Patents

Literature

821 results about "Floor covering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

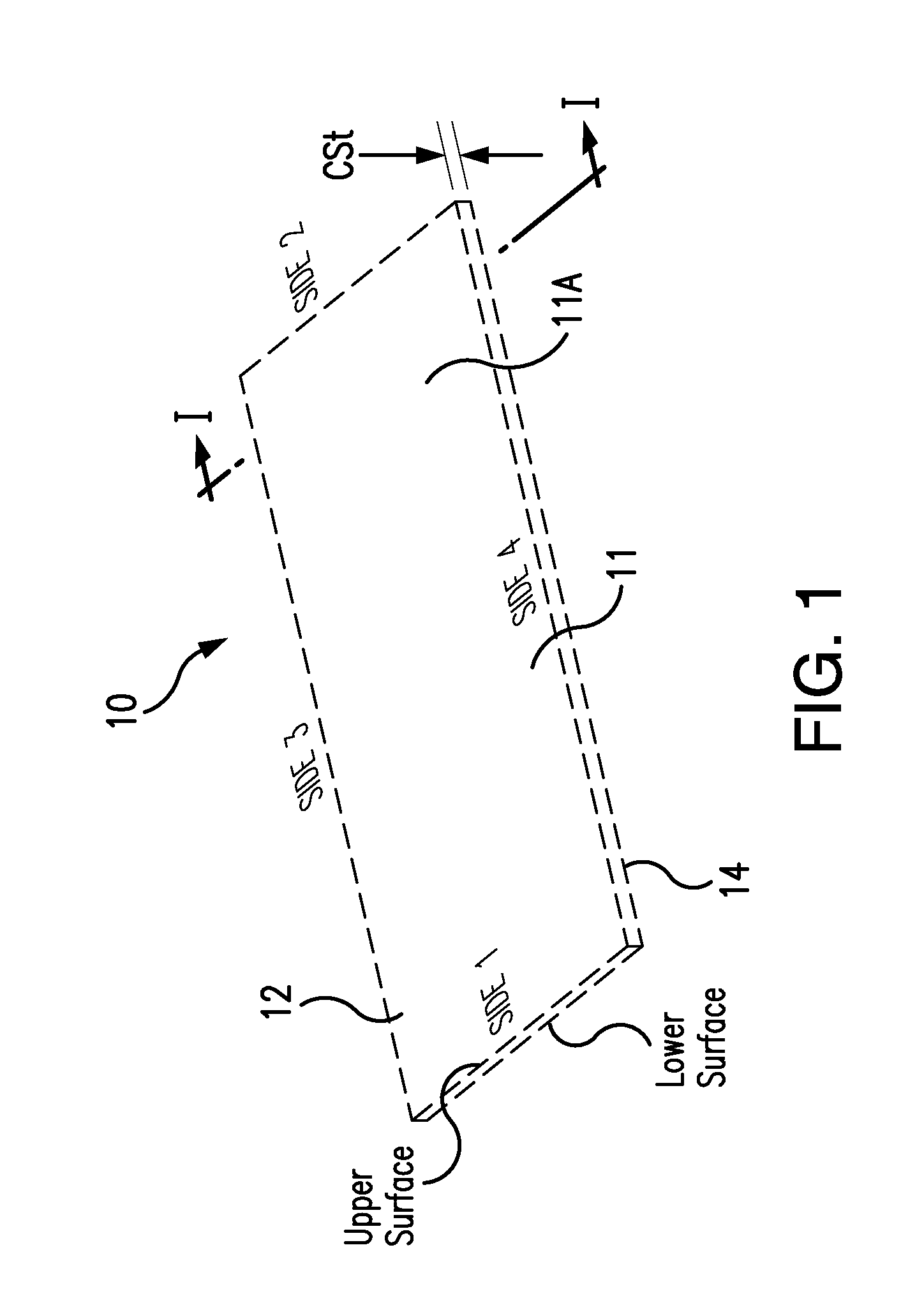

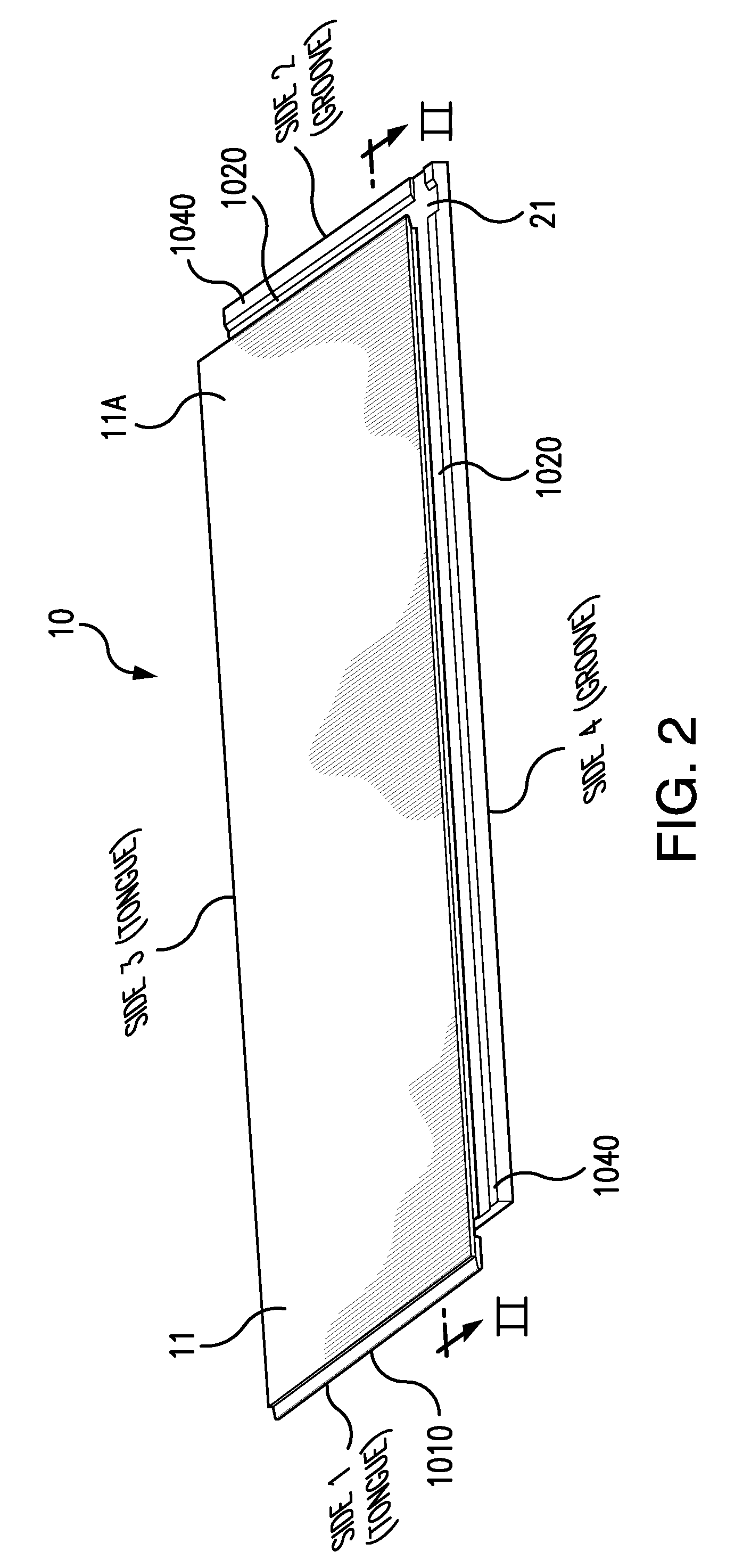

Panel element

InactiveUS6880307B2Simple glueless layingKeep in touchStrutsCovering/liningsEngineeringFloor covering

