Apparatus and a method for bagging debris in a commercially available trash bag which has closure straps

a technology of trash bags and closure straps, which is applied in the field of trash bags, leaf and/or debris bags, can solve the problems of reducing the cost of manufacturing devices, affecting the quality of products, and affecting the appearance of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

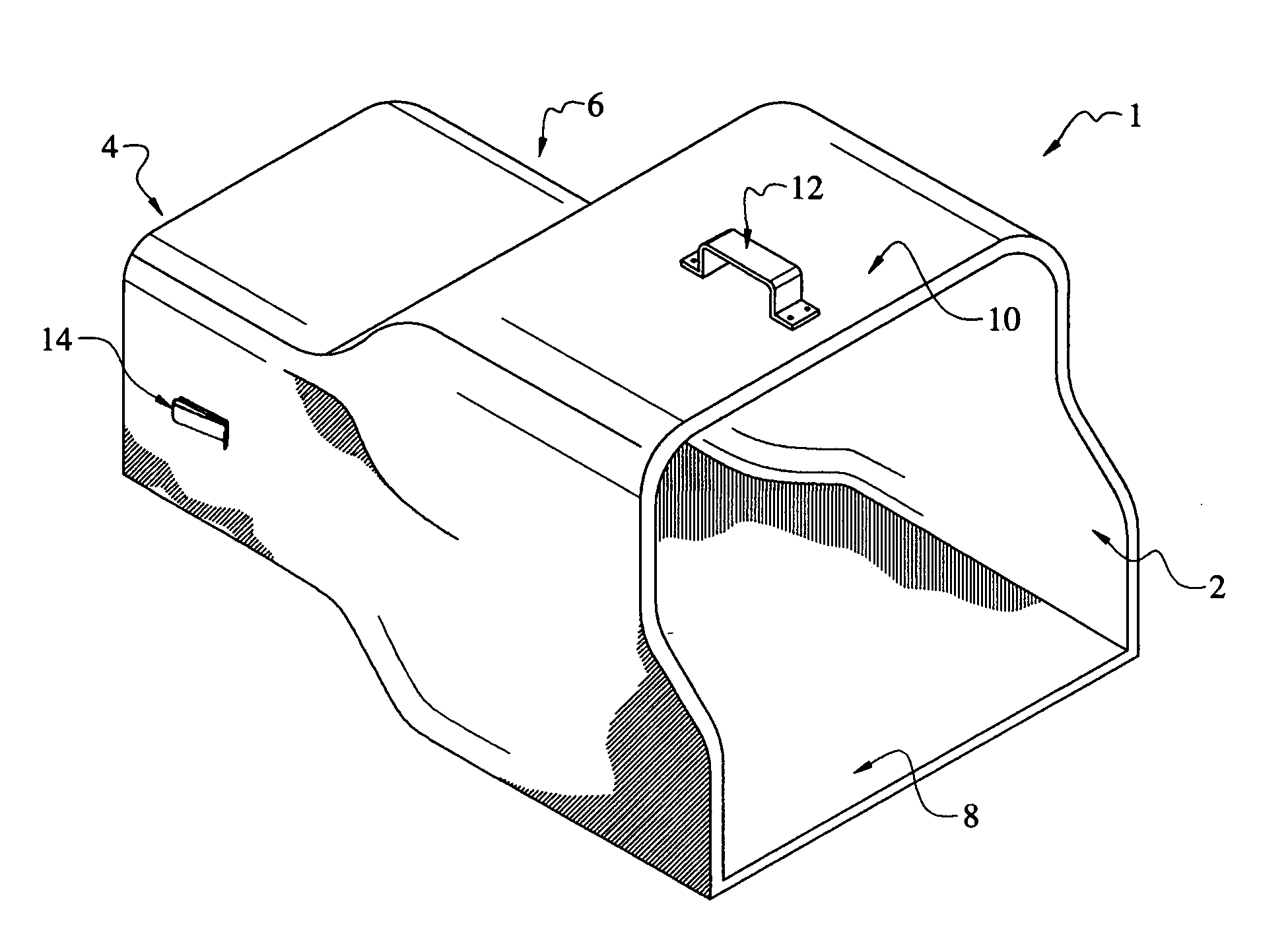

[0025] Referring first to FIG. 1, the leaf bagging device is comprised of a generally cylindrical housing 1 with a two open ends 2 and 4, a handle 12, and clips 14 for attaching a trash bag with closure straps to the housing 1 over the open end 4. The housing 1 is constructed of polypropylene, but could also be constructed of other durable, lightweight materials such as other types of plastic, metal, such as aluminum, or wood. The handle 12 and the clips 14 are also constructed of polypropylene, but could also be constructed of other durable materials such as other types of plastic, metal, such as aluminum, or wood. In the preferred embodiment of the invention, the handle 12 is molded into the housing 1 and the clips are molded separately and inserted into slots in the housing, however, both components could be molded into the housing or molded separately and attached to the housing using tabs, screws, or other conventional means of attachment.

