Patents

Literature

2312 results about "Sheet resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sheet resistance is a measure of resistance of thin films that are nominally uniform in thickness. It is commonly used to characterize materials made by semiconductor doping, metal deposition, resistive paste printing, and glass coating. Examples of these processes are: doped semiconductor regions (e.g., silicon or polysilicon), and the resistors that are screen printed onto the substrates of thick-film hybrid microcircuits.

Touch screen sensor

Owner:3M INNOVATIVE PROPERTIES CO

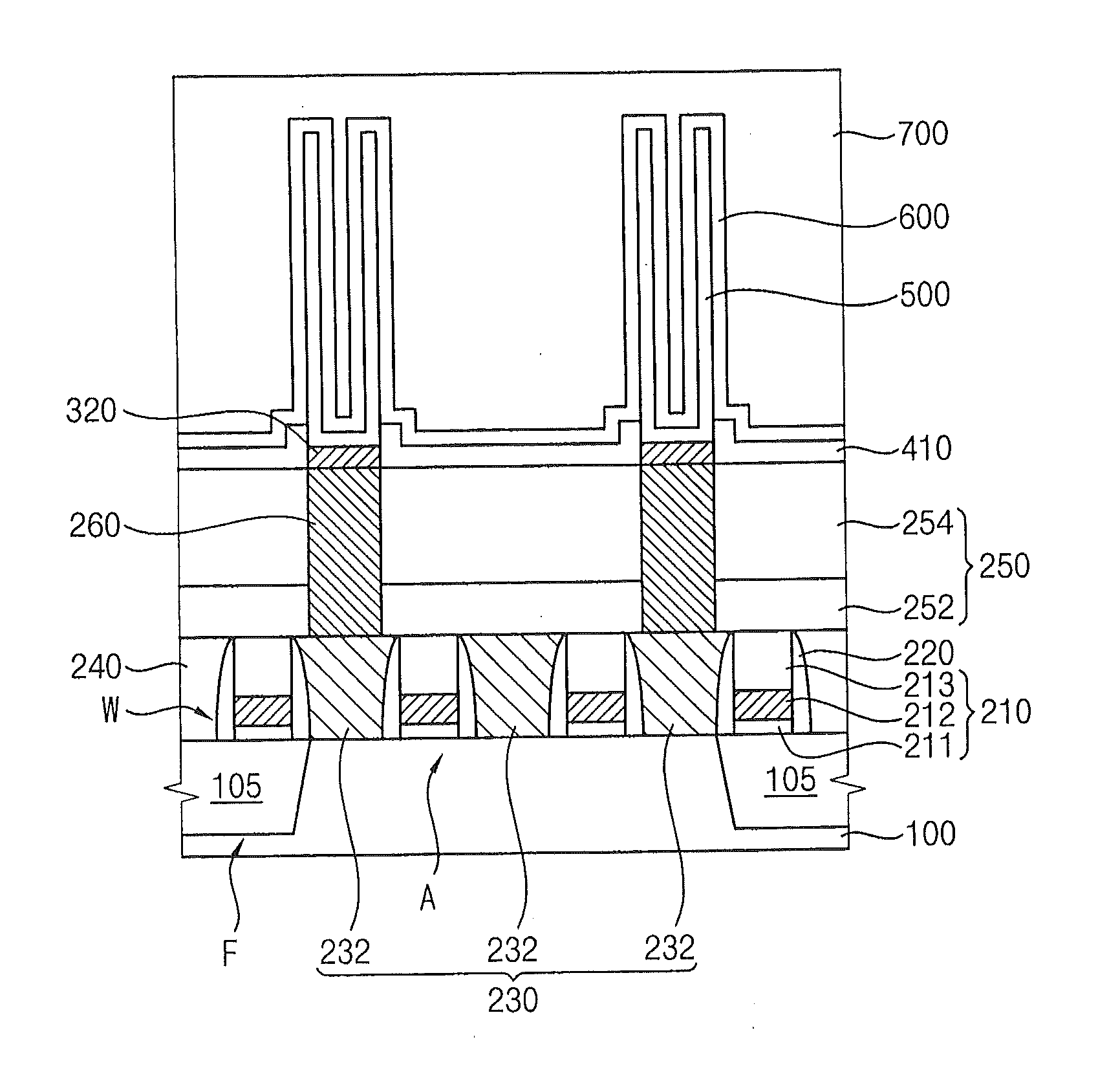

Method of Manufacturing A Semiconductor Device

ActiveUS20130171818A1Improve thermal stabilityStabilize bonding structureSolid-state devicesSemiconductor/solid-state device manufacturingElectrical resistance and conductanceDevice material

Owner:SAMSUNG ELECTRONICS CO LTD

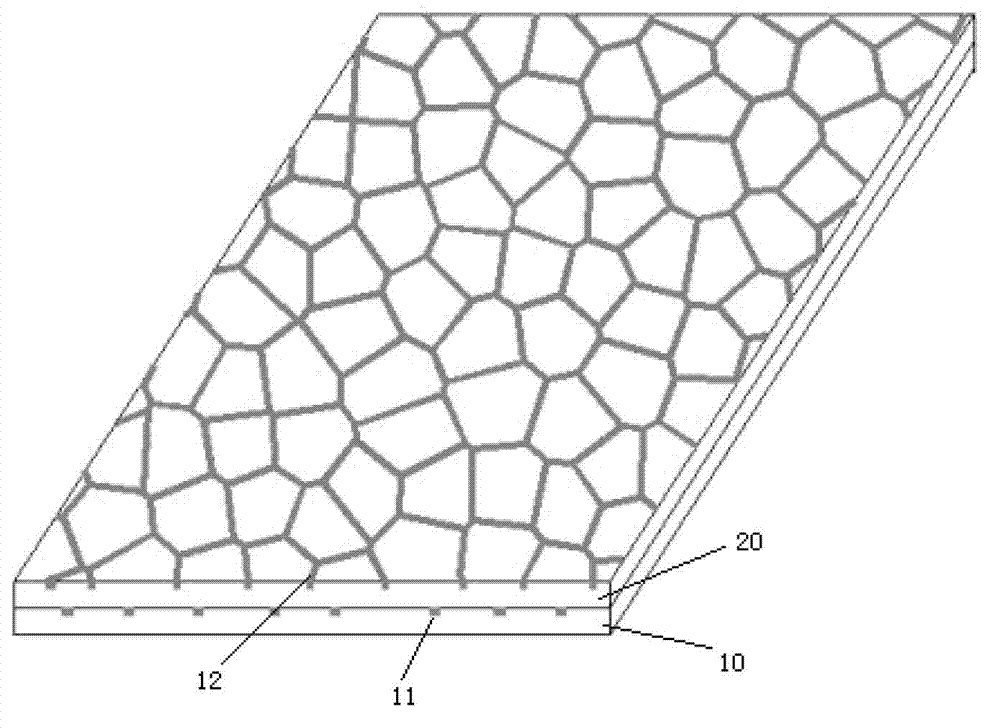

Conduction structure in transparent conduction film, transparent conduction film and manufacture method thereof

ActiveCN102903423AConductive layers on insulating-supportsTransparent dielectricsTransmittanceConductive materials

The invention discloses a transparent conduction film, a conduction structure thereof and a preparation method of the transparent conduction film. The transparent conduction film is of a single-sided dual-layer conduction structure. The conduction structure comprises a first metal embedding layer and a second metal embedding layer, wherein the first metal embedding layer is formed by impressing on a substrate or impressing on a polymer layer on the surface of the substrate; and the second metal embedding layer is formed by coating the polymer layer on the surface of the first metal embedding layer through impressing, the first layer of conduction structure and the second layer of conduction structure have a grid groove structure, and conductive materials are filled in grooves. The single-sided graphical transparent conduction film provided by the invention has the advantages of high resolution and transmittance, independent and adjustable sheet resistance, and the like. According to the transparent conduction film, the cost can be reduced, and the weight and the thickness of a manufactured touch panel can be reduced.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

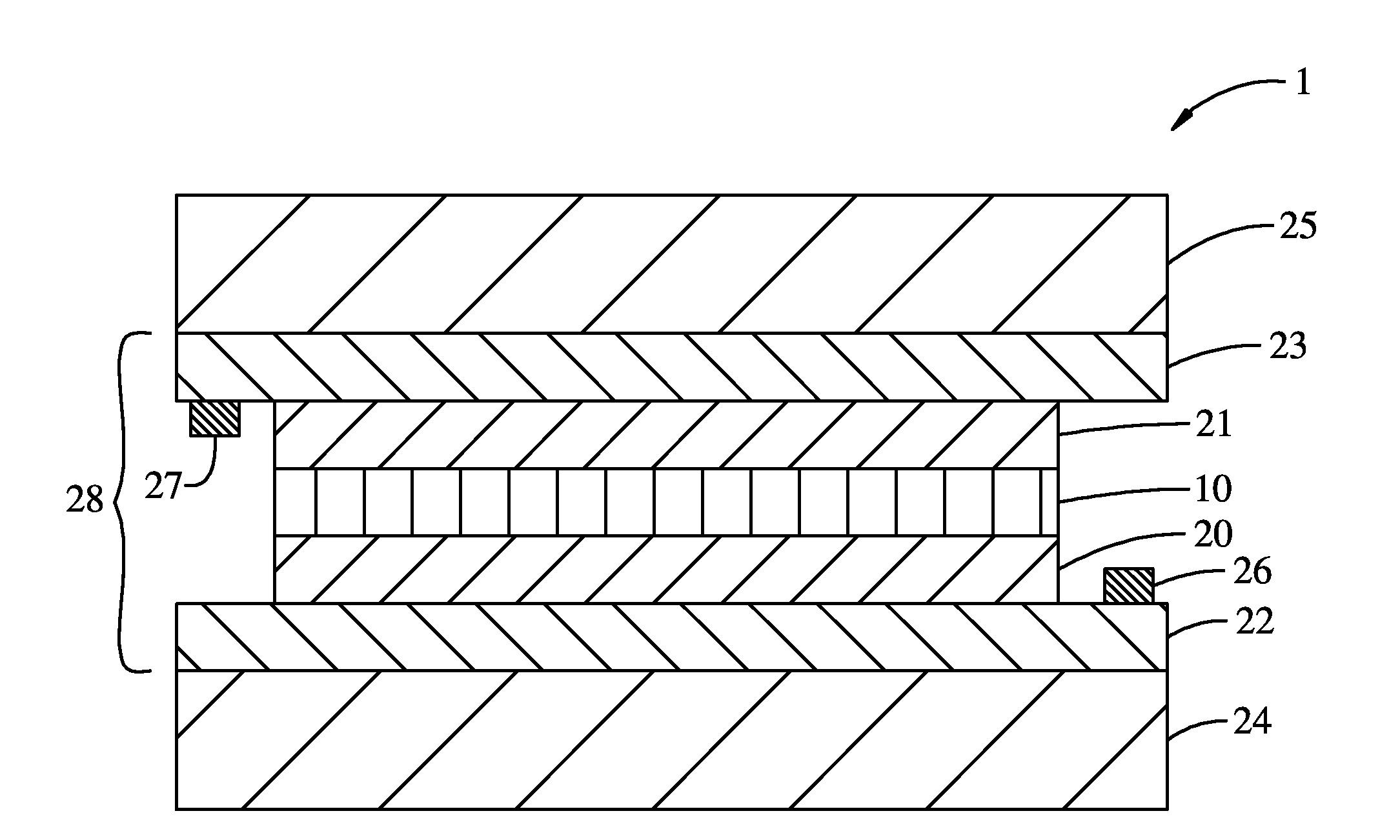

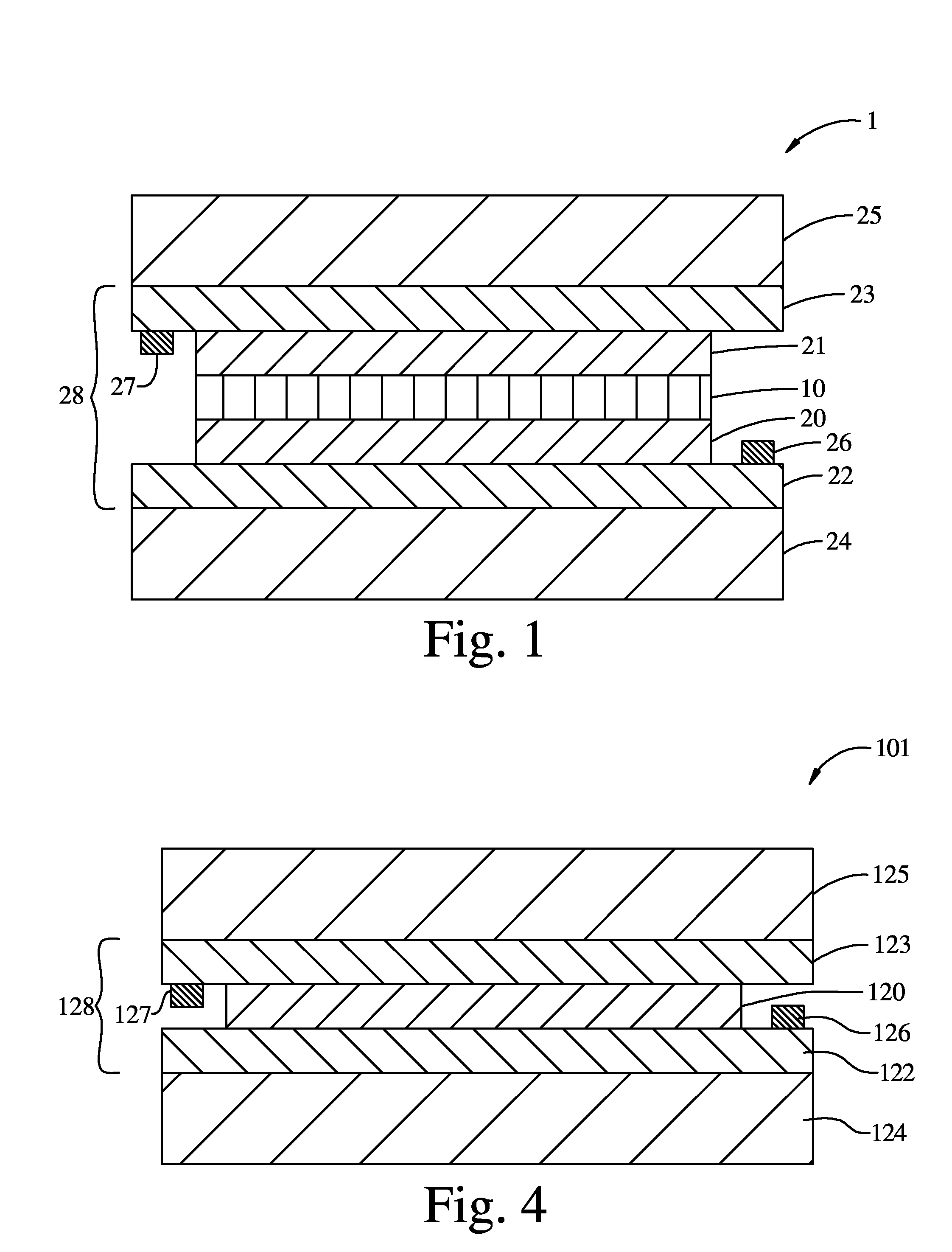

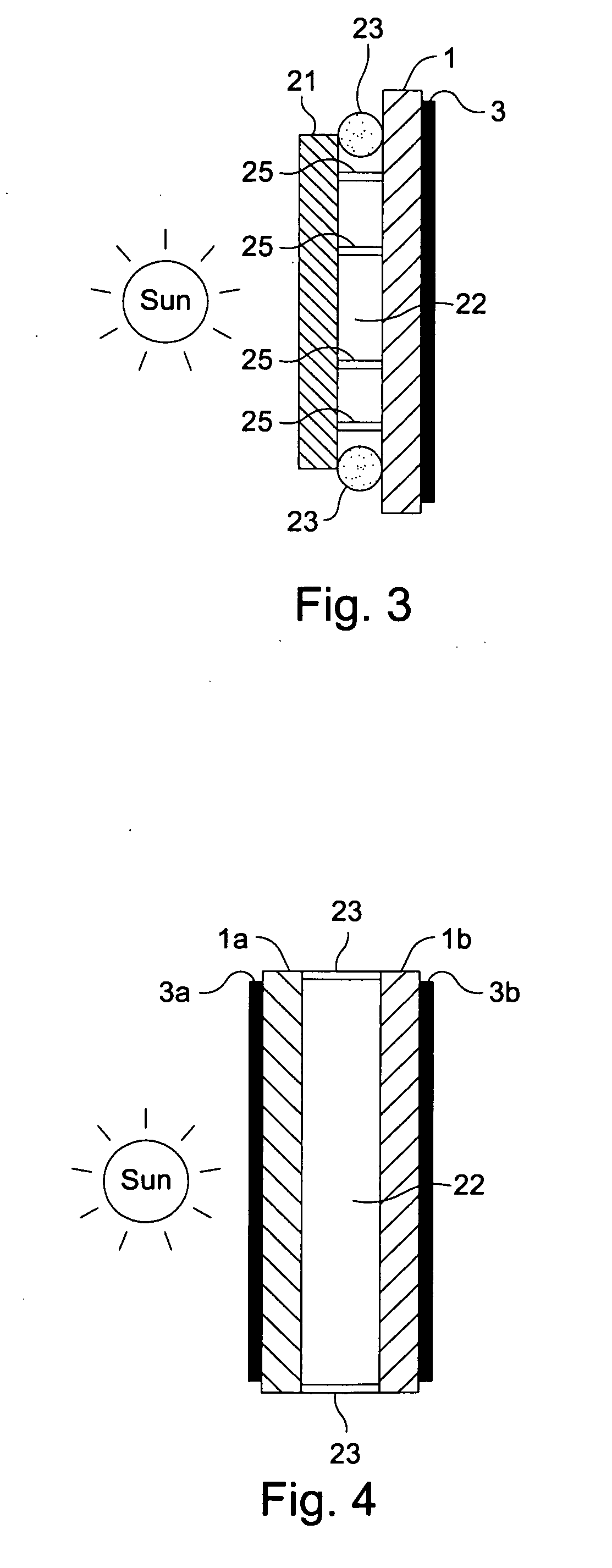

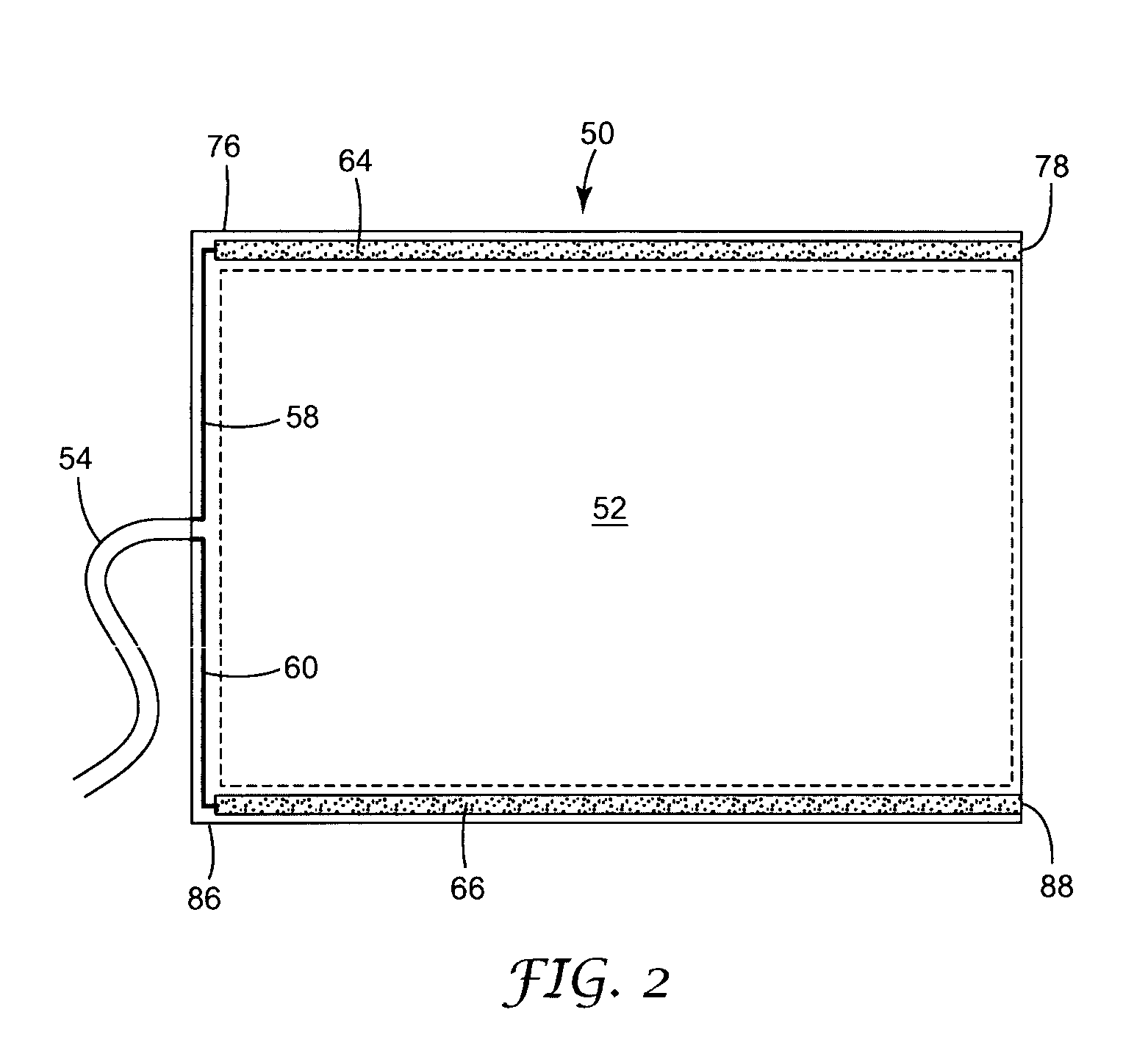

Electrochromic multi-layer devices with spatially coordinated switching

InactiveUS20120200908A1Easy to manufacturePrinted circuit detailsCoatingsElectrical resistance and conductancePower flow

A multi-layer device comprising a first substrate and a first electrically conductive layer on a surface thereof, the first electrically conductive layer having a sheet resistance to the flow of electrical current through the first electrically conductive layer that varies as a function of position.