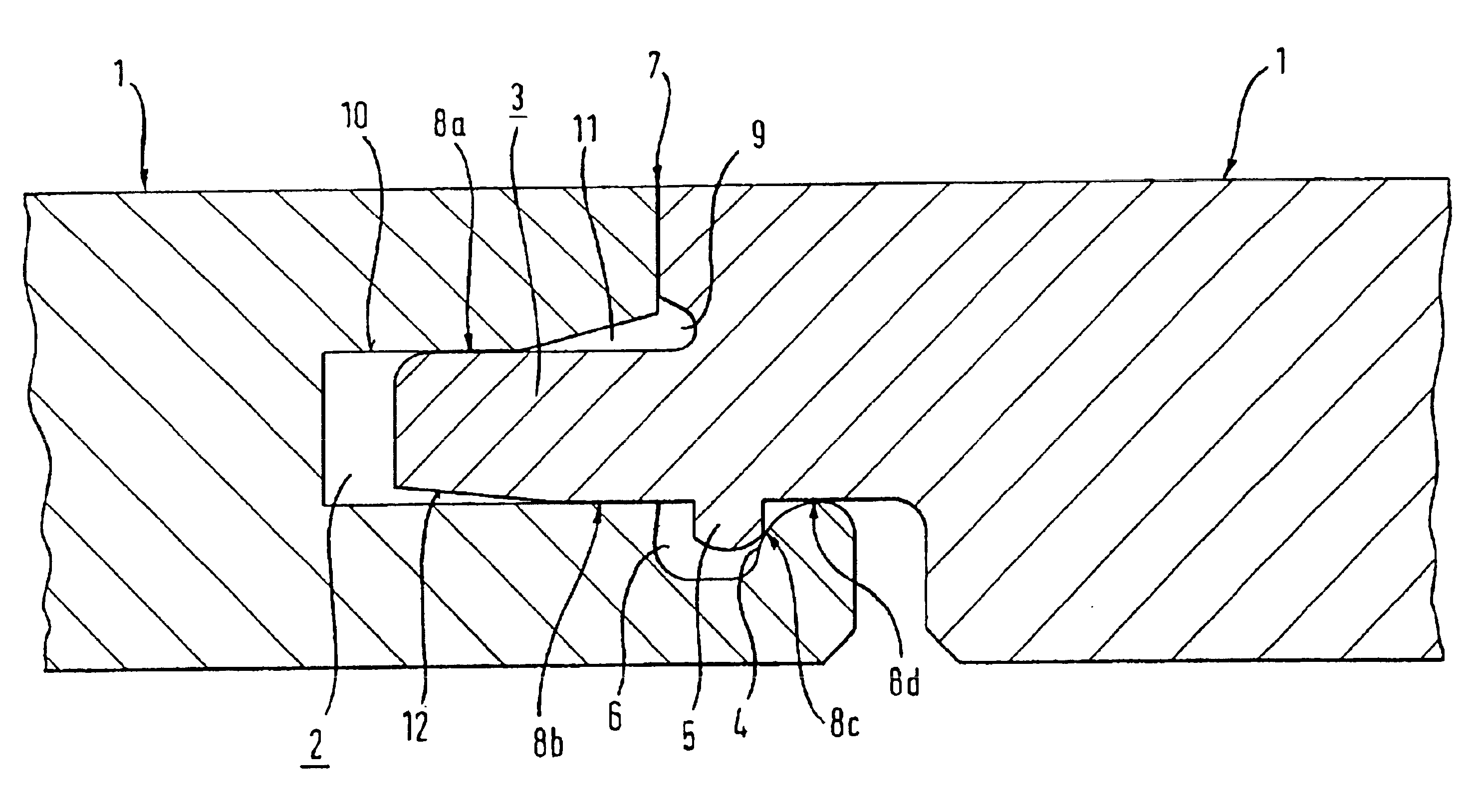

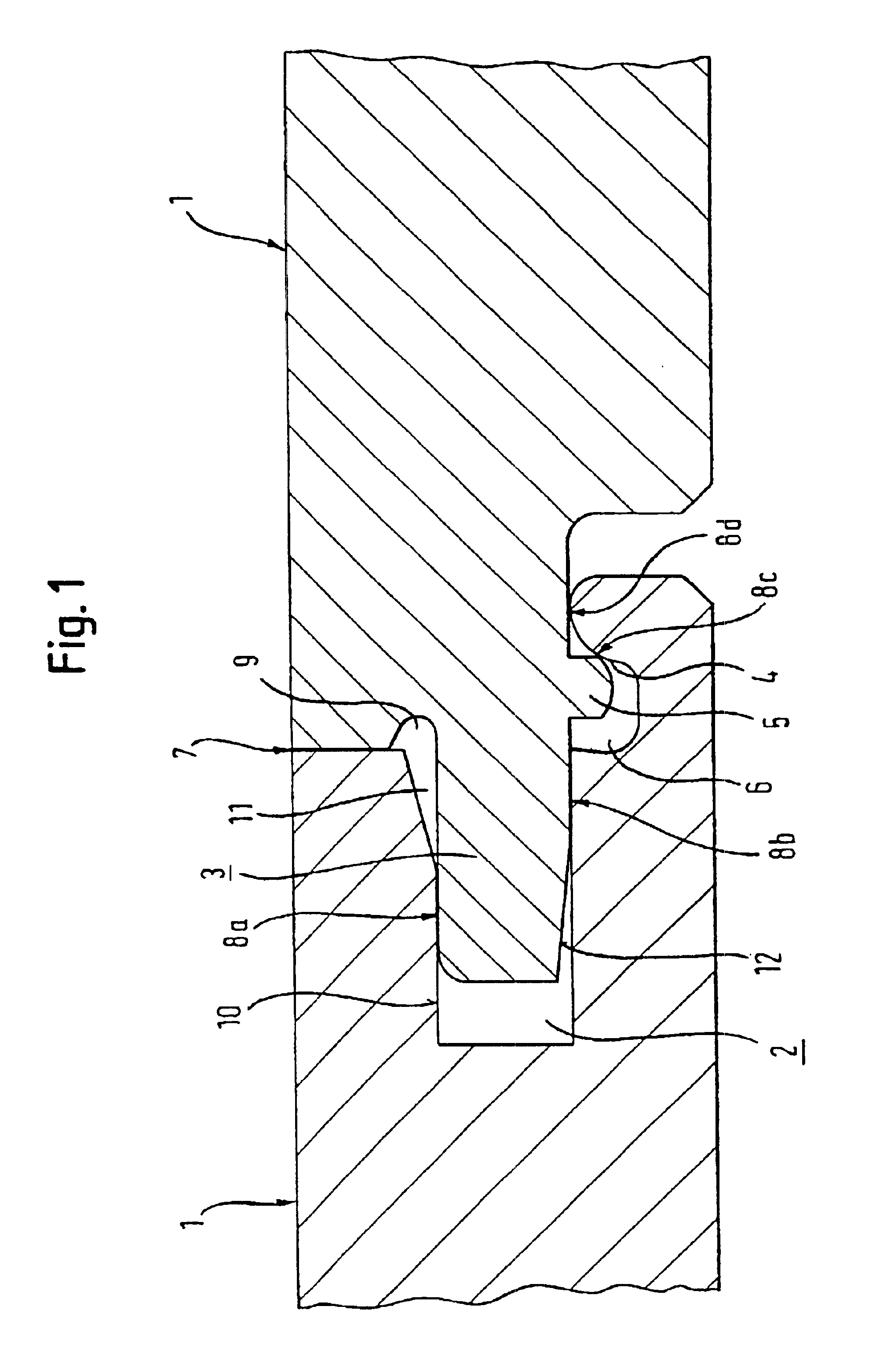

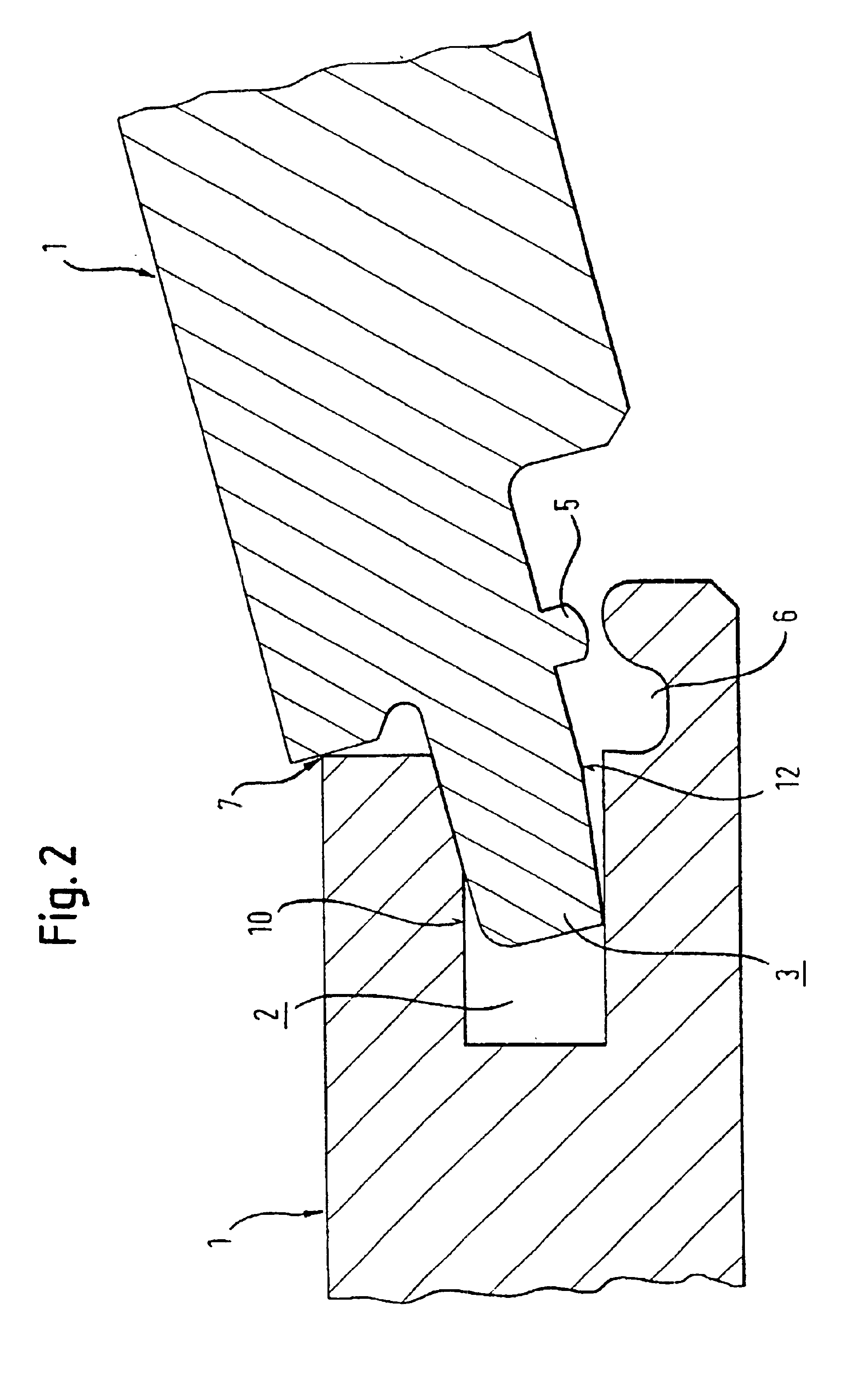

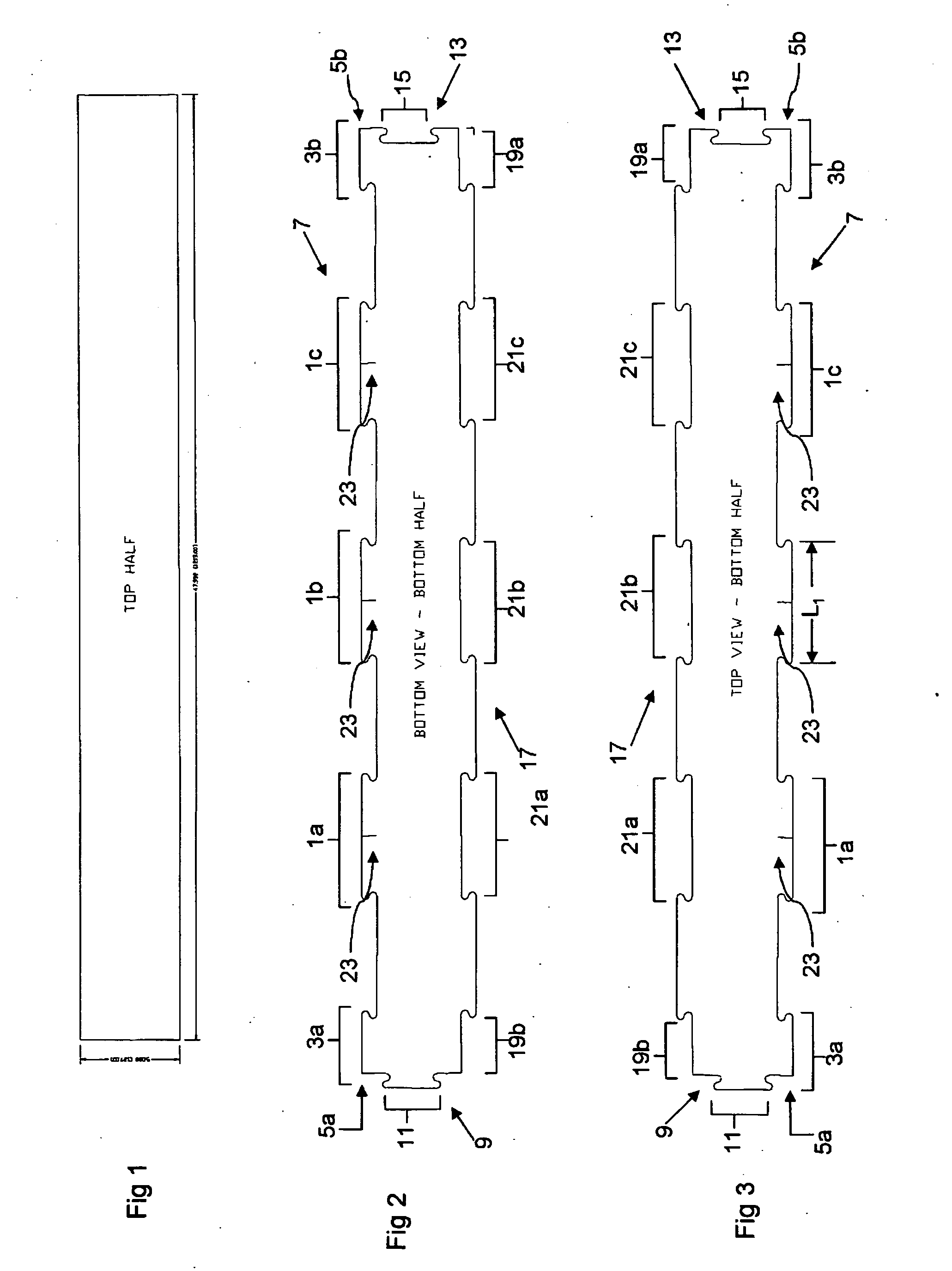

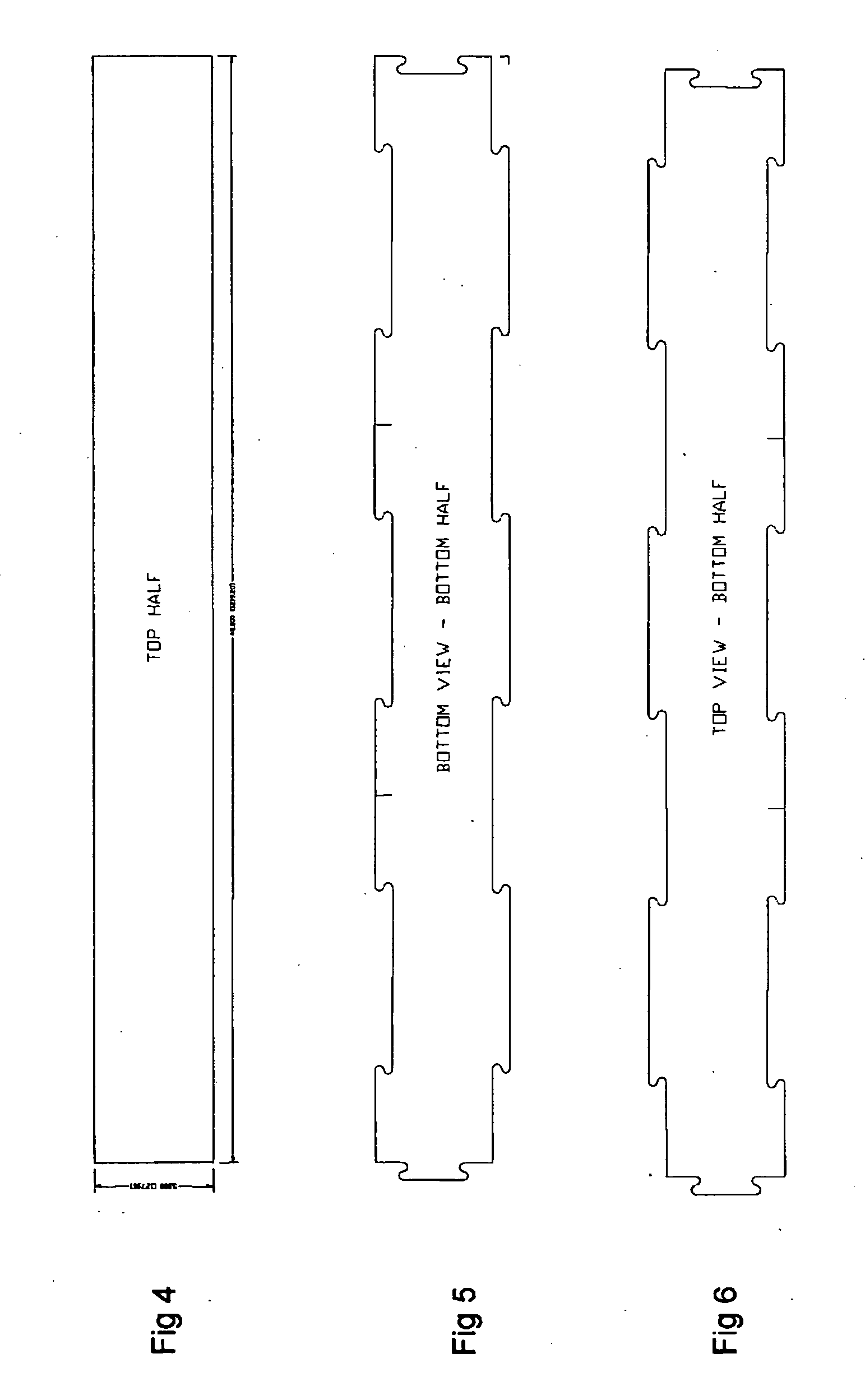

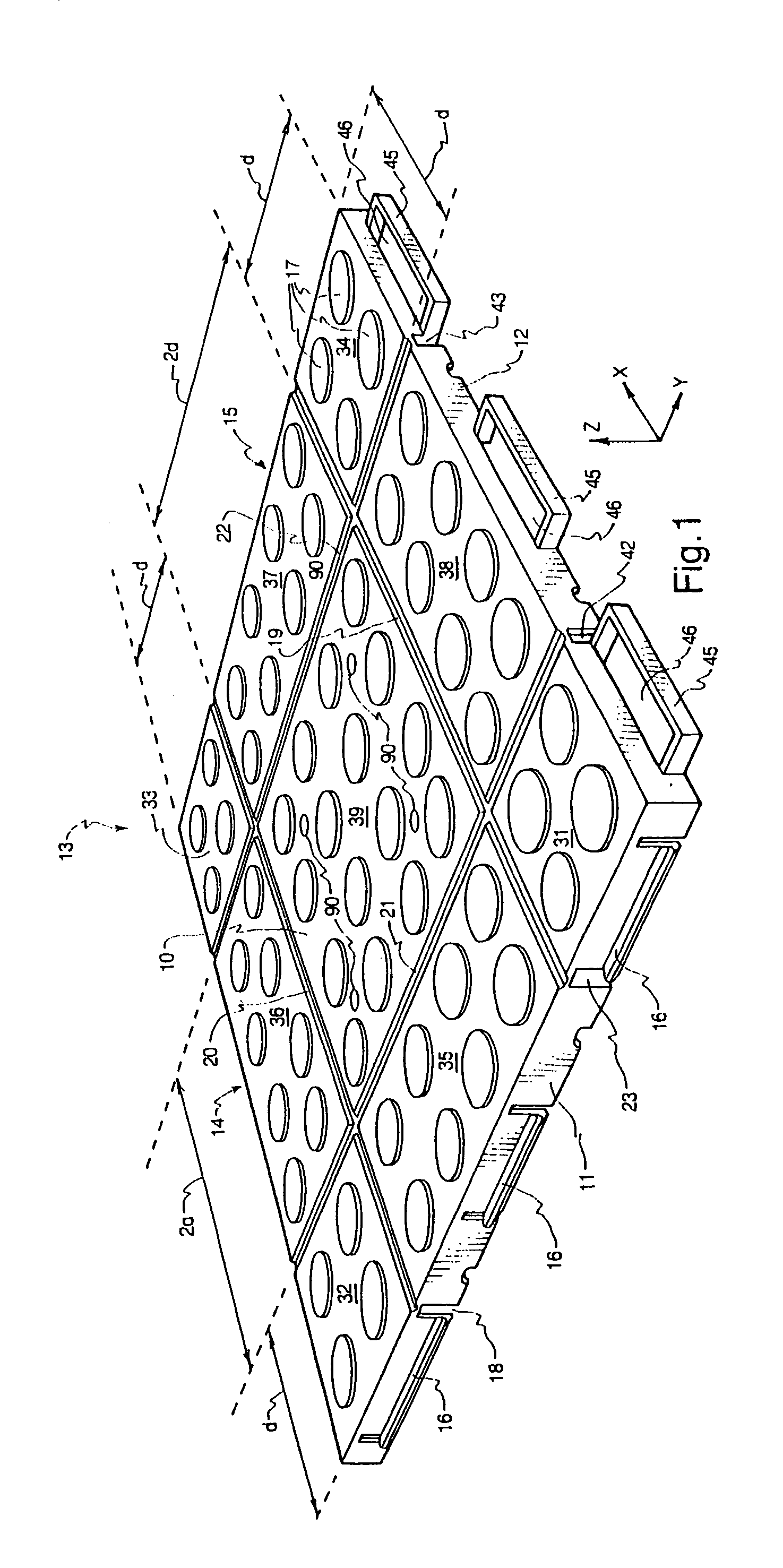

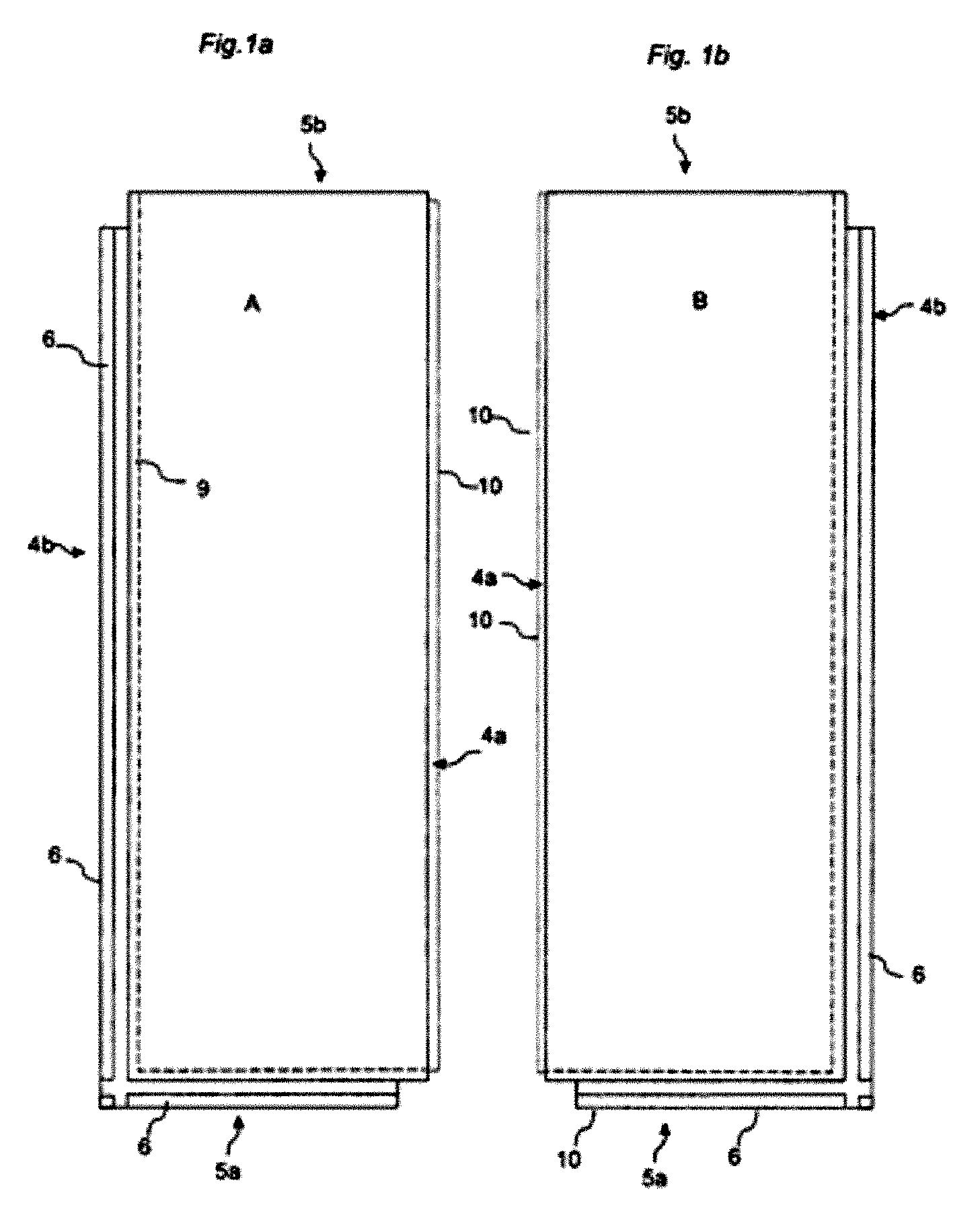

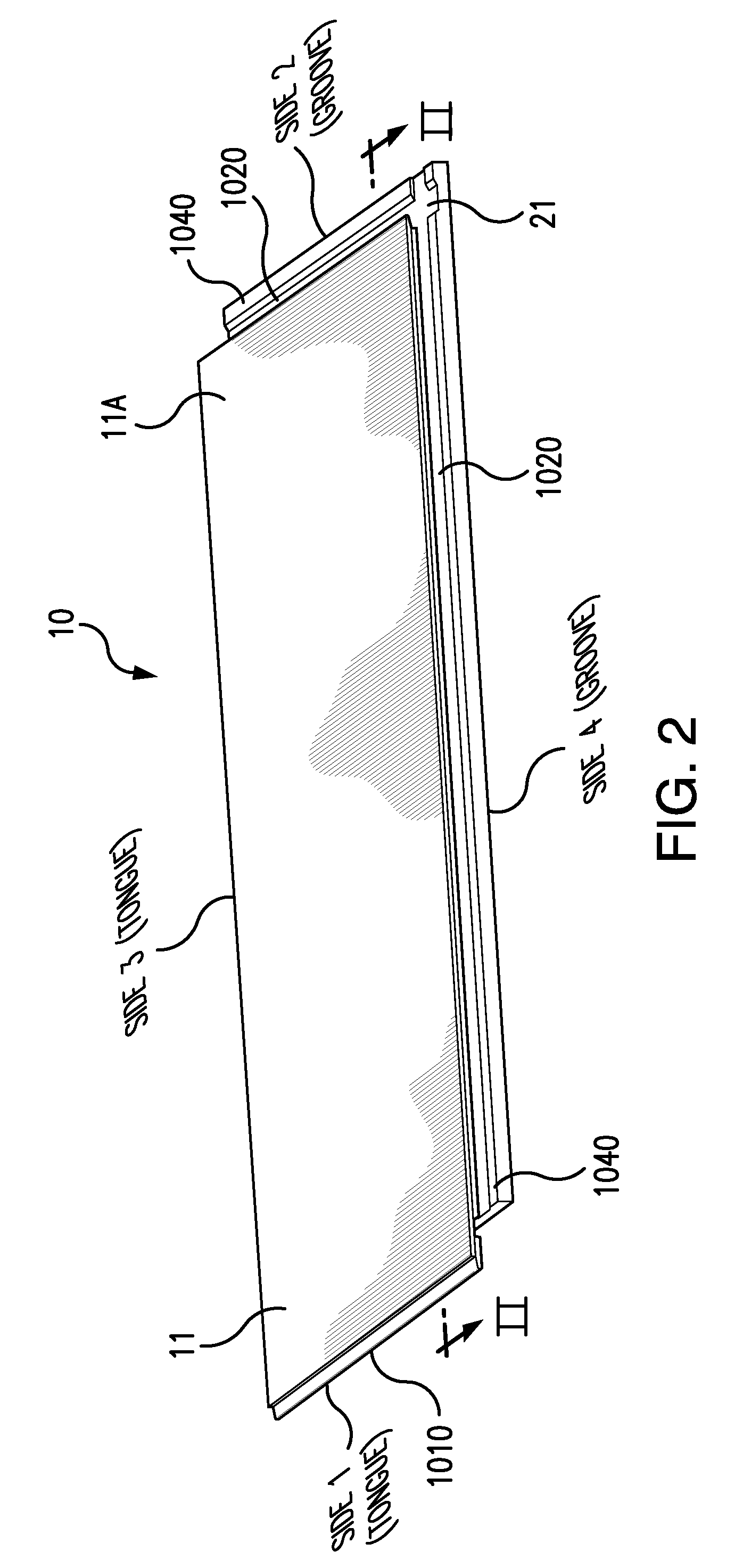

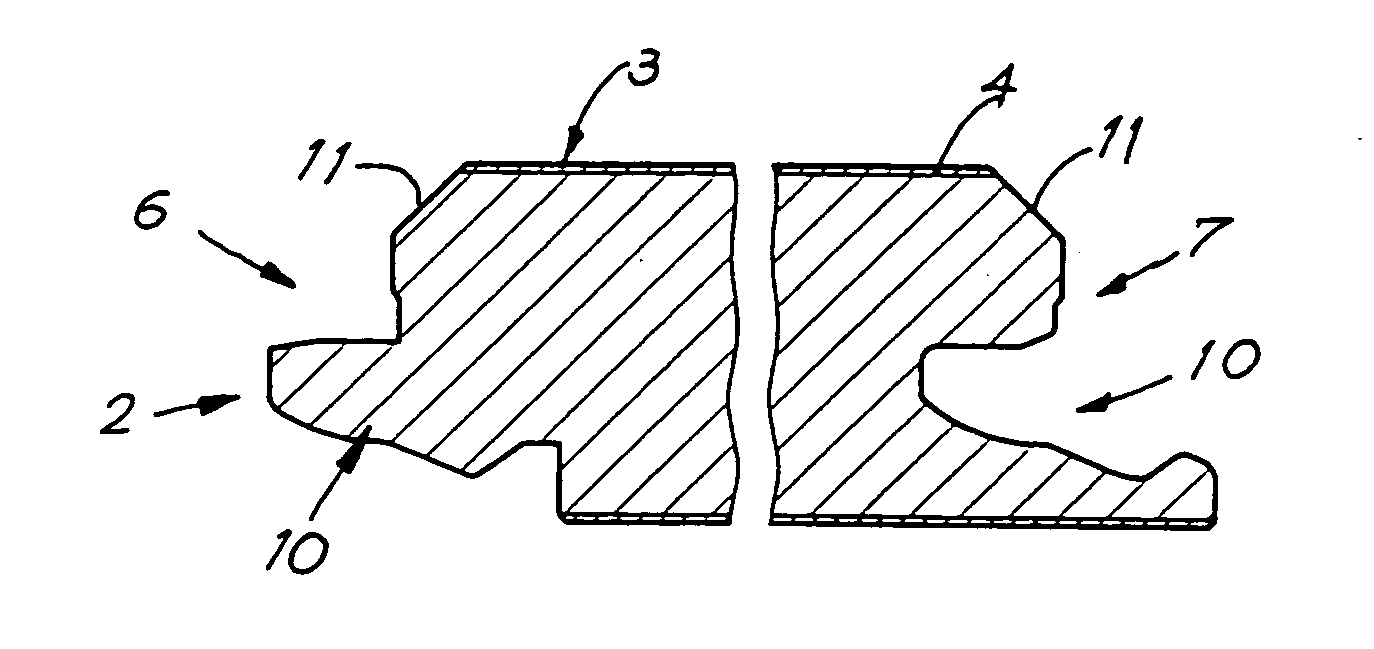

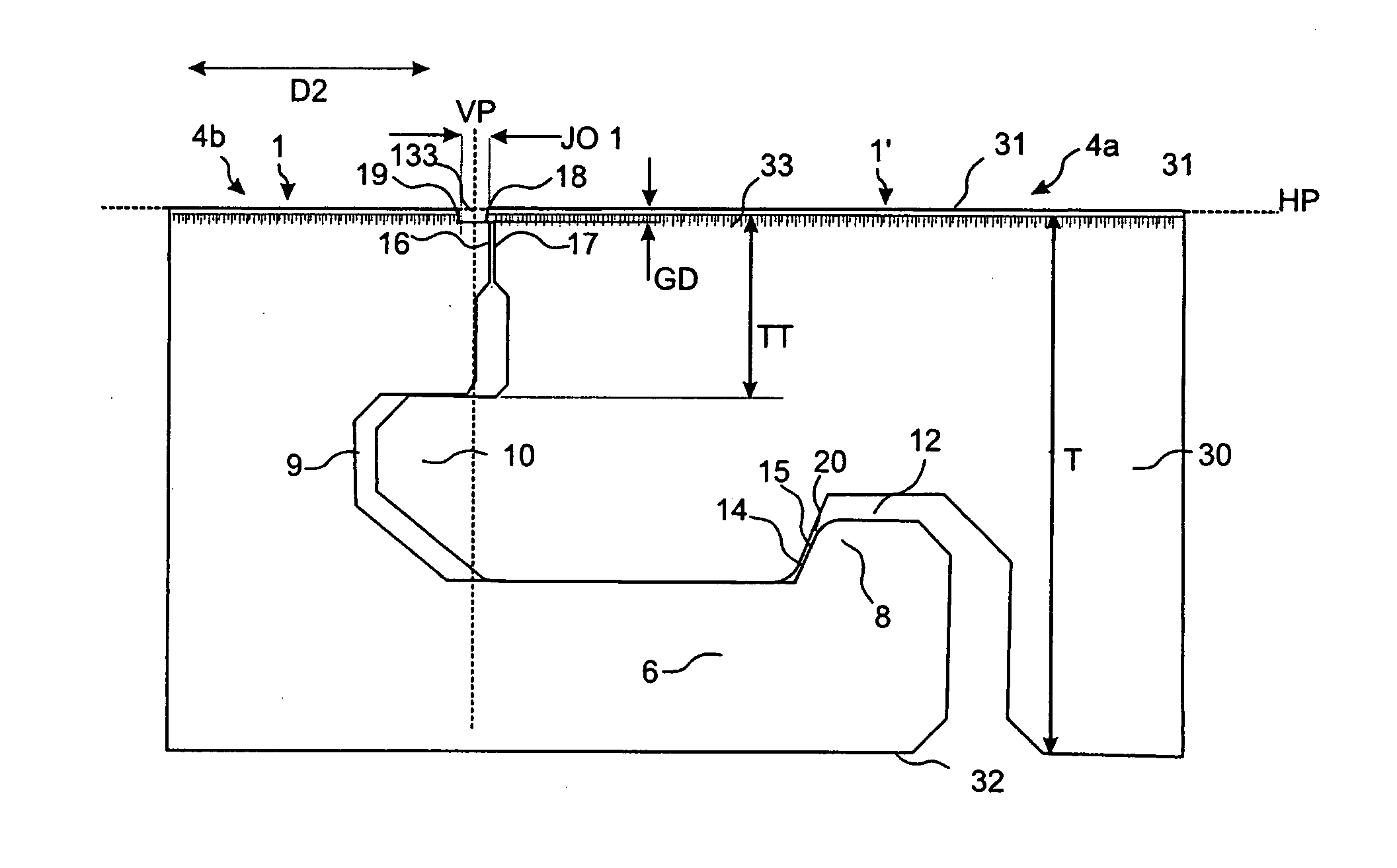

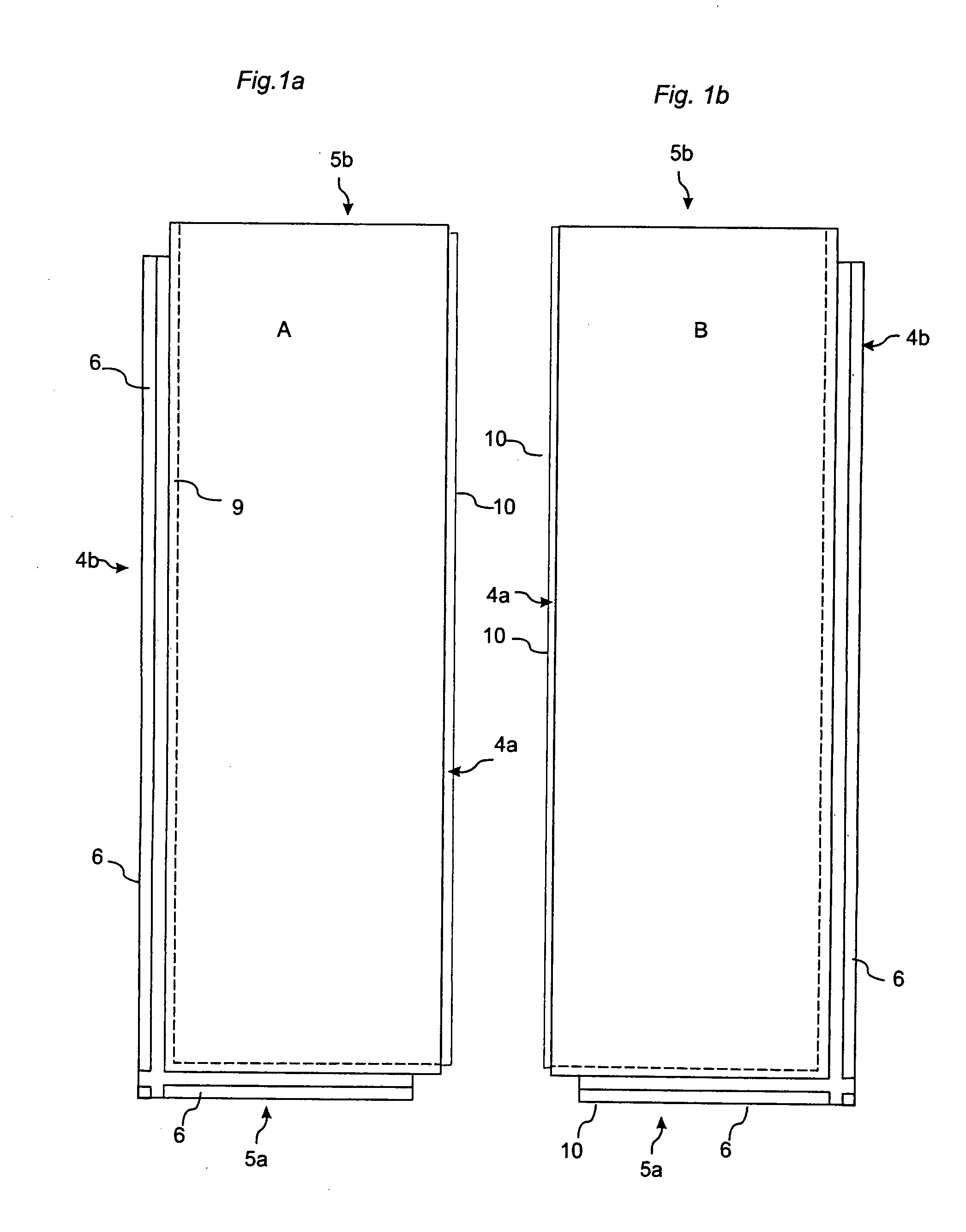

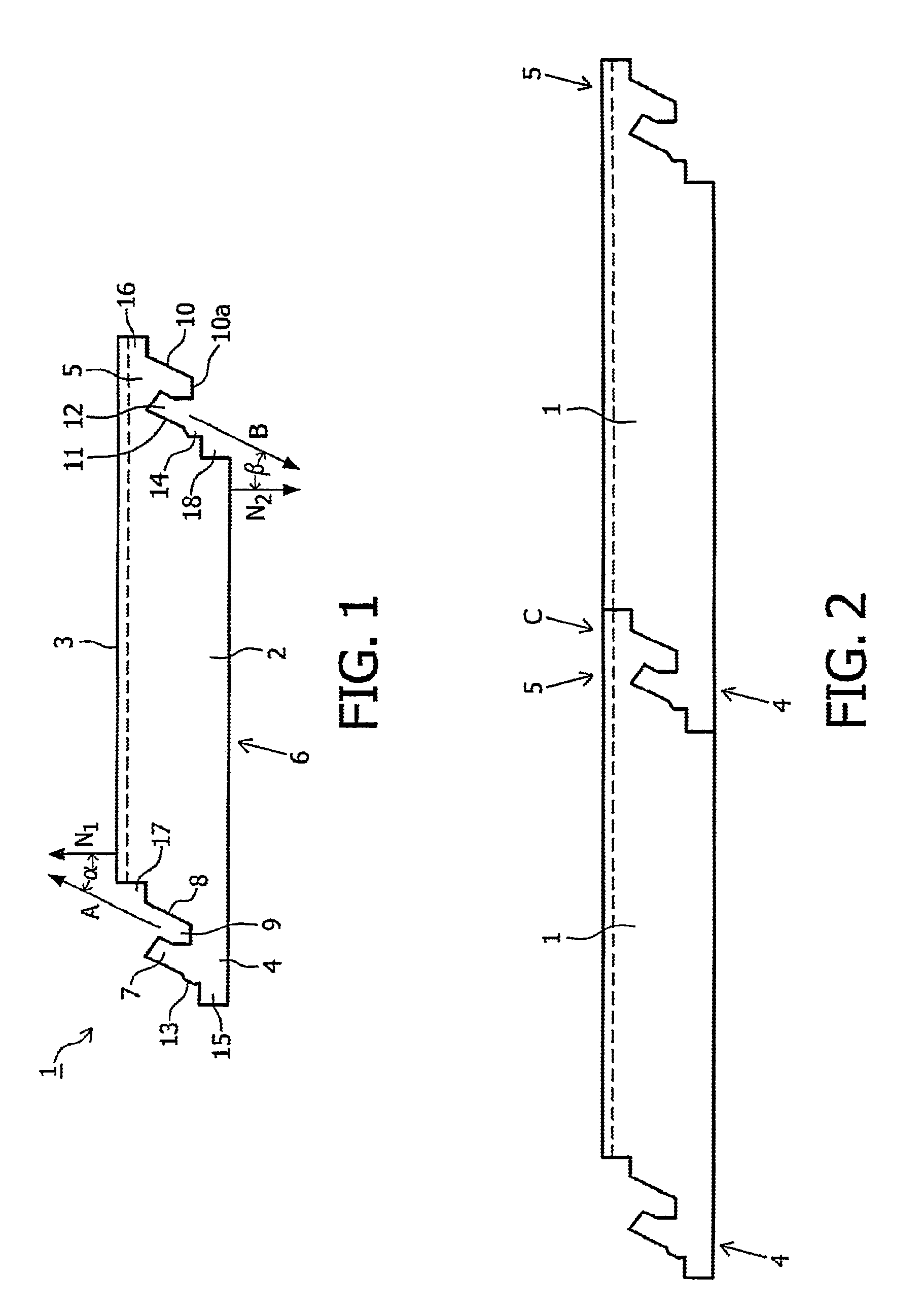

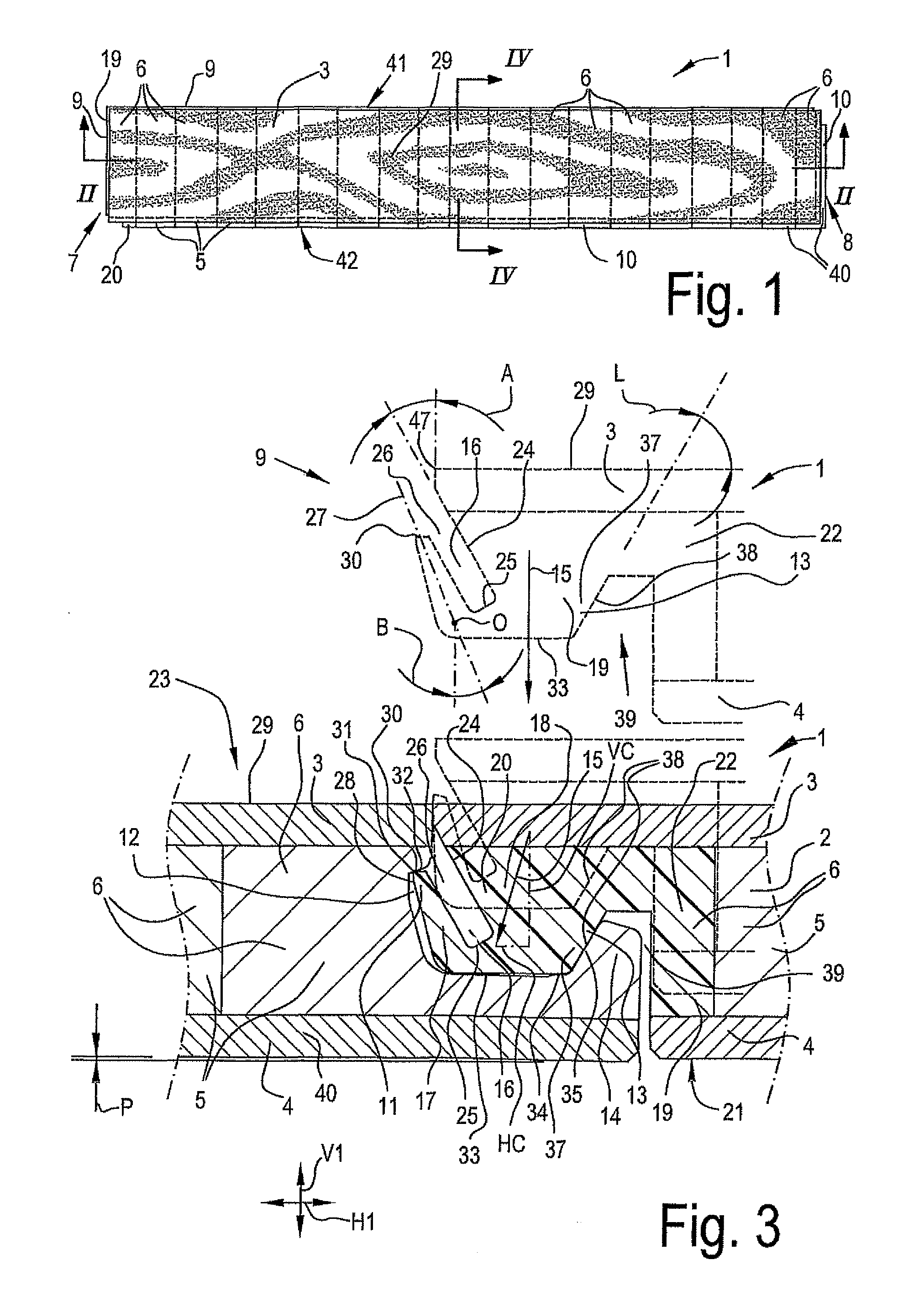

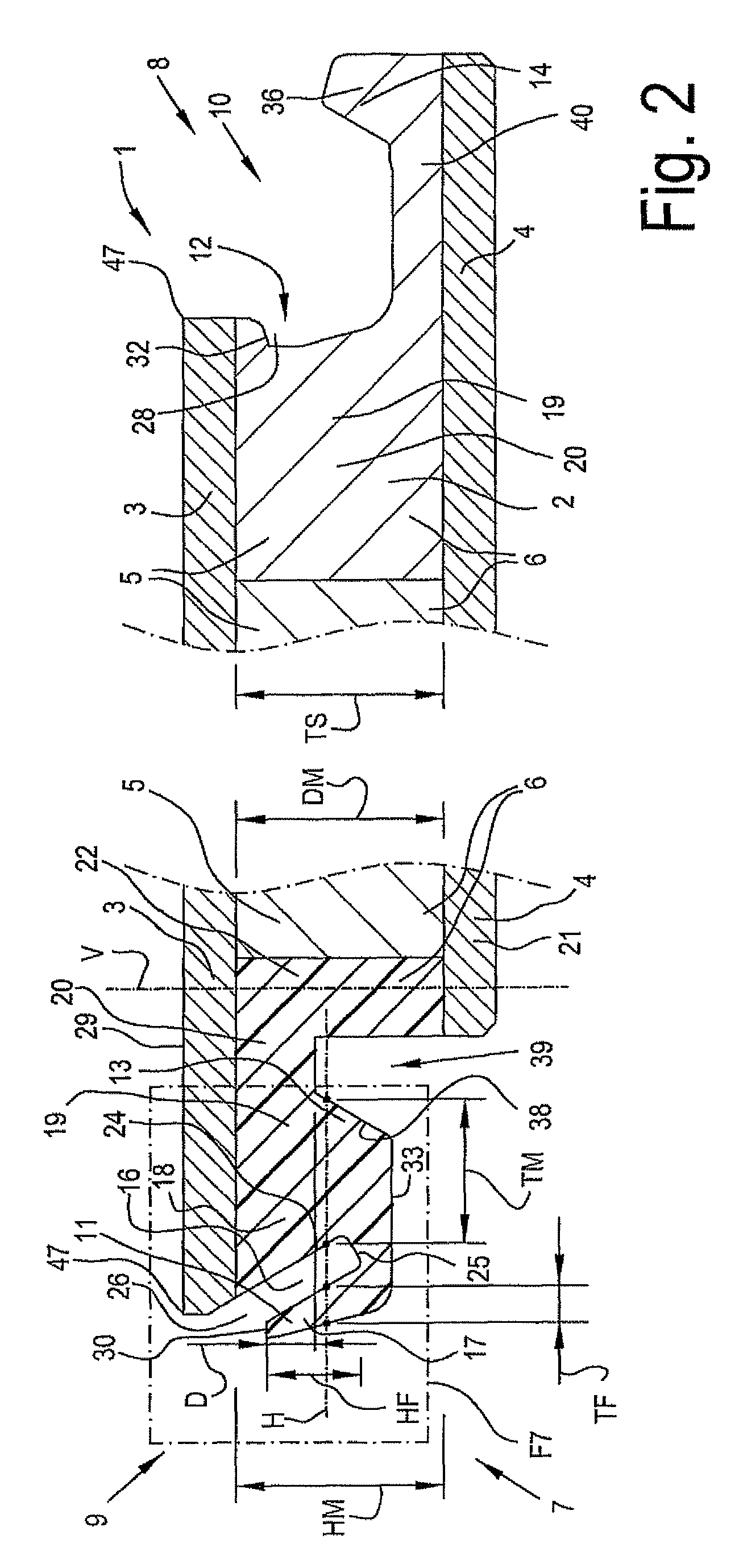

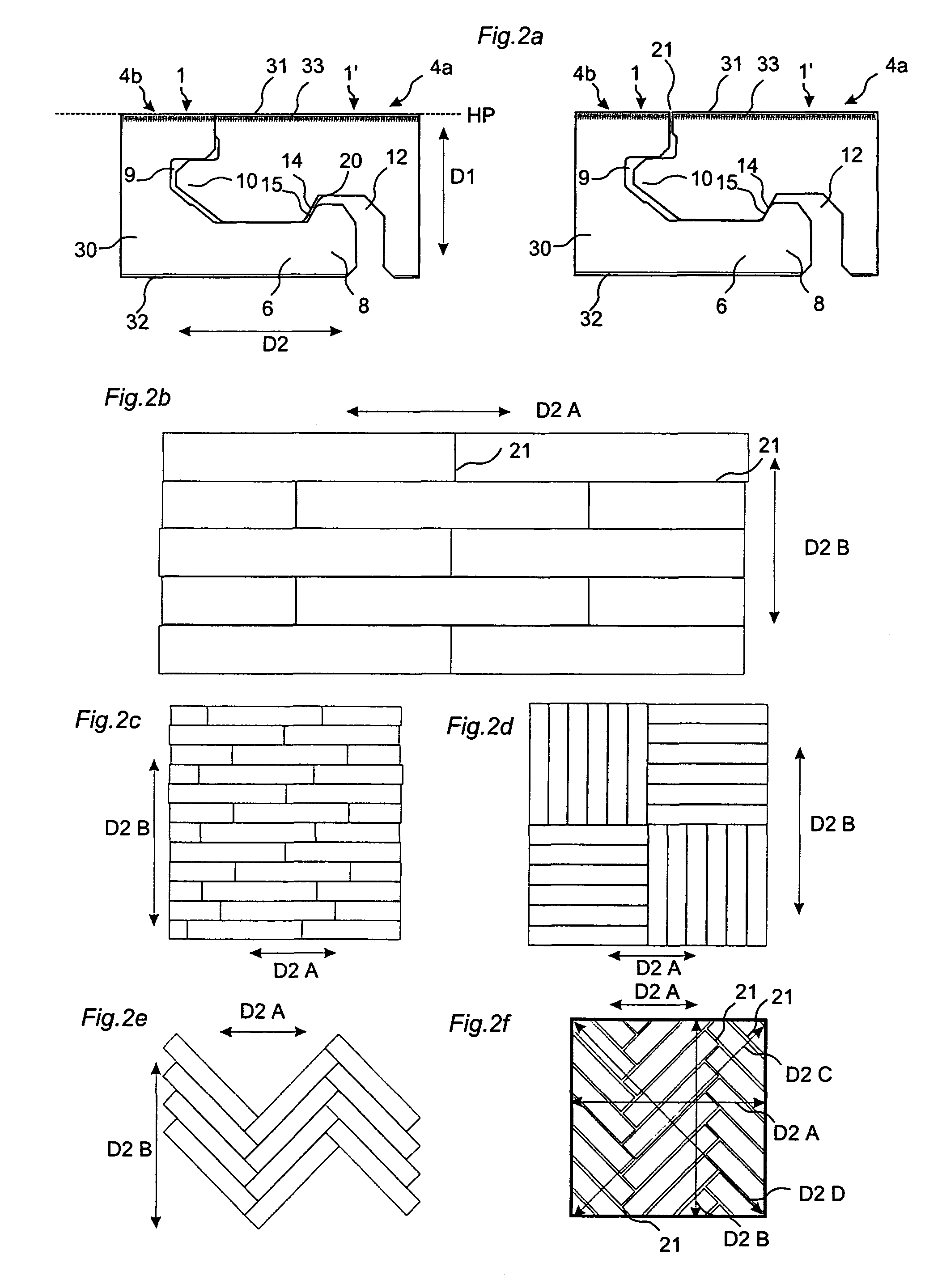

The invention relates to a panel element for forming a floor covering, consisting of several identical interconnectable panel elements and having the following features: two first sides of each panel element, called the “longitudinal sides”, these sides having a groove and a tongue; the tongue of a panel element which is positioned at an angle with an installation level of a first, identical panel element can be introduced into the groove of the first panel element; the tongue interacts with the groove of the adjacent, identical panel element in such a way that two interconnected panel elements are protected against separating forces which are exerted along both of the axes extending perpendicularly to the longitudinal side of the panel elements; two second sides of the panel element, called the end sides, are provided with fixing means and a groove and tongue, these forming an end-side connection between two adjacent panel elements; the end-side grooves and tongue can be interconnected by means of the panel element being lowered onto an identical panel element that has already been installed, essentially crosswise to the installation level, so that the panel element is protected from lifting forces, i.e. forces which are exerted considerably perpendicularly to the installation level.

Owner:FLOORING IND LTD

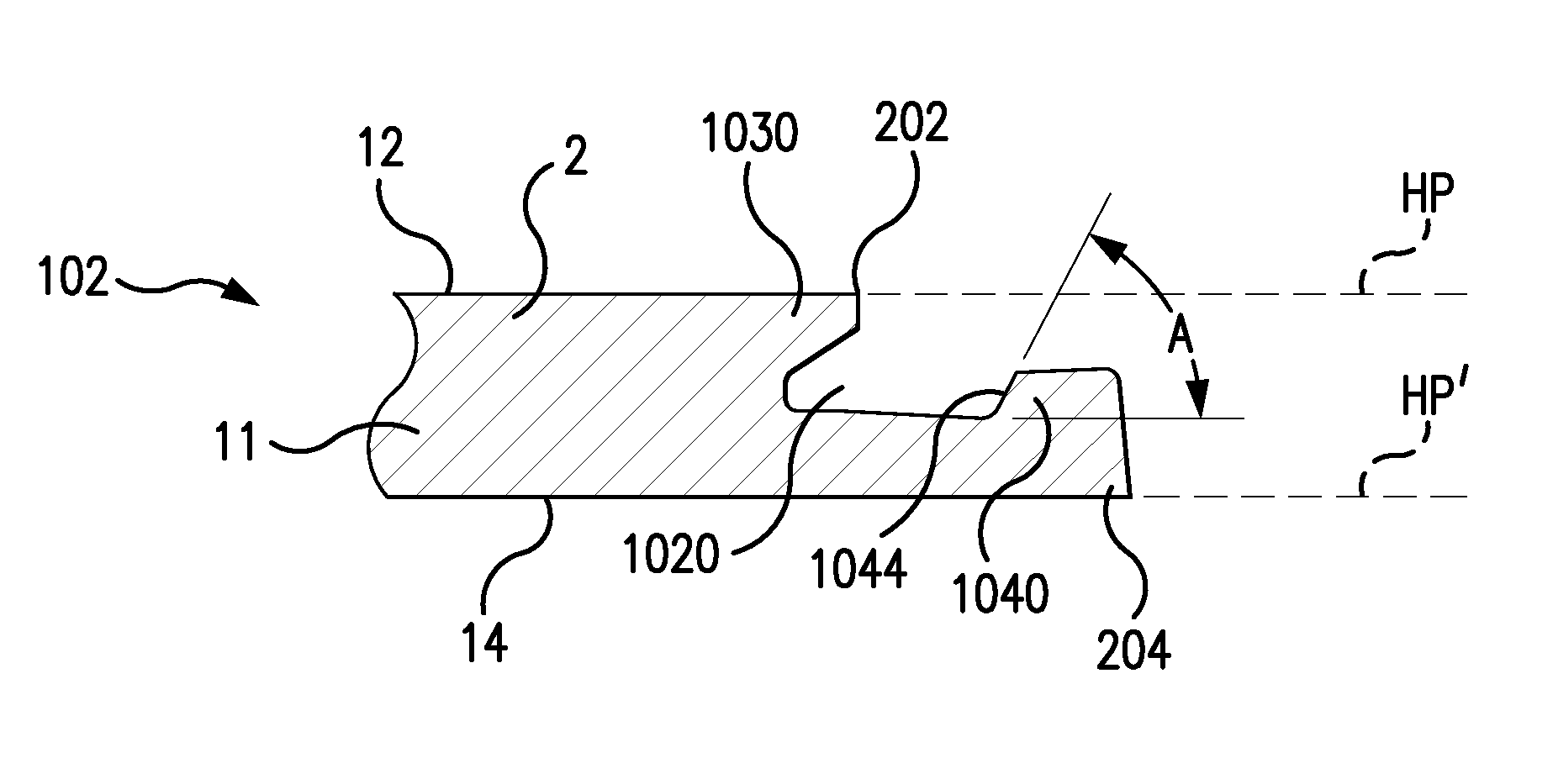

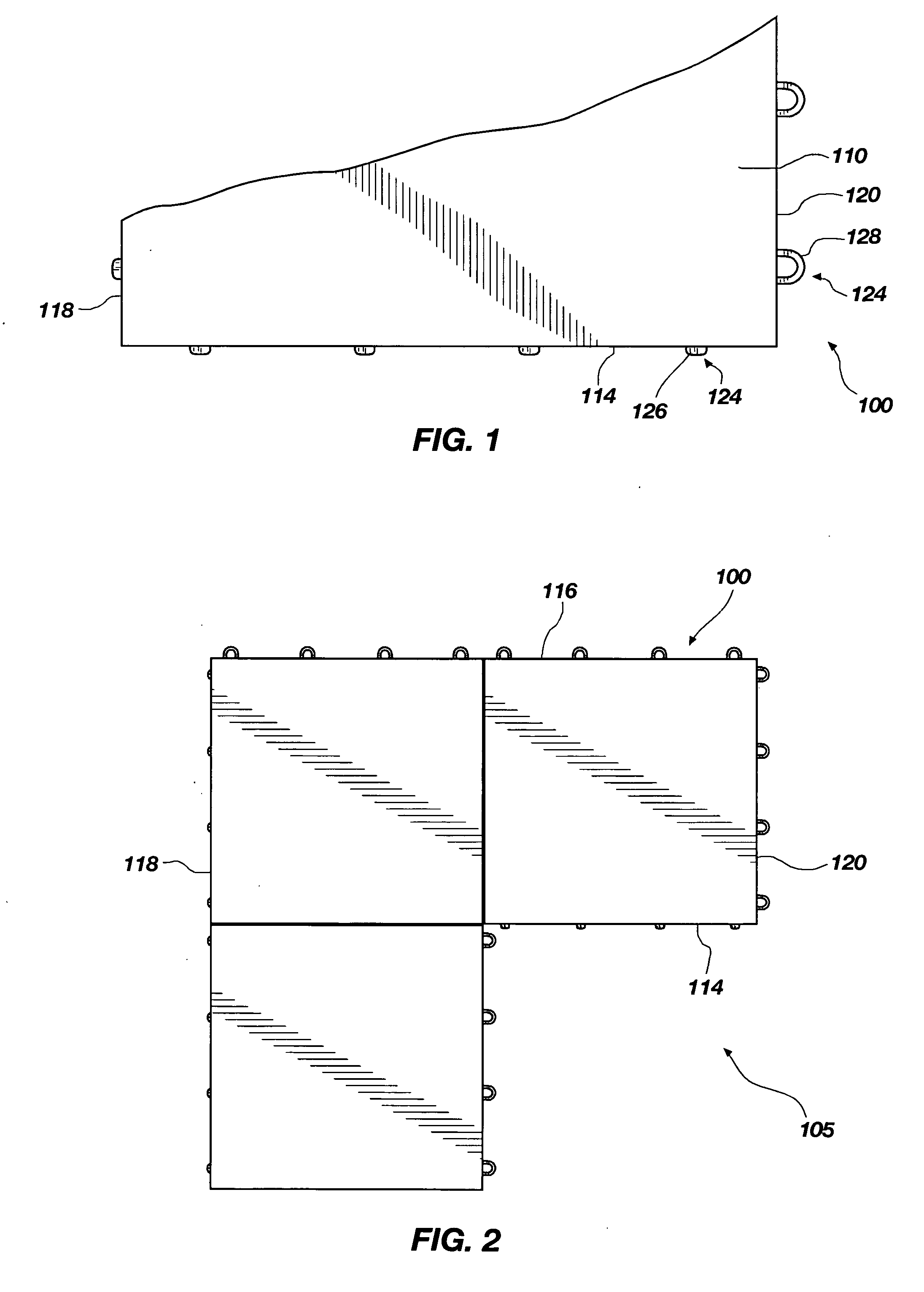

Floor covering and inductive power system

InactiveUS20100314946A1Improving magnetic couplingPrevent short-circuitingRoof covering using slabs/sheetsBatteries circuit arrangementsCharge currentEngineering

