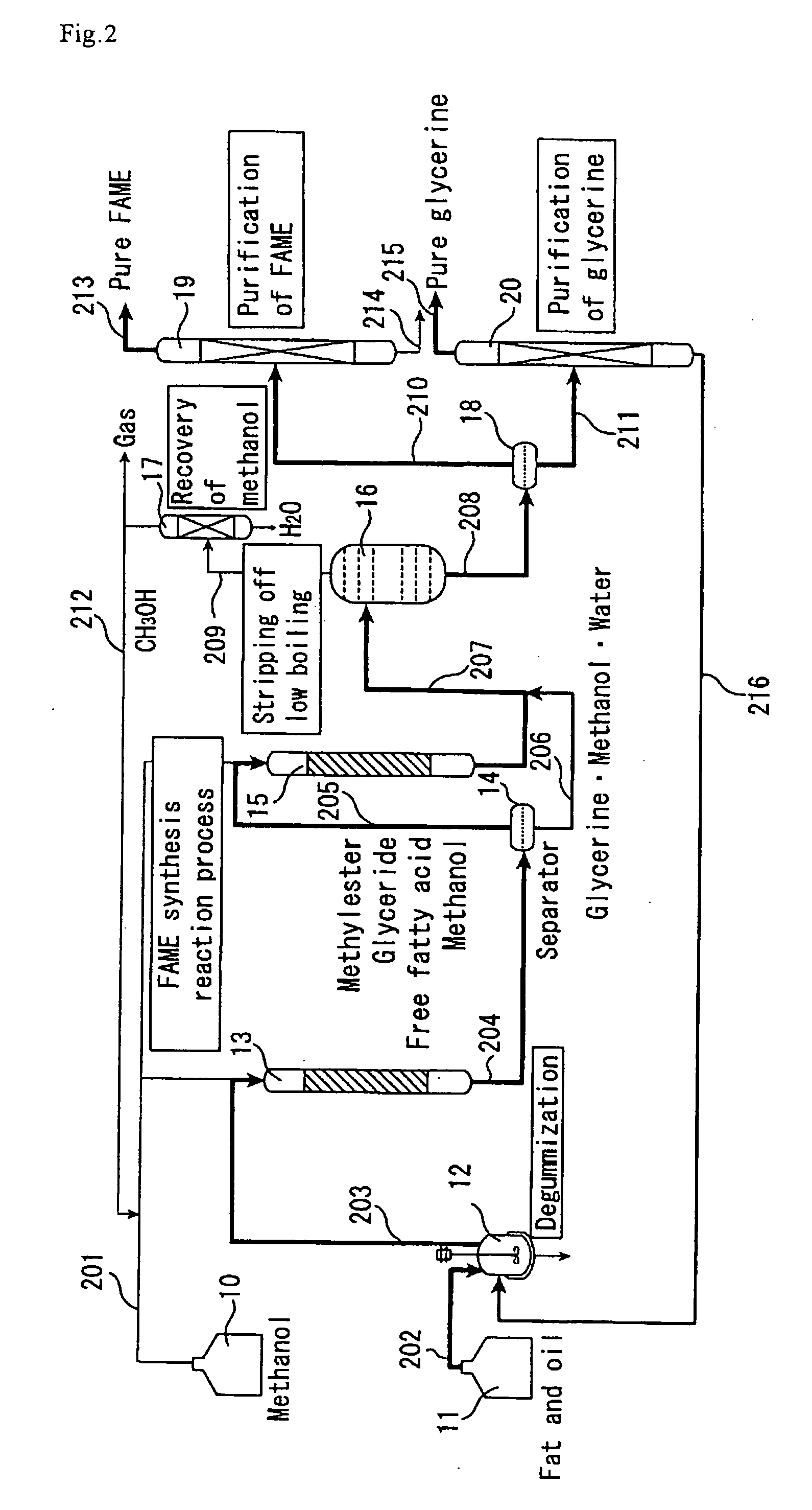

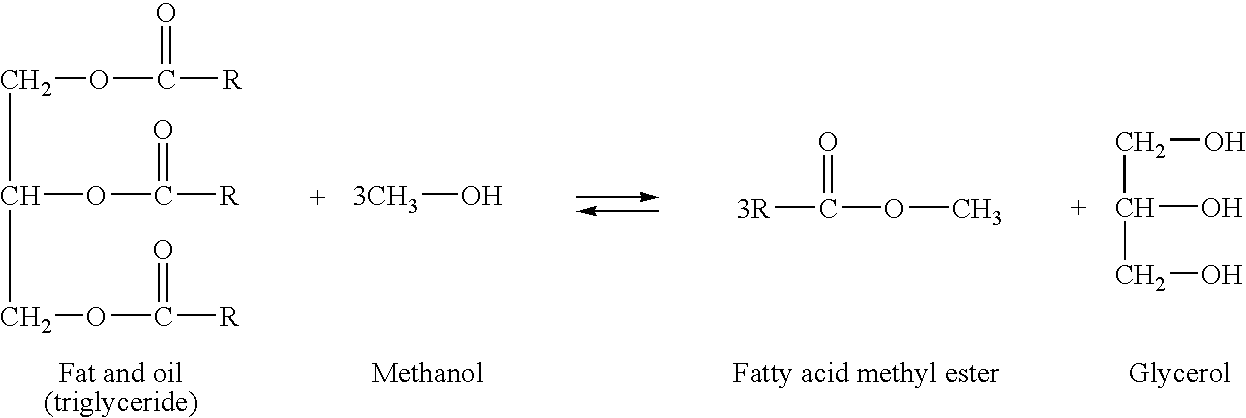

Method of production of fatty acid alkyl esters and/or glycerine and fatty acid alkyl ester-containing composition

InactiveUS20070167642A1Reduce energy consumptionIncrease contentFatty oils/acids recovery from wasteFatty acid esterificationBoiling pointGlycerol

The method of producing fatty acid alkyl esters and / or glycerine of the present invention is a method of producing high-purity fatty acid alkyl esters and / or glycerine advantageously from the energy viewpoint while reducing the energy consumption of the production, and the products can be used in various fields of application, for example in biodiesel fuels, foods, cosmetics and pharmaceuticals. The above-mentioned method of producing fatty acid alkyl esters and / or glycerine by reacting a fat or oil with an alcohol using an insoluble solid catalyst in a reaction apparatus comprising at least one reactor, comprises (a) a step of obtaining low-boiling components removed liquid by removing low-boiling components or fraction from an effluent liquid of a reactor and (b) a step of separating the fatty acid alkyl esters and glycerine from the low-boiling components removed liquid, wherein an eluted active metal component of the insoluble solid catalyst in the effluent liquid of a reactor amounts to a level not higher than 1,000 ppm.

Owner:NIPPON SHOKUBAI CO LTD

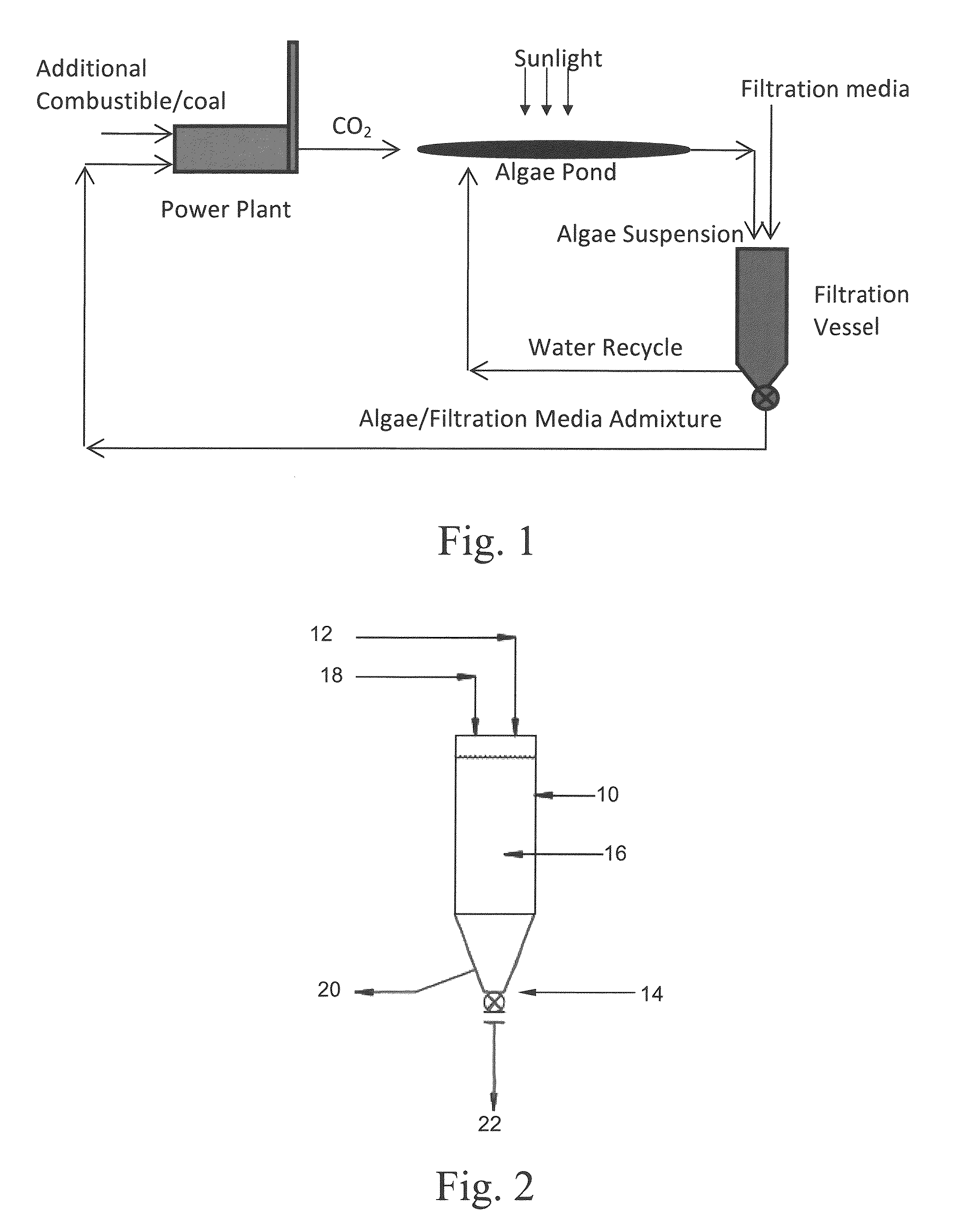

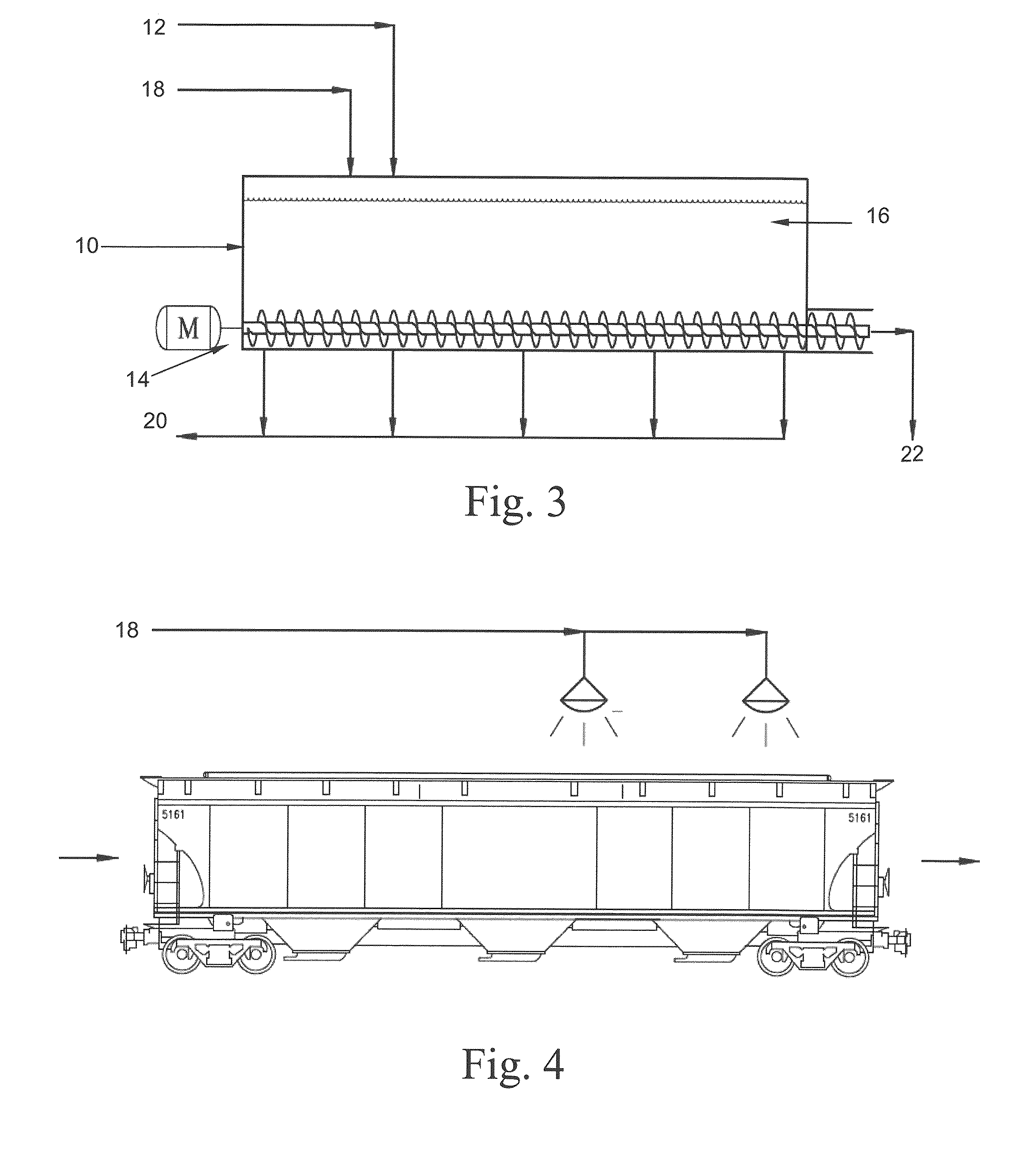

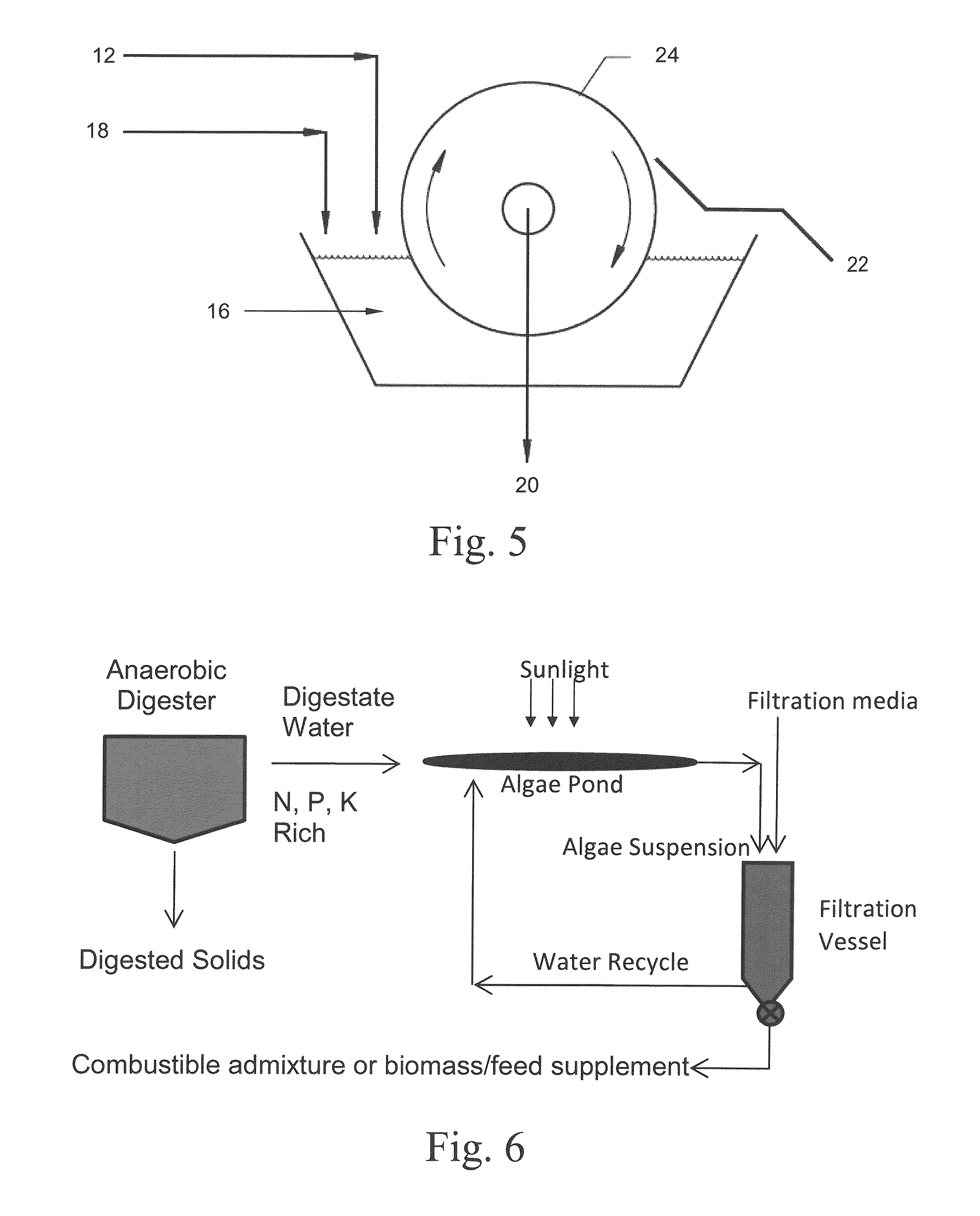

Methods of algae harvesting utilizing a filtering substance and uses therefor

InactiveUS20110143012A1High combustion valueHigh nutritional valueFatty oils/acids recovery from wasteLiquid separation auxillary apparatusFood supplementFiltration

