Patents

Literature

85 results about "Cylindrical enclosure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

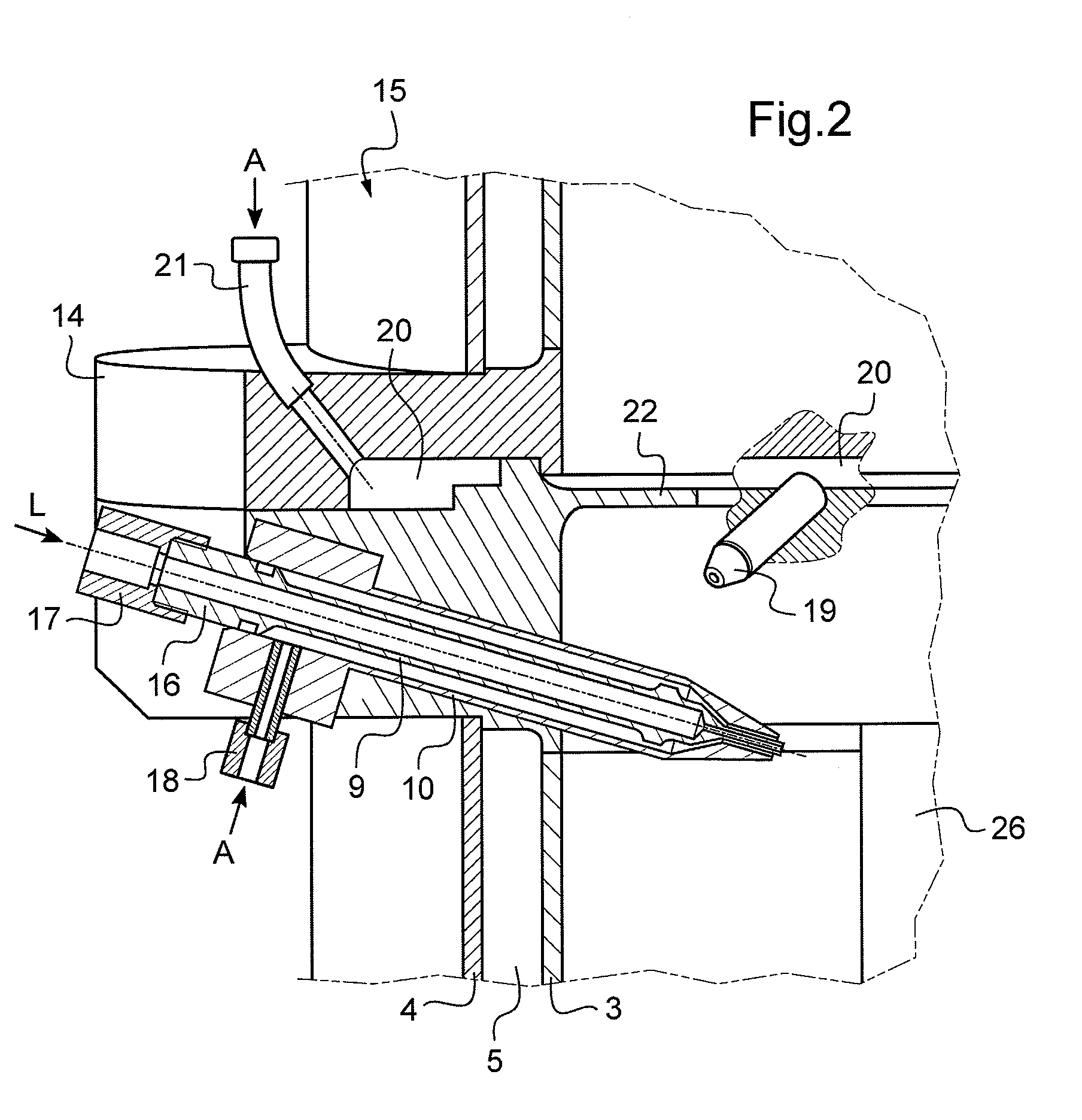

Intussusception and anastomosis apparatus

Apparatus for intratubular intussusception and anastomosis of a hollow organ portion including a cylindrical enclosure, coaxial intratubular intussusception device, for intussusception and clamping means. The apparatus also includes an intratubular anastomosis apparatus for joining organ portions after intussusception thereof with an anastomosis ring and crimping support element. The ring is formed of a shape memory alloy wire, for crimping adjacent organ portions against the crimping support element so as to cause anastomosis therebetween. The ring assumes a plastic or malleable state, at a lower temperature and an elastic state at a higher temperature. The apparatus further includes the crimping support element for intratubular insertion so as to provide a support for crimping the organ portions against the support element. The apparatus additionally includes a surgical excising means, for excising an intussuscepted organ portion, after crimping adjacent intussuscepted organ walls against the crimping support element with the anastomosis ring.

