Patents

Literature

18053 results about "Batch production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Batch production is a method of manufacturing where the products are made as specified groups or amounts, within a time frame. A batch can go through a series of steps in a large manufacturing process to make the final desired product. Batch production is used for many types of manufacturing that may need smaller amounts of production at a time to ensure specific quality standards or changes in the process. This is opposed to large mass production or continuous production methods where the product or process does not need to be checked or changed as frequently or periodically.

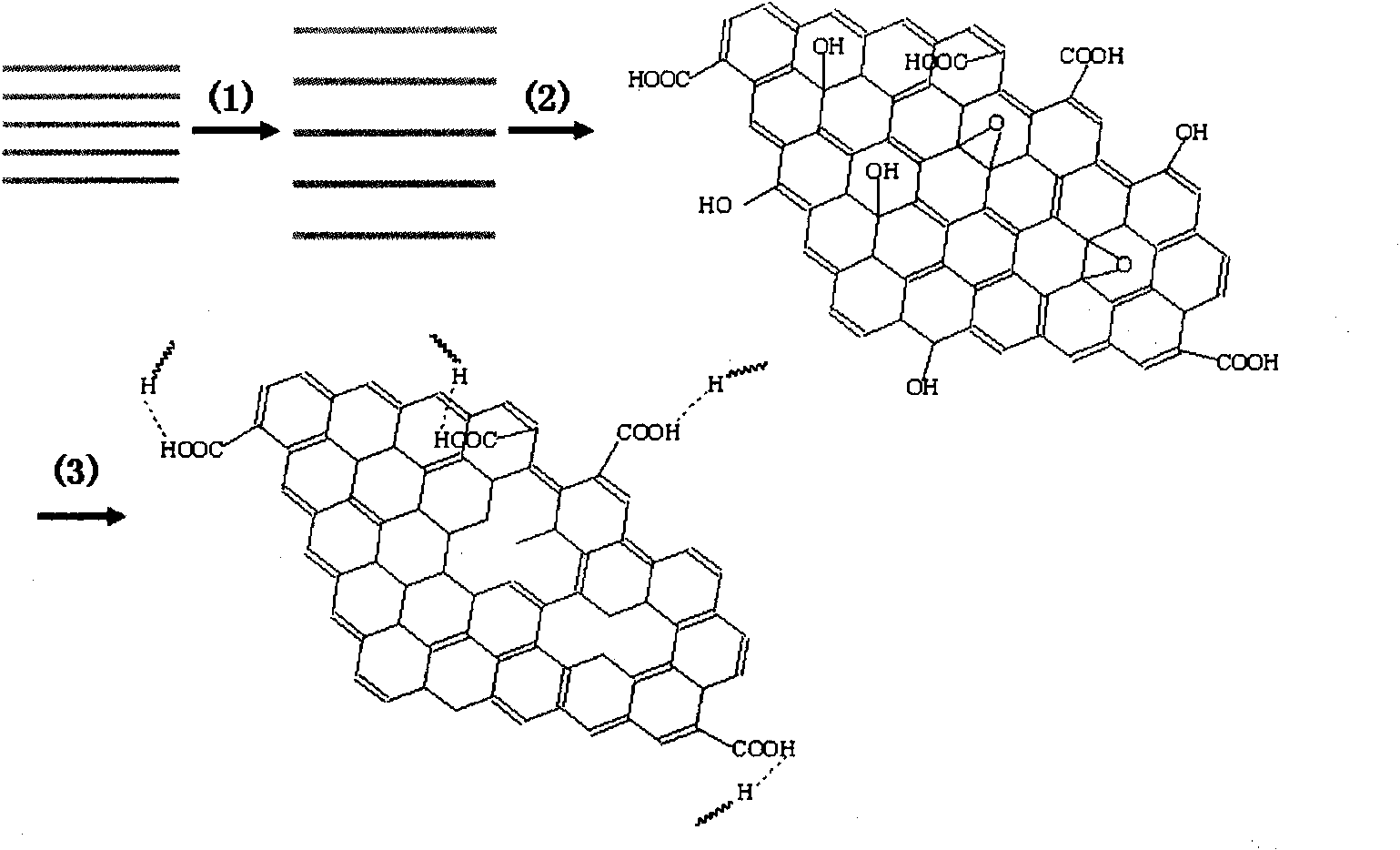

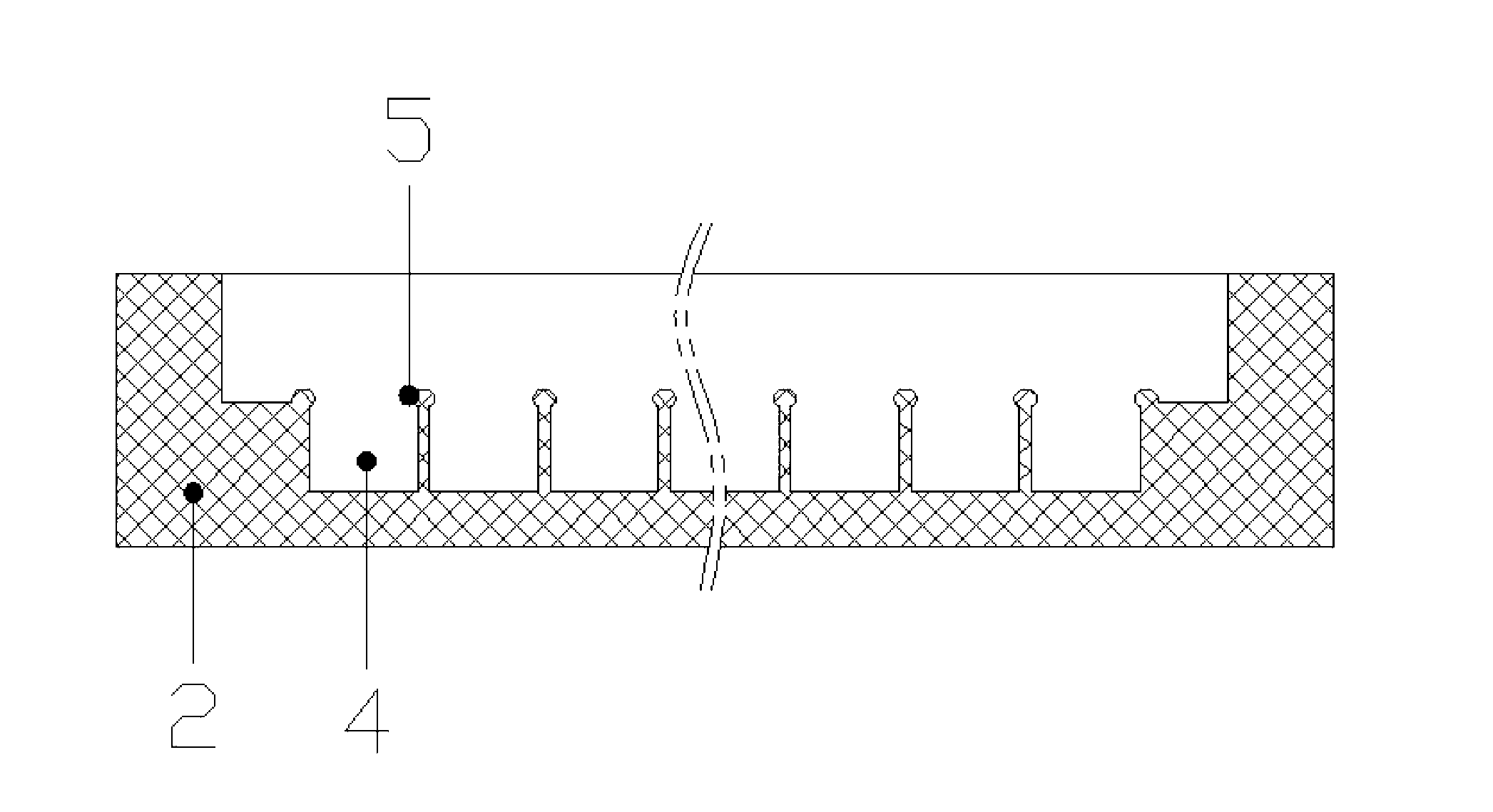

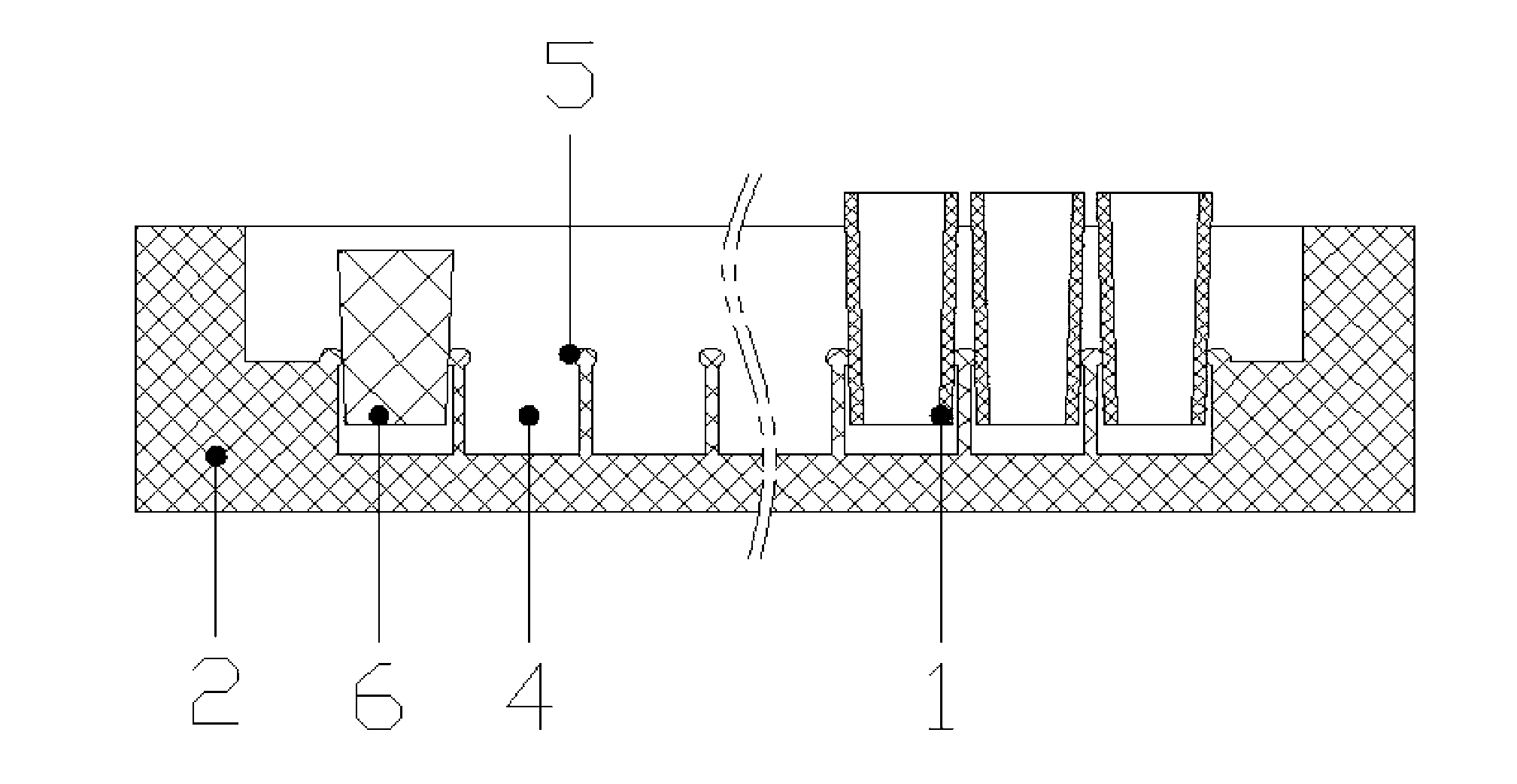

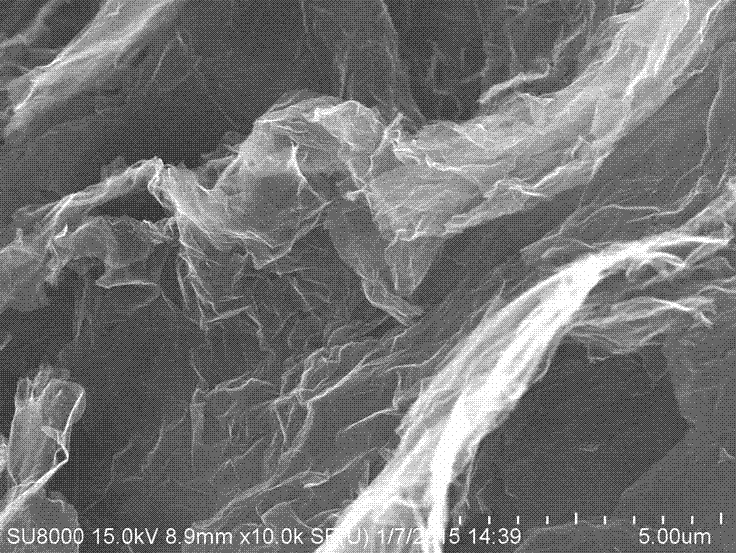

Method for preparing graphene or graphene oxide by using high-efficiency and low-cost mechanical stripping

InactiveCN101817516AImprove stripping efficiencyLight in massHigh volume manufacturingSolid particle

The invention provides a method for preparing graphene or graphene oxide by using high-efficiency and low-cost mechanical stripping and relates to a preparation method of the graphene or the graphene oxide, solving the problems that the traditional micro-mechanical stripping method has low efficiency and can not be used for large-batch production. The method comprises the following step of separating carbon materials by utilizing solid particles and a liquid working medium (or gas working medium) and adopting mechanical stripping to obtain the graphene or the graphene oxide, wherein the carbon materials comprise graphite powder, expanded graphite, expandable graphite or graphite powder oxide. By using automatic machinery and using a great deal of solid particles for assisting stripping processes, the invention greatly increases the contact areas and the stripping times of the stripping processes, the carbon materials are subject to a great amount of stripping processes in a short time through the shearing and impacting functions of the solid particles on the carbon materials, and thereby the method obviously improves the stripping efficiency, has low cost and is suitable for the industrial and large-batch production of the graphene or the graphene oxide.

Owner:HARBIN INST OF TECH

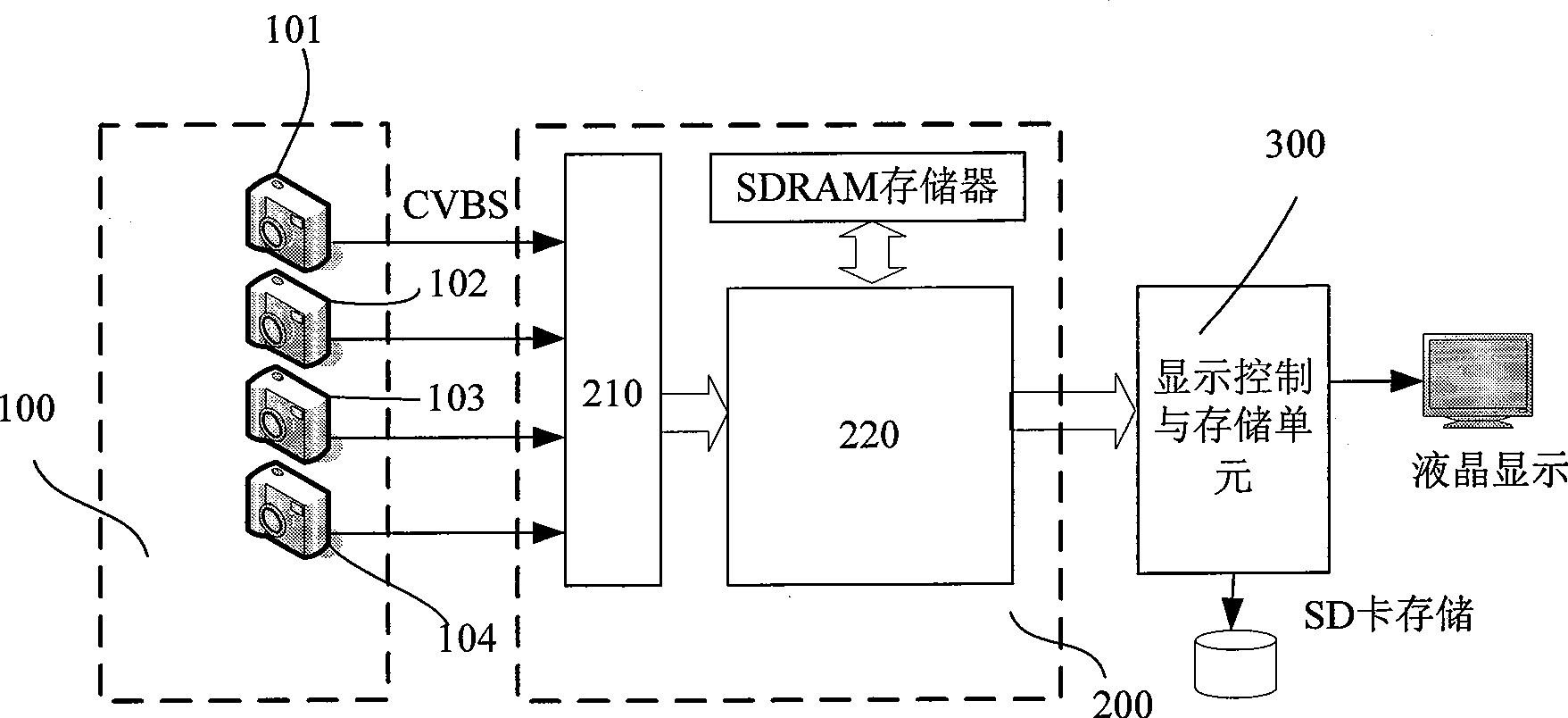

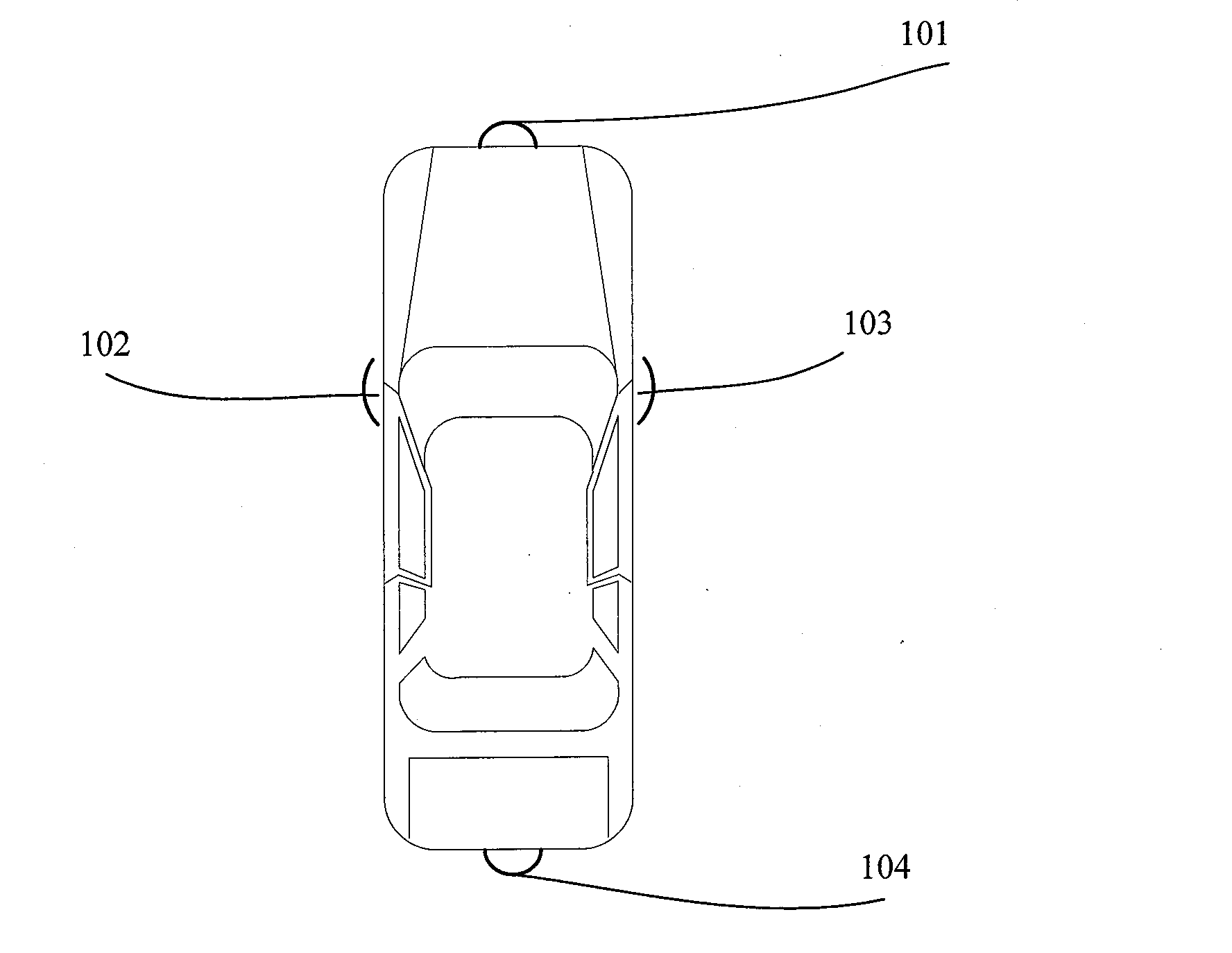

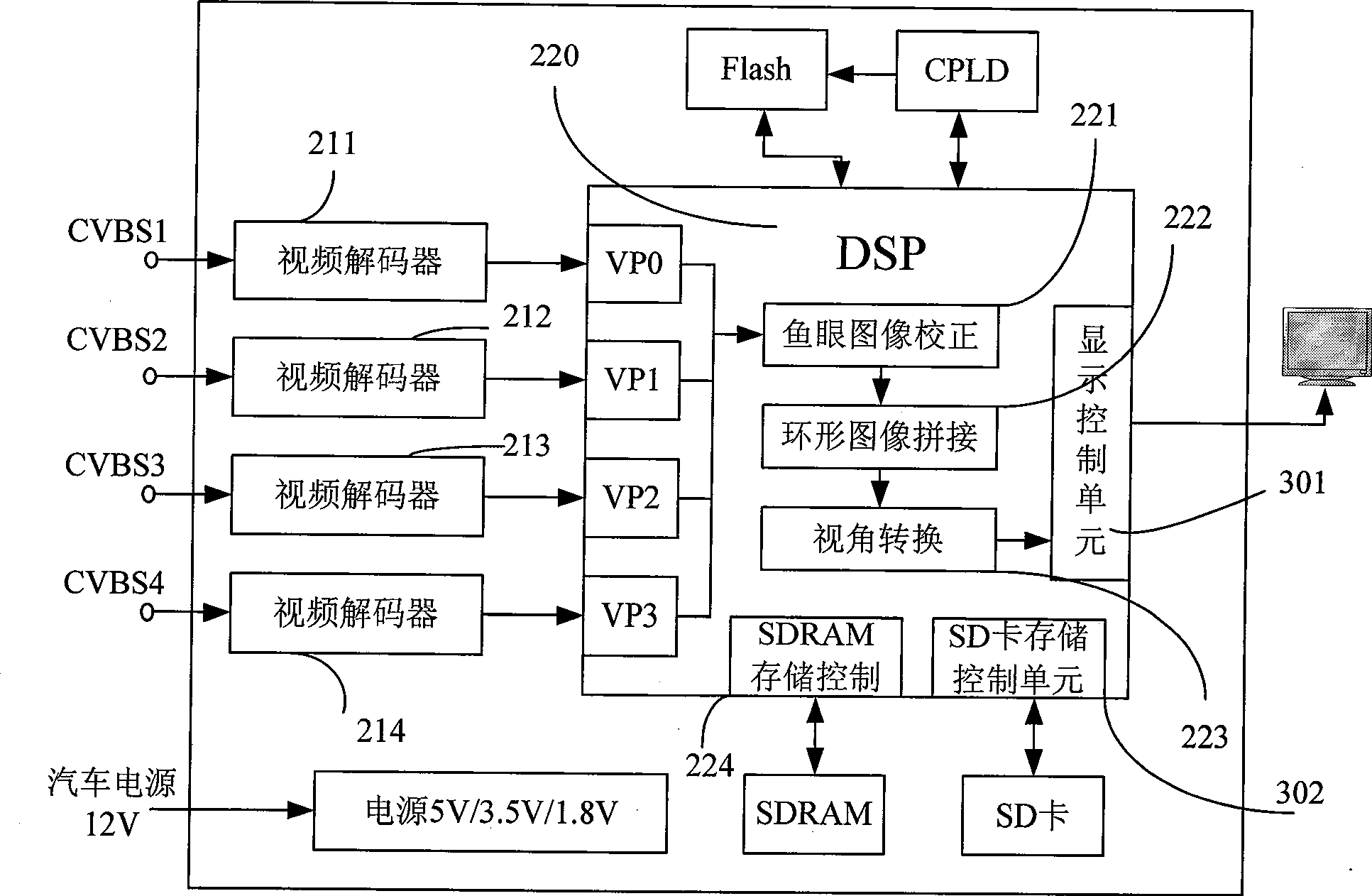

Method for synthesizing 360 DEG ring-shaped video of vehicle assistant drive

InactiveCN101442618ALow costSuitable for mass productionTelevision system detailsColor television detailsBlind zoneDriver/operator

The invention discloses a method for synthesizing annular video of 360 degrees for assistant drive of a vehicle. The method adopts a video acquisition unit, an annular video synthesis unit and a display control and storage unit, and has the characteristics of reliable stability, low cost and suitable batch production. The method can acquire video signals in real time for four super-wide-angle fish-eye cameras arranged at front, back, left and right of the vehicle, carries out treatment of fish-eye image correction, annular image mosaic and vision angle conversion on four channels of the video signals through a video decoding unit and a video synthesizing control unit to generate a panoramic displayed plan view of 360 degrees, achieves multiple display modes through the display control and storage unit, and can selectively store correlated video information. The method can provide surrounding scenes for a driver, and eliminate vision blind area thereof, and is favorable for the driver to achieve safe and accurate vehicle driving operations. The method is used for assistant drive for sedans, business vehicles and heavy trucks of various grades, and passenger coaches of different types.

