Patents

Literature

1394 results about "Tongue and groove" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tongue and groove is a method of fitting similar objects together, edge to edge, used mainly with wood, in flooring, parquetry, panelling, and similar constructions. Tongue and groove joints allow two flat pieces to be joined strongly together to make a single flat surface. Before plywood became common, tongue and groove boards were also used for sheathing buildings and to construct concrete formwork.

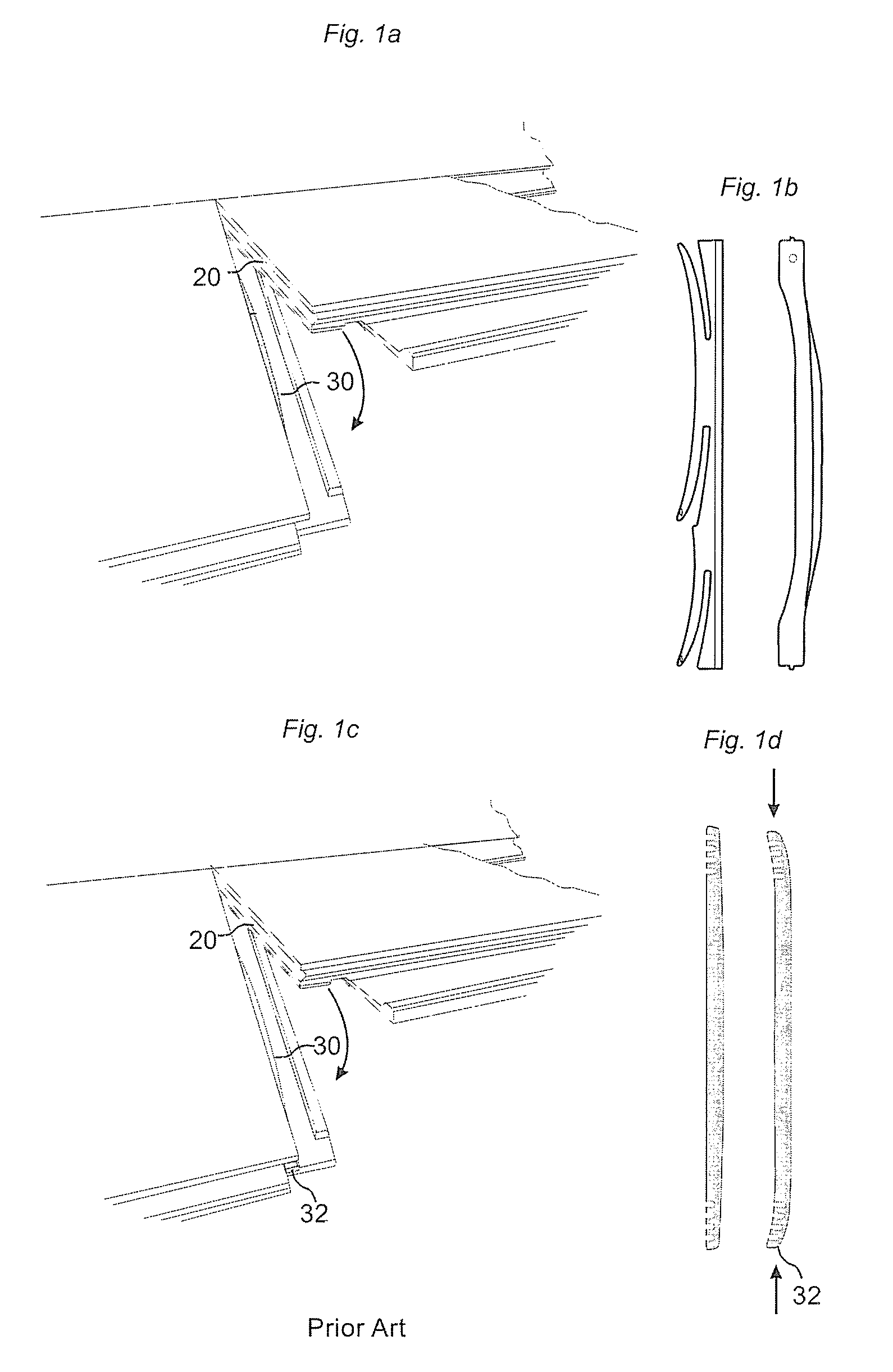

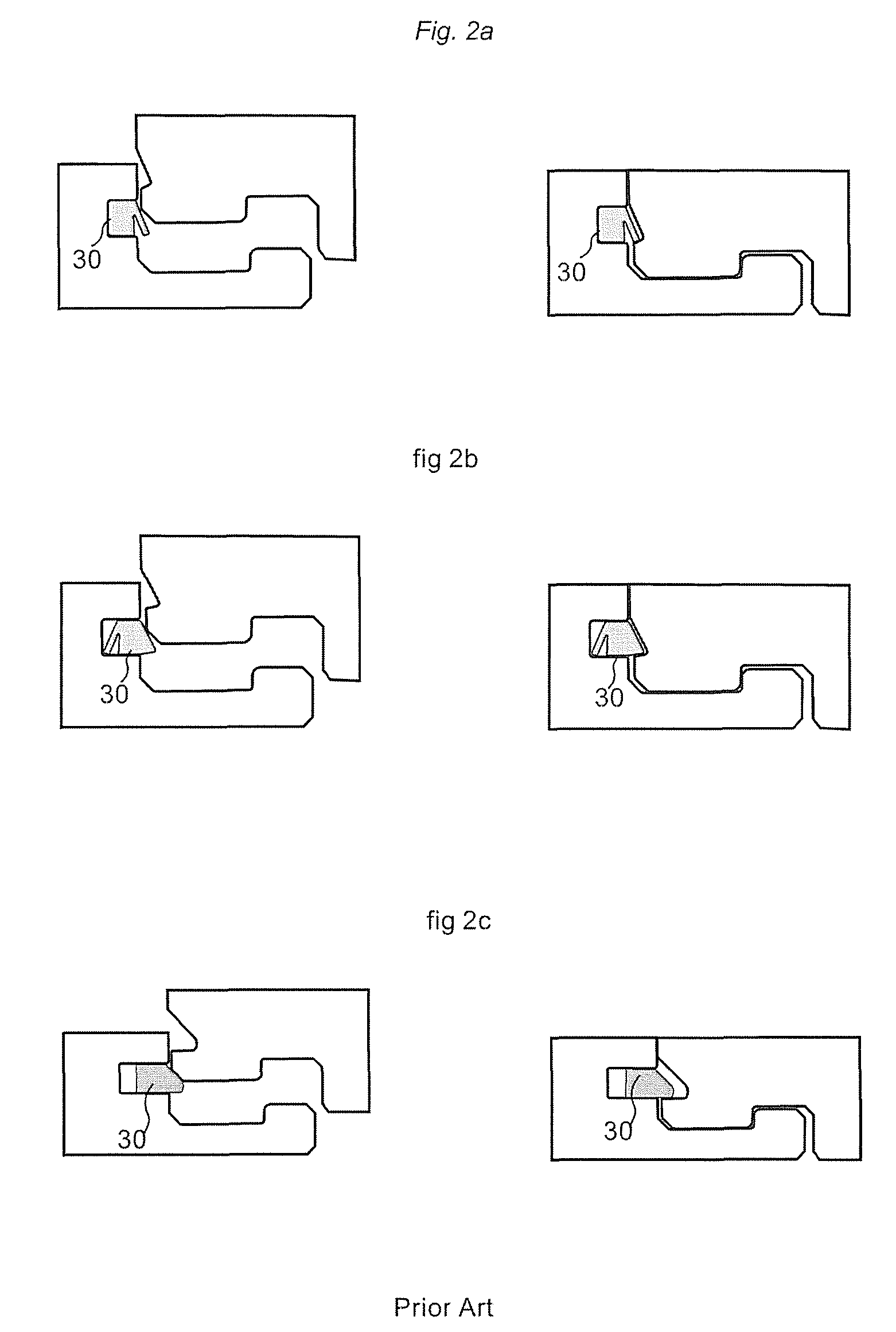

Mechanical locking of floor panels

ActiveUS20090193748A1Avoid vertical displacementReduce vertical frictionTongue/grooves making apparatusWallsEngineeringTongue and groove

