Conduction structure in transparent conduction film, transparent conduction film and manufacture method thereof

A technology of transparent conductive film and conductive structure, which is applied in the direction of transparent dielectric, conductive layer on insulating carrier, printed circuit manufacturing, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

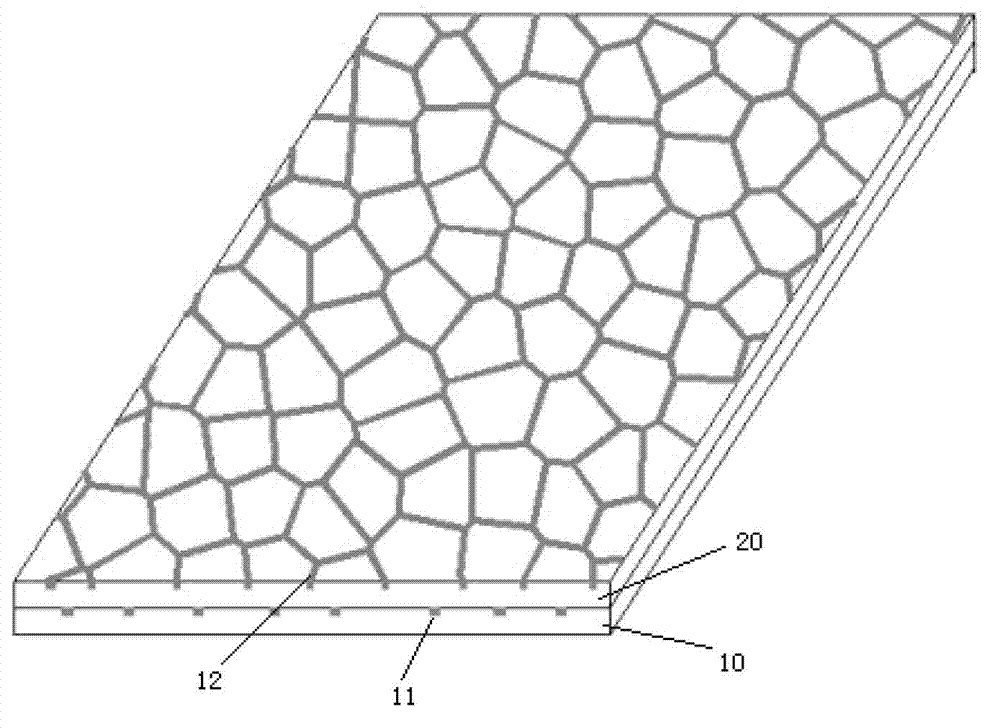

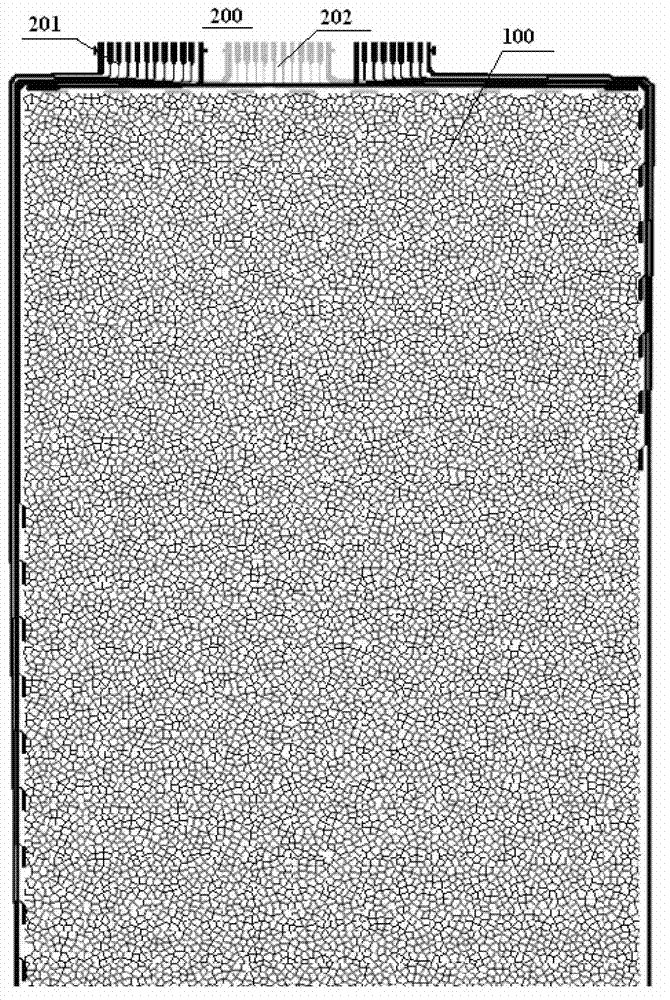

[0043] See figure 1 , figure 1It is a partial schematic diagram of the transparent conductive film according to the first embodiment of the present invention. In this embodiment, the first metal embedding layer in the conductive structure is directly formed on the substrate. As shown in the figure, the transparent conductive film includes a transparent substrate 10 and a transparent polymer layer 20 on the substrate. The conductive structure includes a grid-shaped first metal buried layer 11 disposed in the substrate 1, and a grid-shaped second metal buried layer 21 disposed in the transparent polymer layer 20, in order to ensure that the first metal buried layer 11 and the second metal buried layer 21 are insulated from each other, so that the thickness of the second metal buried layer 21 is smaller than the thickness of the polymer layer 20, so that the first metal buried layer 11 and the second metal layer 21 A part of the polymer layer 20 is separated to play an insulati...

Embodiment 2

[0054] See Figure 8 , Figure 8 It is a partial schematic view of the transparent conductive film according to the second embodiment of the present invention. In this embodiment, the first metal buried layer in the conductive structure is directly fabricated in the first polymer layer on the substrate. As shown in the figure, the transparent conductive film includes a transparent substrate 10 ′, a transparent transparent film on the substrate A first polymer layer 20', and a transparent second polymer layer 30 on the first polymer layer 20'. The conductive structure includes a grid-shaped first metal buried layer 11 ′ disposed in the first polymer layer 20 ′, and a grid-shaped second metal buried layer 21 ′ disposed in the second transparent polymer layer 30 , in order to ensure the insulation between the first buried metal layer 11 ′ and the second buried metal layer 21 ′, the thickness of the second buried metal layer 21 ′ is smaller than the thickness of the second polym...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com