Patents

Literature

2635 results about "Solution polymerization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solution polymerization is a method of industrial polymerization. In this procedure, a monomer is dissolved in a non-reactive solvent that contains a catalyst. The reaction results in a polymer which is also soluble in the chosen solvent. Heat released by the reaction is absorbed by the solvent, and so the reaction rate is reduced. Moreover, the viscosity of the reaction mixture is reduced, not allowing autoacceleration at high monomer concentrations. Decrease of viscosity of reaction mixture by dilution also helps for the heat transfer, one of the major issues connected with polymer production as most of polymerizations are exothermic reactions. Once the maximum or desired conversion is reached, excess solvent has to be removed in order to obtain the pure polymer. Hence, solution polymerization is mainly used for applications where the presence of a solvent is desired anyway, as is the case for varnish and adhesives. Other application of polymer solutions is a manufacture of fibers by wet or dry spinning. It is not useful for the production of dry polymers because of the difficulty of complete solvent removal.

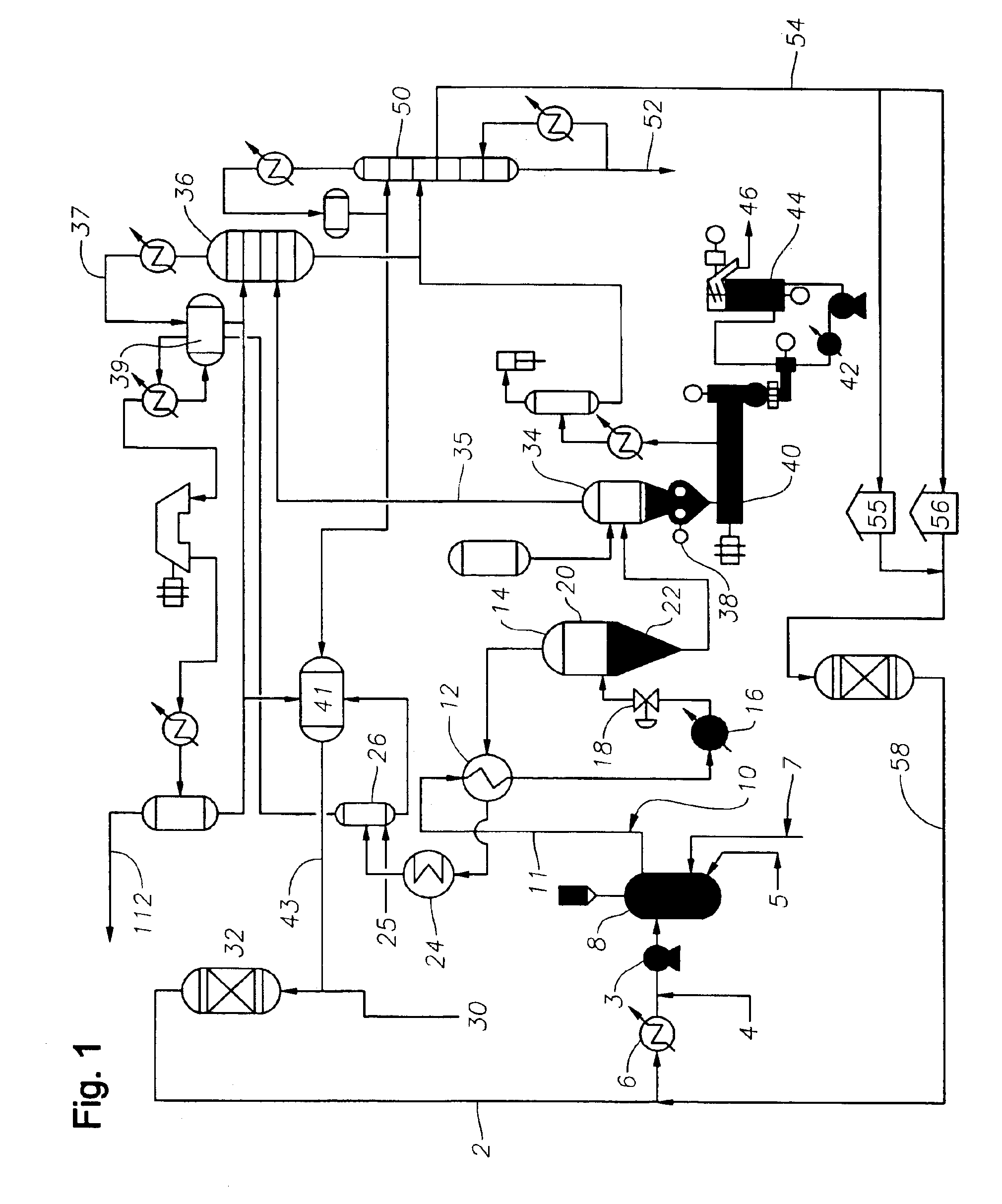

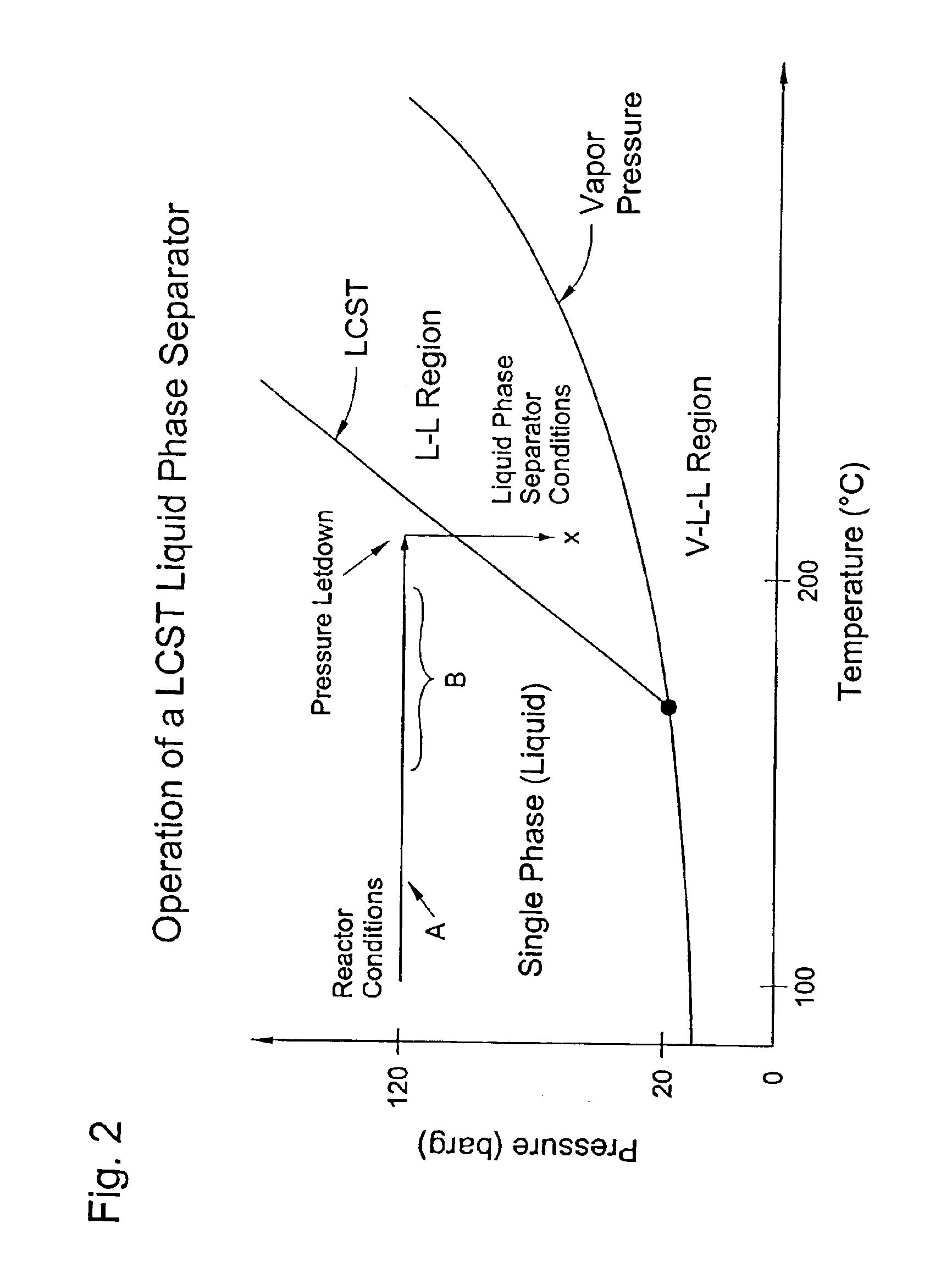

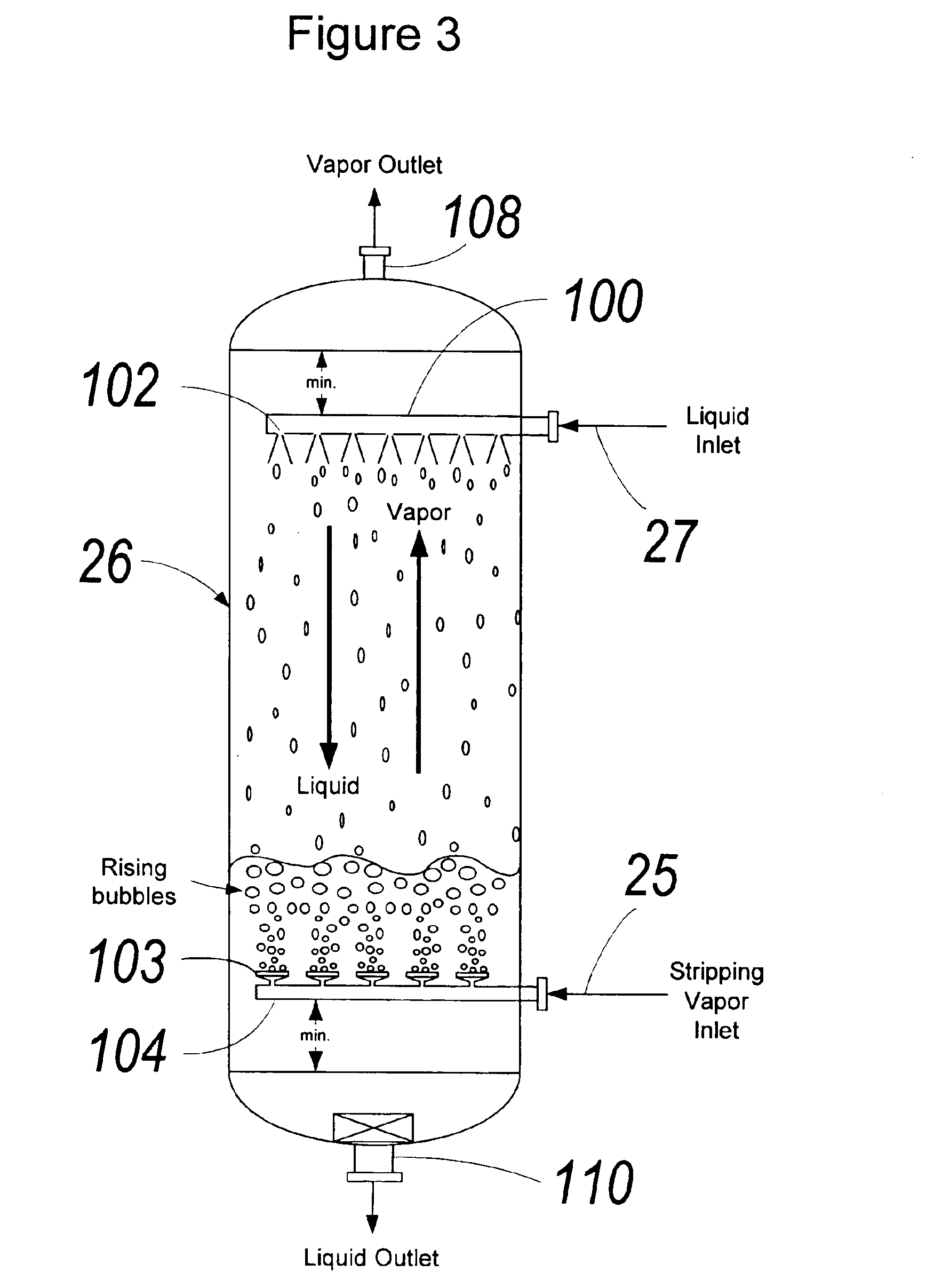

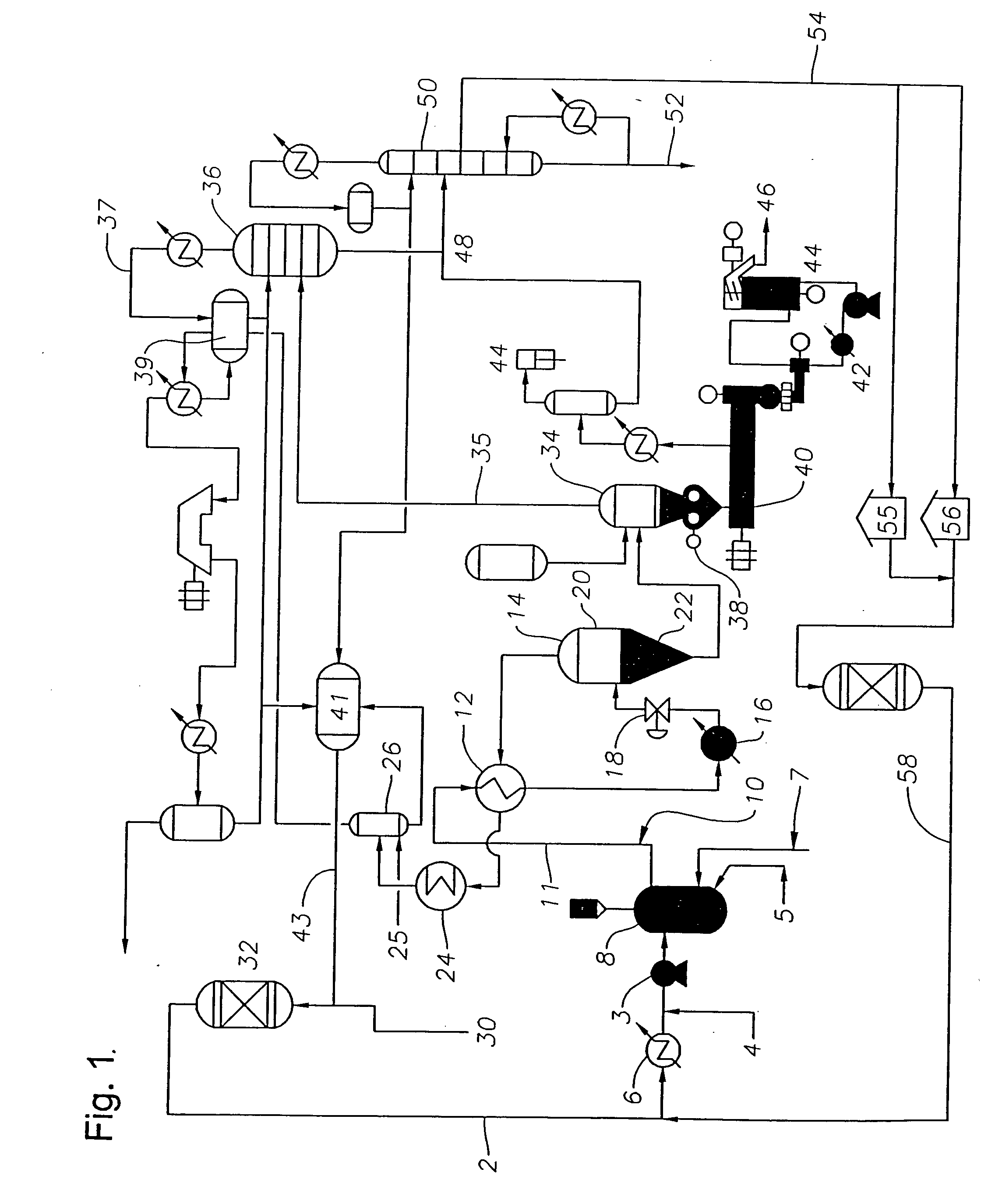

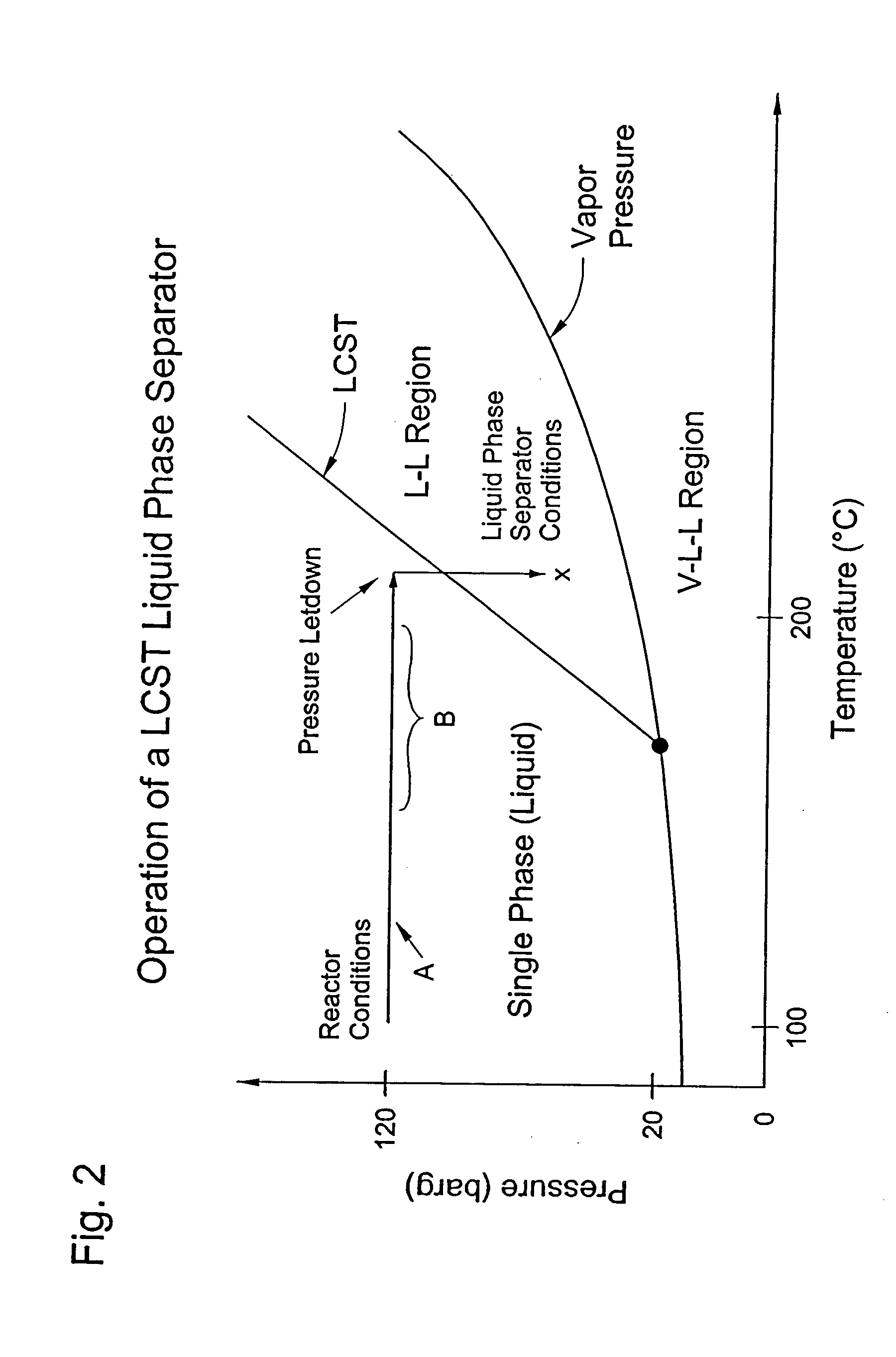

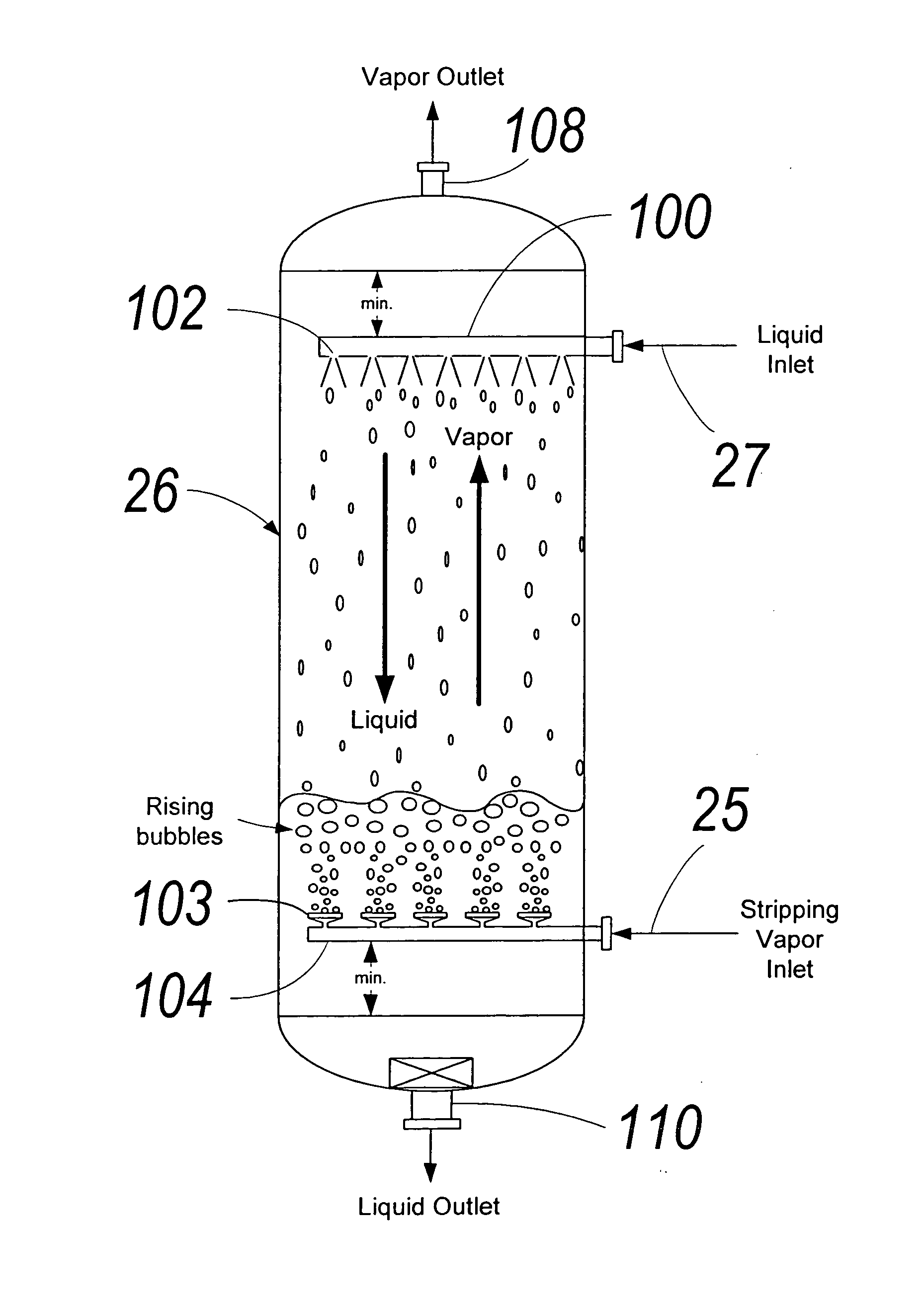

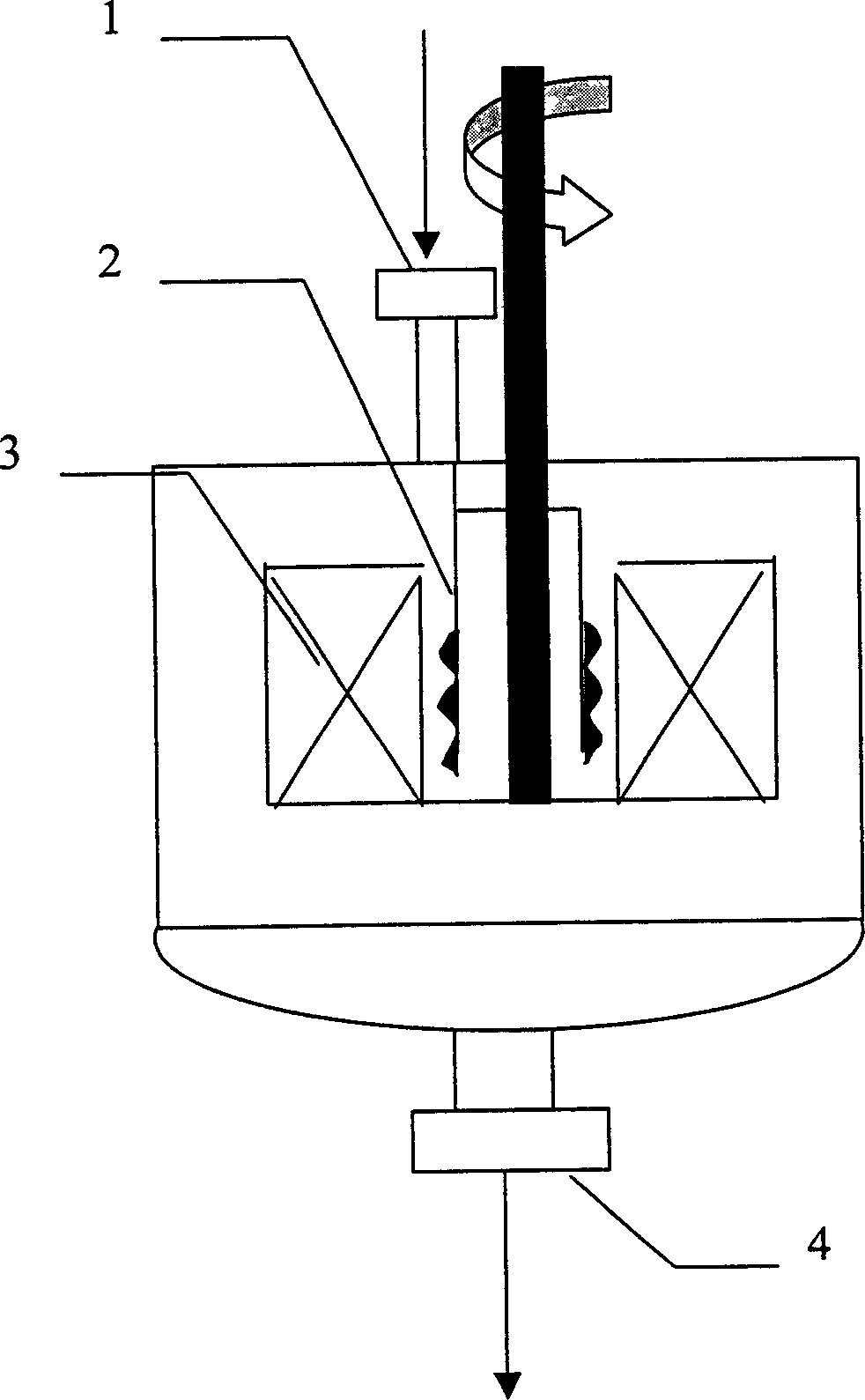

Processes and apparatus for continuous solution polymerization

InactiveUS6881800B2Process control/regulationLiquid-gas reaction as foam/aerosol/bubblesSolution polymerizationProcess plant

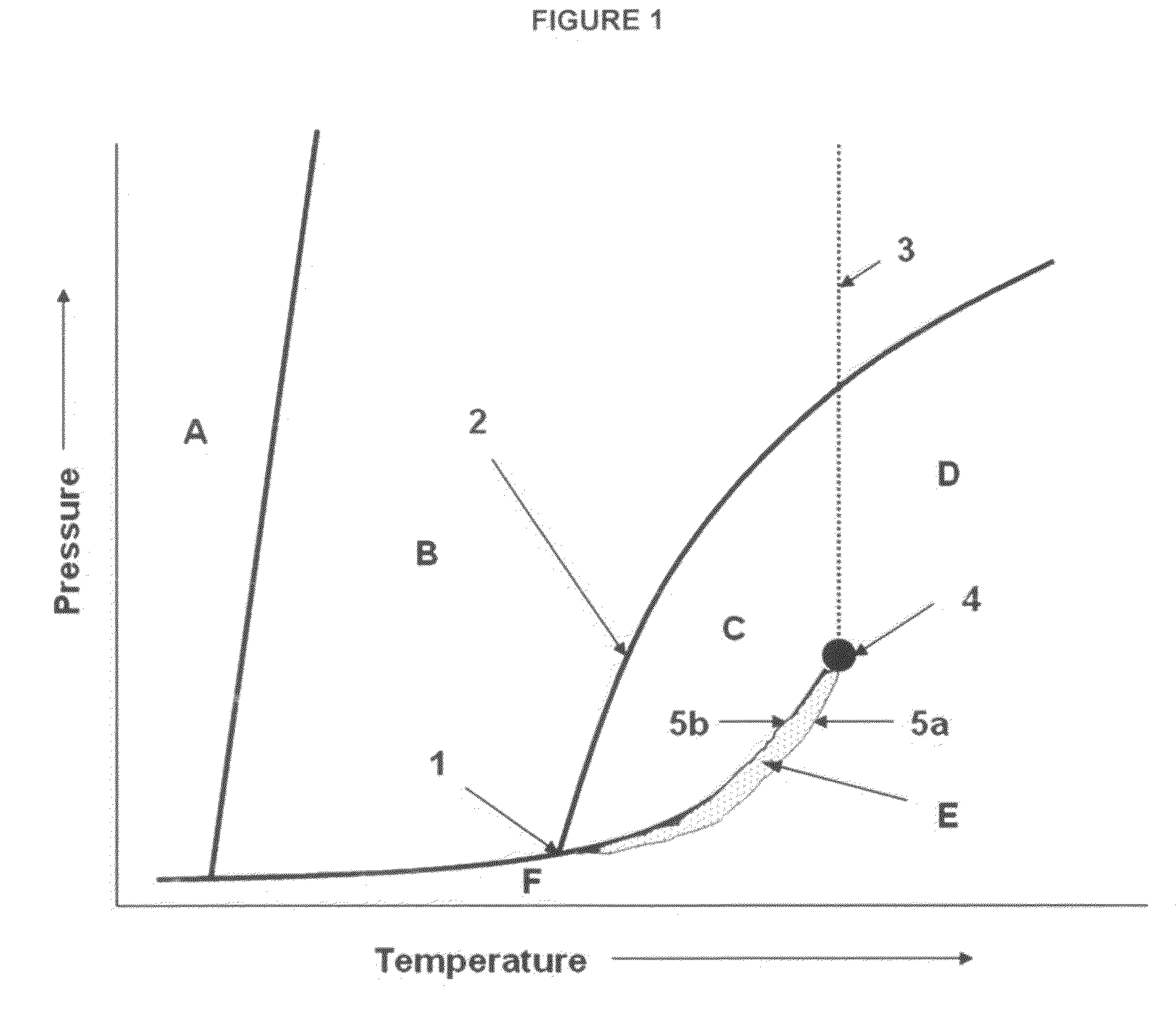

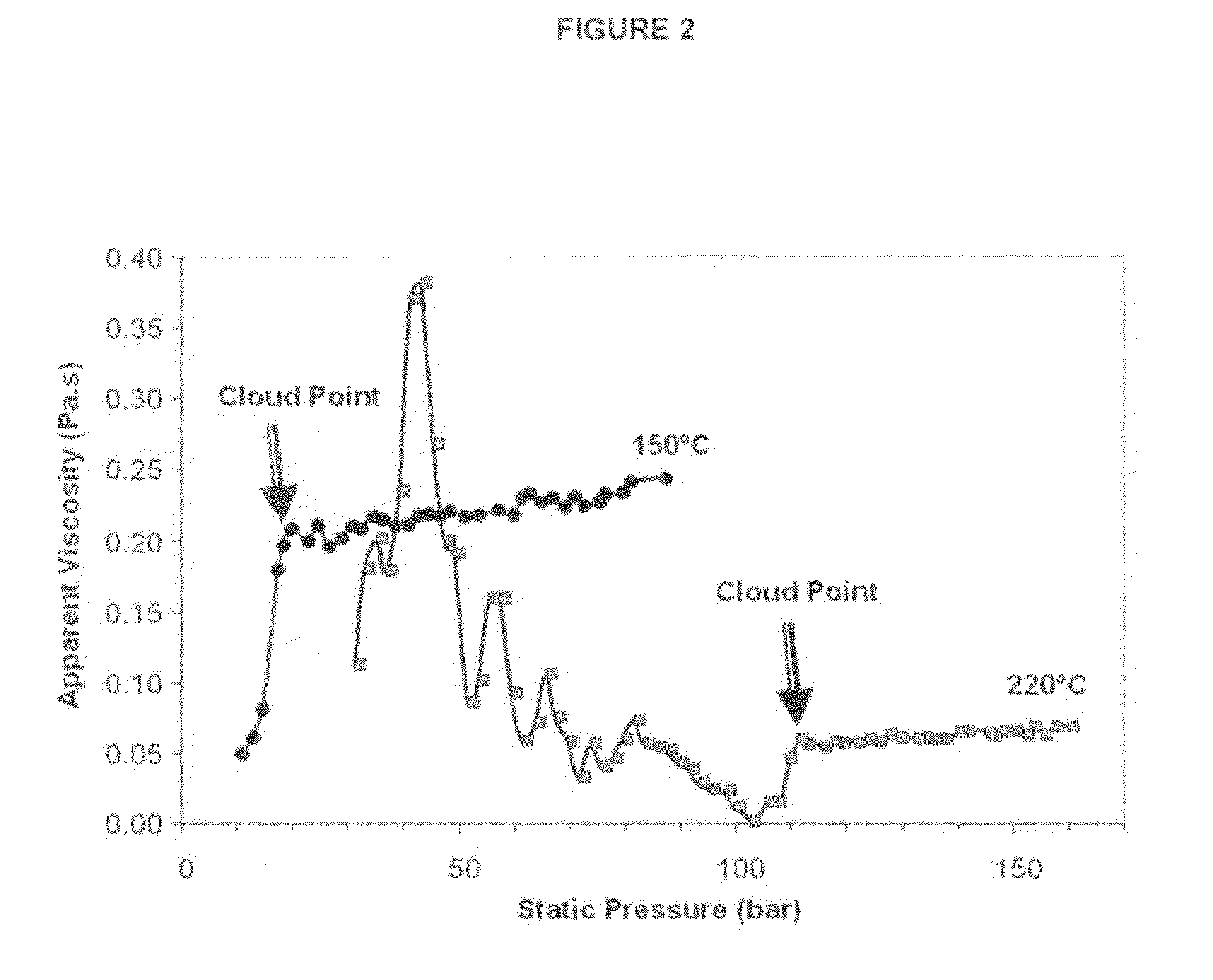

The invention relates to processes and plants for continuous solution polymerization. Such plant and processes include a pressure source, a polymerization reactor, downstream of said pressure source, pressure let-down device, downstream of said polymerization reactor, and a separator, downstream of said pressure let-down device, wherein said pressure source is sufficient to provide pressure to said reaction mixture during operation of said process plant to produce a single-phase liquid reaction mixture in said reactor and a two-phase liquid-liquid reaction mixture in said separator in the absence of an additional pressure source between said reactor and said separator.

