Preparation method for graphene oxide with high barrier property and polymer nanocomposite film

A high-barrier, nano-composite technology, used in flexible coverings, transportation and packaging, packaging, etc., can solve problems such as poor gas barrier properties, and achieve improved barrier properties, high safety, and good environmental protection effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

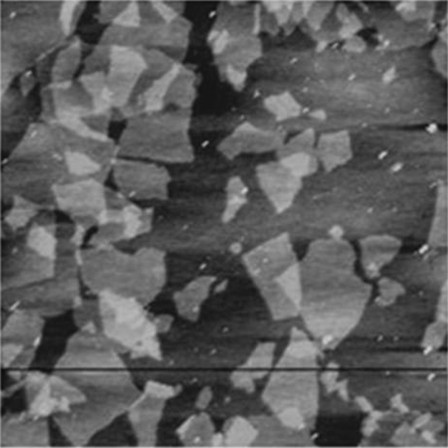

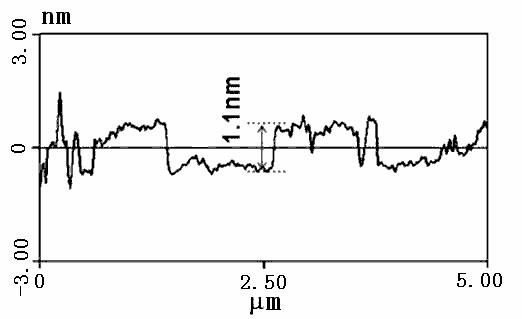

[0021] First add 4g of expandable graphite to 100ml of 98% concentrated H 2 SO 4 Stir in the mixture to obtain the mixture A; then add 28g KMnO to the mixture A while stirring 4 , after adding, stir at 38°C for 1 hour to obtain a homogeneous mixture B; then add 400ml of deionized water and 6ml of 30% H 2 o 2 , stir evenly to obtain mixture C; filter mixture C to obtain 40ml of paste, first wash with 40ml of 3.5% HCl solution, and then repeatedly wash with deionized water until the pH of the paste is 7, then use It was dispersed in 6000ml of deionized water by ultrasonic wave, and finally the dispersion was dehydrated at 60°C to obtain 6g of graphene oxide.

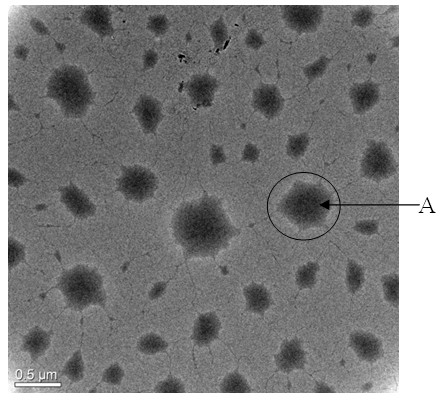

[0022] Add 0.2g of graphene oxide into 200ml of water, and stir at 45°C for 1h while ultrasonically treating (power 400W) to obtain a colloidal suspension of graphene oxide; then add 19.8g of polyvinyl alcohol to the graphene oxide colloidal suspension, Under the condition of 20 ℃, ultrasonic treatment (power 400W) was...

Embodiment 2

[0026] First add 4.35g of expandable graphite to 100ml of 98% concentrated H 2 SO 4 Stir in the mixture to obtain the mixture A; then add 26.1g KMnO to the mixture A while stirring 4 , after adding, stir at 40°C for 1 hour to obtain a homogeneous mixture B; then add 360ml of deionized water and 11ml of 30% H 2 o 2 , stirred evenly to obtain mixture C; mixture C was filtered to obtain 43.5ml of paste, which was first washed with 87ml of 3.5% HCl solution, then repeatedly washed with deionized water until the pH of the paste was 7, and then It was dispersed in 6400ml of deionized water by ultrasonic waves, and finally the dispersion was dehydrated at 60°C to obtain 6.525g of graphene oxide.

[0027] Add 0.02g of graphene oxide into 20ml of dimethylformamide, and stir for 1h while ultrasonically treating (400W power) at 30°C to obtain a colloidal suspension of graphene oxide; then add 19.98 g polystyrene, under the condition of 100°C, ultrasonic treatment (400W power) while s...

Embodiment 3

[0030] First add 4g of expandable graphite to 100ml of 98% concentrated H 2 SO 4 Stir in the mixture to obtain the mixture A; then add 28g KMnO to the mixture A while stirring 4 , after adding, stir at 40°C for 1 hour to obtain a homogeneous mixture B; then add 783ml of deionized water and 8ml of 30% H 2 o 2 , stir evenly to obtain mixture C; filter mixture C to obtain 40ml of paste, first wash with 40ml of 3.5% HCl solution, and then repeatedly wash with deionized water until the pH of the paste is 7, then use It was dispersed in 6000ml of deionized water by ultrasonic wave, and finally the dispersion was dehydrated at 60°C to obtain 6g of graphene oxide.

[0031] Add 0.1g of graphene oxide into 100ml of tetrahydrofuran, and stir at 20°C for 1h while ultrasonically treating (power 400W) to obtain a colloidal suspension of graphene oxide; then add 19.9g of polyformaldehyde to the colloidal suspension of graphene oxide methyl methacrylate, and stirred at 120°C for 3 hours w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com