Patents

Literature

294 results about "Polymer nanocomposite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polymer nanocomposites (PNC) consist of a polymer or copolymer having nanoparticles or nanofillers dispersed in the polymer matrix. These may be of different shape (e.g., platelets, fibers, spheroids), but at least one dimension must be in the range of 1–50 nm. These PNC's belong to the category of multi-phase systems (MPS, viz. blends, composites, and foams) that consume nearly 95% of plastics production. These systems require controlled mixing/compounding, stabilization of the achieved dispersion, orientation of the dispersed phase, and the compounding strategies for all MPS, including PNC, are similar. Alternatively, polymer can be infiltrated into 1D, 2D, 3D preform creating high content polymer nanocomposites.

PVC nanocomposite manufacturing technology and applications

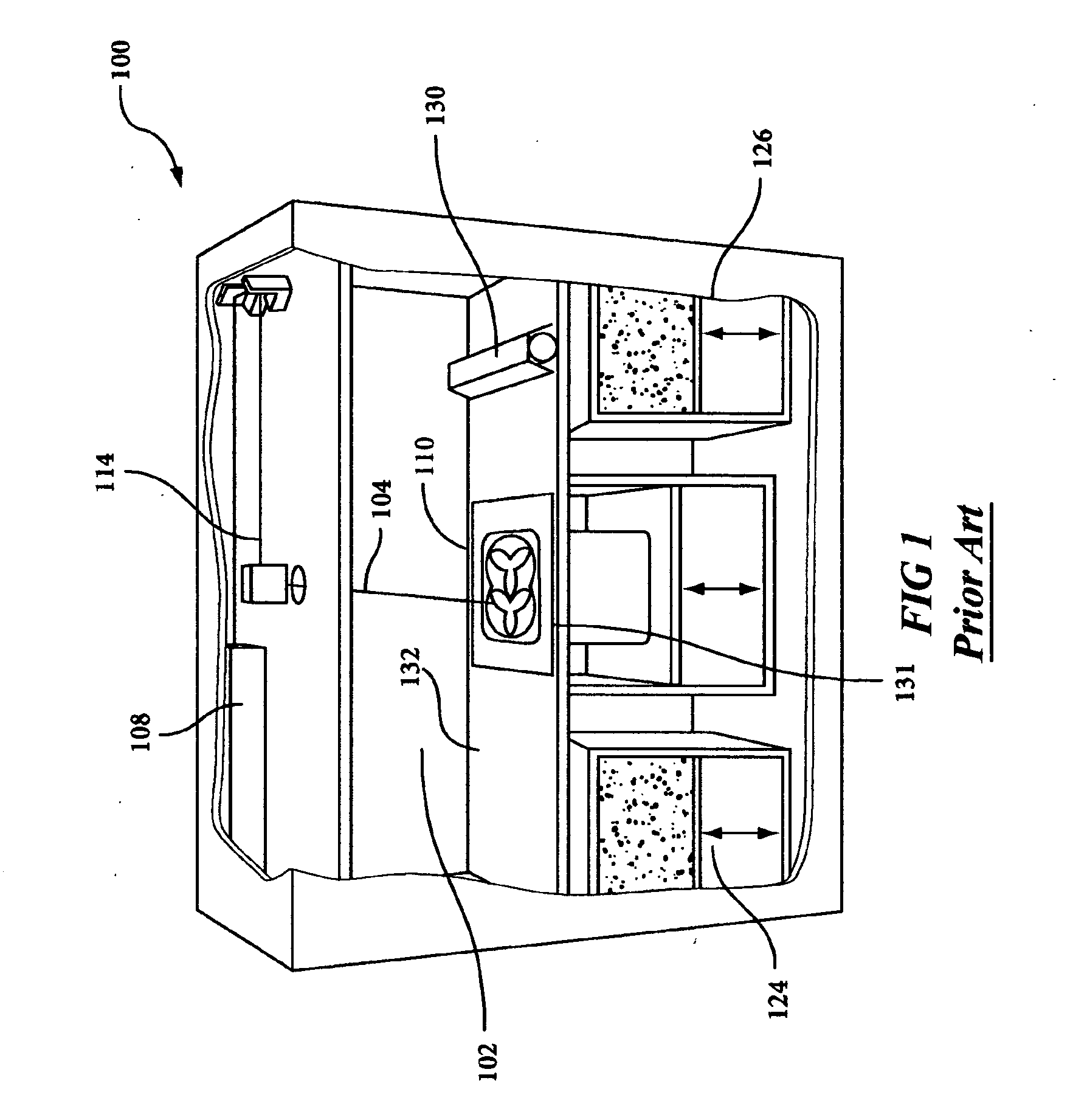

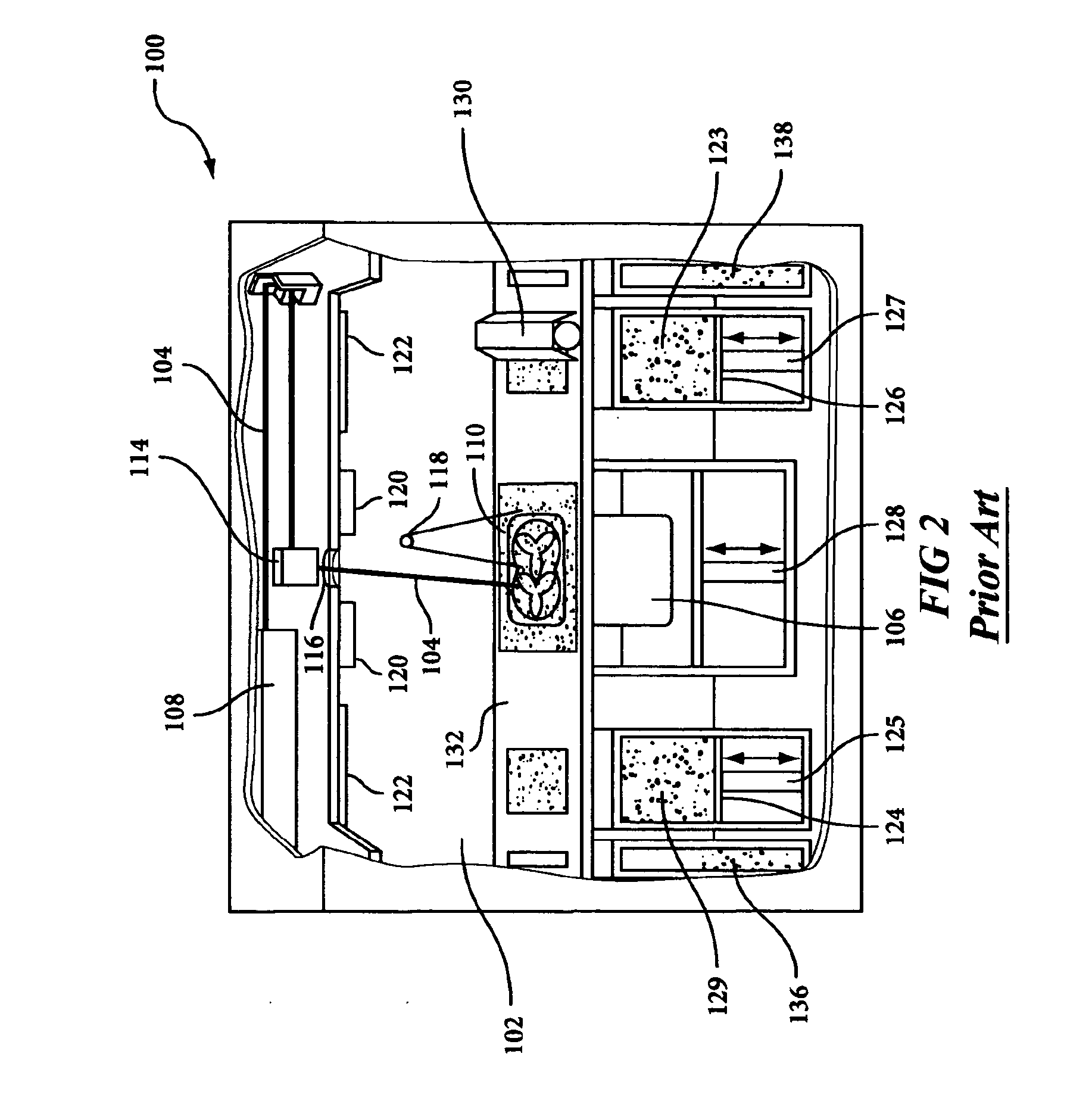

InactiveUS20080194736A1Material nanotechnologyPigmenting treatmentPolymer scienceManufacturing technology

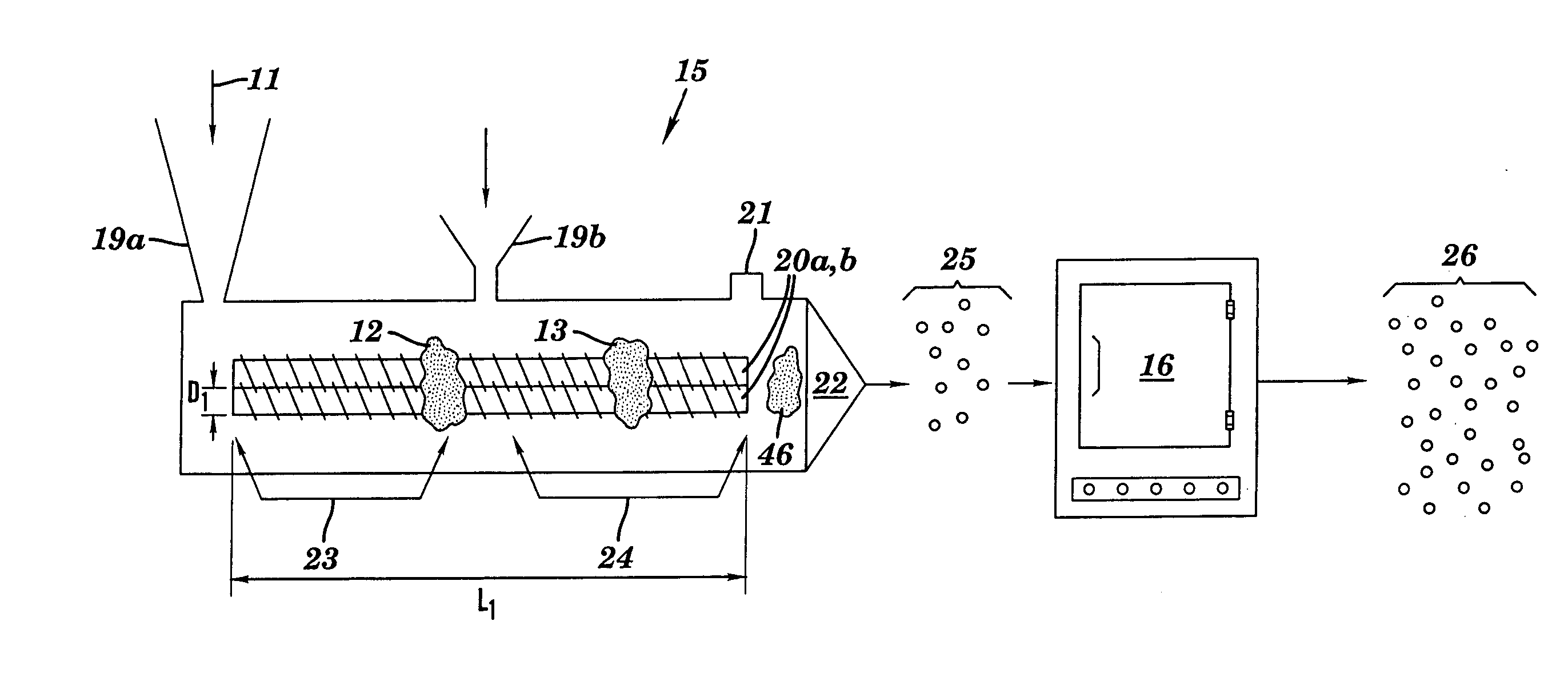

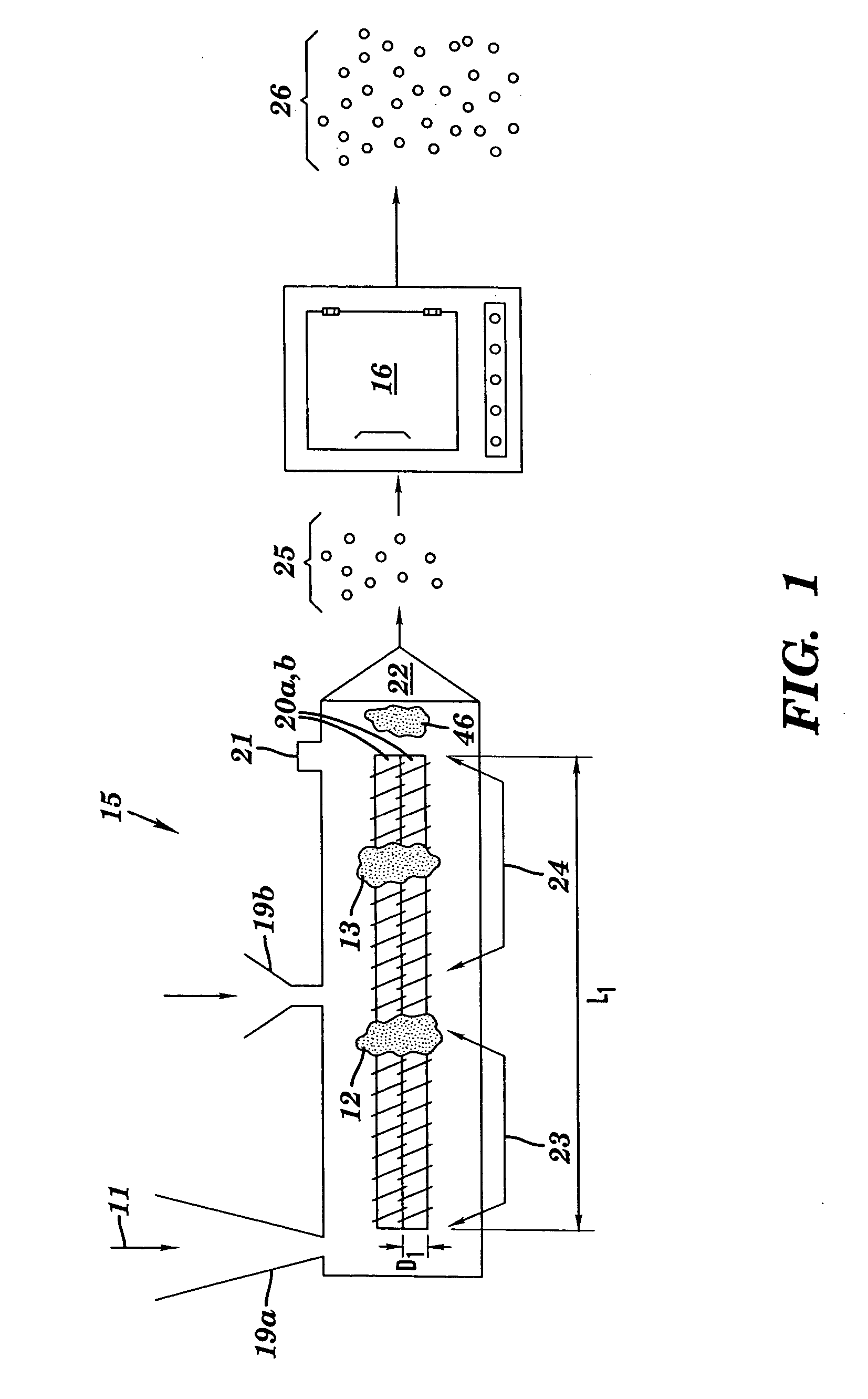

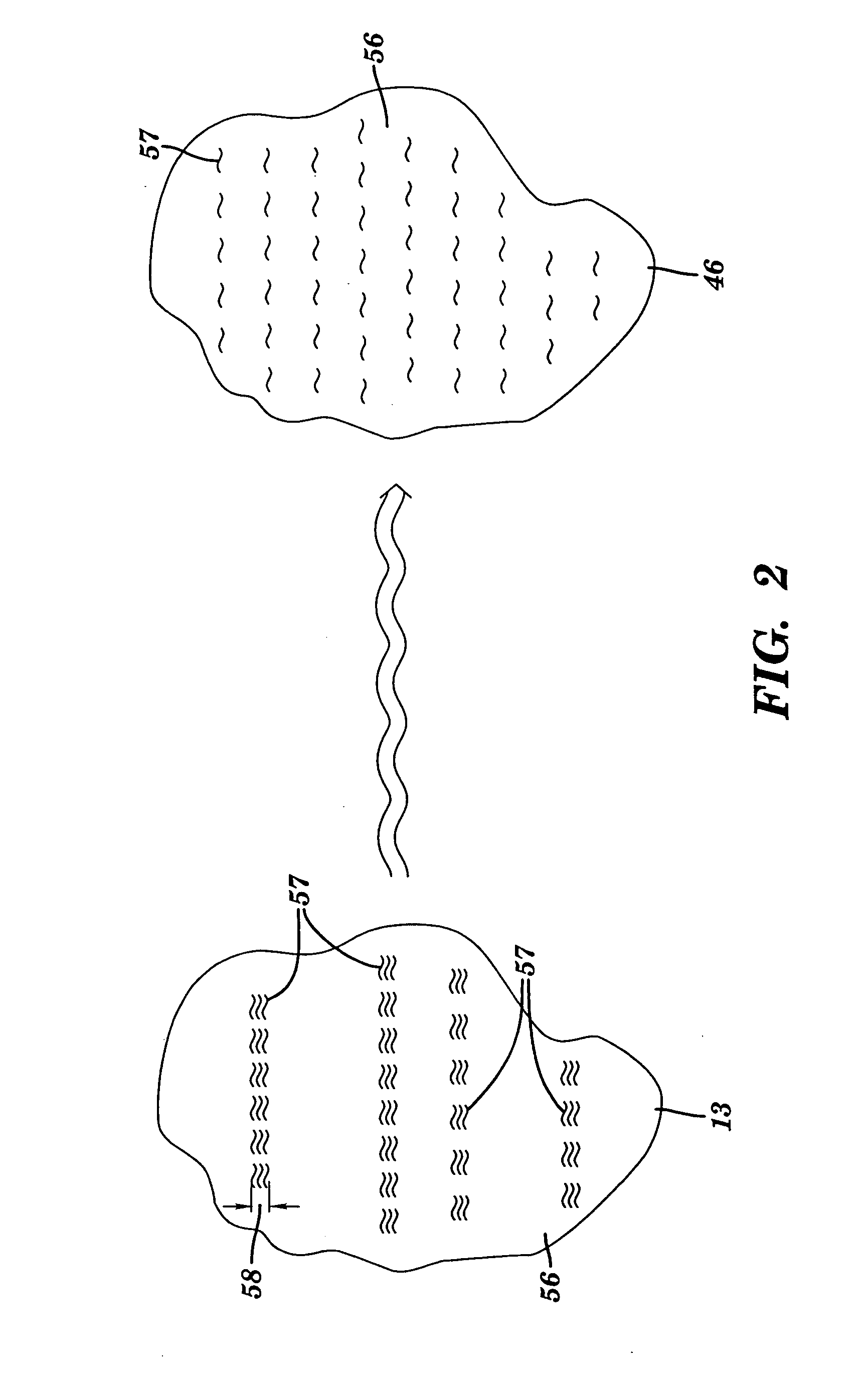

The present invention relates to a process and a product of forming polymer (especially PVC) nanocomposites with a variety of nanofillers. The present invention provides a method for forming a polymer nanocomposite, comprising powder mixing a composition comprising polymer resin, a nanofiller, and a coupling agent for a residence time of about 4 to about 8 minutes to form a dry blend and extruding the dry blend in an extrusion process. Additionally, the present invention relates to a polymer nanocomposite formed by a process, comprising powder mixing a polymer resin, a nanofiller, and a coupling agent for a residence time of about 4 to about 8 minutes to form a dry blend and extruding the dry blend in an extrusion process to achieve homogeneous dispersion of nanofillers in the polymer matrix.

Owner:FORMOSA PLASTICCS CORP

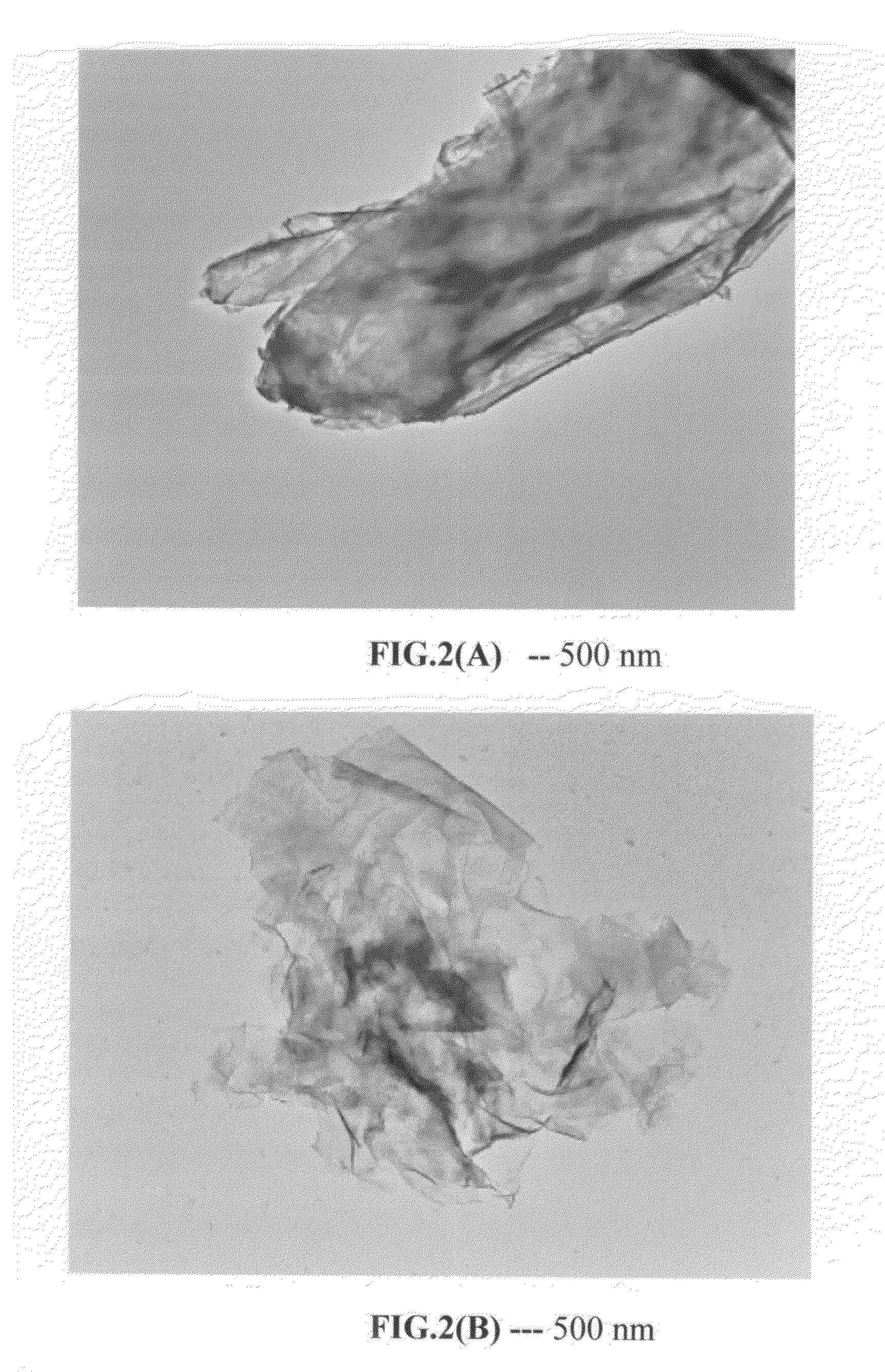

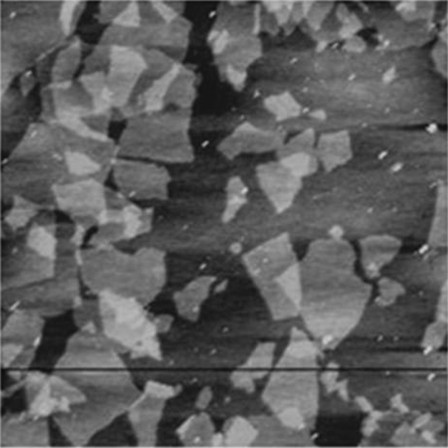

Method of producing exfoliated graphite, flexible graphite, and nano-scaled graphene platelets

ActiveUS20080279756A1Good dispersionImprove conductivityCarbon compoundsFibre chemical featuresFiberLiquid medium