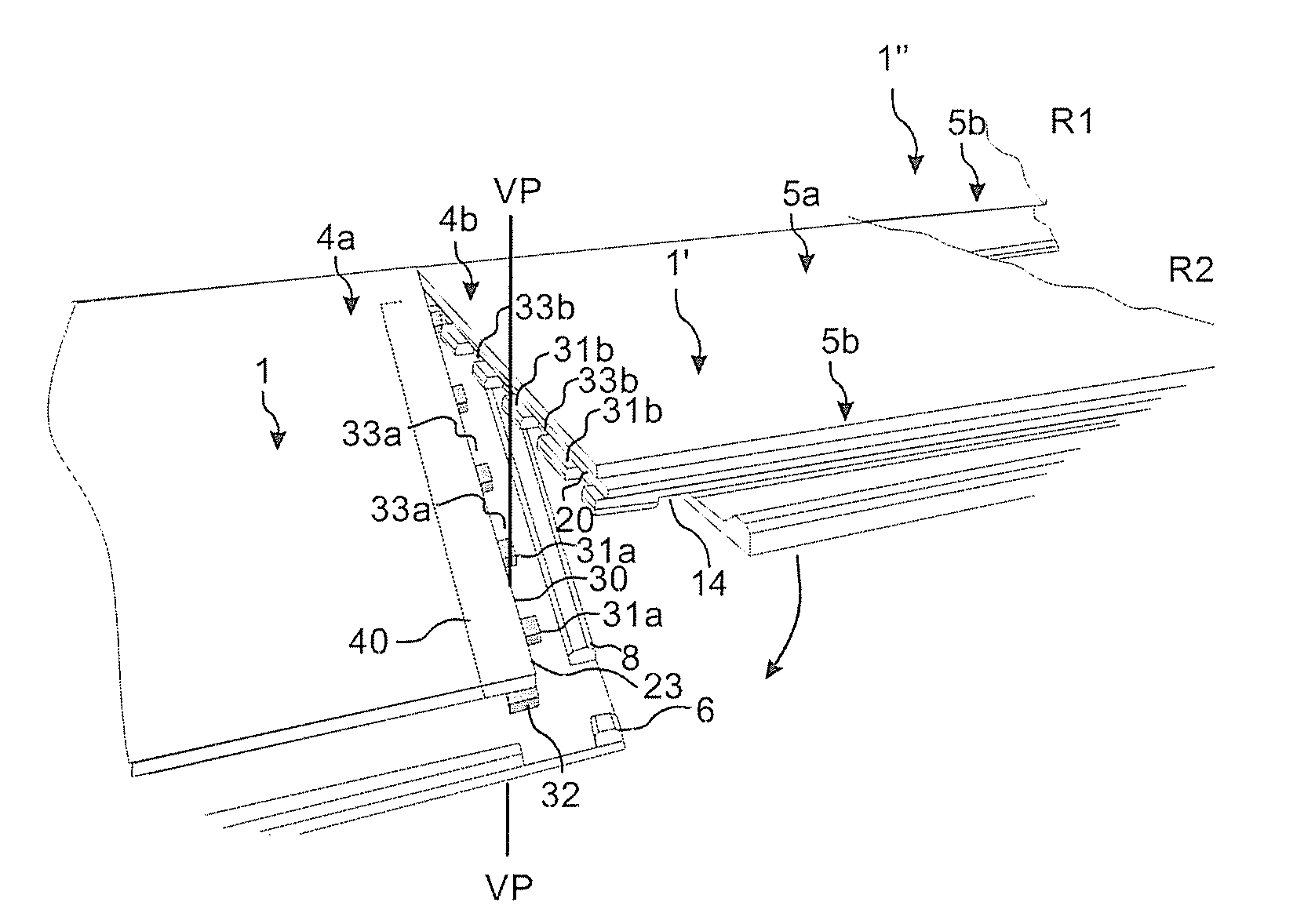

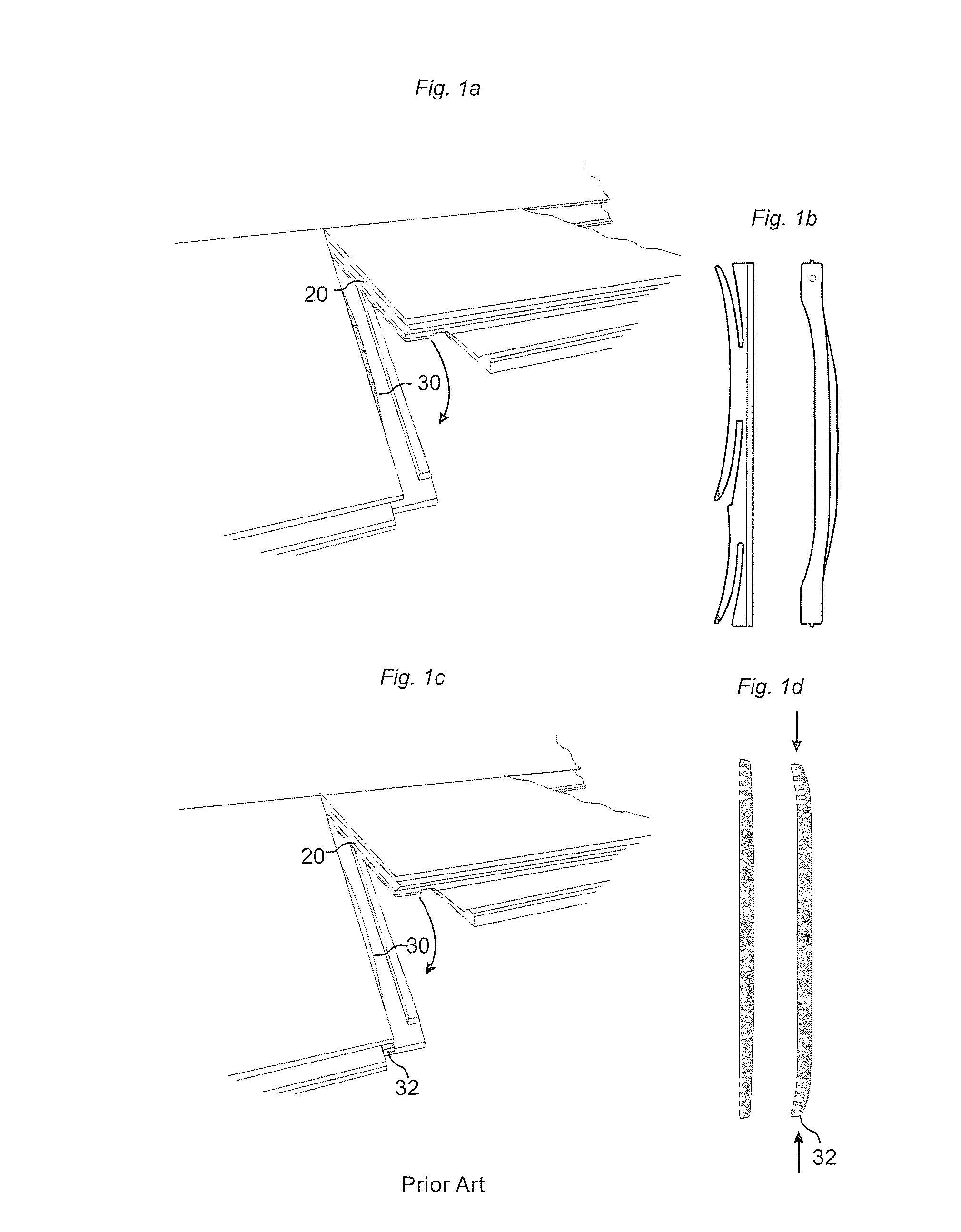

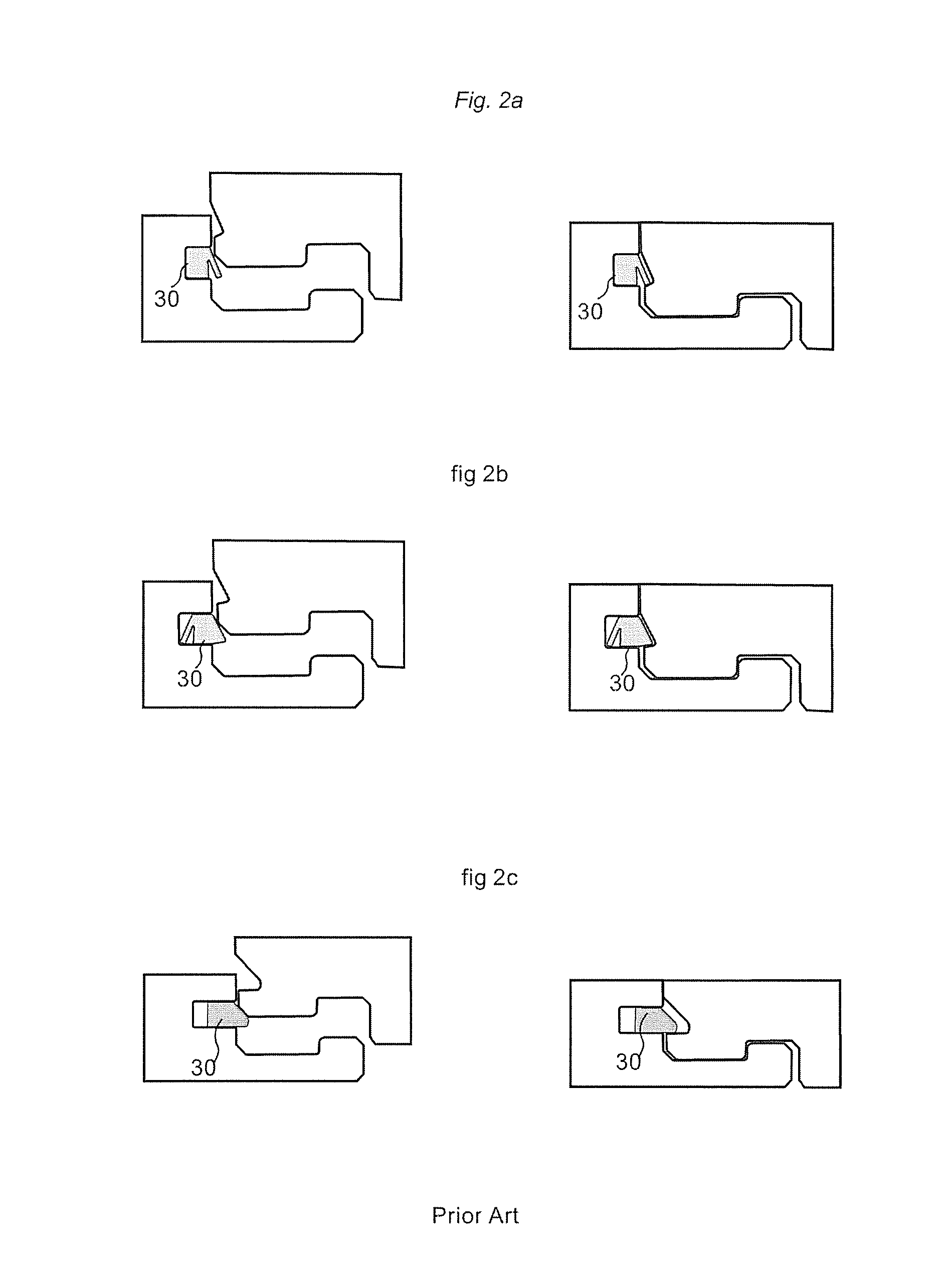

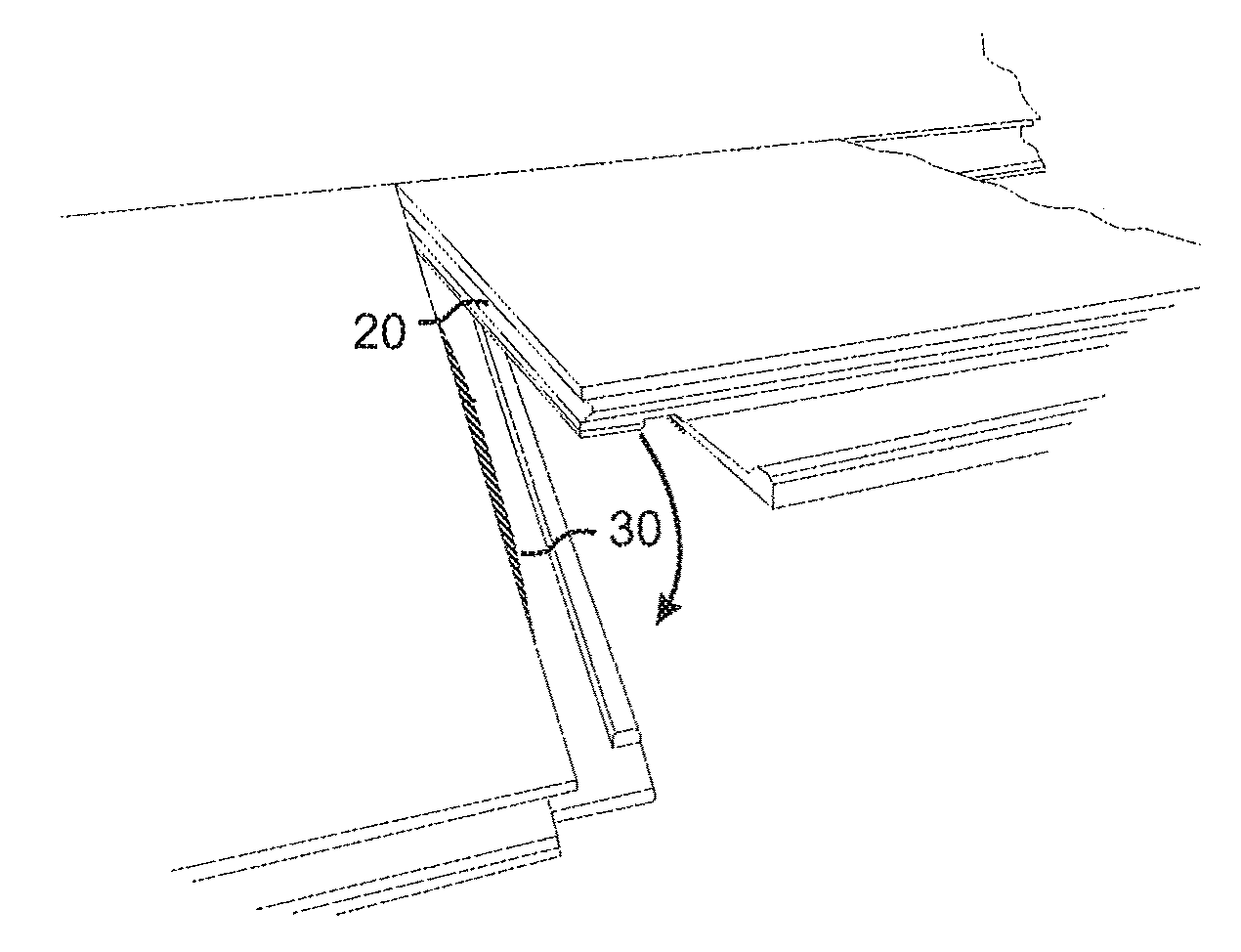

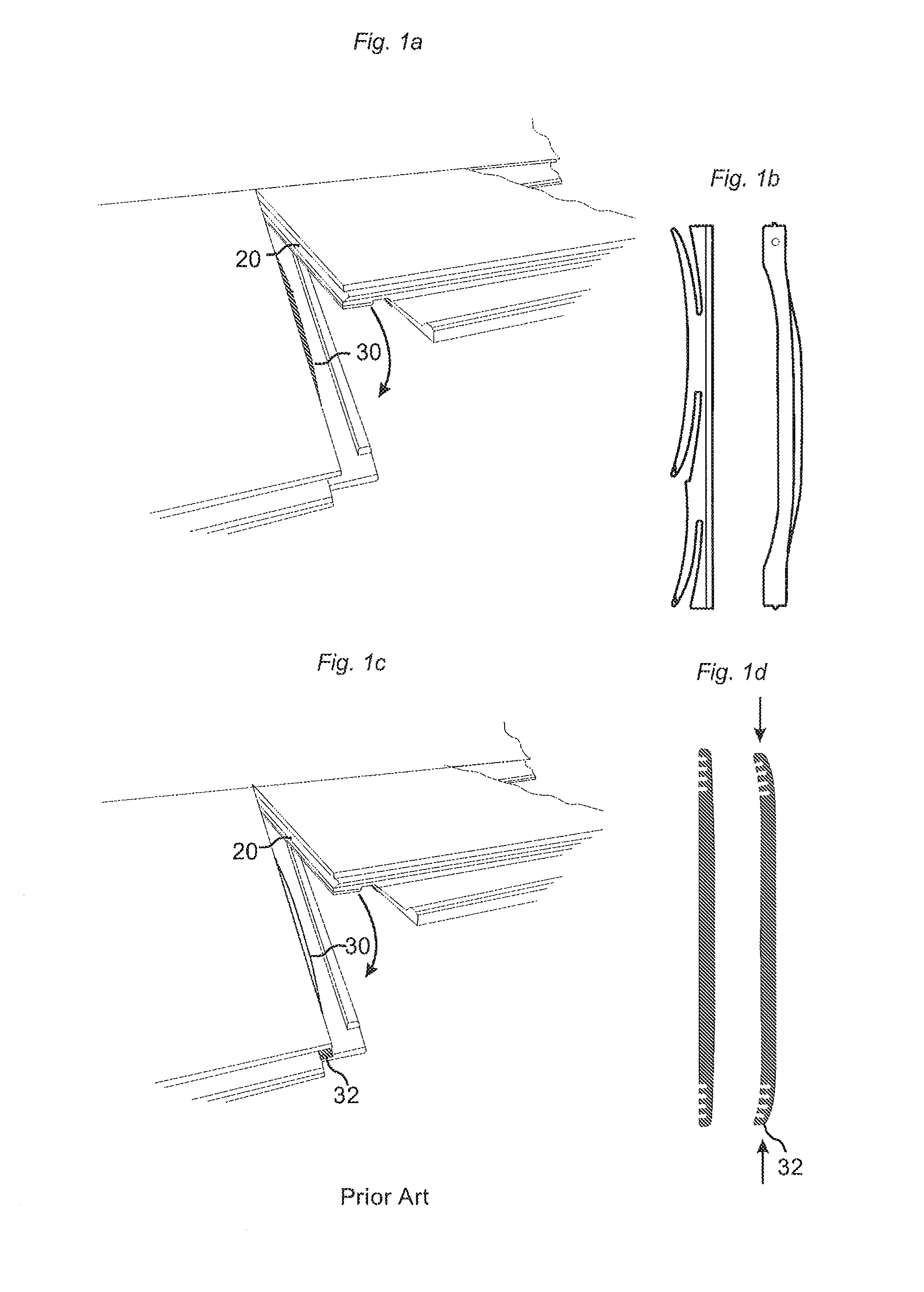

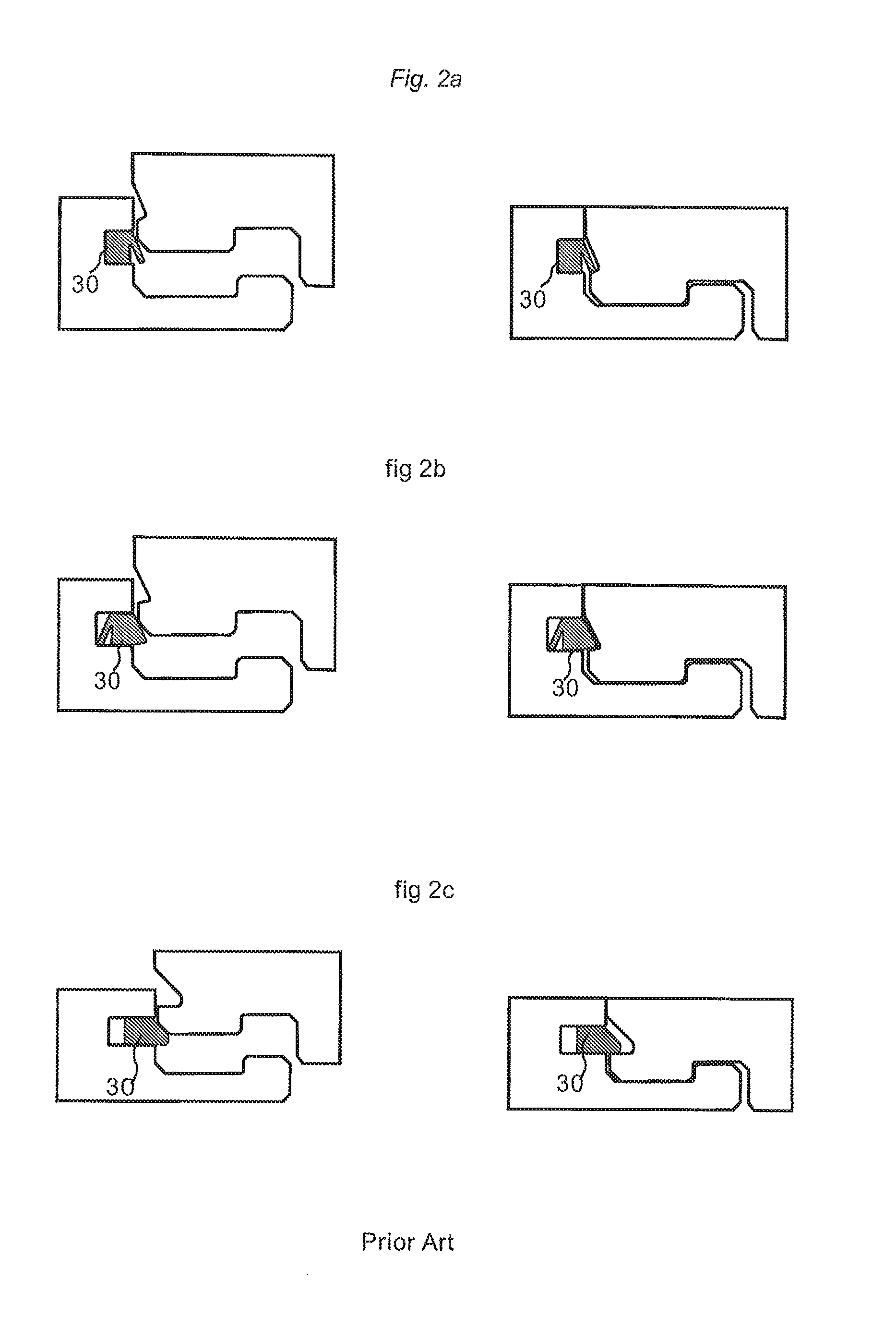

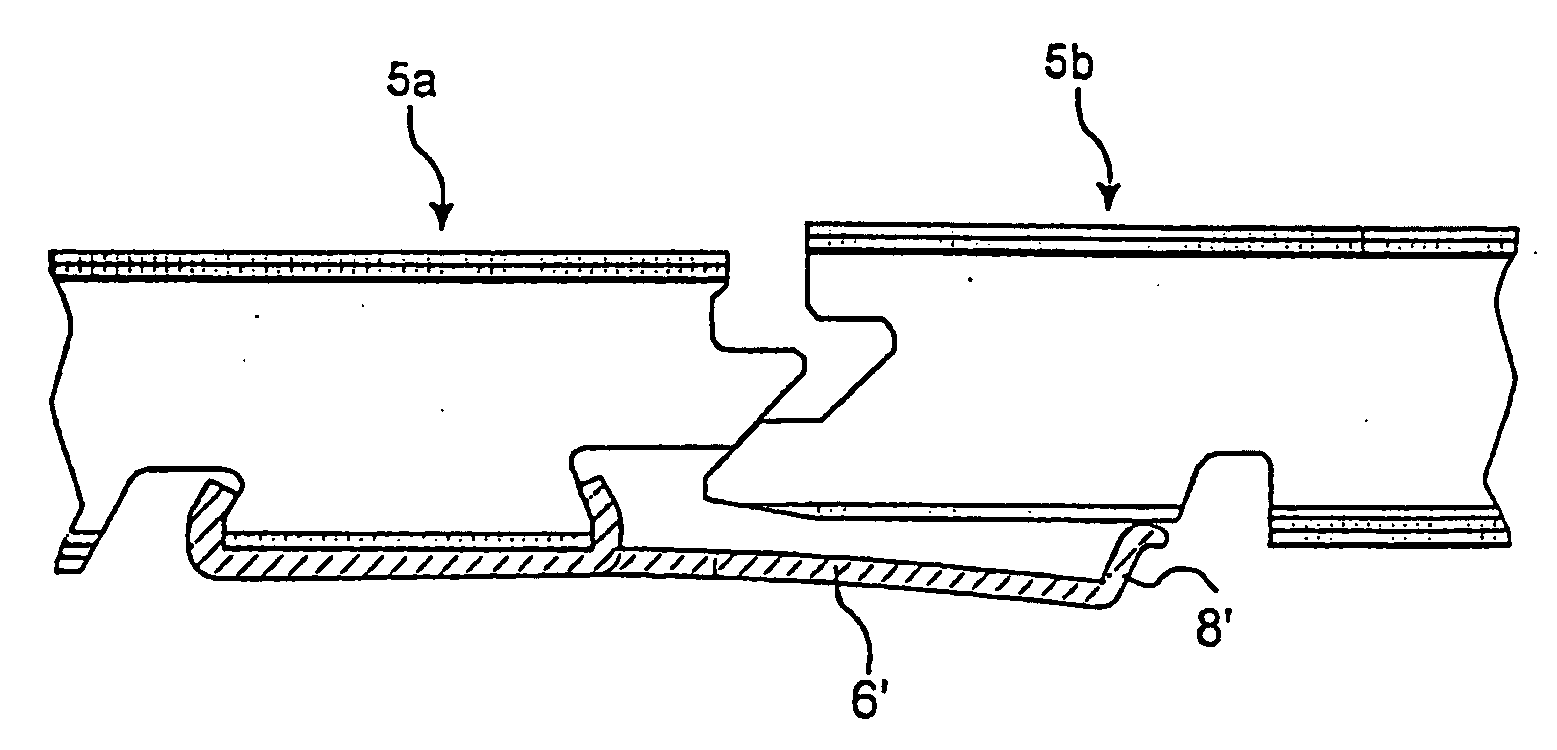

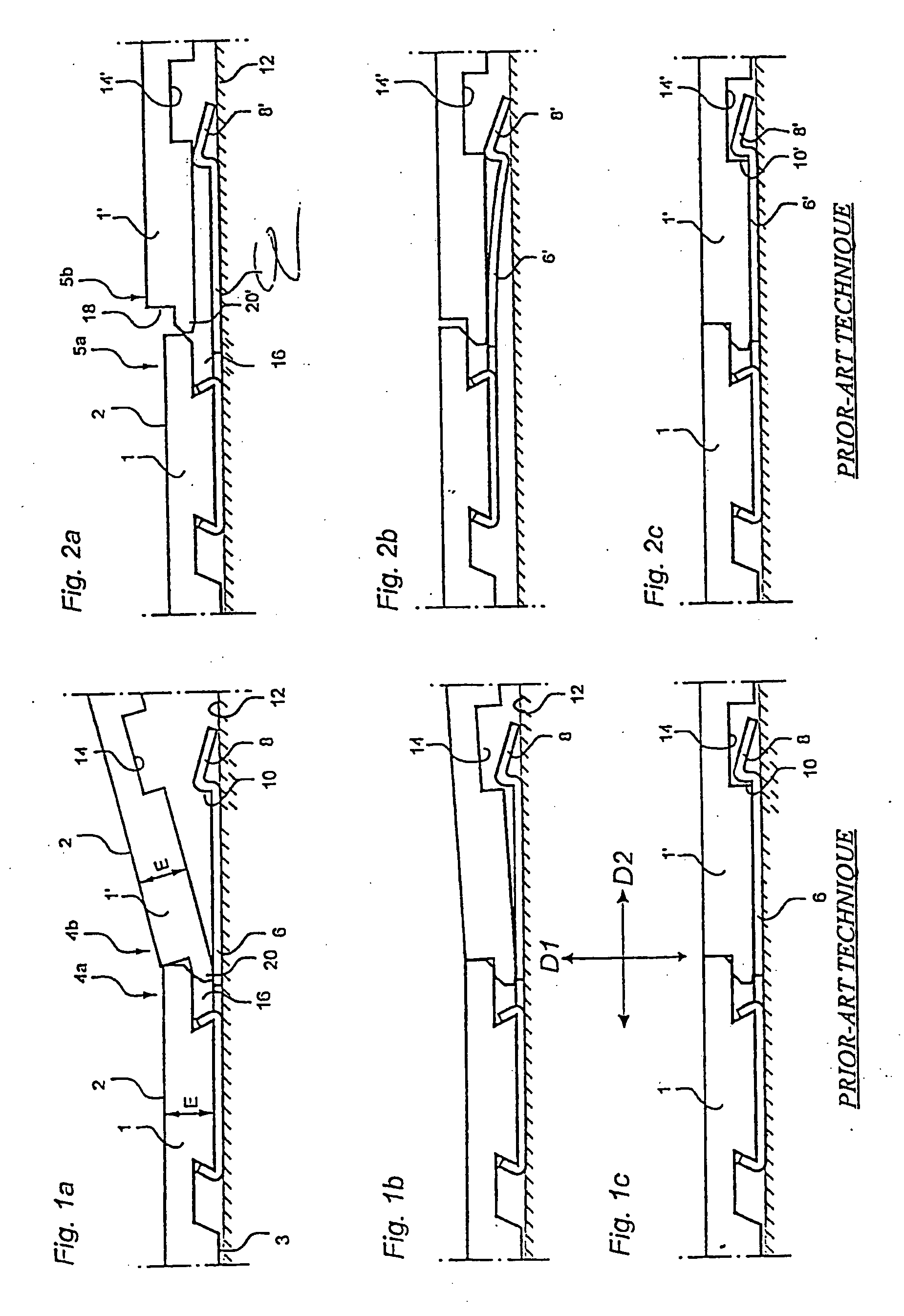

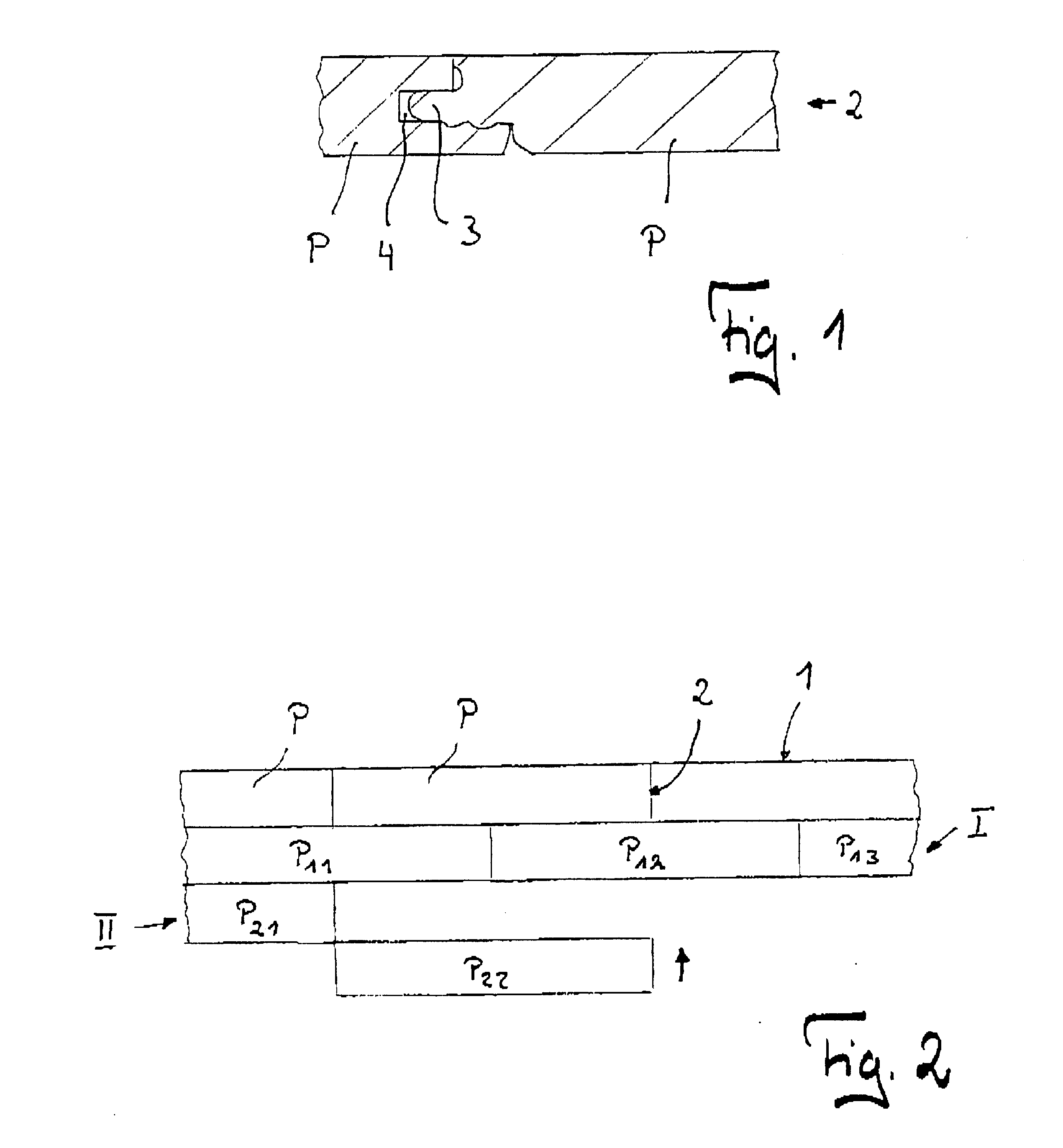

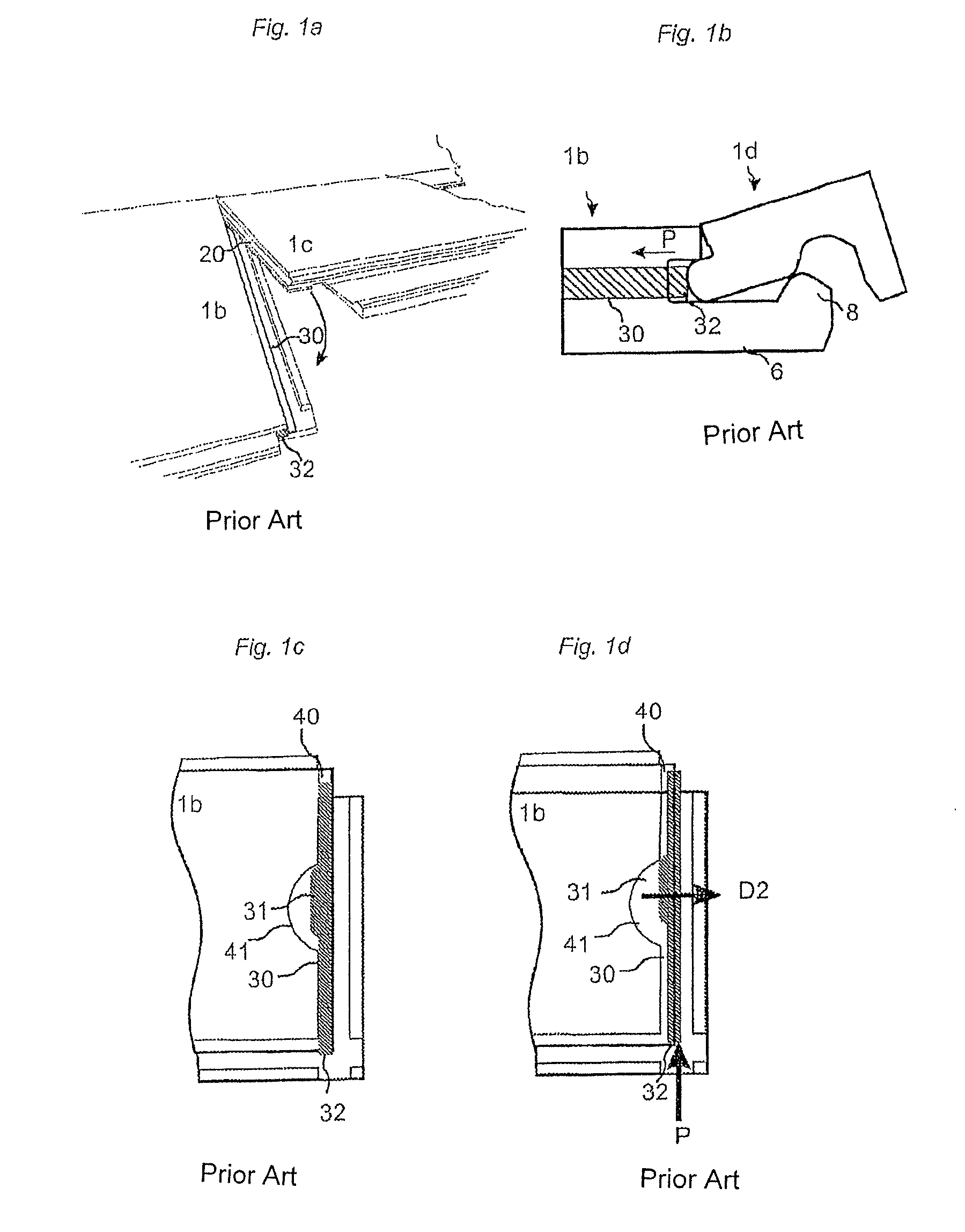

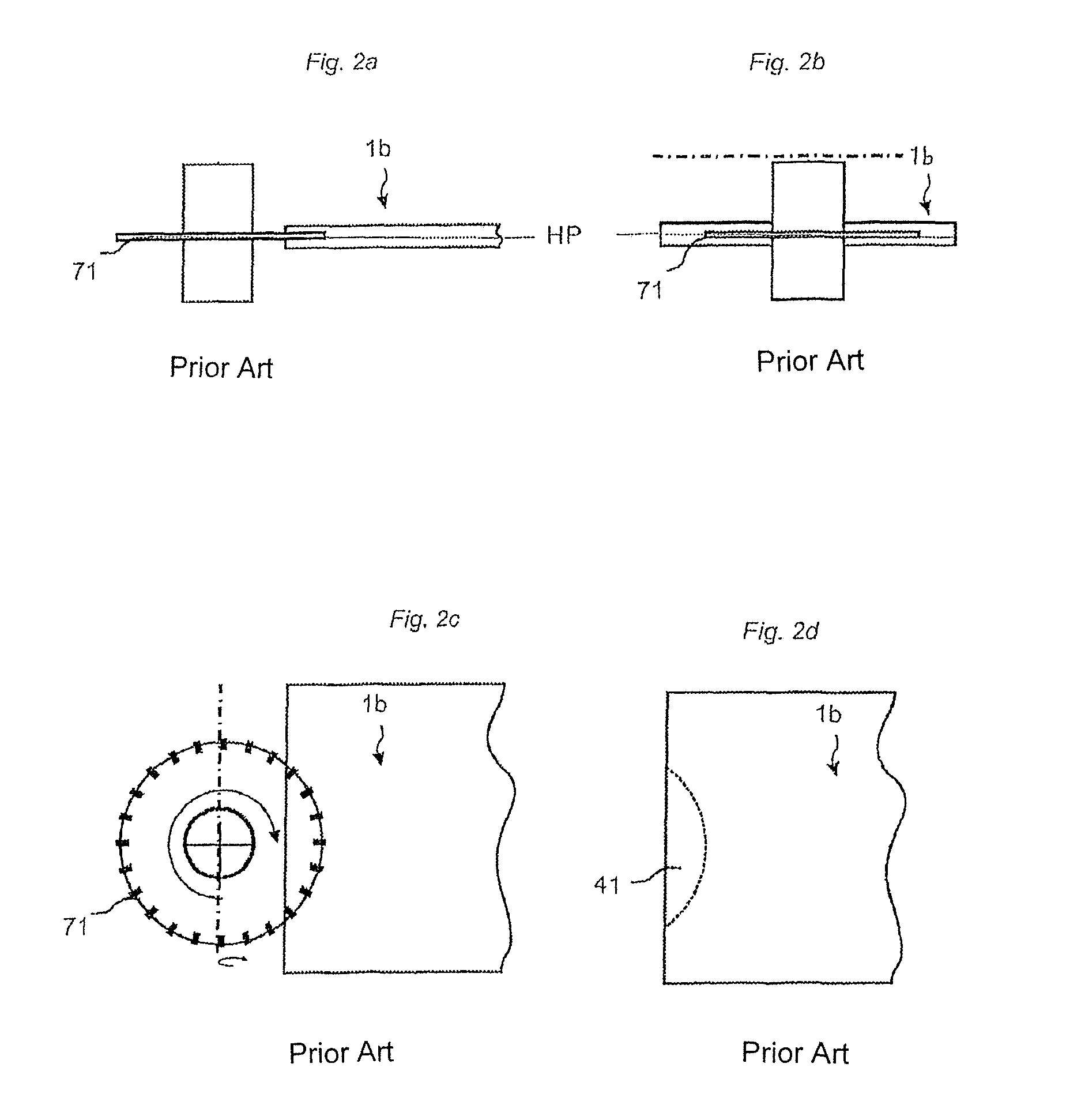

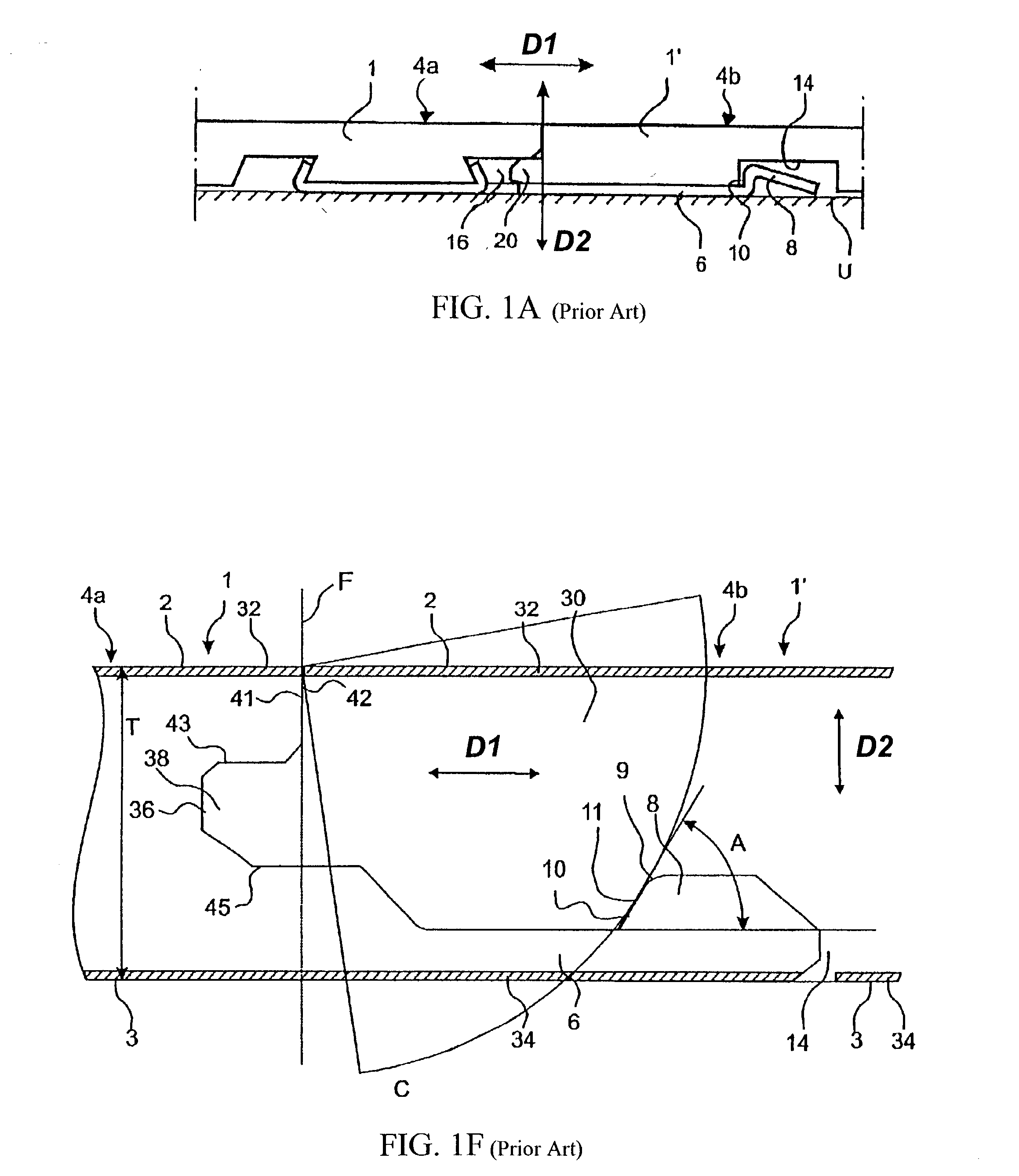

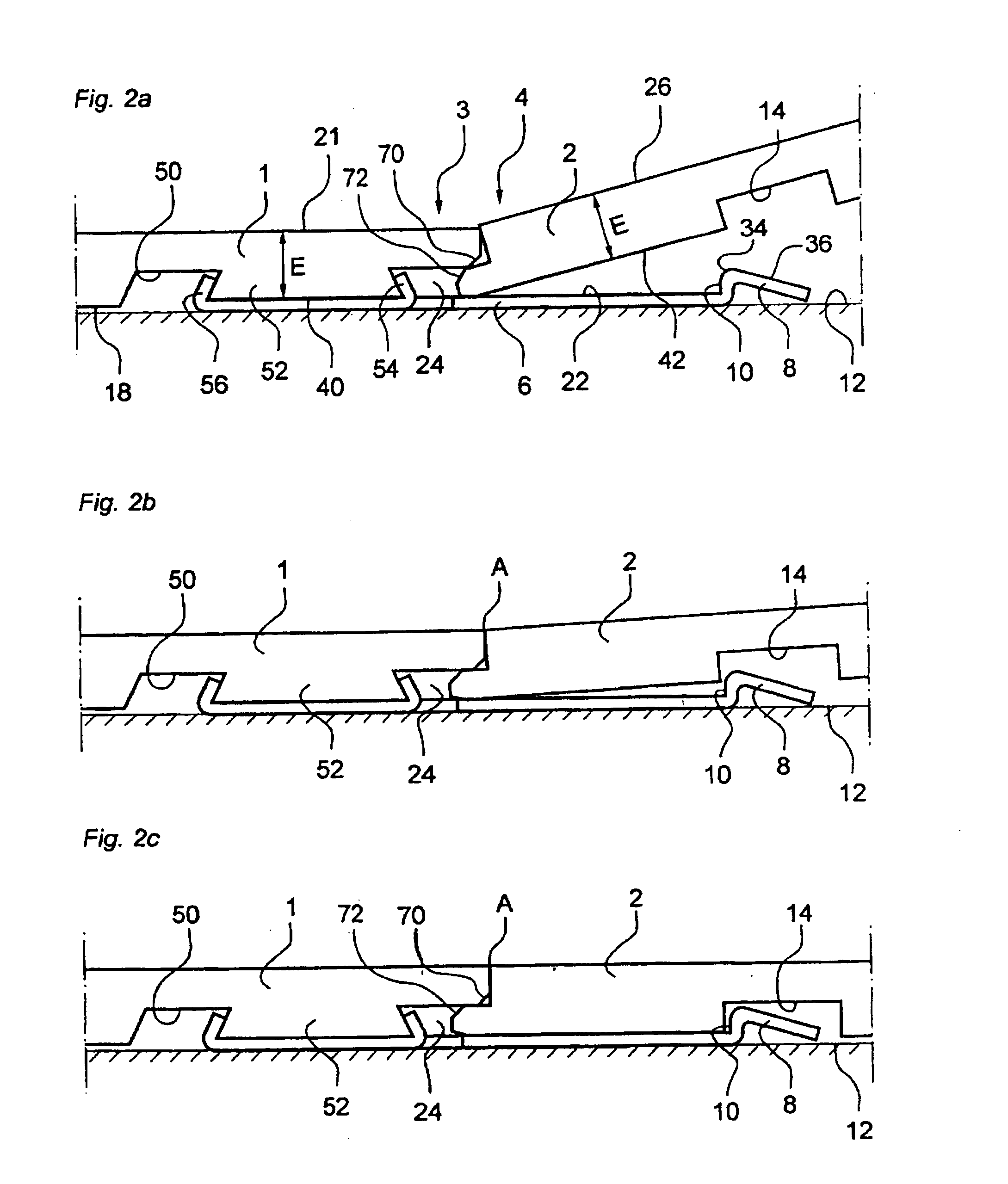

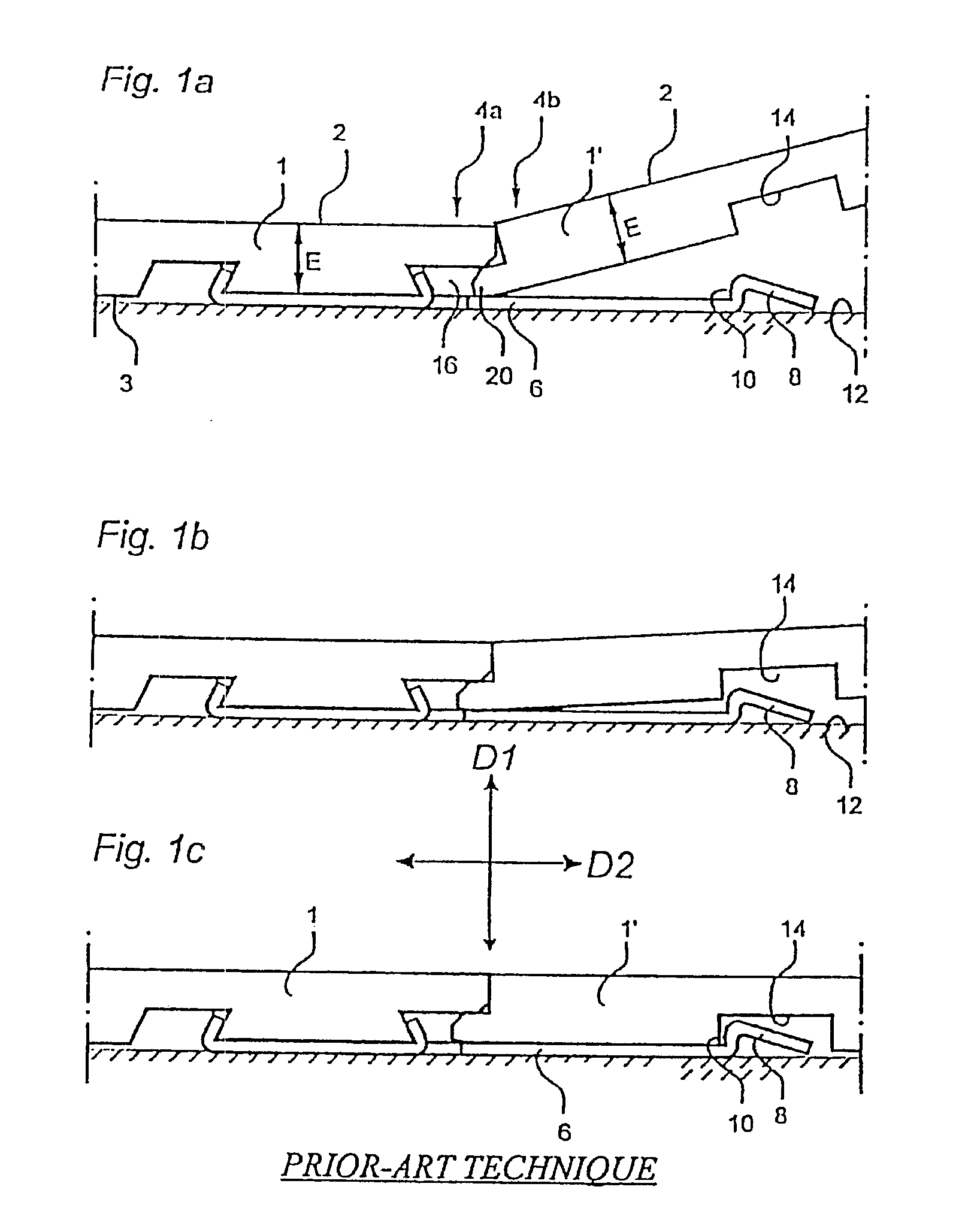

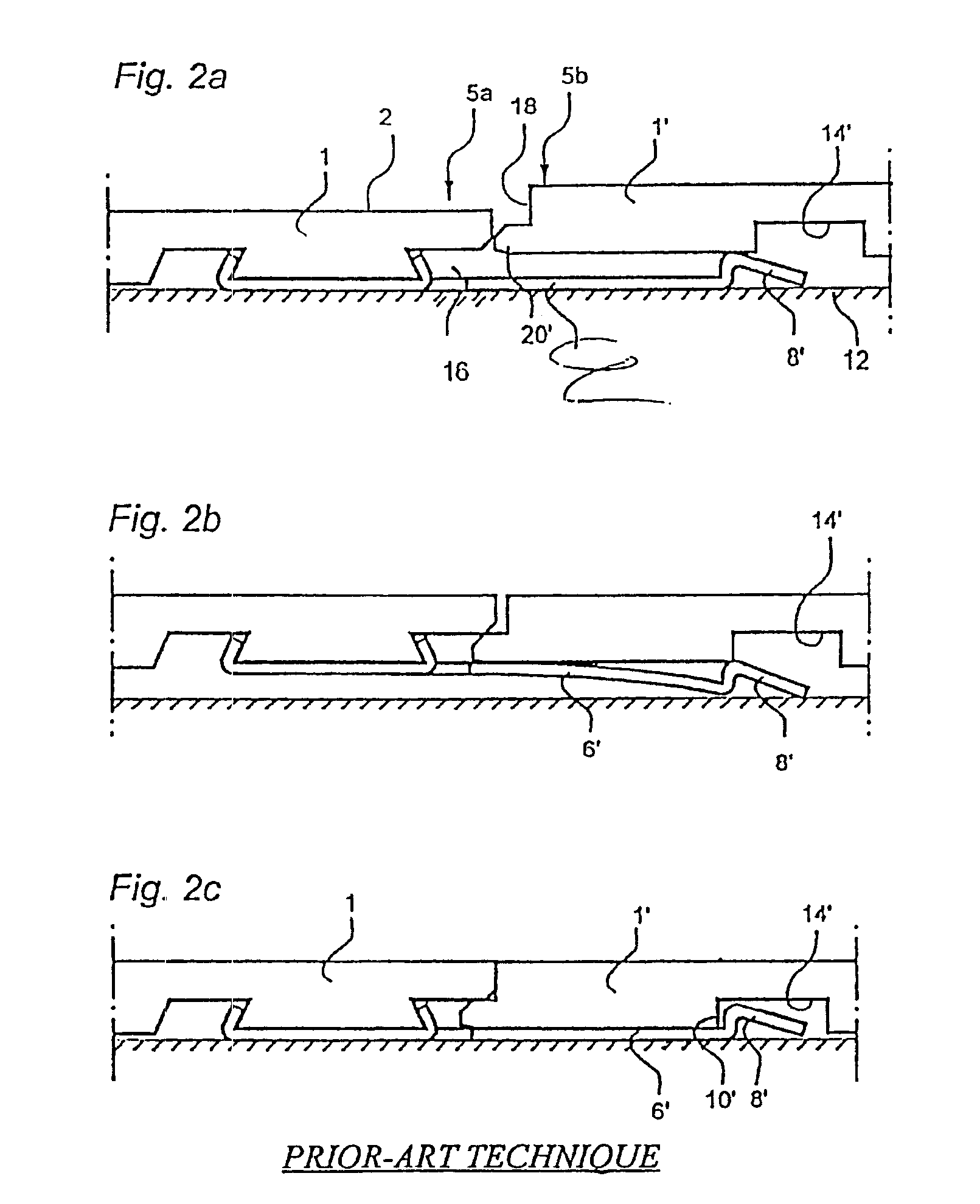

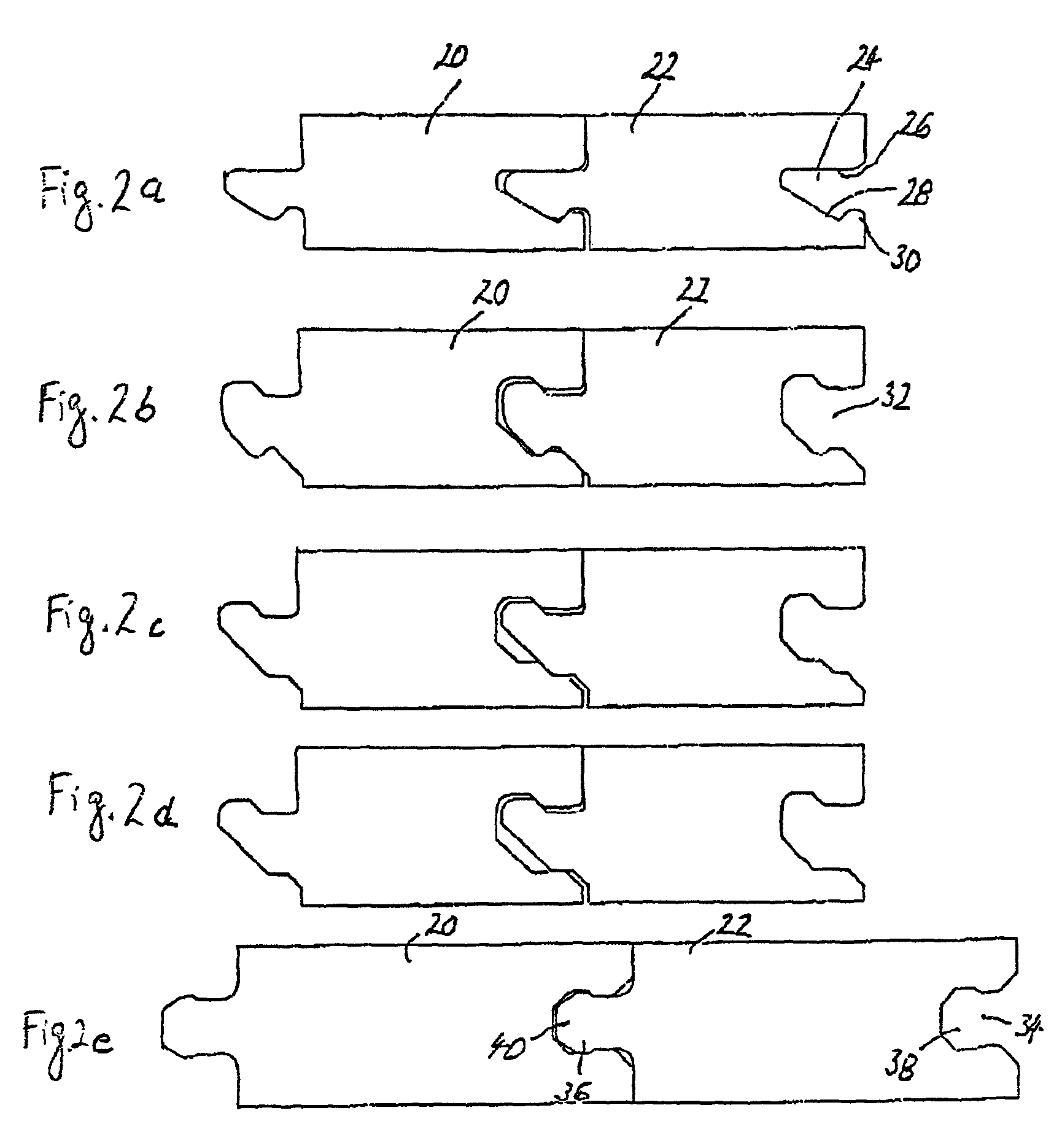

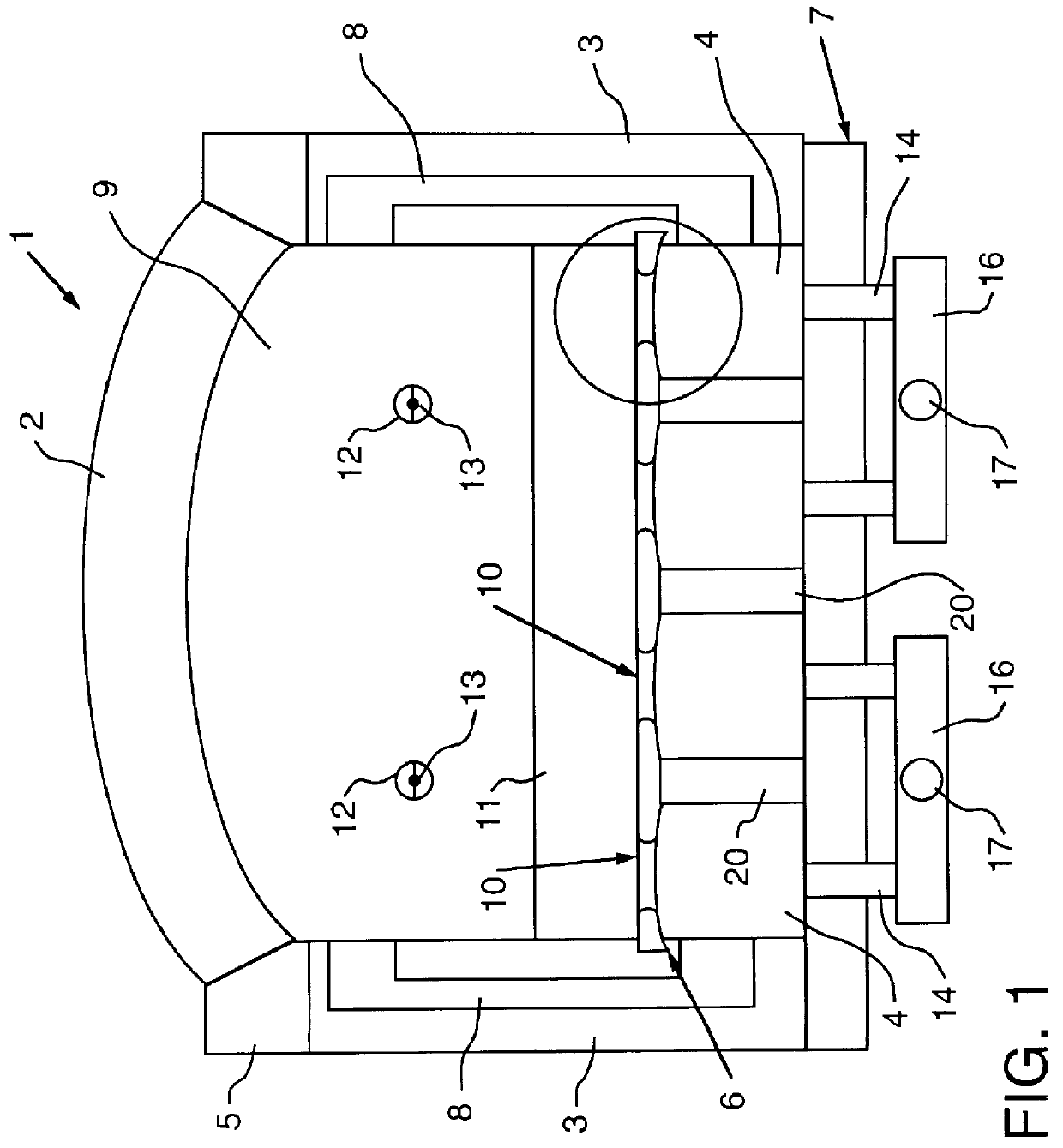

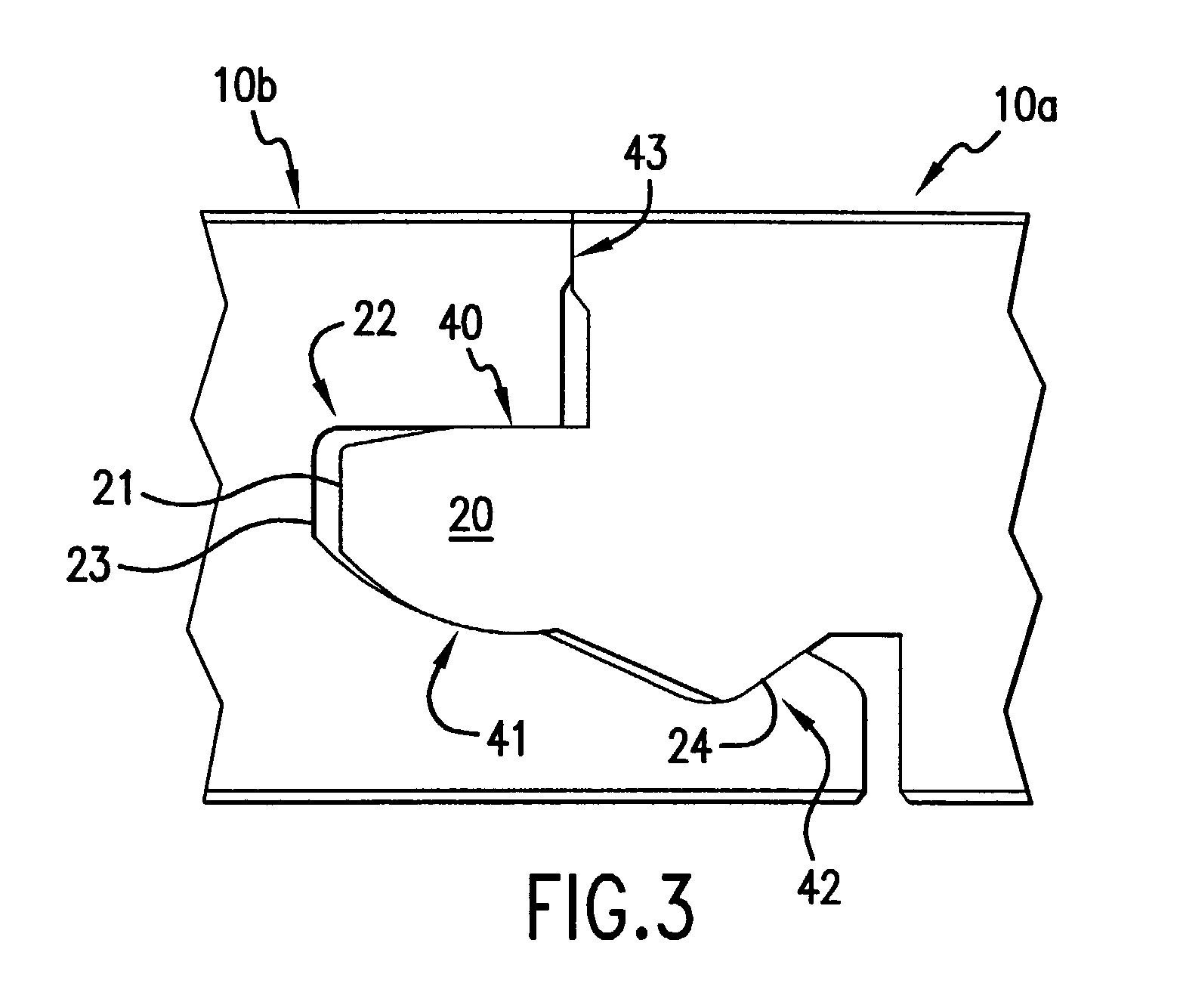

Floor panels are shown, which are provided with a mechanical locking system having tongue and grooves provided with protrusions and cavities which are displaceable in relation to each other and configured such that the protrusions can obtain a vertically unlocked position where they match the cavities and a vertically locked position where the protrusions overlap each other.

Owner:VÄLINGE INNOVATION AB

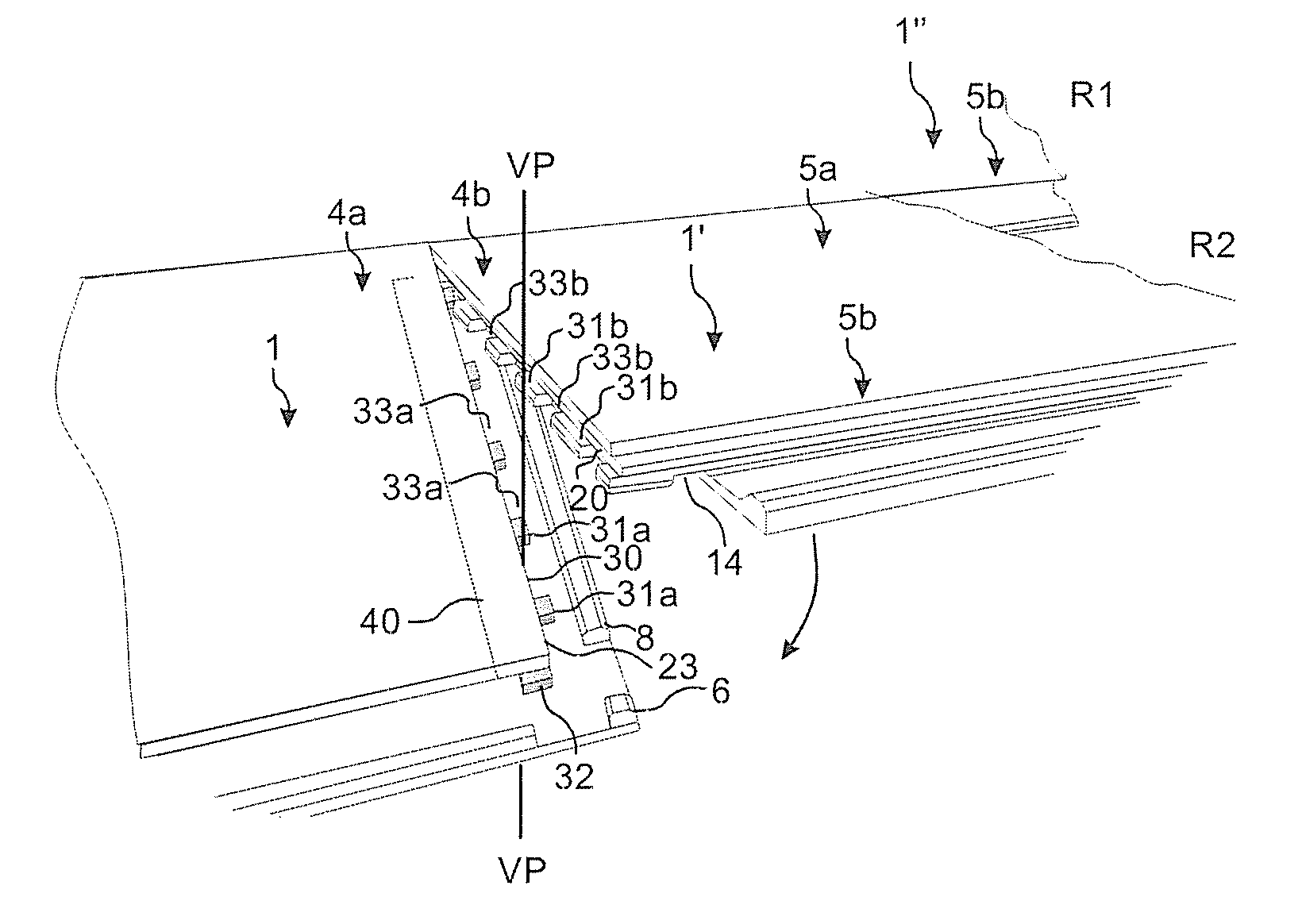

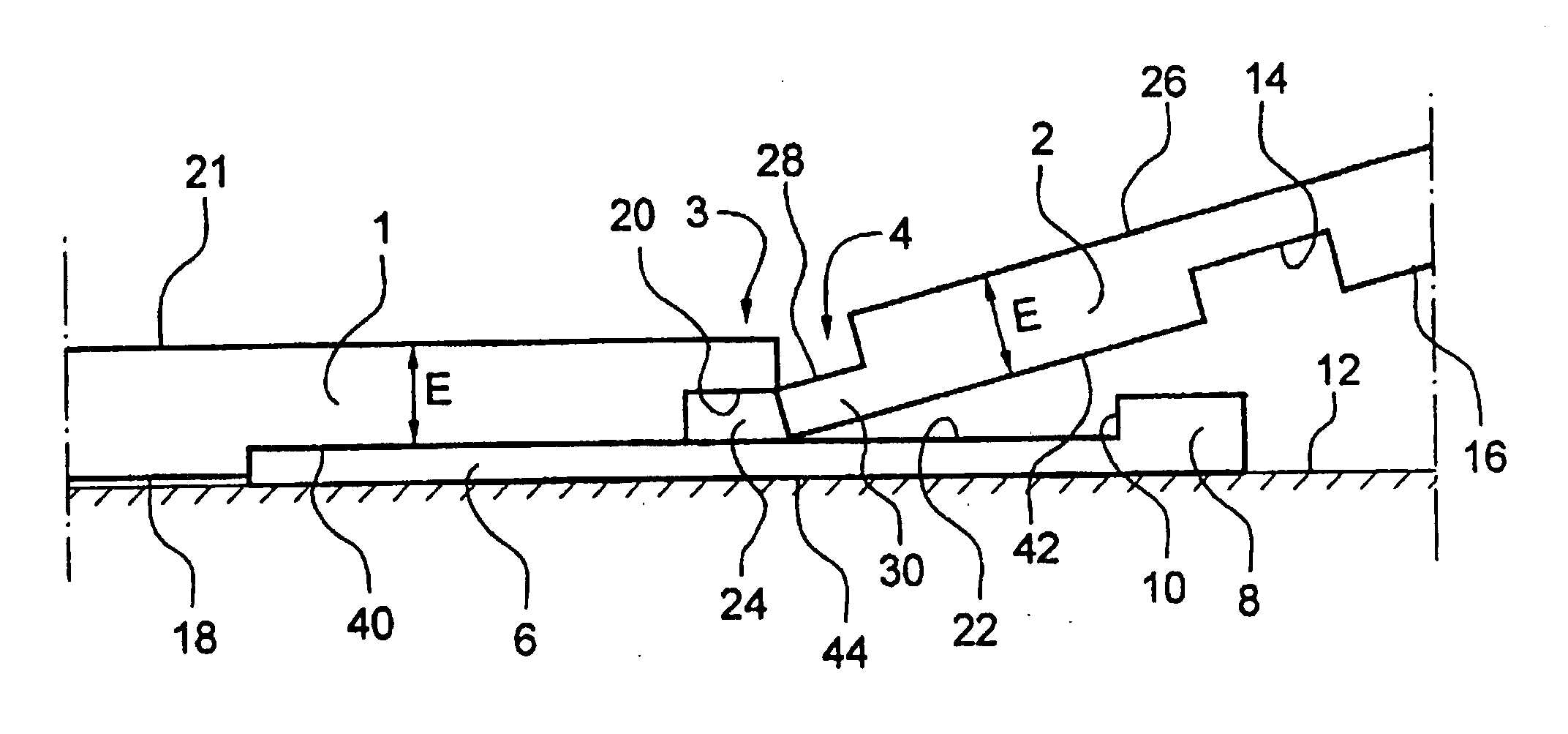

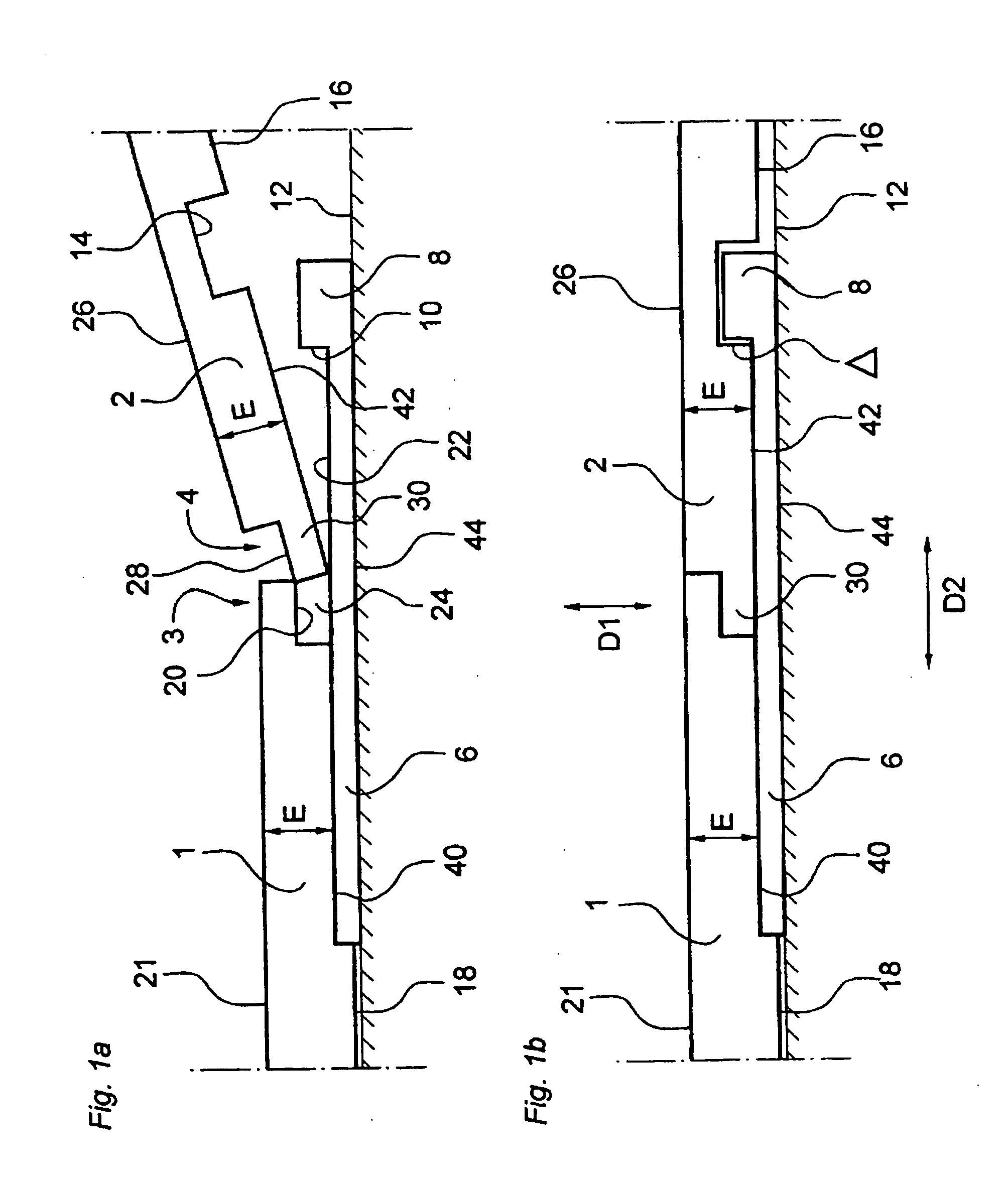

Mechanical locking of floor panels, methods to install and uninstall panels, a method and an equipement to produce the locking system, a method to connect a displaceable tongue to a panel and a tongue blank

ActiveUS20110030303A1Avoid resistanceAvoid separationCovering/liningsTongue/grooves making apparatusTongue and grooveFace sheet

Floor panels are shown, which are provided with a mechanical locking system including tongue and grooves provided with protrusions and cavities which are displaceable in relation to each other and configured such that the protrusions can obtain a vertically unlocked position where they match the cavities and a vertically locked position where the protrusions overlap each other.