Owner:NITI SURGICAL SOLUTIONS

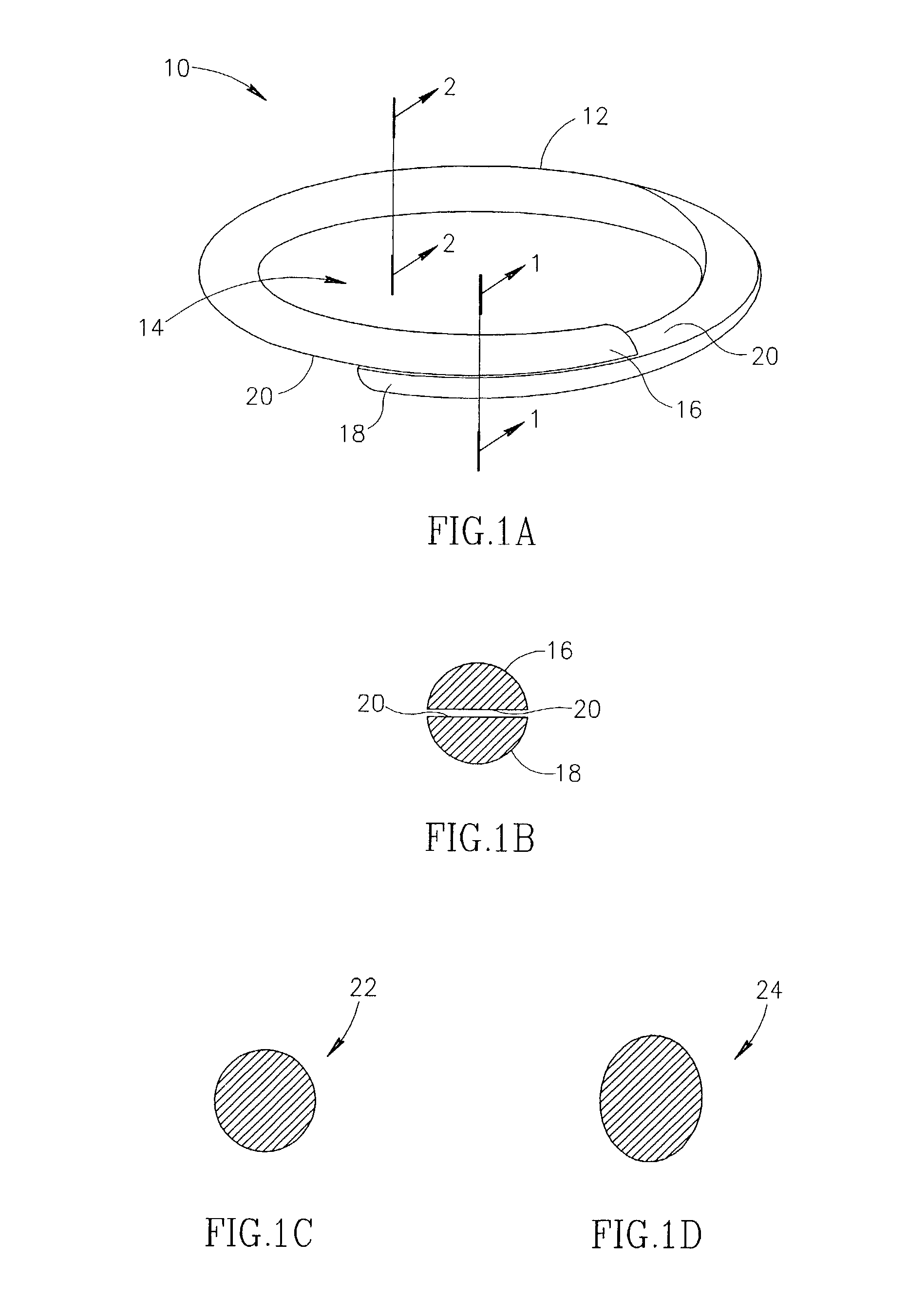

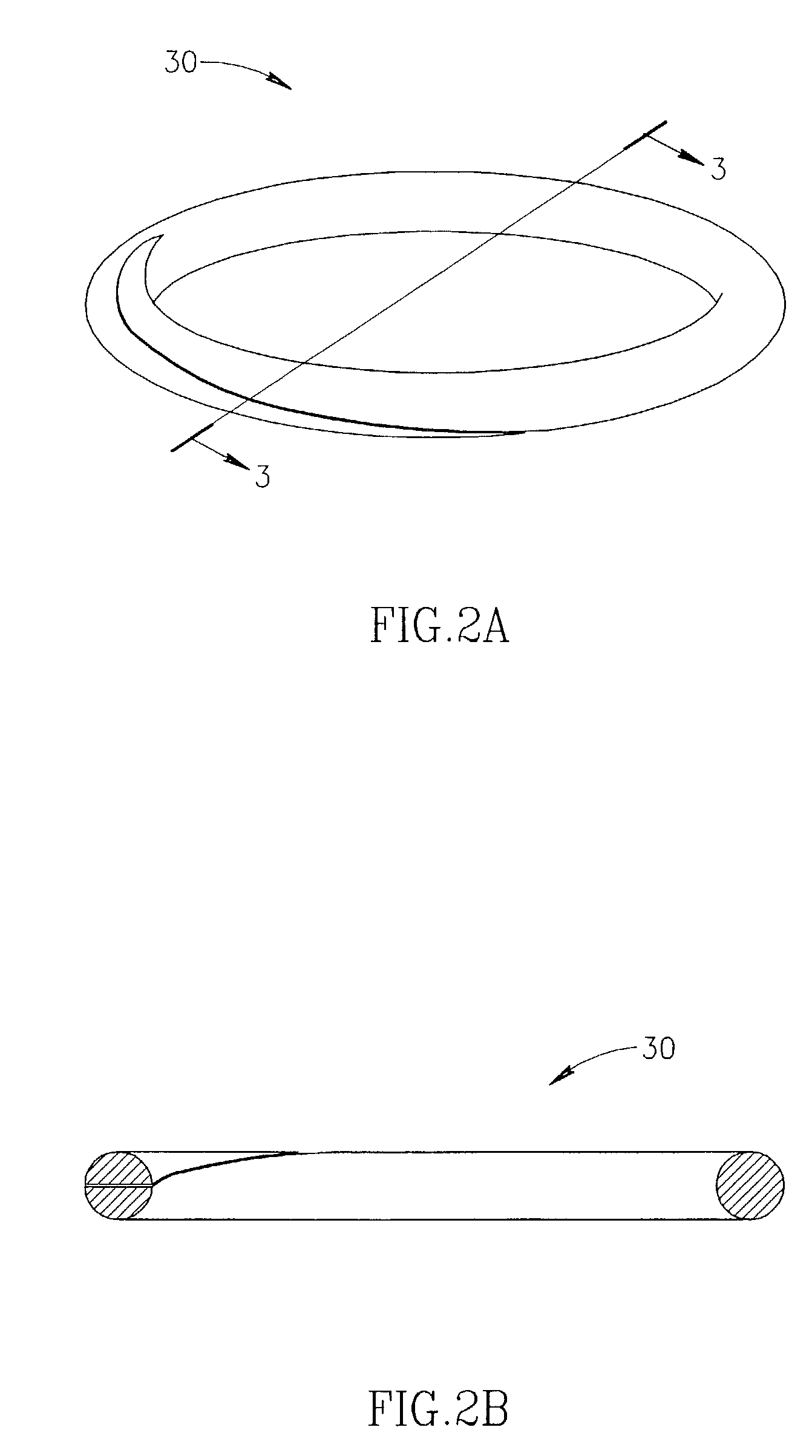

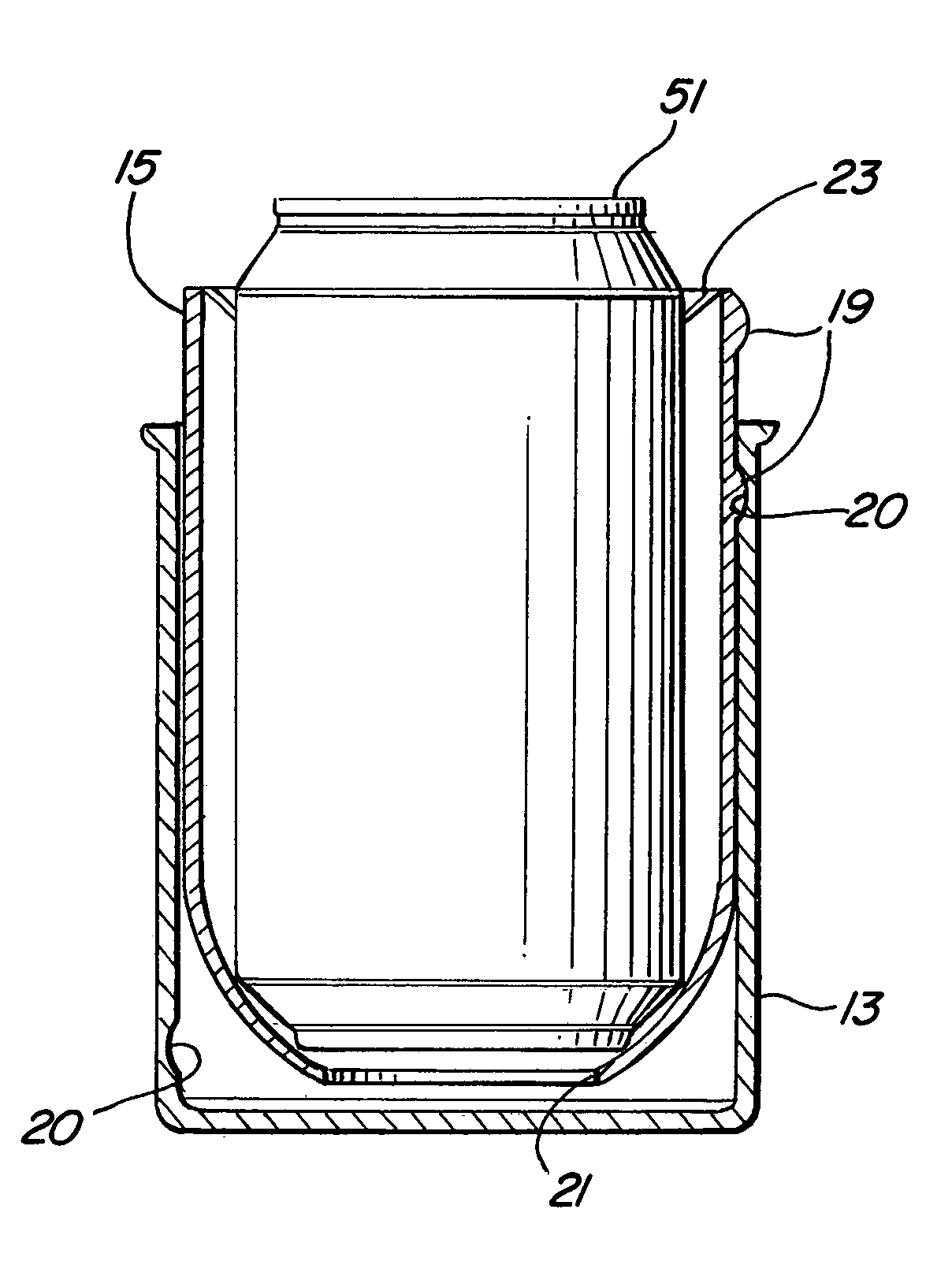

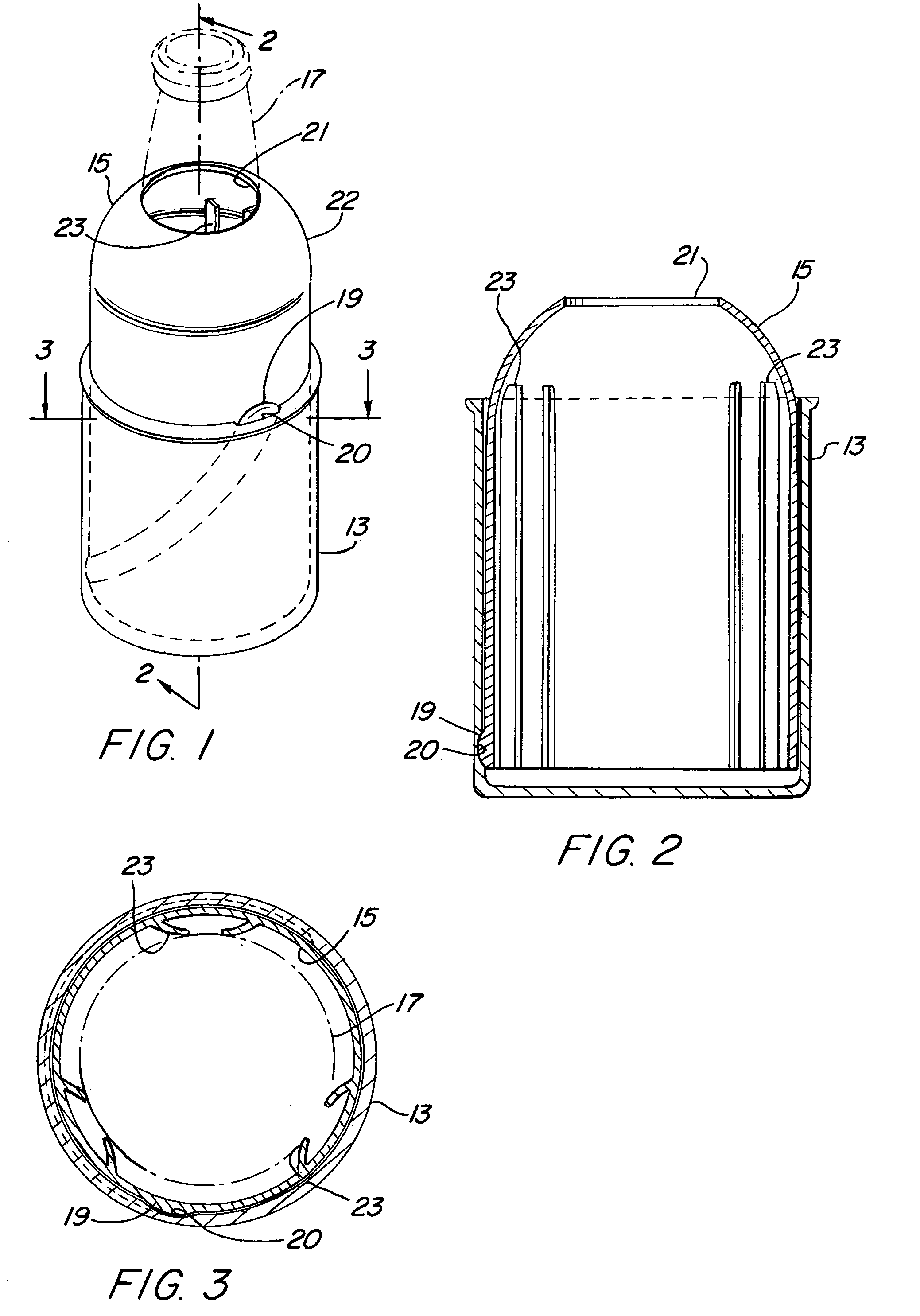

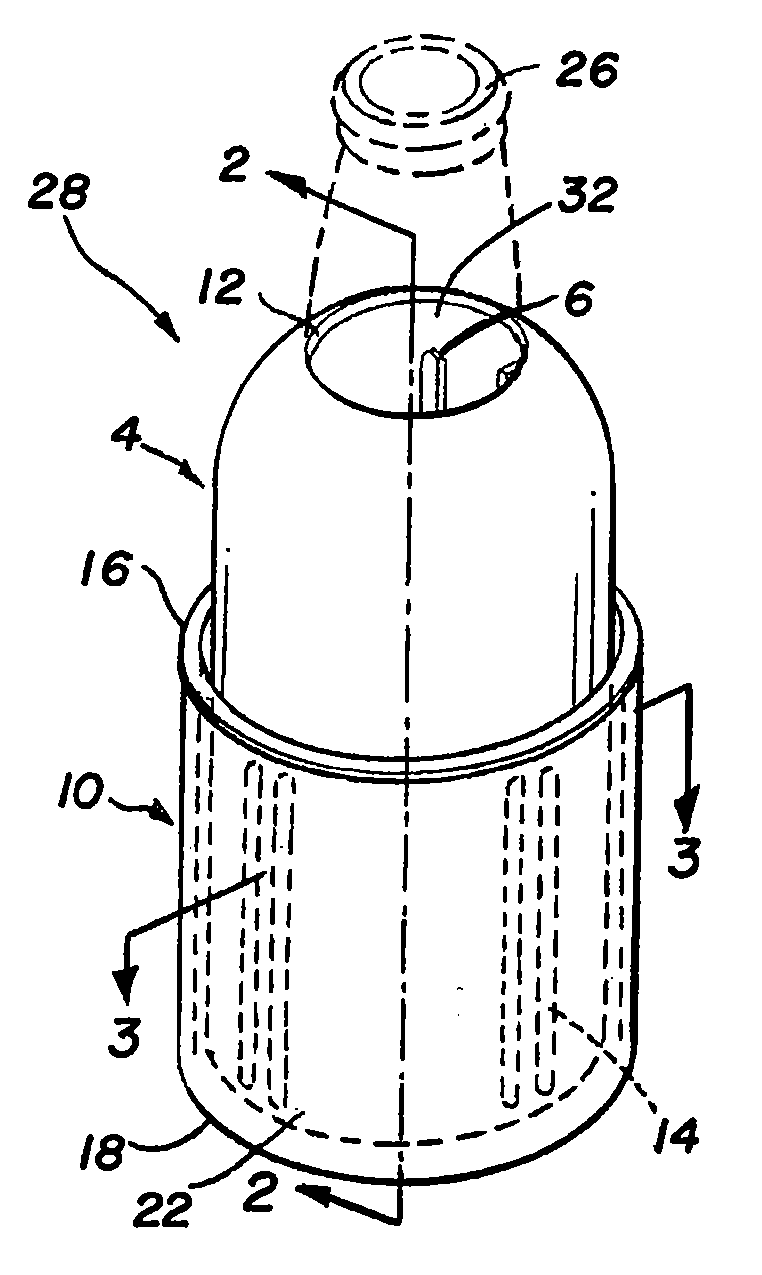

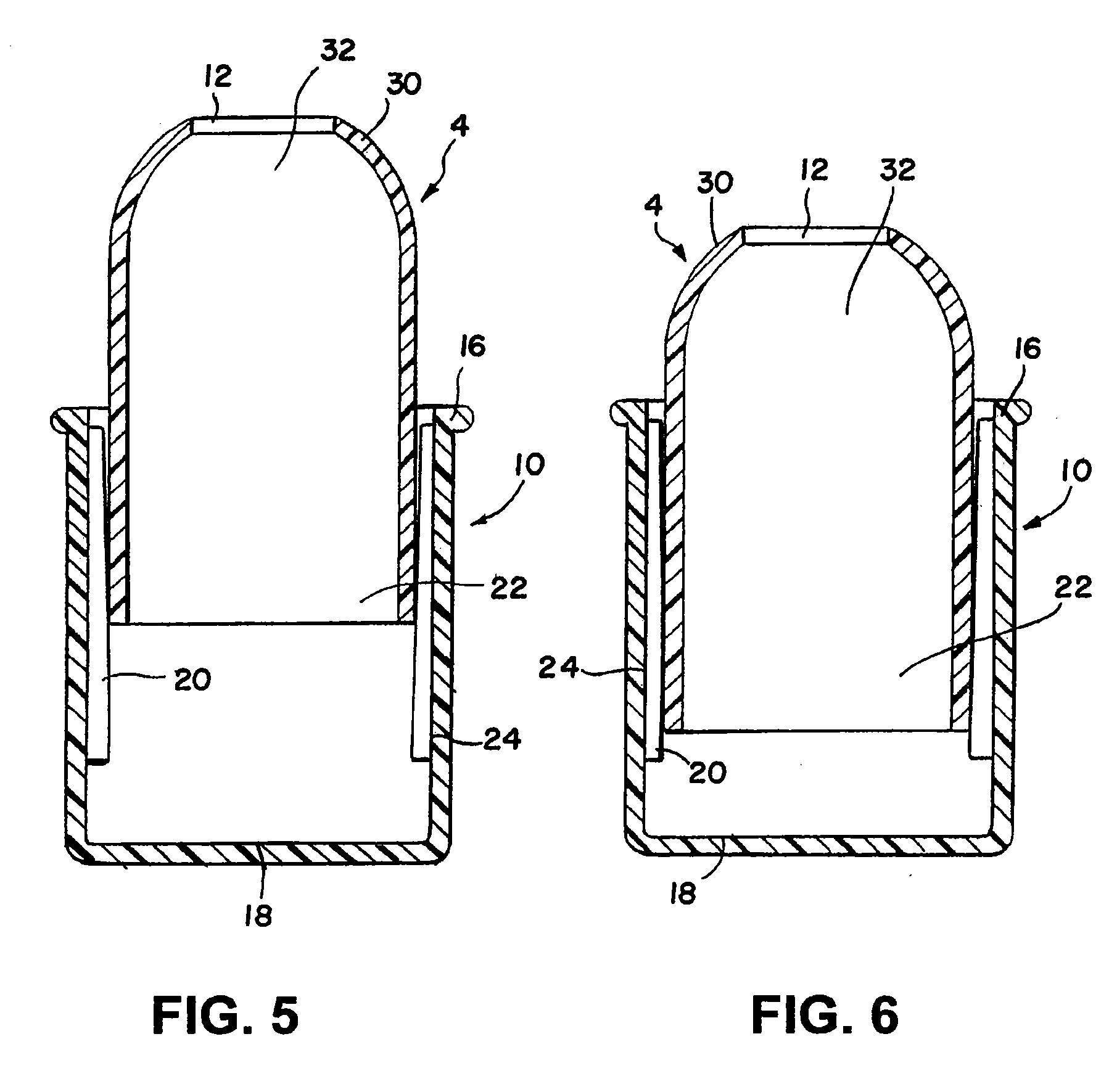

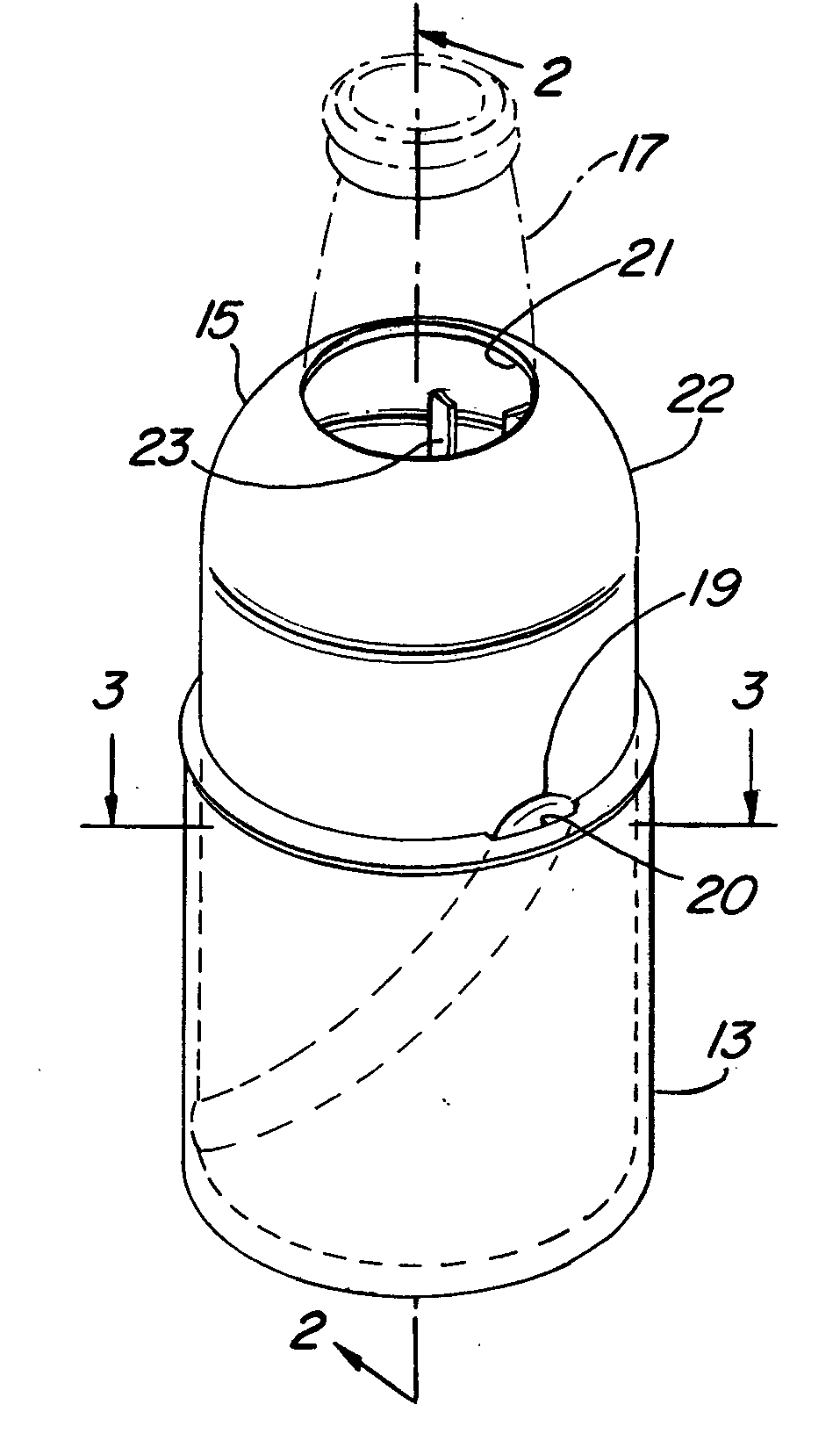

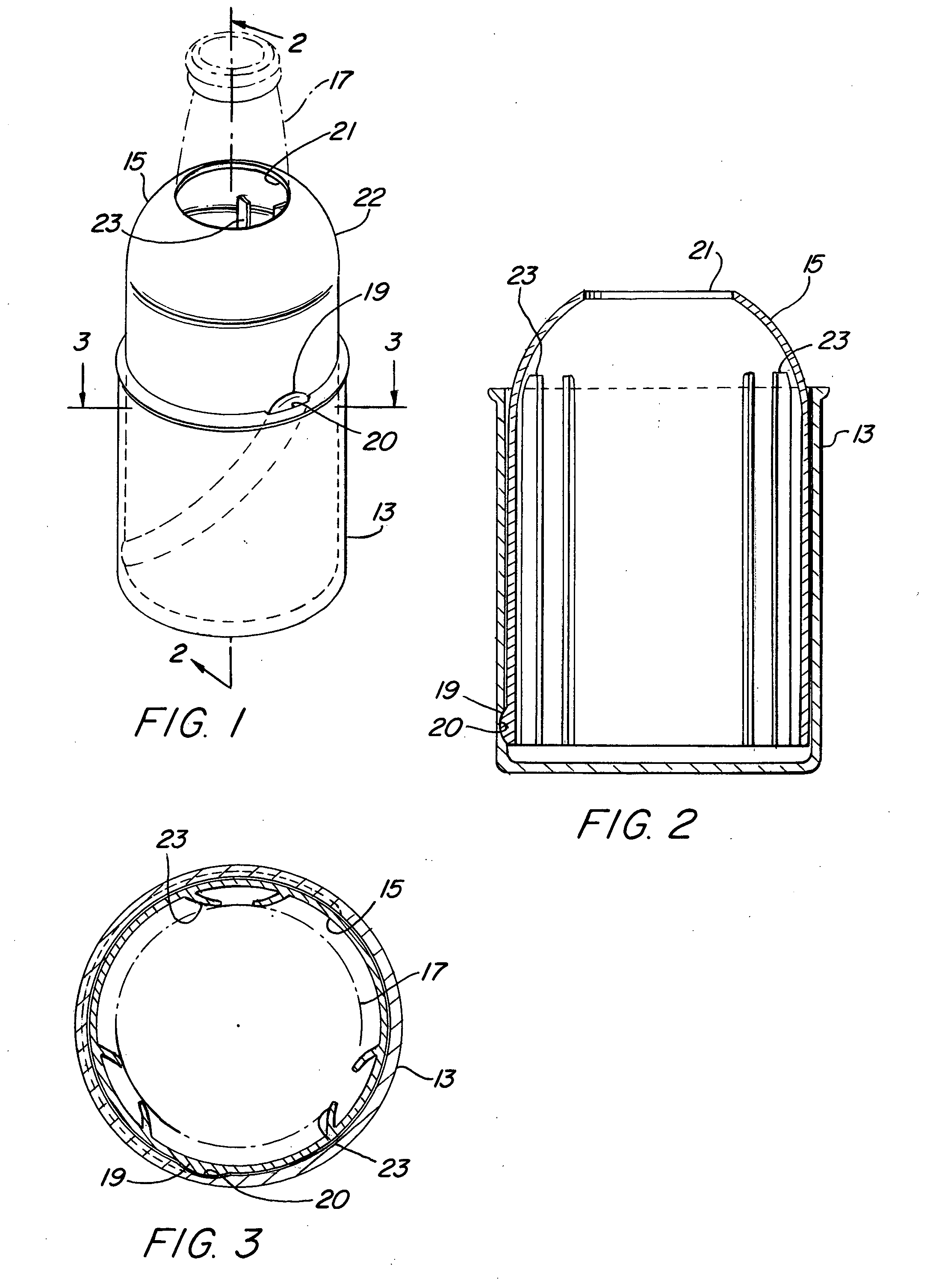

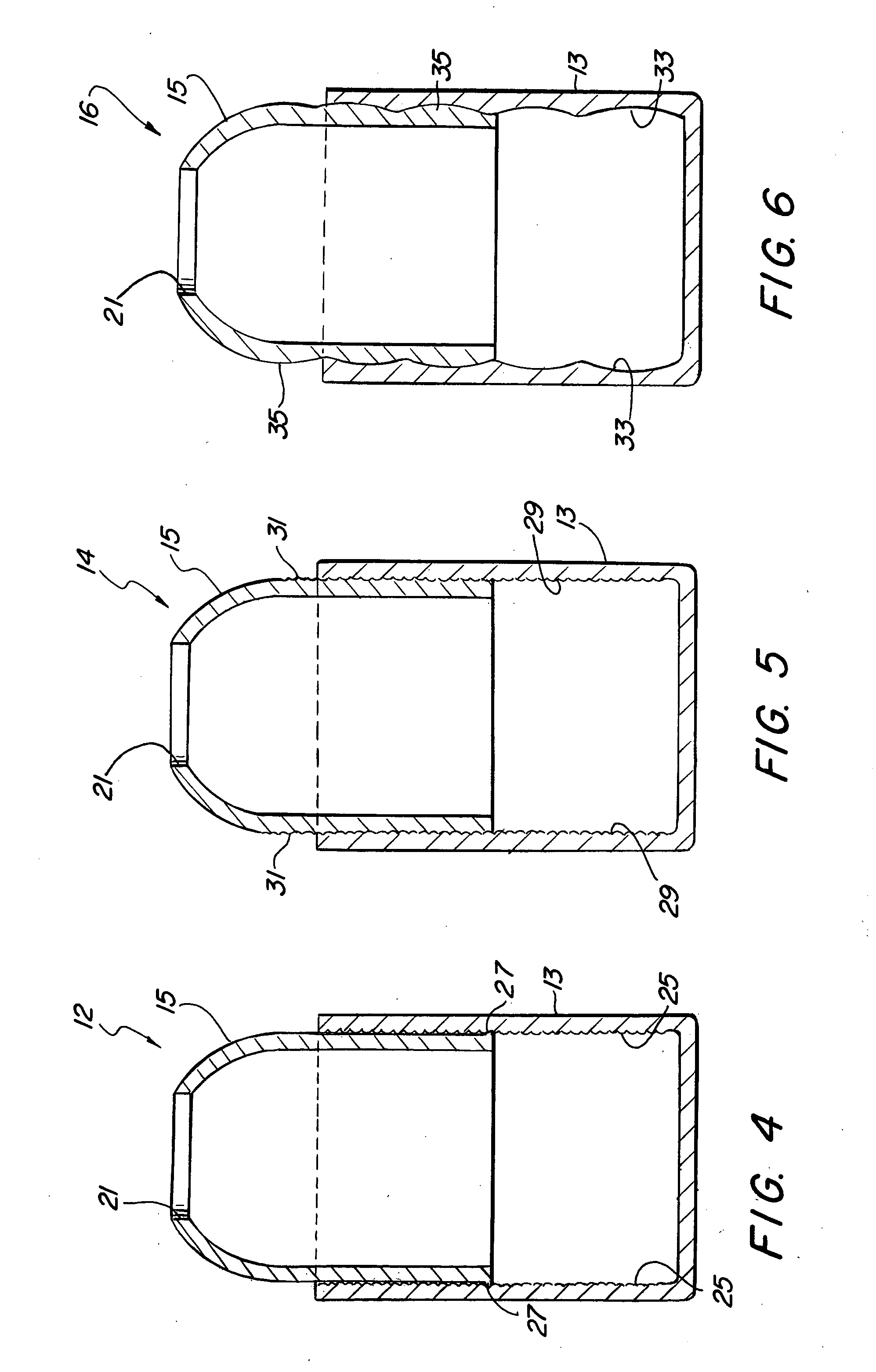

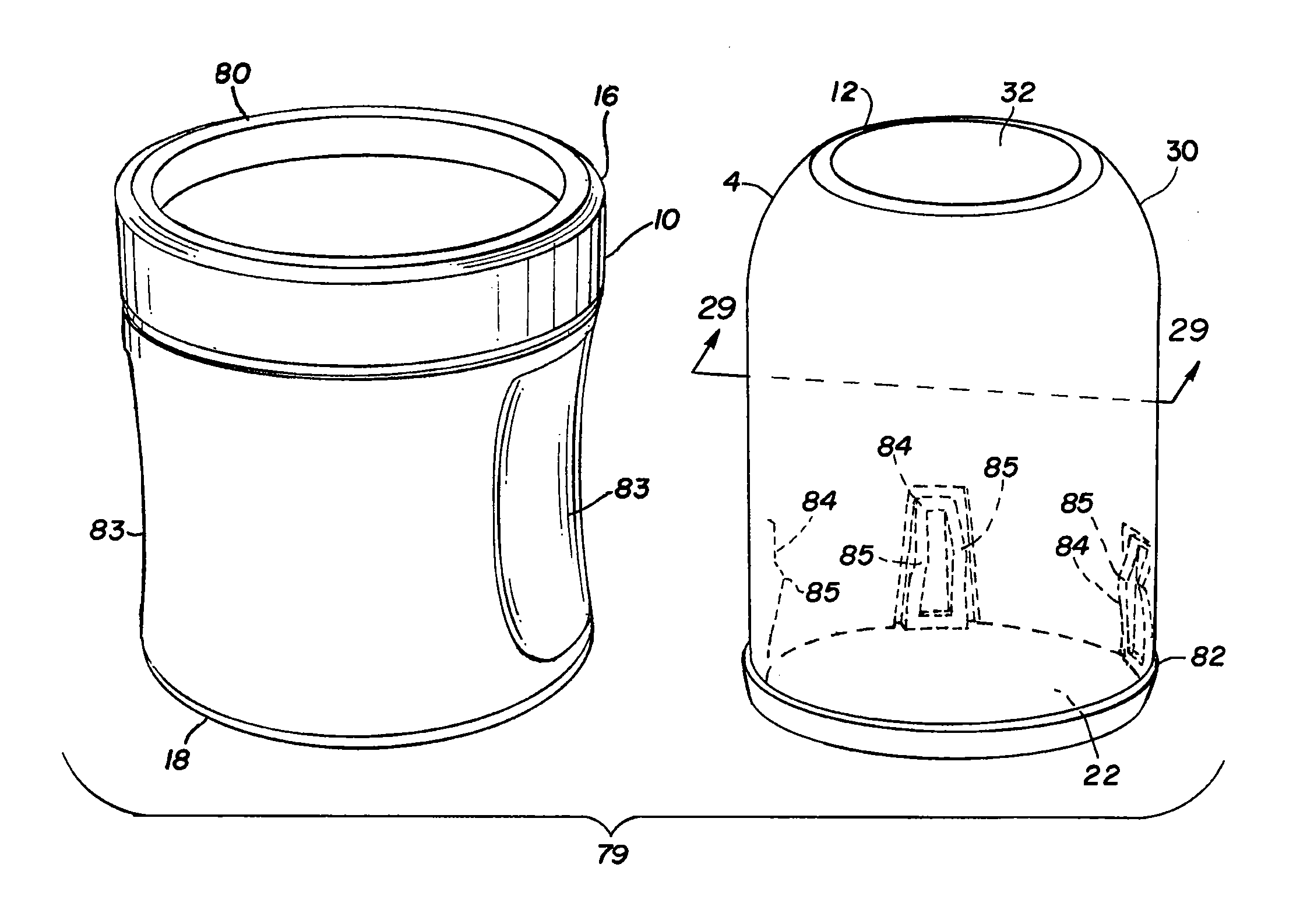

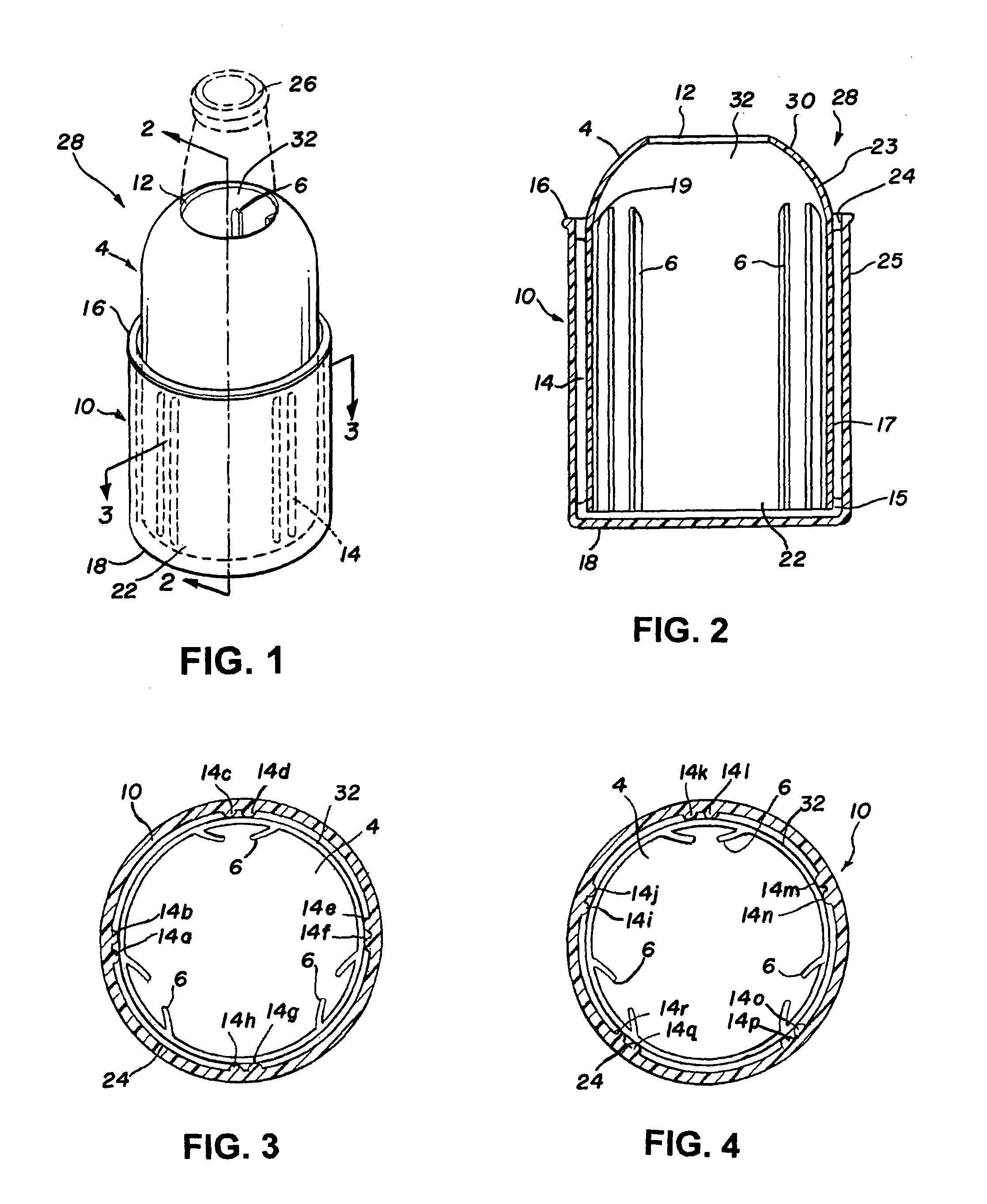

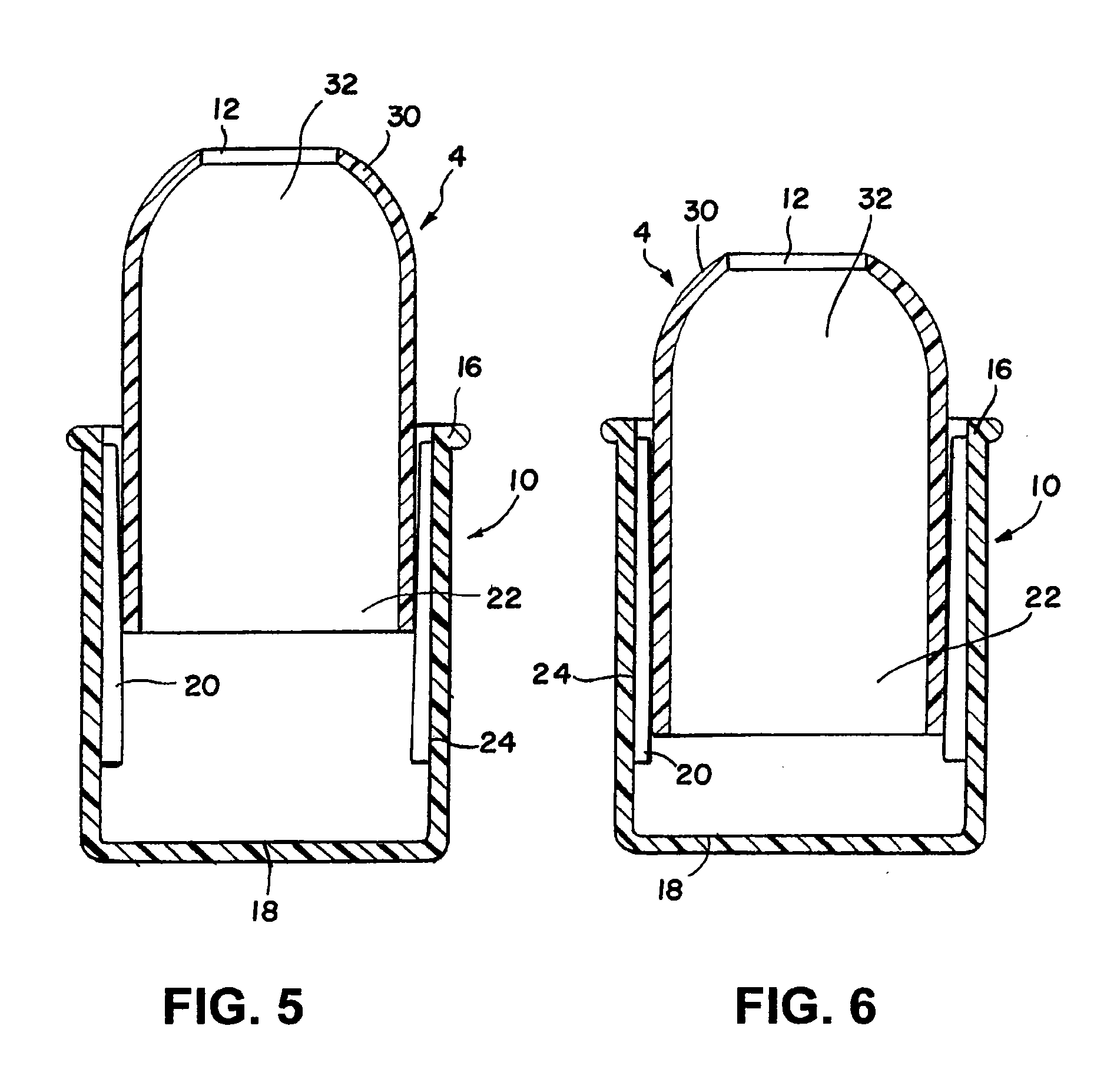

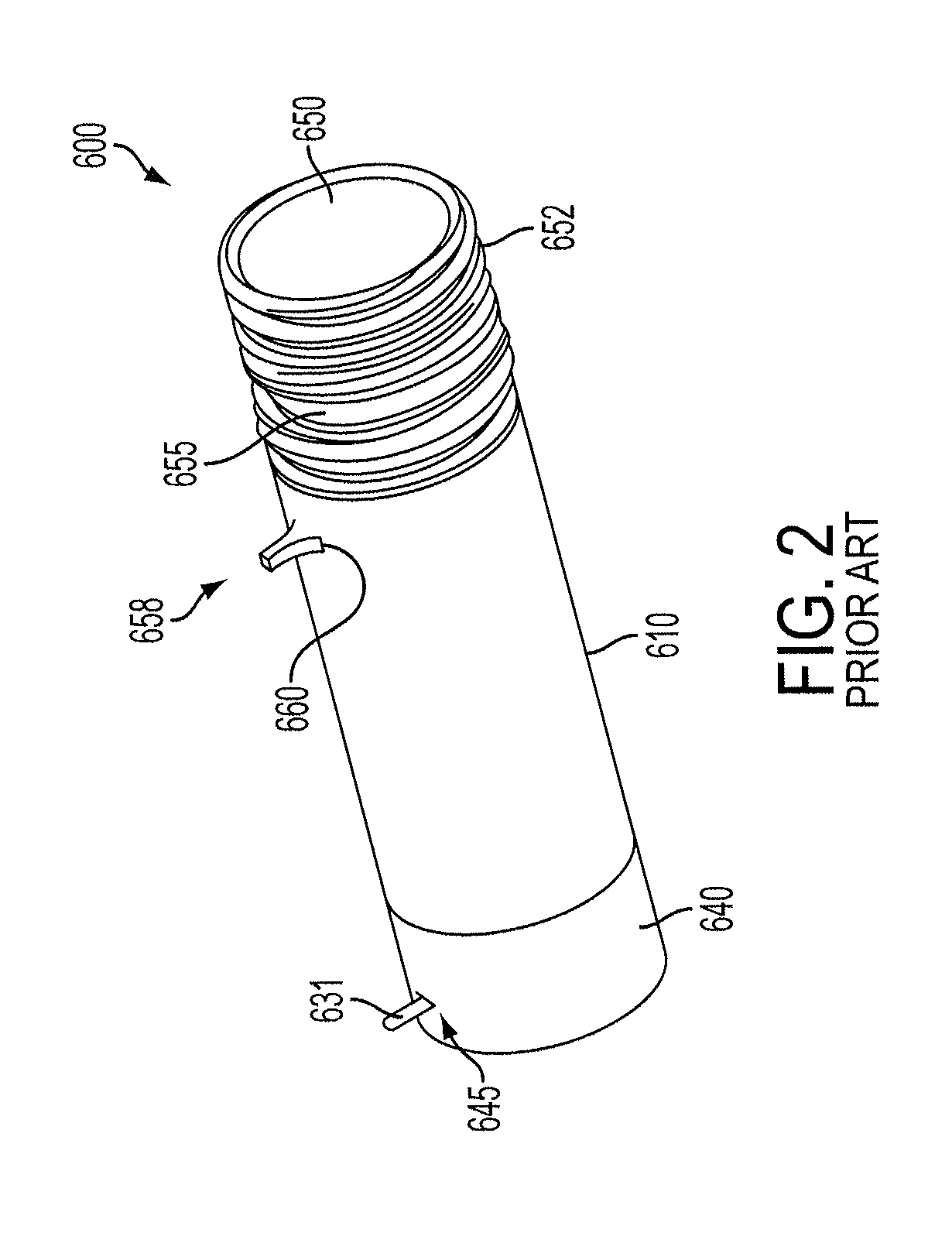

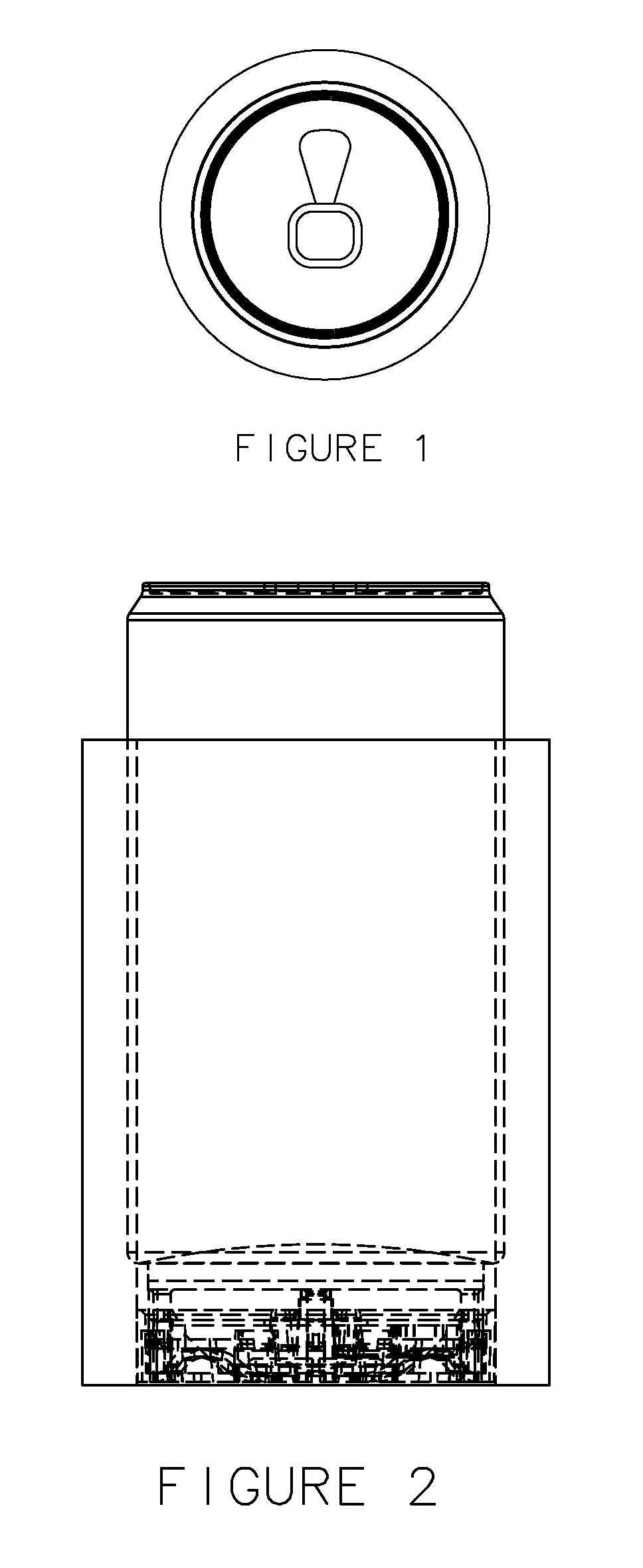

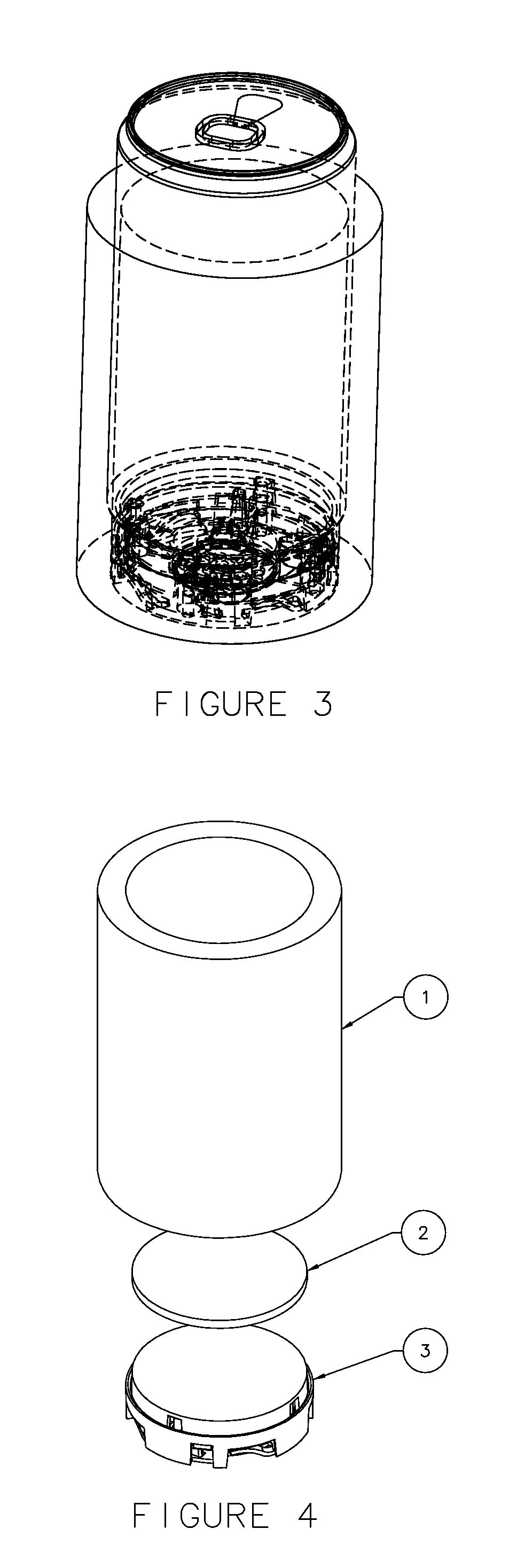

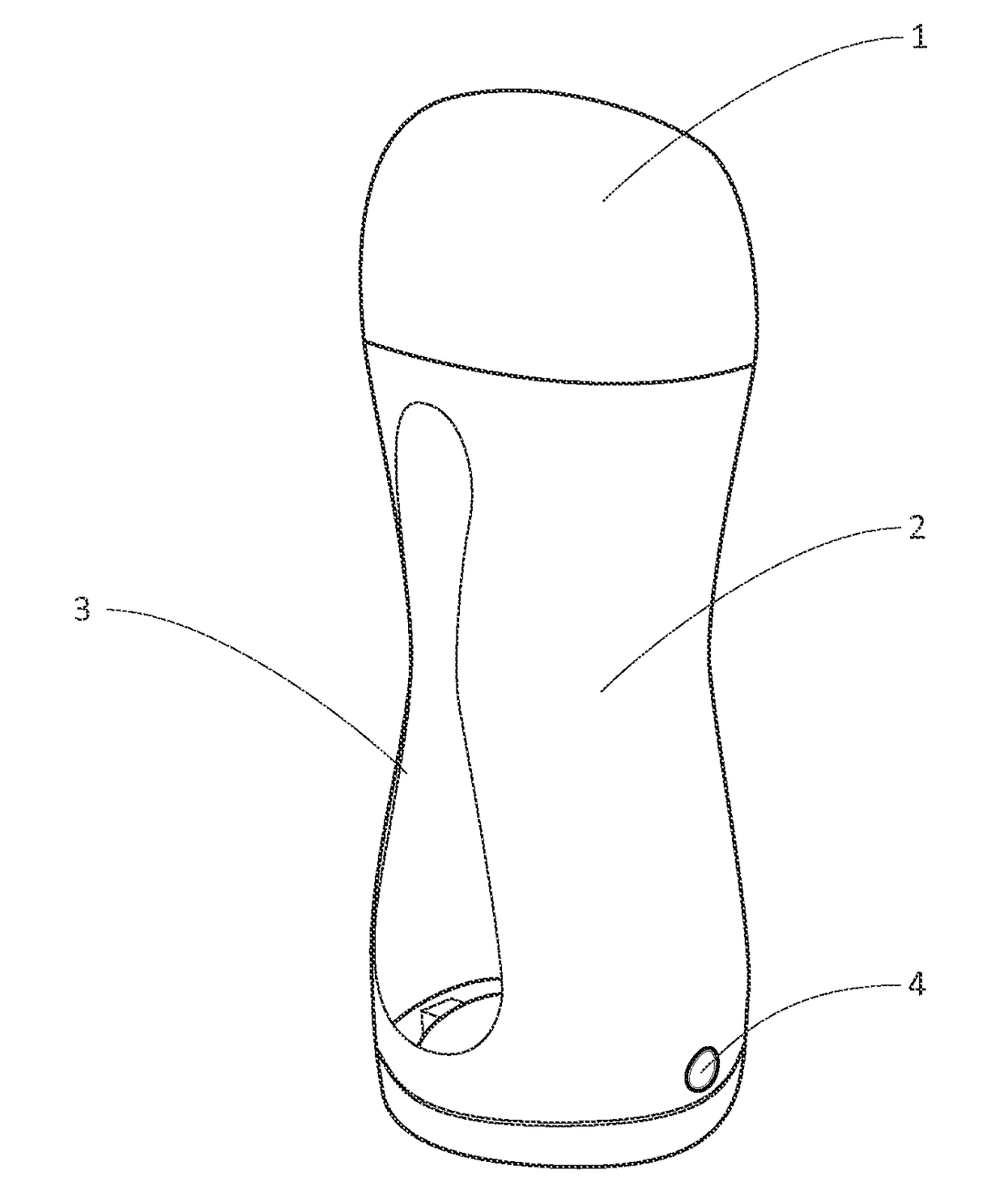

Dual function insulating holder for bottle or can

An insulating holder for holding a beverage in a bottle or a can having a lower cylindrical enclosure which receives an upper enclosure having a dome-shaped upper end. The upper and lower enclosures are provided with mating threads or other mating devices to hold the upper and lower enclosures in place when enjoyed. The upper enclosure is adapted to cover the top portion of a bottle inserted into the lower enclosure and to snuggly receive a can when inverted and inserted into the lower enclosure.

Owner:BEGGINS HLDG LLC

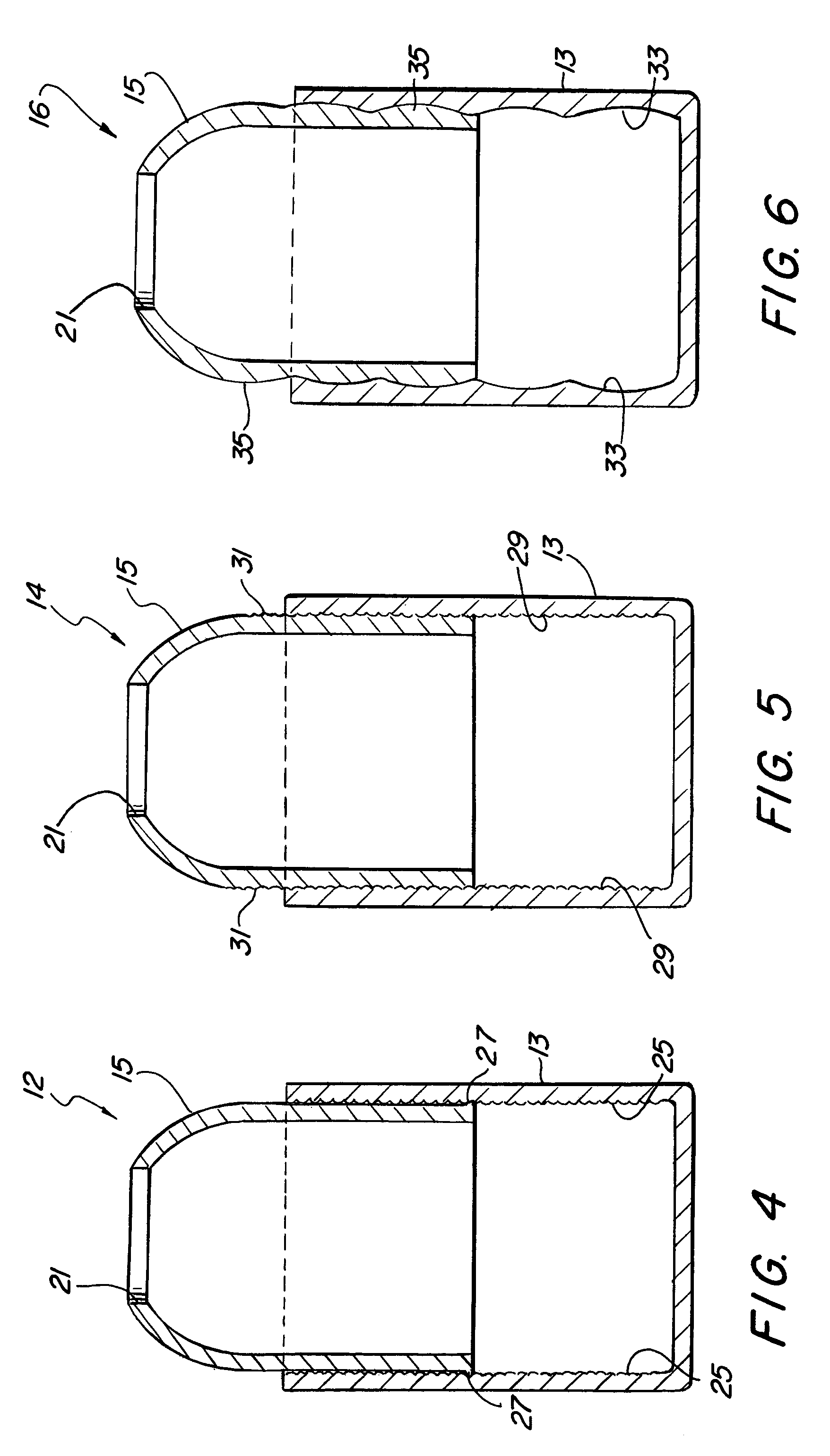

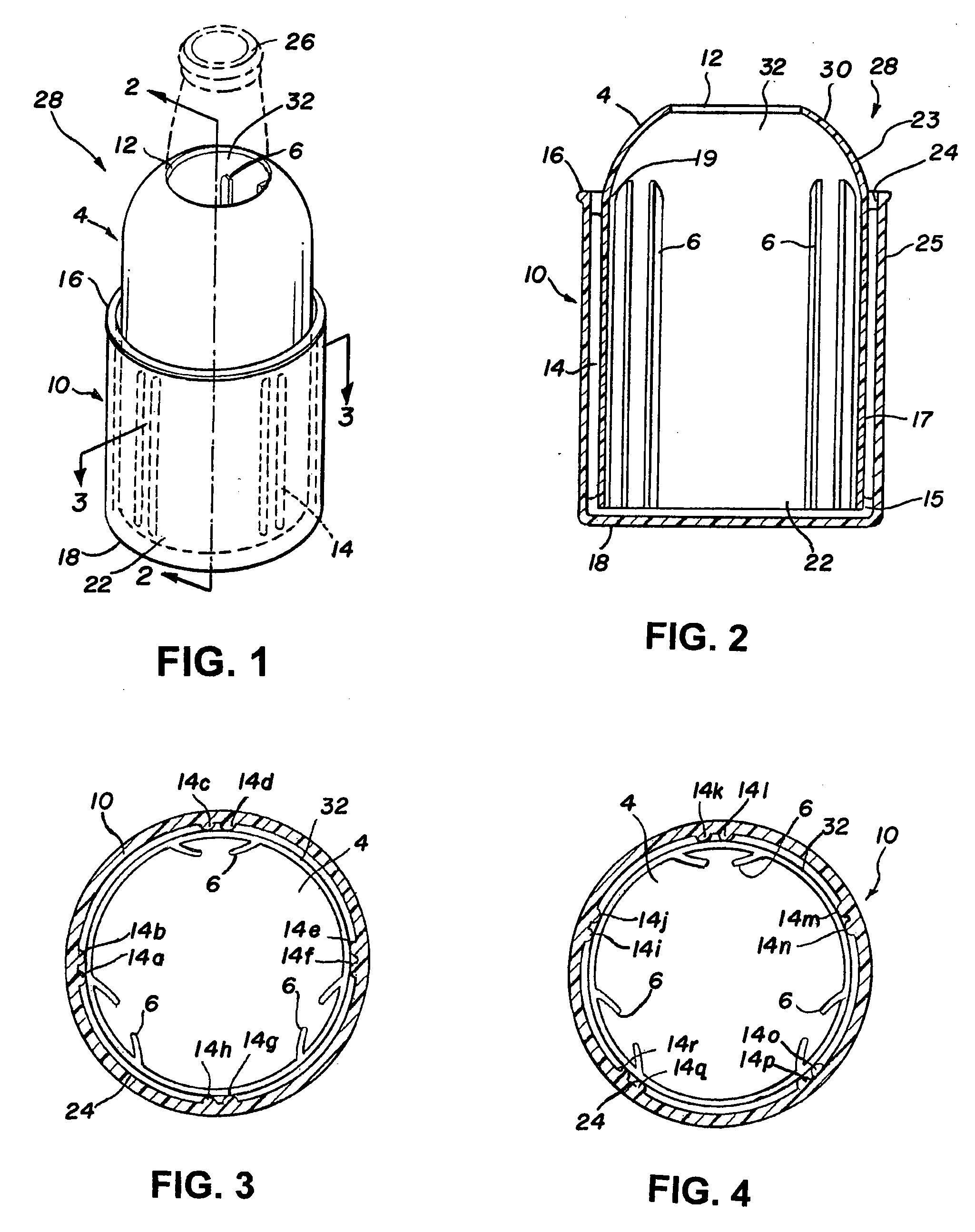

Insulating holder with elastomer foam material

ActiveUS20130240549A1Improve insulation performanceImprove performanceDomestic cooling apparatusLighting and heating apparatusElastomerPolyolefin

An insulating holder for holding a beverage in a bottle or a can having a lower cylindrical enclosure which receives an upper cylindrical enclosure having a dome-shaped upper end. The upper cylindrical enclosure is adapted to cover the top portion of a bottle inserted into the lower cylindrical enclosure and to snuggly receive a can when inverted and inserted into the lower cylindrical enclosure. At least a portion of the lower cylindrical enclosure or upper cylindrical enclosure is made of a polyolefin elastomer foam. The insulating holder may be structured to retain various sizes of wine bottles.

Owner:BEGGINS HLDG LLC

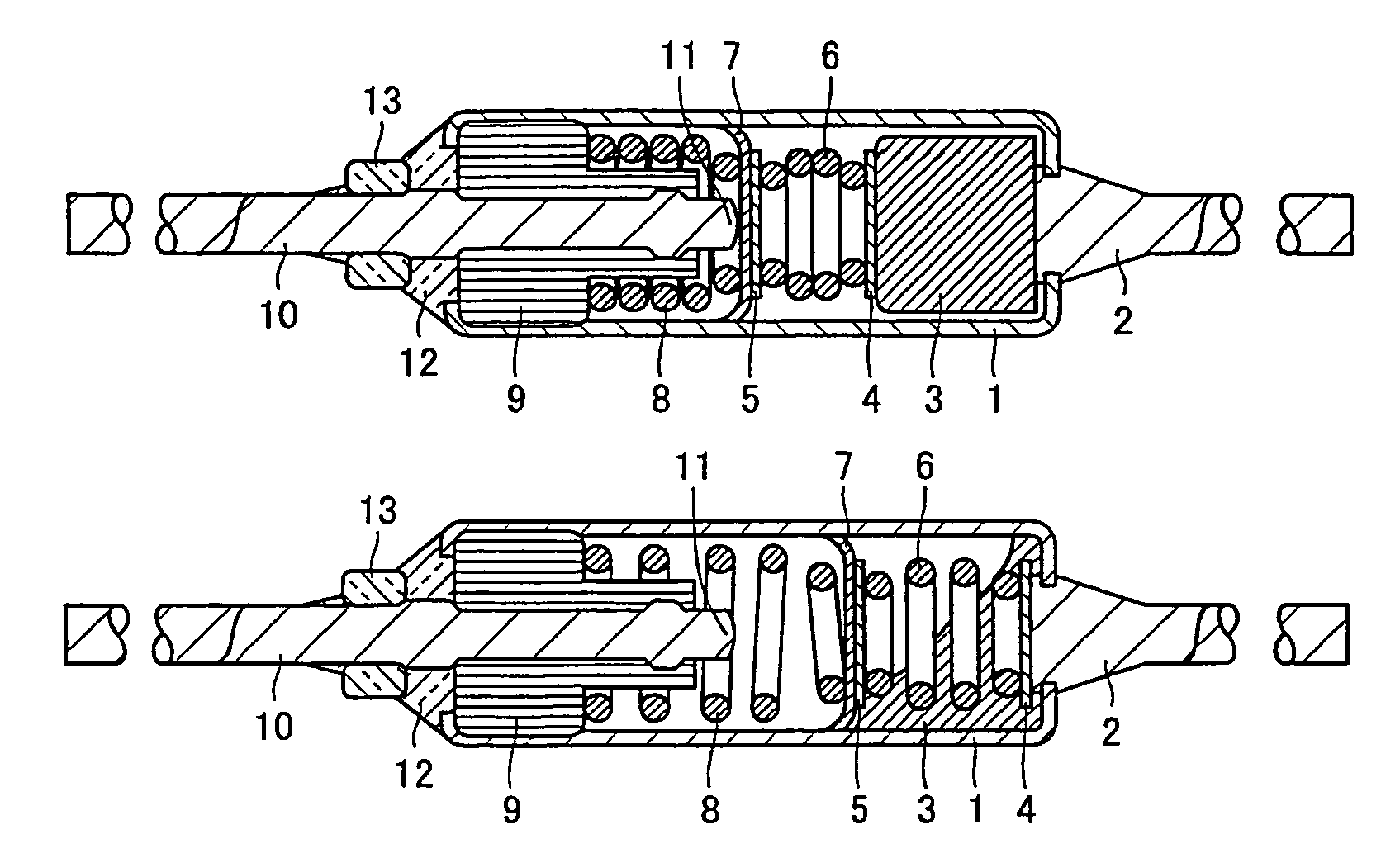

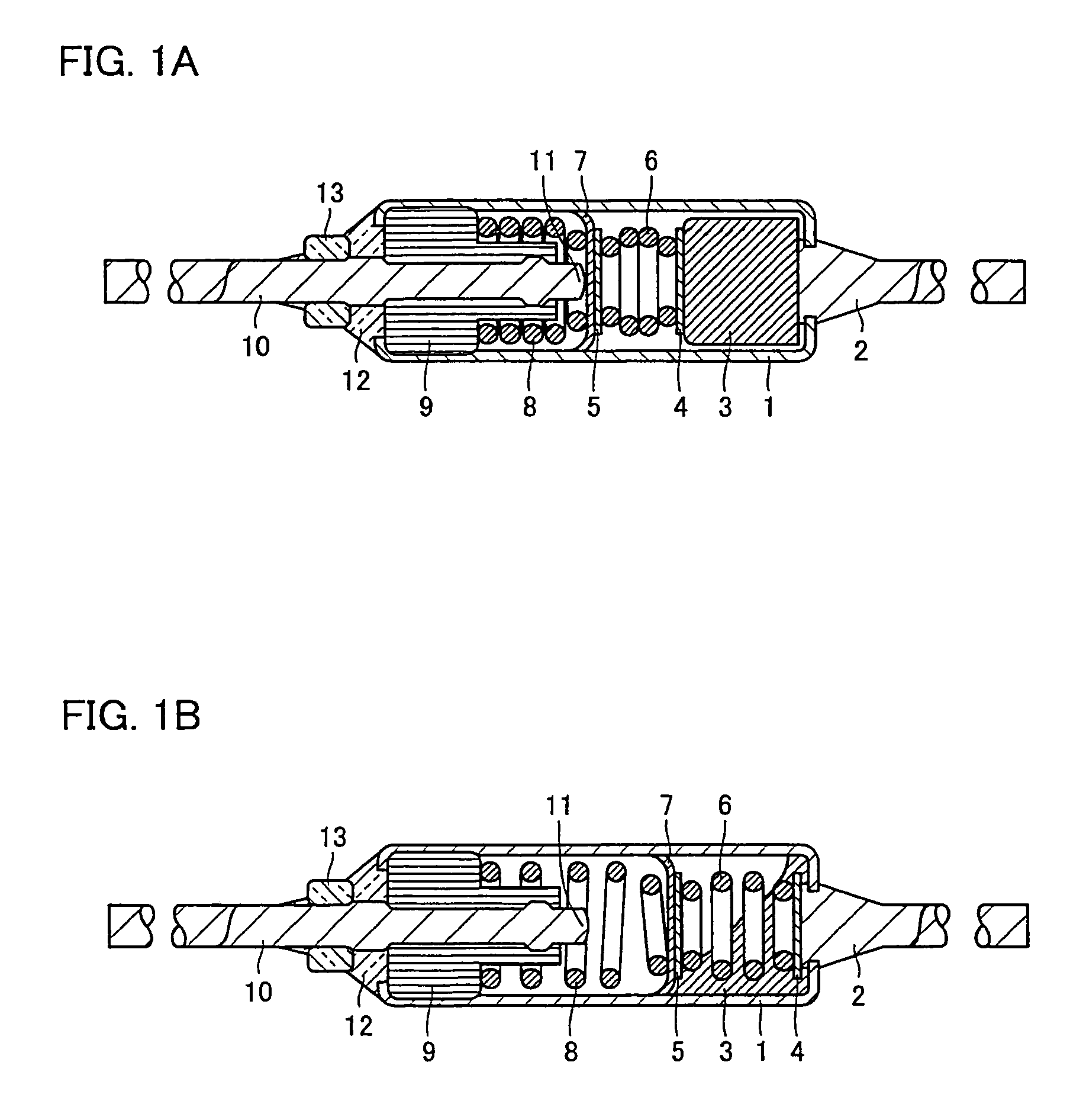

Temperature sensing material type thermal use

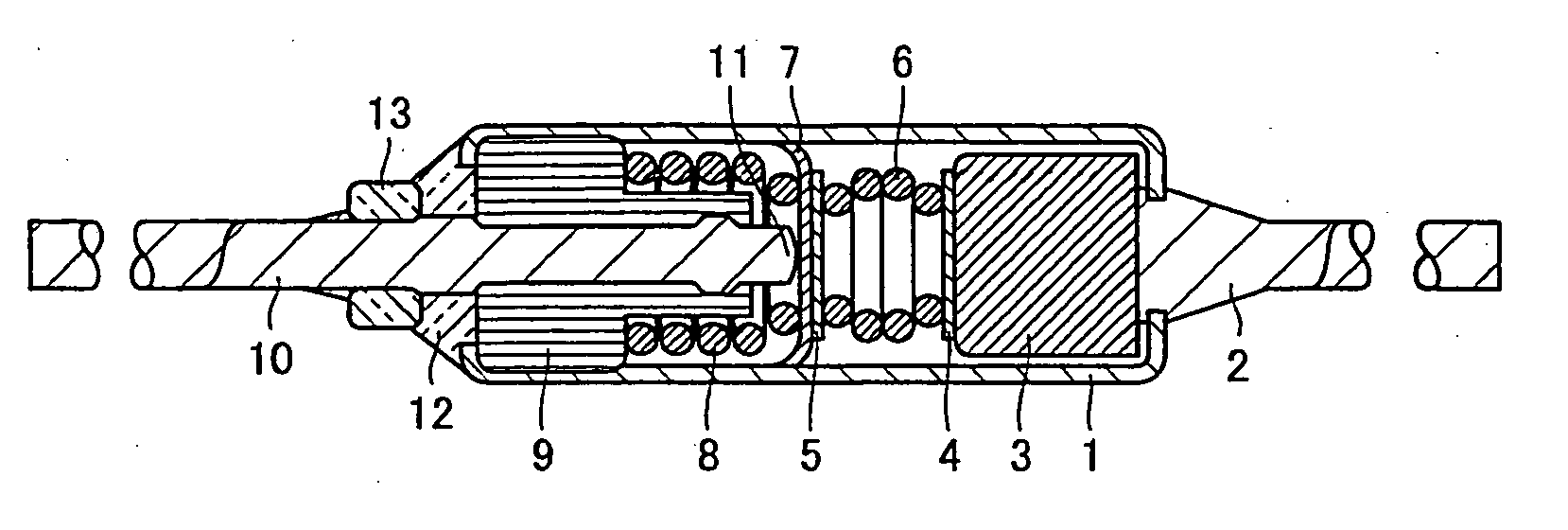

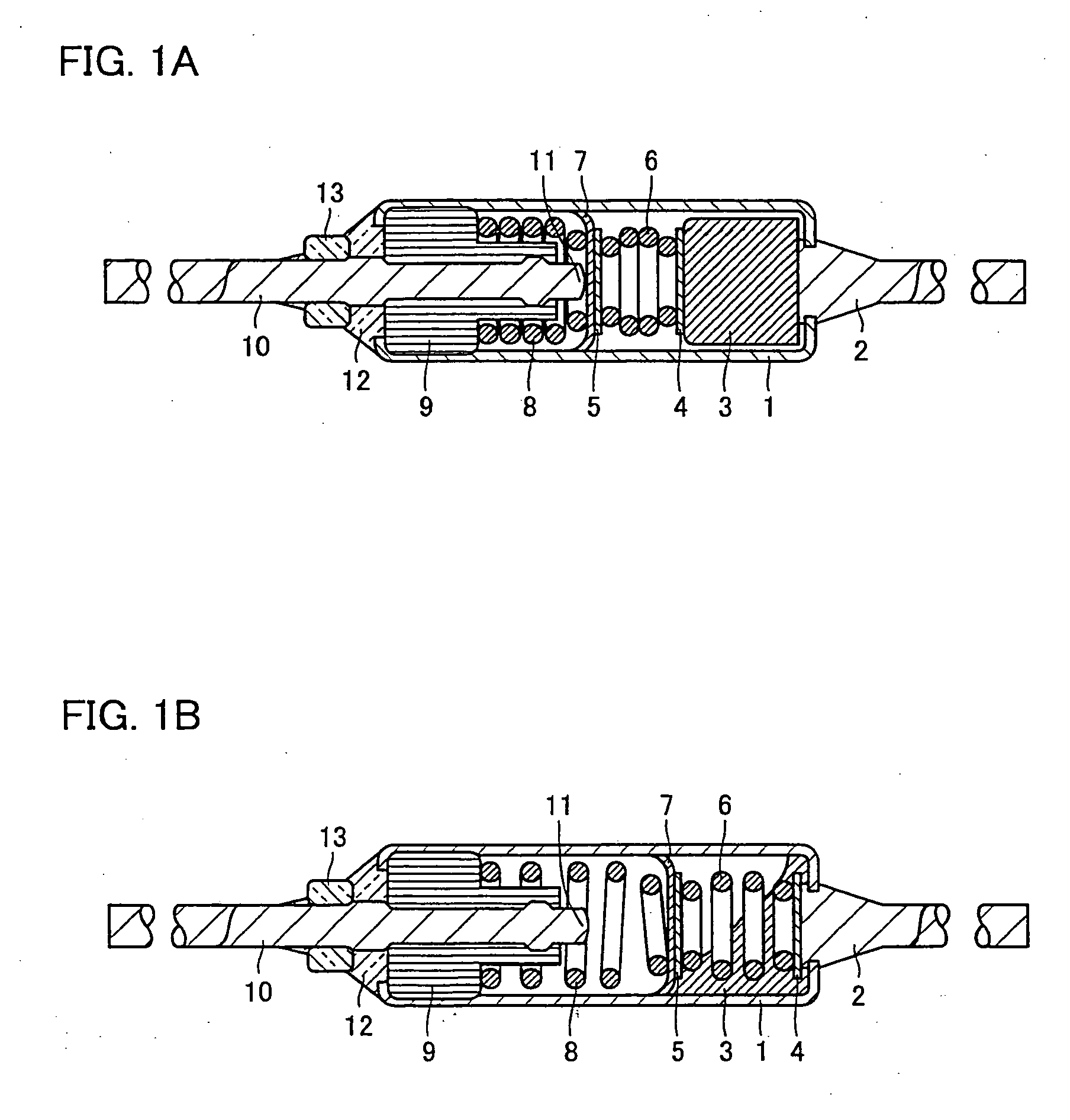

ActiveUS20050179516A1Improve electrical characteristicsReduce deformationHeating/cooling contact switchesEmergency protective devicesMaterial typeEngineering