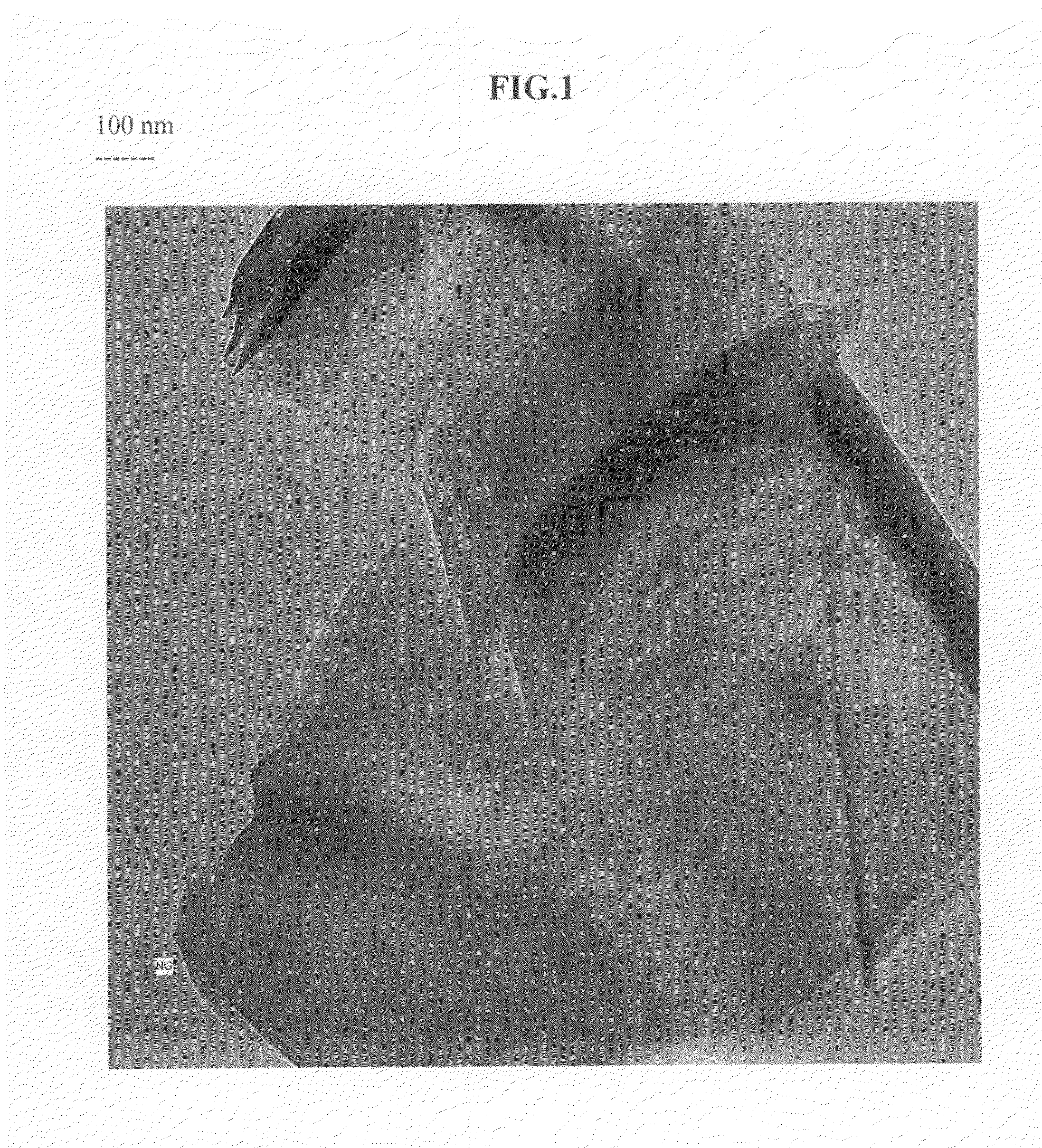

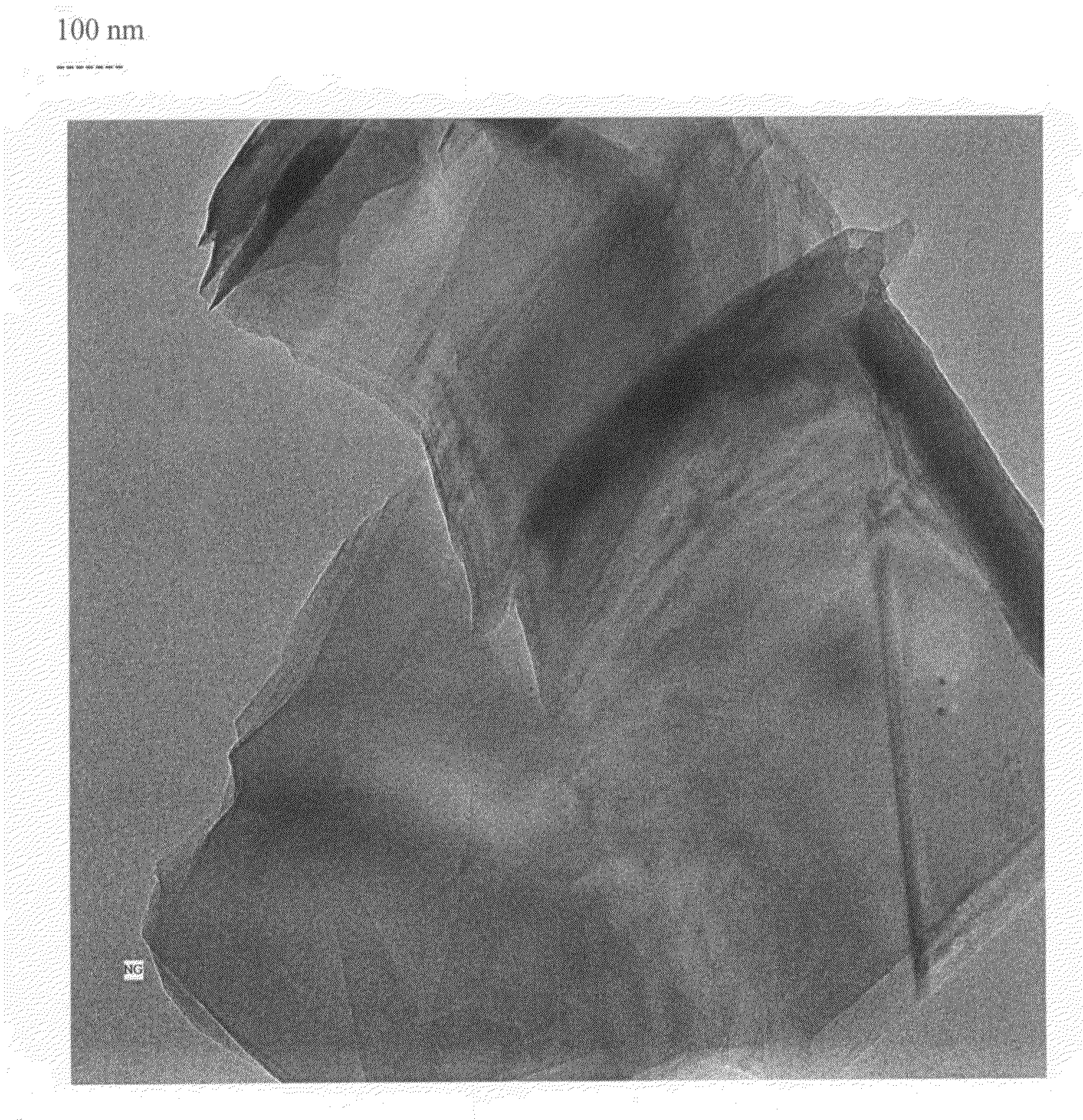

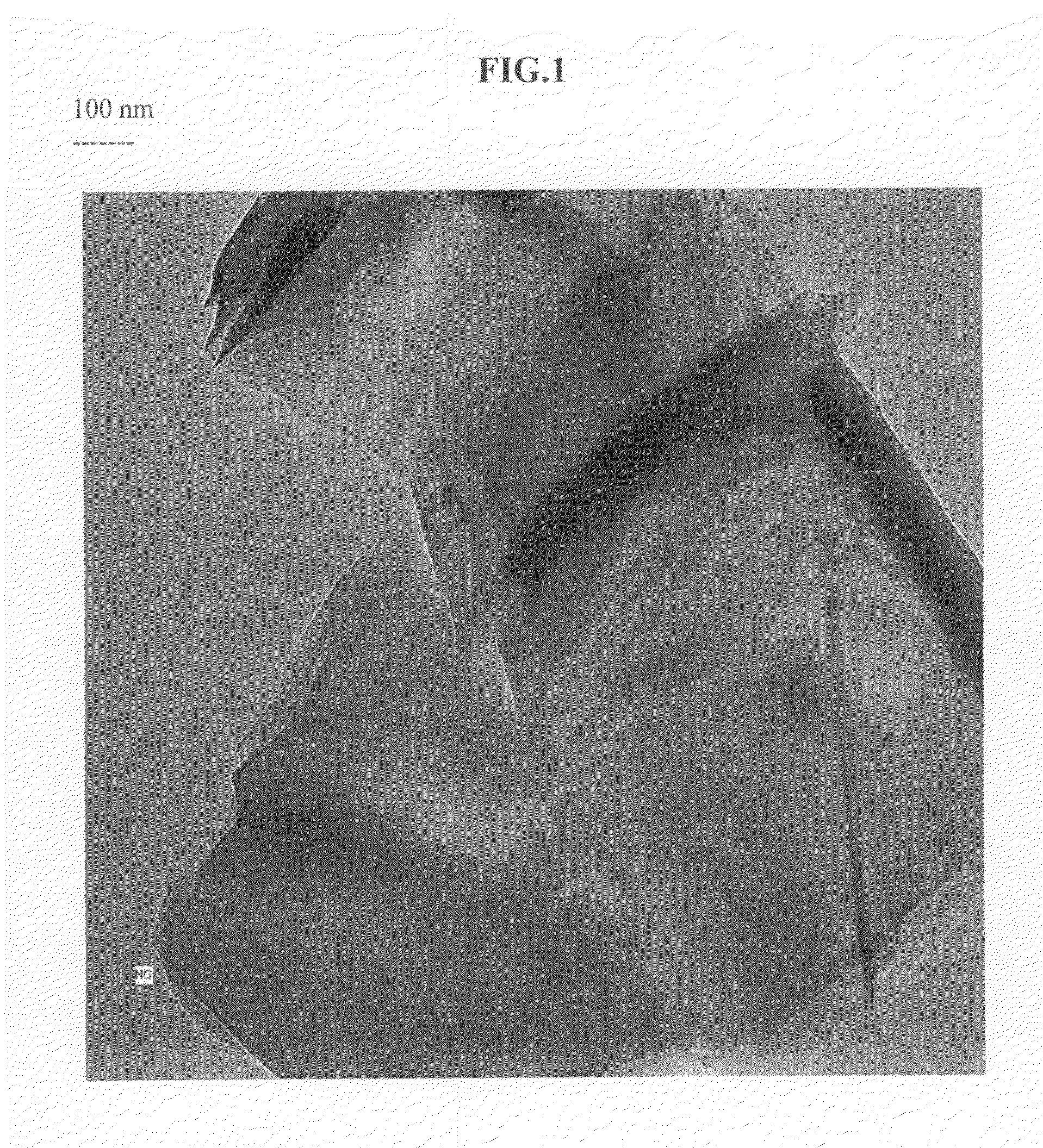

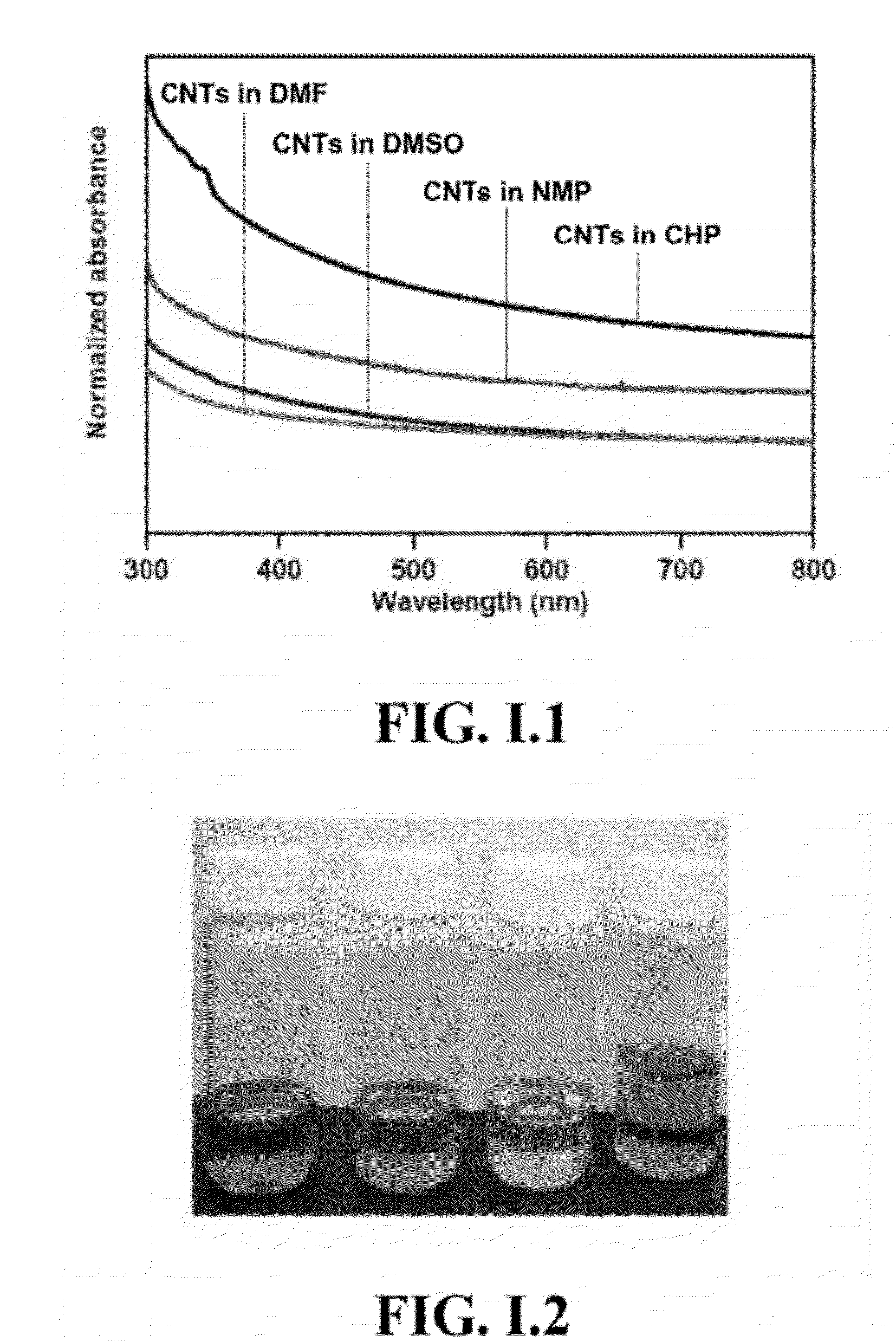

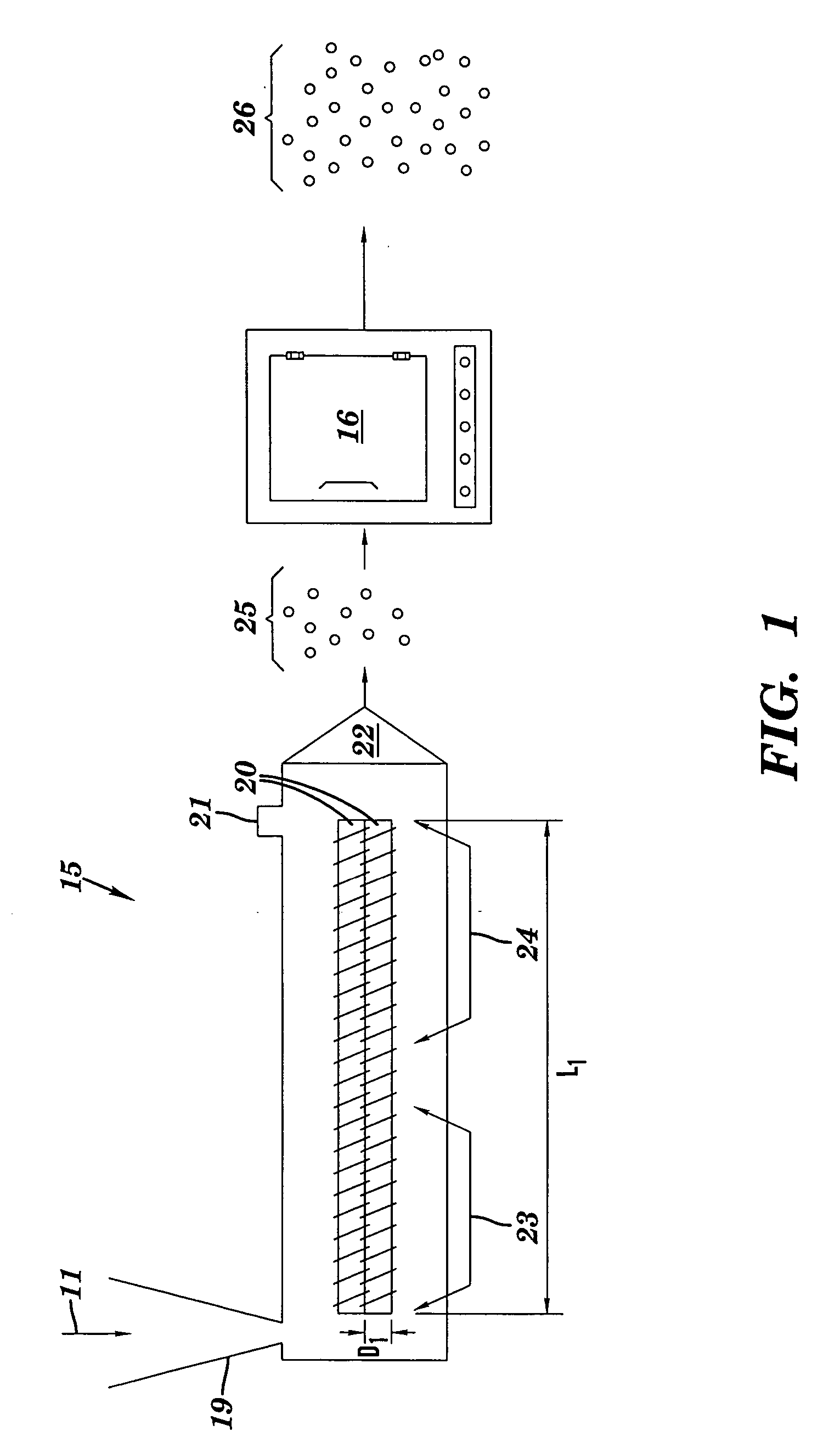

The present invention provides a method of exfoliating a layered material (e.g., graphite and graphite oxide) to produce nano-scaled platelets having a thickness smaller than 100 nm, typically smaller than 10 nm. The method comprises (a) dispersing particles of graphite, graphite oxide, or a non-graphite laminar compound in a liquid medium containing therein a surfactant or dispersing agent to obtain a stable suspension or slurry; and (b) exposing the suspension or slurry to ultrasonic waves at an energy level for a sufficient length of time to produce separated nano-scaled platelets. The nano-scaled platelets are candidate reinforcement fillers for polymer nanocomposites. Nano-scaled graphene platelets are much lower-cost alternatives to carbon nano-tubes or carbon nano-fibers.

Owner:GLOBAL GRAPHENE GRP INC

Nanostructure and nanocomposite based compositions and photovoltaic devices

InactiveUS20050126628A1Improve equipment efficiencyMaterial nanotechnologyFinal product manufactureSemiconductor nanocrystalsPolymer nanocomposite

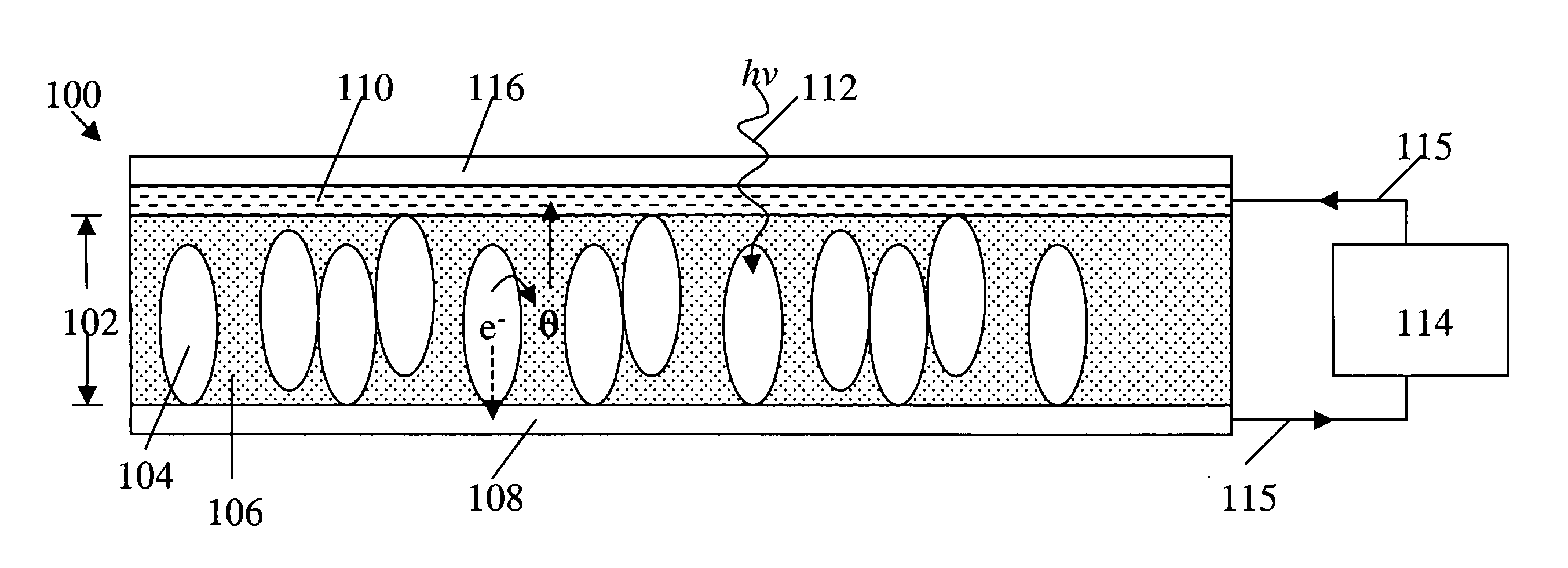

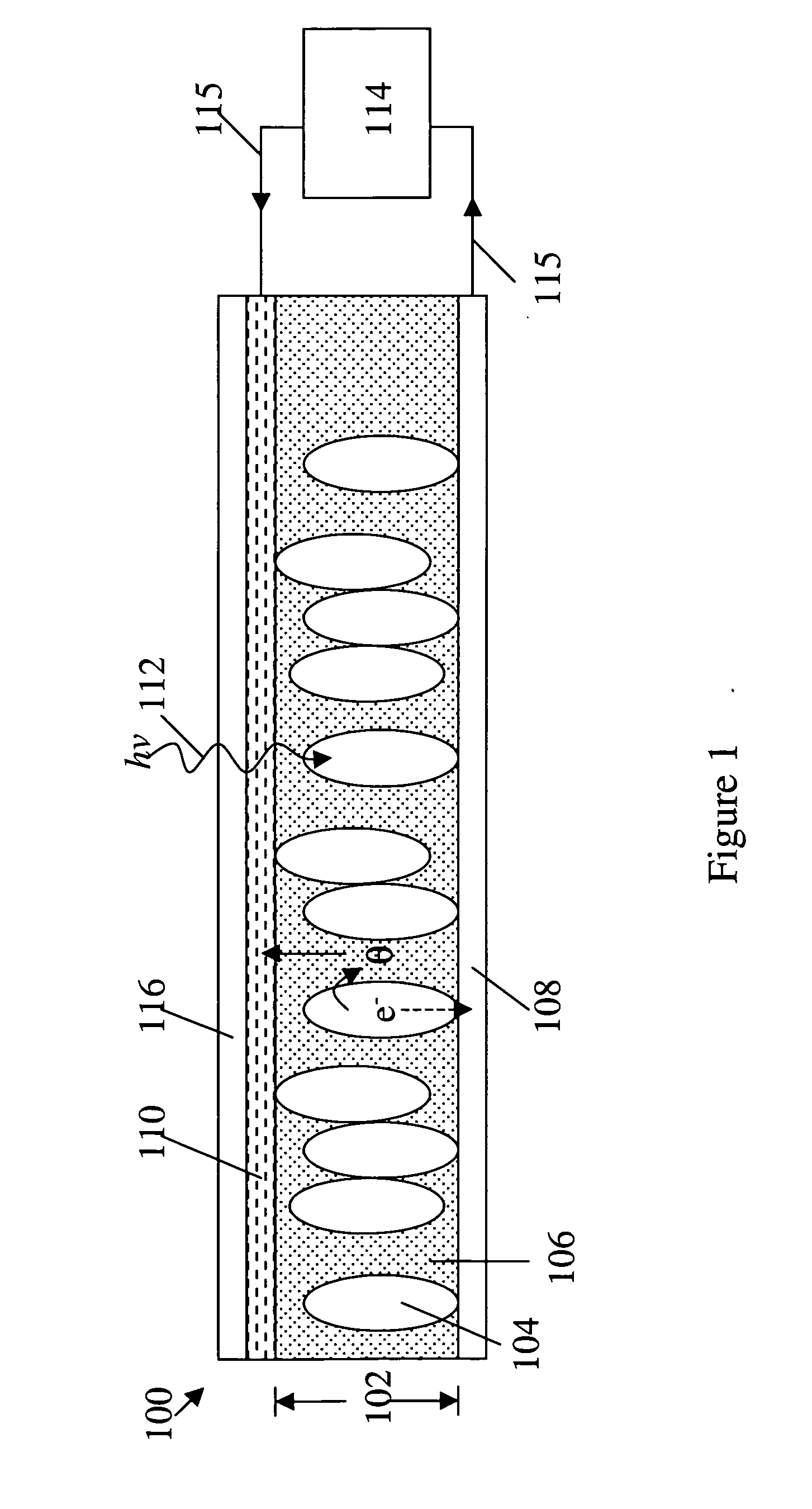

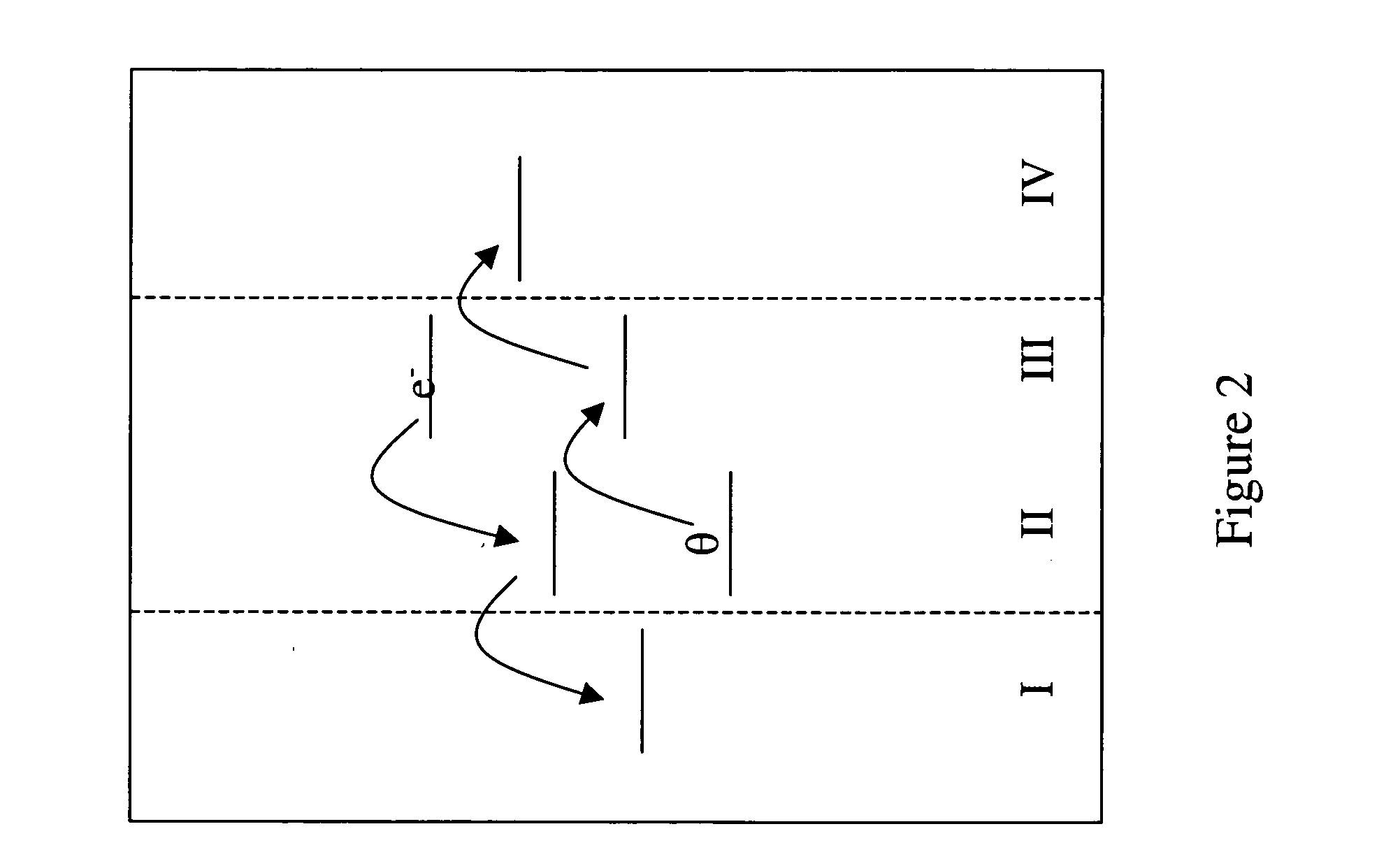

Nanocomposite photovoltaic devices are provided that generally include semiconductor nanocrystals as at least a portion of a photoactive layer. Photovoltaic devices and other layered devices that comprise core-shell nanostructures and / or two populations of nanostructures, where the nanostructures are not necessarily part of a nanocomposite, are also provided, as are devices including a recombination material and / or multiple electrodes. Varied architectures for such devices are also provided, including flexible and rigid architectures, planar and non-planar architectures, and the like, as are systems incorporating such devices, and methods and systems for fabricating such devices. Compositions comprising two populations of nanostructures of different materials or nanostructures and a small molecule are also described, as are doped polymer nanocomposites. Compositions useful for making nanocomposites are also described.