Owner:VÄLINGE INNOVATION AB

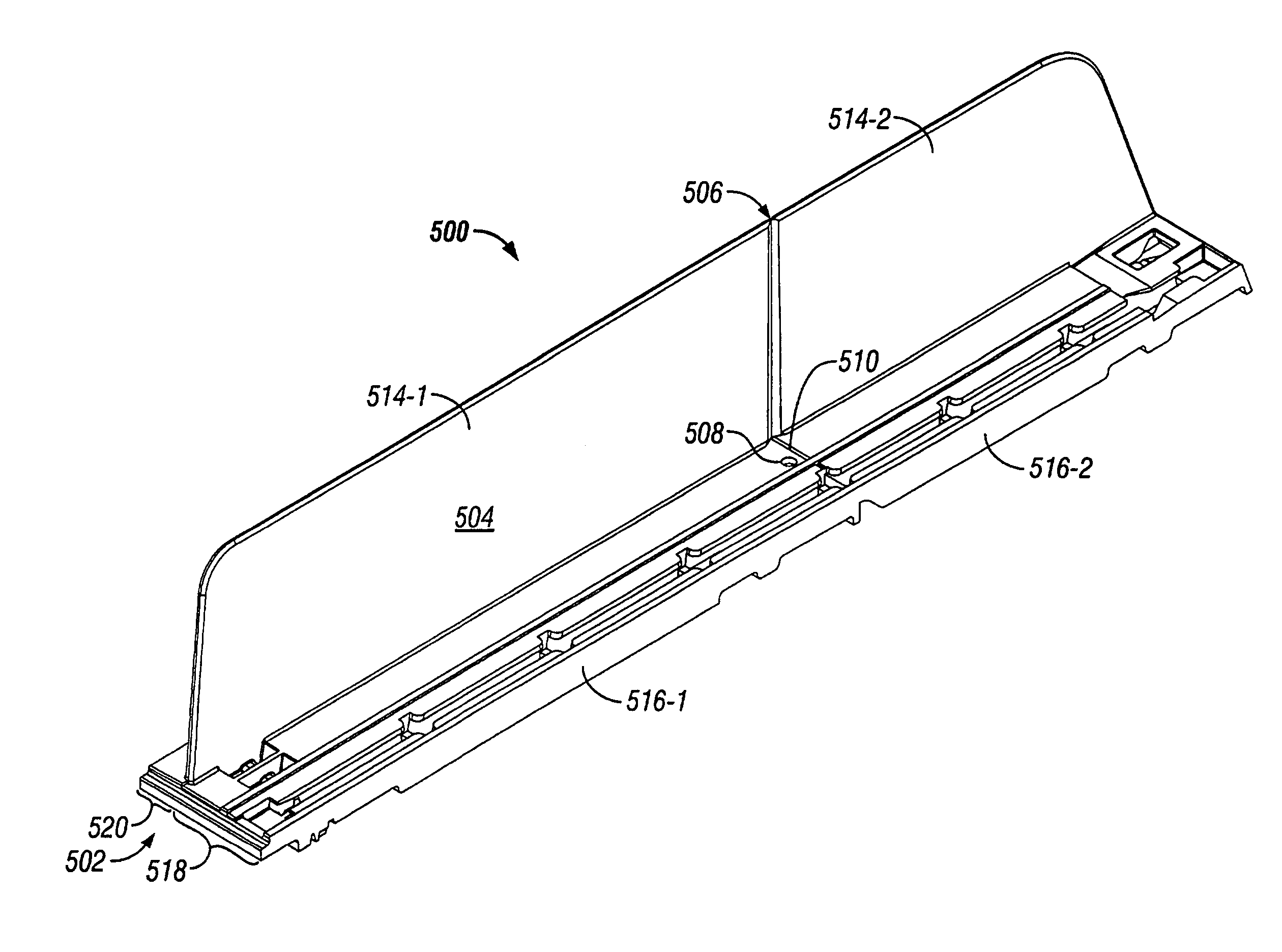

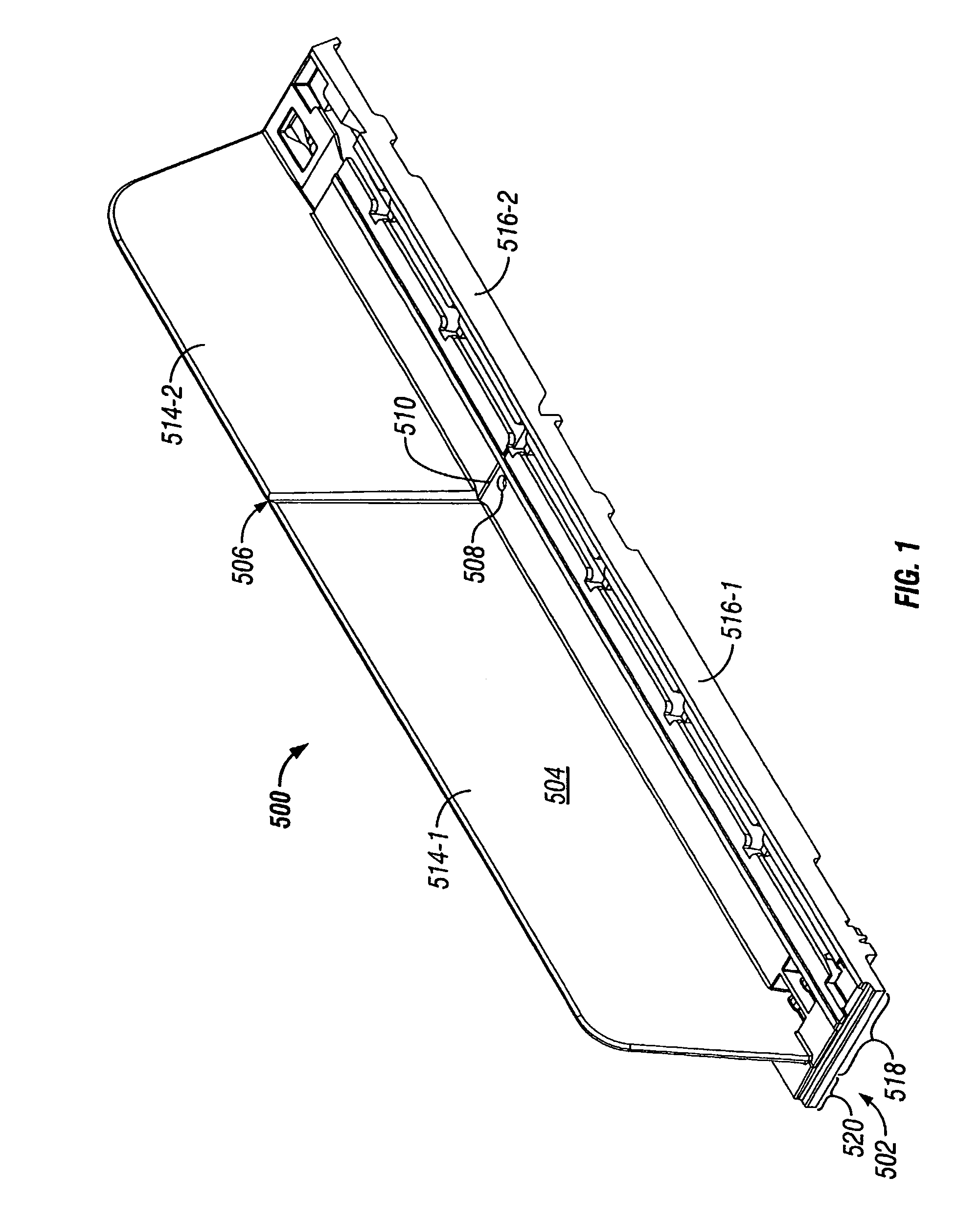

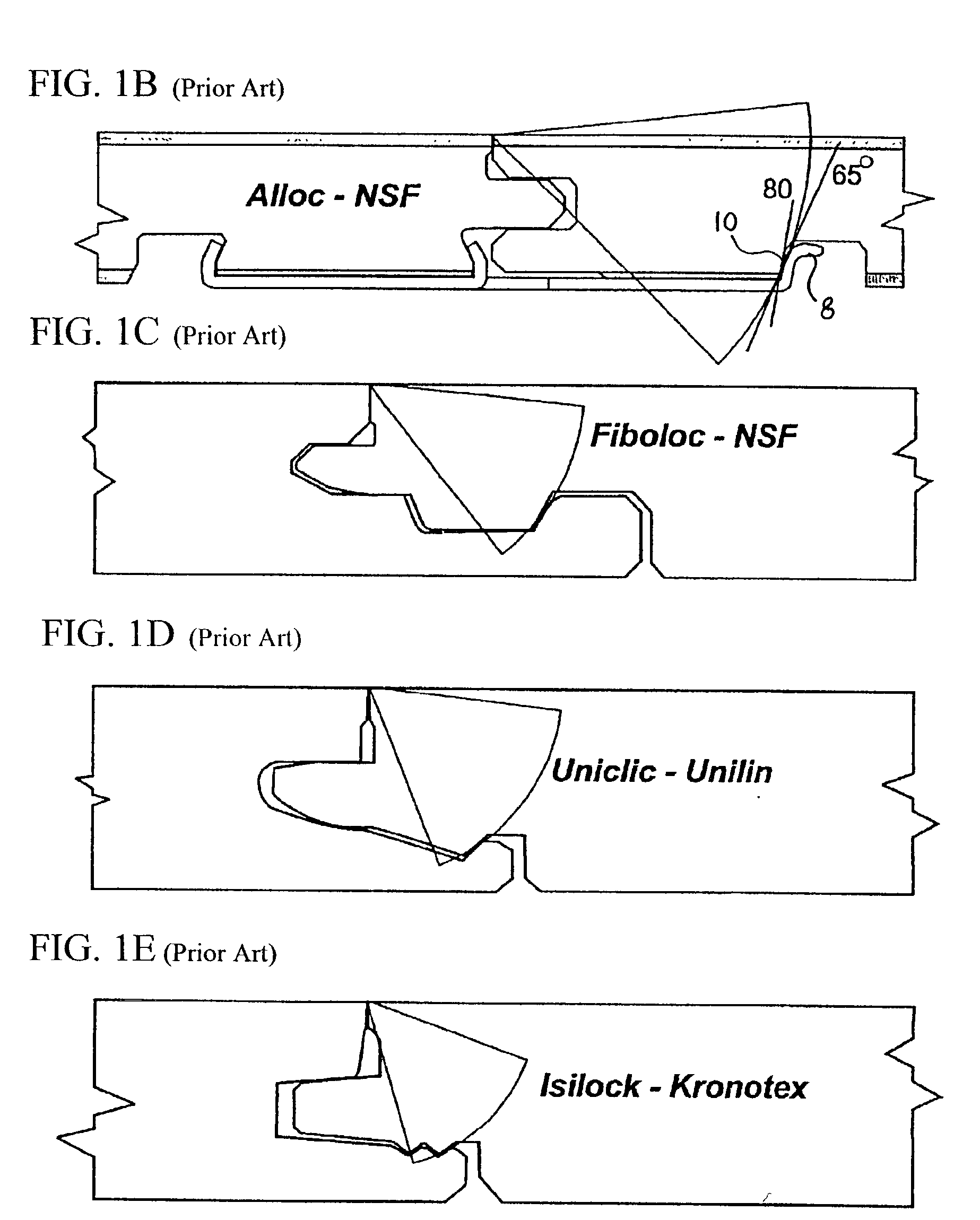

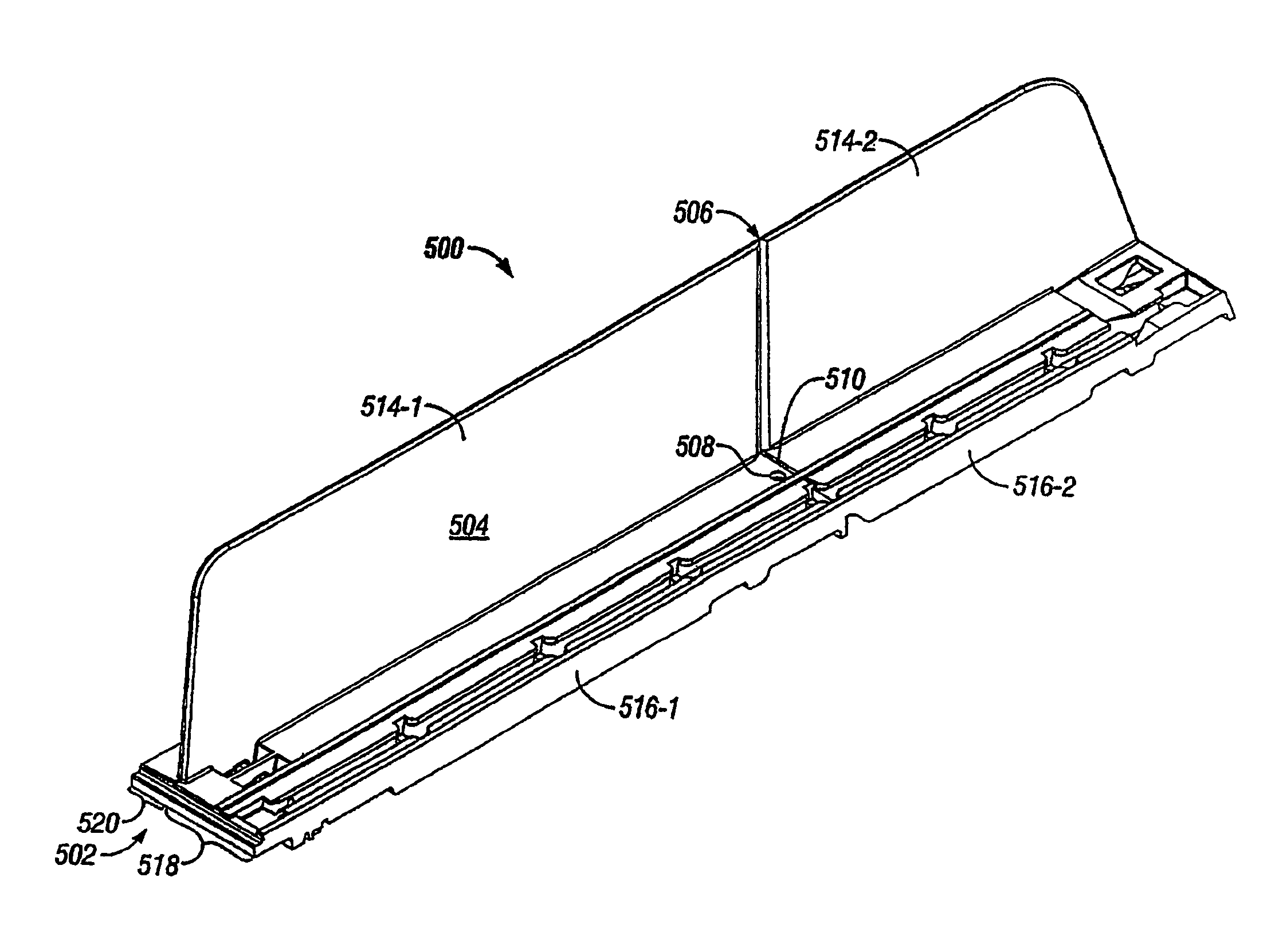

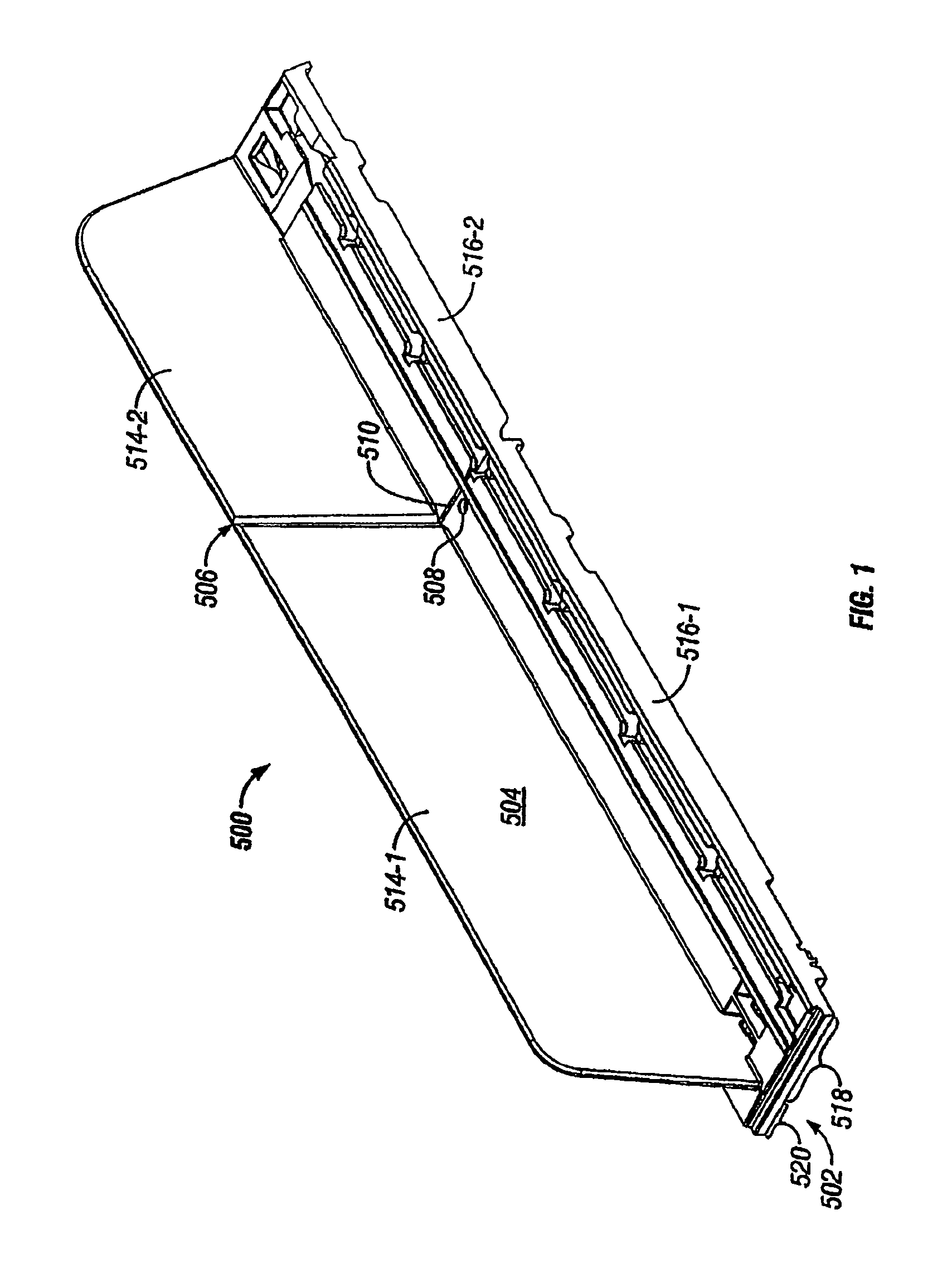

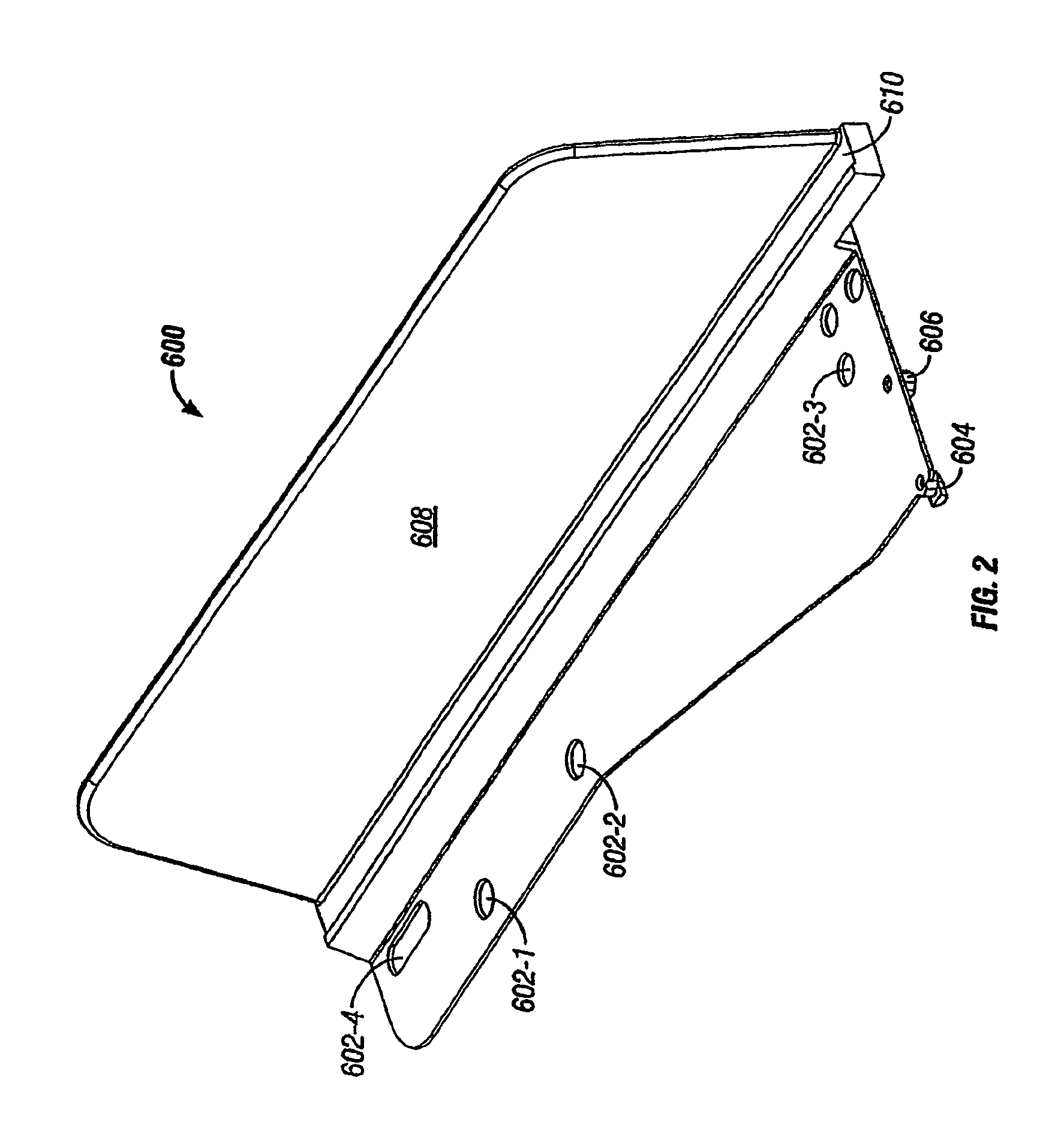

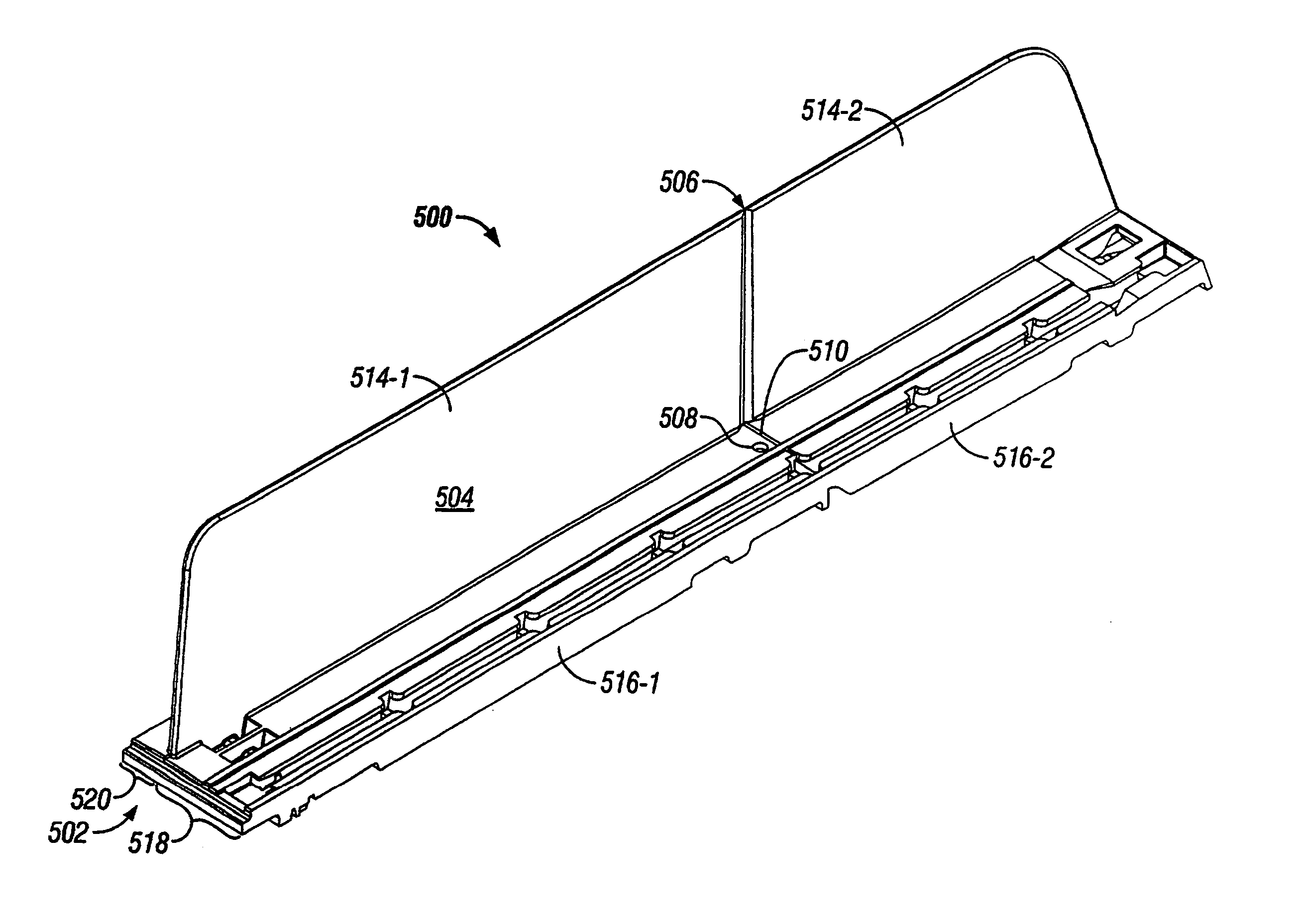

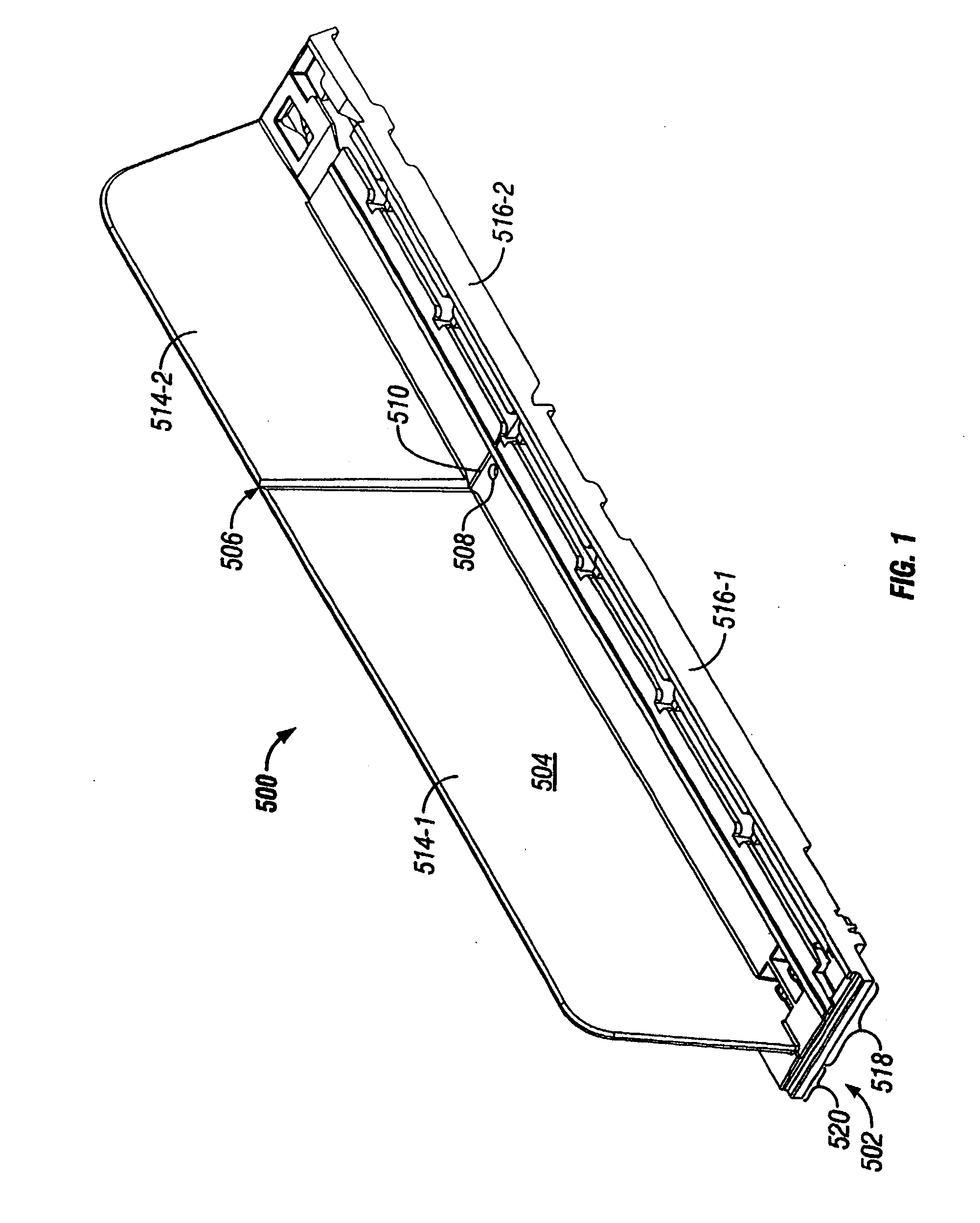

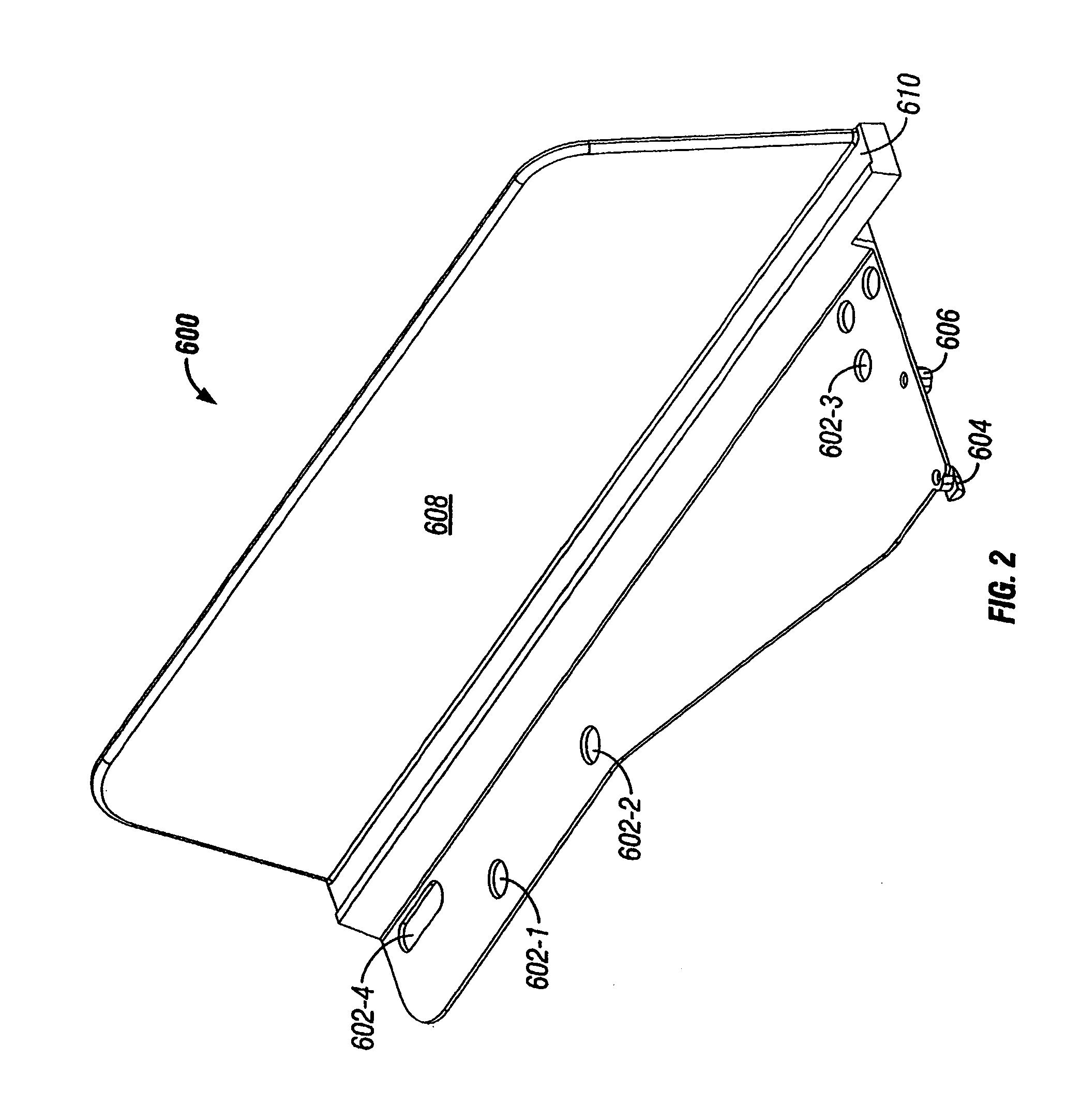

Product management display system

An integrated “T” assembly (500) combines into a single integrated assembly, a track portion along both sides of a divider (504). The T assembly may have a wide-base portion (518), which may include a spring-urged-pusher track, on one side of the divider and a narrow-base portion (520) on the opposite side of the divider. An offset pusher (700) may have an upper portion that is offset, via an angled offset portion, from a lower portion of the pusher. Additional supporting bases, any of which may include spring-urged-pusher tracks and / or a spring-urged pusher, may be used under a wide product. Left and right side finisher (600) components may be paired with T assemblies near the sides of a merchandise-display shelf. The T assembly, base, and / or end finishers may be coupled to a front rail via a complimentary tongue and groove arrangement and / or a non-slidable engagement, such as mating teeth.

