Patents

Literature

1388 results about "Graphene oxide paper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

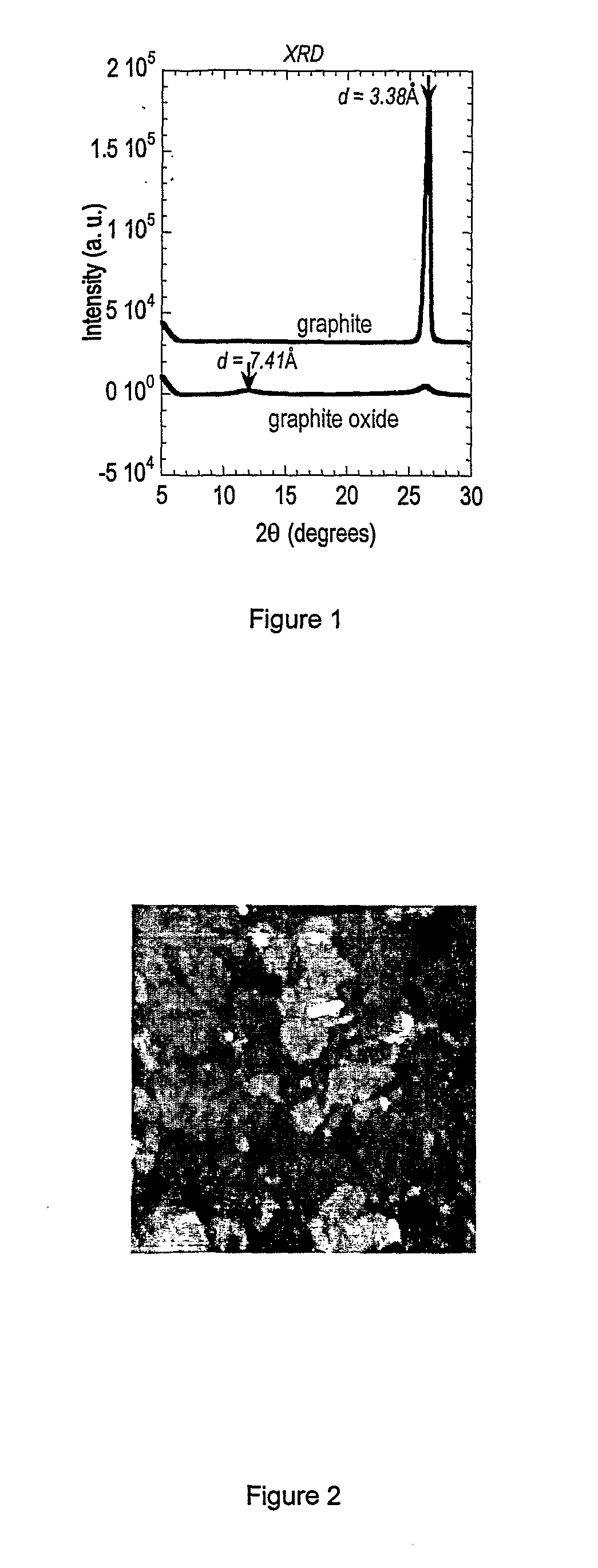

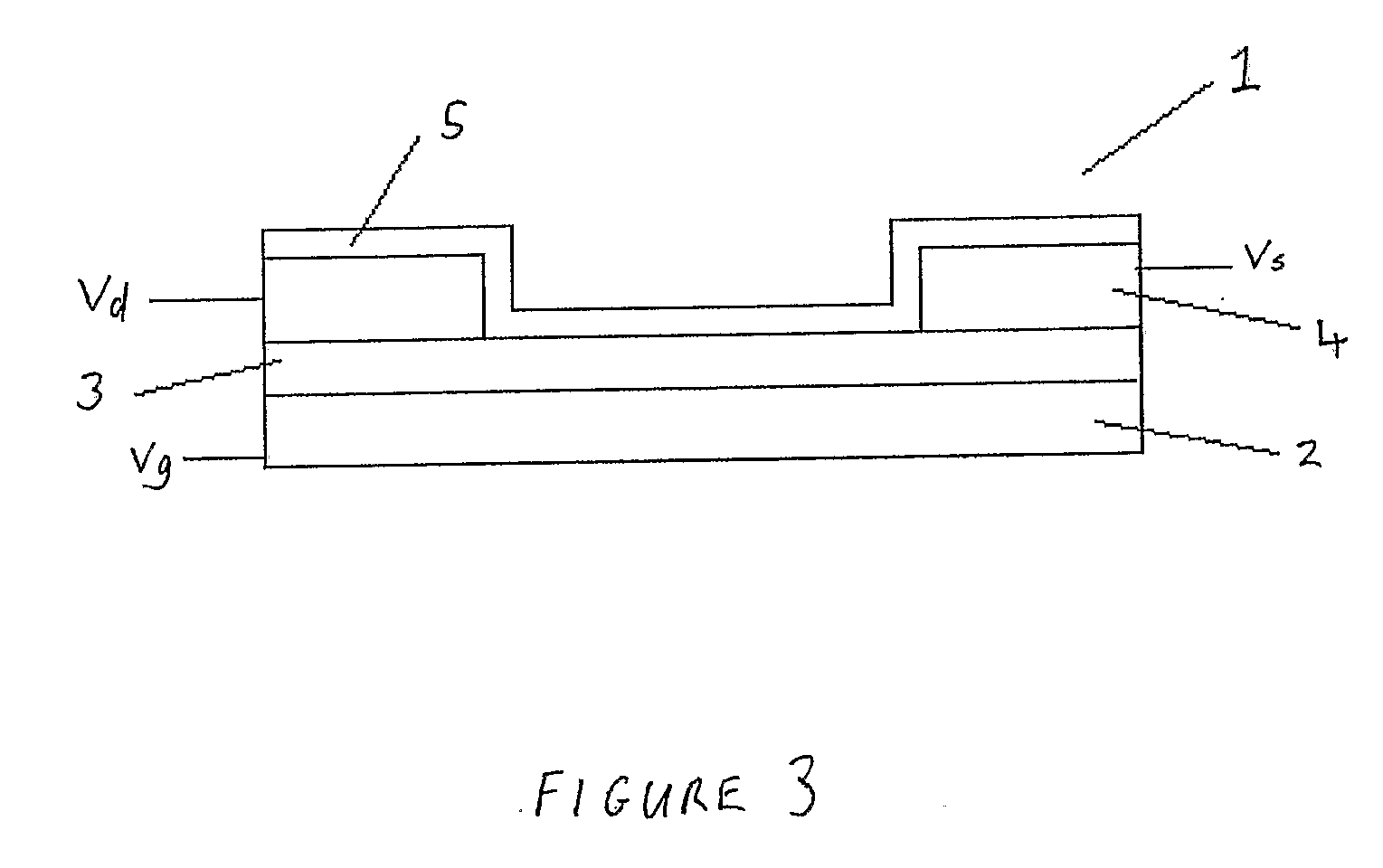

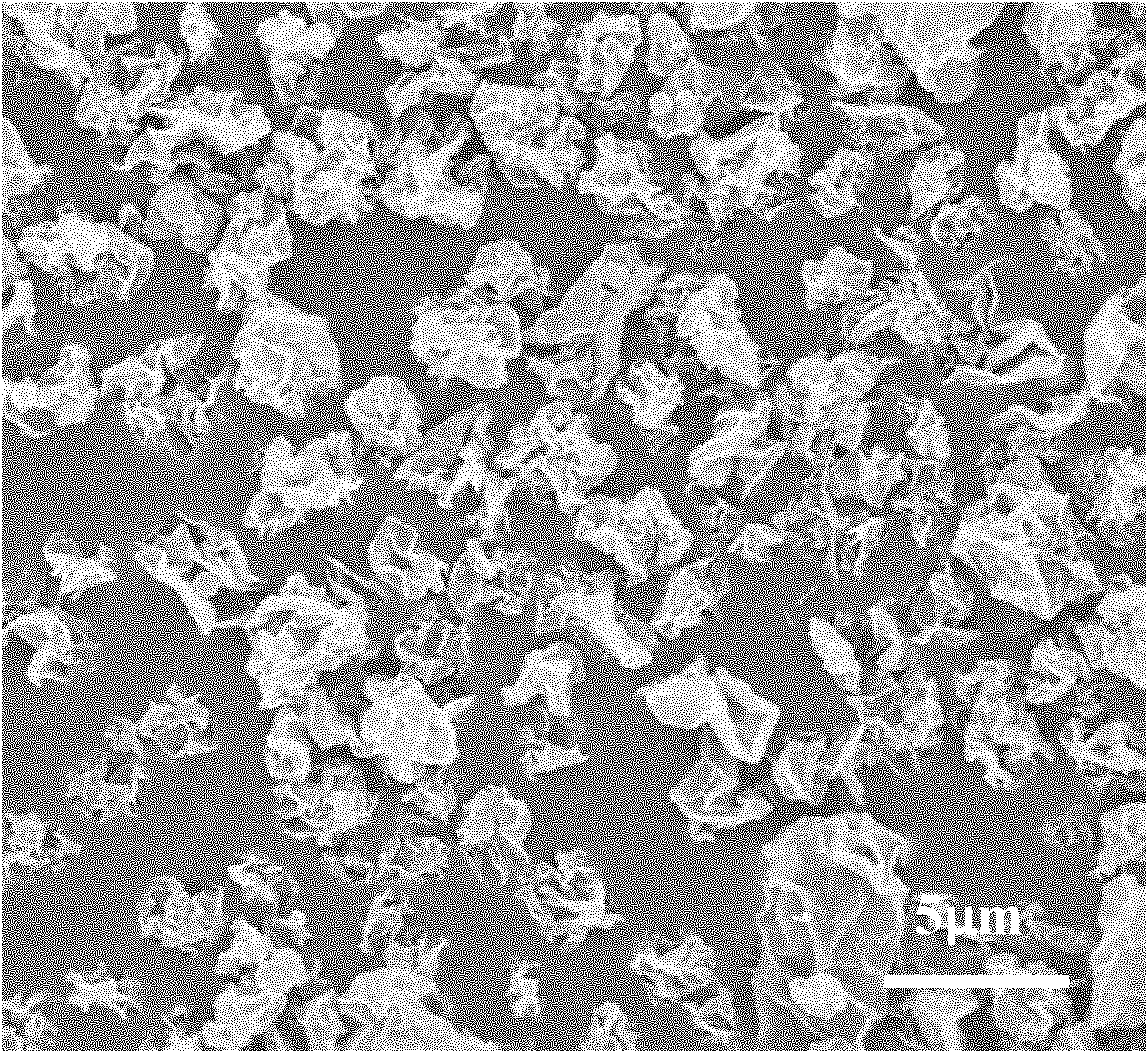

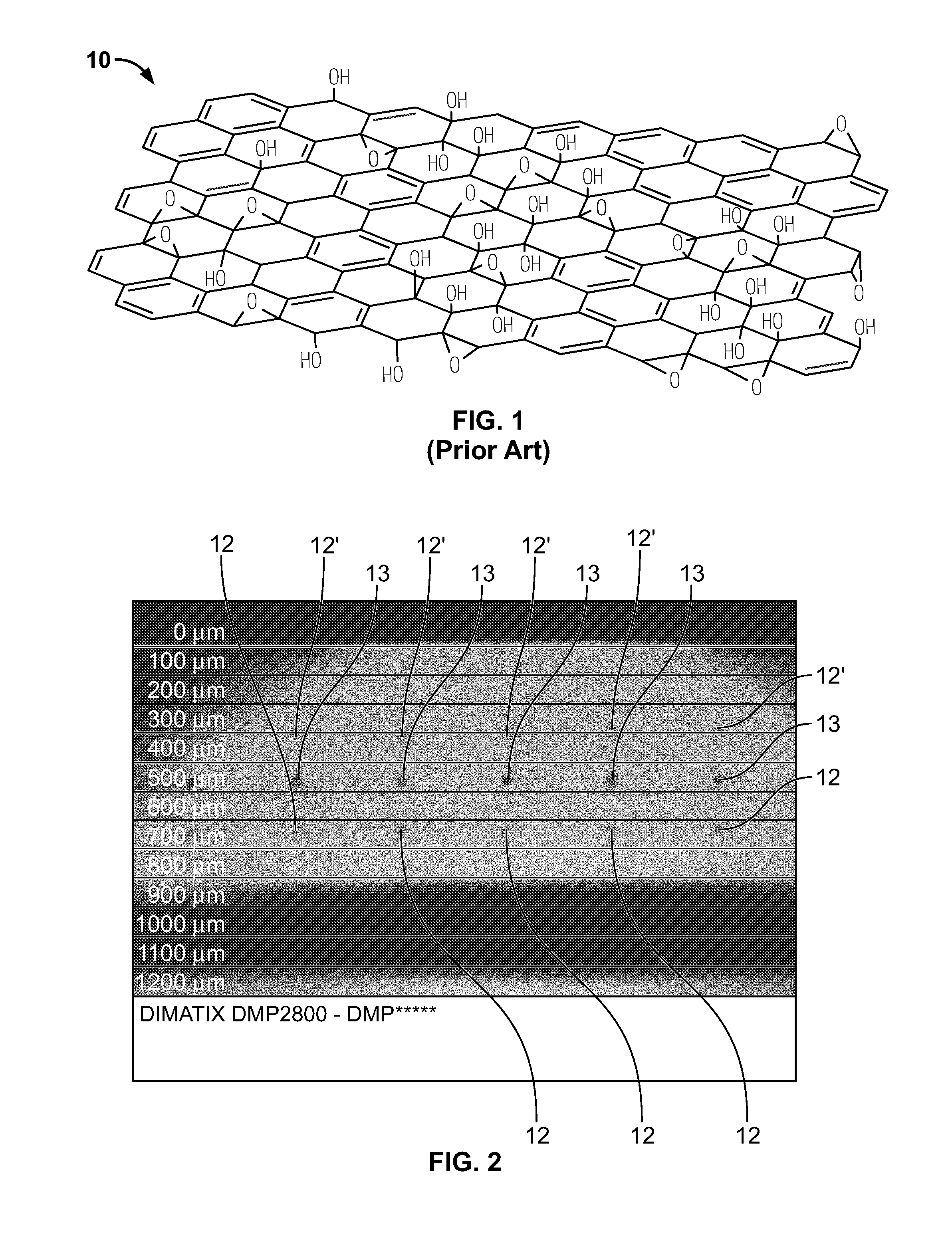

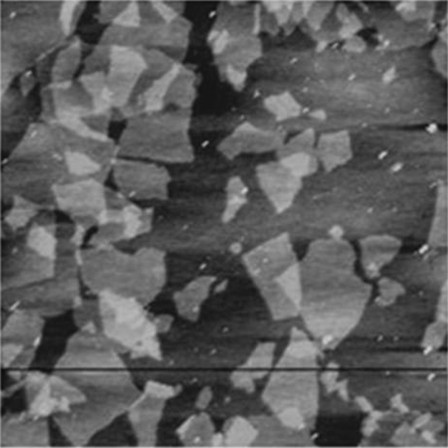

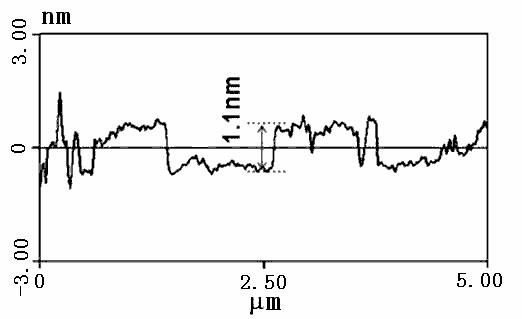

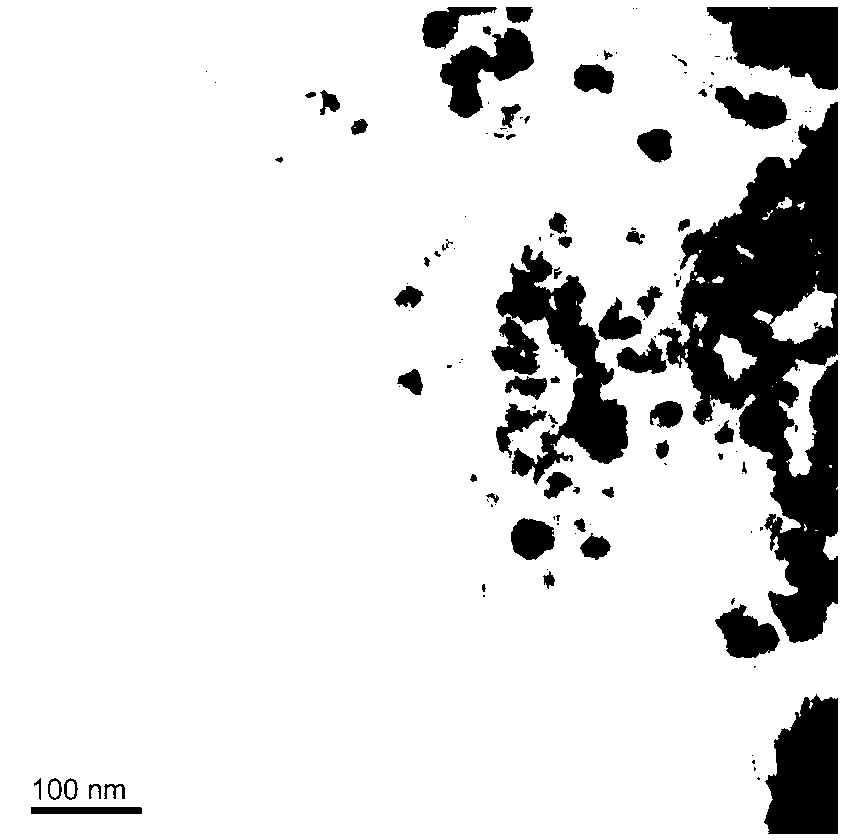

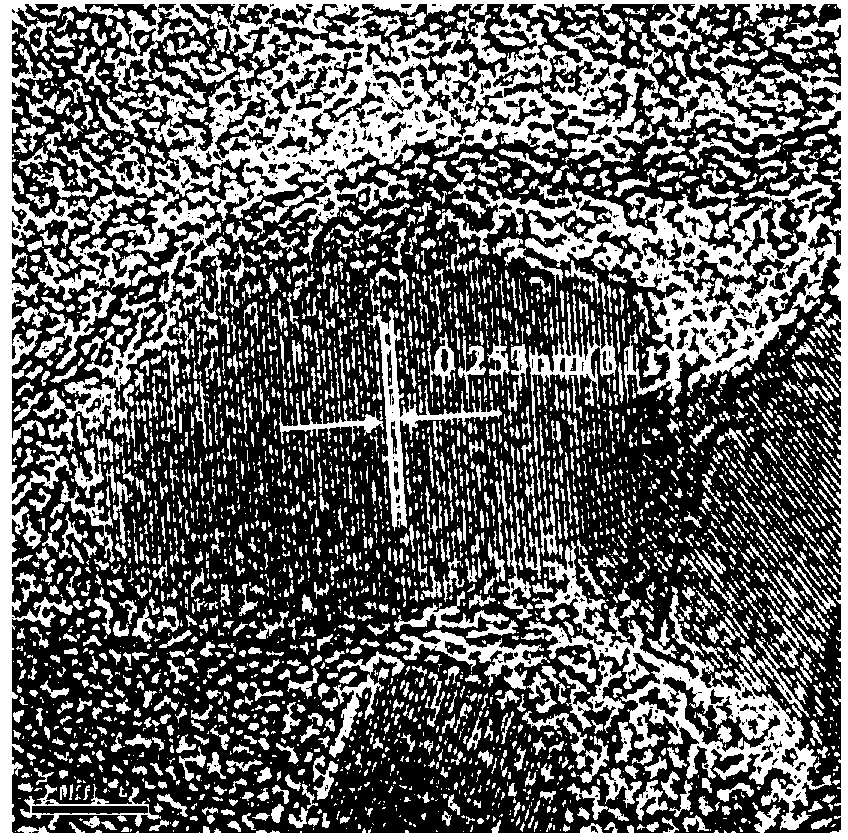

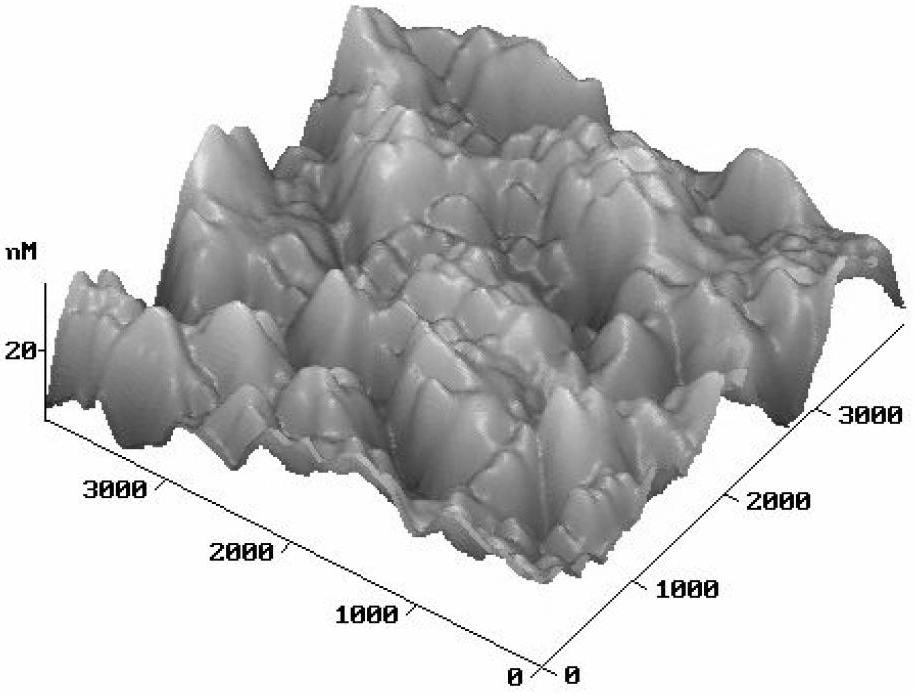

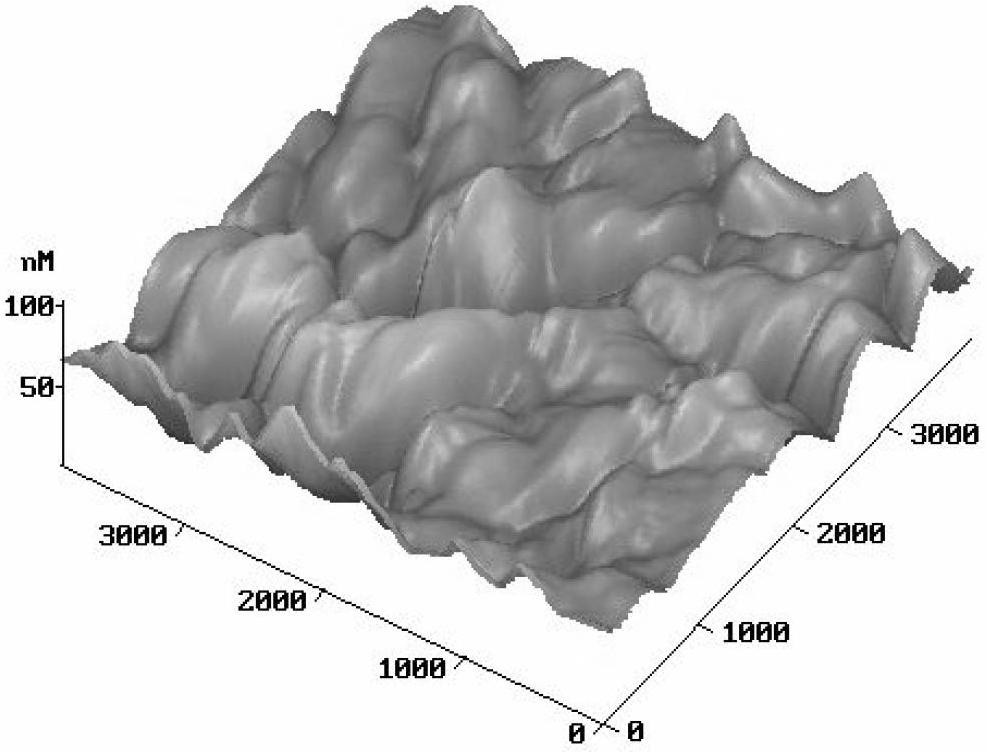

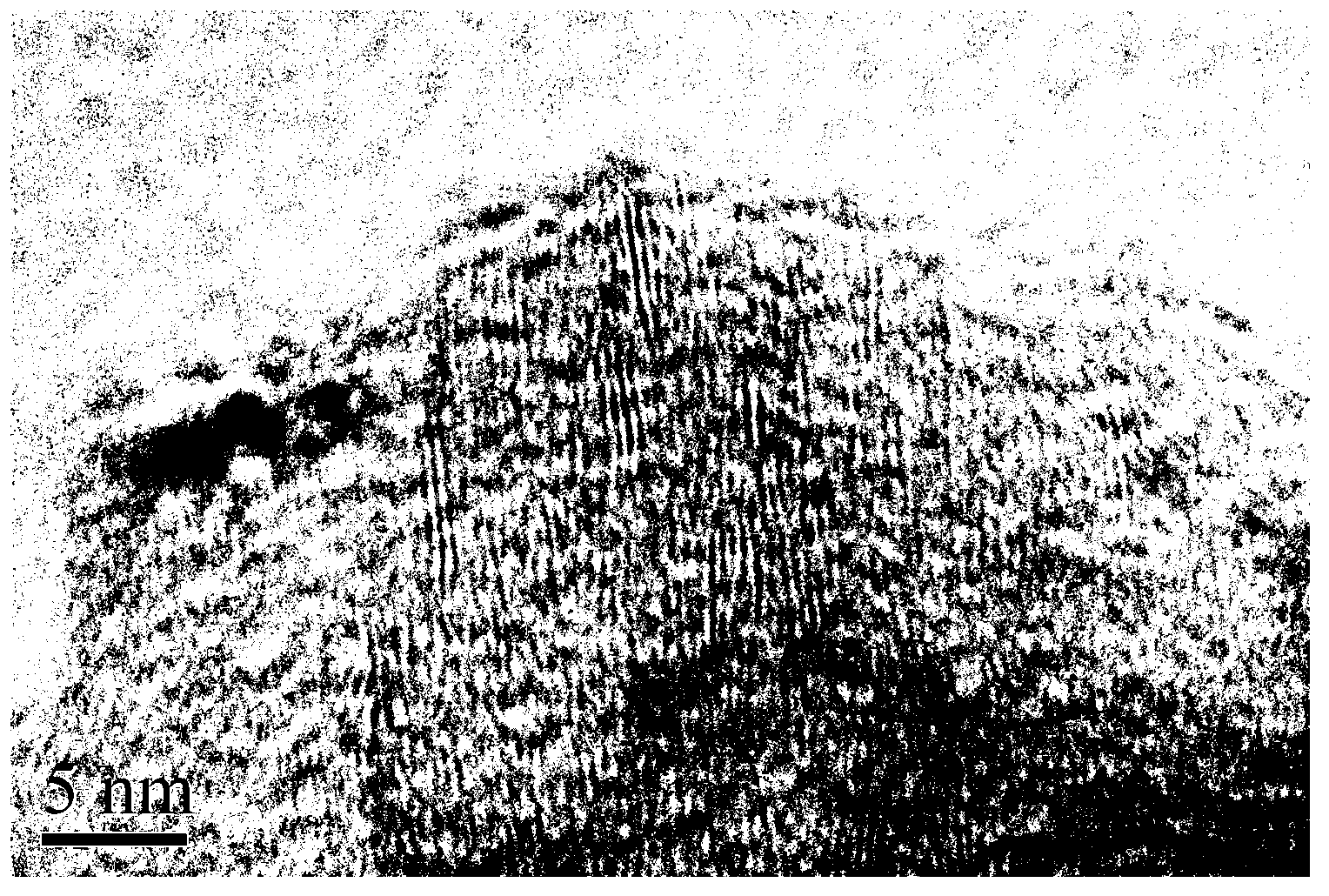

Graphene oxide paper or graphite oxide paper is a material fabricated from graphite oxide. Micrometer thick films of graphene oxide paper are also named as graphite oxide membranes (in the 1960s) or (more recently) graphene oxide membranes. The membranes are typically obtained by slow evaporation of graphene oxide solution or by the filtration method.

Method for preparing graphene or graphene oxide by using high-efficiency and low-cost mechanical stripping

InactiveCN101817516AImprove stripping efficiencyLight in massHigh volume manufacturingSolid particle

The invention provides a method for preparing graphene or graphene oxide by using high-efficiency and low-cost mechanical stripping and relates to a preparation method of the graphene or the graphene oxide, solving the problems that the traditional micro-mechanical stripping method has low efficiency and can not be used for large-batch production. The method comprises the following step of separating carbon materials by utilizing solid particles and a liquid working medium (or gas working medium) and adopting mechanical stripping to obtain the graphene or the graphene oxide, wherein the carbon materials comprise graphite powder, expanded graphite, expandable graphite or graphite powder oxide. By using automatic machinery and using a great deal of solid particles for assisting stripping processes, the invention greatly increases the contact areas and the stripping times of the stripping processes, the carbon materials are subject to a great amount of stripping processes in a short time through the shearing and impacting functions of the solid particles on the carbon materials, and thereby the method obviously improves the stripping efficiency, has low cost and is suitable for the industrial and large-batch production of the graphene or the graphene oxide.

Owner:HARBIN INST OF TECH

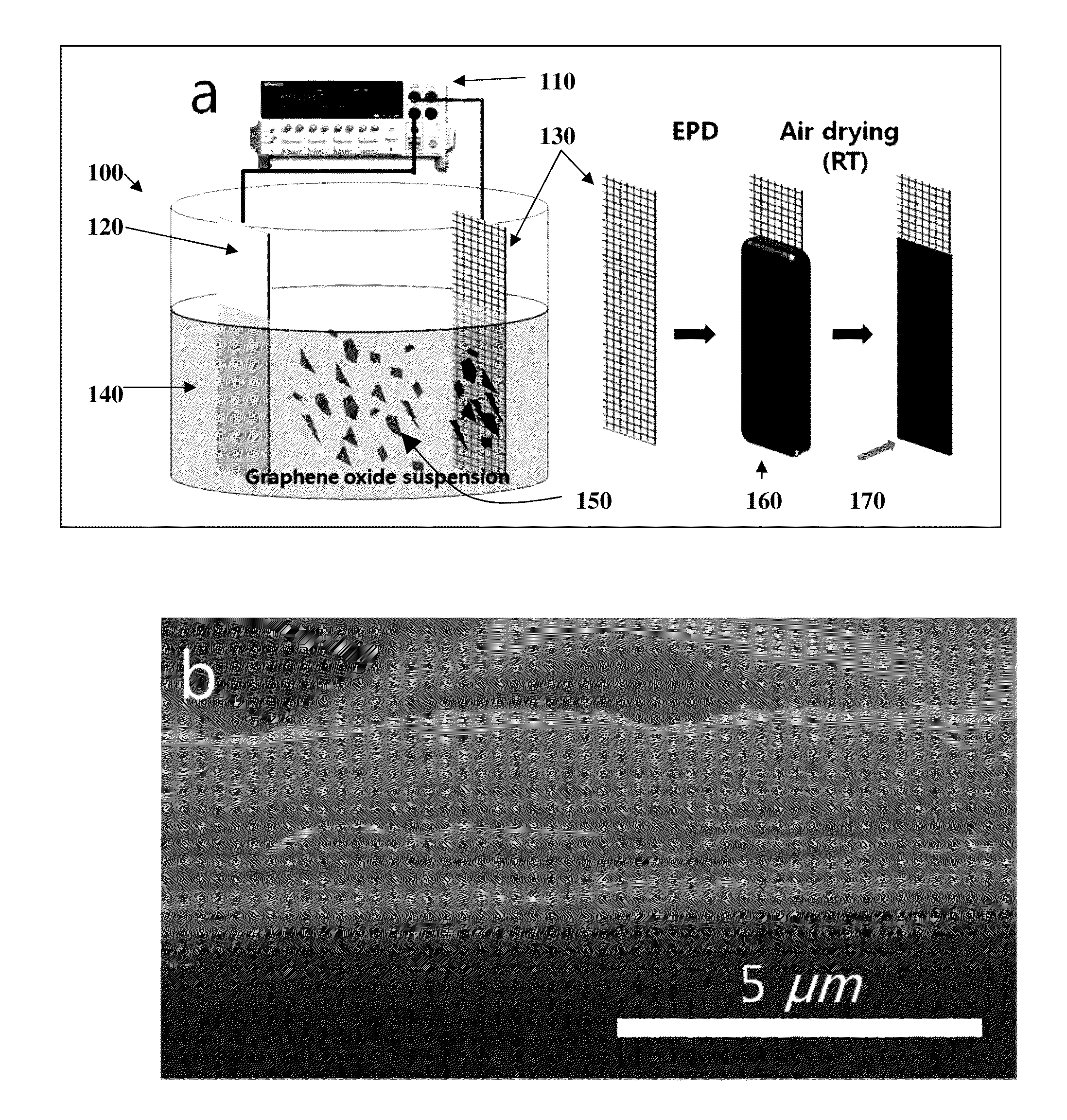

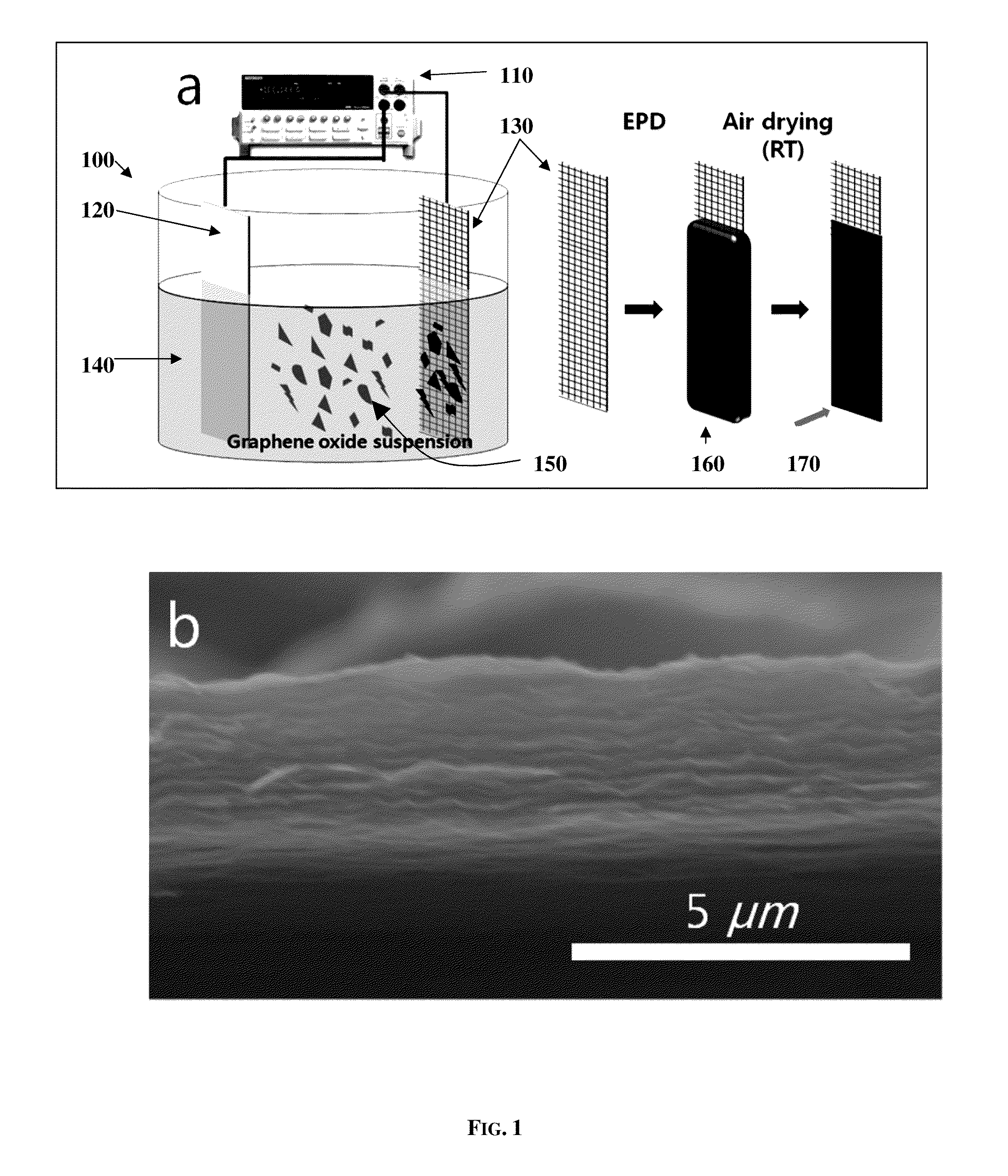

