Patents

Literature

1149results about How to "Convenient coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

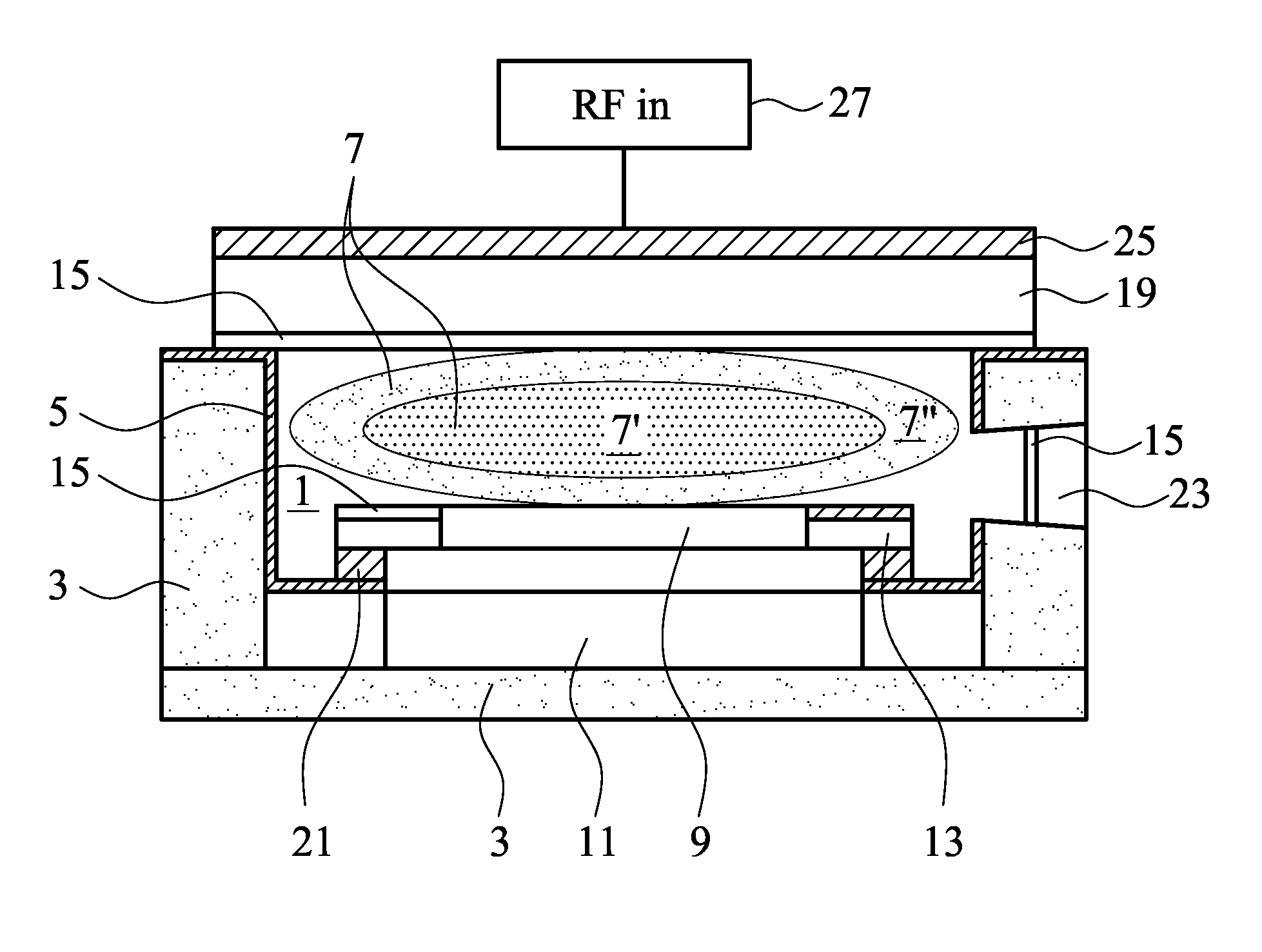

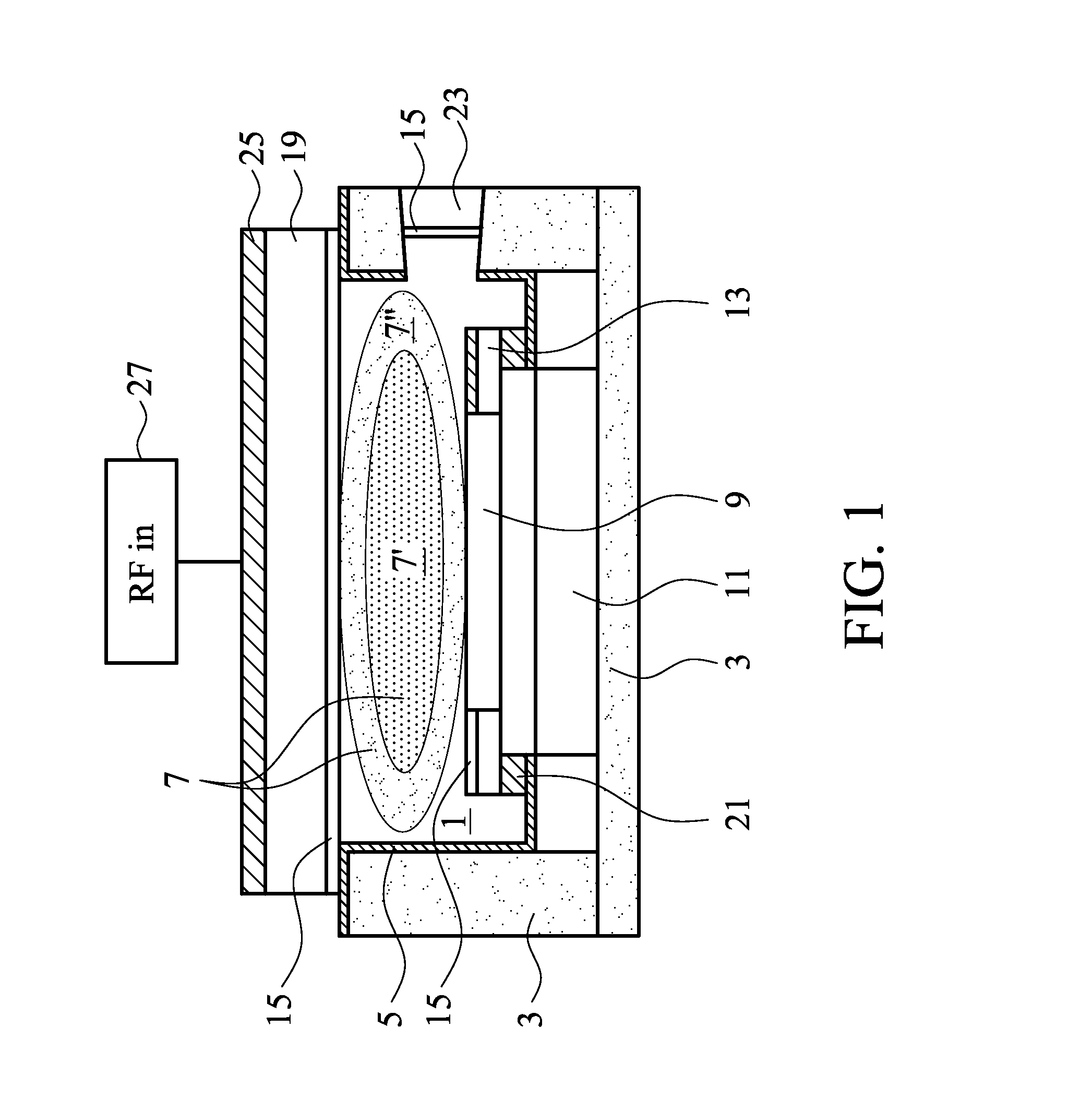

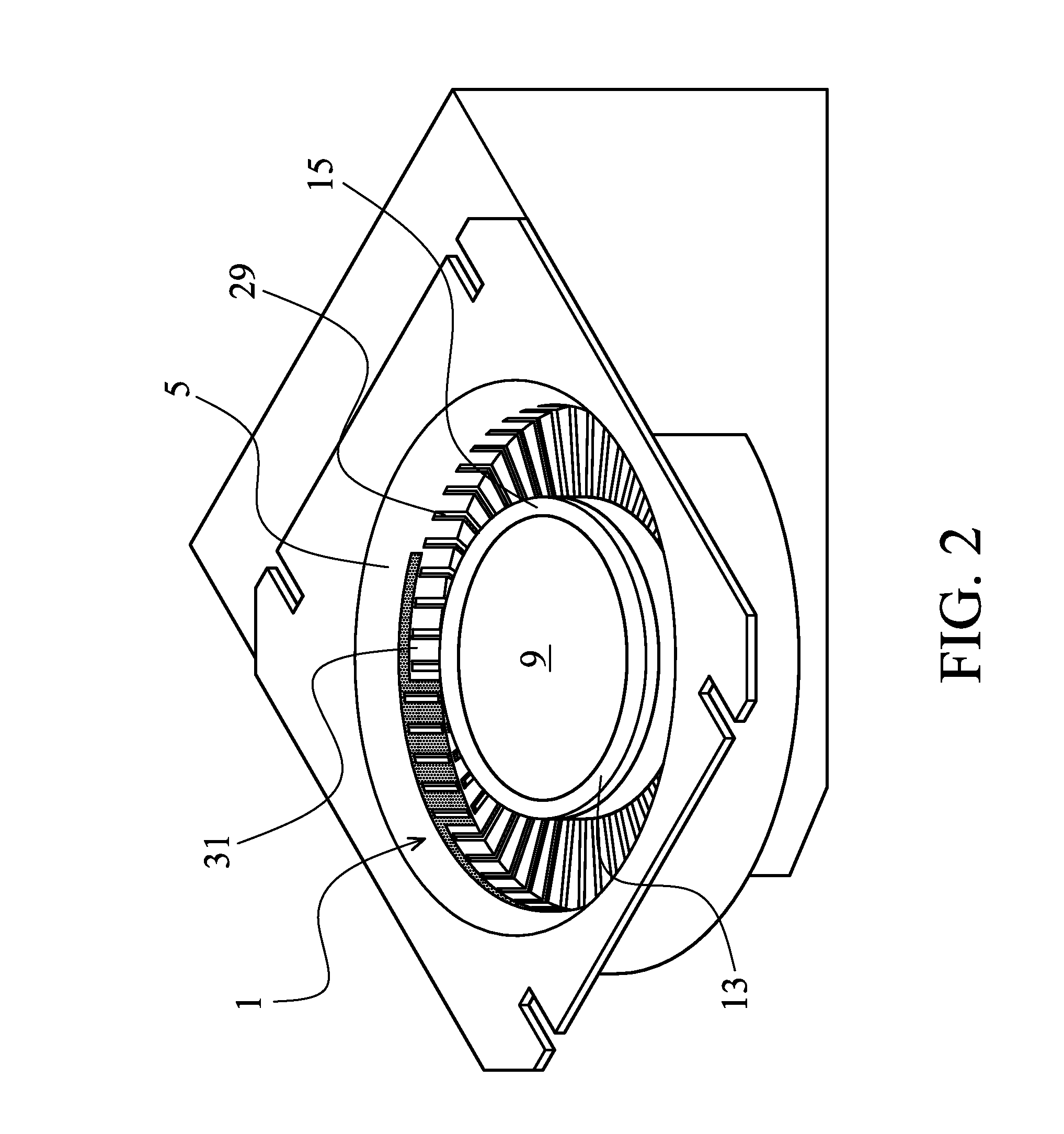

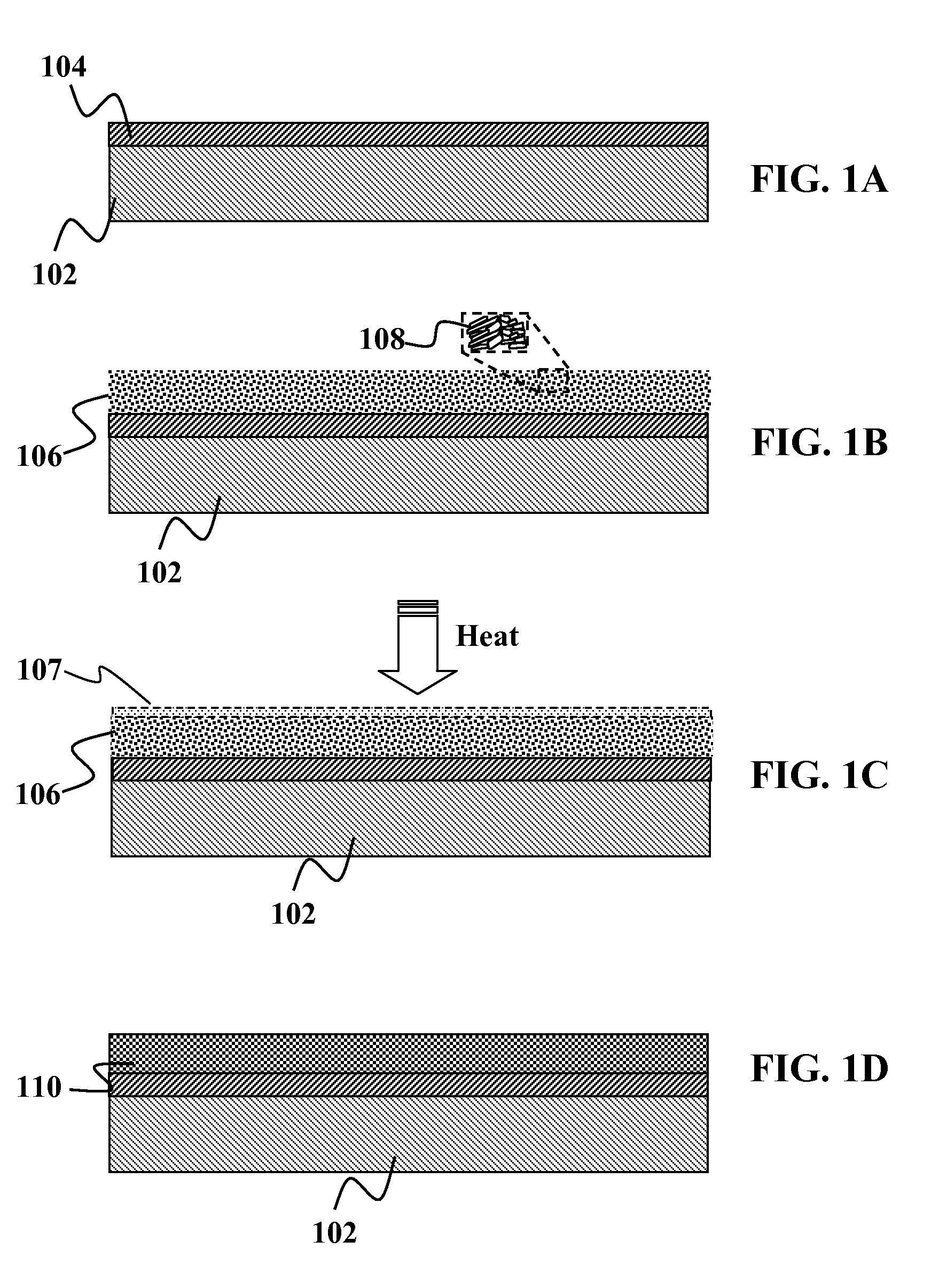

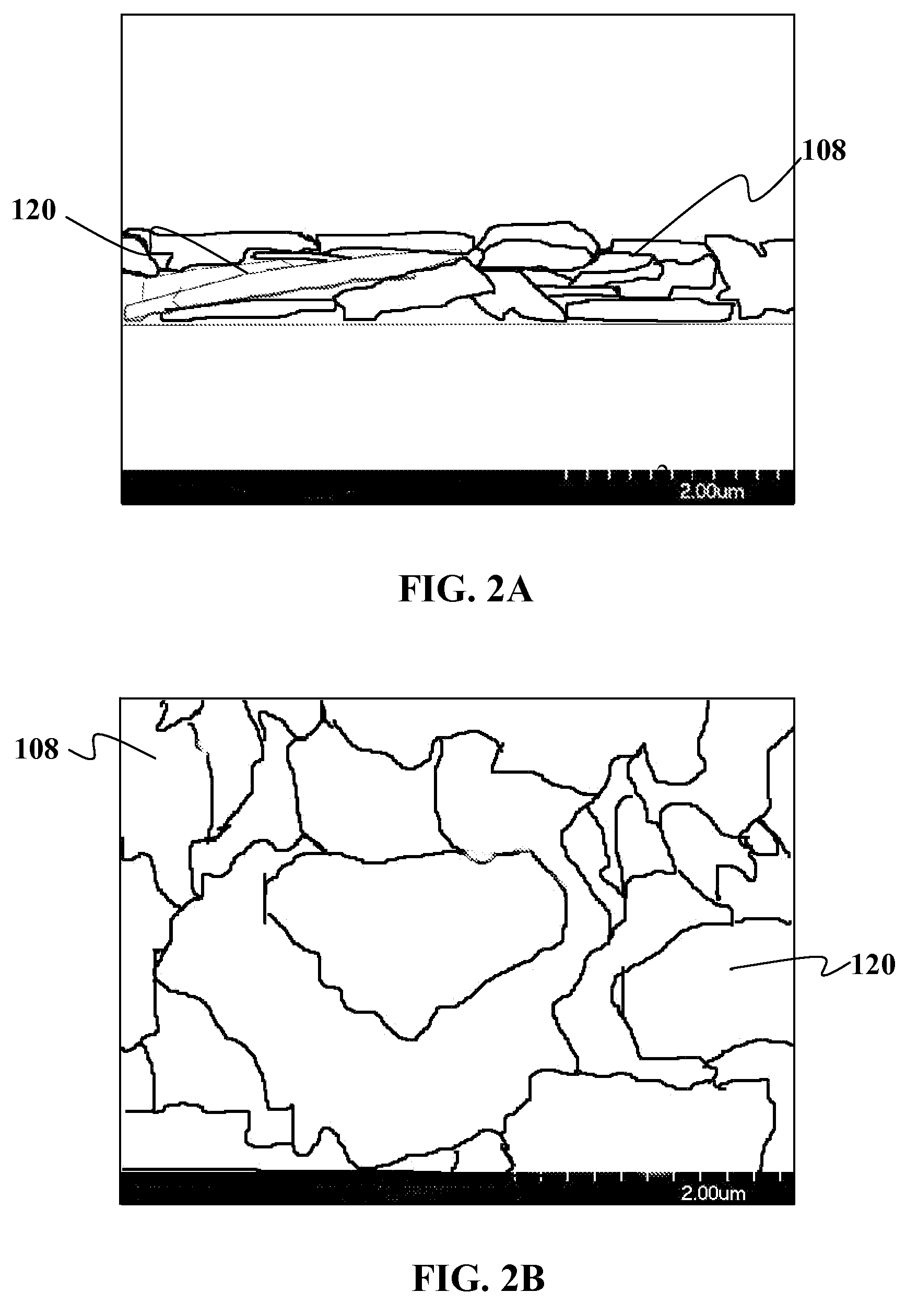

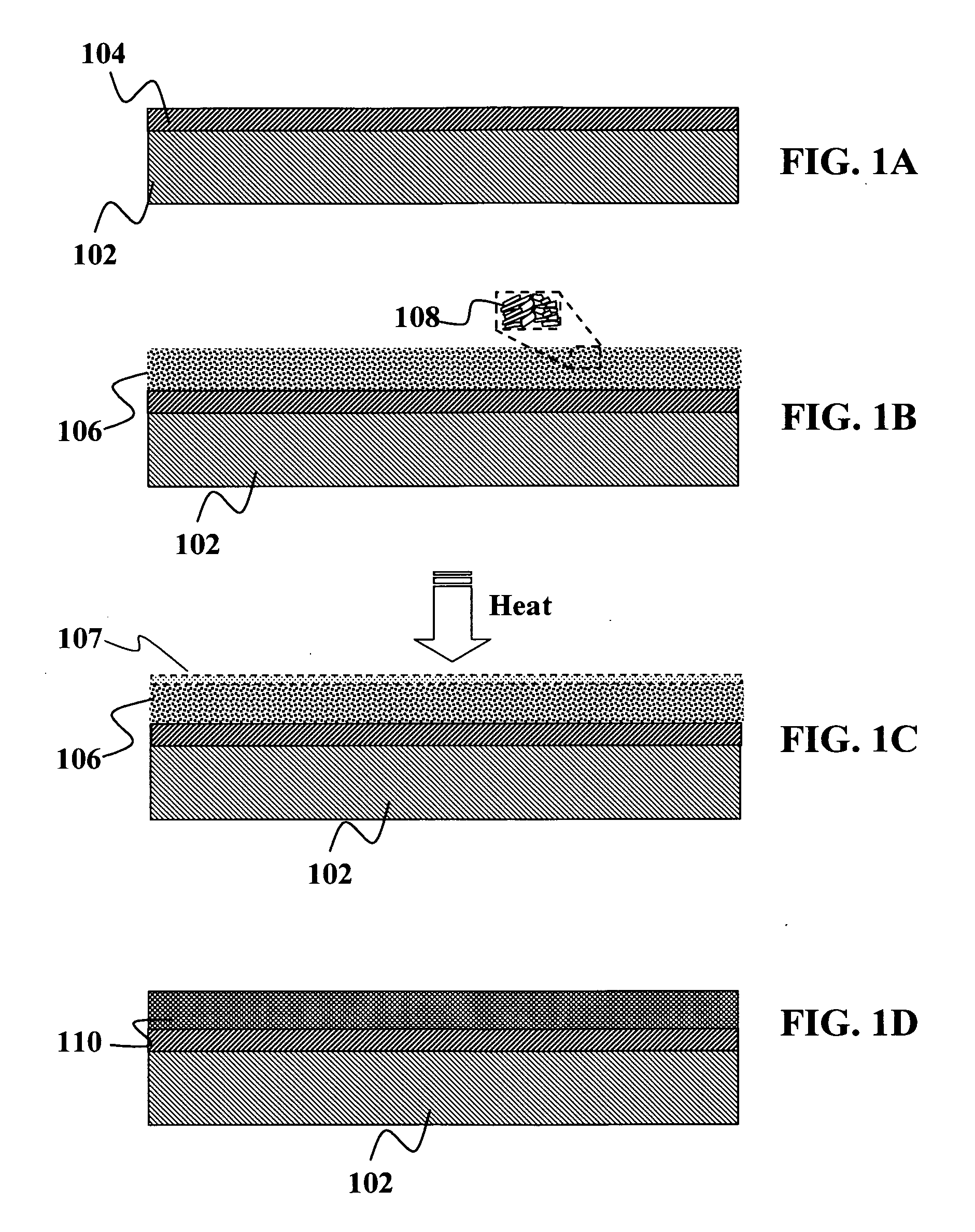

Thin film coated process kits for semiconductor manufacturing tools

InactiveUS20110207332A1Convenient coatingElectric discharge tubesElectrostatic cleaningQuartzSilicon

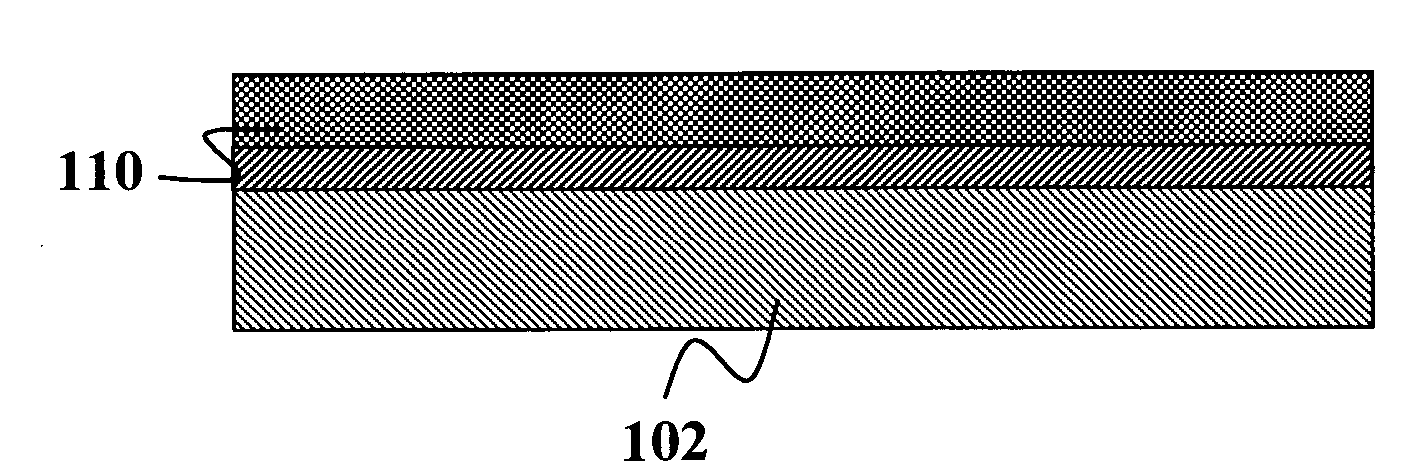

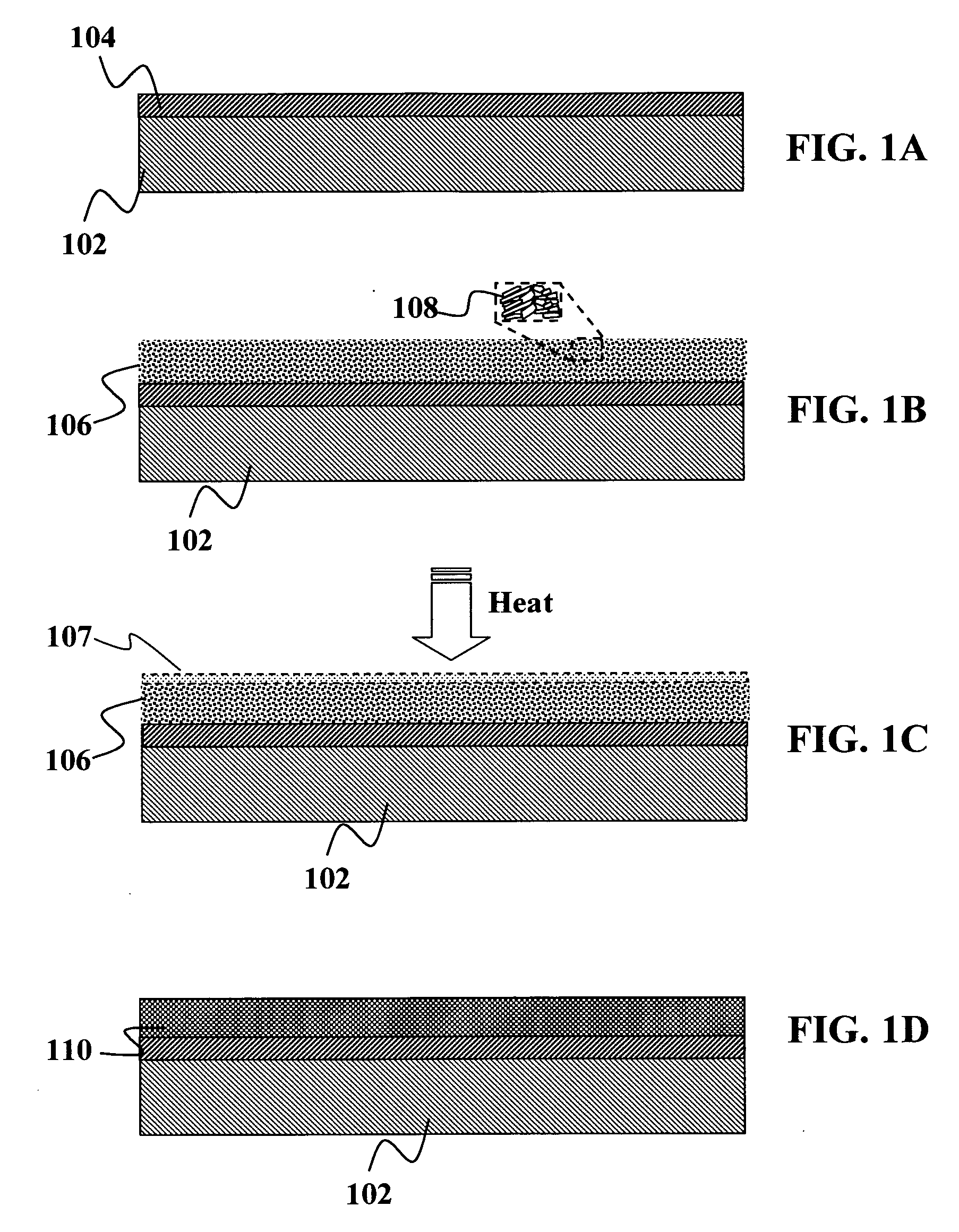

A plasma processing apparatus used in semiconductor device manufacturing includes a process kit formed of insulating materials such as quartz and coated with a Y2O3 coating. The Y2O3 coating is a thin film formed using suitable CVD or PVD operations. The Y2O3 coating is resistant to degradation in fluorine etching chemistries commonly used to etch silicon in semiconductor manufacturing. The plasma processing apparatus may be used in etching, stripping and cleaning operations. Also provided in another embodiment is a plasma processing apparatus having a quartz process kit coated with a sapphire-like film.