Owner:RTC IND

Mechanical locking of floor panels

ActiveUS8505257B2Easy to installImprove installation and strength and quality and production costTongue/grooves making apparatusWallsTongue and grooveEngineering

Owner:VÄLINGE INNOVATION AB

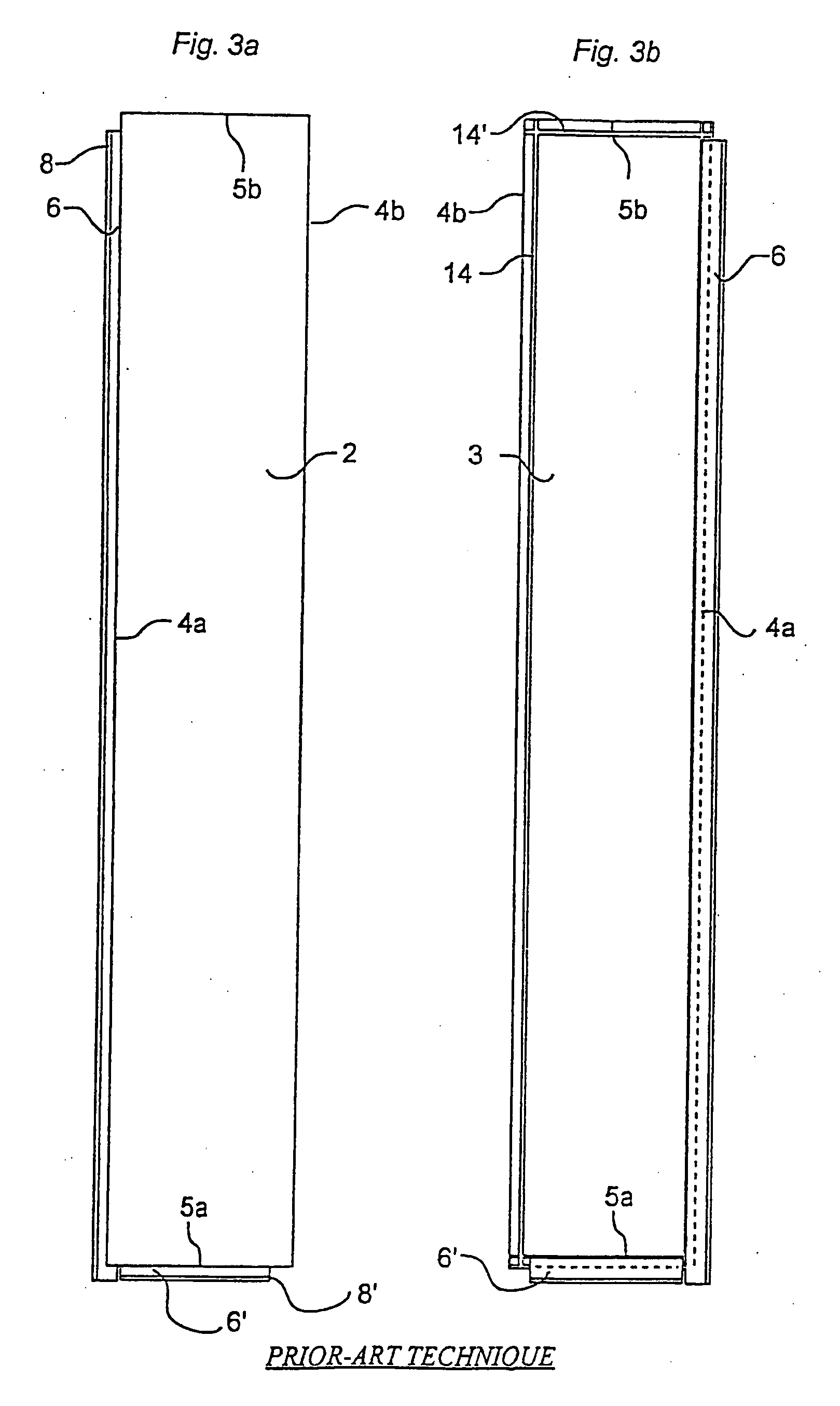

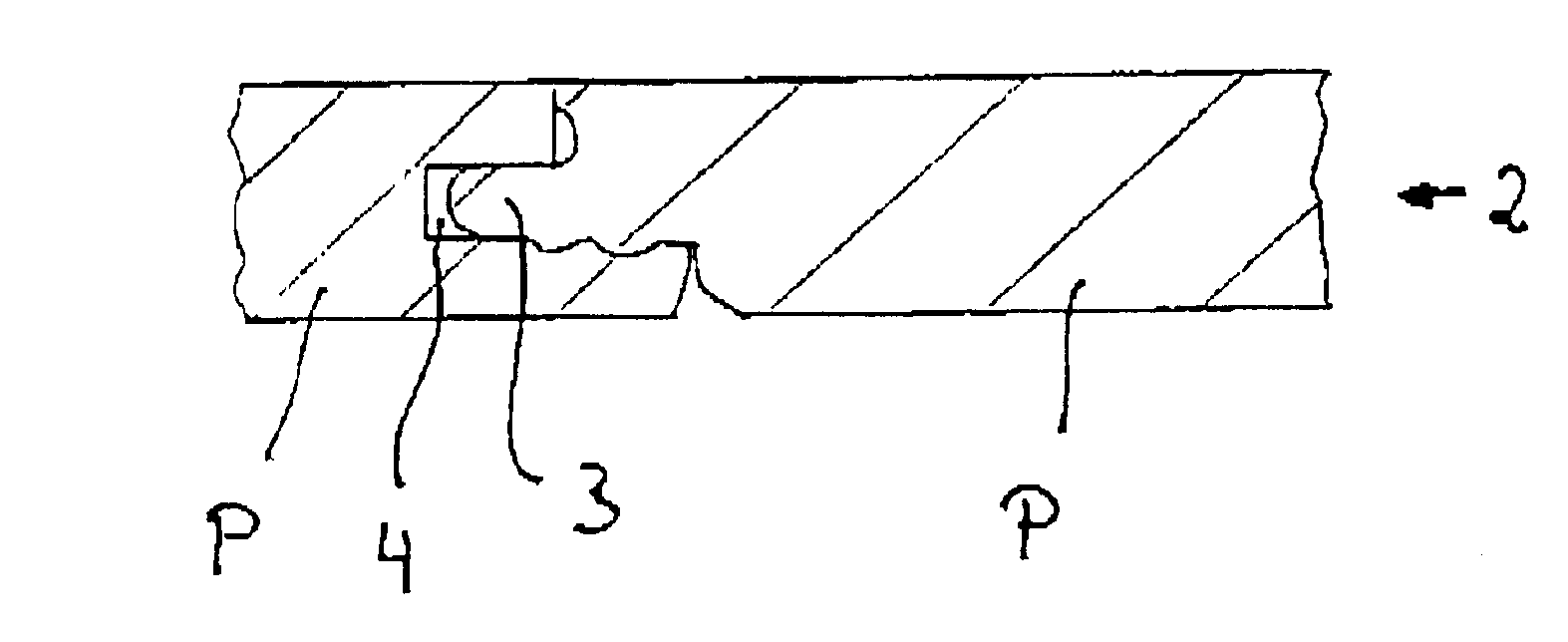

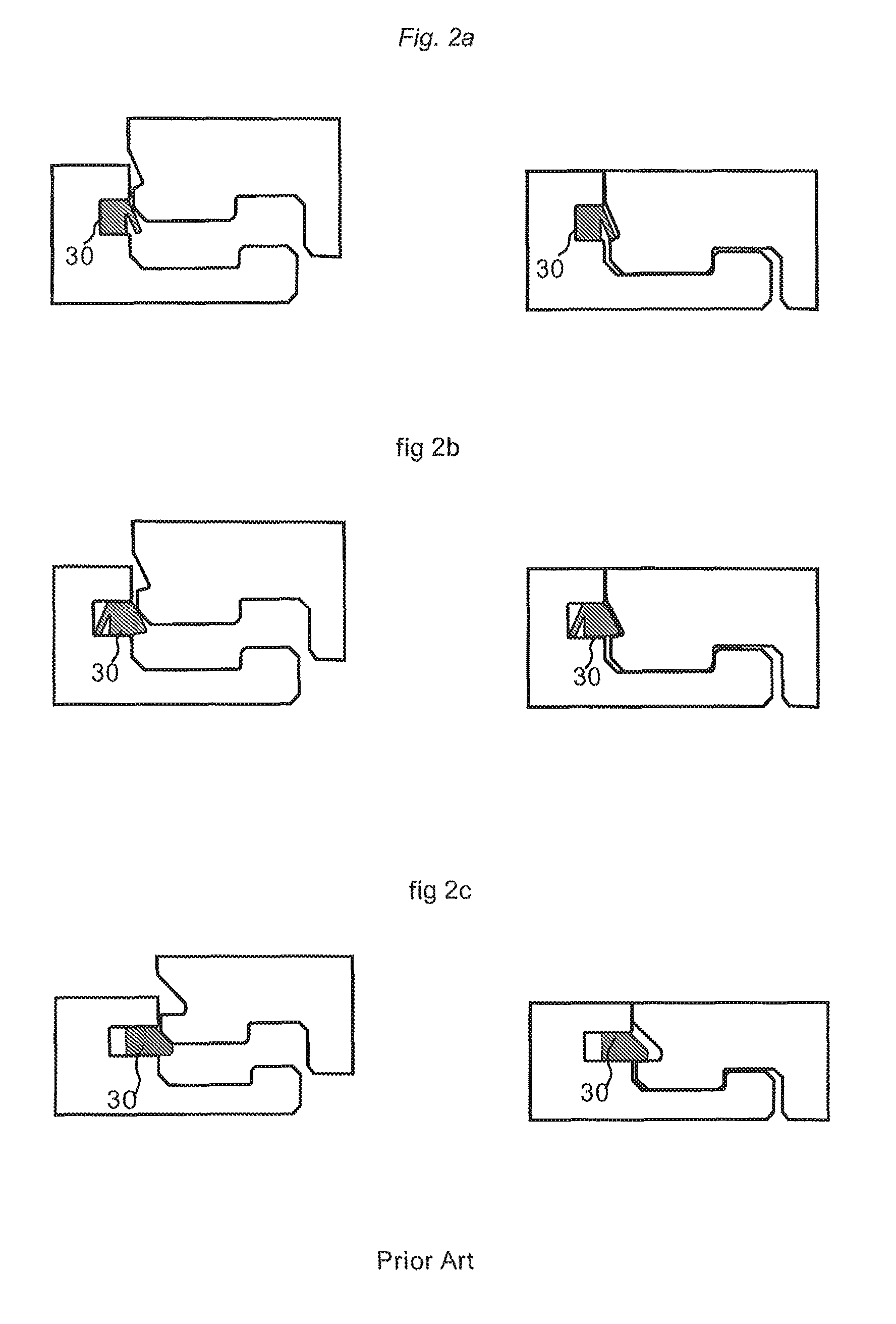

Locking system and flooring board

A locking system for mechanical joining of floorboards. For horizontal mechanical joining there is a projecting portion with a locking element which cooperates with a locking groove in an adjacent board. A tongue-and-groove joint for vertical mechanical joining has cooperating upper abutment surfaces and cooperating lower abutment surfaces which are essentially parallel with the principal plane of the floorboards and of which the lower abutment surfaces are positioned essentially outside the outer vertical plane, i.e. displaced relative to the upper abutment surfaces. The tongue is movable at an angle into the groove and the locking element is insertable into the locking groove by mutual angular movement of the boards about the joint edges.

Owner:VÄLINGE INNOVATION AB

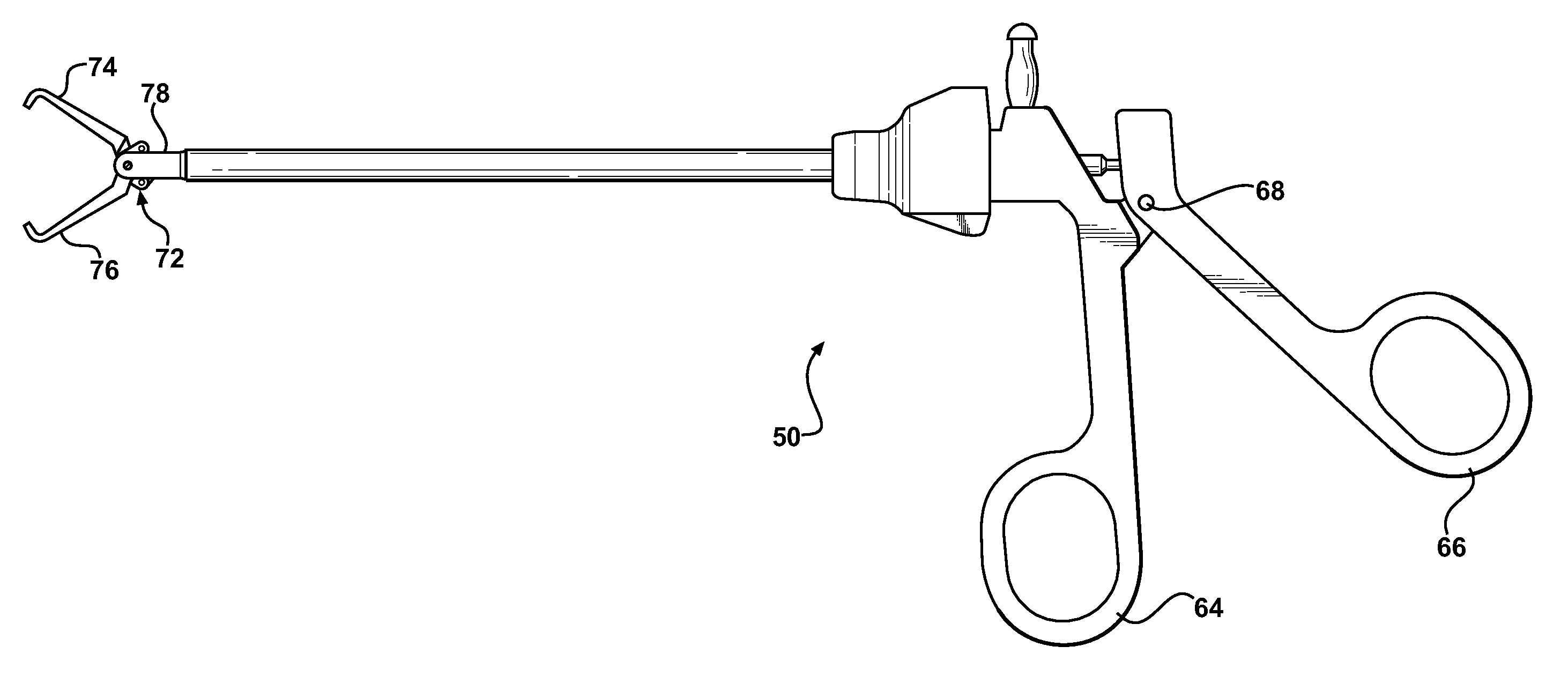

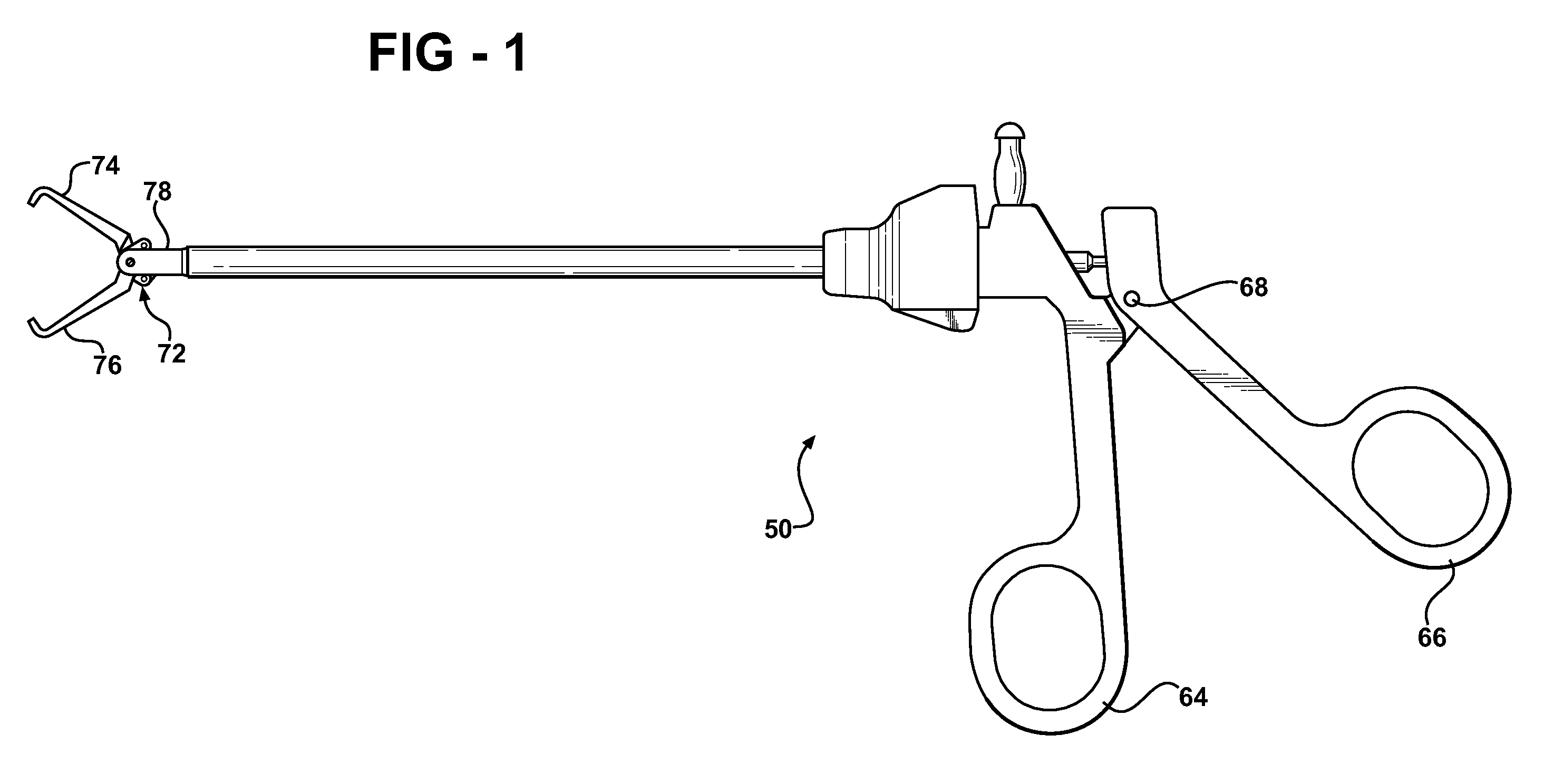

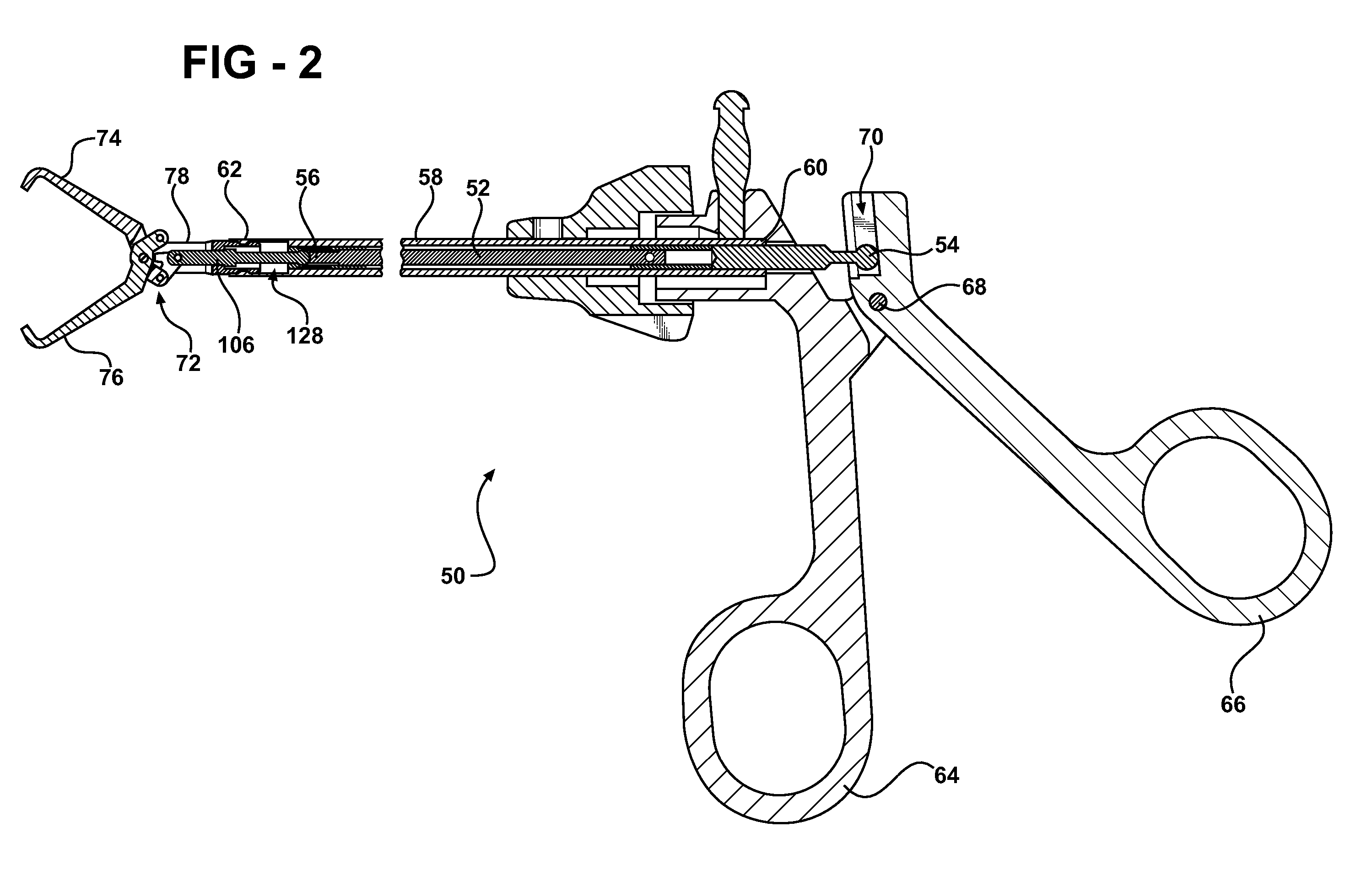

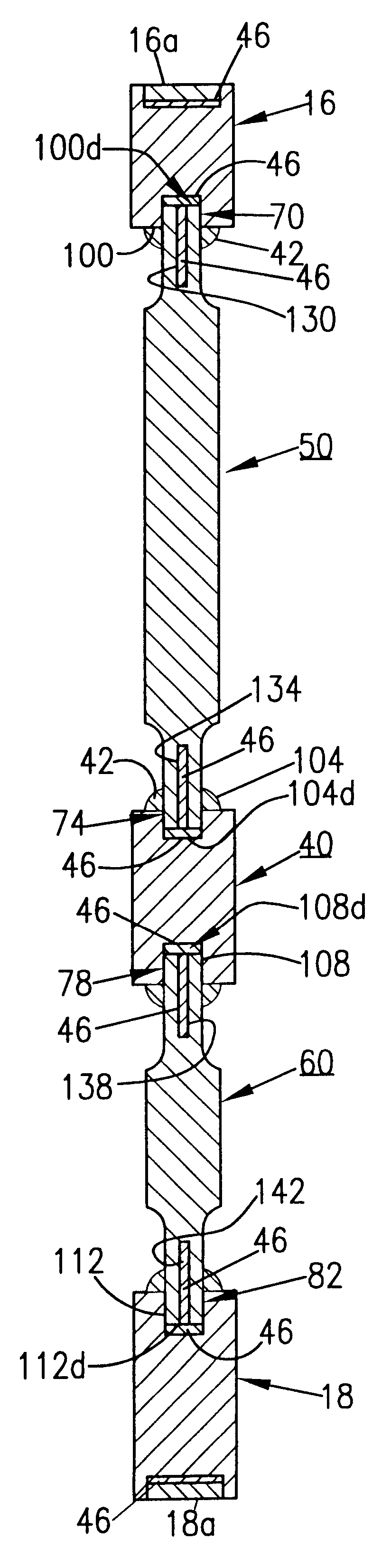

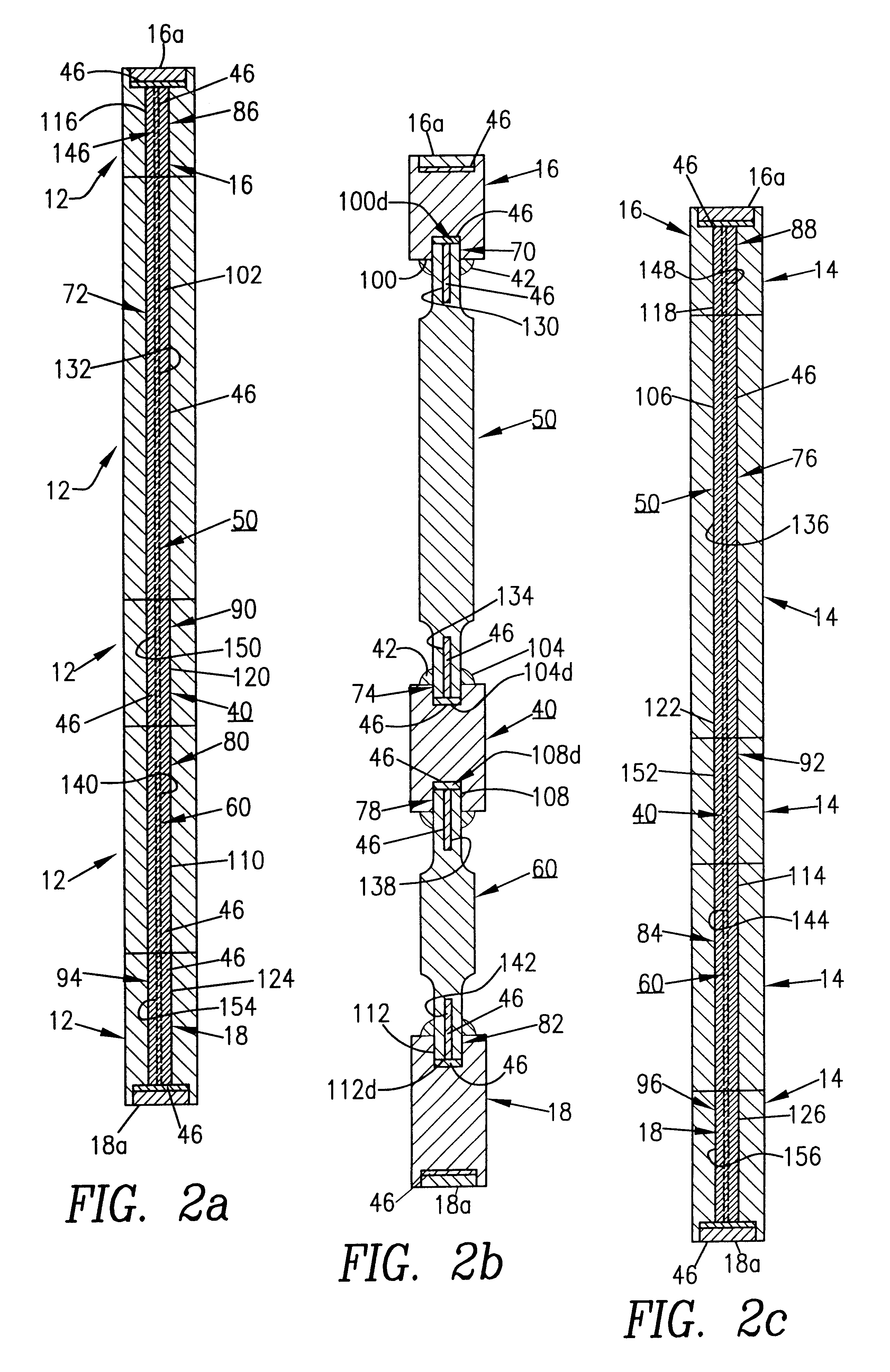

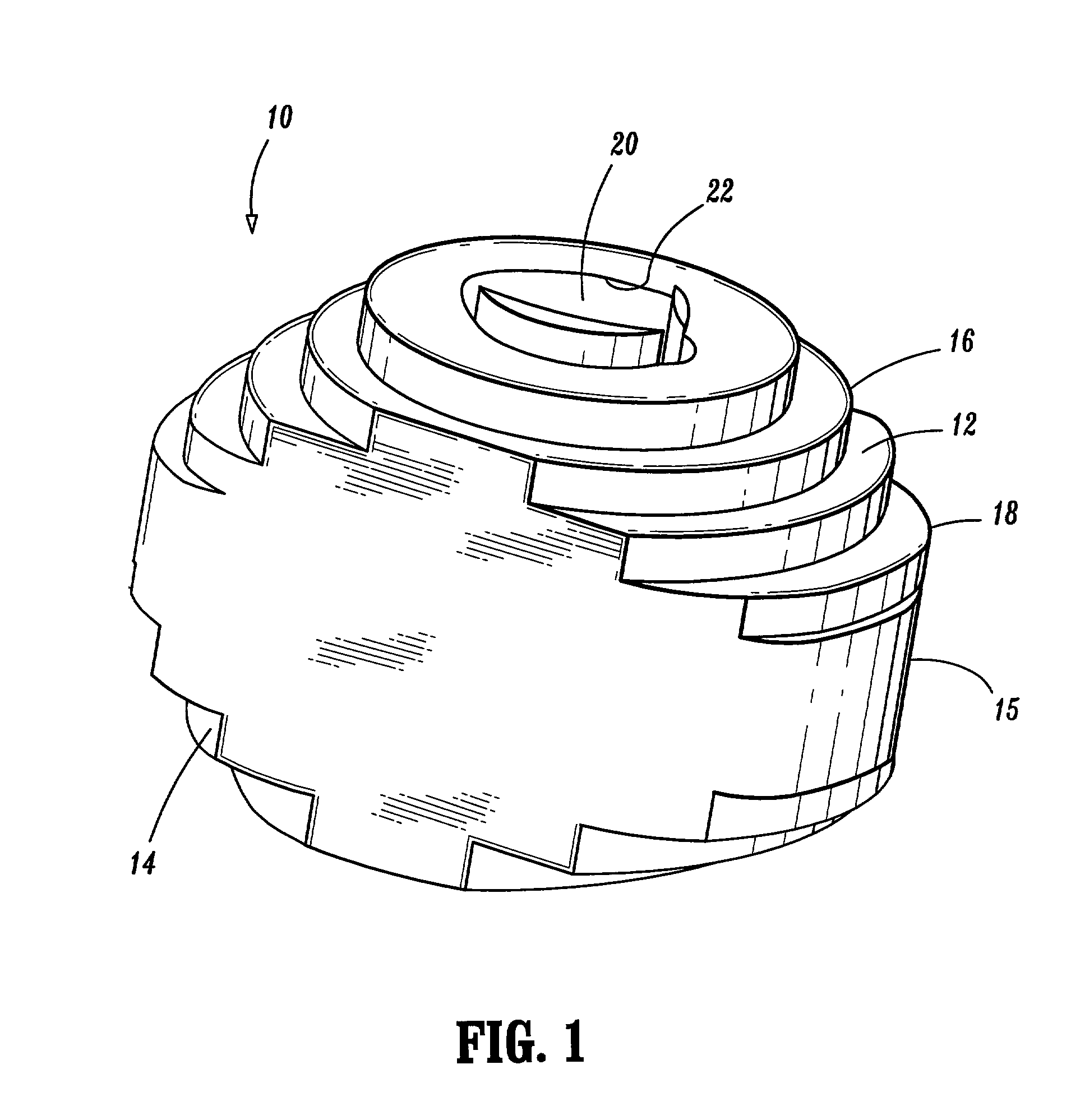

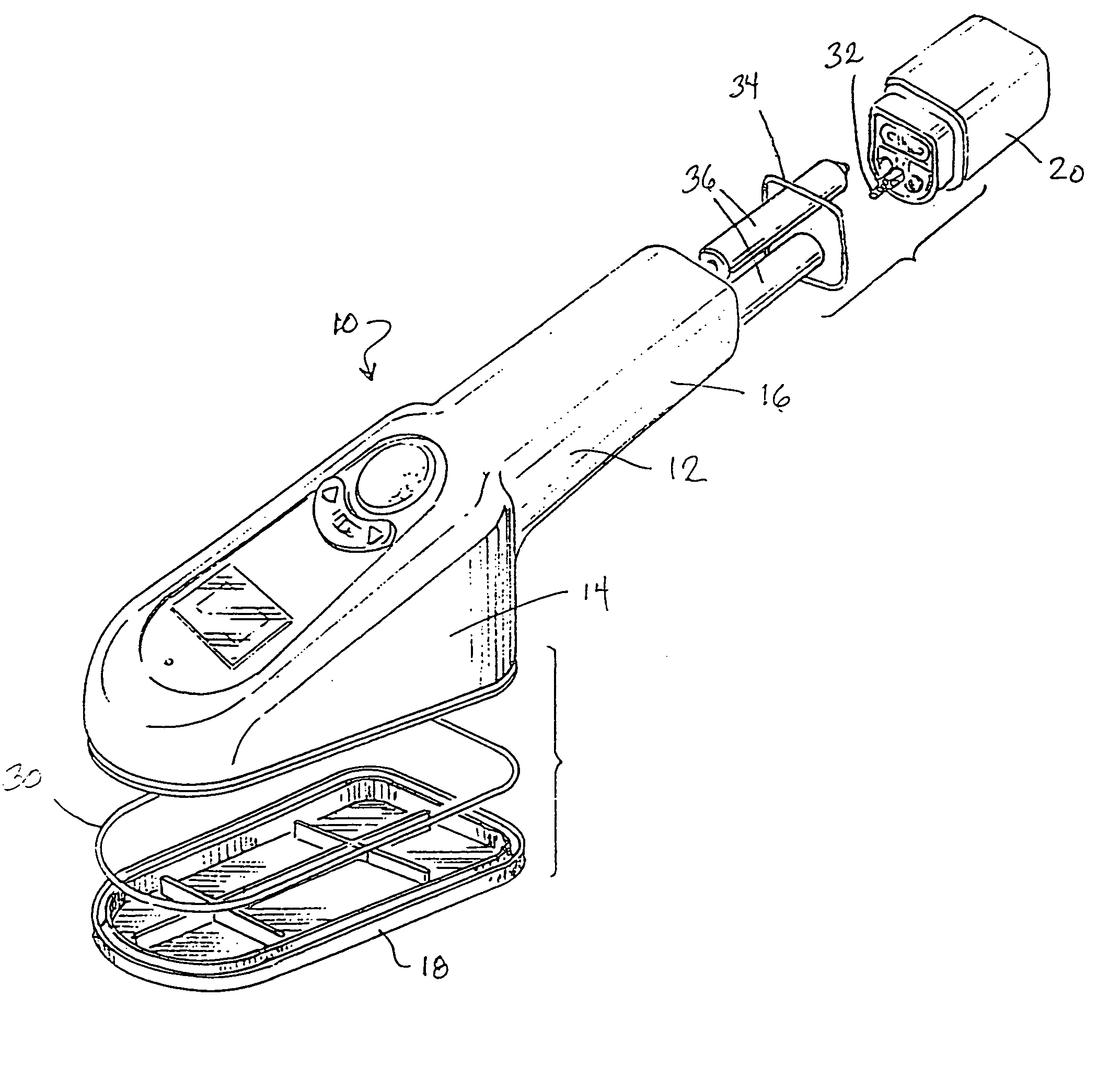

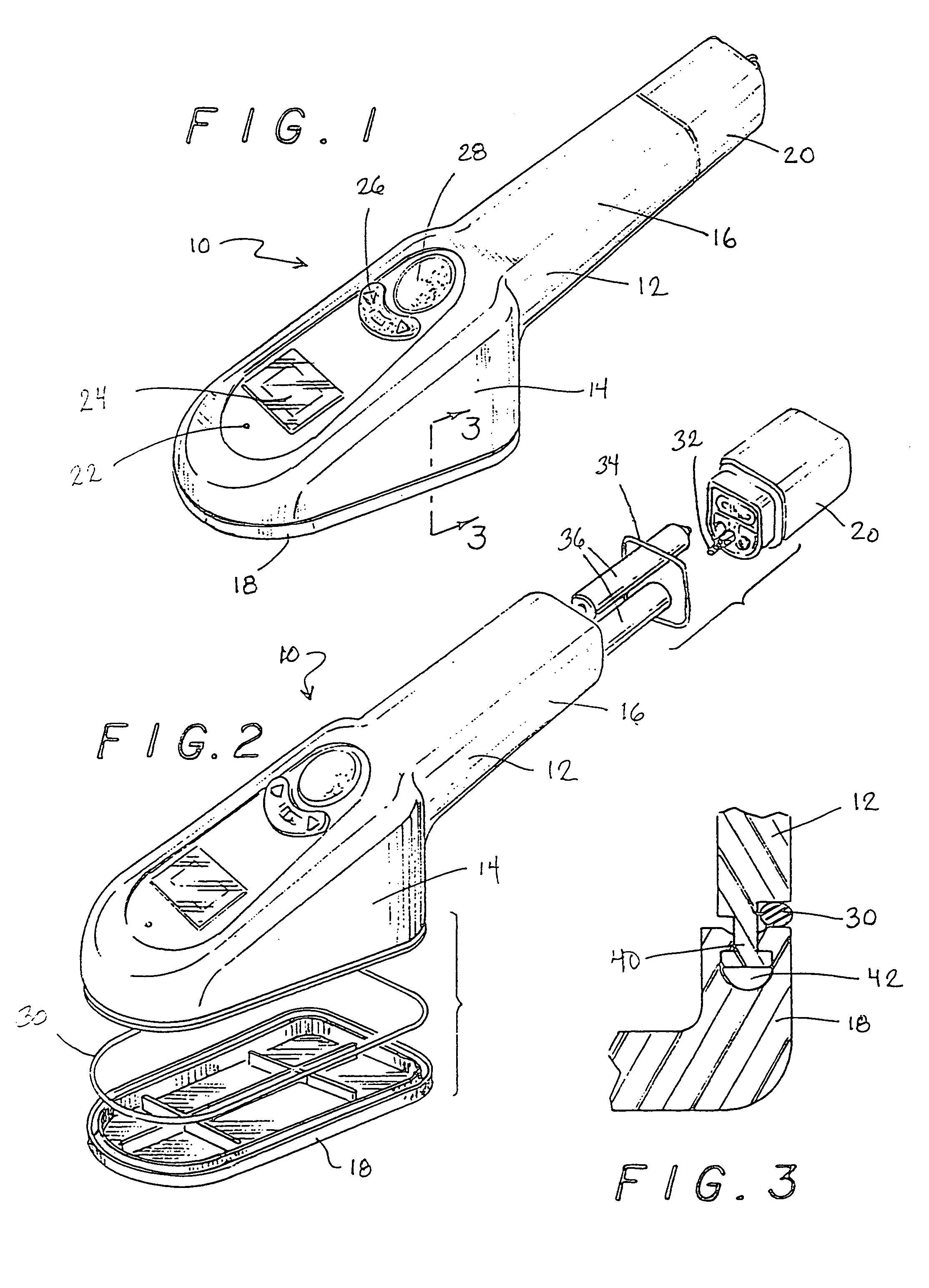

Surgical instrument with detachable tool assembly

InactiveUS20080004656A1Avoid Potential ContaminationEasy to separateSurgical instrument detailsSurgical forcepsCouplingEngineering

A surgical instrument includes a detachable tool assembly. The assembly includes a connection rod and a tool, such as a pair of jaws or an electrode. The instrument also includes a shaft operatively connected to a handle movable between operating positions and an ejected position. A tubular housing encloses the shaft and a collet. The collet is attached to the rod and movable between the positions. The fingers of the collet are flared apart in the ejected position but collapse to capture the connection rod in the operating positions. A tongue-and-groove arrangement provides a secondary coupling between the assembly and the housing when the handle is in the operating positions.

