Patents

Literature

1168 results about "Laser annealing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

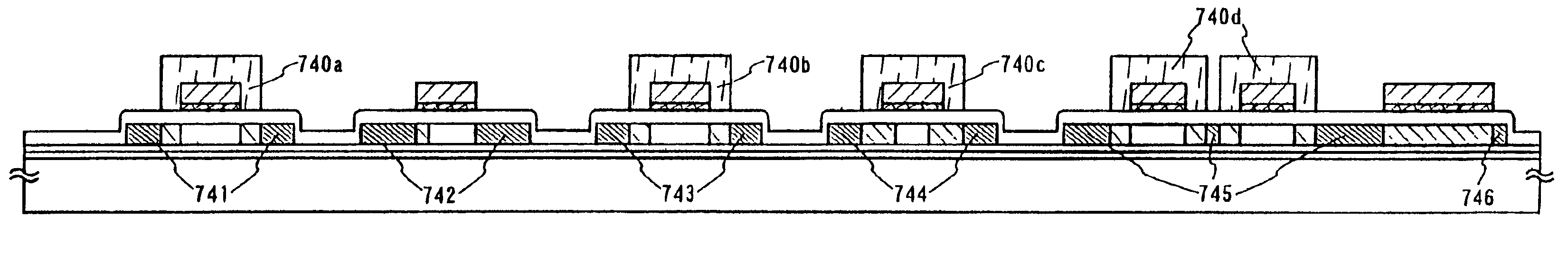

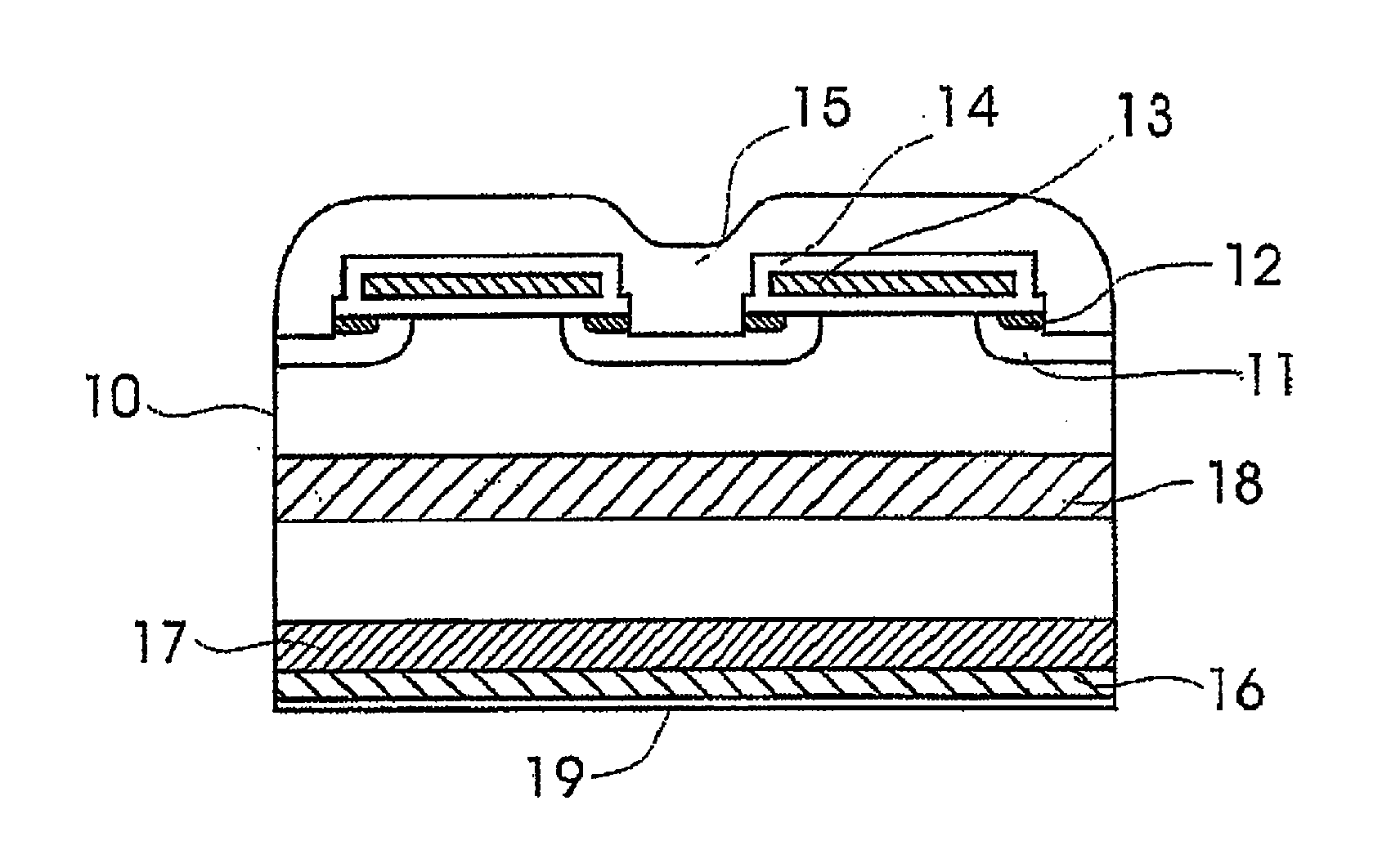

Semiconductor device

InactiveUS20050236623A1Well mixedGood heat dissipationTransistorSolid-state devicesDevice materialEngineering

An integrated circuit is formed on a flexible substrate by using an amorphous semiconductor thin film, or a polycrystalline or a monocrystalline semiconductor thin film crystallized by laser annealing. A plurality of such flexible integrated circuit boards and mounted on a separate support substrate. This can enhance the mechanical strength of devices, such as an IC card and a liquid crystal display, and allow those devices to be manufactured at a low cost. It is also possible to provide a semiconductor device with a higher performance, on which a flexible integrated circuit board and an IC chip made from a silicon and / or glass wafer. Adhering a film substrate having a high thermal conductivity, such as a metal, to the bottom side of the flexible integrated circuit board improves the heat discharging characteristic of the integrated circuit and suppress the problem of self-heating.

Owner:NEC CORP

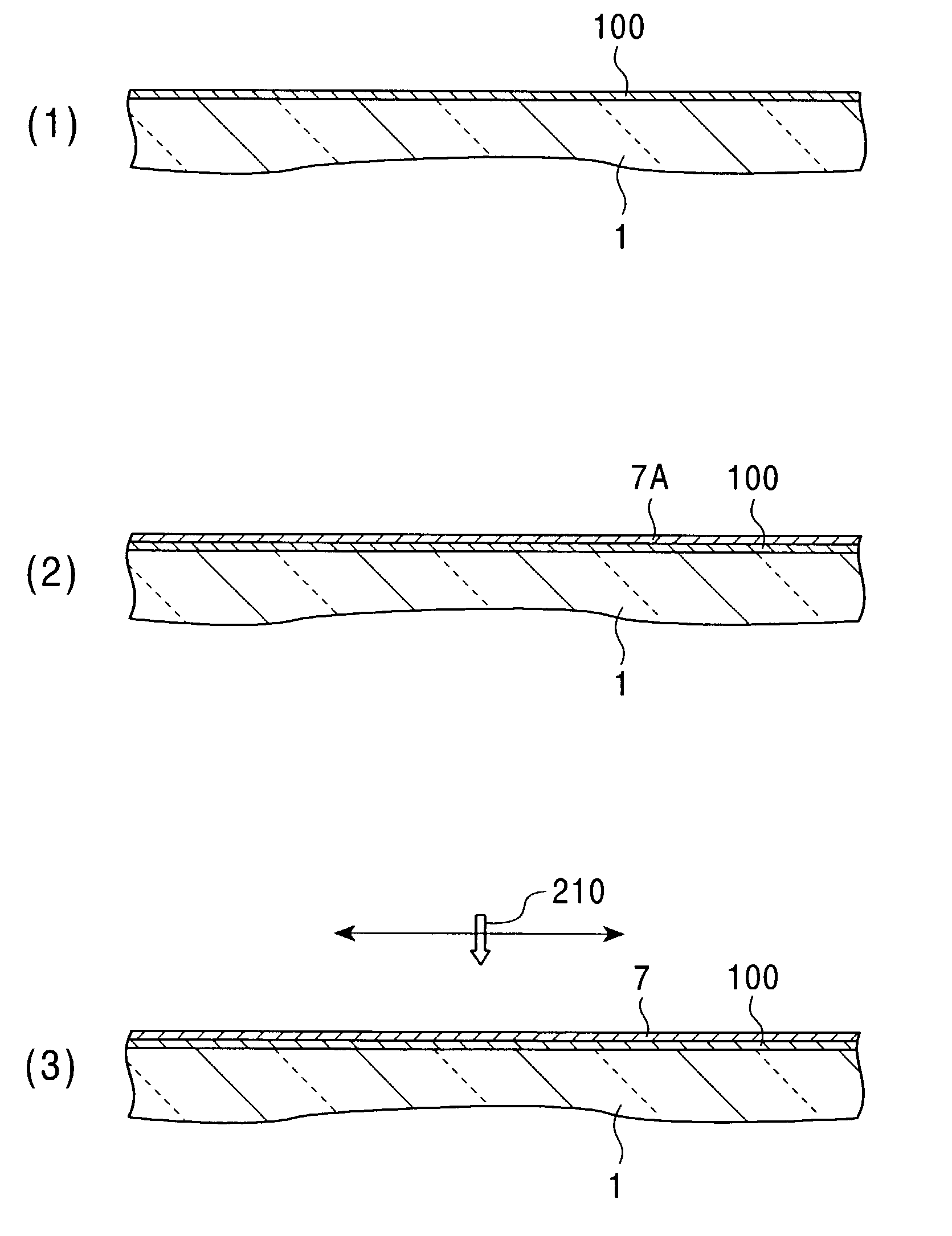

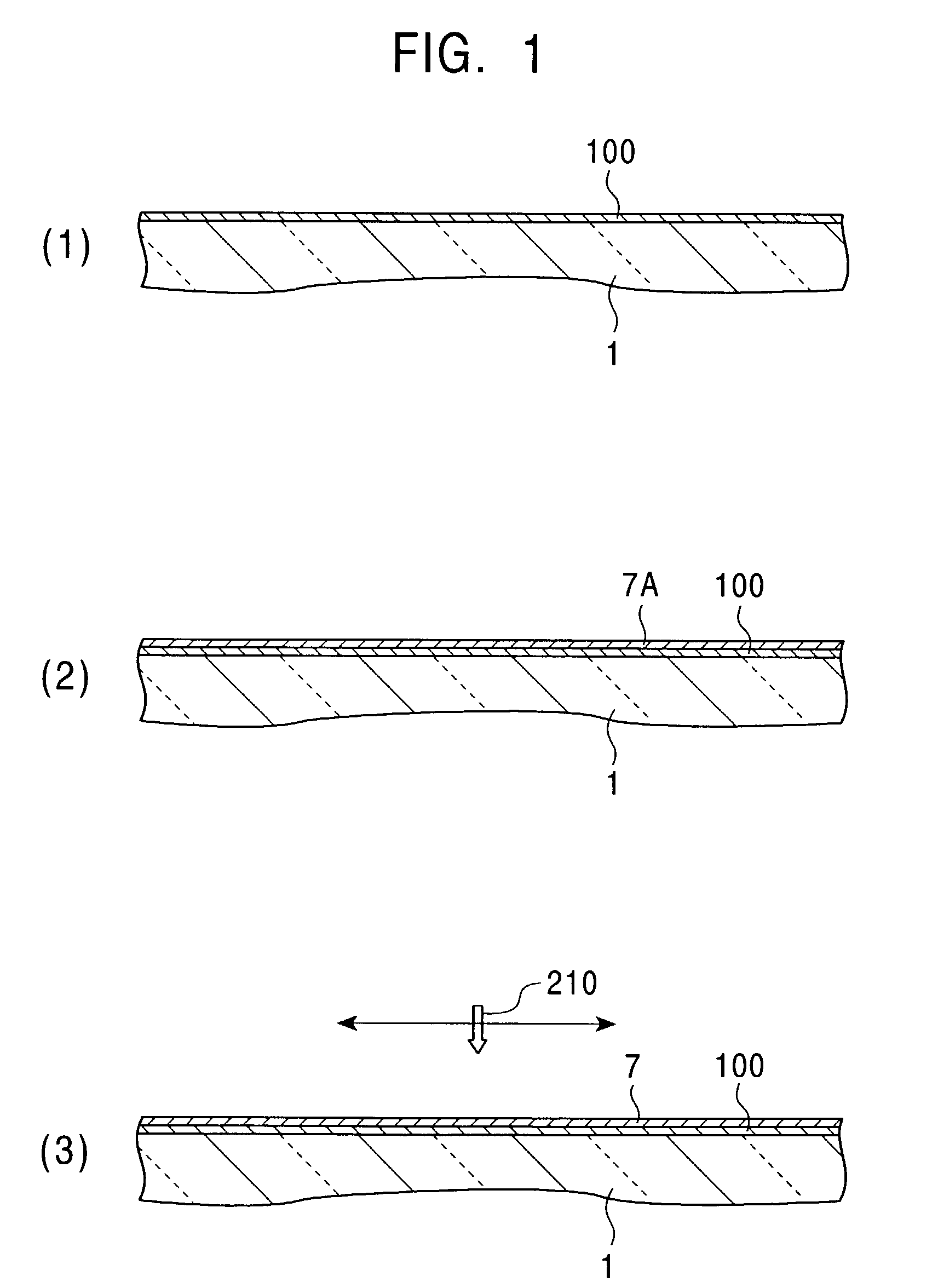

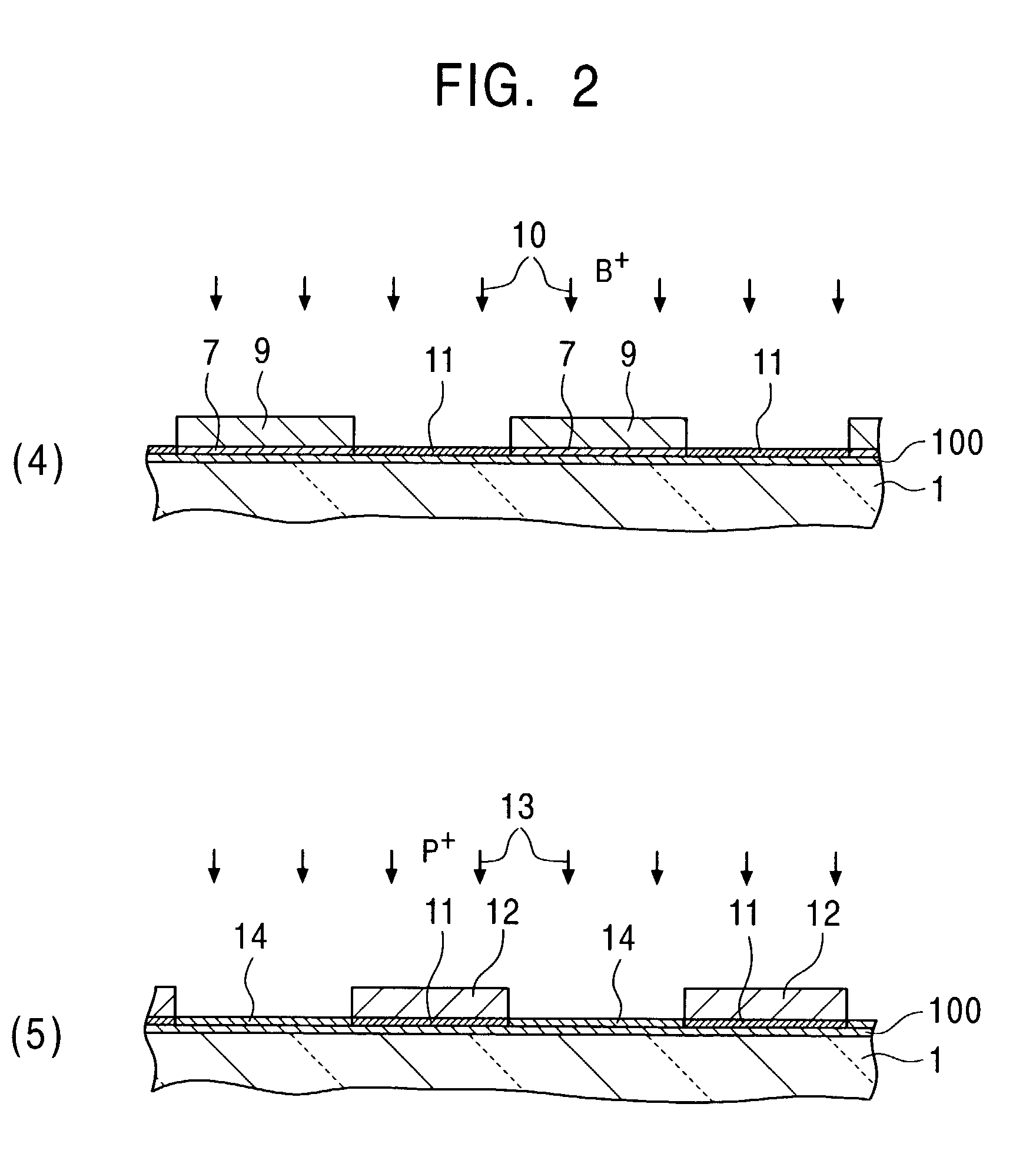

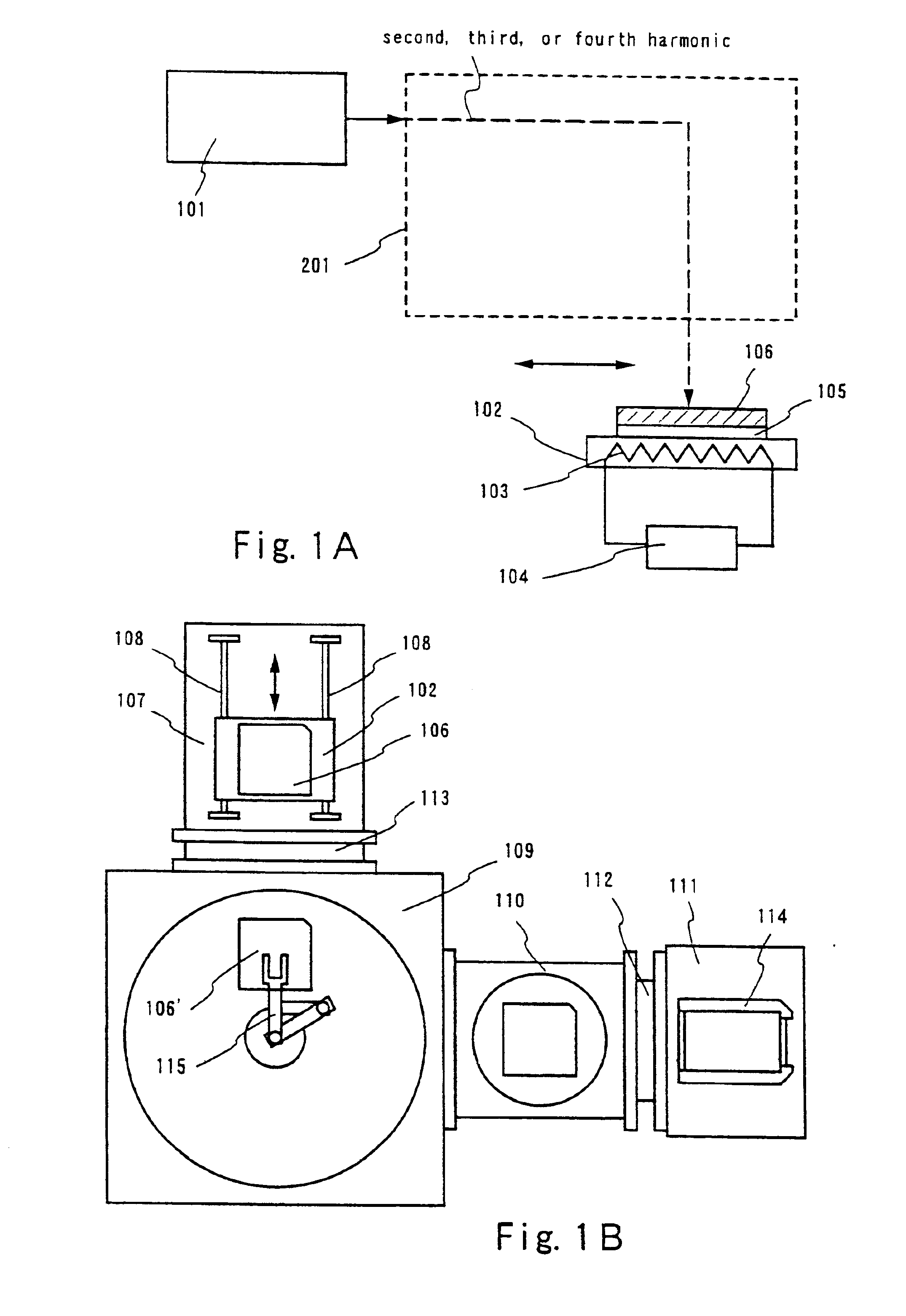

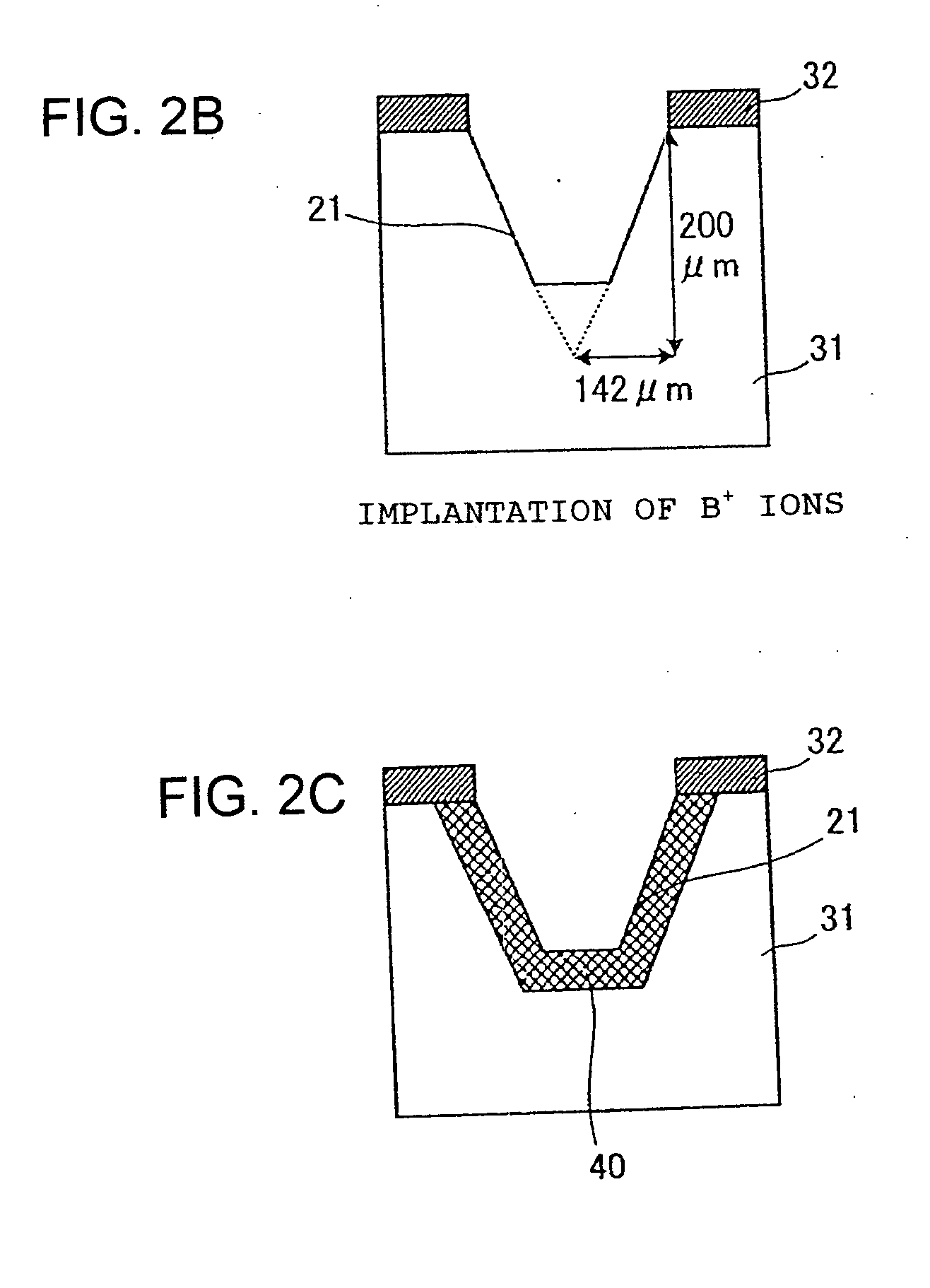

Method for forming thin semiconductor film, method for fabricating semiconductor device, system for executing these methods and electrooptic device

InactiveUS20030148565A1Promote crystallizationEasily realizedTransistorSolid-state devicesMolten stateUltraviolet

The present invention provides a method capable of easily forming a polycrystalline or monocrystalline semiconductor thin film of polycrystalline silicon with a high degree of crystallization and high quality at low cost, and an apparatus for carrying out the method. In a method of forming a polycrystalline (or monocrystalline) semiconductor thin film, a method of manufacturing a semiconductor device and an apparatus for carrying out these methods, in order to form a large-grain polycrystalline (or monocrystalline) semiconductor thin film (7) such as a polycrystalline silicon film with a high degree of crystallization on a substrate (1) or manufacturing a semiconductor device having the polycrystalline (or monocrystalline) semiconductor thin film (7), a low-crystalline semiconductor thin film (7A) is formed on the substrate (1), and then heated in a molten, semi-molten or non-molten state by laser annealing with ultraviolet rays (UV) or / and deep ultraviolet rays (DUV) and cooled to promote crystallization of the low-crystalline semiconductor thin film (7A), obtaining the polycrystalline (or monocrystalline) semiconductor thin film (7).

Owner:SONY CORP

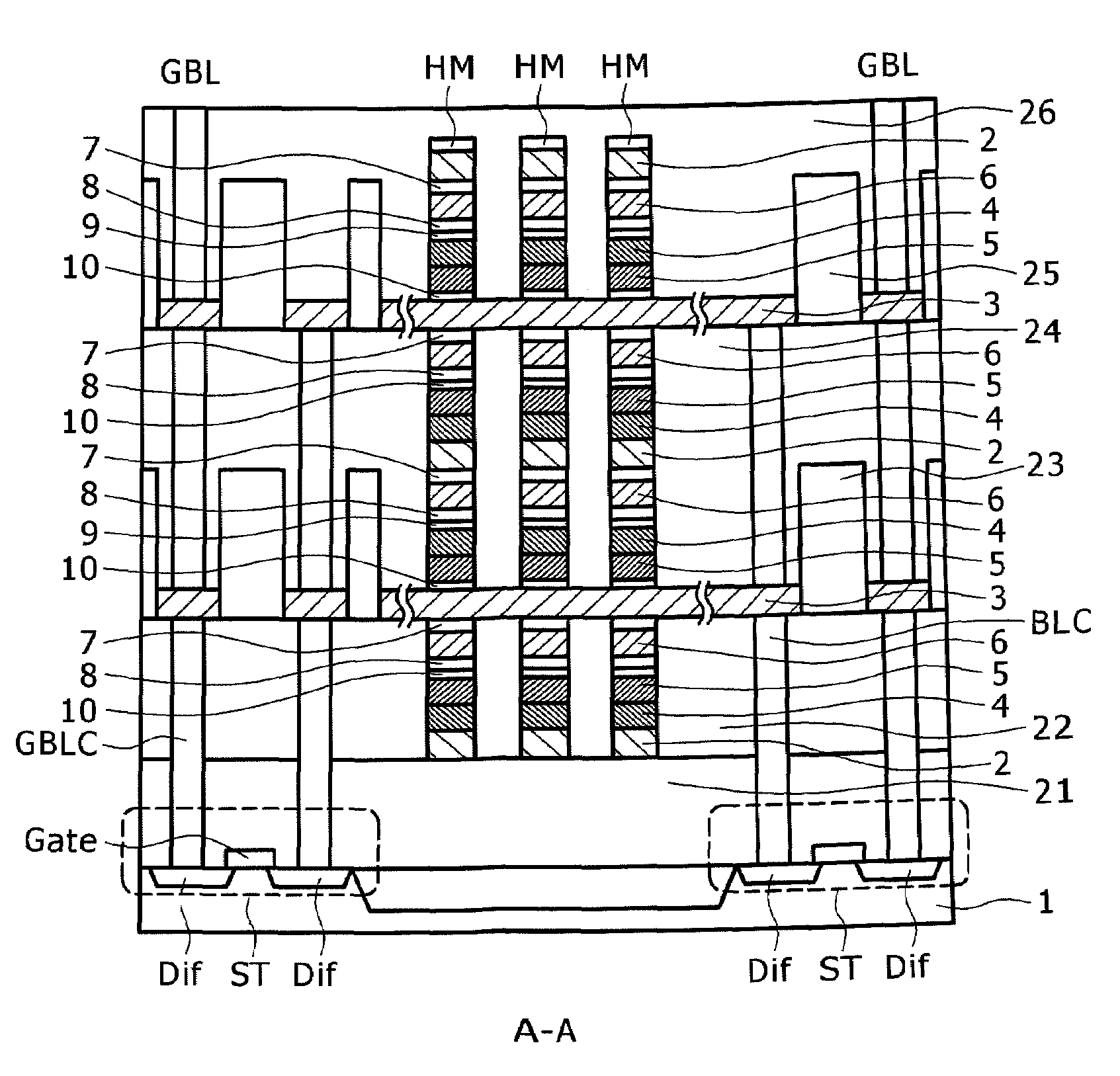

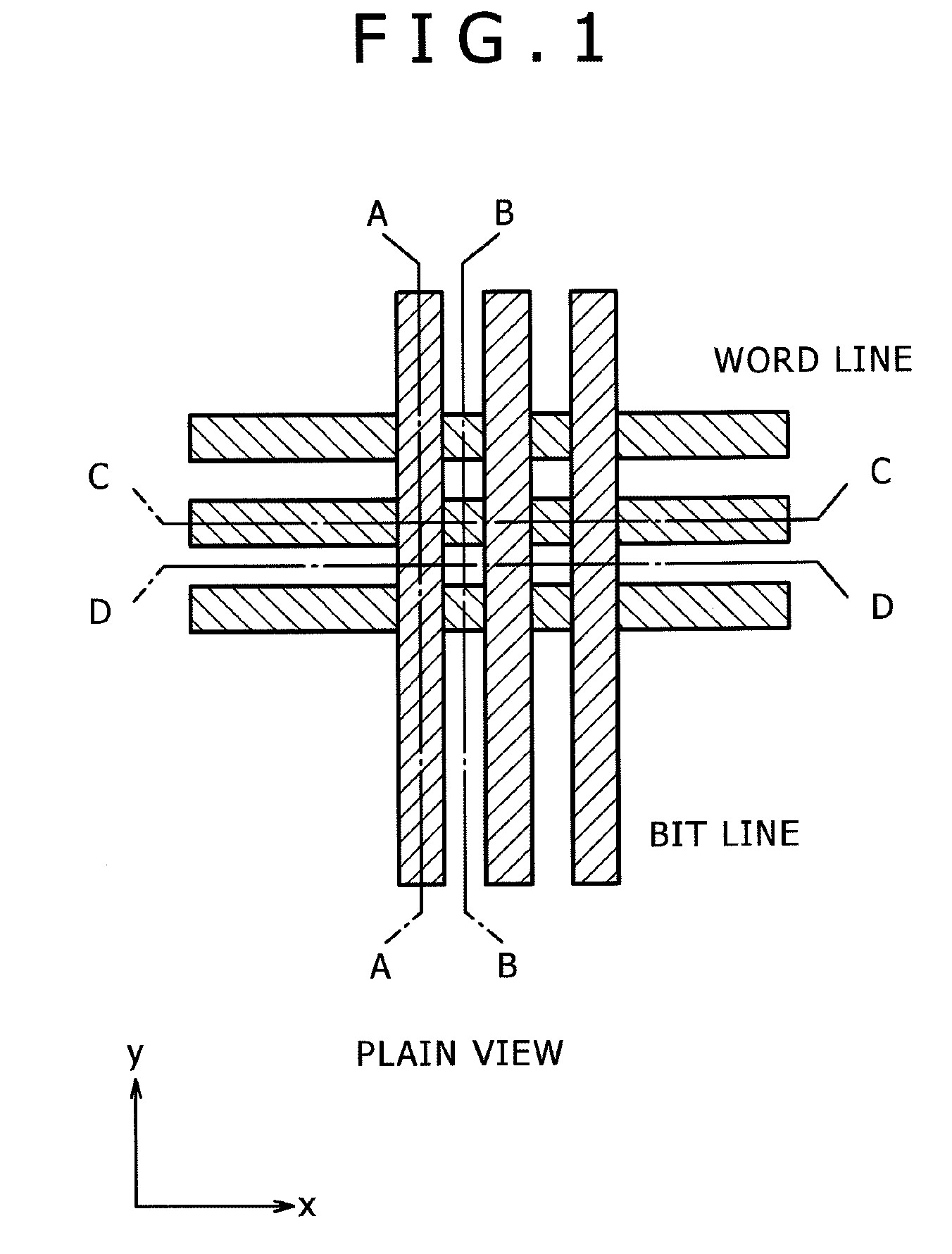

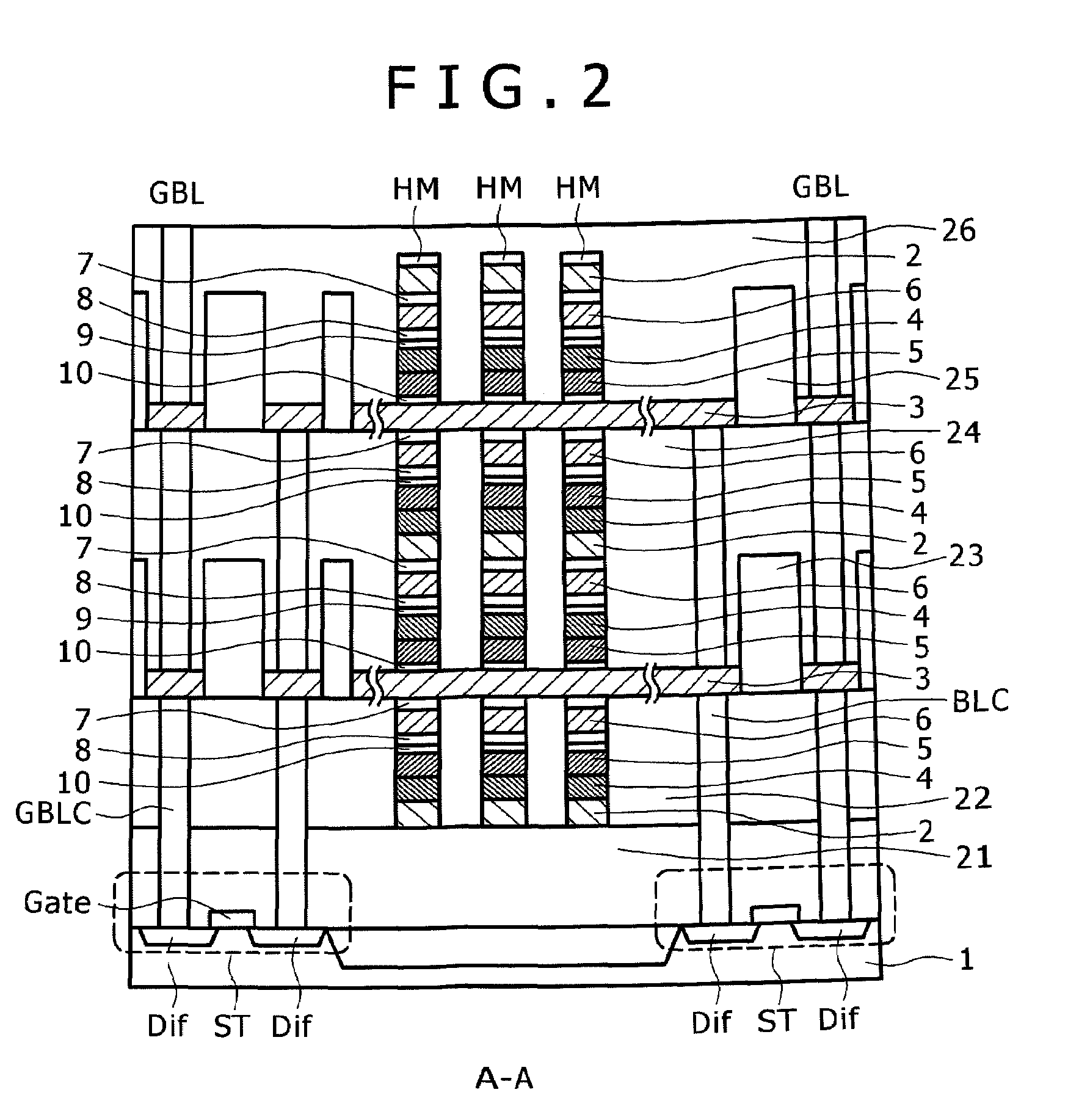

Semiconductor memory device and manufacturing method thereof

InactiveUS20090267047A1Large capacityImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingPhase-change memoryDevice material

The present invention can promote the large capacity, high performance and high reliability of a semiconductor memory device by realizing high-performance of both the semiconductor device and a memory device when the semiconductor memory device is manufactured by stacking a memory device such as ReRAM or the phase change memory and the semiconductor device. After a polysilicon forming a selection device is deposited in an amorphous state at a low temperature, the crystallization of the polysilicon and the activation of impurities are briefly performed with heat treatment by laser annealing. When laser annealing is performed, the recording material located below the silicon subjected to the crystallization is completely covered with a metal film or with the metal film and an insulating film, thereby making it possible to suppress a temperature increase at the time of performing the annealing and to reduce the thermal load of the recording material.