Owner:NANOSYS INC

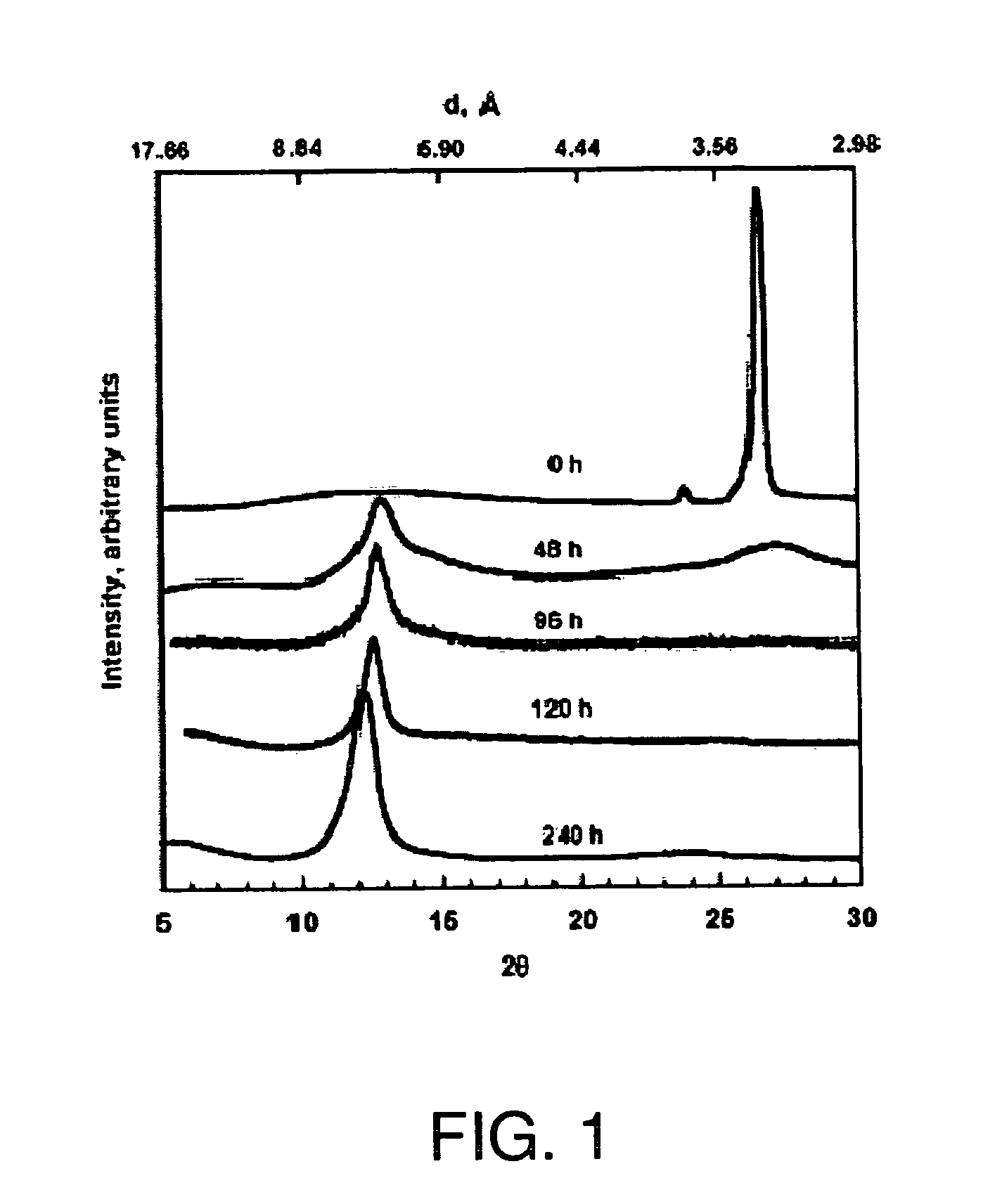

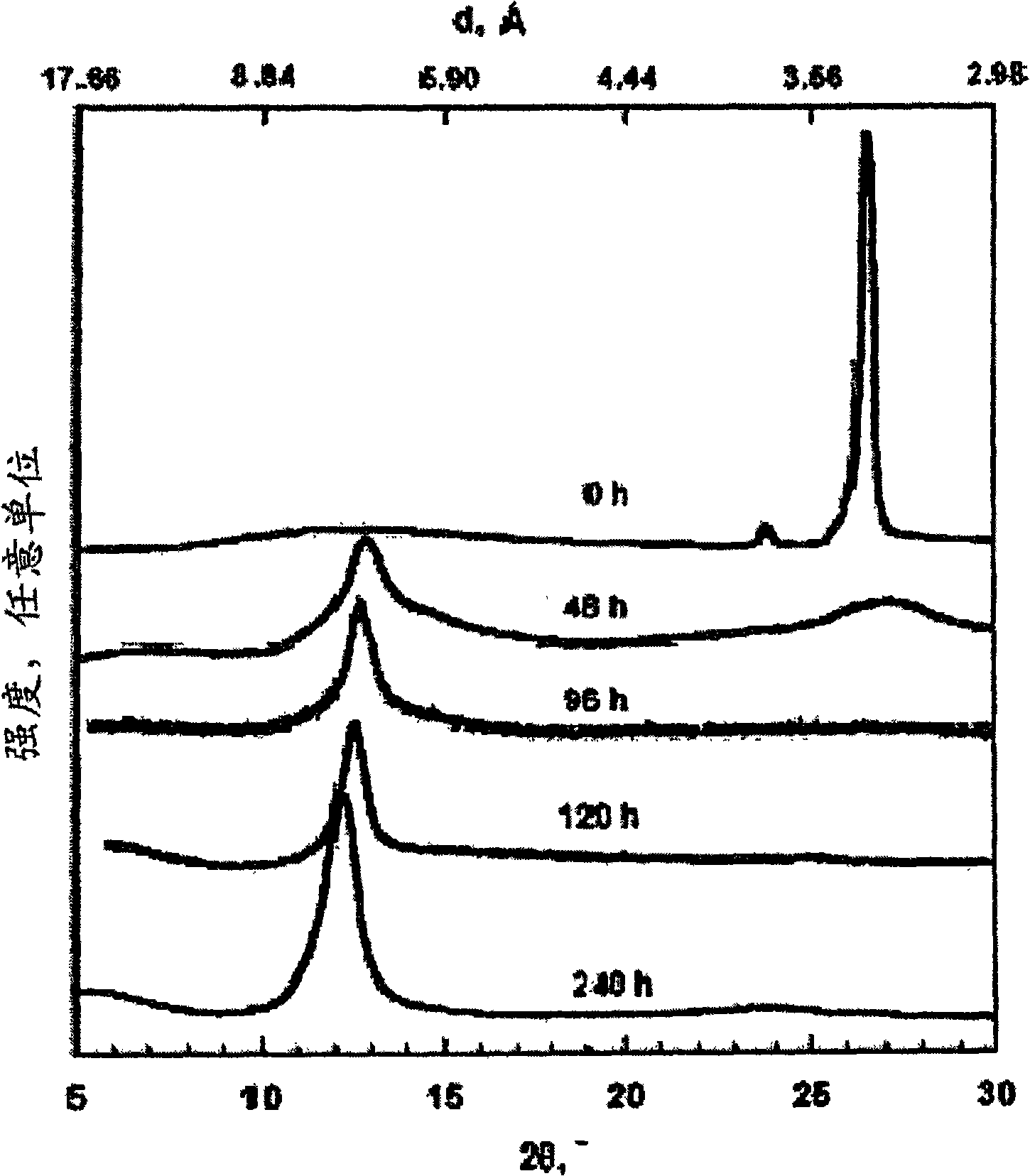

Functional graphene-polymer nanocomposites for gas barrier applications

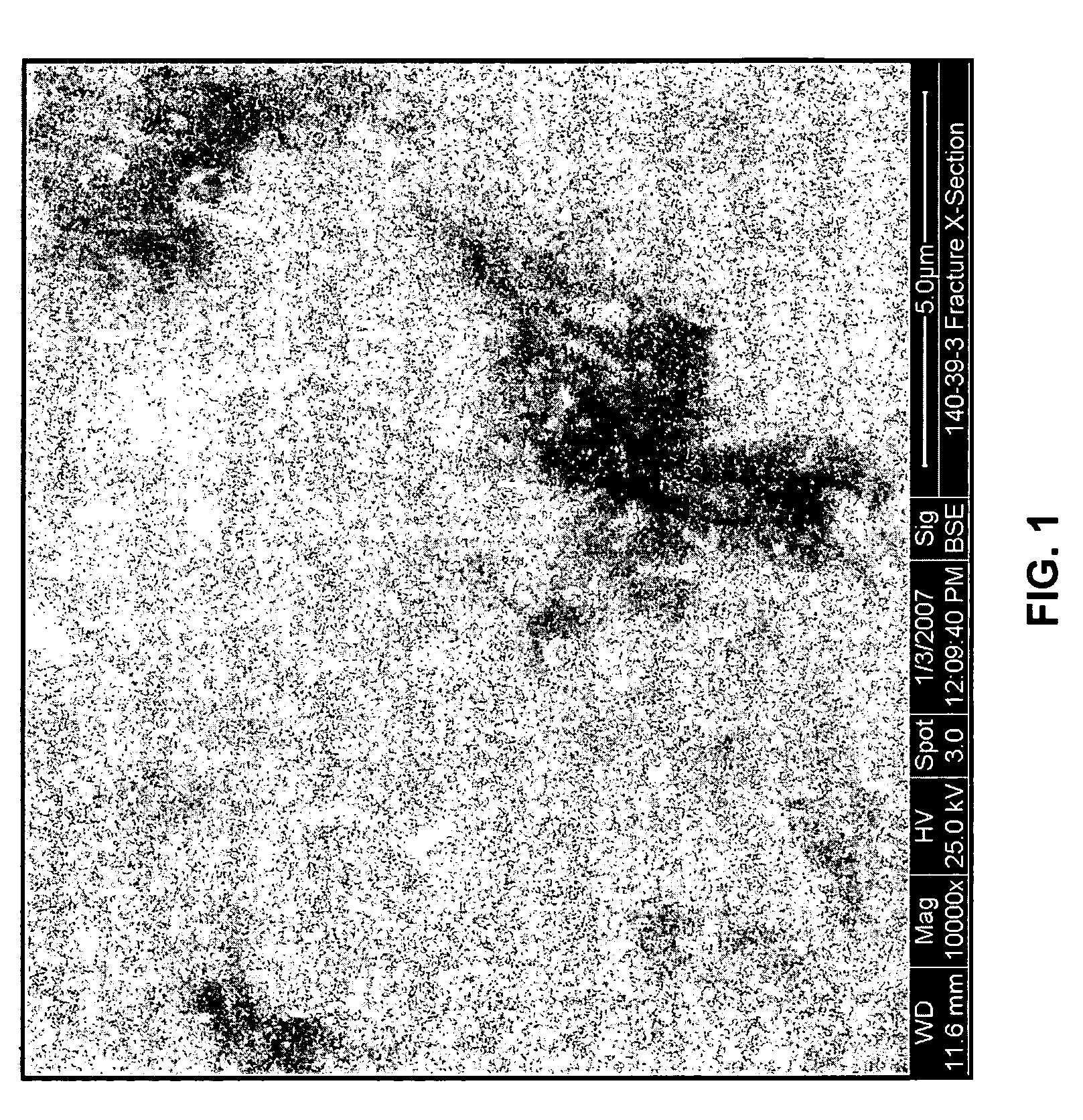

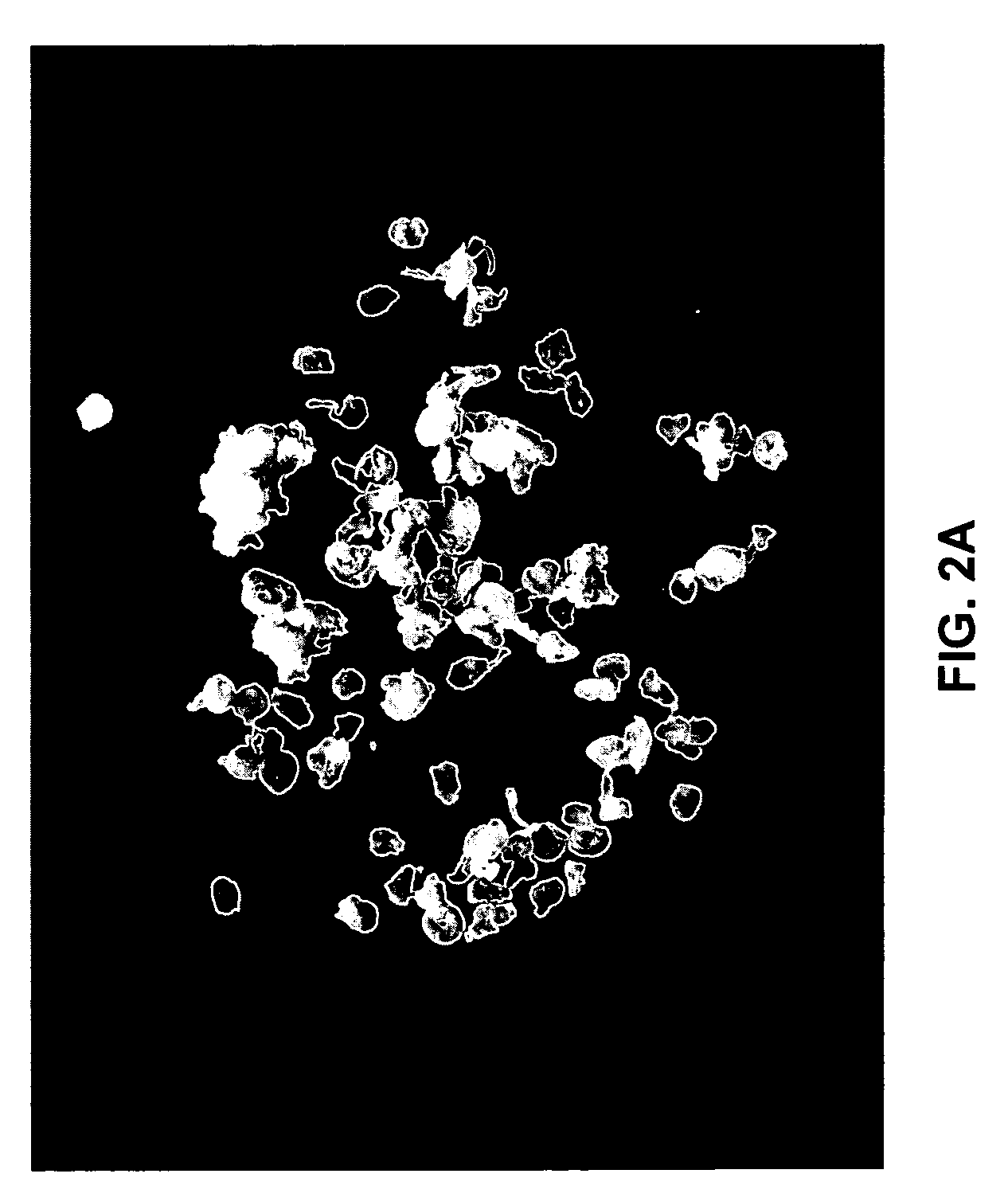

InactiveUS20100096595A1Excellent gas barrier performanceImprove suppression propertiesMaterial nanotechnologyNanostructure manufactureNano compositesX-ray

Owner:THE TRUSTEES FOR PRINCETON UNIV

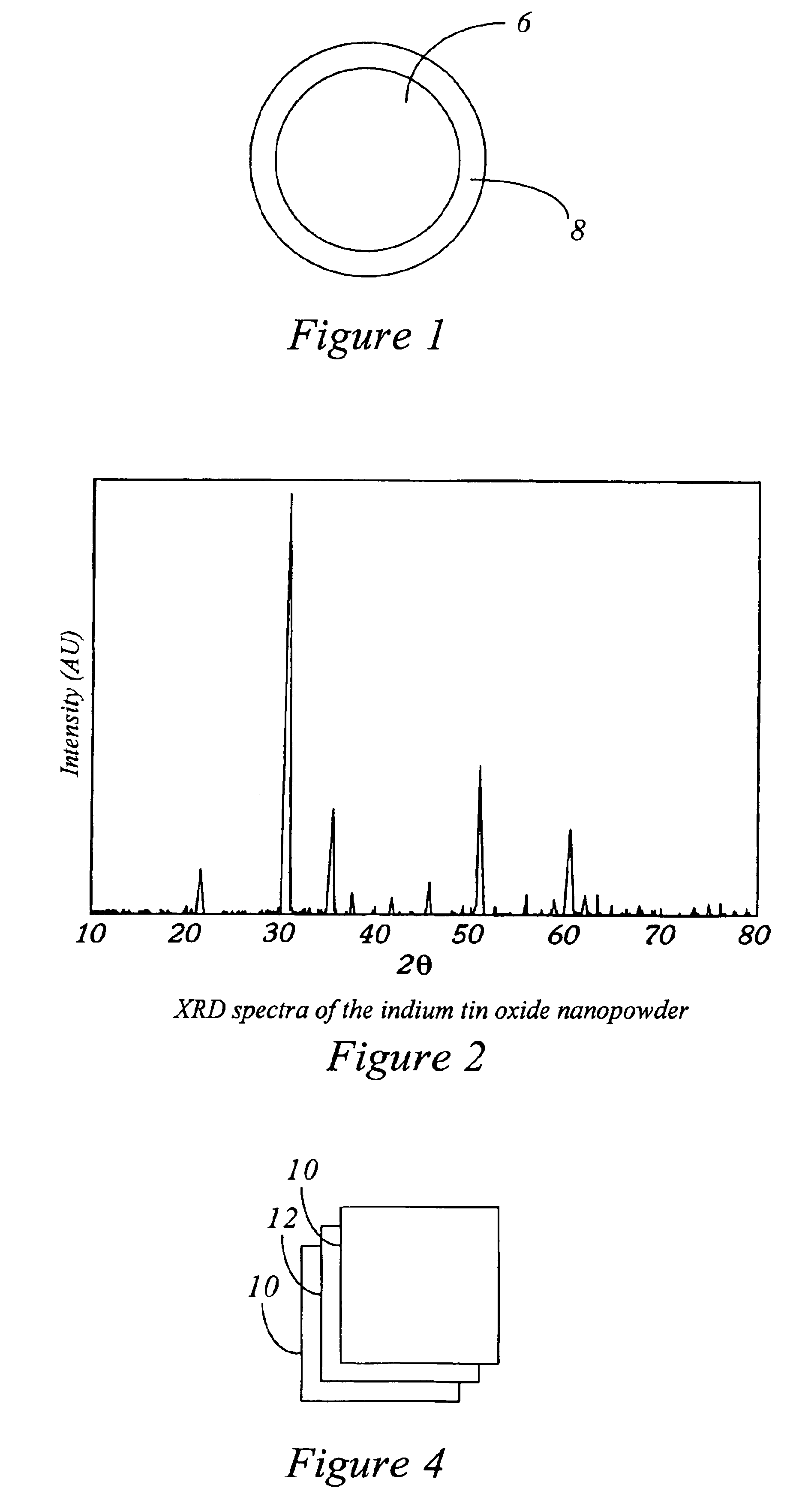

Polymer nanocomposite implants with enhanced transparency and mechanical properties for administration within humans or animals

Polymer nanocomposite implants with nanofillers and additives are described. The nanofillers described can be any composition with the preferred composition being those composing barium, bismuth, cerium, dysprosium, europium, gadolinium, hafnium, indium, lanthanum, neodymium, niobium, praseodymium, strontium, tantalum, tin, tungsten, ytterbium, yttrium, zinc, and zirconium. The additives can be of any composition with the preferred form being inorganic nanopowders comprising aluminum, calcium, gallium, iron, lithium, magnesium, silicon, sodium, strontium, titanium. Such nanocomposites are particularly useful as materials for biological use in applications such as drug delivery, biomed devices, bone or dental implants.

Owner:PPG IND OHIO INC

Method of producing exfoliated graphite, flexible graphite, and nano-scaled graphene platelets

The present invention provides a method of exfoliating a layered material (e.g., graphite and graphite oxide) to produce nano-scaled platelets having a thickness smaller than 100 nm, typically smaller than 10 nm. The method comprises (a) dispersing particles of graphite, graphite oxide, or a non-graphite laminar compound in a liquid medium containing therein a surfactant or dispersing agent to obtain a stable suspension or slurry; and (b) exposing the suspension or slurry to ultrasonic waves at an energy level for a sufficient length of time to produce separated nano-scaled platelets. The nano-scaled platelets are candidate reinforcement fillers for polymer nanocomposites. Nano-scaled graphene platelets are much lower-cost alternatives to carbon nano-tubes or carbon nano-fibers.

Owner:GLOBAL GRAPHENE GRP INC

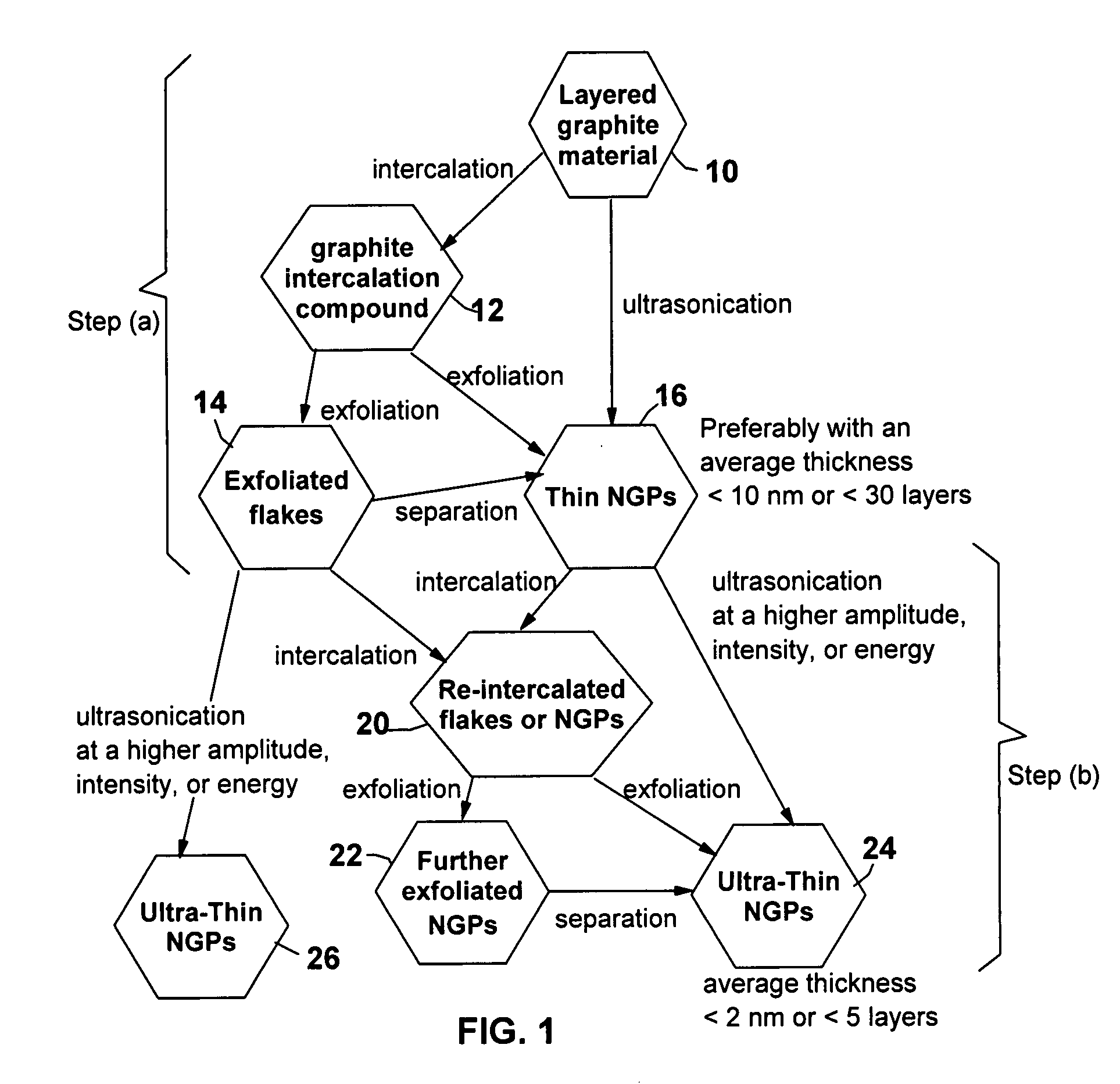

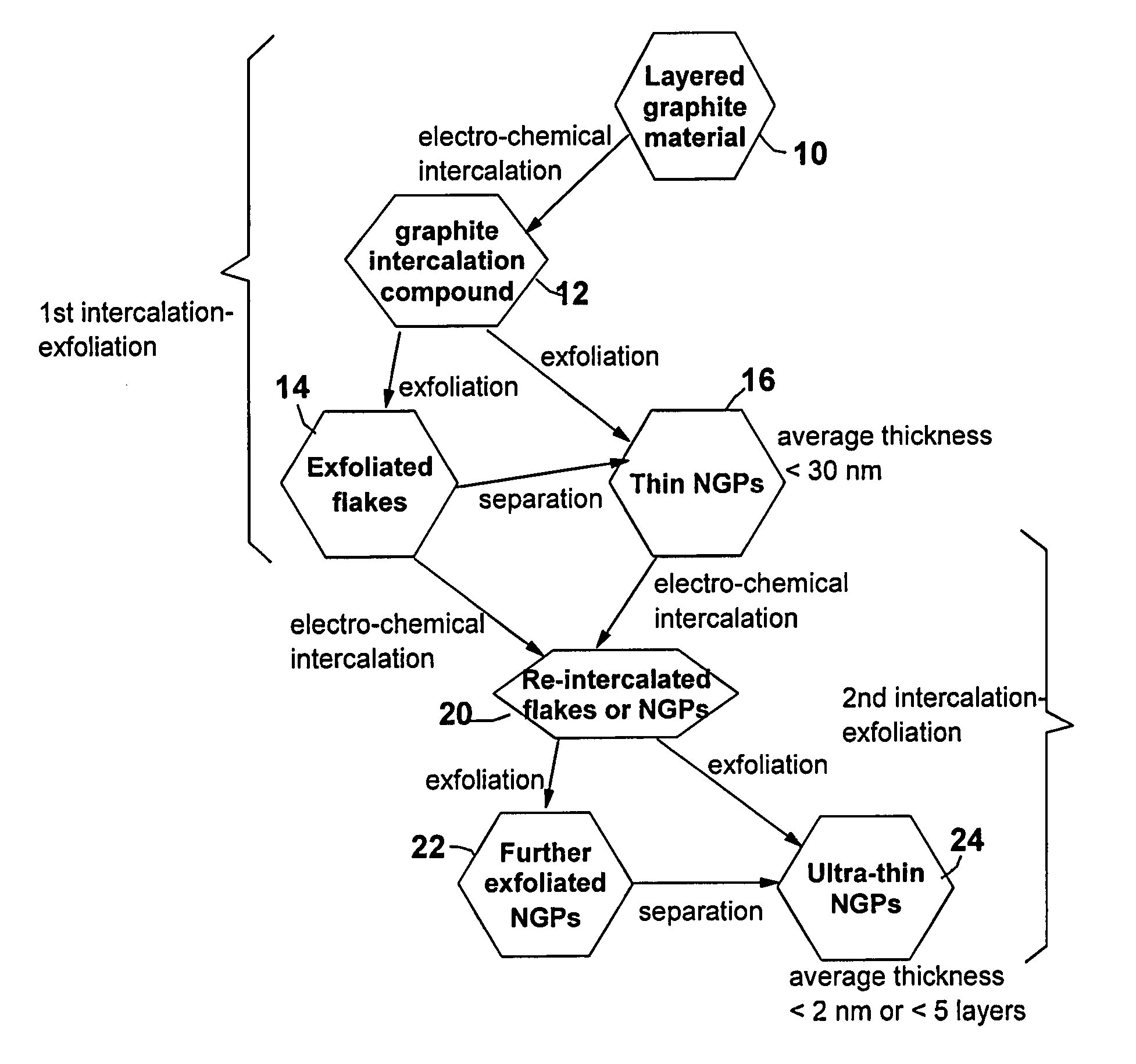

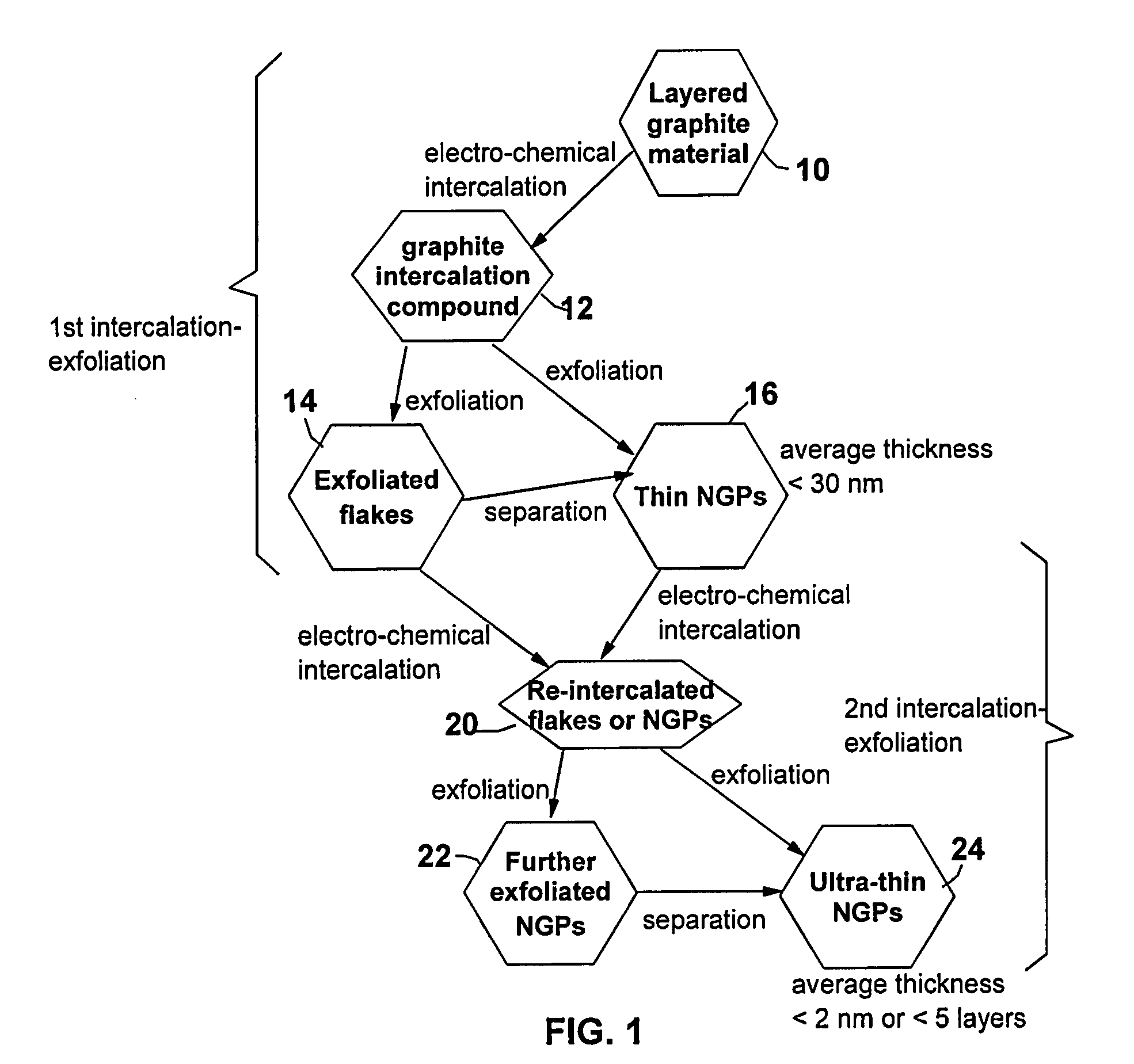

Method for producing ultra-thin nano-scaled graphene platelets

InactiveUS20090022649A1Good dispersionImprove conductivityMaterial nanotechnologyGraphiteFiberCarbon nanotube