Owner:EXXONMOBIL CHEM PAT INC

Olefinic polymerization and copolymerization method of supported non-metallocene catalyst

A method of alkene polymerization and copolymarization with f load non- metallocene catalyst: emplying the load non- metallocene catalyst and catalyst promoter forming the catalytic system, introducing polymer monomer or comonomer for alkene polymerization or copolymarization; adding the load non- metallocene catalyst into dissolvent and mixing with catalyst promoter and then transferring the mixture into polymerization reactor, or adding the load non- metallocene catalyst and catalyst promoter into the polymerization reactor in order or simultaneously. The catalyst promoter is chosen from: alkyl aluminium, aluminium oxane, Lewis acid, boralotano, alkyl borane or alkyl borane ammonium salt. The load non- metallocene catalyst is loaded to multiple poral solid by employing methods of solution dipping, equivoluminal dipping or solution dipping-before-equivoluminal dipping to form organic integral of property stable and strong binding force. The invention is characterized by the high alkene polymerization active, high fusion point and good normalization of the produced polymer, and the sastification of the demand of high level product production.

Owner:YANGZI PETROCHEM

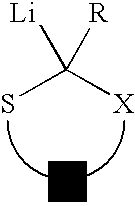

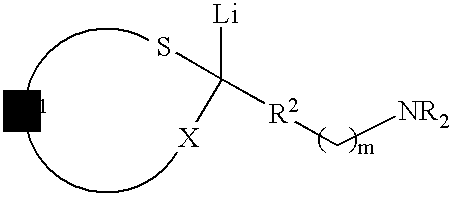

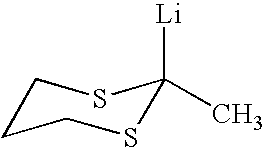

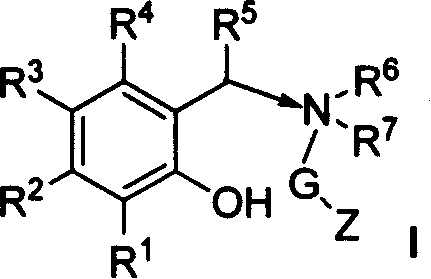

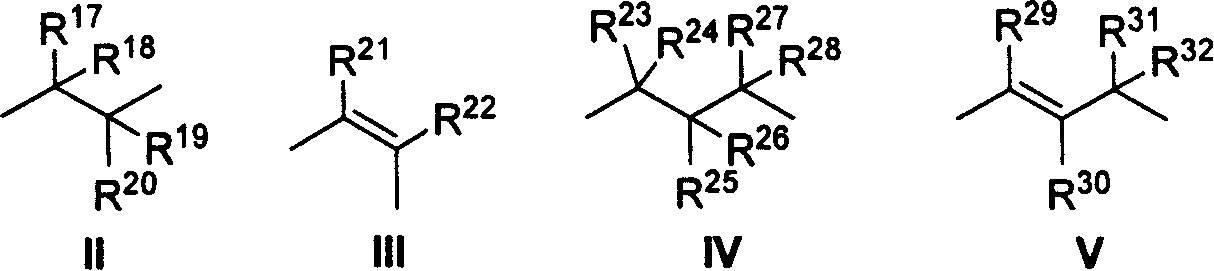

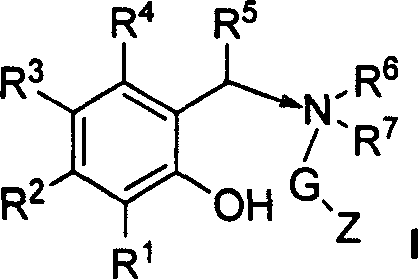

Use of sulfur containing initiators for anionic polymerization of monomers

InactiveUS7153919B2Reduced hysteresis lossSilicon organic compoundsLithium organic compoundsElastomerRolling resistance

An initiator is presented for anionically polymerizing monomers, to provide a functional head group on the polymer. A polymer having a functional head group derived from a sulfur containing anionic initiator, and optionally as additional functional group resulting from the use of a functional terminating reagent, coupling agent or linking agent is also provided. A method is presented for anionically polymerizing monomers comprising the step of polymerizing the monomers with a sulfur containing anionic initiator to provide a functional head group on the polymer. An elastomeric compound, comprising a functional polymer and filler is also described. Also provided is a tire having decreased rolling resistance resulting from a tire component containing a vulcanizable elastomeric compound.

Owner:BRIDGESTONE CORP

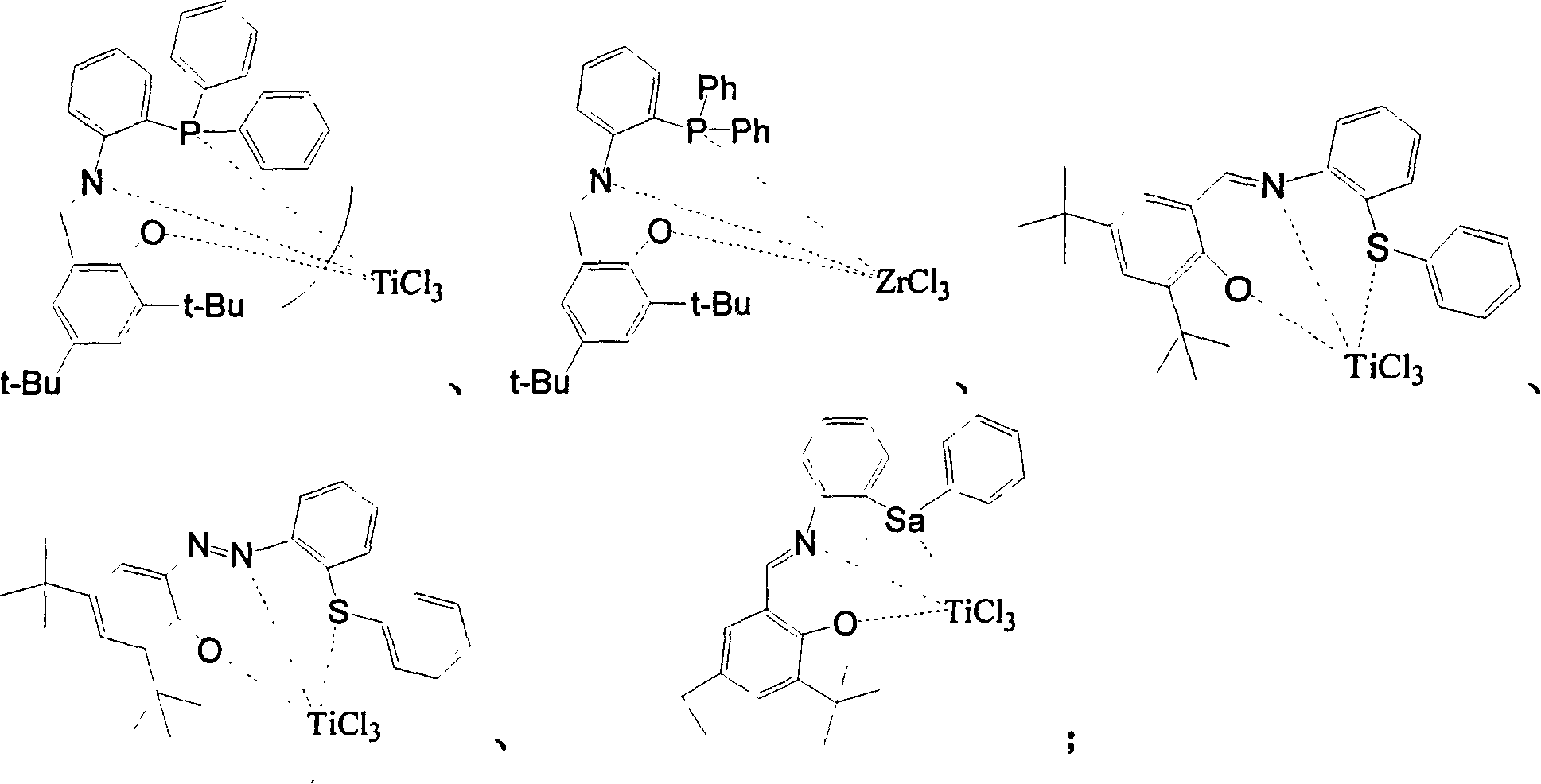

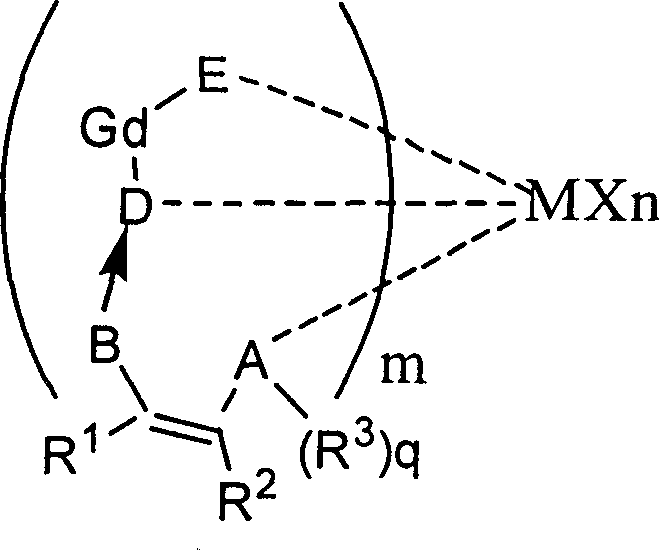

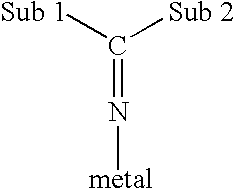

Mono-active center Ziegler-Natta catalyst for olefinic polymerization

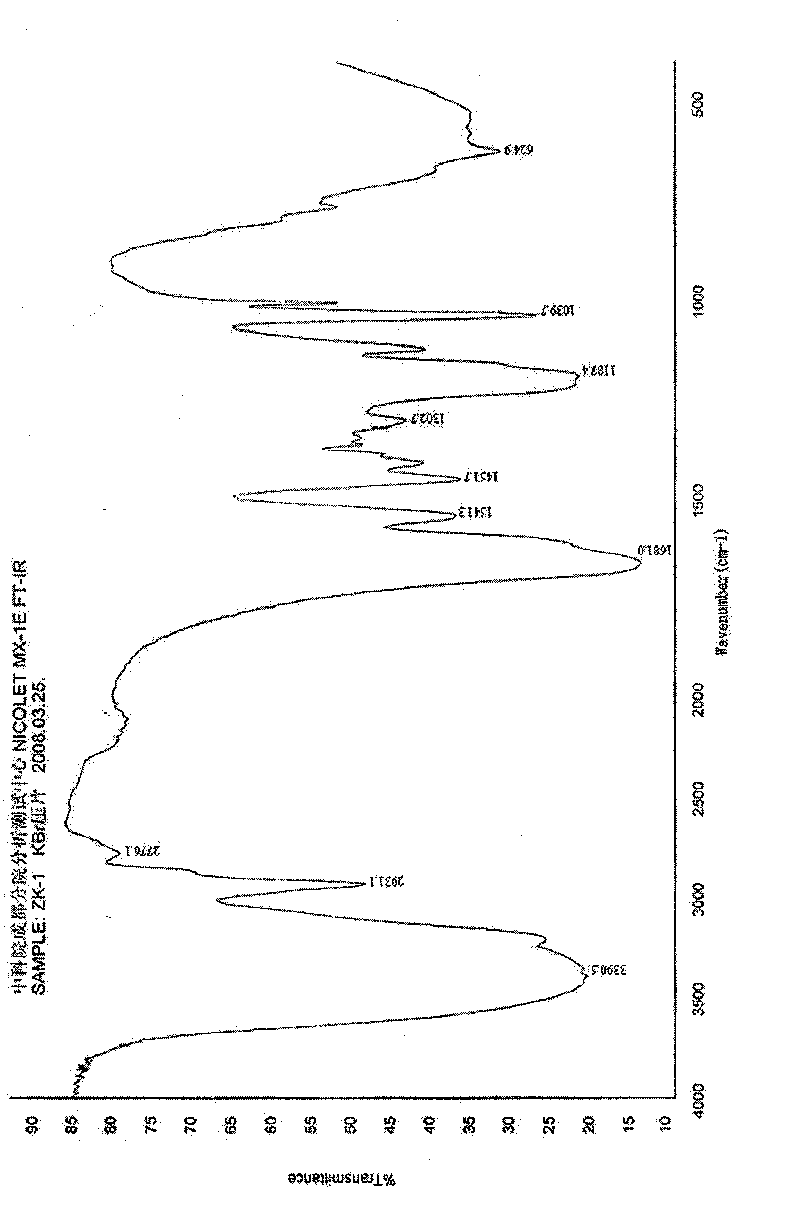

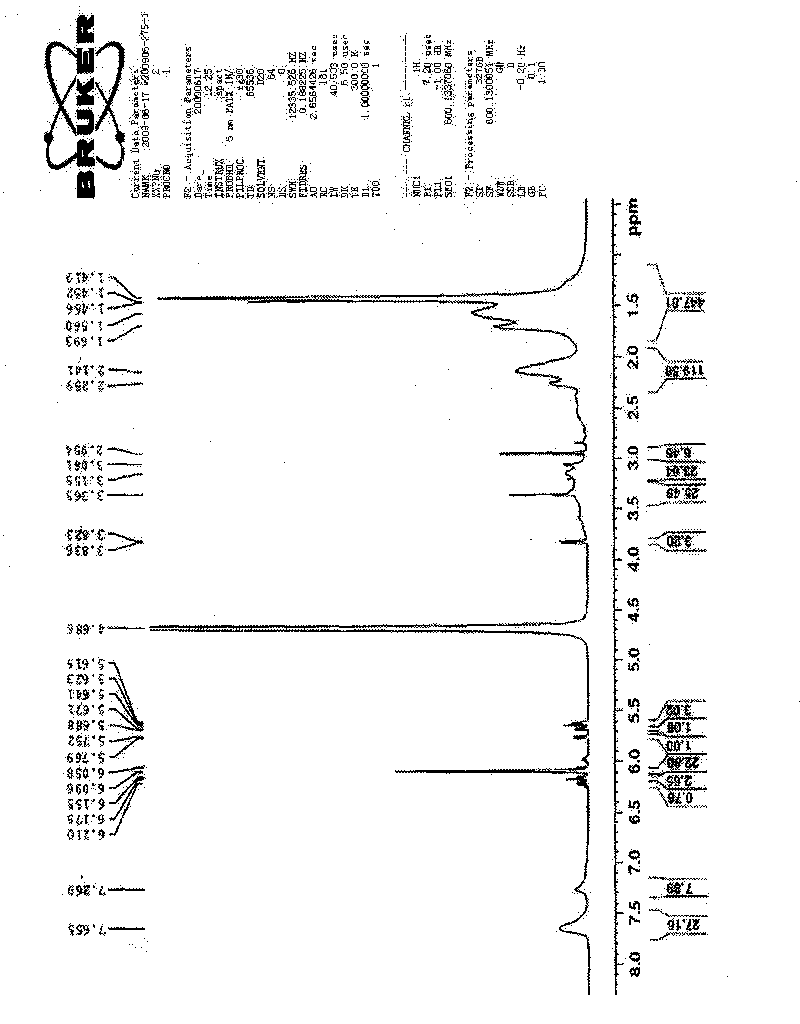

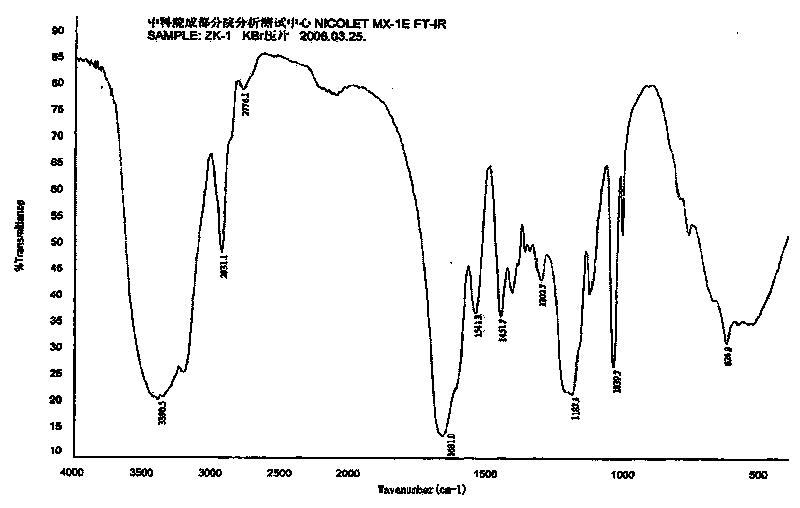

The invention relates to a new catalyst for single active central Ziegler-Natta alkene polymerization. Said catalyst takes salicylal containing dentate or substituted salicylal derivatives as electrons, and is prepared by adding pretreated carrier, metallic compound and electrons into magnesium compound / tetrahydrofuran solution. The catalyst can produce ethane homopolymer and copolymer with narrow molecular weight distribution (1.6-3.8) and even comonomer distribution, with high activity and under action of adjuvant catalyst of alkyl aluminium and alkyl aluminoxanes. The ethane polymerization, homopolymerization or combined polymerization of ethane and 1- olefin, ring olefin and polar monomer through slurry method or gas phase method by using said catalyst can be realized.