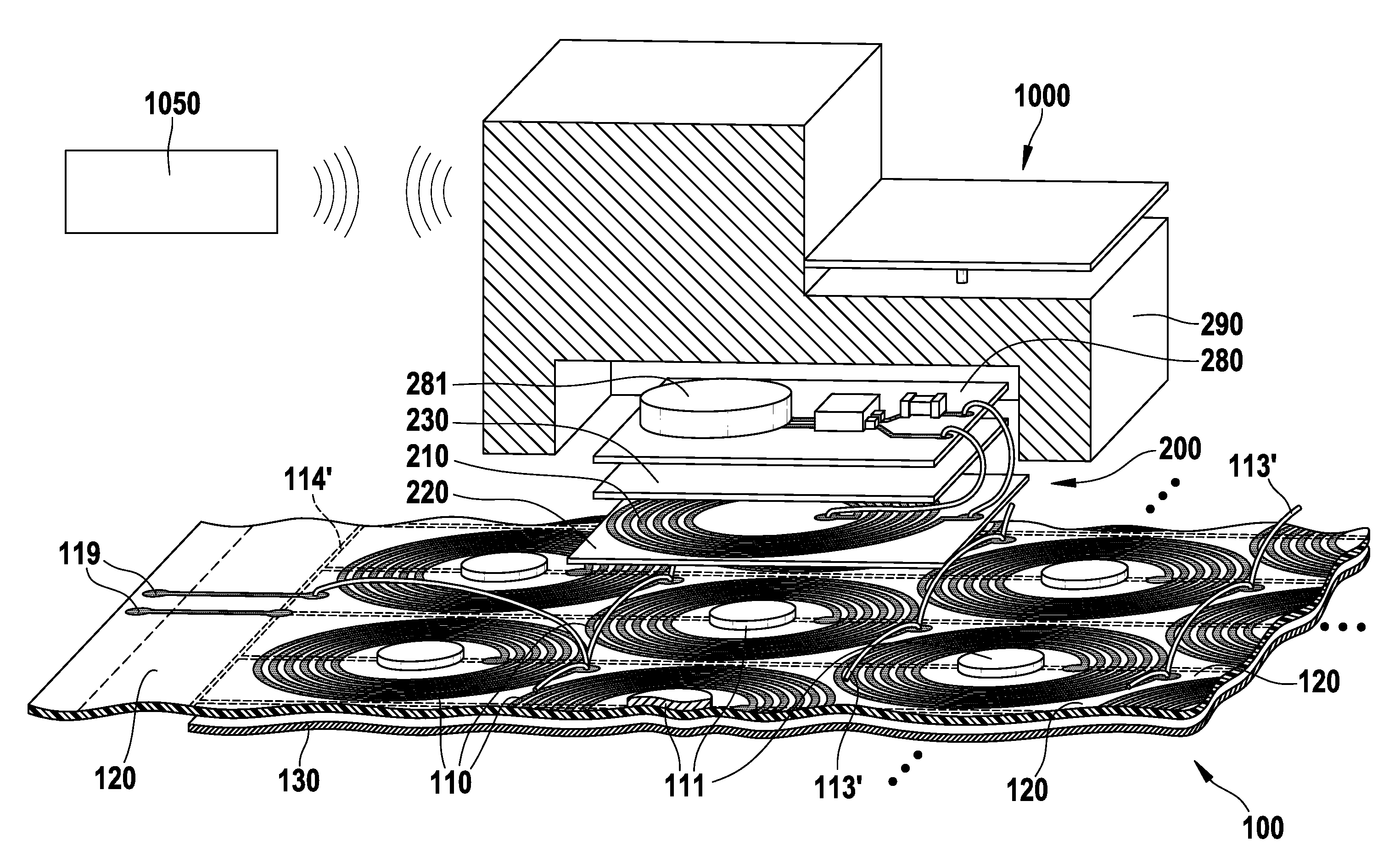

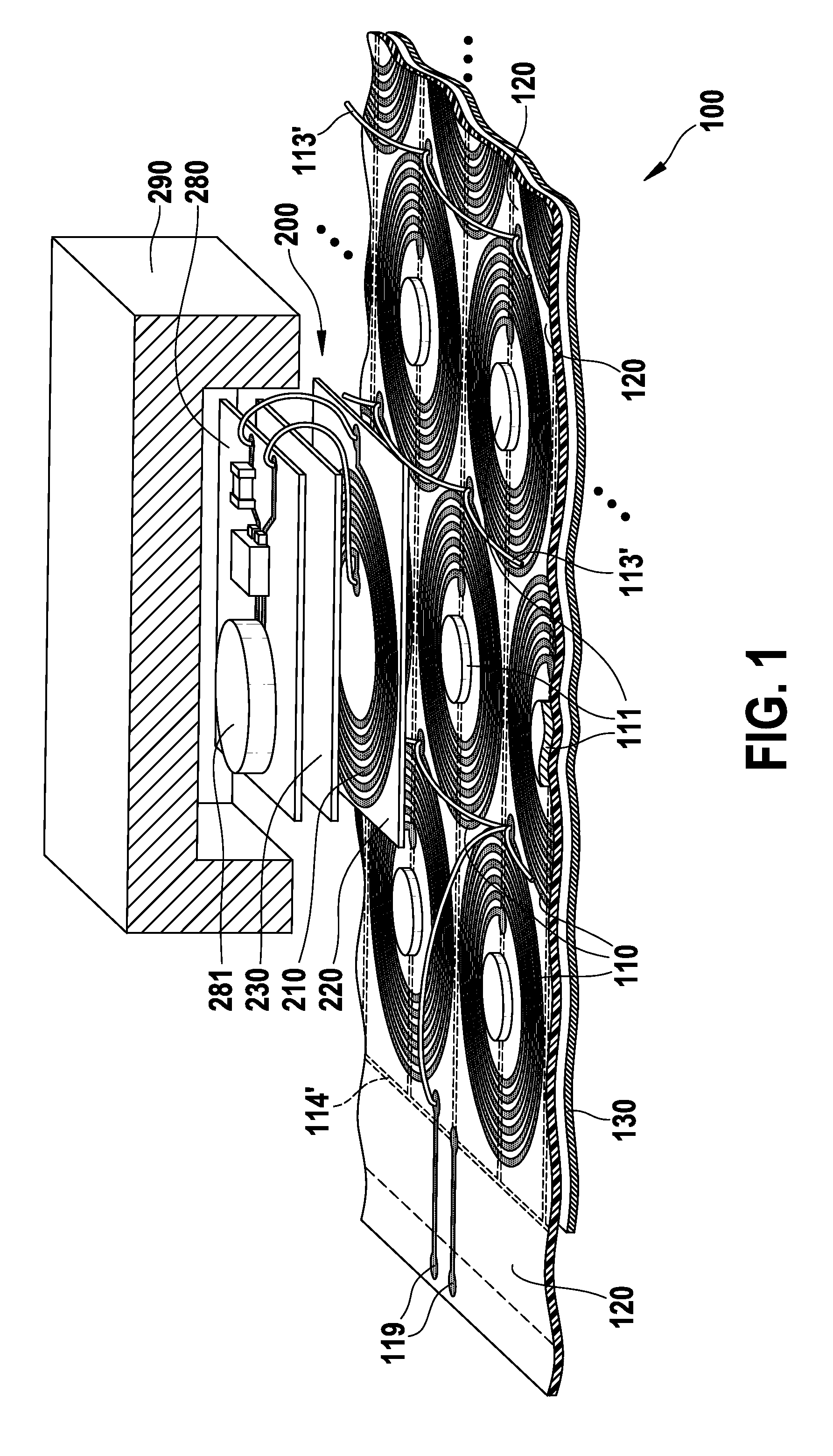

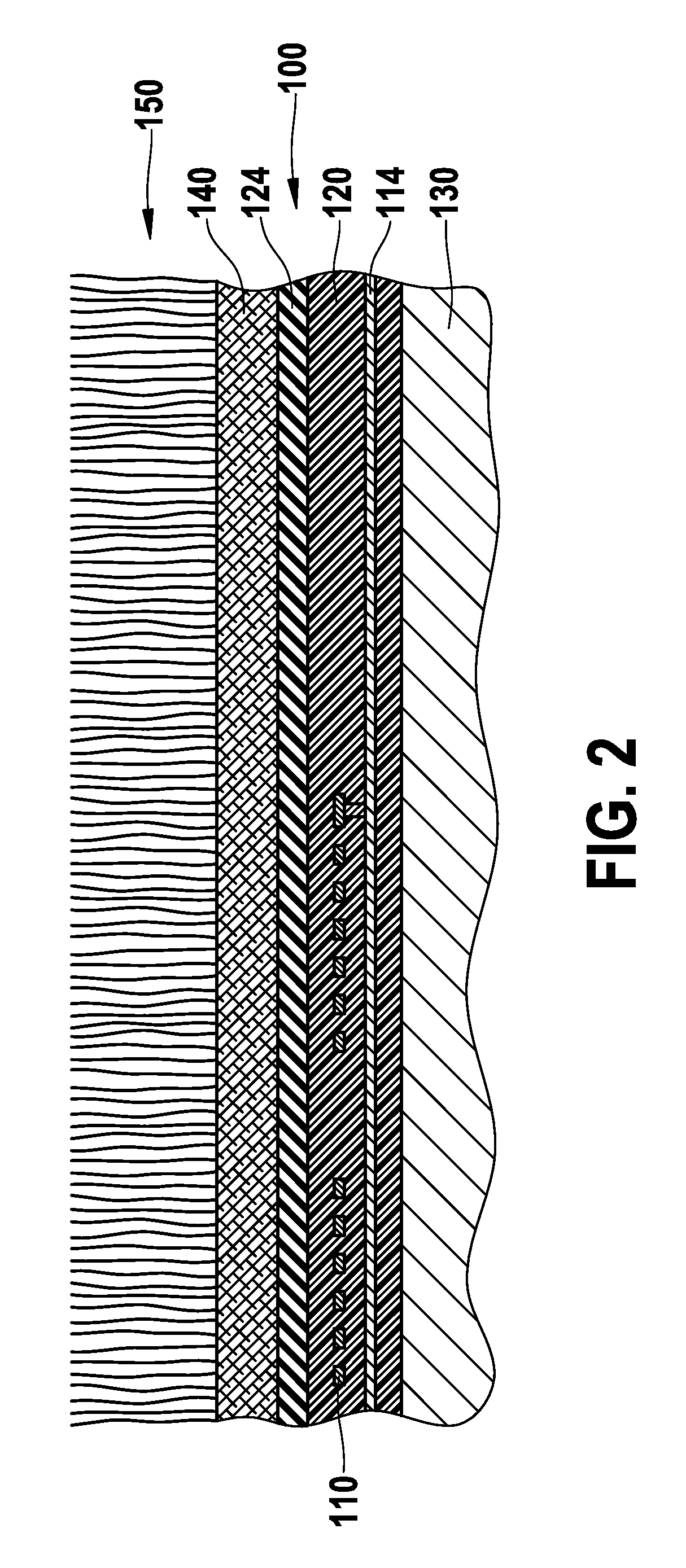

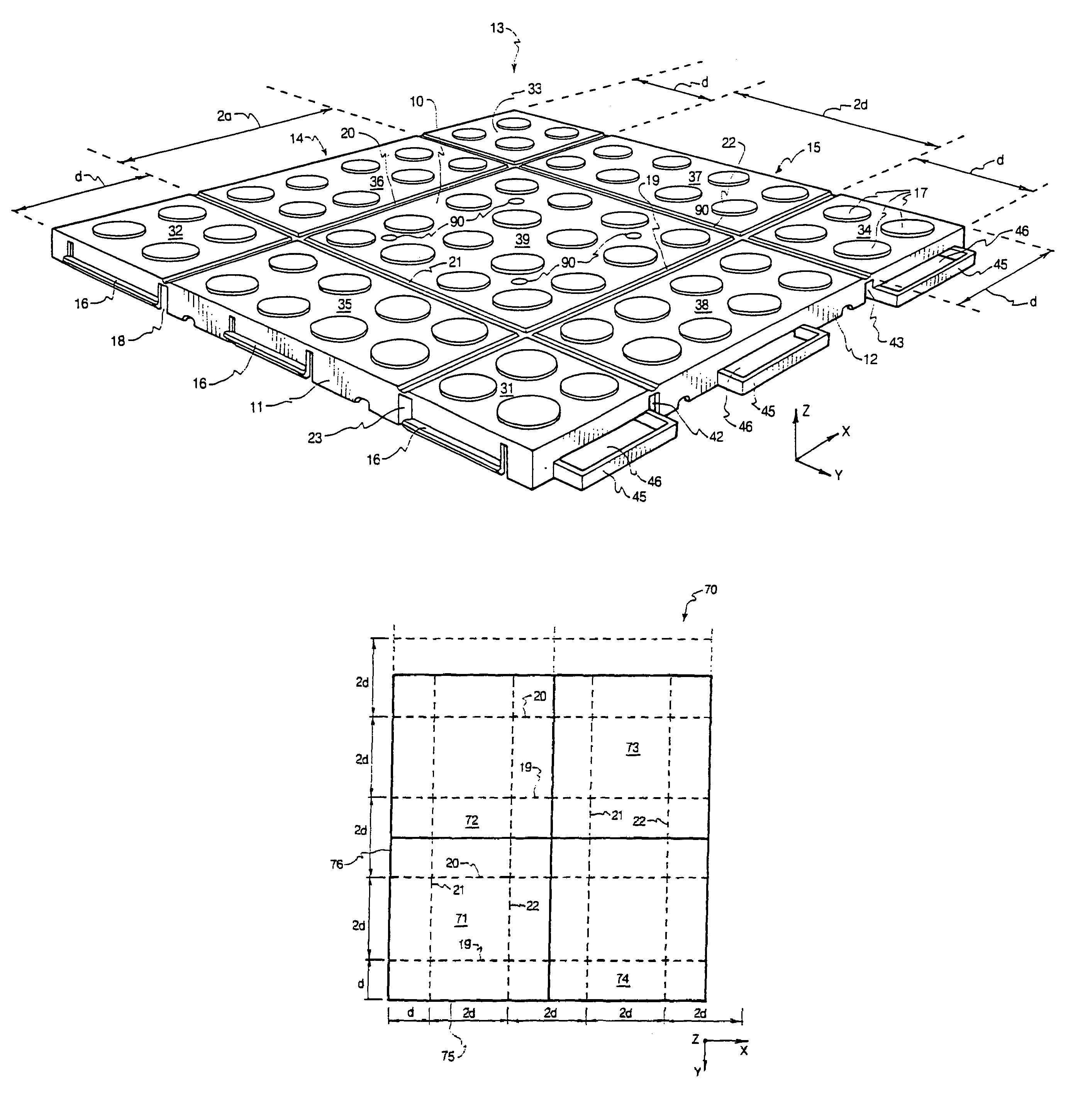

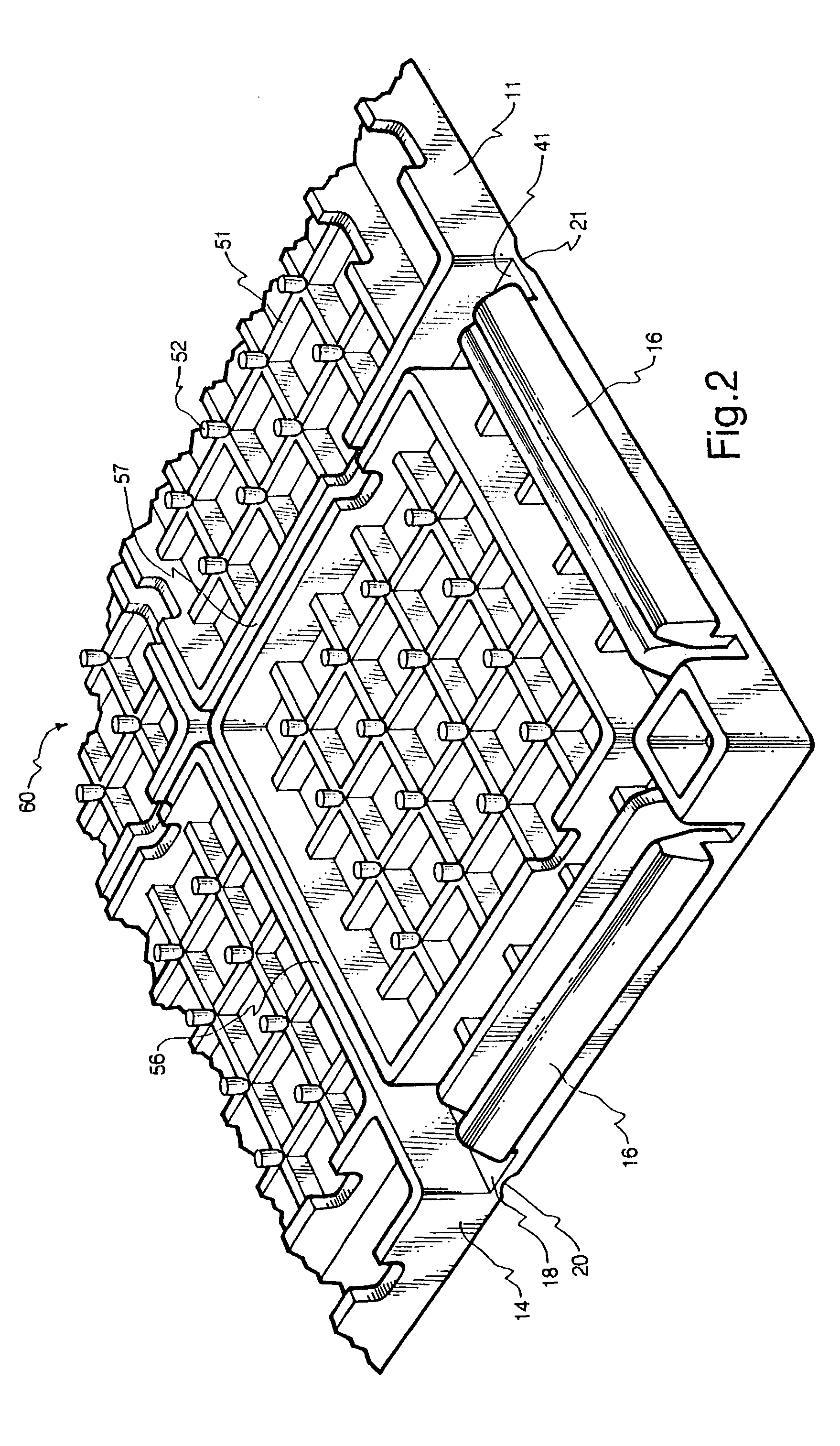

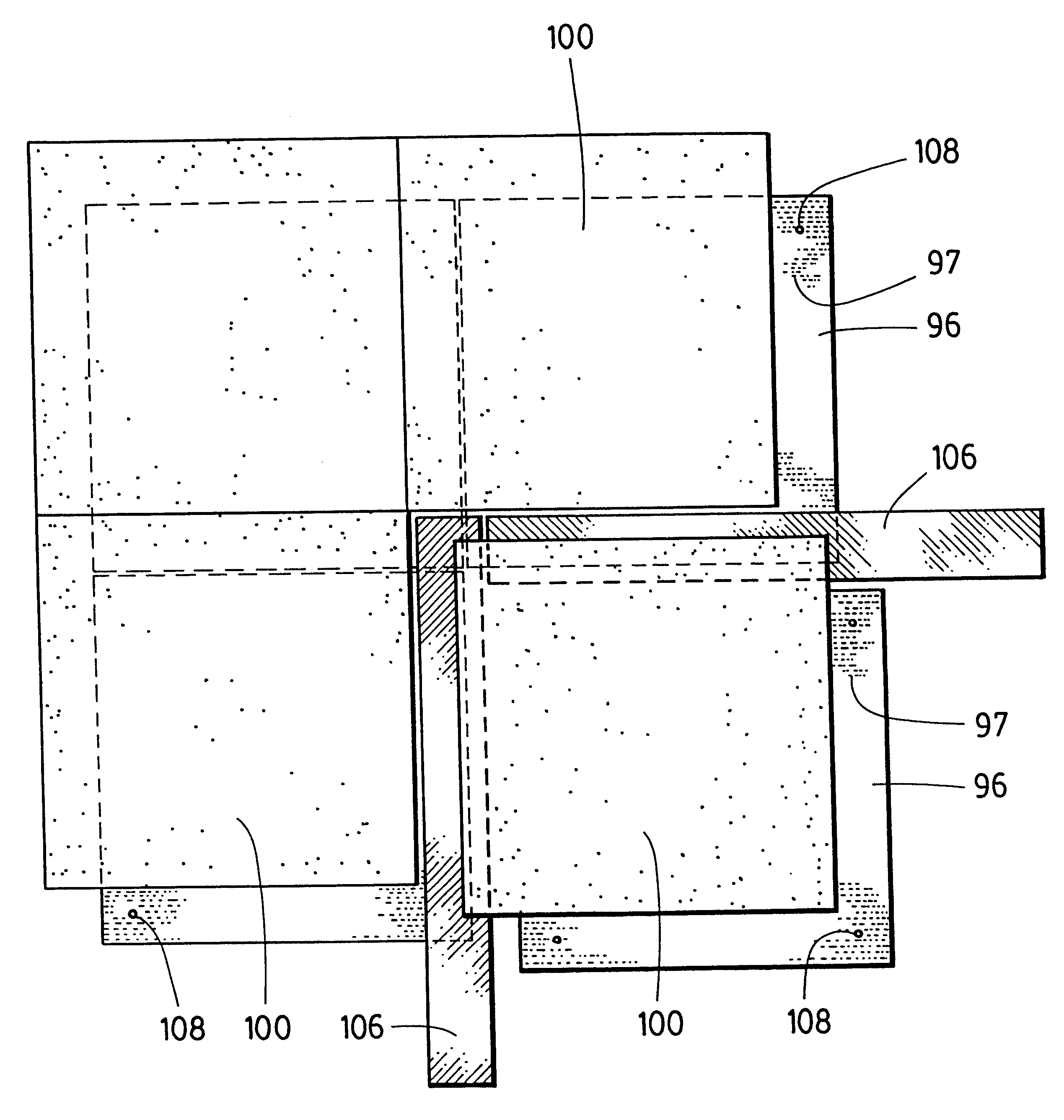

The invention relates to a floor covering (100) comprising: a plurality of coils (110), each coil (110) being operable to supply inductive energy to a power receiver circuit (200); wherein the plurality of coils comprises a transmitter area occupying the largest area of the floor covering (100); and a charging current through the coils is operable to generate said inductive energy.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Panel element

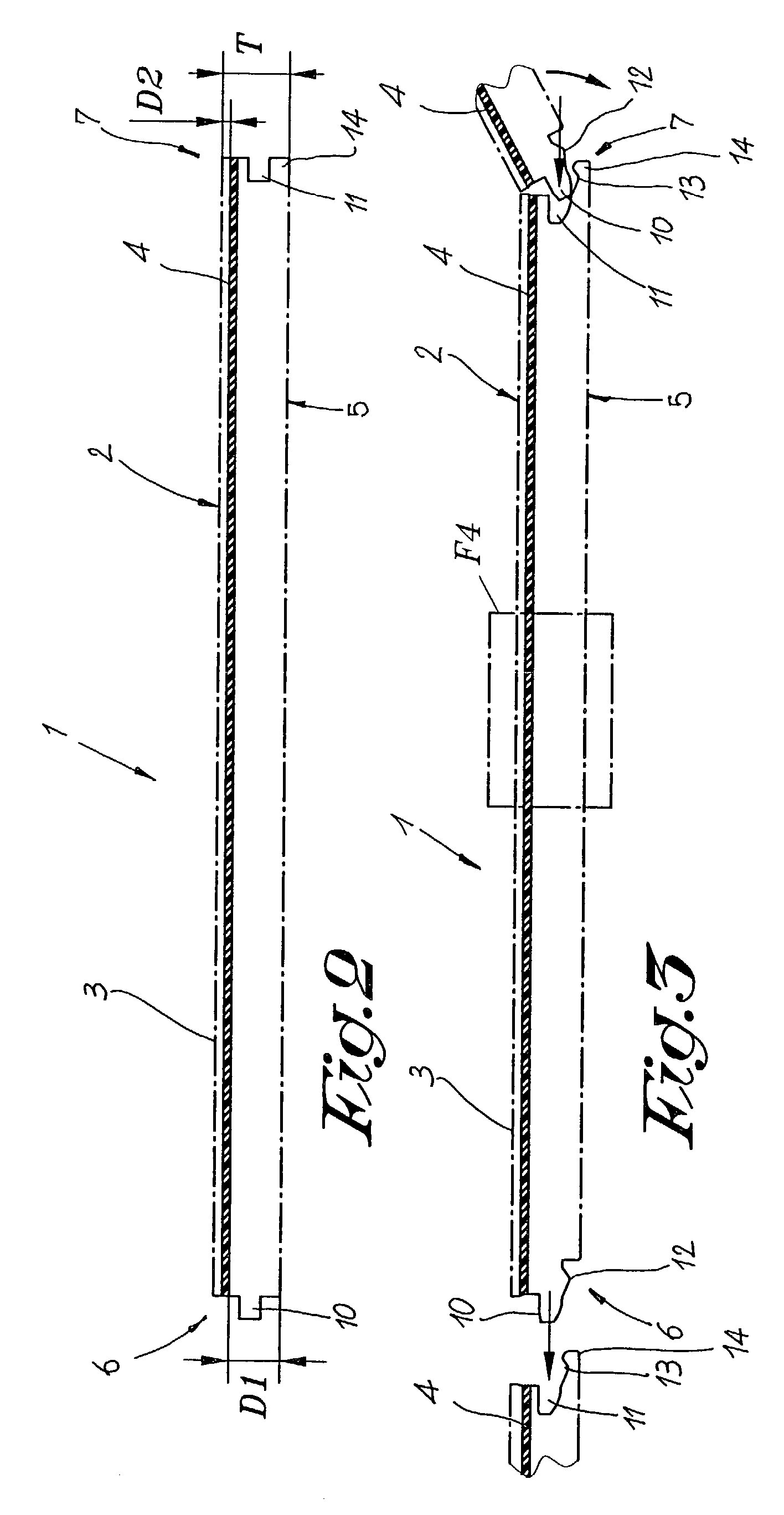

InactiveUS20030037504A1Simple yet reliable layingPrecise arrangementCovering/liningsWallsEngineeringFloor covering

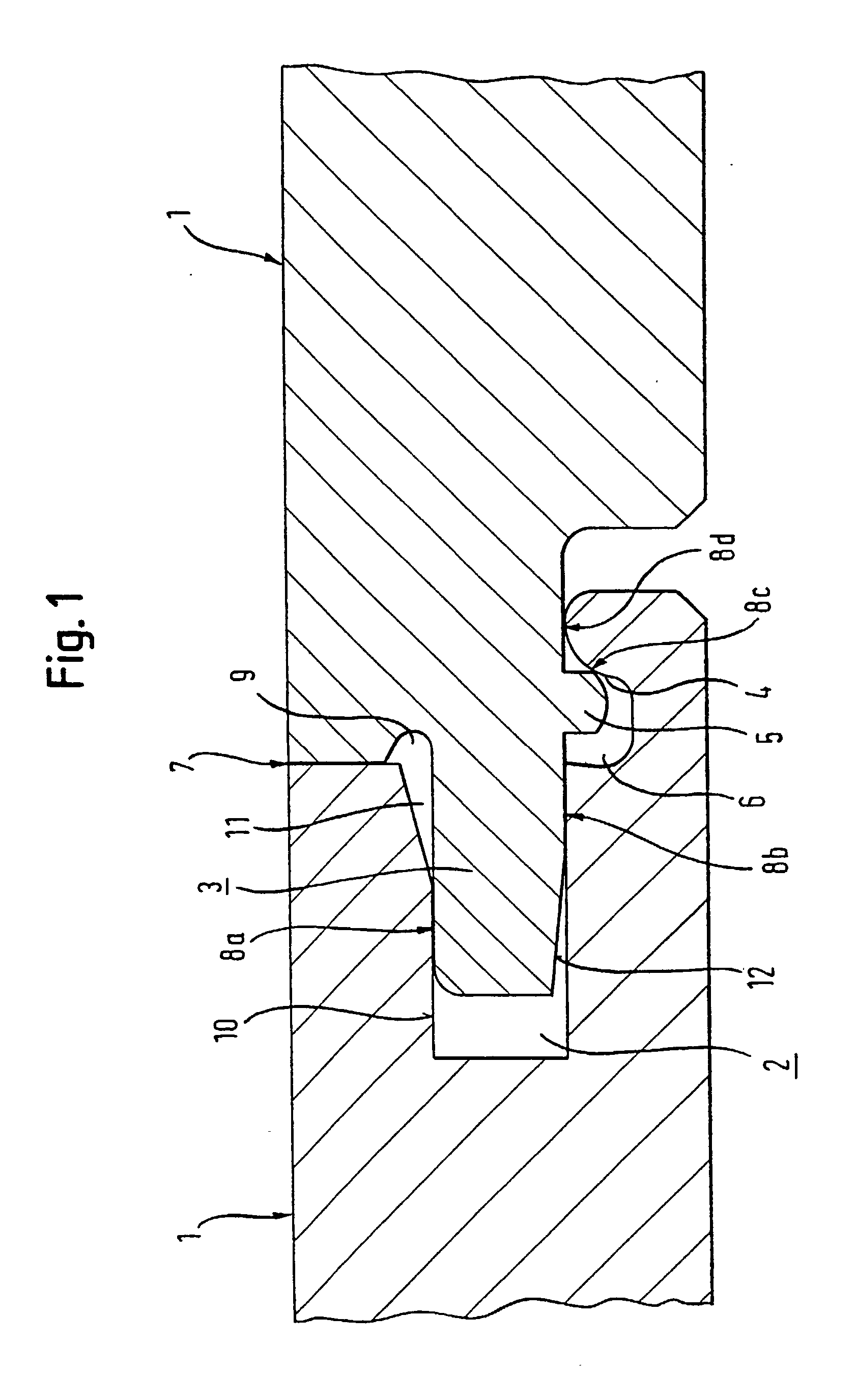

The invention relates to a panel element for forming a floor covering, consisting of several identical interconnectable panel elements and having the following features: two first sides of each panel element, called the "longitudinal sides", these sides having a groove and a tongue; the tongue of a panel element which is positioned at an angle with an installation level of a first, identical panel element can be introduced into the groove of the first panel element; the tongue interacts with the groove of the adjacent, identical panel element in such a way that two interconnected panel elements are protected against separating forces which are exerted along both of the axes extending perpendicularly to the longitudinal side of the panel elements; two second sides of the panel element, called the end sides, are provided with fixing means and a groove and tongue, these forming an end-side connection between two adjacent panel elements; the end-side grooves and tongue can be interconnected by means of the panel element being lowered onto an identical panel element that has already been installed, essentially crosswise to the installation level, so that the panel element is protected from lifting forces, i.e. forces which are exerted considerably perpendicularly to the installation level.

Owner:FLOORING IND LTD

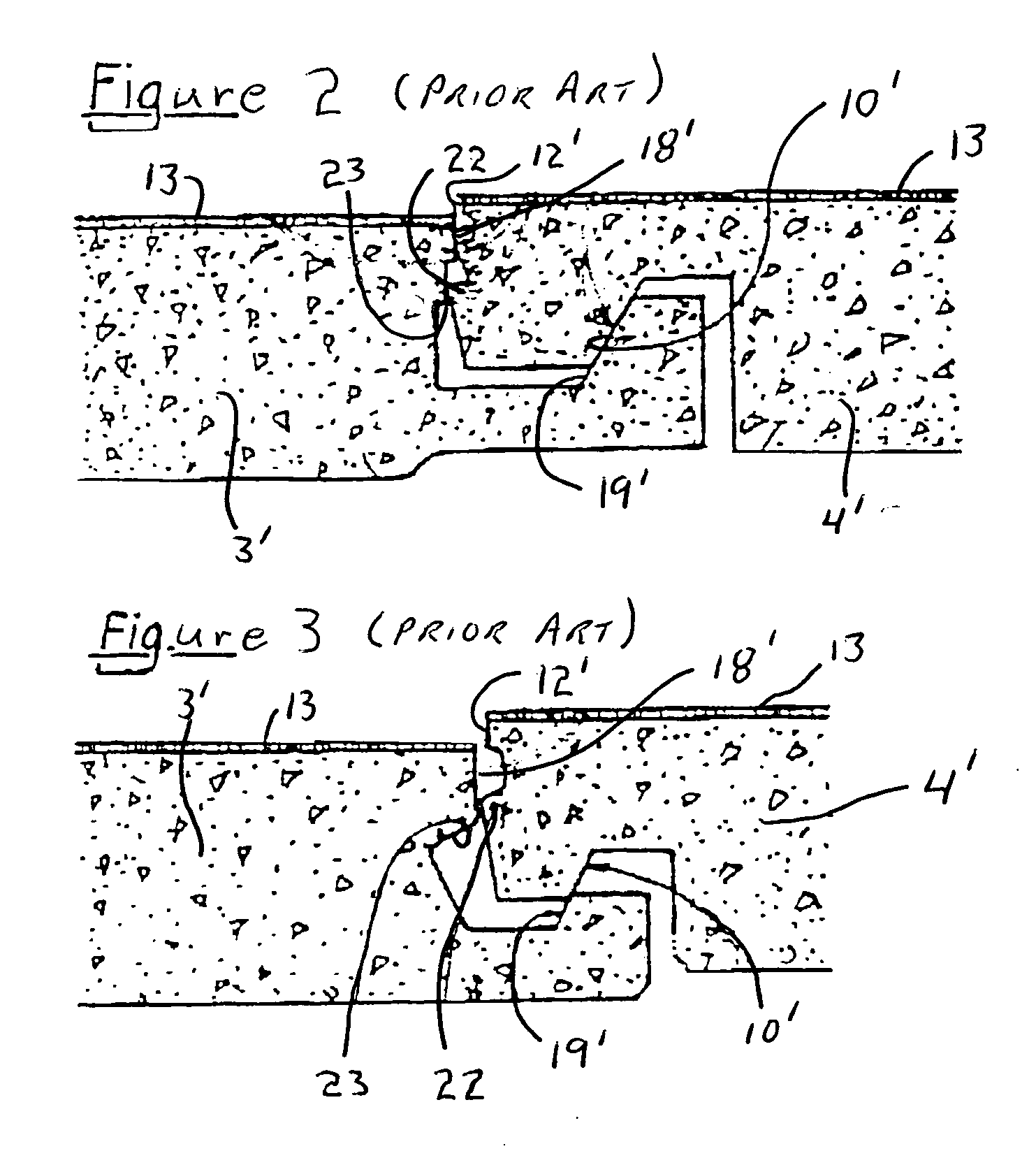

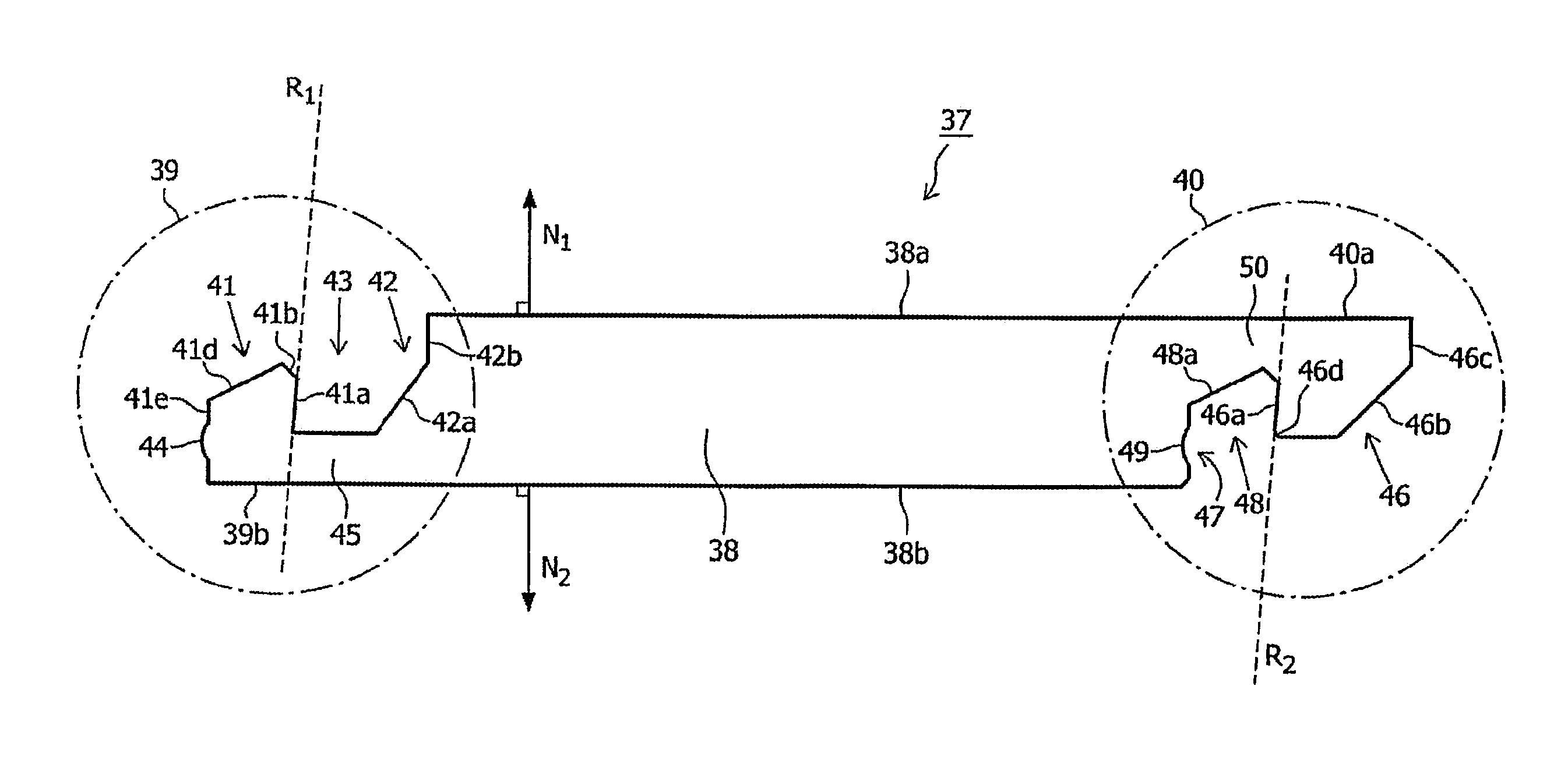

Floor covering and locking systems

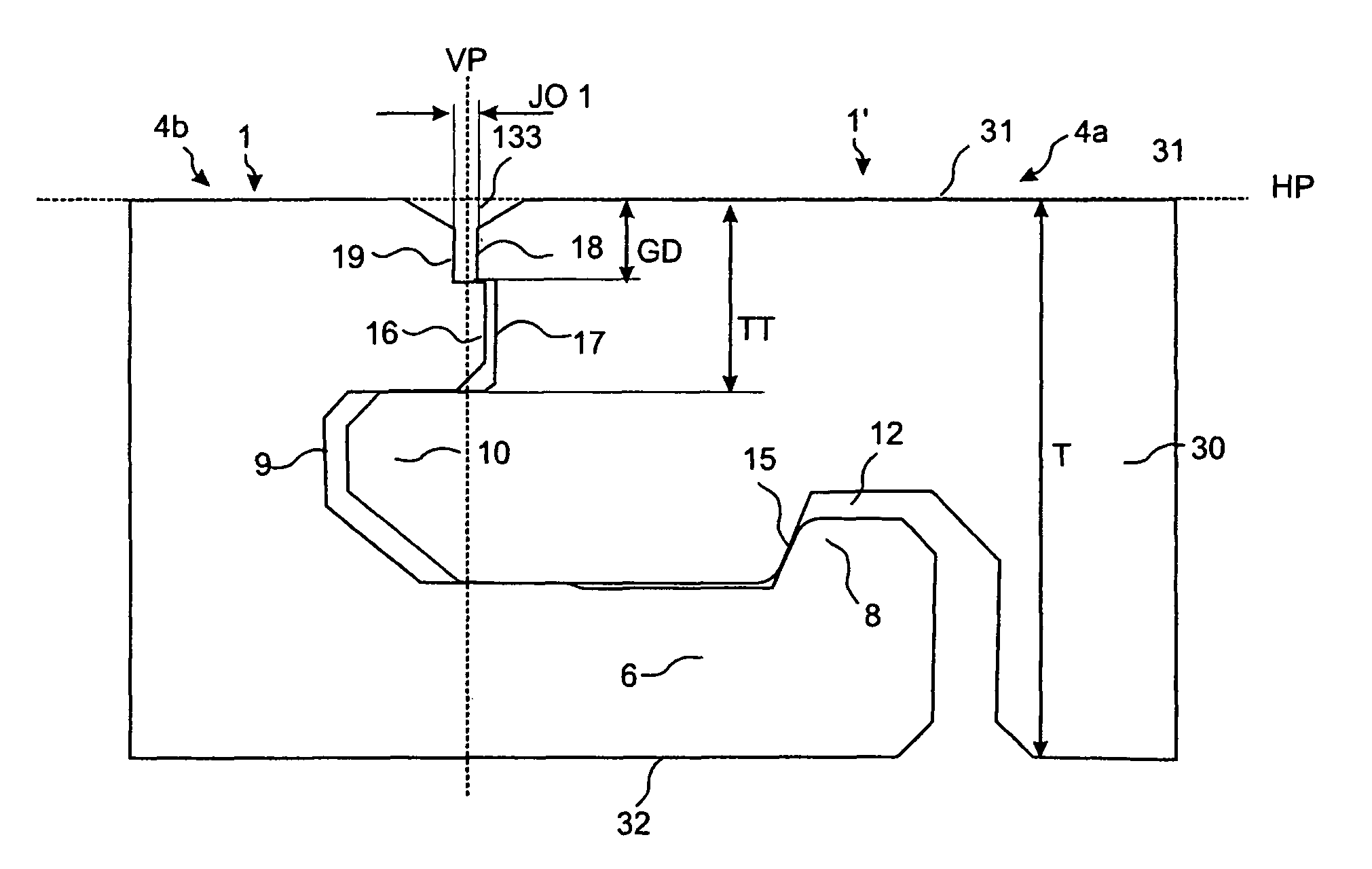

Floorboards with a mechanical locking system that allows movement between the floorboards when they are joined to form a floating floor.