Owner:KINESTRAL TECH

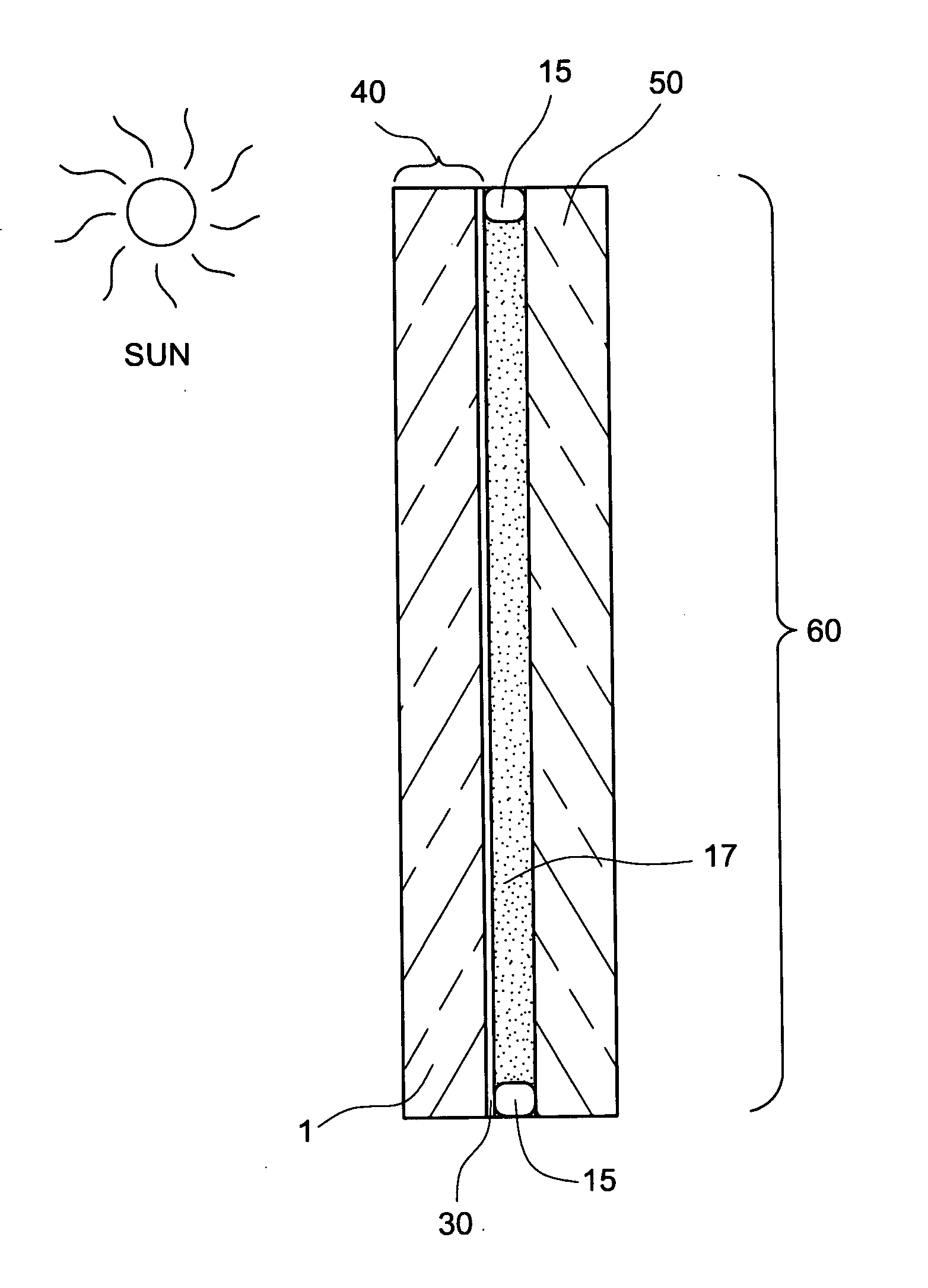

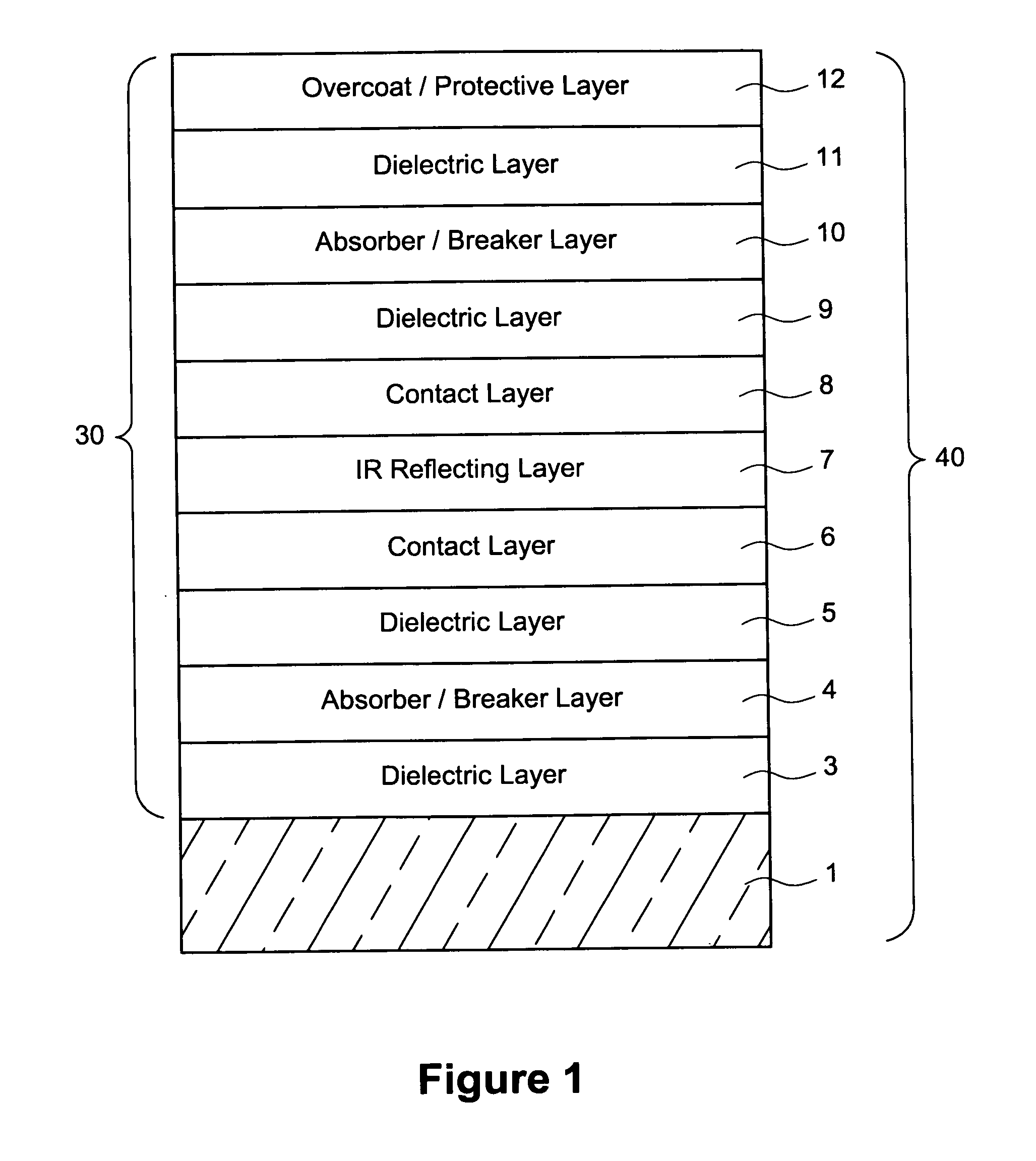

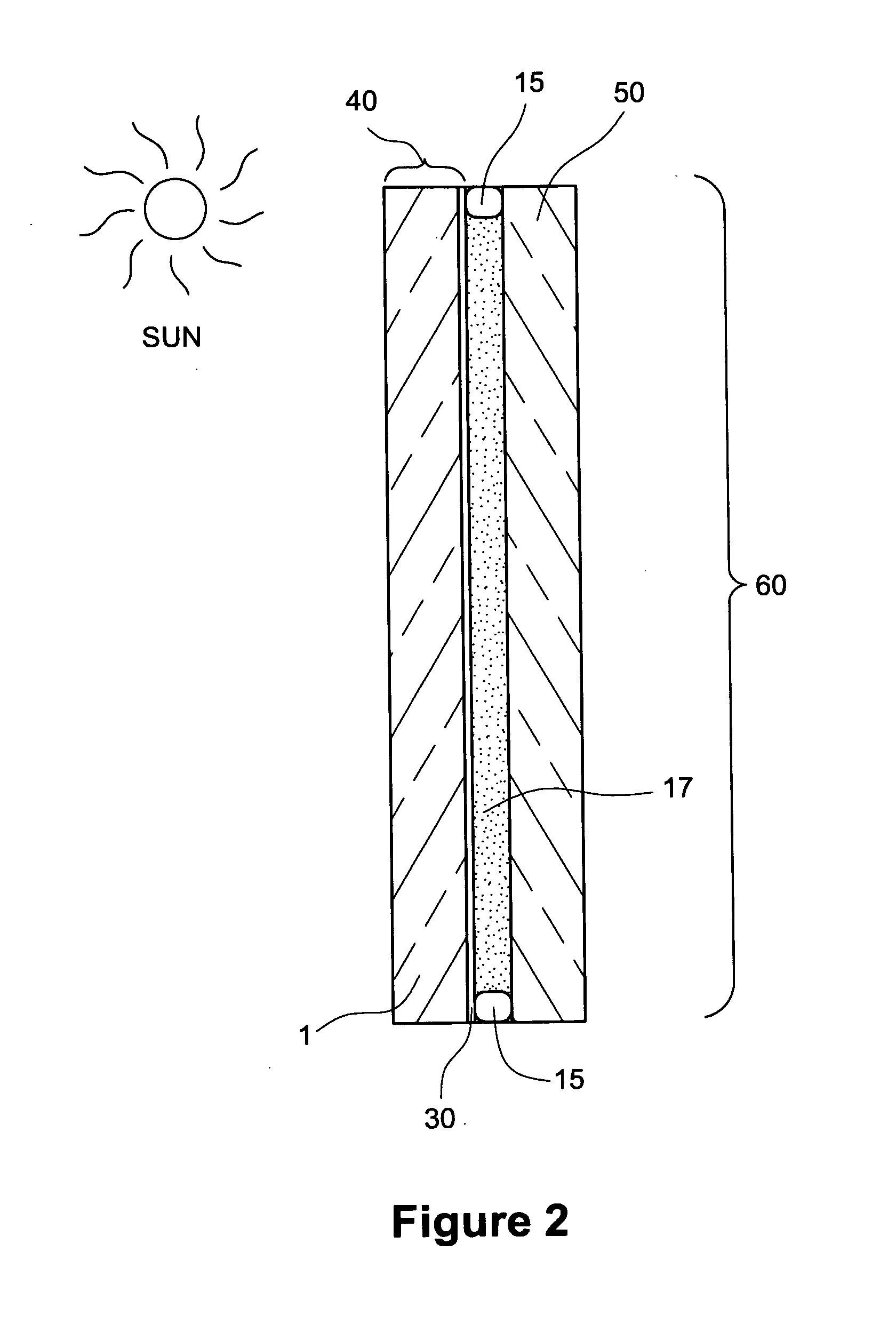

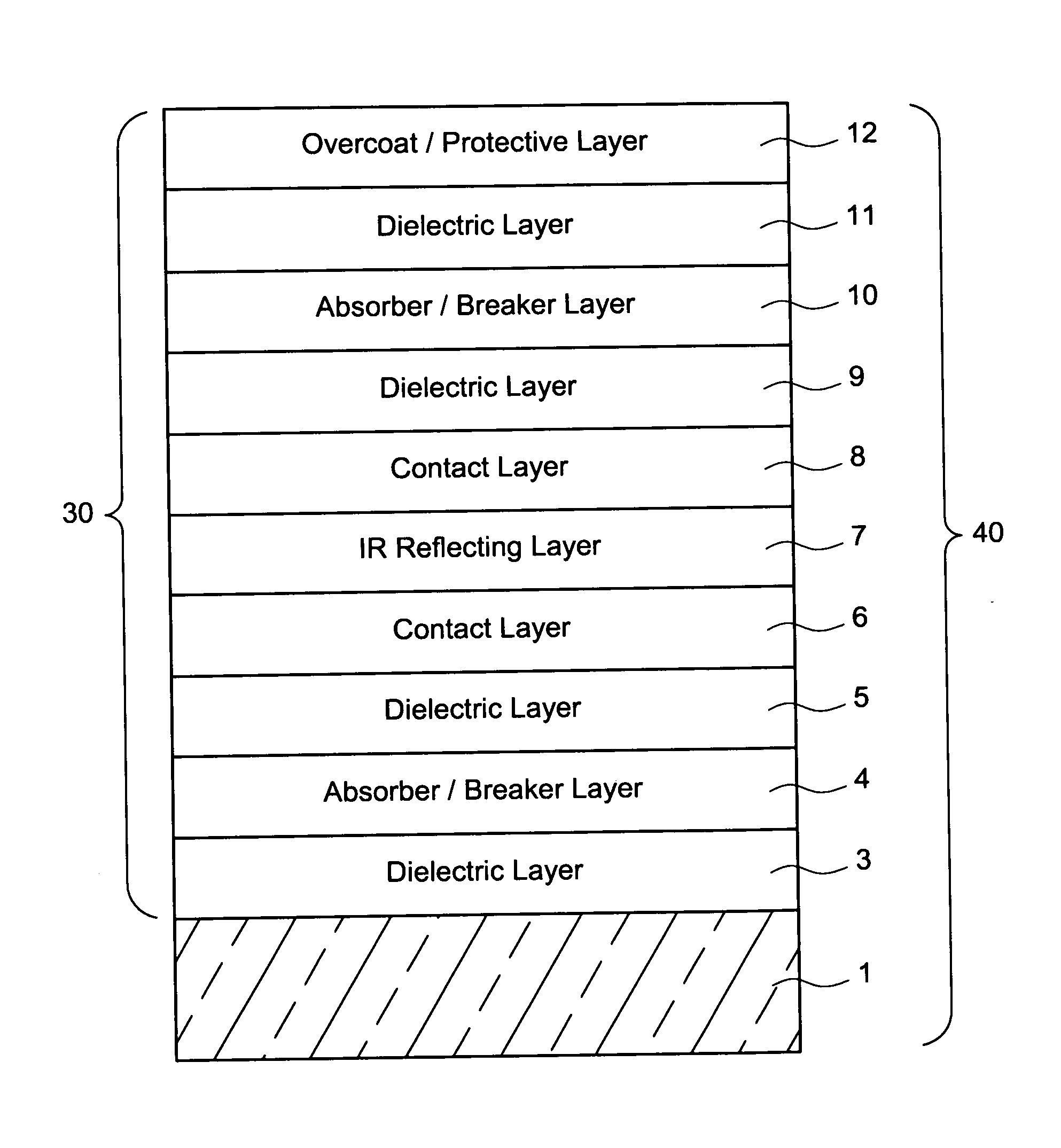

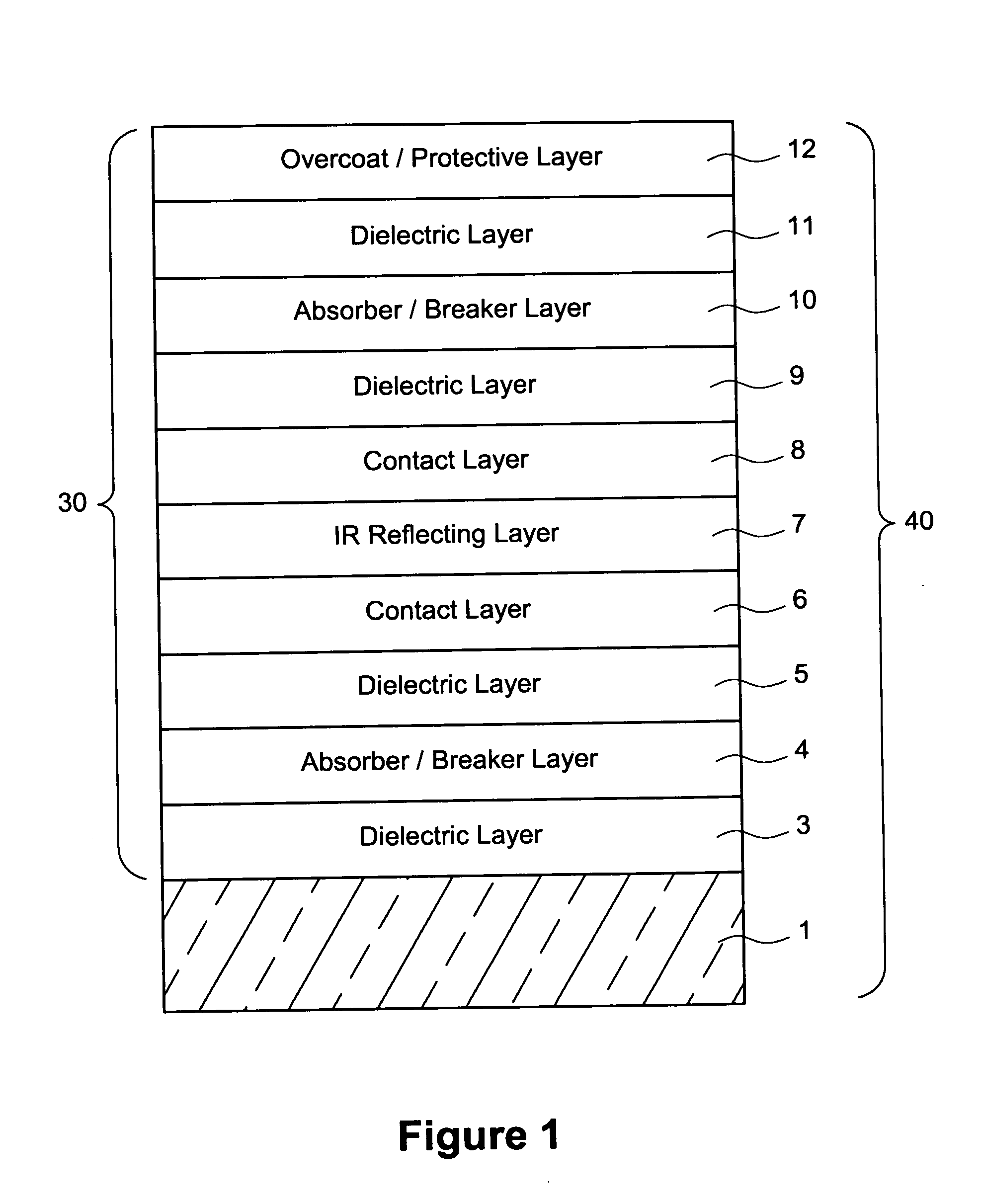

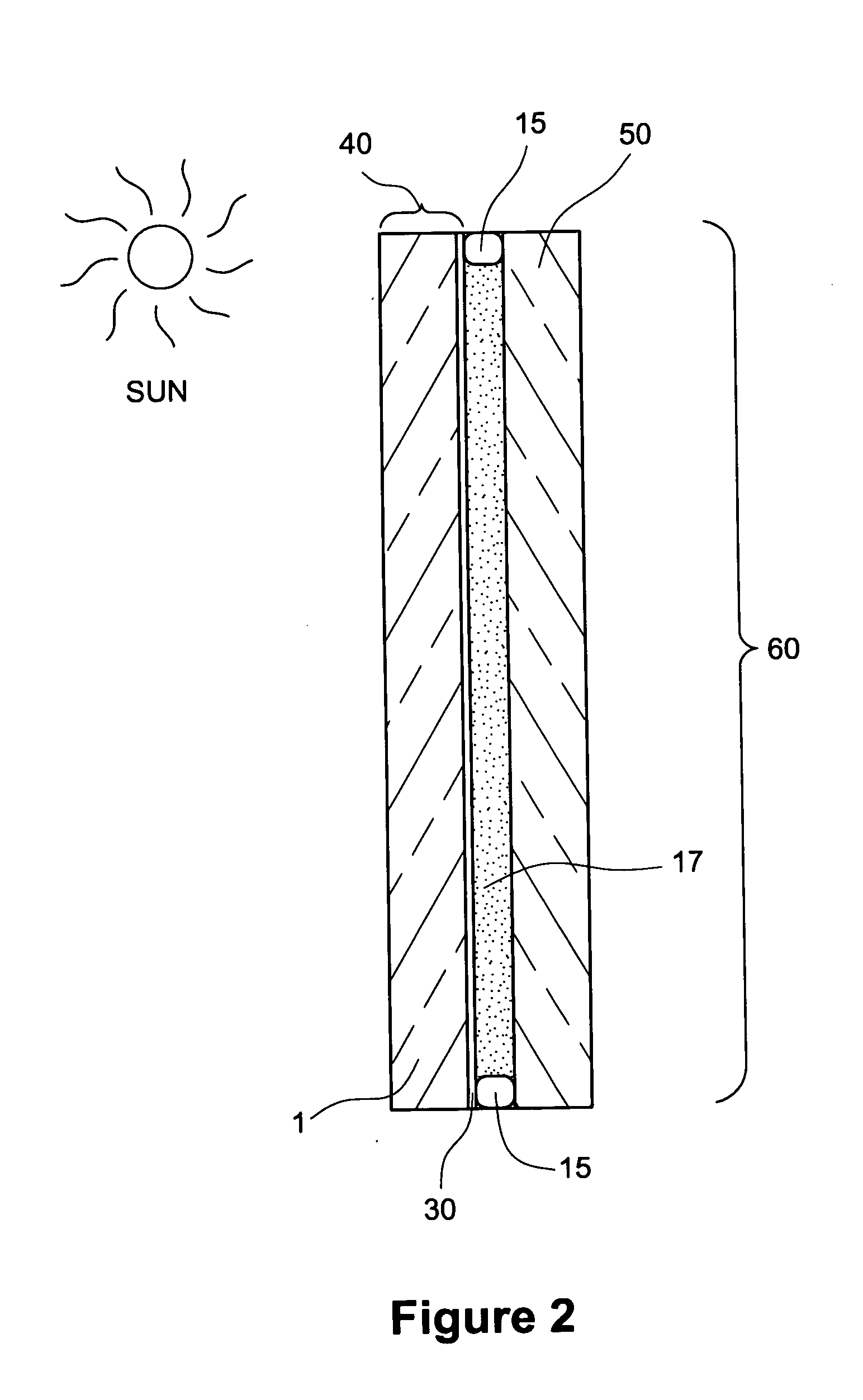

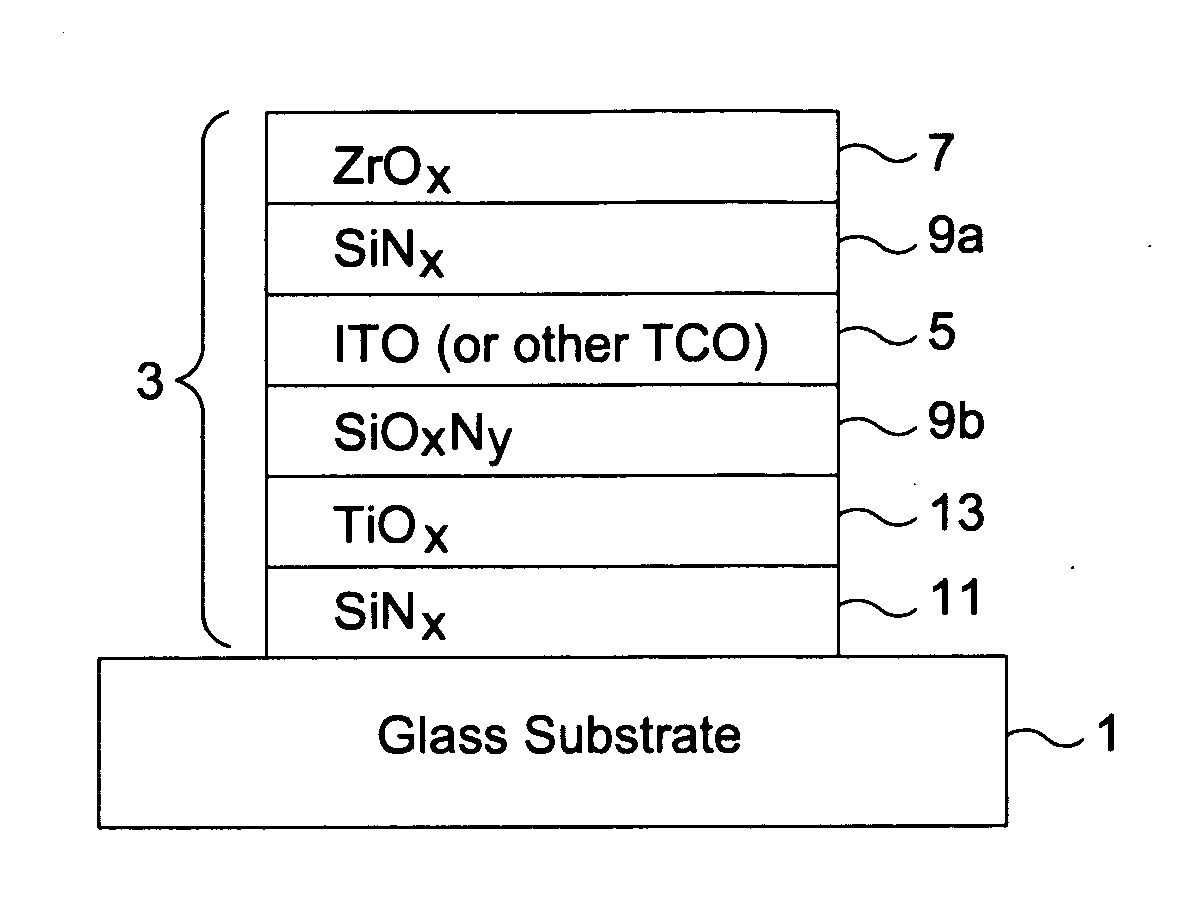

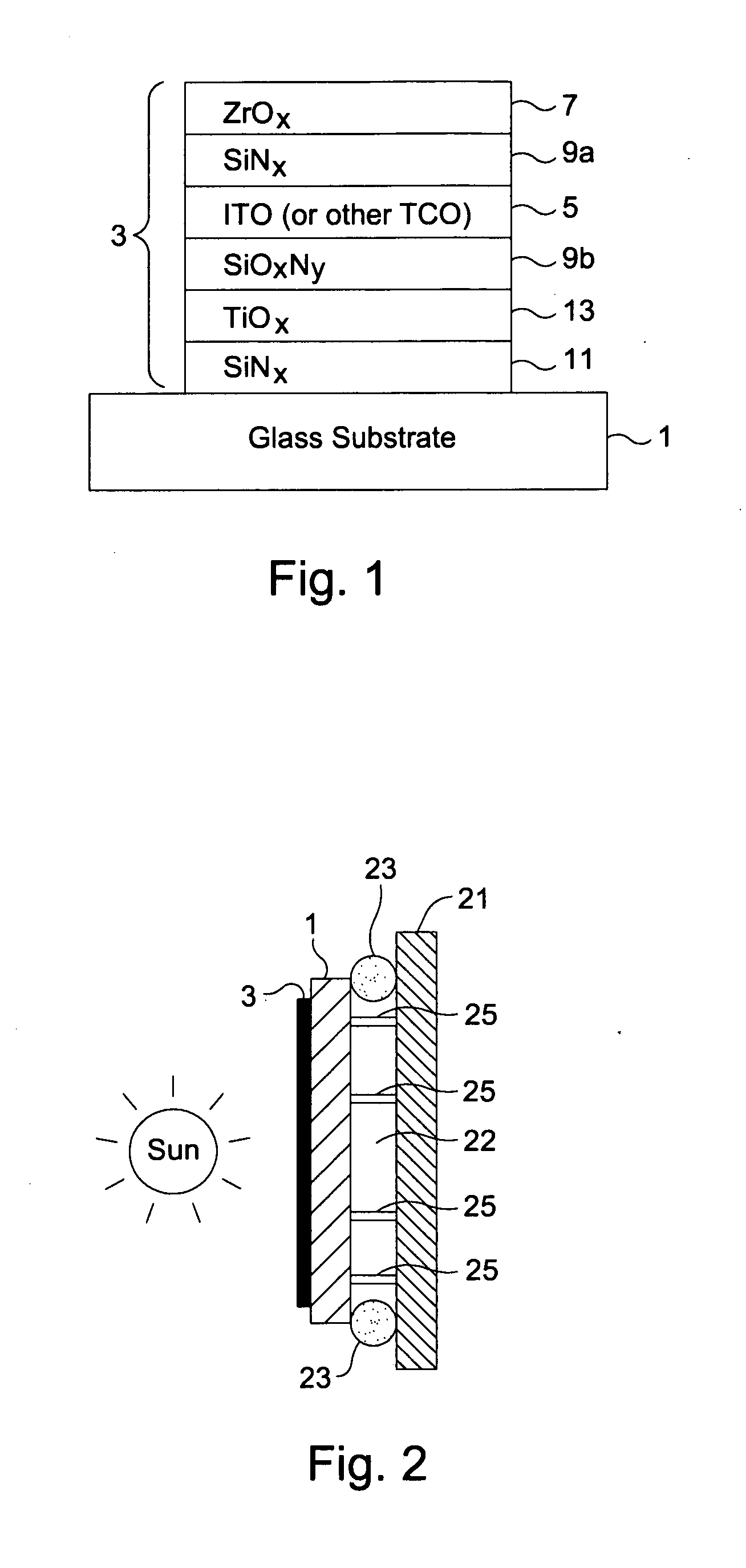

Coated article having low-E coating with absorber layer(s)

ActiveUS20110262726A1Low emissivityReduce sheet resistanceGlass/slag layered productsThin material handlingElectrical resistance and conductanceInsulated glazing

A coated article is provided, having a coating supported by a glass substrate where the coating includes at least one color and / or reflectivity-adjusting absorber layer. The absorber layer(s) allows color tuning, and reduces the glass side reflection of the coated article and / or allows sheet resistance of the coating to be reduced without degrading glass side reflection. In certain example embodiments the absorber layer is provided between first and second dielectric layers which may be of substantially the same material and / or composition. In certain example embodiments, the coated article is capable of achieving desirable transmission, together with desired color, low reflectivity, and low selectivity, when having only one infrared (IR) reflecting layer of silver and / or gold. Coated articles according to certain example embodiments of this invention may be used in the context of insulating glass (IG) window units, monolithic windows, or the like.

Owner:GUARDIAN GLASS LLC +1

Coated article having low-E coating with absorber layer(s)

ActiveUS20110261442A1Low emissivityReduce sheet resistanceMirrorsOptical filtersElectrical resistance and conductanceInsulated glazing

A coated article is provided, having a coating supported by a glass substrate where the coating includes at least one color and / or reflectivity-adjusting absorber layer. The absorber layer(s) allows color tuning, and reduces the glass side reflection of the coated article and / or allows sheet resistance of the coating to be reduced without degrading glass side reflection. In certain example embodiments the absorber layer is provided between first and second dielectric layers which may be of substantially the same material and / or composition. In certain example embodiments, the coated article is capable of achieving desirable transmission, together with desired color, low reflectivity, and low selectivity, when having only one infrared (IR) reflecting layer of silver and / or gold. Coated articles according to certain example embodiments of this invention may be used in the context of insulating glass (IG) window units, monolithic windows, or the like.

Owner:GUARDIAN EURO S A R L +1

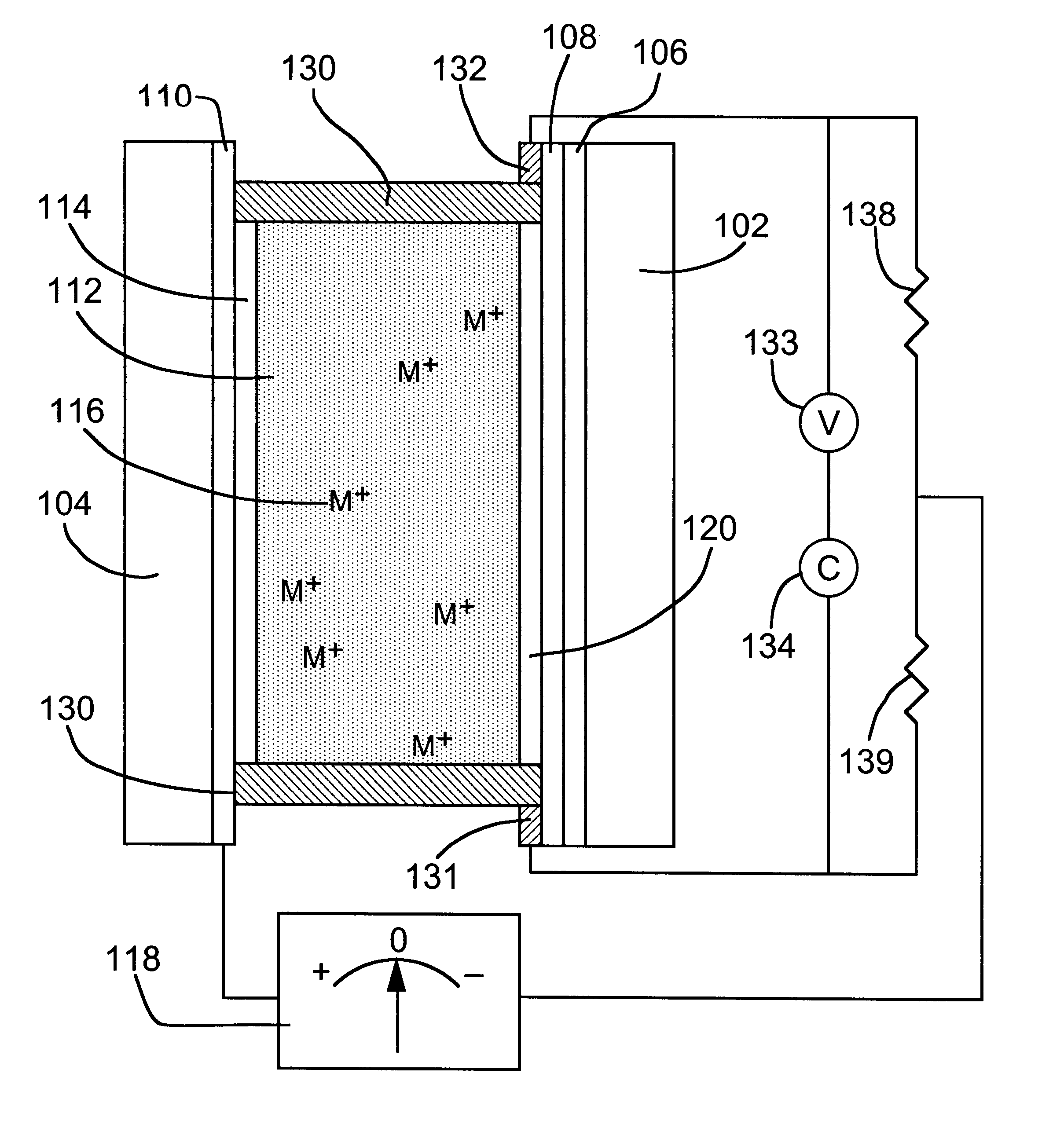

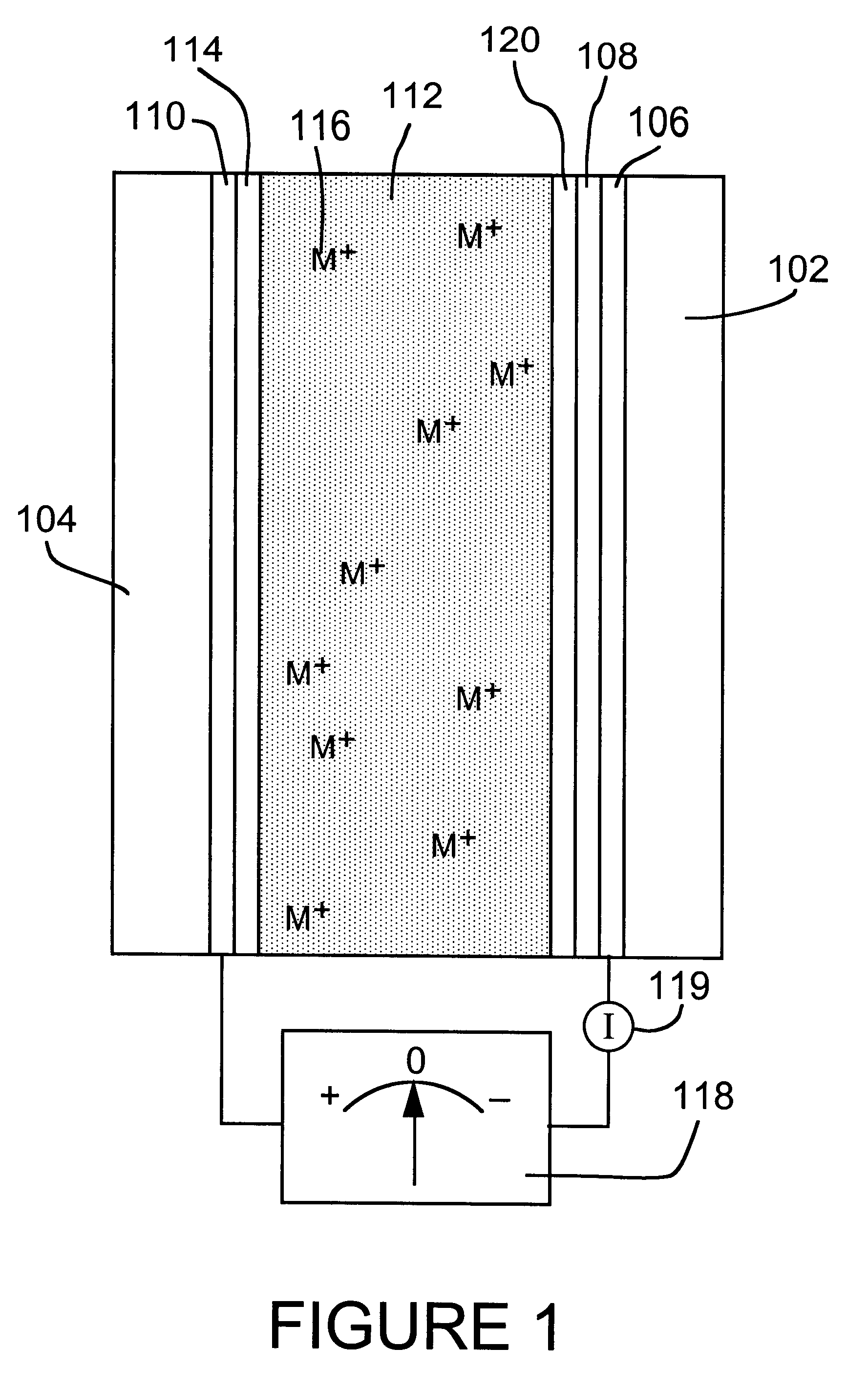

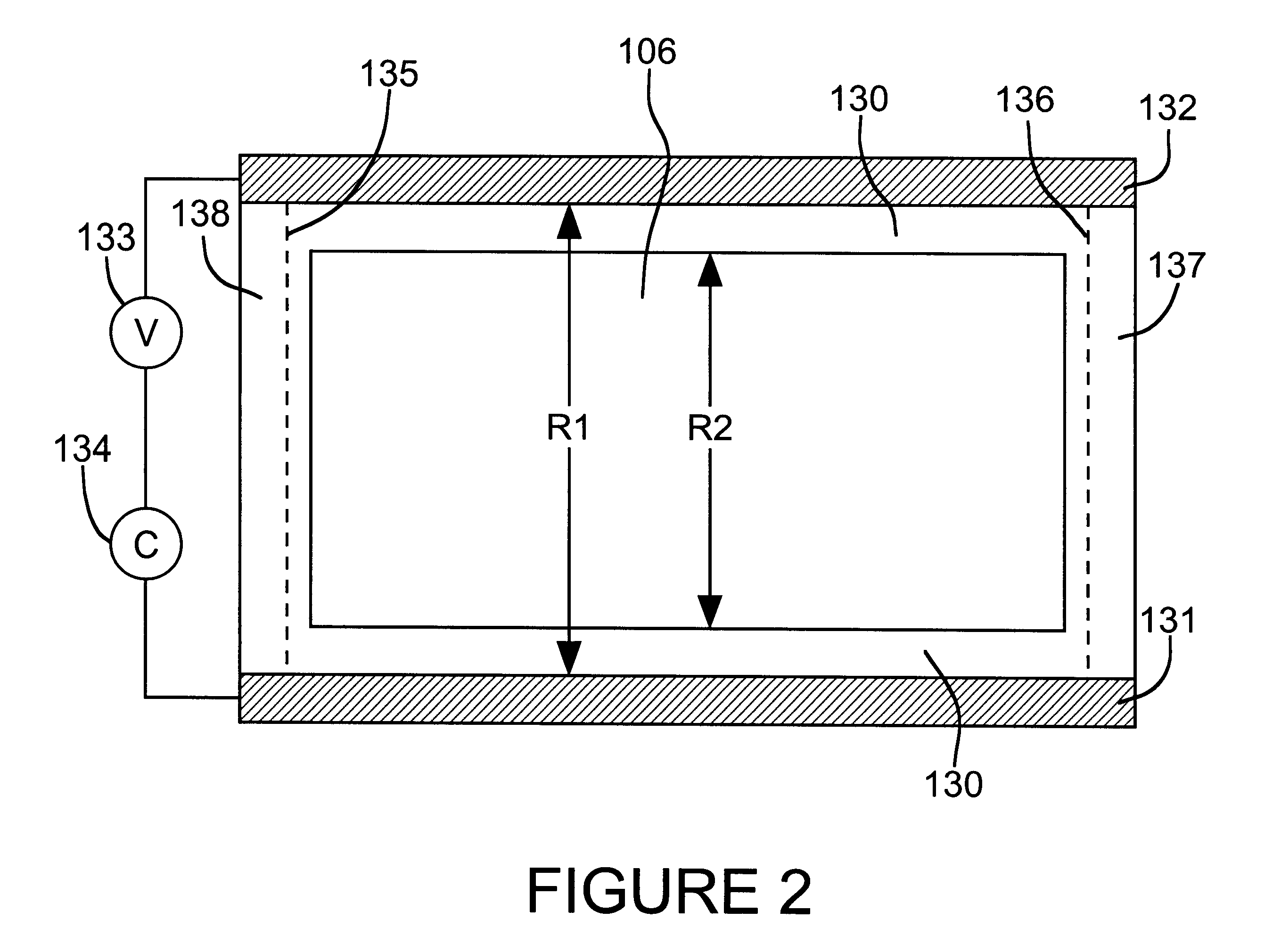

Reversible electrochemical mirror (REM) state monitoring

Reversible electrochemical mirror (REM) devices typically comprise a conductive oxide mirror electrode that is substantially transparent to radiation of some wavelengths, a counter electrode that may also be substantially transparent, and an electrolyte that contains ions of an electrodepositable metal. A voltage applied between the two electrodes causes electrodeposition of a mirror deposit on the mirror electrode and dissolution of the mirror deposit on the counter electrode, and these processes are reversed when the polarity of the applied voltage is changed. Such REM devices provide precise control over the reflection and transmission of radiation and can be used for a variety of applications, including smart windows and automatically adjusting automotive mirrors. According to the present invention, measurements of the sheet resistance of the mirror electrode in a REM device are correlated with the thickness of electrodeposited mirror metal and can be used to monitor the reflectance of the device. Sheet resistance measurements can be performed while the mirror state of the device is being switched if adequate isolation between the measurement and switching circuits is provided. This can be accomplished by use of external resistors or more sophisticated circuitry, or by taking advantage of the relatively high sheet resistance of the mirror electrode itself. Monitoring the reflectance of REM devices according to this invention provides significant cost and performance advantages.

