Patents

Literature

4248results about How to "Easy to keep" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

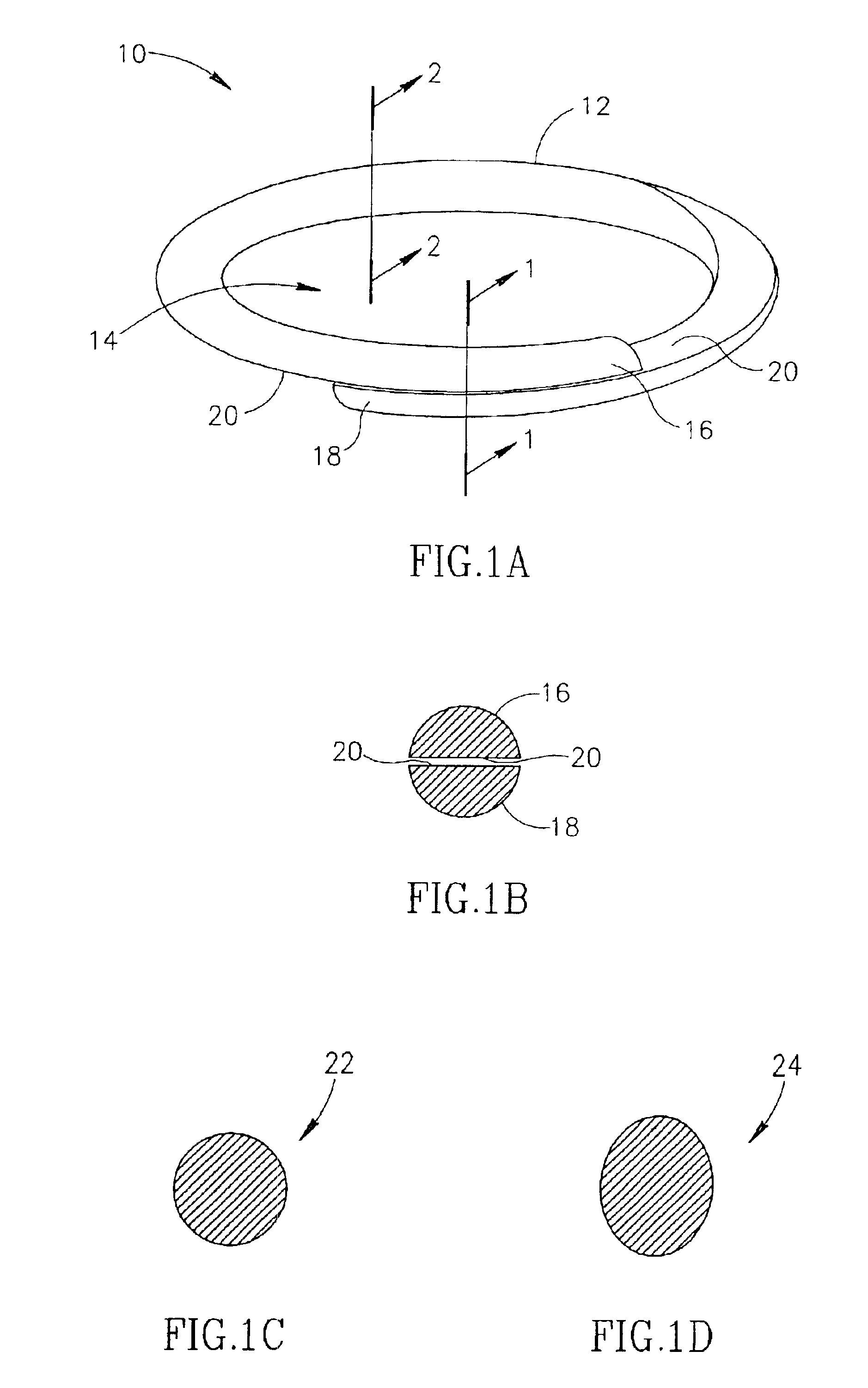

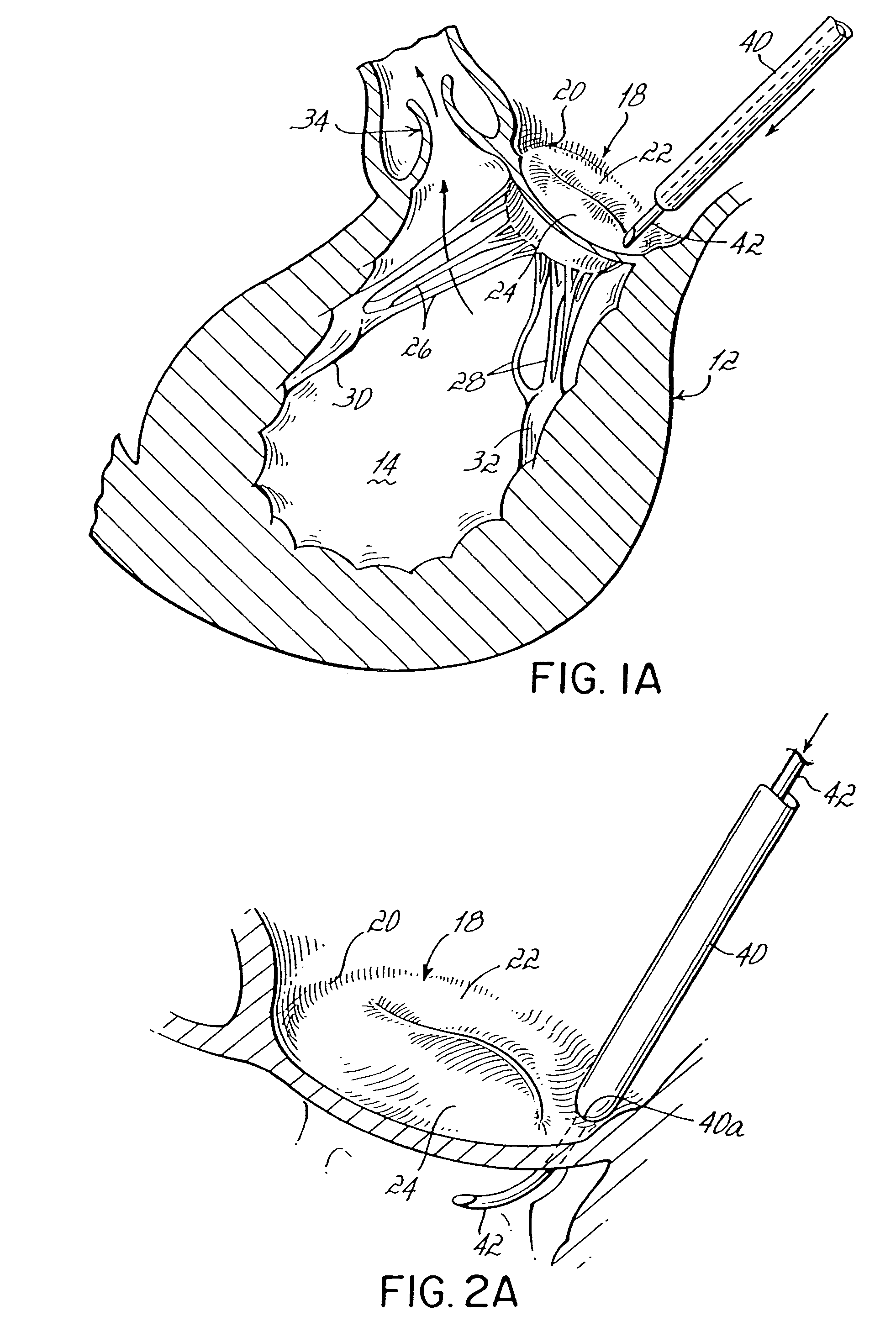

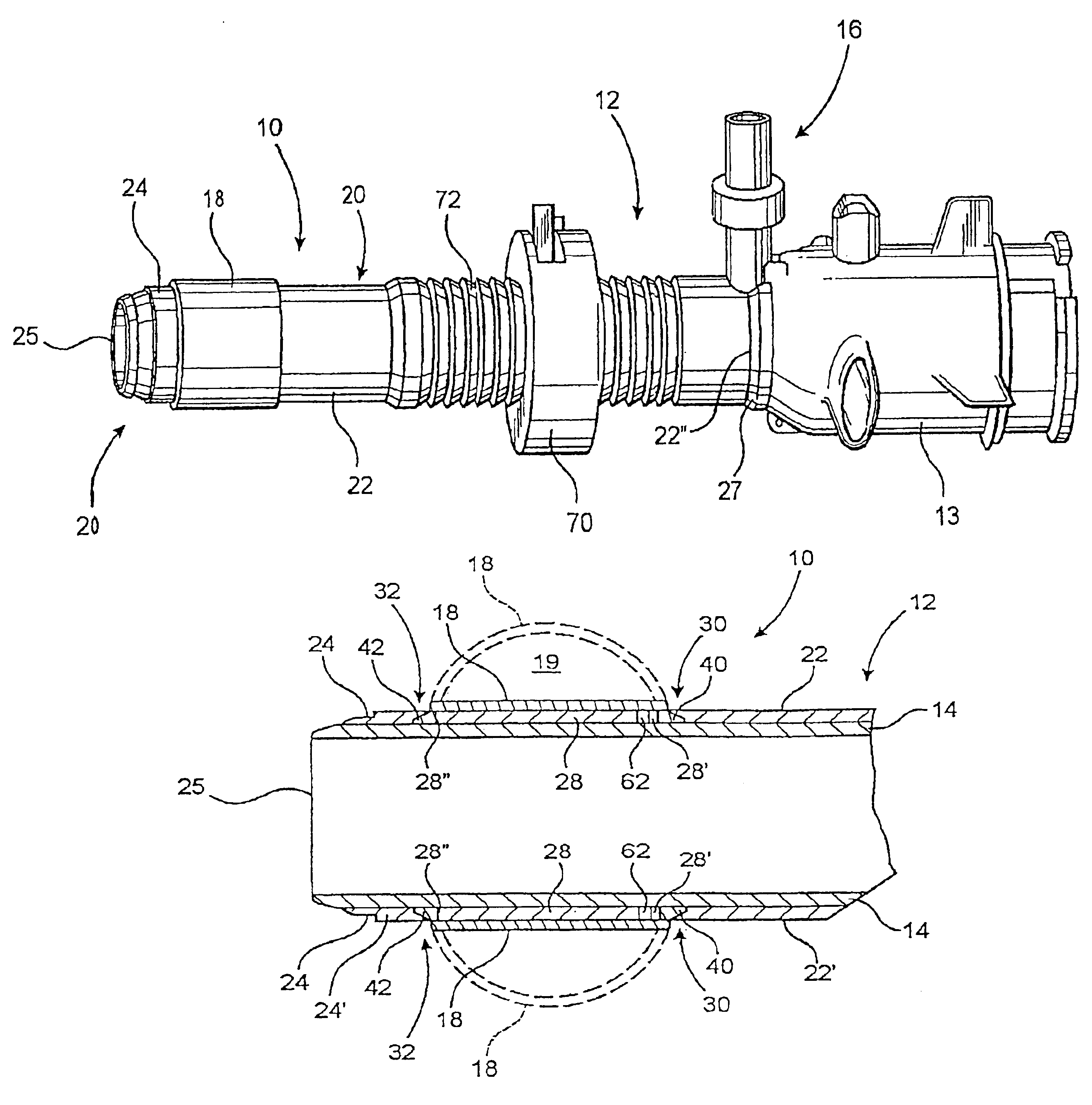

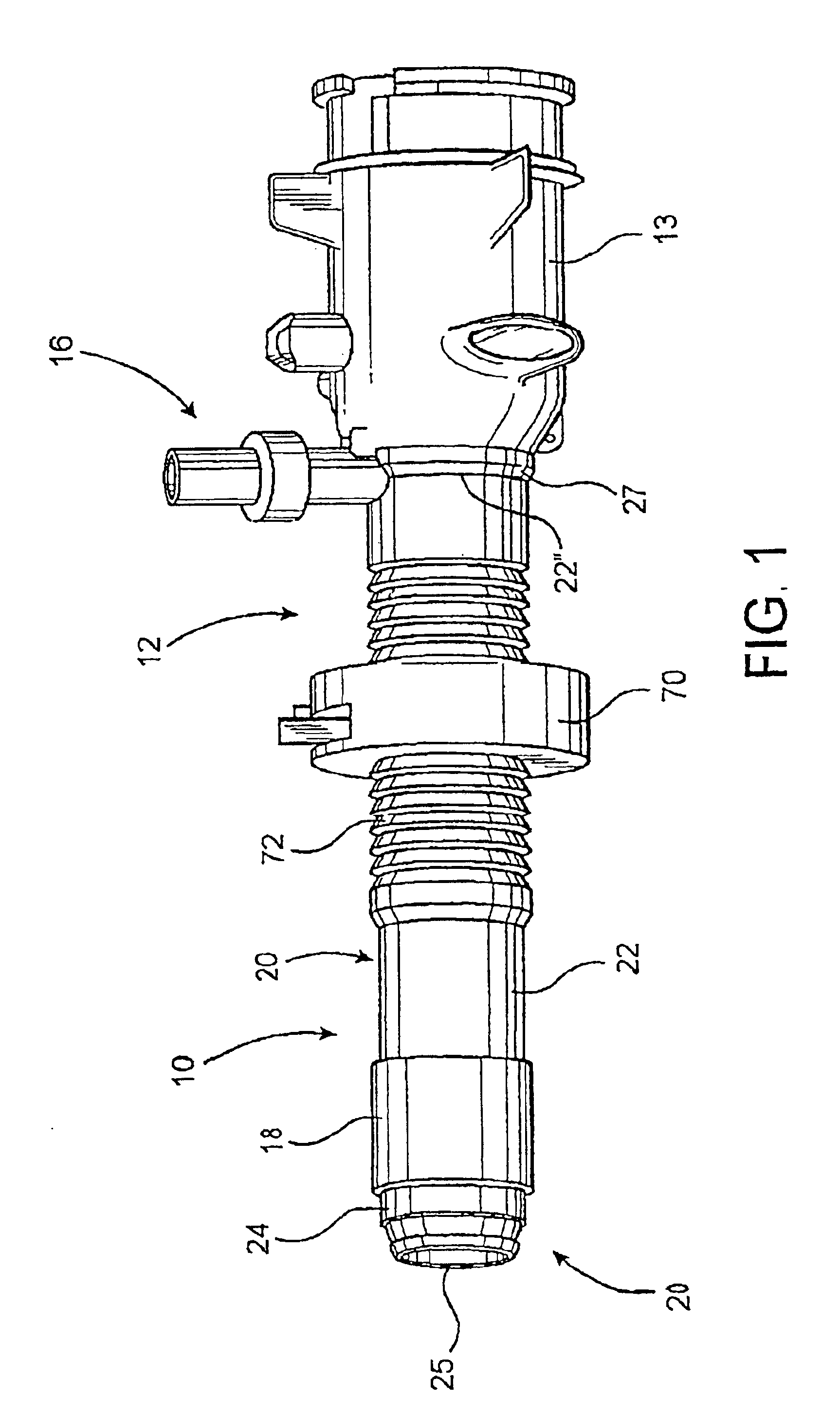

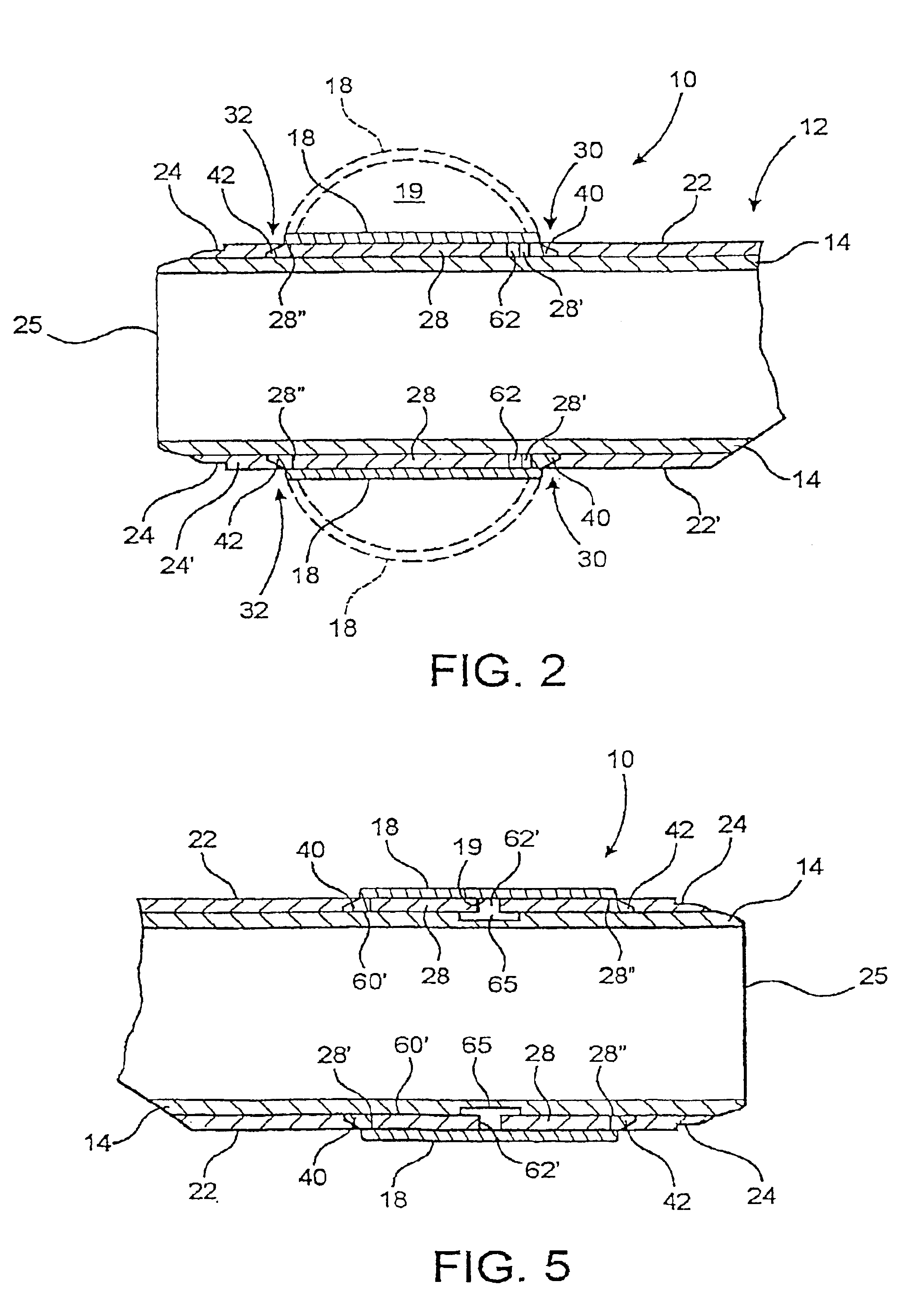

Intussusception and anastomosis apparatus

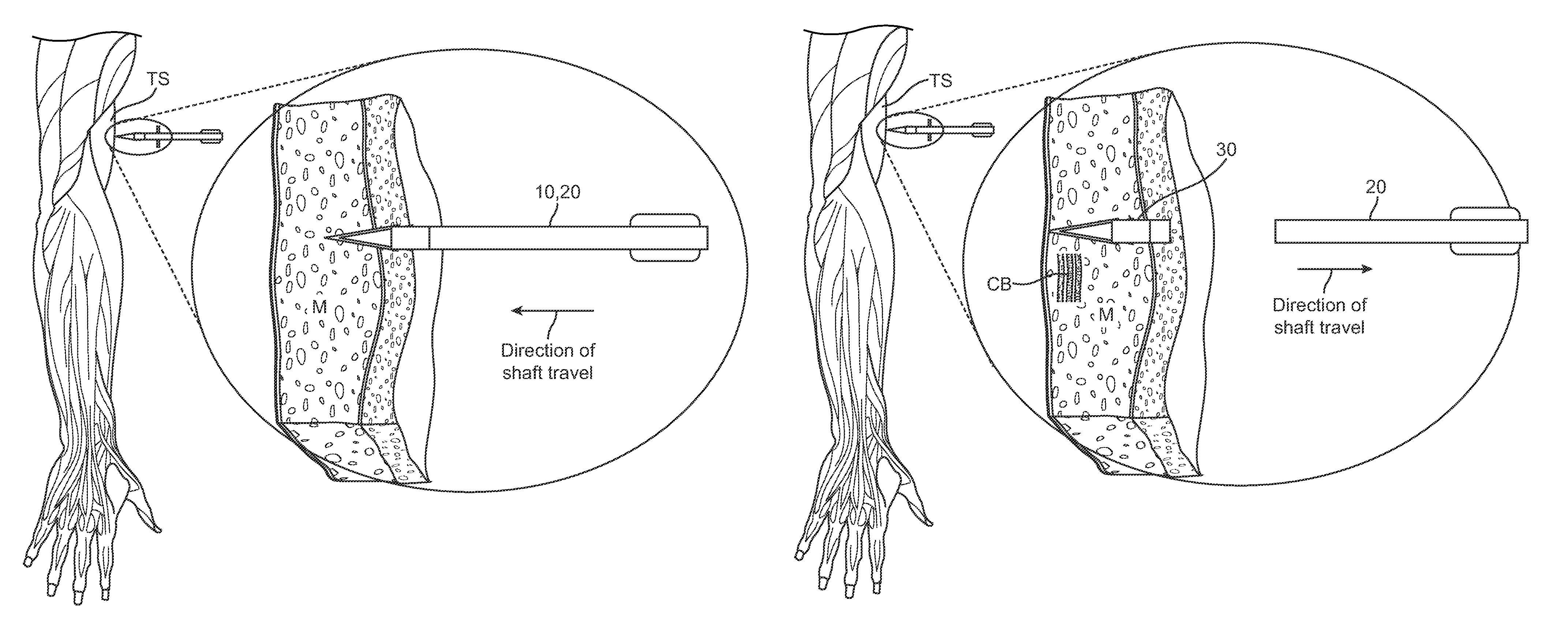

Apparatus for intratubular intussusception and anastomosis of a hollow organ portion including a cylindrical enclosure, coaxial intratubular intussusception device, for intussusception and clamping means. The apparatus also includes an intratubular anastomosis apparatus for joining organ portions after intussusception thereof with an anastomosis ring and crimping support element. The ring is formed of a shape memory alloy wire, for crimping adjacent organ portions against the crimping support element so as to cause anastomosis therebetween. The ring assumes a plastic or malleable state, at a lower temperature and an elastic state at a higher temperature. The apparatus further includes the crimping support element for intratubular insertion so as to provide a support for crimping the organ portions against the support element. The apparatus additionally includes a surgical excising means, for excising an intussuscepted organ portion, after crimping adjacent intussuscepted organ walls against the crimping support element with the anastomosis ring.