In the present invention, a physical and chemical property of thermosensitive material is noted in selecting and using thermosensitive material to provide a noble and improved thermal fuse using thermosensitive material. To achieve this object, the present thermal fuse includes: a thermosensitive material formed of thermoplastic resin fusing at a prescribed temperature; a cylindrical enclosure accommodating the thermosensitive material; a first lead member attached at one opening of the enclosure, forming a first electrode; a second lead member attached at the other opening of the enclosure, forming a second electrode; a movable conductive member accommodated in the enclosure and engaged with the thermosensitive material; and a spring member accommodated in the enclosure, and pressed against and thus acting on the movable conductive member. When the thermosensitive material fuses at an operating temperature an electrical circuit between the first and second electrodes is switched.

Owner:SCHOTT JAPAN CORP

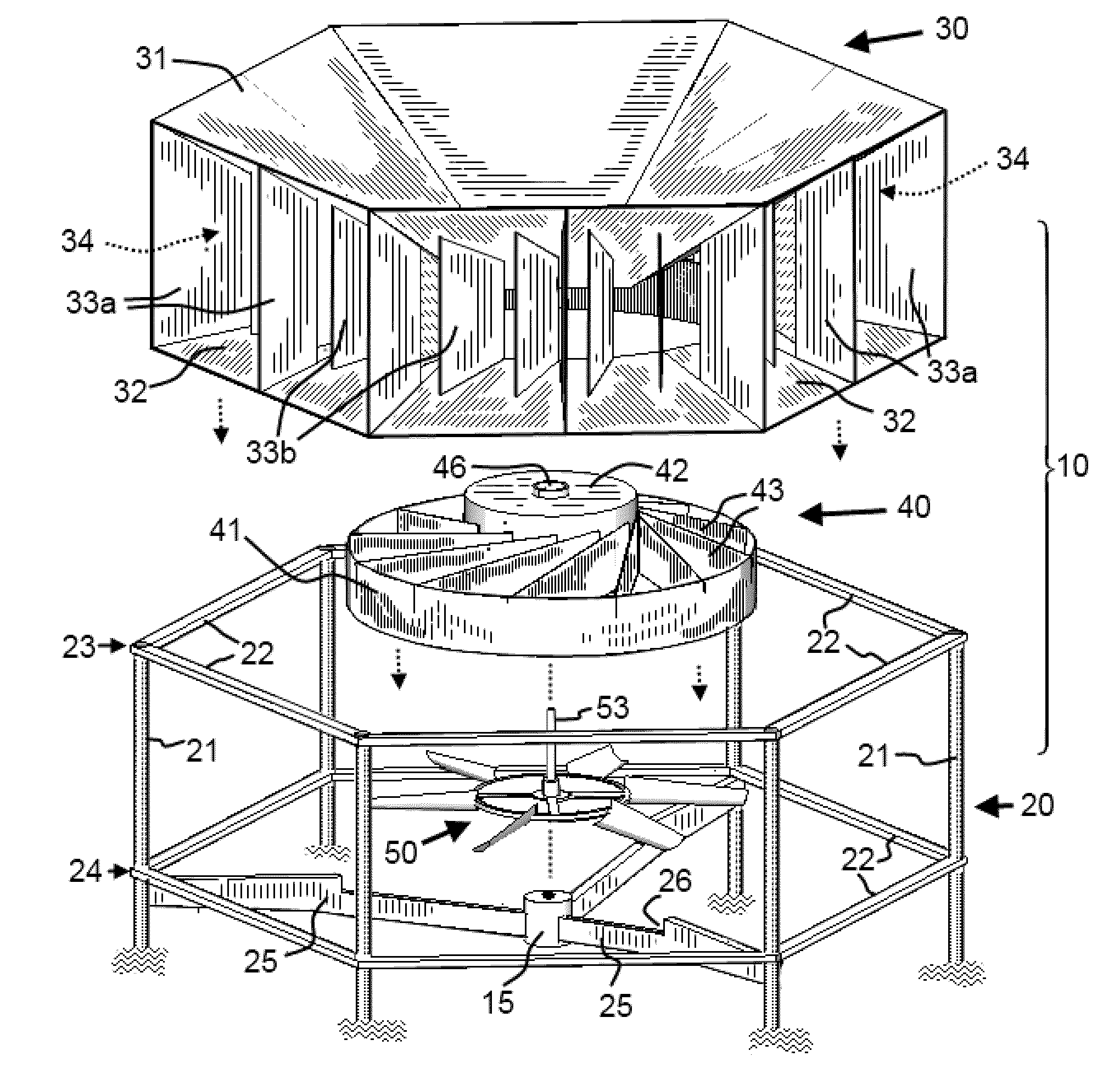

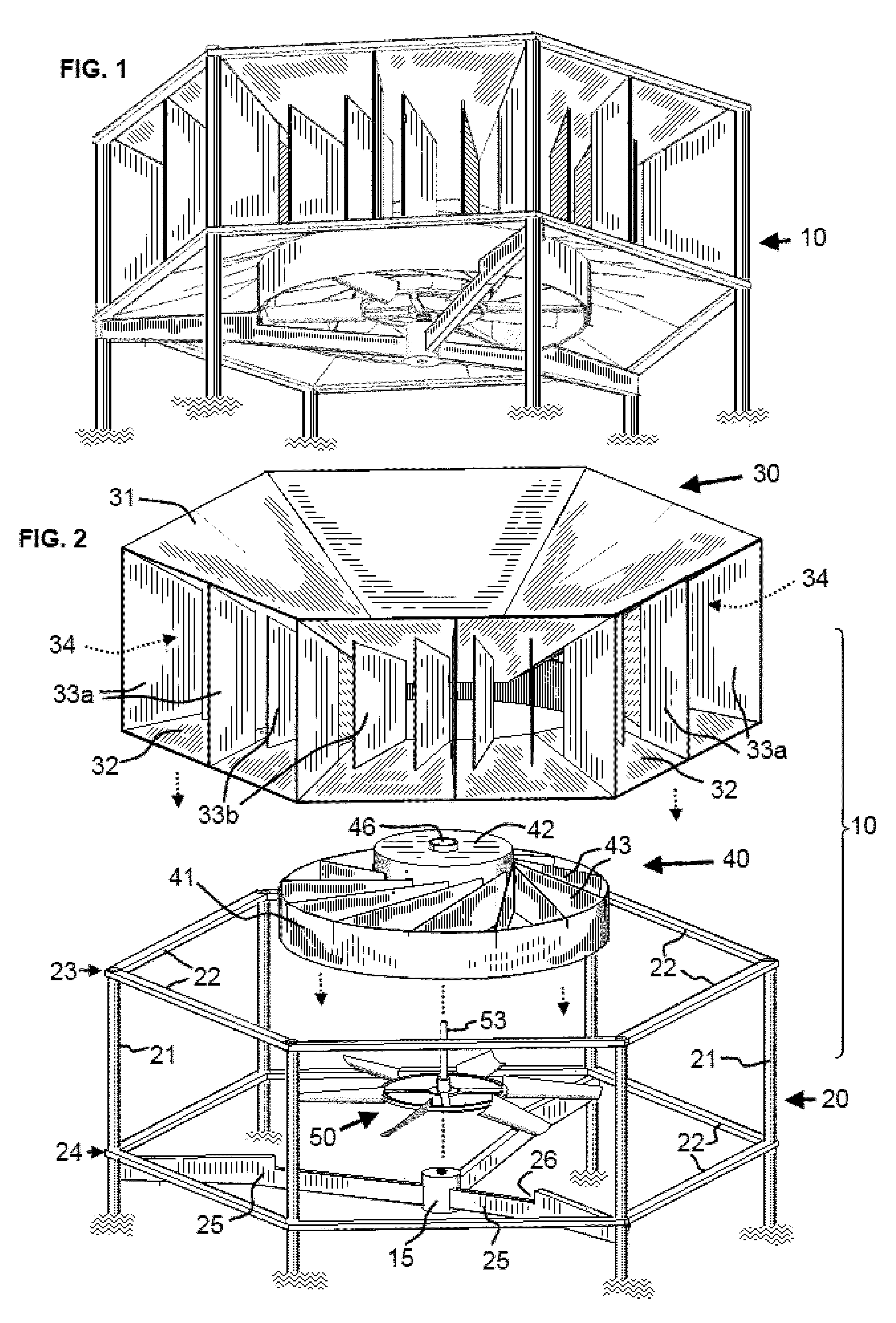

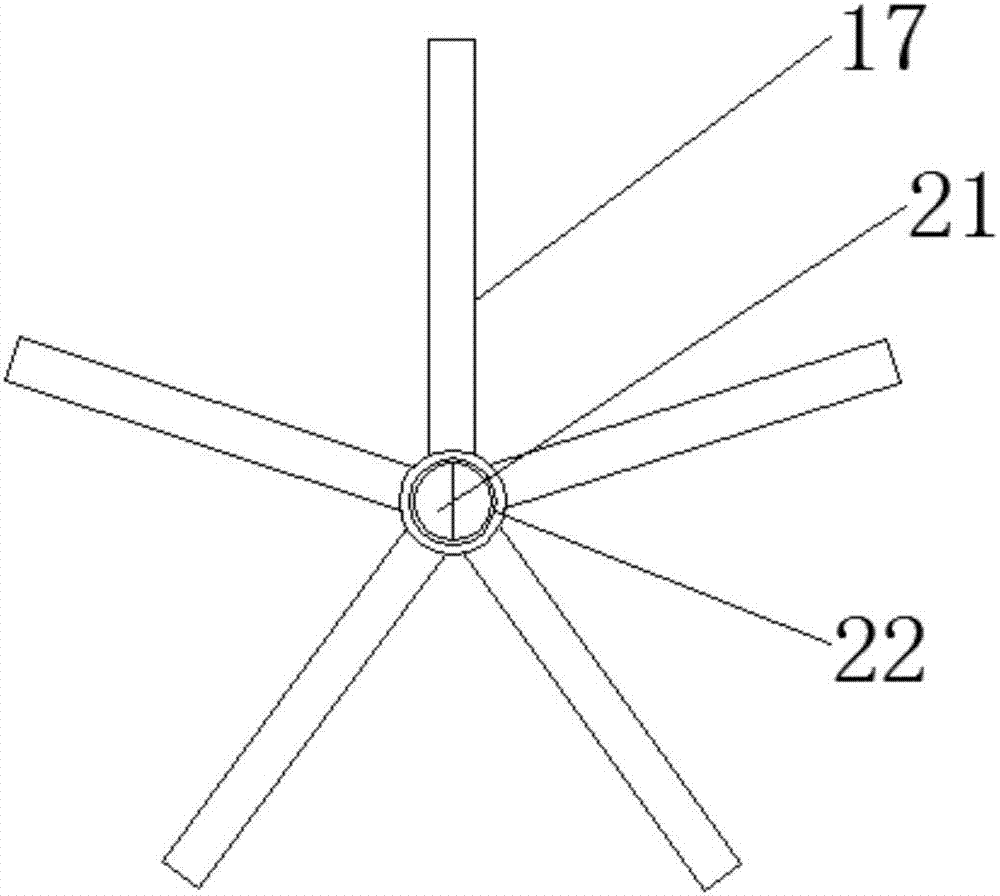

Vertical axis wind turbine with axial flow rotor

InactiveUS8961103B1Optimize power extractionWind motor controlWind motor supports/mountsLeading edgeTurbine blade

An omni-directional vertical axis wind turbine includes an axial flow turbine rotor to supply force to operate an electrical generator mounted for rotation on a vertical shaft. A shroud surrounds the turbine rotor forming a circular chamber coaxially with the turbine rotor, enclosing the airflow entry face and leaving the discharge face uncovered. Wind entering the shroud from any direction flows inwardly through air passages, where a set of baffles surrounding the circular chamber redirect incoming airflow into a stream within the circular chamber. A cylindrical enclosure mounted concentrically with the turbine rotor within the circulation chamber houses an array of stationary vanes positioned to extend across the entry base and in close proximity to the turbine rotor and aligned at angles relative to the axis of rotation, form flow-through passages to intercept the airflow and redirect it vertically into the swept area of the turbine rotor in the form of laminar streams. Entrainment effect of the streams enhances the force of airflow through the sweet area, while leading edges of rotating turbine blades intercept airflow along continuously changing points of intersection from successive passages to create additional torque to power the turbine. Angular alignment and curvature of the stationary vanes can be varied to optimize performance over a variety of wind conditions.

Owner:WOLFF JOHN GEORGE

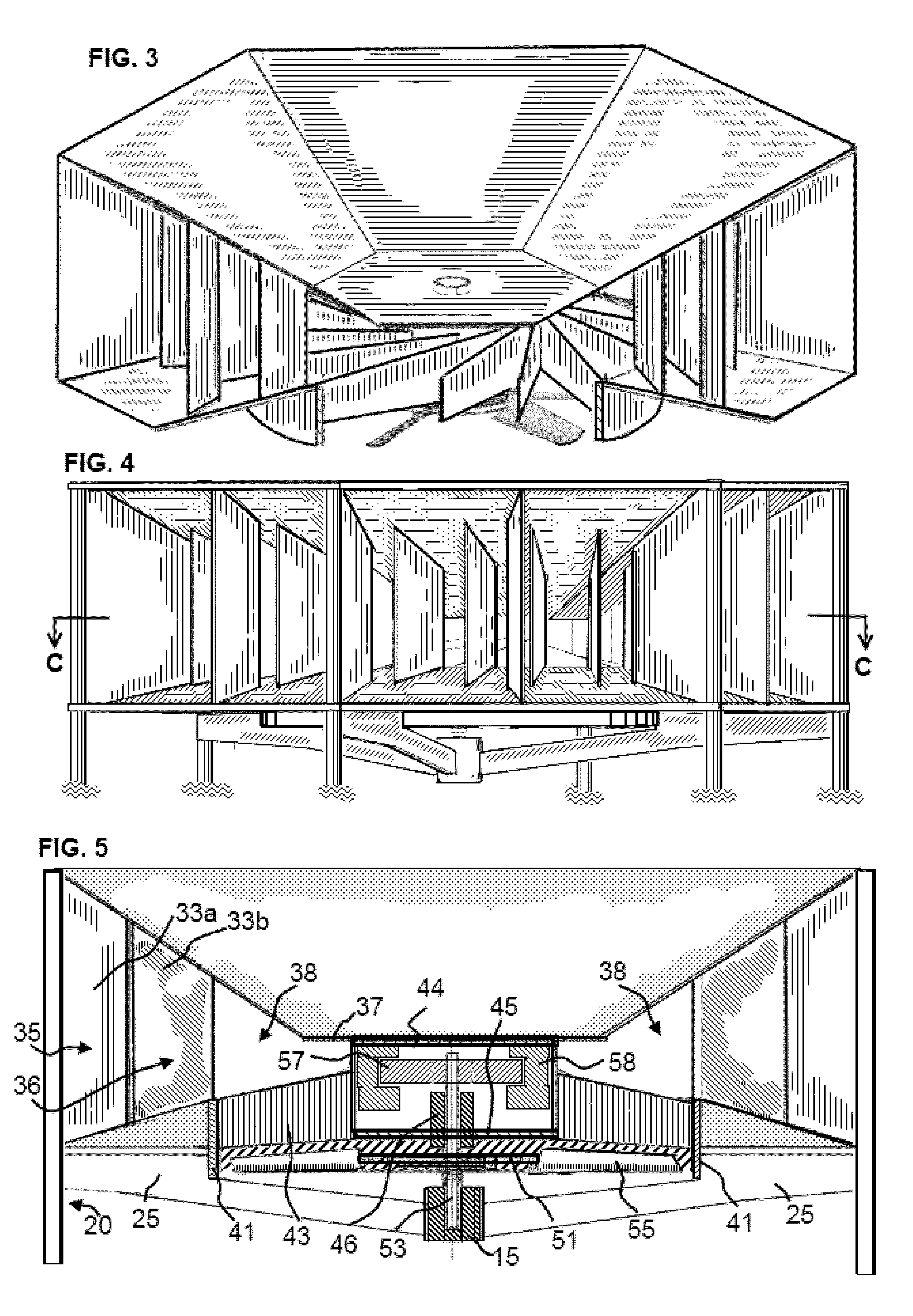

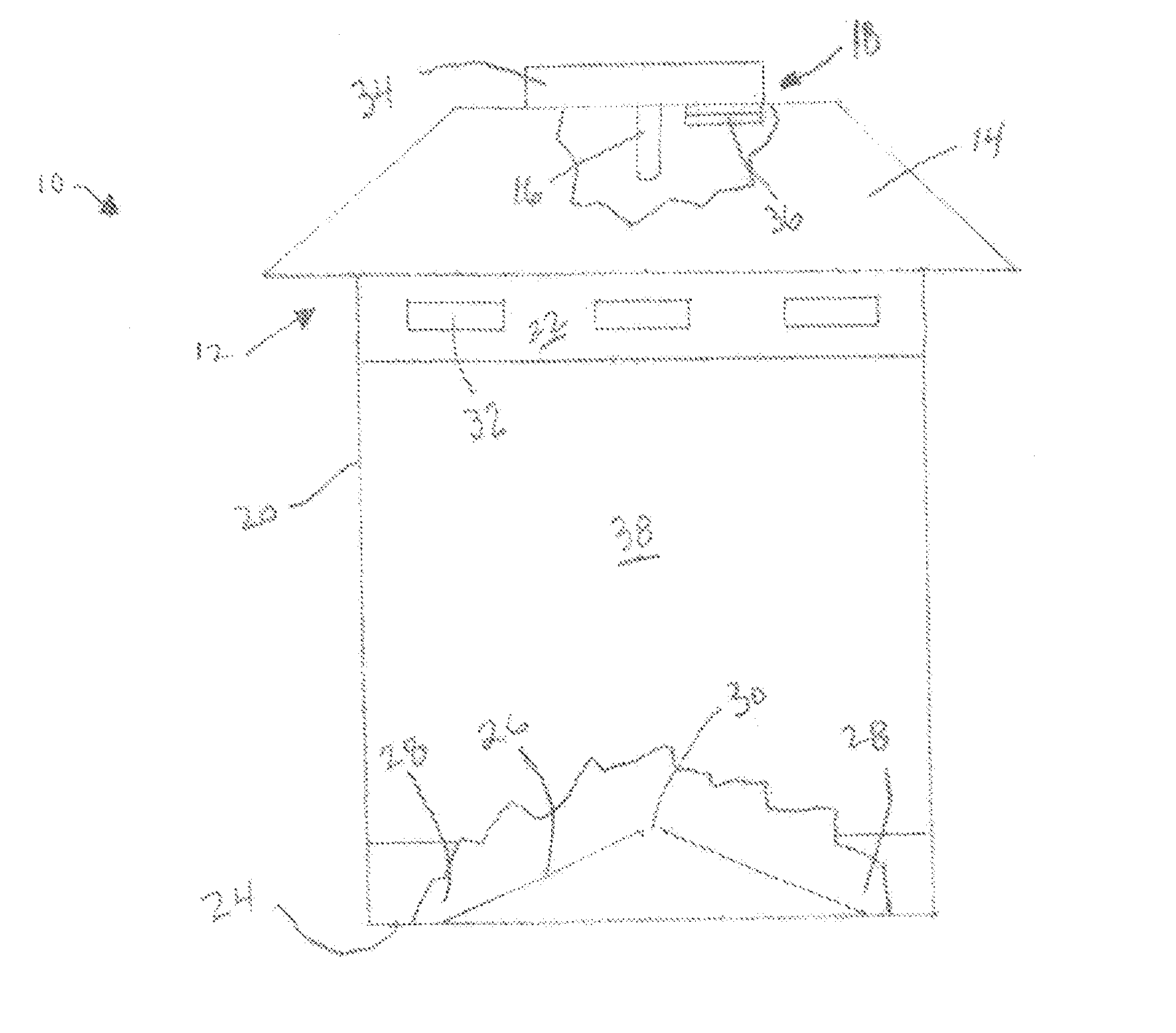

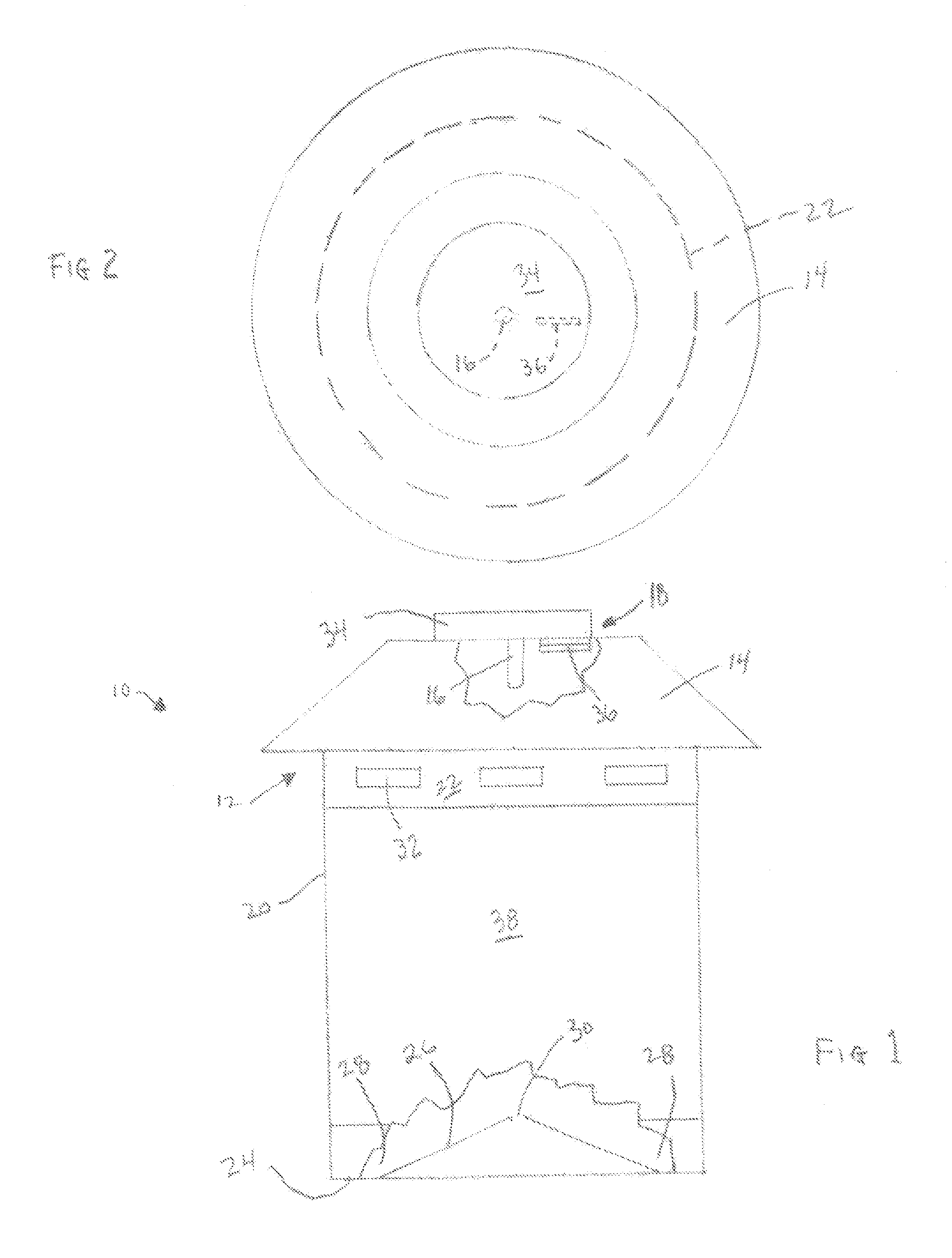

Luminous insect trap

Owner:WRIGHT WILLIAM

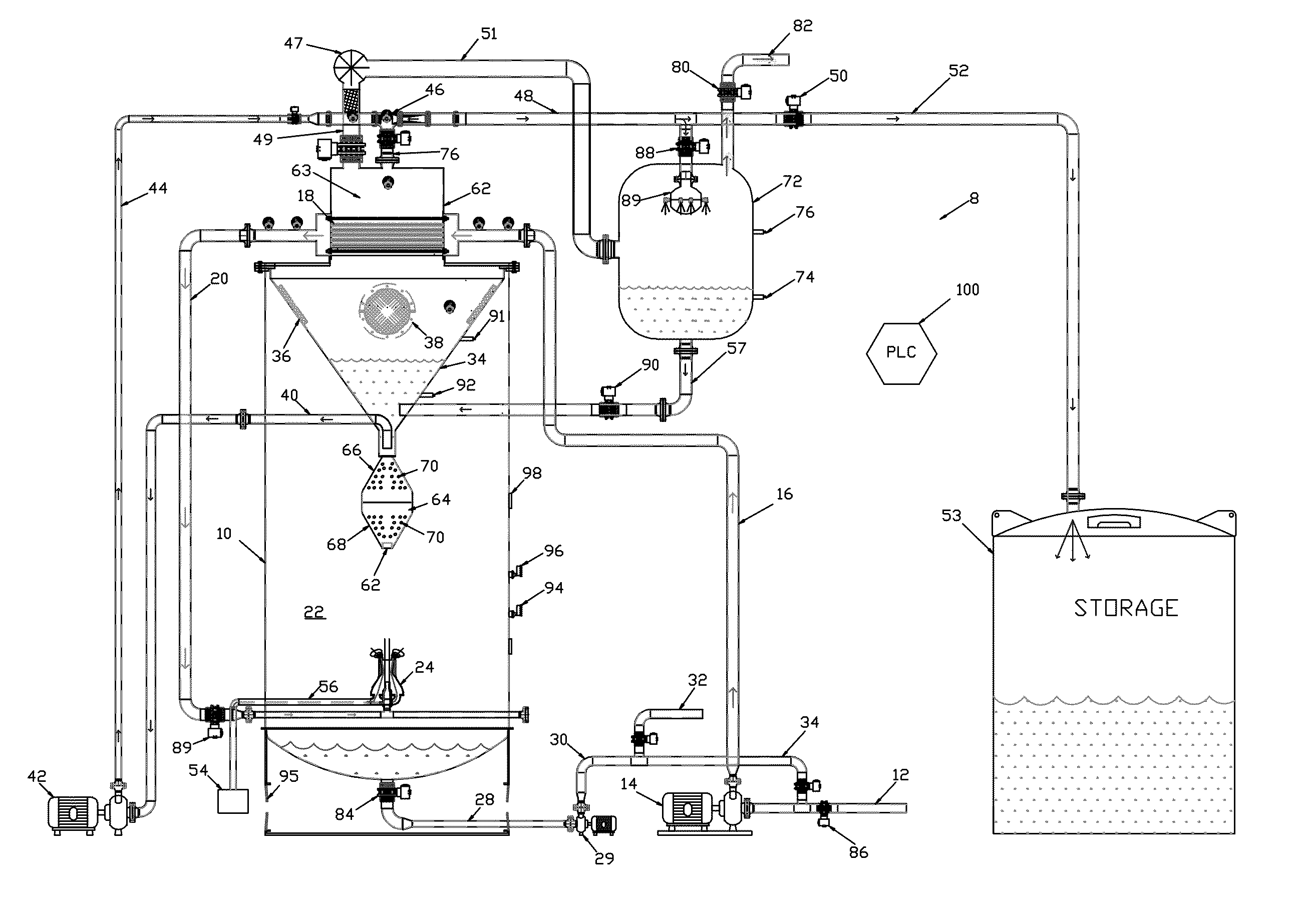

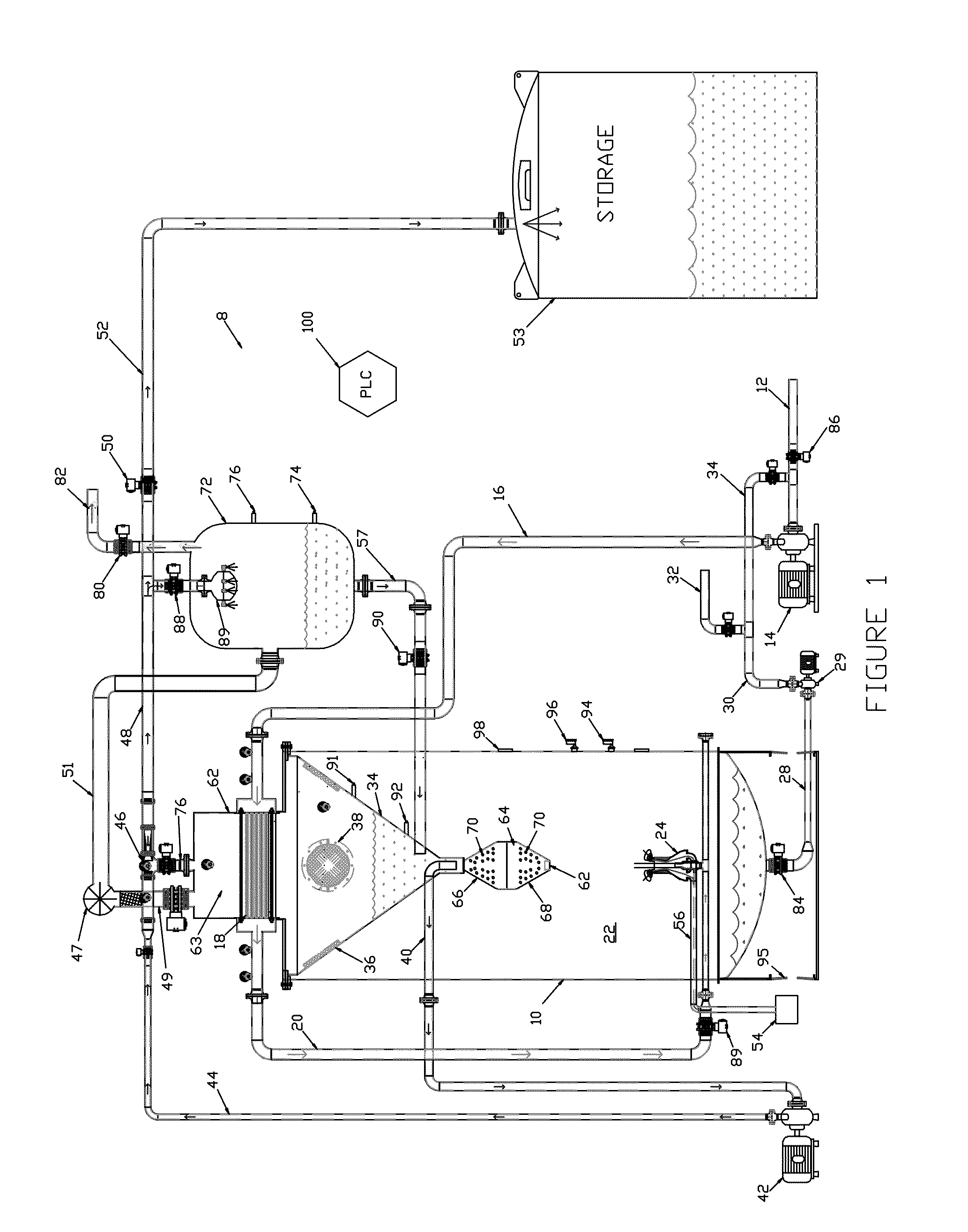

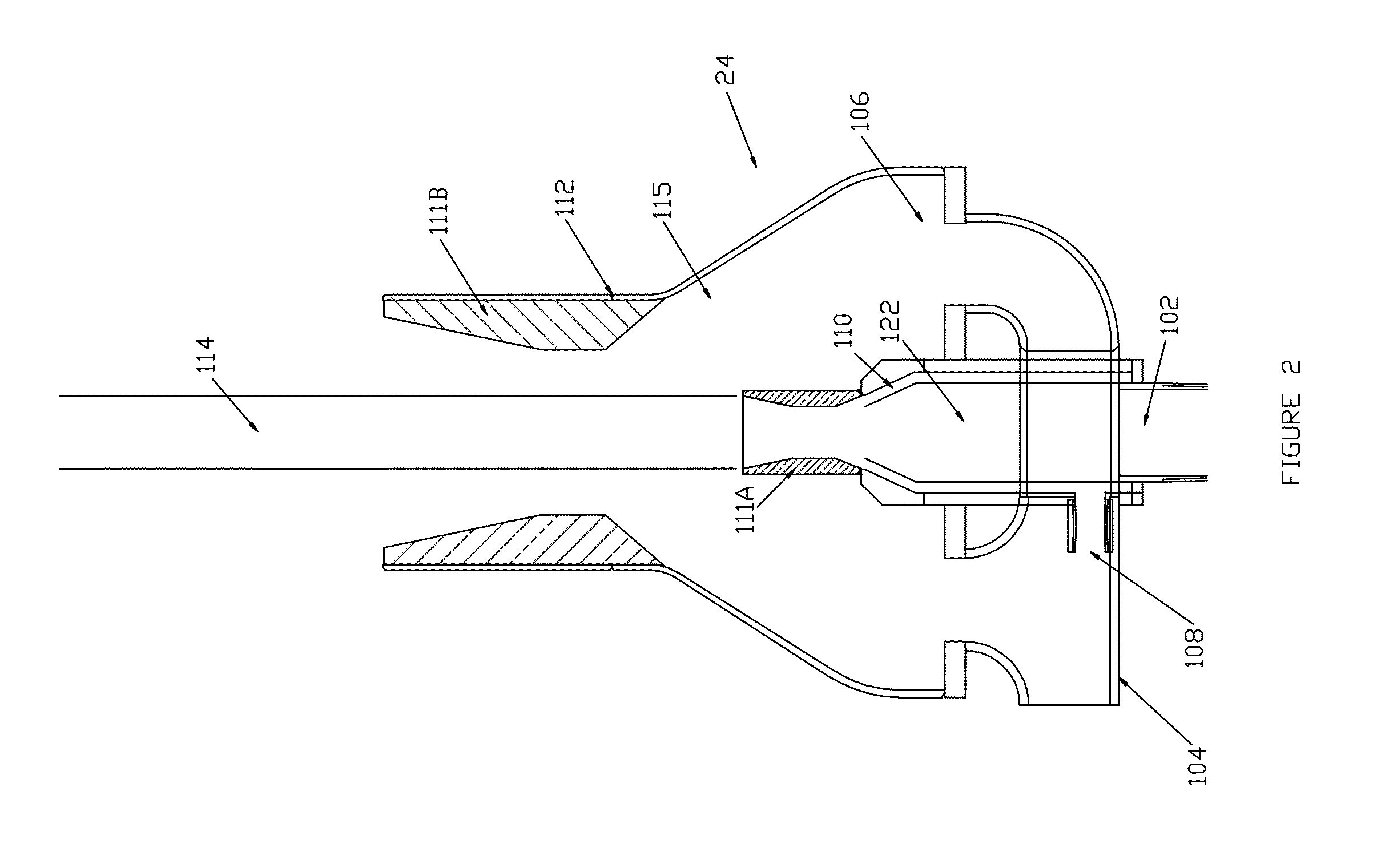

Desalination System and Method

A system for desalinating water includes a generally cylindrical enclosure (10) and a vacuum generator (46) for forming a partial vacuum within the enclosure. Eductor (24) within a lower end of the enclosure receives heated air and brine water, and outputs a mixture of heated air and water vapor and droplets into the enclosure. Condensate collector (34) is positioned above the eductor for collecting desalinated condensate, and heat exchanger (18) above the condensate collector transfers heat within the enclosure to the brine water and condenses the water vapor to desalinated condensate.

