Patents

Literature

2327 results about "Radical initiator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemistry, radical initiators are substances that can produce radical species under mild conditions and promote radical reactions. These substances generally possess weak bonds—bonds that have small bond dissociation energies. Radical initiators are utilized in industrial processes such as polymer synthesis. Typical examples are halogen molecules, azo compounds, and organic and inorganic peroxides.

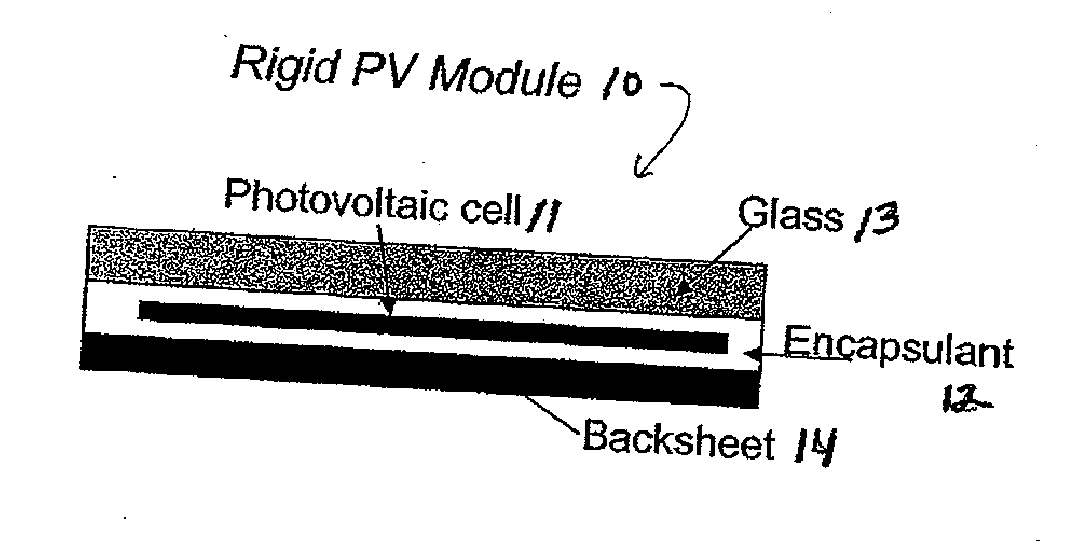

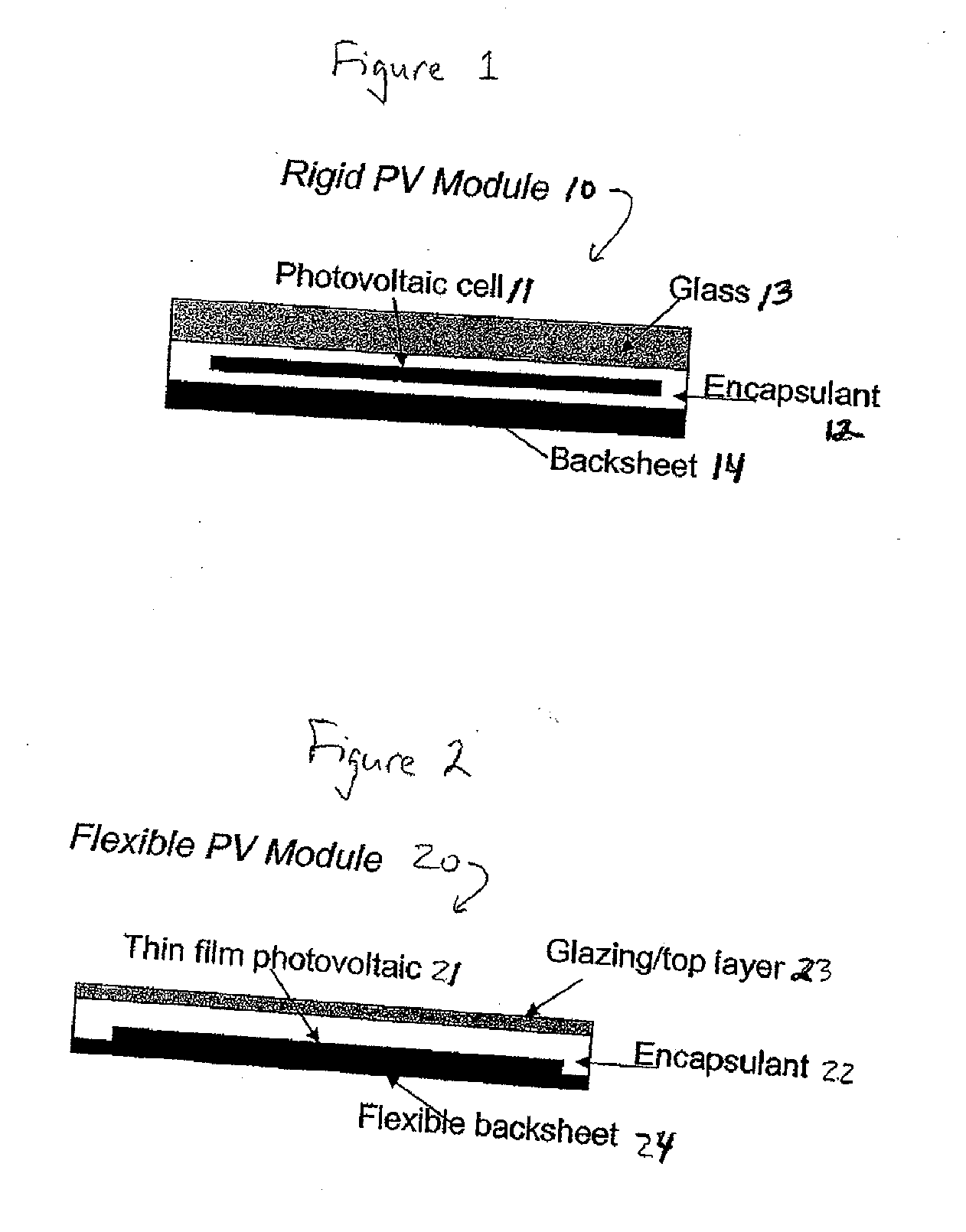

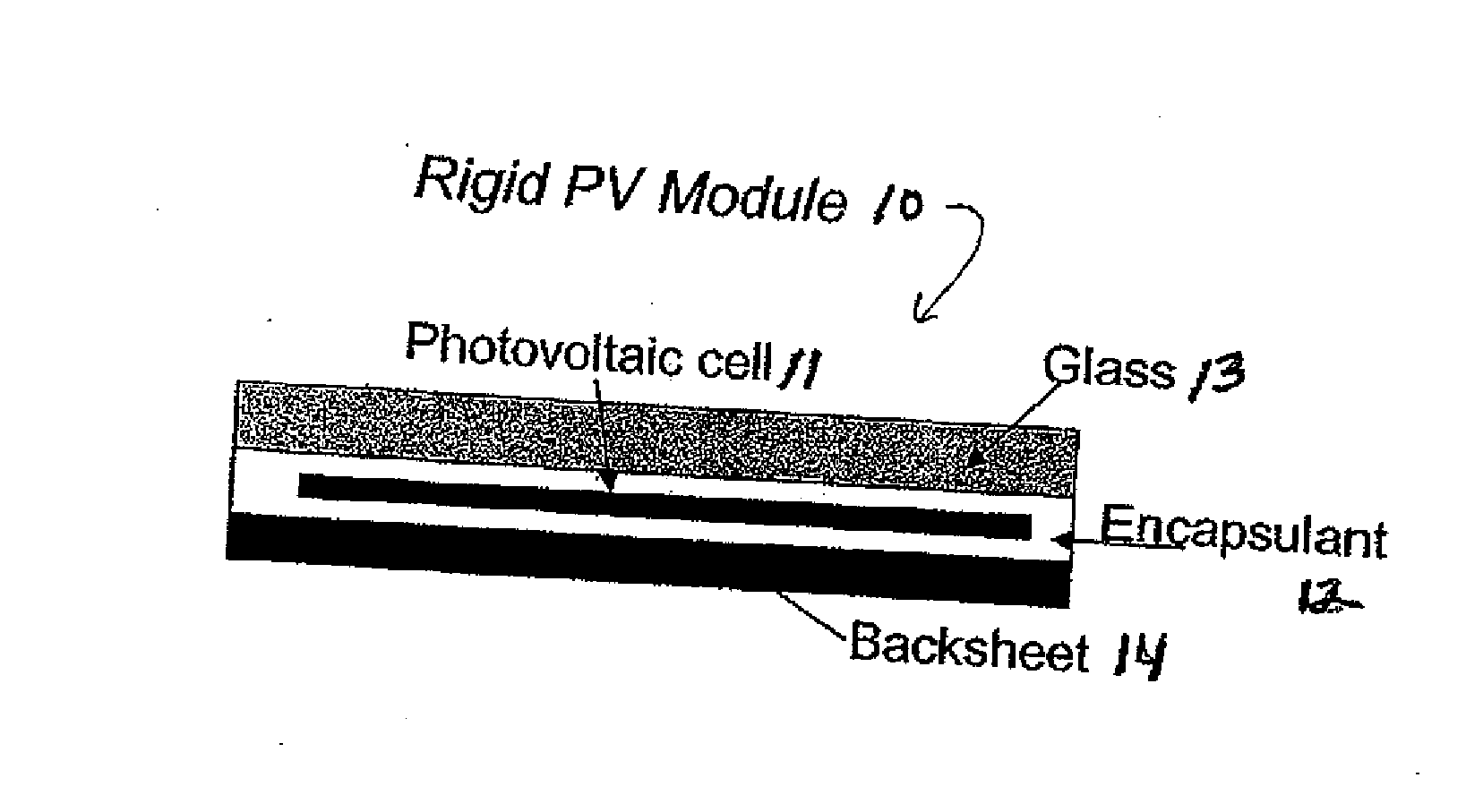

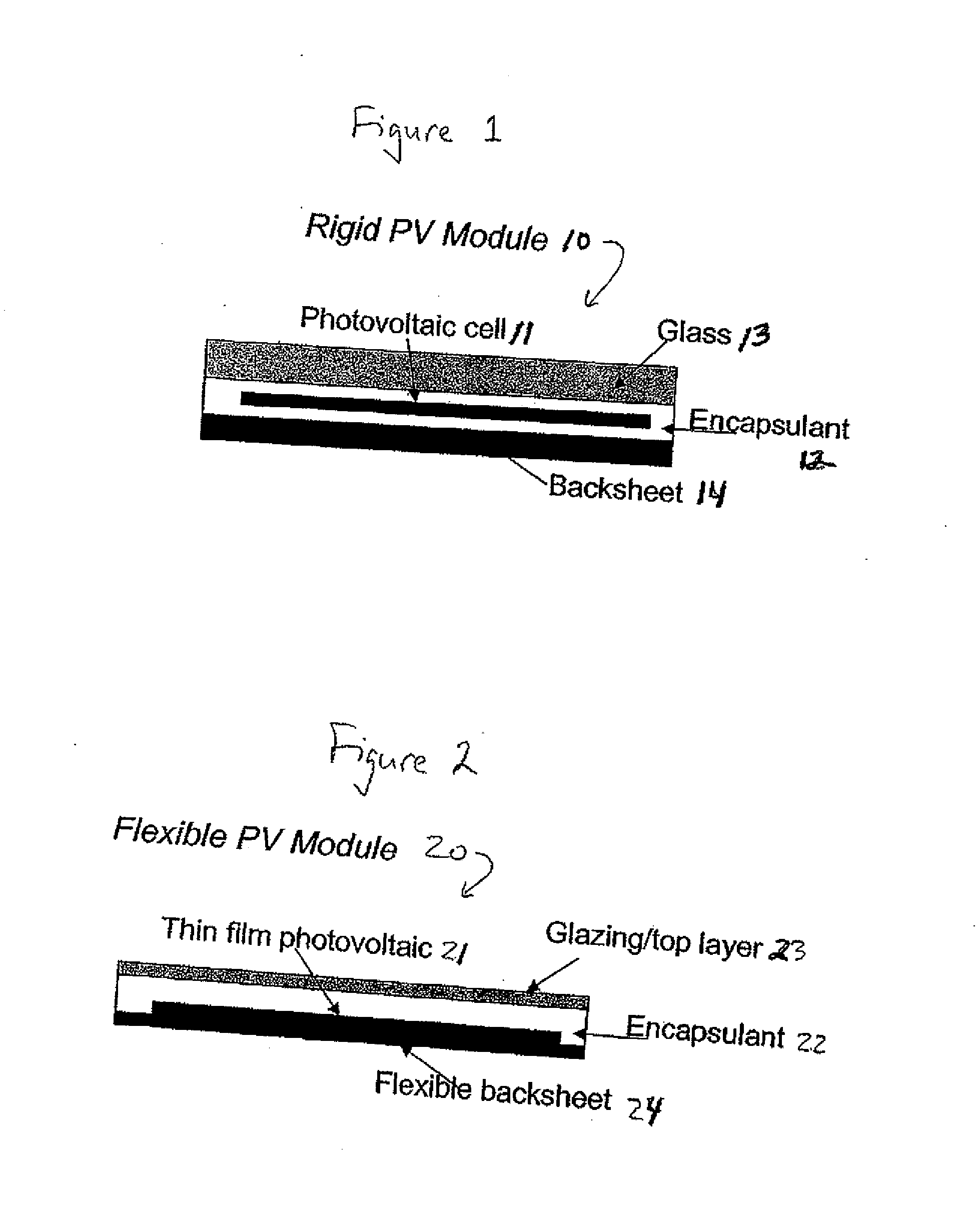

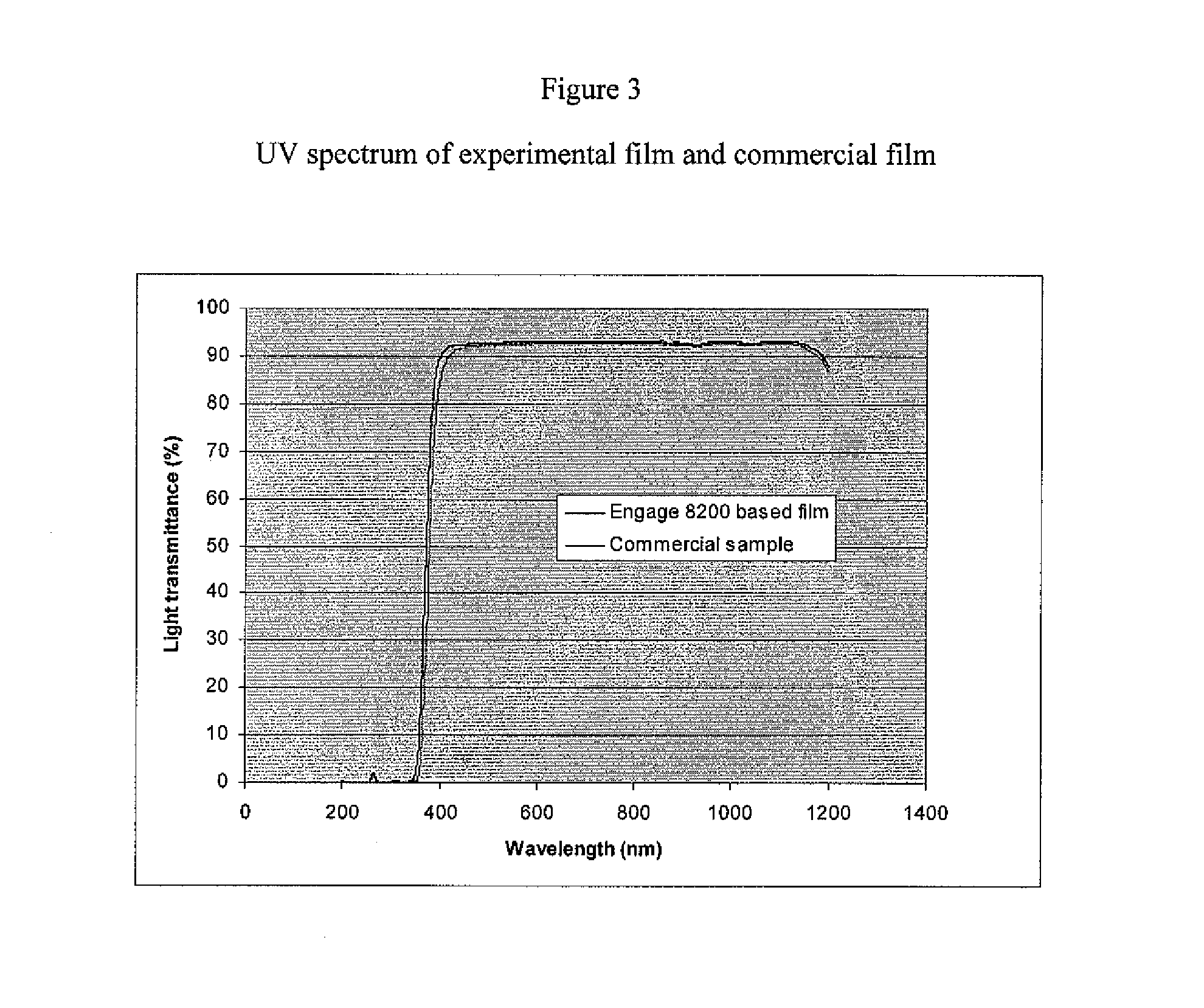

Electronic device module comprising polyolefin copolymer with low unsaturation and optional vinyl silane

InactiveUS20110290317A1Improve adhesionHigh processing temperatureGlass/slag layered productsPhotovoltaic energy generationPolymer sciencePolyolefin