Owner:NITI SURGICAL SOLUTIONS

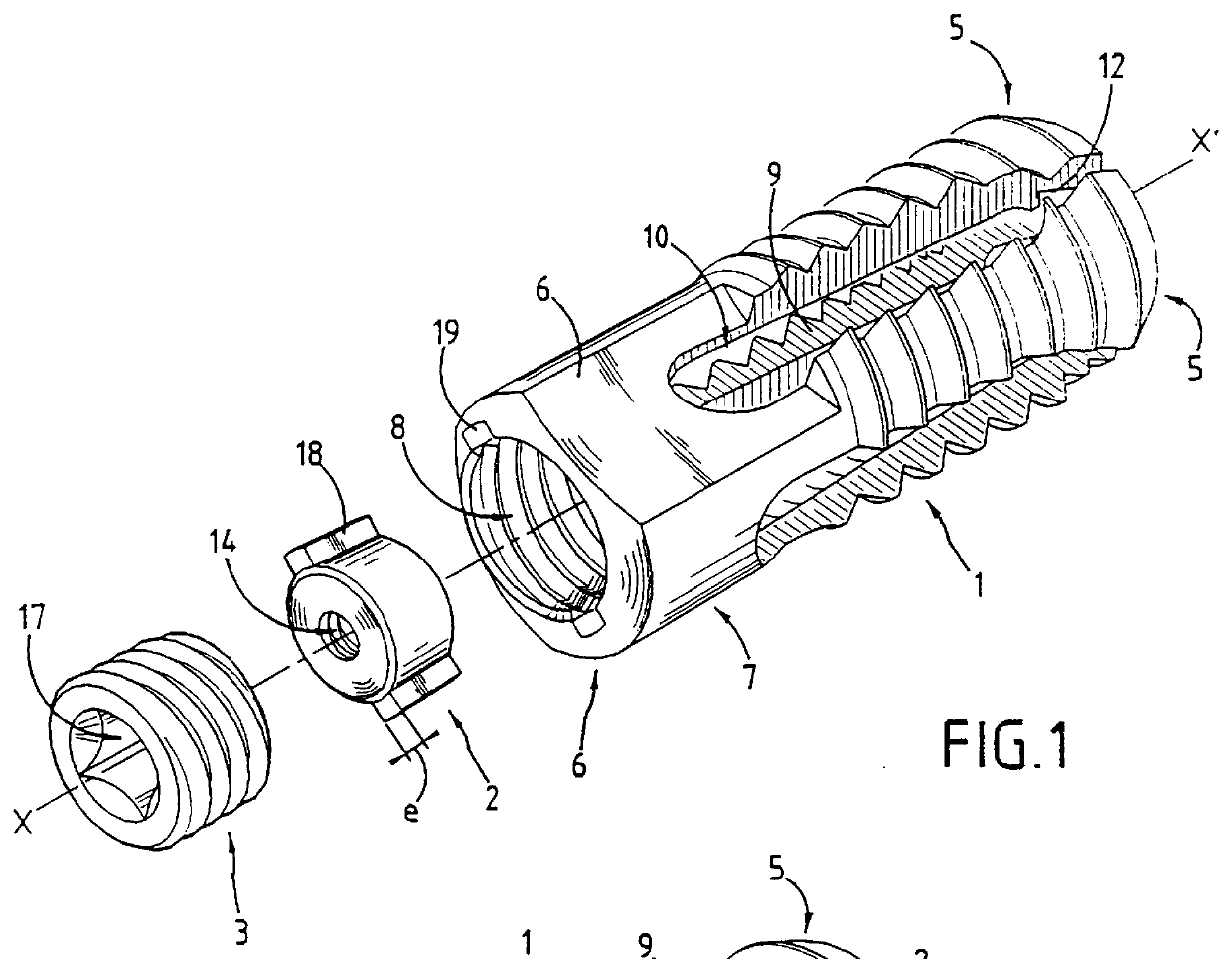

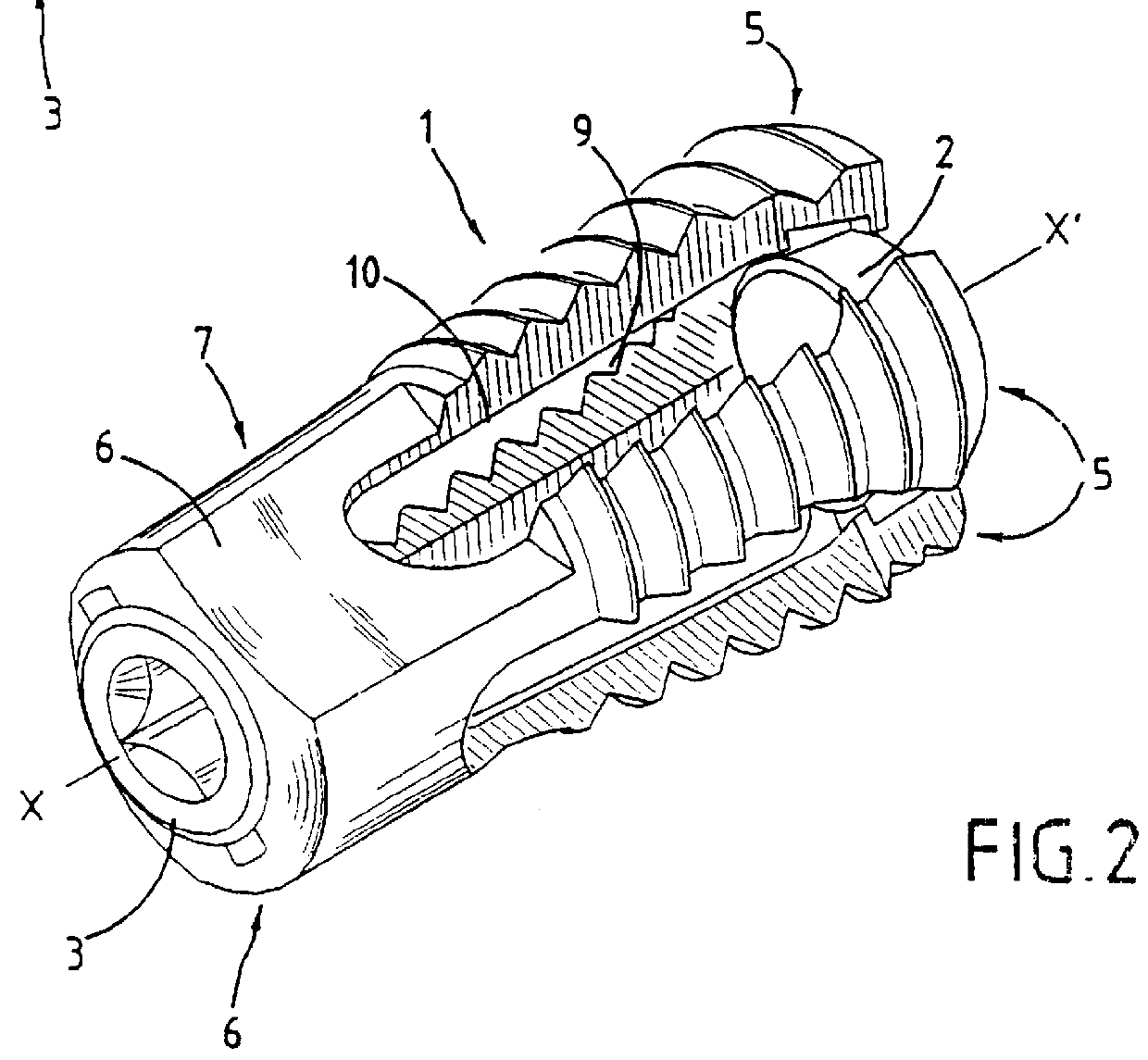

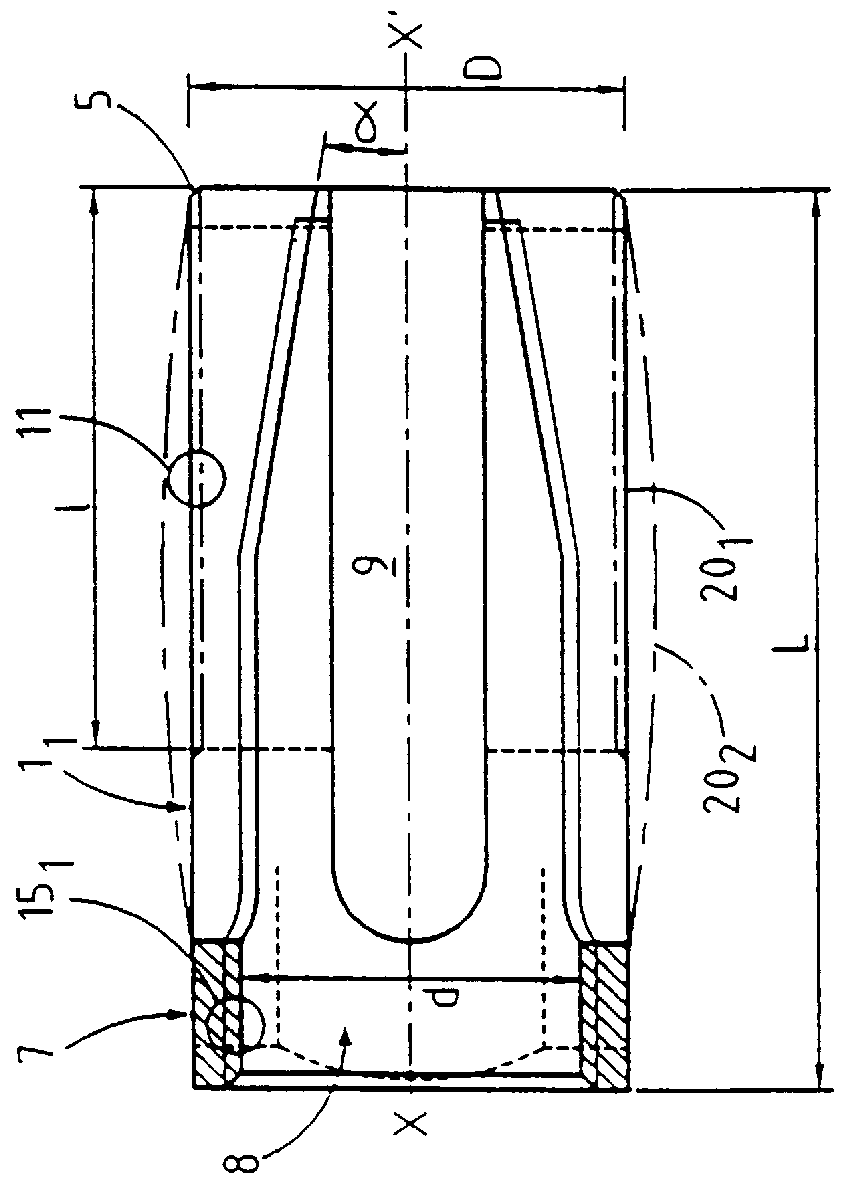

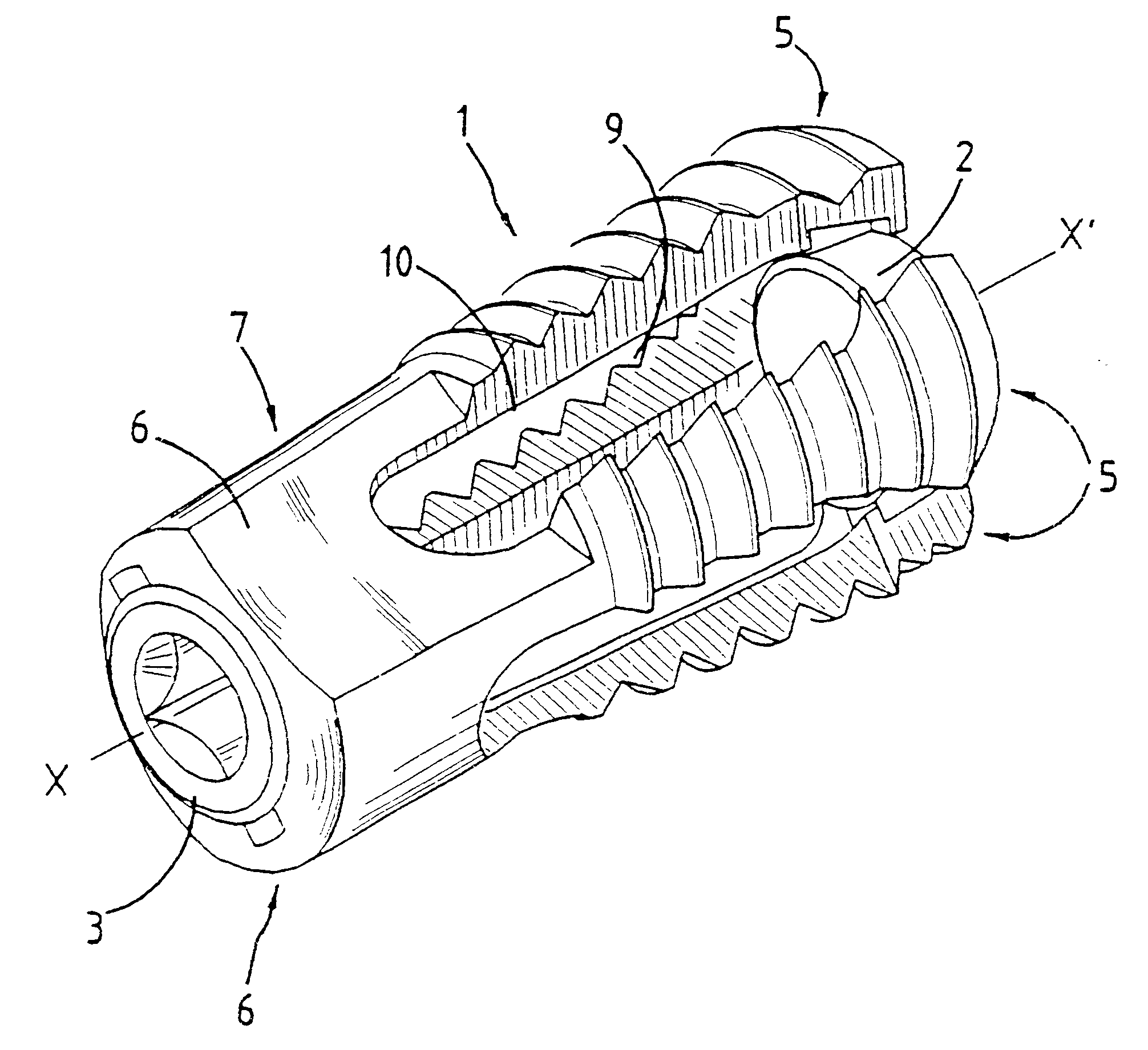

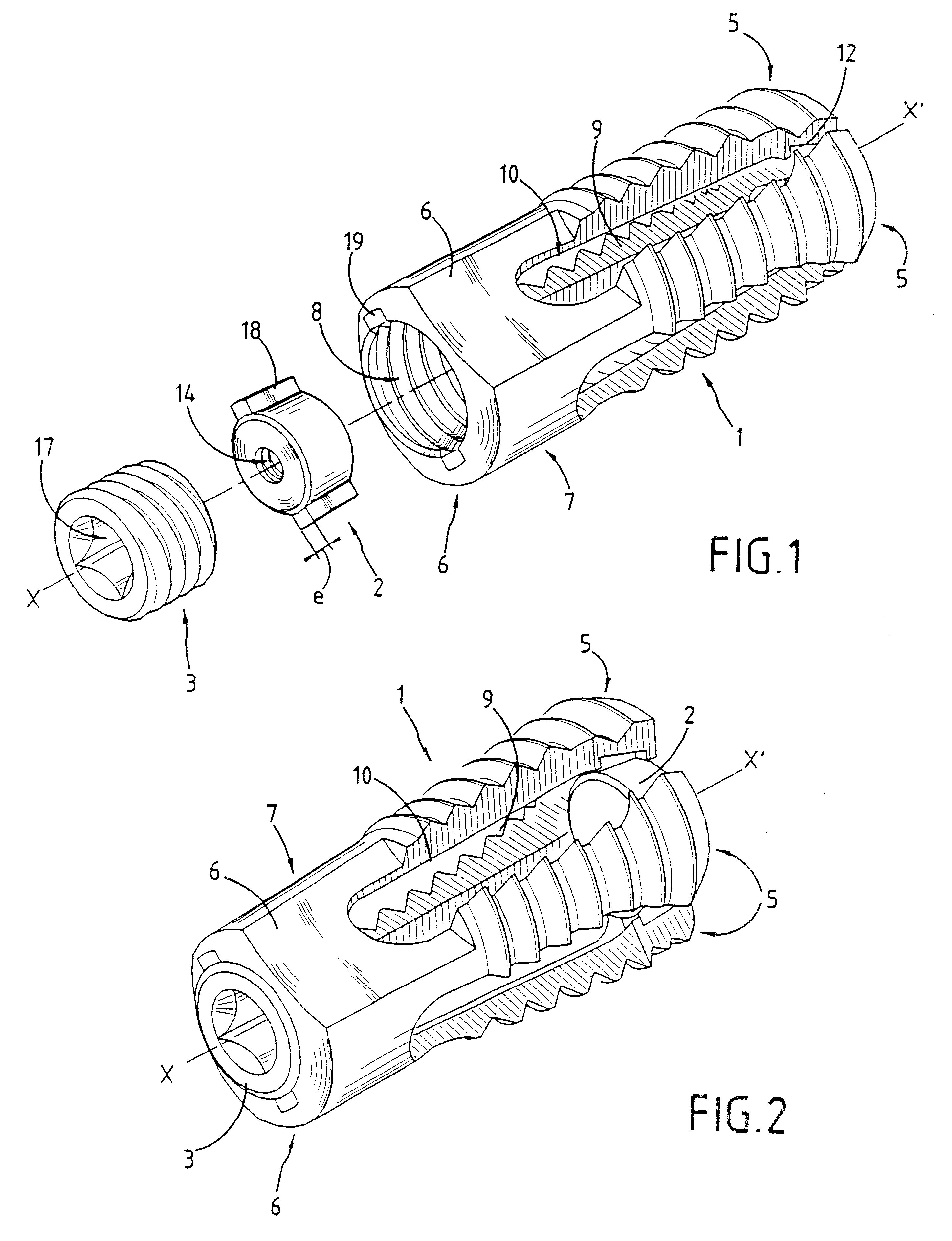

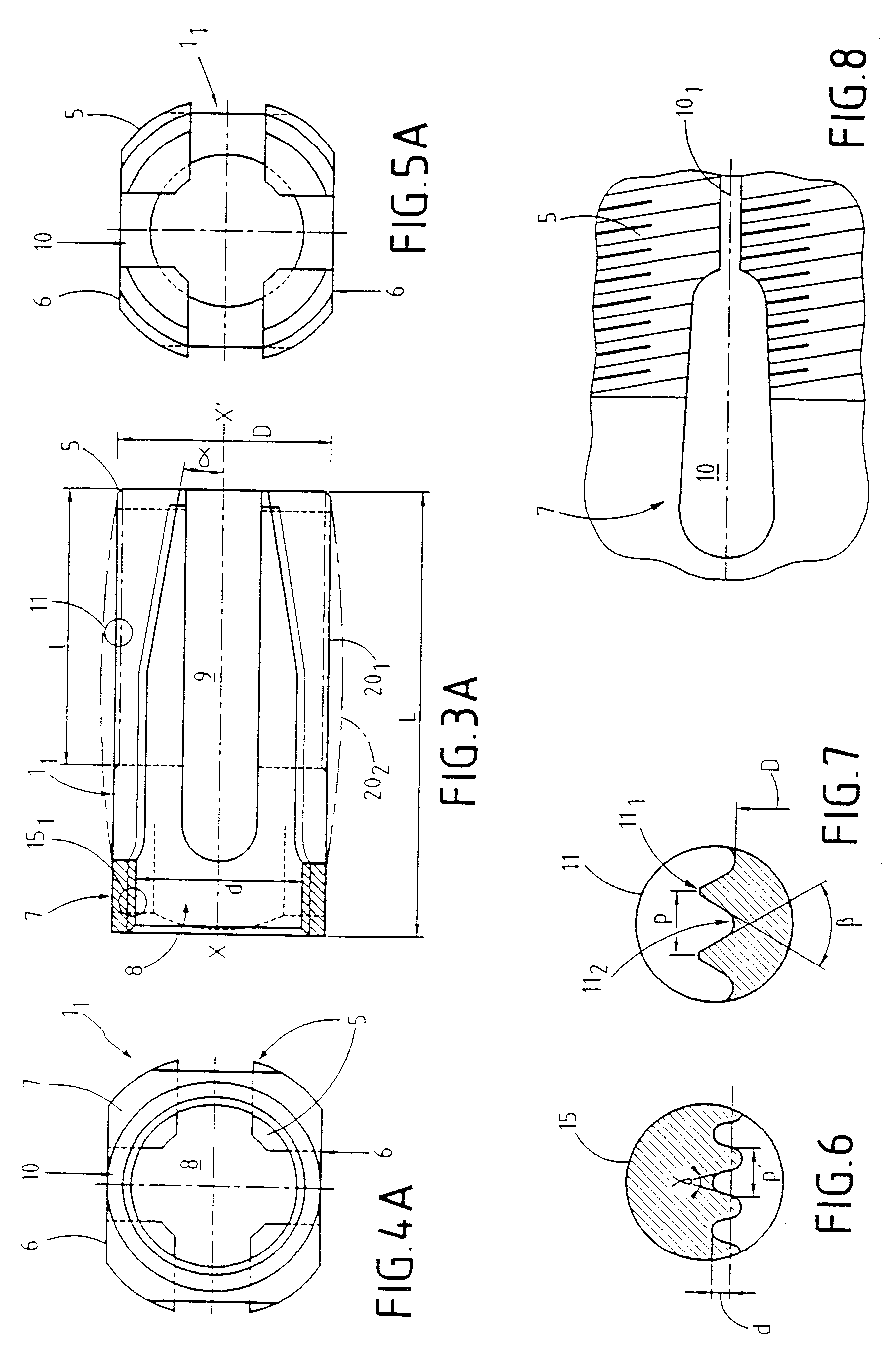

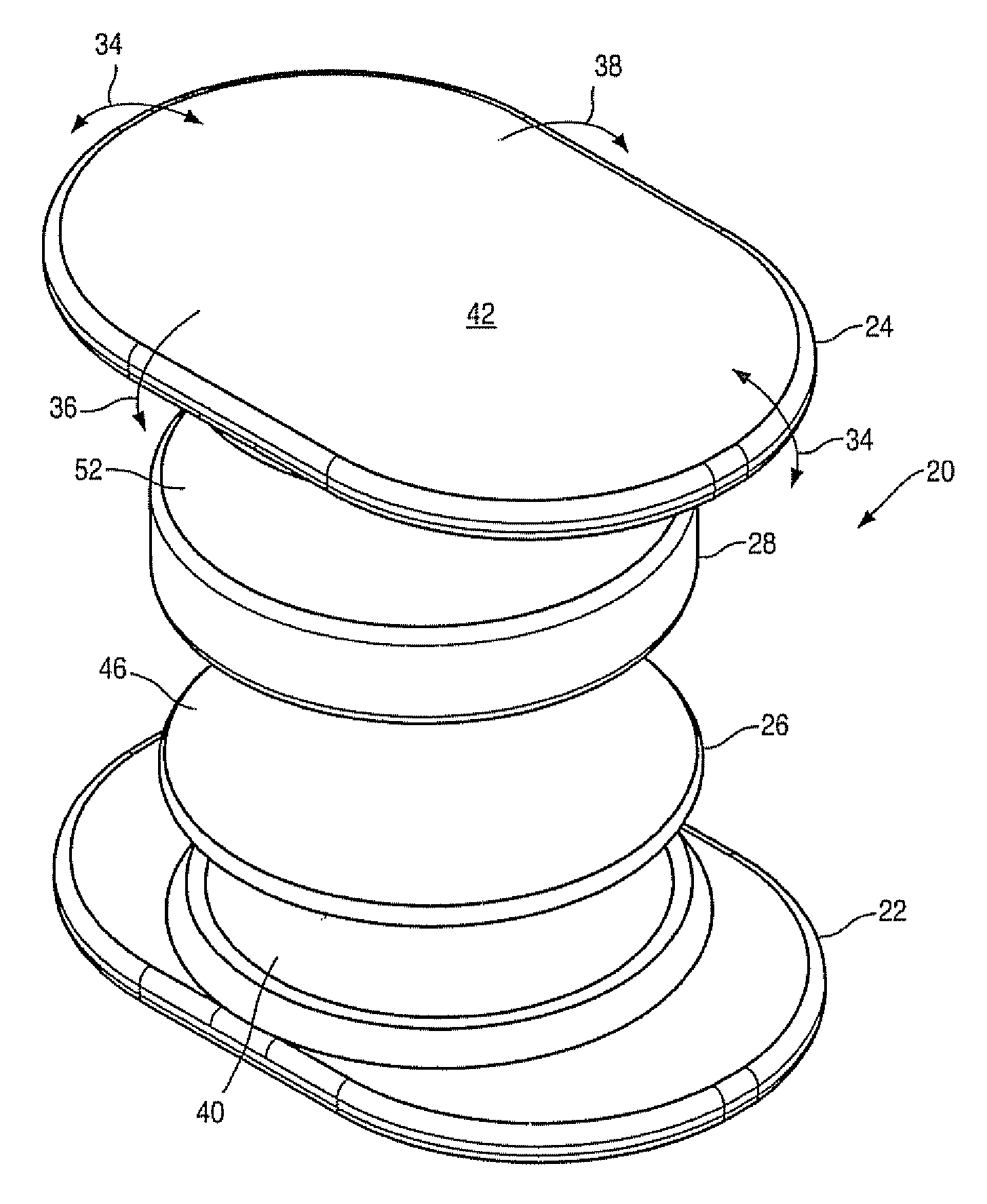

Expandable osteosynthesis cage

InactiveUS6129763AGood jamLarge inside volumeBone implantJoint implantsSpinal columnBiomedical engineering

PCT No. PCT / FR97 / 01617 Sec. 371 Date Jul. 28, 1998 Sec. 102(e) Date Jul. 28, 1998 PCT Filed Sep. 12, 1997 PCT Pub. No. WO98 / 10722 PCT Pub. Date Mar. 19, 1998An expandable osteosynthesis implant has branches (5) each connected at one end to a seat (7) which is pierced by an orifice (8), suitable for being slid from a posterior direction between the facing faces of two consecutive vertebrae in order to hold them a given distance apart and restore stability of the spinal column. According to the invention, the branches (5) and the seat (7) define a hollow cage (1) which, in a "rest" position, has an outside general shape that is a cylinder of circular section, and a portion at least of the inside volume (9) of the cage (1) towards the distal ends of the branches (5) is in the form of a circular truncated cone whose large base is towards the seat (7), which implant has at least three branches (5) and, inside the inside volume (9) at least one spacer (2) suitable for passing through the orifice (8) and the large base of the truncated cone.

Owner:OSTEOIMPLANT TECH

Method of providing proper vertebral spacing

InactiveUS6371989B1Easy to anchorInhibit migrationBone implantJoint implantsSpinal columnBiomedical engineering

An expandable osteosynthesis implant has branches (5) each connected at one end to a seat (7) which is pierced by an orifice (8), suitable for being slid from a posterior direction between the facing faces of two consecutive vertebrae in order to hold them a given distance apart and restore stability of the spinal column. According to the invention, the branches (5) and the seat (7) define a hollow cage (1) which, in a "rest" position, has an outside general shape that is a cylinder of circular section, and a portion at least of the inside volume (9) of the cage (1) towards the distal ends of the branches (5) is in the form of a circular truncated cone whose large base is towards the seat (7), which implant has at least three branches (5) and, inside the inside volume (9) at least one spacer (2) suitable for passing through the orifice (8) and the large base of the truncated cone.

Owner:OSTEOIMPLANT TECH

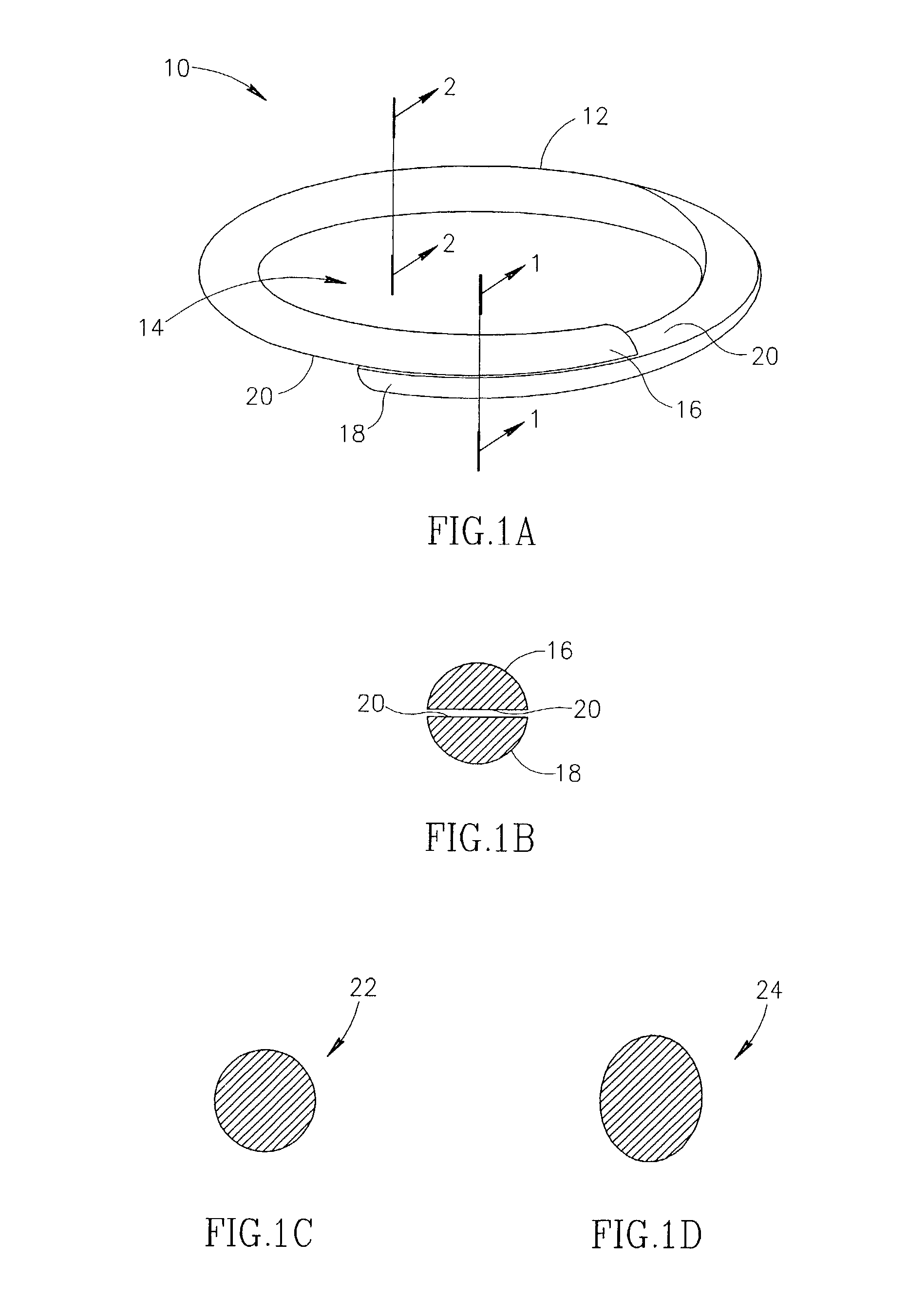

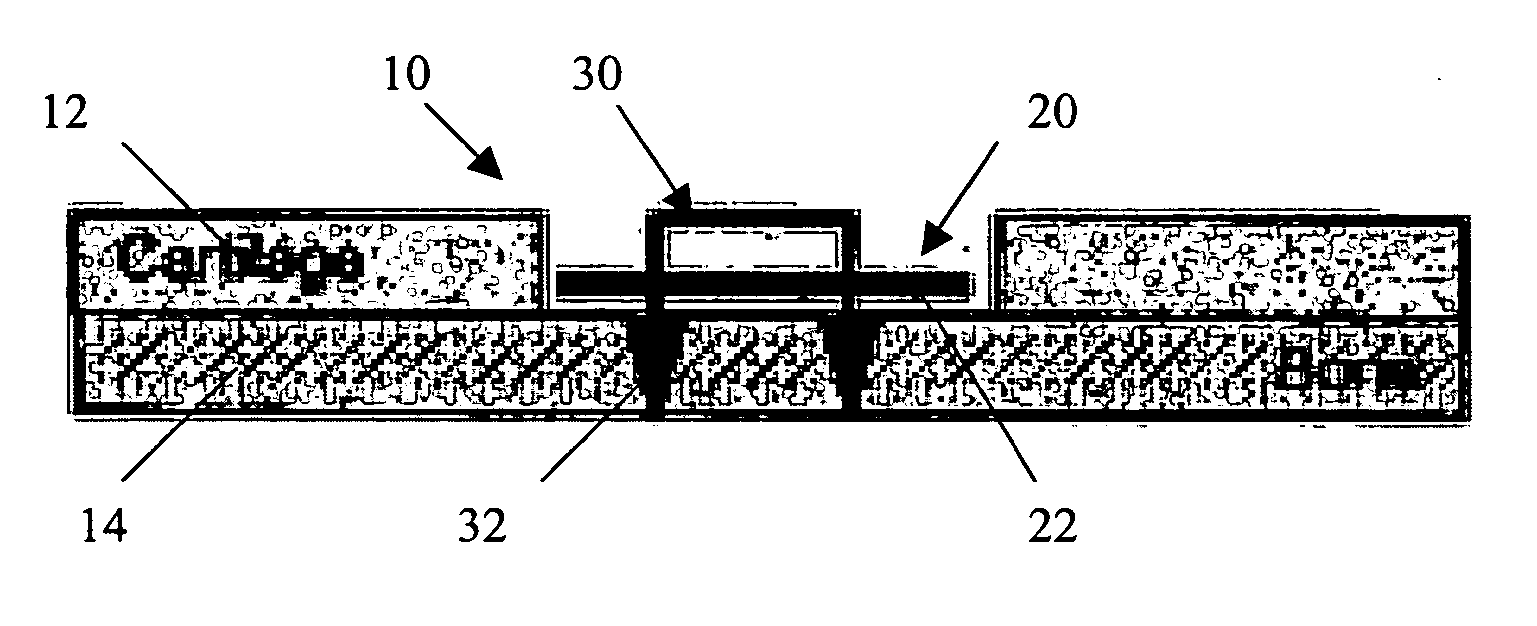

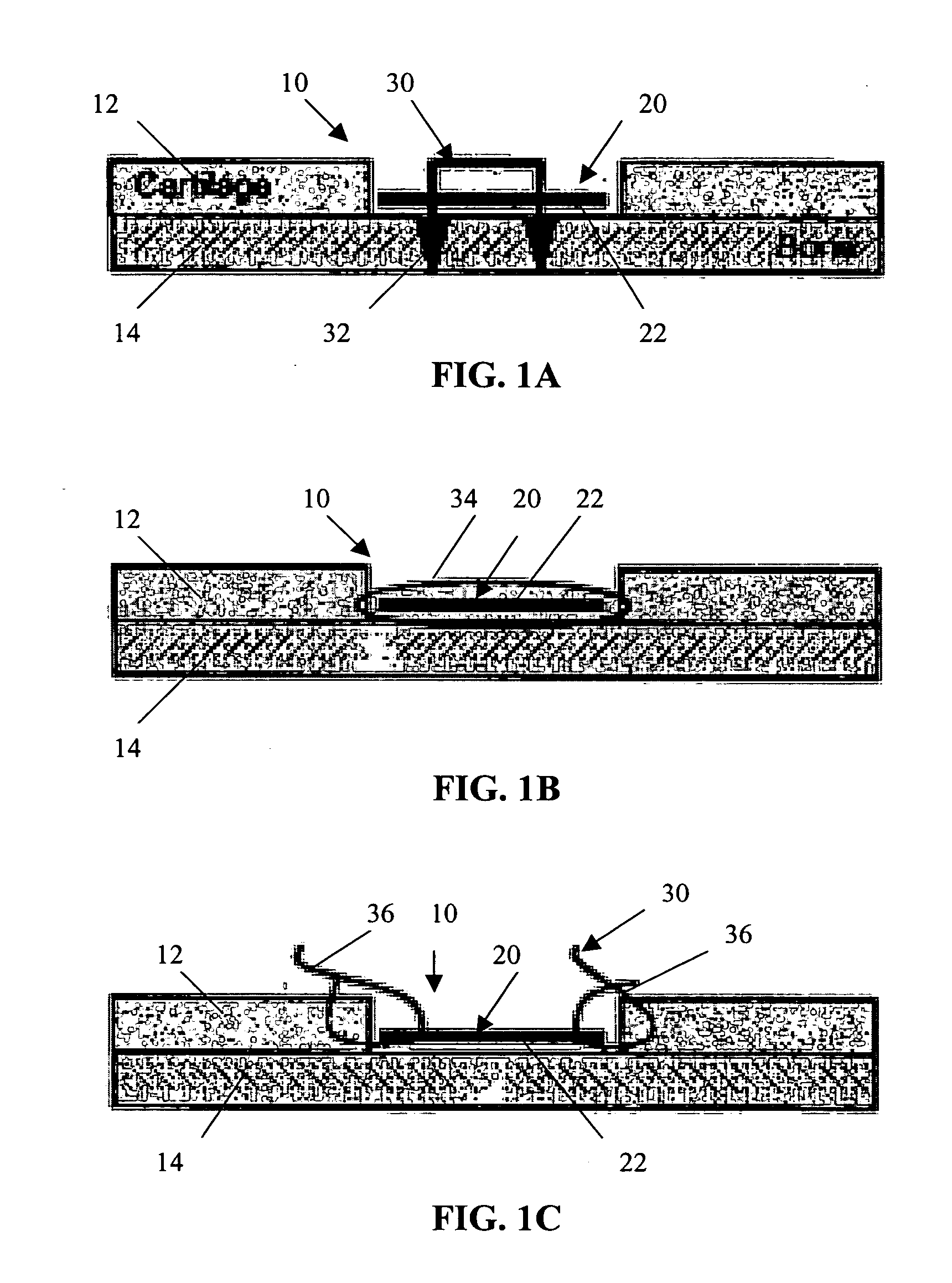

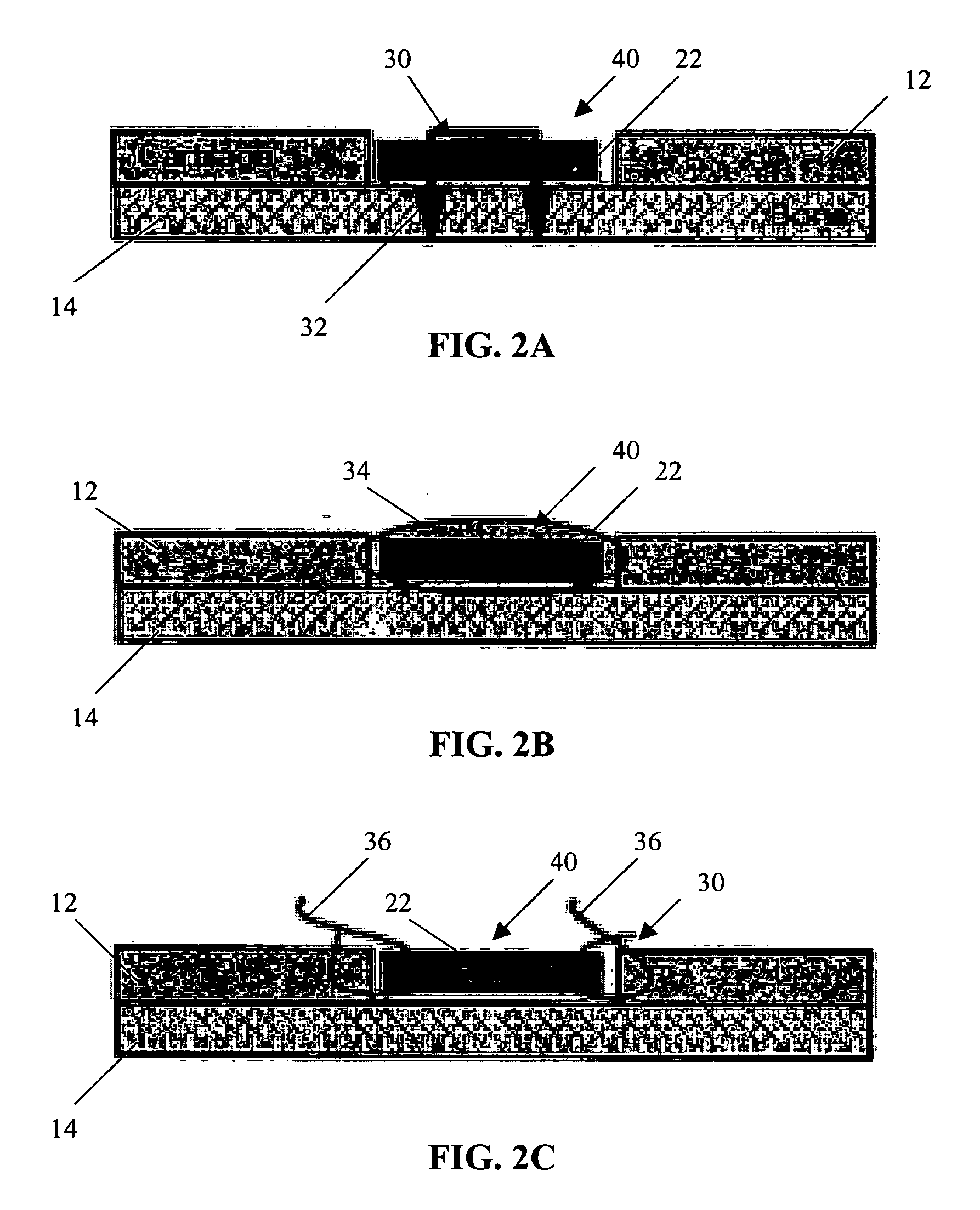

Intratubular anastomosis apparatus

An intratubular anastomosis apparatus for joining organ portions of a hollow organ after intussusception which includes an anastomosis ring, and a crimping support element. The anastomosis ring includes a length of a wire formed of a shape memory alloy for crimping adjacent organ portions against the crimping support element so as to cause anastomosis. The anastomosis ring and the shape memory alloy assumes a plastic state, when at a first, lower temperature and an elastic state, when reaching at least a second, higher temperature. The crimping support element provides a support for crimping the organ portions against the support element. Using the anastomosis ring and crimping support element of the present invention reduces the risk of leakage and no staples or sutures remain within the anastomosed organ portion.