Methods of harvesting algae, and using algae as a biofuel, livestock feed, or food supplement are provided. The methods comprise contacting liquid algae suspensions with a filtration media. Depending upon the filtration media, the resulting algae and filtration media admixture is then utilized as a biofuel, livestock feed, food supplements, or for the extraction of algae oil. Admixtures comprising a combustible filtration media, such as coal, are particularly preferred. The methods are suitable for use with any algae species. Compositions for use as a biofuel, livestock feed, or food supplement are also provided. These compositions comprise an admixture of algae and a filtration media.

Owner:RETTENMAIER ALBERT C

Process for producing alkyl esters from a vegetable or animal oil and an aliphatic monoalcohol

InactiveUS6878837B2High purityImpact on overall process costFatty oils/acids recovery from wasteFatty acid esterificationAluminateTransesterification

Alkyl esters of fatty acids, and high purity glycerin, are produced using a process comprising a set of transesterification reactions between a vegetable or animal oil and an aliphatic monoalcohol employing a heterogeneous catalyst, for example based on zinc aluminate, the water content in the reaction medium being controlled to a value that is below a given limiting value.

Owner:INST FR DU PETROLE

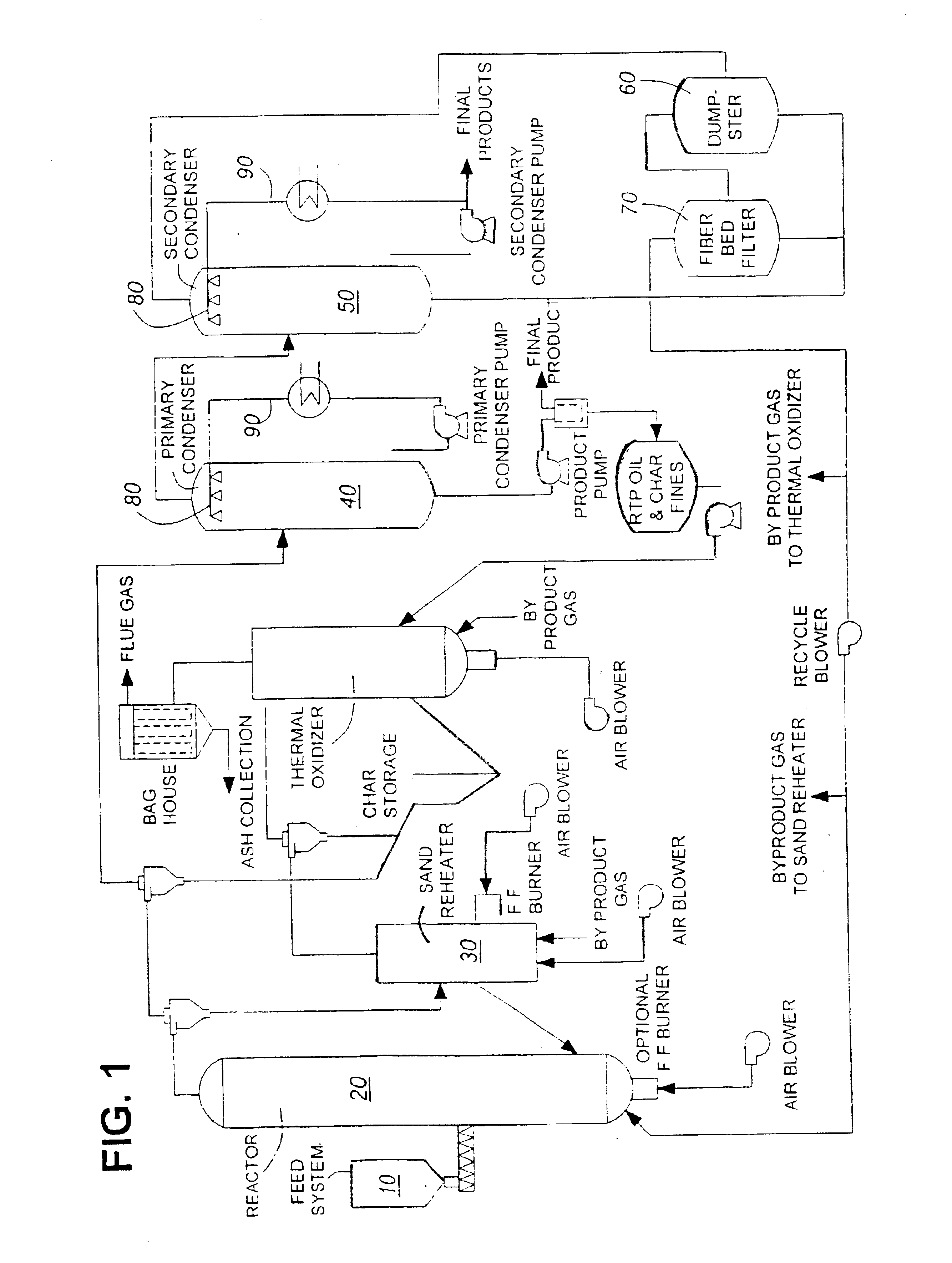

Natural resin formulations

InactiveUS6844420B1Low viscosityImprove liquidityFatty oils/acids recovery from wasteBiofuelsNatural resinDistillation

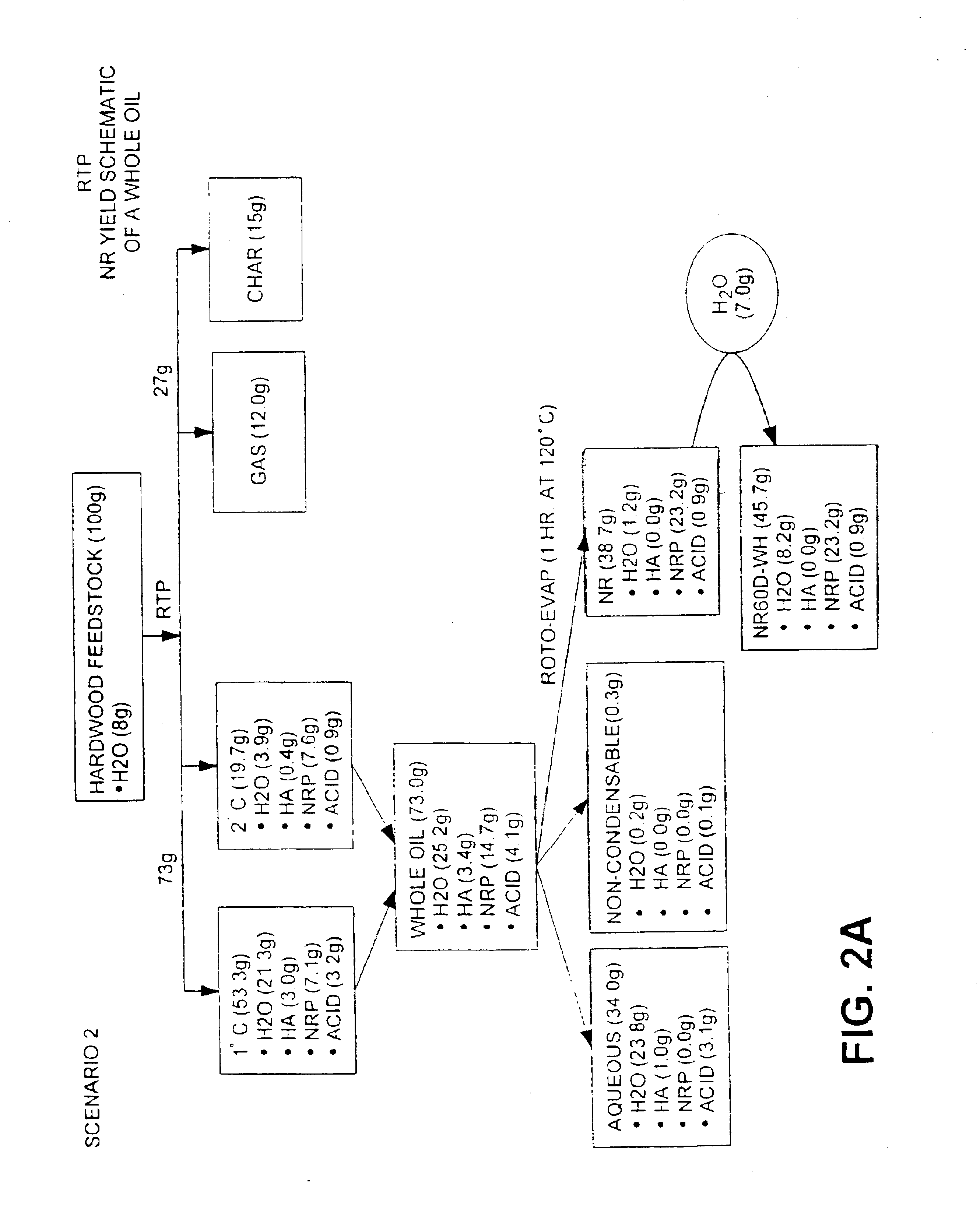

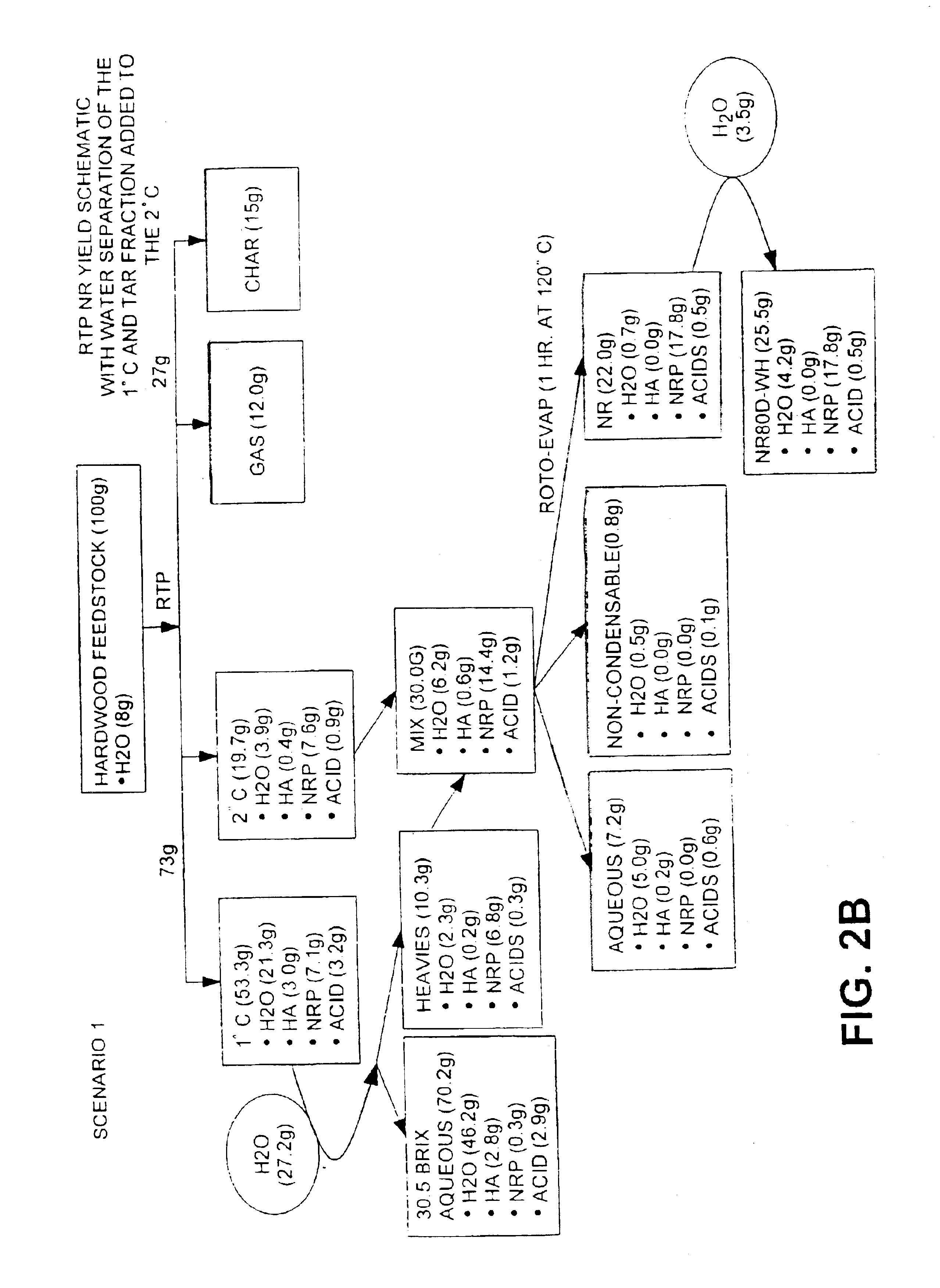

This invention is directed to a method of preparing a natural resin by liquefying wood, bark, forest residues, wood industry residues, or other biomass using rapid destructive distillation (fast pyrolysis). Fast pyrolysis produces both vapors and char from biomass, and following removal of the char from the product vapors, a liquid pitch product is recovered and processed by distillation, evaporation, or a combination thereof, in order to obtain a natural resin which may be in either liquid or solid form. The natural resin comprises a total phenolic content from about 30% to about 80% (w / w), and is a highly-reactive ligninic compound that has been found to be suitable for use within resin formulations without requiring any further extraction or fractionation procedures. Resins comprising up to 60% natural resin have been prepared and tested in board production and found to exhibit similar properties associated with commercially available resins. The natural resin may substitute for phenol, or for both phenol and formaldehyde within phenol-containing resins. Similarly, the natural resin can replace a substantial part of the components within urea-containing resins.