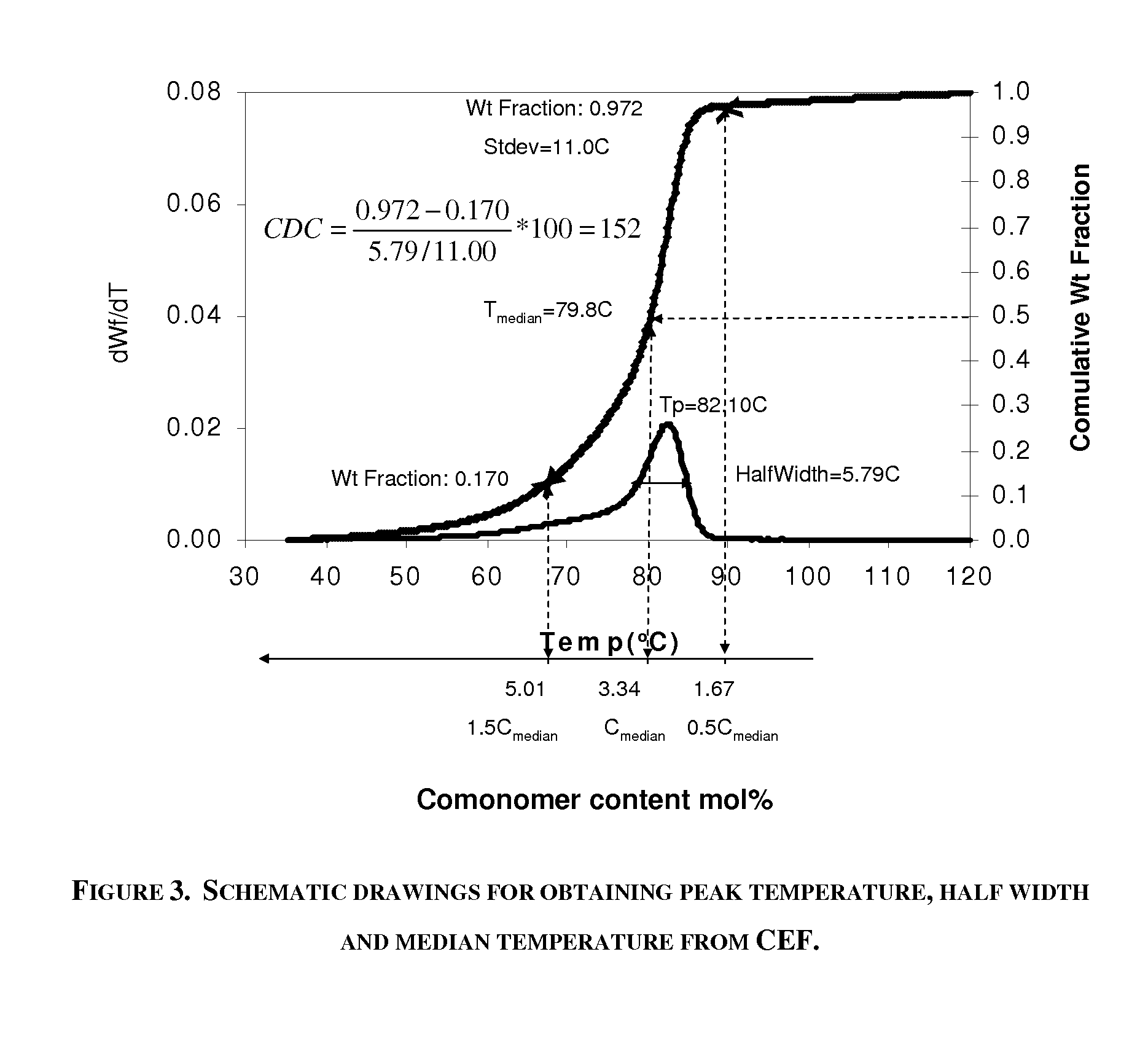

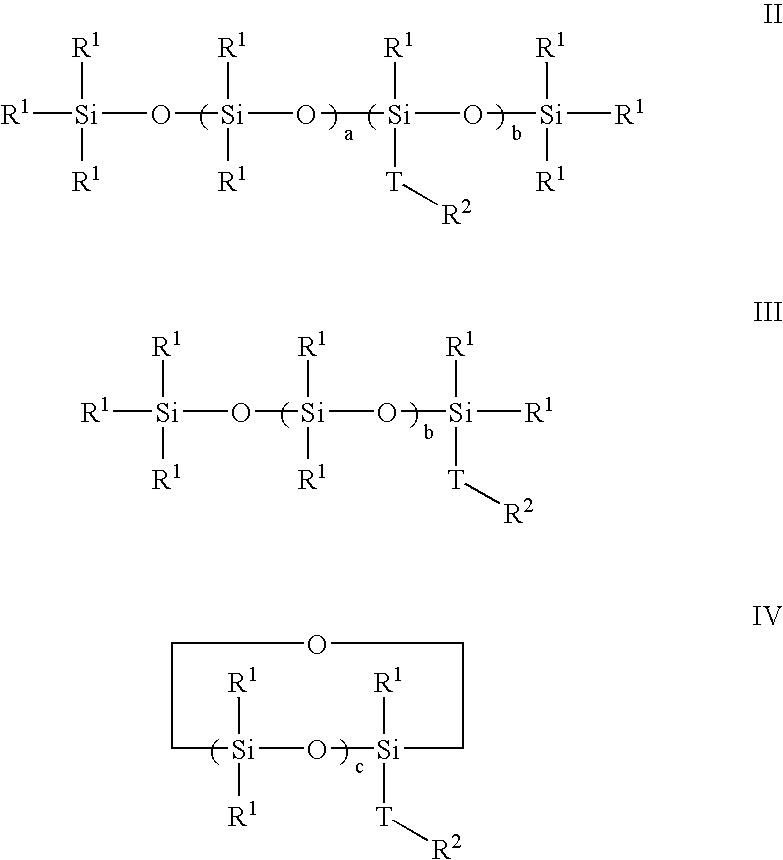

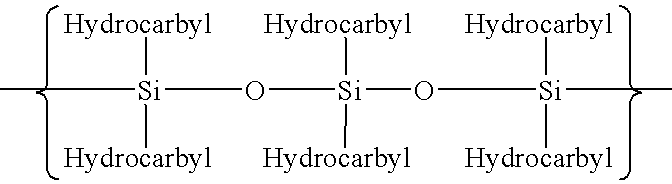

An electronic device module comprising:A. At least one electronic device, e.g., a solar cell, andB. A polymeric material in intimate contact with at least one surface of the electronic device, the polymeric material comprising (1) an ethylene-based polymer composition characterized by a Comonomer Distribution Constant greater than about 45, more preferably greater than 50, most preferably greater than 95, and as high as 400, preferably as high as 200, wherein the composition has less than 120 total unsaturation unit / 1,000,000C, preferably the ethylene-based polymer compositions comprise up to about 3 long chain branches / 1000 carbons, more preferably from about 0.01 to about 3 long chain branches / 1000 carbons; the ethylene-based polymer composition can have a ZSVR of at least 2; the ethylene-based polymer compositions can be further characterized by comprising less than 20 vinylidene unsaturation unit / 1,000,000C; the ethylene-based polymer compositions can have a bimodal molecular weight distribution (MWD) or a multi-modal MWD; the ethylene-based polymer compositions can have a comonomer distribution profile comprising a mono or bimodal distribution from 35° C. to 120° C., excluding purge; the ethylene-based polymer compositions can comprise a single DSC melting peak; the ethylene-based polymer compositions can comprise a weight average molecular weight (Mw) from about 17,000 to about 220,000, (2) optionally, a vinyl silane, (3) optionally, a free radical initiator, e.g., a peroxide or azo compound, or a photoinitiator, e.g., benzophenone, and (4) optionally, a co-agent.

Owner:NAUMOVITZ JOHN +3

Polymerization of halogen-containing monomers using siloxane surfactant

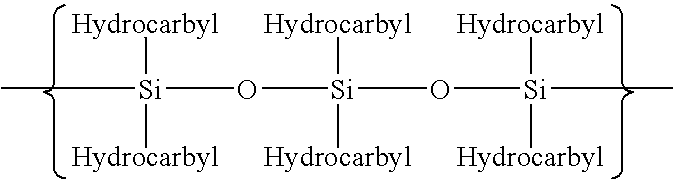

Halogenated polymers are prepared by a process comprising polymerizing at least one halogen-containing monomer in an aqueous medium containing monomer, radical initiator, and siloxane surfactant. The medium may optionally contain one or more of an antifoulant, a buffering agent and a chain-transfer agent.

Owner:ARKEMA INC

Photopolymerizable biodegradable hydrogels as tissue contacting materials and controlled-release carriers

InactiveUS6306922B1Fast gelationRapid polymerizationImmobilised enzymesPowder deliveryThermal energyUltraviolet lights

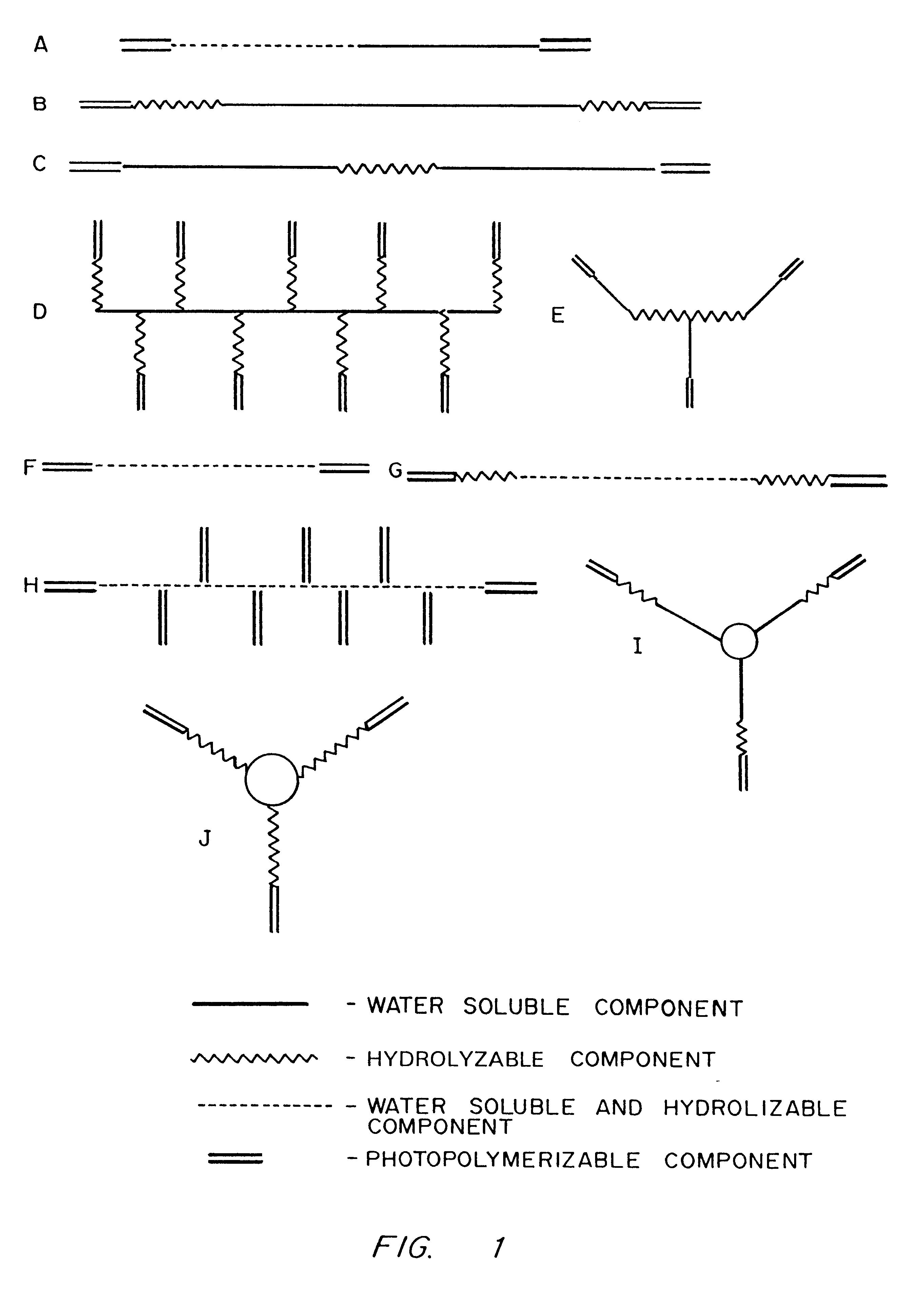

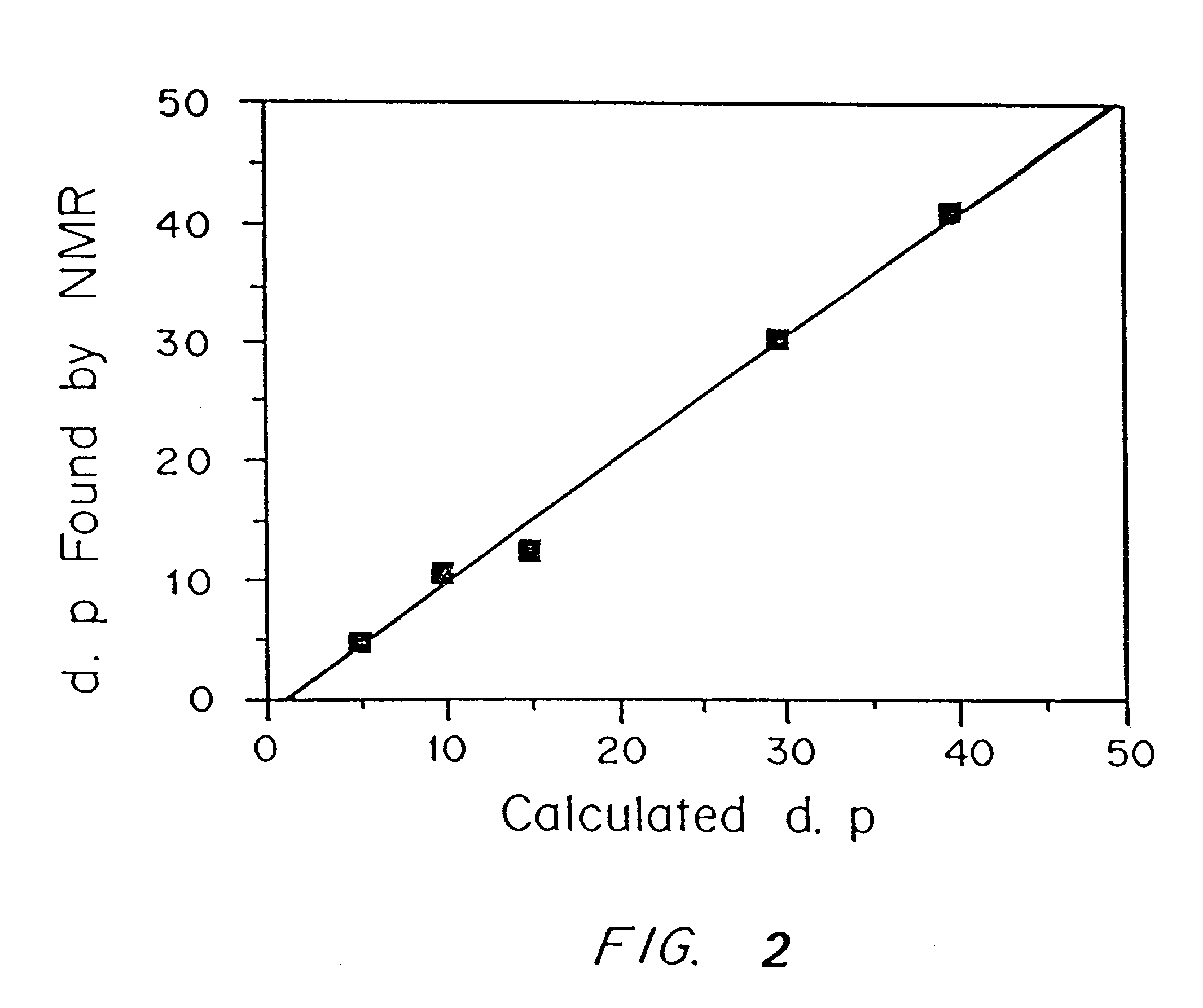

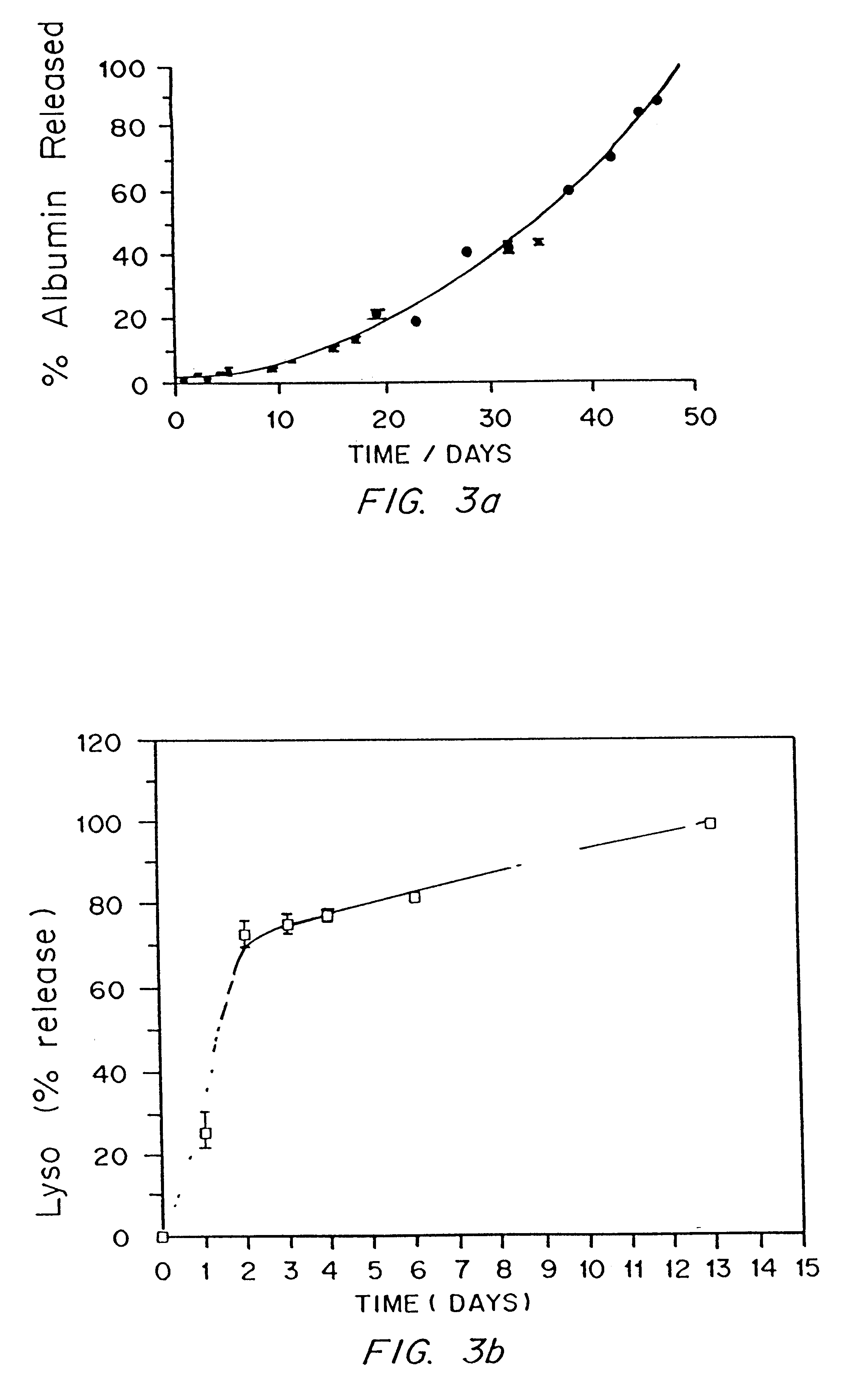

Hydrogels of polymerized and crosslinked macromers comprising hydrophilic oligomers having biodegradable monomeric or oligomeric extensions, which biodegradable extensions are terminated on free ends with end cap monomers or oligomers capable of polymerization and cross linking are described. The hydrophilic core itself may be degradable, thus combining the core and extension functions. Macromers are polymerized using free radical initiators under the influence of long wavelength ultraviolet light, visible light excitation or thermal energy. Biodegradation occurs at the linkages within the extension oligomers and results in fragments which are non-toxic and easily removed from the body. Preferred applications for the hydrogels include prevention of adhesion formation after surgical procedures, controlled release of drugs and other bioactive species, temporary protection or separation of tissue surfaces, adhering of sealing tissues together, and preventing the attachment of cells to tissue surfaces.

Owner:BOARD OF REGENTS

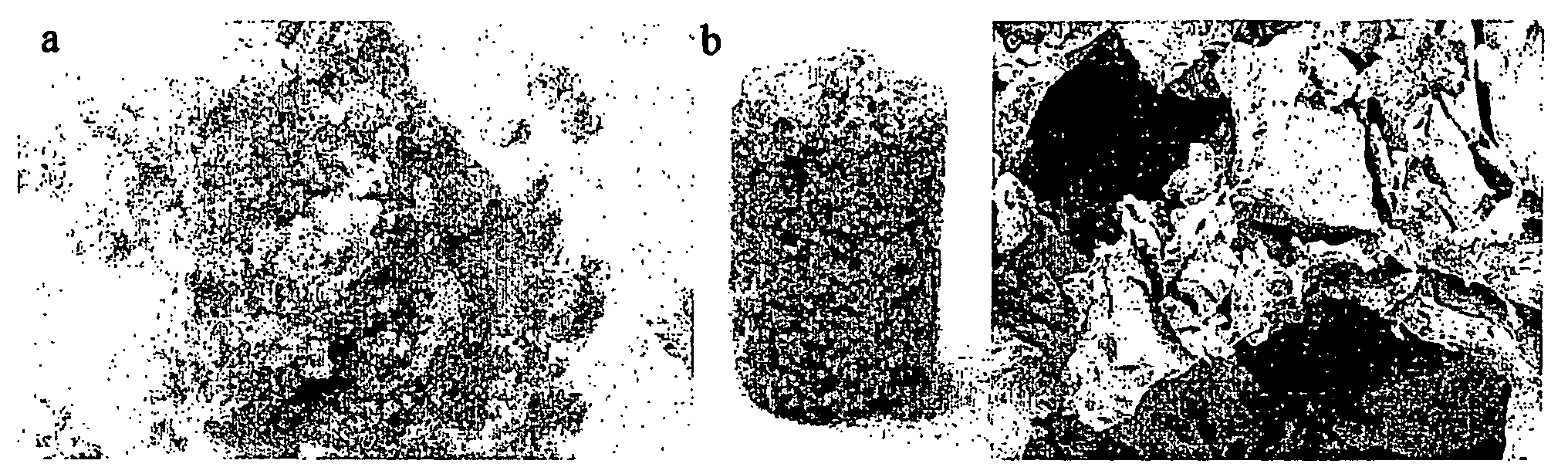

Elastomeric material compositions obtained from castor oil and epoxidized soybean oil

Elastomers are formed from castor oil and / or ricinoleic acid estolides and a polyester formed from an epoxidized vegetable oil such as ESO and a polycarboxylic acid such as sebacic acid, optionally in the presence of a peroxide initiator, or include crosslinked reaction products derived from ricinoleic acid or castor oil estolides, epoxy group-containing compounds such as epoxy resins and / or epoxidized vegetable oil, epoxy hardeners such as polyamine and polycarboxylic acid hardeners, thermally activated free radical initiators such as peroxides, and optionally but preferably include fillers such as limestone or wood flour. The elastomers can be prepared using a two-step, solvent-less procedure at elevated or ambient temperatures. These predominantly “all-natural” elastomers have physical properties comparable to conventional petroleum-based elastomers and composites and exhibit good flexibility, resiliency, abrasion resistance and inertness to hydrolysis. The resulting elastomers display good mechanical strength and resiliency, are resistant to abrasion and hydrolysis, and can be processed into sheet materials, which makes them attractive as floor covering components.