Owner:NITI SURGICAL SOLUTIONS

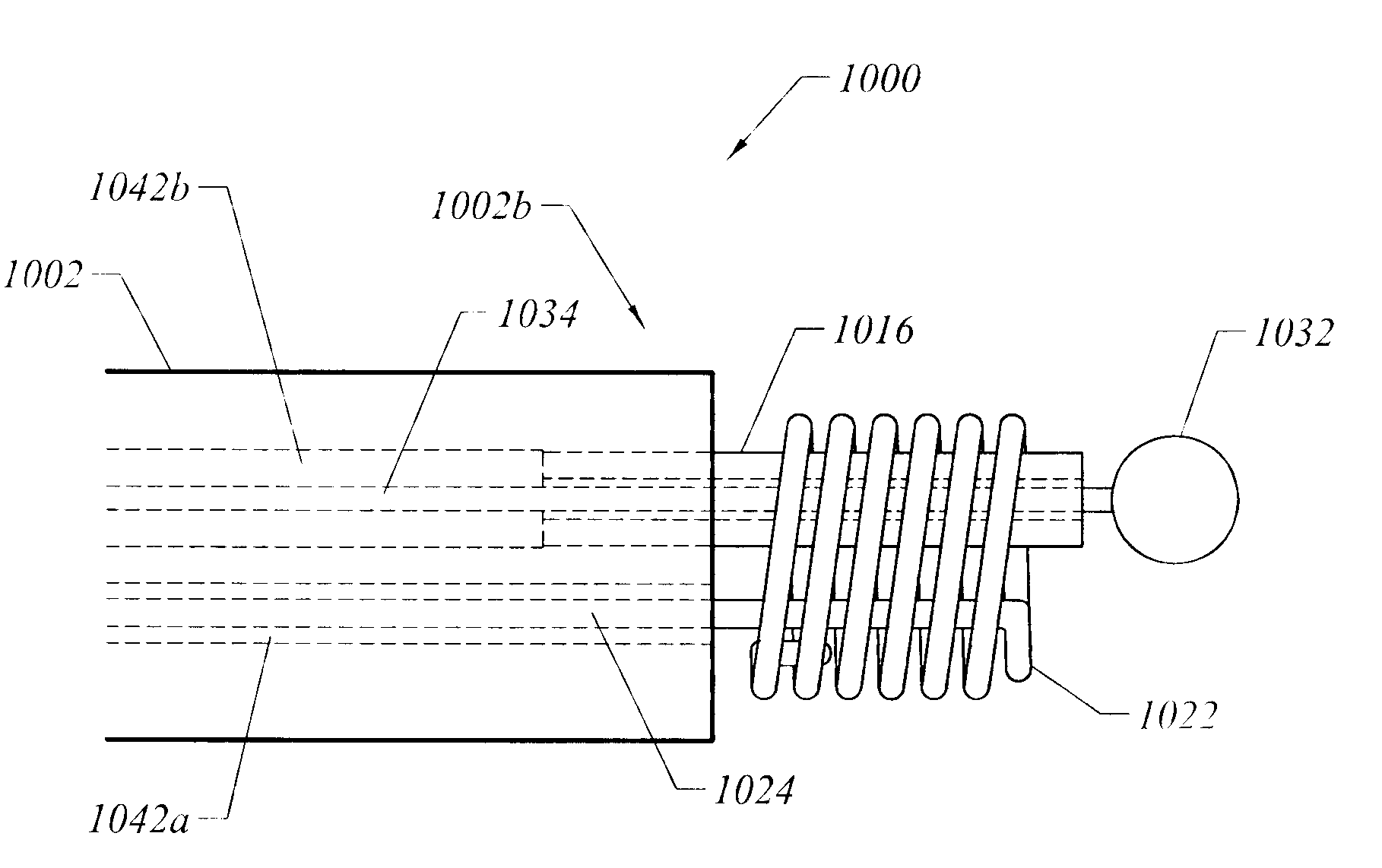

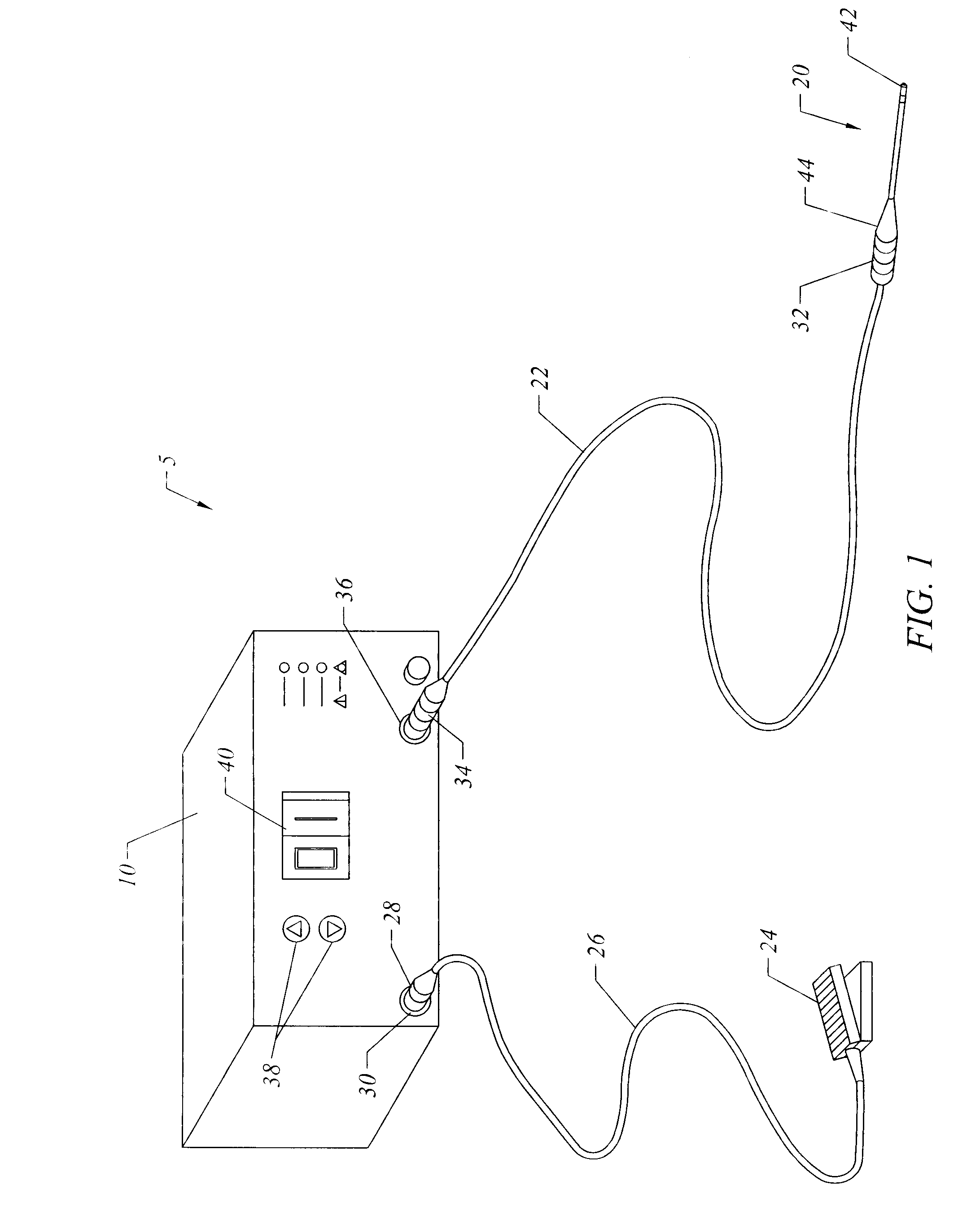

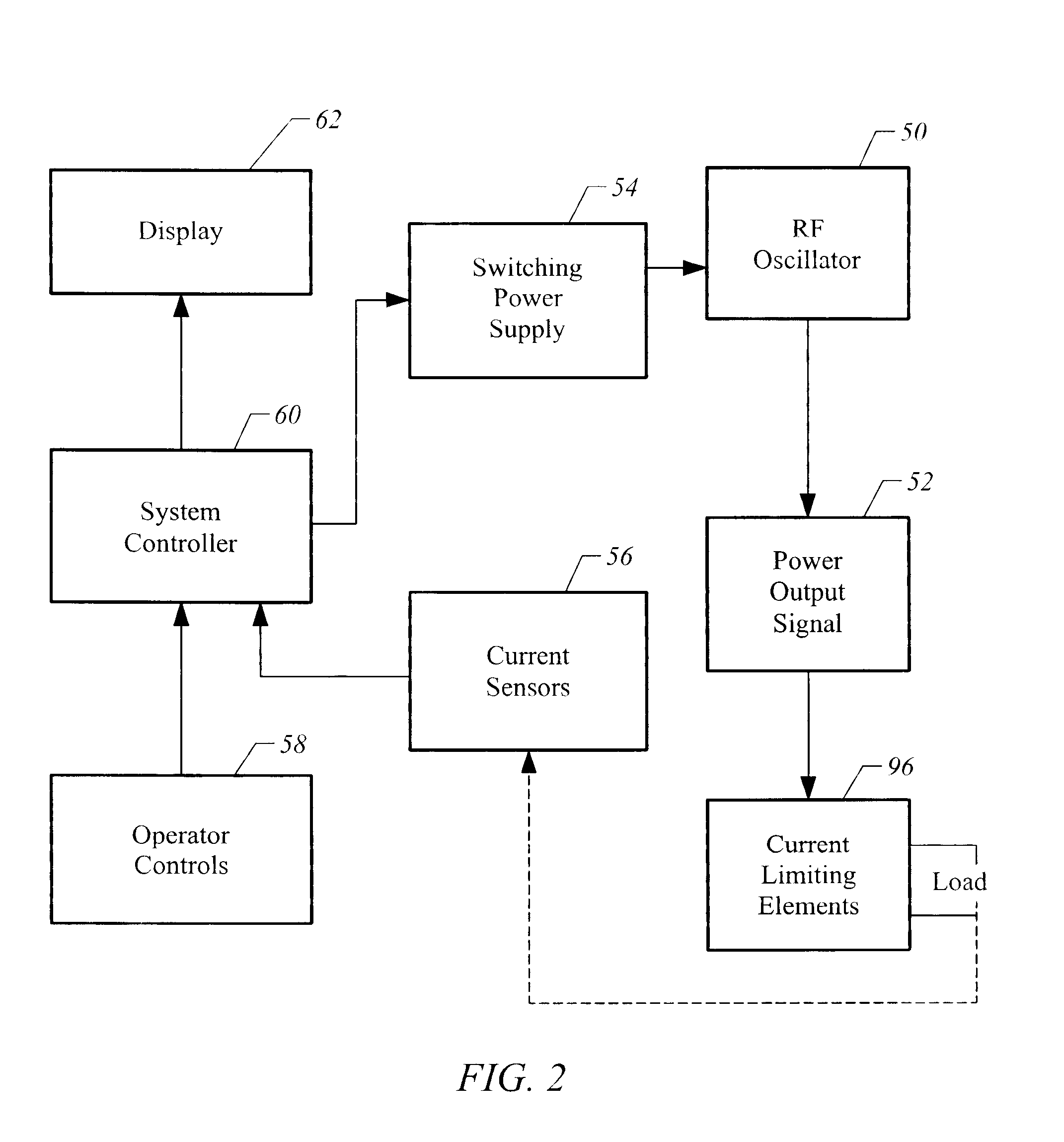

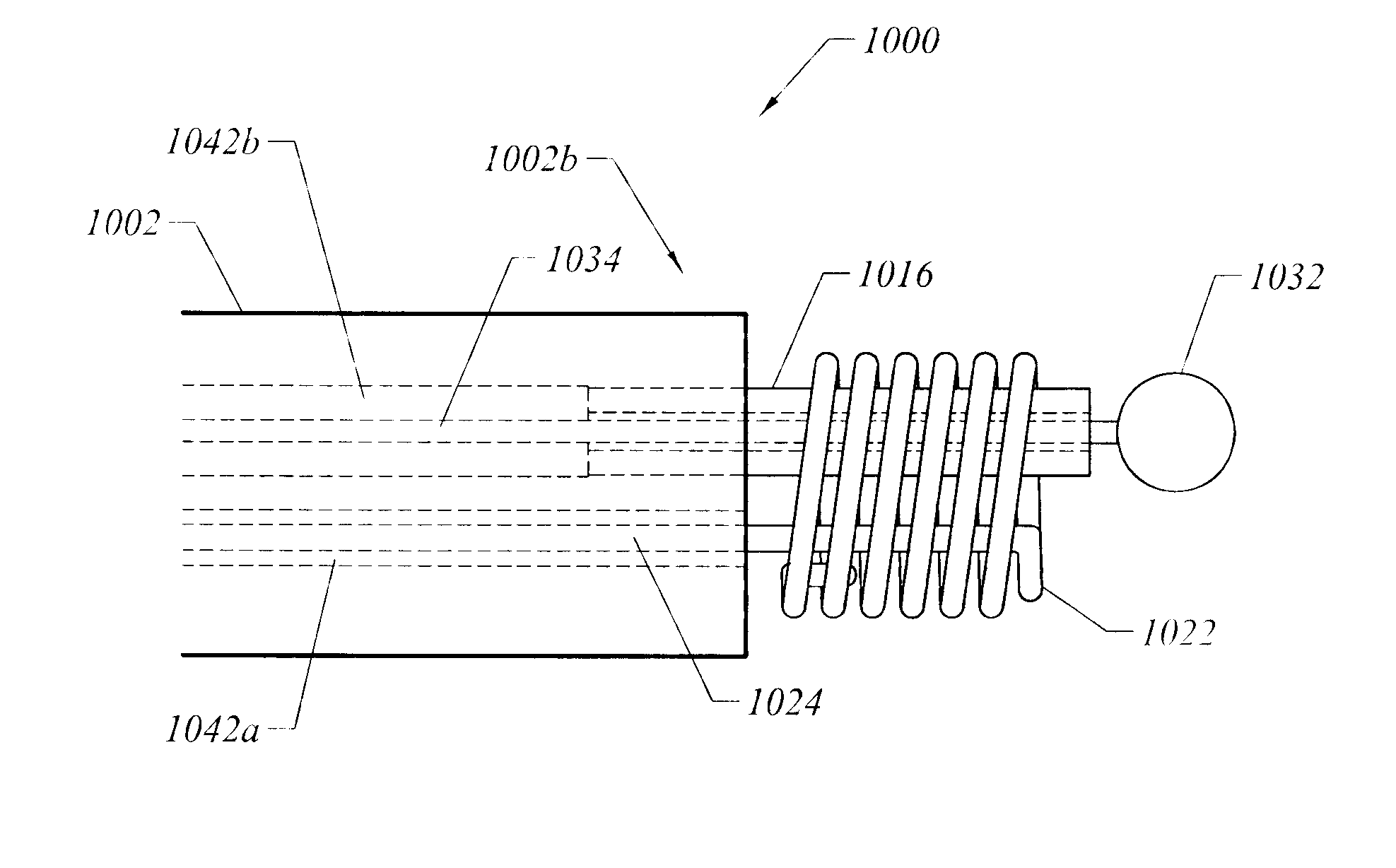

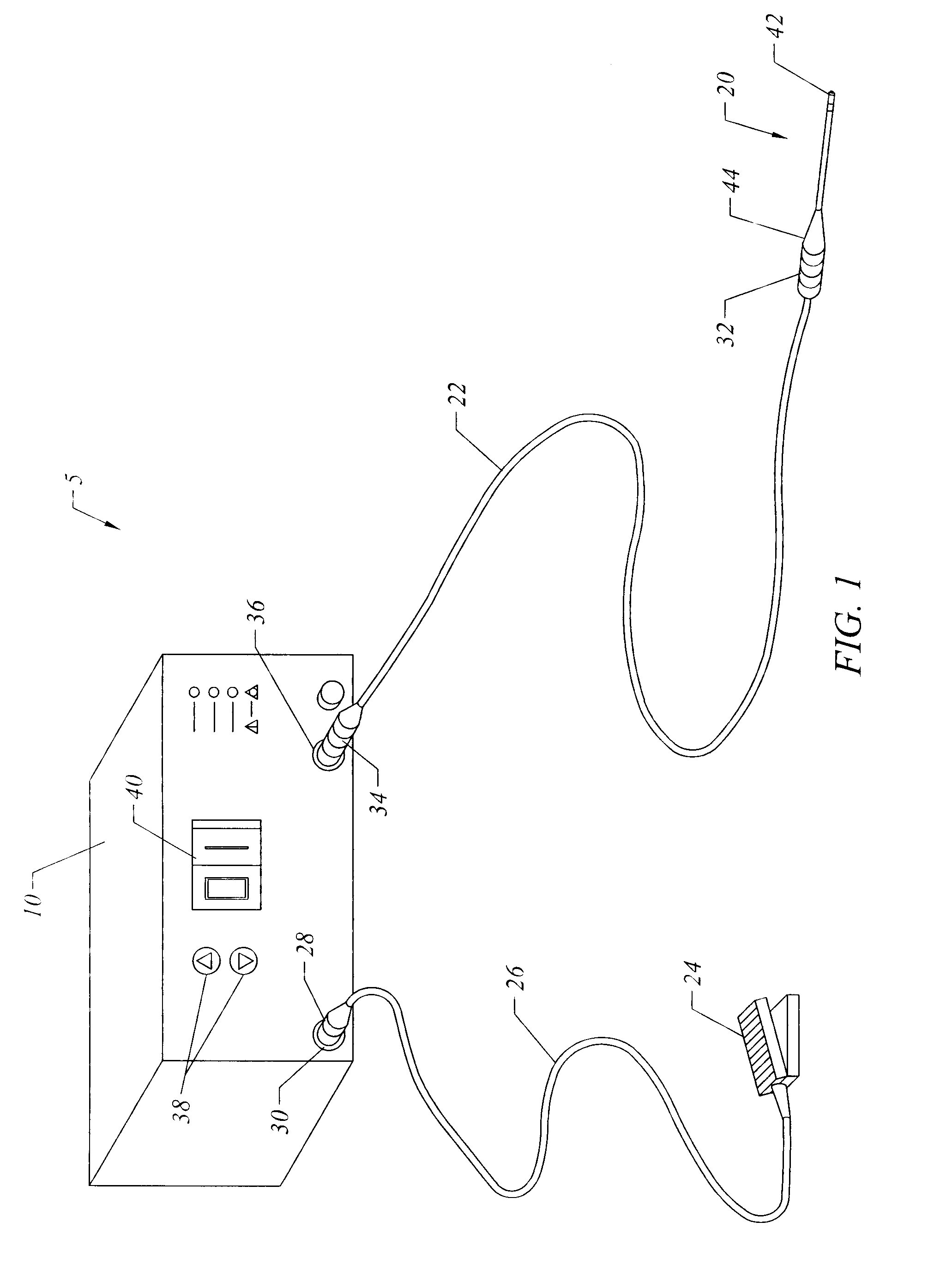

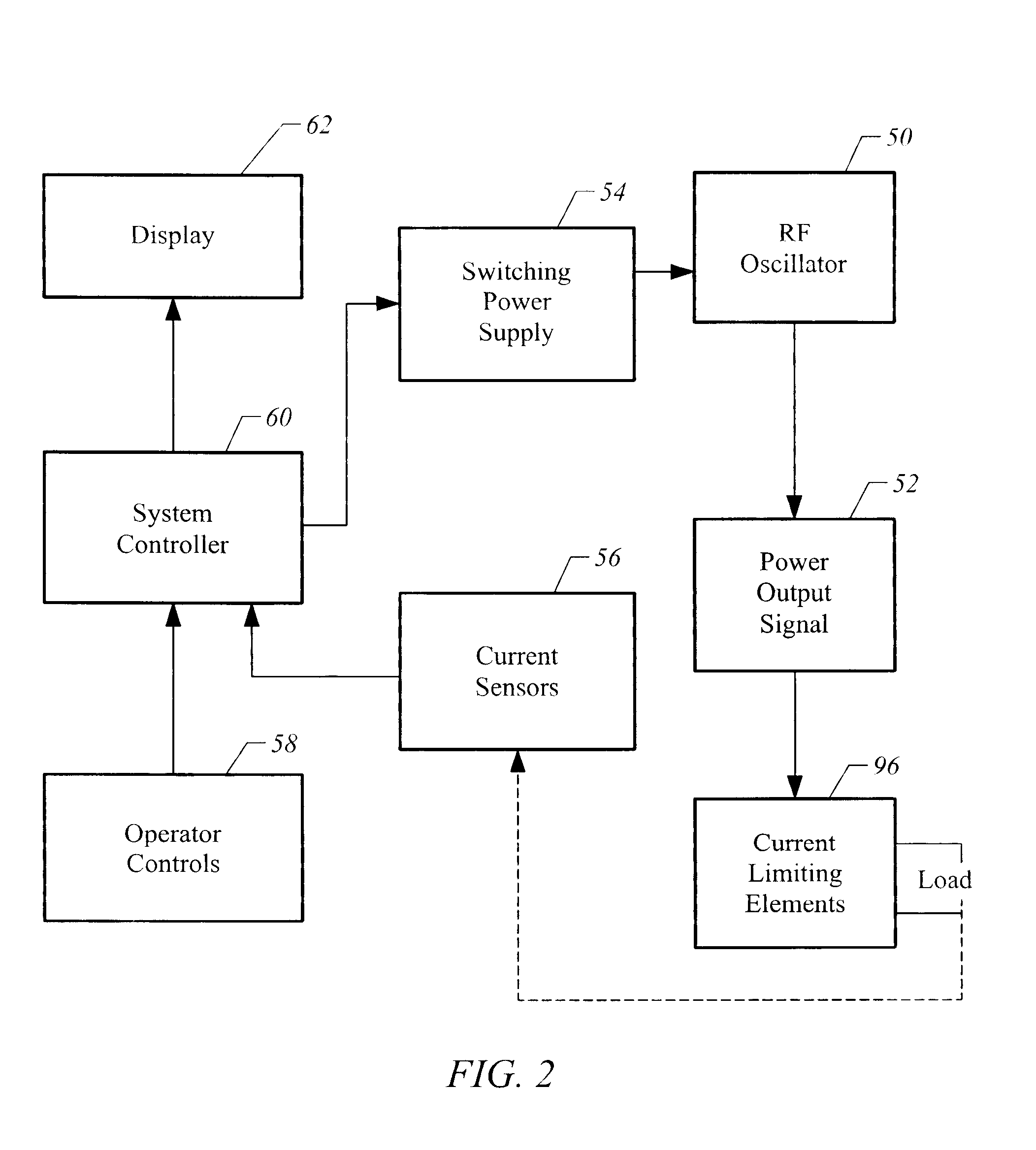

Electrosurgical apparatus and methods for treatment and removal of tissue

InactiveUS7186234B2Promote wettingReduce the possibilitySurgical instruments for heatingActive electrodeTarget tissue

Apparatus and methods for ablating, severing, cutting, shrinking, coagulating, or otherwise modifying a target tissue to be treated. In a method for treating a target tissue, an active electrode of an electrosurgical probe is positioned in at least close proximity to the target tissue in the presence of an electrically conductive fluid. A high frequency voltage is then applied between the active electrode and a return electrode, wherein, the high frequency voltage is sufficient to volumetrically remove (ablate), sever, or modify at least a portion of the target tissue. The probe comprises a multi-lumen shaft having a plurality of internal lumens, and a return electrode coil oriented substantially parallel to the shaft distal end. The active electrode may be in the form of a metal disc, a hook, or an active electrode coil. In the latter embodiment, the active electrode coil is typically arranged substantially orthogonal to the return electrode coil. Methods of making an active electrode coil, a return electrode coil, and an electrosurgical probe are also disclosed.

Owner:ARTHROCARE

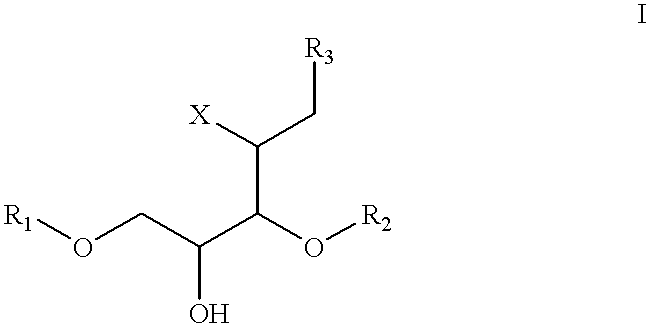

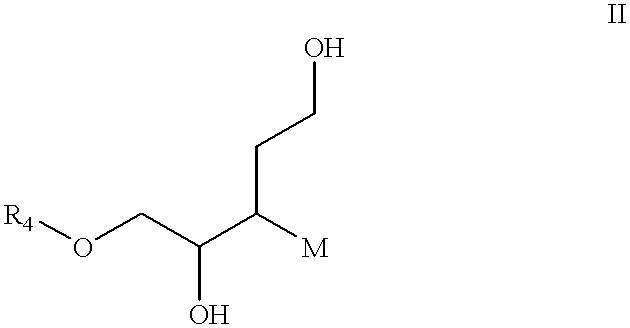

Methods of synthesis and use

InactiveUS6235886B1Increase the number ofGood curative effectSugar derivativesMicrobiological testing/measurementNucleotideOrganic chemistry

Oligonucleotide and nucleotide amine analogs and methods of preparing and using these compounds are provided by the present invention.

Owner:IONIS PHARMA INC

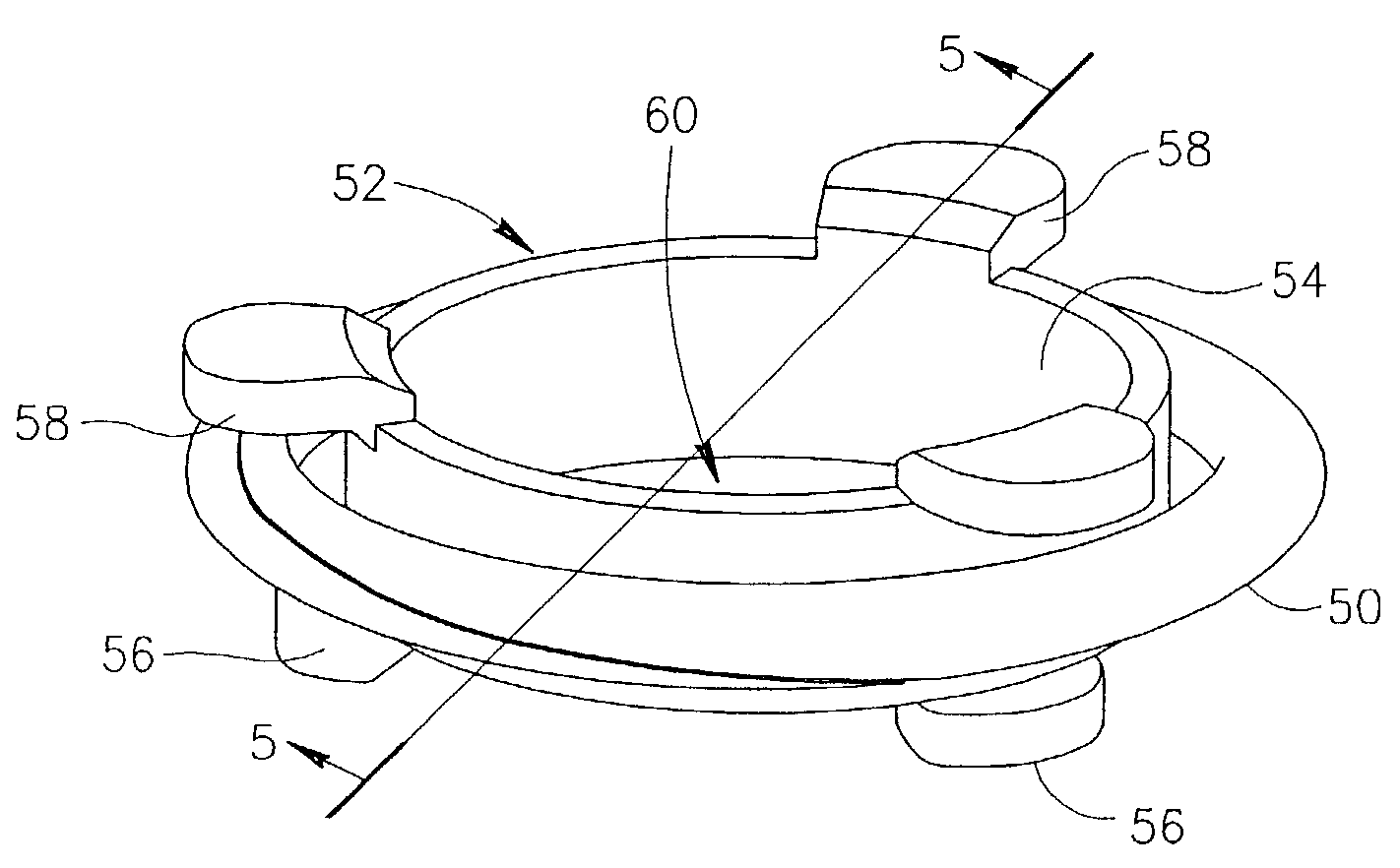

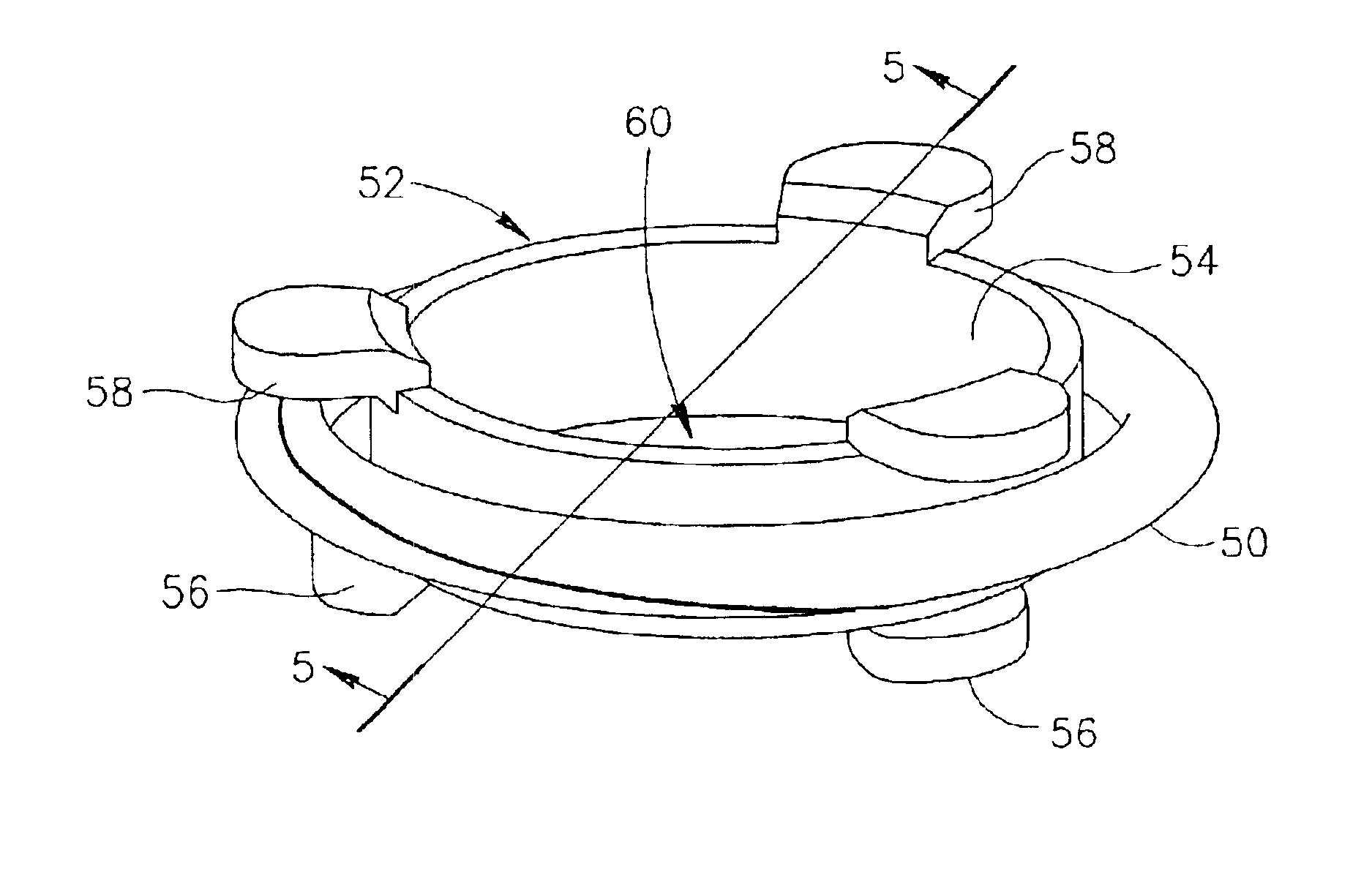

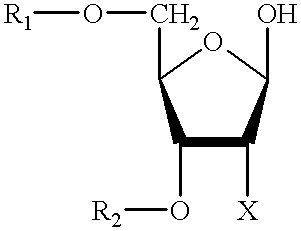

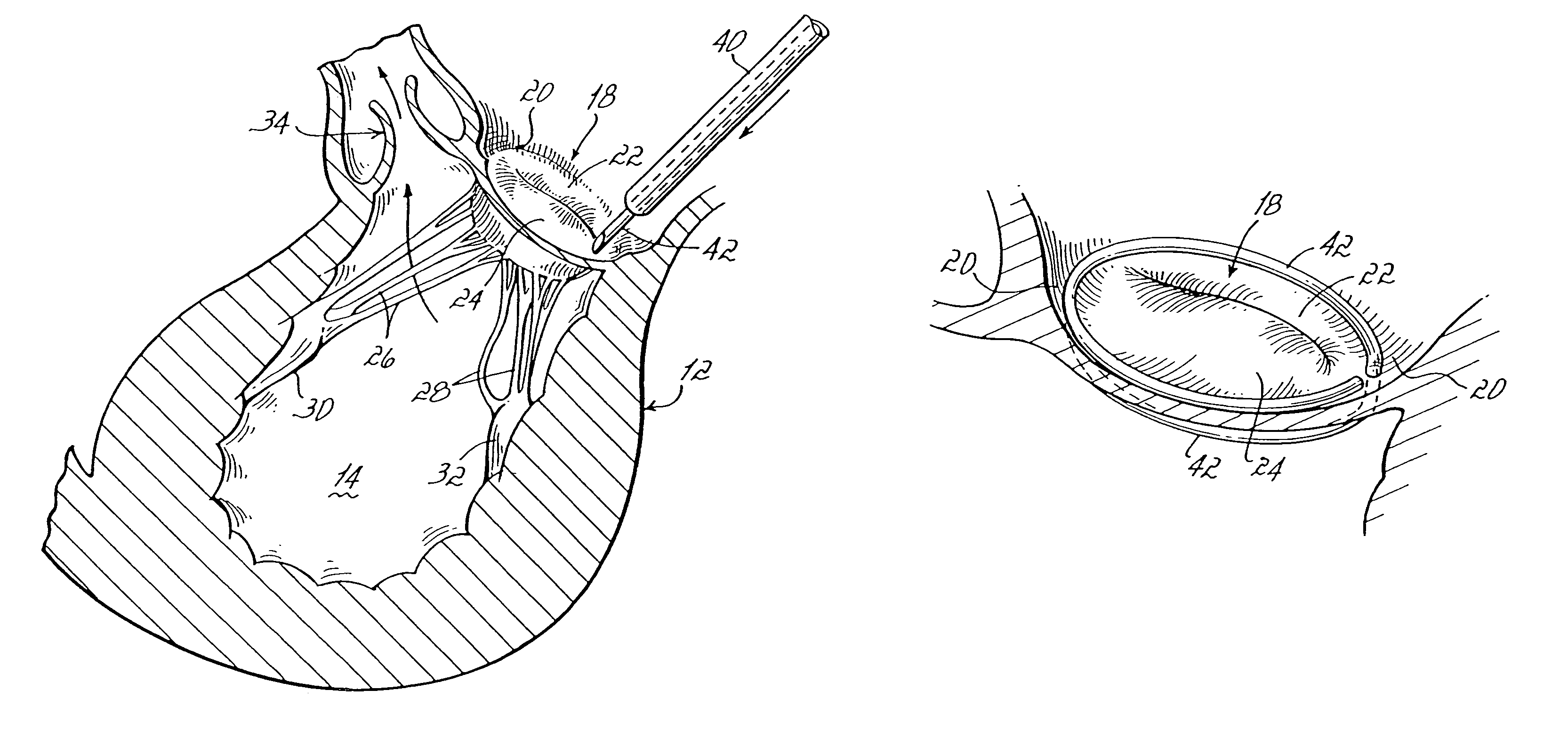

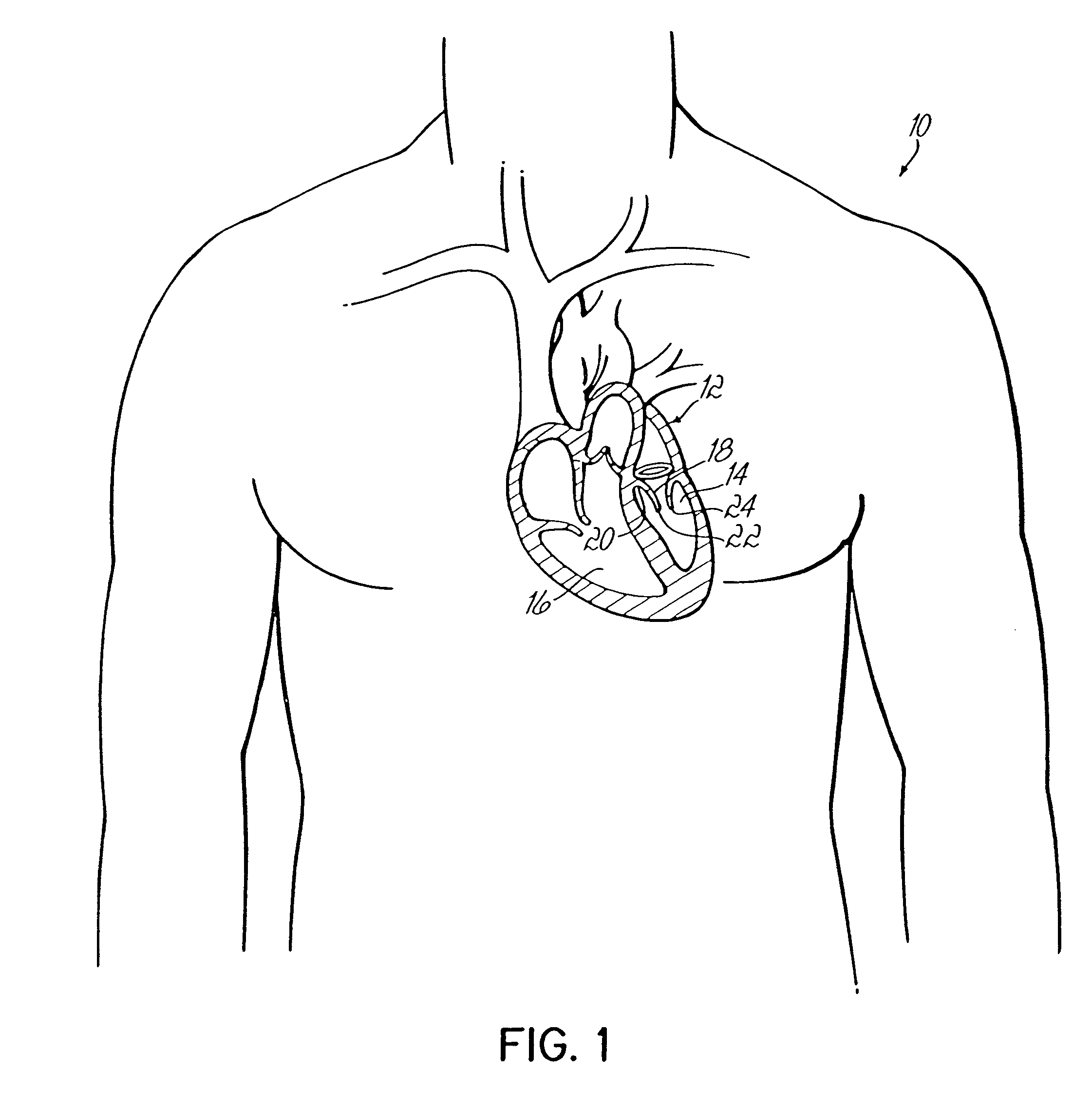

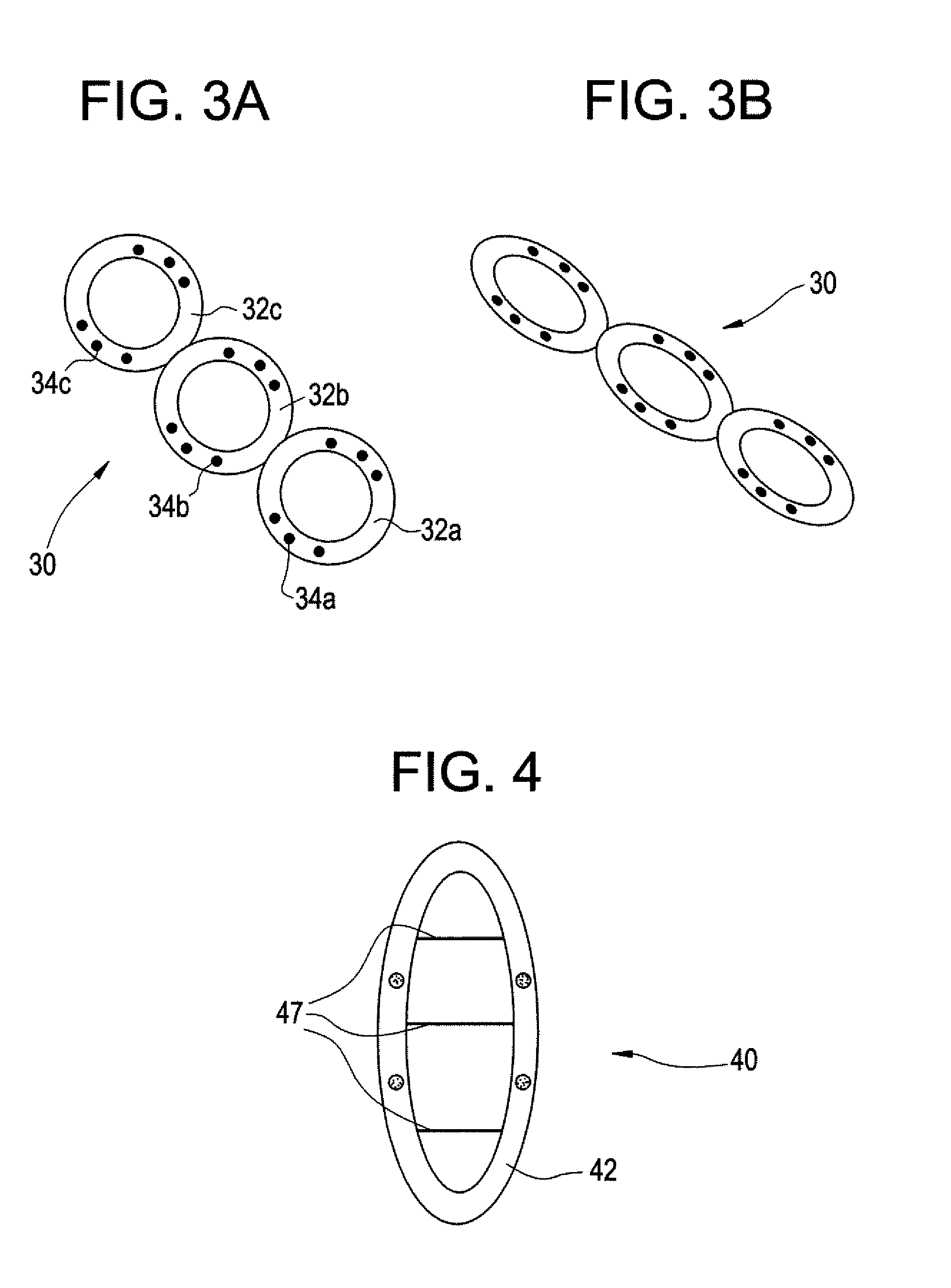

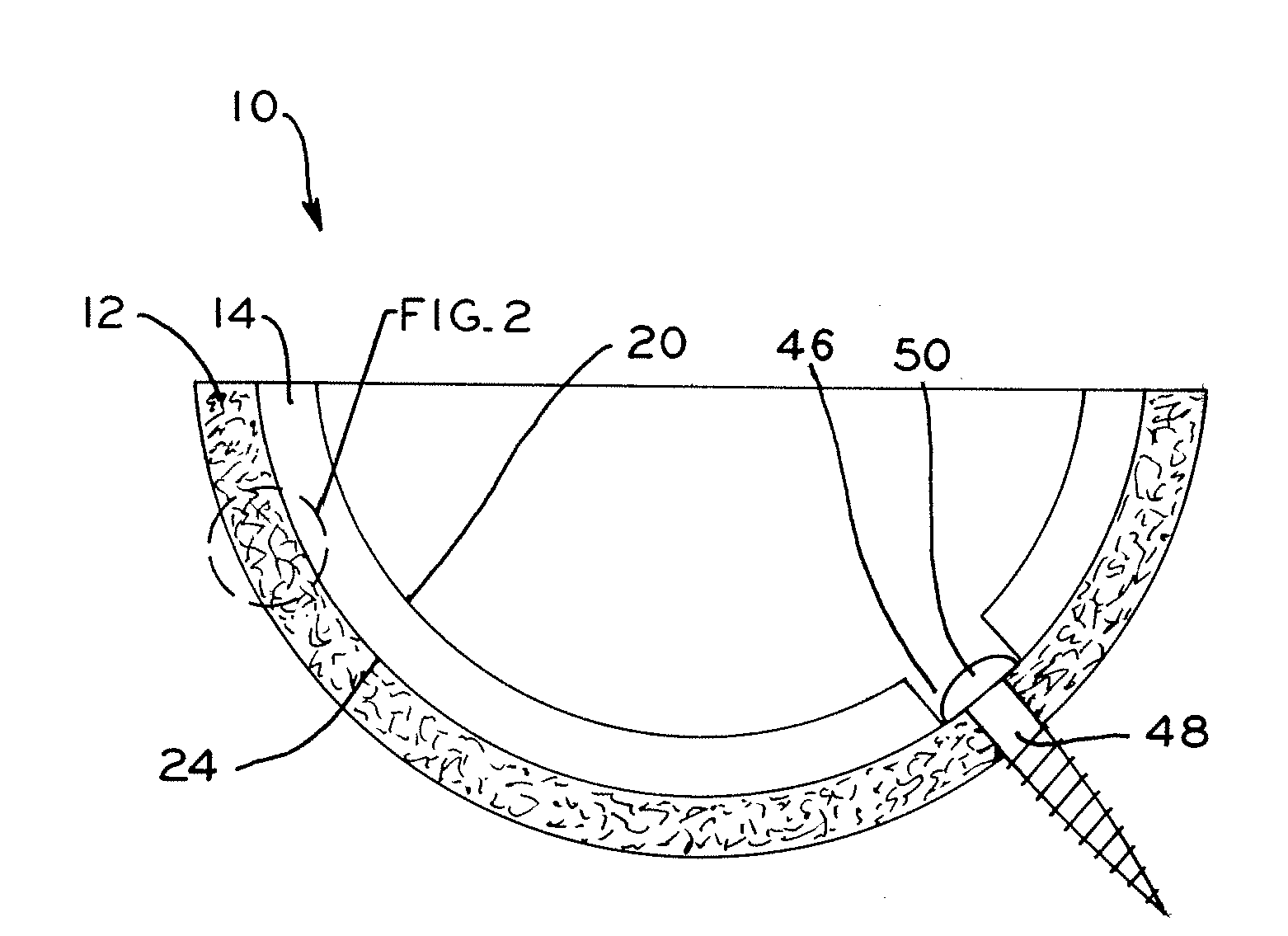

Annuloplasty devices and related heart valve repair methods

InactiveUS6964684B2Facilitate engagement and retentionReduce frictionAnnuloplasty ringsSurgeryShape-memory alloyHeart valve repair

Devices for repairing and replacing a heart valve in various embodiments, the devices include at least first and second support rings connected together in a coiled configuration to abut opposite sides of a valve annulus. A replacement valve may be secured to the coil-shaped device. Various alternative fastening systems include suture fastening systems, mechanical fastening systems, shape memory alloy fastening systems and other fastening systems relying only on the resilience between adjacent coils. A method generally includes inserting a first end of the coil-shaped member through a valve annulus, rotating a first ring of the coil-shaped member into position on one side of the valve annulus and positioning at least a second ring of the coil-shaped member on an opposite side of the valve annulus.