Owner:VÄLINGE INNOVATION AB

Glider bar for flooring system

A flooring system for use with floating floors is described which includes a glider bar having base portions including extending rails in the form of dovetail protrusions. The bases and rails are longitudinally moveable relative to anchoring plates, which anchoring plates are affixed to a subflooring. Flush finished floor moldings are slid longitudinally along the rails and are glued or mechanically fixed, at one side only, to the adjacent floating laminate flooring. By this assembly, smooth transitions between adjacent floating floors, or where floating floors meet another hard floor covering, or carpet, can be achieved. The system can also be used with flush stair nosing elements.

Owner:PERGO

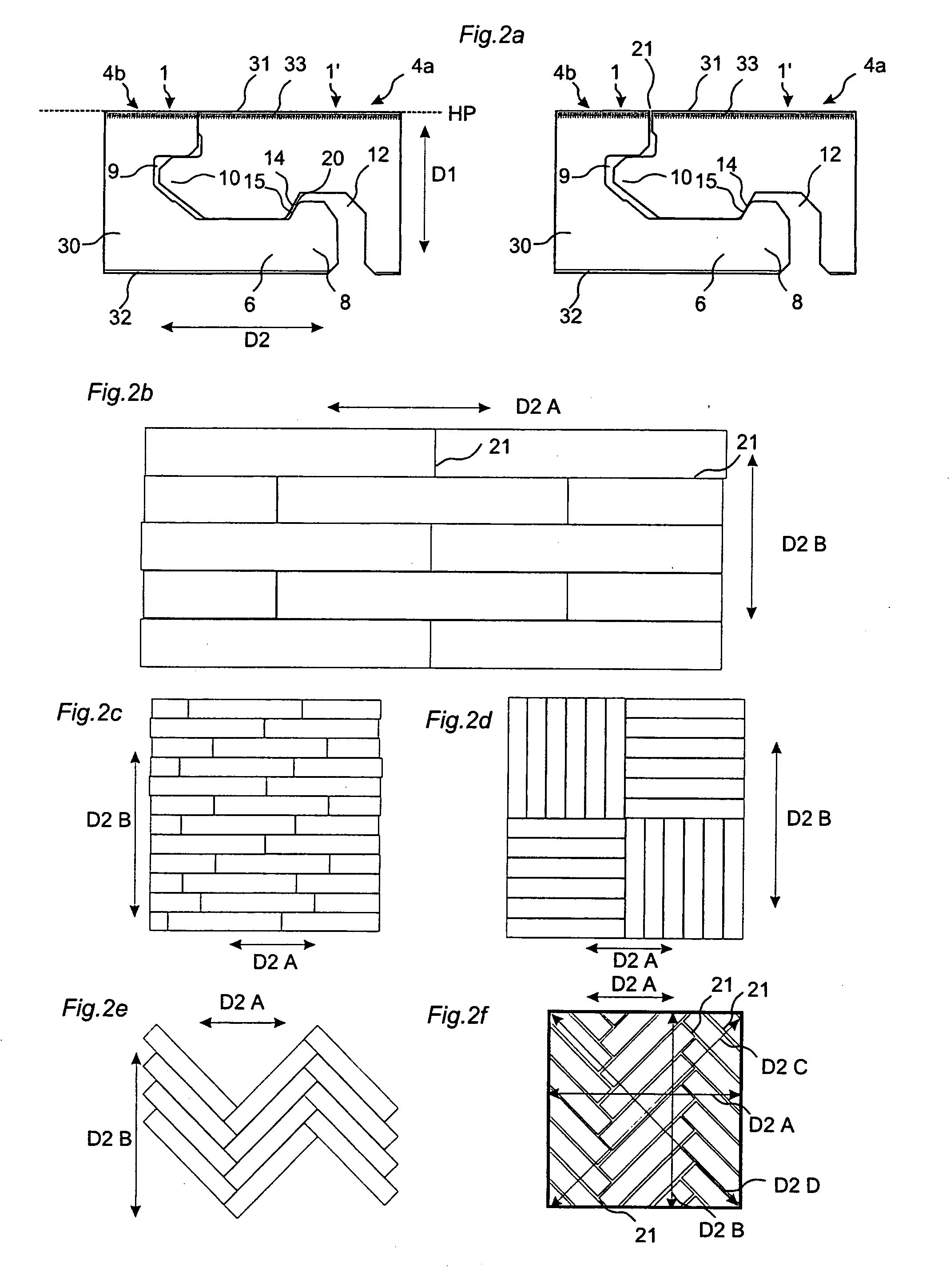

Floor Covering With Interlocking Design

Surface coverings, such as floor coverings, with an interlocking design are described. Methods of making the surface coverings are further described.

Owner:VÄLINGE INNOVATION AB

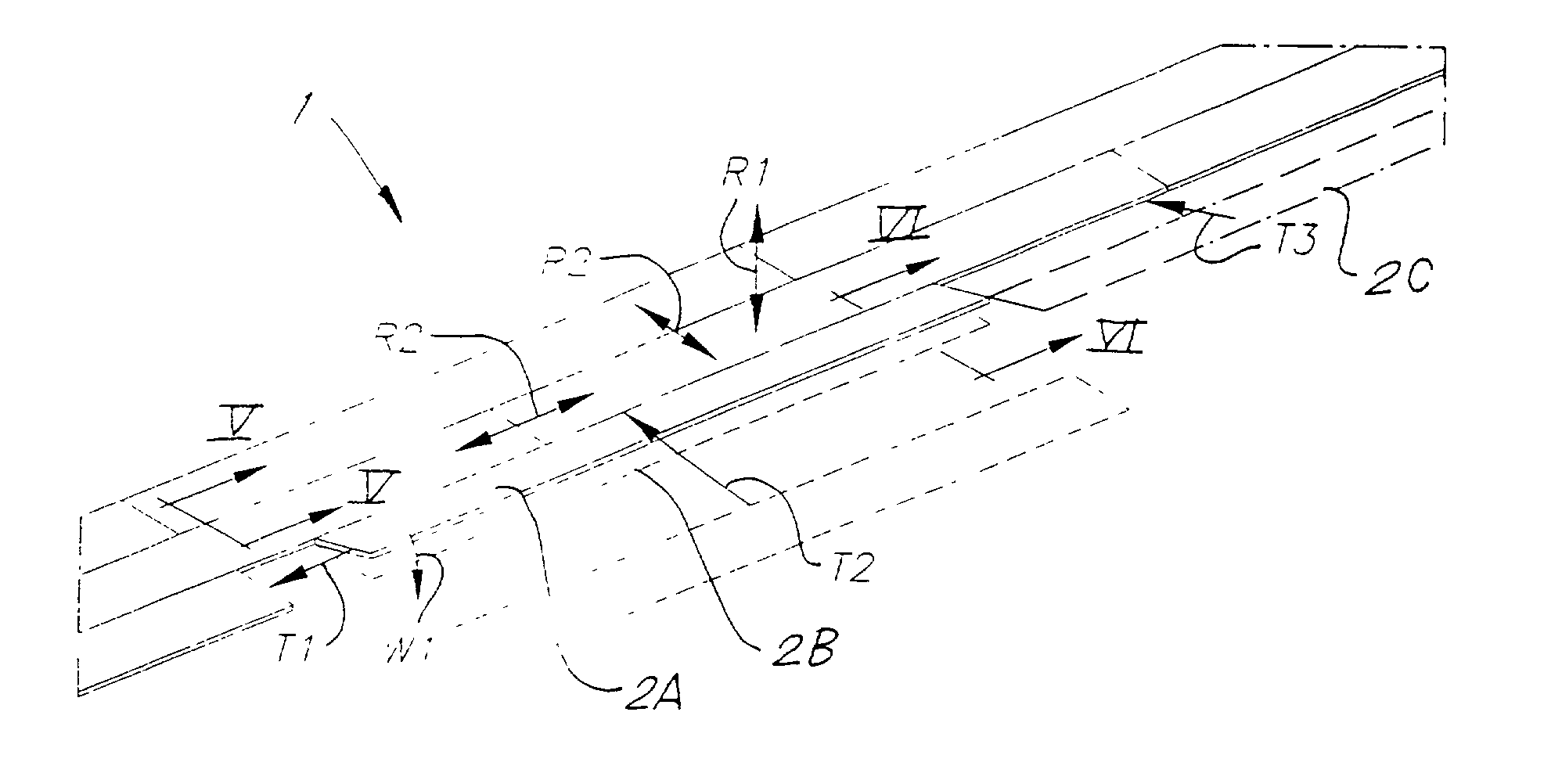

Floor covering

InactiveUS20020056245A1Easy to movePrevent mutual rotationCovering/liningsNatural patternsEngineeringMechanical engineering

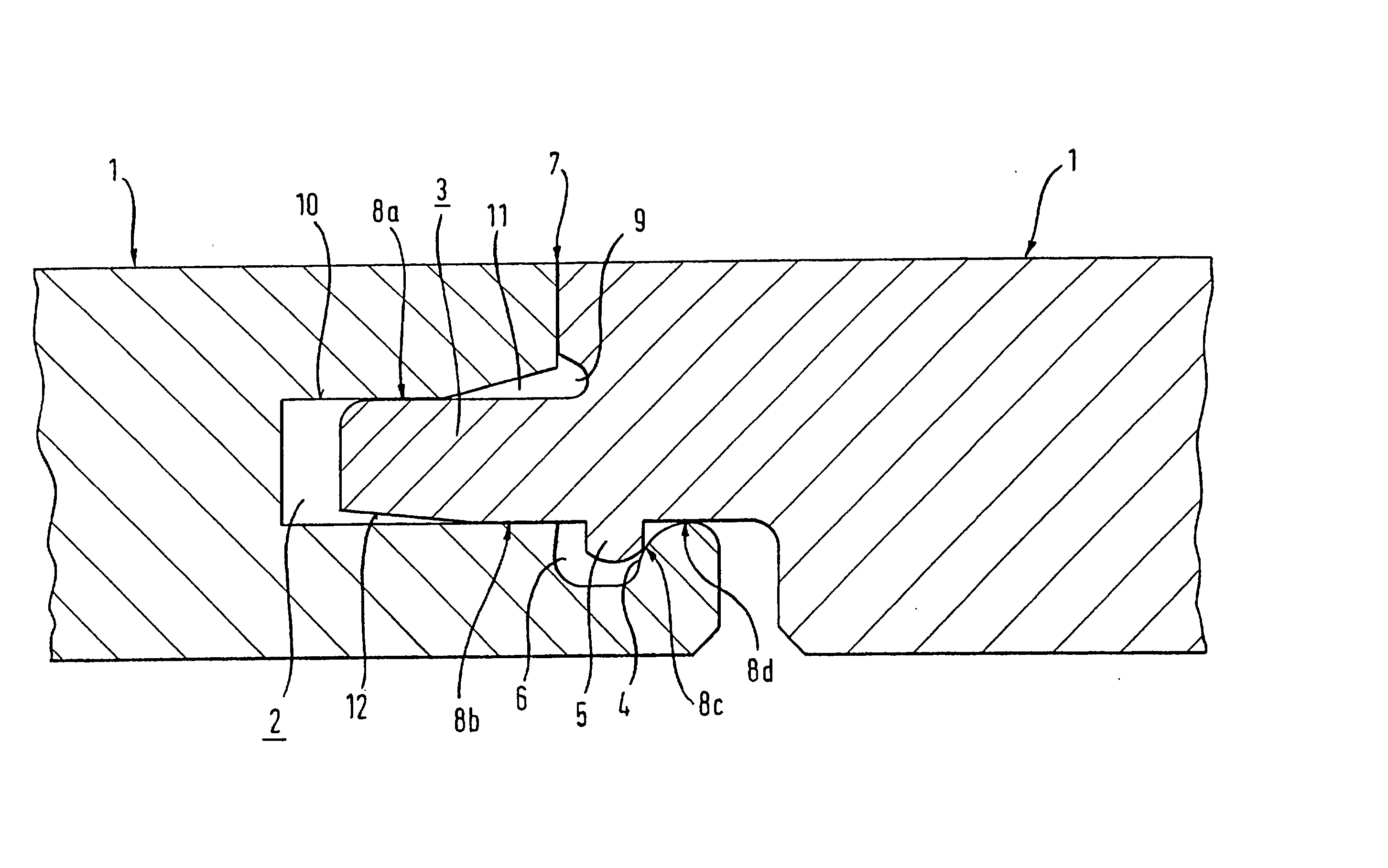

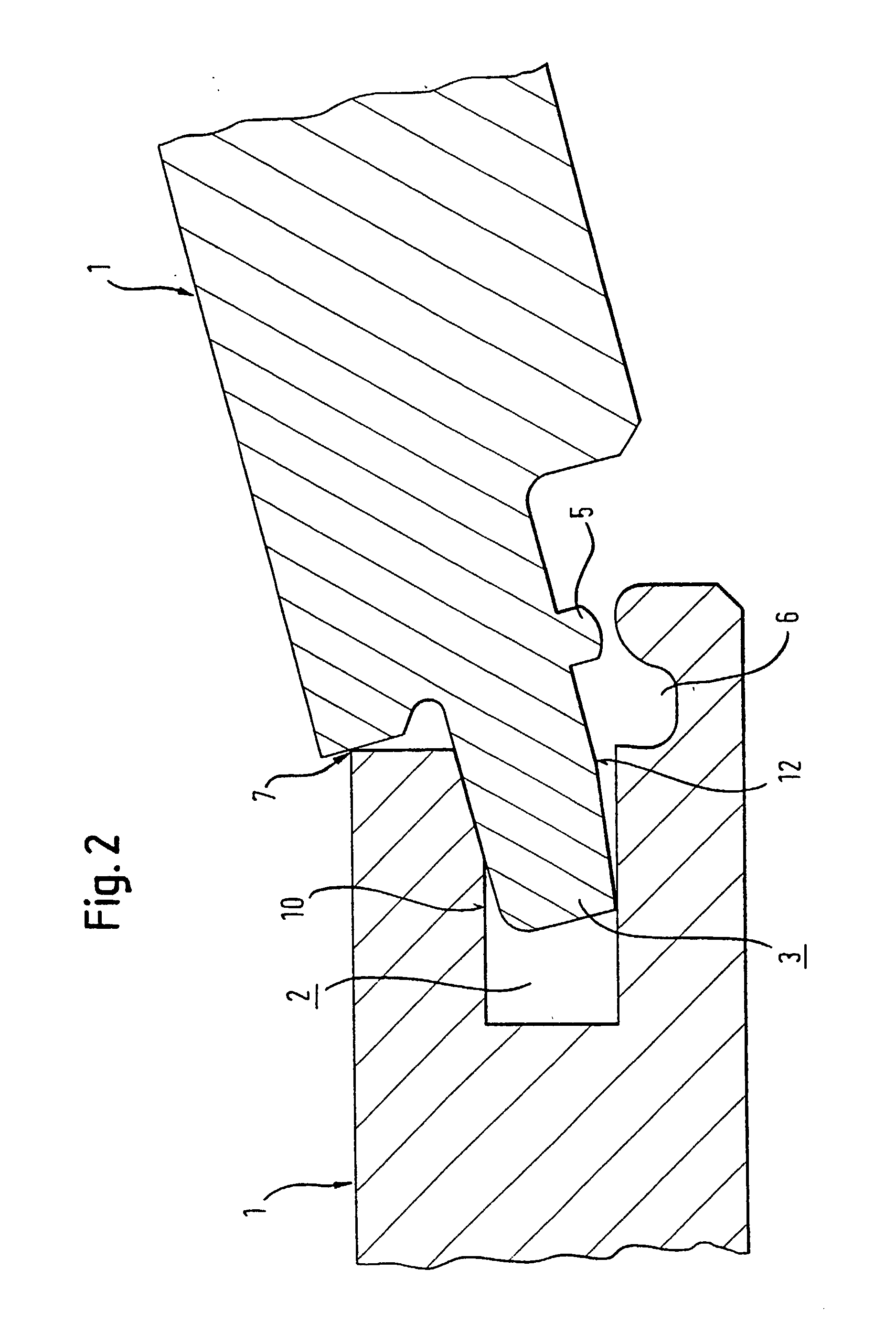

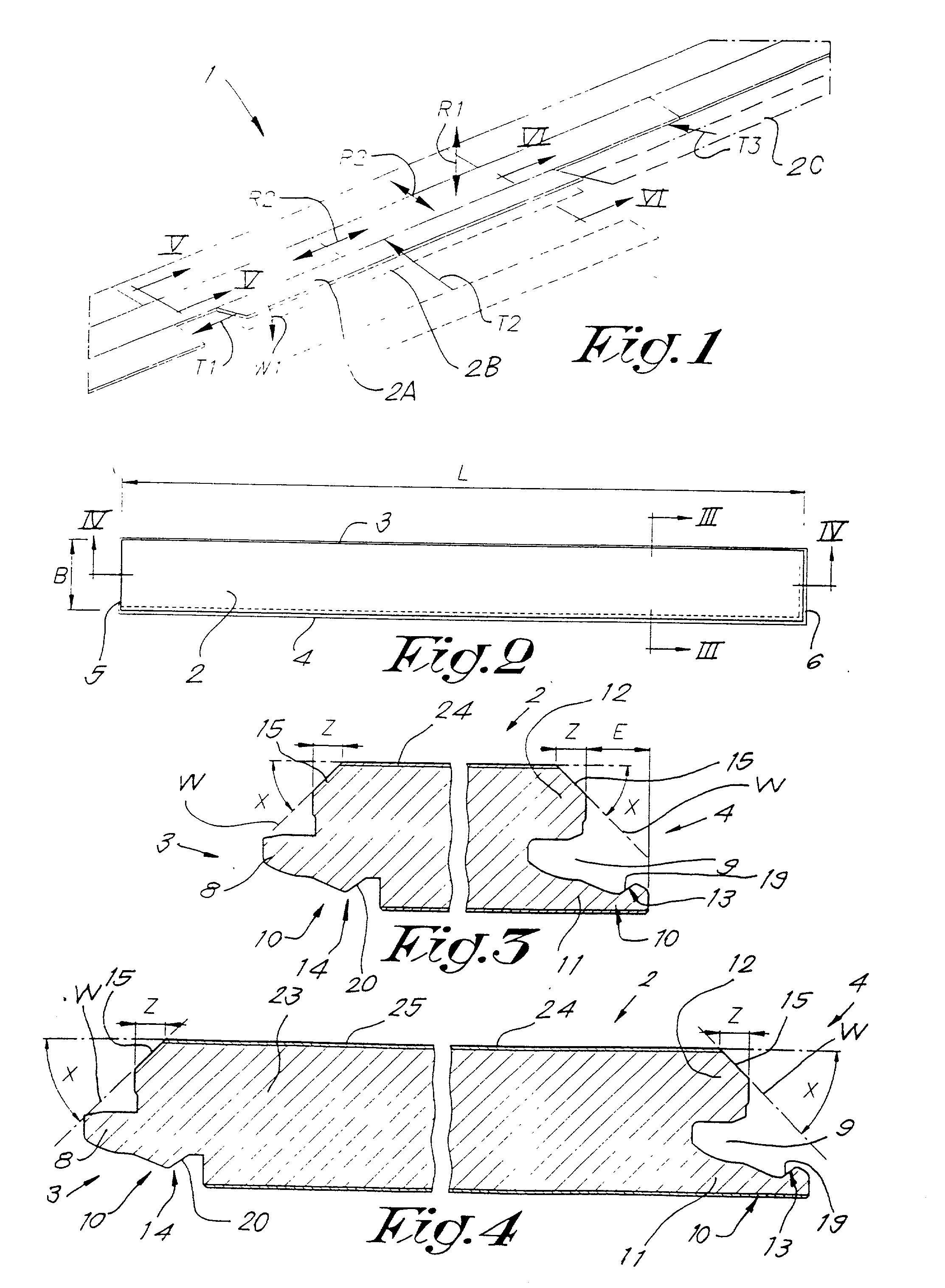

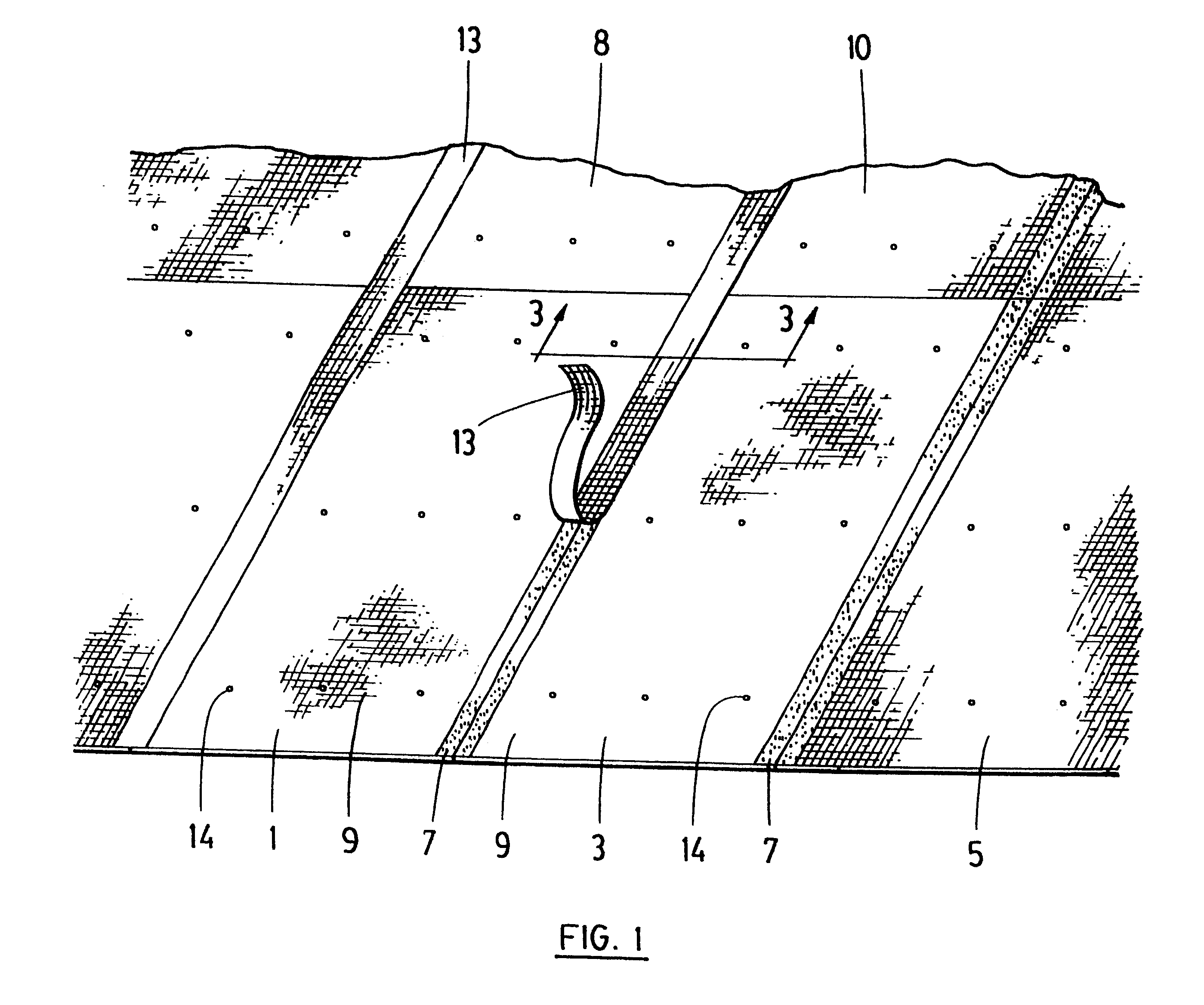

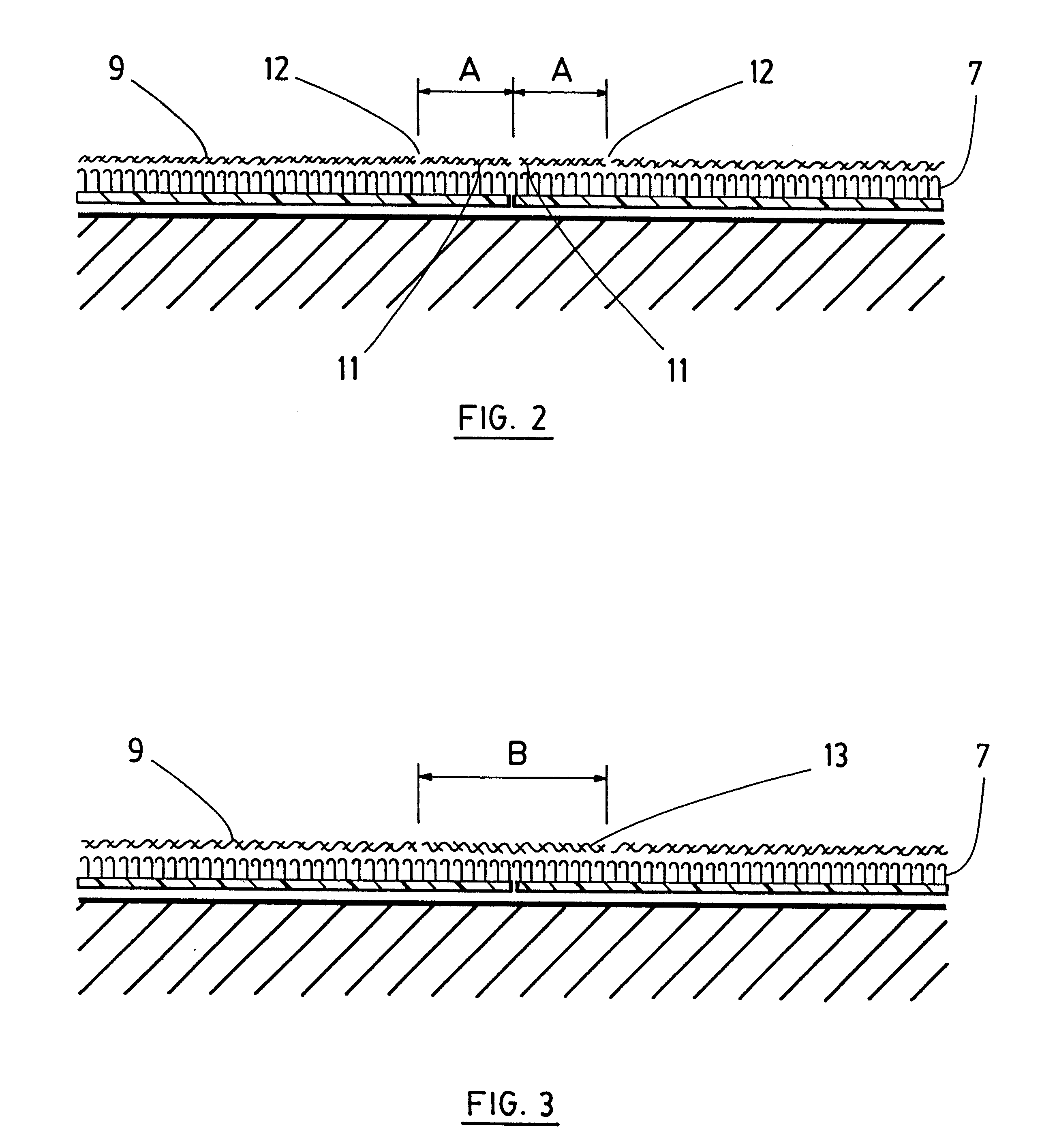

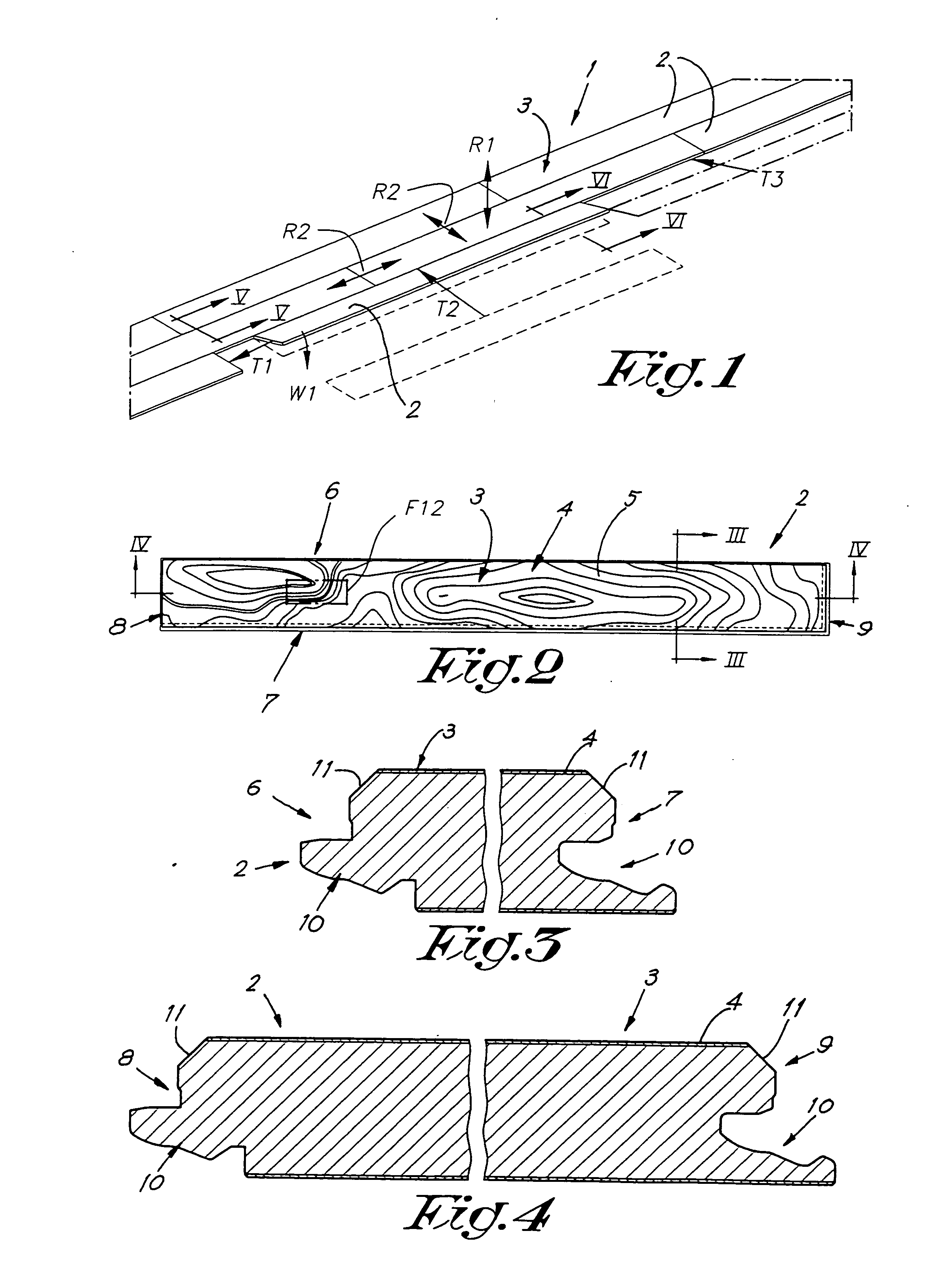

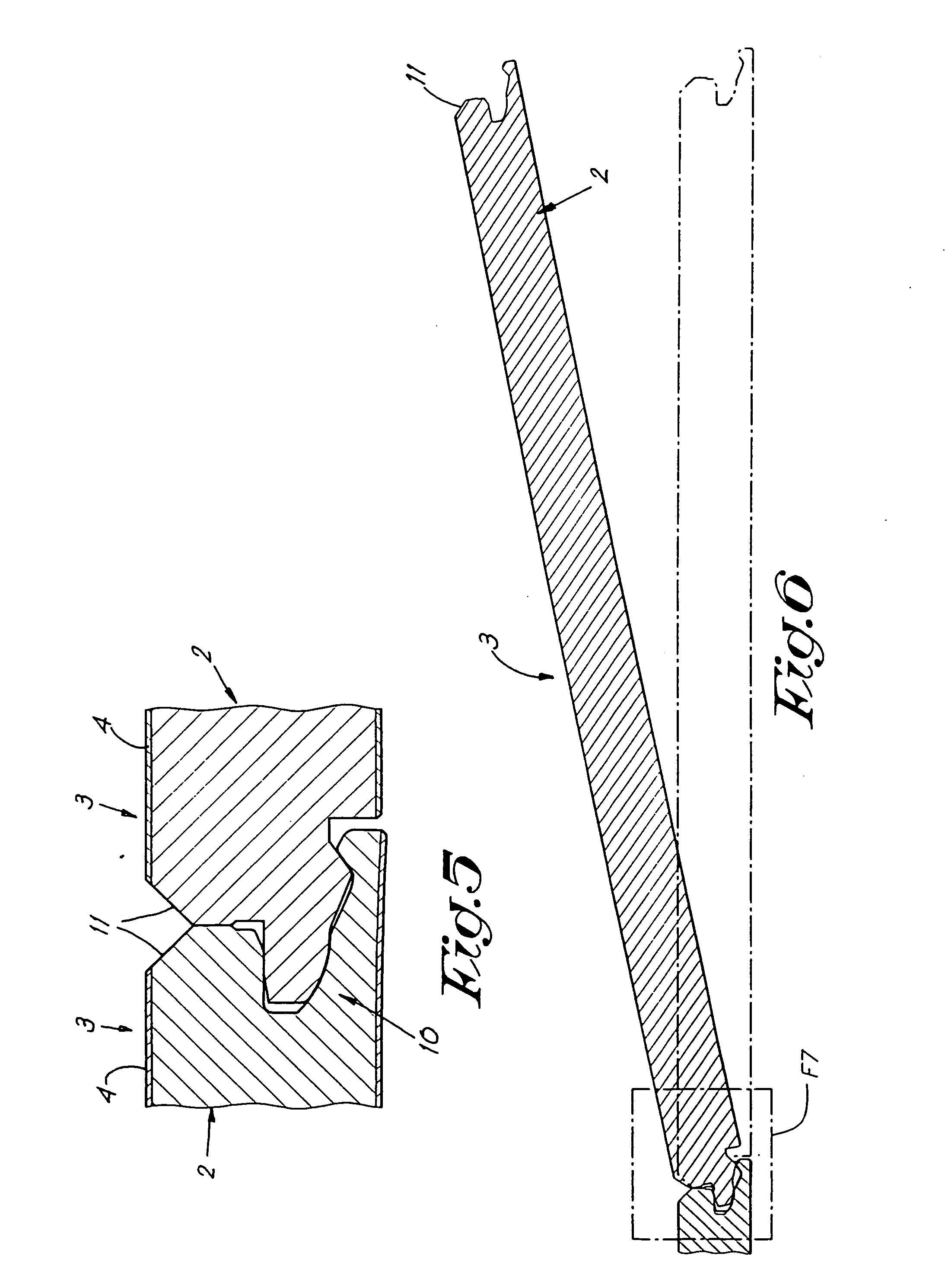

A floor covering of hard panels (2) having at least on two opposite edges (3-4; 5-6), coupling elements (7) made in one piece with the panels (2), so that several of such panels (2) can be mutually coupled, whereby these coupling elements (7) provide for an interlocking in a direction (R1) perpendicular to the plane of the floor covering (1), as well as in a direction (R2) perpendicular to the edges (3-4; 5-6) and parallel to the plane of the floor covering (1), and whereby these coupling elements (7) are made such that the panels (2) can be rotated into and / or out of one another at least along the above-mentioned edges (3-4; 5-6). The panels (2) are provided, at least on the above-mentioned edges (3-4; 5-6), near the top side, with a part from which has been removed an amount of material such as by a level.