Owner:TAIWAN SEMICON MFG CO LTD

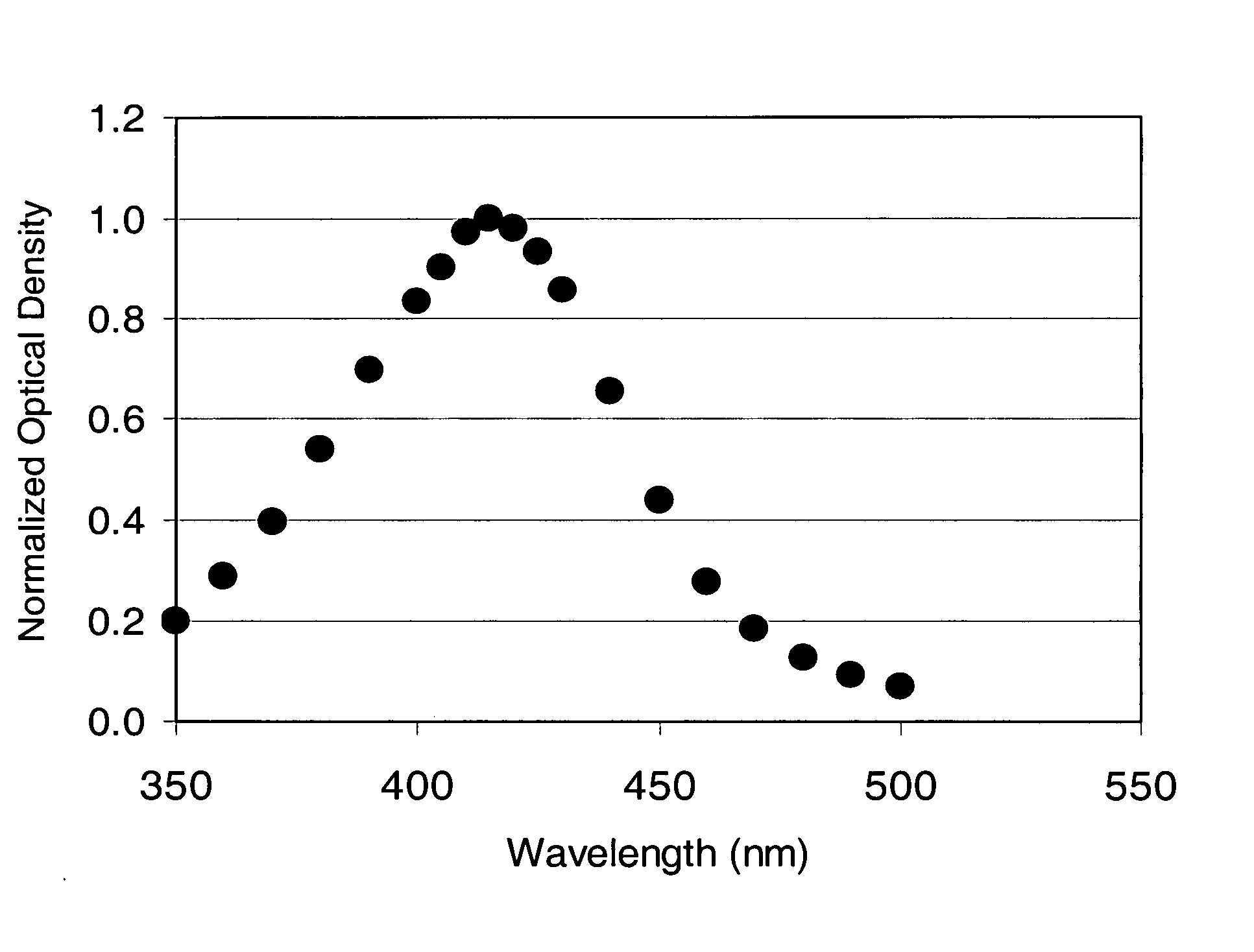

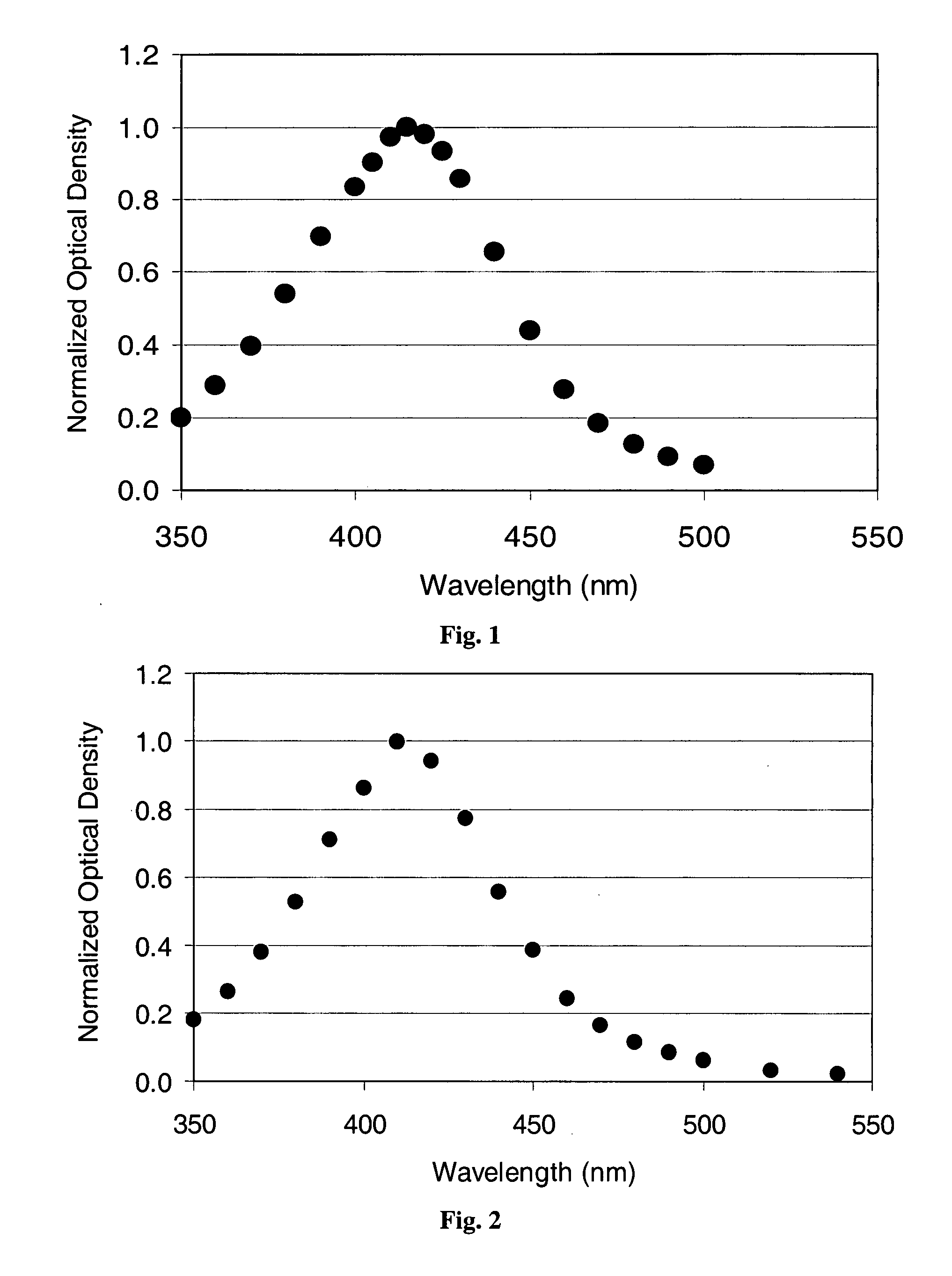

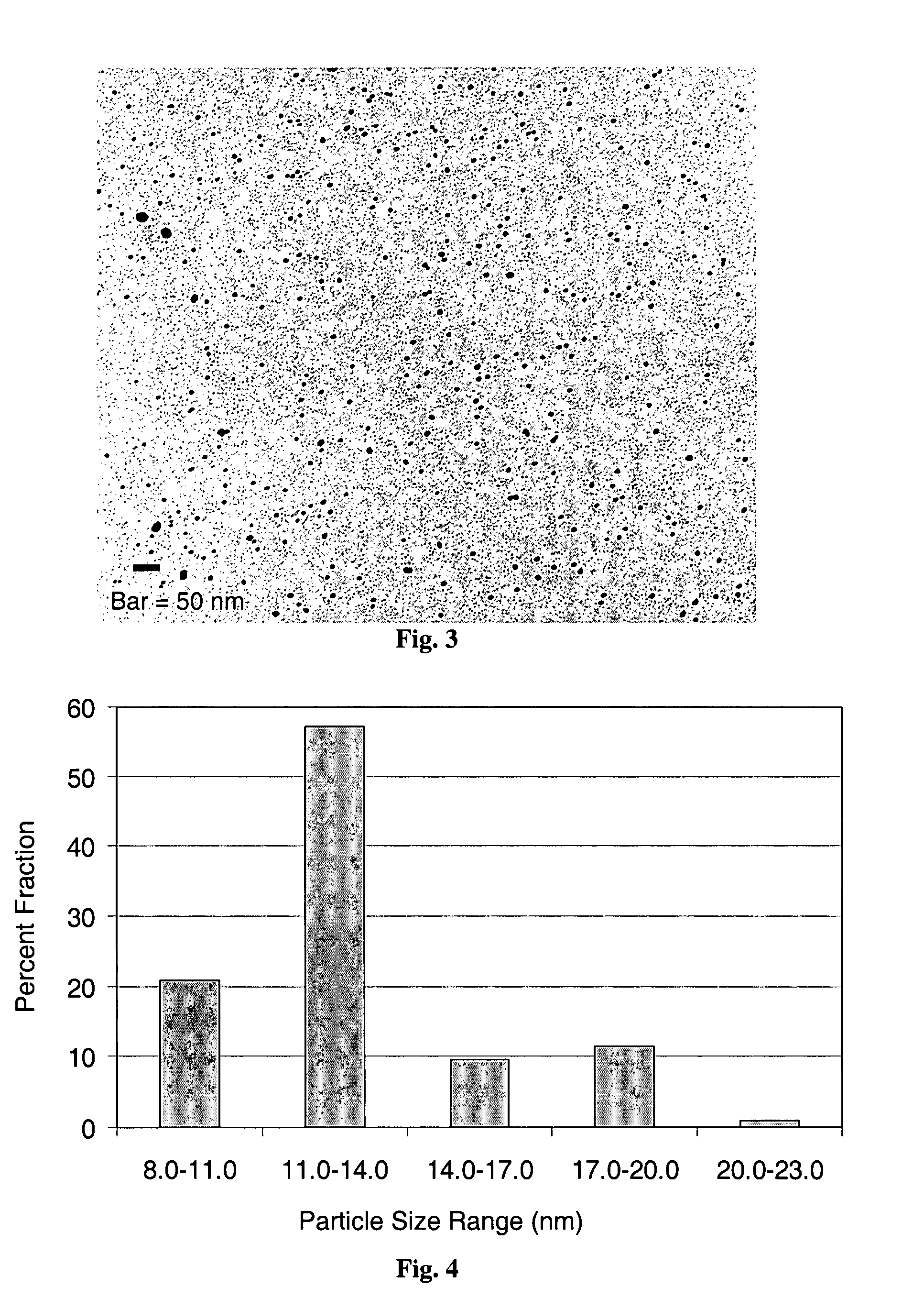

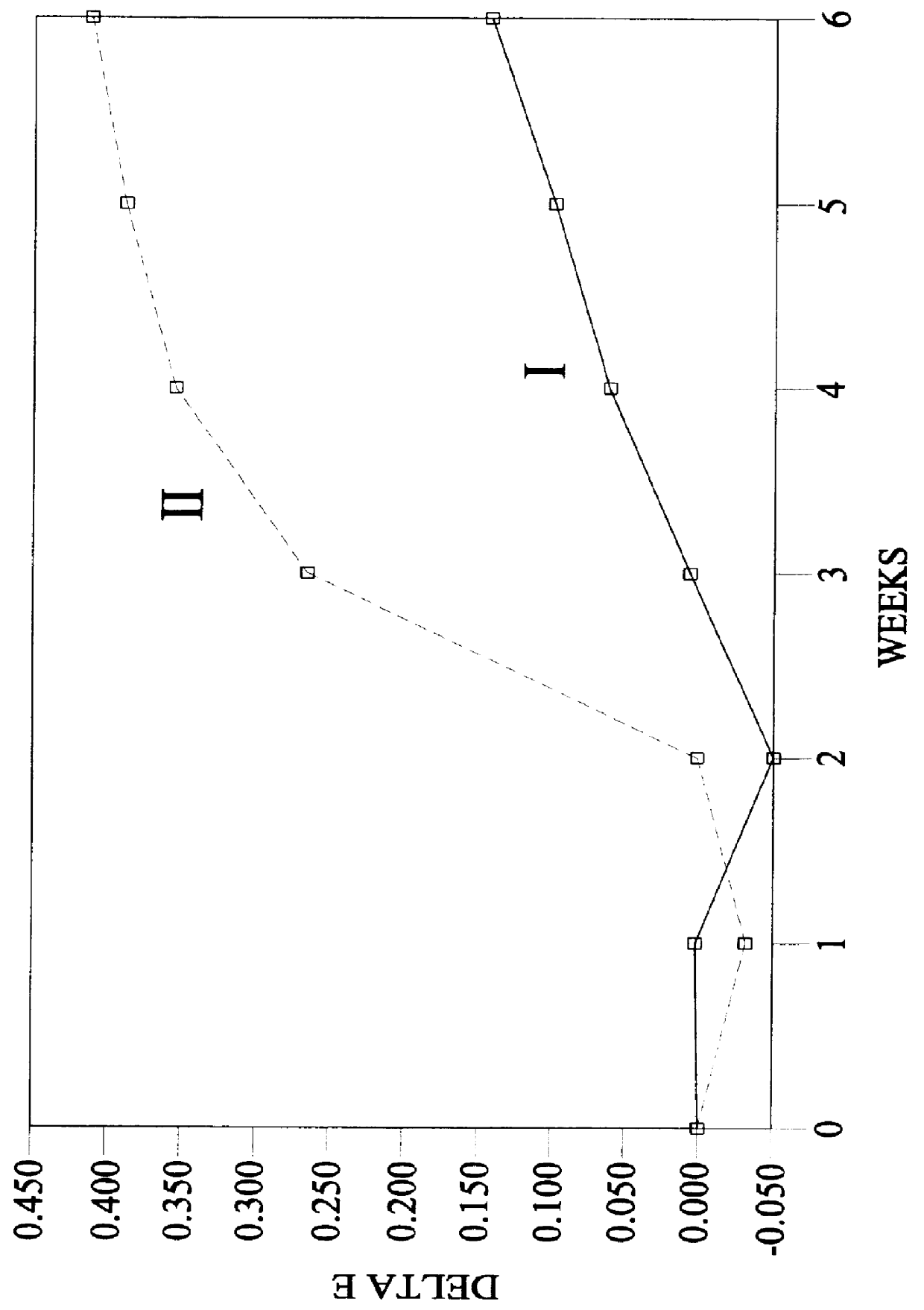

Antireflective coatings comprising poly(oxyalkylene) colorants

InactiveUS6048662AReduce the amplitudeImprove anti-reflectionPhotosensitive materialsRadiation applicationsCounterionThin layer

This invention relates to antireflective coatings comprising polymeric polyoxyalkylenated colorants. More particularly, the present invention relates to antireflective coatings for utilization in forming thin layers between reflective substrates and photoresist coatings. Such antireflective coatings are very useful and beneficial within the production and fabrication of semiconductors through photolithographic procedures due to the liquid, non-crystallizing nature of polyoxyalkylenated colorants, and the lack of potentially damaging counterions, metals, and / or electrolytes within the inventive antireflective colored coatings. The inventive coatings may also be applied on lenses, mirrors, and other optical components. Methods of forming such antireflective coatings are also contemplated within this invention.

Owner:MILLIKEN & CO

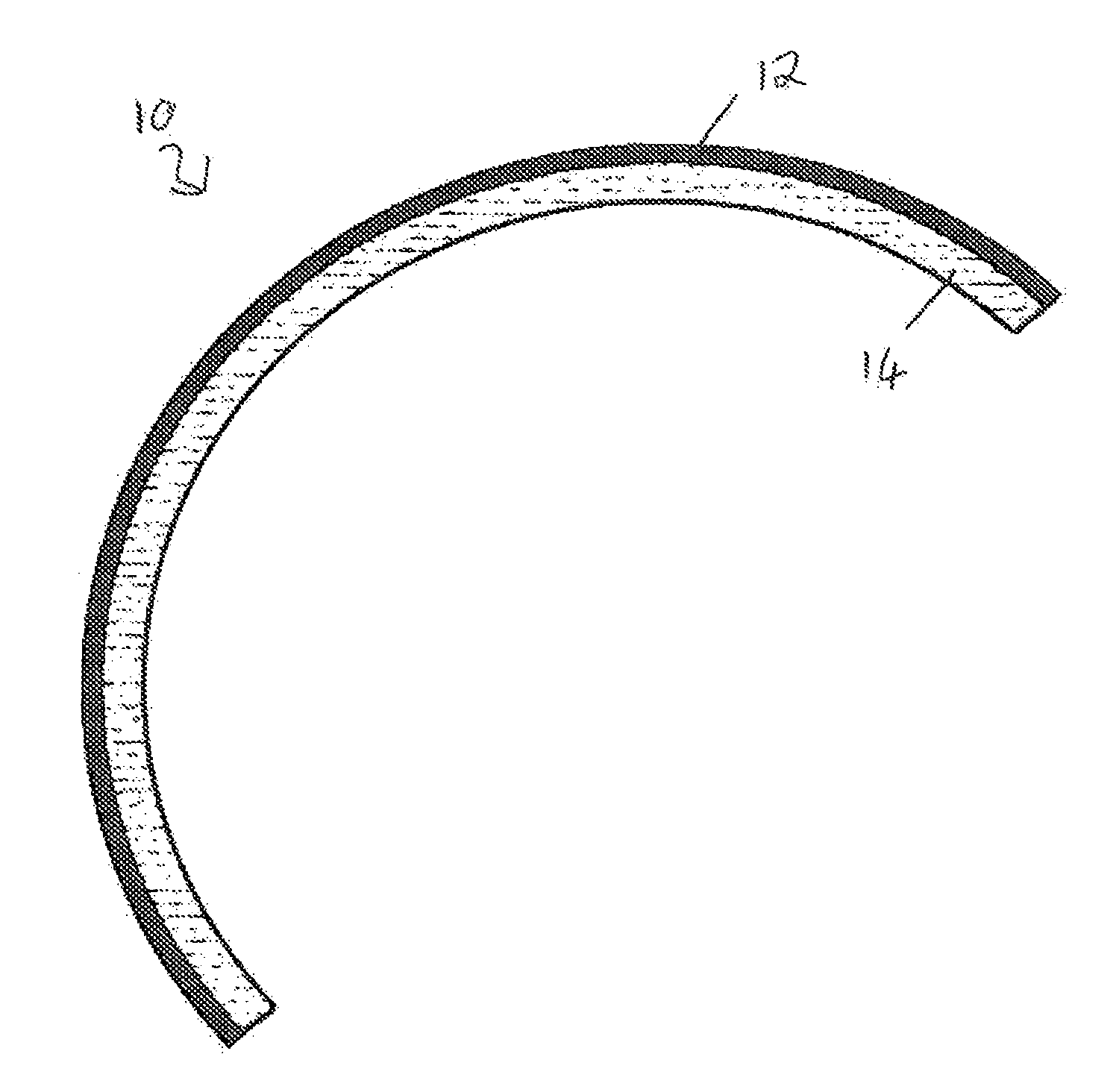

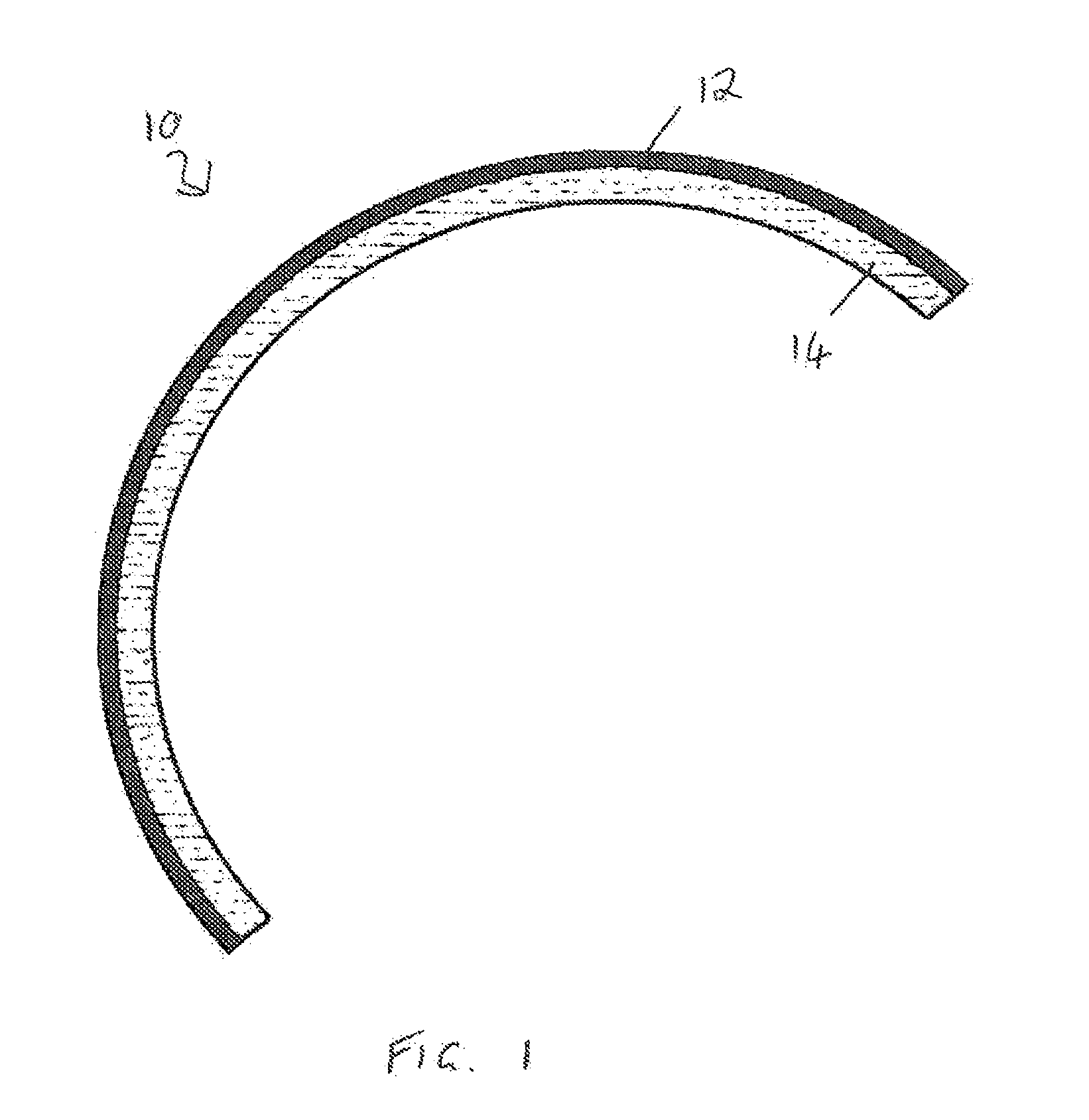

Methods and compositions for metal nanoparticle treated surfaces

ActiveUS20070207335A1Extended shelf lifeConvenient coatingMaterial nanotechnologyBiocidePolyamideSolvent

The present invention comprises methods and compositions comprising metal nanoparticles. The invention comprises metal nanoparticles and surfaces treated with a metal nanoparticle coating. The present invention further comprises compositions for preparing nanoparticles comprising at least one stabilizing agent, one or more metal compounds, at least one reducing agent and a solvent. In one aspect, the stabilizing agent comprises a surfactant or a polymer. The polymer may comprise polymers such as polyacrylamides, polyurethanes, and polyamides. In one aspect, the metal compound comprises a salt comprising a metal cation and an anion. The anion may comprise saccharinate derivatives, long chain fatty acids, and alkyl dicarboxylates.

Owner:AVENT INC

Modified release formulations containing drug-ion exchange resin complexes

ActiveUS20070215511A1Reduction of undesirable tasteConvenient coatingPowder deliverySmall article dispensingDrugPlasticizer

A coated drug-ion exchange resin complex comprising a core composed of a drug complexed with a pharmaceutically acceptable ion-exchange resin is provided. The drug-ion exchange resin complex is in admixture with a release retardant. The coating is a polyvinyl acetate polymer and a plasticizer. Methods of making and products containing this coated complex are described.

Owner:TRIS PHARMA

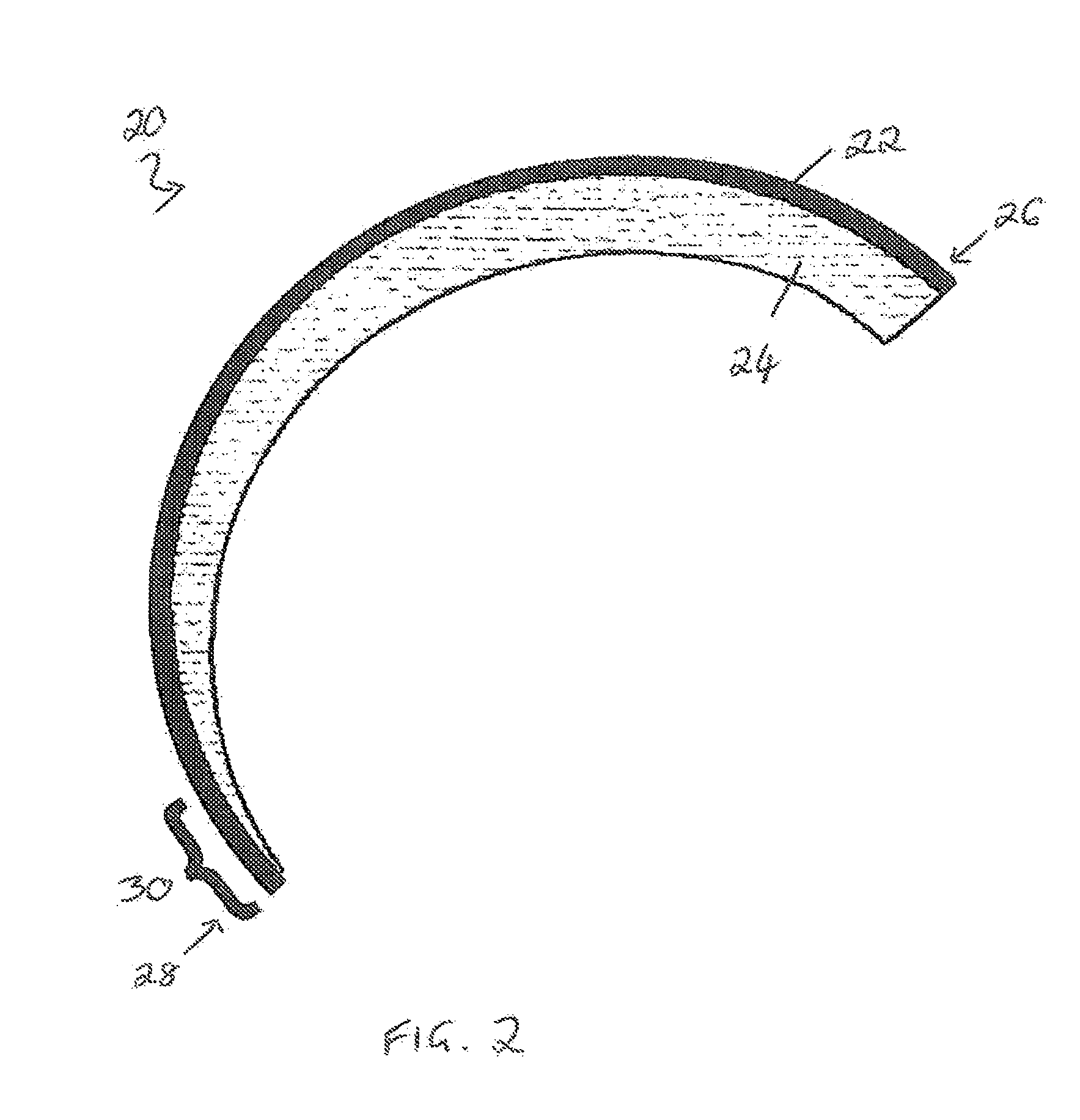

Method of Forming a Polymer Component

ActiveUS20110153025A1Reduce oxidationPrevent oxidationMedical devicesPretreated surfacesCross-linkArticular surfaces

This invention relates to a method of forming a polymer component and comprises blending polymer particles with antioxidant to form a mixture in which the antioxidant coats the polymer particles, irradiating the mixture to cross-link the polymer particles therein and forming the irradiated mixture into a consolidated component. The invention also relates to a method of forming an articular surface for a prosthesis and a prosthesis having a polymer articular bearing surface wherein at least one pre-determined portion of the bearing surface is provided with cross-linked polymer bonds.