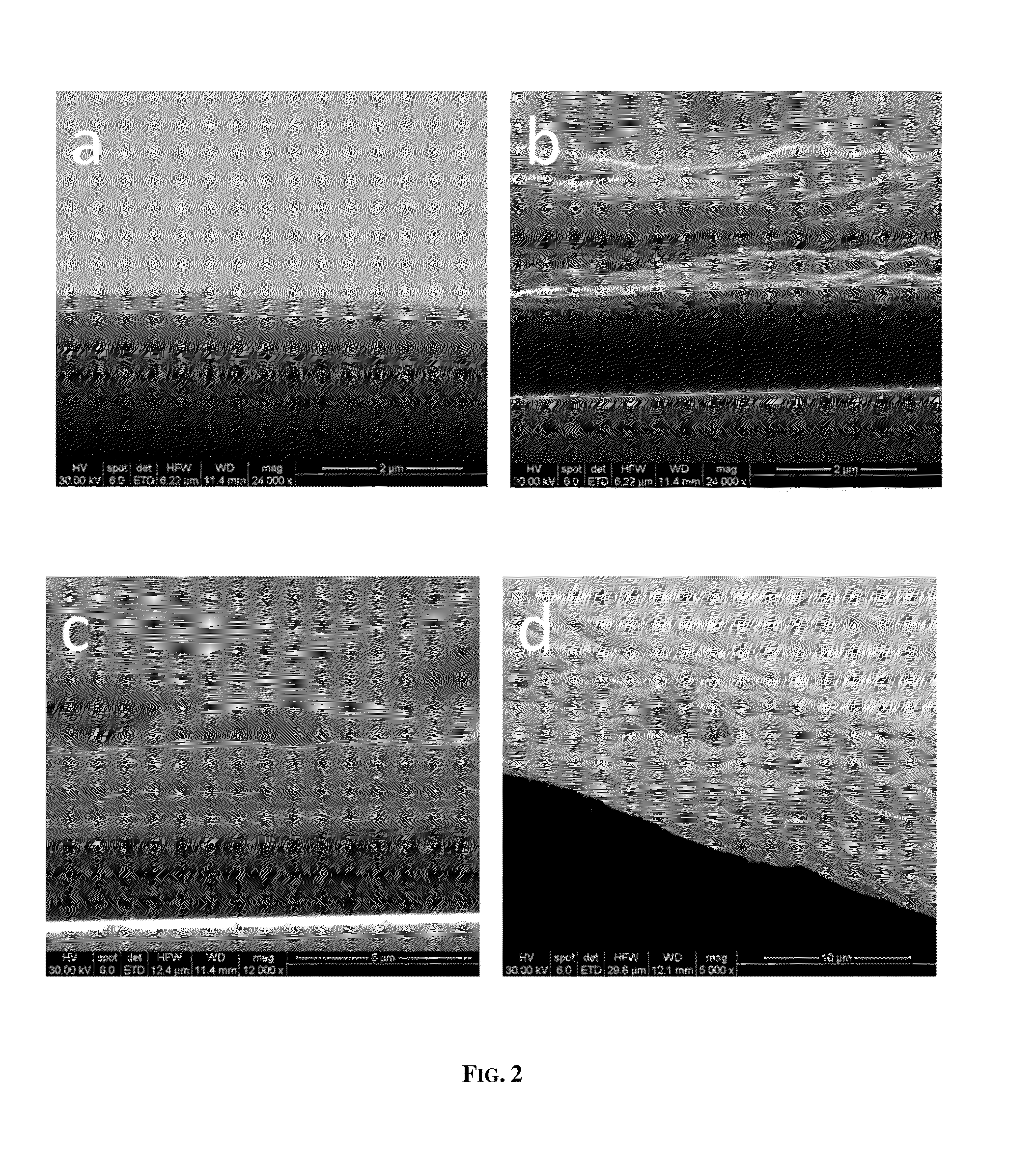

Electrophoretic deposition and reduction of graphene oxide to make graphene film coatings and electrode structures

Owner:RUOFF RODNEY S +4

Functionalised graphene oxide

ActiveUS20110052813A1Good dispersionReadily deoxidised to grapheneMaterial nanotechnologyOrganic chemistryHigh concentrationRoom temperature

A functionalised graphene oxide and a method of making a functionalised graphene oxide comprising: (i) oxidizing graphite to form graphite oxide wherein the graphene sheets which make up the graphite independently of each other have a basal plane fraction of carbon atoms in the sp2-hybridised state between 0.1 and 0.9, wherein the remainder fraction comprises sp3-hybridised carbon atoms which are bonded to oxygen groups selected from hydroxyl and / or epoxy and / or carboxylic acid; and (ii) exfoliating and in-situ functionalizing the graphite oxide surface with one or more functional groups such that functionalisation of the surface is effected at a concentration greater than one functional group per 100 carbon atoms and less than one functional group per six carbon atoms. The functionalised graphene oxide is dispersible at high concentrations in appropriate solvents without aggregating or precipitating over extended periods at room temperature.

Owner:NAT UNIV OF SINGAPORE

Method for preparing graphene powder

The invention relates to a method for preparing graphene powder in large scale, which is characterized by comprising the following steps of: firstly, uniformly peeling graphene oxide into a graphene oxide suspension solution; then, atomizing the graphene oxide solution by using the spray drying technology comprising spray pyrolysis drying and spray freeze drying, and removing a solvent to obtain graphene oxide powder; and finally, oxidizing grapheme by using the non-expansion heat treatment process to obtain non-agglomerative graphene powder. The continuous preparation process of the spray technology and the non-expansion heat treatment process ensure the large-scale preparation of the graphene powder. The prepared graphene powder comprising intermediate product graphene oxide powder does not have agglomeration and has good dispersivity in the solvent. The graphene powder is used as a filling material to prepare high strength composite materials, conductive composite materials, novel air-tight flame-retardant composite materials, novel nanodevices and the like.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

