Patents

Literature

476results about How to "Push smooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

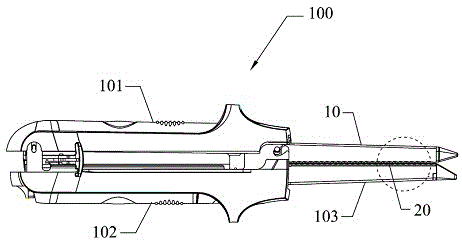

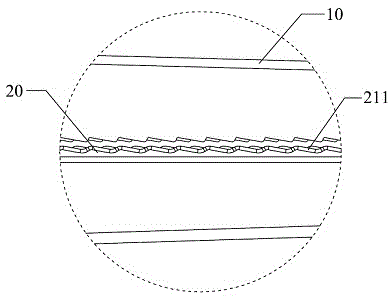

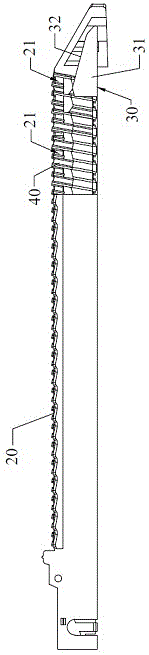

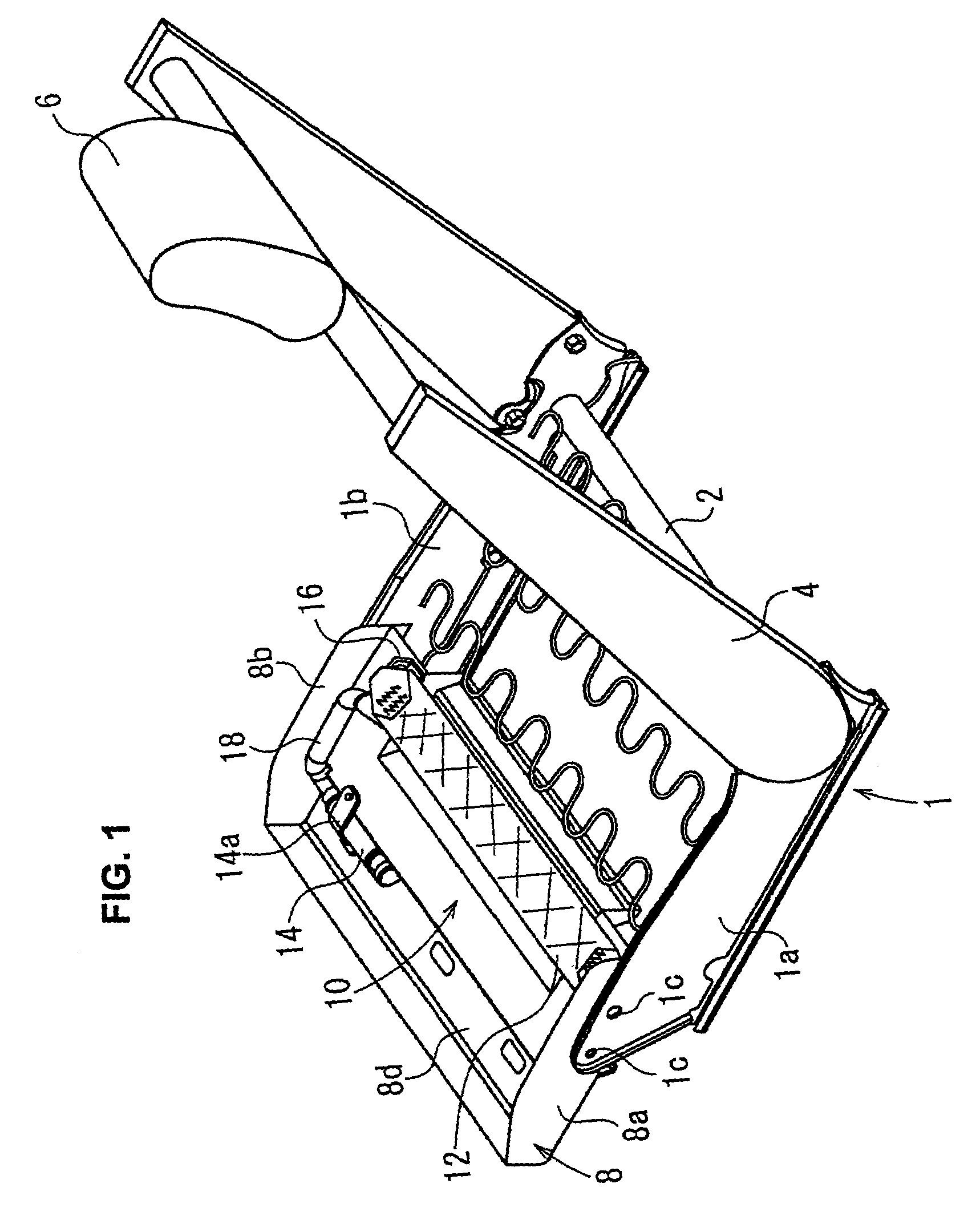

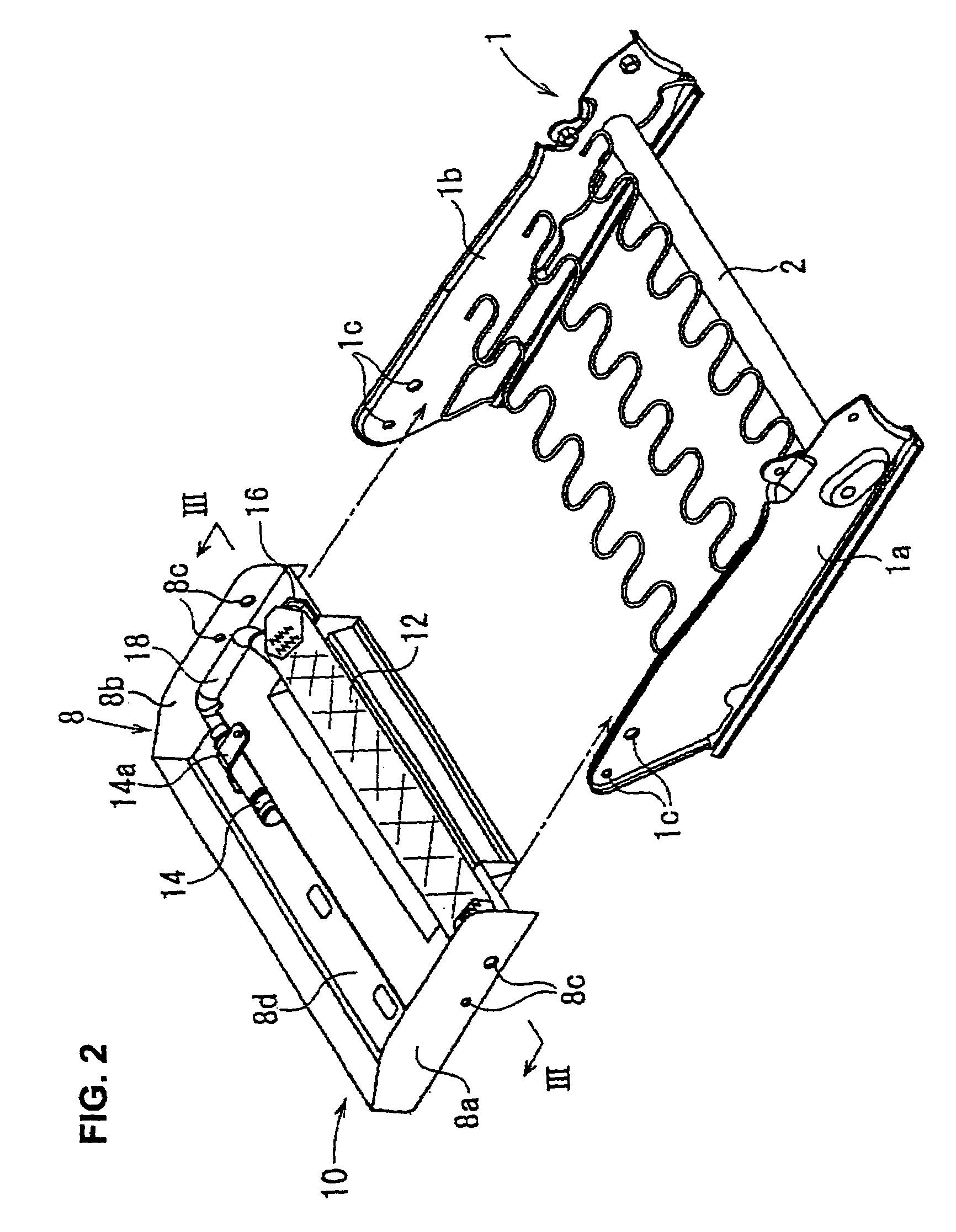

Linear Suture Cutting Device

The invention discloses a linear suturing and cutting device. The linear suturing and cutting device comprises an upper forceps holder and a lower forceps holder which can be closed and opened mutually. The upper forceps holder comprises a nail anvil, the lower forceps holder comprises a nail cartridge rack, the nail cartridge rack is detachably provided with a nail cartridge, and the inside of the nail cartridge is sequentially provided with a nail cartridge hole which penetrates the surface of the nail cartridge and a nail pushing sheet which is arranged inside the nail cartridge and can slide relative to the nail cartridge hole; the inside of the nail cartridge is also slidingly provided with a trigger sheet, the trigger sheet is provided with a wedge-shaped nail pushing unit which can drive the nail pushing sheet to slide inside the nail cartridge hole, and the nail cartridge hole is inclined to the far end of the nail cartridge. Therefore, when the nail pushing sheet inside the nail cartridge sheet is pushed, the stress direction of the nail pushing sheet is identical to the extension direction of the nail cartridge hole, relatively high friction force between the nail pushing sheet and the inner wall of the nail cartridge hole can be avoided, so that the nail pushing sheet can be pushed more smoothly, and further the surgical difficulty can be reduced.