Owner:AFI LICENSING +1

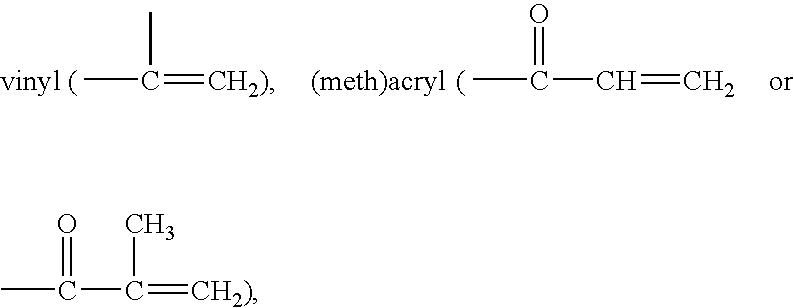

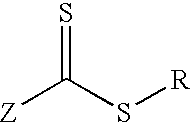

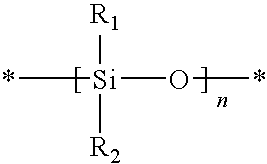

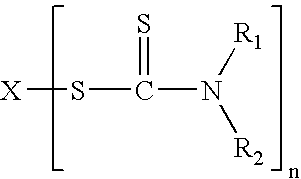

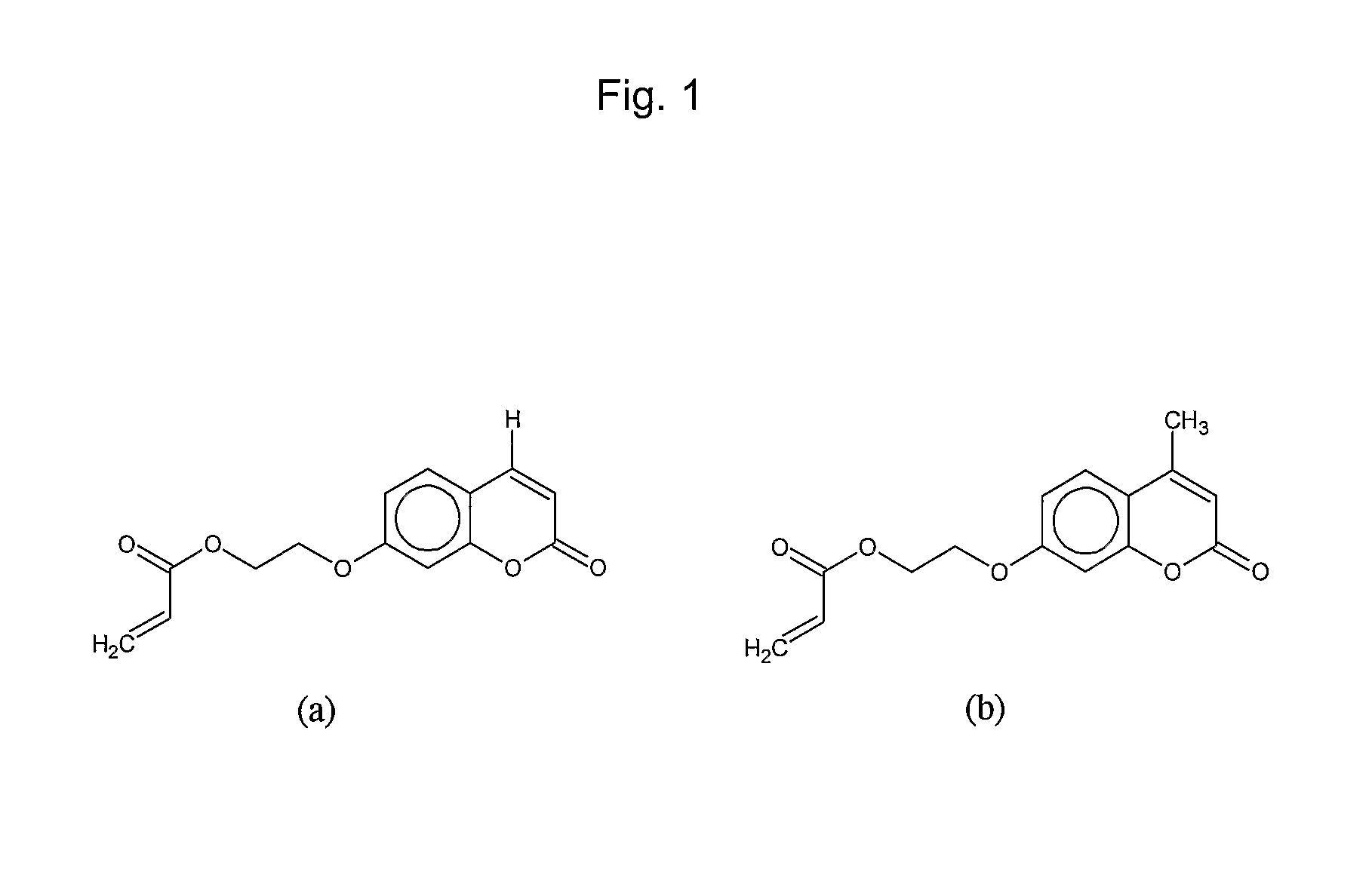

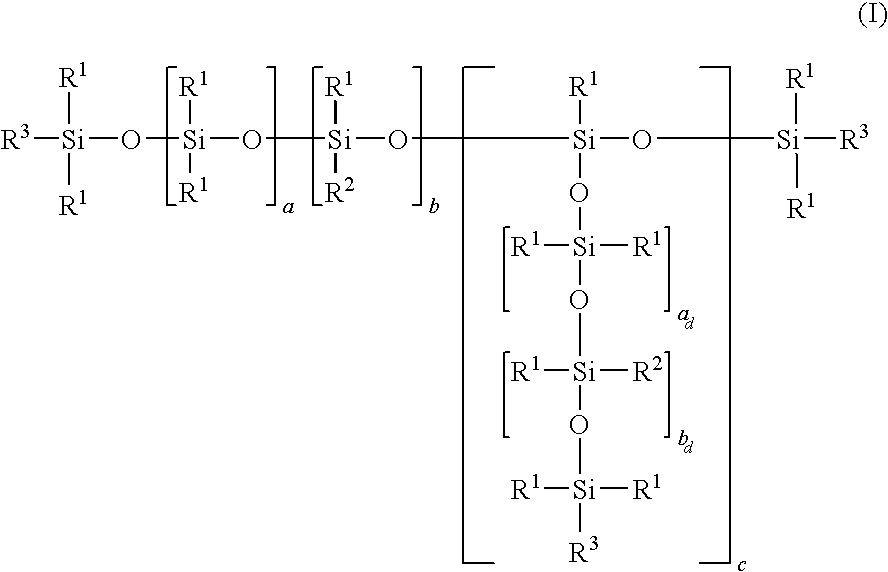

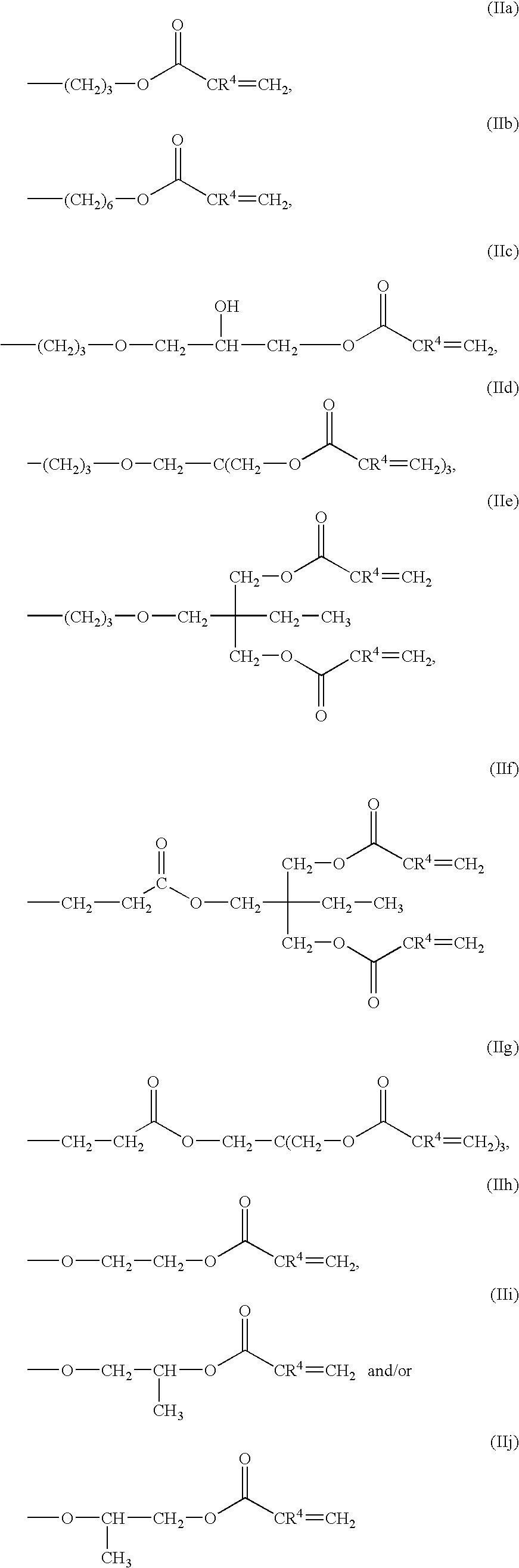

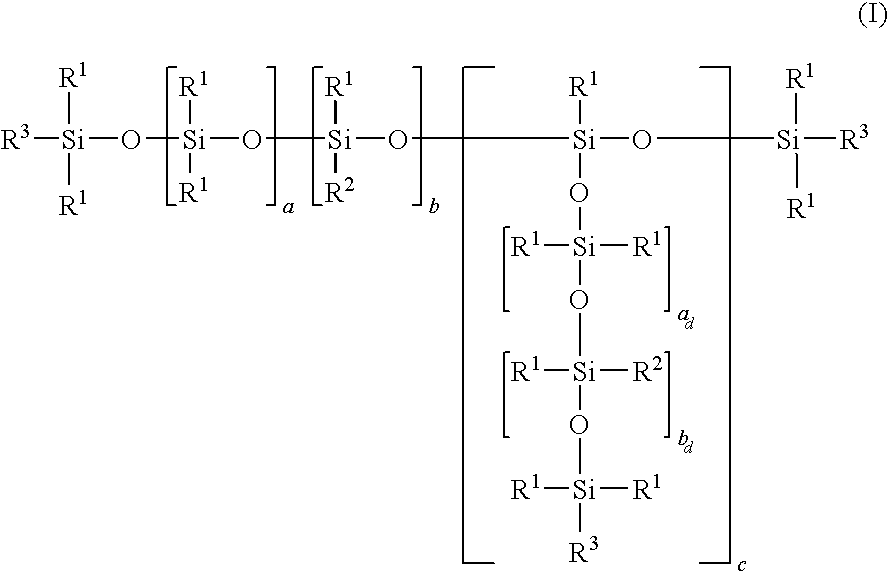

Actinically-crosslinkable siloxane-containing copolymers

The invention provide a class of actinically-crosslinkable silicone-containing prepolymers which comprise dangling polysiloxane chains each having a terminal ethylenically-unsaturated group and are obtained in a one-step of RAFT polymerization of a reactive mixture comprising a polysiloxane crosslinker, a hydrophilic vinylic monomer, a RAFT agent, and a free-radical initiator. The present invention is also related to silicone hydrogel contact lenses made from a prepolymer of the invention and methods for making the contact lenses in a cost-effective way and with high consistency and high fidelity to the original lens design.