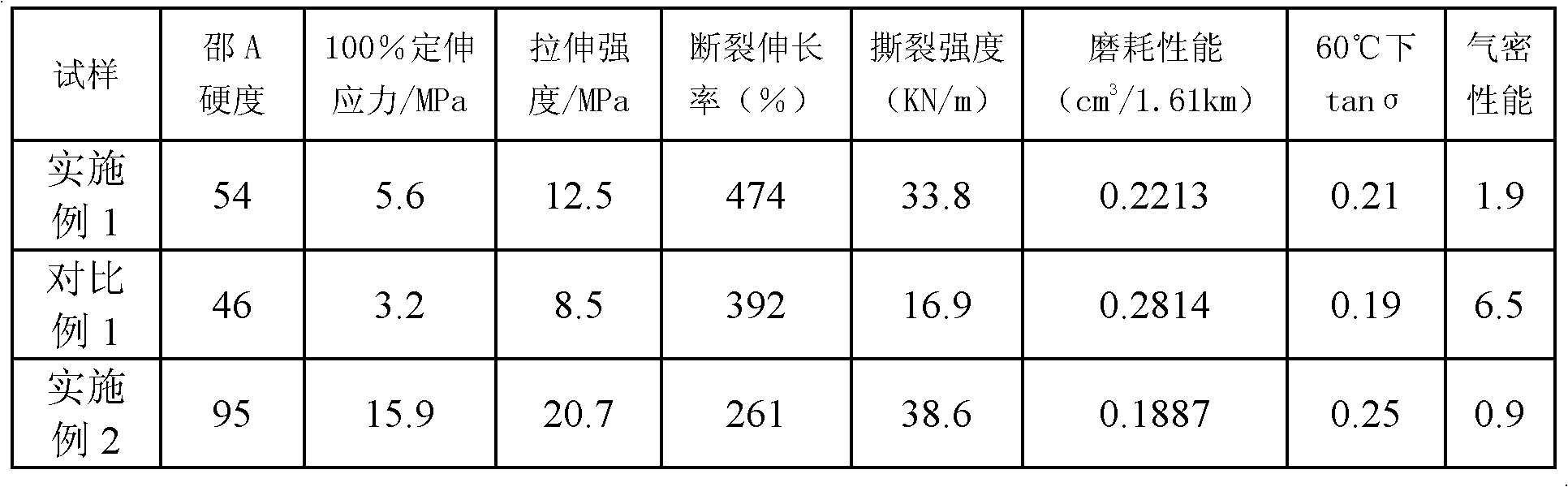

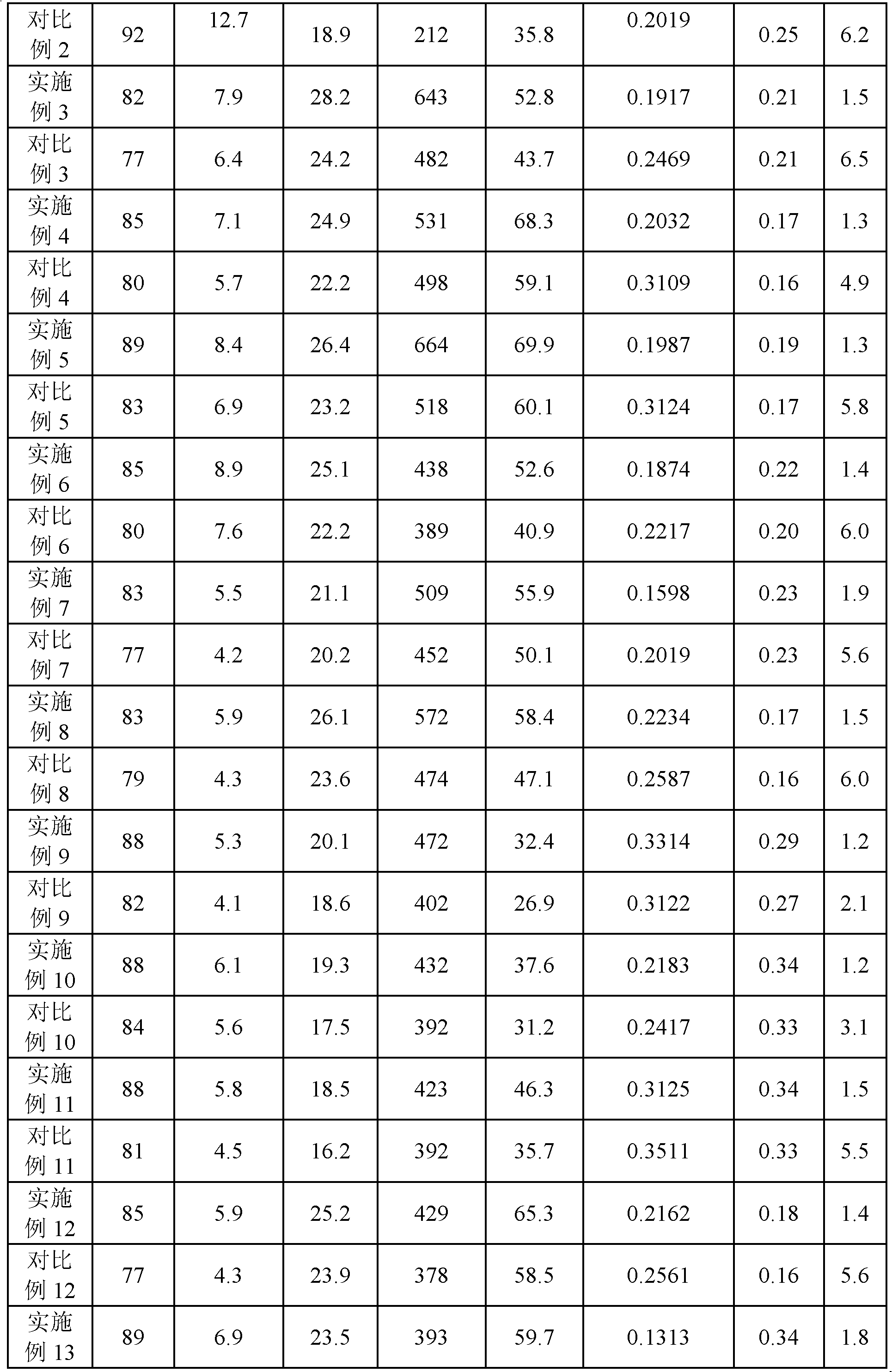

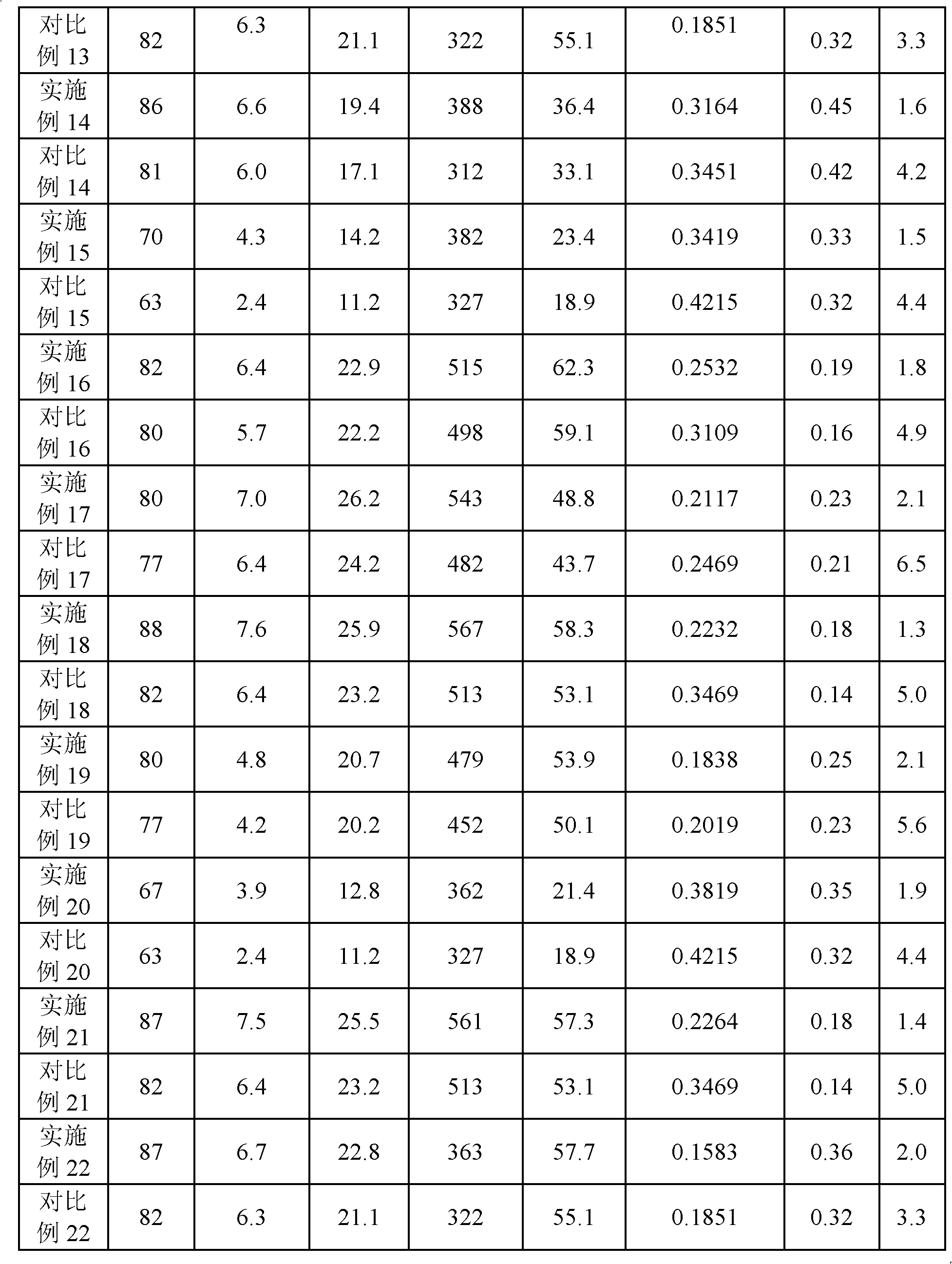

Method for preparing graphene oxide/white carbon black/rubber nanocomposite

The invention relates to a method for preparing a graphene oxide / white carbon black / rubber nanocomposite, which adopts a solution blending method or a mechanical blending method. In the graphene oxide / white carbon black / rubber nanocomposite prepared by the method provided by the invention, graphene and white carbon black are inserted with each other to effectively effective the aggregation of the two fillers, so as to obtain a highly-dispersed highly-stripped nano-sized composite. Not only the composite has high modulus and low rolling resistance, but also the wear resistance of a rubber material is greatly improved, and the modulus and tear resistance of the composite are further improved; in addition, due to the lamellar structure and good self-recovery capability of graphene oxide, the rubber material is also endued with good gas barrier performance and self-recovery capability, and the nanocomposite has the advantages that cannot be matched by any traditional filler. The method provided by the invention is simple and feasible, and suitable for industrial production, and has low cost, wide application range and good economic and social benefits.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing lithium ion battery anode/cathode material from reduced graphene oxide

The invention discloses a method for preparing a lithium ion battery anode / cathode material from reduced graphene oxide. The method comprises the following steps: performing ultrasonic dispersion on graphite oxide in an organic solvent, thereby obtaining a graphene oxide dispersion liquid; reducing by using an appropriate reducing agent or directly using a solvent, oxidizing graphene through oil bath backflow, a hydrothermal method or other reduction methods, thereby obtaining a reduced graphene oxide material containing part of oxygen-containing groups. When the prepared reduced graphene oxide material is used in a lithium ion battery anode material, a relatively high specific discharge capacity can be achieved, that is, is up to 280mAh / g, and good circulation stability and excellent rate performance are achieved. The prepared reduced graphene oxide material can be also used in a lithium ion battery cathode material, the specific discharge capacity can be kept being 900mAh / g and more than 900mAh / g after 100 rounds of charge / discharge circulation, and the circulation stability is relatively good. The method can be a significant study point of high-performance low-cost electrode materials of lithium ion batteries.

Owner:TIANJIN NORMAL UNIVERSITY

Graphene oxide/light cured resin composite and its preparation method and application

The invention provides a graphene oxide / light cured resin composite and its preparation method and application, the graphene oxide / light cured resin composite comprises two phases of graphene oxide and light cured resin, the graphene oxide is evenly dispersed in the light curing resin, the content of the graphene oxide is 0.1-1wt%, and the light cured resin comprises an oligomer, a light initiator and an active diluent. A graphene oxide nano material is dispersed in the light curing resin to obtain the graphene oxide / light cured resin nano composite, elongation at break and maximum bending strain of ordinary light cured resin is improved to a certain extent, and the impact strength of a coating film is increased by 2 times, so that a part printed by a 3D printer has better mechanical property.

Owner:QINGDAO UNIV OF SCI & TECH

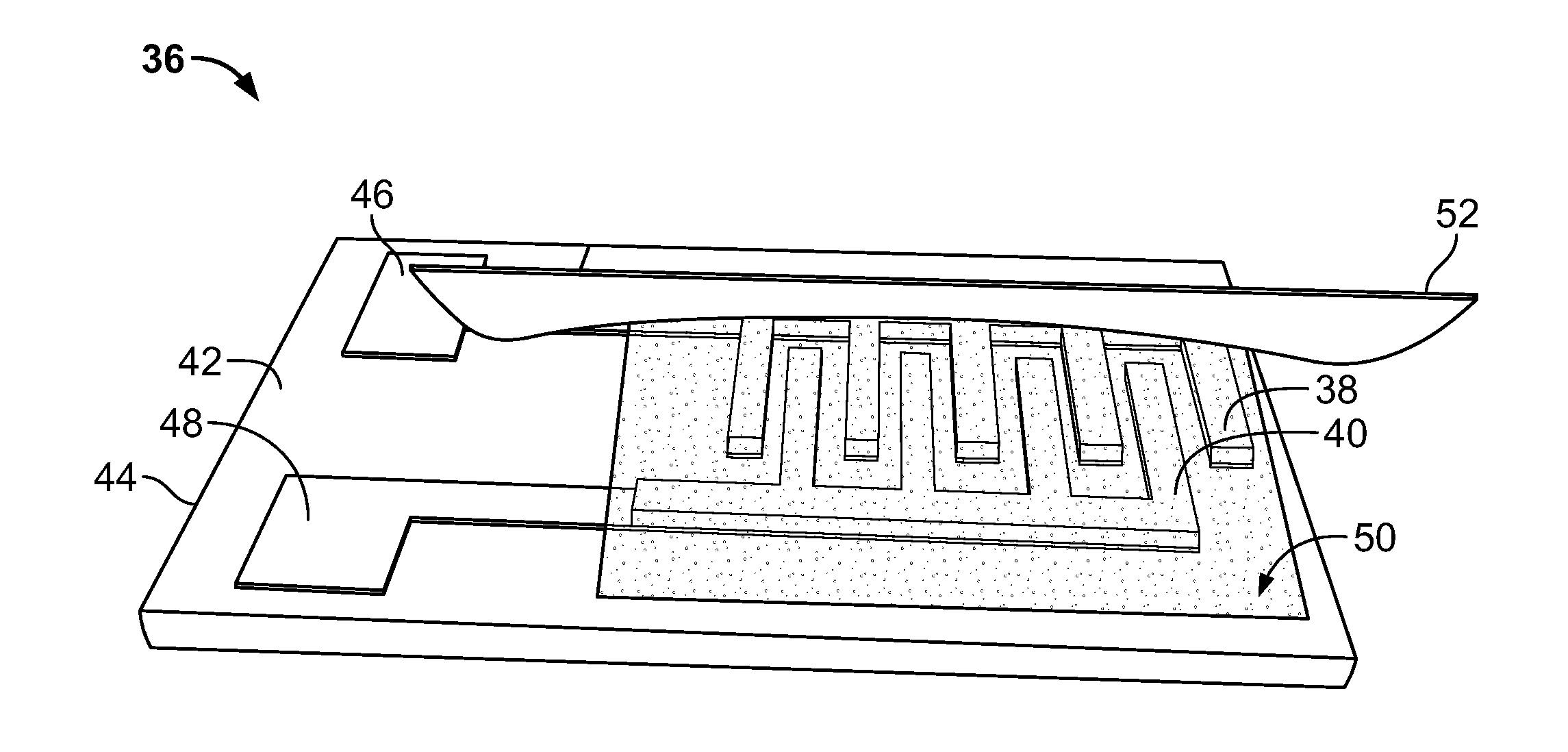

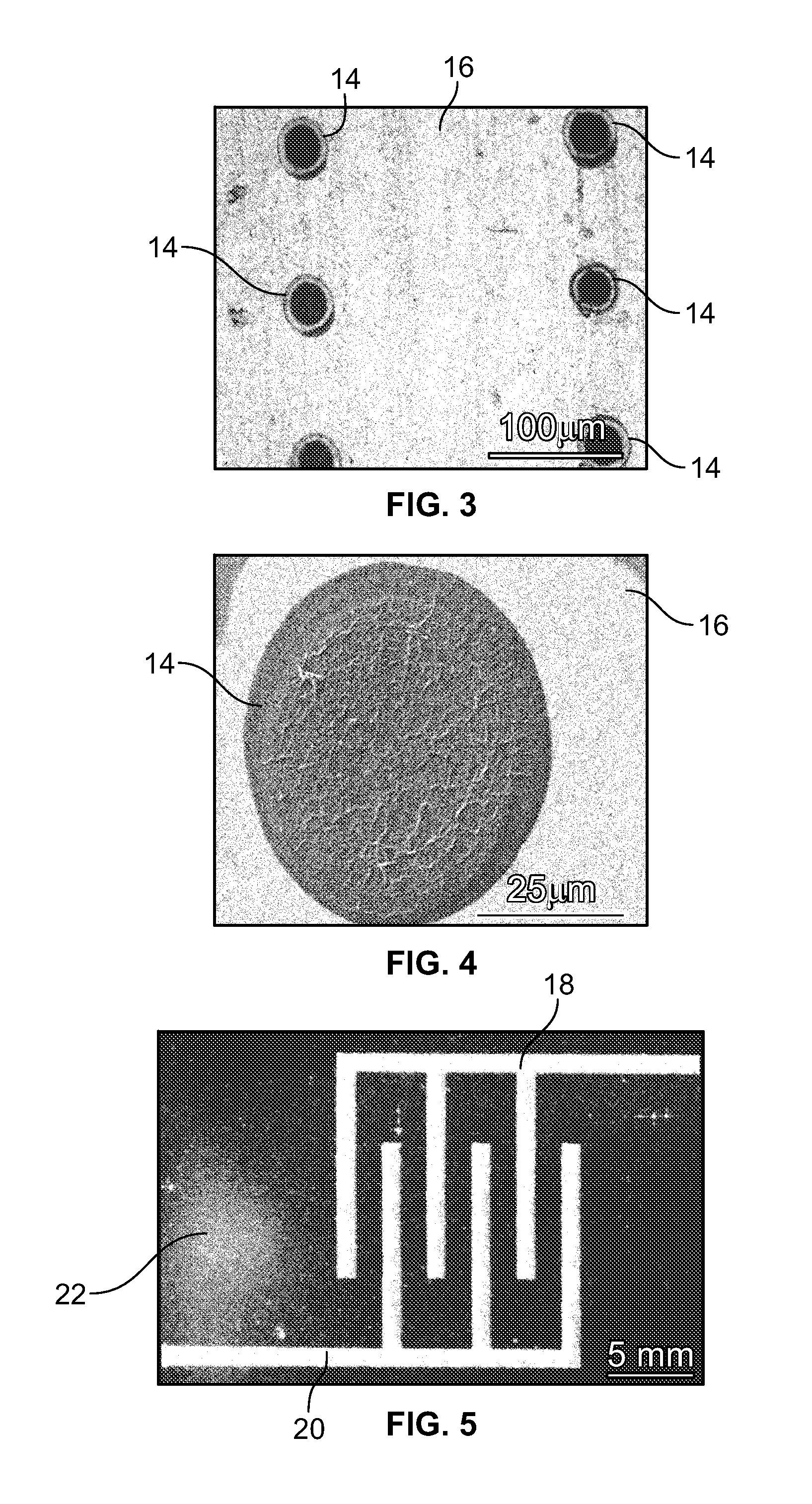

Inkjet-printed flexible electronic components from graphene oxide

InactiveUS20120170171A1Improve conductivityThermally degradedSolid electrolytic capacitorsHybrid capacitor electrodesCarbon nanotubeCharge separation

An electrical component includes an inkjet-printed graphene electrode. Graphene oxide flakes are deposited on a substrate in a graphene oxide ink using an inkjet printer. The deposited graphene oxide is thermally reduced to graphene. The electrical properties of the electrode are comparable to those of electrodes made using activated carbon, carbon nanotubes or graphene made by other methods. The electrical properties of the graphene electrodes may be tailored by adding nanoparticles of other materials to the ink to serve as conductivity enhancers, spacers, or to confer pseudocapacitance. Inkjet-printing can be used to make graphene electrodes of a desired thickness in preselected patterns. Inkjet printing can be used to make highly-transparent graphene electrodes. Inkjet-printed graphene electrodes may be used to fabricate double-layer capacitors that store energy by nanoscale charge separation at the electrode-electrolyte interface (i.e., “supercapacitors”).