Owner:TOUCHSTONE INTERNATIONAL MEDICAL SCIENCE CO LTD

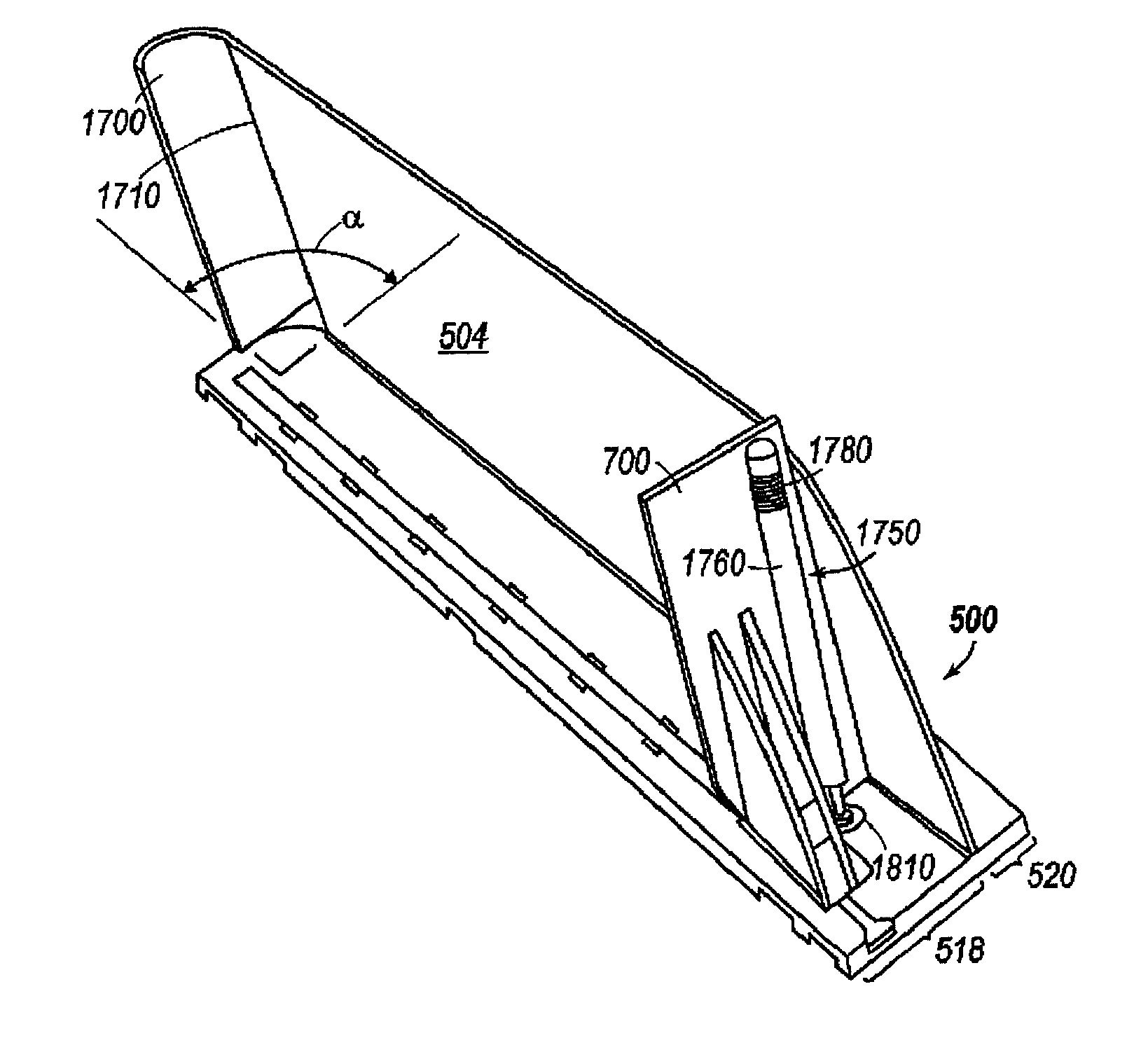

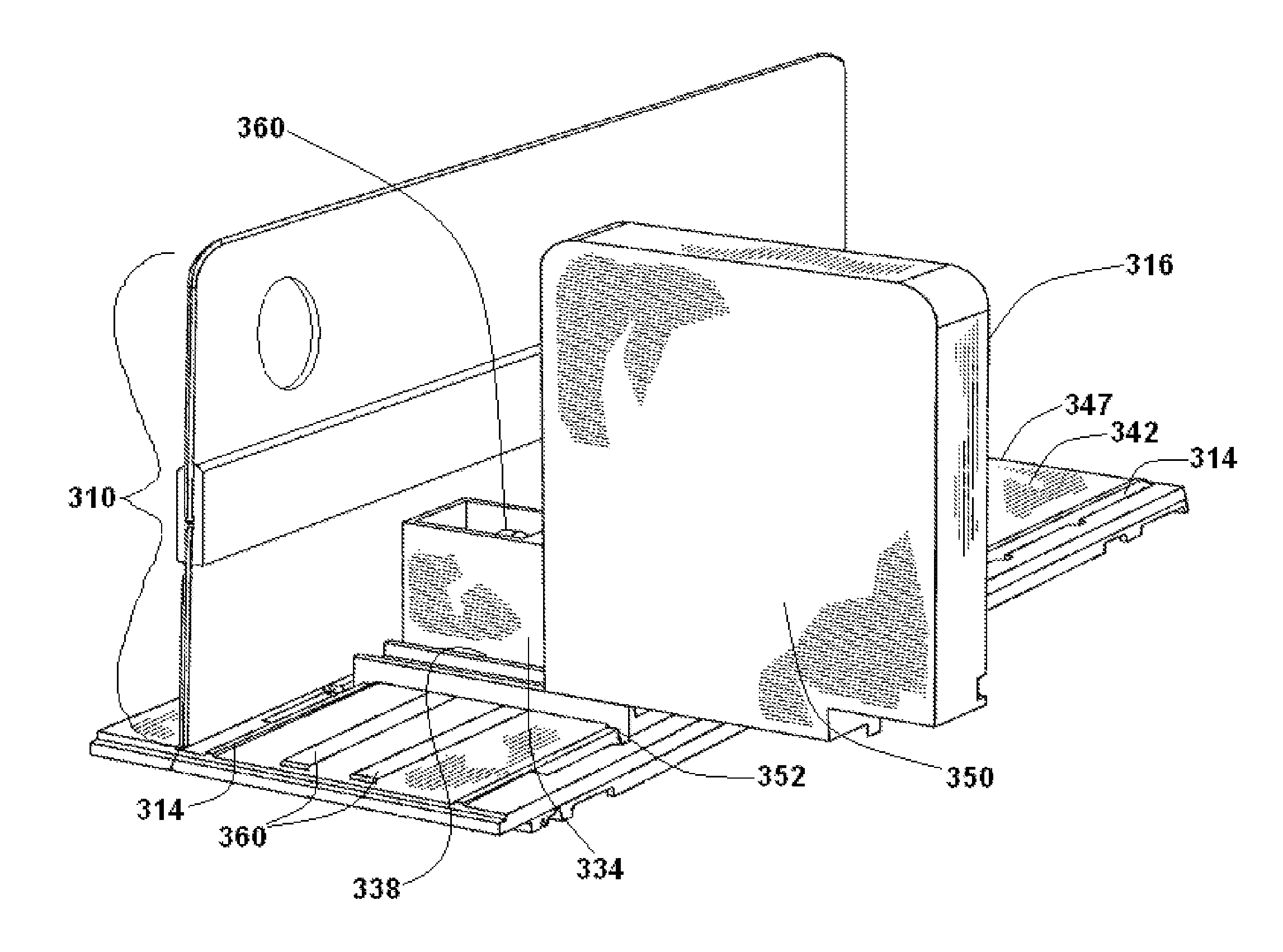

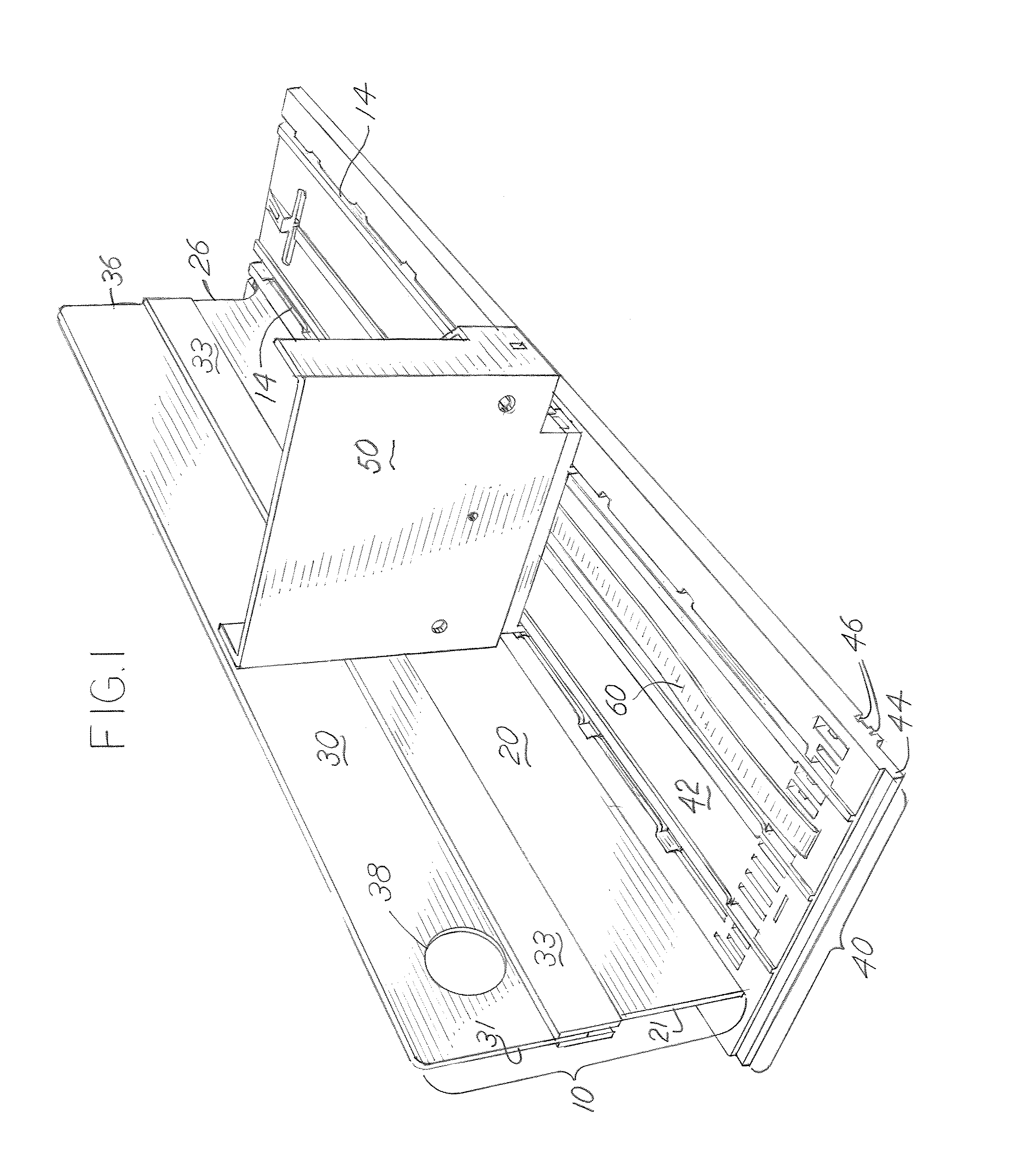

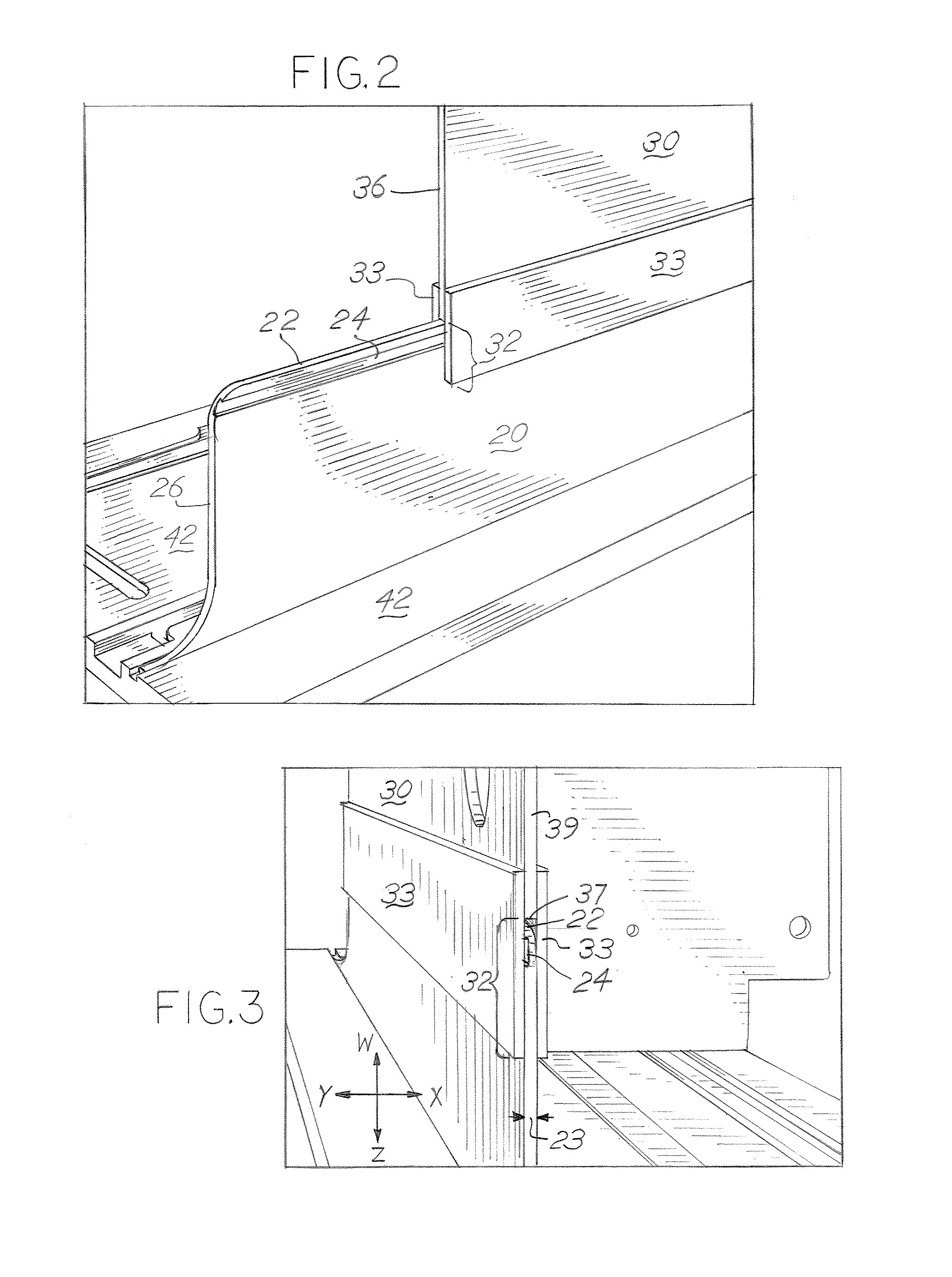

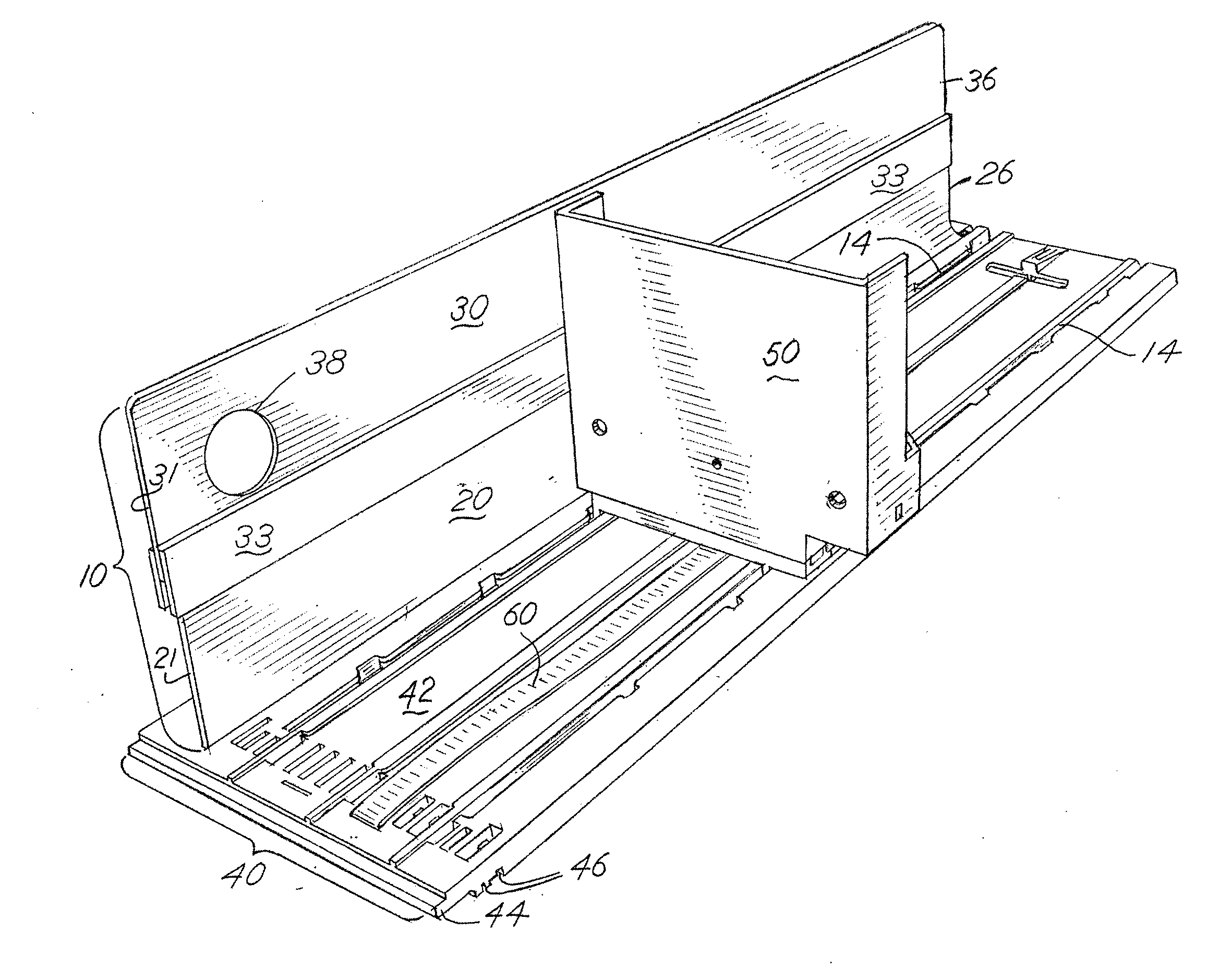

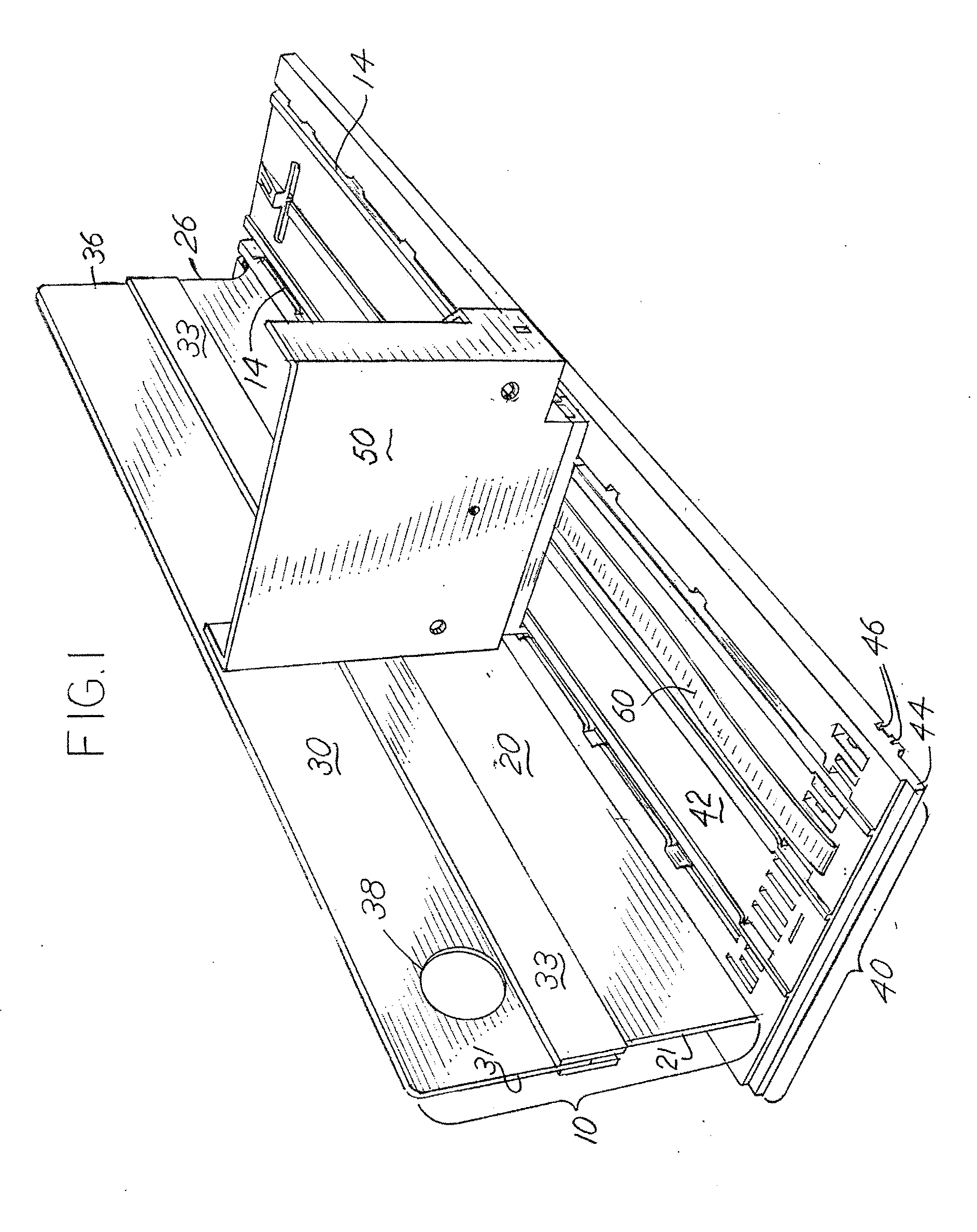

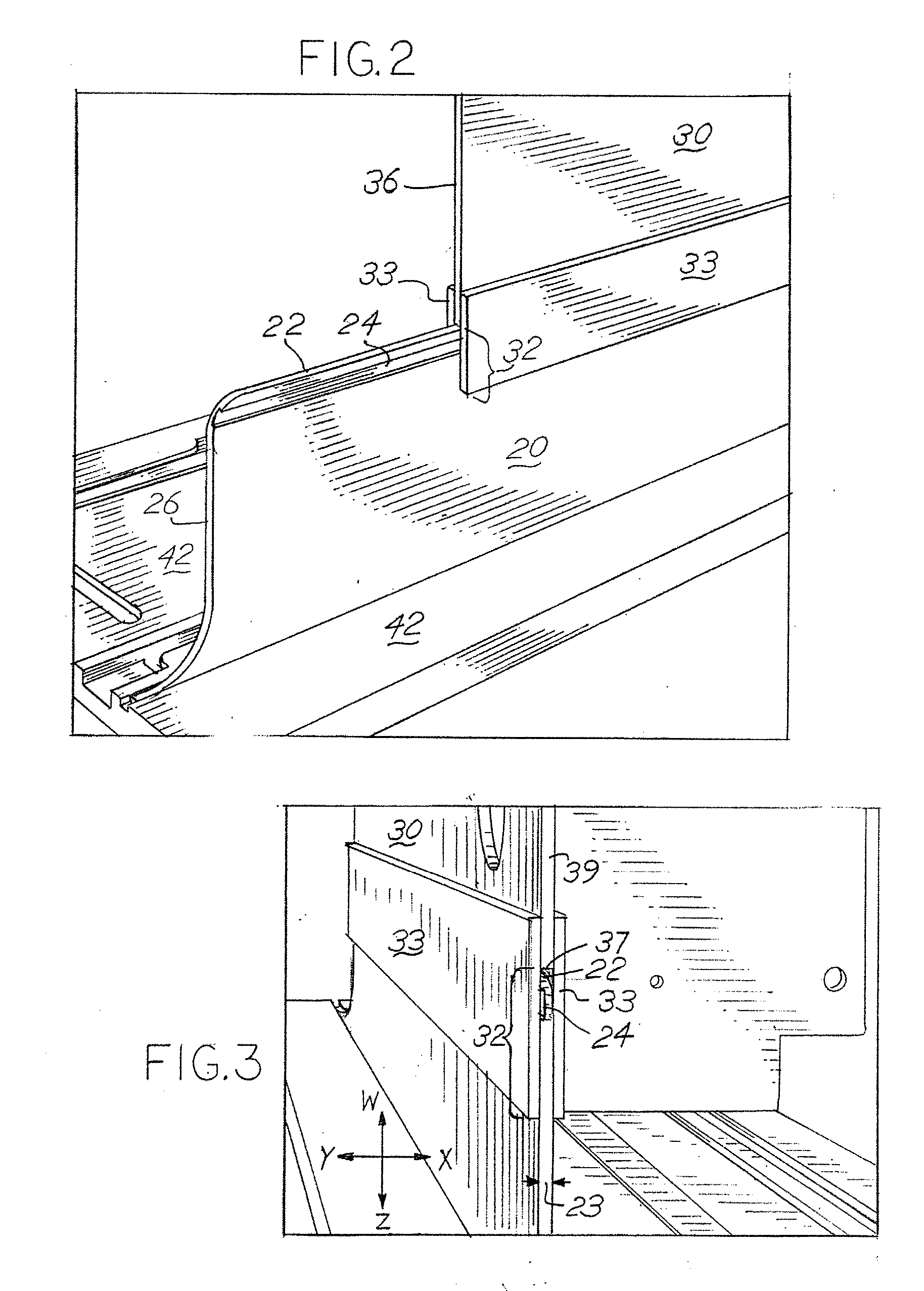

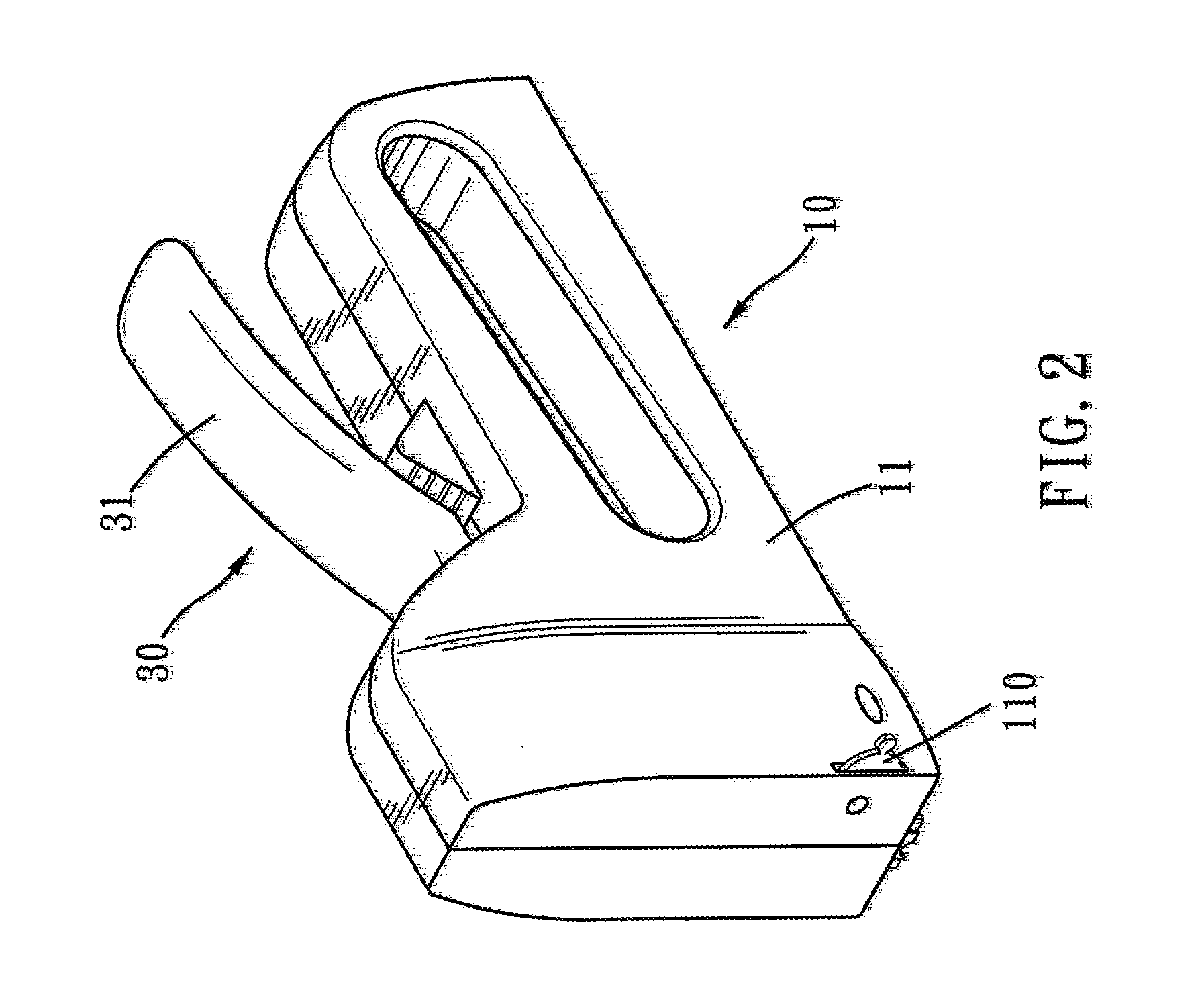

Product management display system with retaining wall

A merchandise display system includes a base-and-divider assembly. The base-and-divider assembly includes a base portion adapted for operative coupling to a front rail, and a divider portion for dividing displayed merchandise into rows. The divider portion protrudes from the base portion such that the divider portion separates the base portion into a first portion and a second portion. A spring-urged pusher is mounted to a pusher track for pushing merchandise toward the front of a shelf. A retaining wall curves inwardly from a front edge of the divider portion along at least a portion of the first portion.

