Patents

Literature

350 results about "Degree Celsius" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Celsius scale, also known as the centigrade scale, is a temperature scale used by the International System of Units (SI). As an SI derived unit, it is used worldwide. In the United States, the Bahamas, Belize, the Cayman Islands and Liberia however, Fahrenheit remains the preferred scale for everyday temperature measurement. The degree Celsius (symbol: °C) can refer to a specific temperature on the Celsius scale or a unit to indicate a difference between two temperatures or an uncertainty. It is named after the Swedish astronomer Anders Celsius (1701–1744), who developed a similar temperature scale. Before being renamed to honor Anders Celsius in 1948, the unit was called centigrade, from the Latin centum, which means 100, and gradus, which means steps.

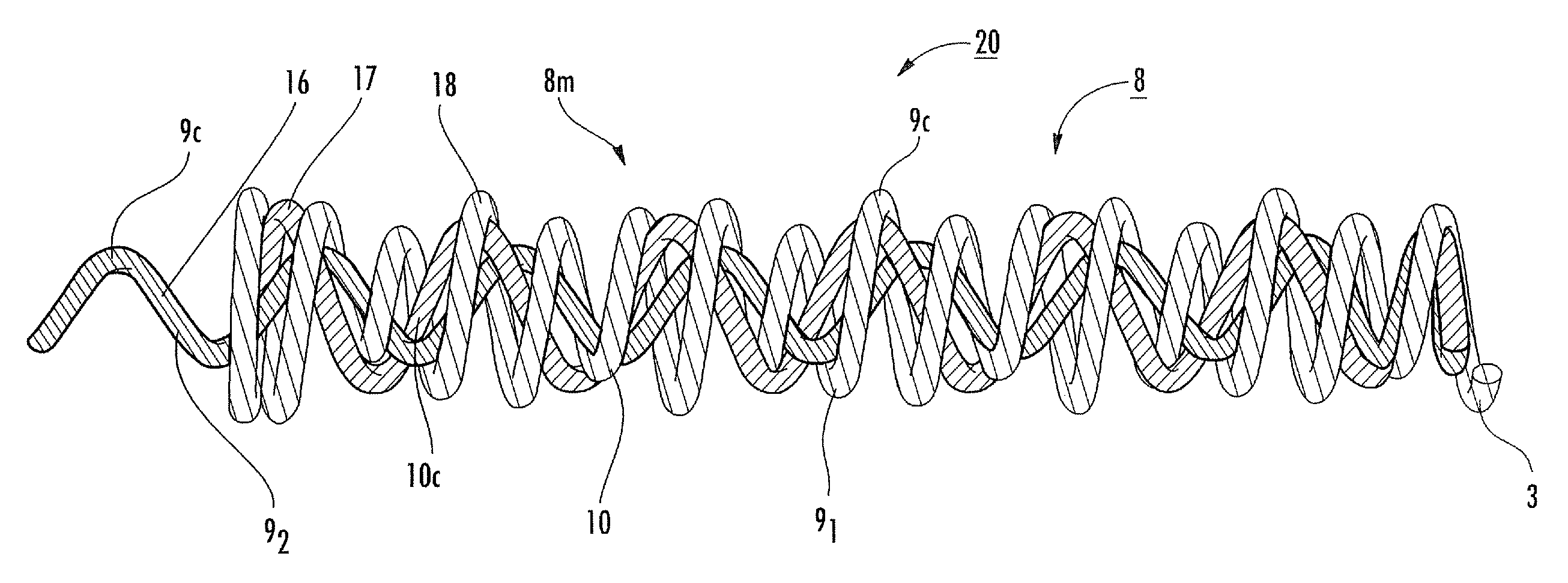

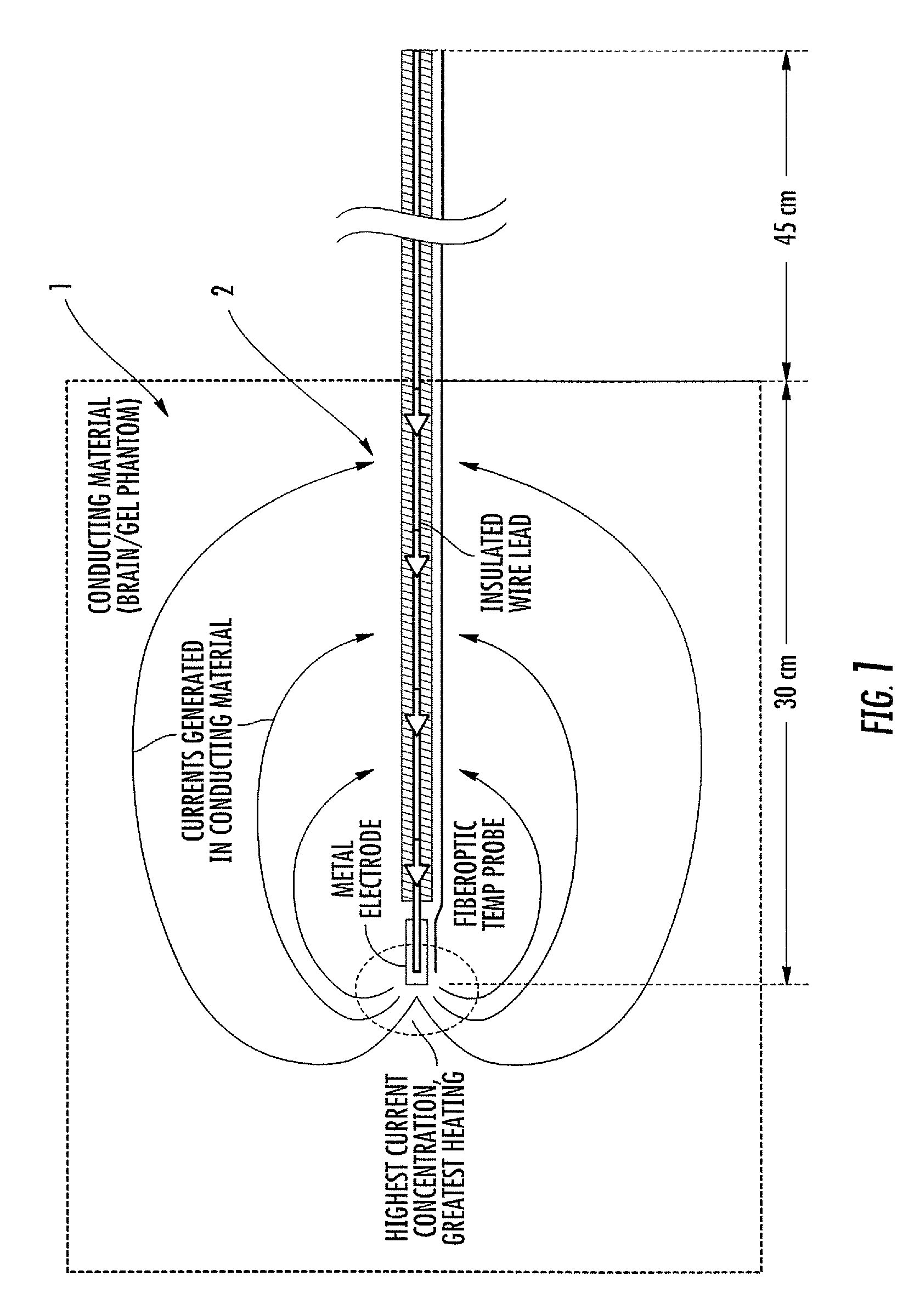

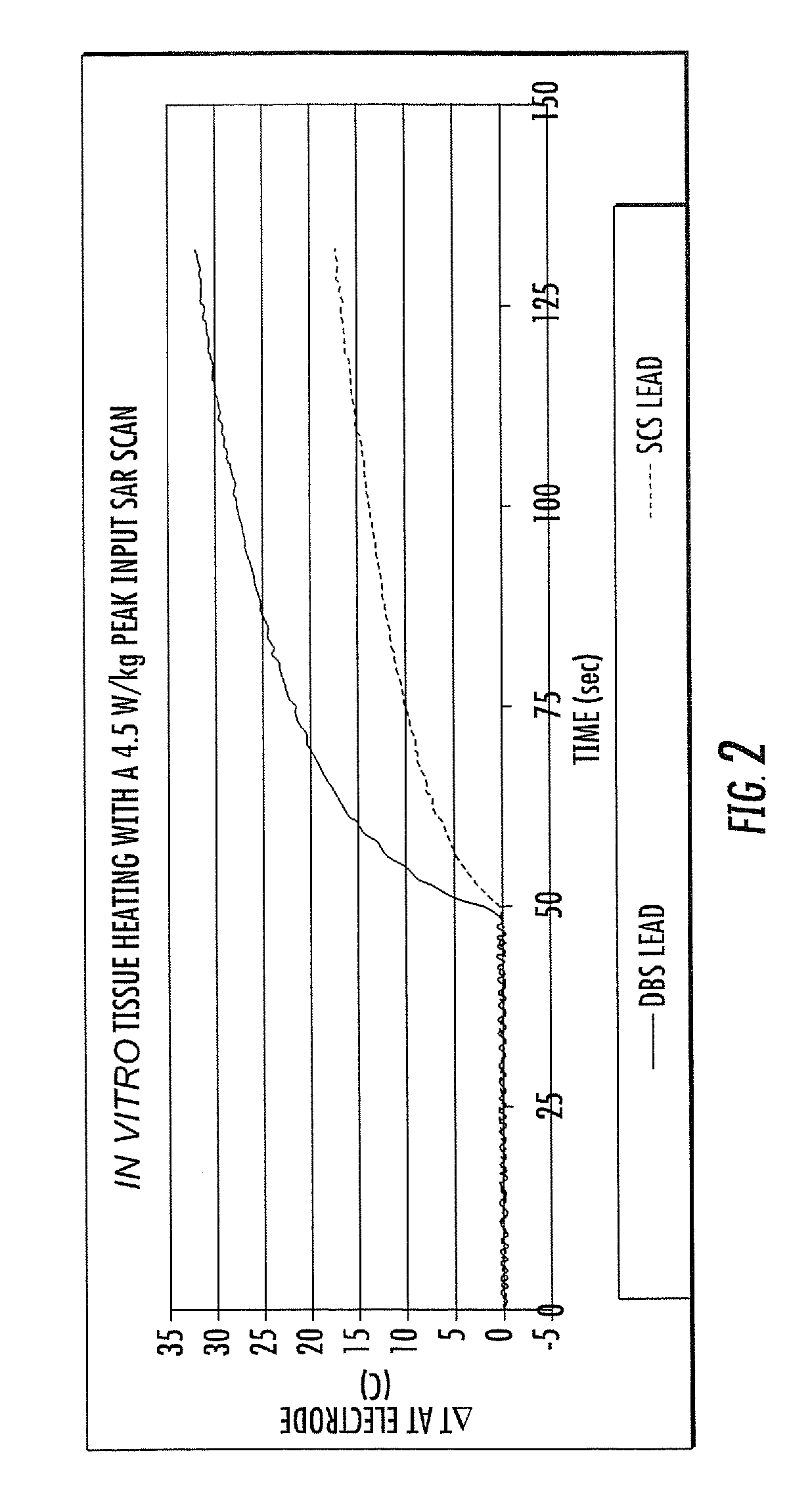

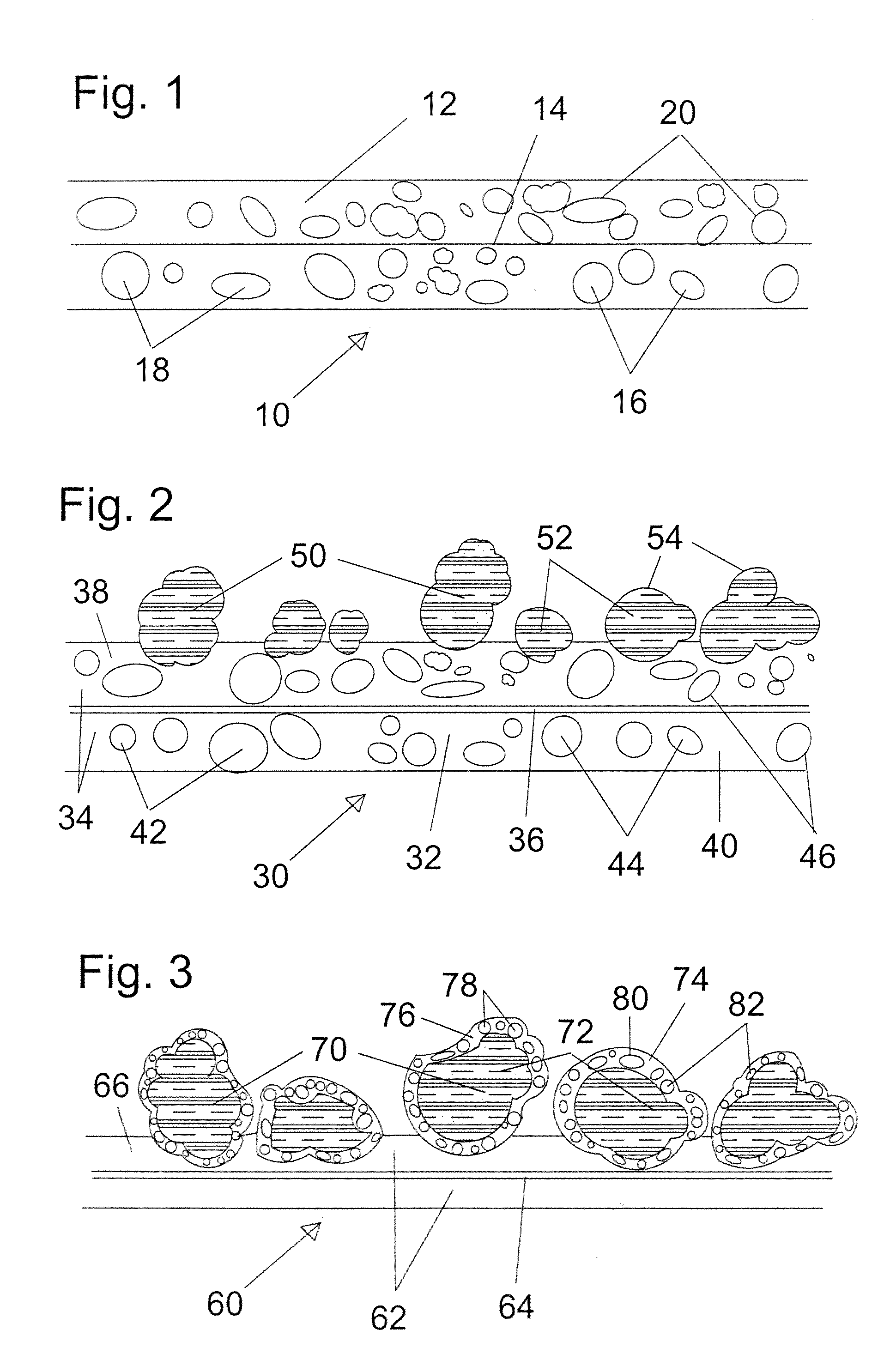

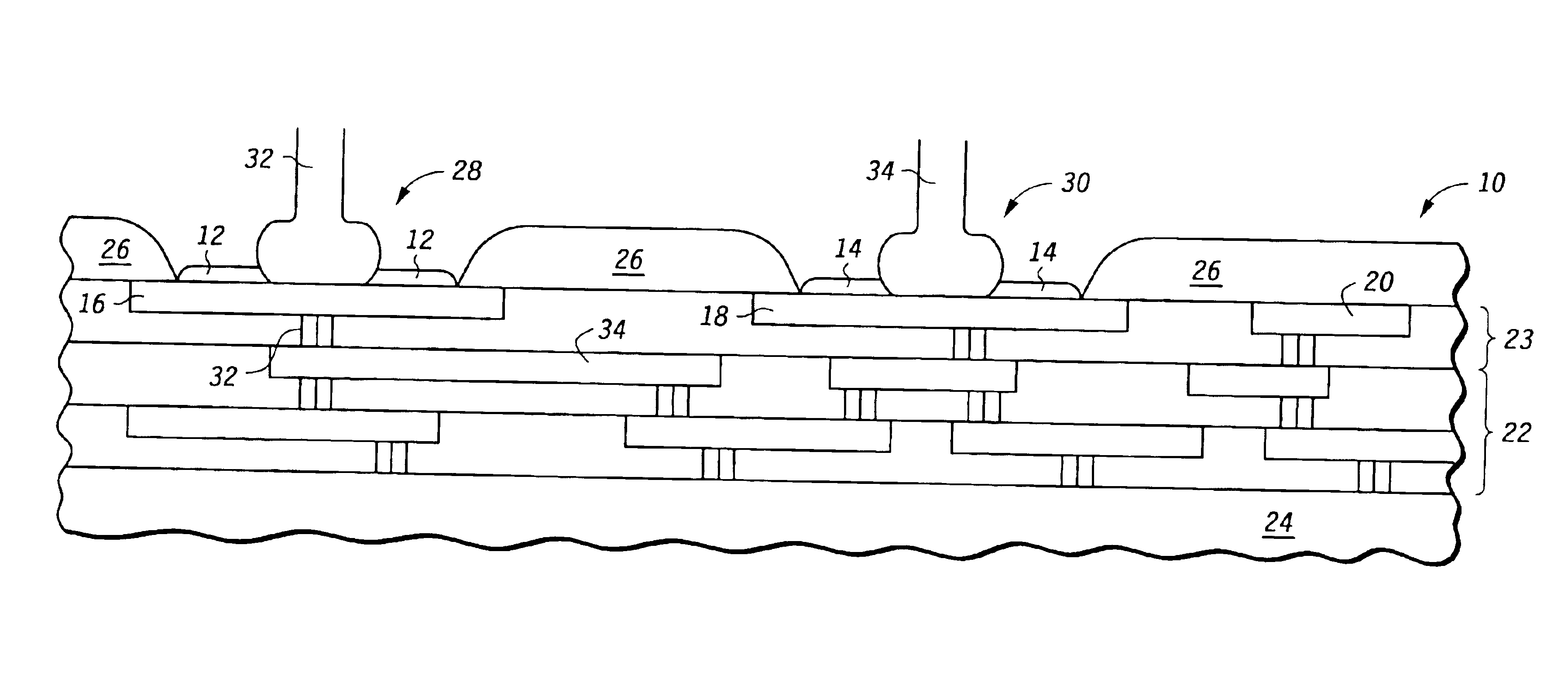

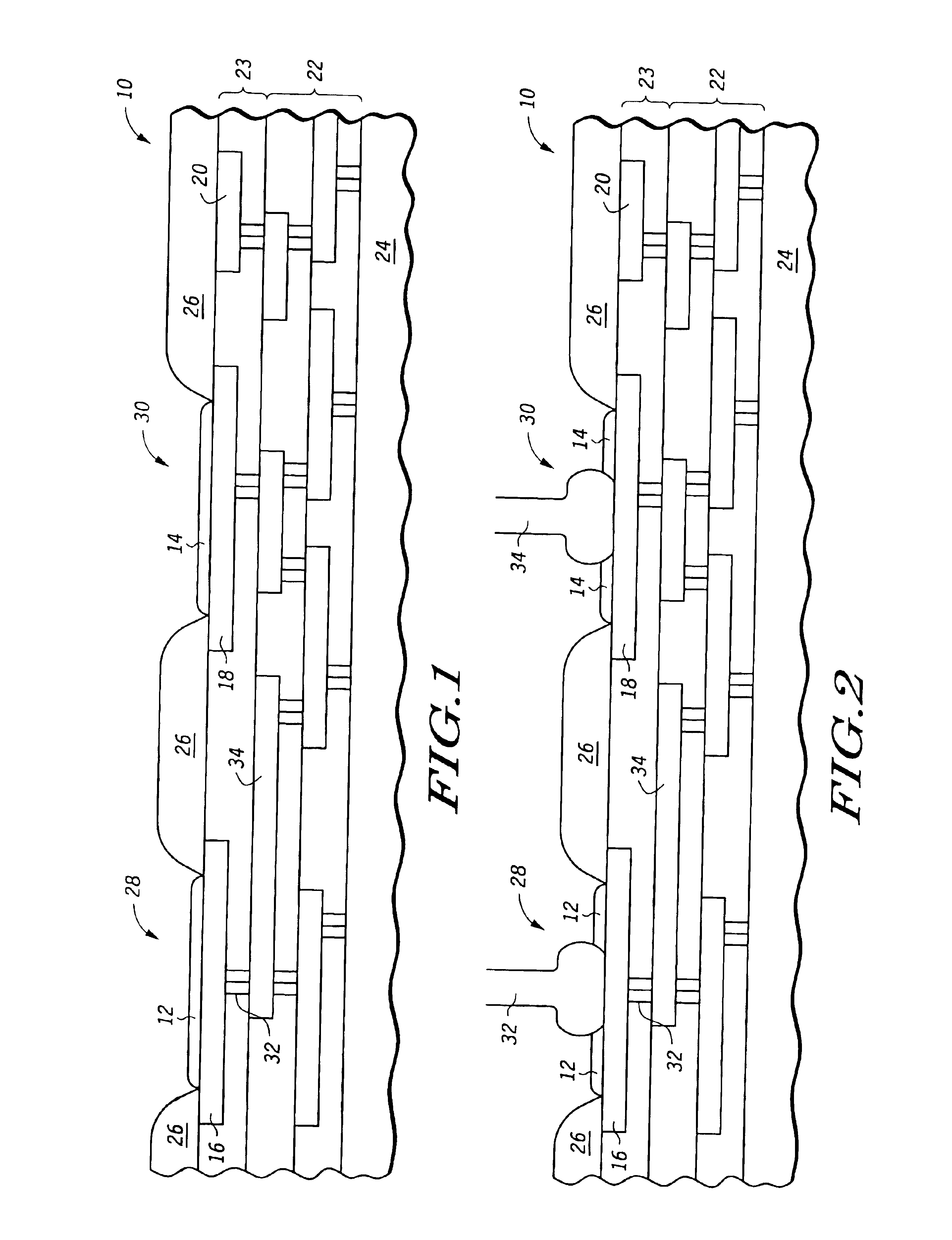

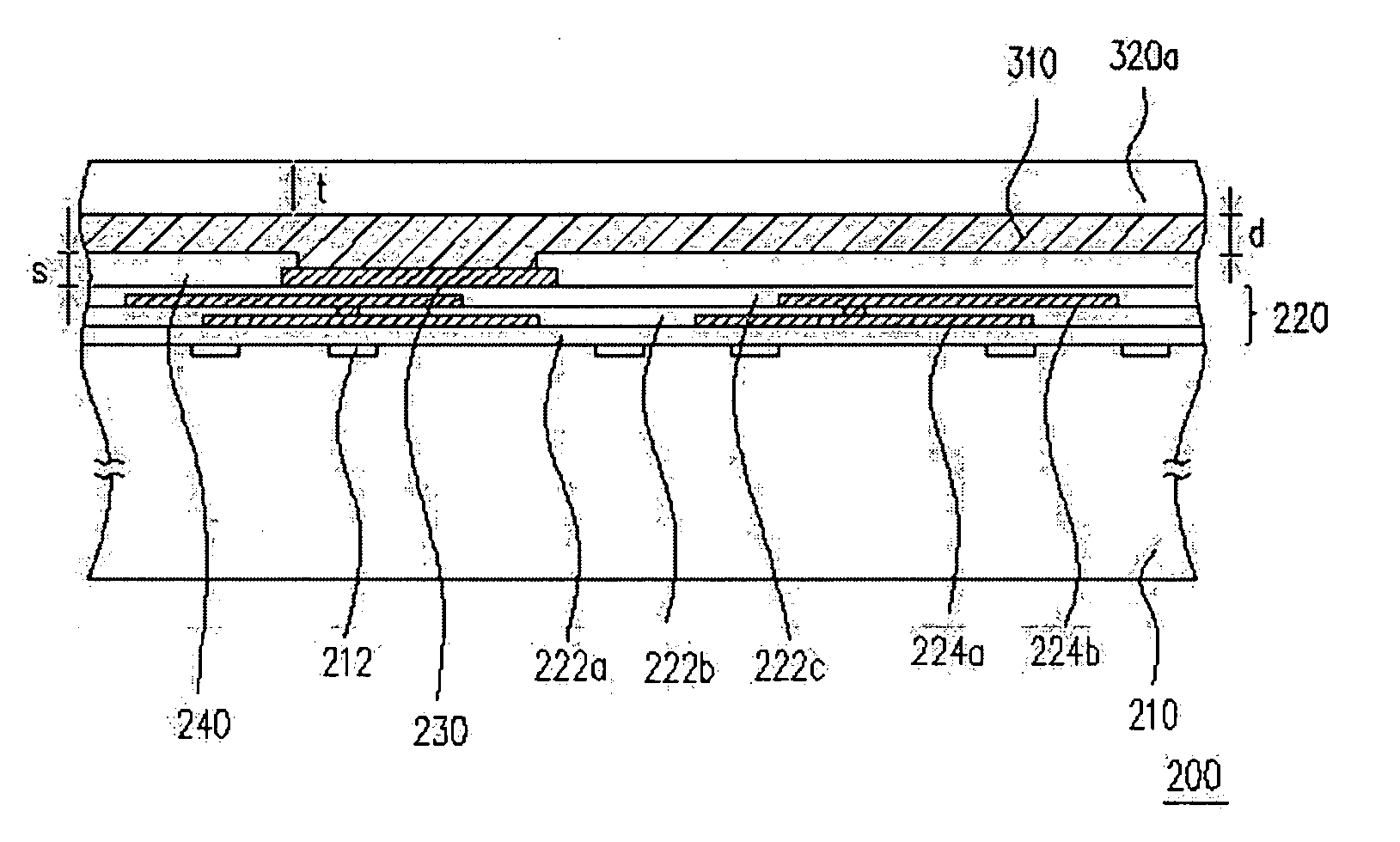

Methods and apparatus for fabricating leads with conductors and related flexible lead configurations

ActiveUS20080262584A1Prevent undesired heatingEasy to useInternal electrodesMaterial strength using steady bending forcesElectrical conductorDegree Celsius

MRI / RF compatible leads include at least one conductor, a respective conductor having at least one segment with a multi-layer stacked coil configuration. The lead can be configured so that the lead heats local tissue less than about 10 degrees Celsius (typically about 5 degrees Celsius or less) or does not heat local tissue when a patient is exposed to target RF frequencies at a peak input SAR of at least about 4 W / kg and / or a whole body average SAR of at least about 2 W / kg. Related leads and methods of fabricating leads are also described.