Owner:CENTRIFORCE TECH

Dual function insulating holder for bottle or can

An insulating holder for holding a beverage in a bottle or a can having a lower cylindrical enclosure which receives an upper enclosure having a dome-shaped upper end. The upper and lower enclosures are provided with mating threads or other mating devices to hold the upper and lower enclosures in place when enjoyed. The upper enclosure is adapted to cover the top portion of a bottle inserted into the lower enclosure and to snuggly receive a can when inverted and inserted into the lower enclosure.

Owner:BEGGINS HLDG LLC

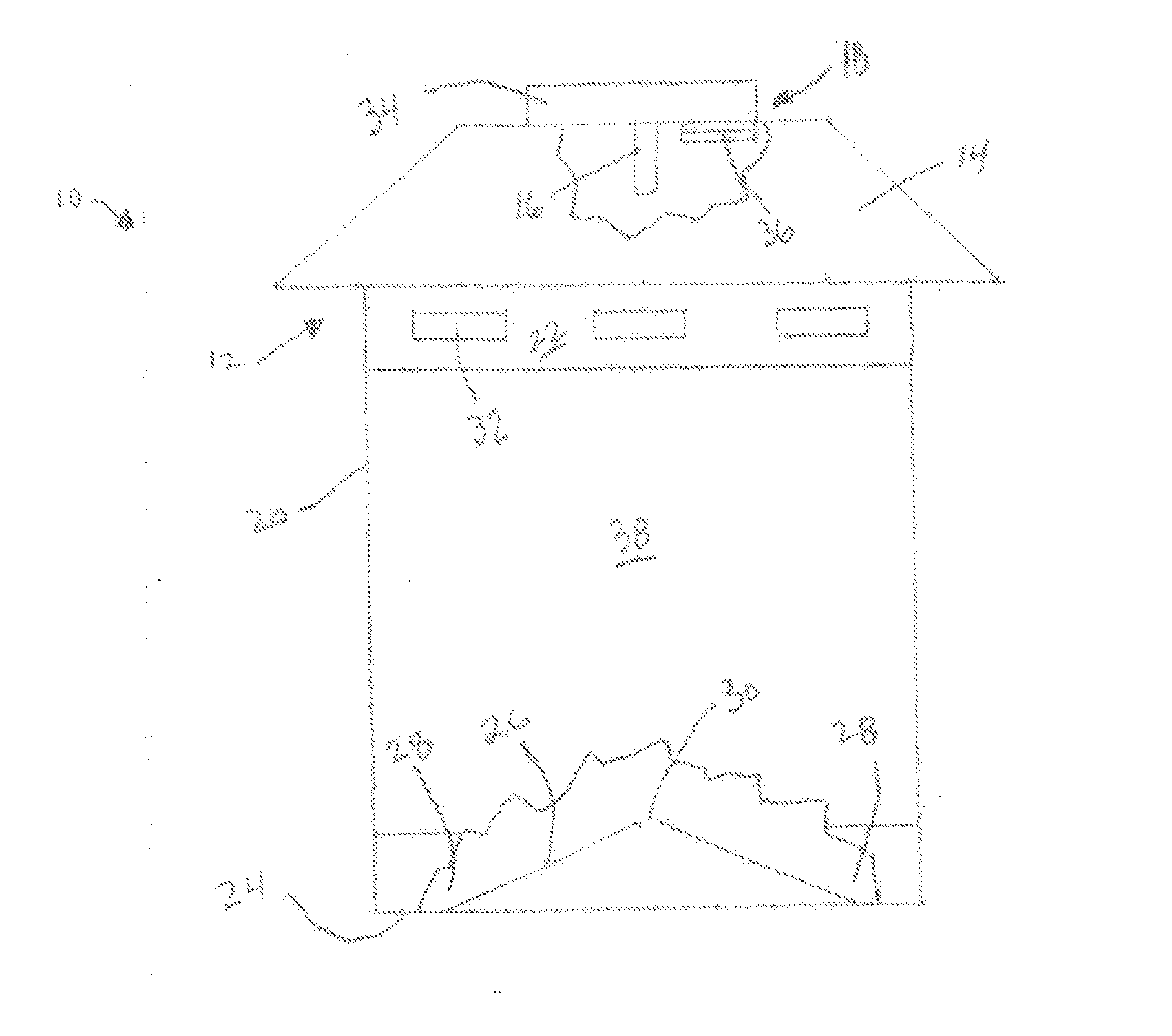

Luminous insect trap

A luminous insect trap for flying or crawling insects includes a hollow cylindrical enclosure having cylindrical side walls and upper and lower ends, a roof member removably closing the upper end, a removable electrical light source within the enclosure, an electrical power source providing electrical power to the light source, transparent, white or lightly colored, flexible glue boards removably overlying a major portion of the cylindrical walls; a bottom wall including a generally centrally disposed aperture, the aperture being just large enough to allow relatively large insects to pass therethrough, the centrally disposed portion of the bottom wall projecting inwardly into the enclosure for defining an annular space between the inwardly projecting bottom wall and the side walls of the enclosure, and a plurality of wall apertures spaced apart about the periphery of the cylindrical walls just below the bottom of the roof member.

Owner:WRIGHT WILLIAM

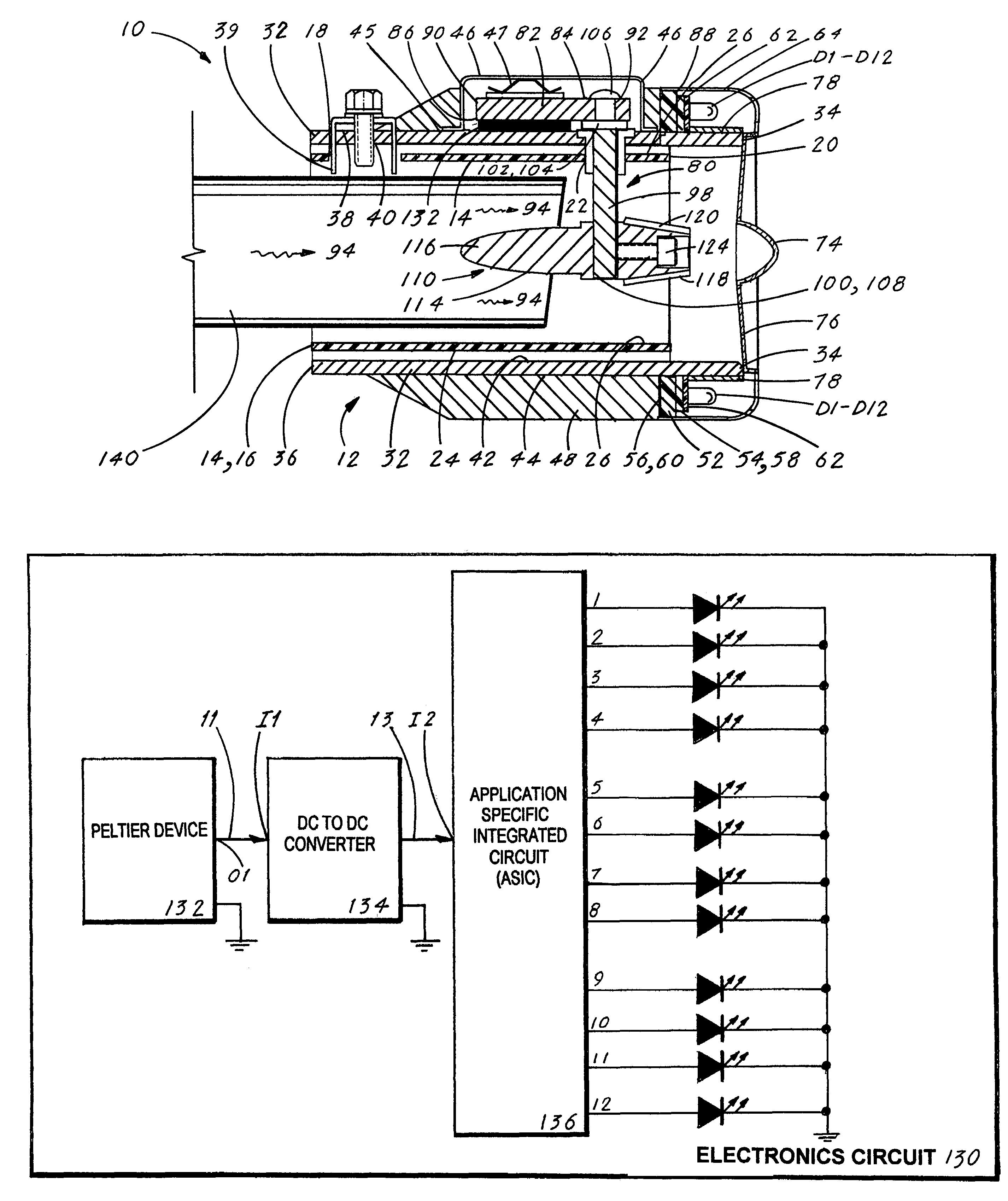

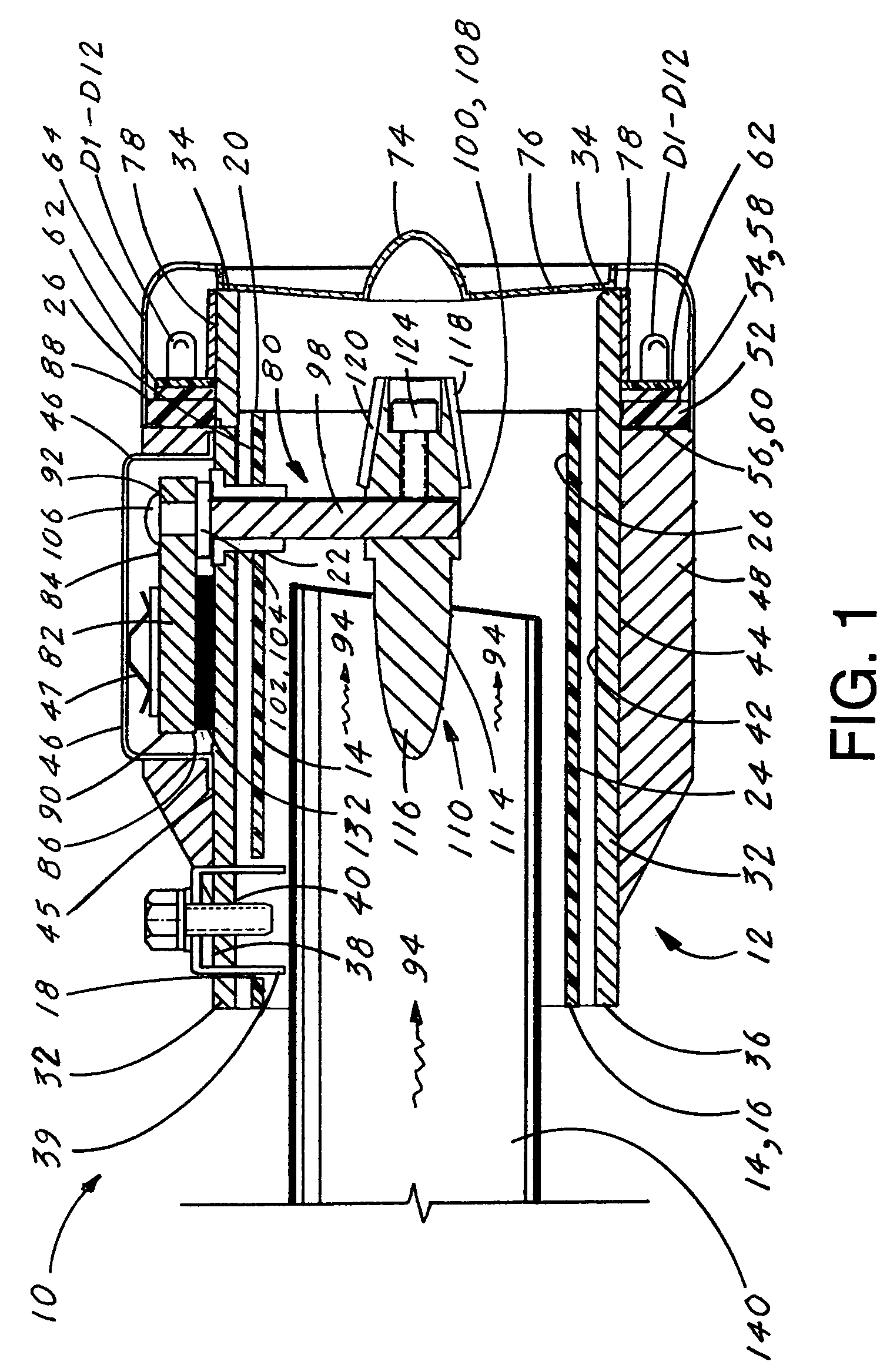

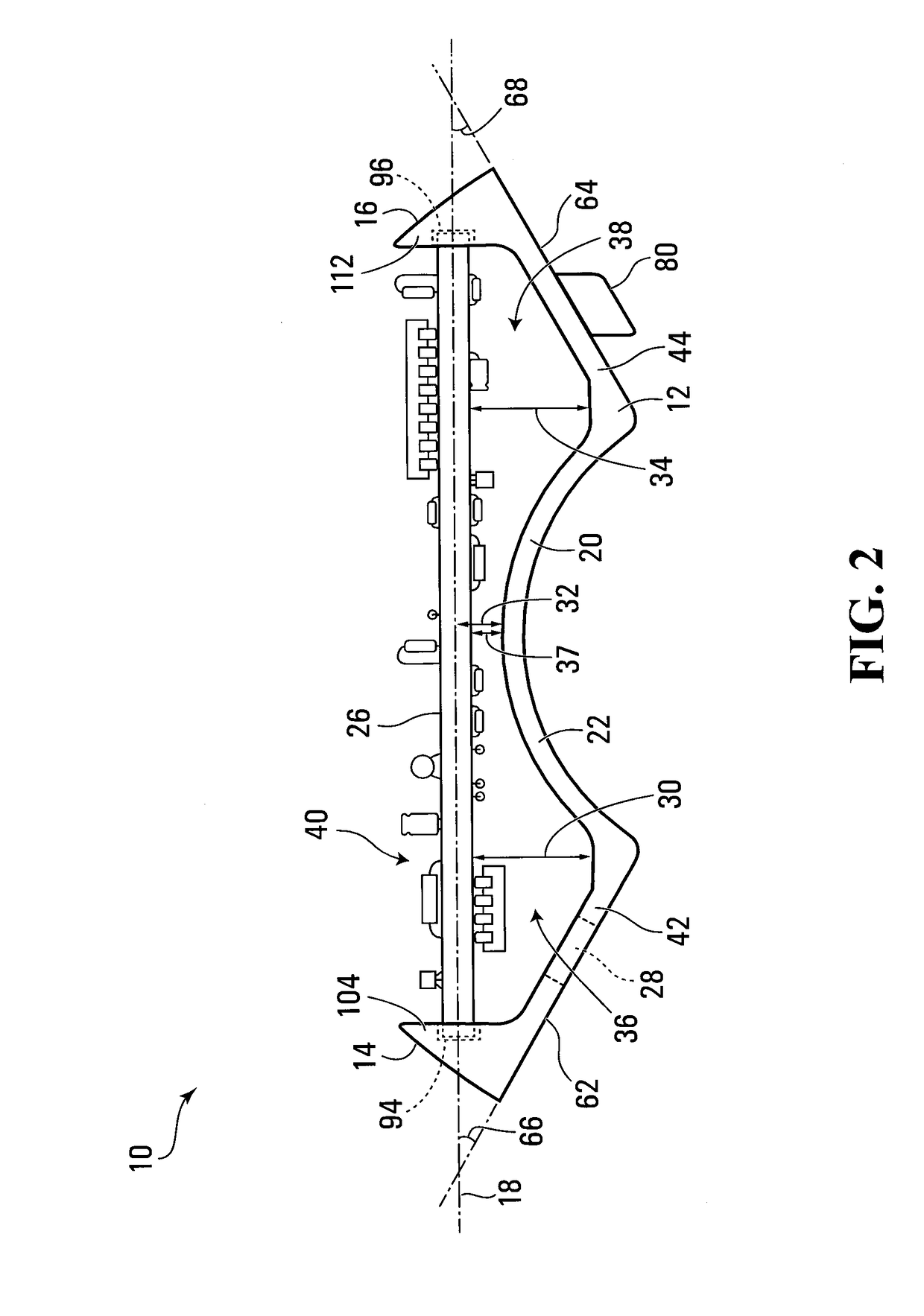

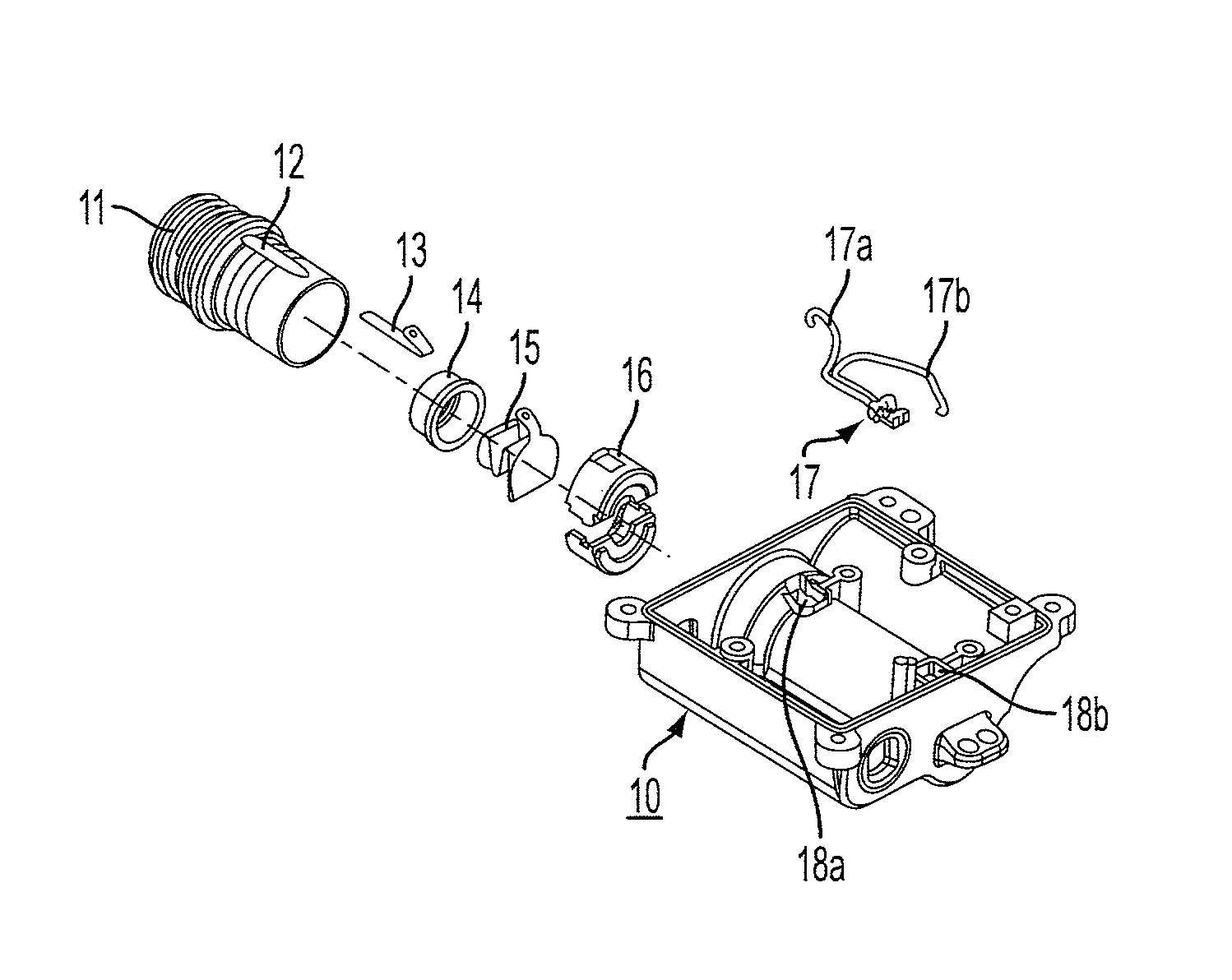

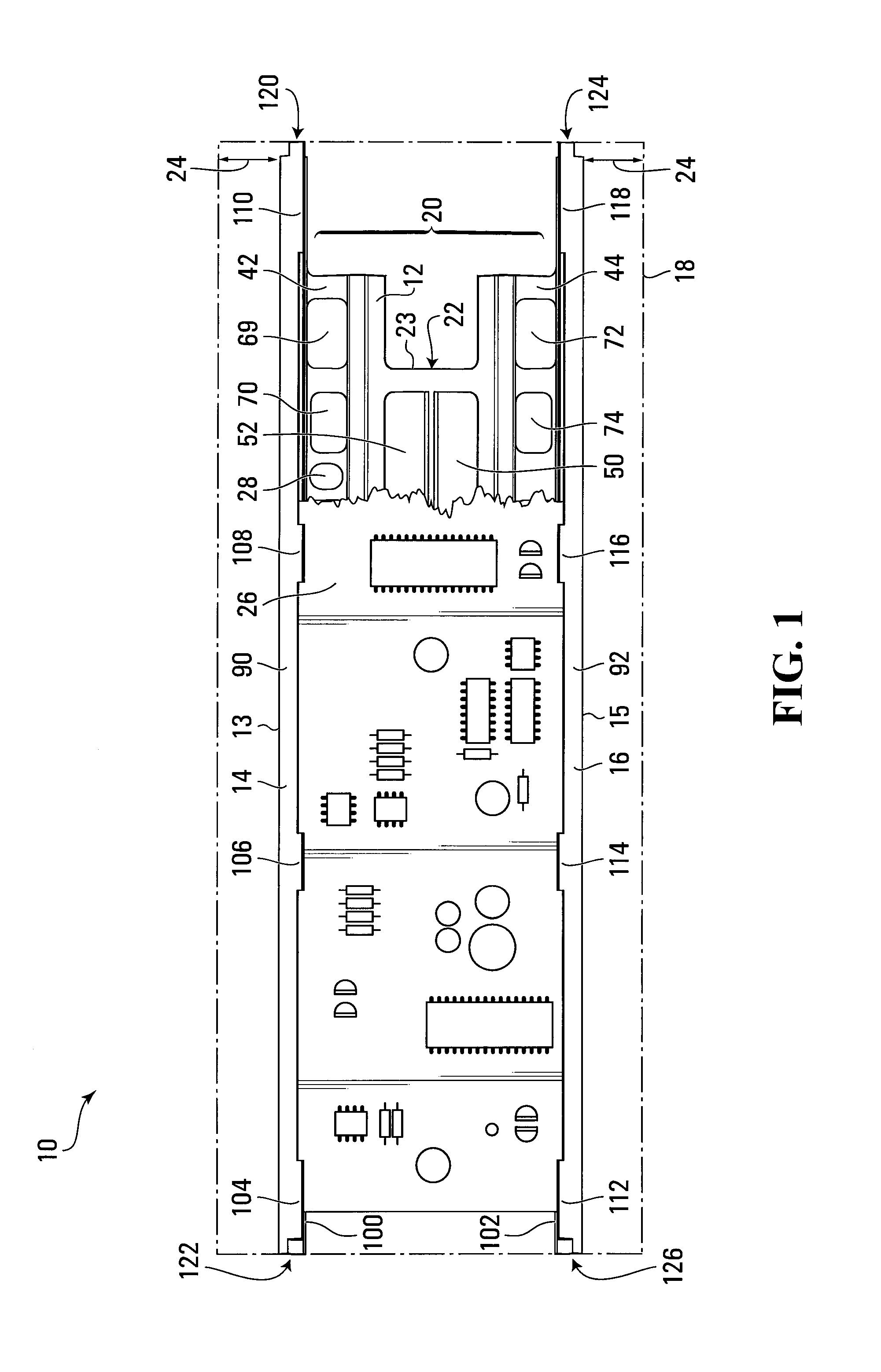

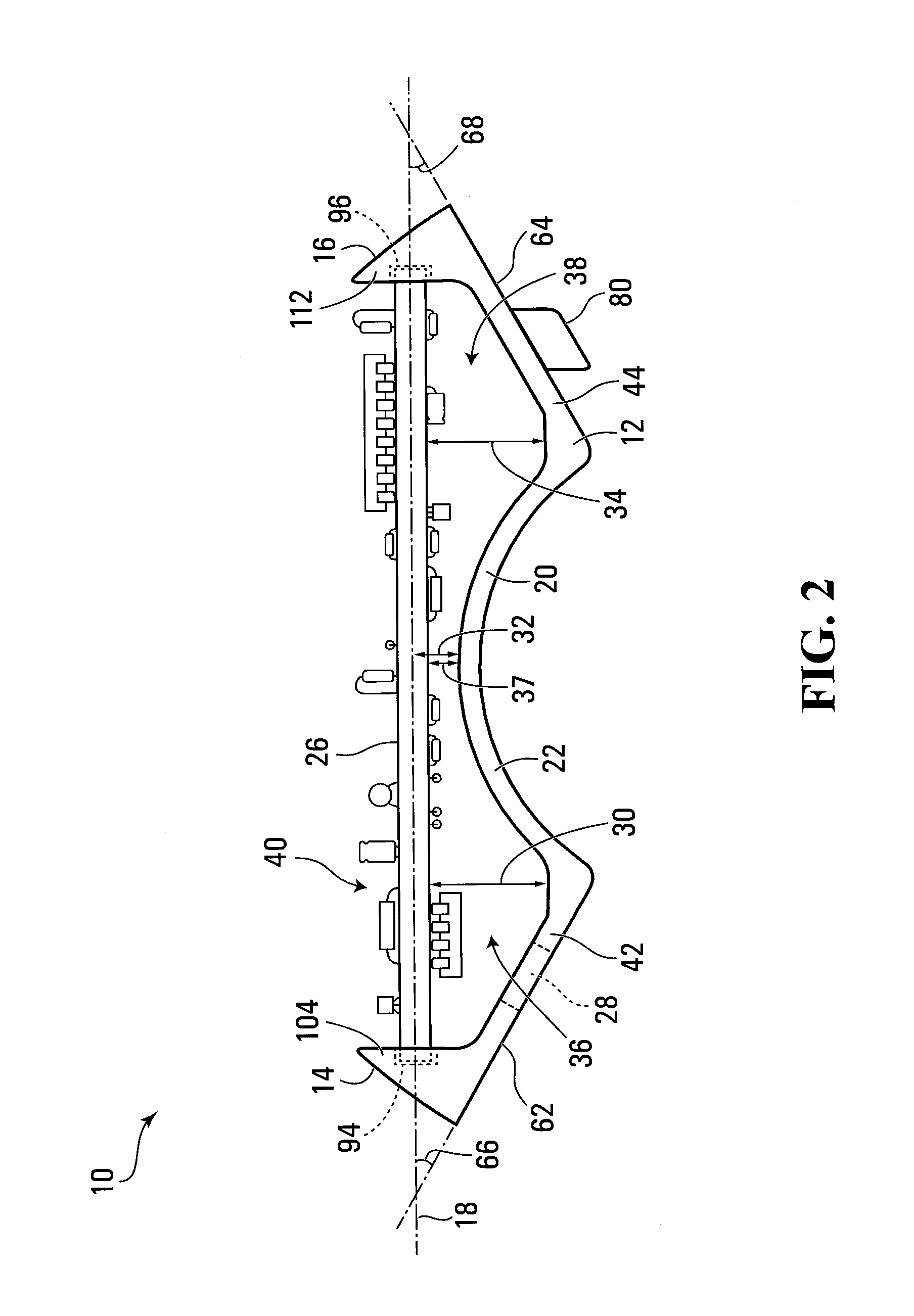

Self-powered, heat-activated LED vehicle exhaust tip assembly

InactiveUS7152710B1Easy to assembleThermoelectric device with peltier/seeback effectExhaust apparatusControl signalHeat conducting

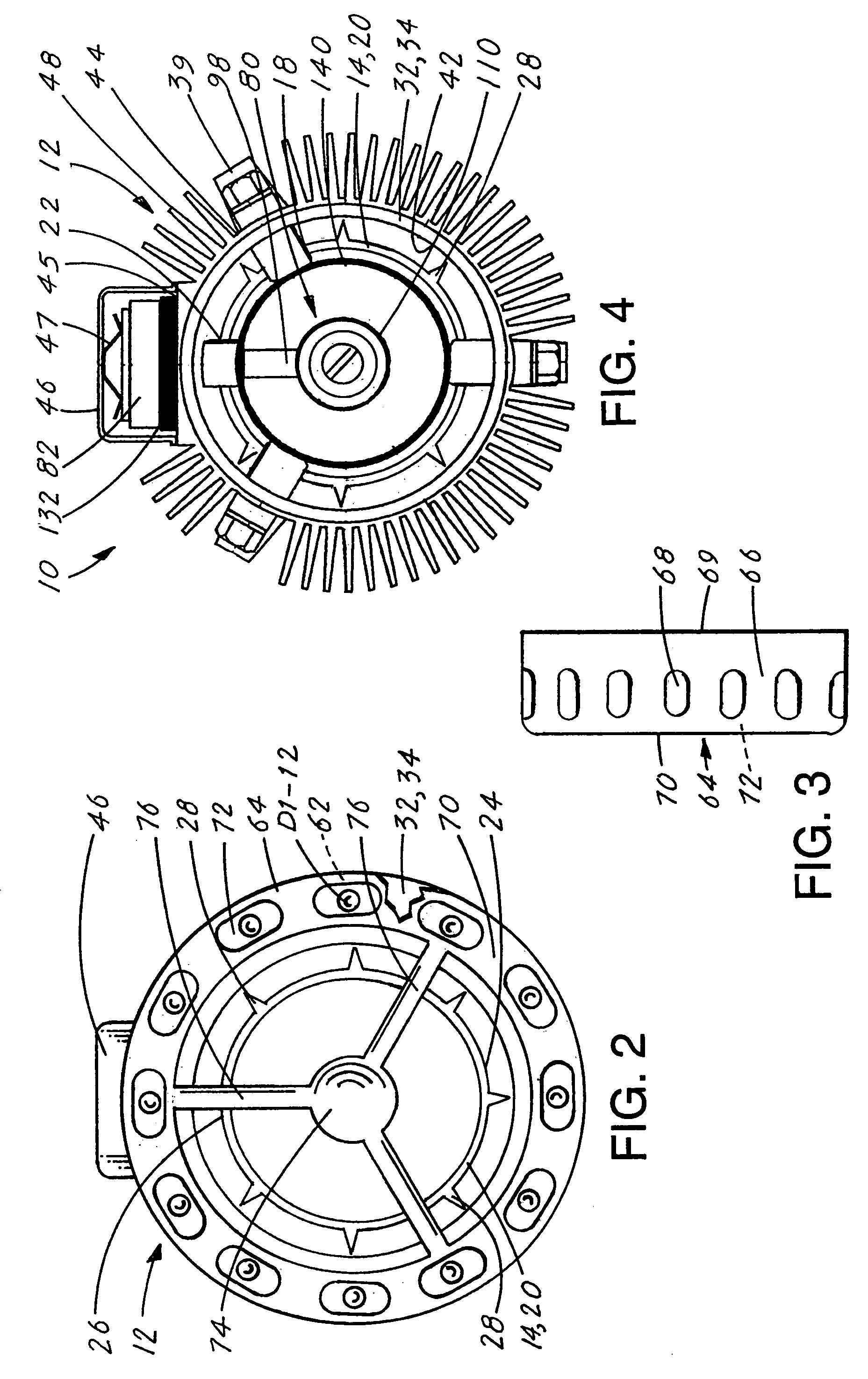

A self-powered, heat-activated LED exhaust tip assembly (10) that is comprised of three major elements: a cylindrical enclosure (12), a heat conducting sub-assembly (80) and an electronics circuit (130). The sub-assembly (80) consists of an external heat conducting plate (82), and an enclosure-internal heat conductive horizontal structure (110) that is attached to the plate (82) through a heat conductive vertical rod (98). When heated vehicle exhaust gases pass through the enclosure (12), the gases heat the structure (110) and the heat is then transferred to the plate (92) via the rod (98). The heat from the plate (82) is transferred to a peltier device (132) that interfaces with the plate (82). The heated peltier device (132) produces a first d-c voltage (11) that is applied to a DC to DC converter (134), where a second d-c voltage (13) is produced. The output of the converter (134) is applied to an application specific integrated circuit (ASIC) (136) that produces a set of LED control signals that illuminate a set of LEDs.