Owner:TELEDYNE SCI & IMAGING

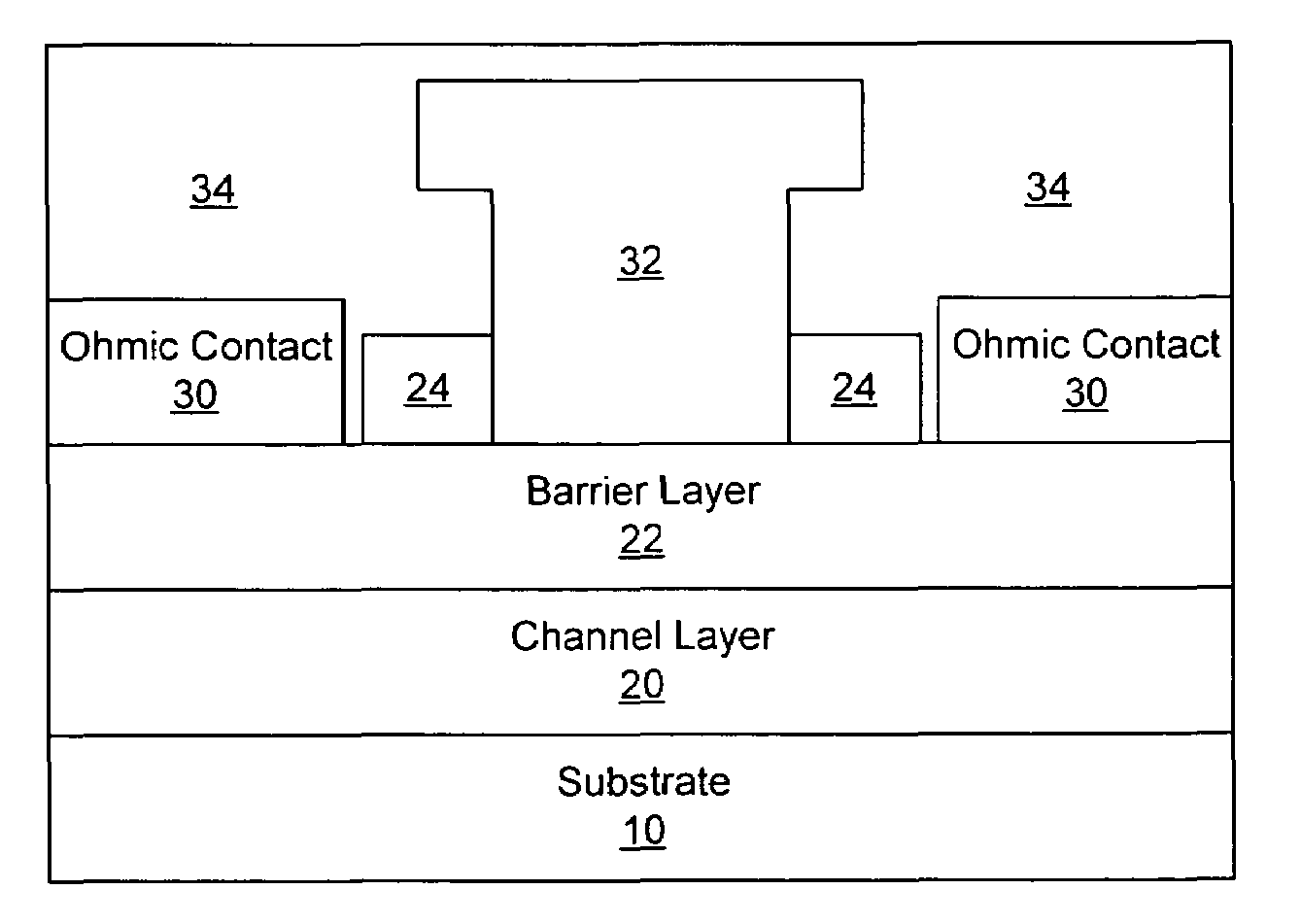

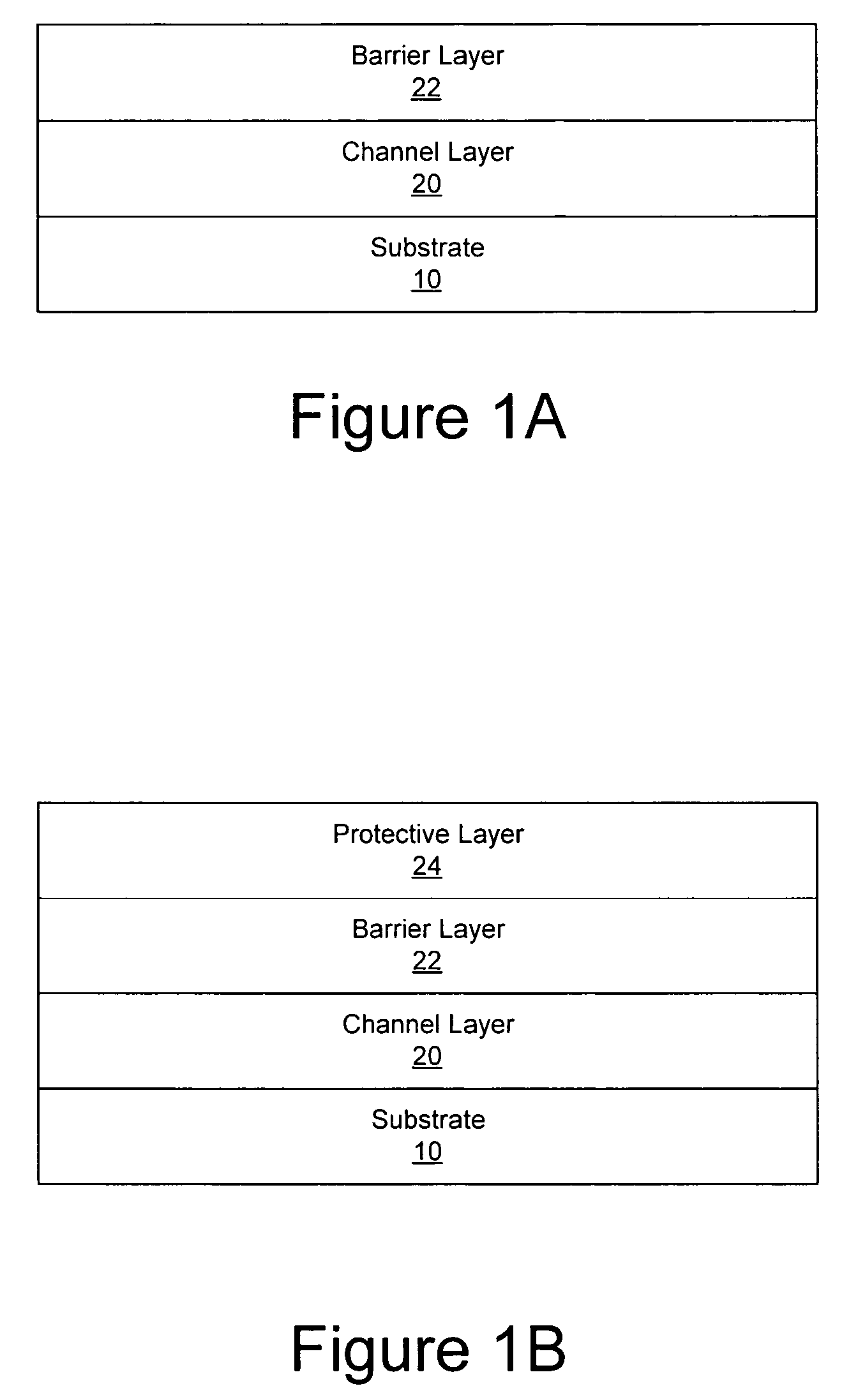

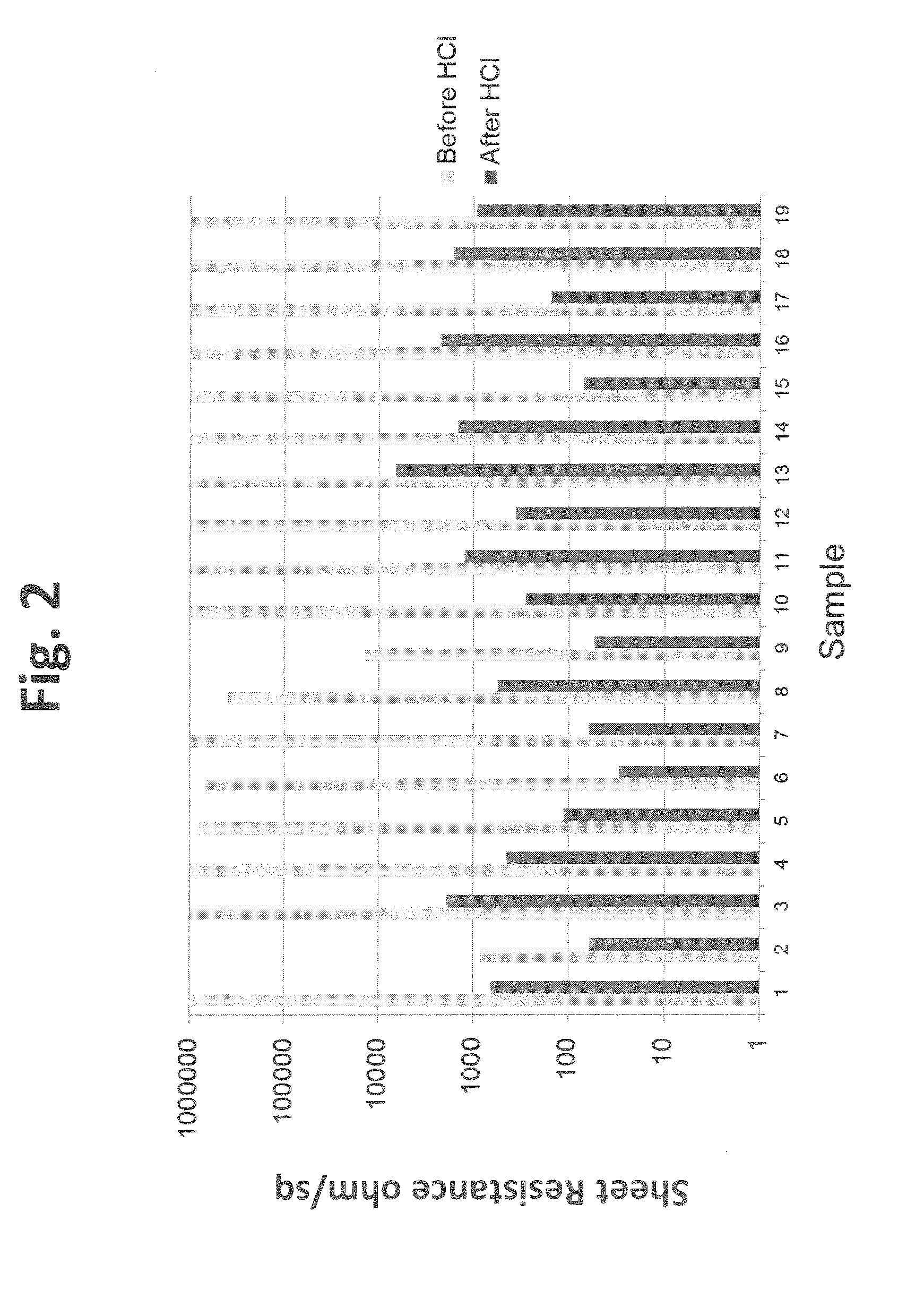

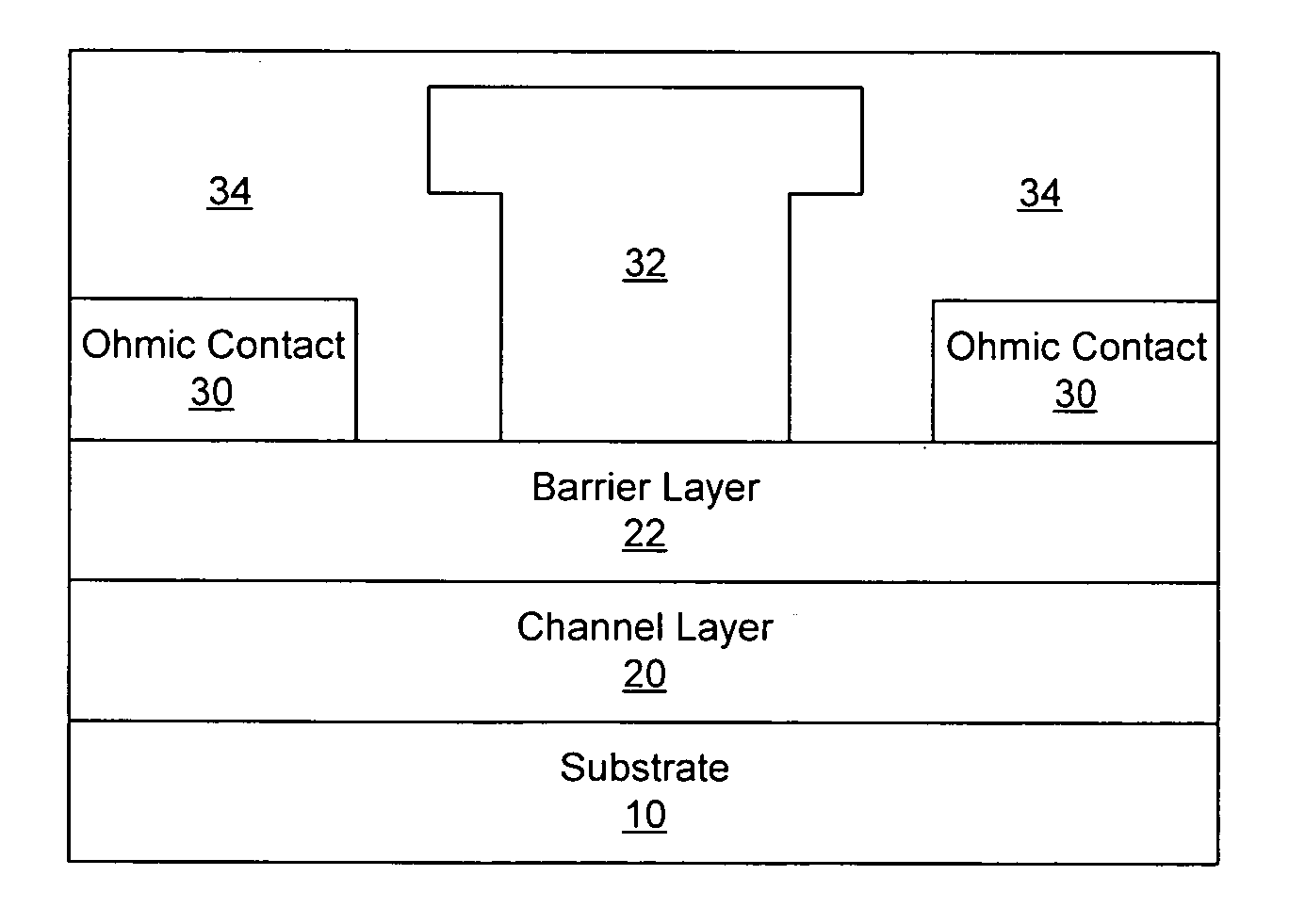

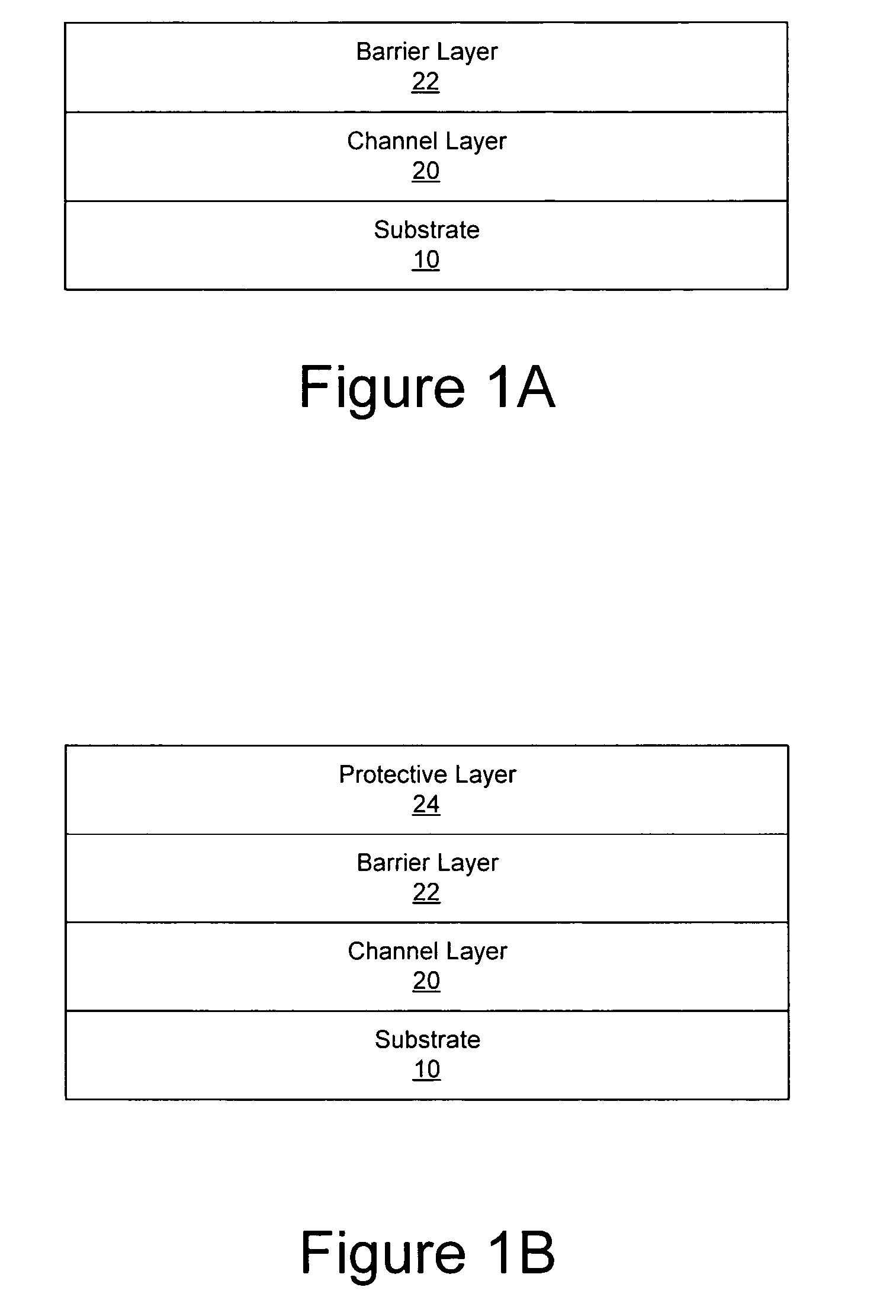

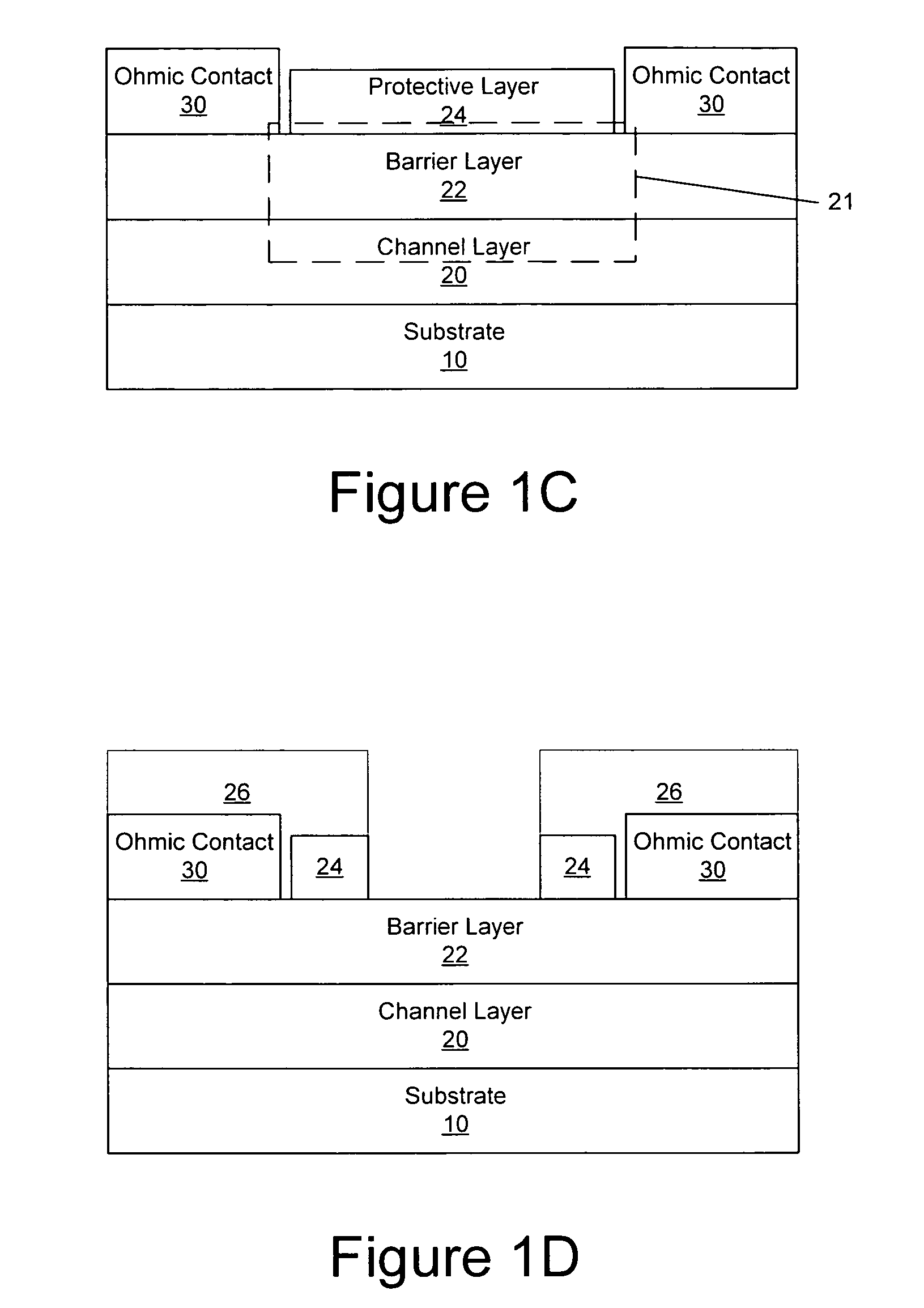

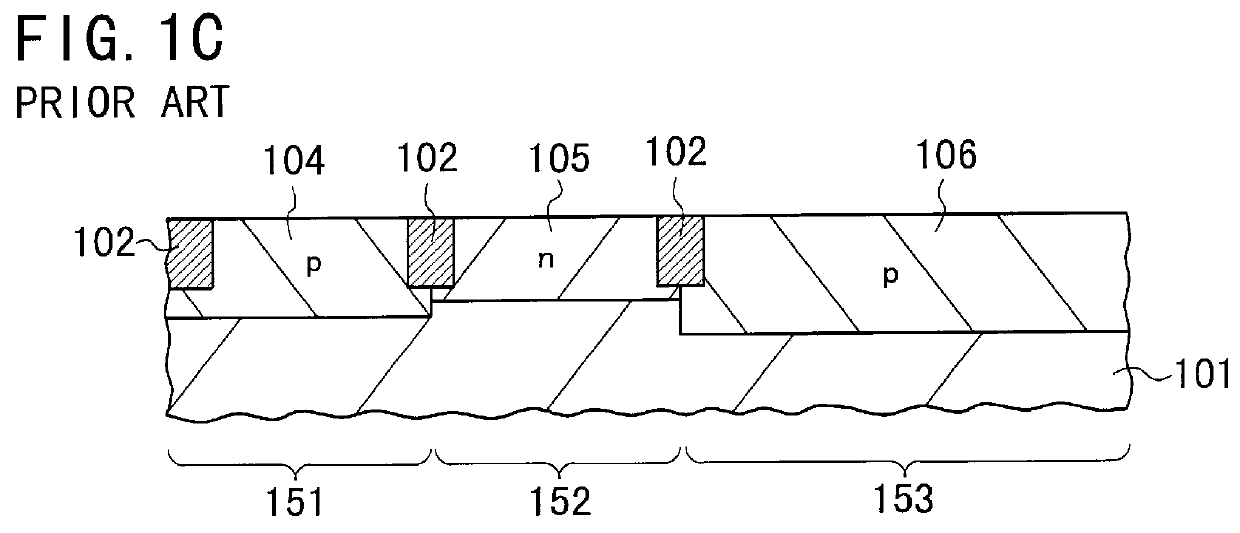

Nitride-based transistors with a protective layer and a low-damage recess and methods of fabrication thereof

ActiveUS7045404B2Semiconductor/solid-state device manufacturingSemiconductor devicesOhmic contactNitride

Transistors are fabricated by forming a nitride-based semiconductor barrier layer on a nitride-based semiconductor channel layer and forming a protective layer on a gate region of the nitride-based semiconductor barrier layer. Patterned ohmic contact metal regions are formed on the barrier layer and annealed to provide first and second ohmic contacts. The annealing is carried out with the protective layer on the gate region. A gate contact is also formed on the gate region of the barrier layer. Transistors having protective layer in the gate region are also provided as are transistors having a barrier layer with a sheet resistance substantially the same as an as-grown sheet resistance of the barrier layer.