Owner:MEDTENTIA INT LTD OY

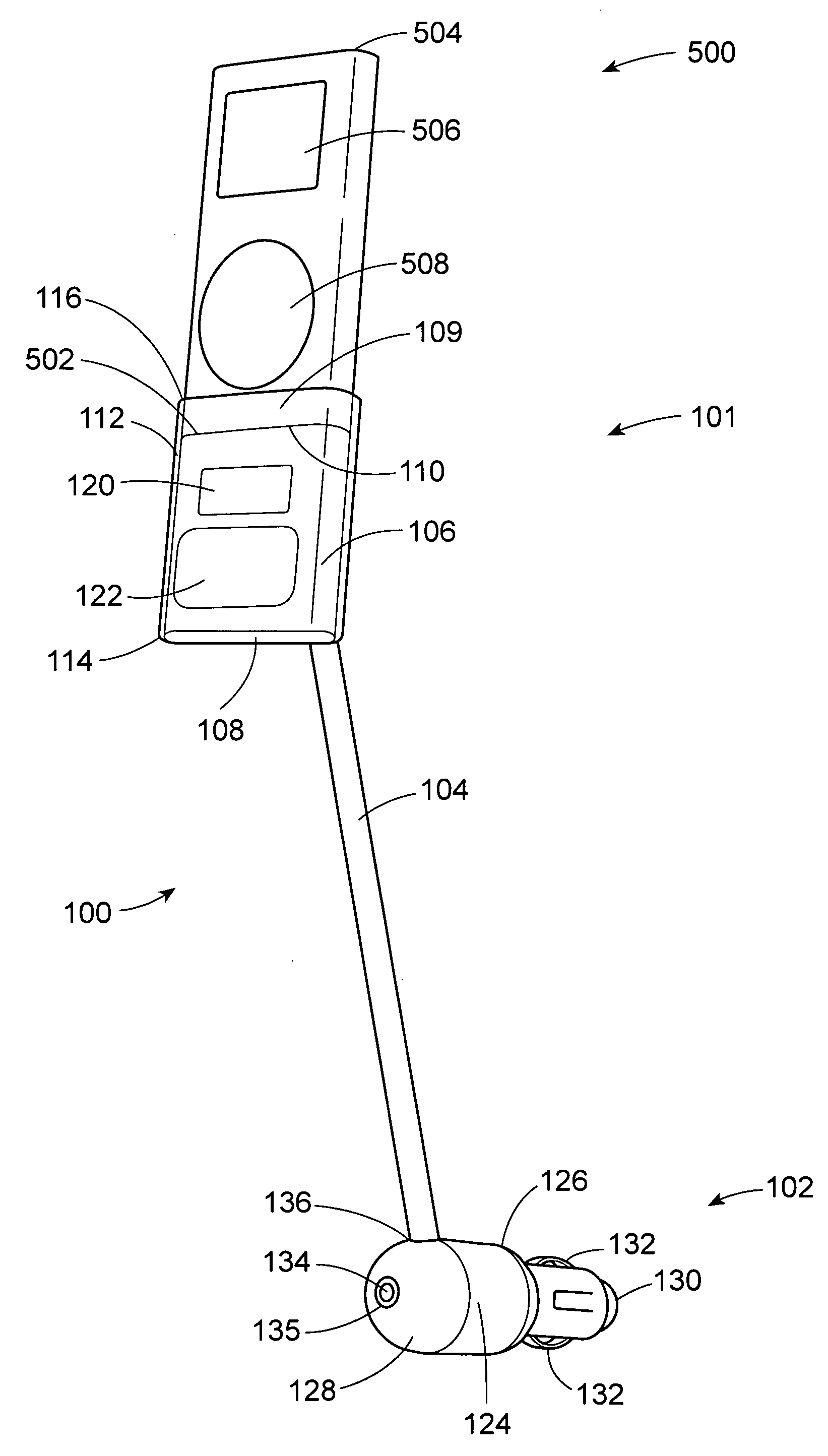

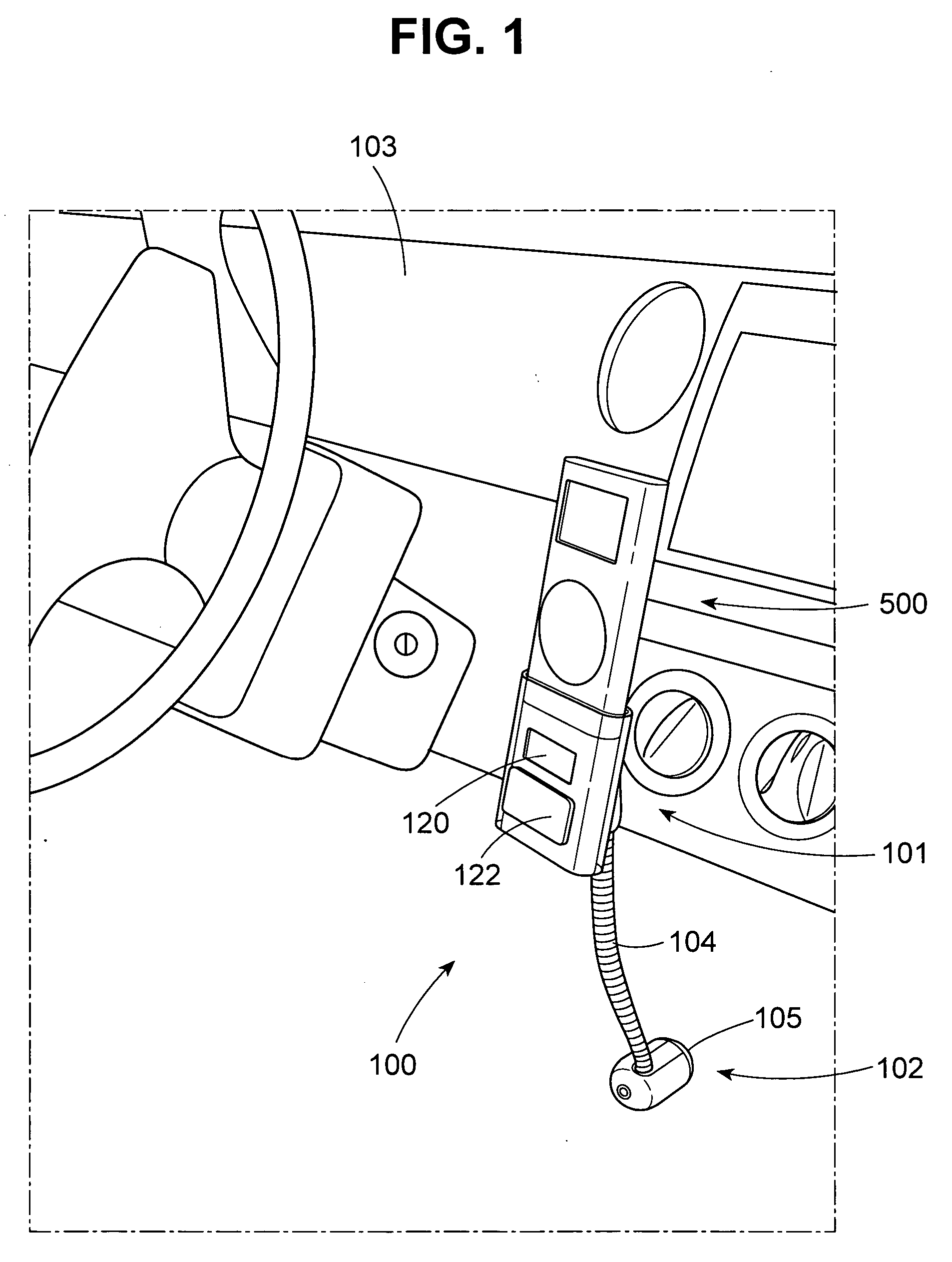

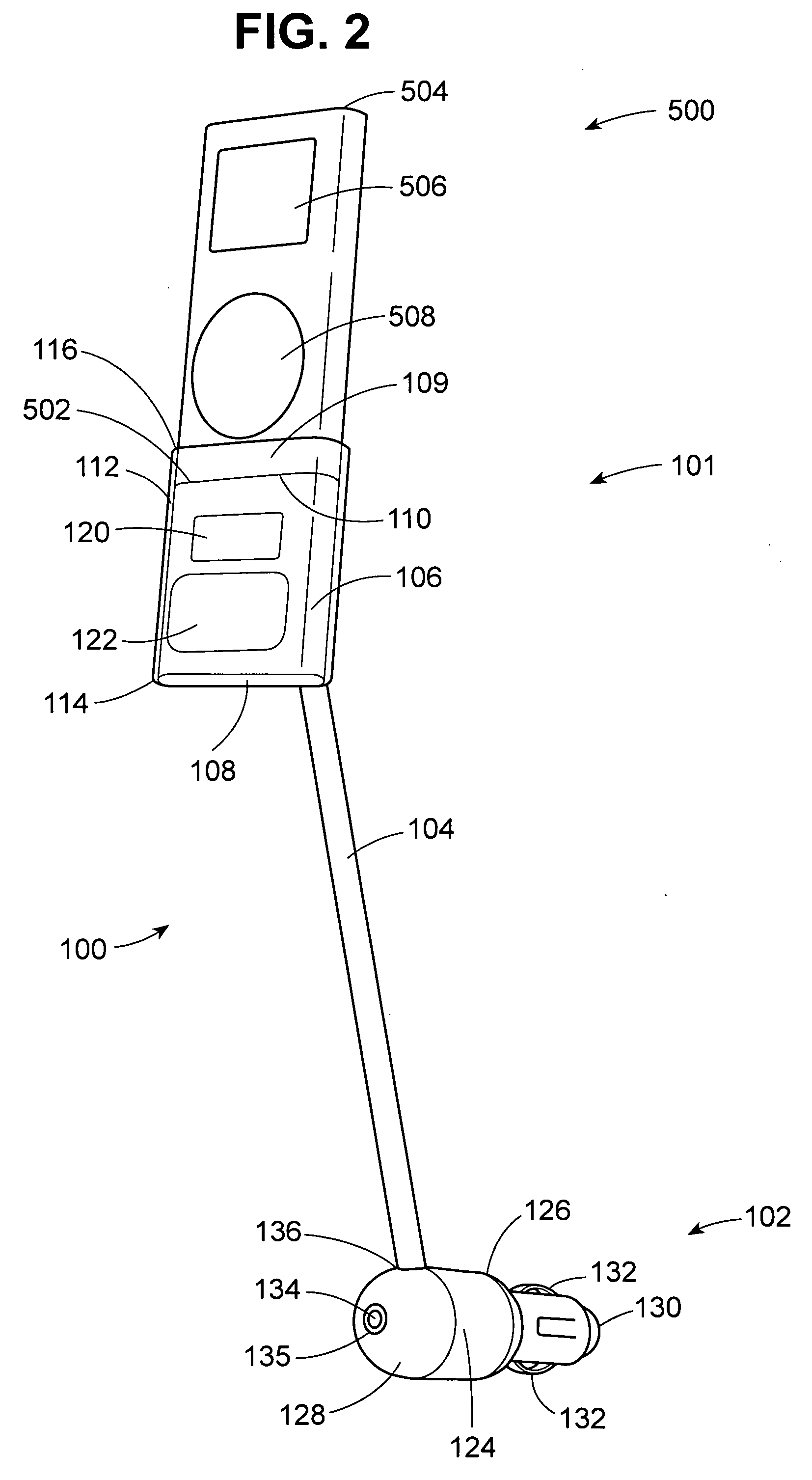

Holder, electrical supply, and RF transmitter unit for electronic devices

InactiveUS20060052144A1Easy to keepEasy to repositionSubstation equipmentVehicle componentsData signalRadio frequency

A holder, electrical supply, and optional RF transmitter unit to hold, supply power to, and receive a data signal from an operating electronic device when the device (e.g., MP3 player) is held in the unit is disclosed. Electrical power enters the unit's power acquisition portion (e.g., cigarette lighter adapter) from an external source and flows to the electronic device via the holder. A data signal from the electronic device is processed by an RF transmitter in the unit, and the resulting RF signal is broadcast by an antenna (e.g., gooseneck) that preferably forms a repositionable mechanical connection between the holder and the power acquisition unit.

Owner:BELKIN INT

Viable tissue repair implants and methods of use

InactiveUS20050125077A1Good retention of cellEasy to integrateBone implantSkeletal disorderTissue repairRepair tissue

Biocompatible tissue implants are provided for repairing a tissue injury or defect. The tissue implants comprise a biological tissue slice that serves as a source of viable cells capable of tissue regeneration and / or repair. The biological tissue slice can be harvested from healthy tissue to have a geometry that is suitable for implantation at the site of the injury or defect. The harvested tissue slice is dimensioned to allow the viable cells contained within the tissue slice to migrate out and proliferate and integrate with tissue surrounding the injury or defect site. Methods for repairing a tissue injury or defect using the tissue implants are also provided.

Owner:DEPUY SYNTHES PROD INC

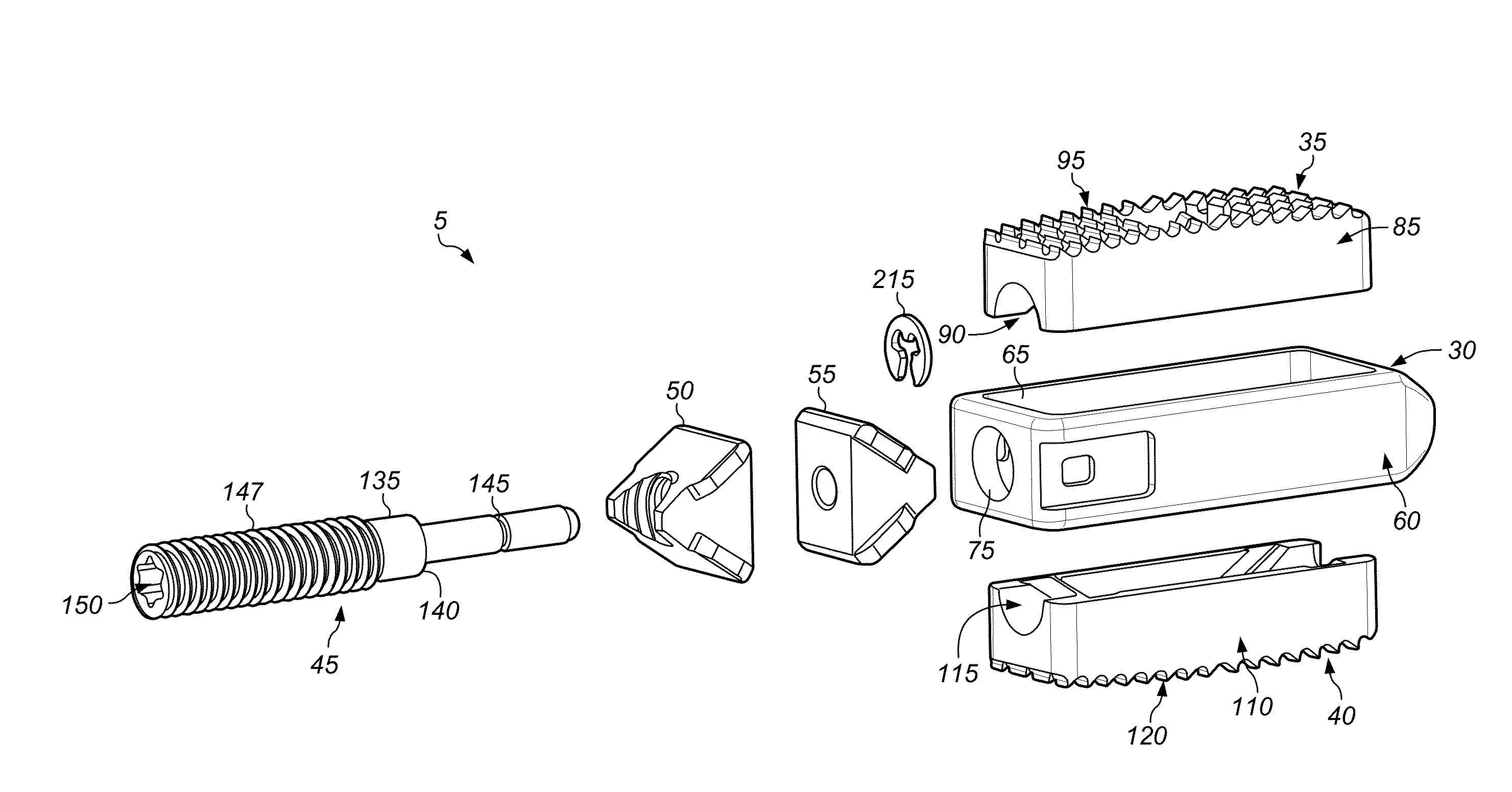

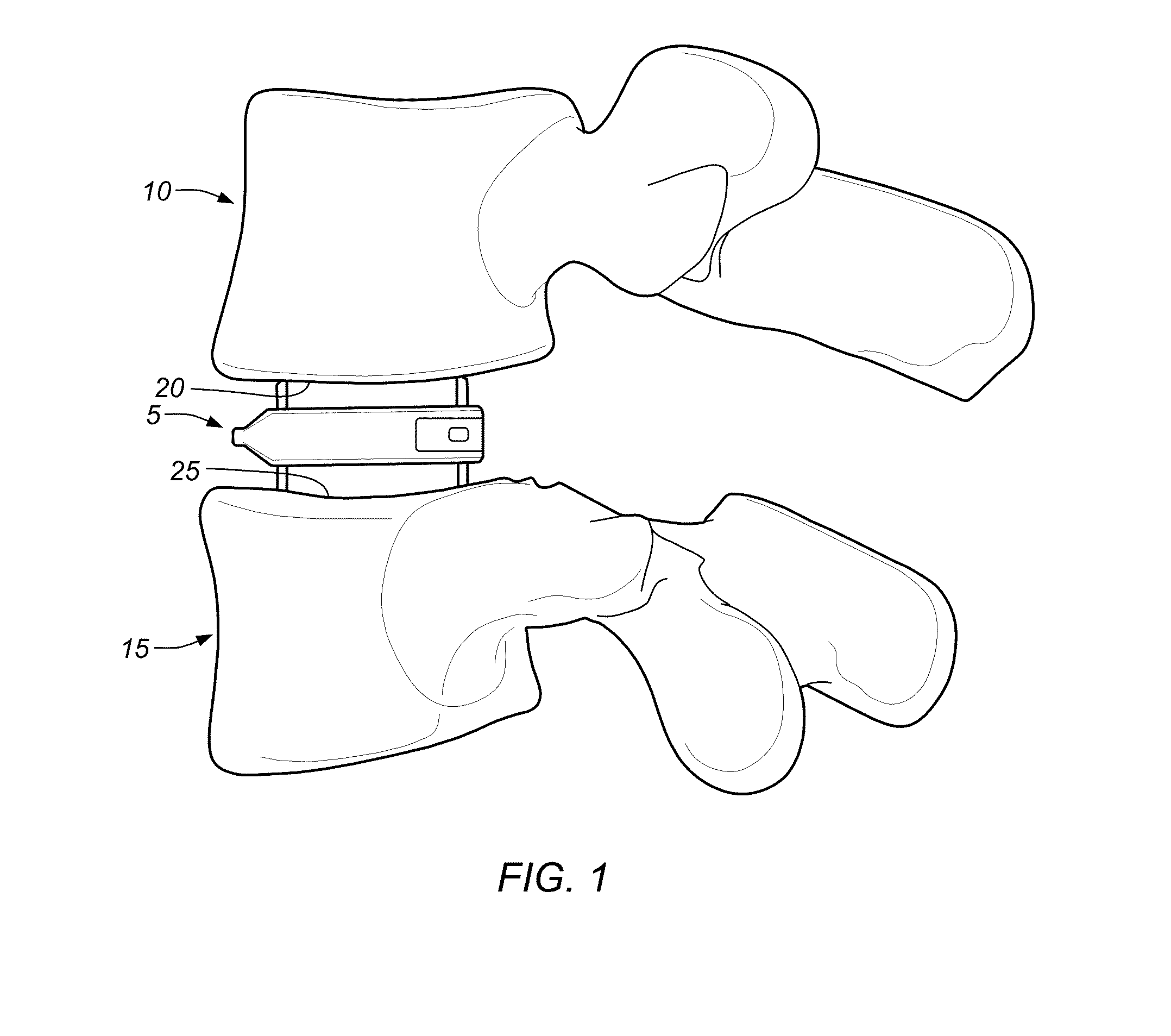

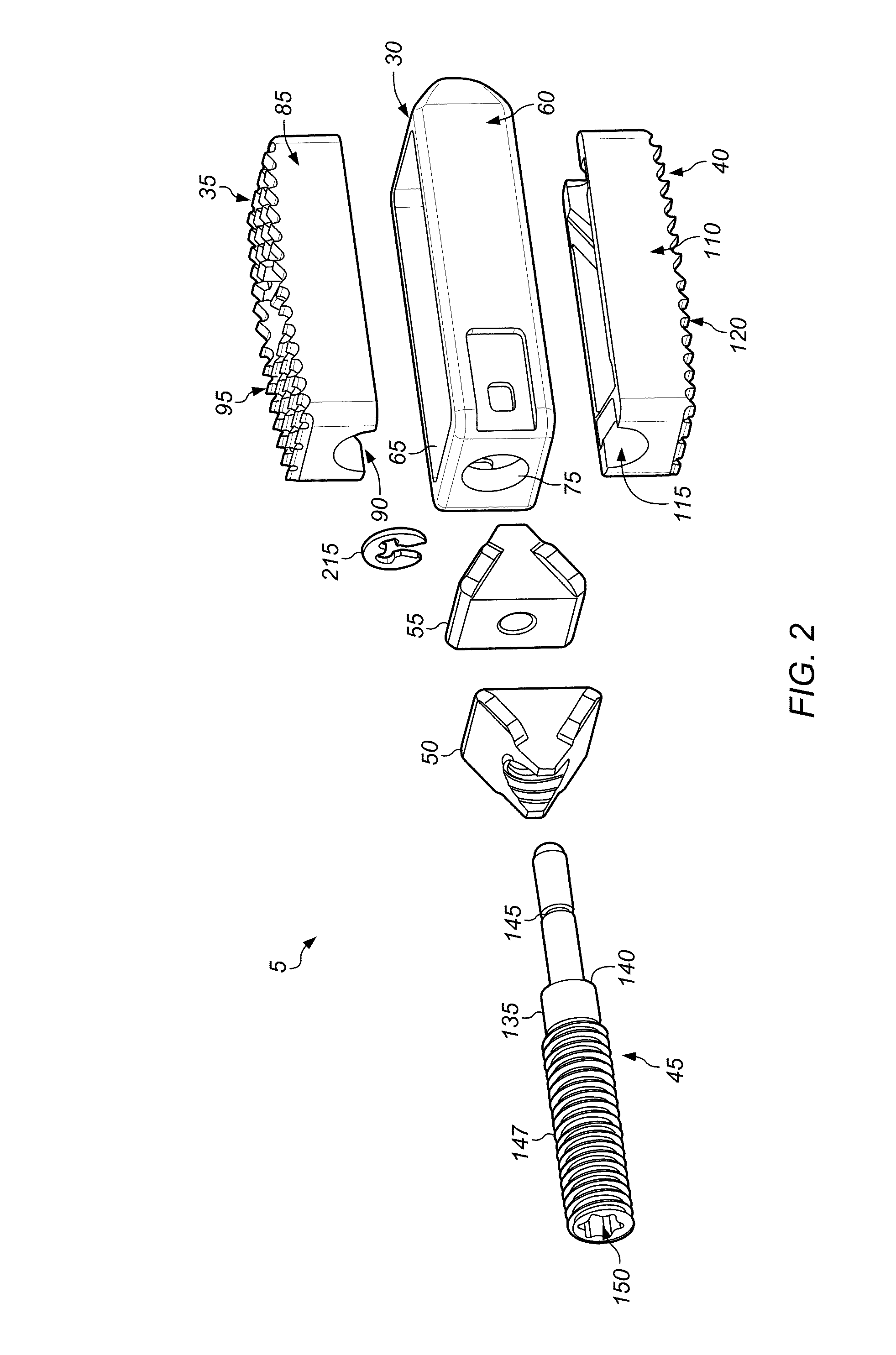

Expandable fusion device for positioning between adjacent vertebral bodies

ActiveUS20140236296A1Facilitates retentionIncrease heightBone implantSpinal implantsVertebraAnesthesia

In some embodiments, system and / or method may include an intervertebral implant for a human spine including an upper body, a lower body, first and second expansion members, and an expansion mechanism. A superior surface of the upper body may function to engage a first vertebra of the human spine. An inferior surface of the lower body may function to engage a second vertebra of the human spine. The first expansion member may include at least a first angled portion positionable, during use, between the upper body and the lower body. The second expansion member may include at least a second angled portion positionable, during use, between the upper body and the lower body. An expansion mechanism may convey, during use, the first and second angled portions in opposing directions increasing a separation distance between the upper body and the lower body.

Owner:FLEXUSPINE

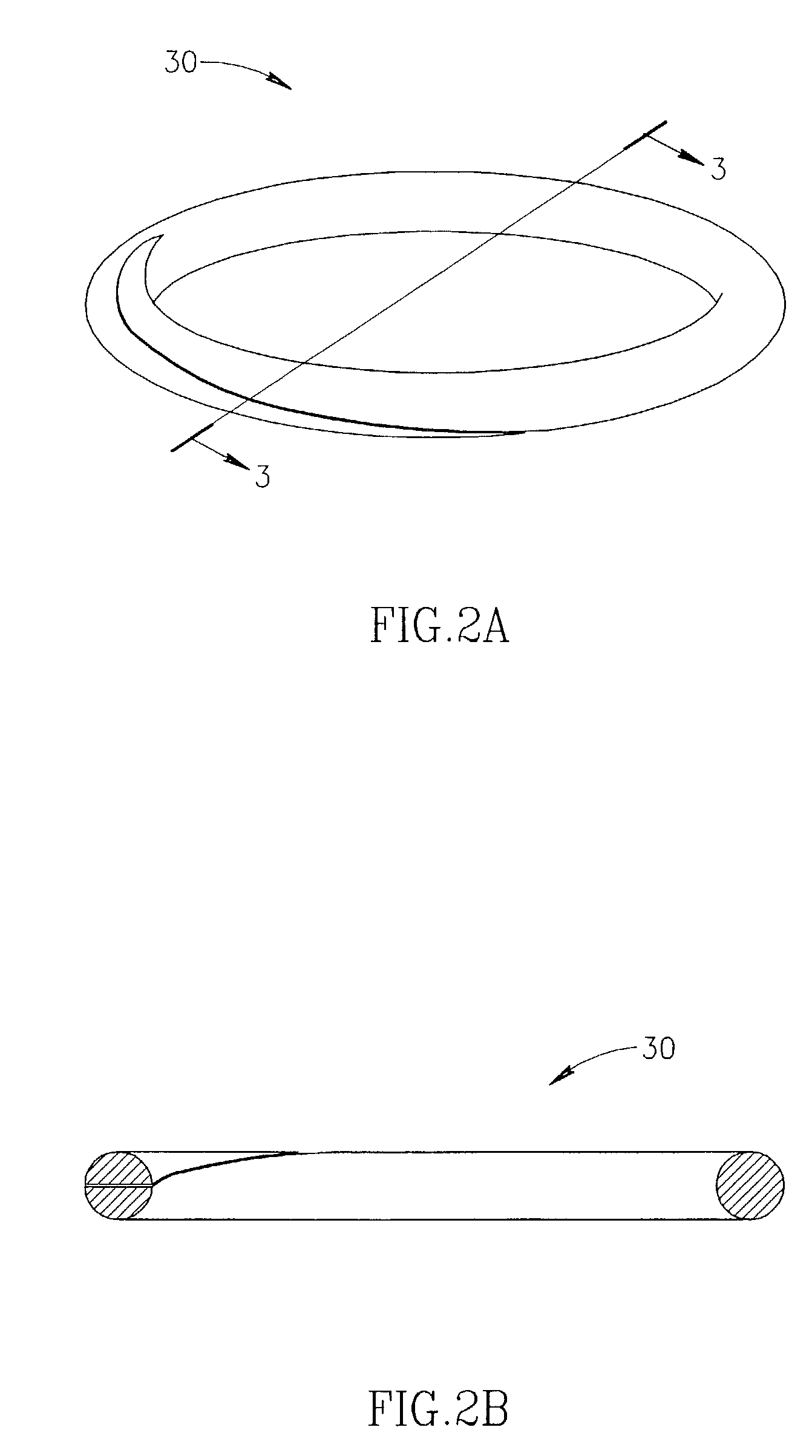

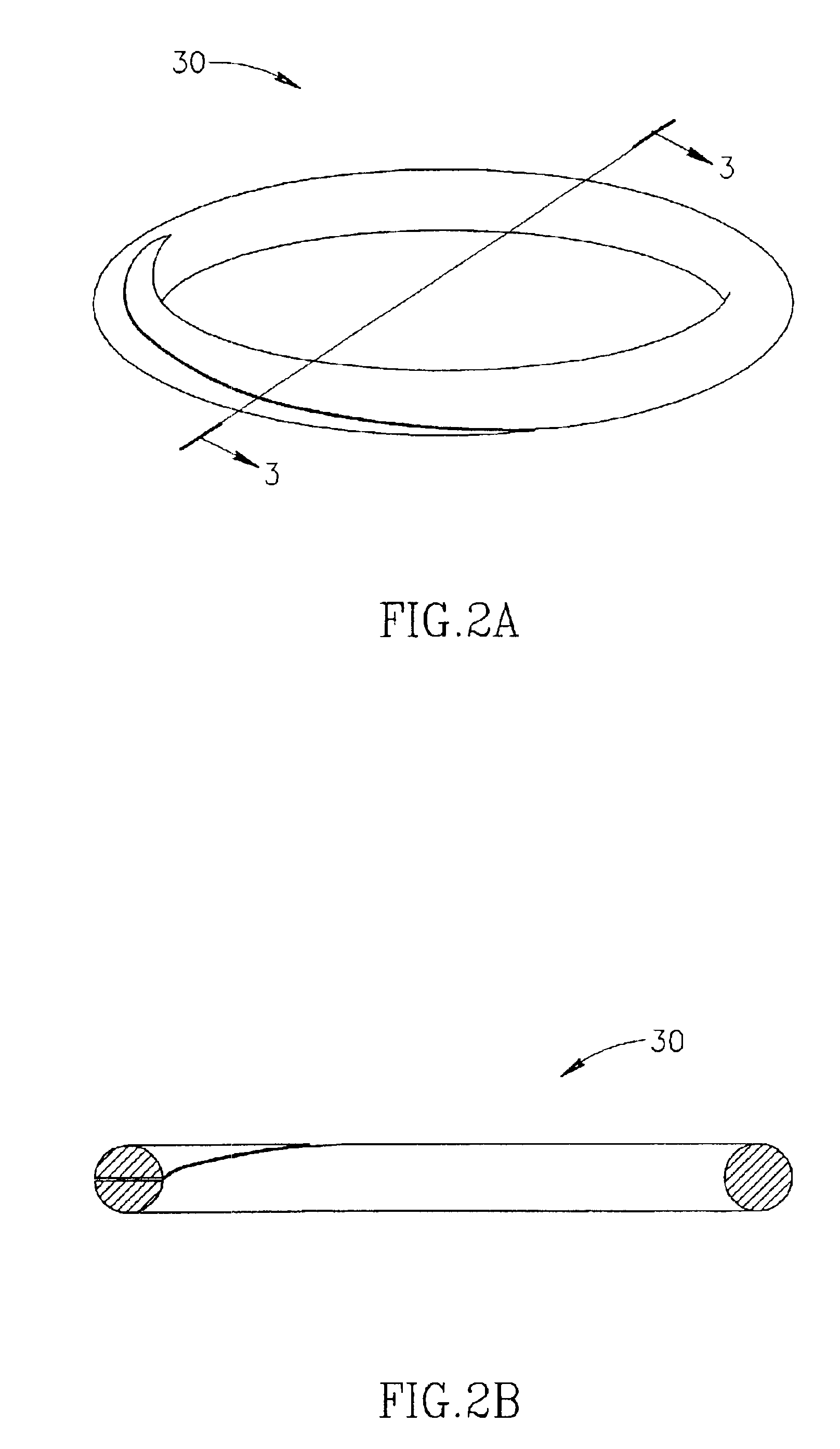

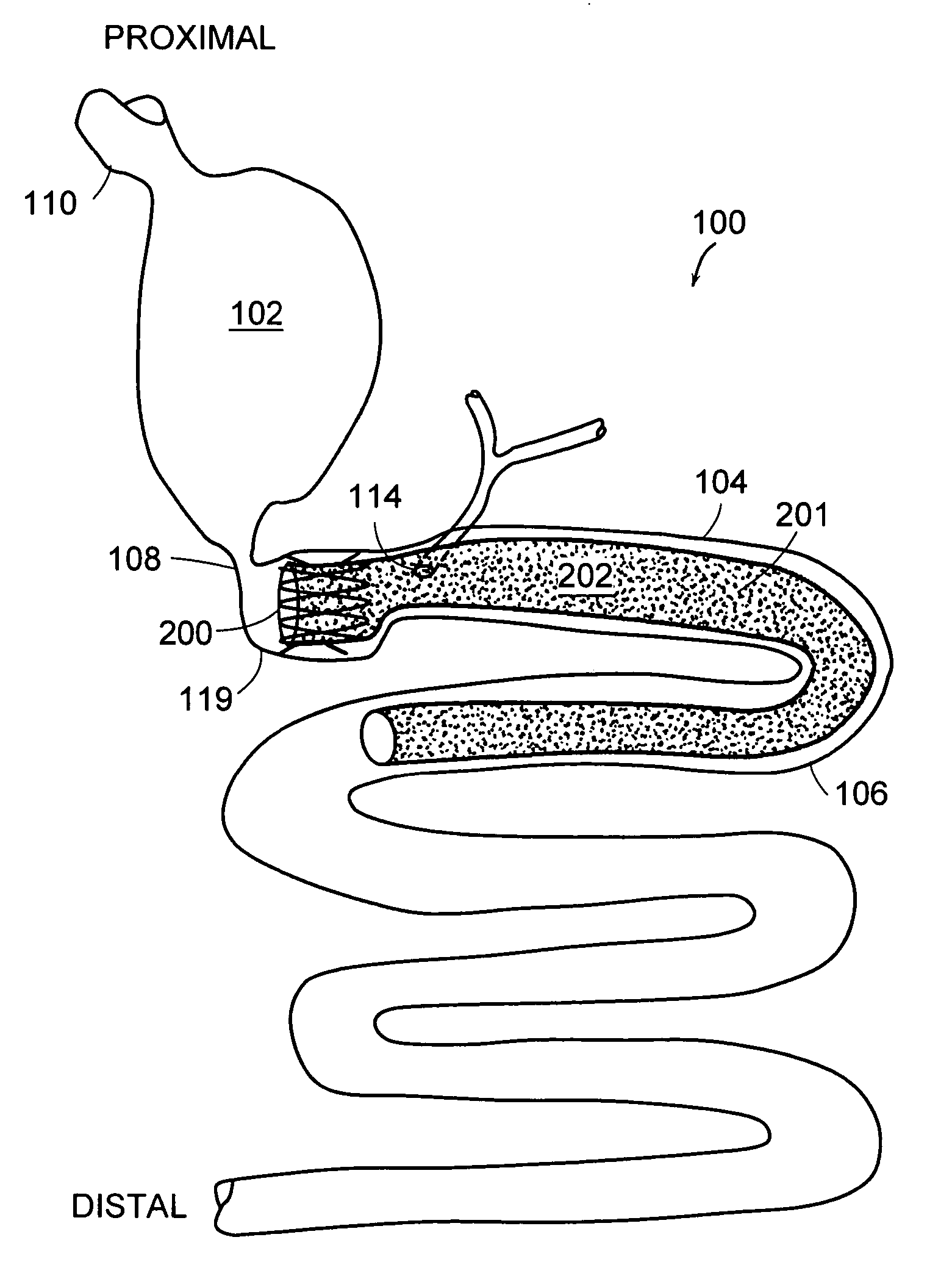

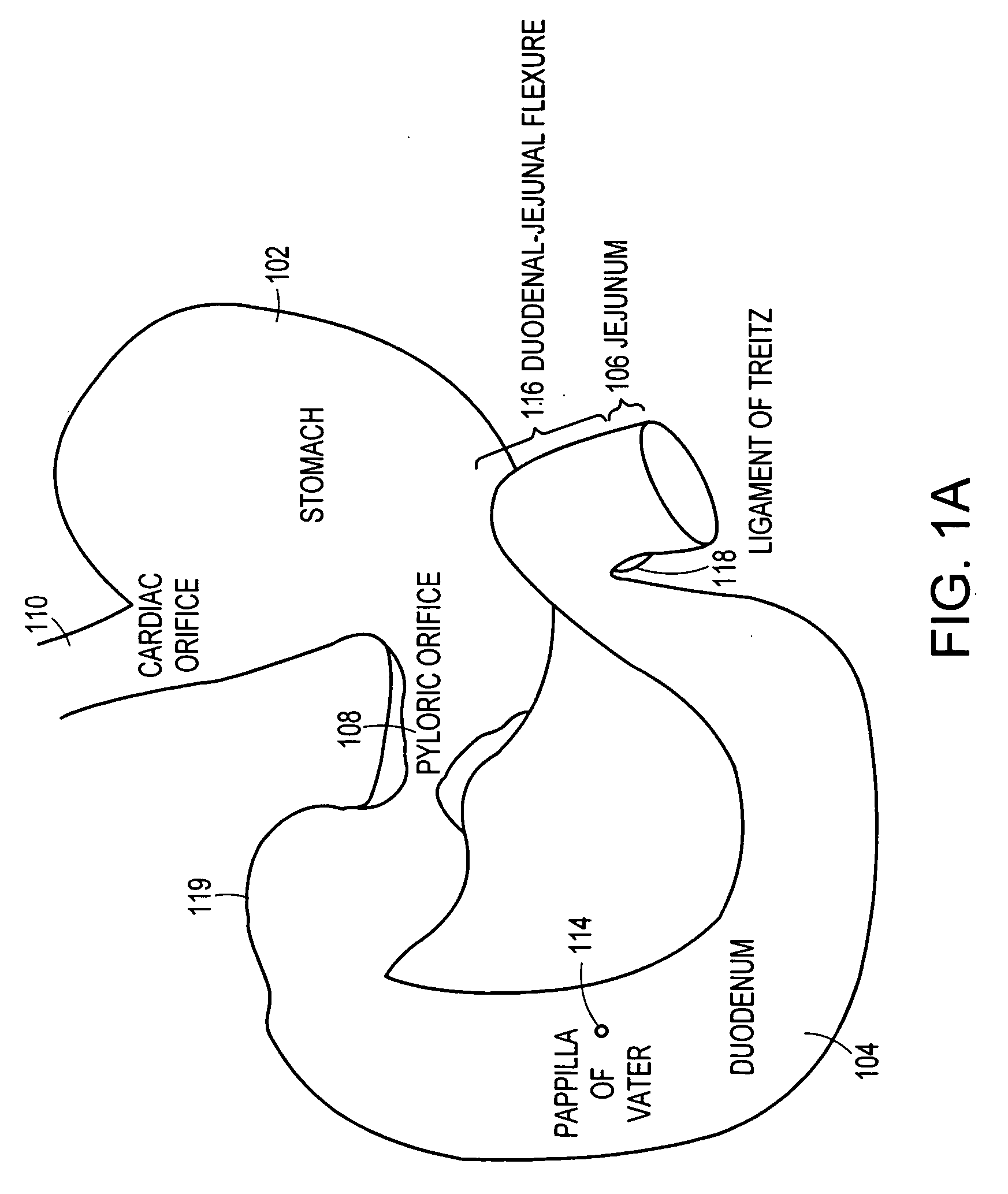

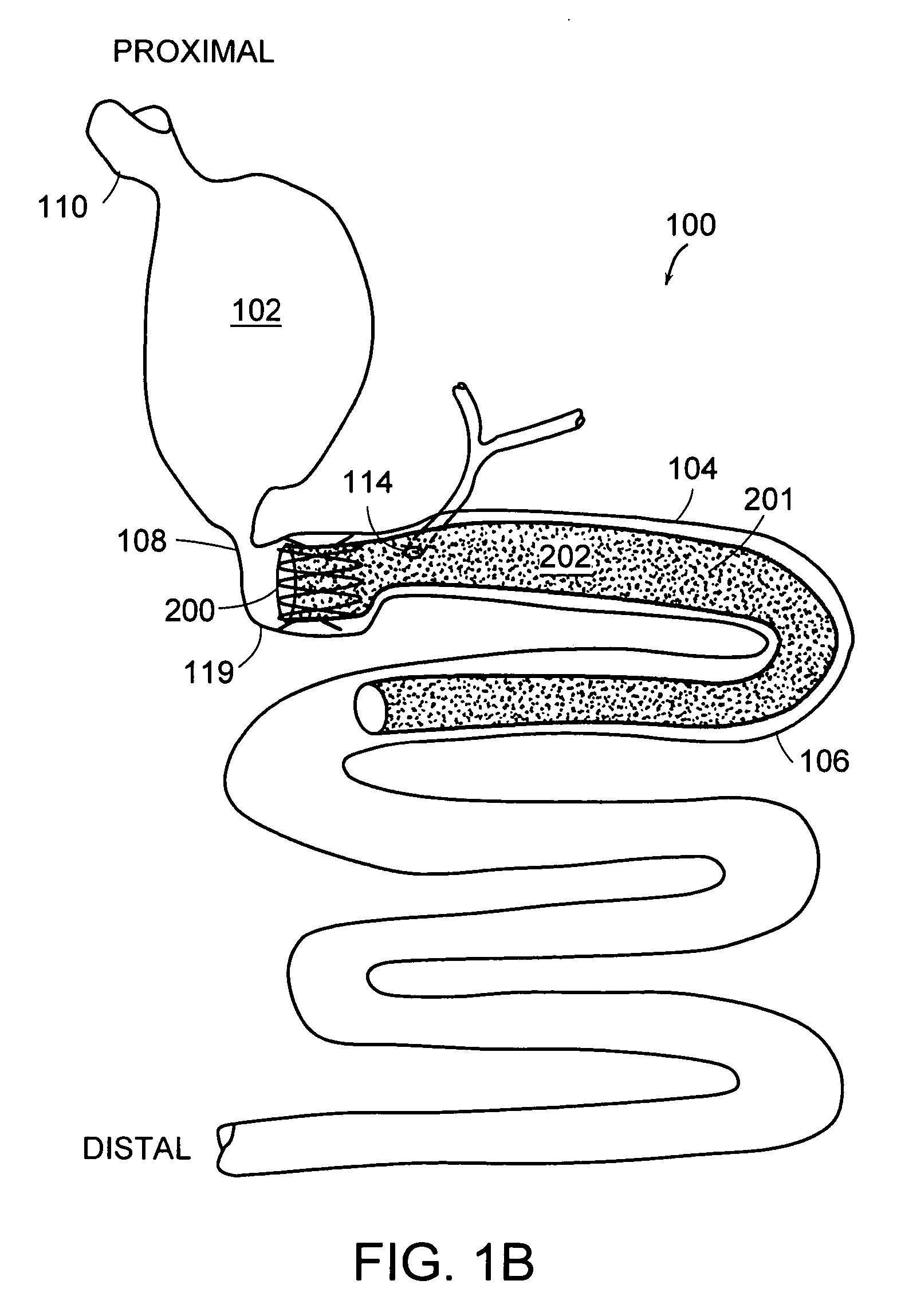

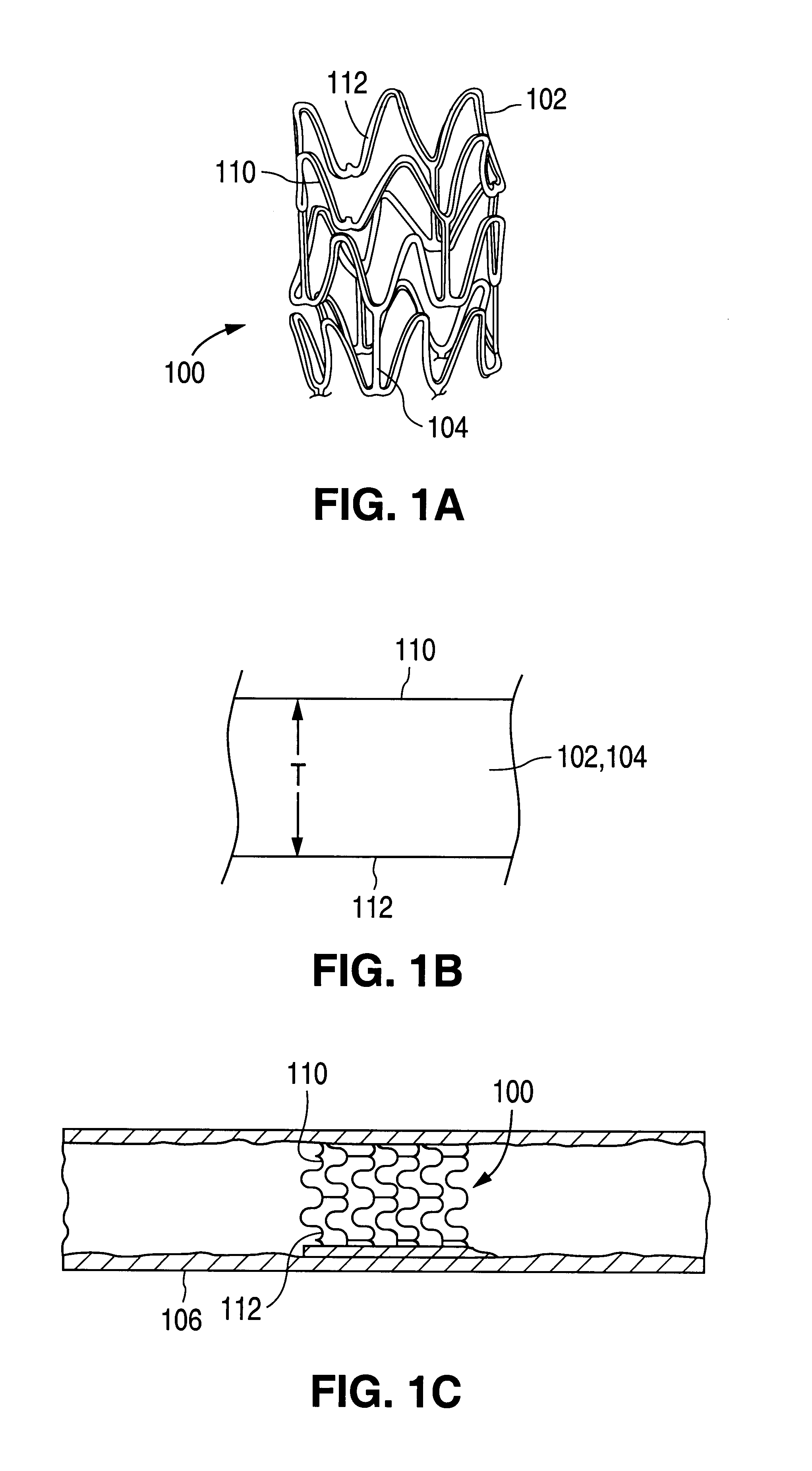

Gastrointestinal anchor compliance

ActiveUS20070005147A1Good retentionImprove abilityOesophagiIntravenous devicesRange of motionDuodenal bulb

A collapsible gastrointestinal anchor can be characterized in various embodiments by a radial force of about 0.1 Newtons (N) or greater at a compressed diameter of 25 millimeters (mm); by an average spring rate of about 13 Newtons / meter (N / m) or greater in a range of motion between a relaxed diameter and a compressive elastic deformation diameter; or by a radial force over the range of motion of about 0.1 N or greater. Typically, the anchor can be adapted to be retained within a subject's intestine, more typically in the duodenum, or particularly in the duodenal bulb just distal to the pylorus. A gastrointestinal implant device includes the collapsible gastrointestinal anchor and a floppy sleeve. The sleeve is open at both ends and adapted to extend into a subject's intestine, the anchor being coupled to a proximal portion of the sleeve. Also include are methods of implanting the gastrointestinal implant device in a subject, and methods of treating a subject for disease. The disclosed gastrointestinal invention leads to an improved ability to secure anchors and devices in the gastrointestinal tract while tending to minimize migration.