Owner:LIVNEH STEVE

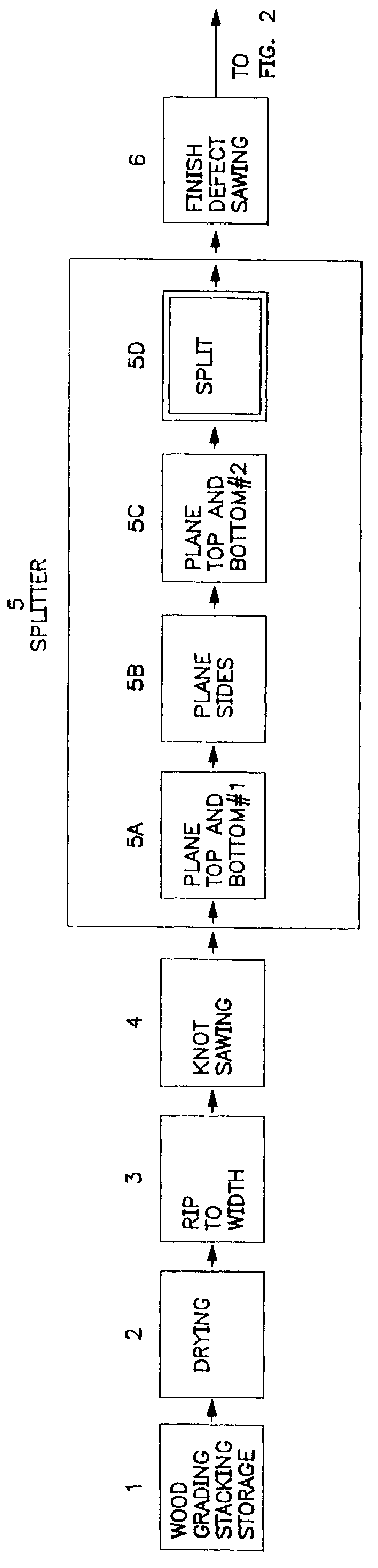

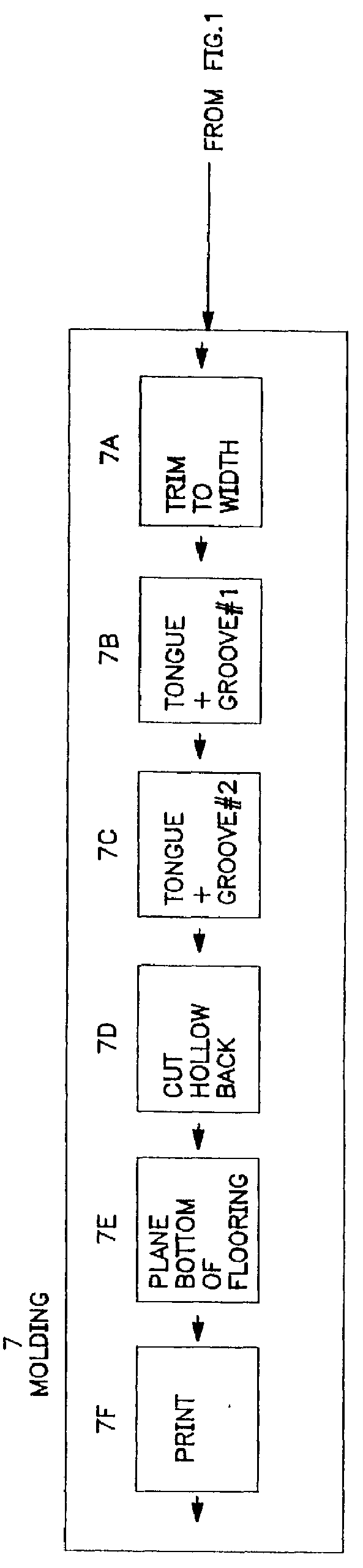

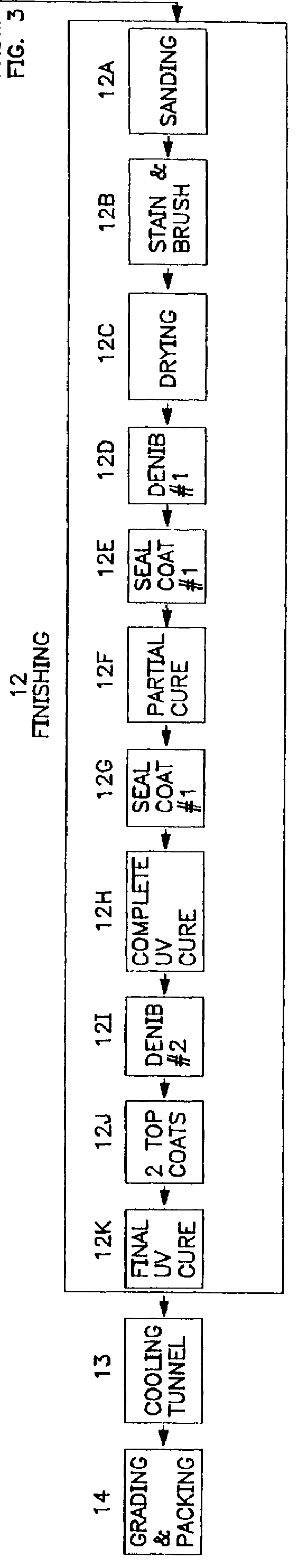

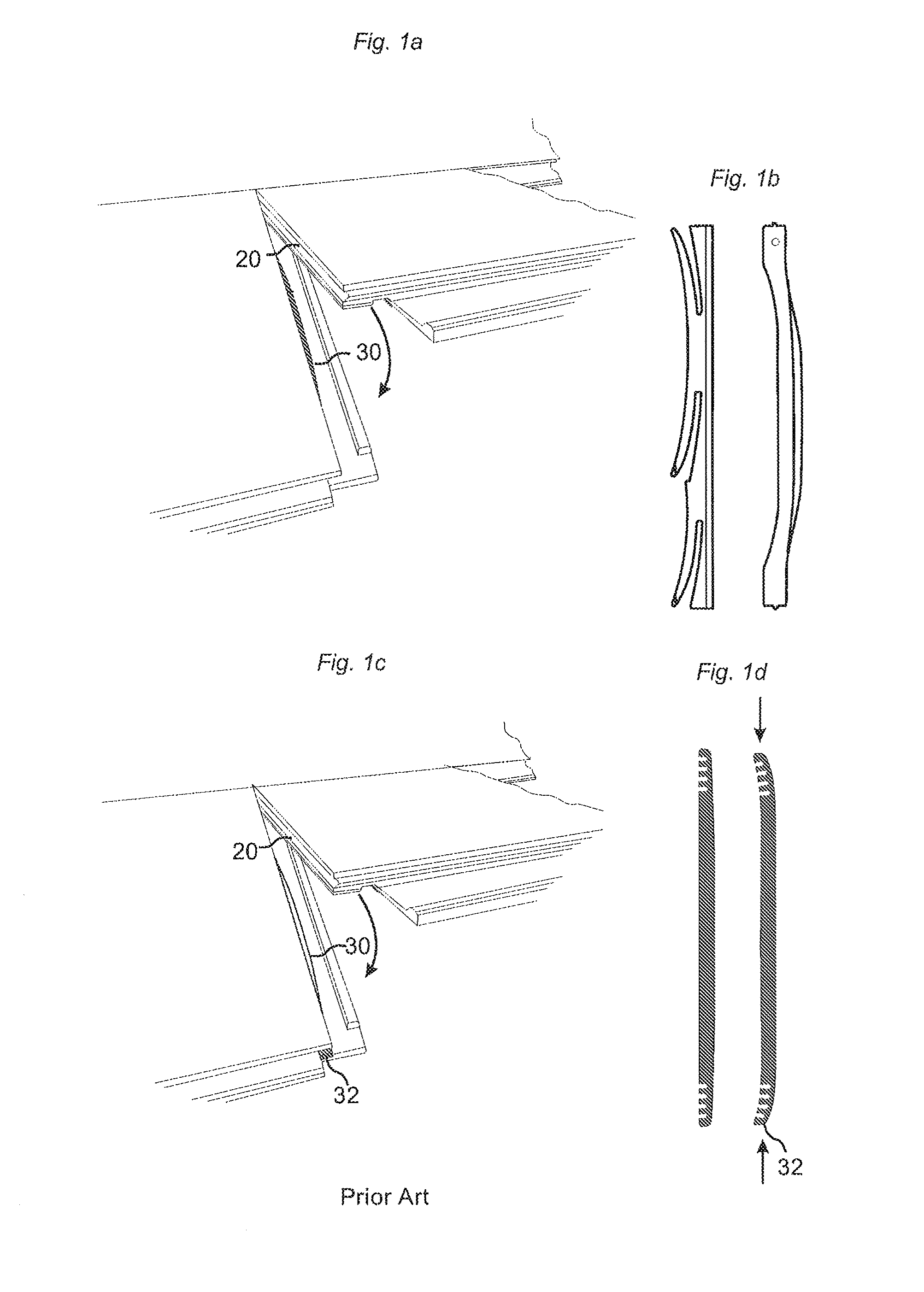

Low profile hardwood flooring strip and method of manufacture

InactiveUS6148884AConsiderable quantityImprove rigidityDovetailed workMulti-purpose machinesCircular sawTongue and groove

A method of producing a hardwood flooring product, including the steps of processing a strip of raw wood into a blank having a predetermined thickness and width, and top and bottom surfaces defining parallel planes relative to each other, and splitting the blank along the width of the blank from one side to the other to form two low profile flooring strips having the same width as the blank and a thickness less than one-half the thickness of the blank. The splitting step includes the steps of providing first and second circular saw blades mounted on spaced-apart vertical axes for rotation in a single plane intermediate and parallel to the planes of the top and bottom surfaces of the blank and positioning the blank on conveying means upstream from the saw blades with the plane of rotation of the saw blades intermediate and parallel to the planes of the top and bottom surfaces of the blank for movement of the blank from an upstream position to a downstream position relative to the saw blades. The blank is moved downstream into the plane of rotation of the saw blades during rotation of the saw blades thereby horizontally splitting the blank to form first and second low-profile flooring strips. Interlocking members, such as molded, mating tongue and groove members, are molded into first and second longitudinally-extending side edges of the flooring strips for securing together the flooring strips when placed side-to-side to form a floor.

Owner:ARMSTRONG HARDWOOD FLOORING CO +2

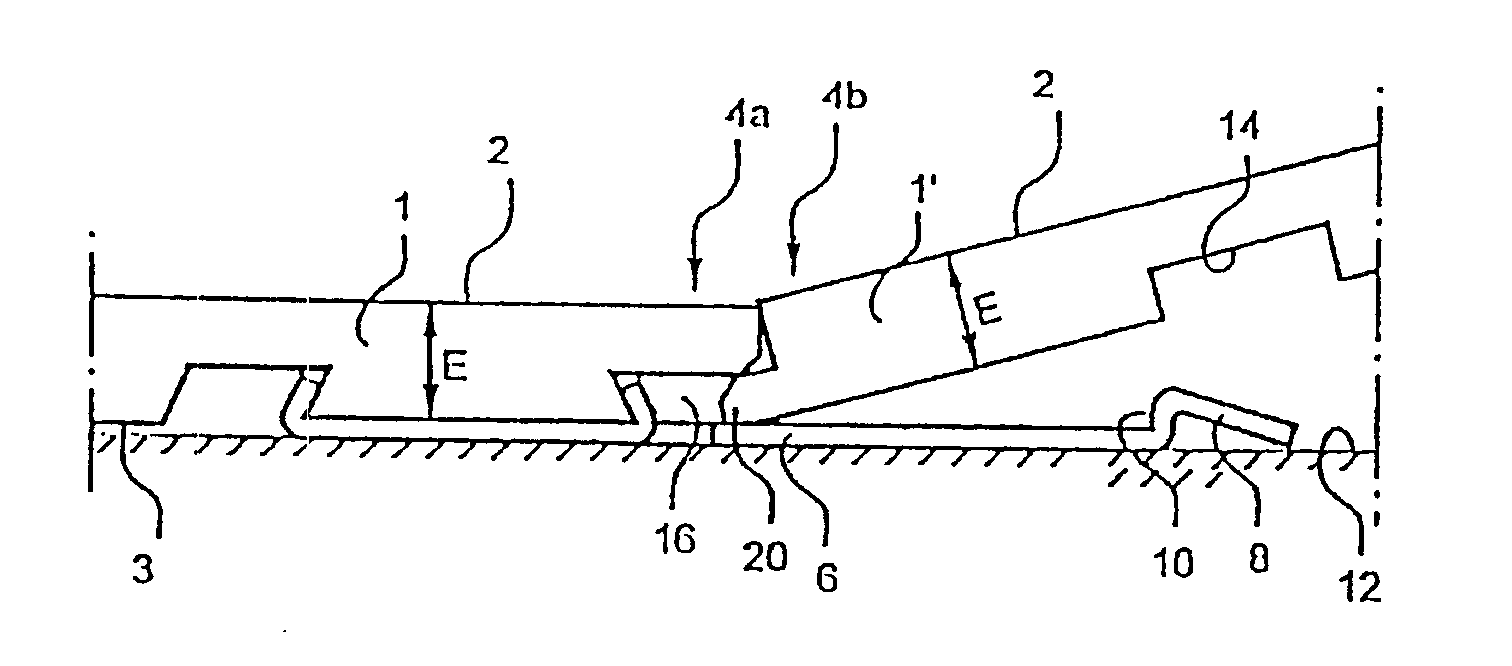

Process of laying floorboards

InactiveUS6711869B2Reduce frictionIncrease frictionCovering/liningsWallsTongue and grooveEngineering

A process is proposed for laying and mechanically jointing floorboards provided with tongue and groove engagements on all sides for horizontal attachment. The process involves a) jointing of a number of boards and making them engage on their transverse sides n order to lay a first row on the floor of a room, b) jointing of a first board for a second row and making it engage with one or two boards in the first row using the tongue and groove joint on the longitudinal side for the purpose of starting a second row, c) pushing the tongue (or groove) of a second board into the groove (or tongue) on the transverse side of the first board in the second row, with movement from the longitudinal side towards the boards in the first row, and d) making the second board engage with one or two boards in the first row.

Owner:KRONOTEX USA

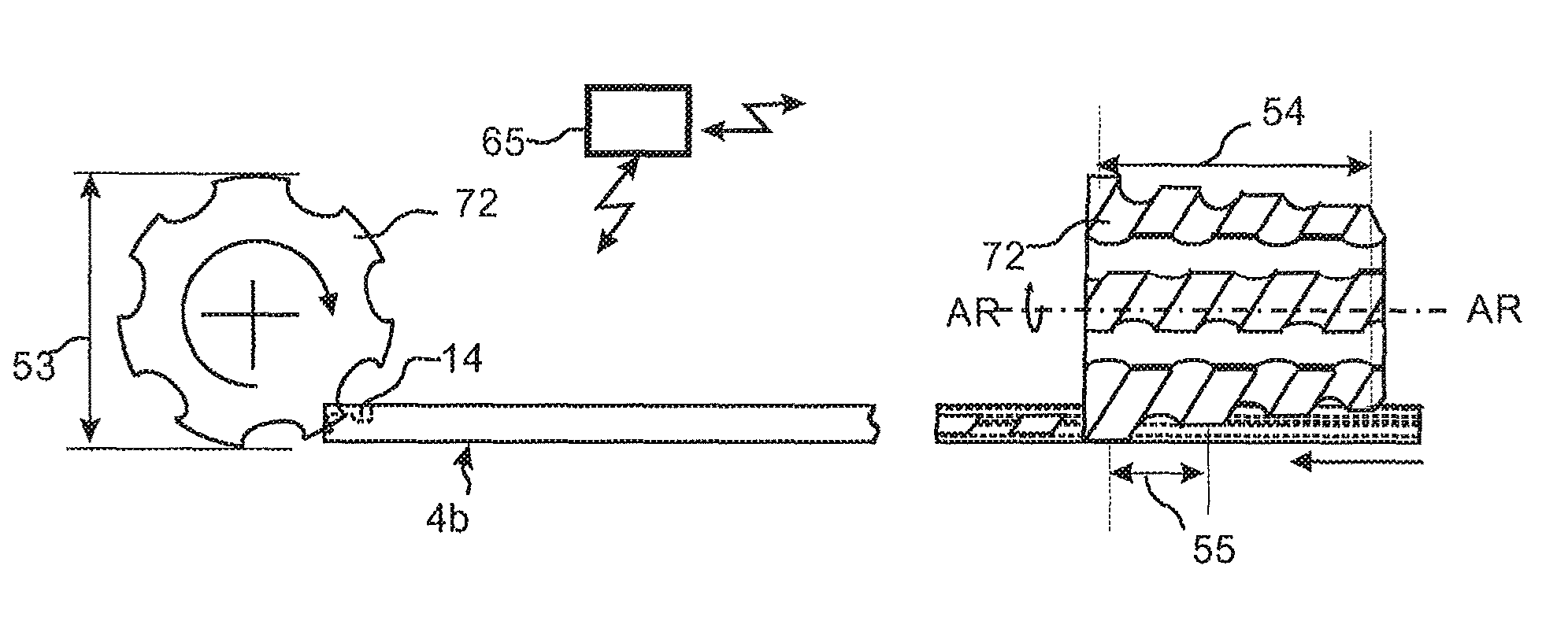

Mechanical lockings of floor panels and a tongue blank

Floor panels which are provided with a mechanical locking system comprising tongue and grooves provided with protrusions and cavities which are displaceable in relation to each other.

Owner:VÄLINGE INNOVATION AB

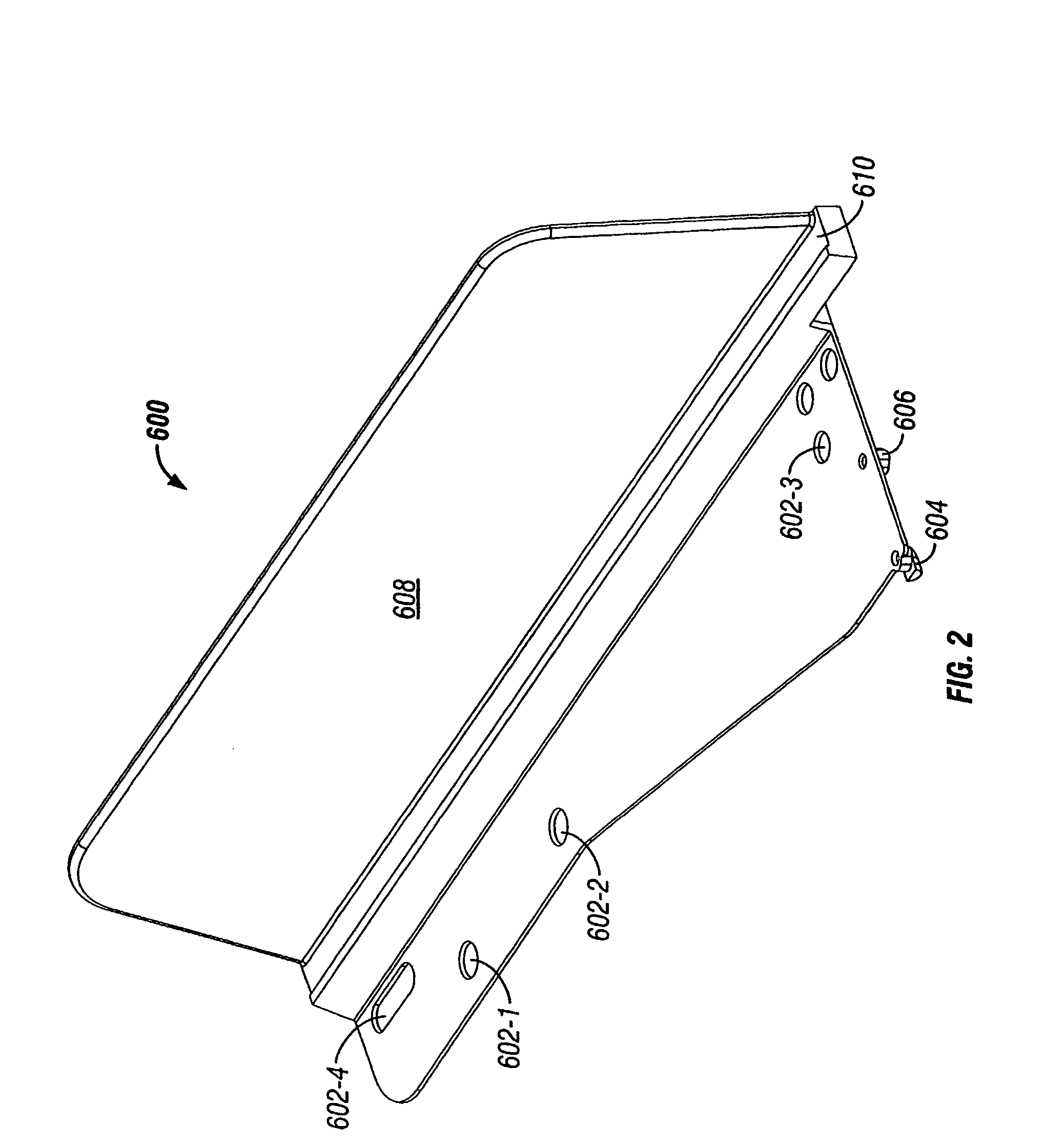

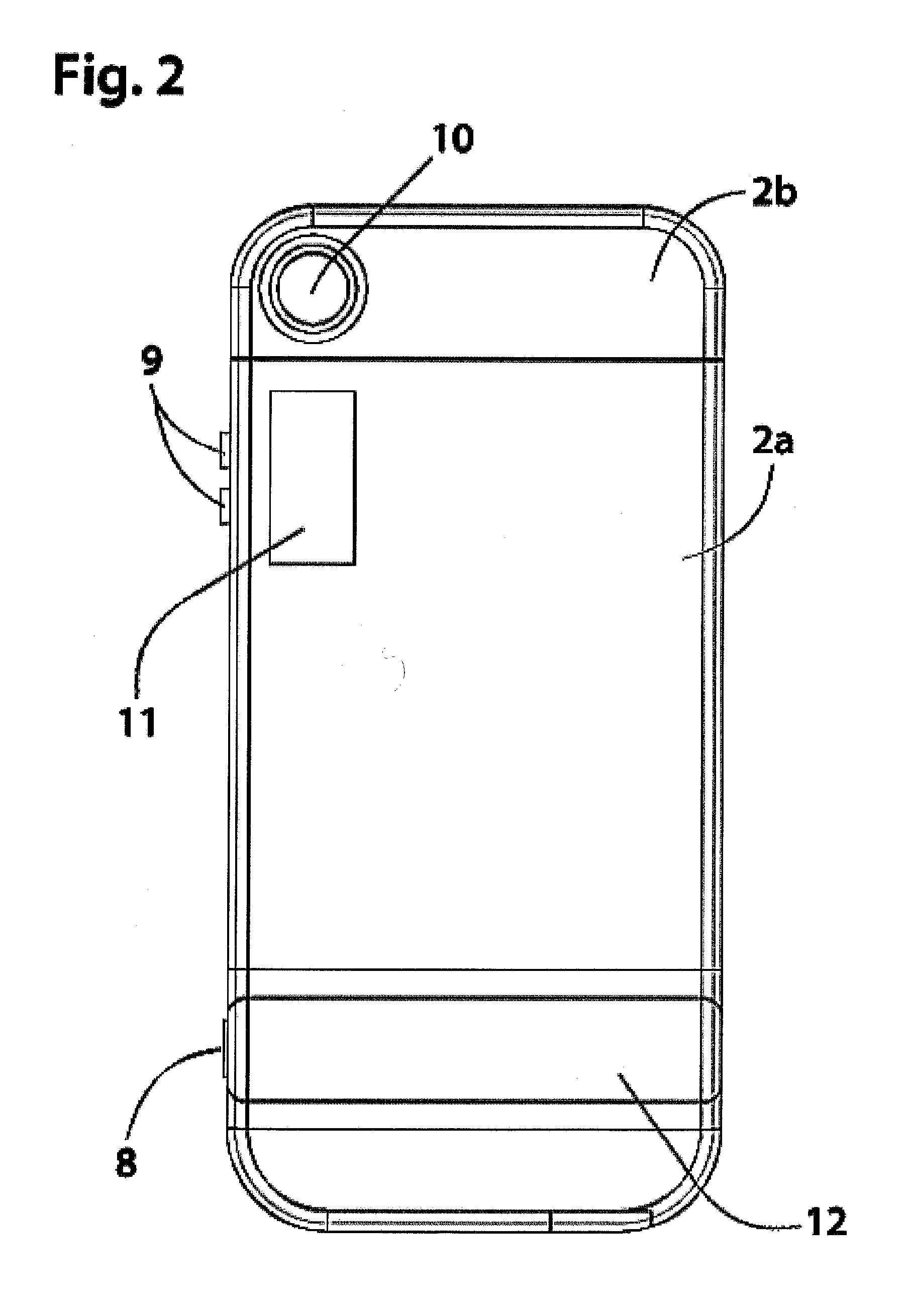

Case for mobile communication device with flash and camera controls

A mobile device case is formed with a hollow case housing for receiving a mobile device and controlling a mobile device camera therein. The mobile device includes a case connector for electronically connecting the case to the mobile device at insertion of the mobile device into the hollow case housing and at least one camera control actuator for controlling operation of the mobile device camera, when the mobile device is present in the hollow case housing. The hollow case housing comprises a first housing section and a second housing section that comes together by respective tongue and groove elements to thereby encapsulate the mobile device.

Owner:HALELUK ROBERT

Mechanical locking of floor panels, methods to install and uninstall panels, a method and an equipment to produce the locking system, a method to connect a displaceable tongue to a panel and a tongue blank

ActiveUS8627862B2Easy to installImprove installation and strength and quality and production costCovering/liningsTongue/grooves making apparatusEngineeringTongue and groove

Floor panels are shown, which are provided with a mechanical locking system including tongue and grooves provided with protrusions and cavities which are displaceable in relation to each other and configured such that the protrusions can obtain a vertically unlocked position where they match the cavities and a vertically locked position where the protrusions overlap each other.

Owner:VÄLINGE INNOVATION AB

Method and apparatus for interconnecting paneling

A paneling system is provided herein that concerns interconnecting panels with opposite connecting sides of substantially tongue in groove joint couplings and opposing adjacent connecting sides that are of substantially hook-joint coupling. The hook joint hinders lateral motion while permitting movement in a direction perpendicular to the plane of the interconnected panels to provide ease of installment and removal. The hook joints also provide proper alignment and spacing between panels.

Owner:EVJEN JOHN M

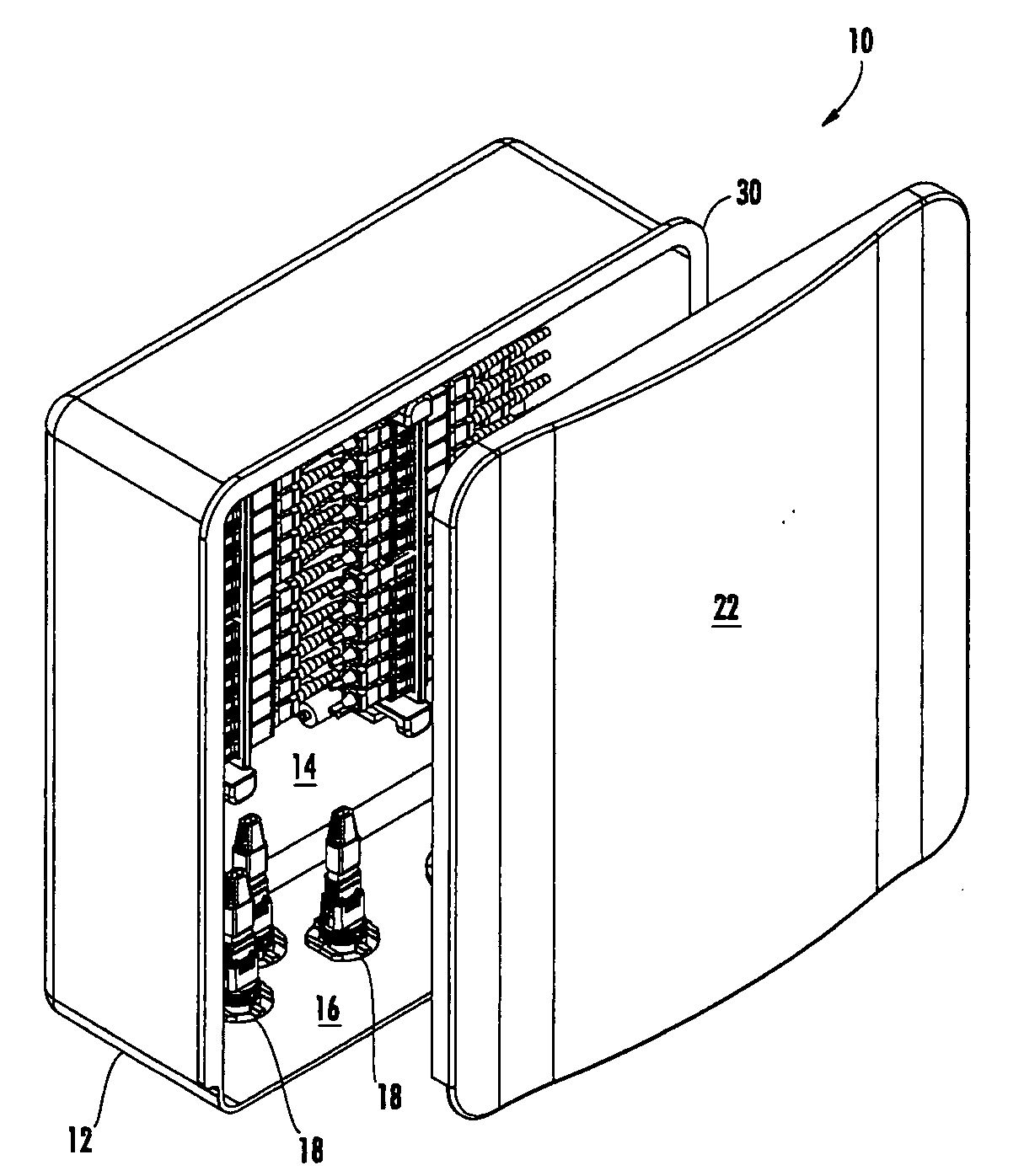

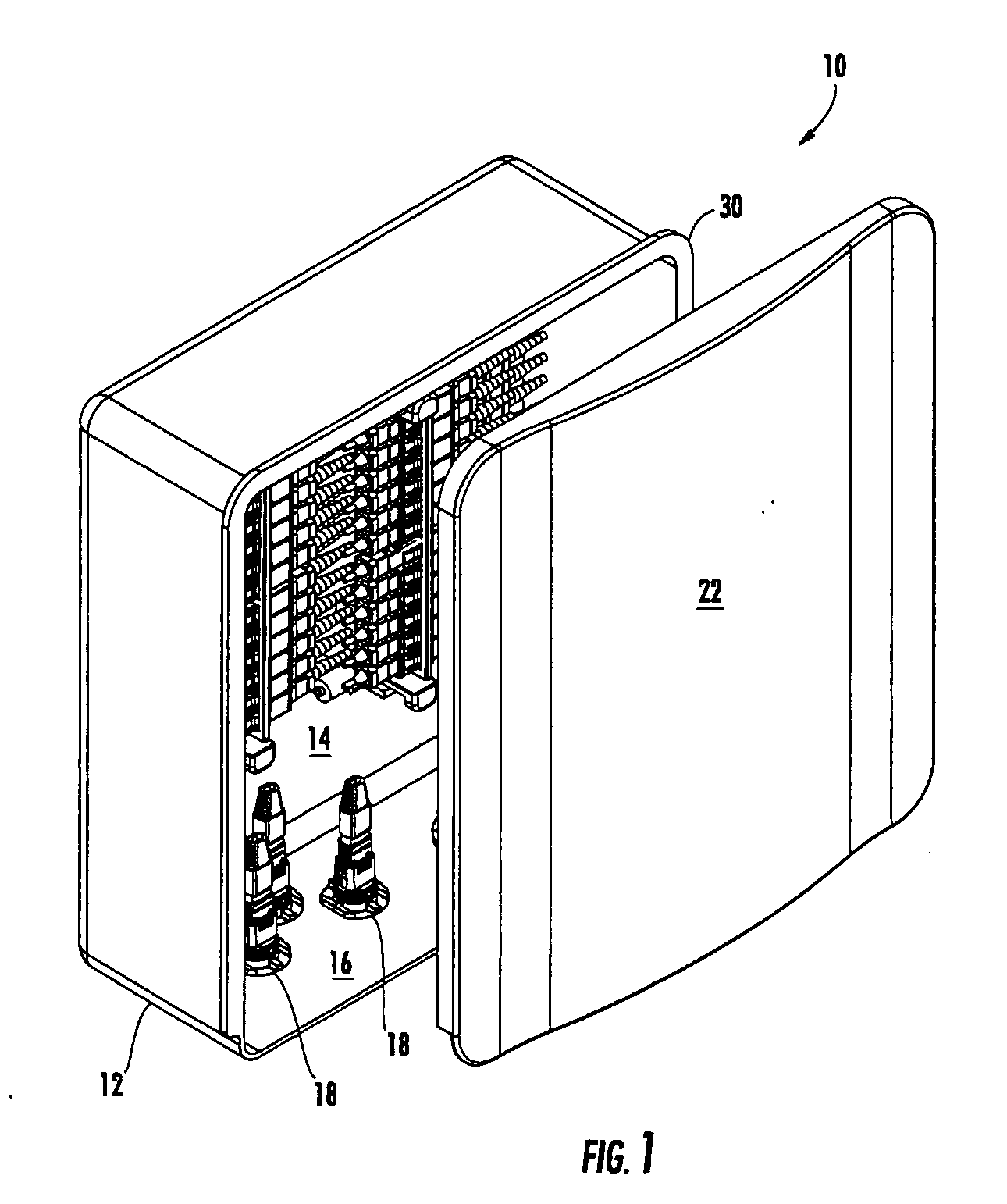

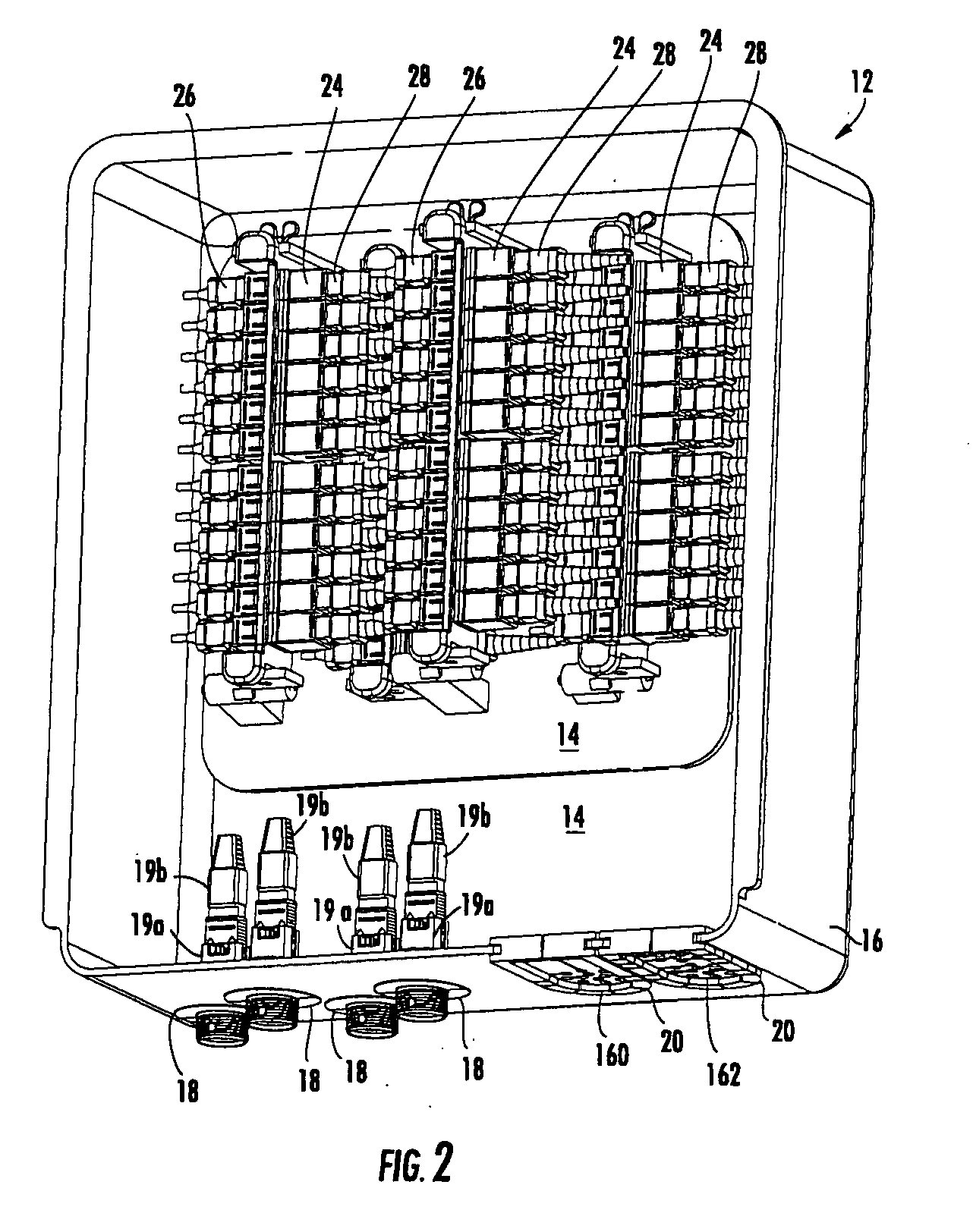

Fiber optic terminal assembly

There is provided fiber drop terminal (“FDT”) assemblies for providing selective connections between optical fibers of distribution cables and optical fibers of drop cables, such as in multiple dwelling units. The FDT assemblies include a base and a cover that define a tongue and groove that selectively engage to seal the base and cover. The FDT assemblies also include a mounting plate for mounting of the base and cover, as well as a mounting plate extension for mounting of a skirt. The skirt provides slack storage for drop cables exiting the FDT. The components of the FDT assembly are selectively interlockable to prevent unauthorized access to the interior cavity of the base and cover and to the slack storage area of the skirt.

Owner:CORNING OPTICAL COMM LLC

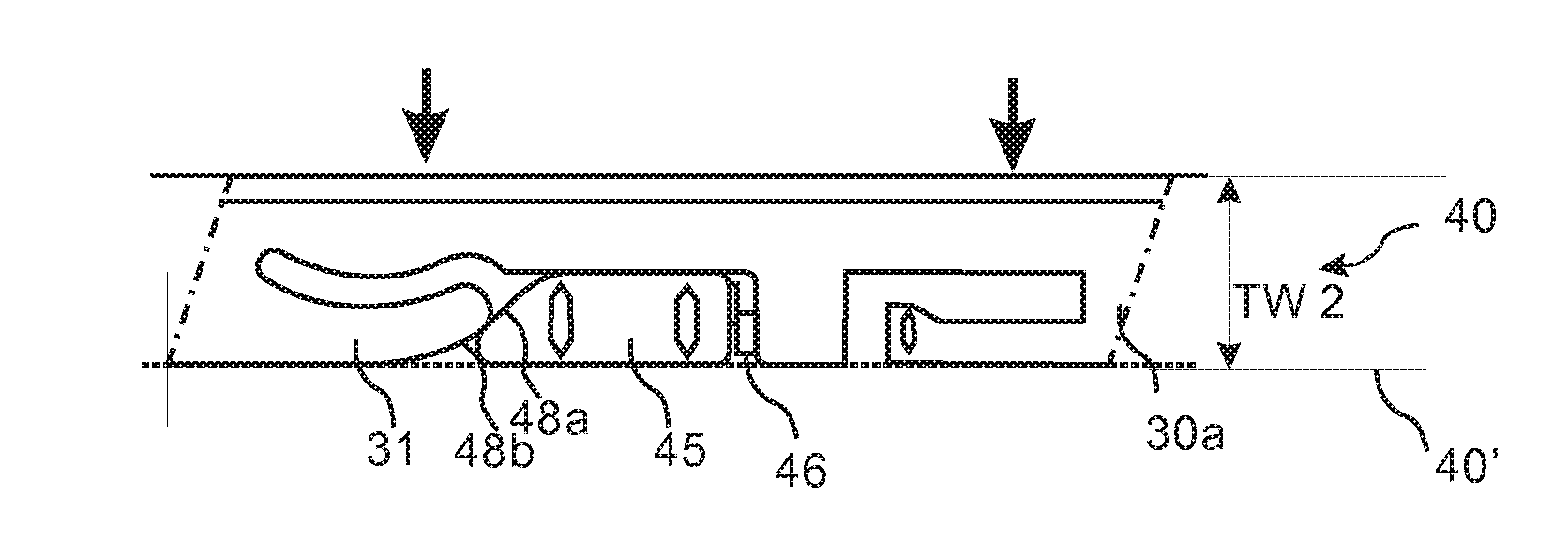

Floor panel with a tongue, groove and a strip

InactiveUS20060283127A1Simpler and cheapImprove accuracyRoof covering using tiles/slatesCovering/liningsDevice formEngineering

Floorboards with substantially planar and parallel upper top sides and lower undersides and panel material located between the upper and lower top sides, and a mechanical locking system for locking a first edge of a first floor board to a second edge of a substantially identical second floor board, the mechanical locking system including a tongue and groove forming a first mechanical connection locking the first and second edges to each other in a first direction at right angles to a principal plane of the floor boards, and a locking device forming a second mechanical connection locking the first and the second edges to each other in a second direction and at right angles to the edges; wherein, when the first edge and the second edge are locked together, there is space in the locking system between the first and the second edges.

Owner:VÄLINGE INNOVATION AB

Product management display system

An integrated “T” assembly combines into a single integrated assembly, a track portion along both sides of a divider. The T assembly may have a wide-base portion, which may include a spring-urged-pusher track, on one side of the divider and a narrow-base portion on the opposite side of the divider. An offset pusher may have an upper portion that is offset, via an angled offset portion, from a lower portion of the pusher. Additional supporting bases, any of which may include spring-urged-pusher tracks and / or a spring-urged pusher, may be used under a wide product. Left and right side finisher components may be paired with T assemblies near the sides of a merchandise-display shelf. The T assembly, base, and / or end finishers may be coupled to a front rail via a complimentary tongue and groove arrangement and / or a non-slidable engagement.