Owner:STEVENS INSTITUTE OF TECHNOLOGY +1

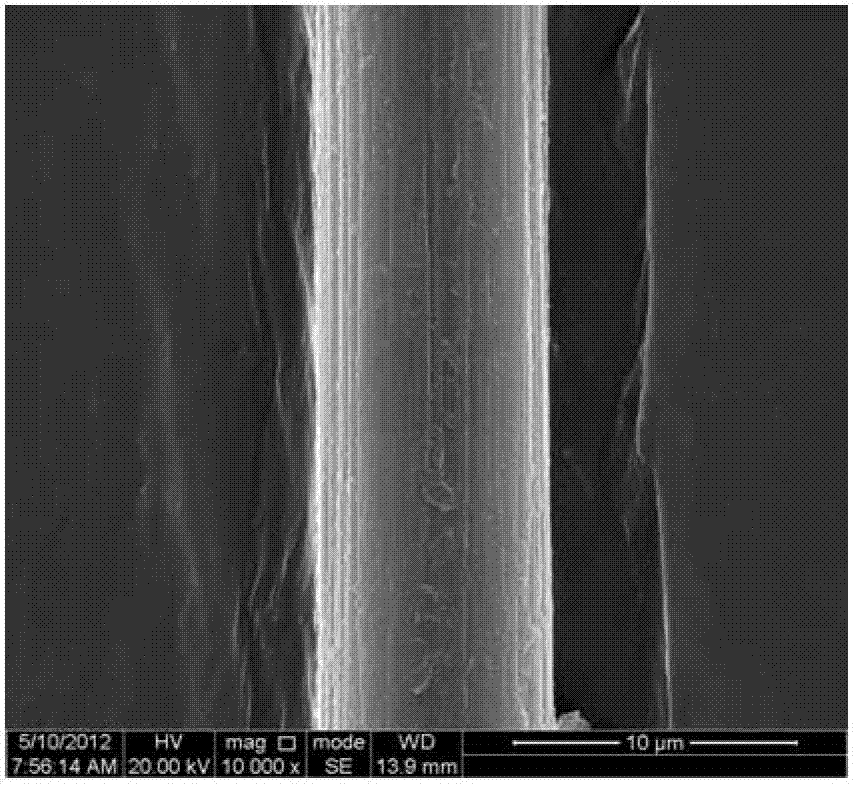

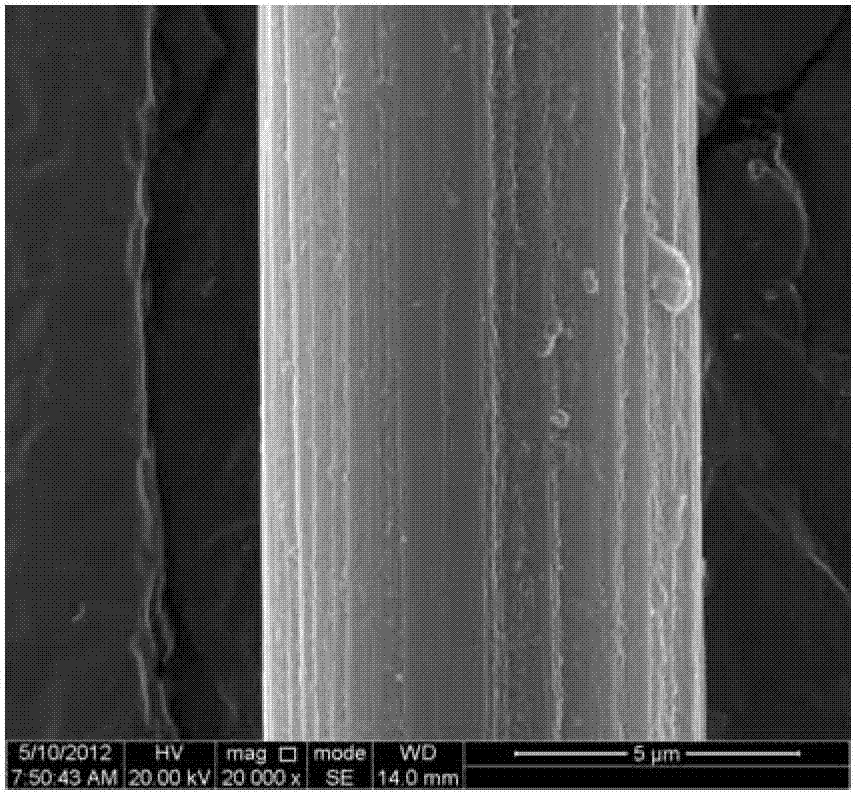

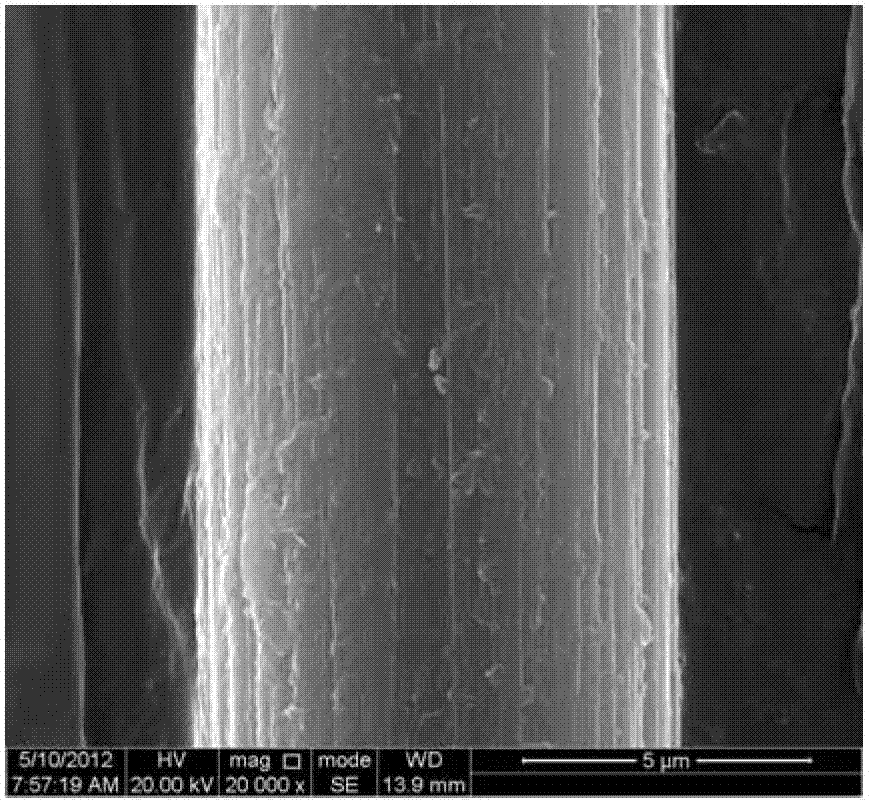

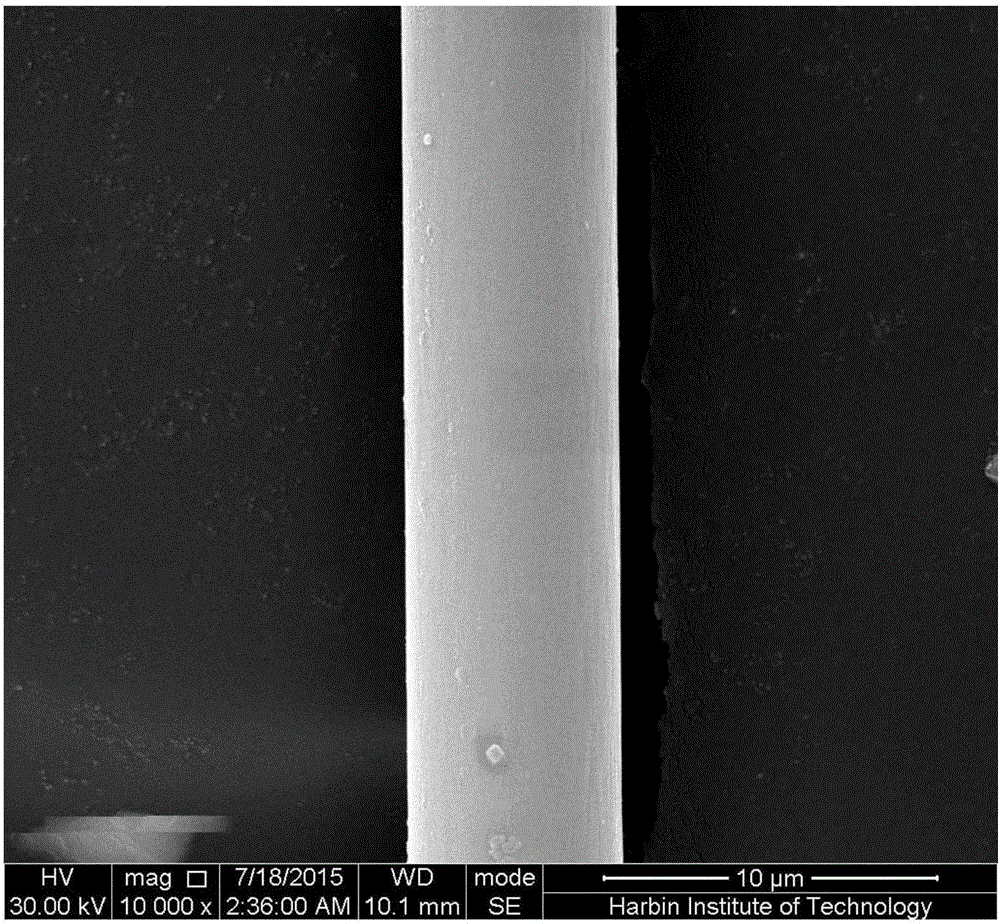

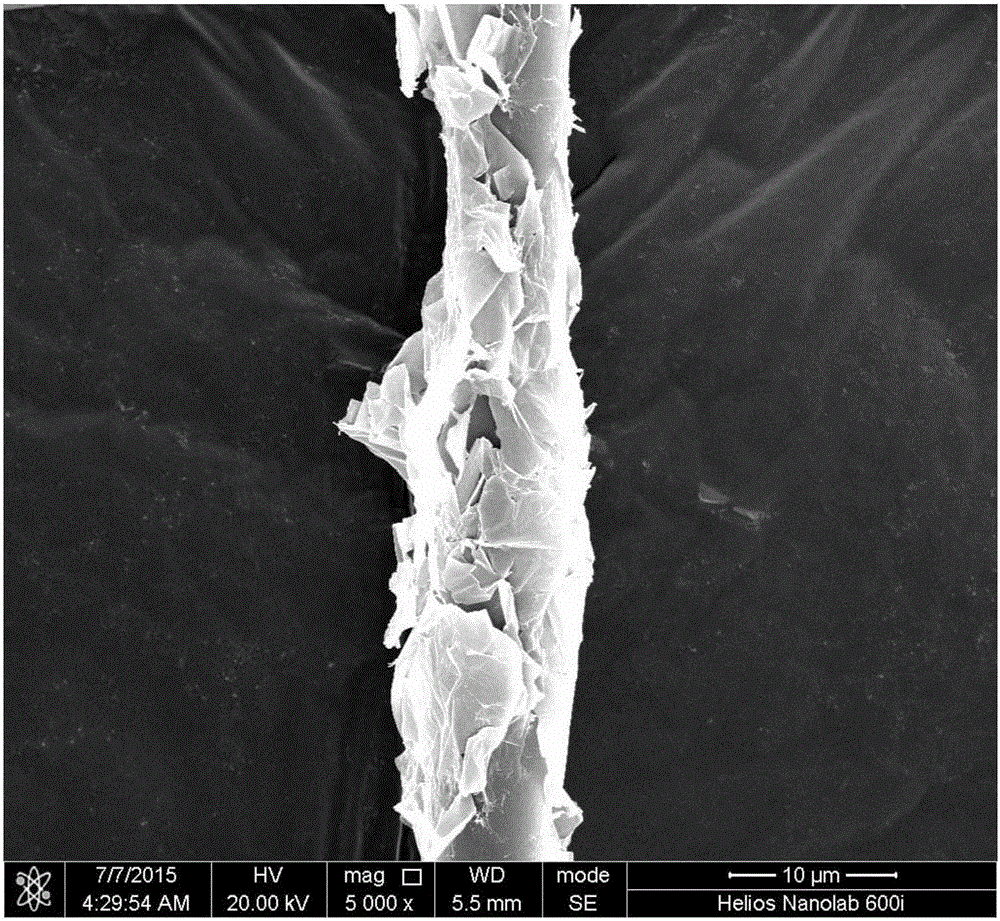

Method for preparing graphene oxide grafting surface modification carbon fiber

ActiveCN102787488AIncrease roughnessImprove interface performanceCarbon compoundsCarbon fibresCarbon compositesResin matrix

A method for preparing a graphene oxide grafting surface modification carbon fiber relates to a carbon fiber modification method, and is used for solving the technical problems that the existing carbon fiber has low surface activity, reduced surface tension and poor wettability with a resin matrix, and the interlaminar shear strength of a composite material is caused to reduce. The method comprises the steps as follows: 1, graphite oxidization; 2, separation of graphite oxide mother liquor; 3, functionalization of graphite oxide; 4, carbon fiber surface functionalization; and 5, carbon fiber surface graphite oxide treatment. The graphite oxide uniformly covers the carbon fiber surface, the roughness of the carbon fiber surface can be greatly improved, and accordingly, the interfacial properties of a carbon fiber reinforced composite material can be improved by an anchoring action. The interfacial shear strength of the surface grafting graphene oxide carbon fiber / carbon composite material which is prepared through graphene oxide grafting modification can be improved by 25% in comparison with that of the untreated surface grafting graphene oxide carbon fiber / carbon composite material.