Owner:RTC IND

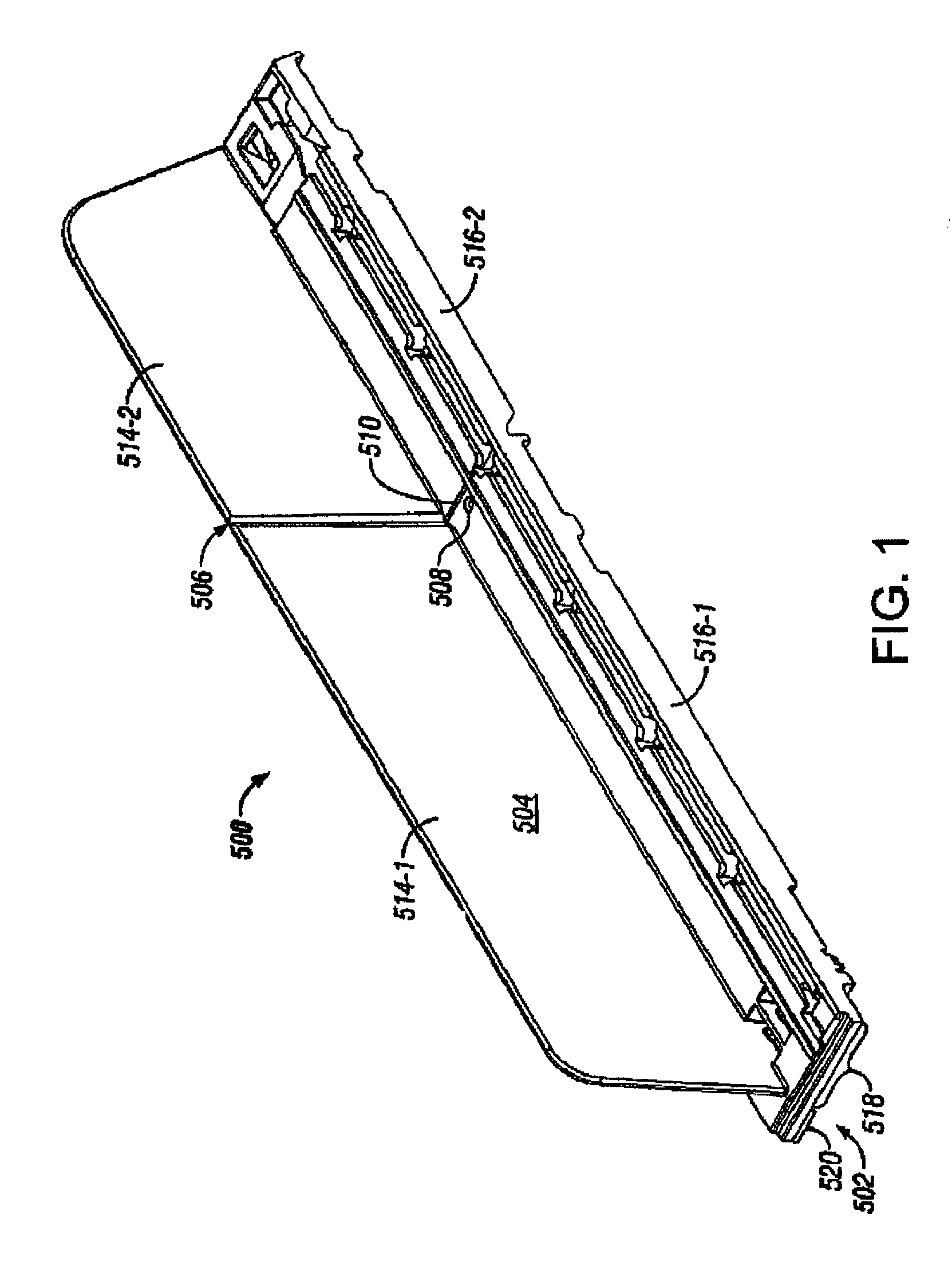

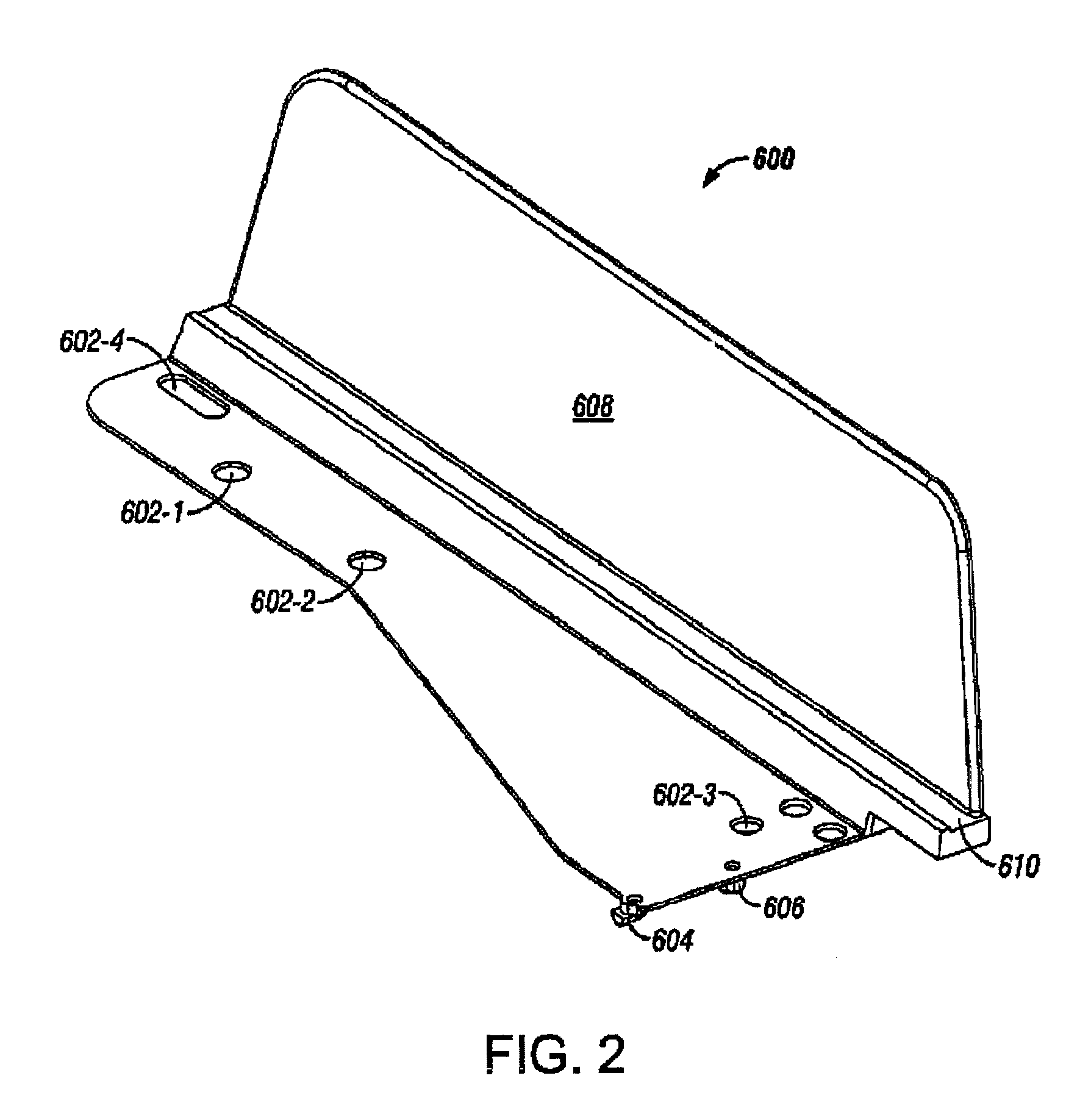

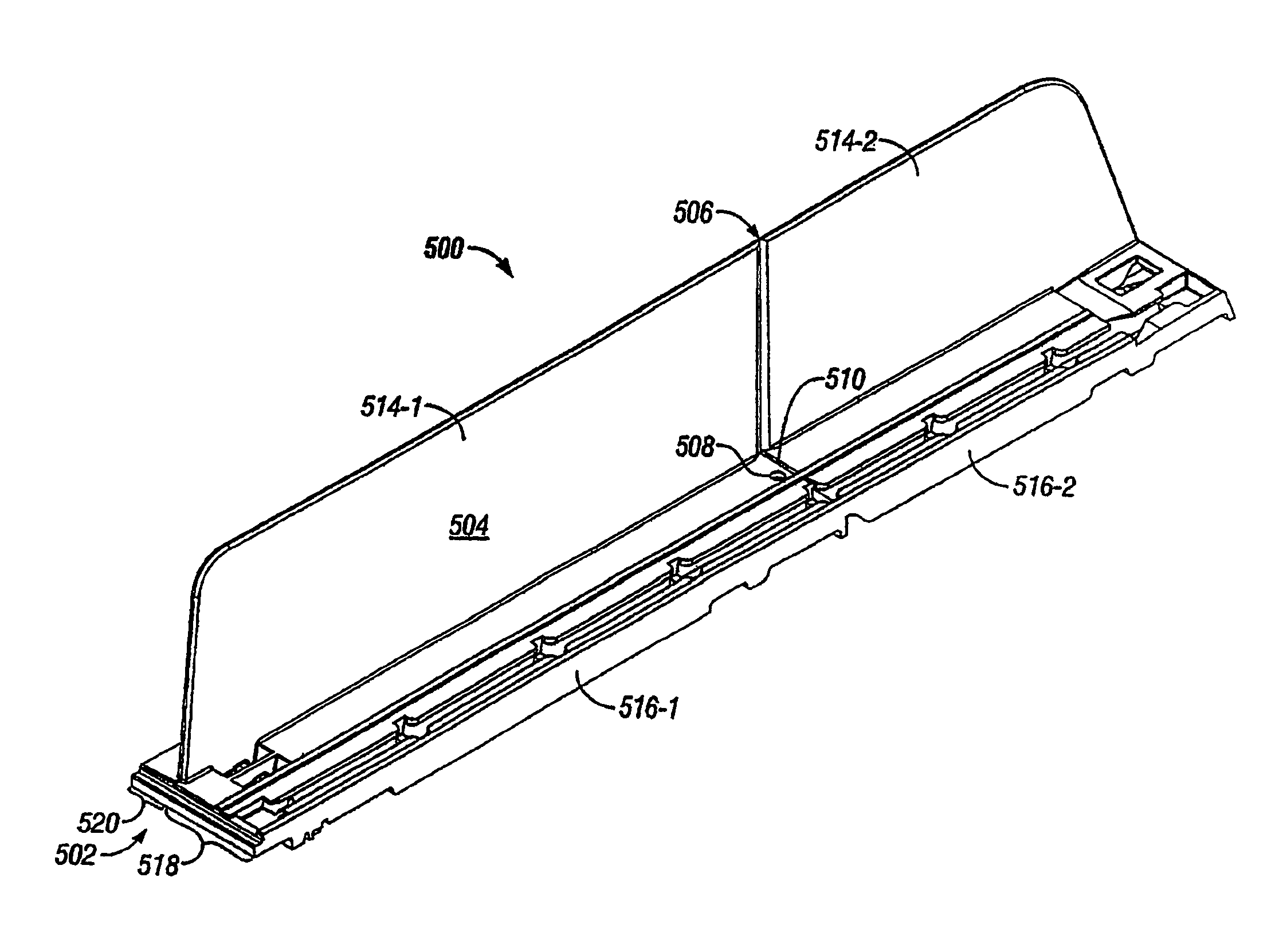

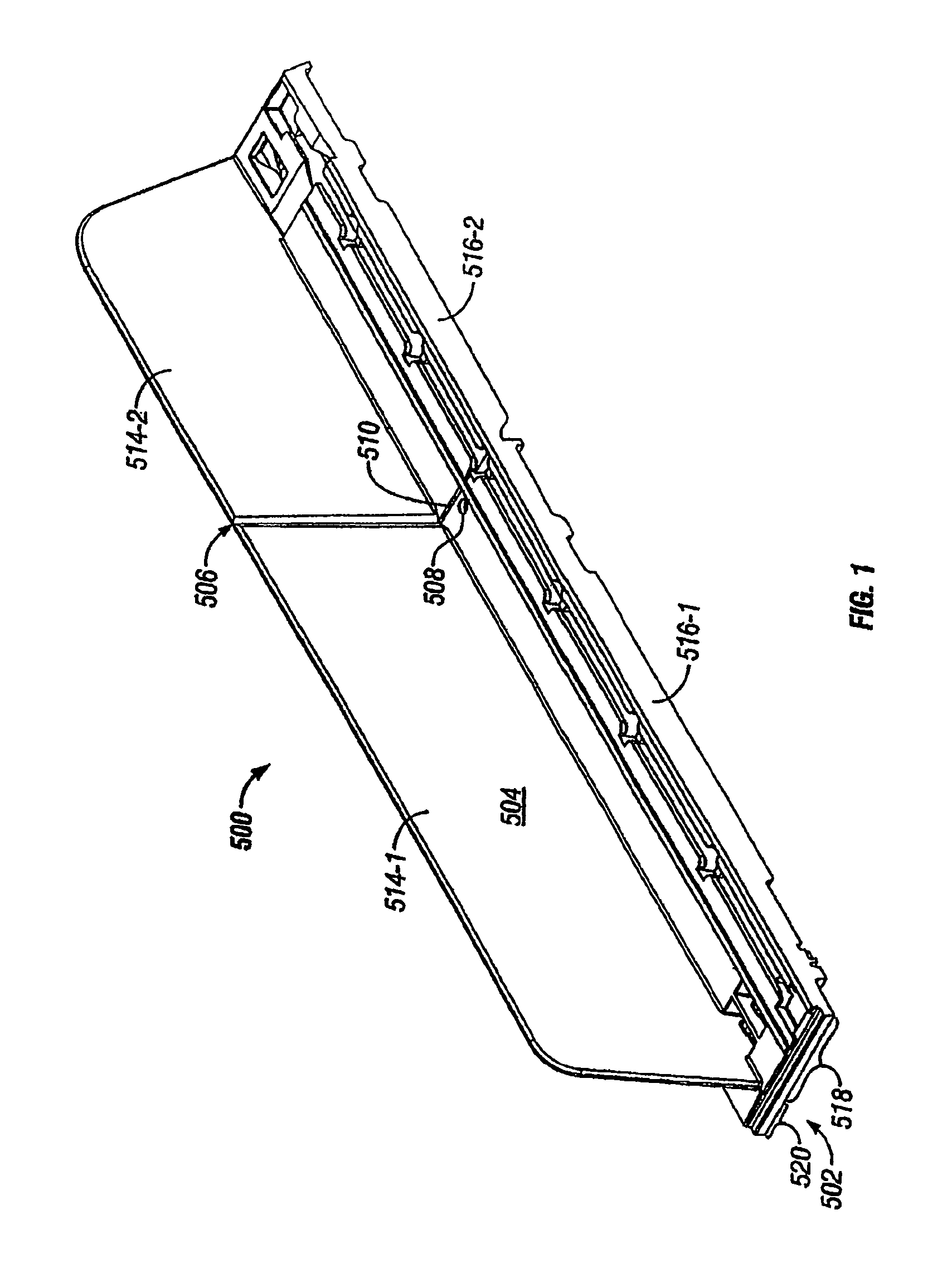

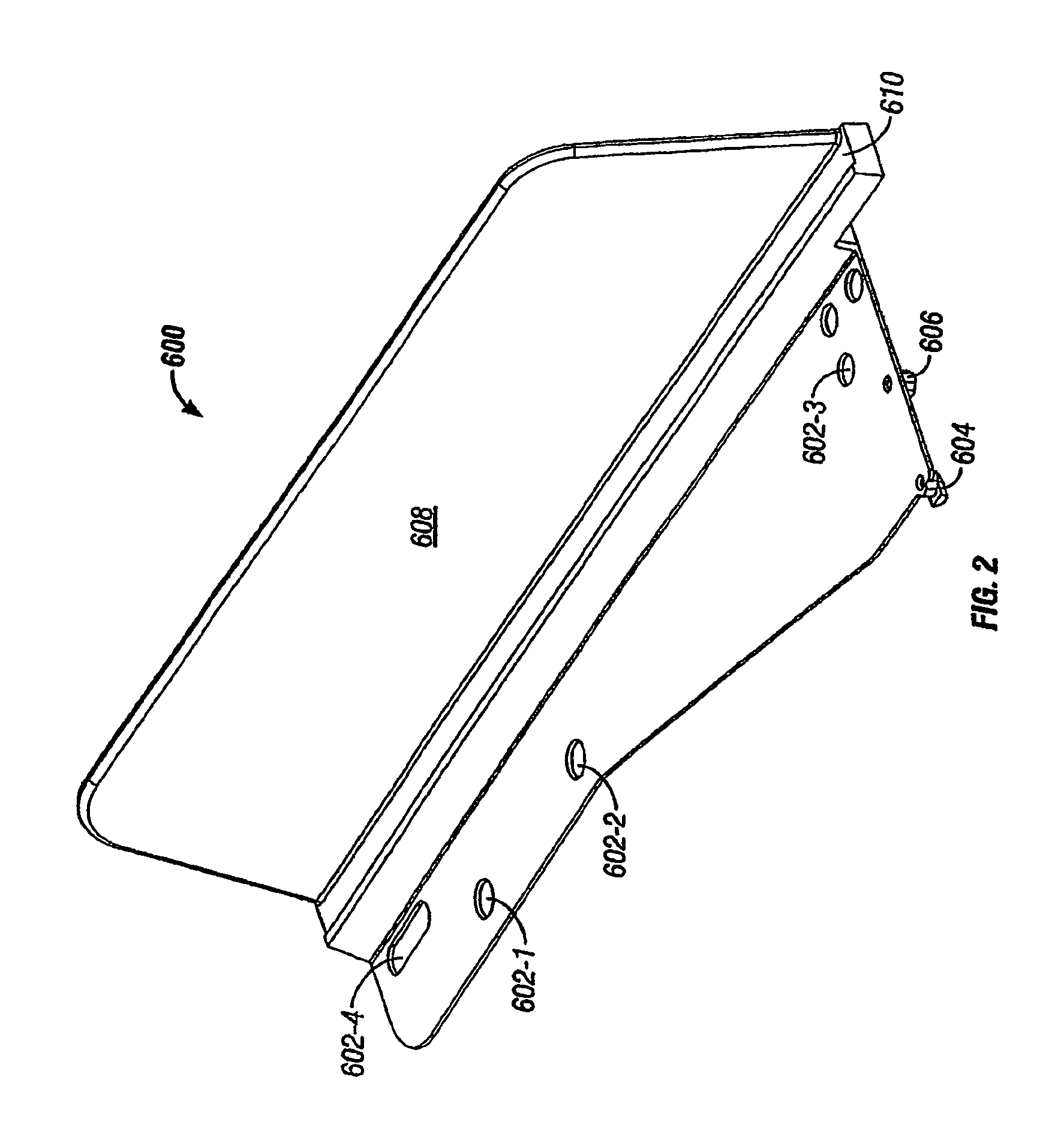

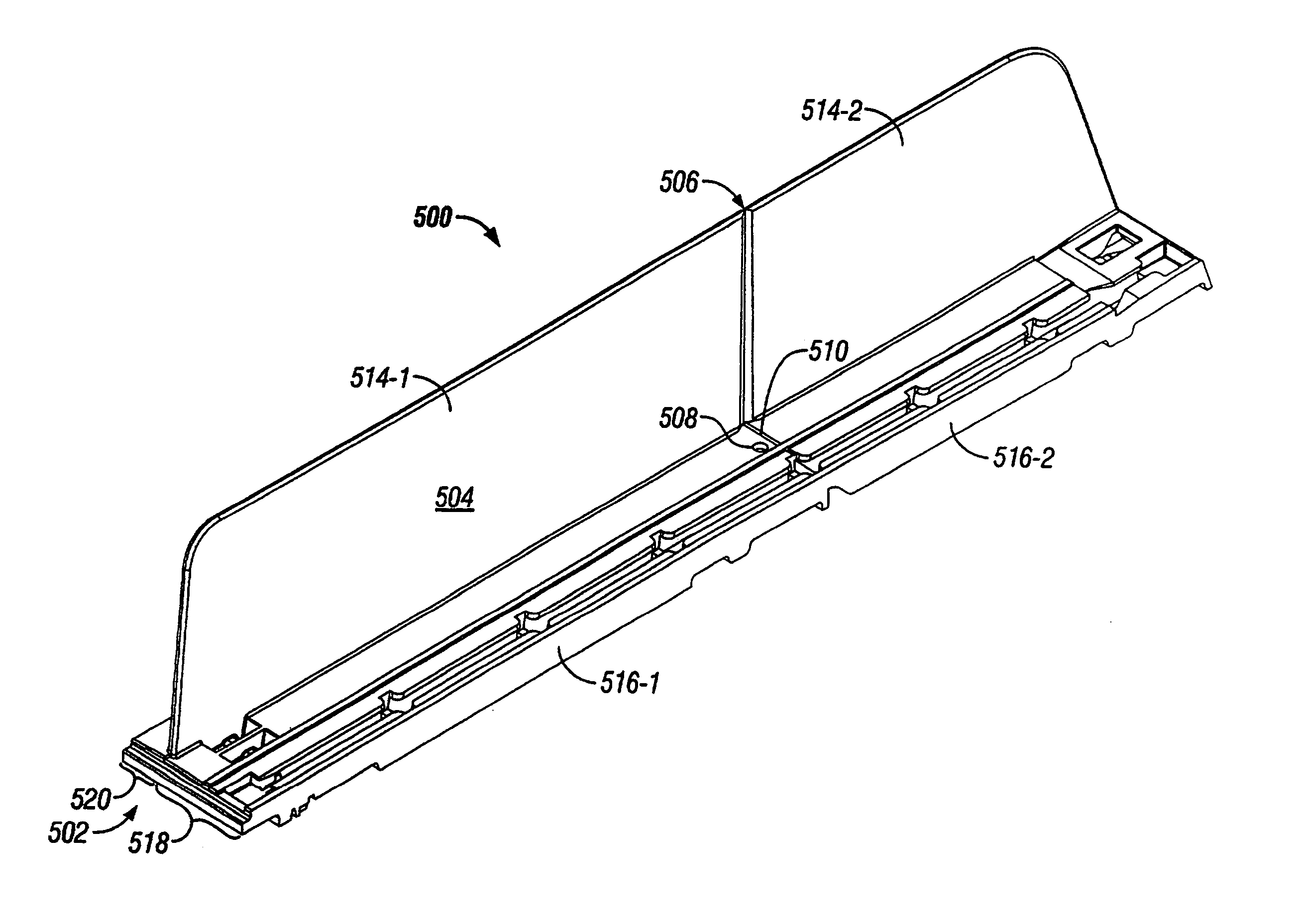

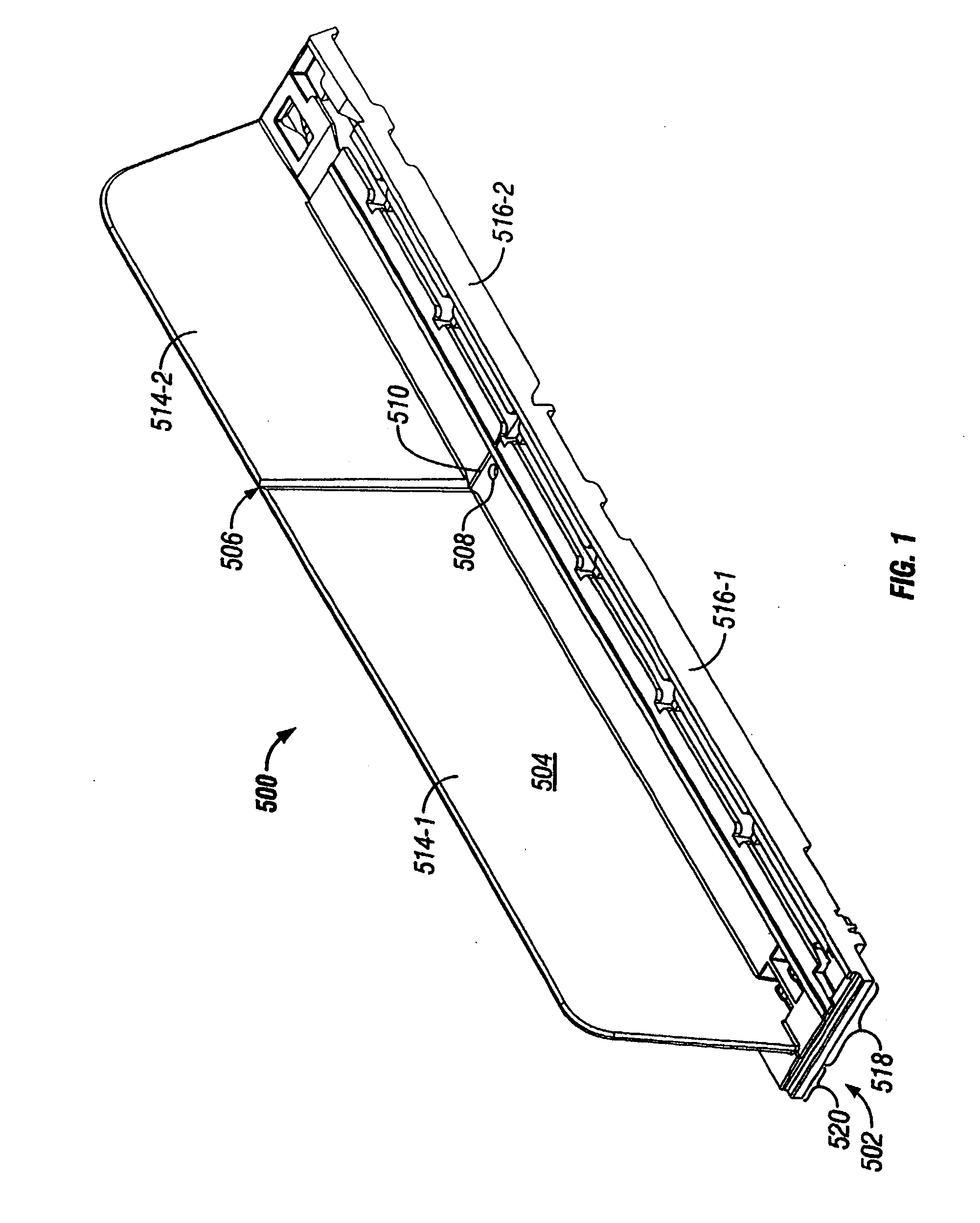

Product management display system

An integrated “T” assembly combines into a single integrated assembly, a track portion along both sides of a divider. The T assembly may have a wide-base portion, which may include a spring-urged-pusher track, on one side of the divider and a narrow-base portion on the opposite side of the divider. An offset pusher may have an upper portion that is offset, via an angled offset portion, from a lower portion of the pusher. Additional supporting bases, any of which may include spring-urged-pusher tracks and / or a spring-urged pusher, may be used under a wide product. Left and right side finisher components may be paired with T assemblies near the sides of a merchandise-display shelf. The T assembly, base, and / or end finishers may be coupled to a front rail via a complimentary tongue and groove arrangement and / or a non-slidable engagement.

Owner:RTC IND

Product management display system

An integrated “T” assembly combines into a single integrated assembly, a track portion along both sides of a divider. The T assembly may have a wide-base portion, which may include a spring-urged-pusher track, on one side of the divider and a narrow-base portion on the opposite side of the divider. An offset pusher may have an upper portion that is offset, via an angled offset portion, from a lower portion of the pusher. Additional supporting bases, any of which may include spring-urged-pusher tracks and / or a spring-urged pusher, may be used under a wide product. Left and right side finisher components may be paired with T assemblies near the sides of a merchandise-display shelf. The T assembly, base, and / or end finishers may be coupled to a front rail via a complimentary tongue and groove arrangement and / or a non-slidable engagement, such as mating teeth.