Owner:RTC IND

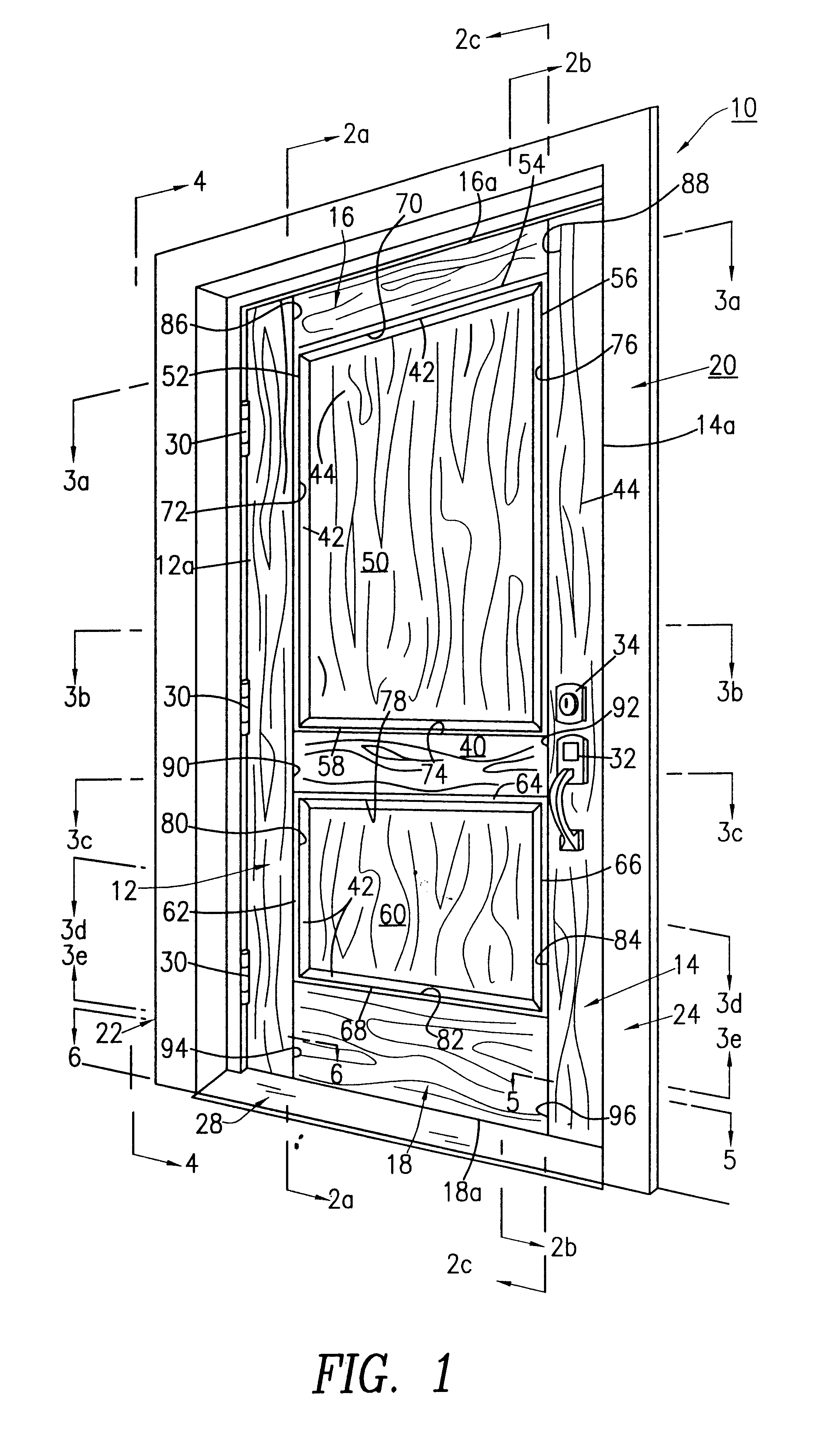

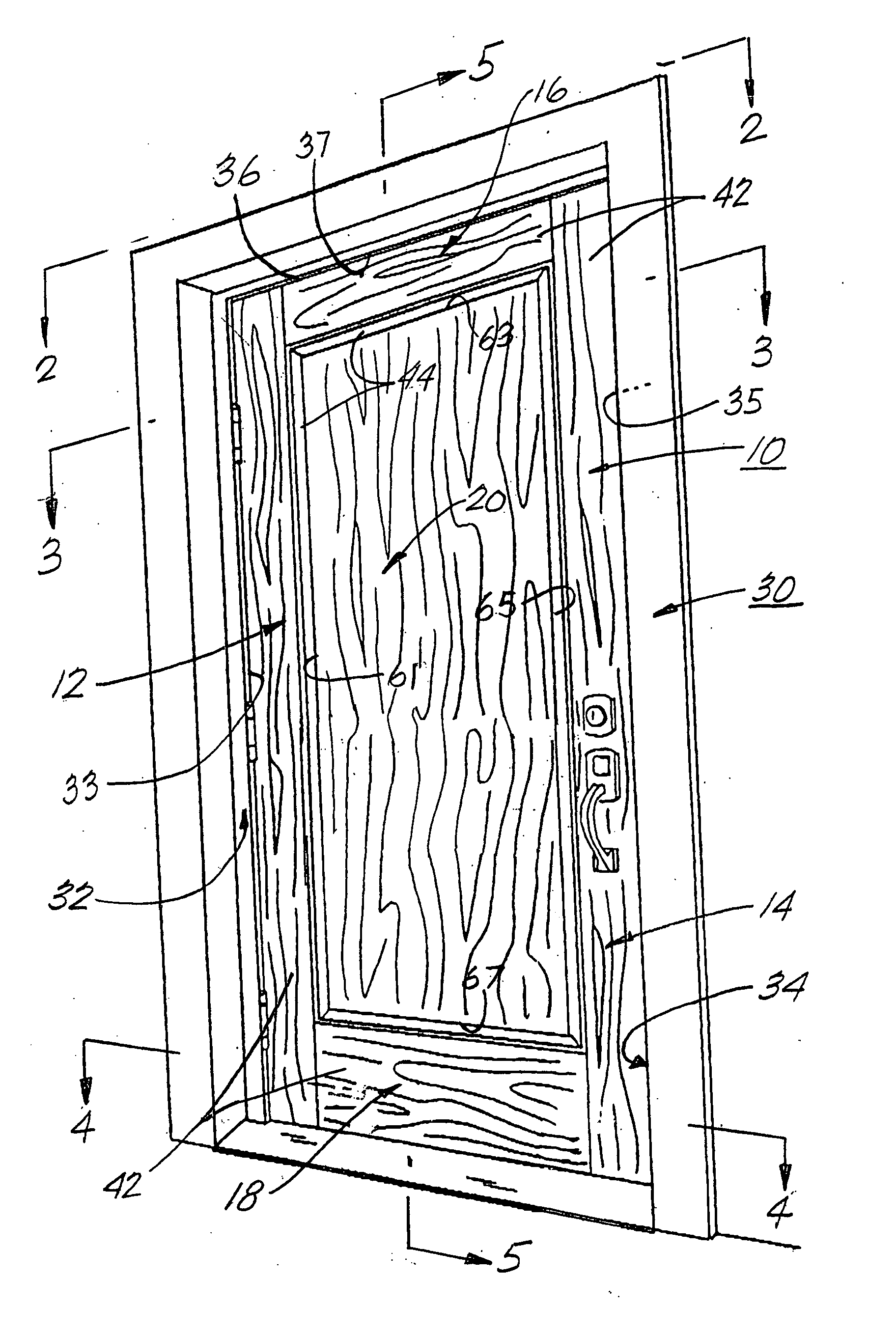

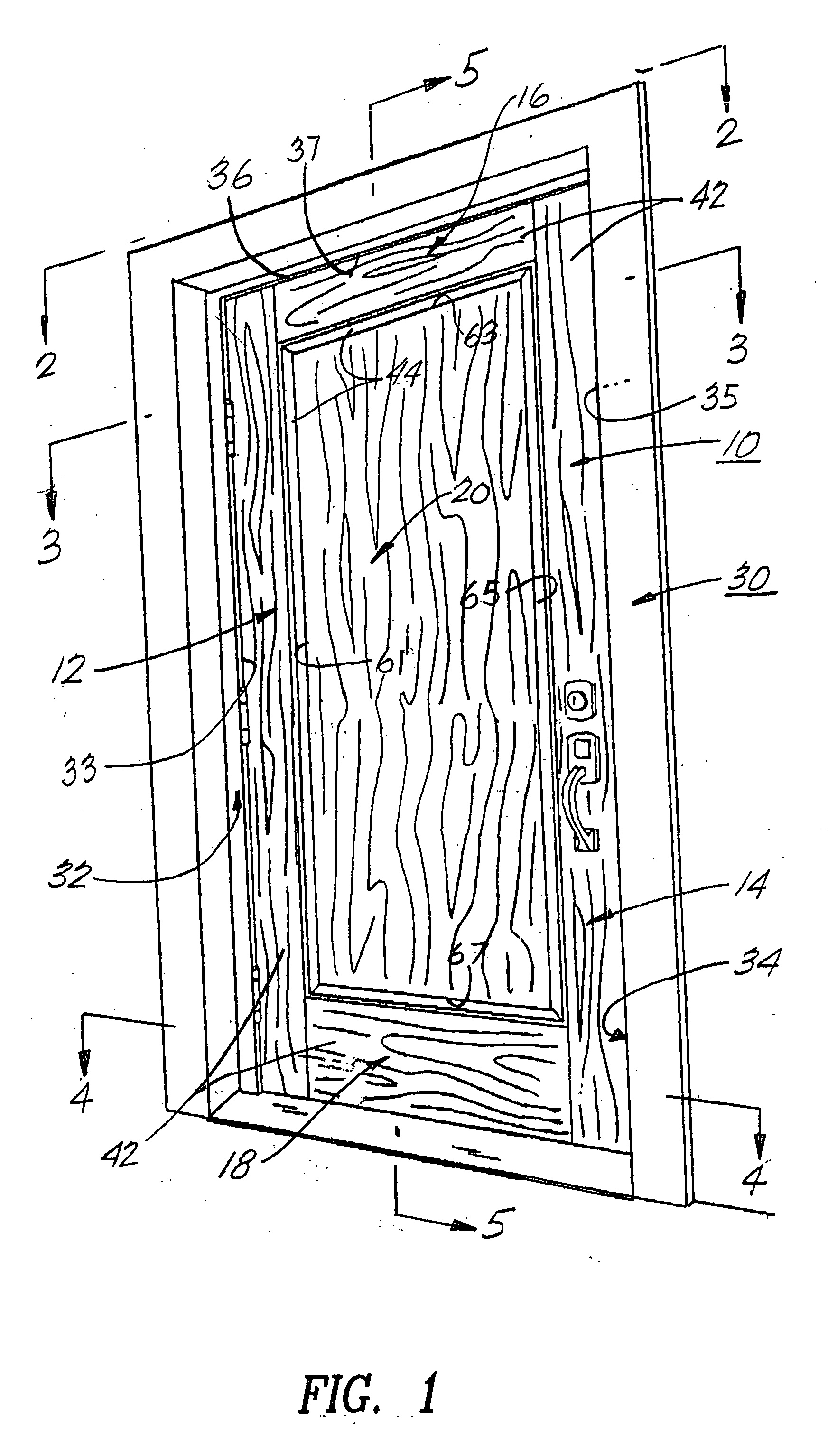

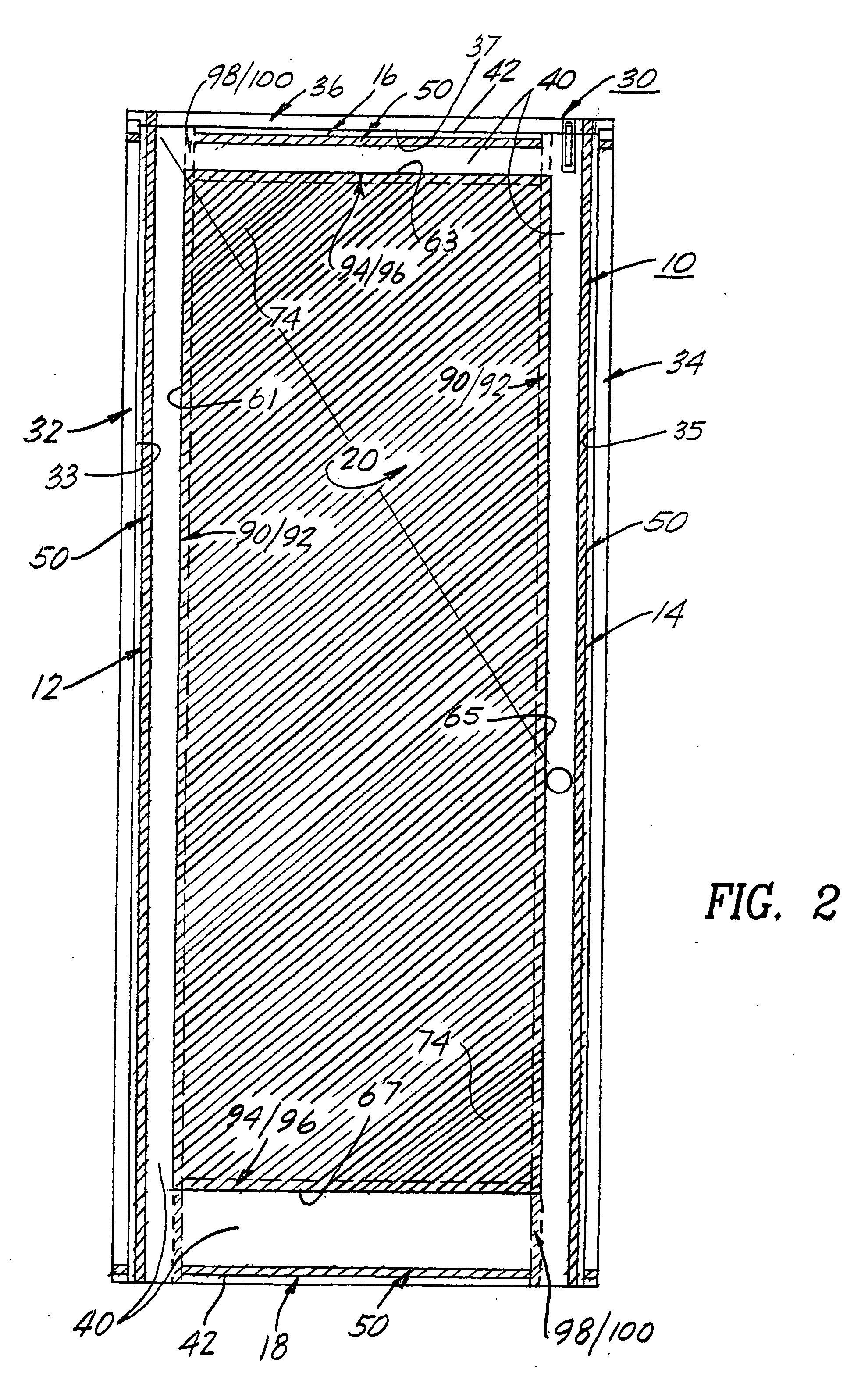

Fire retardant wooden door with intumescent materials

InactiveUS6745526B1Prevent the spread of fireEasy to installFireproof doorsDoor leavesTongue and grooveEngineering

A fire retardant wooden door that prevents the spread of fire through the door during a fire. The fire retardant wooden door has at least one door panel connected to stiles and rails by tongue and groove joints, and the tongue and groove joints have intumescent material therein. Each of the tongue and groove joints includes a tongue section having the intumescent material along a distal edge of the tongue section which expands upon exposure to heat or fire to seal the tongue and groove joints in order to prevent the heat or fire from passing through the door during a fire. Each of the tongue sections includes an interior channel extending along the axis of the tongue section, and the interior channel extends into the door panel. The interior channel has the intumescent material embedded therein which expands upon exposure to heat or fire to further seal the tongue and groove joints in order to prevent the heat or fire from passing through the door during a fire.

Owner:AUTOVINO ENRICO

Locking system and flooring board

A locking system for mechanical joining of floorboards. For horizontal mechanical joining there is a projecting portion with a locking element which cooperates with a locking groove in an adjacent board. A tongue-and-groove joint for vertical mechanical joining has cooperating upper abutment surfaces and cooperating lower abutment surfaces which are essentially parallel with the principal plane of the floorboards and of which the lower abutment surfaces are positioned essentially outside the outer vertical plane, i.e. displaced relative to the upper abutment surfaces. The tongue is movable at an angle into the groove and the locking element is insertable into the locking groove by mutual angular movement of the boards about the joint edges.

Owner:VÄLINGE INNOVATION AB

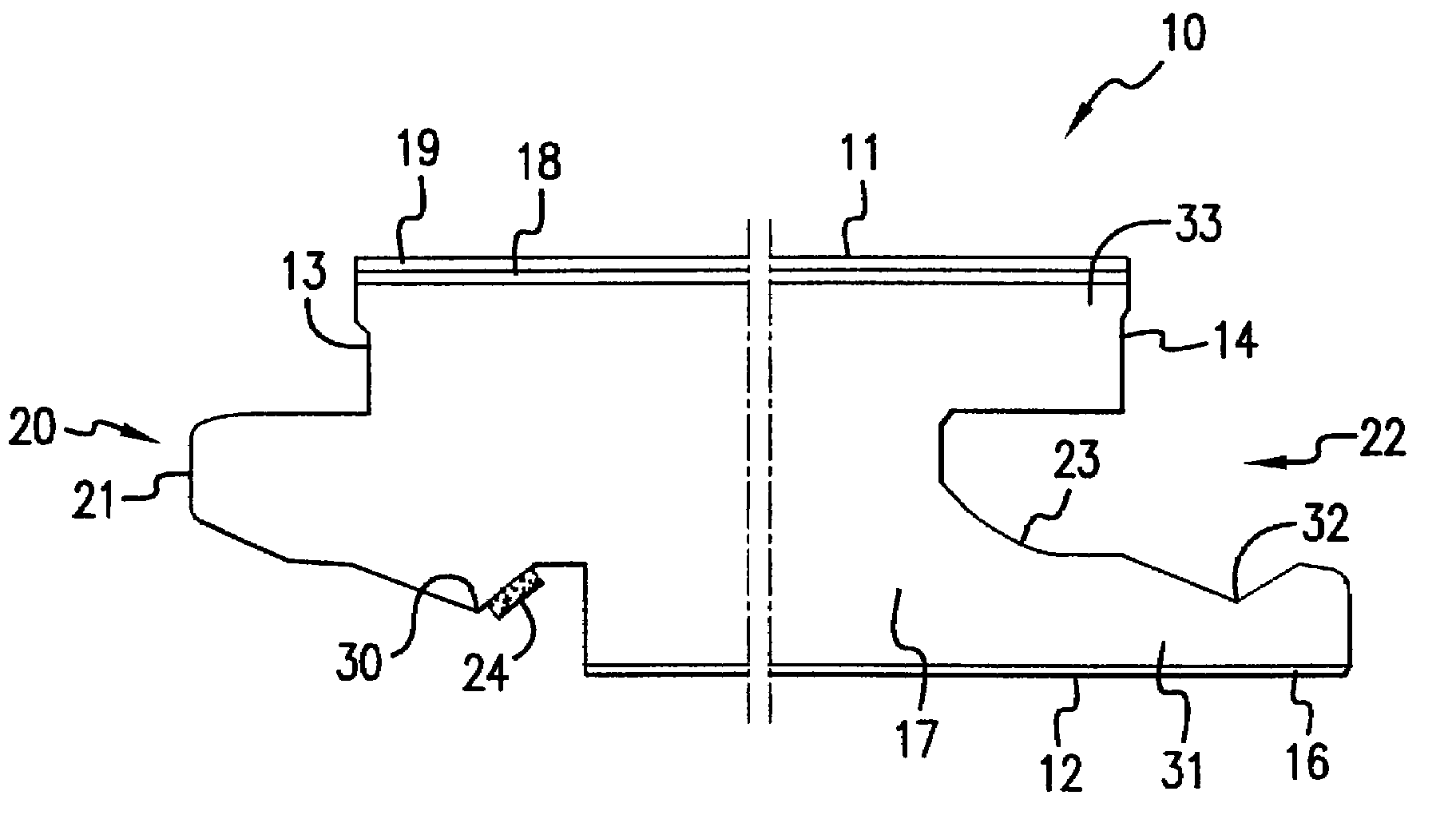

Floor panel

ActiveUS8071193B2Improve noise characteristicsThe process is simple and fastCeilingsWallsLacquerEngineering

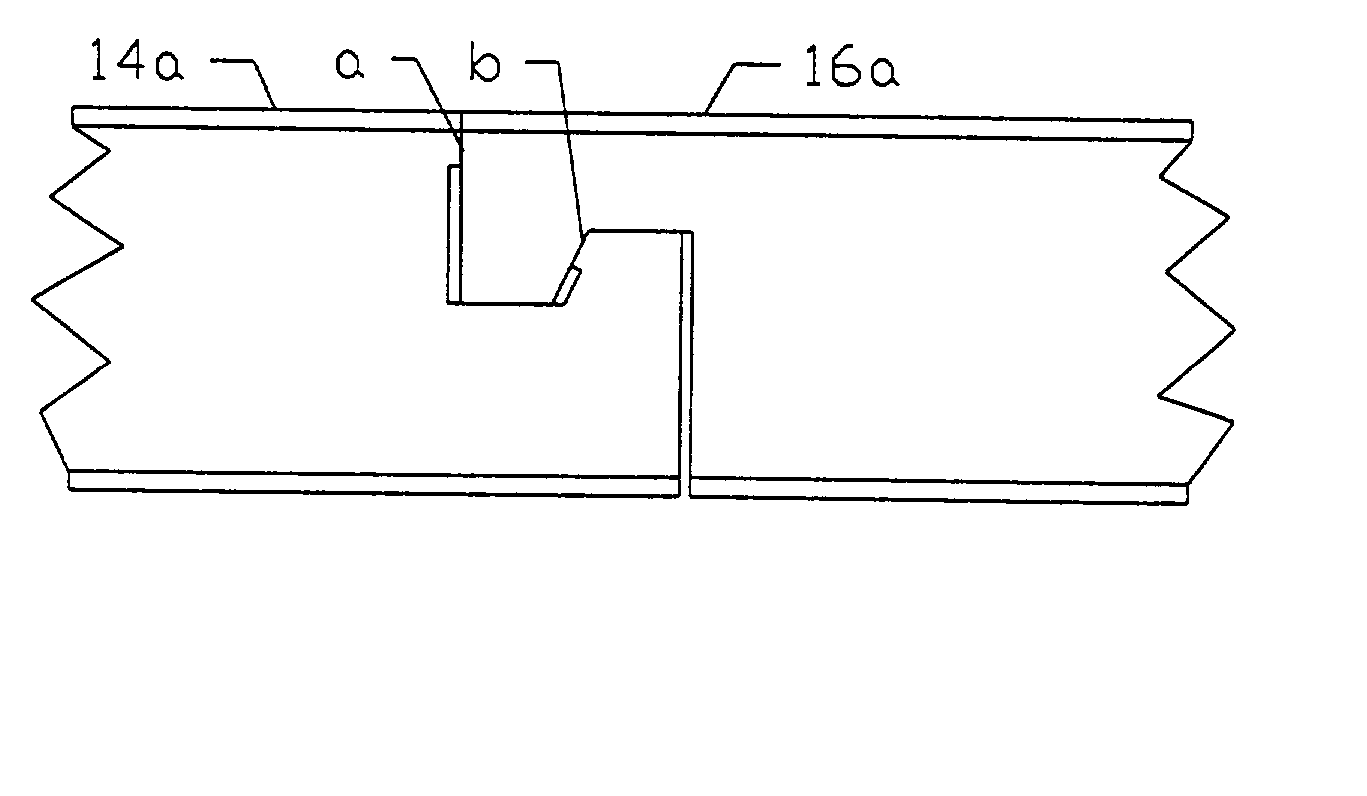

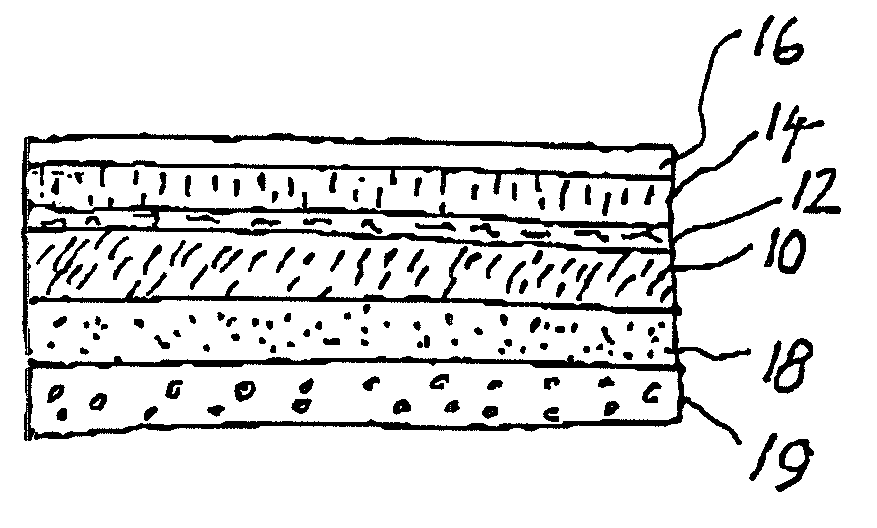

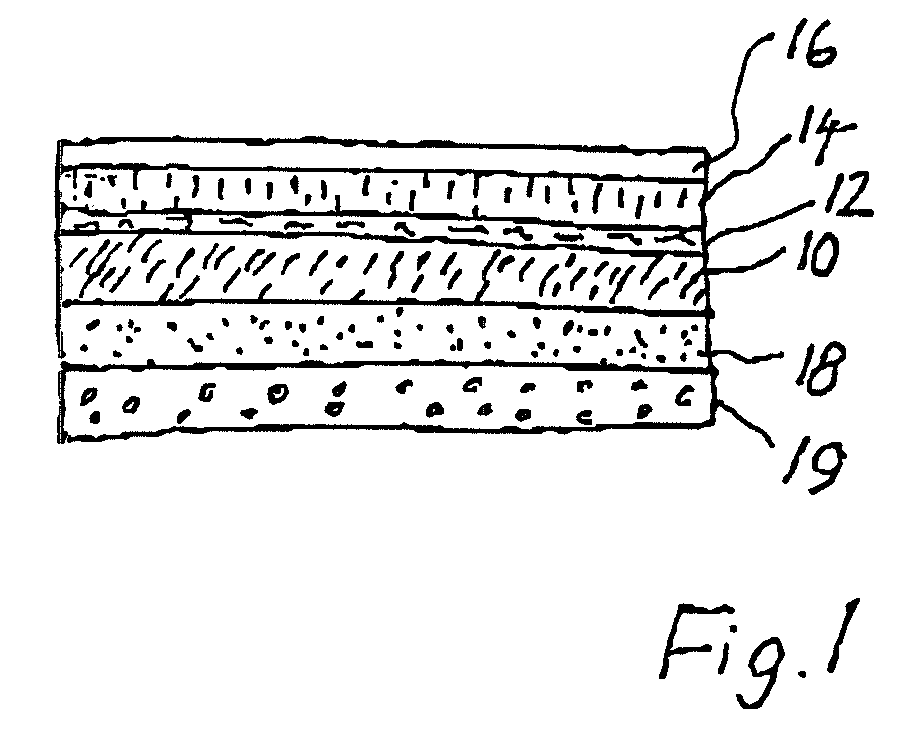

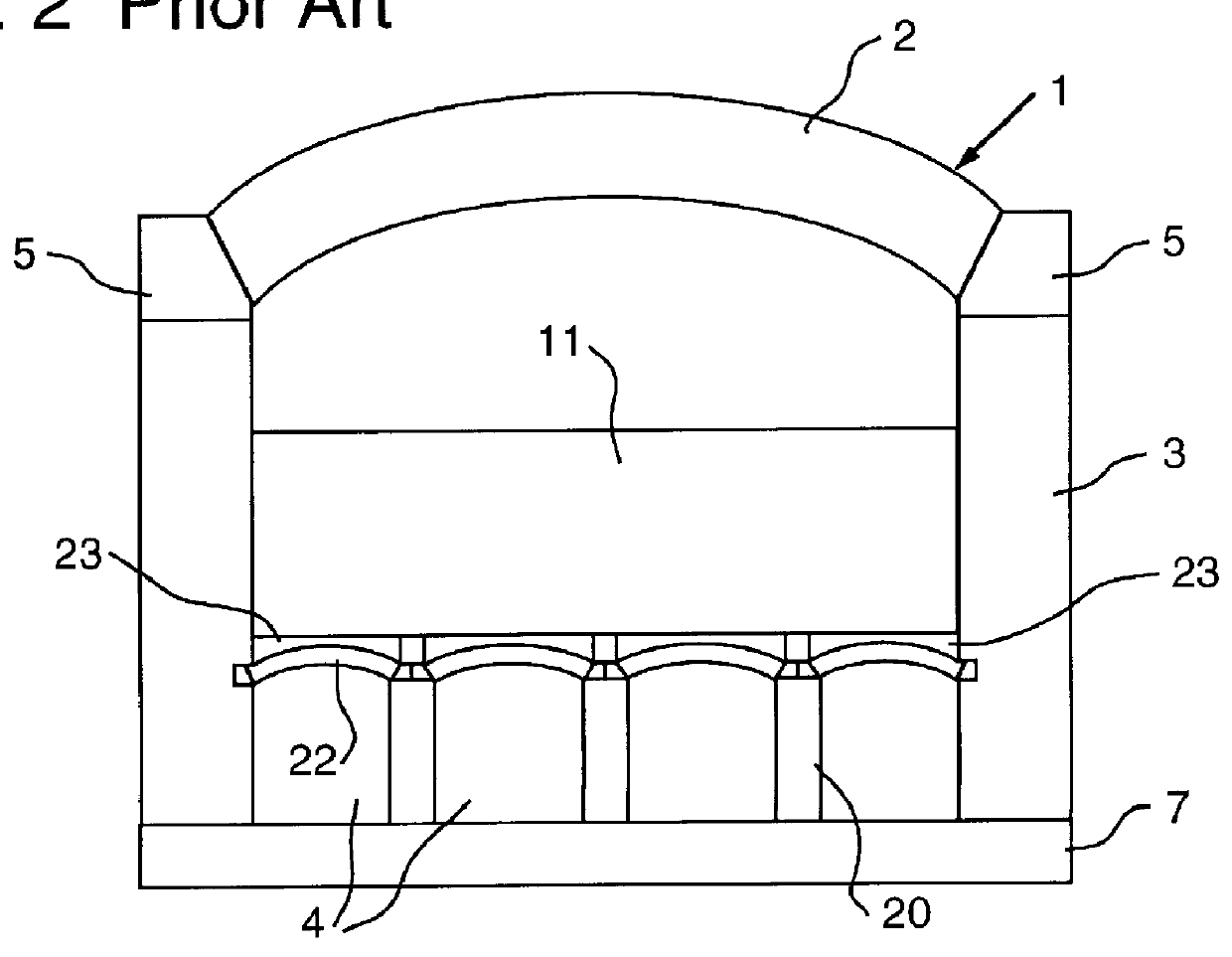

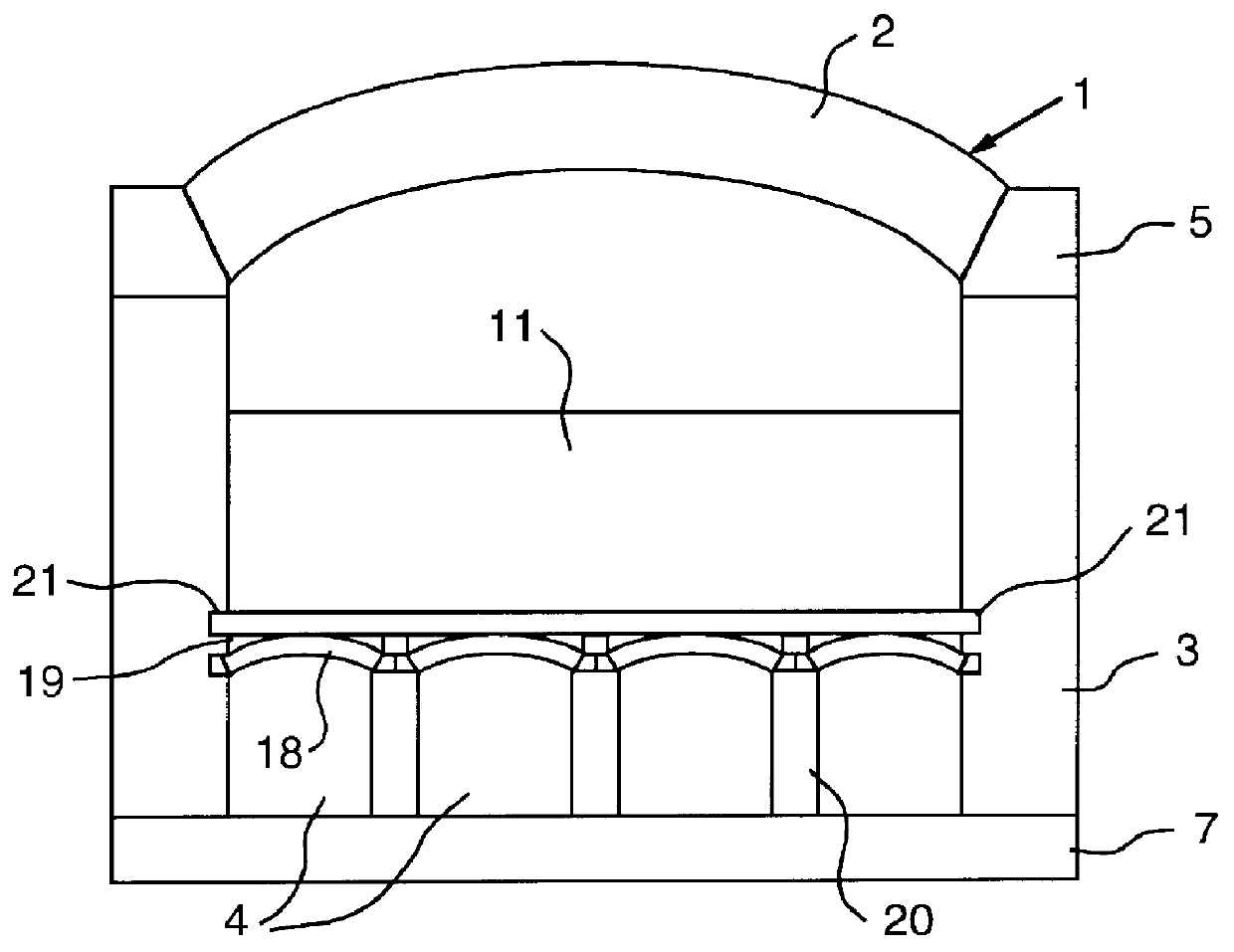

The invention relates to a floor panel in the form of a multilayer, rectangular laminate with a soft core (10) of plastic, a décor film (12) on the upper side of the core (10), a transparent finishing layer (14) and a transparent lacquer layer (16) applied on the finishing layer (16), as well as a back-pull layer (18) on the back of the core (10), with a lockable tongue and groove connection at least at two mutually opposite edges of the panel (20, 22).