Owner:HITACHI LTD

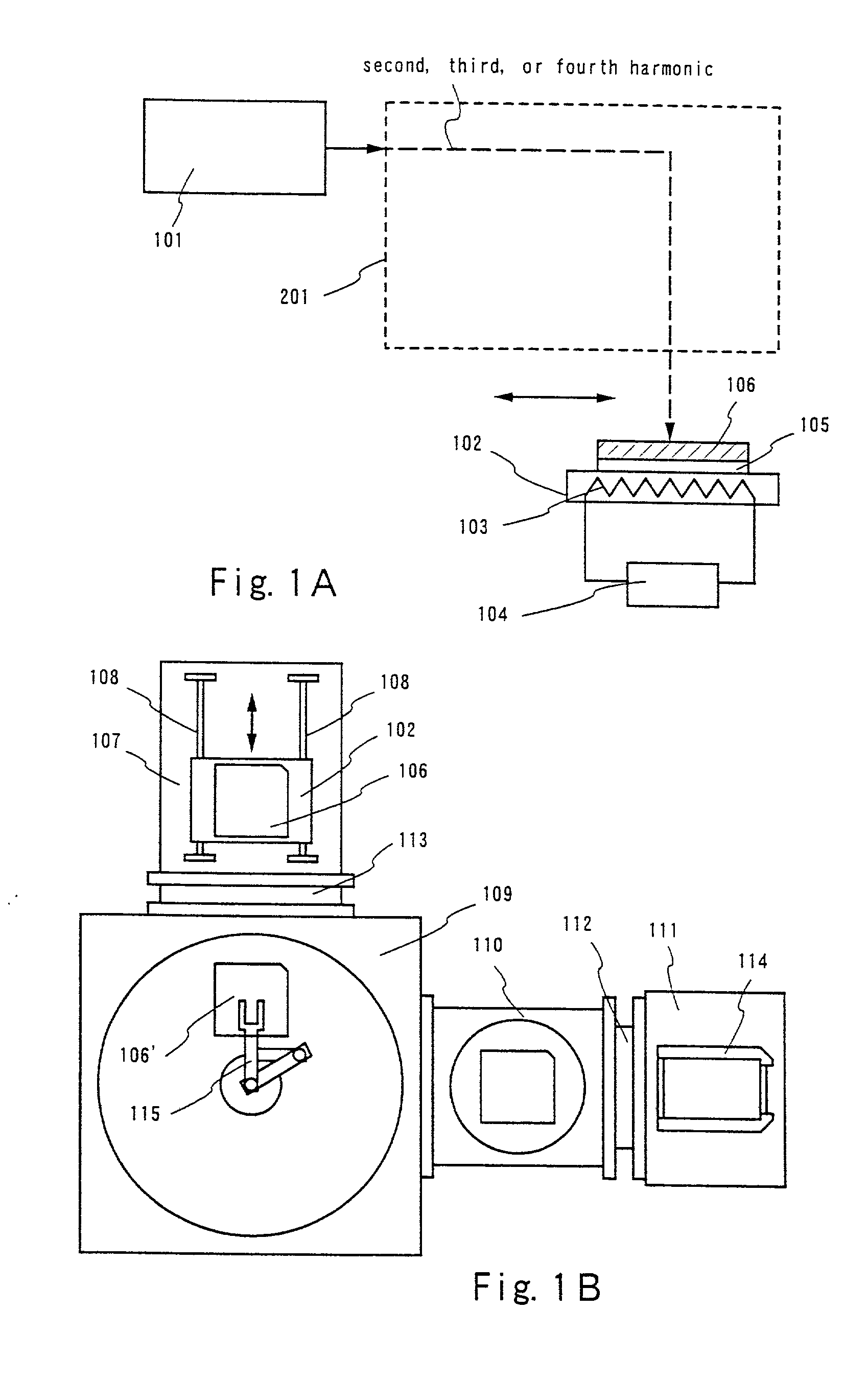

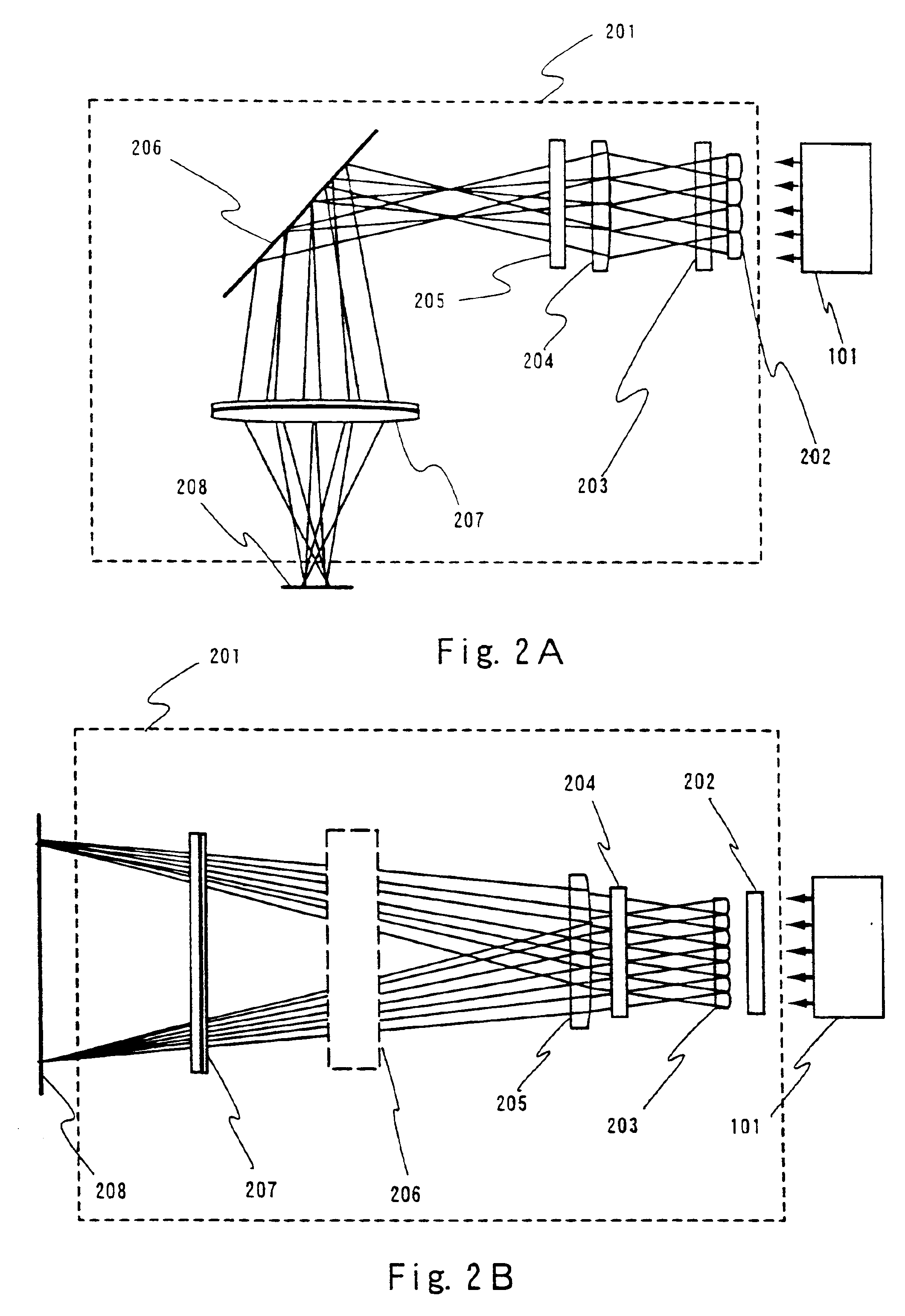

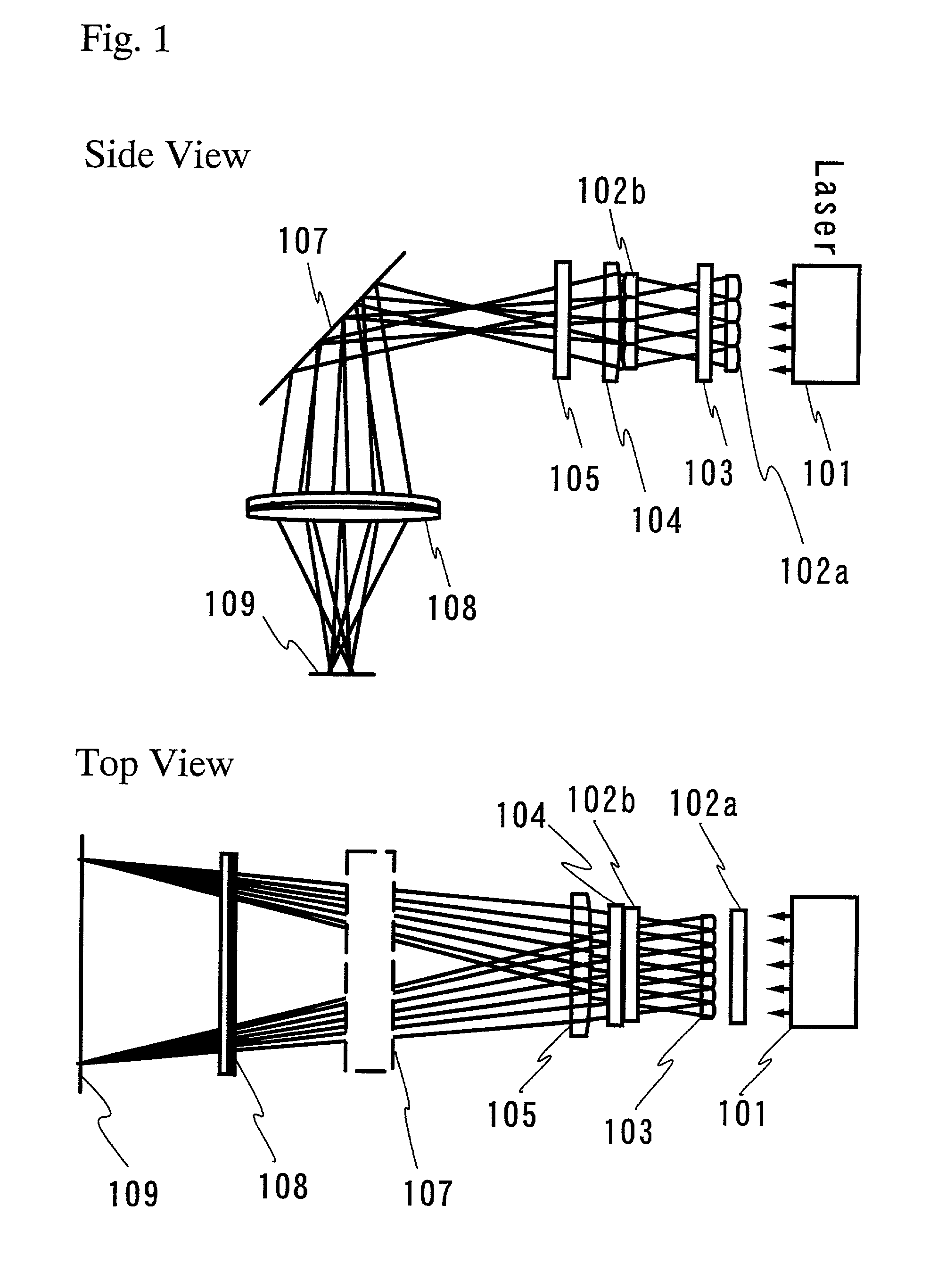

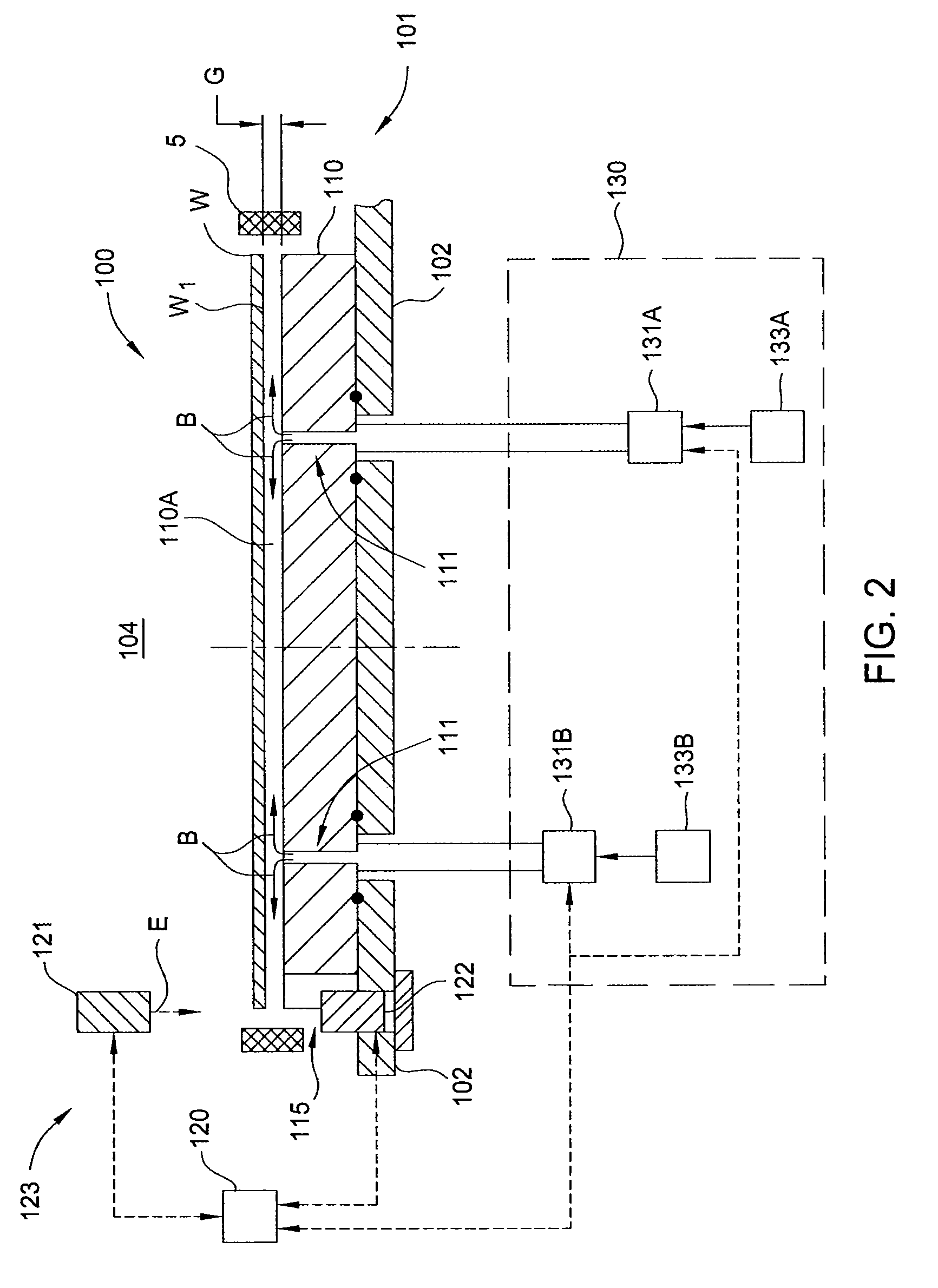

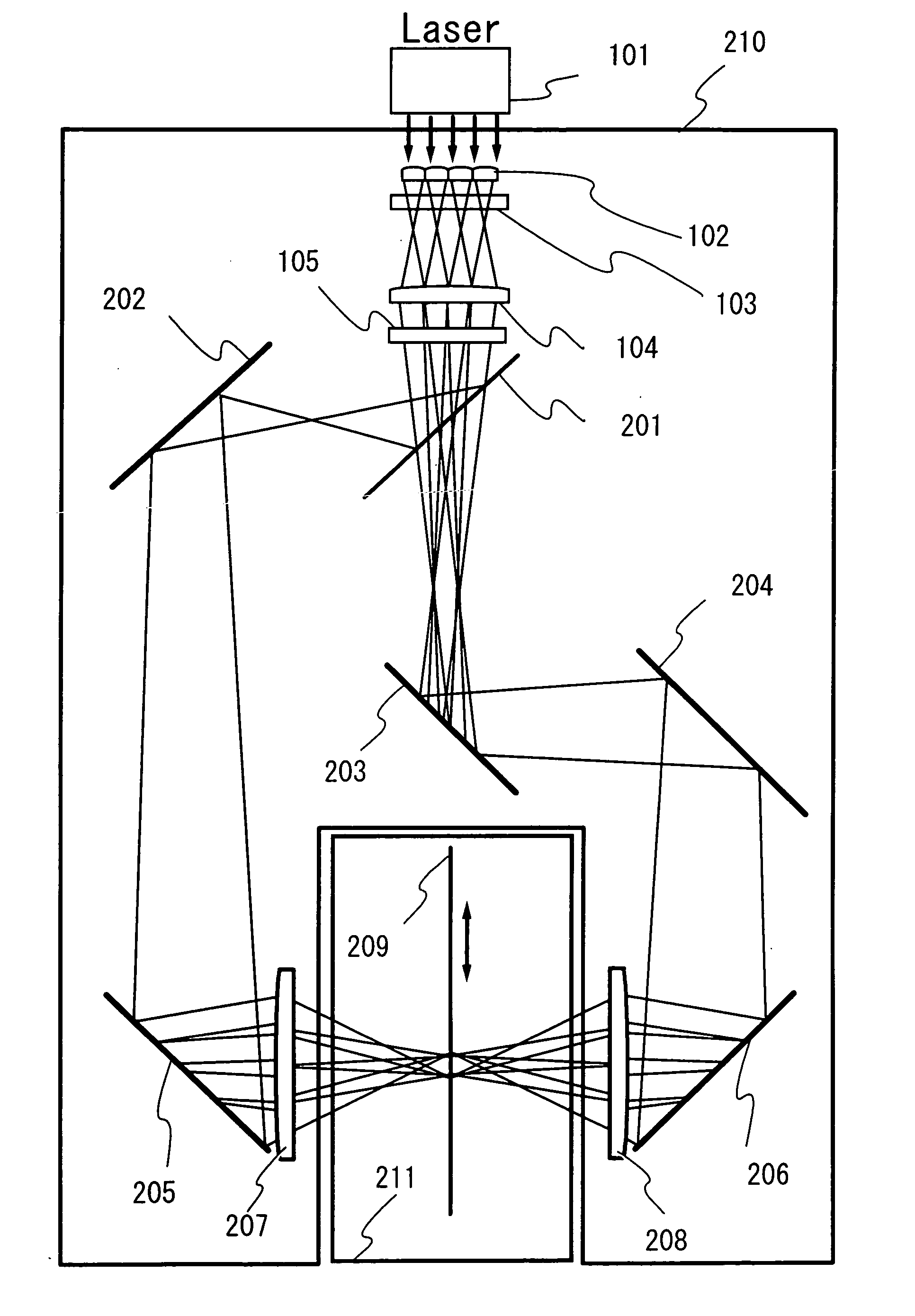

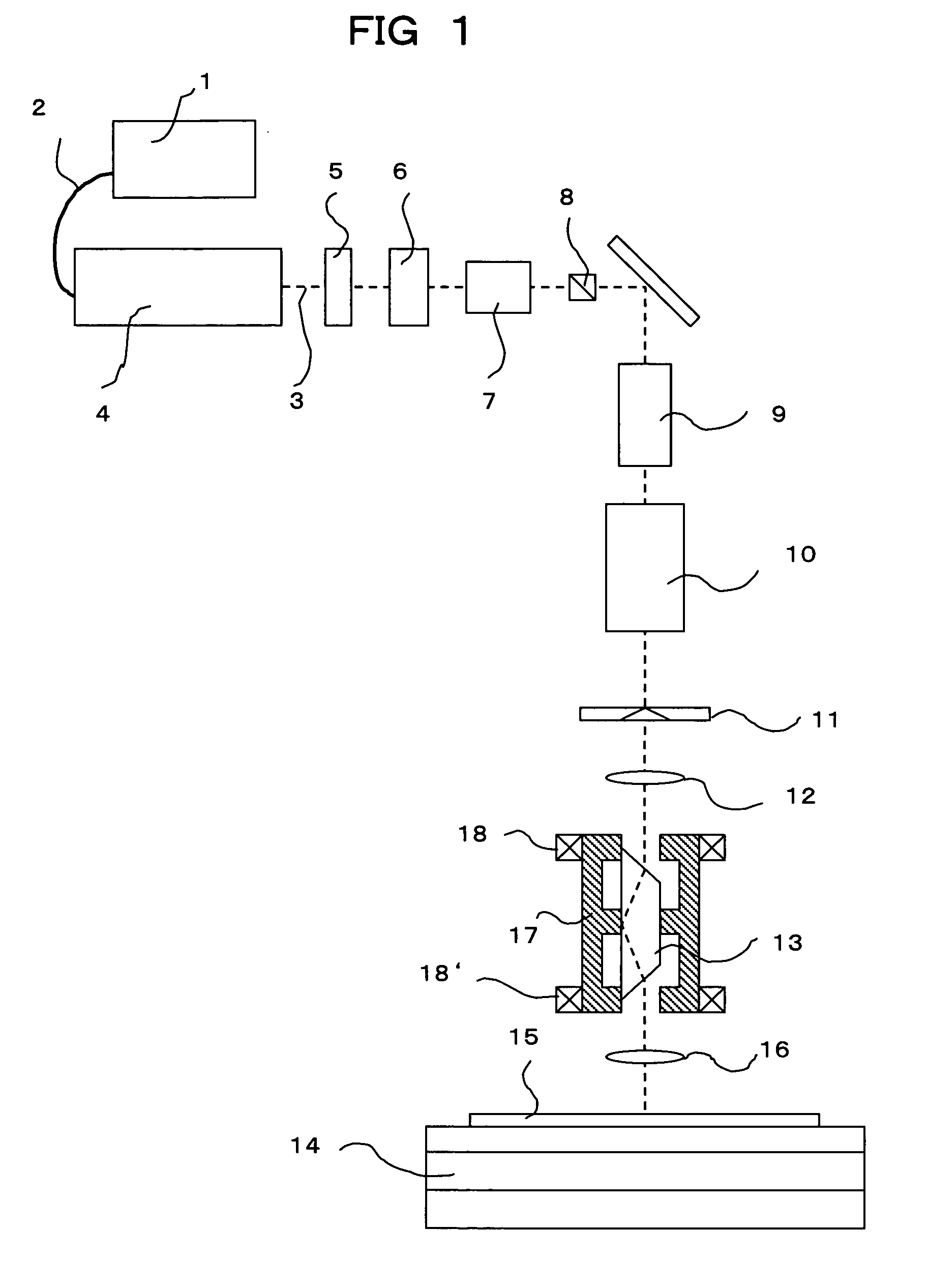

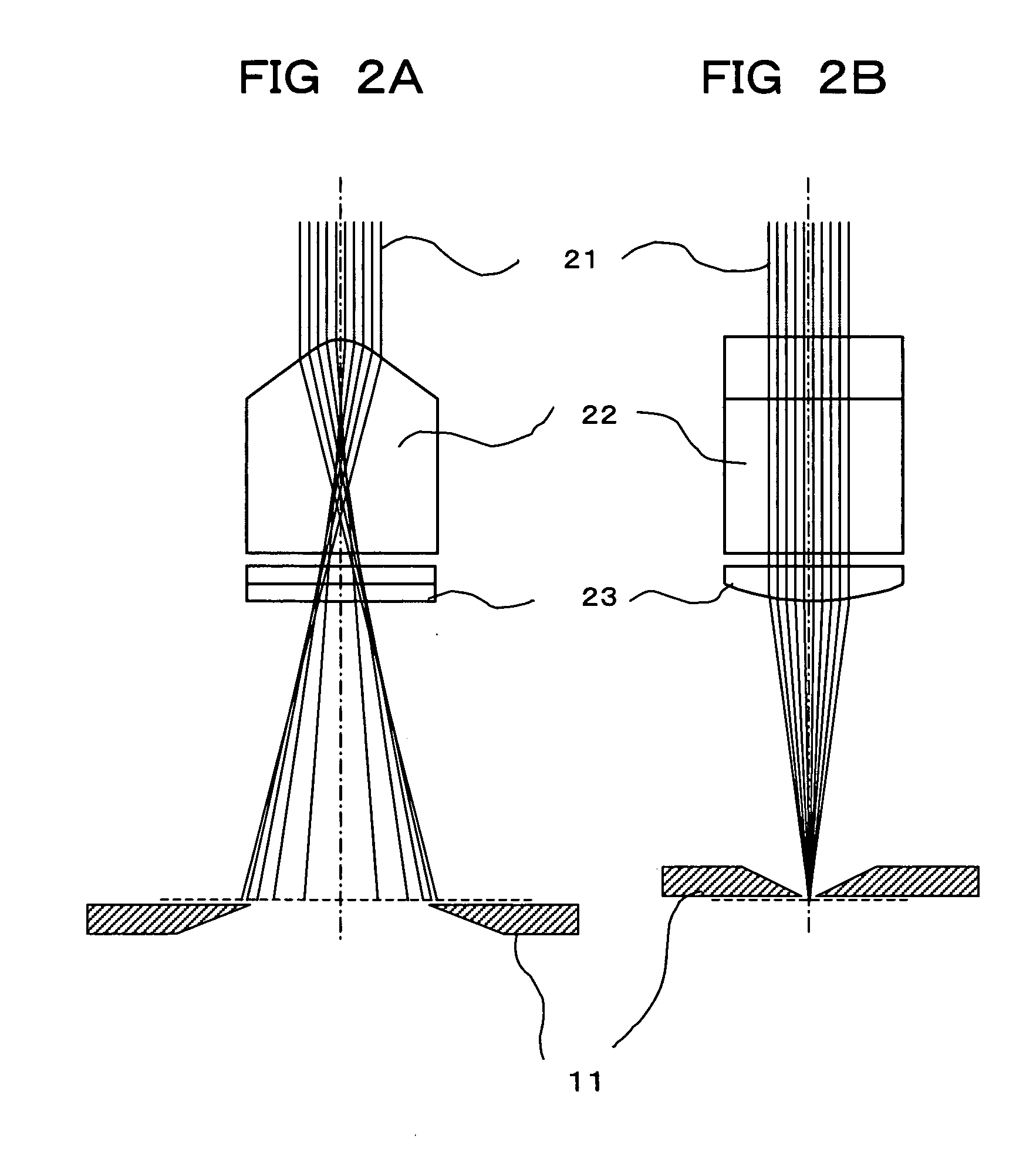

Laser apparatus, laser annealing method, and manufacturing method of a semiconductor device

InactiveUS20020048864A1Solution value is not highIncrease valueSemiconductor/solid-state device testing/measurementSolid-state devicesLaser lightSolid-state laser

To provide a laser apparatus and a laser annealing method with which a crystalline semiconductor film with a larger crystal grain size is obtained and which are low in their running cost. A solid state laser easy to maintenance and high in durability is used as a laser, and laser light emitted therefrom is linearized to increase the throughput and to reduce the production cost as a whole. Further, both the front side and the back side of an amorphous semiconductor film is irradiated with such laser light to obtain the crystalline semiconductor film with a larger crystal grain size.