Owner:MRI INTERVENTIONS INC +1

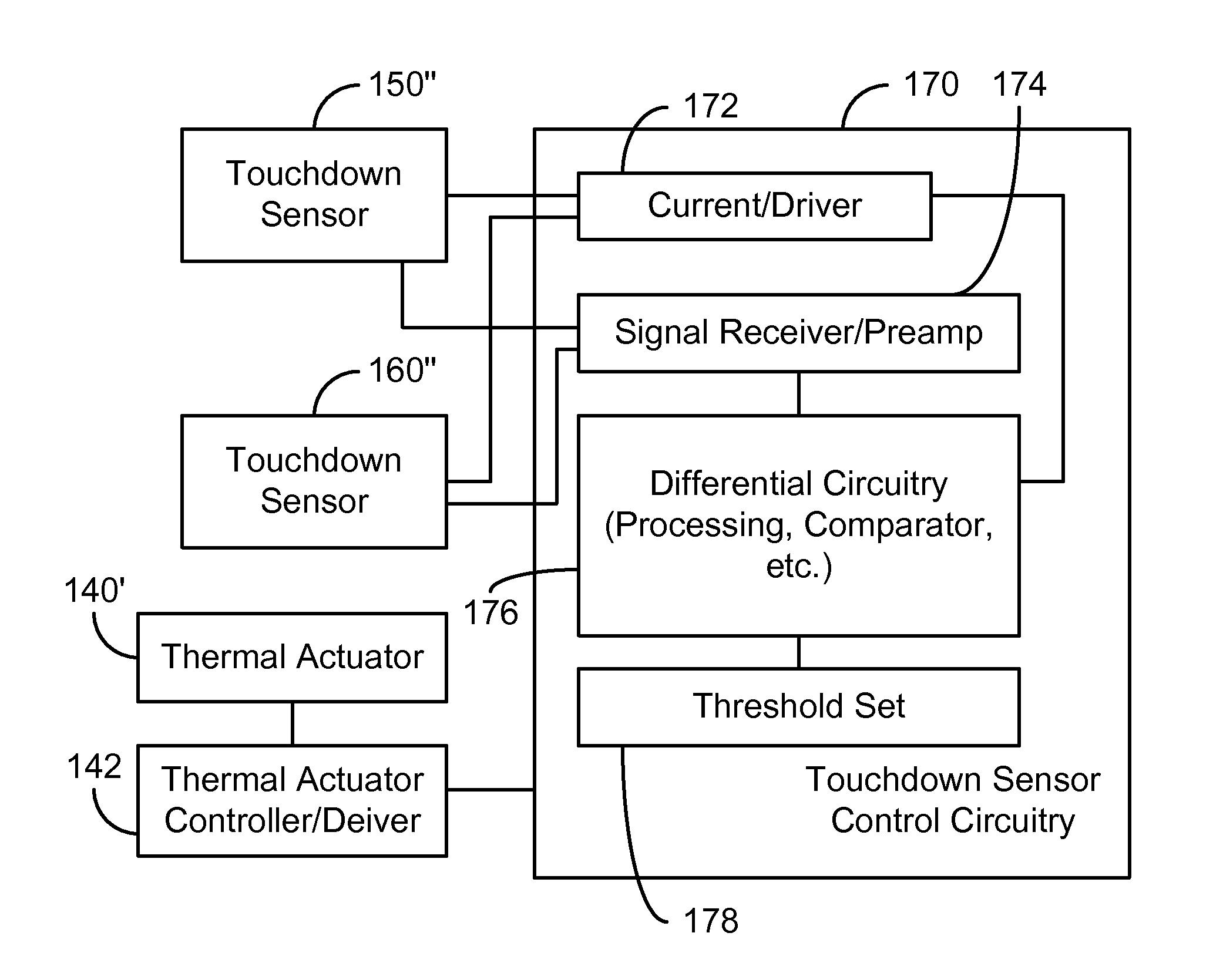

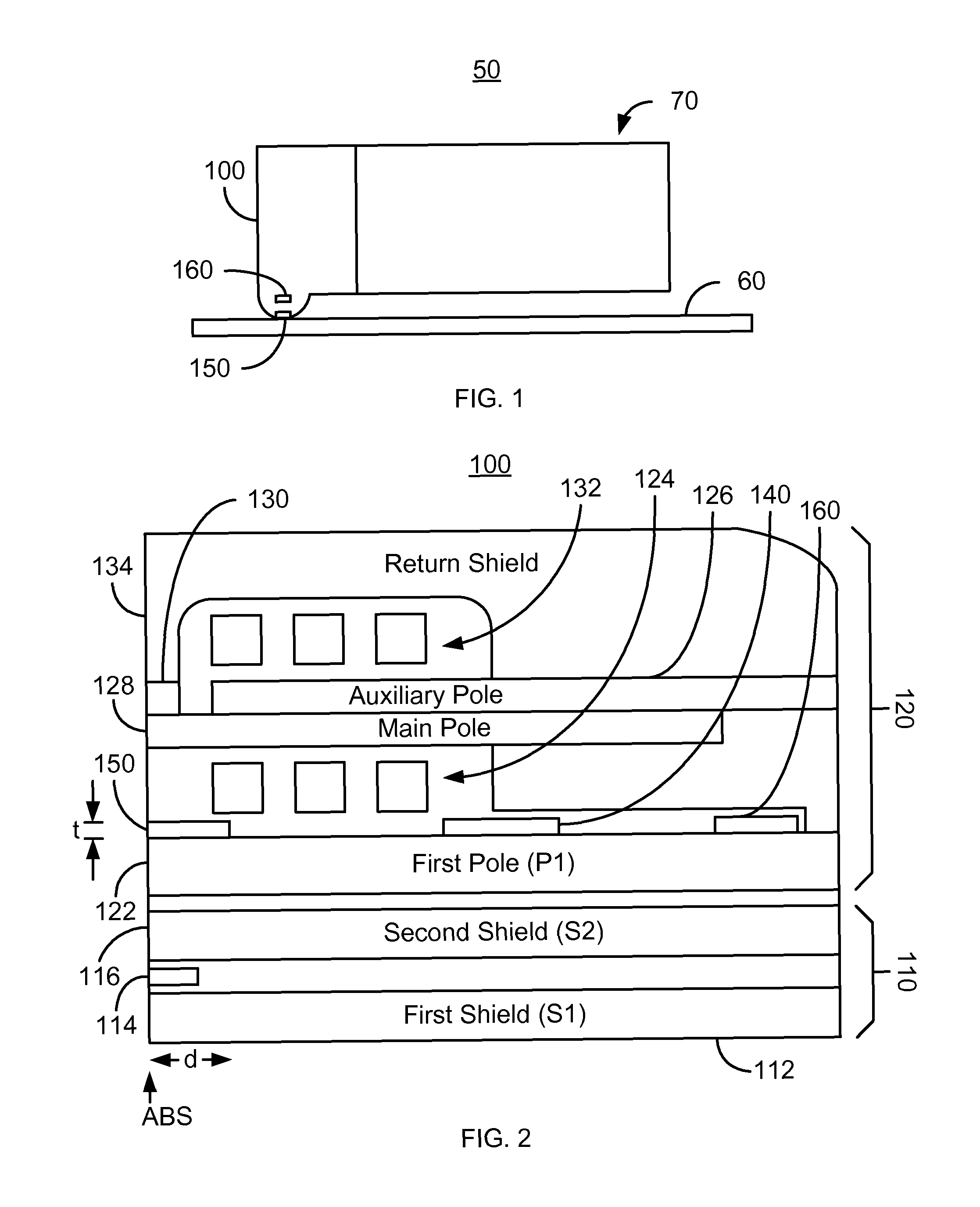

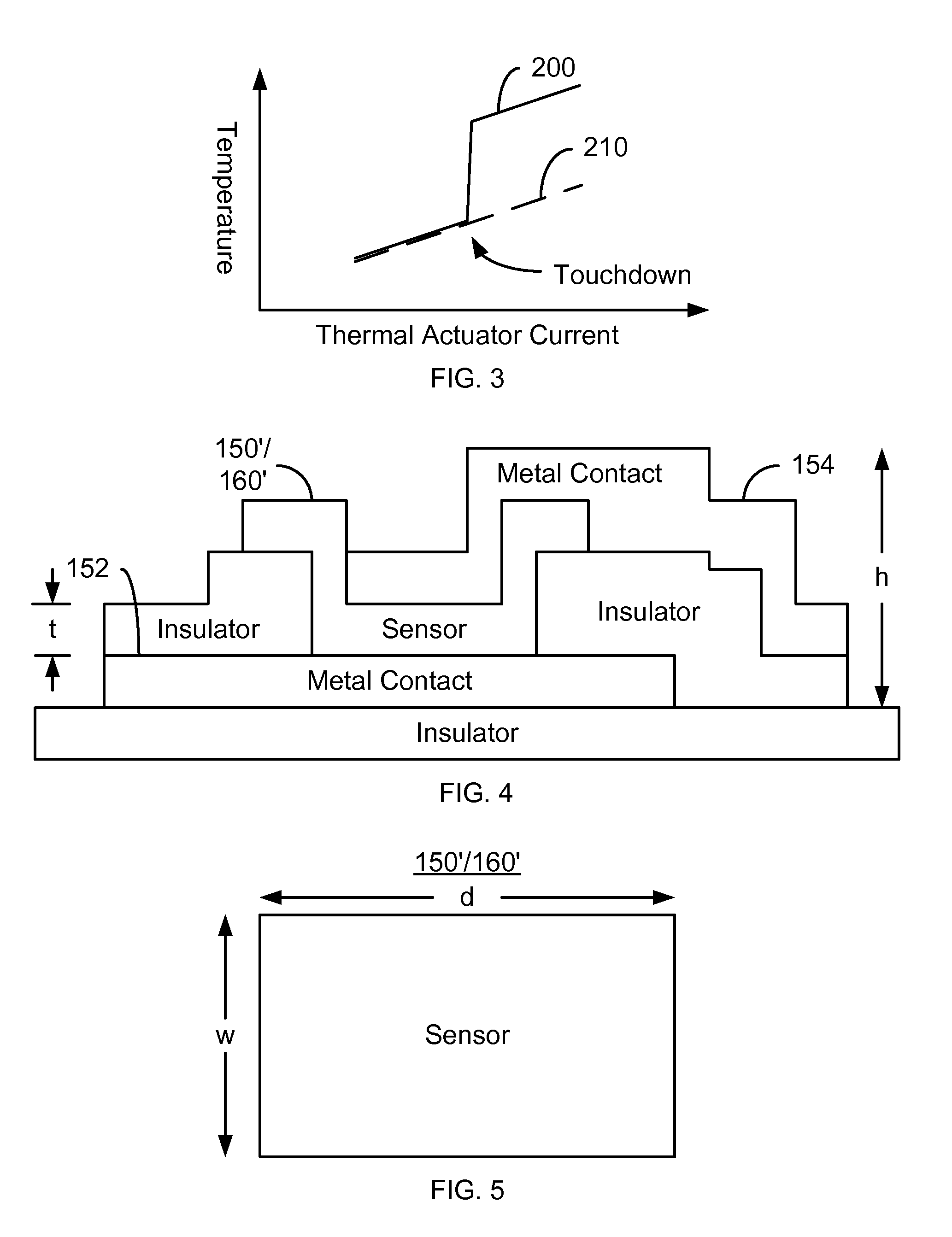

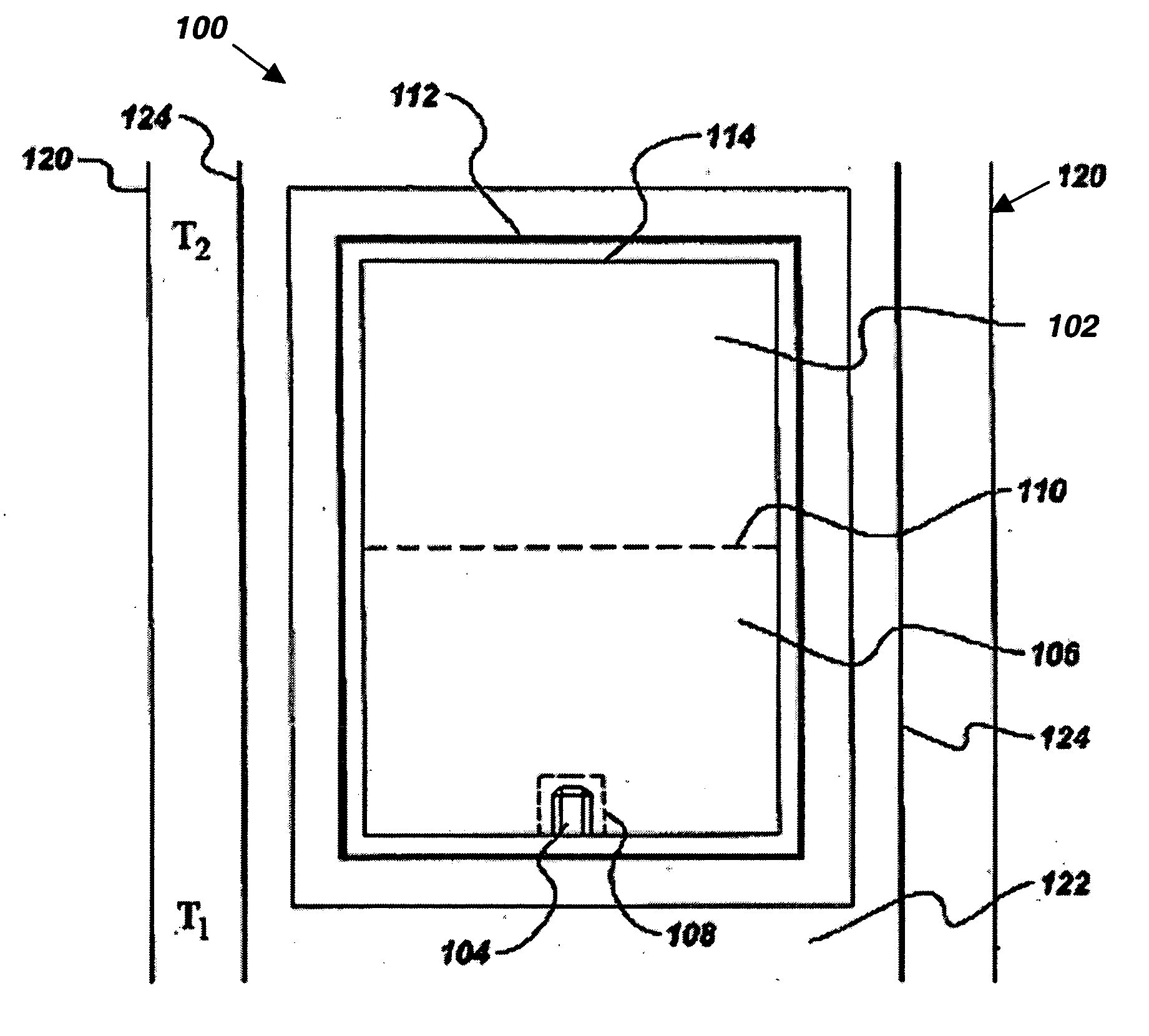

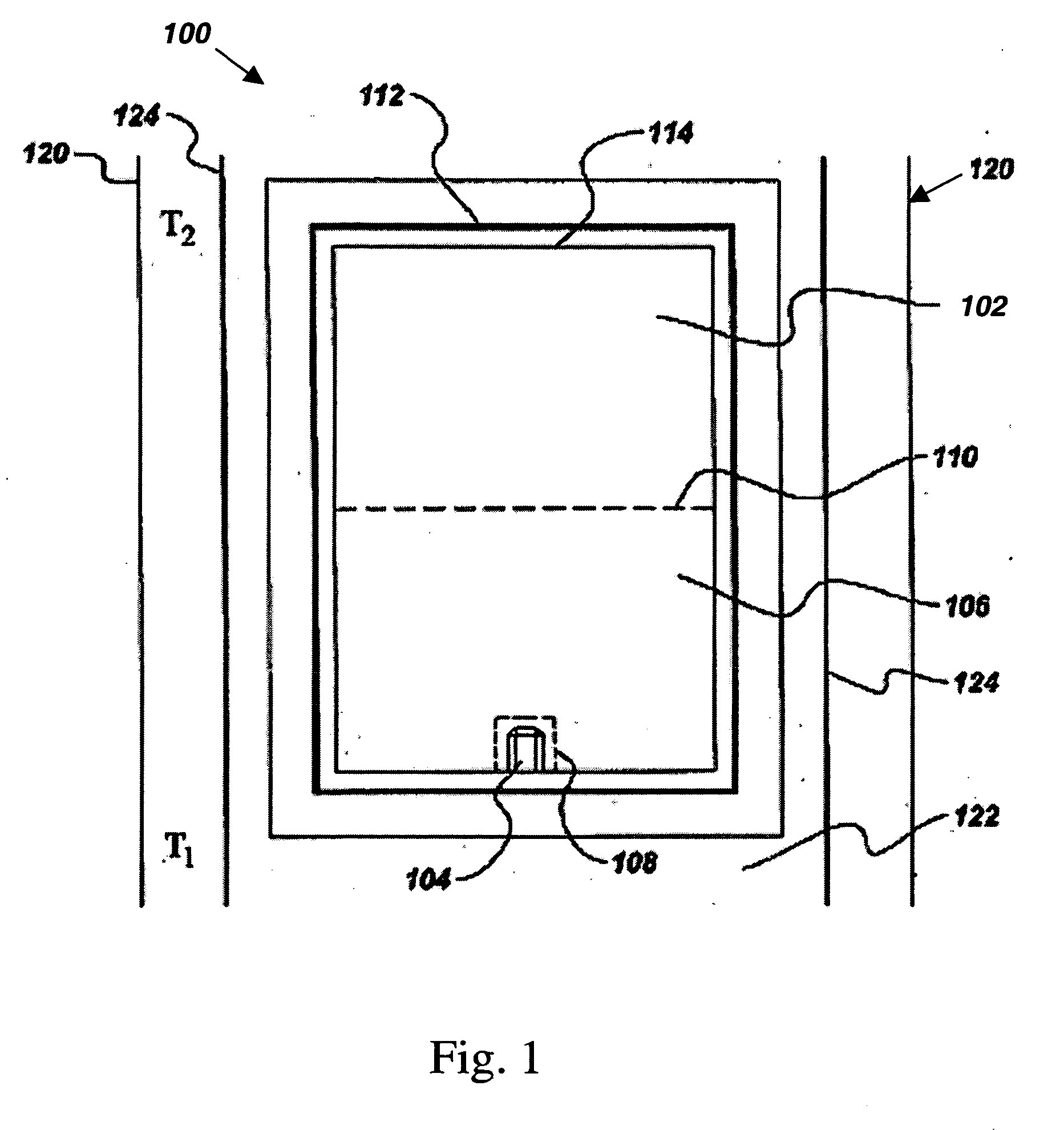

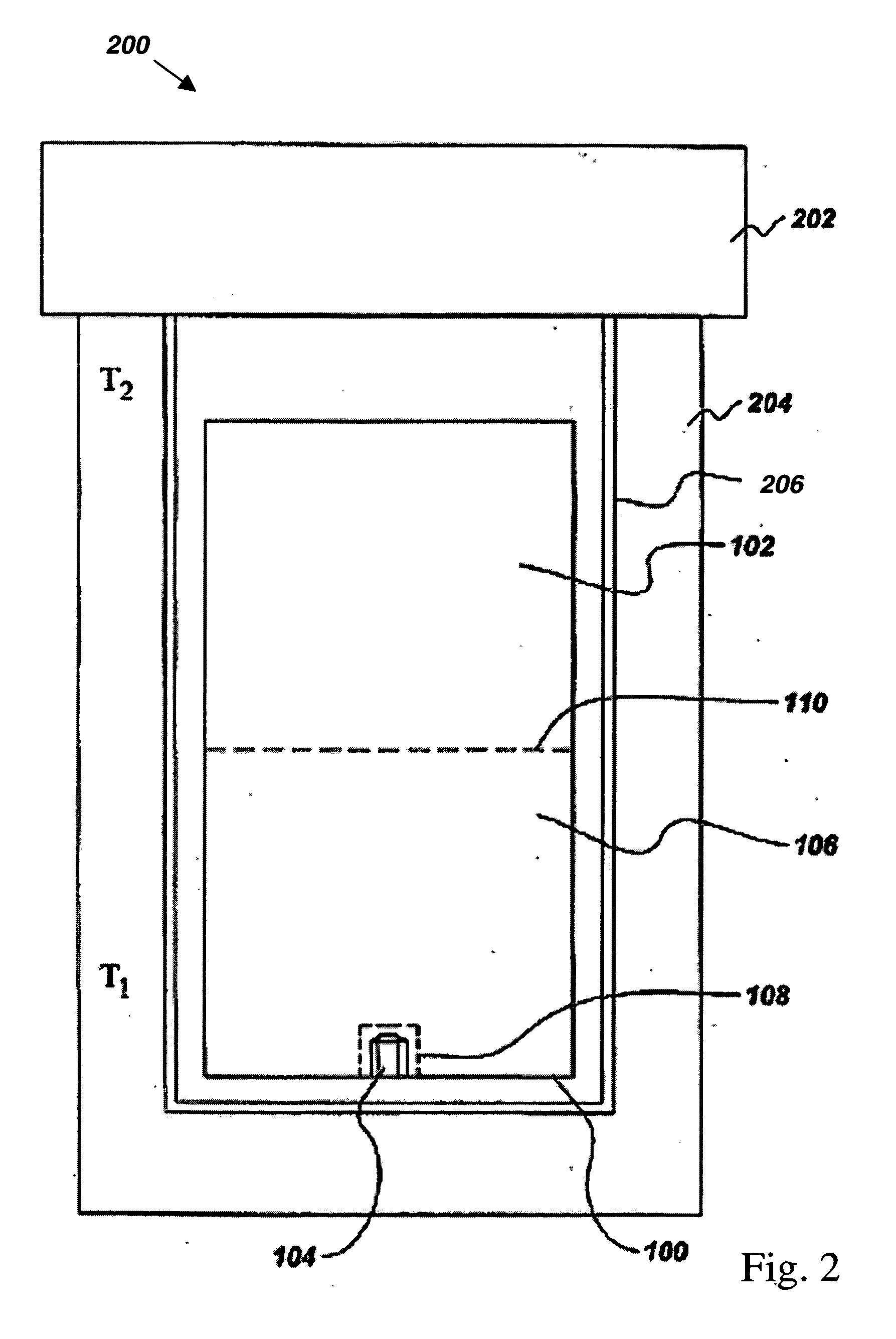

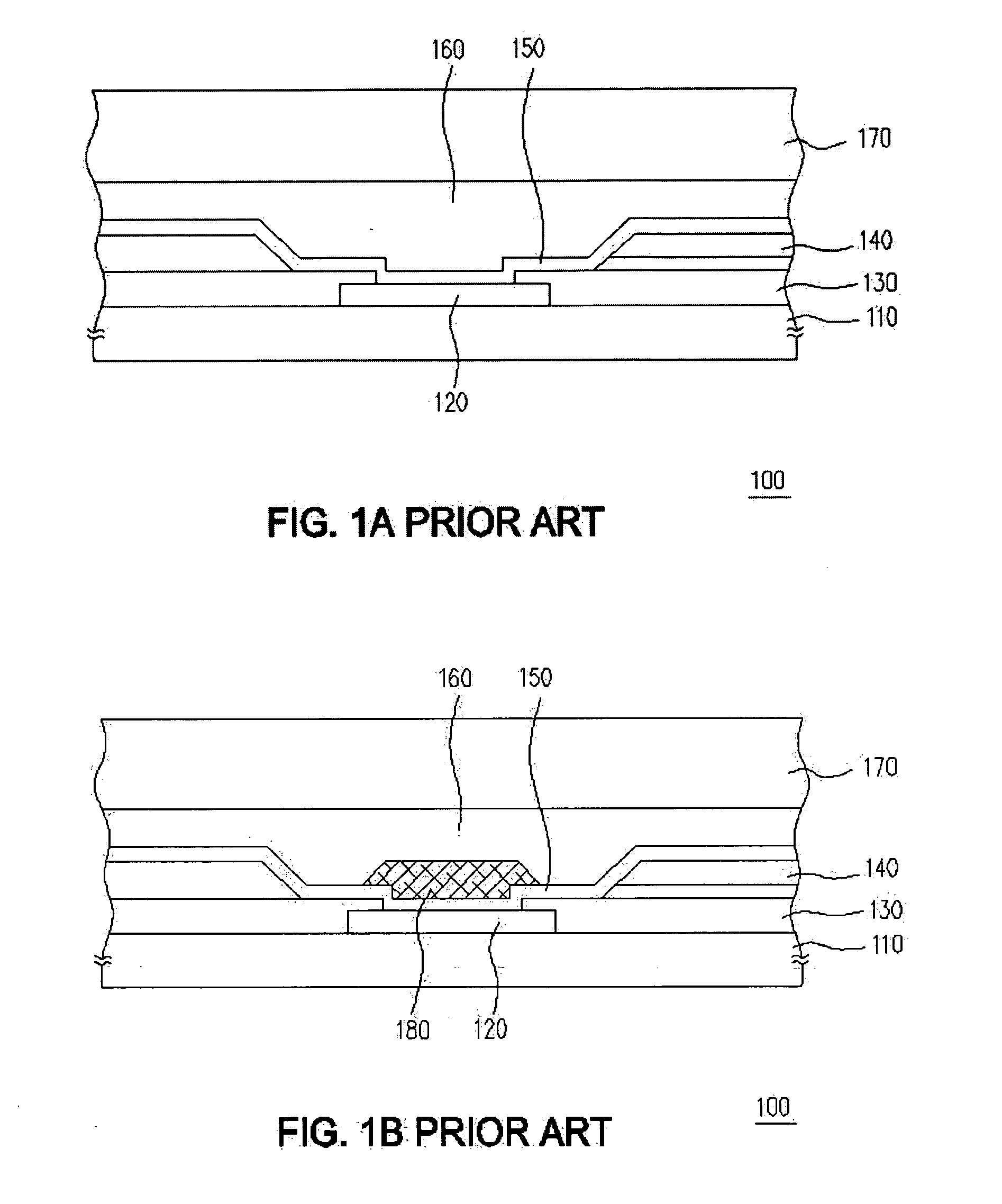

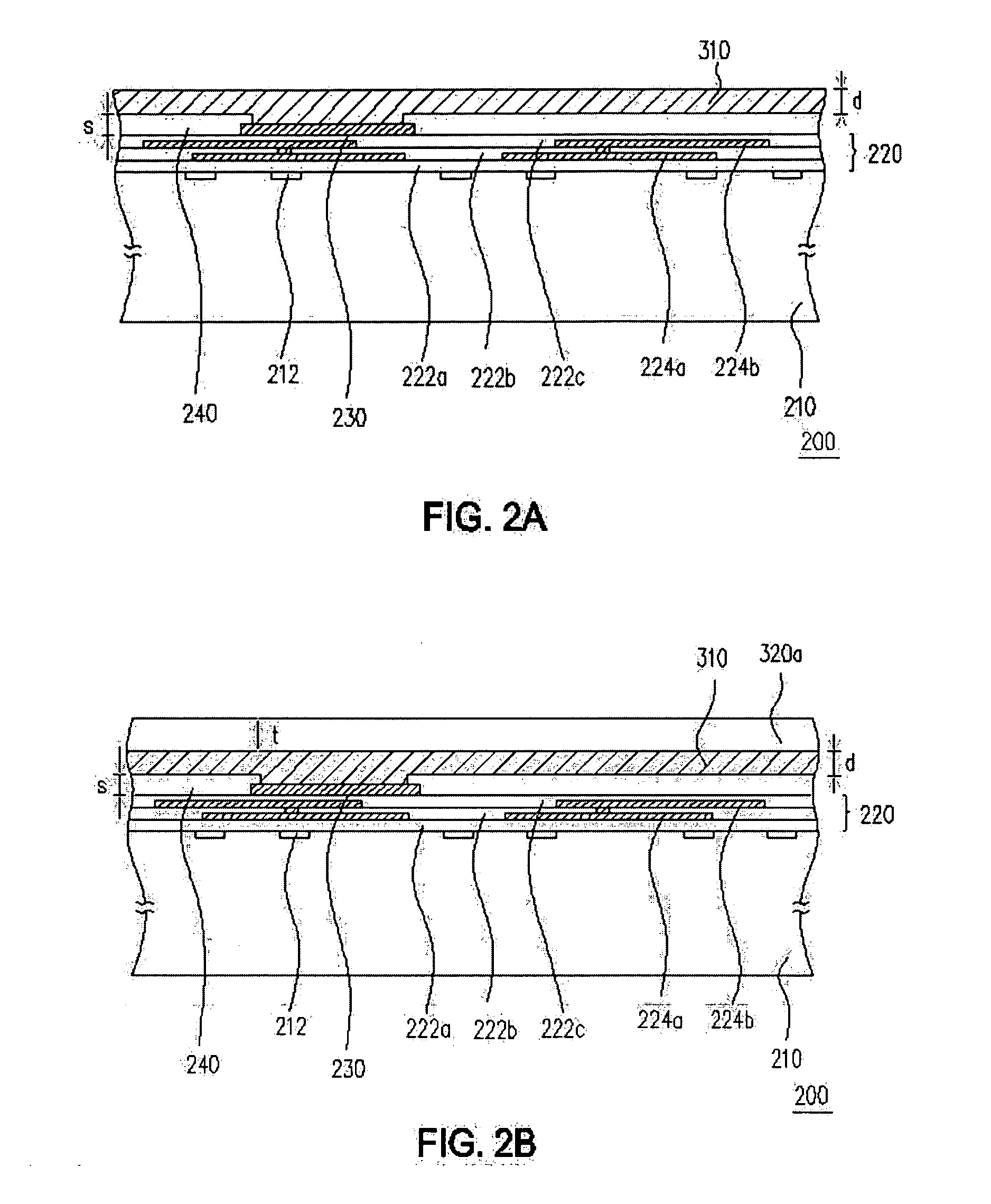

Differential head integrated touchdown sensors for hard disk drives

ActiveUS7800858B1Driving/moving recording headsFilamentary/web record carriersHard disc driveDegree Celsius

A method and system for providing a disk drive is described. The disk drive includes media such as one or more disks, a slider, and a head residing on the slider. The head has an air-bearing surface (ABS), a portion of which contacts the media during touchdown. The head further includes a plurality of touchdown sensors. A first touchdown sensor is proximate to the ABS, while a second touchdown sensor is distal from the ABS. The touchdown sensors are capable of detecting a temperature change of 0.1 degree Celsius or, in some embodiments, smaller.