Owner:SHANGHAI INST OF ORGANIC CHEMISTRY - CHINESE ACAD OF SCI

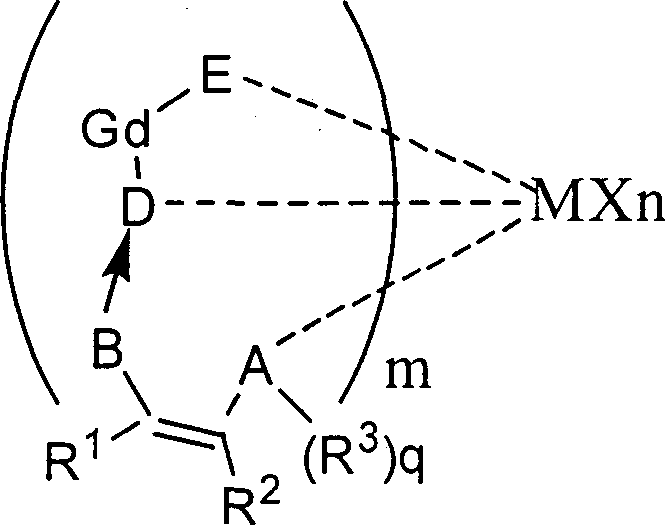

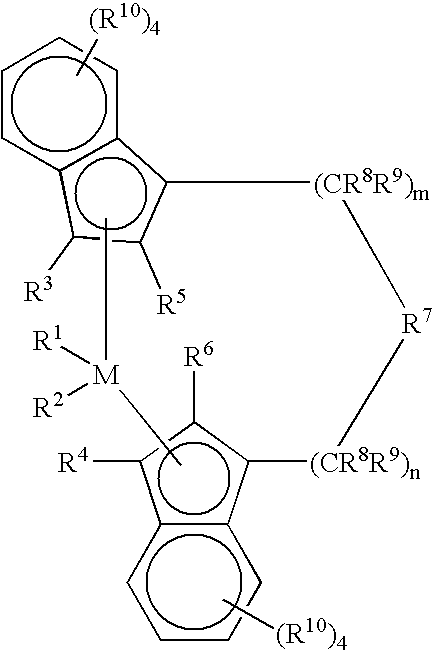

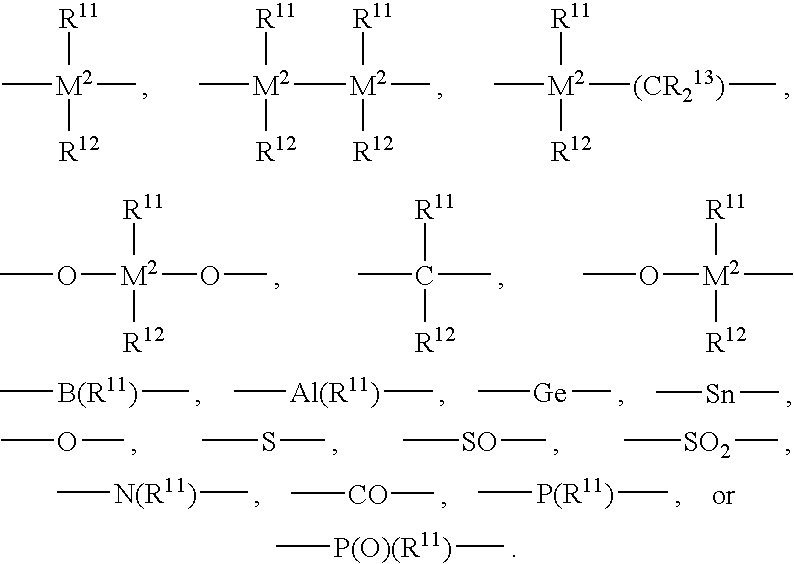

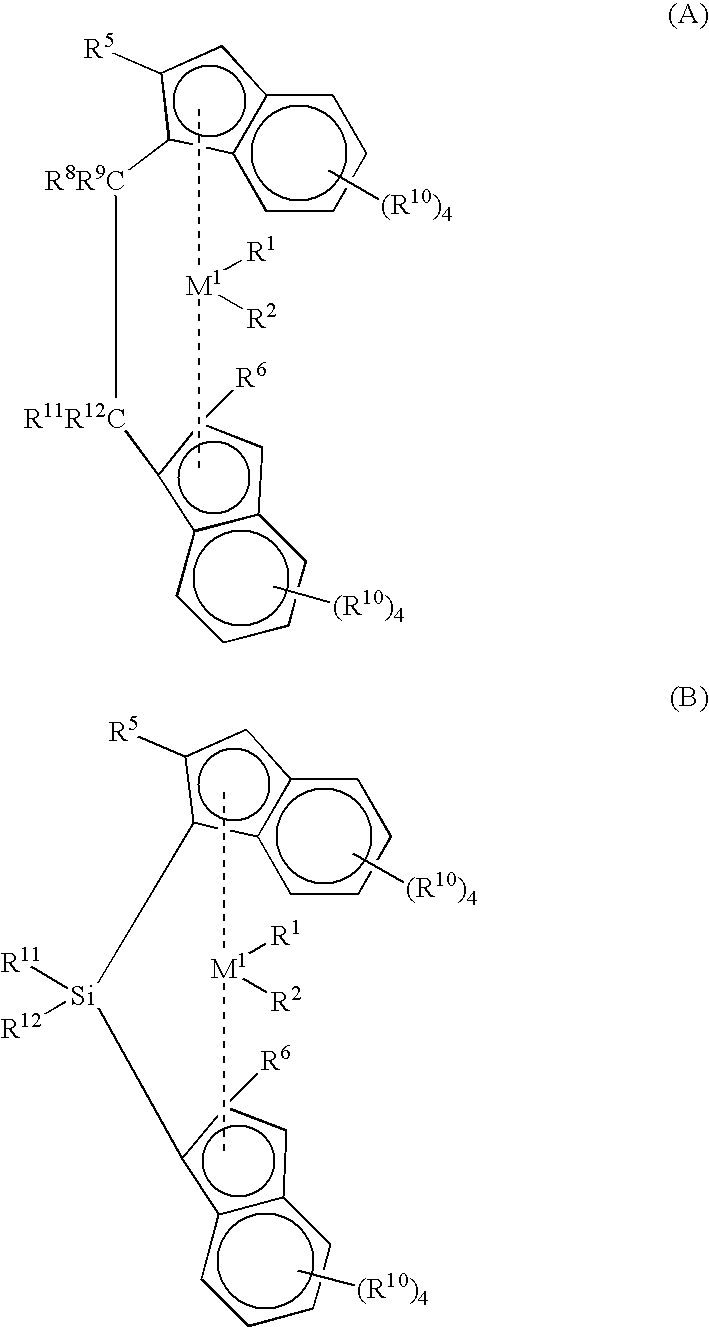

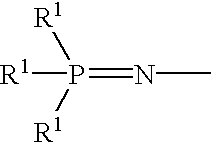

High temperature solution polymerization process with phosphinimine cyclopentadienyl metal (GRP IV) complex

This invention is a solution process for the preparation of high molecular weight ethylene copolymers comprising contacting olefin monomers, with a catalyst system at a polymerization temperature at or above about 80 DEG C. with a catalyst system comprising an unbridged Group 4 metal compound having a monocyclopentadienyl ligand, a phosphinimine ligand and at least one uninegative, activation reactive ligand. The process can be practiced at a reaction temperature of at least 80 DEG C. to obtain high number average molecular weight polymer.

Owner:NOVA CHEM (INT) SA

Oil extended rubber and composition containing low PCA oil

The invention is directed to an oil extended rubber and composition comprising: a solution-polymerized elastomer derived from at least one conjugated diene monomer and at least one vinyl aromatic monomer, the elastomer coupled with at least one metal selected from the group consisting of silicon and tin; and from about 5 to about 70 parts by weight, per 100 parts by weight of elastomer (phr), of a process oil having a glass transition temperature of from about −80° C. to about −40° C., a polycyclic aromatic content of less than 3 percent by weight as determined by the IP346 method, and an aromatic content of less than 20 percent by weight as measured by ASTM D2140.

Owner:THE GOODYEAR TIRE & RUBBER CO

Processes and apparatus for continuous solution polymerization

InactiveUS20040024146A1Suppress further polymerizationProcess control/regulationLiquid-gas reaction as foam/aerosol/bubblesSolution polymerizationProcess plant

The invention relates to processes and plants for continuous solution polymerization. Such plant and processes include a pressure source, a polymerization reactor, downstream of said pressure source, pressure let-down device, downstream of said polymerization reactor, and a separator, downstream of said pressure let-down device, wherein said pressure source is sufficient to provide pressure to said reaction mixture during operation of said process plant to produce a single-phase liquid reaction mixture in said reactor and a two-phase liquid-liquid reaction mixture in said separator in the absence of an additional pressure source between said reactor and said separator.

Owner:EXXONMOBIL CHEM PAT INC

Catalyst component for olefinic polymerization and its catalyst

This invention provides a catalys conponent and catalyst. Said catalyst comprises titanium, magnesium and at least three electron donor compounds a, b and c, in which is selected from mono-aliphatic-carboxylate or mono-aromatic-carboxylate compounds, b is selected from a special diatomic alkoxide compound, and c is selected from binary binary-aliphatic-carboxylate or binary-aromatic-carboxylate or b is ether compound. Advantages: high polymerization activity and stereospecificity when used for olefin polymerization, in particular for propylene polymerization, wide molecular weight distribution of obtained polymer and good shape of polymer granulars.

Owner:CHINA PETROLEUM & CHEM CORP +1

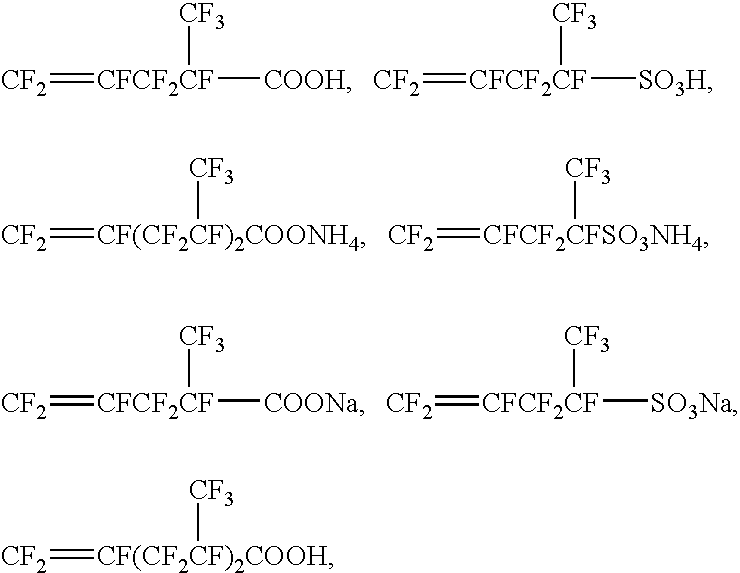

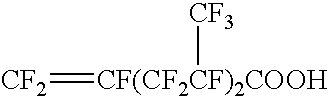

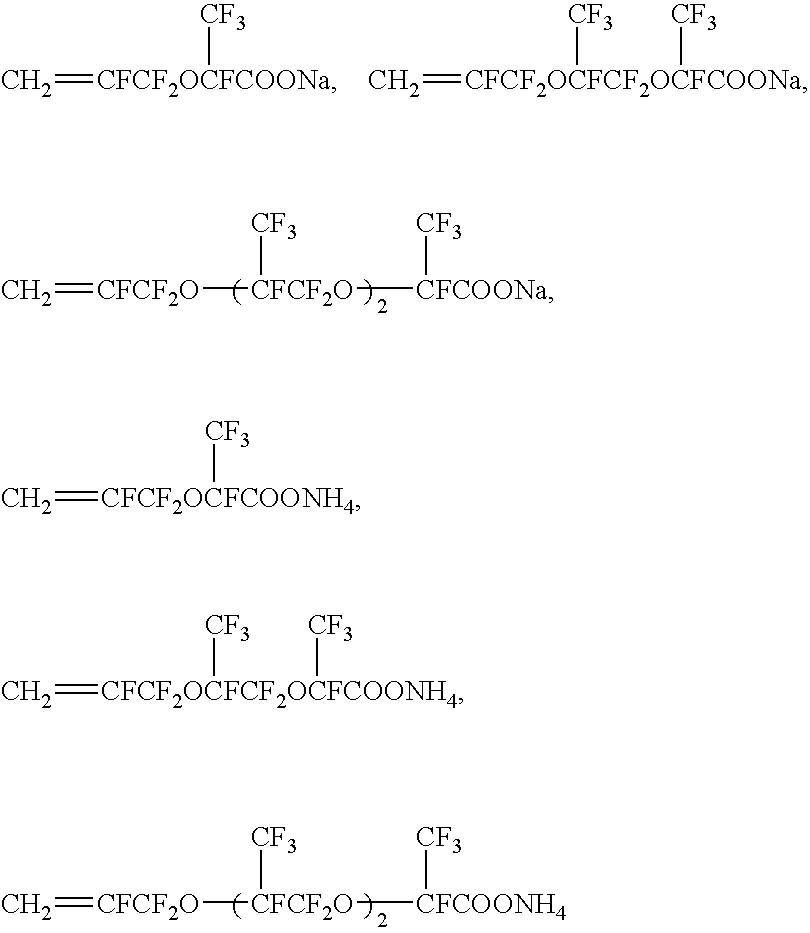

Aqueous tetrafluoroethylene polymer dispersion,process for producing the same, tetrafluoroethylene polymer powder,and molded tetrafluoroethylene polymer

InactiveUS20070060699A1Excellent in moldability/processabilityIncrease concentrationFibre treatmentTetrafluoroethylenePolymer science

The present invention provides a tetrafluoroethylene polymer aqueous dispersion obtained by carrying out a TFE polymerization in an aqueous medium in the presence of a fluorovinyl group-containing emulsifier, wherein the TFE polymer aqueous dispersion contains a particle comprising a TFE polymer dispersed in the aqueous medium, the fluorovinyl group-containing emulsifier comprises a fluorovinyl group-containing compound, and the TFE polymer aqueous dispersion has a fluorine-containing surfactant content of not higher than 1000 ppm by mass.