Owner:I4F LICENSING NV +2

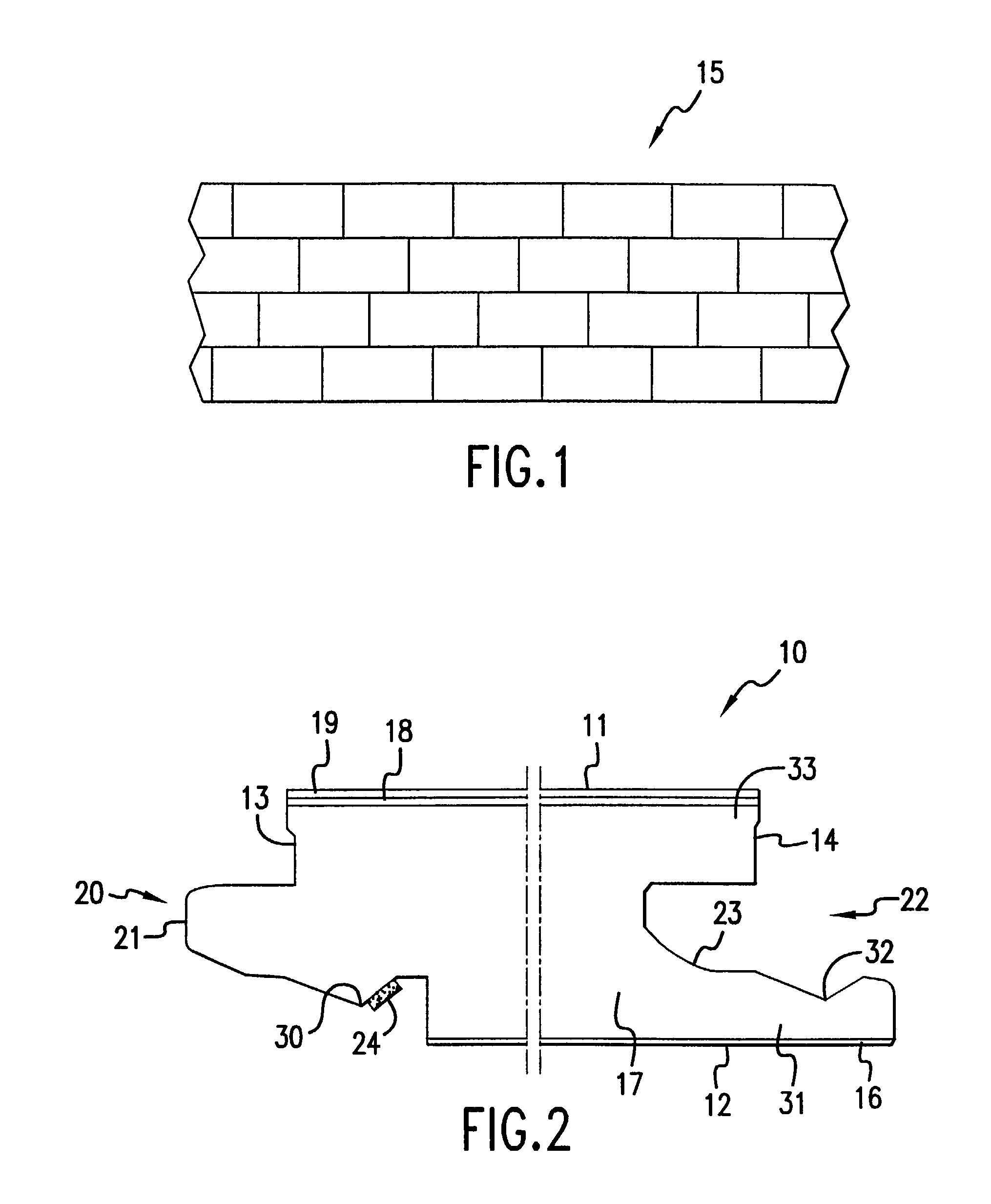

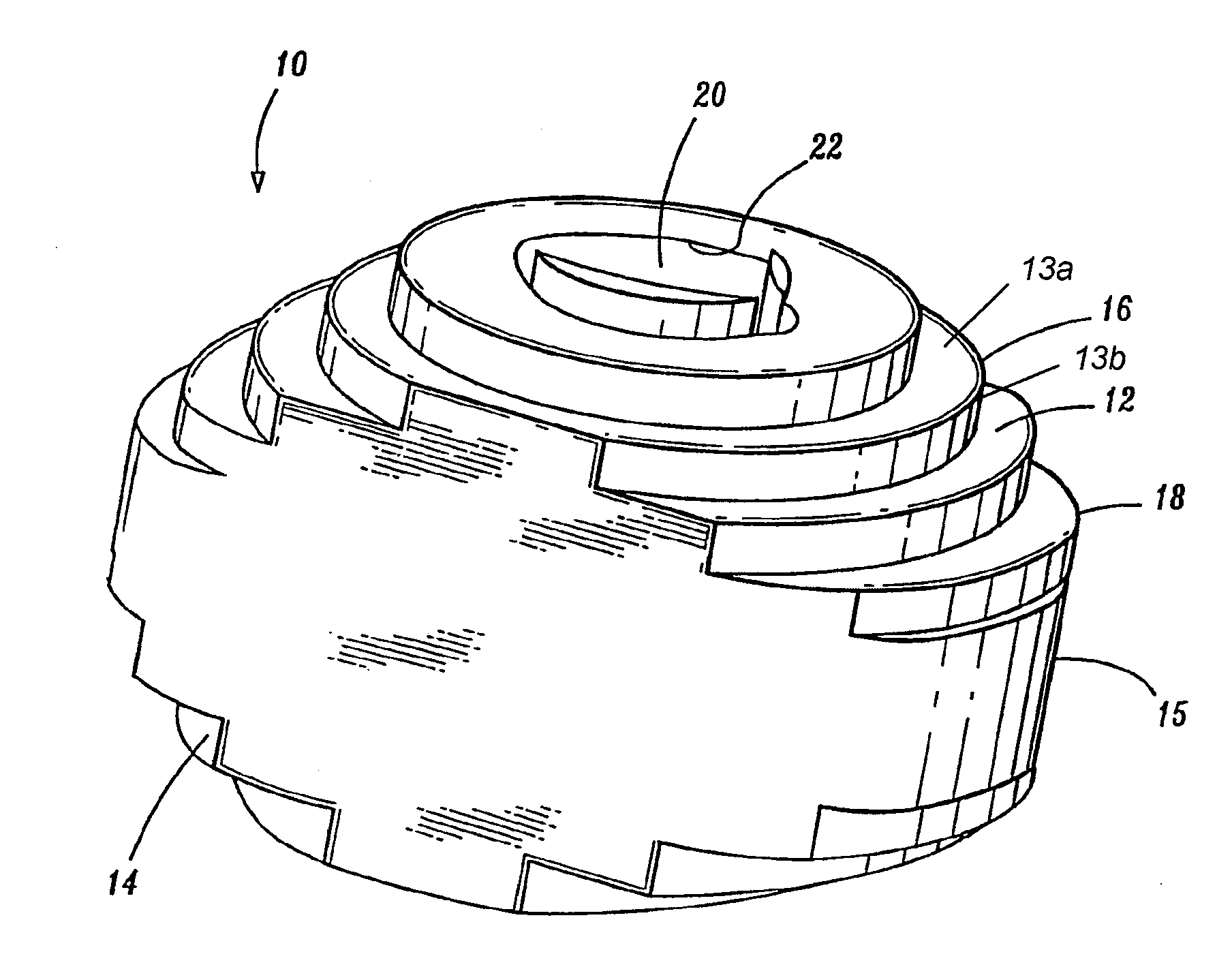

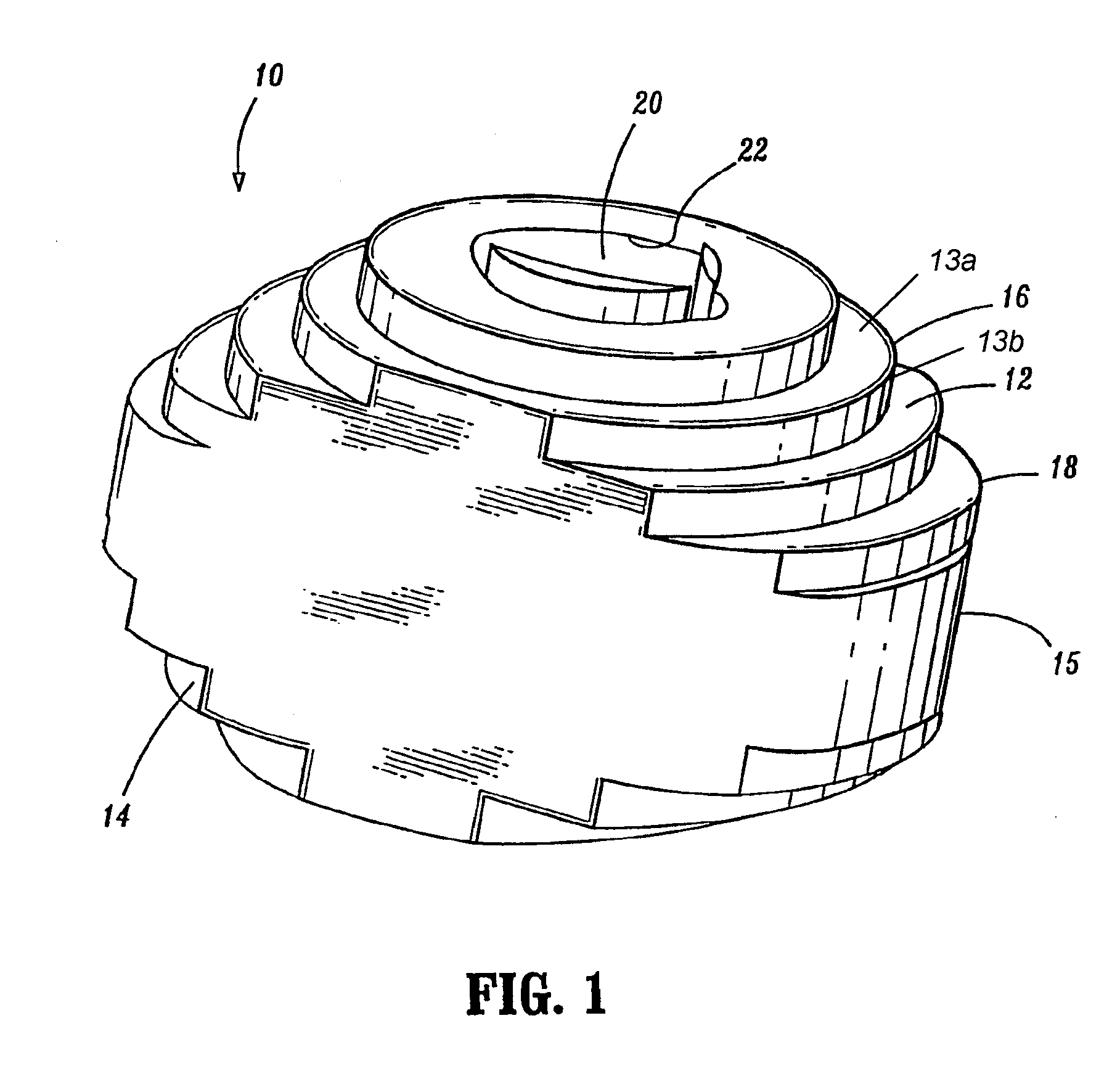

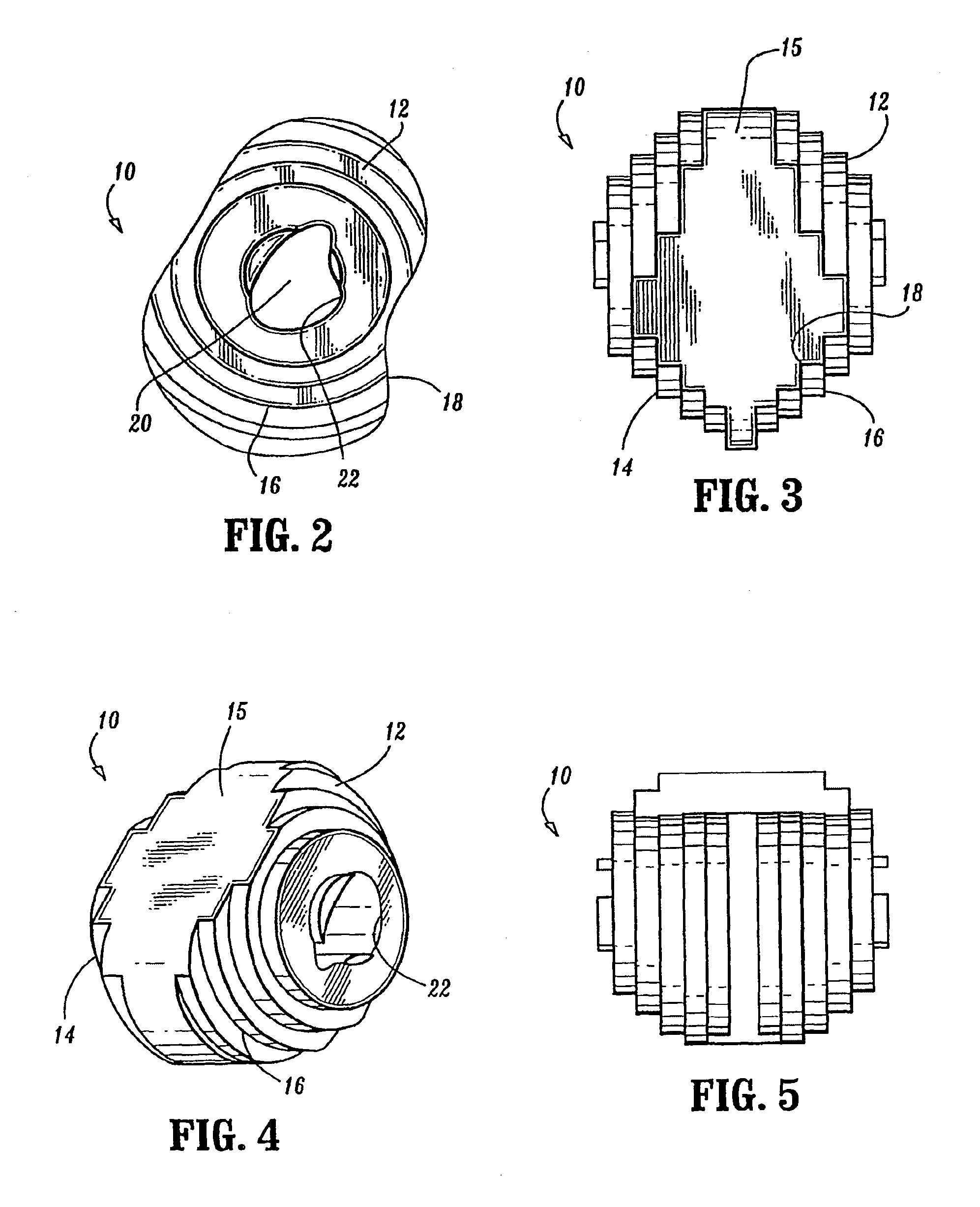

Interlocking floor brick for non-recovery coke oven

An improved non-recovery coke oven floor constructed of a single layer of refractory bricks including, for each oven sole flue, a pair of trunnion bricks and a center bridge brick spanning the width of the flue, having lower brick surfaces in the form of an arch, and joined end-to-end by a tapered tongue-and-groove joint disposed approximately perpendicular to the direction of a compression load transmitted by the center bridge brick to the trunnion bricks.

Owner:PENNSYLVANIA COKE TECH

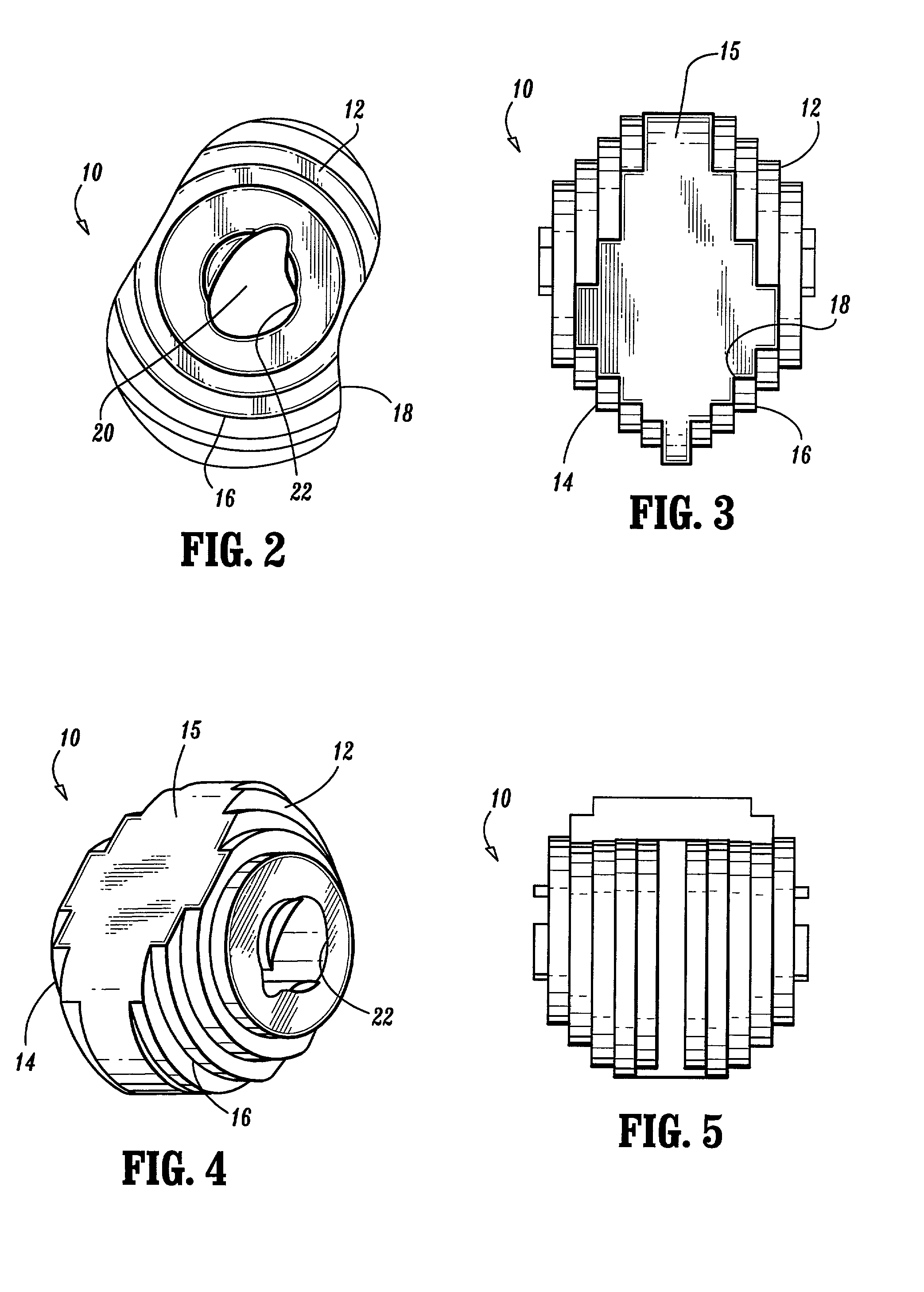

Intervertebral implants

A multipart intervertebral implant is provided which includes an implant portion and an implant extender portion. The implant portion and the implant extender portion can be fastened together using any known fastening means including pins, interlocking structure (e.g., dovetail, tongue and groove, etc.), adhesives, etc. The size of the implant extender portion can be selected during a surgical procedure to provide an implant suitable for a particular intervertebral receiving bed. An intervertebral implant is also provided which may be formed from a multiplicity of implant sections which are fastened together to provide an implant having a desired length. Implants having surface configurations which more closely correspond to the configuration of vertebral endplates are also provided.

Owner:OSTEOTECH

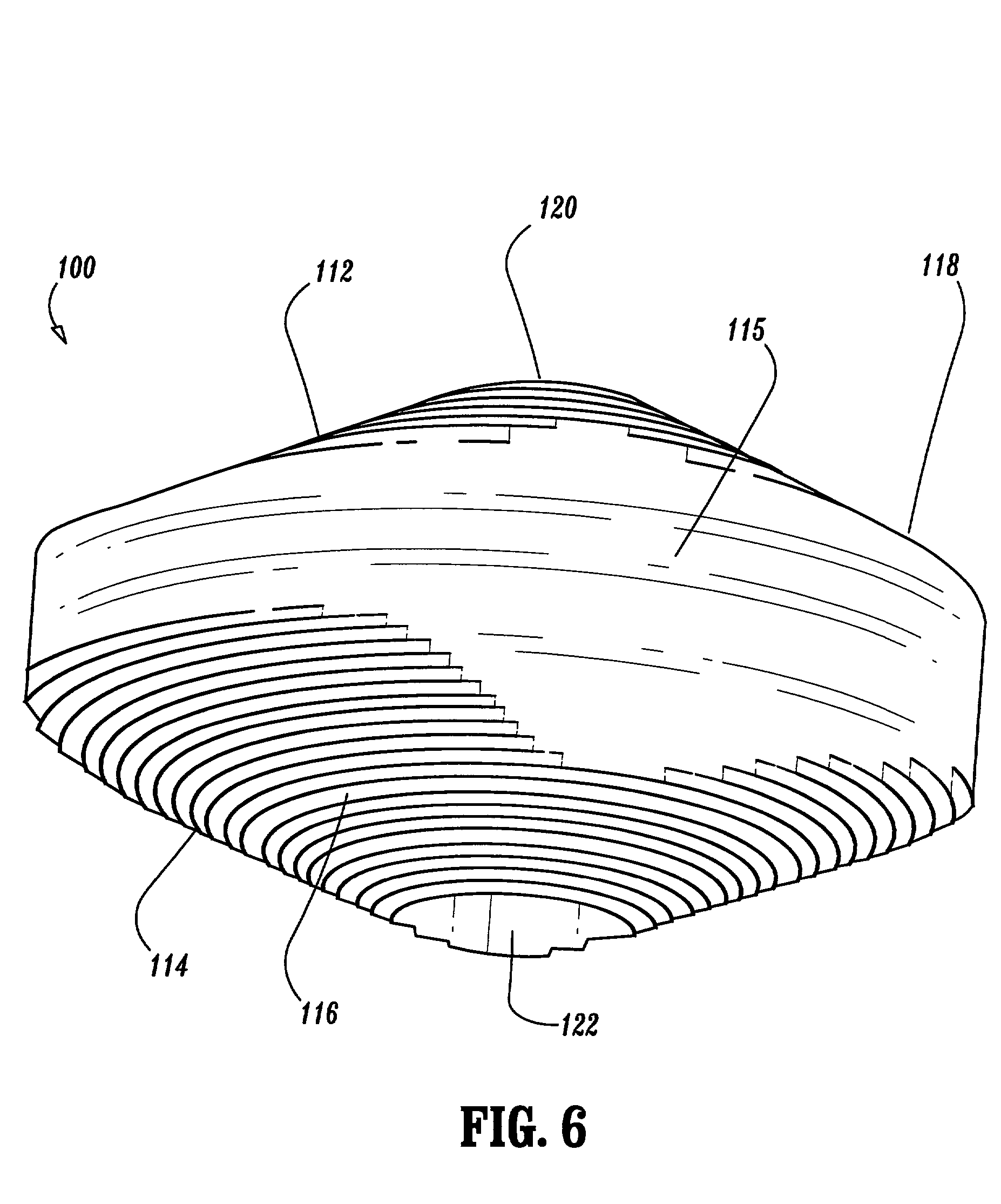

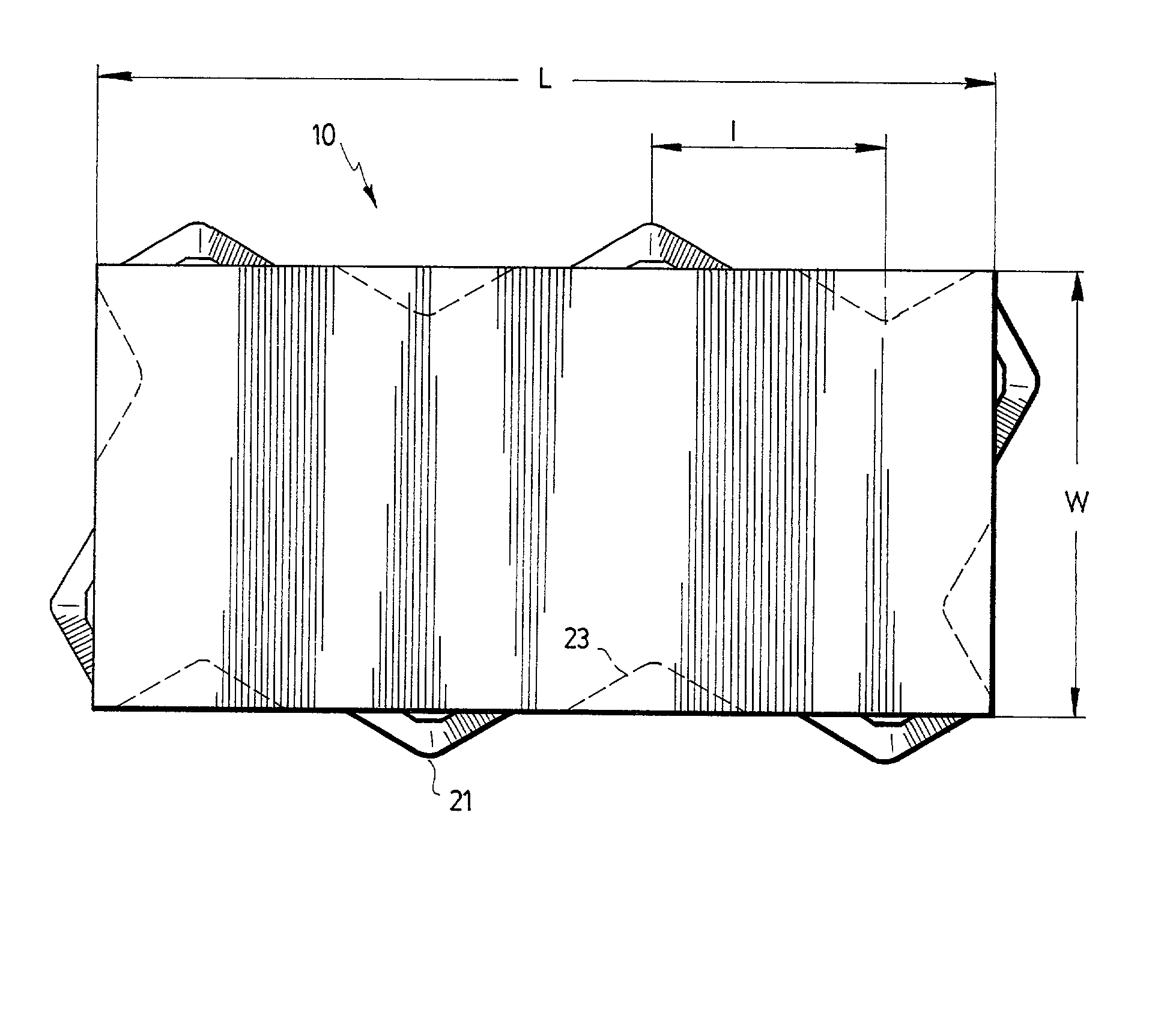

Interlocking paving stone

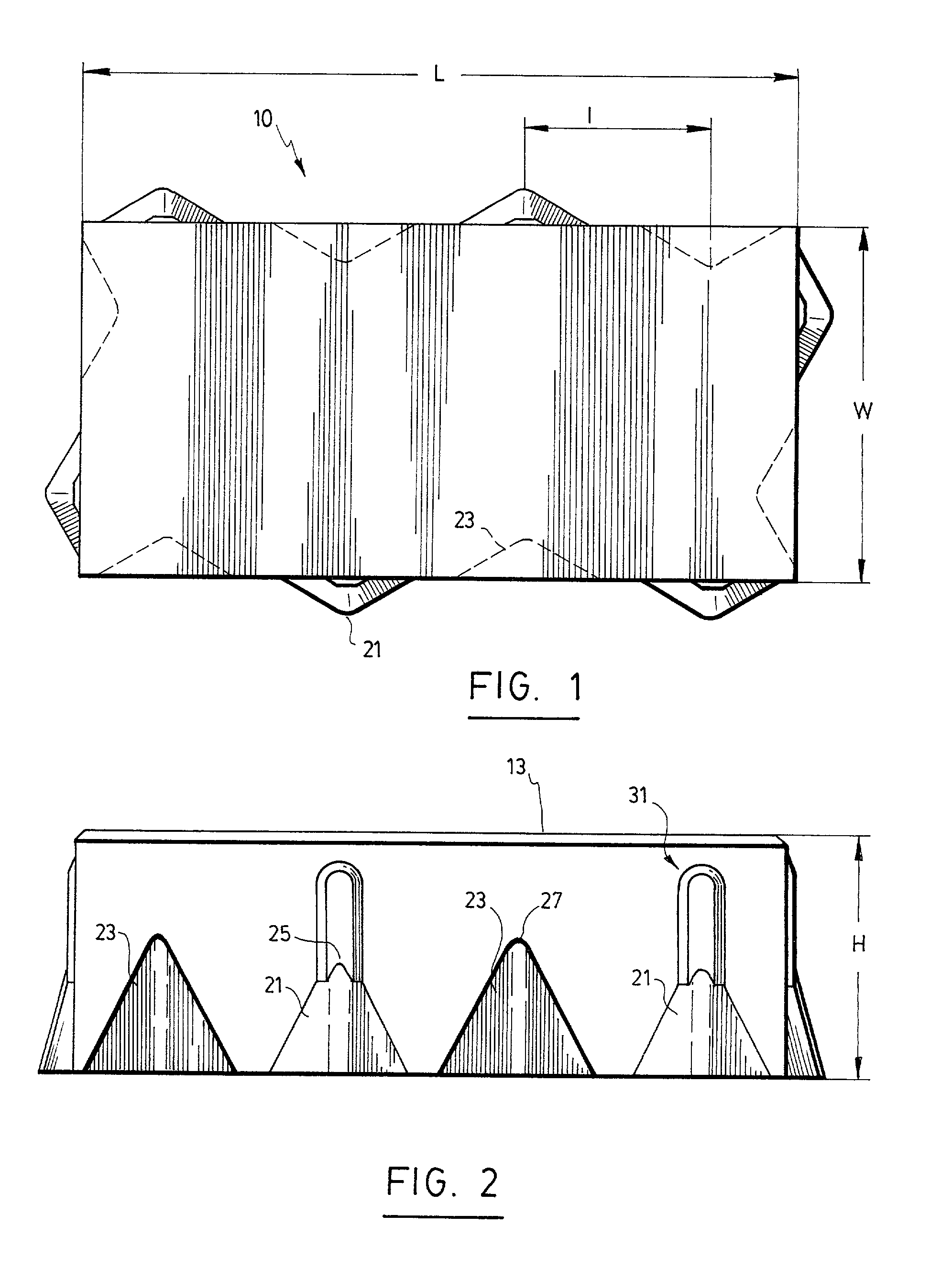

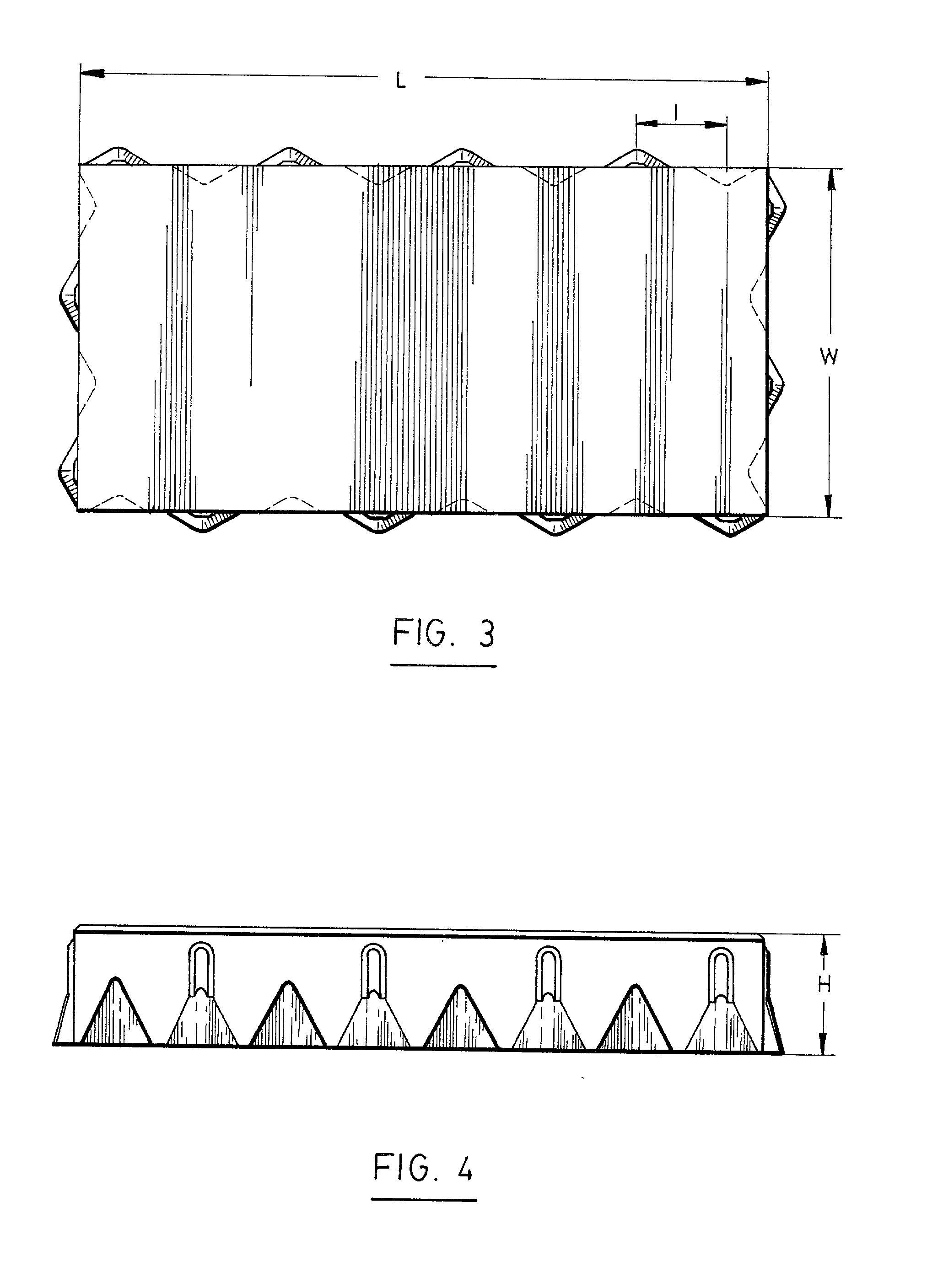

An interlocking paving stone of rectangular or square shape, the stone having a width W, a length L, and a thickness H. Each side of the stone is provided with at least one pair of alternating tongues and grooves on a bottom part thereof, having a size and shape adapted to receive a corresponding tongue or groove of an adjacent block. The groove has an overall volume greater than the volume of the tongue to facilitate the pouring of joint filling materials. The length of a pair of tongue and groove is equal to a length l, where both W and L are whole multiples of l. Furthermore, the tongues and grooves have a generally truncated pyramidal shape, where the peak of the truncated pyramid lies below the top surface of the block by 40 to 50% of the total height of the stones. The stone according to the present invention provides greater lateral and vertical stability to an assembled pavement.

Owner:BETON BOLDUC 1982

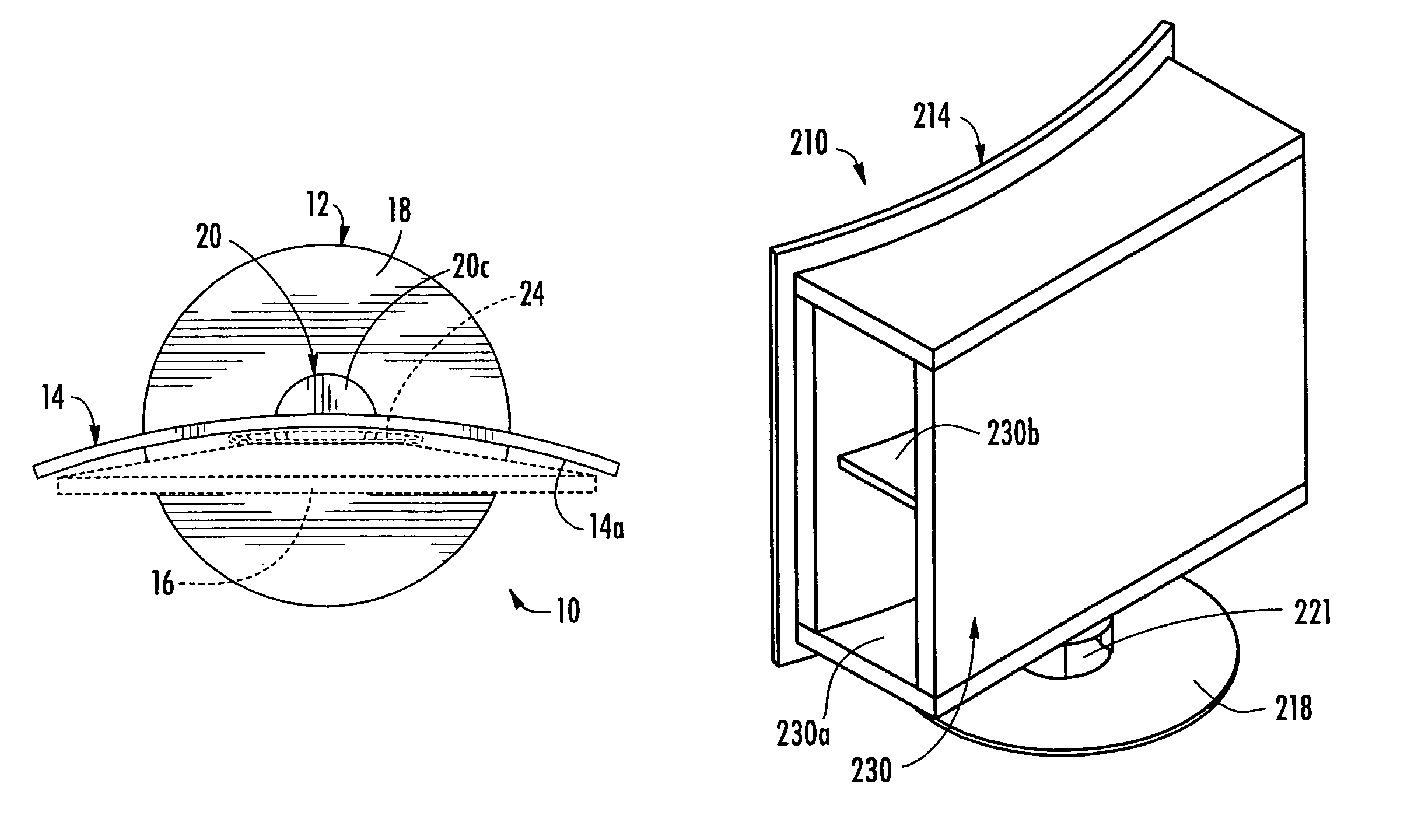

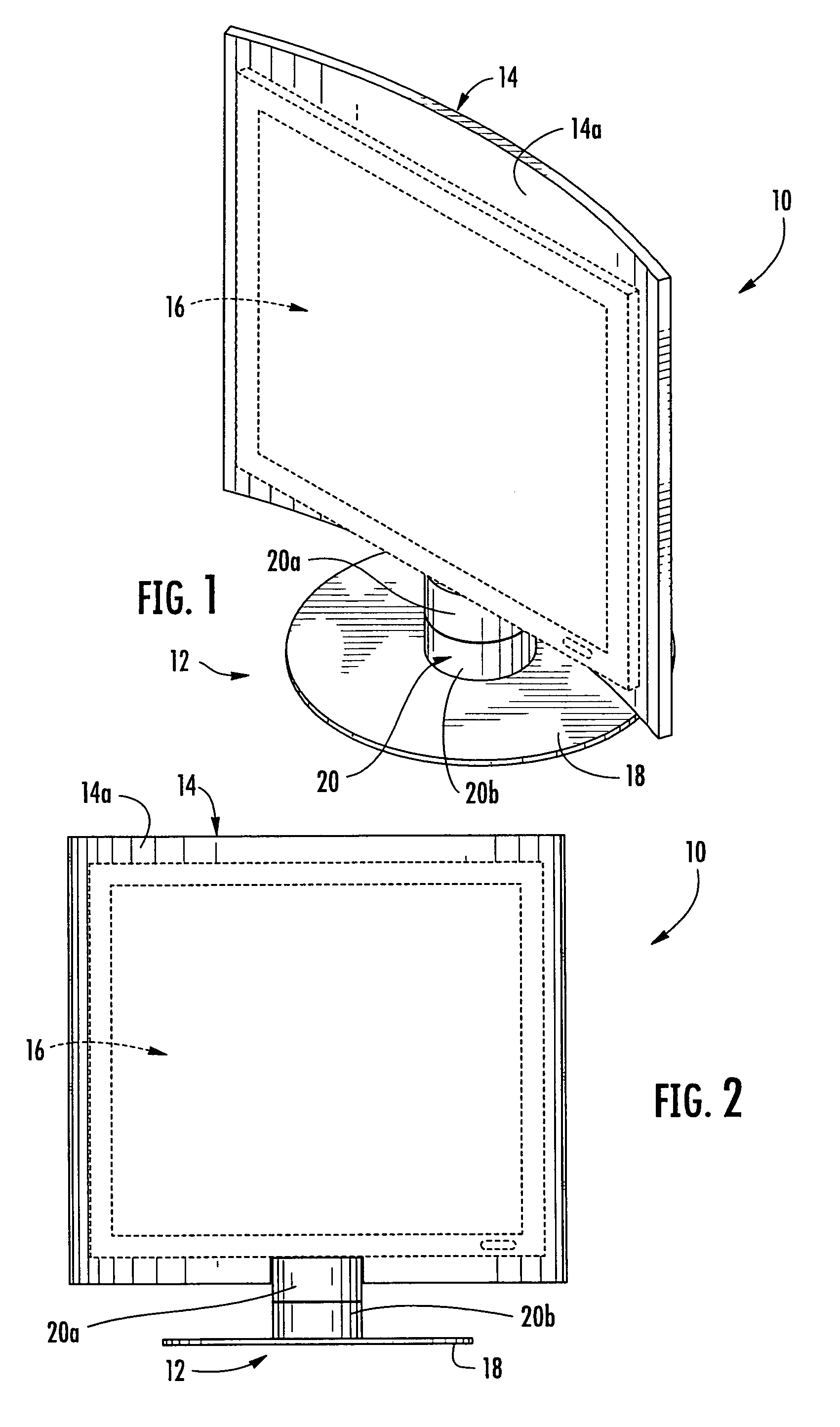

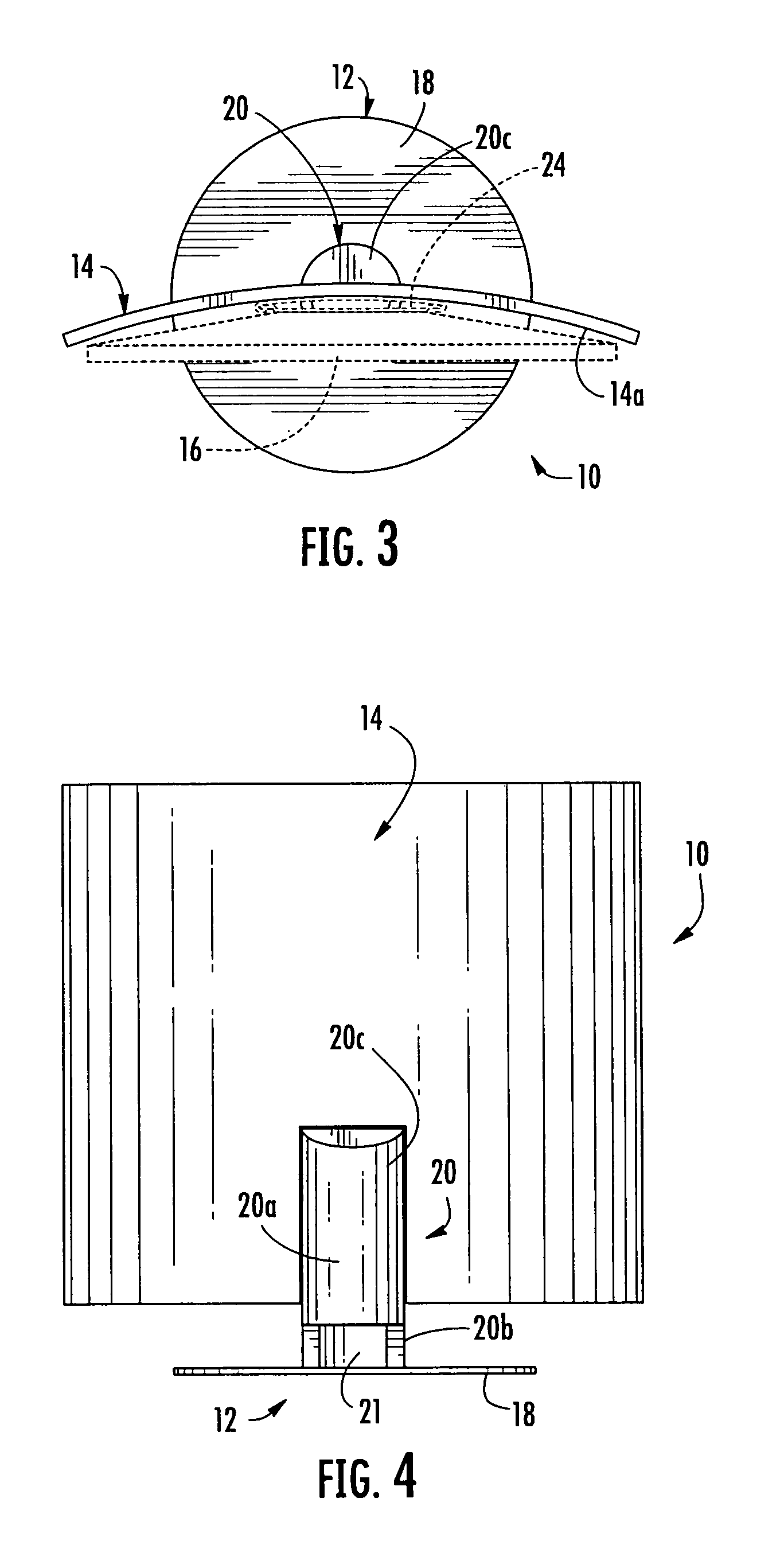

Monitor stand

InactiveUS7551432B1Good lookingDigital data processing detailsStands/trestlesComputer monitorEngineering

A monitor stand for supporting a computer monitor includes a base having a base portion and a support arm extending upward from the base portion, and a support panel attached to the support arm. The support panel may comprise a curved panel having a curved front surface, and the support panel may support a computer monitor at the curved front surface. The monitor stand may include a bracket assembly for attaching the computer monitor to the support panel, such as via a tongue and groove configuration. The monitor stand may include including at least one storage shelf extending from a rear surface of the support panel, and may have housing that substantially encases the storage shelf. The support panel may include an aperture for routing wires or cables of the computer monitor, and the support arm may include a passageway for routing wires or cables of the computer monitor.