Owner:ENSYN RENEWABLES

Fatty acid blends and uses therefor

ActiveUS8029579B2Maintain good propertiesEffect cold flow propertyFatty oils/acids recovery from wasteFatty acid esterificationPolymer scienceFatty acid methyl ester

Owner:CIBUS

Production of biodiesel from combination of corn (maize) and other feed stocks

InactiveUS20070099278A1Increase Biodiesel production outputStable year round productionFatty oils/acids recovery from wasteOrganic compound preparationProcess systemsSodium Bentonite

A method and system to produce biodiesel from a combination of corn (maize) and other agro feedstock may be simarouba, mahua, rice, pongamia etc. Germ is separated (either by wet process or dry process) from corn, crude corn oil extracted from germ and corn starch milk / slurry is heated and cooked in jet cooker to about 105 degree Celsius, enzymes added to convert starch into fermentable sugars in liquification and saccharification process and rapidly cooled down to about 30 degree Celsius. Simarouba fruits syrup, mahua syrup is mixed with corn starch milk (after saccharification). When yeast is added the fermentation takes place for about 72 hours. Thereafter the fermented wash is distilled to produce ethanol. Water consumed in dry process is very less compared to traditional wet process system. Corn oil and mixture of other oils is fed into transesterification (reaction) vessels where ethanol with catalyst, usually sodium hydroxide is added and reaction takes place for about a period of 2-8 hours. Crude biodiesel and crude glycerin as by-products is produced. Excess ethanol removed by distillation process. Crude biodiesel washed with warm water to remove residual soaps or unused catalyst, dried and biodiesel stored for commercial use. Oil extracted from spent bleach mud (used sodium bentonite), a waste product of edible oil refineries may also be utilized for economical production of biodiesel in combination of corn oil and ethanol.

Owner:AARE PALANISWAMY RAMASWAMY

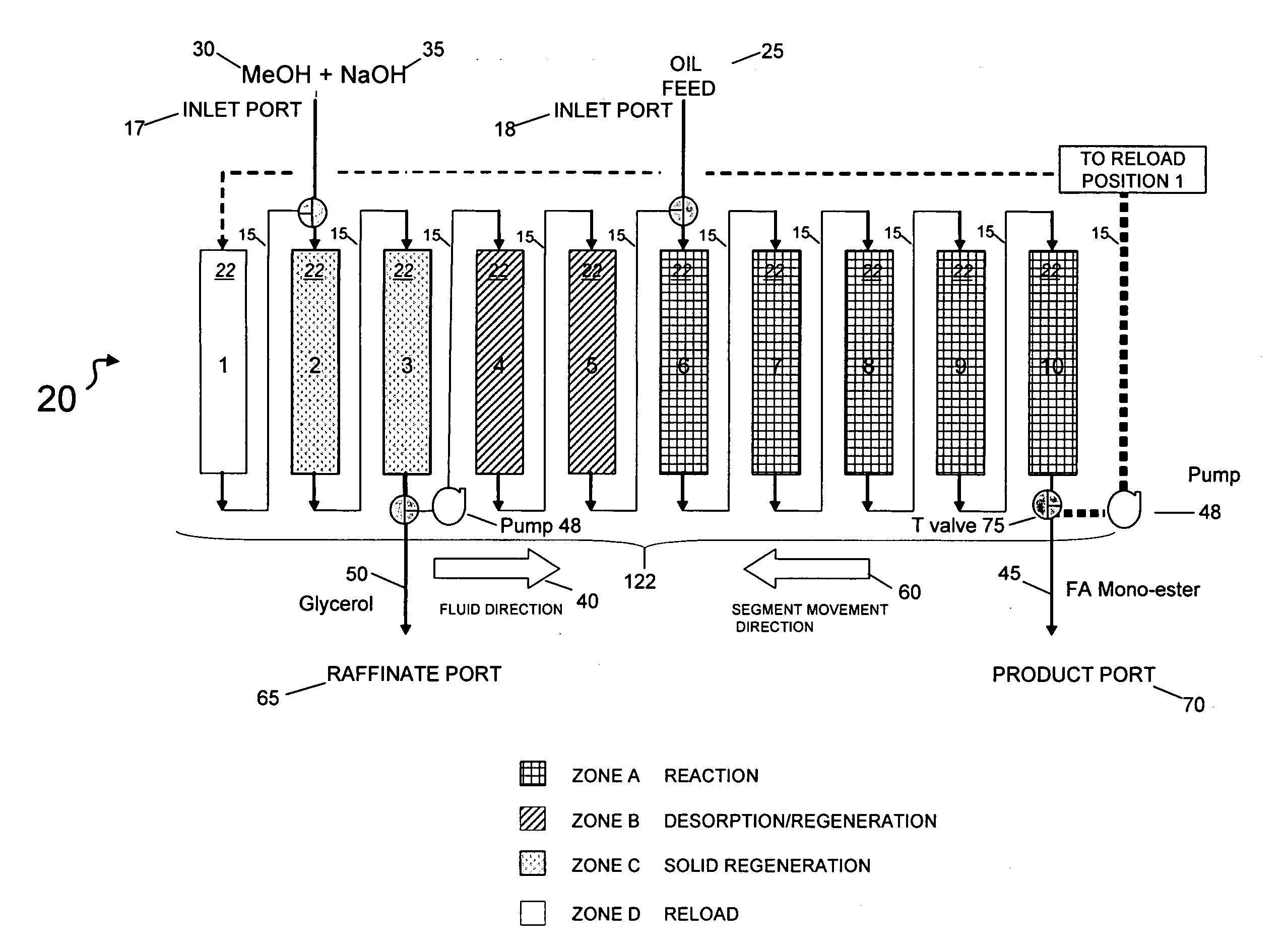

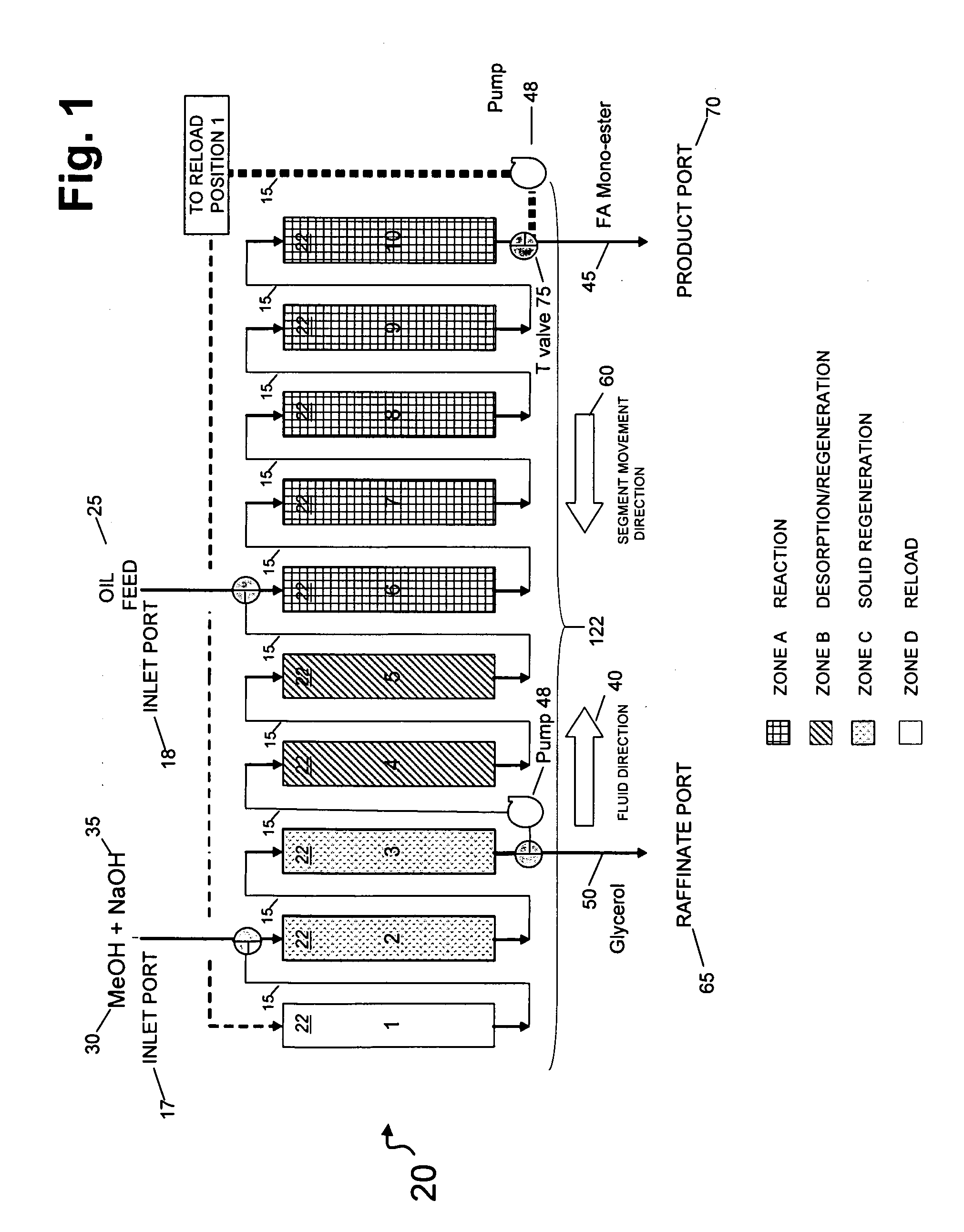

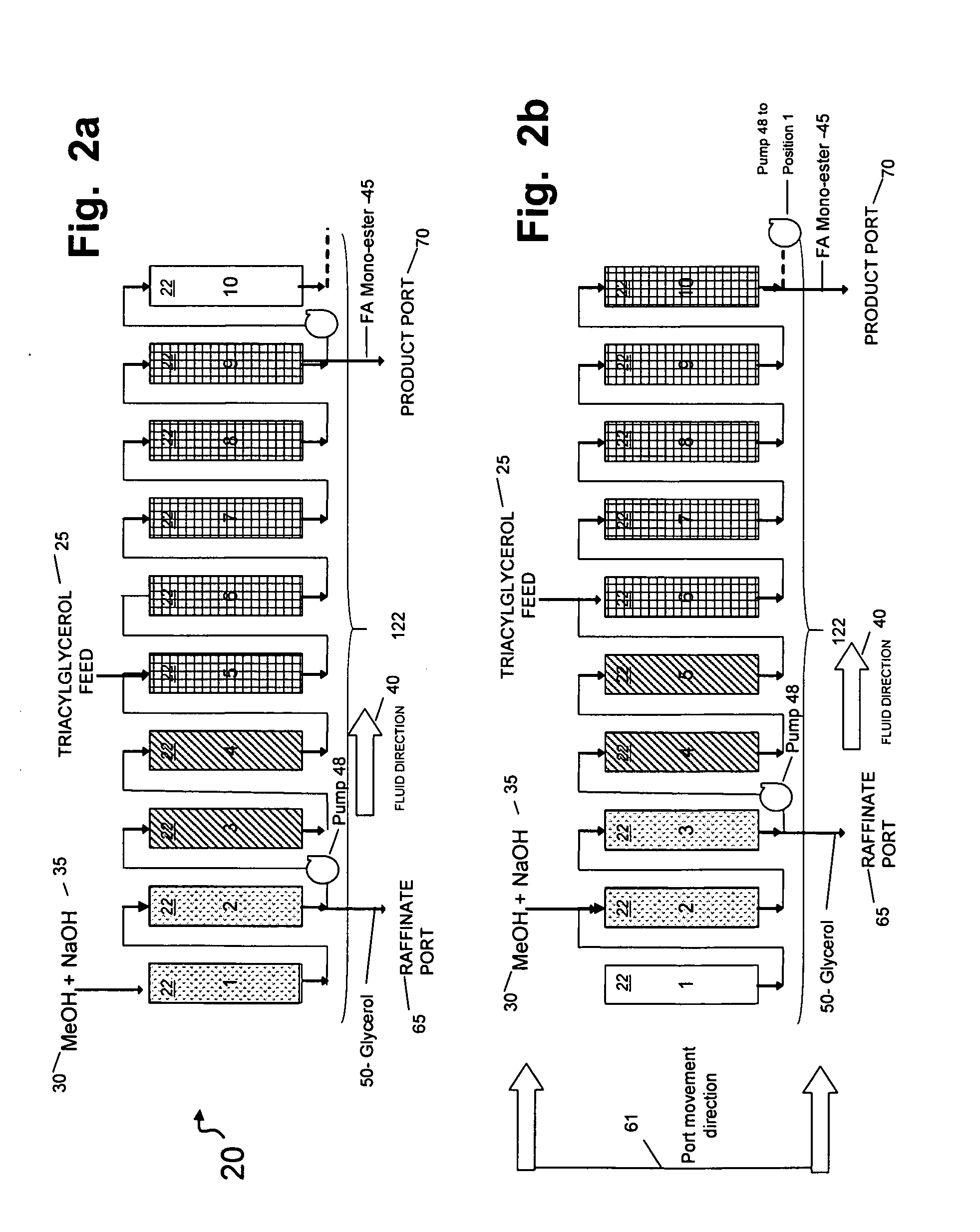

Simultaneous synthesis and purification of a fatty acid monoester biodiesel fuel

ActiveUS20070158270A1Reduce contentLow costFatty oils/acids recovery from wasteFatty acid esterificationBiodieselAlcohol

Simultaneous synthesis and purification of a fatty acid monoester biodiesel fuel from a triacylglycerol feedstock is described. In an exemplary method, the triacylglycerol feedstock is continuously contacted with a catalytic chromatographic bed comprising a first (solid phase) basic catalyst through a first port of a simulated moving bed chromatographic apparatus. A monohydric alcohol and optional second (mobile phase) basic catalyst is continuously contacted with the catalytic chromatographic bed through a second port and pumped in a first direction toward the triacylglycerol feedstock to contact the triacylglycerol in a reaction zone of the catalytic chromatographic bed where the fatty acid monoester and glycerol coproduct are formed. The fatty acid monoester is removed from the reaction zone through a product port of the simulated moving bed apparatus. Segments of the catalytic chromatographic bed are incrementally moved in a second direction, opposite the first direction, and the glycerol is removed from a raffinate port located opposite the product port of the apparatus.