Owner:葛晨阳

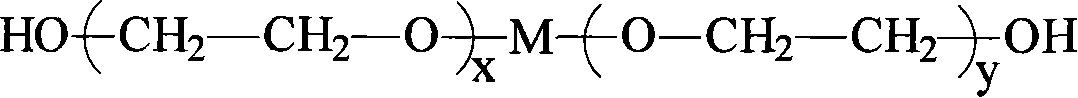

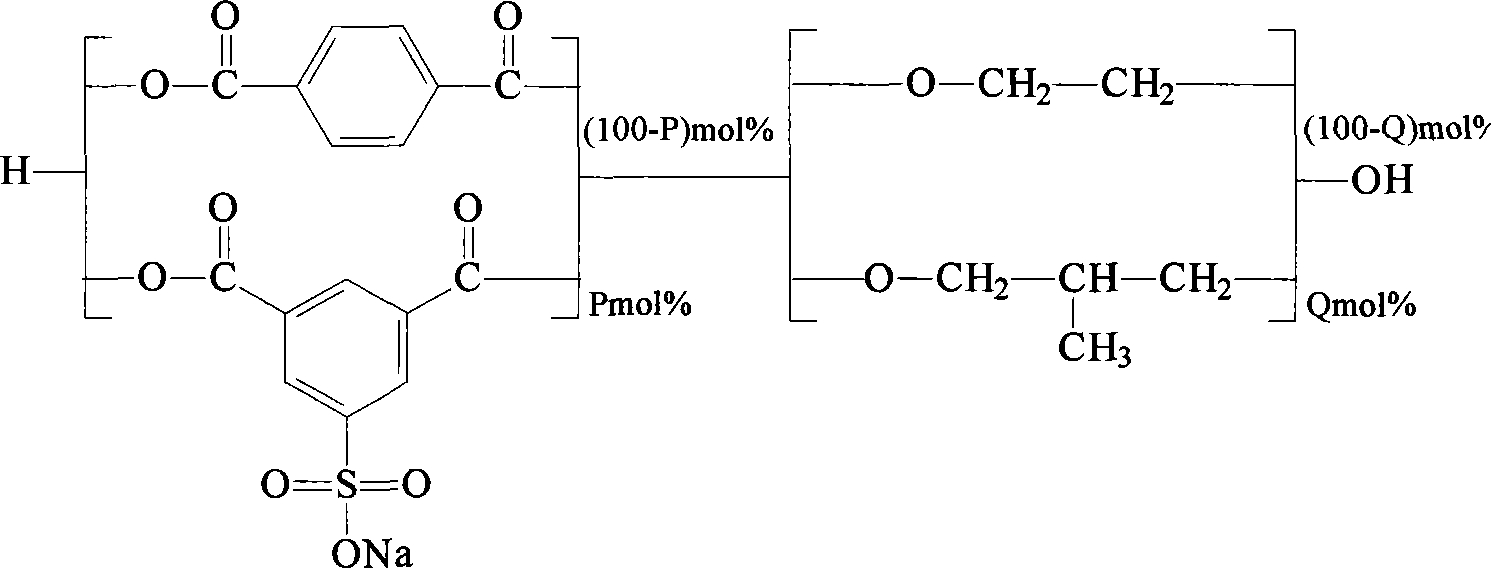

Modified copolyester slicer or fabric and method for making same

InactiveCN101063236ASoft lusterImprove shrinkageMonocomponent polyesters artificial filamentFiberAlcohol

The invention relates to a modified copolyester slice or fiber and a relative preparation, wherein the slice is copolymerized from terephthalic acid, ethandiol, isophthalate esters of sulfonic acid sodium (or potassium), and fatty group dibasic alcohol (or relative alkylate) with side chain. And the preparation comprises that (1), mixing the ethandiol and the fatty group dibasic alcohol (or relative alkylate) into a mixed alcohol, adding catalyzer and stabilizer to esterify the terephthalic acid under 220-260Deg. C, (2), adding 1-9%mol isophthalate esters of sulfonic acid sodium (or potassium) relative to the terephthalic acid for polycondensation at 250-300Deg. C, (3), drying, fusing, spinning, and drawing to obtain the modified copolyester filament. The inventive product can dye anion paint and disperse paint into deep color at normal pressure, with better feeling, high contraction, hidden micro coiled property, simple preparation, low cost and batch production support.

Owner:DONGHUA UNIV

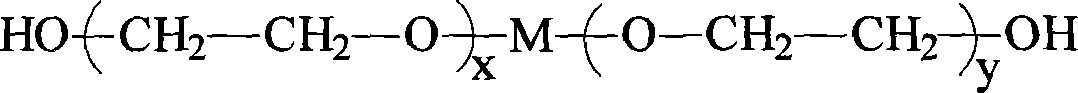

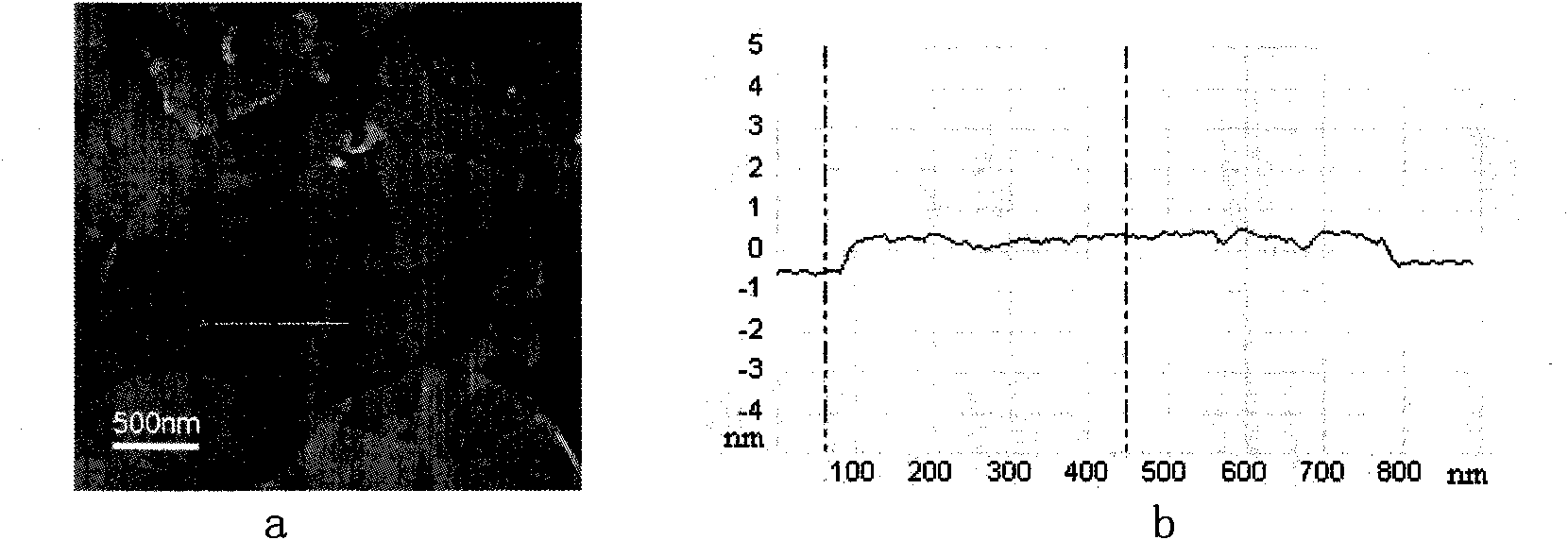

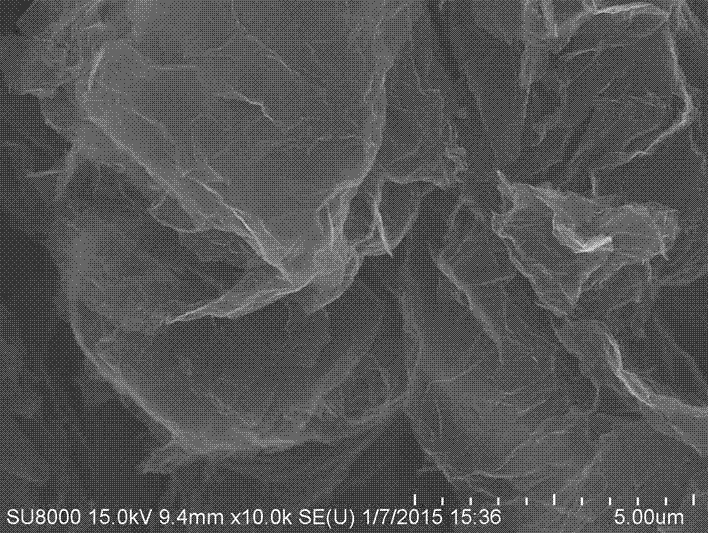

Preparation method of graphene based on ascorbic acid

ActiveCN101602504AEase of mass productionShort reaction timeNanostructure manufactureMaterials scienceReducing agent

The invention relates to a preparation method of graphene based on ascorbic acid, belonging to the technical field of nano materials. The preparation method comprises the following steps: preparing brown graphite suspending liquid; preparing luminous yellow graphite diluent; preparing graphite oxide solid; dispersing graphite oxide into deionized water, separating graphene oxide by ultrasonic separation treatment for 1 hour and preparing graphene oxide solution; and fully mixing the graphene oxide solution and ascorbic acid water solution, stewing and obtaining the graphene solution. The preparation adopts the ascorbic acid as a reducing agent, shortens reaction time under the condition that no stabilizing agent is added, obtains single-layer grapheme with the thickness of 0.8 to 1.2nm and is beneficial to batch production of the grapheme.

Owner:上海碳源汇谷新材料科技有限公司

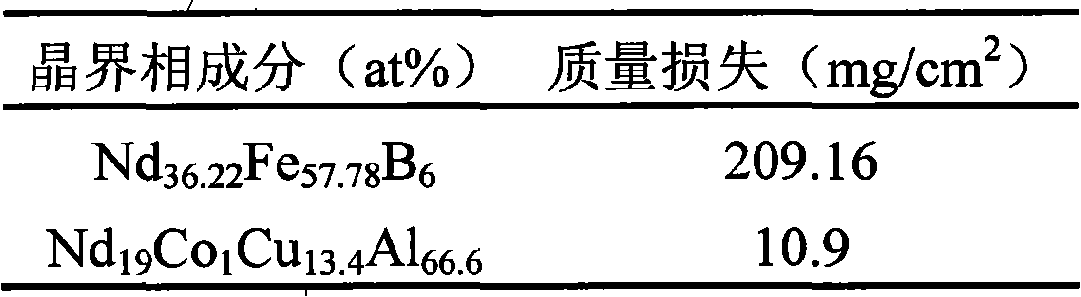

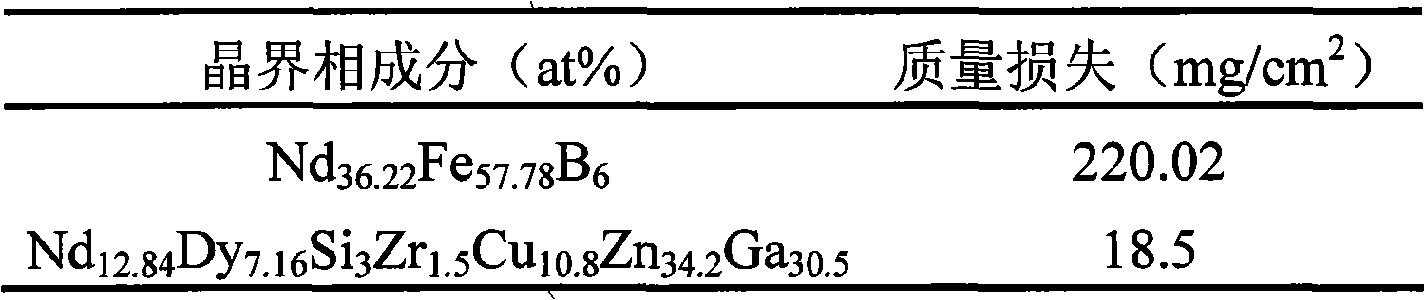

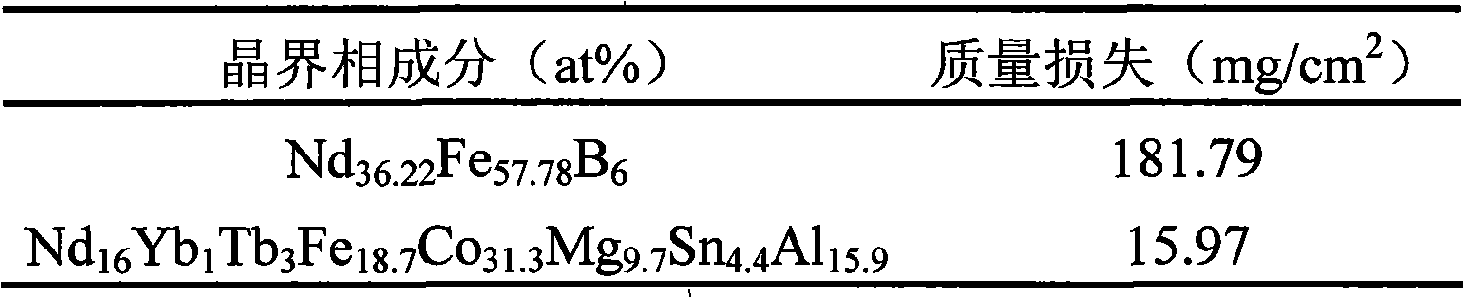

Grain boundary phase-reconstructed high-corrosion resistance Sintered NdFeB magnet and preparation method thereof

ActiveCN101320609ALow melting pointGuaranteed MagneticInorganic material magnetismInductances/transformers/magnets manufactureElectrode potentialPowder mixture

The invention discloses a sintered Nd-Fe-B magnet with high corrosion resistance and the grain boundary reconstruction and a preparation method thereof. The composition of the invention is that: NdeFe100-e-f-gBfMg, wherein, e is greater than or equal to 6 and equal to or less than 24, f is greater than or equal to 5. 6 and equal to or less than 7, g is greater than or equal to 0.03 and equal to or less than 8, M is one or some of elements Dy, Tb, Pr, Sm, Yb, La, Co, Ni, Cr, Nb, Ta, Zr, Si, Ti, Mo, W, V, Ca, Mg, Cu, Al, Zn, Ga, Bi, Sn and In; The method is that: main phrase alloy and reconstructed grain boundary phase alloy are respectively pulverized and mixed uniformly; the powder mixture is pressed to a mould in the magnetic field, and fabricated into a sintering magnet in a high vacuum sintering furnace. By the reconstruction of the grain boundary phase composition, the invention can obtain the grain boundary phase alloy with low melting point and high electrode potential, decrease the potential difference between the main phase and the grain boundary phase on the basis of ensuring the magnetic properties, promote the intrinsic corrosion resistance of magnet, and has the advantages of simple process, low cost and being suitable for the batch production. Therefore, by combining the grain boundary reconstruction and double alloy method, the sintered Nd-Fe-B magnet with high intrinsic corrosion resistance can be prepared.

Owner:ZHEJIANG UNIV

Electronic cigarette and method for supplying constant power therein

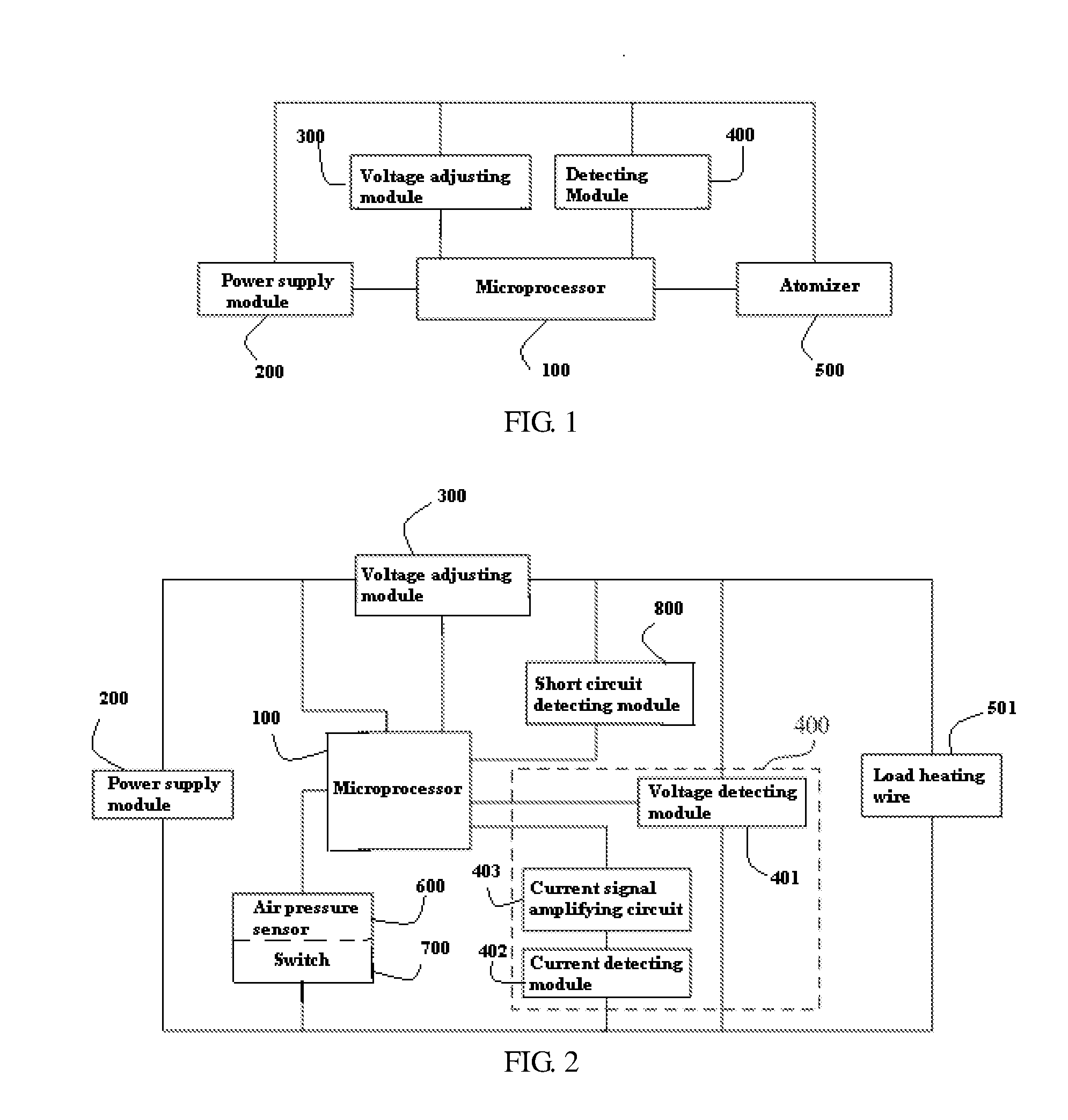

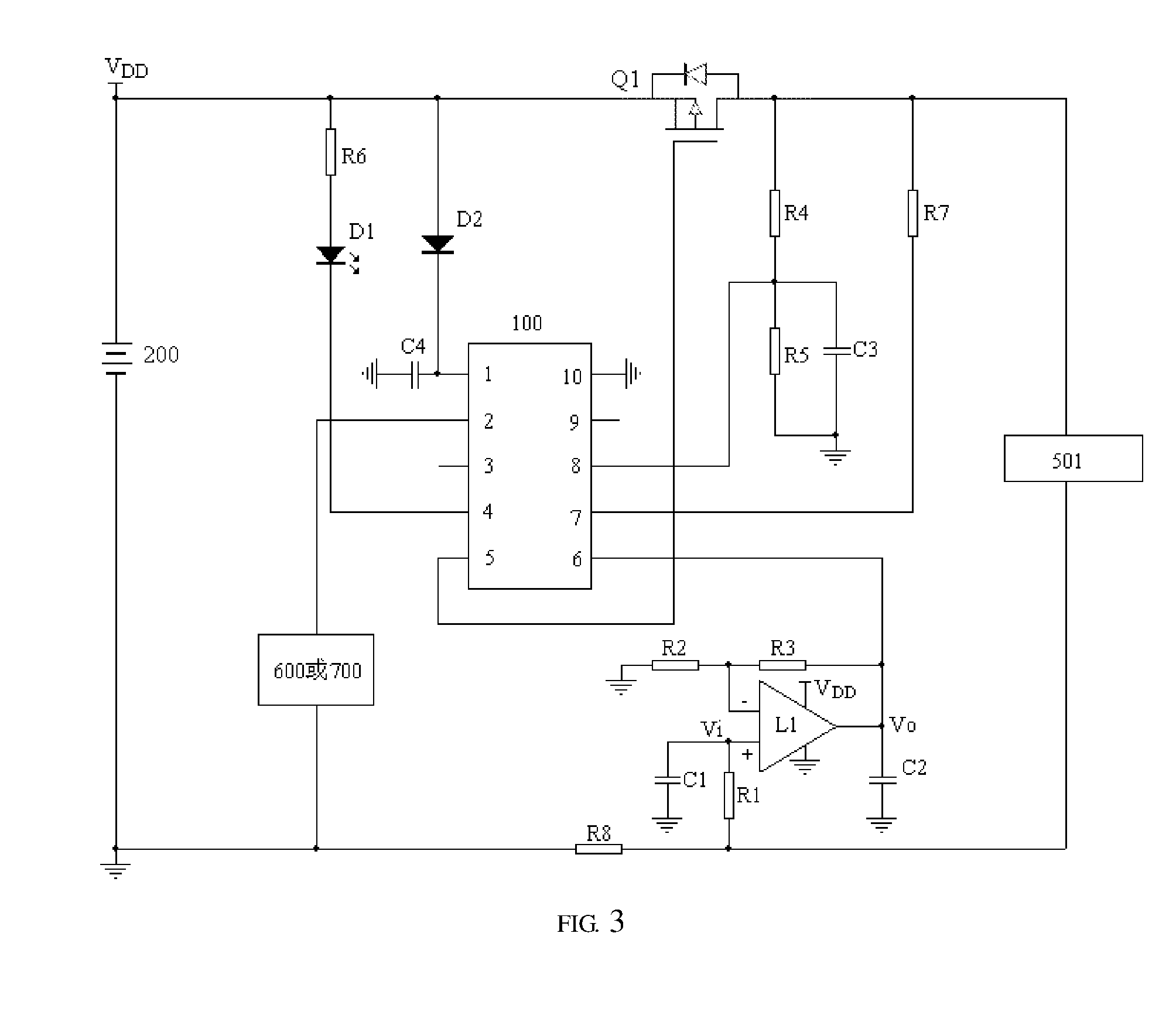

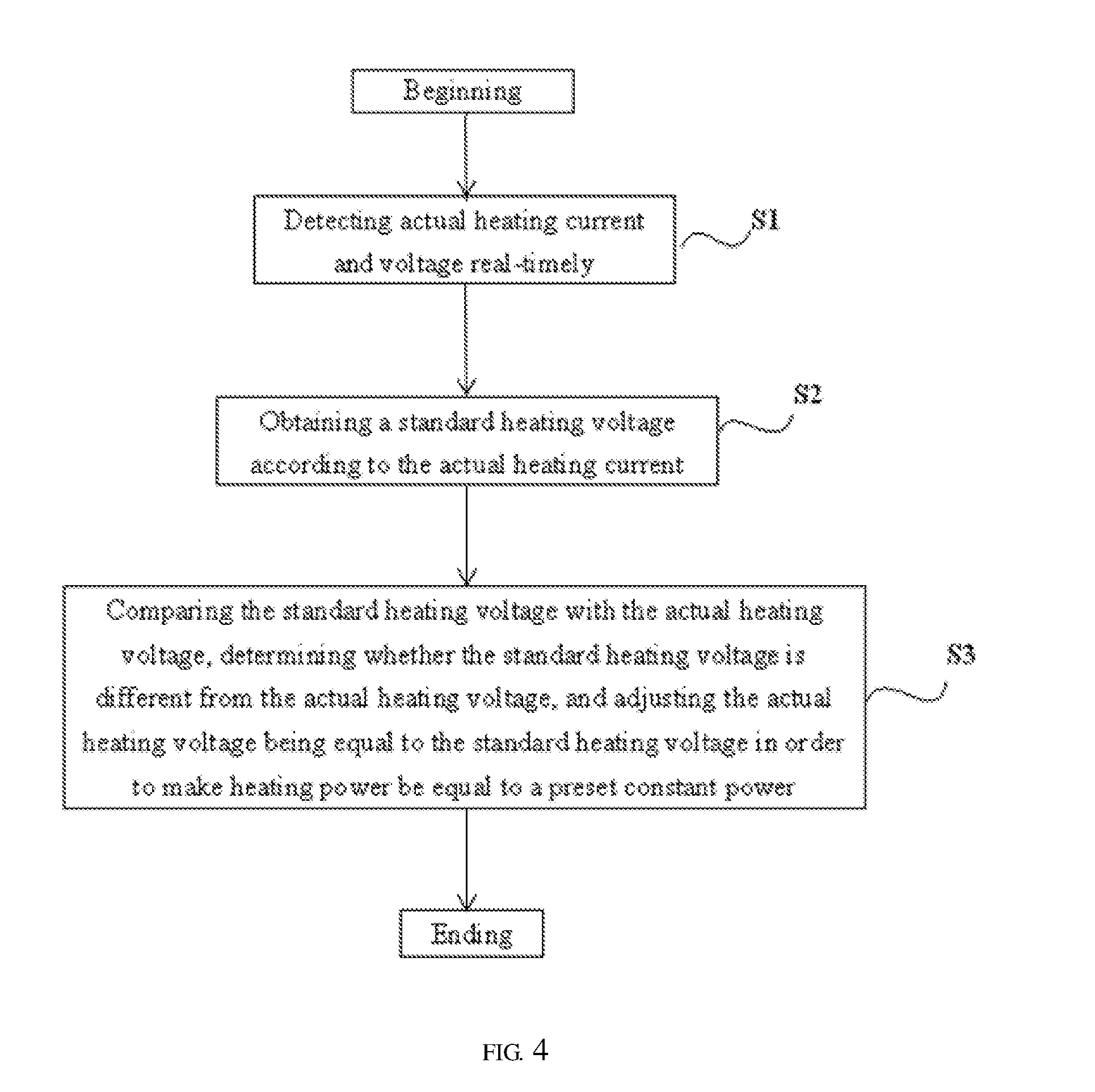

InactiveUS20160143359A1Meeting demandMeet needsSteam generation using steam absorptionElectric heatingVoltage regulator moduleConstant power

An electronic cigarette and a method for supplying a constant power therein, the electronic cigarette comprises an atomizer with a heating wire. The electronic cigarette also comprises a power supply module for supplying power to the heating wire to heat the heating wire, and further comprises a microprocessor, a detecting module connected to the microprocessor, and a voltage adjusting module. A preset constant power can supply to the heating wire of the atomizer in the electronic cigarette, so that a consistent heating power can be applied to each of the electronic cigarettes produced in batch production, and smoke amount and flavor of each of the electronic cigarettes are more consistent, thereby better meeting demands of consumers.

Owner:HUIZHOU KIMREE TECH

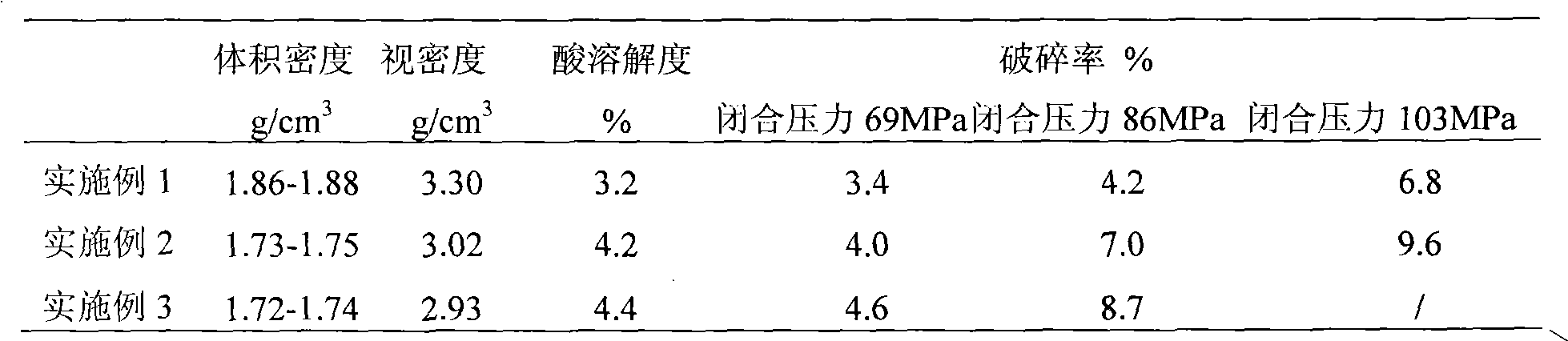

High-strength compress supporting agent for coarse oil and preparation method thereof

ActiveCN101575503AGood effectHas high strengthFluid removalDrilling compositionChemical compositionRed mud

The invention relates to a high-strength compress supporting agent for coarse oil and a preparation method thereof. The high-strength compress supporting agent for the coarse oil is prepared from the following raw materials by mass portion: 60 to 85 portions of ceramic roller waste, 1 to 20 portions of red mud, 0 to 20 portions of fly ash, 0 to 5 portions of manganese oxide or barium carbonate, 0 to 3 portions of dolomite and 5 to 10 portions of ceramic clay. The ceramic roller waste refers to corner waste or / and damaged and broken ceramic roller waste in the processing process of ceramic roller manufactures, and Al2O3 content of chemical compositions of the ceramic roller waste is not less than 68 percent. The high-strength compress supporting agent for the coarse oil prepared from the ceramic roller waste with high alumina content has the characteristics of high strength and acid resistance, and is used for oil fracturing in medium-deep wells; and the preparation method is simple and feasible, and is suitable for batch production.