Owner:RTC IND

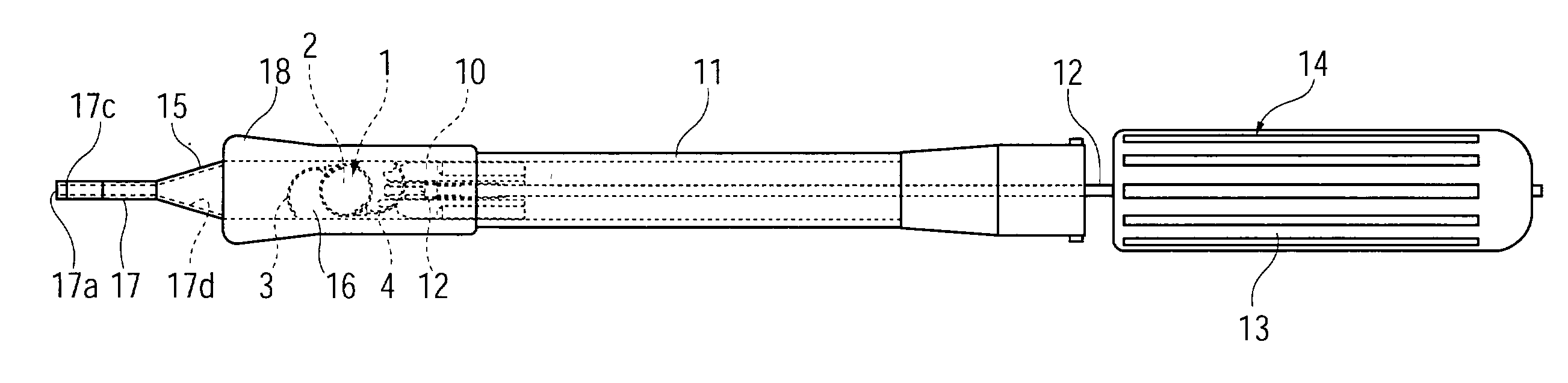

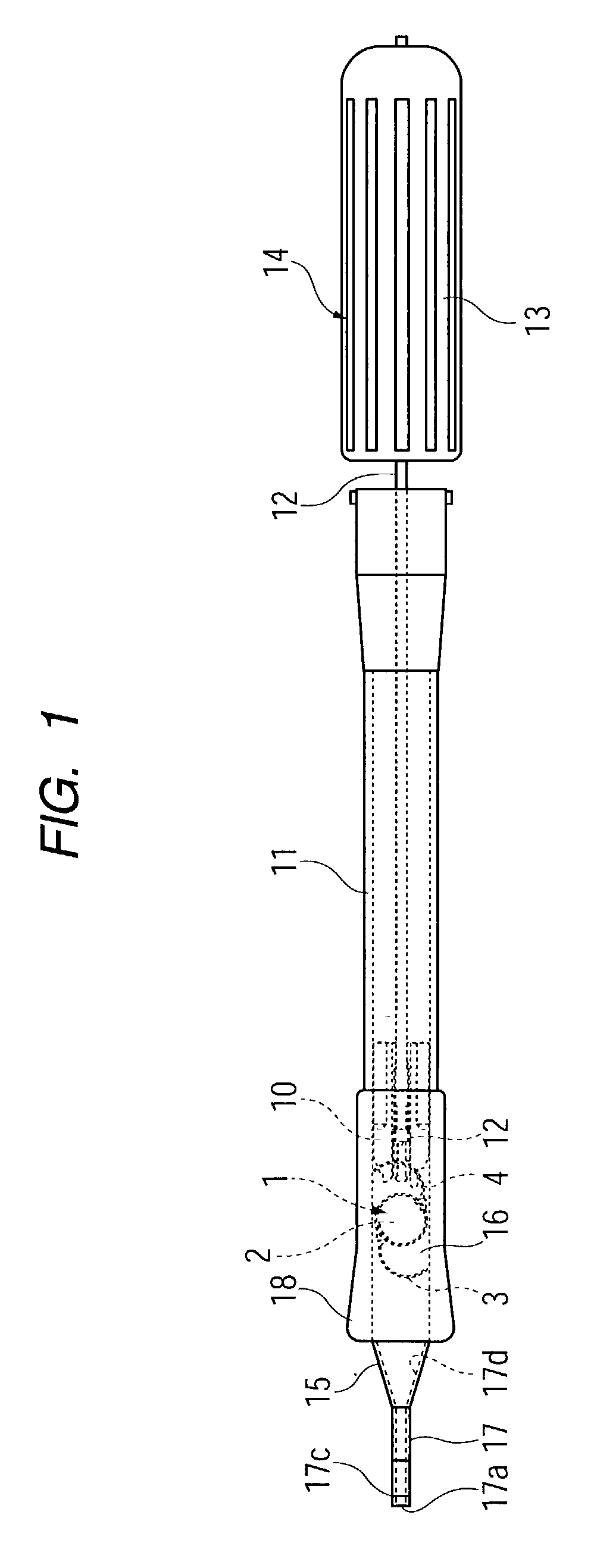

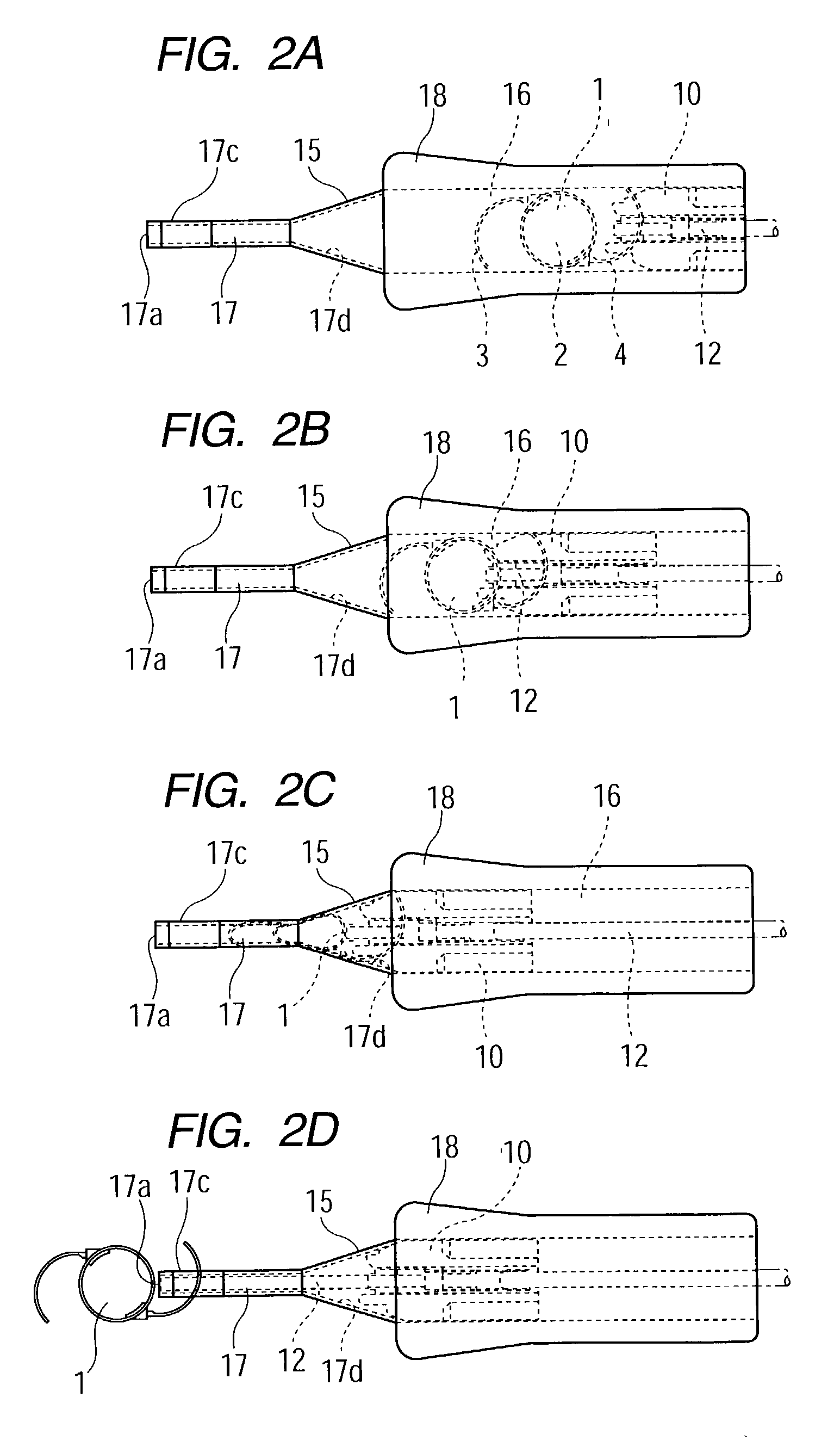

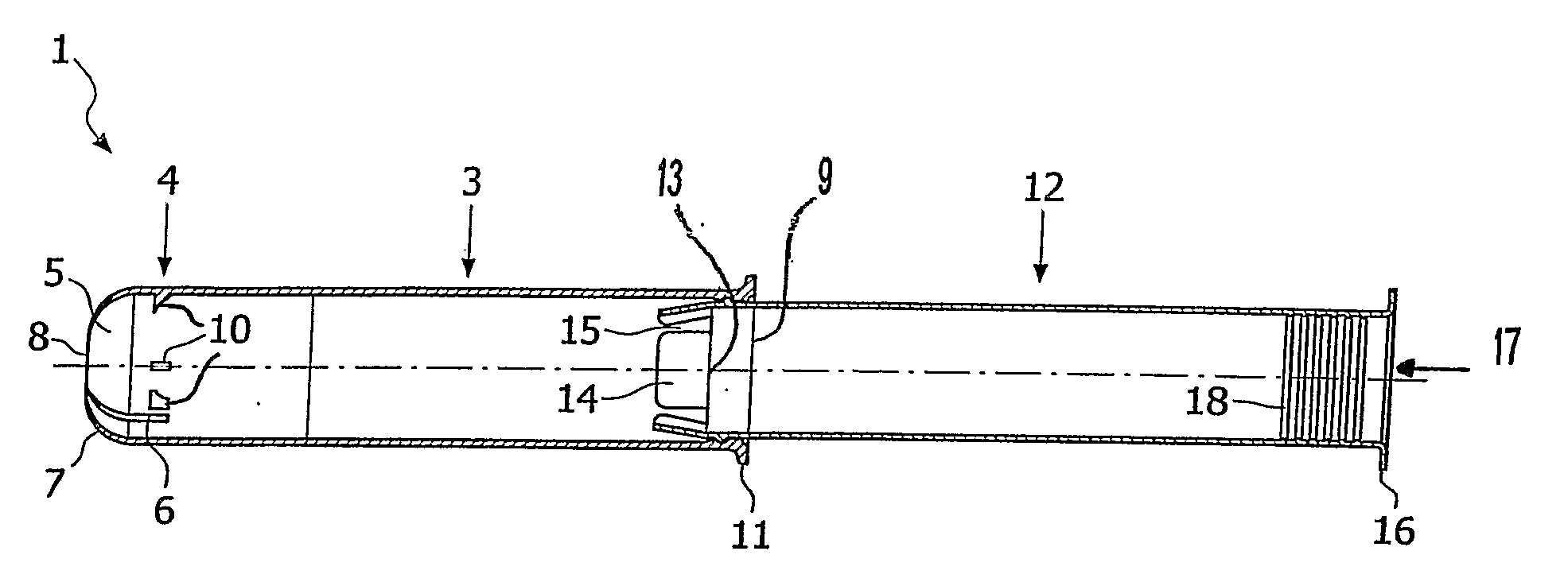

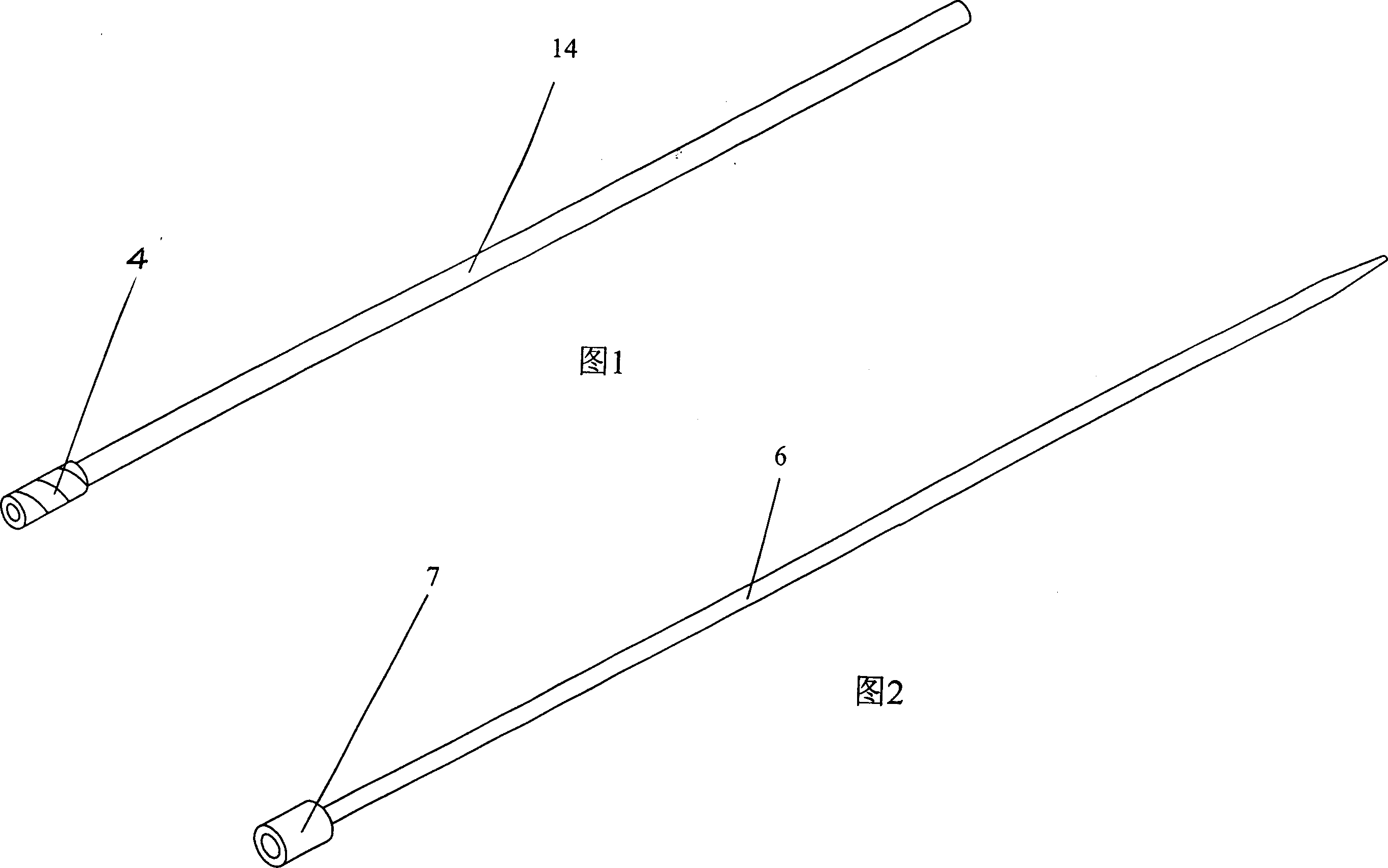

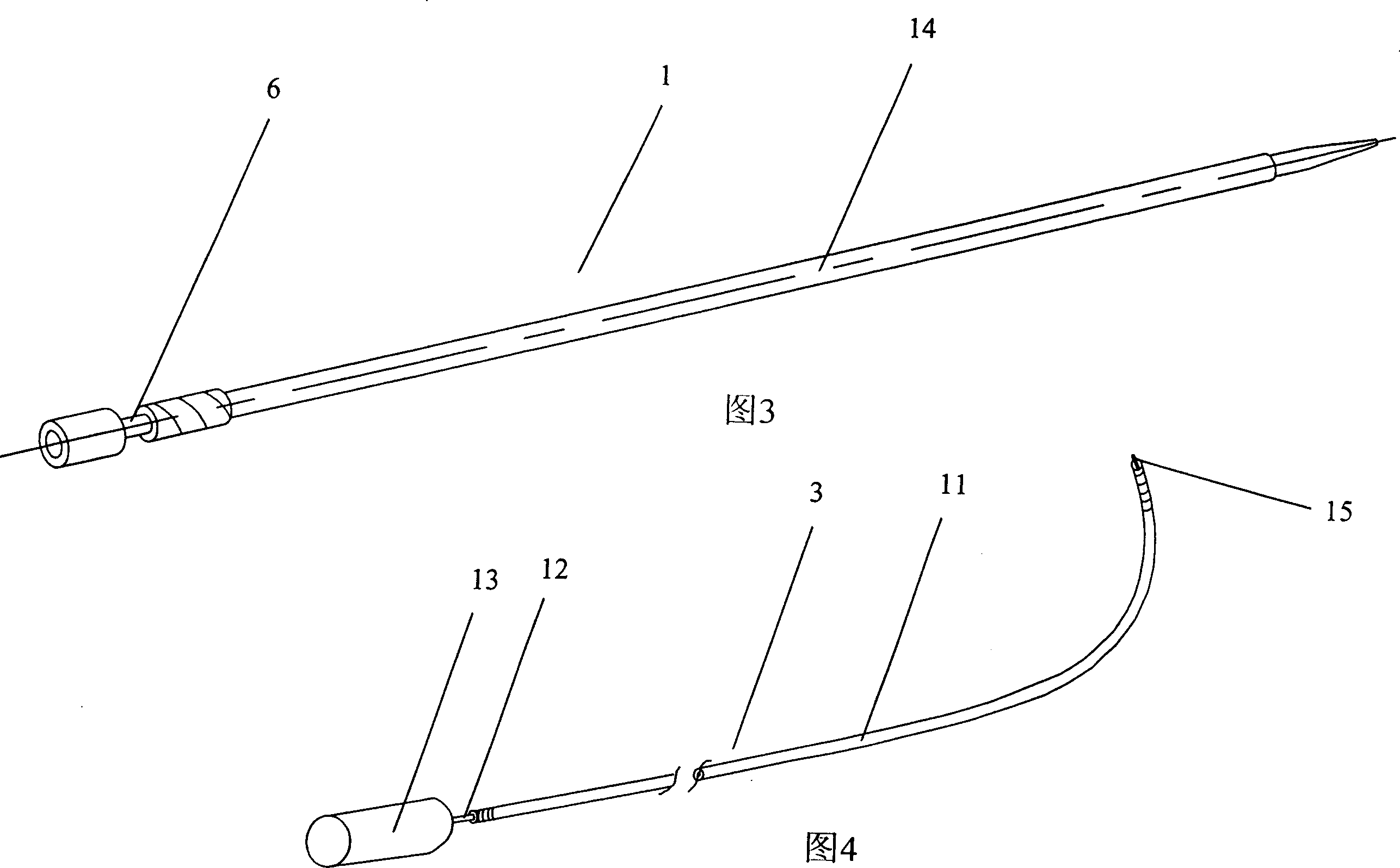

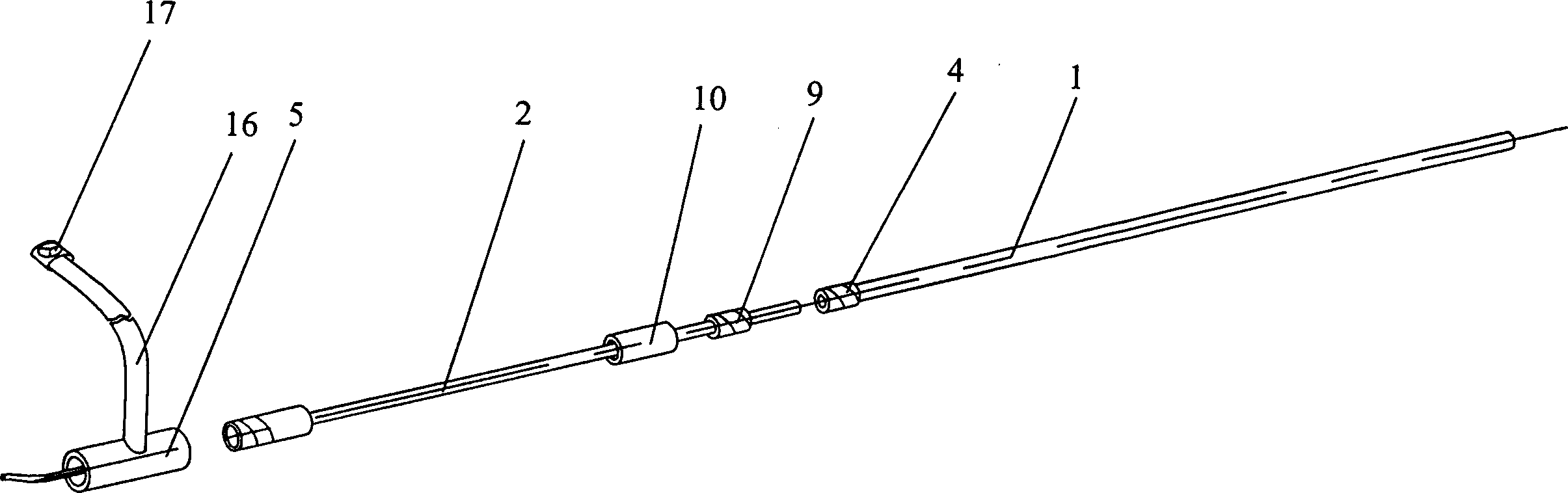

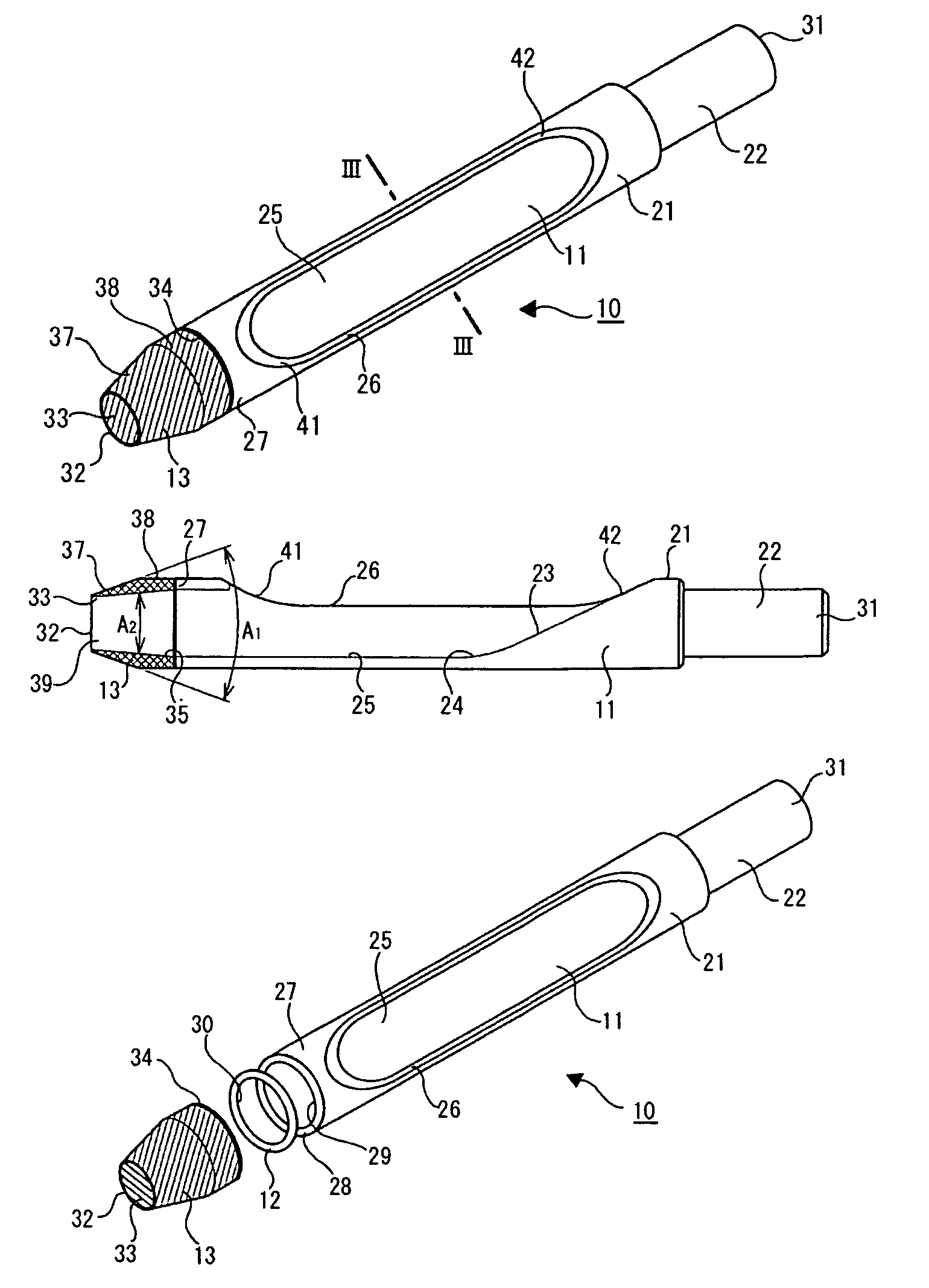

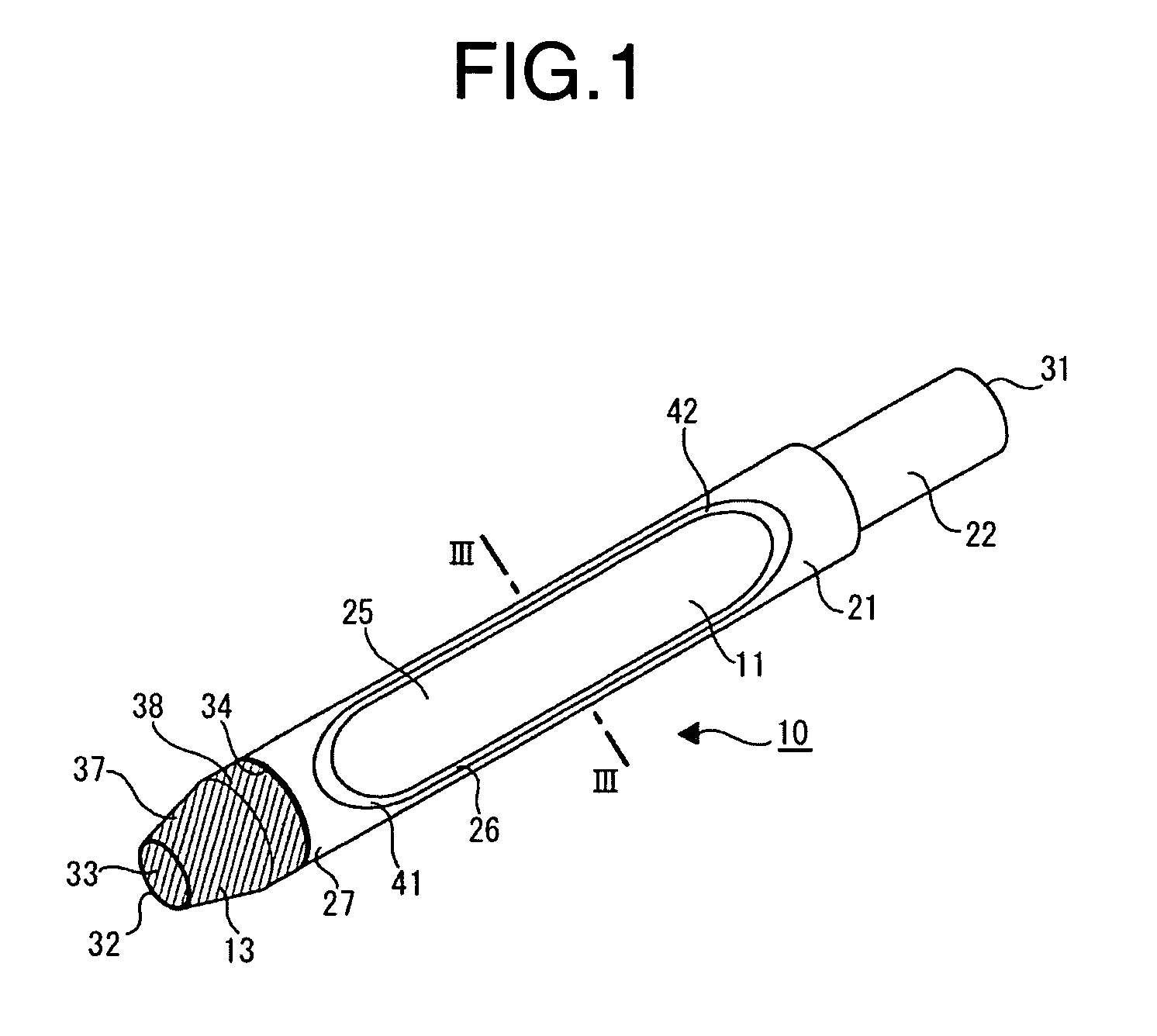