Owner:ARCHER DANIELS MIDLAND CO

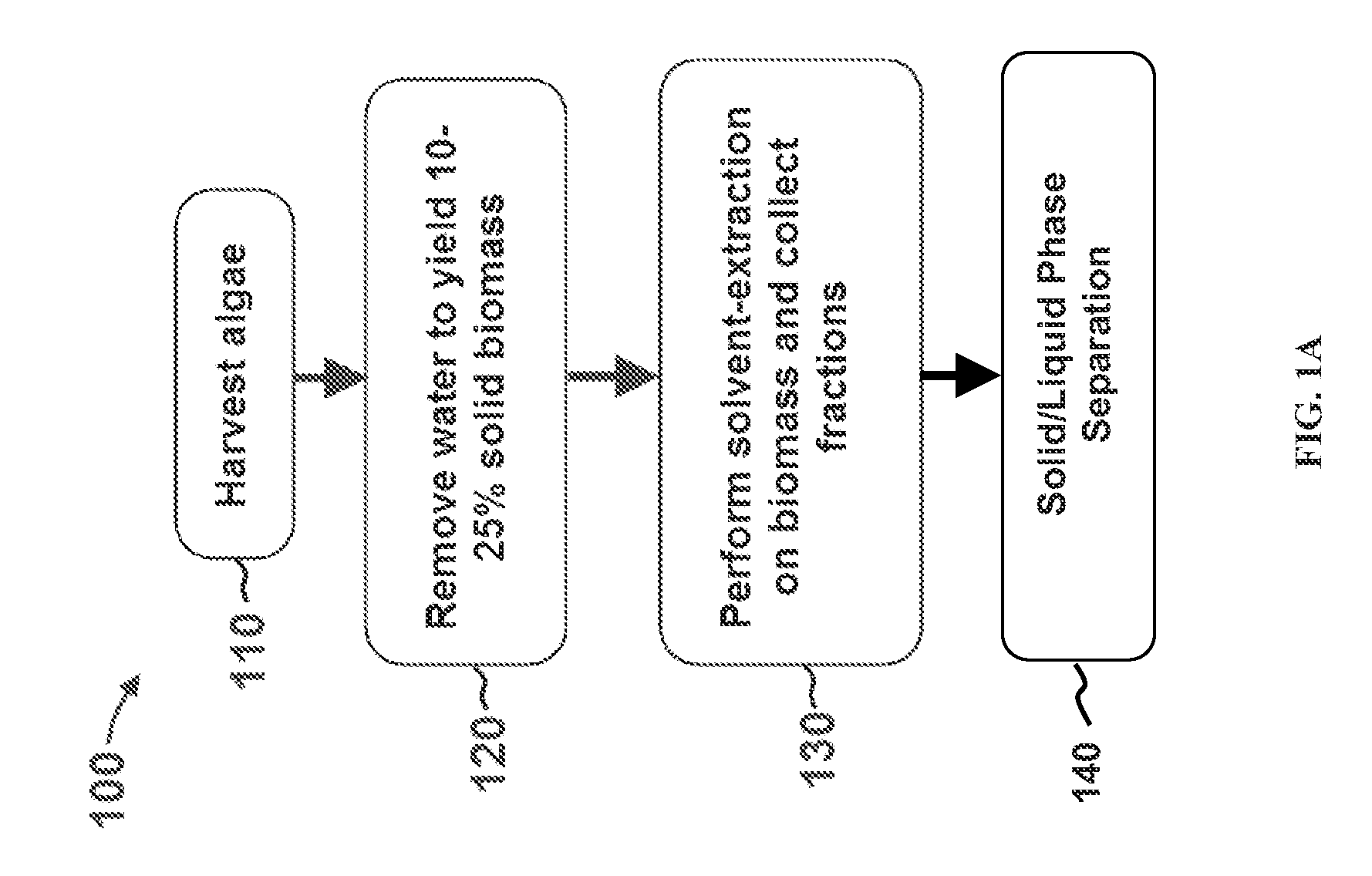

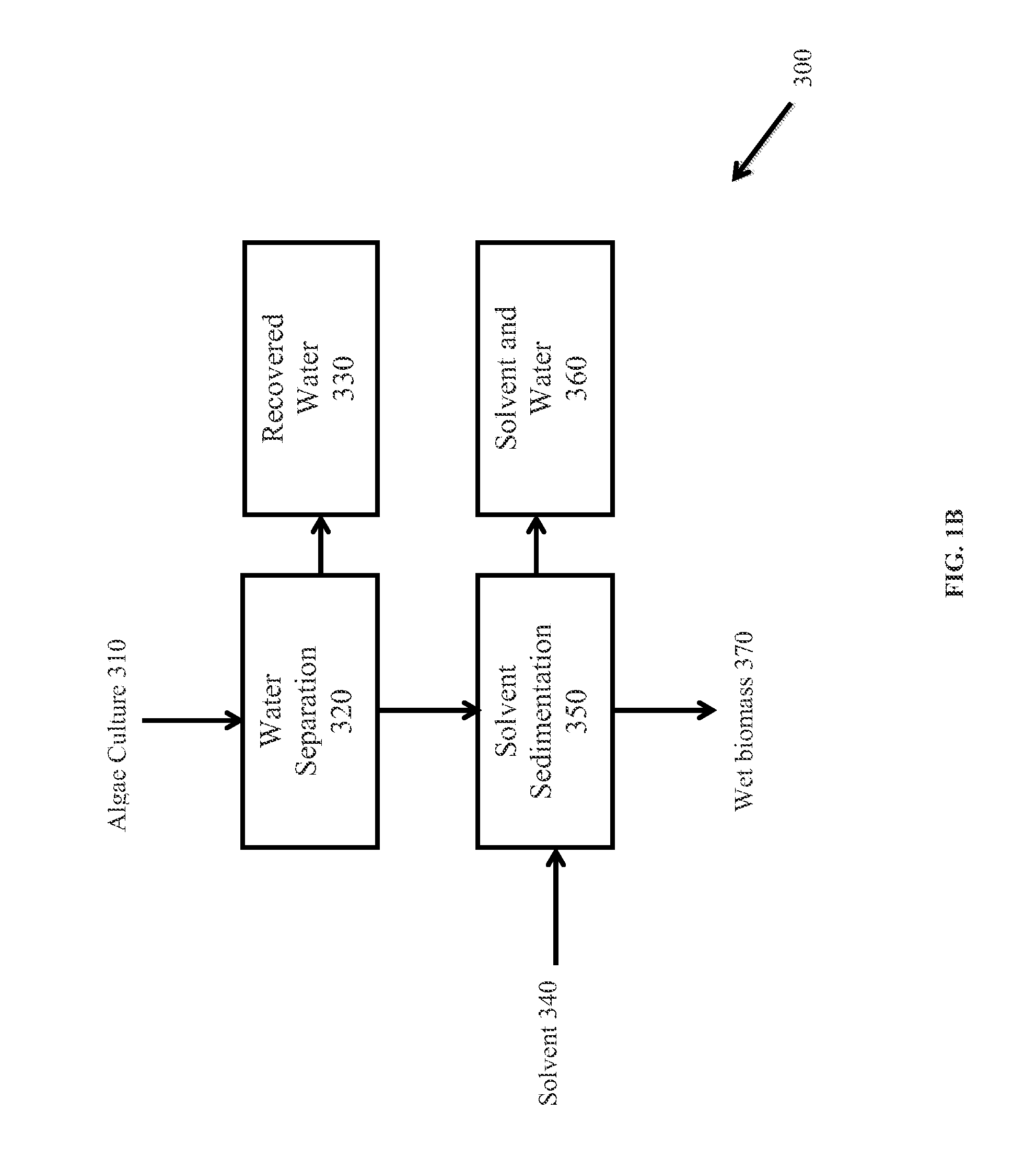

Extraction with fractionation of oil and proteinaceous material from oleaginous material

