Method for measuring the pressure and/or molar mass of a gas in a housing, and corresponding measurement assembly

A gas and cover technology, which can be used in the direction of measuring fluid pressure, measuring fluid pressure through electromagnetic elements, measuring devices, etc., which can solve the problems of low measurement accuracy and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

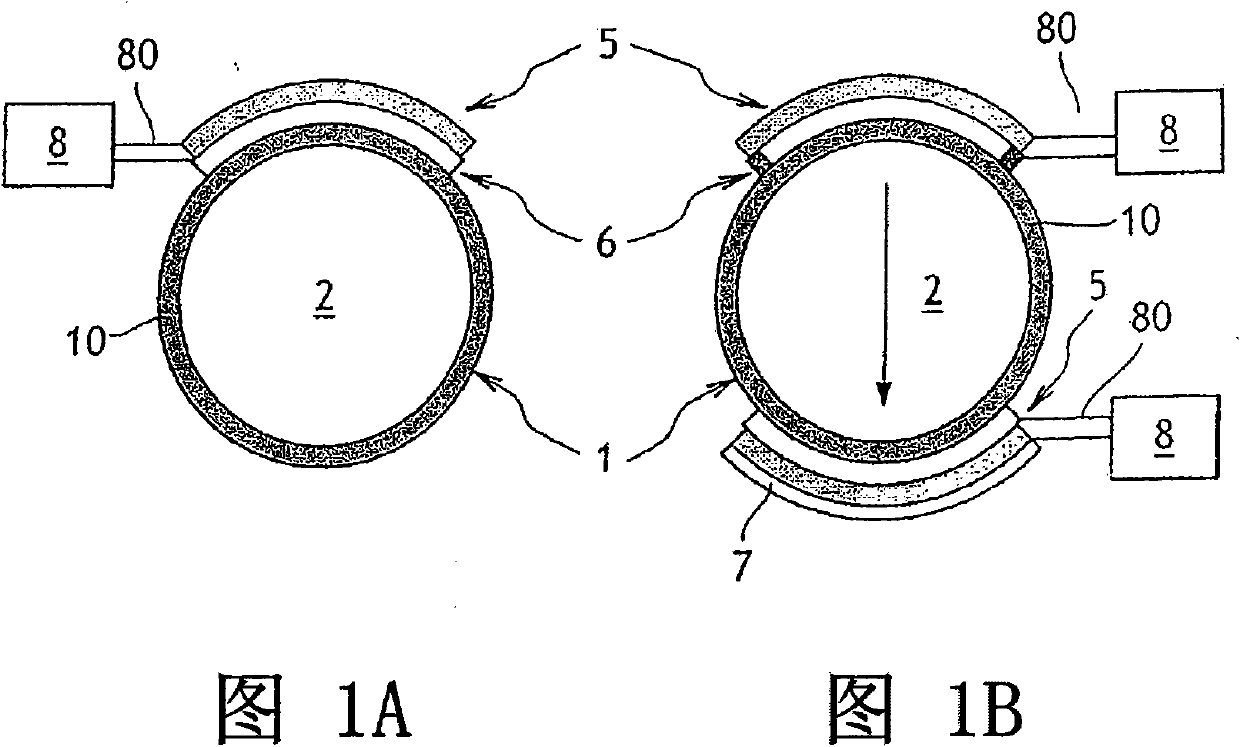

[0046] exist Figure 1A and 1B In , a housing 1 containing a gas 2 is schematically shown.

[0047] The housing 1 is, for example, a fuel rod, and the gas 2 is, for example, helium or a gas mixture.

[0048] The housing 1 supports the acoustic sensor.

[0049] The sensor is connected to the housing thus forming an assembly of the sensor and the housing.

[0050] The acoustic sensor is able to measure at least one physical parameter of the gas 2, such as the pressure and / or the molar mass of the gas in the enclosure.

[0051] Acoustic sensors include:

[0052] - at least one transducer 5 for

[0053] On the one hand, an acoustic signal that vibrates the enclosure and the gas is generated, and

[0054] On the other hand, detect the acoustic response signal characteristics of the vibration of the gas and the housing;

[0055] - bonding layer 6, which is between the transducer 5 and the housing 1;

[0056] - an electrical system 8, which is connected to the transducer 5 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com