Owner:HUANG ZHENQIU +1

Liquid separator for vacuum filter

InactiveUS20060143853A1Avoid liftingCleaning filter meansSuction filtersEngineeringCylindrical enclosure

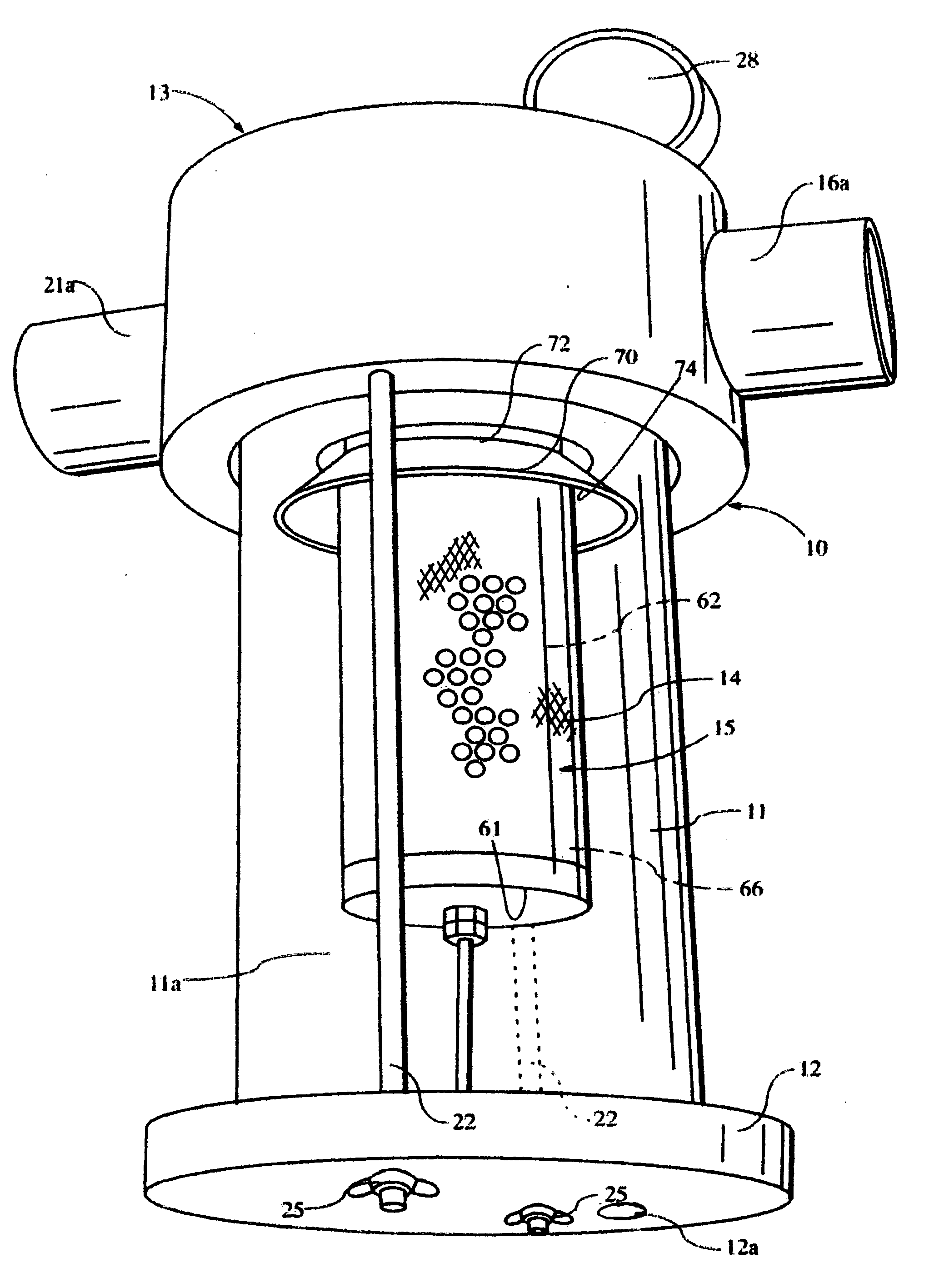

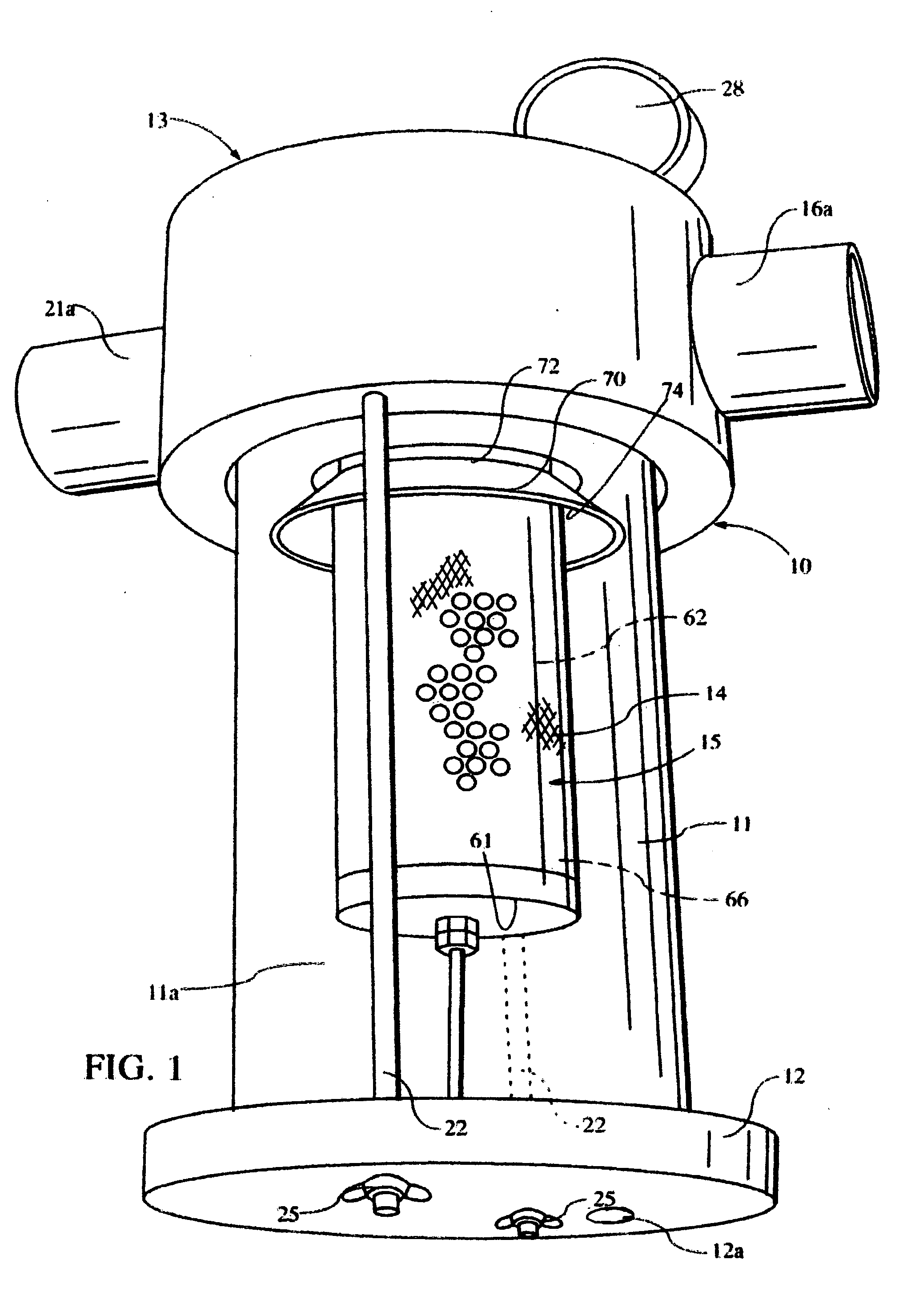

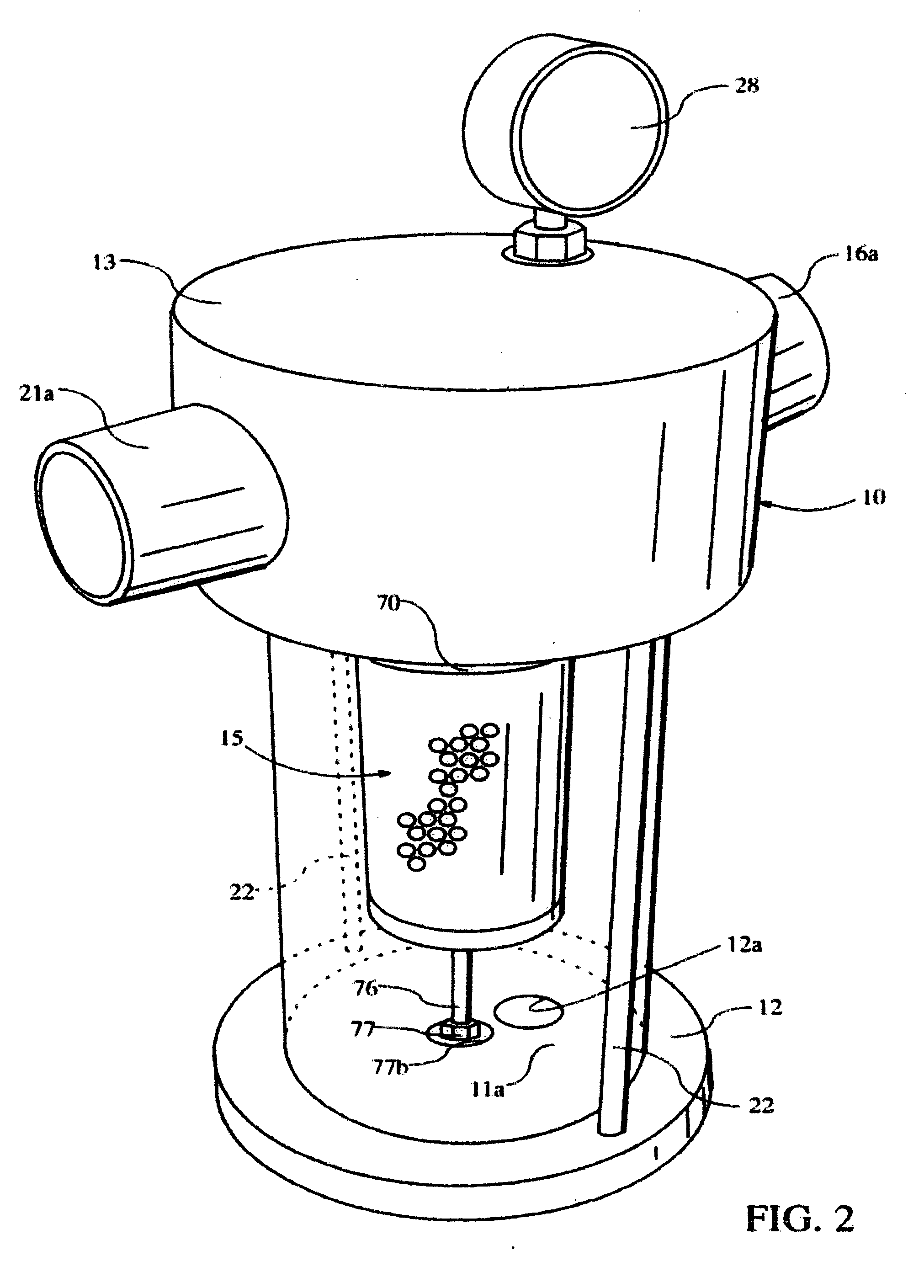

A float valve 80, made of HDPE, is movably mounted in a stainless steel cage 60 in an in-line vacuum filter. The float valve has a chamber 85 formed in a skirt portion 84 thereof. Float valve 80 has a generally cylindrical shaped outer surface 82 encircling the skirt portion 84 and a generally cylindrical shaped inner surface 83 encircling the chamber 85. A upper portion 86 extends across the upper end of valve 80 to form an inverted cup shaped body. The upper portion 86 extending across the upper end of said valve 80 has a threaded hole 87 formed therein to receive a threaded bolt 88 for forming a ballast to permit adjustment of the weight of said valve 80 so that it floats at a level that prevents it being drawn by venturi effect into the central air chamber 19 before a predetermined volume of liquid is collected in the cylindrical enclosure 11 through which air flows en route to the filter element 14. The water line is about 1 inch above the bottom edge of the skirt portion 84 and about 1 inch below the sealing surface 95 to assure that the float valve will engage a seal 98 on said cap 13 adjacent the lower end of central air chamber 19 before liquid is drawn into air chamber 19. The chamber 85 forms an air pocket in which air is trapped to lift the float valve 80 for positioning the sealing surface 95 a predetermined distance above the surface of water or other liquid in which it is floating.

Owner:CHARLES G AGERLID

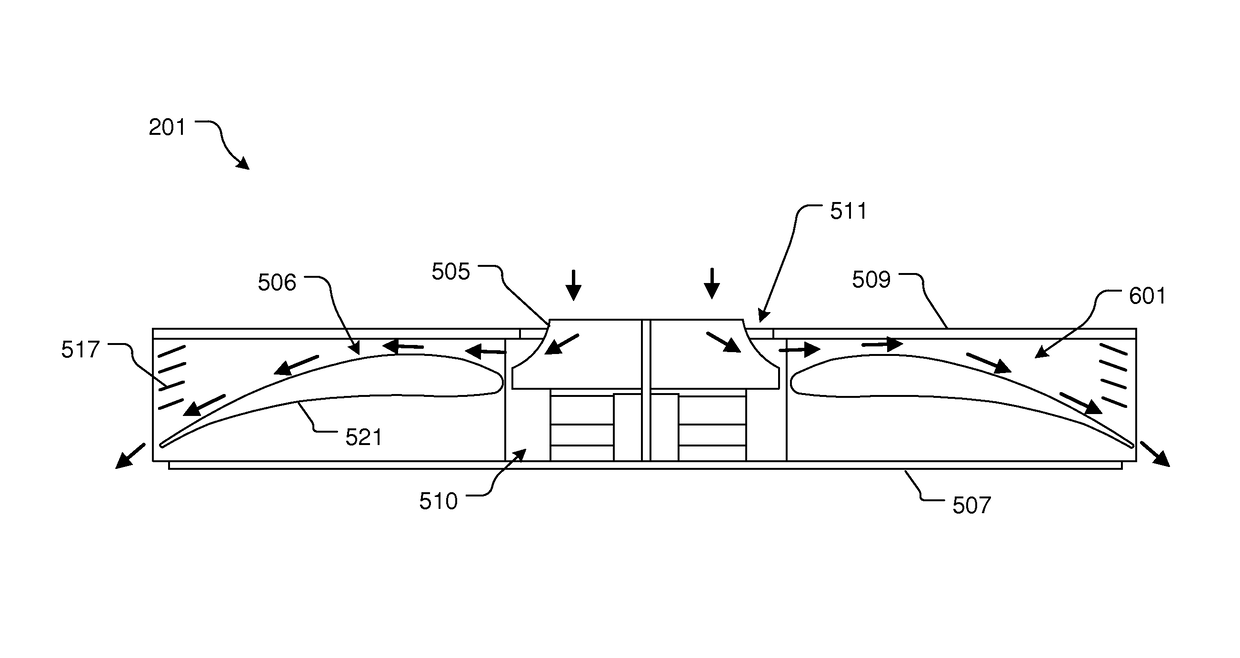

VTOL rotary aircraft and method of use

A rotary aircraft includes a cylindrical enclosure configured to form an open housing with a top opening and a bottom opening; a hover disc disposed within the open housing of the cylindrical enclosure and configured to direct airflow entering through the top opening, the hover disc forming a center opening; and a fan extending through the center opening of the hover disc and configured to direct airflow through the hover disc.

Owner:ESSARY JONATHAN M

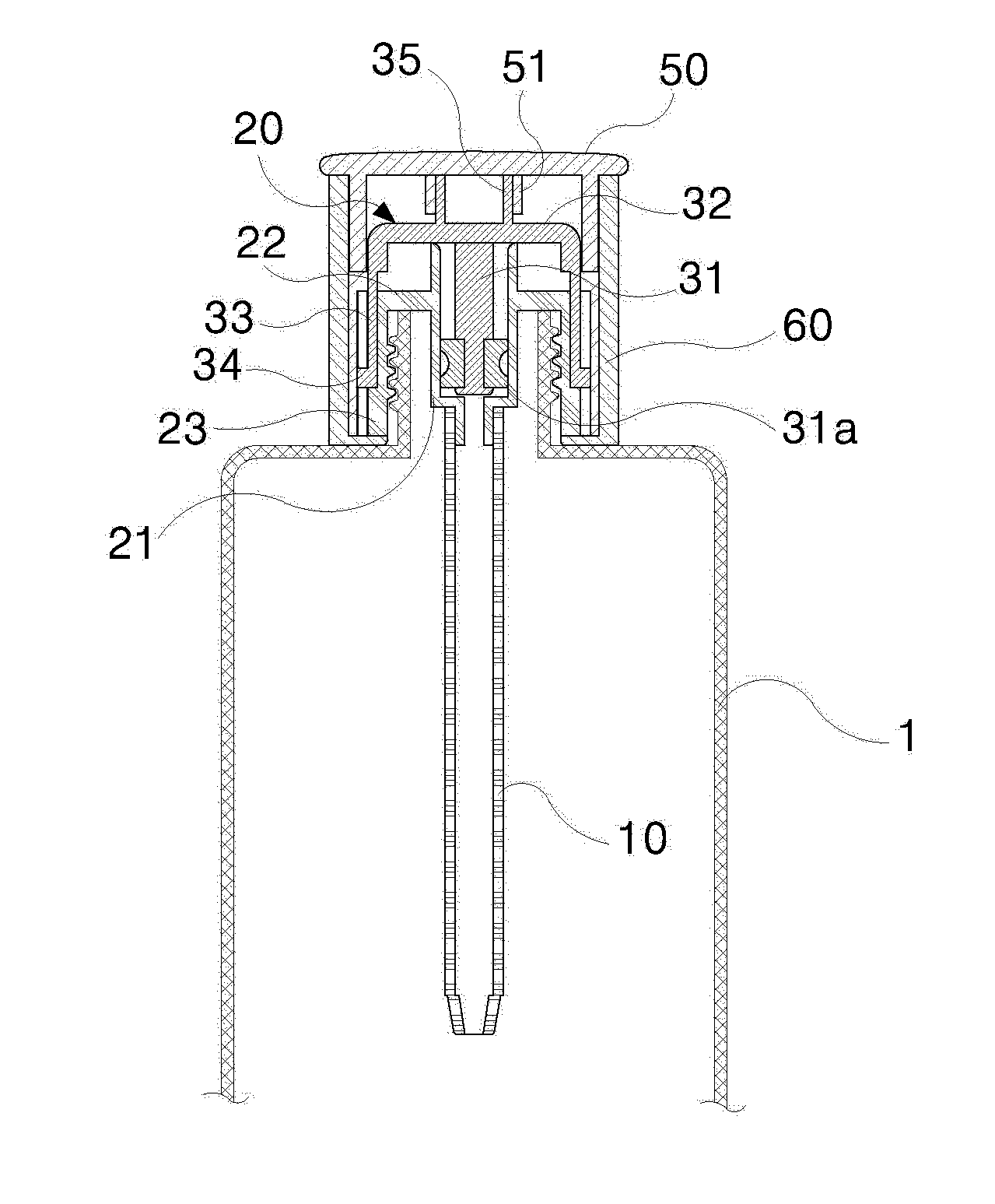

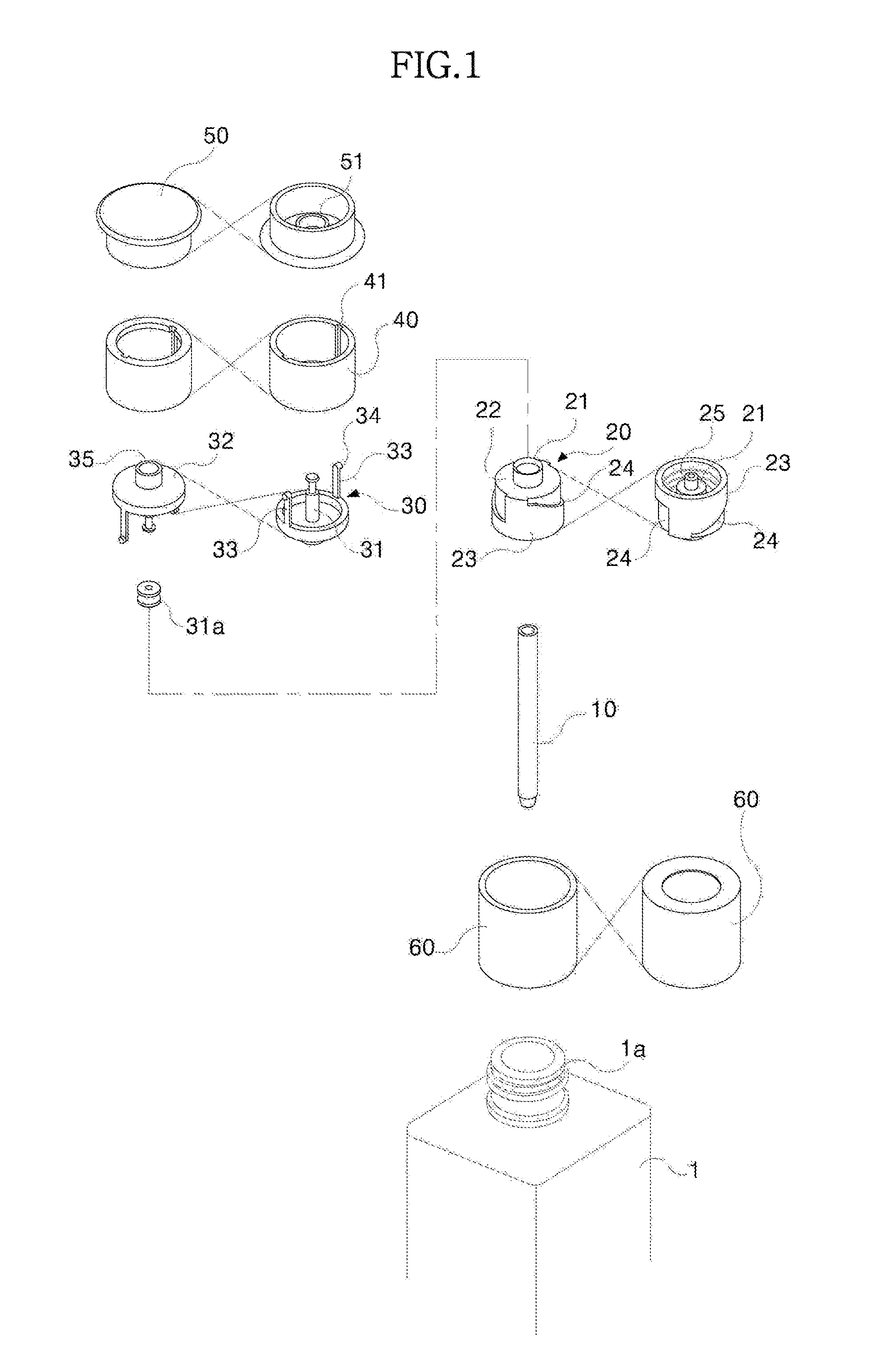

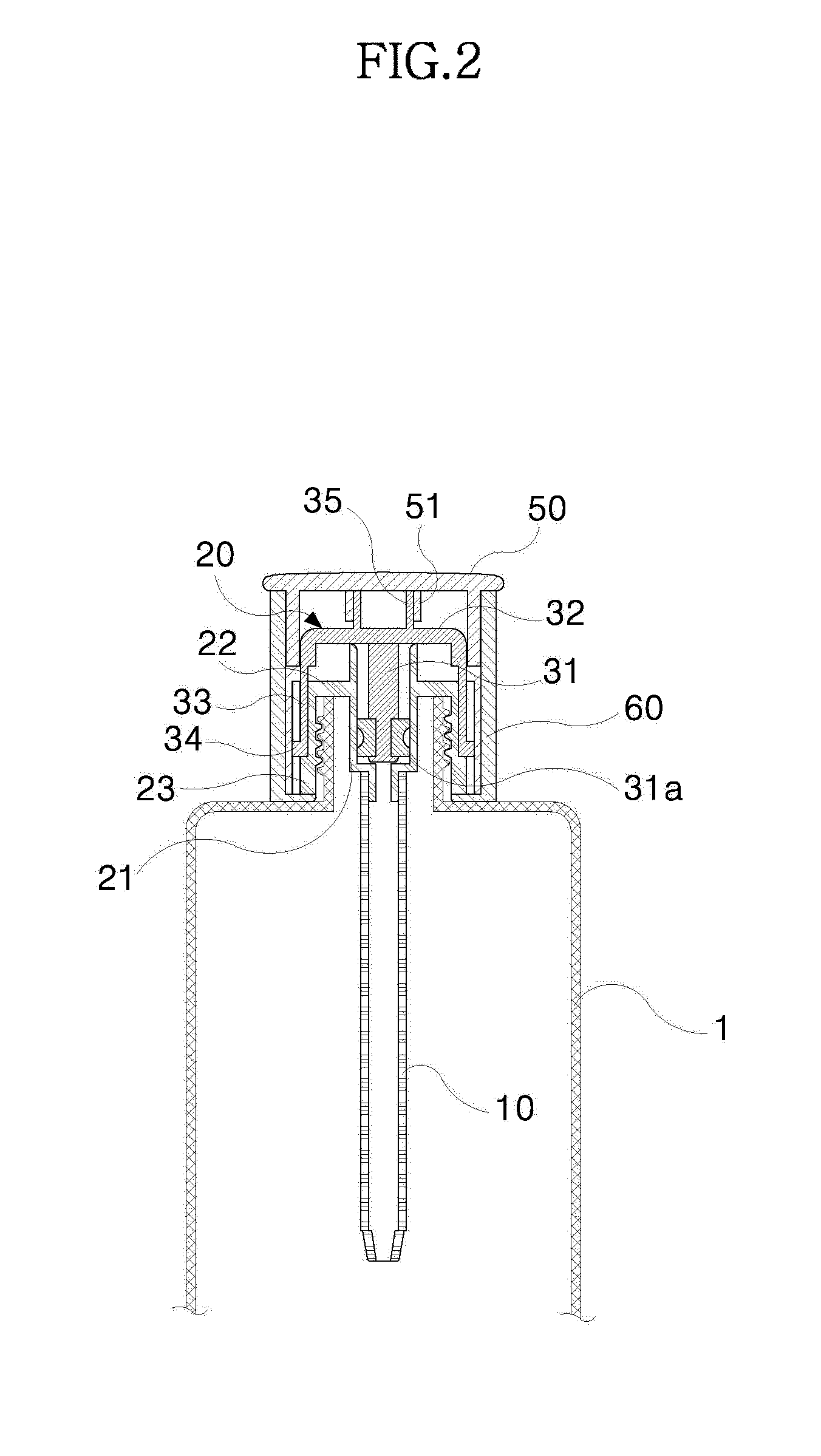

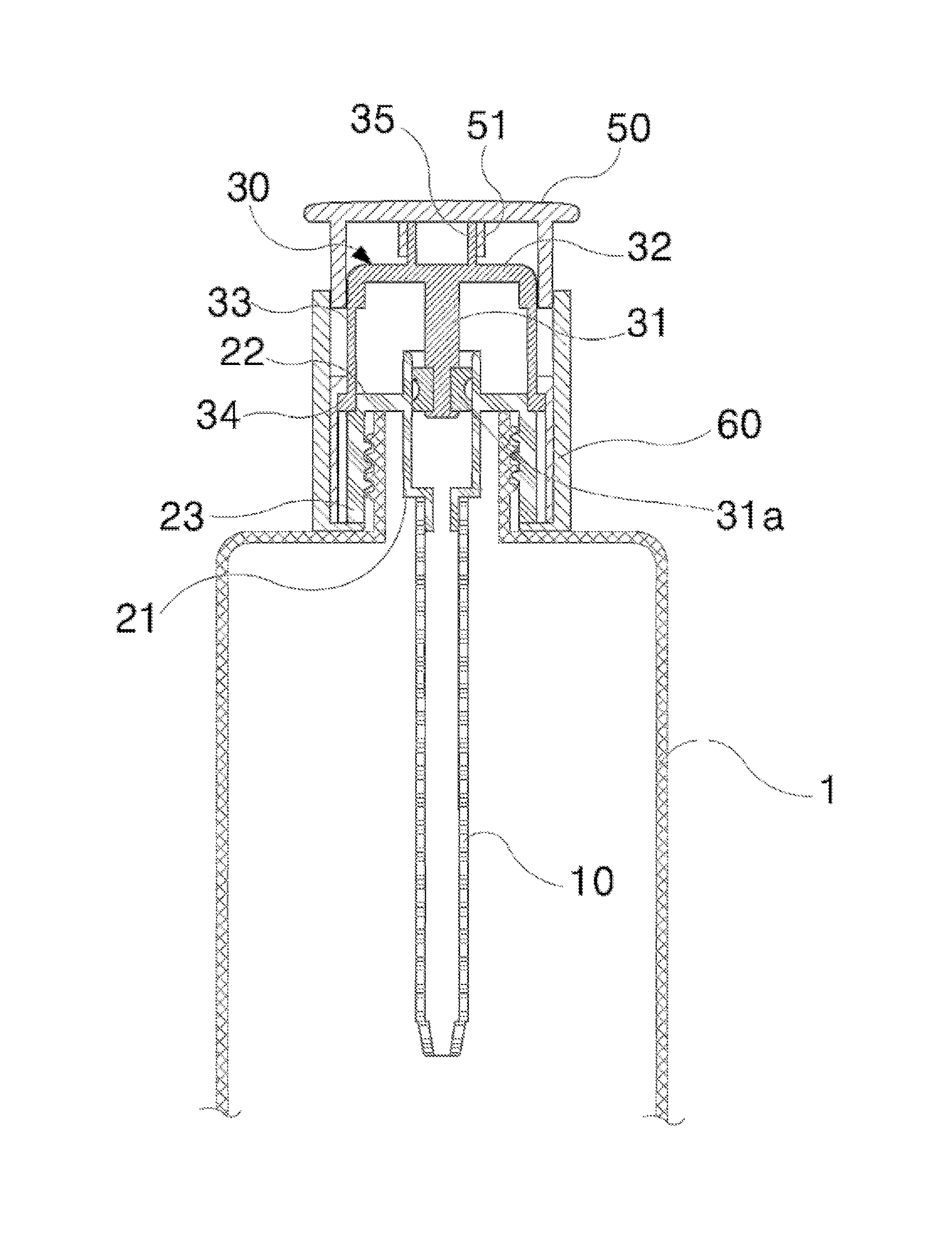

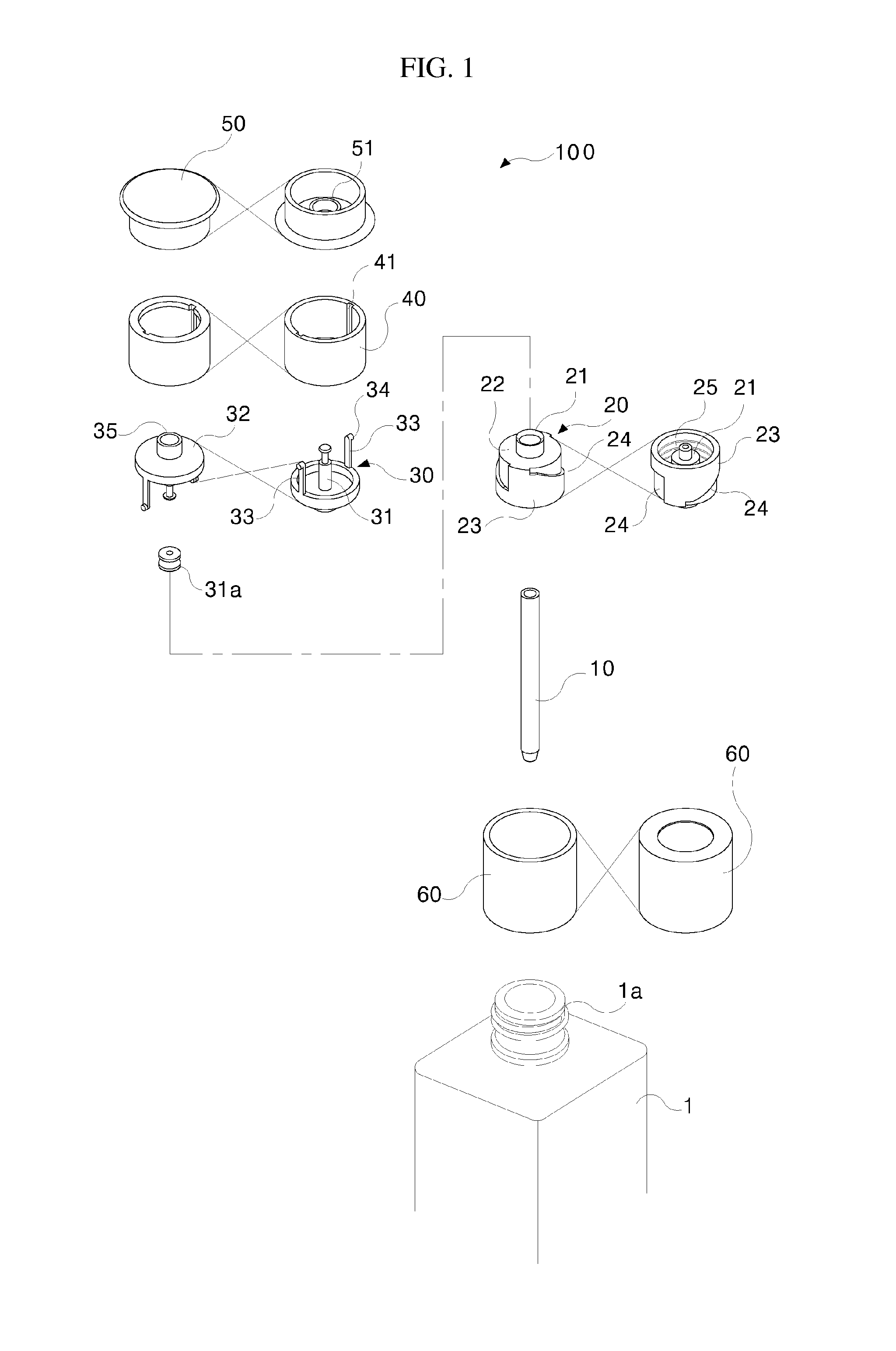

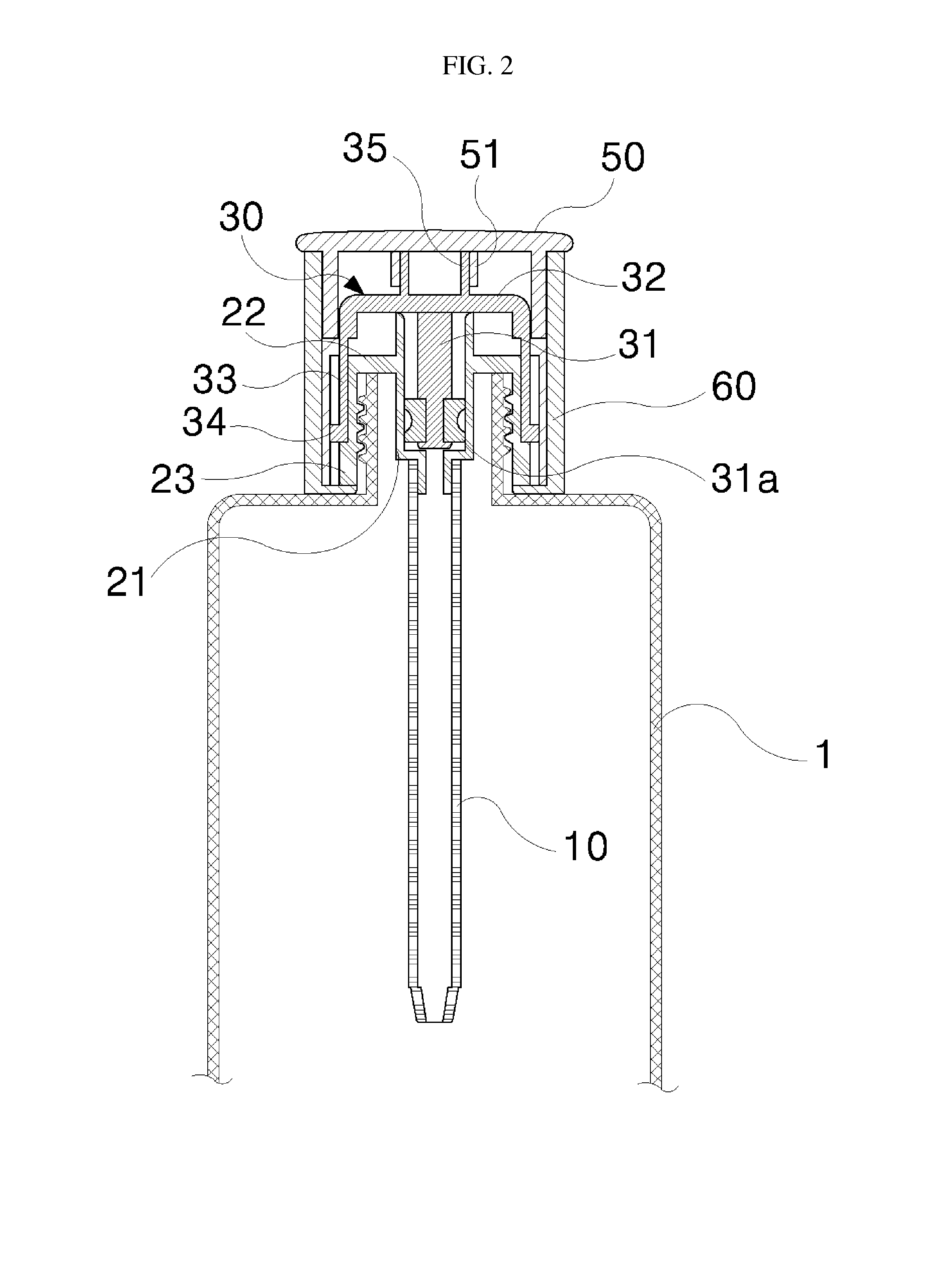

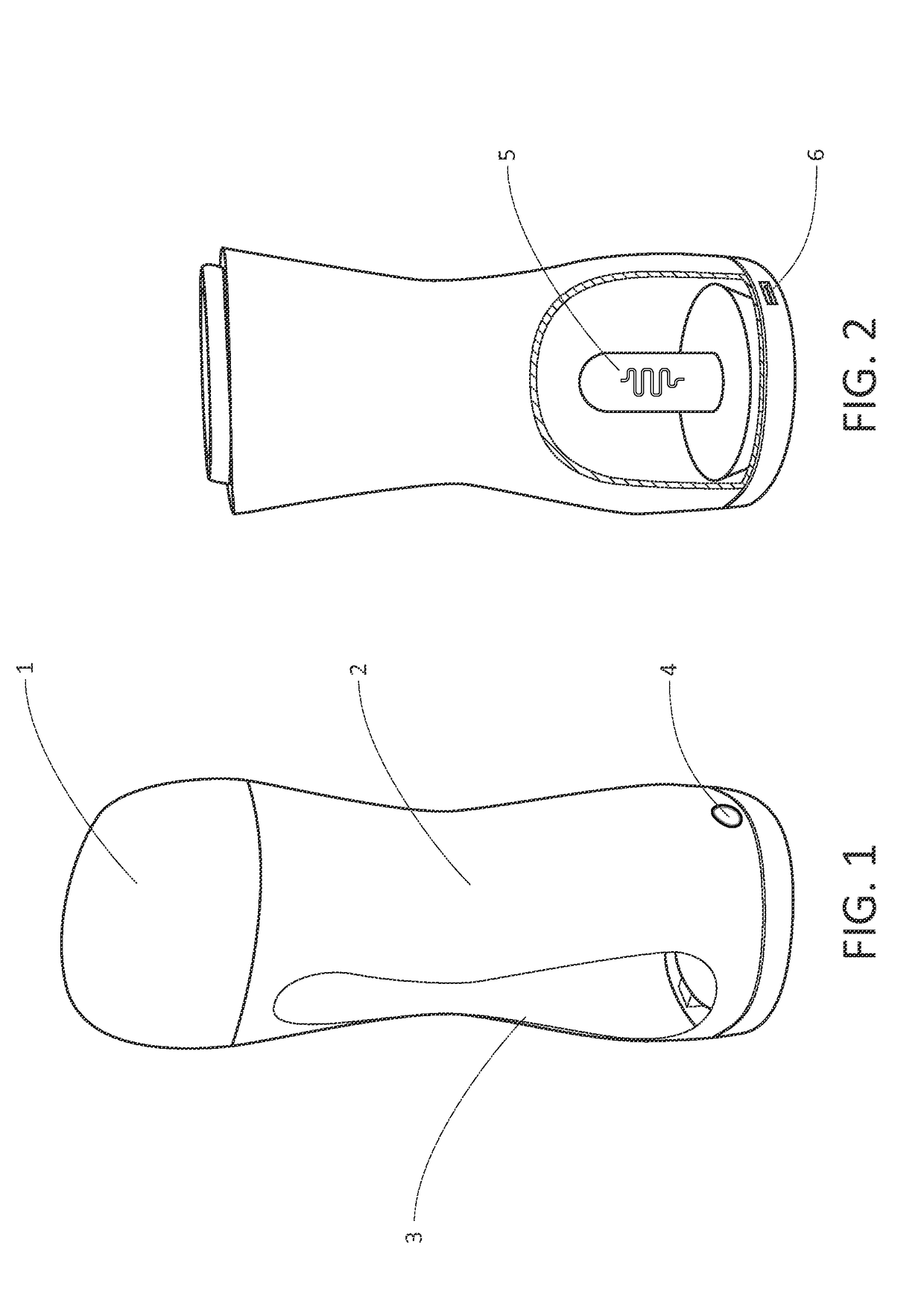

Automatic filling up spuit

ActiveUS20140361047A1Easy to useSimple structureClosure capsLiquid transferring devicesCylindrical enclosureLiquid content

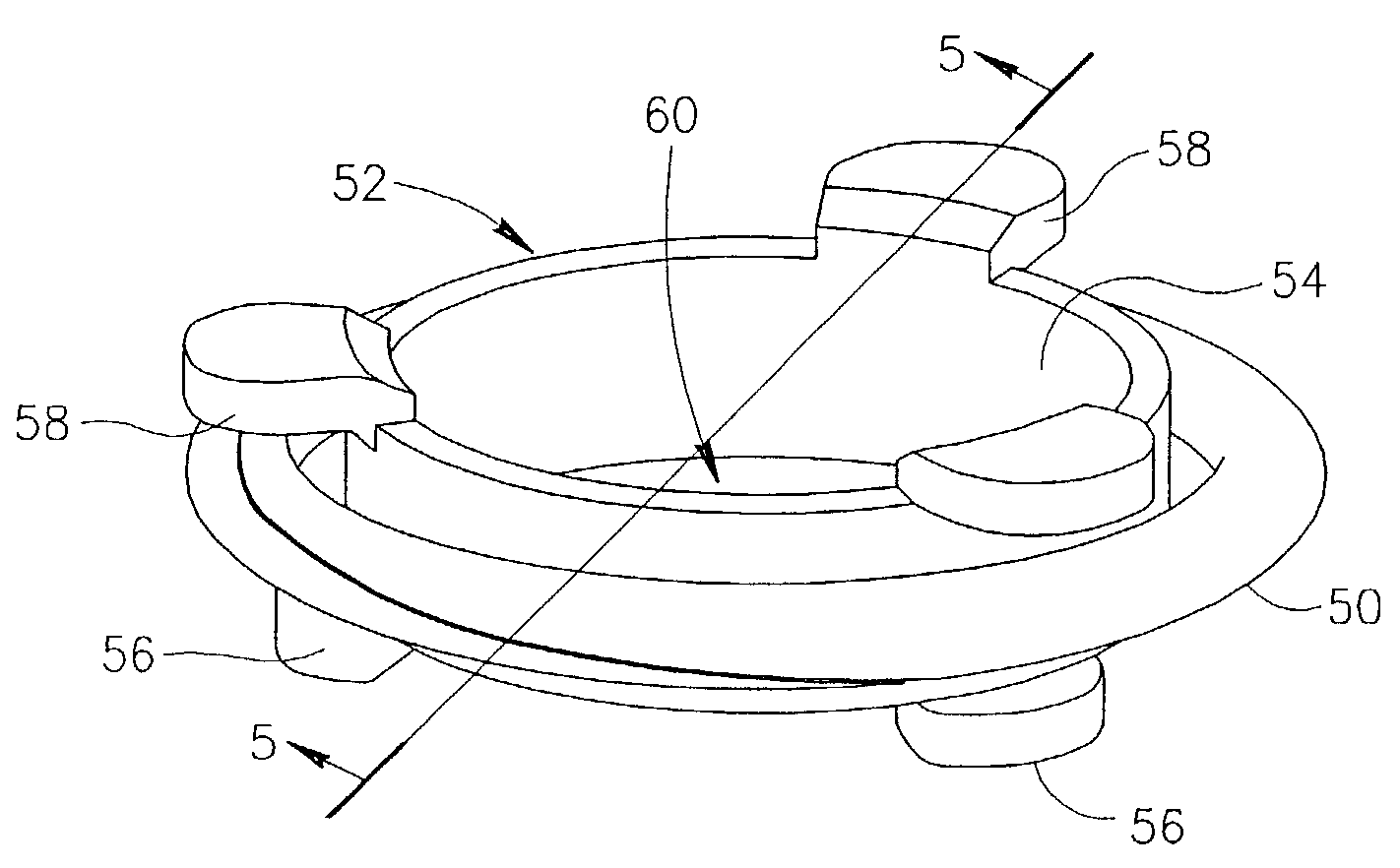

An automatic filling up spuit (100) screwed to an entrance (1a) of a cosmetics container (1) for suctioning and discharging liquid stored in the cosmetics container (1) includes: a spuit pipe (10); a cylinder member (20); a piston member (30); a cylindrical push button (50); and a top / bottom-opened cylindrical enclosure (60). The automatic filling up spuit has an advantage of convenient use in that it is capable of automatically filling up liquid contents in a cosmetics container by a certain amount precisely at all times through joining with the cosmetics container without requiring a separate filling up operation.