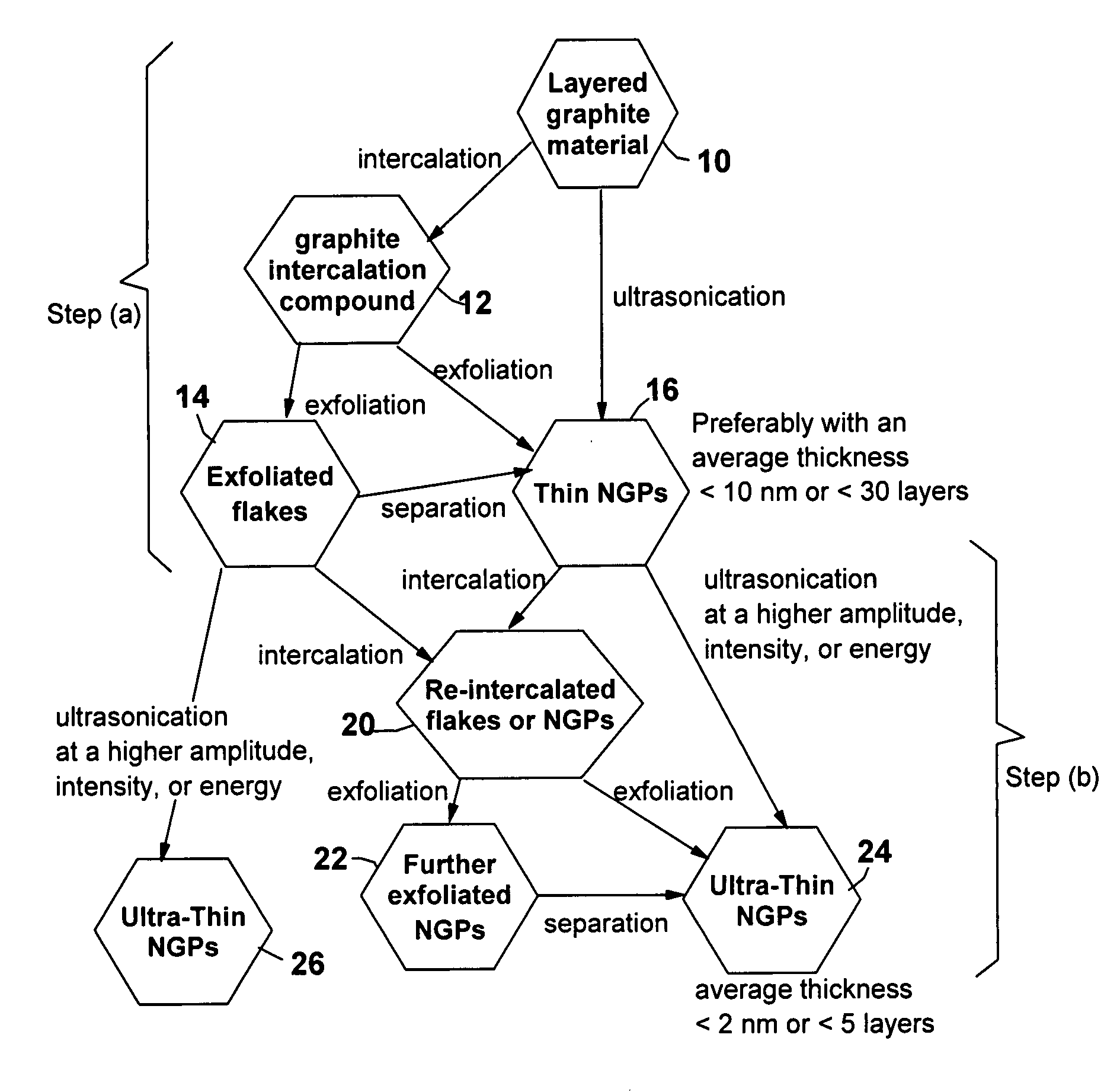

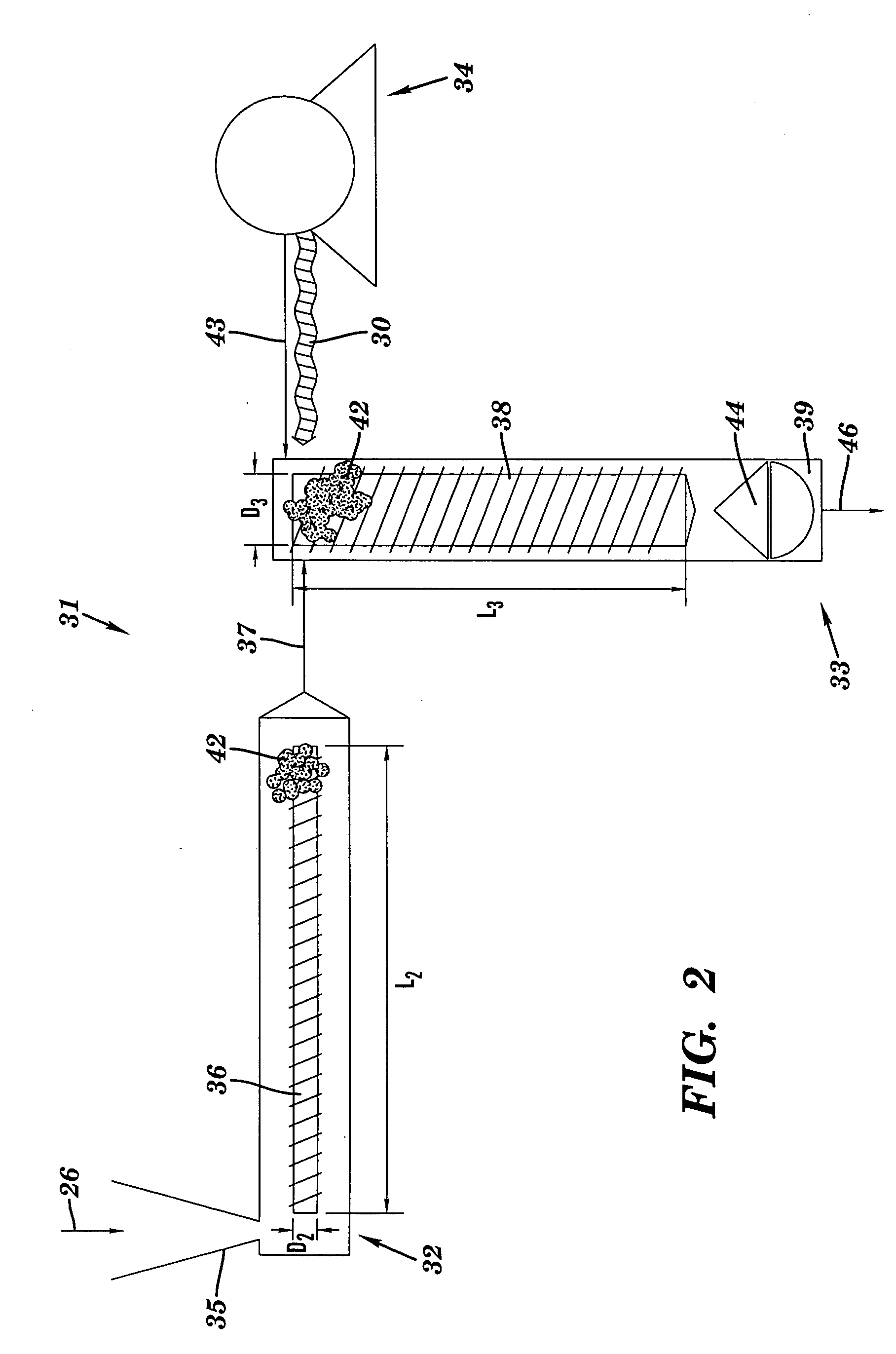

A method of producing ultra-thin, separated nano-scaled platelets having an average thickness no greater than 2 nm or comprising, on average, no more than 5 layers per platelet from a layered graphite material. The method comprises: (a) providing a supply of nano-scaled platelets with an average thickness of no more than 10 nm or having, on average, no more than 30 layers per platelet; and (b) intercalating the supply of nano-scaled platelets to produce intercalated nano platelets and exfoliating the intercalated nano platelets at a temperature and a pressure for a sufficient period of time to produce the ultra-thin nano-scaled platelets. The nano-scaled platelets are candidate reinforcement fillers for polymer nanocomposites. Nano-scaled graphene platelets are much lower-cost alternatives to carbon nano-tubes or carbon nano-fibers.

Owner:NANOTEK INSTR

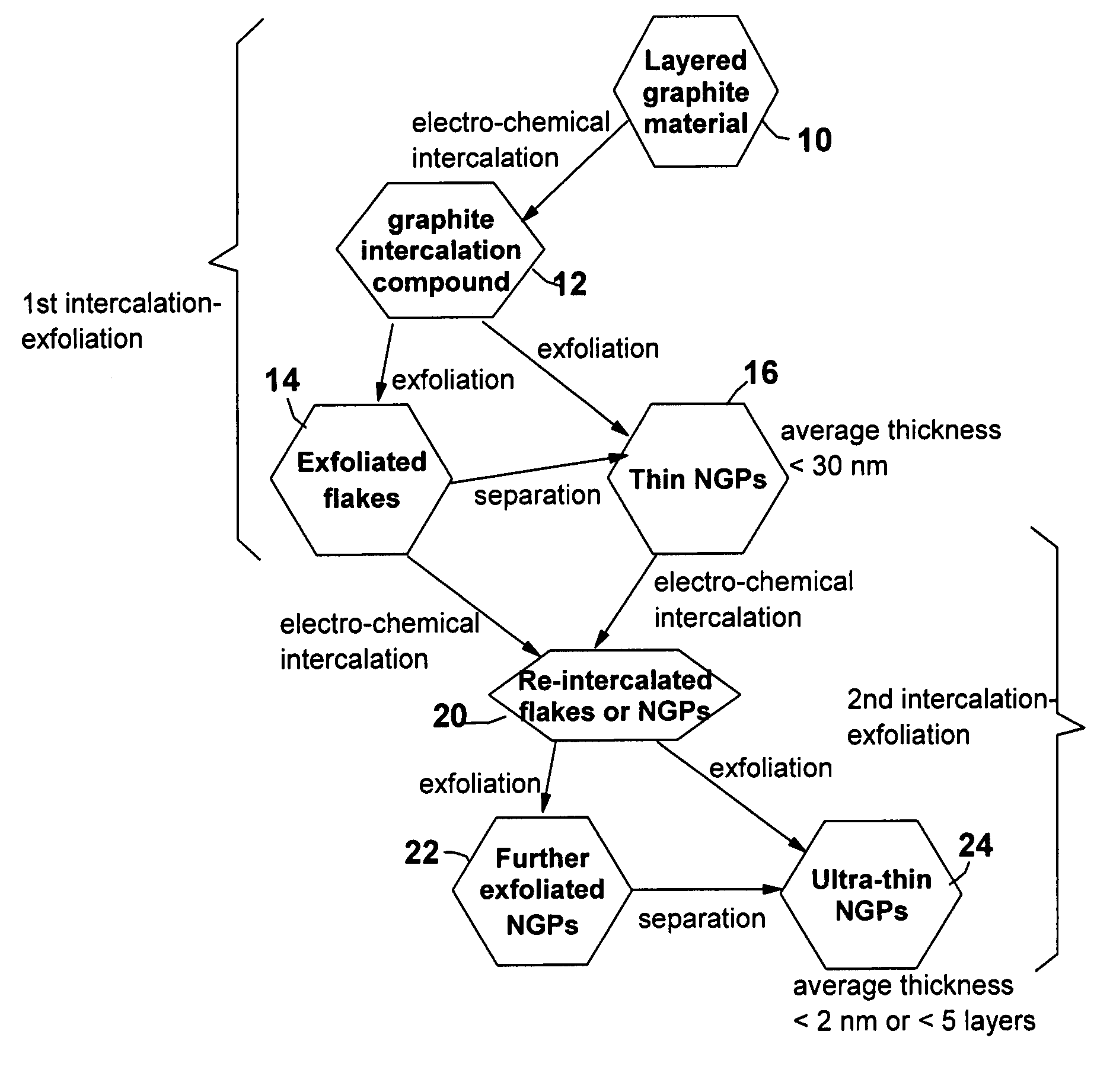

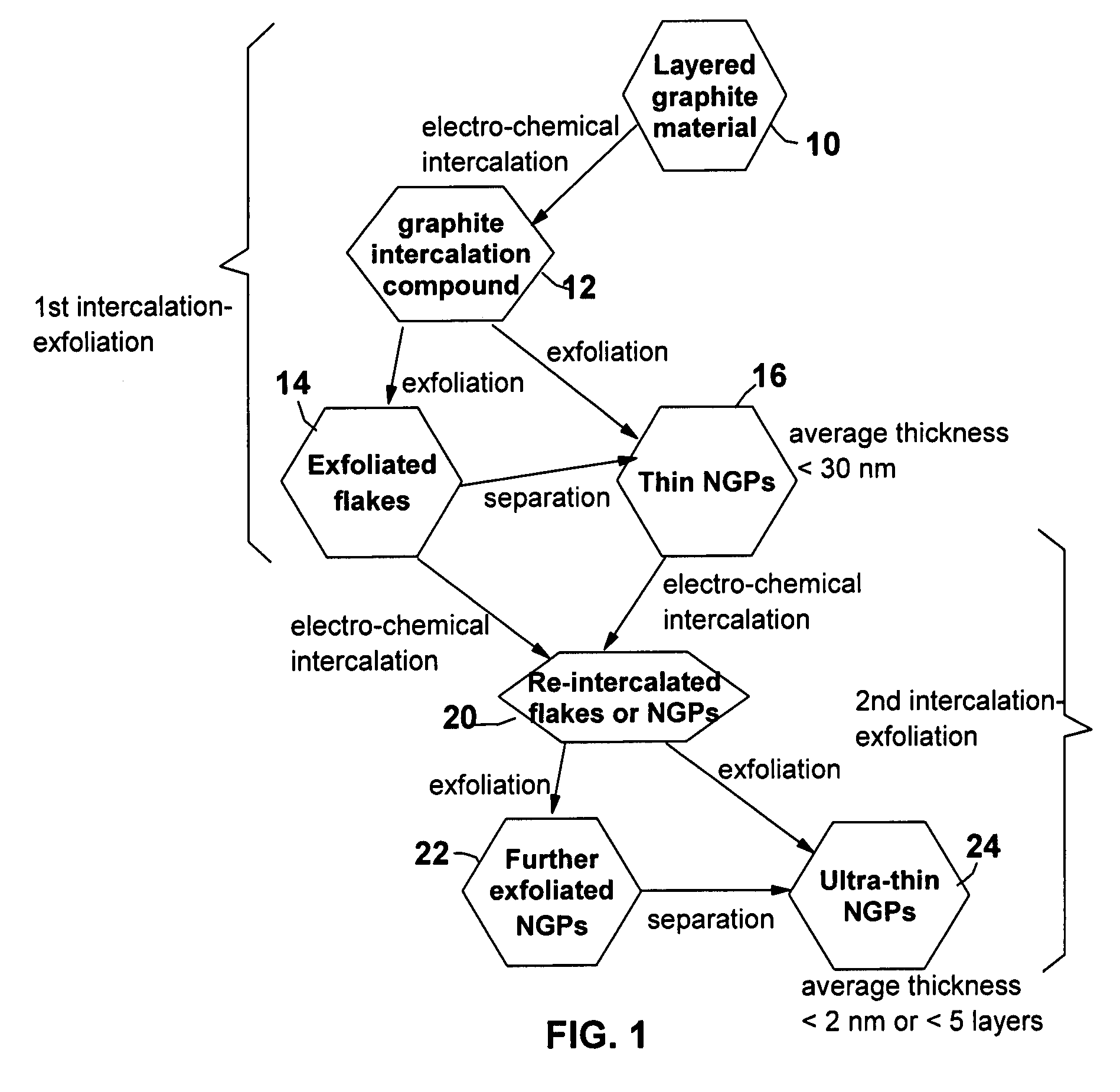

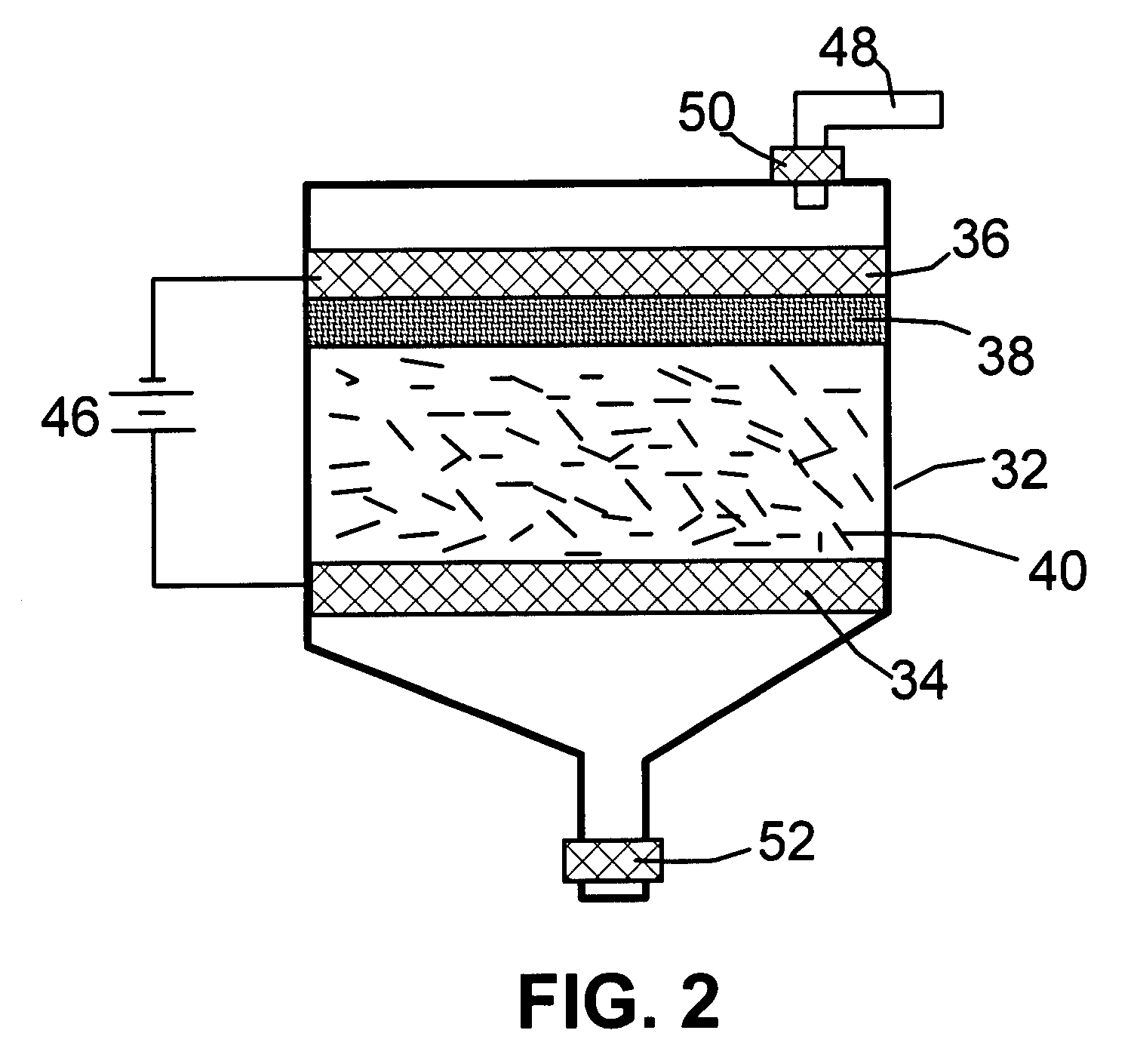

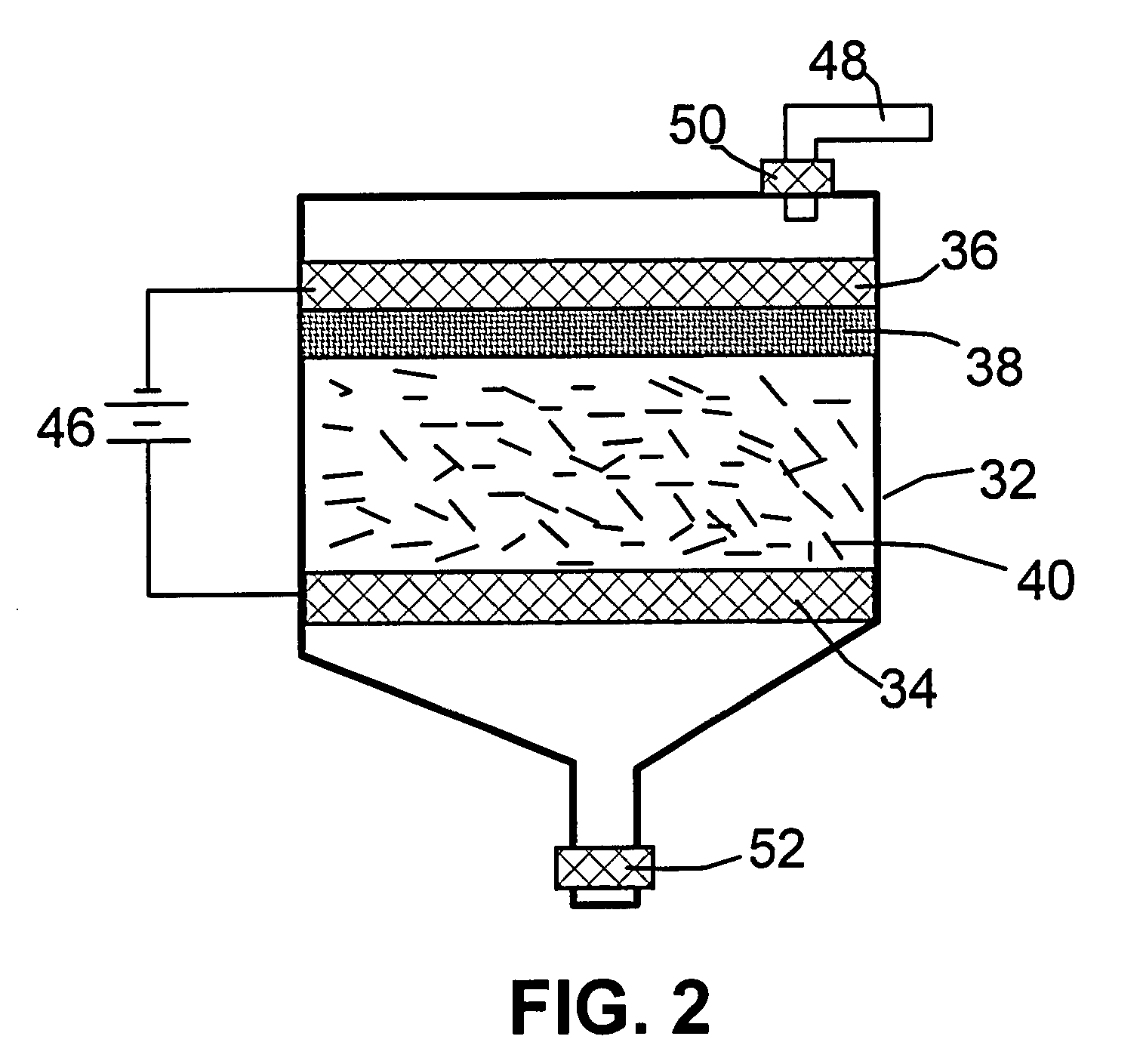

Electrochemical method of producing nano-scaled graphene platelets

A method of producing nano-scaled graphene platelets with an average thickness smaller than 30 nm from a layered graphite material. The method comprises (a) forming a carboxylic acid-intercalated graphite compound by an electrochemical reaction which uses a carboxylic acid as both an electrolyte and an intercalate source, the layered graphite material as an anode material, and a metal or graphite as a cathode material, and wherein a current is imposed upon the cathode and the anode at a current density for a duration of time sufficient for effecting the electrochemical reaction; (b) exposing the intercalated graphite compound to a thermal shock to produce exfoliated graphite; and (c) subjecting the exfoliated graphite to a mechanical shearing treatment to produce the nano-scaled graphene platelets. Preferred carboxylic acids are formic acid and acetic acid. The exfoliation step in the instant invention does not involve the evolution of undesirable species, such as NOx and SOx, which are common by-products of exfoliating conventional sulfuric or nitric acid-intercalated graphite compounds. The nano-scaled platelets are candidate reinforcement fillers for polymer nanocomposites. Nano-scaled graphene platelets are much lower-cost alternatives to carbon nano-tubes or carbon nano-fibers.