Owner:WESTERN DIGITAL TECH INC

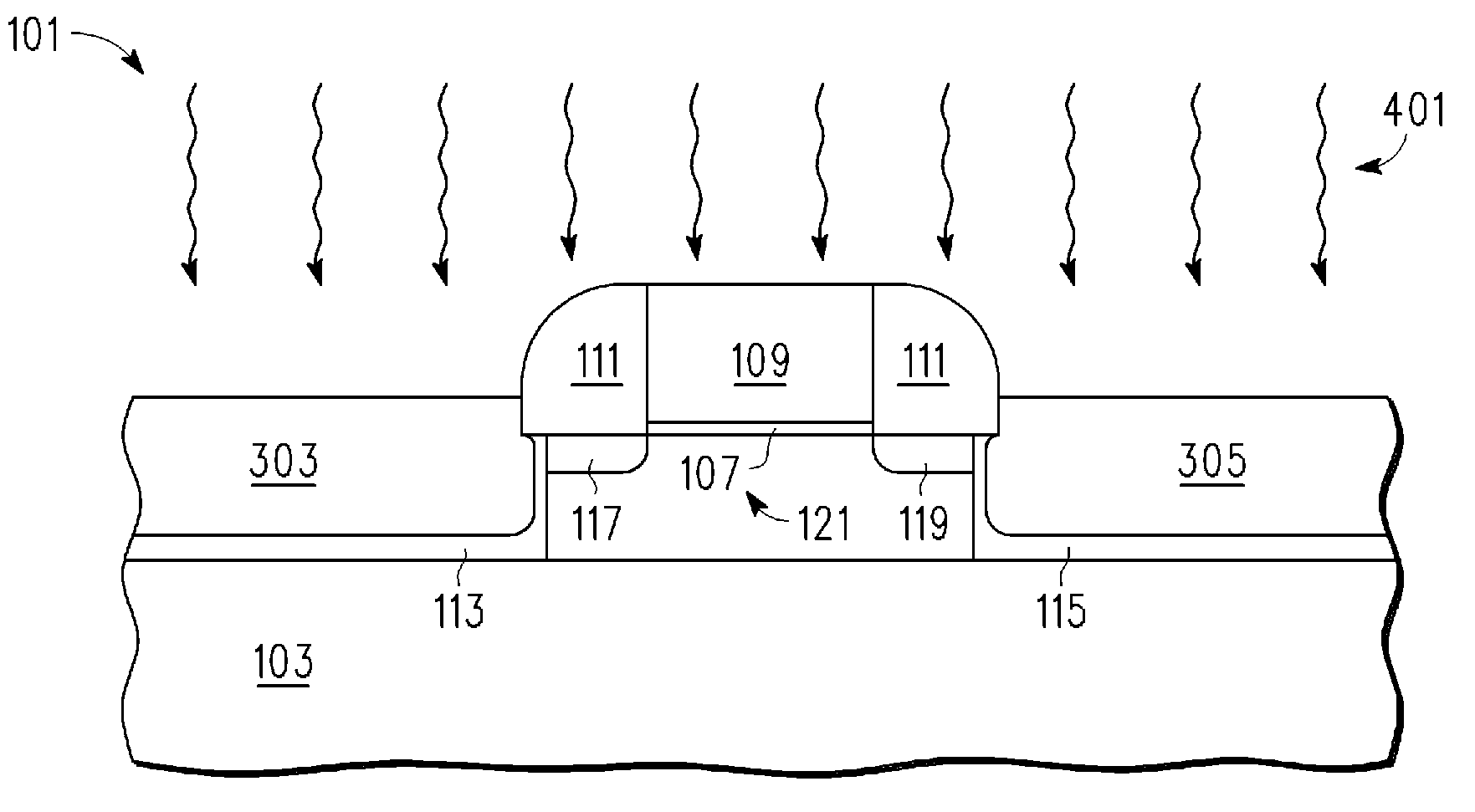

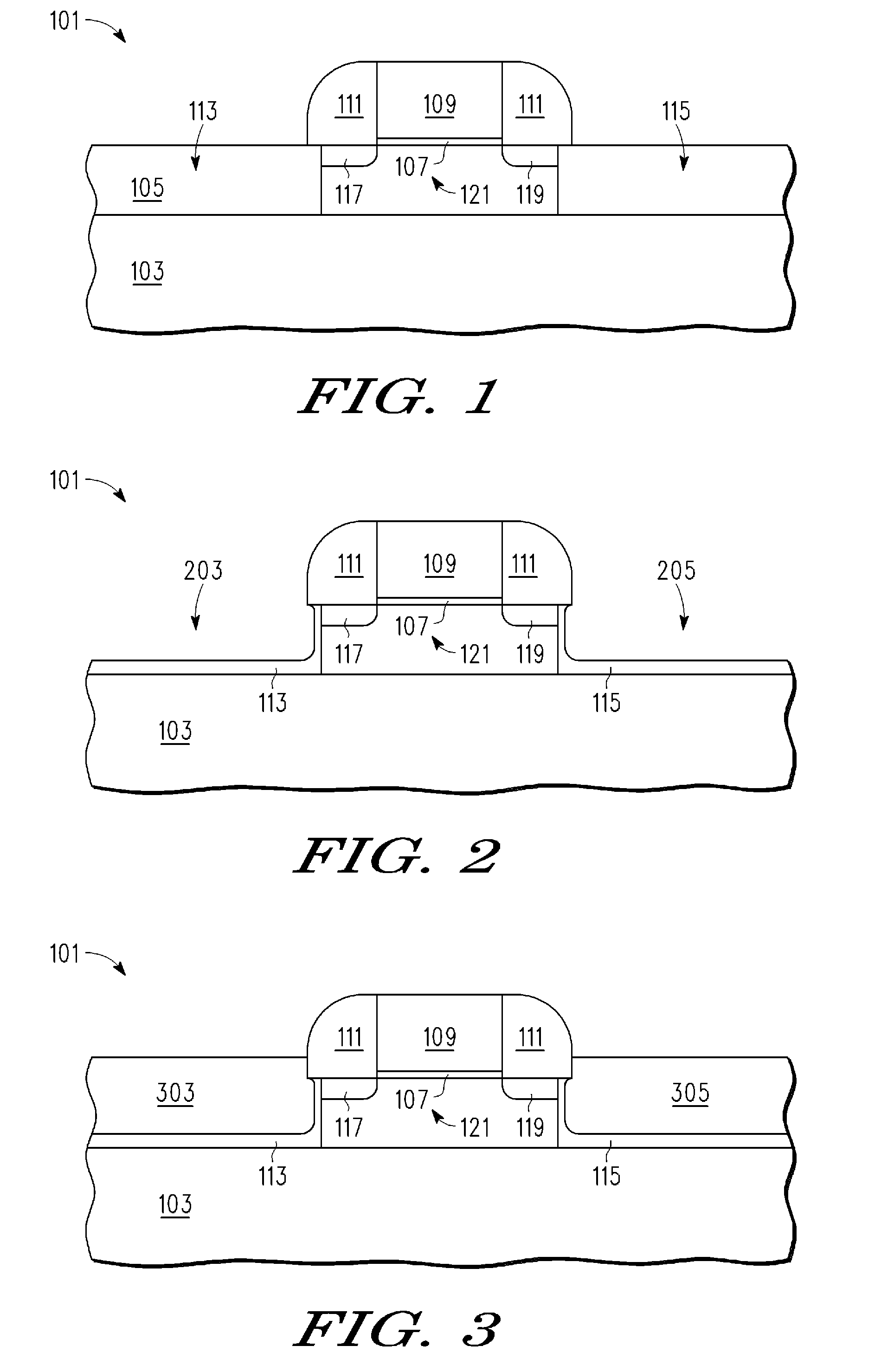

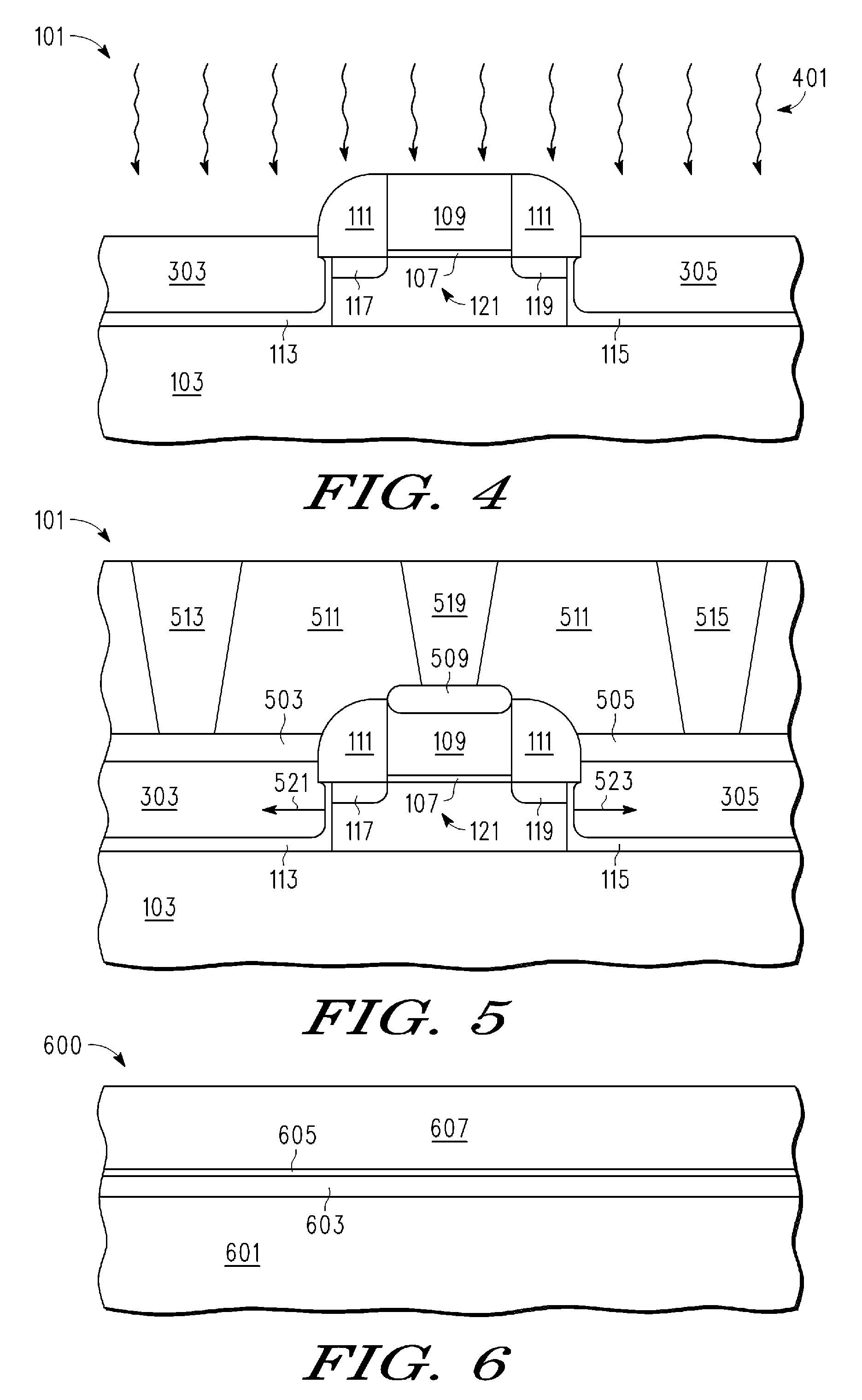

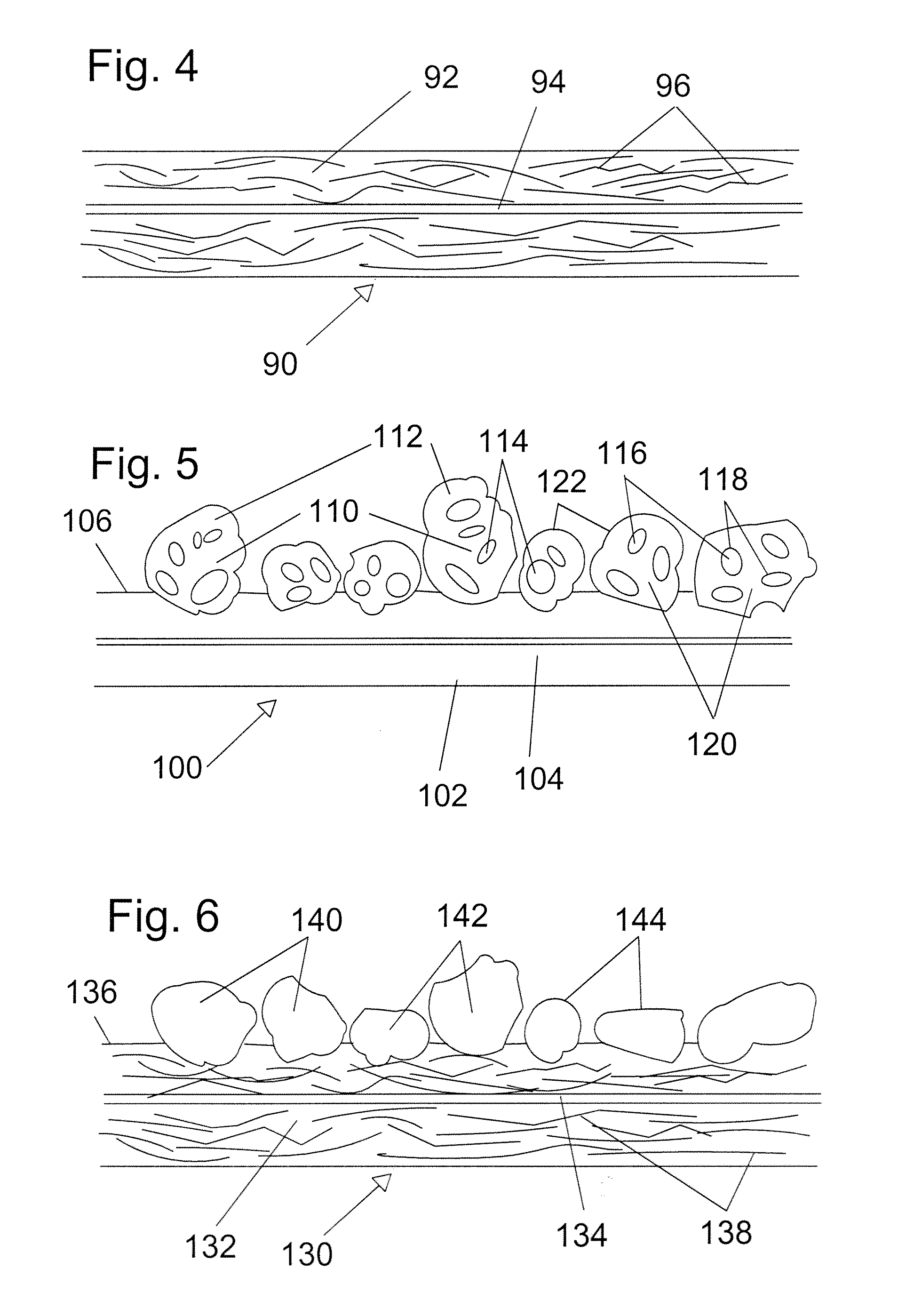

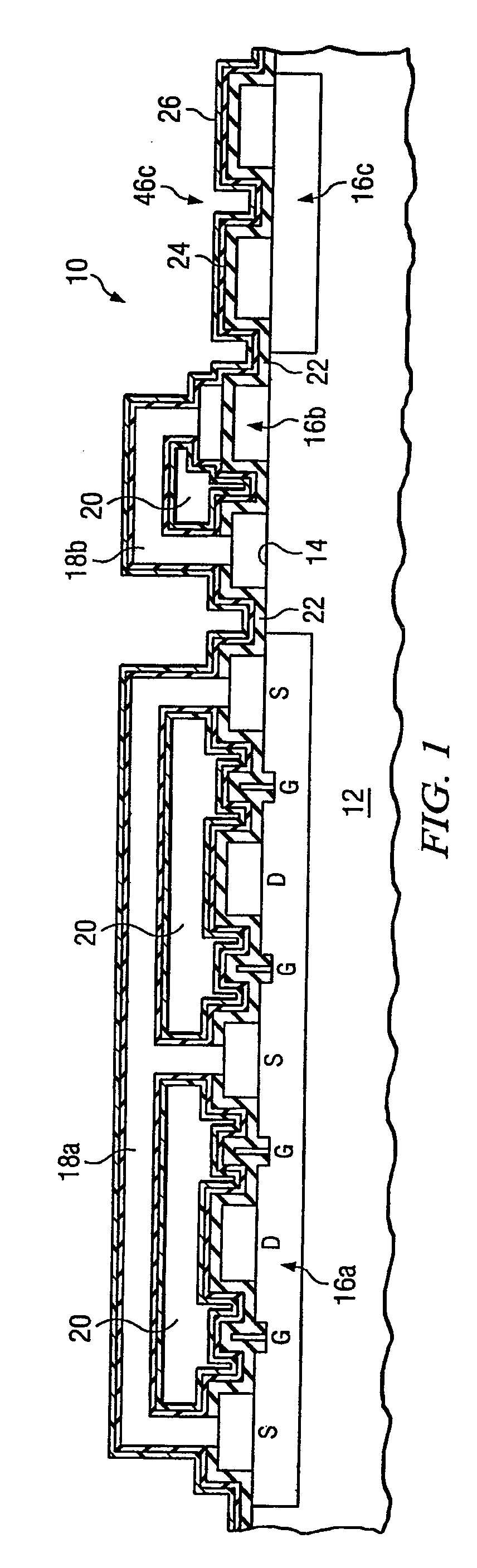

Anneal of epitaxial layer in a semiconductor device

InactiveUS7416605B2From gel statePolycrystalline material growthCharge carrier mobilityDegree Celsius

An anneal of an epitaxially grown crystalline semiconductor layer comprising a combination of group-IV elements. The layer contains at least one of the group of carbon and tin. The layer of epitaxially grown material is annealed at a temperature substantially in a range of 1,000 to 1,400 degrees Celsius for a period not to exceed 100 milliseconds within 10% of the peak temperature. The anneal is performed for example with a laser anneal or a flash lamp anneal. The limited-time anneal may improve carrier mobility of a transistor.

Owner:NORTH STAR INNOVATIONS

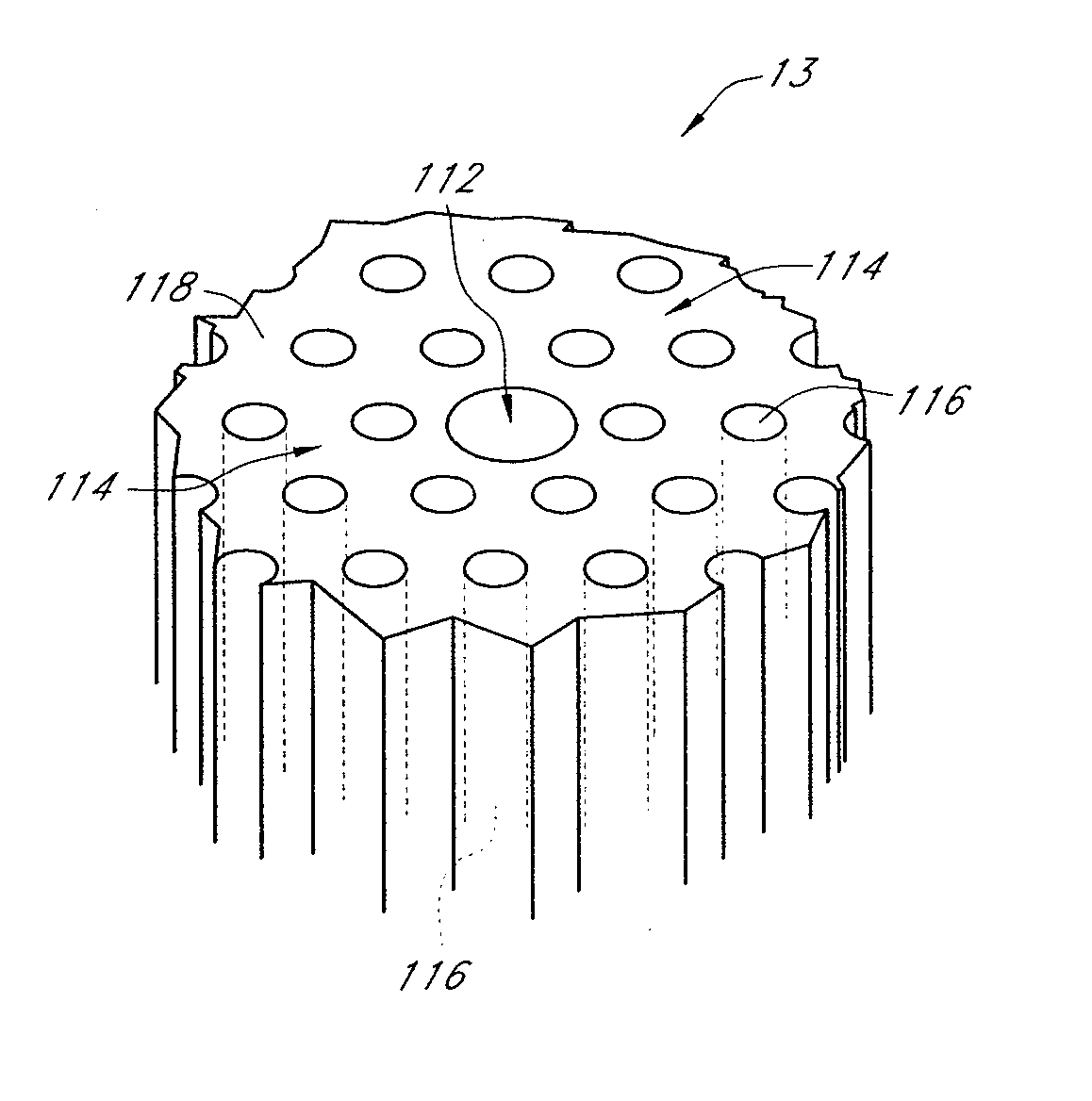

Apparatus for producing single crystal and quasi-single crystal, and associated method

An apparatus including a crucible, an energy source, and a controller is provided. The crucible may be sealed to a nitrogen-containing gas, and may be chemically inert to at least ammonia at a temperature in a range of about 400 degrees Celsius to about 2500 degrees Celsius. The energy source may supply thermal energy to the crucible. The controller may control the energy source to selectively direct sufficient thermal energy to a predefined first volume within the crucible to attain and maintain a temperature in the first volume to be in a range of from about 400 degrees Celsius to about 2500 degrees Celsius. The thermal energy may be sufficient to initiate, sustain, or both initiate and sustain growth of a crystal in the first volume. The first temperature in the first volume may be controllable separately from a second temperature in another volume within the crucible. The first temperature and the second temperature differ from each other. Associated methods are provided.

Owner:SLT TECH

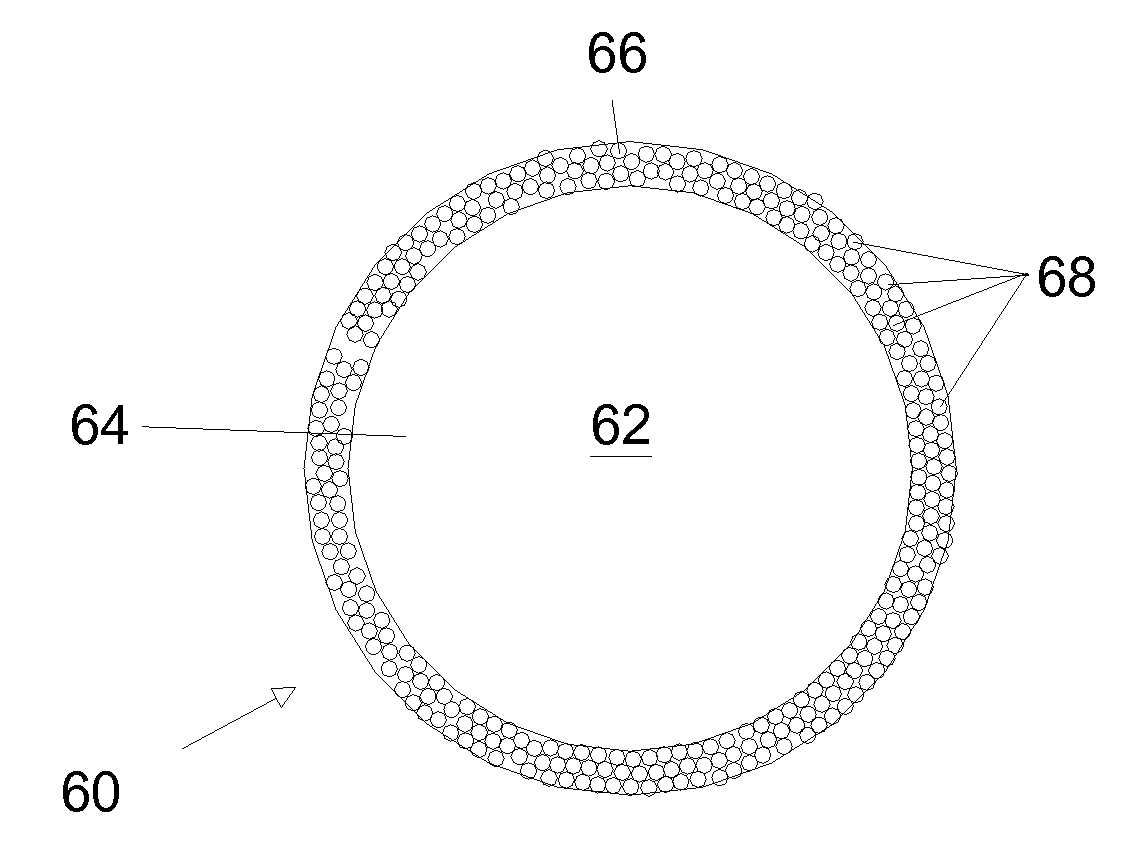

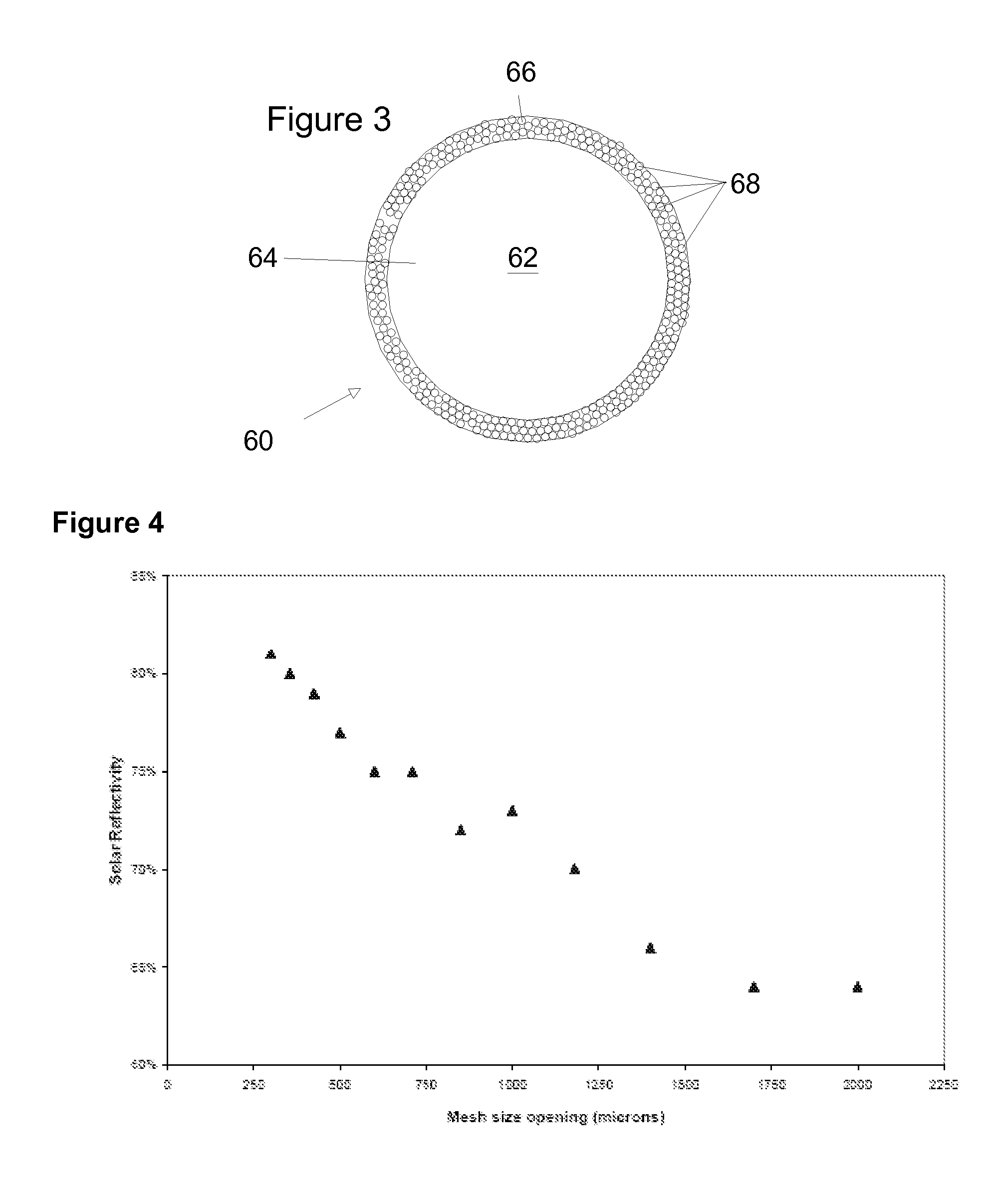

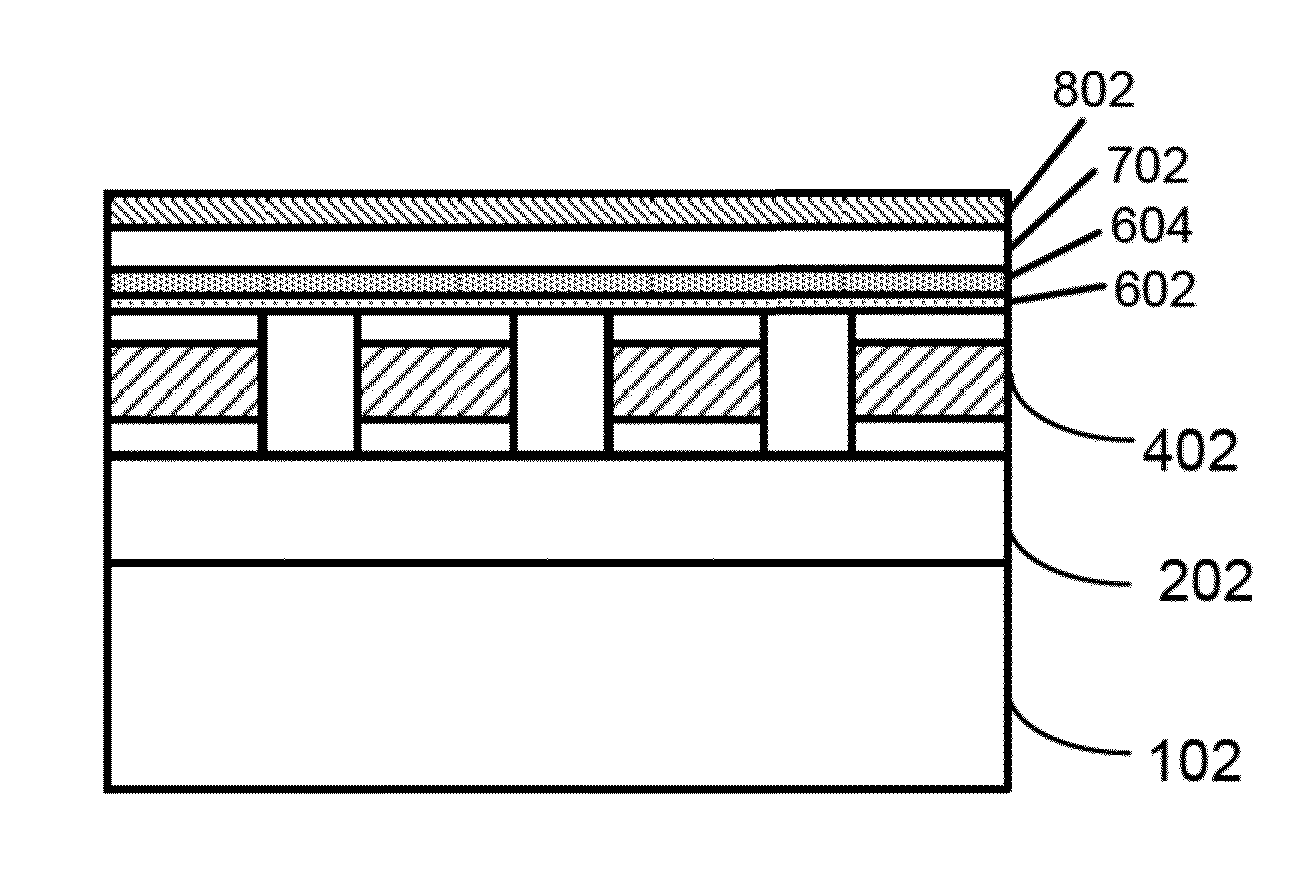

Solar heat-reflective roofing granules, solar heat-reflective shingles, and process for producing the same

ActiveUS20110086201A1Improve solar heat reflectivityRoof covering using tiles/slatesRoof improvementMetallurgyDegree Celsius

A process for preparing roofing granules includes forming kaolin clay into green granules and sintering the green granules at a temperature of at least 900 degrees Celsius to cure the green granules until the crystalline content of the sintered granules is at least ten percent as determined by x-ray diffraction.

Owner:CERTAINTEED CORP

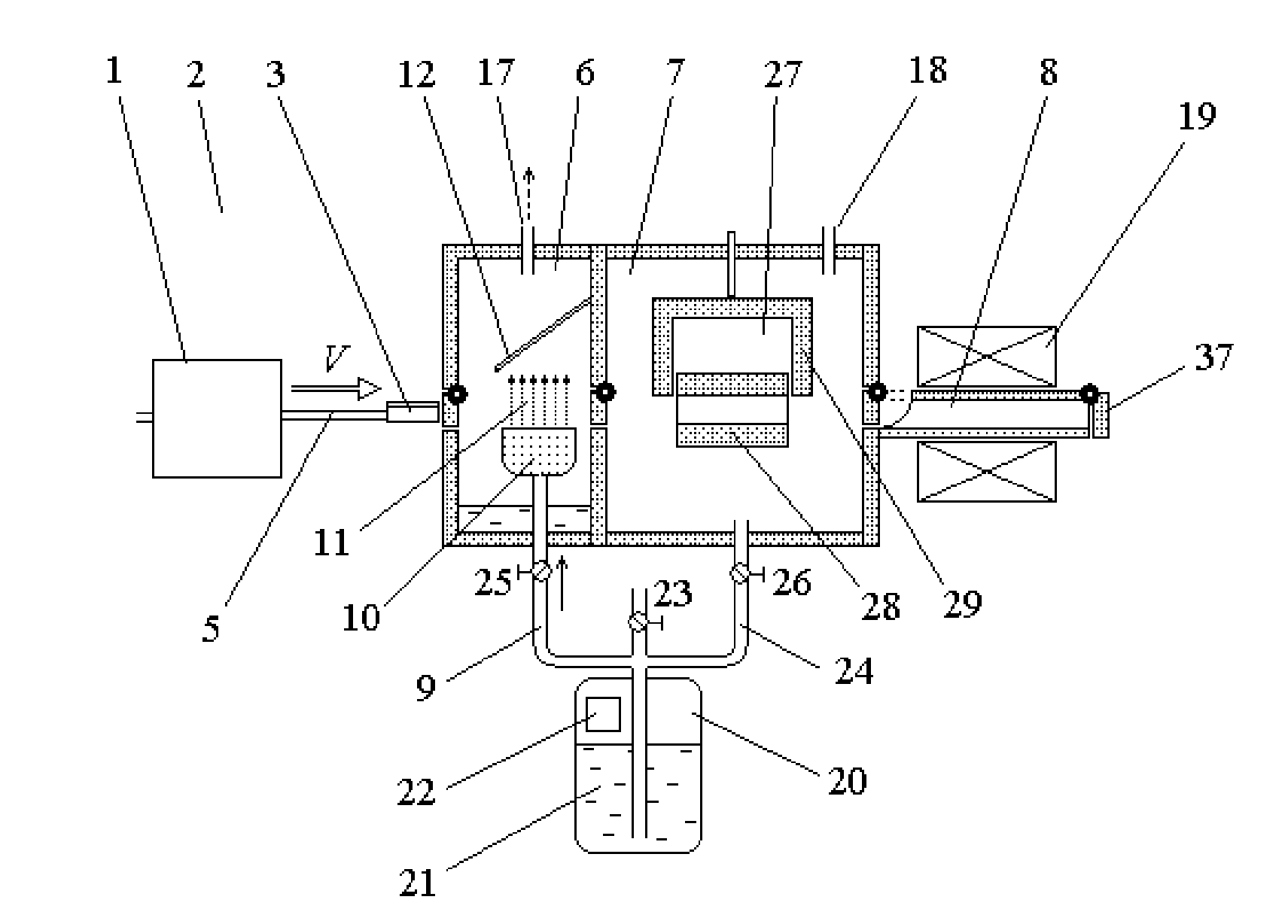

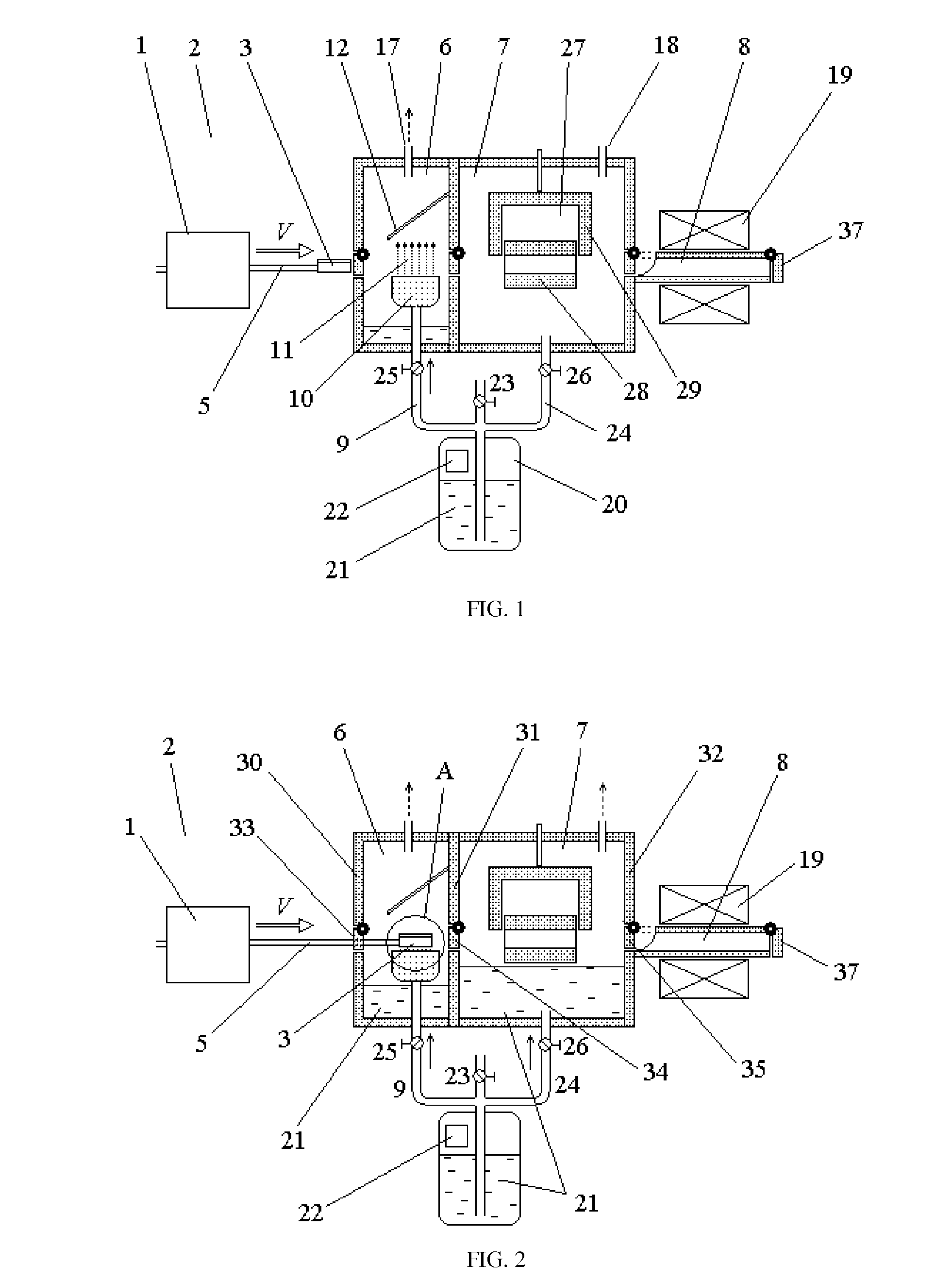

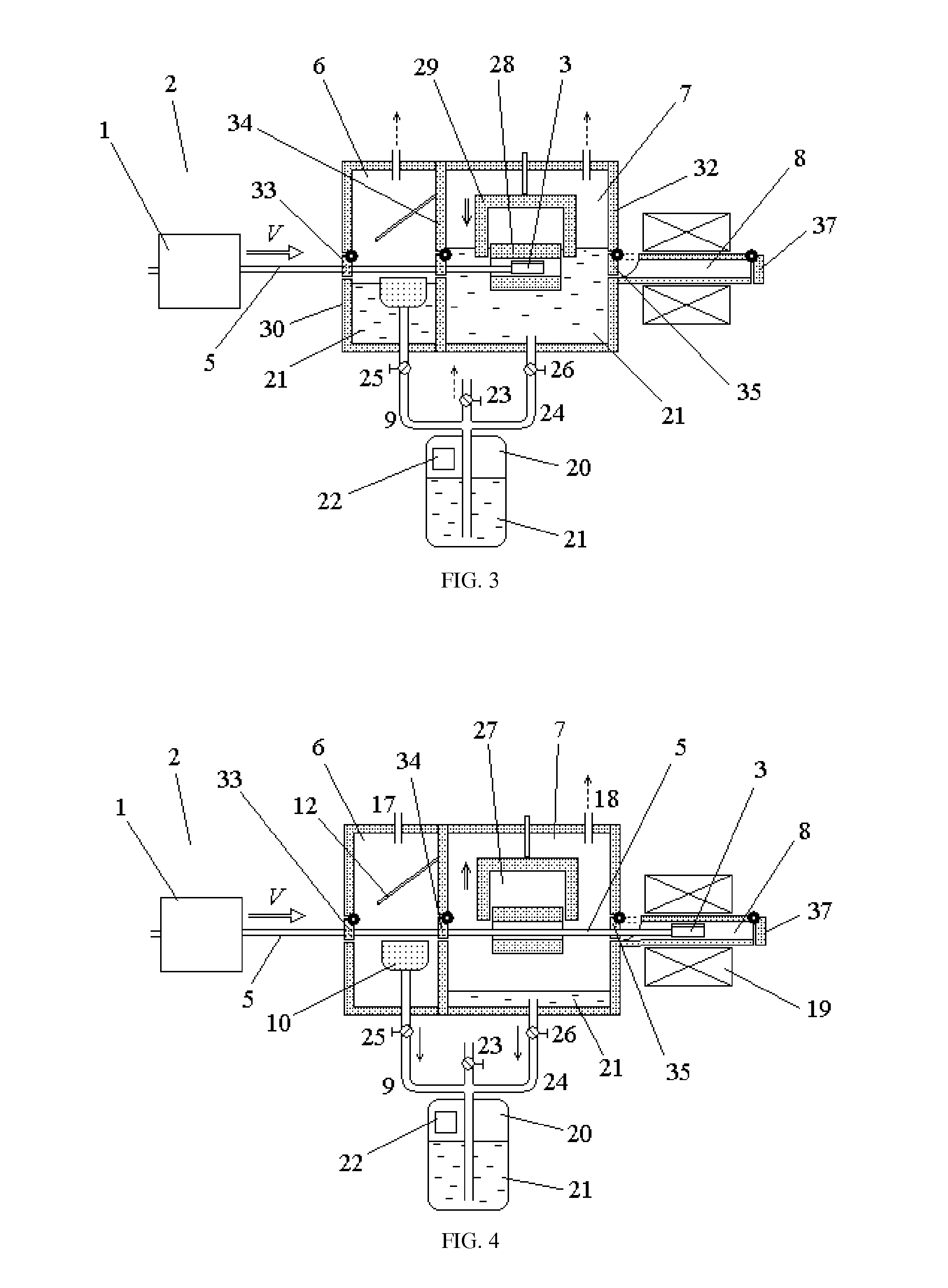

Preservation by Vaporization

ActiveUS20080229609A1Easy to controlImprove efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsIndustrial scaleVacuum chamber

Significant research is being done to develop and improve delivery mechanisms for biopharmaceuticals and vaccines, including pulmonary (inhalation), nasal, transdermal, and oral alternatives. Market projections indicate that the delivery of proteins and vaccines by inhalation and oral formulation has become and will continue to be increasingly important. These delivery mechanisms, to be effective, will require better stabilization of the biologicals so that they can maintain potency and effectiveness at ambient temperatures for extended periods of time. The novel Preservation by Vaporization (PBV) Technology described herein provides cost-effective and efficient industrial scale stabilization of proteins, viruses, bacteria, and other sensitive biologicals, thereby allowing a production of products that are not possible to be produced by existing methods. The suggested new PBV process comprises primary drying under vacuum from a partially frozen state (i.e. slush) at near subzero temperatures followed by stability drying at elevated temperatures (i.e., above 40 degrees Celsius). The new suggested method can be performed aseptically in unit doze format (in vials) and / or in bulk format (in trays, bags, or other containers). The drying can be performed as a continuous load process in a manifold vacuum dryer comprising a plurality (e.g., 30) of vacuum chambers attached to a condenser during the drying.