Owner:DAIKIN IND LTD

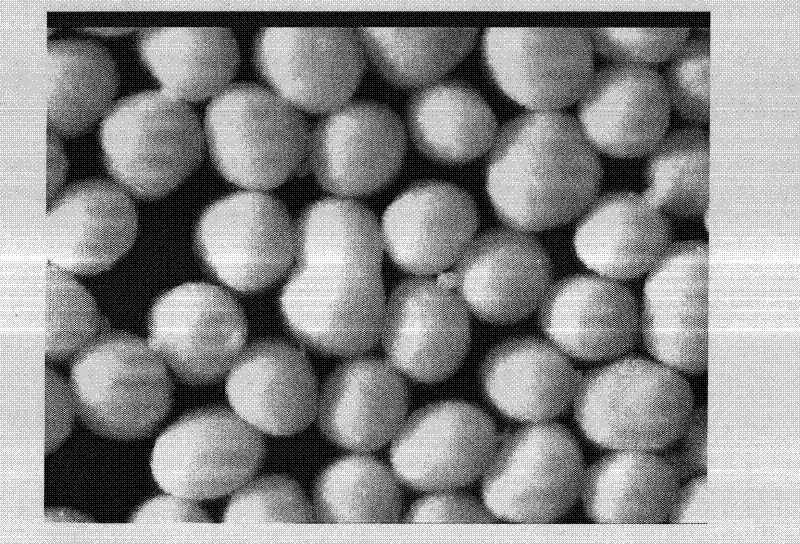

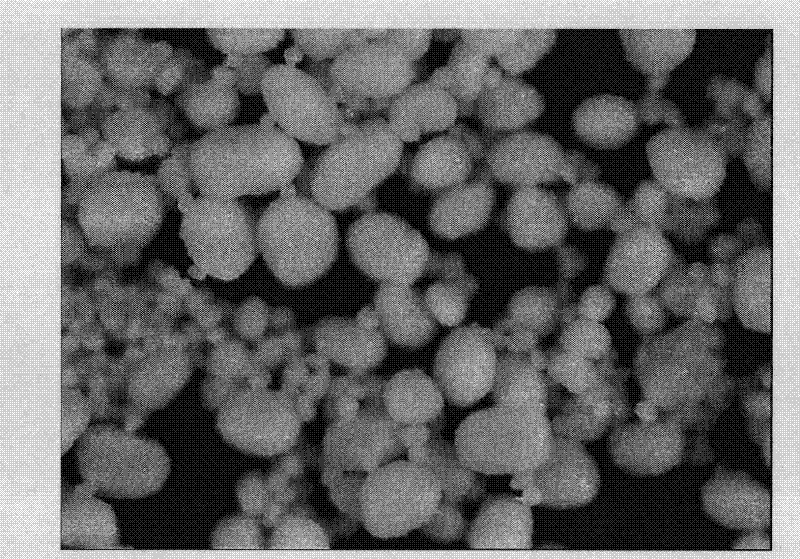

Globular catalyst component used for olefine polymerization and its catalyst

ActiveCN1718595AOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsAlcoholEmulsion polymerization

Owner:CHINA PETROLEUM & CHEM CORP +2

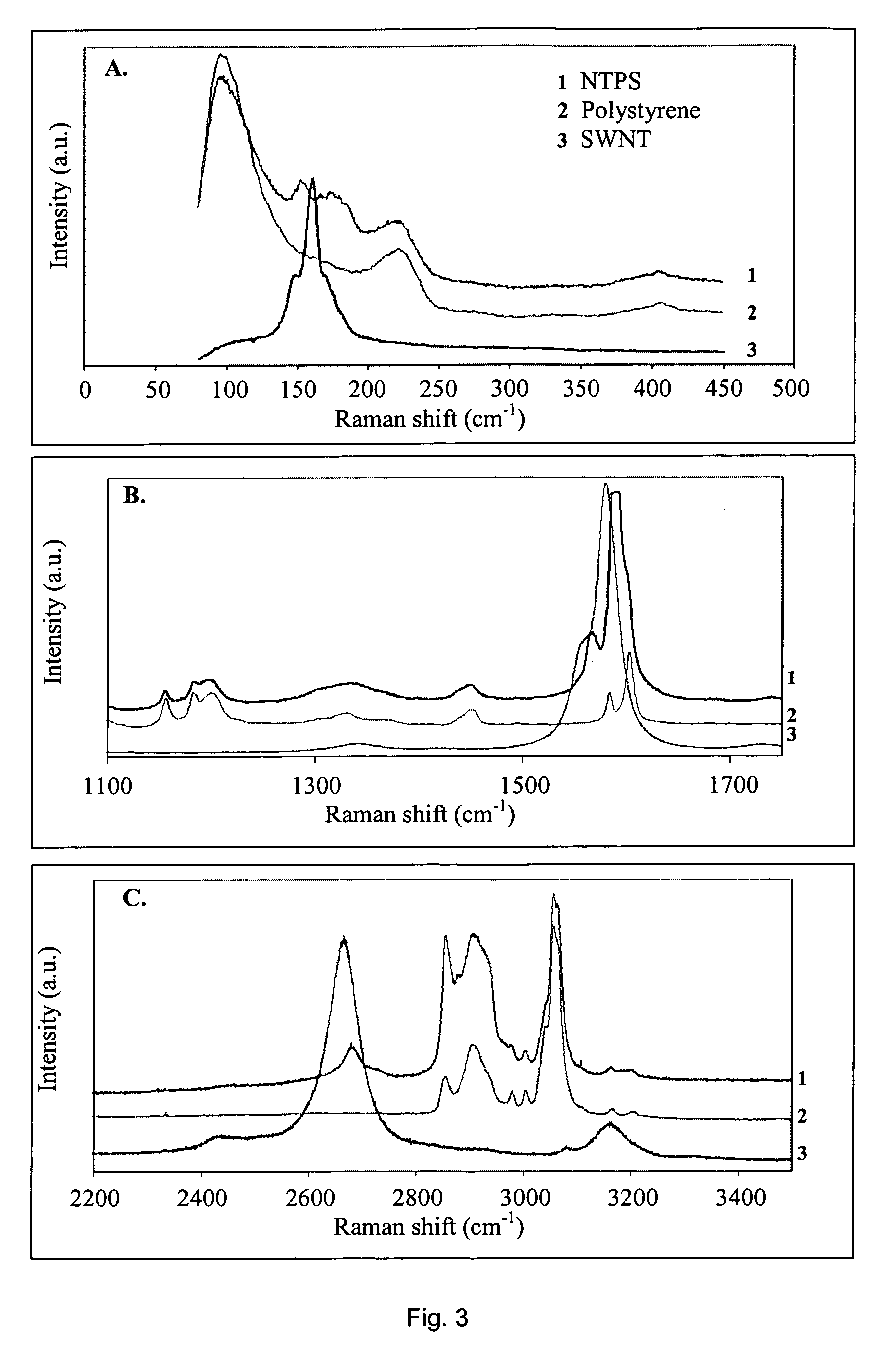

Carbon nanotube-filled composites prepared by in-situ polymerization

ActiveUS7153903B1Material nanotechnologyIndividual molecule manipulationIn situ polymerizationCarbon nanotube

A method of forming carbon nanotube-filled composites using miniemulsion polymerization. The carbon nanotubes are preferably single-walled carbon nanotubes. The carbon nanotubes are highly dispersed within and associated with the polymer comprising the composite.

Owner:THE BOARD OF RGT UNIV OF OKLAHOMA

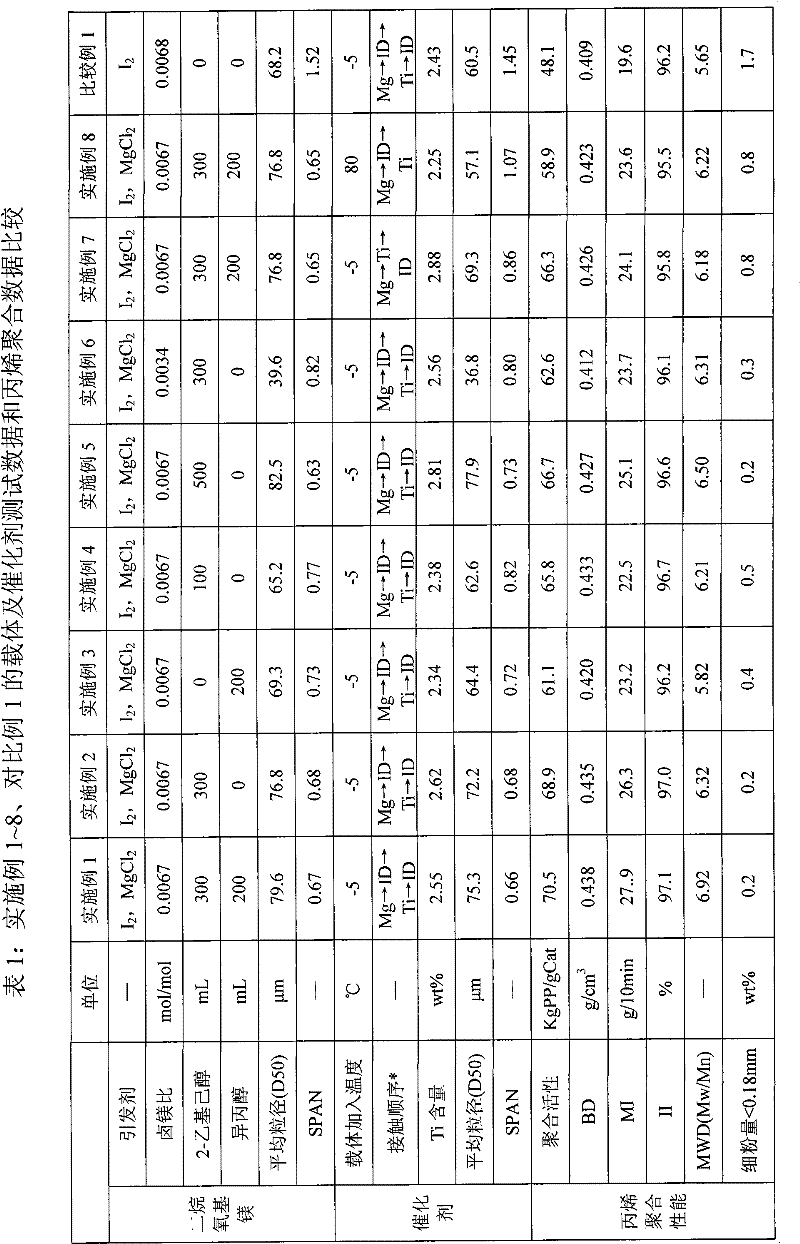

Support of olefinic polymerization catalyst and preparation method thereof, solid catalyst components for olefinic polymerization and olefinic polymerization catalyst

The invention relates to a support of an olefinic polymerization catalyst and a preparation method thereof, solid catalyst components for olefinic polymerization and an olefinic polymerization catalyst. The support of the olefinic polymerization catalyst is dialkoxy magnesium. The preparation method of the support of the olefinic polymerization catalyst comprises the following steps: in an inert gas protective atmosphere, reacting magnesium and alcohol, which serve as raw materials, in the presence of a halogenating agent under reflux to prepare the dialkoxy magnesium, wherein the weight ratio of alcohol to magnesium is (4-50):1; the halogenating agent is at least one of halogen simple substances and halides, and the mol ratio of halogen atom to magnesium is (0.0002-0.2):1; and the dialkoxy magnesium is spherical particles of which the average particle size is 10-150 um and the particle size distribution index SPAN is smaller than 1.1. The olefinic polymerization catalyst prepared by the support has high activity, and the polymer has the advantages of high bulk density, good particle shape and uniform distribution; and thus, the olefinic polymerization catalyst is suitable for producing propylene homopolymer and copolymer.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst component for olefinic polymerization and its catalyst

This invention relates to a catalyst component for olefinic polymerization and its catalyst, said catalyst component comprises titanium compoumd with at least one Ti- halogen bond loaded on MgCl2nROH adduct and reaction product of two electronic doner compounds,wherein electronic doner compound A is chosen from poly alcohol ester compounds, and electronic doner compound B is chosen from ester,ether, ketone, amine and silicane compounds except compound A.The invented catalyst has high catalytic activity for olefinic polymerization ,in particular propylene polymerization, and wider molecular weight distribution.

Owner:CHINA PETROLEUM & CHEM CORP +1

Pneumatic tire having a component containing low PCA oil

There is disclosed a pneumatic tire having a component comprising a vulcanizable rubber composition comprising, based on 100 parts by weight of elastomer (phr), from about 40 to about 90 phr of a solution polymerized styrene-butadiene having a styrene content of greater than 38 percent by weight; from about 10 to about 60 phr of at least one additional elastomer; and from about 10 to about 70 phr of a process oil having a glass transition temperature of from about −80° C. to about −40° C. and a polycyclic aromatic content of less than 3 percent by weight as determined by the IP346 method.

Owner:THE GOODYEAR TIRE & RUBBER CO

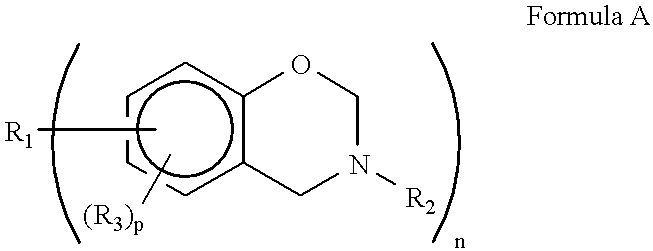

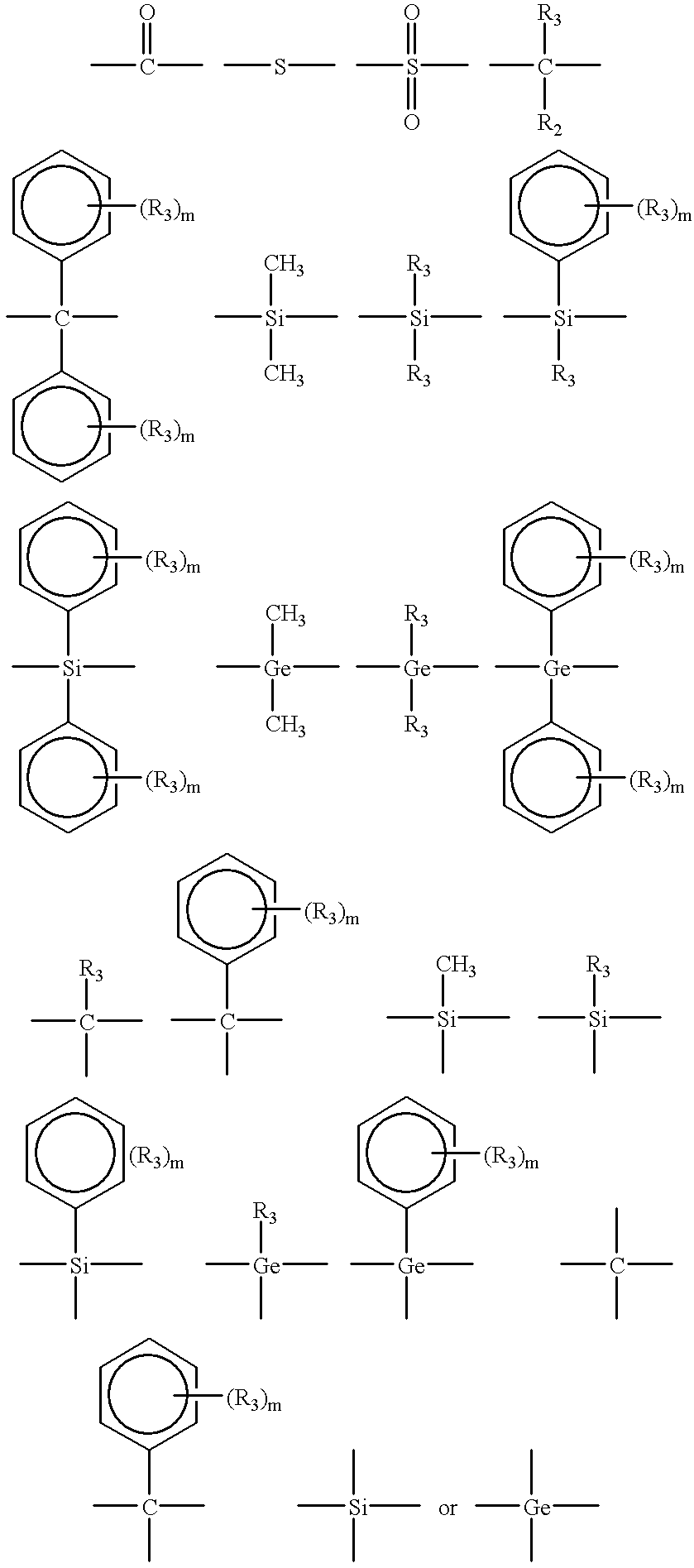

Cationic ring-opening polymerization of benzoxazines

Cationic polymerization of mono and polyfunctional benzoxazine monomers is described. The chemical structure of the polymers from cationic polymerization of benzoxazine monomers has been identified and distinguished from thermally polymerized products from the same monomers. The controllable microstructure of the polymers from benzoxazines prepared by cationic polymerization offers opportunities to prepare and optimize the polymer structure for specific applications.

Owner:EDISON POLYMER INNOVATION EPIC

Latex processes

InactiveUS6503680B1Improve performanceImprove featuresDevelopersEmulsion paintsGlass transitionPolymer chemistry

A process for the preparation of a latex polymer consistent with E / A (emulsion / aggregation / coalescence) toner manufacture. The process utilizes a standard (universal) latex composition and involves chain-transfer agent partitioning, emulsion polymerization that provides a latex polymer with a wide range of molecular properties. In particular, the process customizes a wide range Mw (weight average molecular weight) latex, without substantially varying the Mn (number average molecular weight) and hence, without substantially varying Tg (glass transition temperature) such that good toner performance is maintained. In a preferred process, a latex polymer is prepared by mixing a seed particle latex, generated by aqueous emulsion polymerization of a first portion of a monomer emulsion, with a second portion of the monomer emulsion and at least one chain-transfer agent. The mixing is done in the presence of a free-radical initiator and heated, and wherein the monomer emulsion comprises a mixture of polymerization reagents of at least one monomer, at least one chain-transfer agent, at least one surfactant, and water. This process may be applied to core-shell polymerization as well. These latex polymers are ideally suited in the manufacture of toner and developer for electrophotographic imaging and printing.

Owner:XEROX CORP

Capping reactions in cationic polymerization; kinetic and synthetic utility

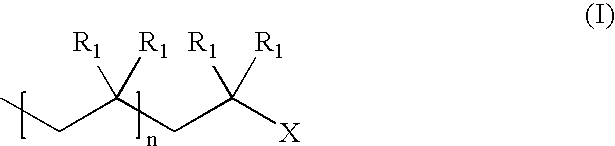

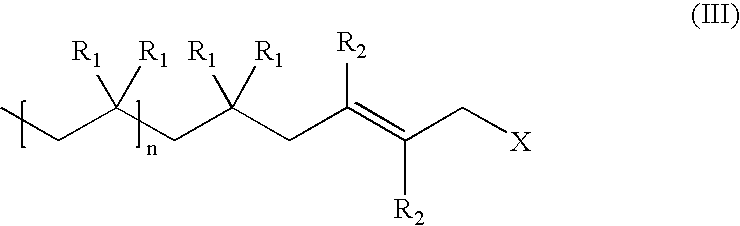

A method of synthesizing an endcapped polymer, comprising reacting in a solvent a cationic living polymer with an optionally substituted conjugated diene as an endcapping reagent, whereby the solvent causes termination by halogenation to be faster than the addition of additional molecules of the conjugated diene, thereby producing an endcapped polymer having a halogenated endcap group.