Owner:ALCON INC

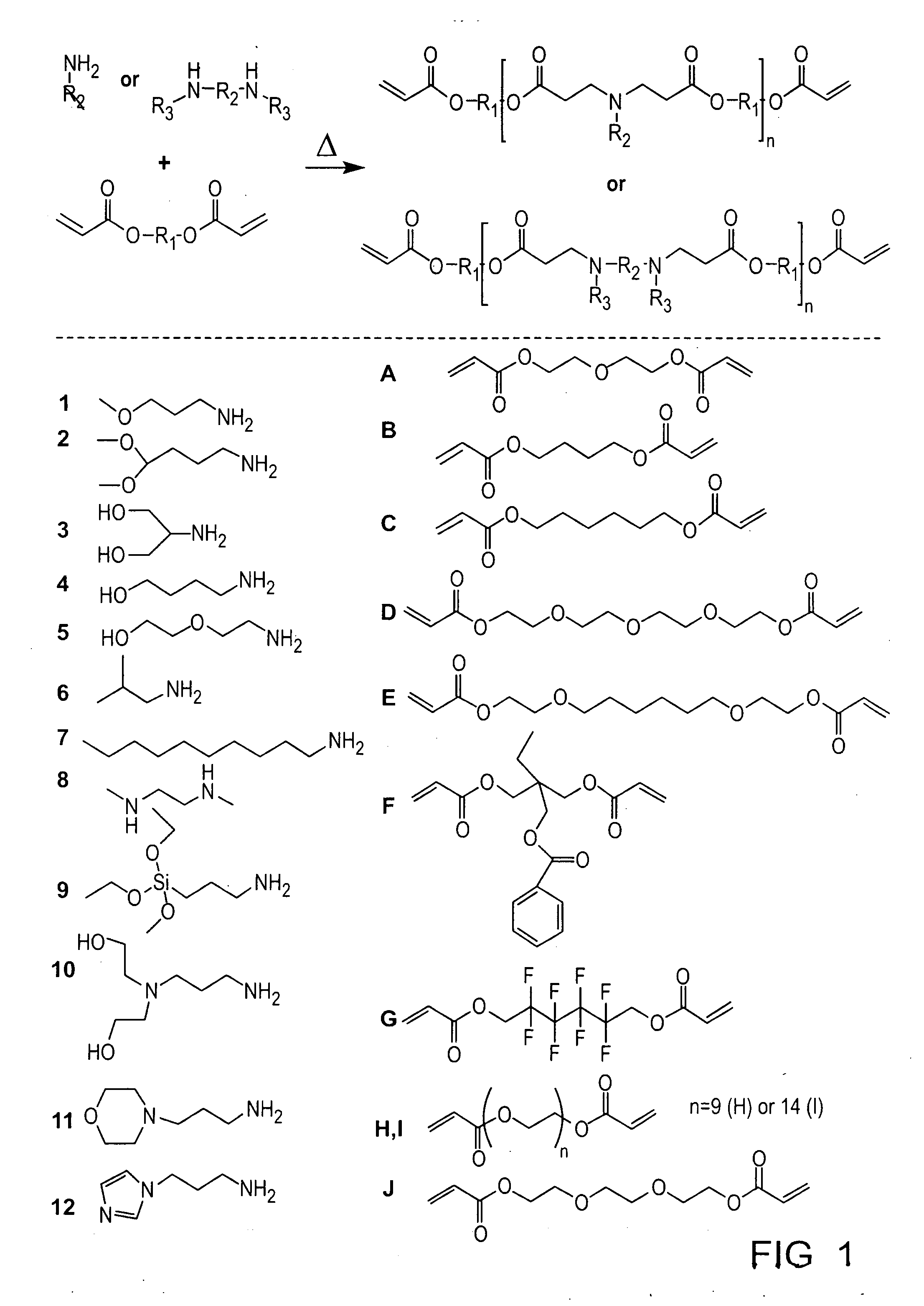

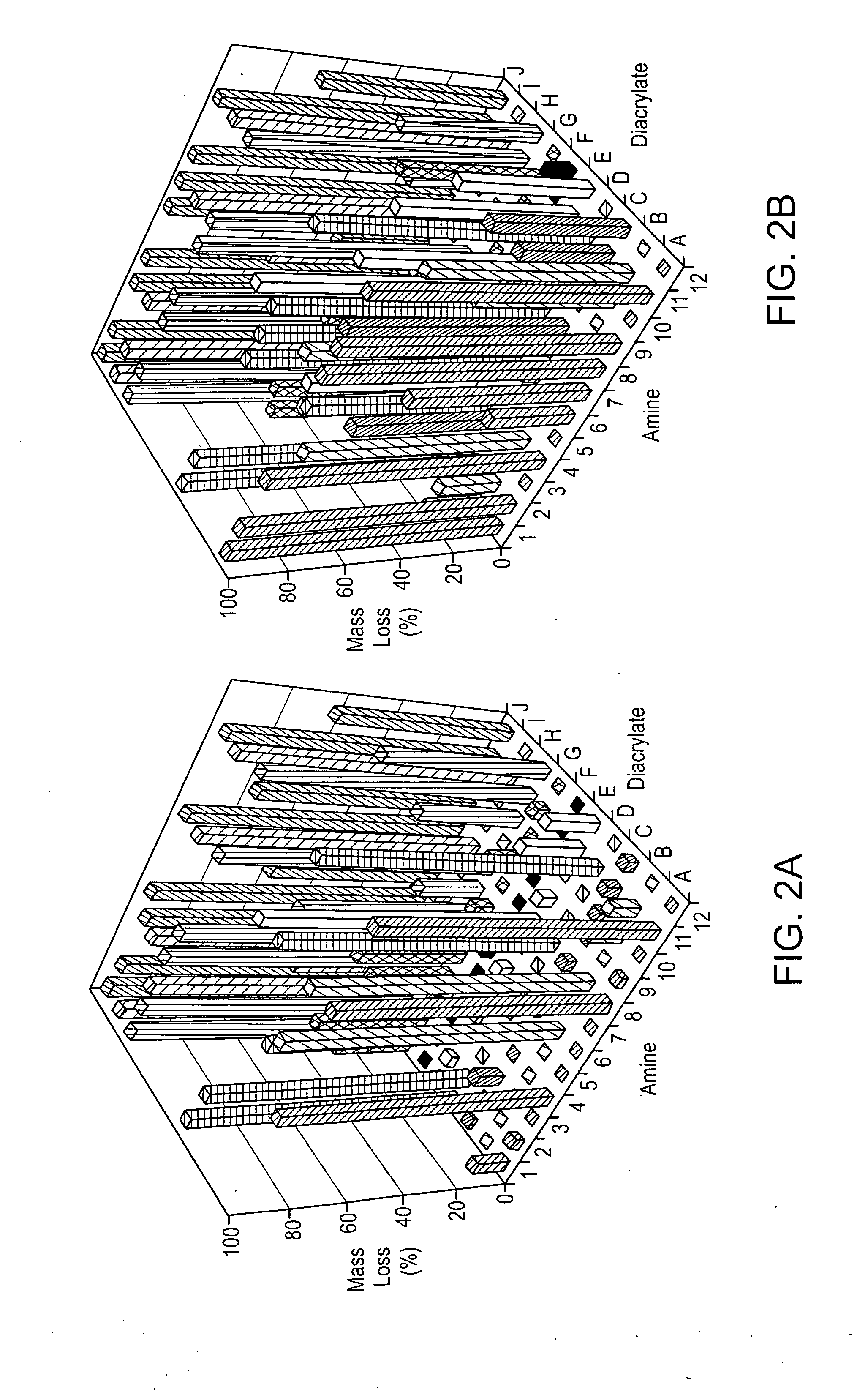

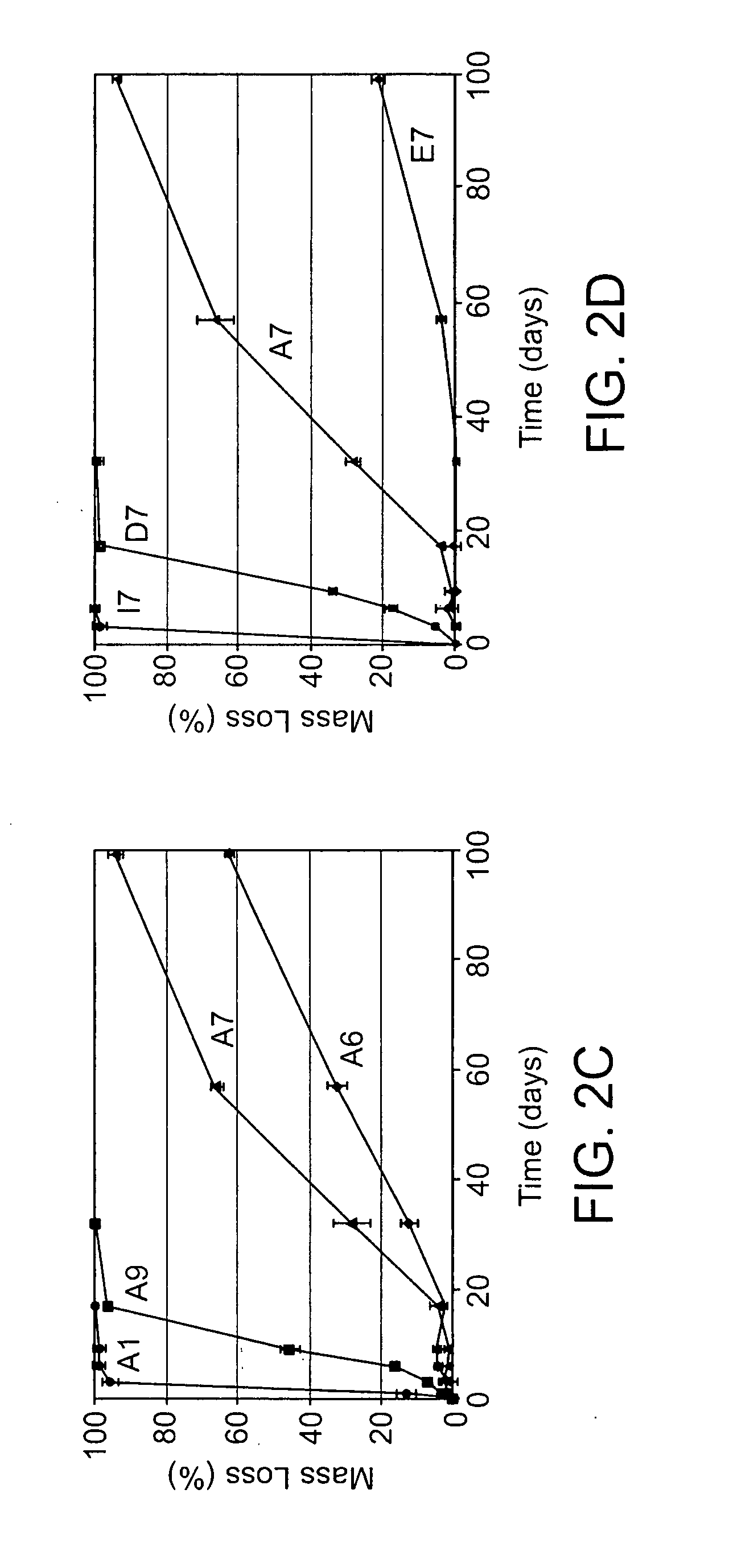

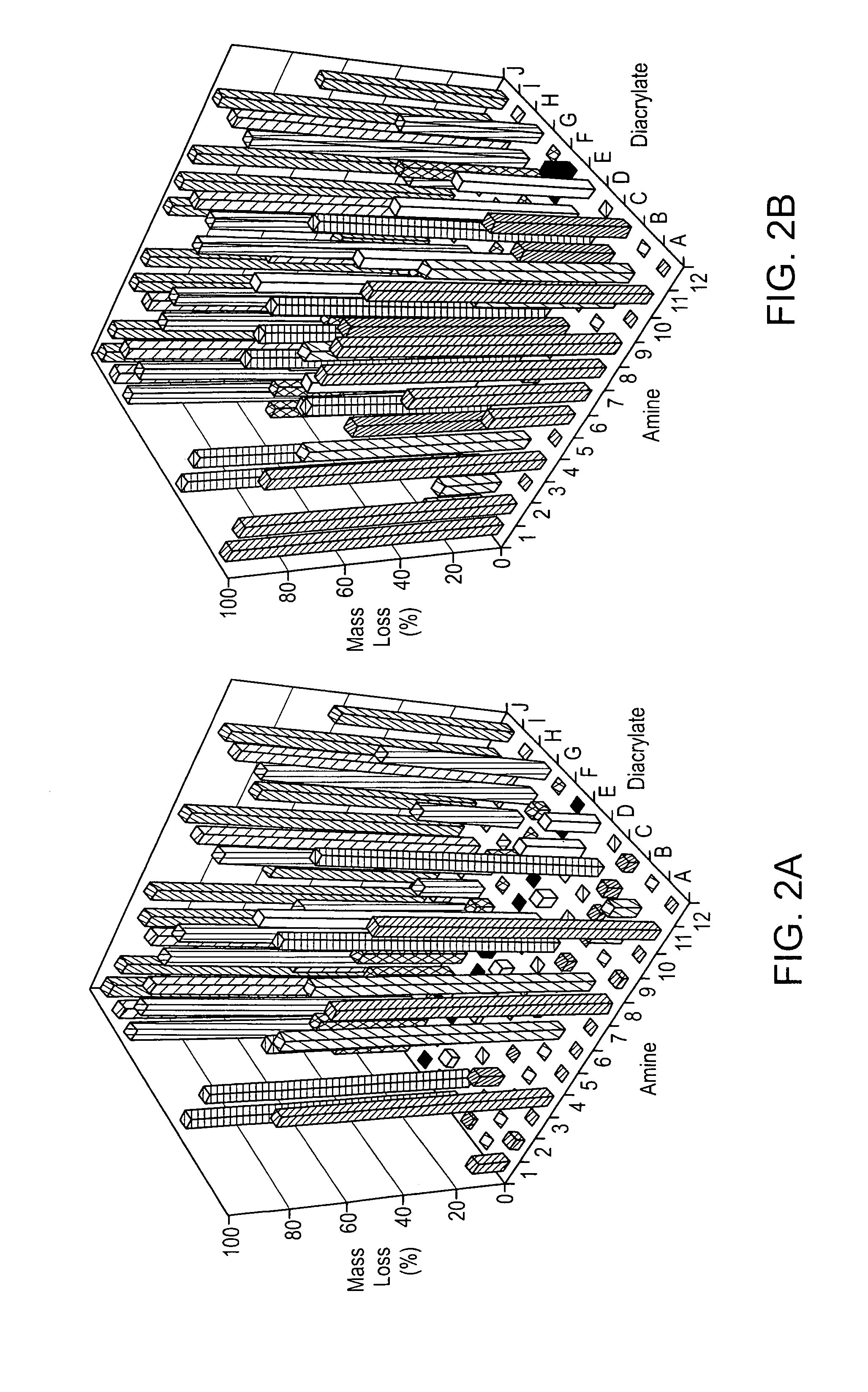

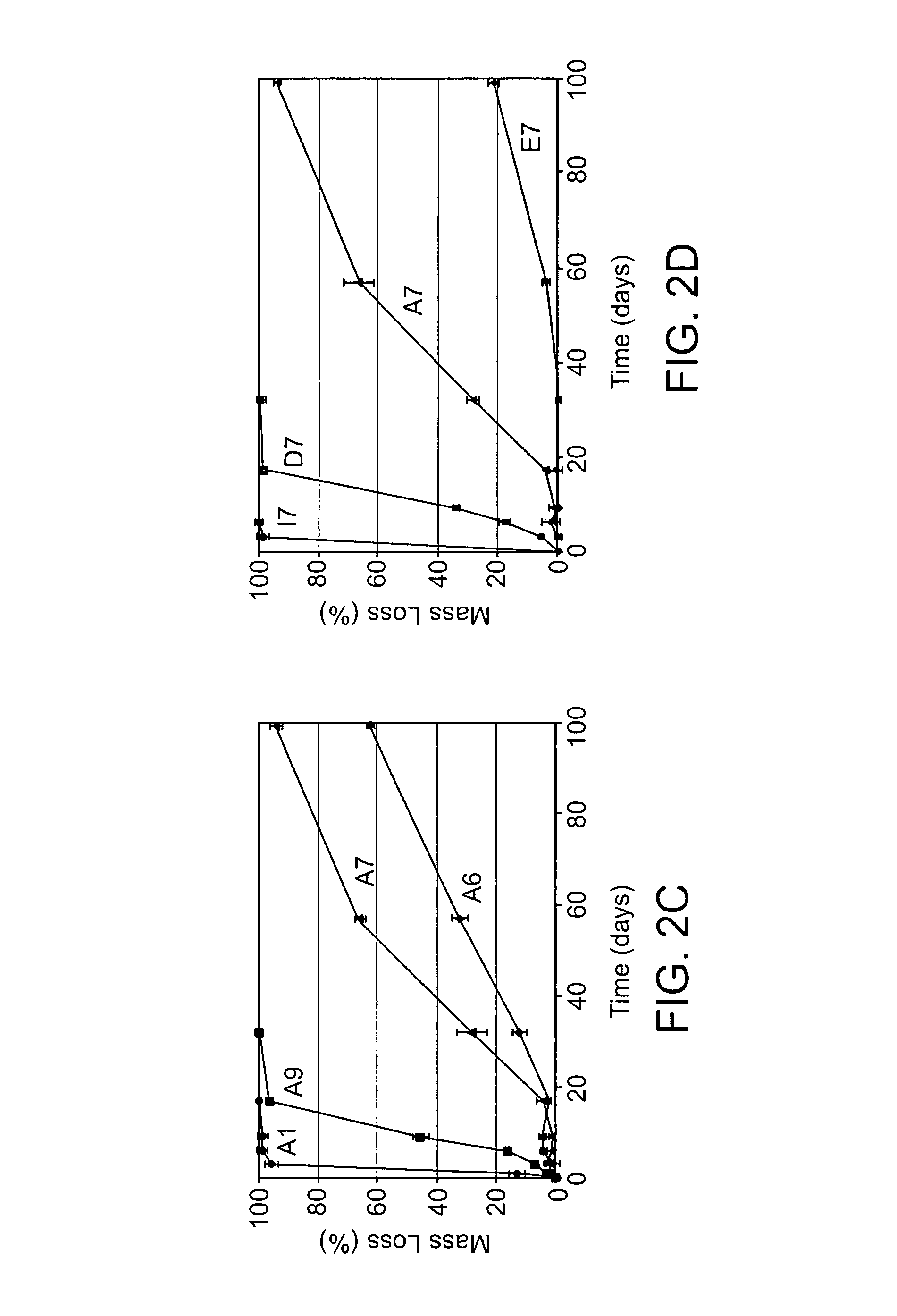

Crosslinked, degradable polymers and uses thereof

Acrylate-terminated poly(beta-amino esters) are cross-linked to form materials useful in the medical as well as non-medical field. The polymeric starting material is combined with a free radical initiator, either a thermal initiator or a photoinitiator, and the mixture for cross-linking is heated or exposed to light depending on the initiator used. The resulting materials due to the hydrolysable ester bond in the polymer backbone are biodegradable under physiological conditions. These cross-linked materials are particular useful as drug delivery vehicles, tissue engineering scaffolds, and in fabricating microdevices. The materials may also be used as plastics, coating, adhesives, inks, etc. The cross-linked materials prepared exhibit a wide range of degradation times, mass loss profiles, and mechanical properties. Therefore, the properties of the material may be tuned for the desired use. The high-throughput approach to preparing a library of cross-linked poly(beta-amino esters) allows for the rapid screening and design of degradable polymers for a variety of applications.

Owner:MASSACHUSETTS INST OF TECH

Polymerization processes

A process for the preparation of a latex polymer by(i) preparing or providing a water aqueous phase containing an anionic surfactant in an optional amount of less than or equal to about 20 percent by weight of the total amount of anionic surfactant used in forming the latex polymer;(ii) preparing or providing a monomer emulsion in water which emulsion contains an anionic surfactant;(iii) adding about 50 percent or less of said monomer emulsion to said aqueous phase to thereby initiate seed polymerization and to form a seed polymer, said aqueous phase containing a free radical initiator; and(iv) adding the remaining percent of said monomer emulsion to the composition of (iii) and heating to complete an emulsion polymerization thus forming a latex polymer.

Owner:XEROX CORP

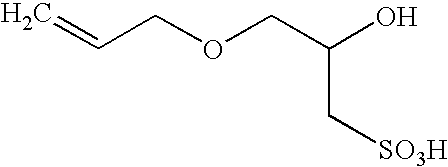

Polymerization of fluoromonomers using a 3-allyloxy-2-hydroxy-1-propanesulfonic acid salt as surfactant

InactiveUS6869997B2Reduce the binding forceOrganic chemistryFibre treatmentFluoropolymerBuffering agent

Fluoropolymers are prepared by a process comprising polymerizing at least one fluoromonomer in an aqueous reaction medium containing monomer, a radical initiator and a 3-allyloxy-2-hydroxy-1-propanesulfonic acid salt as surfactant. The medium may optionally contain one or more of an antifoulant, a buffering agent and a chain-transfer agent.

Owner:ARKEMA INC

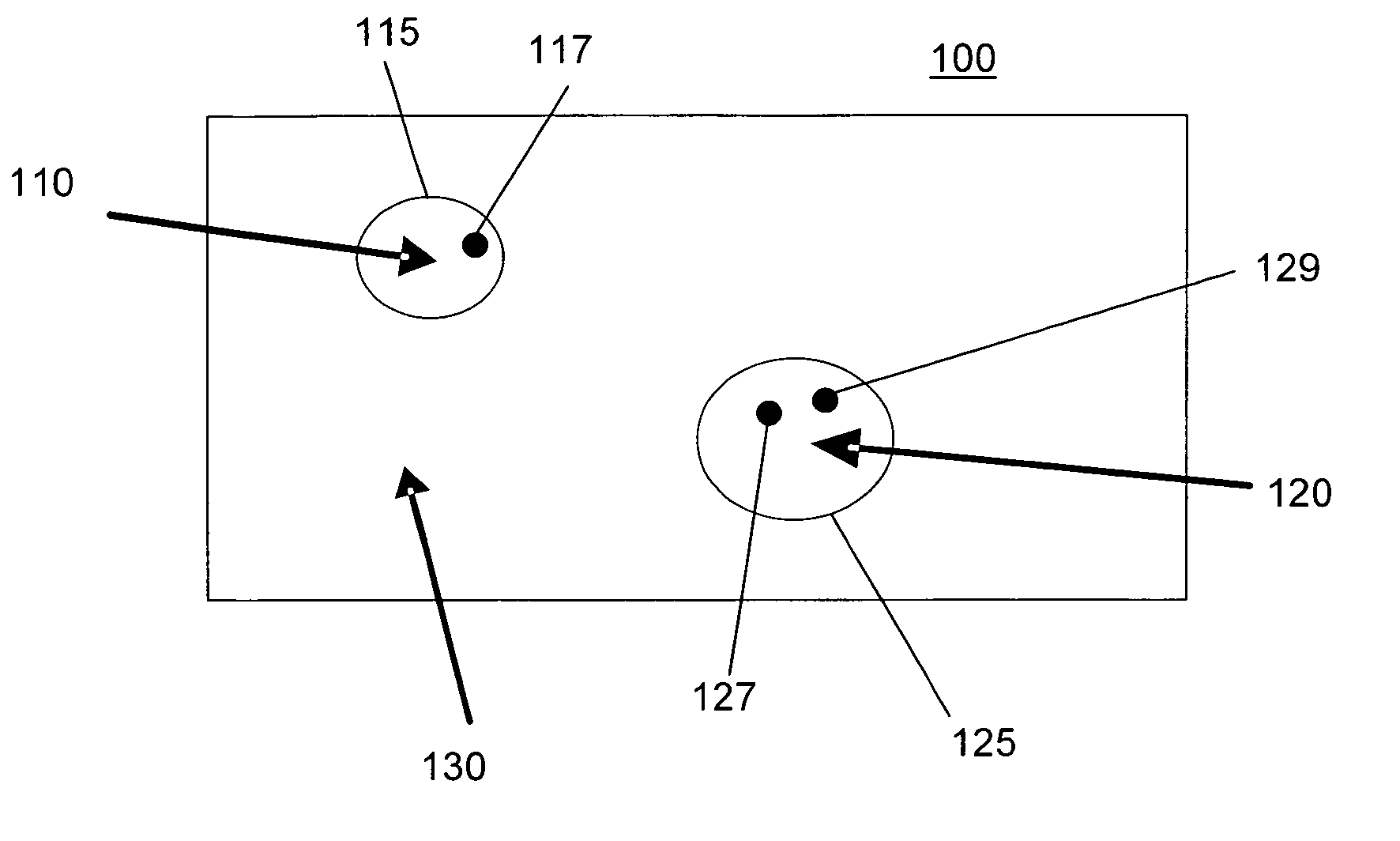

Electronic Device Module Comprising Polyolefin Copolymer

ActiveUS20080078445A1Improve adhesionHigh processing temperaturePV power plantsElectrical equipmentPolyolefinSilanes

An electronic device module comprising: A. At least one electronic device, e.g., a solar cell, and B. A polymeric material in intimate contact with at least one surface of the electronic device, the polymeric material comprising (1) a polyolefin copolymer with at least one of (a) a density of less than about 0.90 g / cc, (b) a 2% secant modulus of less than about 150 megaPascal (mPa) as measured by ASTM D-882-02), (c) a melt point of less than about 95 C, (d) an α-olefin content of at least about 15 and less than about 50 wt % based on the weight of the polymer, (e) a Tg of less than about −35 C, and (f) a SCBDI of at least about 50, (2) optionally, free radical initiator, e.g., a peroxide or azo compound, or a photoinitiator, e.g., benzophenone, and (3) optionally, a co-agent. Typically, the polyolefin copolymer is an ethylene / α-olefin copolymer. Optionally, the polymeric material can further comprise a vinyl silane and / or a scorch inhibitor, and the copolymer can remain uncrosslinked or be crosslinked.

Owner:DOW GLOBAL TECH LLC

Self-Healing dental restorative formulations and related methods

ActiveUS20110071234A1Improve the immunitySpeeds up (accelerates) a chemical reactionImpression capsDentistry preparationsSelf-healingDecomposition

Dental restorative formulations comprising two additives incorporated into the continuous phase of a dental material. One additive contains a capsule with a radical initiator. The other additive contains a capsule with one or more monomers and a radical accelerator. The dental restorative formulation is applied and polymerized to form a composite. When a disturbance occurs in the dental composite, the capsules of the additives rupture so that the radical accelerator of the second capsule decomposes the radical initiator of the first capsule to polymerize the one or more monomers of the second capsule thereby healing the dental composite. The radical accelerator controls the rate of decomposition of the radical initiator.

Owner:PREMIER DENTAL PRODS

Hydrogel Porogents for Fabricating Biodegradable Scaffolds

InactiveUS20080206308A1Rheologic propertyElimination of porogen leaching stepPowder deliveryBiocideBiodegradable scaffoldBiodegradable hydrogels

Hydrogel microparticles with entrapped liquid are used as the porogen to reproducibly form interconnected pore networks in a porous scaffold. In one embodiment, a biodegradable unsaturated polymer, a crosslinking agent, and a porogen comprising biodegradable hydrogel microparticles are mixed together and allowed to form a porous scaffold in an mold or in a body cavity. Example biodegradable unsaturated polymers include poly(propylene fumarate) and poly(e-caprolactone-fumarate). The cosslinking agent may be a free radical initiator, or may include a free radical initiator and a monomer capable of addition polymerization. Example hydrogel microparticles include uncrosslinked or crosslinked collagen , an uncrosslinked or crosslinked collagen derivative, and an uncrosslinked or crosslinked synthetic biodegradable polymer such as oligo(poly(ethylene glycol) fumarate).