Owner:JOINTMEDICA LTD

Silane copolymer coatings

InactiveUS6908681B2Maintain good propertiesImprove adhesionMale contraceptivesSurgerySilanesMedical device

Owner:CR BARD INC

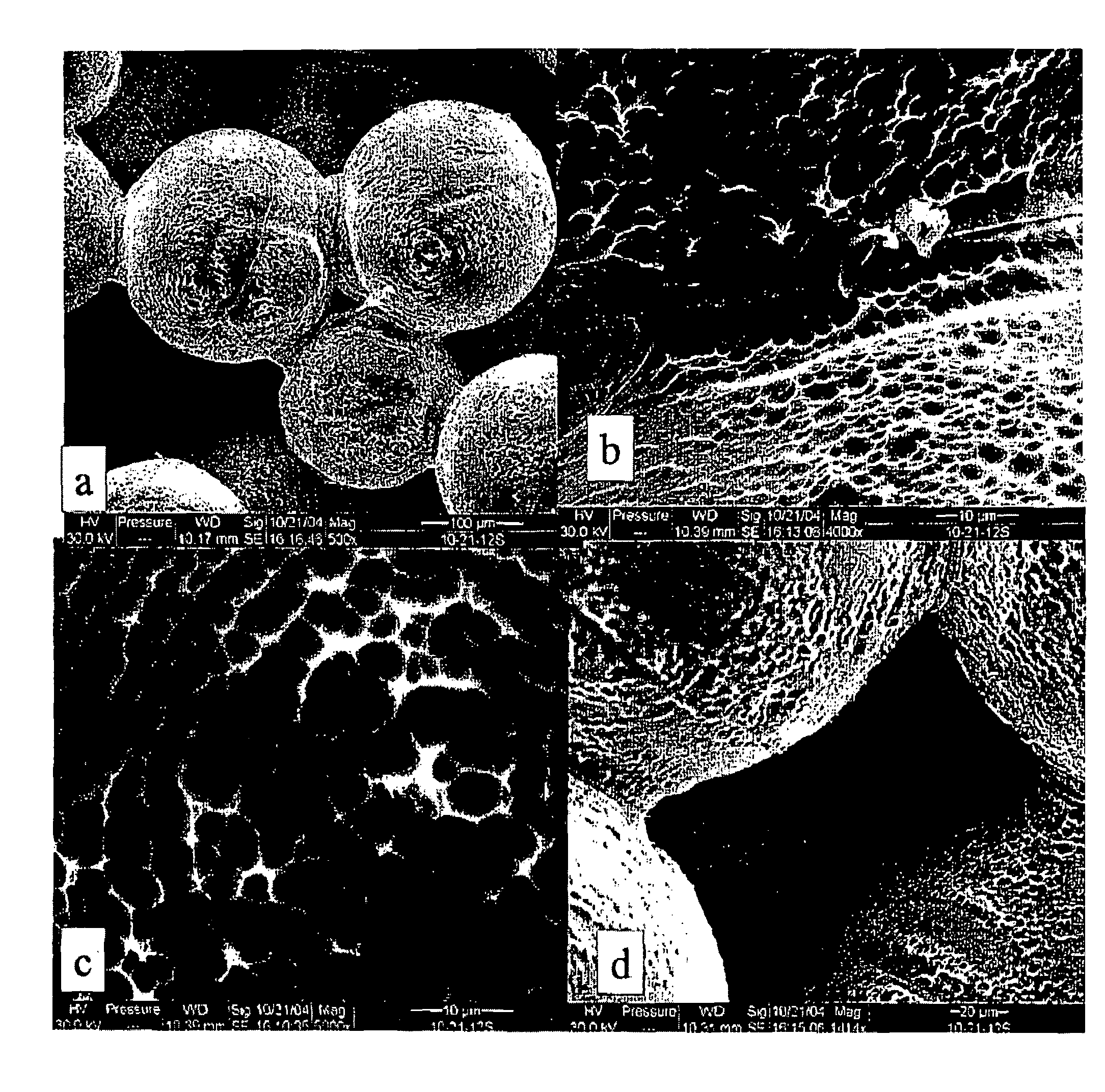

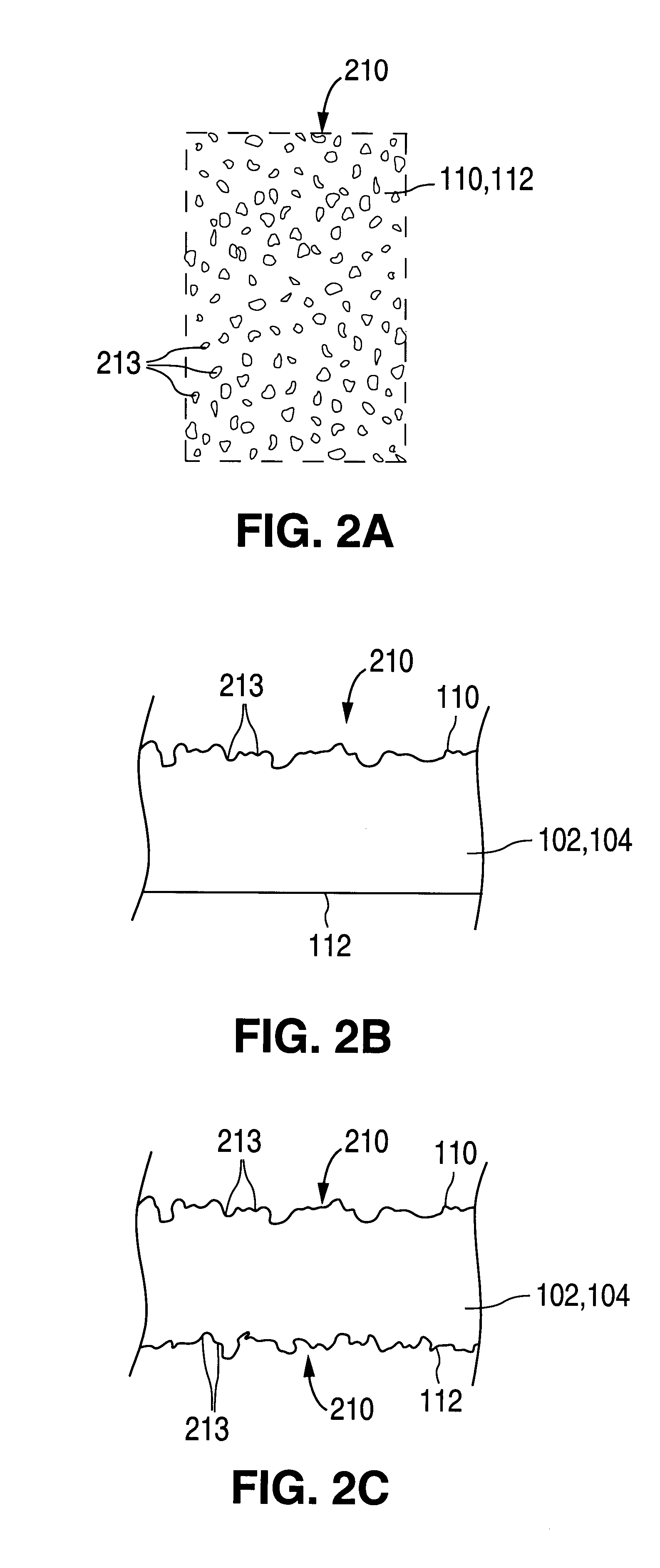

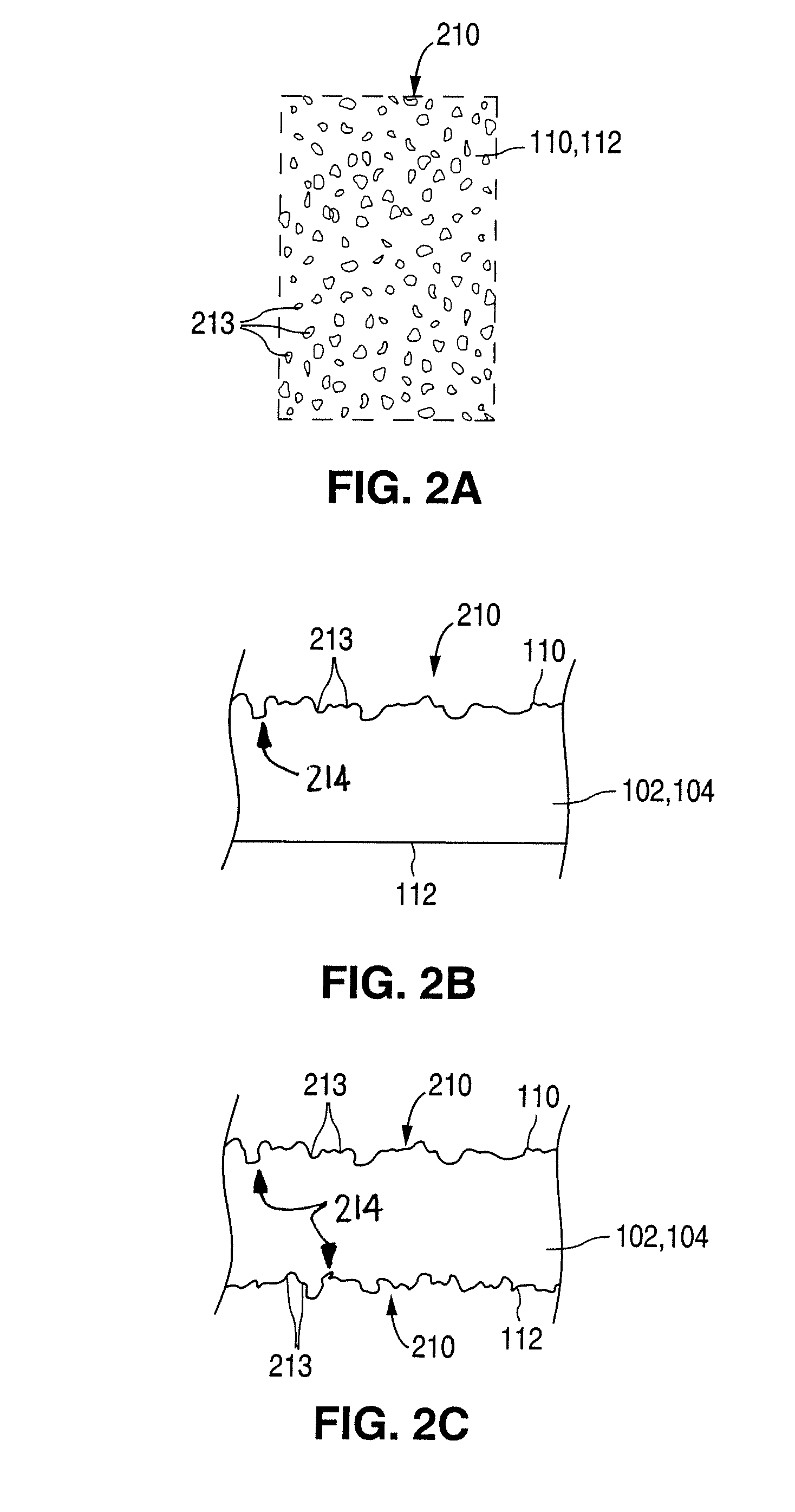

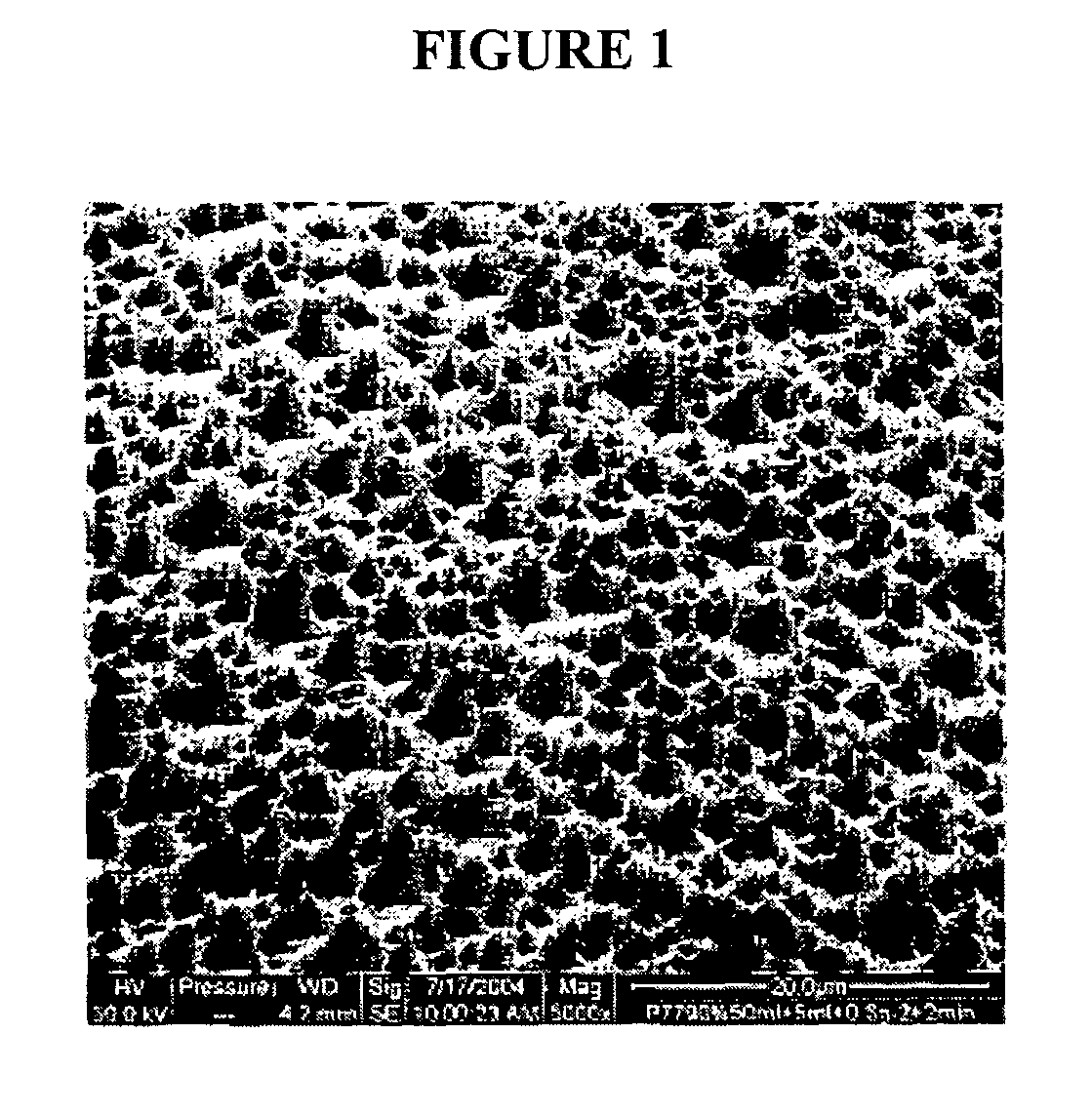

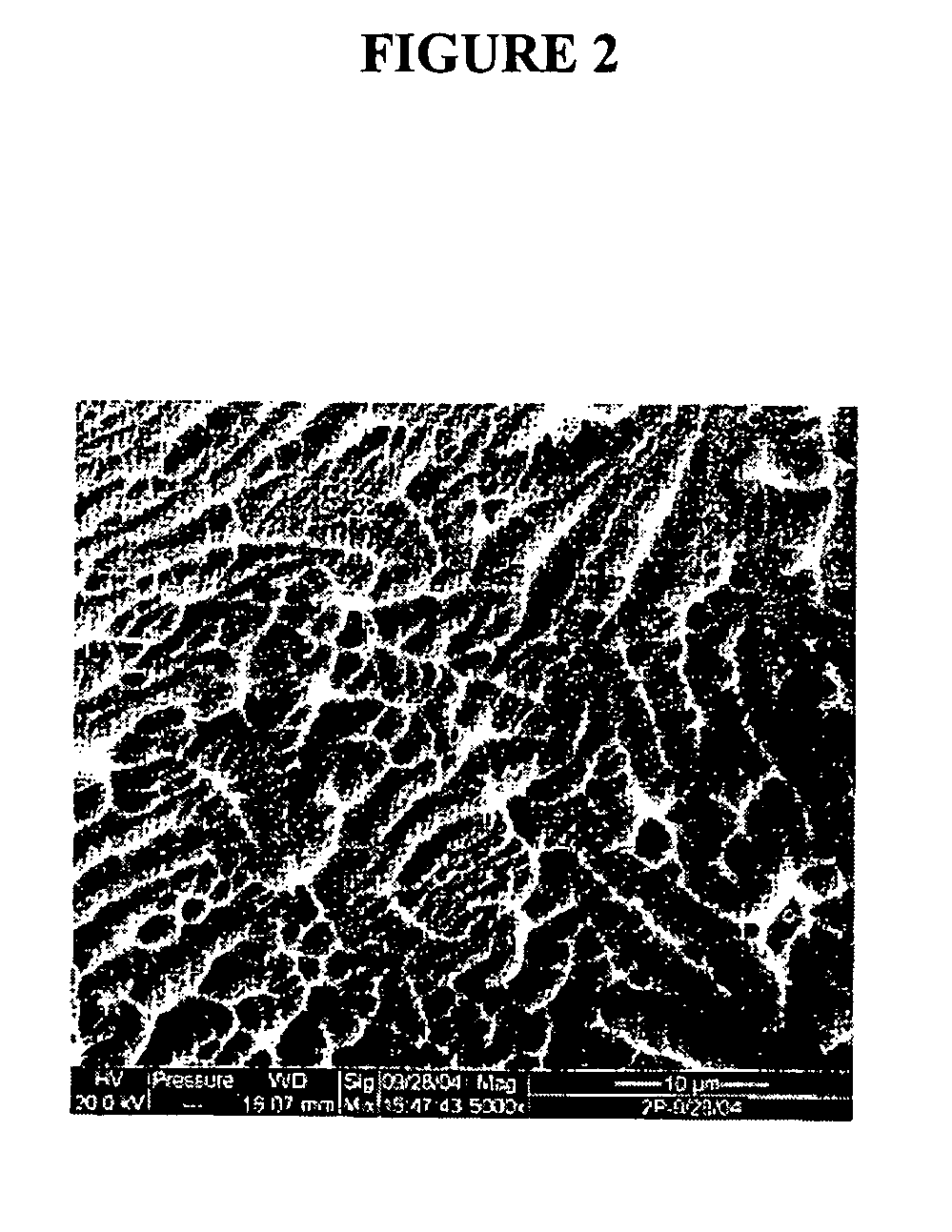

Implants with textured surface and methods for producing the same

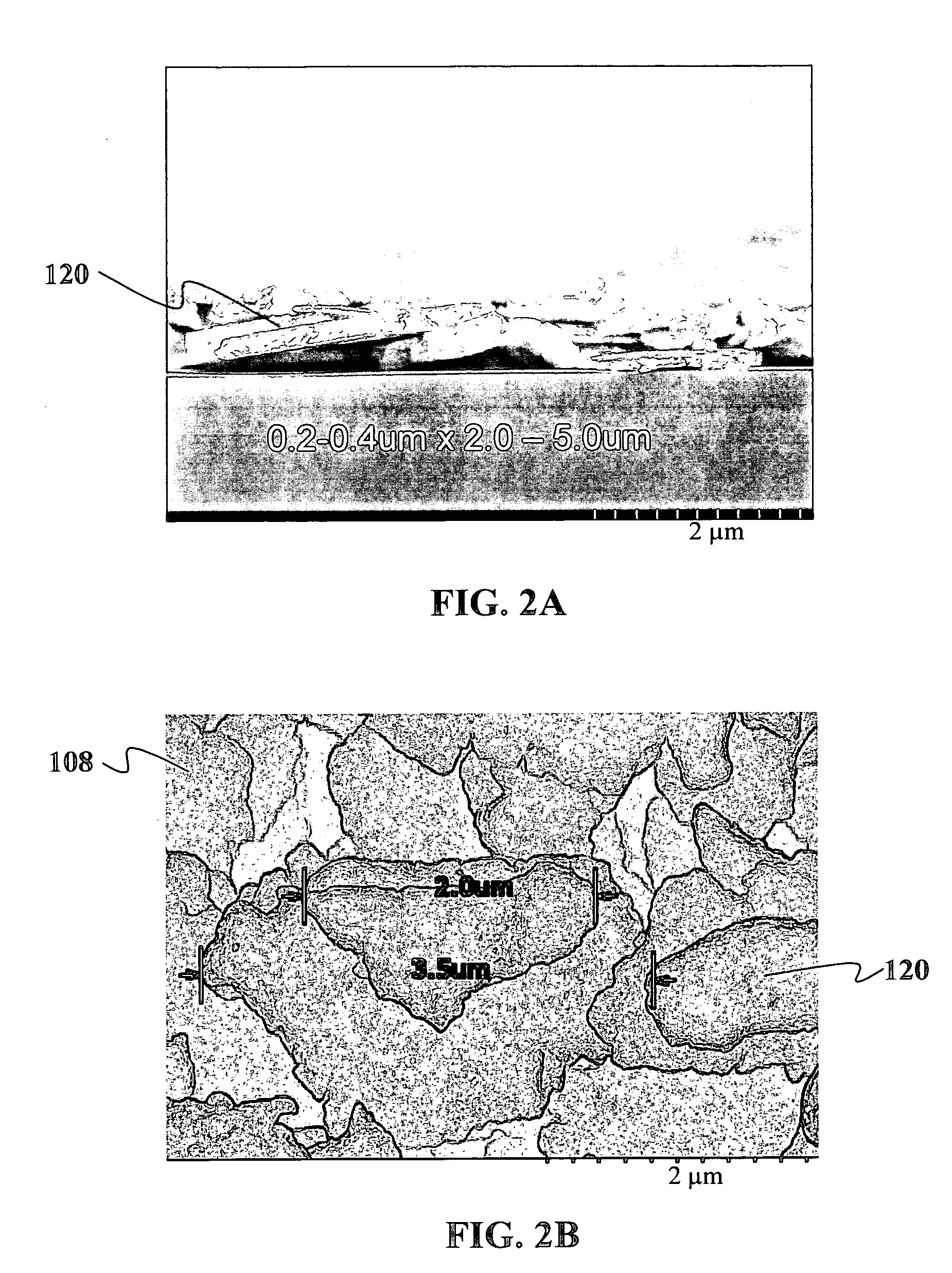

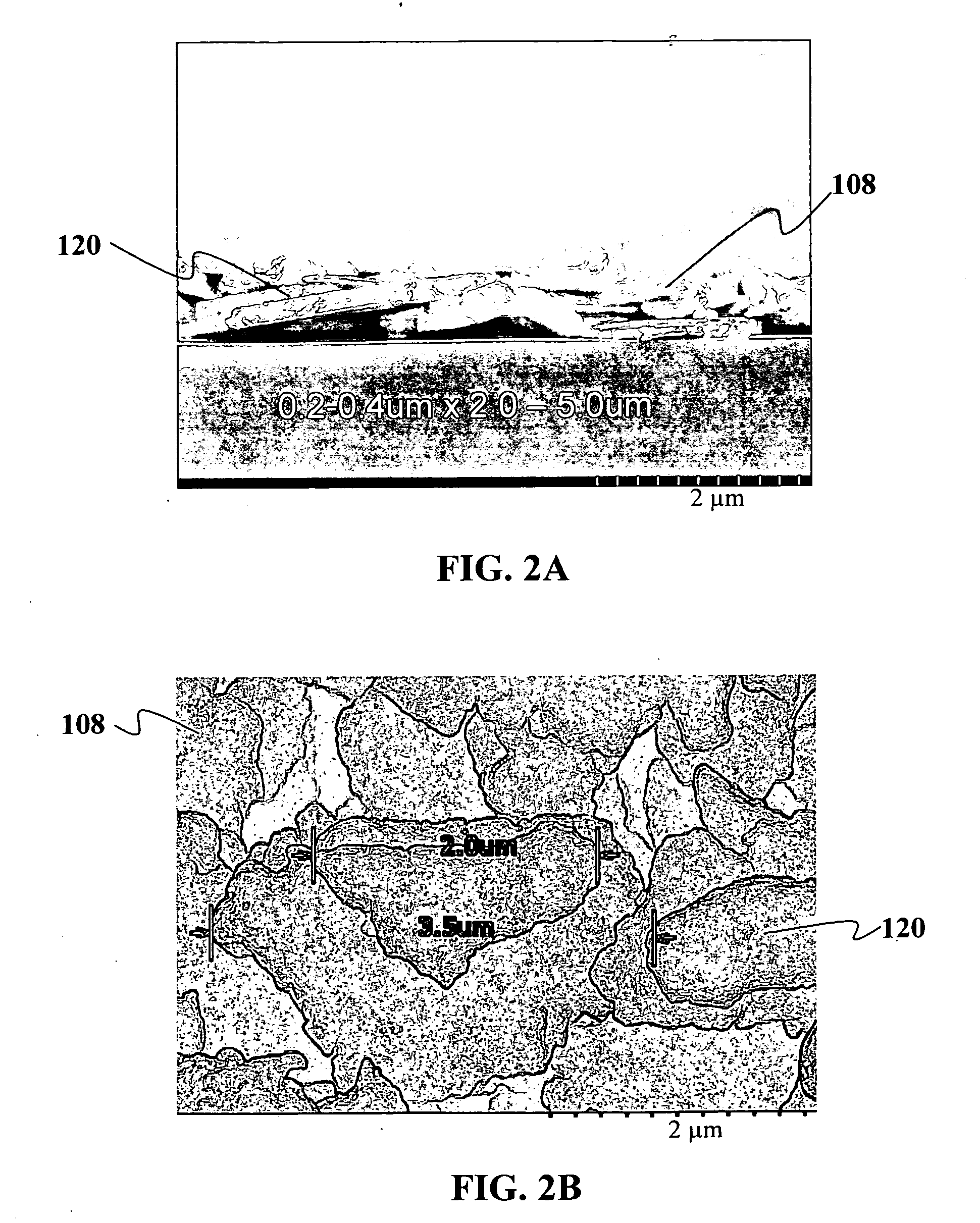

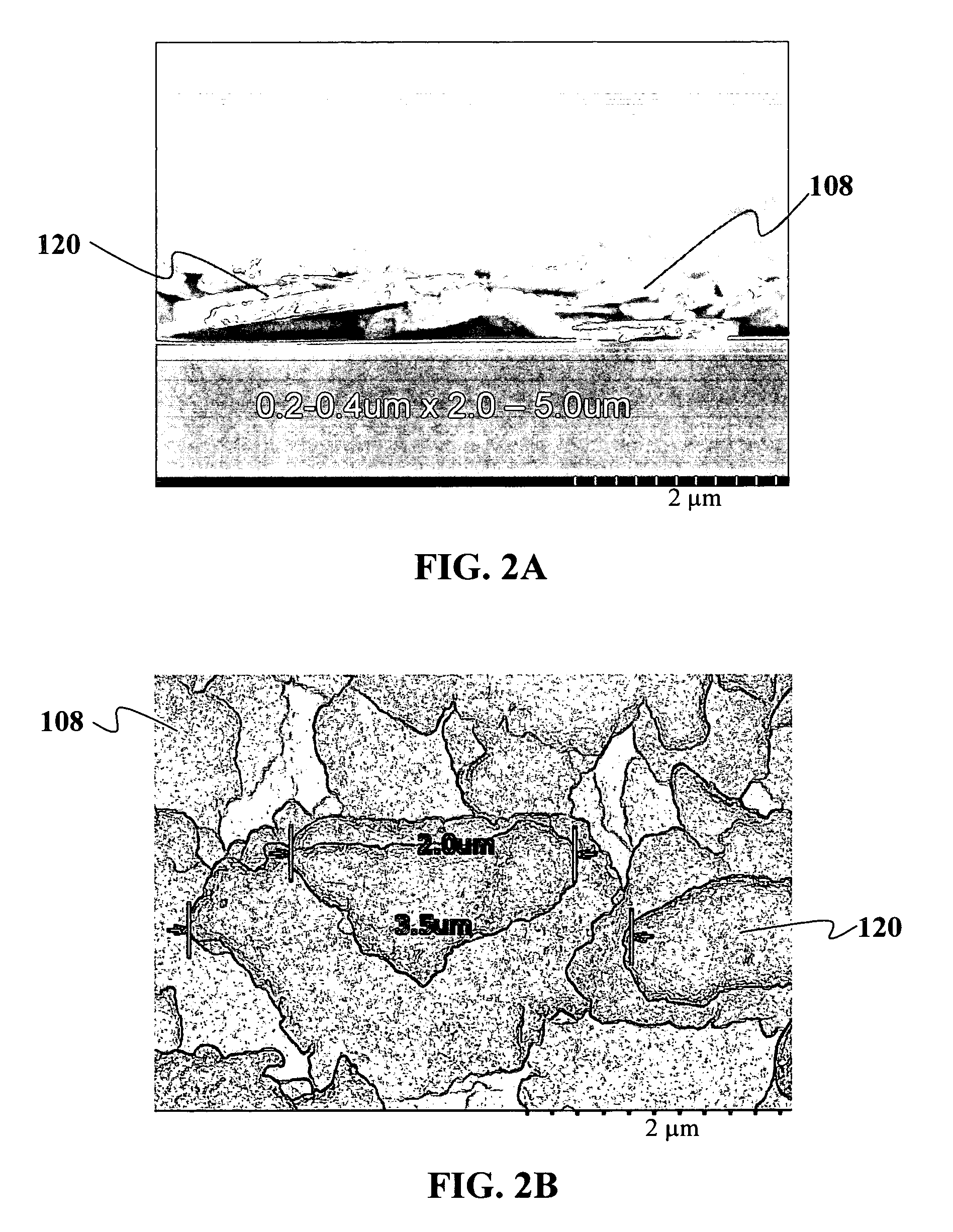

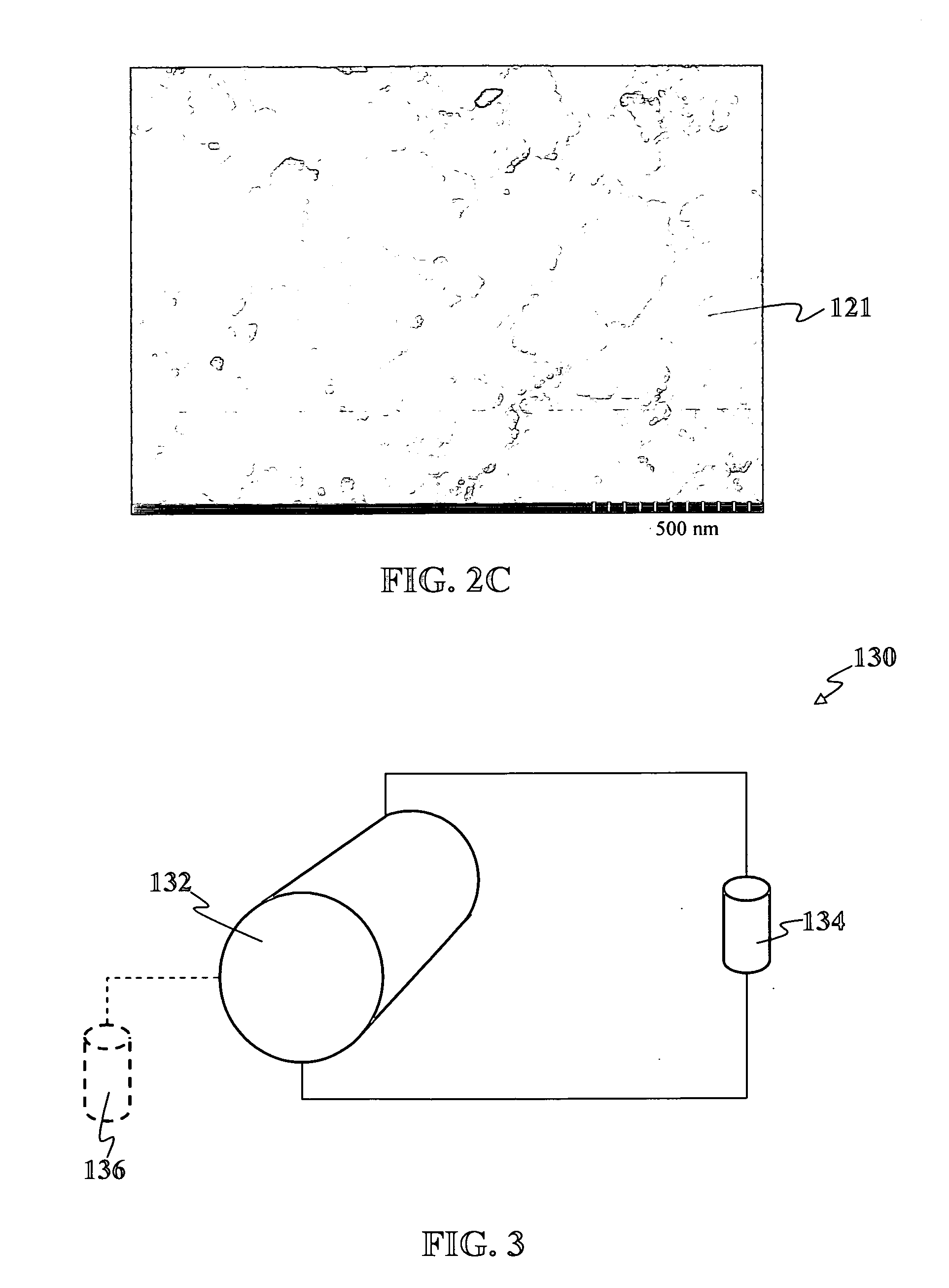

ActiveUS7368065B2High retention rateConvenient coatingImpression capsDecorative surface effectsMicrometerChloride

Compositions and methods are provided for preparing a metal substrate having a uniform textured surface with a plurality of indentations with a diameter in the nanometer and micrometer range. The textured surface is produced by exposing the substrate to an etching fluid comprising a hydrohalic acid and a mixture of a hydrohalic acid and an oxyacid, a chloride containing compound, and an oxidant. The etching solution can be used at ambient temperature. This textured surface enhances adherence of coatings or cells onto the textured surface, improves the retention of proteins on the surface, and encourages bone in-growth.