Owner:FLOORING IND LTD

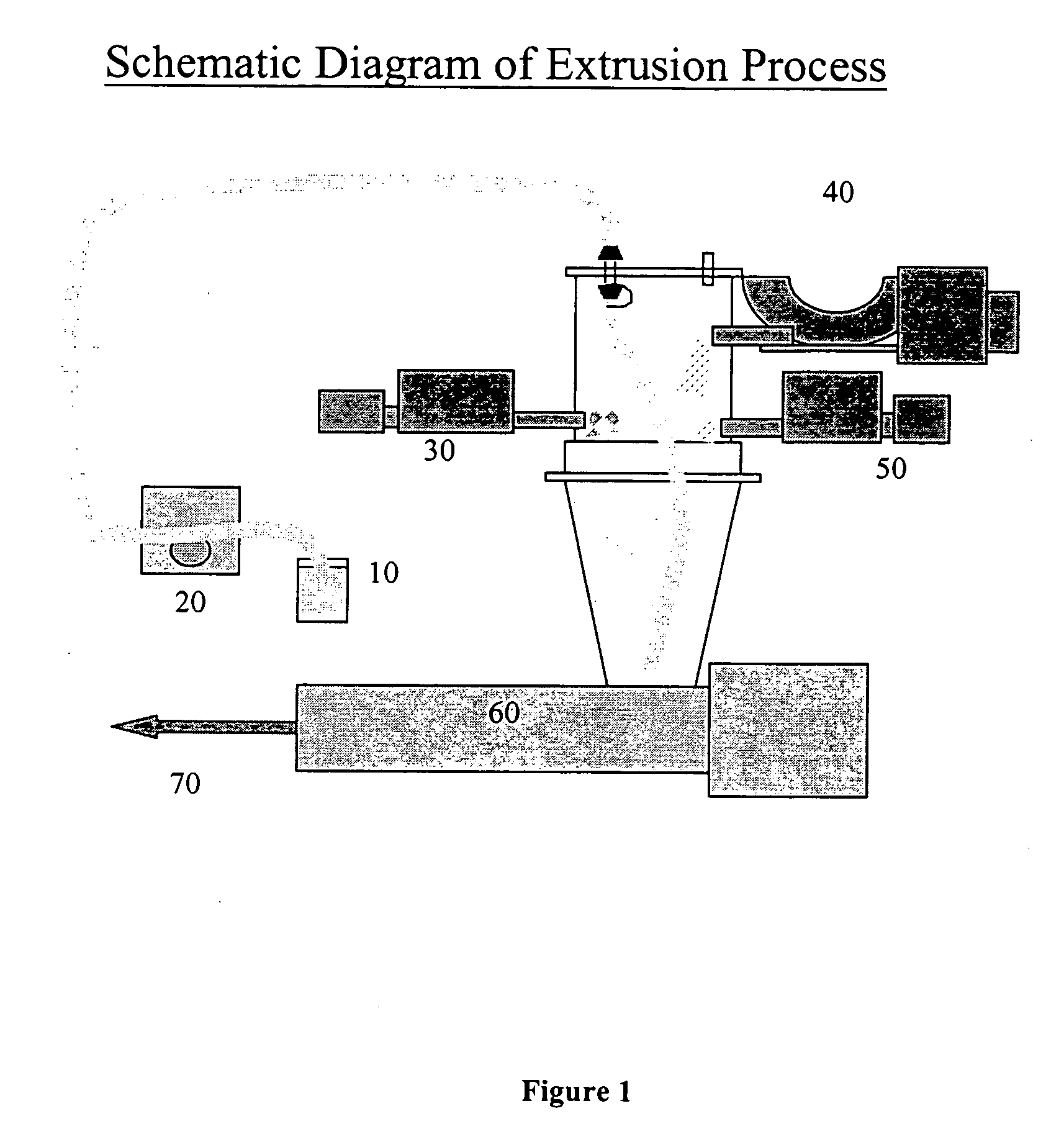

Decorative floor covering comprising polyethylene terephthalate film layer in surface layer and manufacturing method of the same

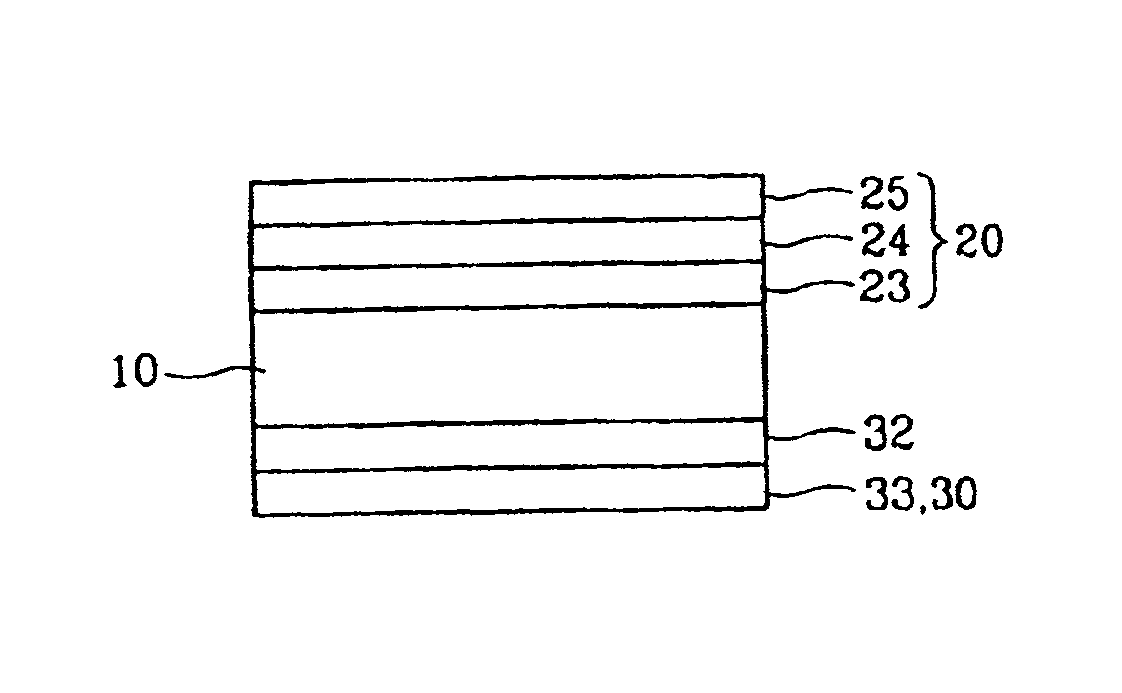

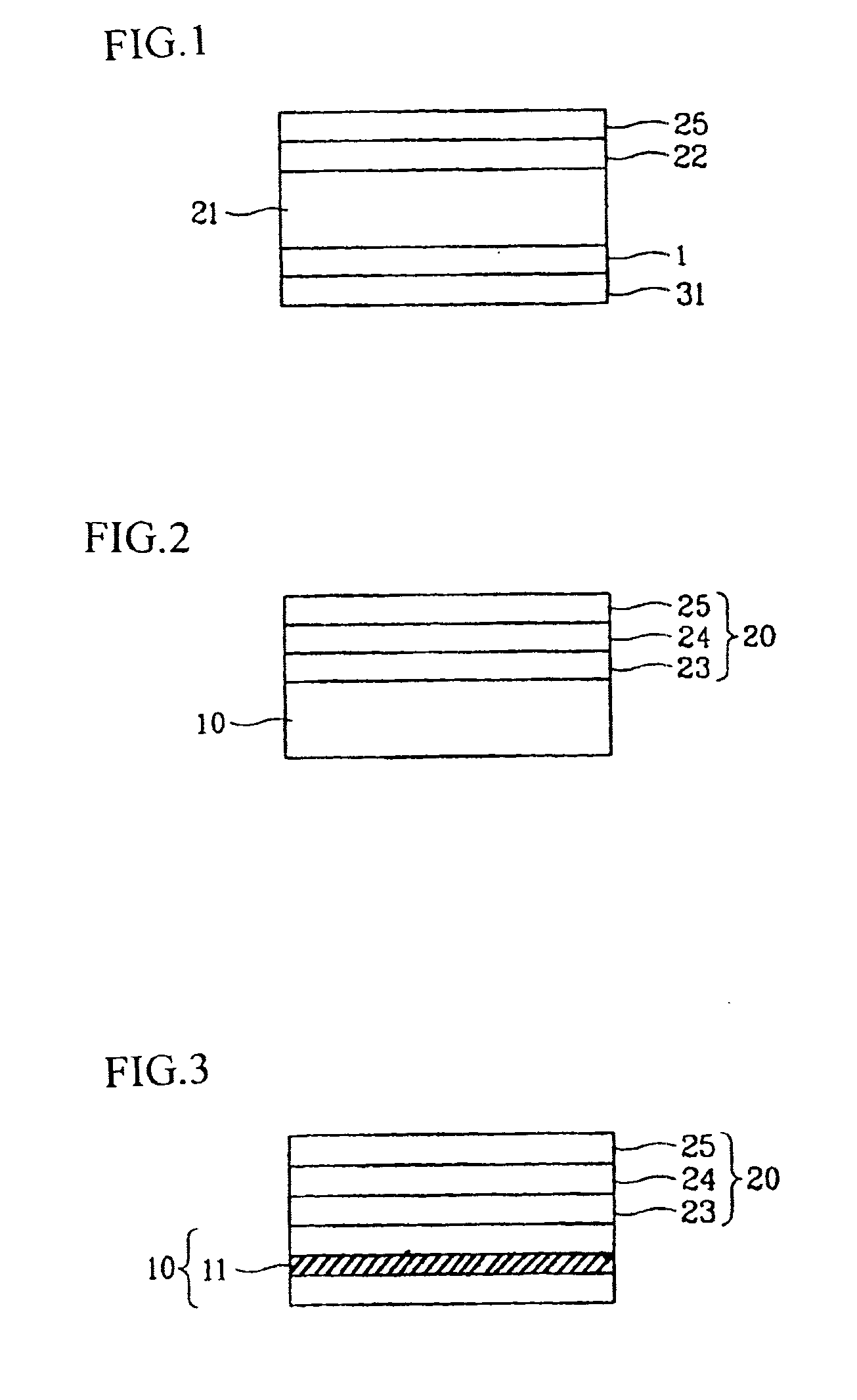

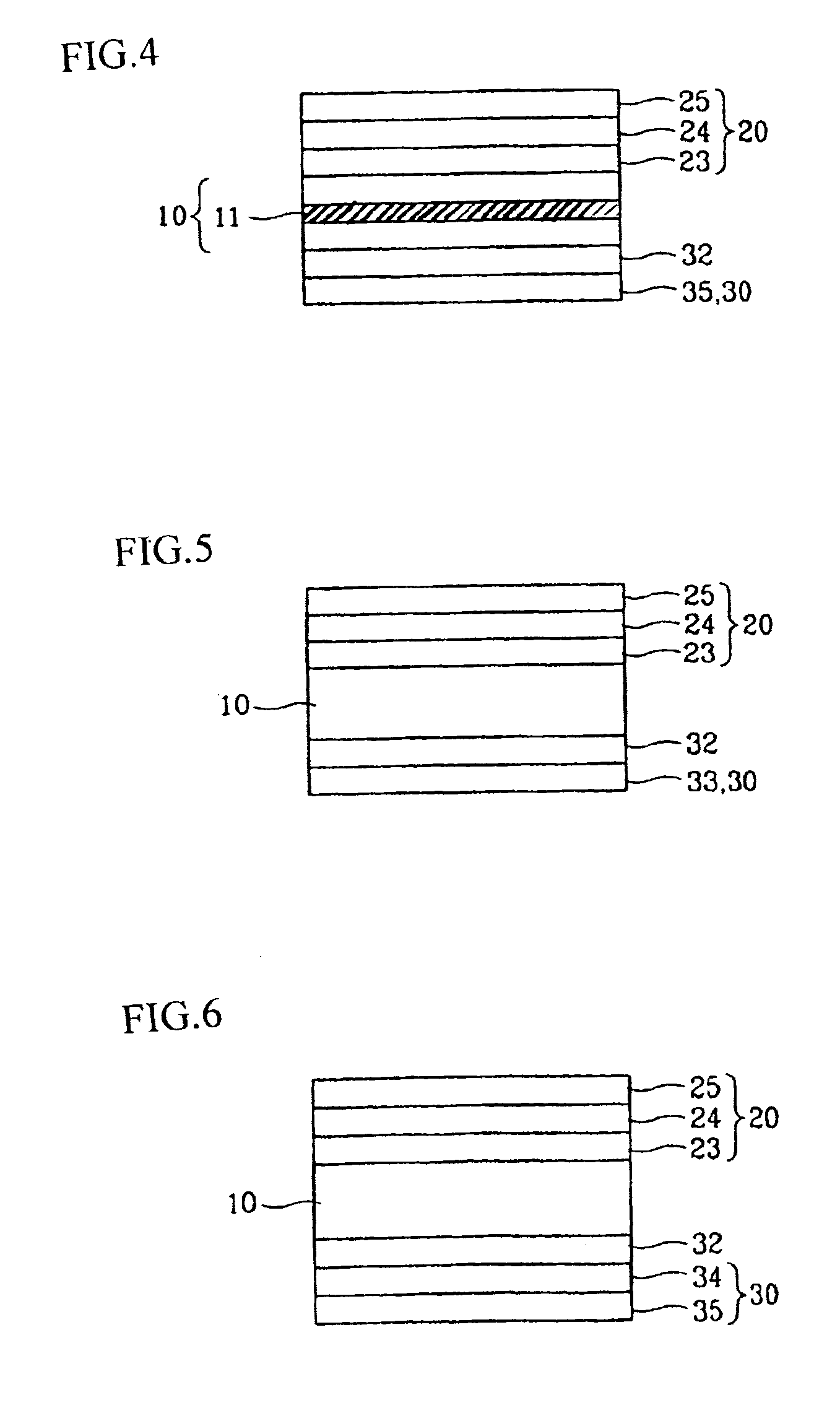

InactiveUS6933043B1Superior surface printing sharpness and realismEasy to installSynthetic resin layered productsPaper/cardboard layered productsSurface layerPolyethylene terephthalate

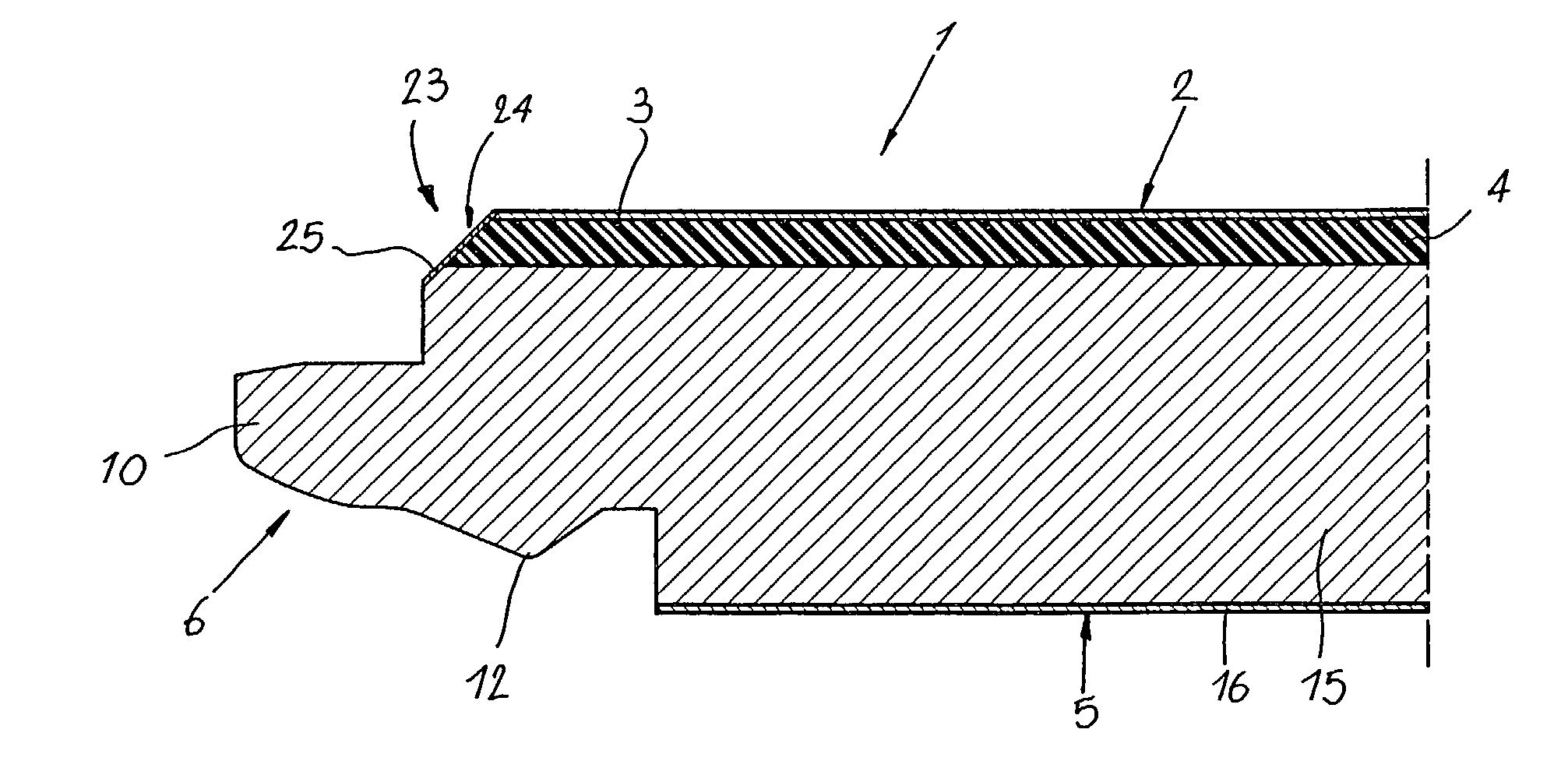

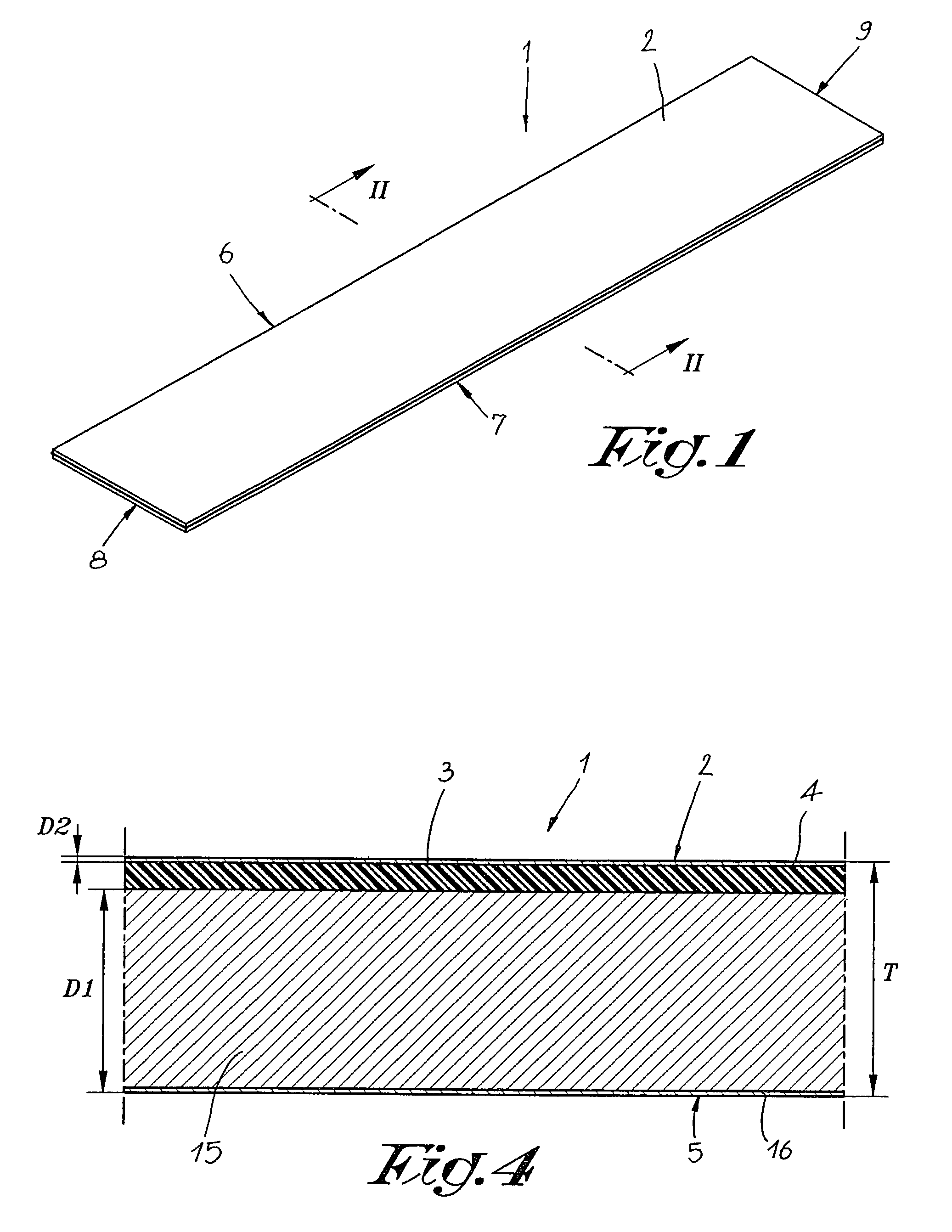

The present invention provides a decorative floor covering comprising a surface layer and a substrate layer underneath, wherein the surface layer comprises a polyethylene terephthalate film layer, and a method for preparing the same. Furthermore, the present invention provides a decorative floor covering comprising a surface layer and a substrate layer underneath, wherein a light weight back layer is further comprised under the substrate layer, and a method for preparing the same. A decorative floor covering of the present invention is a decorative floor covering which has superior surface heat resistance, printing sharpness and realism, and it can be installed conveniently since not only can non-foamed polyvinyl chloride resin be used as a substrate layer, but also the weight of a floor covering is light when a light weight back layer is comprised under the substrate layer.

Owner:LG CHEM LTD

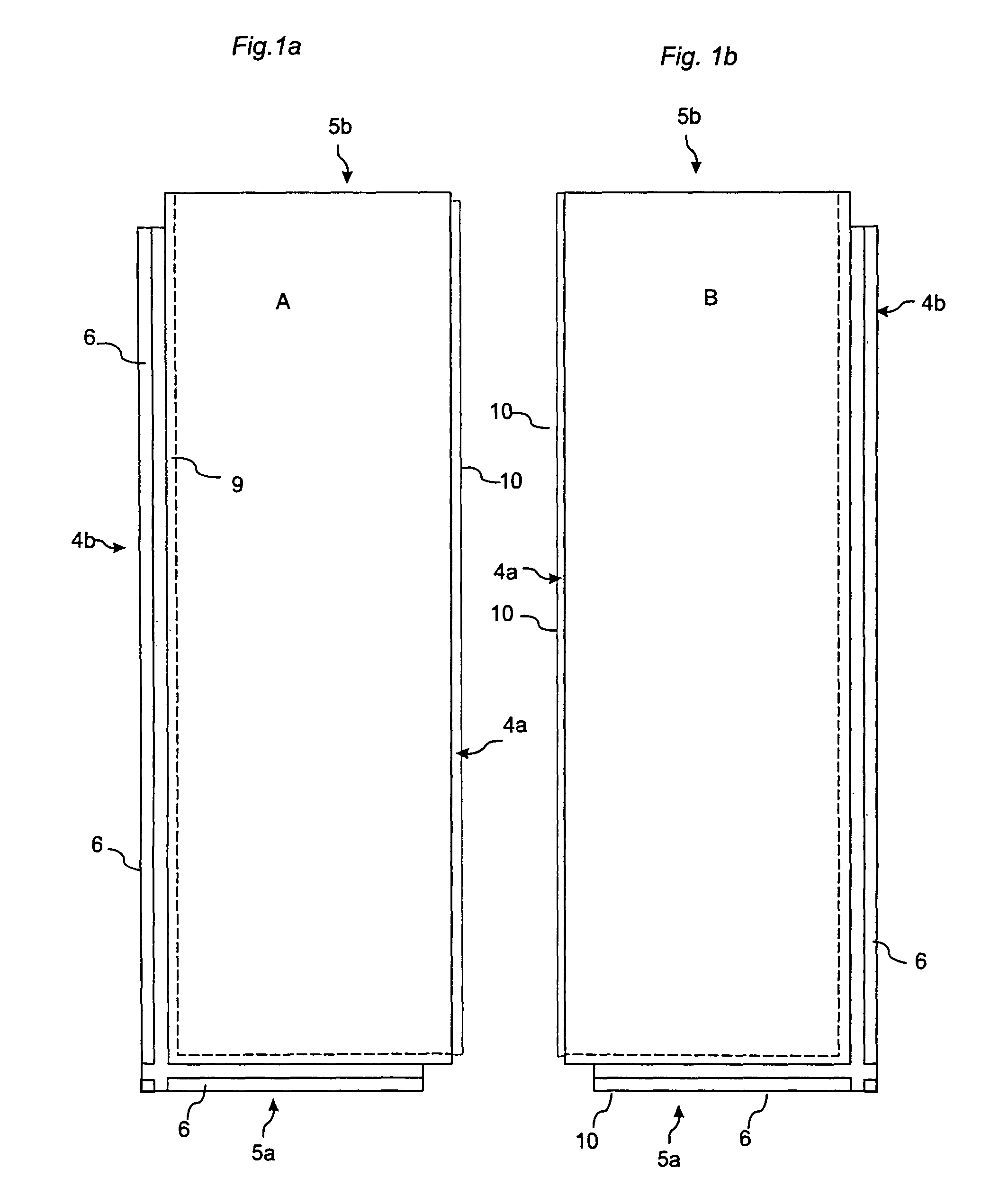

Floor Covering With Interlocking Design

InactiveUS20090031662A1Thin thicknessEasy to assembleCovering/liningsWallsFloor coveringManufacturing engineering

Surface coverings, such as floor coverings, with an interlocking design are described. Methods of making the surface coverings are further described.

Owner:NOVALIS HLDG +1

Roll-up floor tile system and method

A plurality of interlocking tile pieces form a generally flat traffic-carrying surface. The tile are locked together in a manner to form a plurality of non-bendable tile joints. The tile includes a hinge or fold line along a first axis and a hinge or fold line along a second axis. The hinges allow the multi-tile traffic carrying surface to be rolled up into a hollow tube from any direction along one of the axes, beginning at any edge of the traffic carrying surface. The rolled-up floor covering is made up of a plurality of tile panels.

Owner:SNAP LOCK INDS

Floor panel and method for the manufacture thereof

ActiveUS8196366B2Global structure of such floor panel still can be kept relatively thick and stableReduce thicknessCovering/liningsWallsFloor covering

Owner:FLOORING IND LTD

Elastomeric material compositions obtained from castor oil and epoxidized soybean oil

Elastomers are formed from castor oil and / or ricinoleic acid estolides and a polyester formed from an epoxidized vegetable oil such as ESO and a polycarboxylic acid such as sebacic acid, optionally in the presence of a peroxide initiator, or include crosslinked reaction products derived from ricinoleic acid or castor oil estolides, epoxy group-containing compounds such as epoxy resins and / or epoxidized vegetable oil, epoxy hardeners such as polyamine and polycarboxylic acid hardeners, thermally activated free radical initiators such as peroxides, and optionally but preferably include fillers such as limestone or wood flour. The elastomers can be prepared using a two-step, solvent-less procedure at elevated or ambient temperatures. These predominantly “all-natural” elastomers have physical properties comparable to conventional petroleum-based elastomers and composites and exhibit good flexibility, resiliency, abrasion resistance and inertness to hydrolysis. The resulting elastomers display good mechanical strength and resiliency, are resistant to abrasion and hydrolysis, and can be processed into sheet materials, which makes them attractive as floor covering components.

Owner:AFI LICENSING +1

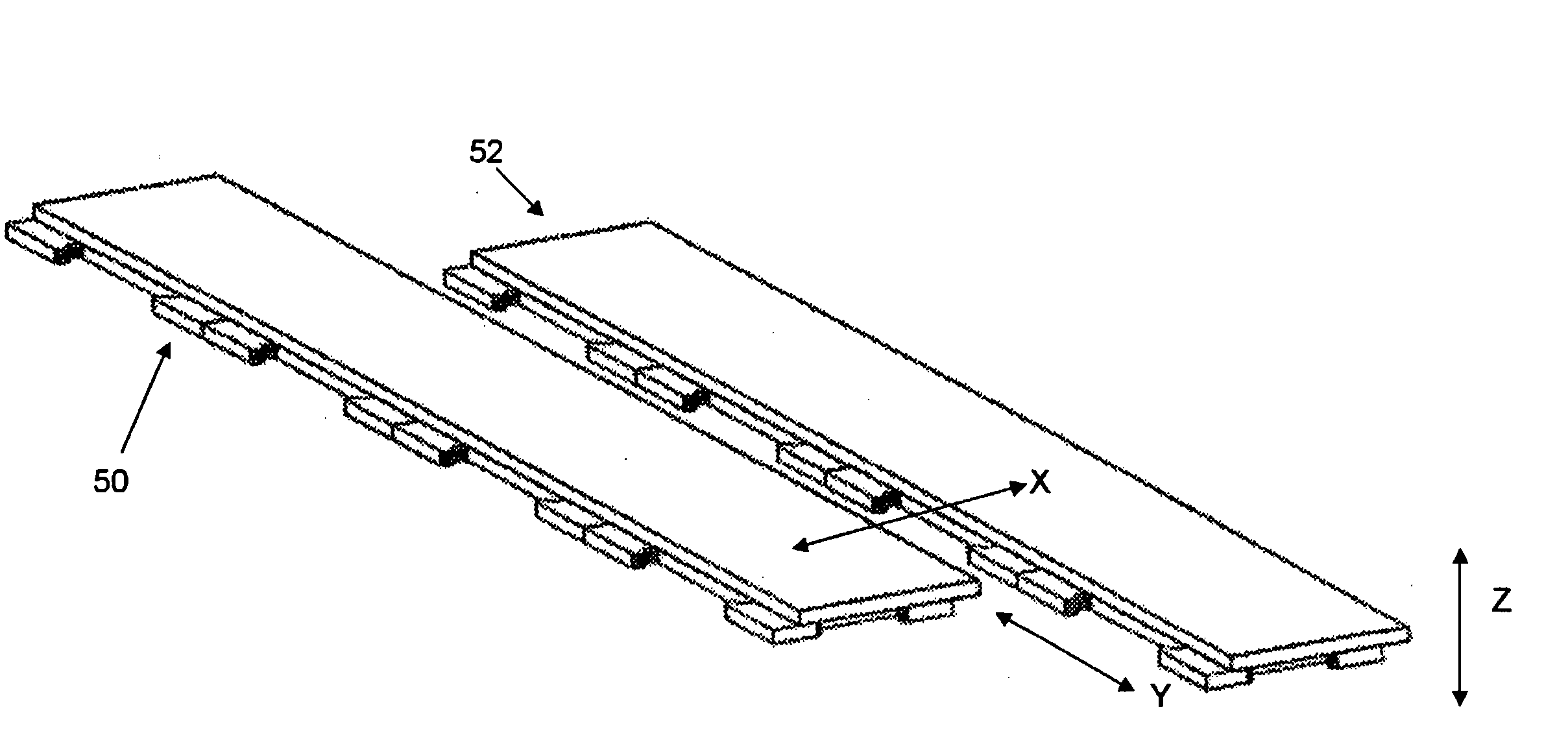

Wide width lock and fold laminate

InactiveUS20070130872A1Frictional resistanceReduce pressureWallsFlooringEngineeringMechanical engineering

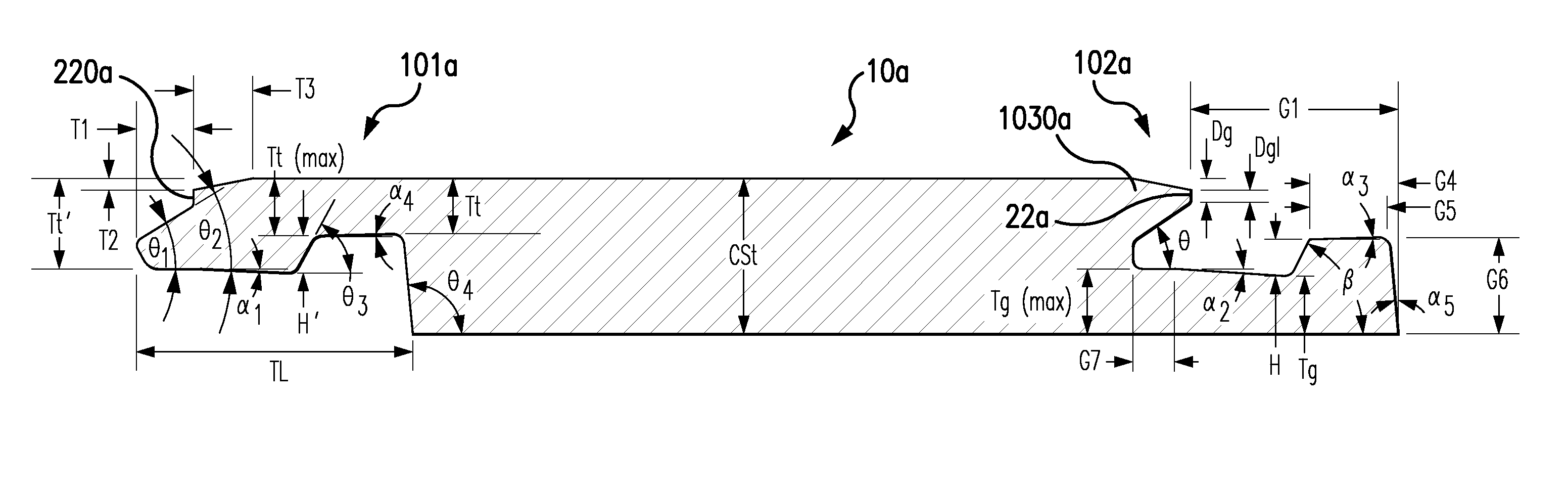

Lock and fold floor covering panels can be installed by angling a long locking edge into a previously installed row of panels and dropping or locking the projection of the tongue of the short side into the depression of the lower lip forming the groove in the short side. By incorporating a force increasing means in the fold joint, the width of the panels that can be installed with a lock and fold system can be increased beyond the conventionally accepted 3.5 inches. The fold joint is designed to permit it to be engaged, disengaged and reengaged without damaging the fold joint.