Owner:MAYO FOUND FOR MEDICAL EDUCATION & RES

Composition for improving scorch conditions in the preparation of grafted and/or crosslinked polymers and of filled plastics

A composition containing (i) at least one silicon-containing compound, (ii) at least one peroxidic free-radical initiator, and (iii) at least one conjugated hydrocarbon and / or at least one organofunctional silane of the general formula I:R—Xn—C(R)═C(R)—C(R)═C(R)—Xn—Si(R1)m(OR2)(3-m) (I),may be used in the preparation of grafted and / or crosslinked polymers, or of filled plastics, in order to improve scorch performance. Processes for preparing polymers or preparing plastics, and polymers and plastics which are obtainable via the Sioplas process or via the Monosil process, and products produced from them can utilize the composition.

Owner:EVONIK DEGUSSA GMBH

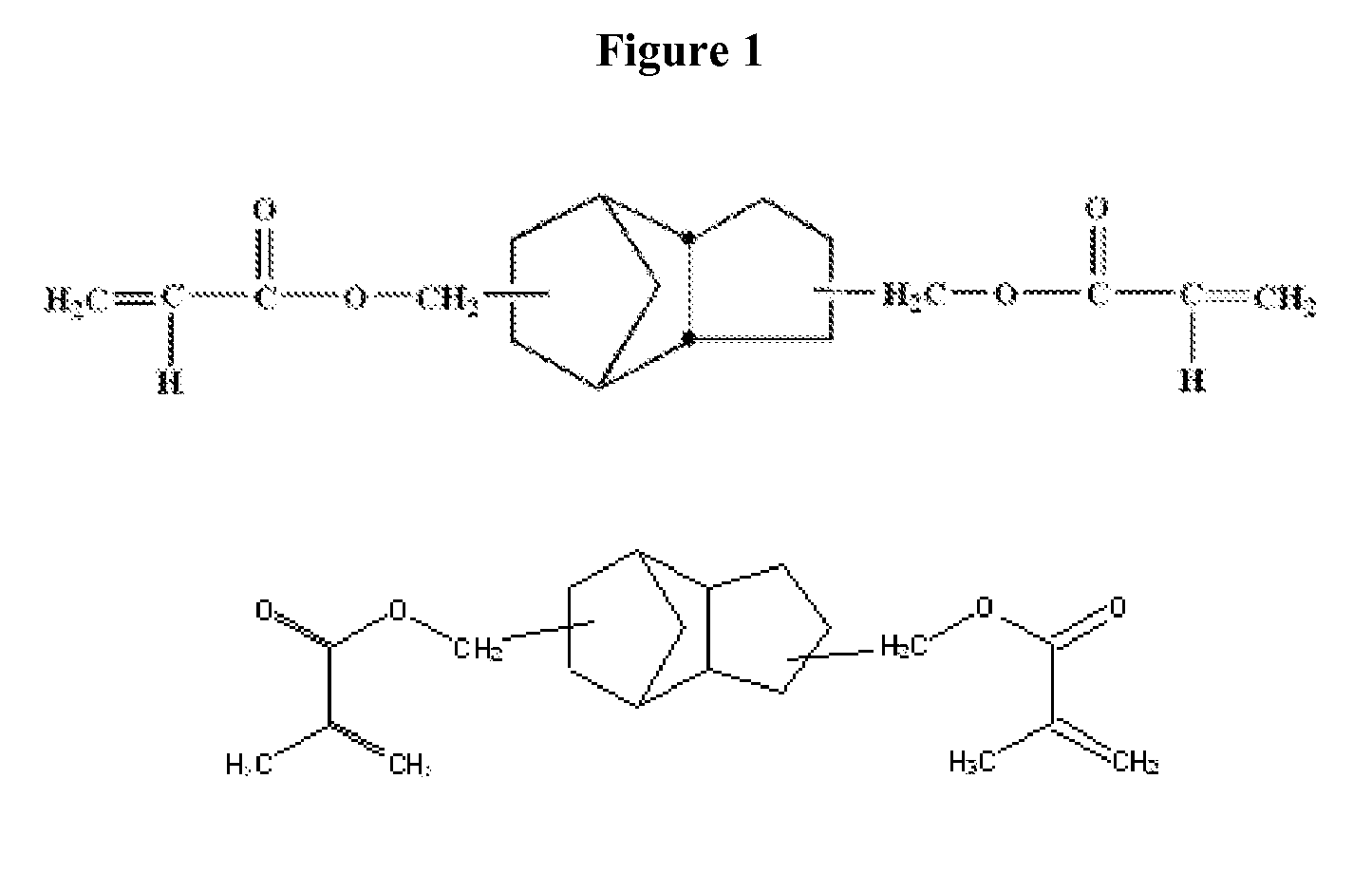

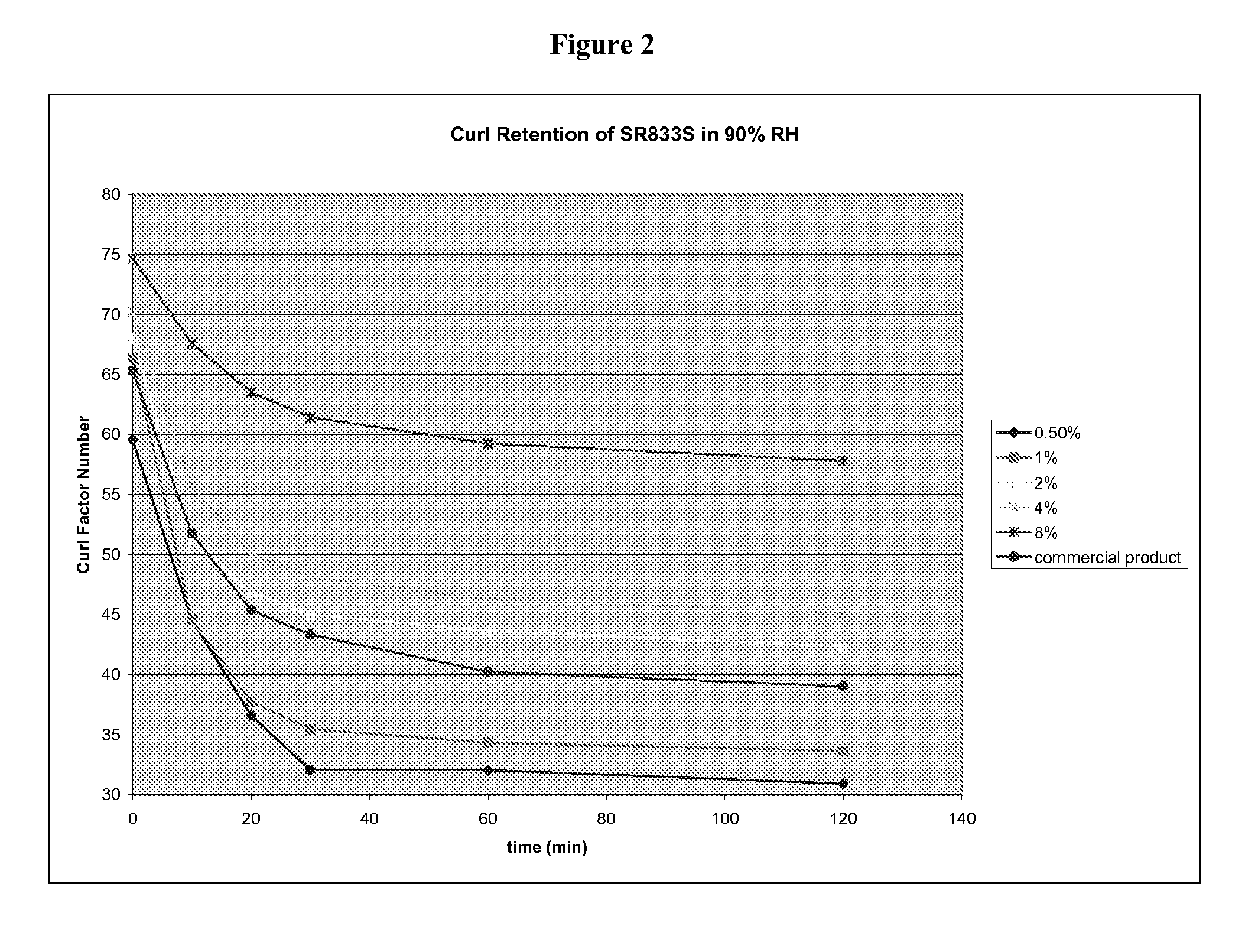

In situ polymerization for hair treatment

InactiveUS20080066773A1Effective for long period of timeImprove hair strengthCosmetic preparationsHair removalSolubilityIn situ polymerization

Hair care products represent a world-wide multi-billion dollar industry. Pre-formed polymers are commonly used in a variety of hair care products including shampoos, conditioners, gels, and hair sprays. The present invention provides technology for polymerizing monomers on hair in situ to produce desired hair characteristics. This eliminates the solubility and application issues found with some polymers. The polymerization of monomers on hair is typically initiated using a thermal or photoinitiatied free radical initiator. In certain embodiments, the monomers are fluorinated thereby producing a fluorinated polymer on the hair upon polymerization. The invention provides monomers, initiators, methods, and kits for use in treating hair with polymers.