Owner:CREE INC

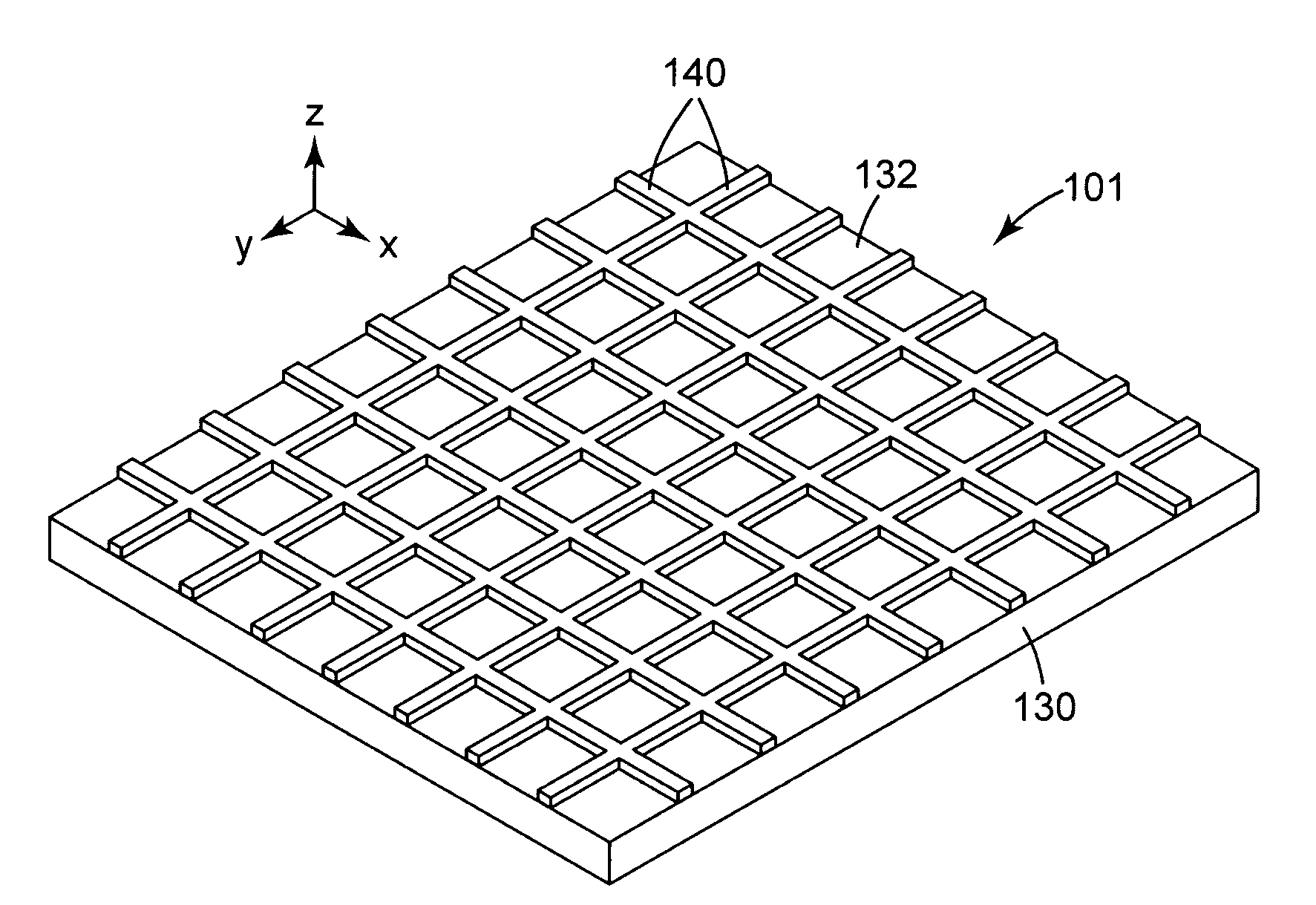

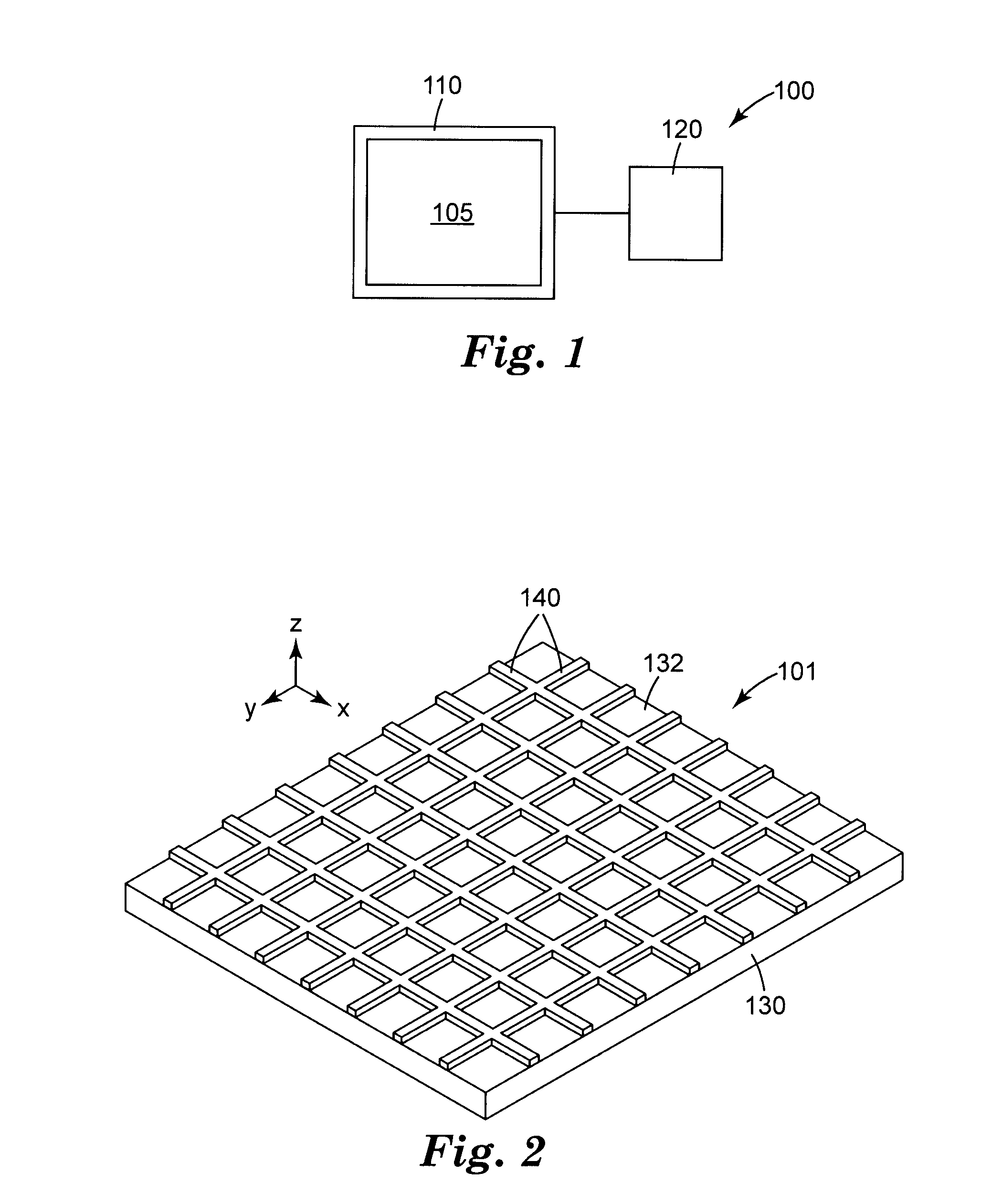

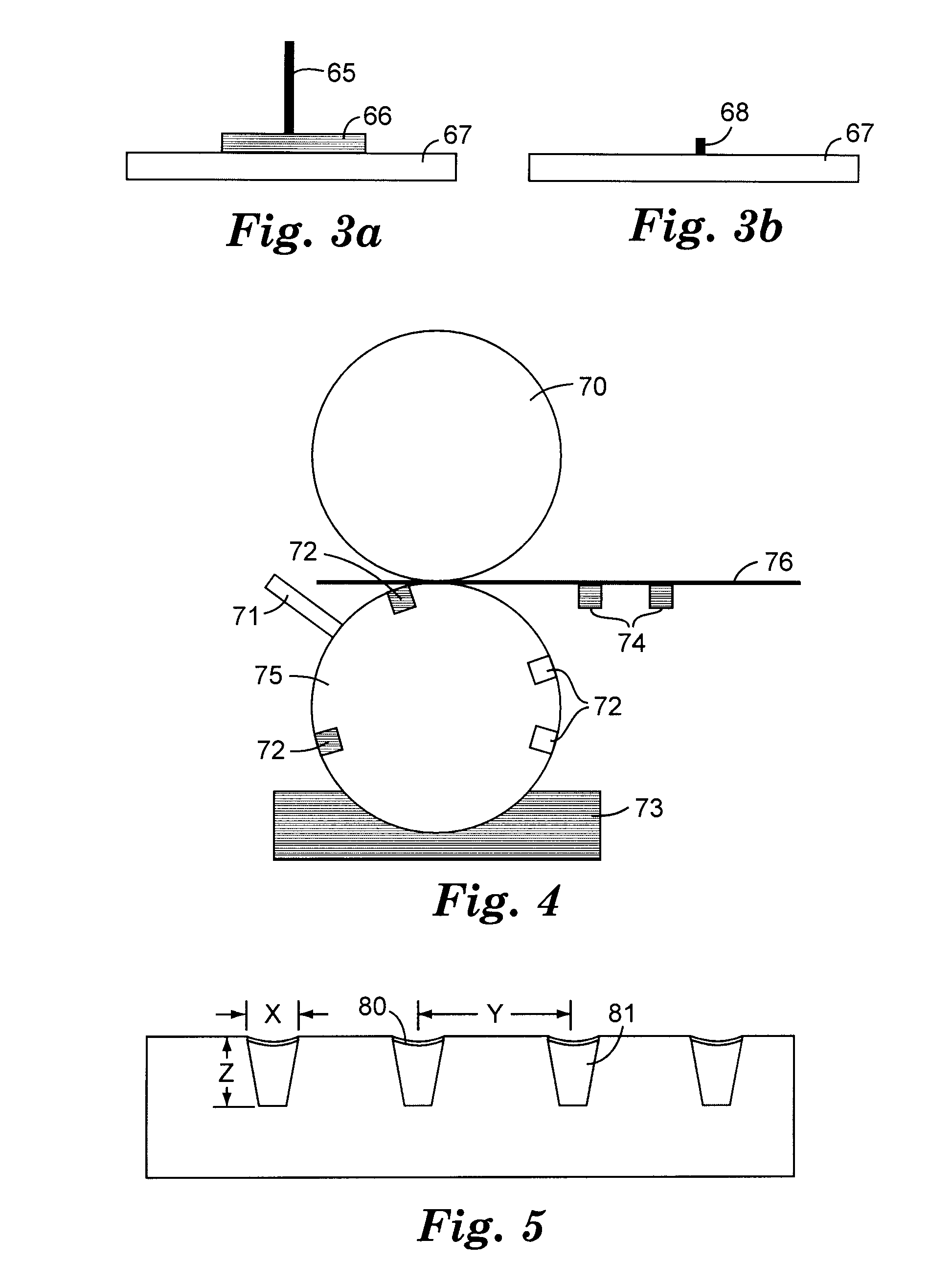

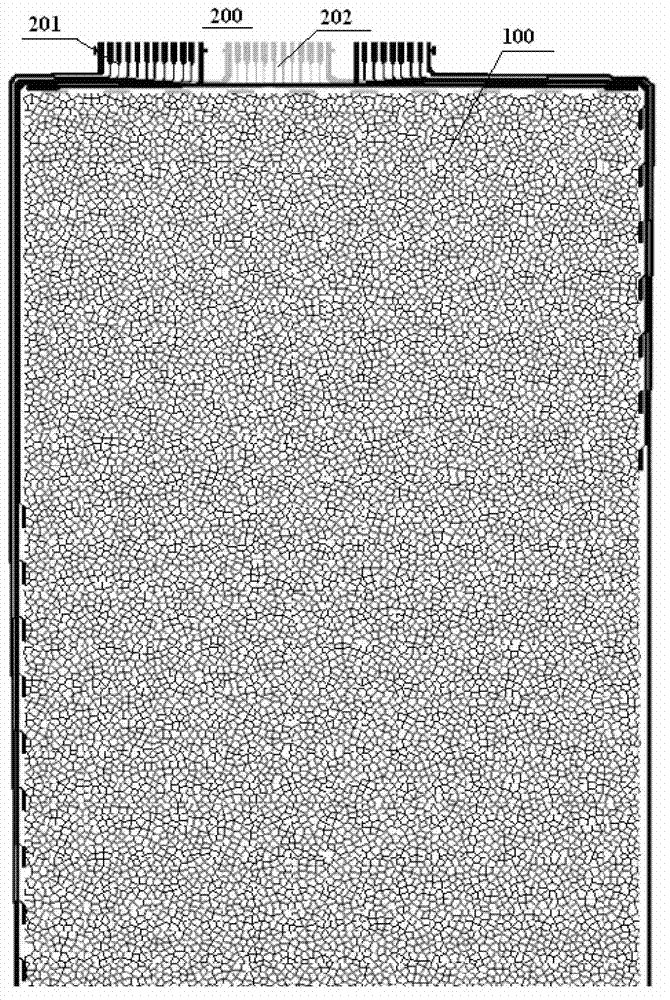

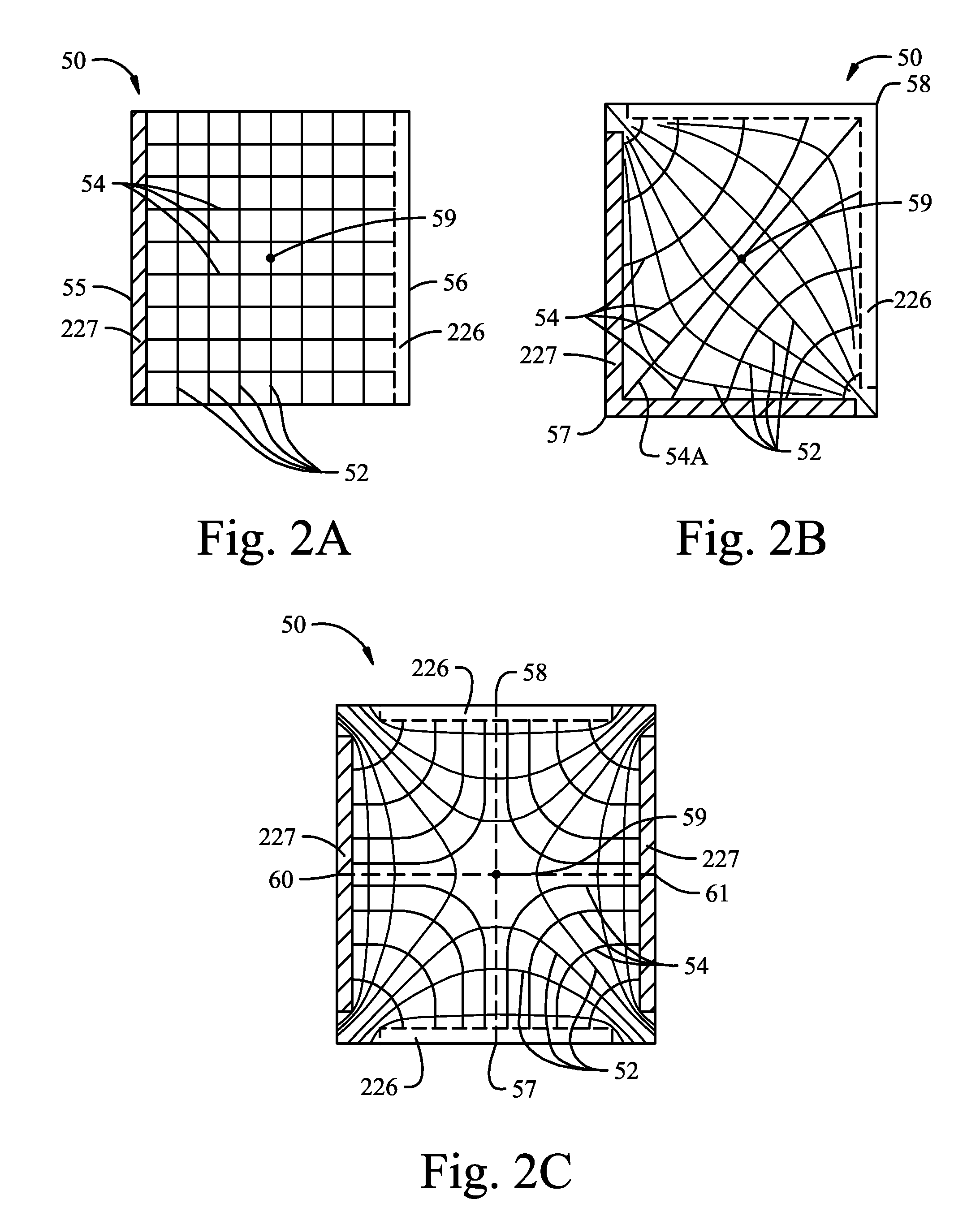

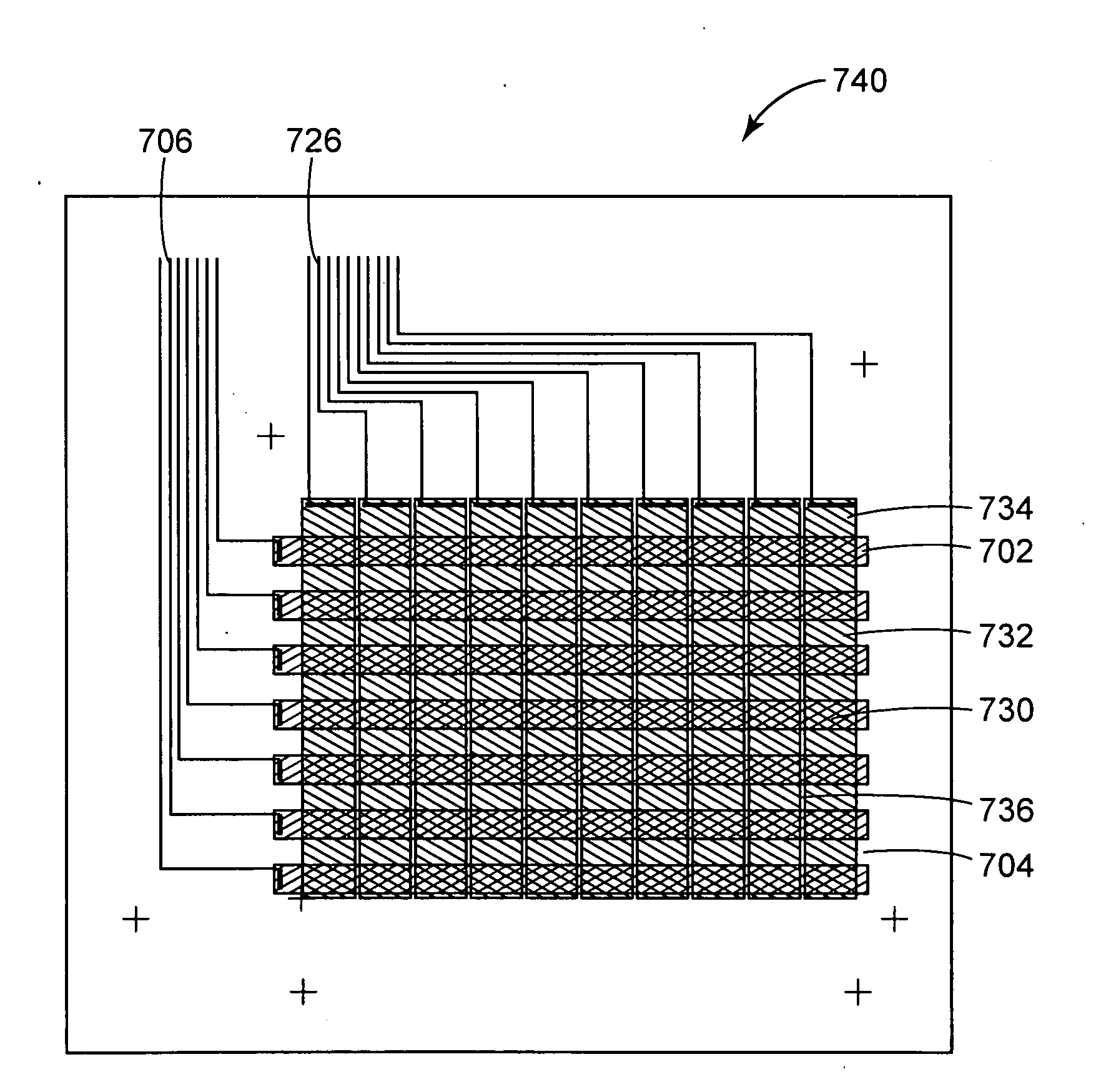

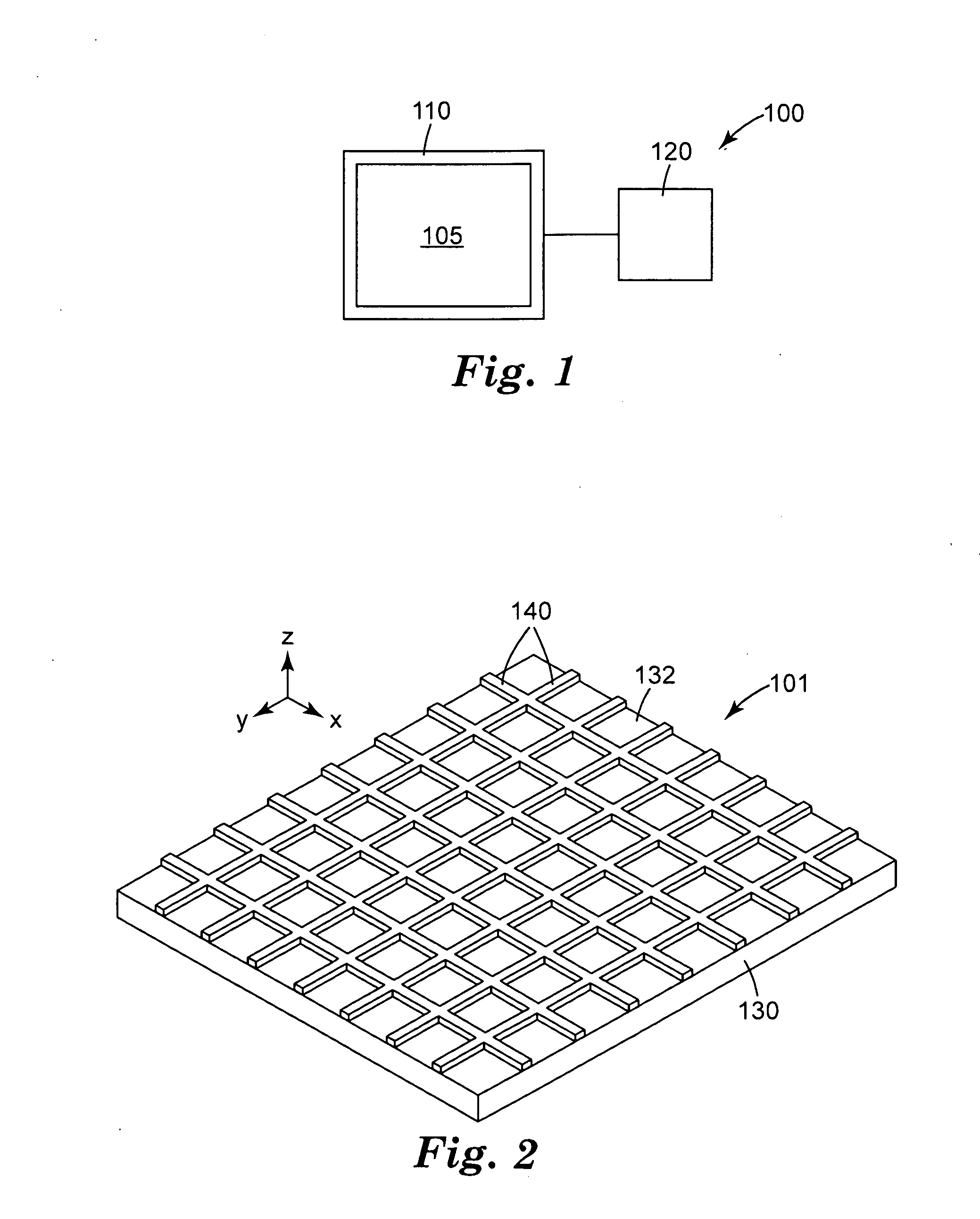

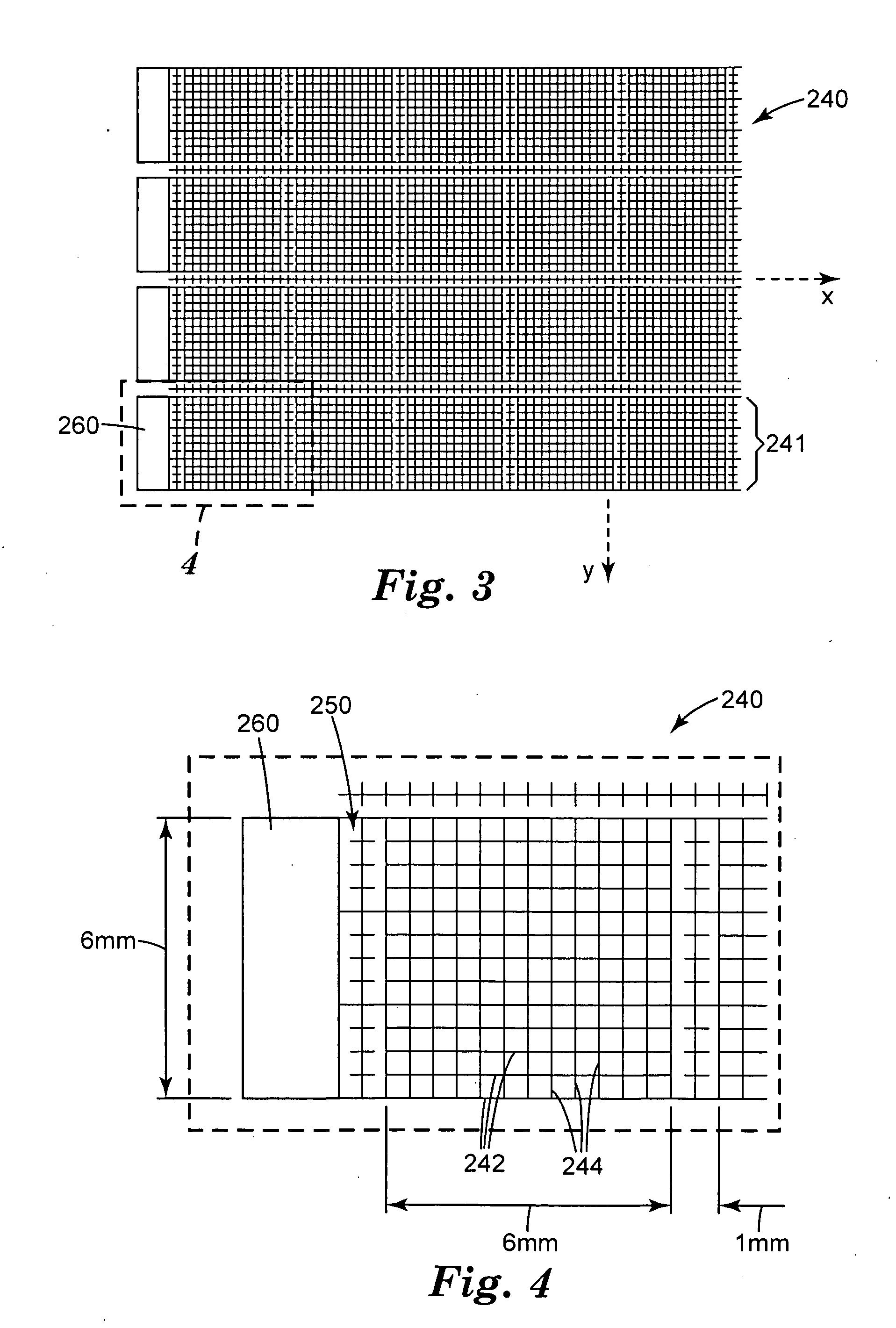

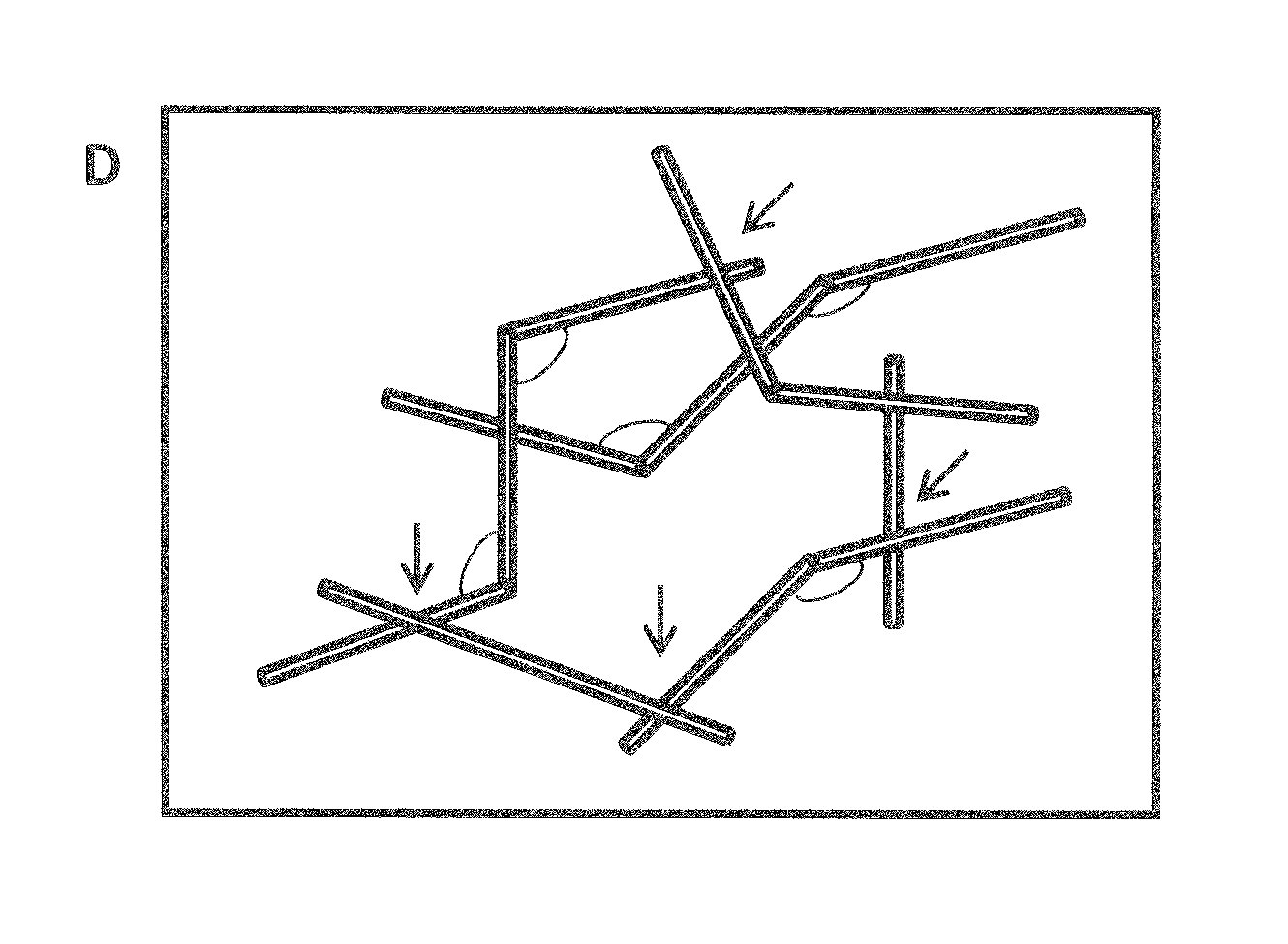

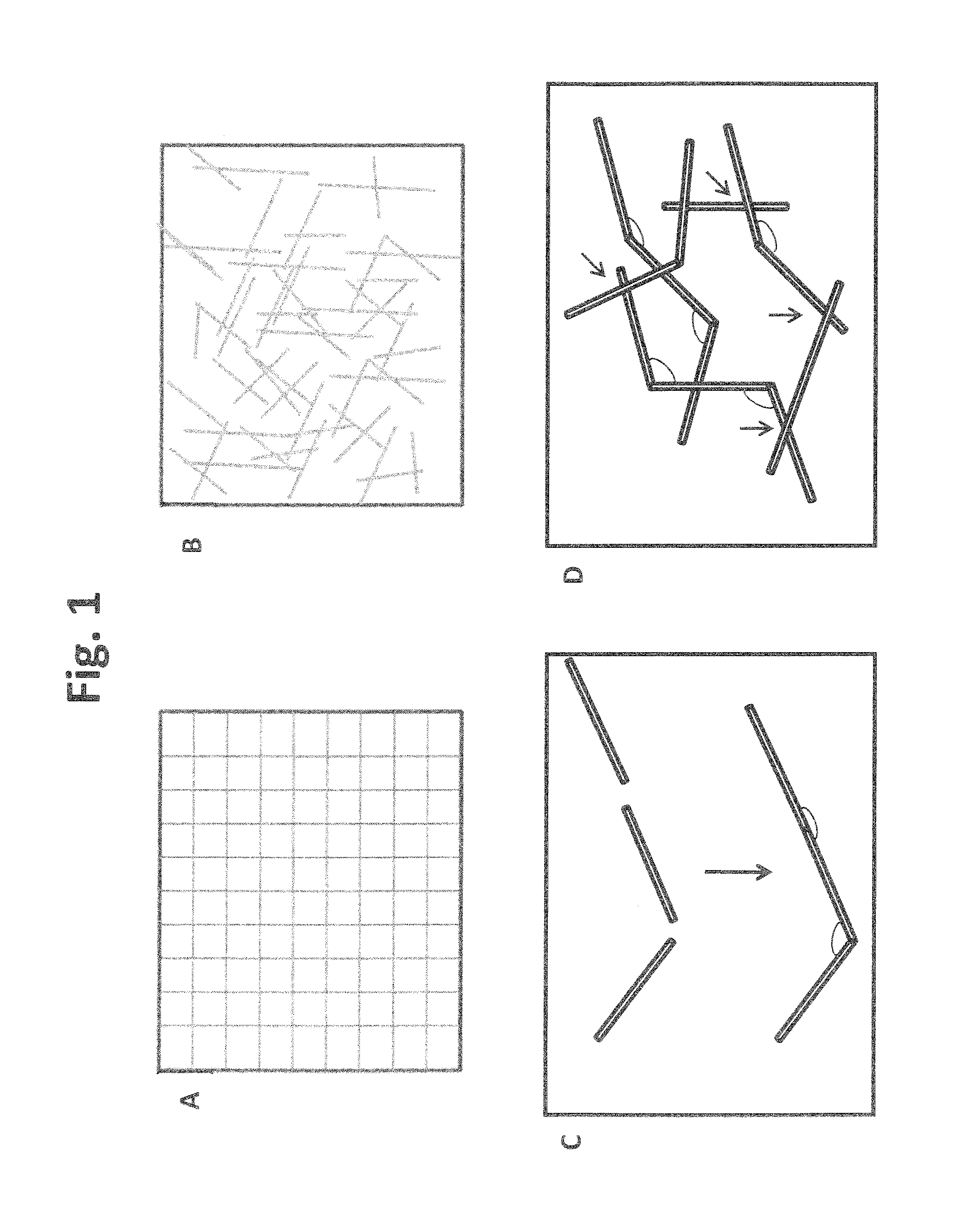

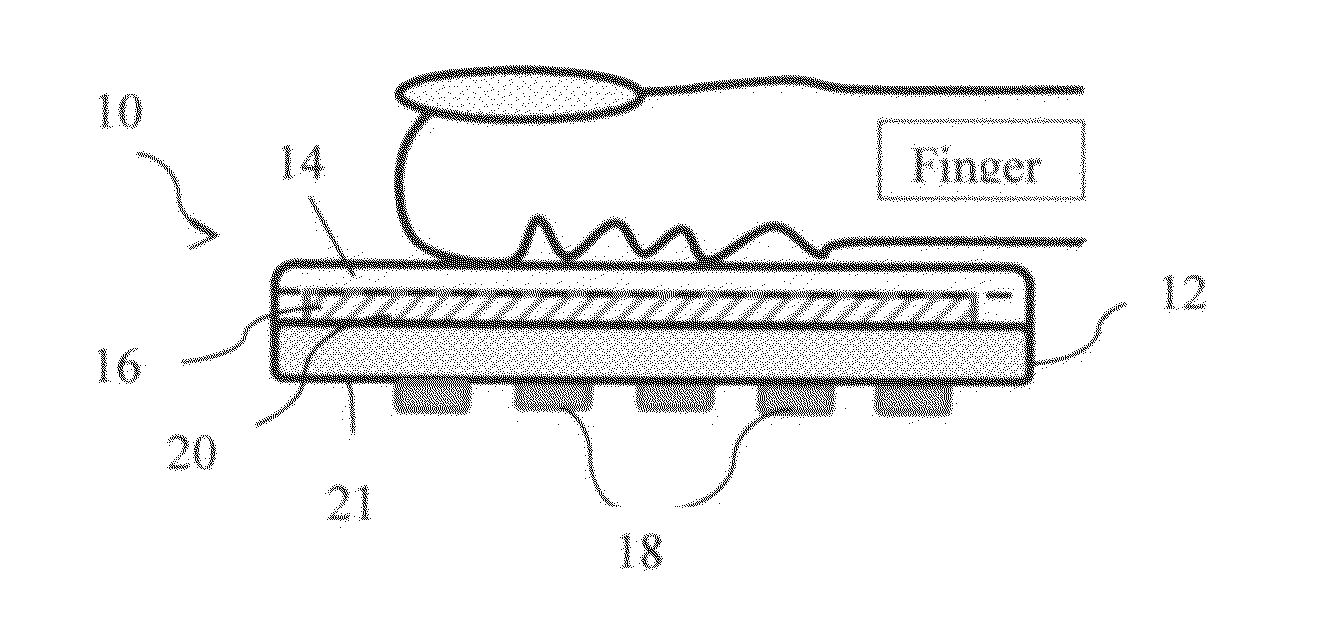

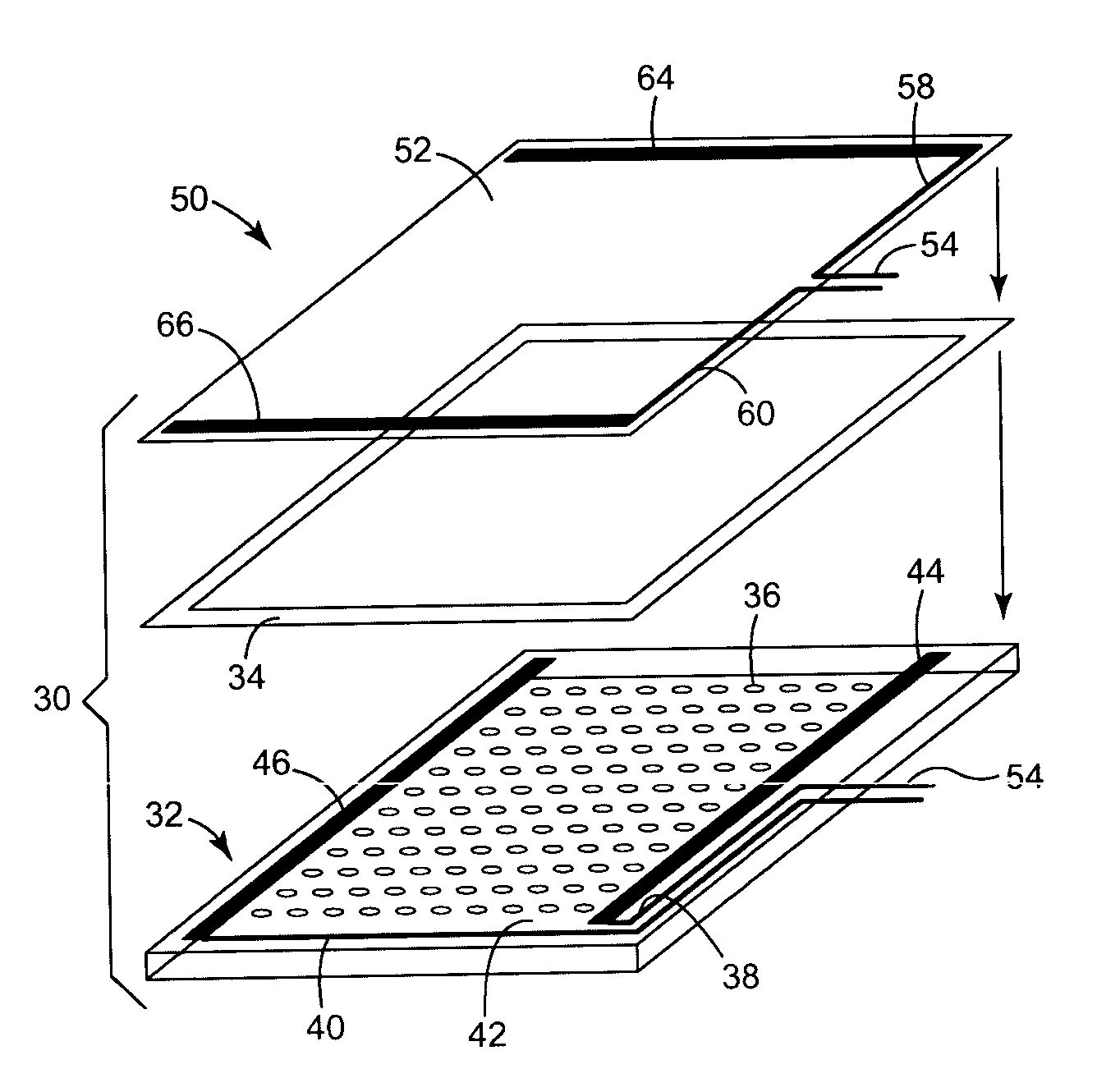

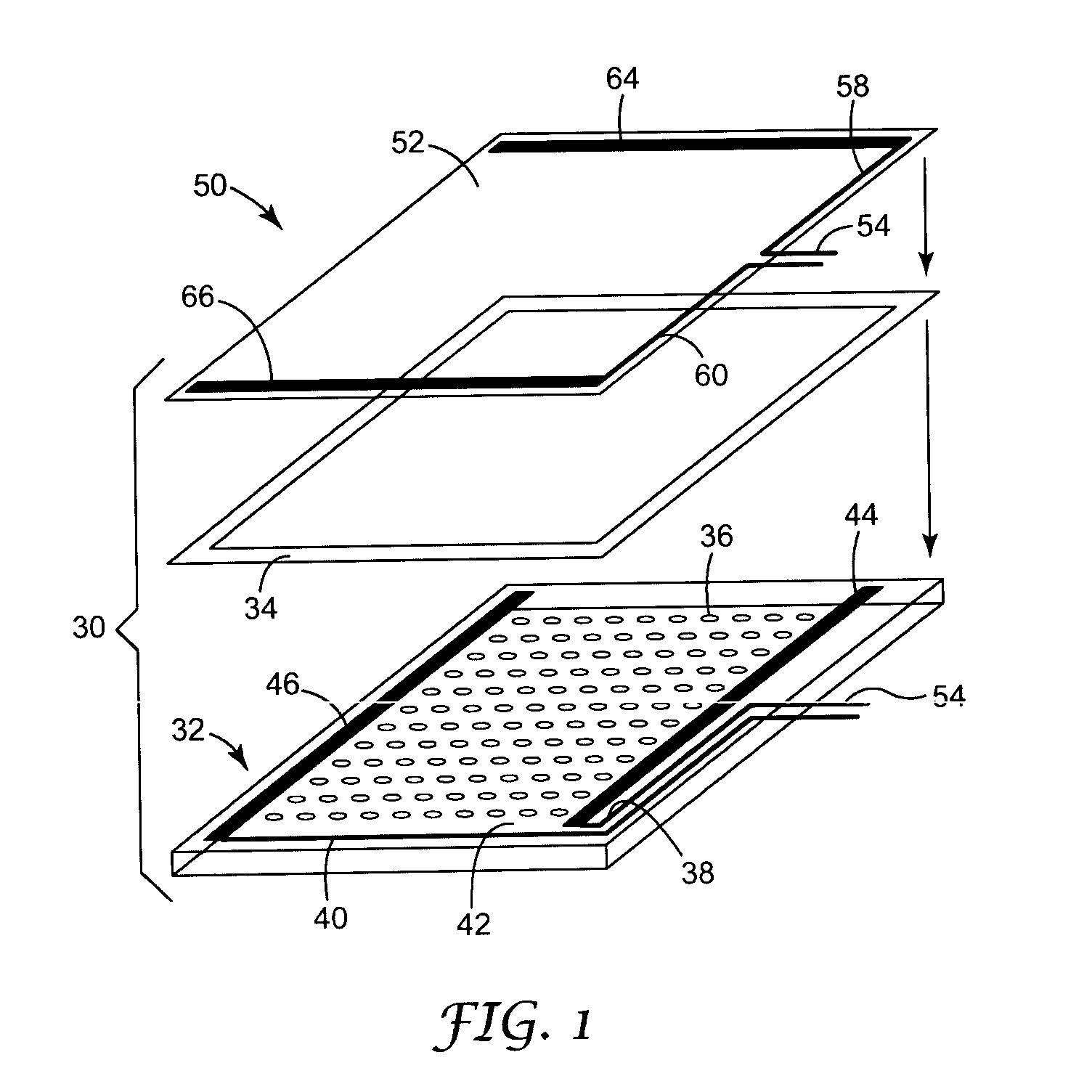

Touch screen sensor having varying sheet resistance

ActiveUS20100156840A1Capacitance measurementsInput/output processes for data processingTouch SensesTouchscreen

A touch screen sensor includes a visible light transparent substrate and an electrically conductive micropattern disposed on or in the visible light transparent substrate. The micropattern includes a first region micropattern within a touch sensing area and a second region micropattern. The first region micropattern has a first sheet resistance value in a first direction, is visible light transparent, and has at least 90% open area. The second region micropattern has a second sheet resistance value in the first direction. The first sheet resistance value is different from the second sheet resistance value.

Owner:3M INNOVATIVE PROPERTIES CO

Heat treatable coated article with zinc oxide inclusive contact layer(s)

InactiveUS6887575B2Reduce sheet resistanceImprove performanceVacuum evaporation coatingSputtering coatingElectrical resistance and conductanceContact layer

A coated article is provided so as to have a fairly high visible transmission (TY or Tvis) to sheet resistance (Rs) ratio (i.e., a ratio Tvis / Rs). The higher this ratio, the better the coated article's combined functionality of providing for both good solar performance (e.g., ability to reflect and / or absorb IR radiation) and high visible transmission. In certain example embodiments, coated articles herein may be heat treatable. Coated articles herein may be used in the context of insulating glass (IG) window units, architectural or residential monolithic window units, vehicle window units, and / or the like.

Owner:GUARDIAN GLASS LLC

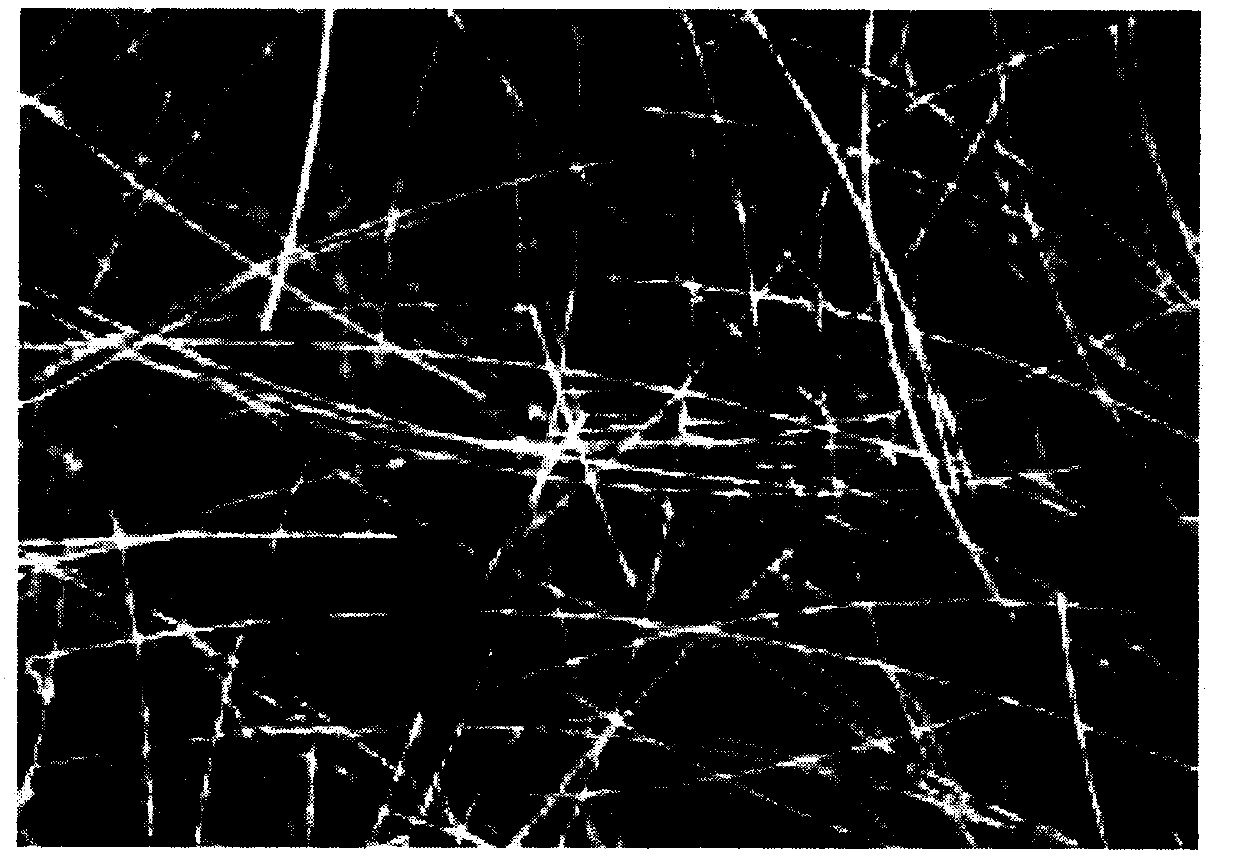

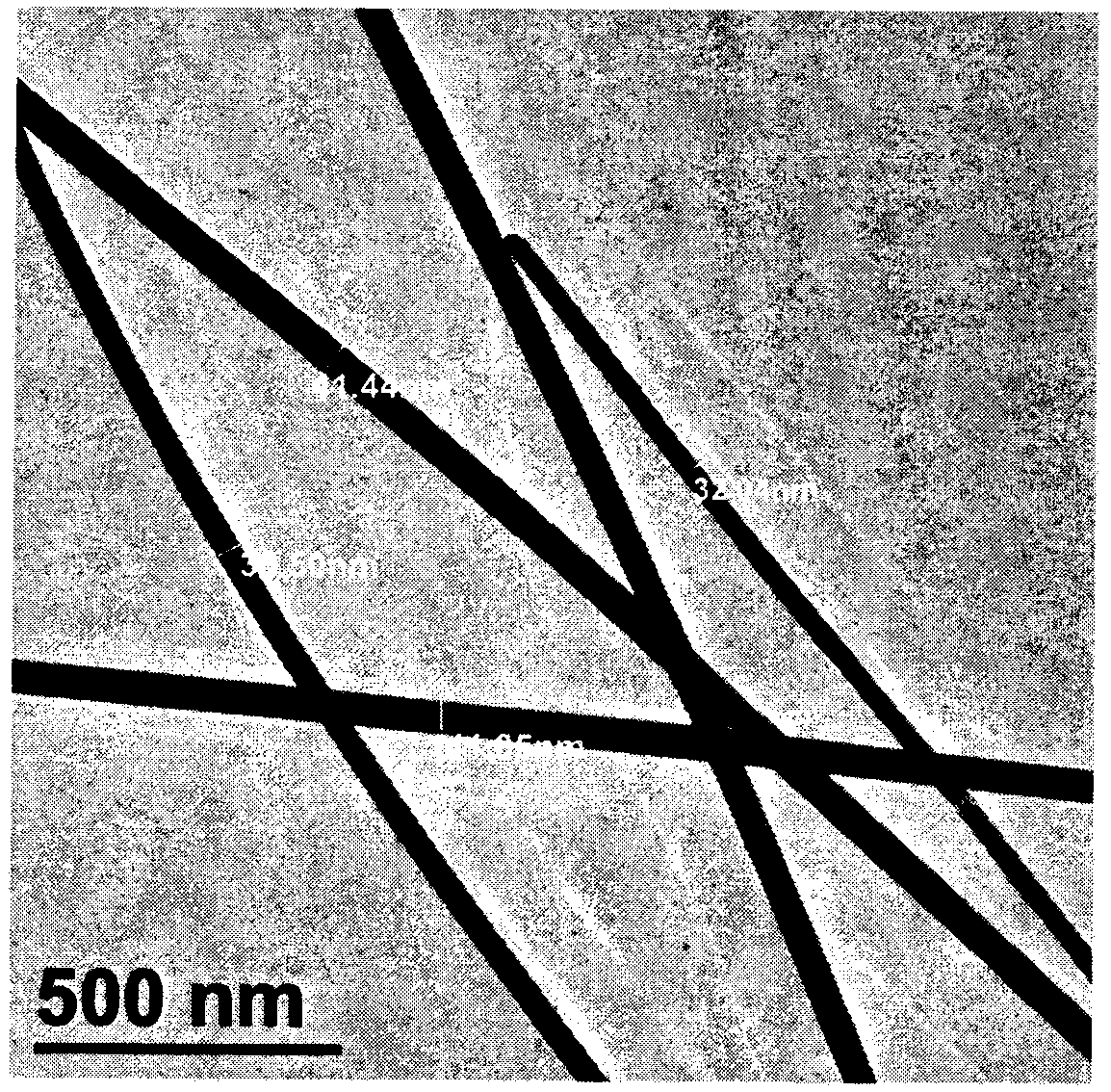

Metal nanowire networks and transparent conductive material

ActiveUS20130341074A1Material nanotechnologyTransparent dielectricsElectrical resistance and conductanceOptical transparency

Metal nanowires, such as silver nanowires coated on a substrate were fused together to form fused metal nanowire networks that have greatly improved conductivity while maintaining good transparency. Materials formed form the fused metal nanowire networks described herein can have a transparency to visible light of at least about 85% and a sheet resistance of no more than about 100 Ohms / square or a transparency to visible light of at least about 90% and a sheet resistance of no more than about 250 Ohms / square. The method of forming such a fused metal nanowire networks are disclosed that involves exposure of metal nanowires to various fusing agents on a short timescale. When formed into a film, materials comprising the metal nanowire network demonstrate low sheet resistance while maintaining desirably high levels of optical transparency, making them suitable for transparent electrode formation.

Owner:C3 NANO INC

Nitride-based transistors with a protective layer and a low-damage recess and methods of fabrication thereof

ActiveUS20050170574A1Semiconductor/solid-state device manufacturingSemiconductor devicesOhmic contactNitride

Transistors are fabricated by forming a nitride-based semiconductor barrier layer on a nitride-based semiconductor channel layer and forming a protective layer on a gate region of the nitride-based semiconductor barrier layer. Patterned ohmic contact metal regions are formed on the barrier layer and annealed to provide first and second ohmic contacts. The annealing is carried out with the protective layer on the gate region. A gate contact is also formed on the gate region of the barrier layer. Transistors having protective layer in the gate region are also provided as are transistors having a barrier layer with a sheet resistance substantially the same as an as-grown sheet resistance of the barrier layer.