Owner:NUCRAFT FURNITURE

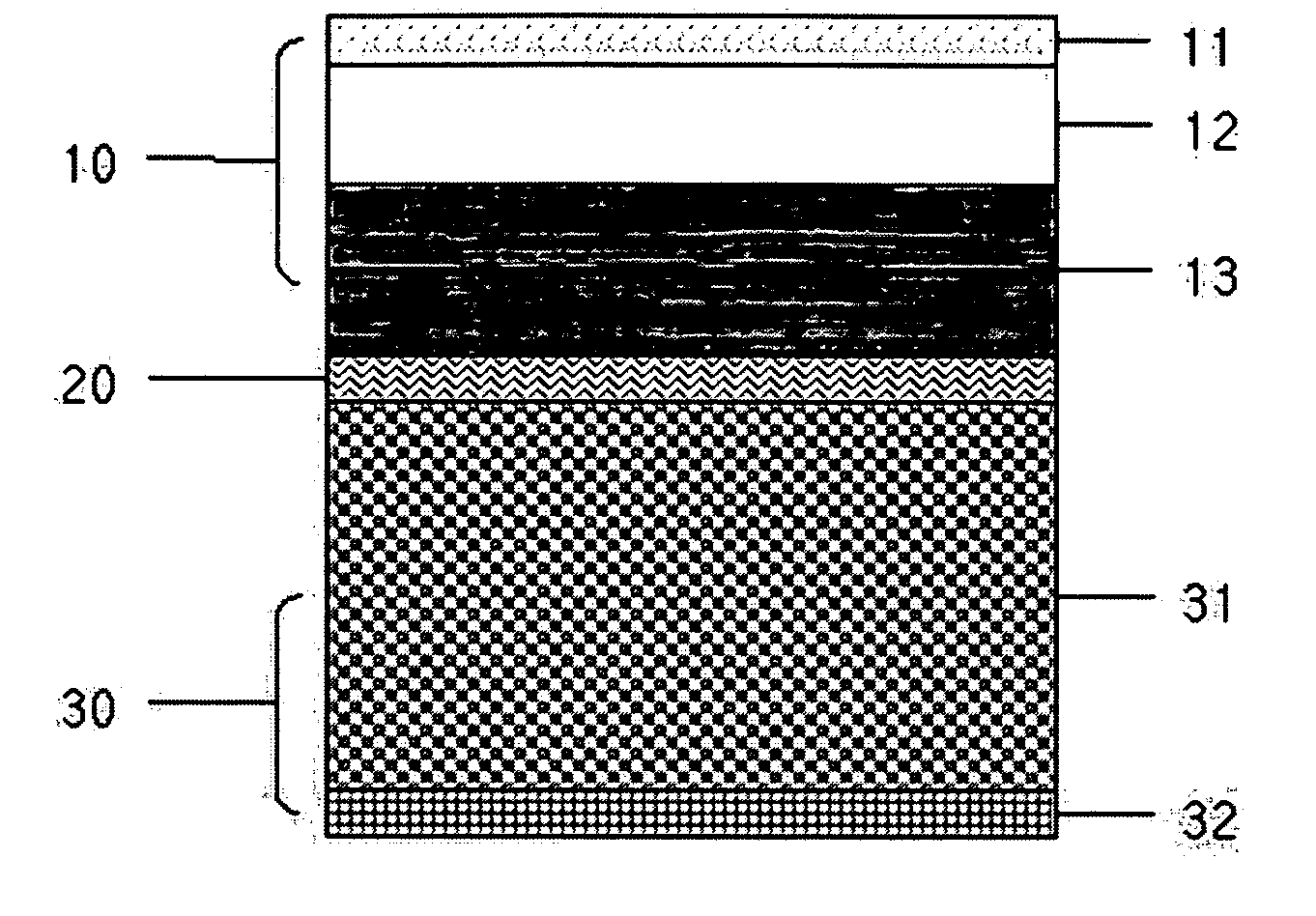

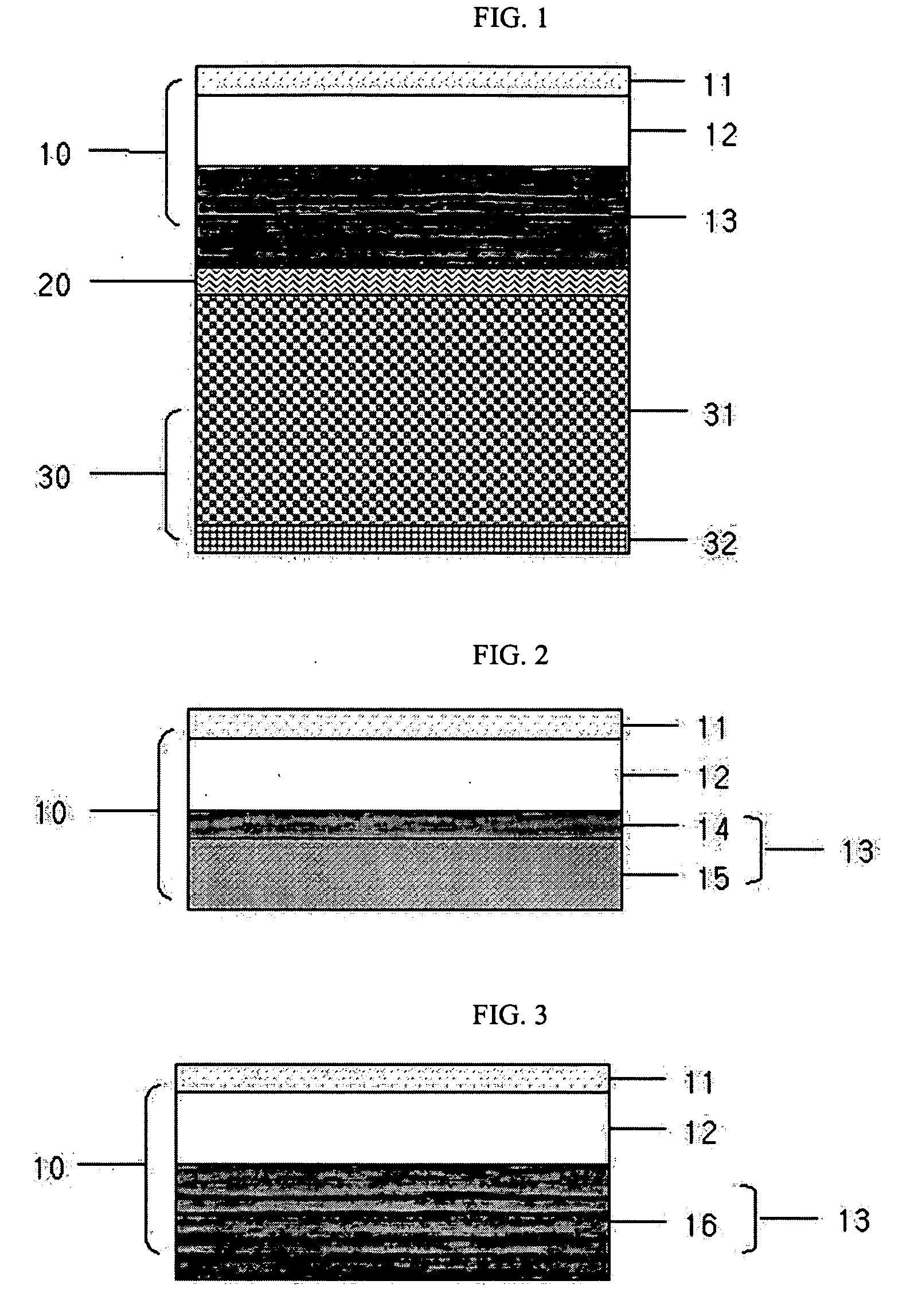

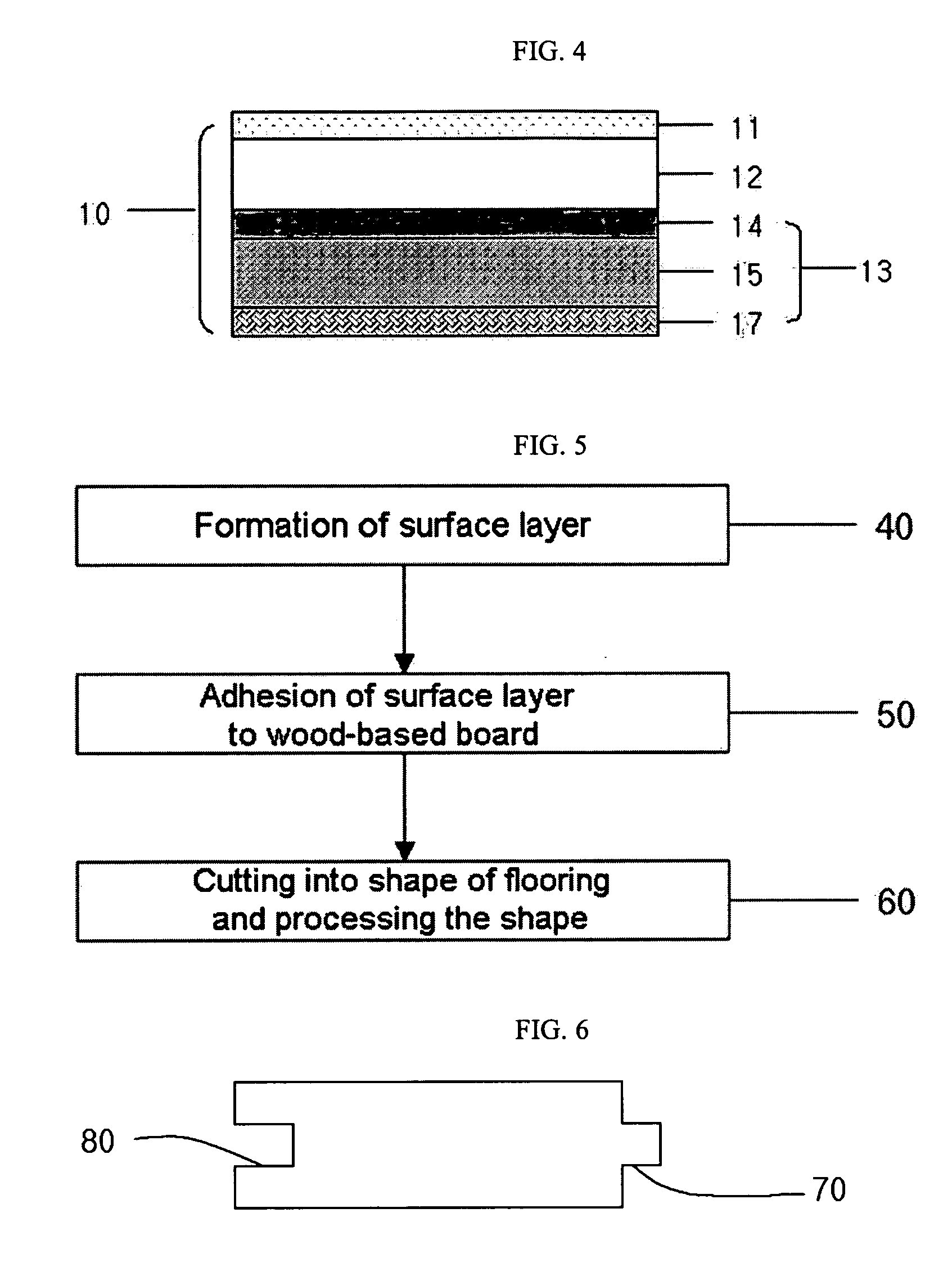

Flooring having surface layer of synthetic resin and wood-based board

InactiveUS20050281986A1Improve surface physical propertiesProtect the surfaceCovering/liningsSynthetic resin layered productsDigital printingTongue and groove

Disclosed herein is a flooring comprising a surface layer made of a synthetic resin, and a wood-based board as a base. Preferably, the surface layer includes a printed layer formed by general gravure, transfer, heat-sublimation, silk screen or digital printing using a printer, a protective made of a synthetic resin, and a UV-curable or heat-curable surface treatment layer. The wood-based board is selected from plywood, medium-density fiberboard (MDF), high-density fiberboard (HDF), particle board, and resin-wood flour composite board. The flooring may further comprise a bottom layer laminated under the wood-based board for protecting the flooring against moisture from the bottom. The flooring is cut into pieces having an appropriate size, and the pieces are processed into a finished product in a tongue and groove (T & G) shape.

Owner:LG CHEM LTD

Product management display system

An integrated “T” assembly combines into a single integrated assembly, a track portion along both sides of a divider. The T assembly may have a wide-base portion, which may include a spring-urged-pusher track, on one side of the divider and a narrow-base portion on the opposite side of the divider. An offset pusher may have an upper portion that is offset, via an angled offset portion, from a lower portion of the pusher. Additional supporting bases, any of which may include spring-urged-pusher tracks and / or a spring-urged pusher, may be used under a wide product. Left and right side finisher components may be paired with T assemblies near the sides of a merchandise-display shelf. The T assembly, base, and / or end finishers may be coupled to a front rail via a complimentary tongue and groove arrangement and / or a non-slidable engagement, such as mating teeth.

Owner:RTC IND

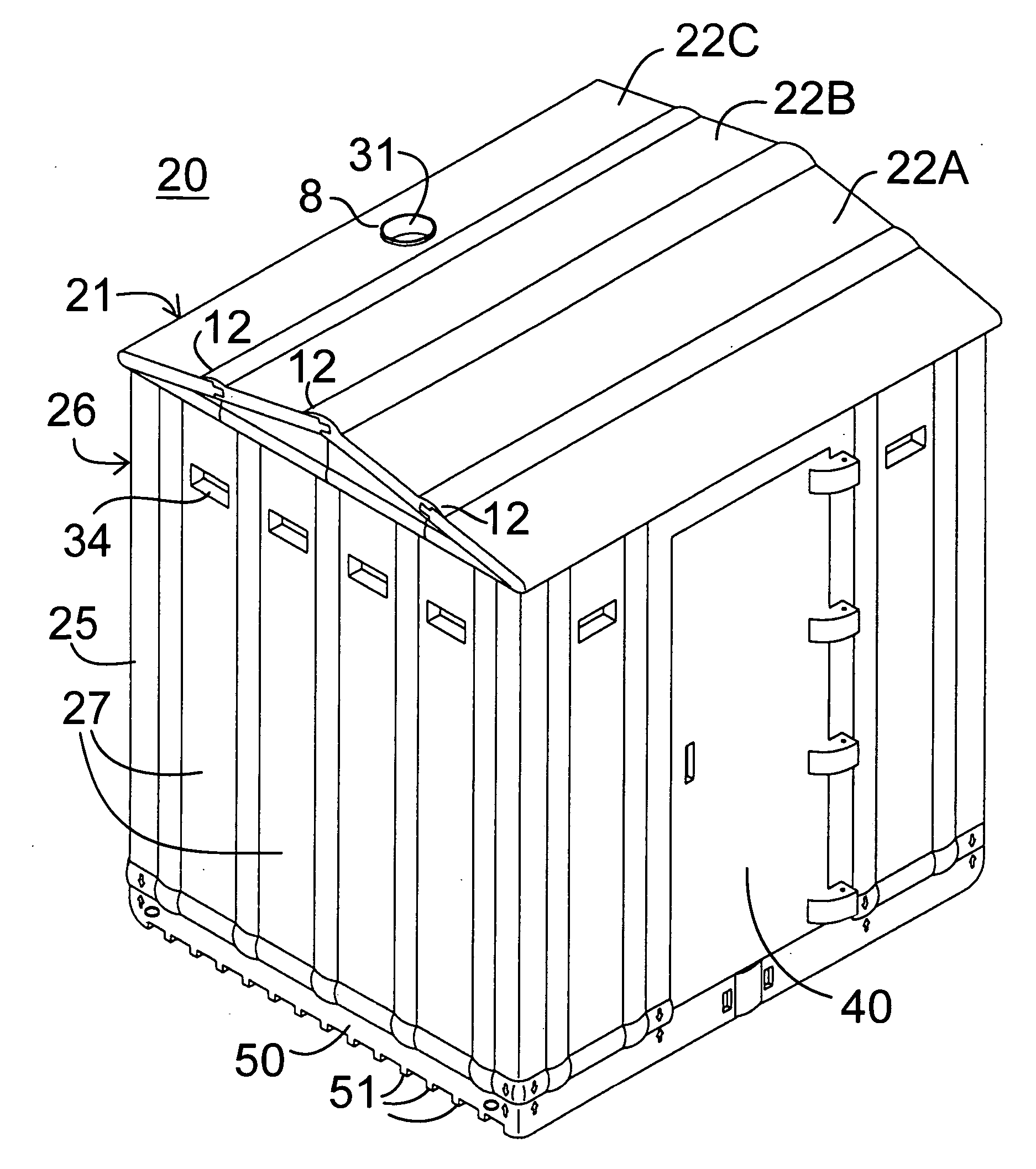

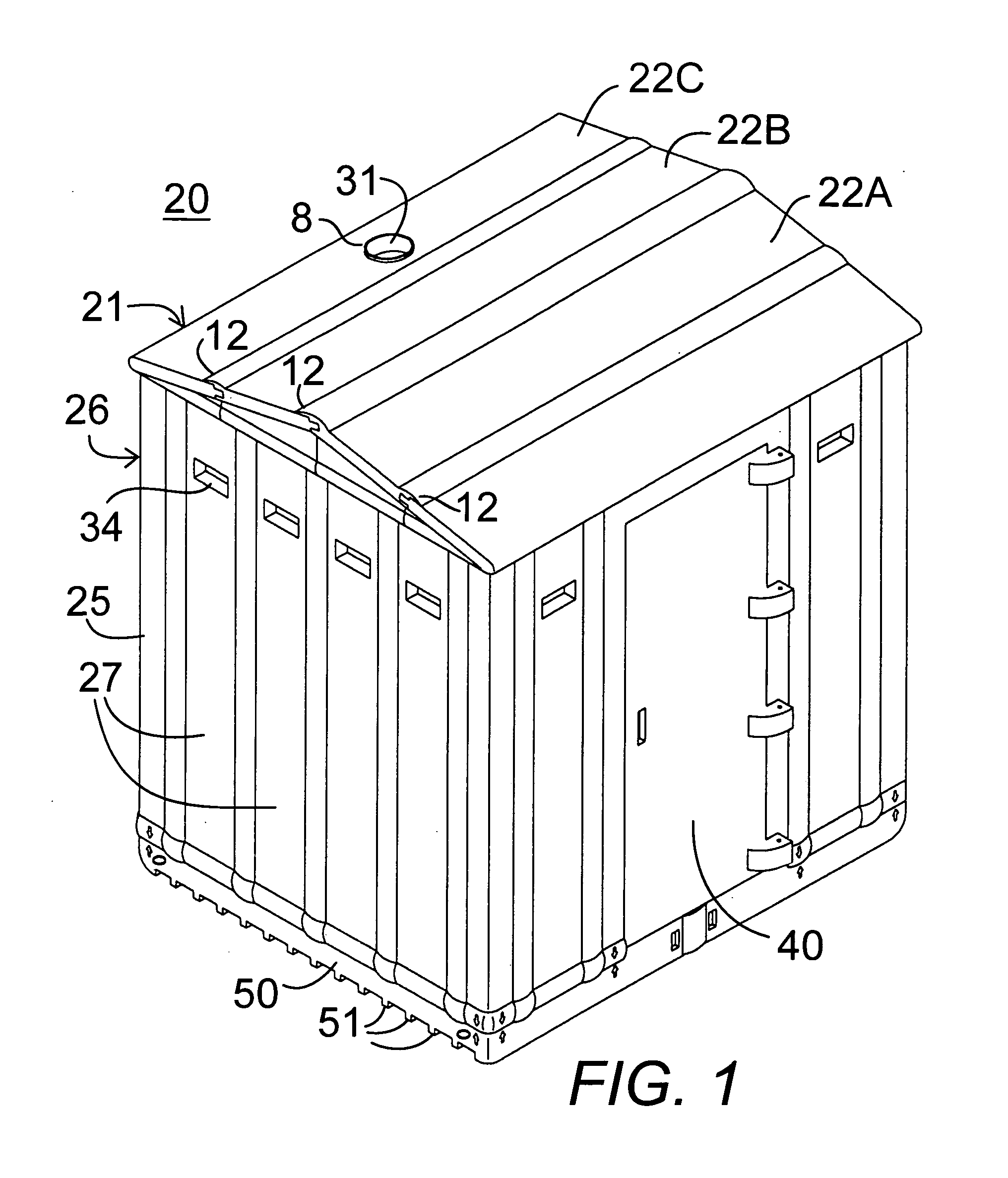

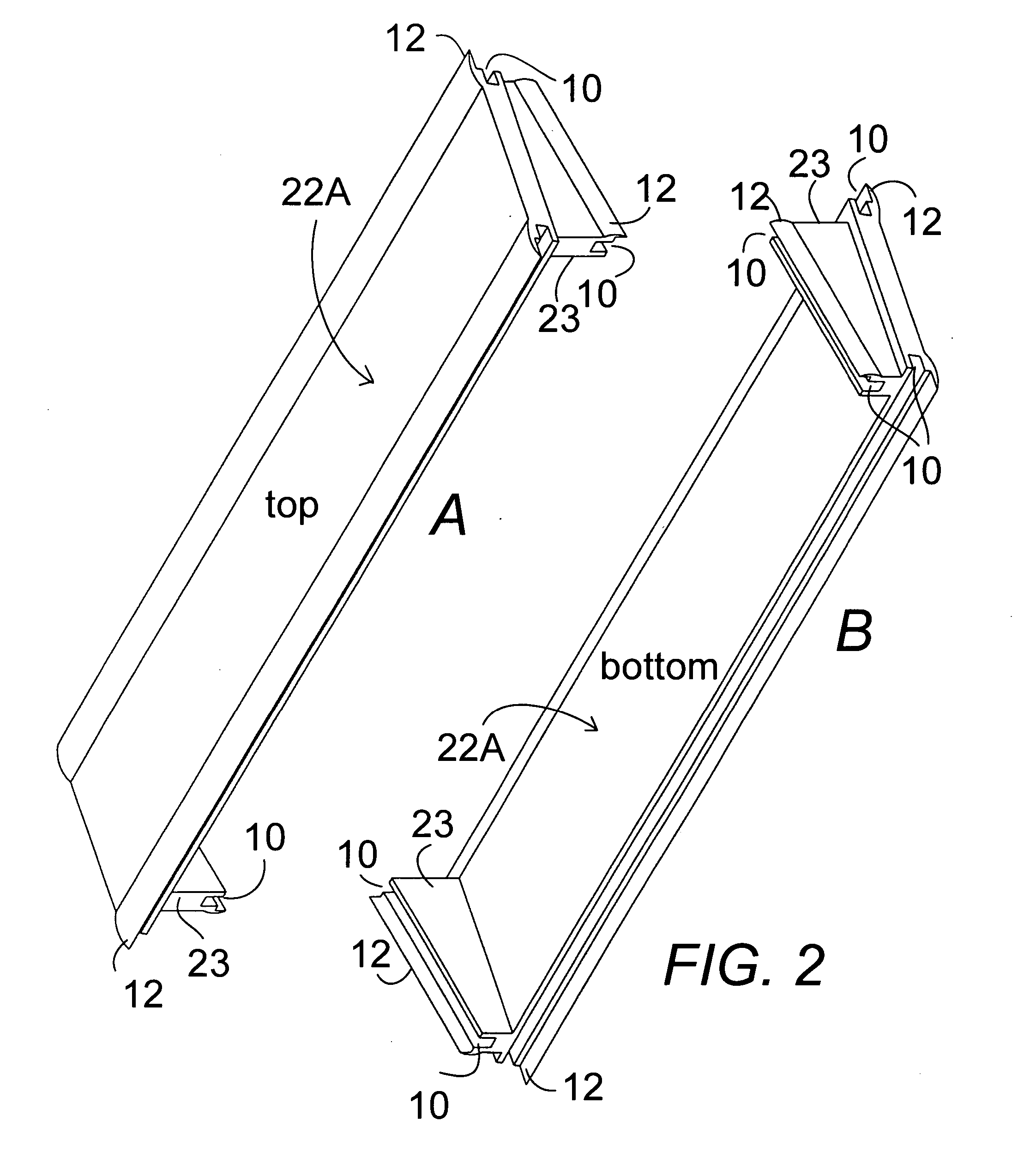

Modular insulated panel collapsible sport/utility shanty

InactiveUS20060048459A1High strengthExcellent aesthetic appealPublic buildingsSpecial buildingTongue and grooveBuilding construction

An enclosure constructed of vinyl foam filled blow-molded panels. These panels are structured with tongue and groove connections built in to provide quick interlock one to another without the need for tools in assembly or disassembly. The construction characteristics provide panels that are rigid, strong, insulated, sound deadened with high flotation qualities. The enclosure is transportable by towing the assembled structure on a built-in sled bottom or dissembling the panels, stacking them and transporting them in a vehicle.

Owner:MOORE THOMAS D

Pre-glued tongue and groove flooring

The invention provides a new floor covering panel and floor covering system in which the floor covering panels include first and second generally planar surfaces, first and second side edges containing first and second complementary coupling members, respectively, and an adhesive composition selectively applied to at least a portion of at least one of the first and second coupling members. The adhesive composition providing the adhesive bond may be applied to at least one of the first or second coupling members during the floor covering manufacturing process. After a floor covering system is assembled, the adhesive composition provides a substantially non-refastenable bond between mated floor covering panels.

Owner:COLUMBIA INSURANCE CO

Housing for portable handheld electronic device

InactiveUS6913201B1Minimal numberCasings/cabinets/drawers detailsFurniture partsThermoplastic elastomerTongue and groove

An injection-molded housing for a handheld portable electronic device employs a minimal number of parts. The housing, made of a thermoplastic elastomer, is watertight, buoyant and exceptionally rugged. Principal components of the housing snap together without the need for adhesive bonding or fasteners using a tongue-and-groove closure mechanism.

Owner:ALLFLEX USA

Intervertebral implants

A multipart intervertebral implant is provided which includes an implant portion and an implant extender portion. The implant portion and the implant extender portion can be fastened together using any known fastening means including pins, interlocking structure (e.g., dovetail, tongue and groove, etc.), adhesives, etc. The size of the implant extender portion can be selected during a surgical procedure to provide an implant suitable for a particular intervertebral receiving bed. An intervertebral implant is also provided which may be formed from a multiplicity of implant sections which are fastened together to provide an implant having a desired length. Implants having surface configurations which more closely correspond to the configuration of vertebral endplates are also provided.

Owner:WARSAW ORTHOPEDIC INC

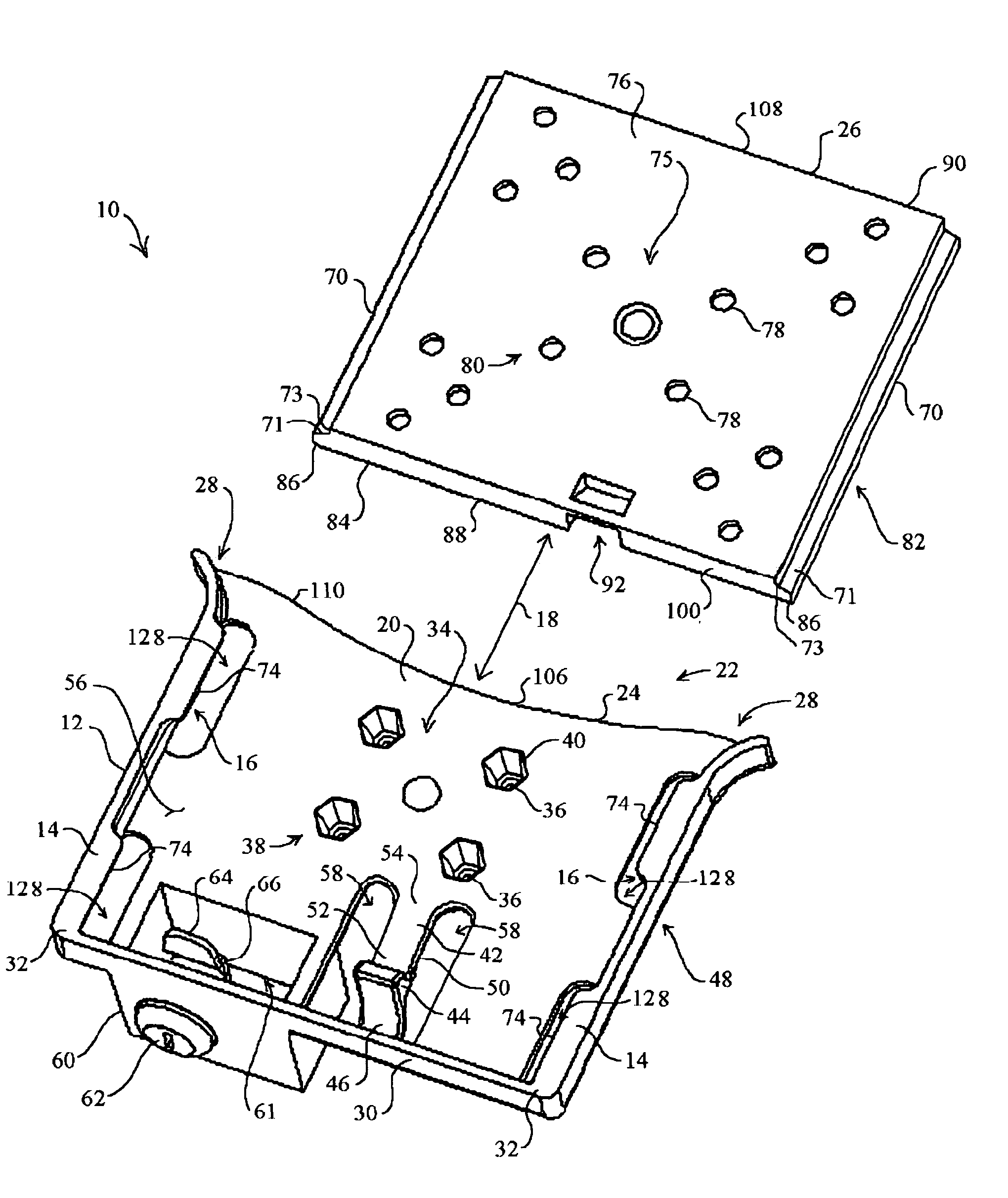

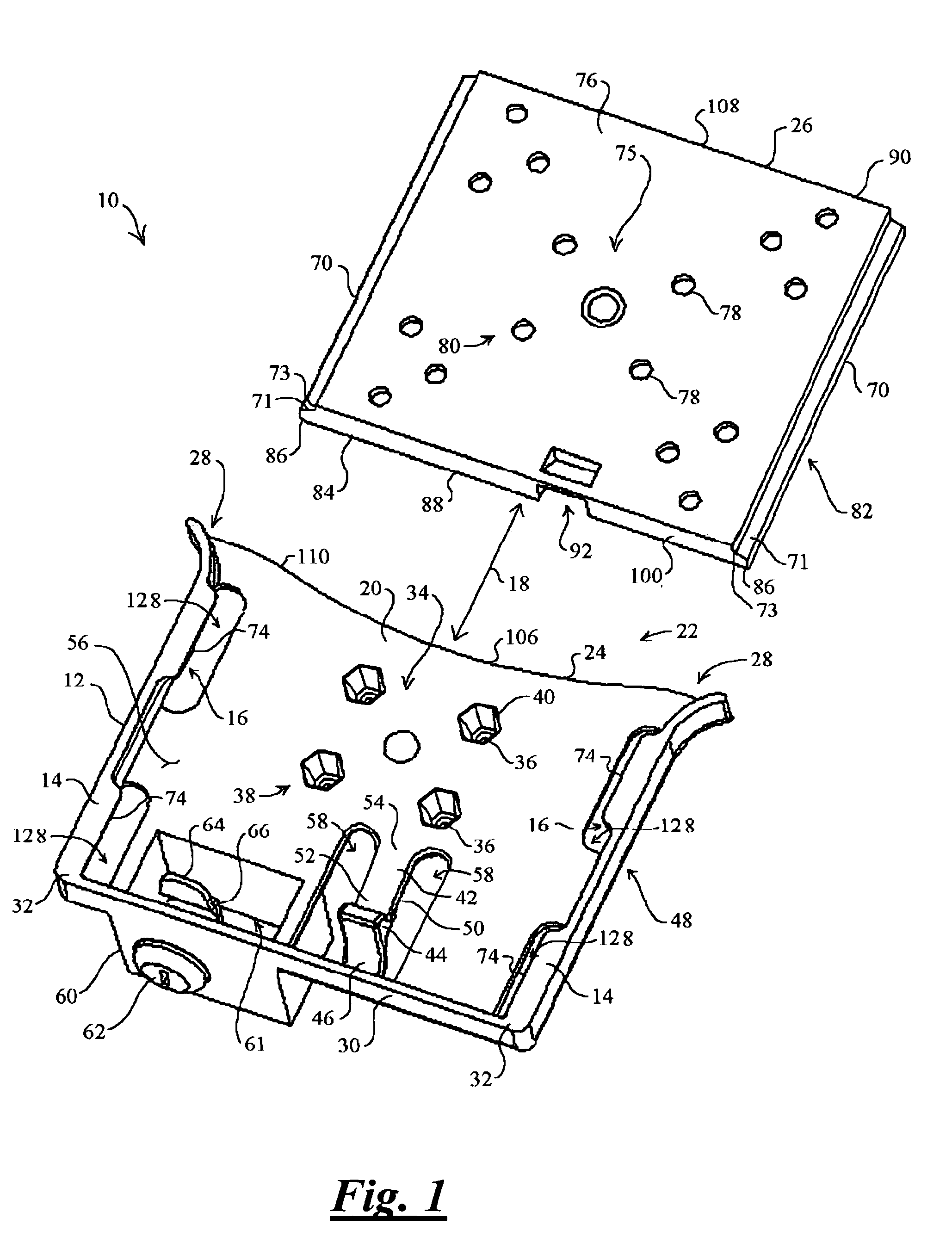

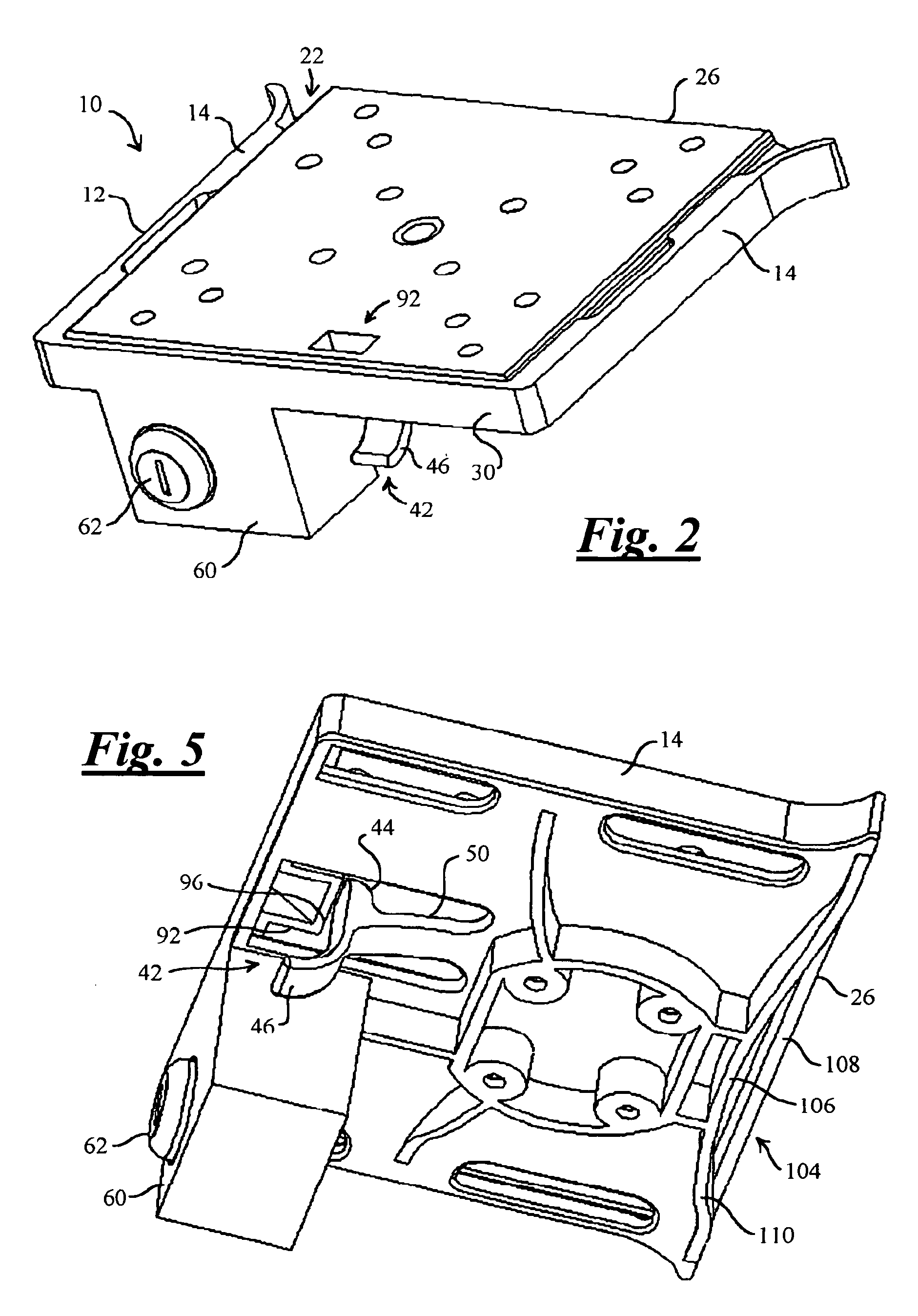

Locking device support

An accessory device mounting platform includes a substantially rigid frame and a substantially rigid mating tray that are slidably interconnected along a first direction, the frame and tray include a tongue-and-groove slide mechanism arranged therebetween for sliding the tray relative to the frame relative to a first direction. A resilient biasing mechanism, such as a cantilevered flexure or tension spring, is coupled between the frame and a latch bolt portion of a clasp mechanism for biasing the latch bolt portion toward a latch strike plate mechanism formed in the tray. The latch strike plate mechanism is formed with an inclined surface that is positioned to engage a latch bolt portion of the clasp mechanism and is structured for deflecting the latch bolt away from the frame, while the resilient biasing mechanism of the clasp mechanism is structured for biasing the latch bolt back toward the frame.

Owner:CARNEVALI JEFFREY D

Fire retardant panel door and door frame having intumescent materials therein

InactiveUS20050284030A1Prevent the spread of fireFireproof doorsBuilding locksComposite laminatesRefractory

A fire retardant panel door and door frame that prevents the spread of fire through the door during a fire. The fire retardant panel door has at least one door panel and stiles and rails. The door panel includes an interior center composite section formed by a first plurality of layers of intumescent materials and a first plurality of layers of fire resistant materials disposed between and laminated to a pair of outer sections formed of wood for enclosing the interior center composite section to form a composite laminated door panel. Each of the stiles includes a first center core formed of wood enclosed by a second plurality of layers of intumescent materials and a second plurality of layers of fire resistant materials; and the second layers of intumescent and fire resistant materials are enclosed by a first applique layer formed of wood to form a composite laminated stile. Each of the rails includes a second center core formed of wood enclosed by a third plurality of layers of intumescent materials and a third plurality of layers of fire resistant materials; and the third layers of intumescent and fire resistant materials are enclosed by a second applique layer formed of wood to form a composite laminated rail. The first, second, and third plurality of layers of intumescent materials are activated to expand upon exposure to heat and / or fire to prevent the heat and / or fire from passing through at least one door panel, the stiles and the rails of the panel door during a fire for at least 90 minutes. At least one door panel is connected to the panel door by tongue and groove joints; and the tongue and groove joints have a fourth plurality of layers of intumescent materials and a fourth plurality of layers of fire resistant materials in the tongue and groove joints; and wherein the fourth plurality of layers of fire resistant materials in the tongue and groove joints are activated to expand upon exposure to heat and / or fire to seal the joints in order to prevent the heat and / or fire from passing through the panel door during a fire for at least 90 minutes.

Owner:ATRISTIC DOORS & WINDOWS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com