Owner:MASSACHUSETTS LOWELL UNIV OF

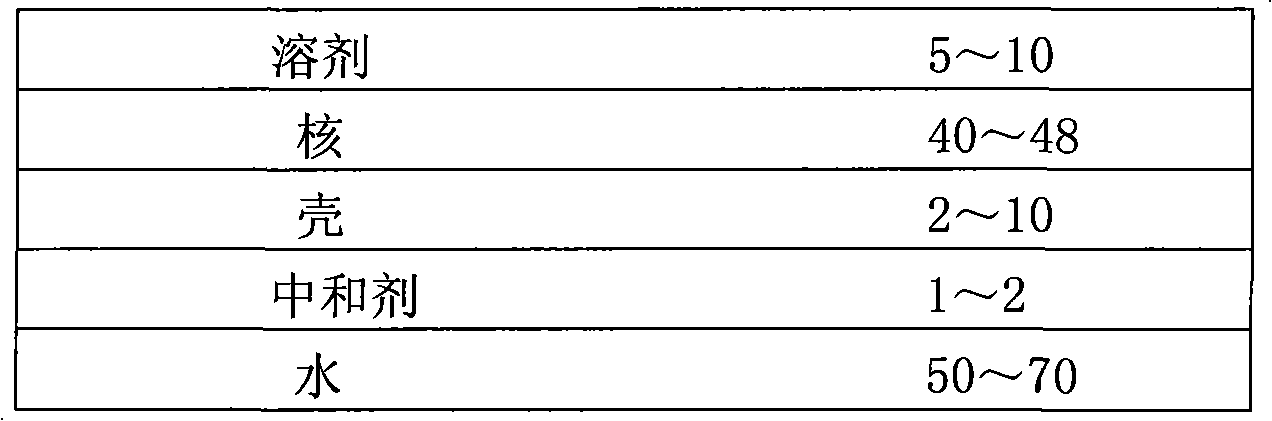

Hydroxy acrylic resin aqueous dispersion and water-based coating prepared therefrom

ActiveCN101914185AImprove anti-corrosion performancePolyurea/polyurethane coatingsWater basedAcrylic resin

The invention discloses a method for preparing a hydroxy acrylic resin aqueous dispersion and the hydroxy acrylic resin aqueous dispersion prepared by the same and water-based coating using the hydroxy acrylic resin aqueous dispersion as a film forming matter. The hydroxy acrylic resin aqueous dispersion is prepared by a step free radical solution polymerization process and obtains a nucleus-shell structure by using an initiator of a specific type and a chain transfer agent and by a high-temperature polymerization reaction. The nucleus has weak hydrophilicity and no carboxyl, and the shell has a strong hydrophilicity and is rich in carboxyl, so stable storage can be realized. The obtained hydroxy acrylic resin aqueous dispersion has the characteristics of low solution content, high solid content and low viscosity. The coating prepared from the hydroxy acrylic resin aqueous dispersion and a water-based amino resin or a water-based polyurethane cross-linking agent has the characteristics of high brightness, good water resistance and excellent weather resistance. The hydroxy acrylic resin aqueous dispersion can be used for preparing an excellent base material of high-performance environment-friendly industrial protective coatings and widely applied to topcoats and primer-topcoat coatings in various fields.

Owner:LANGFANG JINHUILI INDAL PAINT

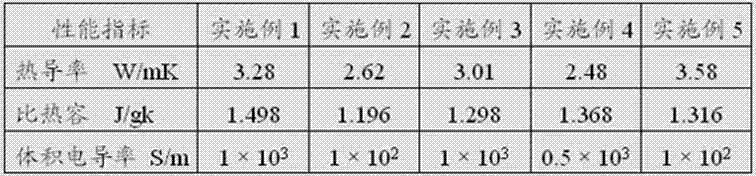

Graphene filled polymer matrix composite material and its preparation method

ActiveCN103087404AImprove conductivityImprove thermal conductivityIn situ polymerizationMechanical property

The invention discloses a graphene filled polymer matrix composite material. The composite material is prepared through using 90-99 parts by weight of a thermoplastic resin, 0.1-10 parts by weight of a graphene microchip, 0.01-1 part of a coupling agent, and 1-10 parts of a lubricant. The invention also discloses a preparation method of the graphene filled polymer matrix composite material. Compared with other carbon system filled composite materials, the graphene filled polymer matrix composite material has the advantages of easy processing, easy forming, less filler filling amount, wide raw material source, environmental protection and the like. The composite material has the characteristics of excellent electric conductivity, excellent thermal conductivity, good mechanical properties, good dimensional stability, good weather resistance and the like; and compared with present technologies for preparing a graphene / polymer composite material through in-situ polymerization or solution polymerization, the melt blending method for preparing the graphene filled polymer matrix composite material in the invention has the advantages of continuous production, suitableness for the large-scale production, and the like.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Hydrophobically modified clay polymer nanocomposites

InactiveUS20020058739A1Control of particle sizeReduced stabilityMaterial nanotechnologyLayered productsColloidSolution polymerization

The present invention is directed, in part, to improved nanocomposite compositions and processes for preparing same. Specifically, in one embodiment, there is provided a process for preparing an aqueous nanocomposite dispersion, wherein the process comprises: polymerizing via suspension polymerization a suspension comprising at least one ethylenically unsaturated monomer and a hydrophobically modified clay to form the nanocomposite dispersion after polymerization, wherein the hydrophobically modified clay is dispersed in the monomer. Other embodiments include processes for preparing aqueous nanocomposite particles, colloids, and dispersions using hydrophobically modified clays in aqueous systems and compositions comprising same.

Owner:ROHM & HAAS CO

High temperature resistant amphoteric ion polymer fluid loss agent used for drilling fluid and preparation method thereof

The invention relates to high temperature resistant amphoteric ion polymer fluid loss agent used for drilling fluid of a high temperature and high pressure drilling and a preparation method thereof. Four monomers, namely, acrylamide (AM), 2-acrylamide-2-methyl propane sulfonic acid (AMPS), dimethyl diallylammonium chloride (DMDAAC) and styrenesulfonate (SSS) are used as raw materials, wherein the mole ratio of AM:AMPS:DMDAAC:SSS is (9-11):(3-4):(0.5-1.5):(1.0-1.5); ammoniumpersulfate-sodium bisulfite as an initiator is added and solution is copolymerized through a polymerization method to compose the fluid loss agent. The fluid loss agent provided by the invention has the advantages of ideal high temperature resistant (more than 220 DEG C) reducing filtrate performance, shale inhibition performance and stable fluid rheology performance and simple preparation method, convenient operation and higher yield.

Owner:SOUTHWEST PETROLEUM UNIV

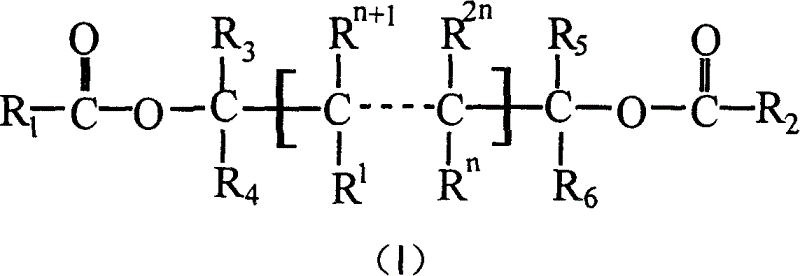

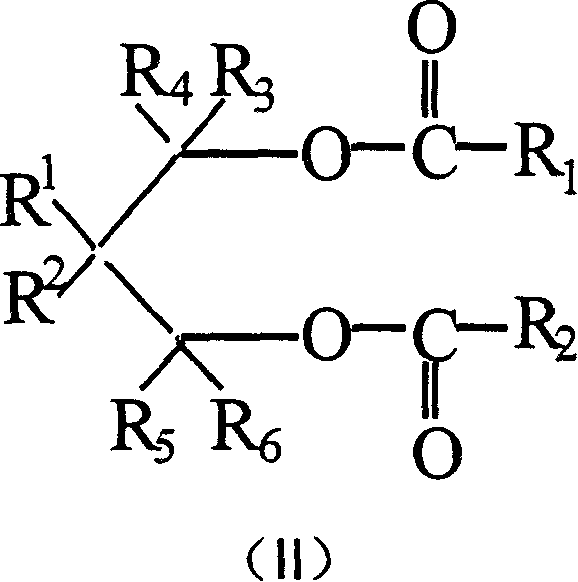

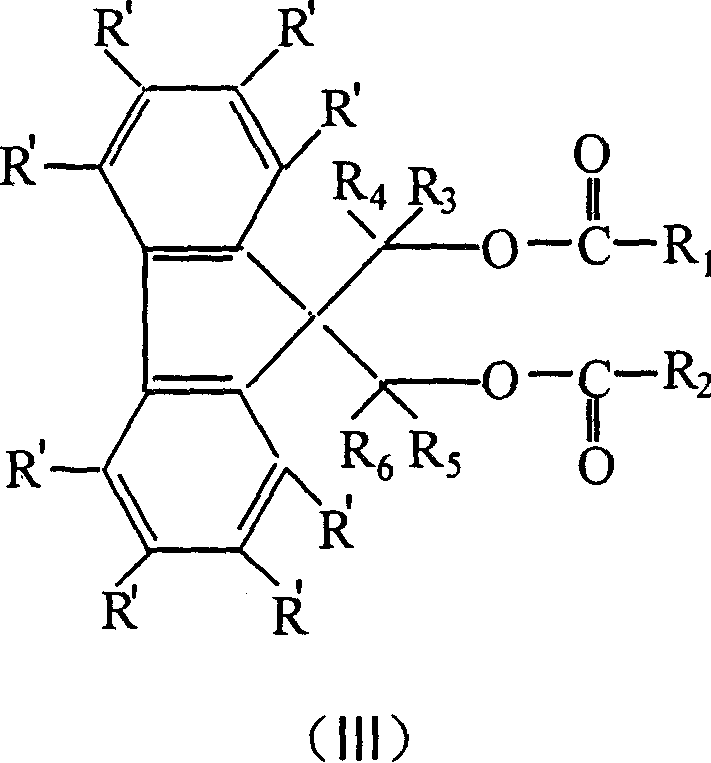

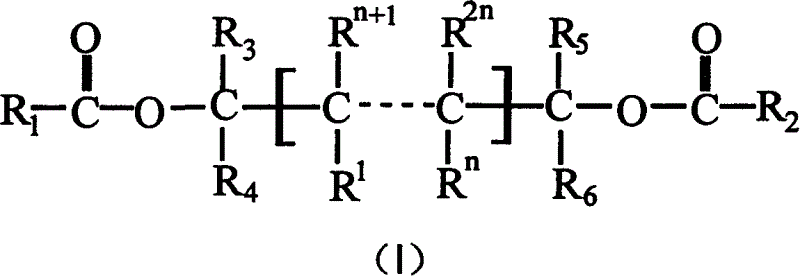

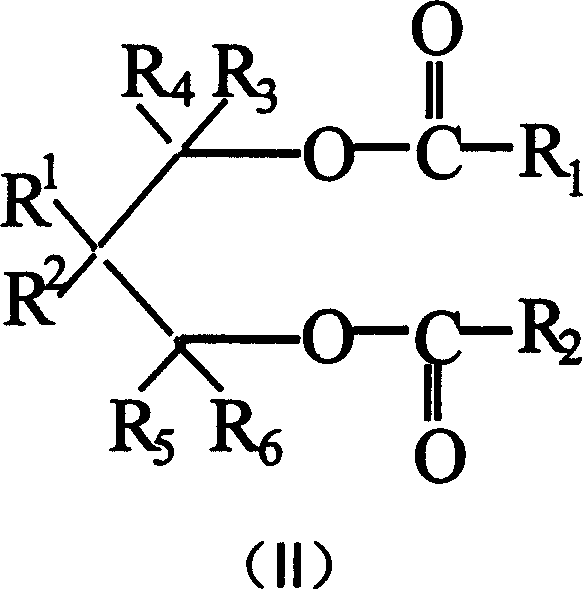

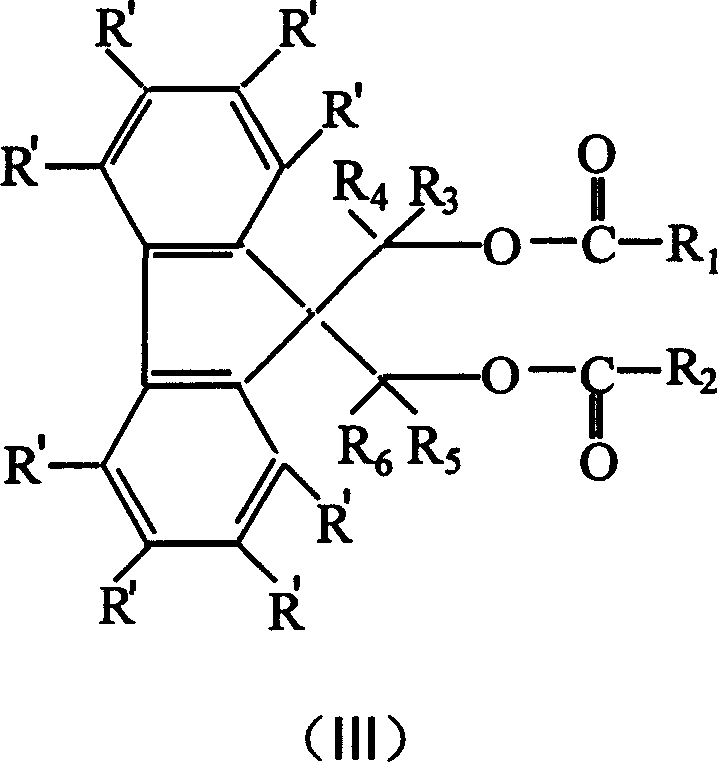

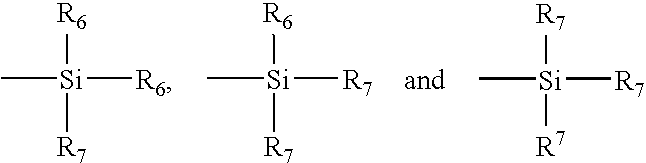

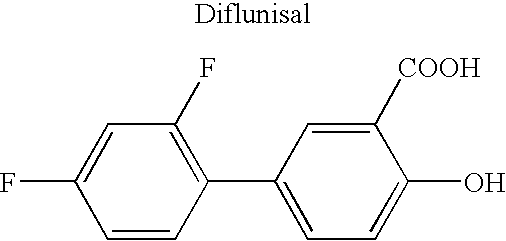

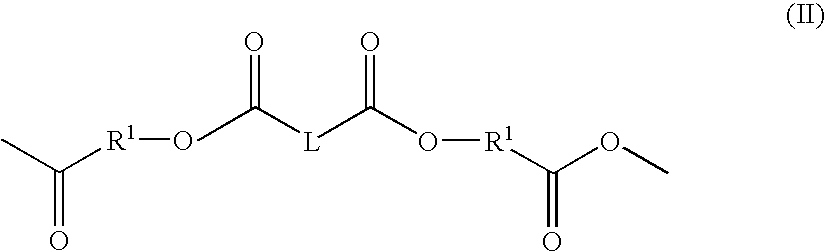

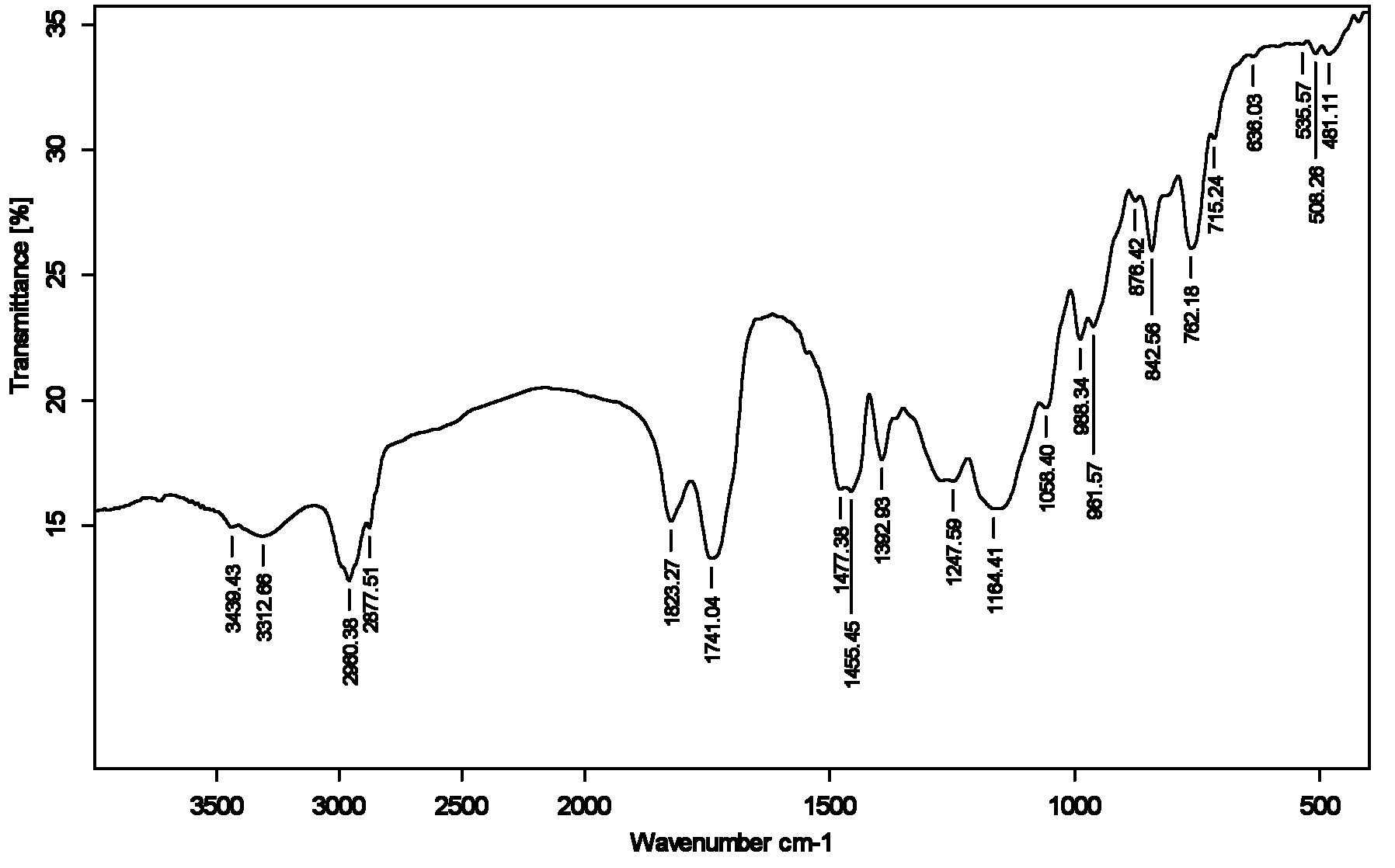

Solution polymerization processes to prepare a polymer that degrades to release a physiologically active agent

Anhydride polymers that release active or activatable agent(s) have pre-selected properties such as molecular weight, flexibility, hardness, adhesiveness, and other valuable properties. The polymers are suitable for use in compositions, formulations, coatings, devices, and the like that benefit from the controlled release of an agent(s) over a period of time. The polymers are prepared by a process involving various alternative and sequential steps that allow the design a priori of products with specific characteristics. The polymers are suitable as delivery systems, either by themselves, as compositions, formulations or devices.