Owner:CREE INC

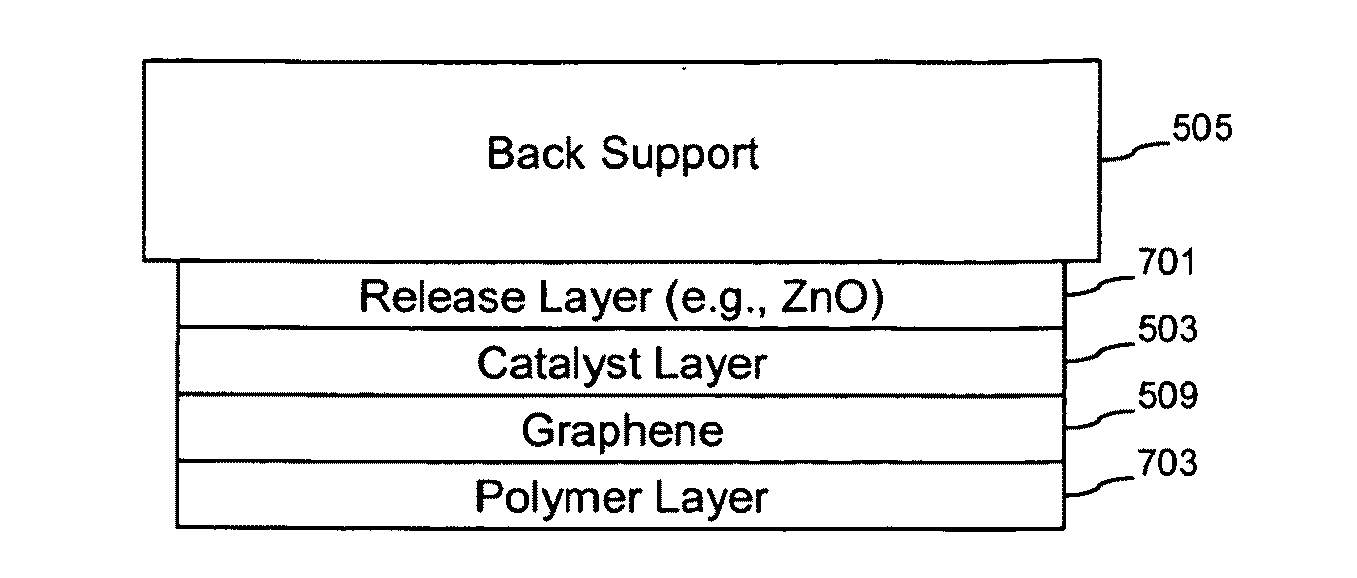

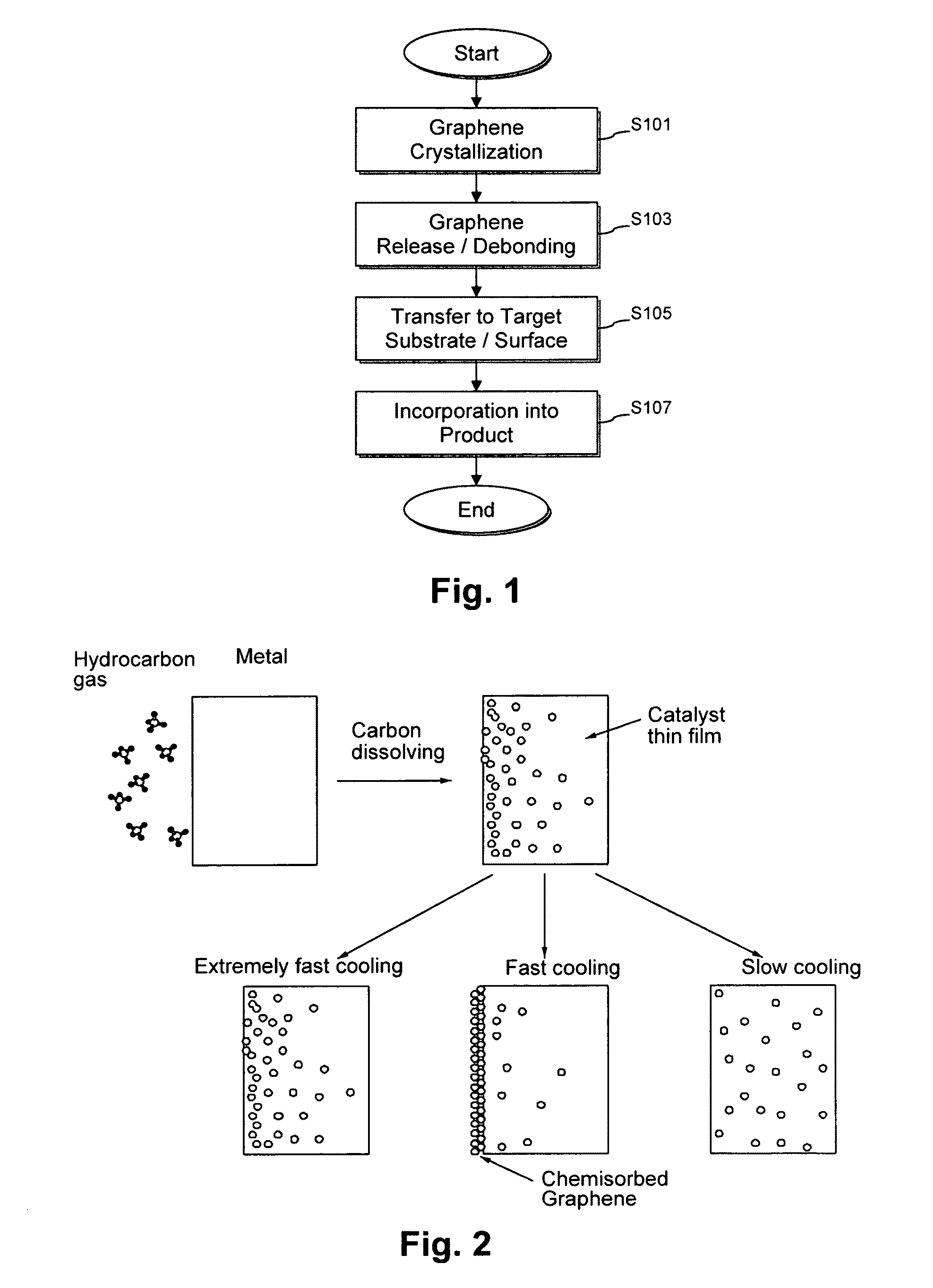

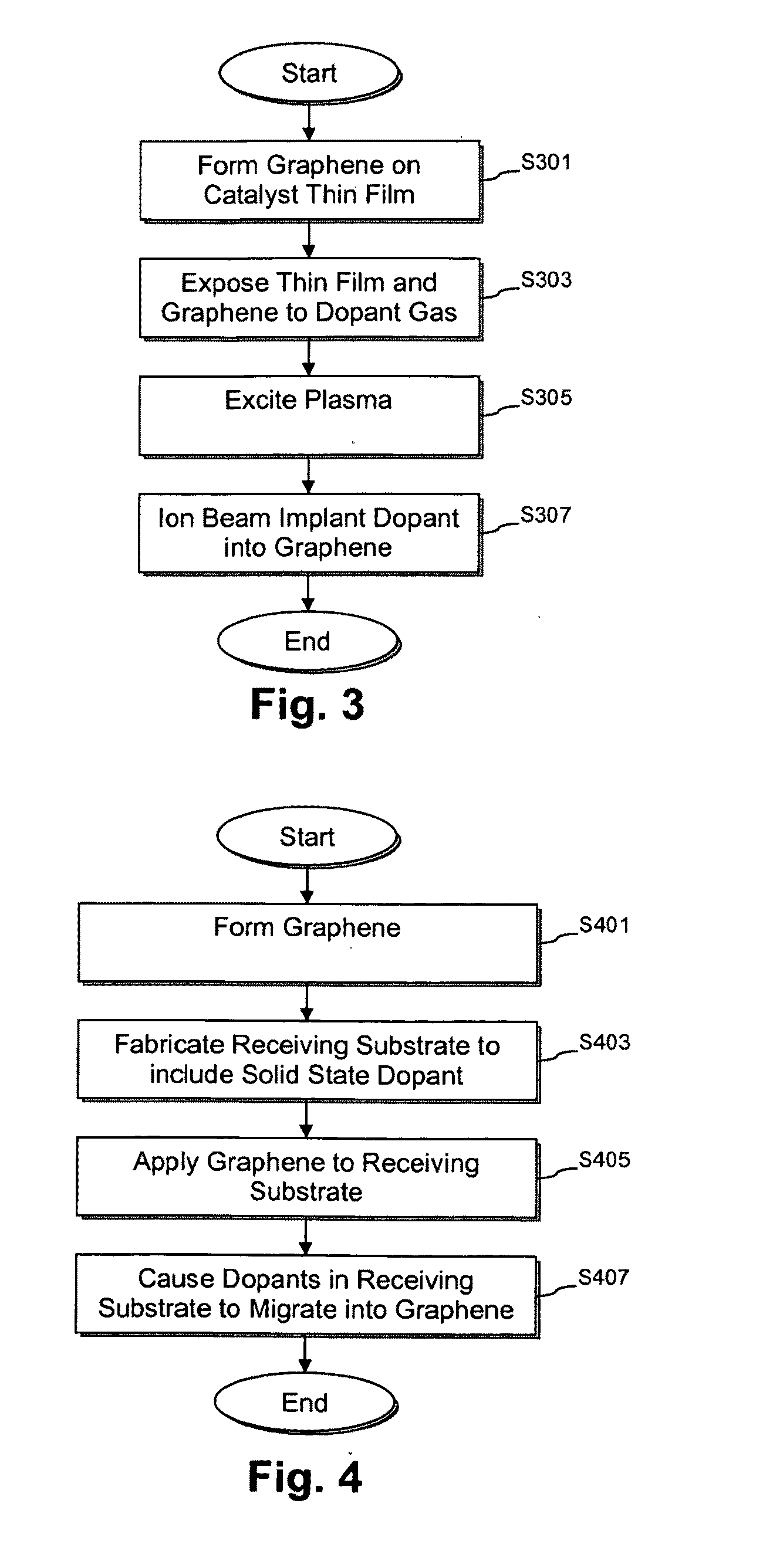

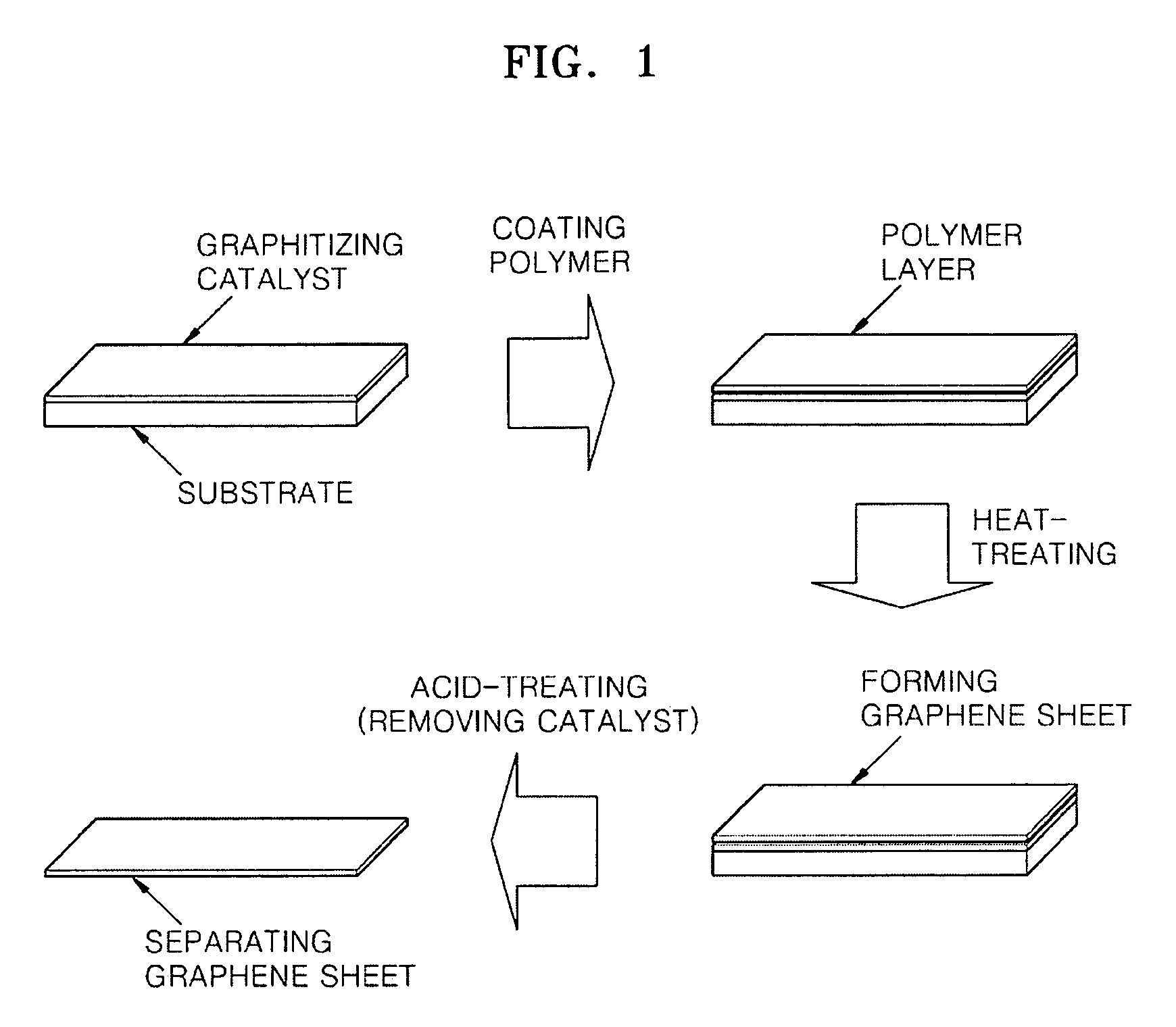

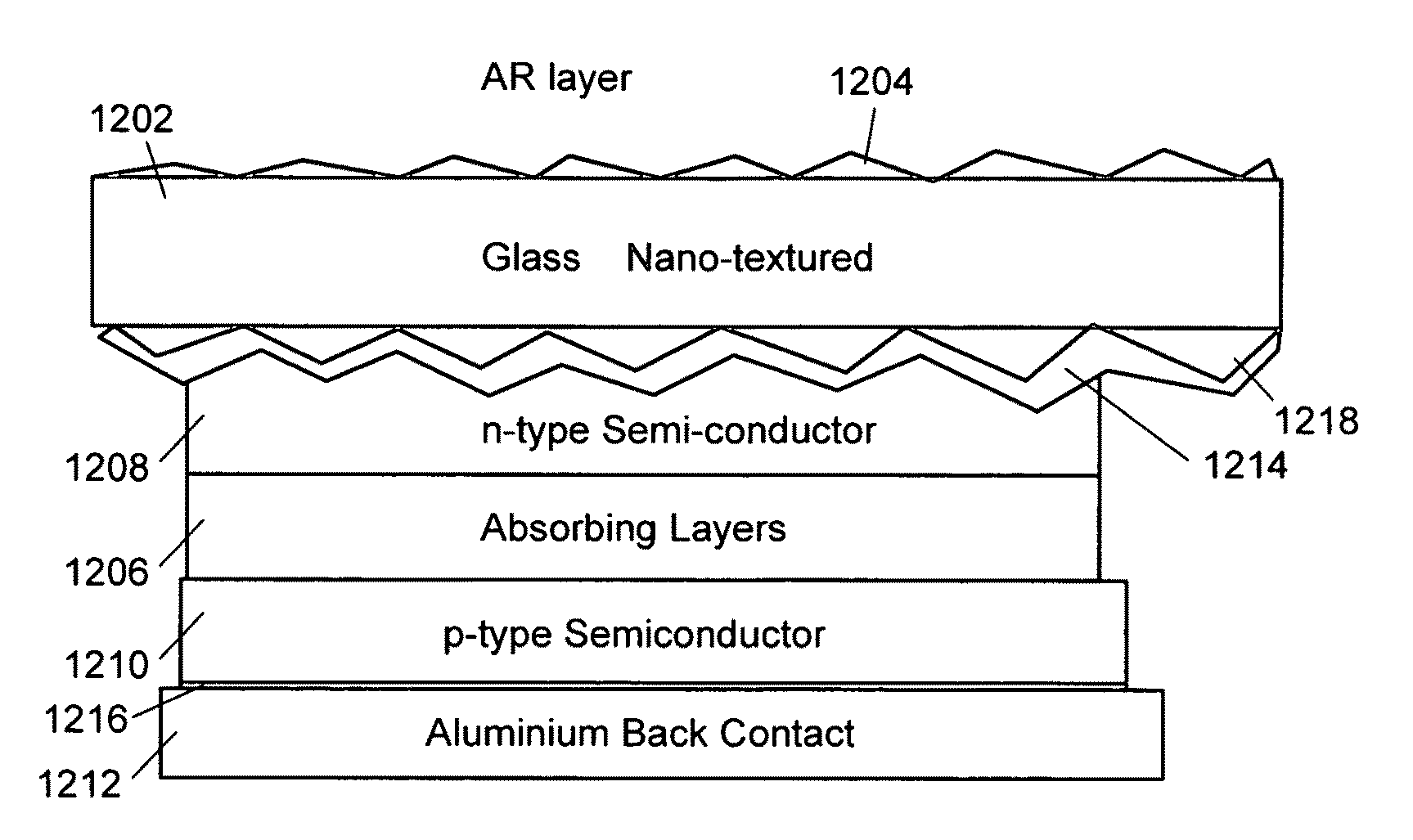

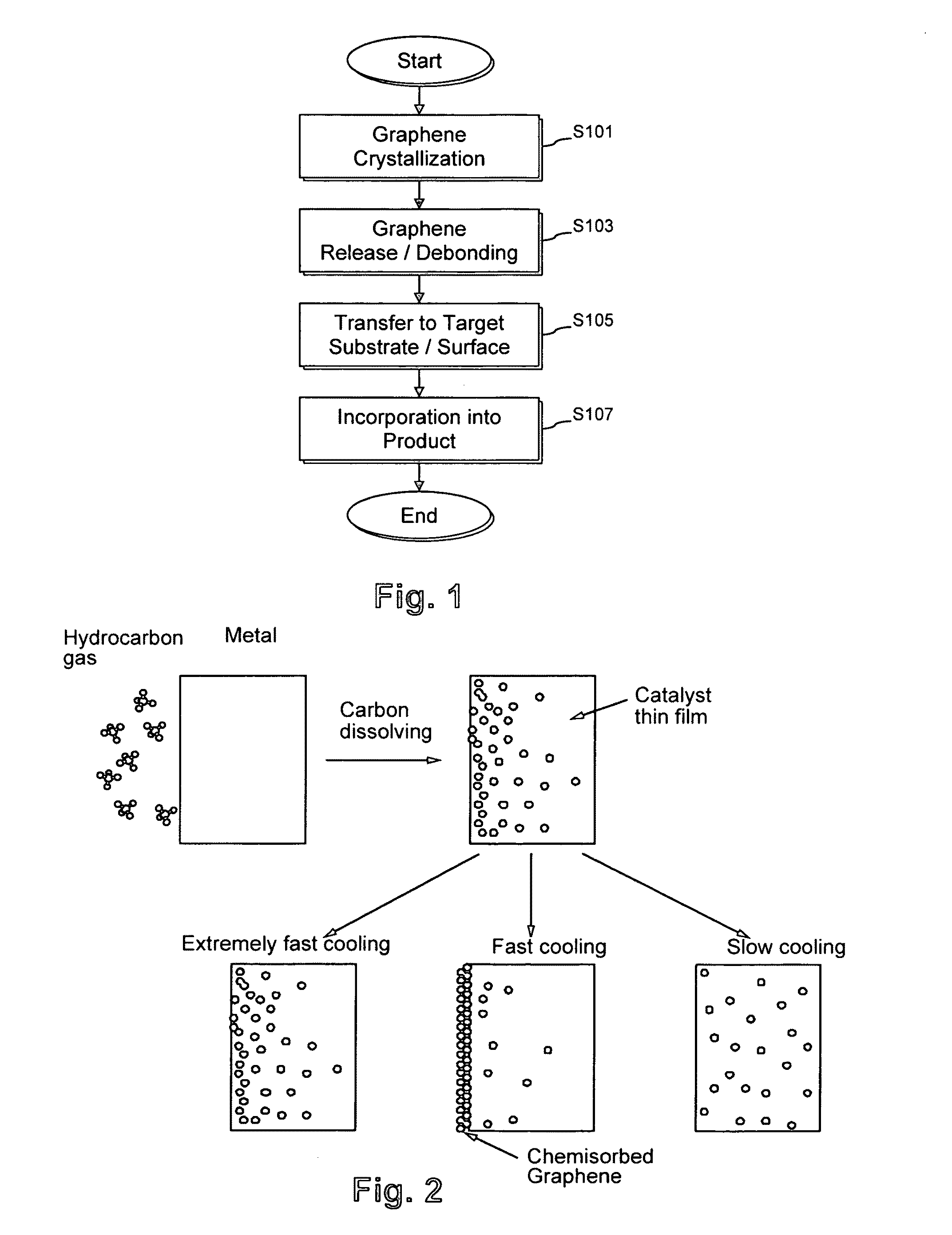

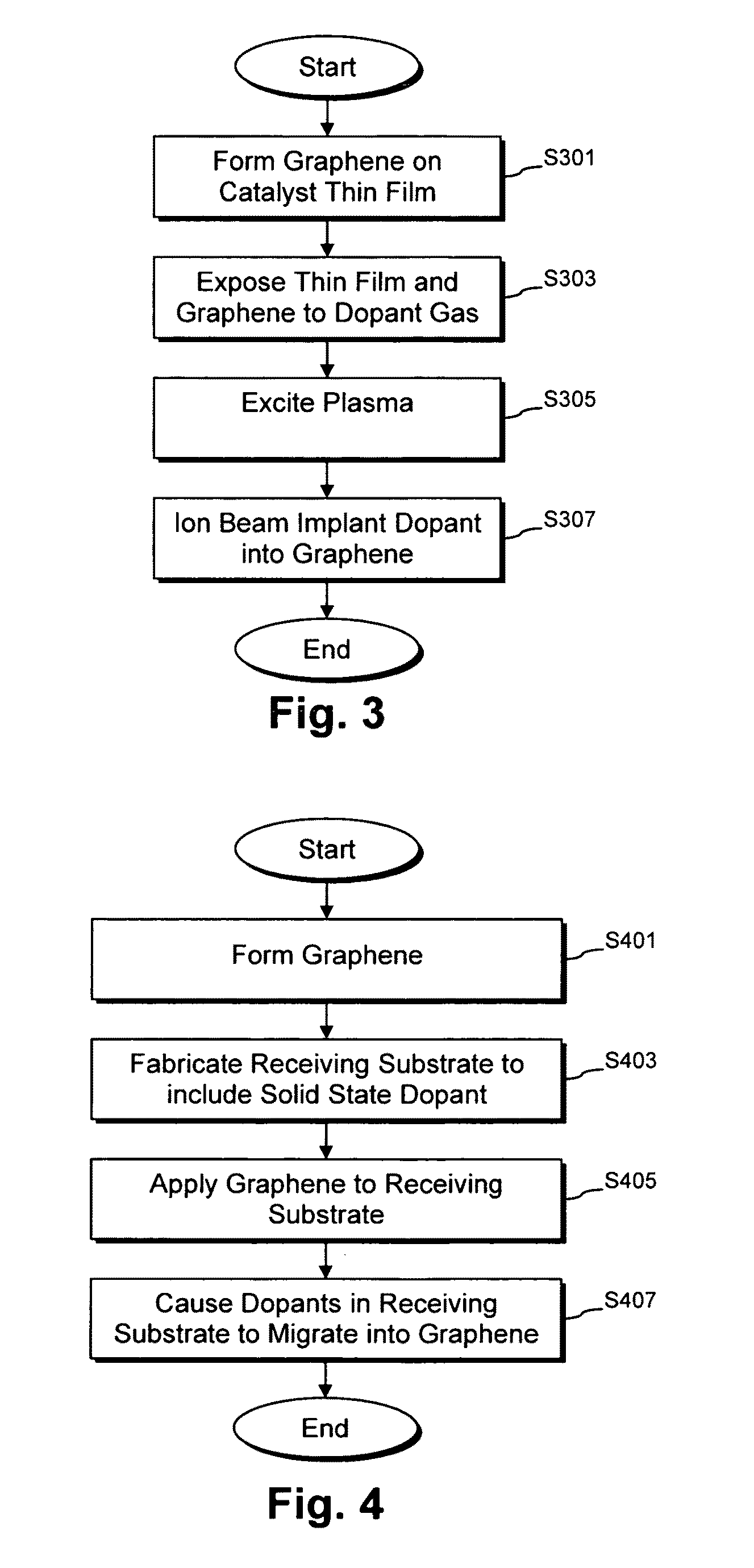

Large area deposition and doping of graphene, and products including the same

InactiveUS20110030991A1Reduced dimensionGood effectMaterial nanotechnologyNon-insulated conductorsConductive coatingTransmittance

Certain example embodiments of this invention relate to the use of graphene as a transparent conductive coating (TCC). In certain example embodiments, graphene thin films grown on large areas hetero-epitaxially, e.g., on a catalyst thin film, from a hydrocarbon gas (such as, for example, C2H2, CH4, or the like). The graphene thin films of certain example embodiments may be doped or undoped. In certain example embodiments, graphene thin films, once formed, may be lifted off of their carrier substrates and transferred to receiving substrates, e.g., for inclusion in an intermediate or final product. Graphene grown, lifted, and transferred in this way may exhibit low sheet resistances (e.g., less than 150 ohms / square and lower when doped) and high transmission values (e.g., at least in the visible and infrared spectra).

Owner:GUARDIAN GLASS LLC

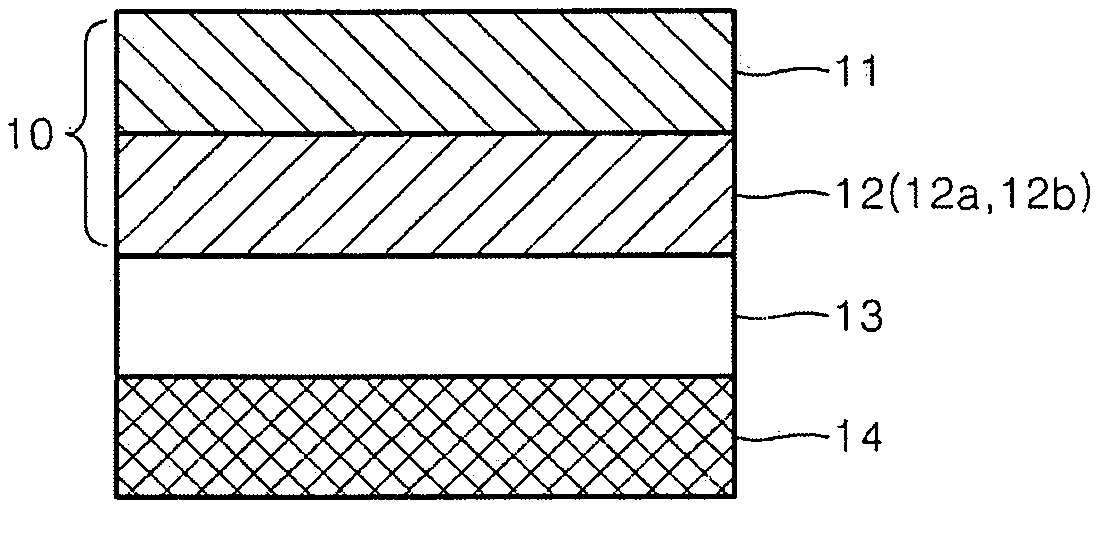

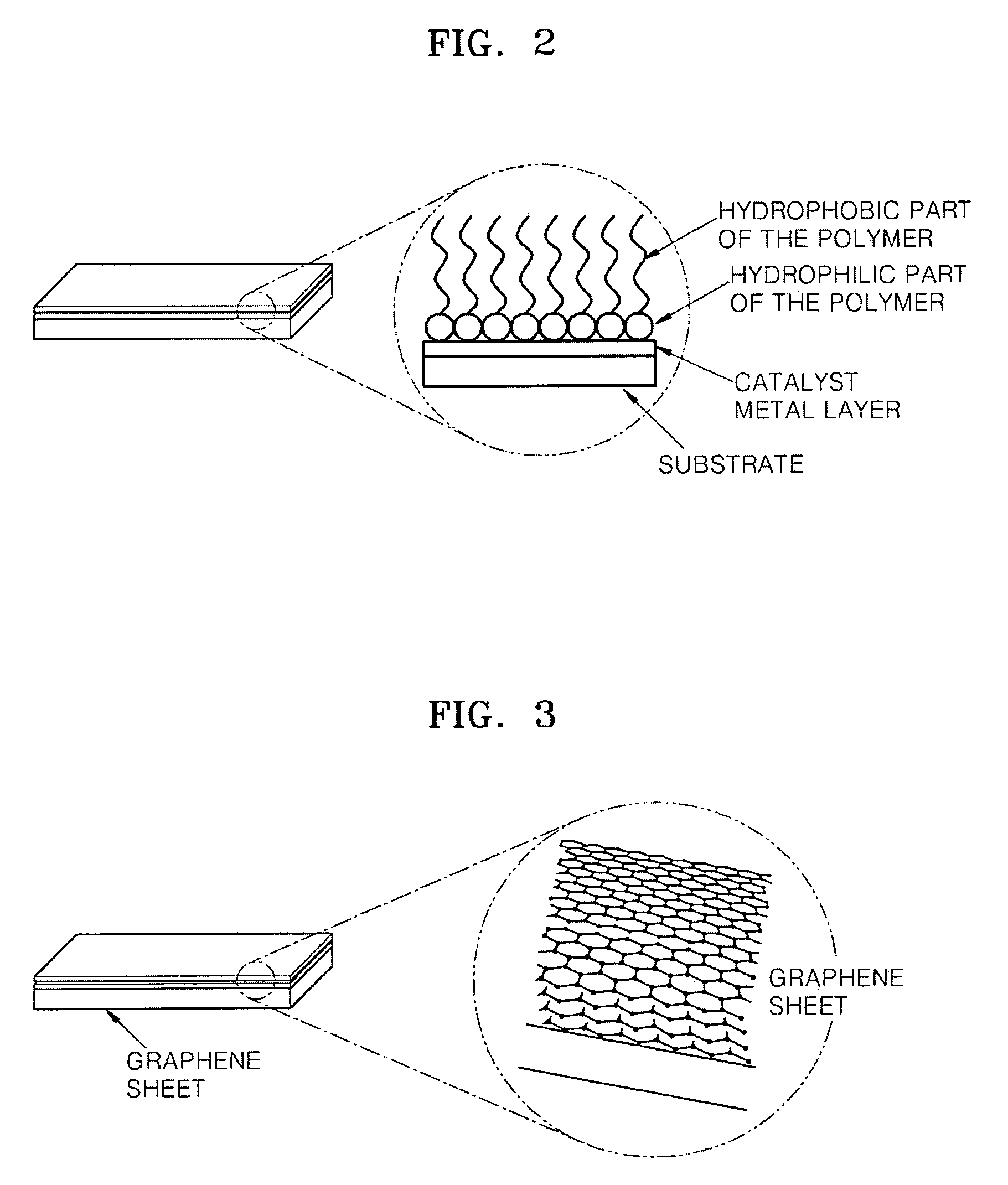

Transparent electrode comprising graphene sheet, and display and solar cell including the electrode

ActiveUS20090071533A1Improve electricityImproved physical characteristicElectroluminescent light sourcesConductive materialDisplay deviceSurface roughness

Provided is a transparent electrode including a graphene sheet. A transparent electrode having high conductivity, low sheet resistance, and low surface roughness can be prepared by employing the graphene sheet.

Owner:SAMSUNG ELECTRONICS CO LTD

Articles including anticondensation and/or low-E coatings and/or methods of making the same

ActiveUS20110212311A1Reduce sheet resistanceLow emissivityWindowsWindscreensEmissivityRefrigerated temperature

Certain example embodiments of this invention relate to articles including anticondensation and / or low-E coatings that are exposed to an external environment, and / or methods of making the same. In certain example embodiments, the anticondensation and / or low-E coatings may be survivable in an outside environment. The coatings also may have a sufficiently low sheet resistance and hemispherical emissivity such that the glass surface is more likely to retain heat from the interior area, thereby reducing (and sometimes completely eliminating) the presence condensation thereon. The articles of certain example embodiments may be, for example, skylights, vehicle windows or windshields, IG units, VIG units, refrigerator / freezer doors, and / or the like.

Owner:GUARDIAN GLASS LLC

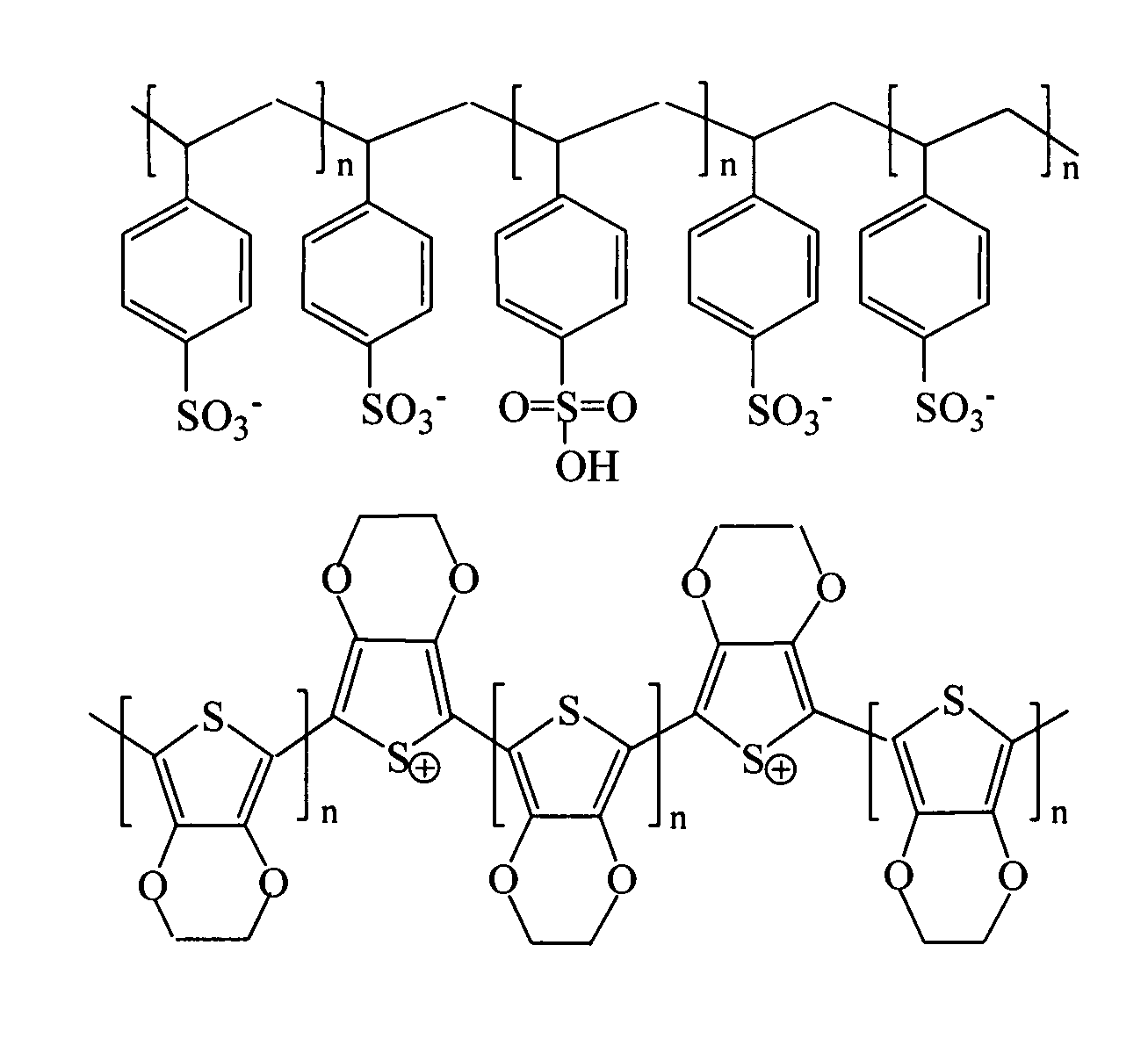

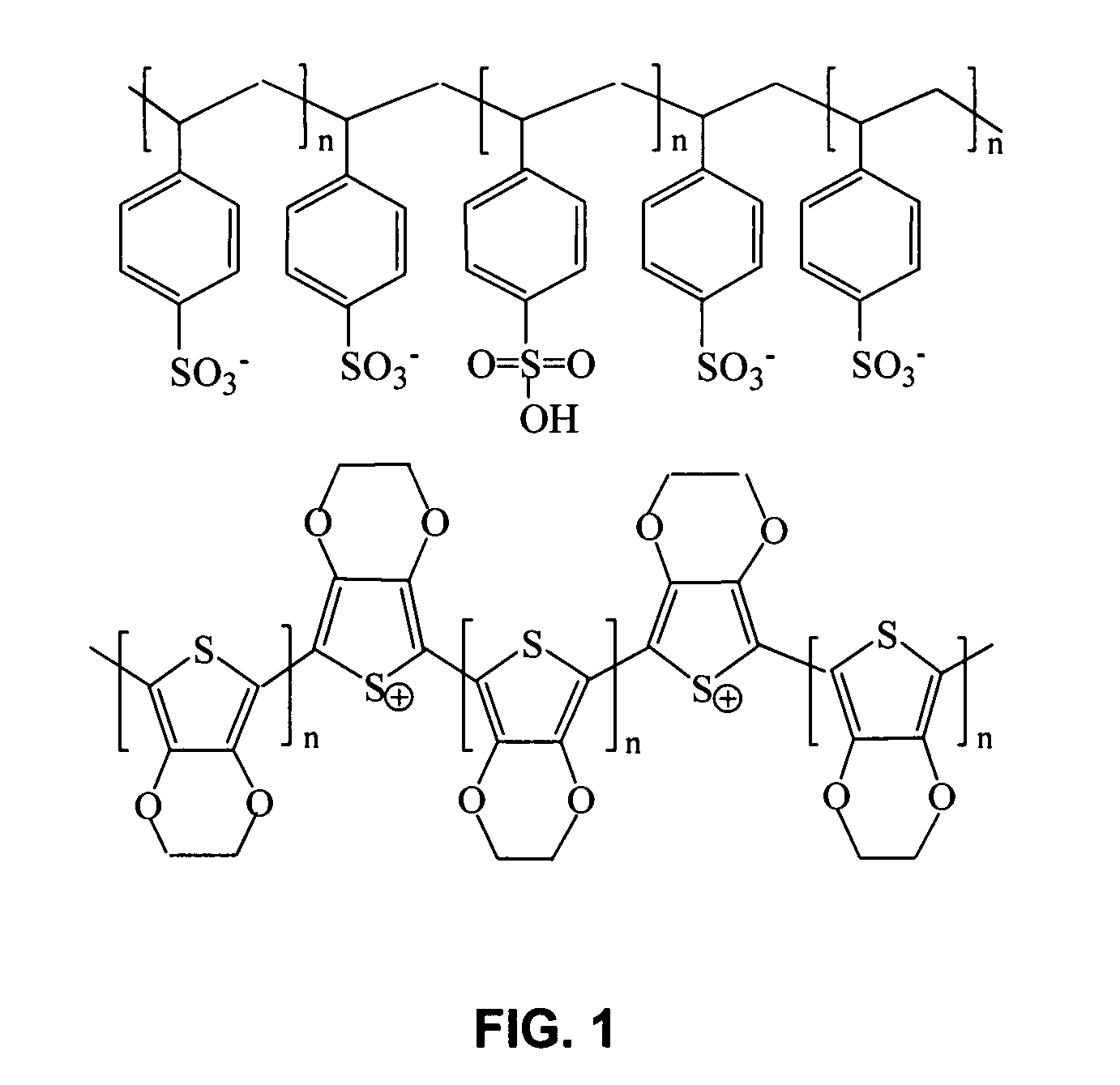

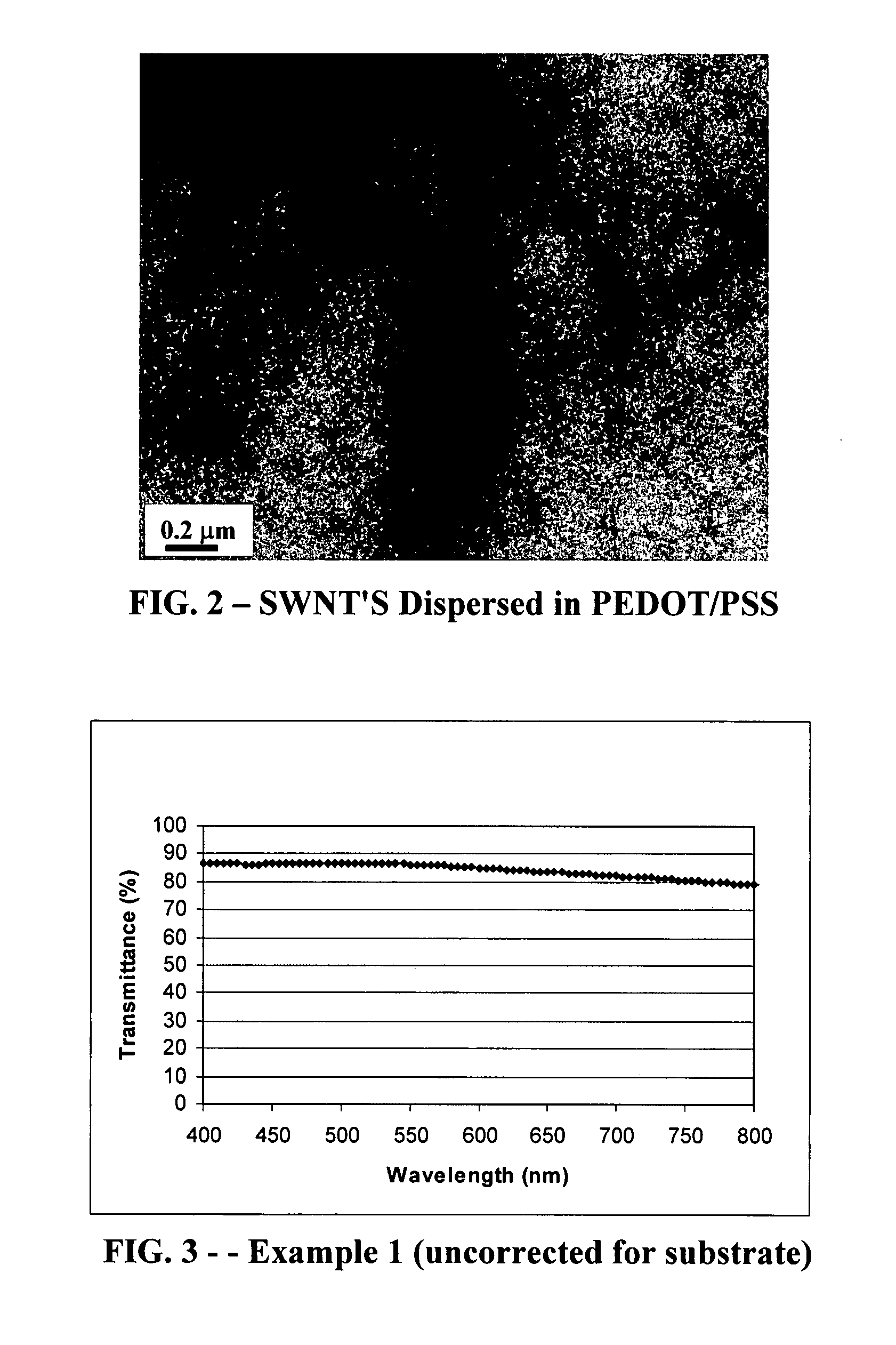

Transparent thin polythiophene films having improved conduction through use of nanomaterials

InactiveUS20070246689A1Low levelHybrid capacitor electrolytesHybrid capacitor electrodesIn situ chemical reductionTransmittance

Optically transparent, conductive polymer compositions and methods for making them are claimed. These conductive polymer compositions comprise an oxidized 3,4-ethylenedioxythiopene polymer, a polysulfonated styrene polymer, single wall carbon nanotubes and / or metallic nanoparticles. The conductive polymer compositions can include both single wall carbon nanotubes and metallic nanoparticles. The conductive polymer compositions have a sheet resistance of less than about 200 Ohms / square, a conductivity of greater than about 300 siemens / cm, and a visible light (380-800 nm) transmission level of greater than about 50%, preferably greater than about 85% and most preferably greater than about 90% (when corrected for substrate). The conductive polymer compositions comprising single wall carbon nanotubes are made by mixing the oxidized 3,4-ethylenedioxythiopene polymer and polysulfonated styrene polymer with single wall carbon nanotubes and then sonicating the mixture. The conductive polymer compositions comprising metallic nanoparticles are made by a process of in situ chemical reduction of metal precursor salts.