Owner:GI DYNAMICS

Electrosurgical Apparatus and Methods for Treatment and Removal of Tissue

InactiveUS20070149966A1Avoid and minimize currentQuantity minimizationSurgical instruments for heatingTreatment targetsActive electrode

Apparatus and methods for ablating, severing, cutting, shrinking, coagulating, or otherwise modifying a target tissue to be treated. In a method for treating a target tissue, an active electrode of an electrosurgical probe is positioned in at least close proximity to the target tissue in the presence of an electrically conductive fluid. A high frequency voltage is then applied between the active electrode and a return electrode, wherein, the high frequency voltage is sufficient to volumetrically remove (ablate), sever, or modify at least a portion of the target tissue. The probe comprises a multi-lumen shaft having a plurality of internal lumens, and a return electrode coil oriented substantially parallel to the shaft distal end. The active electrode may be in the form of a metal disc, a hook, or an active electrode coil. In the latter embodiment, the active electrode coil is typically arranged substantially orthogonal to the return electrode coil. Methods of making an active electrode coil, a return electrode coil, and an electrosurgical probe are also disclosed.

Owner:ARTHROCARE

Heat-expandable microcapsules, process for producing the same, and method of utilizing the same

InactiveUS6235394B1High TgHigh heat-resistanceSynthetic resin layered productsCellulosic plastic layered productsPolymer scienceHeat resistance

A heat-expandable microcapsule comprising a polymer shell formed by polymerizing (I) acrylonitrile, a main monomer component, (II) a monomer having carboxyl and (III) a monomer having groups reactive with the carboxyl of the monomer (II) and of a liquid having a boiling point lower than the softening point of the polymer and being encapsulated in the polymer shell. The heat-expandable microcapsules expand within high temperature range, 240° C. or above, and have heat-resistance.

Owner:MATSUMOTO YUSHI SEIYAKU

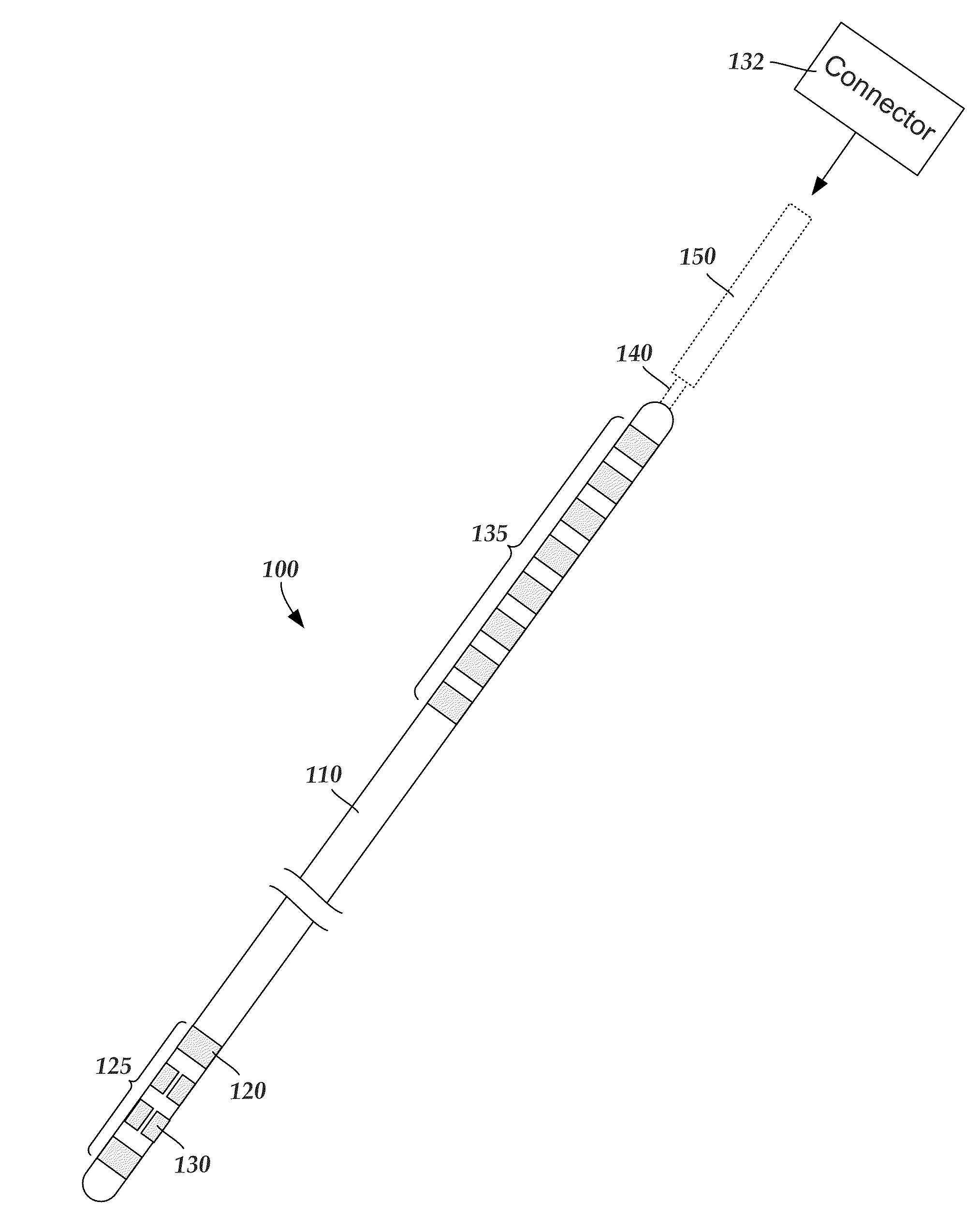

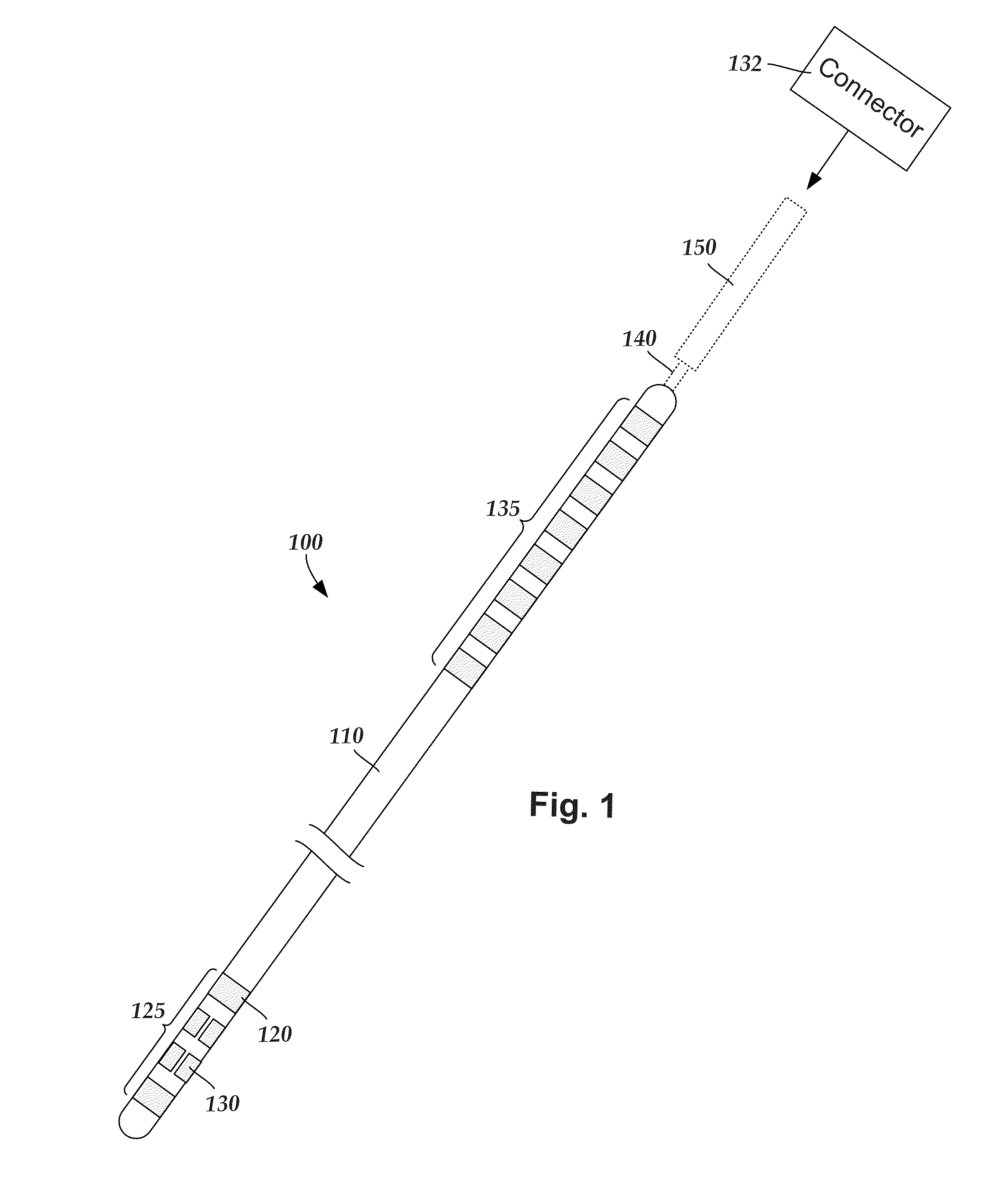

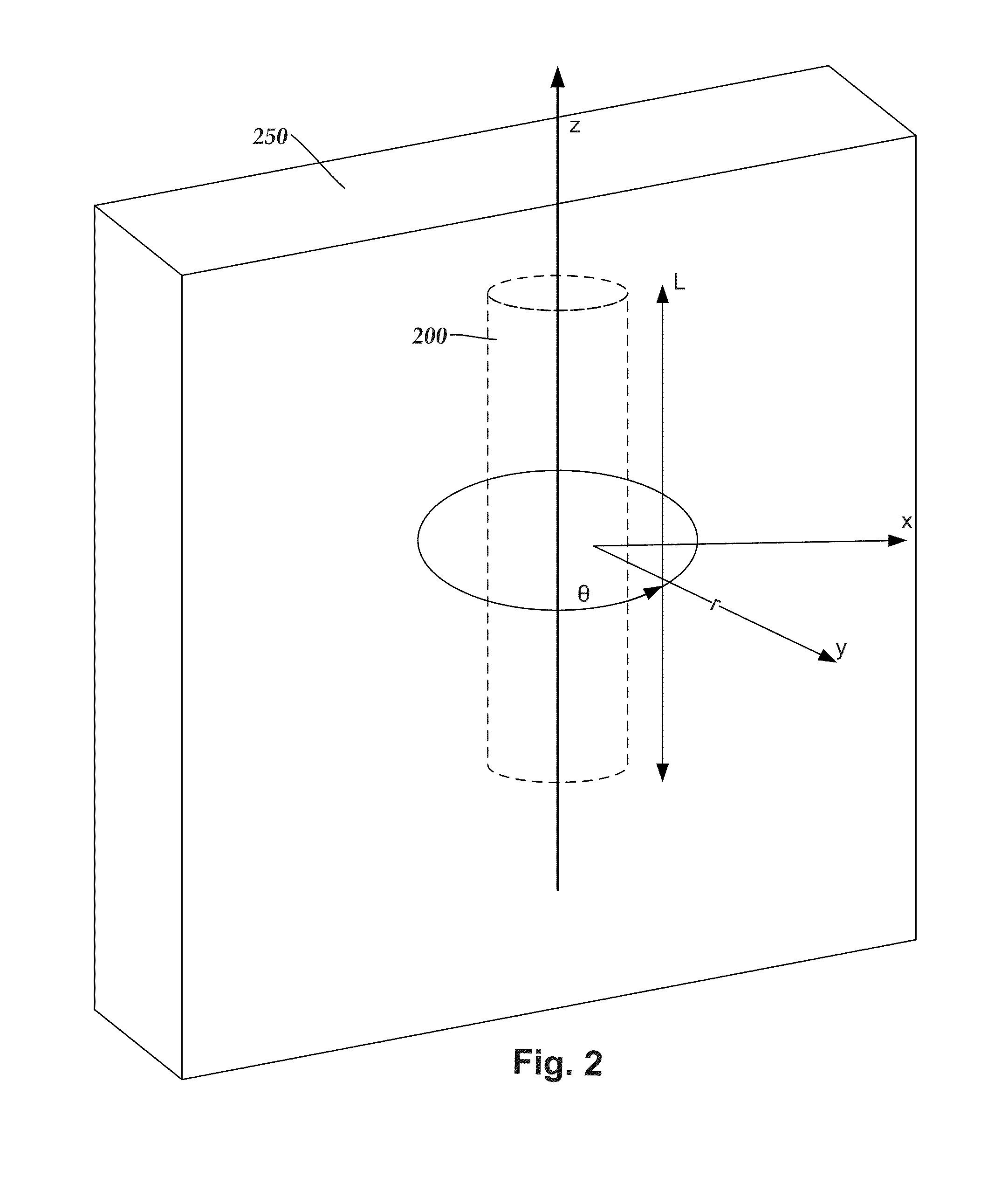

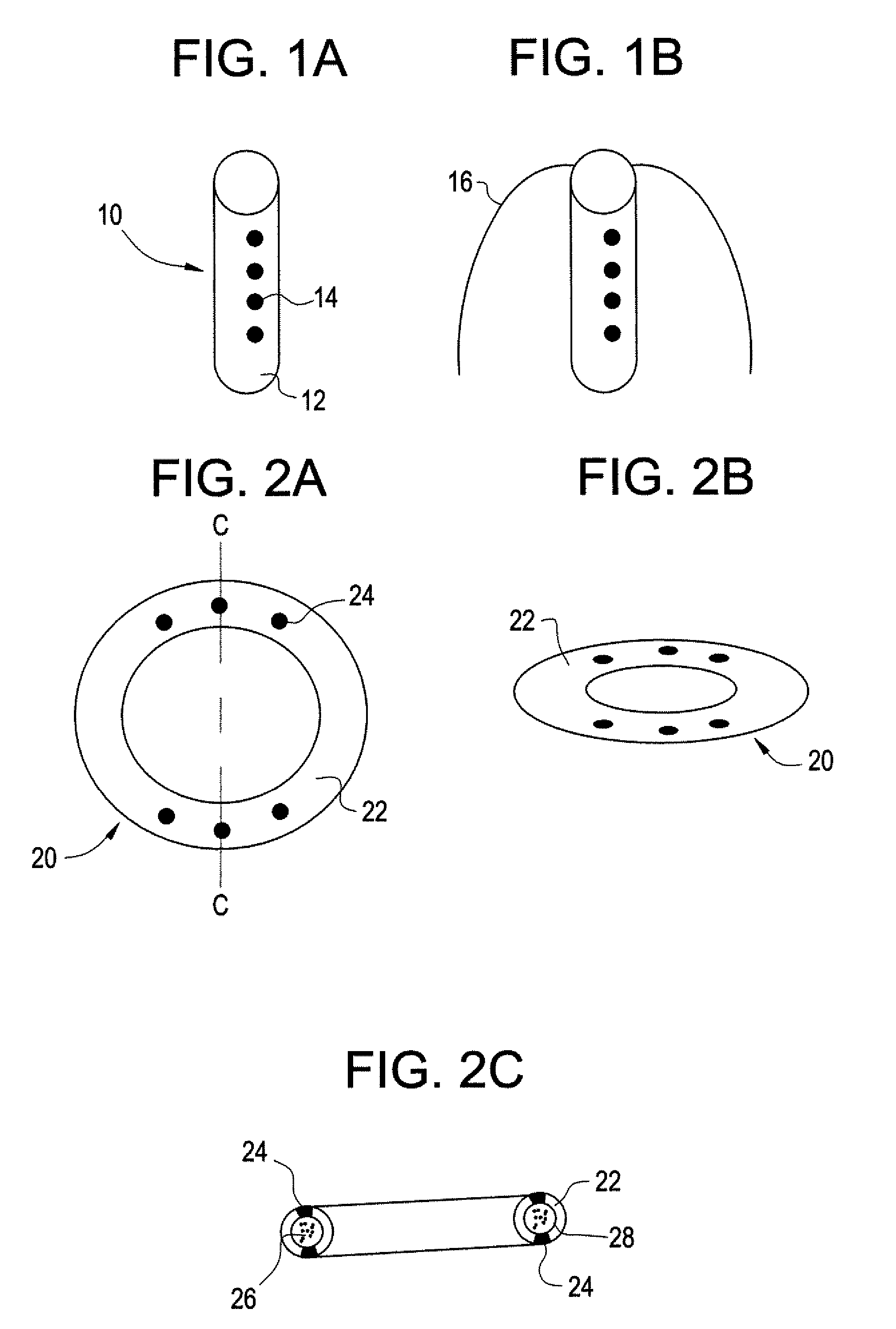

Systems and methods for making and using segmented tip electrodes for leads of electrical stimulation systems

InactiveUS20150045864A1Easy to keepLine/current collector detailsHead electrodesElectricityElectrical conductor

An implantable electrical stimulation lead includes a lead body having a proximal end portion, a distal end portion, a distal tip, a longitudinal length, and a longitudinal surface. Segmented tip electrodes are disposed circumferentially about the distal tip of the lead body and are electrically-isolated from each other. Each segmented tip electrode has an inner surface and an opposing outer stimulating surface exposed along the longitudinal surface of the lead body. A portion of the lead body is disposed against the inner surfaces of each of the segmented tip electrodes and circumferentially between each of the segmented tip electrodes. A non-tip electrode is disposed along the distal end portion of the lead body proximal to the segmented tip electrodes. Terminals are disposed along the proximal end portion of the lead body. Conductors electrically couple the terminals to the segmented tip electrodes and to the non-tip electrode.

Owner:BOSTON SCI NEUROMODULATION CORP

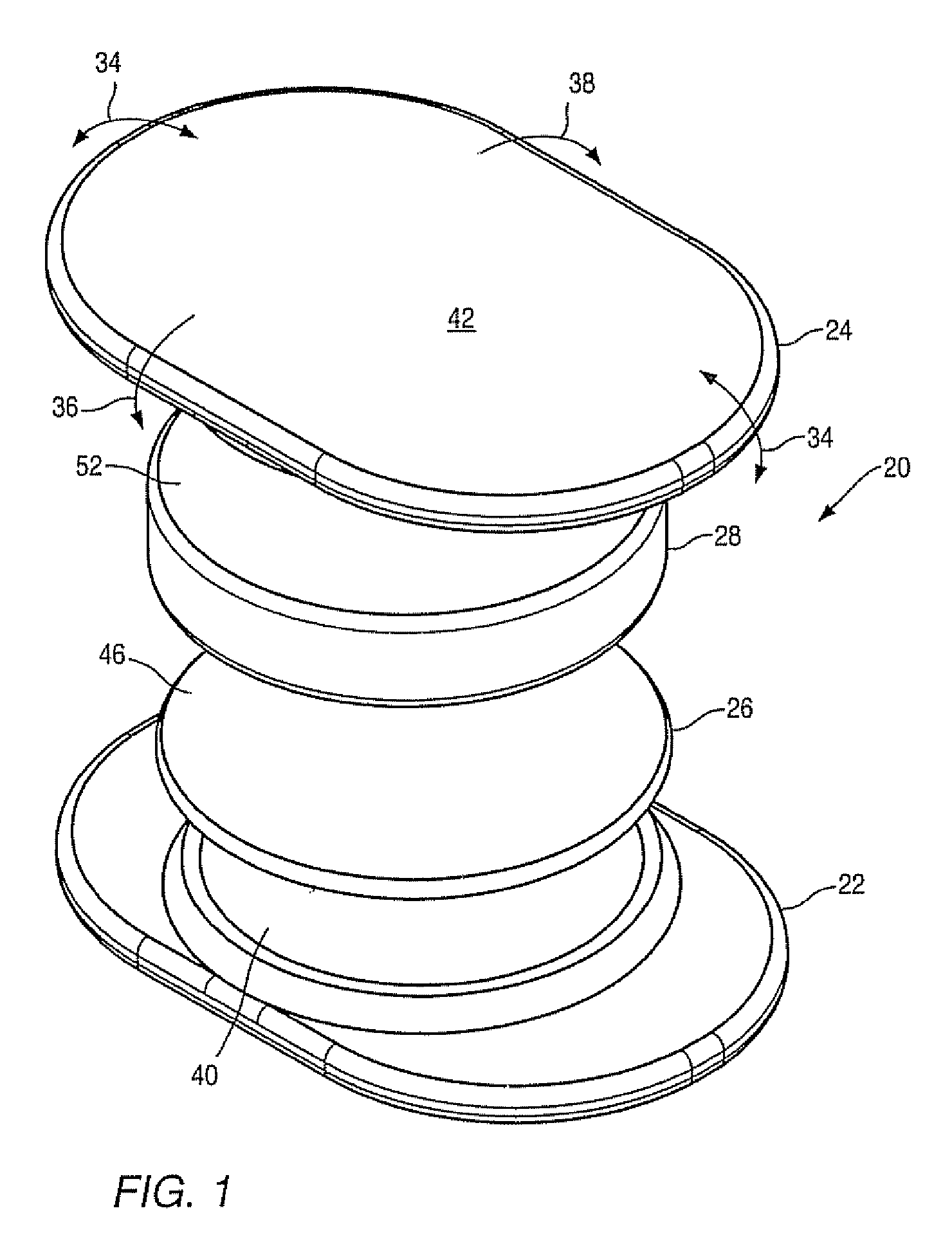

Spinal disc implant

InactiveUS20080015698A1Reduced component wearEasy to keepInternal osteosythesisBone implantBiomedical engineeringAxial rotation

A disc implant is provided which maintains intervertebral spacing and stability of the spine. In an embodiment, a disc implant may include four or more components. Components of the disc implant may include engaging plates and two or more members positioned between the engaging plates. In certain embodiments, a disc implant may include a retainer positioned between one of the engaging plates and one of the members. Complementary portions of the implant components may allow for lateral movement, anteroposterior movement, and / or axial rotation of the engaging members relative to each other during use. In some embodiments, at least one of the members may include a stop to inhibit movement of adjacent vertebrae outside of normal physiological ranges.

Owner:MARINO JAMES F +2

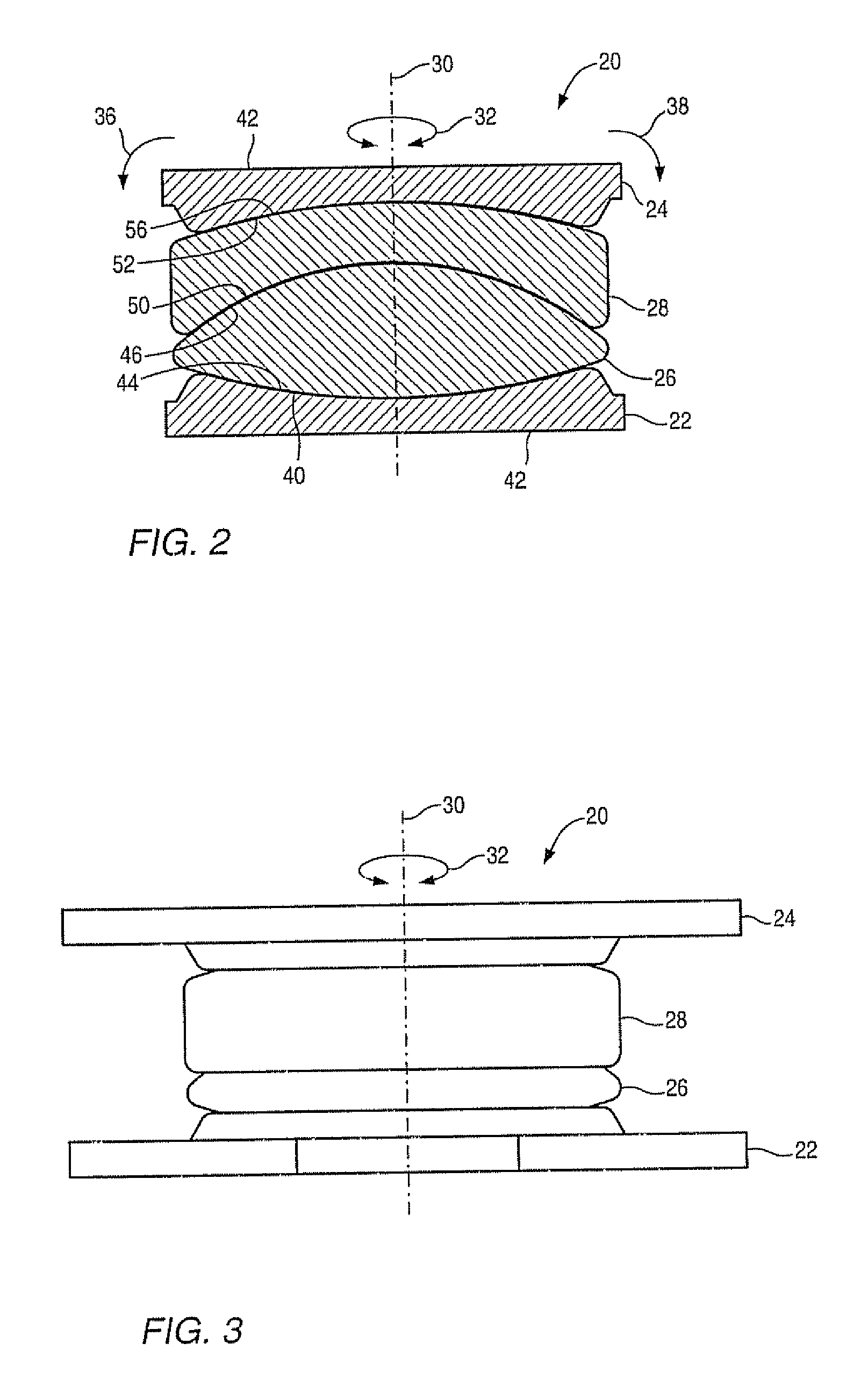

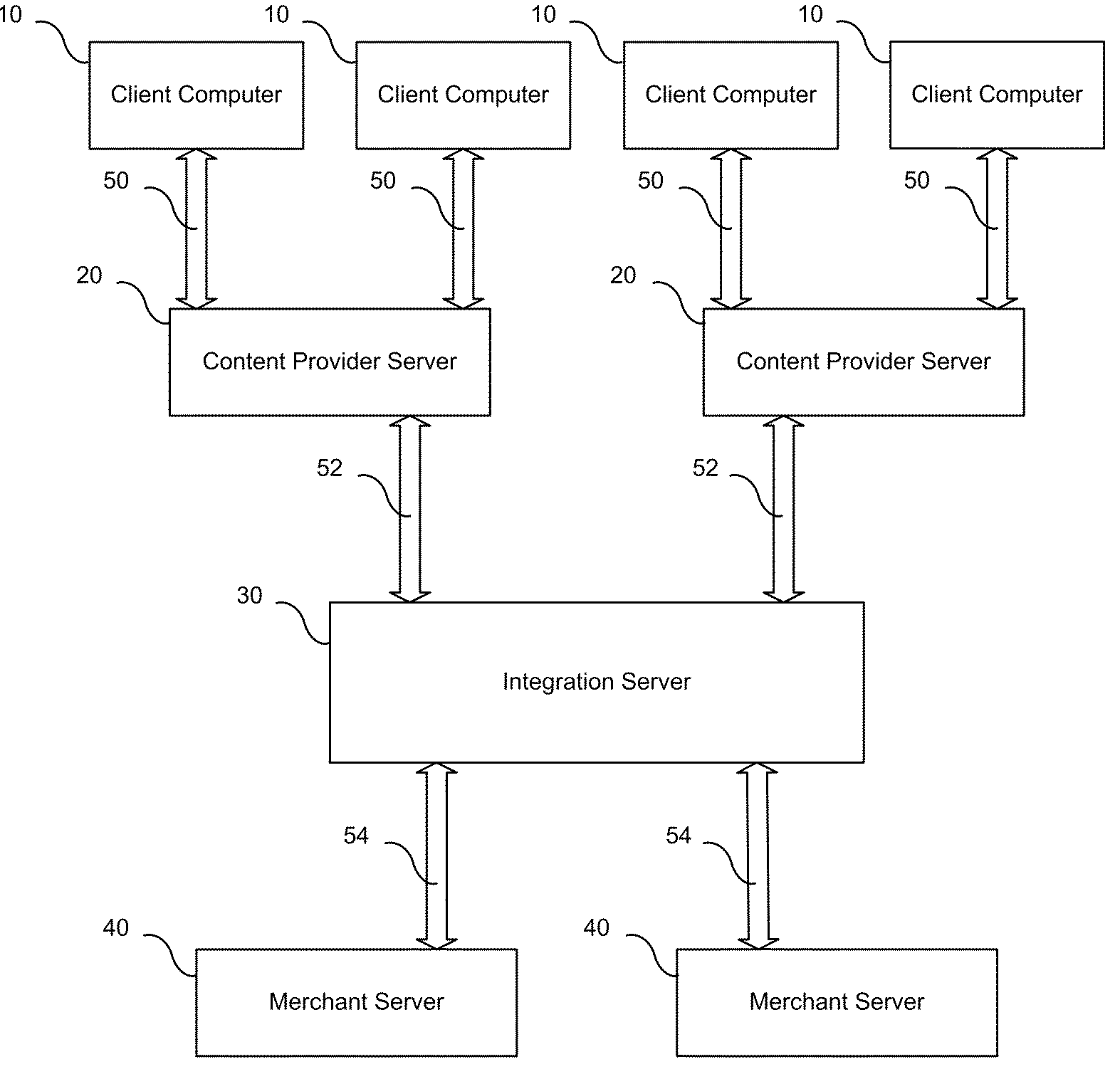

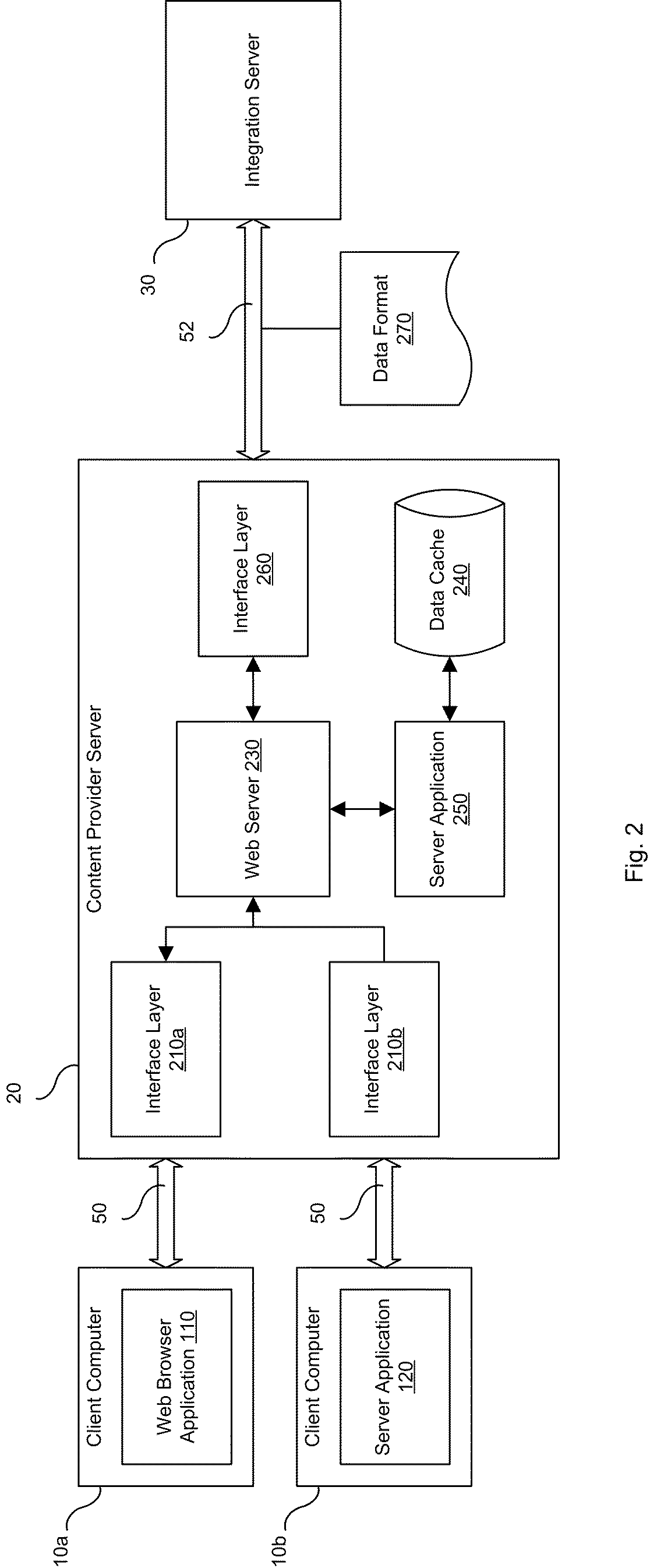

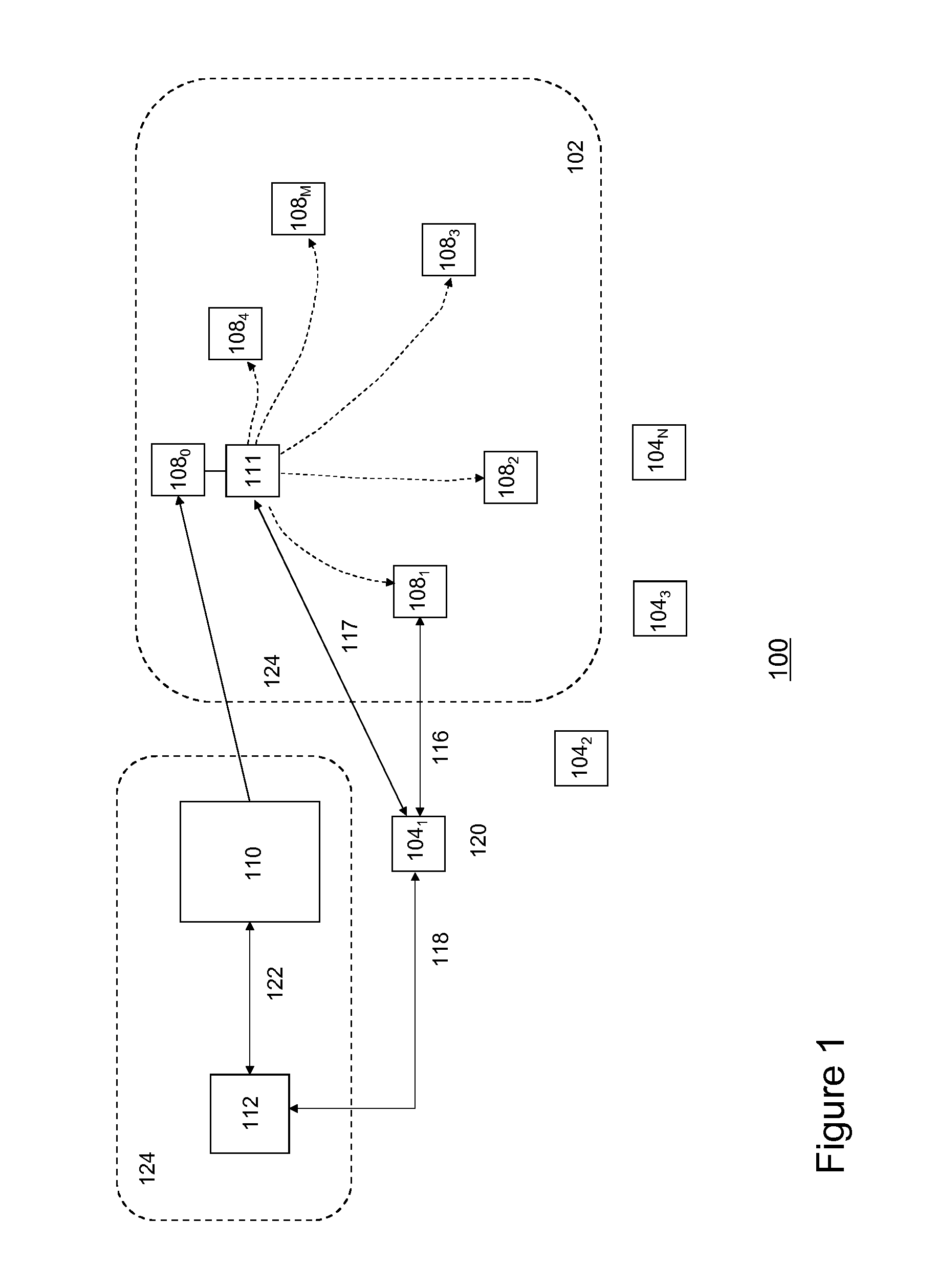

Electronic commerce method and system utilizing integration server

InactiveUS20050102227A1Customer retentionFacilitate and reduce costFinancePayment architectureMerchant servicesE-commerce

An electronic commerce system integrating plurality of content provider servers with plurality of merchant servers having integration server communicating request for commercial transaction to at least one merchant server, thus enabling the user of the client computer connected to the content provider server to initiate commercial transactions to at least one merchant server without being redirected to the merchant server away from the content provider server. The system increases customer retention on the content provider server, thereby increasing incentive for content providers to join the commerce system, thereby increasing the number of sites advertising products offered by merchants. The system also simplifies integration of multitude of servers, thereby reducing cost and time required for such integration.