Owner:SEMICON ENERGY LAB CO LTD

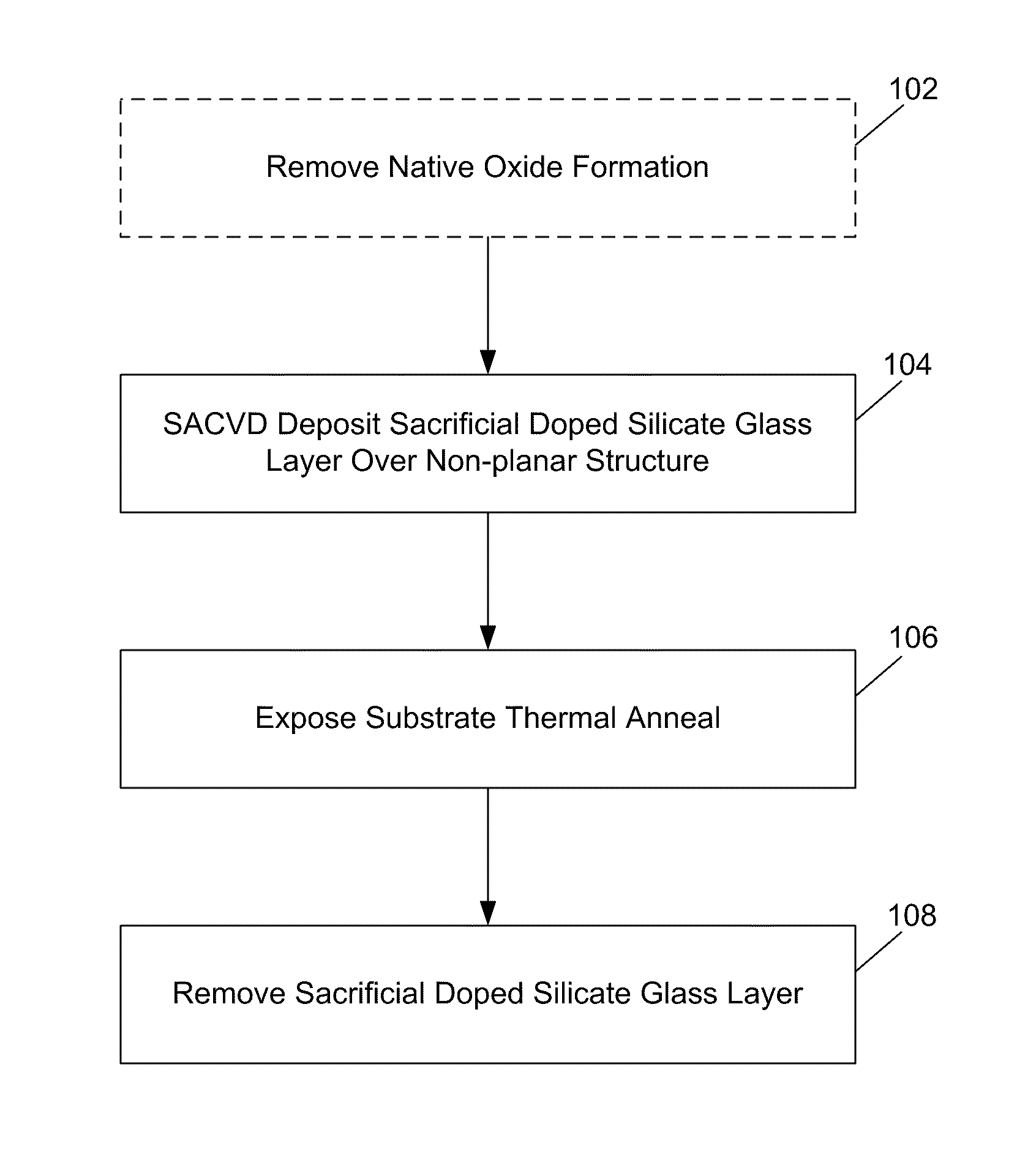

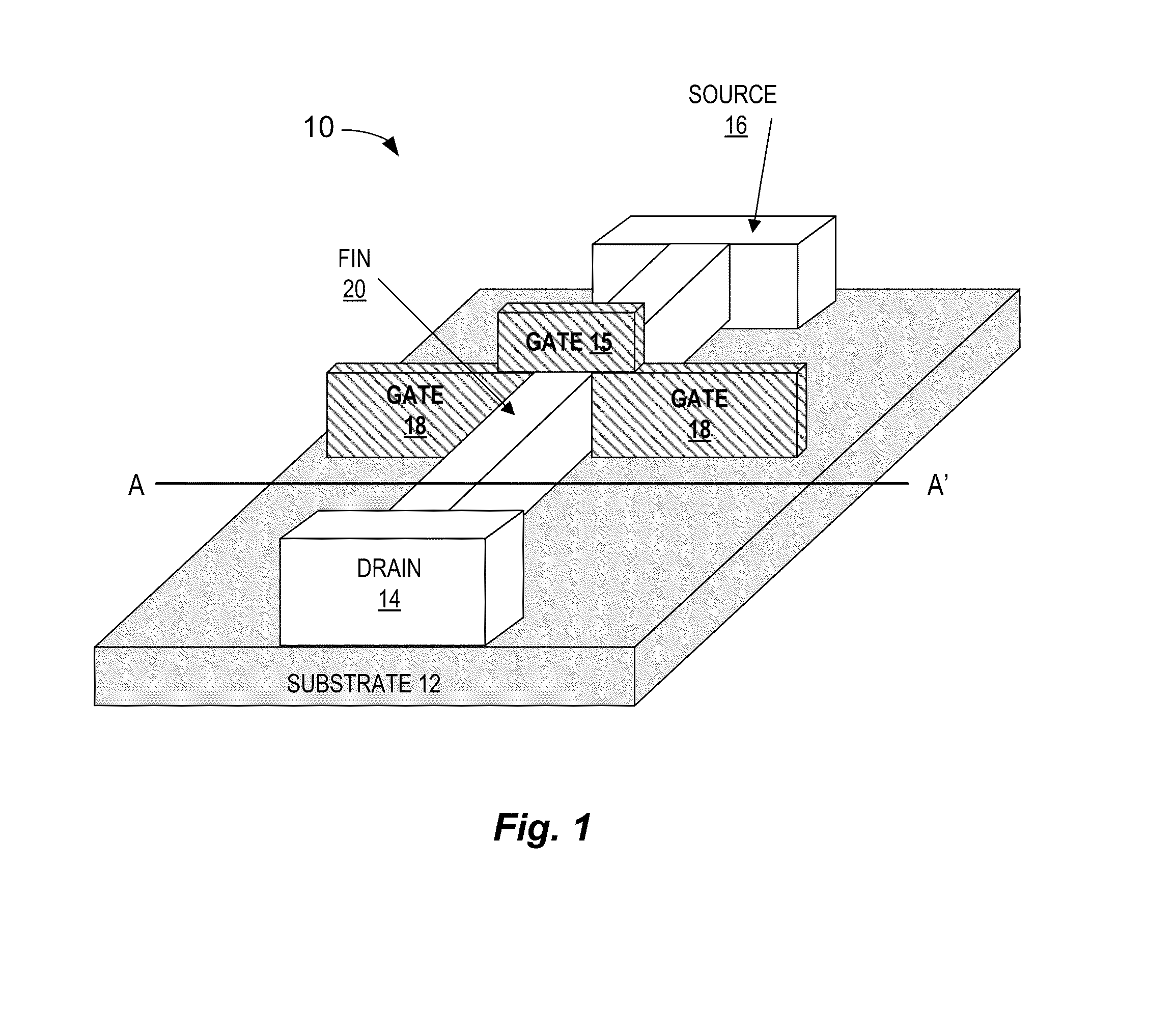

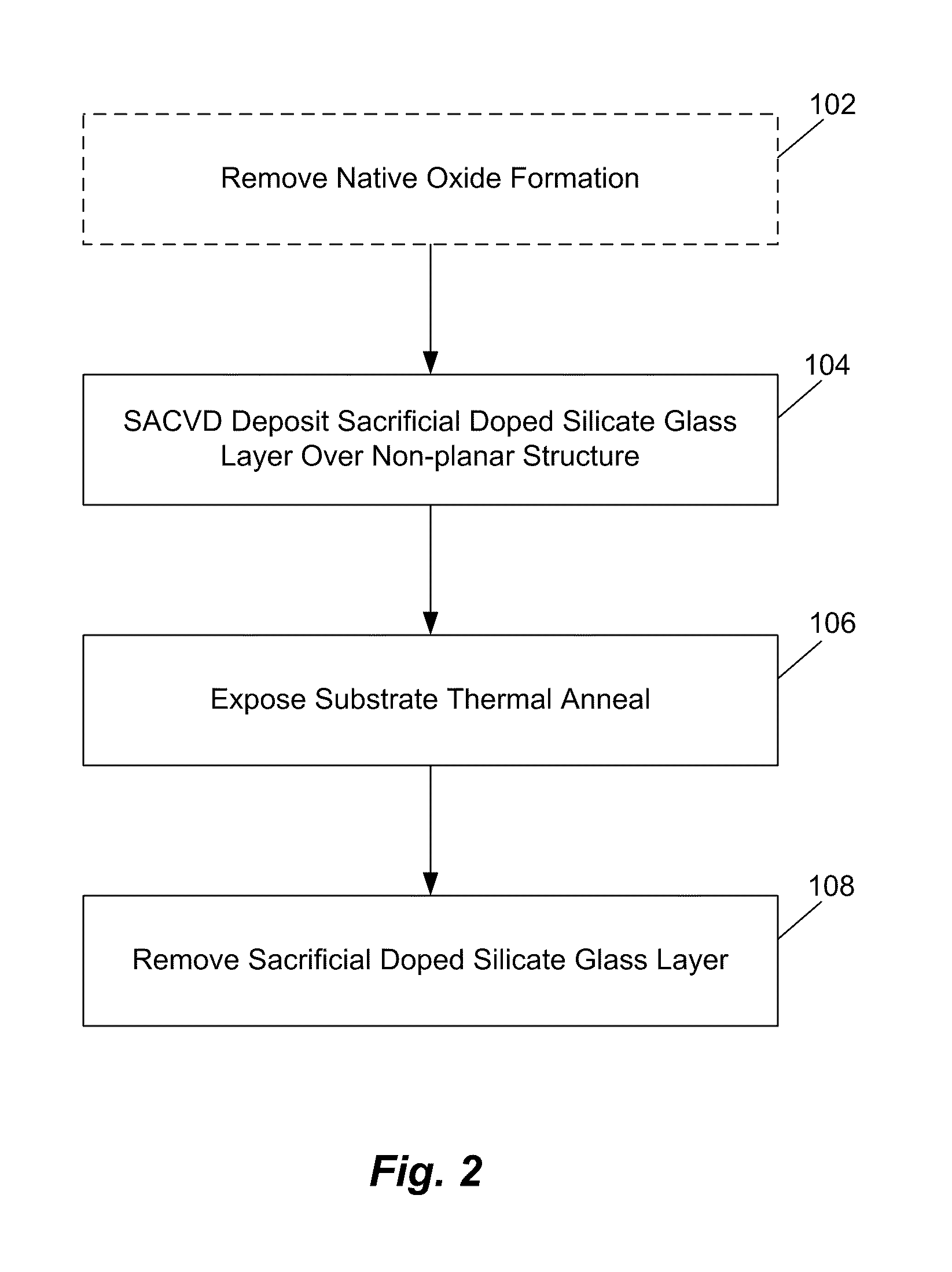

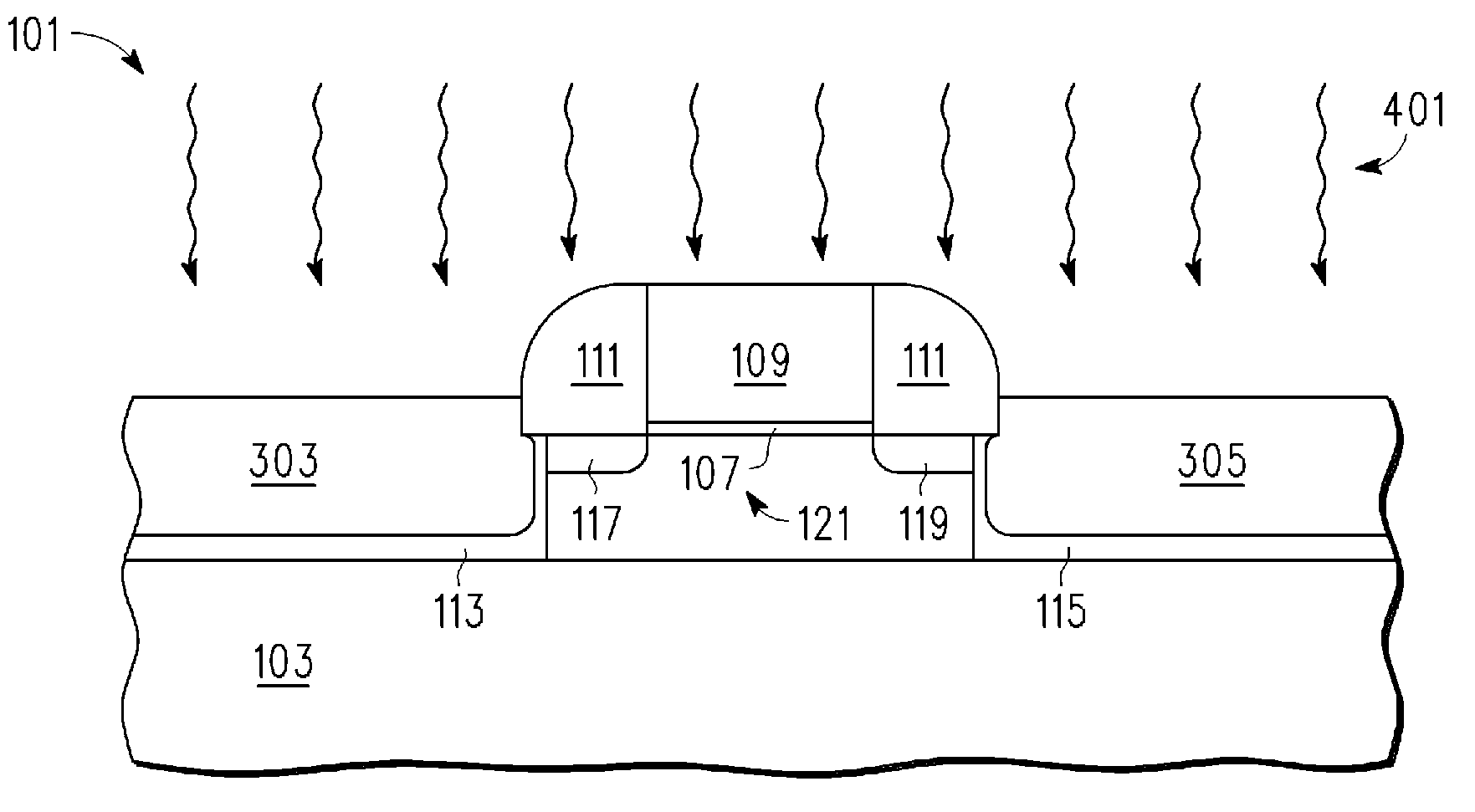

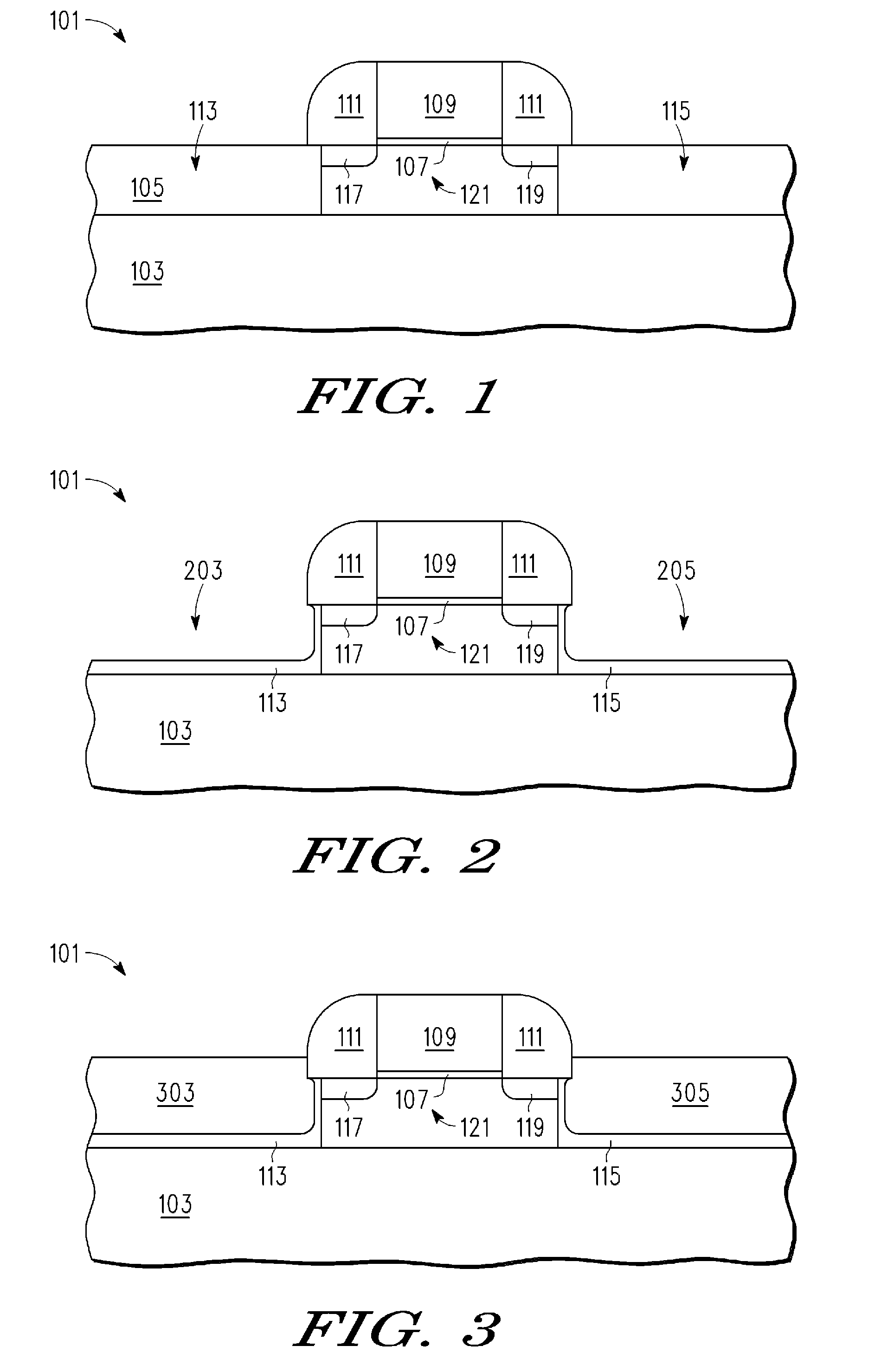

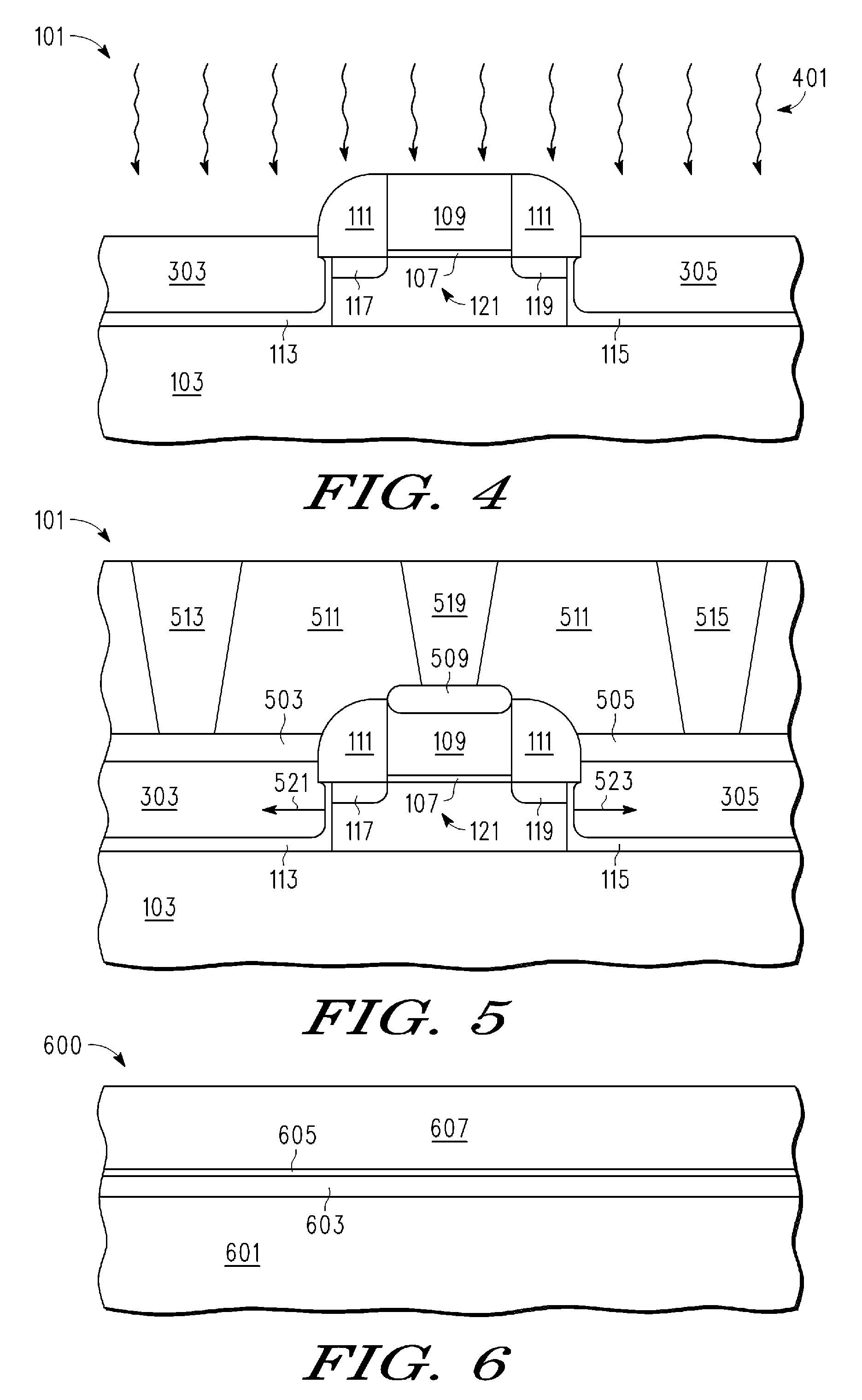

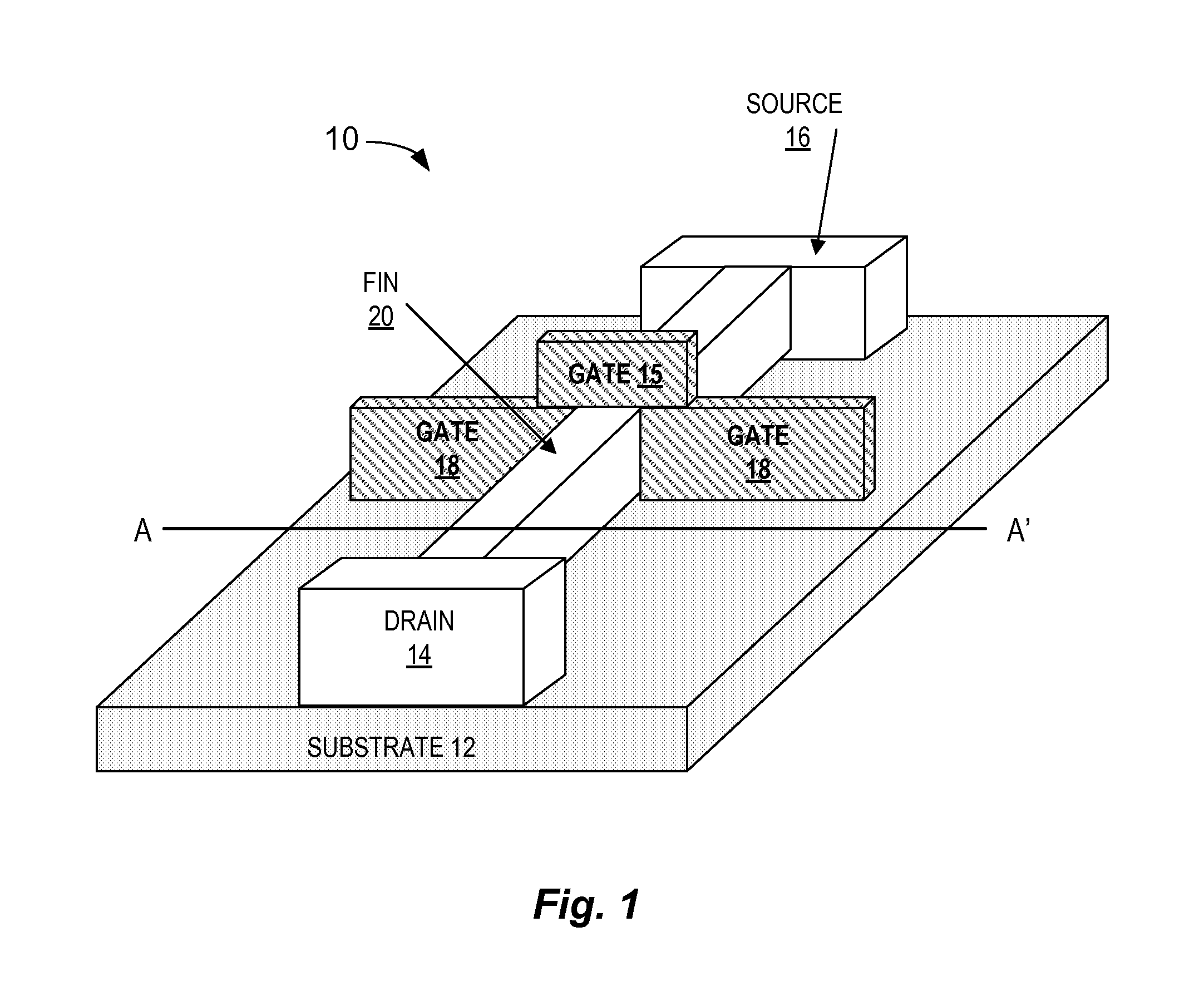

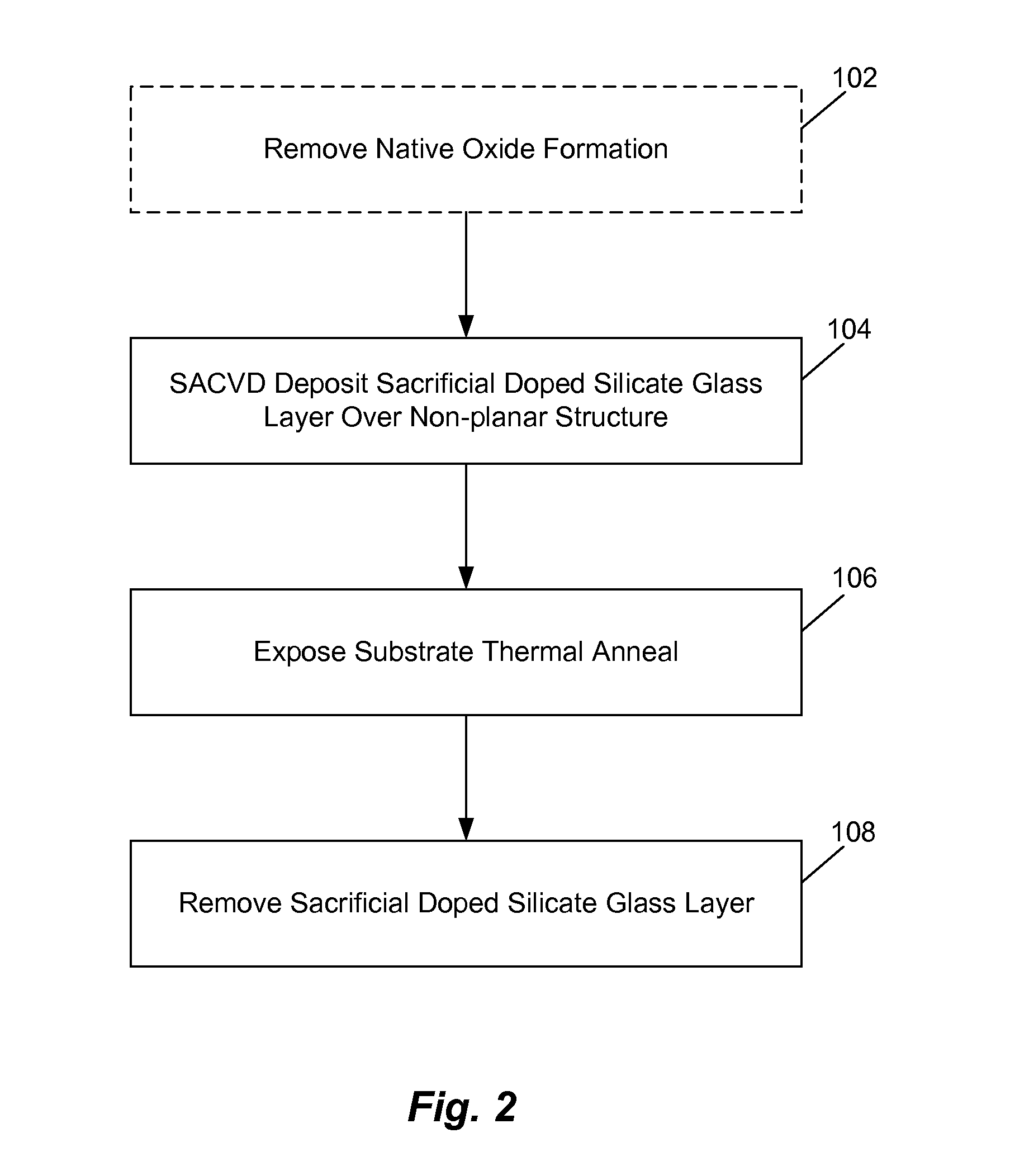

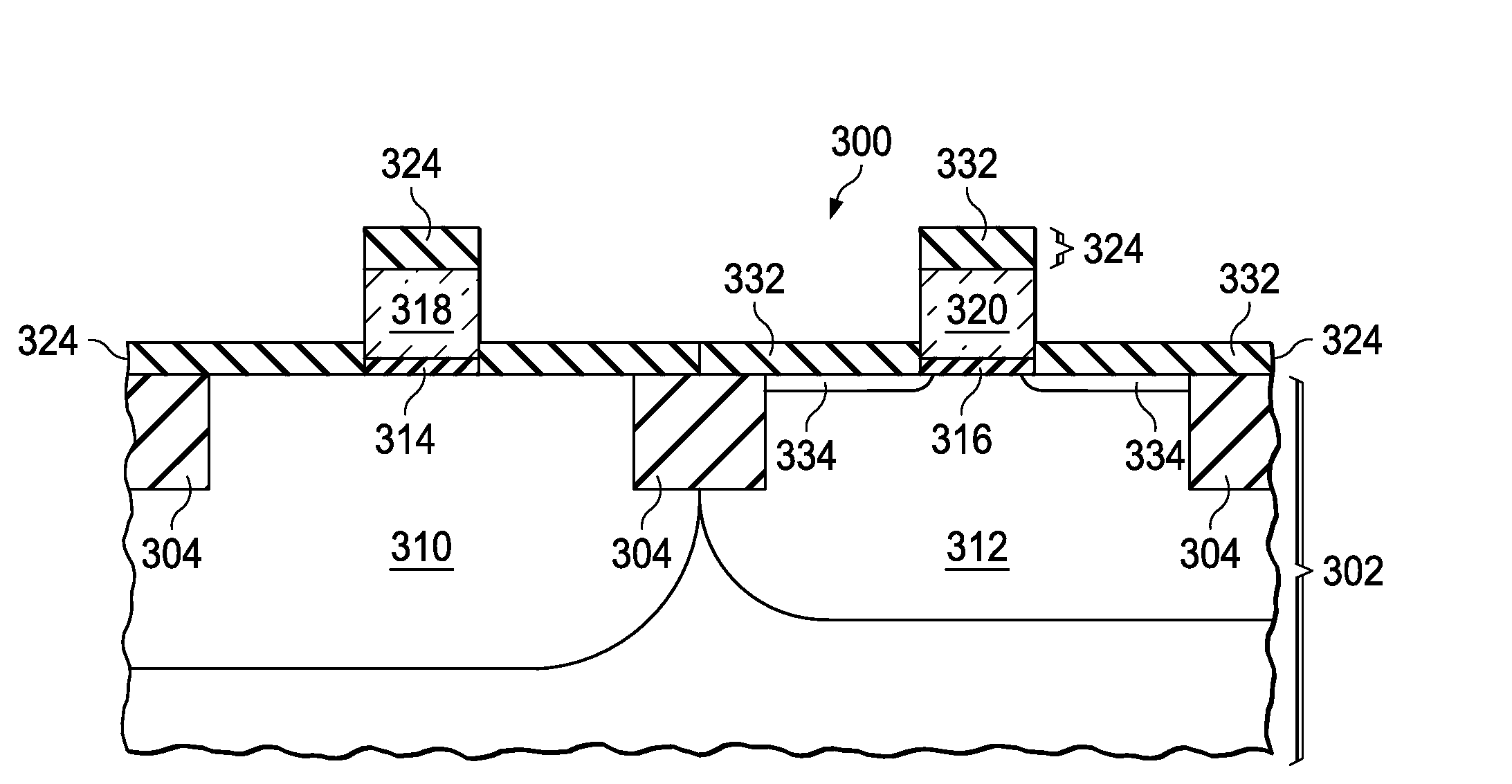

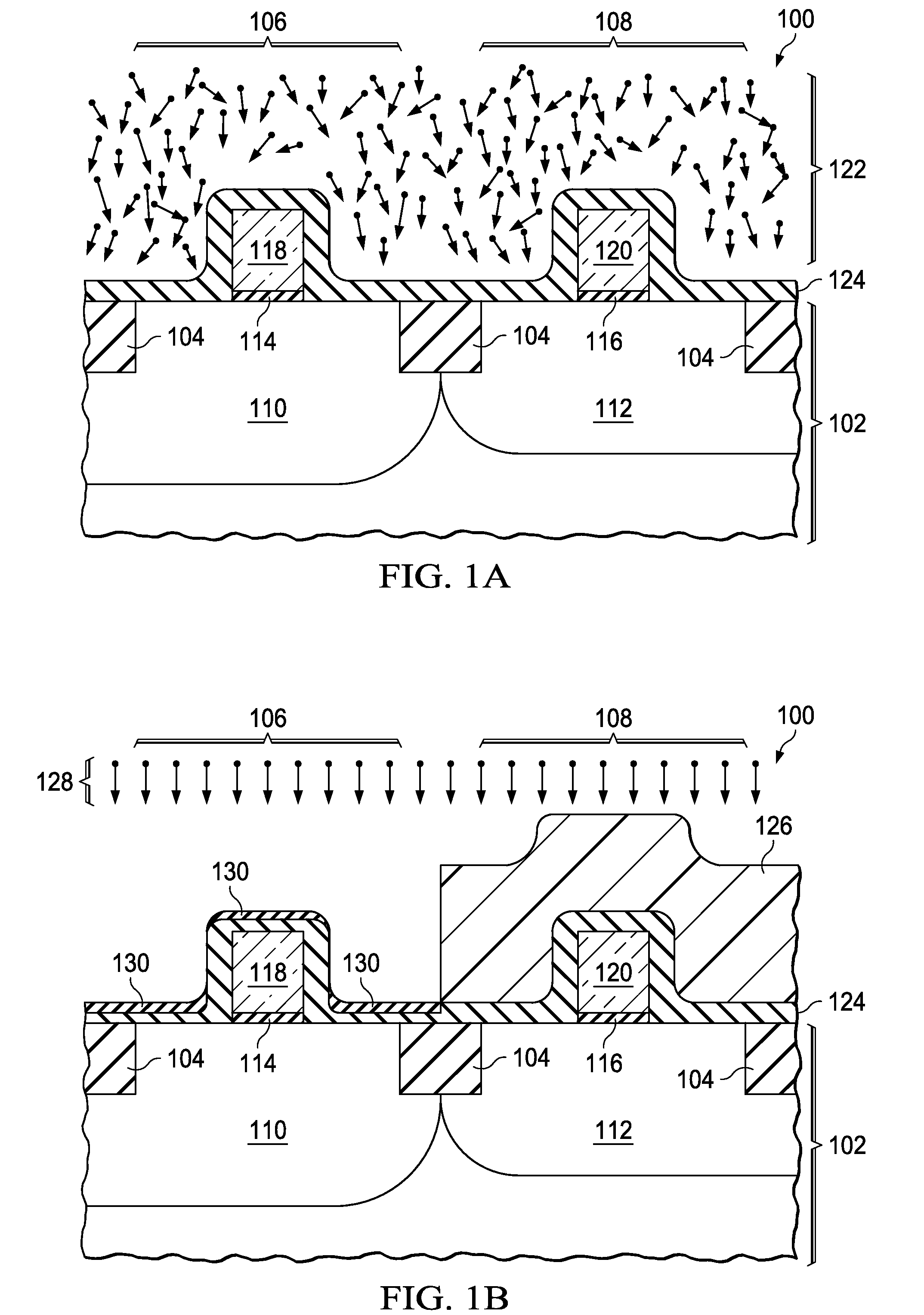

Method for doping non-planar transistors

InactiveUS8114761B2Semiconductor/solid-state device manufacturingSemiconductor devicesDopantPhysical chemistry

Owner:APPLIED MATERIALS INC

Laser apparatus, laser annealing method, and manufacturing method of a semiconductor device

InactiveUS6974731B2Large grainLow running costSolid-state devicesSemiconductor/solid-state device manufacturingLaser lightSolid-state laser

To provide a laser apparatus and a laser annealing method with which a crystalline semiconductor film with a larger crystal grain size is obtained and which are low in their running cost. A solid state laser easy to maintenance and high in durability is used as a laser, and laser light emitted therefrom is linearized to increase the throughput and to reduce the production cost as a whole. Further, both the front side and the back side of an amorphous semiconductor film is irradiated with such laser light to obtain the crystalline semiconductor film with a larger crystal grain size.

Owner:SEMICON ENERGY LAB CO LTD

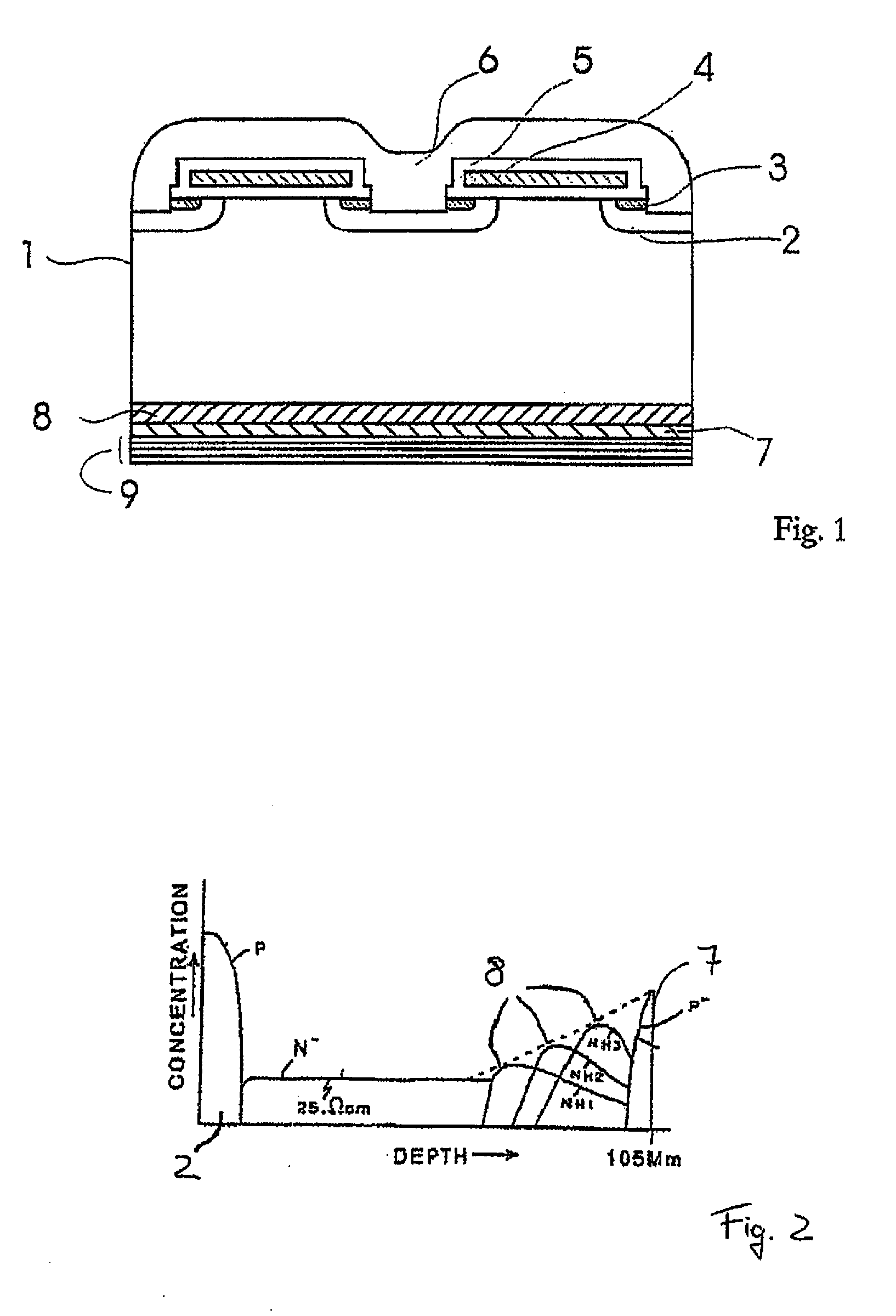

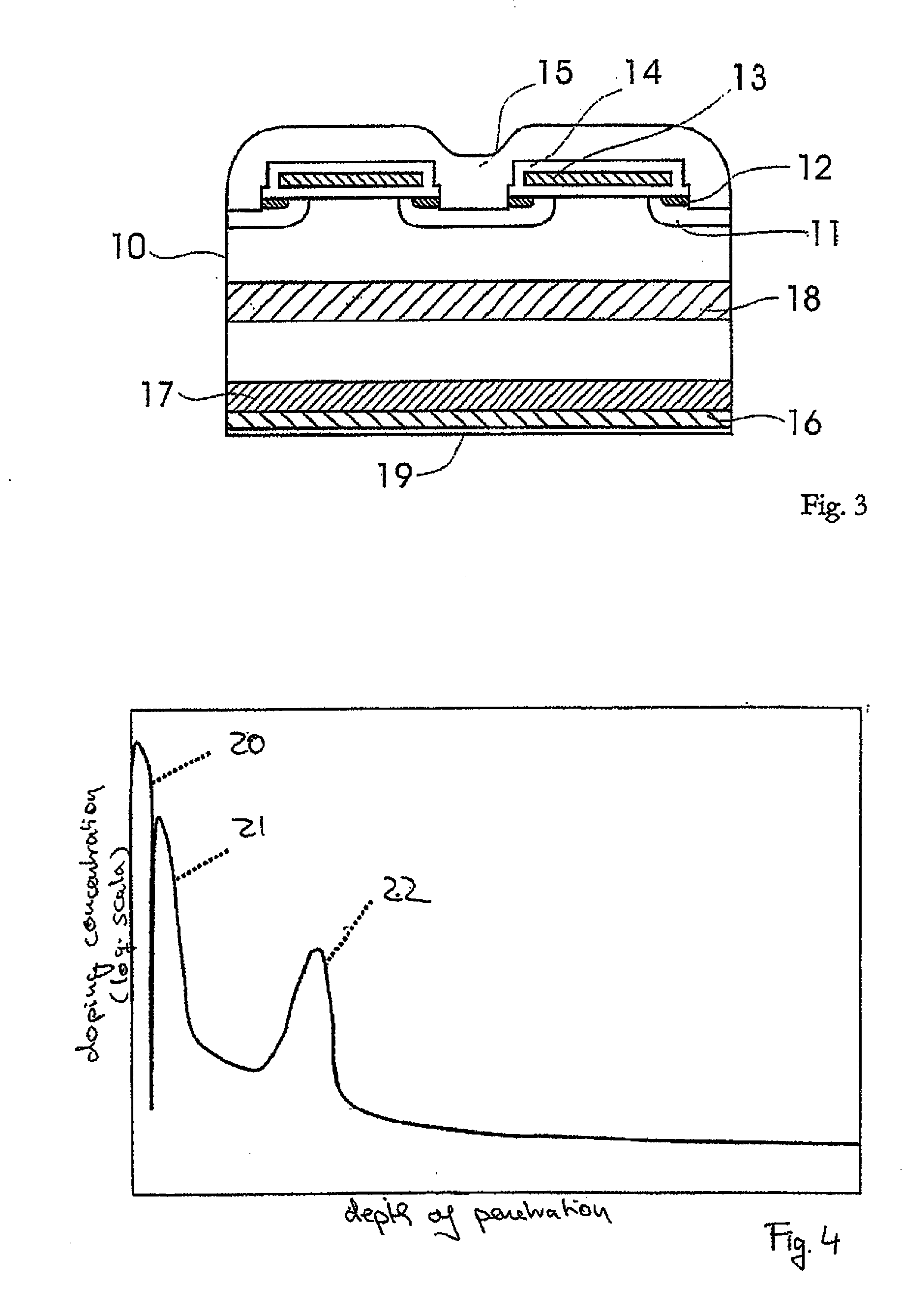

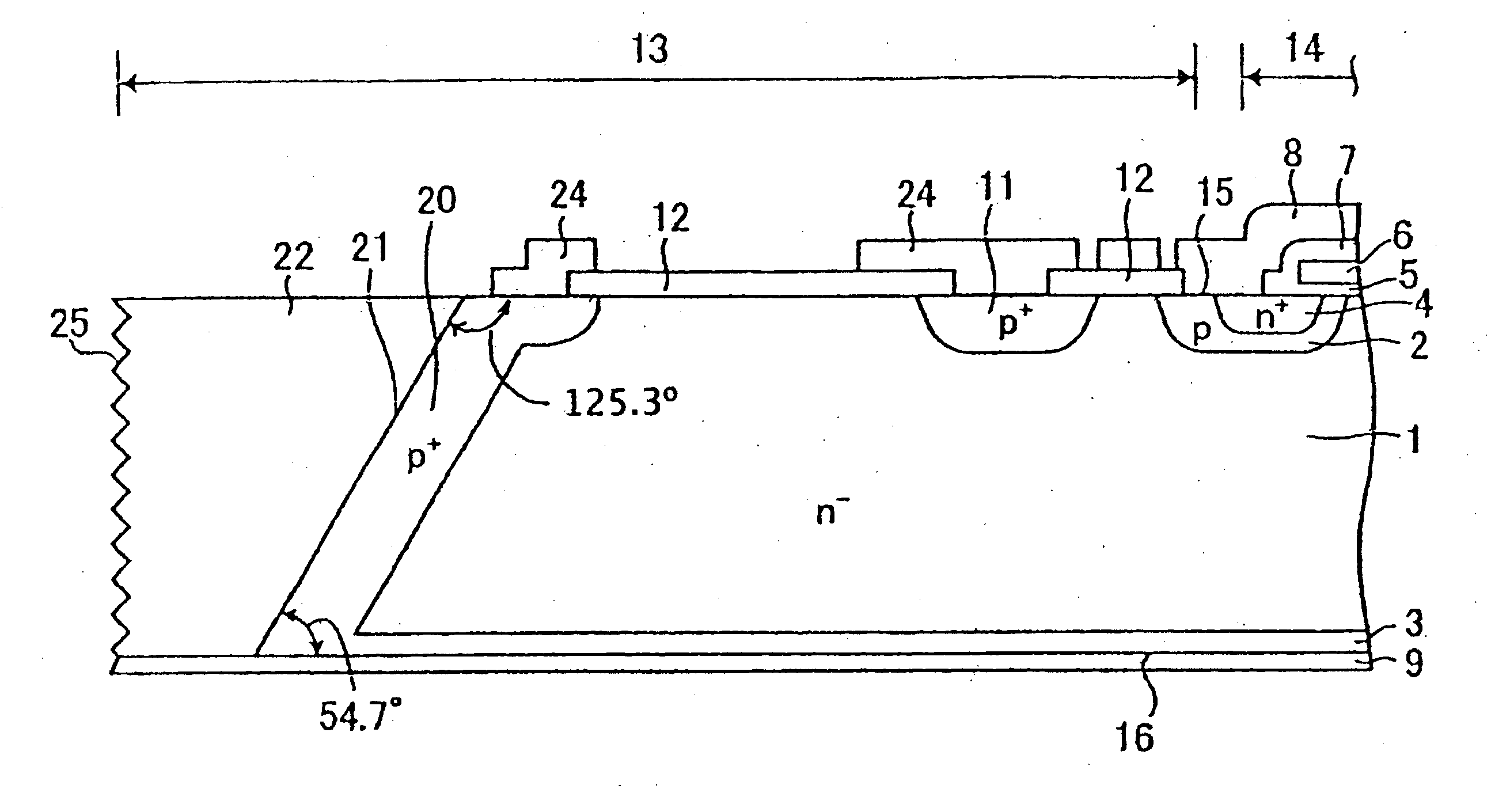

Semiconductor device with a field stop zone and process of producing the same

ActiveUS20080054369A1Semiconductor/solid-state device detailsSolid-state devicesDopantConduction band

Embodiments discussed herein relate to processes of producing a field stop zone within a semiconductor substrate by implanting dopant atoms into the substrate to form a field stop zone between a channel region and a surface of the substrate, at least some of the dopant atoms having energy levels of at least 0.15 eV below the energy level of the conduction band edge of semiconductor substrate; and laser annealing the field stop zone.