Owner:UNIVERSAL STABILIZATION TECH INC

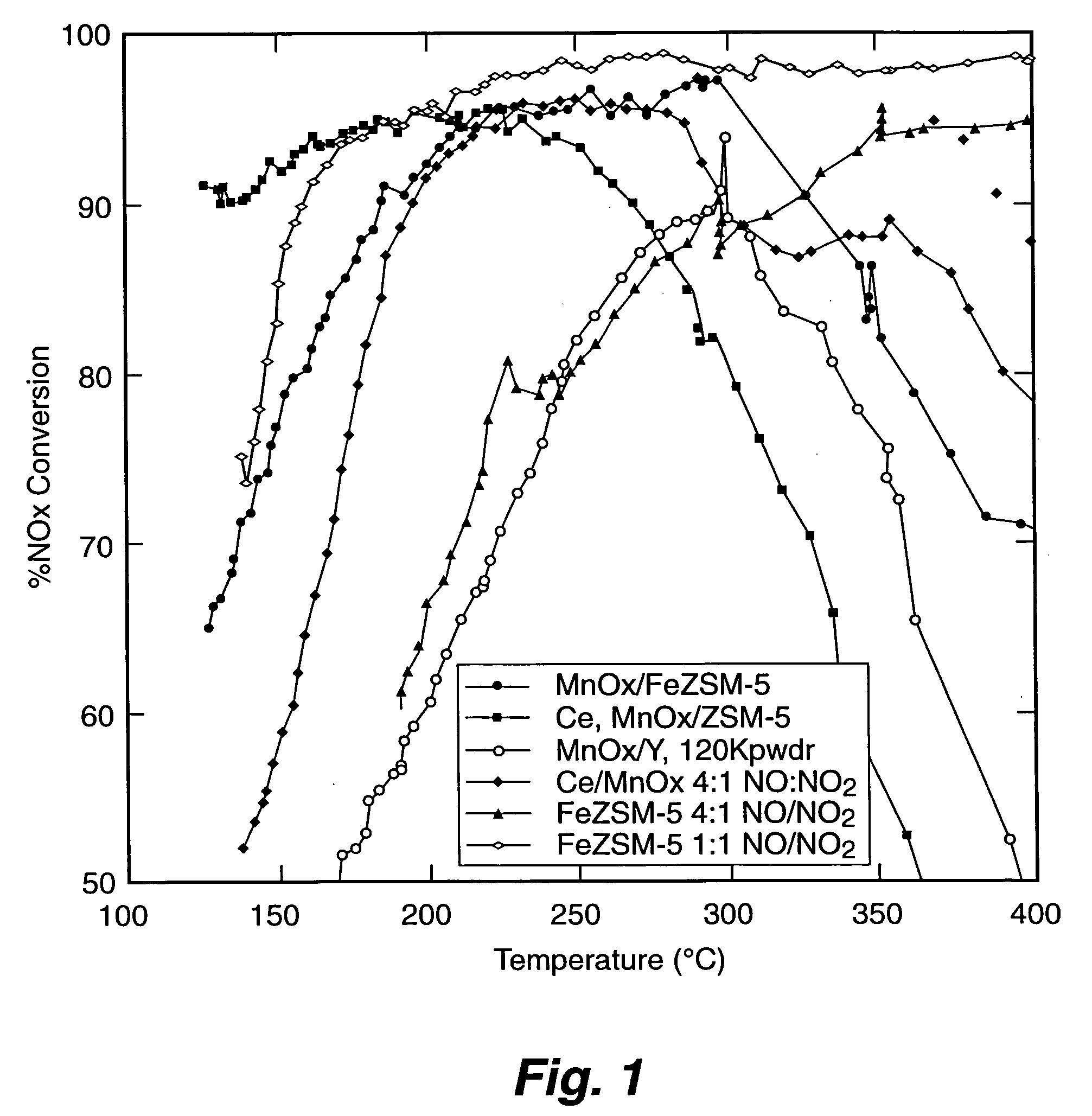

Catalyst and method for reduction of nitrogen oxides

InactiveUS20060029535A1Efficient workSelective catalytic reductionNitrous oxide captureNitrogen compoundsCerium nitrateIron salts

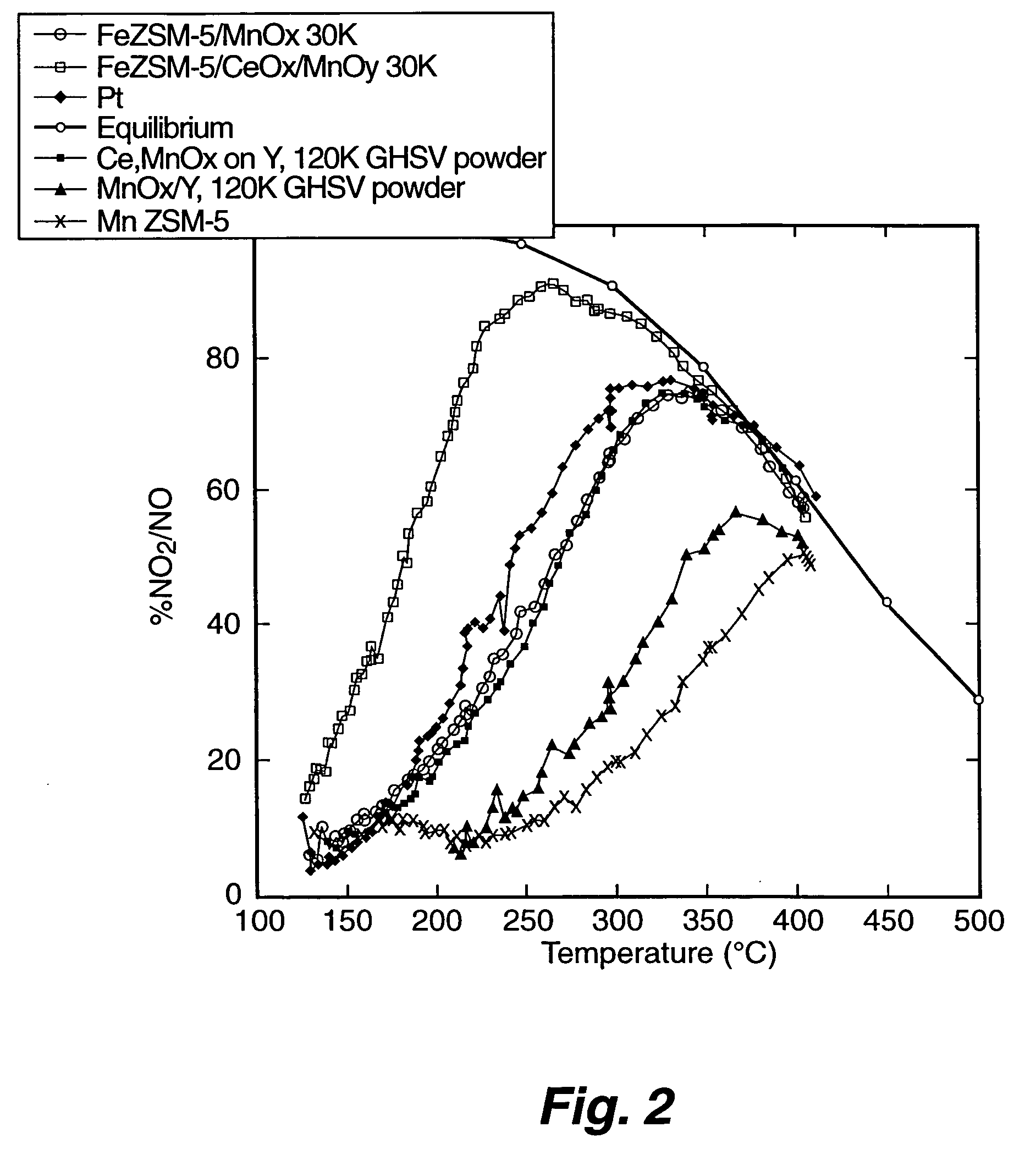

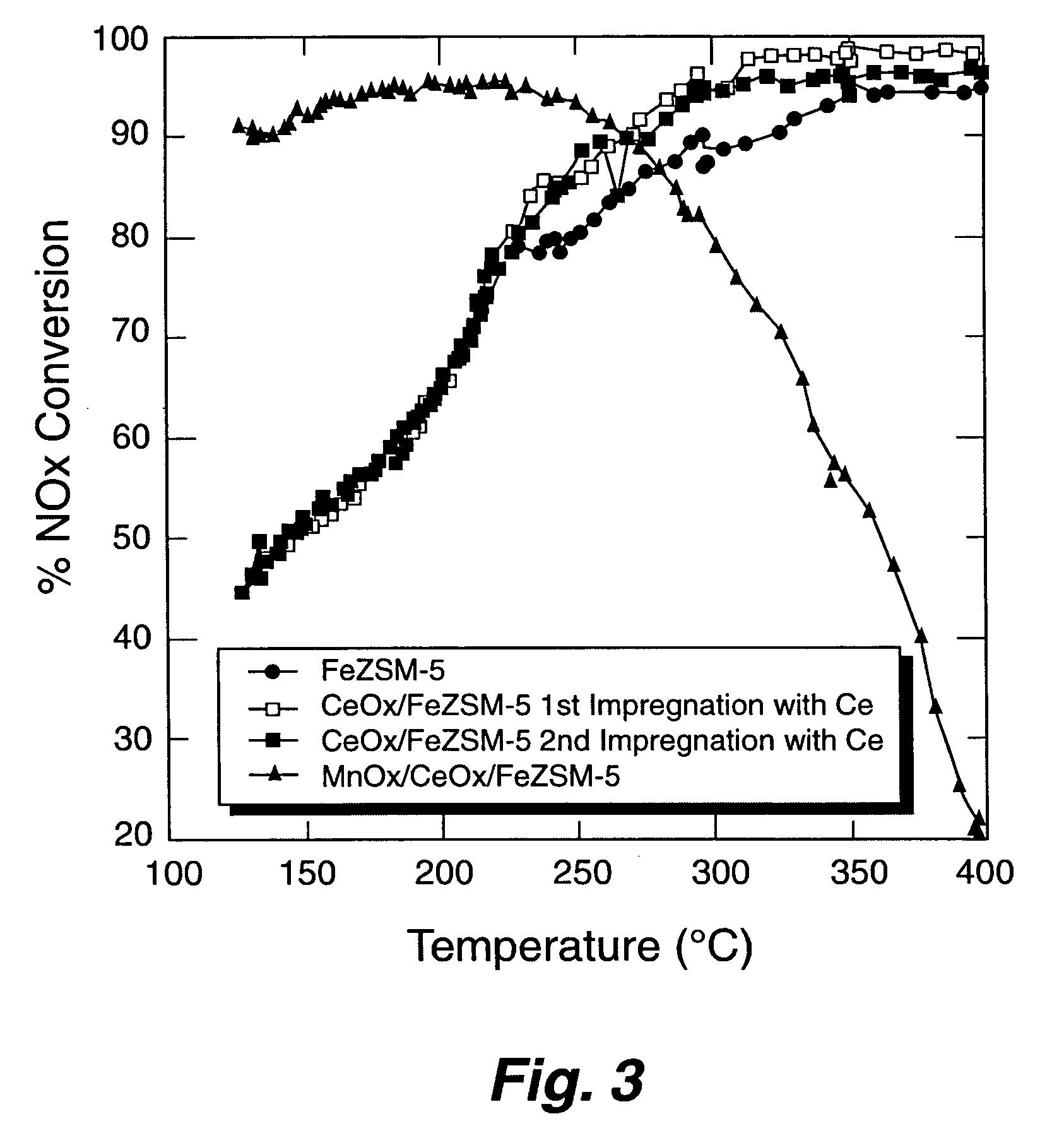

A Selective Catalytic Reduction (SCR) catalyst was prepared by slurry coating ZSM-5 zeolite onto a cordierite monolith, then subliming an iron salt onto the zeolite, calcining the monolith, and then dipping the monolith either into an aqueous solution of manganese nitrate and cerium nitrate and then calcining, or by similar treatment with separate solutions of manganese nitrate and cerium nitrate. The supported catalyst containing iron, manganese, and cerium showed 80 percent conversion at 113 degrees Celsius of a feed gas containing nitrogen oxides having 4 parts NO to one part NO2, about one equivalent ammonia, and excess oxygen; conversion improved to 94 percent at 147 degrees Celsius. N2O was not detected (detection limit: 0.6 percent N2O).

Owner:LOS ALAMOS NATIONAL SECURITY

Production of biodiesel from combination of corn (maize) and other feed stocks

InactiveUS20070099278A1Increase Biodiesel production outputStable year round productionFatty oils/acids recovery from wasteOrganic compound preparationProcess systemsSodium Bentonite

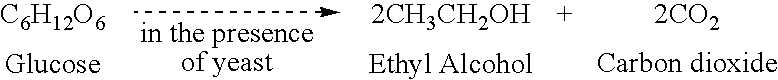

A method and system to produce biodiesel from a combination of corn (maize) and other agro feedstock may be simarouba, mahua, rice, pongamia etc. Germ is separated (either by wet process or dry process) from corn, crude corn oil extracted from germ and corn starch milk / slurry is heated and cooked in jet cooker to about 105 degree Celsius, enzymes added to convert starch into fermentable sugars in liquification and saccharification process and rapidly cooled down to about 30 degree Celsius. Simarouba fruits syrup, mahua syrup is mixed with corn starch milk (after saccharification). When yeast is added the fermentation takes place for about 72 hours. Thereafter the fermented wash is distilled to produce ethanol. Water consumed in dry process is very less compared to traditional wet process system. Corn oil and mixture of other oils is fed into transesterification (reaction) vessels where ethanol with catalyst, usually sodium hydroxide is added and reaction takes place for about a period of 2-8 hours. Crude biodiesel and crude glycerin as by-products is produced. Excess ethanol removed by distillation process. Crude biodiesel washed with warm water to remove residual soaps or unused catalyst, dried and biodiesel stored for commercial use. Oil extracted from spent bleach mud (used sodium bentonite), a waste product of edible oil refineries may also be utilized for economical production of biodiesel in combination of corn oil and ethanol.

Owner:AARE PALANISWAMY RAMASWAMY

Properties of a silica thin film produced by a rapid vapor deposition (RVD) process

InactiveUS6867152B1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingHysteresisSilicon dioxide

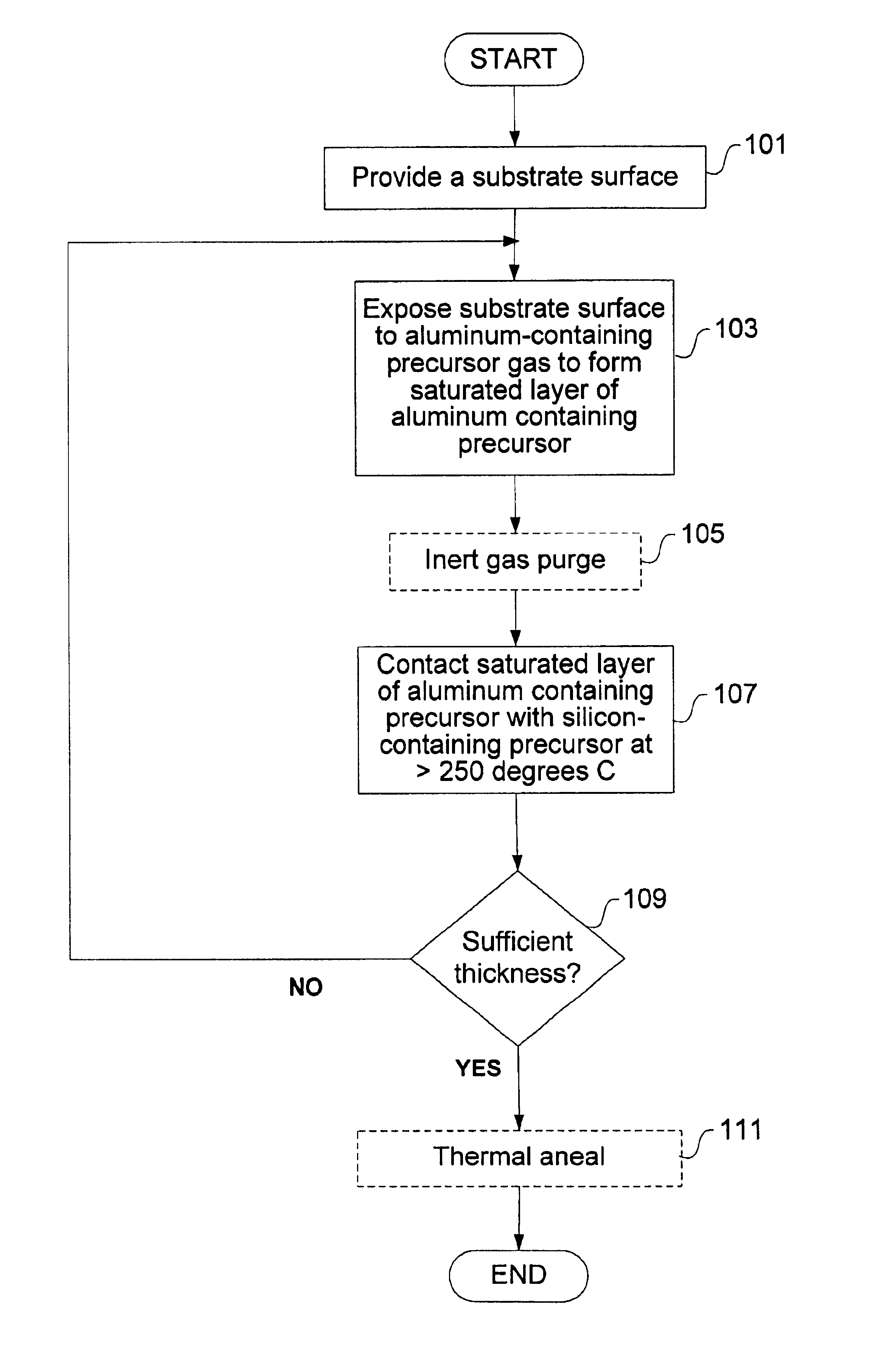

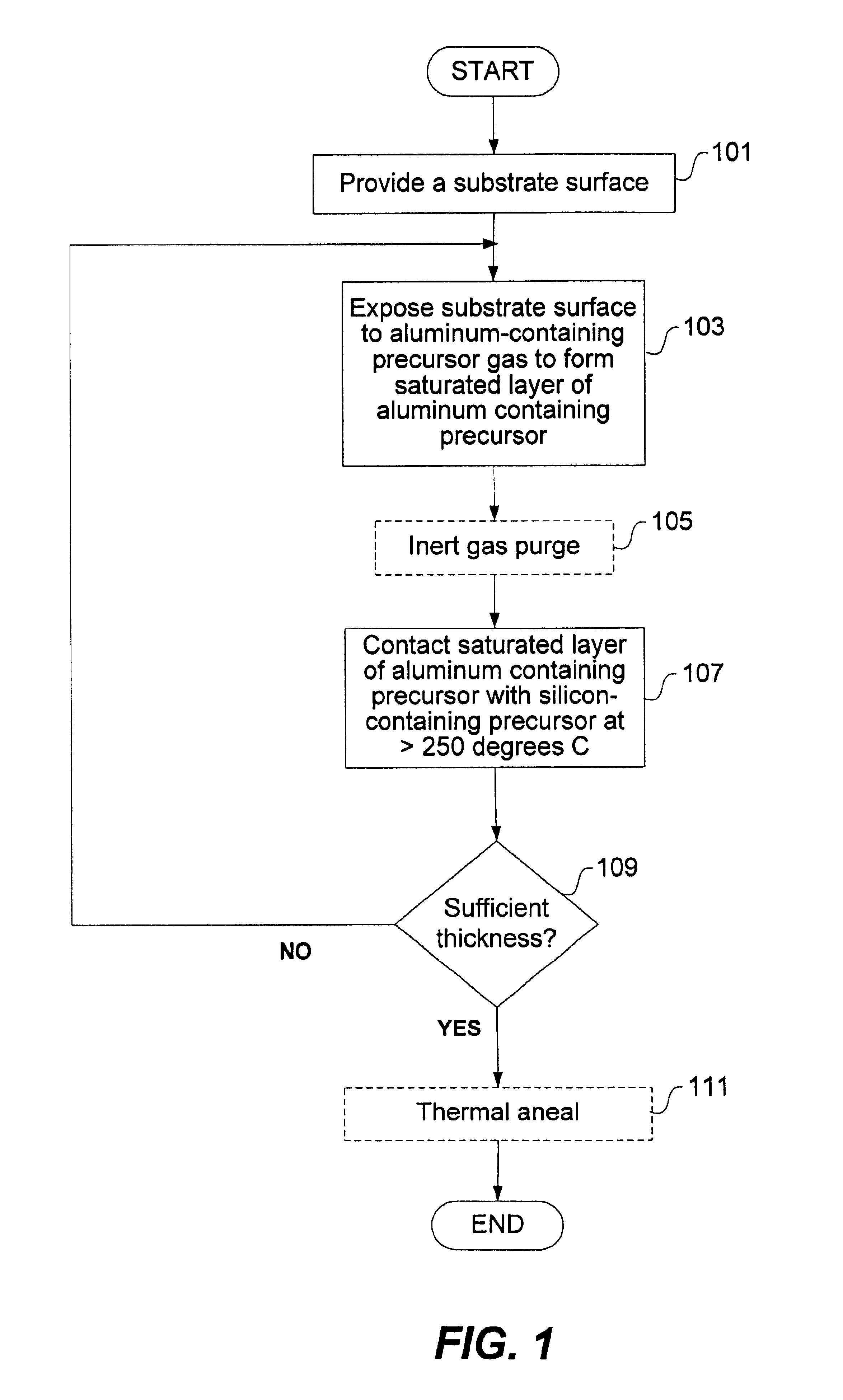

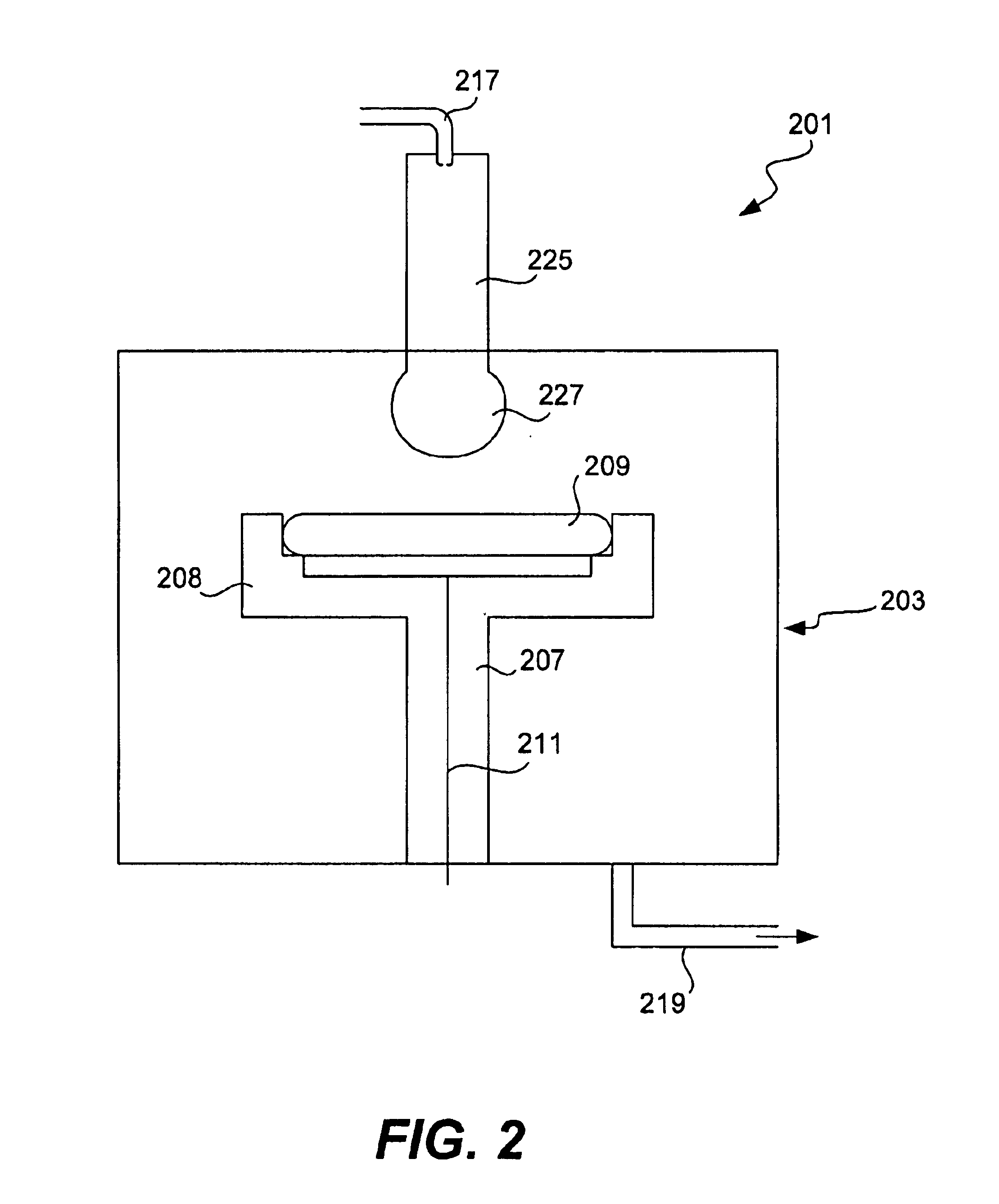

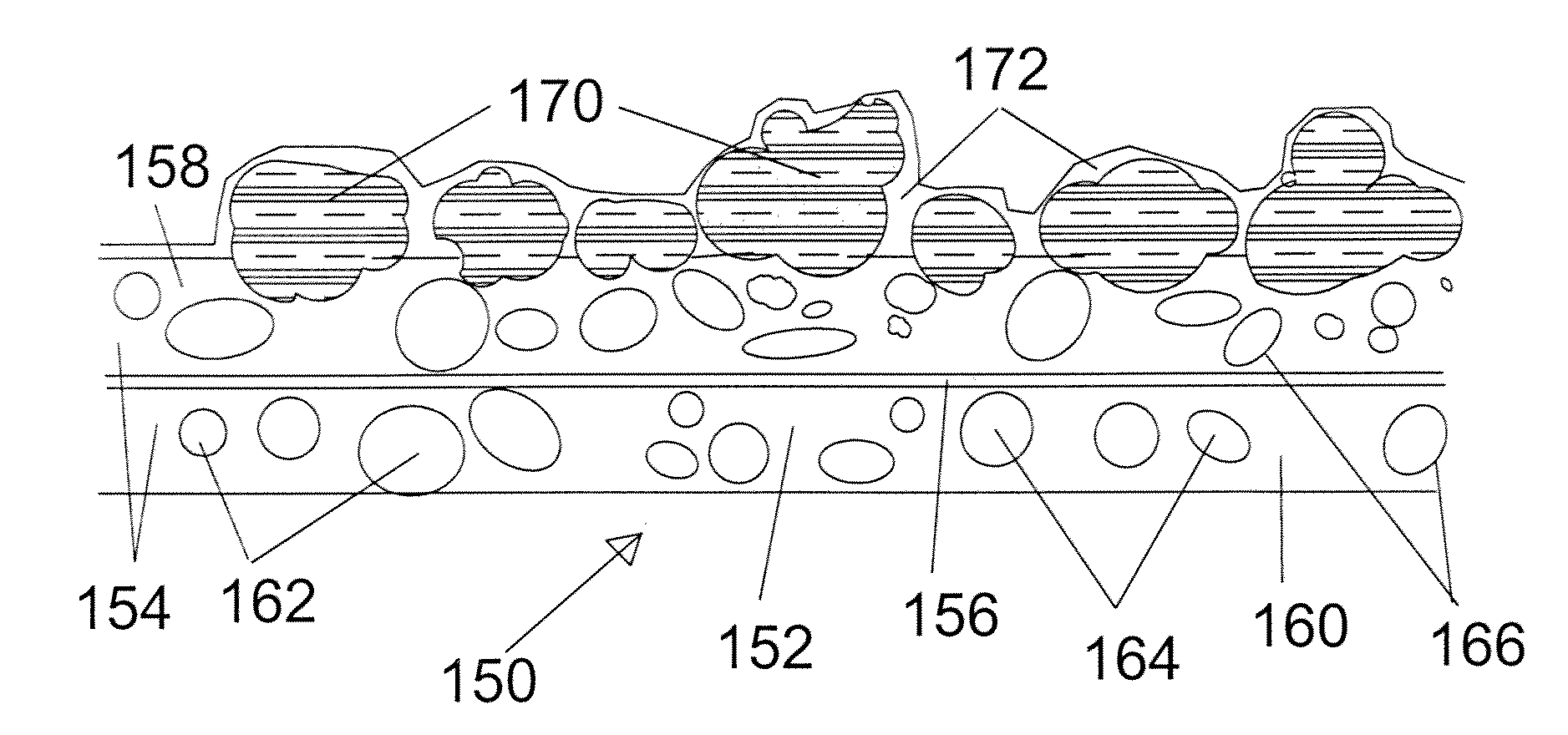

A rapid vapor deposition (RVD) method conformally deposits a dielectric material on small features of a substrate surface. The resulting dielectric film has a low dielectric constant, low wet etch rate, low film shrinkage and low stress hysteresis, appropriate for various integrated circuit dielectric gap fill applications such as shallow trench isolation. The method includes the following two principal operations: depositing a thin conformal and saturated layer of aluminum-containing precursor over some or all of the substrate surface; and exposing the saturated layer of aluminum-containing precursor to a silicon-containing precursor gas to form a dielectric layer. In some cases, the substrate temperatures during contact with silicon-containing precursor are greater than about 250 degree Celsius to produce an improved film. In other cases, post-deposition anneal process may be used to improve properties of the film. Generally an inert gas purge is employed between the introduction of reactant gases to remove byproducts and unused reactants. These operations can be repeated to deposit multiple layers of dielectric material until a desired dielectric thickness is achieved.