Owner:ARMSTRONG WORLD INDUSTRIES

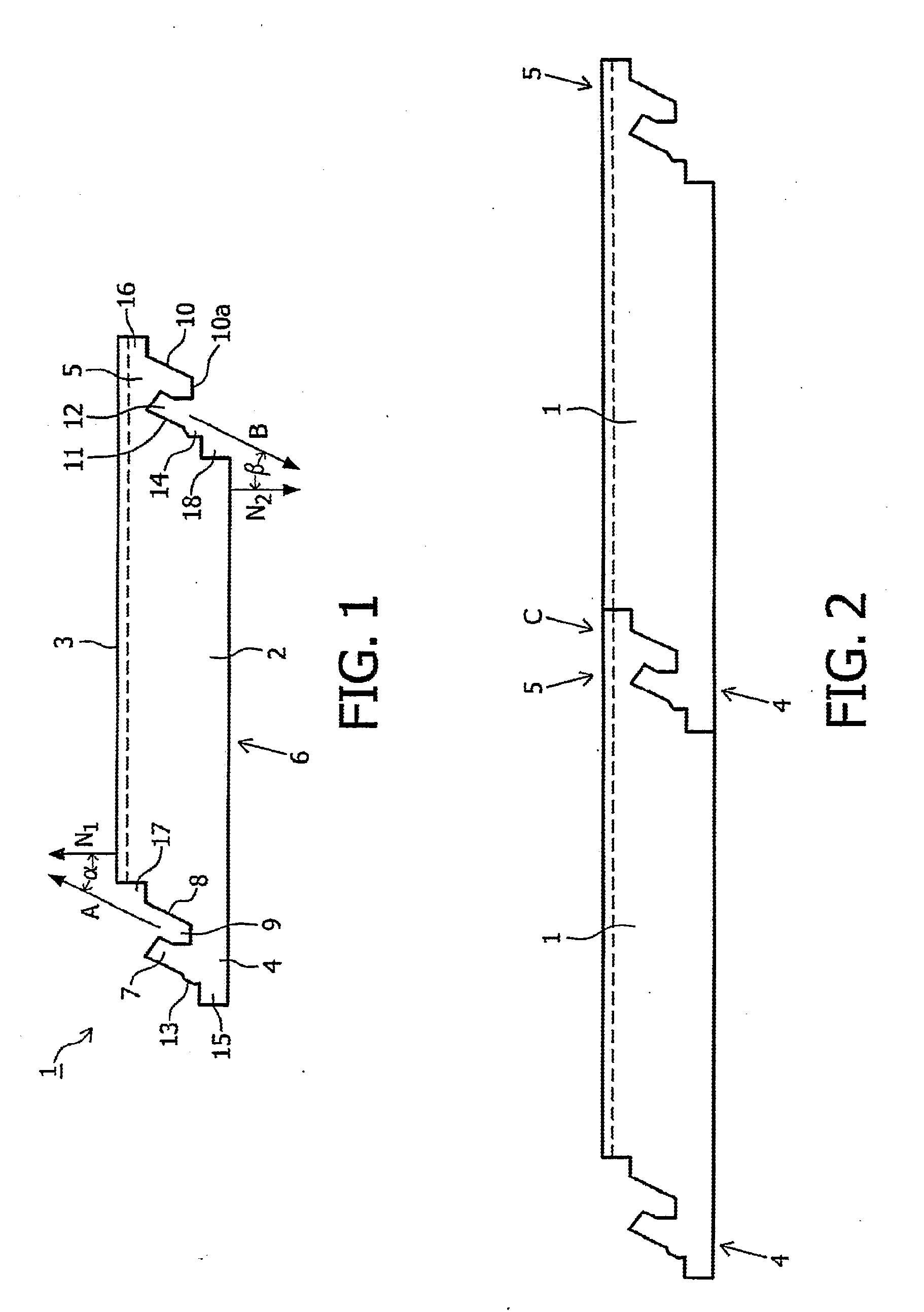

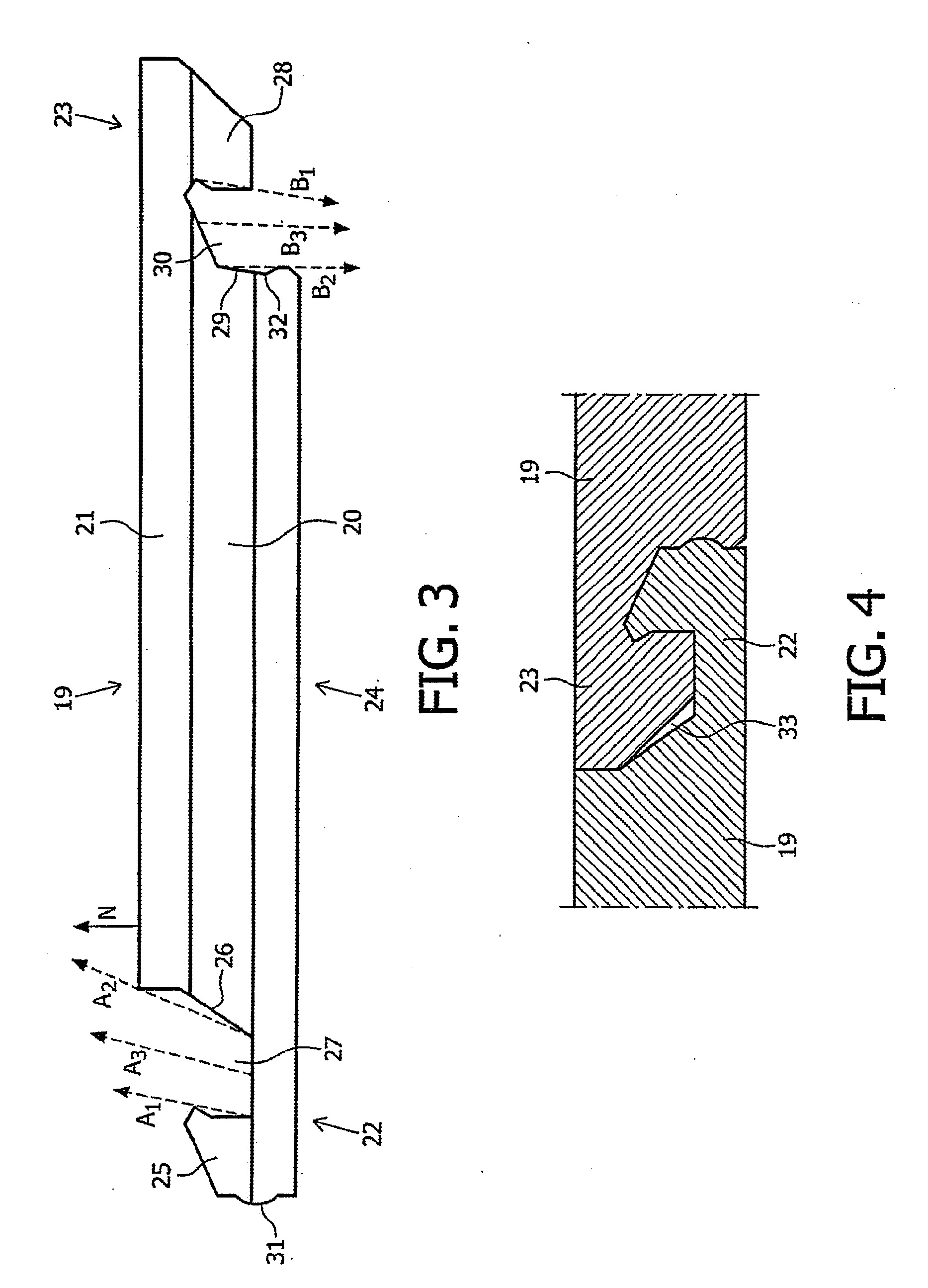

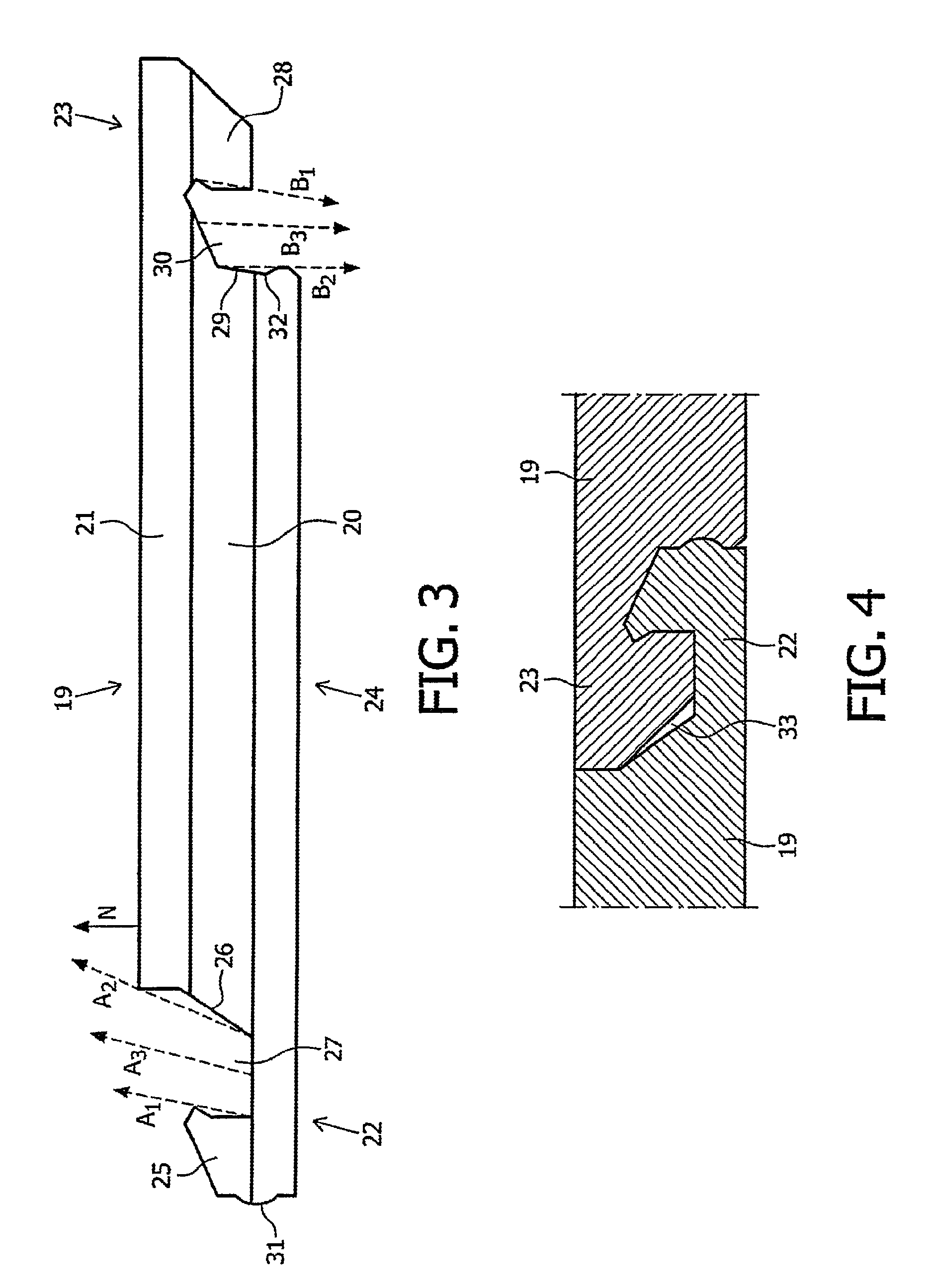

Floor covering and installation method

ActiveUS8302367B2Easy to operateSave a lot of timeCovering/liningsLayered productsBiomedical engineeringFloor covering