Owner:INFINEON TECH AUSTRIA AG

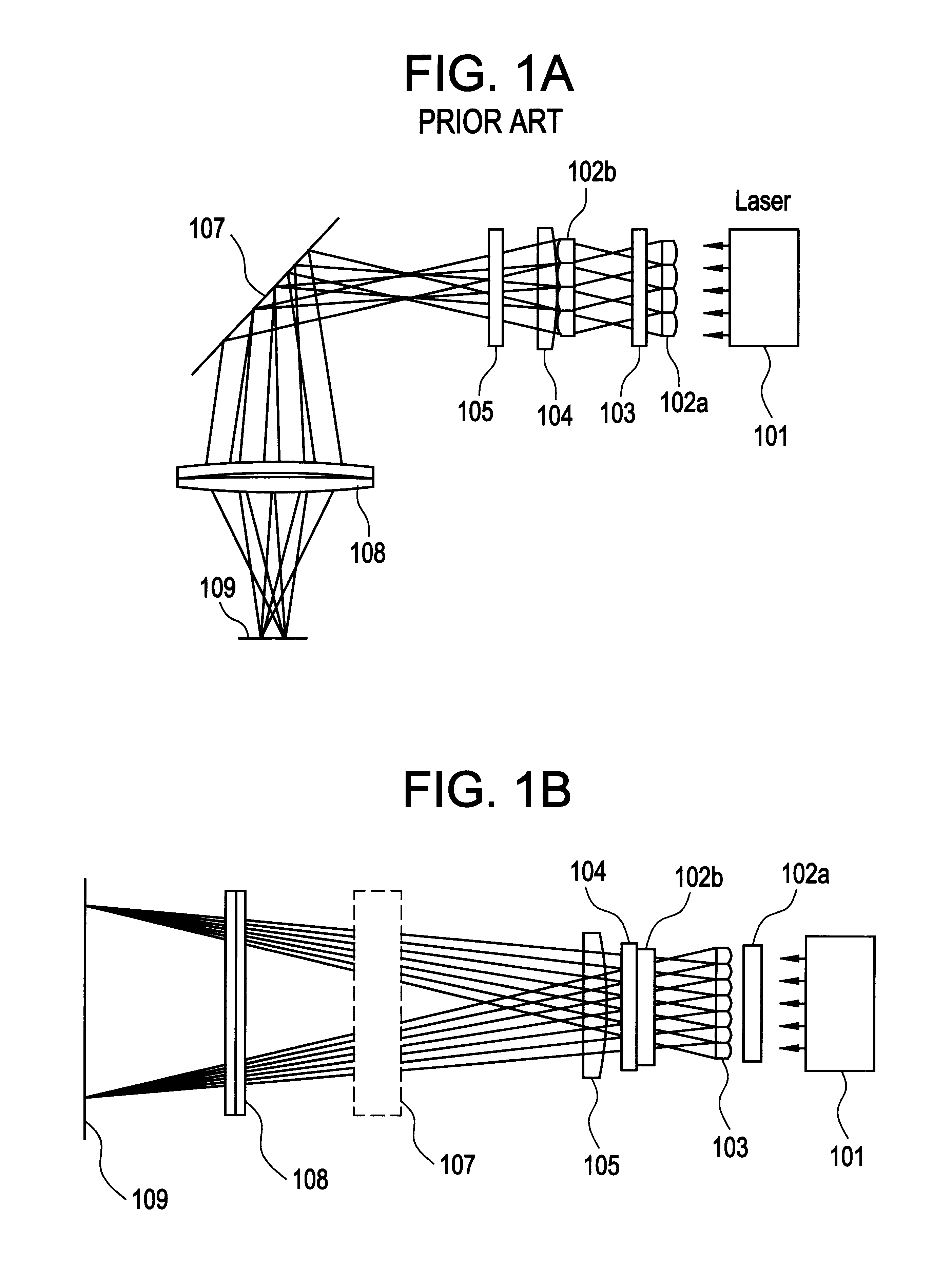

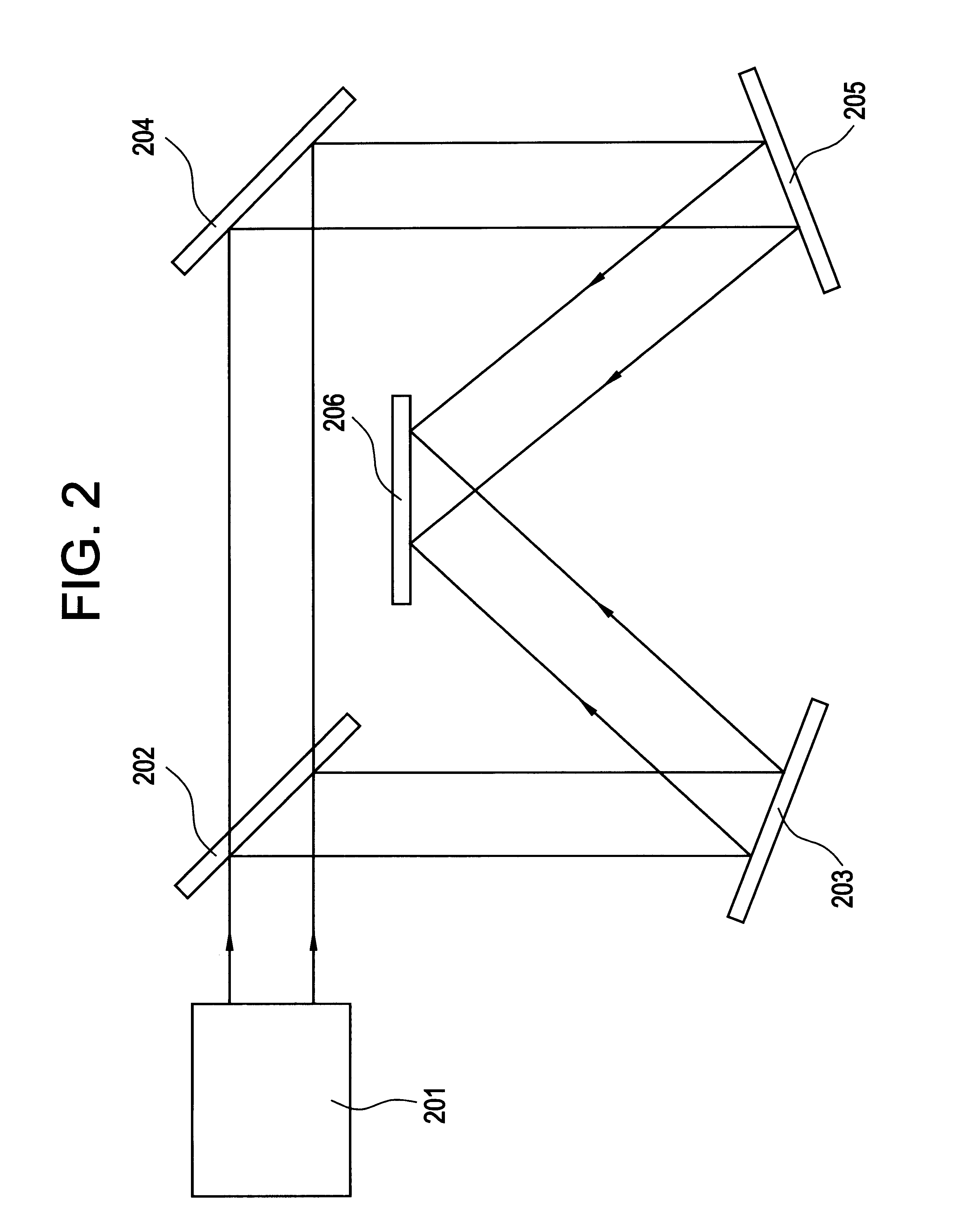

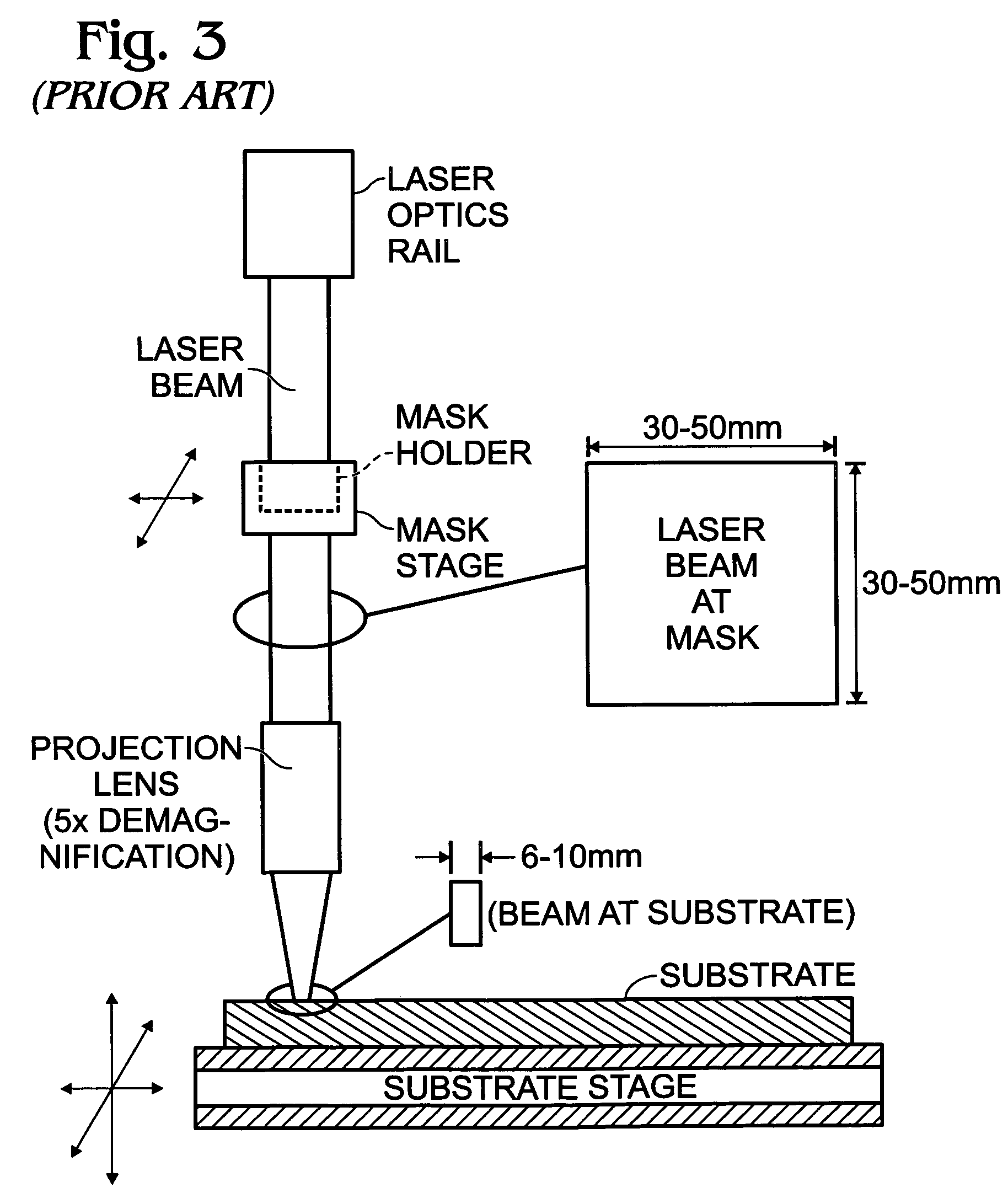

Laser irradiation apparatus and method of fabricating a semiconductor device

There is provided an optical system for reducing faint interference observed when laser annealing is performed to a semiconductor film. The faint interference conventionally observed can be reduced by irradiating the semiconductor film with a laser beam by the use of an optical system using a mirror of the present invention. The optical system for transforming the shape of the laser beam on an irradiation surface into a linear or rectangular shape is used. The optical system may include an optical system serving to convert the laser beam into a parallel light with respect to a traveling direction of the laser beam. When the laser beam having passed through the optical system is irradiated to the semiconductor film through the mirror of the present invention, the conventionally observed faint interference can be reduced. Besides, the optical system which has been difficult to adjust can be simplified.

Owner:SEMICON ENERGY LAB CO LTD

Anneal of epitaxial layer in a semiconductor device

InactiveUS7416605B2From gel statePolycrystalline material growthCharge carrier mobilityDegree Celsius

An anneal of an epitaxially grown crystalline semiconductor layer comprising a combination of group-IV elements. The layer contains at least one of the group of carbon and tin. The layer of epitaxially grown material is annealed at a temperature substantially in a range of 1,000 to 1,400 degrees Celsius for a period not to exceed 100 milliseconds within 10% of the peak temperature. The anneal is performed for example with a laser anneal or a flash lamp anneal. The limited-time anneal may improve carrier mobility of a transistor.

Owner:NORTH STAR INNOVATIONS

Method for doping non-planar transistors

InactiveUS20110129990A1Enhance layeringImprove concentrationSemiconductor/solid-state device manufacturingSemiconductor devicesDopantChemical vapor deposition

Owner:APPLIED MATERIALS INC

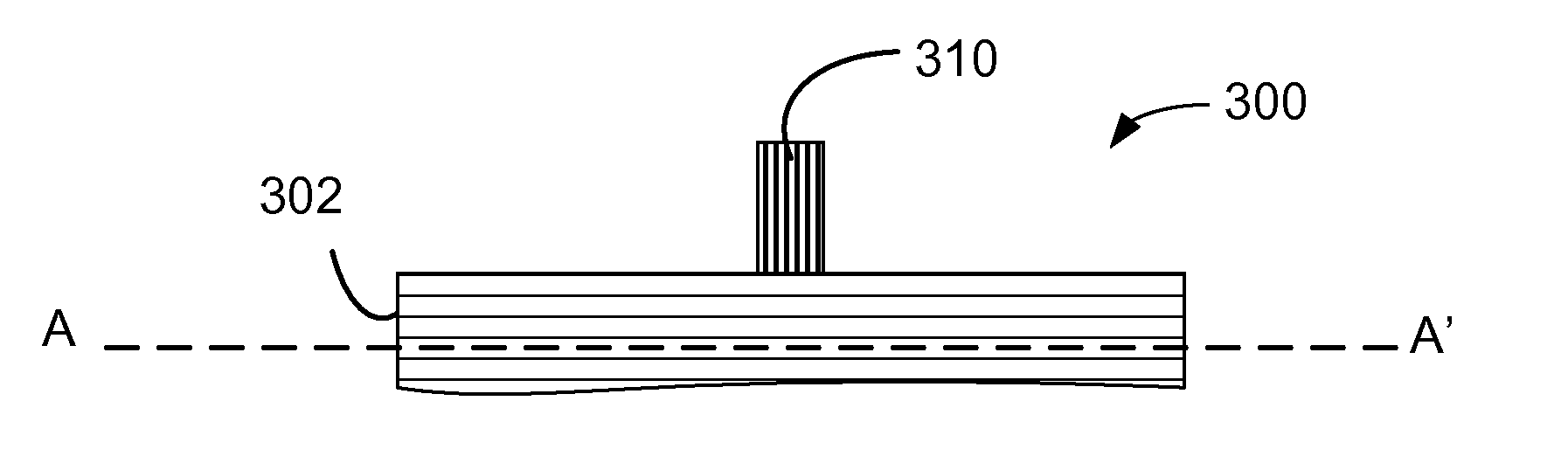

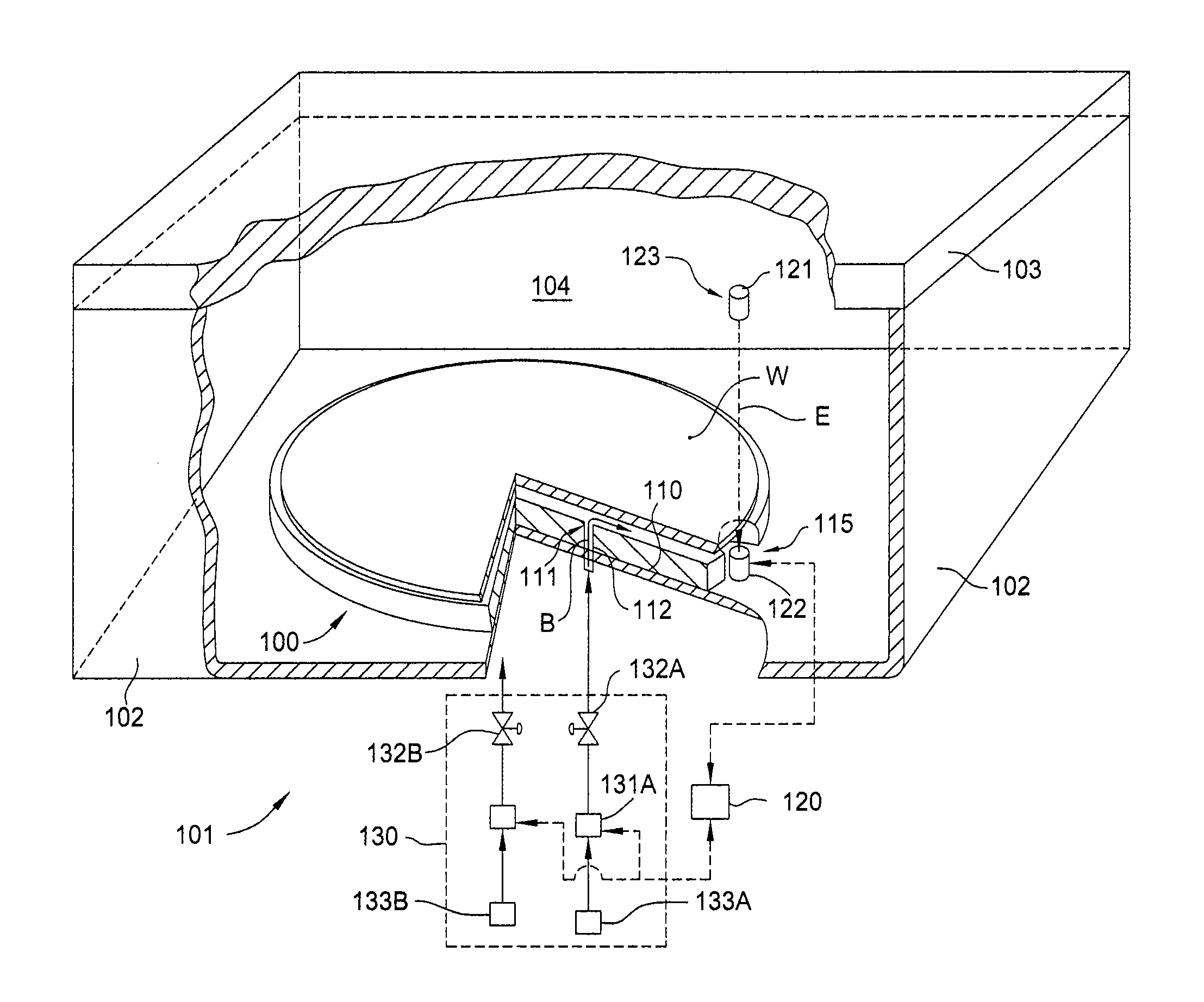

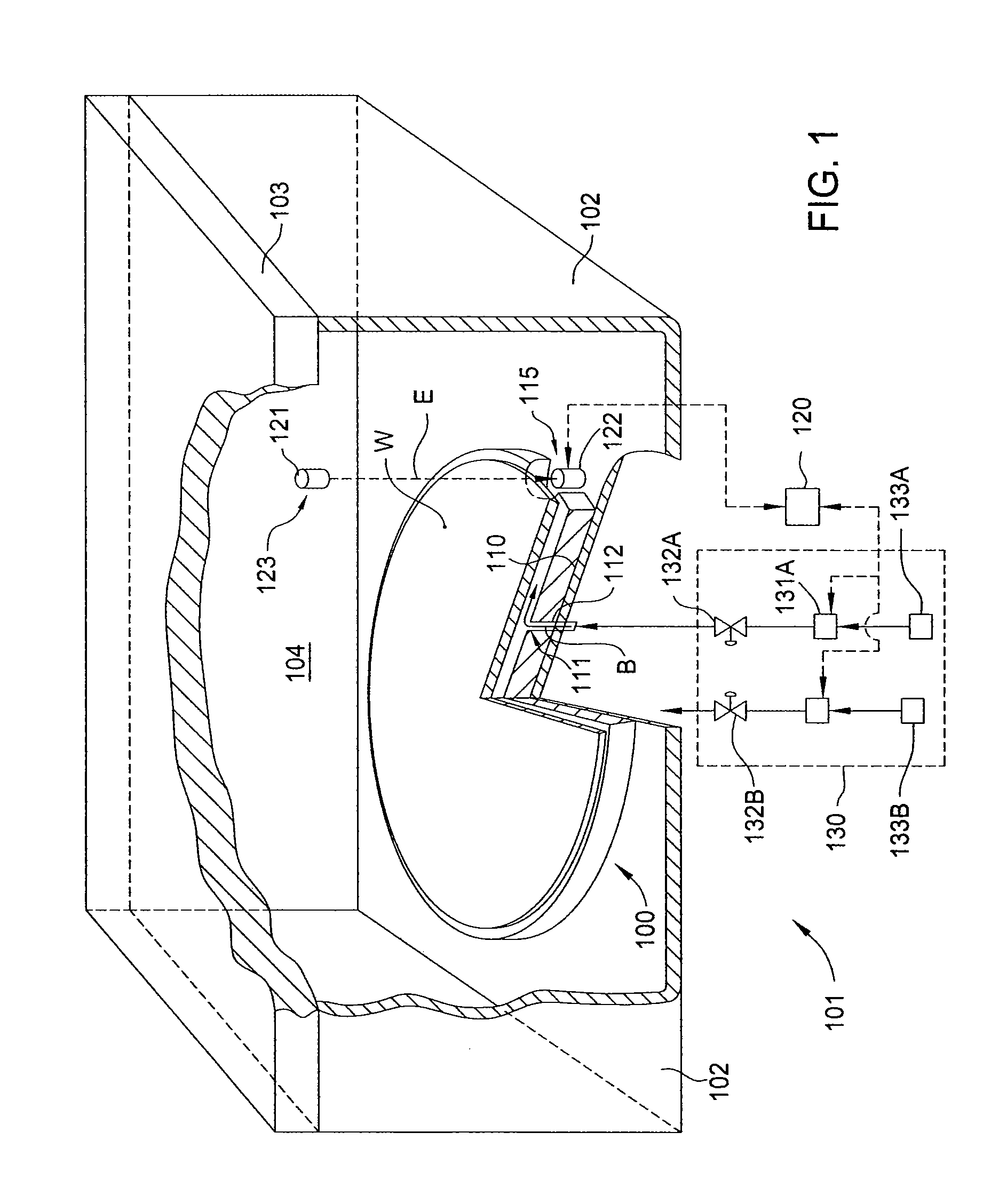

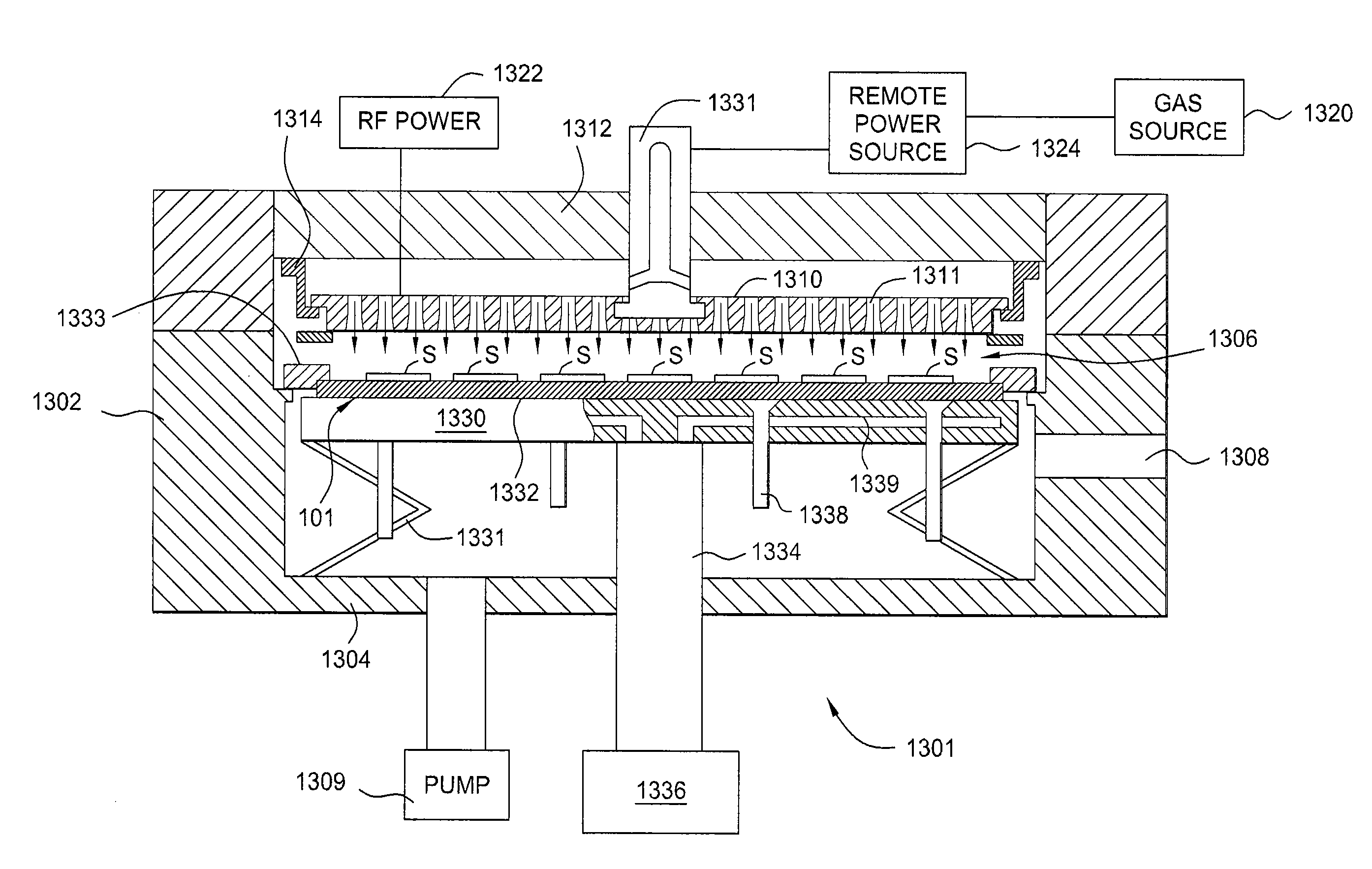

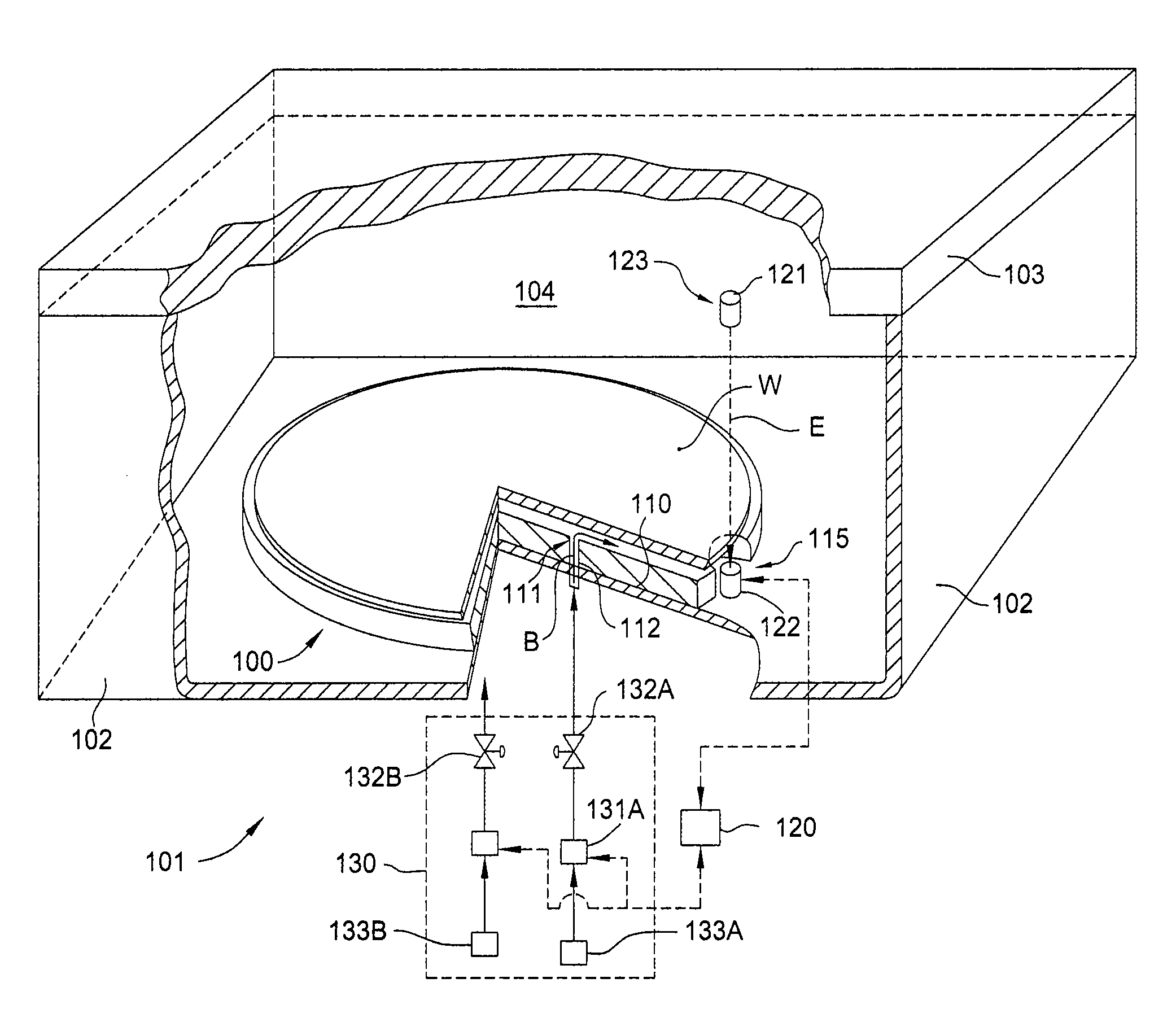

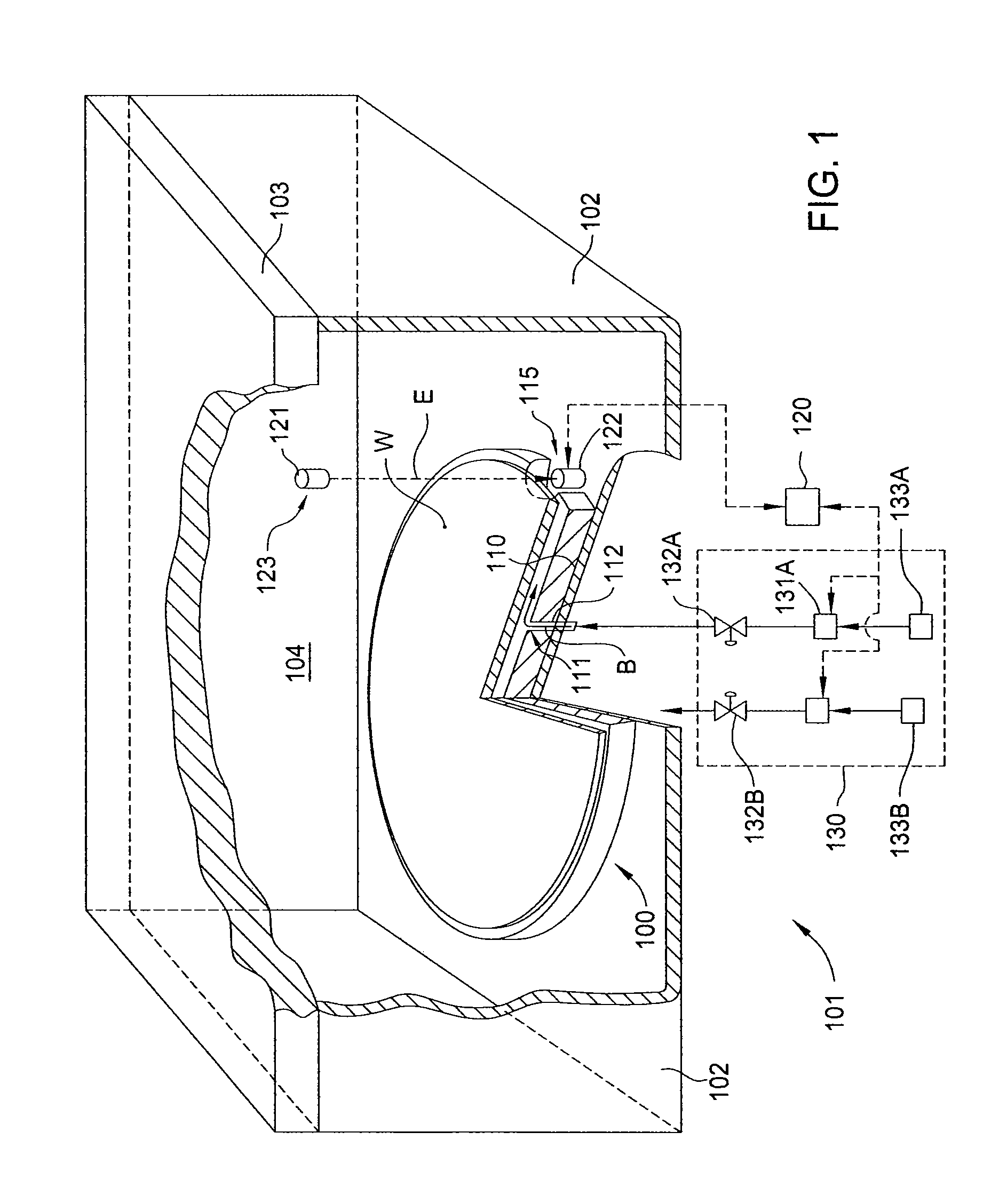

Apparatus and method for supporting, positioning and rotating a substrate in a processing chamber

ActiveUS20080280453A1Liquid surface applicatorsSemiconductor/solid-state device manufacturingGas phaseEngineering

Embodiments of the invention contemplate a method, apparatus and system that are used to support, position, and rotate a substrate during processing. Embodiments of the invention may also include a method of controlling the transfer of heat between a substrate and substrate support positioned in a processing chamber. The apparatus and methods described herein remove the need for complex, costly and often unreliable components that would be required to accurately position and rotate a substrate during one or more processing steps, such as an rapid thermal processing (RTP) process, a chemical vapor deposition (CVD) process, a physical vapor deposition (PVD) process, atomic layer deposition (ALD) process, dry etching process, wet clean, and / or laser annealing process.

Owner:APPLIED MATERIALS INC

Semiconductor on insulator structure made using radiation annealing

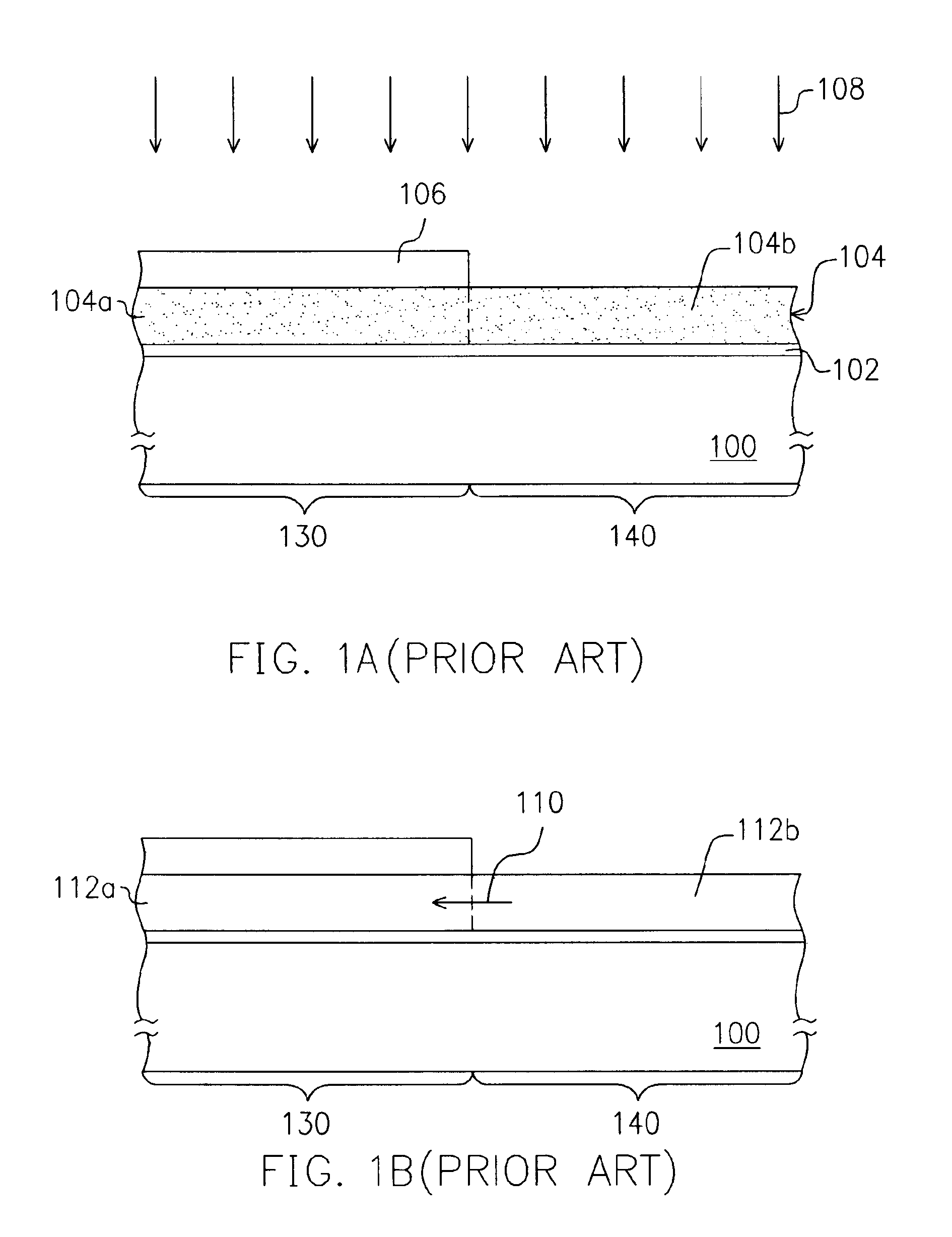

InactiveUS20070281172A1Healing damageReduce roughnessElectric discharge tubesSolid-state devicesWaferingIon implantation

Systems and methods for and products of a semiconductor-on-insulator (SOI) structure including subjecting at least one unfinished surface to a laser annealing process. Production of the SOI structure further may include subjecting an implantation surface of a donor semiconductor wafer to an ion implantation process to create an exfoliation layer in the donor semiconductor wafer; bonding the implantation surface of the exfoliation layer to an insulator substrate; separating the exfoliation layer from the donor semiconductor wafer, thereby exposing at least one cleaved surface; and subjecting the at least one cleaved surface to the laser annealing process.