Owner:HARBIN INST OF TECH

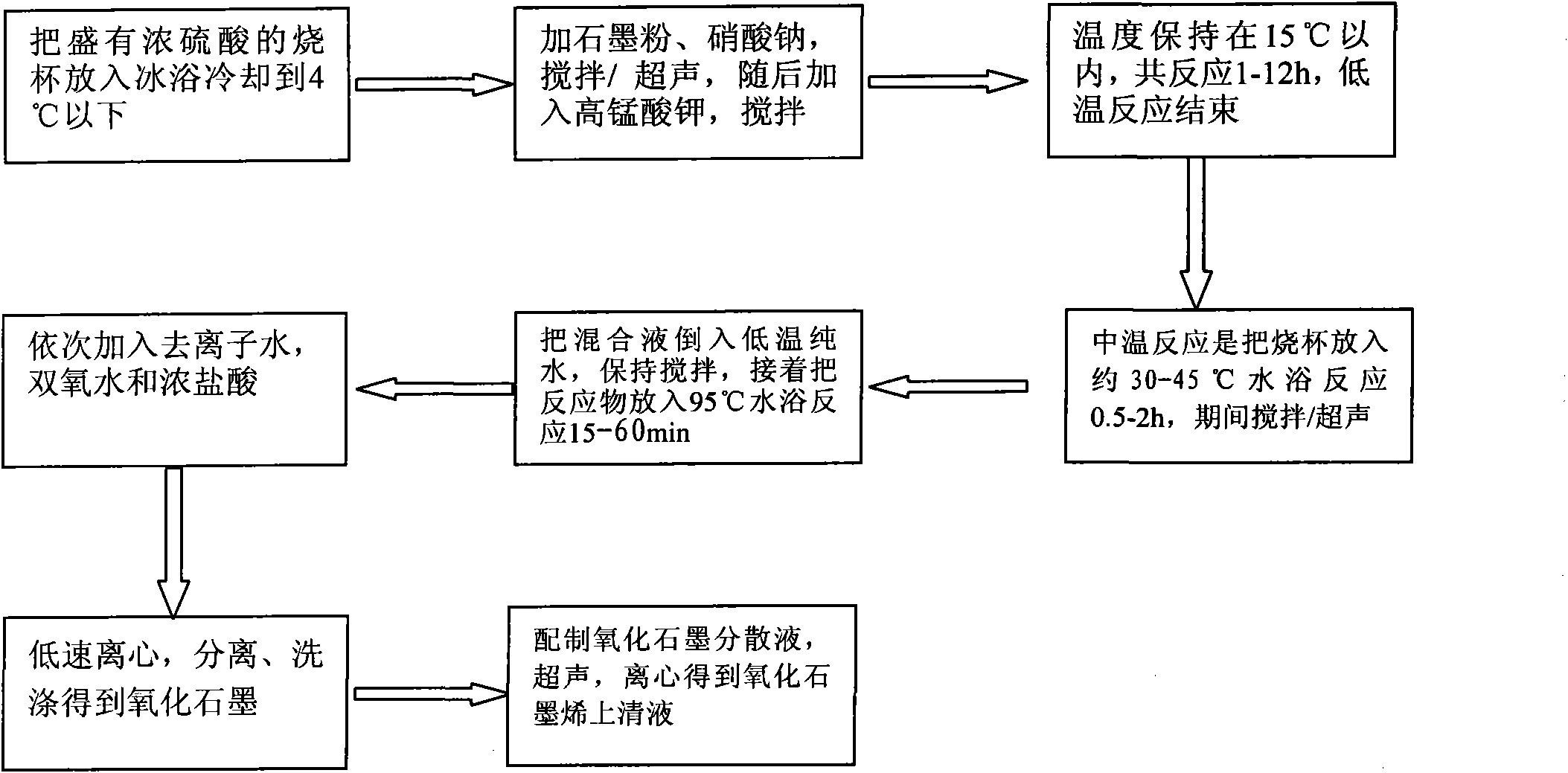

Method for synthesizing graphene oxide by ultrasonic assistance Hummers method

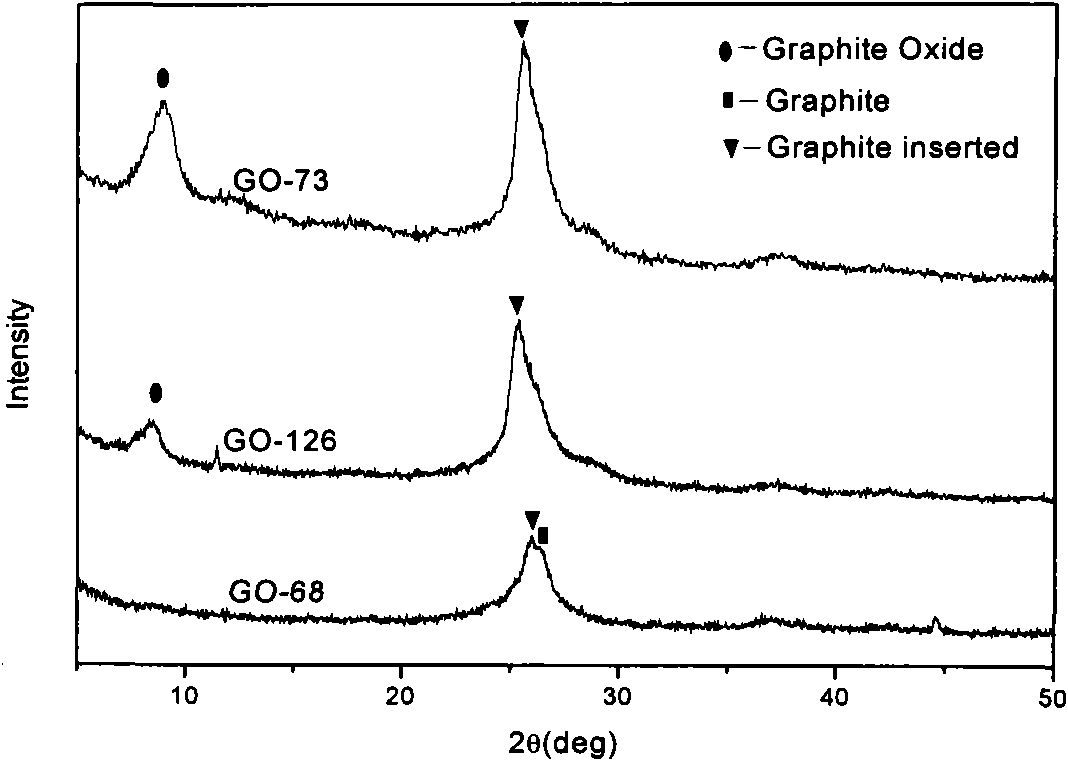

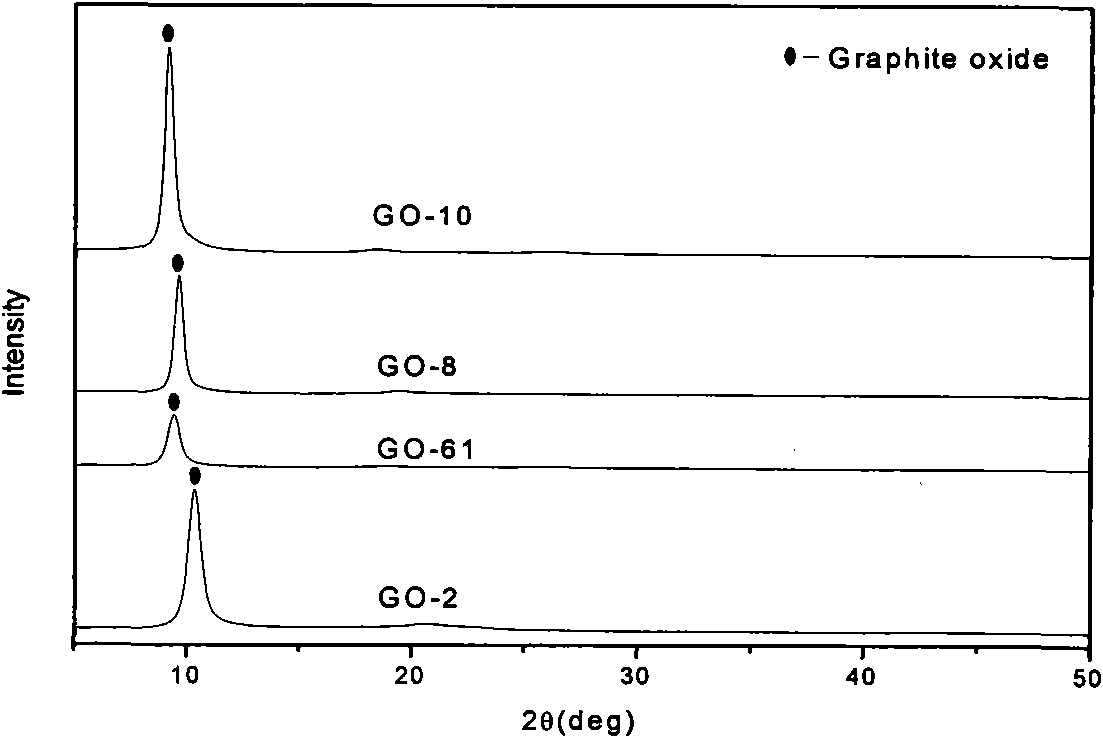

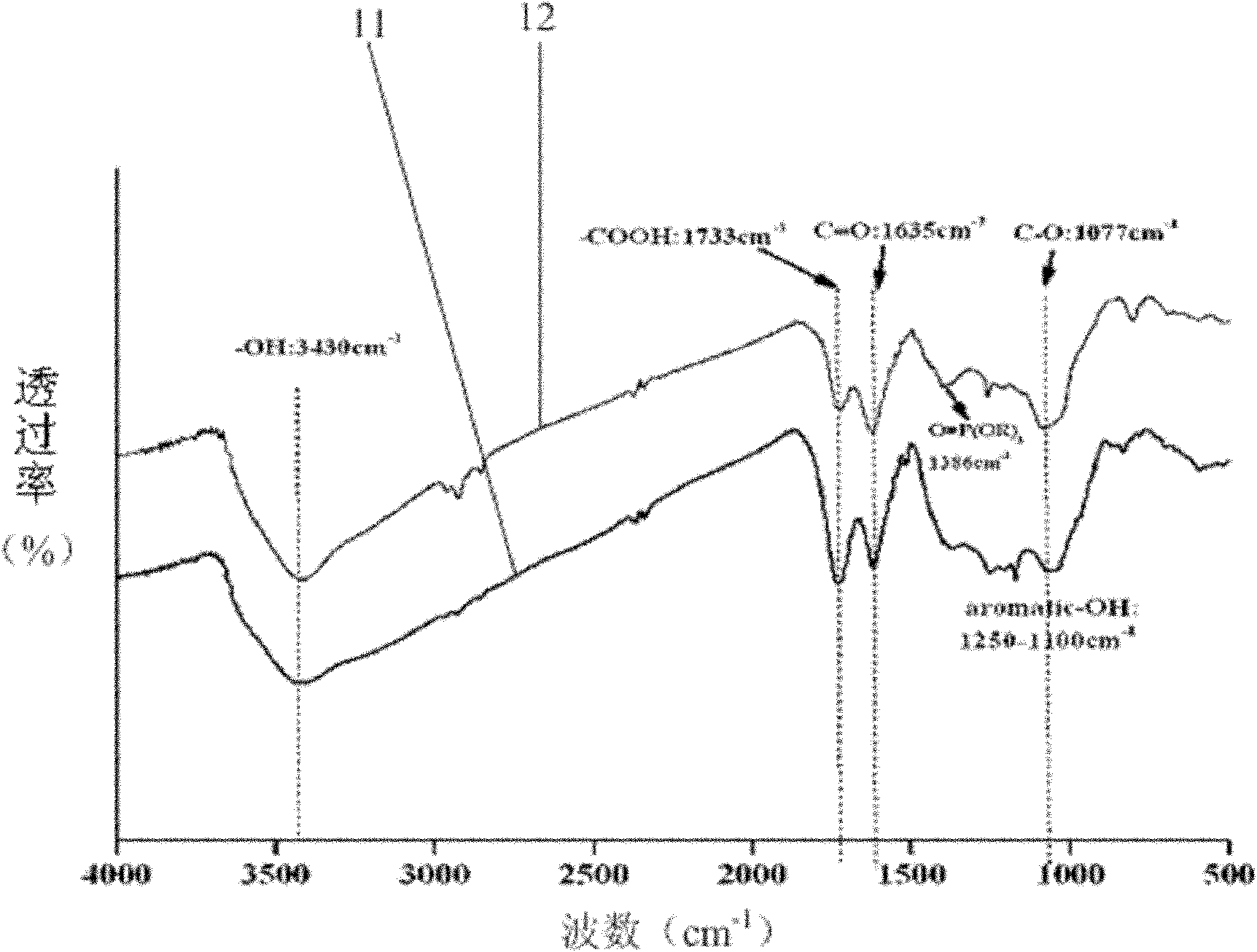

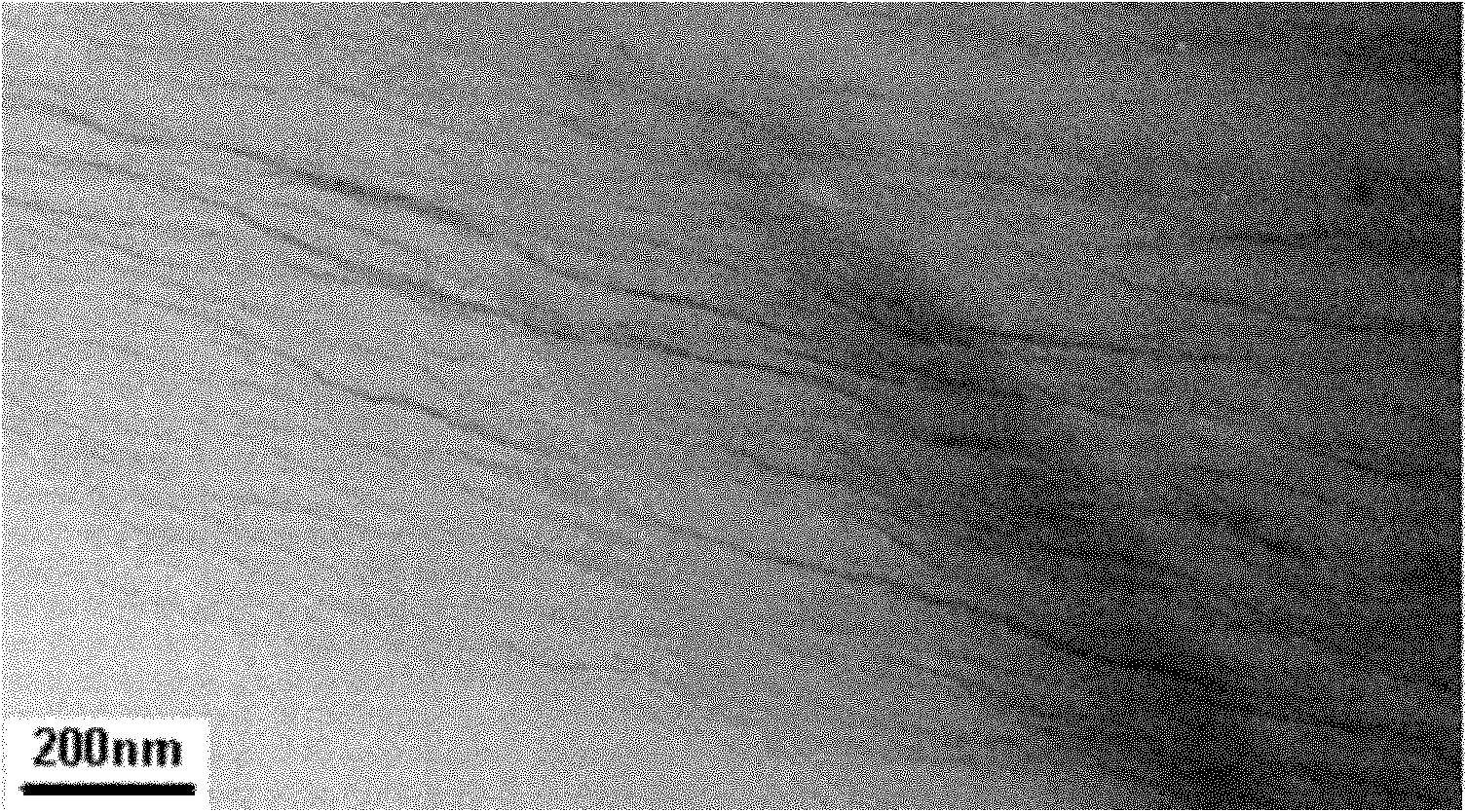

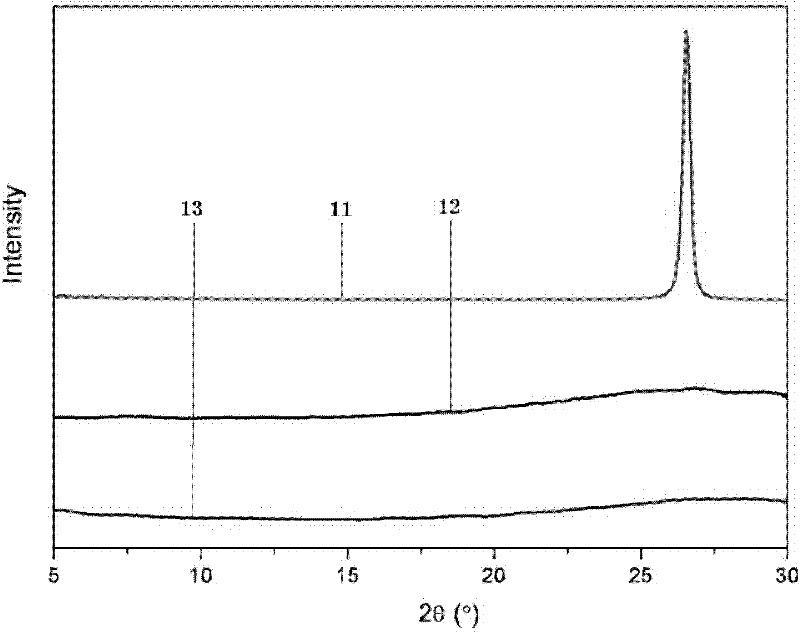

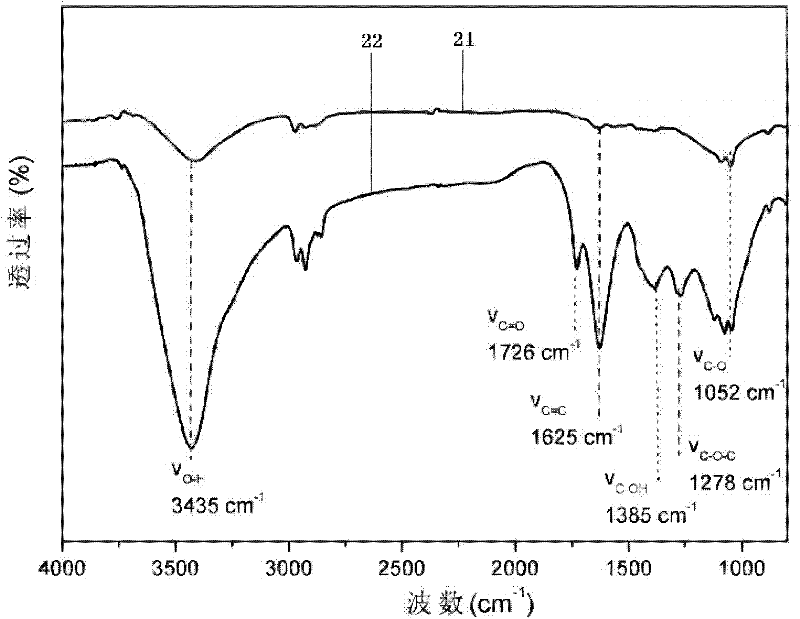

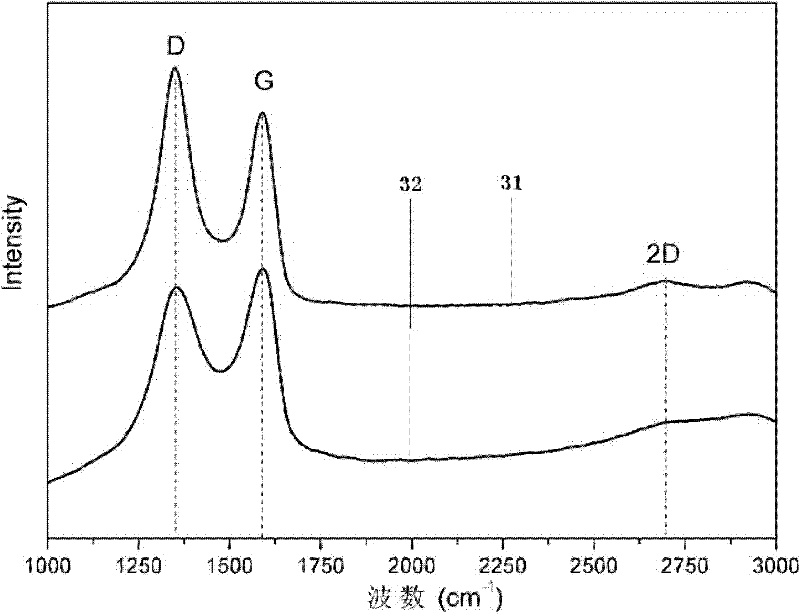

InactiveCN102153075AImprove efficiencyHigh degree of oxidationUltrasonic oscillationMechanical property

The invention relates to a method for synthesizing graphene oxide by an ultrasonic assistance Hummers method. The method for synthesizing the graphene oxide includes the steps as follows: firstly adding ultrasonic oscillation in low-temperature and middle-temperature reaction stages of the Hummers method to improve the intercalation efficiency and the oxidation degree of graphite oxide; secondly slowly dropping mixed liquor containing concentrated sulphuric acid into low-temperature deionized water to increase temperature when high-temperature reaction begins, thus effectively preventing intercalated materials such as sulphuric acid molecules and the like from rapidly escaping from graphite layers due to overhigh local temperature; and finally obtaining the graphite oxide through low-speed centrifugation. The method for synthesizing the graphene oxide by using the ultrasonic assistance Hummers method is convenient and fast, saves resources, and can effectively increase spacings of graphite oxide layers. The prepared graphene oxide can serve as a wild phase of a composite material and papyraceous laminated graphite oxide based composite material with high mechanical property and the like can be prepared. The reduction product graphene can be used for preparing graphene-based composite materials such as transparent electrodes, super capacitors, hydrogen storage materials, chemical / biological sensors, thin film transistors and the like.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Preparation method of modified graphene oxide and preparation method of composite material containing modified graphene oxide

ActiveCN102127324AImprove flame retardant performanceEvenly dispersedPigment treatment with non-polymer organic compoundsEpoxyPolyamide

The invention provides a preparation method of a modified graphene oxide, comprising the following steps of: (a) reacting a phosphorus oxychloride compound, cyanuric chloride or diisocyanate with glycidol to obtain an intermediate product; and (b) dispersing graphite oxide in an organic solvent, dropwise adding to the intermediate product obtained through reaction, and reacting to obtain the modified graphene oxide. The invention also provides a preparation method of a composite material containing the modified graphene oxide, comprising the following steps of: dispersing the modified graphene oxide obtained through the preparation method in the technical scheme in an organic solvent, mixing the modified graphene oxide containing epoxide groups with epoxy resin oligomers and a polyamide curing agent, and curing to obtain the composite material containing the modified graphene oxide. In the composite material provided by the invention, the modified graphene oxide reacts with a resin substrate, is more uniform to disperse in the obtained composite material, and has better flame-retarding performance.

Owner:UNIV OF SCI & TECH OF CHINA

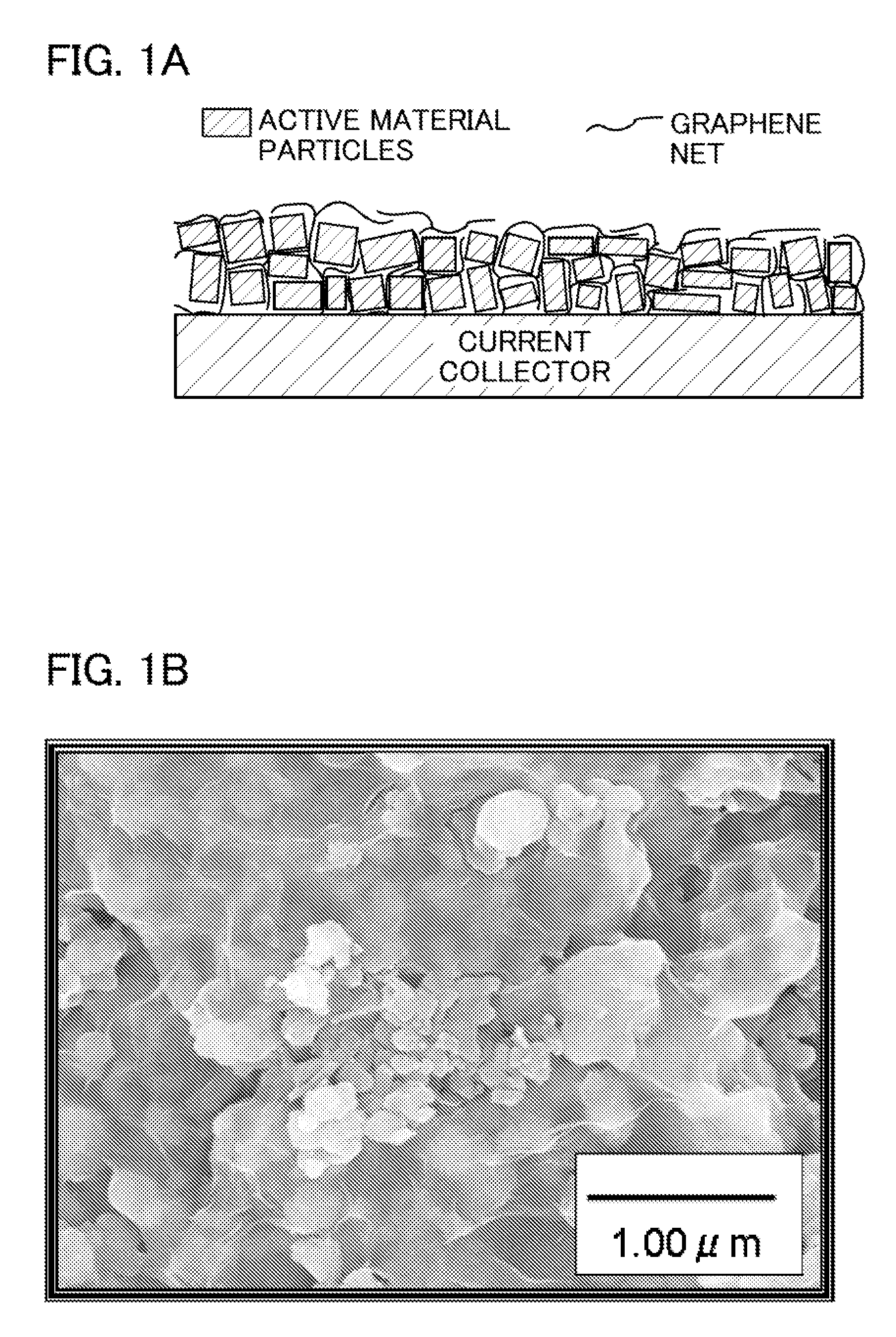

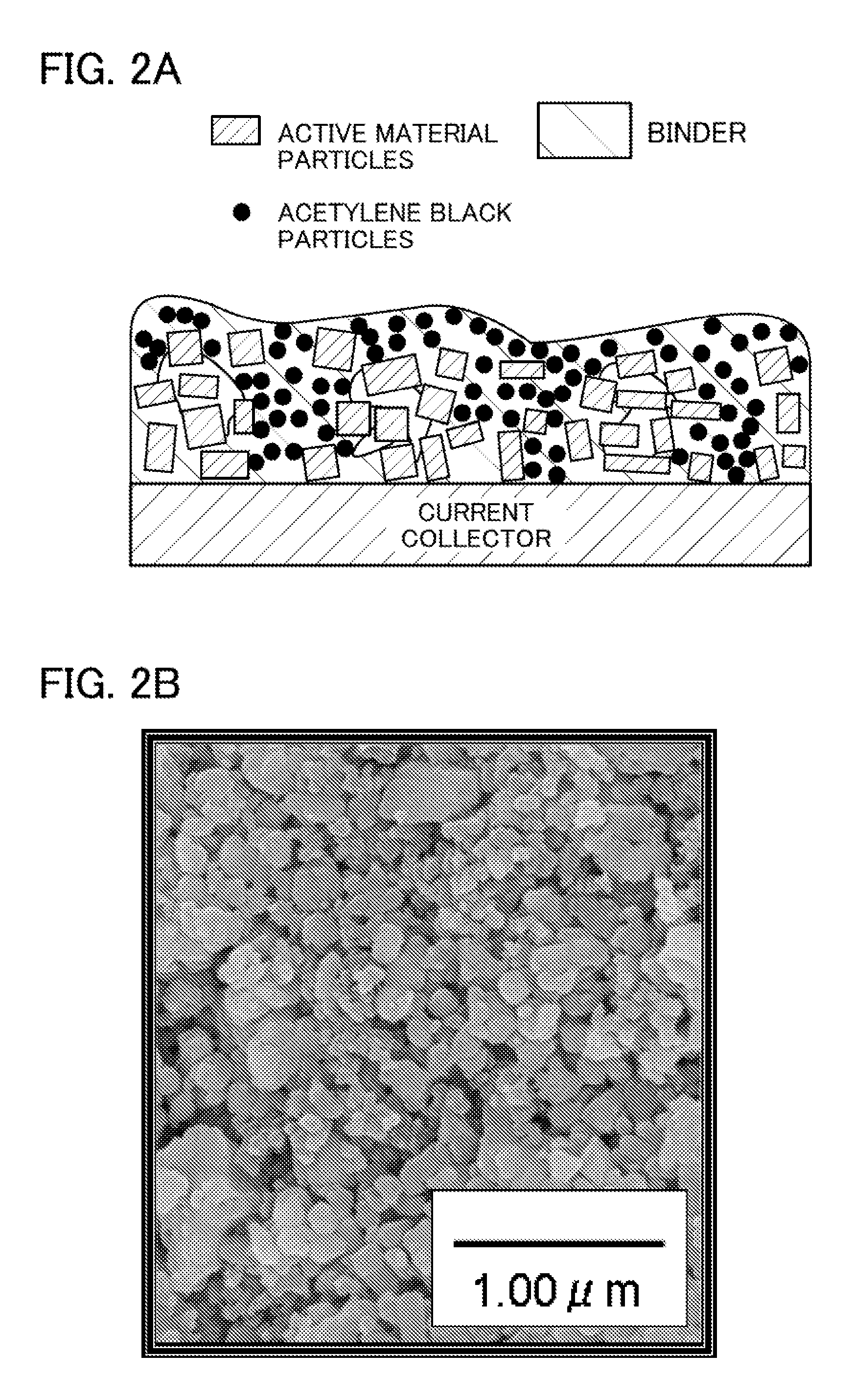

Method of manufacturing electrode

ActiveUS20120308891A1Large electric capacityExcellent electrical propertiesMaterial nanotechnologyElectrode thermal treatmentElectric capacityReducing atmosphere

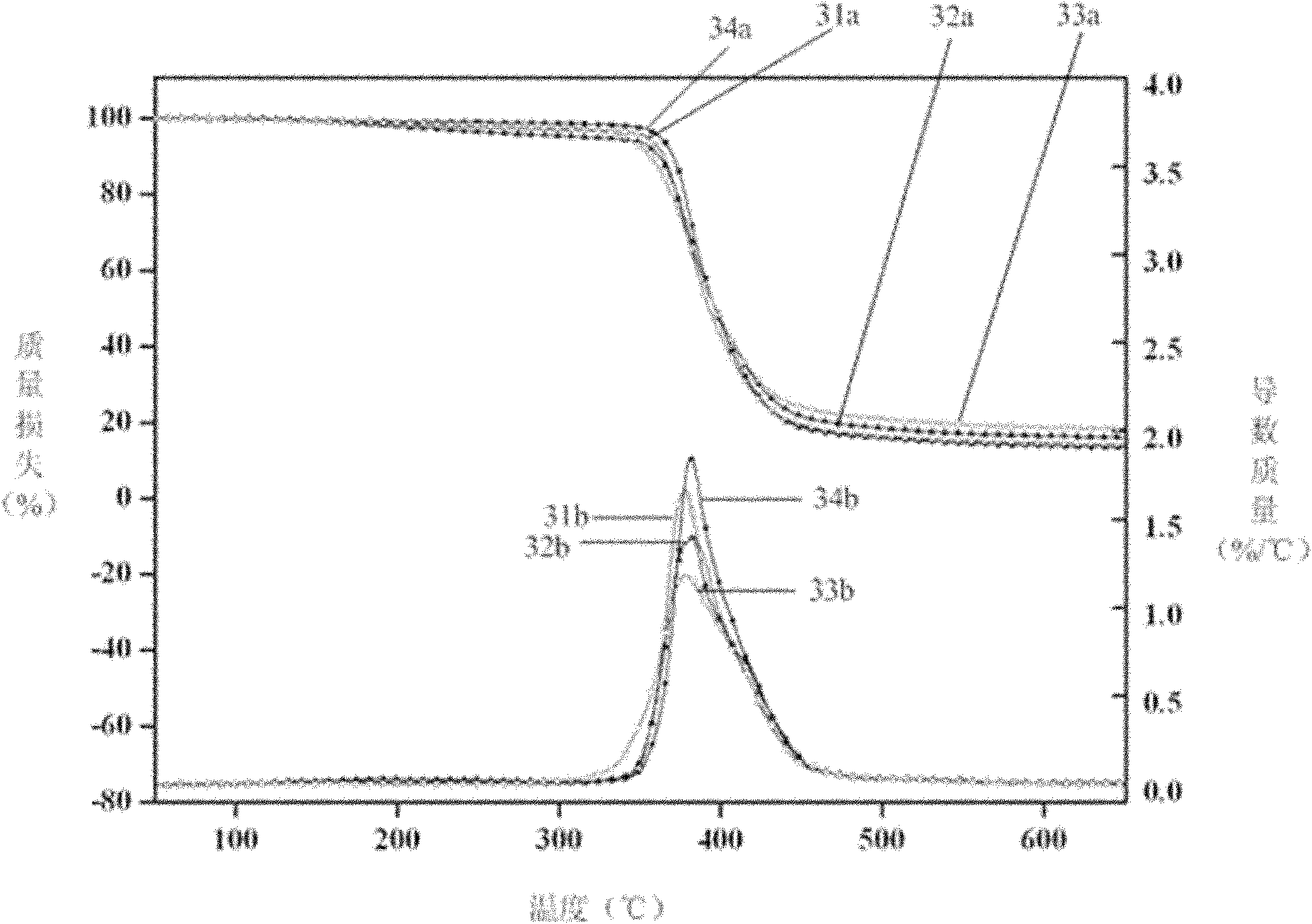

To increase the conductivity and electric capacity of an electrode which includes active material particles and the like and is used in a battery, a graphene net including 1 to 100 graphene sheets is used instead of a conventionally used conduction auxiliary agent add binder. The graphene net which has a two-dimensional expansion and a three-dimensional structure is more likely to touch active material particles or another conduction auxiliary agent, thereby increasing the conductivity and the bonding strength between active material particles. This graphene net is obtained by mixing graphene oxide and active material particles and then heating the mixture in a vacuum or a reducing atmosphere.

Owner:SEMICON ENERGY LAB CO LTD

Preparation method for graphene oxide with high barrier property and polymer nanocomposite film

The invention provides a preparation method for graphene oxide with high barrier property and a polymer nanocomposite film. The preparation method comprises the following steps: graphene oxide is added in solvent for stirring to obtain a colloidal suspension of graphene oxide during the ultrasonic processing at the temperature of 20 to 45 DEG C; a polymer is added in the colloidal suspension of graphene oxide for stirring during the ultrasonic processing at the temperature of 20 to 120 DEG C, until the polymer is completely dissolved to obtain a solution of graphene oxide / polymer; and after air bubbles in the solution of graphene oxide / polymer are removed, the graphene oxide / polymer nanocomposite film is obtained by a casting method or blow molding method. The carbon dioxide transmission coefficient of the prepared nanocomposite film containing graphene oxide is reduced by more than 150 times, and the prepared nanocomposite film containing graphene oxide can be used for packaging food and drugs with higher requirements of barrier property.