Owner:RUTGERS THE STATE UNIV

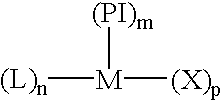

Polymerization process with mixed catalyst compositions

InactiveUS7192902B2Selectively activateEffectively tailor-makeOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationEmulsion polymerizationOlefin polymerization

The application describes a mixed olefin polymerization catalyst composition comprising a support, a reaction product of at least one first organometallic compound and a first activator capable of rendering the first organometallic compound active for insertion polymerization, and at least one second organometallic compound, the activator incapable of rendering the second organometallic compound active for polymerization of the monomers. The mixed catalyst composition can be used to prepare a first polymer component in a first polymerization reactor stage and then, when an effective activator is added for the second organometallic compound, the catalyst composition can be used to prepare a second polymer composition that is homogeneously blended with the first polymer component.

Owner:EXXONMOBIL CHEM PAT INC

Water-absorbent resin and production prcess therefor

InactiveUS20040110913A1Solve problemsHigh propertyAbsorbent padsEmulsion paintsWater solubleAqueous solution

To provide: a process in which a coarse gel itself is made not to form in the case of applying the aqueous solution polymerization; and a process in which the polymerization is mildly controlled and the production is stably carried out in the case of applying the reversed-phase suspension polymerization or static polymerization, in a production of a water-absorbent resin. In a production process for a water-absorbent resin, which comprises a polymerization step that includes the steps of carrying out polymerization, involving crosslinking, of an aqueous solution of a water-soluble unsaturated monomer including acrylic acid(salt);and at the same time carrying out fine division of the resultant hydrogel, or in a production process for a water-absorbent resin, which comprises the steps of carrying out polymerization, involving crosslinking, of an aqueous solution of a water-soluble unsaturated monomer including acrylic acid(salt);and carrying out fine division of the resultant hydrogel, or in a production process for a water-absorbent resin, which comprises a polymerization step that includes the steps of carrying out polymerization, involving crosslinking, of an aqueous solution of a water-soluble unsaturated monomer including acrylic acid(salt); and at the same time obtaining a finely divided hydrogel, the water-soluble unsaturated monomer is adjusted in order to contain furfural in an amount of 11 to 1,000 weight ppm (relative to the monomer).

Owner:NIPPON SHOKUBAI CO LTD

Catalyst used for olefine polymerization or copolymerization, its preparation method and application

A catalyst for the polymerization or copdymerization of olefin is composed of Ti-contained solid component A, organoaluminium compound B and organosilicon compound C. Said A is prepared through dissolving magnesium halide in the mixture of organic epoxy compound, organophosphorus compound and inertial diluent, adding educing agent and magnesium halide or its derivatives to educe out Mg / Ti contained deposit, and carrying a surface modifier, a titanium halide or derivative and an electronic doner. It can be used for the polymerization of propene or copolymerization of propene-ethene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Multimodal polyolefin pipe

A solution polymerization process in a series or parallel of two or more reactors at different temperatures is used to prepare a multimodal polyolefin resin of narrow molecular weight distribution. This resin is used to manufacture melt extruded pipe that has an improved performance at elevated temperatures and an improved hydrostatic design.