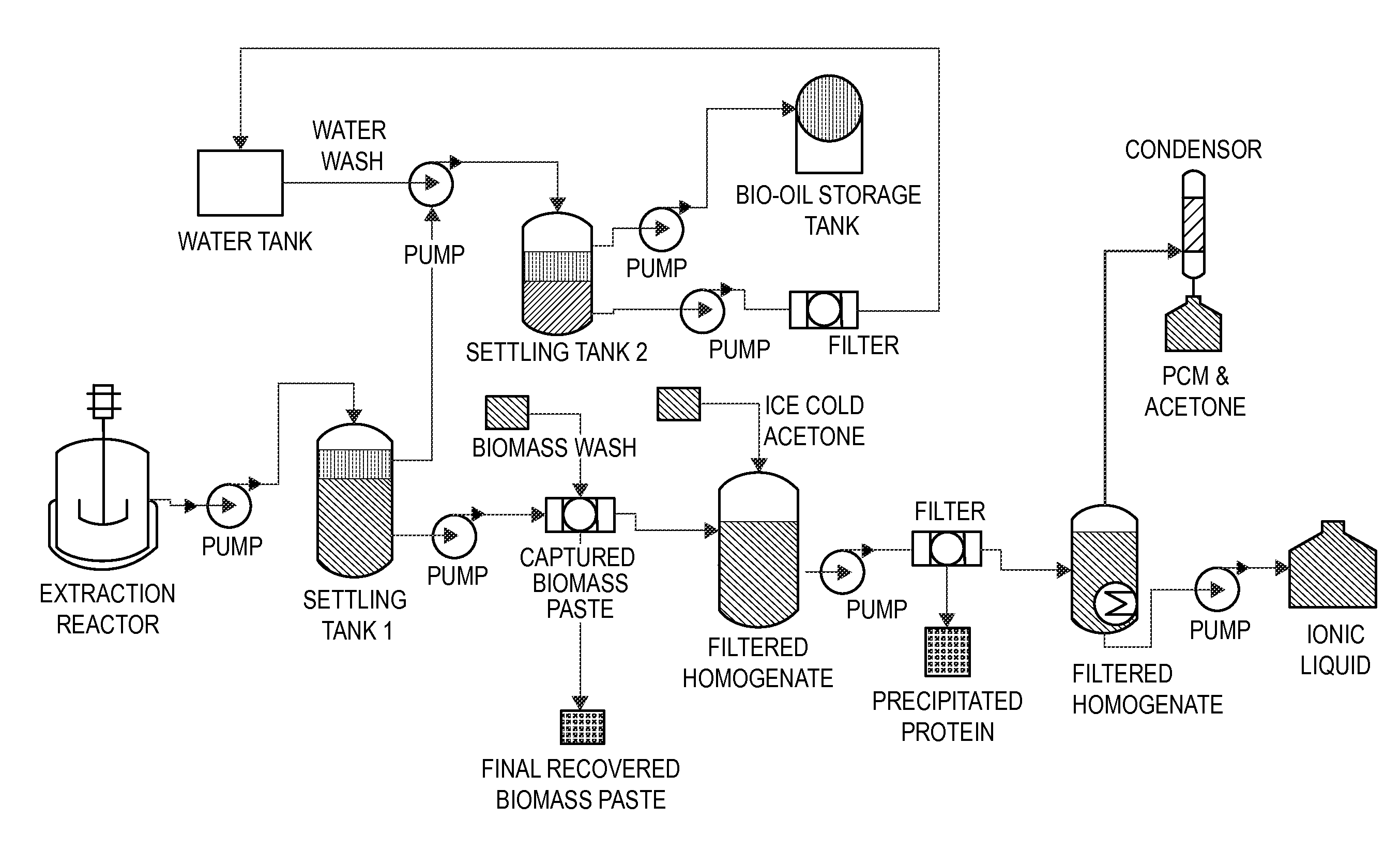

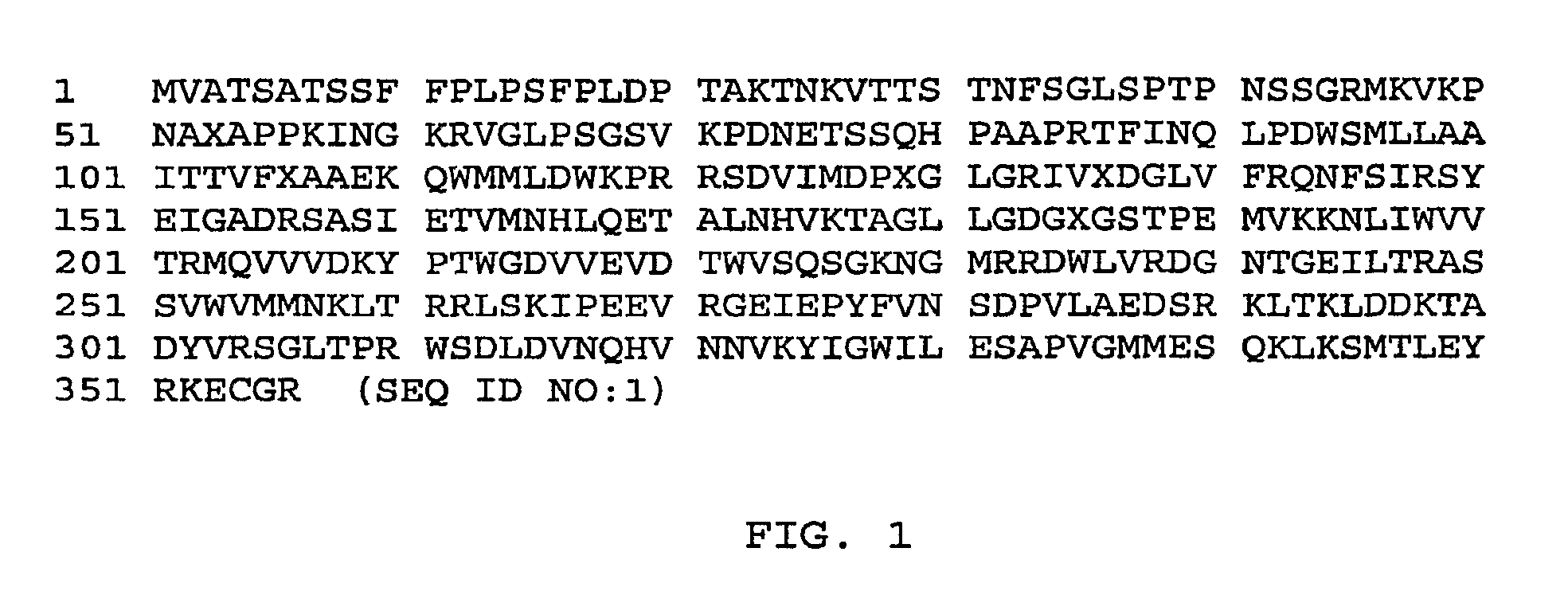

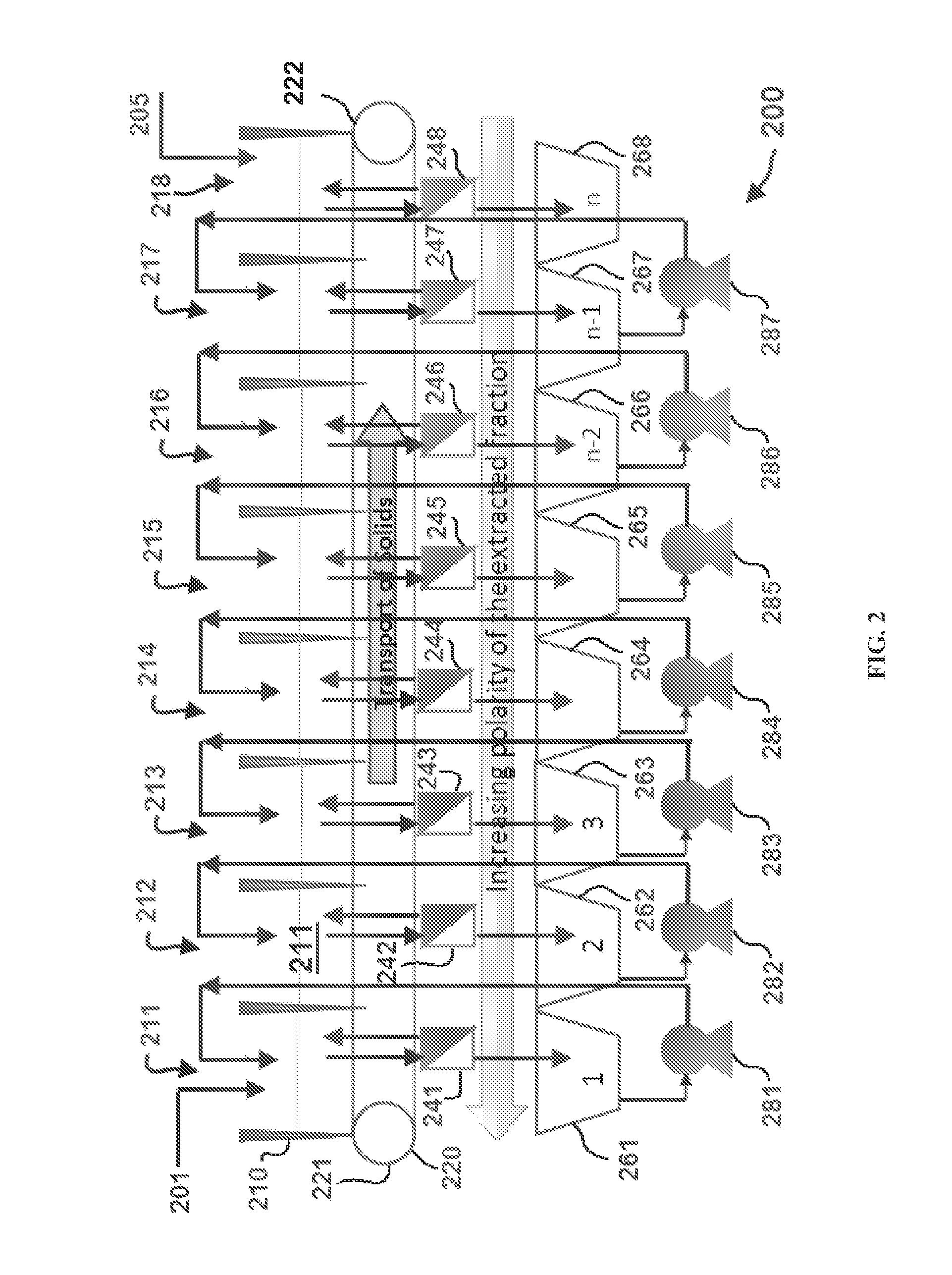

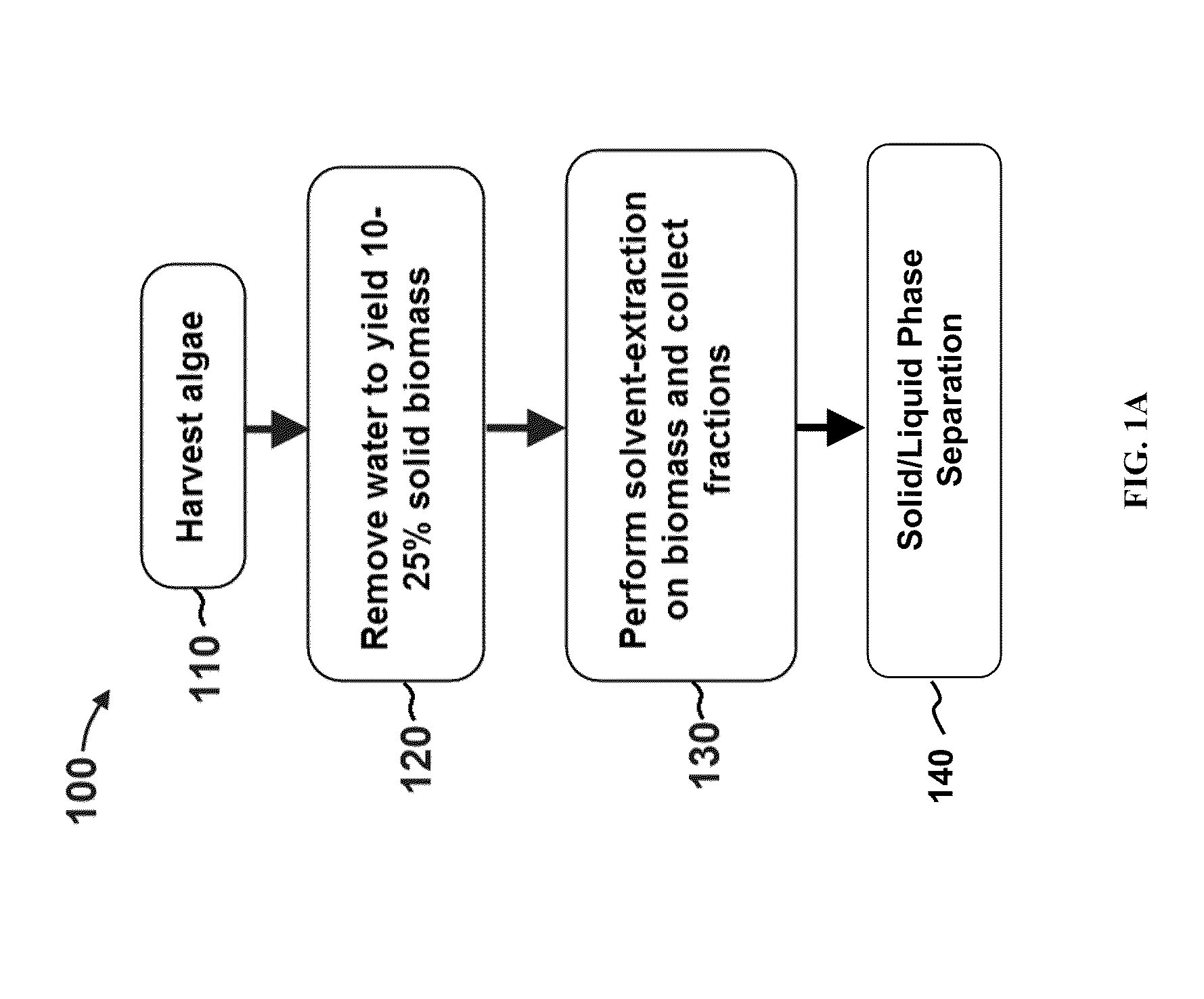

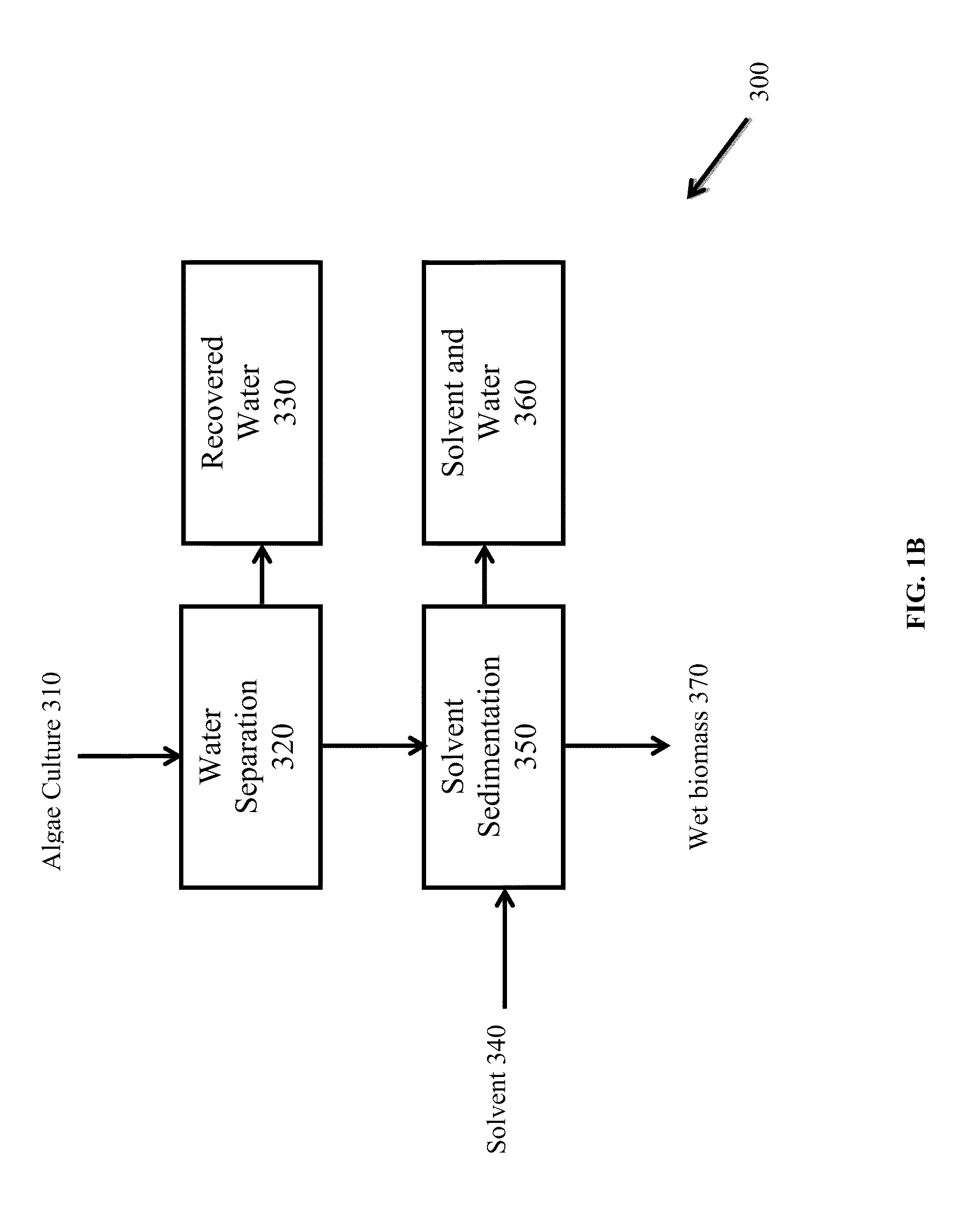

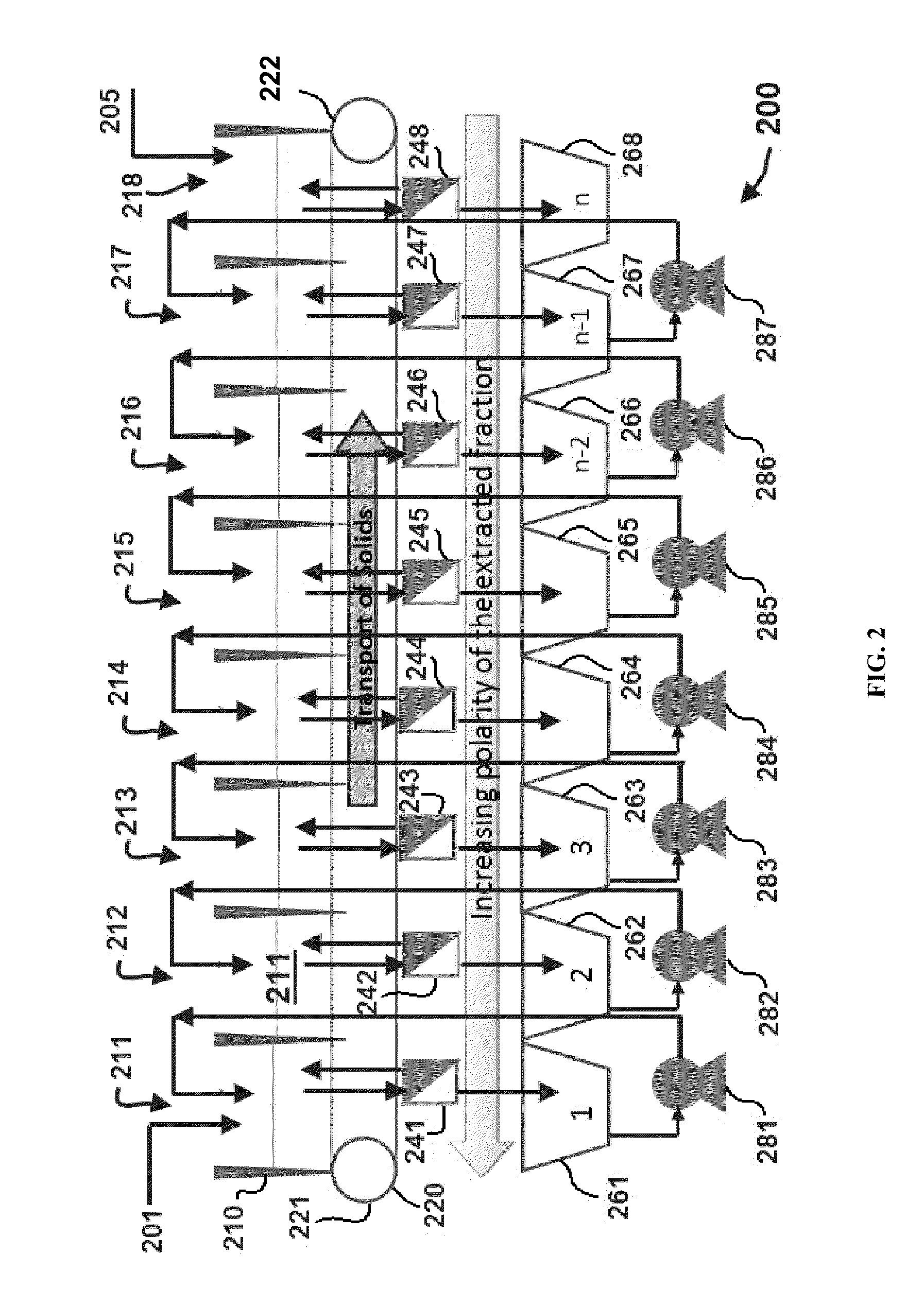

Methods for selective extraction and fractionation of algal lipids and algal products are disclosed. A method of selective removal of products from an algal biomass provides for single and multistep extraction processes which enable efficient separation of algal components. Among these components are neutral lipids synthesized by algae, which are extracted by the methods disclosed herein for the production of renewable fuels.

Owner:HELIAE DEVMENT

Methods of producing biofuels, chlorophylls and carotenoids

InactiveUS20110263886A1Fatty oils/acids recovery from wasteFatty acid esterificationWater insolubleBiofuel

A method for producing biofuels along with valuable food and neutraceutical products is provided. A method of making biofuels includes dewatering substantially intact algal cells to make an algal biomass, extracting neutral lipids along with carotenoids and chlorophylls from the algal biomass, and separation of the carotenoids and chlorophylls using adsorption or membrane diafiltration or other methods. The remaining neutral lipids are esterified with a catalyst in the presence of an alcohol. The method also includes separating a water soluble fraction comprising glycerin from a water insoluble fraction comprising fuel esters and distilling the fuel esters under vacuum to obtain a C16 or shorter fuel esters fraction, a C16 or longer fuel ester fraction, and a residue comprising omega-3 fatty acids esters and remaining carotenoids. The method further includes hydrogenating and deoxygenating at least one of (i) the C16 or shorter fuel esters to obtain a jet fuel blend stock and (ii) the C16 or longer fuel esters to obtain a diesel blend stock.

Owner:HELIAE DEVMENT

Process for the preparation of fatty acid methyl ester from triglyceride oil by transesterification

InactiveUS20060080891A1Produced cost-effectivelyReduce water contentFatty oils/acids recovery from wasteFatty acid esterificationTransesterificationUnit operation

The present invention relates to an improved process for the preparation of biodiesel from triglyceride oils through transesterification, particularly the fatty acid methyl ester of oil mechanically expelled from whole seeds of Jatropha curcas, a plant with potential for cultivation on wastelands in India and other countries, all unit operations being carried out at ambient temperature.

Owner:COUNCIL OF SCI & IND RES

Fractionation process

InactiveUS6552208B1Fatty oils/acids recovery from wasteCosmetic preparationsVegetable oilActive component

The invention refers to a process for fractionating a vegetable oil giving one or more solid fractions suitable for confectionary applications as well as a liquid fraction rich in unsaponifiable biologically active components. The liquid fractions of shea butter and rapeseed oil having a high content of phytosterols and tocoferols, respectively, are useful for cosmetical and pharmaceutical preparations.

Owner:KARLSHAMNS AB KARLSHAMN

Method of separating anionic fluorochemical surfactant

InactiveUS20040010156A1Short elution timeHigh recovery rateFatty oils/acids recovery from wasteIon-exchanger regenerationOrganic solventIon-exchange resin

Separation of an anionic fluorochemical surfactant from an aqueous solution containing the anionic fluorochemical surfactant is carried out by i) contacting the aqueous solution with a basic anion-exchange resin so that the anionic fluorochemical surfactant is adsorbed on the resin, and ii) eluting the anionic fluorochemical surfactant adsorbed on the resin with an eluent which is an alkaline solution containing water and an organic solvent.