Owner:NOVELLUS SYSTEMS

Roofing Products Containing Phase Change Materials

InactiveUS20080008858A1Improve the immunityAttractive appearanceRoof covering using tiles/slatesRoof covering using flexible materialsDegree CelsiusPhase change

Owner:CERTAINTEED CORP

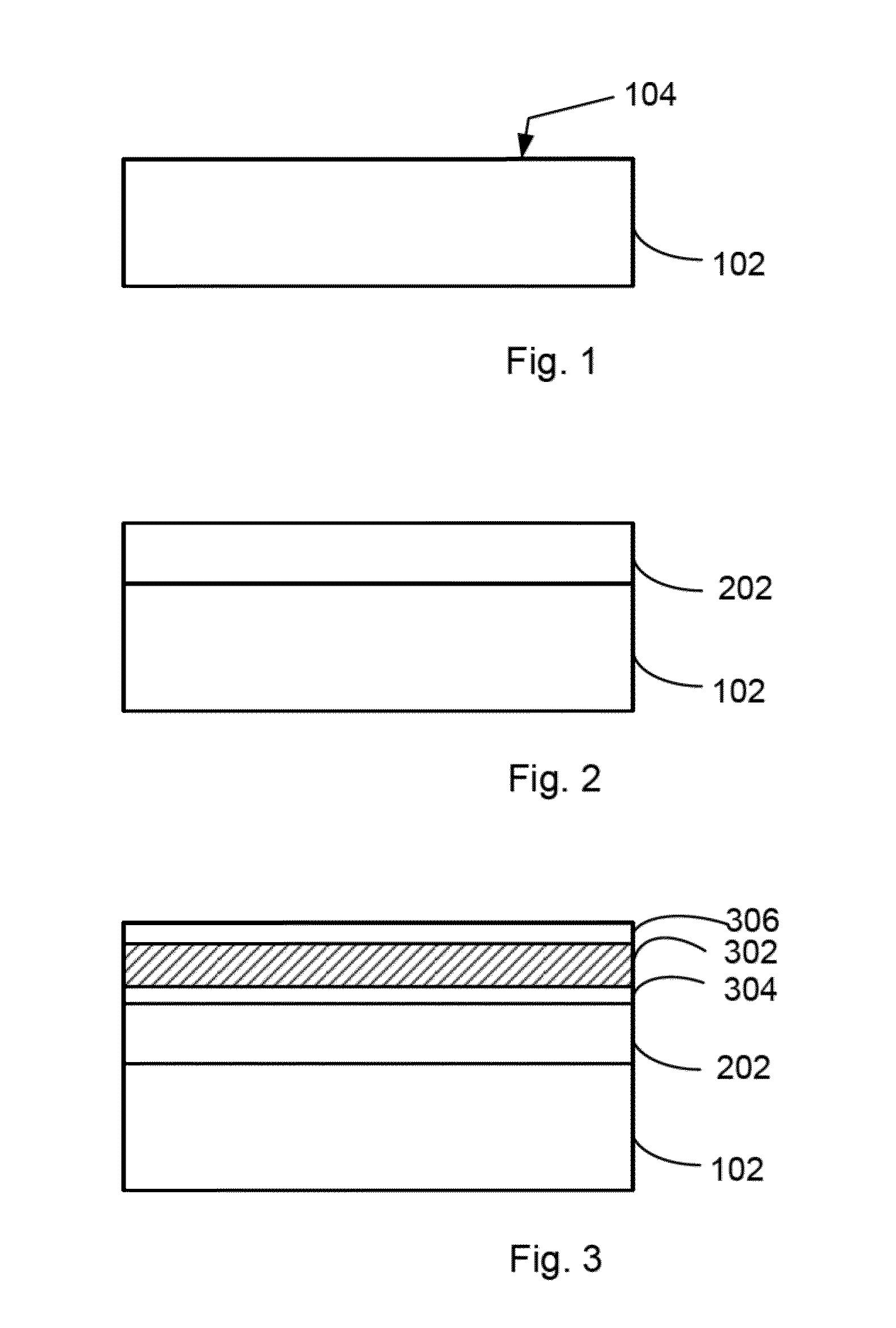

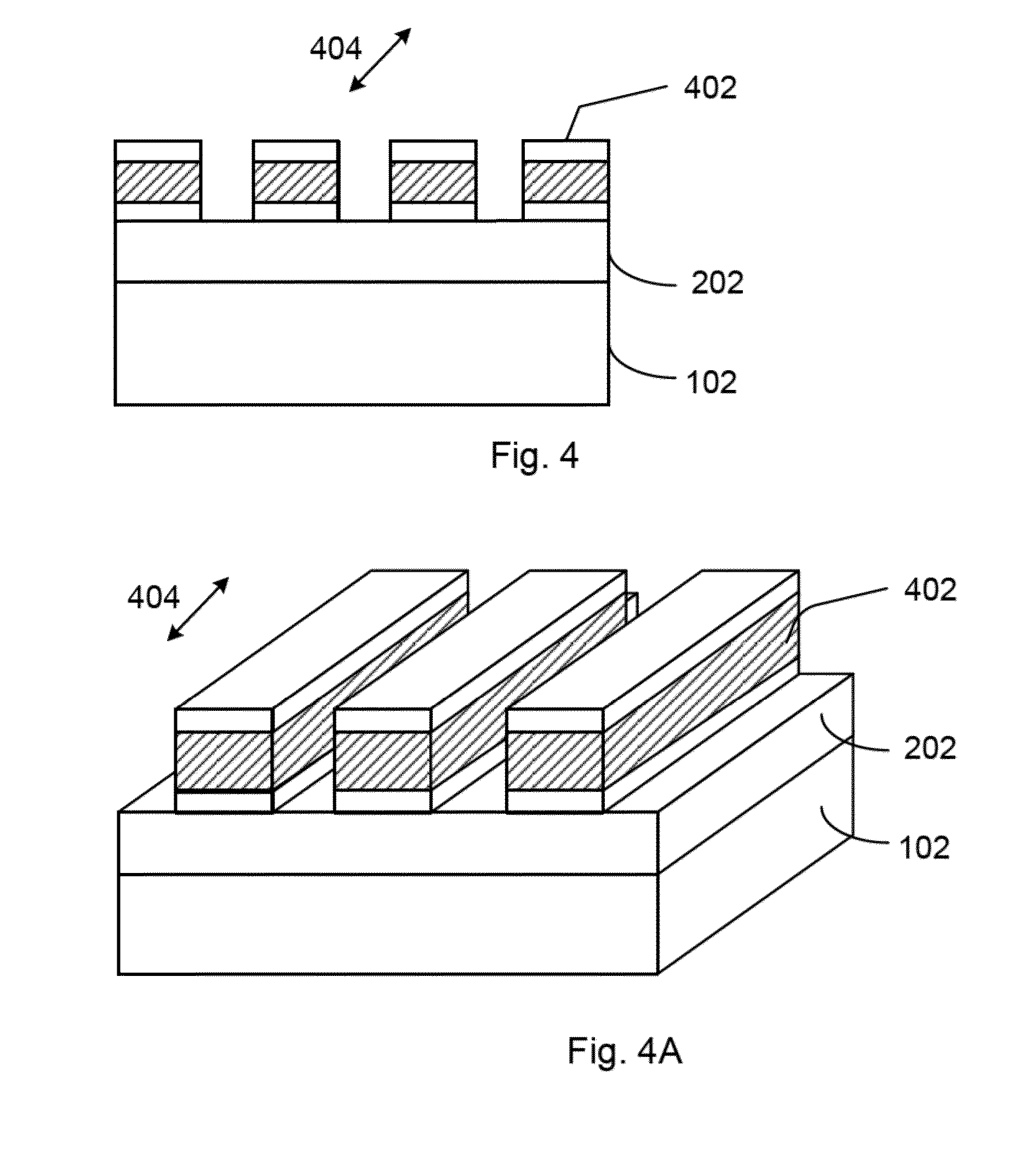

Low temperature P+ polycrystalline silicon material for non-volatile memory device

ActiveUS8658476B1Simplify the manufacturing processImprove device yieldSolid-state devicesSemiconductor/solid-state device manufacturingDeposition temperatureDegree Celsius

A method of forming a non-volatile memory device. The method includes providing a substrate having a surface region and forming a first dielectric material overlying the surface region of the substrate. A first electrode structure is formed overlying the first dielectric material and a p+ polycrystalline silicon germanium material is formed overlying the first electrode structure. A p+ polycrystalline silicon material is formed overlying the first electrode structure using the polycrystalline silicon germanium material as a seed layer at a deposition temperature ranging from about 430 Degree Celsius to about 475 Degree Celsius without further anneal. The method forms a resistive switching material overlying the polycrystalline silicon material, and a second electrode structure including an active metal material overlying the resistive switching material.

Owner:INNOSTAR SEMICON SHANGHAI CO LTD

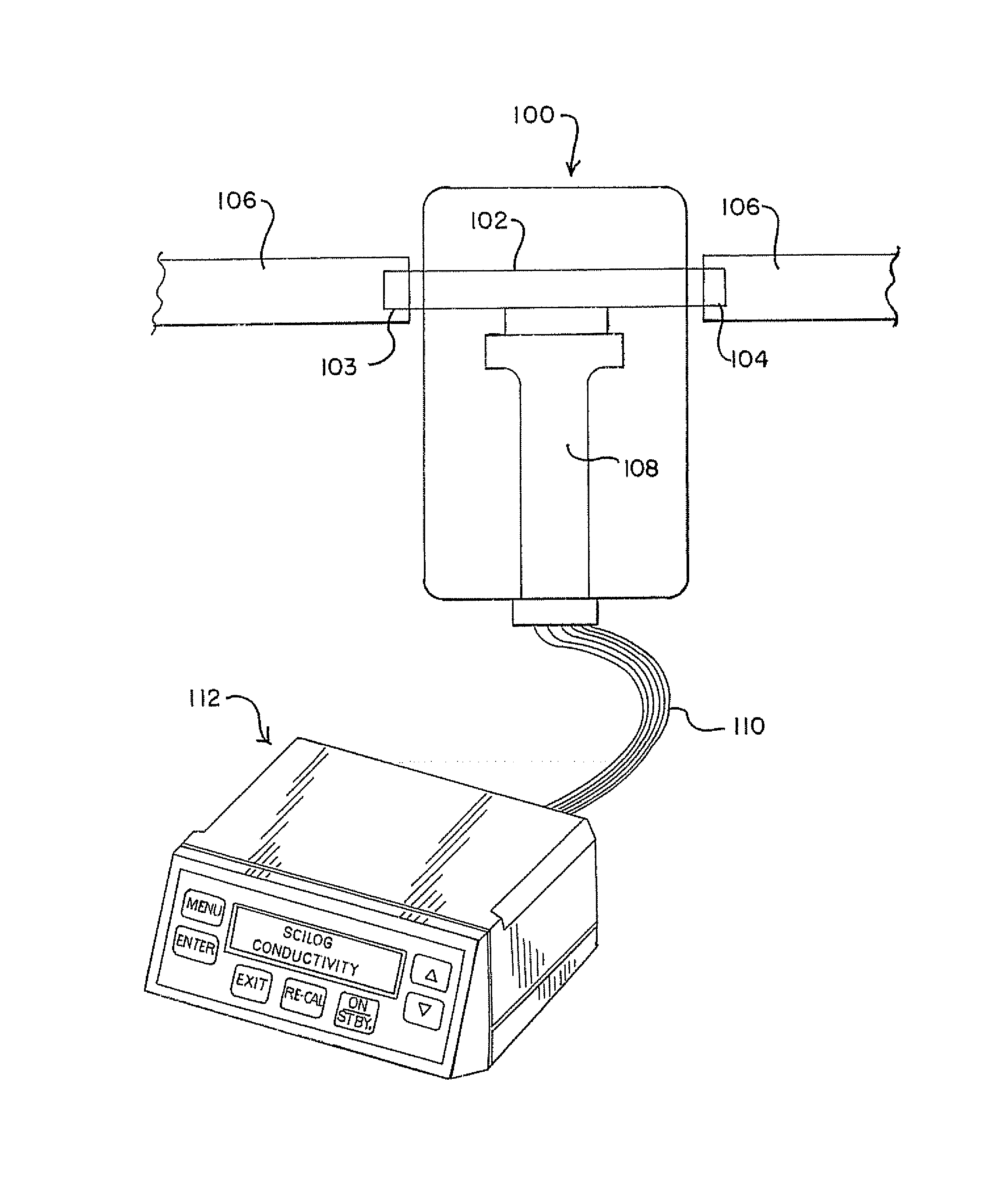

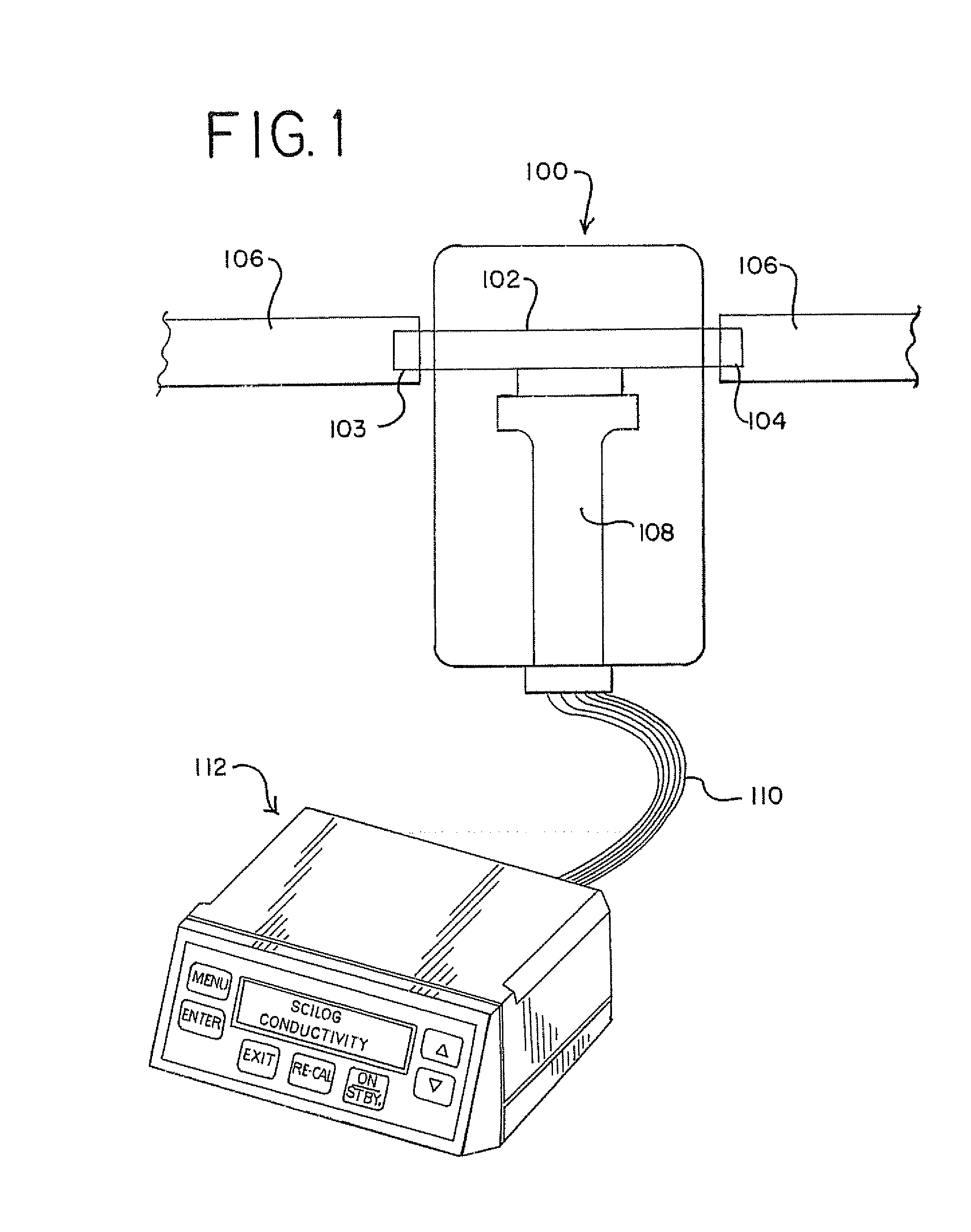

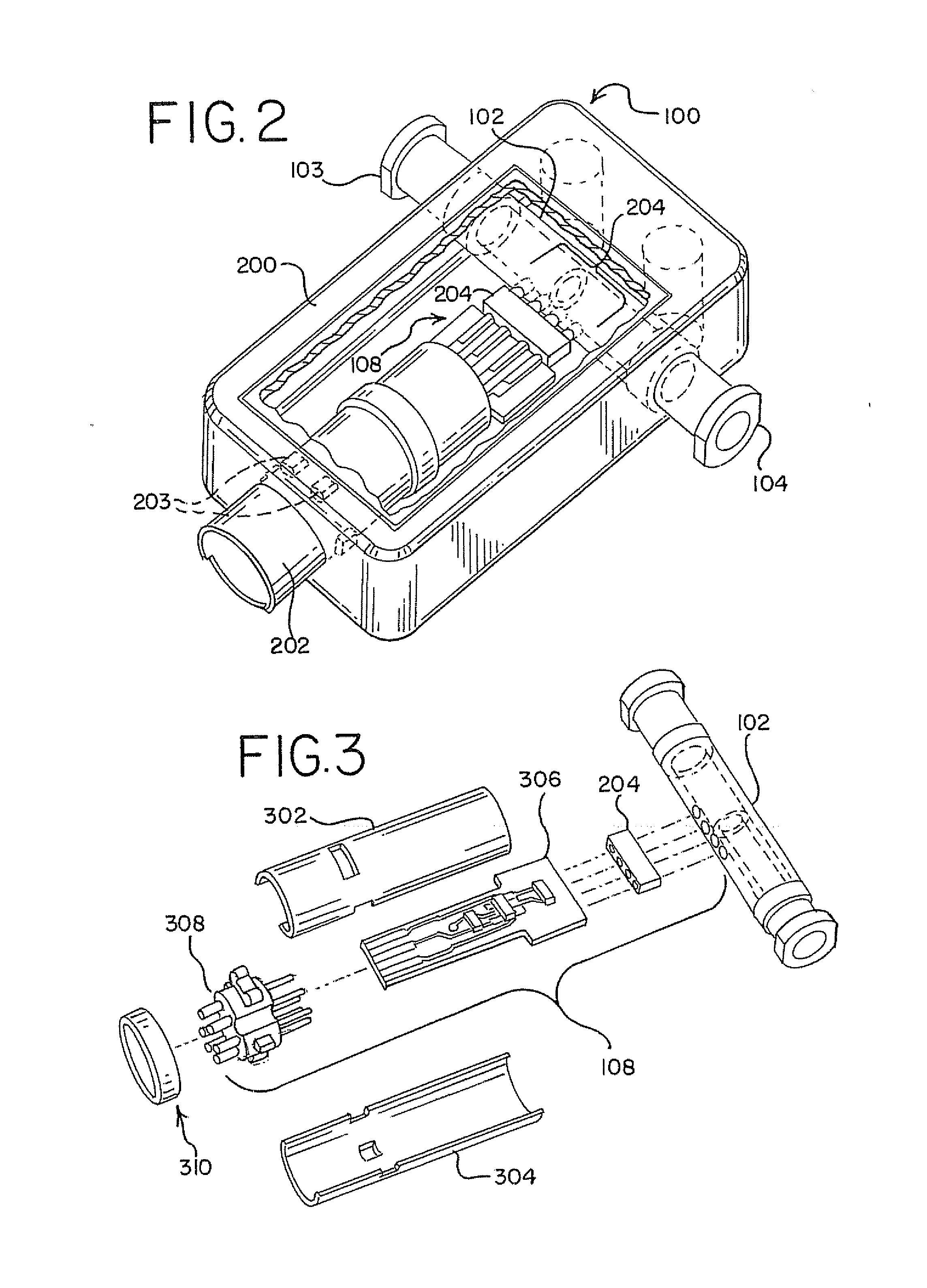

Disposable, pre-calibrated, pre-validated sensors for use in bio-processing applications

ActiveUS20070255527A1Low costProduction of permanent recordsResistance/reactance/impedenceQuality assuranceBarcode

Disposable, pre-sterilized, and pre-calibrated, pre-validated conductivity sensors are provided. These sensors are designed to store sensor-specific information, such as calibration and production information, in a non-volatile memory chip on the sensor on in a barcode printed on the sensor The sensors are calibrated using 0100 molar potassium chloride (KCl) solutions at 25 degrees Celsius. These sensors may be utilize with in-line systems, closed fluid circuits, bioprocessing systems, or systems which require an aseptic environment while avoiding or reducing cleaning procedures and quality assurance variances.

Owner:PARKER INTANGIBLES LLC

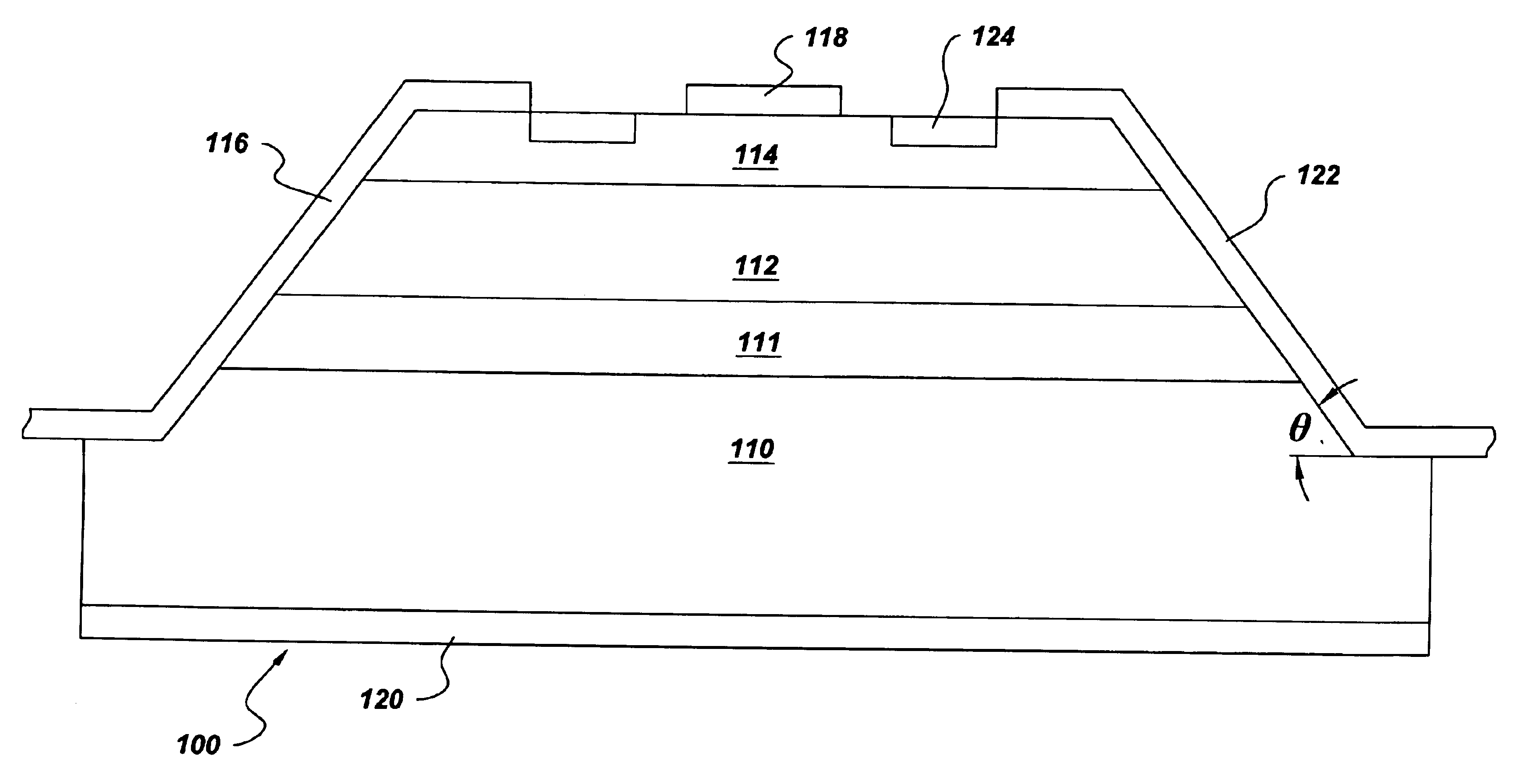

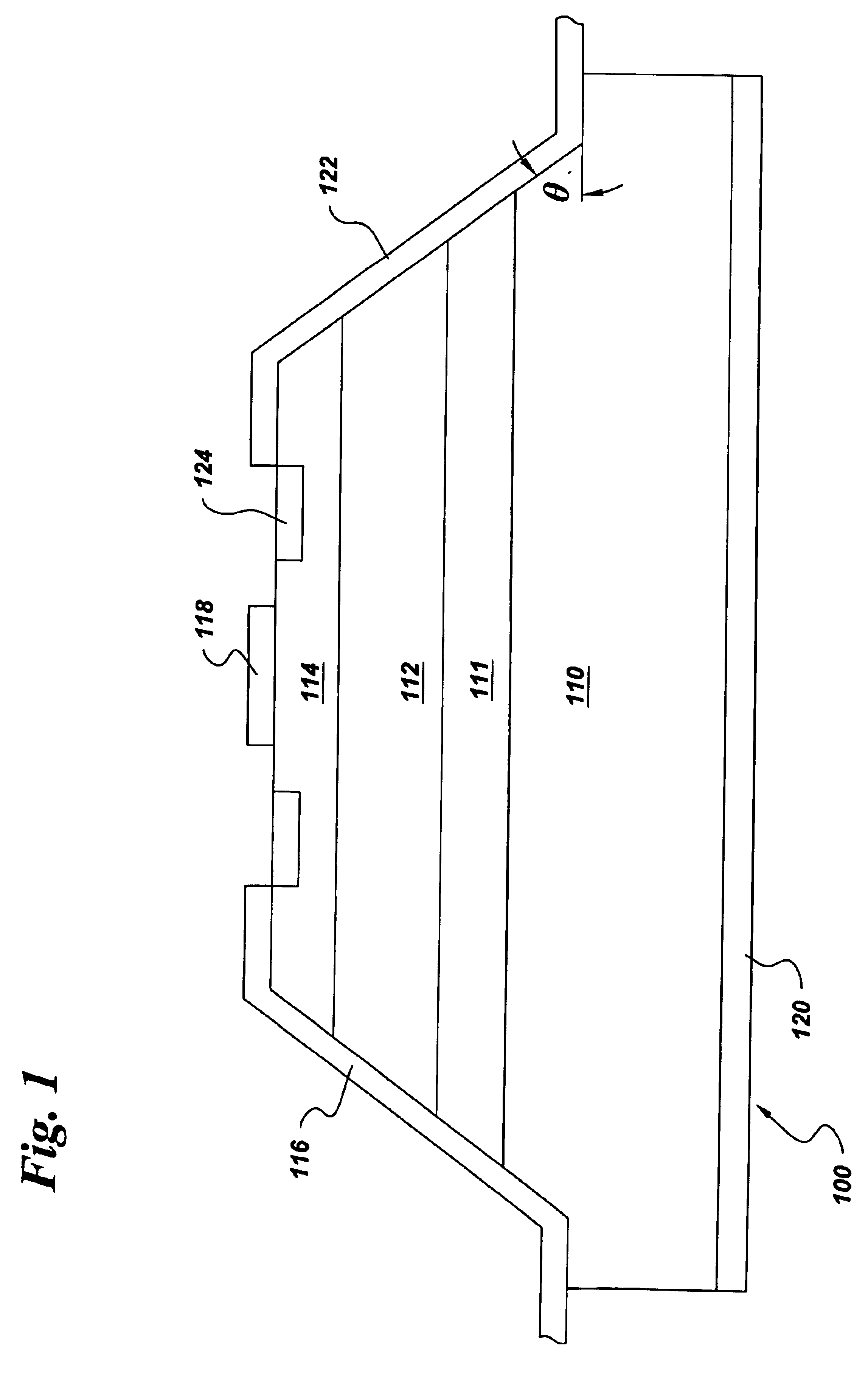

Avalanche photodiode for use in harsh environments

An aspect of the present invention is directed to an avalanche photodiode (APD) device for use in oil well drilling applications in harsh, down-hole environments where shock levels are near 250 gravitational acceleration (G) and / or temperatures approach or exceed 150° C. Another aspect of the present invention is directed to an APD device fabricated using SiC materials. Another aspect of the present invention is directed to an APD device fabricated using GaN materials. According to an embodiment of the present invention, an avalanche photodiode for detecting ultraviolet photons comprises a substrate having a first dopant; a first layer having the first dopant, positioned on top of the substrate; a second layer having a second dopant, positioned on top of the first layer; a third layer having a second dopant, positioned on top of the second layer; a passivation layer for providing electrical passivation on a surface of the avalanche photodiode; a phosphorous silicate glass layer for limiting mobile ion transport, positioned on top of the third layer; and a pair of metal electrodes for providing an ohmic contact wherein a first electrode is positioned below the substrate and a second electrode is positioned above the third layer; wherein the avalanche photodiode comprises a first sidewall and a second sidewall forming a sloped mesa shape; and wherein the avalanche photodiode operates in an environment comprising a temperature approximately equal to 150 degrees Celsius.

Owner:GENERAL ELECTRIC CO

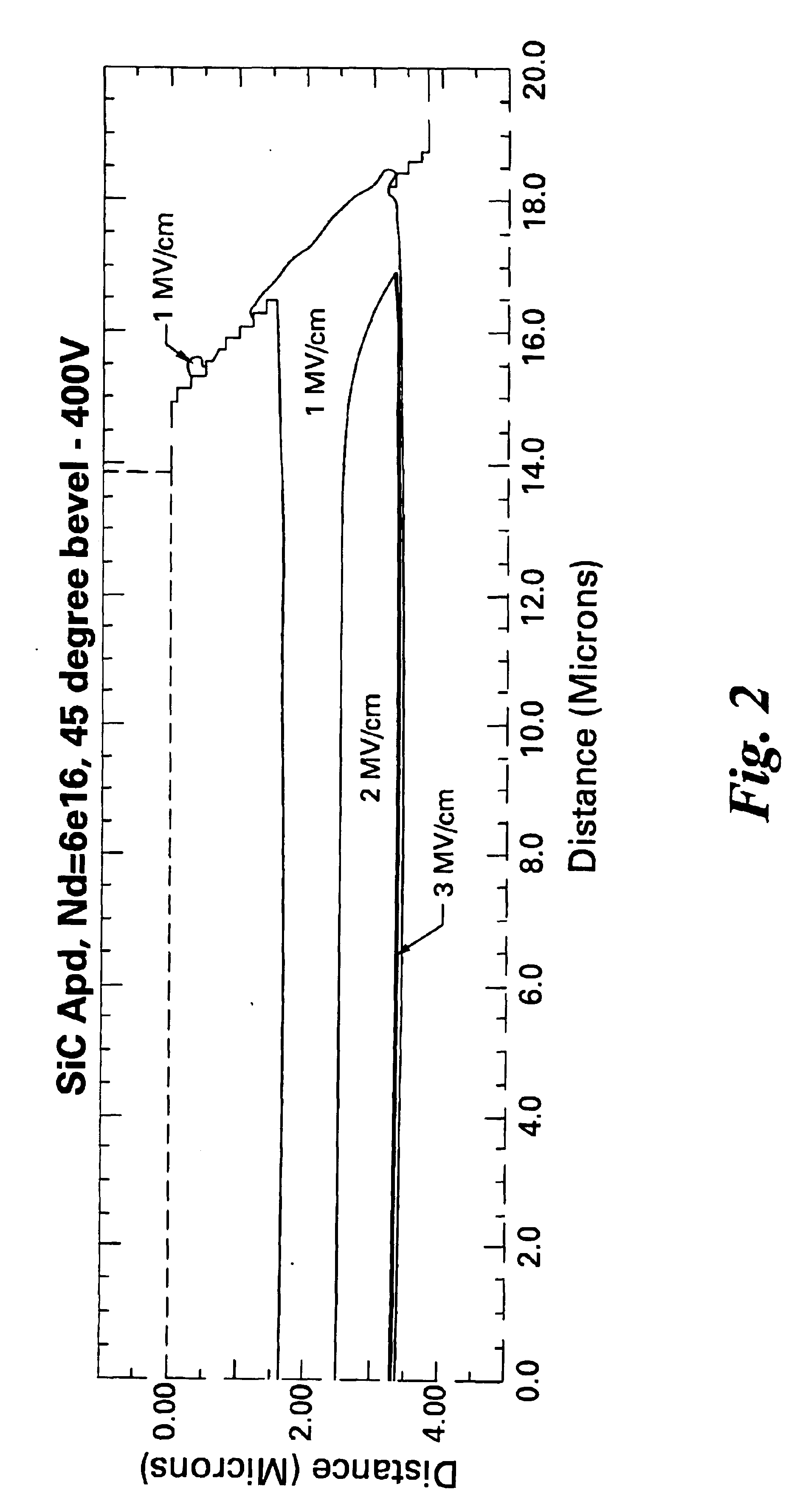

Non-invasive method and system for the treatment of snoring and nasal obstruction

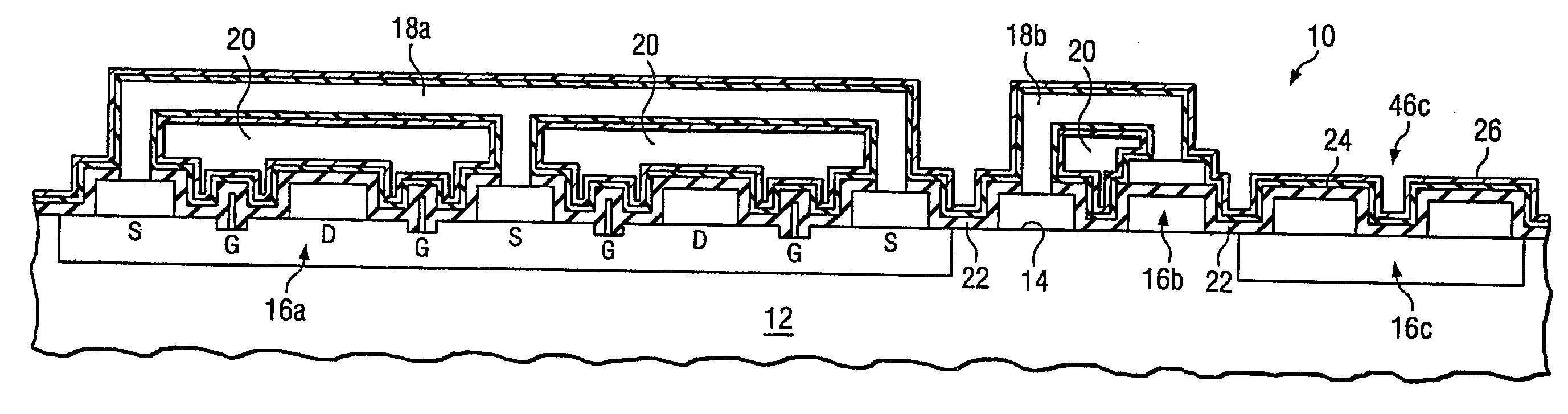

InactiveUS20060276861A1Efficient thermal shrinkage of treated areaSurgical instrument detailsLight therapyHigh power diode laserPalate muscle

Laser for thermal shrinkage of soft tissue of uvula, soft palate, nasal turbinate or tongue base for the treatment of snoring, nasal obstruction or sleep apnea are disclosed. The preferred laser includes infrared laser about 0.7 to 1.85 micron, pulse duration about 100 microsecond to 5 seconds, spot size of about 2 to 5 mm and power of about 2 to 20 W at the treated area. The laser energy is delivered to the treated area by an optical fiber and a hand piece to cause a localized temperature about 65 to 85 degree Celsius for sufficient shrinkage of the treated soft tissues. Optical fiber bundles to produce high-power diode laser output or multi-wavelength are also disclosed.