Owner:LEE YOUNG JU +1

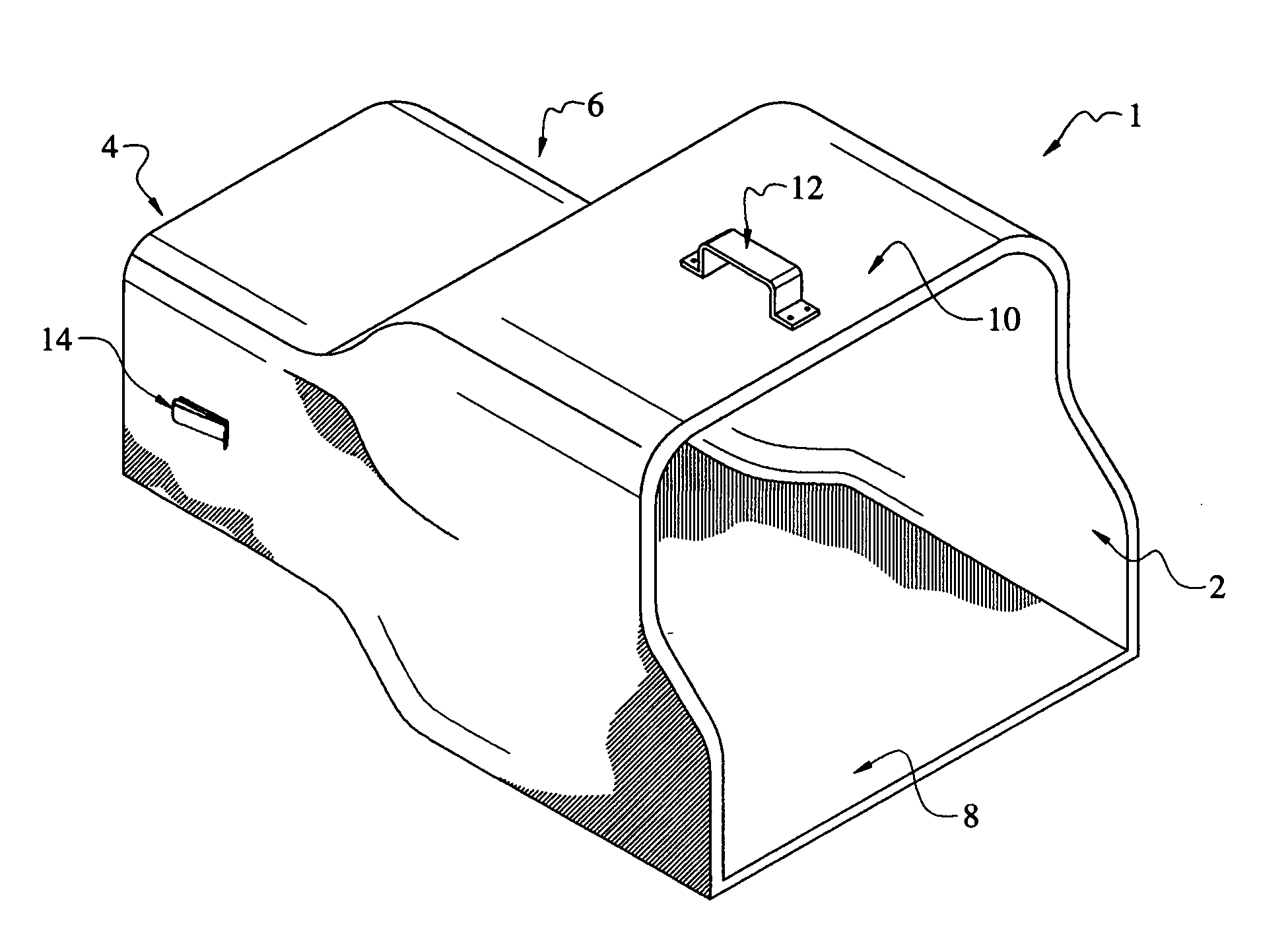

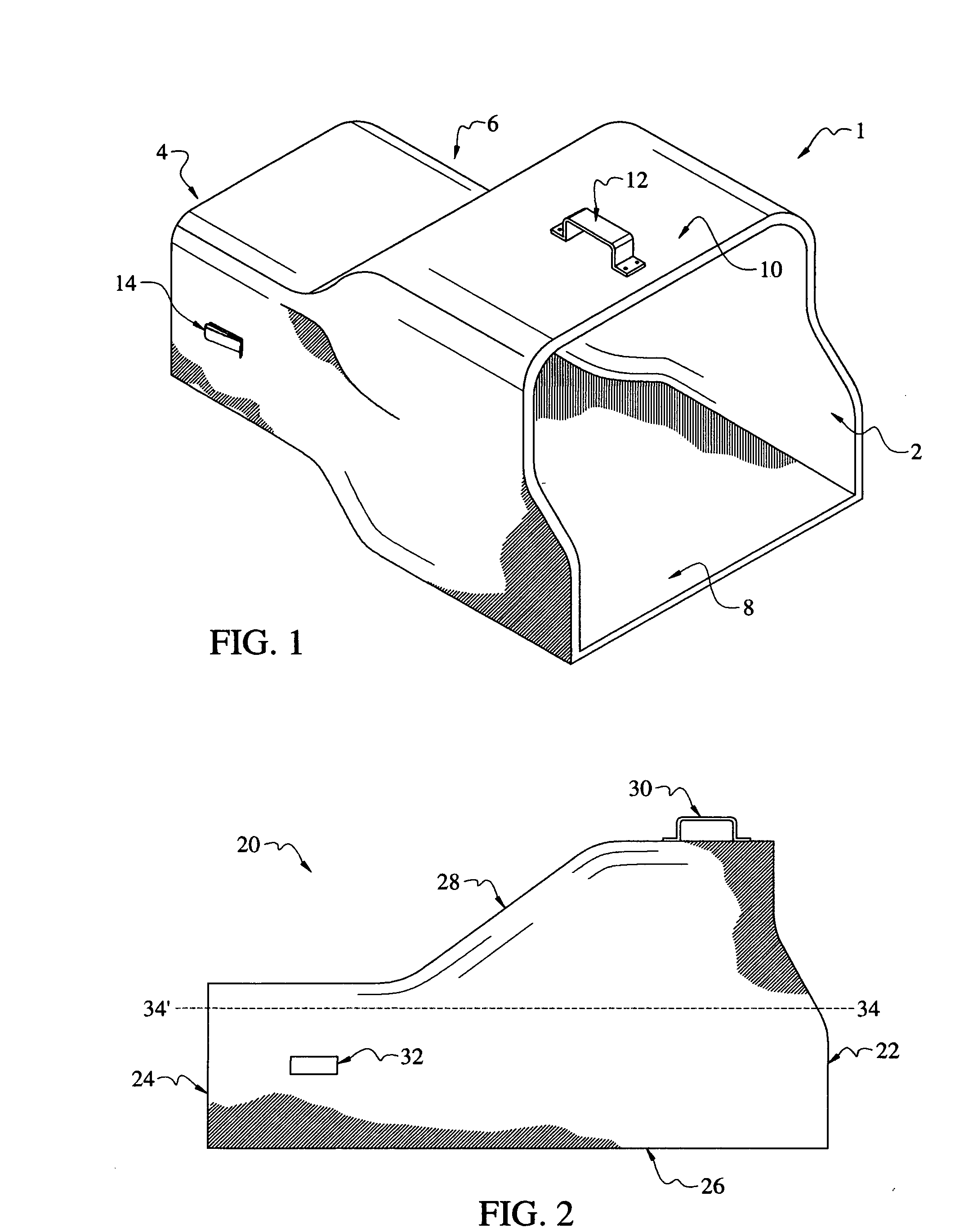

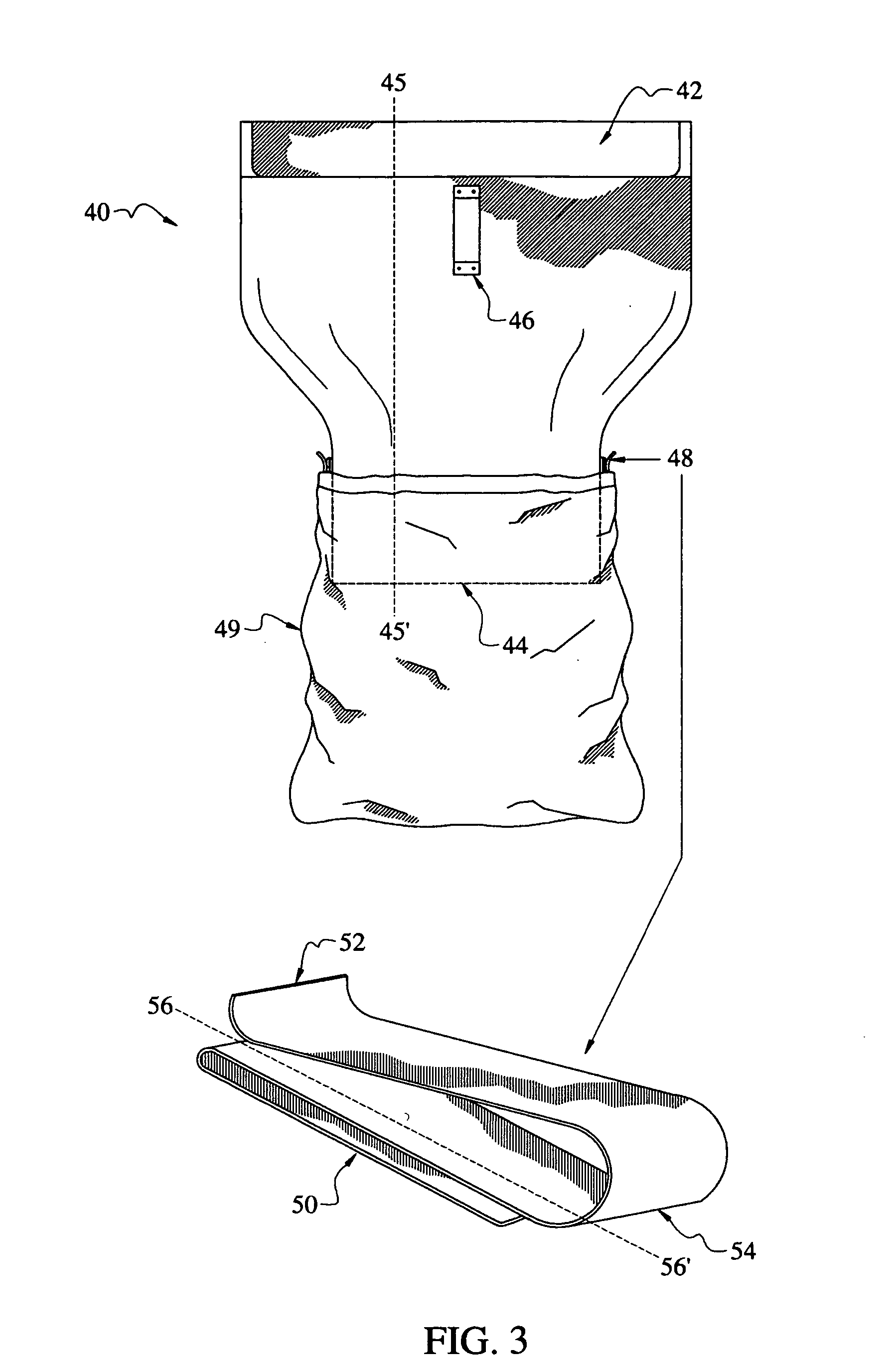

Apparatus and a method for bagging debris in a commercially available trash bag which has closure straps

An apparatus and a method for bagging debris in a commercially available trash bag which has closure straps. The device is composed of a housing defining a generally cylindrical enclosure whose ends are in open communication with the exterior of the housing. The housing is flattened on one side to maintain the device in a stable position when it is placed on the ground. The housing has a handle attached to its exterior to enable a user to lift and maneuver the device. The housing has a means for attaching a trash bag which has one or more closure straps to one end of the housing using the trash bag's closure straps such that the generally cylindrical enclosure of the housing is in open communication with the interior of the trash bag.

Owner:STRICKLAND KYLE +1

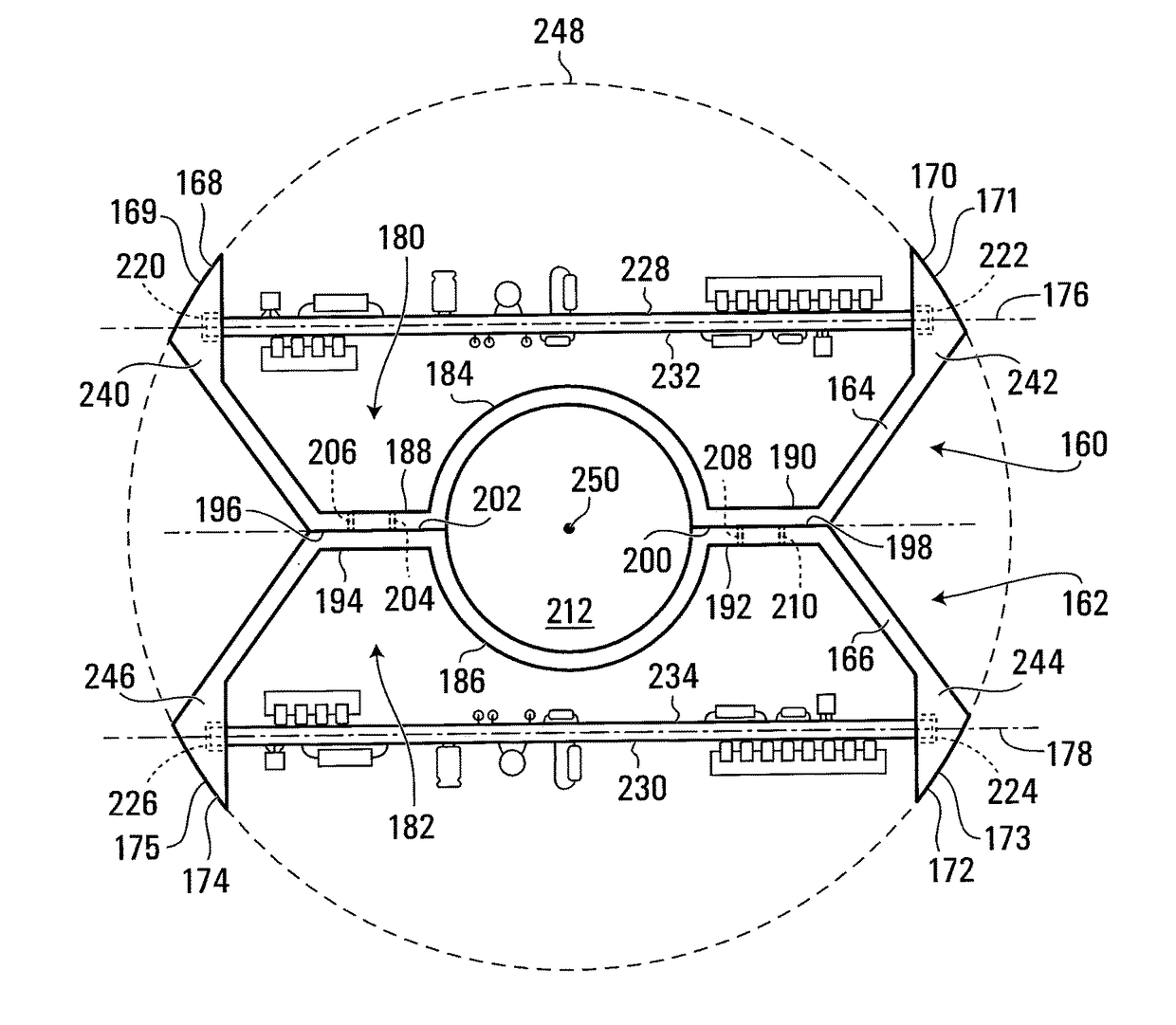

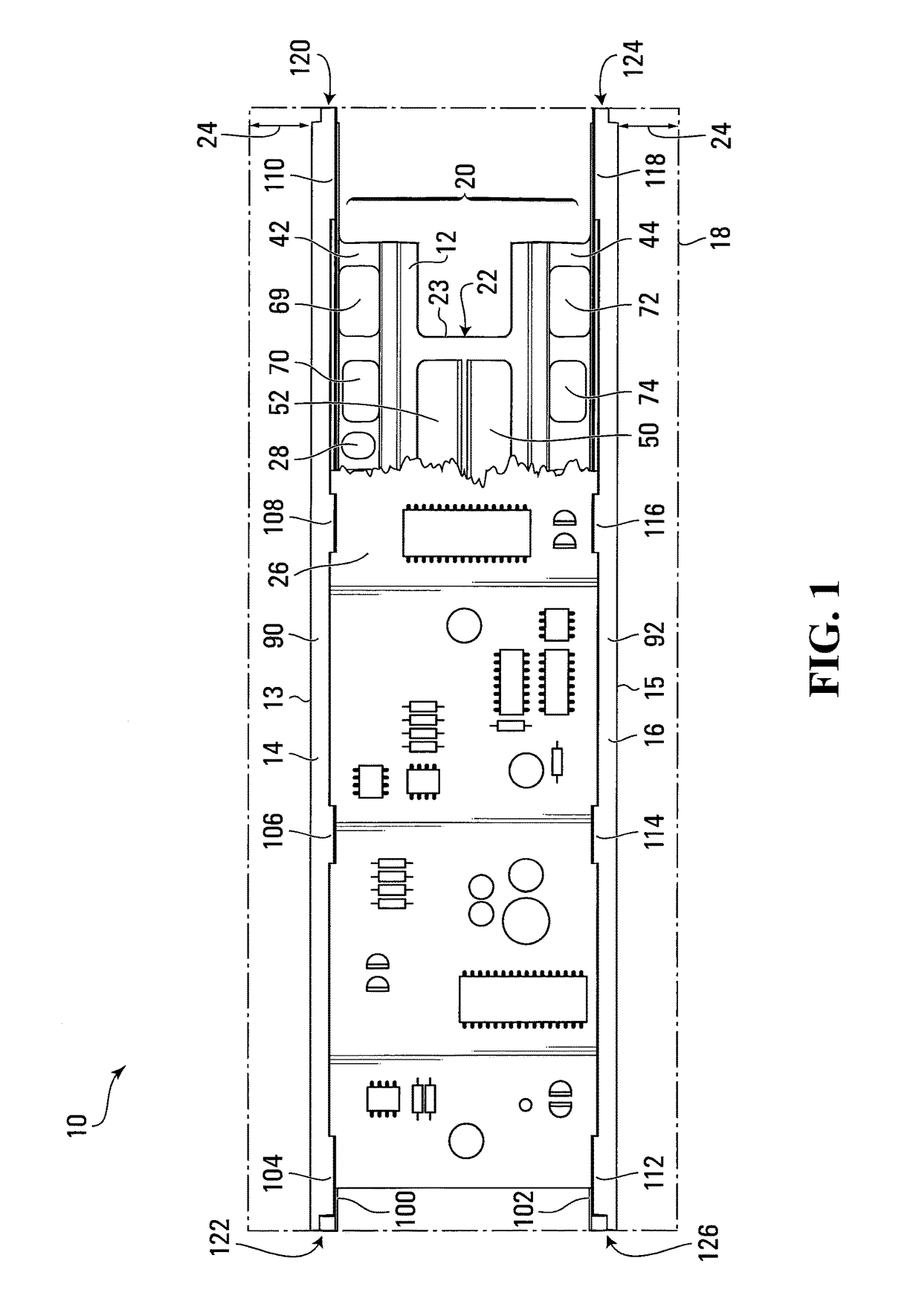

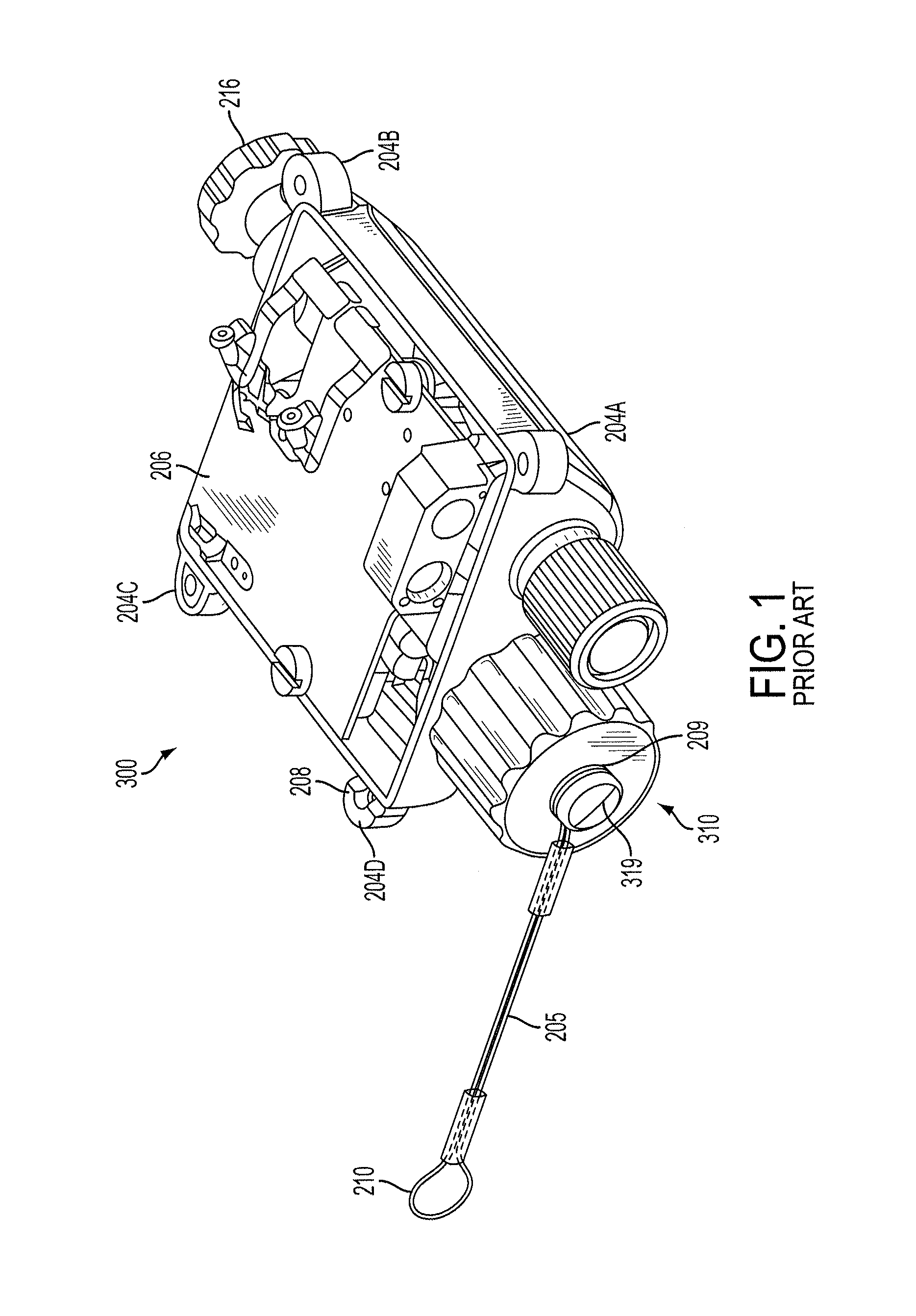

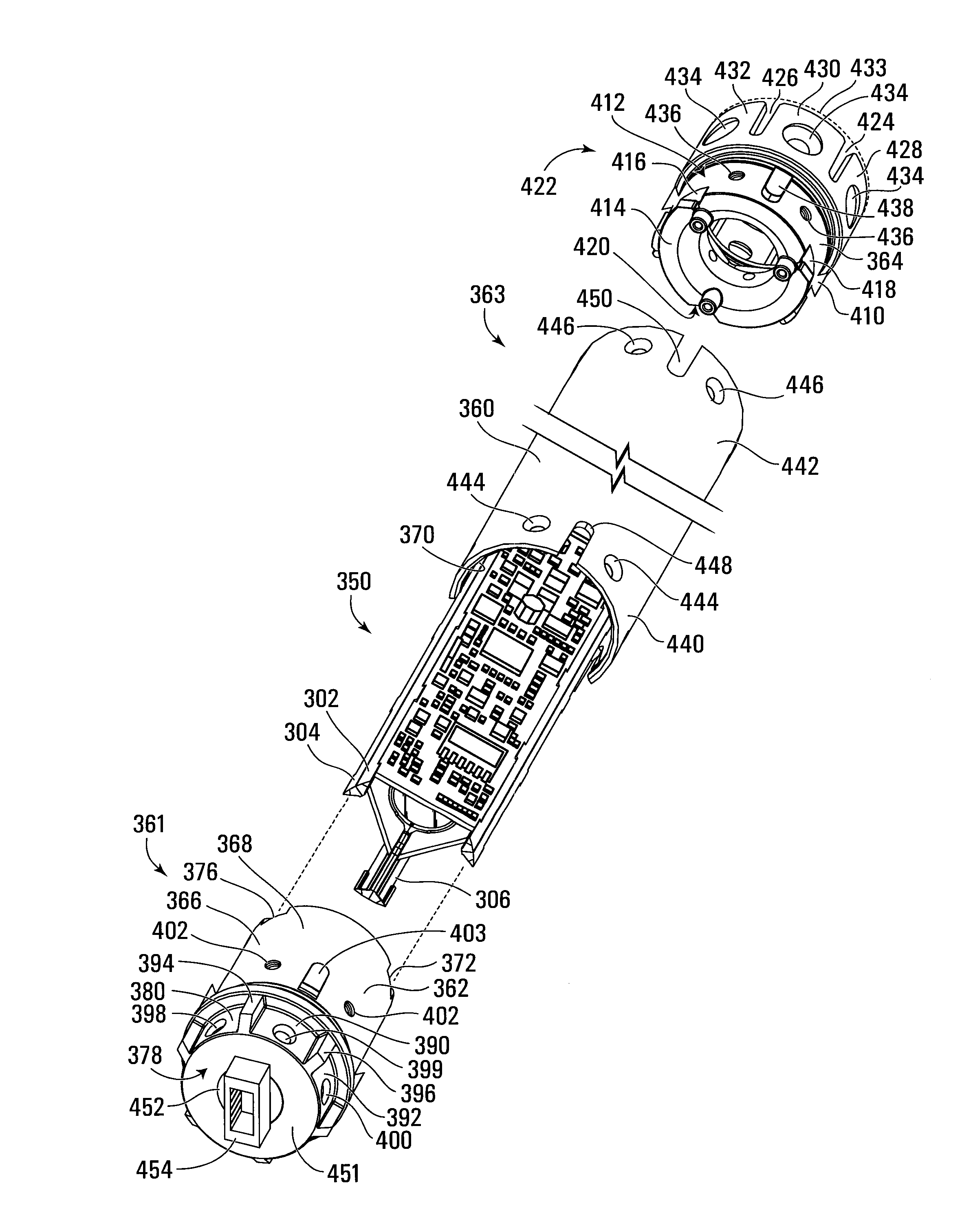

Mounting and component holder apparatuses and assemblies for holding rigid components

A component mounting apparatus for holding a rigid component in a downhole bore or a downhole collar based application includes a first body including first and second parallel spaced apart component holders disposed in a first common plane and a first support connecting the component holders together. The first and second parallel spaced apart component holders are operable to receive and grip a rigid component between the first and second parallel spaced apart component holders. Various component mounting assemblies and configurations may be realized using the component mounting apparatus described. The component mounting apparatus and various mounting assemblies may be used to mount a printed circuit board in a cylindrical enclosure or tubular housing, for example.

Owner:EVOLUTION ENG

Confectioneries Dispenser

InactiveUS20130206786A1Small article dispensingCoin-freed apparatus detailsEngineeringCylindrical enclosure

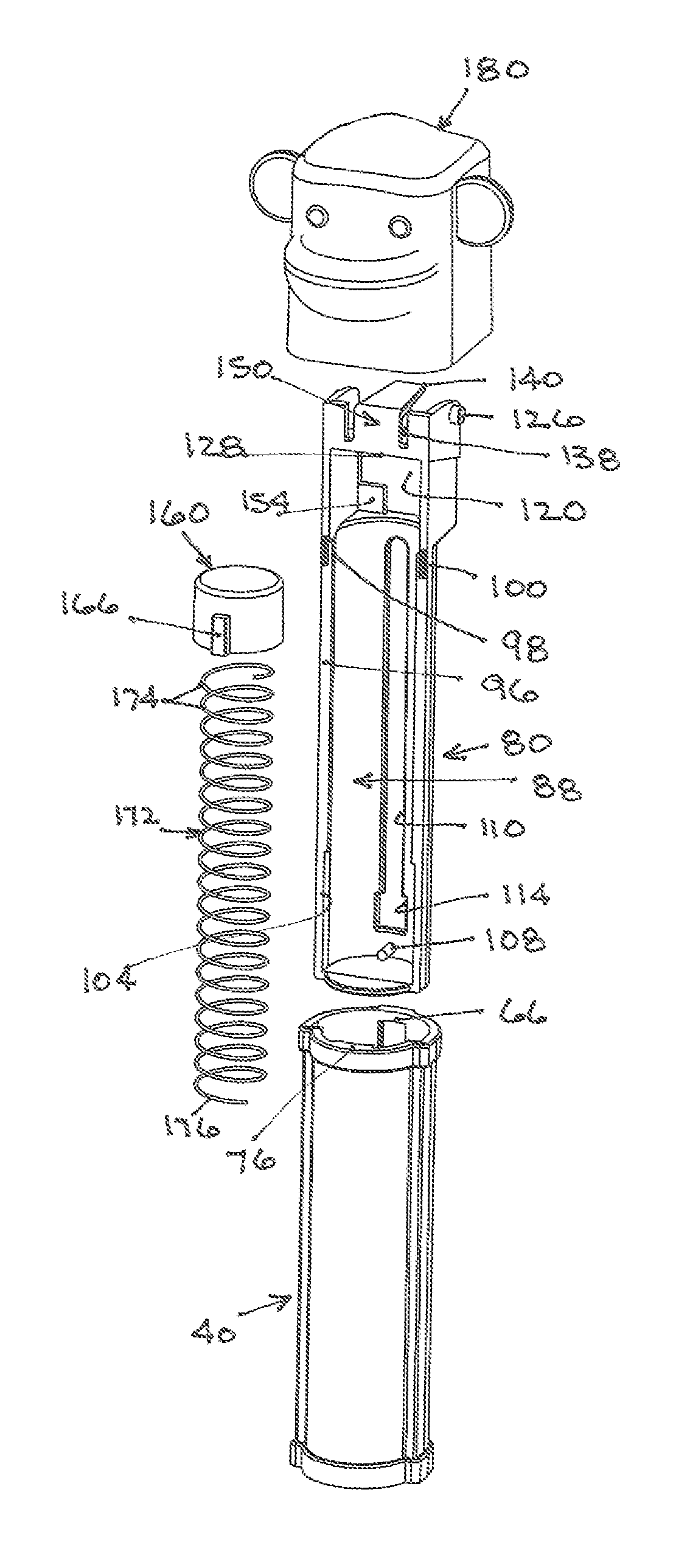

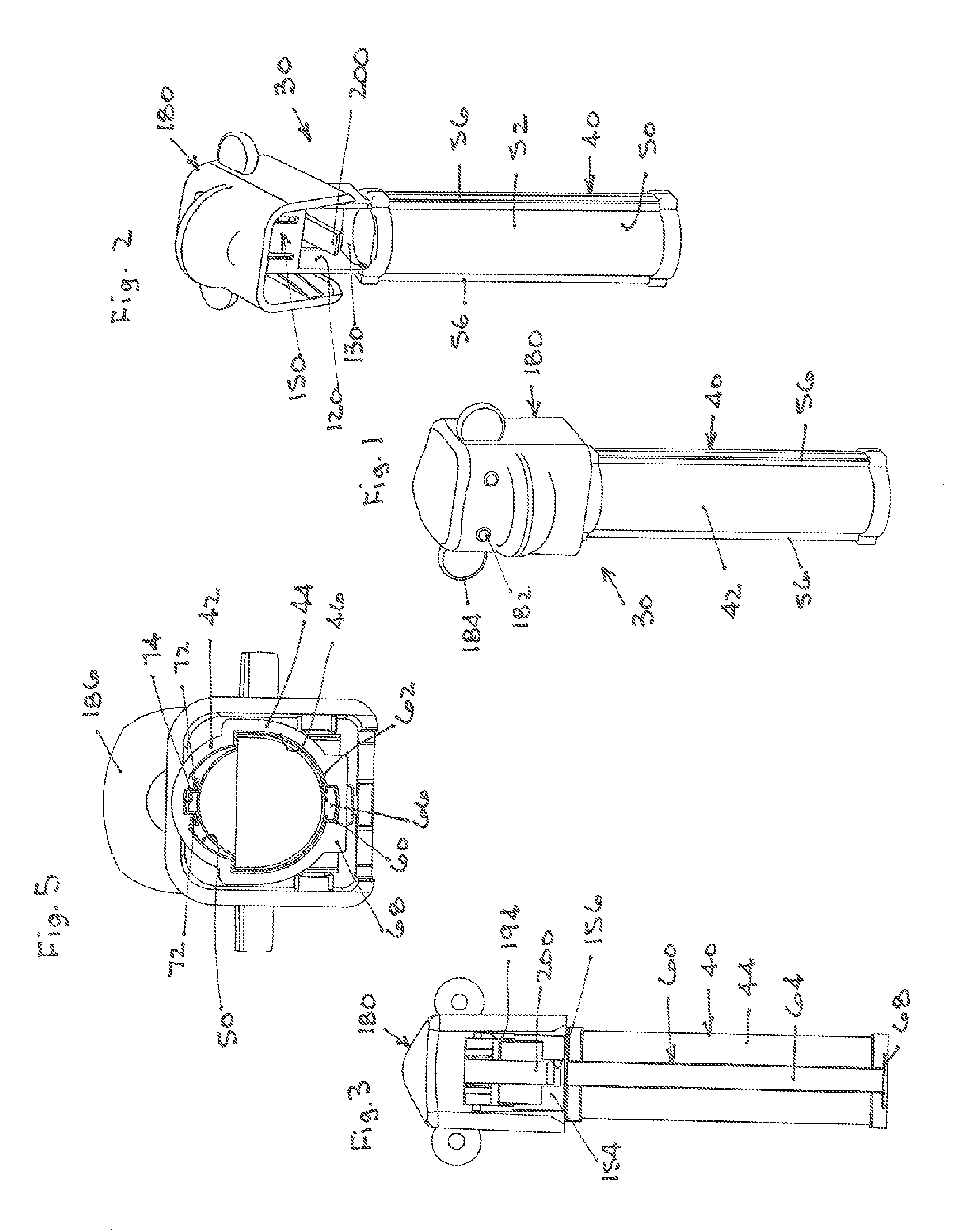

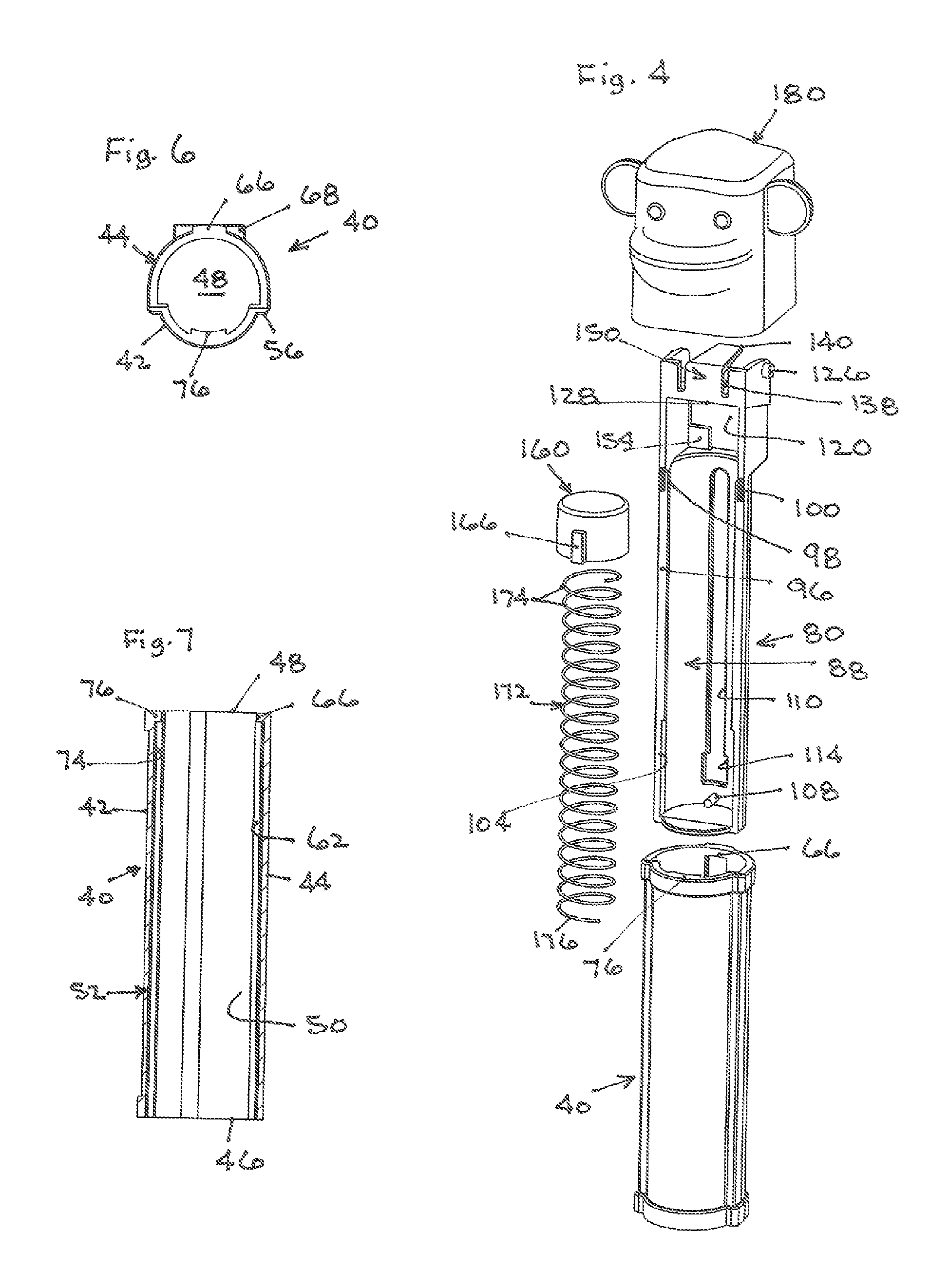

A confectioneries dispenser including a magazine for carrying a number of the confectioneries for dispensing and a head mounted for movement from a closed position to a dispensing position dispensing the outermost of the confectioneries from the magazine. For returning the head from the dispensing position to the closed position a spring is integrally formed as part of the magazine. To carry spherical confectioneries the magazine is integrally molded with a partially cylindrical enclosure of greater than one hundred and eighty degrees having a semi-cylindrical portion with a pair of straight tangential edge extensions, and a wedge shaped track inside of each extension. An outer case which receives a lower portion of the magazine has an upper projection corresponding and cooperating with a projection on a lower part of the head to simulate the lower and upper parts of a character's mouth.