Owner:CORNING INC

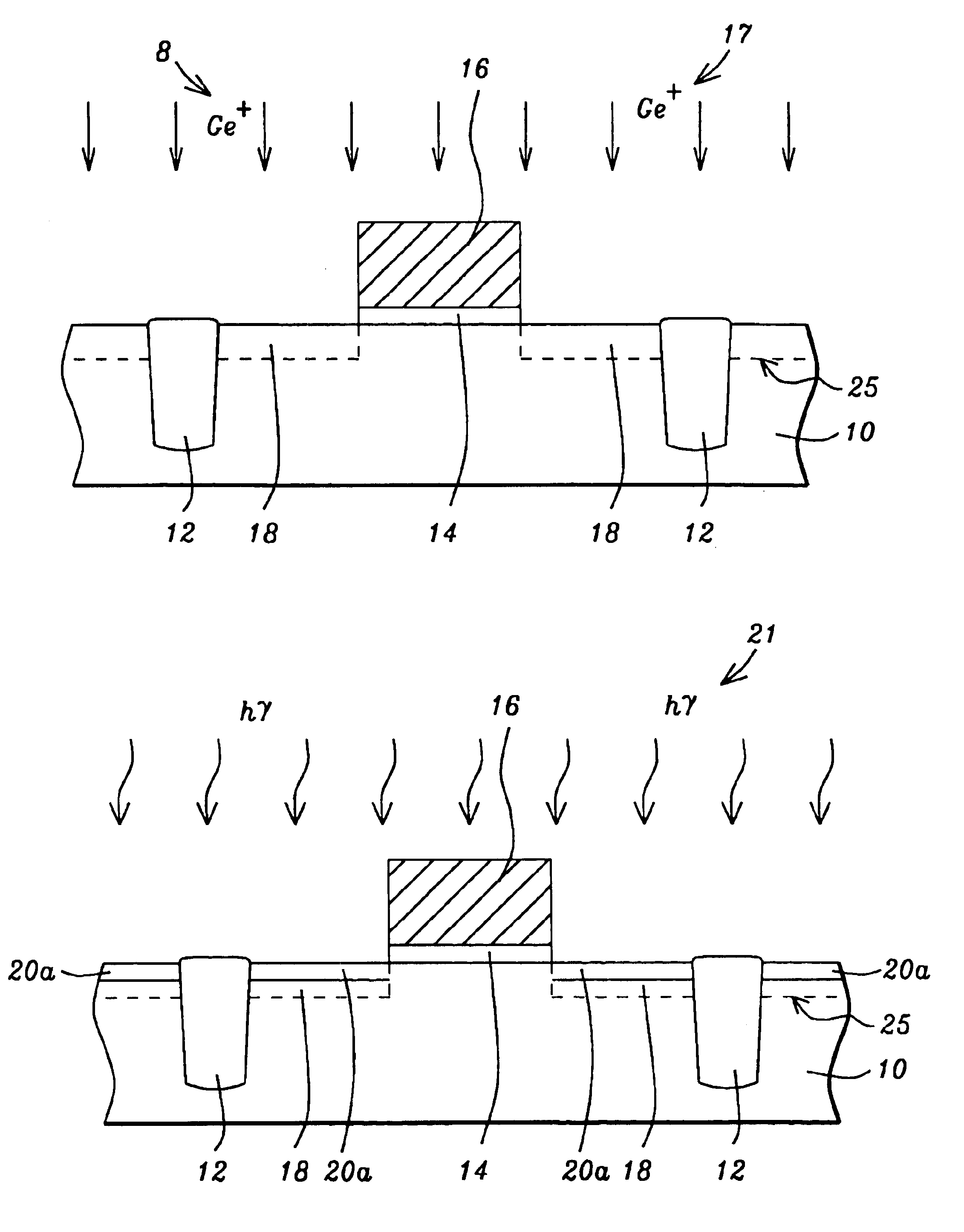

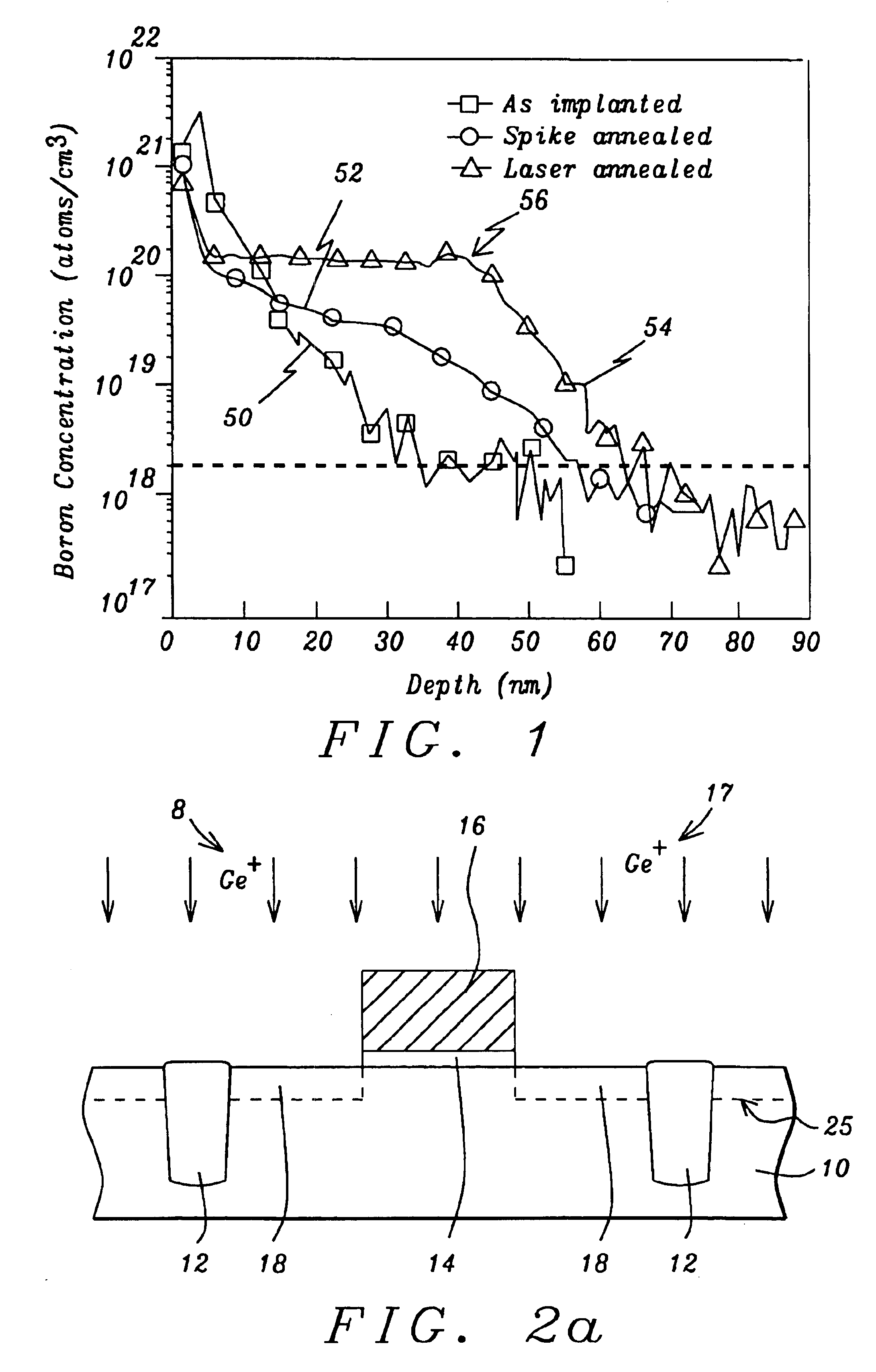

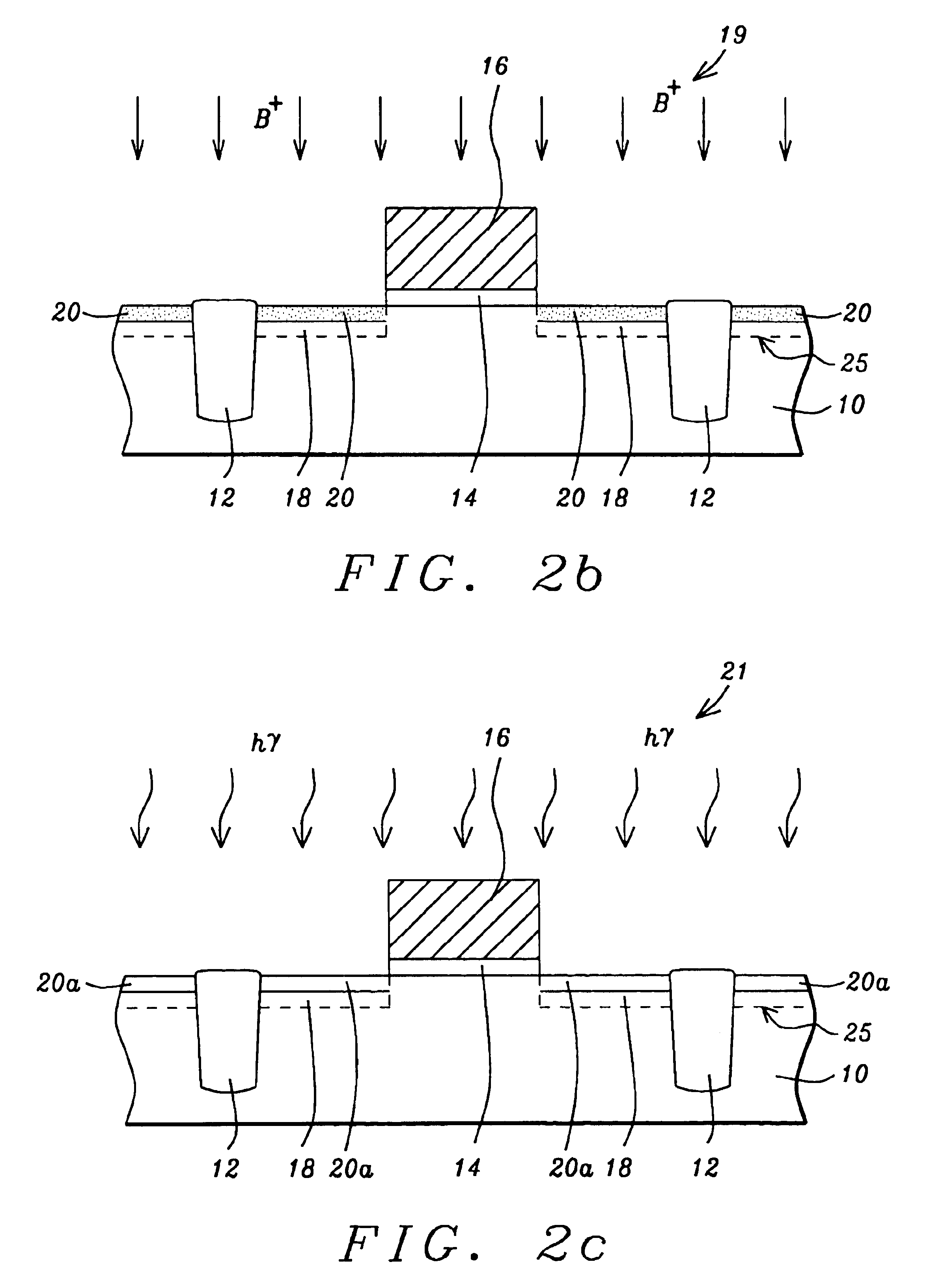

Method of multiple pulse laser annealing to activate ultra-shallow junctions

A method for forming a highly activated ultra shallow ion implanted semiconductive elements for use in sub-tenth micron MOSFET technology is described. A key feature of the method is the ability to activate the implanted impurity to a highly active state without permitting the dopant to diffuse further to deepen the junction. A selected single crystalline silicon active region is first amorphized by implanting a heavy ion such as silicon or germanium. A semiconductive impurity for example boron is then implanted and activated by pulsed laser annealing whereby the pulse fluence, frequency, and duration are chosen to maintain the amorphized region just below it's melting temperature. It is found that just below the melting temperature there is sufficient local ion mobility to secure the dopant into active positions within the silicon matrix to achieve a high degree of activation with essentially no change in concentration profile. The selection of the proper laser annealing parameters is optimized by observation of the reduction of sheet resistance and concentration profile as measured on a test site. Application of the method is applied to forming a MOS FET and a CMOS device. The additional processing steps required by the invention are applied simultaneously to both n-channel and p-channel devices of the CMOS device pair.

Owner:CHARTERED SEMICONDUCTOR MANUFACTURING

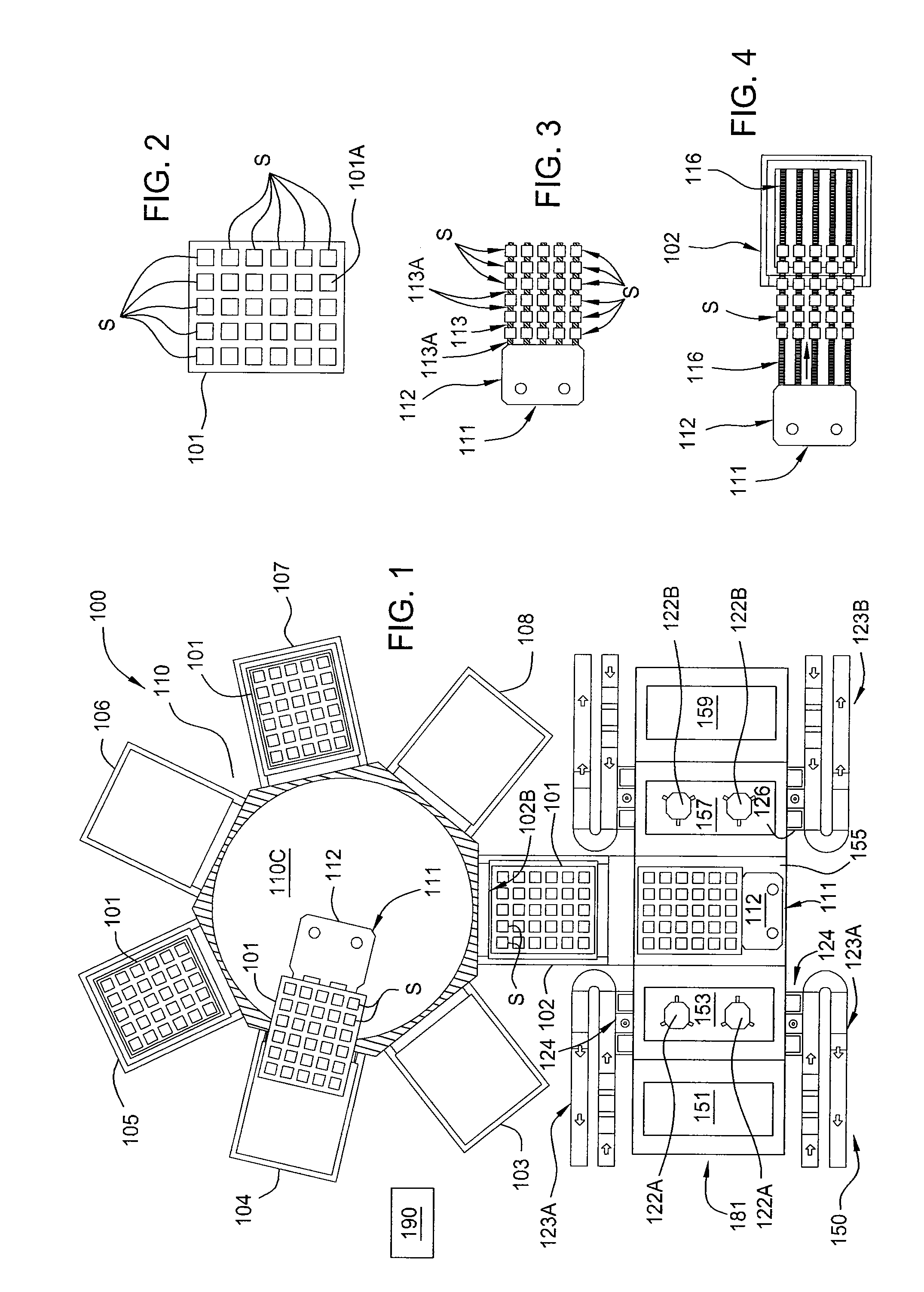

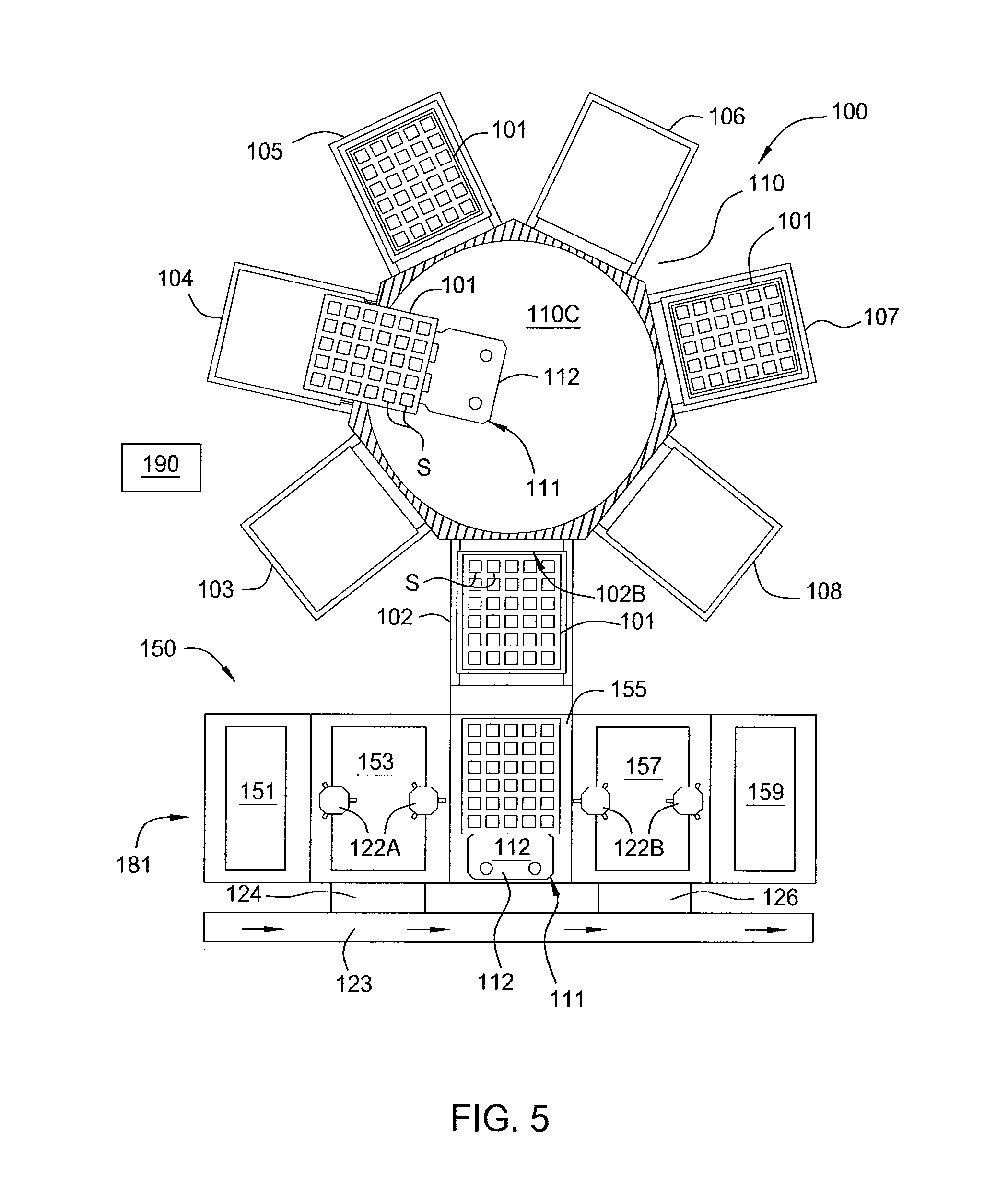

Advanced platform for processing crystalline silicon solar cells

InactiveUS20100087028A1Final product manufactureSemiconductor/solid-state device manufacturingGas phaseEngineering

The present invention generally provides a batch substrate processing system, or cluster tool, for in-situ processing of a film stack used to form regions of a solar cell device. In one configuration, the film stack formed on each of the substrates in the batch contains one or more silicon-containing layers and one or more metal layers that are deposited and further processed within the various chambers contained in the substrate processing system. The processing chambers may be, for example, physical vapor deposition (PVD) or sputtering chambers, plasma enhanced chemical vapor deposition (PECVD) chambers, low pressure chemical vapor deposition (LPCVD) chambers, hot wire chemical vapor deposition (HWCVD) chambers, plasma nitridation (DPN) chambers, ion implant / doping chambers, atomic layer deposition (ALD) chambers, plasma etching chambers, annealing chambers, rapid thermal oxidation (RTO) chambers, rapid thermal annealing (RTA) chambers, substrate reorientation chambers, laser annealing chambers, and / or plasma cleaning stations. In one embodiment, a batch of solar cell substrates is simultaneously transferred in a vacuum or inert environment to prevent contamination from affecting the solar cell formation process.

Owner:APPLIED MATERIALS INC

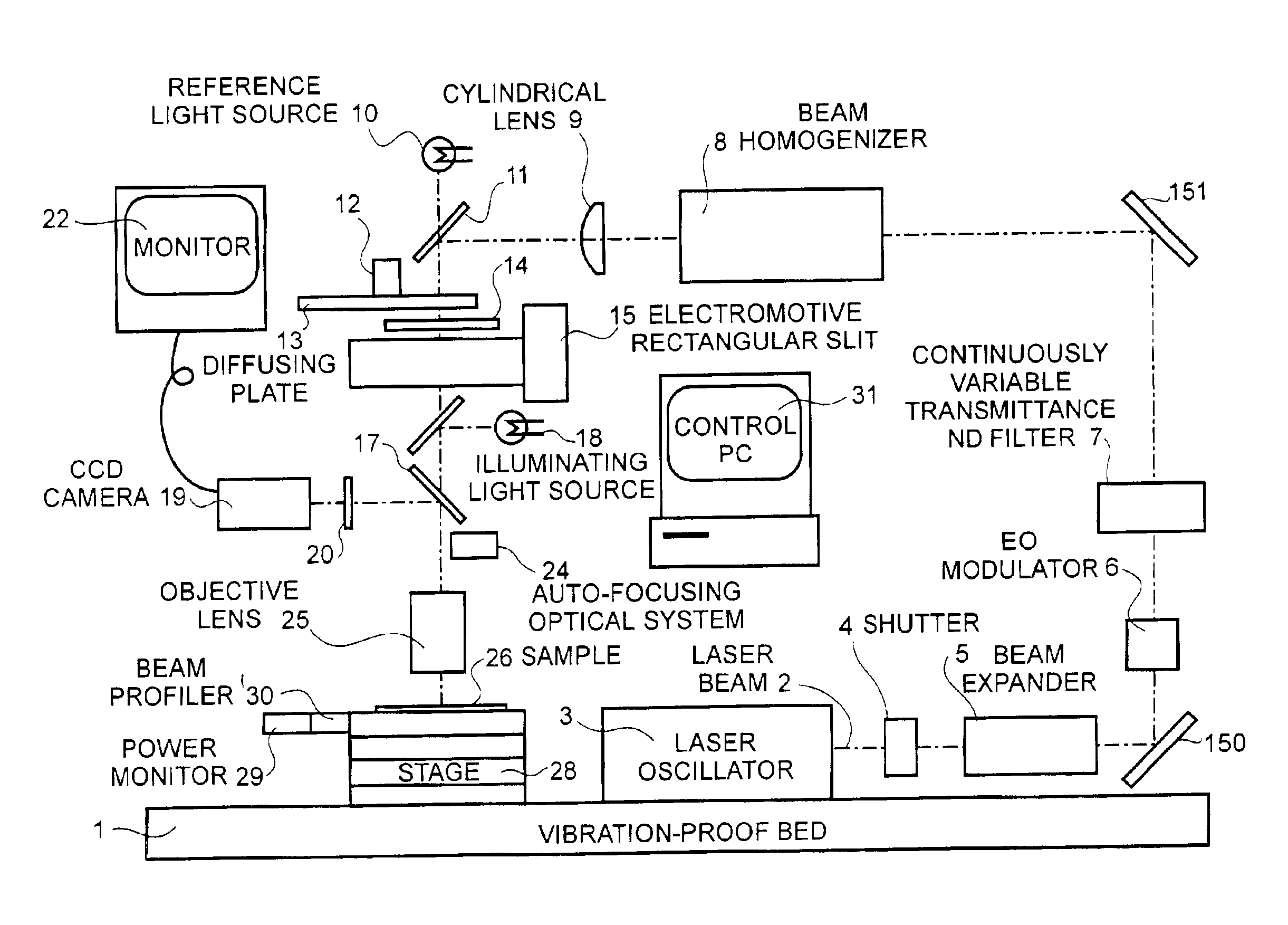

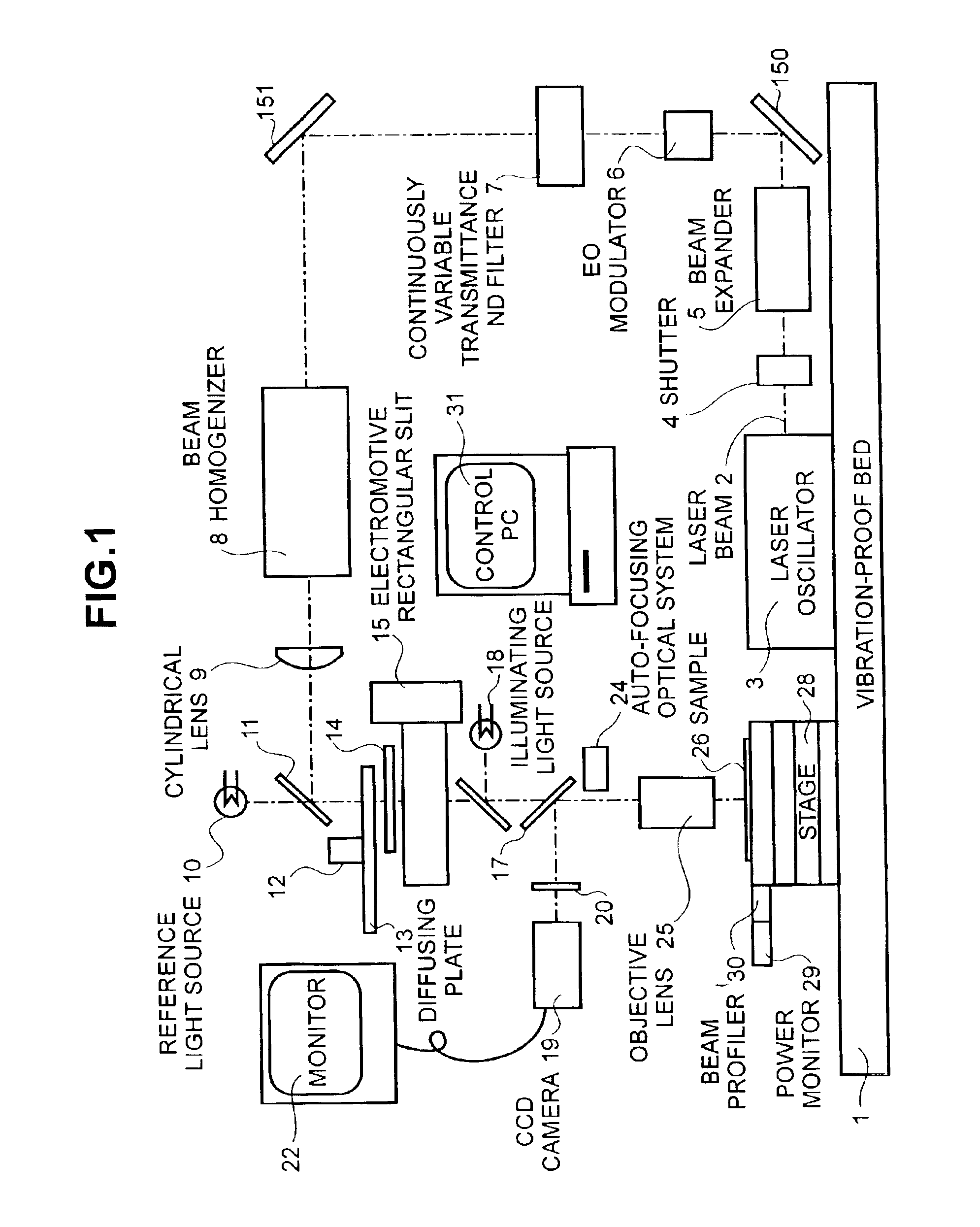

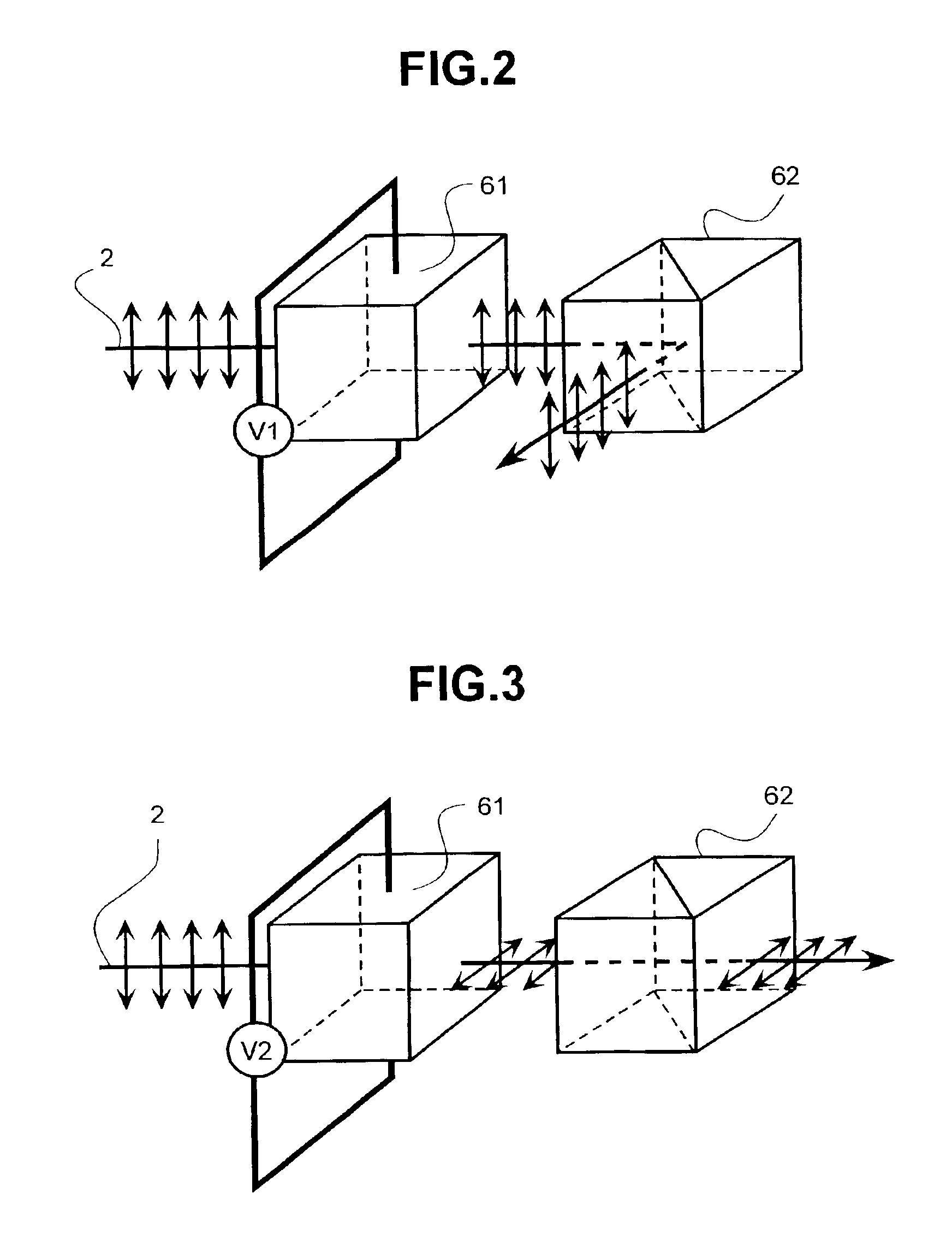

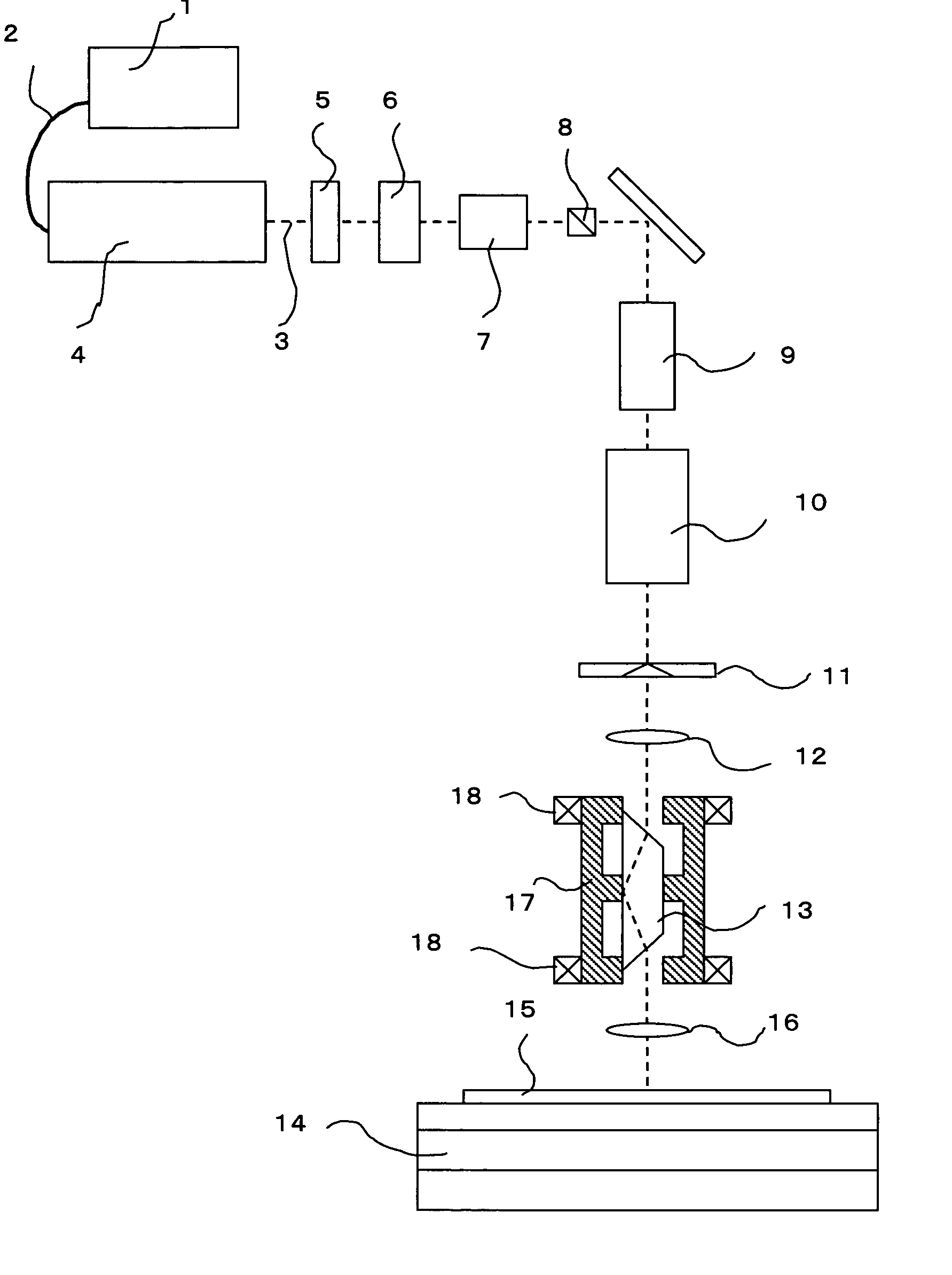

Laser annealing apparatus, TFT device and annealing method of the same

InactiveUS6943086B2Reducing and eliminating influenceTransistorSolid-state devicesEnergy variationSingle crystal

A laser beam is concentrated using an objective lens and radiated on a amorphous silicon film or polycrystalline silicon film having a grain size of one micron or less, the laser beam being processed from a continuous wave laser beam (1) to be pulsed using an EO modulator and to have arbitrary temporal energy change while pulsing ; (2) to have an arbitrary spatial energy distribution using a beam-homogenizer, filter having an arbitrary transmittance distribution, and rectangular slit; and (3) to eliminate coherency thereof using a high-speed rotating diffuser. In this manner, it is possible to realize a liquid crystal display device in which a driving circuit comprising a polycrystalline silicon film having substantially the same properties as a single crystal is incorporated in a TFT panel device.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

Laser irradiation method, laser irradiation apparatus and method for manufacturing semiconductor device

InactiveUS20070178672A1High output powerImprove mobilityPolycrystalline material growthBy zone-melting liquidsNonlinear opticsDevice material

In conducting laser annealing using a CW laser or a quasi-CW laser, productivity is not high as compared with an excimer laser and thus, it is necessary to further enhance productivity. According to the present invention, a fundamental wave is used without putting laser light into a non linear optical element, and laser annealing is conducted by irradiating a semiconductor thin film with pulsed laser light having a high repetition rate. A laser oscillator having a high output power can be used for laser annealing, since a non linear optical element is not used and thus light is not converted to a harmonic. Therefore, the width of a region having large grain crystals that is formed by scanning once can be increased, and thus the productivity can be enhanced dramatically.