Owner:XIAN UNIV OF TECH

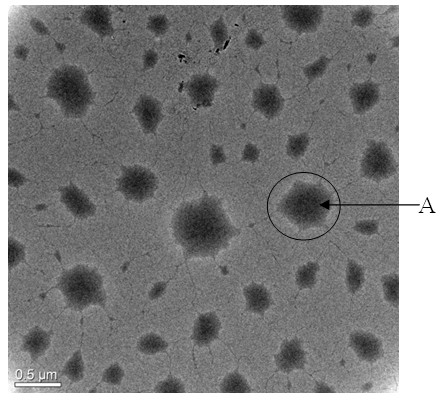

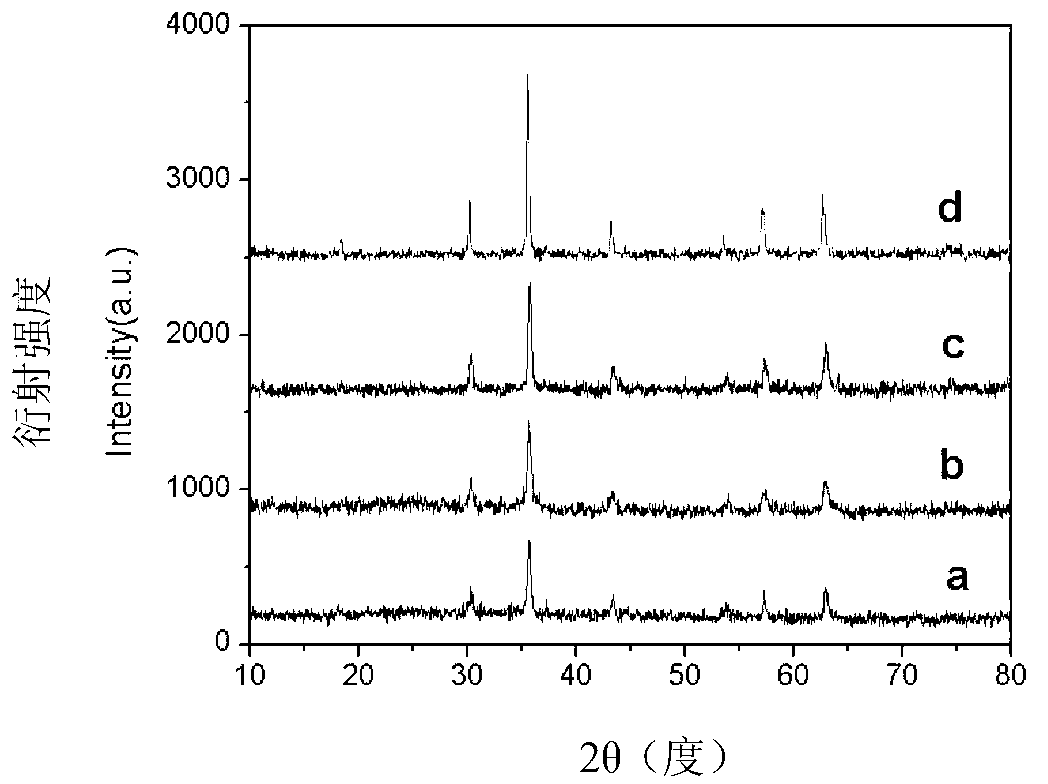

Method for preparing reduced graphene oxide/ferroferric oxide nano-grade wave-absorbing materials

InactiveCN103173189ASimple preparation conditionsEasy to makeOther chemical processesWave bandGraphene oxide paper

The invention relates to a method for preparing a reduced graphene oxide / ferroferric oxide nano-grade wave-absorbing material. With the method, the RGO-Fe3O4 composite wave-absorbing material can be easily and rapidly produced with large scale. The RGO-Fe3O4 composite wave-absorbing material is prepared with one step with a simplified co-precipitation method. The preparation method is simple and fast, and assists in realizing large-scale production. The prepared composite material has good wave-absorbing performance. Through the adjustment upon the ratio of RGO and Fe3O4 and the thickness of the composite material, effective absorption of different wave bands can be realized.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for preparing graphene oxide/white carbon black/rubber nanocomposite material

A method for preparing a graphene oxide / white carbon black / rubber nanocomposite material is described. The prepared graphene oxide / white carbon black / rubber nanocomposite material contains nanoscale graphene oxide and white carbon black that are highly dispersed. The nanocomposite material has a relatively high modulus, excellent wear resistance and tear resistance, a relatively low rolling resistance, and at the same time has a low air-permeability and excellent self-healing capability.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method for graphene oxide/polyvinylidene fluoride composite ultrafiltration membrane

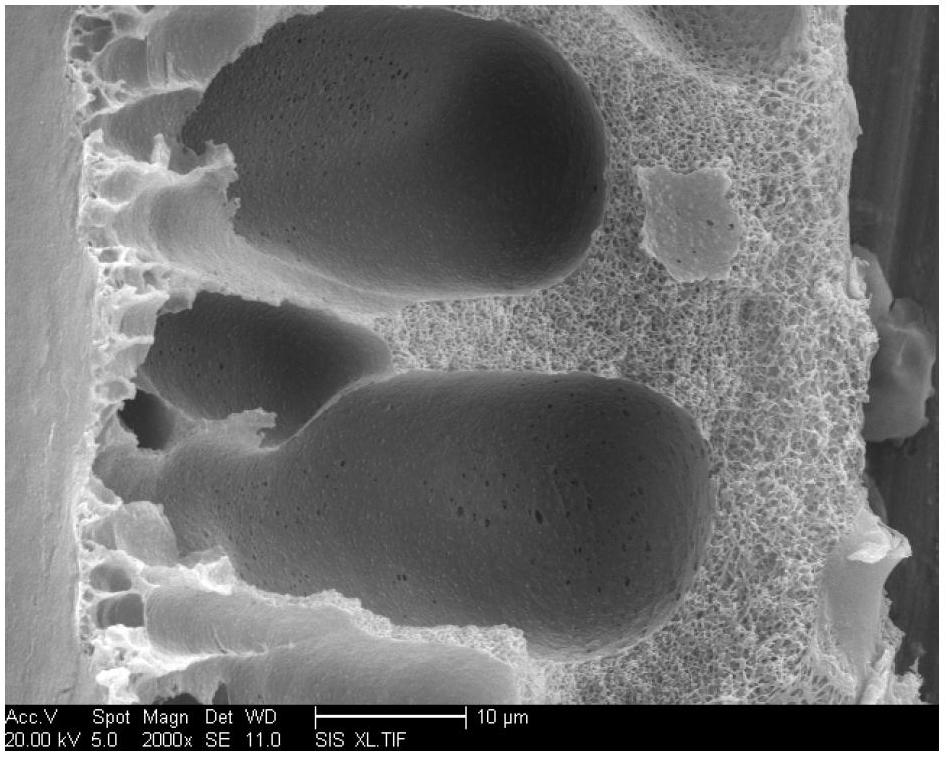

InactiveCN102688707AImprove hydrophilicityStrong stain resistanceUltrafiltrationUltrafiltrationGlass sheet

The invnetion provides a preparation method for a graphene oxide / polyvinylidene fluoride composite ultrafiltration membrane and relates to the preparation method of the graphene oxide / polyvinylidene fluoride composite ultrafiltration membrane. The invention aims to solve the problem of poor hydrophilicity and stain resistance of the existing polyvinylidene fluoride ultrafiltration membrane. The method provided by the invention comprises the following steps of: 1. respectively adding graphene oxide, polyvinylpyrrolidone and polyvinylidene fluoride with N-methylpyrrolidone as solvent, heating and stirring to obtain casting membrane solution; 2. putting the casting membrane solution on a clean glass plate and scrapping to a certain thickness by a coating device, and then immersing distilled water, shedding and drying to obtain the graphene oxide / polyvinylidene fluoride composite ultrafiltration membrane. The preparation method provided by the invention can be applied to the fields of drinking water preparation, food industry, pharmaceutical industry, biotechnology, chemical process and environmental engineering.

Owner:HARBIN INST OF TECH

Preparation method of graphene oxide and preparation method of graphene

The invention provides a preparation method of graphene oxide, which comprises the following steps of: uniformly mixing graphite, a concentrated acid and a strong oxidant; and carrying out reaction in a sealed environment at 80-130 DEG C to obtain grapheme oxide. The invention also provides a preparation method of graphene, which comprises the following steps of: uniformly mixing graphite, a concentrated acid and a strong oxidant; carrying out reaction in a sealed environment at 80-130 DEG C to obtain grapheme oxide; adding hydrazine hydrate to the grapheme oxide; and carrying out reduction reaction to obtain graphene. The methods provided by the invention do not need step-by-step precise control of reaction temperature and reaction time, and the process is simple and easy to operate. Graphene oxide prepared by the preparation method provided by the invention has multiple oxygen-containing functional groups, facilitates surface modification, and widens the application of graphene oxide.

Owner:UNIV OF SCI & TECH OF CHINA

Preparation method for graphene aerogel

The invention discloses a preparation method for graphene aerogel. The method comprises the following steps: preparing an aqueous polyvinyl alcohol solution containing graphene oxide so as to obtain a graphene oxide dispersion liquid with a concentration of 1 to 10 mg / cm<3>; subjecting the graphene oxide dispersion liquid to freezing in the condition of no higher than minus 196 DEG C so as to obtain a frozen sample; subjecting the frozen sample to freezing and drying so as to obtain a frozen-dried sample; and subjecting the frozen-dried sample in an argon-hydrogen mixed gas environment to high-temperature reduction so as to obtain the required graphene aerogel, wherein the high-temperature reduction comprises the steps of burning at 350 to 450 DEG C for 2 to 3 hours and burning again at 900 to 1100 DEG C for 2 to 3 hours. The preparation method for the graphene aerogel provided by the invention adopts a liquid nitrogen freezing manner to obtain a graphene oxide aerogel precursor, the subsequent segmented high-temperature reduction process is combined, the frozen-dried sample undergoes high-temperature burning at different temperatures, polyvinyl alcohol is removed and graphene oxide is reduced at high temperature, so the graphene aerogel is finally obtained; meanwhile, the graphene aerogel obtained by using the method in the invention has stable structure, good homogeneity and stable material performance.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

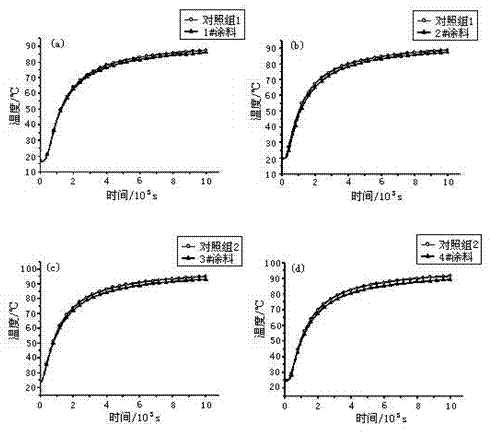

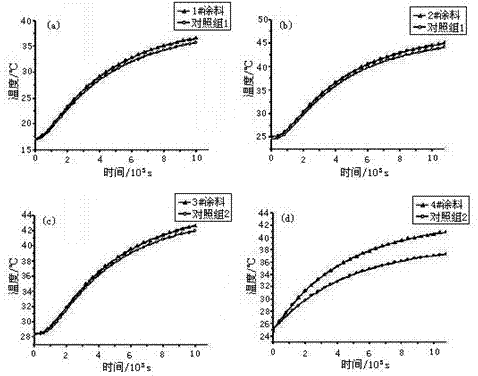

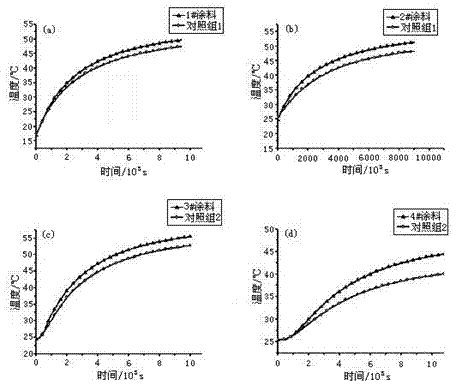

Composite intensified heat dissipation coating containing graphene or graphene oxide and preparation method of coating

ActiveCN102964972AHigh infrared emissivityIncrease the areaPolyester coatingsComparative testTemperature resistance

The invention discloses a composite intensified heat dissipation coating containing graphene or graphene oxide and a preparation method of the coating. The performances of the coating are combined with the performances of infrared ray radiation of tourmaline and transition metal oxide, larger specific surface areas and high thermal conductivity coefficients of the graphene and the graphene oxide, excellent adhesive property of resin, high strength and excellent high-temperature resistance. The functional powder and the graphene or the graphene oxide are dispersed in the resin under the synergistic effect of various auxiliaries so as to prepare the composite intensified heat dissipation coating. In the preparation method, the graphene or the graphene oxide wraps the surface of the infrared emission powder by a reflux method; based on the higher thermal conductivity coefficient of the graphene or the graphene oxide, the thermal resistance of infrared particles can be lowered effectively and the infrared emissivity of the infrared particles is improved; in comparative test with the normal heat dissipation coating, the infrared emissivity of the coating provided by the invention can be 0.96 and is improved by 6.6%, 6.37% of energy is saved, and better energy-saving effect is realized.

Owner:HEBEI UNIV OF TECH

Preparation method of grapheme capable of dispersing in organic solvent

ActiveCN101863465AExcellent solvent dispersion performanceEasy to synthesizeOrganic solventHydrazine compound

The invention relates to a preparation method of grapheme capable of dispersing in an organic solvent, comprising chemical reduction of a graphene oxide stem grafting arborization substituent group and graphene oxide. In the invention, the arborization substituent group with huge volume is utilized to functionalize graphene oxide, thereby the obtained graphene oxide can be dispersed in a majority of organic solvents, and after the graphene oxide is reduced by hydrazine hydrate, the obtained graphene still keeps excellent organic solvent dispersibility. In the invention, excess reactants, impurities and solvent in the preparation process of a solution method are removed by utilizing means of filtering and washing so that a purified graphene product is obtained, and the graphene product is powdery, is convenient to store and transport, and meets the requirement of preparation in macroscopic quantity. The graphene prepared by utilizing the invention has excellent solvent dispersibility, therefore, a powdery graphene sample can be dispersed in a specific organic solvent again as required to obtain required graphene sol for large-scale application.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

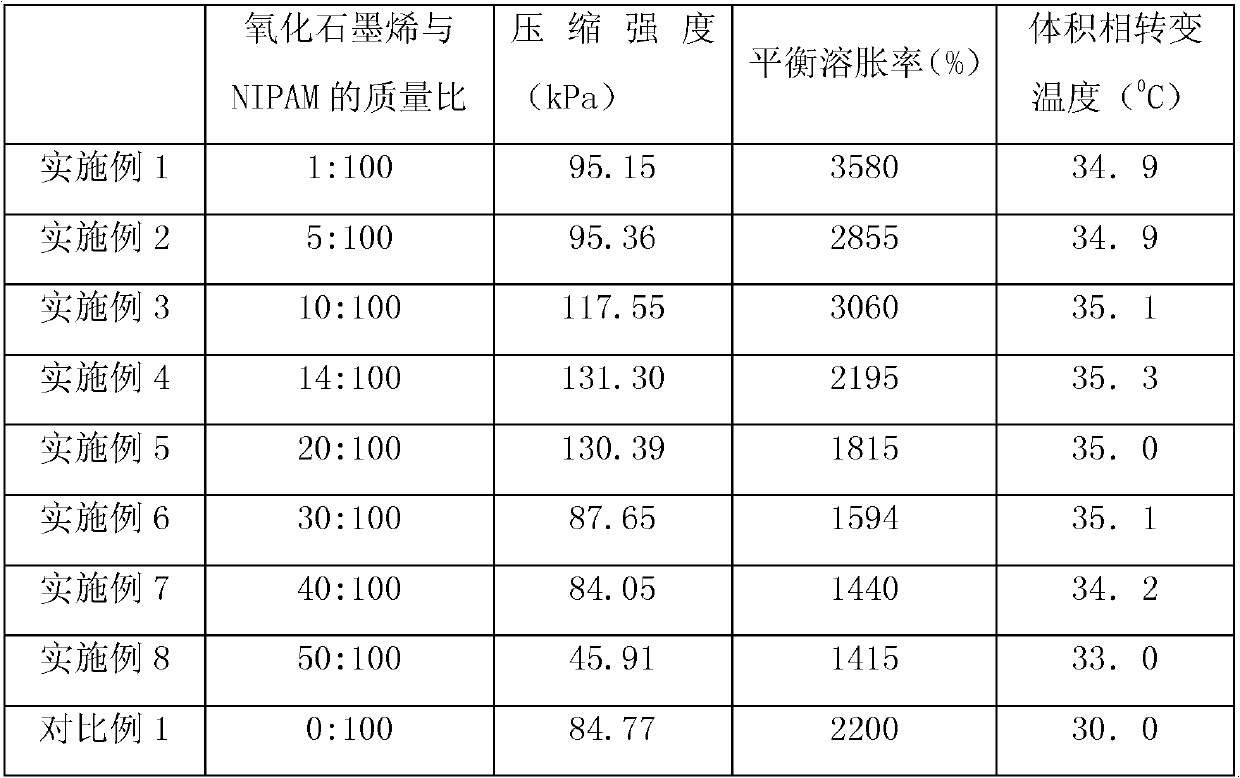

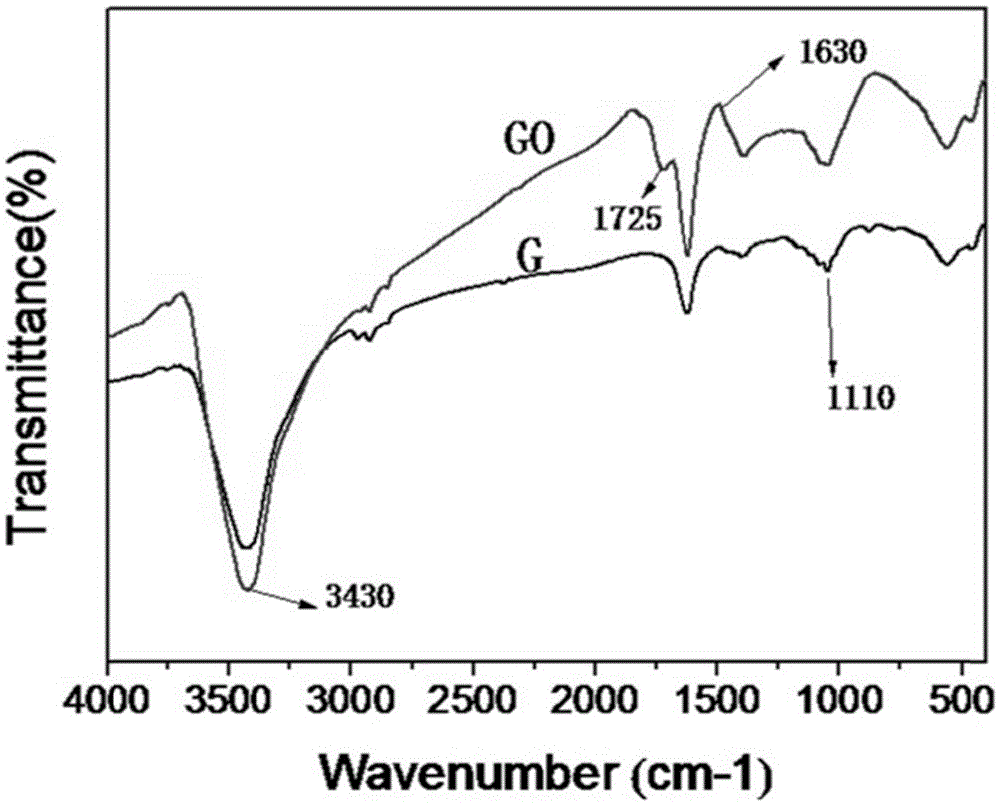

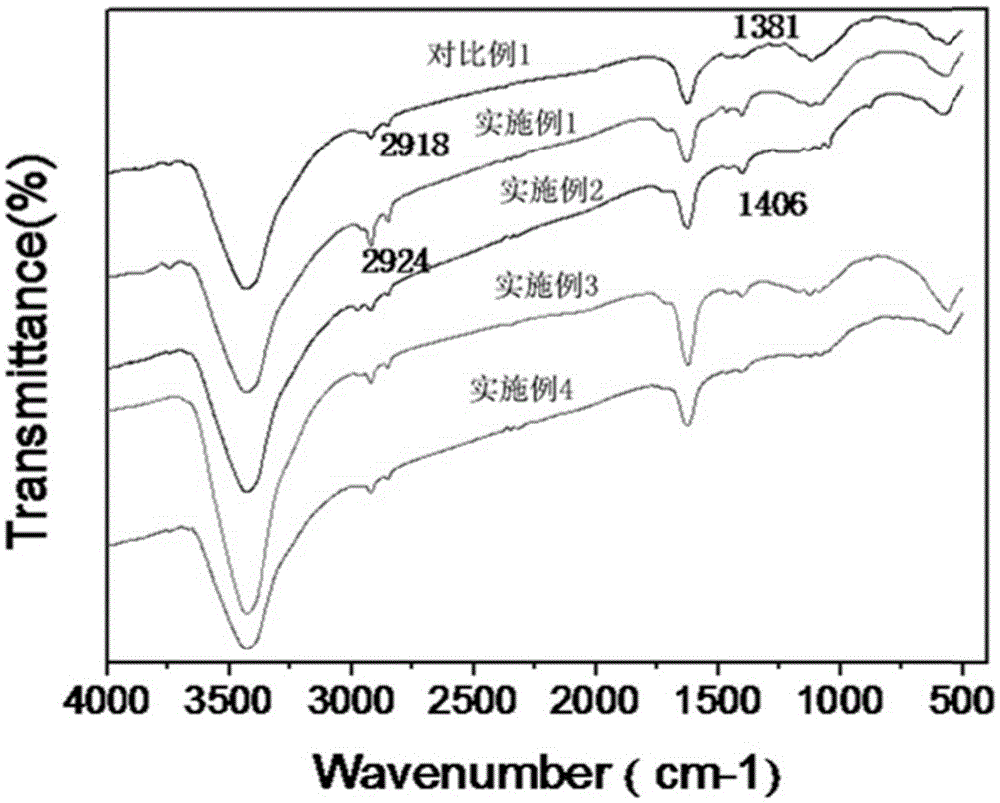

Preparation method of graphene oxide/poly(N-isopropylacrylamide) composite hydrogel

InactiveCN102580633AIncrease temperatureImprove mechanical propertiesColloidal chemistry detailsWater bathsCross-link

The invention discloses a preparation method of graphene oxide / poly(N-isopropylacrylamide) composite hydrogel. The preparation method comprises the steps of: firstly, placing the graphene oxide in water and ultrasonically dispersing the graphene oxide for 30-60 min to obtain a graphene oxide colloidal solution; then adding N-isopropylacrylamide, a cross-linking agent and an initiator 1 in the graphene oxide colloidal solution; stirring for dissolving so as to obtain a mixed solution; then inflating nitrogen in the mixed solution to deoxidize fully, then adding an initiator 2 in the deoxidized mixed solution, mixing uniformly and placing the mixture in a thermostatic water bath at 25+ / -1 DEG C so as to obtain the graphene oxide / poly(N-isopropylacrylamide) composite hydrogel. The graphene oxide / poly(N-isopropylacrylamide) composite hydrogel prepared by the method disclosed by the invention has the advantages of good temperature responsiveness and mechanical property and wide application prospect in the biomedical field (such as tissue engineering and drug controlled release).