Owner:SOLONCHEV ALEKSEY

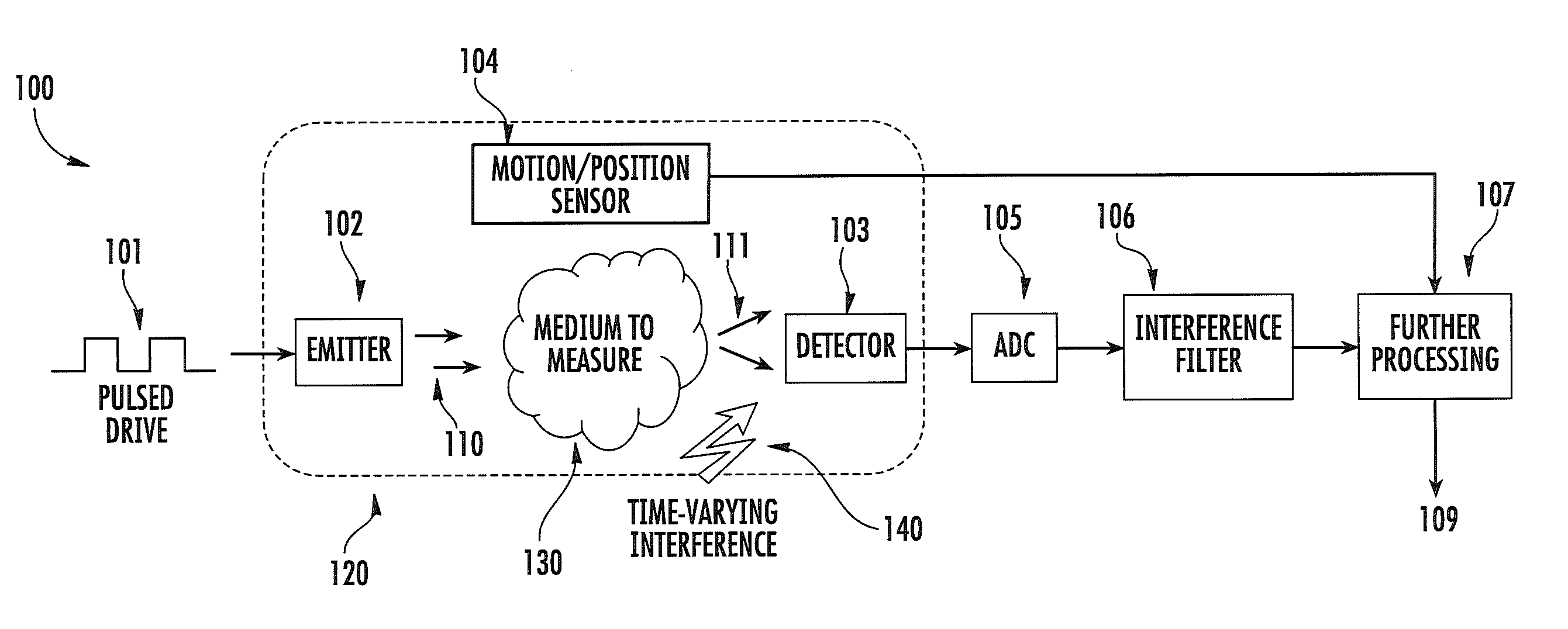

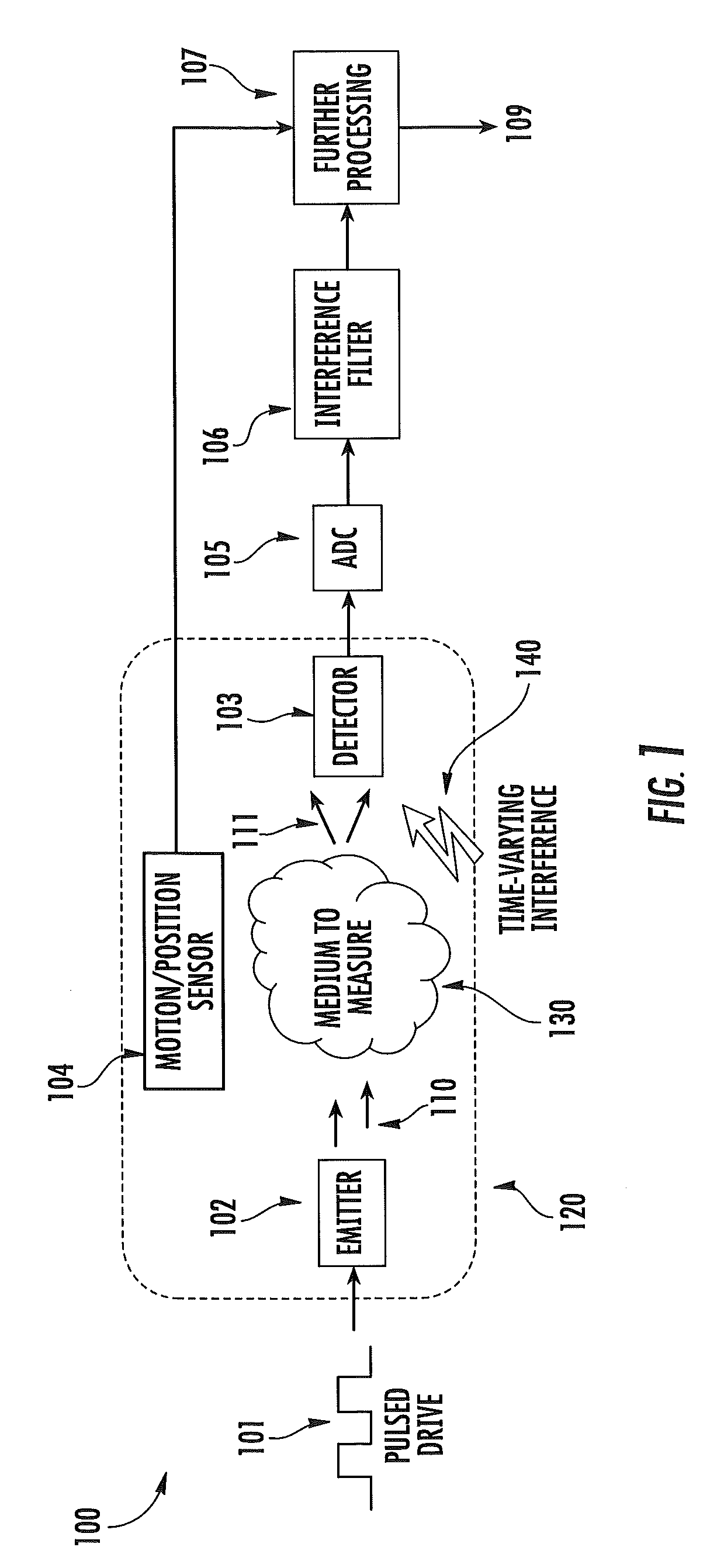

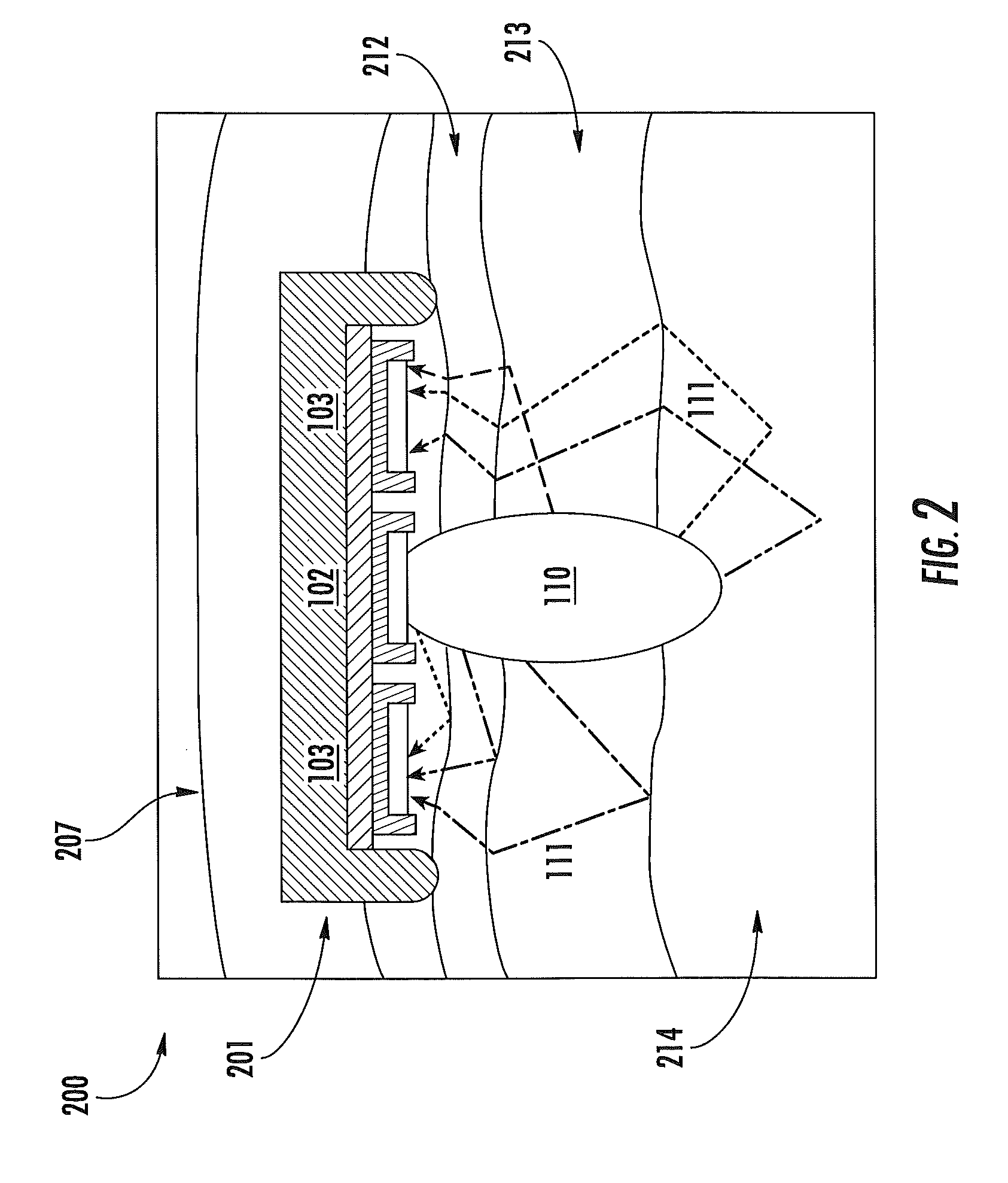

Apparatus and methods for monitoring physiological data during environmental interference

ActiveUS8888701B2Easy to keepMaximize collectionHeart/pulse rate measurement devicesRespiratory organ evaluationTemporal changeEngineering

Apparatus and methods for attenuating environmental interference are described. A wearable monitoring apparatus includes a housing configured to be attached to the body of a subject and a sensor module that includes an energy emitter that directs energy at a target region of the subject, a detector that detects an energy response signal—or physiological condition—from the subject, a filter that removes time-varying environmental interference from the energy response signal, and at least one processor that controls operations of the energy emitter, detector, and filter.

Owner:VALENCELL INC

Skin penetrating device and method for subcutaneous solid drug delivery

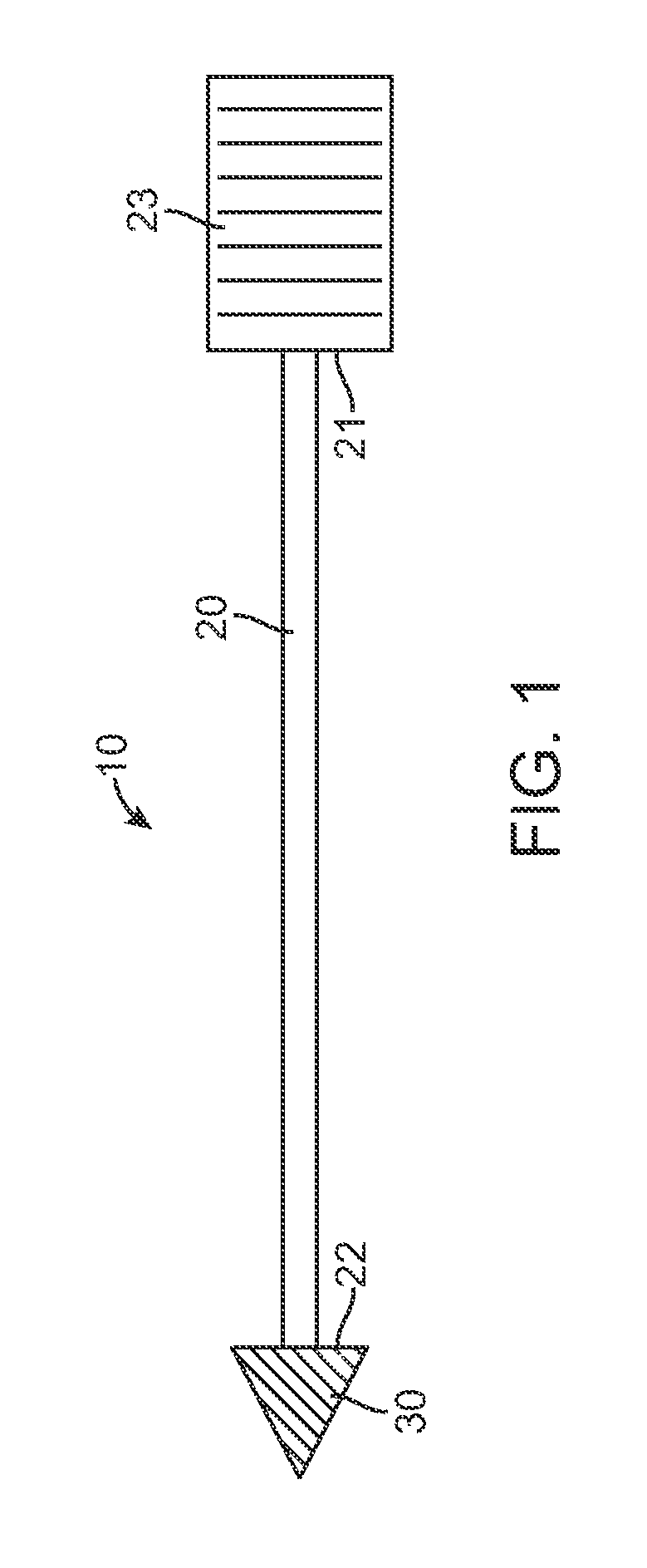

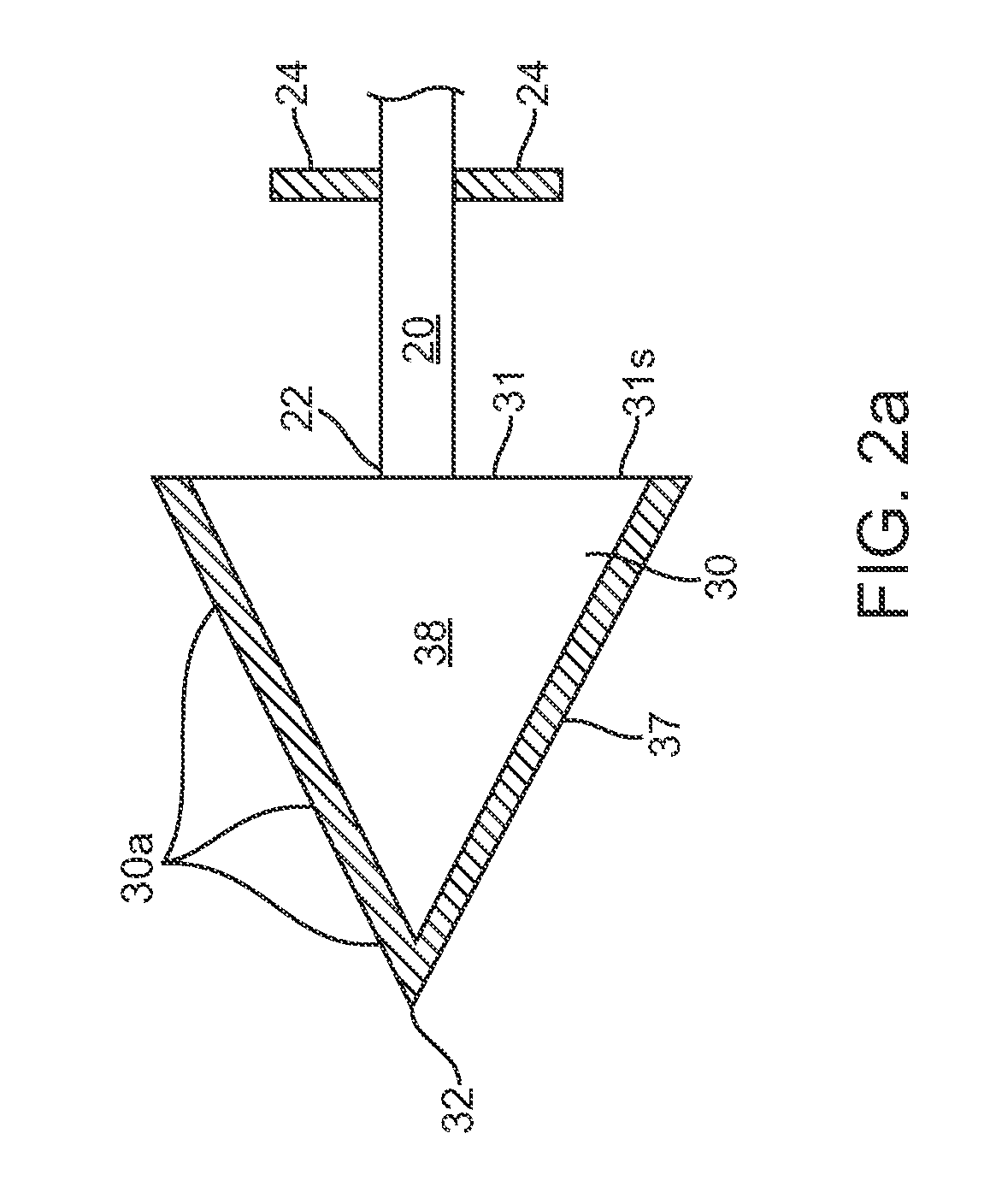

ActiveUS8353863B2Easy to keepHigh hardnessMedical devicesIntravenous devicesTherapeutic effectBody tissue

Embodiments described herein provide a skin penetrating device and method for the subcutaneous delivery of therapeutic agents in solid form. One embodiment provides such a device comprising an elongated shaft having proximal and distal ends and a skin penetrating element detachably coupled to the shaft. At least a portion of the penetrating element is fabricated from a solid form therapeutic agent composition that dissolves in body tissue and is absorbed into the blood stream so as to produce a therapeutic effect. The penetrating element has shape for penetrating and lodging beneath the skin when inserted through the skin by force applied from the shaft. The penetrating element is configured to detach from the shaft when the shaft is pulled away from the skin so as to leave the element in place beneath the skin where it is absorbed by body tissue and the therapeutic agent is released.

Owner:INCUBE LABS

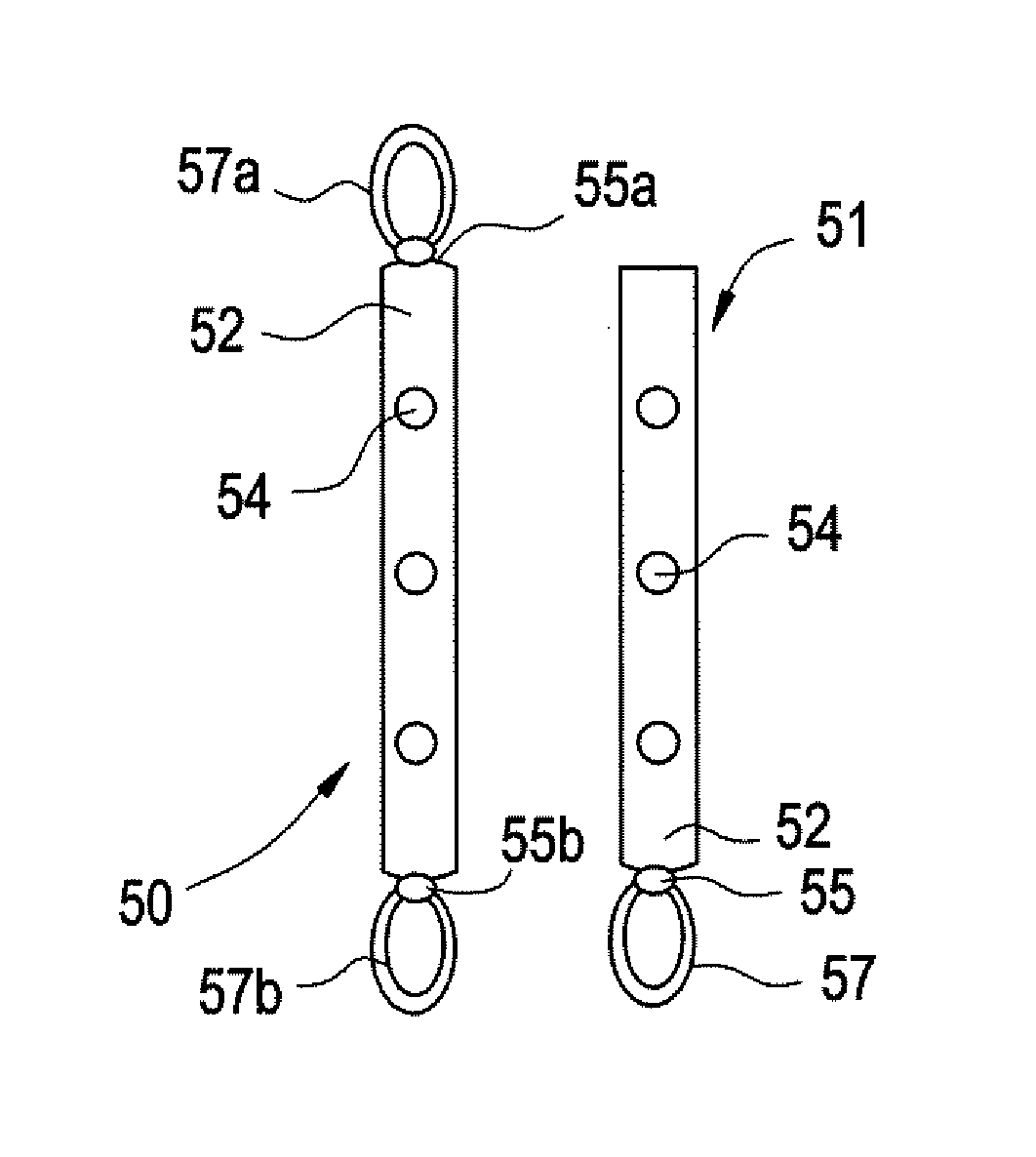

Intravesical drug delivery device and method

ActiveUS20070202151A1Easy to keepMedical devicesPharmaceutical delivery mechanismImplanted deviceBody cavity

Implant devices for intravesical administration and local drug delivery. The device has a body which includes a hollow tube formed of a biocompatible material; at least one reservoir in the tube which contains a drug; and one or more apertures through which the drug can be released. The device is configured for minimally invasive insertion into a body cavity, such as the bladder. The hollow tube may be elastomeric to permit the device to be elastically deformed from its initial shape into an elongated shape for passage through a catheter, where following such passage the device can return to or toward its initial shape to facilitate retention of the device in the body cavity. The body may have a narrow, elongated shape effective to permit insertion of the drug delivery device through a catheter without necessarily deforming the body, yet include flexible projections which effect retention within the body cavity.

Owner:MASSACHUSETTS INST OF TECH +1

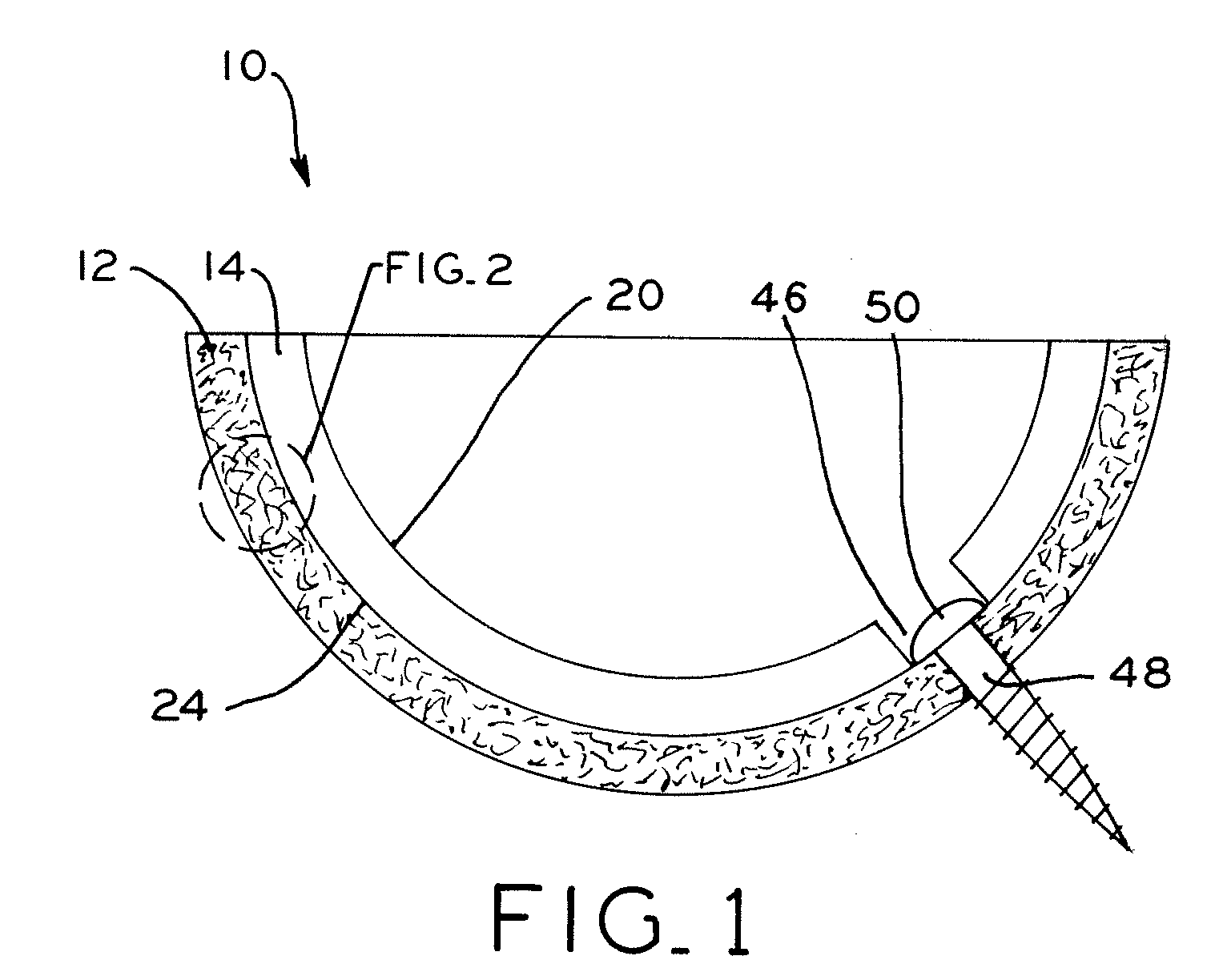

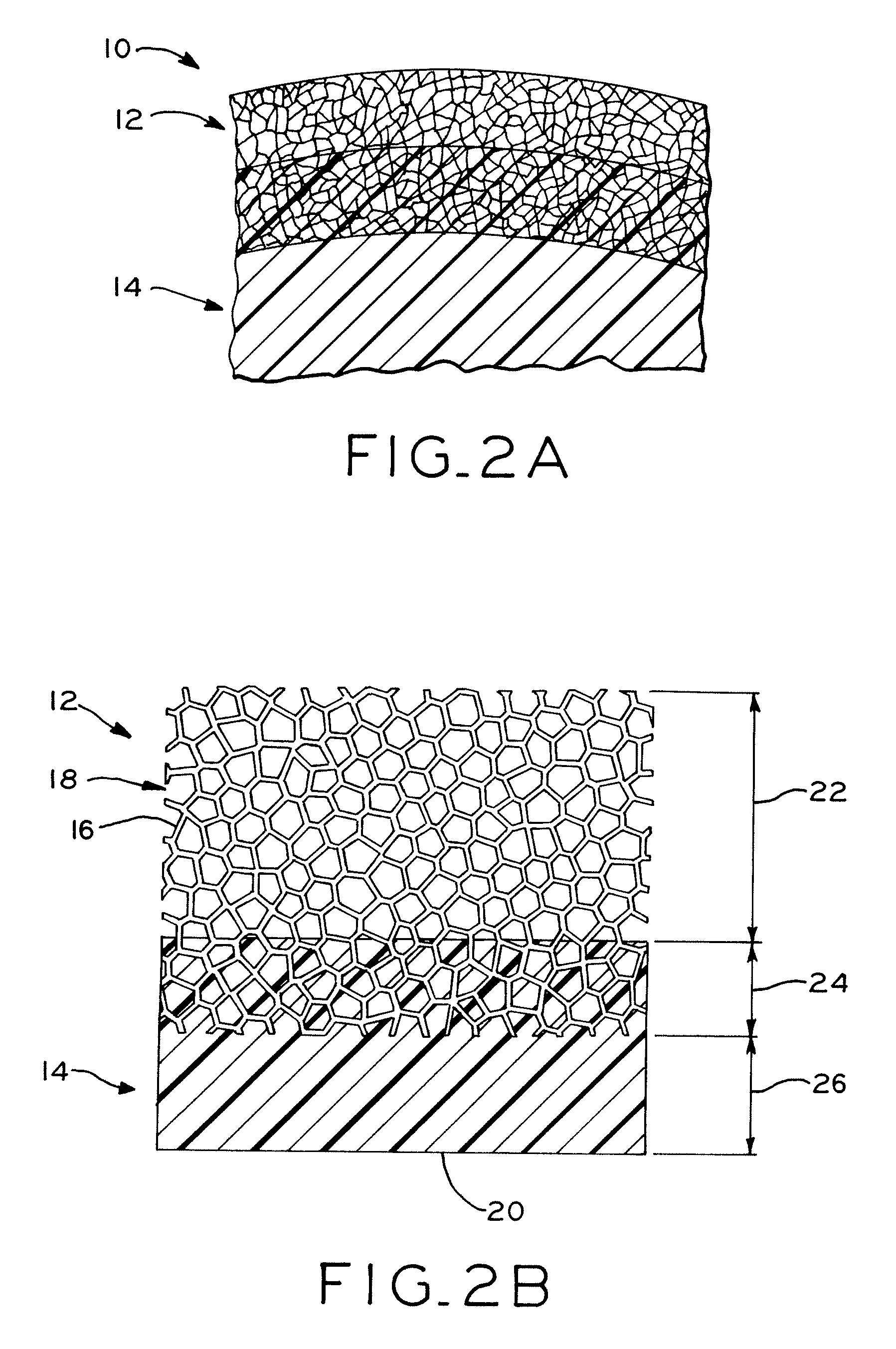

Orthopedic component of low stiffness

ActiveUS20090192610A1Component can be removedReduce the impactBone implantSynthetic resin layered productsAcetabular linerPlastic surgery

An orthopedic component having multiple layers that are selected to provide an overall modulus that is substantially lower than the modulus of known orthopedic components to more closely approximate the modulus of the bone into which the orthopedic component is implanted. In one exemplary embodiment, the orthopedic component is an acetabular shell. For example, the acetabular shell may include an outer layer configured for securement to the natural acetabulum of a patient and an inner layer configured to receive an acetabular liner. The head of a femoral prosthesis articulates against the acetabular liner to replicate the function of a natural hip joint. Alternatively, the inner layer of the acetabular shell may act as an integral acetabular liner against which the head of the femoral prosthesis articulates.