Owner:DEPUY PROD INC

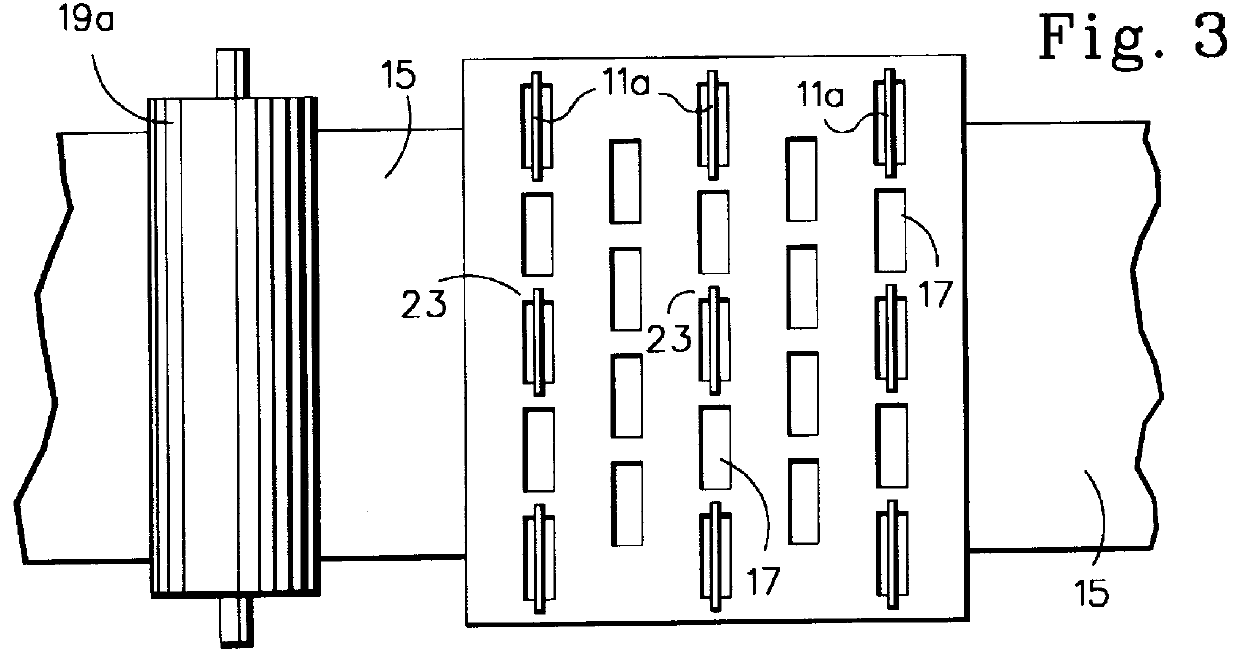

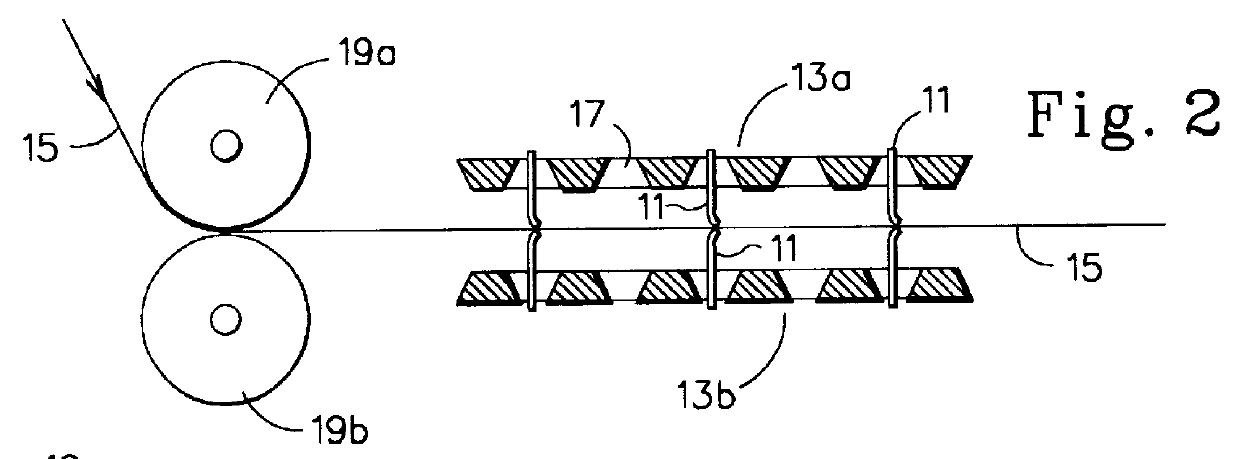

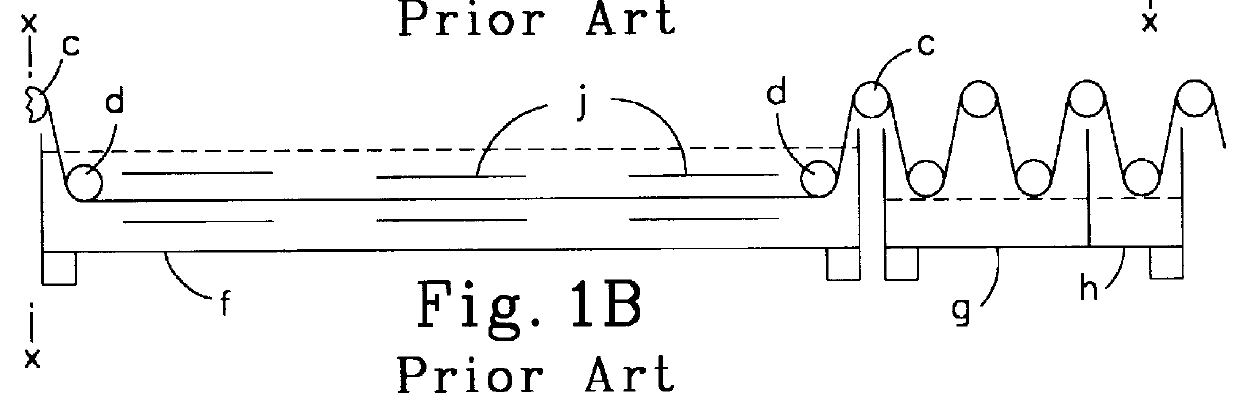

Method and apparatus for electrochemical processing

InactiveUS6149781AEffective expansionPreventing gradual depletionElectrolysis componentsDielectricAnodizing

A continuous strip is electrochemically processed in an electrolytic processing bath using either a thin flexible or resilient dielectric wiping blade or an open web, plastic mesh to wipe bubbles of gas from the surface, sever dendritic material, if such is present, and to remove a surface layer of partially depleted electrolytic solution in the form of a barrier or depletion layer including a heat zone, replacing with fresh cooler solution and to stabilize strip portions extending between support rolls. The resilient dielectric wiper blade is preferably used with perforated anodes which allow fresh electrolytic solution to flow into the space between the anodes and the strip surface after being expelled by passage of the strip past the wiping blade. It may also be used with electrode baskets in electroplating, however. The open web, plastic mesh wiper is particularly effective as a separator to provide the best spacing between the strip and the electrodes to prevent arcing and also prevents any filter cloth used over the electrodes in electroplating from catching upon the strip. The resilient wiper blade and open web, plastic mesh are preferably used in combination, but may also be used separately in electroplating, anodizing or electrolytic cleaning.