Owner:NOVA CHEM (INT) SA

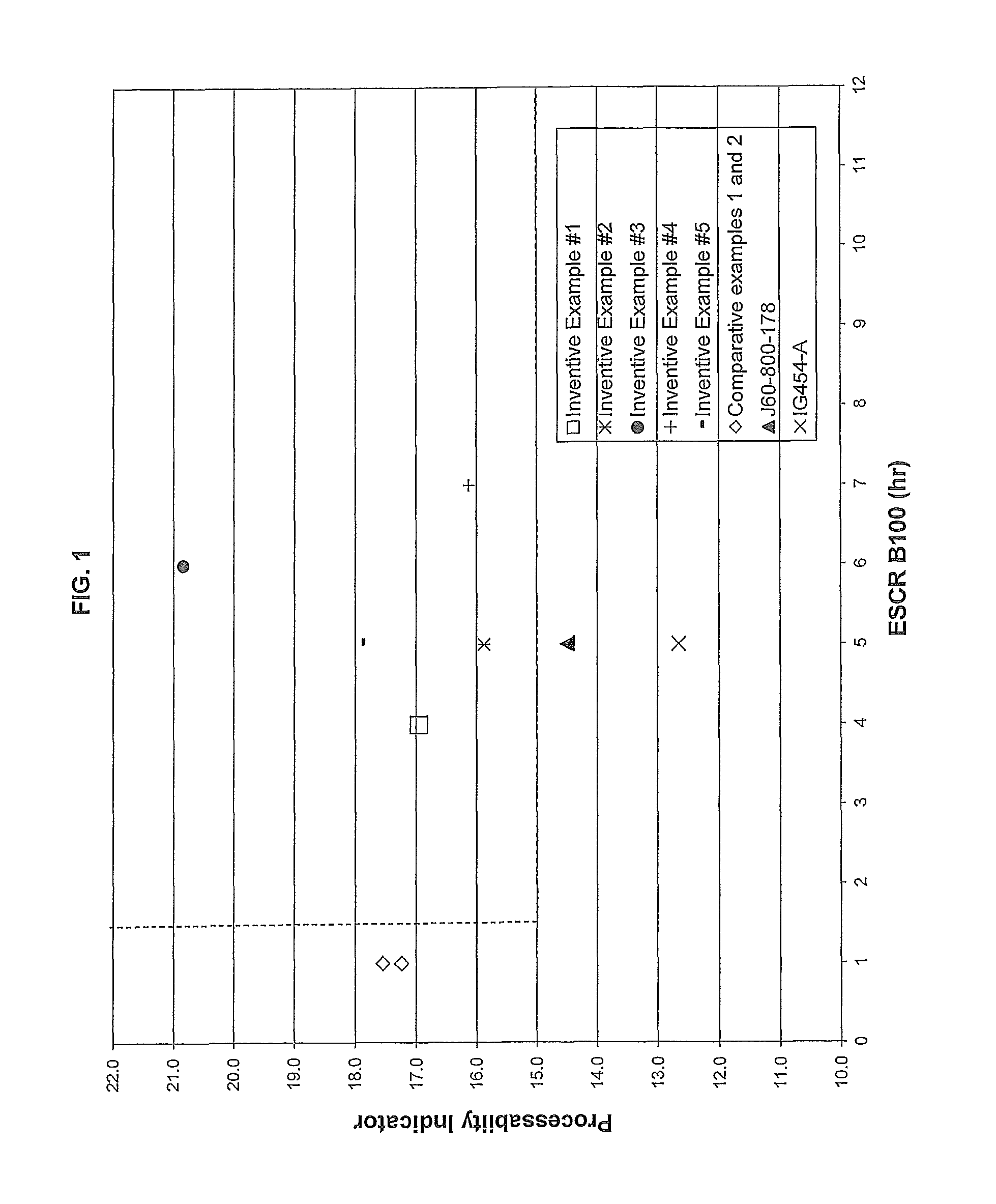

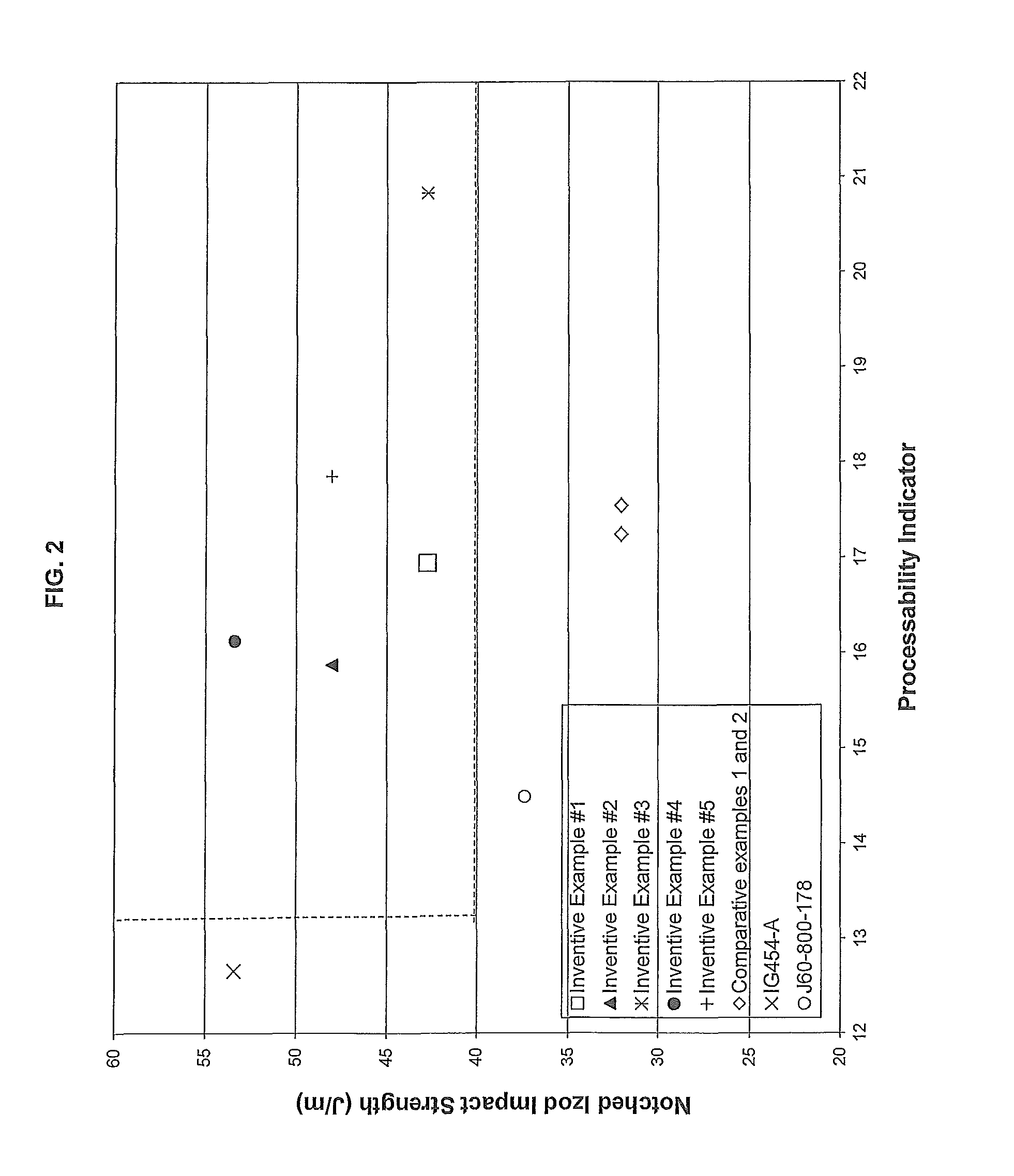

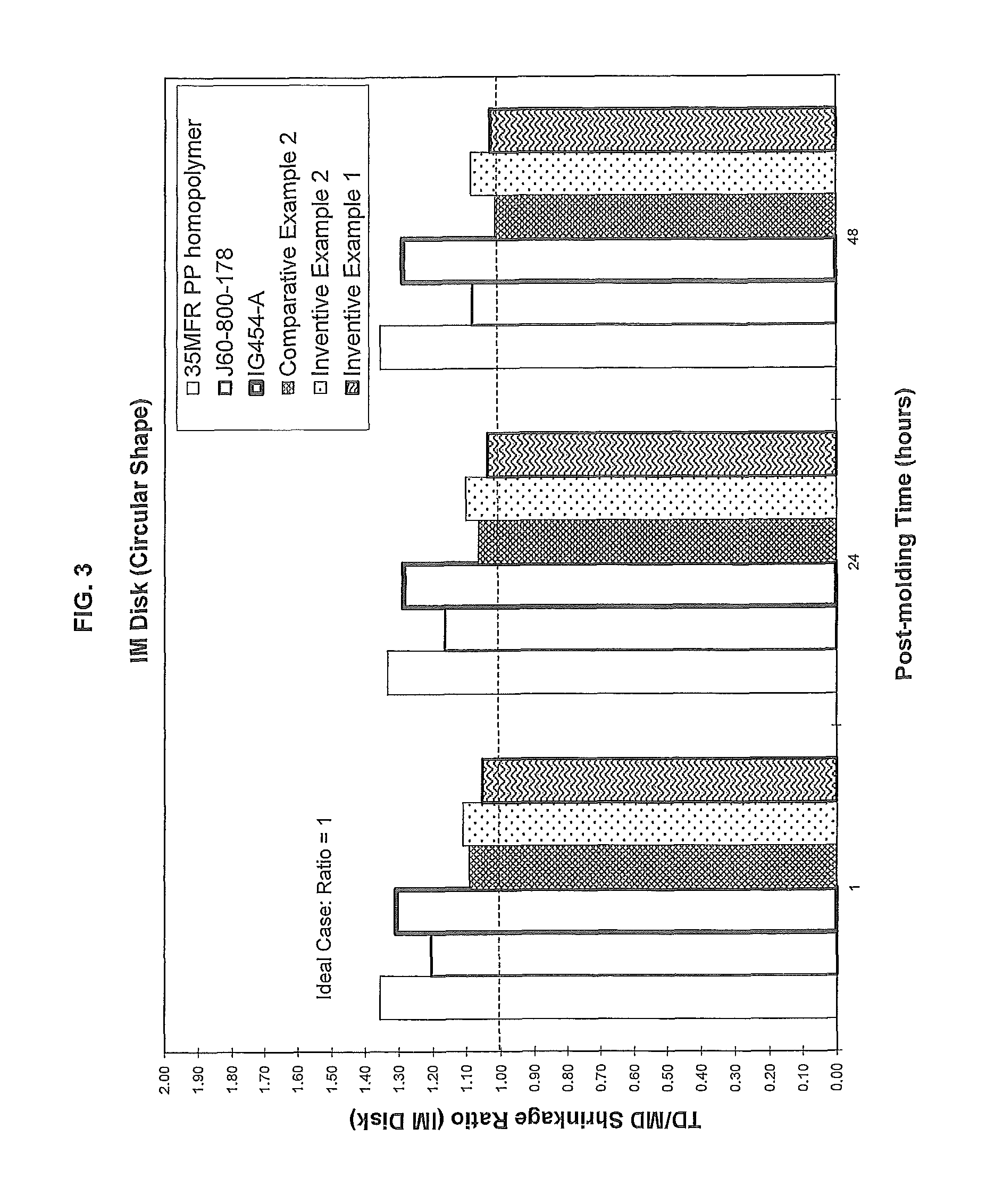

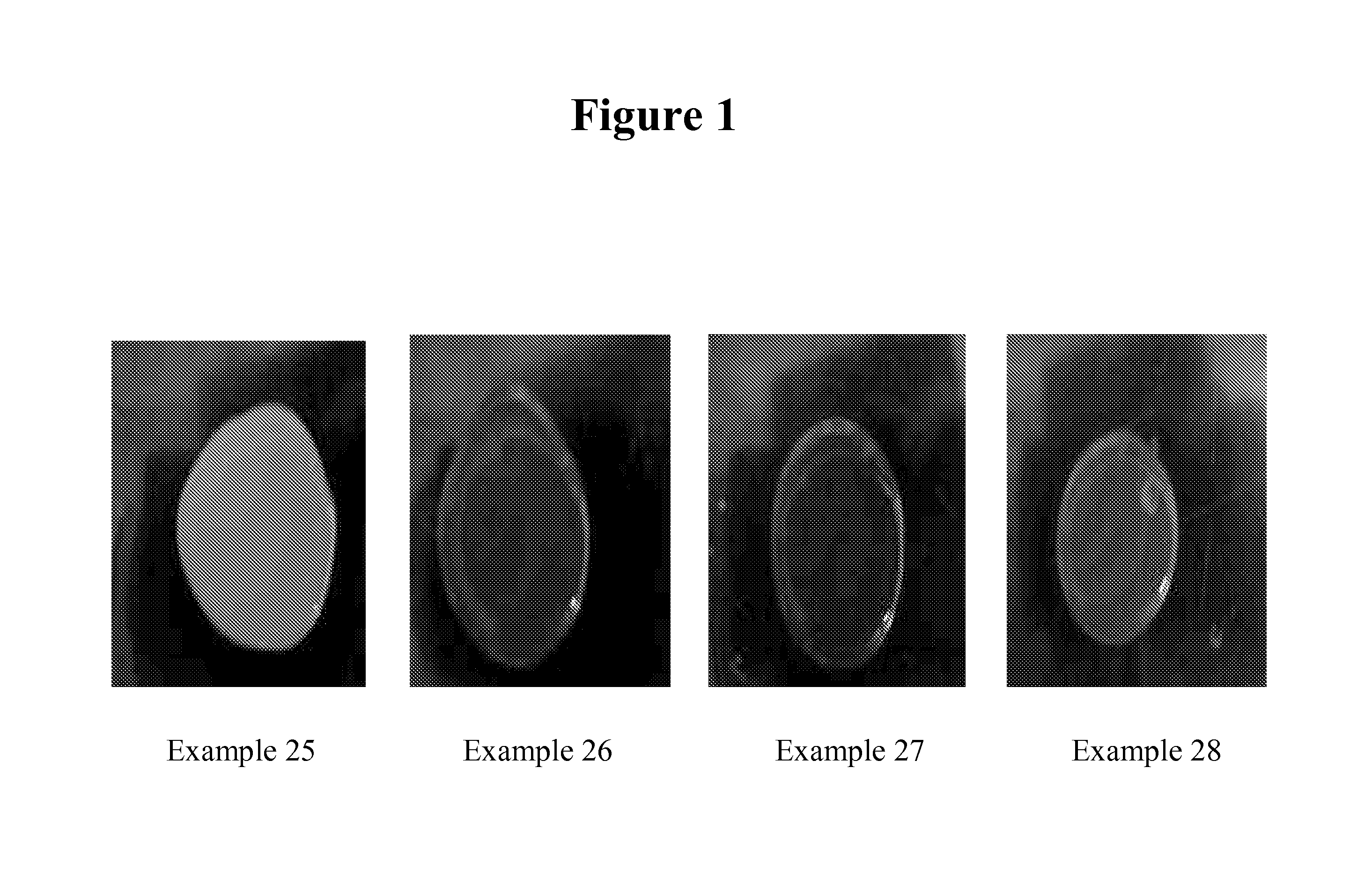

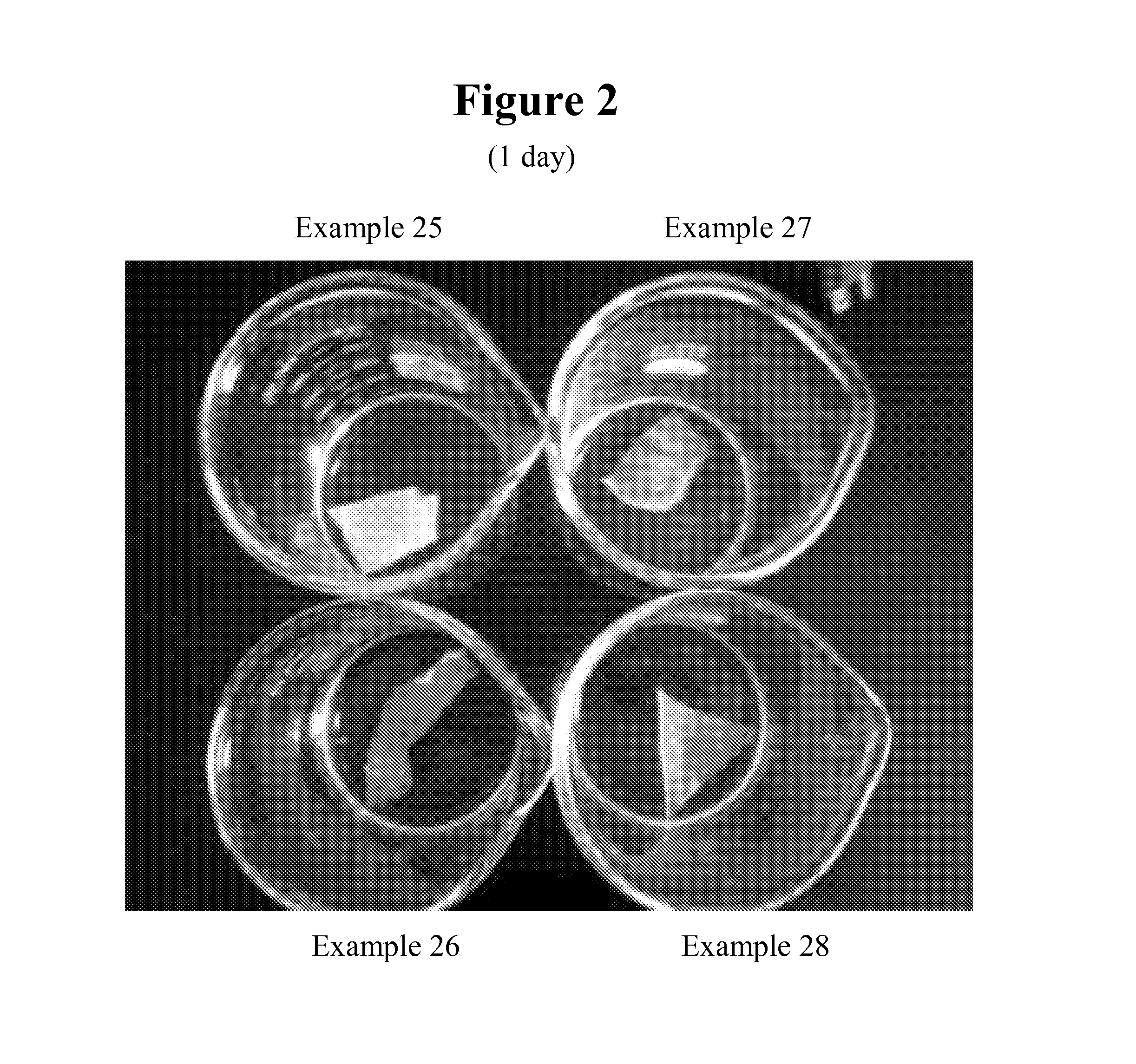

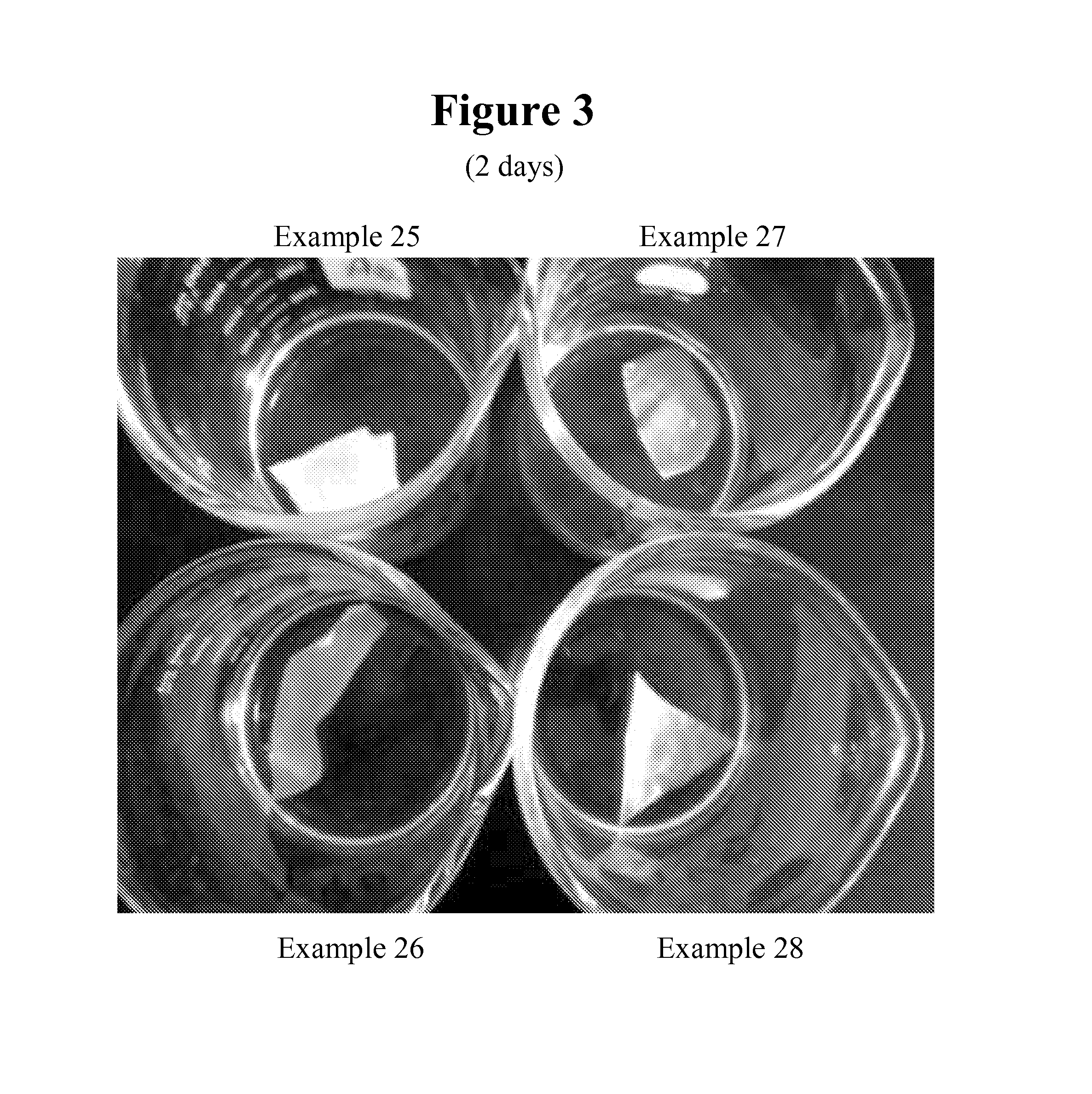

Polyethylene compositions having high dimensional stability and excellent processability for caps and closures

ActiveUS9074082B2Isotropic shrinkage ratioShrinkage differentialCapsClosure capsCompression moldingPolymer science

A dual reactor solution polymerization process gives high density polyethylene compositions containing a first ethylene copolymer and a second ethylene copolymer and which have high dimensional stability, excellent processability as well as good organoleptic properties and reasonable stress cracking resistance. The polyethylene compositions are suitable for compression molding or injection molding applications and are useful, for example, in the manufacture of caps and closures for bottles, and for example, in bottles containing non-pressurized liquids.

Owner:NOVA CHEM (INT) SA

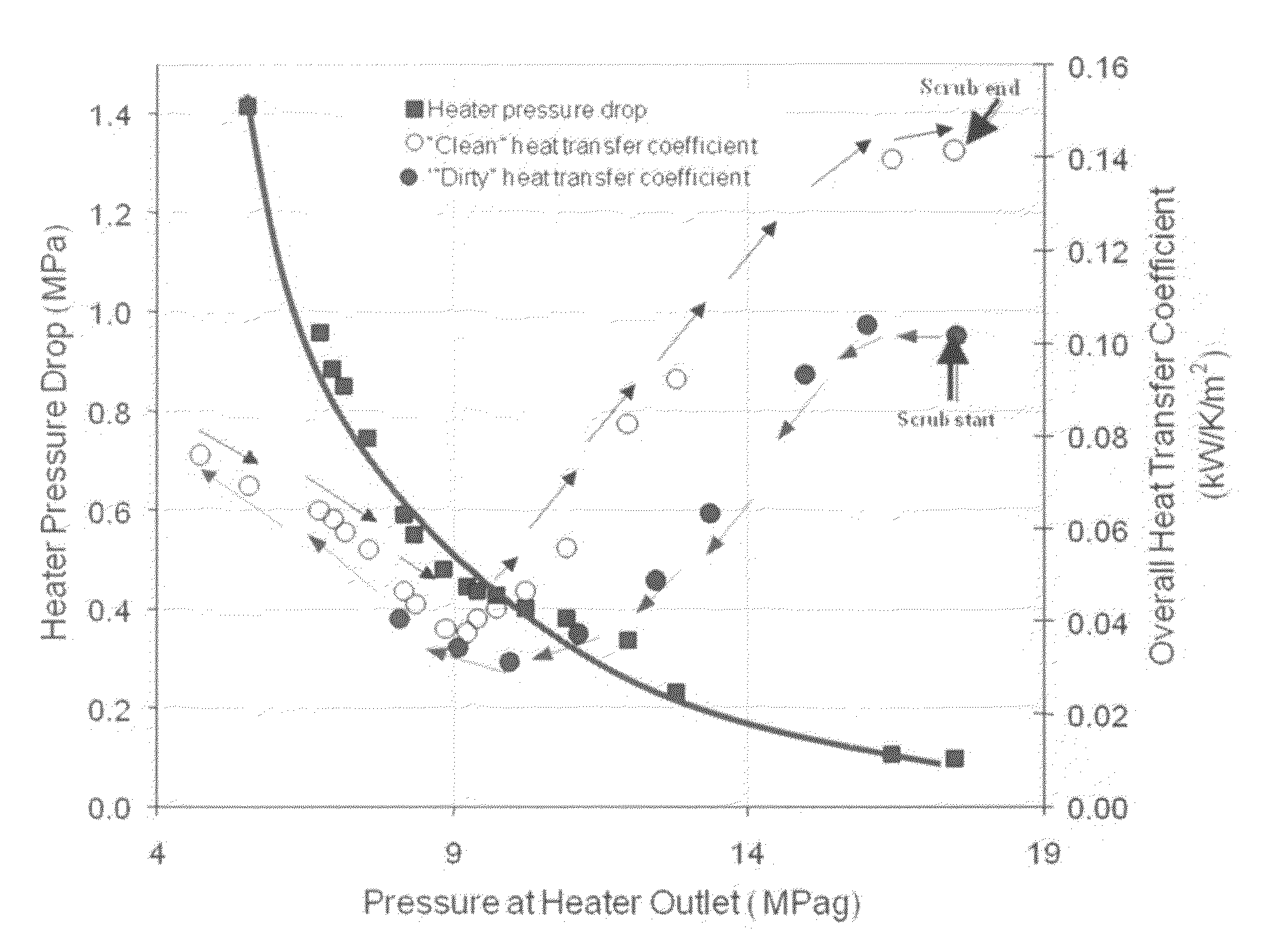

High temperature process for solution polymerization

ActiveUS7650930B2Avoid accumulationIncrease forceHollow article cleaningVapor condensationPlate heat exchangerEmulsion polymerization

A process for the solution polymerization of olefins with improved on-stream time is provided. The solution polymerization process of the current invention comprises a method for the on-line removal of foulant material from one or more heat exchangers downstream of a polymerization reactor. Removal of foulant material is accomplished by deliberately applying a positive pressure differential across a heat exchanger. In the process of the current invention, reactor shut down is not required for the purpose of cleaning foulant material from a heat exchanger.

Owner:NOVA CHEM (INT) SA

Water-based non-isocyanate polyurethane and preparation method thereof

The invention provides water-based non-isocyanate polyurethane (NIPU) and a preparation method thereof. The water-based non-isocyanate polyurethane provided by the invention is water-dispersed or water-soluble resin prepared with cyclic carbonate functionalized prepolymer and dual or multi-element amino compounds. Compared with the traditional polyurethane, the water-based non-isocyanate polyurethane contains no isocyanate and thus has no toxicity. Therefore, the water-based non-isocyanate polyurethane can be used as film-forming resin for a water-based coating. The preparation method comprises the following steps: polymerization of one or a plurality of unsaturated monomer(s) containing cyclic carbonate groups and a hydrophilic unsaturated monomer through free radical solution, neutralization and emulsification for preparation of a water dispersion of cyclic carbonate functionalized prepolymer, and reaction of the water-dispersed cyclic carbonate functionalized prepolymer and a dual amino compound or a multi-element amino compound, thereby preparing the dispersion of the water-based non-isocyanate polyurethane (NIPU).

Owner:HUAZHONG UNIV OF SCI & TECH

Reactive surfactants for emulsion polymerization, pigment dispersion, and UV coatings

ActiveUS20130047892A1Reduce the amount requiredIncrease in coating repellencyPigmenting treatmentTransportation and packagingArylEmulsion polymerization

The present invention provides reactive surfactants of the formulaR1O—(CH2CHR2O)x—(CH2CH2O)y—(CH2CHR3O)z—R4 where R1 is either alkyl, aryl, alkylaryl, or aralkylaryl of 8-30 carbon atoms, R2 is —CH2OCH2CH═CH2 (AGE); R3 is either H, CH3, or CH2CH3; R4 is H or —SO3M or —PO3M where M is H or K, Na, NH4, NR4, alkanolamine, or other cationic species and x=2-100; y=4-200 and z=0-50.

Owner:ETHOX CHEM LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com