Owner:ZIMMER INC

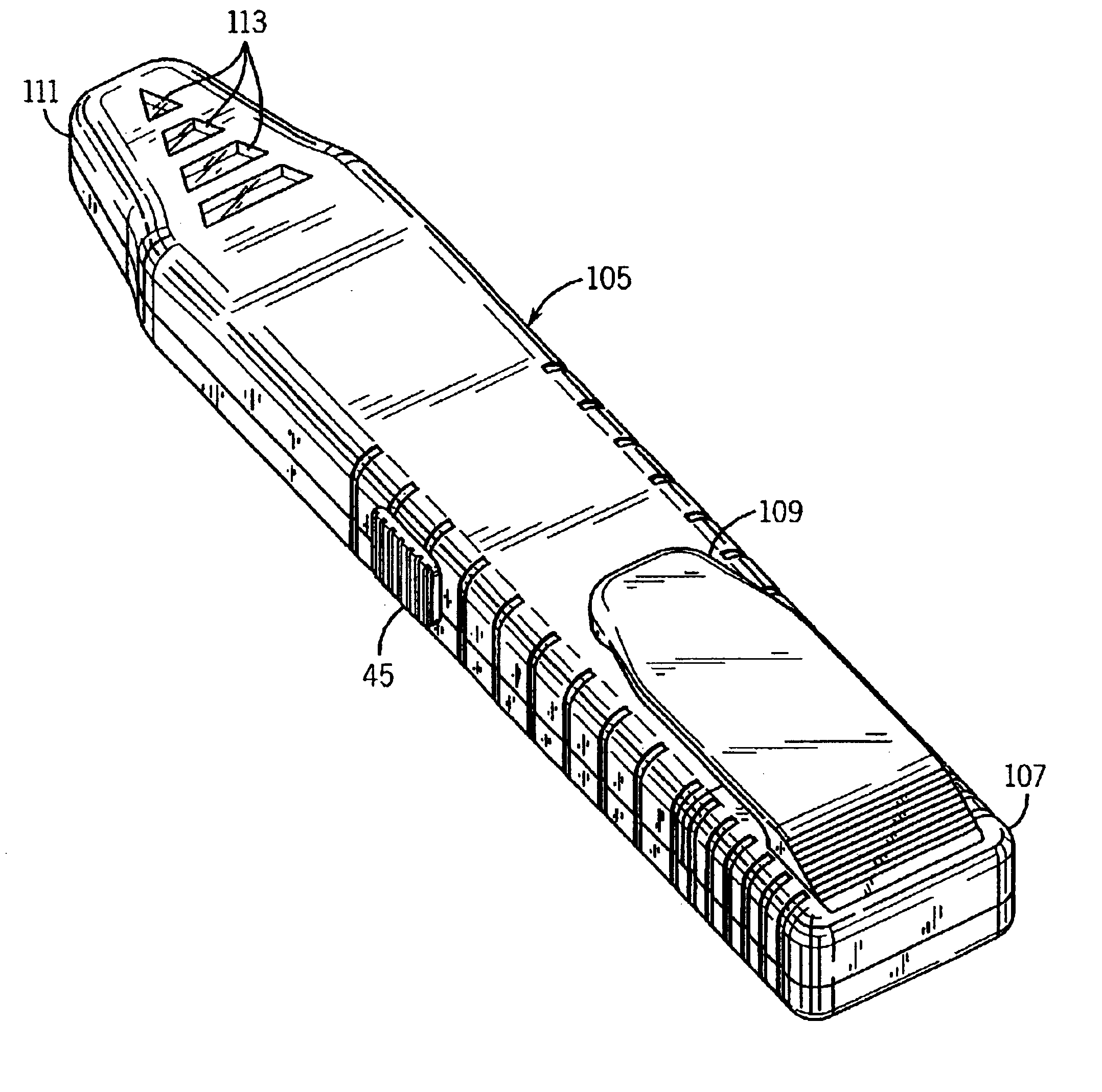

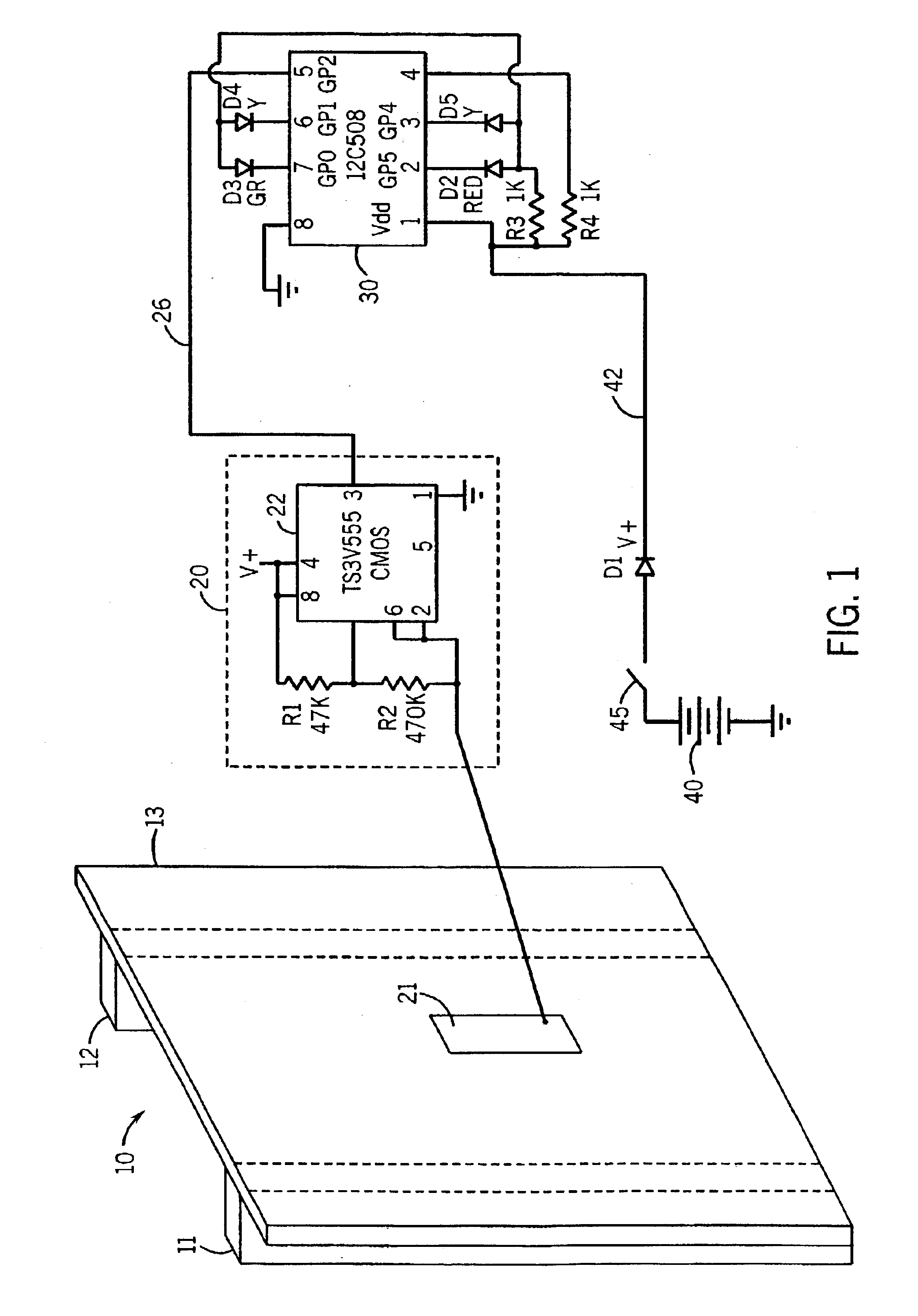

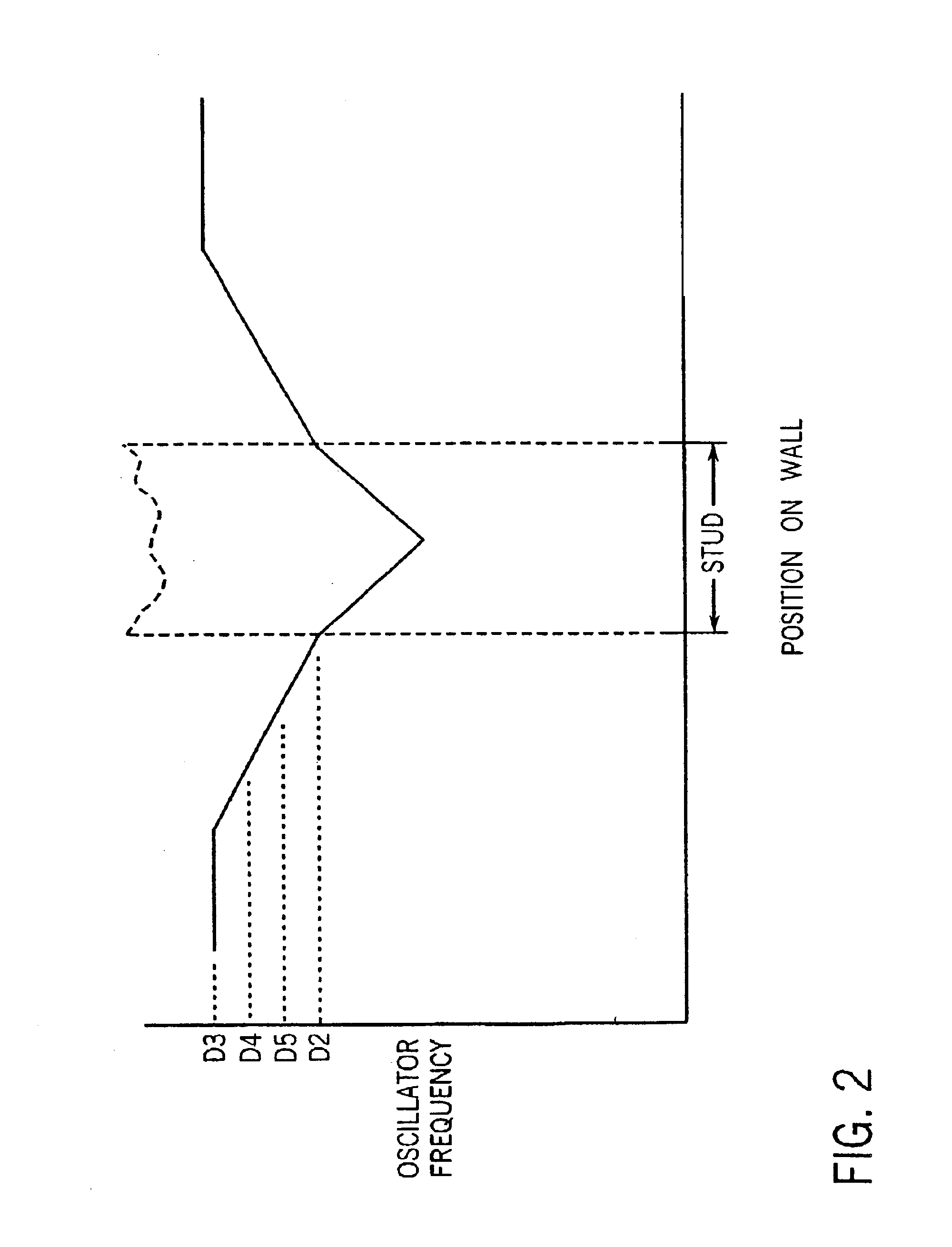

Compact stud finder

InactiveUS6844713B2Efficiently finding locationEasy to keepResistance/reactance/impedenceCurrent/voltage measurementCapacitanceCapacitor

A pocket-sized object finder has a compact housing containing a battery, circuitry and a capacitor plate for detecting an object hidden behind a wall. The battery powered circuitry includes multiple signal indicators that illuminate in a serial manner when the object is being detected. The signal indicators are successively tapered and are mounted at a front side of a tapered end of the housing. The capacitor plate is disposed in the housing along its rear wall and is responsive to variations in capacitance that occur as the object finder is brought near and over the object. The compact housing defines a cavity with a width that is no more than two inches and one third its length. A removable access door, with a pocket clip, at an end opposite the signal indicators allows access to the battery within the housing cavity.

Owner:ACTUANT CORP

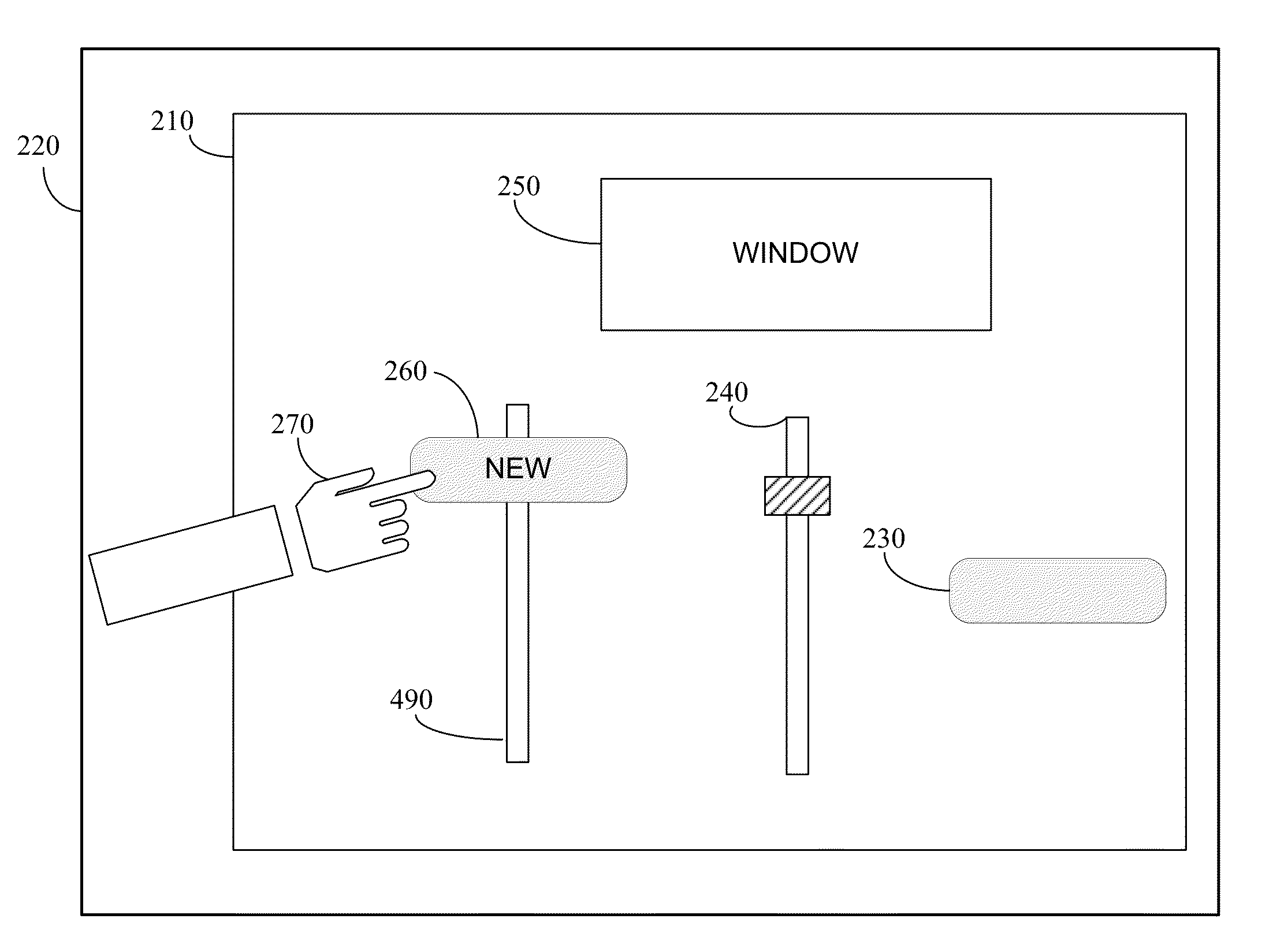

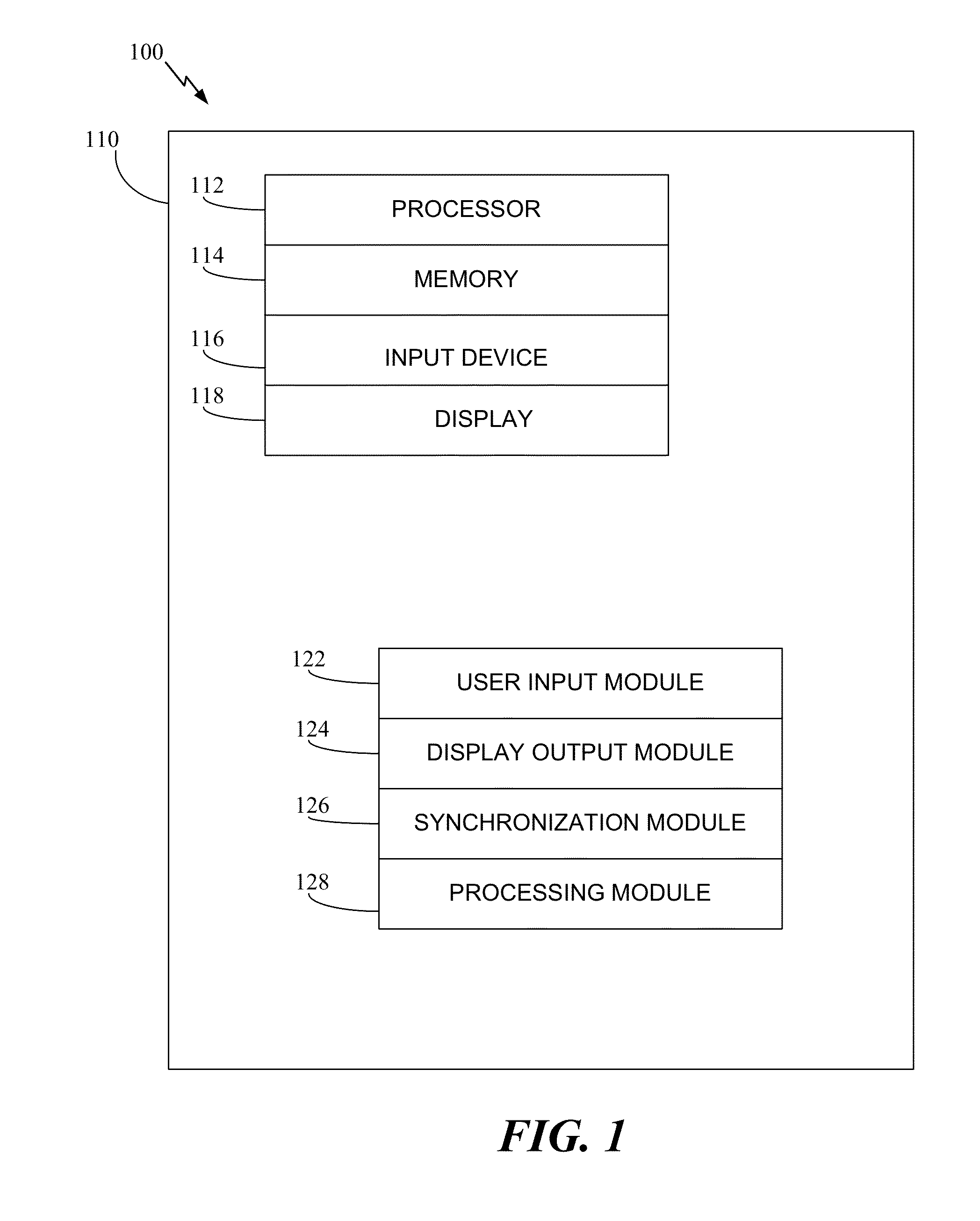

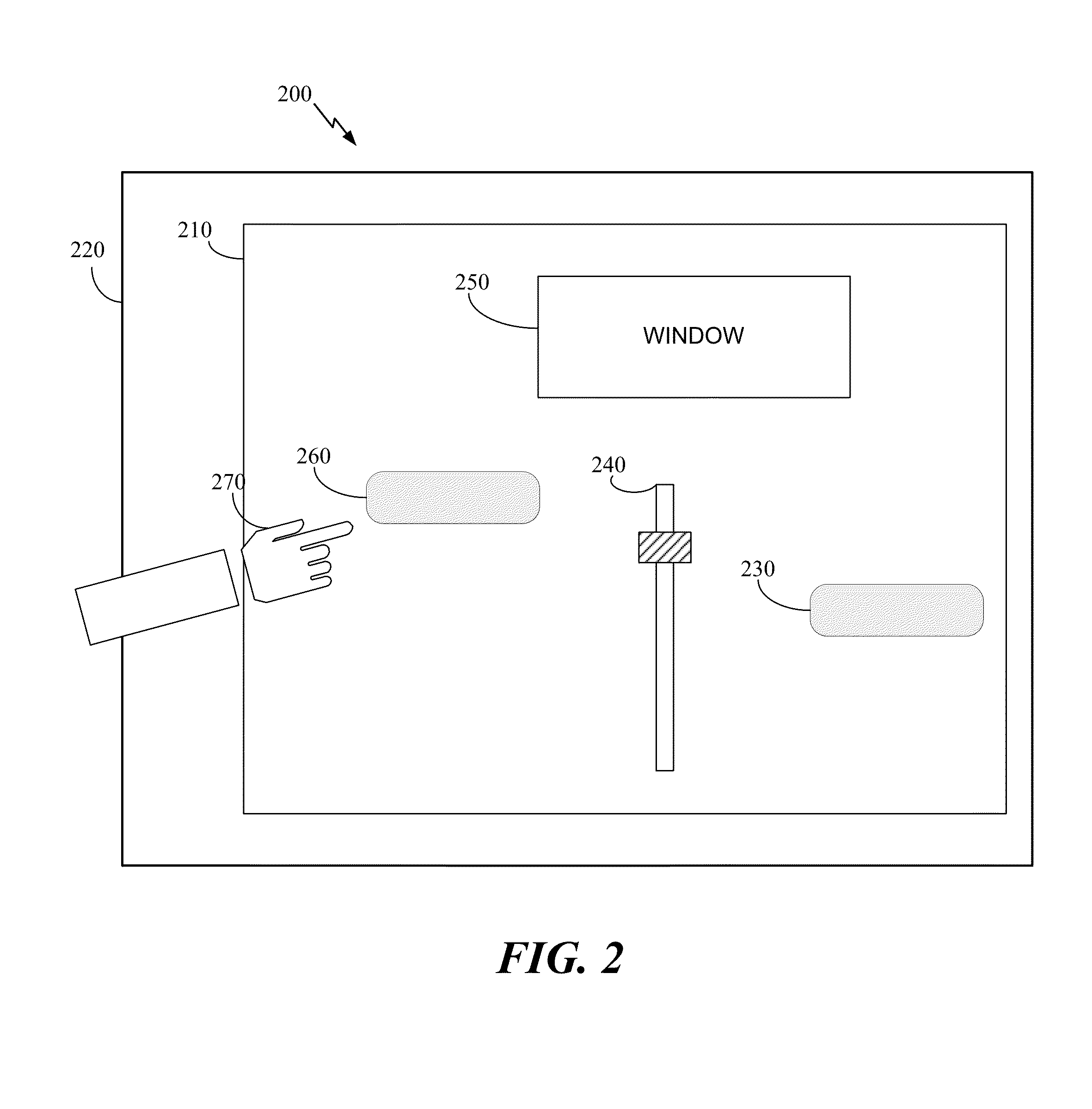

Composite control for a graphical user interface

InactiveUS20130014057A1Easy to keepGood lookingInput/output processes for data processingGraphicsGraphical user interface

A system and method for manipulating computer data using a new GUI element is disclosed. In a particular embodiment, the new GUI element is a composite of a traditional GUI button control and a traditional GUI slider control. In one embodiment, a composite slidable button control appears and functions similar to a traditional button control on the GUI. Dragging the composite control past its predetermined anchor distance un-anchors the composite control allowing it to travel similar to a traditional slider control, optionally constrained in direction(s) and distance(s) by predetermined settings. During the slider adjustment phase, the composite control can optionally overlap other GUI elements realizing a more compact and efficient GUI appearance. In another embodiment, a composite clickable slider control appears and functions similar to a traditional slider control on the GUI. Clicking on the composite control's slider handle invokes the button functionality while dragging the handle invokes the slider functionality, again affording the composite control the ability to function as both a button and a slider control.

Owner:THERMAL MATRIX USA

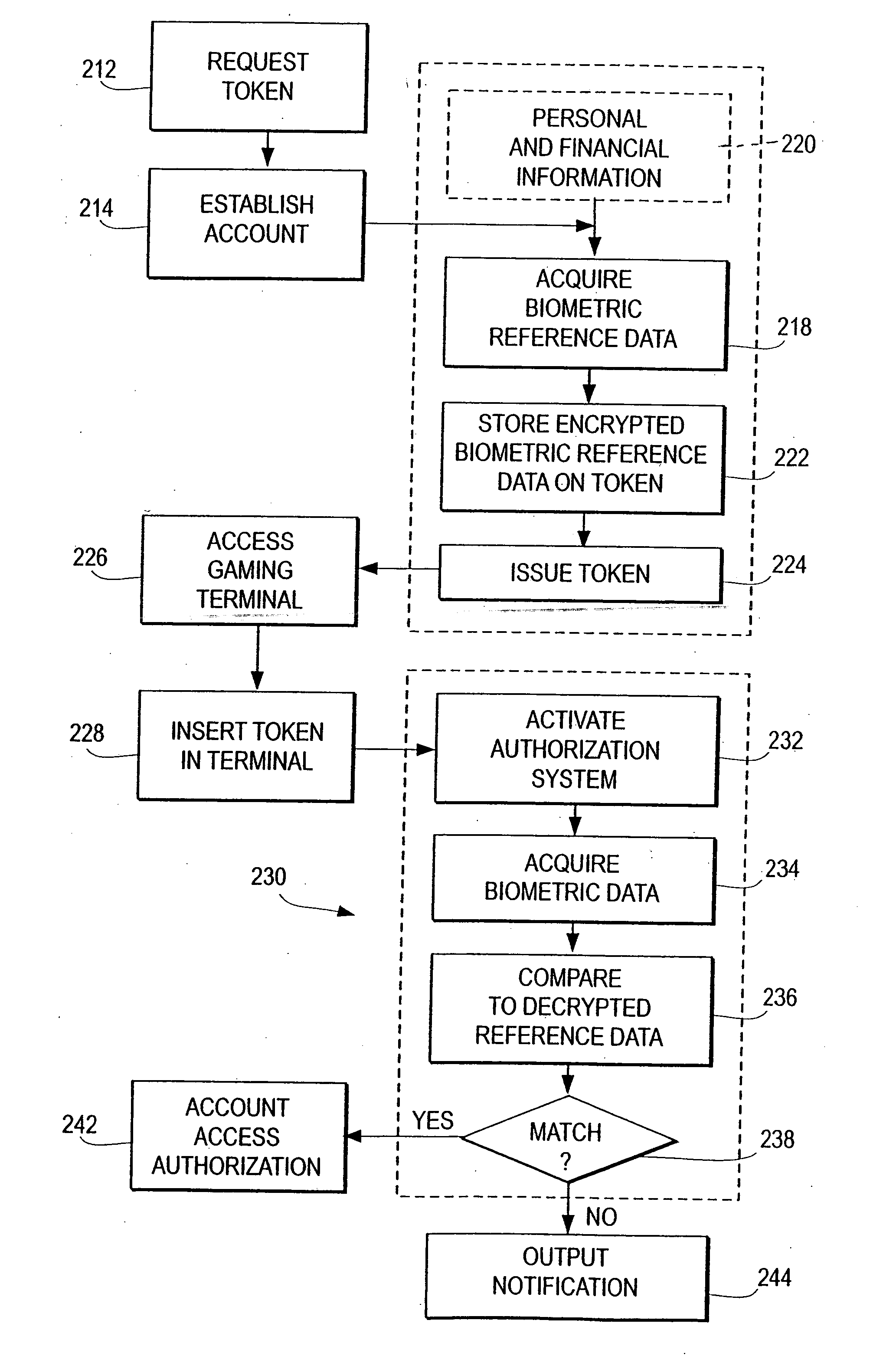

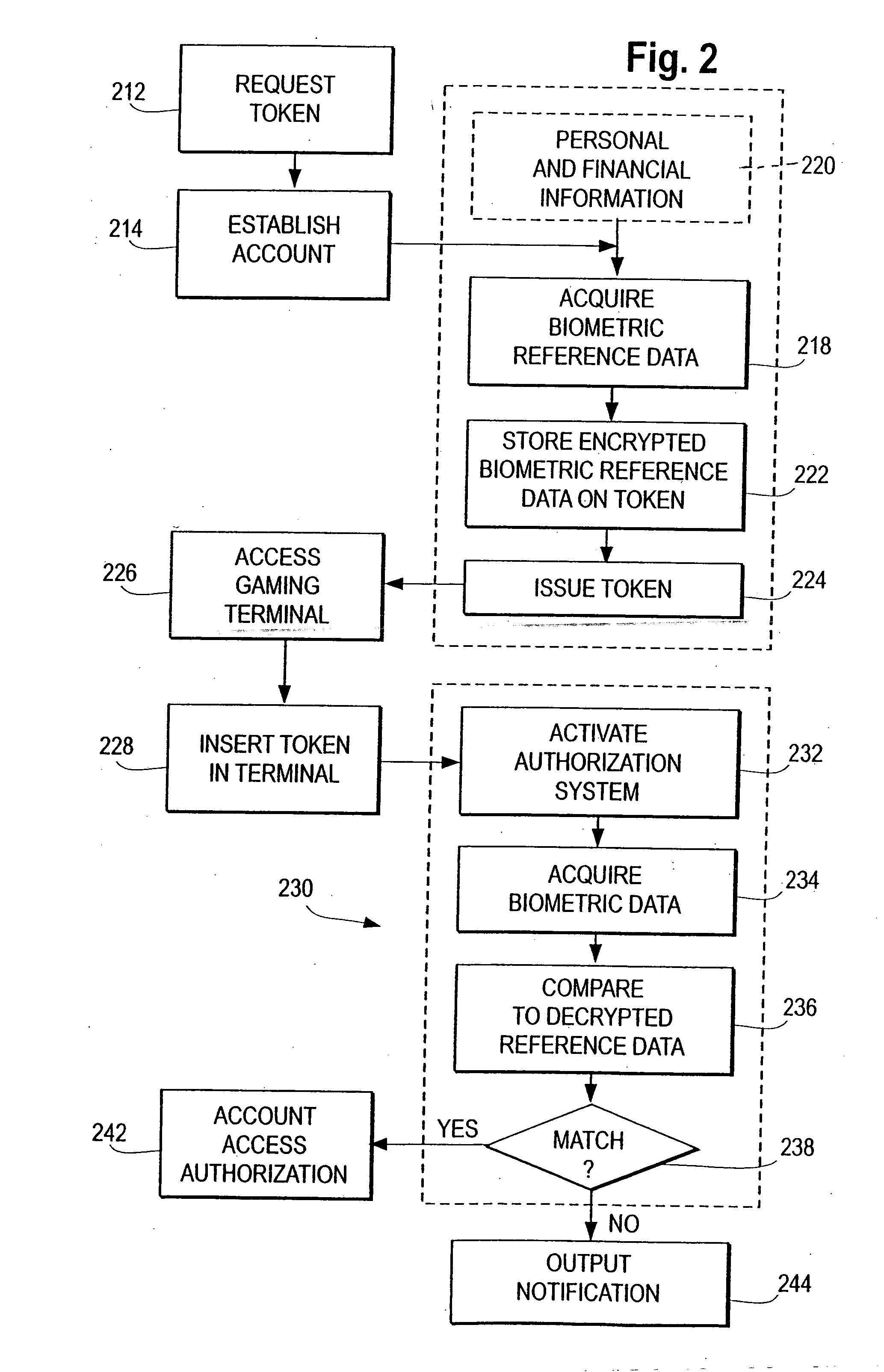

Gaming terminal and system with biometric identification

ActiveUS20060205497A1Low costAvoid delayBoard gamesComputer security arrangementsBiometric dataSmart card

A gaming system is provided with biometric facilities for identifying or verifying the identity of a player or perspective player. In one aspect reference biometric data is stored in a portable biometric data storage device such as a smart card, PCMCIA card or the like and is preferably left in the possession or control of the individual or individuals to whom the biometric data relates. The reference biometric data is read in individual gaming terminals and compared, in individual gaming terminals to measured biometric data of a player or perspective player. In one aspect, gaming terminals use biometric verification or indication to implement a practical and feasible cashless gaming terminal.

Owner:IGT

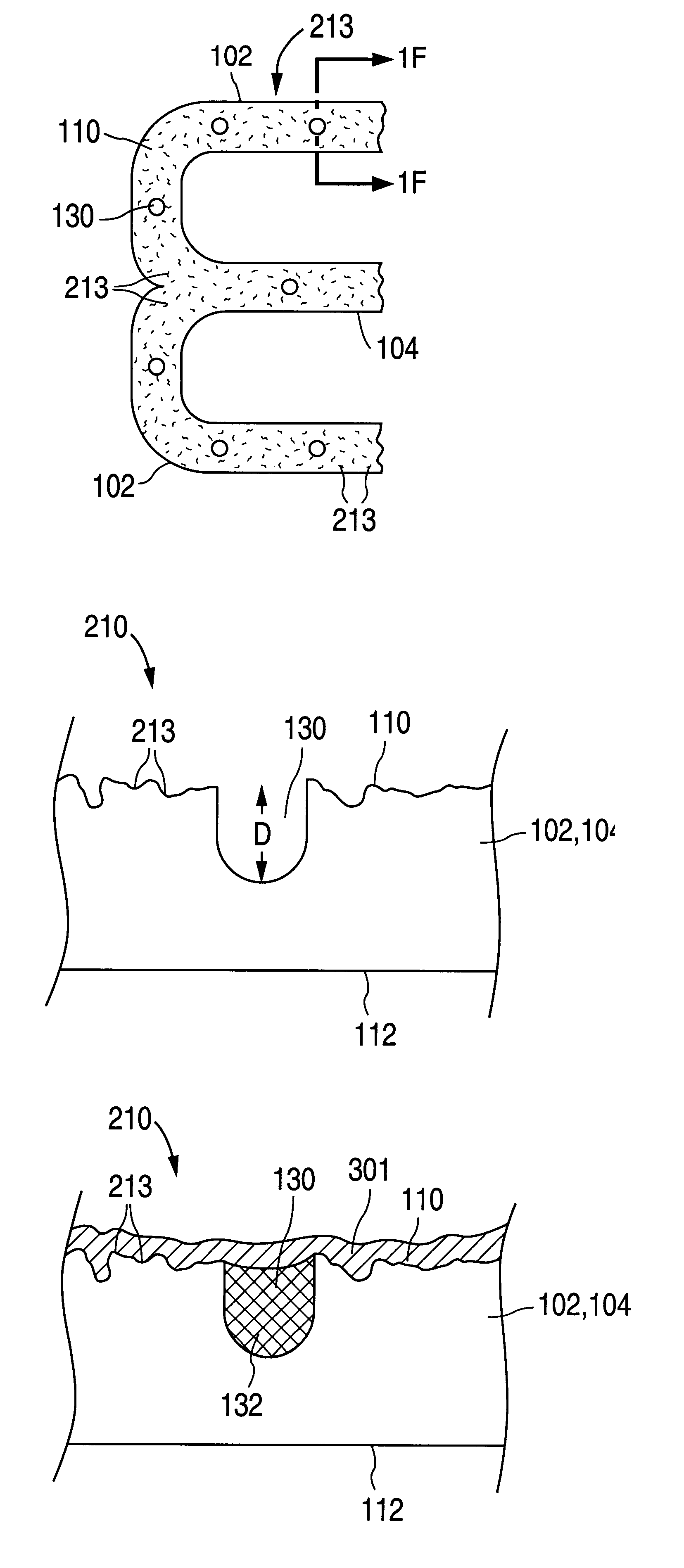

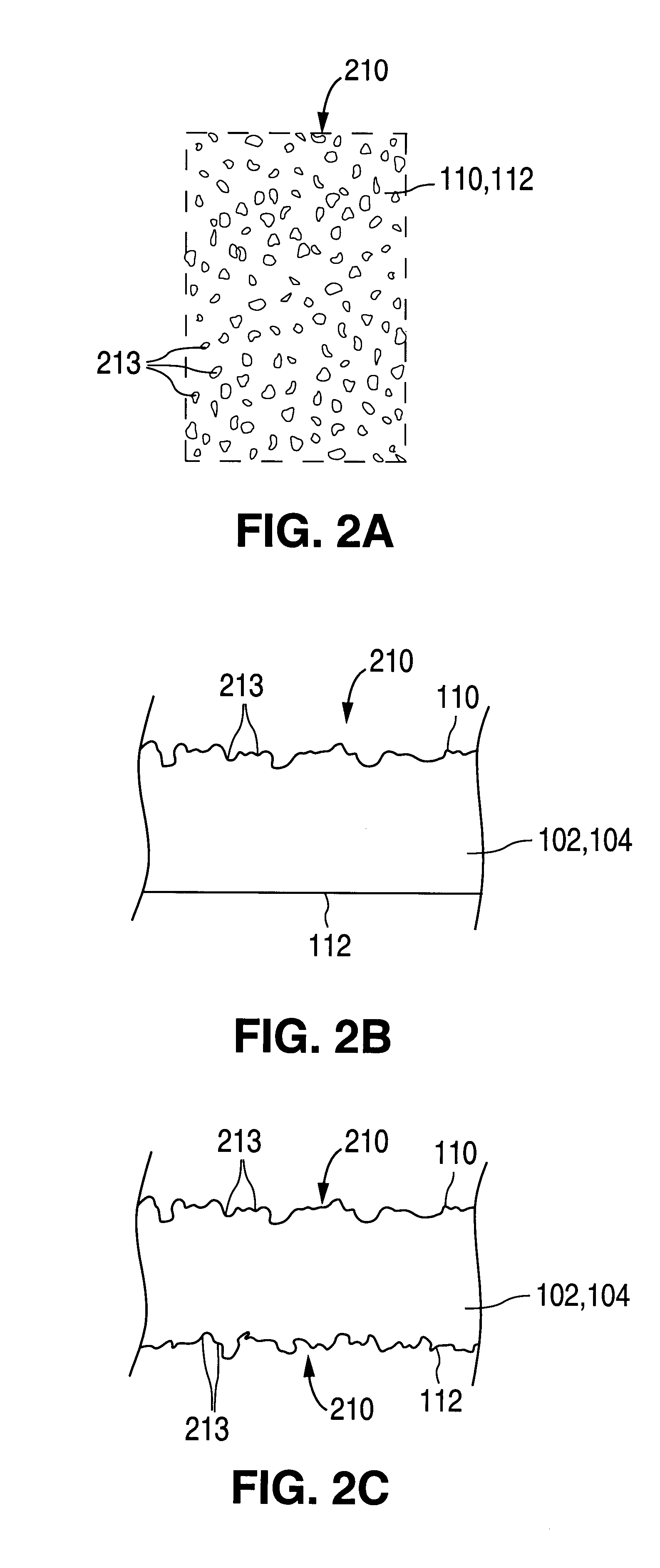

Method for creating a textured surface on an implantable medical device

InactiveUS6913617B1Great amount of therapeuticEasy to keepBlood vesselsElectricityElectric discharge

A method for forming an implantable medical device, such as a stent, is provided, in which electric discharges are applied to a metal surface of the implantable medical device. The electric discharges pit the surface. The pitted surface improves retention of a coating on the device and increases the amount of coating that can be carried by the device. An electric discharge machining process is described for applying electric discharges to the surface of the implantable medical device or portion thereof.