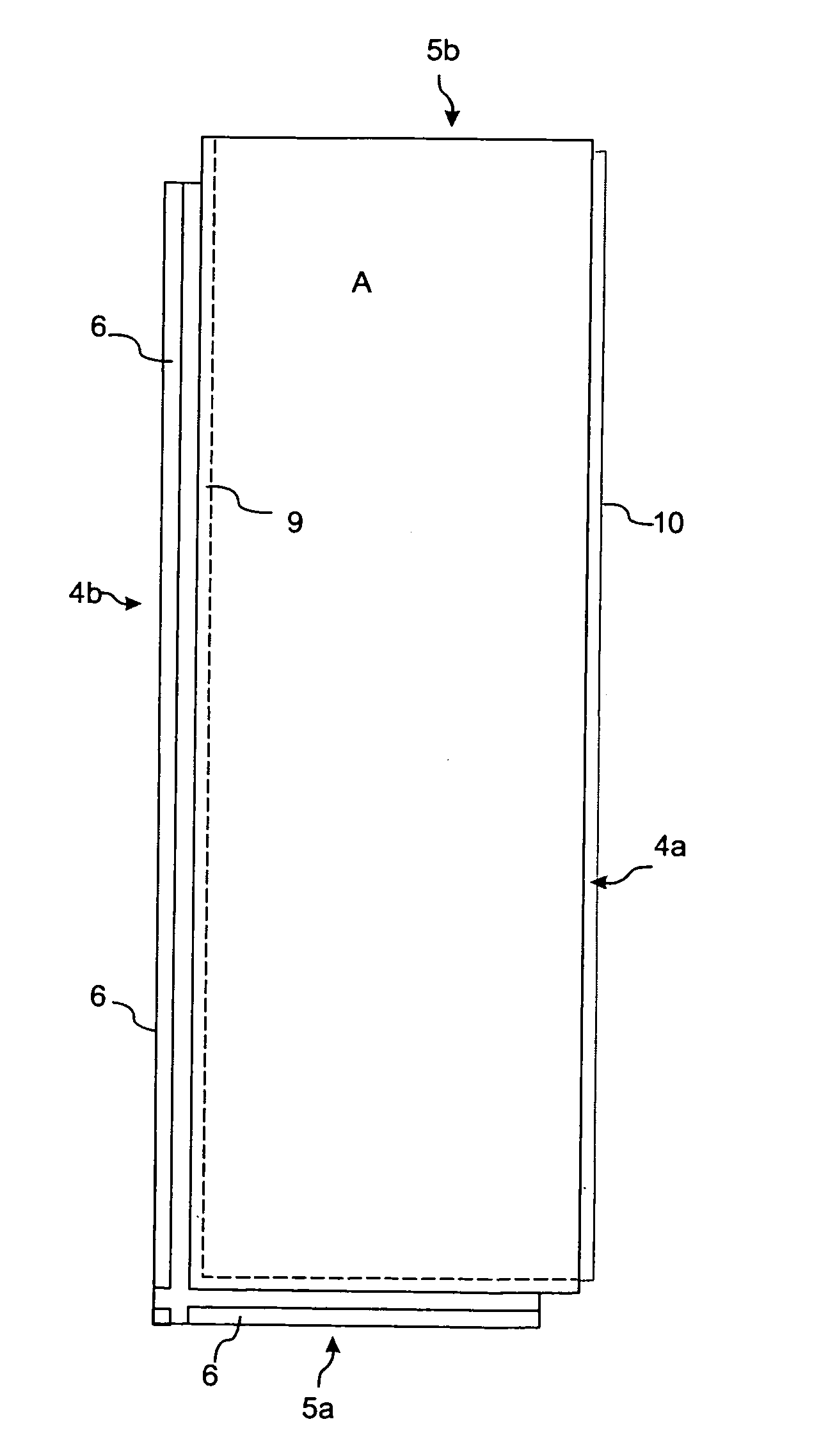

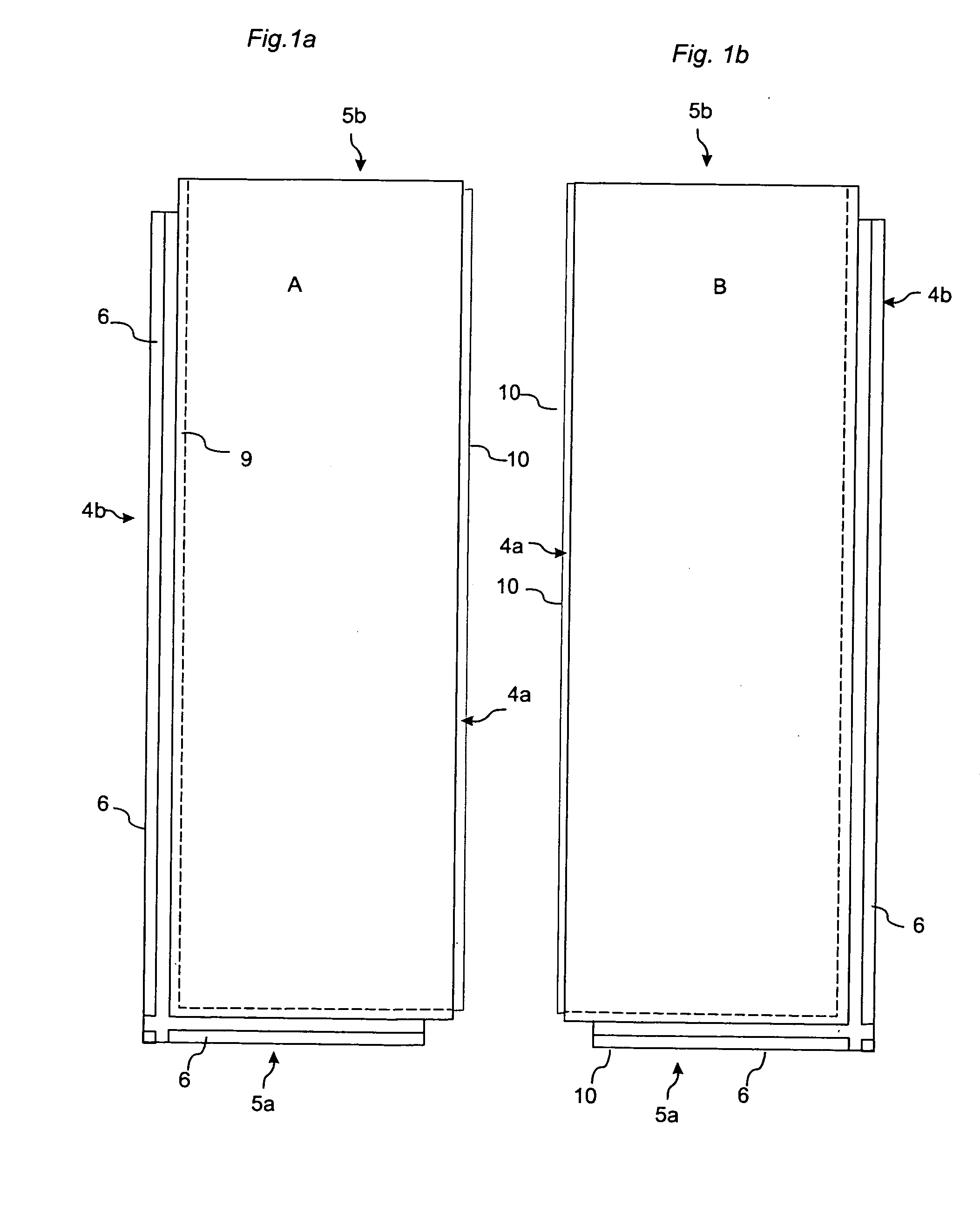

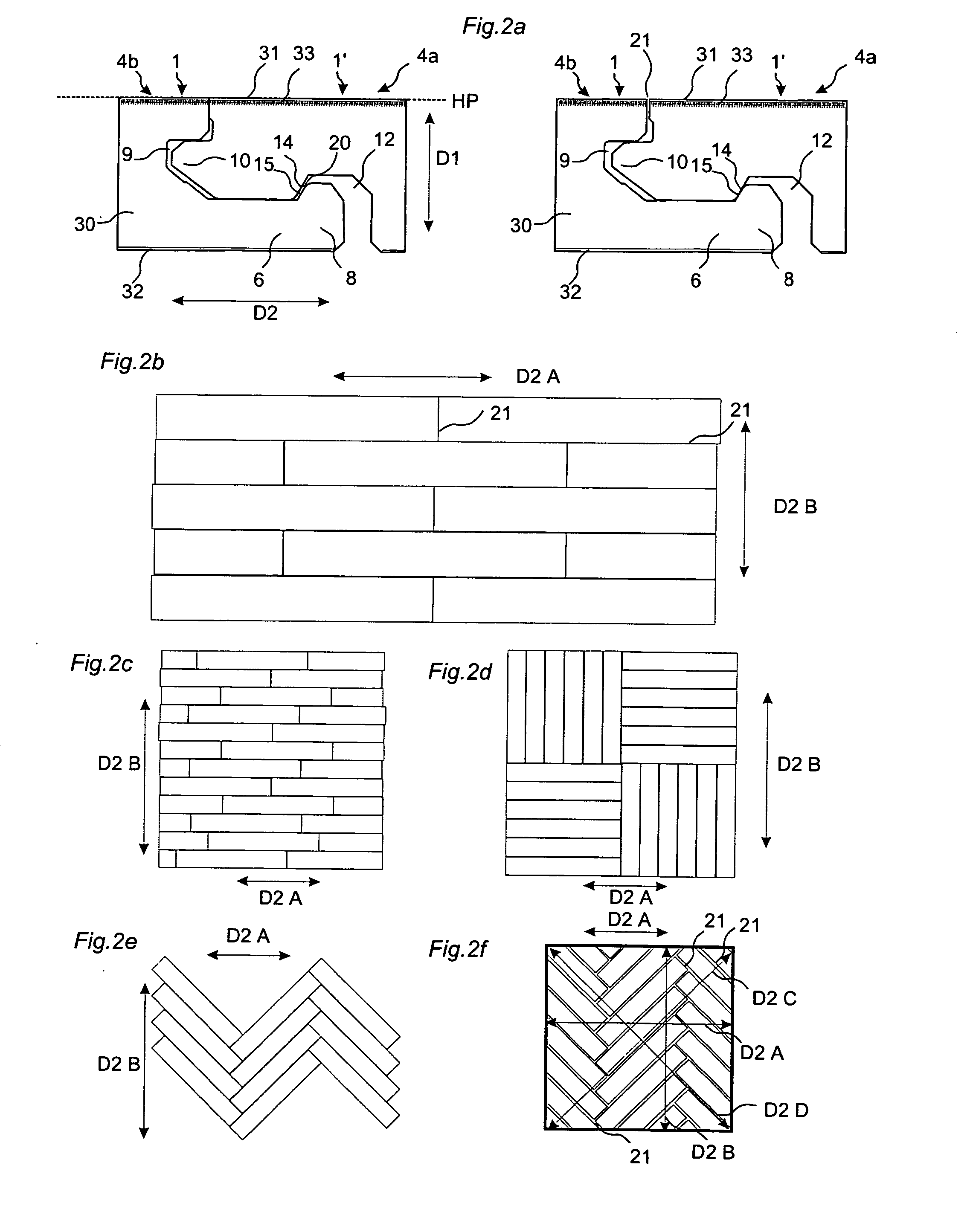

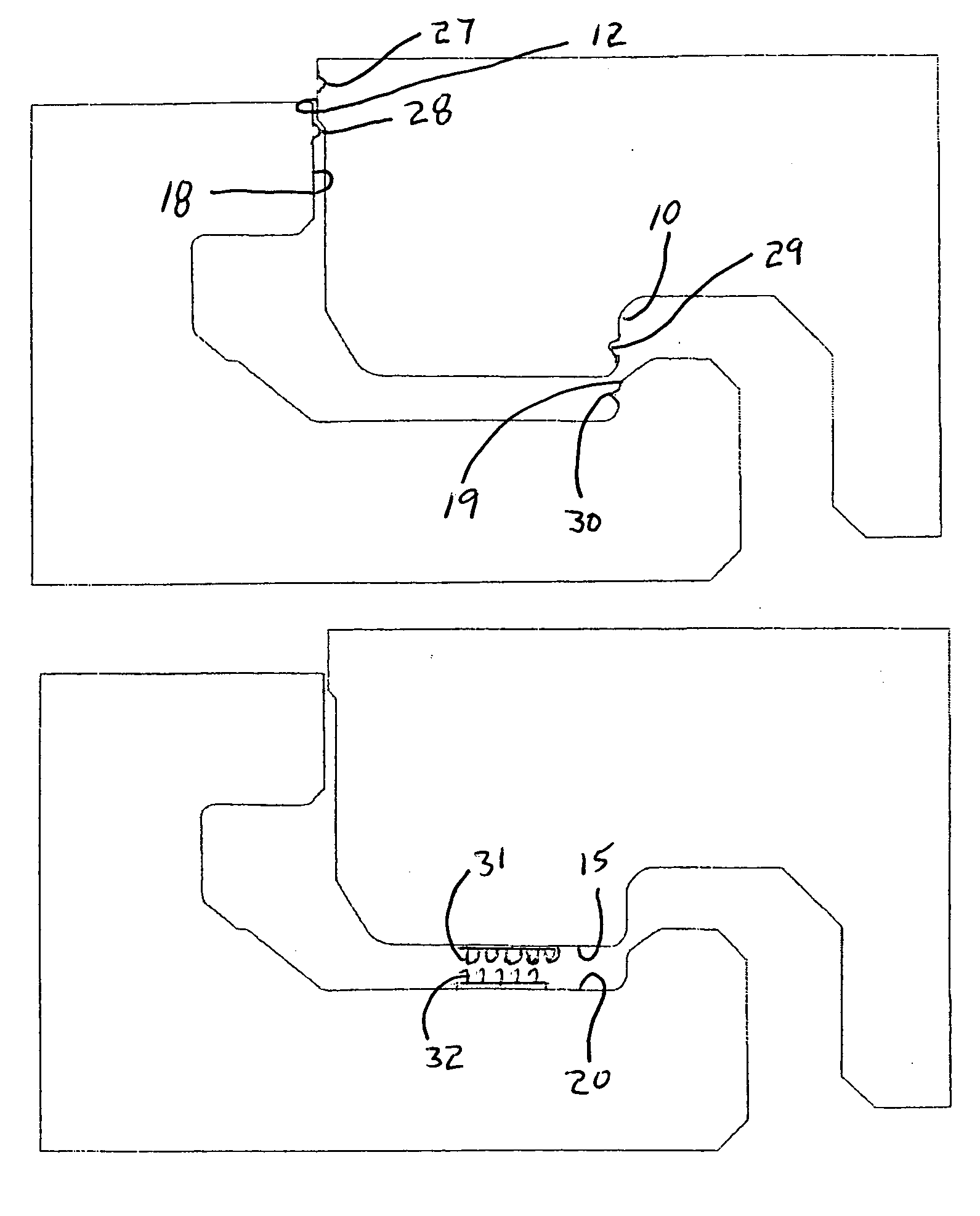

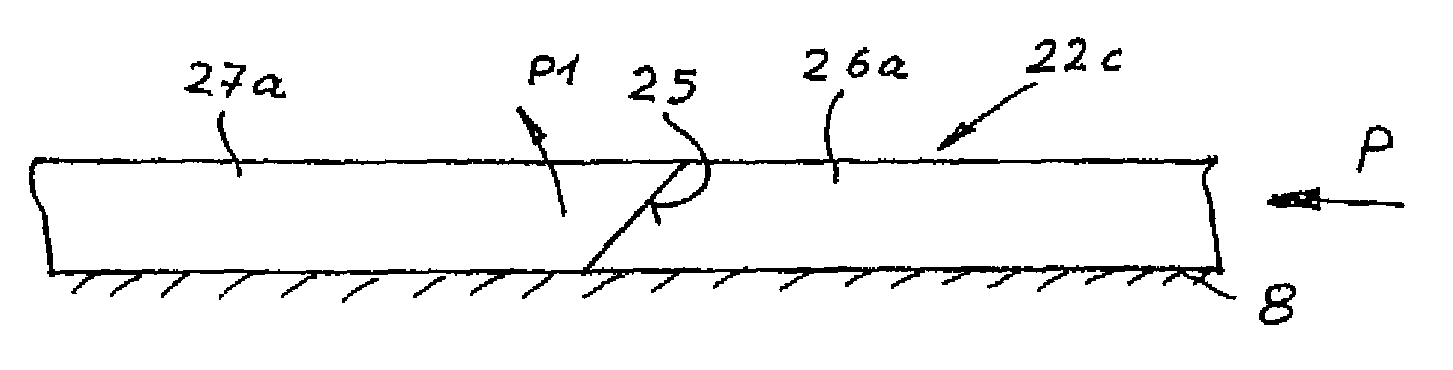

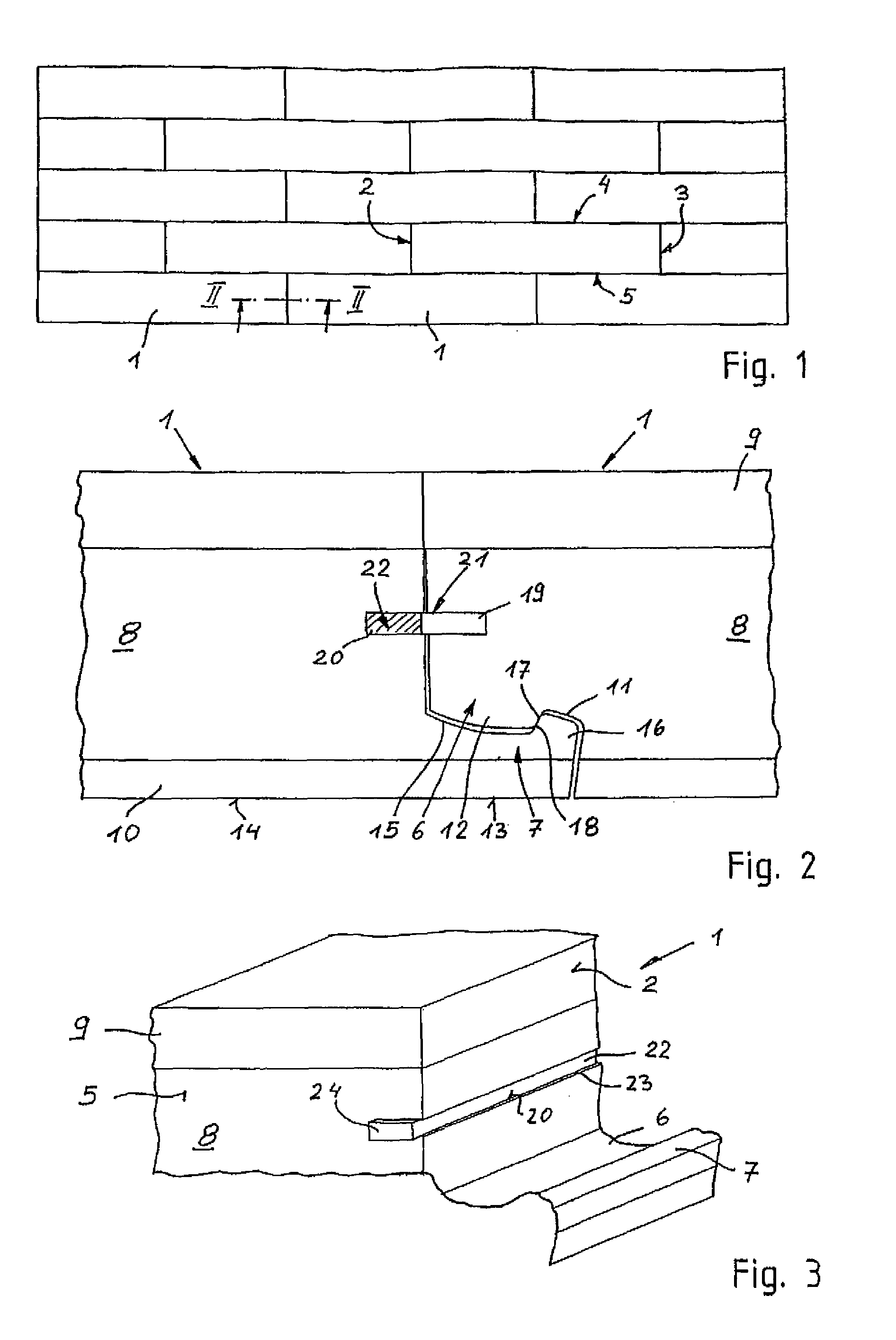

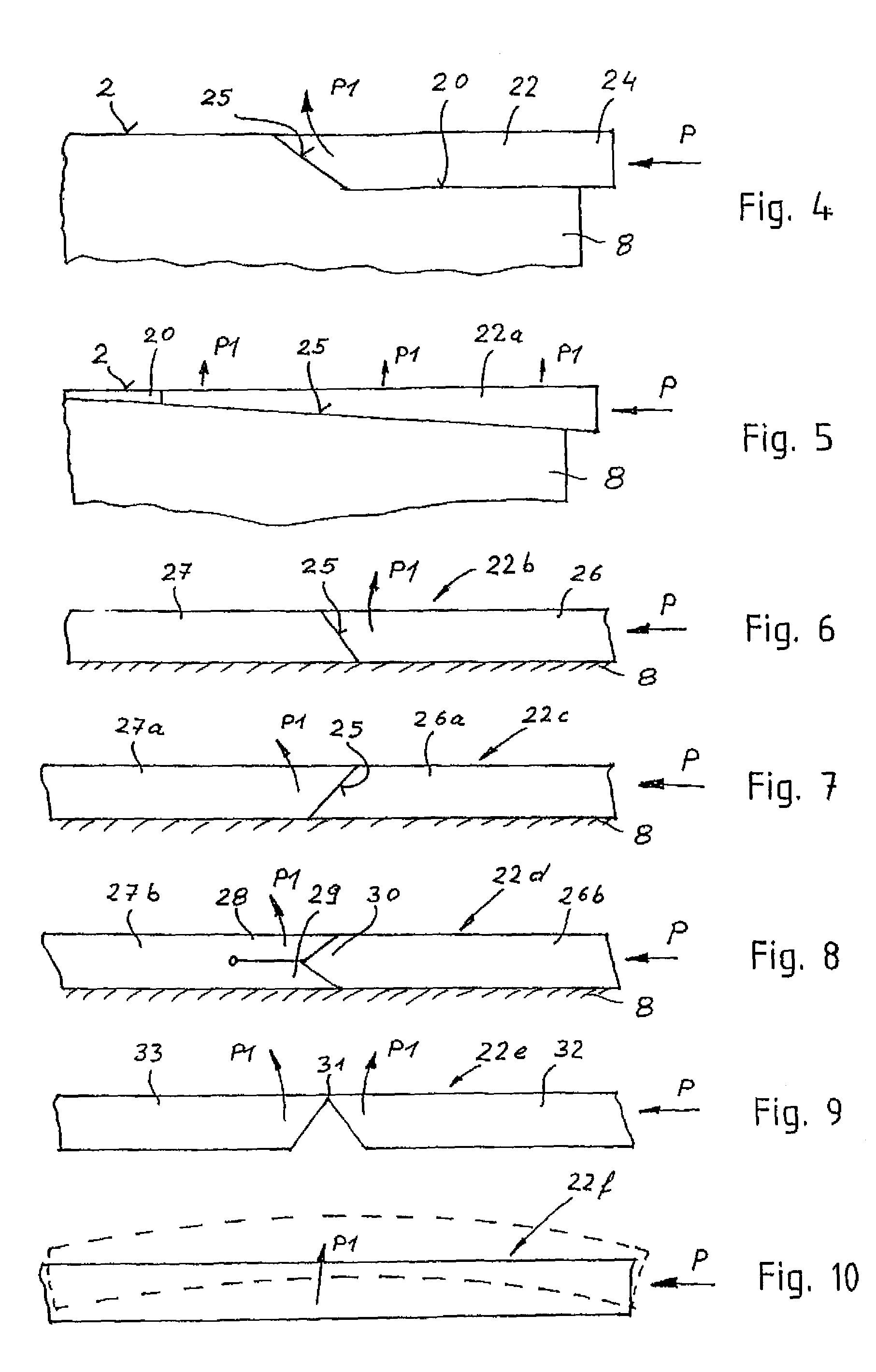

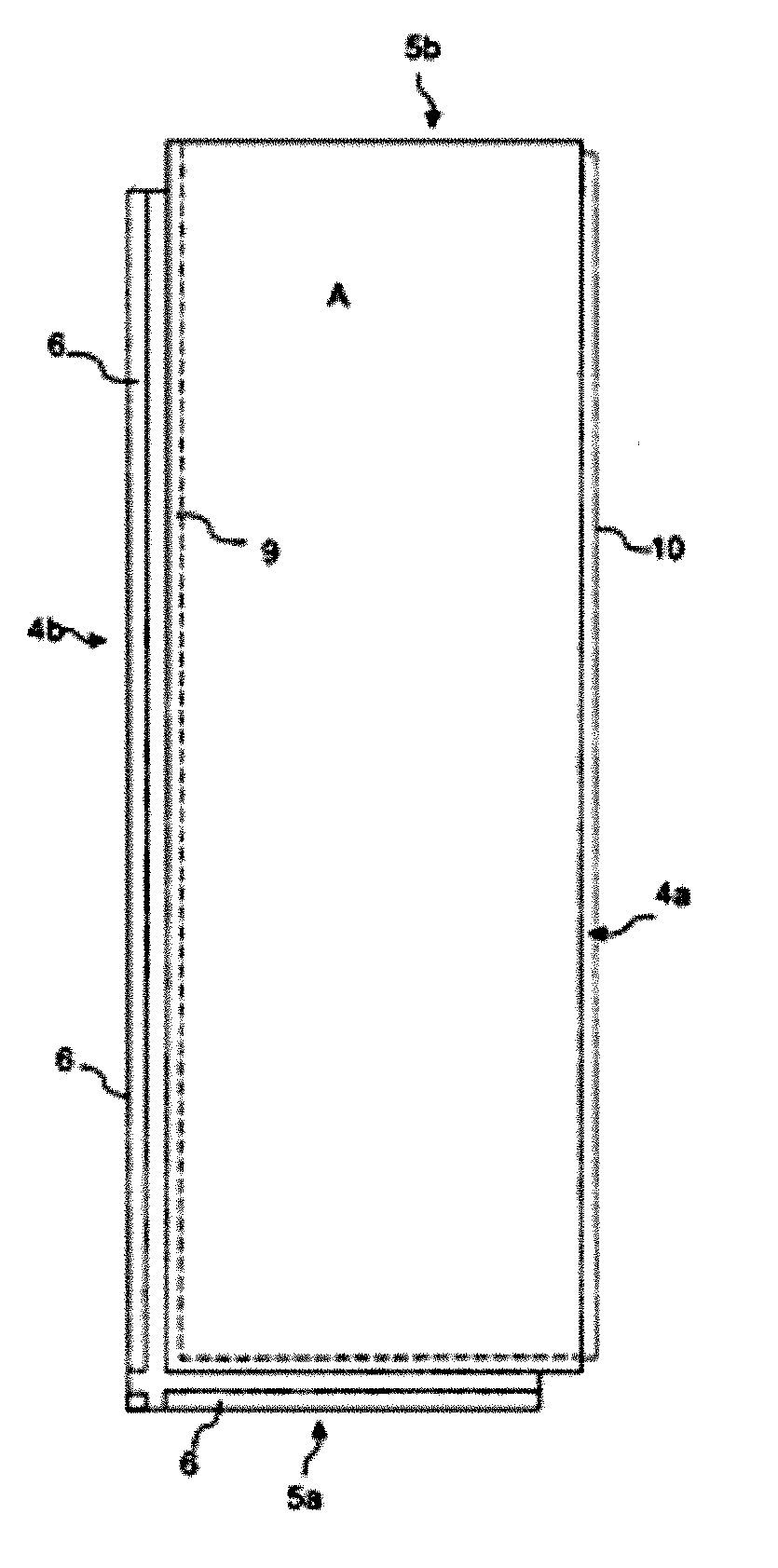

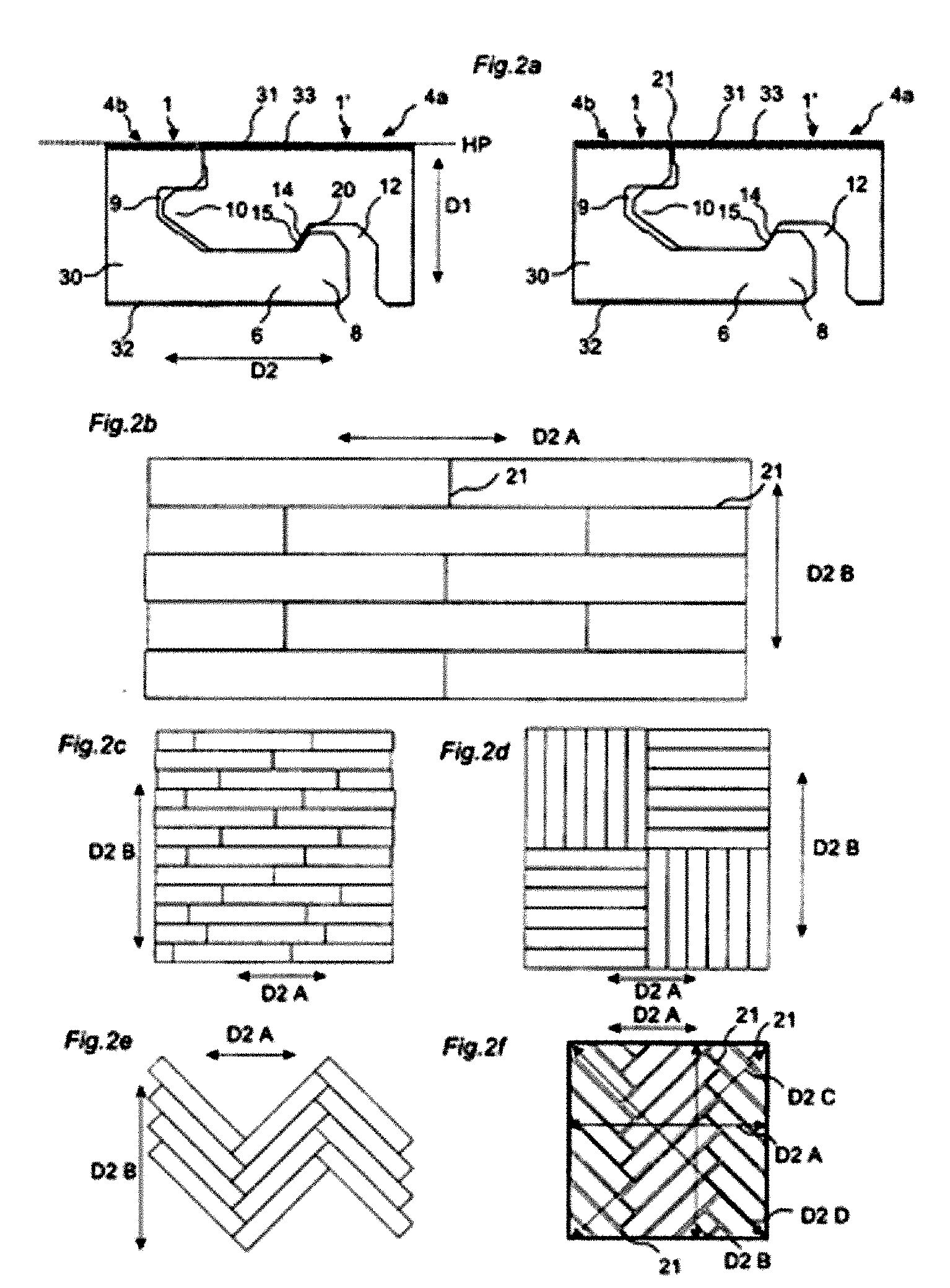

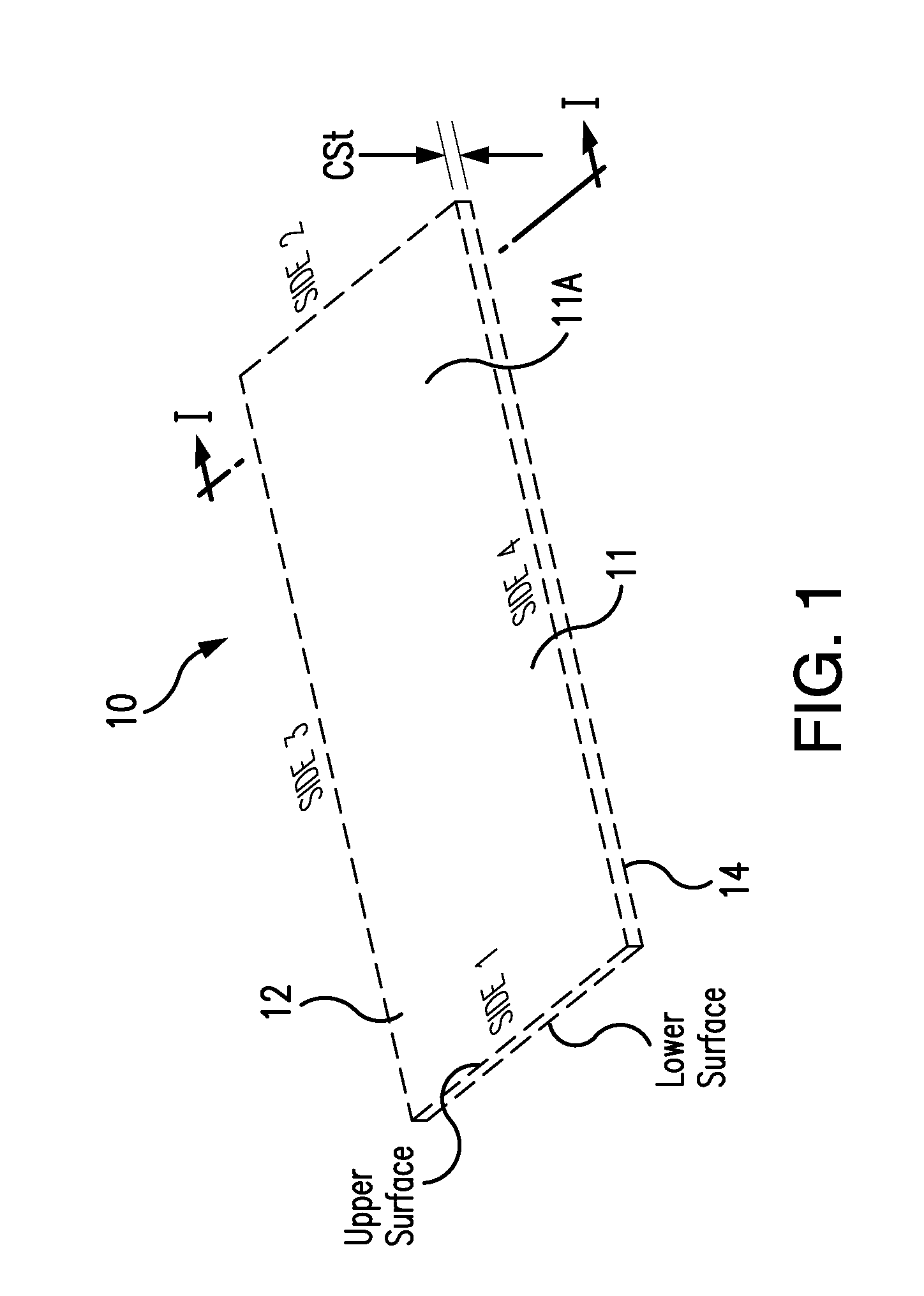

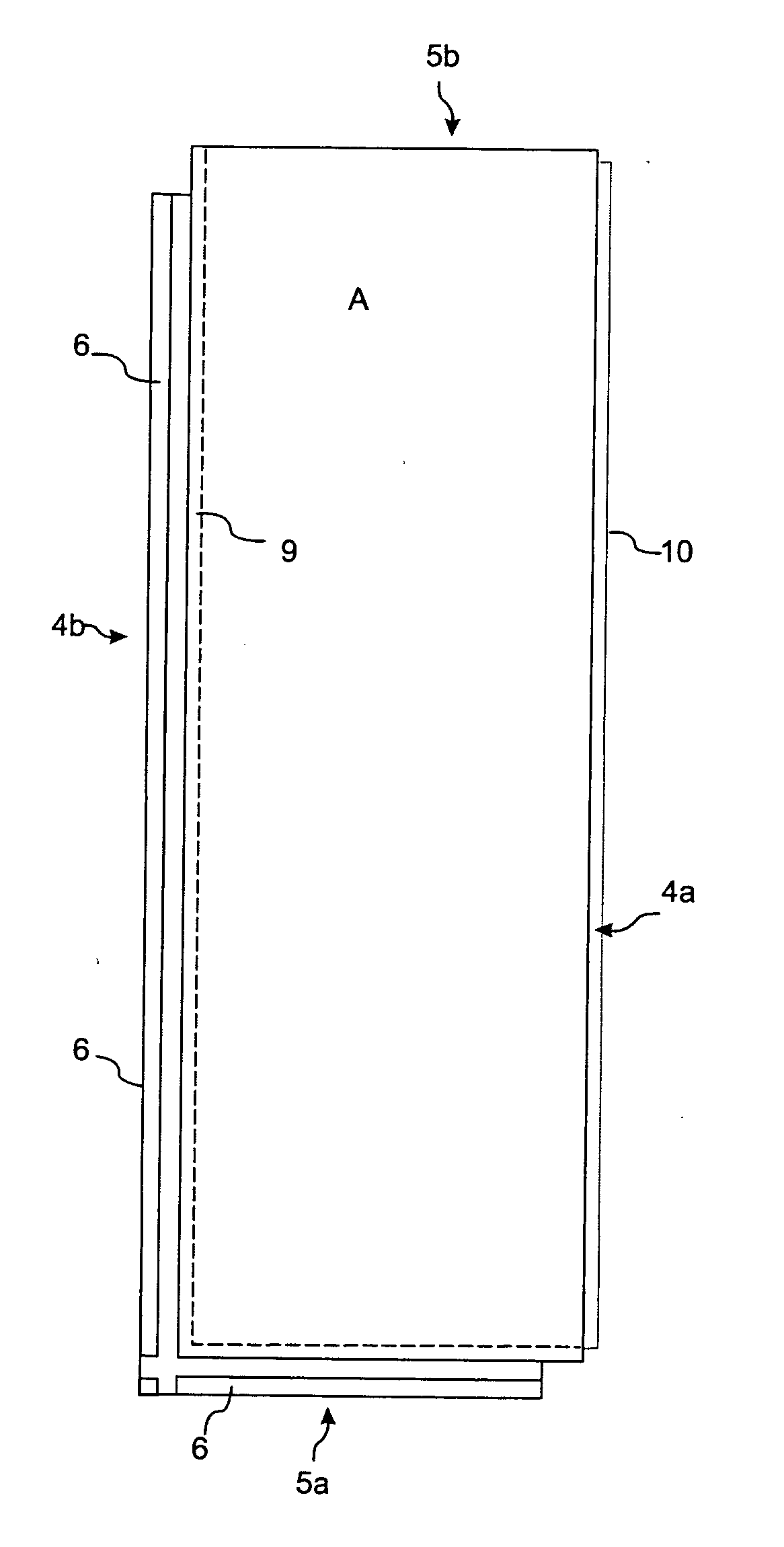

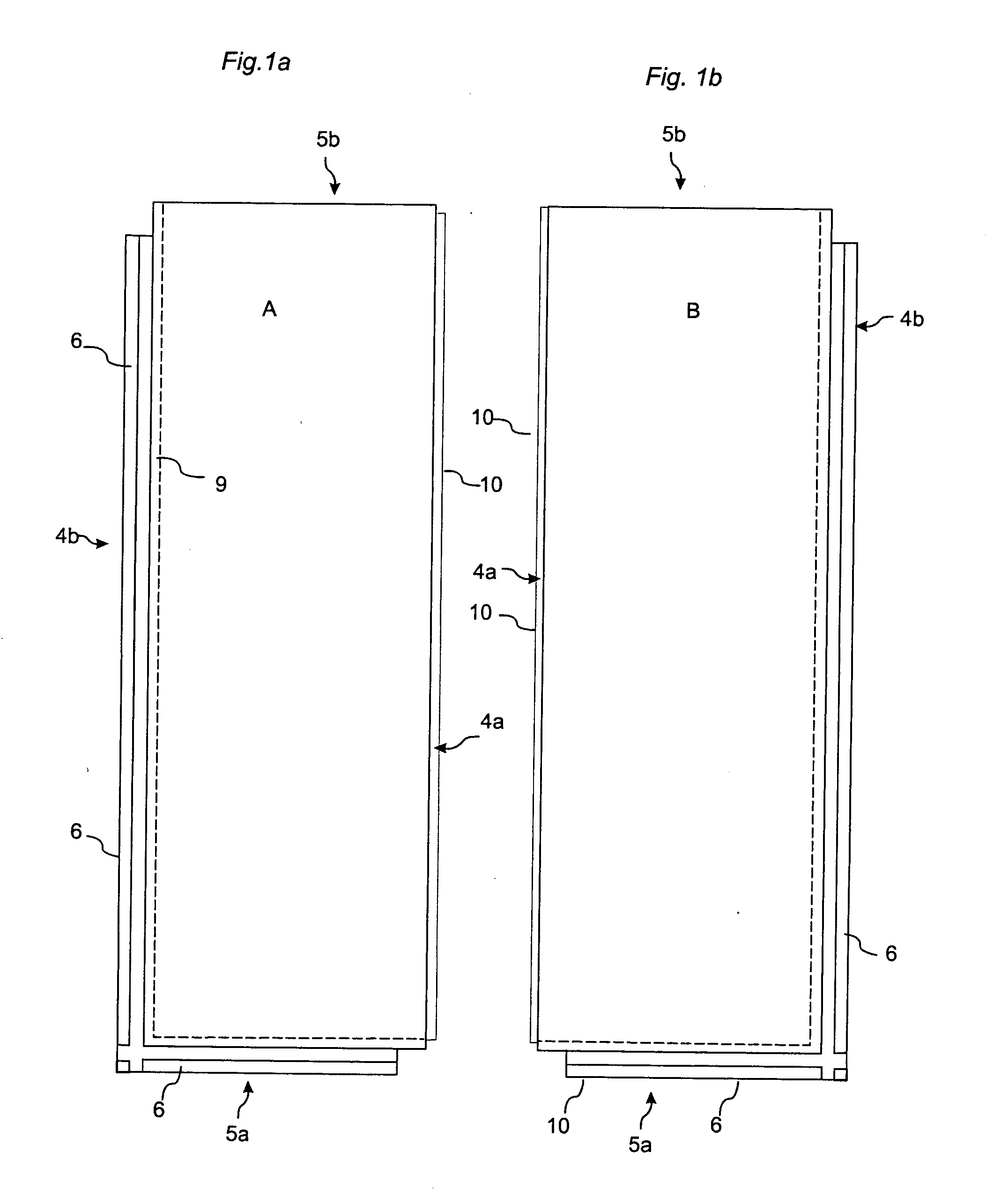

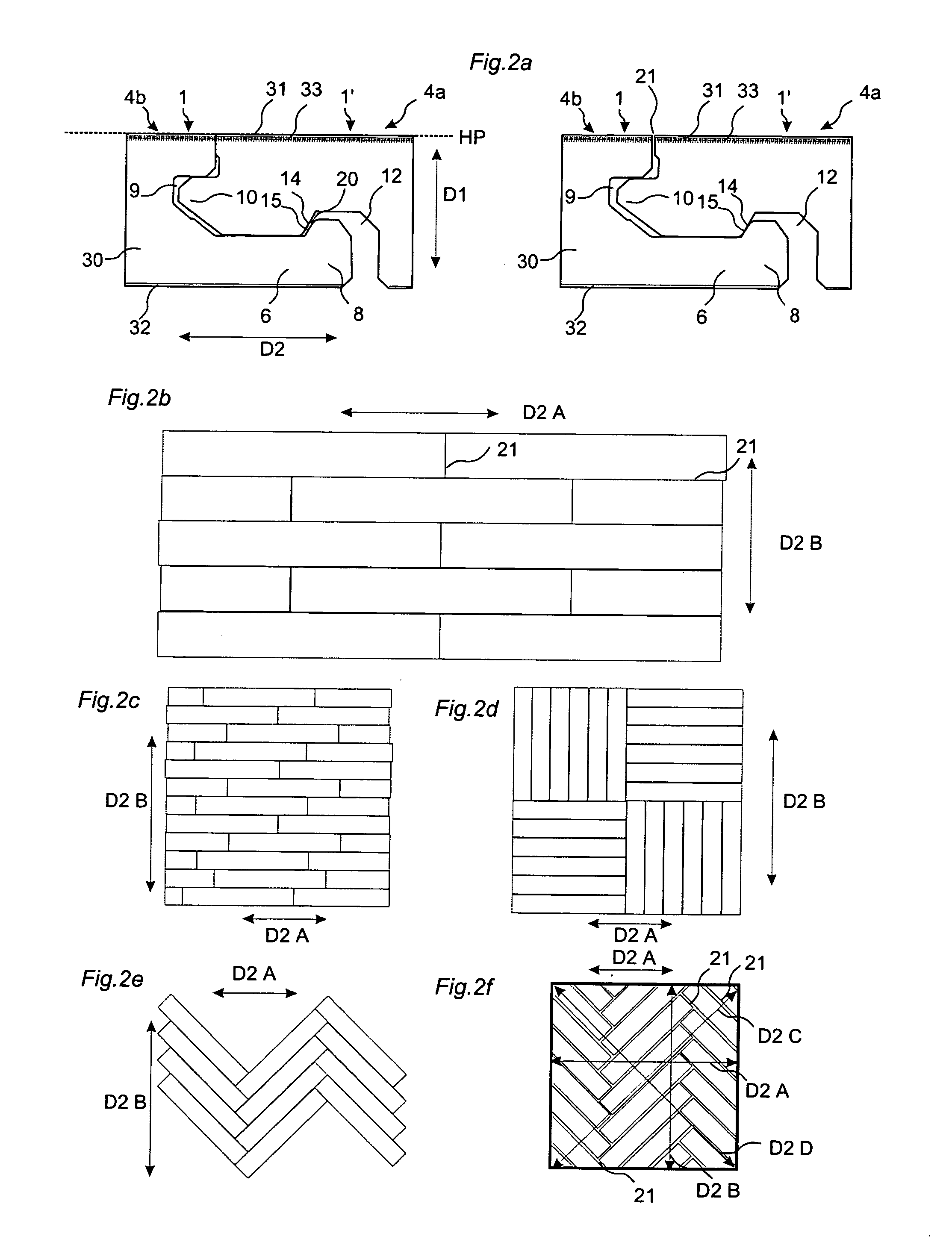

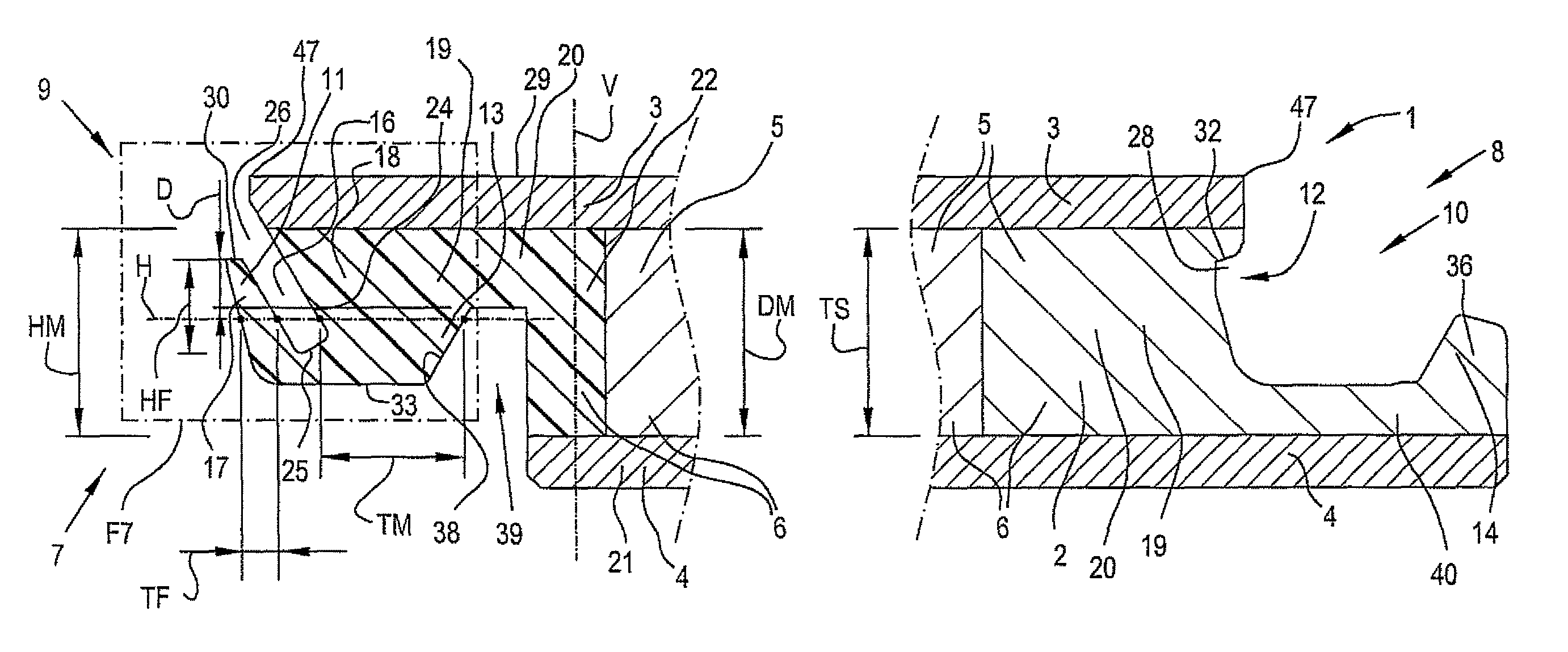

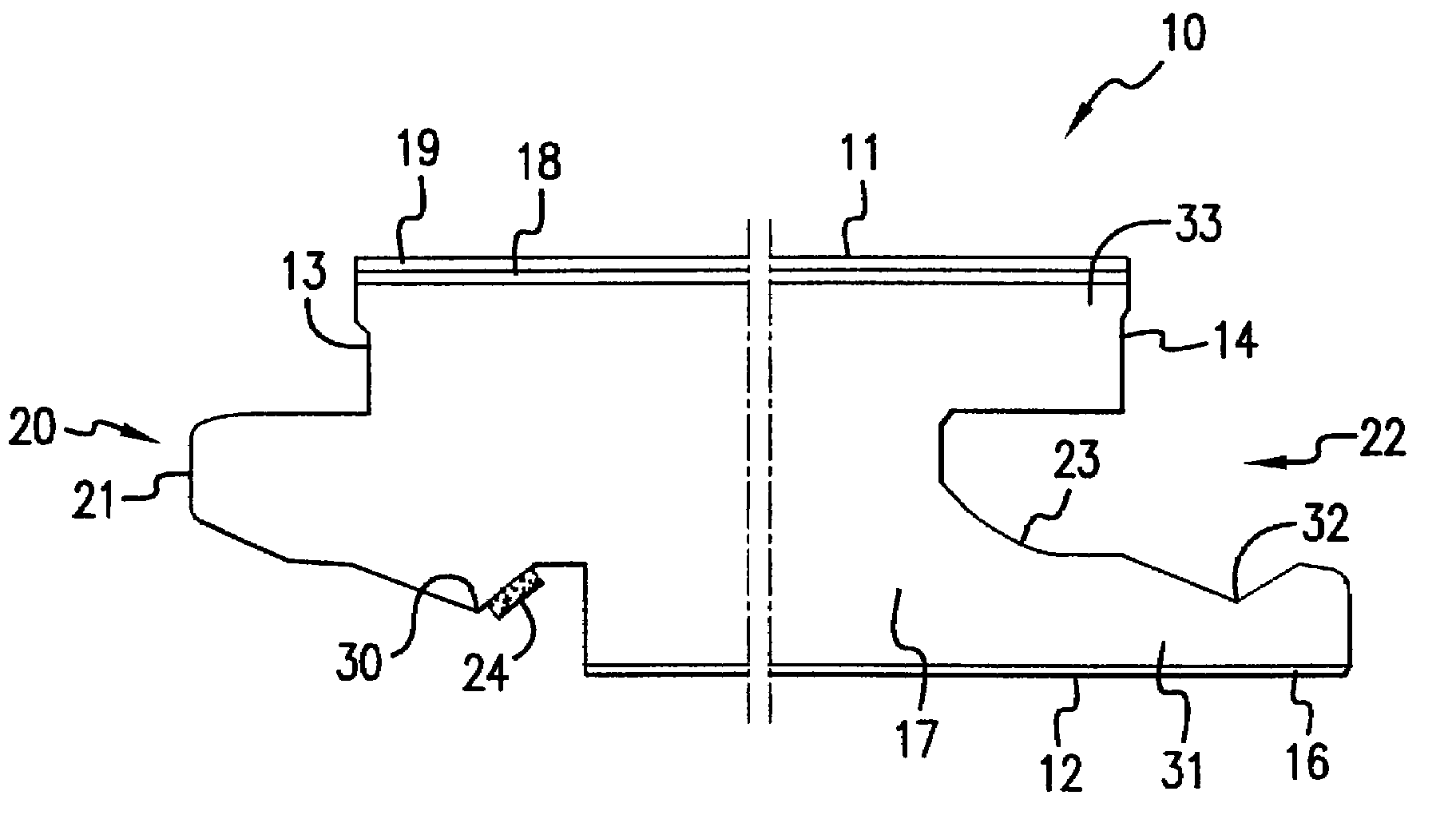

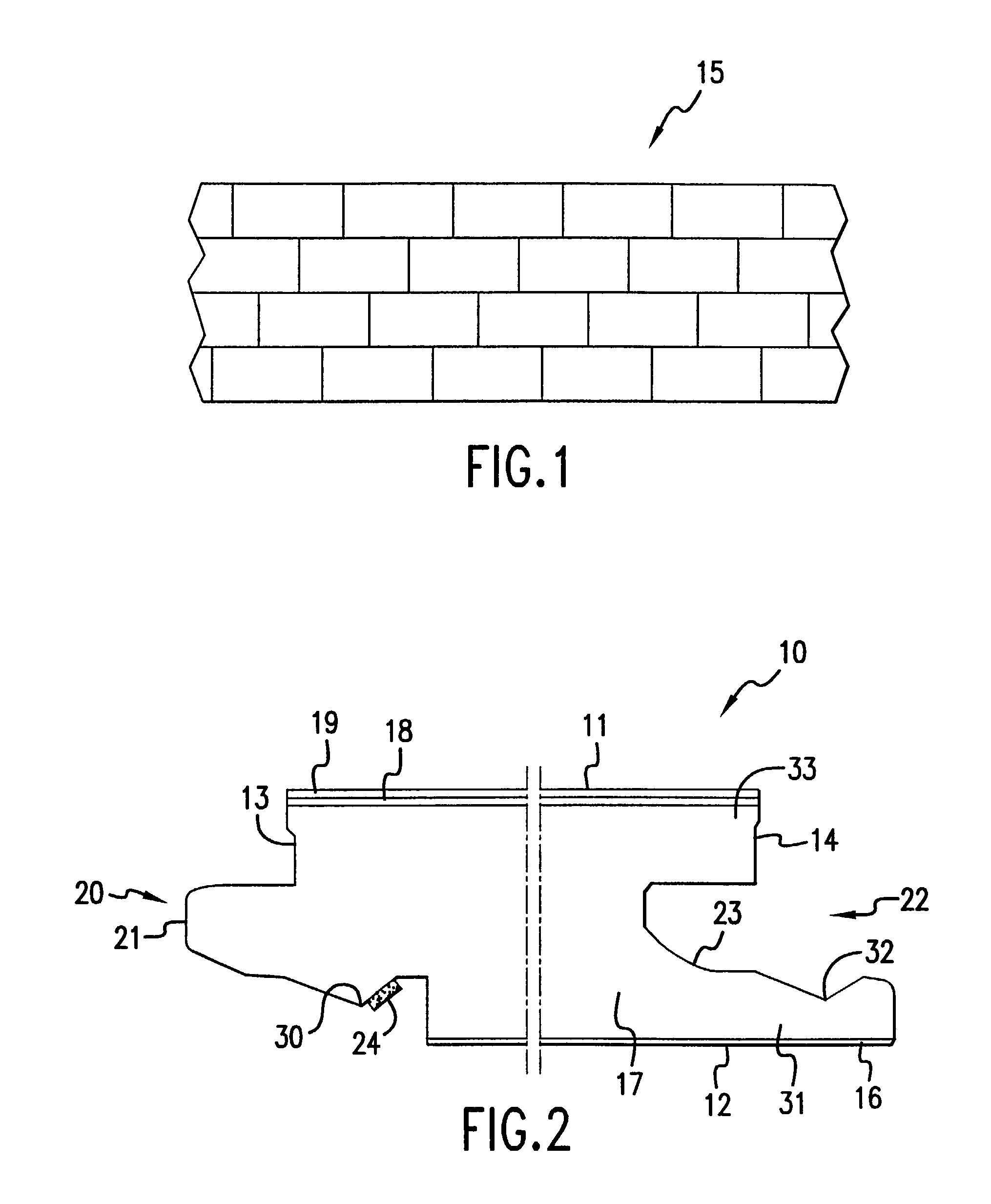

Floor covering comprising a plurality of unit panels (1) laid in a pattern, these panels being provided on their head sides (2, 3) and on their longitudinal sides (4, 5) with locking strips (6, 7) which engage with one another in the assembled position in which unit panels (1) are arranged adjacently within a covering, wherein grooves (19, 20) are provided in the head sides (2, 3) and wherein the grooves (19, 20) of two abutting head sides (2, 3) correspond and form a locking channel (21) intended to accommodate a head tongue (22, 22a-k). The head tongue (22) is preassembled in the groove (20) and projects beyond an end of the groove (20) that faces the longitudinal side (5) of the unit panel (1). At the same time, the head tongue (22) in the preassembled state is embedded completely within the groove (20) and can be displaced at least partially from one groove (20) into the corresponding groove (19) of the adjacent unit panel (1) by sliding the projecting end (24) of the head tongue (22) into the groove (20).

Owner:SCHULTE GUIDO

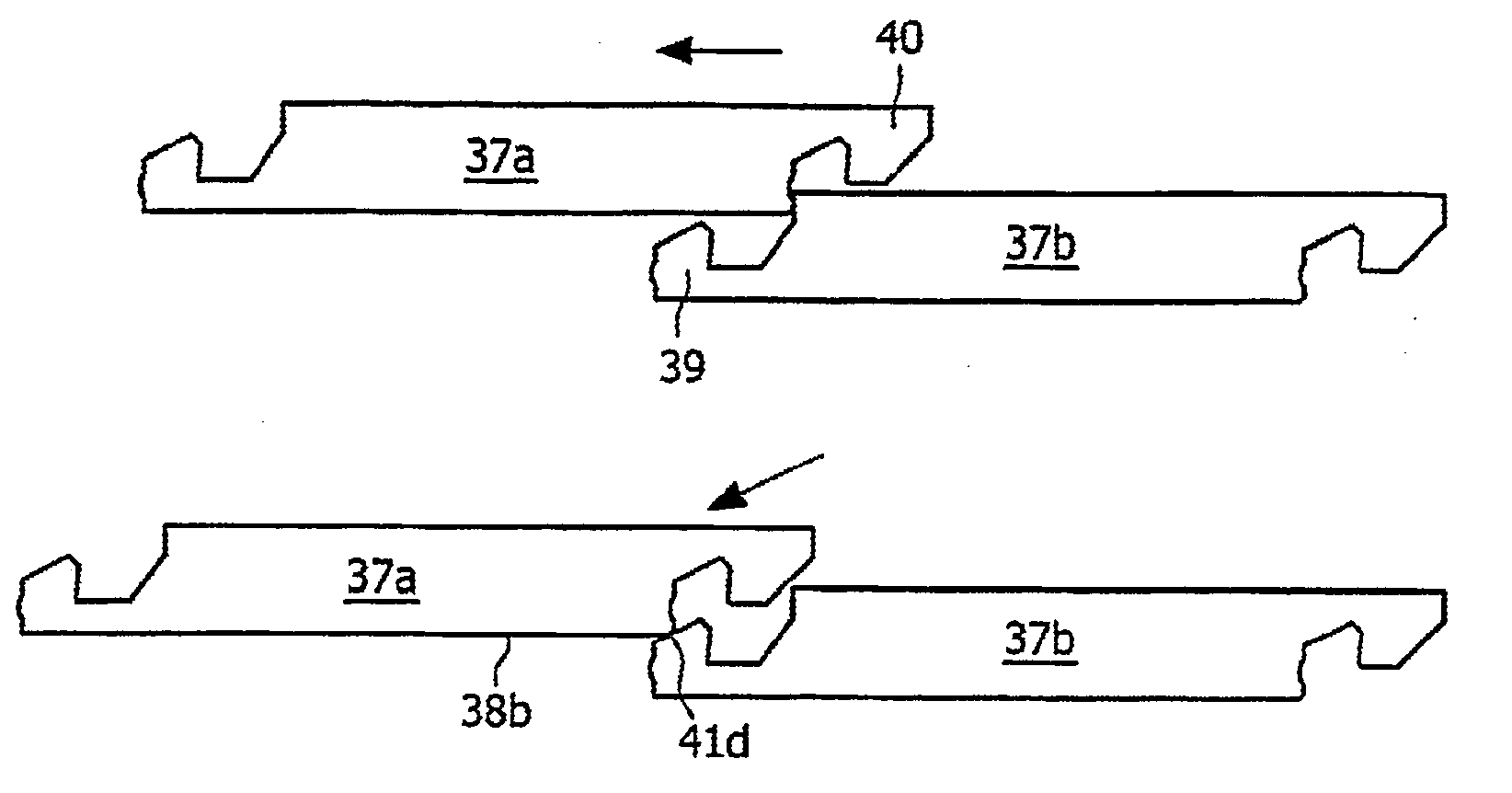

Floor Covering And Locking Systems

Abstract of the DisclosureFloorboards with a mechanical locking system that allows movement between the floorboards when they are joined to form a floating floor.