Owner:JINGANG NEW MATERIALS

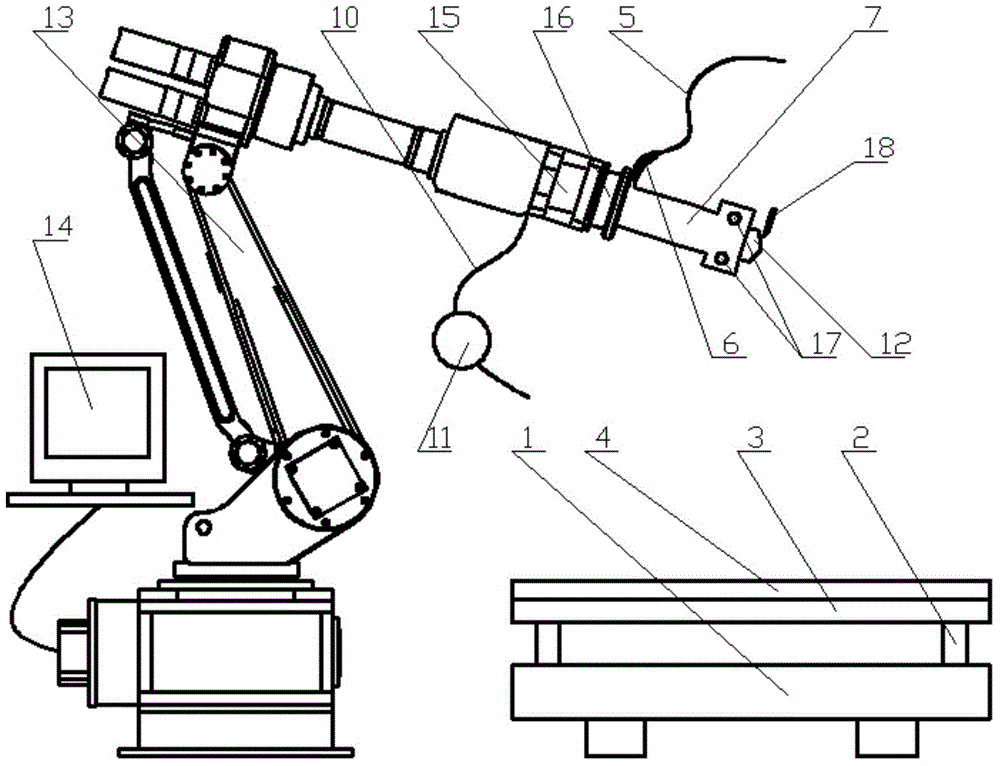

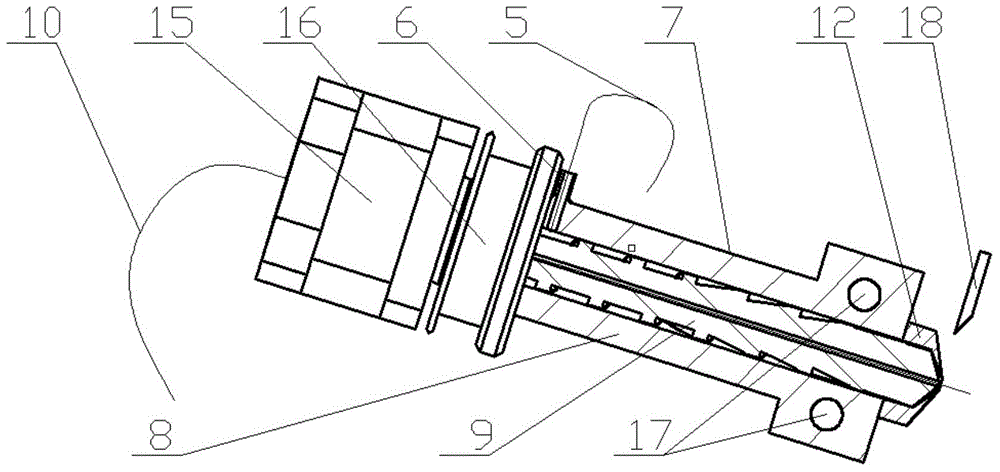

Multi-degree-of-freedom 3D printer of fiber reinforced composite material and printing method thereof

The invention discloses a multi-degree-of-freedom 3D printer of a fiber reinforced composite material and a printing method thereof. The 3D printing can be performed with any angle and any movement locus by making use of the flexibility of a manipulator; and a 3D printing head mounted on the multi-degree-of-freedom 3D printer can perform the 3D printing of a high-strength short fiber reinforced composite material, and can perform the splicing and the weaving of continuous resin-based long fiber to produce a structural body of a continuous fiber reinforced resin-based composite material. The multi-degree-of-freedom 3D printer can precisely control the orientation of reinforced fiber in a composite material part in the 3D printing process, and can realize the quick production of the composite material part with specific mechanical, electric and thermal performances and a complex structure. Meanwhile, a mold customized beforehand and a pretreated fiber prepreg tape are not needed in the process; and the multi-degree-of-freedom 3D printer is not only suitable for the production of large parts, but also suitable for the large-batch production of small parts, so that the production cost and the production period are largely reduced, and the wide application of the composite material parts is further promoted.

Owner:XI AN JIAOTONG UNIV

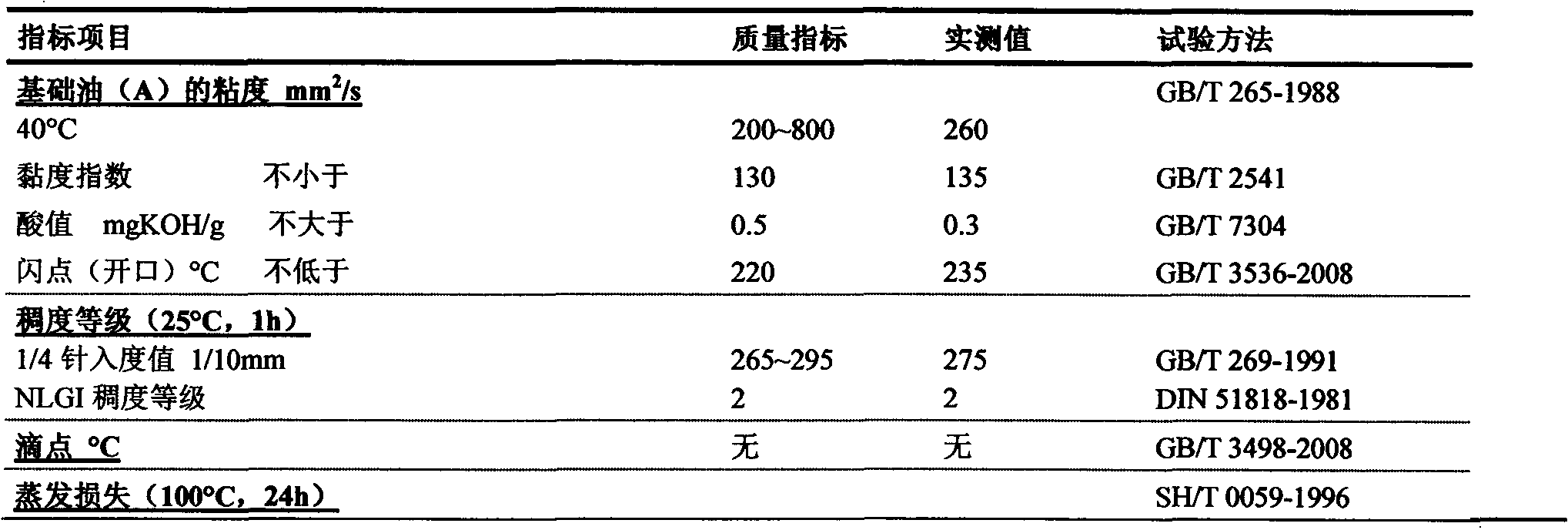

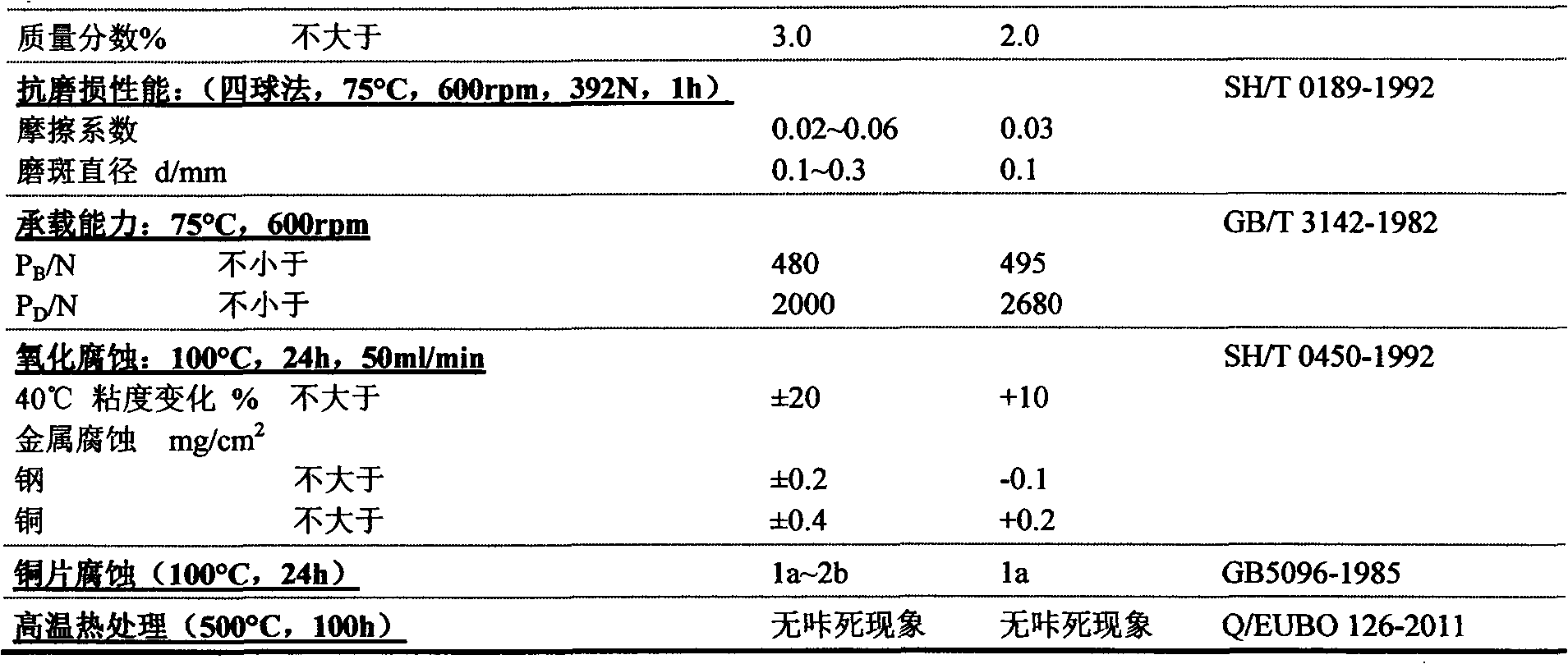

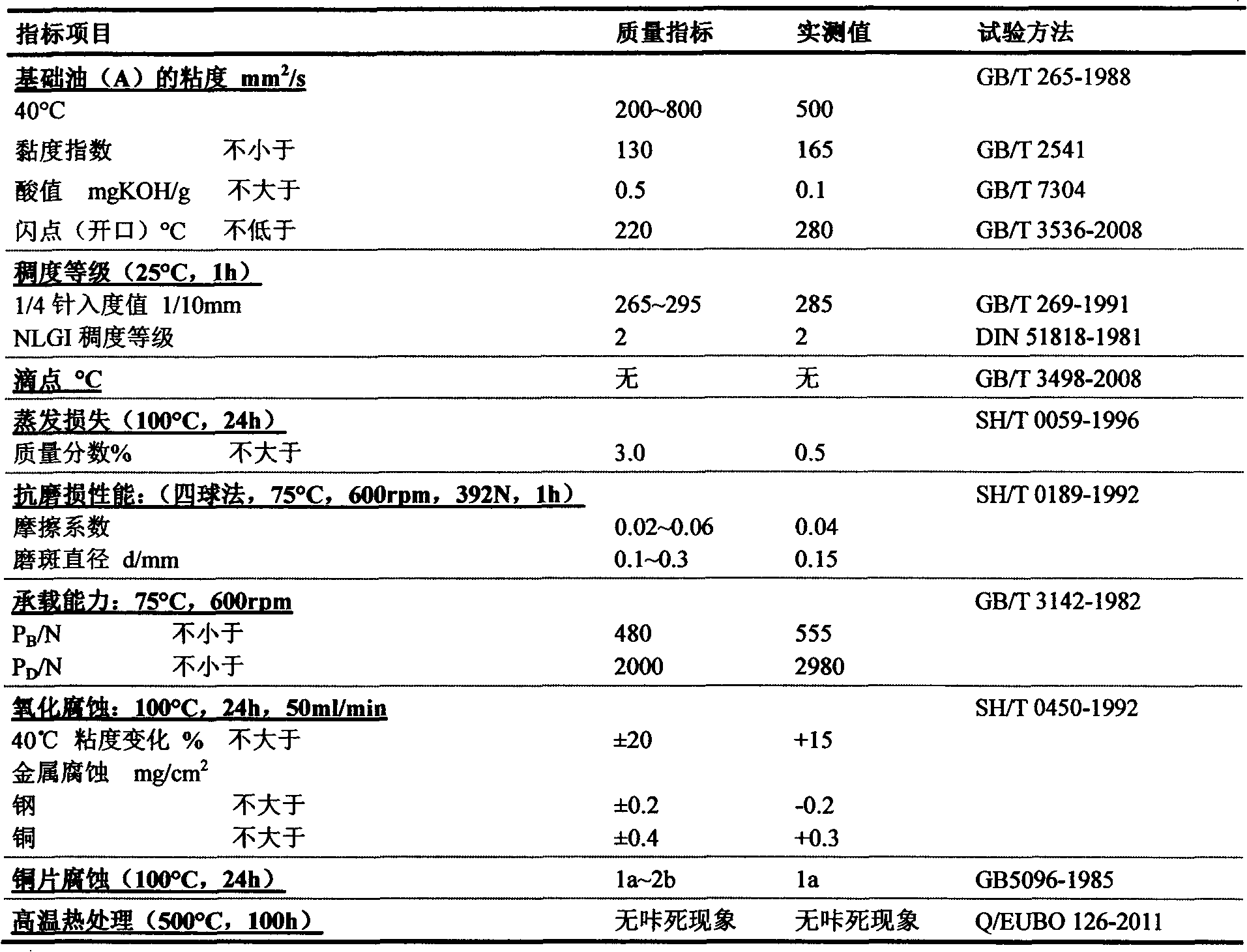

Valve element sealing lubricating agent composition

InactiveCN102433204ASimple production methodImprove high temperature resistanceLubricant compositionBase oilWear resistance

The invention relates to the field of lubricating materials, in particular to a valve core sealing lubricating agent composition, which comprises: (A) 100.0 weight parts of base oil; (B) 5.0 to 35.0 weight parts of thickening agent; (C) 3.0 to 55.0 weight parts of solid lubricating agent; (D) 0.1 to 3.0 weight parts of surfactant; (E) 0.1 to 2.5 weight parts of antioxygen; (F) 0.1 to 4.0 weight parts of extreme pressure antiwear agent; (G) 0.1 to 2.0 weight parts of metal passivating agent; and (H) 0.1 to 1.5 weight parts of antimicrobial agent. The finished lubricating agent prepared according to the mixing ratio has high high-temperature resistance, high antiwear and wear-resistance performance and high dead-locking-preventing performance. Meanwhile, the production and preparation method of the lubricating agent are simple, convenient and easy to implement and is suitable for large-scale batch production.

Owner:SHENZHEN EUBO NEW MATERIAL TECH

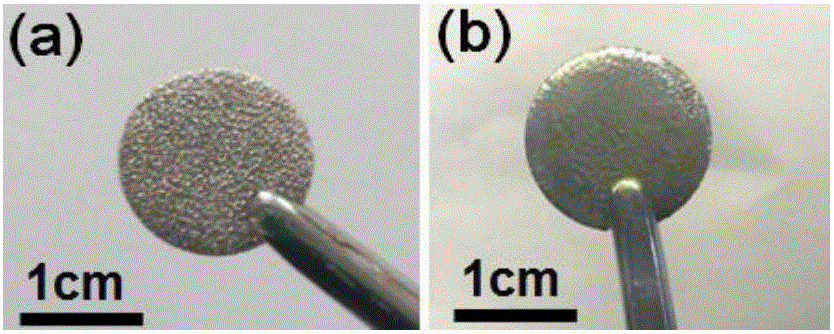

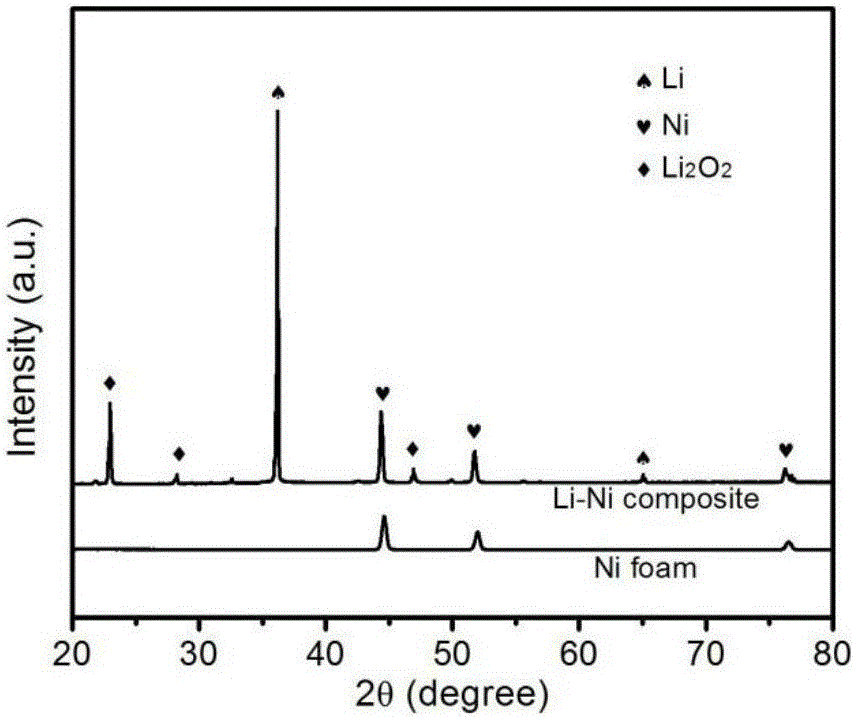

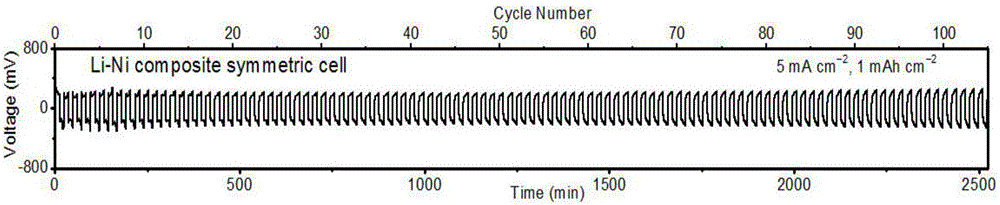

Preparation method of complex lithium negative pole of solid state battery

The present invention discloses a preparation method of a complex lithium negative pole of a solid state battery, and belongs to the technical field of electrochemistry and new energy resources. The preparation method mainly comprises the steps: depositing lithium metal on three-dimensional carbon material or foam porous material gaps by using a heat infusing melting method or an electrodeposition method to obtain the complex lithium negative pole, wherein the application of a three-dimensional framework plays two roles, namely, providing adequate space for pre-storing lithium in the preparation process; providing a carrier for receiving metal lithium in a battery circulation process. The complex lithium negative pole can be widely applied in lithium metal batteries such as lithium ion batteries, lithium-air batteries, lithium-sulfur batteries, and solid state batteries. In the assembled symmetric solid state battery, under large electric current density of 5mA cm-2, a stable voltage decay (200mV) can still be kept after circulation for 100 times, in the battery circulation, the growth of lithium dendrites can be inhibited and the pole volume change can be stabilized, and the advantages of being good in circulation stability, and long service life can be realized; in the present invention, a carrier material is rich, and low in price; the process is controlled, the cost is low, and the batch production can be realized.

Owner:UNIV OF SCI & TECH BEIJING

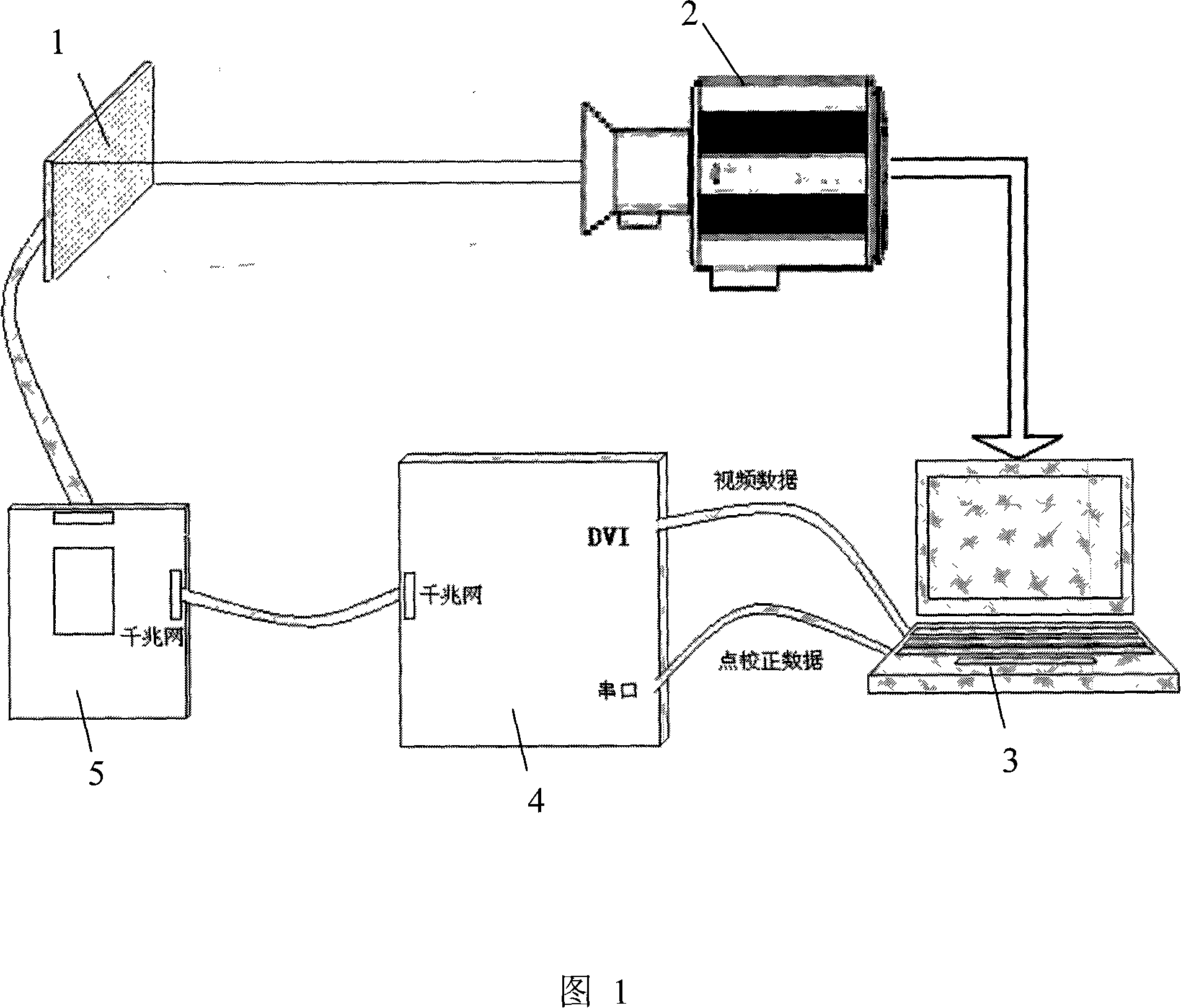

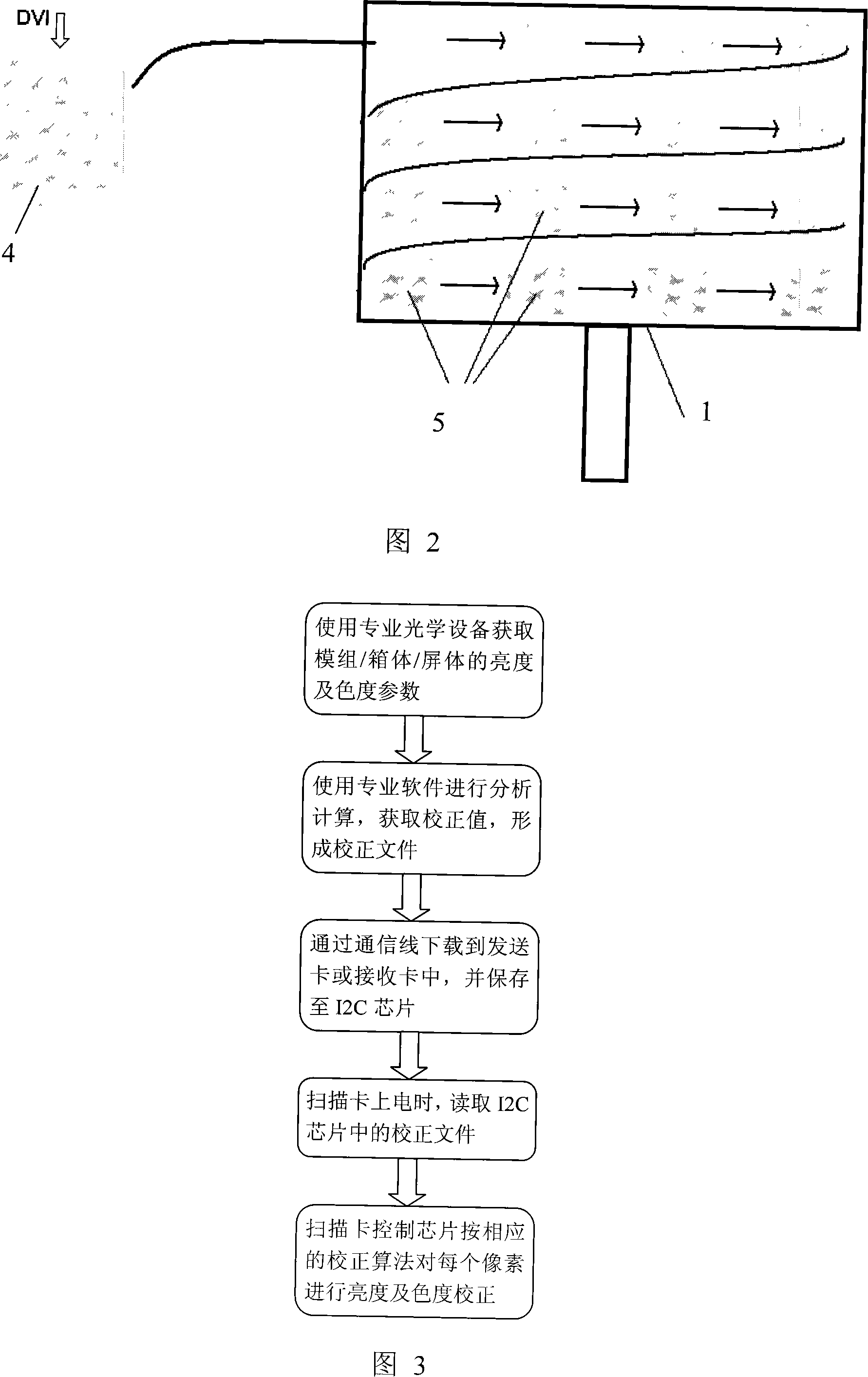

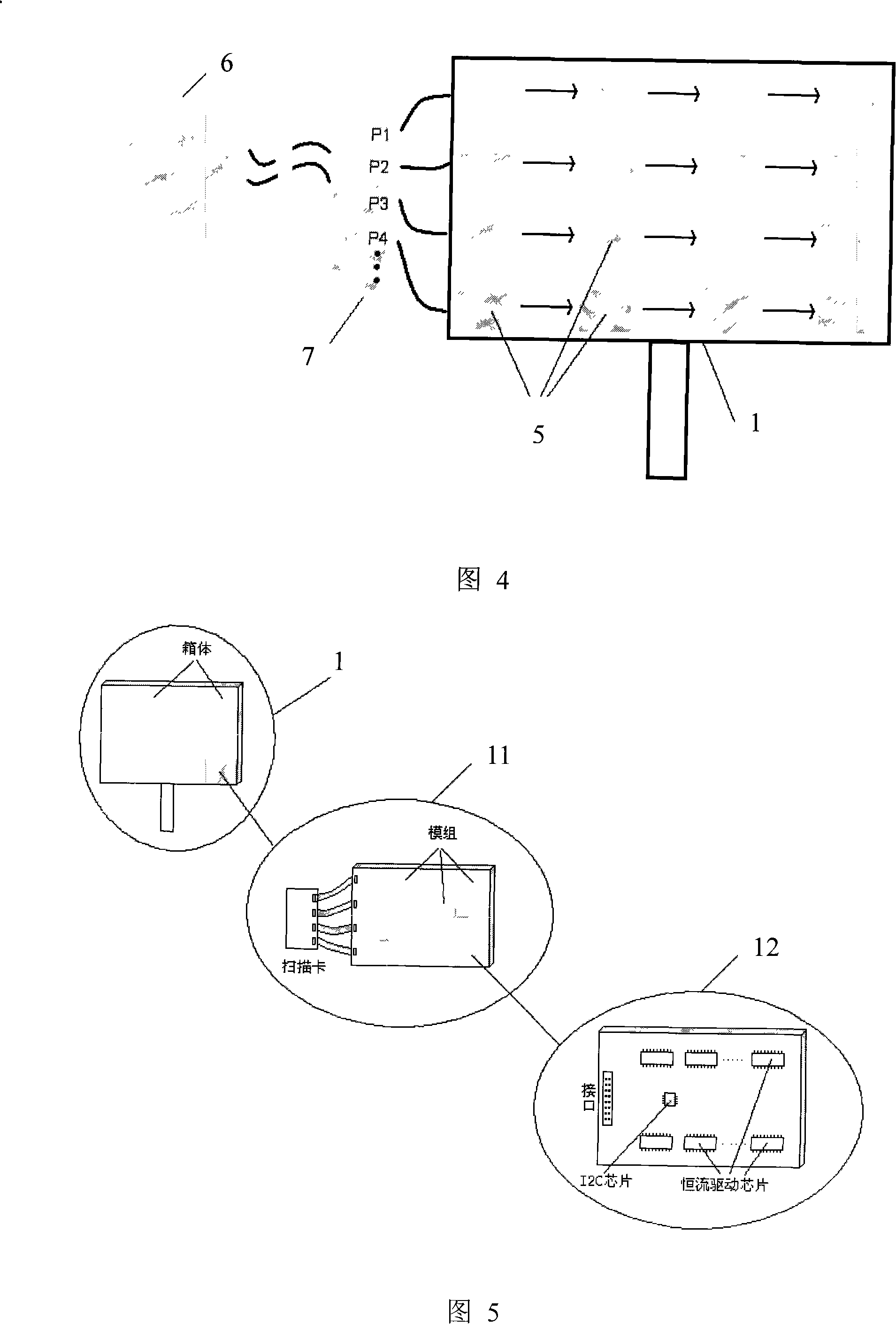

A LED display screen display calibration system and calibration method

ActiveCN101217022AReduce bandwidth requirementsSolve complexityCathode-ray tube indicatorsBandwidth requirementDistributor