Owner:ELECTROPLATING TECH

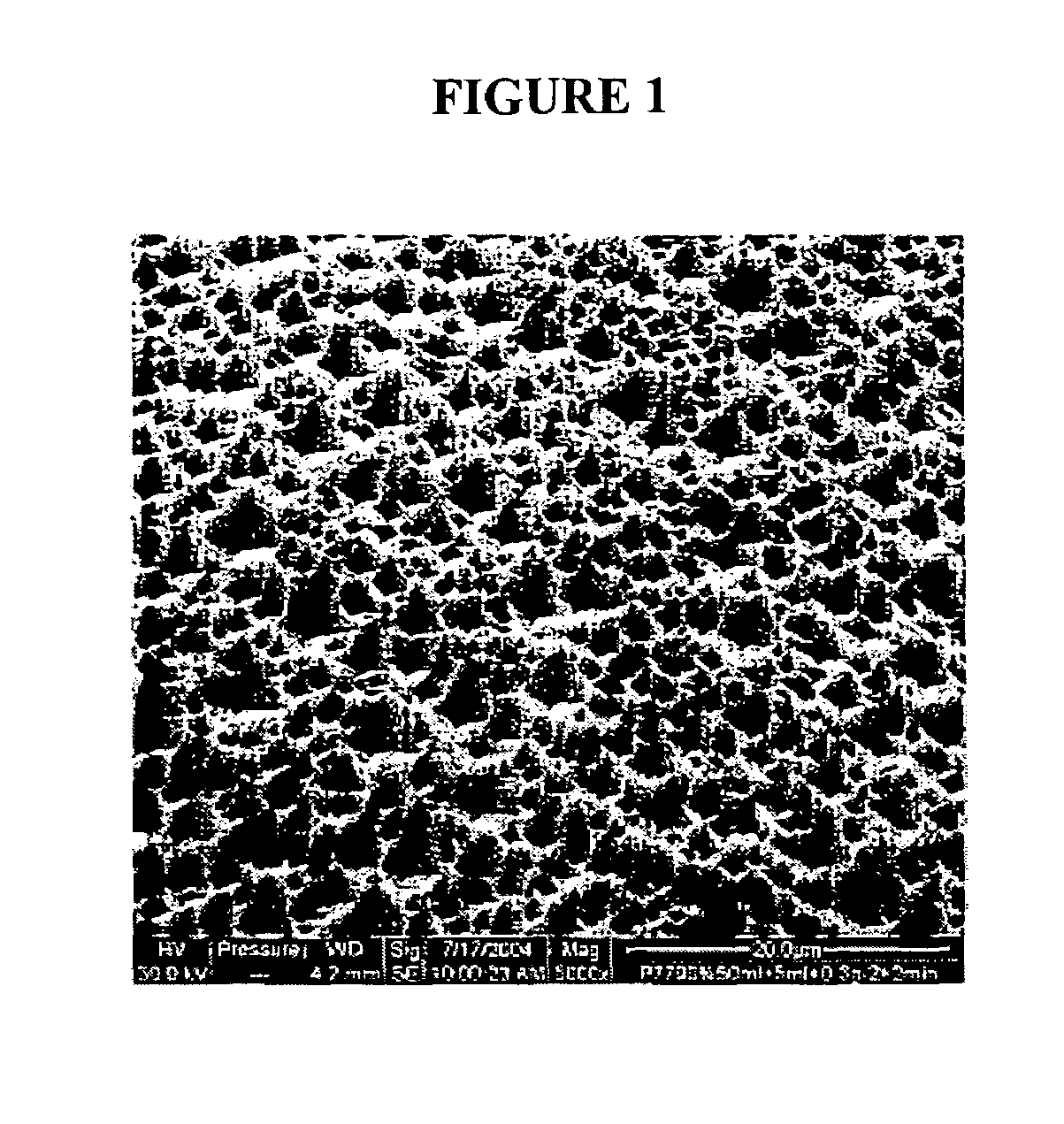

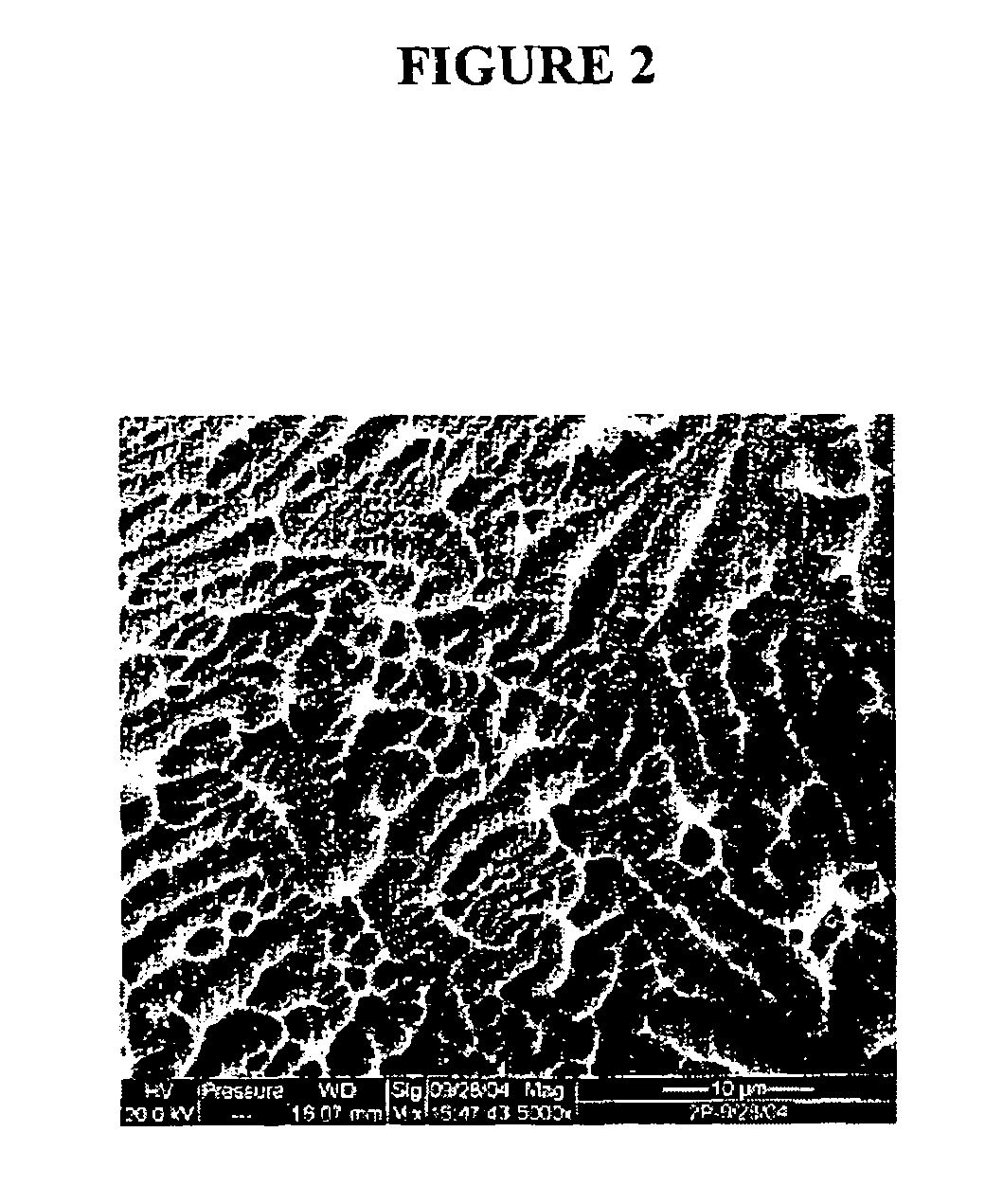

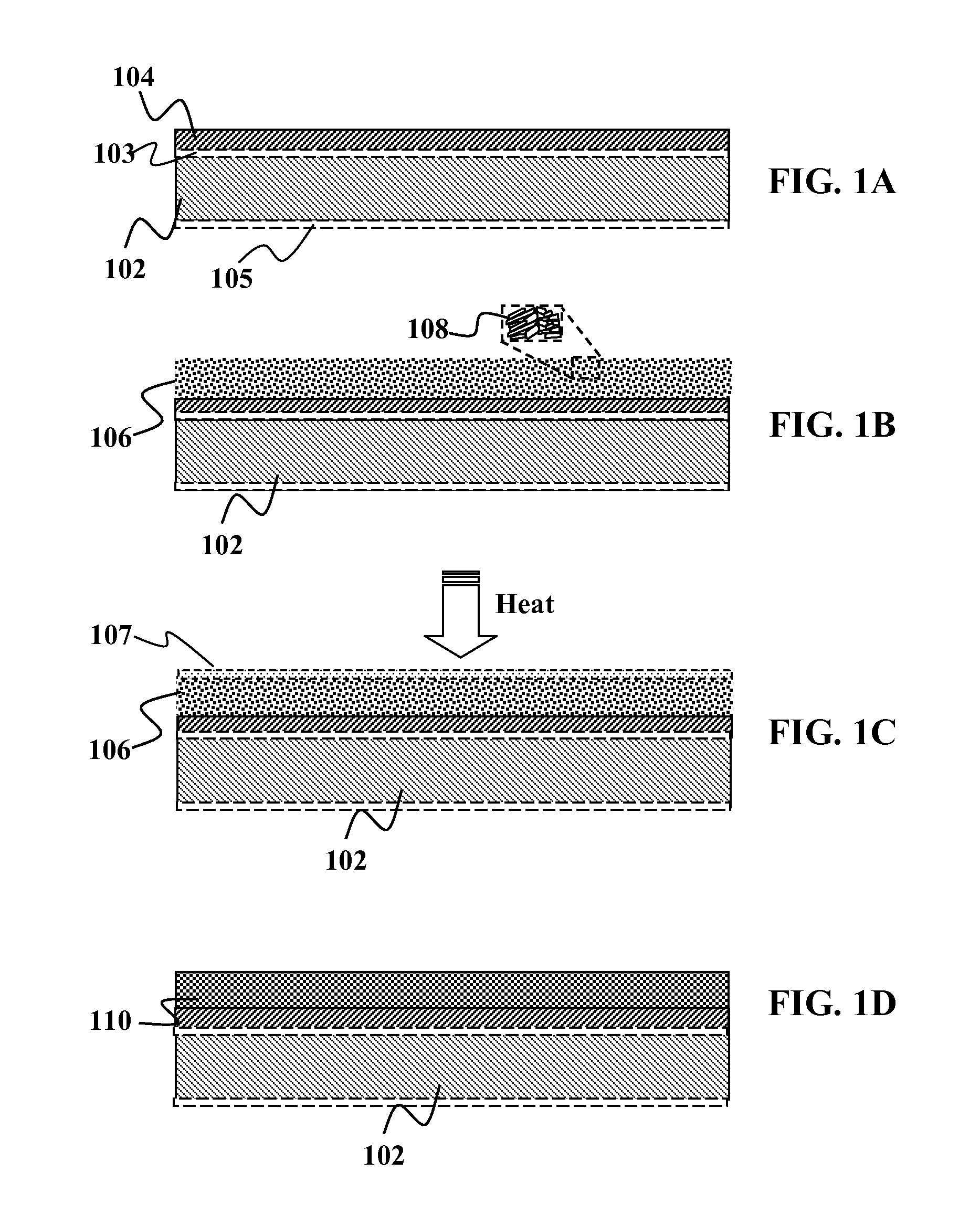

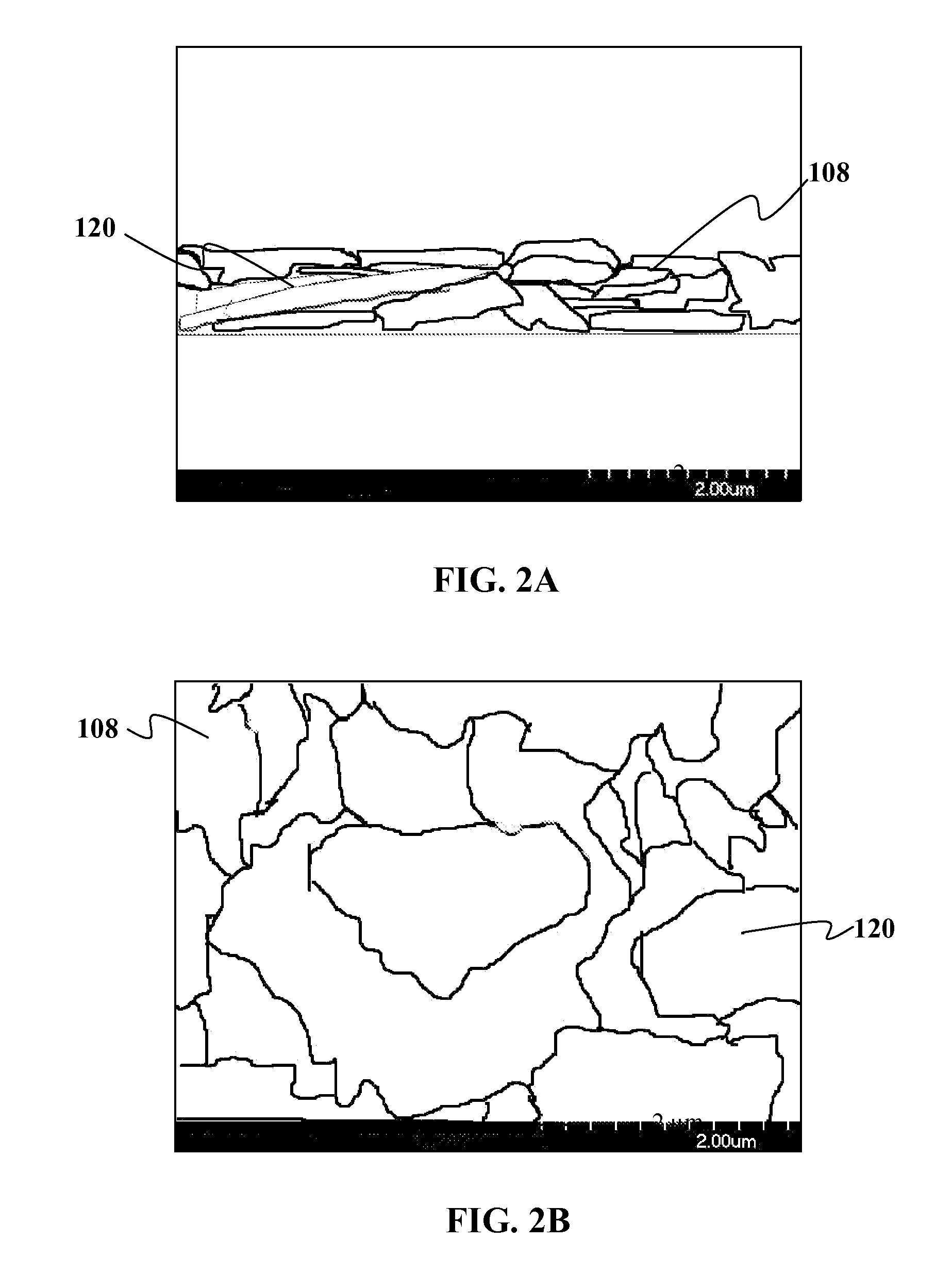

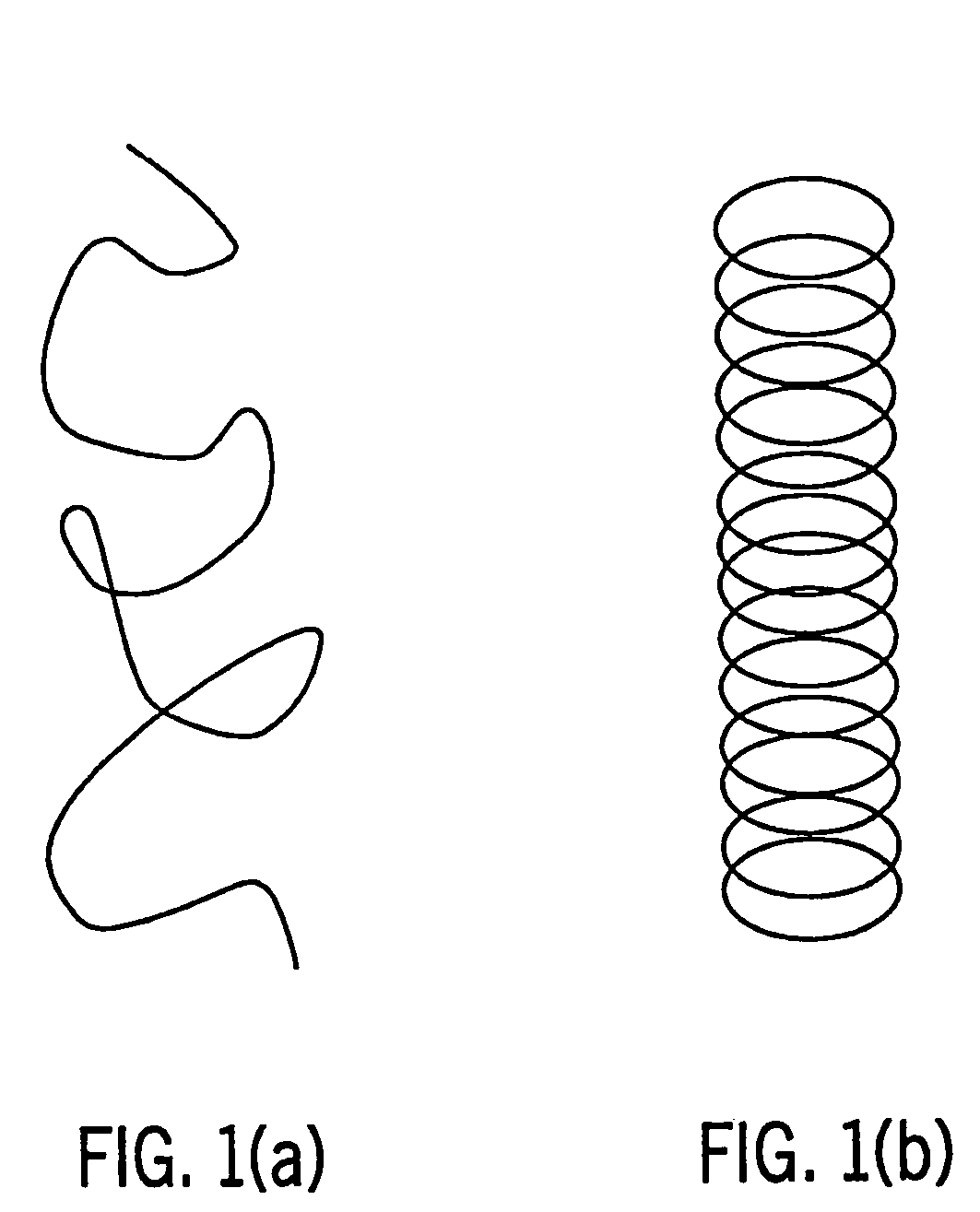

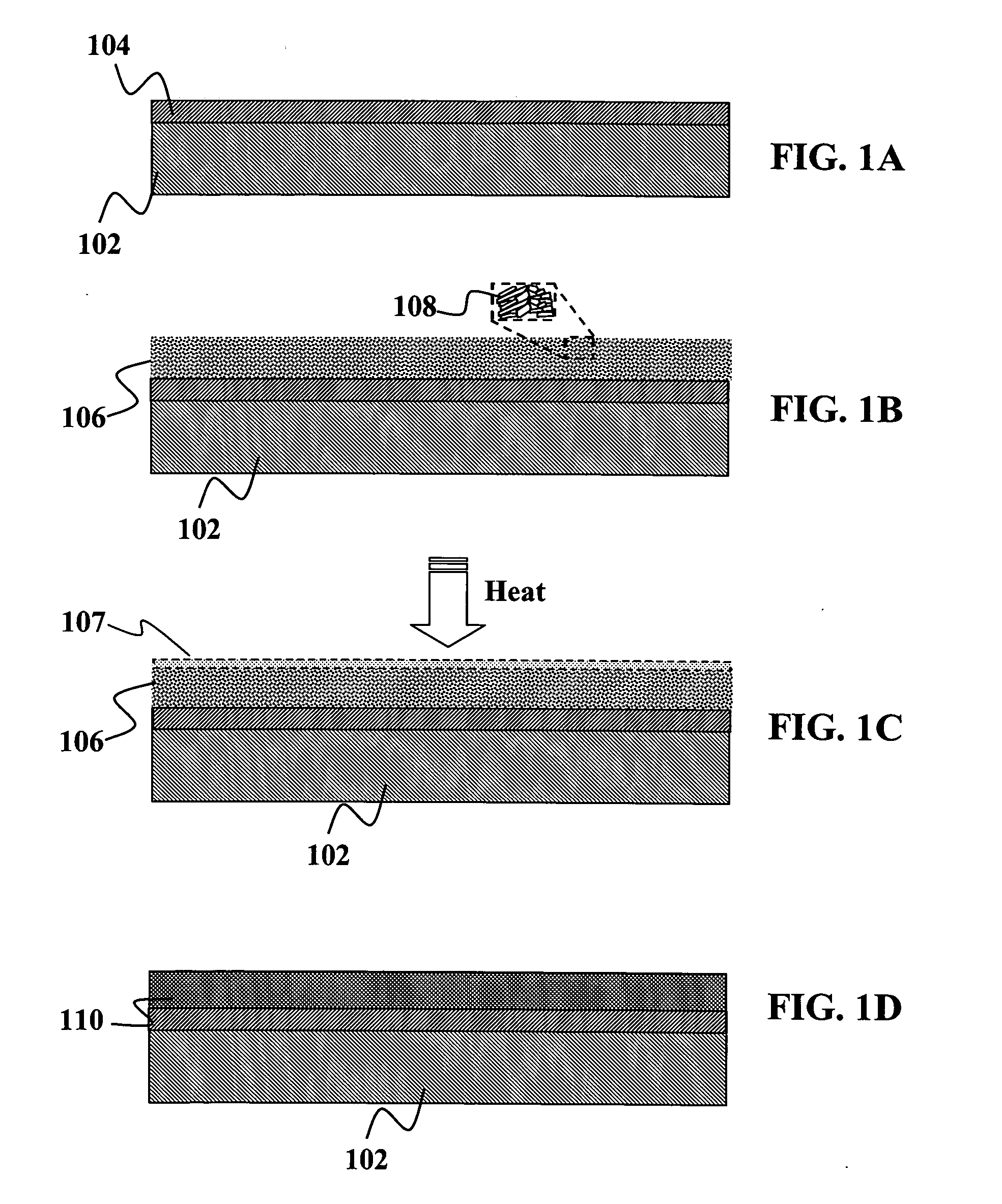

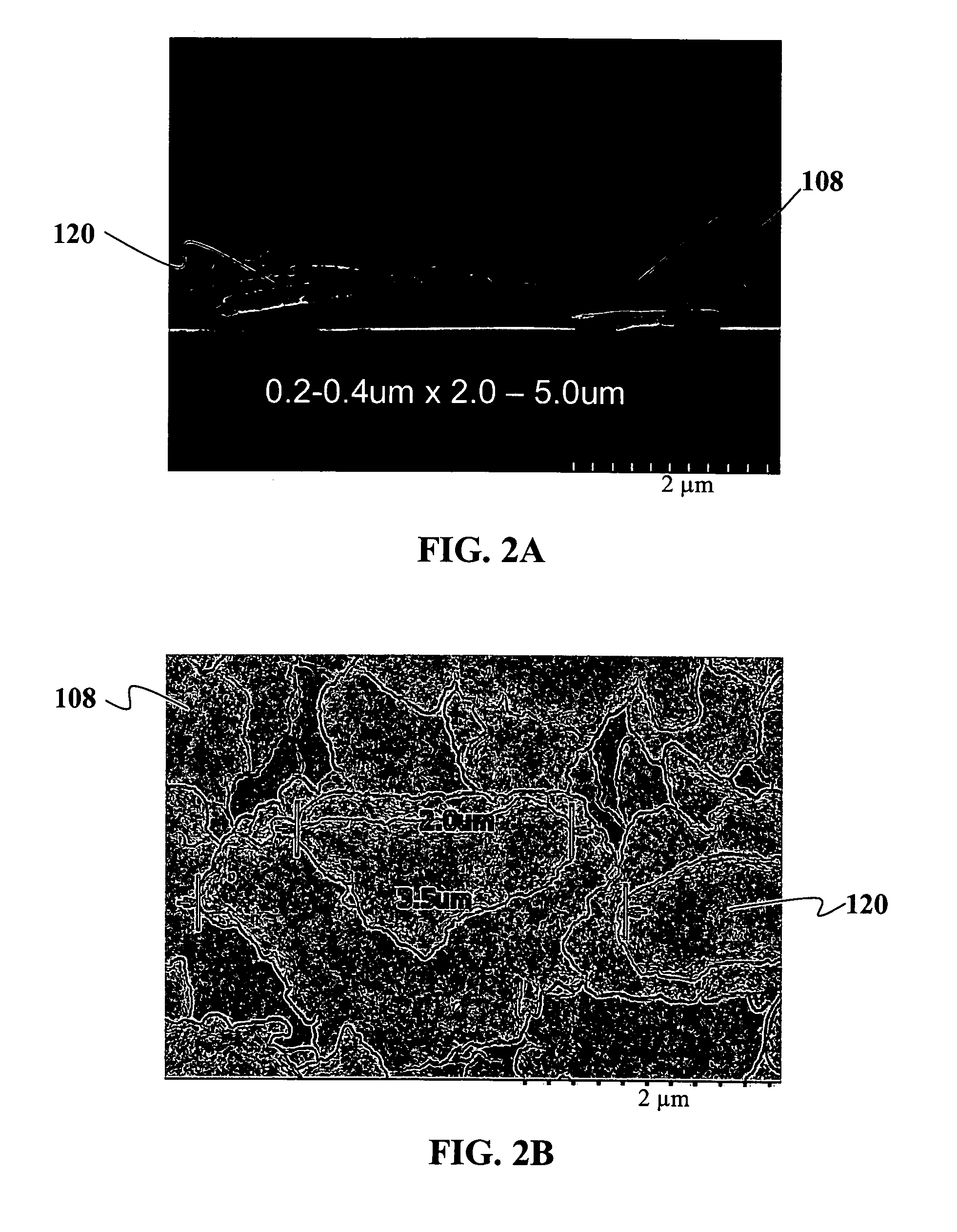

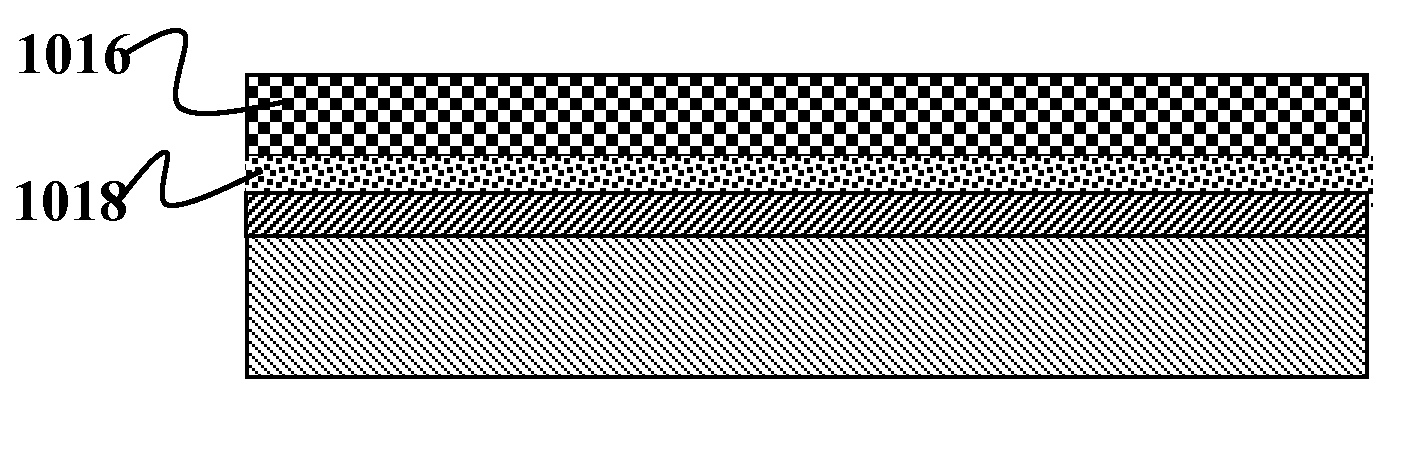

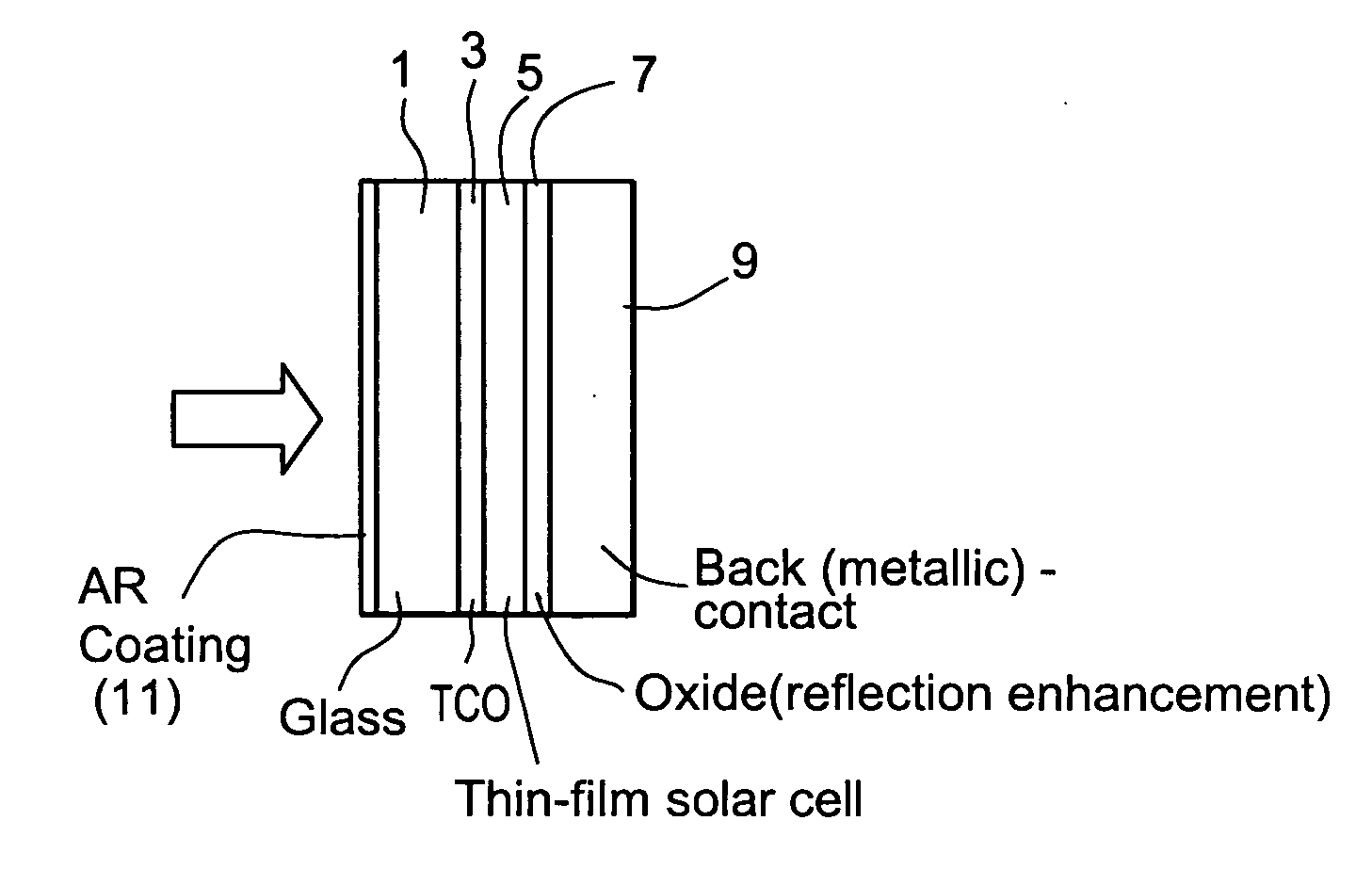

High-throughput printing of semiconductor precursor layer from chalcogenide microflake particles

InactiveUS20080121277A1Efficient and simplified creationIncrease contactMolten spray coatingTransportation and packagingNanoparticleParticle method

Methods and devices are provided for high-throughput printing of semiconductor precursor layer from microflake particles. In one embodiment, the method comprises of transforming non-planar or planar precursor materials in an appropriate vehicle under the appropriate conditions to create dispersions of planar particles with stoichiometric ratios of elements equal to that of the feedstock or precursor materials, even after settling. In particular, planar particles disperse more easily, form much denser coatings (or form coatings with more interparticle contact area), and anneal into fused, dense films at a lower temperature and / or time than their counterparts made from spherical nanoparticles. These planar particles may be microflakes that have a high aspect ratio. The resulting dense film formed from microflakes is particularly useful in forming photovoltaic devices. In one embodiment, at least one set of the particles in the ink may be inter-metallic flake particles (microflake or nanoflake) containing at least one group IB-IIIA inter-metallic alloy phase.

Owner:AERIS CAPITAL SUSTAINABLE IP

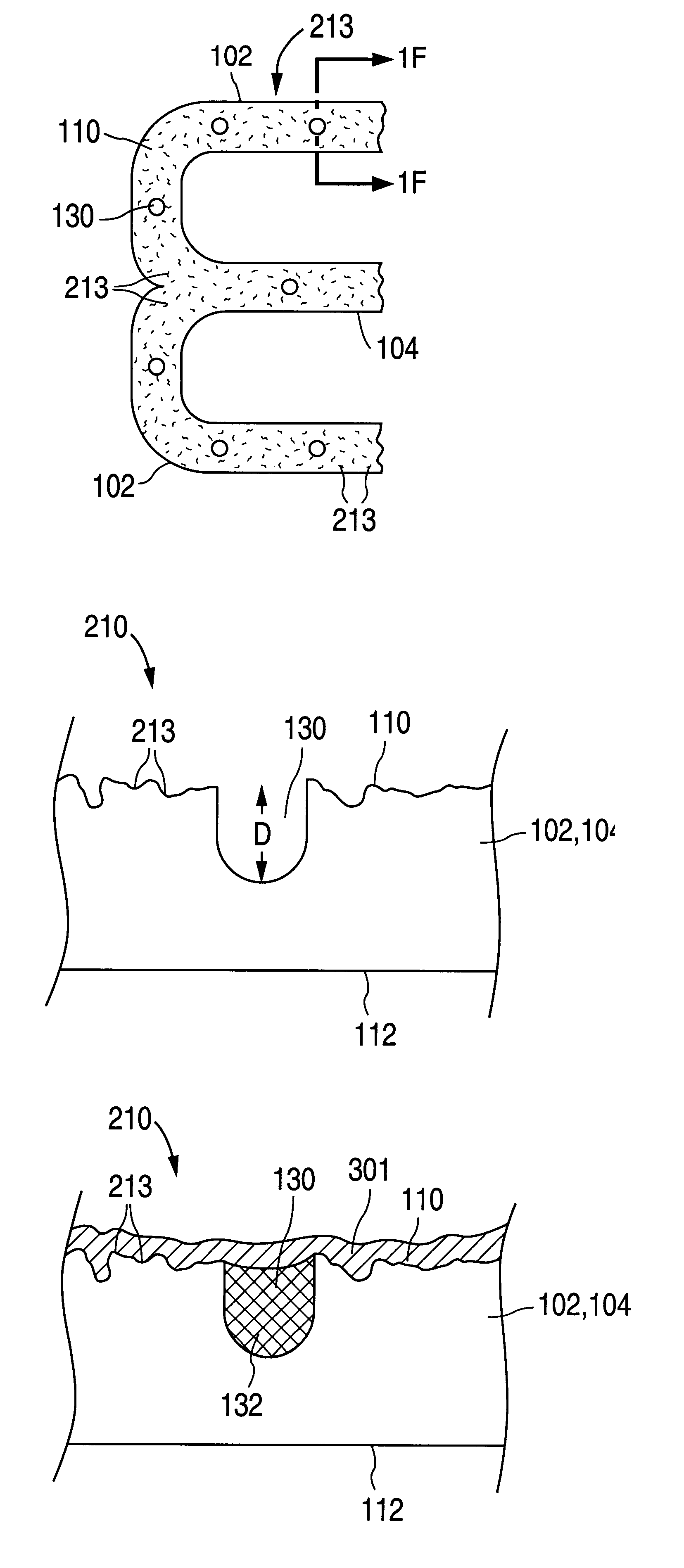

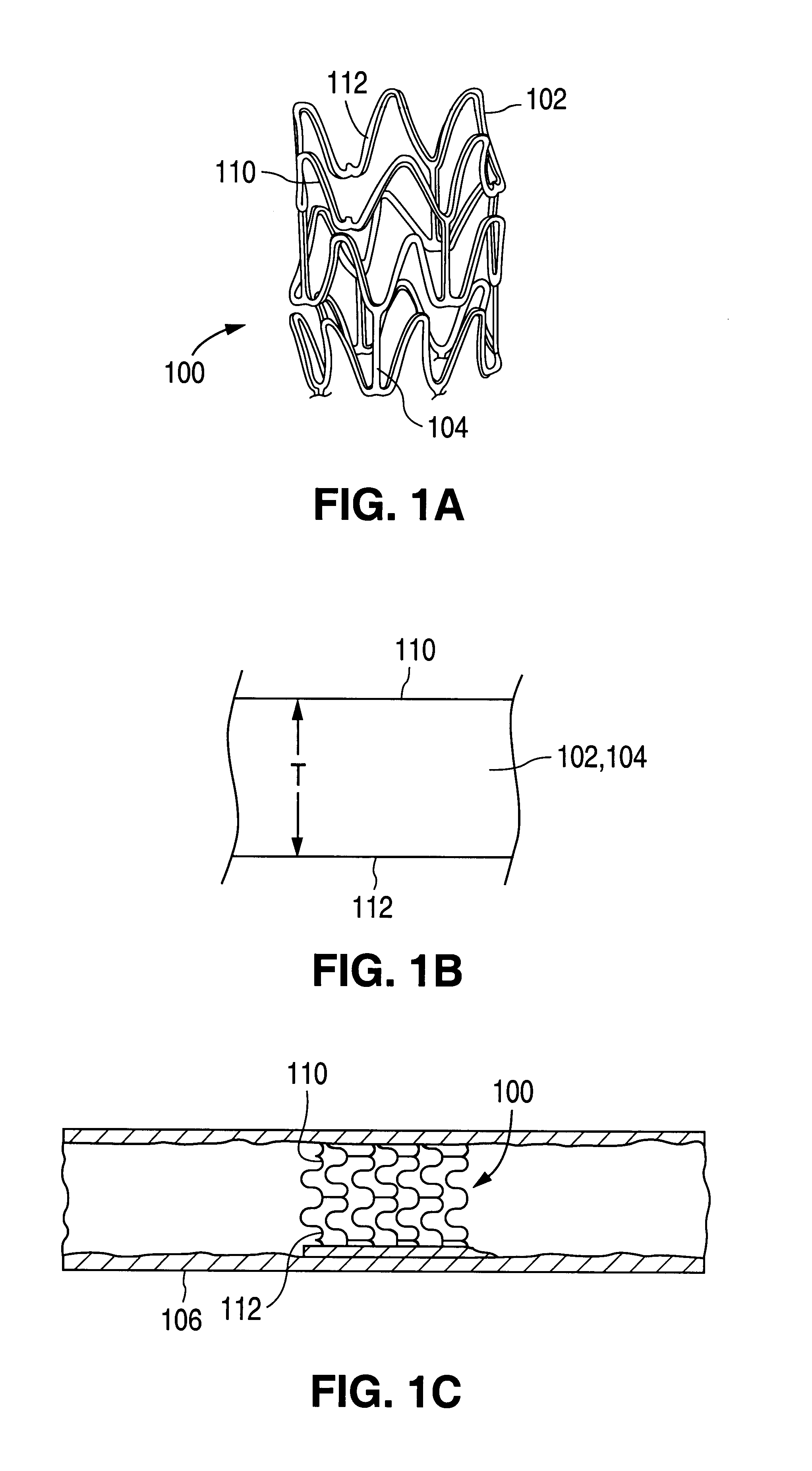

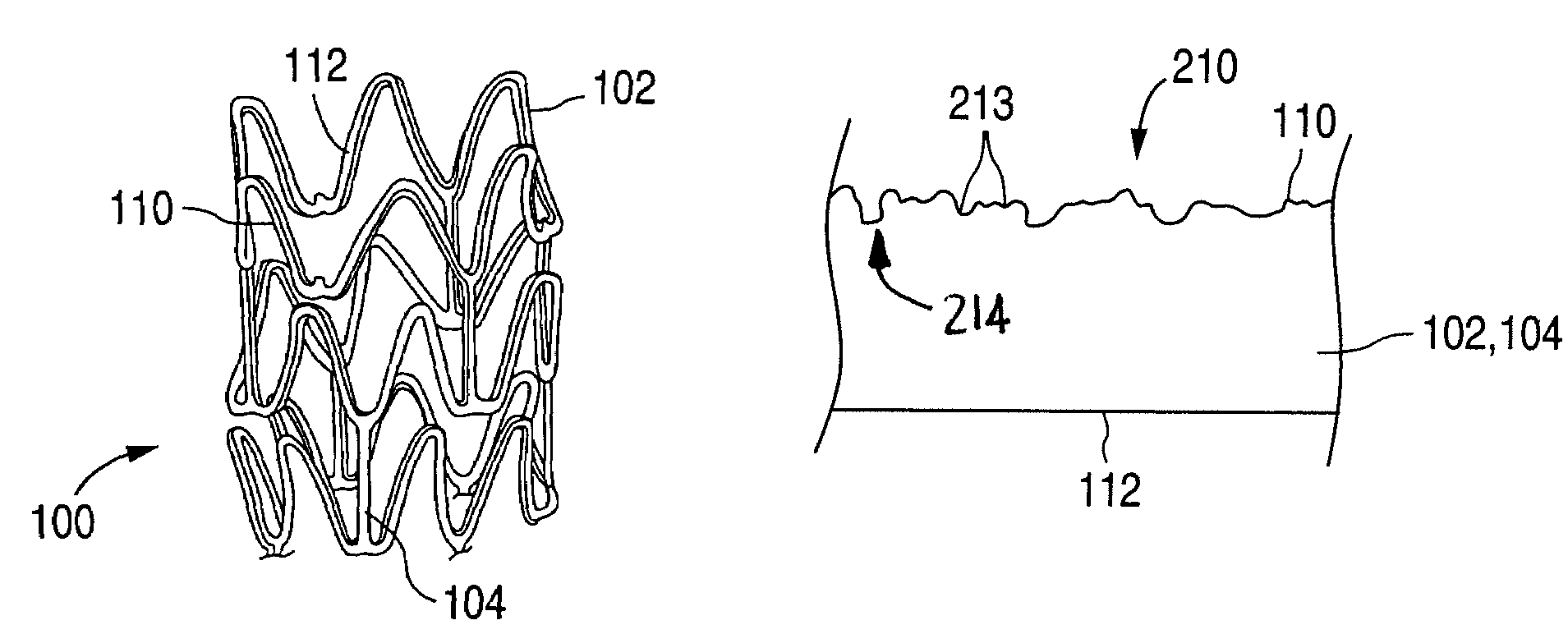

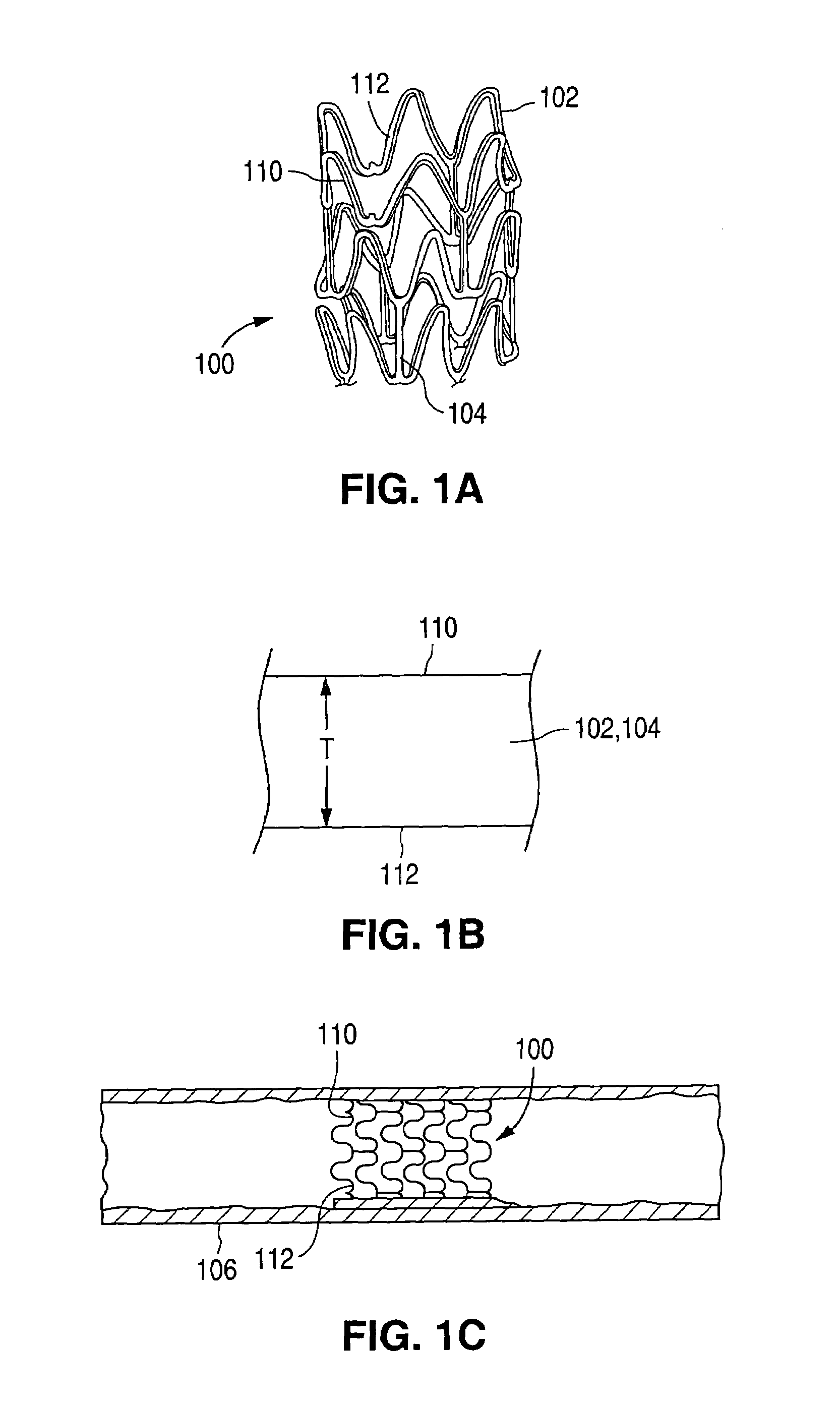

Method for creating a textured surface on an implantable medical device

InactiveUS6913617B1Great amount of therapeuticEasy to keepBlood vesselsElectricityElectric discharge

A method for forming an implantable medical device, such as a stent, is provided, in which electric discharges are applied to a metal surface of the implantable medical device. The electric discharges pit the surface. The pitted surface improves retention of a coating on the device and increases the amount of coating that can be carried by the device. An electric discharge machining process is described for applying electric discharges to the surface of the implantable medical device or portion thereof.

Owner:ABBOTT CARDIOVASCULAR

Method of selective coating of articles

InactiveUS6106889AConvenient coatingImprove production efficiencyGlovesPharmaceutical containersWater soluble polymersWater soluble

Articles such as medical devices are selectively coated with a lubricious coating. A temporary coating, formed from an aqueous solution of a water-soluble polymer of low to moderate molecular weight, is painted onto those portions of the article which are to remain free of any coating in the final product. Then, the entire article is coated with a material which forms a lubricious coating. The article is then soaked in water to loosen the coatings at the locations at which the temporary coating was applied. The coatings are cleanly removed from those locations, leaving an article with a lubricious coating in some portions, and which is uncoated in the remaining portions. The process can be used in coating portions of catheters, surgical gloves, contact lenses, and any other articles which require a lubricious coating only on a portion of the surface of the article.

Owner:BIOCOAT

Radiation-curable liquid resin composition for coating optical fibers

InactiveUS6136880AConvenient coatingLow viscositySynthetic resin layered productsYarnPhotoinitiatorChemistry

Owner:DSM IP ASSETS BV

Hot melt adhesive composition based on a random copolymer of isotactic polypropylene and a secondary polymer

InactiveUS7262251B2Broad processibilityImprove thermal stabilityOther chemical processesFilm/foil adhesivesWaxPlasticizer

Owner:ATO FINDLEY

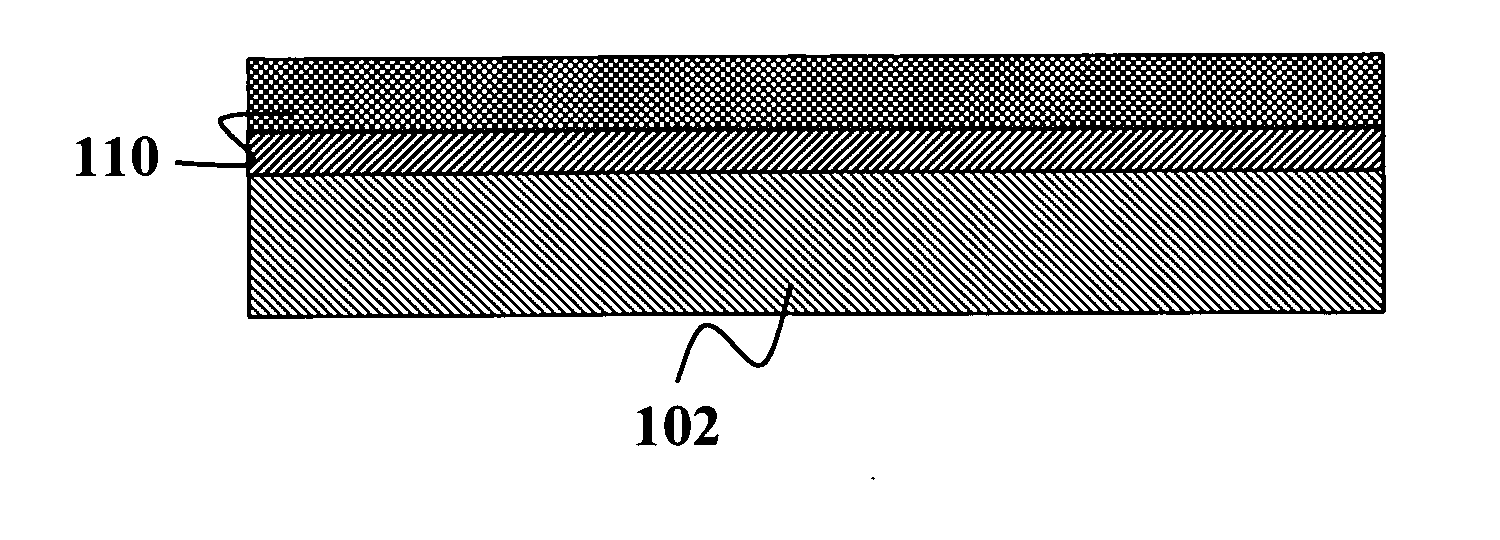

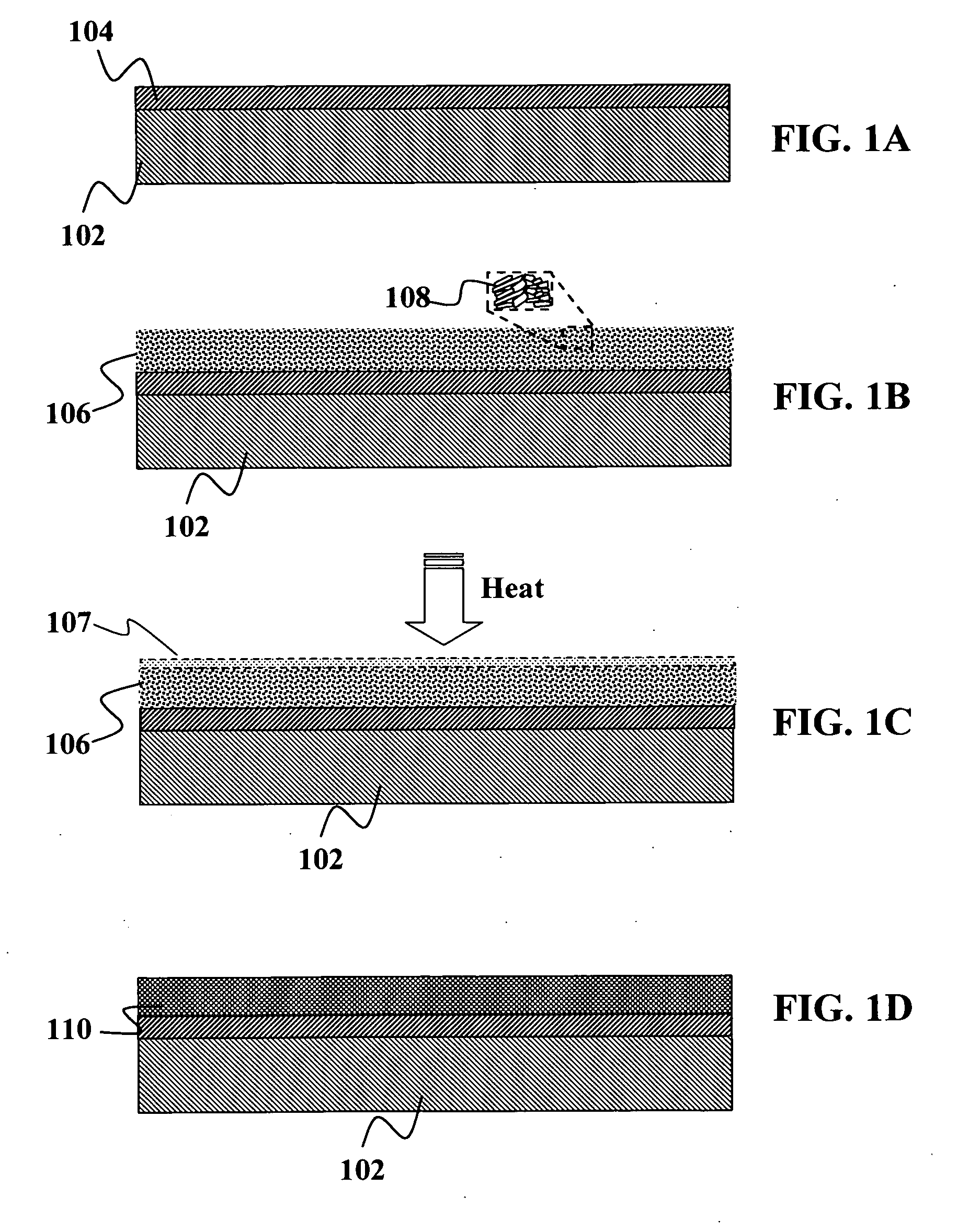

Photovoltaic devices printed from nanostructured particles

InactiveUS20070163638A1Efficient and simplified creationIncrease contactMolten spray coatingTransportation and packagingParticle methodSolar cell

Methods and devices are provided for high-throughput printing of semiconductor precursor layer from microflake particles. In one embodiment, a solar cell is provided that comprises of a substrate, a back electrode formed over the substrate, a p-type semiconductor thin film formed over the back electrode, an n-type semiconductor thin film formed so as to constitute a pn junction with the p-type semiconductor thin film, and a transparent electrode formed over the n-type semiconductor thin film. The p-type semiconductor thin film results by processing a dense film formed from a plurality of microflakes having a material composition containing at least one element from Groups IB, IIIA, and / or VIA, wherein the dense film has a void volume of about 26% or less. The dense film may be a substantially void free film.