Owner:LIVING PROOF INC

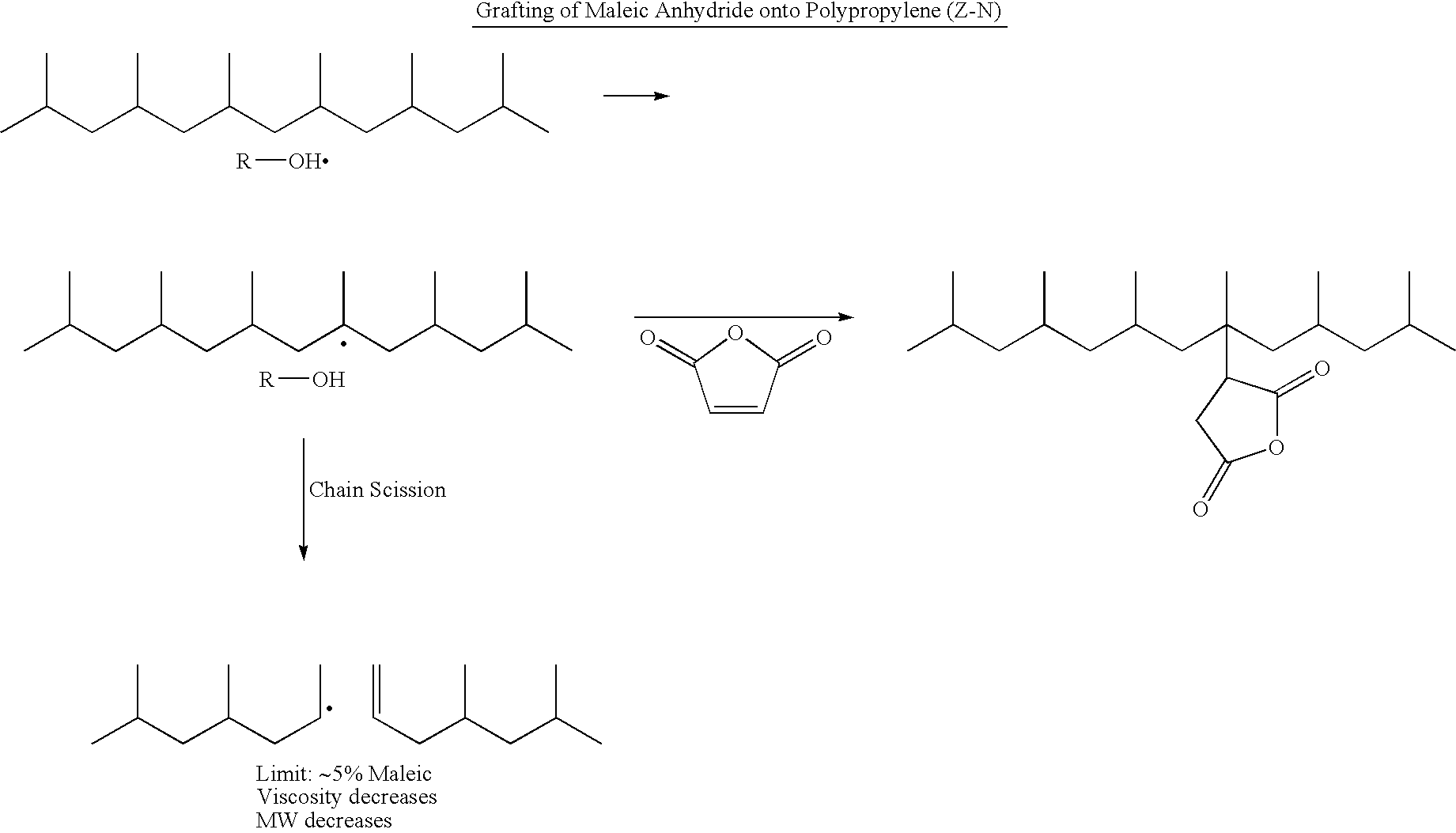

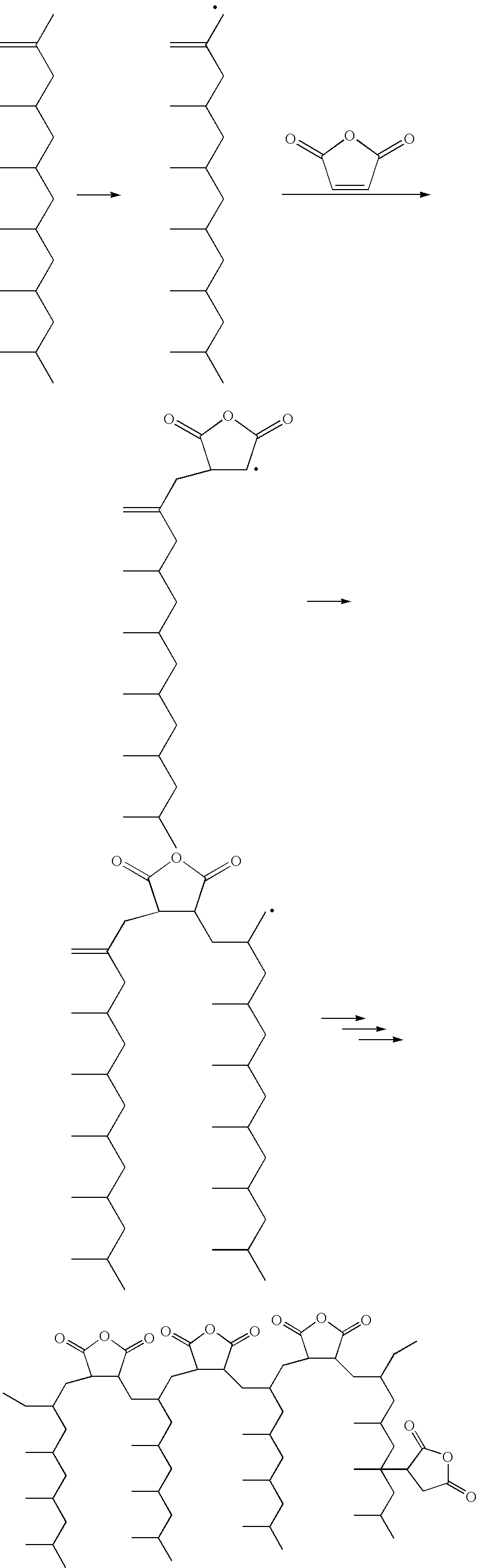

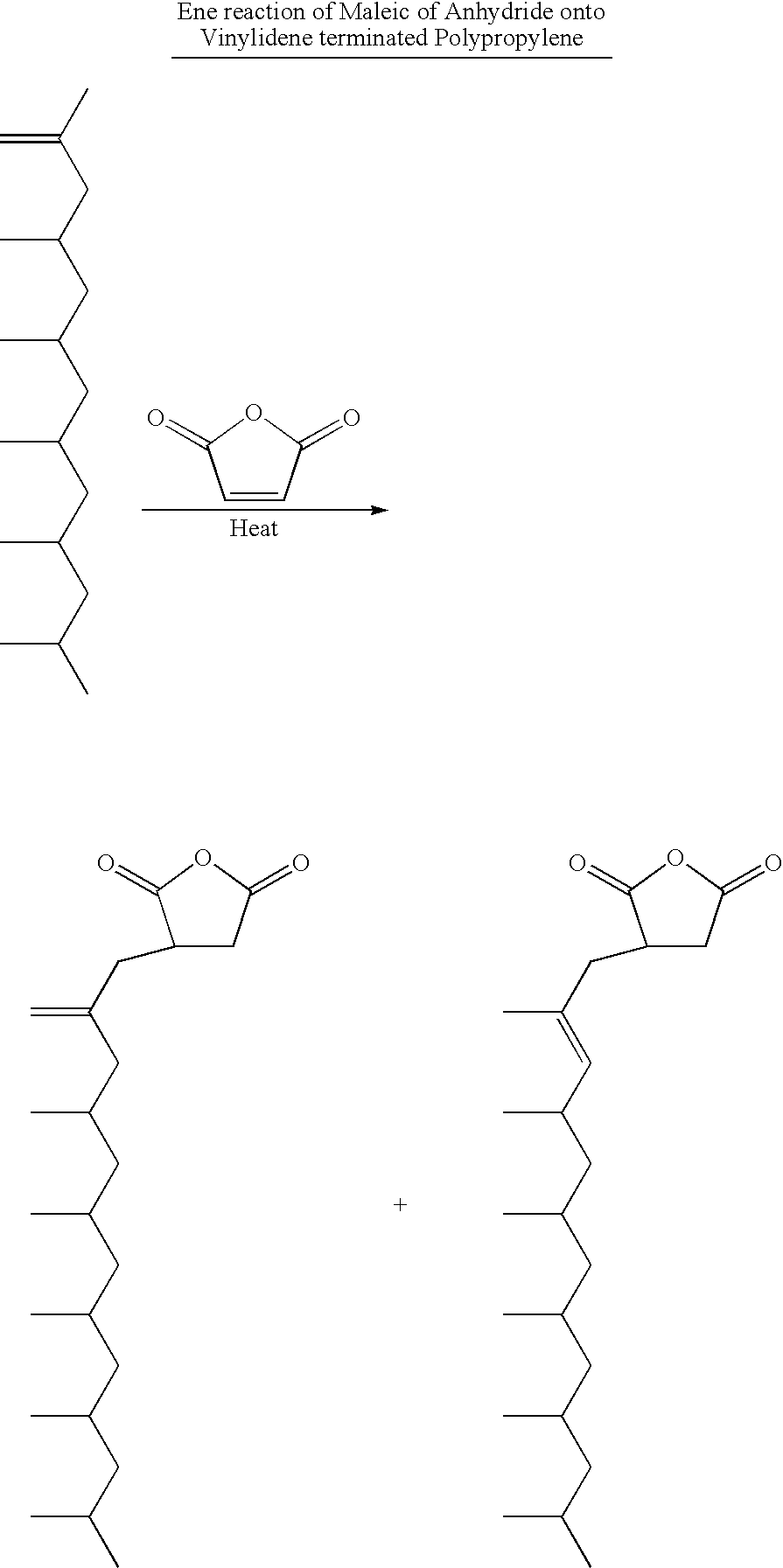

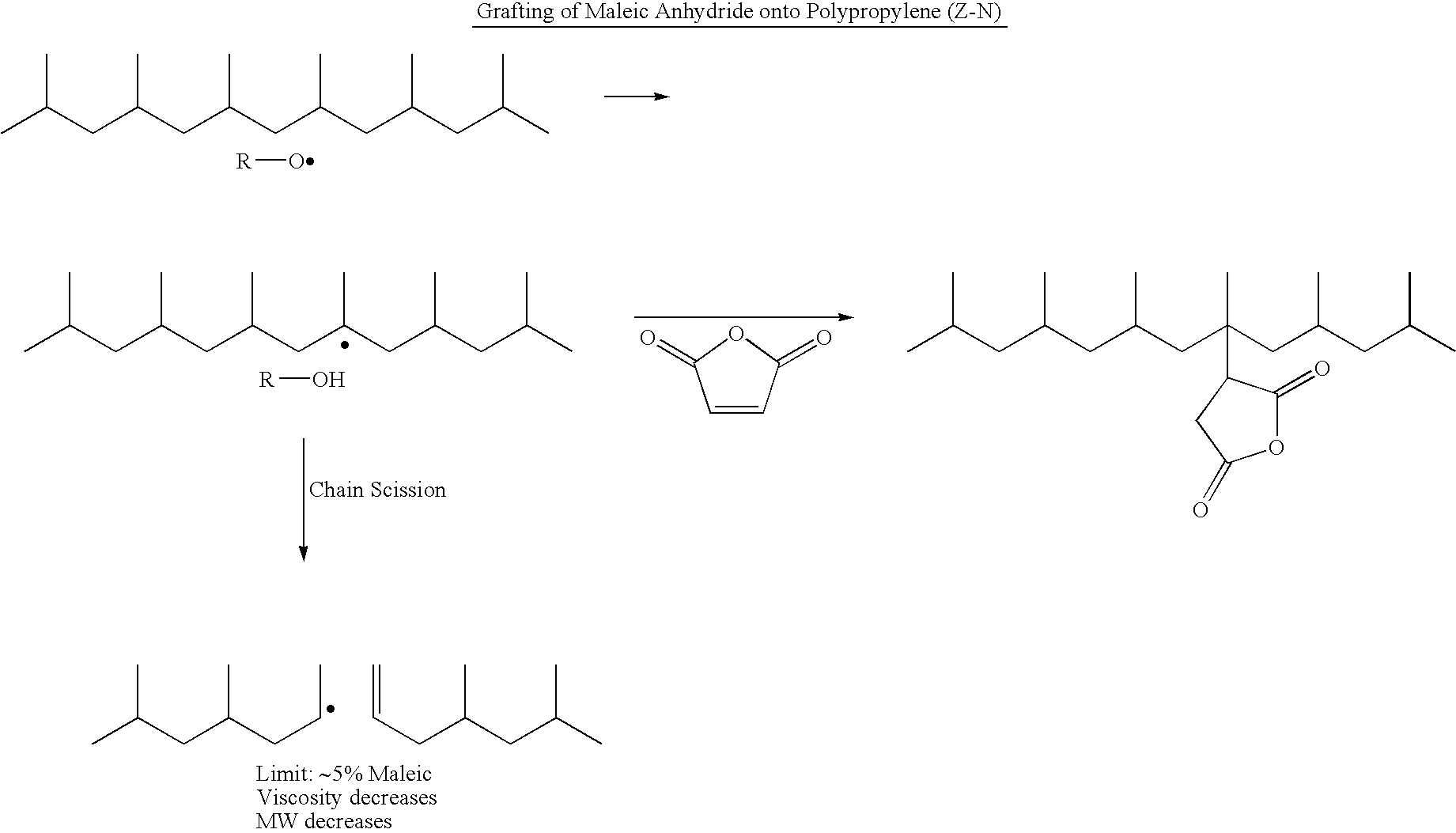

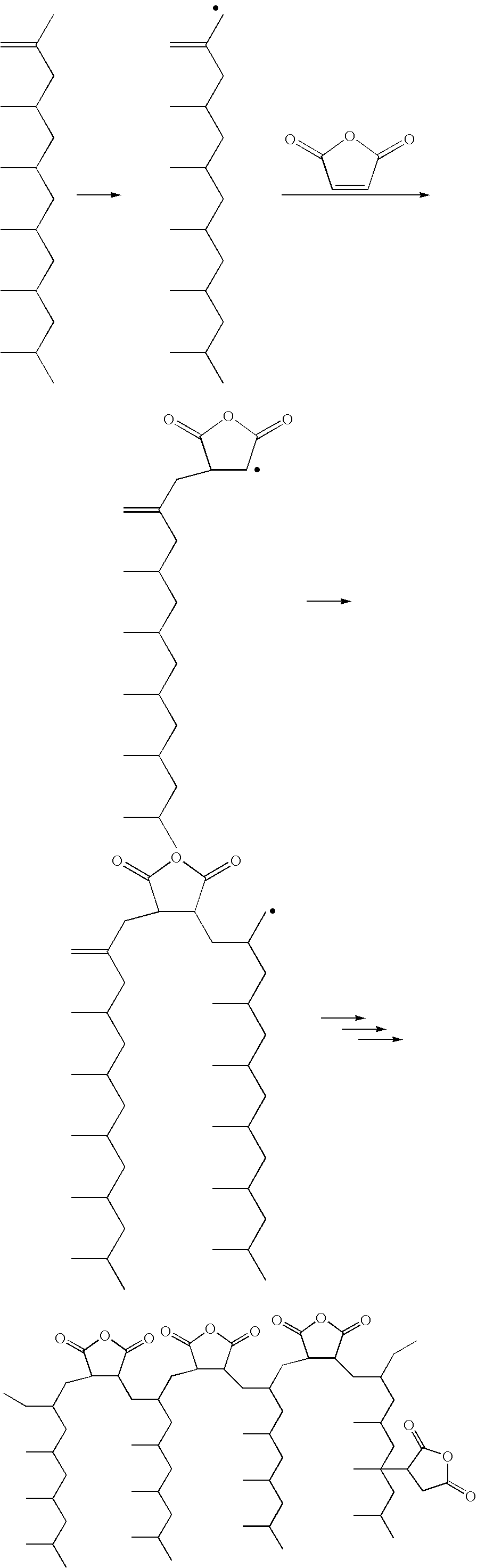

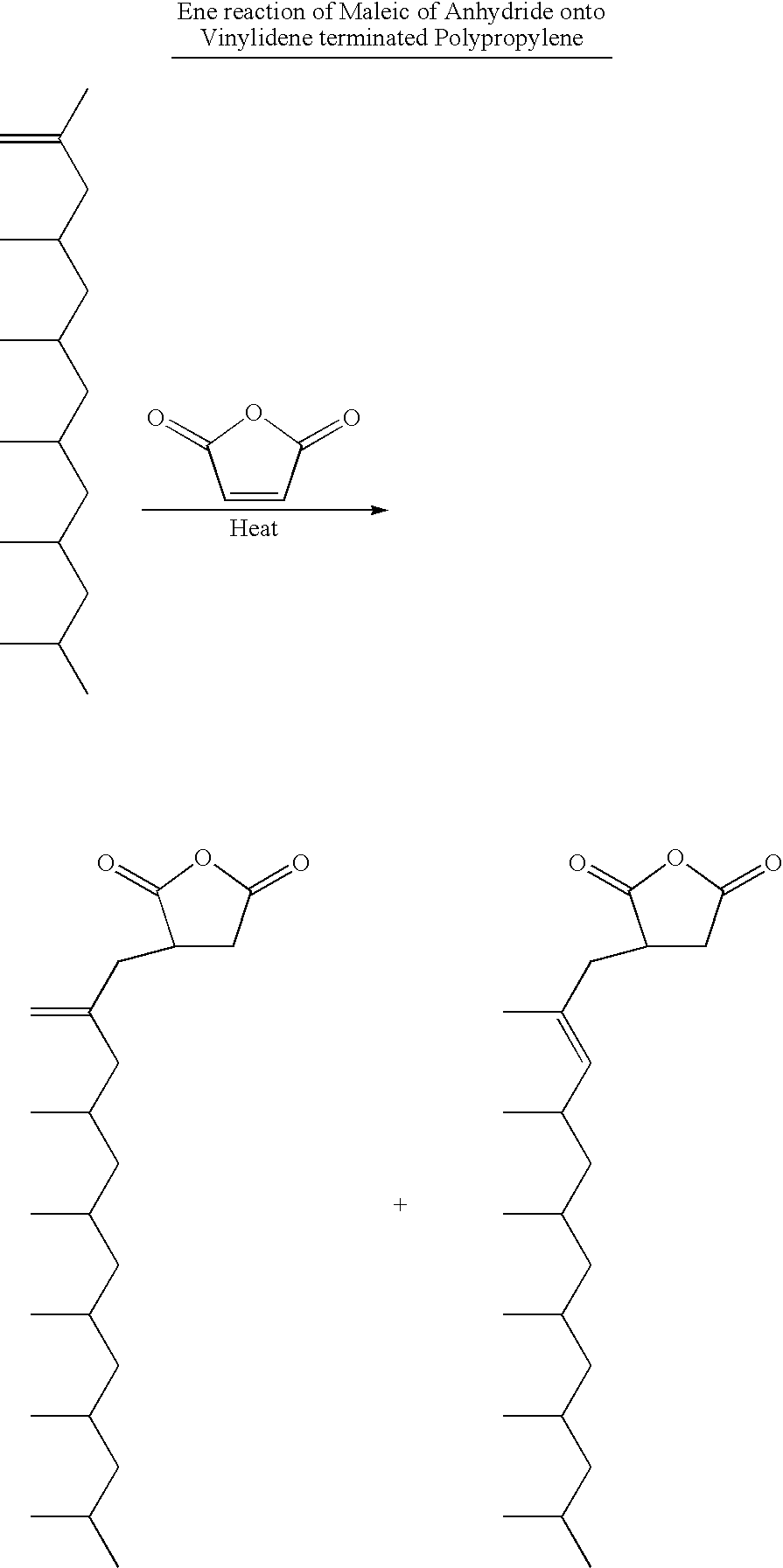

Polypropylene having a high maleic anhydride content

InactiveUS20060084764A1Increased succinic anhydride contentIncrease and decrease and viscosityPolymer sciencePolypropylene

Polypropylene having high maleic anhydride content, between about 5 and about 45 g wt %, may be prepared by first reacting a metallocene-prepared polypropylene having terminal unsaturation with one mole equivalent of maleic anhydride to give polypropylene having a single unsaturation and a terminal succinic anhydride moiety. This product is then reacted with additional maleic anhydride in the presence of a free radical initiator (such as a peroxide or UV radiation) to give a polypropylene with maleic anhydride moieties along the backbone. The polypropylene product does not suffer scission or crosslinking with subsequently undesirable increases in molecular weight or viscosity. The maleic anhydride moieties provide reactivity to the polypropylene and thus expand its uses and applications.

Owner:BAKER HUGHES INC

Functionalized polyalphaolefins

Disclosed is a composition of a functionalized polyalphaolefin comprising the reaction product of admixing (a) an alpha-olefin monomer having at least 10 carbon atoms; (b) an unsaturated functionalizing compound; and (c) a polymerization initializer, under reaction conditions sufficient to polymerize the alpha-olefin monomer and unsaturated functionalizing compound. Free radical initiators, especially peroxides are disclosed to be useful in preparing the functionalized polyalphaolefin. The functionalized polyalphaolefins are disclosed to be useful in preparing inks, toners, coatings, candle waxes, lubricating oils, and personal care products.

Owner:BAKER HUGHES INC

Latex processes

InactiveUS6503680B1Improve performanceImprove featuresDevelopersEmulsion paintsGlass transitionPolymer chemistry

A process for the preparation of a latex polymer consistent with E / A (emulsion / aggregation / coalescence) toner manufacture. The process utilizes a standard (universal) latex composition and involves chain-transfer agent partitioning, emulsion polymerization that provides a latex polymer with a wide range of molecular properties. In particular, the process customizes a wide range Mw (weight average molecular weight) latex, without substantially varying the Mn (number average molecular weight) and hence, without substantially varying Tg (glass transition temperature) such that good toner performance is maintained. In a preferred process, a latex polymer is prepared by mixing a seed particle latex, generated by aqueous emulsion polymerization of a first portion of a monomer emulsion, with a second portion of the monomer emulsion and at least one chain-transfer agent. The mixing is done in the presence of a free-radical initiator and heated, and wherein the monomer emulsion comprises a mixture of polymerization reagents of at least one monomer, at least one chain-transfer agent, at least one surfactant, and water. This process may be applied to core-shell polymerization as well. These latex polymers are ideally suited in the manufacture of toner and developer for electrophotographic imaging and printing.

Owner:XEROX CORP

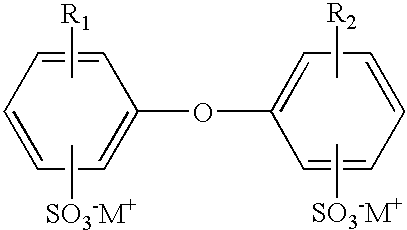

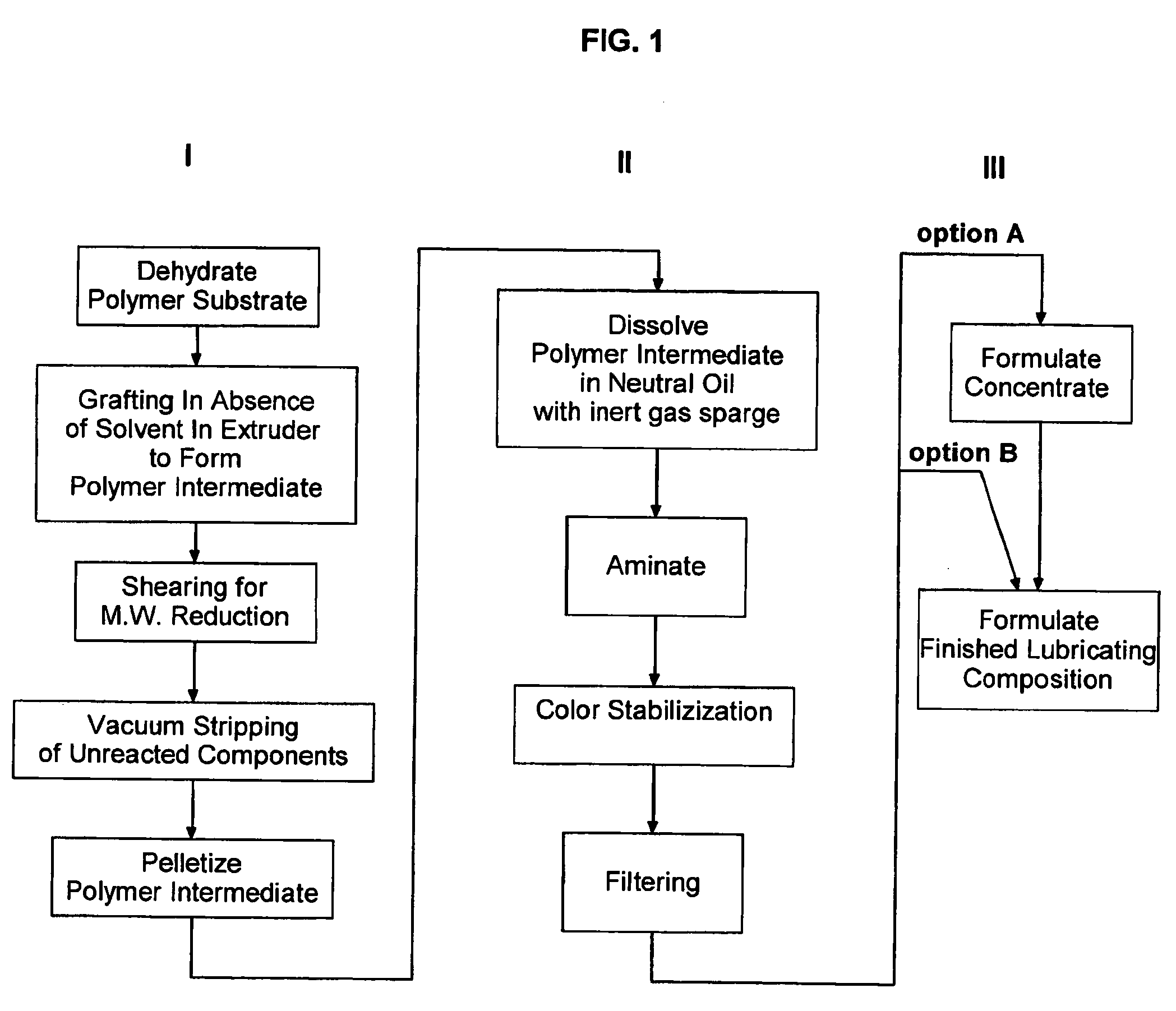

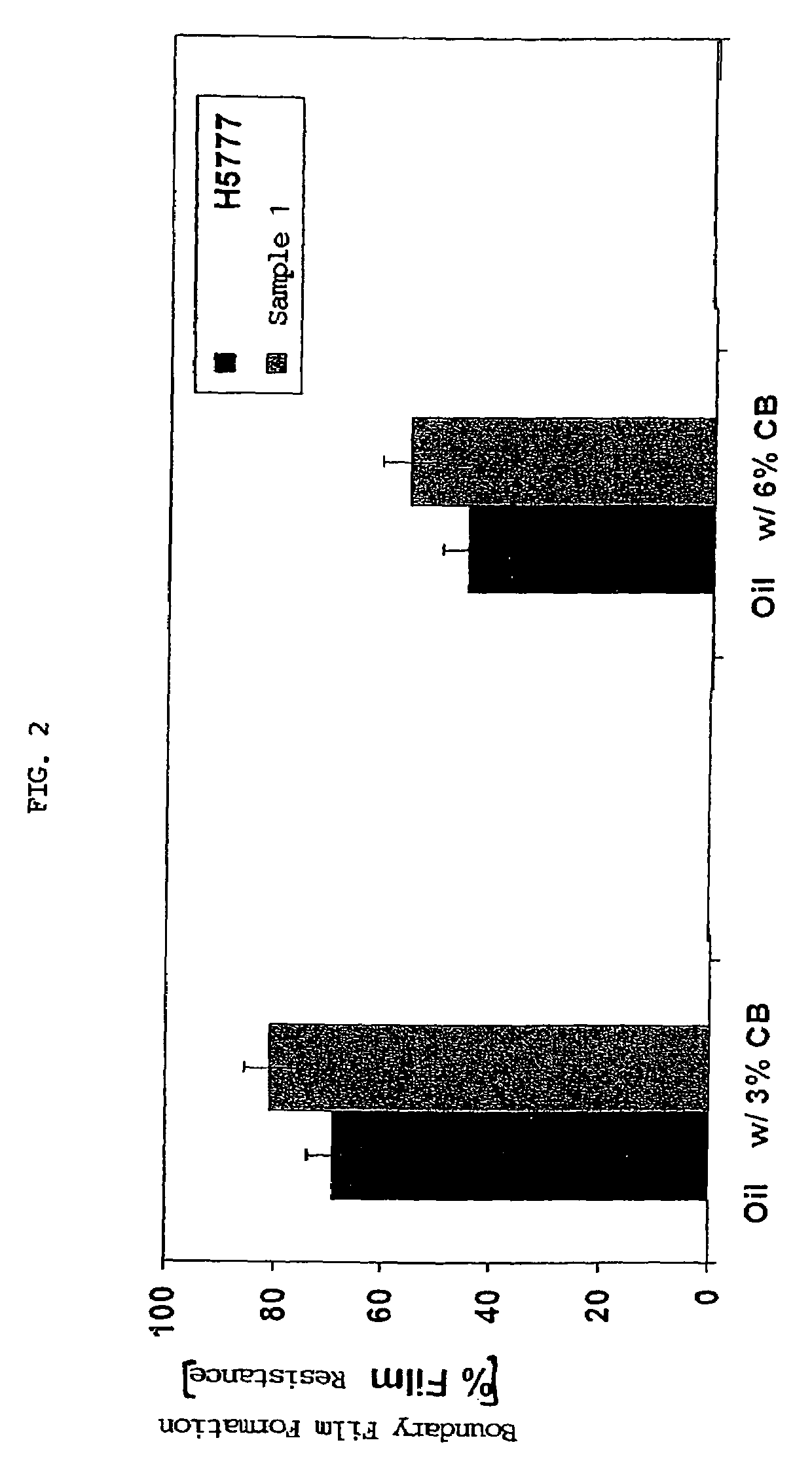

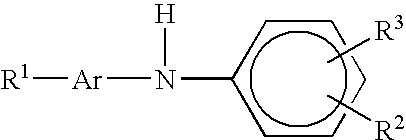

Grafted multi-functional olefin copolymer VI modifiers and uses thereof

ActiveUS7253231B2High activityImprove functionalityLiquid carbonaceous fuelsAdditivesHydrocarbon solventsCanis lupus familiaris

Owner:ARLANXEO NETHERLANDS +1

Polypropylene having a high maleic anhydride content

InactiveUS7183359B2Increase and decrease and viscosityIncrease or decrease weightPolymer sciencePolypropylene

Polypropylene having high maleic anhydride content, between about 5 and about 45 wt %, may be prepared by first reacting a metallocene-prepared polypropylene having terminal unsaturation with one mole equivalent of maleic anhydride to give polypropylene having a single unsaturation and a terminal succinic anhydride moiety. This product is then reacted with additional maleic anhydride in the presence of a free radical initiator (such as a peroxide or UV radiation) to give a polypropylene with maleic anhydride moieties along the backbone. The polypropylene product does not suffer scission or crosslinking with subsequently undesirable increases in molecular weight or viscosity. The maleic anhydride moieties provide reactivity to the polypropylene and thus expand its uses and applications.