Owner:NANOFILM LTD

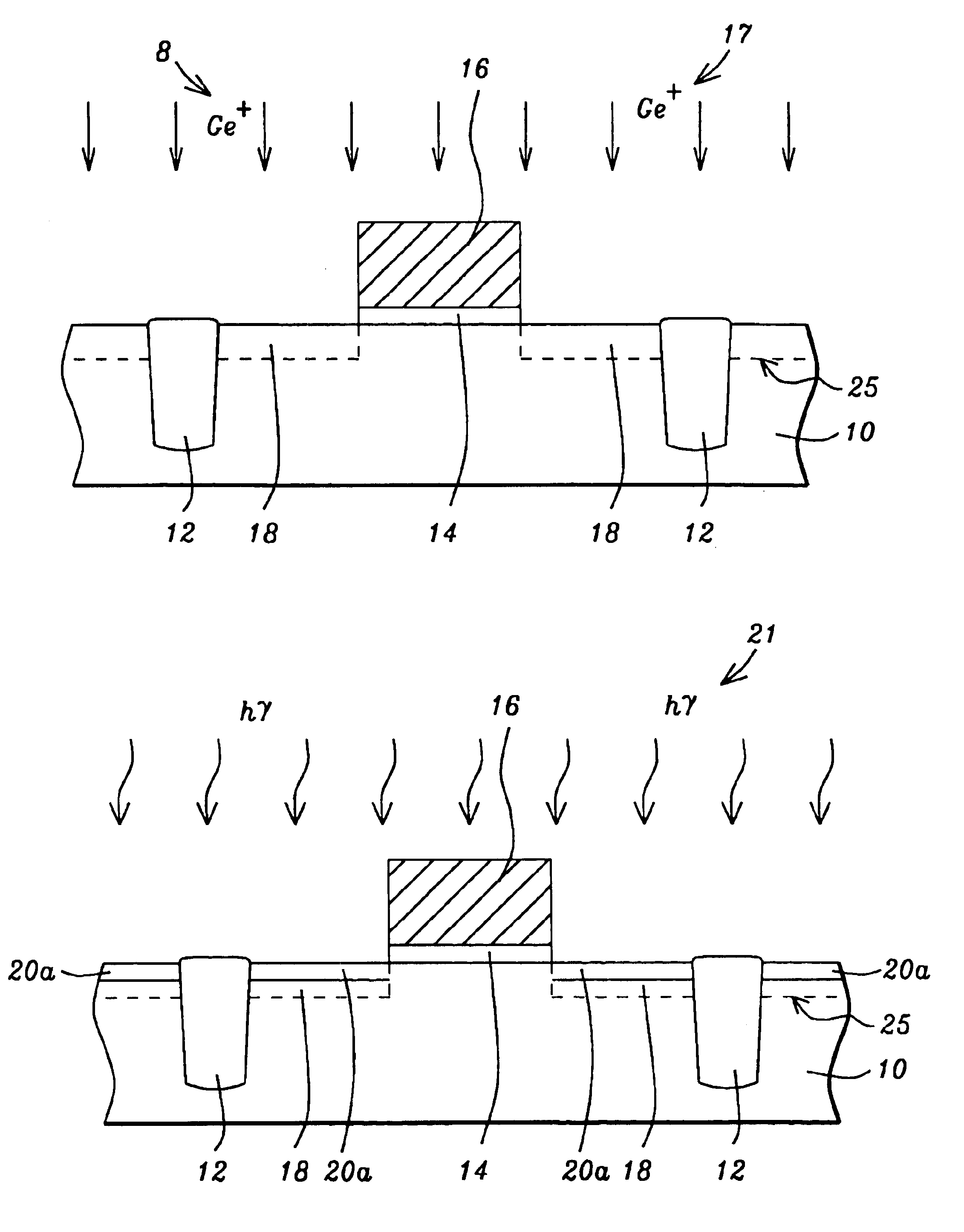

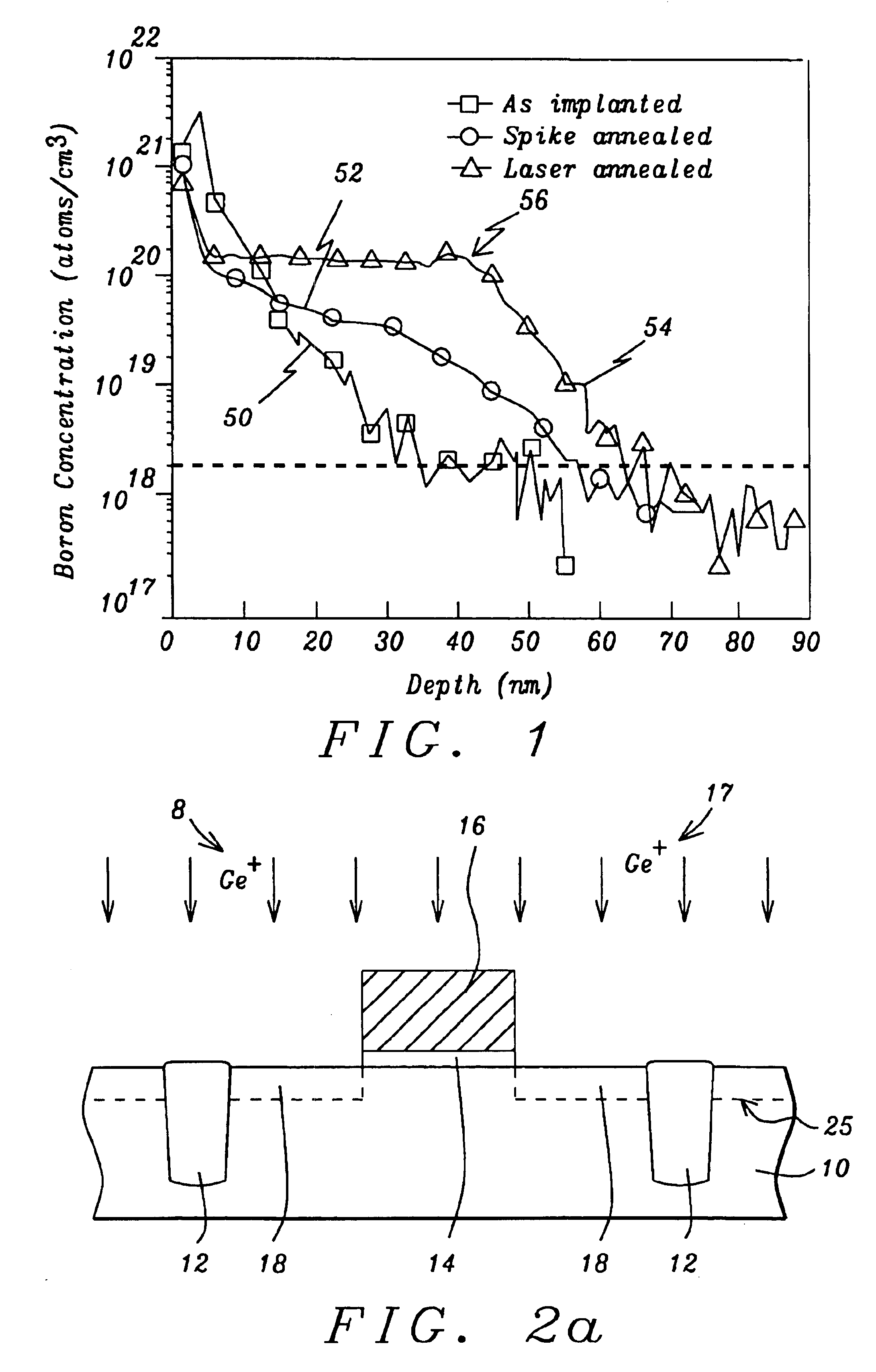

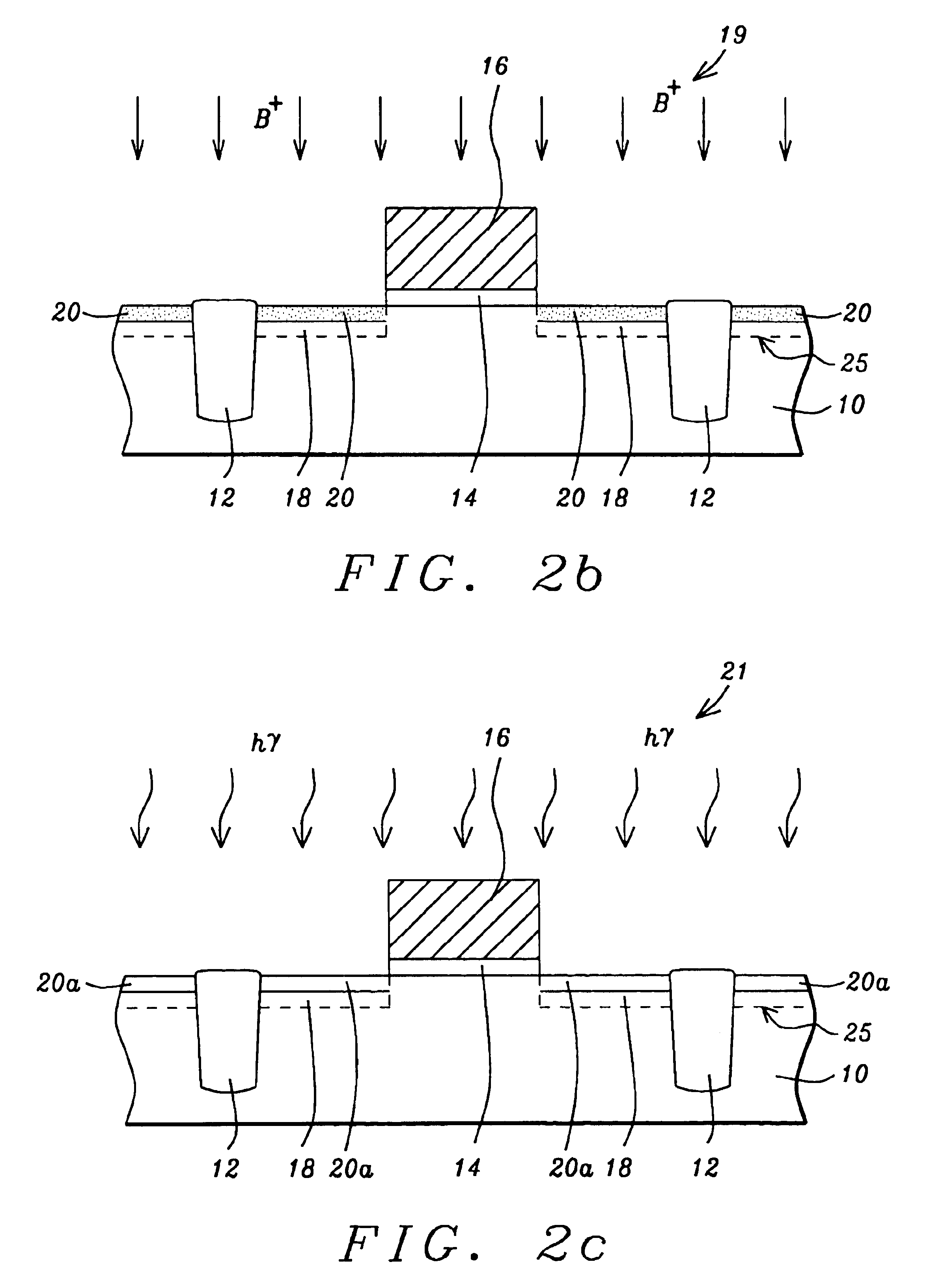

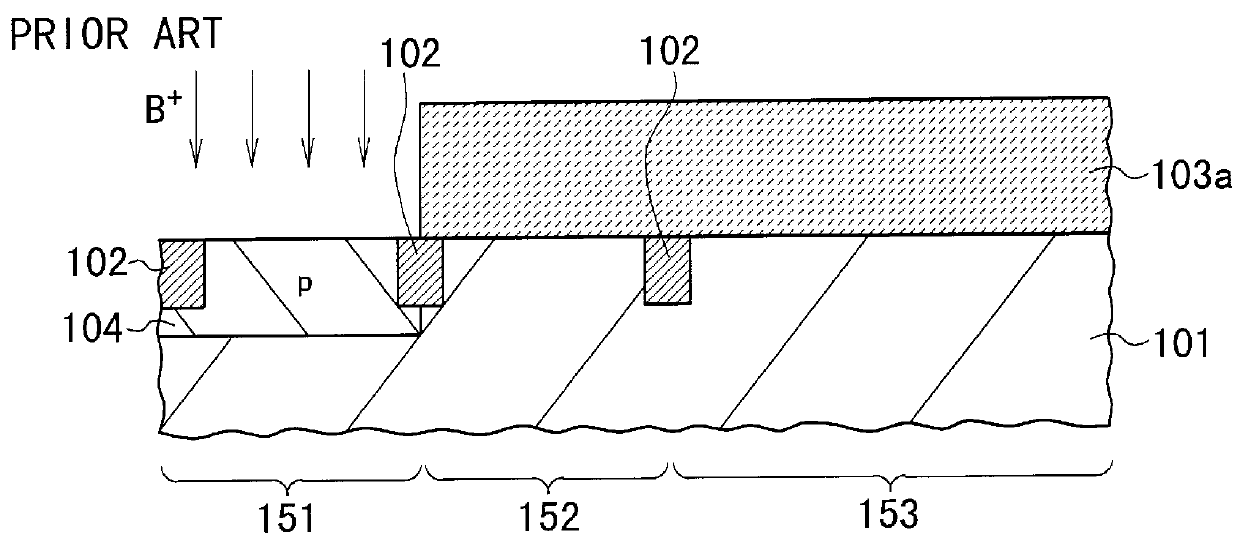

Method of multiple pulse laser annealing to activate ultra-shallow junctions

A method for forming a highly activated ultra shallow ion implanted semiconductive elements for use in sub-tenth micron MOSFET technology is described. A key feature of the method is the ability to activate the implanted impurity to a highly active state without permitting the dopant to diffuse further to deepen the junction. A selected single crystalline silicon active region is first amorphized by implanting a heavy ion such as silicon or germanium. A semiconductive impurity for example boron is then implanted and activated by pulsed laser annealing whereby the pulse fluence, frequency, and duration are chosen to maintain the amorphized region just below it's melting temperature. It is found that just below the melting temperature there is sufficient local ion mobility to secure the dopant into active positions within the silicon matrix to achieve a high degree of activation with essentially no change in concentration profile. The selection of the proper laser annealing parameters is optimized by observation of the reduction of sheet resistance and concentration profile as measured on a test site. Application of the method is applied to forming a MOS FET and a CMOS device. The additional processing steps required by the invention are applied simultaneously to both n-channel and p-channel devices of the CMOS device pair.

Owner:CHARTERED SEMICONDUCTOR MANUFACTURING

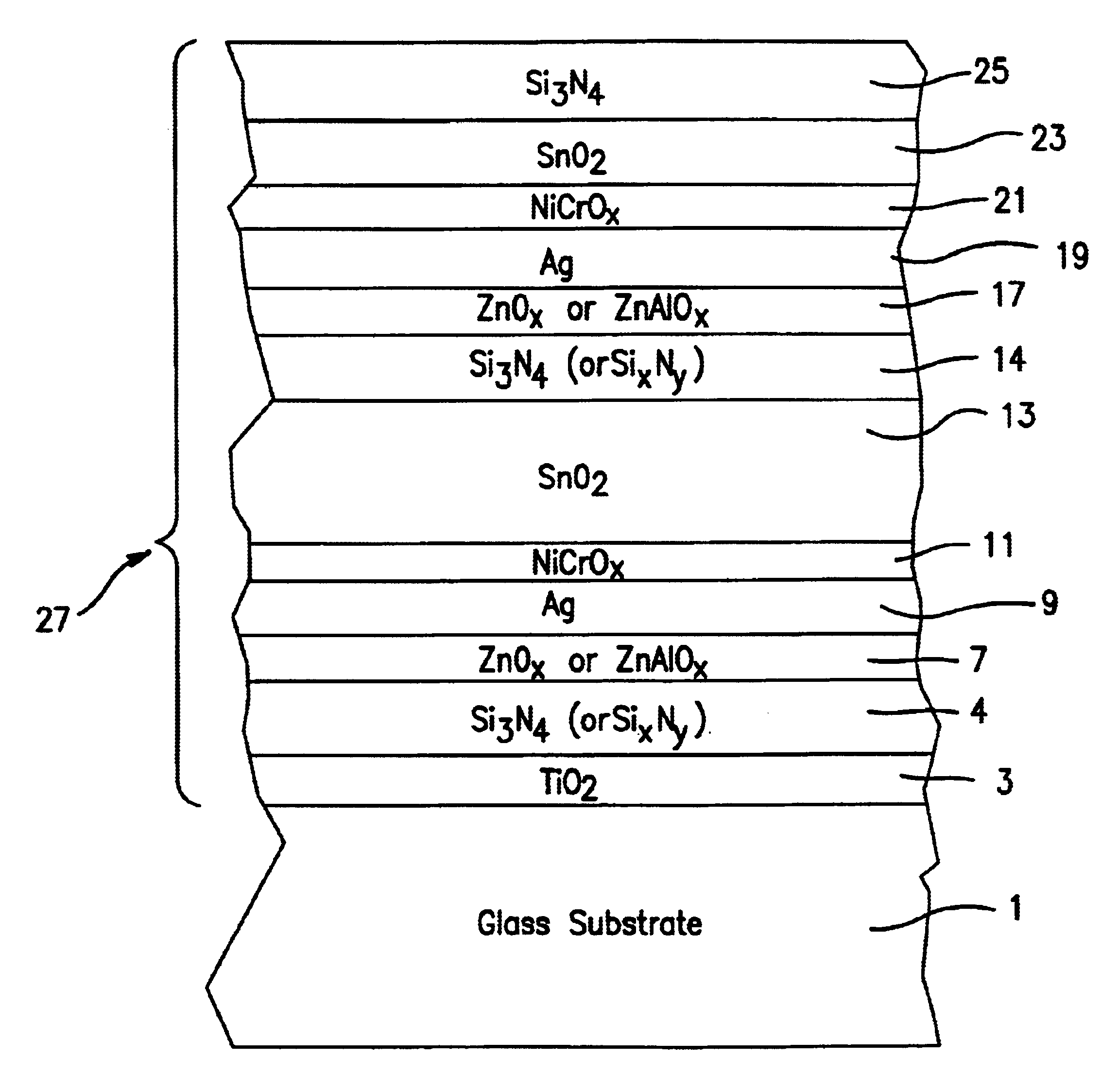

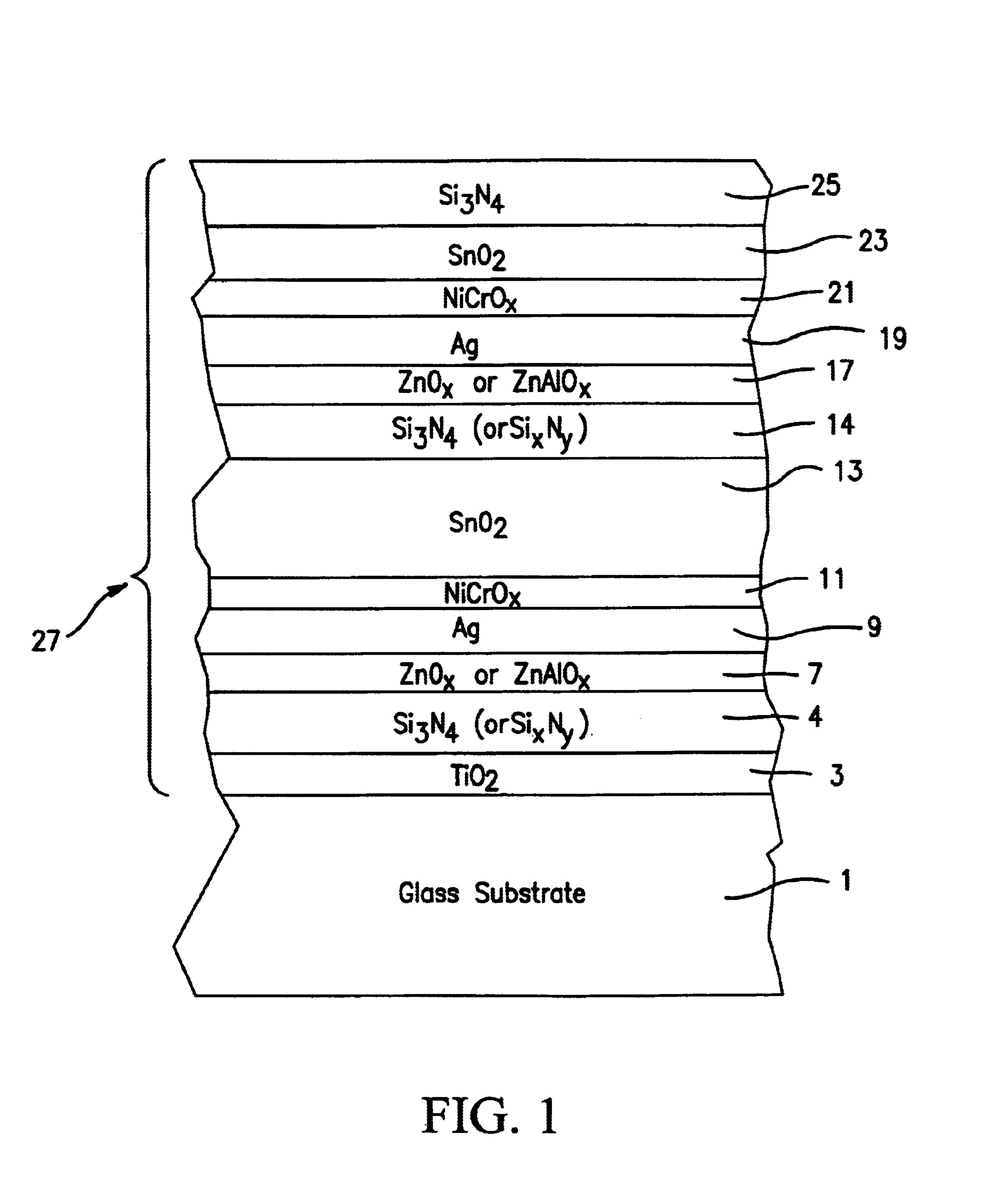

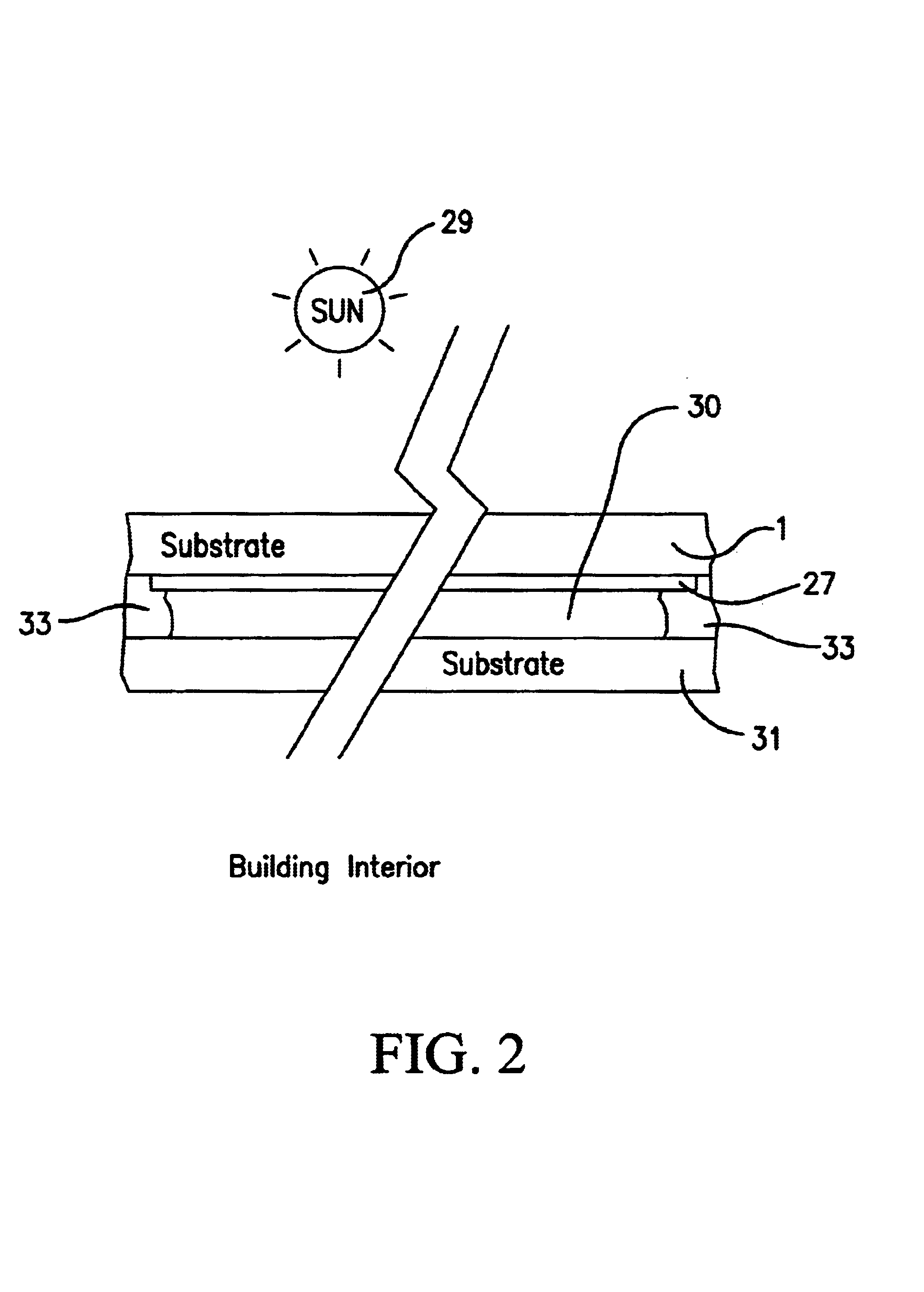

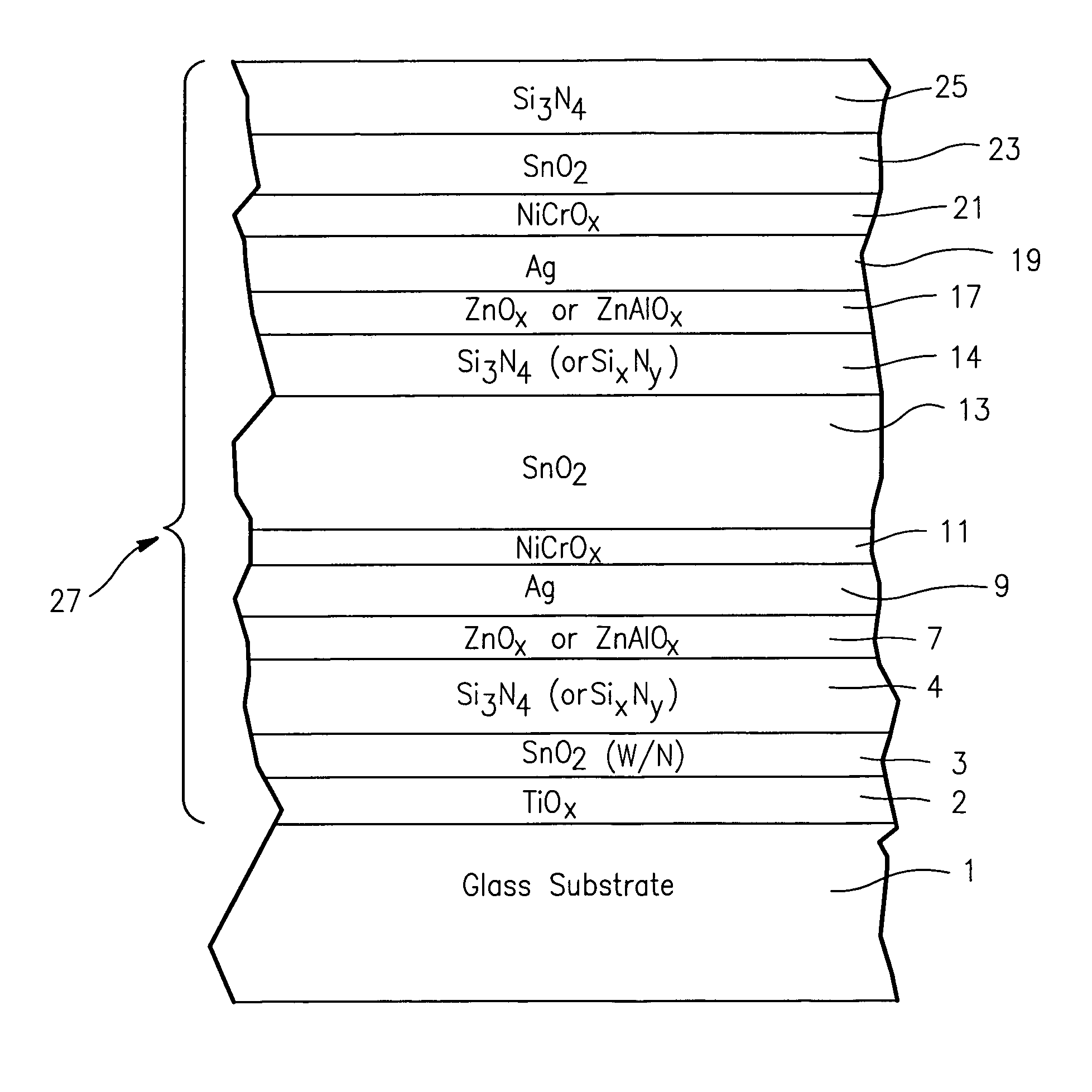

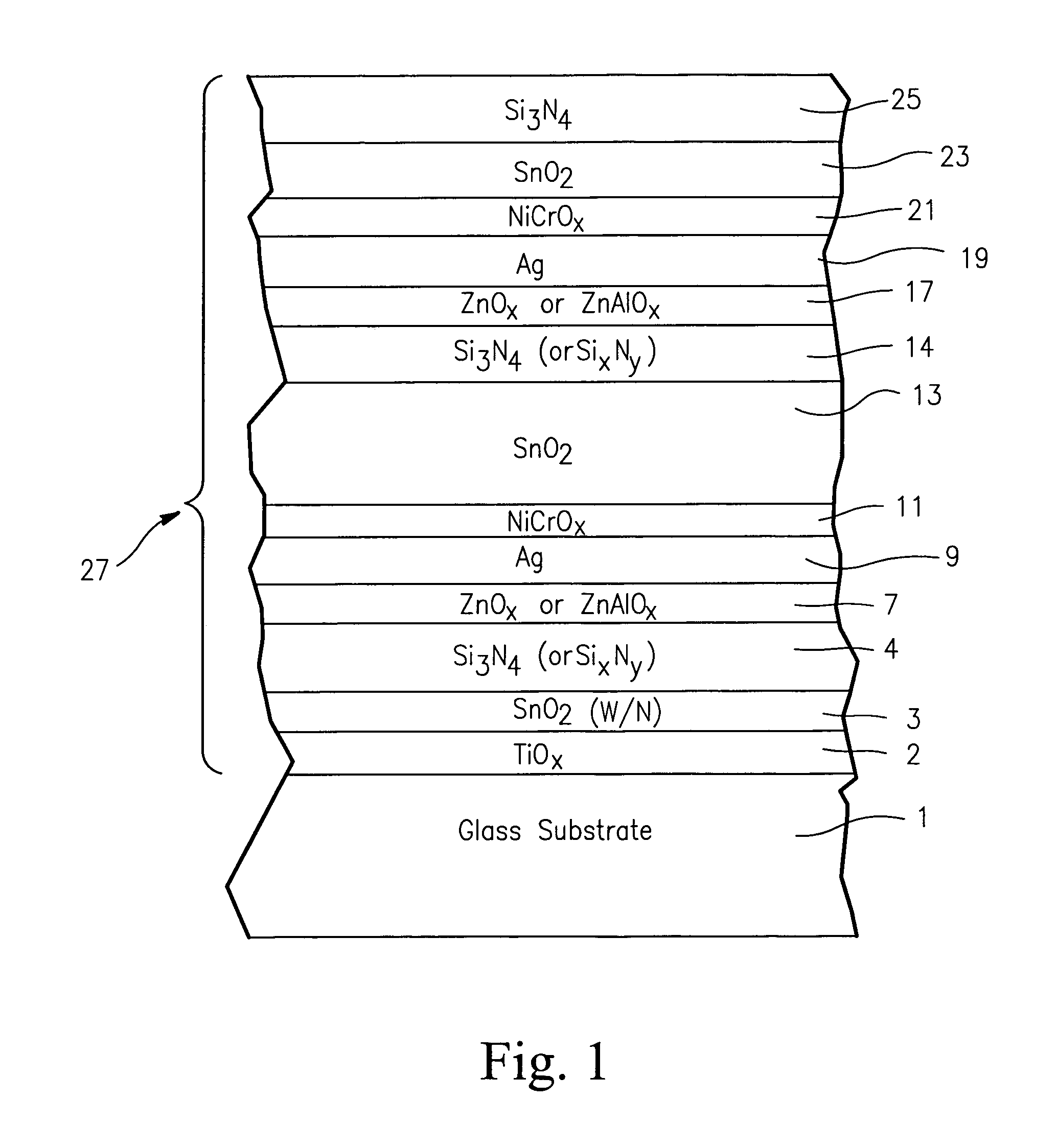

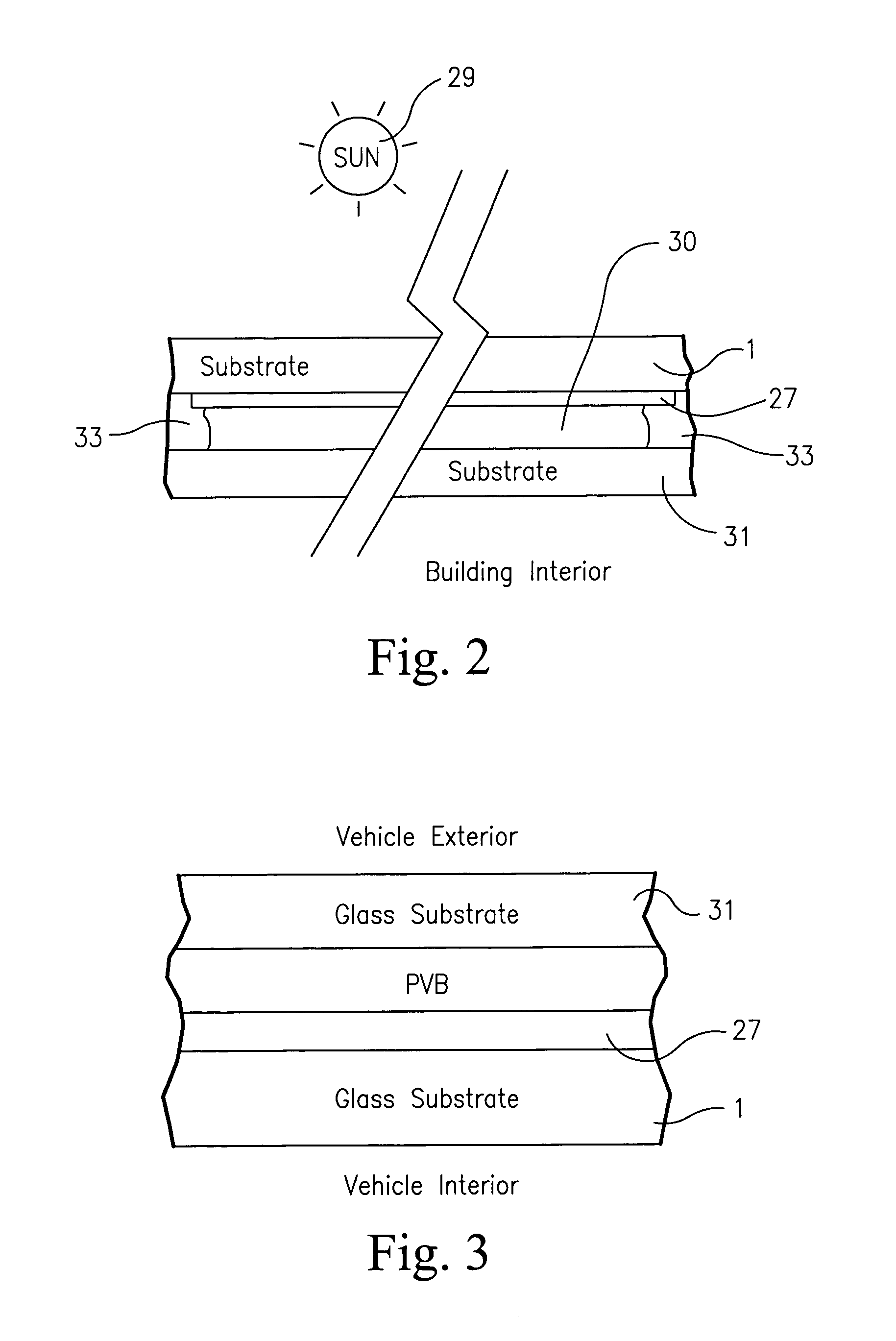

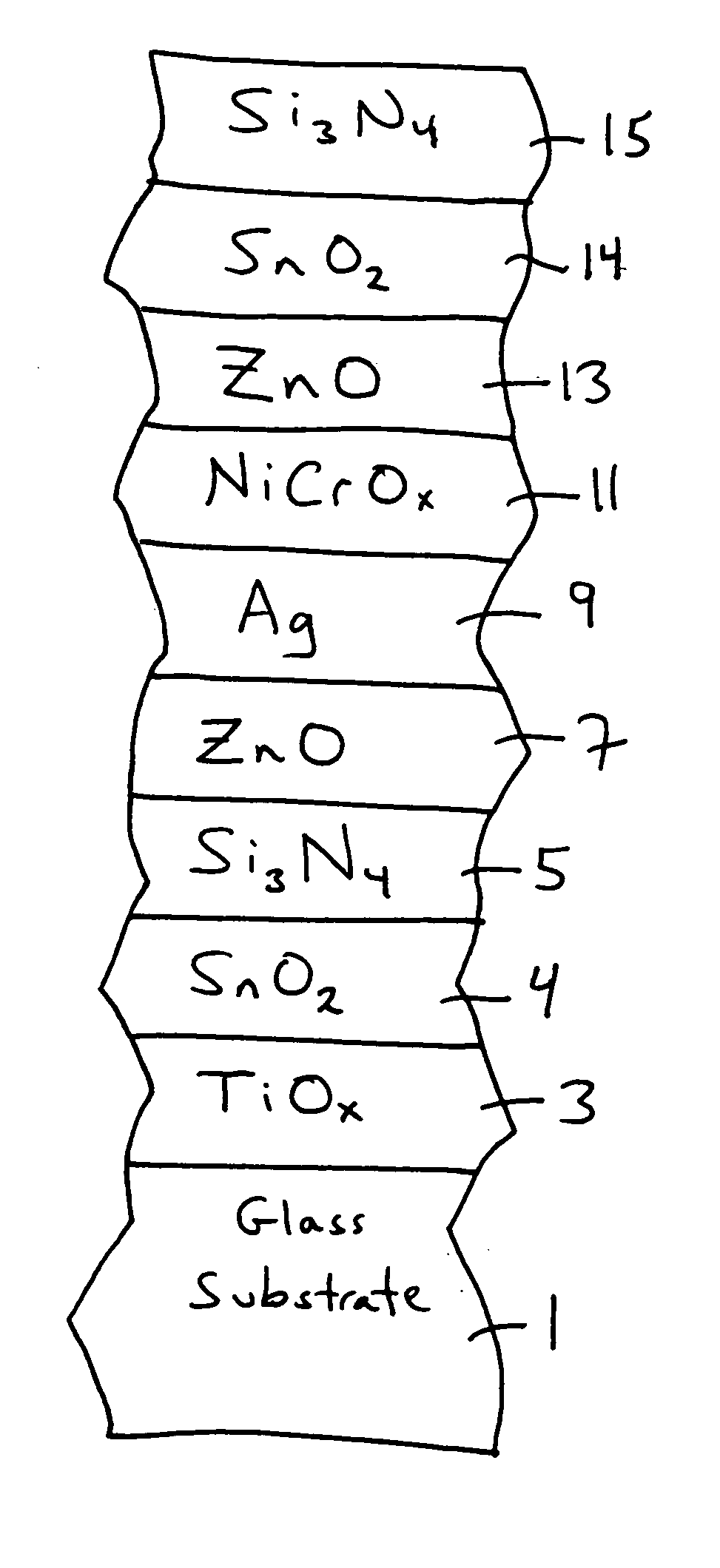

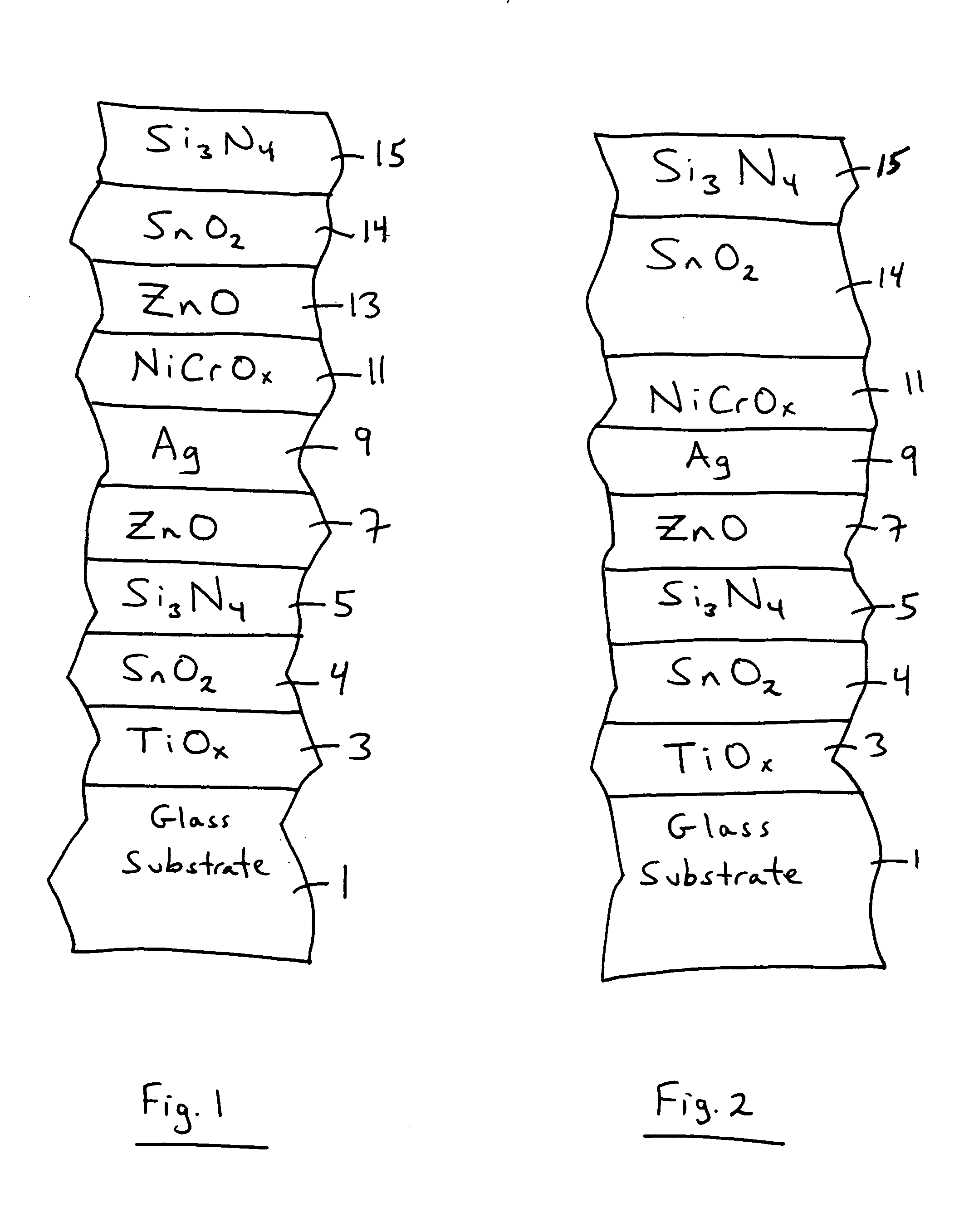

Heat treatable coated article with tin oxide inclusive layer between titanium oxide and silicon nitride

InactiveUS7153579B2Increased durabilityConvenient coatingGlass/slag layered productsCoatingsElectrical resistance and conductanceMetallurgy

A low-E coated article is provided, in certain example embodiments, with a layer including tin oxide provided between a layer including titanium oxide and a layer including silicon nitride. It has been found that the provision of such a tin oxide inclusive layer between silicon nitride and titanium oxide can significantly improve durability of the resulting coated article, especially after heat treatment (HT). In certain example embodiments, the coated article may be formed so as to have a fairly high visible transmission (TY or Tvis) to sheet resistance (Rs) ratio (i.e., a ratio Tvis / Rs). Coated articles herein may be used in the context of windows or the like (e.g., laminated vehicle windshields).