Owner:IMAGININGS 3

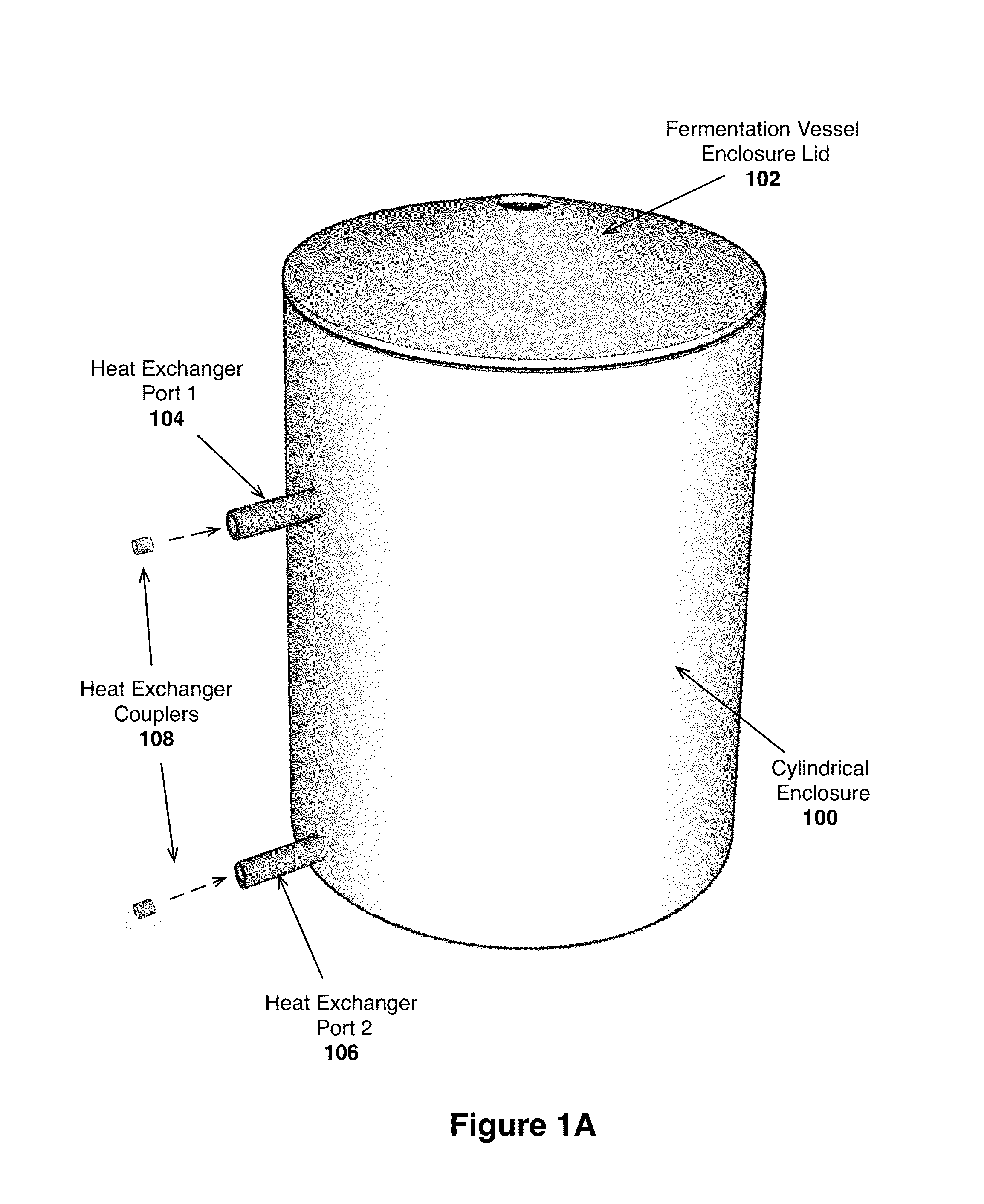

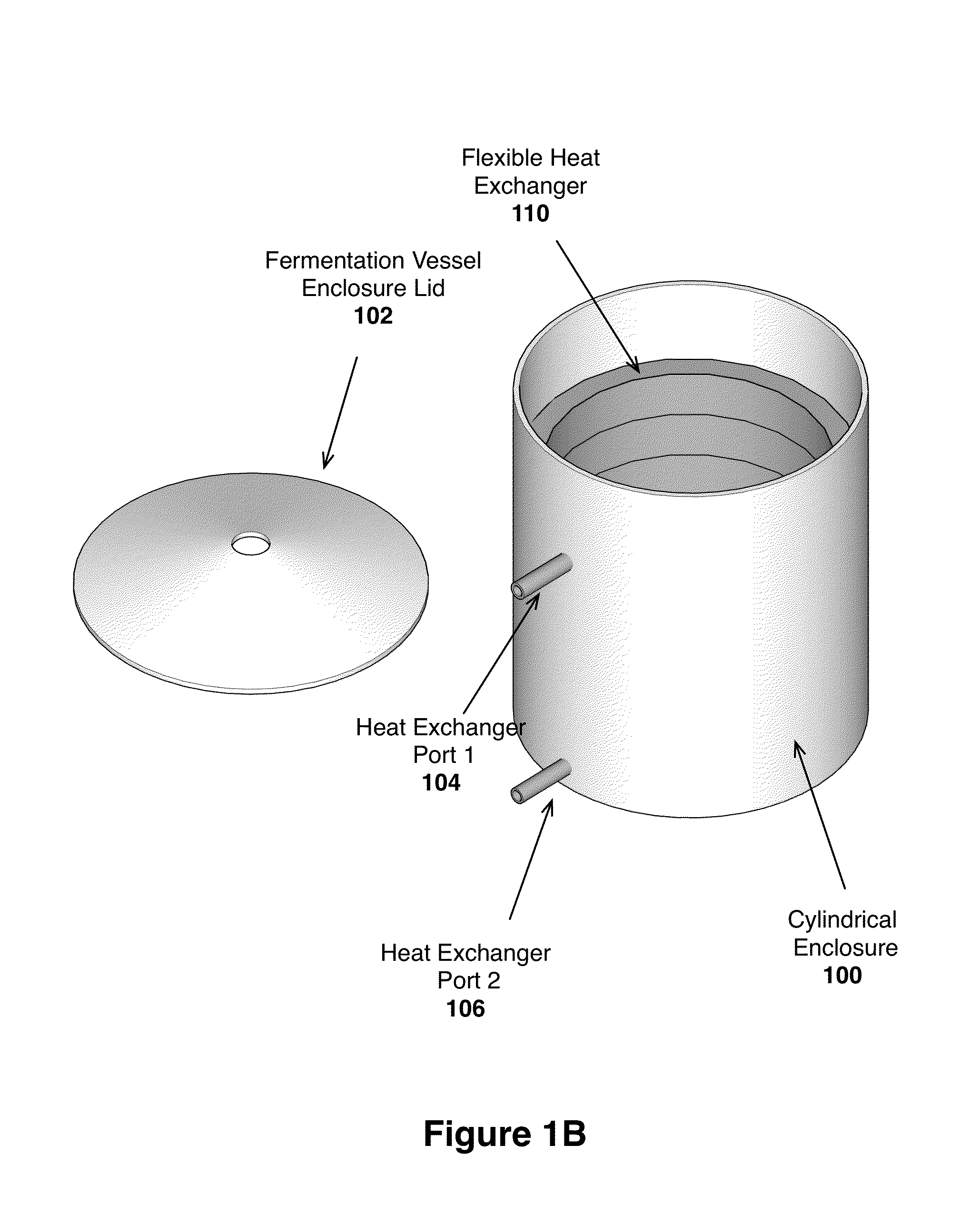

Fermentation temperature management

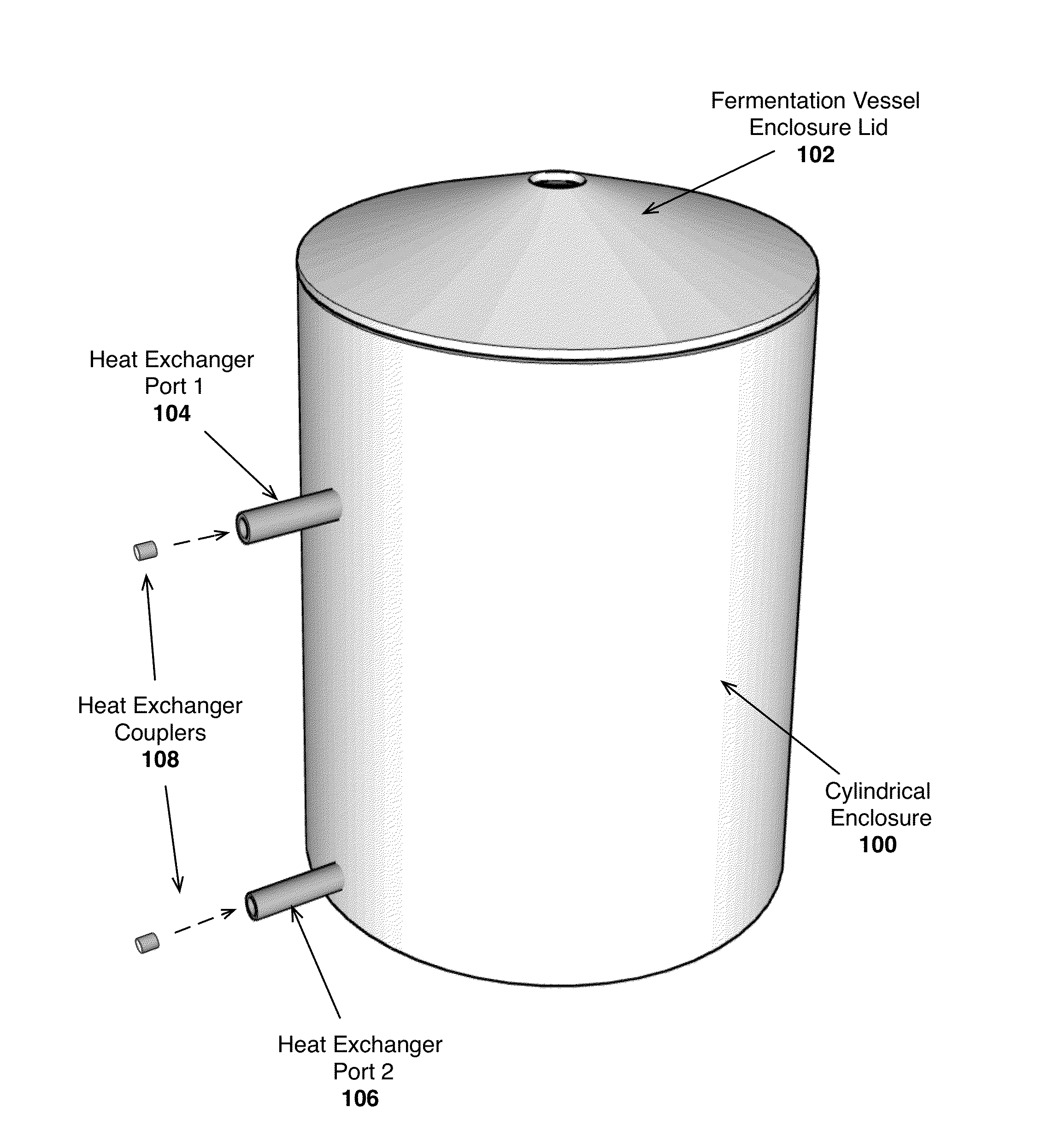

A portable assembly for cooling the contents of a fermentation vessel is provided. In one embodiment, the assembly comprises an insulated, cylindrical enclosure having a fixed bottom and a removable lid. A flexible heat exchanger is cylindrically disposed within the enclosure and encircles the fermentation vessel. In one embodiment, the flexible heat exchanger is connected to a vessel containing thermally conductive fluid by flexible tubes that extend outside the enclosure. In one embodiment, a heating element is used to heat the fermentation vessel.

Owner:WEBBER STEVEN DEE WAYNE

Insulating holder with elastomer foam material

ActiveUS9022252B2Improve insulation performanceImprove performanceDomestic cooling apparatusLighting and heating apparatusElastomerPolyolefin

An insulating holder for holding a beverage in a bottle or a can having a lower cylindrical enclosure which receives an upper cylindrical enclosure having a dome-shaped upper end. The upper cylindrical enclosure is adapted to cover the top portion of a bottle inserted into the lower cylindrical enclosure and to snuggly receive a can when inverted and inserted into the lower cylindrical enclosure. At least a portion of the lower cylindrical enclosure or upper cylindrical enclosure is made of a polyolefin elastomer foam. The insulating holder may be structured to retain various sizes of wine bottles.

Owner:BEGGINS HLDG LLC

Thermal fuse using thermosensitive material

InactiveUS7323965B2Improve featuresGood molding effectHeating/cooling contact switchesEmergency protective devicesHot meltEngineering

Owner:SCHOTT JAPAN CORP

Automatic filling up spuit

ActiveUS9234781B2Simple structureFillCapsContracting/expanding measuring chambersEngineeringCylindrical enclosure

An automatic filling up spuit (100) screwed to an entrance (1a) of a cosmetics container (1) for suctioning and discharging liquid stored in the cosmetics container (1) includes: a spuit pipe (10); a cylinder member (20); a piston member (30); a cylindrical push button (50); and a top / bottom-opened cylindrical enclosure (60). The automatic filling up spuit has an advantage of convenient use in that it is capable of automatically filling up liquid contents in a cosmetics container by a certain amount precisely at all times through joining with the cosmetics container without requiring a separate filling up operation.

Owner:LEE YOUNG JU +1

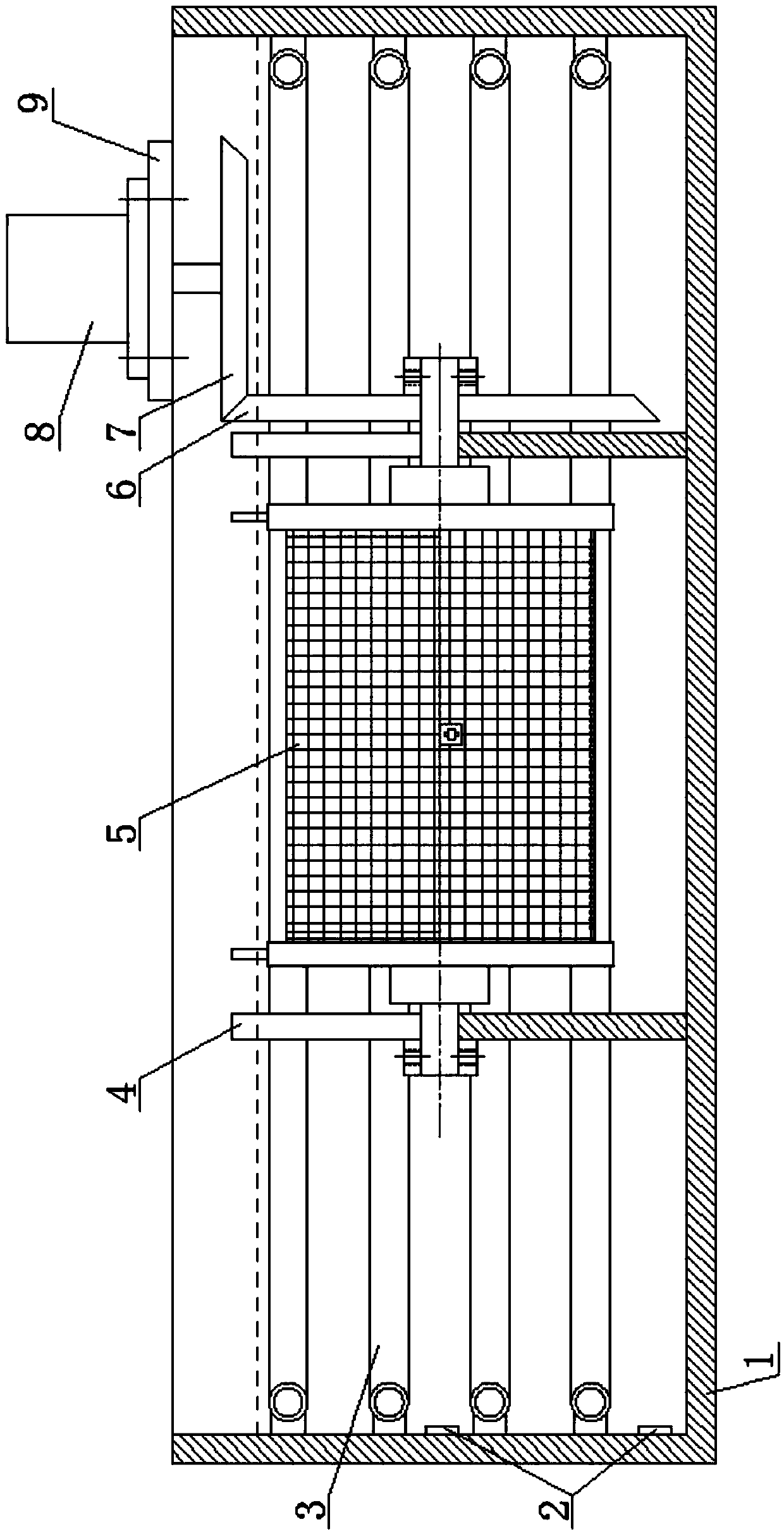

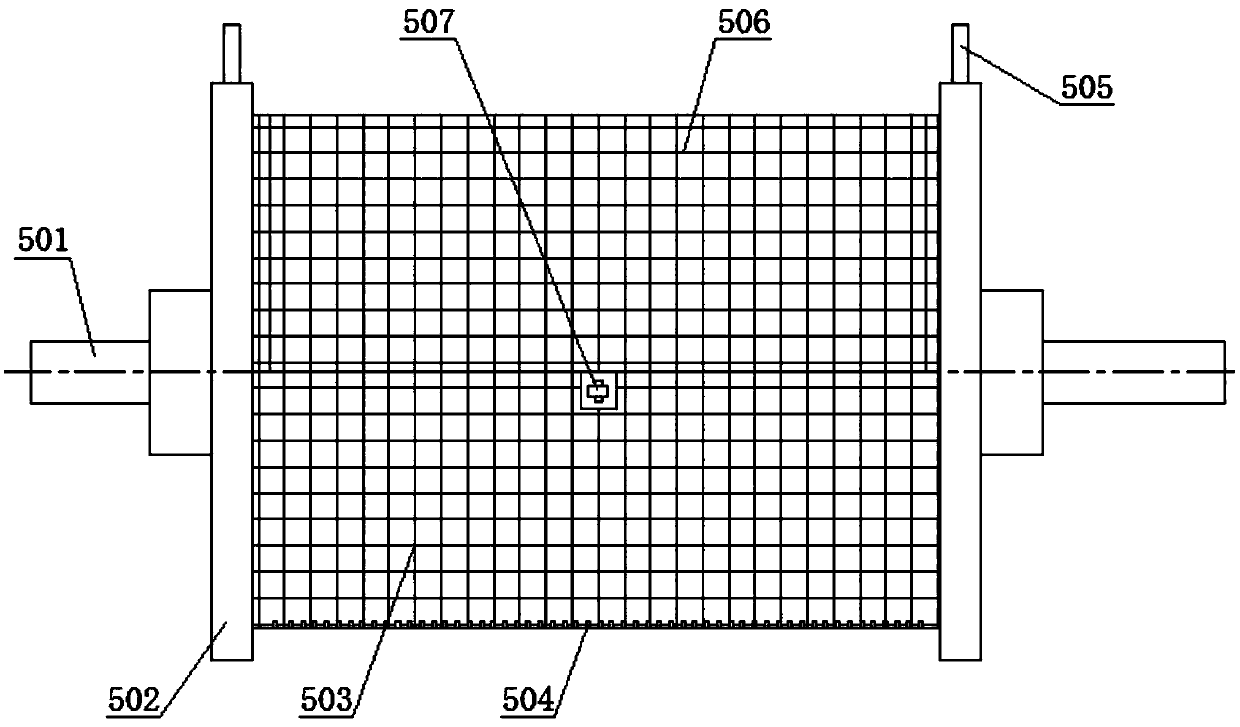

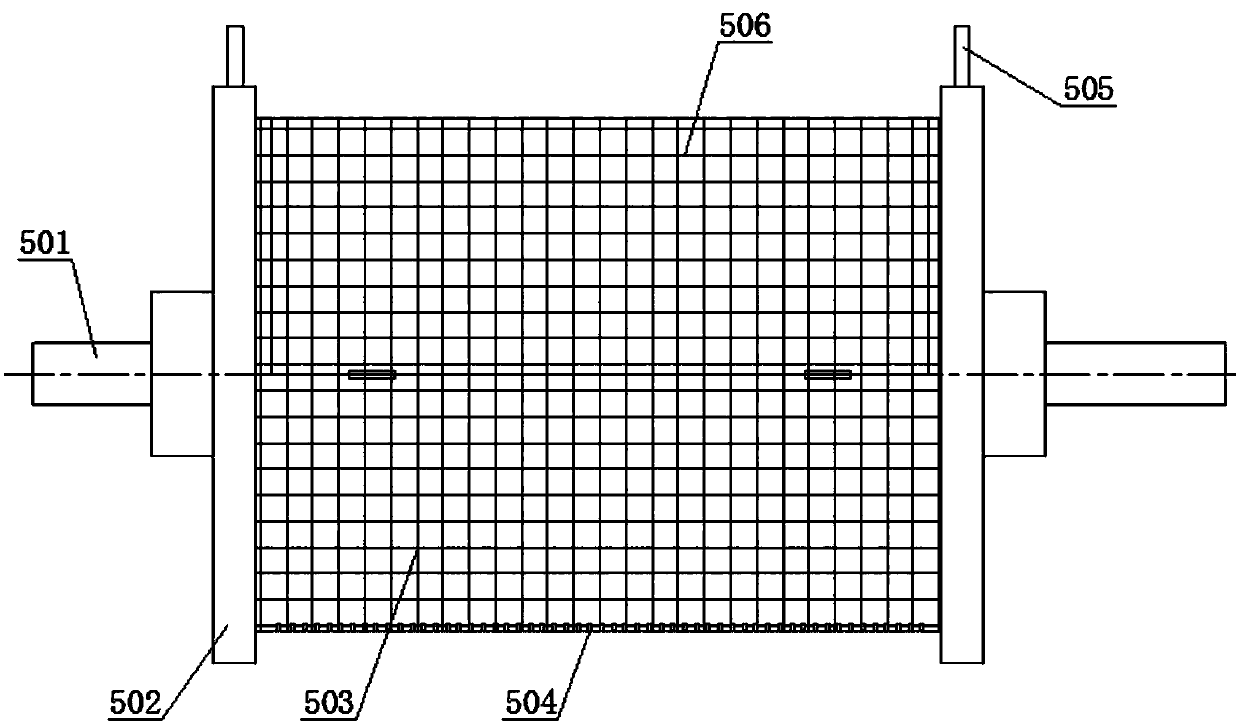

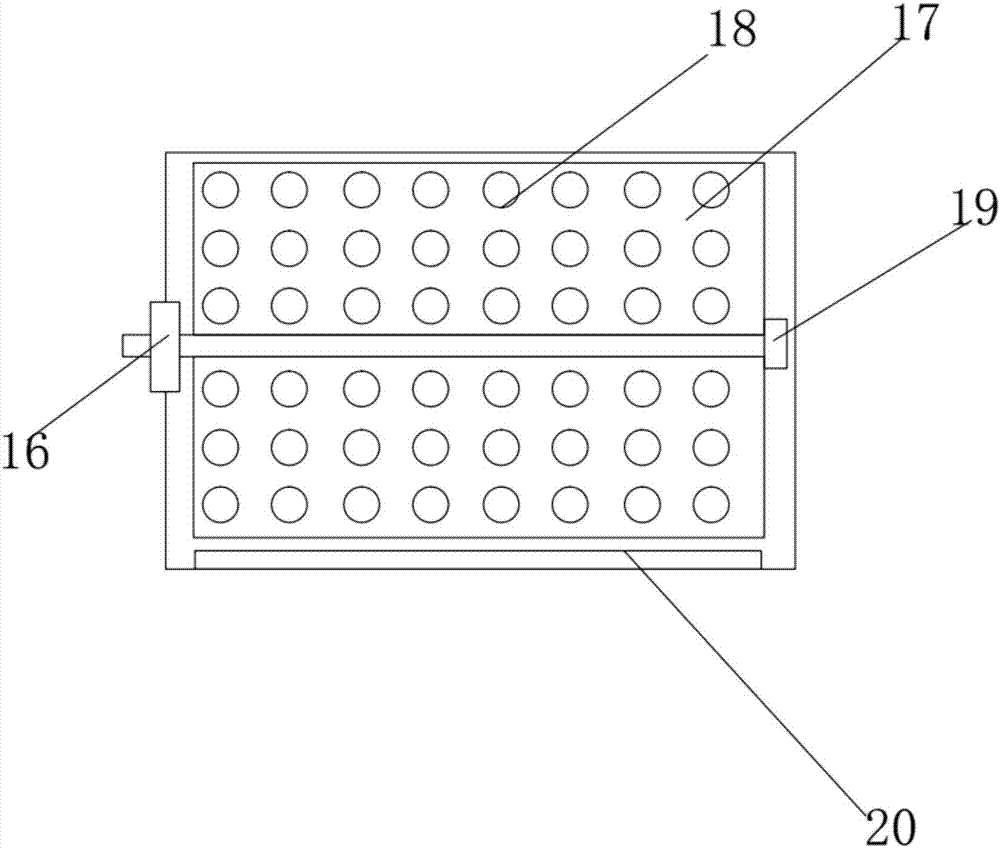

Silicon chip pickling thinning machine

ActiveCN105374663AControl UniformityControl repeatabilitySemiconductor/solid-state device manufacturingEngineeringCylindrical enclosure

The invention relates to a silicon chip pickling thinning machine comprising a box body and characterized in that a rotary hand basket is supported in the box body and is composed of two circular fixing plates, a cylindrical enclosures transversely connected between the two circular fixing plates, rotating shafts, and handles, wherein the rotating shafts and the handles are arranged on the outer side surfaces of the circular fixing plates; the cylindrical enclosure is composed of an enclosure body and a semicircular enclosure cover hinged to the enclosure body; the opening side edge of the semicircular enclosure cover is connected with the cylindrical enclosure by a lock; multiple ribs are uniformly arranged on the bottom of the enclosure body at intervals; a slideway is fixed to one end of the outer side of the box body, a support base is in sliding connection with the top of the slideway; an inverted servo motor is fixed to the horizontal plate surface of the support base; the motor shaft of the servo motor is connected with the rotating shafts of the rotary hand basket through a transmission mechanism, and a circulating water pipe is fixed to the inner sidewall of the box body. The silicon chip pickling thinning machine is reasonable in structural design and easy to operate, achieves single-side chemical thinning on a silicon chip and a large batch production, increases yield, saves resources, and reduces production cost.

Owner:锦州佑华硅材料有限公司

Battery housing with reverse polarity protection

ActiveUS9269943B1Contact member assembly/disassemblyFinal product manufactureEngineeringCylindrical enclosure

A battery housing includes a contact cage forming a longitudinal cylindrical enclosure having a lateral opening. A leaf spring is included having first and second compressible ends, in which the first end is received by the contact cage through the lateral opening. A longitudinal insulating cup is also included having opposing cylindrical openings, in which the second compressible end of the leaf spring is received by the insulating cup through one of the cylindrical openings. The leaf spring forms a positive terminal in the battery housing and is held in position by the contact cage and the insulating cup.

Owner:ELBIT SYSTEMS OF AMERICA LLC

Mounting and component holder apparatuses and assemblies for holding rigid components

A component mounting apparatus for holding a rigid component in a downhole bore or a downhole collar based application includes a first body including first and second parallel spaced apart component holders disposed in a first common plane and a first support connecting the component holders together. The first and second parallel spaced apart component holders are operable to receive and grip a rigid component between the first and second parallel spaced apart component holders. Various component mounting assemblies and configurations may be realized using the component mounting apparatus described. The component mounting apparatus and various mounting assemblies may be used to mount a printed circuit board in a cylindrical enclosure or to bular housing, for example.