Owner:BAKER HUGHES INC

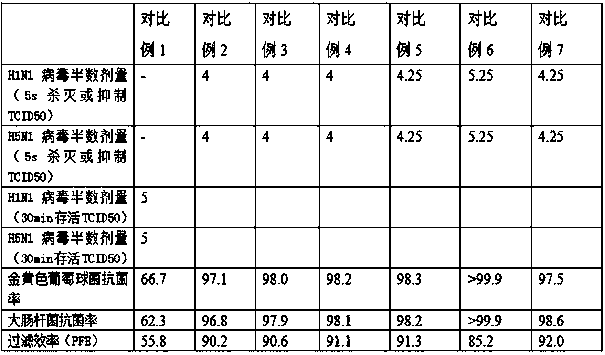

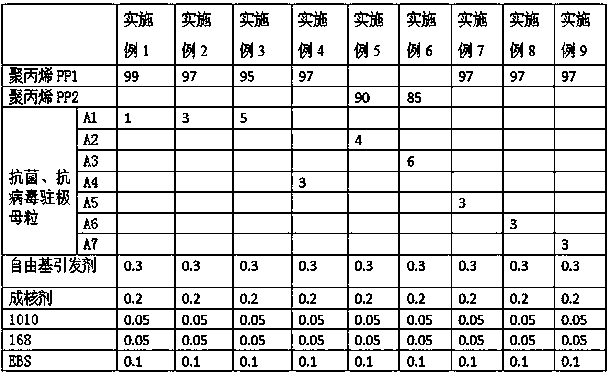

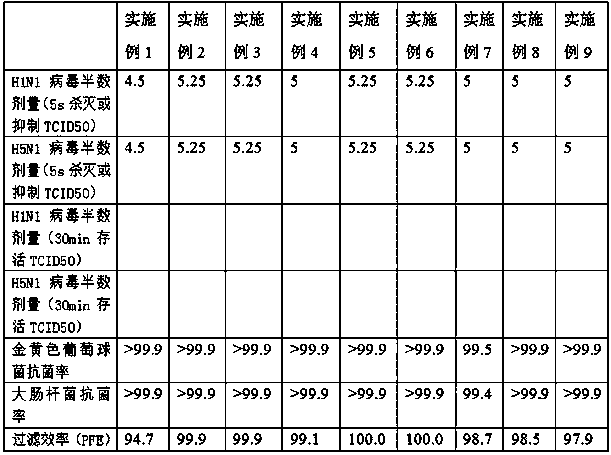

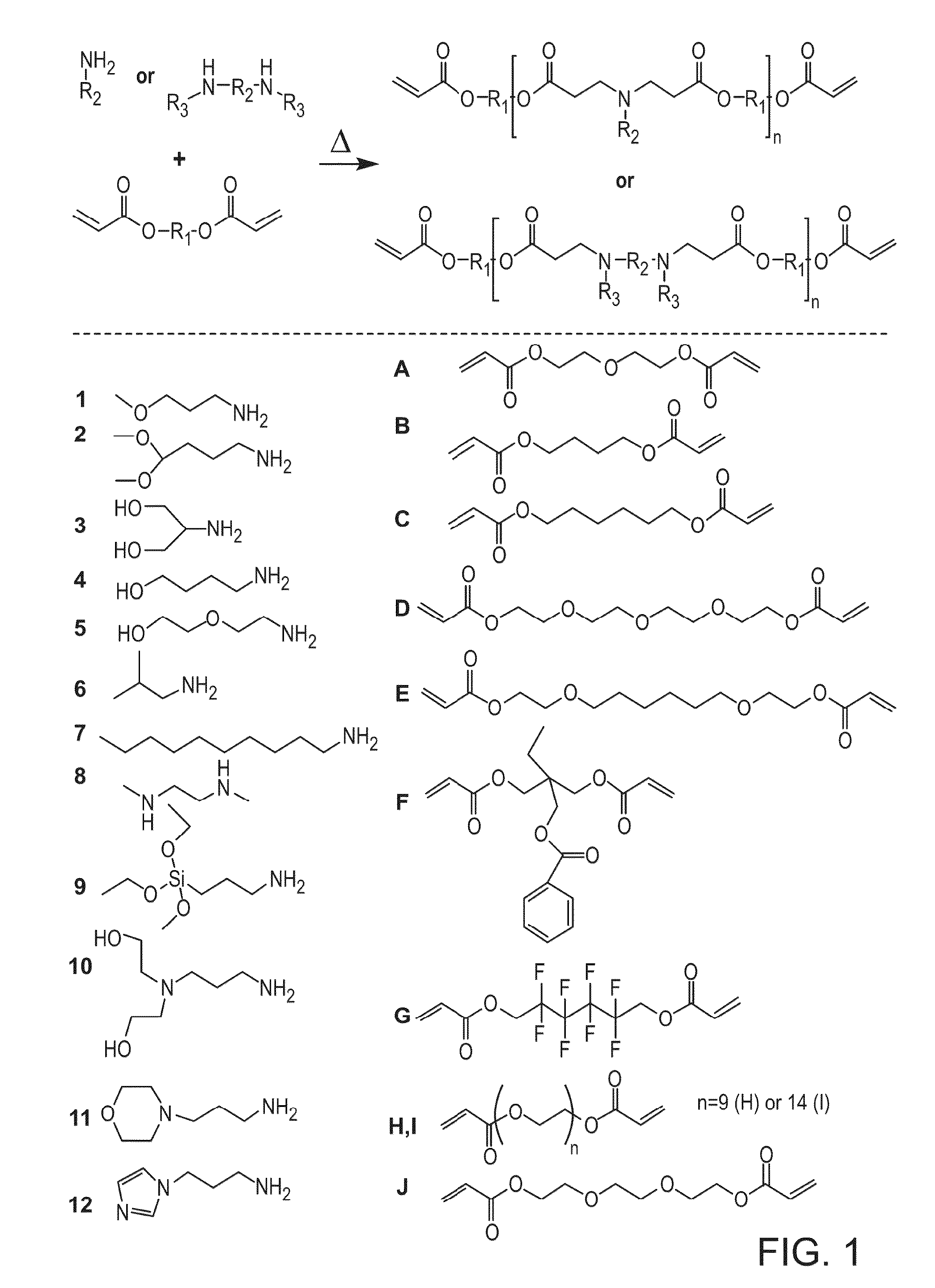

Melt-blown polypropylene material as well as preparation method and application thereof

ActiveCN111393754AReach killImprove filtration efficiencyDispersed particle filtrationNon-woven fabricsMasterbatchNonwoven fabric

The invention discloses a melt-blown polypropylene material as well as a preparation method and application thereof. The melt-blown polypropylene material comprises the following components: 80-99 parts of polypropylene resin; 0.5 to 10 parts of antibacterial and antiviral electret masterbatch; 0.1 to 1 part of a free radical initiator; 0.1 to 0.5 part of a nucleating agent; 0.01 to 3 parts of anantioxidant; 0-3 parts of a lubricant. According to the invention, inorganic antibacterial and antiviral particles are introduced into melt-blown polypropylene; the material is endowed with intrinsicantibacterial and antiviral characteristics; after the melt-blown non-woven fabric is prepared, when viruses and bacteria are filtered, the viruses and bacteria remain on the melt-blown layer, the nano material on the composite material can rapidly wrap the viruses and bacteria, attack the bacteria and viruses, synergistically destroy the structure of the bacteria and viruses and block electron transfer of the bacteria and viruses, so that the effects of killing the viruses and bacteria and the like are achieved, and the material has excellent antibacterial performance and antiviral performance and high filtering efficiency.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD +2

Crosslinked, degradable polymers and uses thereof

Acrylate-terminated poly(beta-amino esters) are cross-linked to form materials useful in the medical as well as non-medical field. The polymeric starting material is combined with a free radical initiator, either a thermal initiator or a photoinitiator, and the mixture for cross-linking is heated or exposed to light depending on the initiator used. The resulting materials due to the hydrolysable ester bond in the polymer backbone are biodegradable under physiological conditions. These cross-linked materials are particular useful as drug delivery vehicles, tissue engineering scaffolds, and in fabricating microdevices. The materials may also be used as plastics, coating, adhesives, inks, etc. The cross-linked materials prepared exhibit a wide range of degradation times, mass loss profiles, and mechanical properties. Therefore, the properties of the material may be tuned for the desired use. The high-throughput approach to preparing a library of cross-linked poly(beta-amino esters) allows for the rapid screening and design of degradable polymers for a variety of applications.

Owner:MASSACHUSETTS INST OF TECH

Heat sealable films

InactiveUS6503637B1High mechanical strengthExcellent stiffness strengthFlexible coversWrappersEthylene HomopolymersHigh pressure

A film comprising a blend of:i) a homopolymer of ethylene having a Mw / Mn of 3 or a copolymer of ethylene and up to 50% weight % of a C3 to C20 olefm, the copolymer having a CBDI of 50% or more;ii) a homopolymer of propylene or a copolymer of propylene and up to 50 weight % of a comonomer selected from the group consisting of ethylene and C4 to C20 alpha-olefms; andiii) a polymer produced in a high pressure process using a free radical initiator.

Owner:EXXONMOBIL CHEM PAT INC

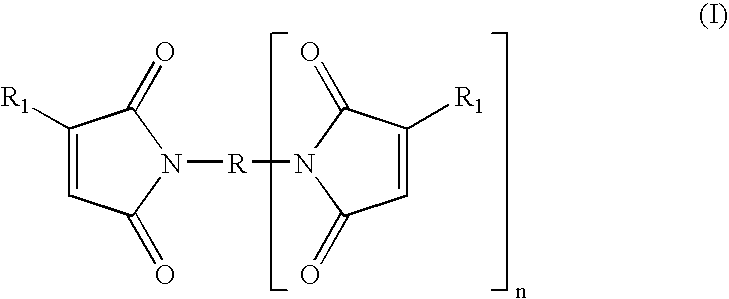

Tack free surface cures of polymers by organic peroxides in the presence of air

Compositions are disclosed which comprise mixtures of at least one compound selected from silicone elastomers, bis-, tri- or higher polymaleimides and / or bis-, tri- or higher polycitraconimides, and at least one compound selected from p-phenylene-diamine based antiozonants, sulfur compounds capable of accelerating sulfur vulcanization of polymers capable of being crosslinked by sulfur and polysulfide polymers which when compounded into polymers curable by free radical initiators in the presence of free radical initiators permit substantially tack free surface cure of the polymers by decomposition of the free radical initiator in the presence of molecular oxygen. Compositions containing the above ingredients and at least one free radical initiator, curable compositions containing the combination and processes for making and using the compositions are also disclosed.

Owner:ARKEMA INC

Methods of making functional biodegradable polymers

There is provided a method to modify biodegradable polymers using the direct reaction of a biodegradable polymer in a vinyl monomer and may take place in the presence of initiators. The initiator may be free radical initiators, heat, ionic initiators, UV irradiation, ionizing irradiation and other high energy irradiation. Suitable biodegradable polymer include polycaprolactone, poly(lactic acid), poly(glycolic acid) and poly(lactic-co-glycolic acid). Suitable vinyl monomers include acrylates, methacrylates and the like.

Owner:KIMBERLY-CLARK WORLDWIDE INC

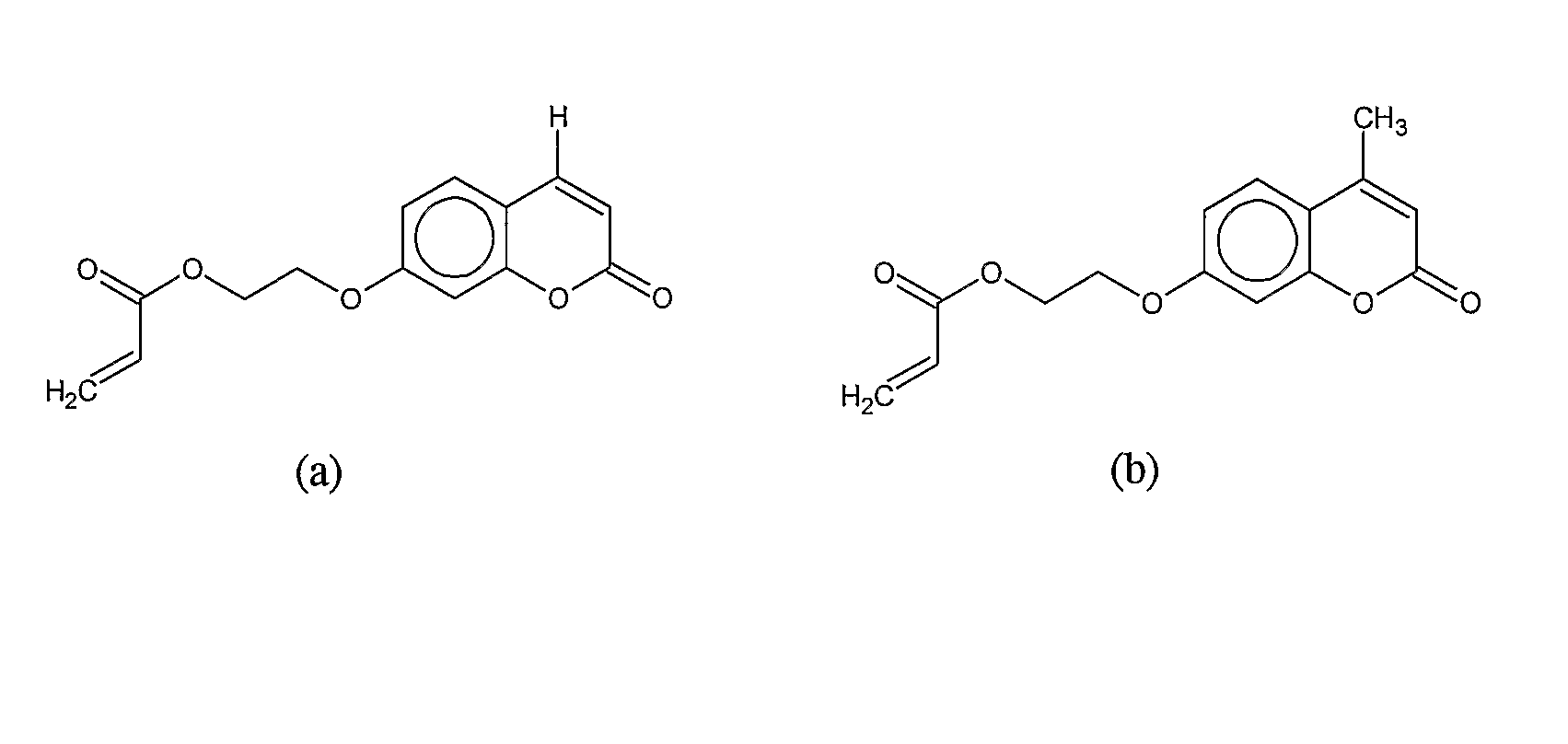

Light Activated Shape Memory Co-Polymers

The present discovery uses monomers which contain reversible photo-crosslinkable groups in addition to primary polymerizable groups. The mechanical properties of these materials and the reversibility of the photo-activated shape memory effect demonstrate the effectiveness of using photo-irradiation to effect change in modulus and shape memory effect. In the preferred embodiment the reaction mixture includes a photo-reactive monomer comprising a photo reactive group and a polymerizable group; a second monomer, which is more preferably a mixture of monomers, which are acrylate based; a multi-functional crosslinking agent, preferably 1,6 hexanediol diacrylate (HDODA); an initiator, preferably a free radical initiator; and a fifth, optional, component which is a modifying polymer. The mixture of the second monomer, crosslinking agent, and initiator comprise the base polymer matrix into which the photo-reactive monomer is incorporated. The polymeriziable group of the photo reactive monomer allows the photo reactive monomer to polymerize with the base polymer matrix.

Owner:CORNERSTONE RES GROUP

One component resin composition curable with combination of light and heat and use of the same

InactiveUS20070096056A1Improve curing effectAvoid pollutionLiquid crystal compositionsPhotomechanical apparatusEpoxyMethacrylate

A one component resin composition curable with a combination of light and heat, which comprises (1) an epoxy resin, (2) an acrylic ester monomer and / or methacrylic ester monomer, or an oligomer thereof, (3) a latent epoxy curing agent, (4) a photo radical initiator, and (5) a compound having two or more thiol groups per molecule, wherein the ingredient (5) is contained in an amount of 0.001 to 5.0 parts by weight per 100 parts by weight of this resin composition. According to the present invention, a one component resin composition curable with a combination of light and heat, which has excellent curability especially in a light-shielded area can be provided. Also, a liquid crystal sealant composition curable with a combination of light and heat, which is applicable to the one-drop-fill method and has excellent curability in light-shielded areas and adhesion reliability, especially high-temperature and high-humidity adhesion reliability, can be provided.