Owner:DAIKIN IND LTD

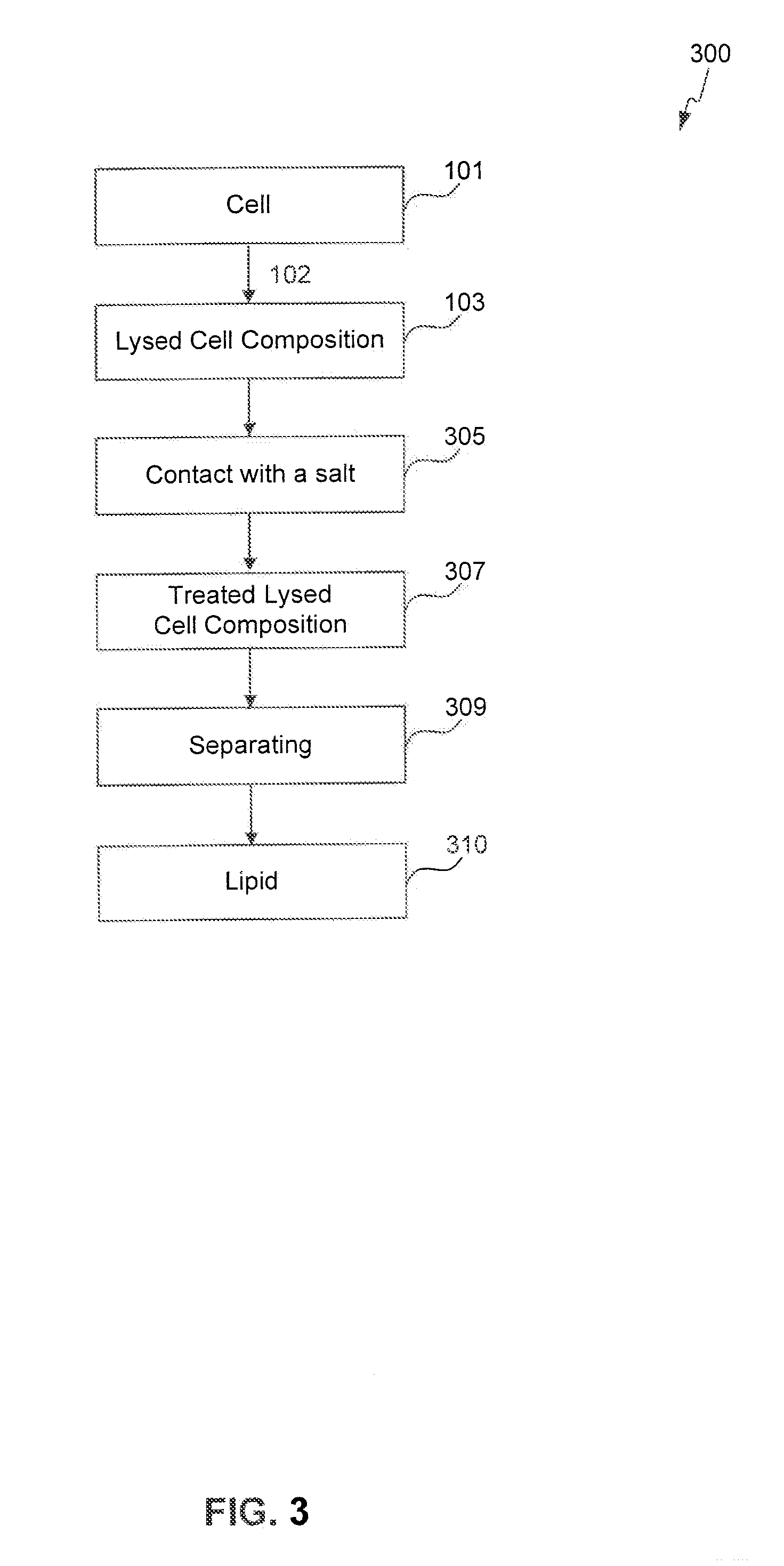

Methods of microbial oil extraction and separation

ActiveUS20120130099A1Increase productionFatty oils/acids recovery from wasteFatty acid esterificationMicrobial oilMoisture

Lipids can be extracted from a microbial biomass that constitutes at least 20% lipids by weight and has a moisture content of less than 4% by weight by applying pressure to the biomass so as to release lipids therefrom, thereby leaving a biomass of reduced lipid content; and collecting the lipids.

Owner:CORBION BIOTECH INC

Elimination of trans-unsaturated fatty acid compounds by selective adsorption with zeolites

InactiveUS6229032B1Low yieldLow costFatty oils/acids recovery from wasteFatty acid hydrogenationPartial hydrogenationDouble bond

A novel process for the selective elimination of fatty acid compounds containing carbon-carbon double bonds in trans configuration from a substrate containing cis- and trans-isomers of said fatty acid compounds, by selective adsorption by a microporous zeolite material is disclosed. The pore size and shape of usable zeolite materials enable differentiation between cis- and trans-isomers of unsaturated fatty acid chains. The zeolite materials used have a selectivity ratio alphatrans / cis higher than 1.00; this ratio is defined based on the elution properties of cis and trans double bond containing fatty acid methylesters dissolved in n-hexane during a column chromatography experiment with the zeolite material as the stationary phase and n-hexane as the mobile phase. Besides selective adsorption of trans-unsaturated fatty acid compounds, simultaneous or subsequent total or partial hydrogenation of the double bonds in said compounds can be carried out while using the same or similar zeolite material, containing finely dispersed catalytic active metals. The majority of these catalytic active sites must be inside the pores.

Owner:K U LEUVEN RES & DEV

Green biodiesel

InactiveUS7563915B2Reduce wasteSignificant energyFatty oils/acids recovery from wasteFatty acid esterificationCalcium silicateBiodiesel

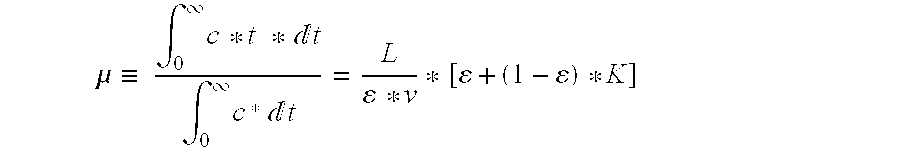

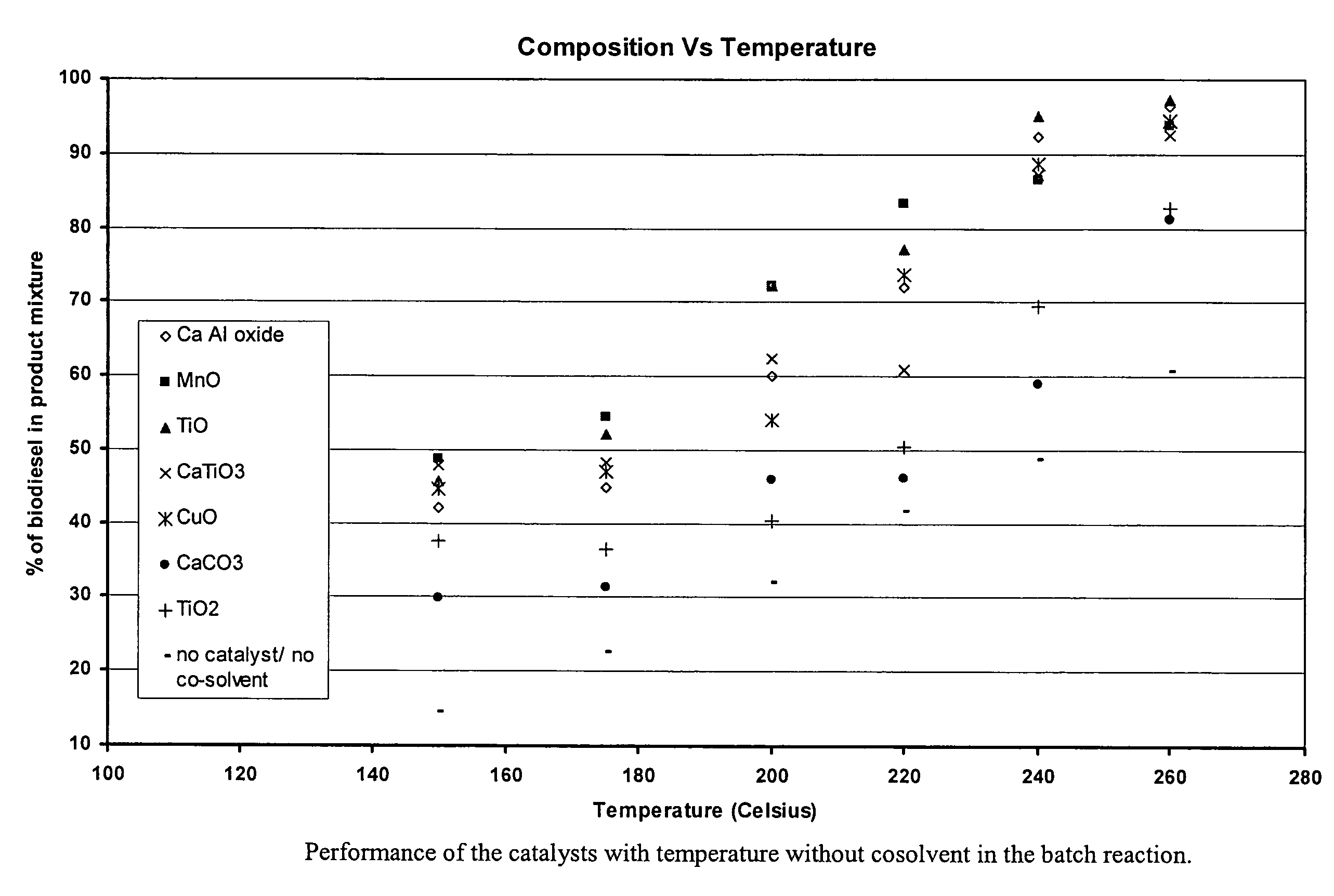

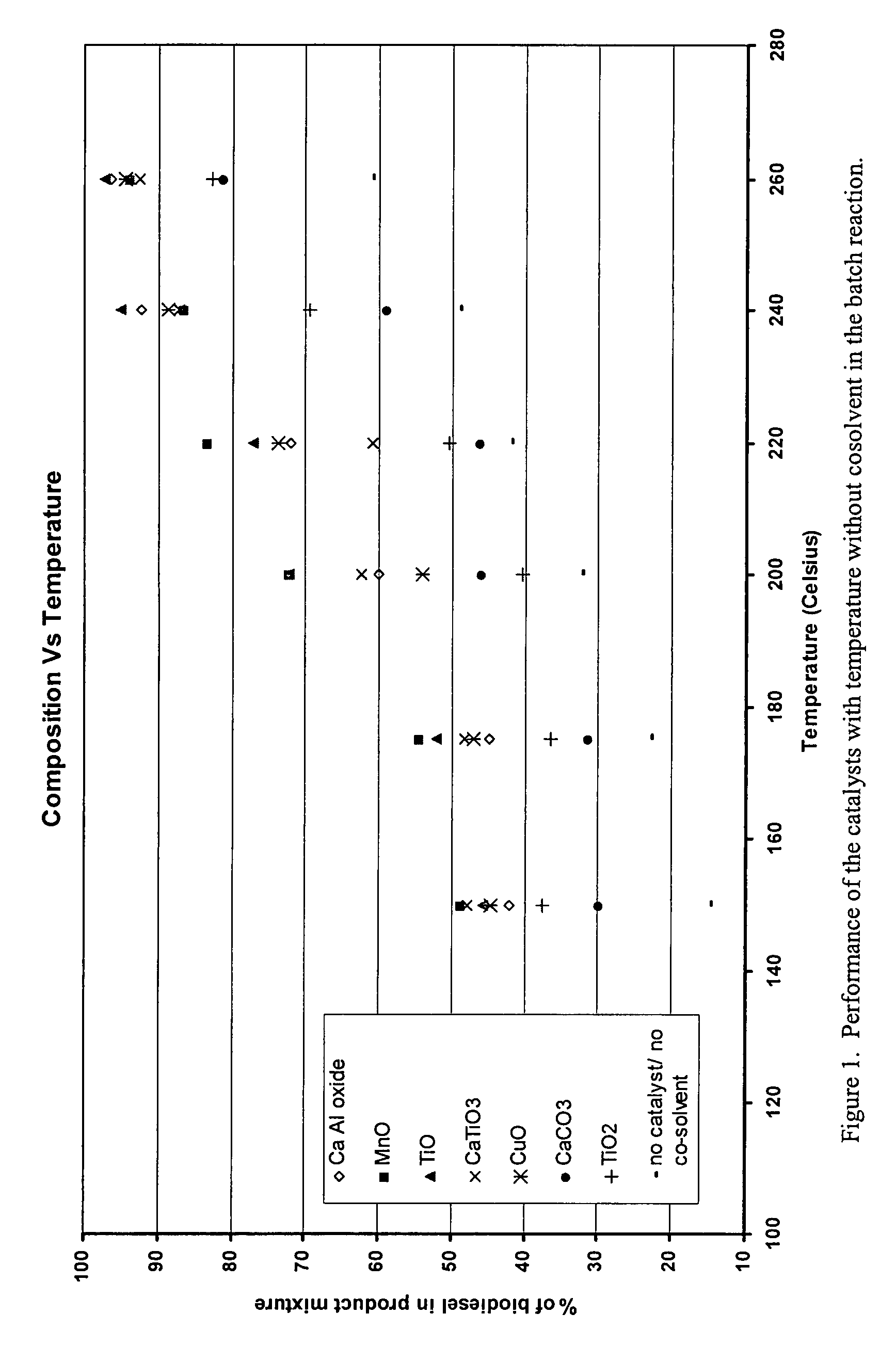

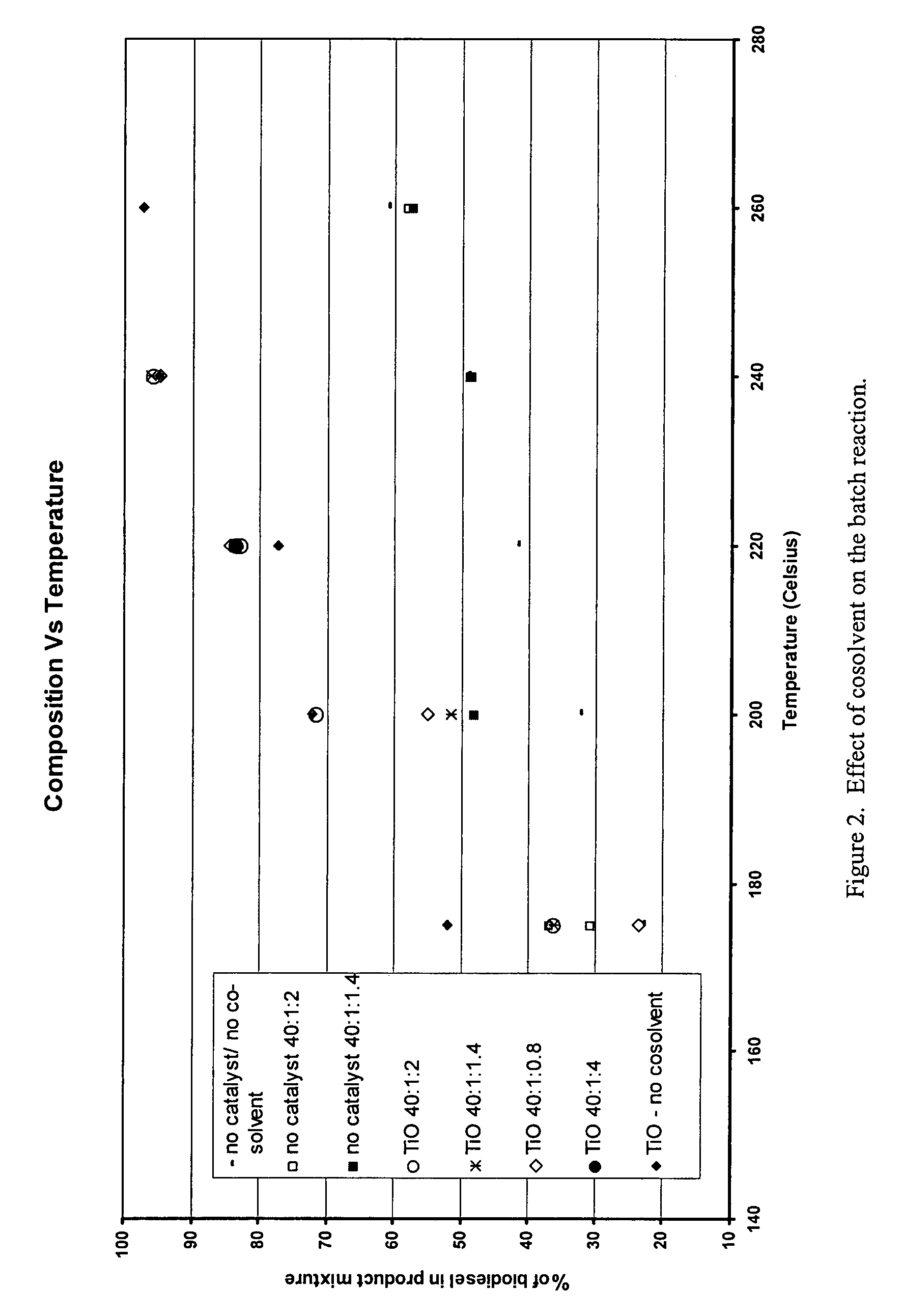

Methods for improved manufacture of green biodiesel focus on the selection and use of one or more solid metallic oxide base catalyst(s) selected from the group consisting of calcium oxide (CaO), calcium aluminum oxide (CaO—Al2O3), calcium titanate (CaTiO3), barium titanate (BaTiO3), magnesium aluminum oxide (MgO—Al2O3), zinc oxide (ZnO), copper (II) oxide (CuO), nickel oxide (NiO), manganese oxide (MnO), titanium oxide (TiO), vanadium oxide (VO), cobalt oxide (CoO), iron oxide (FeO), chromite (FeCr2O4), hydrotalcite (Mg6Al2(CO3)(OH)16.4(H2O), magnetite (Fe3O4), magnesium silicate and calcium silicate.