Owner:GLOBAL GRAPHENE GRP INC

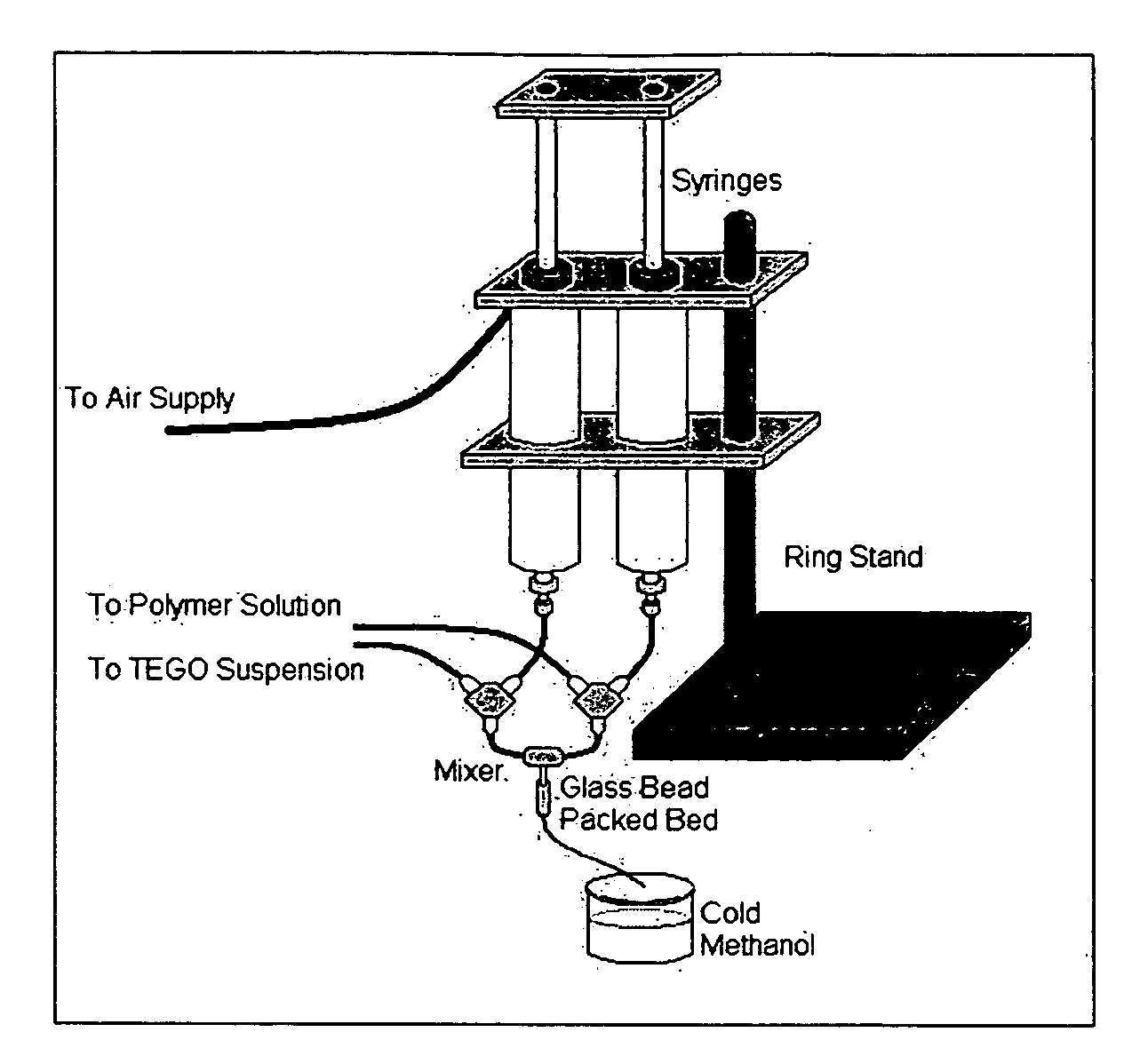

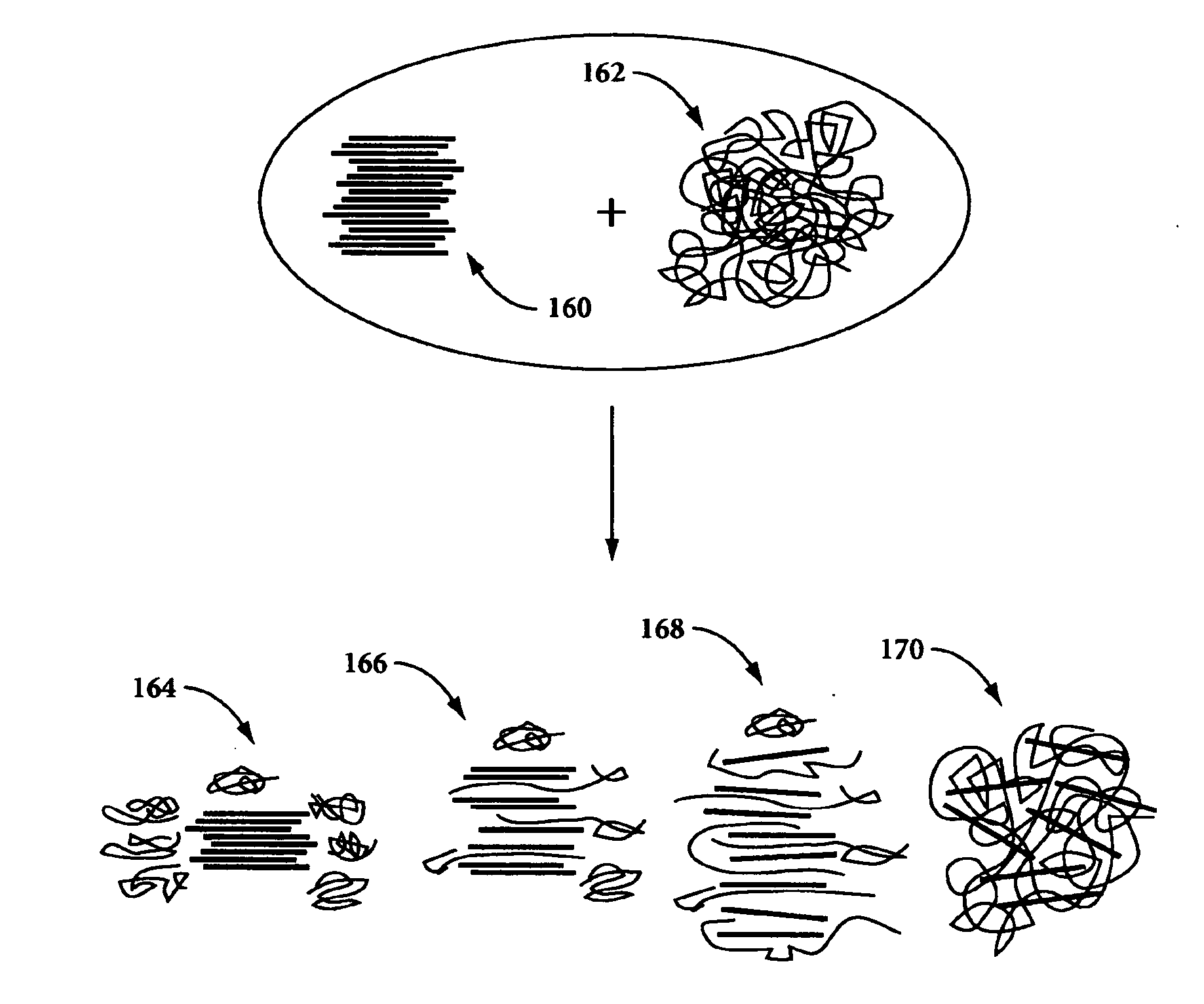

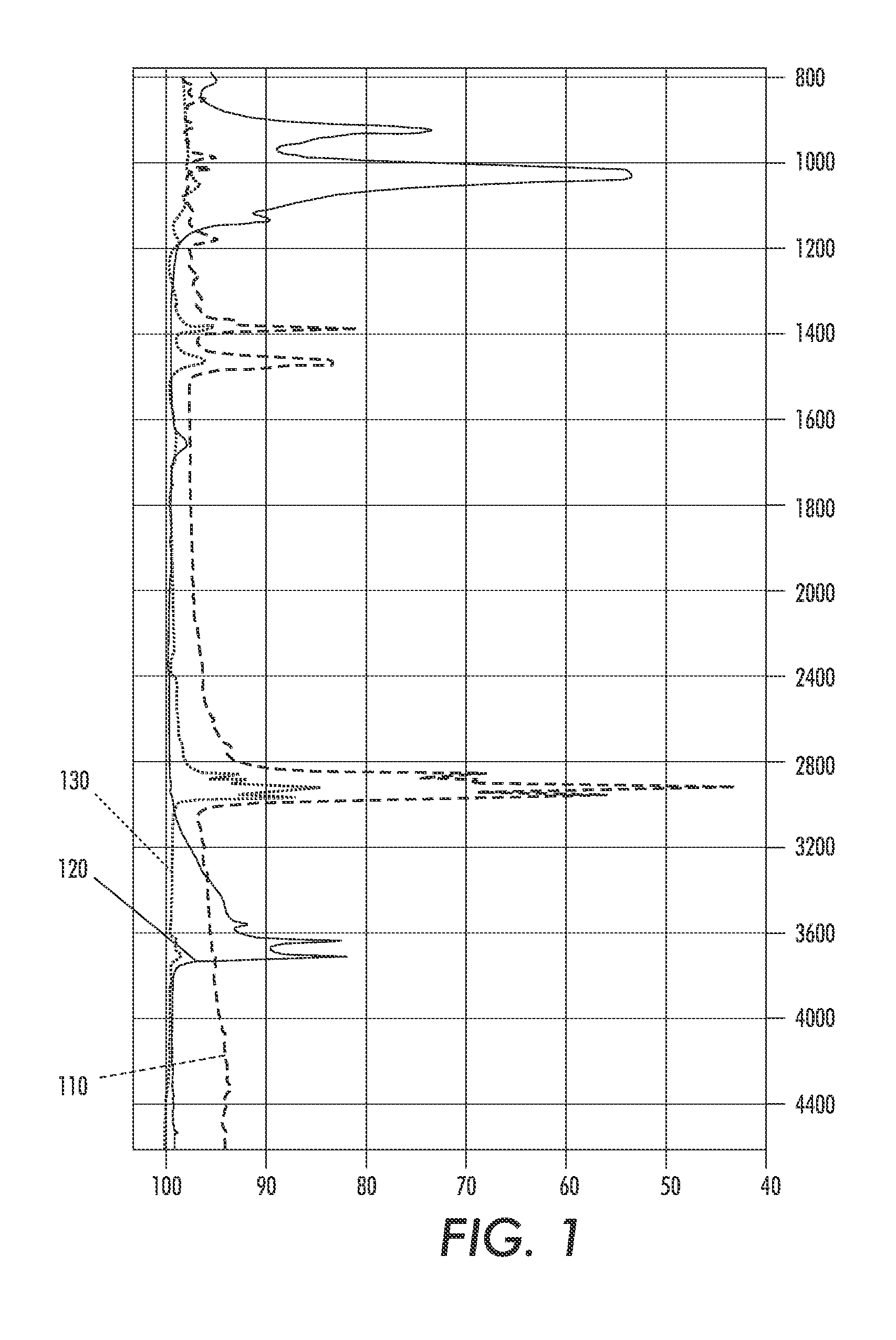

Preparation of polymer nanocomposites by dispersion destabilization

Nanocomposites may be produced by mixing dispersions of polymers and dispersions of clay minerals. After mixing, the dispersions may be destabilized with the addition of appropriate compounds. The flocculated solid material exhibits characteristics of a nanocomposite, such as exfoliation of the clay mineral platelets as indicated by x-ray diffraction analysis.

Owner:BYK ADDITIVES

Method for the fracture stimulation of a subterranean formation having a wellbore by using thermoset polymer nanocomposite particles as proppants, where said particles are prepared by using formulations containing reactive ingredients obtained or derived from renewable feedstocks

InactiveUS20070181302A1Generality is degradedHigh trafficFluid removalDrilling compositionLiquid mediumHigh rate

A method for fracture stimulation of a subterranean formation having a wellbore includes providing a thermoset polymer nanocomposite particle precursor composition comprising a polymer precursor mixture, dispersed within a liquid medium, containing at least one of a monomer, an oligomer or combinations thereof having three or more reactive functionalities capable of creating crosslinks between polymer chains, wherein 1% to 100% by weight of said polymer precursor mixture is obtained or derived from a renewable feedstock; and from 0.001 to 60 volume percent of nanofiller particles possessing a length that is less than 0.5 microns in at least one principal axis direction; subjecting the nanocomposite particle precursor composition to polymerizing conditions to form the polymeric nanocomposite particle, whereby said nanofiller particles are substantially incorporated into a polymer; forming a slurry comprising a fluid and a proppant, wherein said proppant comprises the nanocomposite particles, said nanocomposite particles being formed from a rigid thermoset polymer matrix; and injecting into the wellbore said slurry at sufficiently high rates and pressures such that said formation fails and fractures to accept said slurry.

Owner:SUN DRILLING PRODS

Halogen containing-polymer nanocomposite compositions, methods, and products employing such compositions

InactiveUS7265174B2Reduce load levelIncorporation flexibilityMaterial nanotechnologySpecial tyresHalogenPolymer nanocomposite

The disclosure provides compositions prepared by combining nanomaterials with a halide-containing polymer, thereby forming a combined polymer matrix having dispersed nanomaterials within the matrix. The nanomaterials may be carbon-based nanotubes, in some applications. A halide-containing monomer is combined with nanotubes, and then polymerized in some compositions. In other applications, a halide-containing polymer is solution processed with nanotubes to form useful compositions in the invention. Also disclosed are probes for near field detection of radiation.

Owner:CLEMSON UNIVERSITY

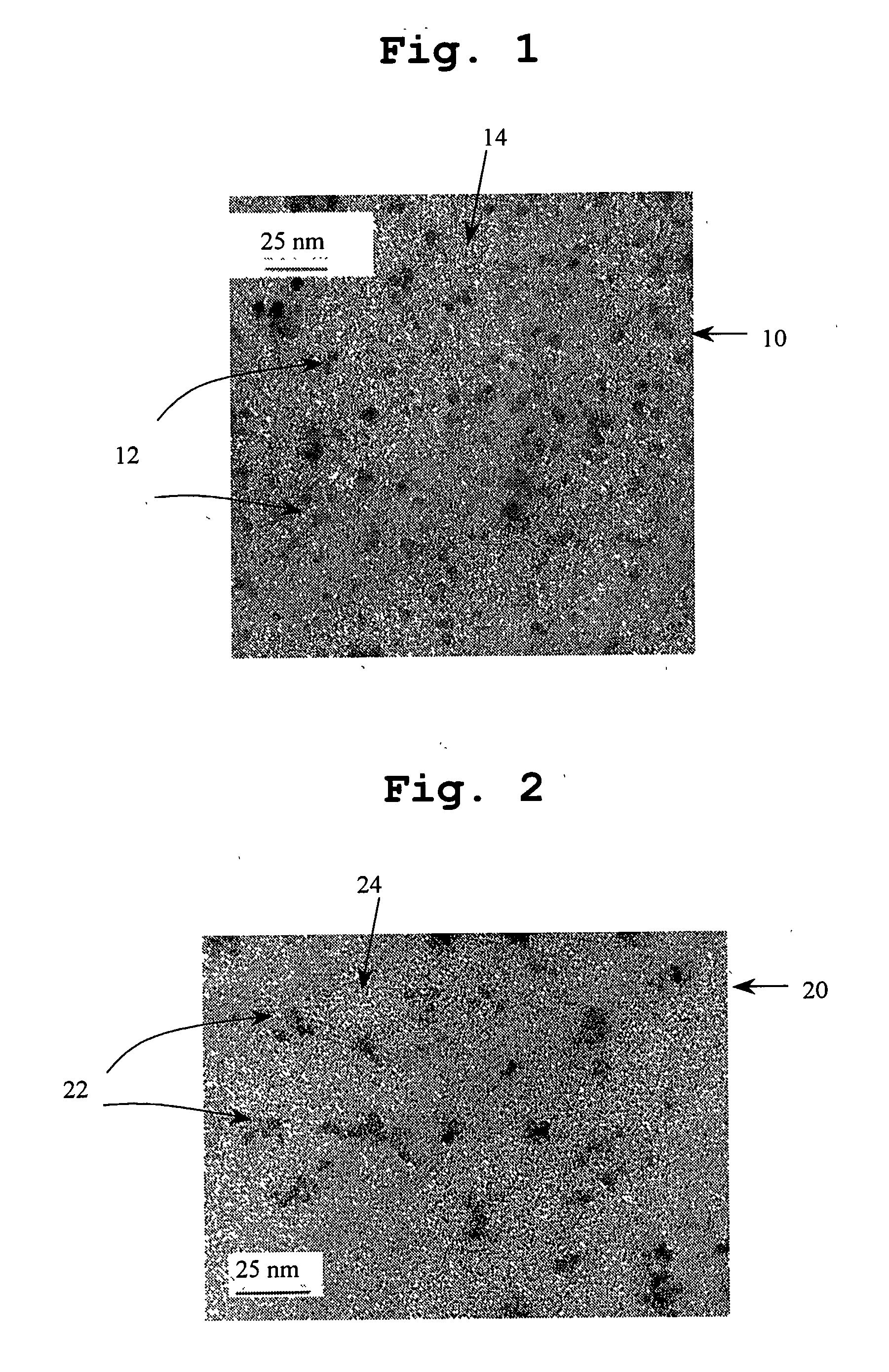

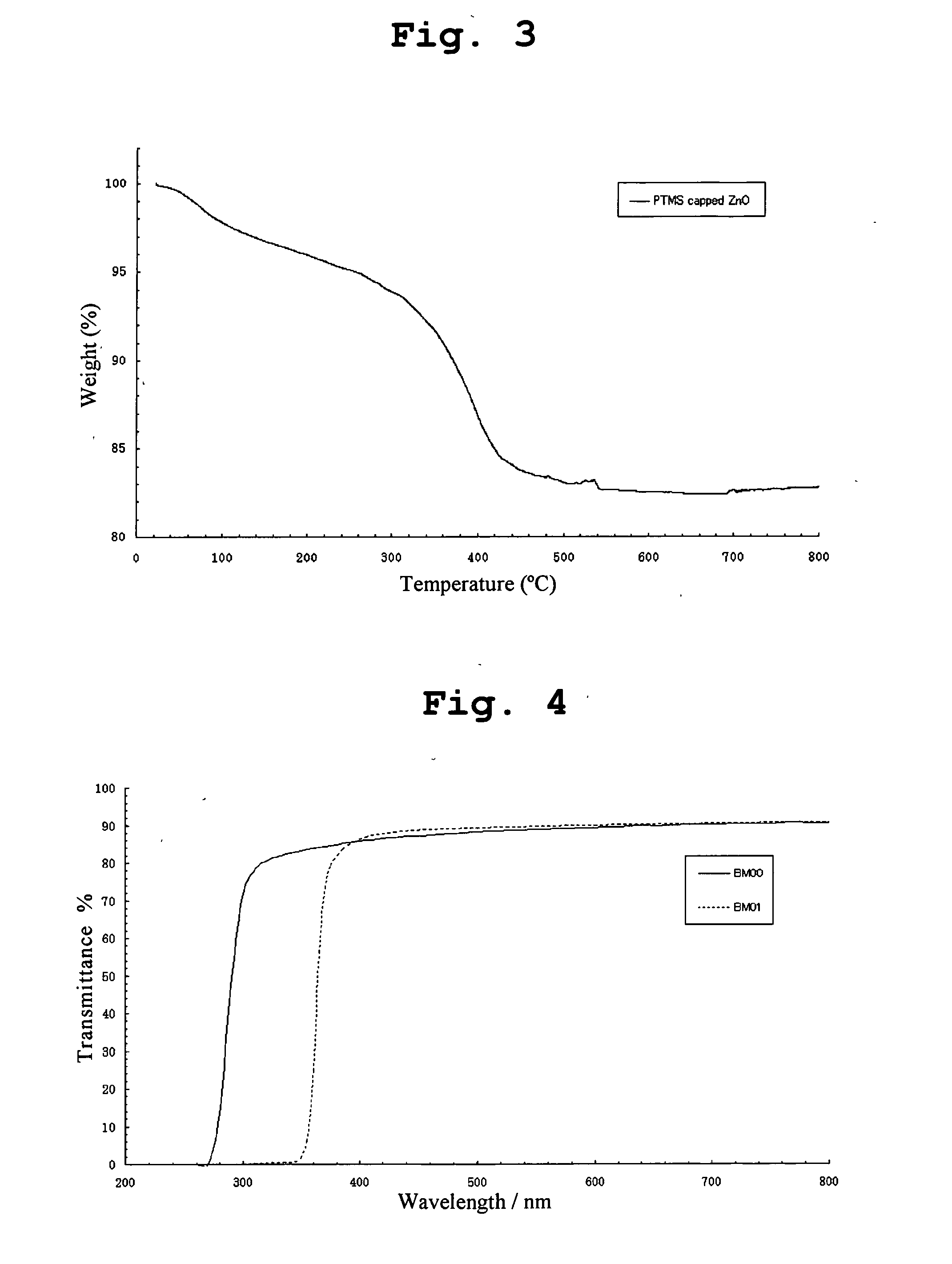

Transparent polymer nanocomposites containing nanoparticles and method of making same

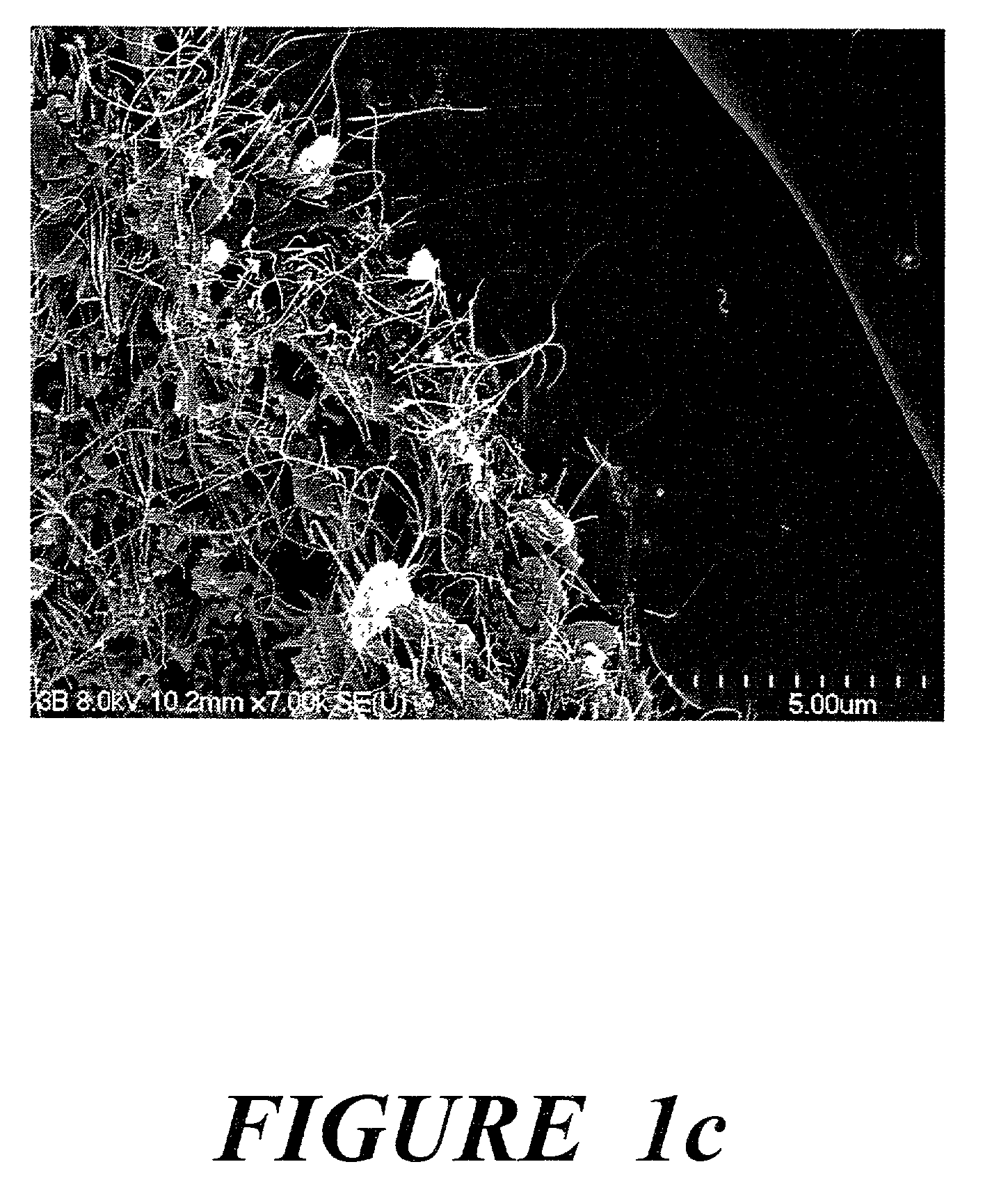

InactiveUS20090233090A1High transparencyIncrease contentMaterial nanotechnologyPigmenting treatmentMetal oxide nanoparticlesThermal stability

The present invention relates to transparent nanocomposites comprising of metal oxide nanoparticles dispersed in polymer matrix. The nanoparticles have capping agents attached onto the nanoparticle surfaces and a precursor solution of capped nanoparticles and polymer is prepared and dried to obtain the nanocomposites. The nanocomposites exhibit UV absorption, low haze, and improved thermal stability. The present invention also relates to the methods associated with the preparation of capped nanoparticles, precursor solution and nanocomposites.

Owner:KANEKA CORP

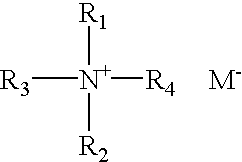

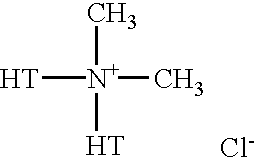

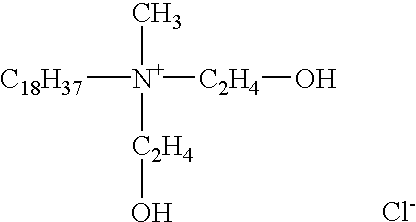

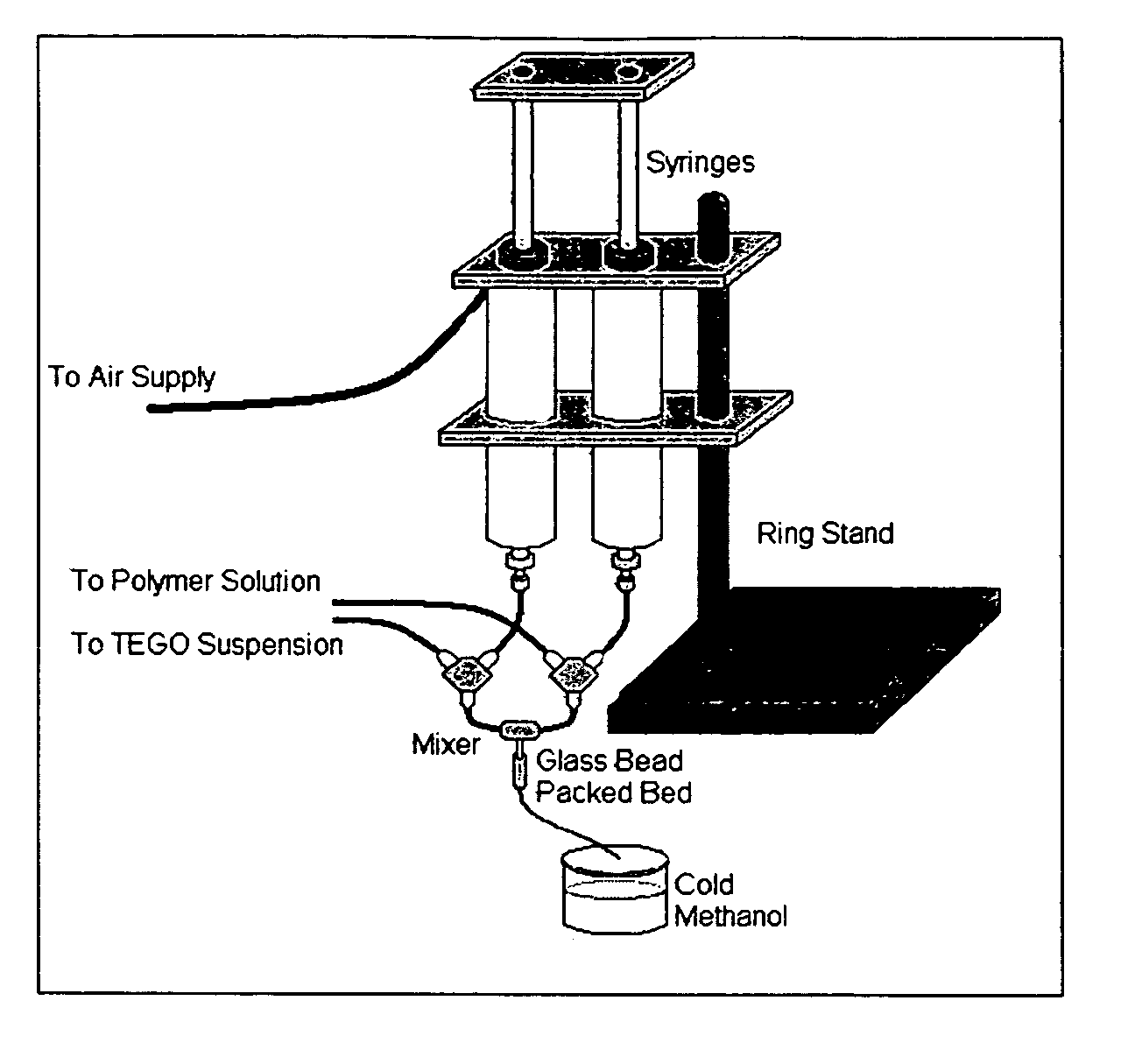

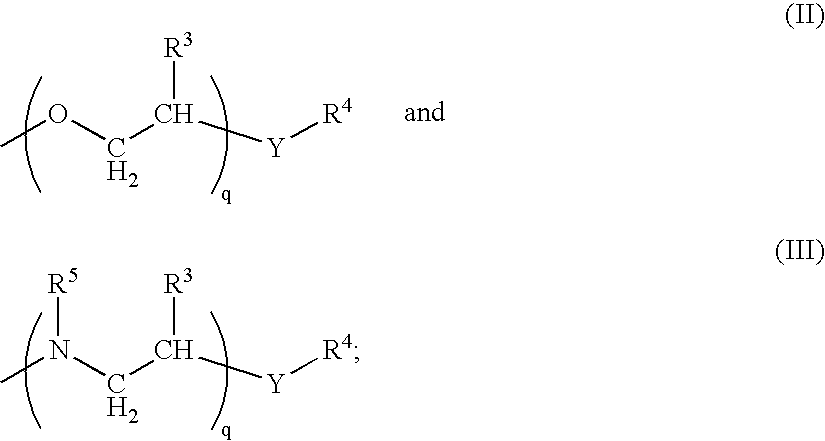

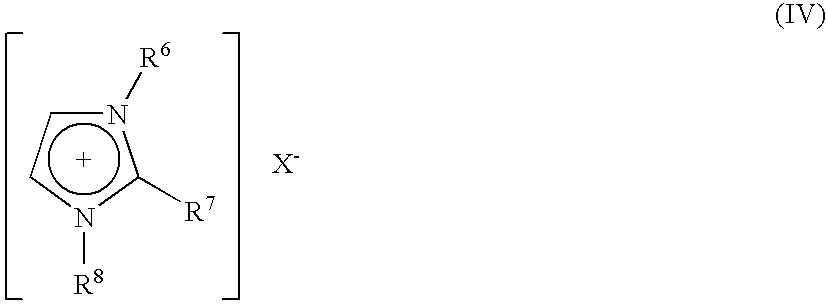

Hydrophobically modified clay polymer nanocomposites

InactiveUS20020058739A1Control of particle sizeReduced stabilityMaterial nanotechnologyLayered productsColloidSolution polymerization

The present invention is directed, in part, to improved nanocomposite compositions and processes for preparing same. Specifically, in one embodiment, there is provided a process for preparing an aqueous nanocomposite dispersion, wherein the process comprises: polymerizing via suspension polymerization a suspension comprising at least one ethylenically unsaturated monomer and a hydrophobically modified clay to form the nanocomposite dispersion after polymerization, wherein the hydrophobically modified clay is dispersed in the monomer. Other embodiments include processes for preparing aqueous nanocomposite particles, colloids, and dispersions using hydrophobically modified clays in aqueous systems and compositions comprising same.

Owner:ROHM & HAAS CO

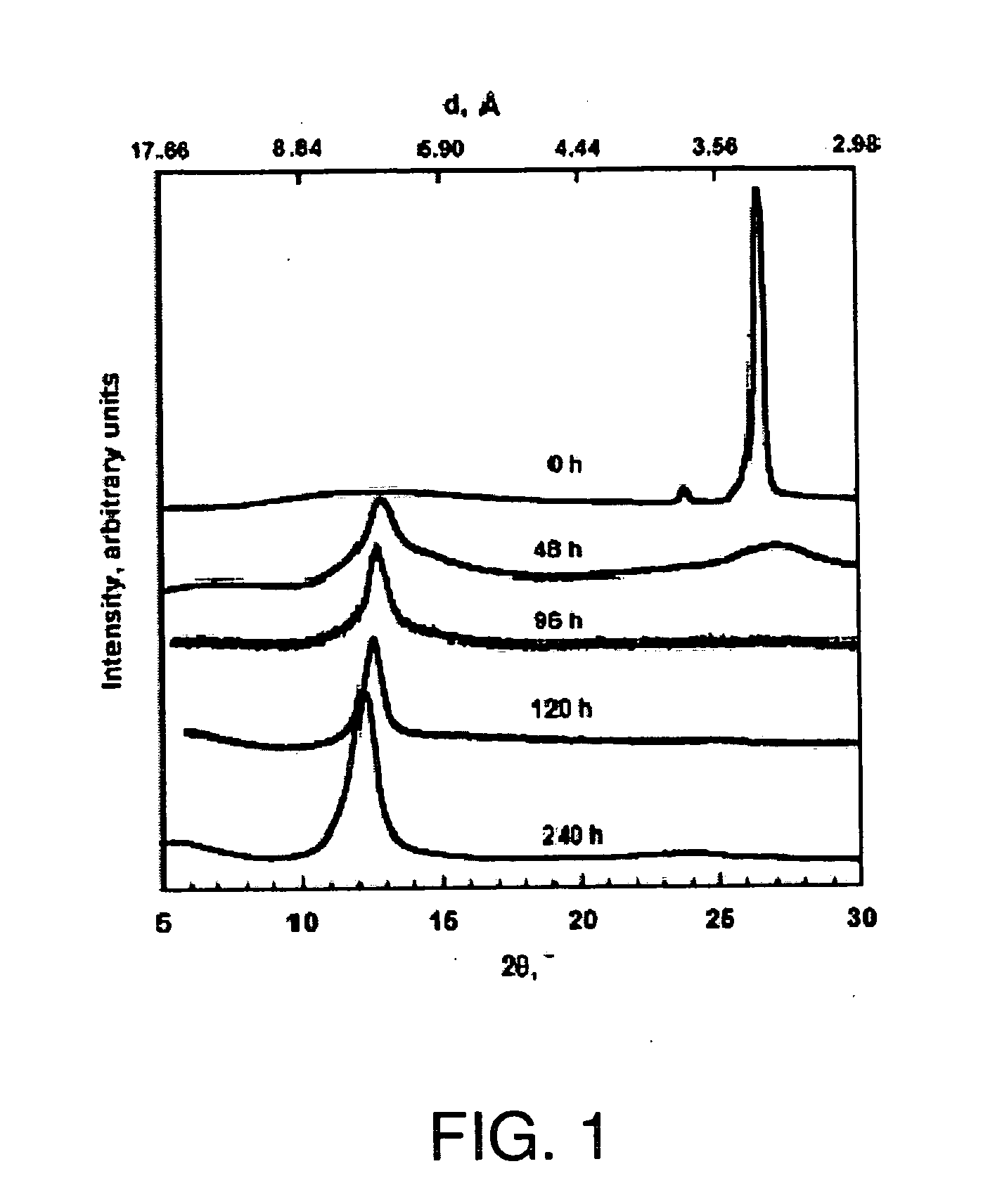

Functional graphene-polymer nanocomposites for gas barrier applications

InactiveUS8110026B2Excellent gas barrier performanceImprove suppression propertiesMaterial nanotechnologySemi-permeable membranesX-rayDiffusion barrier

Owner:THE TRUSTEES FOR PRINCETON UNIV

Preparation method for graphene oxide with high barrier property and polymer nanocomposite film

The invention provides a preparation method for graphene oxide with high barrier property and a polymer nanocomposite film. The preparation method comprises the following steps: graphene oxide is added in solvent for stirring to obtain a colloidal suspension of graphene oxide during the ultrasonic processing at the temperature of 20 to 45 DEG C; a polymer is added in the colloidal suspension of graphene oxide for stirring during the ultrasonic processing at the temperature of 20 to 120 DEG C, until the polymer is completely dissolved to obtain a solution of graphene oxide / polymer; and after air bubbles in the solution of graphene oxide / polymer are removed, the graphene oxide / polymer nanocomposite film is obtained by a casting method or blow molding method. The carbon dioxide transmission coefficient of the prepared nanocomposite film containing graphene oxide is reduced by more than 150 times, and the prepared nanocomposite film containing graphene oxide can be used for packaging food and drugs with higher requirements of barrier property.