Owner:GUARDIAN EURO S A R L +1

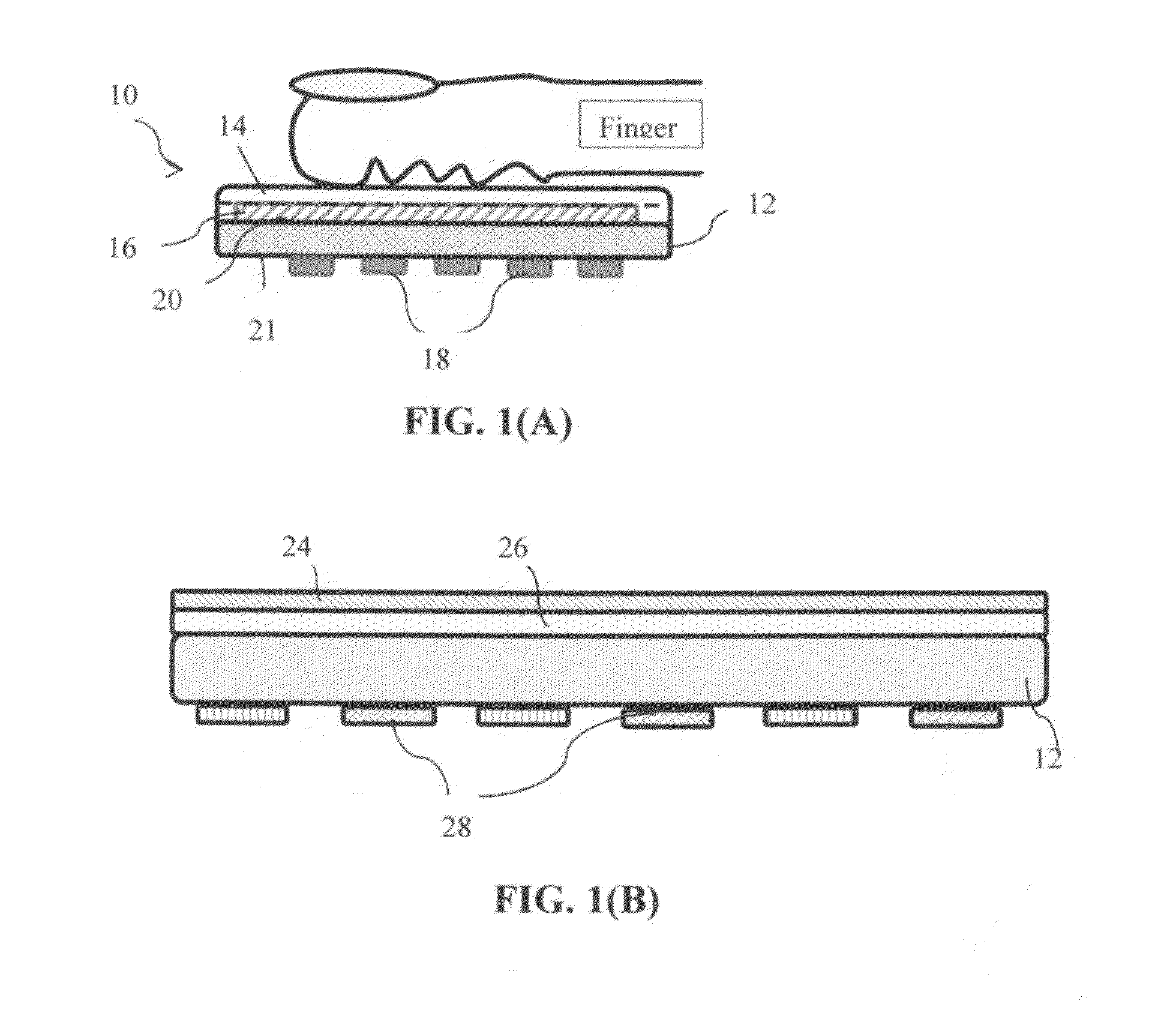

Flexible fingerprint sensor materials and processes

ActiveUS20160026846A1Improve mechanical propertiesGood thermal propertiesSemiconductor/solid-state device manufacturingPrint image acquisitionElectrical resistance and conductanceMechanical integrity

A flexible fingerprint sensor laminate comprising: a layer of flexible substrate having a front surface and a back surface, at least a domain of electrically conductive material deposited on the front surface, a protective hard coating layer that covers the domain of electrically conductive material, and a plurality of sensor electrodes deposited preferably on the back surface and related circuitry (e.g. integrated circuit for driving and sensing). Preferably, the layer of flexible substrate is no greater than 20 μm in thickness, the domain of electrically conductive material has a thickness no greater than 2 μm, the protective hard coating has a thickness no greater than 1 μm, and the laminate has a surface sheet resistance no greater than 200 Ohm per square and surface scratch resistance no less than 3 H. The laminate exhibits good scratch resistance, low sheet resistance, good flexibility and mechanical integrity. The invention also provides a biometric sensor, such as a fingerprint sensor. The invention further provides a process for producing such a sensor laminate.

Owner:GLOBAL GRAPHENE GRP INC

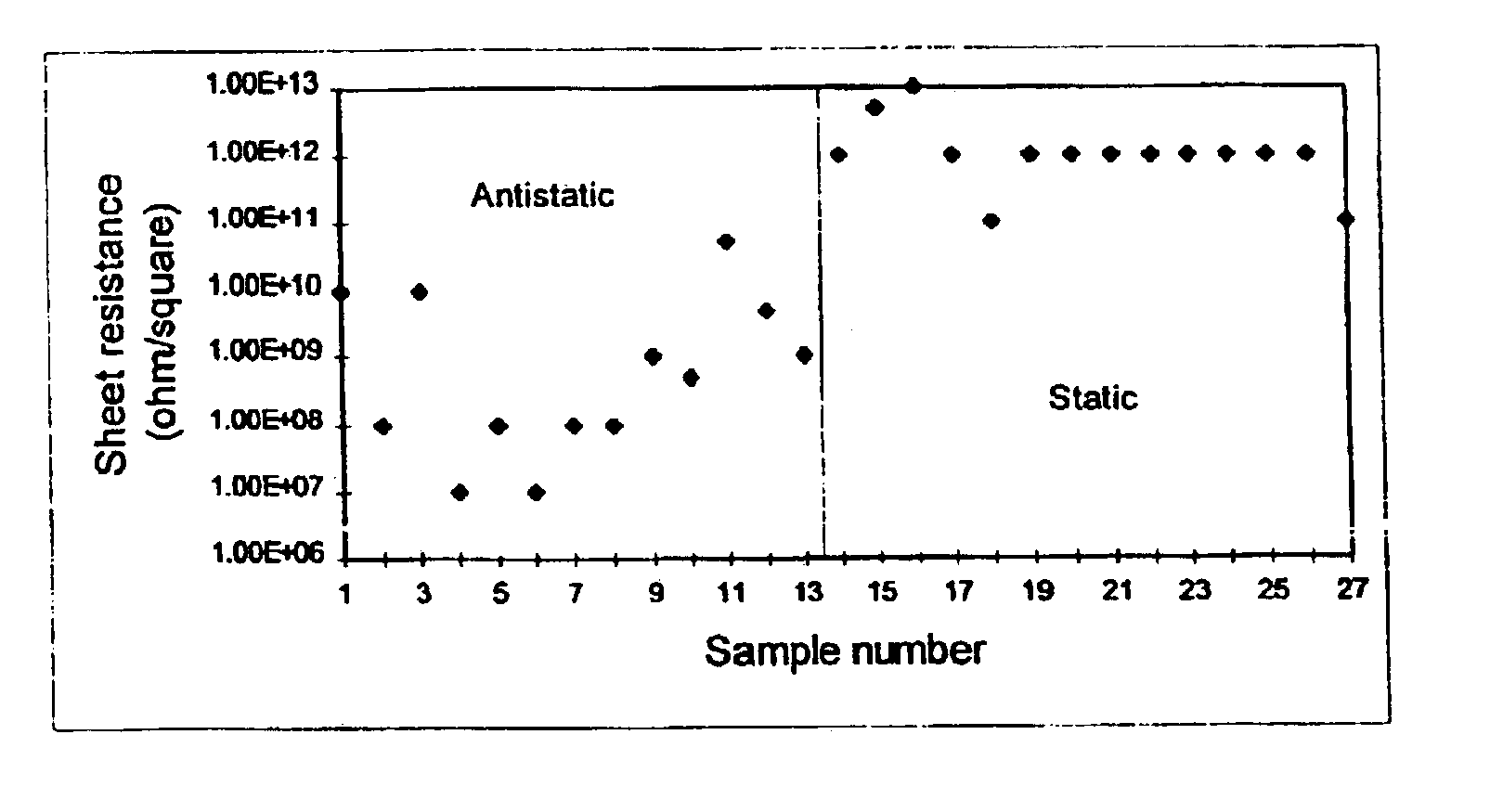

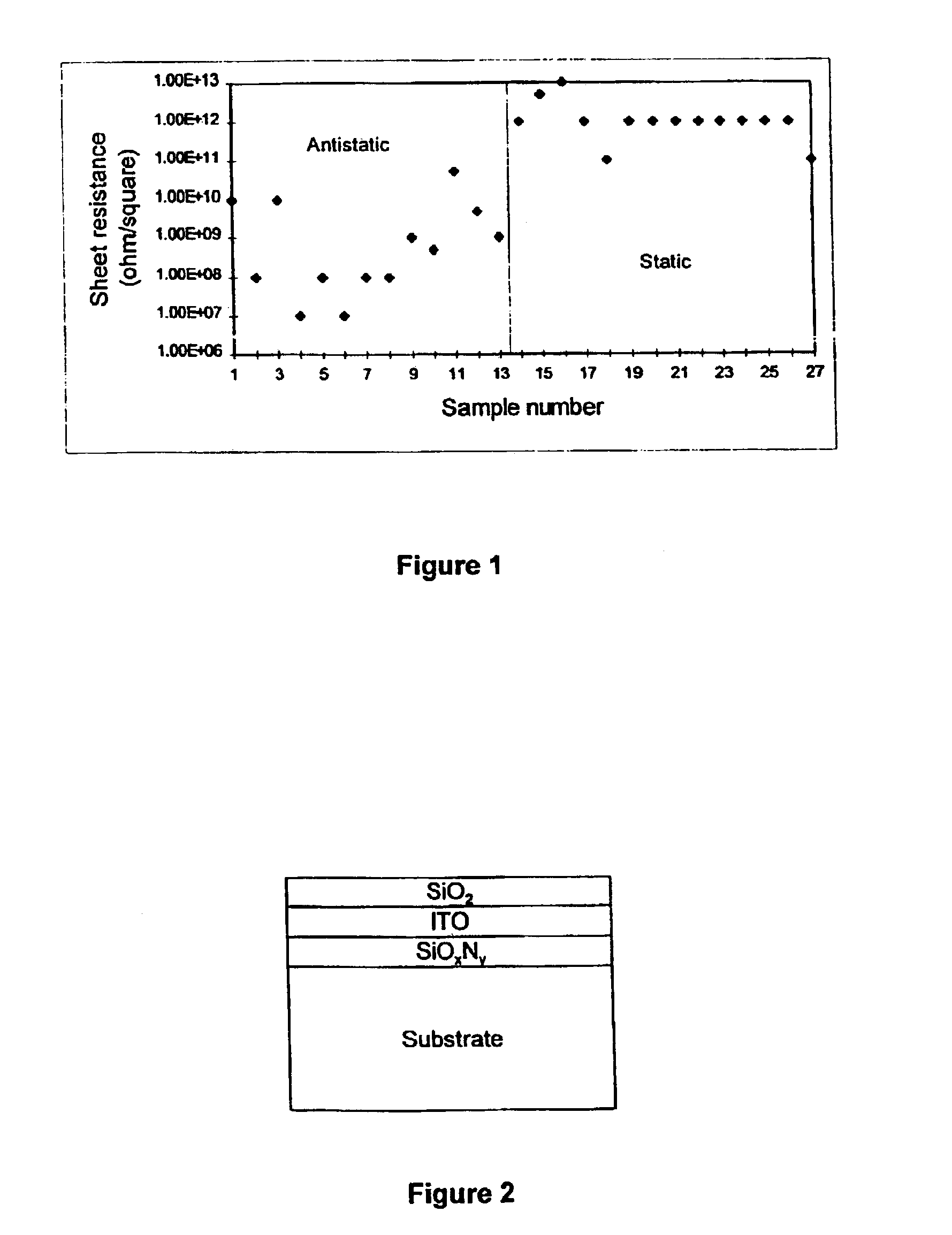

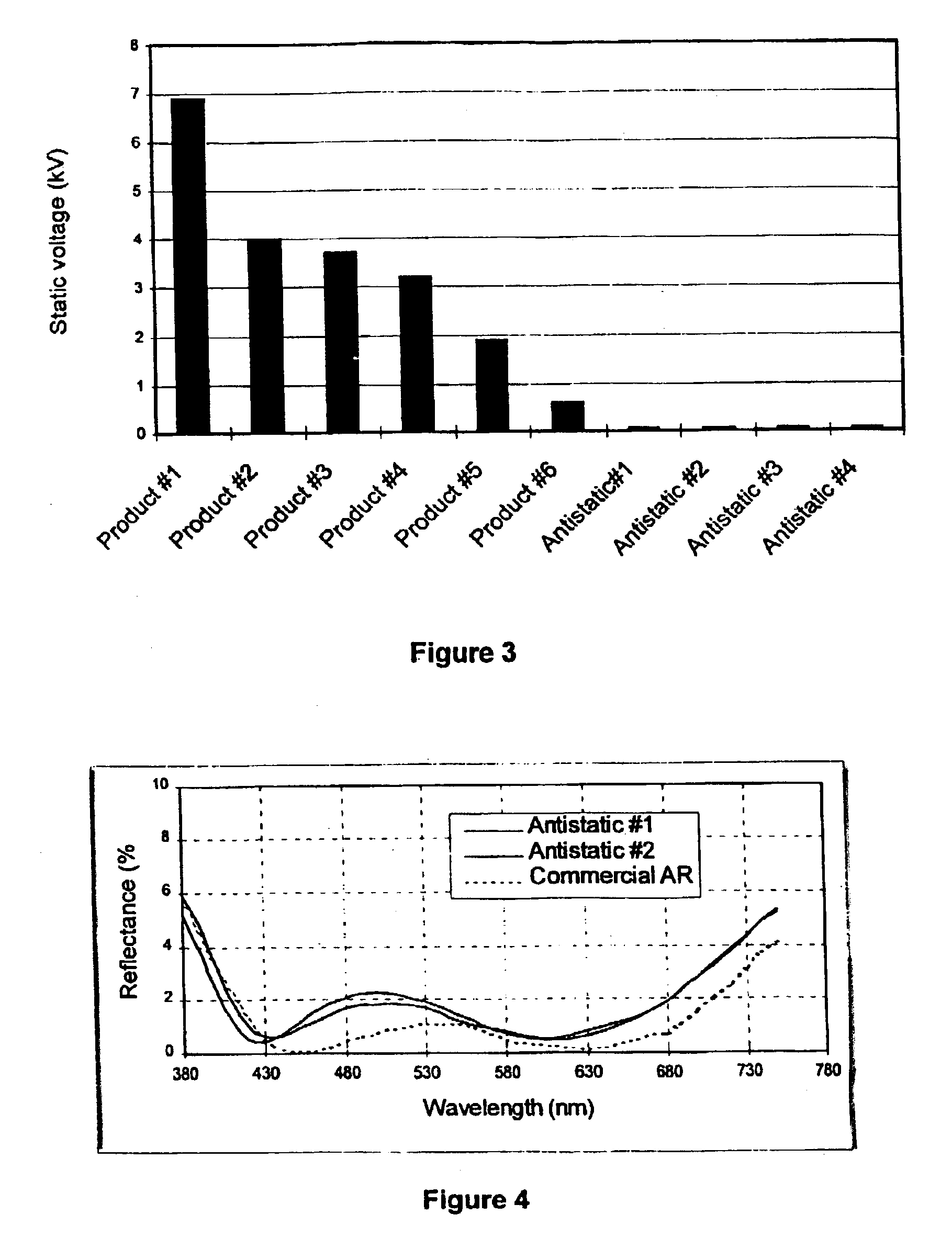

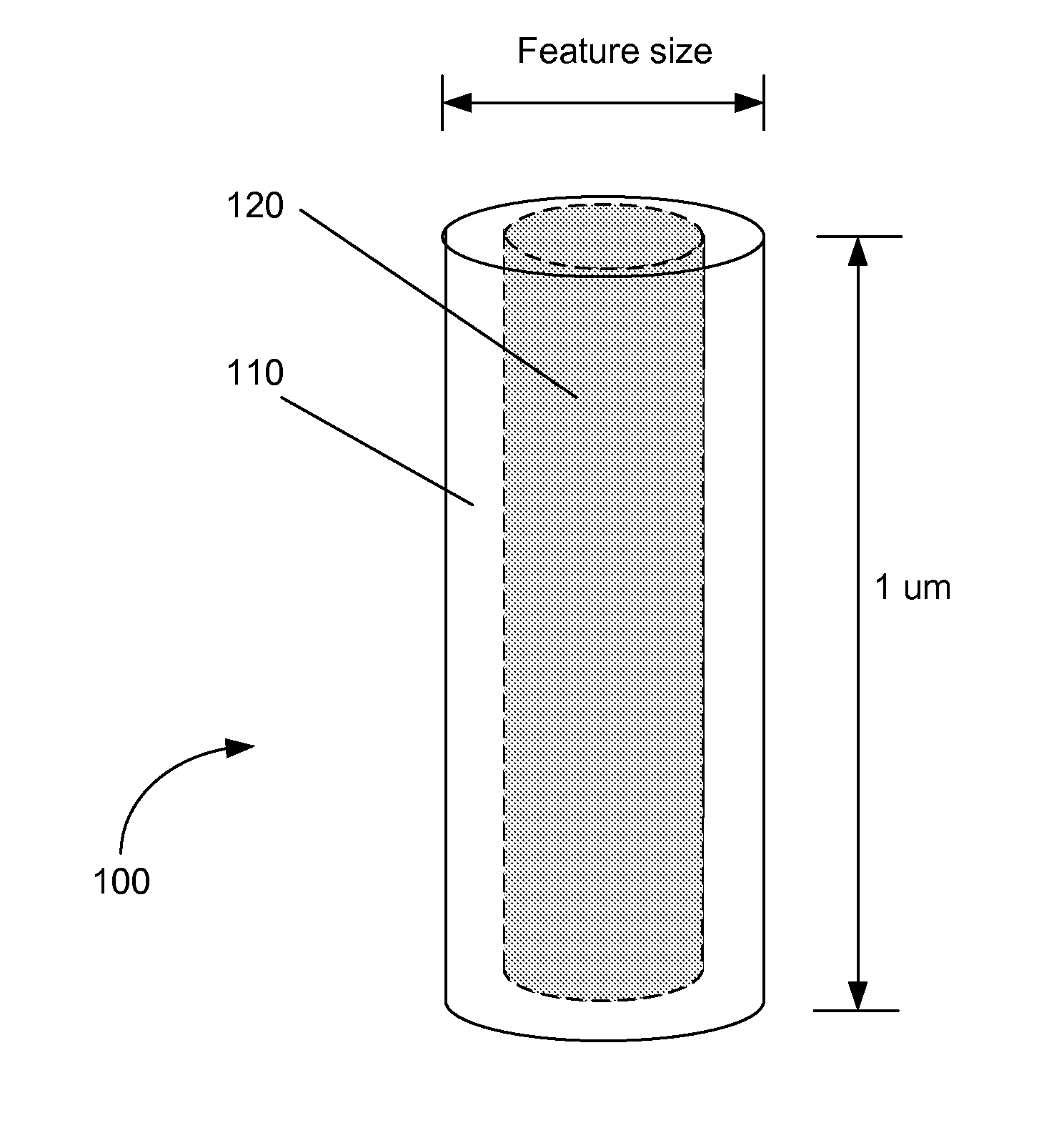

Anti-static, anti-reflection coating

InactiveUS6852406B2Promote growthQuality improvementVacuum evaporation coatingSputtering coatingSheet resistanceElectrically conductive

Owner:CARL ZEISS VISION AUSTRALIA HO

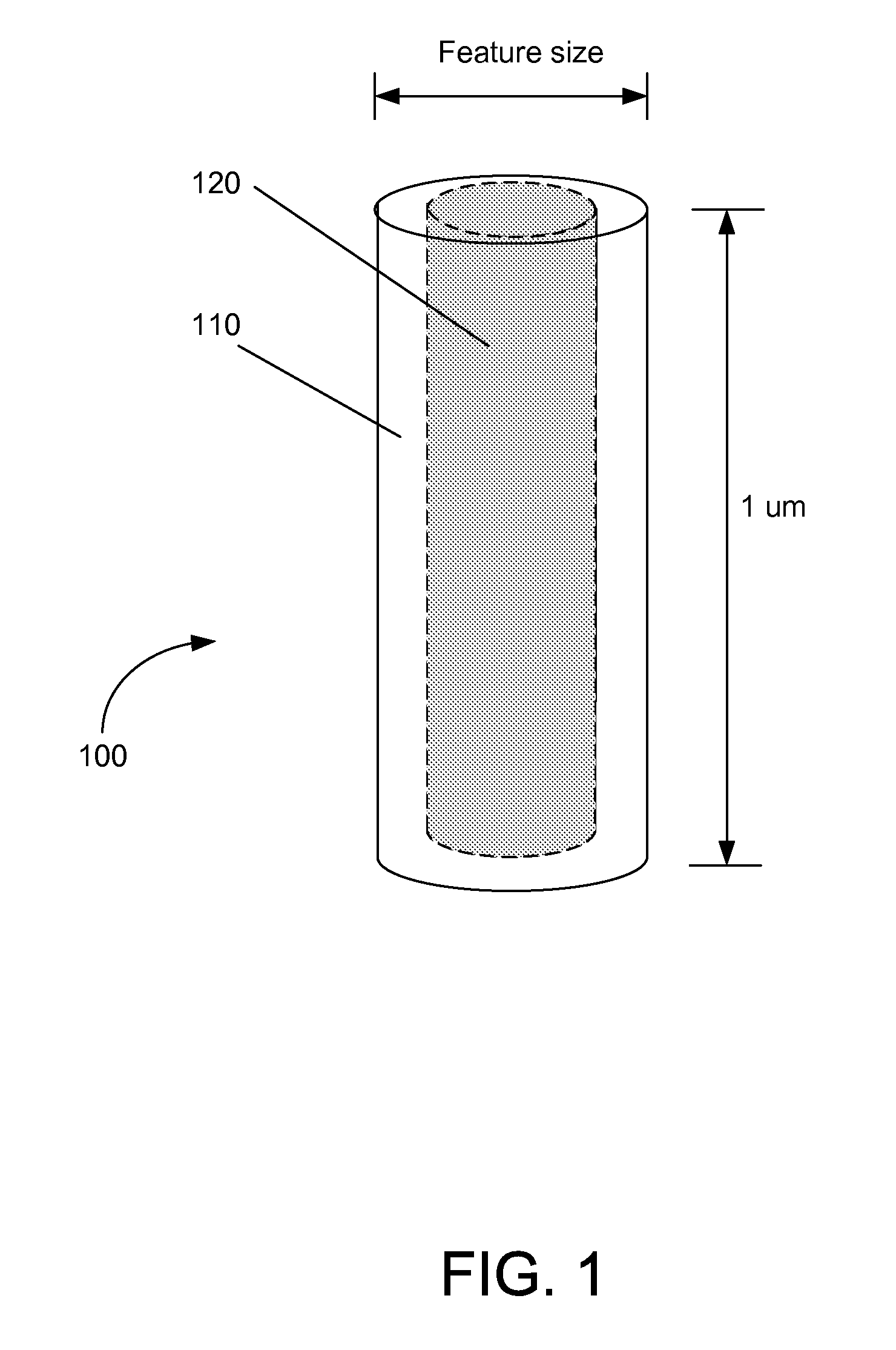

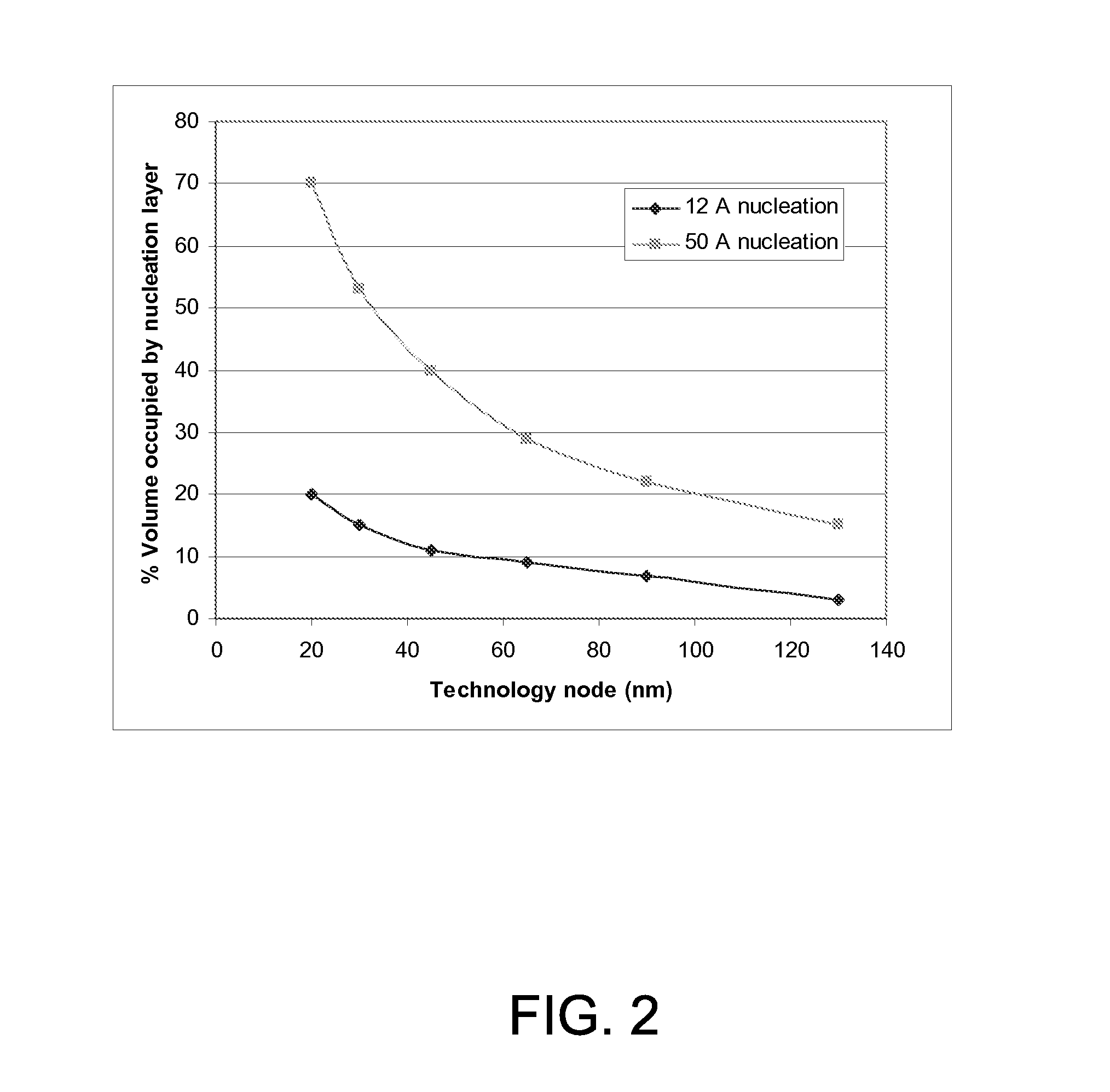

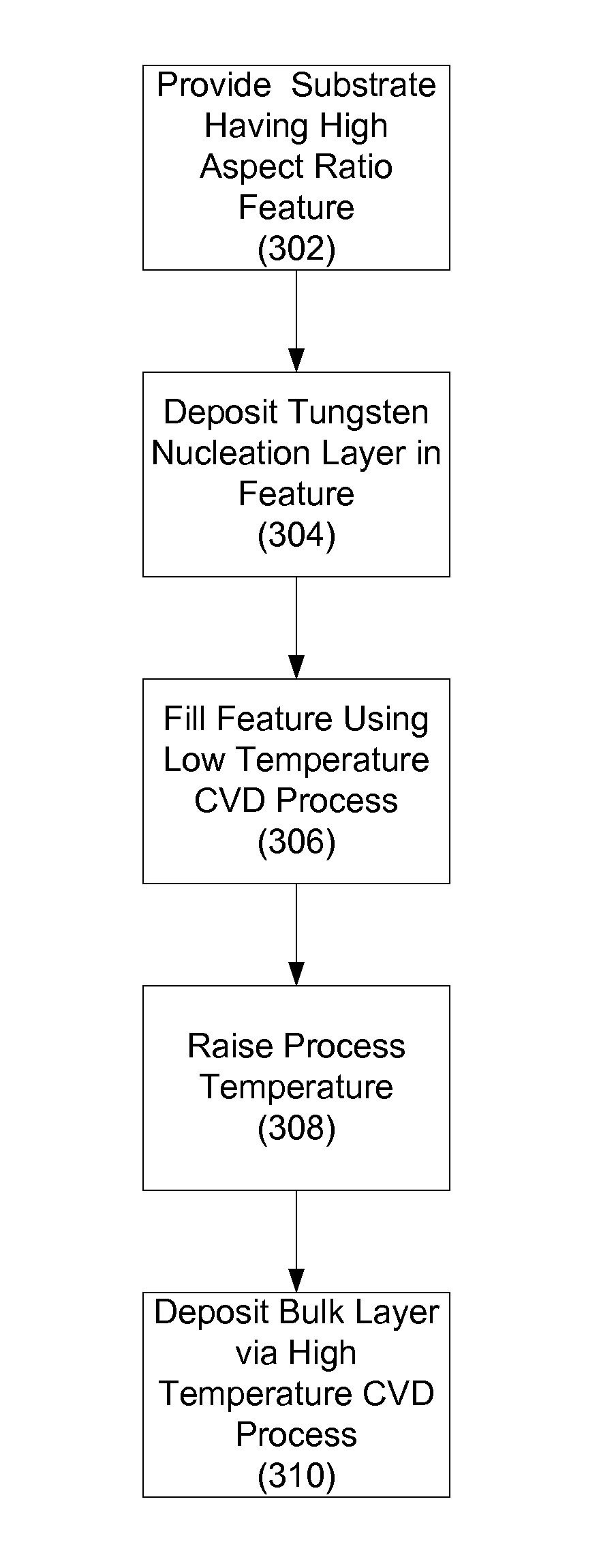

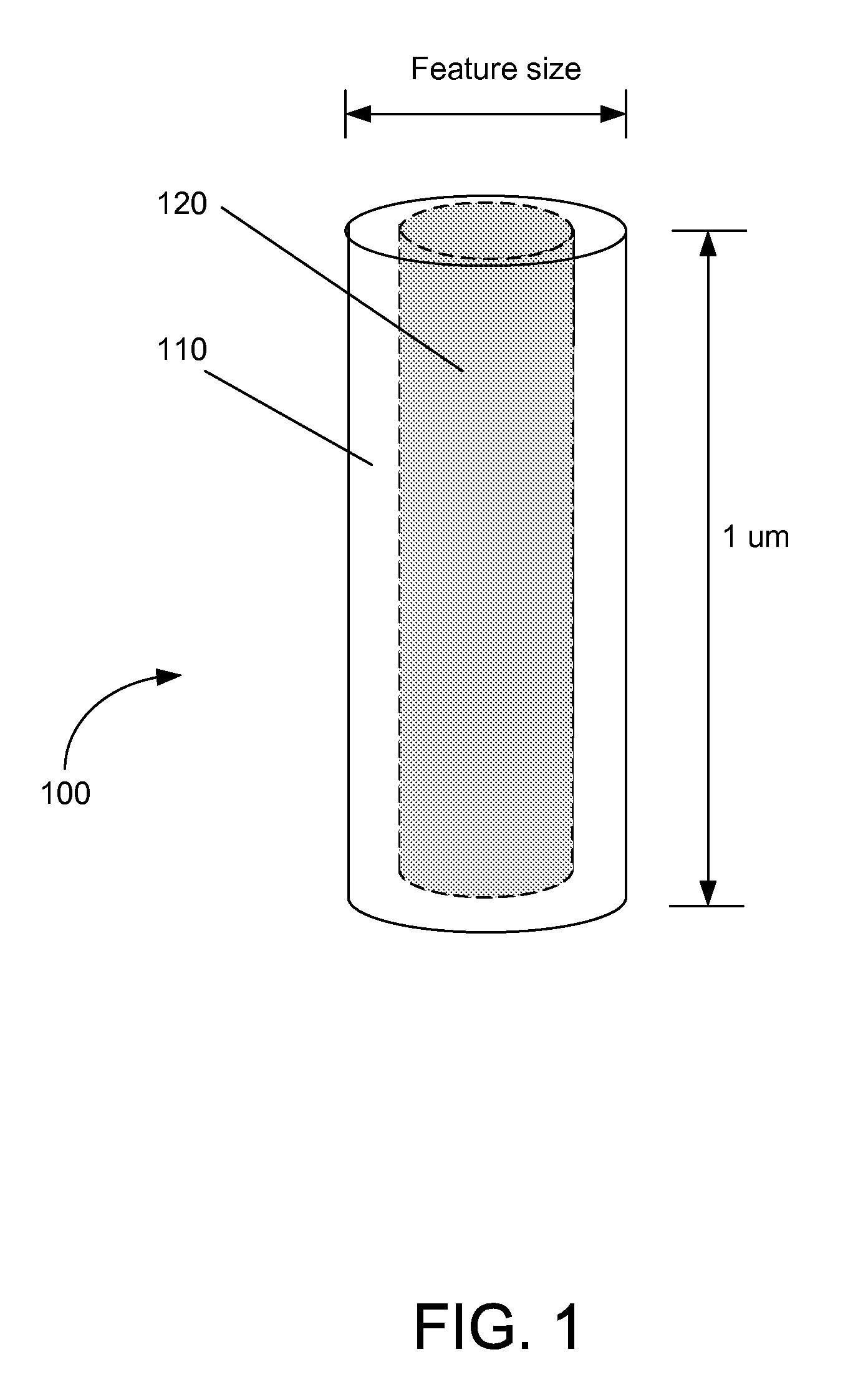

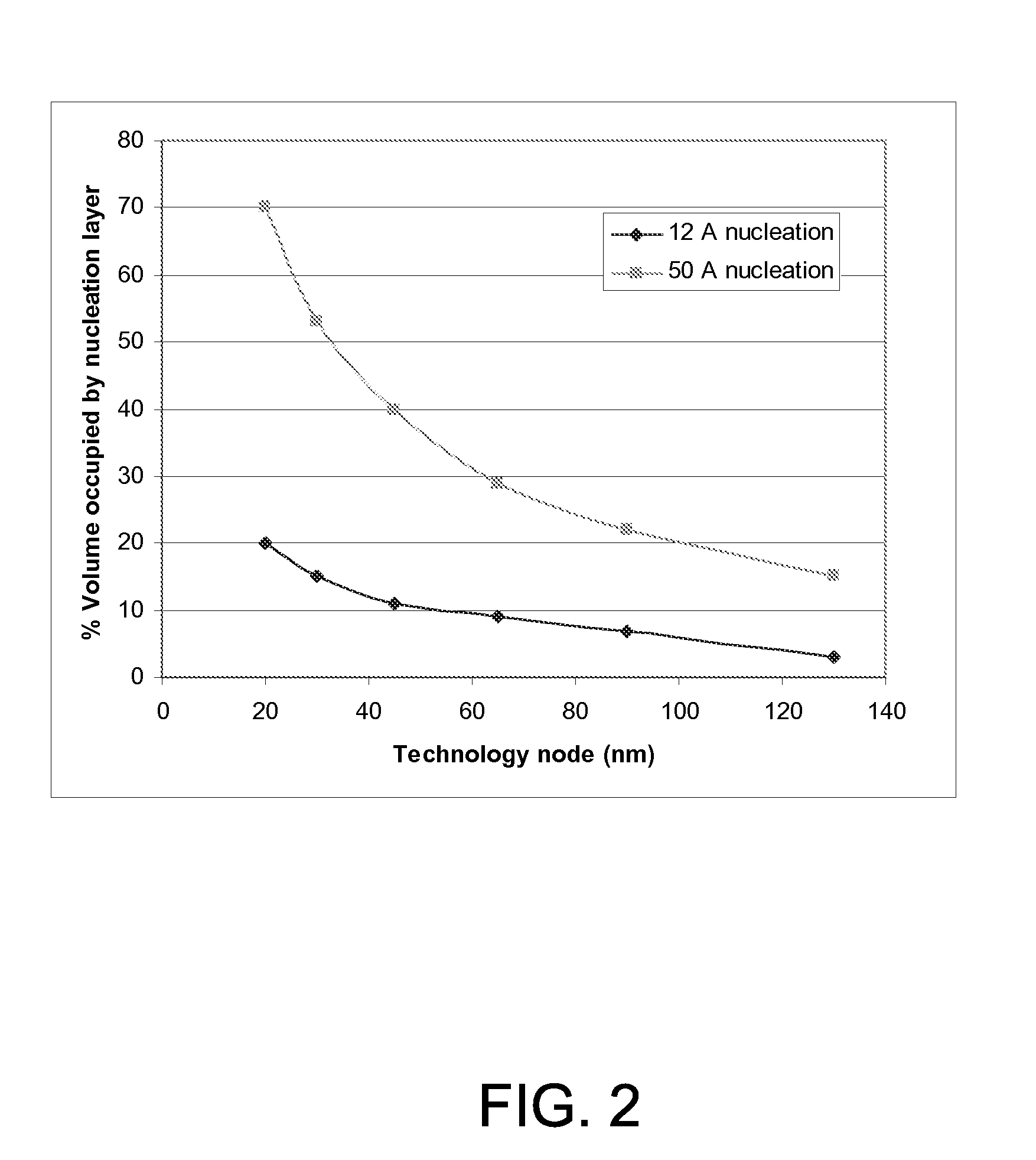

Methods for depositing ultra thin low resistivity tungsten film for small critical dimension contacts and interconnects

ActiveUS20100267235A1High aspect ratio featurePromote migrationSemiconductor/solid-state device detailsSolid-state devicesGas phaseNucleation

Provided are methods of void-free tungsten fill of high aspect ratio features. According to various embodiments, the methods involve a reduced temperature chemical vapor deposition (CVD) process to fill the features with tungsten. In certain embodiments, the process temperature is maintained at less than about 350° C. during the chemical vapor deposition to fill the feature. The reduced-temperature CVD tungsten fill provides improved tungsten fill in high aspect ratio features, provides improved barriers to fluorine migration into underlying layers, while achieving similar thin film resistivity as standard CVD fill. Also provided are methods of depositing thin tungsten films having low-resistivity. According to various embodiments, the methods involve performing a reduced temperature low resistivity treatment on a deposited nucleation layer prior to depositing a tungsten bulk layer and / or depositing a bulk layer via a reduced temperature CVD process followed by a high temperature CVD process.