Owner:NEW VISION

Energy storage device and method

A composition is provided that includes a ternary electrolyte having a melting point greater than about 150 degree Celsius. The ternary electrolyte includes an alkali metal halide, an aluminum halide and a zinc halide. The amount of the zinc halide present in the ternary electrolyte is greater than about 20 mole percent relative to an amount of the aluminum halide. An energy storage device including the composition is provided. A system and a method are also provided.

Owner:GENERAL ELECTRIC CO

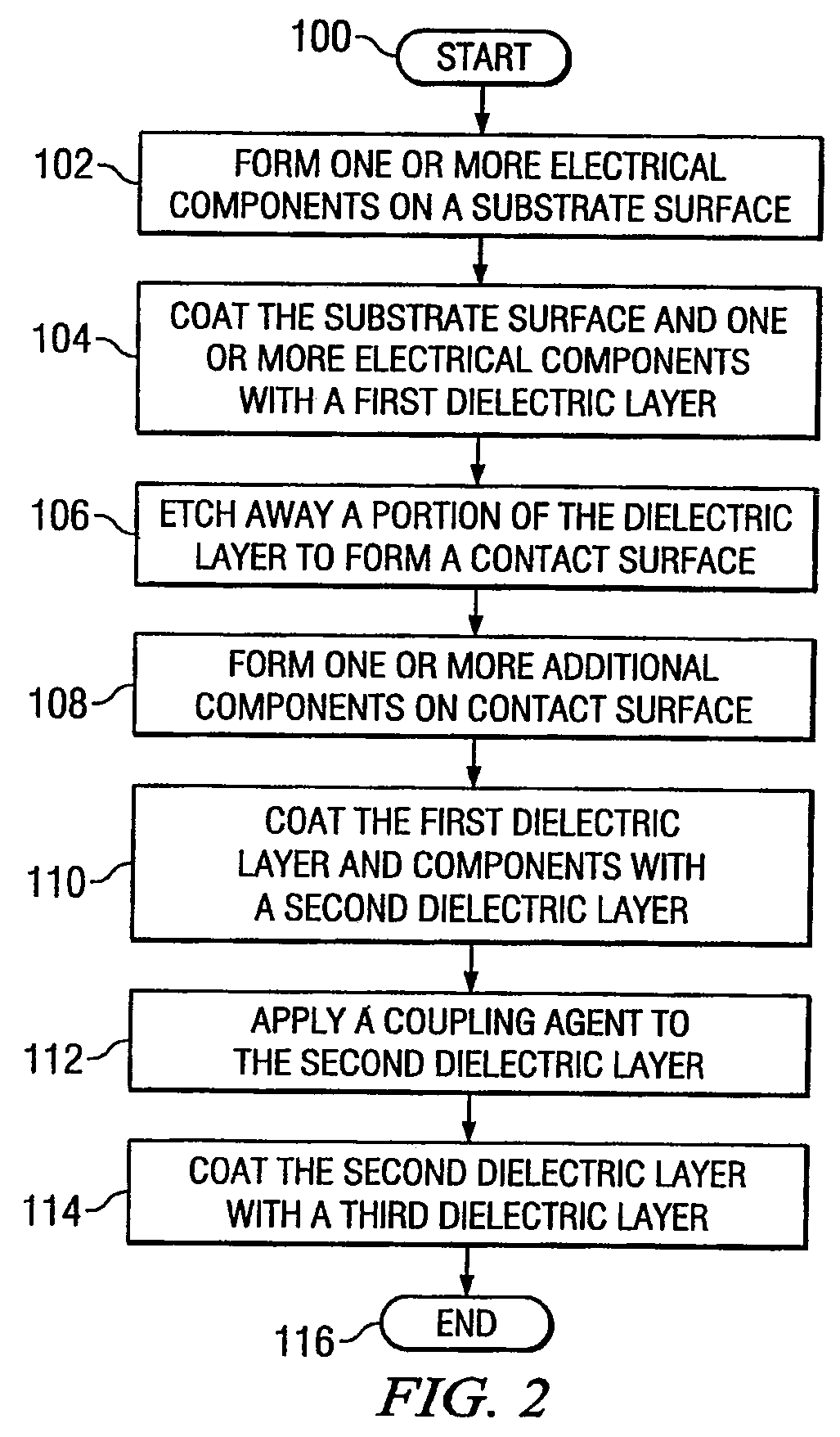

Environmental Protection Coating System and Method

ActiveUS20080185173A1Improve electrical performanceGood mechanical protectionPrinted circuit assemblingSemiconductor/solid-state device detailsDielectric lossCoating system

According to one embodiment of the disclosure, an environmental protection coating comprises a circuit assembly having a first protective dielectric layer and a second dielectric layer. The circuit assembly has an outer surface on which a plurality of discrete electrical components are attached. The first protective dielectric layer overlays the circuit assembly. The second dielectric layer overlays the first protective dielectric layer and is made of a dielectric material having modulus of elasticity less than 3.5 Giga-Pascal (GPa), dielectric constant less than 2.7, dielectric loss less than 0.008, breakdown voltage strength in excess of 2 million volts / centimeter (MV / cm), temperature stability to 3000 Celsius, defect densities less than 0.5 / centimeter, pinhole free in films greater than 50 Angstroms, capable of being deposited conformally over and under 3D structures with thickness uniformity less than or equal to 10%.

Owner:RAYTHEON CO

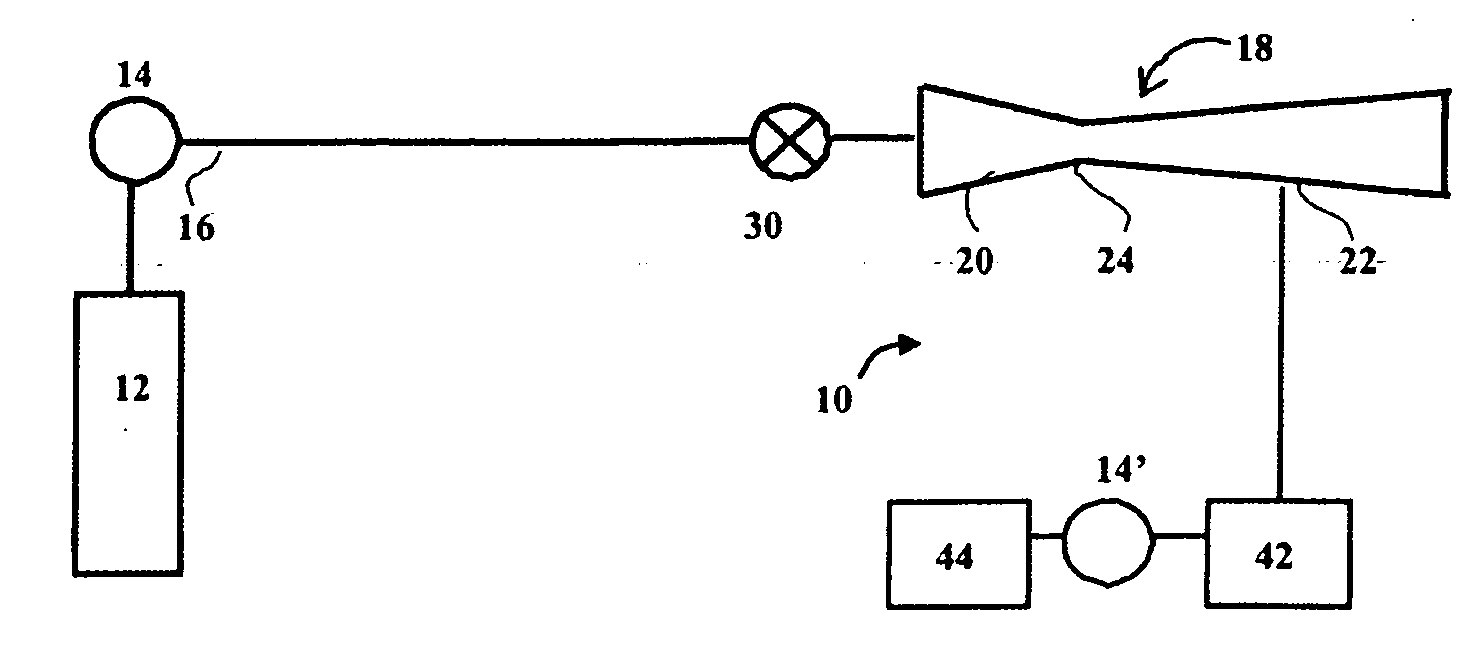

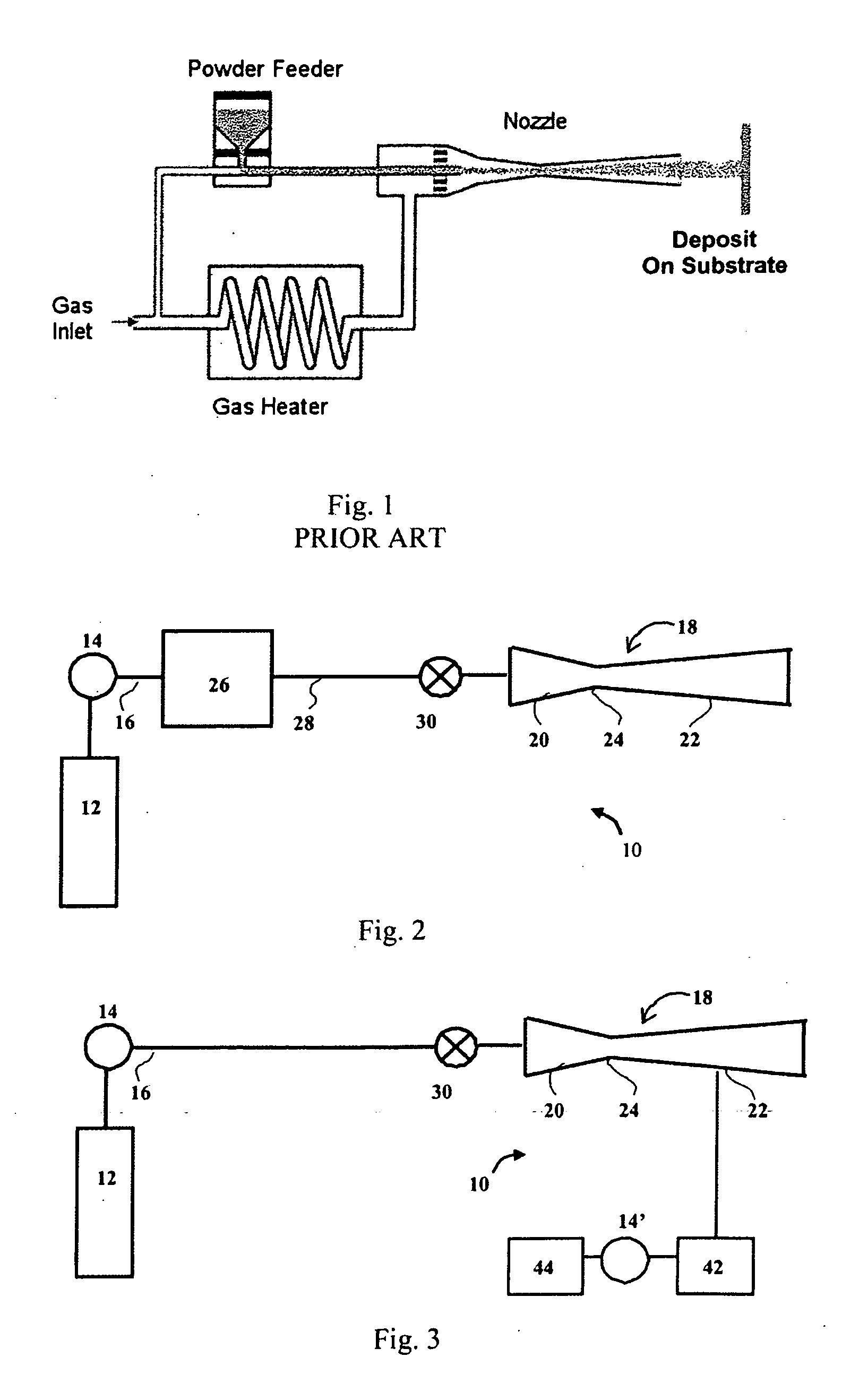

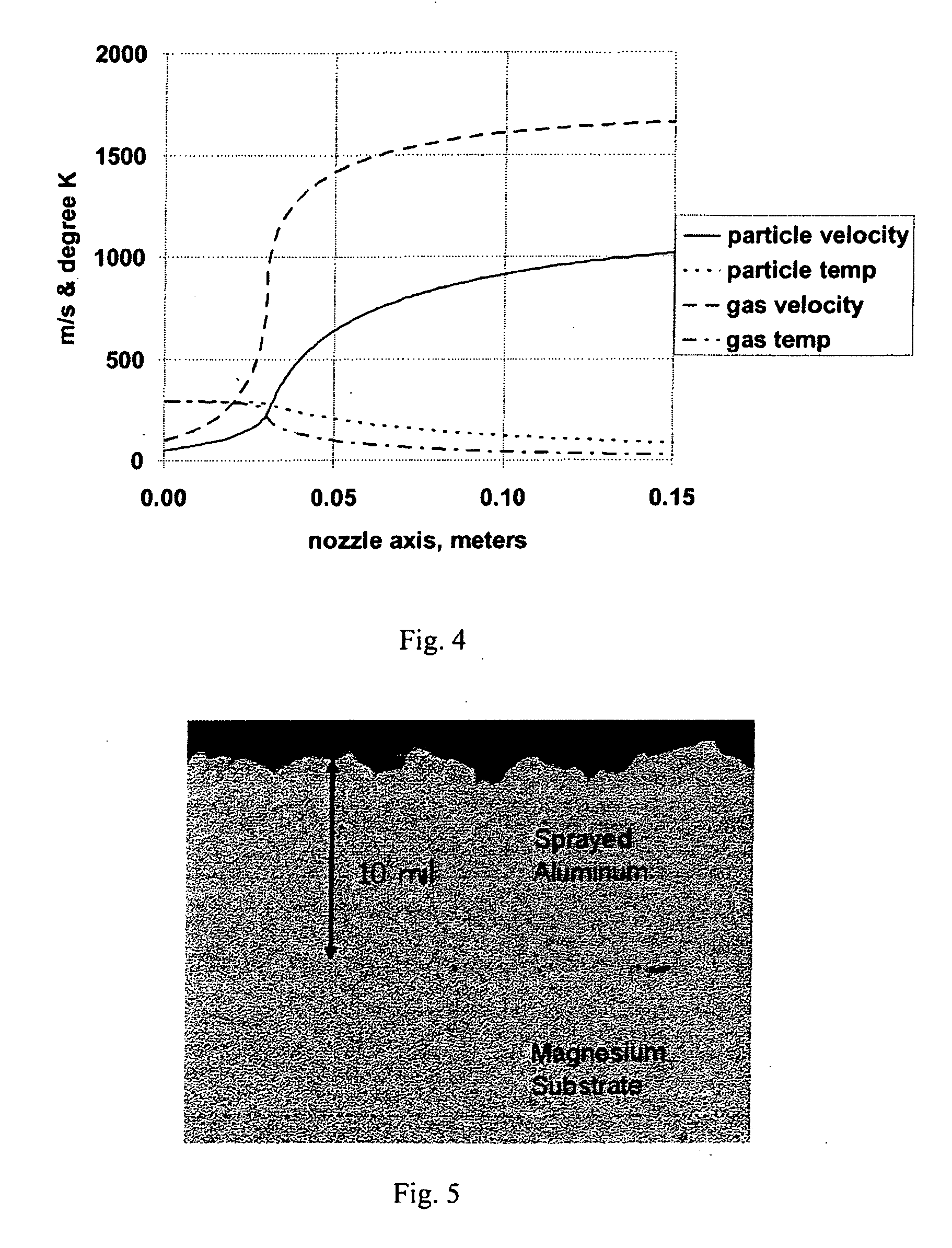

Cold spray impact deposition system and coating process

A cold spray apparatus is provided that includes a nozzle having a converging section and a diverging terminal section. A gas supply meters a majority by atomic percent helium gas to the nozzle at an incident gas temperature of less than 30° Celsius and at an incident velocity of between 2 and 6 MPa. A particulate feeder provides ductile material particulate having a mean x-y-z axially averaged linear dimension of between 0.9 and 95 microns to the nozzle. A composition is also provided that includes a substrate and a coating of ductile metal. The coating has a void density of less than 1% by volume, and an average domain size of between 0.9 and 95 microns. The coating has a compressive residual stress.

Owner:US SEC THE ARMY THE

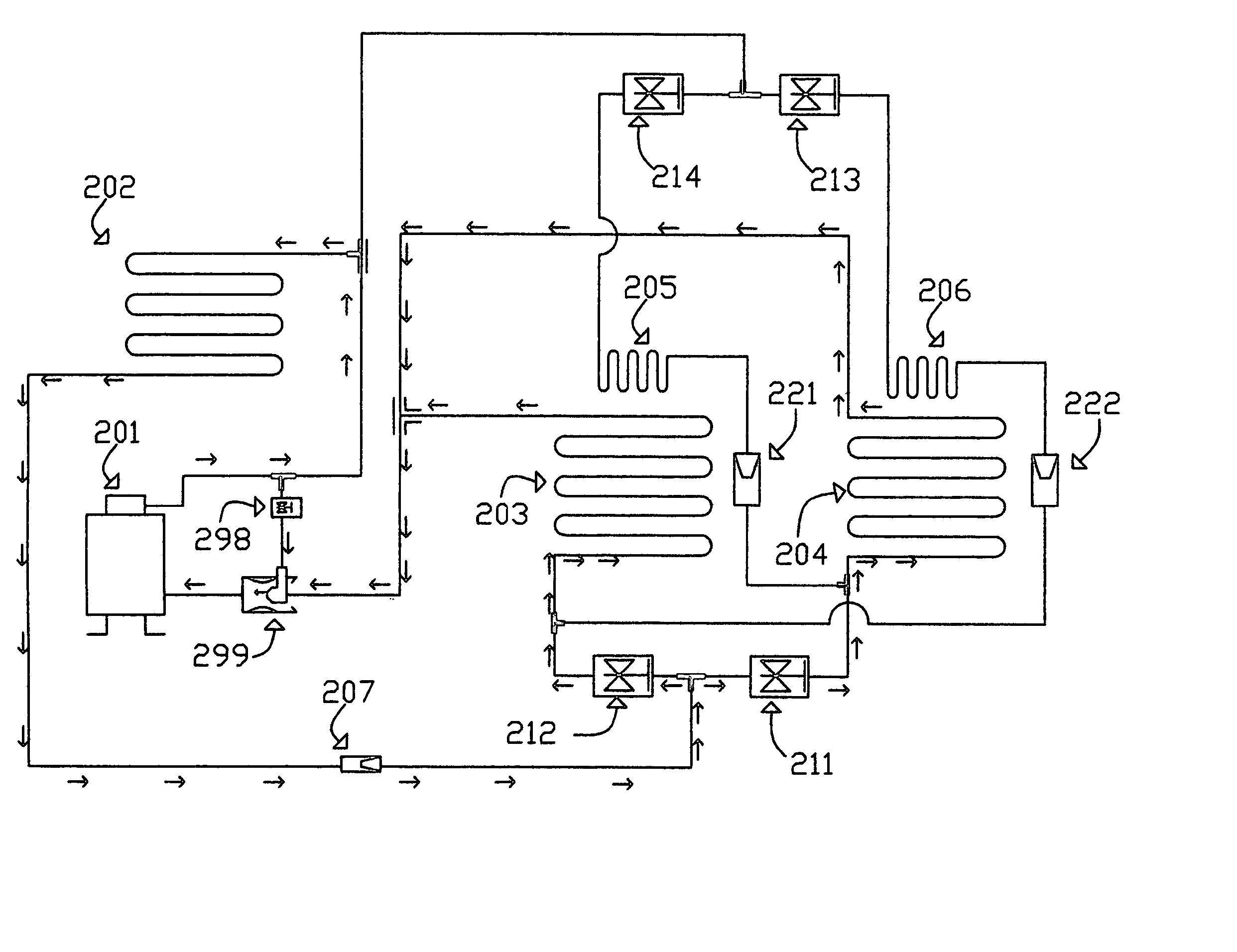

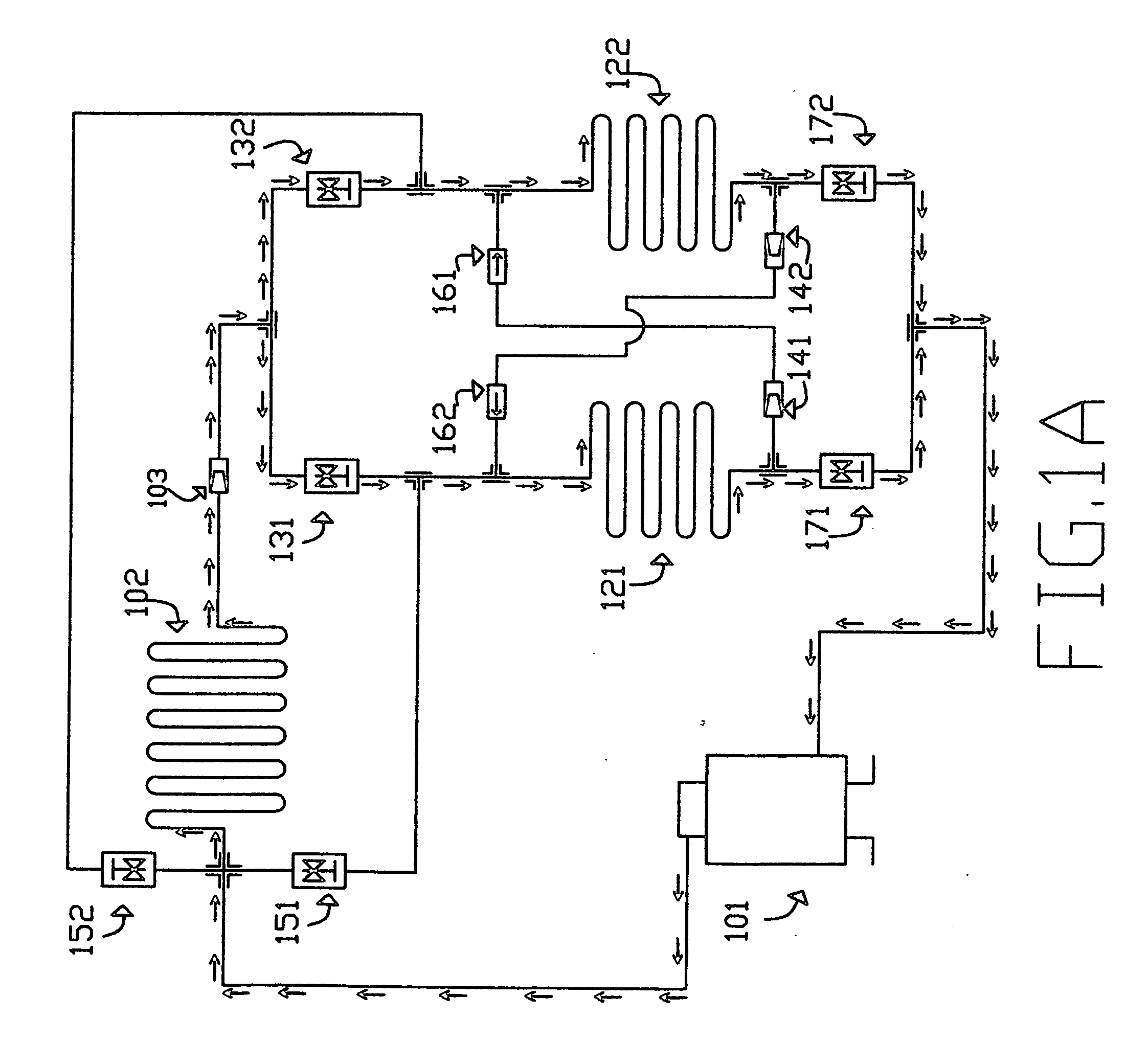

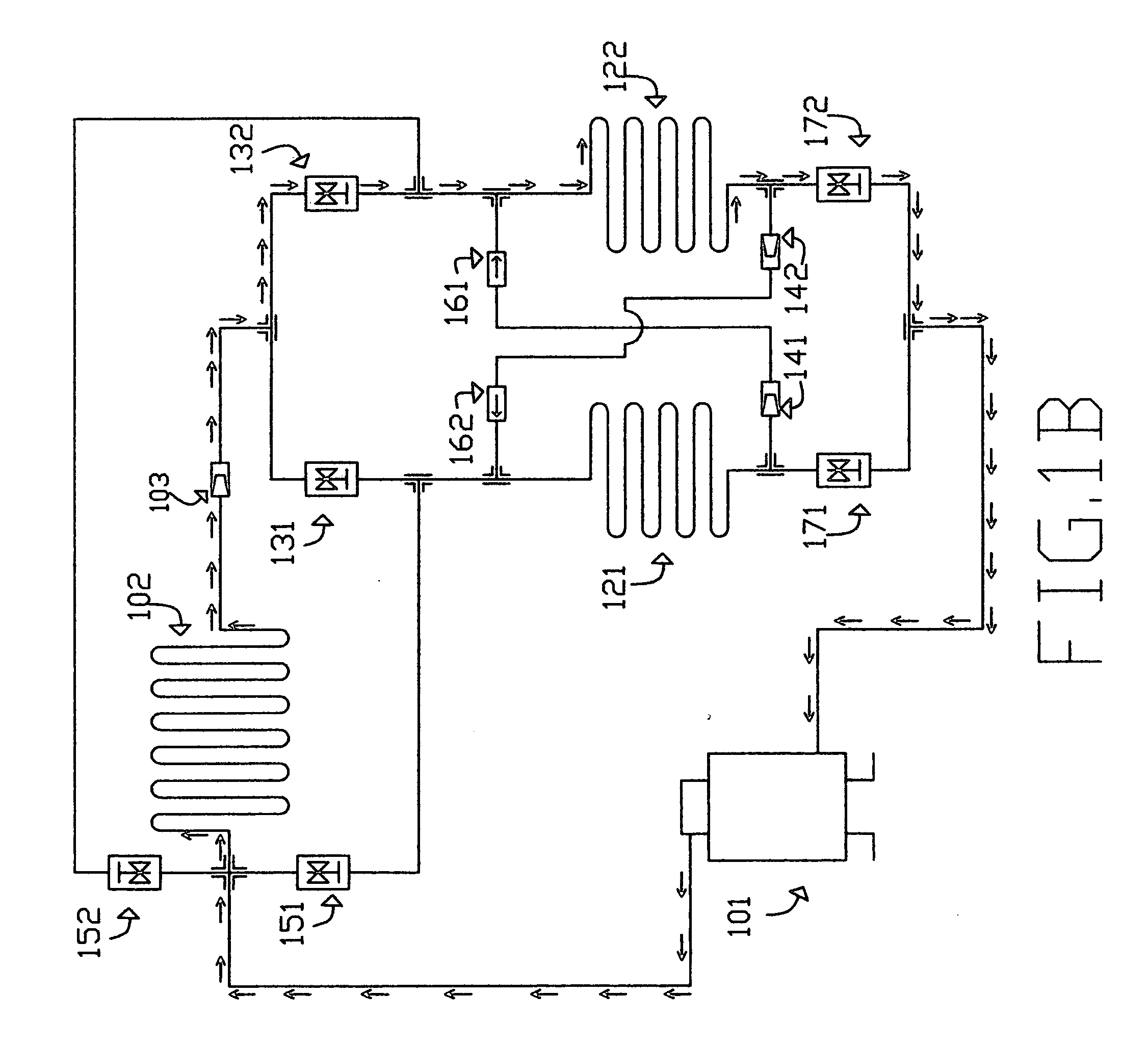

Multi-range cross defrosting heat pump system and humidity control system

InactiveUS20070137238A1Minimizing overall energy requiredCompression machines with non-reversible cycleCompression machines with several evaporatorsControl systemDegree Celsius

The present invention provides an air-condition heat pump system and two-stage defrosting control method for continuous operation under an environment temperature range from 20 degree to negative 40 degree Celsius or lower. The heat pump system employs different defrosting methods under different temperature and humidity conditions. A ventilation and humidity control system is also provided for implementing the cross defrosting heat pump system within an indoor dimension.