Owner:SEMICON ENERGY LAB CO LTD

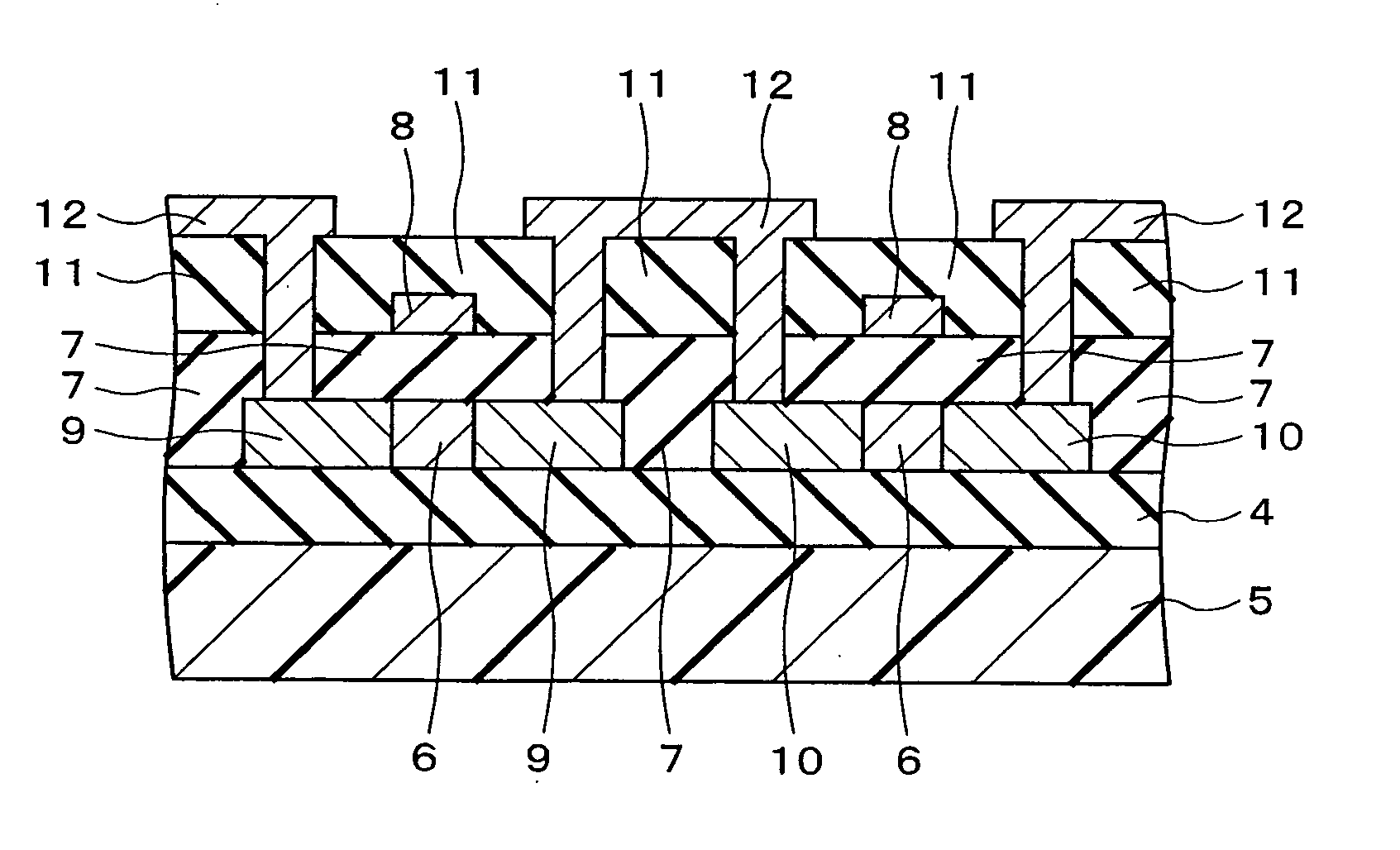

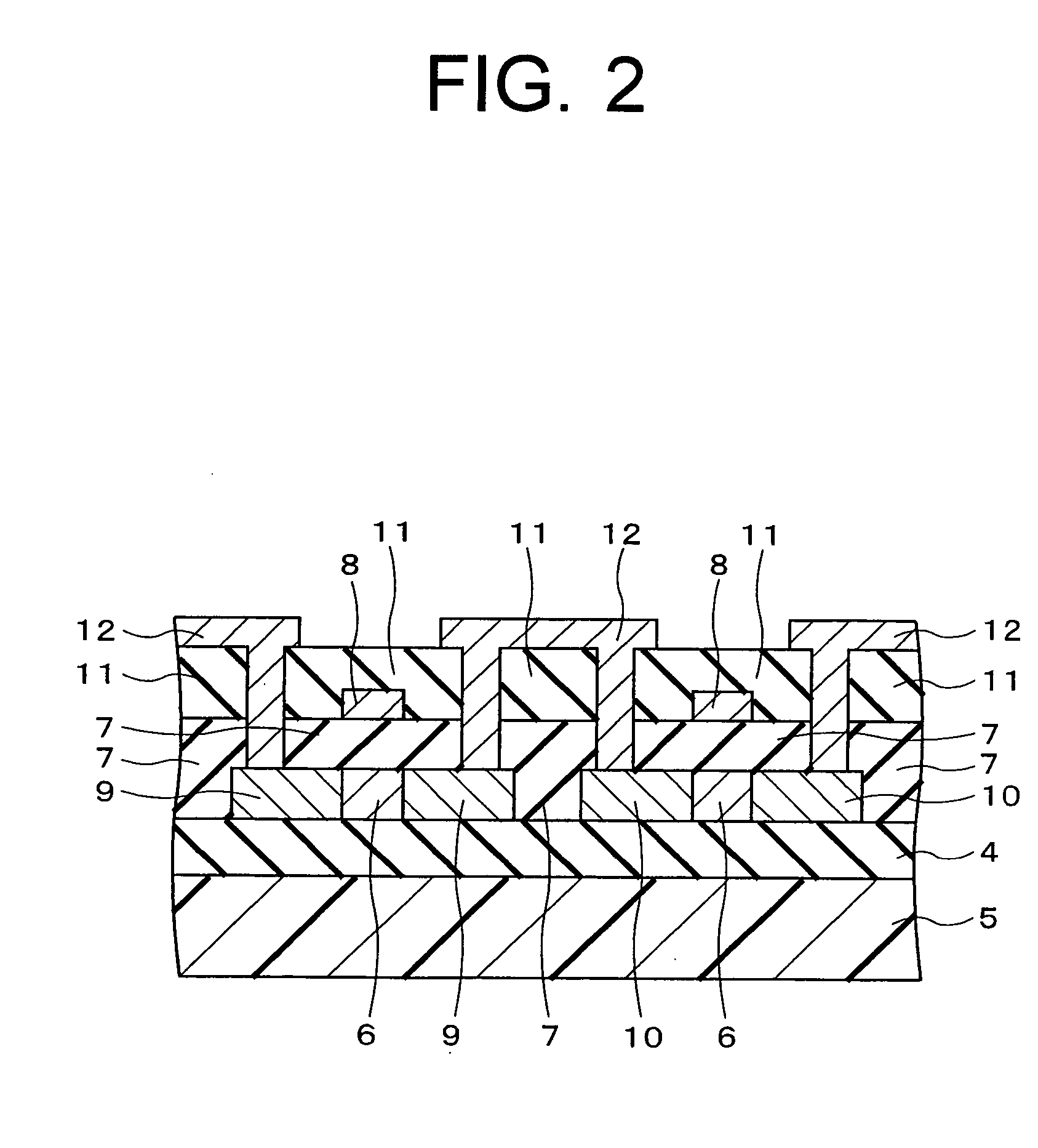

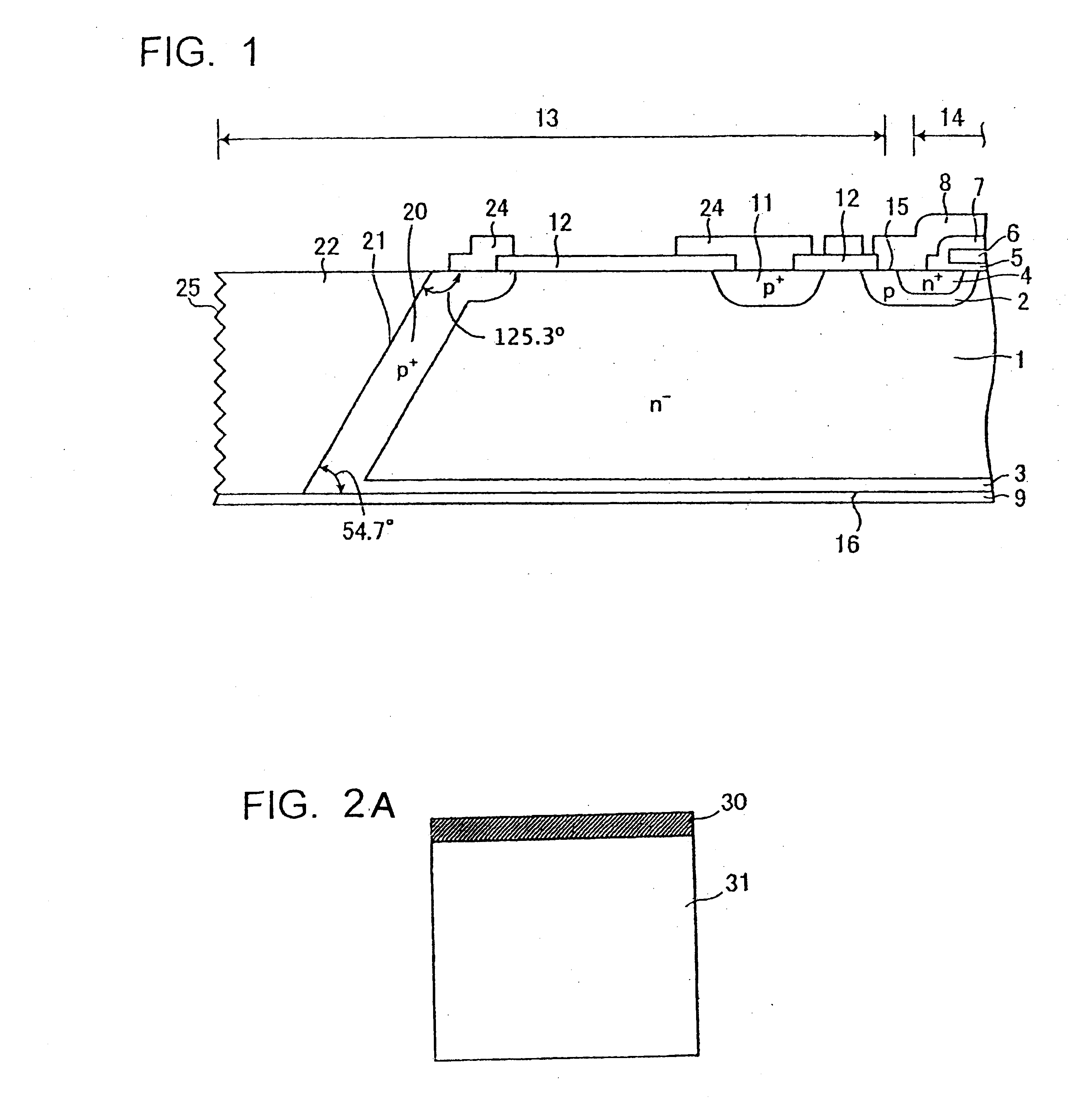

Semiconductor device and manufacturing method thereof

InactiveUS20060038206A1Improve reliabilityLow costTransistorSolid-state devicesDevice materialSemiconductor chip

A thin semiconductor wafer, on which a top surface structure and a bottom surface structure that form a semiconductor chip are formed, is affixed to a supporting substrate by a double-sided adhesive tape. Then, on the thin semiconductor wafer, a trench to become a scribing line is formed by wet anisotropic etching with a crystal face exposed so as to form a side wall of the trench. On the side wall of the trench with the crystal face thus exposed, an isolation layer for holding a reverse breakdown voltage is formed by ion implantation and low temperature annealing or laser annealing so as to be extended to the top surface side while being in contact with a p collector region as a bottom surface diffused layer. Then, laser dicing is carried out to neatly dice a collector electrode, formed on the p collector region, together with the p collector region, without presenting any excessive portions and any insufficient portions under the isolation layer. Thereafter, the double-sided adhesive tape is removed from the collector electrode to produce semiconductor chips. A highly reliable reverse-blocking semiconductor device can thus be formed at a low cost.

Owner:FUJI ELECTRIC HLDG CO LTD

Laser irradiation apparatus and method of fabricating a semiconductor device

Owner:SEMICON ENERGY LAB CO LTD

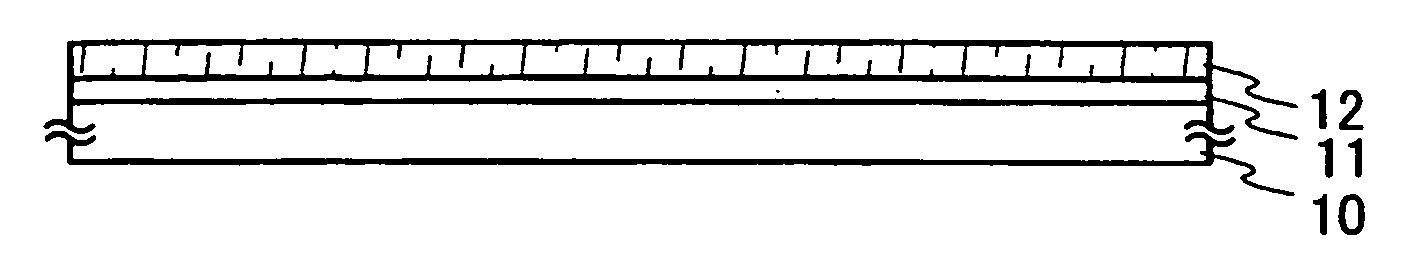

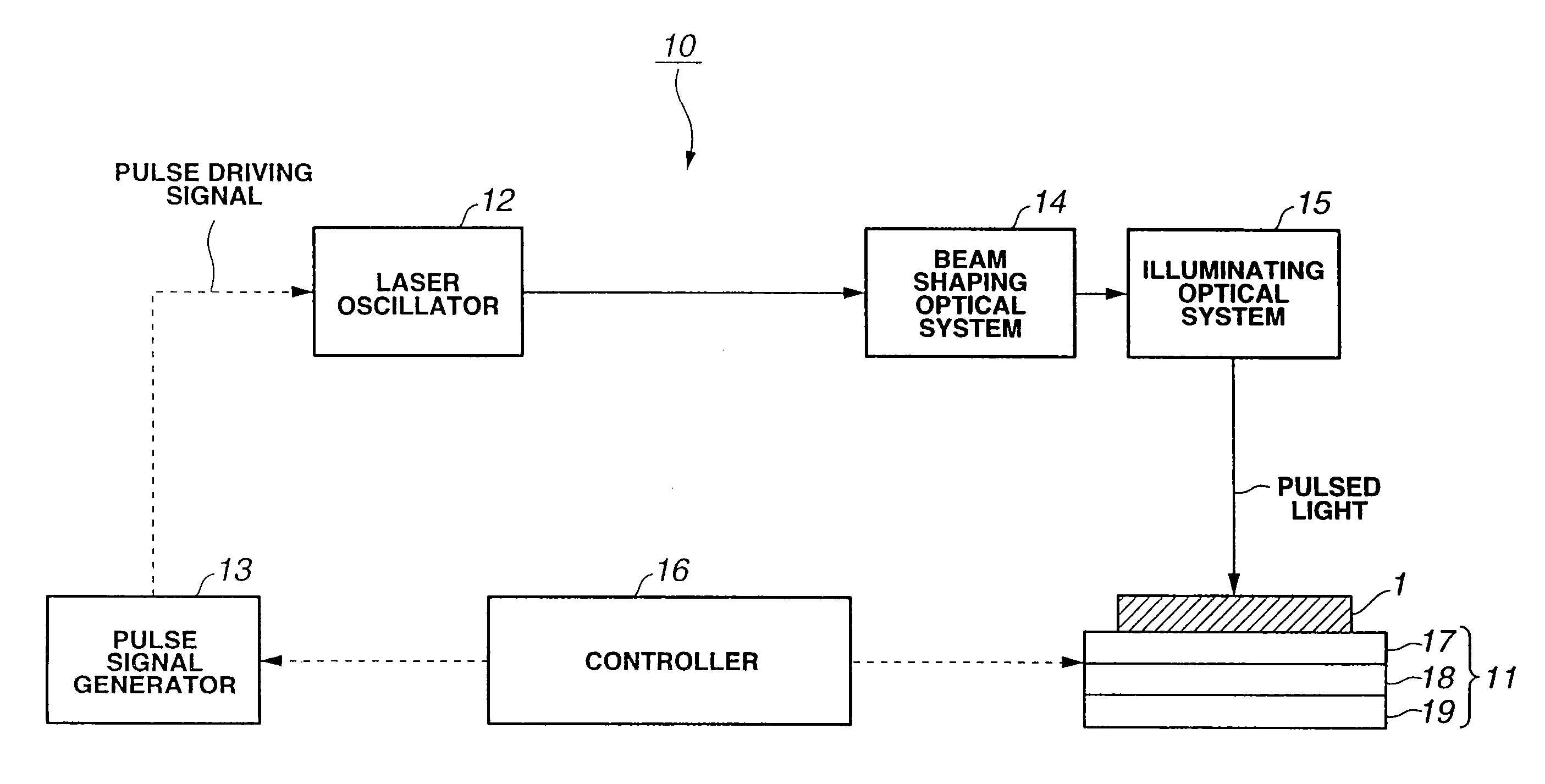

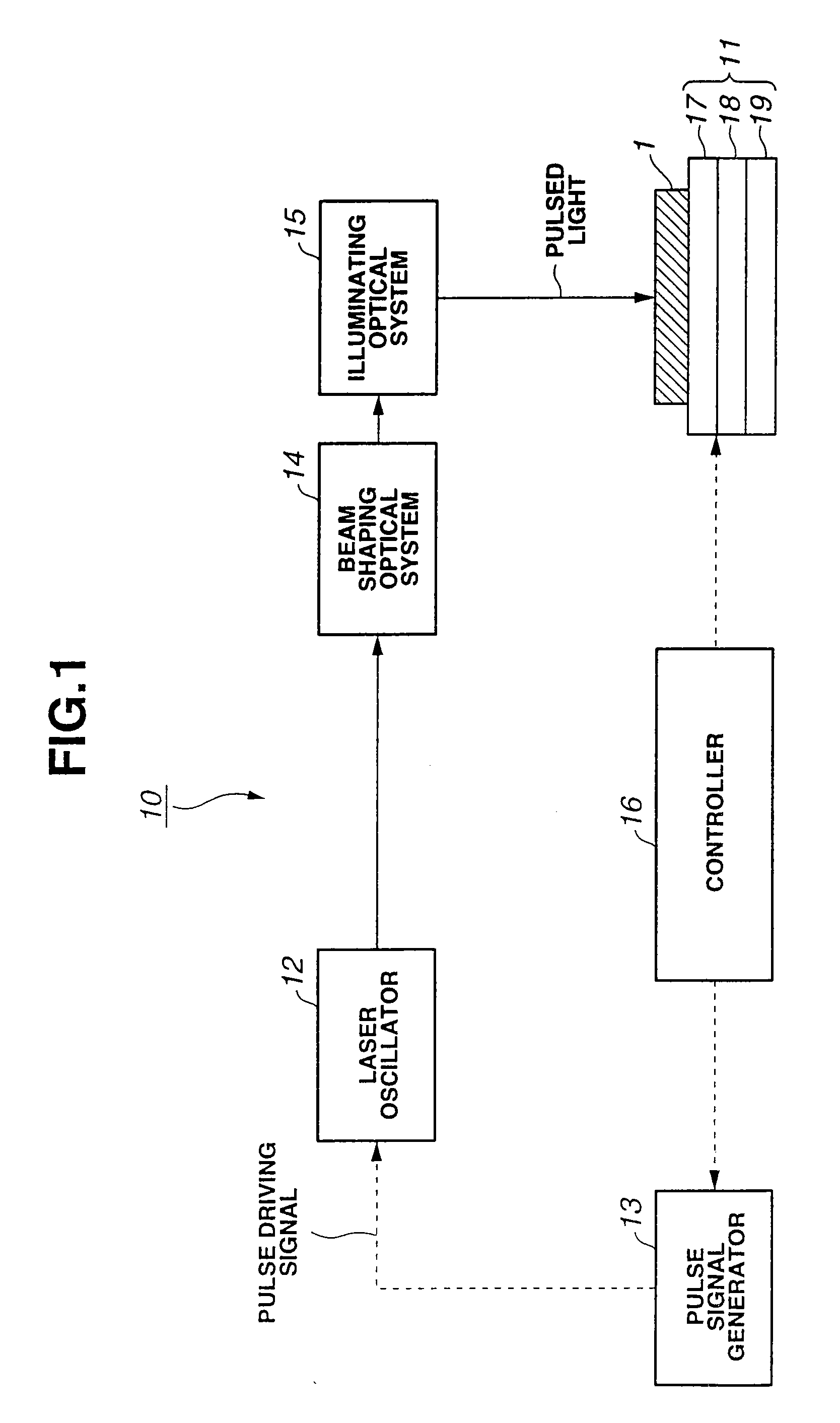

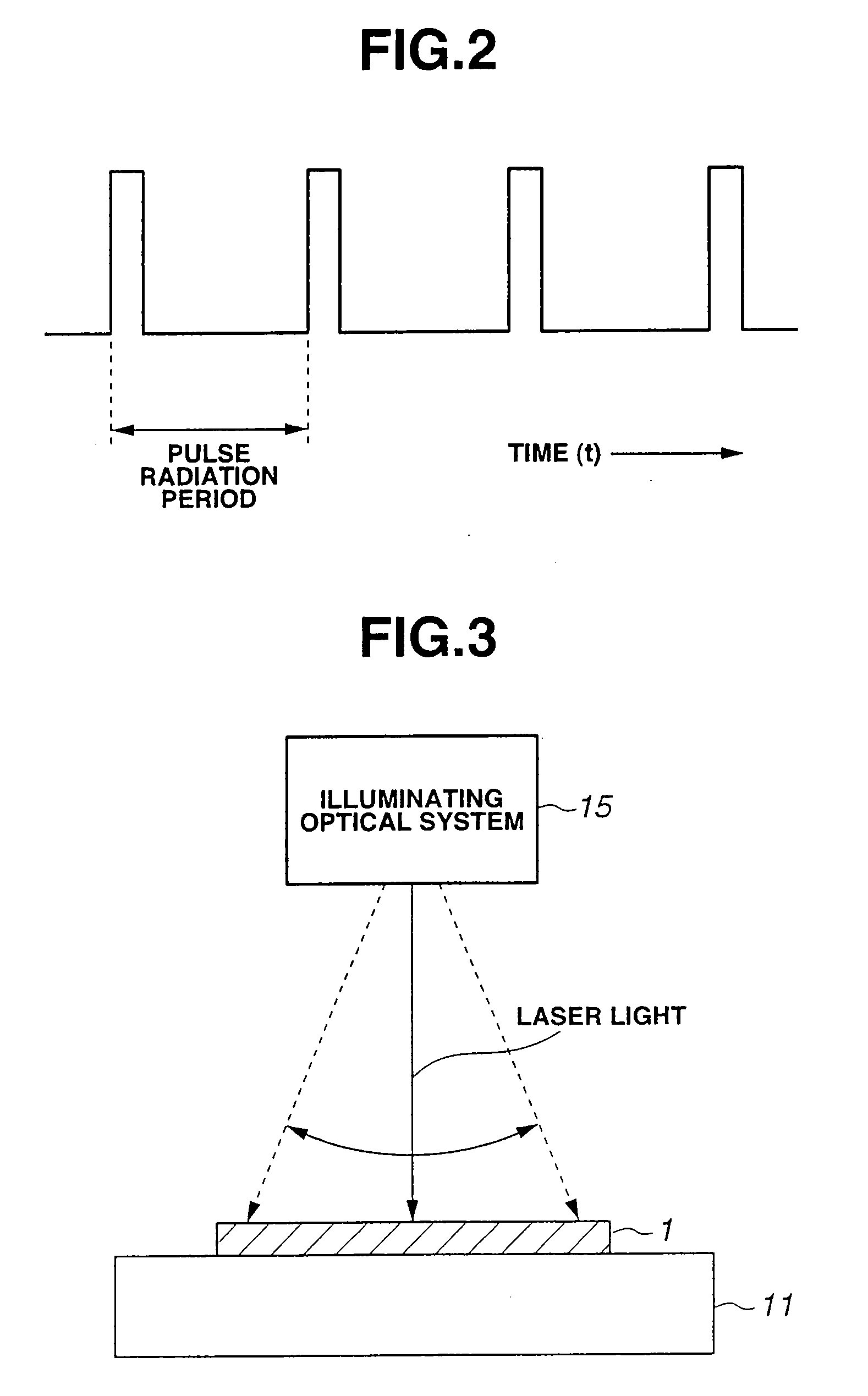

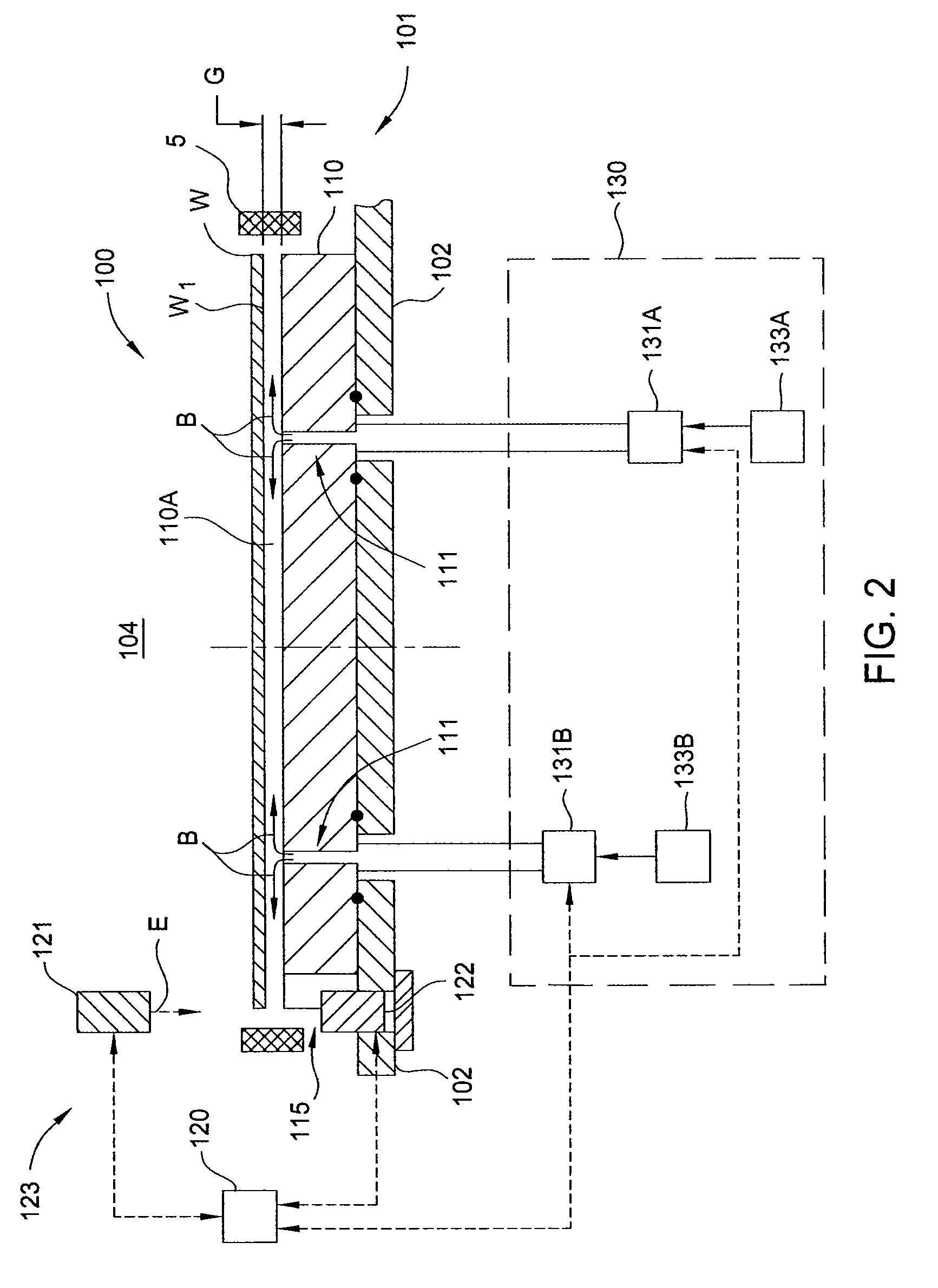

Laser annealing device and method for producing thin-film transistor

InactiveUS20070178674A1Increase in sizeTransistorSolid-state devicesReference PeriodAmorphous silicon

A laser annealing device (10) includes a laser oscillator (12), radiating a pulsed laser light beam of a preset period, and an illuminating optical system (15) for illuminating a pulsed laser light beam to an amorphous silicon film (1). The illuminating optical system (15) manages control for moving a laser spot so that a plural number of light pulses will be illuminated on the same location on the amorphous silicon film (1). The laser oscillator (12) radiates a laser light beam of a pulse generation period shorter than the reference period. The reference period is a time interval as from the radiation timing of illumination of a pulsed laser light beam on the surface of the film (1) until the timing of reversion of the substrate temperature raised due to the illumination of the laser light beam to the original substrate temperature.

Owner:SONY CORP

Apparatus and method for supporting, positioning and rotating a substrate in a processing chamber

InactiveUS8057602B2Semiconductor/solid-state device manufacturingPackaging by pressurising/gasifyingEngineeringChemical vapor deposition

Embodiments of the invention contemplate a method, apparatus and system that are used to support, position, and rotate a substrate during processing. Embodiments of the invention may also include a method of controlling the transfer of heat between a substrate and substrate support positioned in a processing chamber. The apparatus and methods described herein remove the need for complex, costly and often unreliable components that would be required to accurately position and rotate a substrate during one or more processing steps, such as an rapid thermal processing (RTP) process, a chemical vapor deposition (CVD) process, a physical vapor deposition (PVD) process, atomic layer deposition (ALD) process, dry etching process, wet clean, and / or laser annealing process.