The invention relates to a display calibration system of a LED display screen and a calibration method thereof. The system comprises a video capture controller, a data distributor, scanning control cards and LED display modules; the memory chips of the display modules save simple-point calibration data of the display modules, which is uniformly arrayed in a LED display box in the light of a row or column cascade; a plurality of LED display boxes are uniformly arrayed in the light of the row or column cascade to constitute the LED display screen; the head end scanning control cards of each row cascade or each column cascade of the LED display screen are respectively connected with a GigE communication interface circuit of the data distributor, and the data distributor is connected with the GigE communication interface circuit of the video capture controller via the GigE communication interface circuit thereof; based on the systems, the method takes the LED display modules for saving the simple-point calibration data as units, thus realizing the calibration of display screen pixel. The invention reduces the bandwidth requirements on the connection among the scanning control cards, realizes the function of plug and play of the display modules, is convenient for batch production and simple in maintenance operation, and improves the synchronicity of calibration of the display screen.

Owner:SHENZHEN AOTO ELECTRONICS

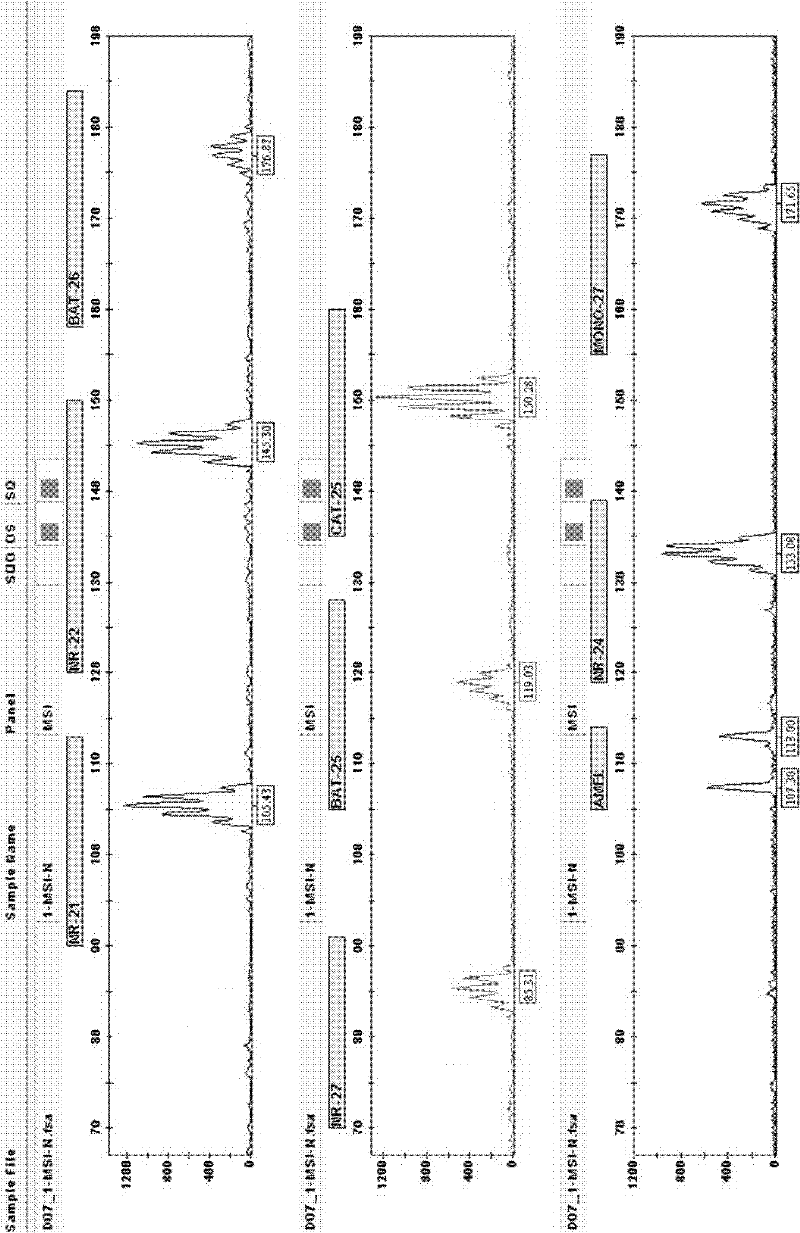

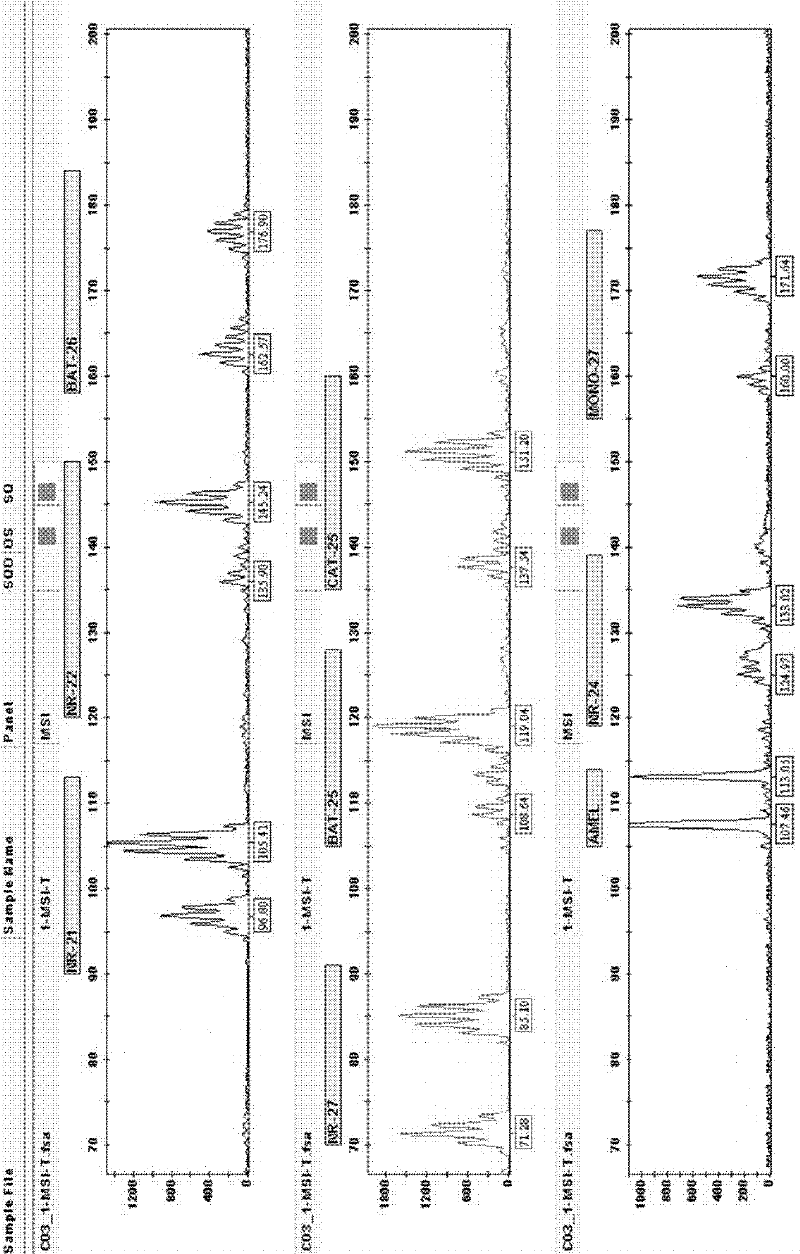

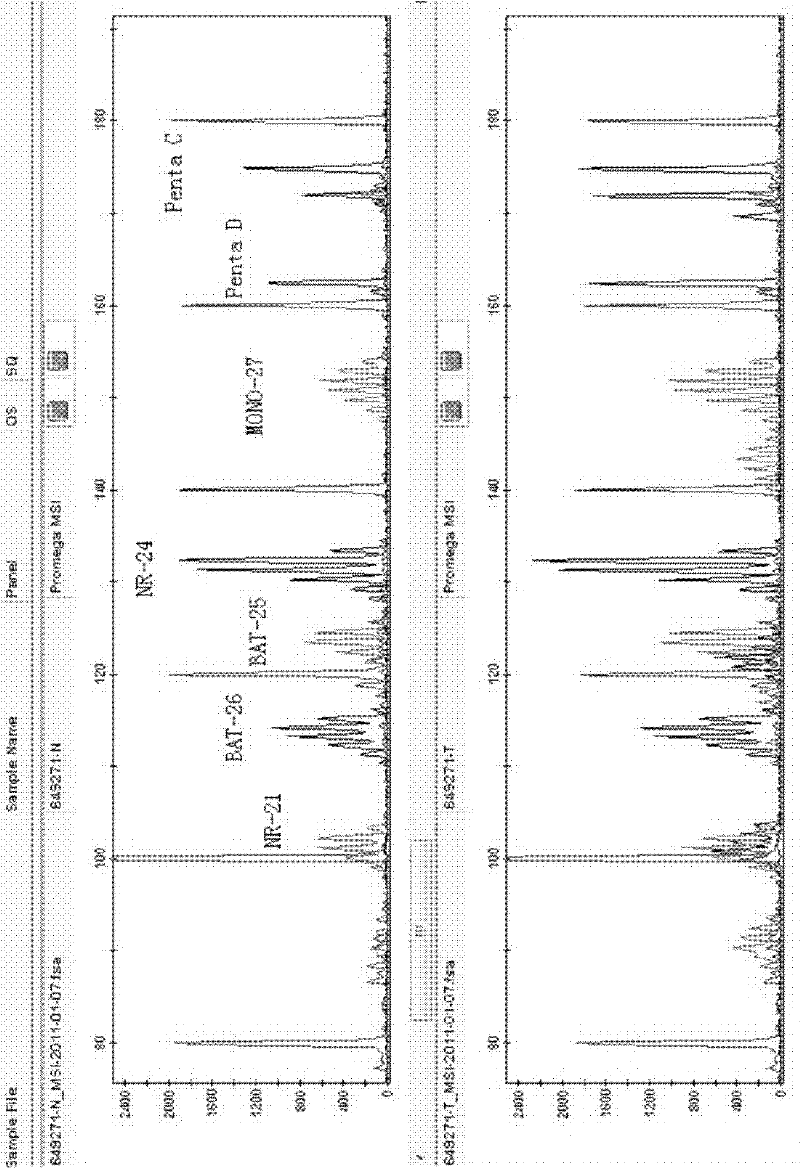

Tumor cell microsatellite instable state complex amplification system and detection kit

ActiveCN102230004AHigh sensitivityImprove accuracyMicrobiological testing/measurementTrue positive rateWilms' tumor

The invention relates to a tumor cell microsatellite instable state complex amplification system and a detection kit and belongs to the field of biotechnology. In the invention, 8 quasi-monomorphic nucleotide repeated loci with high sensitivity and specificity (including NR-21, NR-22, NR-24, NR-27, BAT-25, BAT-26, MONO-27 and CAT-25) are selected to detect microsatellite instability (MSI). Meanwhile, an amelo (AMEL) is added and a 9-loci multiplex amplification system is constructed, so the result is more accurate. The addition of the gender determining locus can prevent an experiment operator from mixing up samples and delivering wrong results to a certain extent. In the invention, the operation is simple, and large-scale promotion is convenient. With the success of the development of the kit, the method can be used for batch production; the use conditions of the method can be modularized; automatic equipment is applied in the whole process, so the whole process is independent of theoperational experiment of people; and the total detection time is about 6 hours.

Owner:BEIJING MICROREAD GENE TECH

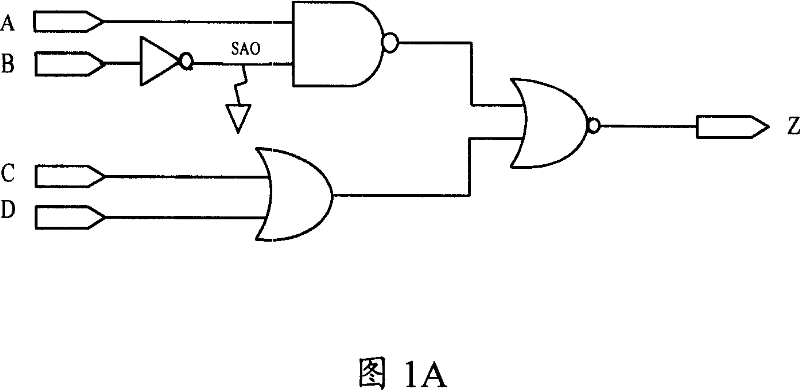

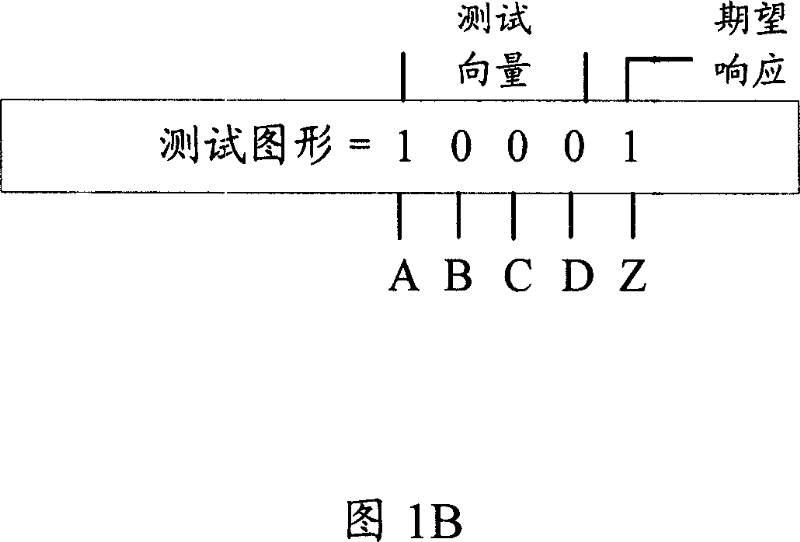

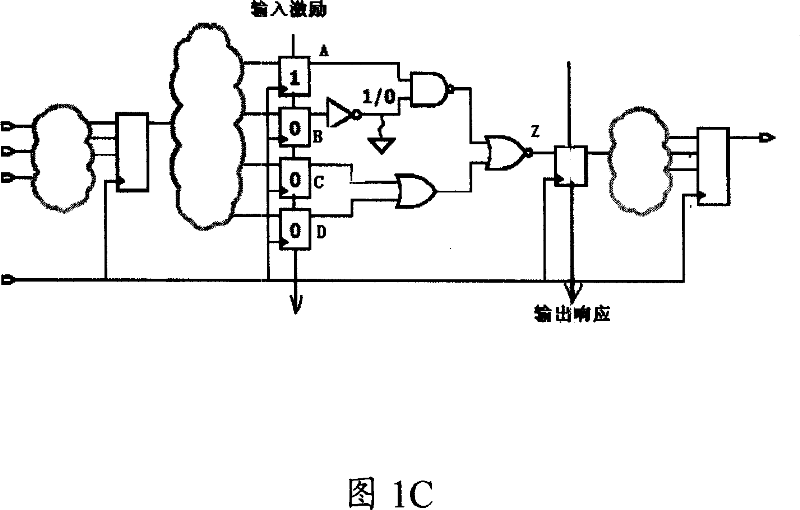

Method and device for testing chip

InactiveCN101038325AEasy to debugReduce testing costsDigital circuit testingTester deviceTest response

The invention discloses a device for testing the chip, including the mutually stand-alone server, simulator, control circuit board and running circuit board, in which: the server is used for creating the test program according to the test tasks, and output to the simulator; the simulator is connected with the server for simulation processing of the test program, and creating the simulation document with test data and sending to the control circuit board; the control circuit board is connected with the simulator for reading the relevant test vectors from the simulation document, and sending this test vector to the running circuit board, and decide whether the relevant chip is in good conditions or not according to the test response feedback from the running circuit board; the running circuit board is connected with the control circuit board for testing the relevant chip according to the test vector from the control circuit board, and sending the test response to the control circuit board. Thus, during the batch production testing of chip, the automatic tester with expensive rent may be not rented, thereby greatly reduce the test cost. The invention still discloses a test method for chip.

Owner:VIMICRO CORP

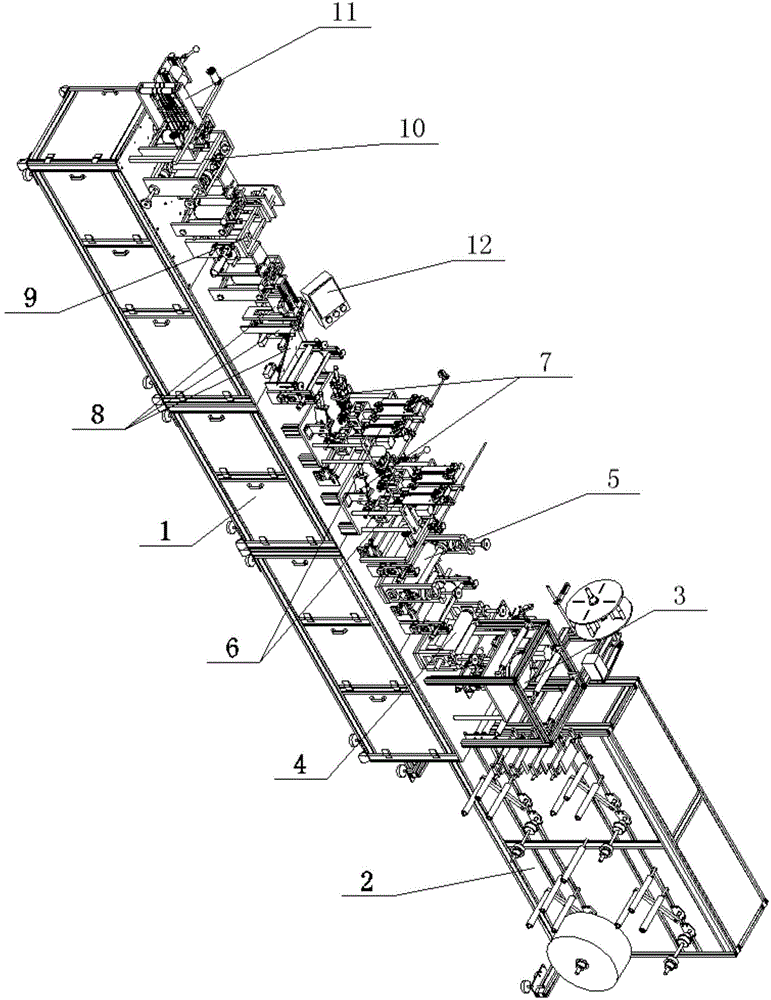

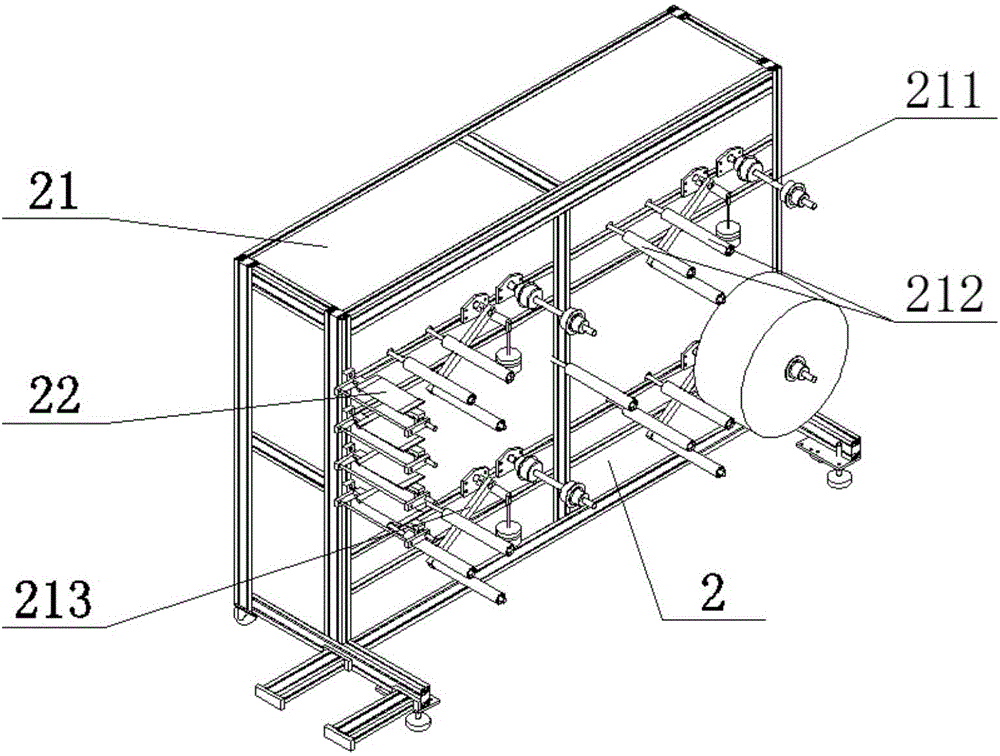

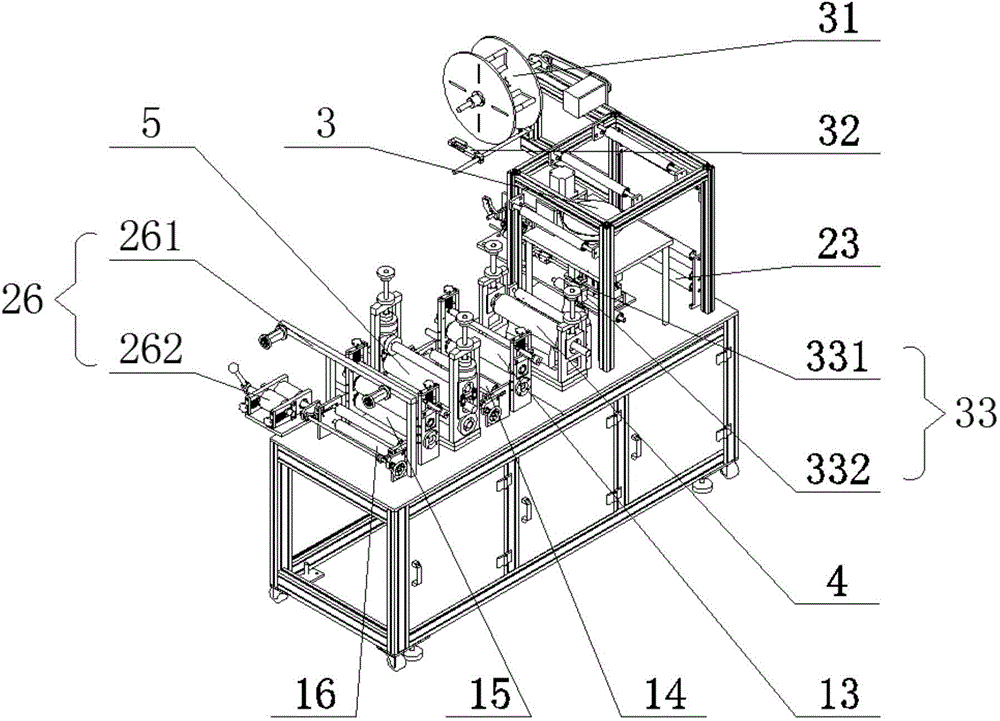

Full-automatic machine for producing foldable masks

ActiveCN104872866AImprove aestheticsRealize automated productionProtective garmentProduction lineRespirator

The invention relates to the technical field of mask machining equipment, in particular to a full-automatic machine for producing foldable masks. The full-automatic machine comprises a frame body. A mask body feeding device, a nose bridge part gripping and welding device, a roller welding device, a roller cutting device, an ear strap welding device, an ear strap cutting device, a folding device, a crease welding device, and a finished product cutting device, wherein the frame body is provided with a control device, and the control device is connected with the mask body feeding device, the nose bridge part gripping and welding device, the roller welding device, the roller cutting device, the ear strap welding device, the ear strap cutting device, the folding device, the crease welding device, and the finished product cutting device. Compared with the prior art, the full-automatic machine has the advantages that the full-automatic machine is a full-automatic production line for producing the foldable masks, batch production is achieved, manpower cost is saved, work efficiency is increased, and product quality is increased.