Owner:HU LUNG TAN

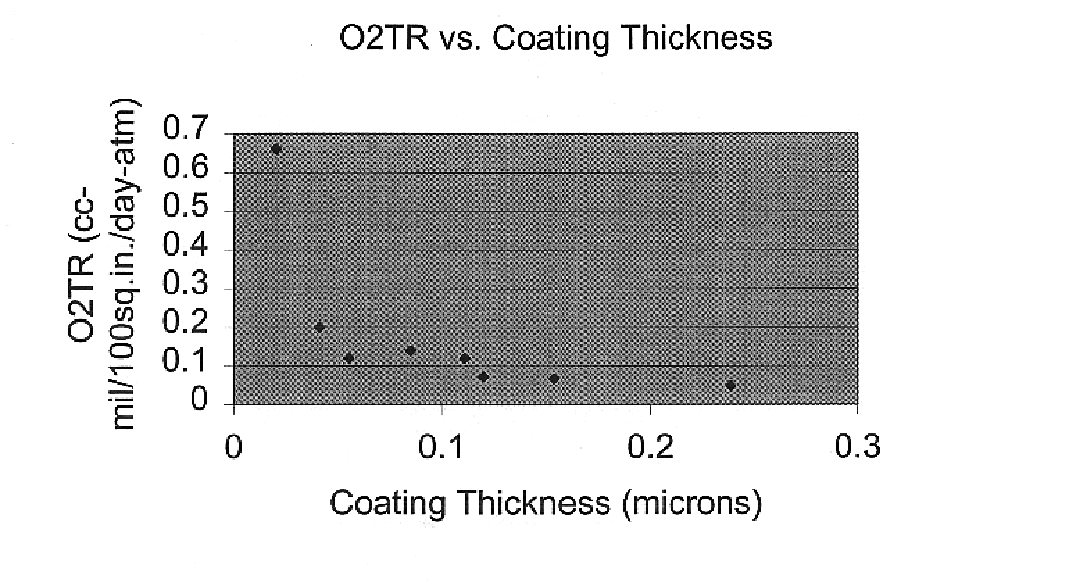

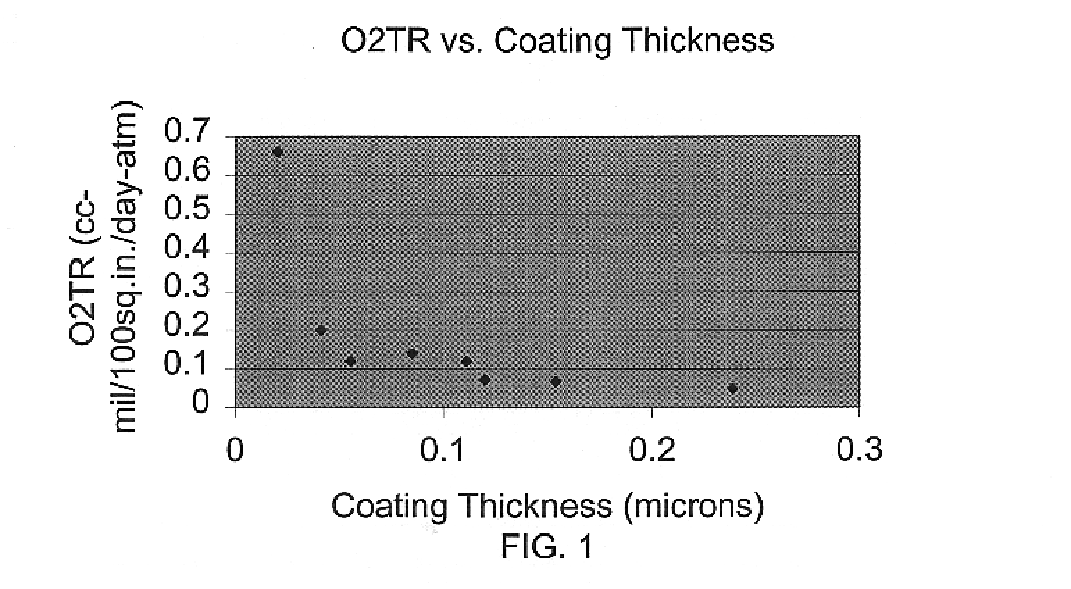

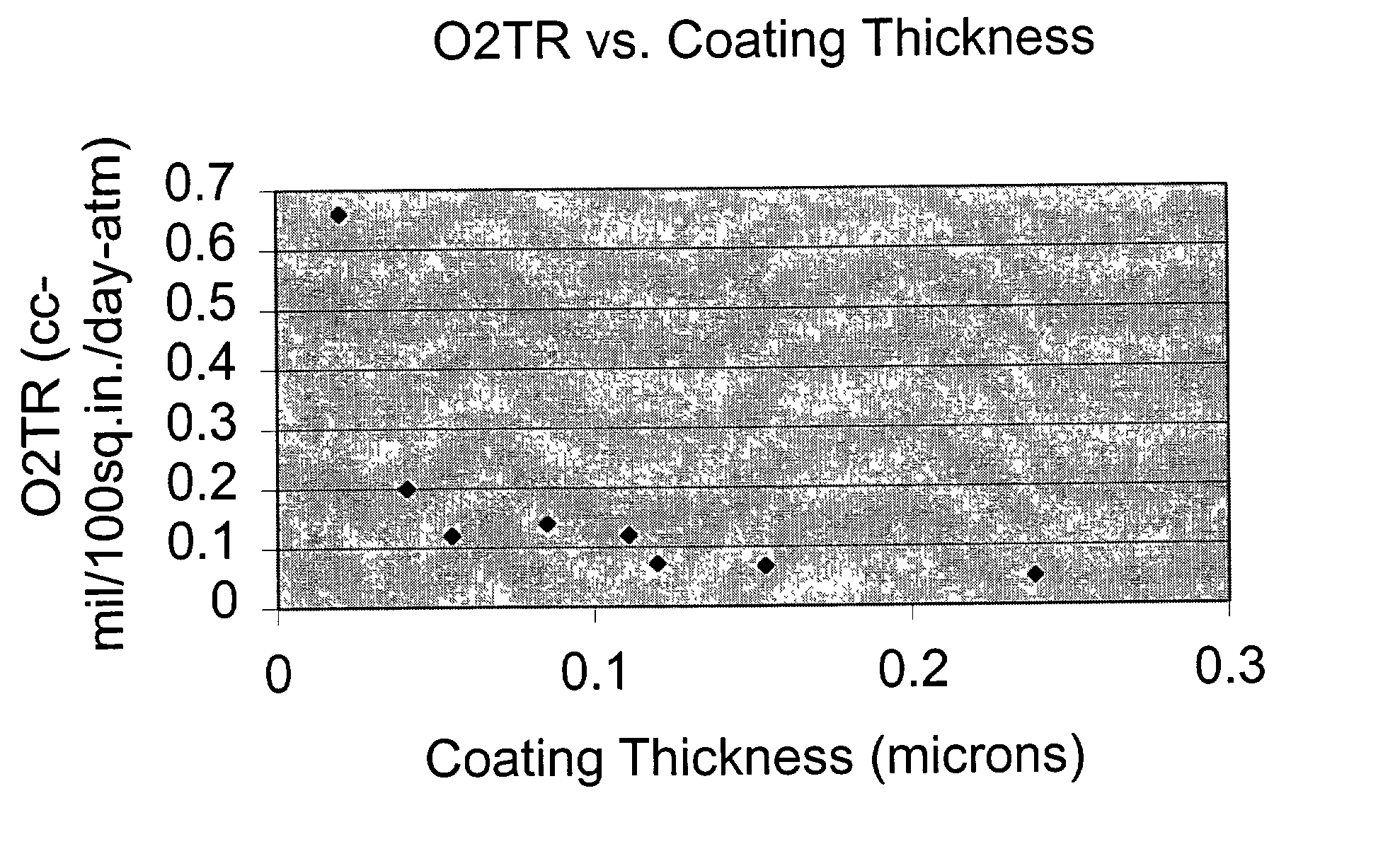

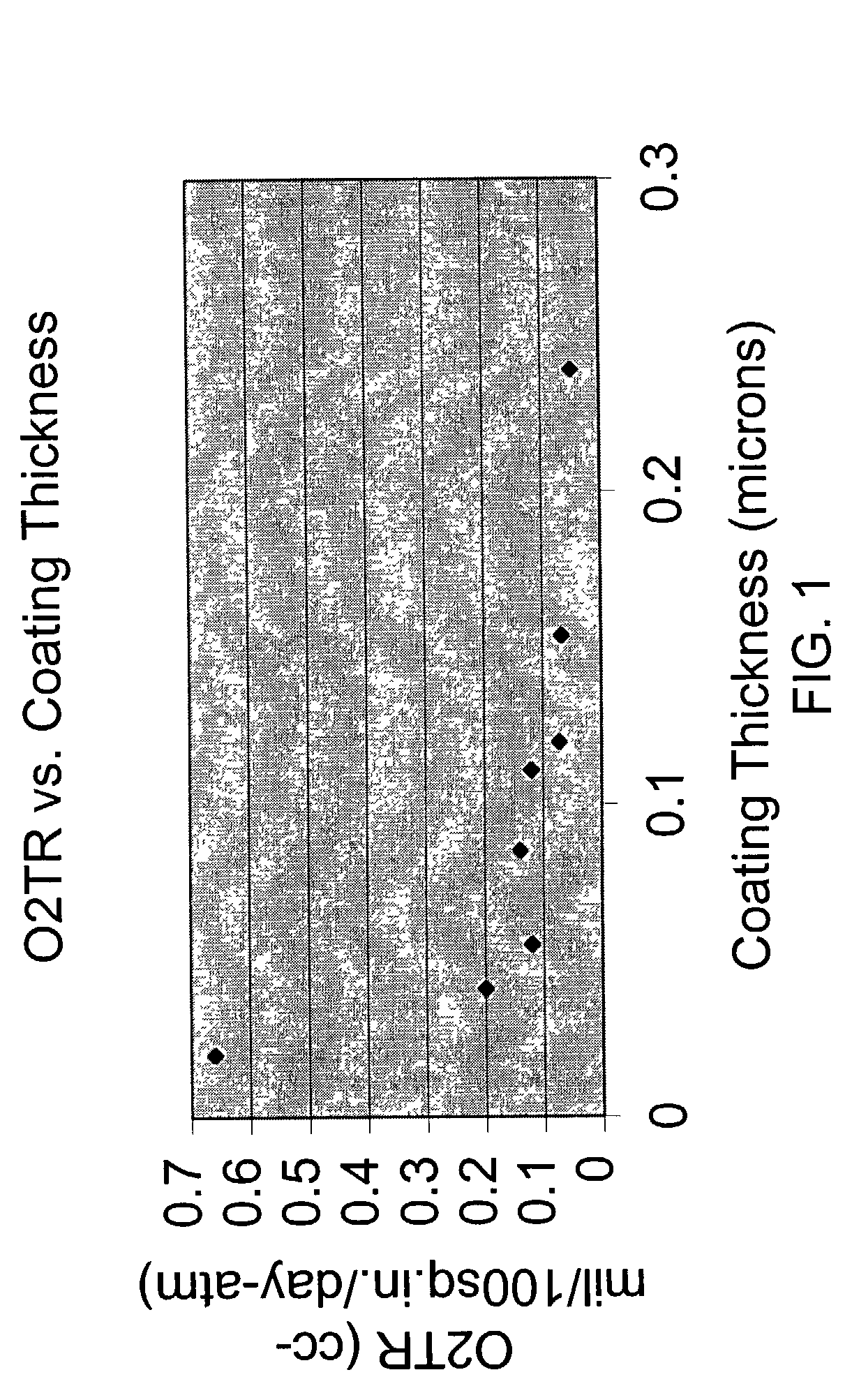

Oxygen barrier coating and coated film

A film with excellent oxygen barrier properties is disclosed. A barrier coating used thereon is also disclosed, including polyvinyl alcohol and a copolymer of maleic acid and acrylic acid, and wherein the copolymer of maleic acid and acrylic acid has a weight average molecular weight of about 3500 to about 5000. The barrier coating is typically less than about 1 micrometer in thickness and provides an oxygen barrier of less than about 0.3 cc.mil / 100 in<2> / day / atm when tested at 23 degrees Celsius and 0 percent relative humidity according to ASTM D3985. A method of stripping low molecular eight fractions from the copolymer is also disclosed. Metallized coated film according to the present invention shows surprising barrier properties.

Owner:MITSUBISHI POLYESTER FILM

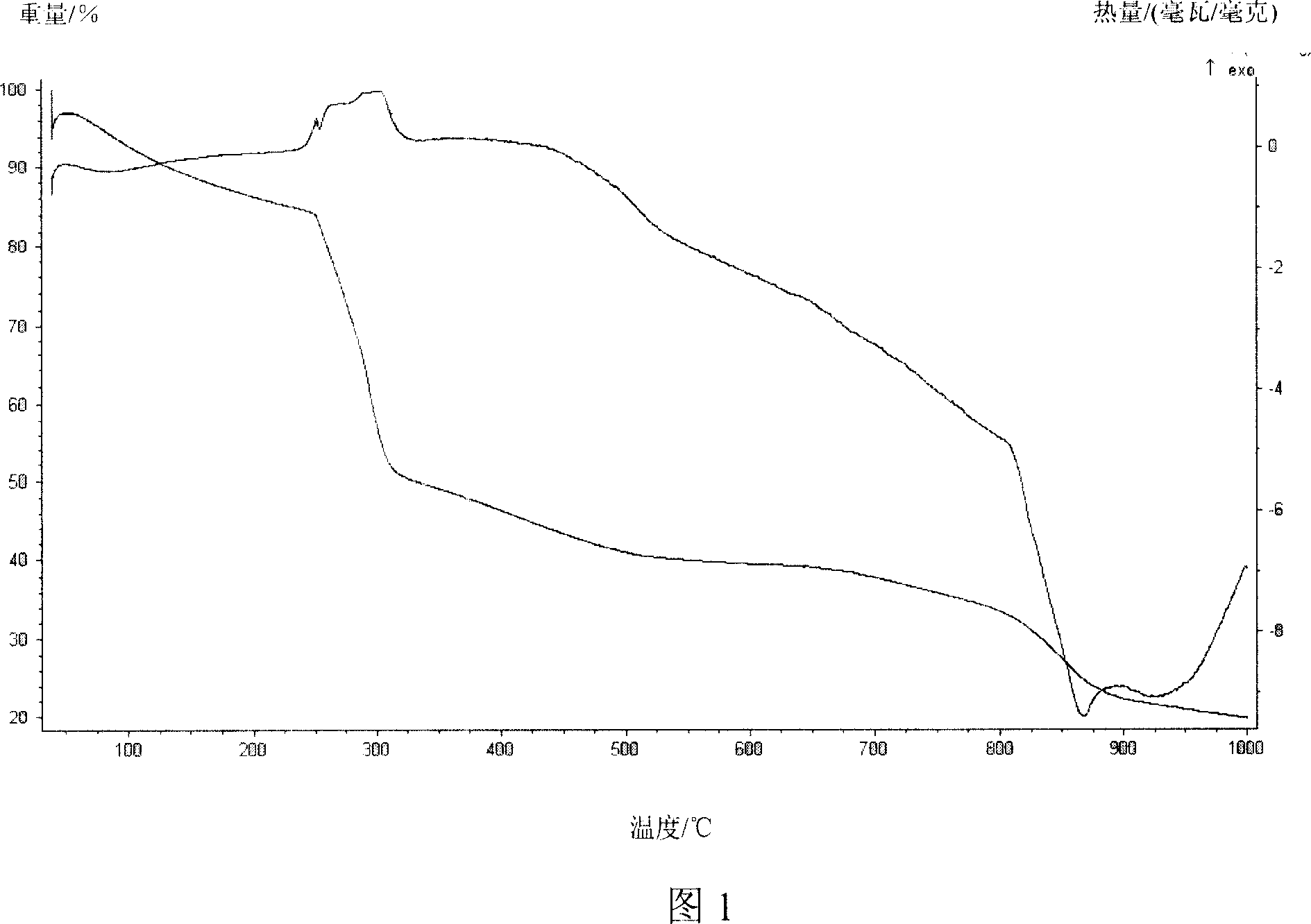

Process for recovering carbon materials of battery cathode

ActiveCN101154757APromote circulationImprove cycle performanceSolid waste disposalReclaiming serviceable partsRecovery methodRoom temperature

The invention discloses a method for recycling cathode carbolic materials of battery, wherein, the cathode carbolic materials are loaded on a current collection body by binding agents, forming a cathode piece of battery; the method includes the following steps that: firstly, according to the solid-liquid weight ratio of 1:3 to 30, the cathode piece of battery is put into the soaking agent with the temperature of 30 to 10 Celsius degrees for complete soaking, until the cathode materials are separated from the current collection body; secondly, the current collection body is taken out and filtered to get the solid materials; thirdly, under the protection of the non-oxidizing gas, the solid materials are heated at the temperature of 400 to 800 Celsius, getting the carbolic materials. The discharging capacity at the normal temperature and the multiplying power discharging performance of the battery of which the carbolic materials are recovered by the method of the invention are very close to those of the battery with the finished product carbolic materials for manufacturing, thereby the carbolic materials are recycled by the method of the invention complies with the production requirement.

Owner:BYD CO LTD

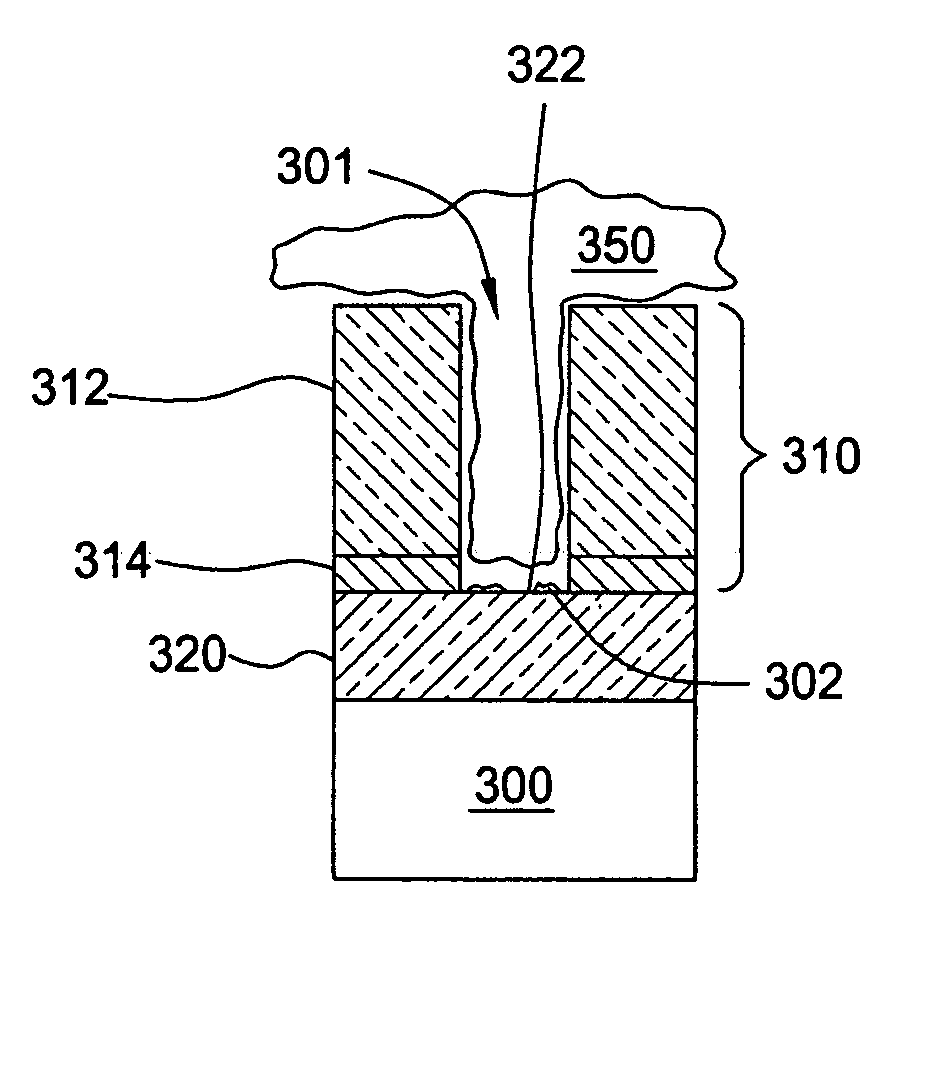

Post-etch treatment to remove residues

InactiveUS20060102197A1Semiconductor/solid-state device manufacturingElectrostatic cleaningHydrogenTime segment

A method for removing residue from a layer of conductive material on a substrate is provided herein. In one embodiment, the method includes introducing a process gas into a vacuum chamber having a substrate surface with residue from exposure to a fluorine-containing environment. The process gas includes a hydrogen-containing gas. Optionally, the process gas may further include an oxygen-containing or a nitrogen containing gas. A plasma of the process gas is thereafter maintained in the vacuum chamber for a predetermined period of time to remove the residue from the surface. The temperature of the substrate is maintained at a temperature between about 10 degrees Celsius and about 90 degrees Celsius during the plasma step.

Owner:APPLIED MATERIALS INC

Preservation by vaporization

ActiveUS9469835B2Maximize potencyMaximize viabilityBioreactor/fermenter combinationsBiological substance pretreatmentsIndustrial scaleVacuum chamber

Significant research is being done to develop and improve delivery mechanisms for biopharmaceuticals and vaccines, including pulmonary (inhalation), nasal, transdermal, and oral alternatives. Market projections indicate that the delivery of proteins and vaccines by inhalation and oral formulation has become and will continue to be increasingly important. These delivery mechanisms, to be effective, will require better stabilization of the biologicals so that they can maintain potency and effectiveness at ambient temperatures for extended periods of time. The novel Preservation by Vaporization (PBV) Technology described herein provides cost-effective and efficient industrial scale stabilization of proteins, viruses, bacteria, and other sensitive biologicals, thereby allowing a production of products that are not possible to be produced by existing methods. The suggested new PBV process comprises primary drying under vacuum from a partially frozen state (i.e. slush) at near subzero temperatures followed by stability drying at elevated temperatures (i.e., above 40 degrees Celsius). The new suggested method can be performed aseptically in unit doze format (in vials) and / or in bulk format (in trays, bags, or other containers). The drying can be performed as a continuous load process in a manifold vacuum dryer comprising a plurality (e.g., 30) of vacuum chambers attached to a condenser during the drying.

Owner:UNIVERSAL STABILIZATION TECH INC

Oxygen barrier coating and coated film

InactiveUS20030124365A1Improve the immunityReduce thicknessLiquid surface applicatorsLamination ancillary operationsPolyvinyl alcoholMicrometer

A film with excellent oxygen barrier properties is disclosed. A barrier coating used thereon is also disclosed, including polyvinyl alcohol and a copolymer of maleic acid and acrylic acid, and wherein the copolymer of maleic acid and acrylic acid has a weight average molecular weight of about 3500 to about 5000. The barrier coating is typically less than about 1 micrometer in thickness and provides an oxygen barrier of less than about 0.3 cc.mil / 100 in2 / day / atm when tested at 23 degrees Celsius and 0 percent relative humidity according to ASTM D3985. A method of stripping low molecular weight fractions from the copolymer is also disclosed. Metallized coated film according to the present invention shows surprising barrier properties.

Owner:MITSUBISHI POLYESTER FILM

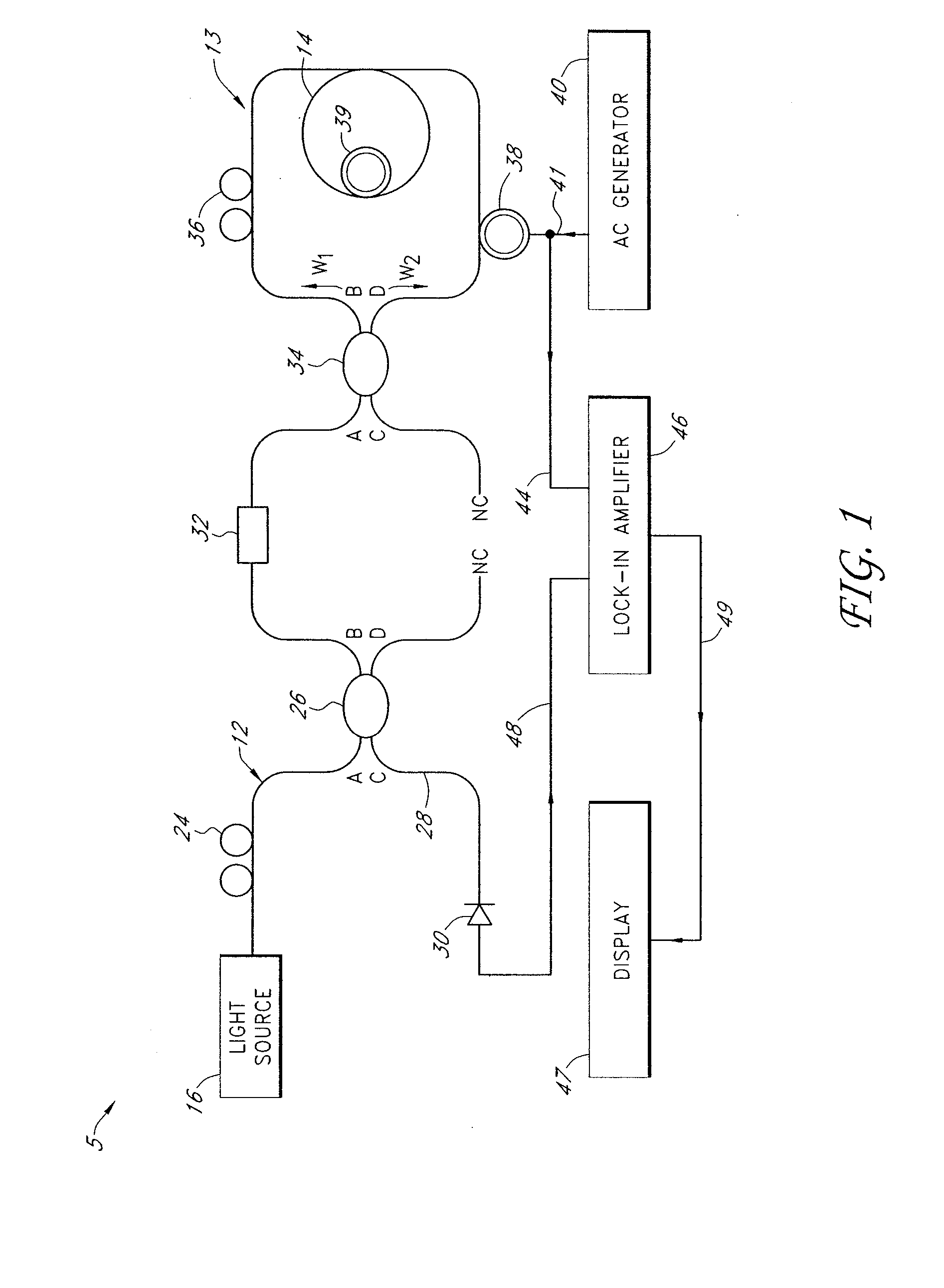

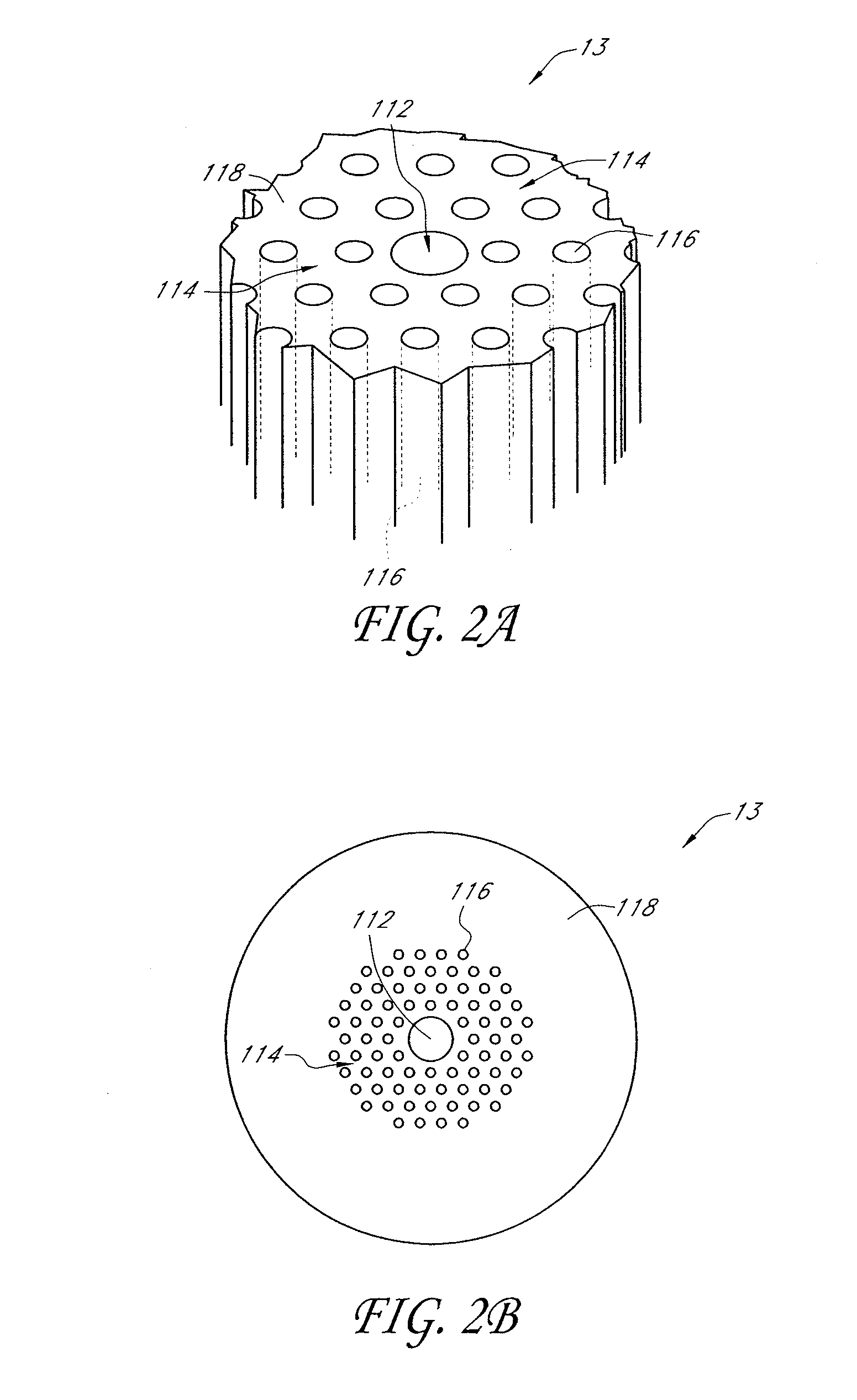

Optical sensor utilizing hollow-core photonic bandgap fiber with low phase thermal constant

ActiveUS20080030741A1Reduce the impactReduced VerdetSagnac effect gyrometersSpeed measurement using gyroscopic effectsPhotonic bandgapDegree Celsius

An optical sensor includes a directional coupler comprising at least a first port, a second port, and a third port. The first port is in optical communication with the second port and with the third port such that a first optical signal received by the first port is split into a second optical signal that propagates to the second port and a third optical signal that propagates to the third port. The optical sensor further includes a photonic bandgap fiber having a hollow core and an inner cladding generally surrounding the core. The photonic bandgap fiber is in optical communication with the second port and with the third port. The second optical signal and the third optical signal counterpropagate through the photonic bandgap fiber and return to the third port and the second port, respectively. The photonic bandgap fiber has a phase thermal constant S less than 8 parts-per-million per degree Celsius.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Method for preparing ethylene by ethanol dehydration

ActiveCN101121624AReduce carbon deposition rateExtended service lifeMolecular sieve catalystsHydrocarbonsDegree CelsiusReaction temperature

The present invention relates to a preparation method of ethylene using the dehydration of ethanol, which is to solve the problem in the prior technology that: the reaction temperature is higher; the hollow speed is lower and the energy consumption is higher. The present invention uses ethanol as the raw material and water as the thinner; under the condition that the reaction temperature is 200- 400 Celsius system, the reaction pressure calculated by a pressure meter is 0-2MPa and the reaction weight hollow speed is 0.1-10 hours, the raw material is contacted with ZSM molecule screen catalyzer to produce a ethylene flow; thereinto the molar ratio between water and ethanol is 0-10: 1. The technical scheme can solve the problem greatly, which can be used in the industrial production of ethylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