Owner:XIAN UNIV OF TECH

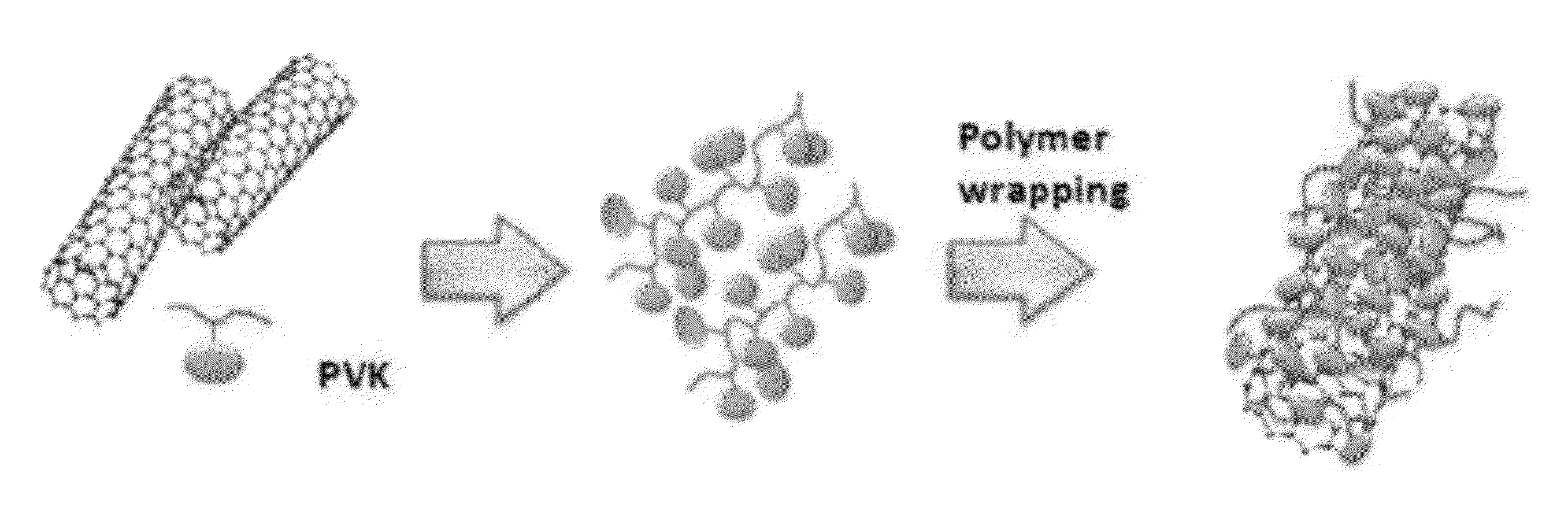

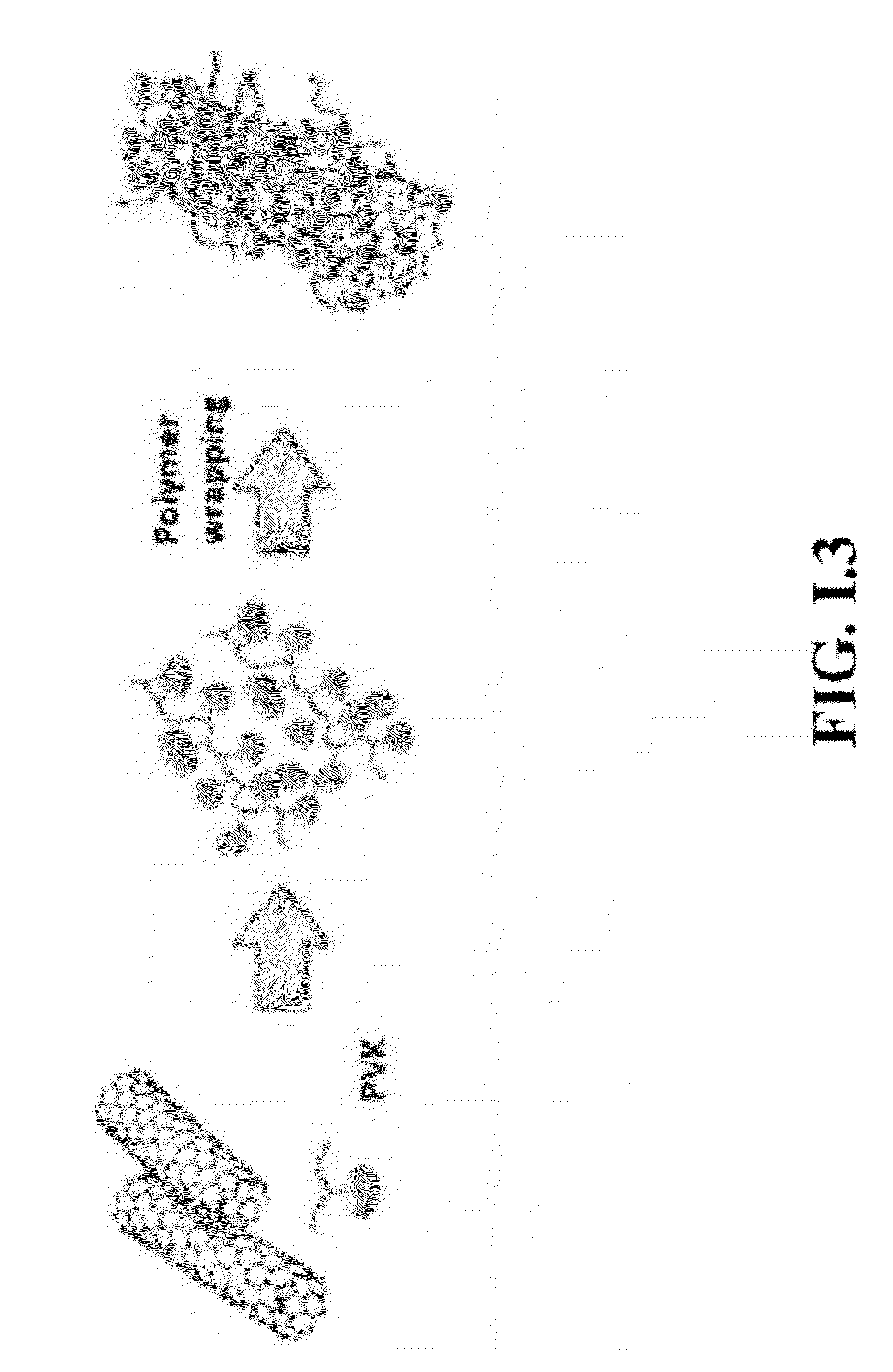

Polymer nanocomposite precursors with carbon nanotubes and/or graphene and related thin films and patterning

ActiveUS20120164433A1Simple materialIncrease productionMaterial nanotechnologyPigmenting treatmentNano compositesCarbon nanotube

Nano-composites include a graphite material such as nanotubes or graphene sheets and a partial or complete coating of a polymer including sufficient π-conjugated moieties to interact with surfaces of the graphite material. The polymers may also include electropolymerizable or oxidatively polymerizable moieties so the films may be crosslinked. The films may be used to form layers on substrates or patterned layers on substrates.

Owner:UNIV HOUSTON SYST

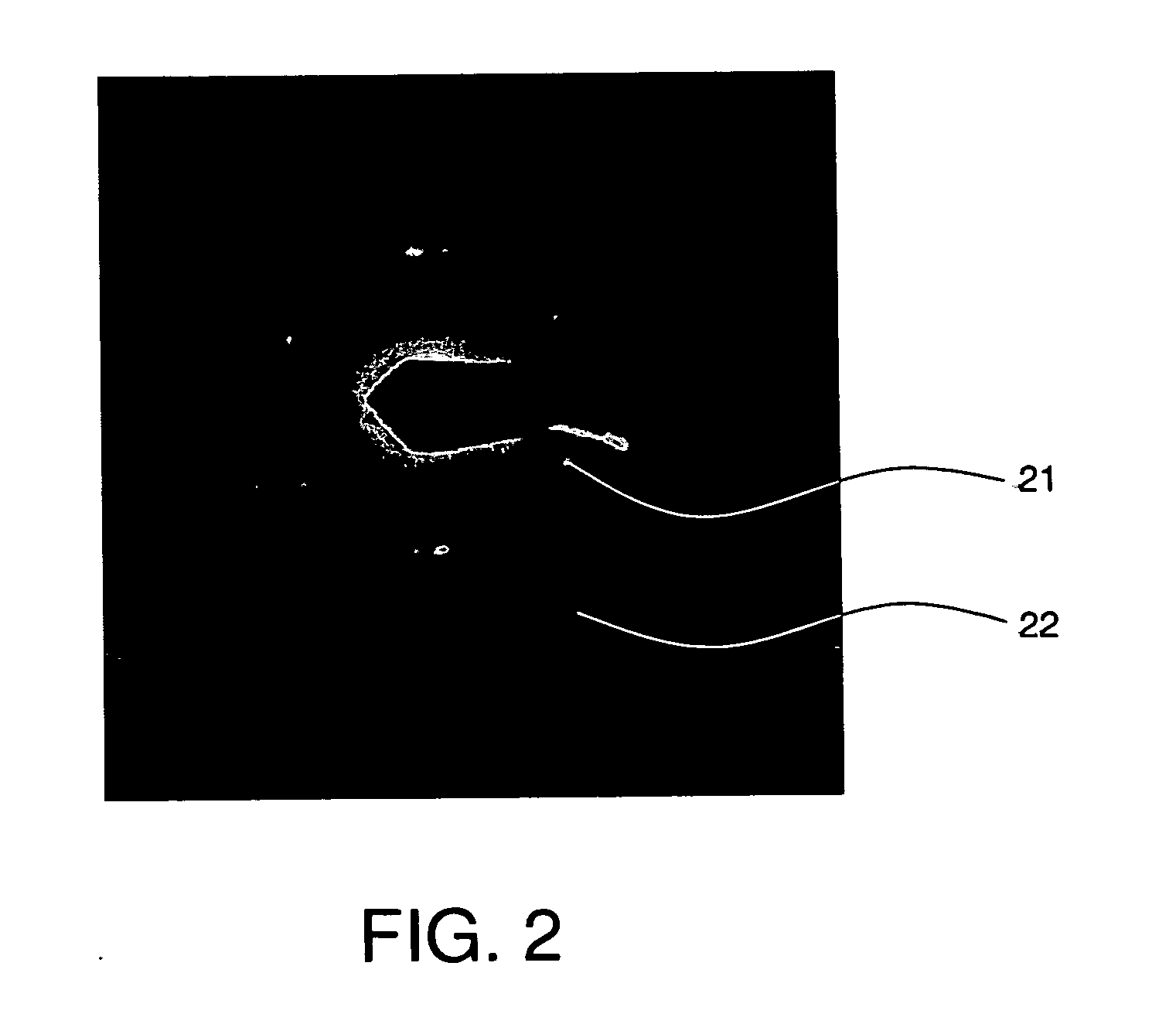

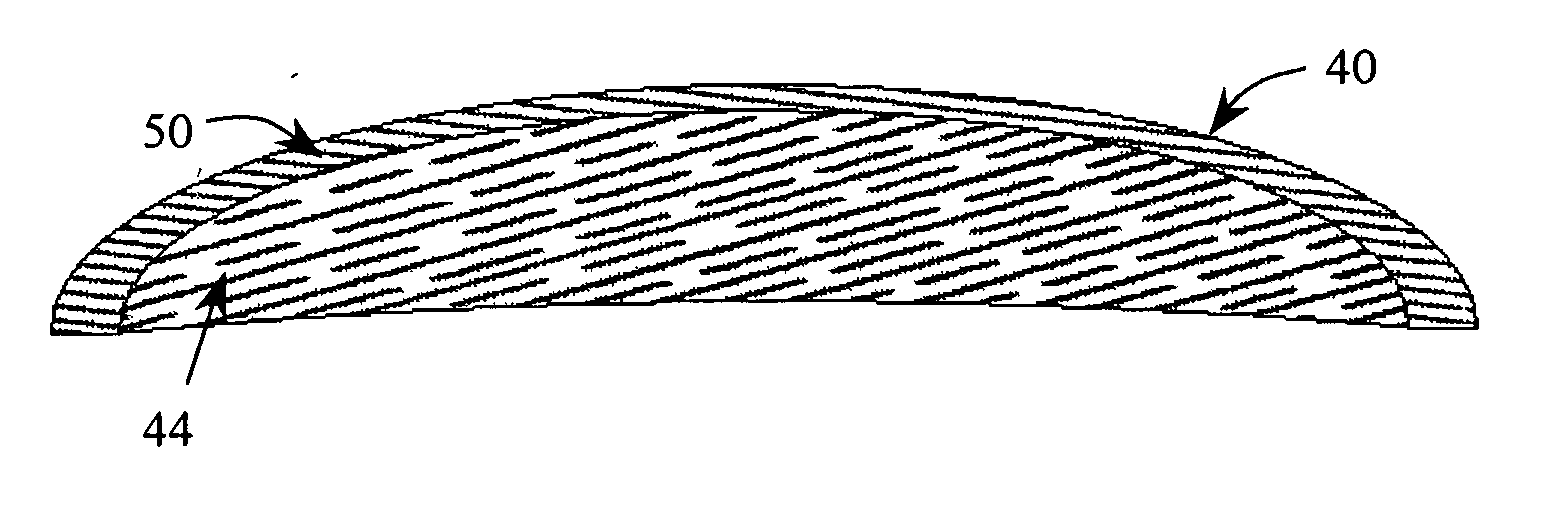

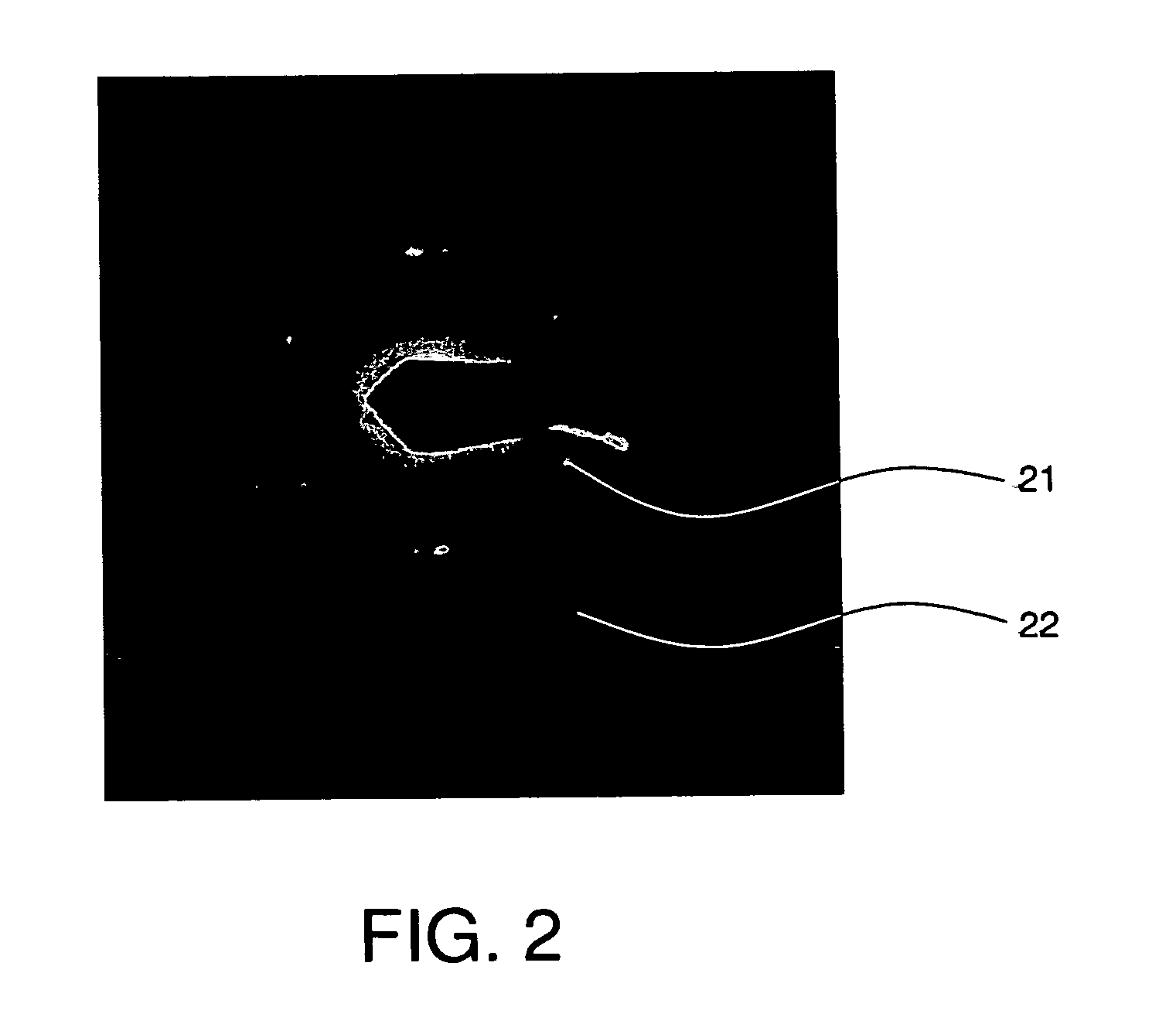

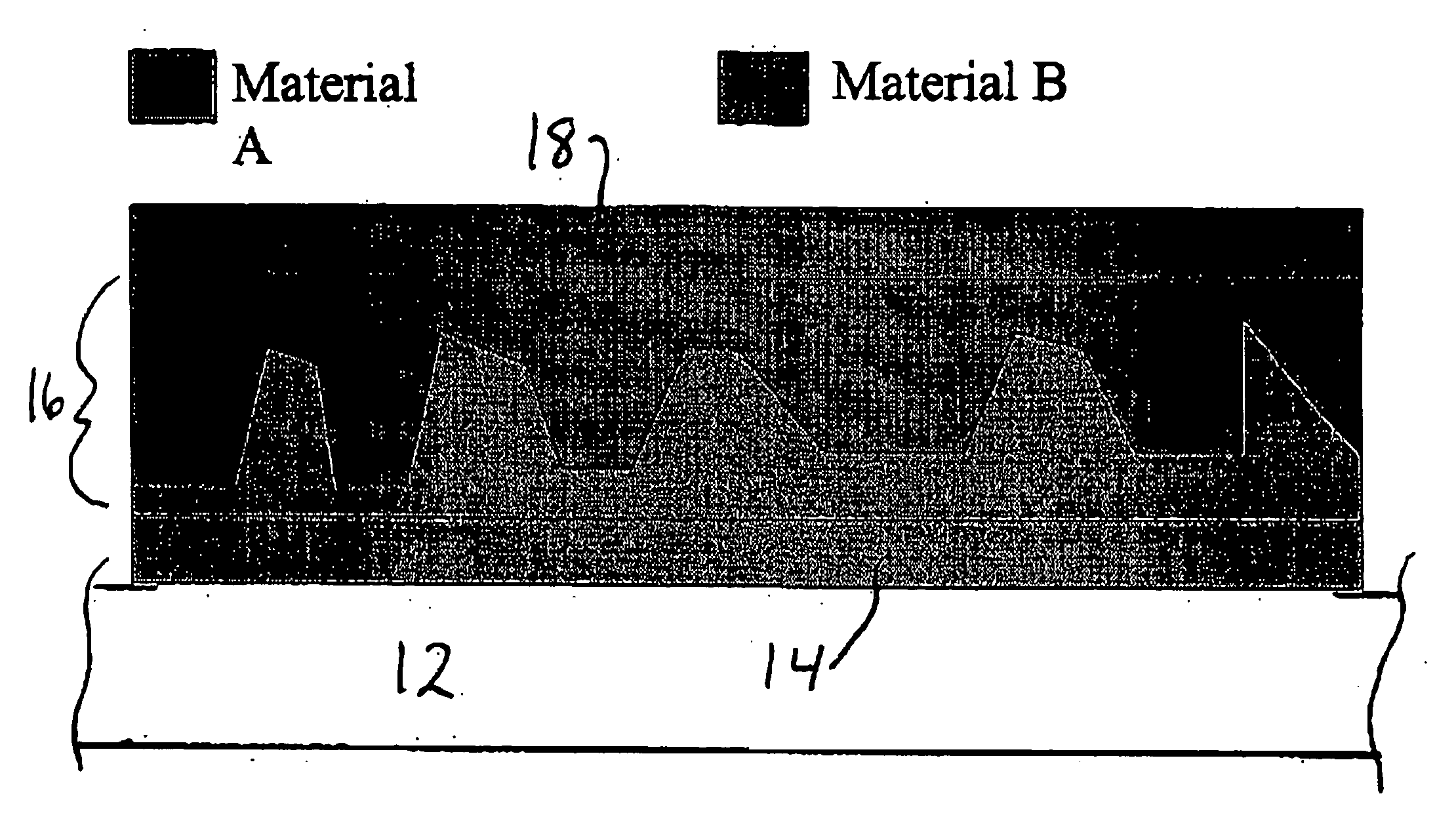

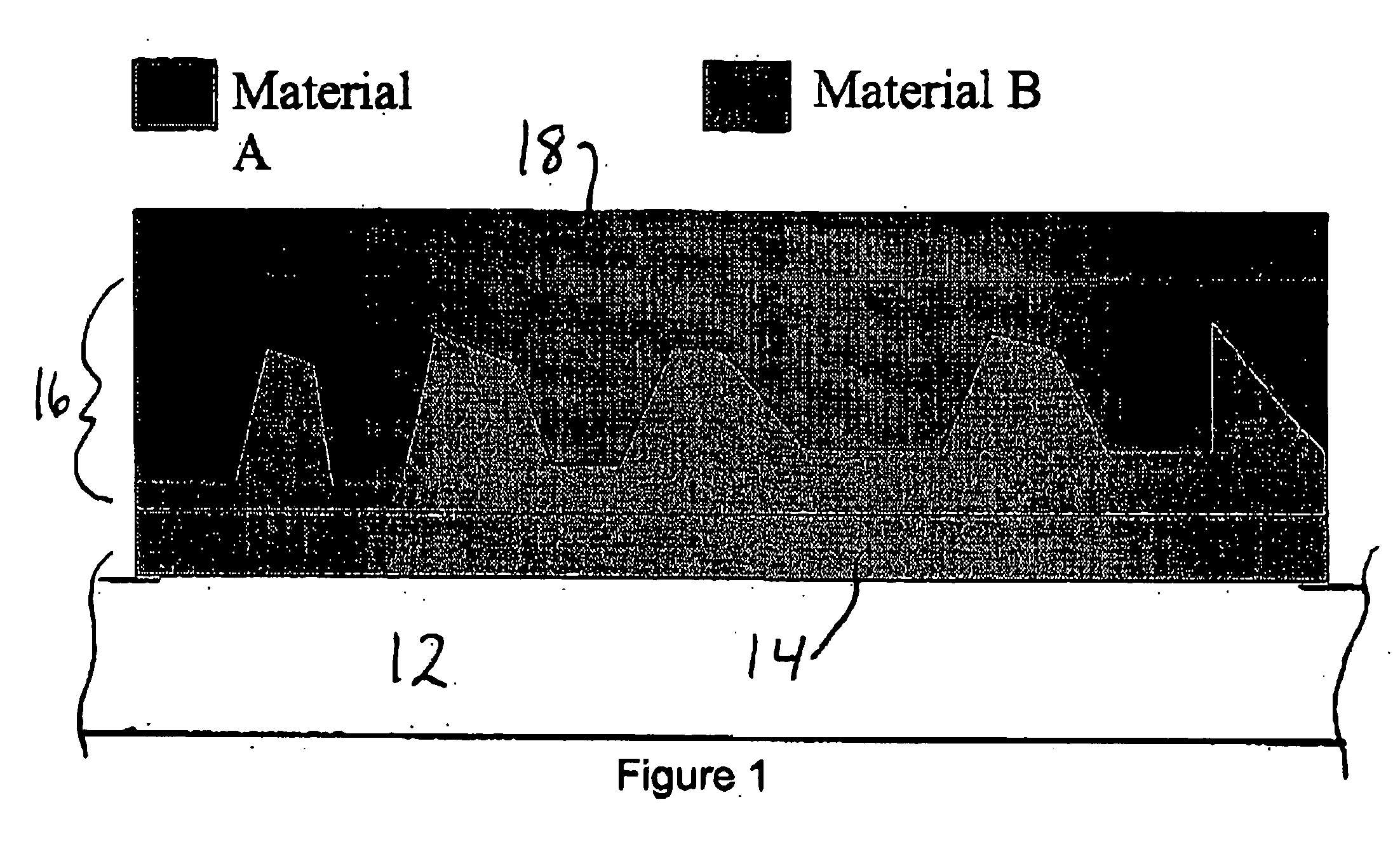

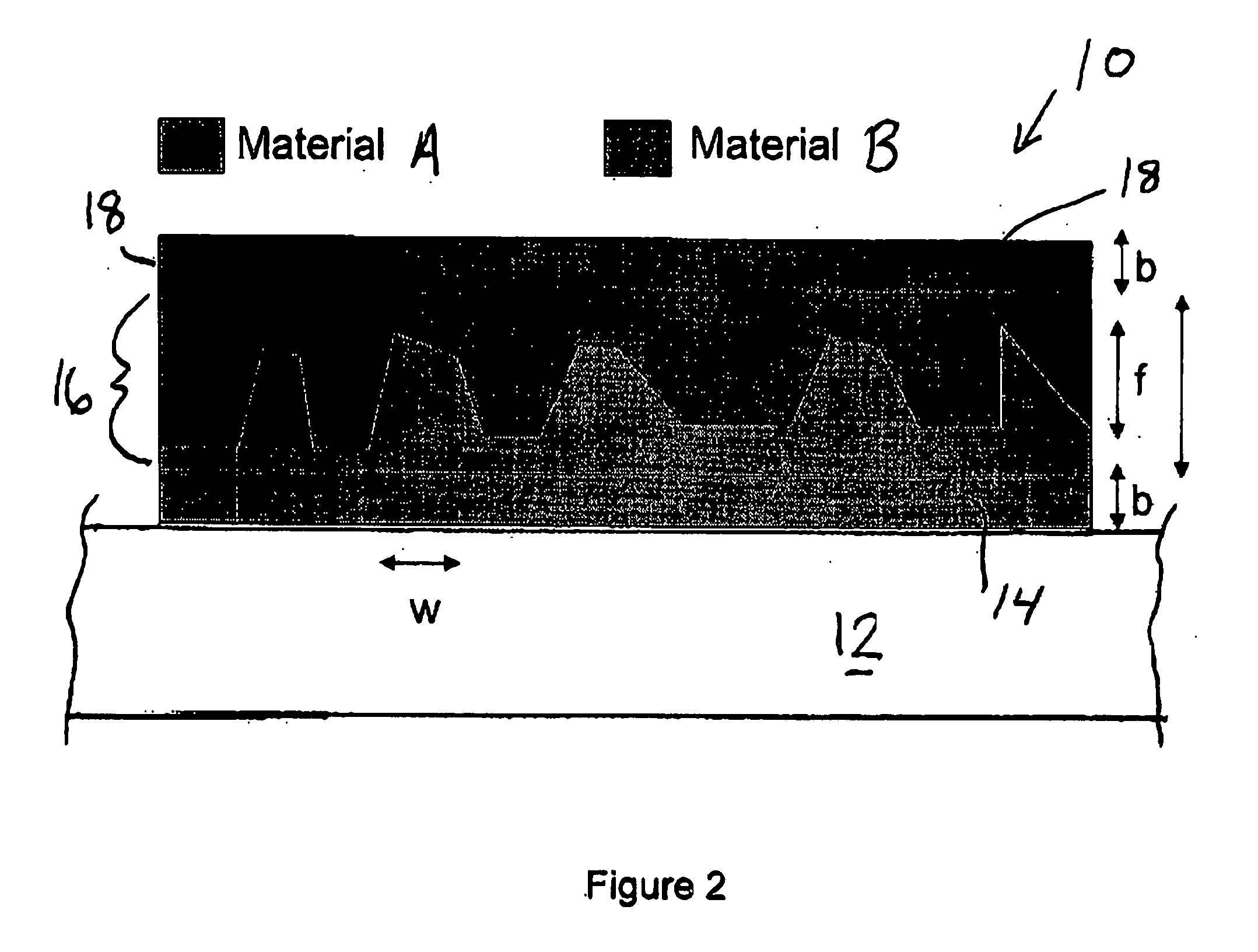

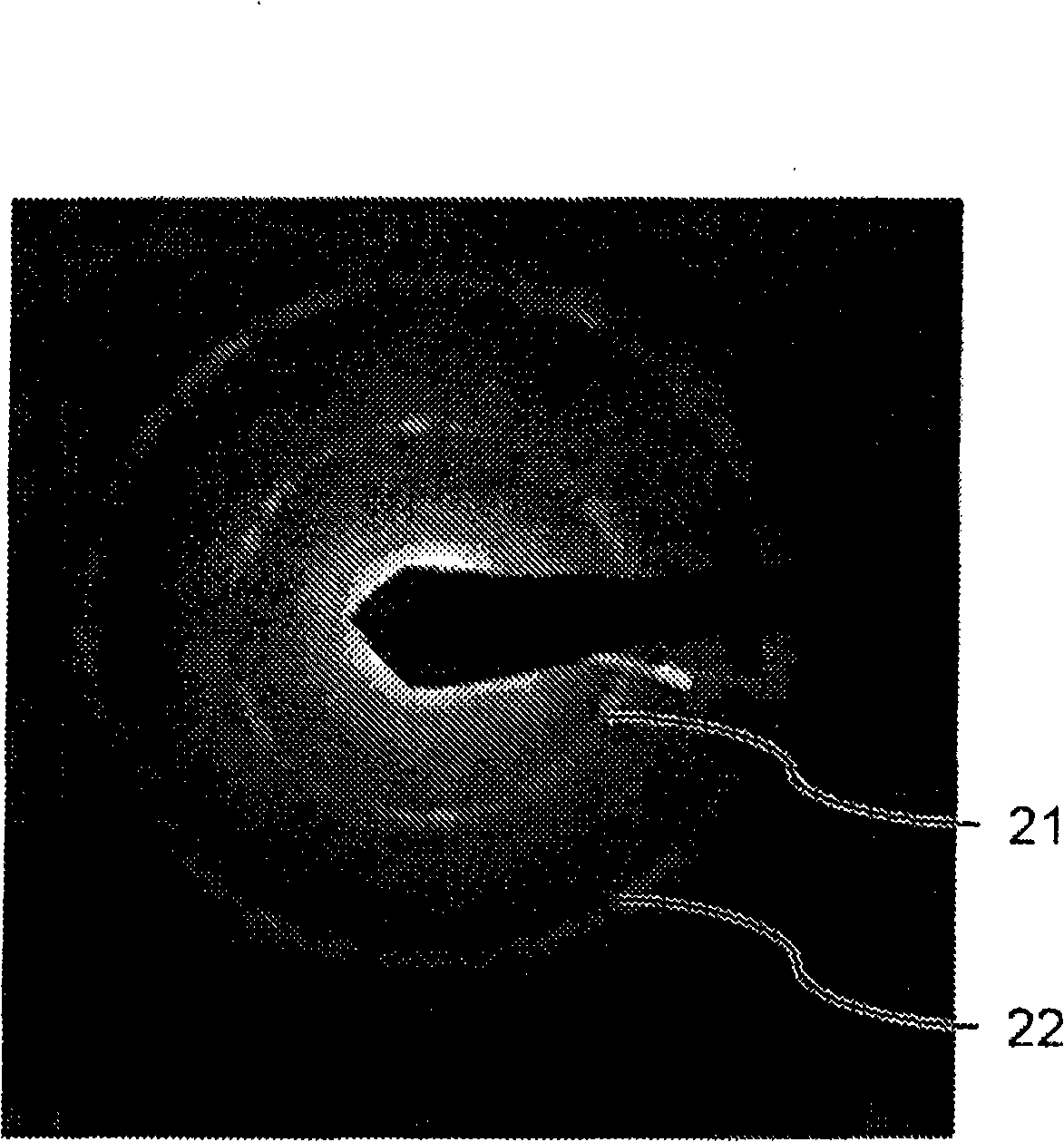

Three-dimensional bicontinuous heterostructures, a method of making them, and their application in quantum dot-polymer nanocomposite photodetectors and photovoltaics

The present invention provides of a three-dimensional bicontinuous heterostructure, a method of producing same, and the application of this structure towards the realization of photodetecting and photovoltaic devices working in the visible and the near-infrared. The three-dimensional bicontinuous heterostructure includes two interpenetrating layers which are spatially continuous, they are include only protrusions or peninsulas, and no islands. The method of producing the three-dimensional biontinuous heterostructure relies on forming an essentially planar continuous bottom layer of a first material; forming a layer of this first material on top of the bottom layer which is textured to produce protrusions for subsequent interpenetration with a second material, coating this second material onto this structure; and forming a final coating with the second material that ensures that only the second material is contacted by subsequent layer. One of the materials includes visible and / or infrared-absorbing semiconducting quantum dot nanoparticles, and one of materials is a hole conductor and the other is an electron conductor.