Owner:NOVELLUS SYSTEMS

Resistive touch screen incorporating conductive polymer

InactiveUS20050076824A1Analysis using chemical indicatorsMeasurement apparatus componentsElectricityElectrical resistance and conductance

Conductive polymers can be used as the signal carrying layers in resistive touch screens. Using conductive polymers can allow higher sheet resistance than is conventionally obtained using indium tin oxide while maintaining electrical continuity and durability of the layer. Higher sheet resistance can also lead to reduced errors and reduced power consumption, as well as better optical transmission. Sheet resistance may be limited on an upper end by desired data sampling rates. Also disclosed are resistive touch screens that employ a conductive polymer on both the topsheet and bottom substrate and that can be operated with the use of conventional electronics.

Owner:3M INNOVATIVE PROPERTIES CO

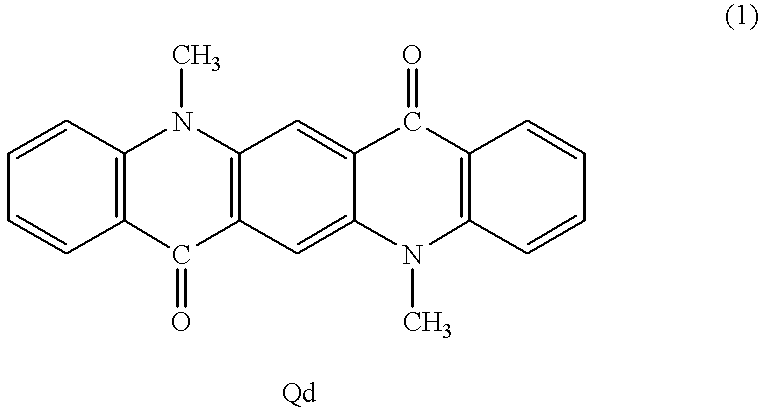

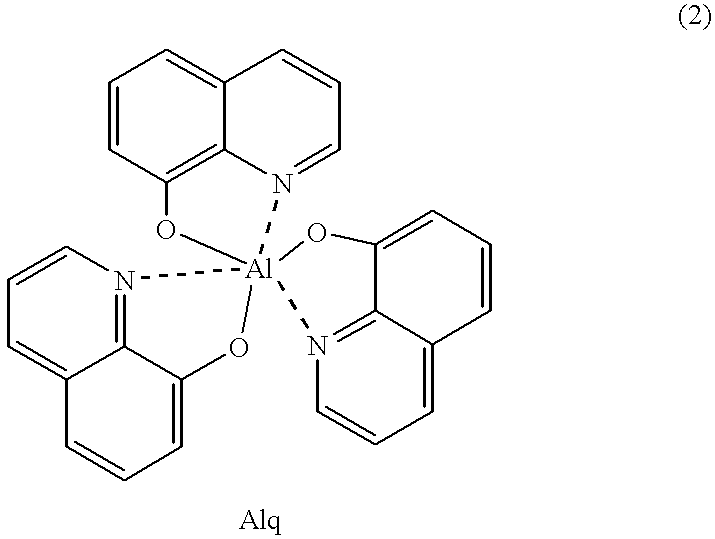

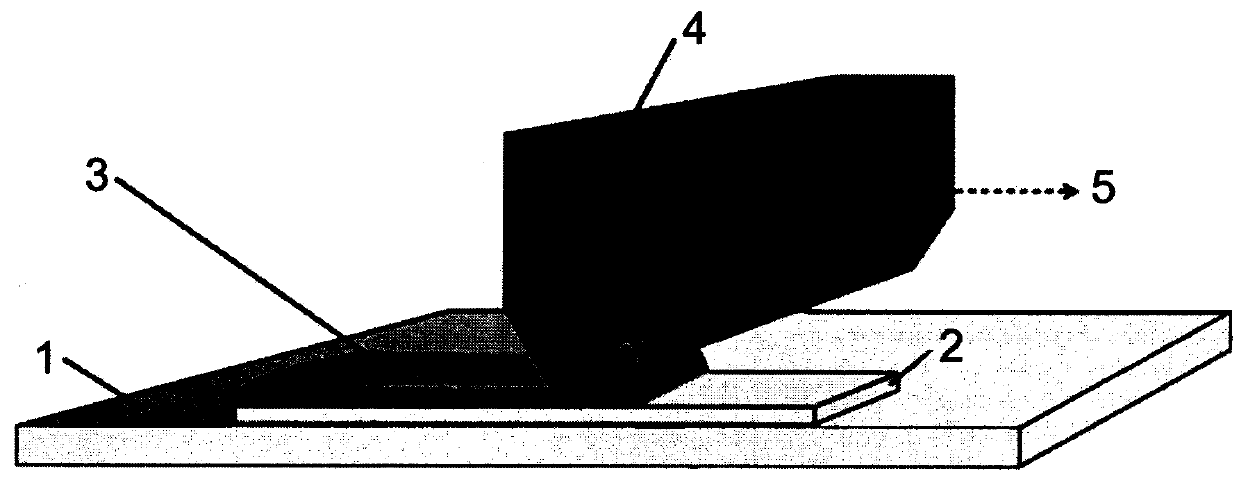

Optical resonator type organic electroluminescent element

InactiveUS6406801B1Characteristic can be preventedHigh currentDischarge tube luminescnet screensElectroluminescent light sourcesElectron holeMetallic electrode

An optical resonator type organic electroluminescent element has a multilayered film mirror 30, a transparent electrode 12, an electron hole transportation layer 14 and a luminescent layer 16 configuring an organic layer, and a metallic electrode mirror 20, formed on a glass substrate 10. The optical resonator type organic electroluminescent element amplifies a specific wavelength (especially, in a range of about 30 nm toward a shorter wavelength side from a luminescence peak wavelength of the organic layer) in luminescence light by a minute optical resonator, which comprises the multilayered film mirror 30 and the metallic electrode mirror 20. It is determined that the minute optical resonator has an optical length L which is twice as long as a resonance wavelength, the organic layer has a thickness of 100 nm or more, and the transparent electrode has a thickness of 50 nm or more or a thickness so to have a sheet resistance of 30 OMEGA / square or less. Thus, the transparent electrode can be prevented from generating heat even when a large current is caused to flow into it, and the element characteristics can be reliably prevented from being deteriorated. Moreover, the reliability of this element can be improved because the organic layer containing the luminescent layer has a sufficient thickness.

Owner:TOYOTA CENT RES & DEV LAB INC

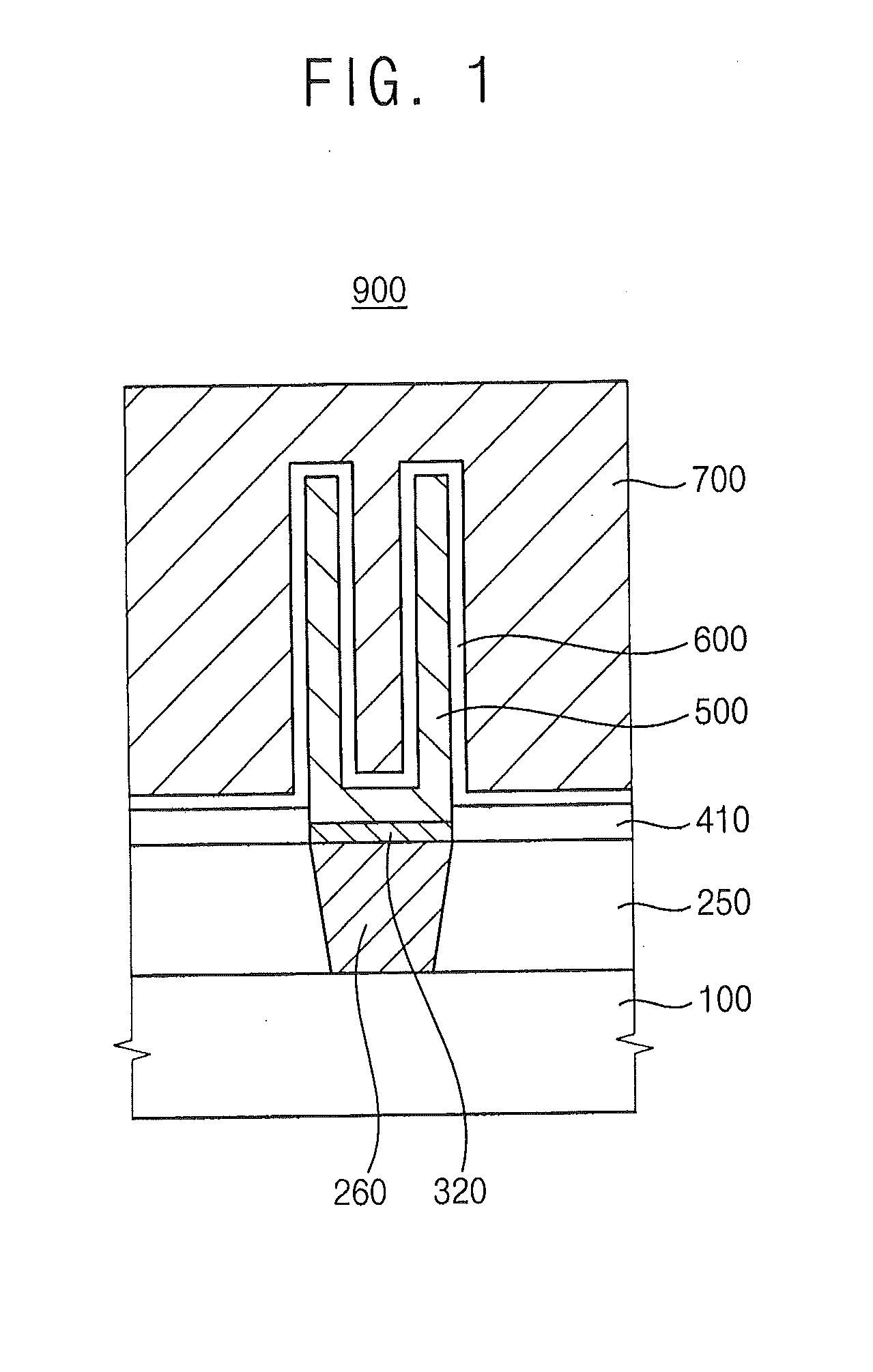

Method for forming tungsten contacts and interconnects with small critical dimensions

InactiveUS20100267230A1High aspect ratio featurePromote migrationLiquid surface applicatorsSemiconductor/solid-state device detailsElectrical resistance and conductanceGas phase

Provided are methods of void-free tungsten fill of high aspect ratio features. According to various embodiments, the methods involve a reduced temperature chemical vapor deposition (CVD) process to fill the features with tungsten. In certain embodiments, the process temperature is maintained at less than about 350° C. during the chemical vapor deposition to fill the feature. The reduced-temperature CVD tungsten fill provides improved tungsten fill in high aspect ratio features, provides improved barriers to fluorine migration into underlying layers, while achieving similar thin film resistivity as standard CVD fill. Also provided are methods of depositing thin tungsten films having low-resistivity. According to various embodiments, the methods involve performing a reduced temperature low resistivity treatment on a deposited nucleation layer prior to depositing a tungsten bulk layer and / or depositing a bulk layer via a reduced temperature CVD process followed by a high temperature CVD process.

Owner:NOVELLUS SYSTEMS

Nano-silver conductive ink and conductive film prepared by employing same

ActiveCN103627255AApplicable productionSimple production processConductive layers on insulating-supportsInksTransmittanceDisplay device

The invention discloses nano-silver conductive ink and a conductive film prepared by employing the same. The technical scheme is characterized in that the nano-silver conductive ink is prepared, satisfies the requirements on light transmittance, film electrical resistance and adhesive force, is applicable to production of the conductive film; and the prepared conductive film is effectively controlled in flatness and easy to etch, is capable of effectively satisfying the requirements on patterning of touch-control screens and display panels, and has extremely good utility value.

Owner:珠海纳金科技有限公司

Coated article with tin oxide, silicon nitride and/or zinc oxide under IR reflecting layer and corresponding method

ActiveUS20050042460A1Improve thermal stabilityReduce sheet resistanceDoors/windowsGlass/slag layered productsElectrical resistance and conductanceLow emissivity

A coated article is provided that may be heat treated in certain example embodiments. A coating of the coated article includes a tin oxide inclusive layer, a silicon nitride inclusive layer and / or a zinc oxide inclusive layer located under an infrared (IR) reflecting layer of a material such as silver. It has been found that this may result in improved thermal stability upon heat treatment, higher visible transmission, desirable coloration, lower sheet resistance (Rs), and / or lower emissivity in certain example embodiments of this invention. In certain embodiments, a zinc oxide inclusive layer may be provided above a contact layer over the IR reflecting layer, again for improving thermal stability, coloration, sheet resistance and / or visible transmission.

Owner:GUARDIAN EURO S A R L +1

Electronic device including graphene-based layer(s), and/or method or making the same

InactiveUS20110030772A1Improve stabilityHigh transparencyMaterial nanotechnologyFinal product manufactureElectrical resistance and conductanceConductive coating

Certain example embodiments of this invention relate to the use of graphene as a transparent conductive coating (TCC). In certain example embodiments, graphene thin films grown on large areas hetero-epitaxially, e.g., on a catalyst thin film, from a hydrocarbon gas (such as, for example, C2H2, CH4, or the like). The graphene thin films of certain example embodiments may be doped or undoped. In certain example embodiments, graphene thin films, once formed, may be lifted off of their carrier substrates and transferred to receiving substrates, e.g., for inclusion in an intermediate or final product. Graphene grown, lifted, and transferred in this way may exhibit low sheet resistances (e.g., less than 150 ohms / square and lower when doped) and high transmission values (e.g., at least in the visible and infrared spectra).

Owner:GUARDIAN GLASS LLC

Semiconductor device with salicide structure and fabrication method thereof

A semiconductor device is provided, which makes it possible to decrease the electric sheet resistance of source / drain regions of MOSFETs in a peripheral circuitry without degradation of the data writing speed in nonvolatile memory cells. This device is comprised of nonvolatile memory cells and a peripheral circuitry provided on a same semiconductor substrate. The nonvolatile memory cells are formed by a first plurality of MOSFETs of a first conductivity type. The peripheral circuitry includes a second plurality of MOSFETs of the first conductivity type. Each of the first plurality of MOSFETs is equipped with a gate electrode having a floating gate for data storing and source / drain regions having substantially no silicide films. Each of the second plurality of MOSFETs is equipped with source / drain regions having silicide films and a doping concentration lower than that of the source / drain regions of each of the first plurality of MOSFETs. It is preferred that the doping concentration of the source / drain regions of the first plurality of MOSFETs is equal to 1x1019 atoms / cm3 or higher and the doping concentration of the source / drain regions of the second plurality of MOSFETs is lower than 1x1019 atoms / cm3.

Owner:NEC ELECTRONICS CORP

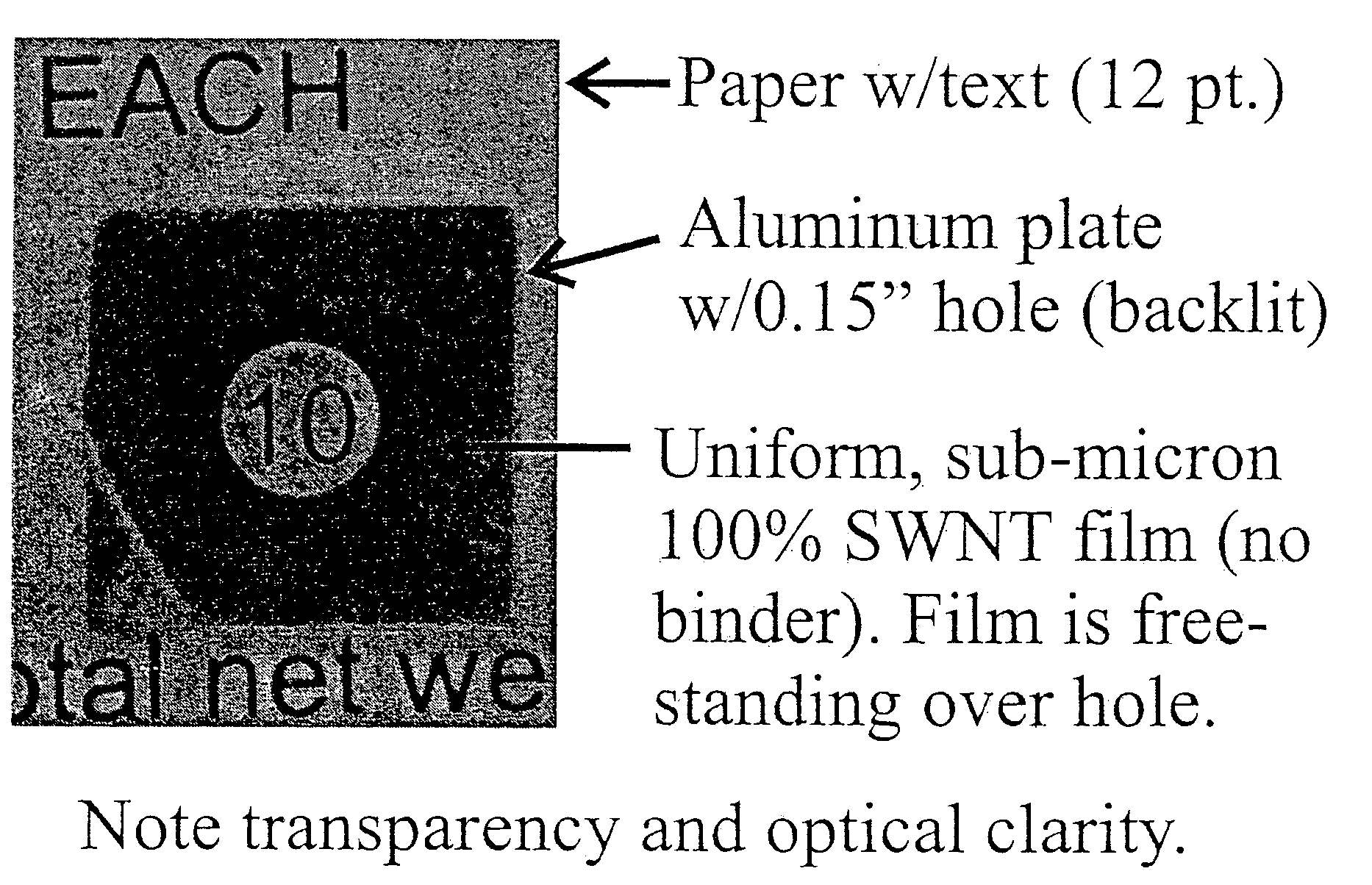

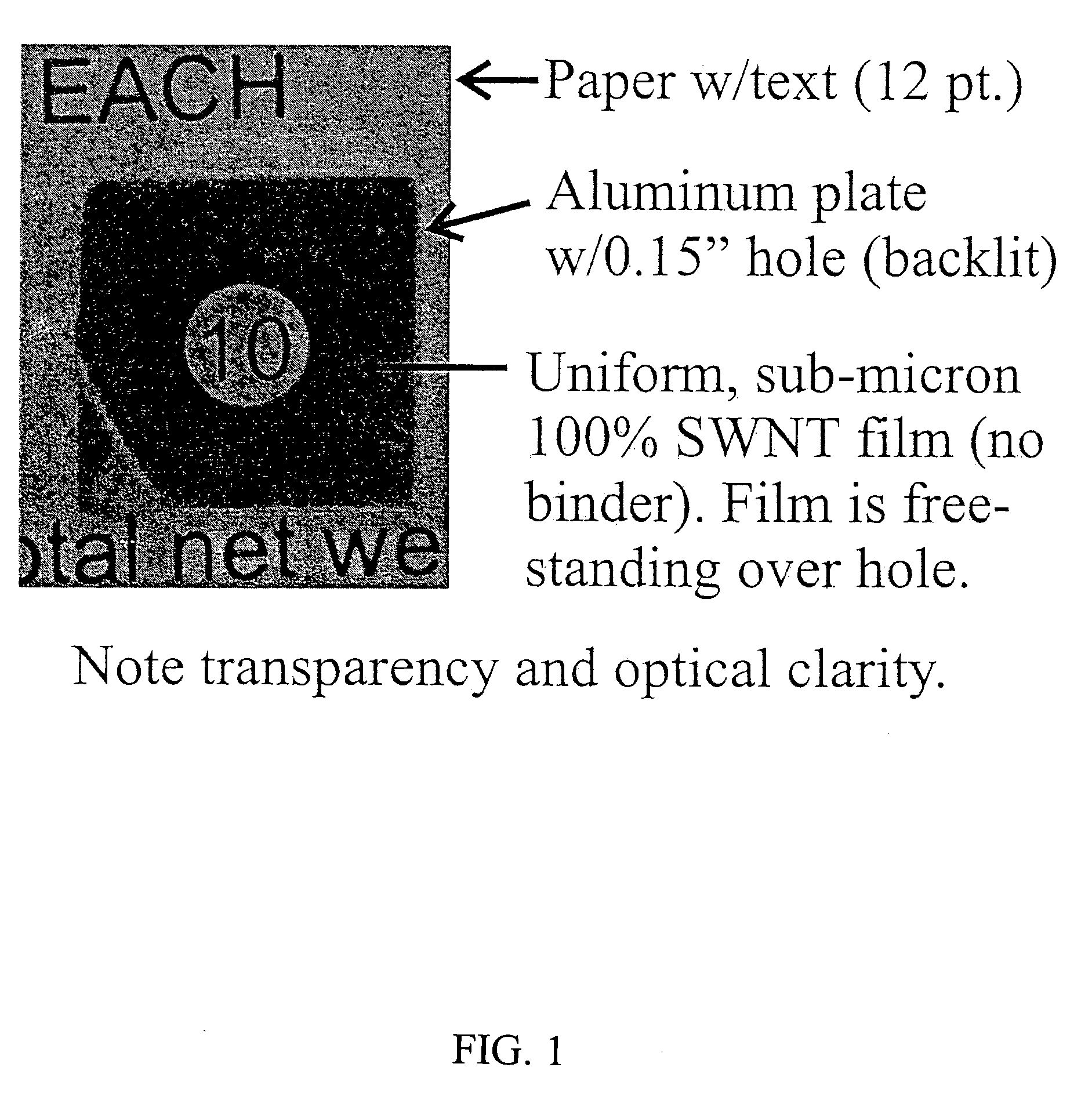

Transparent electrodes from single wall carbon nanotubes

ActiveUS7261852B2Improve conductivityMaterial nanotechnologyLiquid surface applicatorsElectrical resistance and conductanceCarbon nanotube

A method of forming optically transparent and electrically conductive SWNT films includes the steps of providing a porous membrane and dispersing a plurality of SWNTs into a solution, the solution including at least one surface stabilizing agent for preventing the SWNTs from flocculating out of suspension. The solution is then applied to the membrane. The solution is then removed, wherein the SWNTs are forced onto the surface of the porous membrane to form a SWNT film on the membrane. The method can include the step of separating the SWNT film from the porous membrane, such as by dissolving the membrane. An electrically conducting and optically transparent single wall carbon nanotube (SWNT) film provides a sheet resistance of less than 200 ohm / sq and at least 30% transmission at a wavelength of 3 μm.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

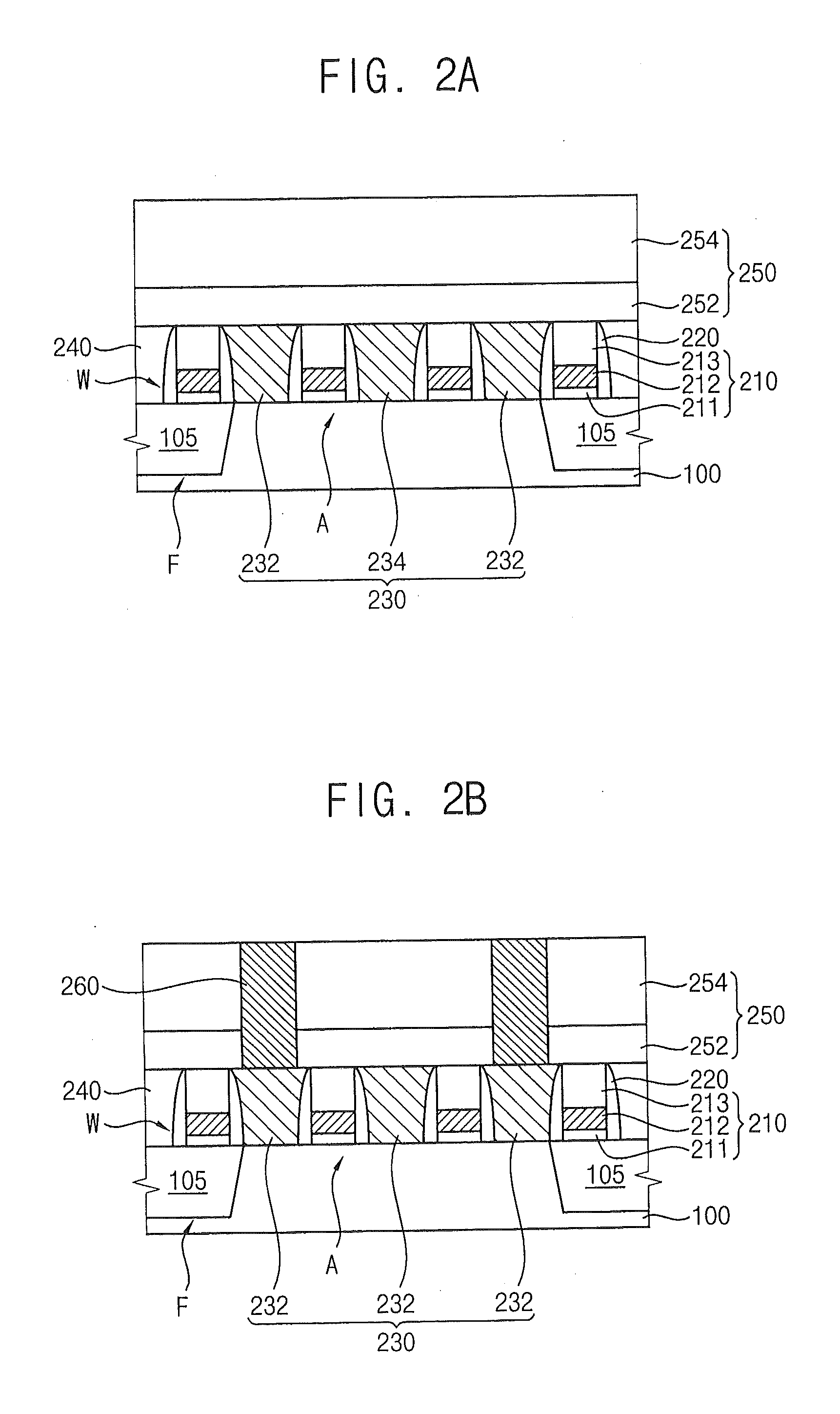

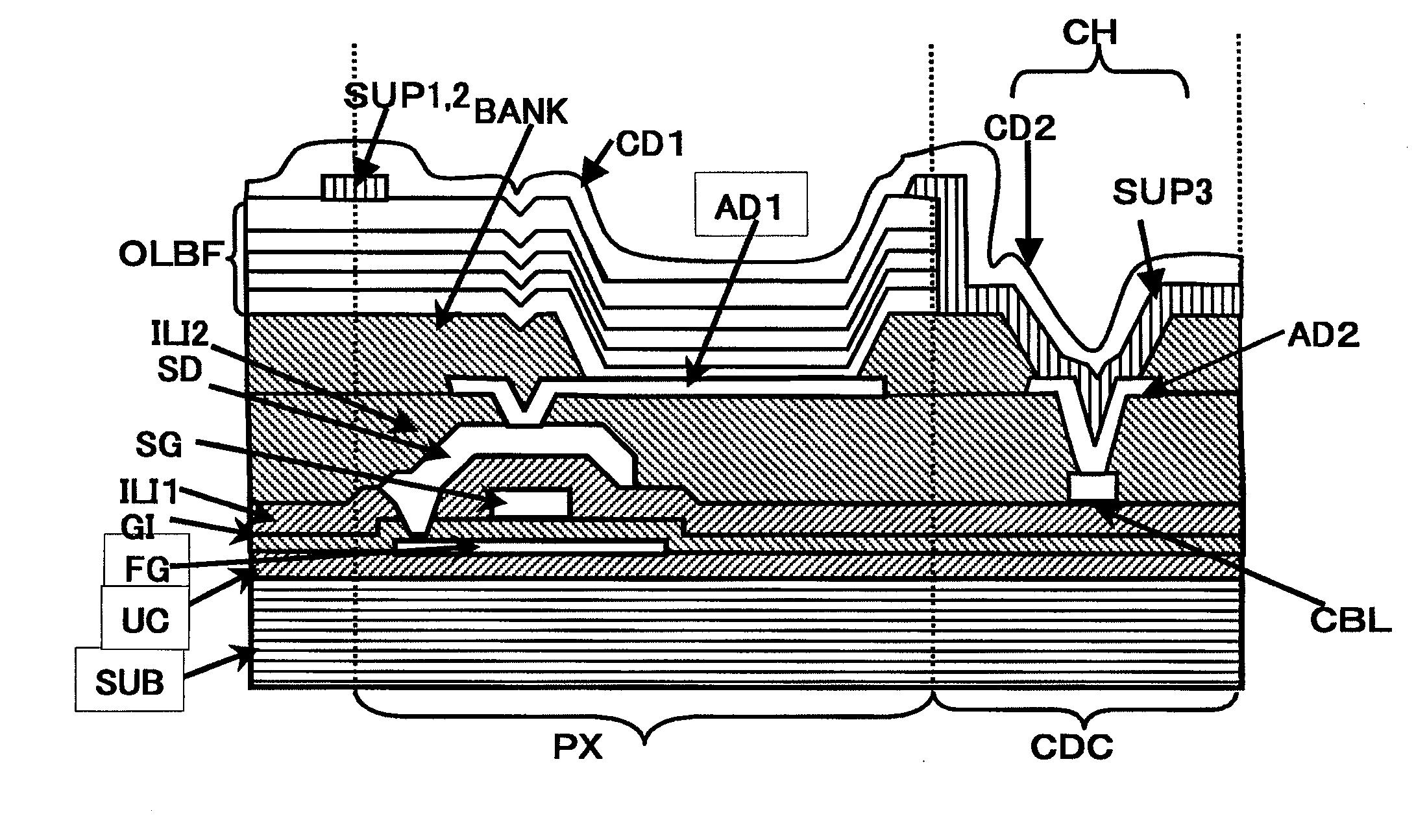

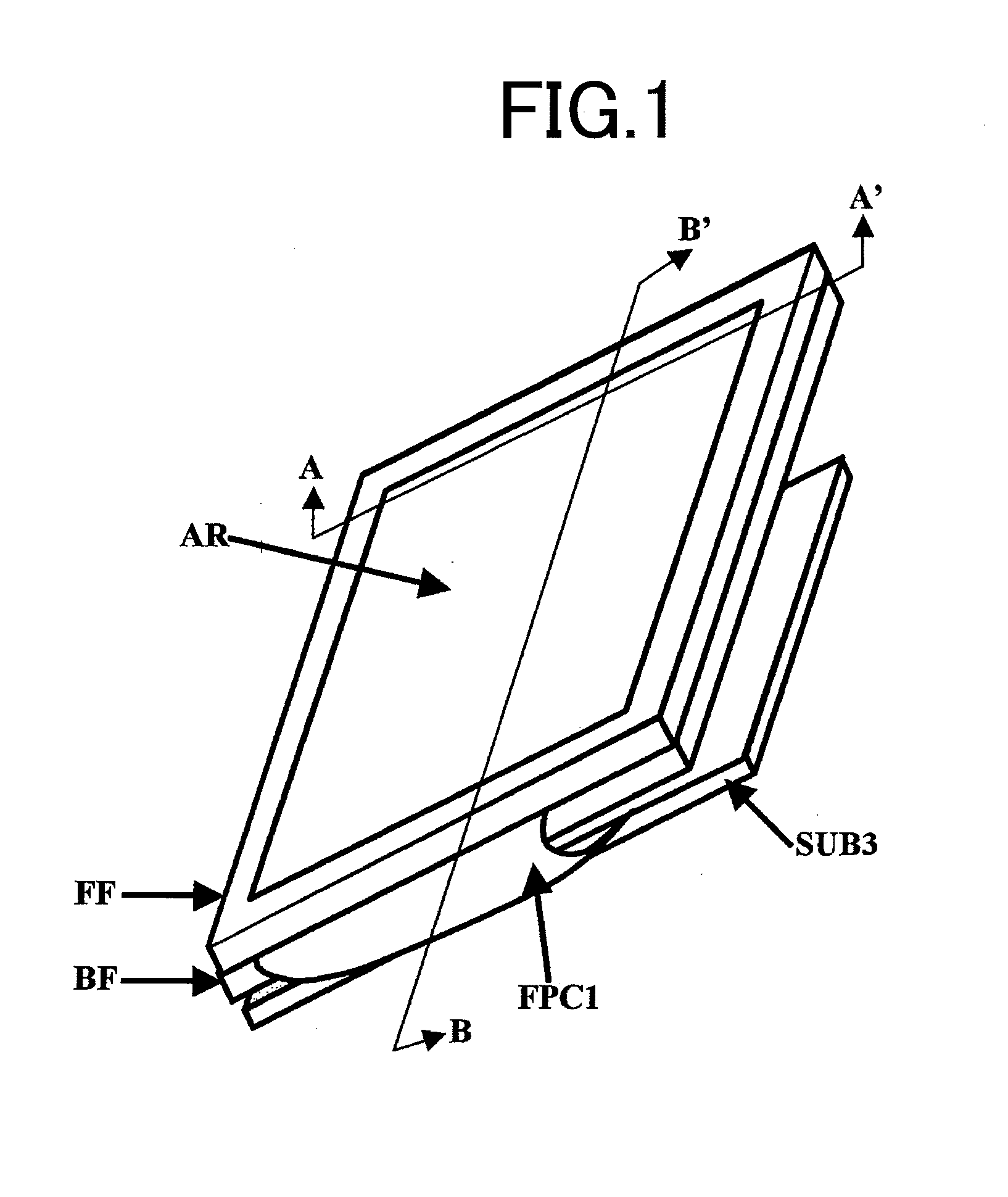

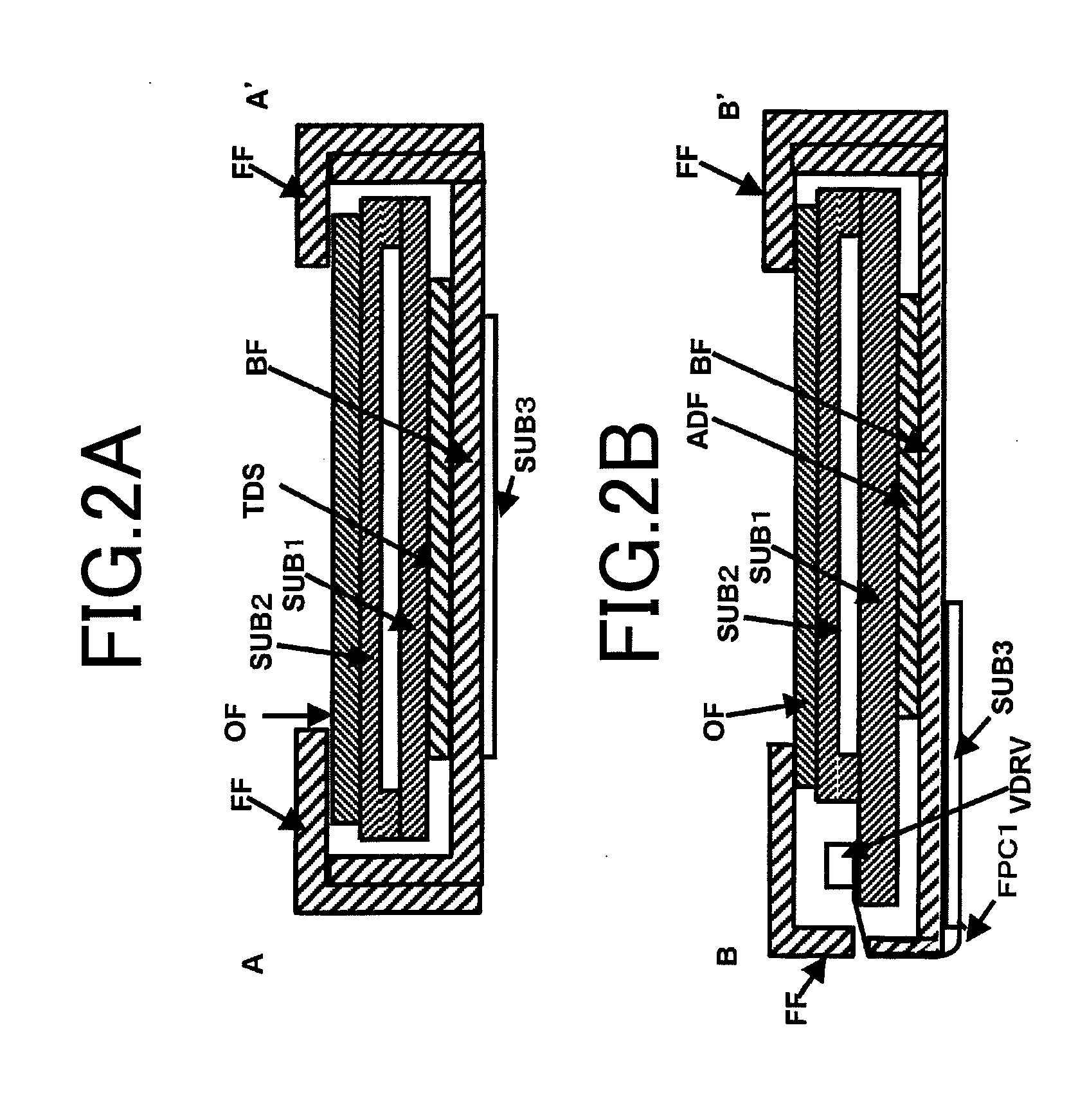

Organic Electroluminescence Display Device

InactiveUS20070241664A1Suppress on-screen luminance unevennessWithout reducing opening ratioDischarge tube luminescnet screensElectroluminescent light sourcesOrganic layerDisplay device

An organic electroluminescence display device with high luminescence and high display quality comprises a plurality of active elements, and a plurality of organic electroluminescence elements which produce luminescence through control by the active elements, on a substrate; wherein the organic electroluminescence element has a structure in which a lower electrode, an organic layer, and an upper electrode CD are laminated in this order from the substrate side; the upper electrode CD of the plurality of organic electroluminescence elements is formed as an electrode common to all the organic electroluminescence elements; an electrode is prepared between the upper electrode CD and the organic layer; and the sheet resistance between two points on the upper electrode CD which sandwich the electrode is lower than that between two points which do not sandwich the metal electrode.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com