Owner:EVOLUTION ENG

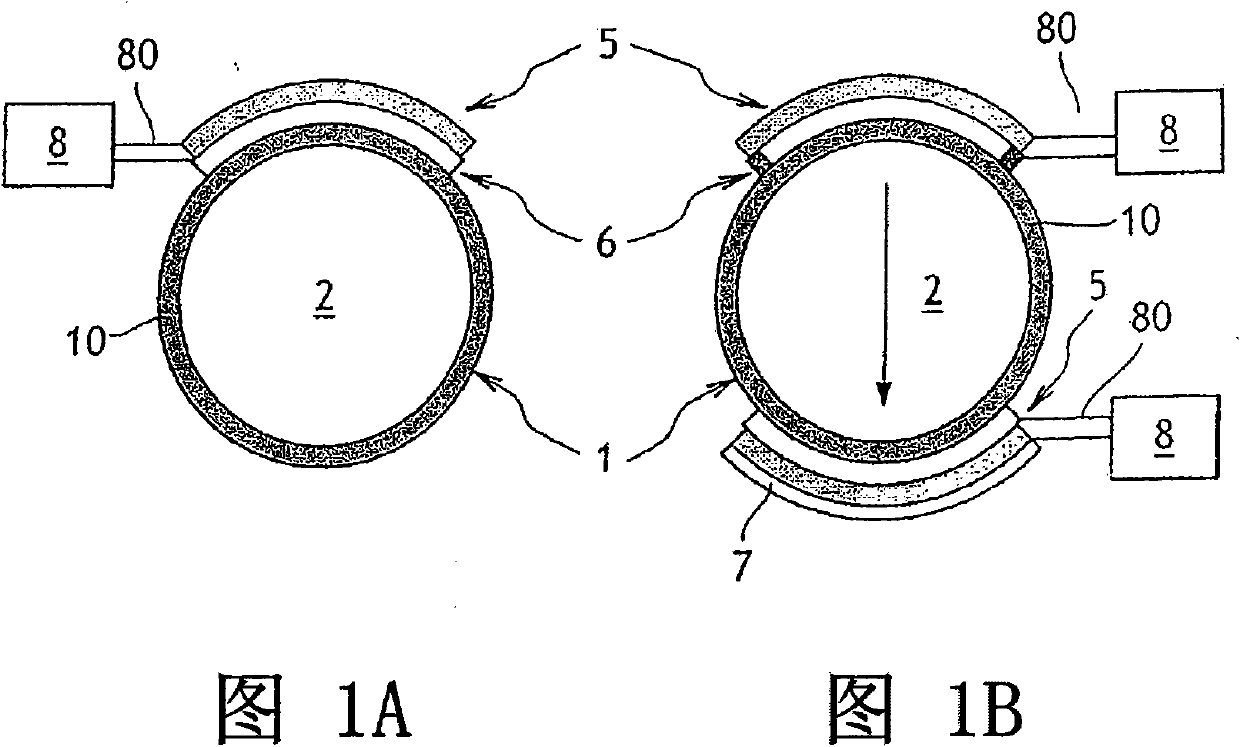

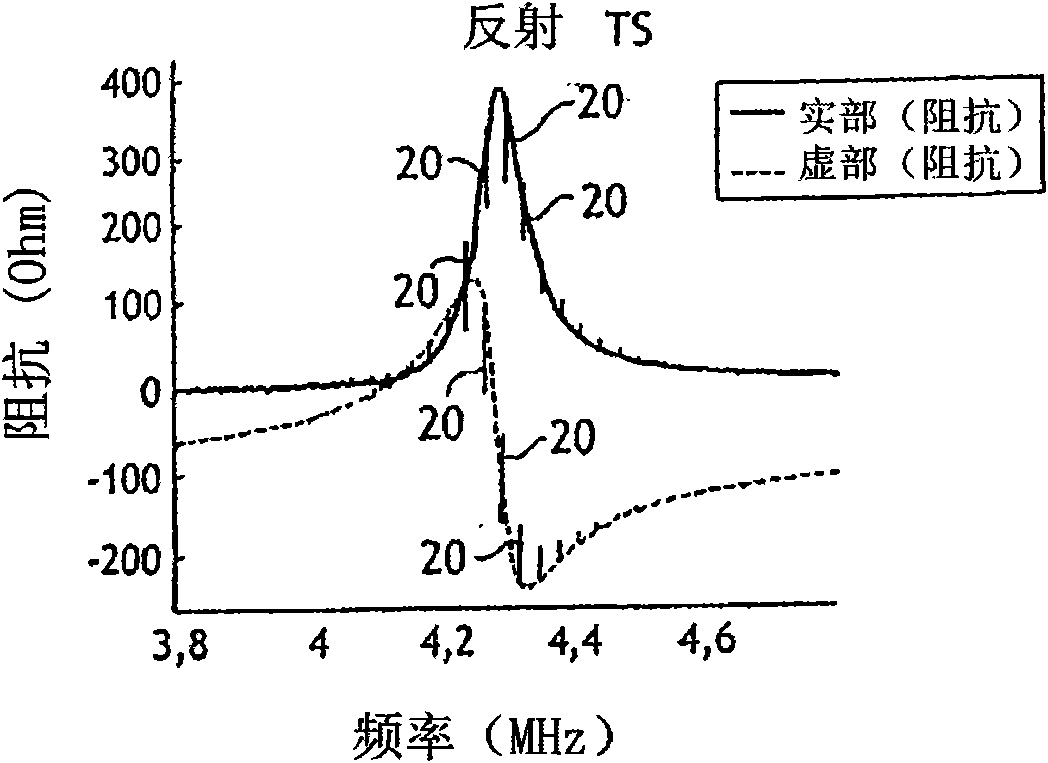

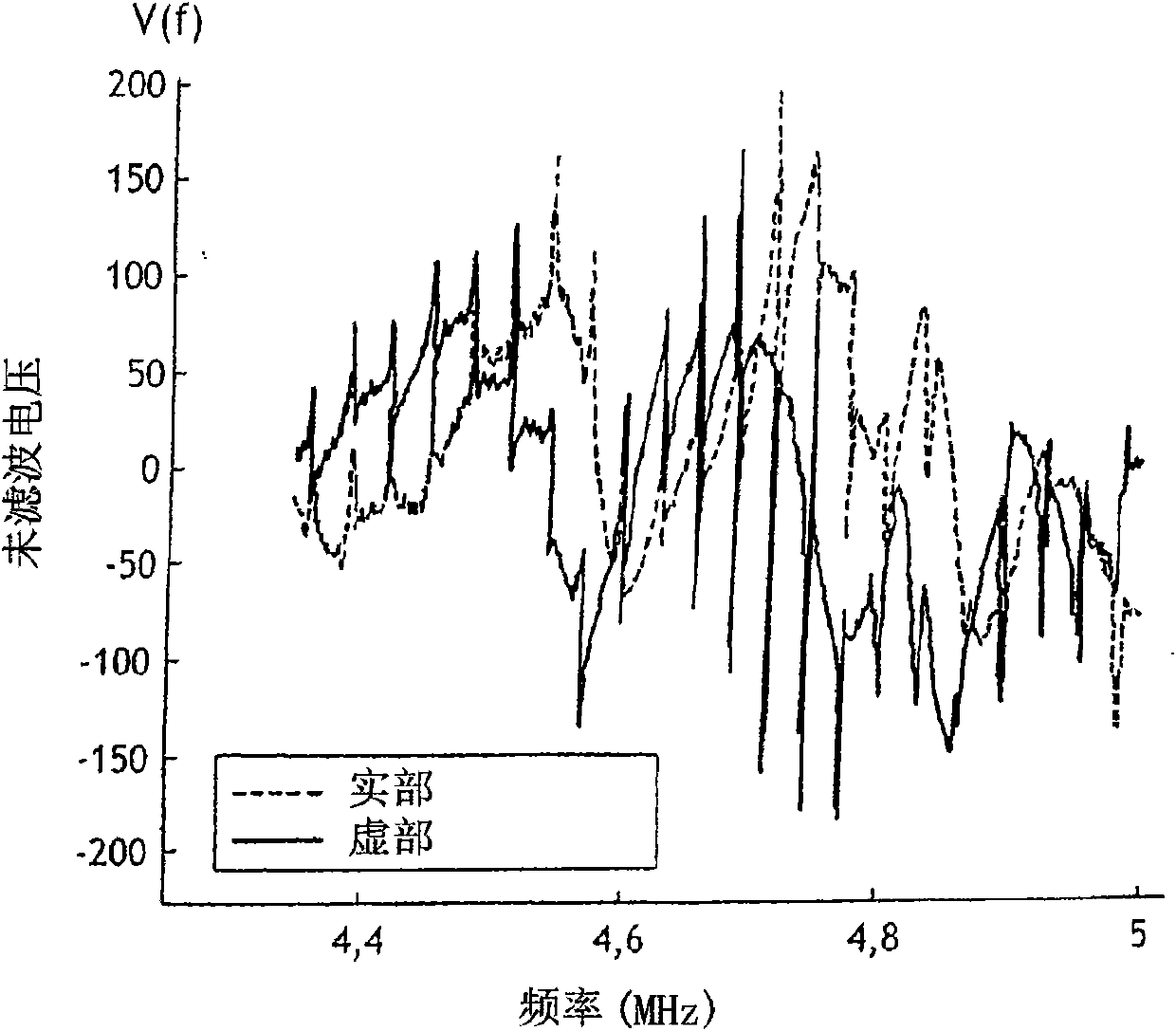

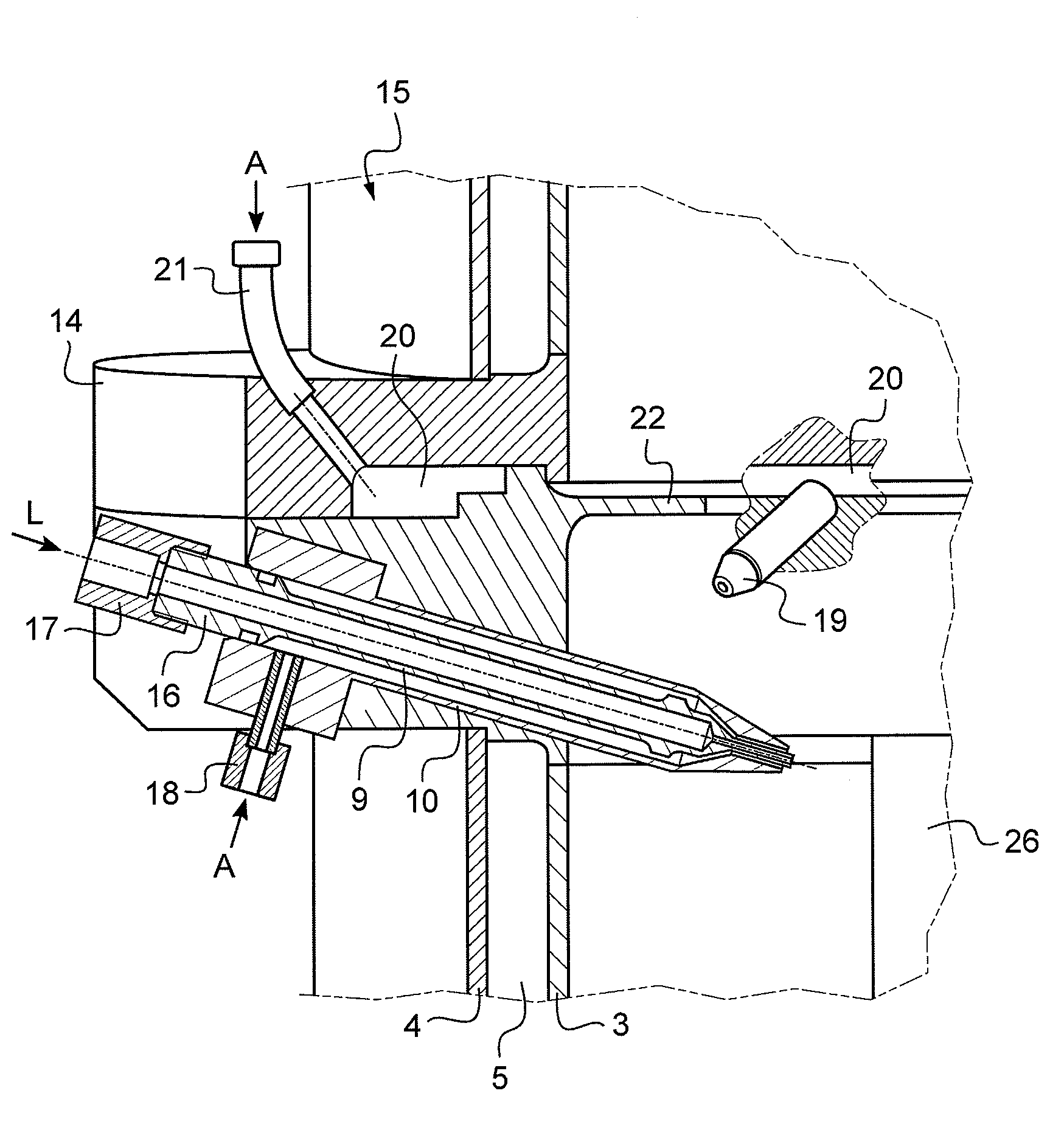

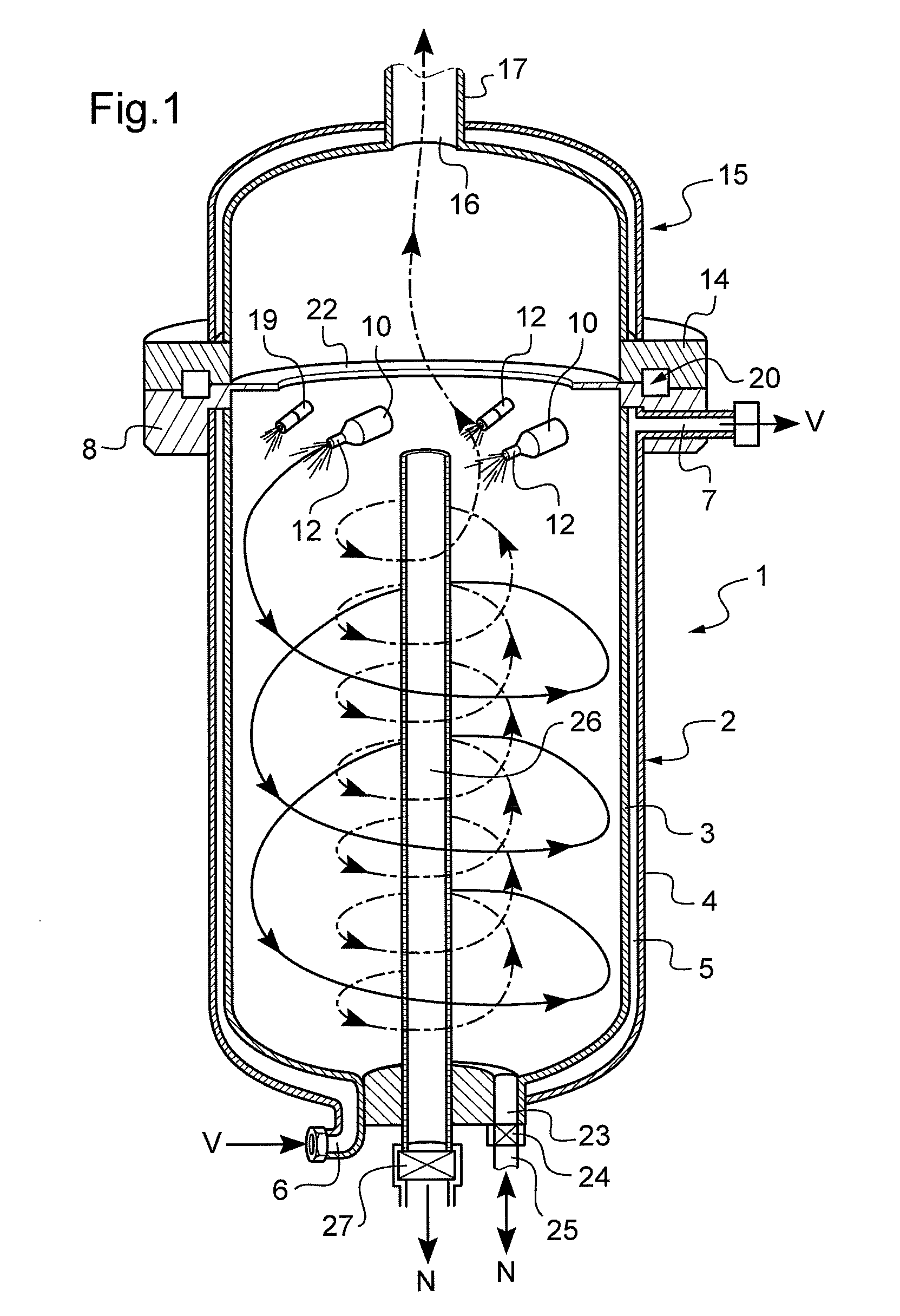

Method for measuring the pressure and/or molar mass of a gas in a housing, and corresponding measurement assembly

ActiveCN101646937AAvoid absorptionFar from imperfectionAnalysing fluids using sonic/ultrasonic/infrasonic wavesNuclear energy generationRadioactive tracerTransducer

The sensor has a piezo-electric type transducer (5) generating an acoustic excitation signal to vibrate a cylindrical enclosure (1) i.e. fuel rod, and radioactive tracer gas (2) e.g. helium, and detecting an acoustic characteristics response signal of vibration of the enclosure and gas. An electrical system (8) excites the transducer and analyzes the response signal. Transmission frequency bands of the signals have a width of 25 percentage of f0 that is a free vibration frequency of a wall (10) at which the sensor is coupled, during measurement of a gas physical parameter e.g. molar mass. An independent claim is also included for a method of measuring a physical parameter of a gas in an enclosure.

Owner:CENT NAT DE LA RECH SCI (C N R S) +1

Device for evaporating a treatment liquid

InactiveUS20110203914A1Simple structureReliable extractionCharging-discharging device combinationsEvaporation by sprayingEngineeringCylindrical enclosure

The device for evaporating a treatment liquid comprises a cylindrical enclosure having an outlet orifice opening out into the top end of the enclosure, the enclosure being placed vertically and having a heated inside wall, and liquid nozzles associated with a blow pipe for blowing air under pressure so as to form a jet comprising a mixture of air and of pulverized treatment liquid in a direction that is tangential to the inside wall of the enclosure, each liquid nozzle and the associated blow pipe being arranged so that the jet of mixture is formed in an upper portion of the enclosure and is downwardly inclined.

Owner:SERAC GROUP

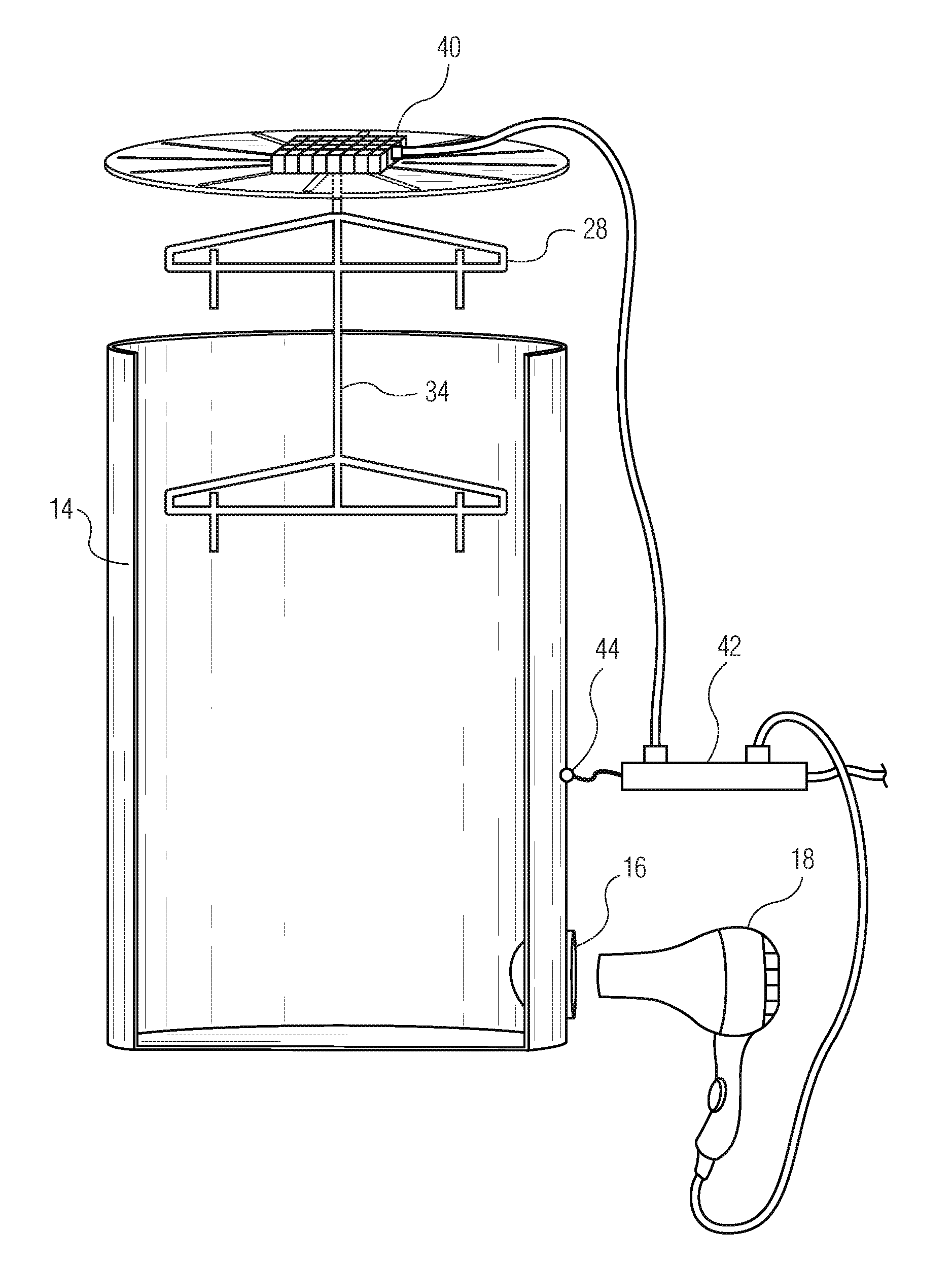

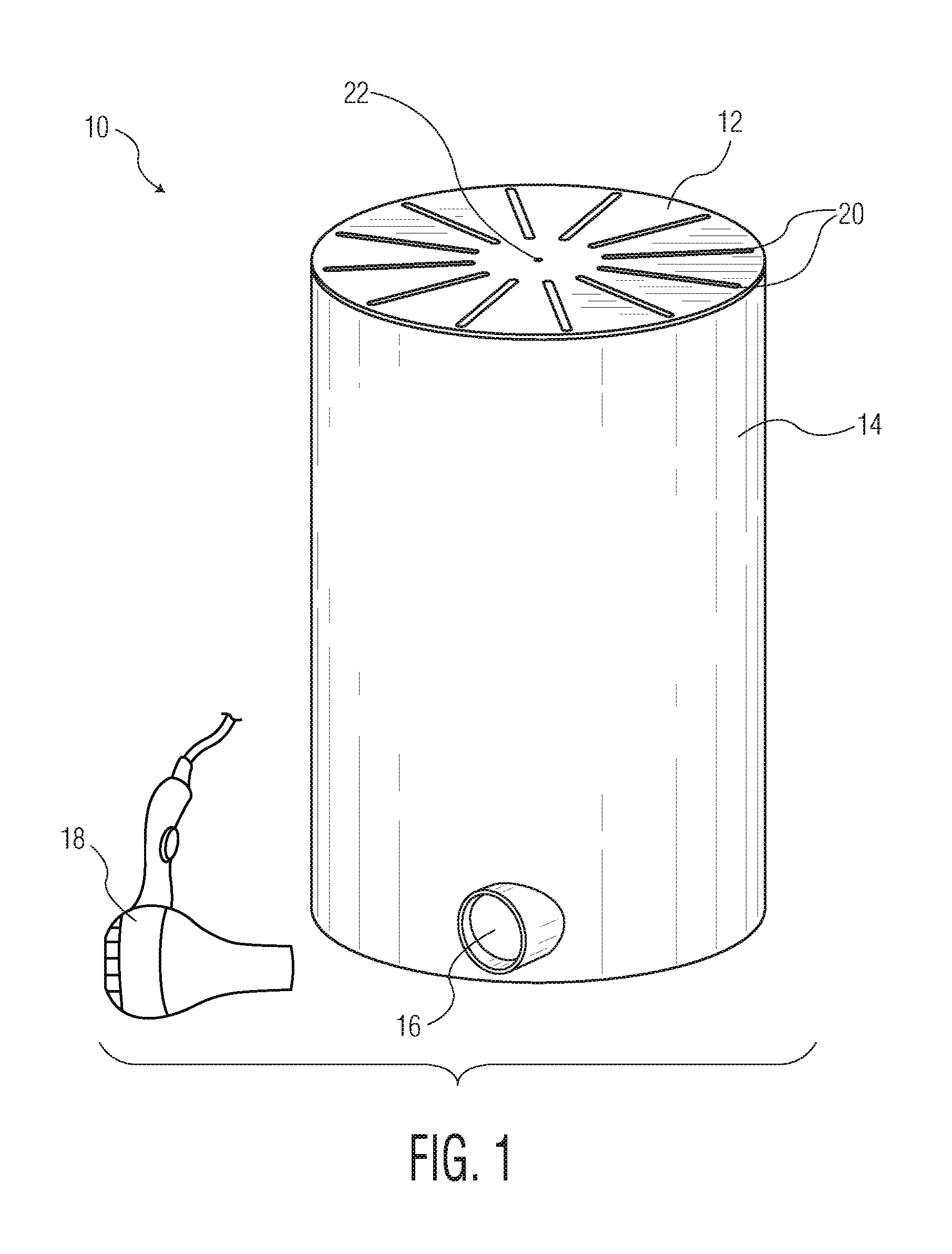

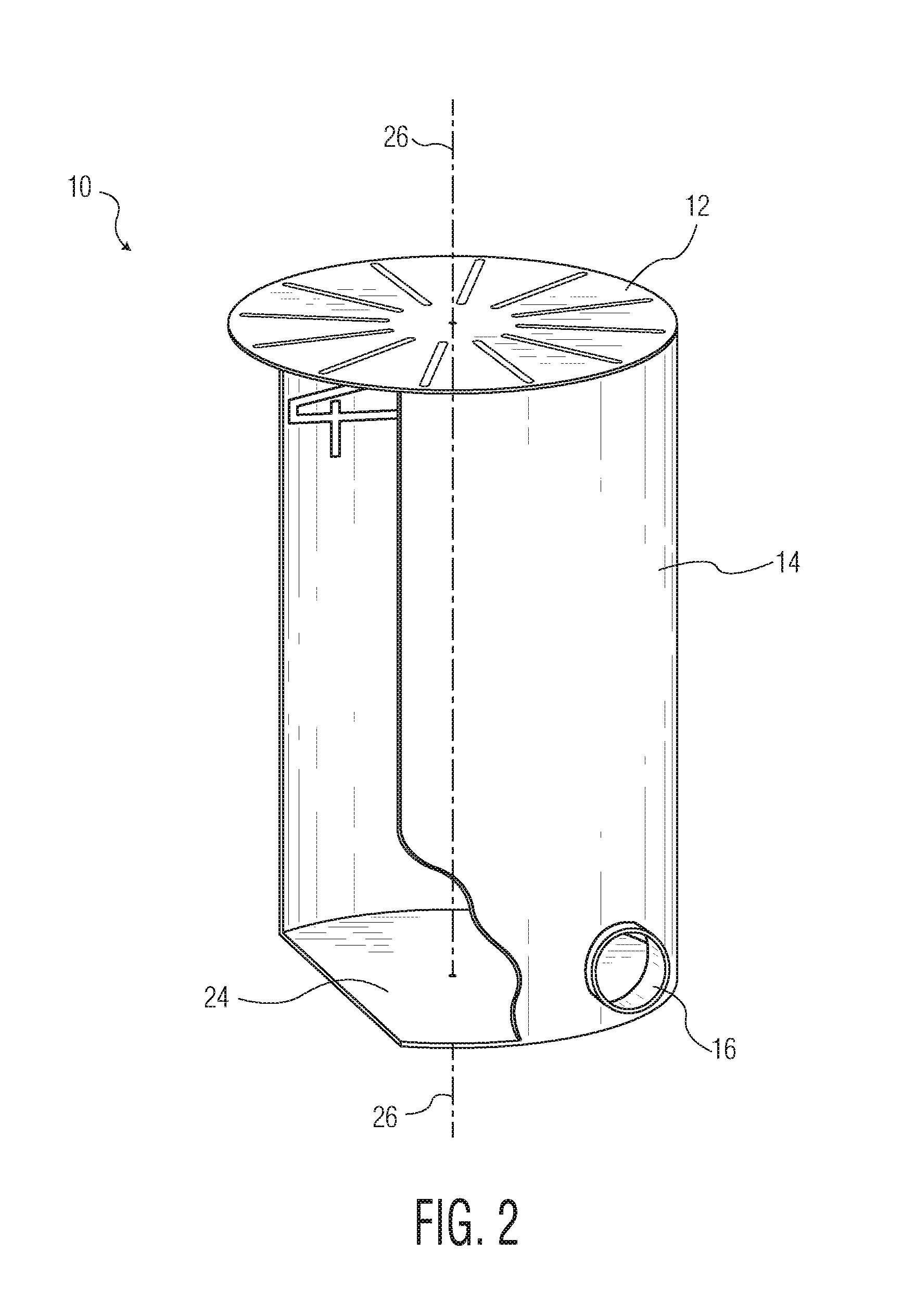

Portable, collapsible clothes dryer

ActiveUS20160348301A1Fast dryingEasy to installTextiles and paperLaundry driersEngineeringCylindrical enclosure

A portable, collapsible clothes dryer, for use in drying small articles of clothing while traveling and / or for use in households with limited space, is composed of a cylindrical collapsible central housing with an inlet opening at the bottom, an airflow adapter at the inlet to attach a portable hair dryer, a spin-able clothes hanger, and a removable top member with air exhaust vents. When collapsed, the assembly assumes a compact, flat disk shape. When expanded, the portable hair dryer can blow hot air into the housing, forming a vortex stream within the cylindrical enclosure that exits through the exhaust vents in the top. The top member can be removed to attach articles of clothing to the spin-able clothes hanger. The unit is designed such that the vortex air stream that flows upward within the cylindrical enclosure and out the upper exhaust vents spins the clothes hanger with the articles of clothing, thereby ensuring complete coverage of the hot air over the clothing surfaces and speeding the drying time.

Owner:SPITZ ROBERT K +3

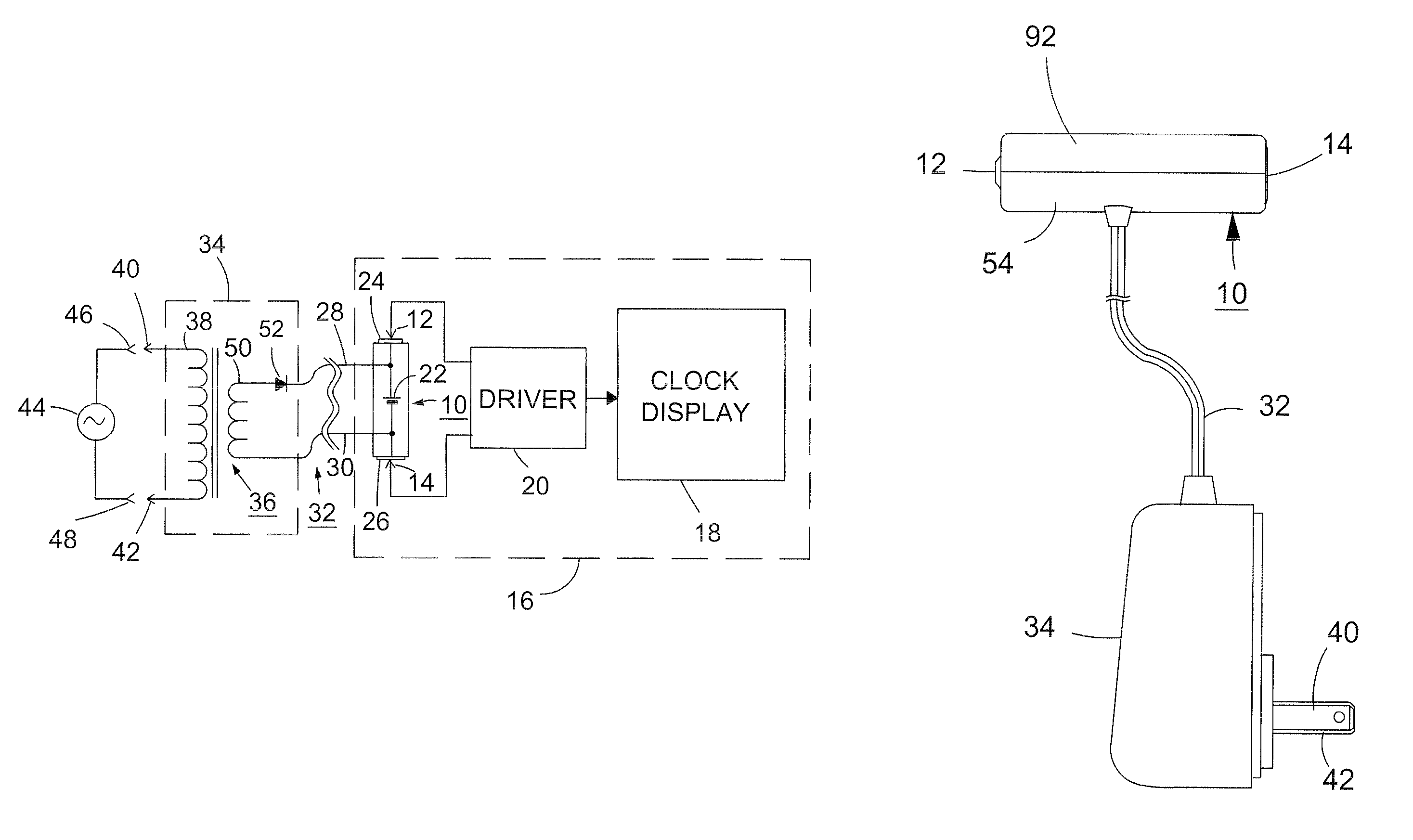

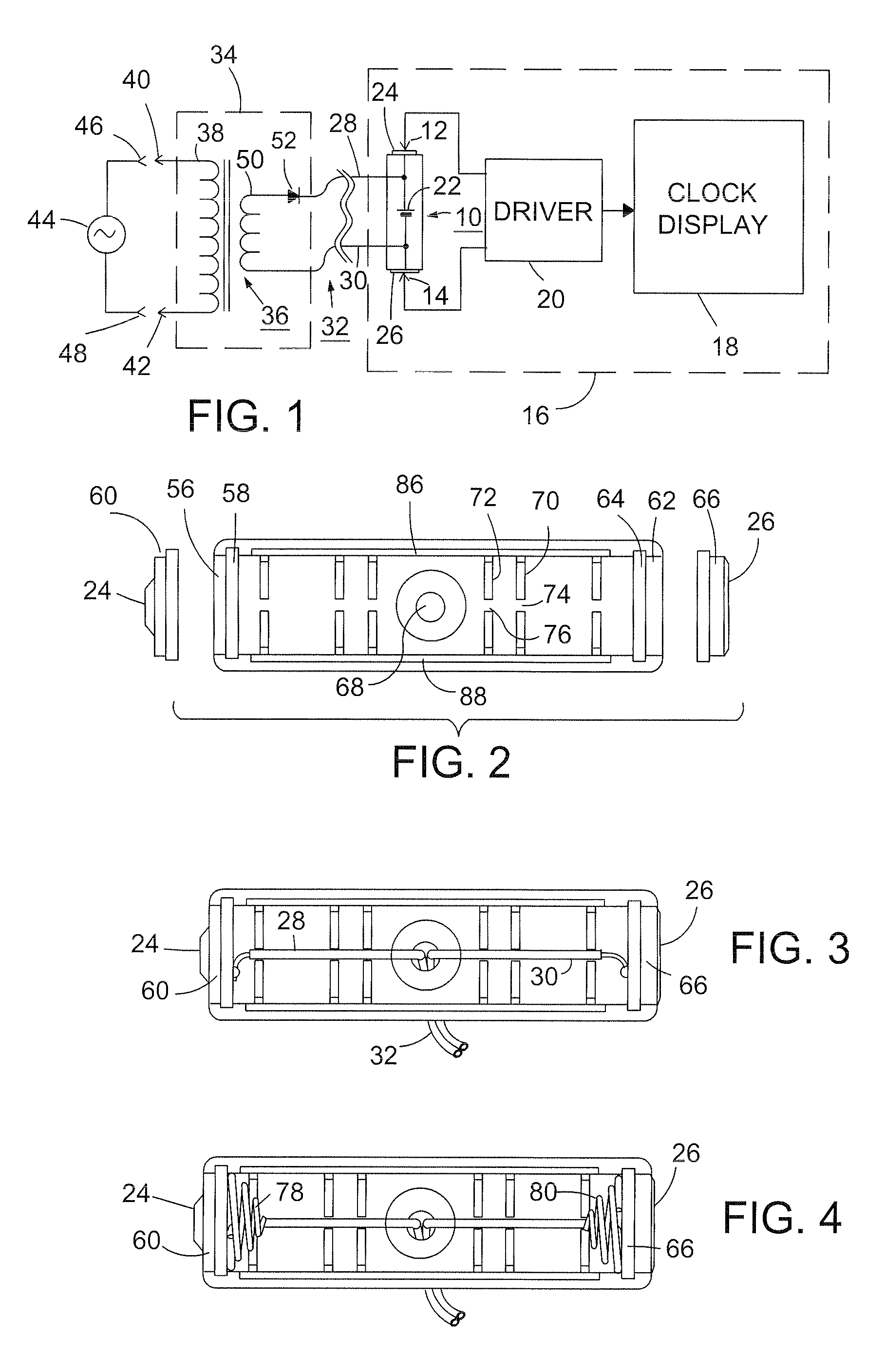

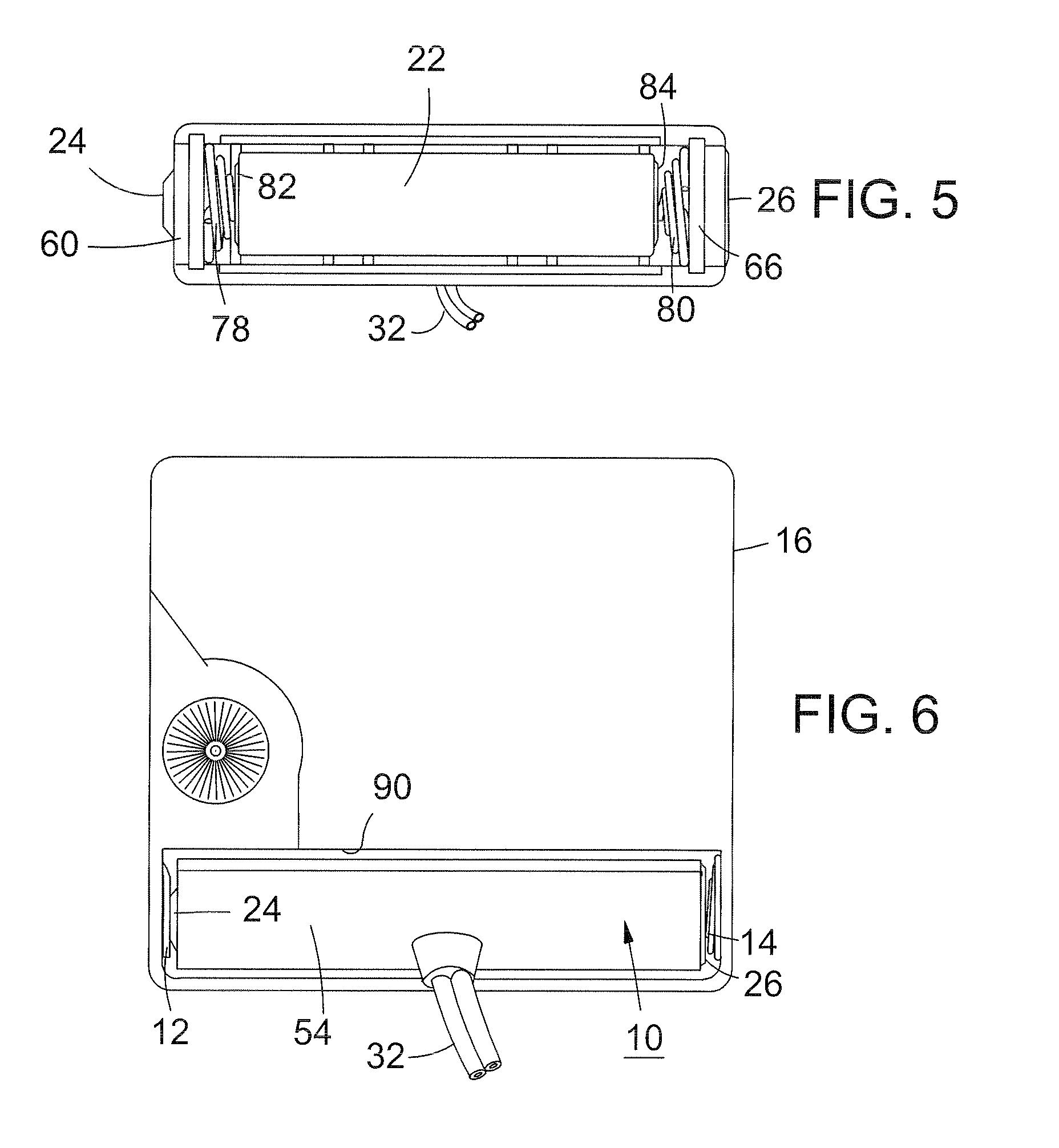

Power supply for clock

InactiveUS8351302B2Batteries circuit arrangementsElectric windingElectrical batteryRechargeable cell

A line current power supply delivers operating current to a clock designed to be powered by a conventional electrochemical cell disposed in a power source compartment within the clock housing, and at the same time supplies recharging current to a rechargeable electrochemical cell for powering the clock in the absence of an external power supply. The rechargeable cell is contained within a cylindrical enclosure having a shape such that it can fit into the power source compartment of the clock, and having contacts allowing it to be substituted for the conventional electrochemical power source.

Owner:FISCHER JEREMY LAURENCE

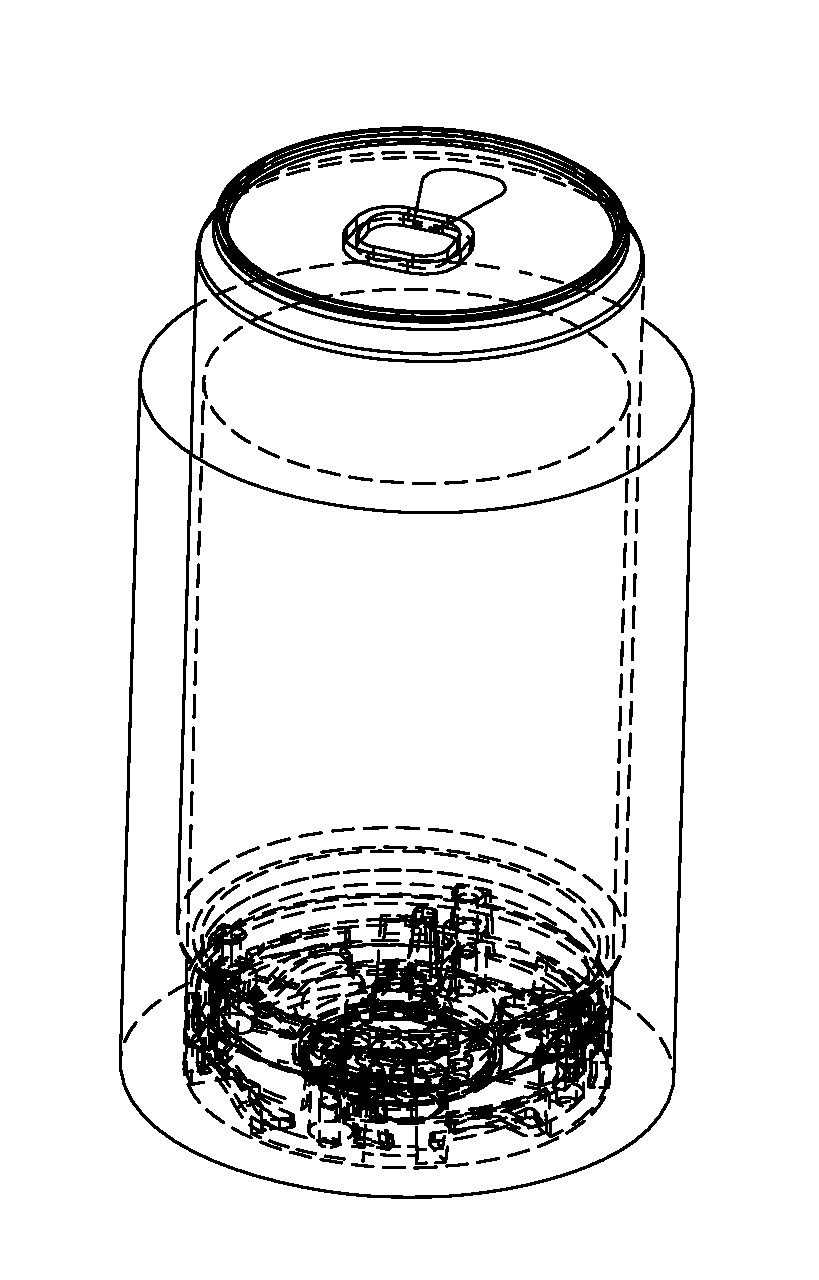

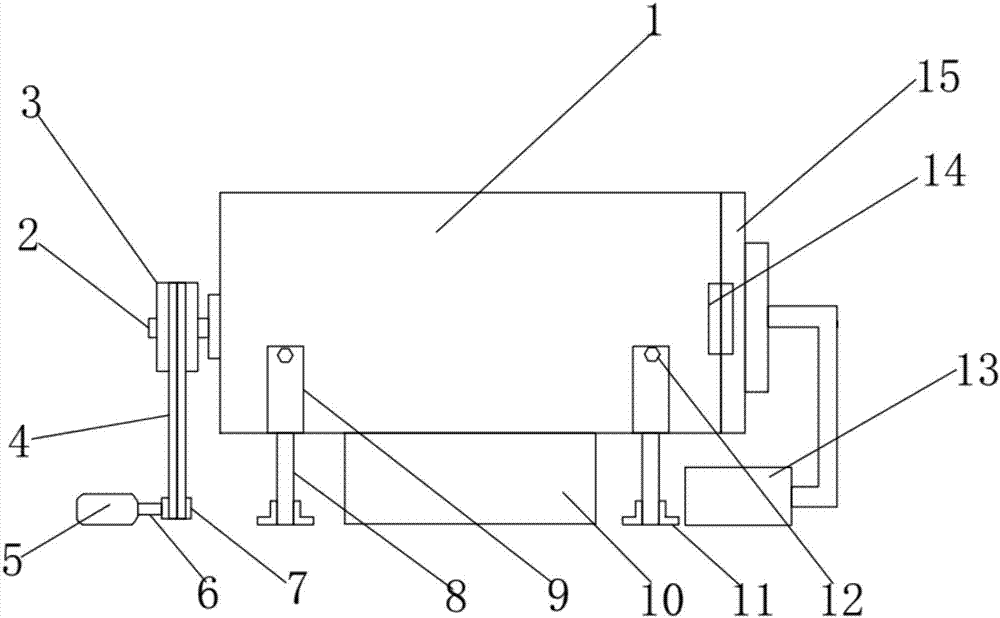

Beverage can cooler with sound device in bottom

InactiveUS20110041544A1Easy extractionEasy to insertMusical toysContainer decorationsEngineeringBottle

An insulating can cooler, which plays sounds. The cooler consists of a cylindrical enclosure, which is open on top and enclosed on the bottom. The cooler also consists of a sound device that will activate when a can or bottle is inserted in or extracted from the cooler. Have the ability to record a sound when a button is held in for a period of time; and the ability to download music from the Internet or other devices; and the ability to shut off and change the sound with a switch.

Owner:FERGUSON TOM +4

Vibration type tea leaf enzyme deactivating machine

PendingCN106942409ADoes not avoid deformationQuality improvementPre-extraction tea treatmentDrive shaftCylindrical enclosure

The invention discloses a vibration type tea leaf enzyme deactivating machine. The vibration type tea leaf enzyme deactivating machine comprises a cylindrical machine box, wherein the machine box is arranged in the horizontal direction; a semi-circular support frame is fixed at the lower part of the side wall of the machine box through a tightening bolt, and a base is in welded connection with the lower part of the support frame; the right end part of the machine box is of an opening structure, a tank door is arranged at the right end part of the machine box, and one end of the tank door is hinged to the outer wall of the machine box through a hinge. The vibration type tea leaf enzyme deactivating machine has the advantages that because the whole tank door adopts the turnover structure, the tea leaves are turned up by a stirring plate in the actual tea frying process, a main shaft is driven by a vibration rod to vibrate, the whole stirring plate can produce the vibration effect, the tea leaves which are turned up to the stirring plate are shaken off via screen holes under the vibration action, and the effect of rolling in the traditional tea frying method is realized in the whole tea leaf frying process; the deformation of tea leaves in the traditional rubbing method will not be caused by the high-frequency vibration type.

Owner:湖南天爱农业科技有限公司

Sip N Soothe

InactiveUS20170094721A1Easy to useEasy and efficient to manufactureLighting applicationsCapsElectrical batteryEngineering

A baby's feeding bottle warmer comprising a bottle, a cylindrical enclosure provided with a clear sidewall with the sealed bottom end and an opening at the top, covered with the cap, capable of heating its contents at a certain constant temperature. The bottle also having a heating element embedded at the bottom end of the bottle, provided for effective heat distribution and accurate control of the temperature throughout the contents of a baby bottle. It is operated by the electrical power source and / or a battery.

Owner:MOORE CHERYL E +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com