Owner:MITSUI CHEM INC +1

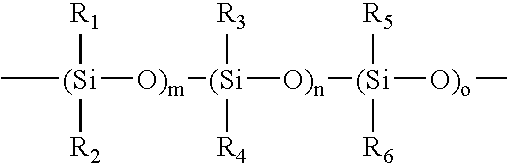

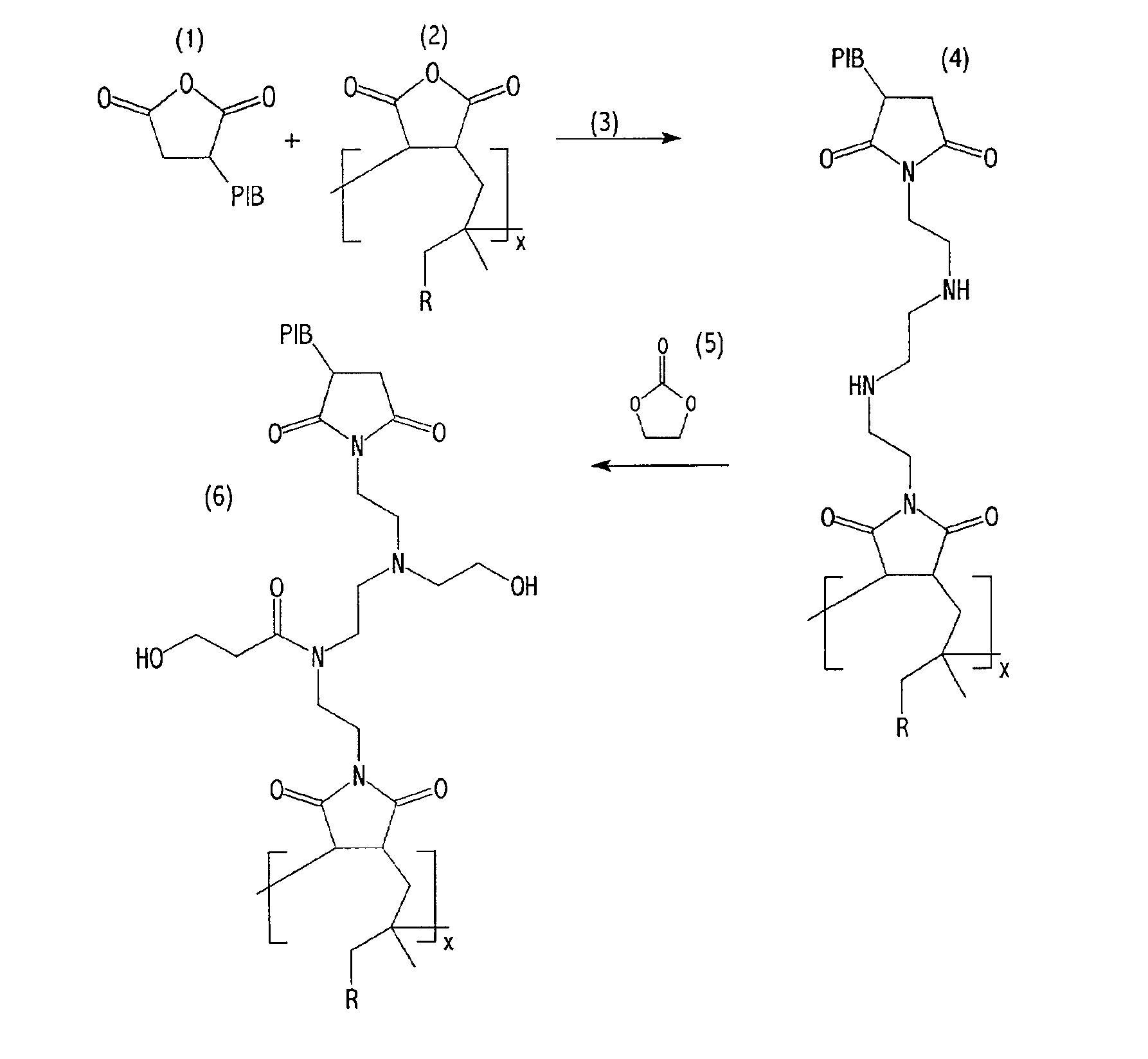

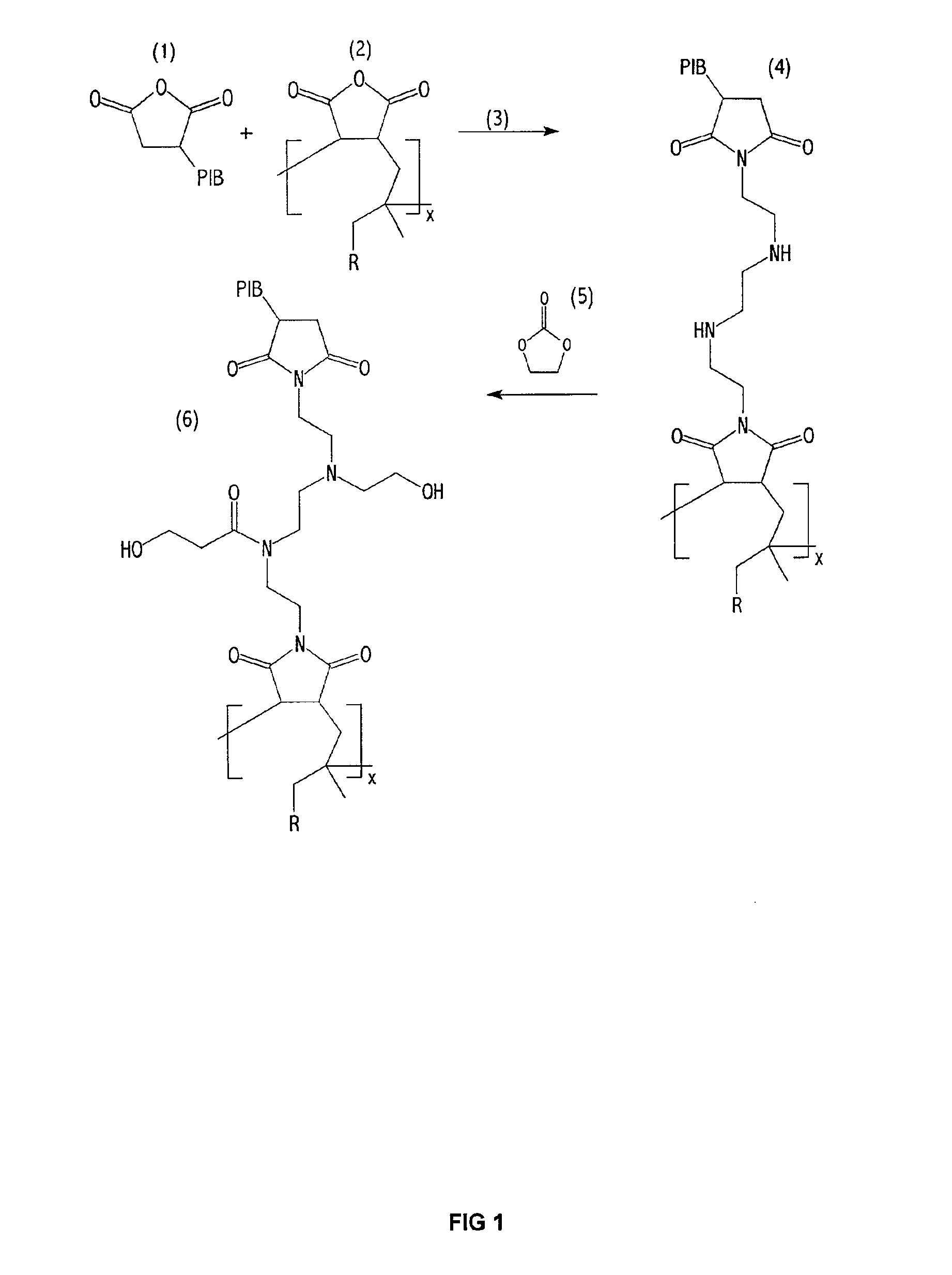

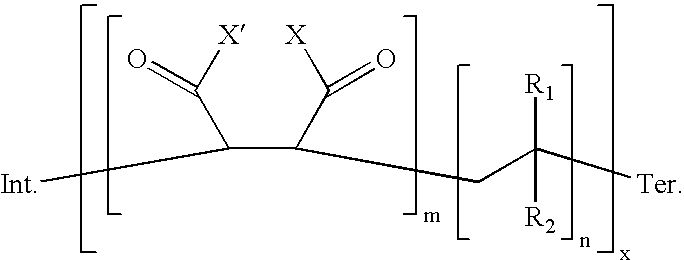

Polymeric dispersants prepared from copolymers of low molecular weight polyisobutene and unsaturated acidic reagent

This invention is directed to a new low molecular weight copolymer (The PIB / UAR copolymer) that may be prepared by reacting a low molecular weight polyisobutene (PIB) having less than about 32 carbon atoms with an unsaturated acidic reagent in the presence of a free radical initiator. No chain transfer agent is required to prepare the low molecular weight PIB / UAR copolymer. The PIB / UAR copolymer may be useful as is, or as an intermediate for (1) polysuccinimides, (2) detergents or dispersants for lube oil or fuels, (3) pour point depressants and (4) surface sizing agents for paper. The PIB / UAR copolymer may be used by itself or as the ester, amide, imide or metal salt derivative of the PIB / UAR copolymer. The PIB / UAR copolymer may be liquid at ambient temperature.

Owner:CHEVRON ORONITE CO LLC

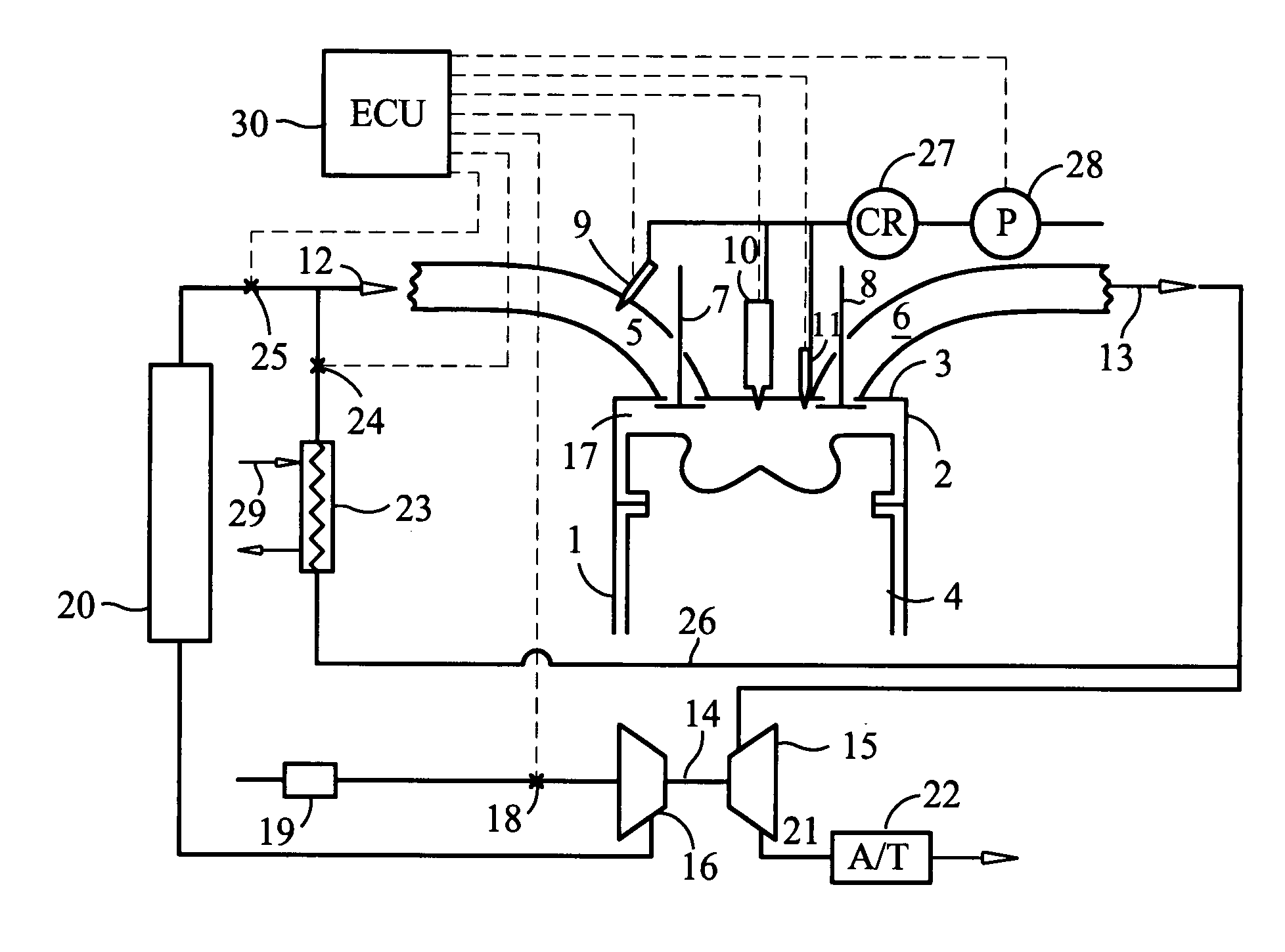

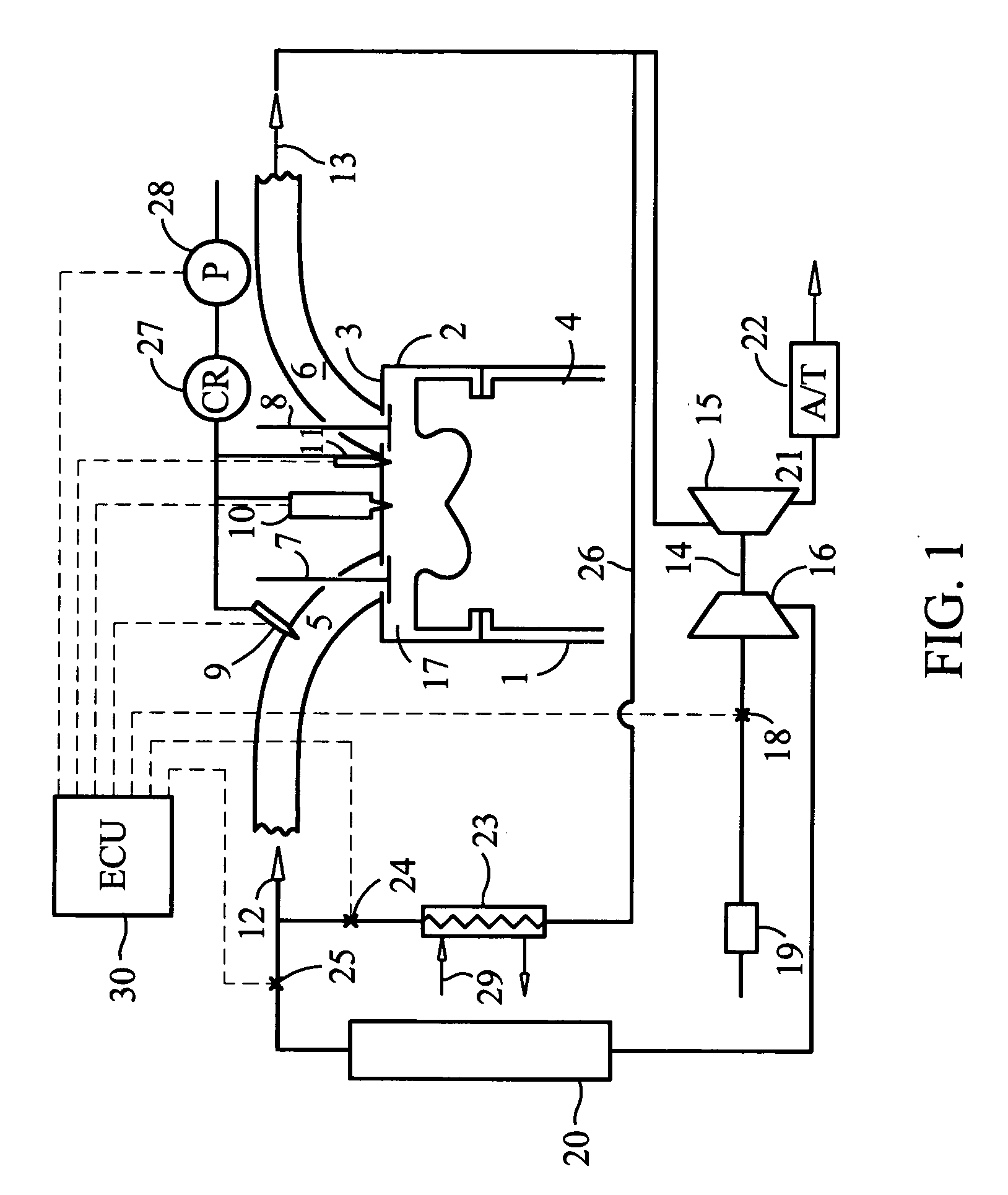

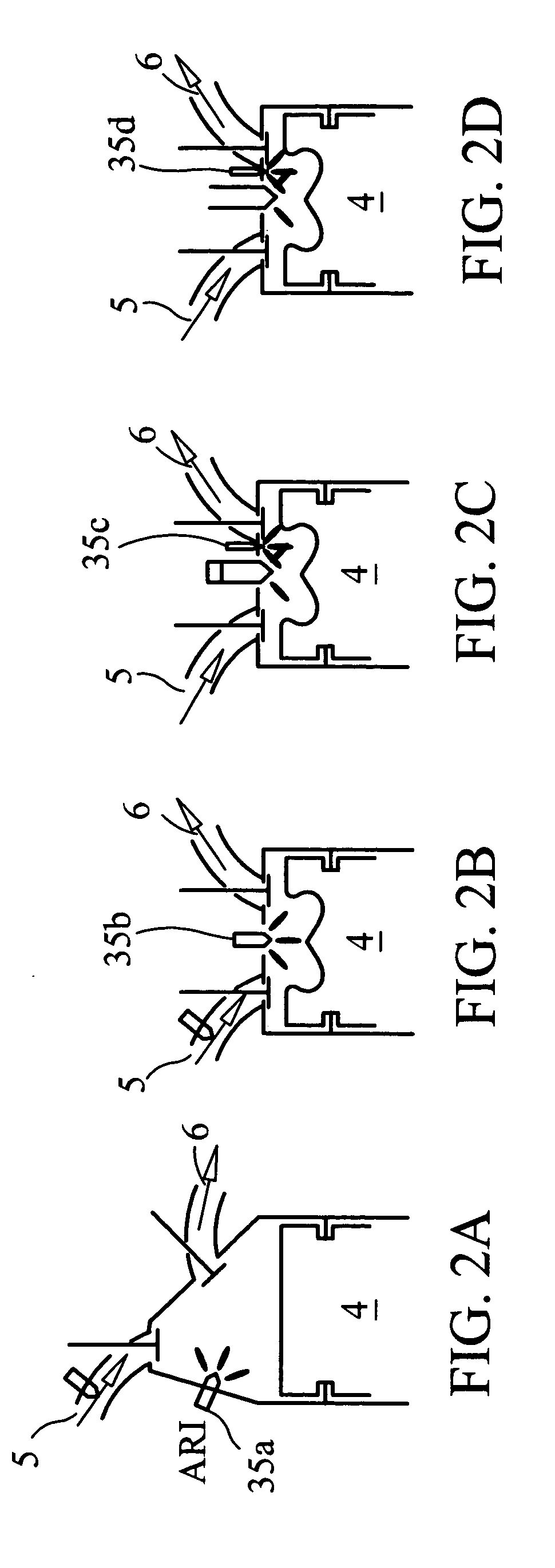

Active radical initiator for internal combustion engines

InactiveUS20070137611A1Proceed efficientlyElectrical controlInternal combustion piston enginesEngineeringInternal combustion engine

In an internal combustion engine a fuel-air mixture having compression temperatures and pressures sufficiently low as not to support auto ignition, ignition is achieved by injecting igniting active radicals into the air-fuel mixture. In one embodiment the active radicals are provided by withdrawing a portion of the mixture, treating it to produce active radicals in the portion and returning the portion to the mixture. Treatment of the portion typically includes simultaneously injecting, mixing, and compression of a predetermined amount of pilot fuel within the portion.

Owner:YU ROBERT C +2

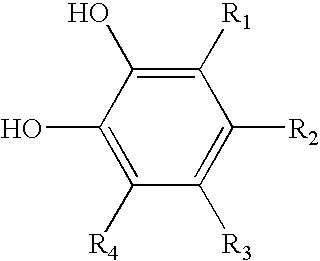

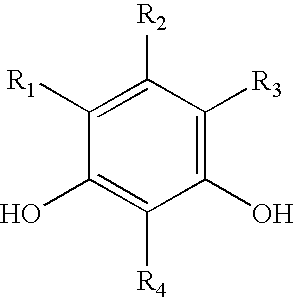

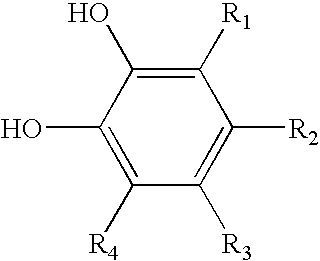

Rubber compositions comprising catechols and/or resorcinols and the use thereof in golf balls

The present invention is directed to a golf ball having at least one layer formed from a rubber composition comprising a base rubber, a free radical initiator, and a catechol. The present invention is also directed to a golf ball having at least one layer formed from a rubber composition comprising a base rubber, a free radical initiator, and a resorcinol. Rubber compositions of the present invention may be present in any one or more of a core layer, a cover layer, or an intermediate layer.

Owner:ACUSHNET CO

Silicone (METH)acrylate particles, process for preparation thereof and use thereof

InactiveUS20090149573A1Broaden applicationPromote free movementCosmetic preparationsMake-upMeth-Sealant

The present invention relates to silicone (meth)acrylate particles, to a process for preparing such silicone (meth)acrylate particles including the steps of:a) obtaining an emulsion composed of water and an organic phase comprising organopolysiloxanes modified terminally and / or laterally with acrylate groups, andb) polymerizing the inner phase to completion by means of a free-radical initiator, the free-radical initiator being added to the outer phase (aqueous phase) in a concentration of 0.1 to 40% by weight based on the inner phase, and to the use of the particles alone or in a mixture with further particles, pigments and / or further customary additives in the form of powders or dispersions in coating, adhesive or sealant materials, in polymers, in defoamers, in wetting and levelling aids, in cosmetic or pharmaceutical formulations and care products, in cleaning and detergent compositions, or in applications for modifying the interface properties of solid and liquid substrates, for example tactile properties, hydrophobization, or sliding and / or release properties.

Owner:EVONIK DEGUSSA GMBH

Elastomeric material compositions obtained from castor oil and epoxidized soybean oil

Elastomers are formed from castor oil and / or ricinoleic acid estolides and a polyester formed from an epoxidized vegetable oil such as ESO and a polycarboxylic acid such as sebacic acid, optionally in the presence of a peroxide initiator, or include crosslinked reaction products derived from ricinoleic acid or castor oil estolides, epoxy group-containing compounds such as epoxy resins and / or epoxidized vegetable oil, epoxy hardeners such as polyamine and polycarboxylic acid hardeners, thermally activated free radical initiators such as peroxides, and optionally but preferably include fillers such as limestone or wood flour. The elastomers can be prepared using a two-step, solvent-less procedure at elevated or ambient temperatures. These predominantly "all-natural" elastomers have physical properties comparable to conventional petroleum-based elastomers and composites and exhibit good flexibility, resiliency, abrasion resistance and inertness to hydrolysis. The resulting elastomers display good mechanical strength and resiliency, are resistant to abrasion and hydrolysis, and can be processed into sheet materials, which makes them attractive as floor covering components.

Owner:AFI LICENSING +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com