Owner:QINGDAO UNIV

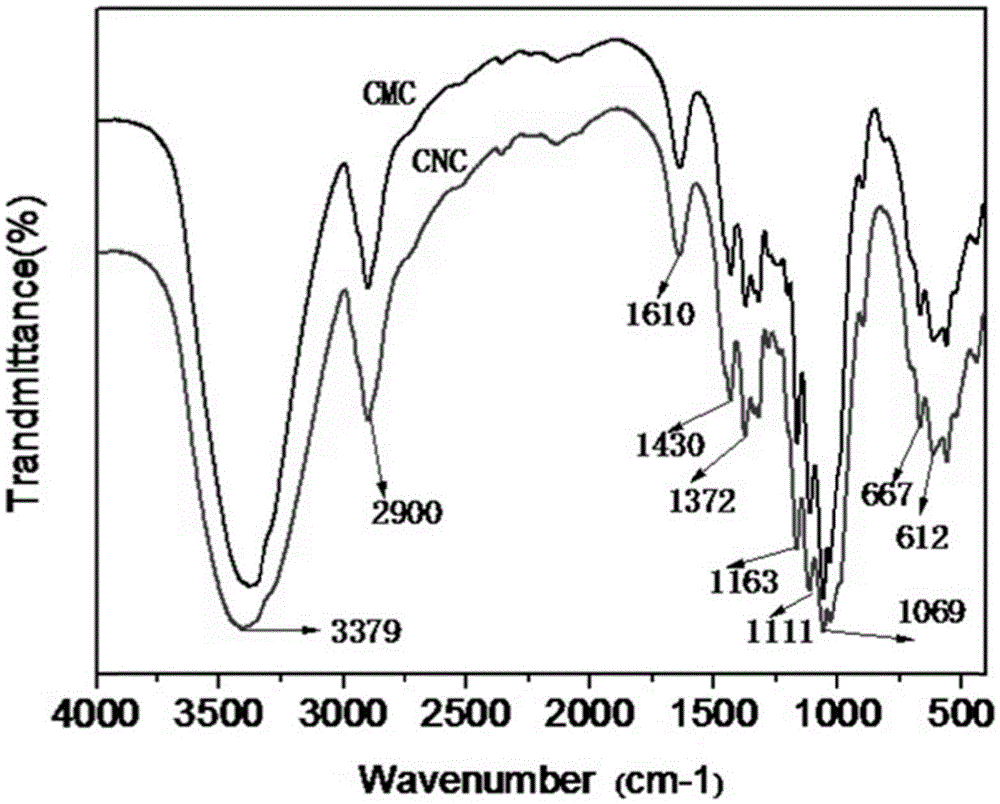

Graphene oxide/nano cellulose aerogel and preparation method and application thereof

ActiveCN105566659AGood removal effectEfficient purificationWater/sewage treatment by sorptionOrganic dyePhenol

The invention discloses a graphene oxide / nano cellulose aerogel and a preparation method and an application thereof, and belongs to the technical field of aerogel material. The aerogel is prepared by the method including the following steps: 1) dispersing nano cellulose in hydrochloric acid to prepare a nano cellulose dispersion liquid; 2) mixing a graphene oxide dispersion liquid with the nano cellulose dispersion liquid obtained in the step 1) evenly, and carrying out a hydrothermal reaction at the temperature of 170-190 DEG C to obtain a hydrogel; and 3) carrying out freeze drying of the hydrogel obtained in the step 2) to obtain the aerogel. According to the graphene oxide / nano cellulose aerogel provided by the invention, nano cellulose and graphene oxide as raw materials are subjected to hydrothermal reaction to prepare the hydrogel, the hydrogel is further subjected to freeze drying to obtain the final product. Compared with a graphene oxide aerogel, the aerogel has better removal effect on phenol in a phenol aqueous solution, can be used for removal of organic dye molecules or other impurities in sewage, and efficiently purifies the sewage.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

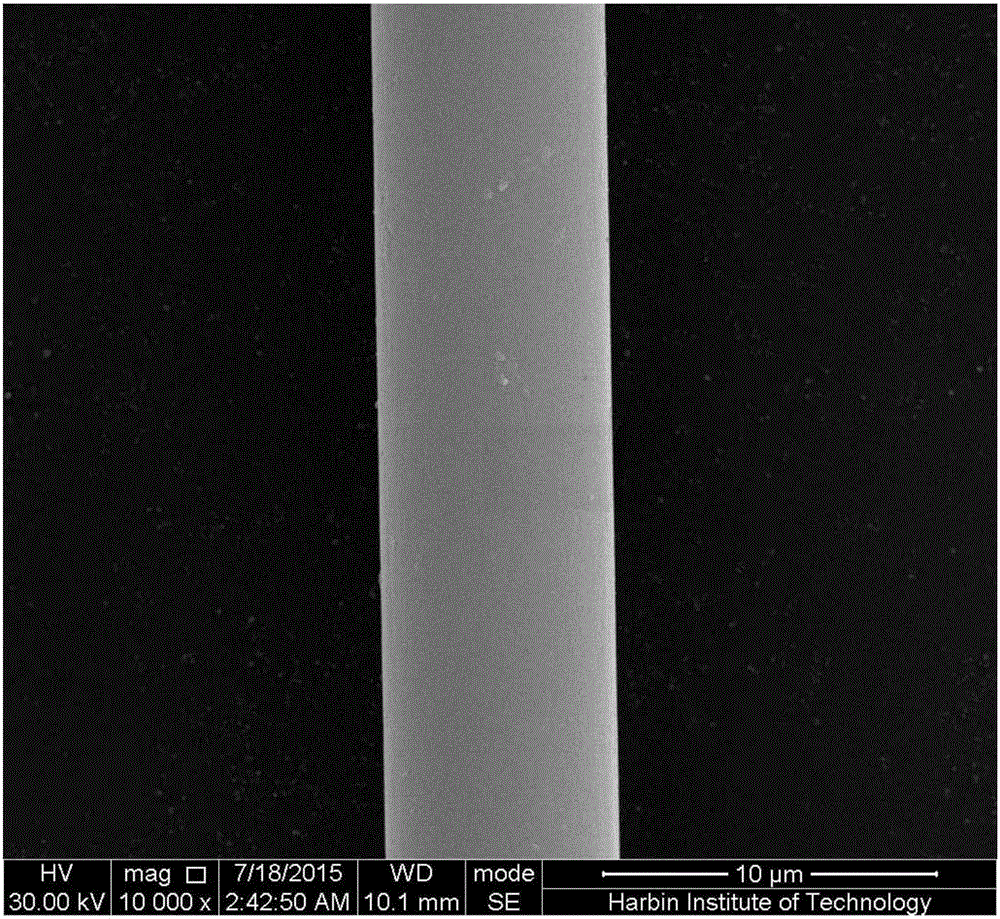

Method of chemically-grafting graphene oxide onto surface of carbon fiber

InactiveCN105239357AImprove surface roughnessImprove surface wettabilityCarbon fibresFiberCarbon fibers

A method of chemically-grafting graphene oxide onto surface of carbon fibers. The invention relates to a surface modification method of the carbon fibers and aims to solve the problems of high surface inertia, low surface energy and poor mechanical and thermal performances of the carbon fibers in the prior art. The method includes following steps: (1) preparing graphene oxide through improved Hummer's method; (2) oxidizing the carbon fibers; (3) performing surface modification amination treatment to the carbon fibers; and (4) chemically-grafting the graphene oxide onto the surface of the carbon fibers. The surface of the carbon fibers is improved significantly in wettability and adhesivity and is significantly improved in roughness after grafting, so that the strength and toughness of the carbon fiber are significantly improved, wherein the strength is increased by 20-25% than carbon fiber raw filament and the toughness is increased by 35-40% that the carbon fiber raw filament. The method is used for surface modification of the carbon fibers.

Owner:HARBIN INST OF TECH

Preparation method of graphene oxide/bacterial cellulose antibacterial compound material

InactiveCN104072809AEasy to prepareFew stepsMicroorganism based processesAbsorbent padsUltrasonic dispersionCvd graphene

The invention discloses a preparation method of a graphene oxide / bacterial cellulose antibacterial compound material. The preparation method comprises the following steps: (1) inoculating activated bacterial cellulose into a seed medium to culture, then, inoculating the activated bacterial cellulose into a fermentation medium according to an inoculum size of 5-10%, and after fully and uniformly mixing, putting in a constant-temperature culture box at 30+ / -2 DEG C, standing and fermenting for 1-2 weeks to obtain a bacterial cellulose wet film; (2) after alkali-washing the bacterial cellulose wet film, pulping to a homogeneous phase suspension liquid by virtue of a mechanical method; (3) mixing a graphene oxide solution with the bacterial cellulose homogeneous phase suspension liquid, and carrying out ultrasonic dispersion to prepare a homogeneous phase mixed liquid; (4) decompressing and filtering the homogeneous phase mixed liquid, and freezing and drying to separate the graphene oxide / bacterial cellulose antibacterial compound material. The preparation method of the graphene oxide / bacterial cellulose antibacterial compound material disclosed by the invention is simple, few in step and easy to operate, and the prepared graphene oxide / bacterial cellulose antibacterial compound material has excellent antibacterial performance and can be widely applied to the fields such as medical dressing and artificial skins.

Owner:NANJING FORESTRY UNIV

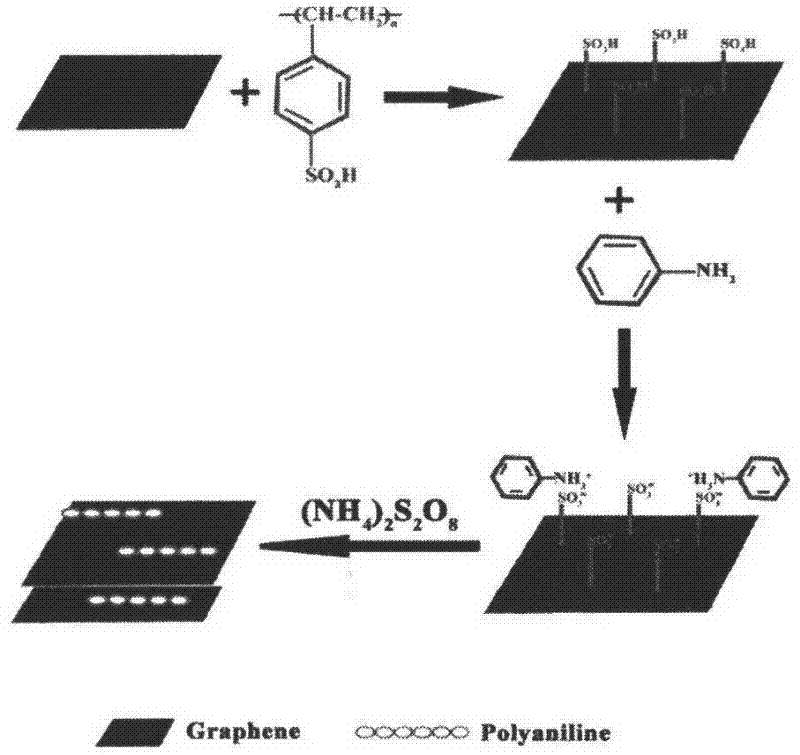

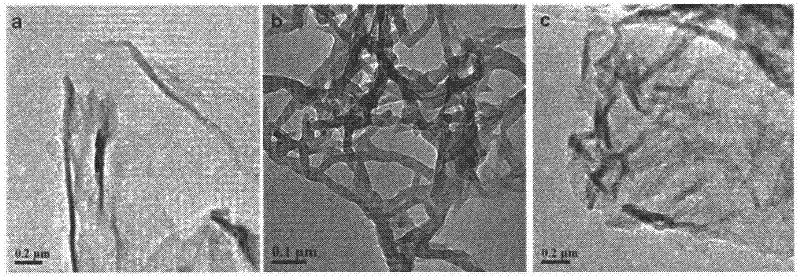

Synthesis method of water dispersible polyaniline/graphene composite material

Belonging to the field of composite material preparation, the invention provides a preparation method of a polyaniline / graphene composite material able to disperse in water stably. The material is prepared by the following steps of: 1) reducing graphene oxide to graphene with hydrazine hydrate; 2) dispersing the newly prepared graphene in a solution containing a macromolecular dispersant; 3) then adding aniline for dispersing; 4) at a low temperature, adding a solution of an oxidizing agent and an inorganic acid into the obtained mixed solution dropwisely, and conducting stirring for polymerization; and 5) carrying out centrifugation and washing, thus obtaining the polyaniline / graphene composite material. Due to the auxiliary effect of the macromolecular dispersant, the polyaniline / graphene composite material obtained in the invention can disperse uniformly in water and can be stored stably. And the obtained dispersed solution generates no sediment after 6 months of placement. Thus, the method of the invention solves the problem of difficult processing of a polyaniline / graphene composite material.

Owner:JIANGNAN UNIV

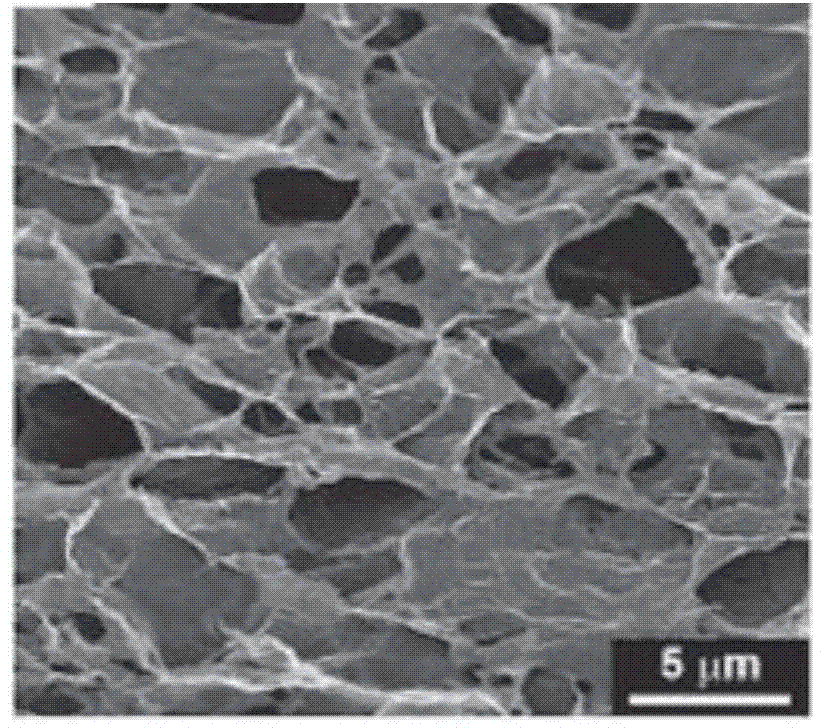

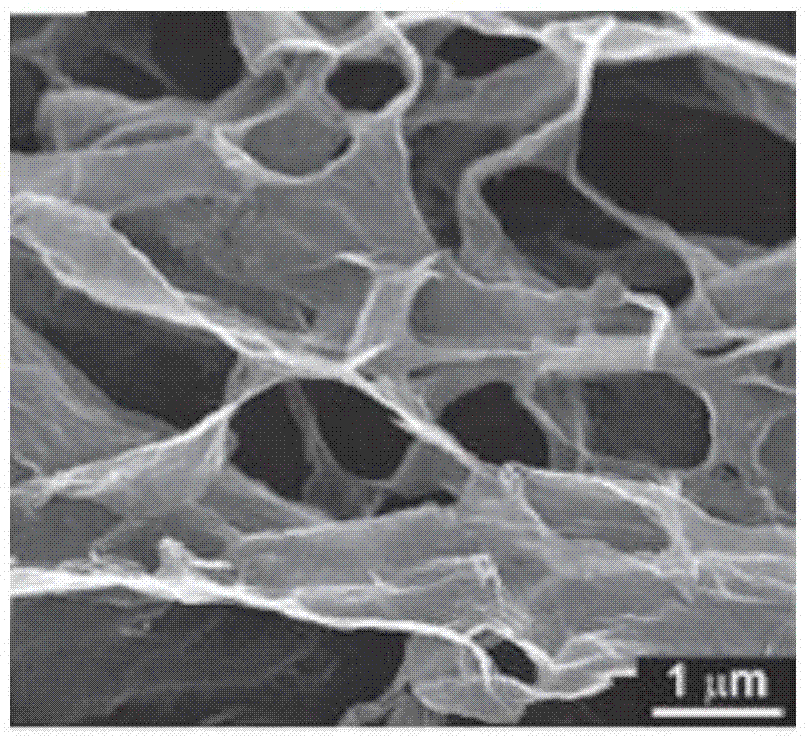

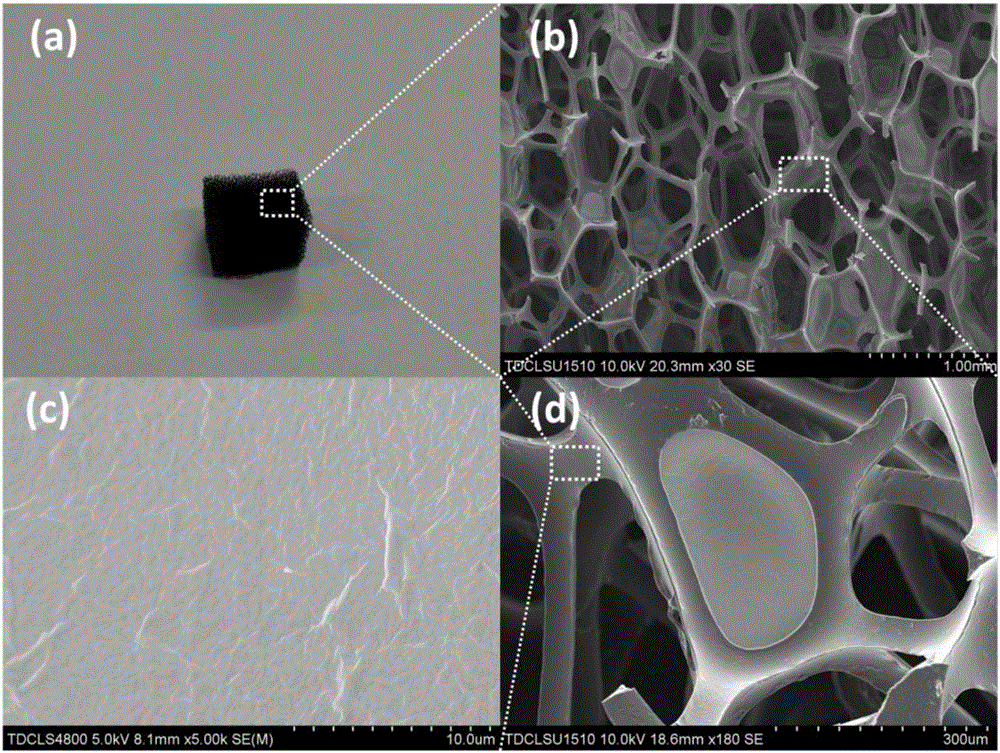

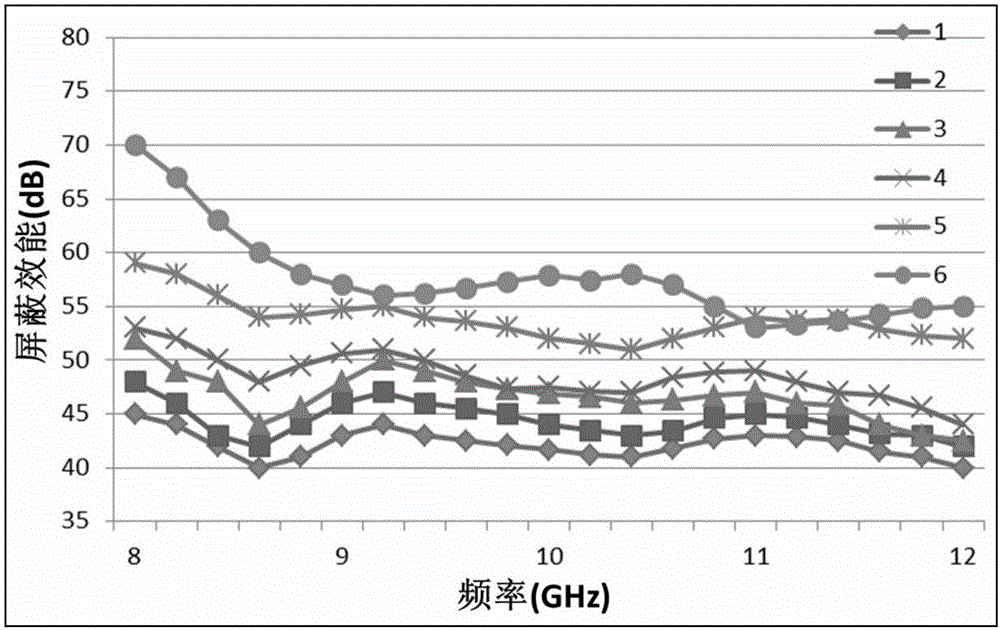

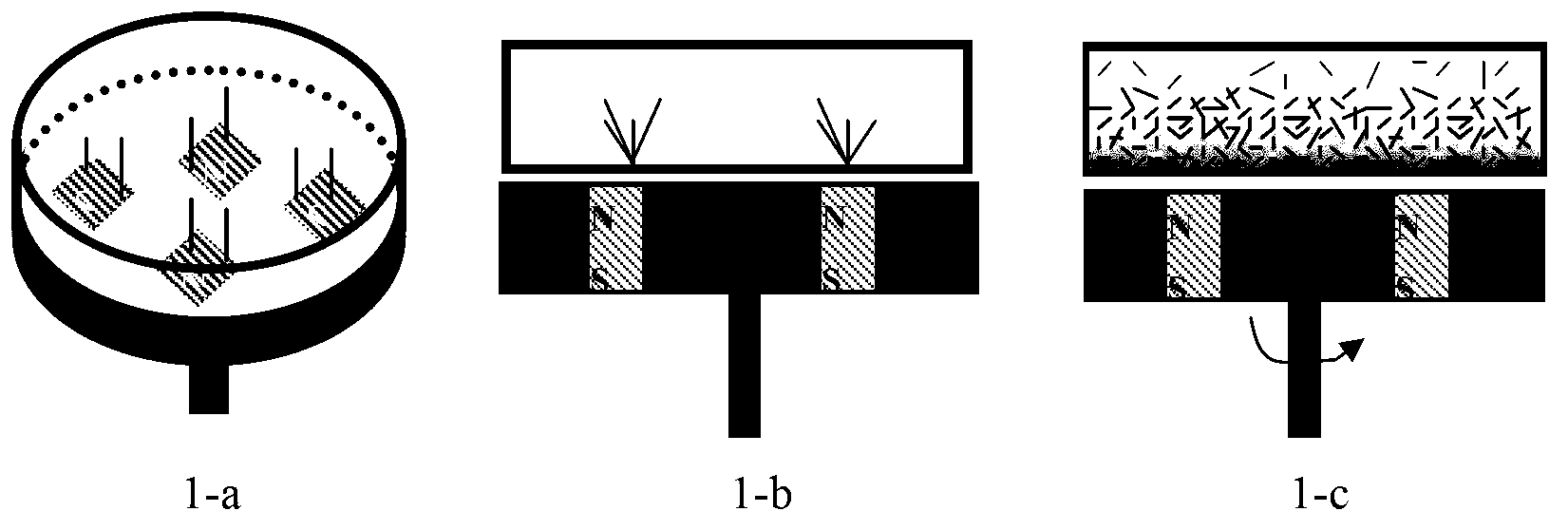

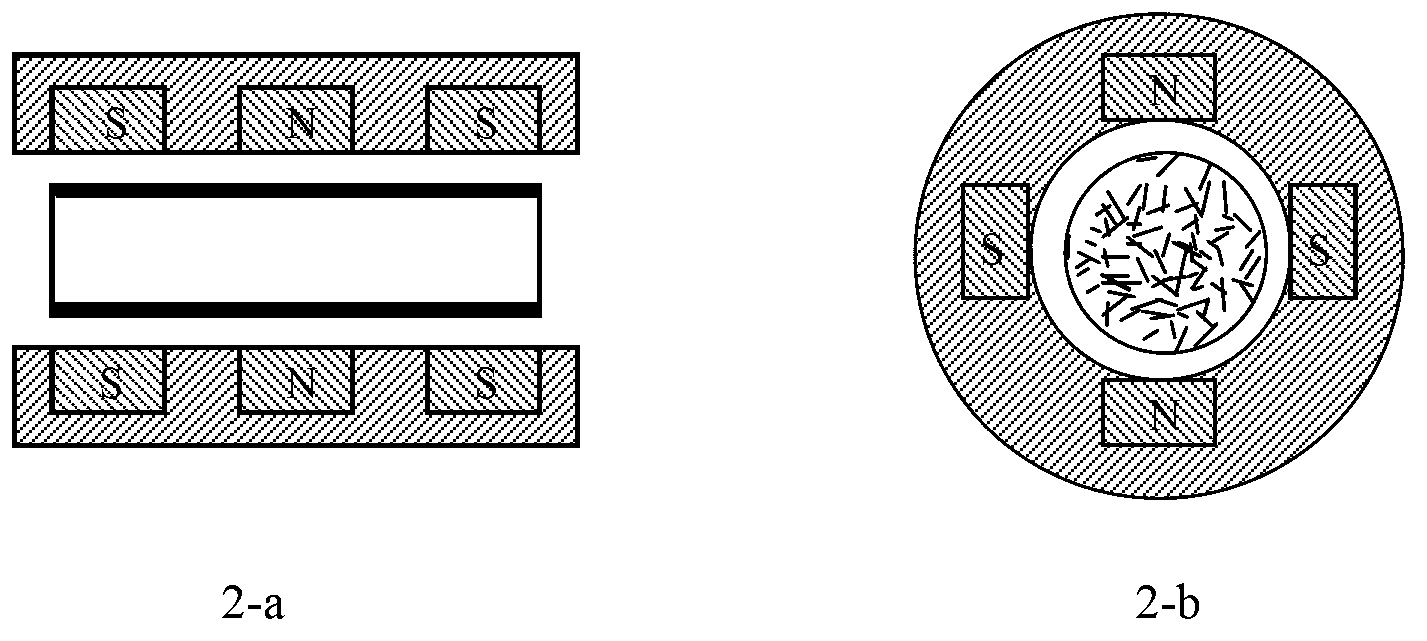

Graphene oxide and polymer based electromagnetic shielding foam composite material and preparation method thereof

The invention relates to a graphene oxide and polymer based electromagnetic shielding foam composite material and a preparation method thereof. Flexible polymer foams are selected and are immersed in a graphene oxide aqueous dispersion, then the immersed polymer foams are dried and reduced, and a layer of three-dimensional continuous graphene film structure is formed between a foam skeleton and a skeleton. The graphene film between the skeletons is conducive to improving the electromagnetic wave reflecting surface and beneficial to electromagnetic wave absorption. Through compounding and reduction of the polymer foams and graphene oxide, compounding of flexible polymer foams and graphene with high electromagnetic shielding properties can be realized, the three-dimensional continuous network structure of the polymer foams and graphene guarantees maximization of mechanical and electromagnetic shielding properties, under 80% compressive strain, the obtained foam composite material is compressed repeatedly for 1000 times, the recovery rate is greater than or equal to 95%, and the electromagnetic shielding effectiveness is greater than or equal to 40dB. The method provided by the invention has a simple compounding process, and can realize large-scale production.