Owner:INVISAGE TECHNOLOGIES

Polymer nanocomposites and methods for their preparation

Polymer nanocomposites comprising an untreated phyllosilicate, a delaminating agent, a swelling agent, and a polyorganosiloxane-polycarbonate copolymer are disclosed. The polymer nanocomposites are valuable for producing articles having a combination of improved performance characteristics, such as tensile modulus, low temperature ductility, and melt volume rate.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Functional graphene-polymer nanocomposites for gas barrier applications

InactiveCN101558457AHigh gas barrierImprove mechanical (strengthMaterial nanotechnologyGraphitePolymer scienceDiffusion barrier

Owner:THE TRUSTEES OF PRINCETON UNIV

Method for the fracture stimulation of a subterranean formation having a wellbore by using impact-modified thermoset polymer nanocomposite particles as proppants

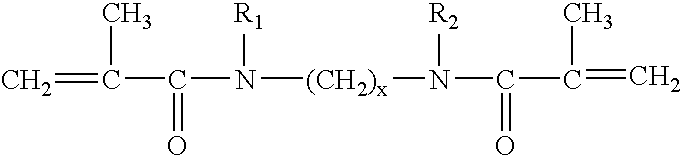

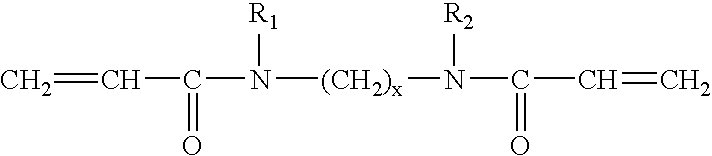

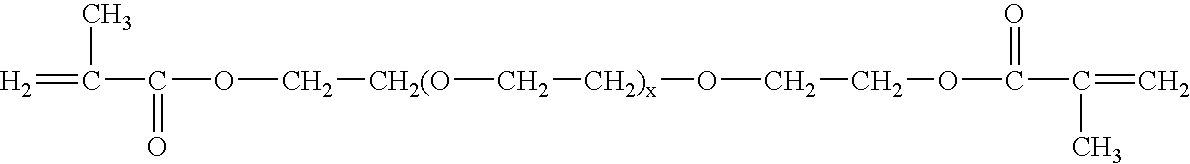

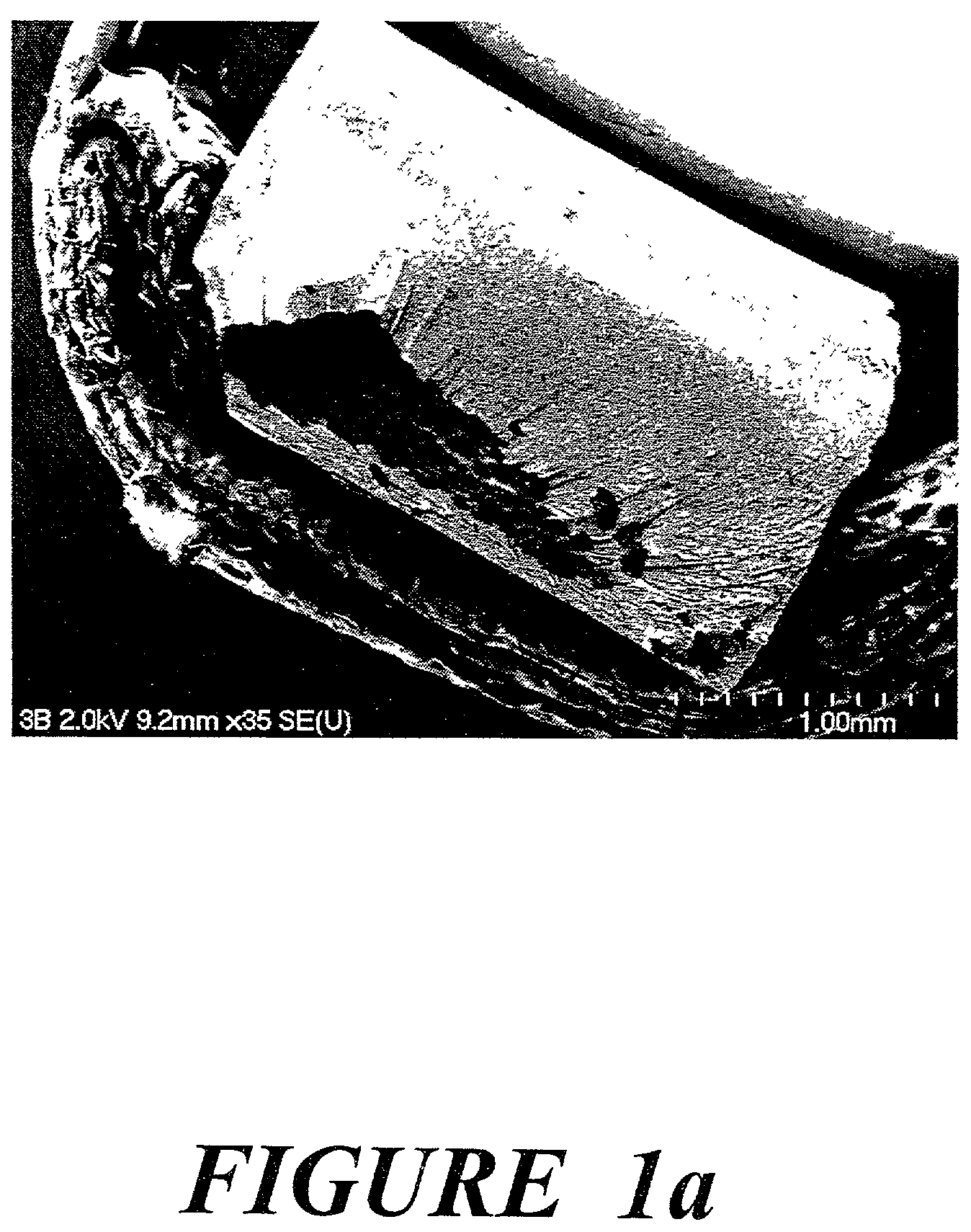

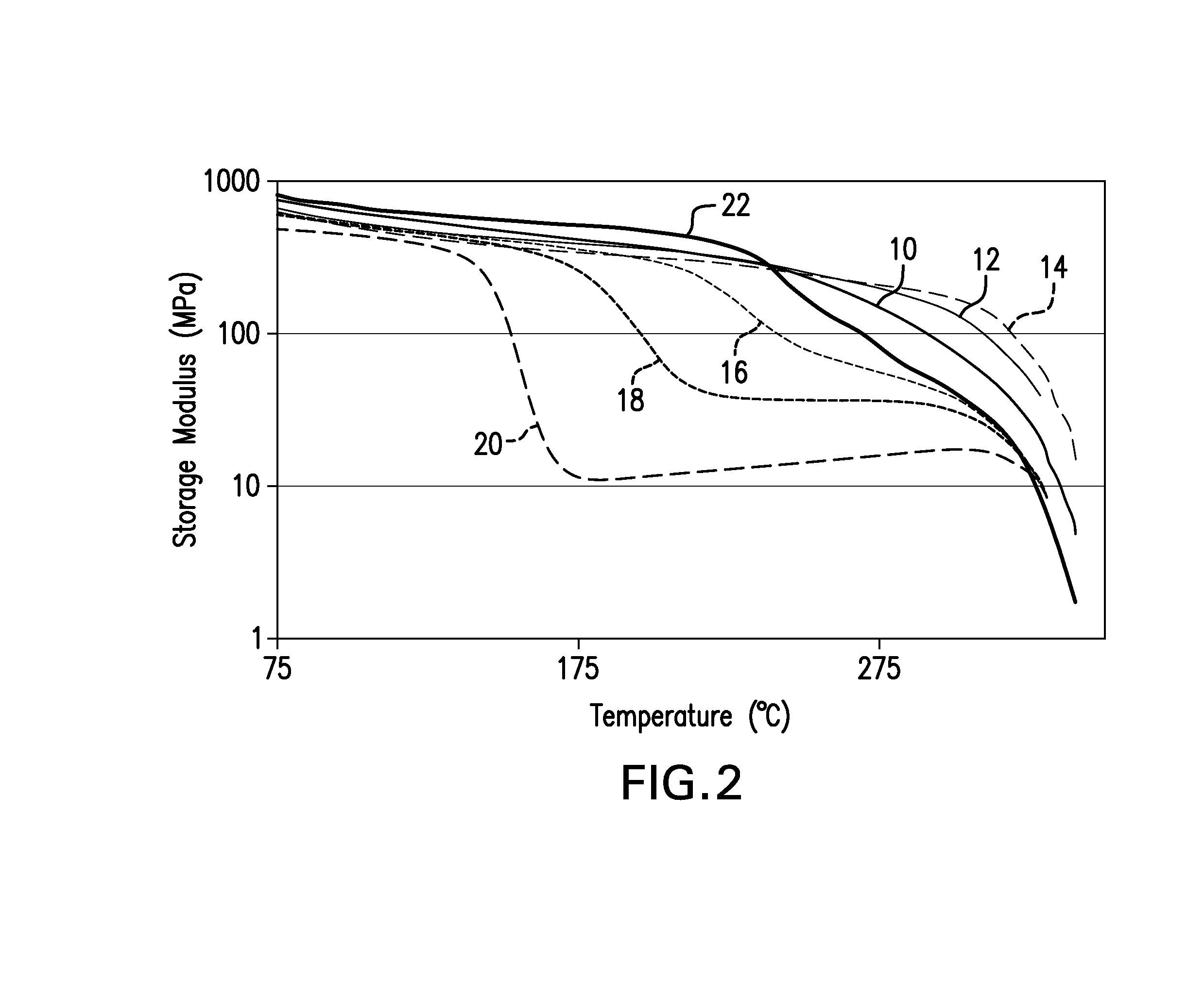

ActiveUS20130045901A1High elastic modulusHigh glass transition temperatureMaterial nanotechnologySynthetic resin layered productsLiquid mediumOligomer

A method for fracture stimulation of a subterranean formation includes providing a thermoset polymer nanocomposite particle precursor composition comprising a polymer precursor mixture, dispersed within a liquid medium, containing at least one of an initiator; at least one of a monomer, an oligomer or combinations thereof, said monomer and oligomer having three or more reactive functionalities capable of creating crosslinks between polymer chains; at least one of an impact modifier; and nanofiller particles substantially dispersed within the liquid medium; subjecting the nanocomposite particle precursor composition to suspension polymerizing conditions; subjecting the resulting nanocomposite particles to heat treatment; forming a slurry comprising a fluid and a proppant that includes the heat-treated nanocomposite particles; injecting the slurry into a wellbore; and emplacing the proppant within a fracture network in the formation.

Owner:SUN DRILLING PRODS

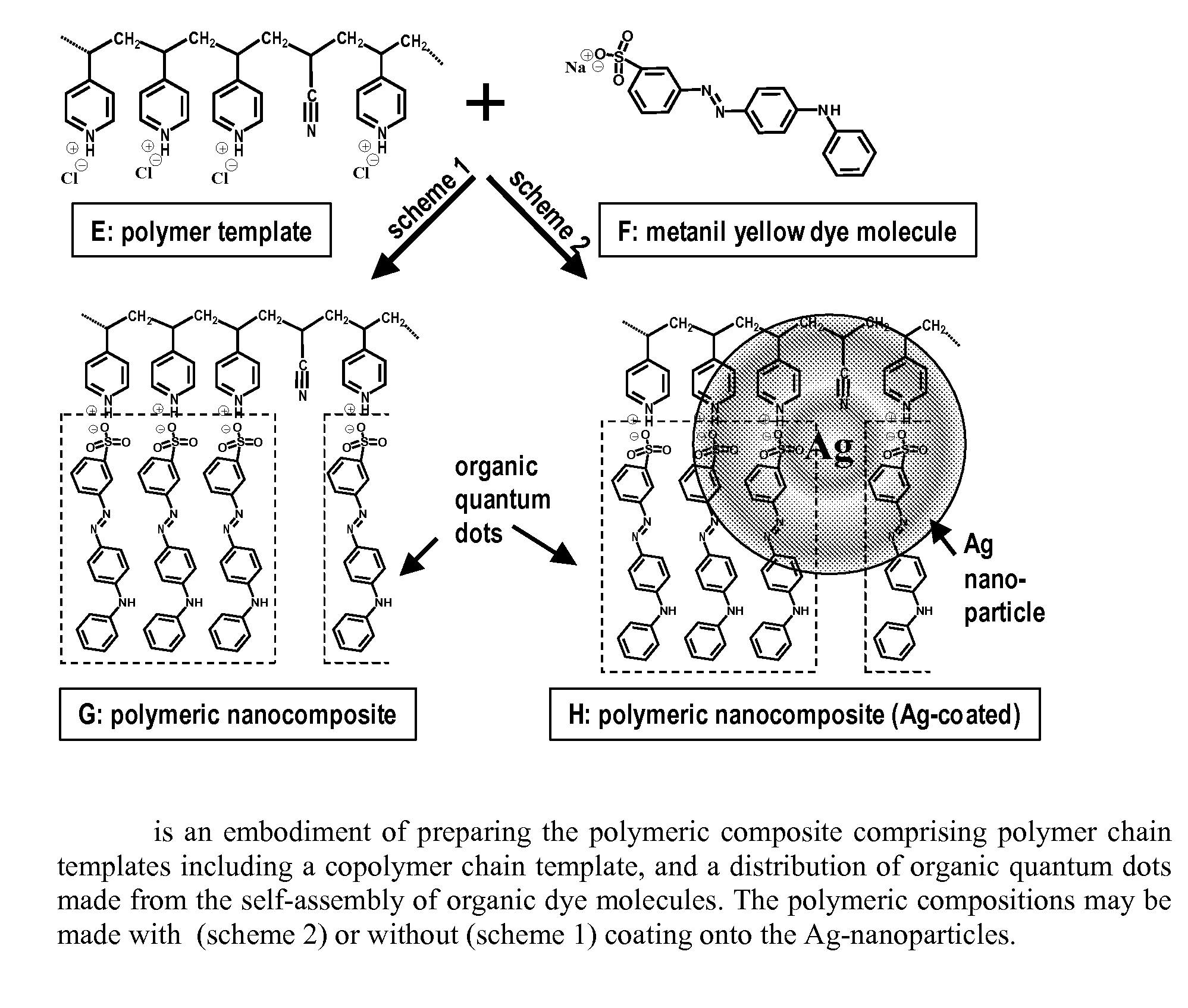

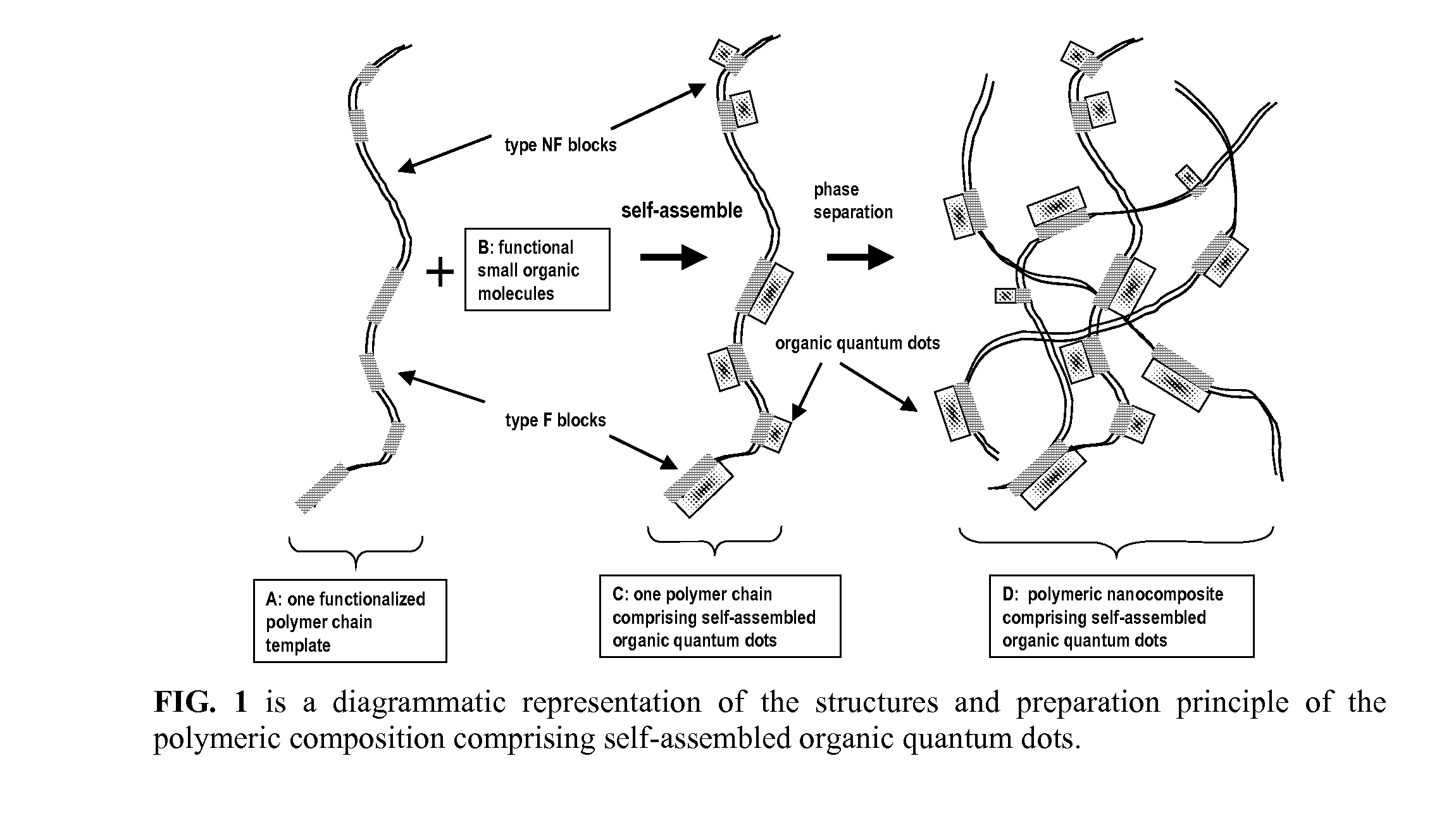

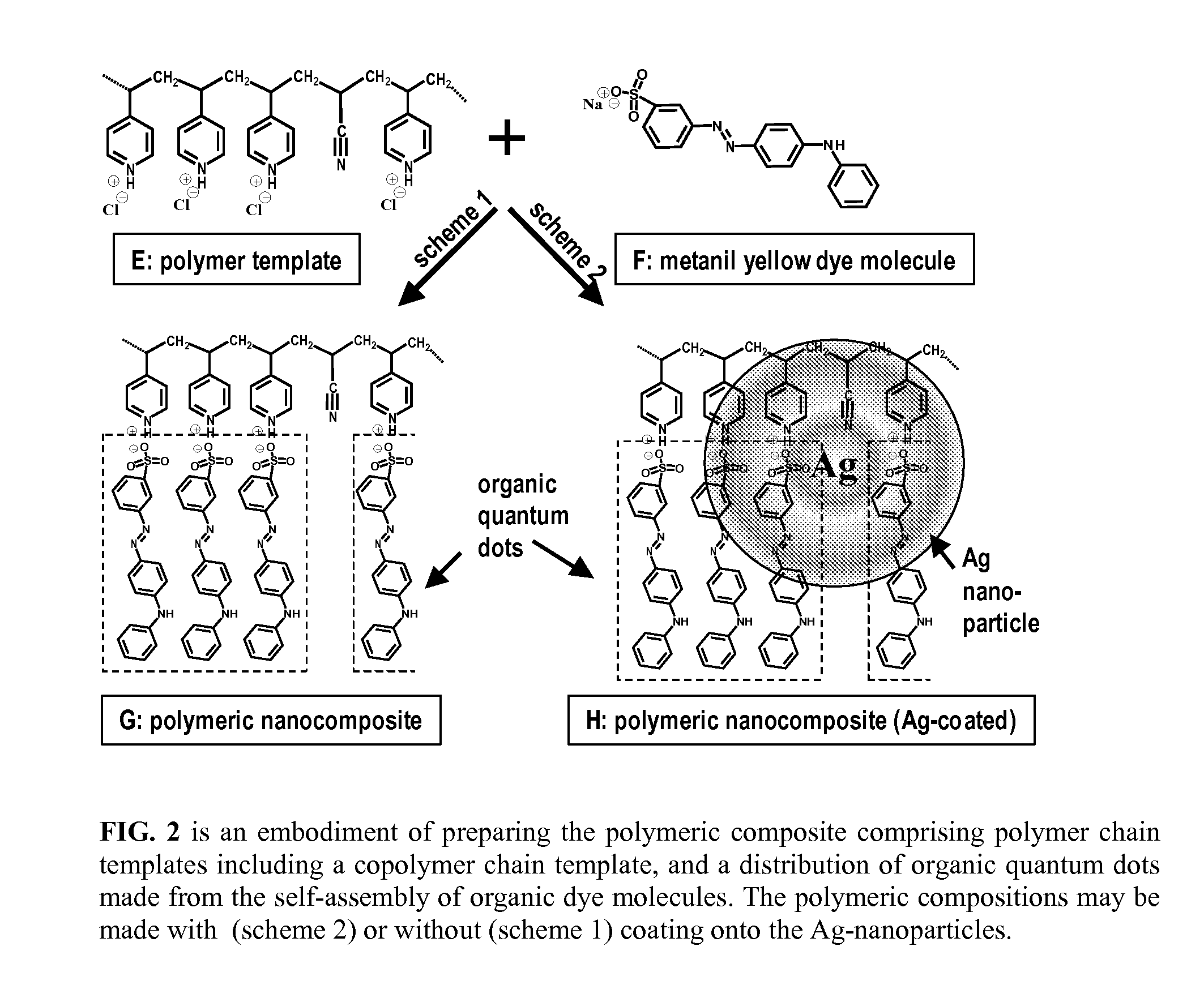

Polymeric nanocompositions comprising self-assembled organic quantum dots

InactiveUS20090074958A1Improve propertiesEnhanced Raman effectBleaching apparatusElectrostatic spraying apparatusRaman amplifiersWaveguide

The present invention relates to a polymeric nanocomposition of matter comprising a plurality of organic quantum dots. The composition includes at least one functionalized polymer chain template and a plurality of size-tunable organic quantum dots self-assembled onto the functionalized polymer chain template. The self-assembled organic quantum dots may be nanometer-scale molecular aggregates with size tunable by the functionalized polymer chain template. The polymer nanocomposite may be coated onto the surface of Ag or Au nanoparticles to achieve surface enhanced properties, such as, surface enhanced Raman effect. One embodiment of the polymer nanocomposites has shown unusual physicochemical property, which is especially suitable for use in optical devices including optical fibers, waveguides, Raman amplifiers, splitters, multiplexers, demultiplexers, attenuators, modulators, switches, and combination of such structures.

Owner:XIAO DEQUAN

Polymer nanocomposite, process for making and use of same

A process for stabilizing particles includes disposing reactive nanoparticles in a borehole; contacting the reactive nanoparticles with a resin; introducing a curing agent; and curing the resin and reactive nanoparticles with the curing agent to form a nanocomposite, wherein, during curing, the nanocomposite is bonded to the particles to stabilize the particles. A process for consolidating particles includes coating the particles with a resin; introducing reactive nanoparticles; curing the resin and reactive nanoparticles with a curing agent to form a nanocomposite which is bonded to the particles; and controlling a rate of the curing by an amount of the curing agent which is present with the resin, wherein the nanocomposite bonded to the particles is thermally stable up to at least 600° F. (315° C.). A system comprises a resin; reactive nanoparticles; a curing agent to form a nanocomposite; and particles disposed in a downhole location to which the nanocomposite binds.