Owner:东莞快裕达自动化设备有限公司

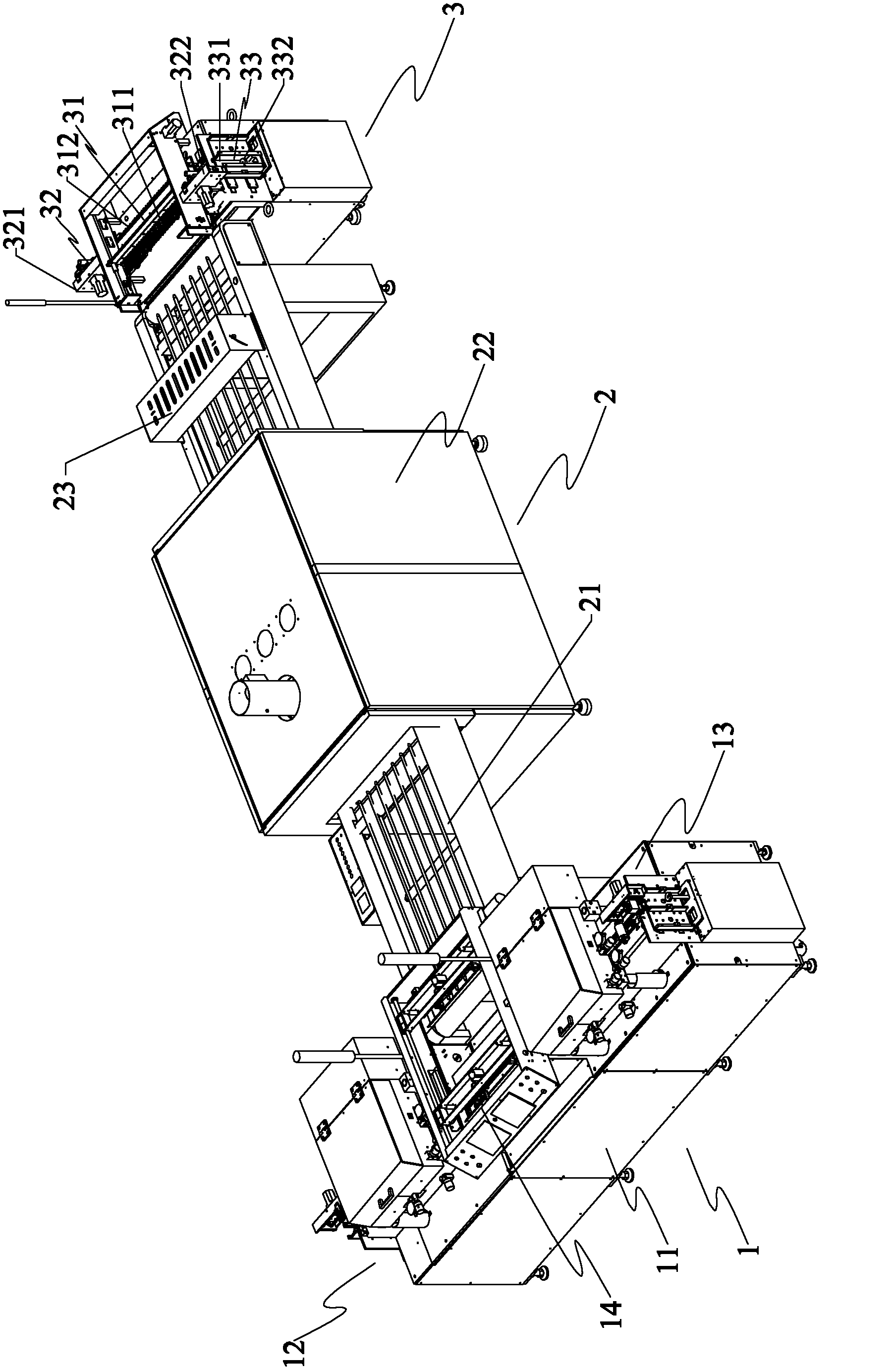

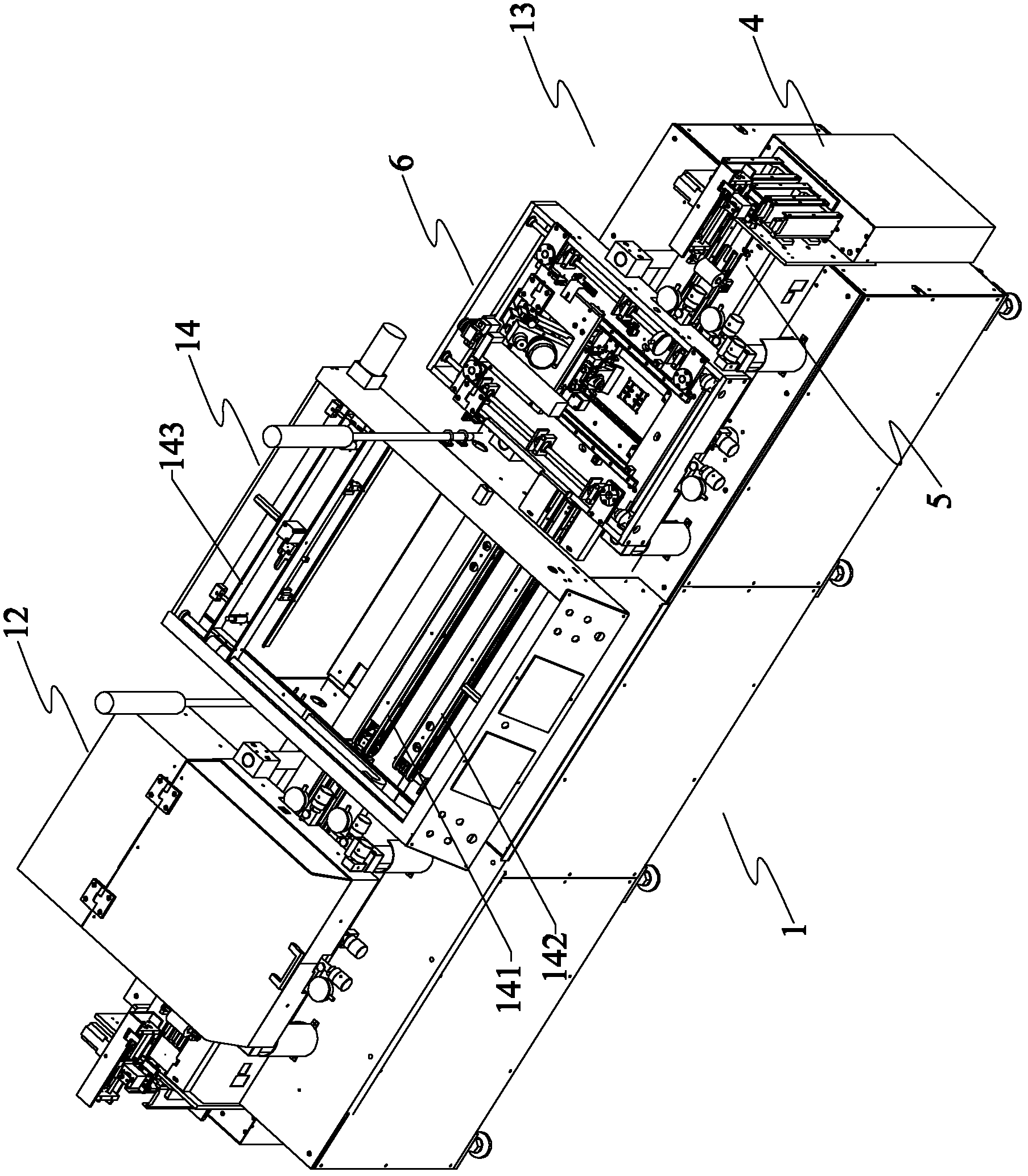

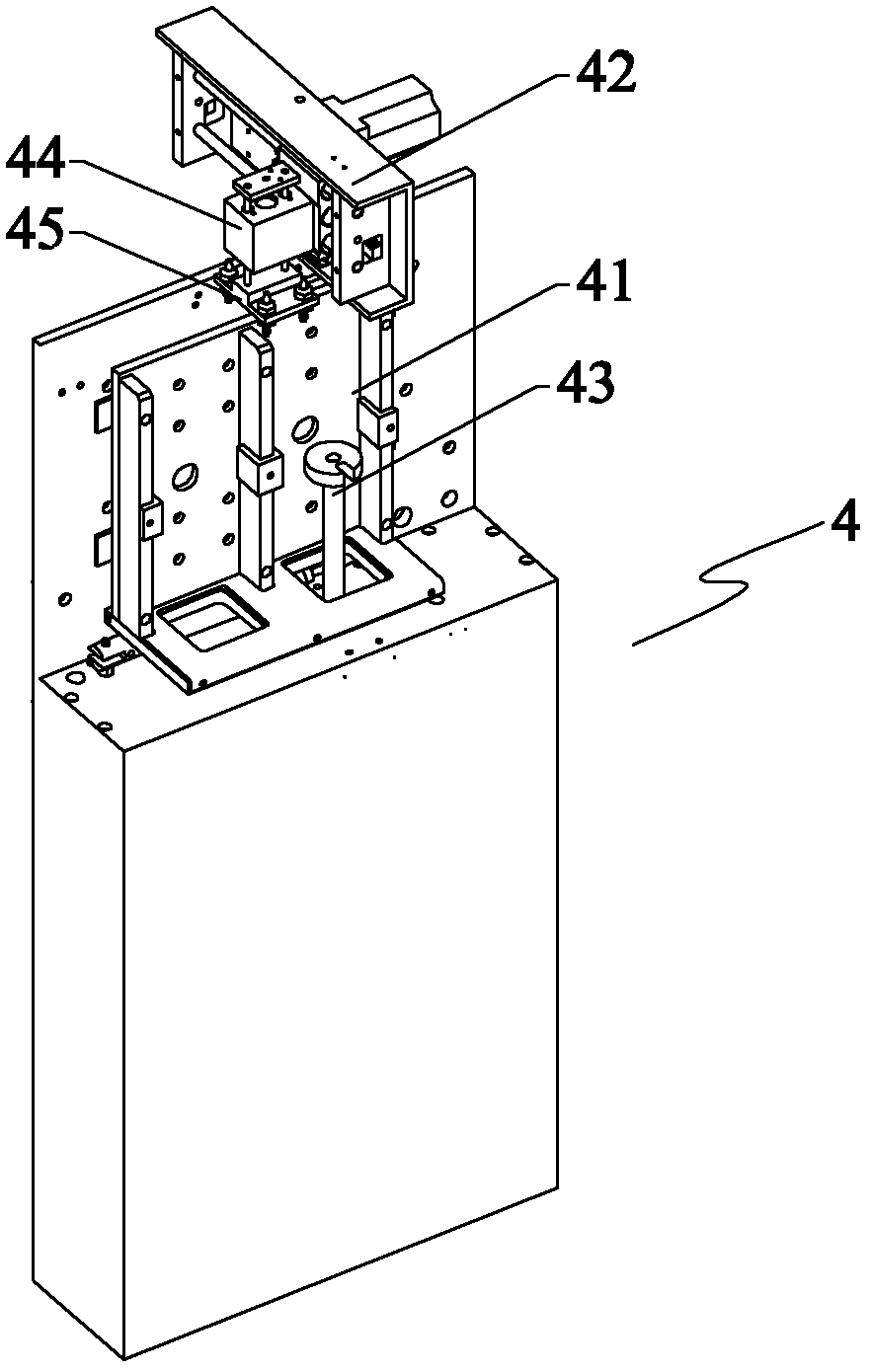

Full-automatic double-work-station screen printing machine

The invention discloses a full-automatic double-work-station screen printing machine, which comprises a printing system, a drying system and an electronic control system, wherein the printing system comprises a base, a left work station printing device, a right work station printing device and a leveling device, wherein the left work station printing device and the right work station printing device are mutually independent and mounted above the base; the leveling device is arranged between the left work station printing device and the right work station printing device; each work station printing device comprises a material loading mechanism, a substrate transmitting and positioning mechanism and a screen printing mechanism which move in a matched manner. Compared with the prior art, the full-automatic double-work-station screen printing machine has the beneficial effects that the full-automatic double-work-station screen printing machine is provided with the left and the right double-work-station printing systems, each work station printing system can independently complete the printing operation, the whole process of material feeding, transmitting, positioning, printing, leveling, drying and collection is automatically controlled at the same time, the efficiency is high, the cost is low, the maintenance is convenient, and the requirements of batch production and the production requirements of high-end products can be effectively met.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

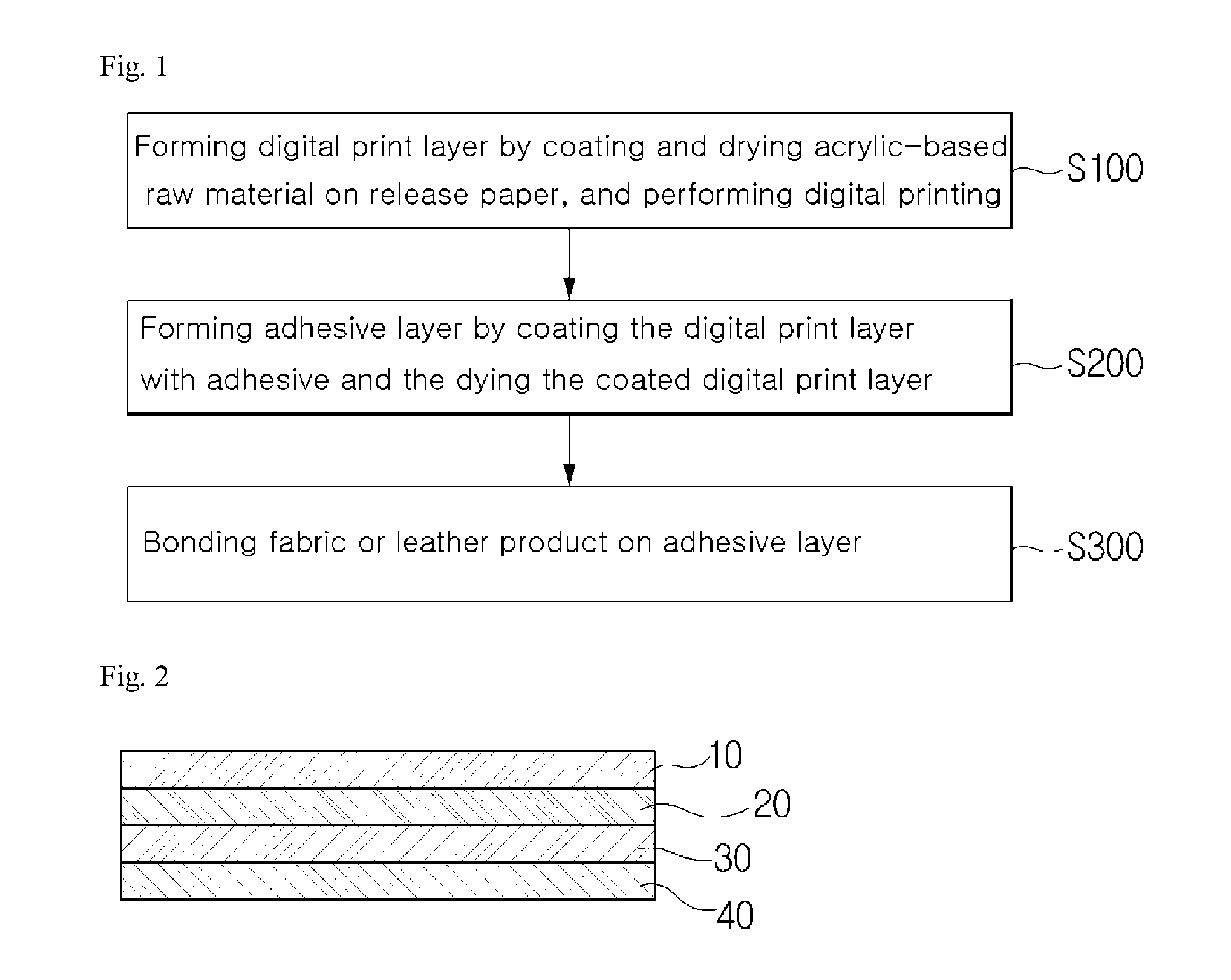

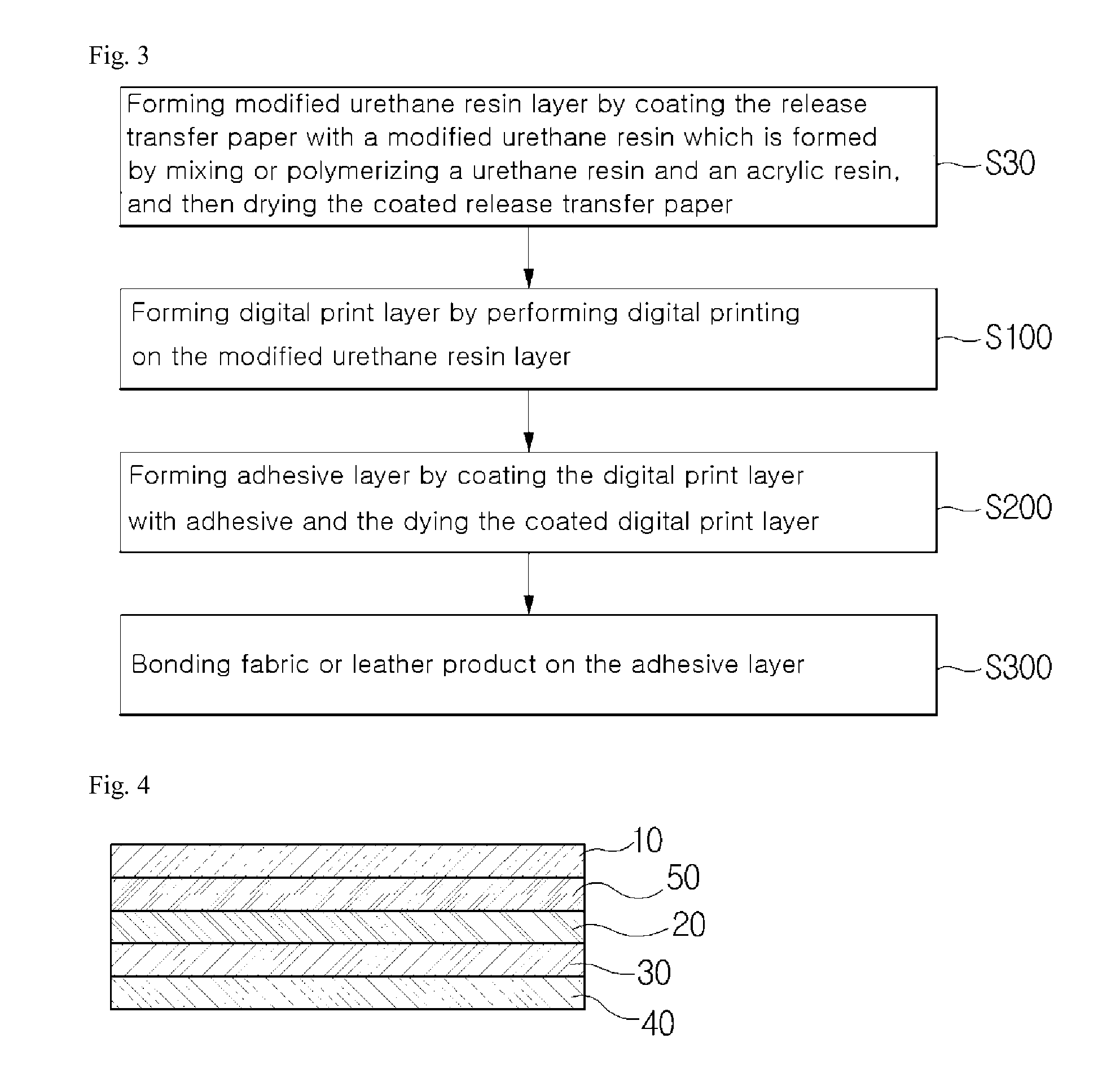

Method for printing fabric or leather product, and printed matter printed by using the same

ActiveUS20160067984A1Simple processReduce manufacturing costDecorative surface effectsDuplicating/marking methodsAdhesiveComputer printing

The present invention relates to a method for printing fabric or leather product, and printed matter printed by using the same, the method comprising the steps of: a) forming a digital print layer by performing digital printing on a release transfer paper by using an inkjet printer; b) forming adhesive layer by coating the digital print layer with an adhesive, and drying for a predetermined time; and c) bonding fabric or leather product to the adhesive layer. Thus, the present invention can precisely print fabric or leather product with high resolution and can enable customized printing so as to allow small quantity batch production.

Owner:CHUNG DOO HO

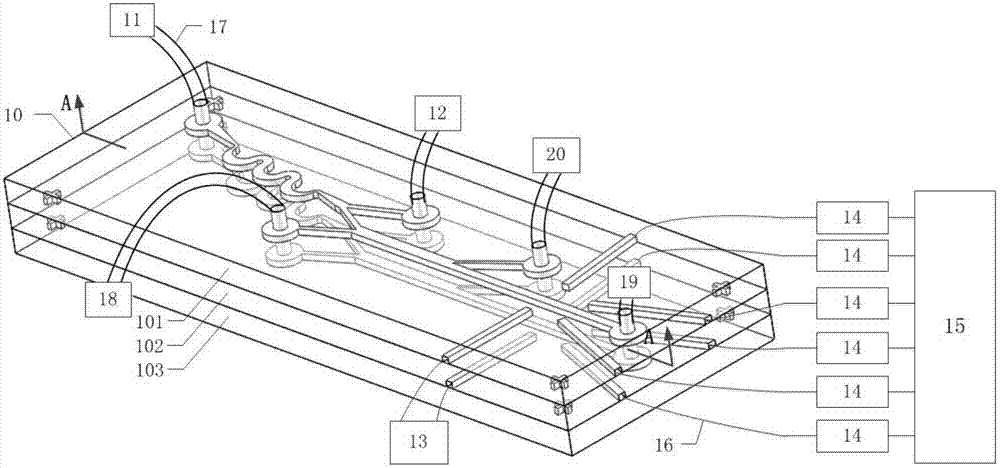

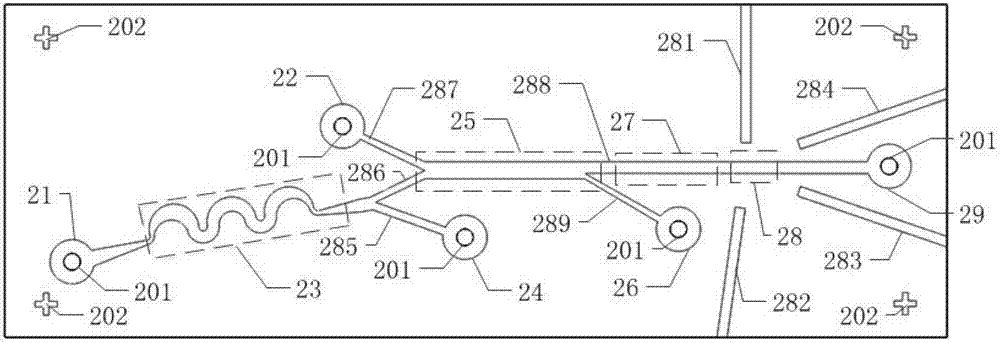

Integrated chip system for high-throughput sorting and counting detection of biological particles, and application

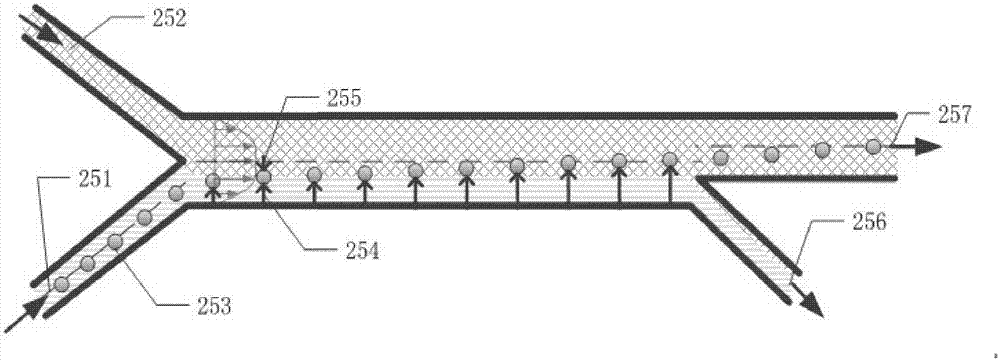

ActiveCN103191791AMeet the damageNo damageMaterial analysis by optical meansLaboratory glasswaresInertial effectLiquid Change

The invention discloses an integrated chip system for high-throughput sorting and counting detection of biological particles, and an application. The chip system comprises a main microfluidic chip, a micropipe, a sample liquid micropump, an exchange liquid micropump, a first waste liquid collecting device, a second waste liquid collecting device, a third waste liquid collecting device, laser emitters, photoelectric conversion devices, optical fibers and a computer, wherein the main microfluidic chip comprises an asymmetric curved flow path, a first branch channel, a second branch channel, a third branch channel, a main flow path, a branch flow path, aligning marks, etc. The system utilizes the asymmetric curved flow path to realize pre-focusing and sorting for the particles, utilizes a liquid changing flow channel to realize change of a carrier liquid of to-be-tested particles and particle cleaning, and utilizes a viscoelastic effect and an inertial effect of a viscoelastic fluid to realize focus of single equilibrium position of section centers of the particles. The system does not need a sheath liquid, complex pre-cleaning of the particles, and optical alignment, has advantages of high speed, high precision, integration, miniaturization, automation, low cost, simple production process, easy batch production, etc.