Owner:AERIS CAPITAL SUSTAINABLE IP

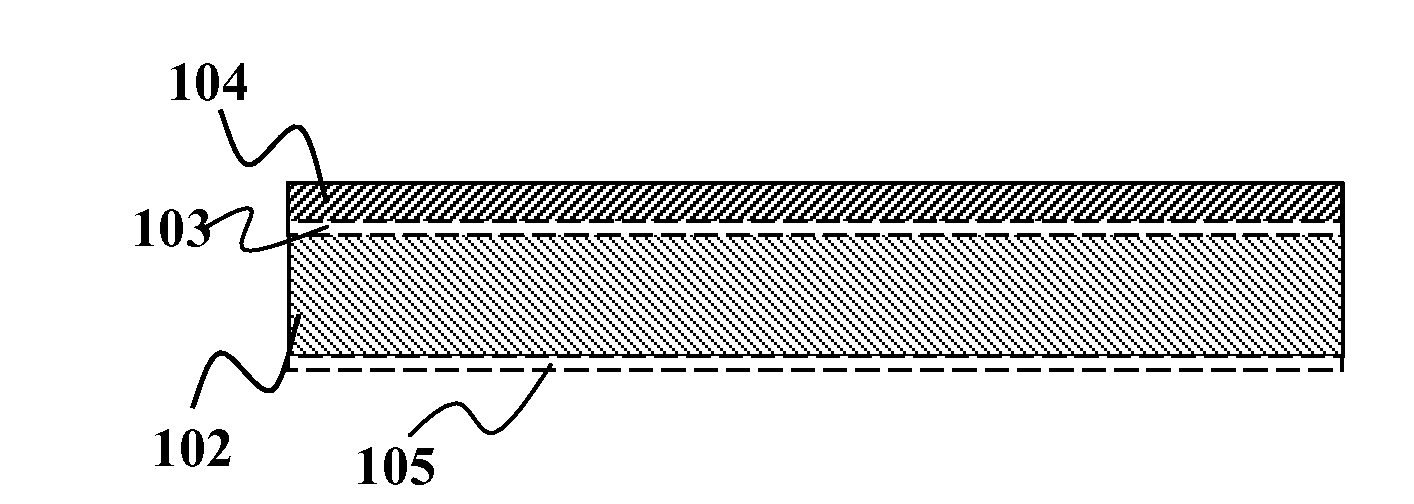

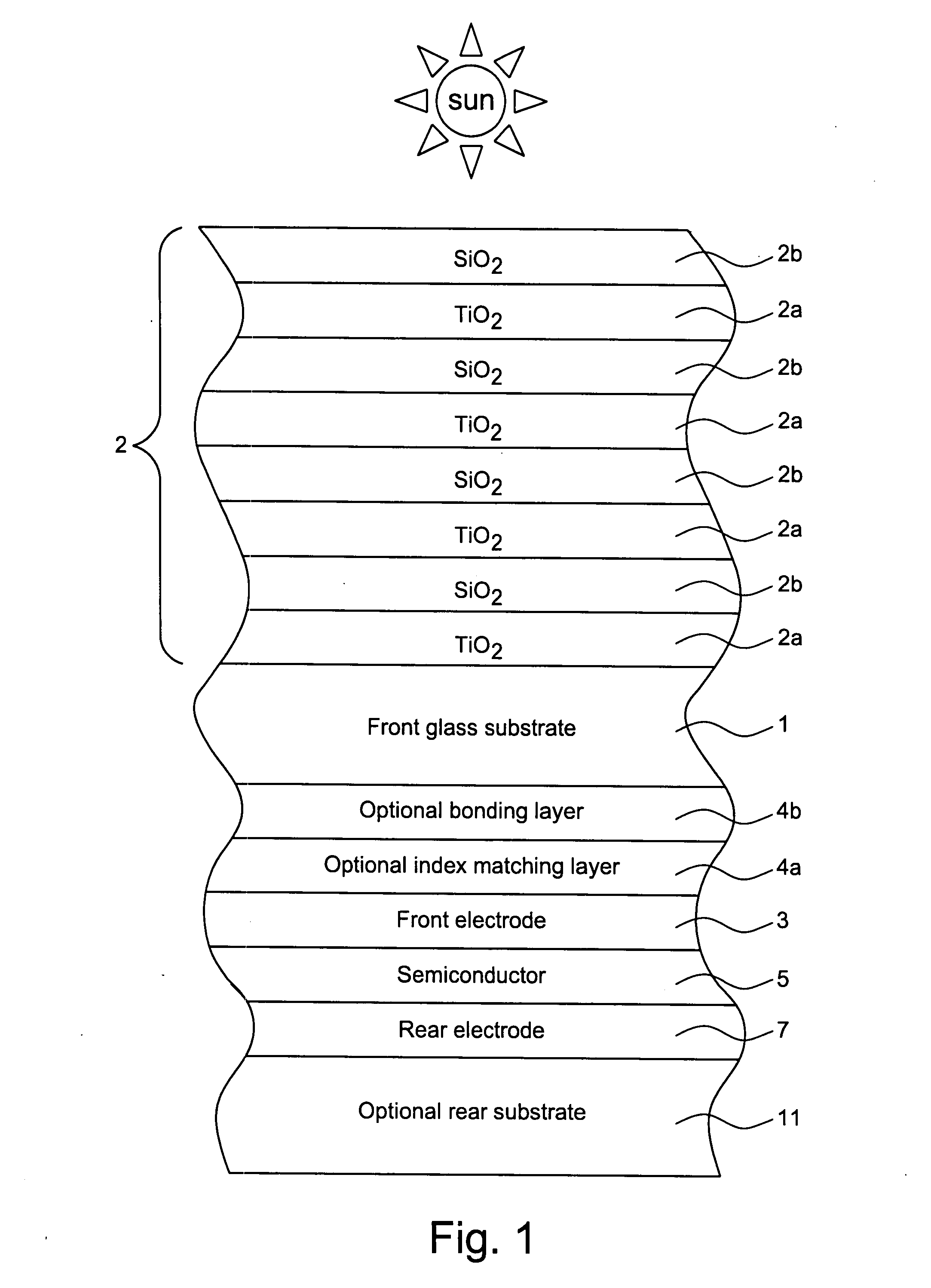

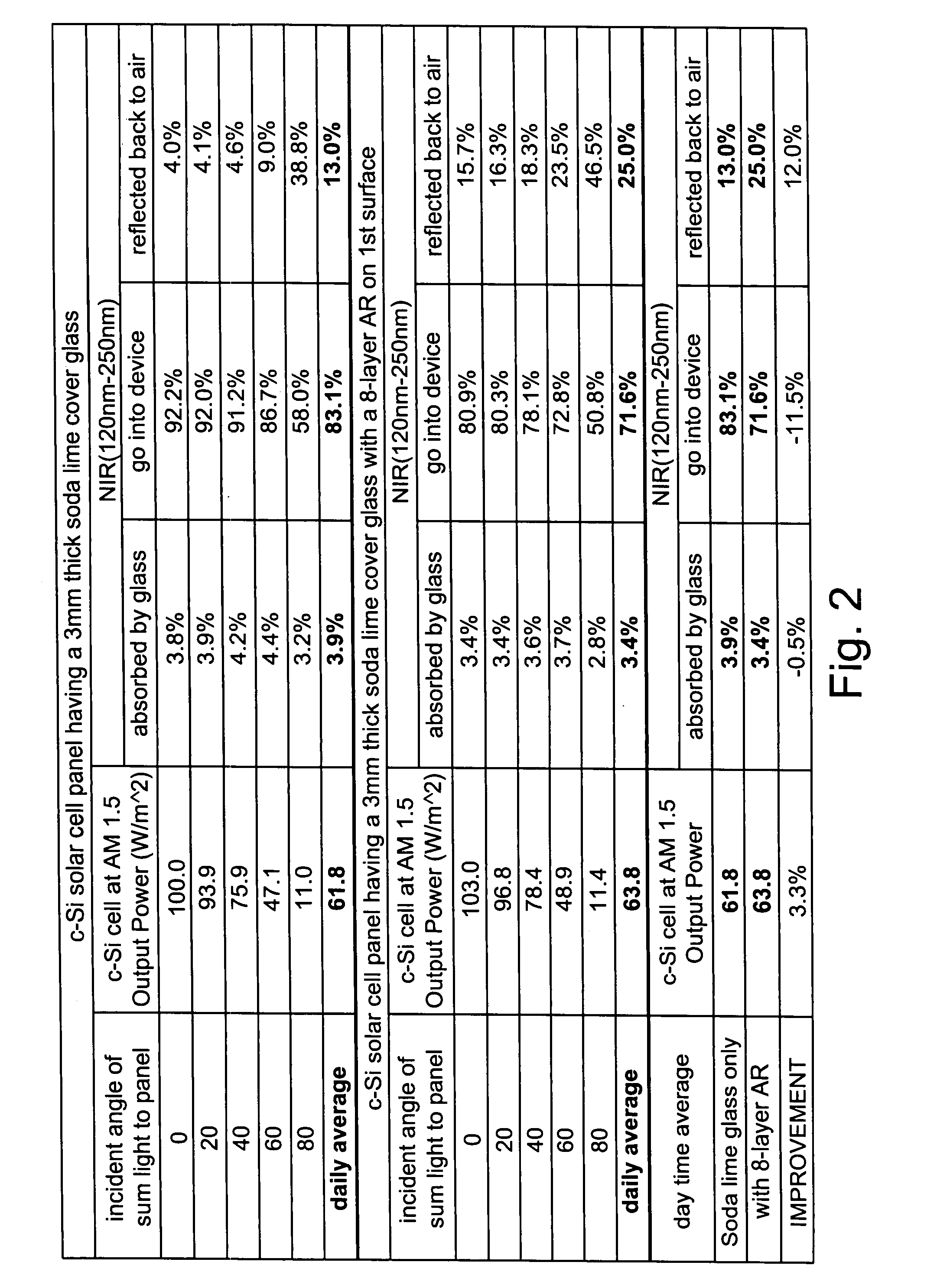

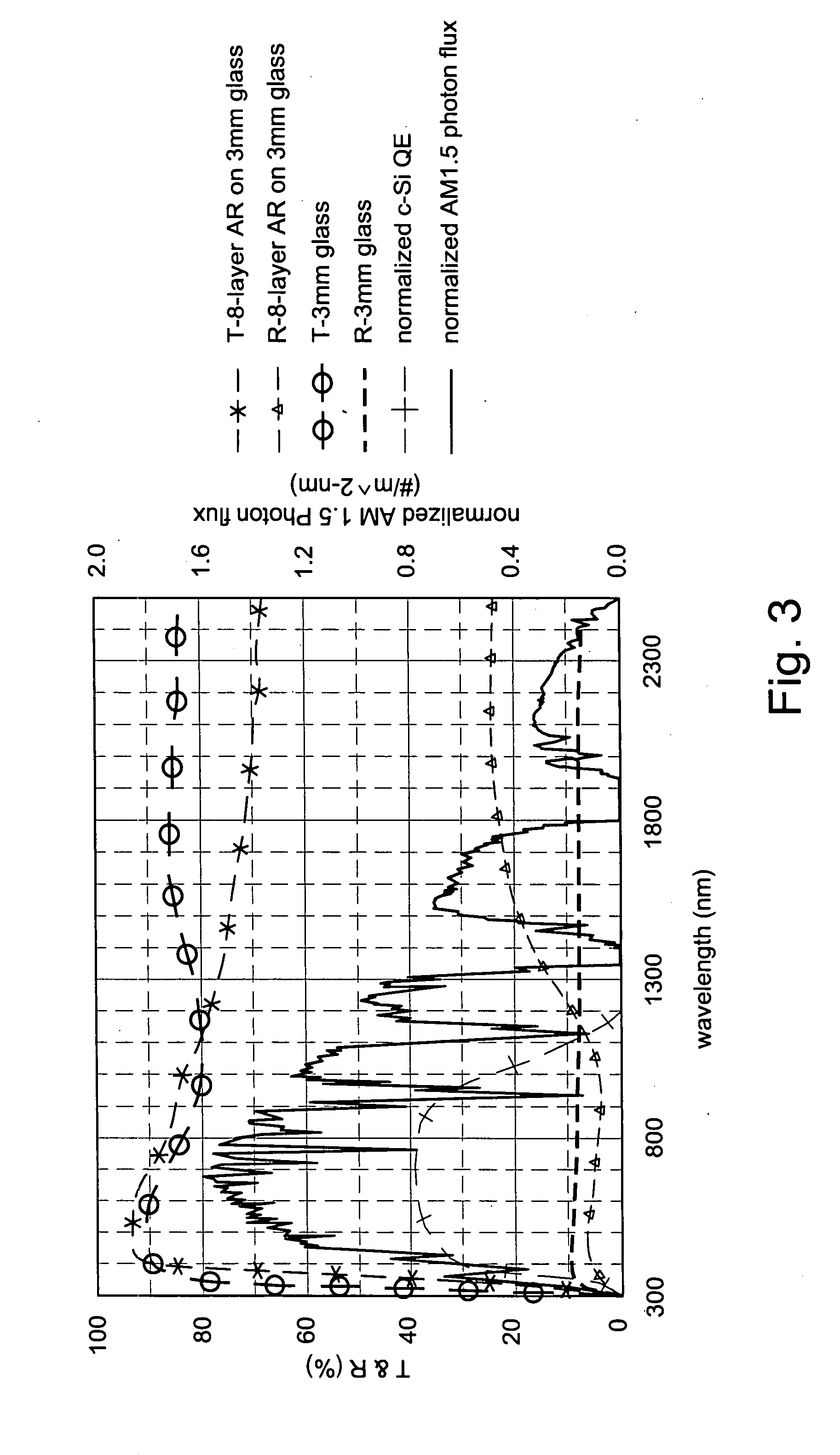

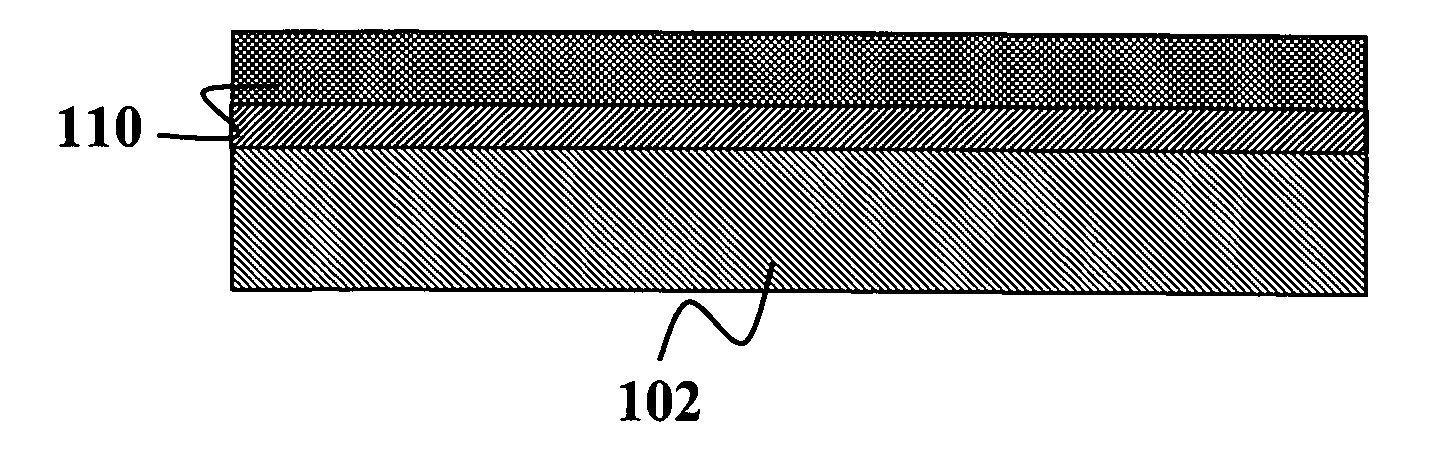

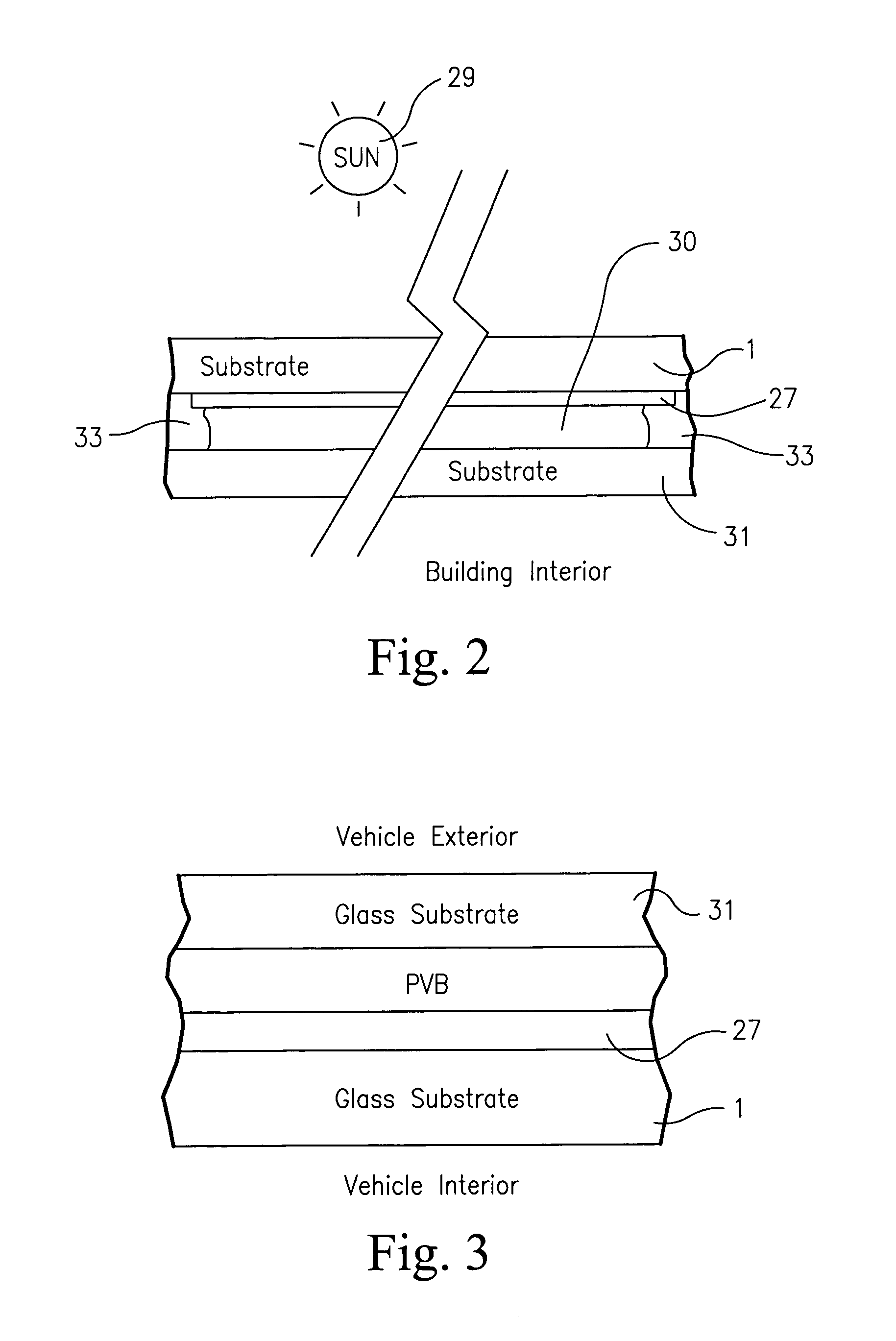

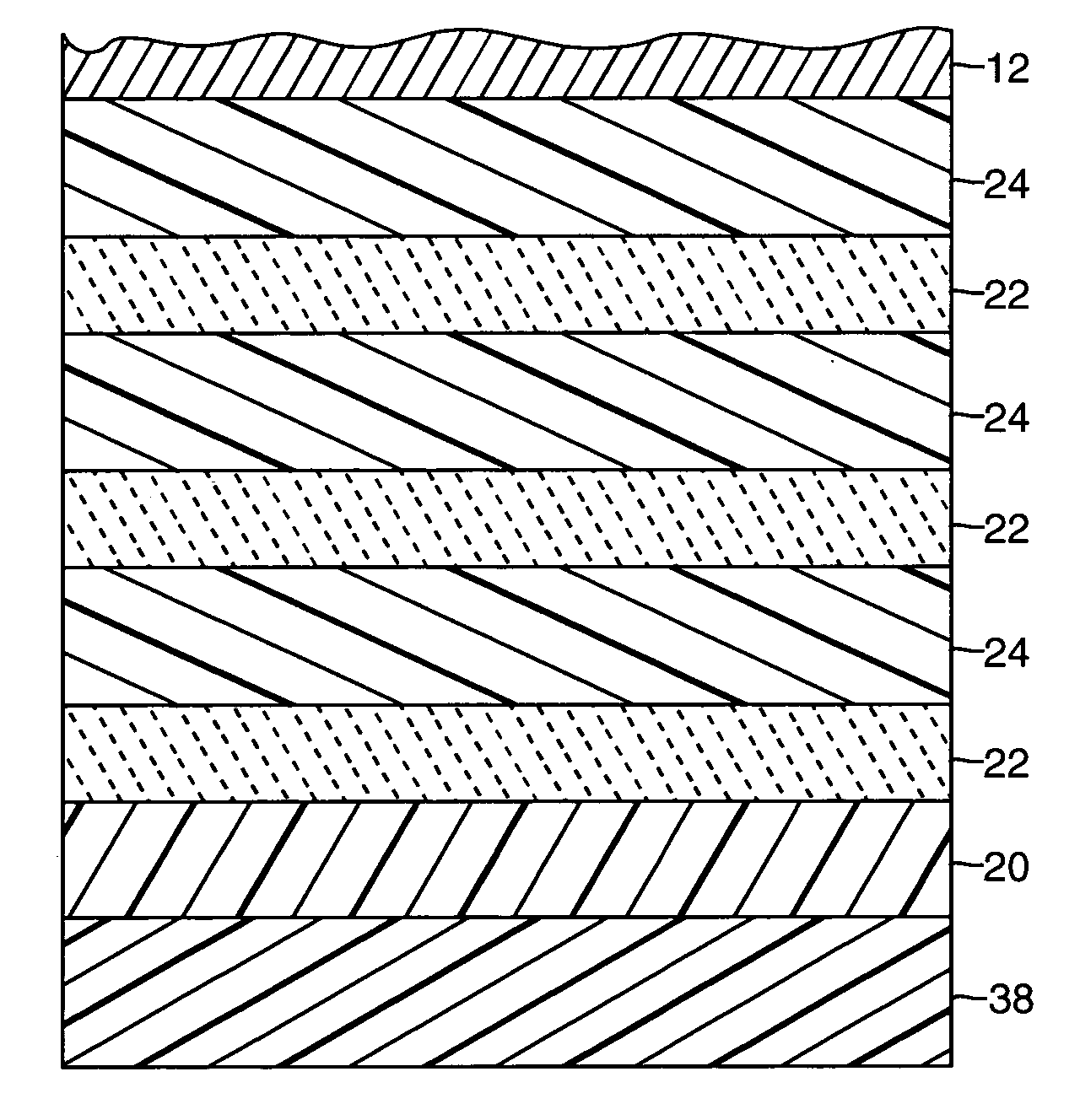

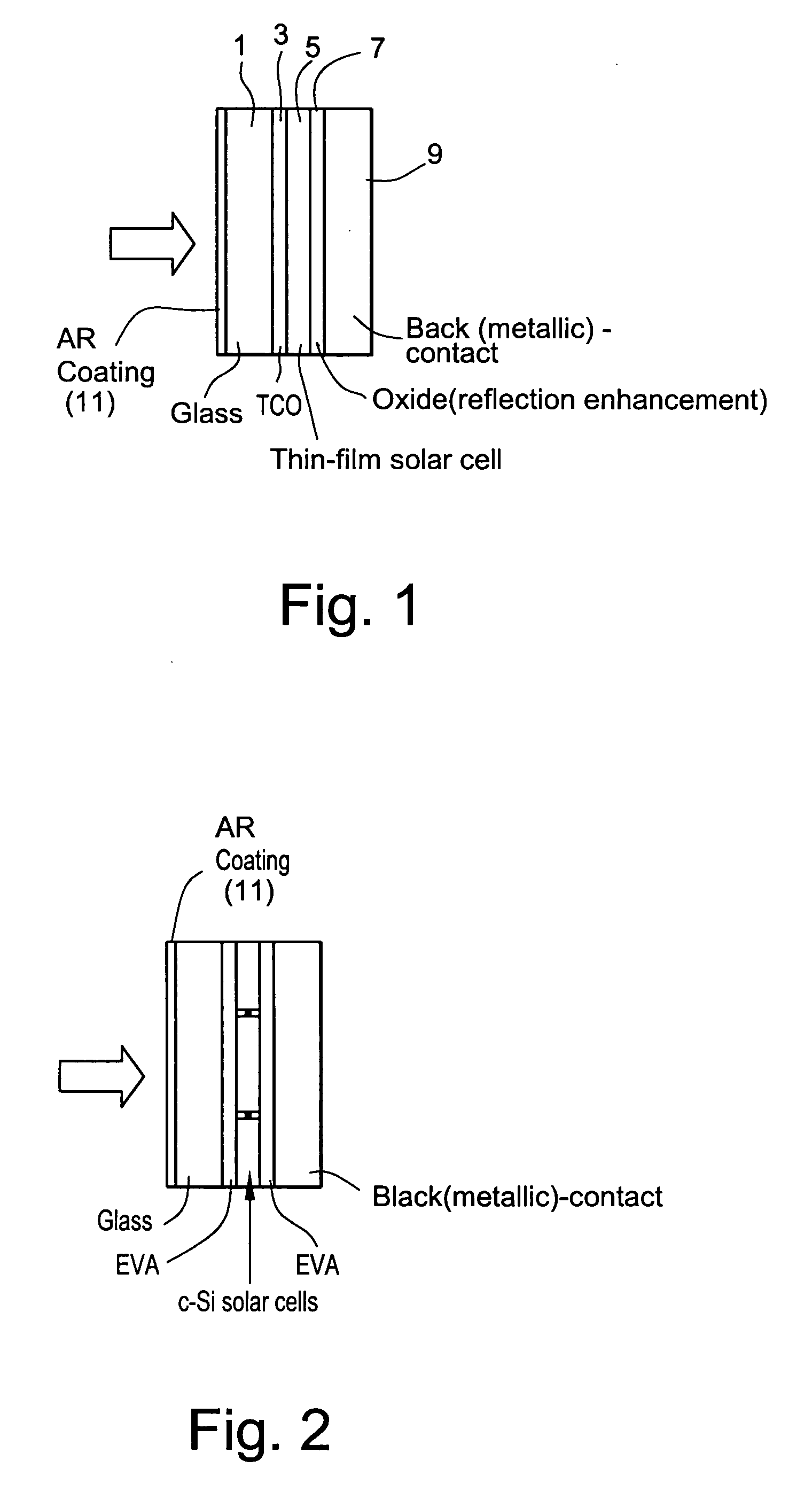

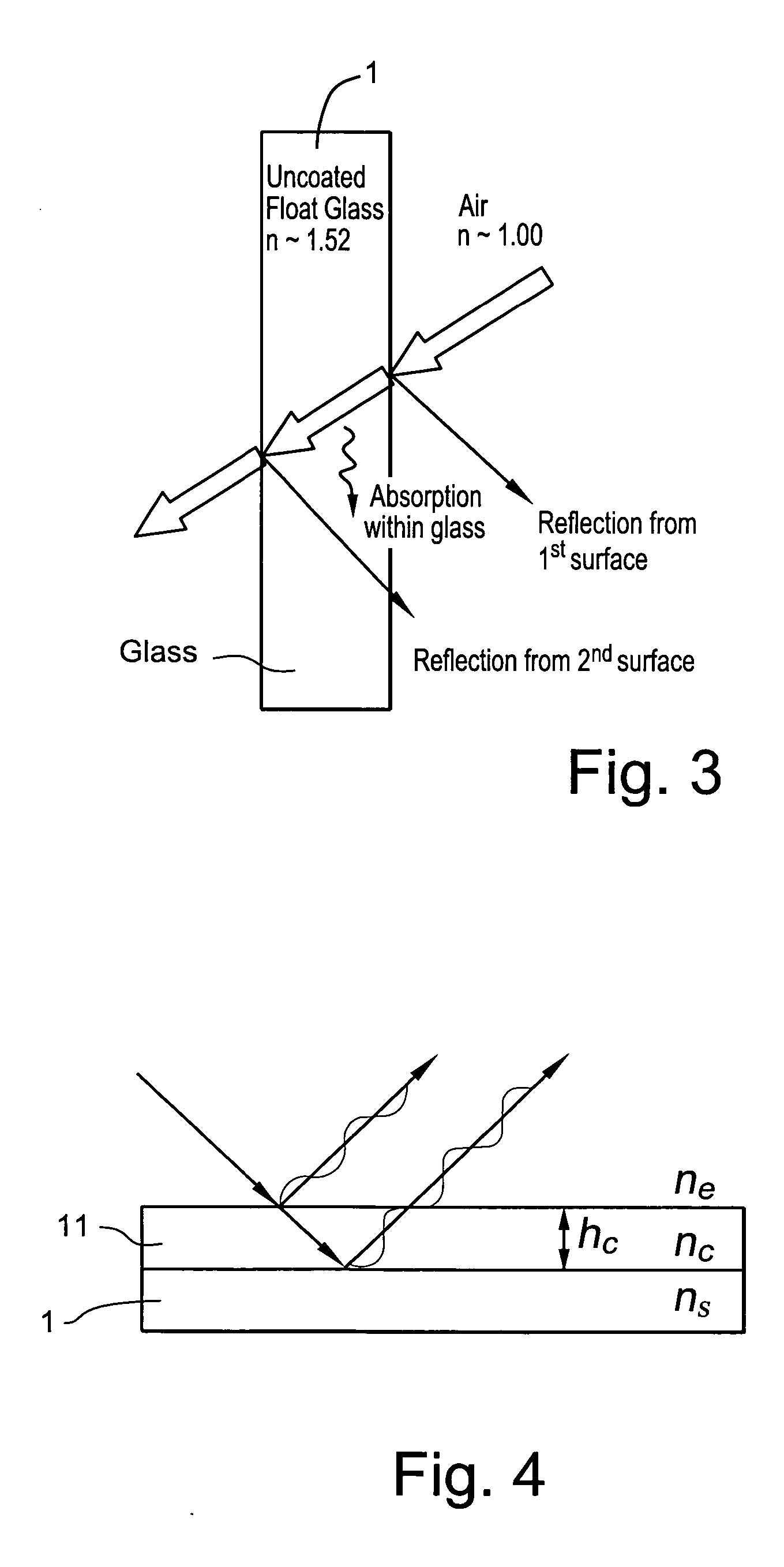

Photovoltaic device having multilayer antireflective layer supported by front substrate

InactiveUS20090032098A1Reduce reflectionConvenient coatingCoatingsPhotovoltaic energy generationRefractive indexLength wave

In certain embodiments of this invention, an improved multilayer anti-reflection (AR) coating is provided on the exterior surface of the front glass substrate of a photovoltaic device. This AR coating functions to reduce reflection of desirable wavelengths from the front glass substrate, thereby allowing more light within the desirable solar spectrum to pass through the incident glass substrate and reach the photovoltaic semiconductor film so that the photovoltaic device can operate more efficiently. Also, the AR coating can reduce the amount of undesirable light (e.g., at least some IR and / or UV radiation) which reaches the semiconductor film of the device. In certain example embodiments, the multilayer AR coating includes a plurality of pairs of alternating high refractive index and low refractive index layers.

Owner:GUARDIAN GLASS LLC

High-throughput printing of semiconductor precursor layer from inter-metallic microflake articles

InactiveUS20070163642A1Efficient and simplified creationIncrease contactFinal product manufactureLiquid/solution decomposition chemical coatingNanometreAspect ratio

Methods and devices are provided for high-throughput printing of semiconductor precursor layer from microflake particles. In one embodiment, the method comprises of transforming non-planar or planar precursor materials in an appropriate vehicle under the appropriate conditions to create dispersions of planar particles with stoichiometric ratios of elements equal to that of the feedstock or precursor materials, even after settling. In particular, planar particles disperse more easily, form much denser coatings (or form coatings with more interparticle contact area), and anneal into fused, dense films at a lower temperature and / or time than their counterparts made from spherical nanoparticles. These planar particles may be microflakes that have a high aspect ratio. The resulting dense film formed from microflakes are particularly useful in forming photovoltaic devices. In one embodiment, at least one set of the particles in the ink may be inter-metallic flake particles (microflake or nanoflake) containing at least one group IB-IIIA inter-metallic alloy phase.