Owner:PENN STATE RES FOUND

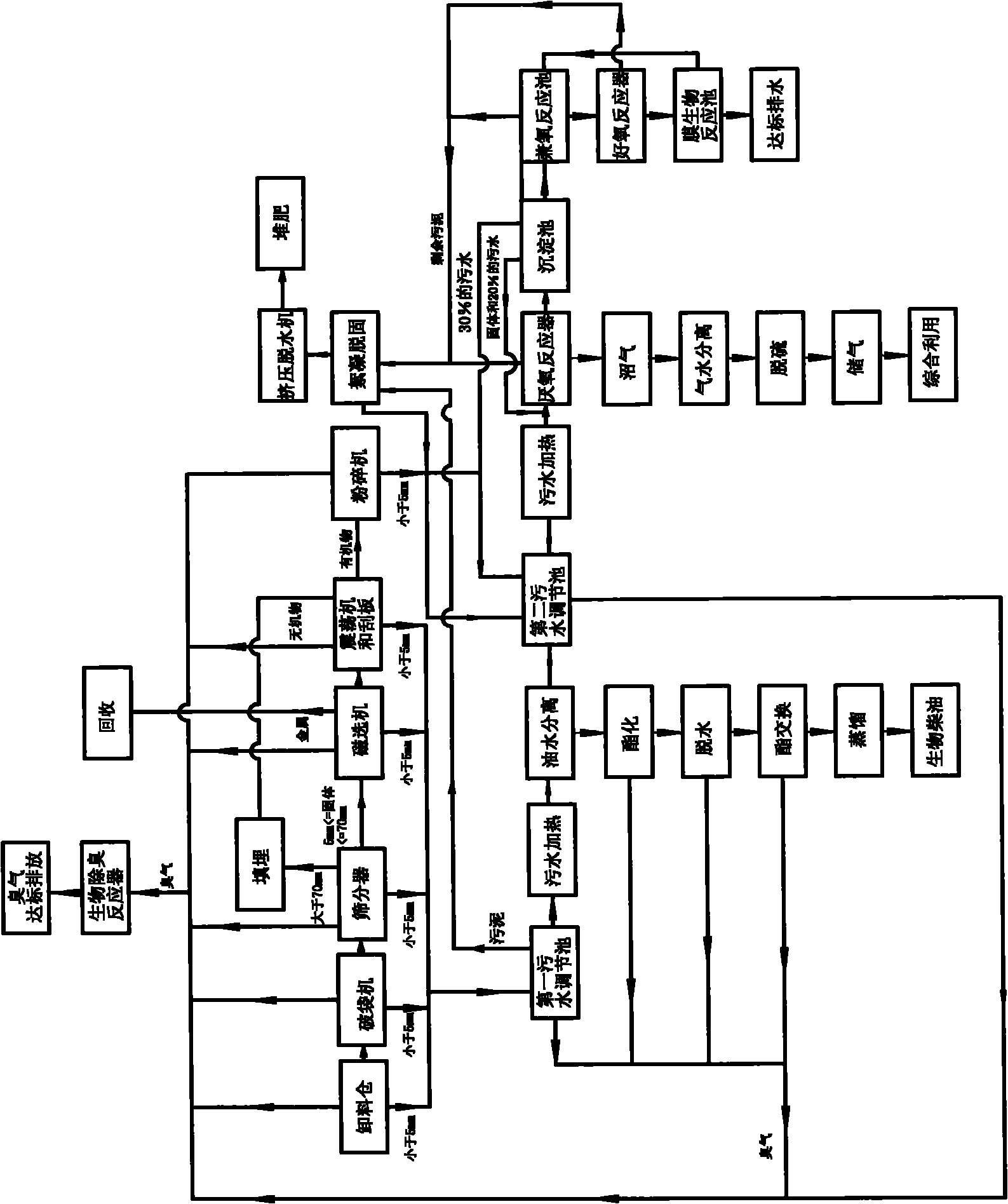

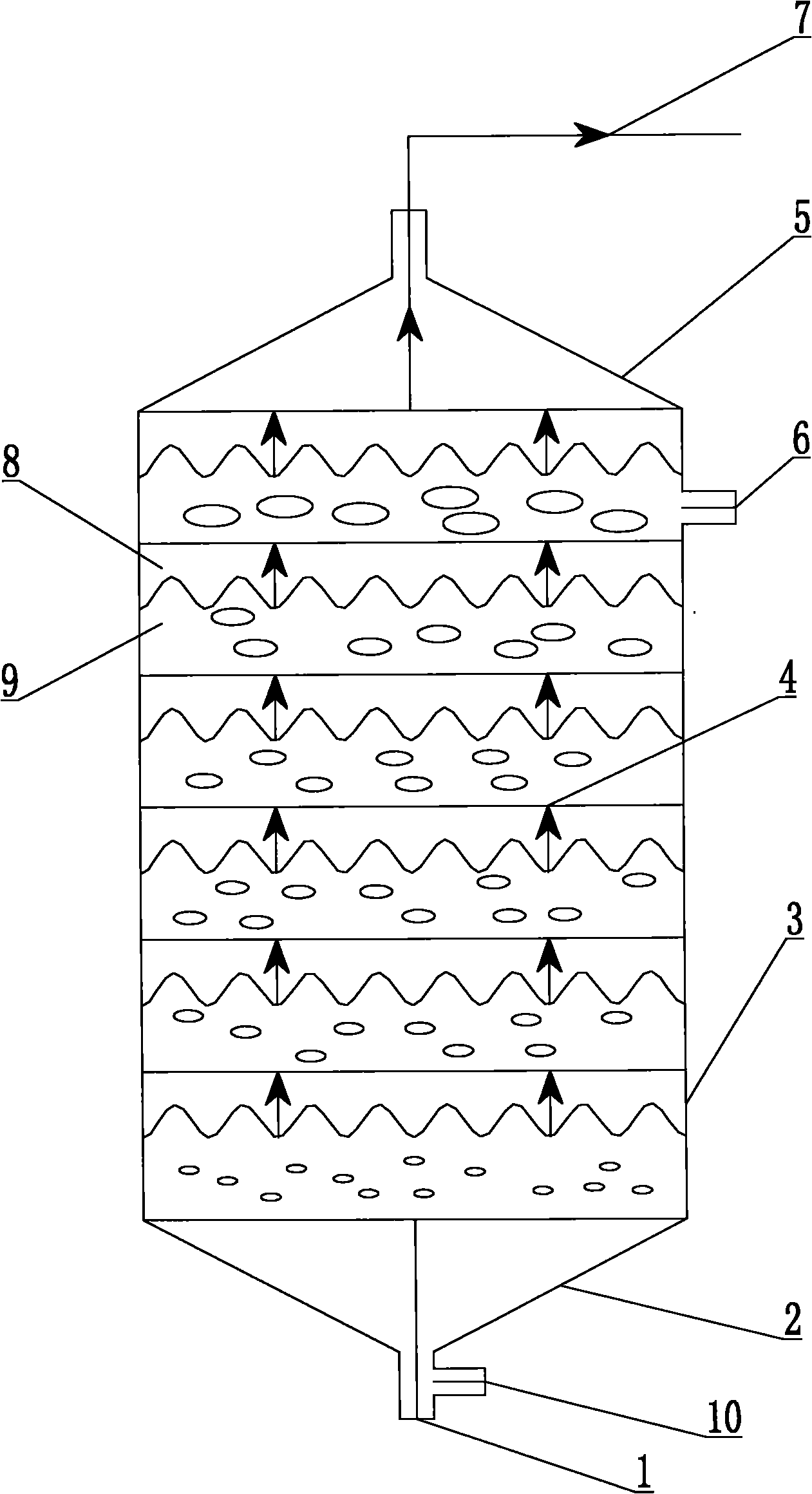

Centralized kitchen waste treatment method

ActiveCN101837366ARealize harmless treatmentRecycling is possibleFatty oils/acids recovery from wasteBio-organic fraction processingResource utilizationOil water

The invention relates to a centralized kitchen waste treatment method which comprises the following steps of: (A) sorting kitchen waste; (B) separating oil from water; (C) treating oil; (D) treating sewage; and (E) treating odor. Compared with a traditional kitchen waste burying method, by using the centralized kitchen waste treatment method, a great amount of soil is saved and an available methane resource is generated, kitchen waste reaches 100 percent of harmlessness, more than 95 percent of resource utilization and more than 95 percent of quantitative reduction, and the harmless treatmentof waste and the recycle of resources are truly realized.

Owner:北京昊业怡生科技有限公司

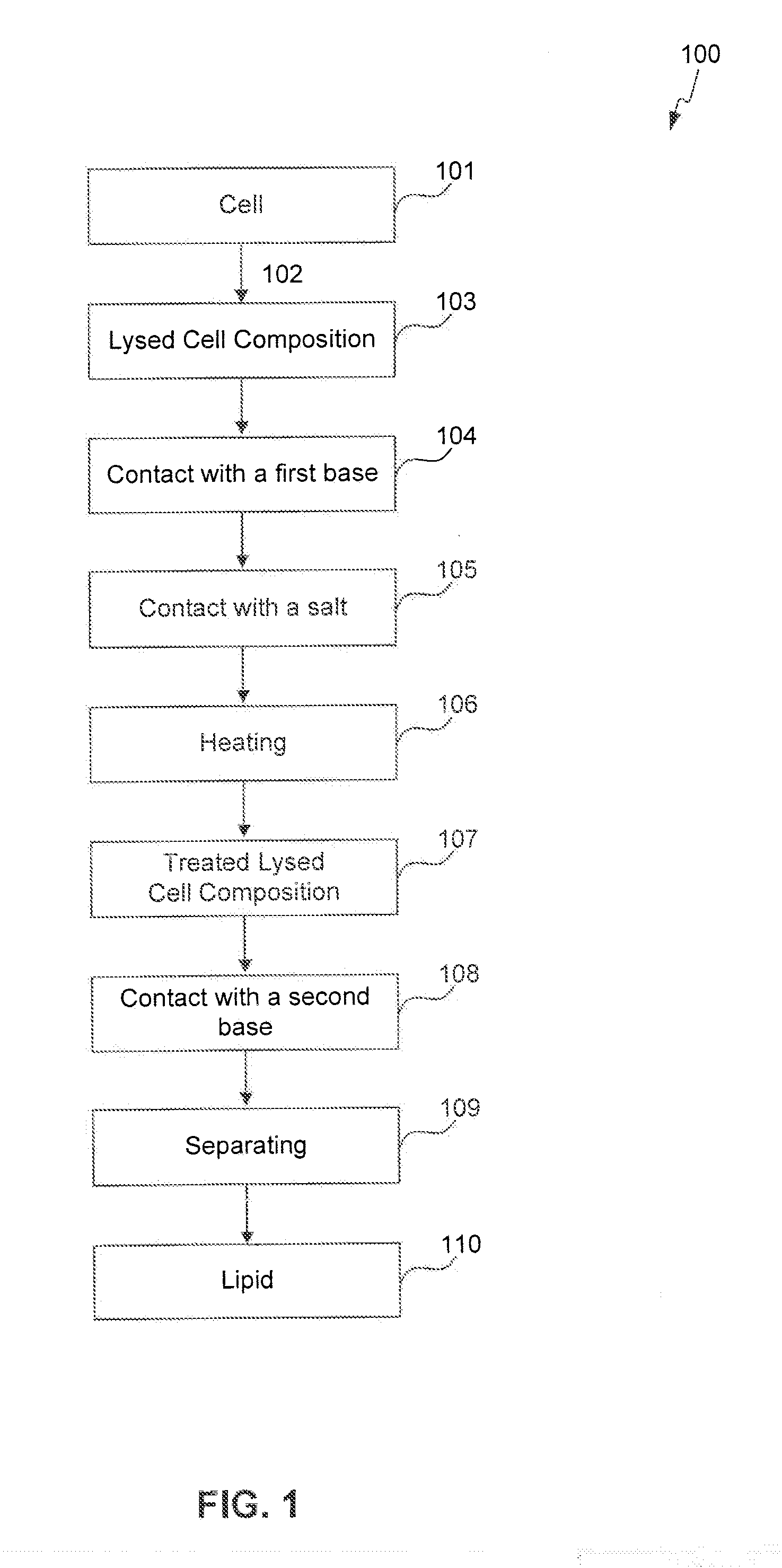

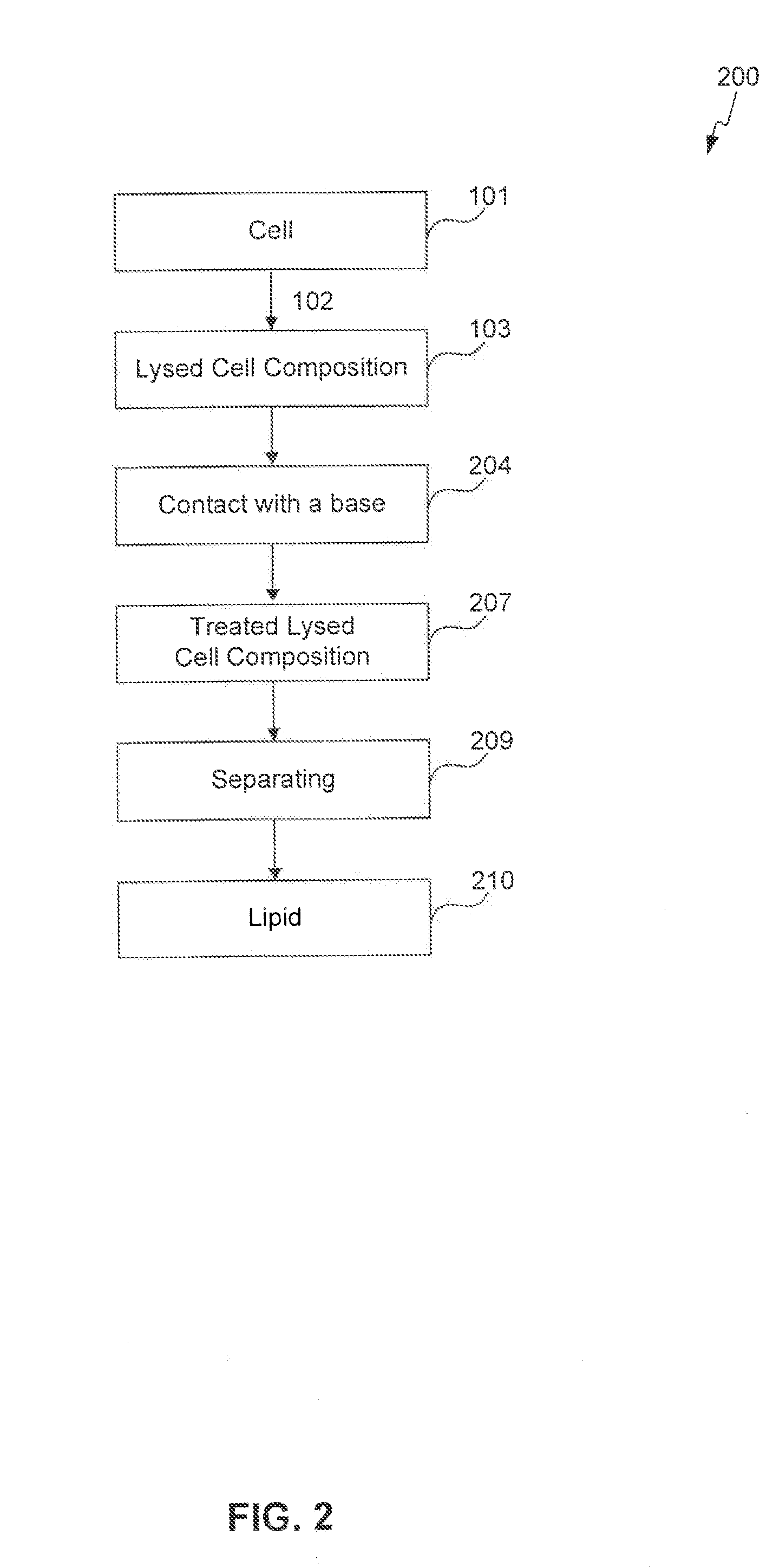

Extraction of Lipid From Cells and Products Therefrom

ActiveUS20110295028A1Fatty oils/acids recovery from wasteOrganic compound preparationBiochemistryPeroxide value

The present invention relates to processes for obtaining a lipid from a cell by lysing the cell, contacting the cell with a base and / or salt, and separating the lipid. The present invention is also directed to a lipid prepared by the processes of the present invention. The present invention is also directed to microbial lipids having a particular anisidine value, peroxide value, and / or phosphorus content.