Owner:TIANJIN UNIV

Methods for preparing graphene or graphene oxide

ActiveCN102701193AAvoid damageIncrease the frequency of collisionsMaterial nanotechnologyGrapheneGraphiteSolvent

The invention relates to methods for preparing graphene or graphene oxide, and belongs to the technical field of preparation of nanometer materials. A wet method comprises the following steps of: putting a carbon material, a magnetic steel needle grinding body and a solvent into a grinding container, and closing; putting the container into a space with a changing magnetic field, and peeling to obtain a mixture of graphite nanometer microchip-graphene; and separating the graphite nanometer microchip-graphene from a steel needle, settling, and performing centrifugal separation to obtain transparent suspension of the graphene. A dry method comprises the following steps of: putting a carbon material and a magnetic steel needle grinding body into a grinding container, and closing; and putting the container into a space with a changing magnetic field, and peeling to obtain mixture dry powder of graphite nanometer microchip-graphene. The methods have the characteristics of high collision frequency and grinding efficiency and short preparation time.

Owner:SHANDONG UNIV OF TECH

Method for preparing graphene oxide and polyving akohol composite membrane through electrostatic spinning

InactiveCN103938366AEvenly dispersedHigh mechanical strengthFilament/thread formingNon-woven fabricsCross-linkPolyvinyl alcohol

The invention relates to a method for preparing a graphene oxide and polyving akohol composite membrane through electrostatic spinning. The method comprises the steps that graphene oxide is added into deionized water, ultrasonic dispersion is conducted, the evenly-dispersed graphene oxide aqueous solution and polyving akohol are mixed, the mixed solution is heated and reacts for a period of time on the condition of stirring, the mixed solution is cooled to reach indoor temperature, a spinning solution of the graphene oxide and the polyving akohol is obtained, electrospinning is conducted on the spinning solution of the graphene oxide and the polyving akohol, the graphene oxide and polyving akohol composite membrane is obtained, the graphene oxide and polyving akohol composite membrane is processed in the mixed solution of acetone, deionized water, hydrochloric acid and a cross-linking agent, and then cross-linked graphene oxide and polyving akohol composite membrane is obtained.

Owner:JIANGNAN GRAPHENE RES INST +1

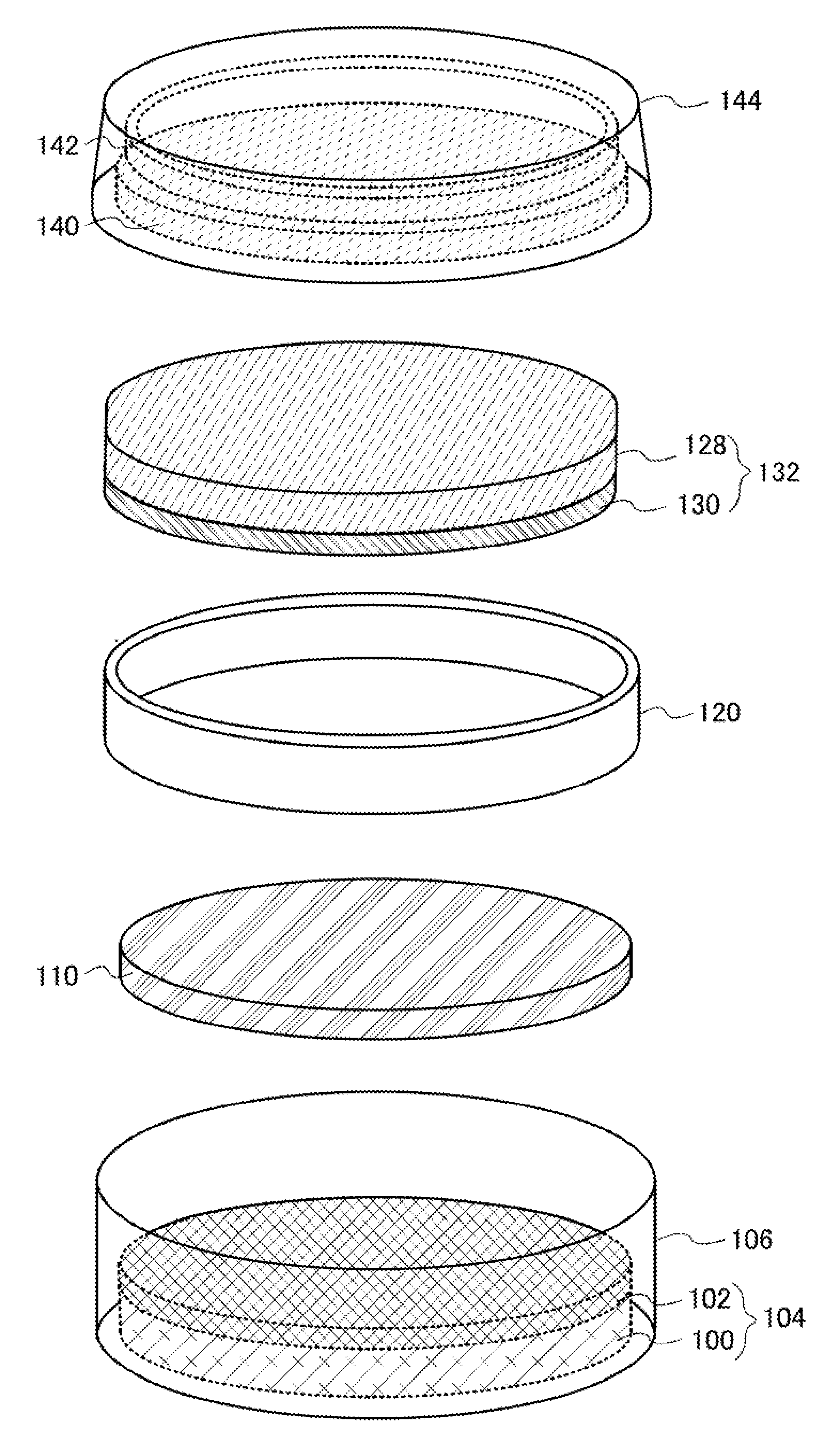

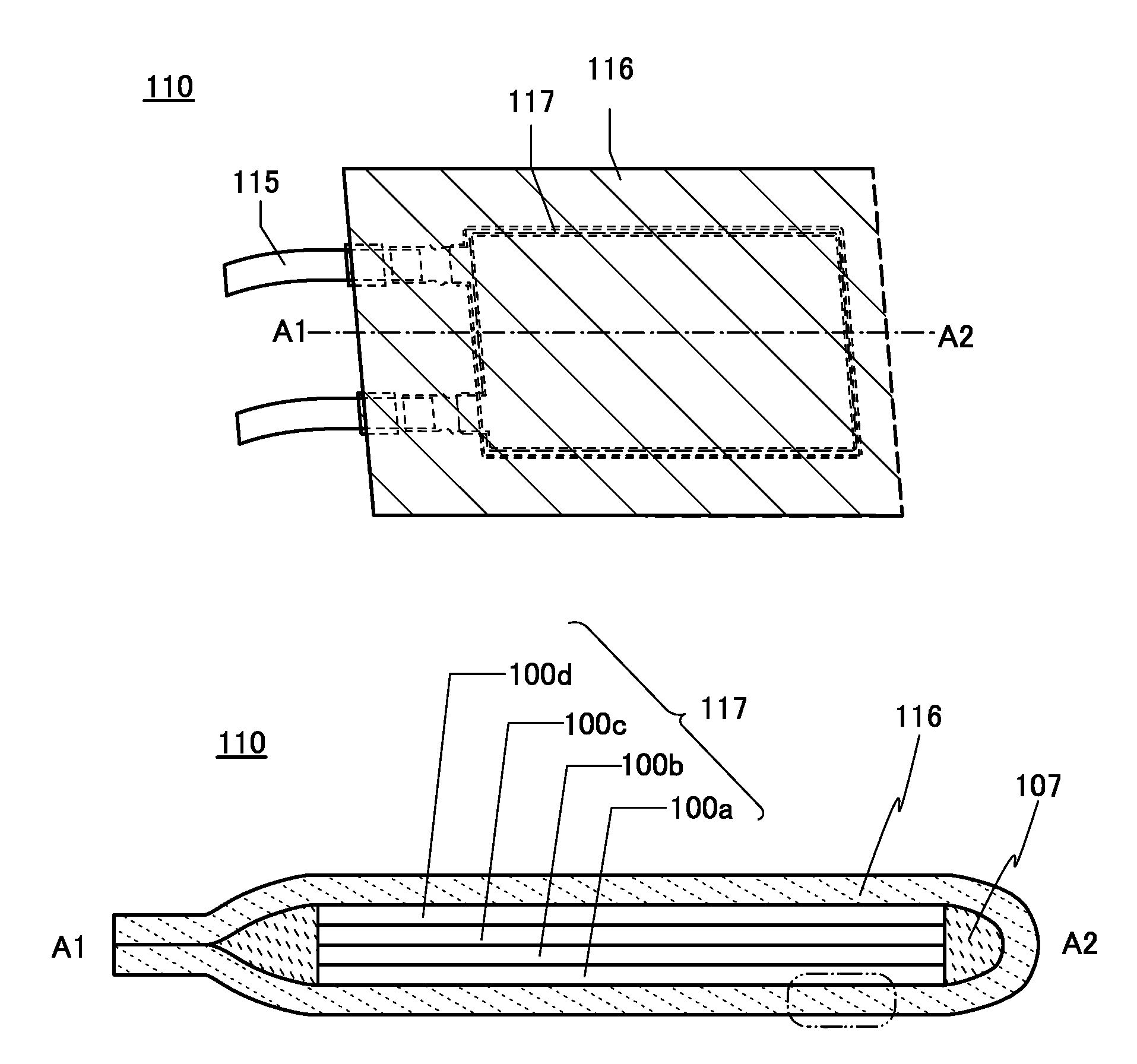

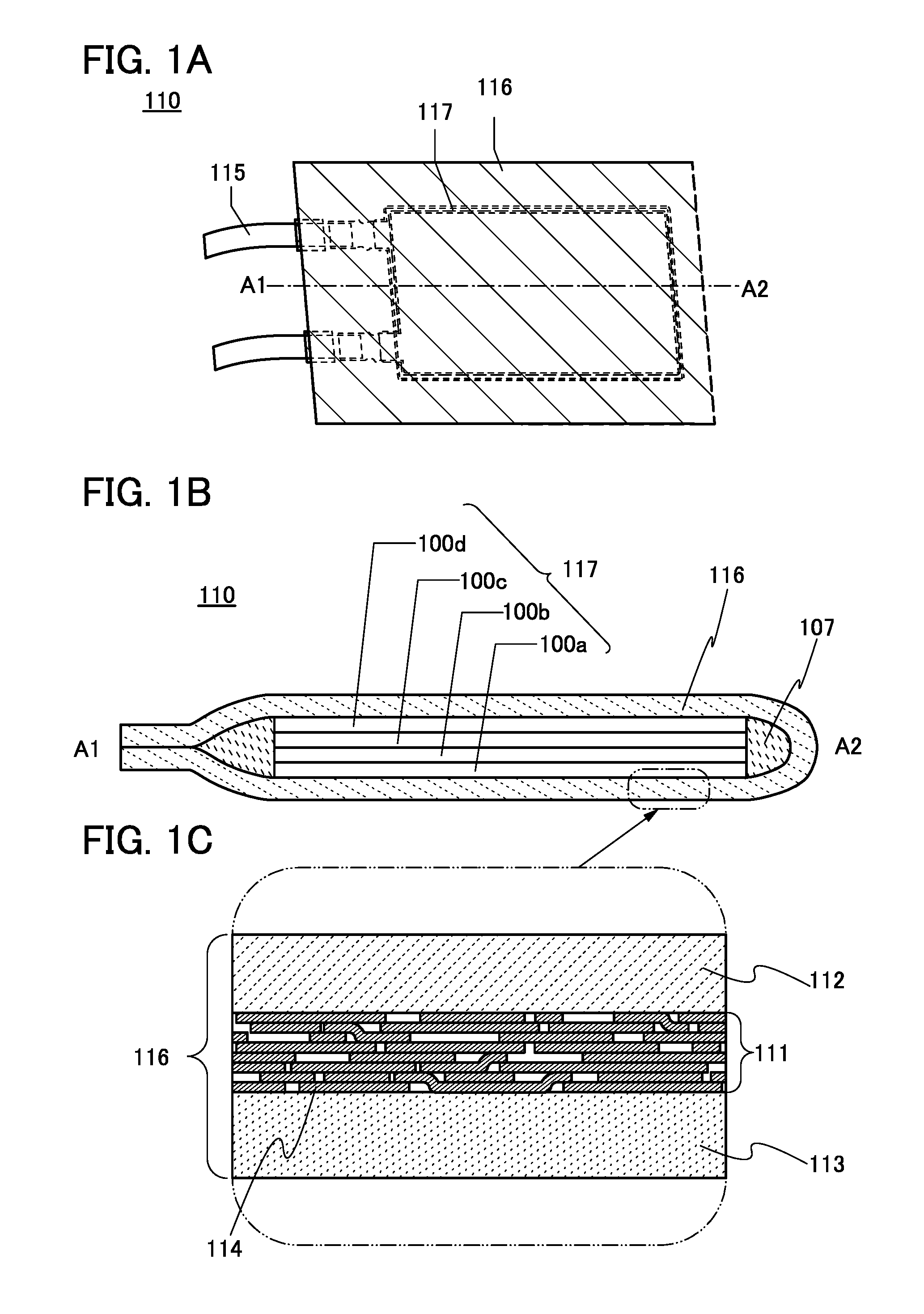

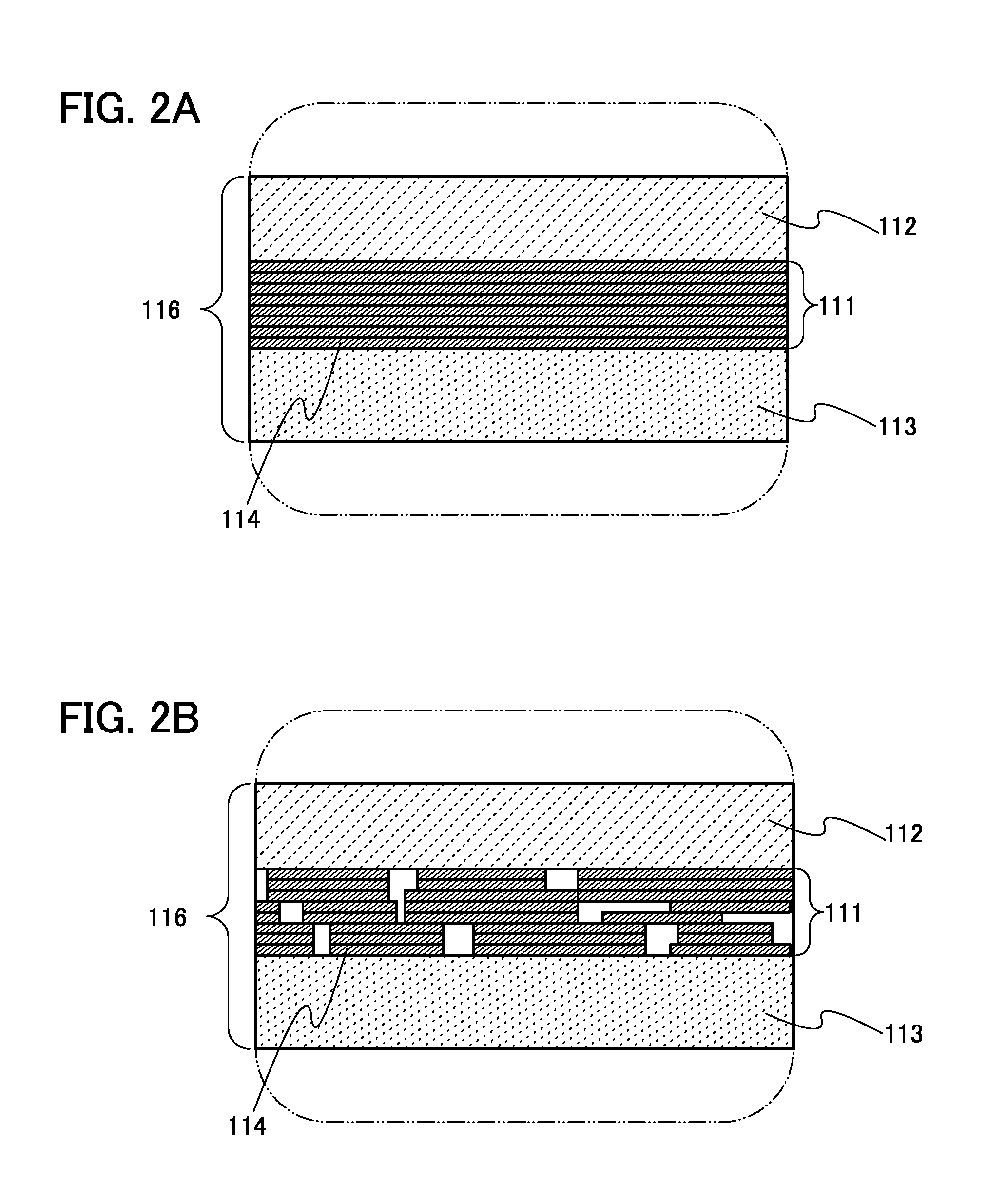

Secondary battery and electronic device

ActiveUS20160329533A1Large capacityNovel structureCell electrodesFinal product manufactureElectrical batteryEngineering

A secondary battery with high capacity per unit volume can be provided. A flexible secondary battery with a novel structure can be provided. A secondary battery that can be bent repeatedly can be provided. A highly reliable secondary battery can be provided. A long-life secondary battery can be provided. A secondary battery comprises an inner structure and an exterior body that surrounds the inner structure. The inner structure comprises a positive electrode and a negative electrode. The exterior body comprises a first exterior film and a second exterior film. A region comprising reduced graphene oxide lies between the first exterior film and the second exterior film. The graphene oxide preferably comprises a region where the concentration of oxygen is higher than or equal to 2 atomic percent and lower than or equal to 20 atomic percent.

Owner:SEMICON ENERGY LAB CO LTD

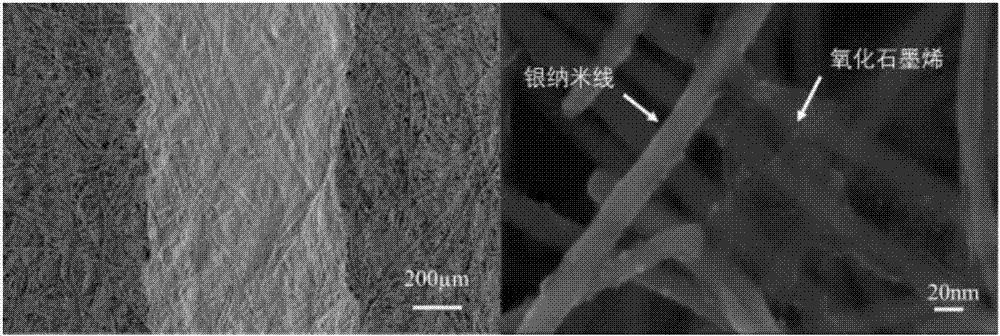

Preparation method and application of conductive ink based on metal nanowire and graphene oxide

ActiveCN106867315AEasy to prepareEasy to operateInksMetallic pattern materialsSurface-active agentsFlashlight

The invention provides a preparation method and application of conductive ink based on metal nanowire and graphene oxide. The graphene oxide is simultaneously used as a dispersing agent, a thickening agent and a stabilizing agent. The metal nanowire, the graphene oxide, the deionized water, the alcohol solvent, the dispersing agent, the surface active agent, the flatting agent and the de-foaming agent are uniformly mixed at a certain mass ratio, so as to acquire the conductive ink product. The acquired ink can be directly written or printed on various substrate materials so as to construct a conductive circuit with high conductivity, stability, flexibility and high adhesion; the constructed conductive circuit is dried for 3-10 minutes under room temperature, so that ultrahigh conductivity is achieved; furthermore, the graphene oxide is reduced and the metal nanowire is sintered according to the methods, such as, selecting sintering temperature at 50-200 DEG C or performing chemical reduction under room temperature or utilizing an xenon flashlight to sinter, so that the conductivity of the conductive circuit is further increased.

Owner:XUZHOU LANOXENE INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com