Owner:BAKER HUGHES INC

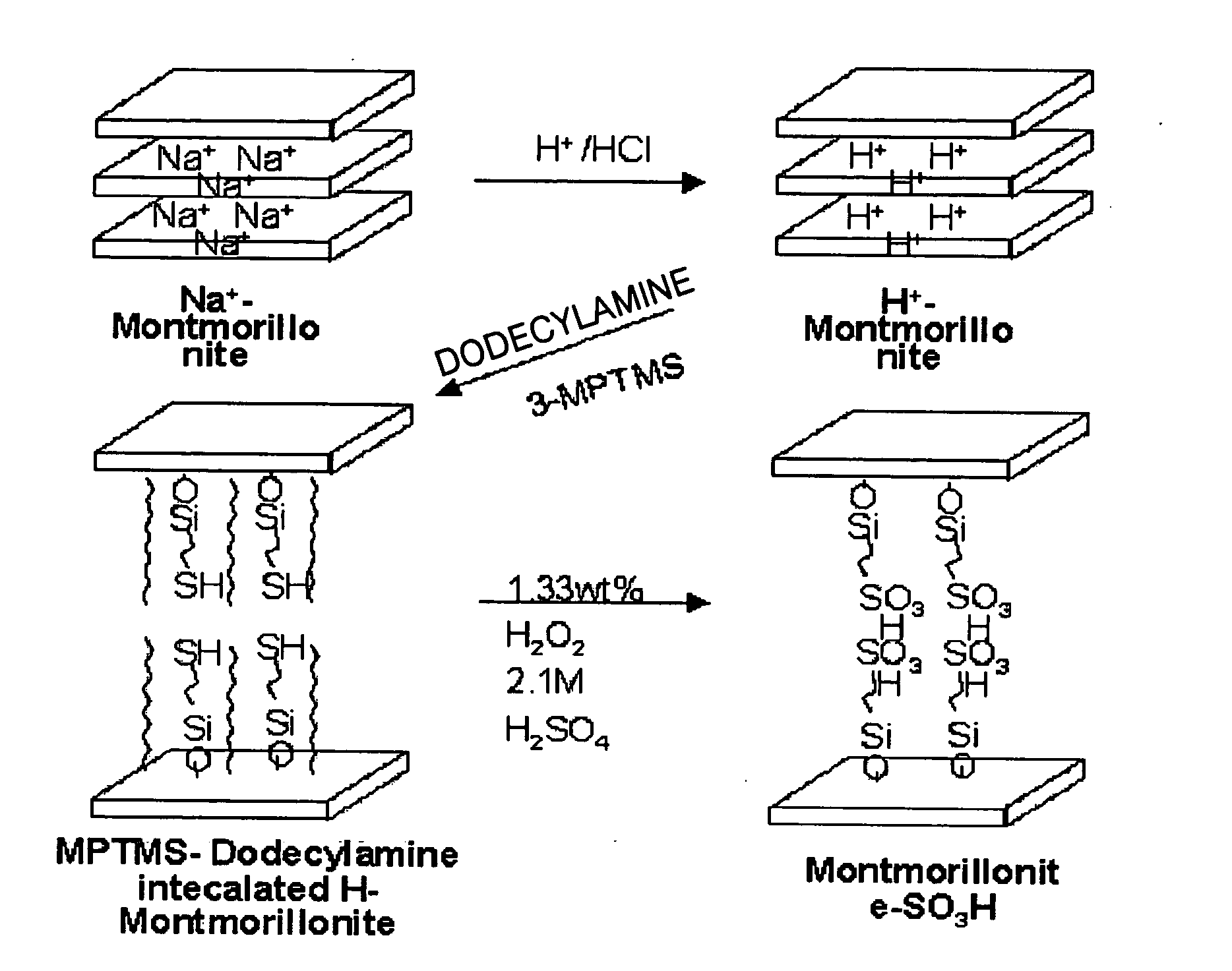

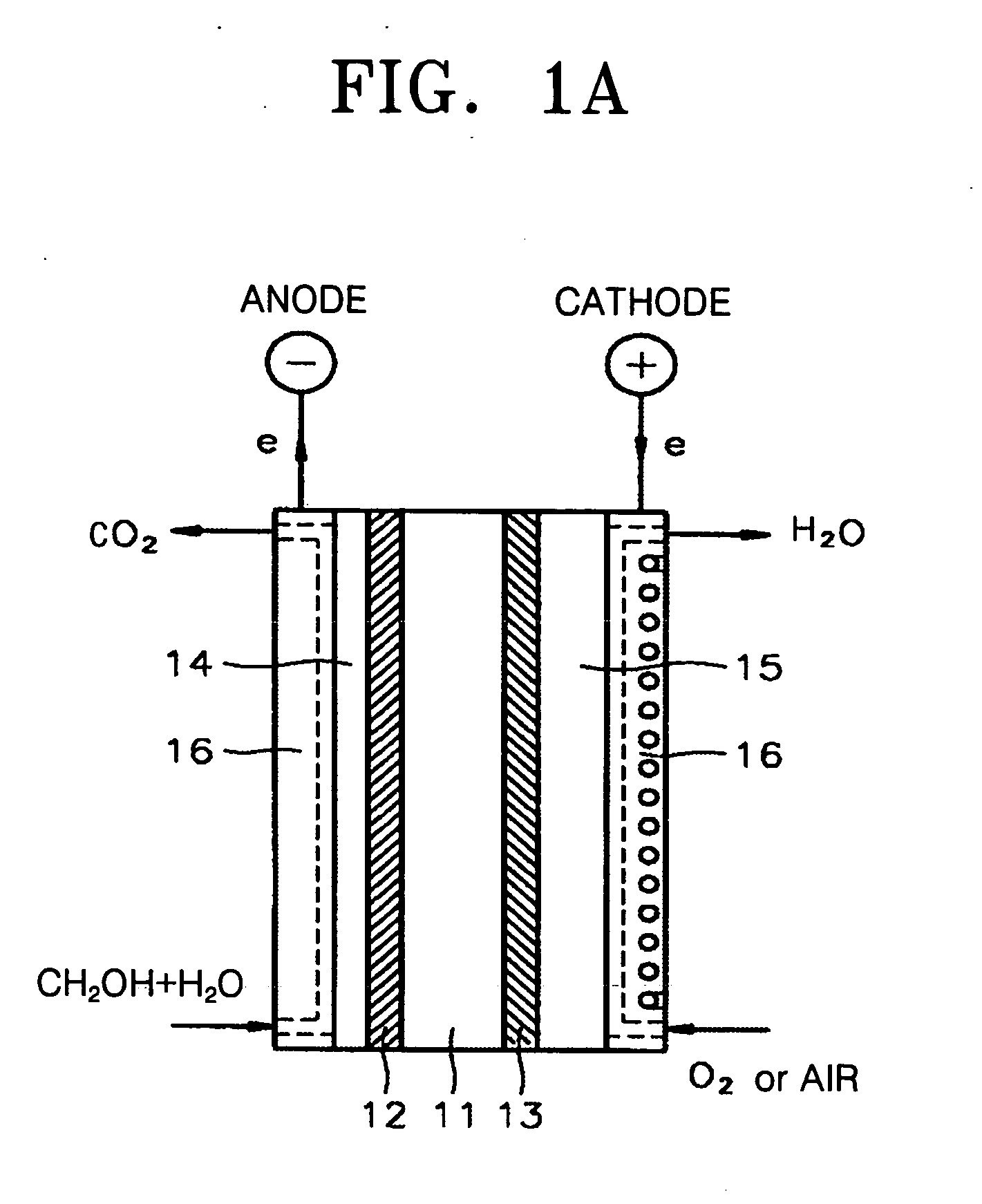

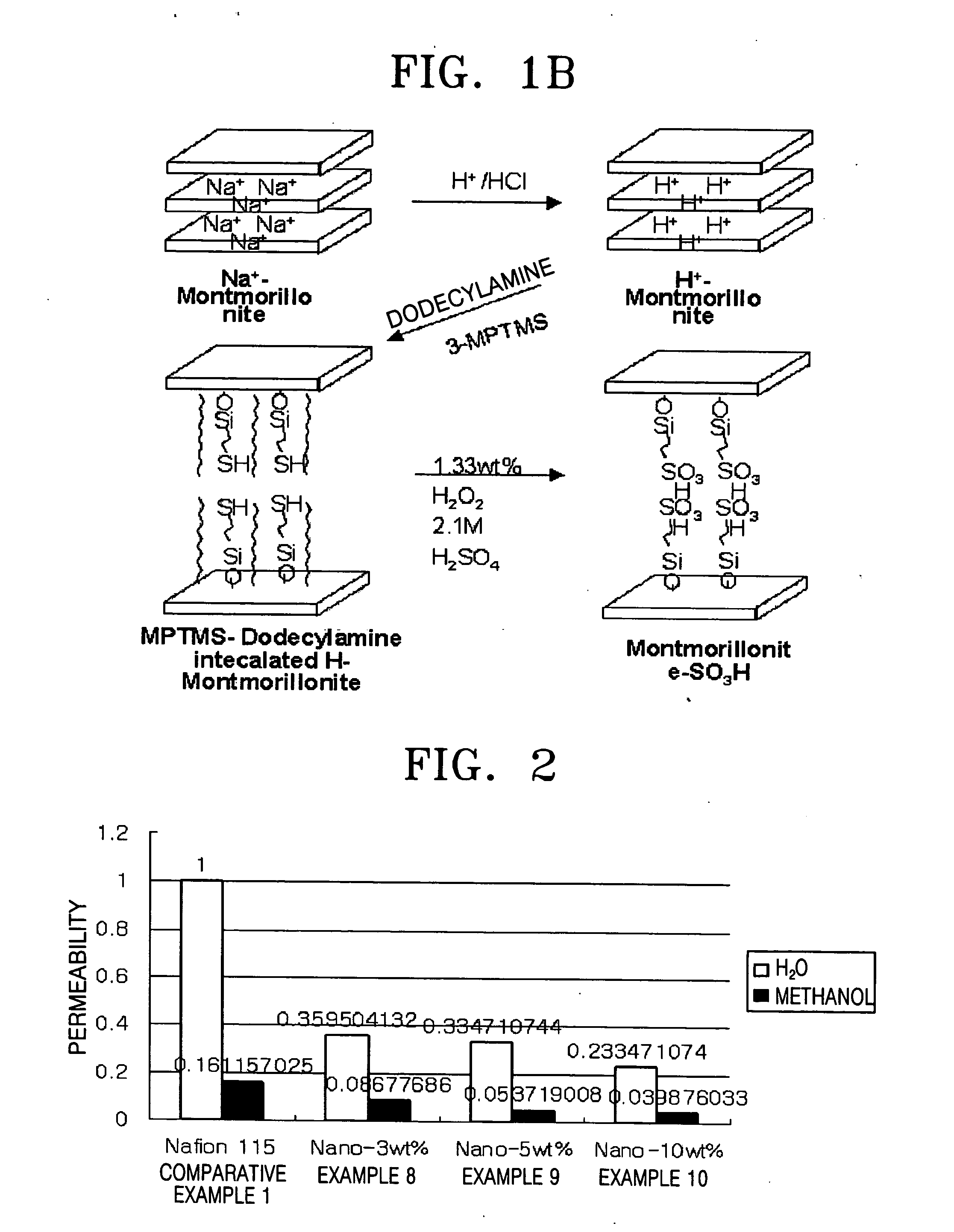

Polymer nanocomposite membrane and fuel cell using the same

InactiveUS20050084728A1Improve fuel efficiencyMaterial nanotechnologySolid electrolytesHydrogenFuel cells

A hydrogen ionic conductive inorganic material having a layered structure, wherein a moiety containing a functional group with hydrogen ionic conductivity is introduced between layers of an inorganic material having a nano-sized interlayer distance. A polymer nanocomposite membrane including a reaction product of the hydrogen ionic conductive inorganic material and a conductive polymer, and a fuel cell using the same, are also provided. In the polymer nanocomposite membrane, a conductive polymer may be intercalated to a hydrogen ionic conductive inorganic material having a layered structure or products exfoliated from an inorganic material having a layered structure are dispersed in a conductive polymer.

Owner:SAMSUNG SDI CO LTD

Polyolefin nanocomposites

InactiveUS7157516B2Growth of polymer is lessenedIncrease in sizeMaterial nanotechnologyPigmenting treatmentVitrificationPolyolefin

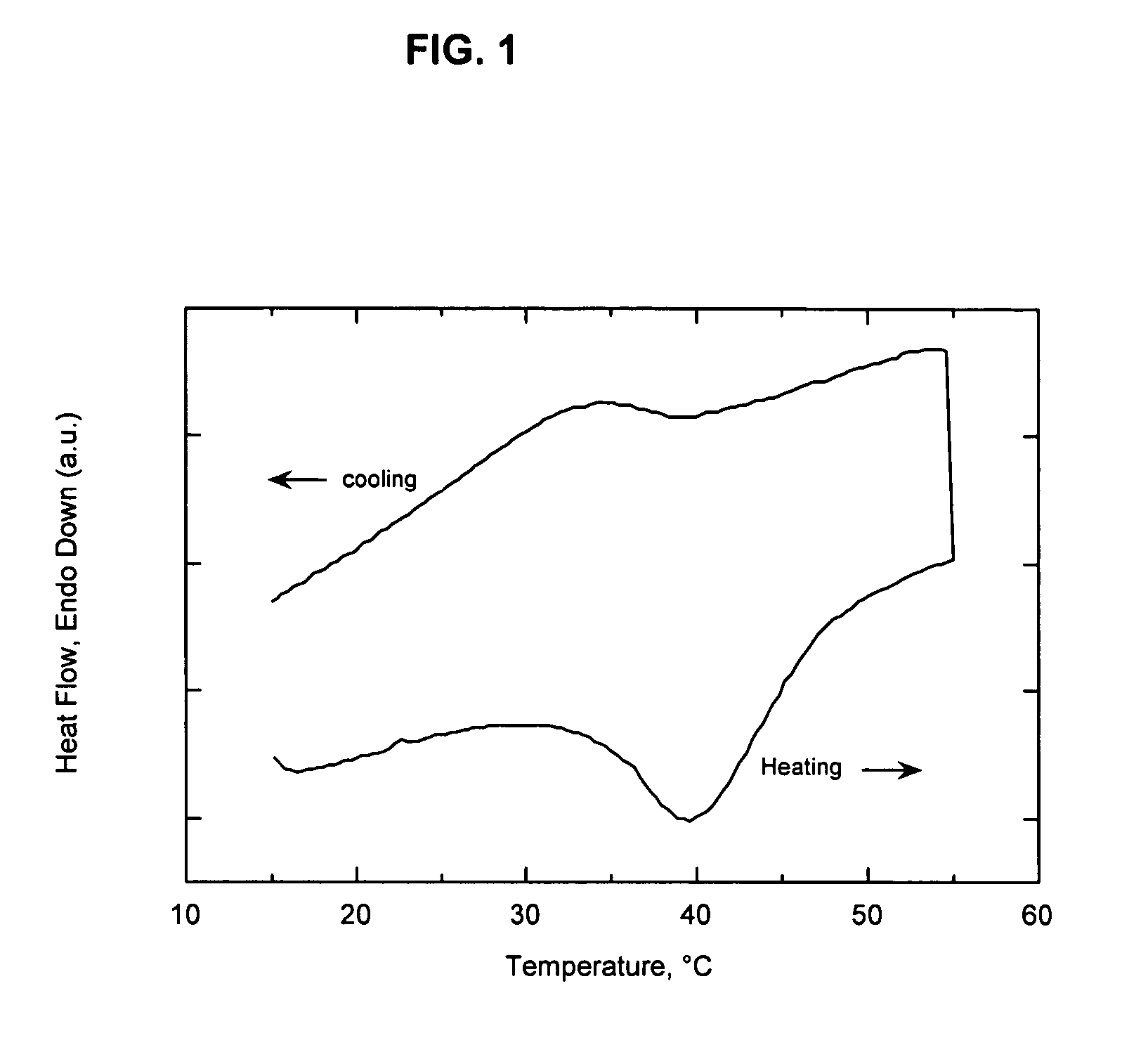

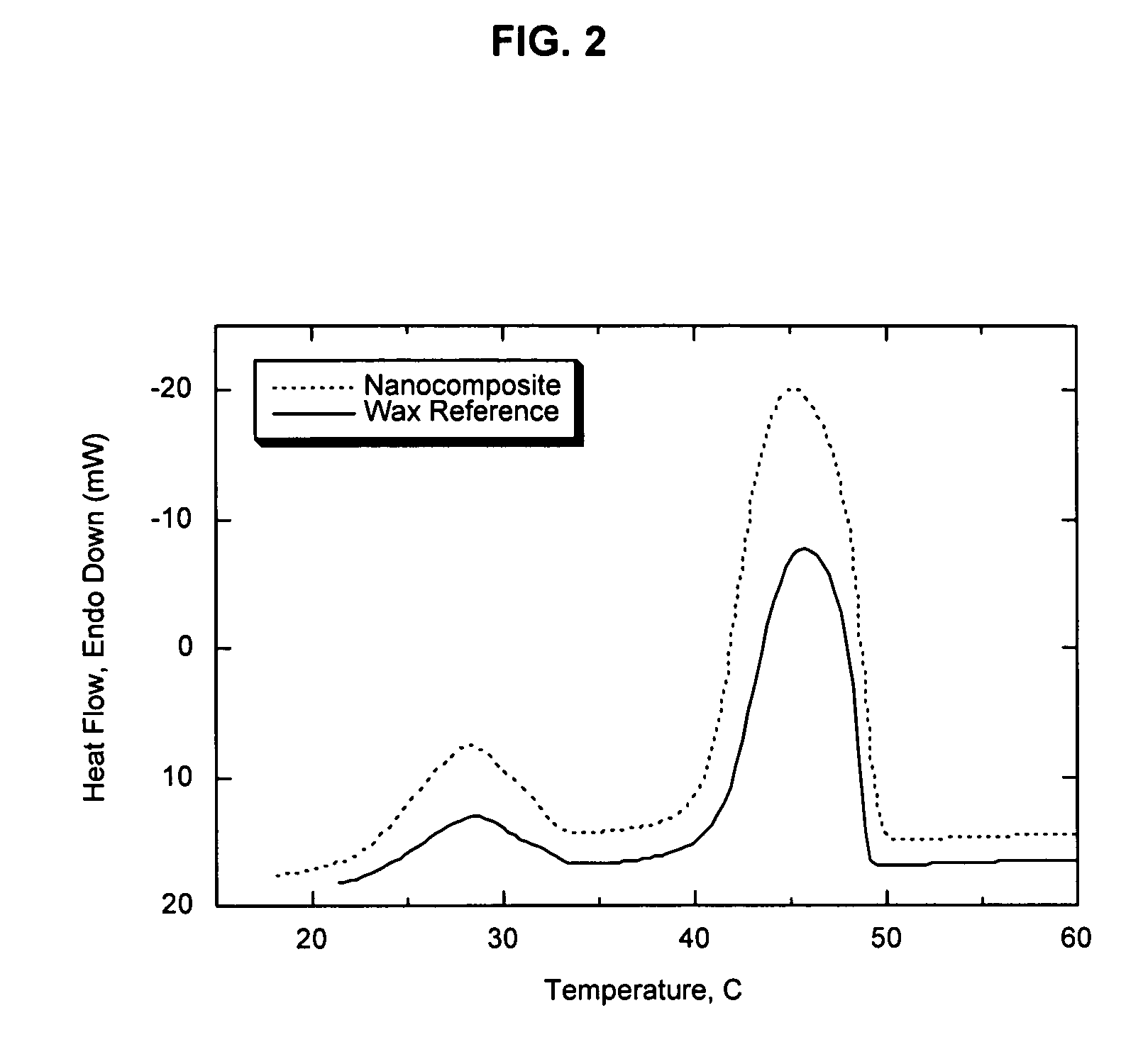

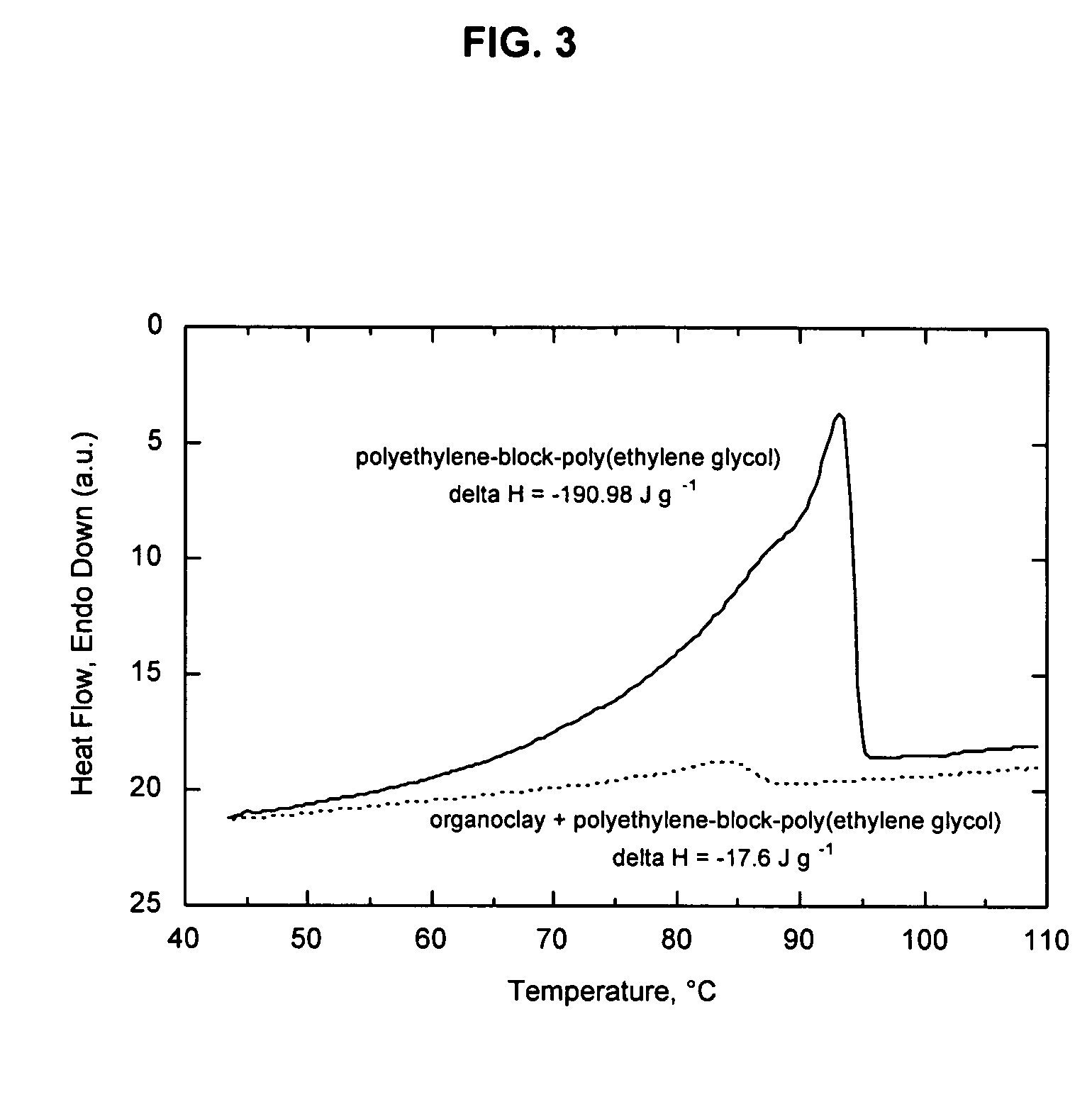

The present invention relates to methods for the preparation of clay / polymer nanocomposites. The methods include combining an organophilic clay and a polymer to form a nanocomposite, wherein the organophilic clay and the polymer each have a peak recrystallization temperature, and wherein the organophilic clay peak recrystallization temperature sufficiently matches the polymer peak recrystallization temperature such that the nanocomposite formed has less permeability to a gas than the polymer. Such nanocomposites exhibit 2, 5, 10, or even 100 fold or greater reductions in permeability to, e.g., oxygen, carbon dioxide, or both compared to the polymer. The invention also provides a method of preparing a nanocomposite that includes combining an amorphous organophilic clay and an amorphous polymer, each having a glass transition temperature, wherein the organophilic clay glass transition temperature sufficiently matches the polymer glass transition temperature such that the nanocomposite formed has less permeability to a gas than the polymer.

Owner:UCHICAGO ARGONNE LLC

Fire retardant polymer nanocomposites for laser sintering

InactiveUS20070290410A1Improve flame retardant performanceConfectionerySweetmeatsOptoelectronicsFire retardant

Owner:KOO JOSEPH H +2

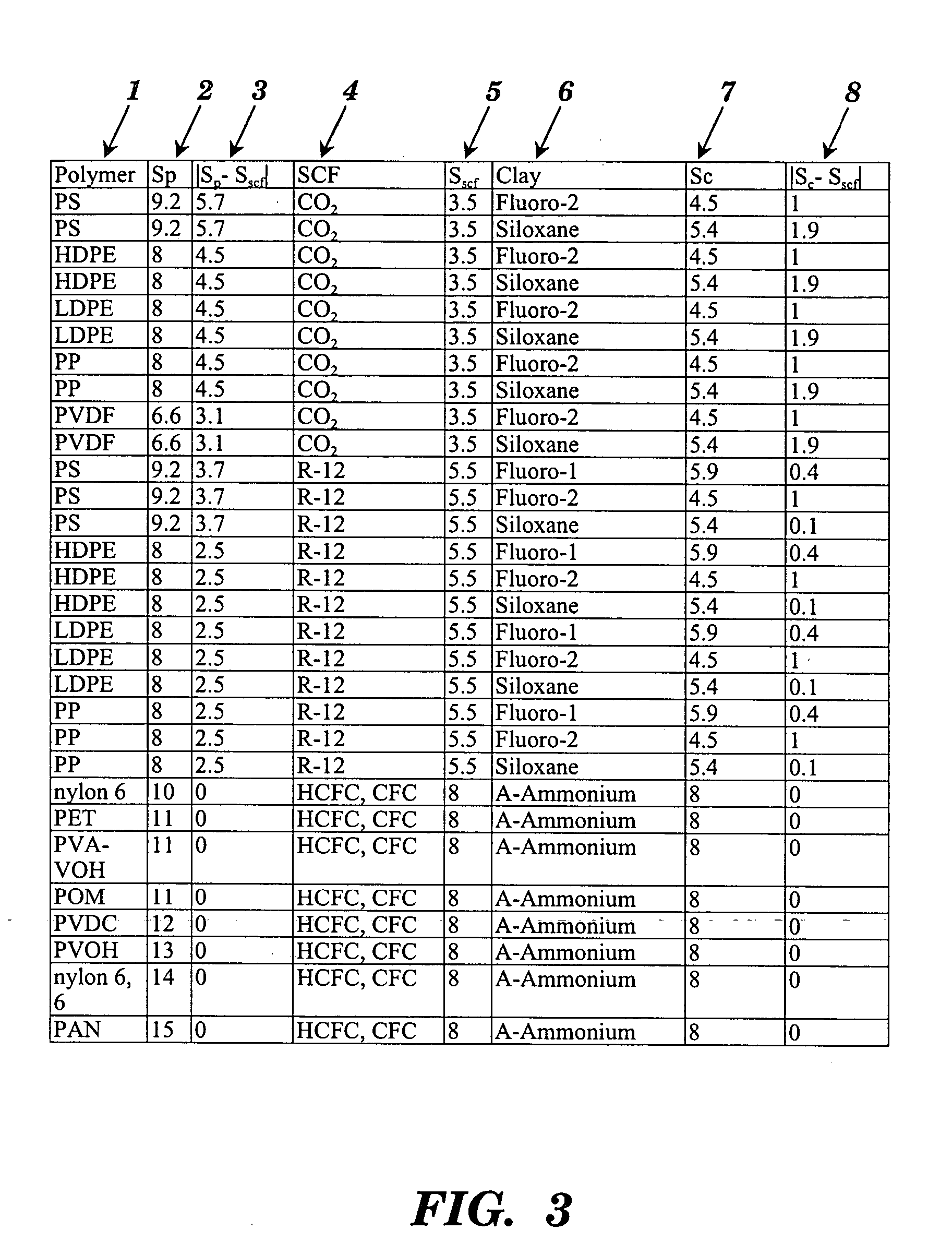

Production of polymer nanocomposites using supercritical fluids

InactiveUS20050131126A1Maximum and efficient dispersionMaterial nanotechnologyBulk chemical productionSolubilityPolymer nanocomposite

A method and system of forming a polymer nanocomposite. A layered clay and polymer are selected wherein |Sp−Sscf|>|Sc−Sscf| and |Sc−Sscf|≦2.0 (cal / cm3)0.5 are satisfied. Sp, Sc, and Sscf is a solubility parameter of the polymer, clay, and a supercritical fluid (SCF), respectively. The polymer and clay are mixed to form a polymer-clay mixture. The polymer-clay mixture is melted to form a polymer-clay melt. The polymer-clay melt is initially contacted with the SCF while the SCF is subject to an initial pressure exceeding the critical pressure of the SCF and to a temperature exceeding the critical temperature of the SCF. The polymer-clay melt is further contacted with the SCF while the SCF is at a lower pressure below the critical pressure of the SCF to exfoliate the clay to form the nanocomposite having the exfoliated clay being substantially dispersed throughout the polymer of the polymer-clay.

Owner:RENESSELAER POLYTECHNIC INST

Electrochemical method of producing nano-scaled graphene platelets

A method of producing nano-scaled graphene platelets with an average thickness smaller than 30 nm from a layered graphite material. The method comprises (a) forming a carboxylic acid-intercalated graphite compound by an electrochemical reaction; (b) exposing the intercalated graphite compound to a thermal shock to produce exfoliated graphite; and (c) subjecting the exfoliated graphite to a mechanical shearing treatment to produce the nano-scaled graphene platelets. Preferred carboxylic acids are formic acid and acetic acid. The exfoliation step in the instant invention does not involve the evolution of undesirable species, such as NOx and SOx, which are common by-products of exfoliating conventional sulfuric or nitric acid-intercalated graphite compounds. The nano-scaled platelets are candidate reinforcement fillers for polymer nanocomposites. Nano-scaled graphene platelets are much lower-cost alternatives to carbon nano-tubes or carbon nano-fibers.

Owner:GLOBAL GRAPHENE GRP INC

Nanocomposite method of manufacture

ActiveUS20080262126A1Improved and equivalent mechanical performanceImprove mechanical propertiesMaterial nanotechnologyCeramic shaping apparatusMasterbatchHigh concentration

Disclosed are systems and methods for the formation of a polymer nanocomposite material using a high-concentration masterbatch as a source of nanocomposite filler.

Owner:NATURALNANO CORP

Production of polymer nanocomposites using peroxides

InactiveUS20060066012A1Maximum and efficient dispersionMaterial nanotechnologyMixer accessoriesPolymer sciencePolymer nanocomposite

A method and system for forming a polymer nanocomposite. A peroxide-degradable polymer, a clay, and a peroxide are mixed to form a polymer-clay-peroxide mixture. The polymer-clay-peroxide mixture is then heated forming a polymer-clay-peroxide melt containing peroxide radicals. The result is a degradation of the peroxide-degradable polymer within the melt to form smaller molecular weight polymer chains using the peroxide radicals and a diffusion of said polymer chains into the clay within the melt so as to exfoliate the clay to form the polymer nanocomposite having exfoliated clay being randomly dispersed throughout the polymer nanocomposite.

Owner:YANG KUMIN +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com