Owner:APPLIED MATERIALS INC

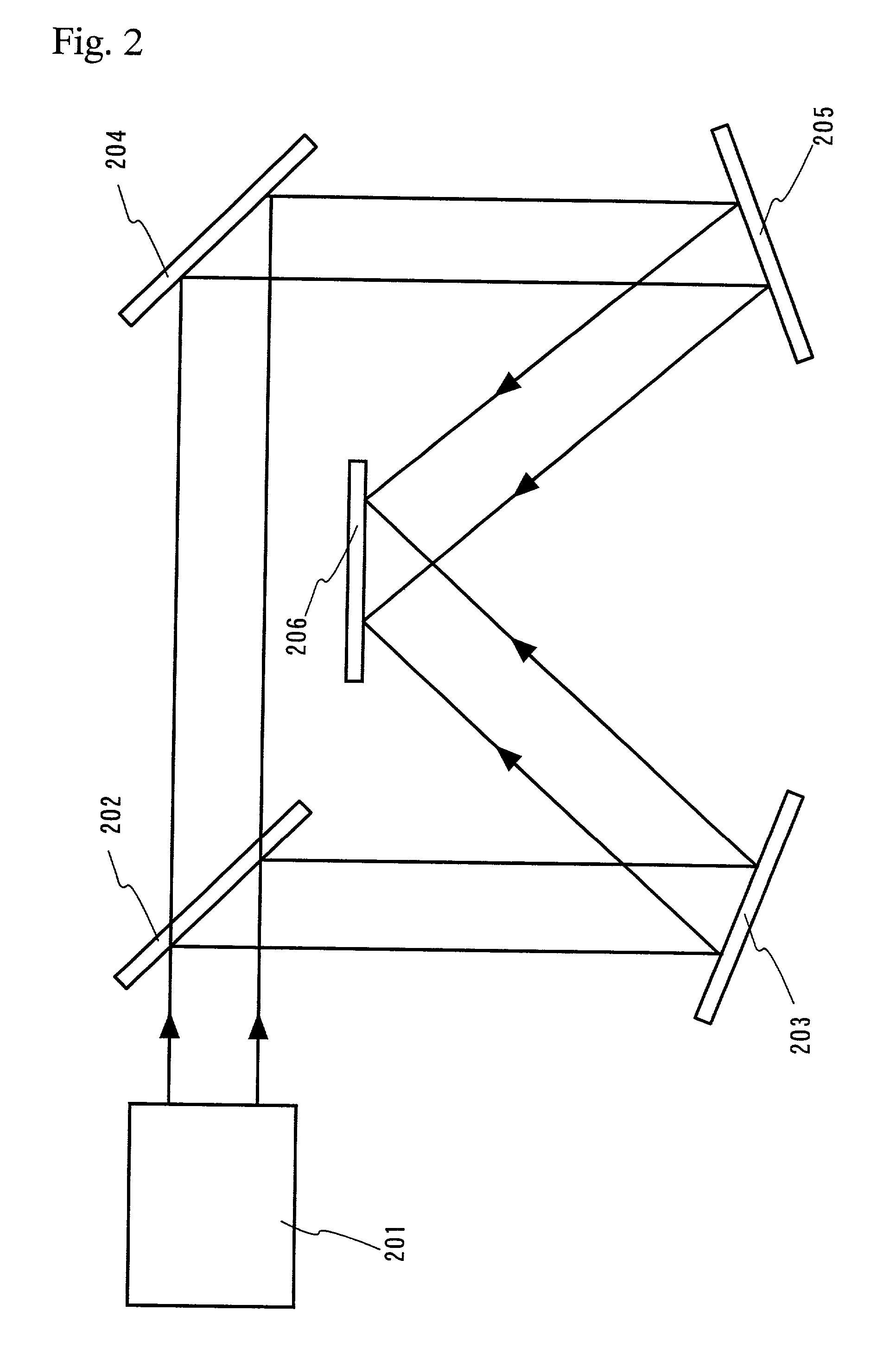

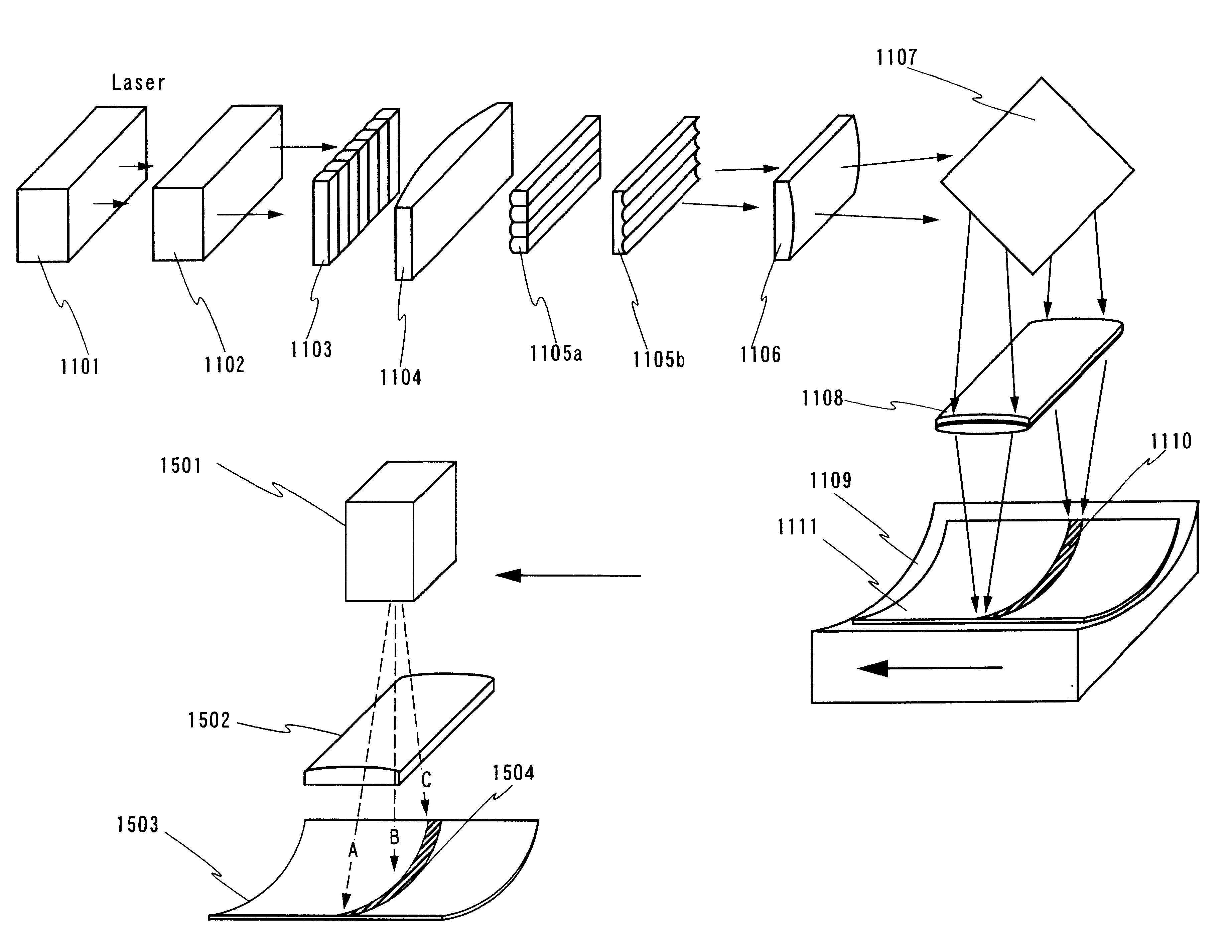

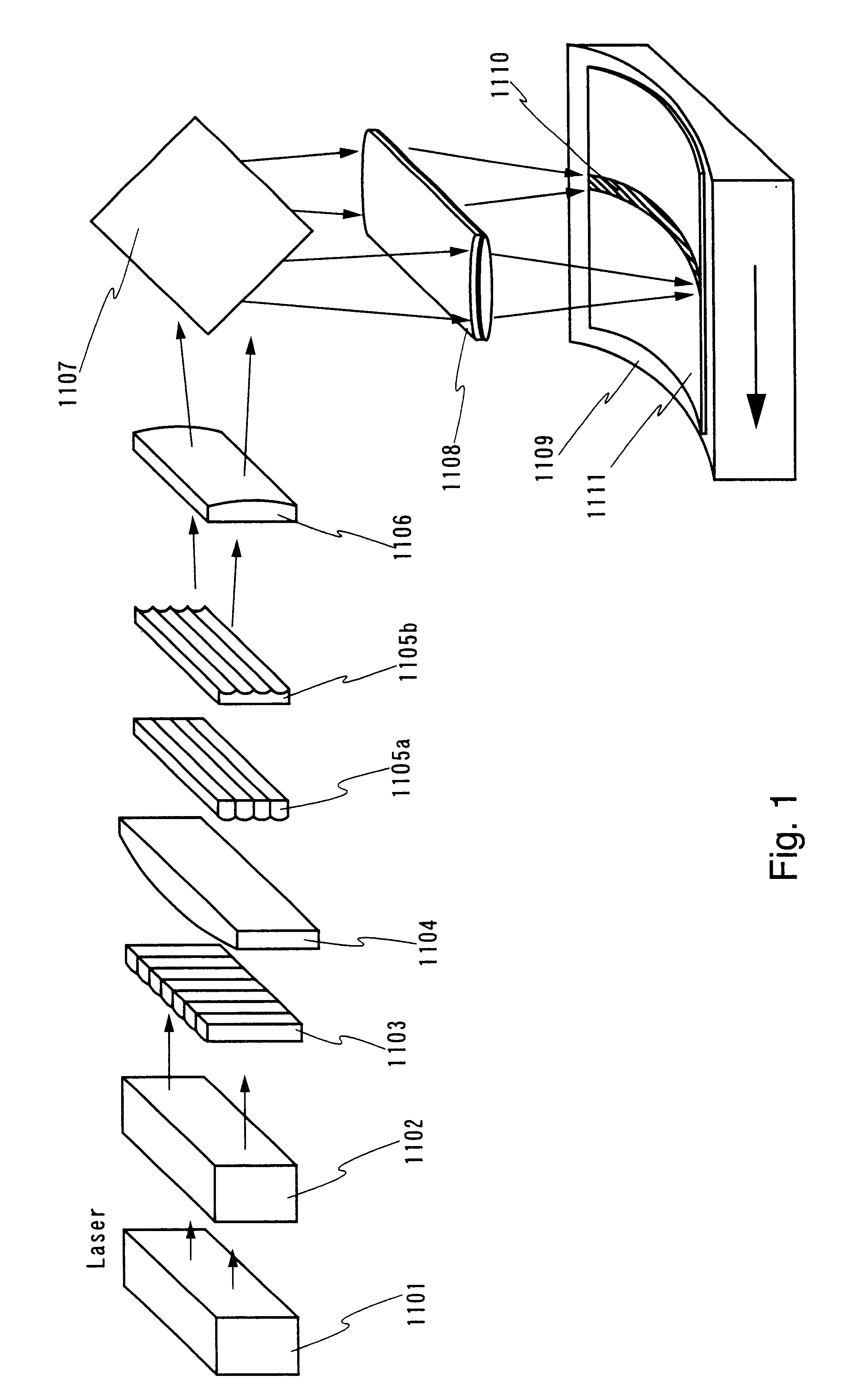

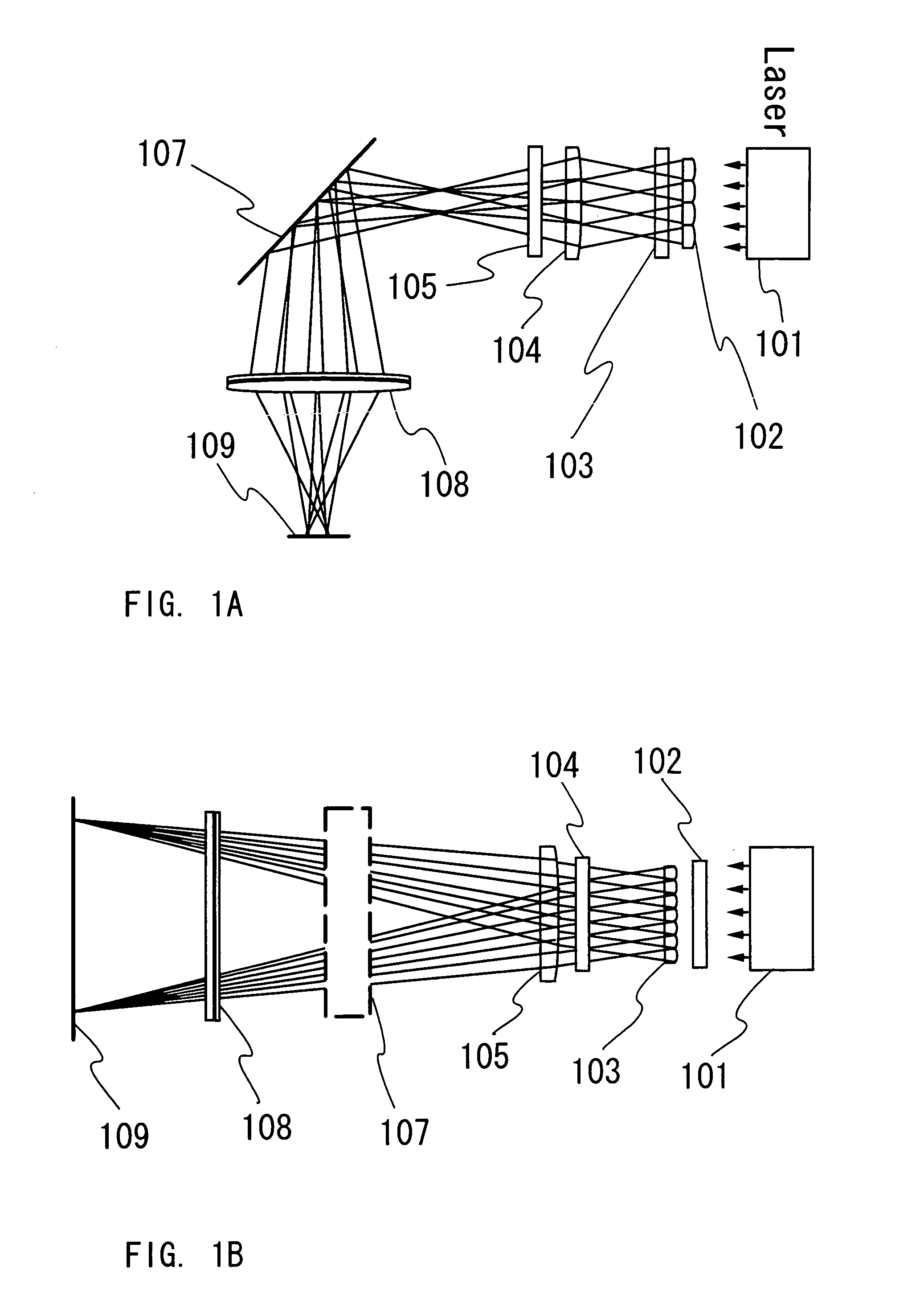

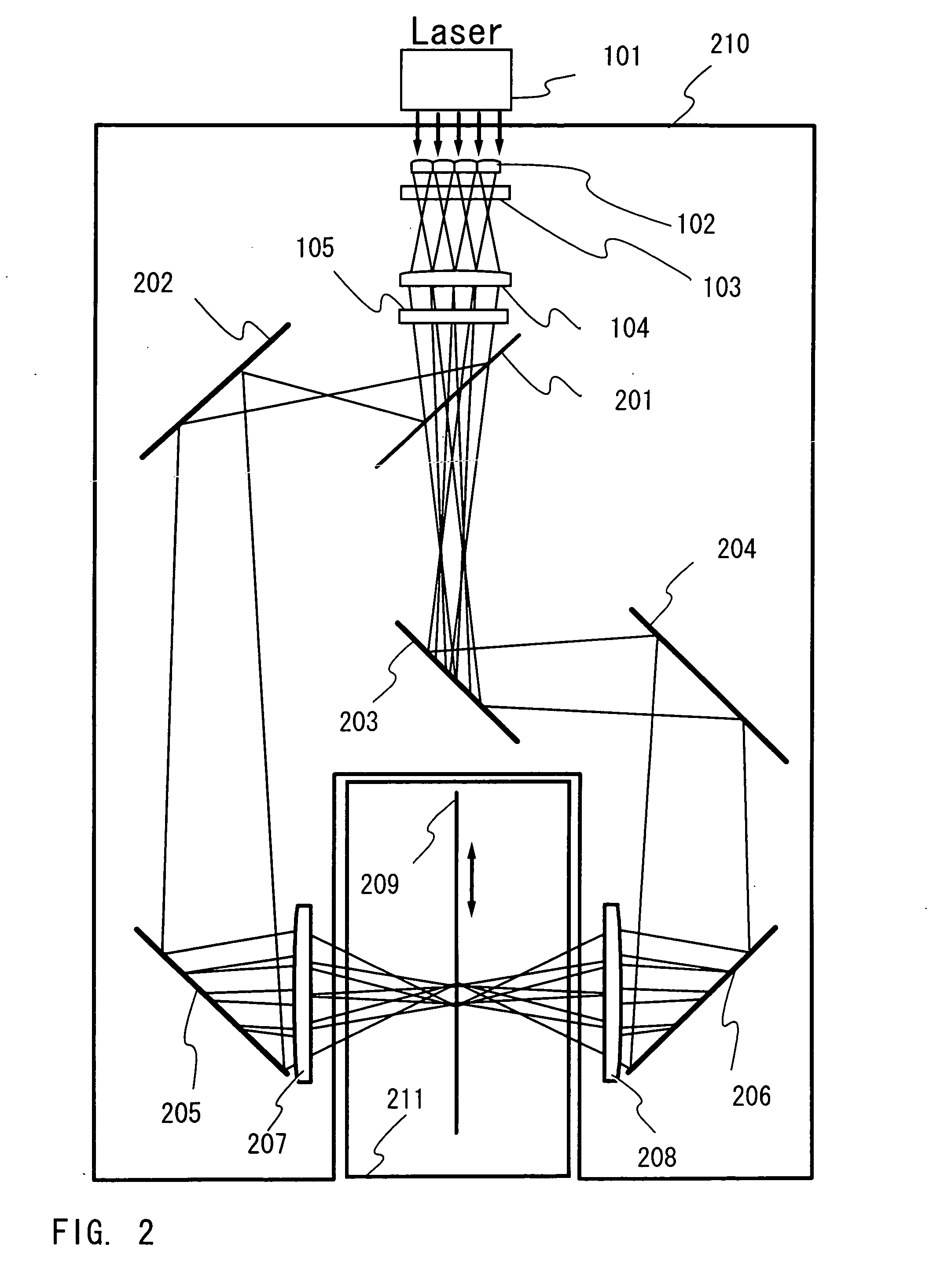

Laser irradiation stage, laser irradiation optical system, laser irradiation apparatus, laser irradiation method, and method of manufacturing a semiconductor device

InactiveUS6707614B2Shorten the lengthSmall footprintTransistorSemiconductor laser arrangementsLight beamOptical pathlength

As the output of laser oscillators become higher, it becomes necessary to develop a longer linear shape beam for a process of laser annealing of a semiconductor film. However, if the length of the linear shape beam is from 300 to 1000 mm, or greater, then the optical path length of an optical system for forming the linear shape beam becomes very long, thereby increasing its footprint size. The present invention shortens the optical path length. In order to make the optical path length of the optical system as short as possible, and to increase only the length of the linear shape beam, curvature may be given to the semiconductor film in the longitudinal direction of the linear shape beam. For example, if the size of the linear shape beam is taken as 1 mx0.4 mm, then it is necessary for the optical path length of the optical system to be on the order of 10 m. If, however, the semiconductor film is given curvature with a radius of curvature of 40,000 mm, then the optical path length of the optical system can be halved to approximately 5 m, and a linear shape beam having an extremely uniform energy distribution can be obtained.

Owner:SEMICON ENERGY LAB CO LTD

Formation of shallow junctions by diffusion from a dielectric doped by cluster or molecular ion beams

ActiveUS20090047768A1TransistorSemiconductor/solid-state device manufacturingDopantGas cluster ion beam

A process for forming diffused region less than 20 nanometers deep with an average doping dose above 1014 cm−2 in an IC substrate, particularly LDD region in an MOS transistor, is disclosed. Dopants are implanted into a source dielectric layer using gas cluster ion beam (GCIB) implantation, molecular ion implantation or atomic ion implantation resulting in negligible damage in the IC substrate. A spike anneal or a laser anneal diffuses the implanted dopants into the IC substrate. The inventive process may also be applied to forming source and drain (S / D) regions. One source dielectric layer may be used for forming both NLDD and PLDD regions.

Owner:TEXAS INSTR INC

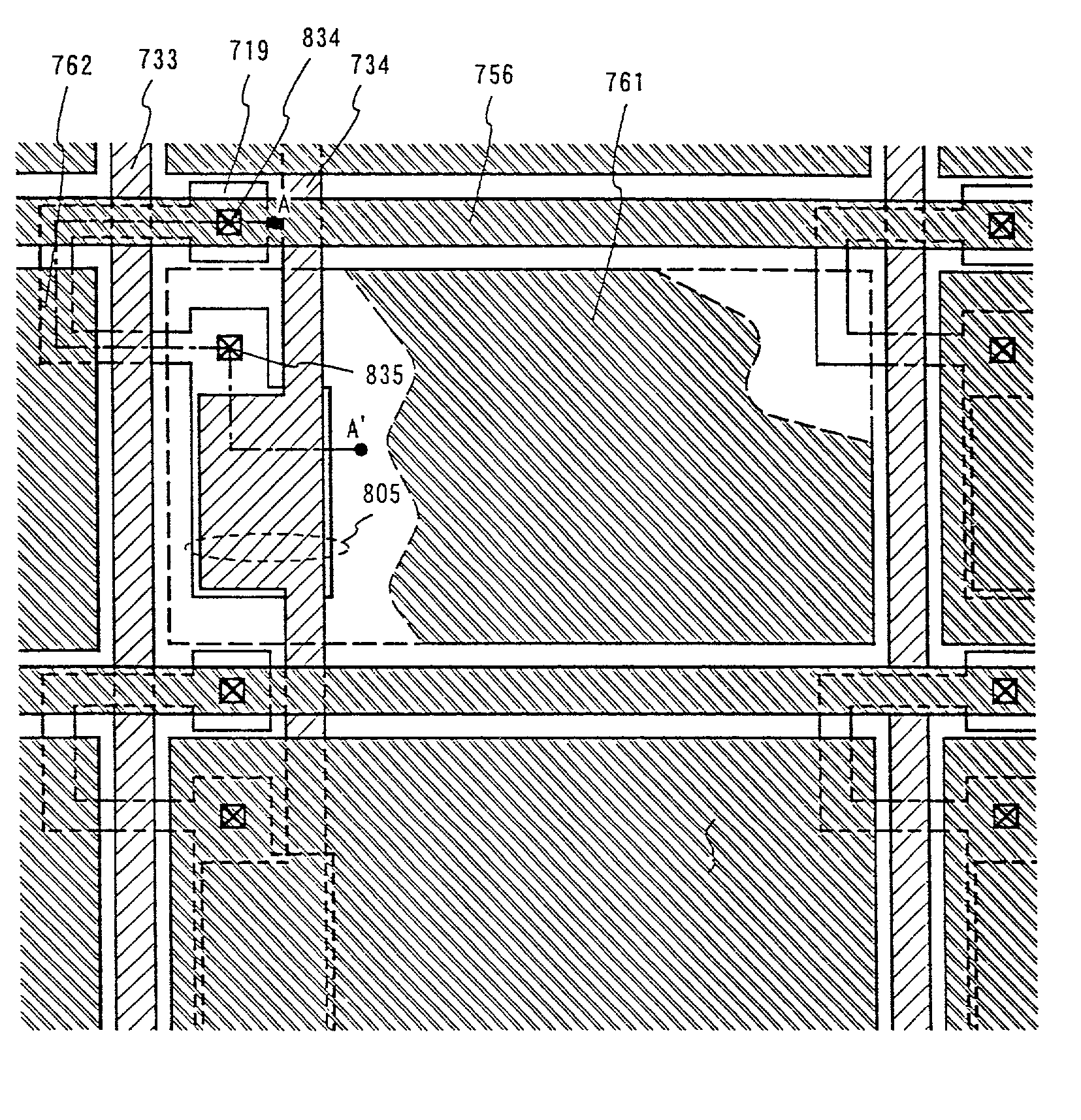

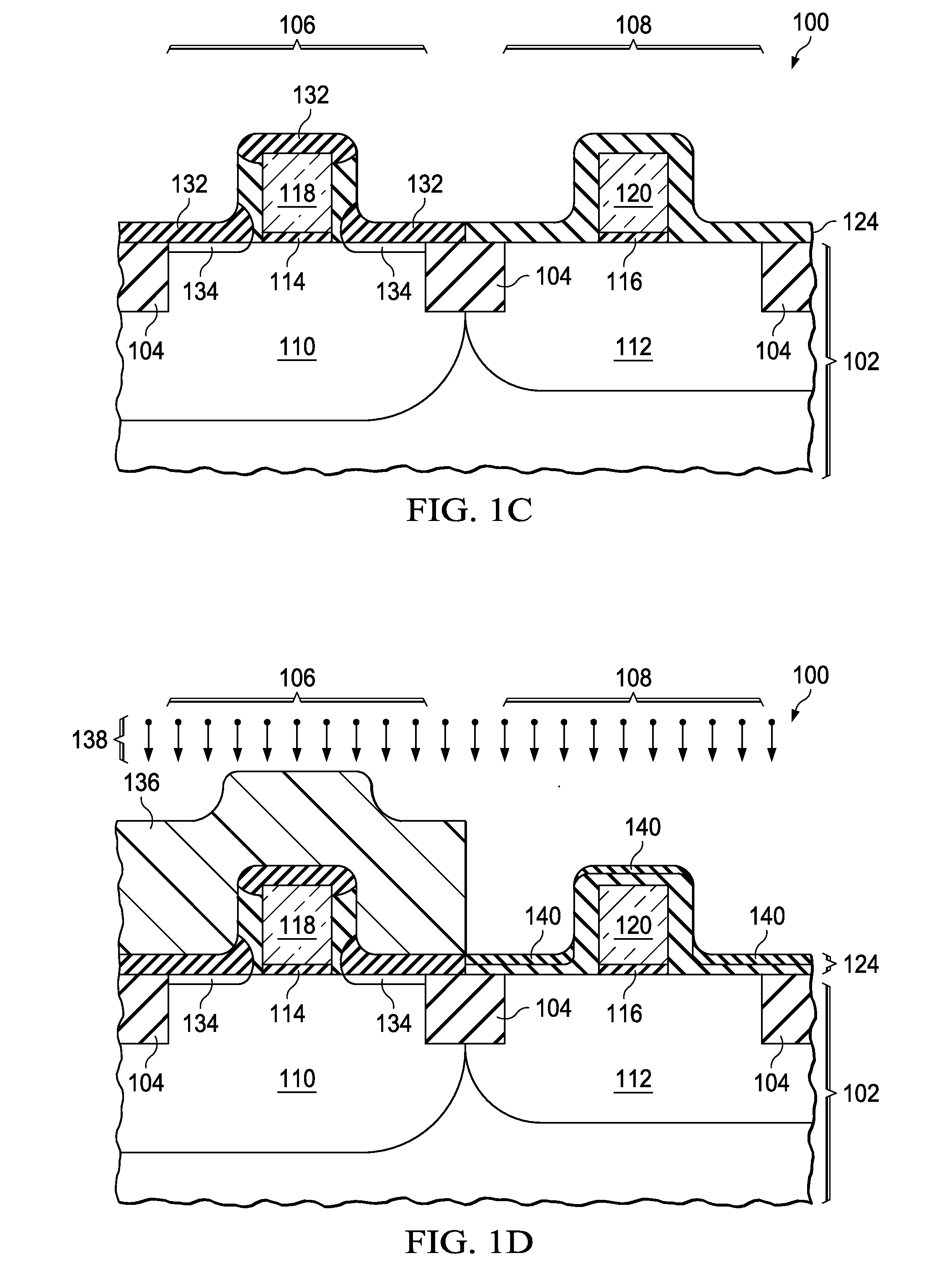

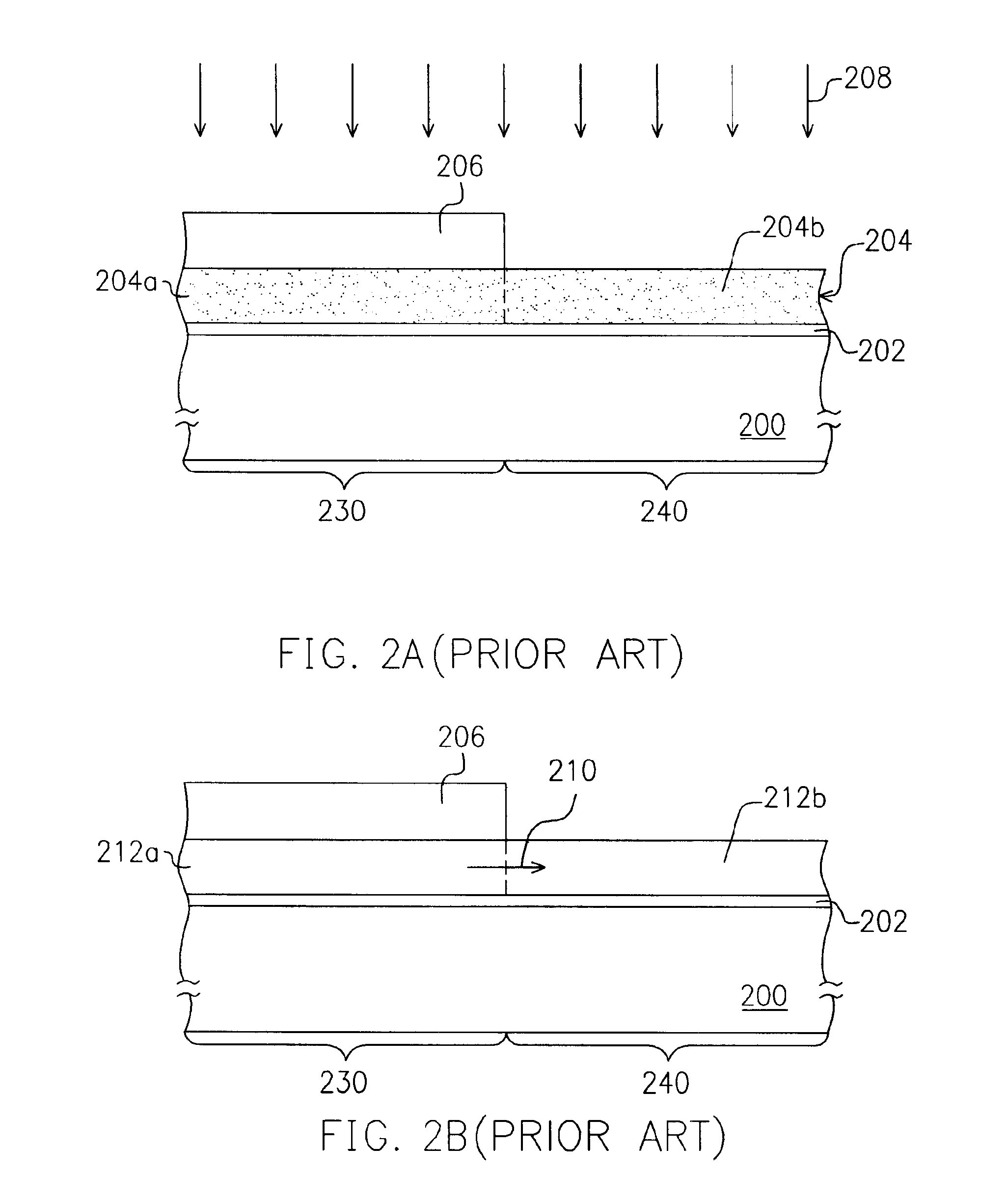

Laser annealing mask and method for smoothing an annealed surface

ActiveUS7192479B2Improve TFT performanceImprovement in TFT reliabilityFrom gel stateFrom solid stateLaser annealingEnergy density

A mask with sub-resolution aperture features and a method for smoothing an annealed surface using a sub-resolution mask pattern are provided. The method comprises: supplying a laser beam having a first wavelength; supplying a mask with a first mask section having apertures with a first dimension and a second mask section with apertures having a second dimension, less than the first dimension; applying a laser beam having a first energy density to a substrate region; melting a substrate region in response to the first energy density; crystallizing the substrate region; applying a diffracted laser beam to the substrate region; and, in response to the diffracted laser beam, smoothing the substrate region surface. In some aspects of the method, applying a diffracted laser beam to the substrate area includes applying a diffracted laser beam having a second energy density, less than the first energy density, to the substrate region. The second energy density is in the range of 40% to 70% of the first energy density, and preferably in the range of 50% to 60% of the first energy density.

Owner:SHARP KK

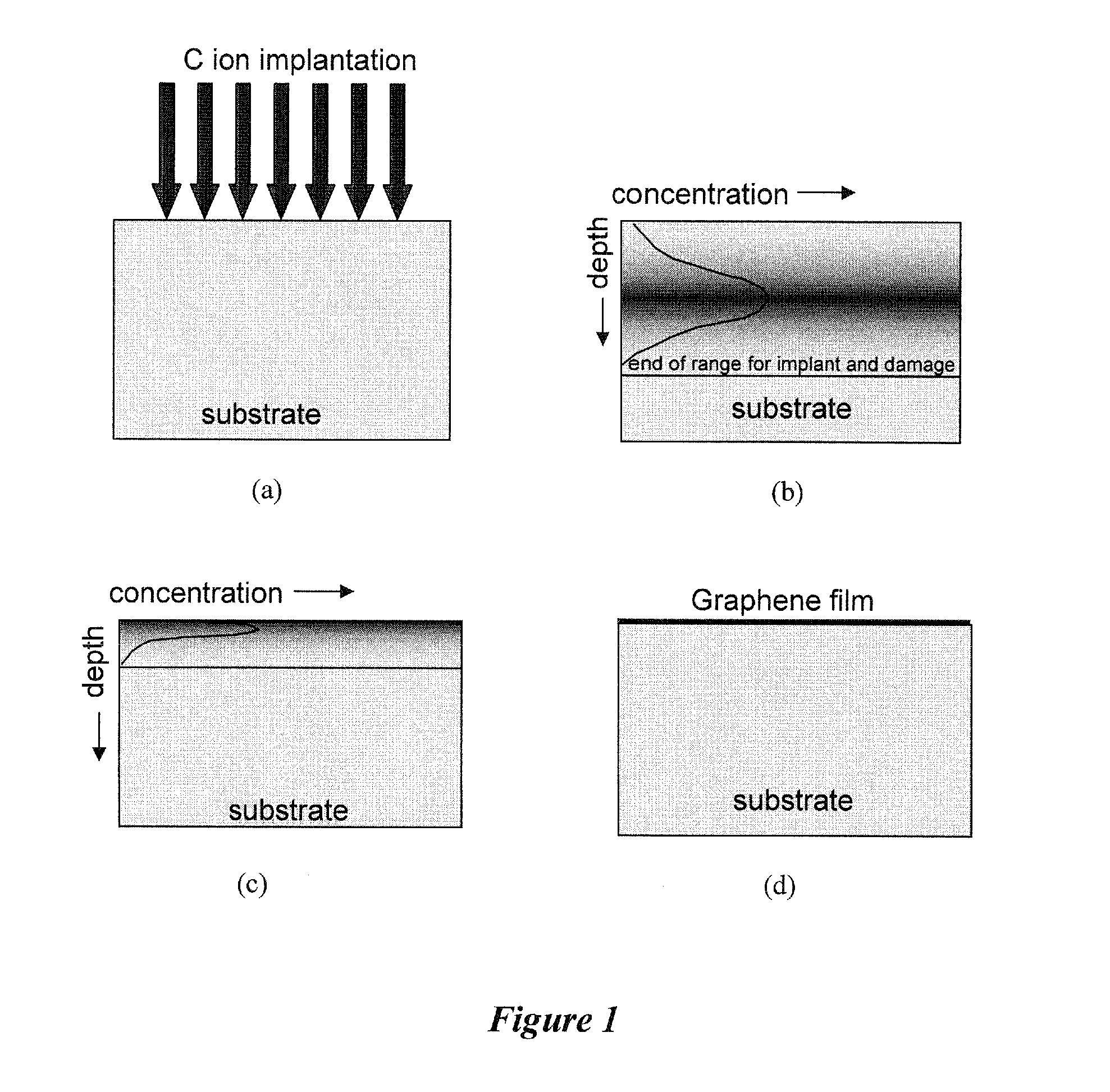

Graphene processing for device and sensor applications

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Semiconductor on insulator structure made using radiation annealing

InactiveUS7579654B2Healing damageReduce roughnessElectric discharge tubesSolid-state devicesIon implantationSemiconductor

Owner:CORNING INC

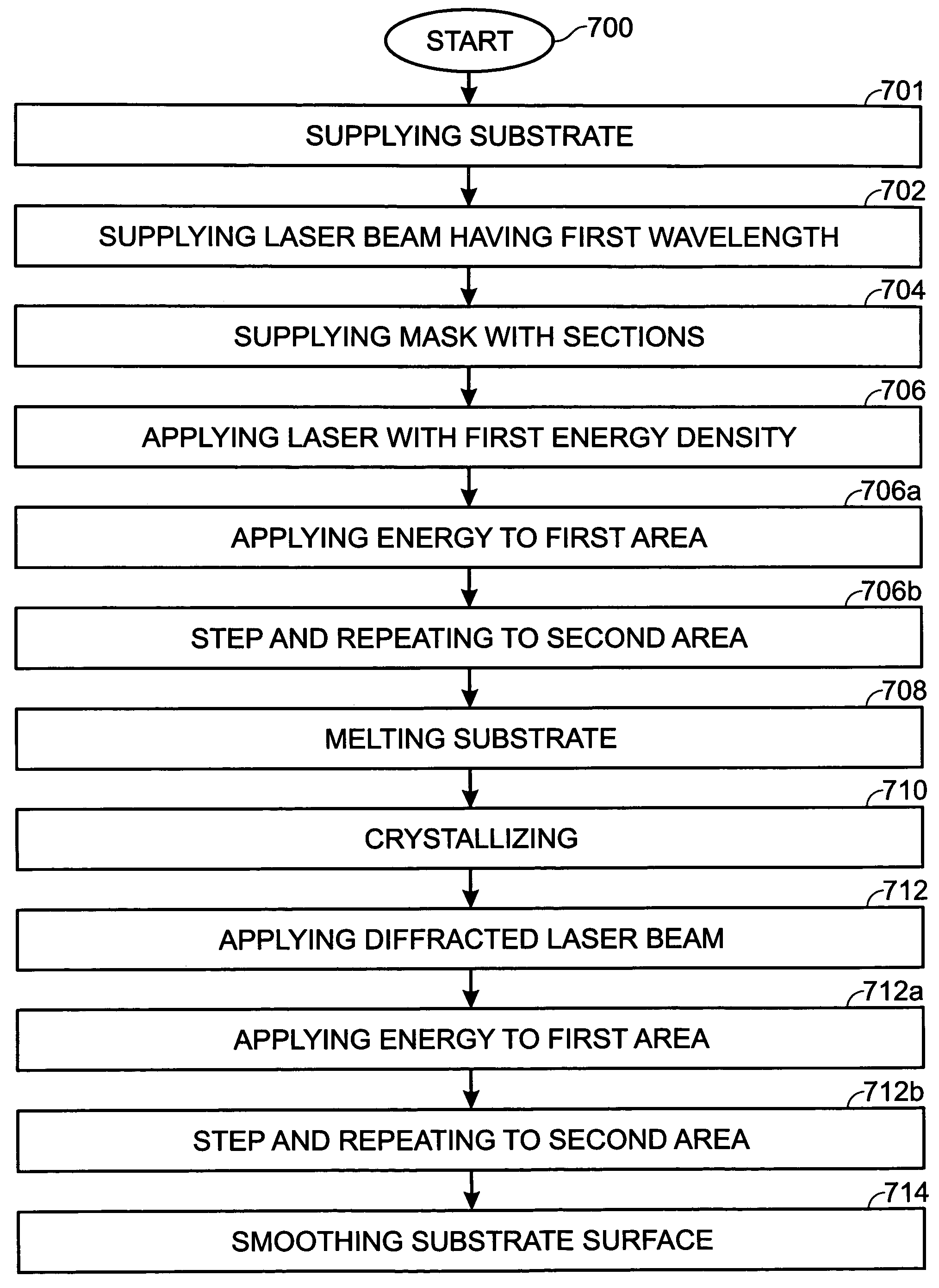

Method of fabricating polysilicon film

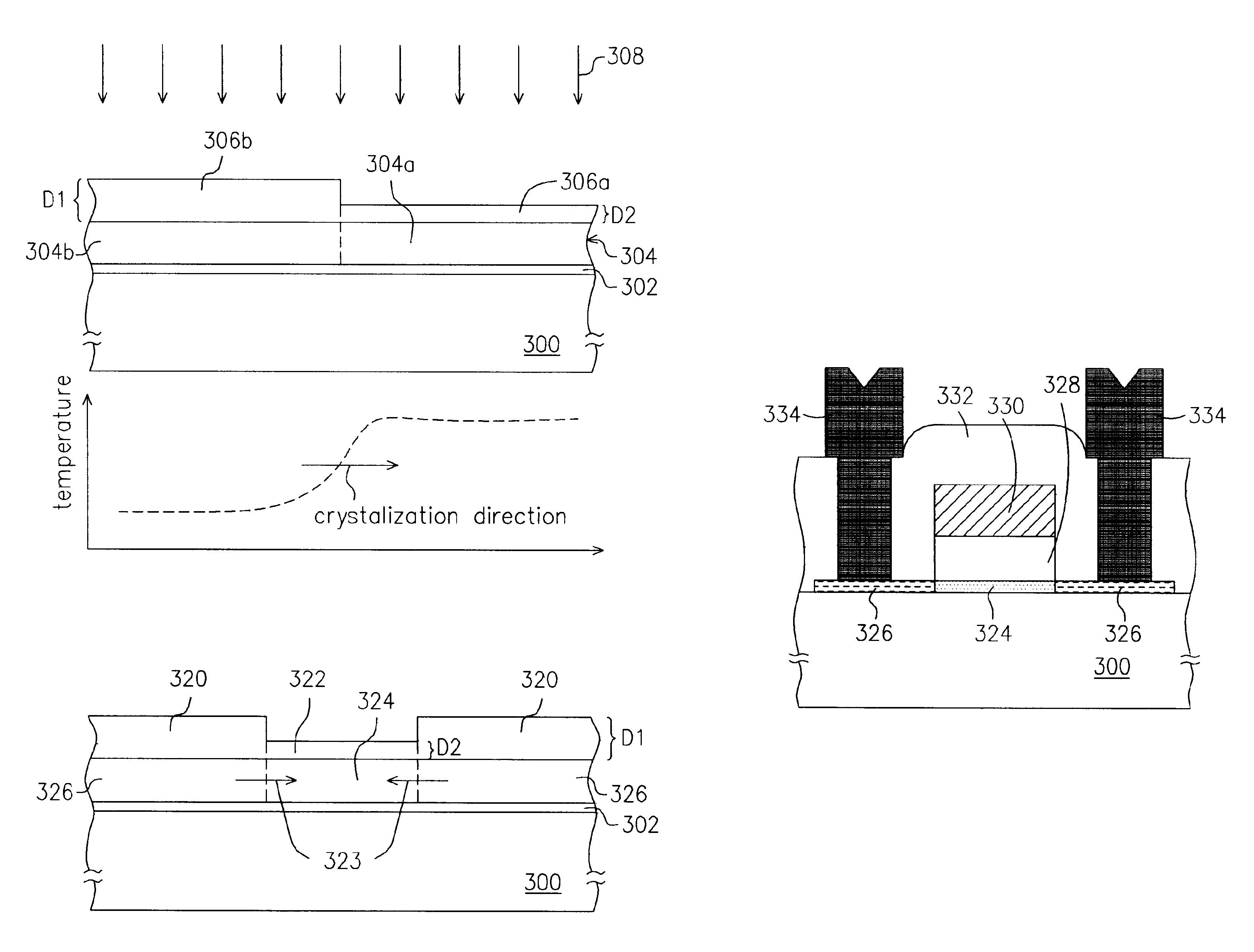

InactiveUS6916690B2Increasing lateral temperature gradientInduce lateral crystallizationTransistorSolid-state devicesAmorphous siliconLaser annealing

A method of fabricating polysilicon film is described. An amorphous silicon layer is formed on the substrate, an optical layer is formed on the amorphous silicon layer, wherein the optical has a first region having a first thickness and a second region having a second thickness, and the reflectivity of the first region for an excimer laser is higher than that of the second region. A laser annealing process is then preformed to transform the amorphous silicon layer into a polysilicon film.