Owner:SOUTHEAST UNIV

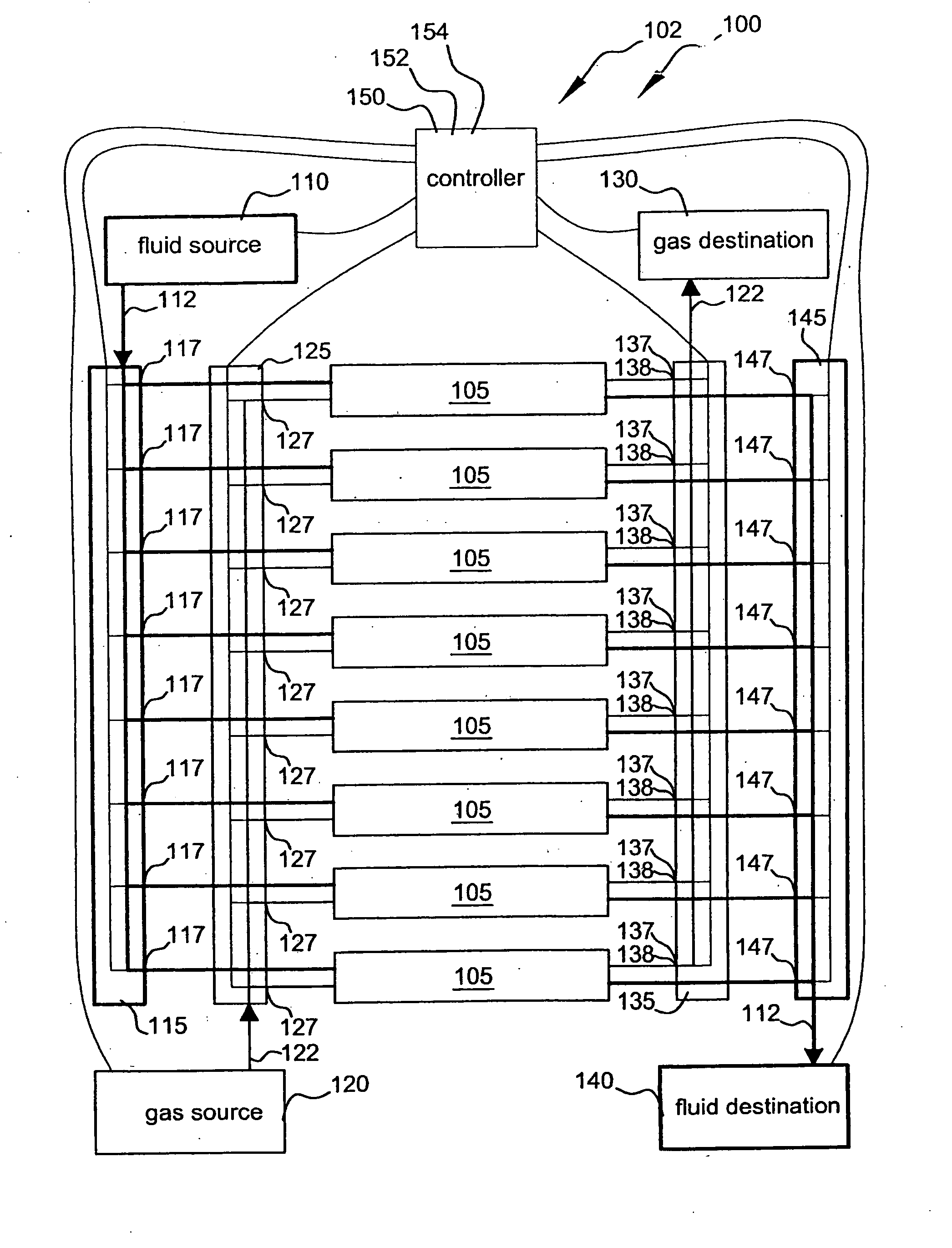

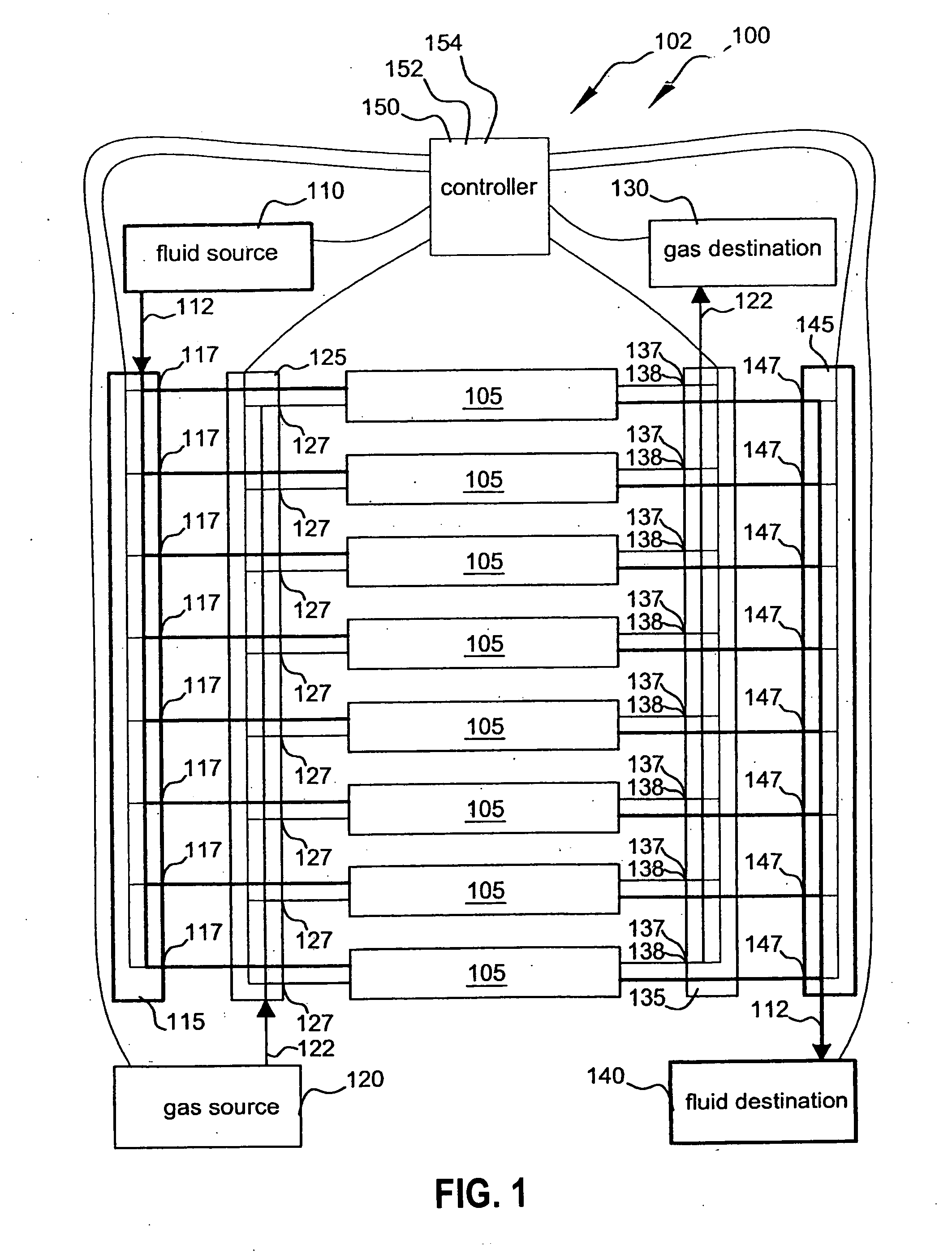

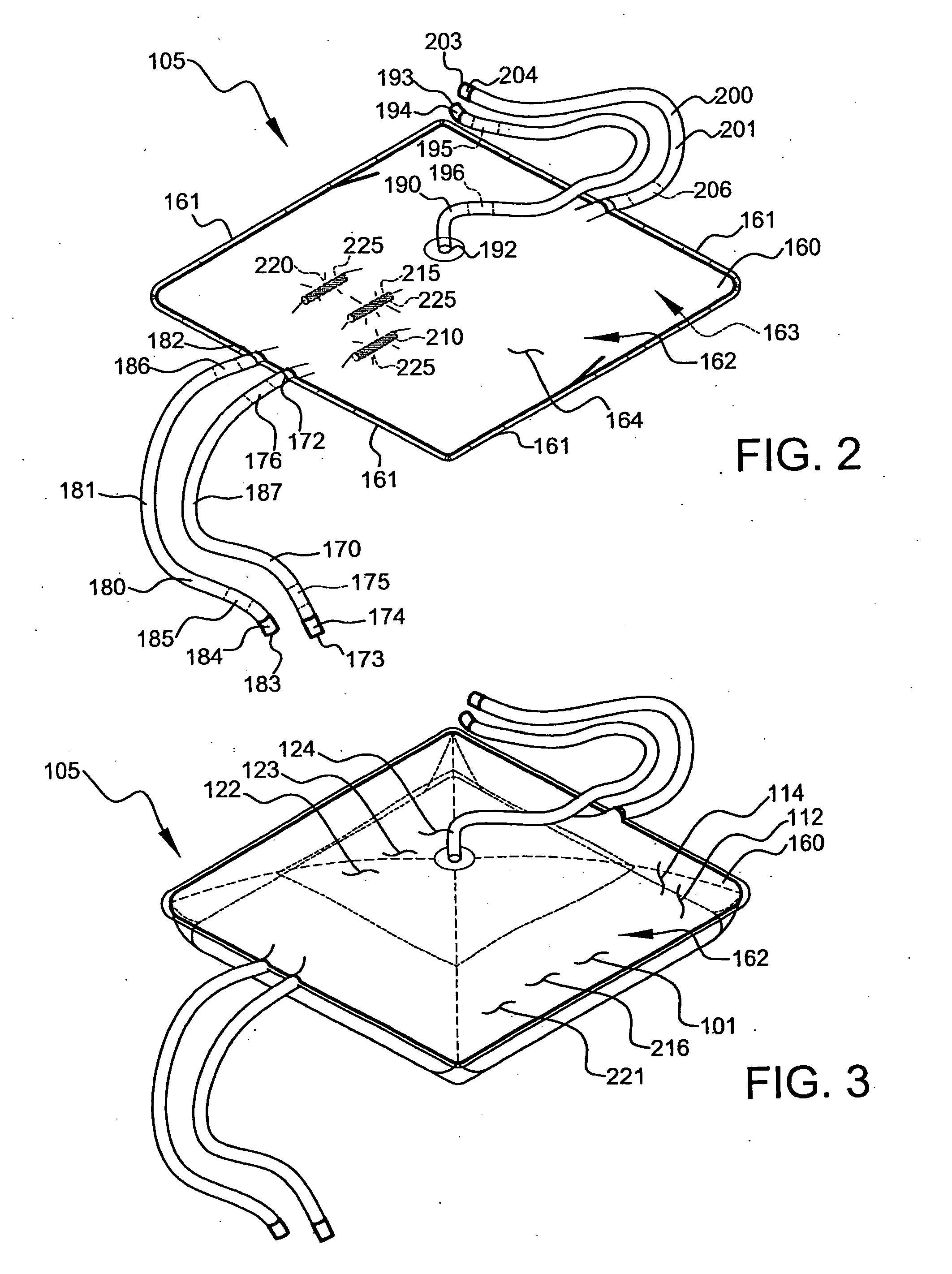

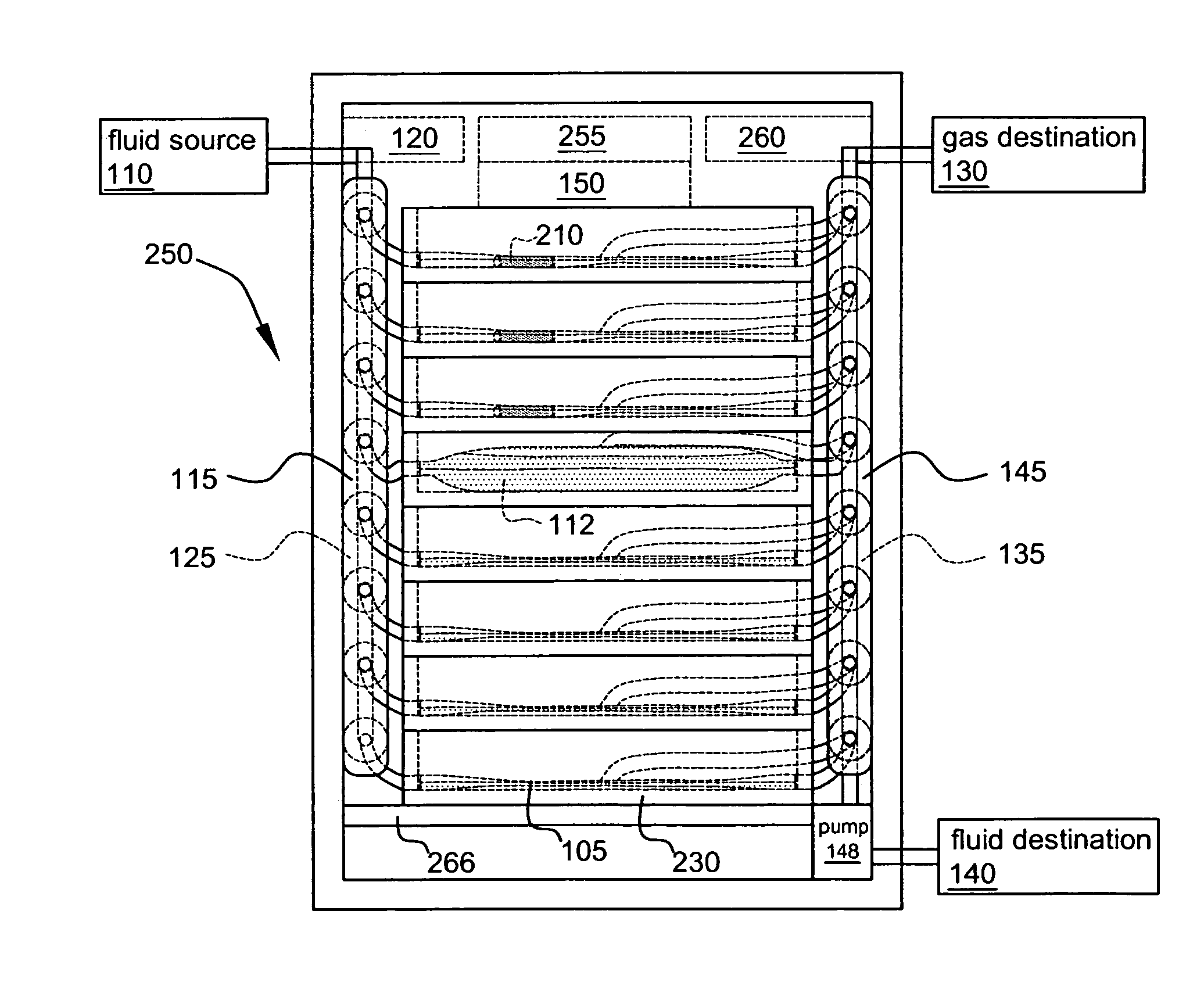

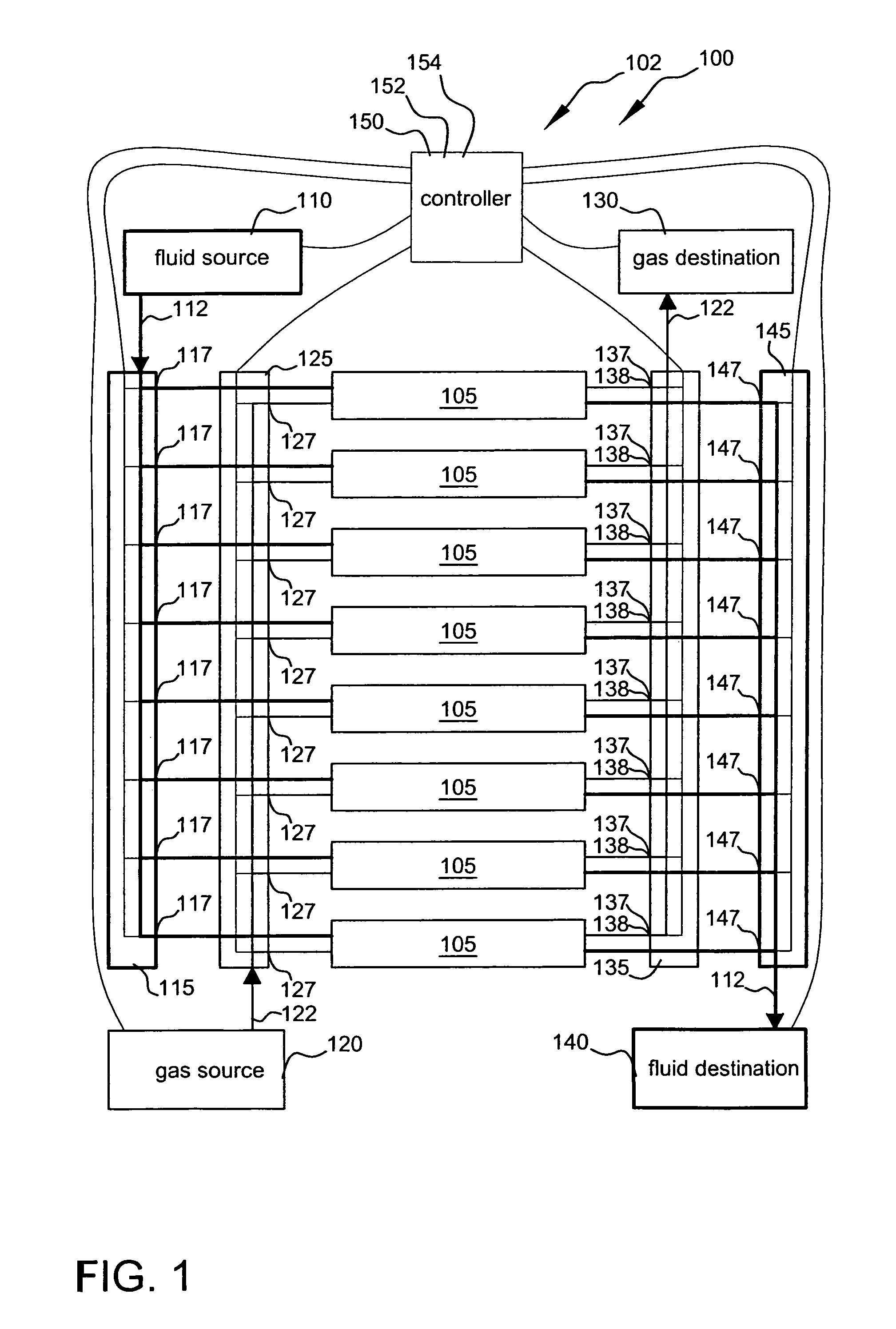

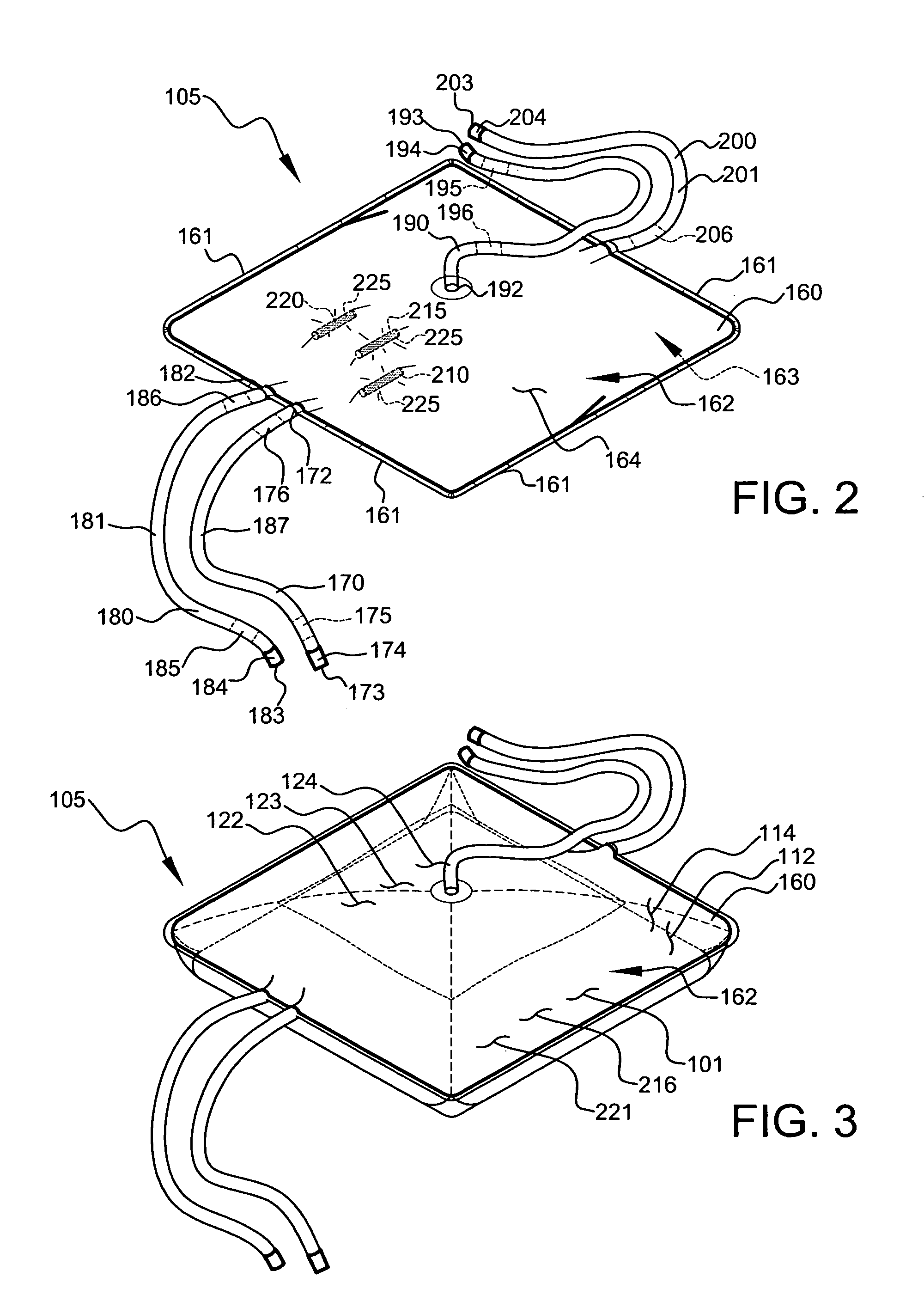

Method and system for bioreaction

InactiveUS20100316446A1Function increaseBioreactor/fermenter combinationsBiological substance pretreatmentsBiologyDisposable bioreactors

Novel bioreactor systems, adapted to provide continuous batch incubation of microbes, especially bacteria, are provided. Bioreactor bags are preloaded with inert microbes prior to being shipped to the user. The inert microbes may be substantially dry or in other inert forms, and are stored in soluble containers within the bioreactor bags. Multiple sterile, preloaded, disposable bioreactor bags are used in a self-contained housing. The bags are automatically incubated in the housing and dispensed, preferably into an irrigation system. The system provides serial batch production of useful microbes for a week or more, without further supervision or intervention. Methods of manufacture, methods of use, methods of sales, and methods of farming are also provided.

Owner:RUNYON LARRY

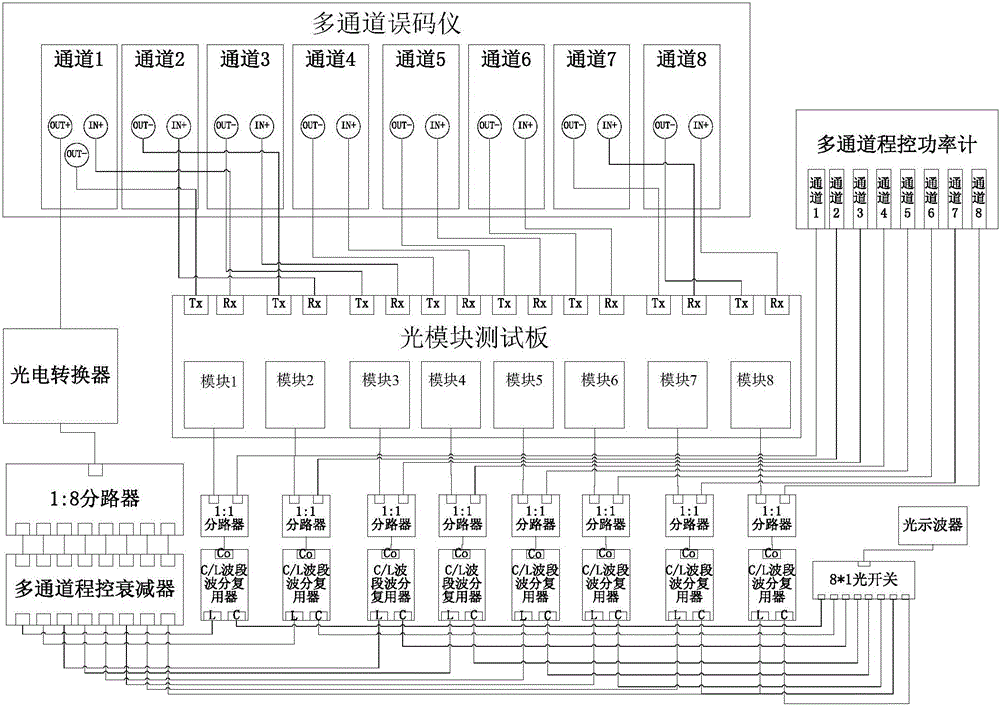

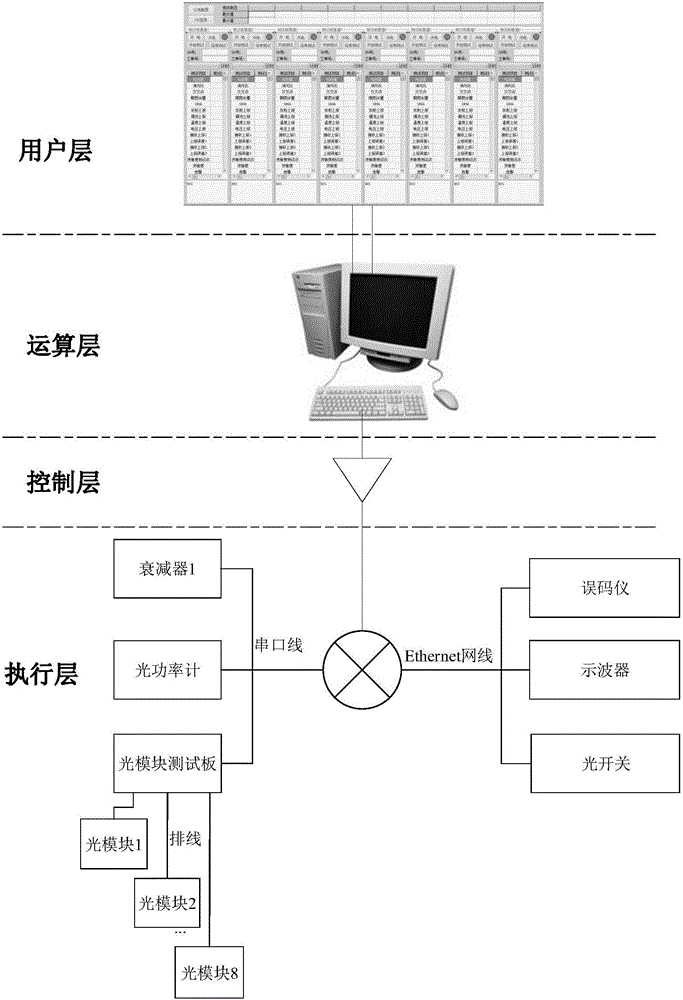

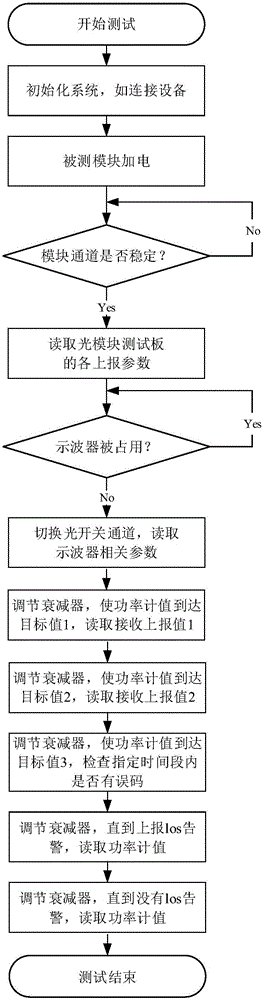

Active optical module multi-channel automatic test system and method

ActiveCN105049113AIncrease profitIncrease productivityTransmission monitoring/testing/fault-measurement systemsOptical power meterTime-sharing

The invention provides an active optical module multi-channel automatic test system and a method. optimal signals emitted by a tested optical module are monitored, and indexes of the incident light power, emission current, bias current, temperature, voltage, extinction ratio, eye diagram allowance, crossing point, OMA (optical modulation amplitude) etc. are measured and calculated; if the above indexes are all in accordance with the standard, the sensitivity of the optical module is tested, the emission optical power of the tested module is enabled to reach the sensitivity of the test standard via the adjustment of an attenuator, and error code tests are conducted; and if there is no error code, indexes of alarm value and alarm recovery etc. of the optical module are tested. According to the test system, an error detector, an optical module test board, an optical power meter, and the attenuator employed by the test system are all multi-channel devices, an optical switch and an optical splitter are combined for time-sharing multiplexing of one oscilloscope, at least 8 modules can be simultaneously tested, the utilization rate of the oscilloscope and the test efficiency of the optical module are greatly optimized, the equipment cost and the manual cost are reduced, and automatic and batch production of the optical modules is realized.

Owner:GUANGXUN SCI & TECH WUHAN

Preparation method of C/C-SIC ceramic composite material

The invention discloses a preparation method of a C / C-SIC ceramic composite material, comprising the following steps: using a cheap low-density PAN-based flat carbon felt as a precursor, and preparing a protective layer on the surface of carbon fibers through chemical vapor deposition; preparing phenolic resin, acetone, ethanol and silicon carbide powder in proportion into a slurry, immersing the carbon felt with the protective layer in the slurry and vacuumizing, then pressing for impregnating; pressing the pre-impregnated carbon felt into shape, then carrying out solidification and carbonization; then putting the carbonized precursor in a furnace, carrying out high temperature siliconizing reaction and filling to obtain a compact base substrate, and then removing residual silicon from the surface to obtain the high-performance high-density C / C-SIC ceramic composite material having a density of 2.30-2.70 g / cm<3>. According to the invention, the preparation process is simple, the raw materials are cheap, the production time and procedures are greatly reduced. The invention can be suitable for batch production and is easy to industrialization.