Owner:AERIS CAPITAL SUSTAINABLE IP

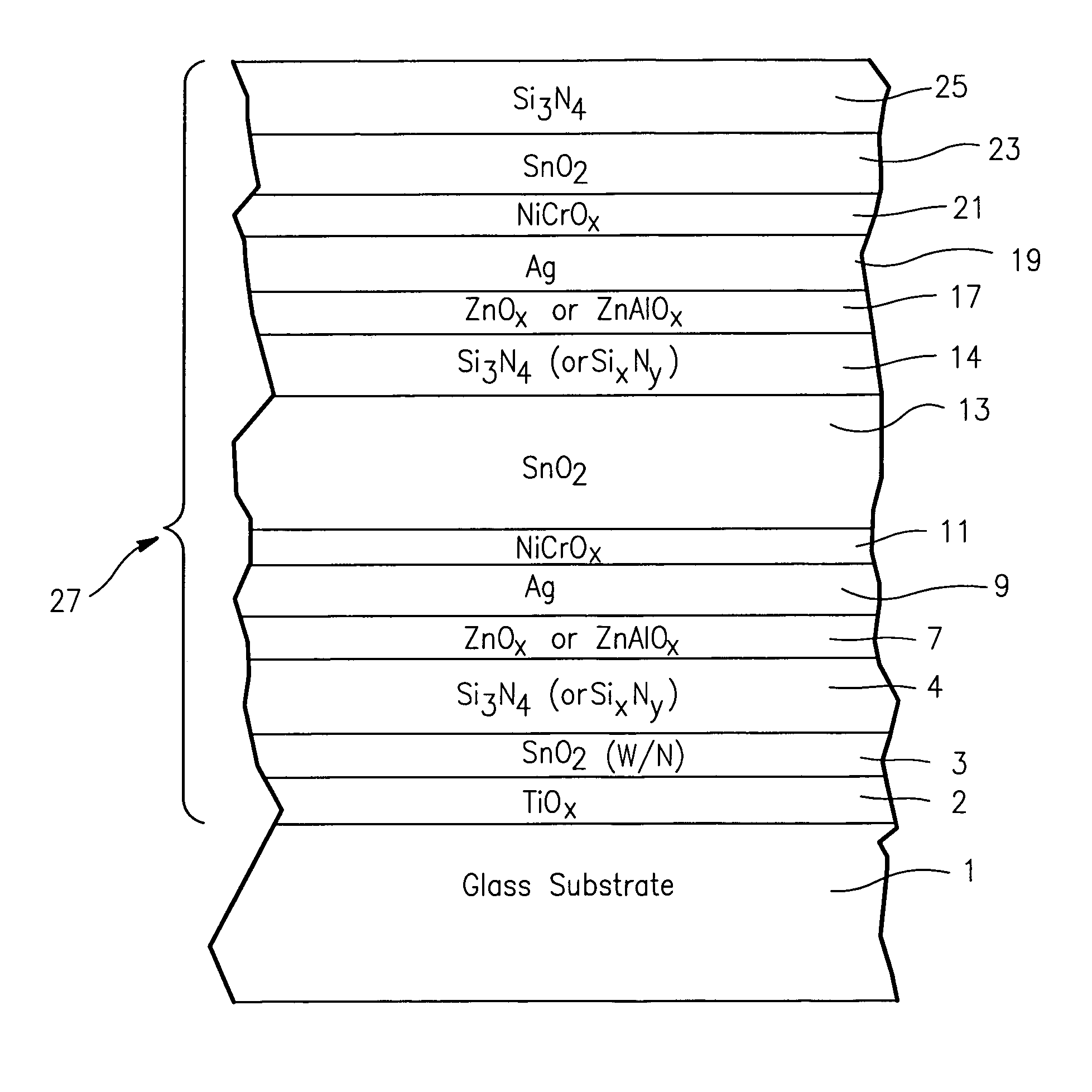

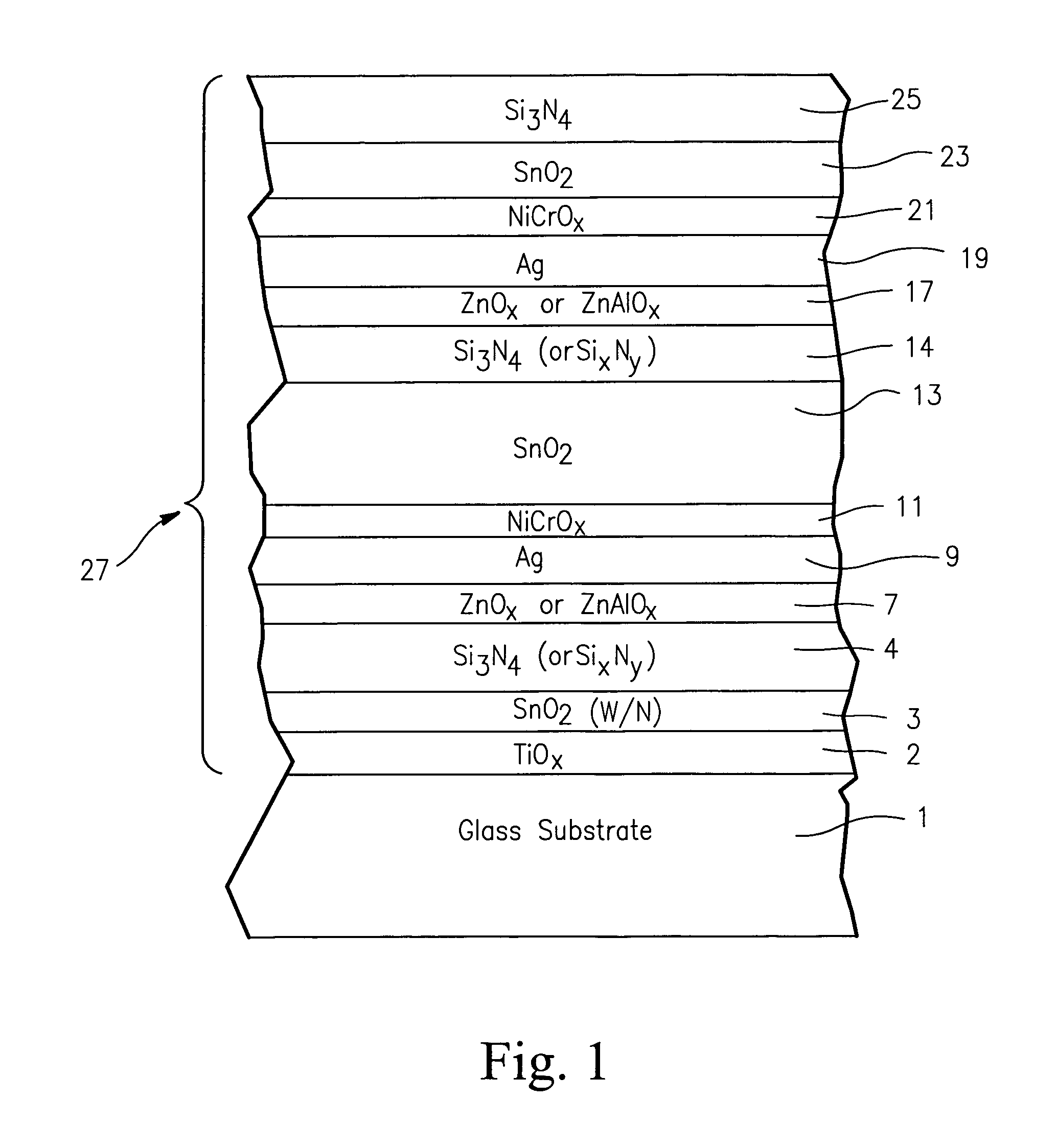

Heat treatable coated article with tin oxide inclusive layer between titanium oxide and silicon nitride

InactiveUS7153579B2Increased durabilityConvenient coatingGlass/slag layered productsCoatingsElectrical resistance and conductanceMetallurgy

A low-E coated article is provided, in certain example embodiments, with a layer including tin oxide provided between a layer including titanium oxide and a layer including silicon nitride. It has been found that the provision of such a tin oxide inclusive layer between silicon nitride and titanium oxide can significantly improve durability of the resulting coated article, especially after heat treatment (HT). In certain example embodiments, the coated article may be formed so as to have a fairly high visible transmission (TY or Tvis) to sheet resistance (Rs) ratio (i.e., a ratio Tvis / Rs). Coated articles herein may be used in the context of windows or the like (e.g., laminated vehicle windshields).

Owner:GUARDIAN EURO S A R L +1

Method and system for creating a textured surface on an implantable medical device

InactiveUS7537610B2Convenient amountEasy to keepPharmaceutical containersPretreated surfacesElectricityElectric discharge

A method for forming an implantable medical device, such as a stent, is provided, in which electric discharges are applied to a metal surface of the implantable medical device. The electric discharges pit the surface. The pitted surface improves retention of a coating on the device and increases the amount of coating that can be carried by the device. An electric discharge machining process is described for applying electric discharges to the surface of the implantable medical device or portion thereof.

Owner:ABBOTT CARDIOVASCULAR

Biodegradable or compostable containers

The present invention provides an improved method and materials for forming biodegradable containers that can hold food products in dry, damp or wet conditions and provides the biodegradable containers prepared according to the disclosed process. The containers are produced through the use of a pre-gelled starch suspension that is unique in its ability to form hydrated gels and to maintain this gel structure in the presence of many other types of materials and at low temperatures.

Owner:NEW ICE LTD

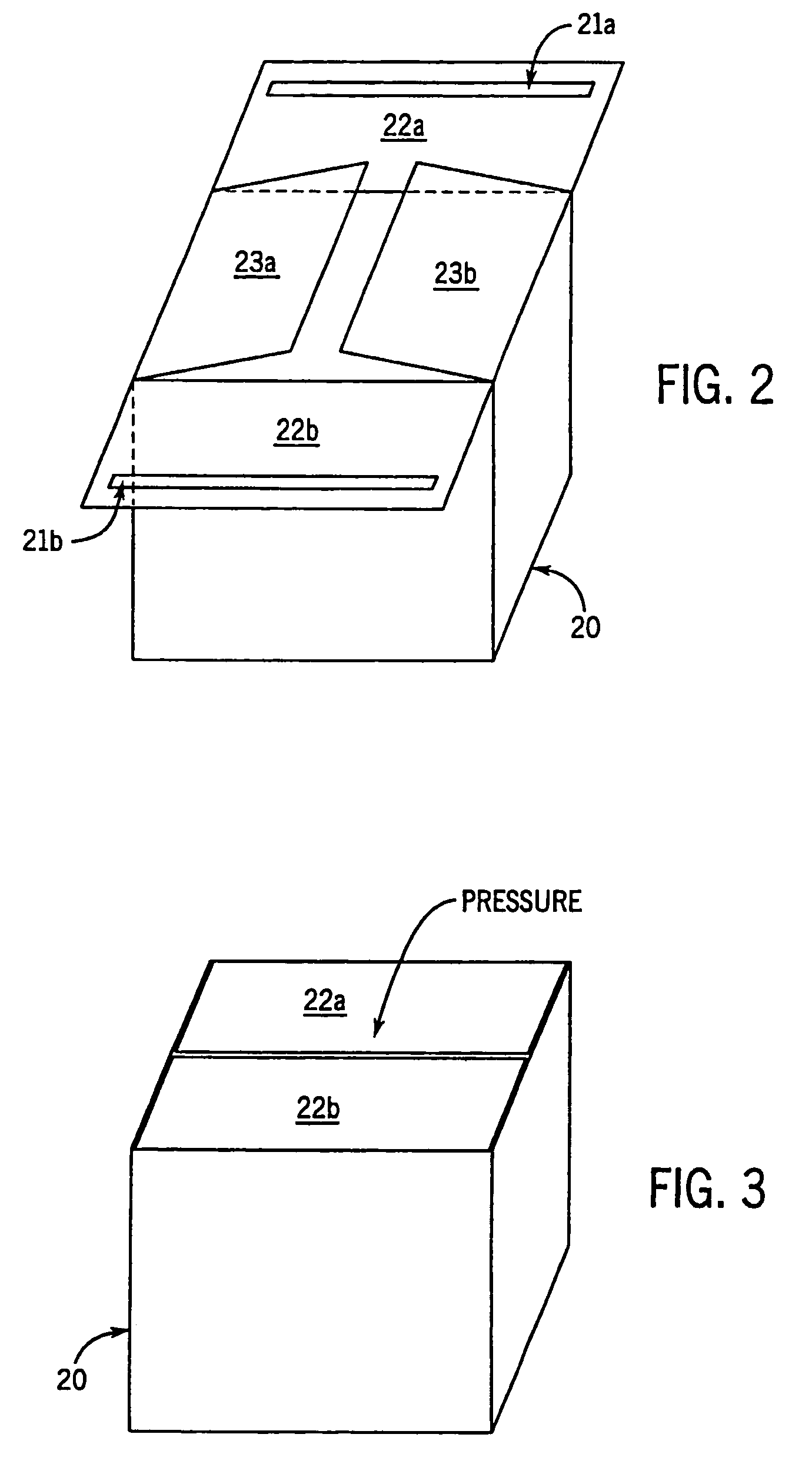

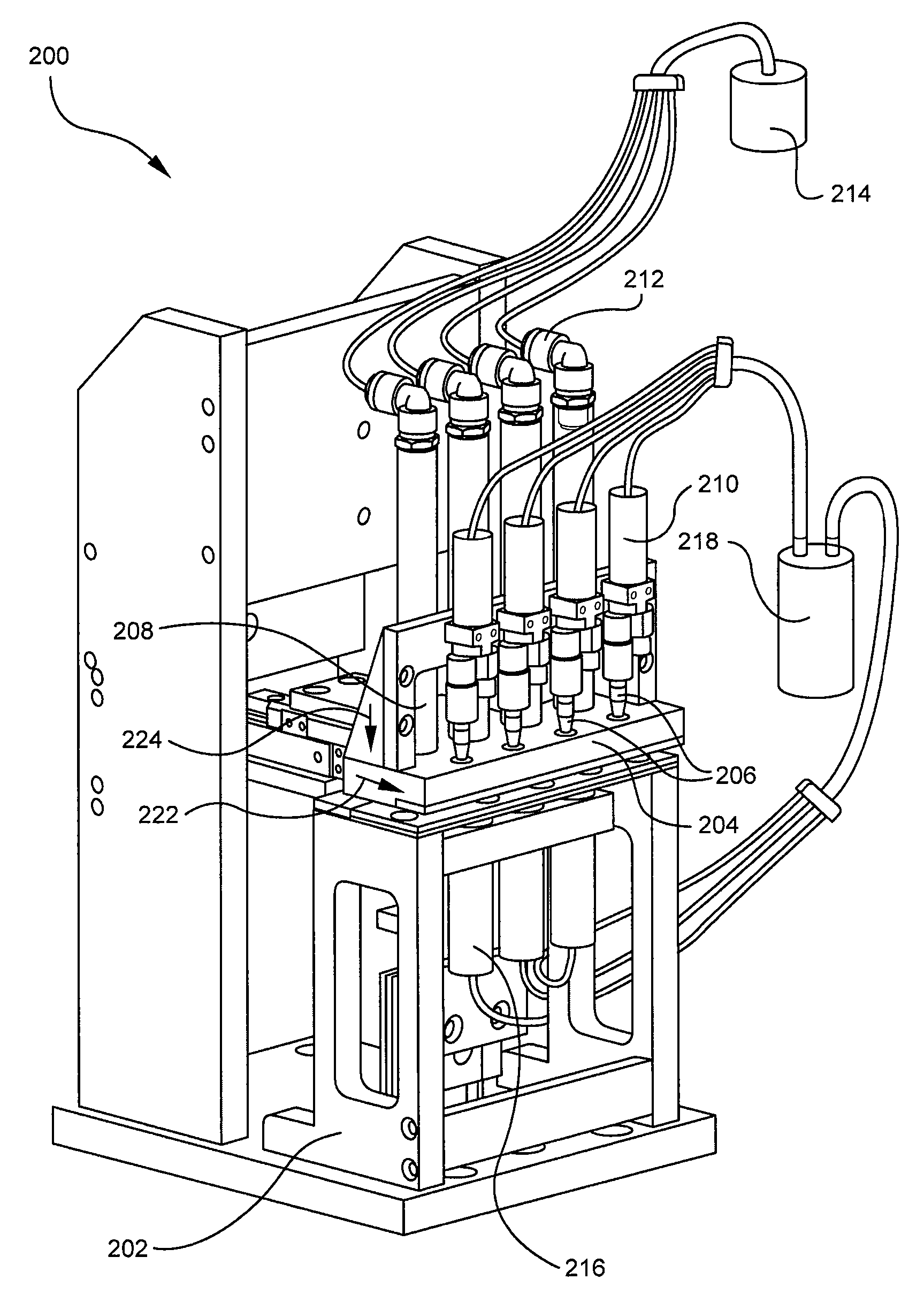

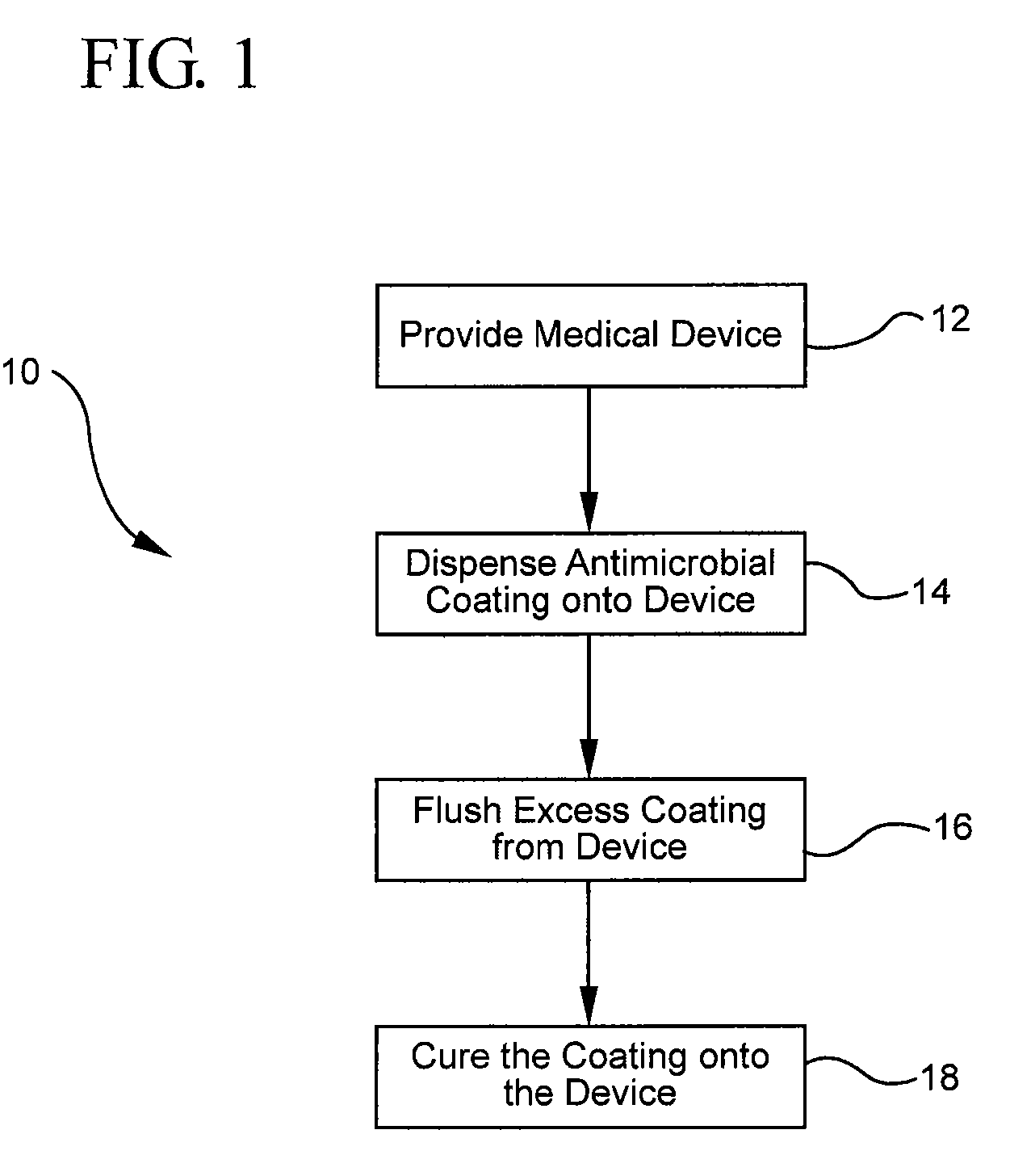

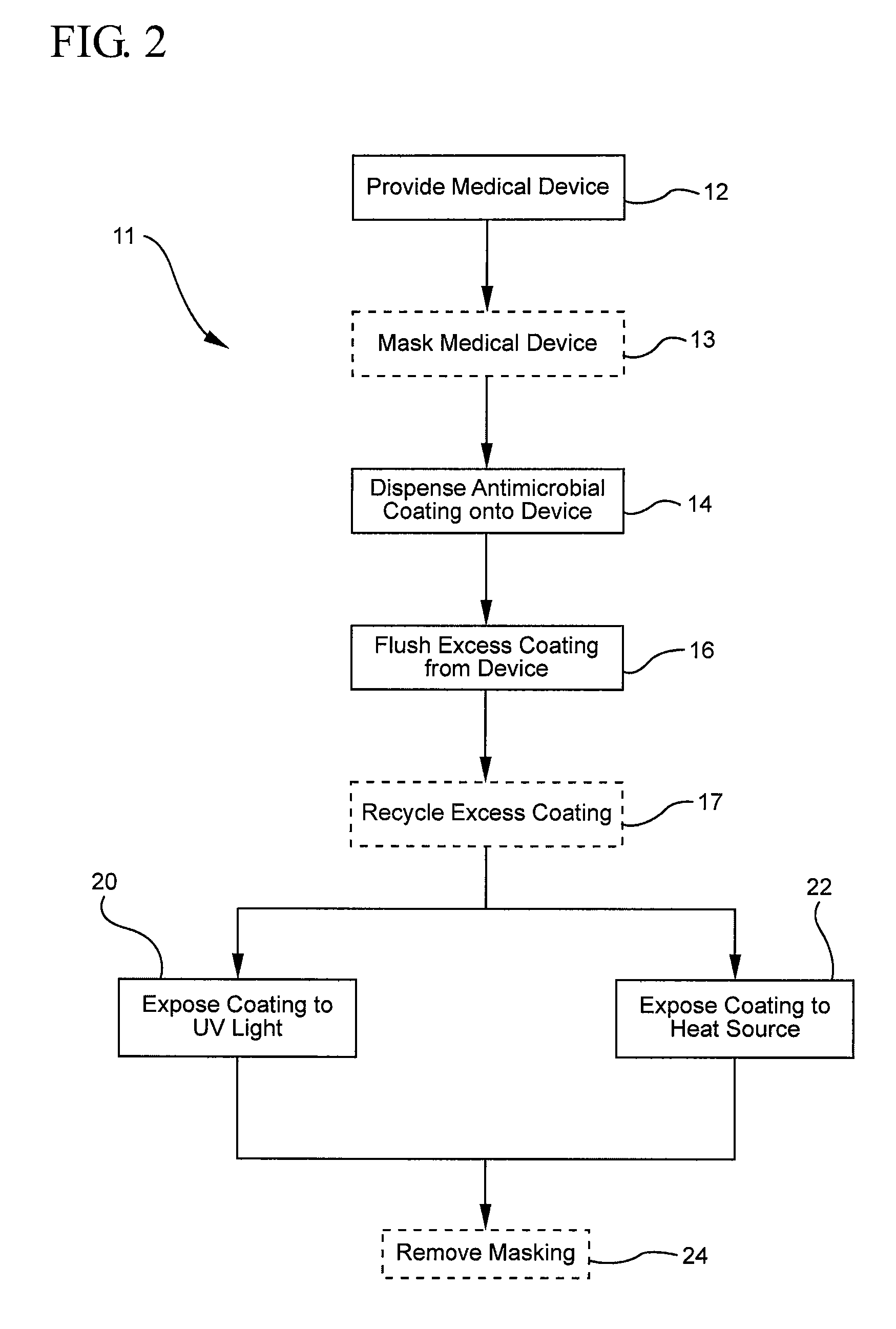

Systems and methods for applying an antimicrobial coating to a medical device

InactiveUS20100136209A1Reduce complicationsConvenient coatingPharmaceutical containersPretreated surfacesMedical deviceBiomedical engineering

Methods for applying an antimicrobial coating to a medical device is disclosed. Generally, the methods comprise providing a medical device, dispensing an antimicrobial coating onto the device, flushing excess coating from the device, and curing the coating onto the device. In one aspect, the coating includes a UV-curable, antimicrobial composition. In this aspect, the medical device can be coated and the coating can be cured with UV light in a manner of seconds. In another aspect, the coating includes an antimicrobial solution that contains an acrylate-type polymer or copolymer. In this aspect, the medical device can be coated and the coating can be heat-cured in a manner of minutes. Both the UV-curable composition and the antimicrobial solution can also include rheological modifiers, as necessary. Additionally, the compositions include one or more antimicrobial agents, which may be selected from a wide array of agents.