Owner:VÄLINGE INNOVATION AB

Floor covering with interlocking design

Surface coverings, such as floor coverings, with an interlocking design are described. Methods of making the surface coverings are further described.

Owner:VÄLINGE INNOVATION AB

Anchor sheet and anchor sheet module

This application discloses a relatively thin flexible anchor sheet for installation under carpets or other decorative coverings and a covering module composed of a pre-attached decorative covering and anchor sheet which can be assembled by overlapping hook and loop attachment to an additional covering module to create a complete floor covering of carpet, tile, stone or other material and without substantial attachment to a floor.

Owner:TAC FAST GEORGIA

Floor covering, floor panels for forming such floor covering, and method for realizing such floor panels

InactiveUS20050025934A1Improvement of imitationReduce disadvantagesCovering/liningsNatural patternsSynthetic materialsPanelling

Floor covering, consisting of hard panels, with a laminated structure, whereby at least at the upper surface a printed decorative layer with a wood pattern is present, with thereupon a transparent layer of synthetic material in which impressions are formed, wherein the impressions substantially follow the wood pattern.

Owner:FLOORING IND LTD

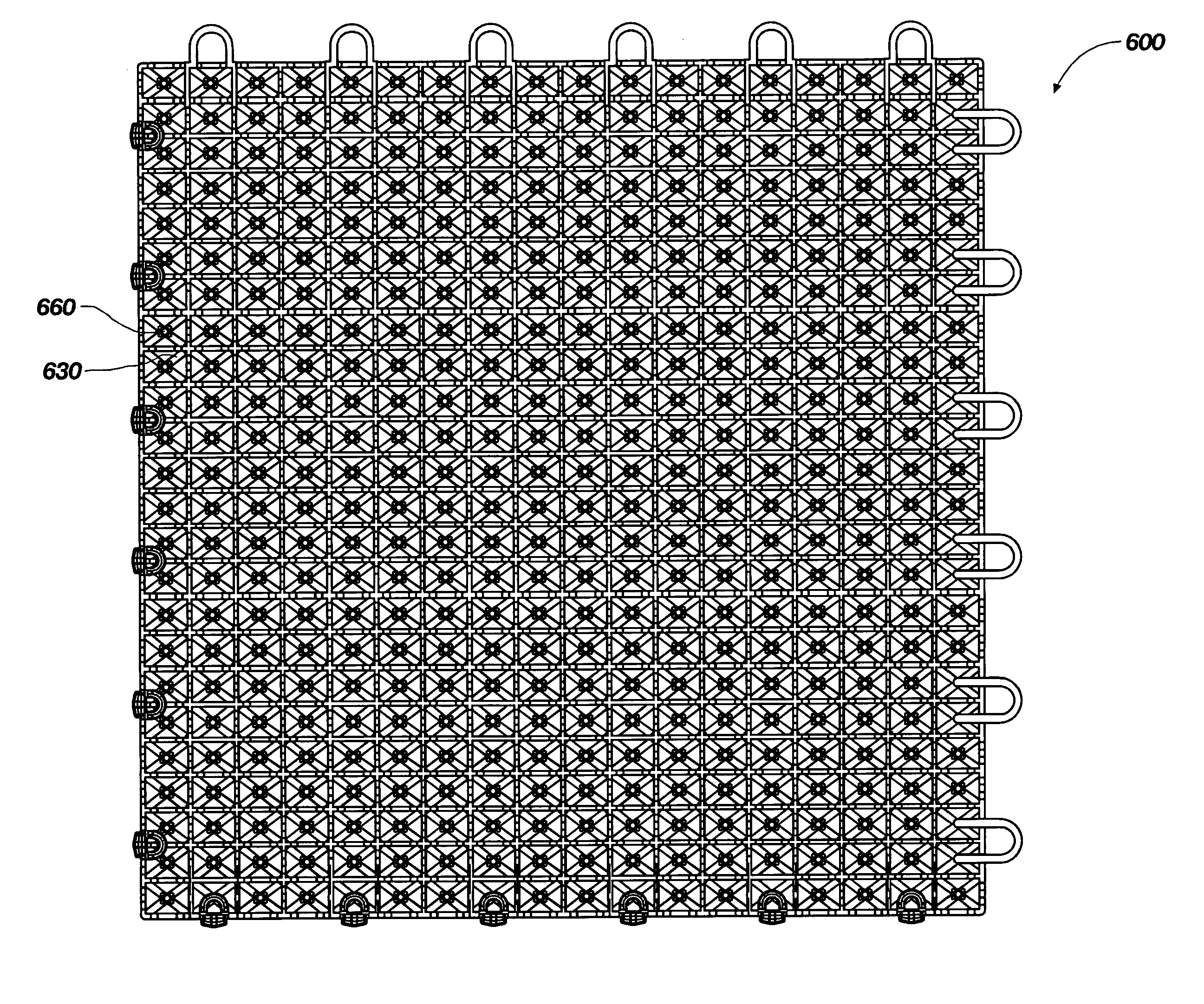

Modular tile with controlled deflection

A modular tile configured to interlock with multiple tiles to form a modular floor covering over a floor. The tile includes a top surface having a periphery defining side walls extending downward from the top surface, the side walls having a coupling portion configured to couple with other tiles adjacent thereto to form the modular floor covering. The tile also includes a bottom side, opposite the top surface, having a support grid including an array of downward extending polymeric post structures, at least some of the post structures including at least one resilient end portion with a radial end surface configured to be positioned against the floor to facilitate controlled deflection of the post structures. The post structures may comprise primary and secondary post structures, with the secondary post structures limiting the deflection of the primary post structures.

Owner:CONNOR SPORT COURT INT

Floor Panel and Floor Covering Consisting of a Plurality of Such Floor Panels

ActiveUS20120180416A1Increased durabilityEnhanced couplingConstruction materialFloorsPanellingEngineering

The invention relates to a floor panel; in particular a laminated floor panel. The invention also relates to a floor covering consisting of a plurality of mutually coupled floor panels according to the invention. The invention further relates to a method for mutually coupling two floor panels, in particular laminated floor panels, according to the invention.

Owner:I4F LICENSING NV

Floor covering and locking systems

ActiveUS20080168737A1Remove changeChange shapeTongue/grooves making apparatusWallsEngineeringMechanical engineering

Floorboards with a mechanical locking system that allows movement between the floorboards when they are joined to form a floating floor.

Owner:VÄLINGE INNOVATION AB

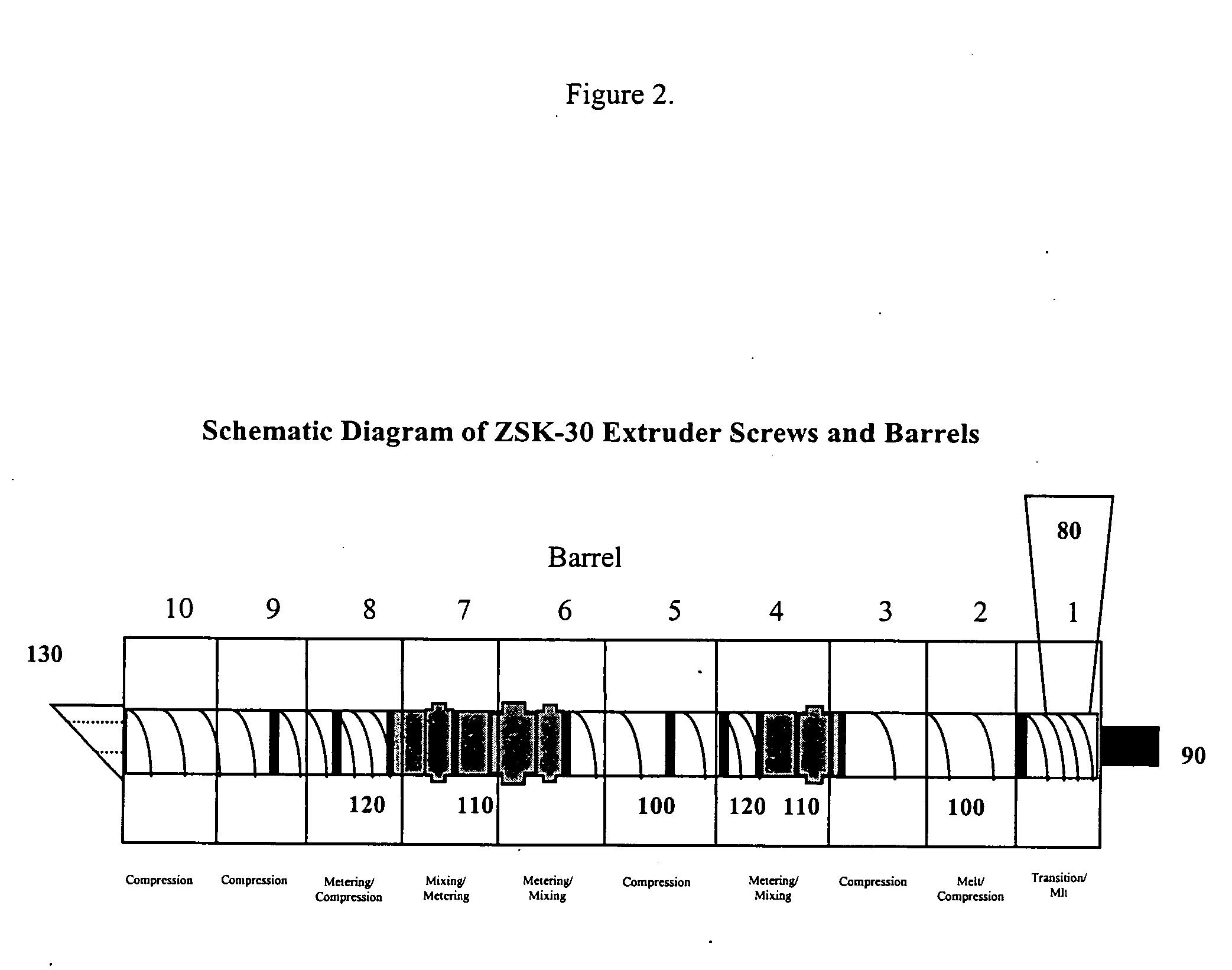

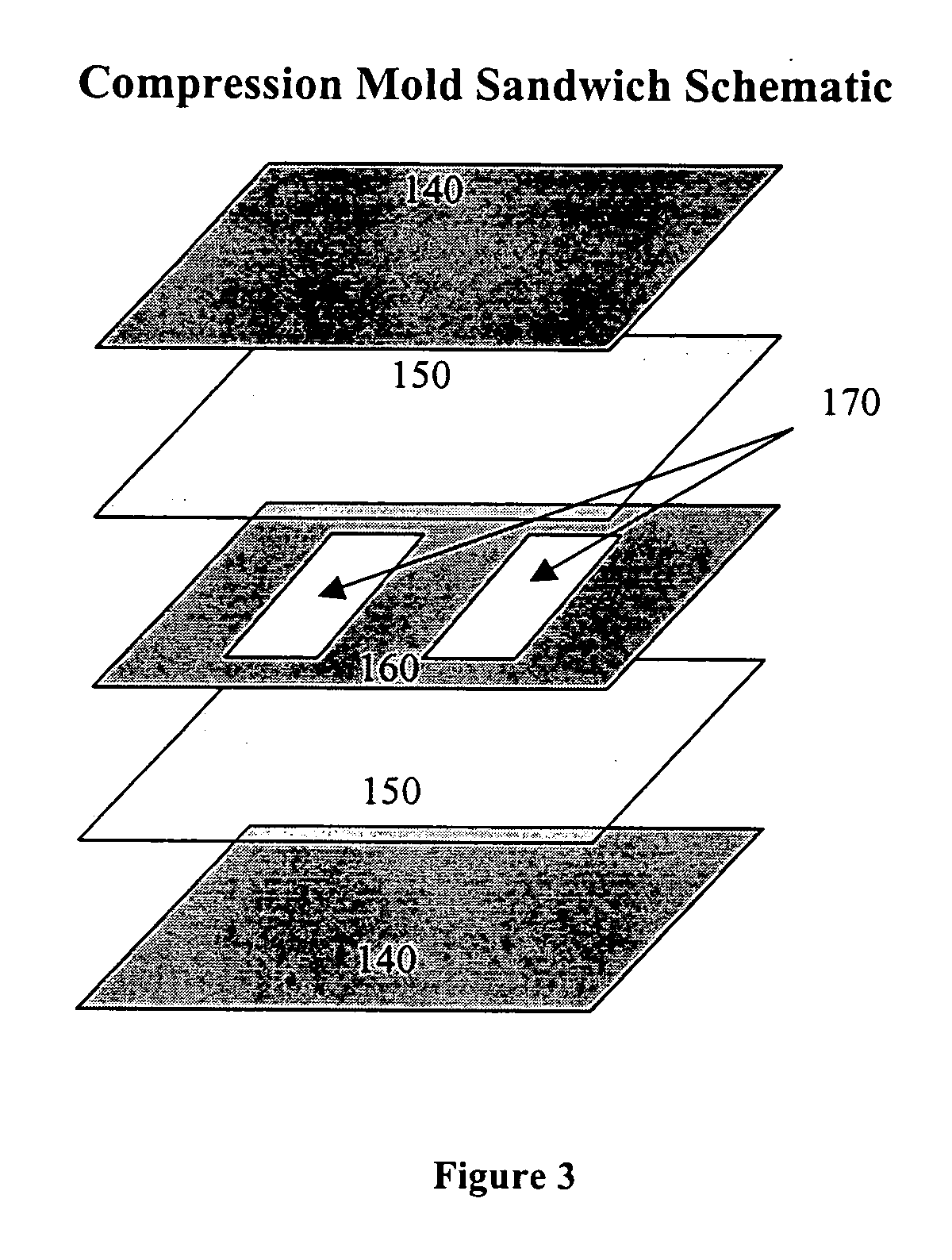

Environmentally friendly polylactide-based composite formulations

Polymeric materials and products, including sheet flooring materials prepared from the polymeric materials, and processes for preparing the polymeric materials, are disclosed. The polymeric materials include a polylactic acid-based polymer in combination with plasticizer and a compatibilizer, and optionally include a filler. The polymeric material can include between about 30 to about 50 percent by weight polyvinyl chloride, polyethylene glycol, polyglycolide, ethylene vinyl acetate, polycarbonate, polycaprolactone, polyhydroxyalkanoates, or polyolefins modified with polar groups, for example, ionomers. The plasticizer is typically an epoxidized vegetable oil or esterified and epoxidized vegetable oil and is typically present in an amount of between about 10 and about 50% by weight. In some embodiments, the compatibilizer is a polyolefin modified with one or more polar functional groups, and is typically present in an amount of between about 5 and about 10% by weight. The material can be used in decorative surface coverings, such as a floor coverings, particularly when it is in the form of a polymeric sheet. The polymeric material can be present in at least one layer of a floor covering, which floor covering can also include one or more additional layers such as wear layers, foamed or foamable layers, top coat layers and design layers. The additional layers can also include the polymeric material.

Owner:AFI LICENSING

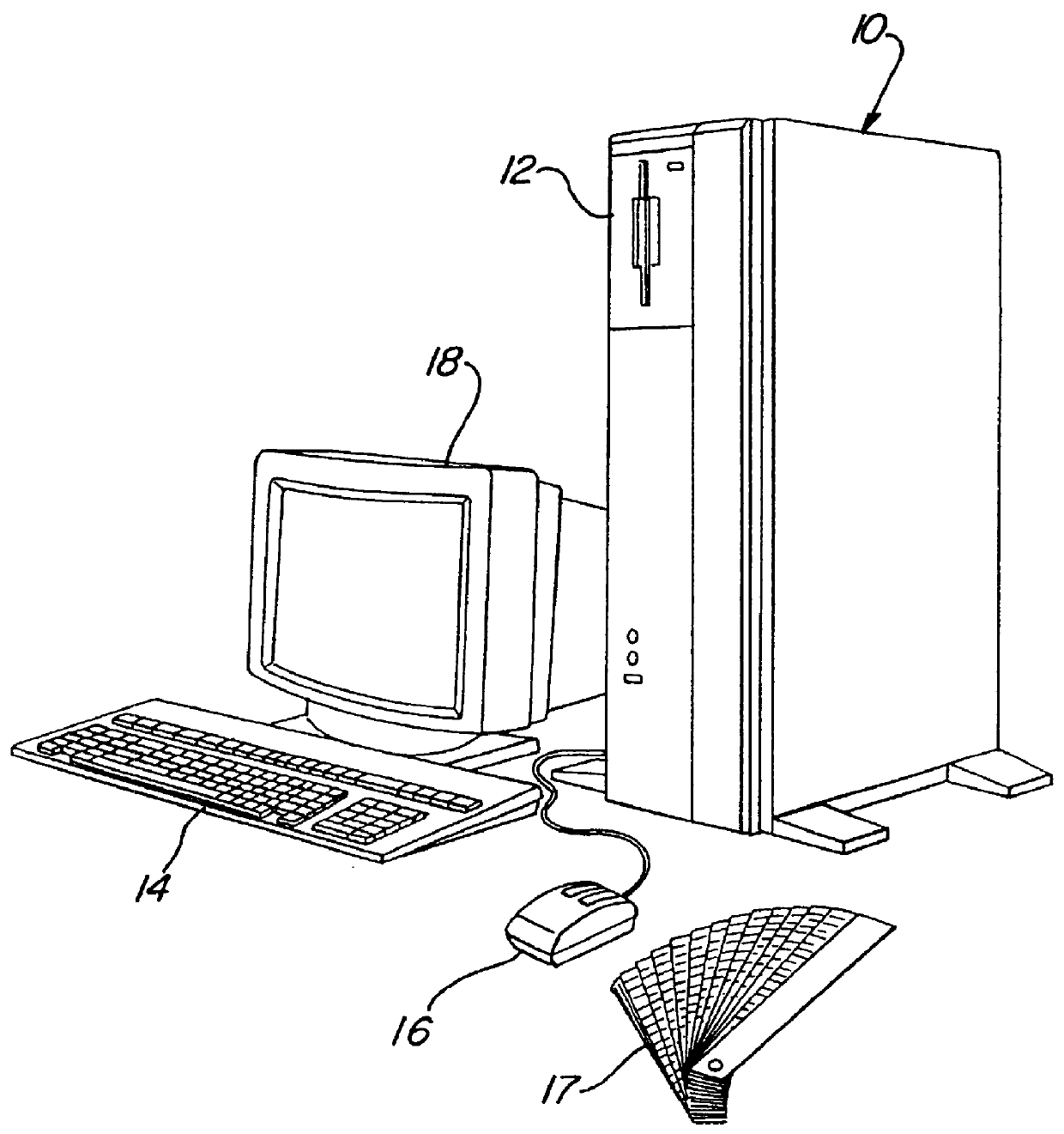

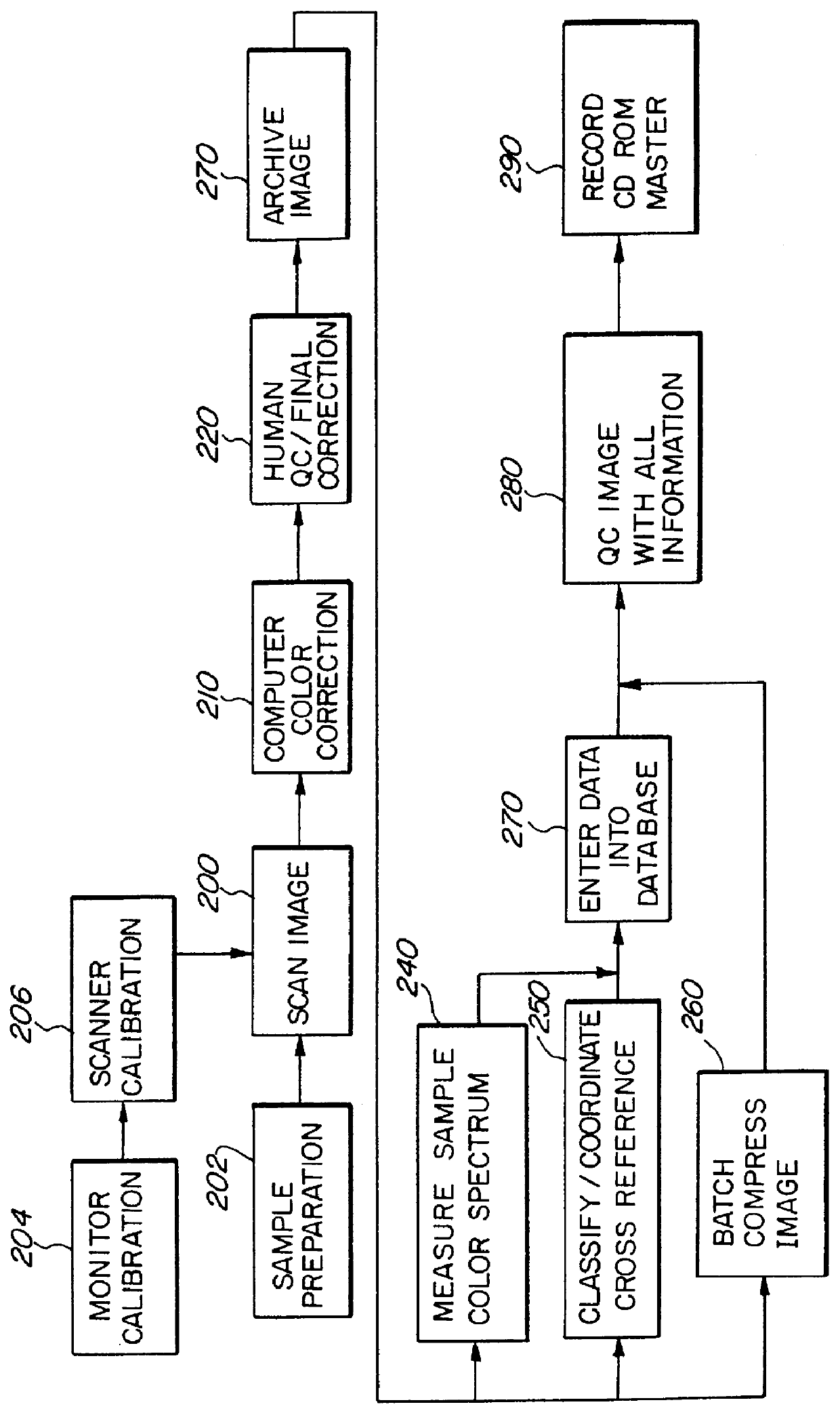

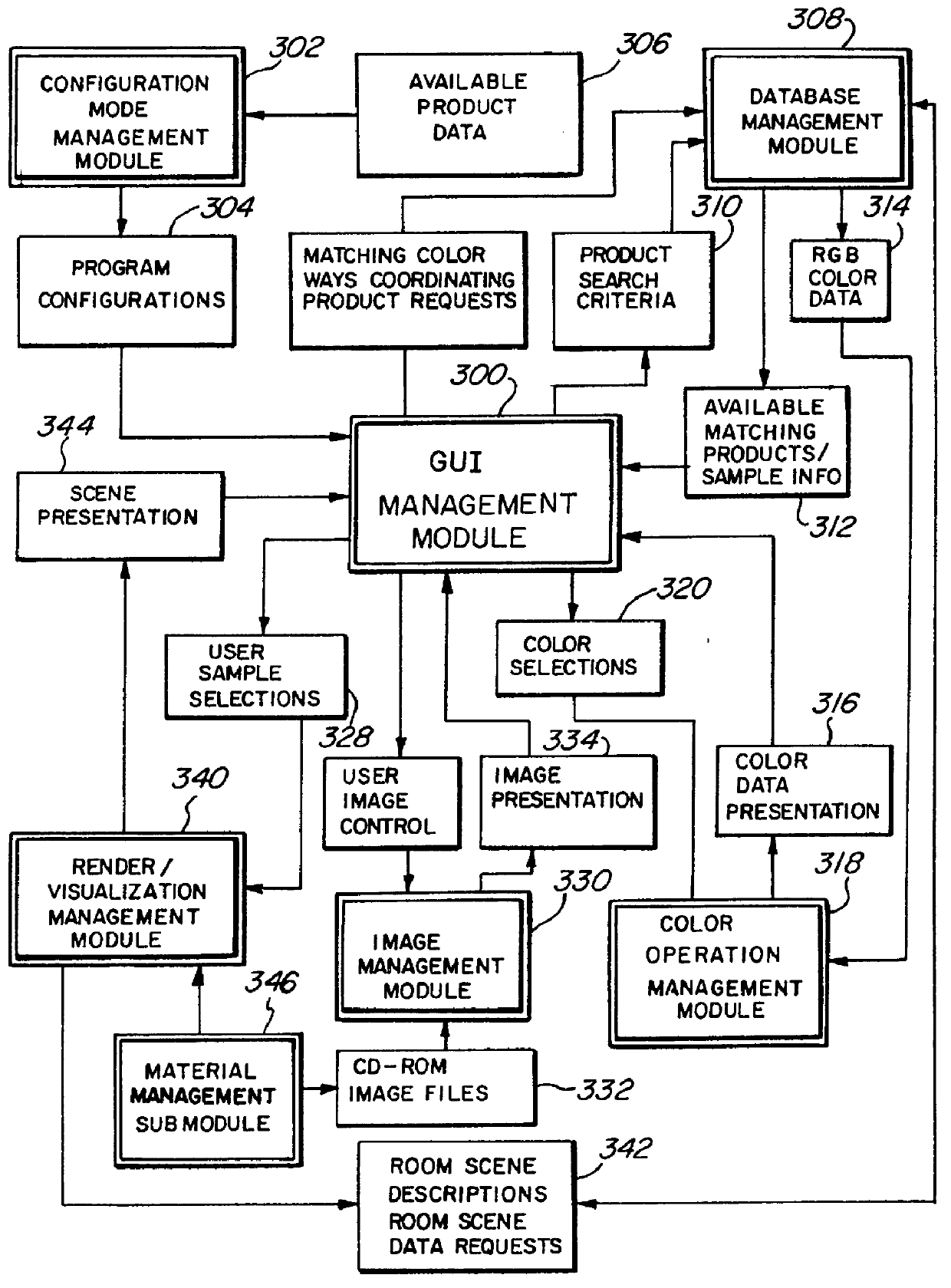

Spectrally coordinated pattern search-imaging system and method

InactiveUS6122391AChoose simpleDigital data information retrievalTexturing/coloringColor imageCD-ROM

A system for selecting decorative materials is based on large numbers of high-resolution, full color images of decorative materials stored in a compressed format on an inexpensive medium such as a CD-ROM. In creating the ROM, each image is coordinated with additional information such as style of pattern, type of material, and other auxiliary information. Before final compression and storage of the image data color information is added by spectrophotometrically analyzing the decorative material. Color values for a background color and up to four foreground colors are determined. Individual colors are then referenced to a comprehensive color standard system containing a large number of standardized color swatches. Spectrophotometric color referencing allows the data records to be rapidly searched on the basis of color, as well as the other information in the record. Wallpaper patterns, drapery material, floor covering, or paint can then be rapidly selected on the basis of matching color. Various patterns and paints can be compared side by side on a high-resolution computer monitor that has been calibrated to produce an accurate color image. Finally, the chosen paints and other decorating materials can be rendered onto a room image so that the consumer can view an accurate simulation of the chosen materials.

Owner:AUTODESK INC

Floor panel and floor covering consisting of a plurality of such floor panels

ActiveUS8745952B2CouplingEnhanced couplingRoof covering using tiles/slatesBuilding repairsEngineeringFloor covering

The invention relates to a floor panel; in particular a laminated floor panel. The invention also relates to a floor covering consisting of a plurality of mutually coupled floor panels according to the invention. The invention further relates to a method for mutually coupling two floor panels, in particular laminated floor panels, according to the invention.

Owner:I4F LICENSING NV

Topical application of solid antimicrobials to carpet pile fibers during carpet manufacture

InactiveUS6641829B1Good light fastnessShampoo durabilityBiocideBiochemical fibre treatmentFiberLiquid medium

Carpeted floor covering articles comprising carpet pile fibers to which a topical antimicrobial application of solid particles has been applied either during or after product manufacture (such as part of a cleaning or treatment process) are provided. Such a topical treatment includes specific inorganic antimicrobial metal ion-based solid compounds, such as silver ion-exchange compounds, silver zeolites, and / or silver glasses, which may or may not be dispersed within a liquid medium for ease in handling and application. Such treatments also optionally include compositions of stain resistant agents, anti soil-redeposition compounds and liquids, surfactants, antistatic agents, and the like, to impart other characteristics to the target carpeted products. Such carpeted products thus exhibit excellent antimicrobial characteristics at both the surface of the carpet pile, as well as within the pile itself. Furthermore, it has been found that application of such solid metal-ion based antimicrobials permits the ability to increase antimicrobial activity for the target carpet product after vacuuming.

Owner:SAGE AUTOMOTIVE INTERIORS INC

Floor covering and locking systems

InactiveUS20050166516A1Remove changeChange shapeTongue/grooves making apparatusWallsEngineeringMechanical engineering

Floorboards with a mechanical locking system that allows movement between the floorboards when they are joined to form a floating floor.

Owner:VÄLINGE INNOVATION AB

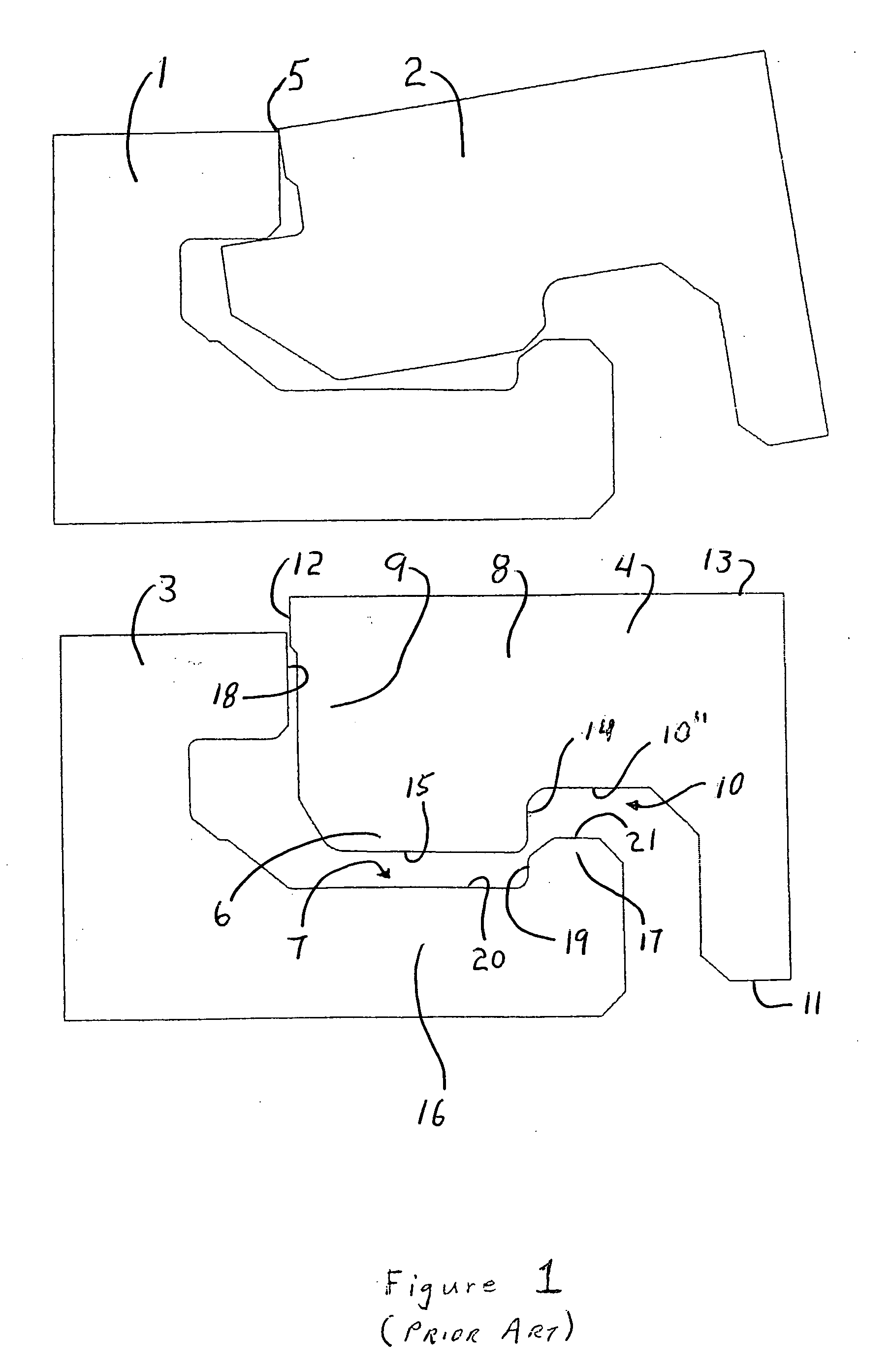

Floor covering, floor element and method for manufacturing floor elements

ActiveUS8991055B2Sturdy and simpler to manufacture couplingMetal-working apparatusDomestic articlesSynthetic materialsCoupling

Floor covering, made of floor elements, which, at least at two opposite sides, comprise a male and a female coupling part, which allow that two of such floor elements can be interconnected at the respective sides at the respective sides by pushing one of these floor elements with the associated male coupling part, by means of a downward movement, home into the female coupling part of the other floor element, wherein at least one of said coupling parts, either the male coupling part or the female coupling part, is made as least partially in a filled synthetic material composite, such as extruded wood.

Owner:FLOORING IND LTD

Floor covering and locking systems

ActiveUS8495849B2Remove changeChange shapeTongue/grooves making apparatusWallsMechanical engineeringFloor covering

Floorboards with a mechanical locking system that allows movement between the floorboards when they are joined to form a floating floor.

Owner:VÄLINGE INNOVATION AB

Pre-glued tongue and groove flooring

The invention provides a new floor covering panel and floor covering system in which the floor covering panels include first and second generally planar surfaces, first and second side edges containing first and second complementary coupling members, respectively, and an adhesive composition selectively applied to at least a portion of at least one of the first and second coupling members. The adhesive composition providing the adhesive bond may be applied to at least one of the first or second coupling members during the floor covering manufacturing process. After a floor covering system is assembled, the adhesive composition provides a substantially non-refastenable bond between mated floor covering panels.

Owner:COLUMBIA INSURANCE CO

Plastic floor covering and method for obtaining same

InactiveUS20040102120A1Retention characteristicImprove featuresClosuresLayered productsThermoplasticEngineering

The invention concerns a floor covering produced by coating and comprising a thermoplastic-based structure, in particular plasticized PVC, reinforced with a textile reinforcement, optionally combined with a foam backing and whereof the visible surface consists of a surface coating providing decoration and wear resistance to the product. The invention is characterised in that the back surface designed to be in contact with the floor, consists of a textile web, the bonding between the textile structure and the supporting back surface being produced by means of an additional plastisol layer, which penetrates over a minor part the thickness of the textile structure and which, after gelling, bonds said textile to the thermoplastic substrate back surface.

Owner:GERFLOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com