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

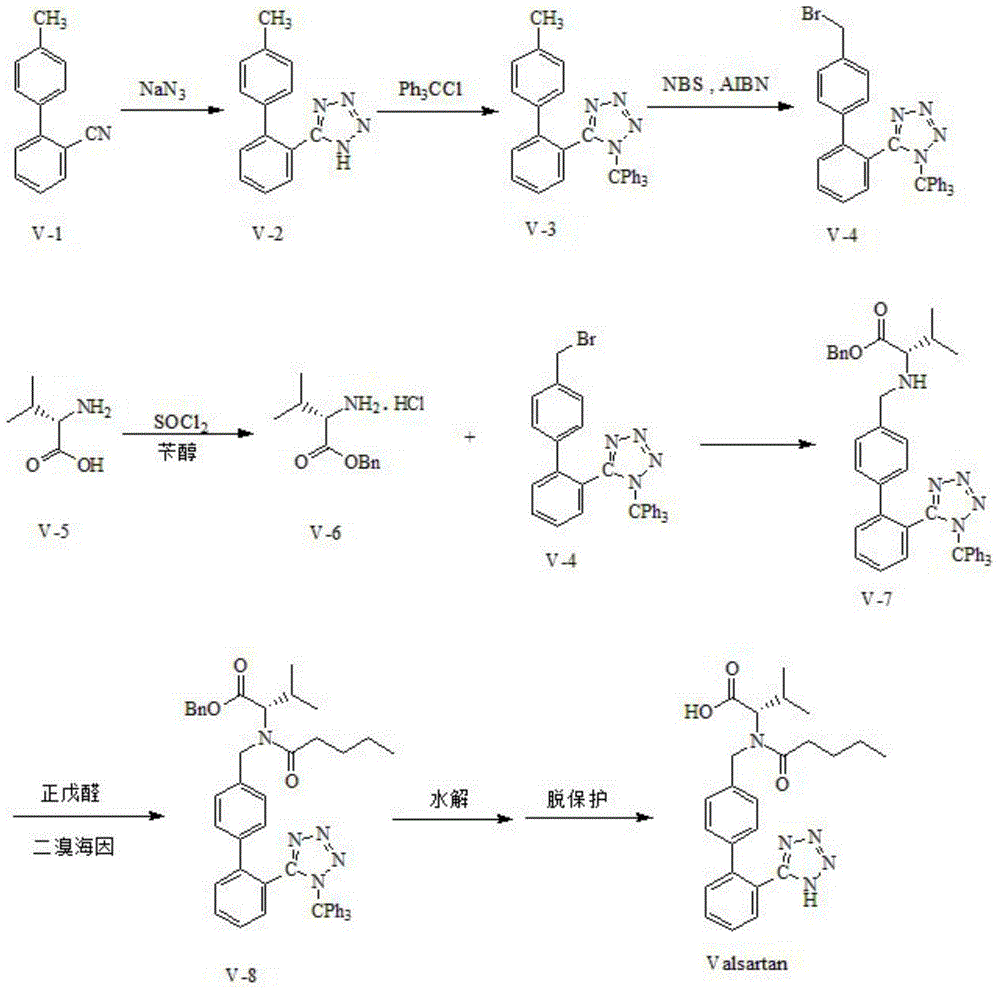

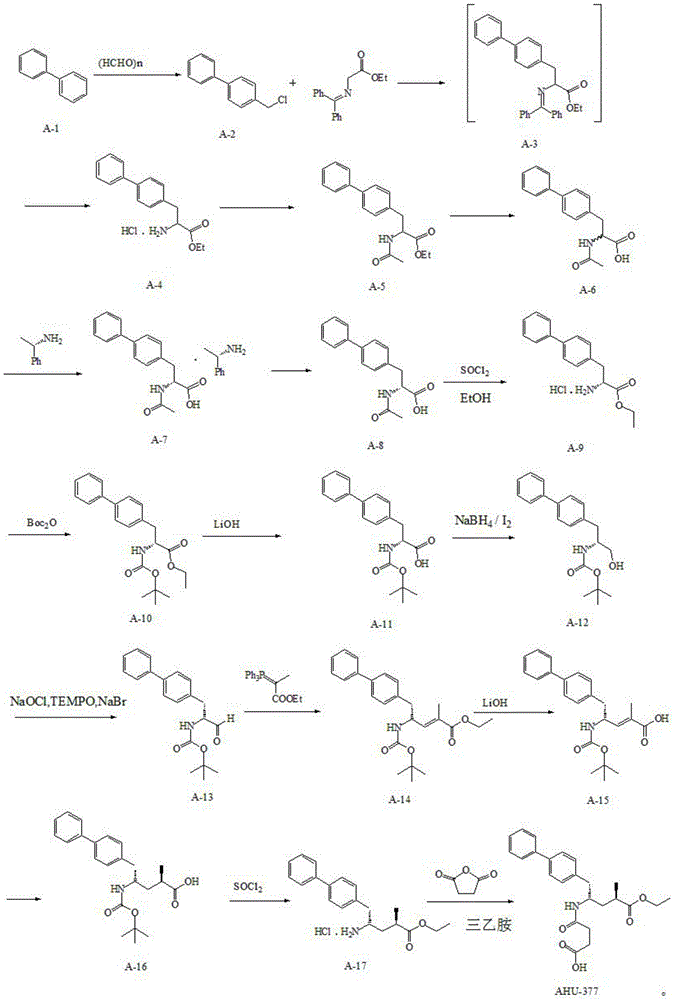

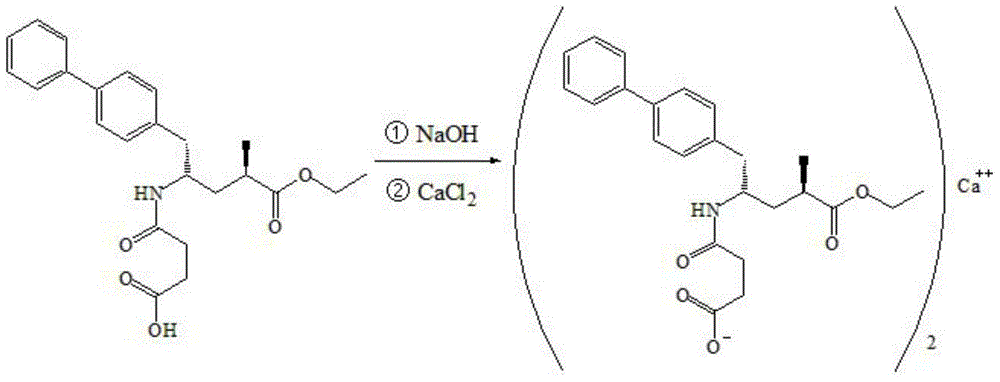

Preparation method for dual inhibitor LCZ696 of angiotensin II receptor and neprilysin

InactiveCN105168205AQuality improvementHigh purityOrganic compound preparationCarboxylic acid amides preparationValsartanHigh volume manufacturing

The invention specifically relates to a preparation method for a dual inhibitor LCZ696 of angiotensin II receptor and neprilysin, which belongs to the technical field of drug synthesis. The preparation method comprises the following steps: preparing valsartan and AHU-377 or AHU-377 calcium salt at first; and then mixing valsartan with AHU-377 or AHU-377 calcium salt under stirring so as to prepare LCZ696. The LCZ696 prepared in the invention has good quality and high purity; and the preparation method has the advantages of simplicity, low energy consumption, low cost and suitability for large batch production.

Owner:TAILITE MEDICINE HUBEI

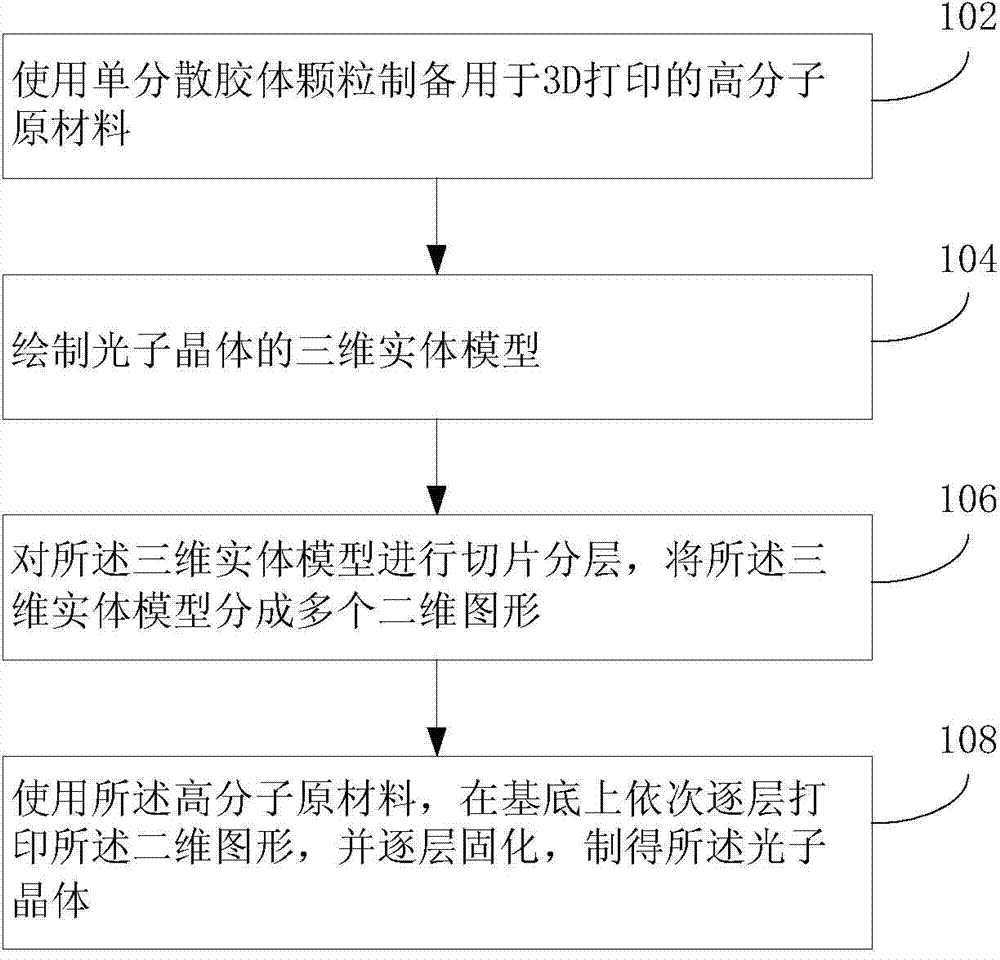

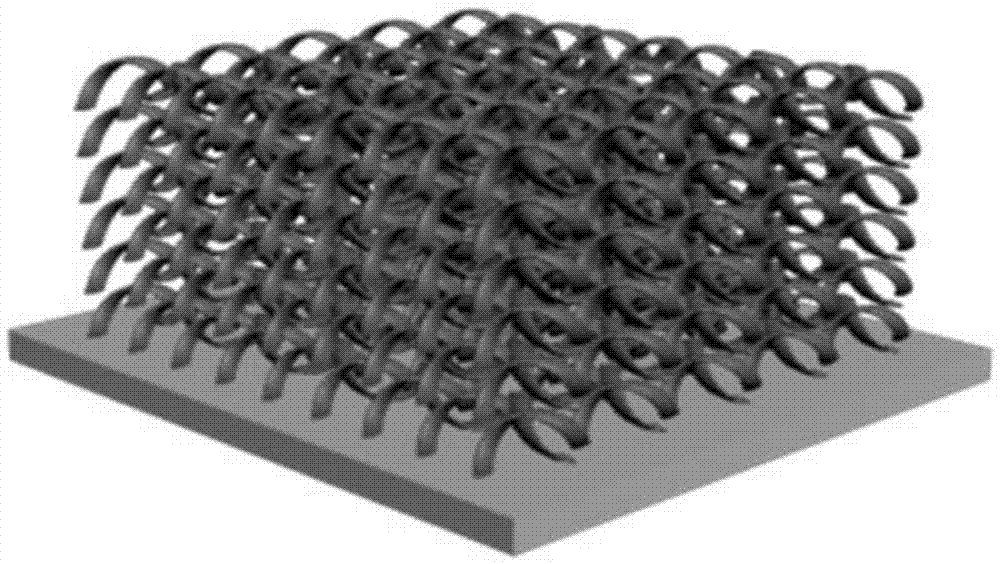

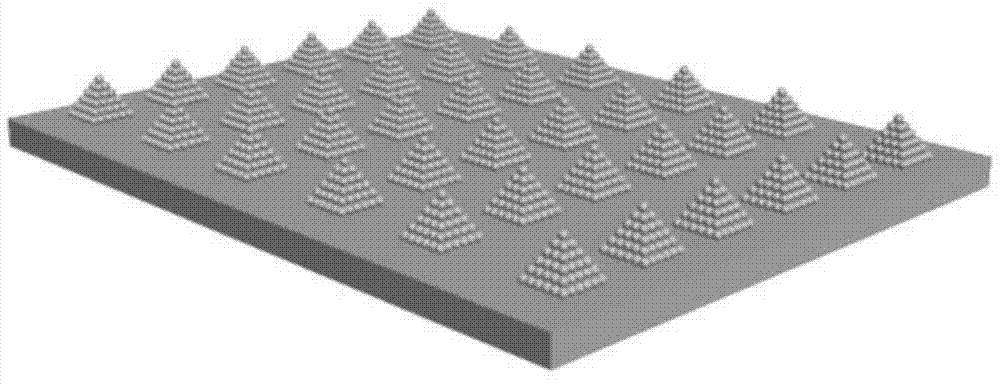

Method for preparing photonic crystals through 3D (Three-Dimensional) printing

ActiveCN103802315ADiversified structure and morphologyGeneralization of structural morphologyPhotonicsEngineering

The invention discloses a method for preparing photonic crystals through 3D (Three-Dimensional) printing. The method comprises the following steps of preparing macromolecule raw materials for 3D printing by using monodisperse colloidal particles, layering a three-dimensional solid model of photonic crystals into a plurality of two-dimensional patterns, printing the two-dimensional patterns layer by layer in sequence on a substrate and curing layer by layer to prepare three-dimensional photonic crystals which having high dielectric ratios or are suitable for network topology structures. Compared with a current preparation method of the photonic crystals, the method is quick and convenient, lo in investment costs of devices, simple in process, energy-saving and environmentally friendly and short in consumed time, and three-dimensional structure shapes of the prepared photonic crystals are diversified and extensive. The method is an ideal manner of preparing special-purpose photonic crystals in the future. The method is capable of realizing batch production; the prepared photonic crystals can be widely applicable to the scientific research and life of optical devices, tissue culture frames, super lyophobic liquid surface, anti-counterfeiting marks and ornaments, so that the photonic crystals are wide in market prospects.

Owner:SHENZHEN INST OF ADVANCED TECH

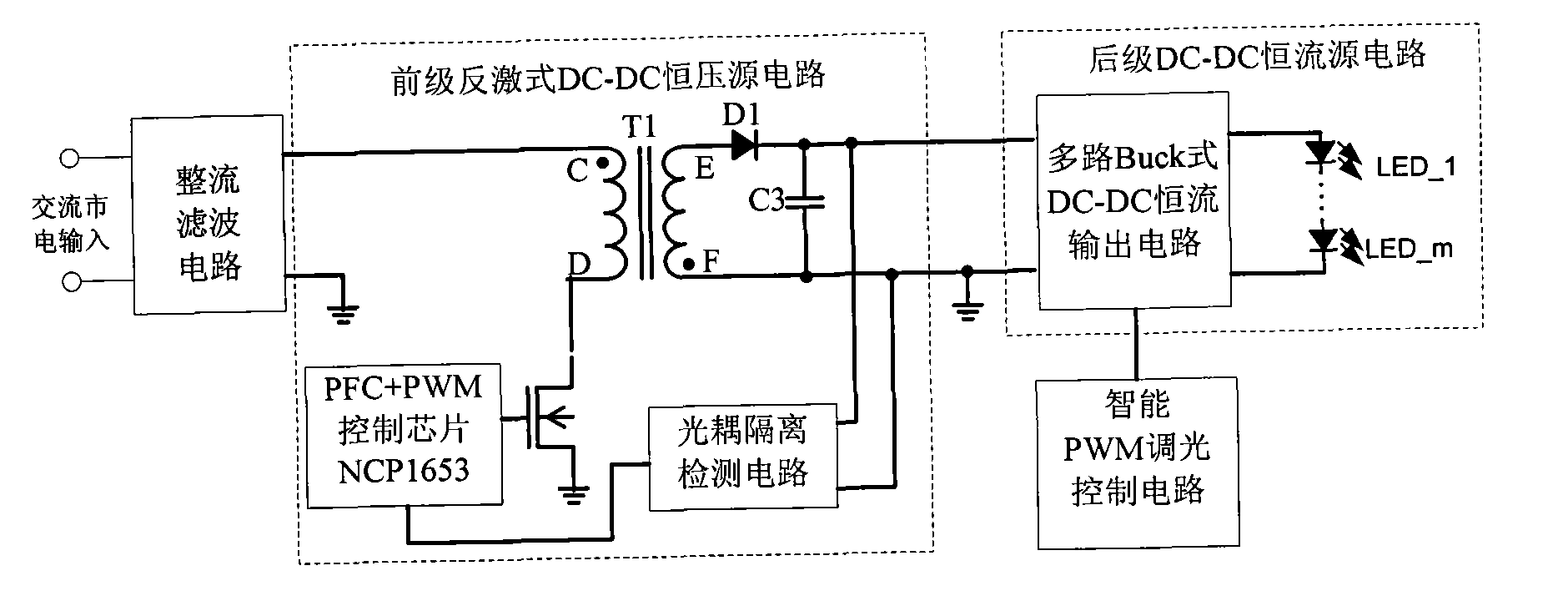

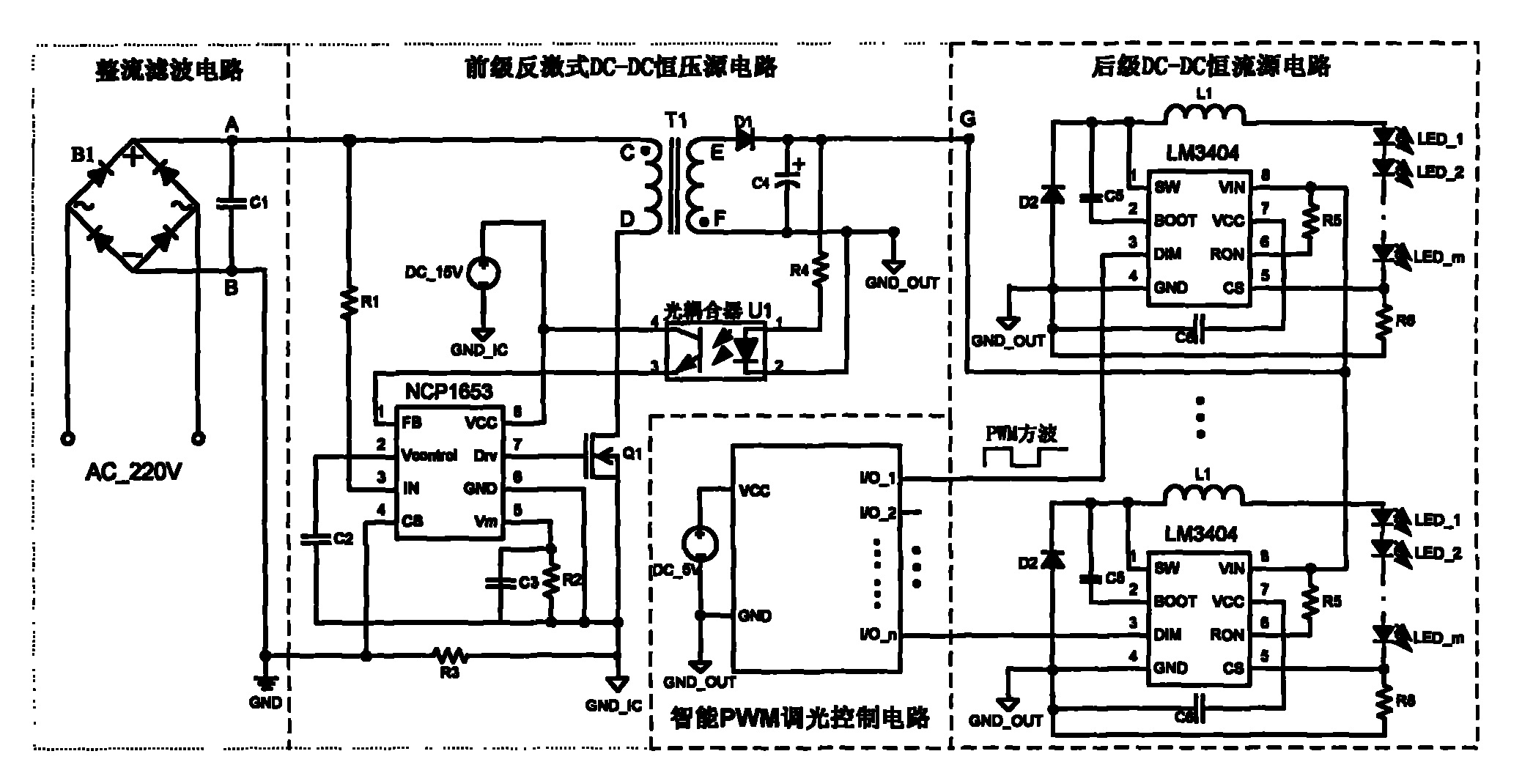

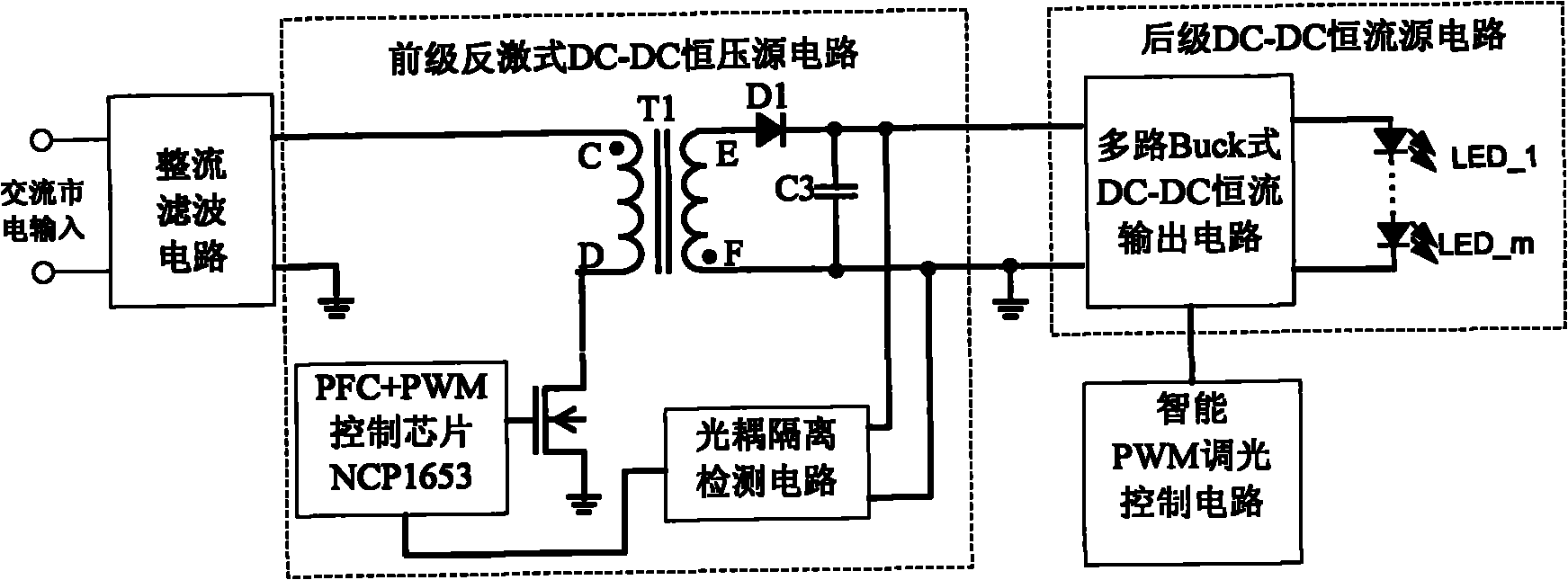

Fly-back street lamp illumination LED constant-current driving power supply with intelligent dimming function

InactiveCN101835317AIncrease profitImprove power factorElectric light circuit arrangementEnergy saving control techniquesDc dc converterTransformer

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

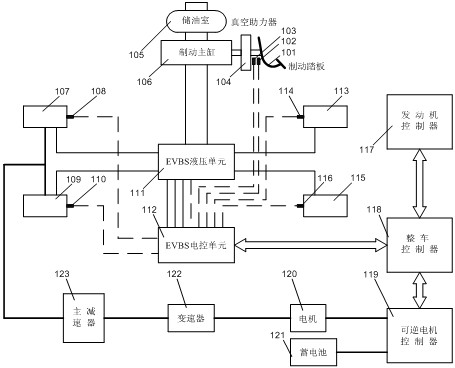

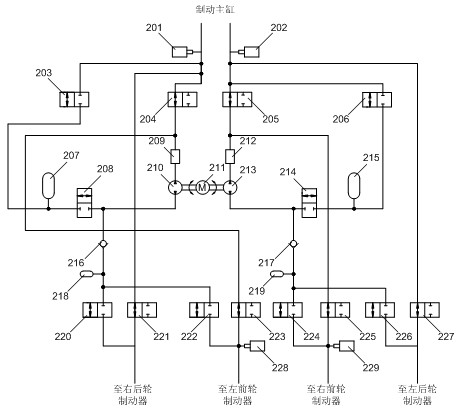

Electric vehicle braking system capable of reclaiming braking energy

ActiveCN102310850AMinor changesLow costBraking action transmissionElectrodynamic brake systemsElectric machineReducer

The invention discloses an electric vehicle braking system (EVBS) capable of reclaiming braking energy. The EVBS comprises a hydraulic braking subsystem, a braking energy reclaiming subsystem and a whole vehicle controller. The hydraulic braking subsystem comprises a braking pedal, a vacuum booster, a braking main cylinder, an oil storage chamber, an EVBS hydraulic unit, and an EVBS electric control unit for controlling the operation of the EVBS hydraulic unit; the braking energy reclaiming subsystem comprises a storage battery, a reversible motor controller, a motor, a transmission and a main speed reducer; and the whole vehicle controller is respectively connected with the EVBS electric control unit and the reversible motor controller. According to the system, a hydraulic brake and a motor reclaiming brake are coordinated; the whole vehicle controller cooperatively controls the reversible motor controller and the EVBS electric control unit, so that the braking safety is ensured; when the motor reclaiming brake fails, the hydraulic braking system can still work reliably; the whole hydraulic unit has a simple structure and is easy for batch production; and the EVBS has a consistent braking effect in a reclaiming or non-reclaiming state, and has the same braking sensation.