Owner:BECTON DICKINSON & CO

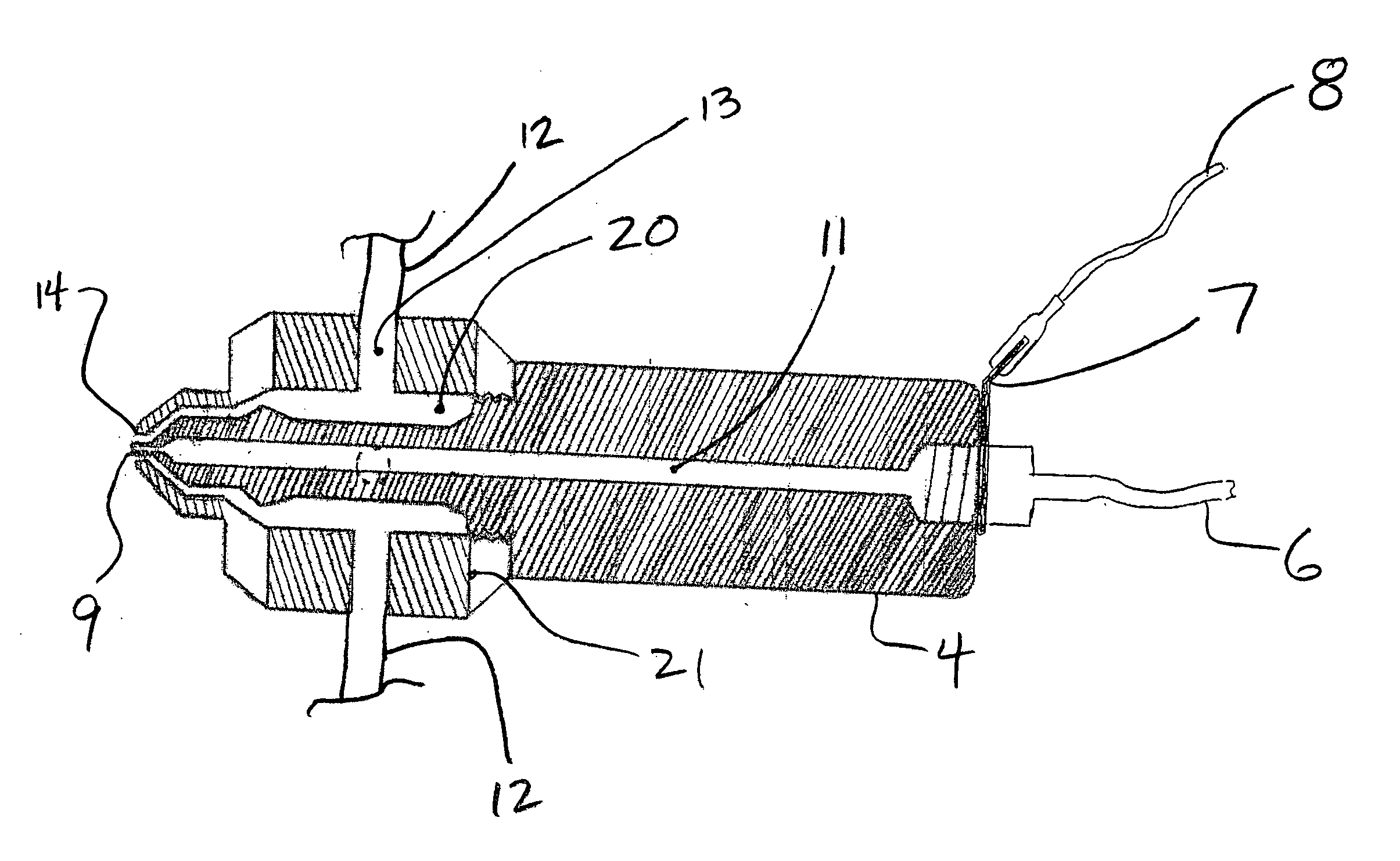

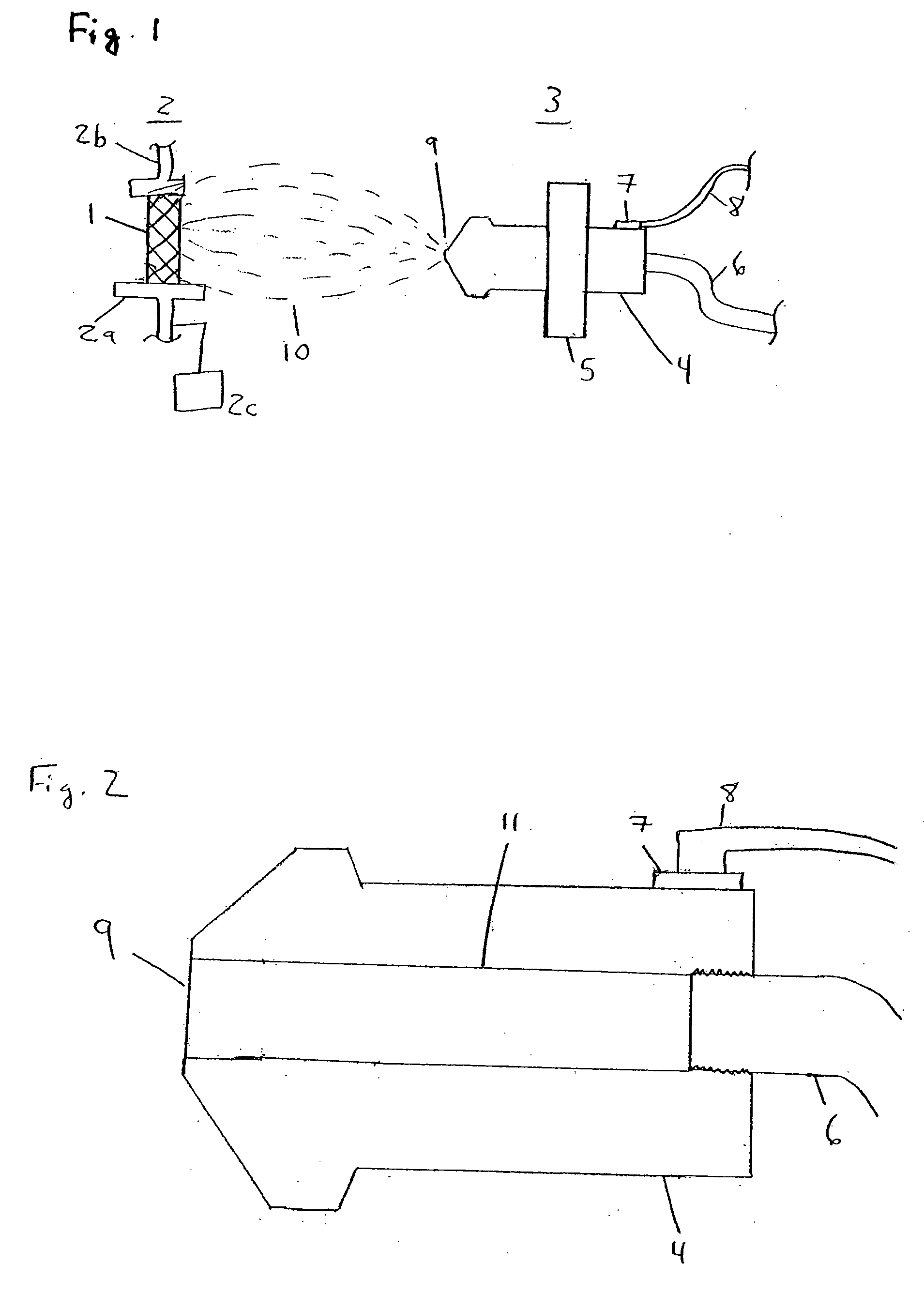

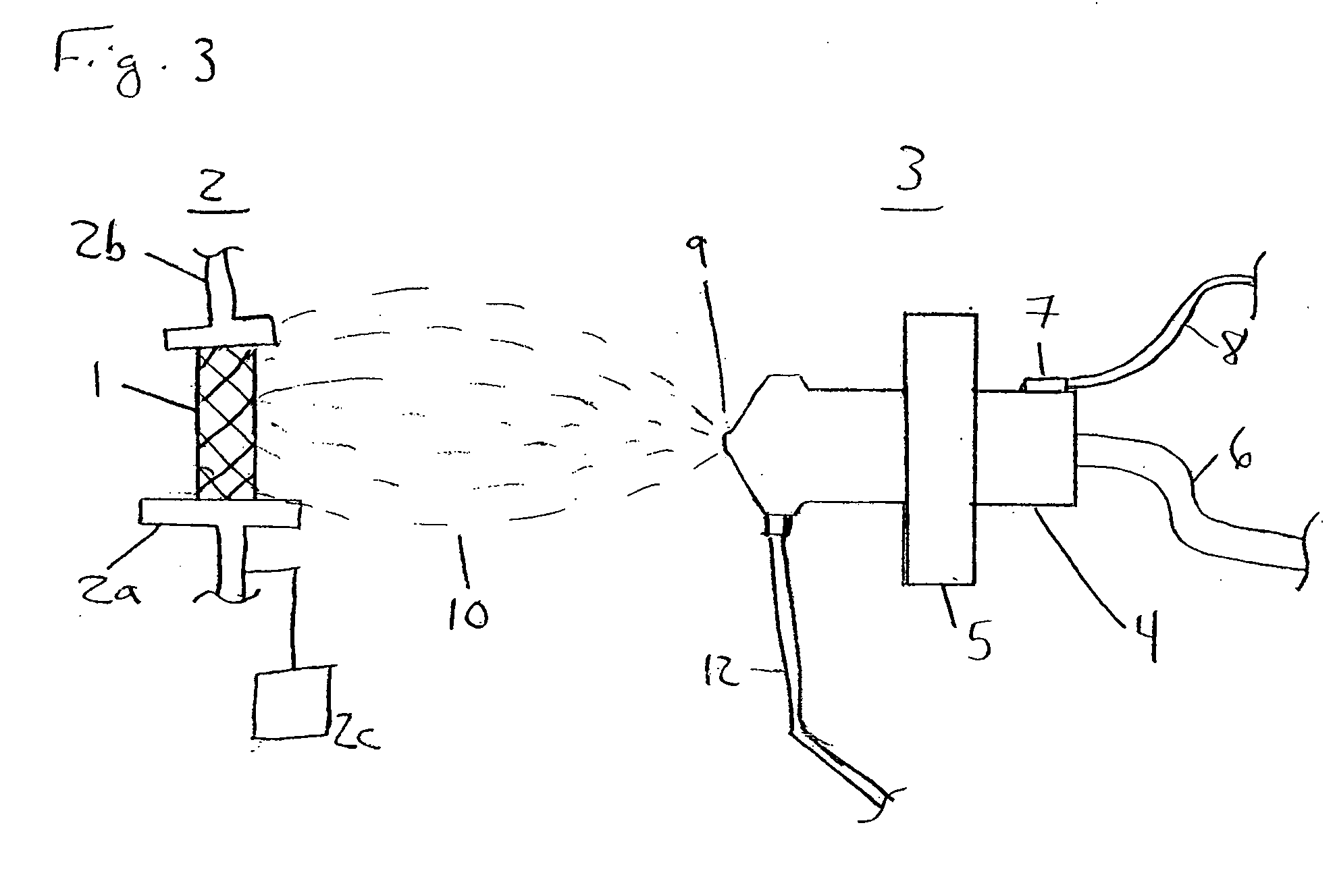

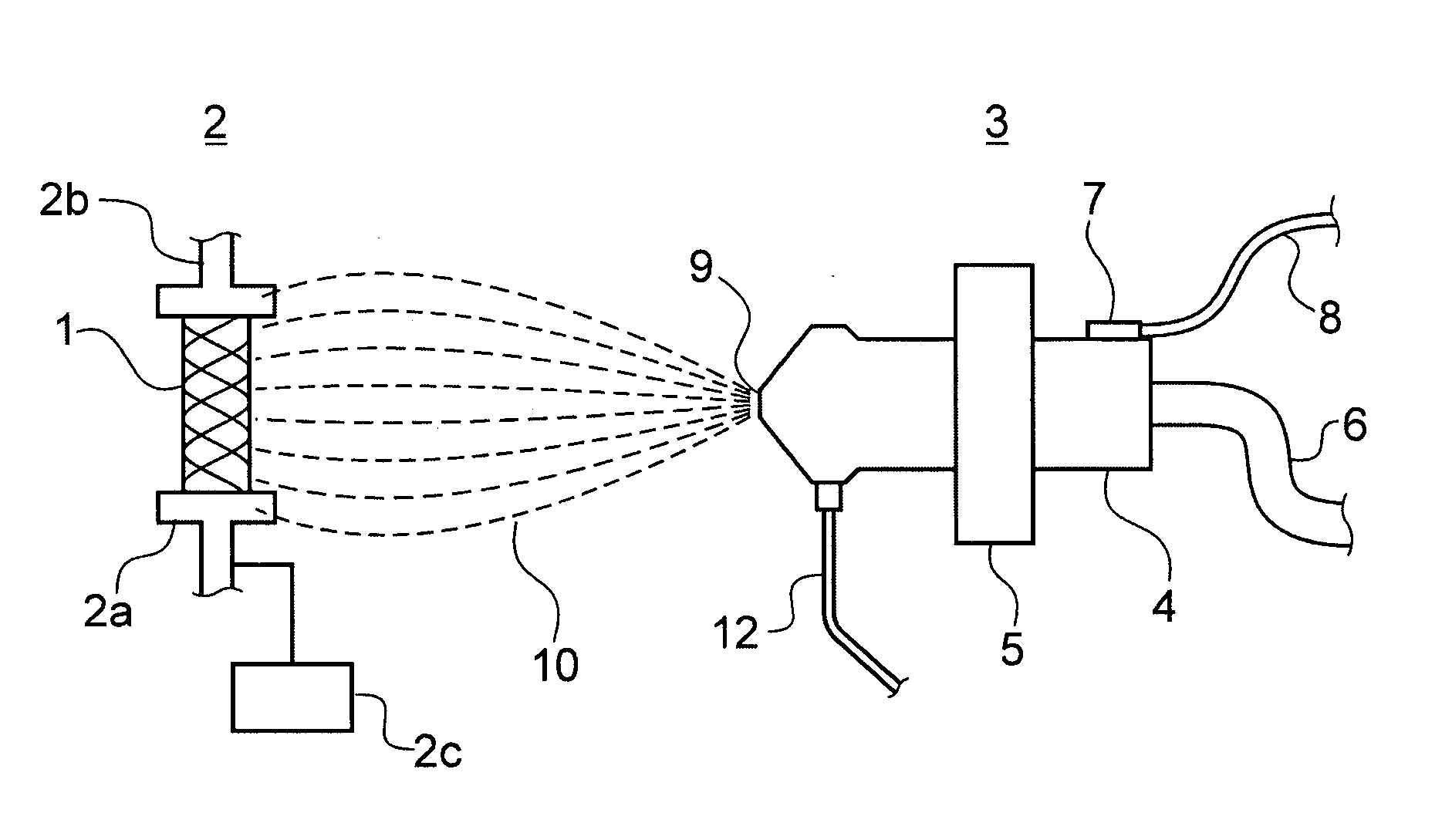

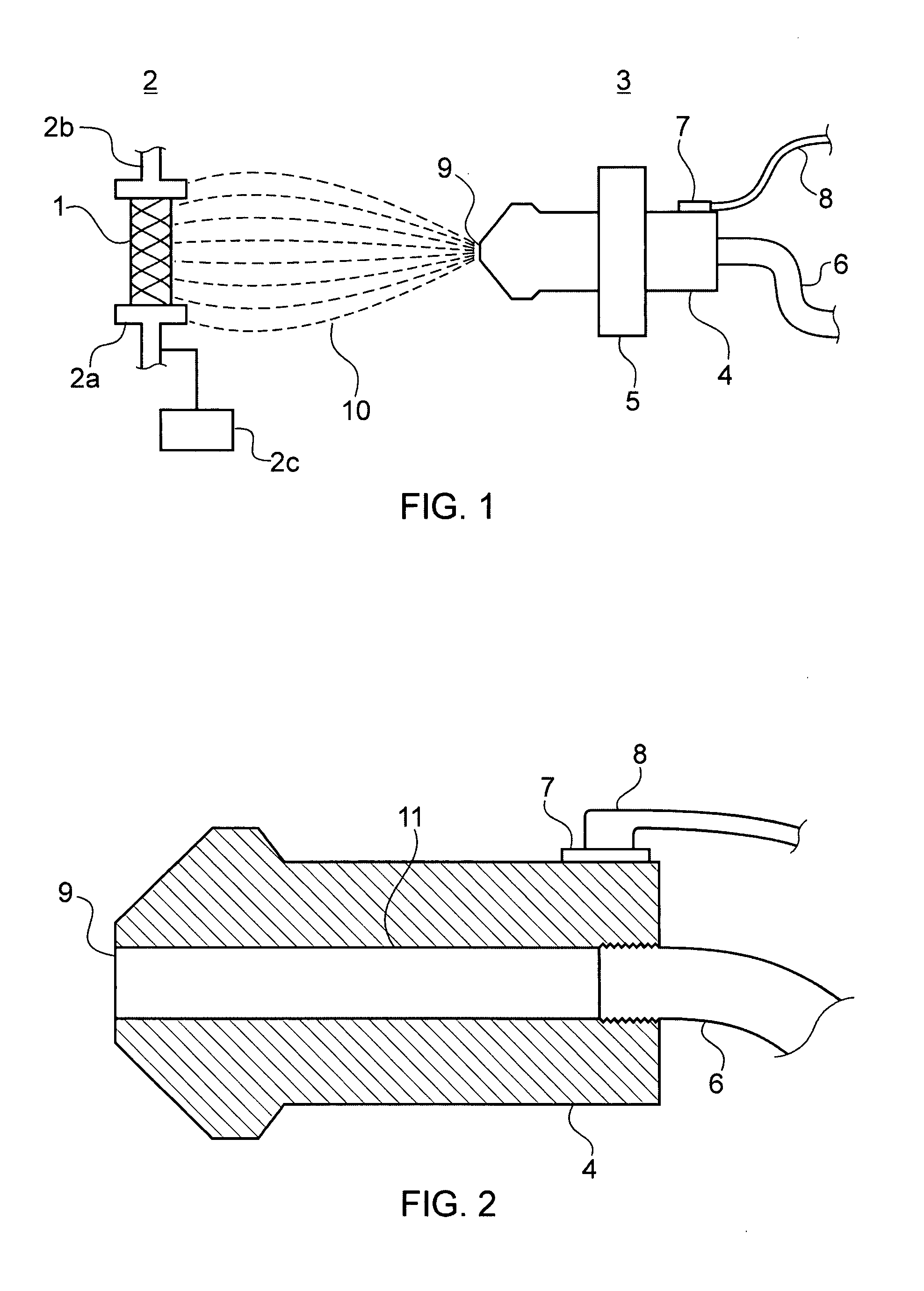

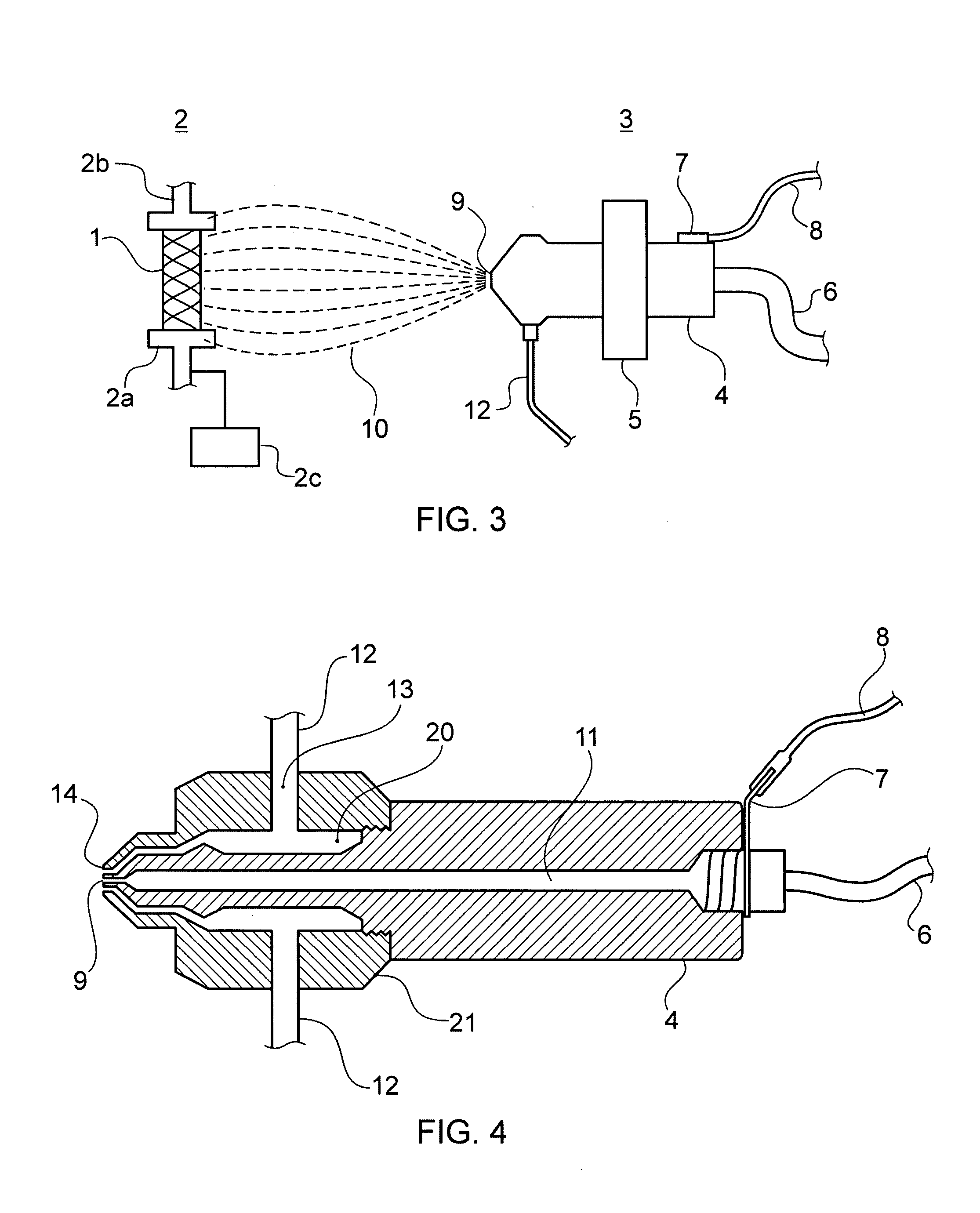

Apparatus and method for electrostatic spray coating of medical devices

ActiveUS20050175772A1Increased ionization increases the fraction of coating spray attractedIncrease electrode surface areaLiquid spraying plantsElectric shock equipmentsVoltage spikeSpray coating

An apparatus and method for electrostatic spray deposition of small targets, such as medical devices like stents. The apparatus includes a target holder which applies a first electrical potential to the target, and an electrostatic dispensing nozzle which applies a second potential sufficient to attract the coating fluid from the nozzle toward the target. Because the entire dispensing nozzle is conductive, the coating fluid may receive a greater charge than may be obtained with internal electrode-type nozzles. Electrostatic attraction of the coating fluid to the target is enhanced by the combination of higher charge density imparted to the coating fluid by the conductive nozzle, and application of a momentary voltage spike to the target to provide consistent conductivity between the target and its holder, thereby ensuring the target is presents the full first potential applied to the holder. The voltage spike may also be used independently of the conductive nozzle.

Owner:BOSTON SCI SCIMED INC

High-throughput printing of semiconductor precursor layer from microflake particles

InactiveUS20070163639A1Efficient and simplified creationIncrease contactMolten spray coatingFinal product manufactureNanoparticleParticle method

Methods and devices are provided for high-throughput printing of semiconductor precursor layer from microflake particles. In one embodiment, the method comprises of transforming non-planar or planar precursor materials in an appropriate vehicle under the appropriate conditions to create dispersions of planar particles with stoichiometric ratios of elements equal to that of the feedstock or precursor materials, even after settling. In particular, planar particles disperse more easily, form much denser coatings (or form coatings with more interparticle contact area), and anneal into fused, dense films at a lower temperature and / or time than their counterparts made from spherical nanoparticles. These planar particles may be microflakes that have a high aspect ratio. The resulting dense film formed from microflakes are particularly useful in forming photovoltaic devices.

Owner:AERIS CAPITAL SUSTAINABLE IP

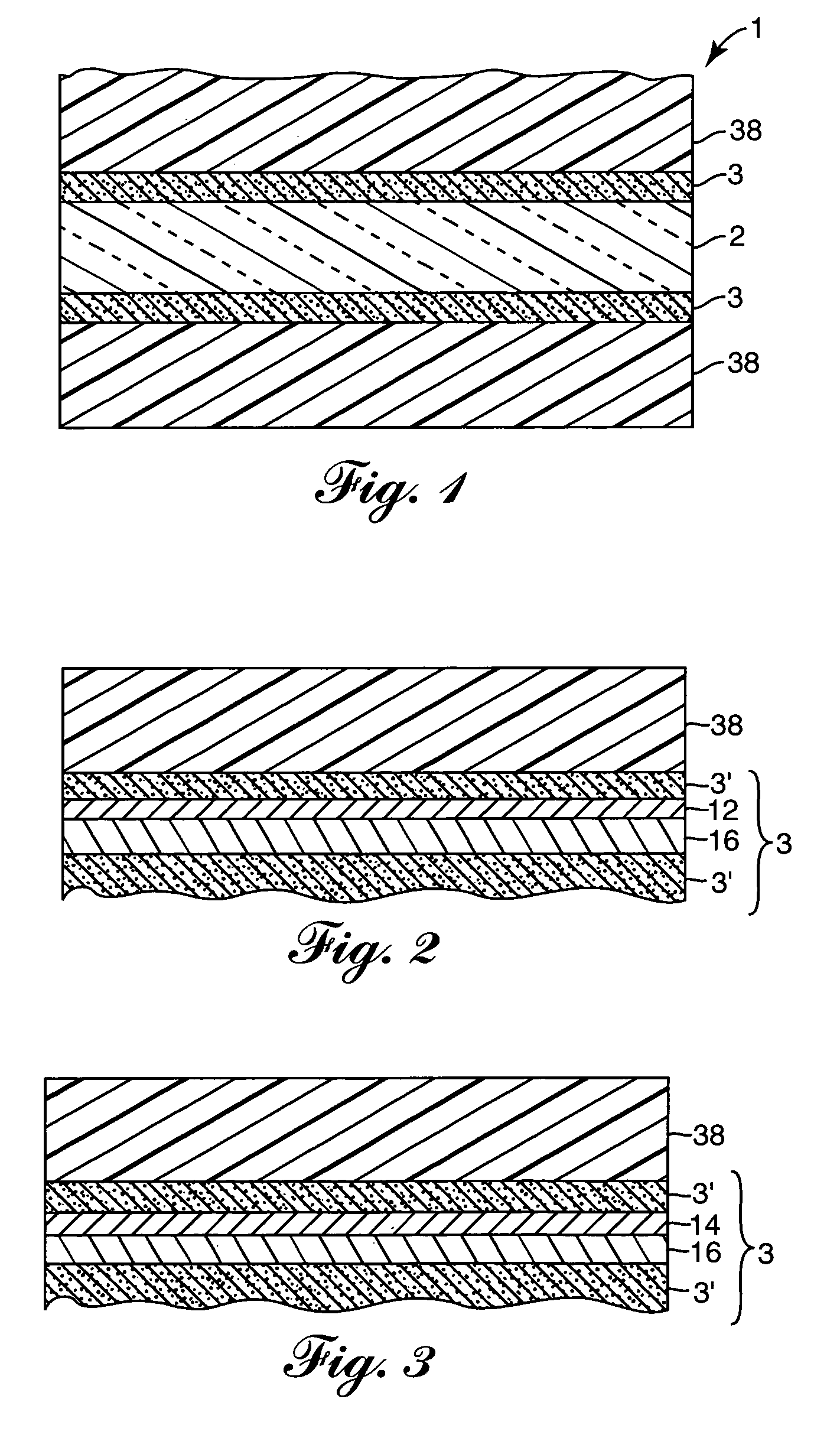

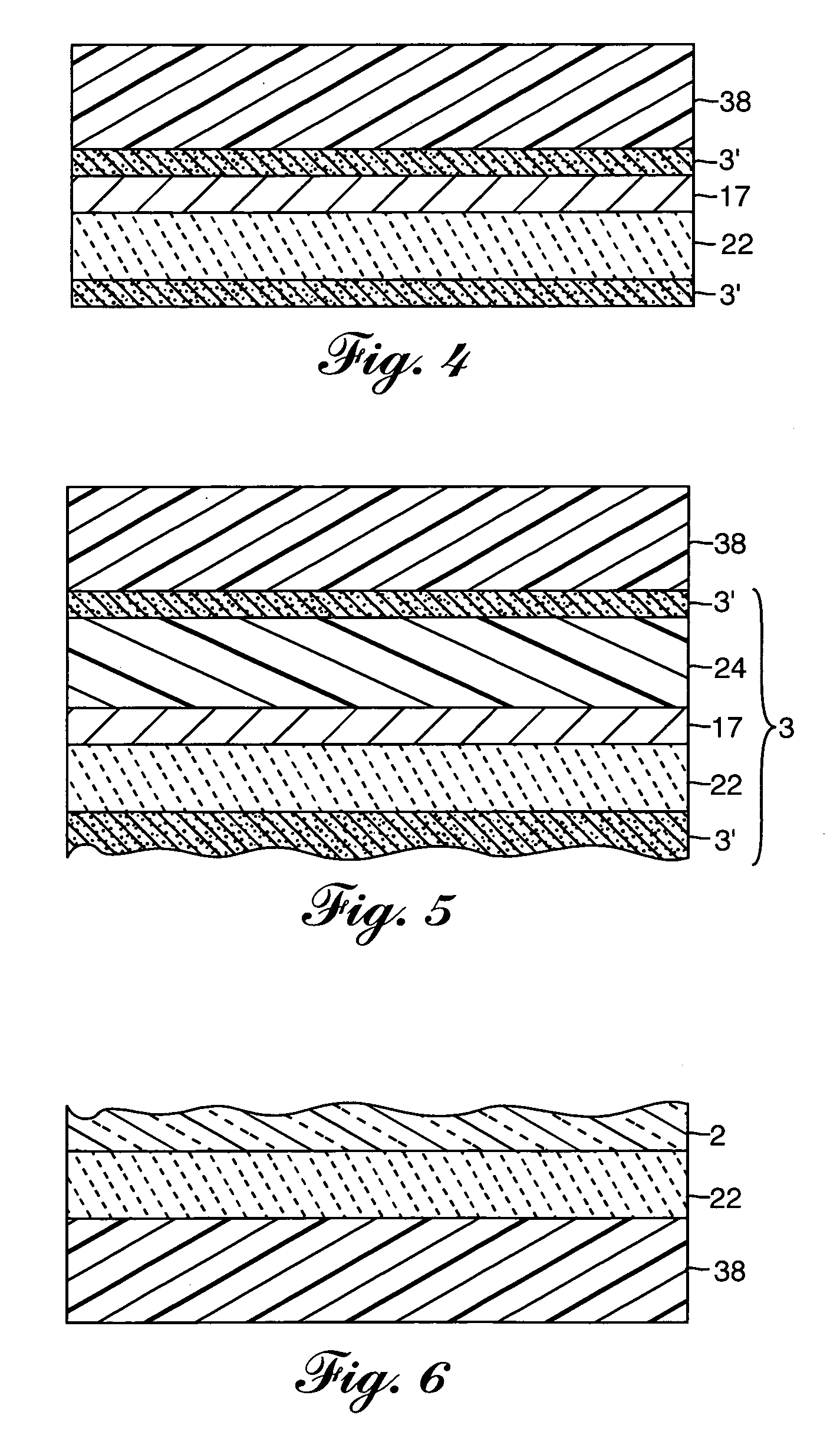

Transparent conductive oxides for plastic flat panel displays

InactiveUS7186465B2Reduce manufacturing costIncreased durabilityDischarge tube luminescnet screensFinal product manufactureOrganic layerDisplay device

An electronic device on a plastic substrate, at least one side of the device being protected from reaction with or incorporation of moisture by a composite barrier. The composite barrier may contain, for example, multiple layers of transparent conductive oxide separated by one or more vacuum-evaporated in-situ polymerized organic layers, or may contain multiple barrier layers of transparent conductive oxide, transparent metal, or transparent conductive metal nitride, separated by at least one layer of organic dielectric polymer.

Owner:3M INNOVATIVE PROPERTIES CO

High-throughput printing of semiconductor precursor layer from chalcogenide particles

InactiveUS20080124831A1Efficient and simplified creationIncrease contactSemiconductor/solid-state device manufacturingLiquid/solution decomposition chemical coatingNanoparticleParticle method

Methods and devices are provided for high-throughput printing of semiconductor precursor layer from microflake particles. In one embodiment, the method comprises of transforming non-planar or planar precursor materials in an appropriate vehicle under the appropriate conditions to create dispersions of planar particles with stoichiometric ratios of elements equal to that of the feedstock or precursor materials, even after settling. In particular, planar particles disperse more easily, form much denser coatings (or form coatings with more interparticle contact area), and anneal into fused, dense films at a lower temperature and / or time than their counterparts made from spherical nanoparticles. These planar particles may be microflakes that have a high aspect ratio. The resulting dense film formed from microflakes are particularly useful in forming photovoltaic devices.

Owner:AERIS CAPITAL SUSTAINABLE IP

High-throughput printing of nanostructured semiconductor precursor layer

InactiveUS20070163383A1Increase contactReduce the temperatureMolten spray coatingFinal product manufactureHigh fluxNanostructure

Materials and devices are provided for high-throughput printing of nanostructured semiconductor precursor layer. In one embodiment, a material is provided that comprises of a plurality of microflakes having a material composition containing at least one element from Groups IB, IIIA, and / or VIA. The microflakes may be created by milling precursor particles characterized by a precursor composition that provides sufficient malleability to form a planar shape from a non-planar starting shape when milled, and wherein overall amounts of elements from Groups IB, IIIA and / or VIA contained in the precursor particles combined are at a desired stoichiometric ratio of the elements. It should also be understood that other flakes such as but not limited to nanoflakes may also be used to form the precursor material.

Owner:AERIS CAPITAL SUSTAINABLE IP

Method of making solar cell/module with porous silica antireflective coating

InactiveUS20070074757A1Improved anti-reflection (AR) coatingReduce reflectionCoatingsPhotovoltaic energy generationColloidal silicaAnti-reflective coating

A solar cell includes an improved anti-reflection (AR) coating provided on an incident glass substrate. In certain example embodiments, the AR coating includes a layer comprising porous silica. The porous nature of the silica inclusive layer permits the refractive index (n) of the silica inclusive layer to be reduced, thereby decreasing reflection and permitting more radiation to make its way to the active layer(s) of the solar cell. In certain example embodiments, a coating solution may be formed by mixing a colloidal silica solution and a polymeric silica solution, then applying the coating solution to a substrate and curing the same in order to form an AR coating.

Owner:GUARDIAN GLASS LLC

Apparatus and method for electrostatic spray coating of medical devices

ActiveUS7241344B2Increased ionization increases the fraction of coating spray attractedIncrease electrode surface areaLiquid spraying plantsElectric shock equipmentsVoltage spikeSpray coating

An apparatus and method for electrostatic spray deposition of small targets, such as medical devices like stents. The apparatus includes a target holder which applies a first electrical potential to the target, and an electrostatic dispensing nozzle which applies a second potential sufficient to attract the coating fluid from the nozzle toward the target. Because the entire dispensing nozzle is conductive, the coating fluid may receive a greater charge than may be obtained with internal electrode-type nozzles. Electrostatic attraction of the coating fluid to the target is enhanced by the combination of higher charge density imparted to the coating fluid by the conductive nozzle, and application of a momentary voltage spike to the target to provide consistent conductivity between the target and its holder, thereby ensuring the target is presents the full first potential applied to the holder. The voltage spike may also be used independently of the conductive nozzle.

Owner:BOSTON SCI SCIMED INC

Silane copolymer coatings

InactiveUS20020128419A1Simple and efficientMaintain good propertiesMale contraceptivesLayered productsSilanesMedical device

The invention is drawn to silane copolymers prepared from the reaction of one or more polyisocyanates with one or more lubricious polymers having at least two functional groups, which may be the same or different, that are reactive with an isocyanate functional group and with one or more organo-functional silanes having at least two functional groups, which may be the same or different, that are reactive with an isocyanate functional group and at least one functional group reactive with a silicone rubber substrate. The silane copolymer coatings of the invention are elastic, lubricious, and resist wet abrasion. They are useful as coatings for polysiloxane (rubber) and other difficult to coat substrates, especially for medical devices, such catheters.

Owner:CR BARD INC

Implants with textured surface and methods for producing the same

ActiveUS7901462B2High retention rateConvenient coatingDental implantsBone implantHydrogen halideChloride

Compositions and methods are provided for preparing a metal substrate having a uniform textured surface with a plurality of indentations with a diameter in the nanometer and micrometer range. The textured surface is produced by exposing the substrate to an etching fluid comprising a hydrogen halide acid and / or an oxyacid, a chloride containing compound, and an oxidizing agent. The etching solution can be used at ambient temperature without damaging the metal elements on the substrate surface. This textured surface enhances adherence of coatings or cells onto the textured surface, improves the retention of proteins on the surface, and encourages bone in-growth.

Owner:DEPUY PROD INC

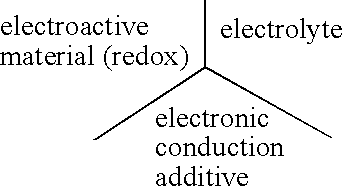

Electrode materials with high surface conductivity

InactiveUS20040140458A1Simple structureHigh crystallinityElectrode manufacturing processesDouble layer capacitorsSurface conductivityIon exchange

The present invention concerns electrode materials capable of redox reactions by electrons and alkaline ions exchange with an electrolyte. The applications are in the field of primary (batteries) or secondary electrochemical generators, super capacitors and light modulating system of the super capacitor type.

Owner:CENT NAT DE LA RECHERCHE SCI +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com