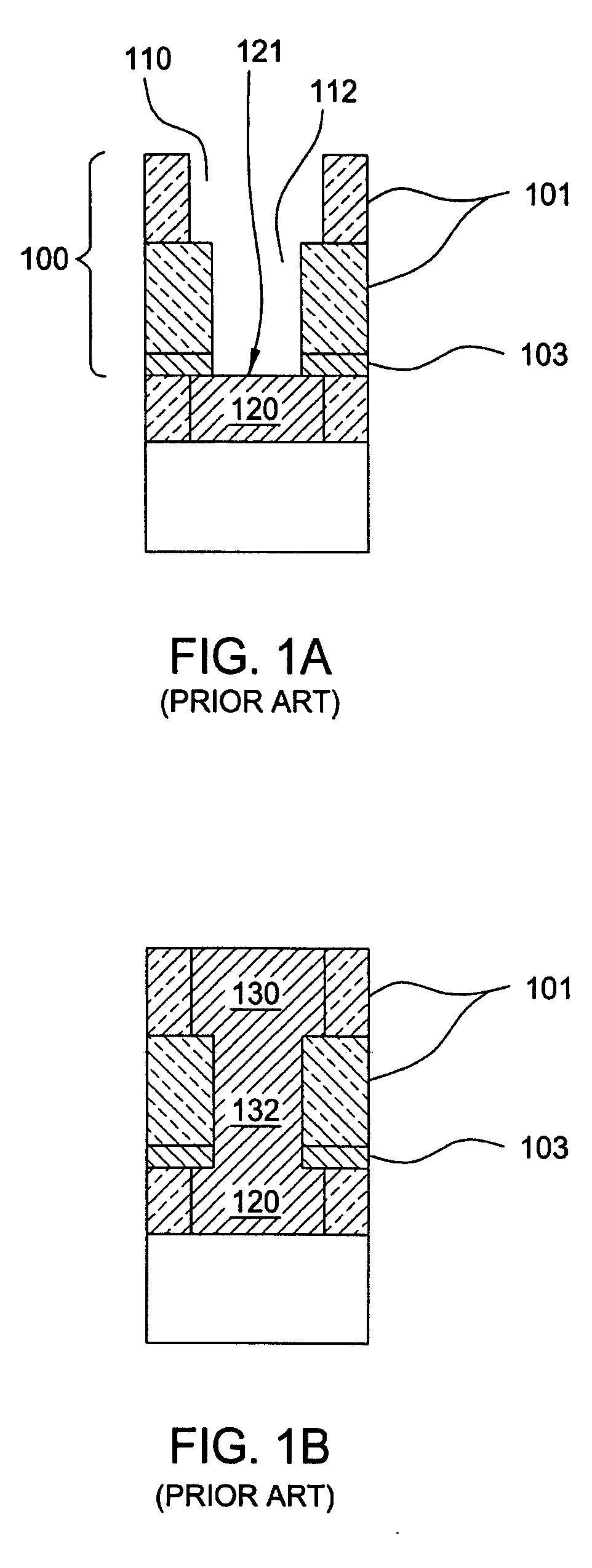

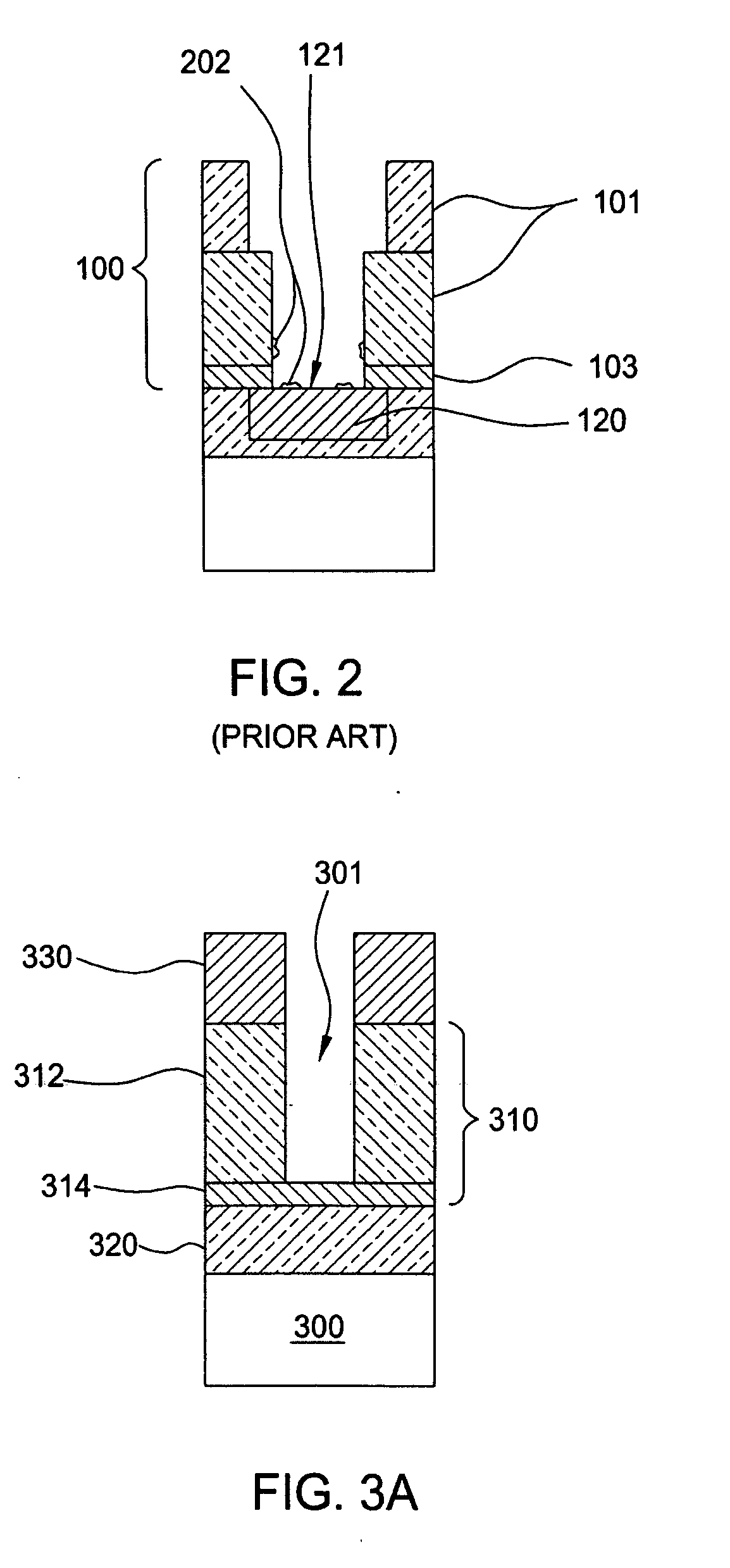

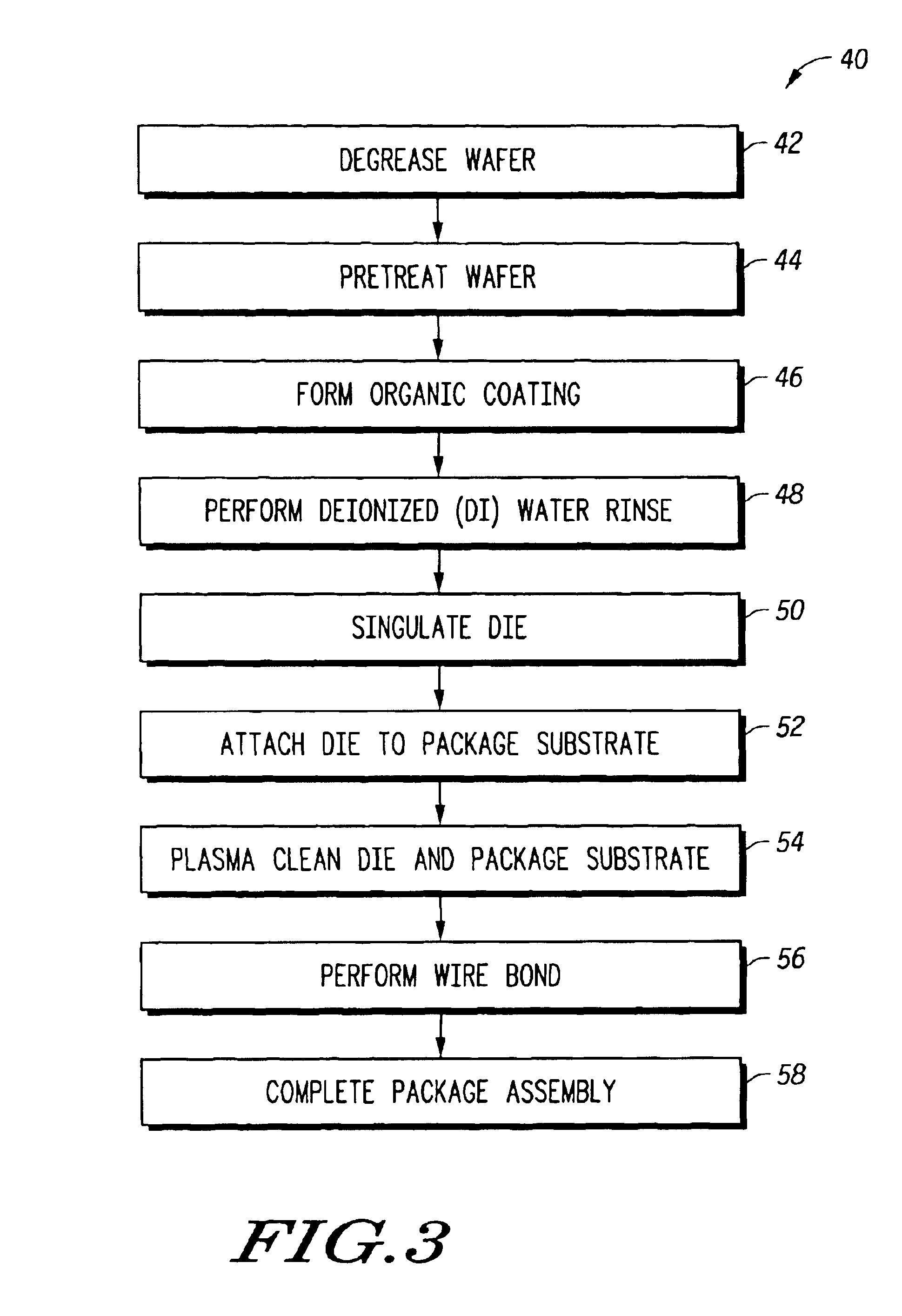

Integrated circuit die having a copper contact and method therefor

InactiveUS6933614B2Semiconductor/solid-state device detailsSolid-state devicesLead bondingBonding process

An integrated circuit die (10) has a copper contact (16, 18), which, upon exposure to the ambient air, forms a native copper oxide. An organic material is applied to the copper contact which reacts with the native copper oxide to form an organic coating (12, 14) on the copper contact in order to prevent further copper oxidation. In this manner, further processing at higher temperatures, such as those greater than 100 degrees Celsius, is not inhibited by excessive copper oxidation. For example, due to the organic coating, the high temperature of the wire bond process does not result in excessive oxidation which would prevent reliable wire bonding. Thus, the formation of the organic coating allows for a reliable and thermal resistance wire bond (32, 34). Alternatively, the organic coating can be formed over exposed copper at any time during the formation of the integrated circuit die to prevent or limit the formation of copper oxidation.

Owner:APPLE INC

Method and Scalable Devices for Hyper-Fast Cooling and Warming

InactiveUS20140069119A1Simple designEliminates spatial temperature gradientPreparing sample for investigationStationary refrigeration devicesVitrificationMotor drive

The present invention, in some embodiments thereof, relates to a method and scalable devices for hyperfast cooling and re-warming of samples. More specifically, it relates to cryogenic preservation of biological samples via vitrification. It includes: a liquid sample placed at ambient temperature in a flat thermo conductive container that in some embodiments additionally contains a detachable disposable or sterilizable thermo conductive spiral; transferring the sample to a cooling chamber using a linear percussion stepping motor drive; hyperfast cooling of the sample using streams of pressurized liquid coolant; transferring the sample to a detachable shipping / storage chamber filled with liquid coolant, from which the sample can be transferred to another vessel that contains liquid cryogenic coolant and moved back to the shipping / storage chamber. This chamber can be then attached to a re-warming chamber, in which the sample is heated to a biologically tolerant temperature above 0 degrees Celsius in a hyperfast manner.

Owner:CELLTRONIX

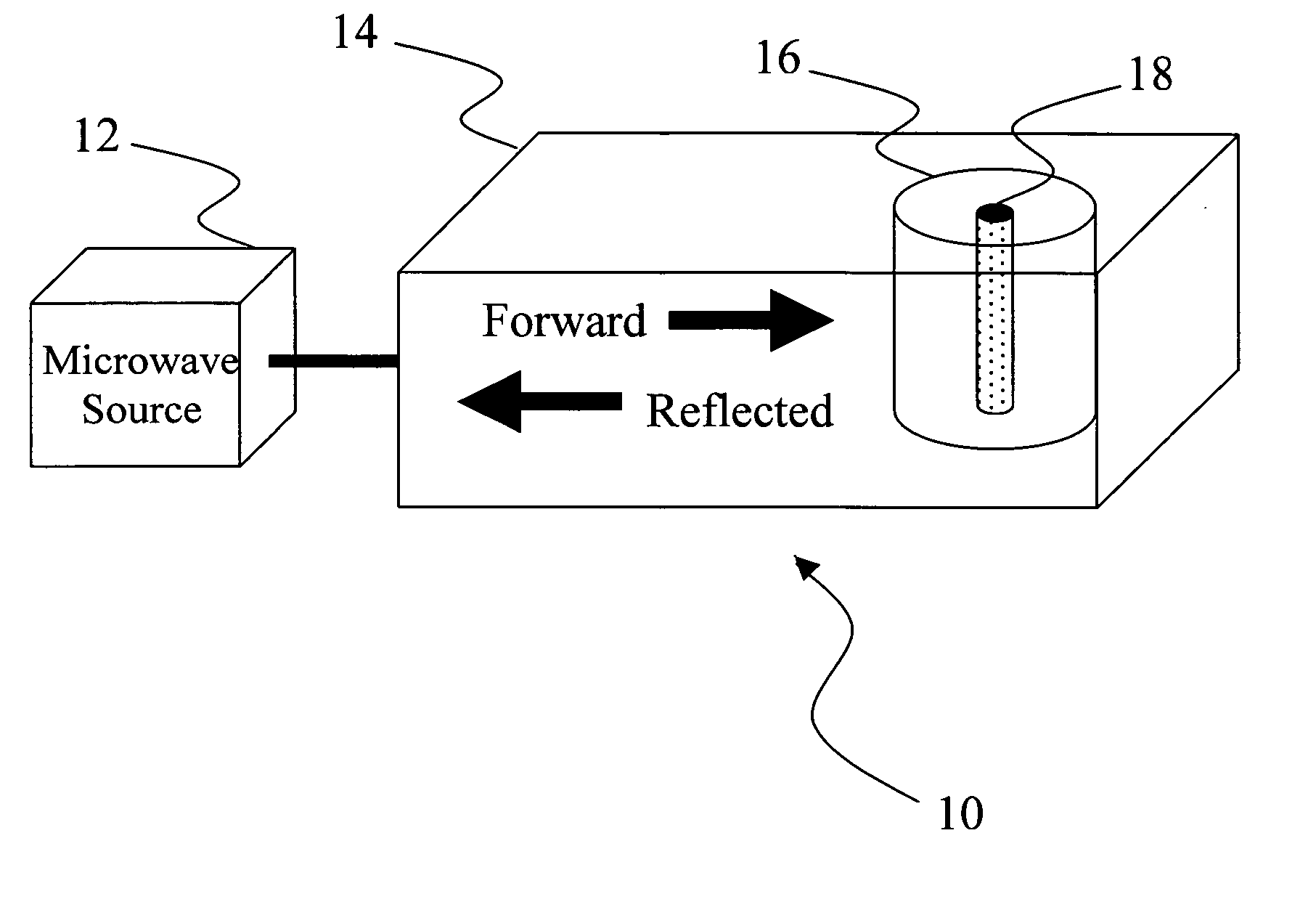

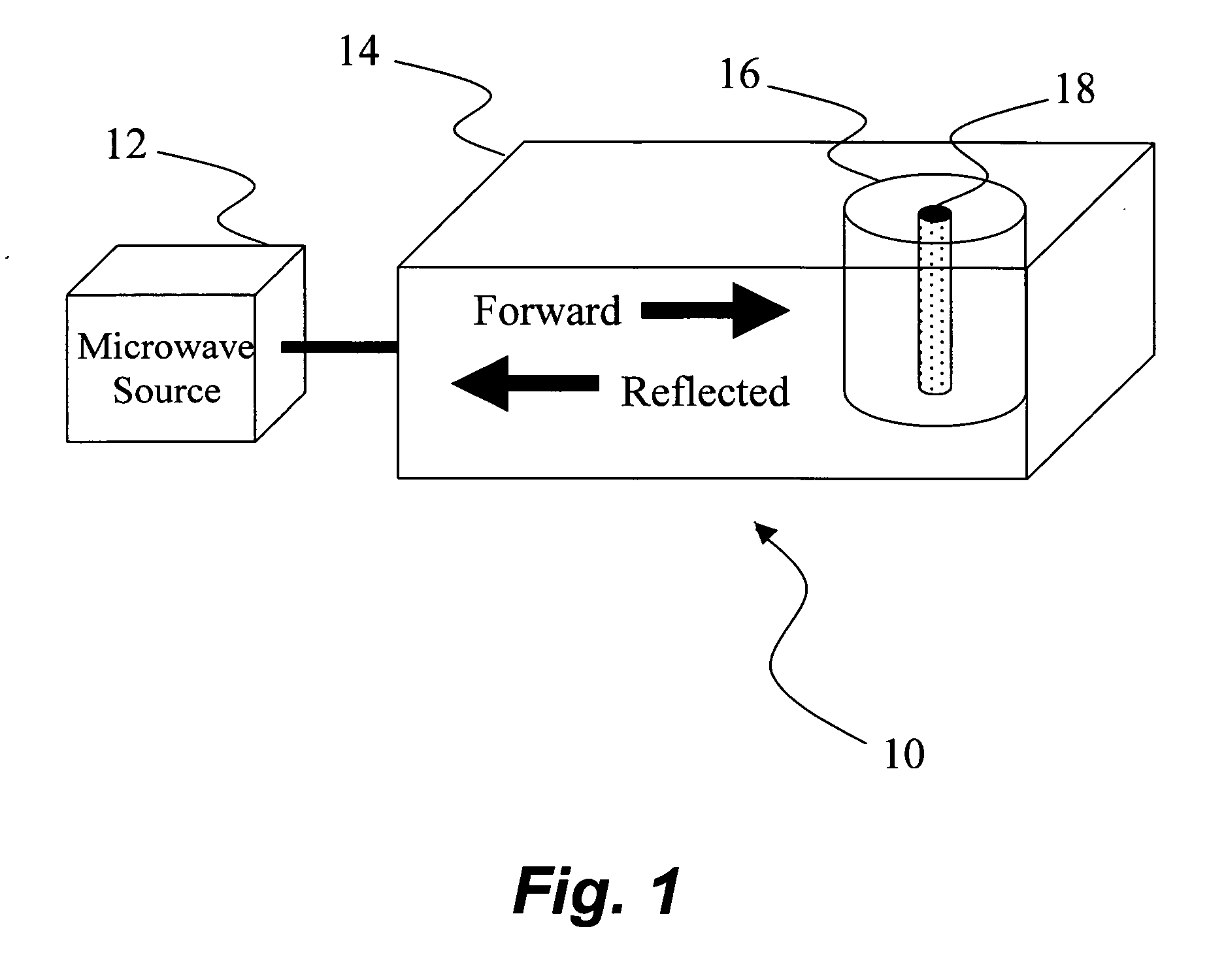

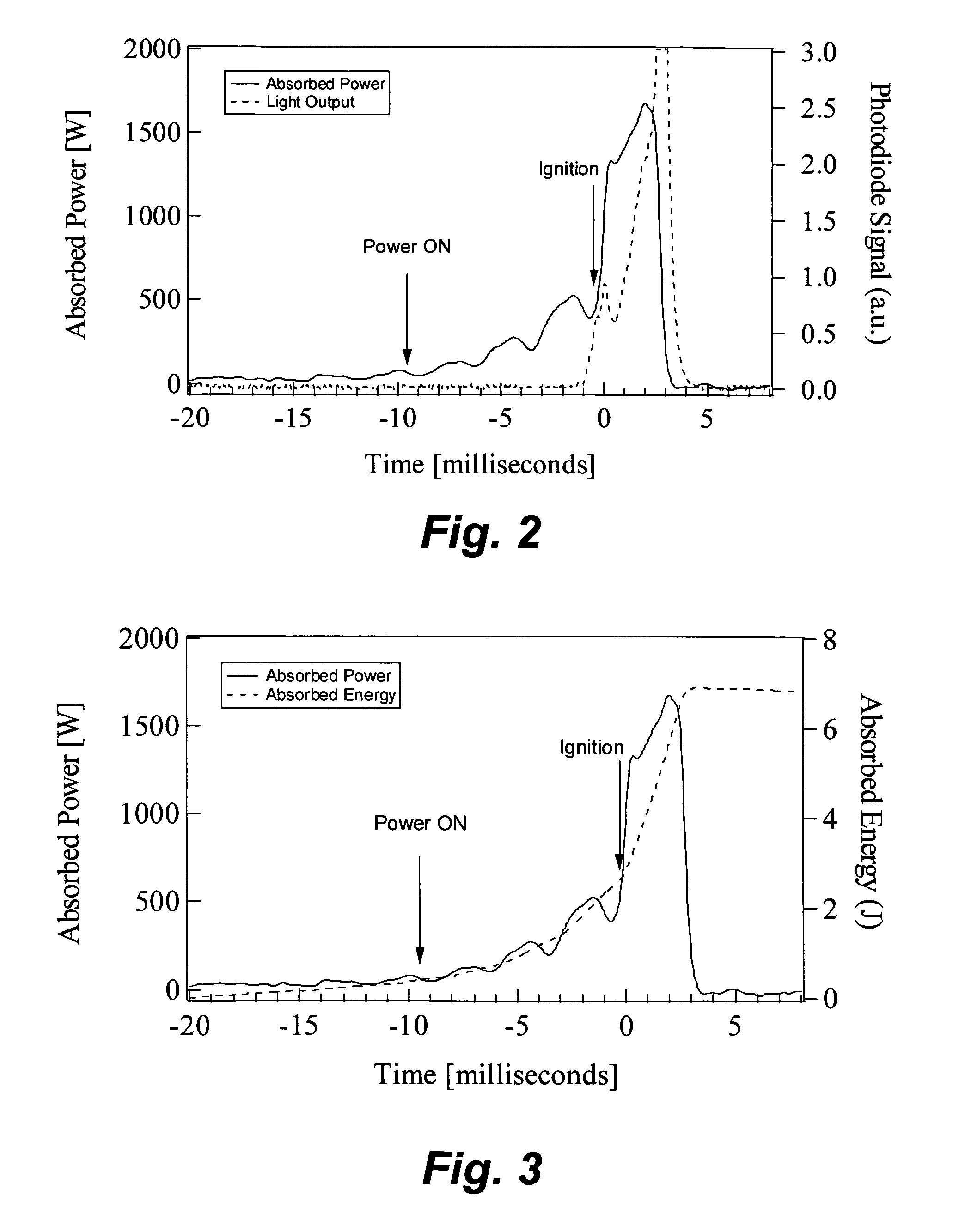

Microwave heating of energetic materials

InactiveUS20060011083A1Material nanotechnologyNon-explosive fillers/gelling/thickening agentsGramDegree Celsius

Mixtures of high explosives with materials that readily absorb microwaves ignite more readily when exposed to microwave energy than the corresponding neat explosives. A charge of HMX (0.5 gram) mixed with carbon nanotubes (1 percent by mass) ignited with 7.5 joules at an average rate of 750 W for 10 milliseconds. To raise a charge of the same mass of neat HMX to an autoignition temperature of 200 degrees Celsius would require much more energy (about 110 joules) for a longer duration (about 150 milliseconds).

Owner:LOS ALAMOS NATIONAL SECURITY

Over-passivation process of forming polymer layer over IC chip

InactiveUS20050250255A1Reduce generationBudget is reducedSemiconductor/solid-state device detailsSolid-state devicesDegree CelsiusSemiconductor chip

A method for forming a semiconductor chip or wafer includes following steps. A semiconductor substrate is provided, and then a polymer layer is deposited over the semiconductor substrate, wherein the polymer layer comprises polyimide. The polymer layer with a temperature profile having a peak temperature between 200 and 320 degrees Celsius. Alternatively, the temperature profile may comprises a period of time with a temperature higher than 320 degree Celsius, wherein the period of time is shorter than 45 minutes.

Owner:QUALCOMM INC

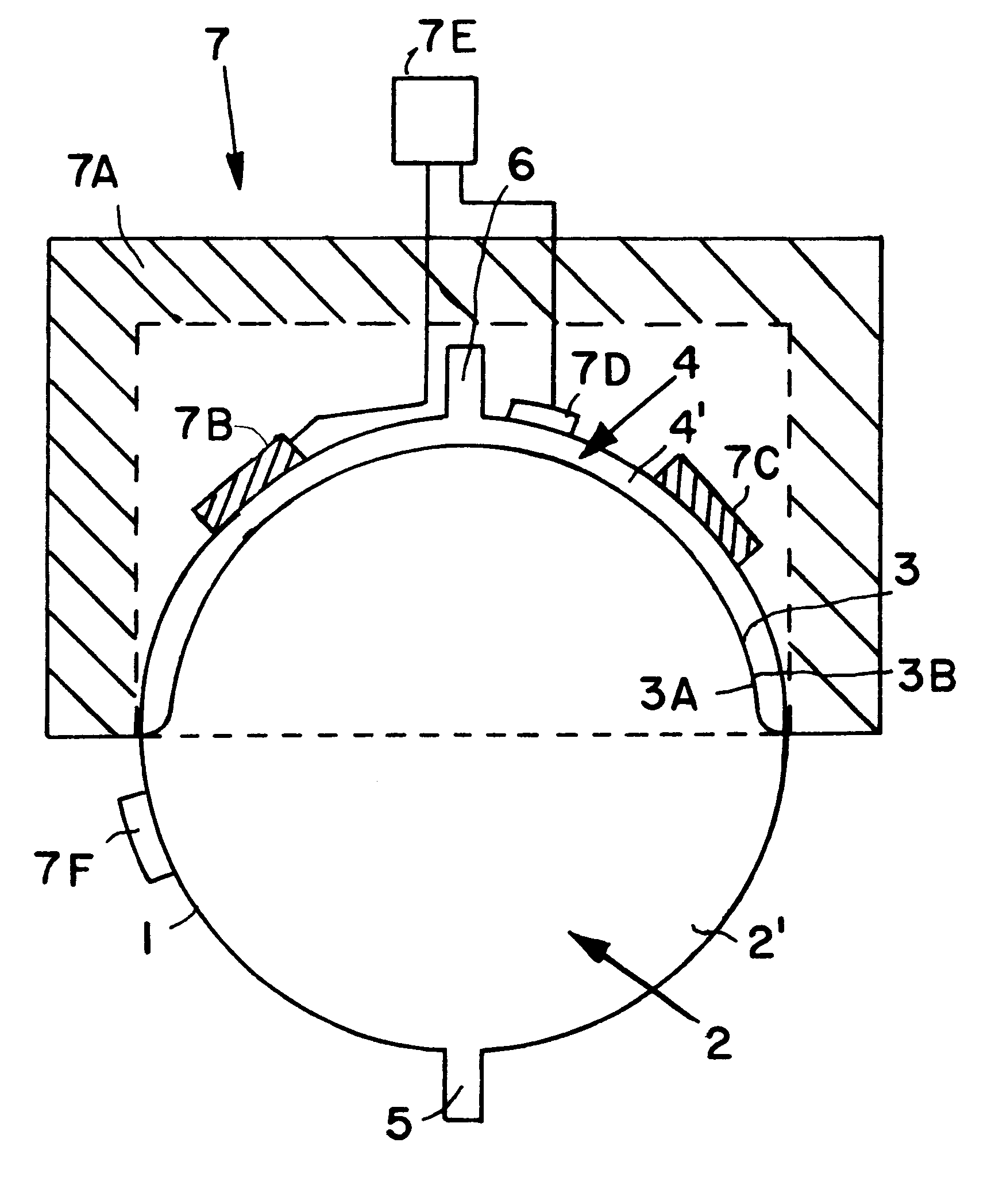

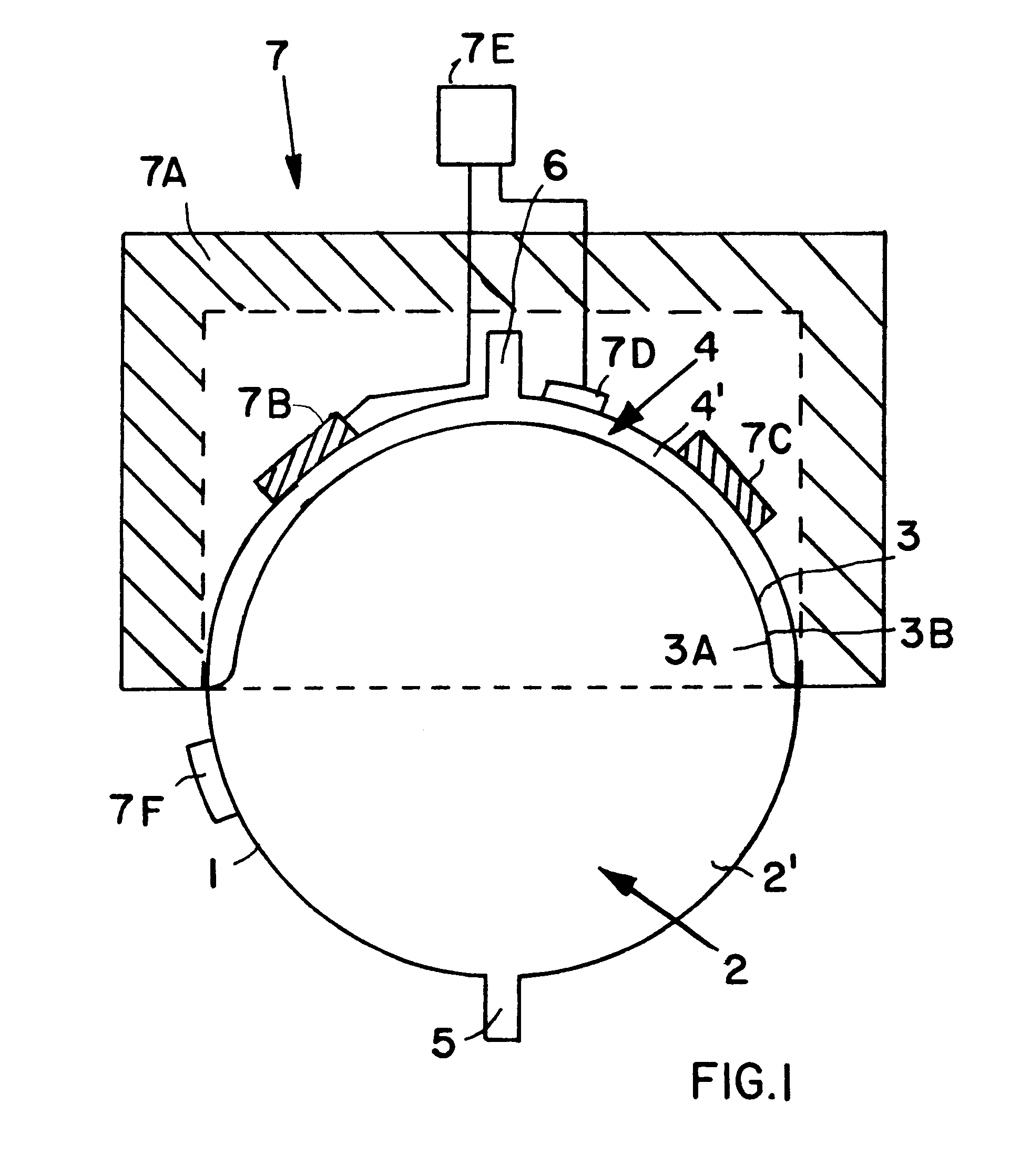

Method and liquid storage tank for minimizing permeation of liquid vapors through a tank dividing membrane

InactiveUS6231008B1Prevent penetrationAvoid condensationCosmonautic vehiclesPower plant fuel tanksThermal insulationLiquid storage tank

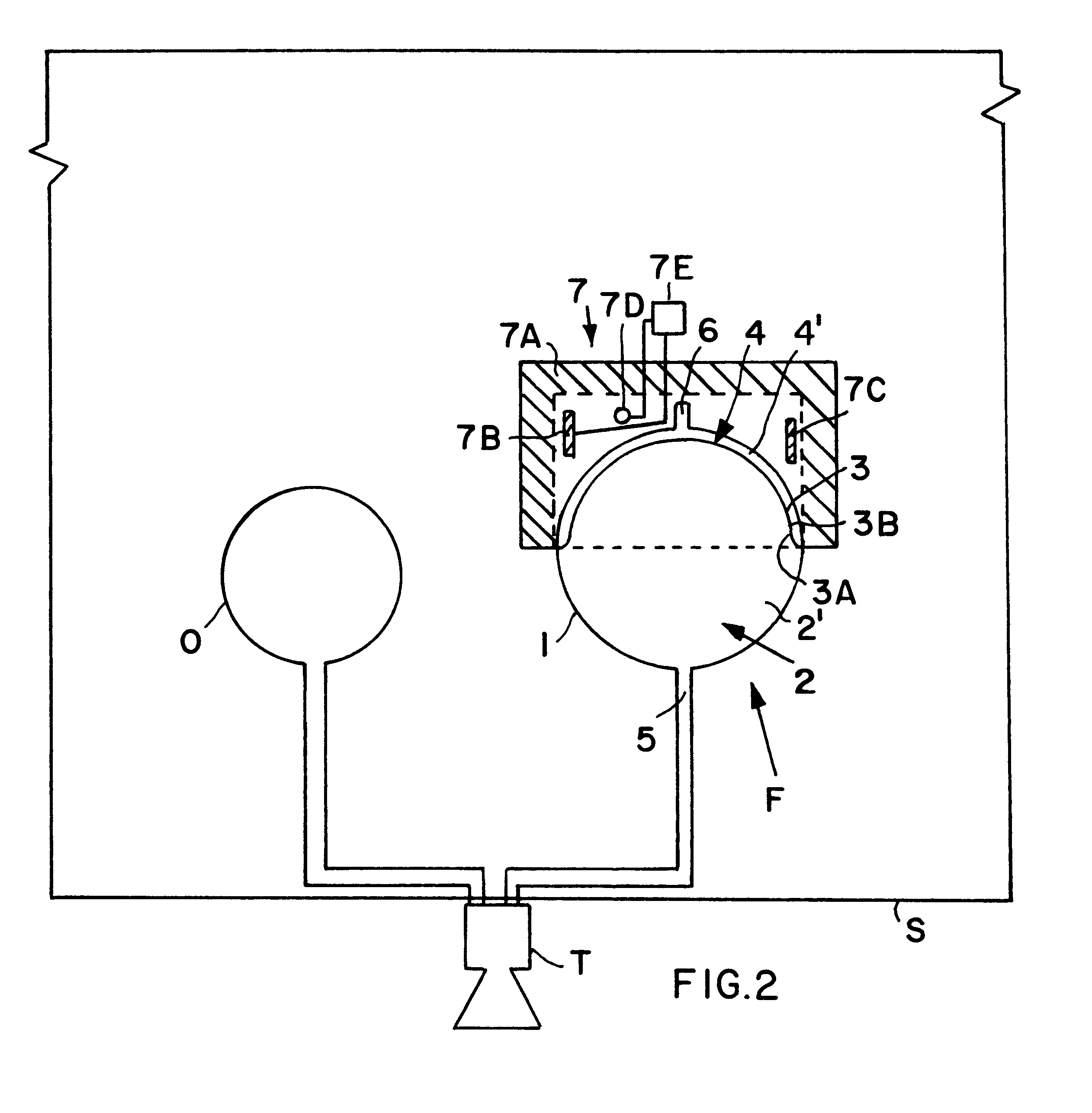

A temperature regulating arrangement (7) at least partially surrounds a fuel or oxidizer storage tank (1). The tank (1) is divided by a polymer membrane (3) into a first partial chamber (2) receiving the fuel (2') therein, and a second partial chamber (4) receiving a gaseous pressure medium (4') therein. The temperature regulating arrangement (7) includes thermal insulation, at least one heater, at least one heat sensor, and a temperature control and regulating unit. By heating the second partial chamber containing the gaseous pressure medium, any fuel vapor permeating through the membrane (3) from the first partial chamber (2) into the second partial chamber (4) is prevented from condensing within the second partial chamber (4). The permeation process is also limited. It is simply necessary to maintain the second partial chamber (4) at a temperature a few degrees Celsius higher than the temperature of the liquid fuel. This tank arrangement is especially suitable for use as a fuel tank or oxidizer tank in a satellite or orbital space station.

Owner:DAMELERKLESLER AVIATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com