Owner:ZHEJIANG ASIA PACIFIC MECHANICAL & ELECTRONICS

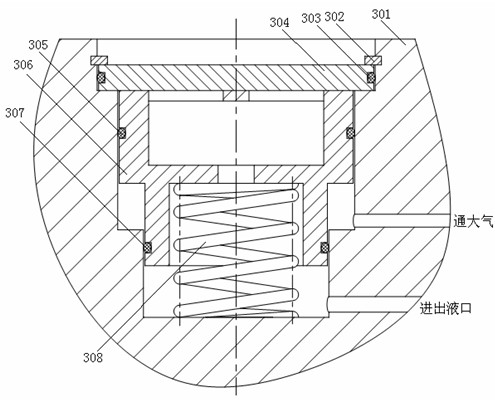

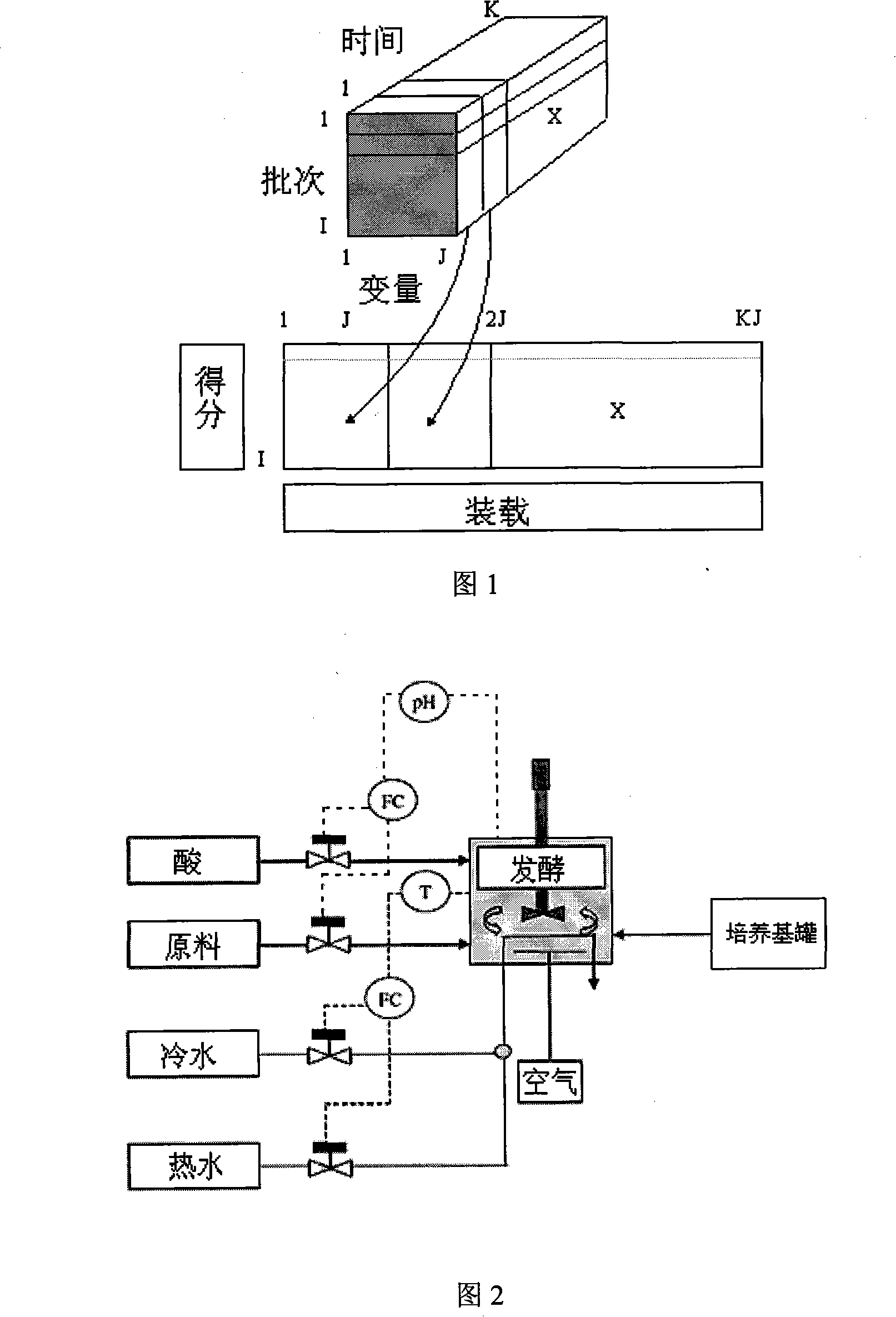

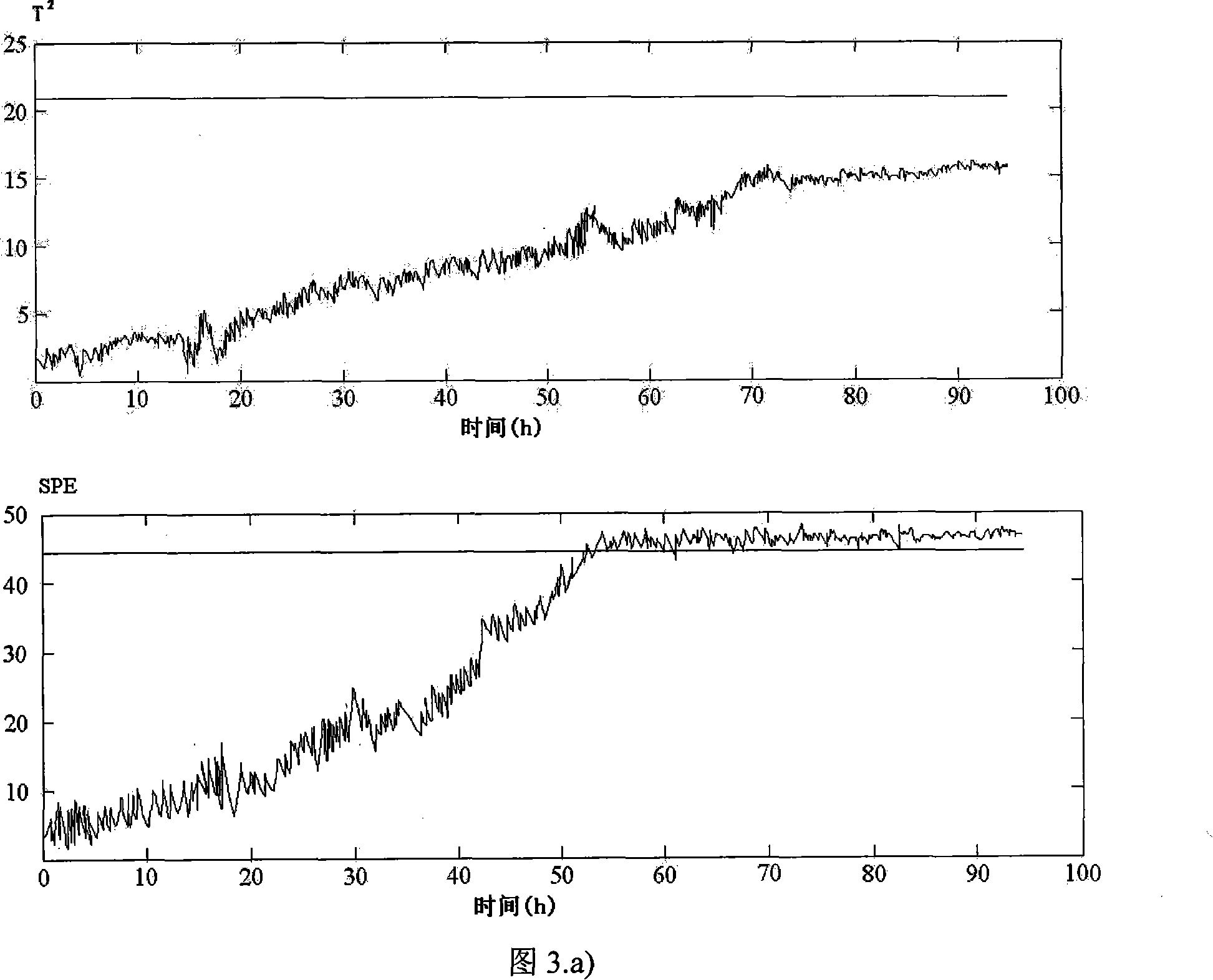

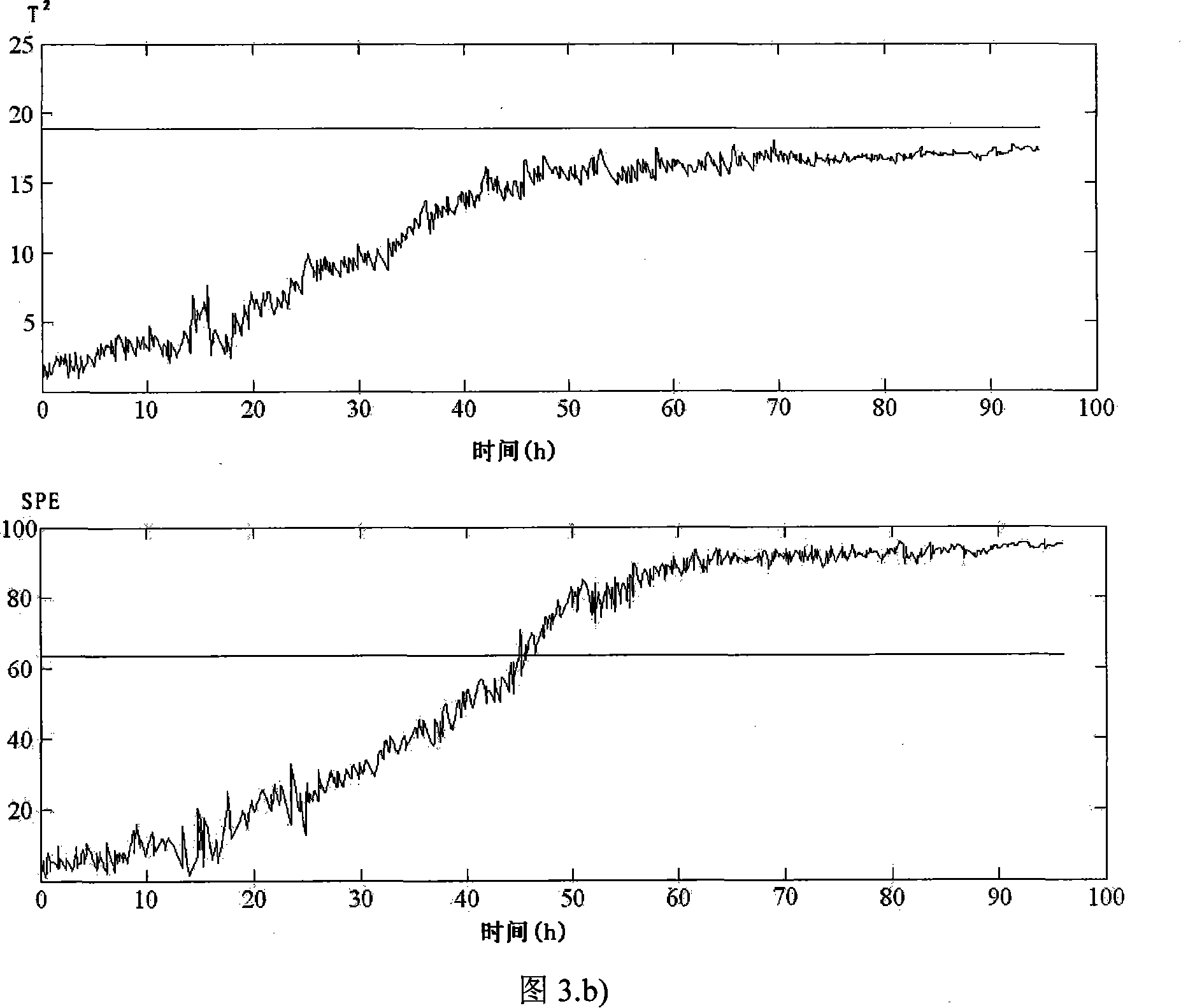

Bulk production process malfunction detection method based on multiple nucleus independent elements analyse

InactiveCN101158693AReduce lossesTotal factory controlSpecial data processing applicationsIndependent elementComputer science

The present invention provides a fault detection method for batched production process based on analysis of multinuclear independent element, which comprises data collection, data processing, and a process makes use of analysis of a nuclear principle element for whitening of the data, makes use corrective ICA for extraction of an independent element and makes use of T2 and SPE statistics for detection of the faults. The present invention initially provides a detection method for the batched production process based on MKICA, realizes the detection of the complicated processes and can detect the faults earlier, thereby reducing the loss occurred in the industrial production processes.

Owner:NORTHEASTERN UNIV

Bioreactor systems

InactiveUS7682823B1Function increaseBiocideBioreactor/fermenter combinationsBiologyDisposable bioreactors

The present invention provides novel bioreactor systems, adapted to provide continuous batch incubation of microbes, especially bacteria. The bioreactor bags are preloaded with dry, inert microbes prior to being shipped to the user. Multiple sterile, preloaded, disposable bioreactor bags are used in a self-contained housing. The bags are automatically incubated in the housing and dispensed, preferably into an irrigation system. The system will provide serial batch production of useful microbes for a week or more, without further supervision or intervention.Methods of manufacture, methods of use, methods of sales, and methods of farming are also provided.

Owner:RUNYON LARRY

Production method for partitioned unit glued lattice structural bodies of graphic fireworks

The invention discloses a production method for partitioned unit glued lattice structural bodies of graphic fireworks. Partitioned units, a lattice body forming jig and a production method of finished lattice structural bodies are included. The lattice body forming jig is provided with jig inserting holes, and the jig inserting holes are distributed in a lattice shape and used for insertion of the partitioned units. The production method of finished lattice structural bodies comprises step one, presetting contour shapes after graphic fireworks are set off; step two, producing a height-limit lantern ring according to contour shapes; step three, placing the lattice body forming jig; step four, inserting the partitioned units and process plugs into the lattice body forming jig; step five, sleeving the height-limit lantern ring, and using a lattice pressing jig for compaction; and step six, applying glue, performing curing and the like. The production method is simple in implementation and convenient to produce, the complex lattice structural bodies are simplified, the production method is suitable for batch production, costs of graphic fireworks can be reduced substantially, and the production method is the key for graphic fireworks to enter thousands of families at low prices.

Owner:SUZHOU ZZH INTPROP SERVICES

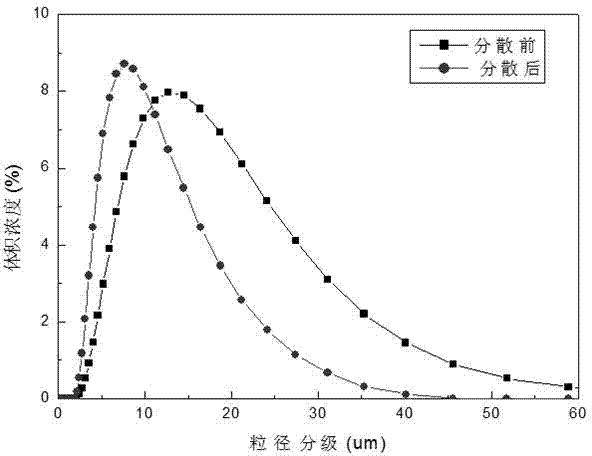

Method for preparing grapheme dispersion liquid

ActiveCN104772064AShorten dispersion timeIncrease productivityMixer accessoriesDispersion stabilityColloid

The invention discloses a method for preparing grapheme dispersion liquid. The method comprises the following steps: (1) uniformly mixing grapheme and a dispersant in a solvent to obtain a uniformly mixed solution; and (2) dispersing the uniformly mixed solution by a dispersing device for 0.5-24 hours to obtain the grapheme dispersion liquid, wherein the rotation speeds of a high shearing dispersion head and a colloid grinding disc are regulated to be within 100-14000rpm, the rotation speed of an electric mixer is at 10-2000rpm, an energy-concentration ultrasonic probe is additionally arranged, the ultrasonic frequency is within 20-80kHz and the dispersion temperature is 0-20 DEG C after being regulated by a cooling system. According to the method for preparing the grapheme dispersion liquid, the dispersion time is saved and the production efficiency is improved due to the adoption of multiple dispersion methods and synergic action, the cost is low, the operation is easy, and the method is nontoxic, free of pollution and beneficial for batch production, has high dispersion stability and a bright prospect of large-scale industrial application.

Owner:SHANDONG YUHUANG NEW ENERGY TECH +1

Preparation method of carbon nano-tube loaded nano-cobalt catalyst

ActiveCN103816905ALow costSimple production processMetal/metal-oxides/metal-hydroxide catalystsFiltrationCarbon nanotube

The invention discloses a preparation method of a carbon nano-tube loaded nano-cobalt catalyst. The method comprises the following steps: (1) dissolving a cobalt salt in an organic solvent and then adding a ligand to obtain a mixed liquid; (2) transferring the mixed liquid to a high-pressure kettle, performing a thermostatic heating reaction, naturally cooling to room temperature and then orderly performing filtration, washing and vacuum drying treatment on the generated crystal or powder to obtain a metal organic skeleton product Co-MOF of cobalt; and (3) roasting the metal organic skeleton product Co-MOF for 100-180 minutes at a roasting temperature of 400 DEG C to 1000 DEG C in a calcination atmosphere of argon inside a tubular furnace so as to obtain the carbon nano-tube loaded nano-cobalt catalyst. The preparation method disclosed by the invention has the advantages that the raw materials are low in cost, the production process is also simple, the reaction condition is easy to control, no template agent and surfactant are needed, the prepared product is good in consistency and environment-friendly; and the preparation method is beneficial to batch production and application of carbon nano-tube loaded nano-cobalt.

Owner:NANKAI UNIV

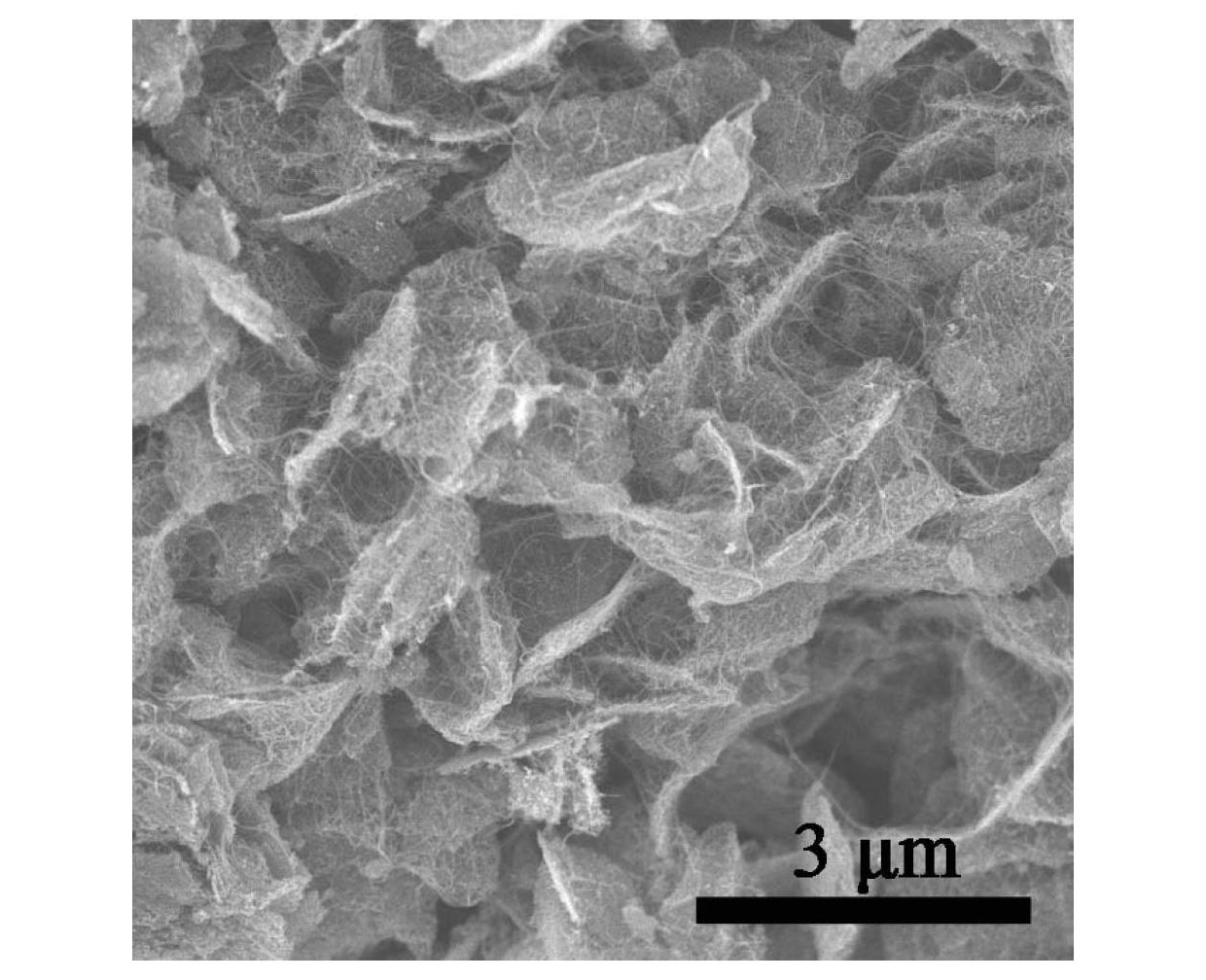

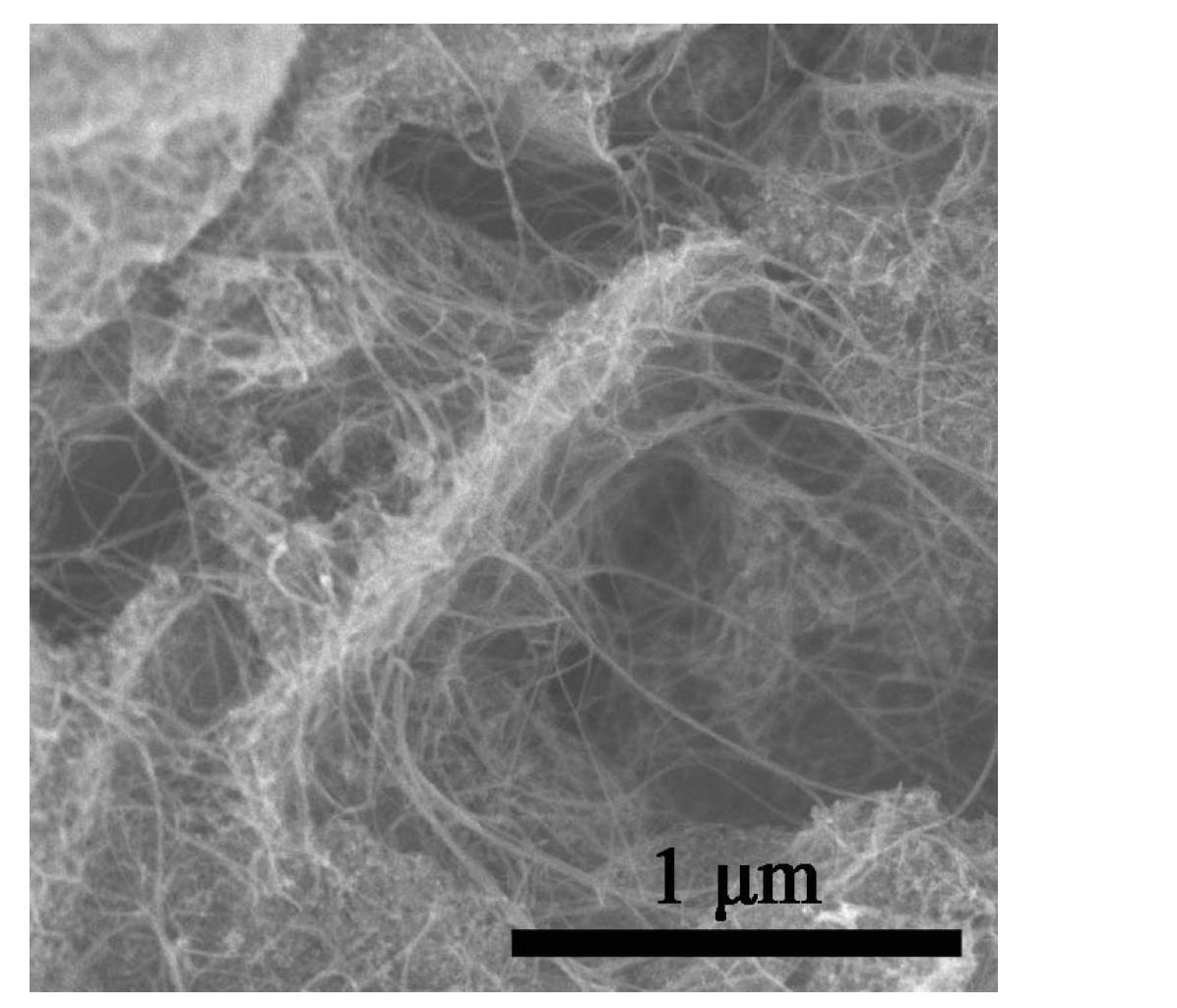

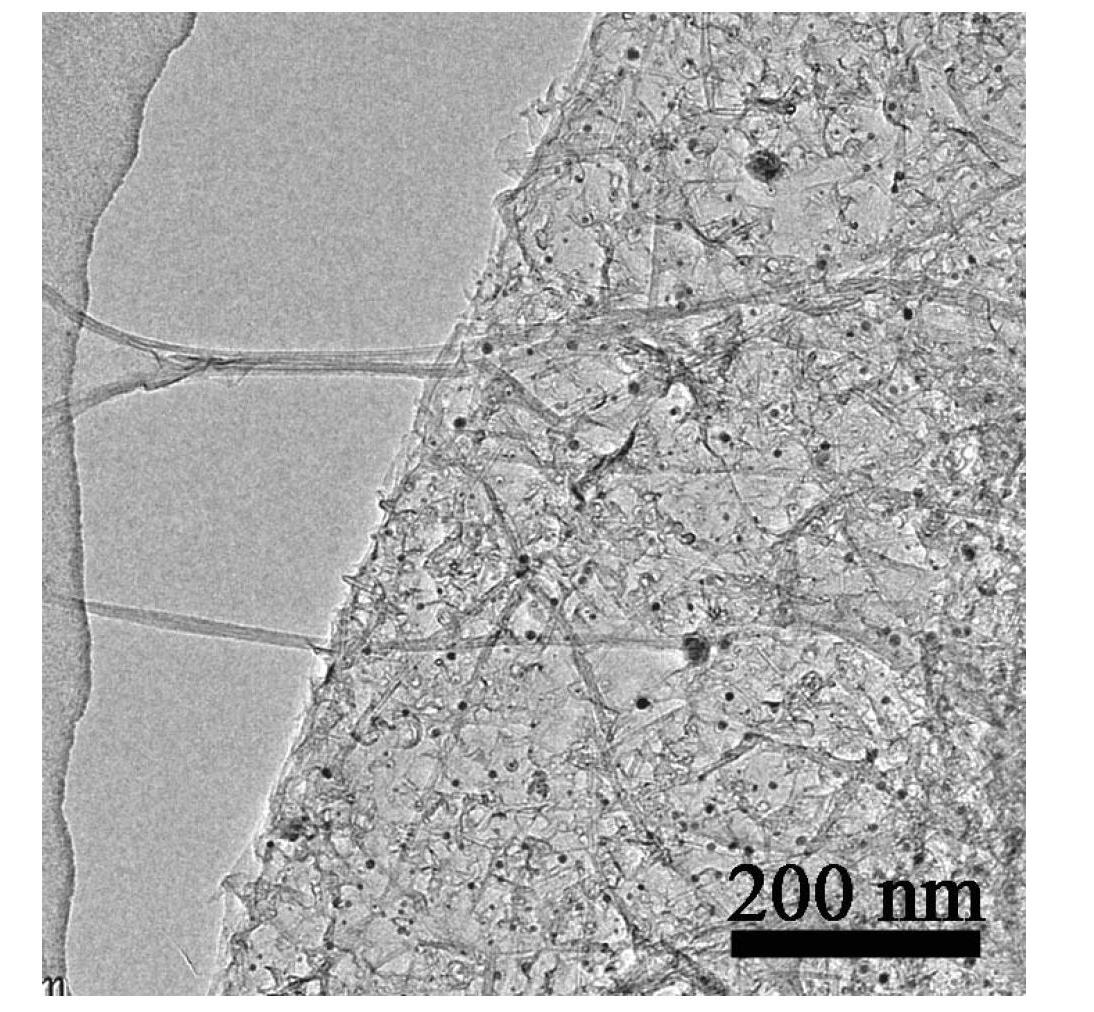

Method for preparing composition of carbon nano tube and graphene by using sheet material

ActiveCN102674316AIncrease production capacityMaterial nanotechnologyGrapheneGas phaseActive component

The invention relates to a method for preparing composition of a carbon nano tube and graphene by using a sheet material; the composition comprises the carbon nano tube and the graphene material, wherein the carbon nano tube directly grows on the surface of graphene. According to the preparation method, the sheet material loaded with a catalyst active component is used as a catalyst, the carbon nano tube and the graphene are deposited on the sheet material by chemical vapor deposition, and the composition of carbon nano tube and graphene can be obtained after purification. The method enriches the variety of nano carbon materials; and the method can be easily applied to industrial production to realize batch production, thus promoting the application study of the composition of carbon nano tube and graphene.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com