Owner:DSM IP ASSETS BV

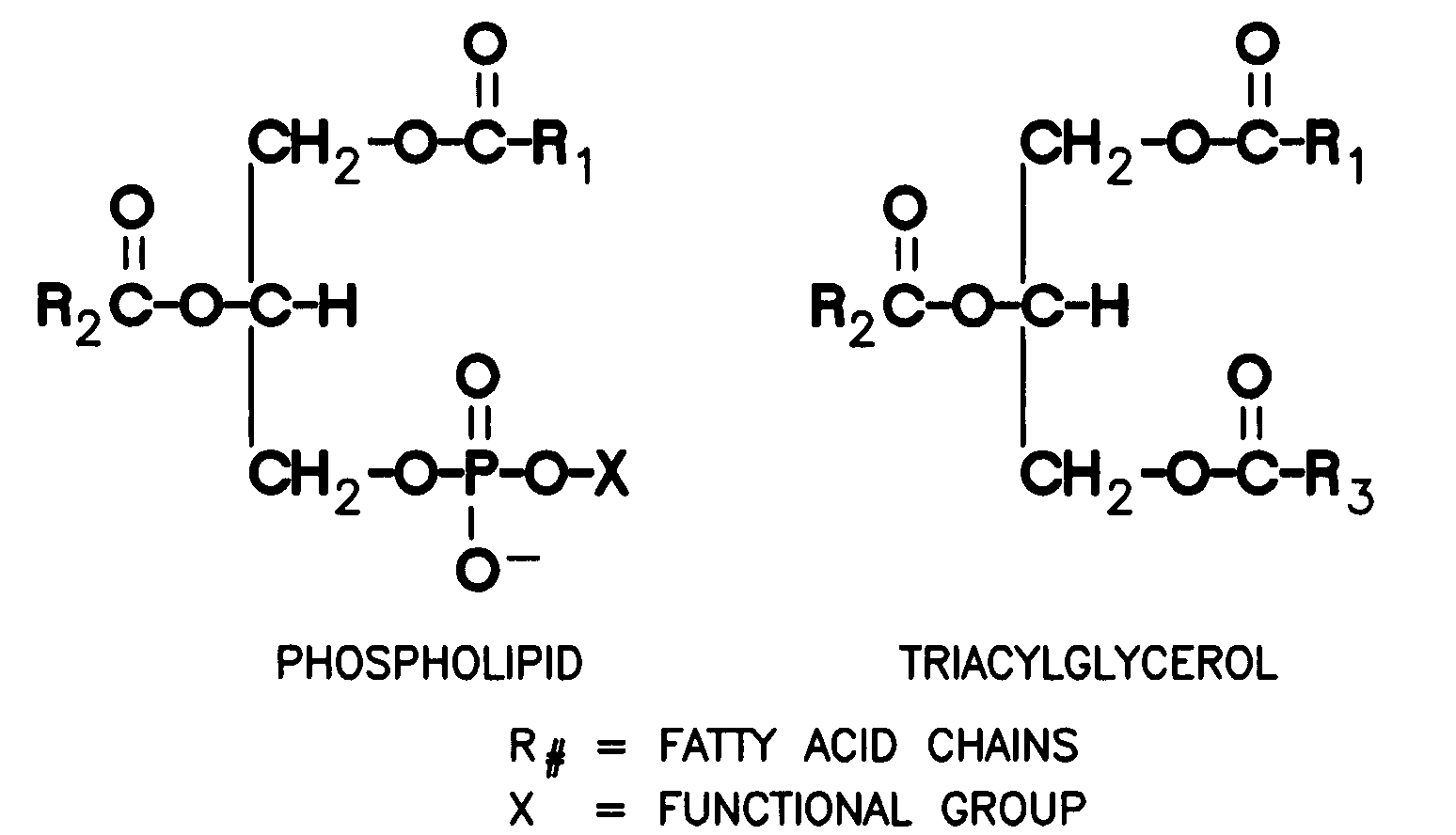

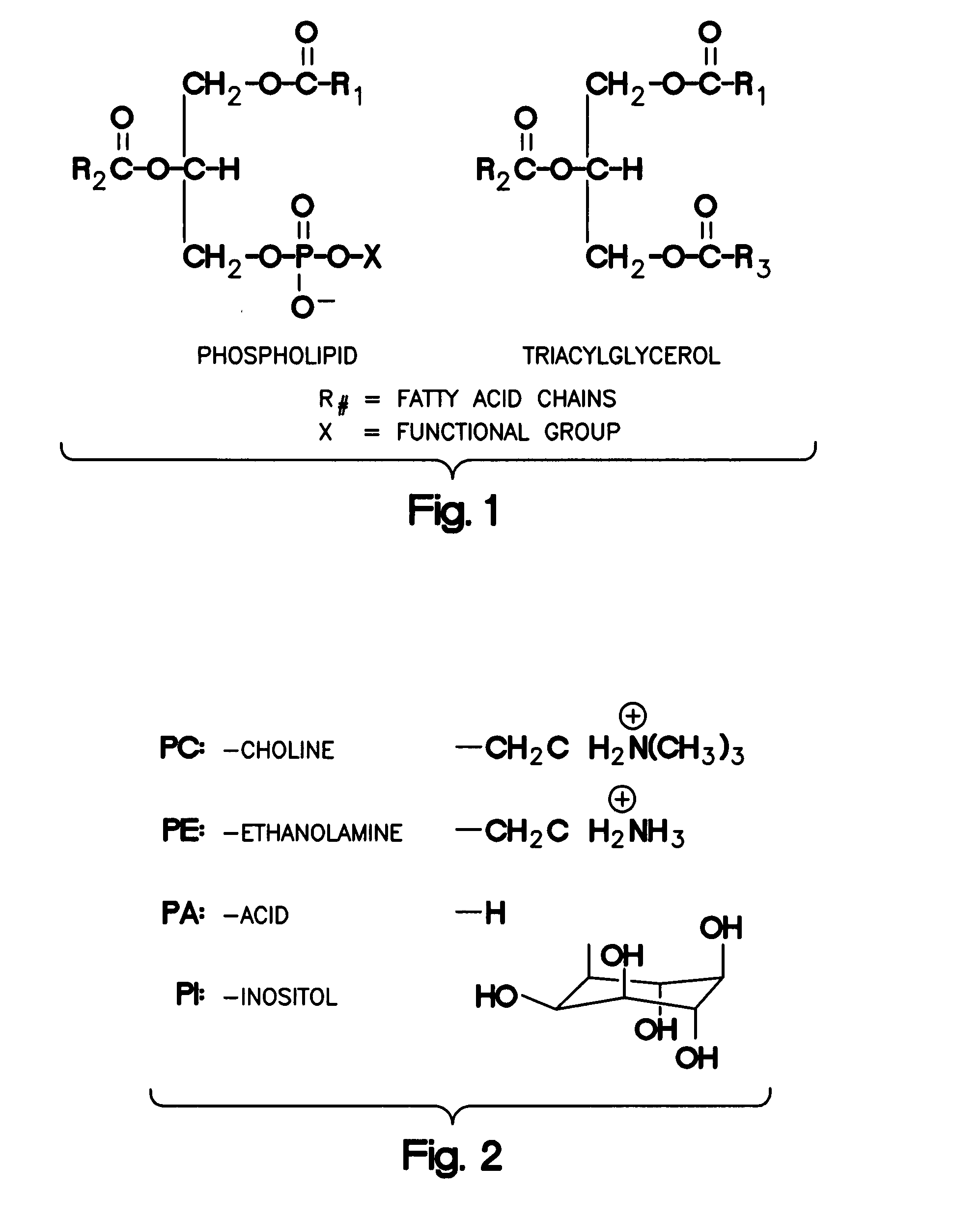

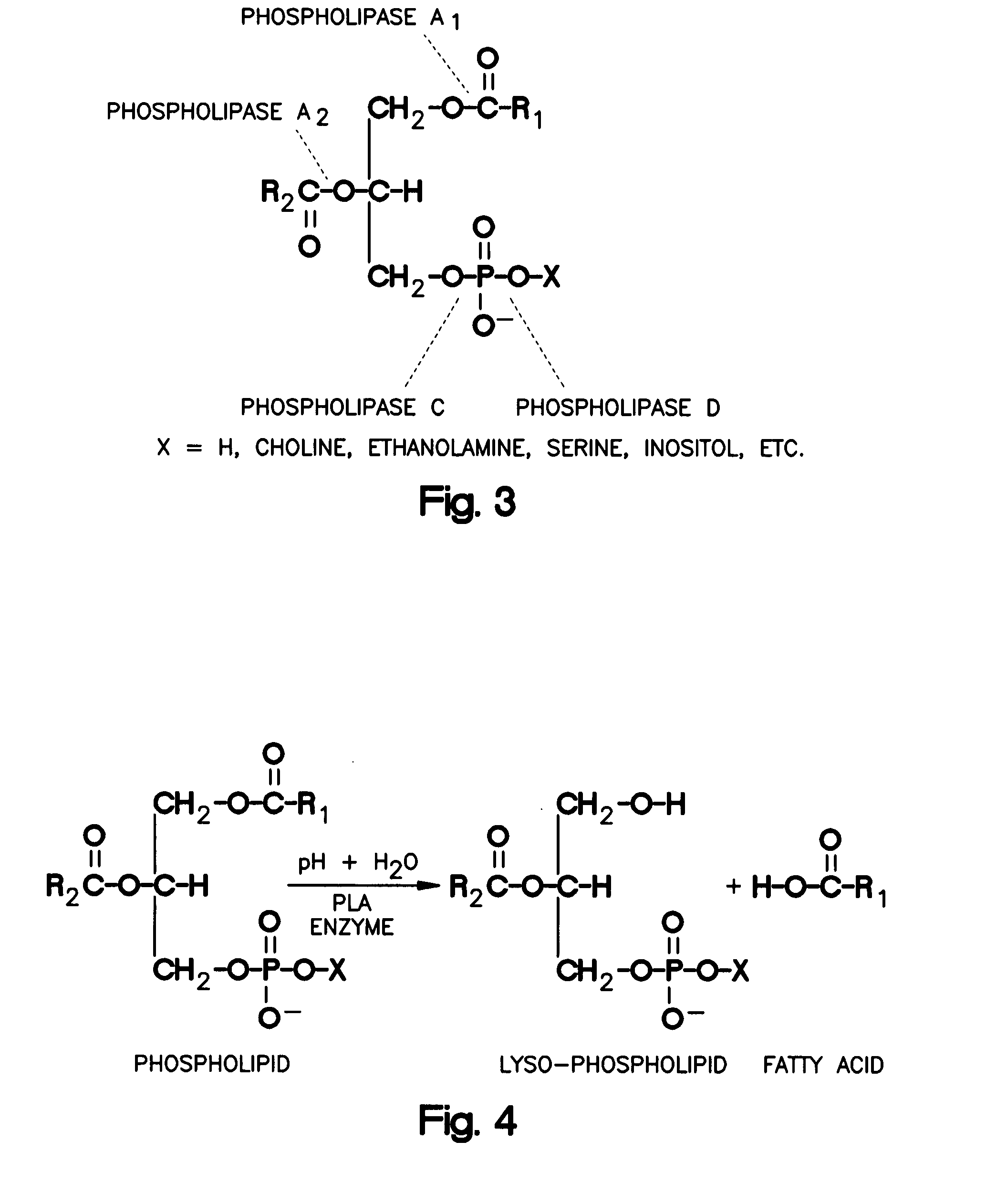

Enzymatic Degumming Utilizing a Mixture of PLA and PLC Phospholipases

ActiveUS20080182322A1Suitable for useLow in phospholipidsFatty oils/acids recovery from wasteFatty acids production/refiningPhospholipidPhospholipases C

A method for degumming an oil composition comprises the steps of (a) providing an oil composition containing a quantity of phospholipids, (b) contacting said oil composition simultaneously with one or more phospholipase A enzymes and one or more phospholipase C enzymes, under conditions sufficient for the enzymes to react with the phospholipids to create phospholipid reaction products, and (c) separating the phospholipids reaction products from the oil composition, the remaining oil composition after the separation being a degummed oil composition, whereby during step (b) the reaction of said one or more phospholipase A enzymes proceeds at a faster rate than it would in the absence of said one or more phospholipase C enzymes.

Owner:BUNGE OILS INC

Apparatus and method for the production of fatty acid alkyl ester

InactiveUS20050027137A1Eliminate operationShort possible reaction timeFatty oils/acids recovery from wasteAnalysis using chemical indicatorsAlcoholVegetable oil

An apparatus and method for producing fatty acid alkyl esters from fatty acids derived from vegetable oils and animal fats with an alkaline solution dissolved in stoichiometric or near stoichiometric levels of a monoalkyl alcohol to form a mixture. The method further comprises emulsifying the mixture as a means to reach a completed chemical reaction state in a reactor section, wherein the oils or fats are transesterified into fatty acid alkyl esters. The transesterification occurs when the natural boundary surfaces of the immiscible mixture are enlarged by ultrasonic cavitation in the reaction section and the transesterification is performed at, or near atmospheric pressure. The method finally includes, after reaching the chemical reaction state, separating residues from the fatty acid alkyl ester in a gravitational phase separation section.

Owner:HOOKER JEFFREY D

Popular searches

Refining to change hydrocarbon structural skeleton Hydrocarbon by hydrogenation Fatty-oils/fats refining Fatty-oils/fats separation Liquid hydrocarbon mixture production Treatment with hydrotreatment processes Bio-feedstock Hydrocarbon oils treatment products Refining to eliminate hetero atoms Molecular sieve catalyst

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com