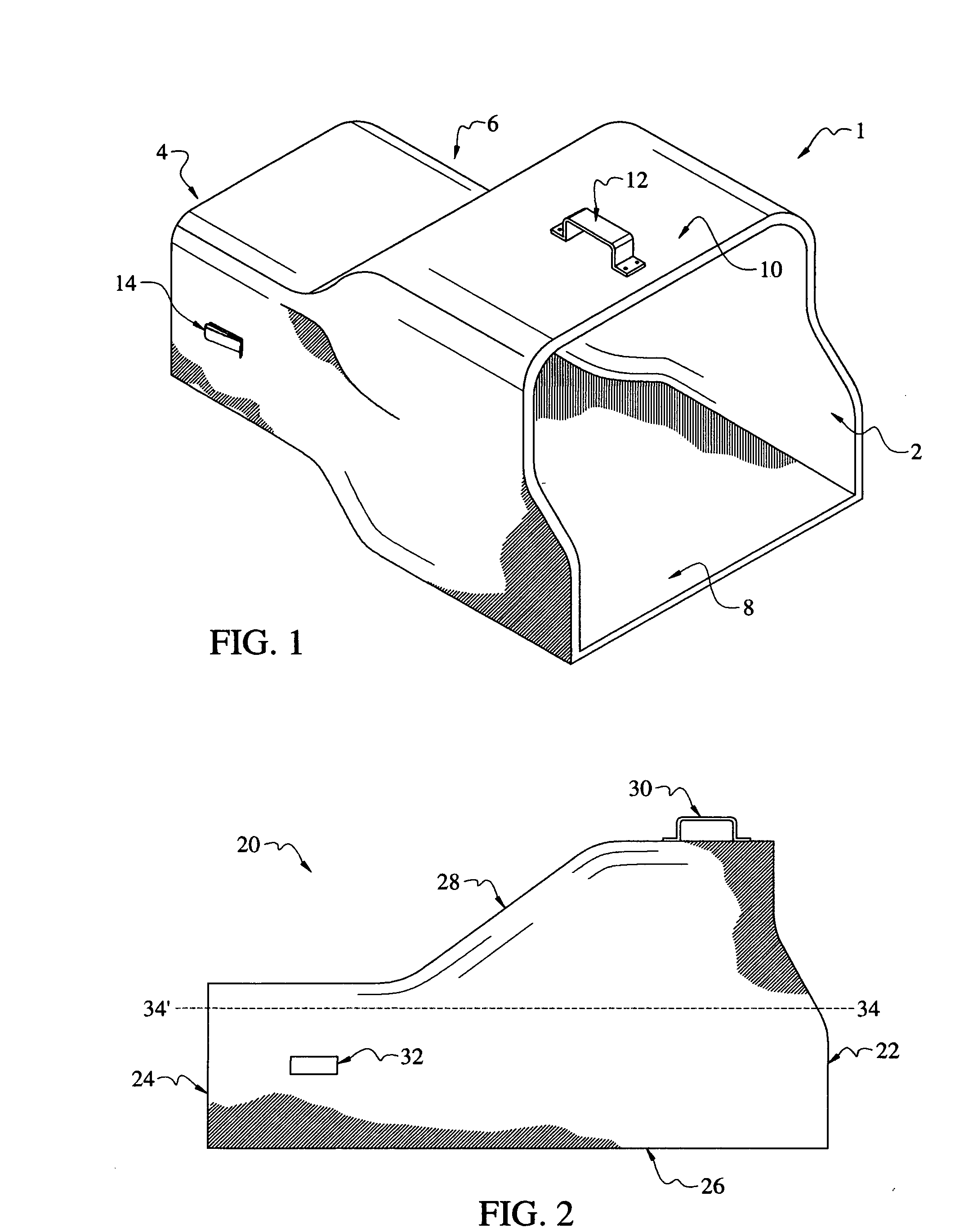

[0026] One wall of the housing 8 is fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com