Owner:ABBOTT CARDIOVASCULAR

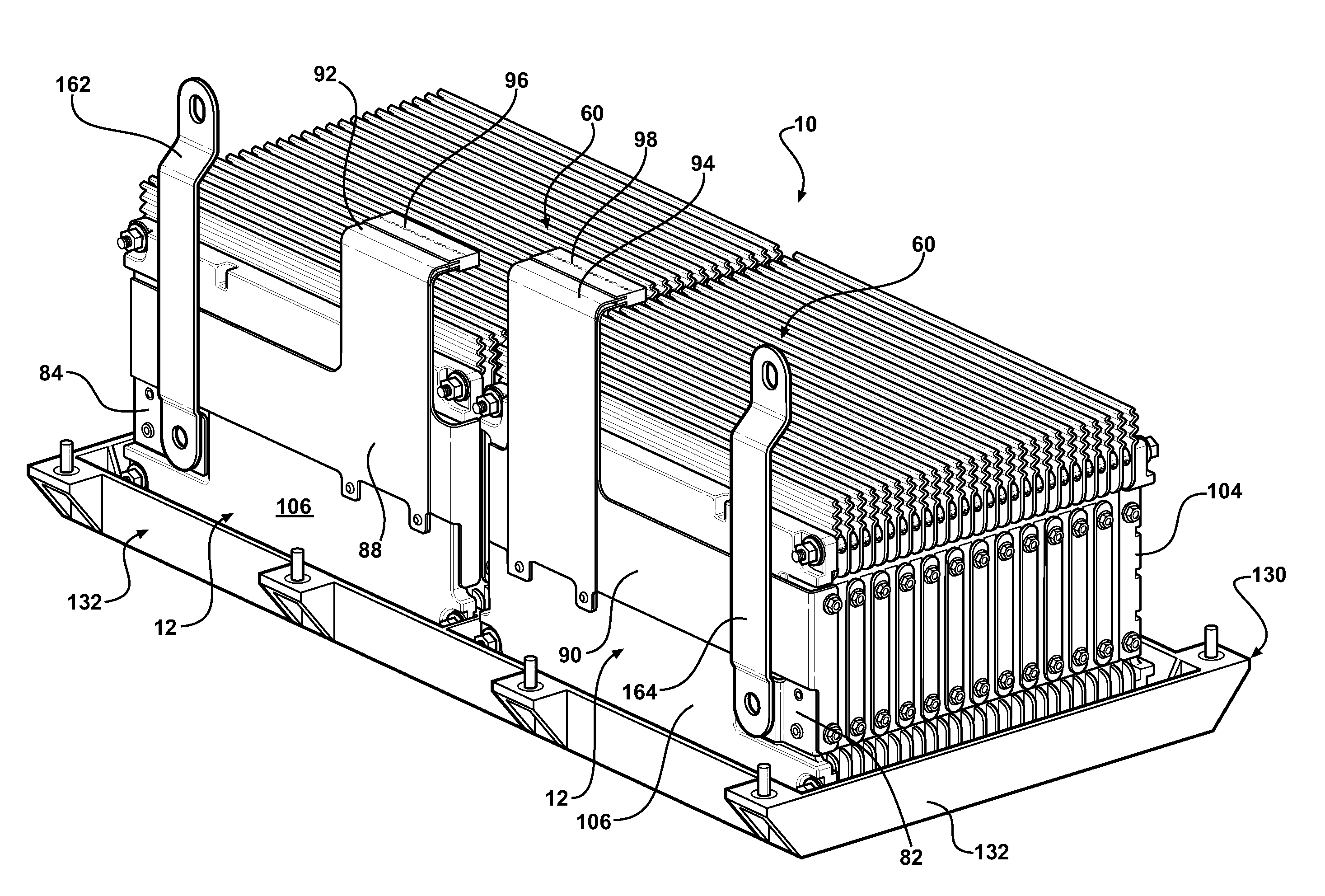

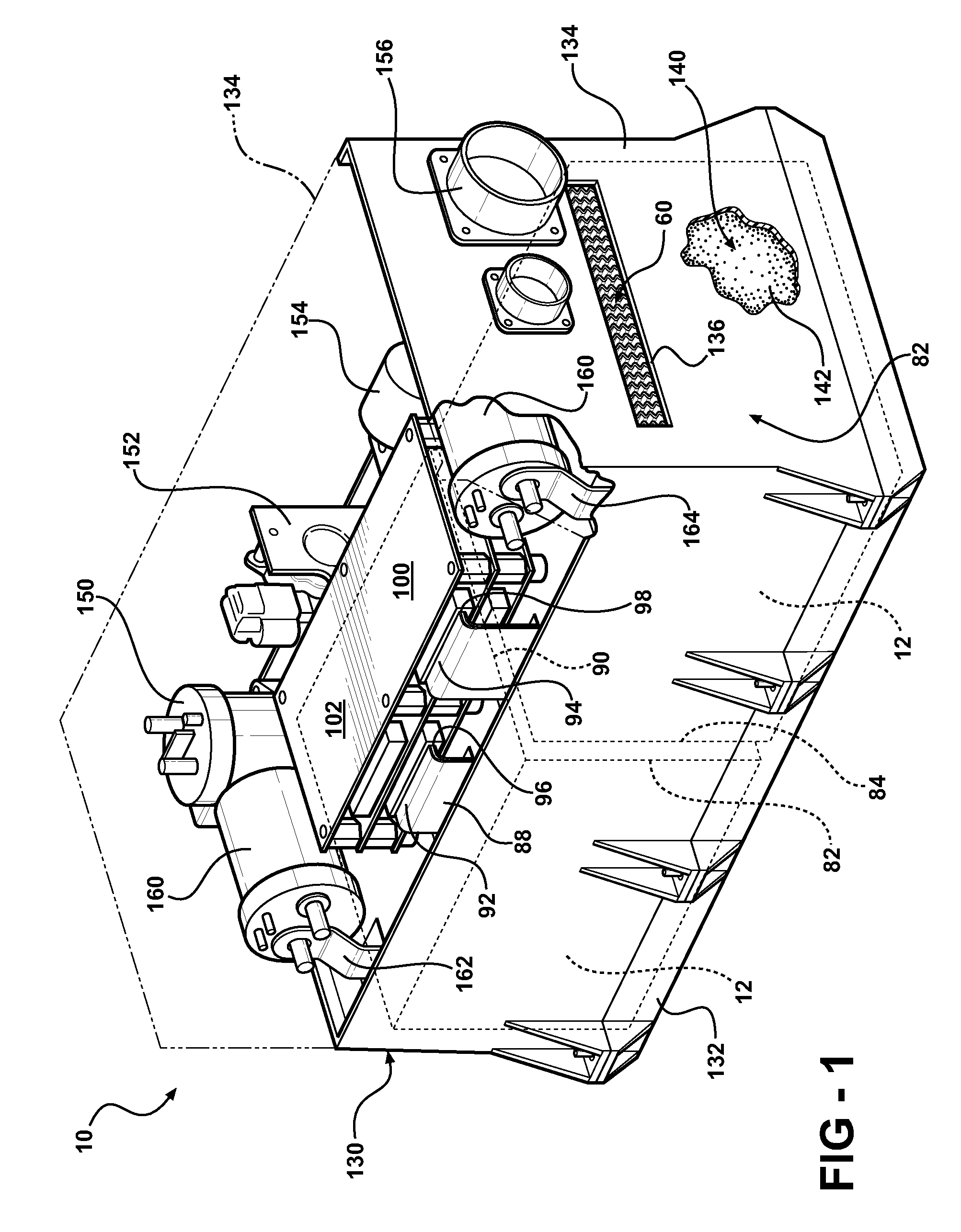

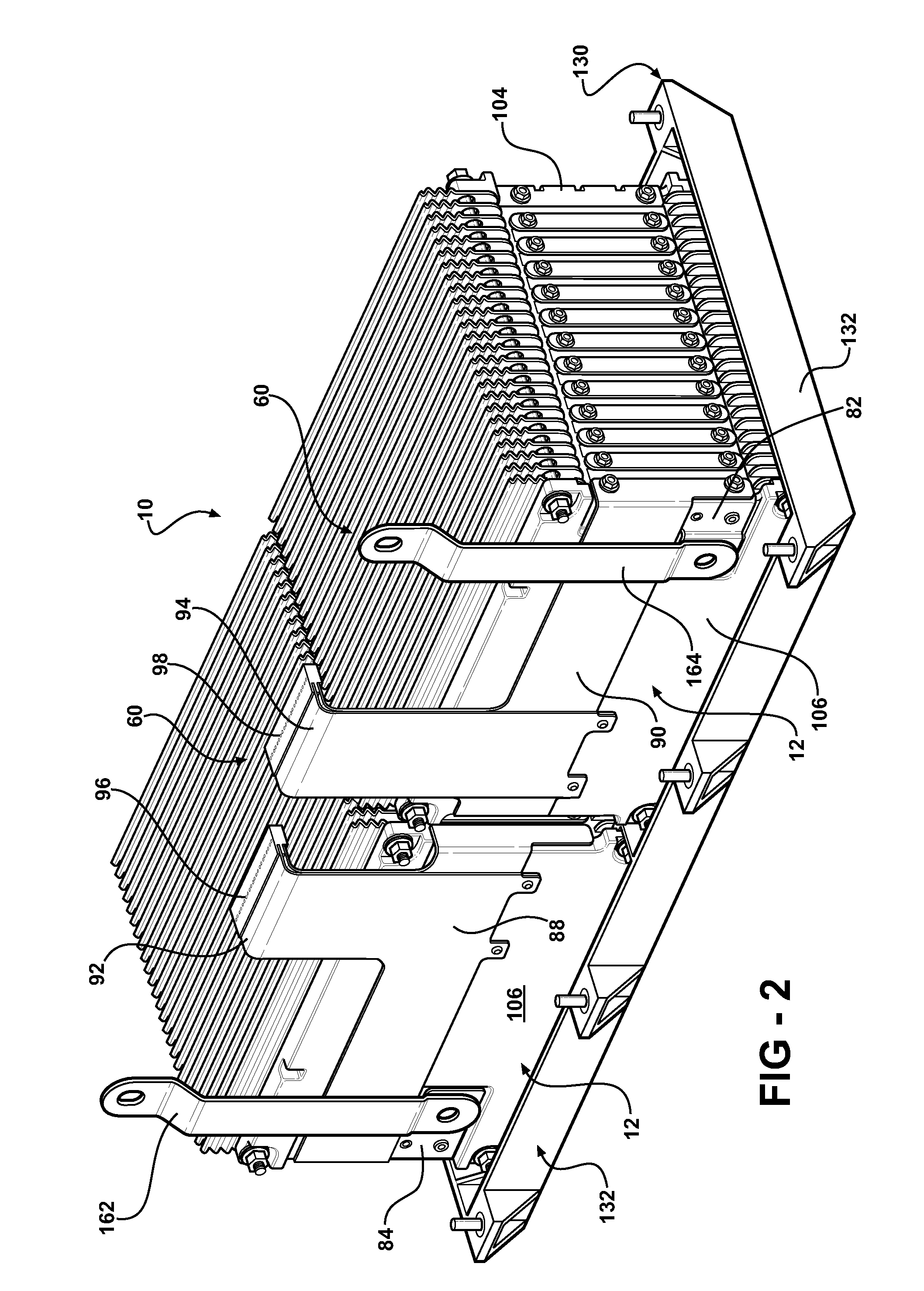

Battery pack with integral cooling and bussing devices

ActiveUS7531270B2High densityIncrease energy densityFinal product manufactureCell temperature controlMobile vehicleBattery cell

A battery module of the present invention is adaptable to be utilized in various configurations including and not limited to an overlapping battery cell packaging configuration and a vertical stack battery cell packaging configuration used in an automotive vehicle. The battery module has a plurality of battery heatsink assemblies with the cells disposed therebetween. A plurality of rods extend through the each heatsink assemblies to secure the heatsink assemblies and the cell with one another to form the battery module.

Owner:ENERDEL

Seed coatings, coating compositions and methods for use

InactiveUS20120220454A1Promote seedling establishmentEasy to keepBiocideDead plant preservationCoatingFood science

Coating compositions and methods of use, allowing for improved water and / or nutrient usage by seeds, plants, shrubs, and vegetation, among others, are disclosed.

Owner:RHODIA OPERATIONS SAS

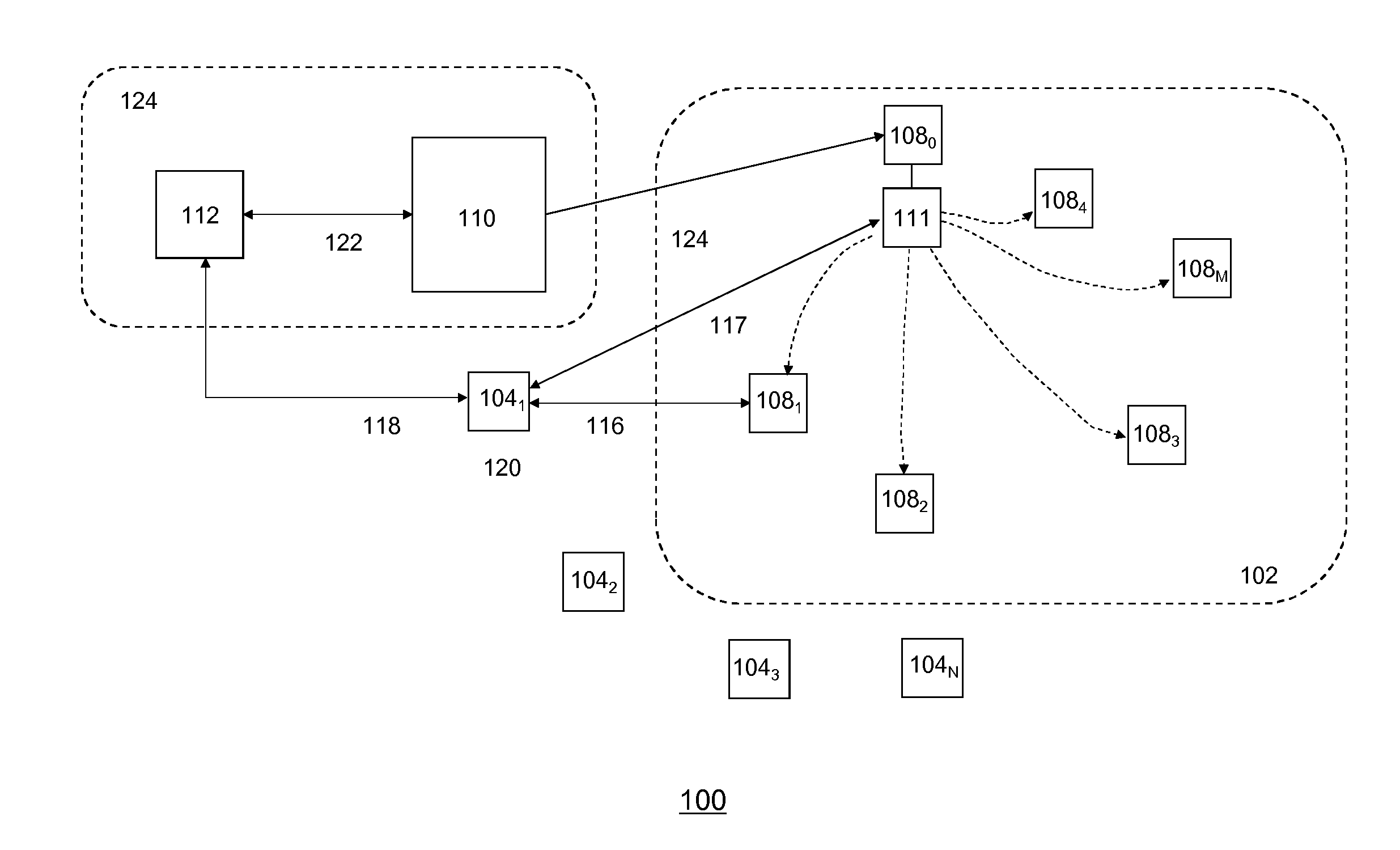

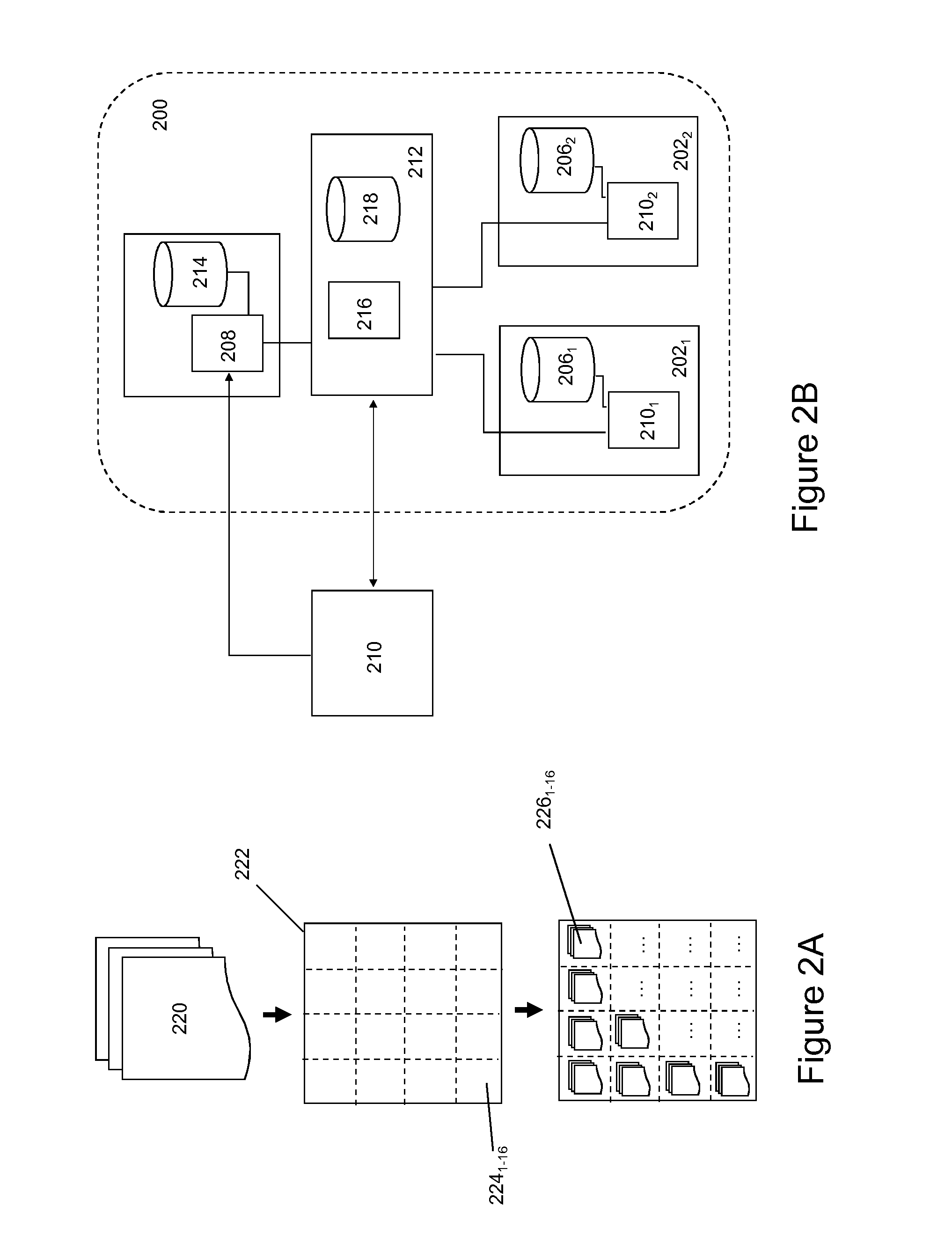

Spatially-Segmented Content Delivery

ActiveUS20140089990A1Effectively actFunction increaseTelevision system detailsColor television detailsClient-sideContent delivery network

Methods and systems are described for processing spatially segmented content originating from a content delivery network. One method comprises a client in a media processing device receiving a spatial manifest information comprising one or more spatial representations of a source stream, each spatial representation identifying one or more spatial segment streams, location information for locating one or more delivery nodes in said content delivery network and, optionally, position information for stitching spatial segment frames in said segment streams into a video frame for display; selecting one or more spatial segment streams and on the basis of said spatial manifest information requesting at least one delivery node in said content delivery network to transmit said one or more selected spatial segment streams to said client; and, receiving said one or more selected spatial segment streams from said at least one delivery node.

Owner:KONINK KPN NV

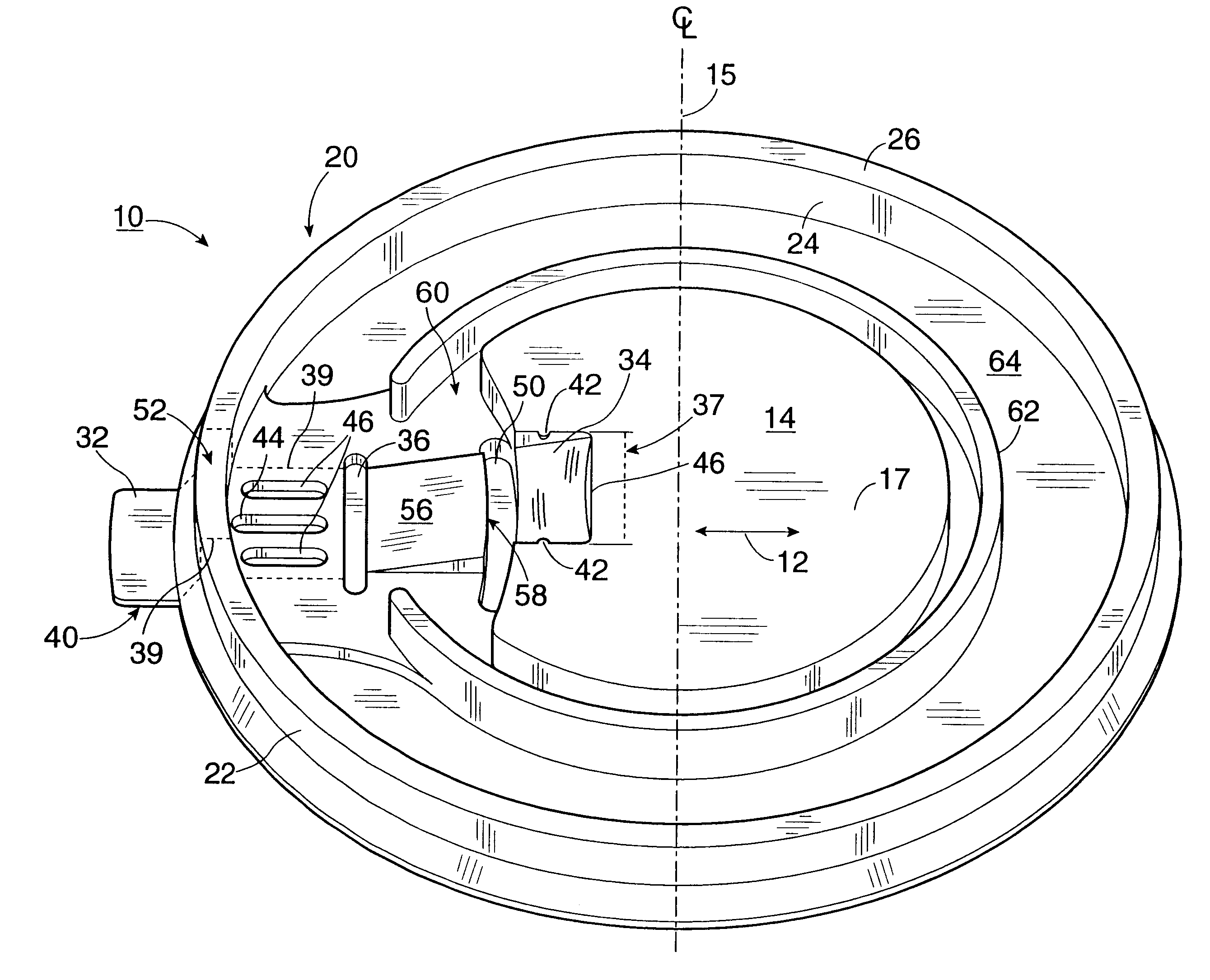

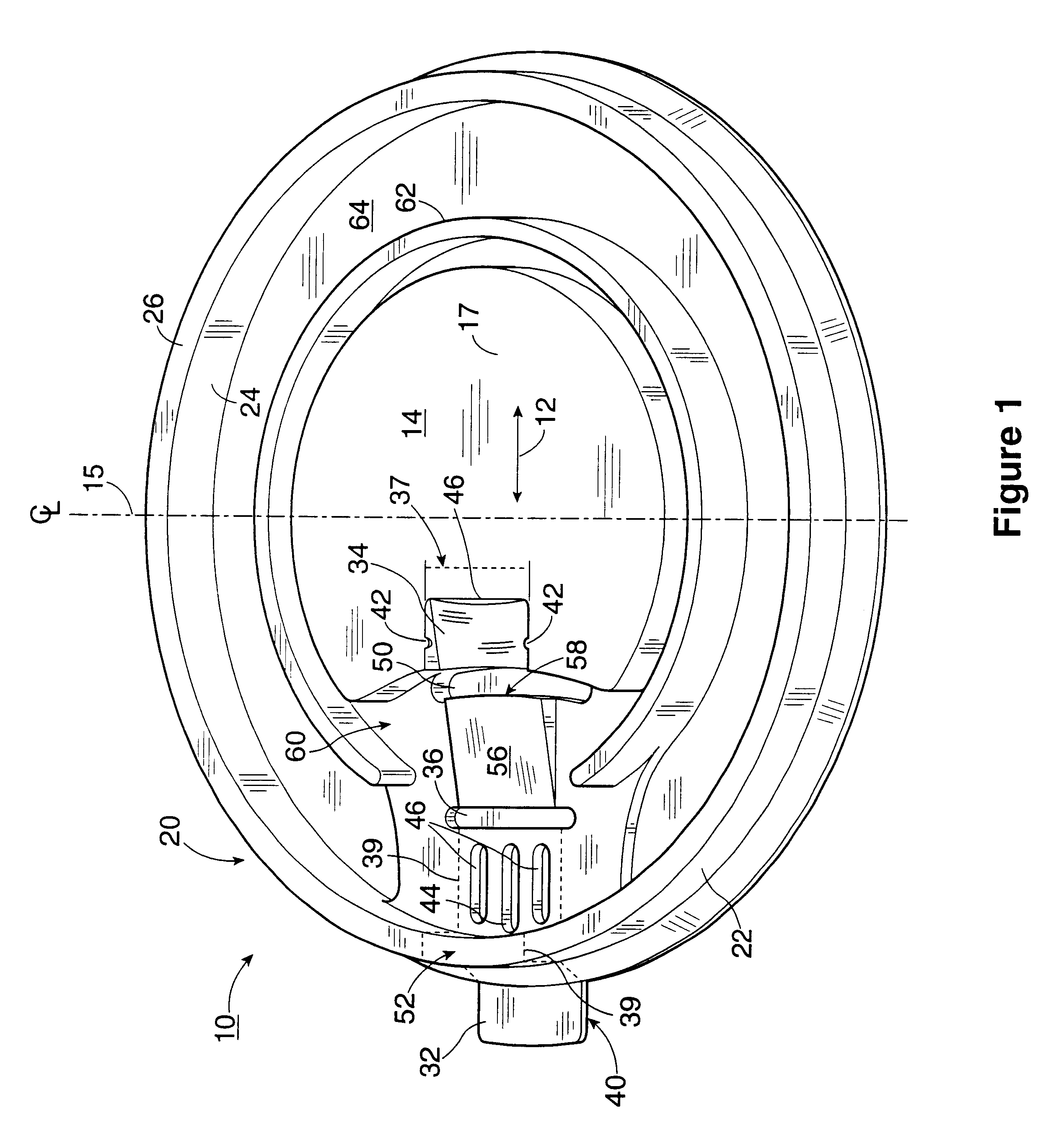

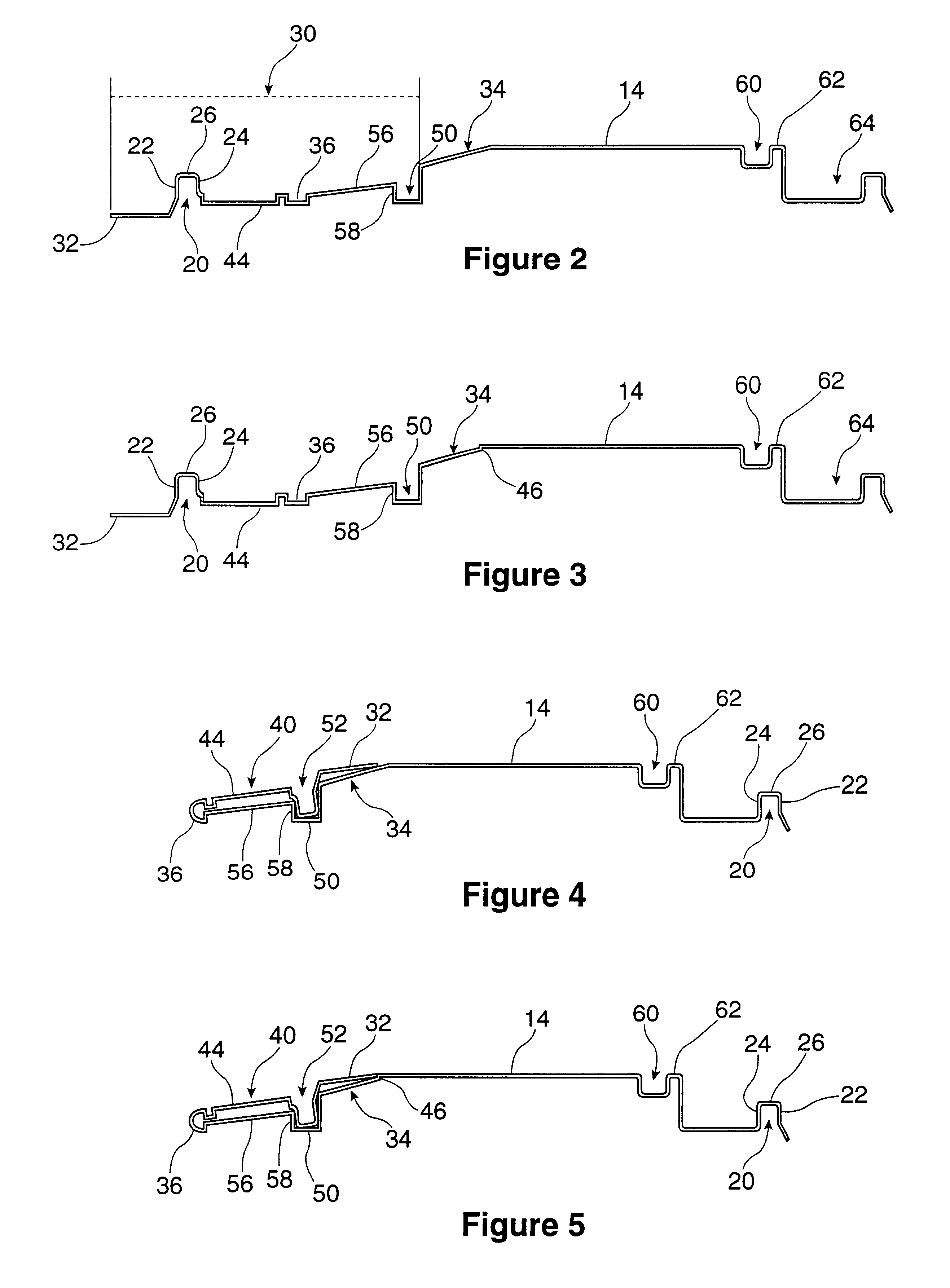

Disposable cup lid having fold back retainer

A disposable cup lid for placement onto a drinking cup is provided, having a tear tab which is generally aligned with the orientation of the extruded plastic sheet material from which the cup lid is made. There is a first, generally centrally located region in the lid, which has a higher elevation than the cup rim receiving recess at the periphery of the lid; and there is an indentation formed in the central region which is provided so as to accommodate the tear tab when it is folded back around a U-shaped hinge to create a drink-through opening in the cup lid. The indentation has a pair of detents located at its edges so as to hold and retain the tear tab in place when the foldback flap is folded back about the U-shaped hinge and the tear tab is inserted into the indentation. The tear tab is retained below the plane of the central region of the cup lid.

Owner:AMHIL ENTERPRISES

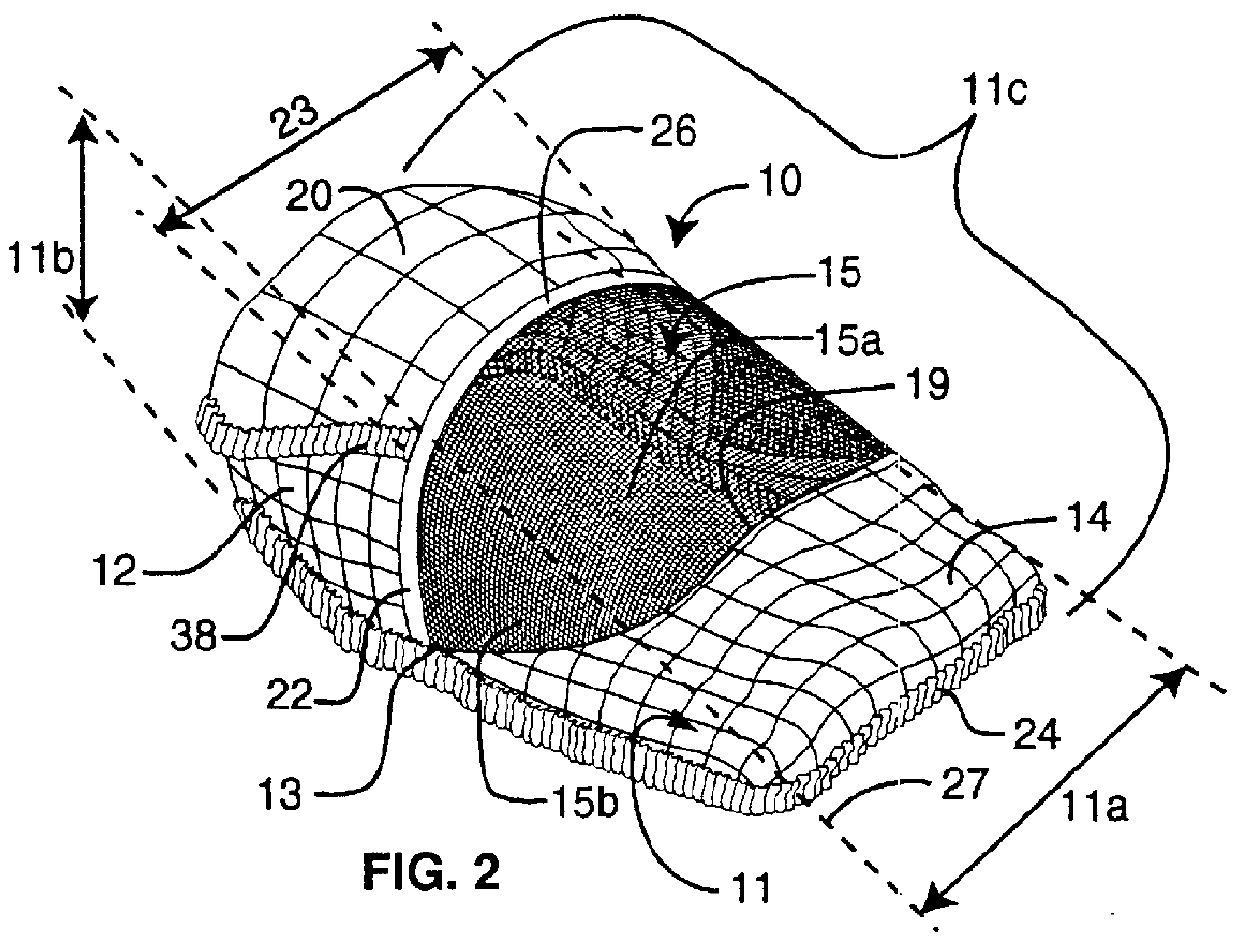

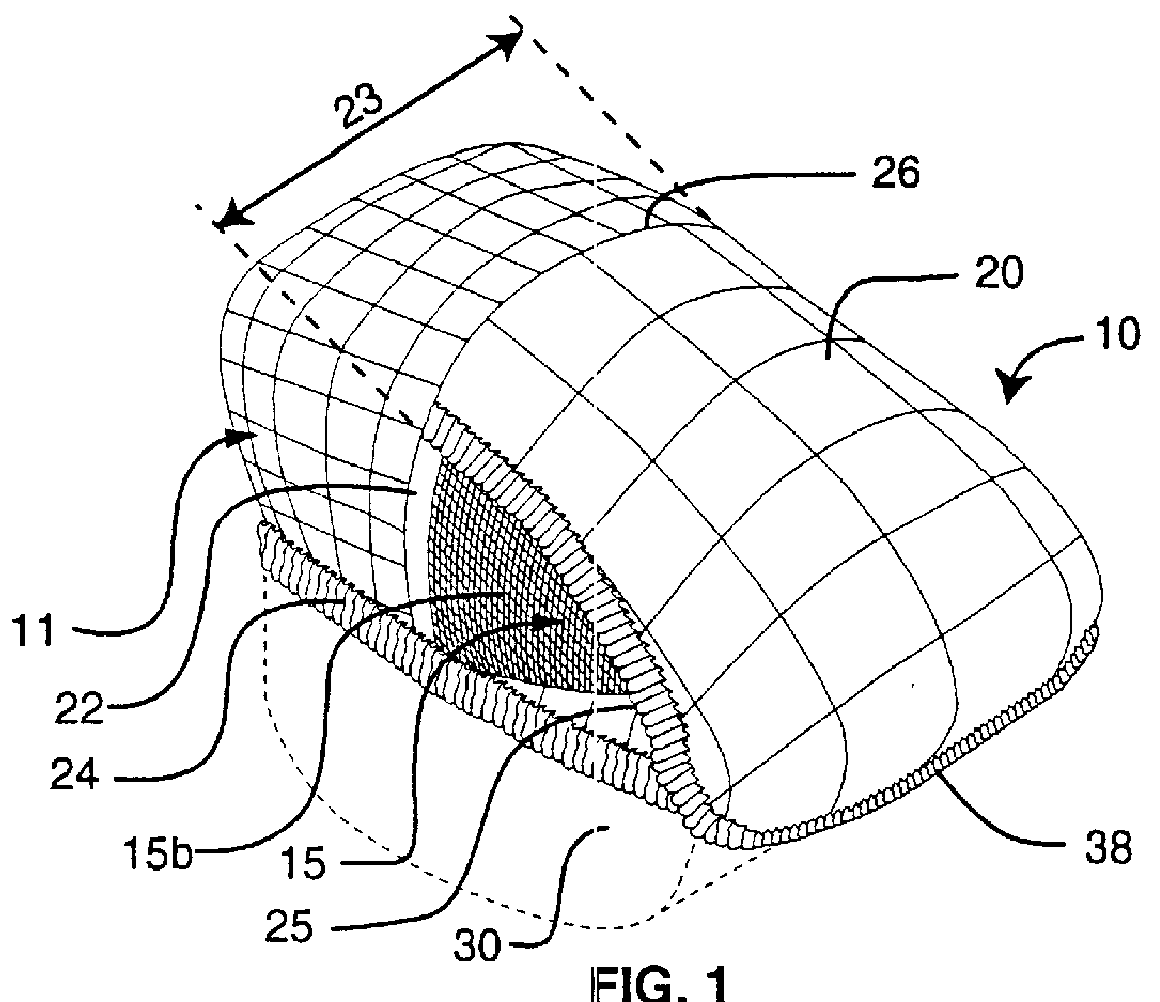

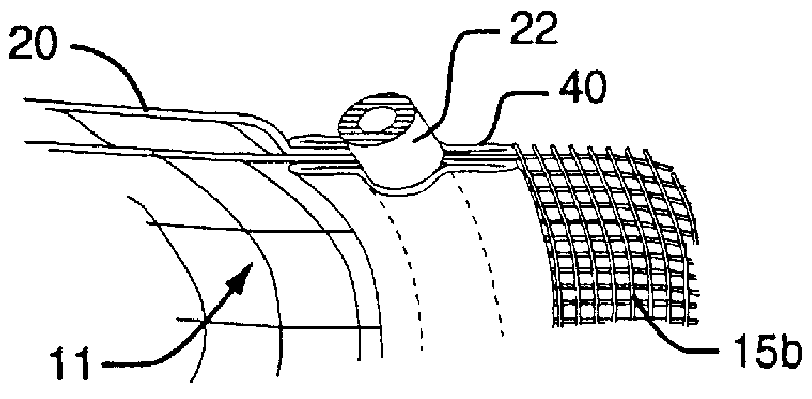

Protective cover for baby seats

A protective cover (10) is disclosed that can be interchanged among a variety of baby seats. It includes a canopy (11) and a sealing element (22) that can interchangeably and flexibly seal around a variety of baby seats. It may also contain a removable hood (20) that may shield a portion of an insect resistant mesh (15) so that a side mesh (15b) remains open for air and viewing of the occupant under the protective cover (10). Furthermore, the hood (20) may be attached at an approximate midpoint (26) of the canopy (11) to allow versatility in deploying the hood in a rearward direction and fastening the hood with attachment element (38). Likewise, the hood (20) may be folded in a forward direction and attached with attachment element (38) to a forward contour of a baby seat. The protective cover may include a protective foot shield (14) located under the hood (20) that may protect, for instance, feet of an occupant from a stinger or biting proboscis of a flying insect when the feet may touch the inside surfaces of the cover. Another feature of the present invention may include the ability of the present invention to be folded to a reduced state for easy storage and held in the reduced state by an integral restraining element which could be the hood (20). Another feature could be an inclement weather filtering configuration of mesh that could be located on the side to filter light, for instance, to a reduced level for the occupant's comfort.

Owner:ROH WARREN E

Anchoring assembly for a medical instrument

InactiveUS6908454B2Overcome disadvantagesOvercome problemsCannulasSurgical needlesEngineeringBody cavity

An anchor assembly for retaining a cannula or other medical instrument within a body cavity and including an inflatable member selectively disposed between an expanded position and a collapsed position. A mounting assembly is cooperatively disposed and structured with a base, underlying the inflatable member, so as to mechanically attach the inflatable member to an exterior of the cannula. The mechanical attachment is accomplished by one or more retaining segments on the inflatable member being disposed in a compressed or sandwiched orientation between the base and the mounting assembly.

Owner:TELEFLEX MEDICAL INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com