Owner:AU OPTRONICS CORP

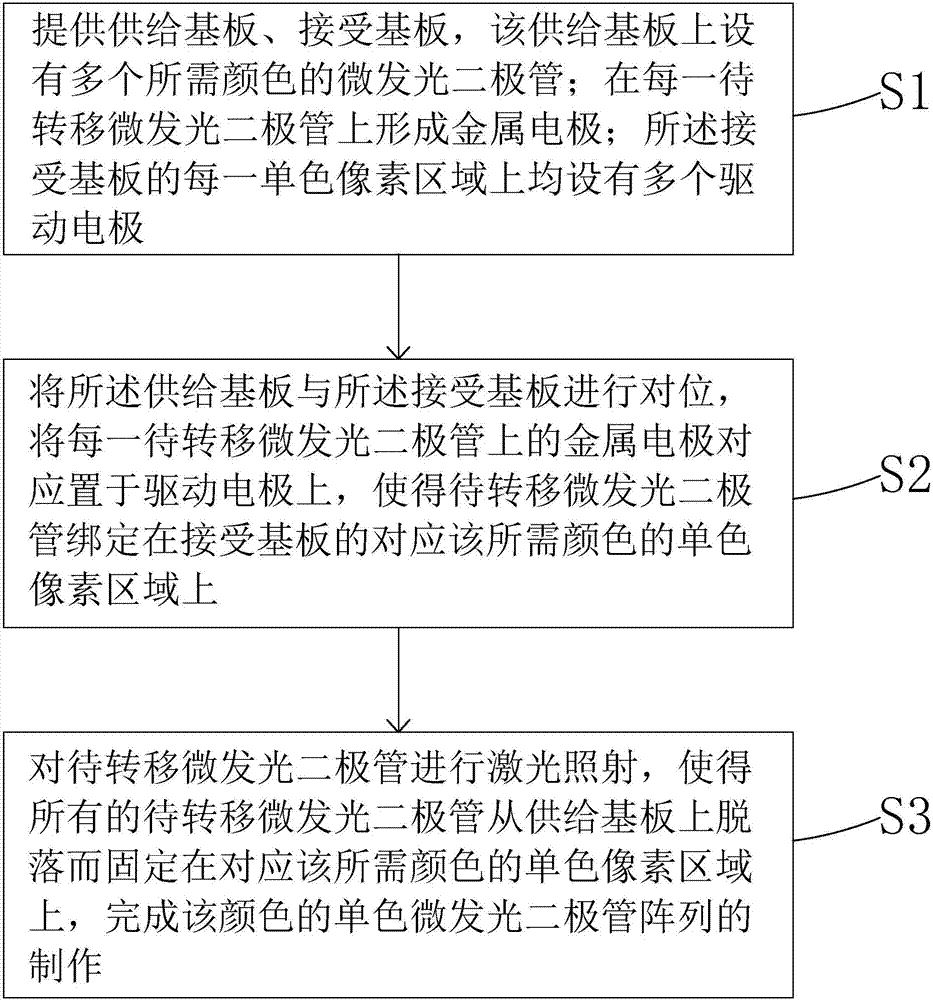

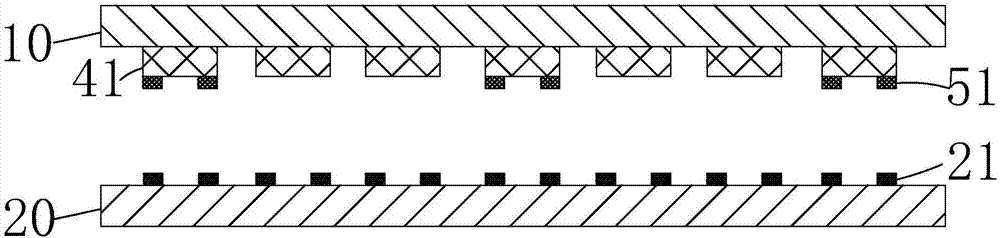

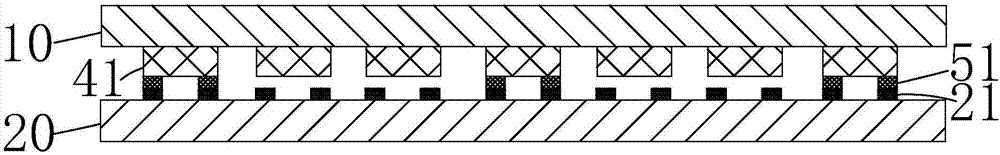

Manufacturing method for color micro-light-emitting diode array substrate

InactiveCN107017319ASimple manufacturing methodSolid-state devicesSemiconductor devicesMetal electrodesIrradiation

The invention provides a manufacturing method for a color micro-light-emitting diode array substrate, and the method comprises the steps: manufacturing a plurality of color micro-light-emitting diode arrays which are respectively formed by a plurality of single-color micro-light-emitting diode arrays with different colors on a receiving substrate, wherein the manufacturing of the single-color micro-light-emitting diode array with one color is combined with the binding technology and the laser falling-off technology; selectively forming a metal electrode on the micro-light-emitting diode in a specific region on a feeding substrate, selectively binding the micro-light-emitting diode in the specific region on the receiving substrate, and selectively carrying out laser irradiation of the micro-light-emitting diode in the specific region, thereby enabling the micro-light-emitting diode in the specific region to be separated from the feeding substrate through binding and laser annealing; forming the single-color micro-light-emitting diode arrays on the receiving substrate, thereby achieving the manufacturing of the single-color micro-light-emitting diode arrays with different colors on the receiving substrate. Moreover, the manufacturing method is simple and easy.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

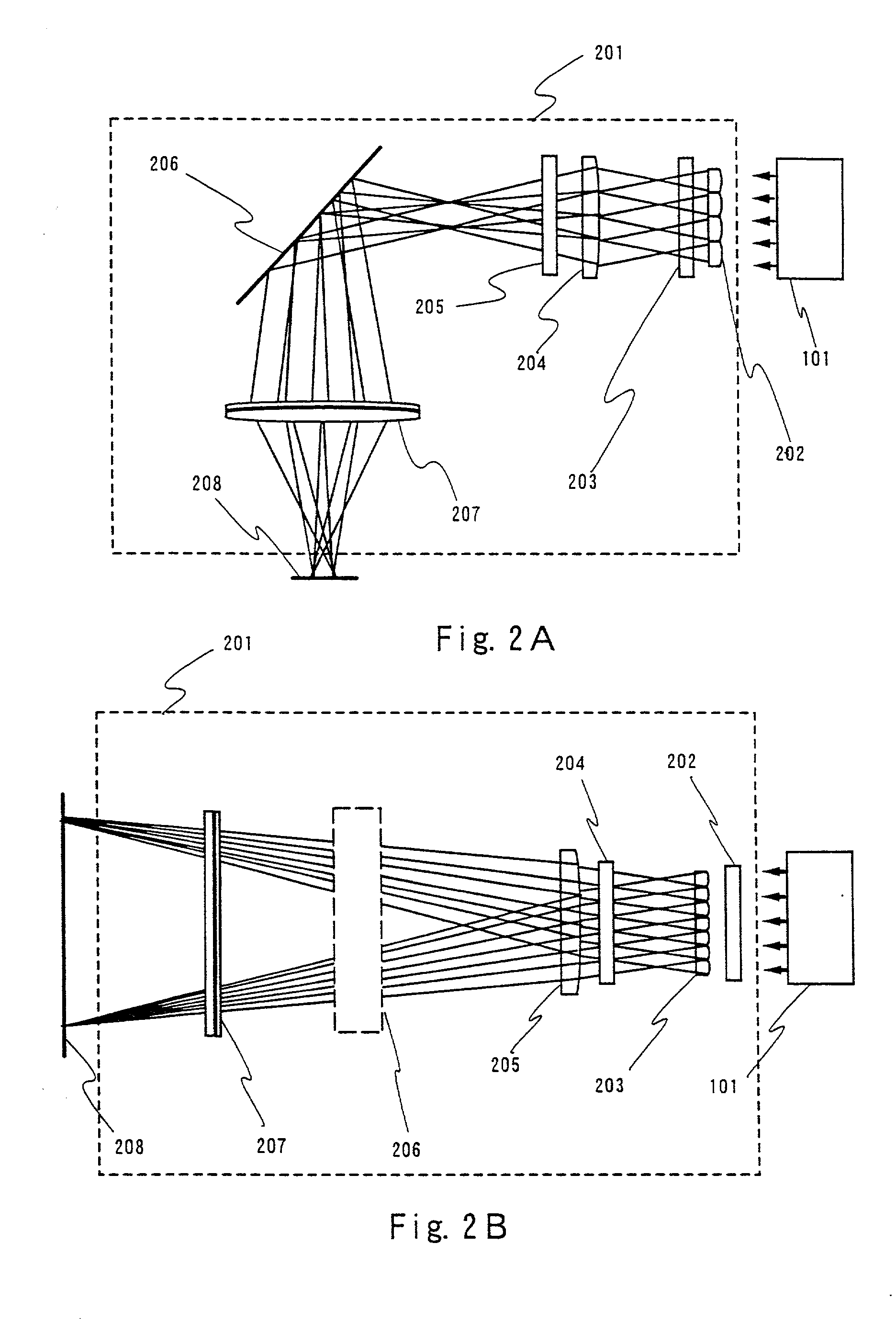

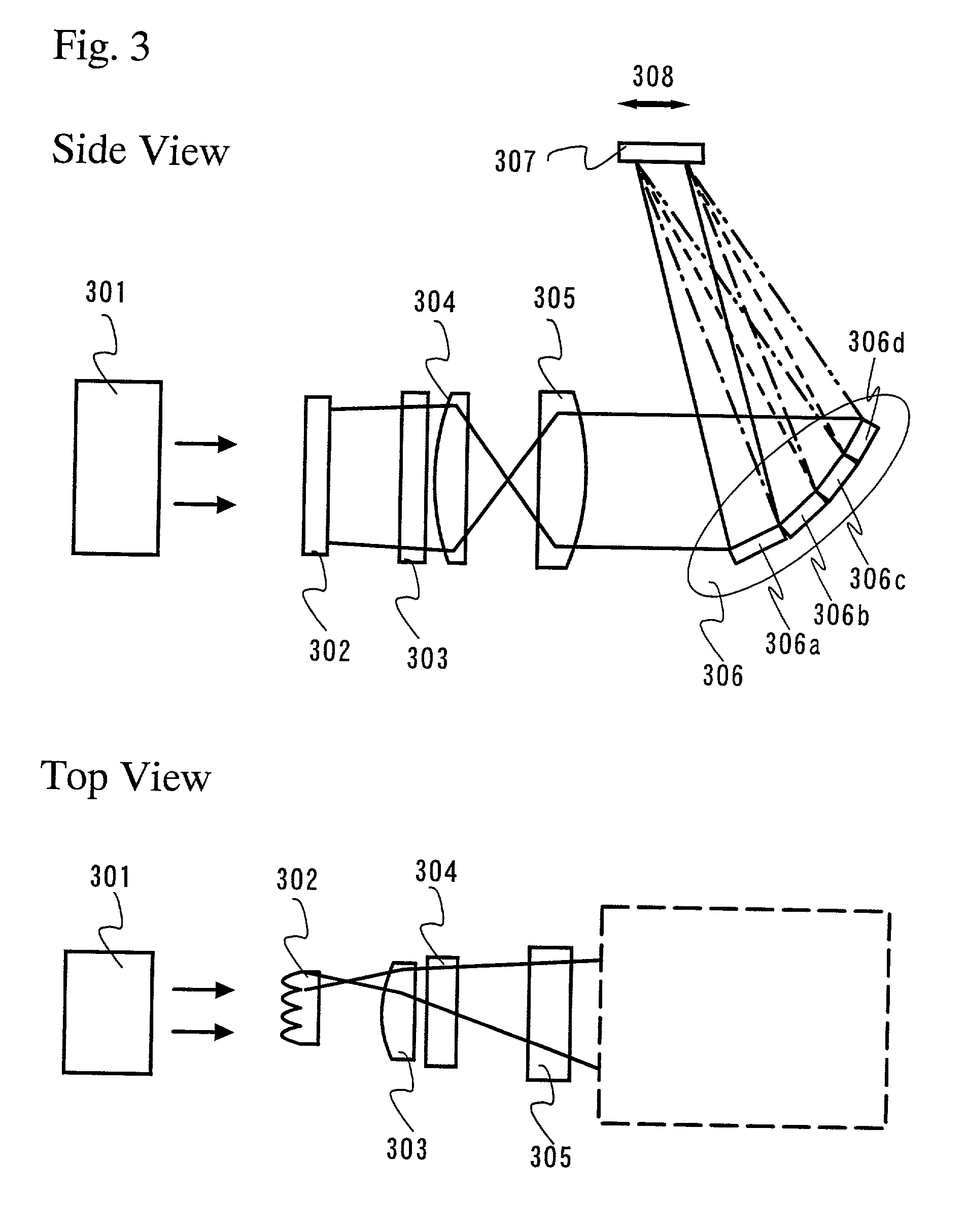

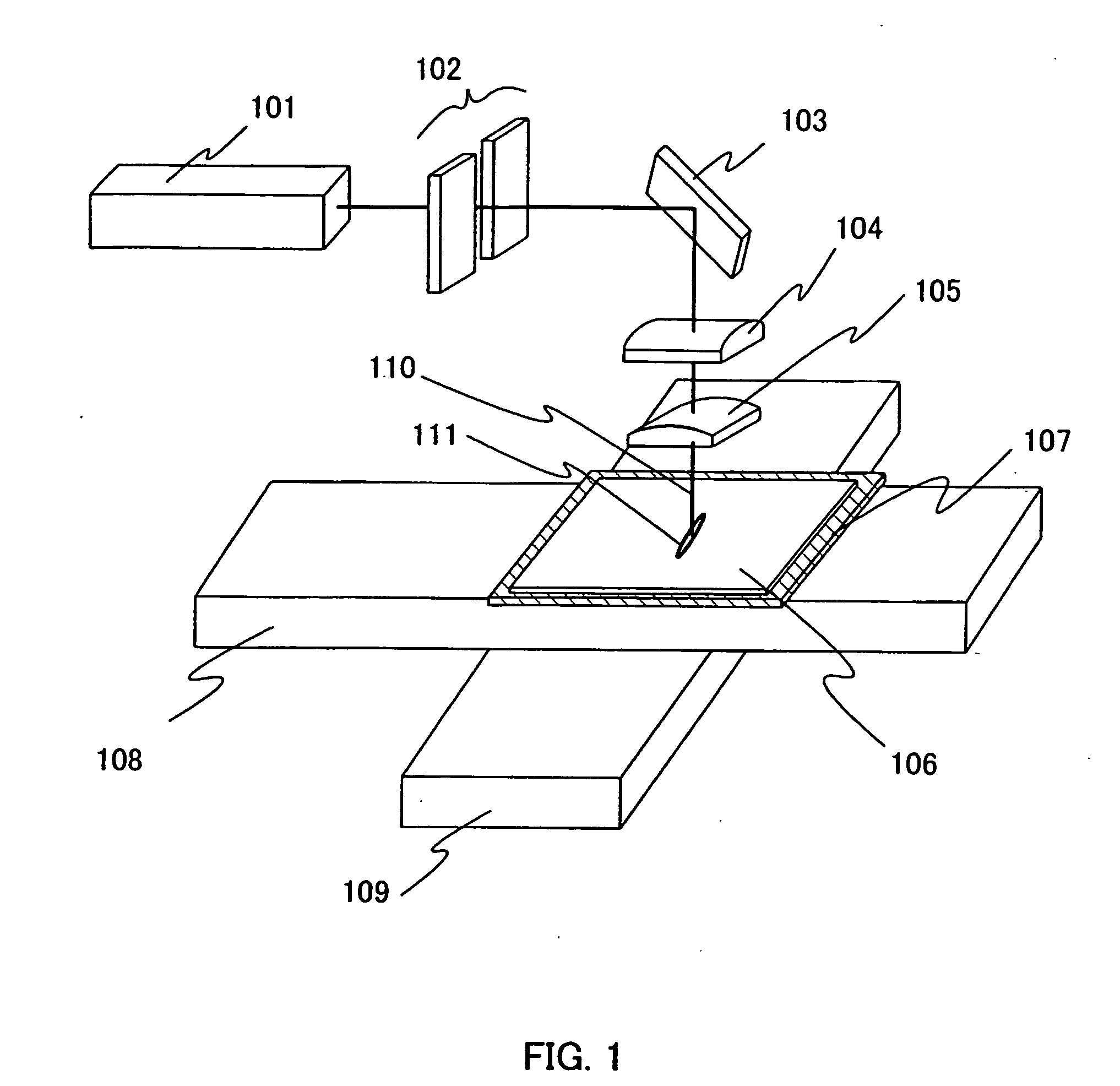

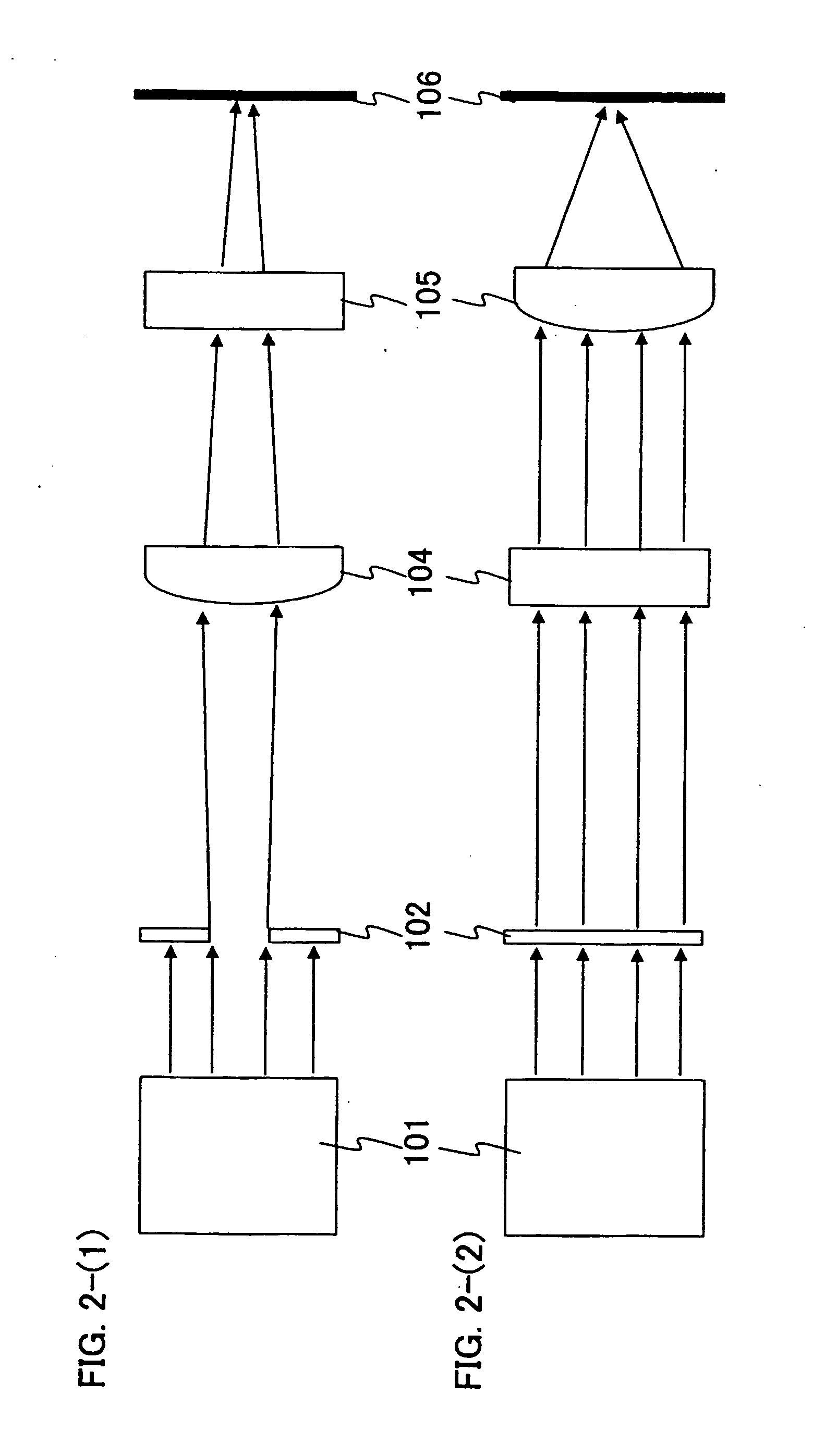

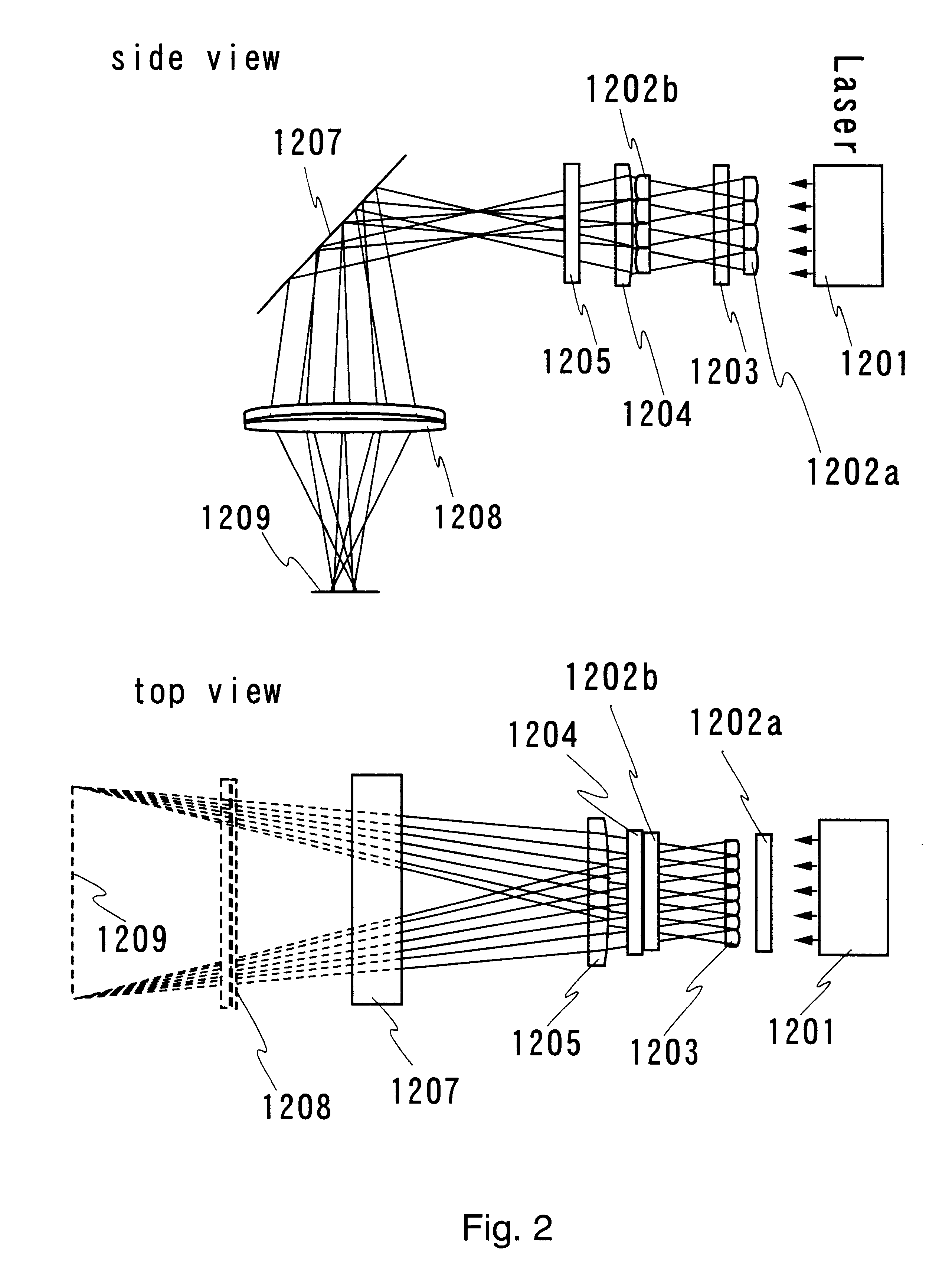

Laser irradiation apparatus laser irradiation method, semiconductor device and method of manufacturing a semiconductor device

InactiveUS6927109B1Reduce hydrogen concentrationHigh energy laserSolid-state devicesSemiconductor/solid-state device manufacturingAmorphous siliconLight beam

To form a polycrystalline silicon film having a grain size of 1 μm or greater by means of laser annealing. A beam emitted from a laser apparatus (101) is split in two by a half mirror. The split beams are processed into linear shapes by cylindrical lenses (102) to (105), and (207), then simultaneously irradiate an irradiation surface (209). If an amorphous silicon film formed on a glass substrate is disposed on the irradiation surface (209), an area will be irradiated by both a linear shape beam entering from a front surface and a linear shape beam that has transmitted through the glass surface. Both linear shape beams irradiate the same area to thereby crystallize the amorphous silicon film.

Owner:SEMICON ENERGY LAB CO LTD

Laser annealing apparatus and annealing method of semiconductor thin film using the same

InactiveUS20050170572A1Prolong lifeCost of apparatus can be reducedLaser detailsElectrode and associated part arrangementsOptical axisLight beam

A laser beam temporally modulated in amplitude by a modulator and shaped into a long and narrow shape by a beam shaper is rotated around the optical axis of an image rotator inserted between the beam shaper and a substrate. Thus, the longitudinal direction of the laser beam having the long and narrow shape is rotated around the optical axis on the substrate. In order to perform annealing in a plurality of directions on the substrate, the laser beam shaped into the long and narrow shape is rotated on the substrate while a stage mounted with the substrate is moved only in two directions, that is, X- and Y-directions. In such a manner, the substrate can be scanned at a high speed with a continuous wave laser beam modulated temporally in amplitude and shaped into a long and narrow shape, without rotating the substrate. Thus, a semiconductor film can be annealed.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

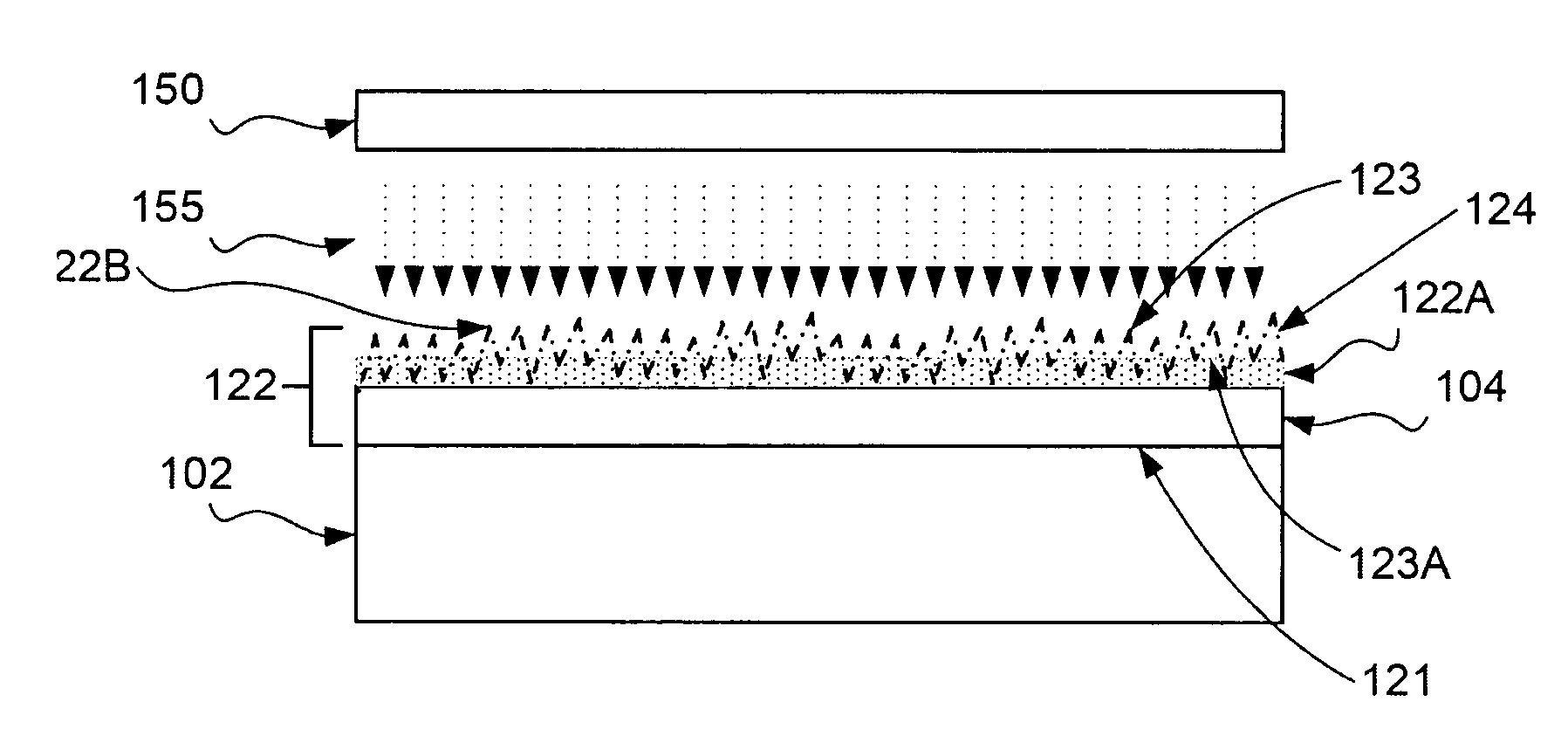

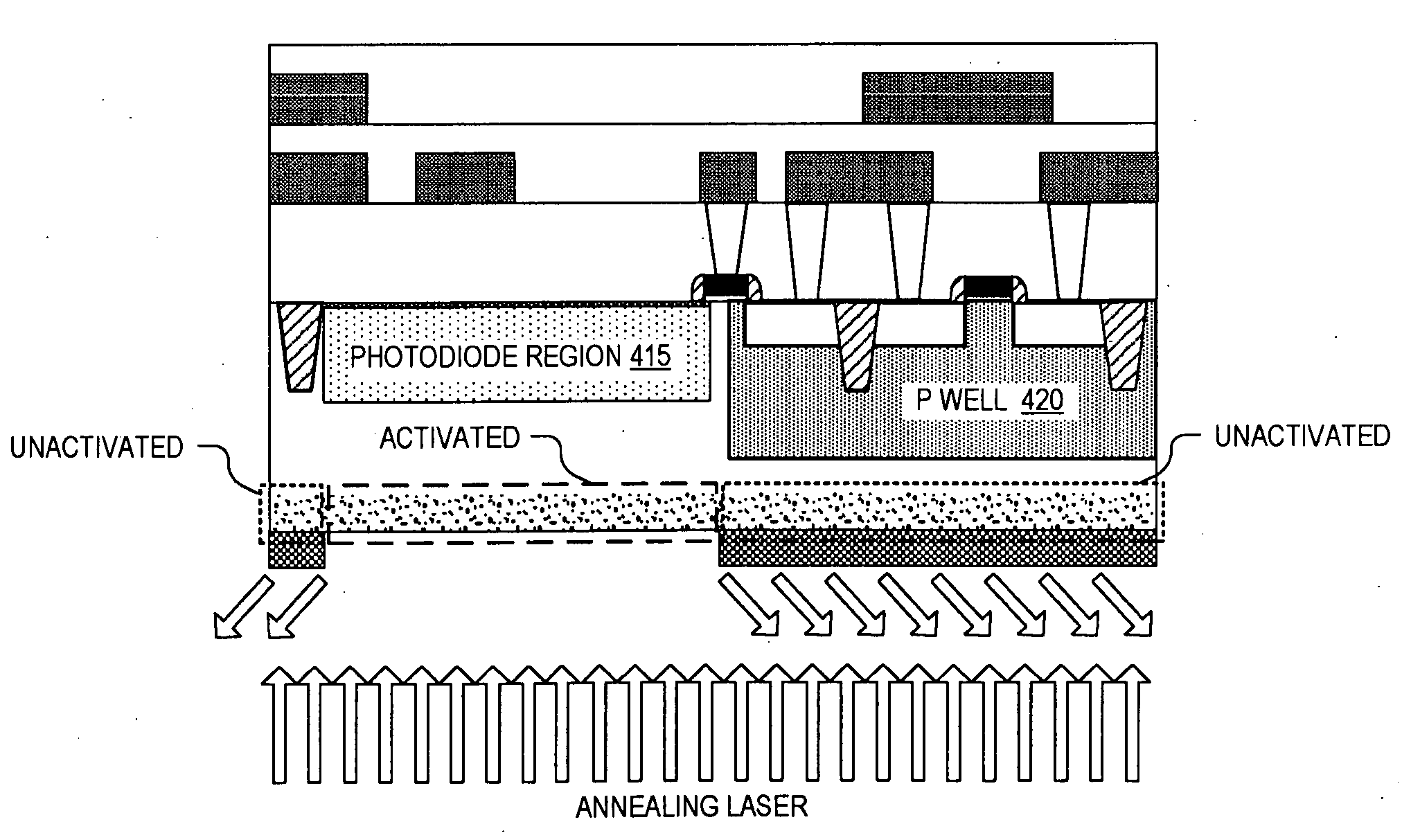

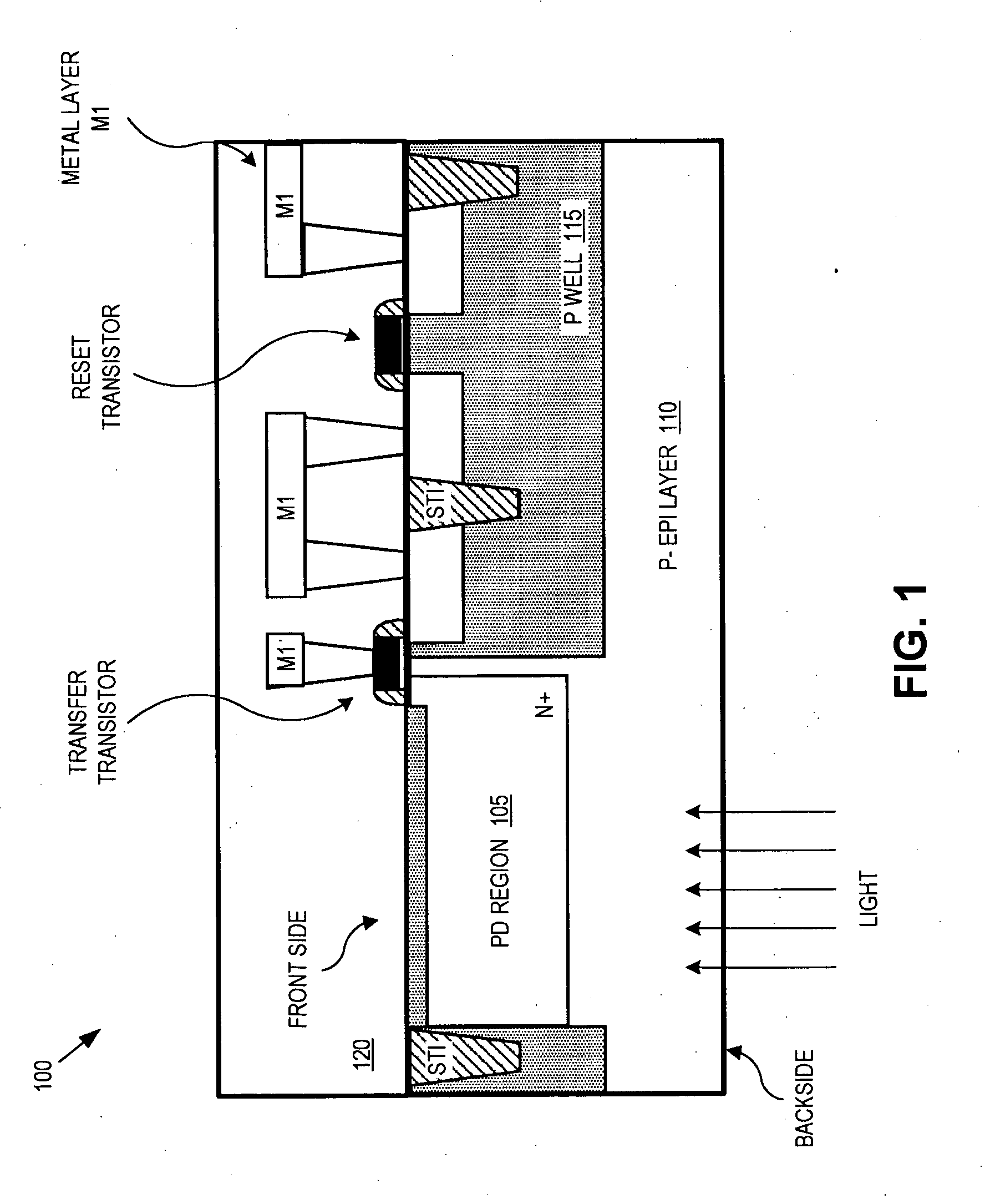

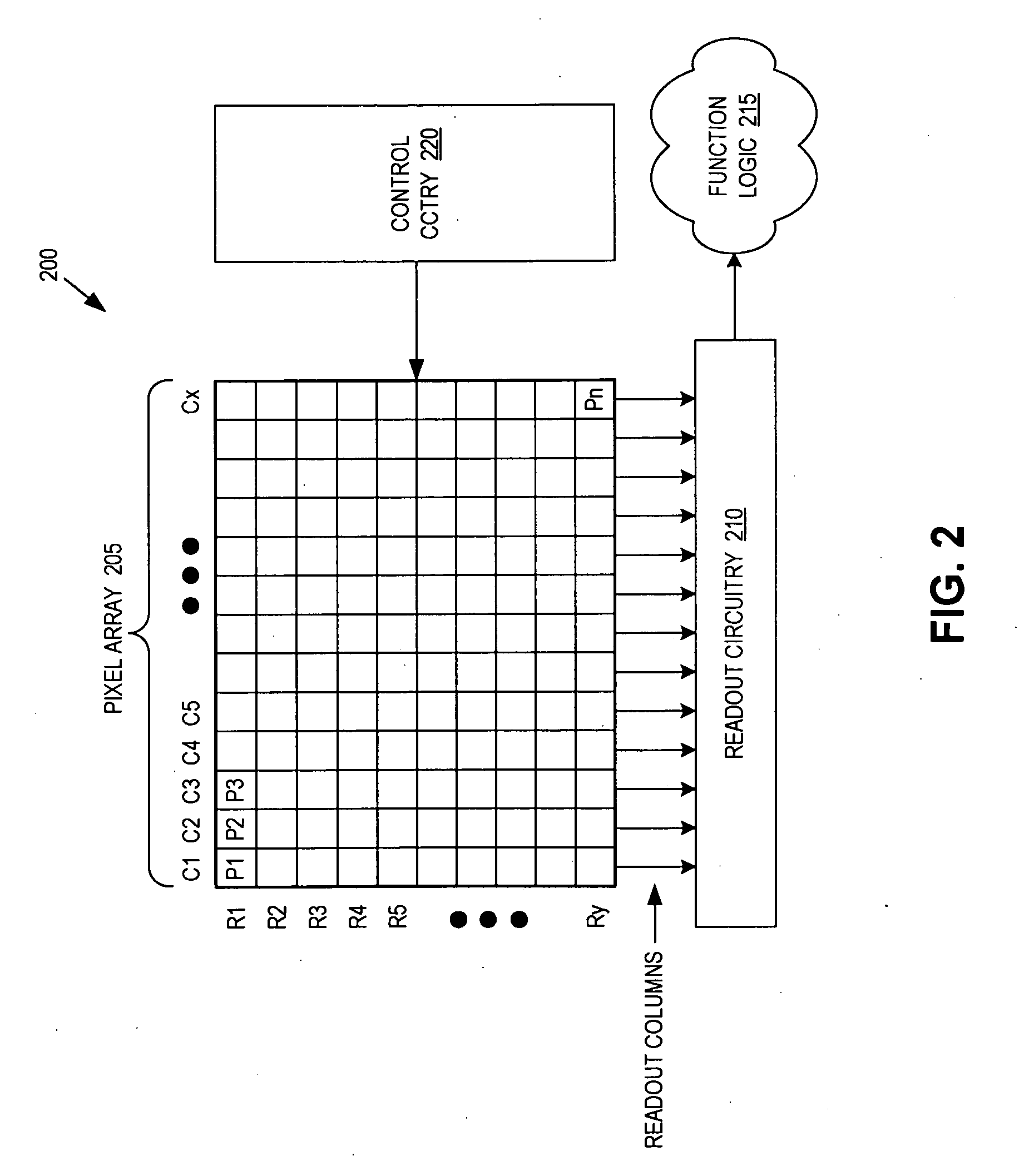

Masked laser anneal during fabrication of backside illuminated image sensors

ActiveUS20090200587A1Solid-state devicesSemiconductor/solid-state device manufacturingLaser annealingImage sensor

A technique for fabricating an array of imaging pixels includes fabricating front side components on a front side of the array. After fabricating the front side components, a dopant layer is implanted on a backside of the array. A mask is formed over the dopant layer to selectively expose portions of the dopant layer. Next, the exposed portions of the dopant layer are laser annealed. Alternatively, the mask may be disposed over the backside prior to the formation of the dopant layer and the dopants implanted through the exposed portions and subsequently laser annealed.

Owner:OMNIVISION TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com