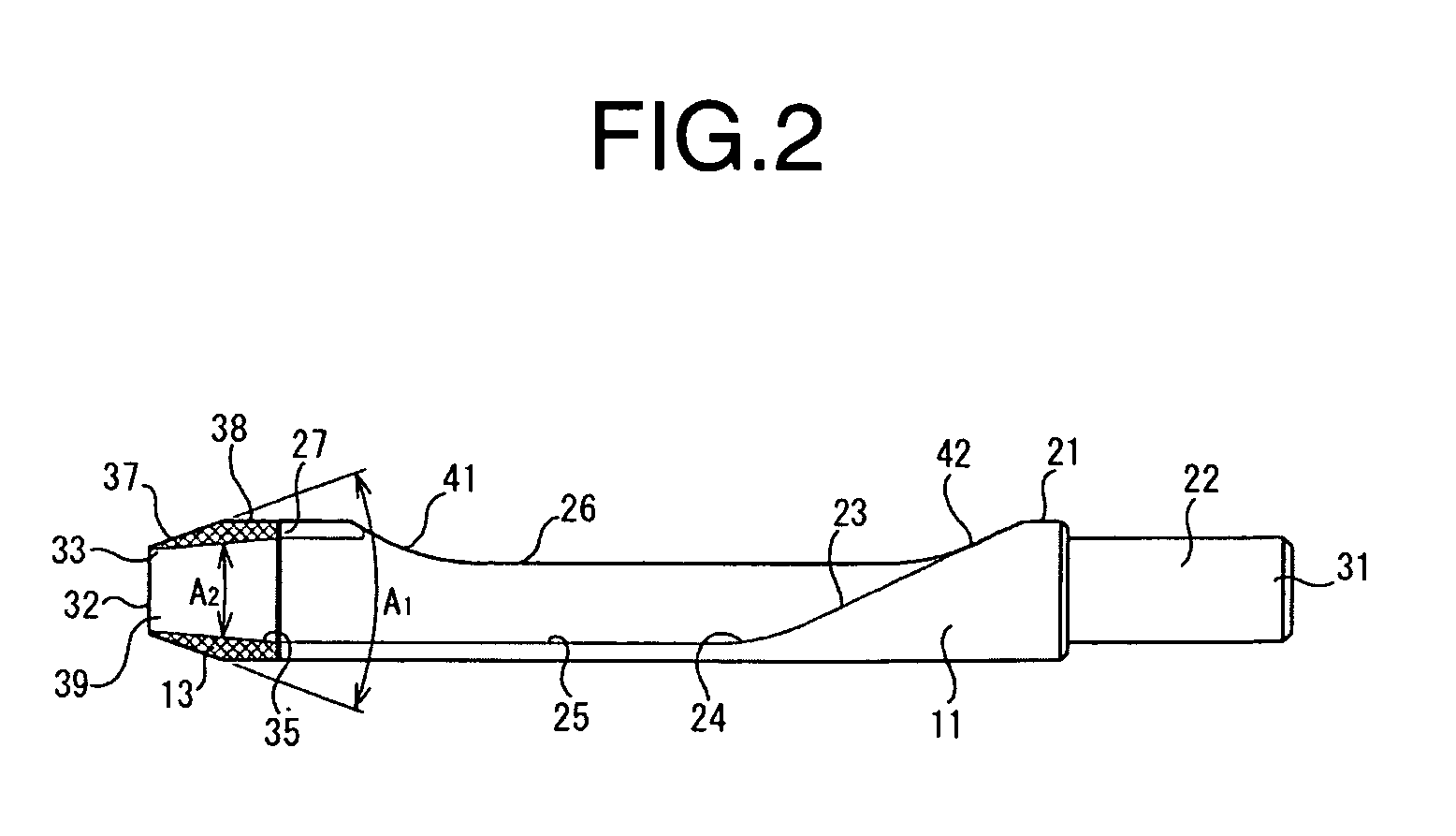

Insertion device for intraocular lens

ActiveUS20030212409A1Reduce load capacitySmall sizeEye treatmentIntraocular lensIntraocular lensReduced size

An insertion device is used to deform a deformable intraocular lens to a reduced size and insert the deformed lens into an eye through an insertion tube. The insertion device includes a push rod for pushing and inserting the lens into the eye, and a posture control member disengagably engaged with a tip end portion of the push rod. The posture control member prevents deflection of the push rod from a center axis. The engagement between the posture control member and the push rod is broken when the push rod arrives at a predetermined position during a step of advancing the push rod.

Owner:STAAR JAPAN

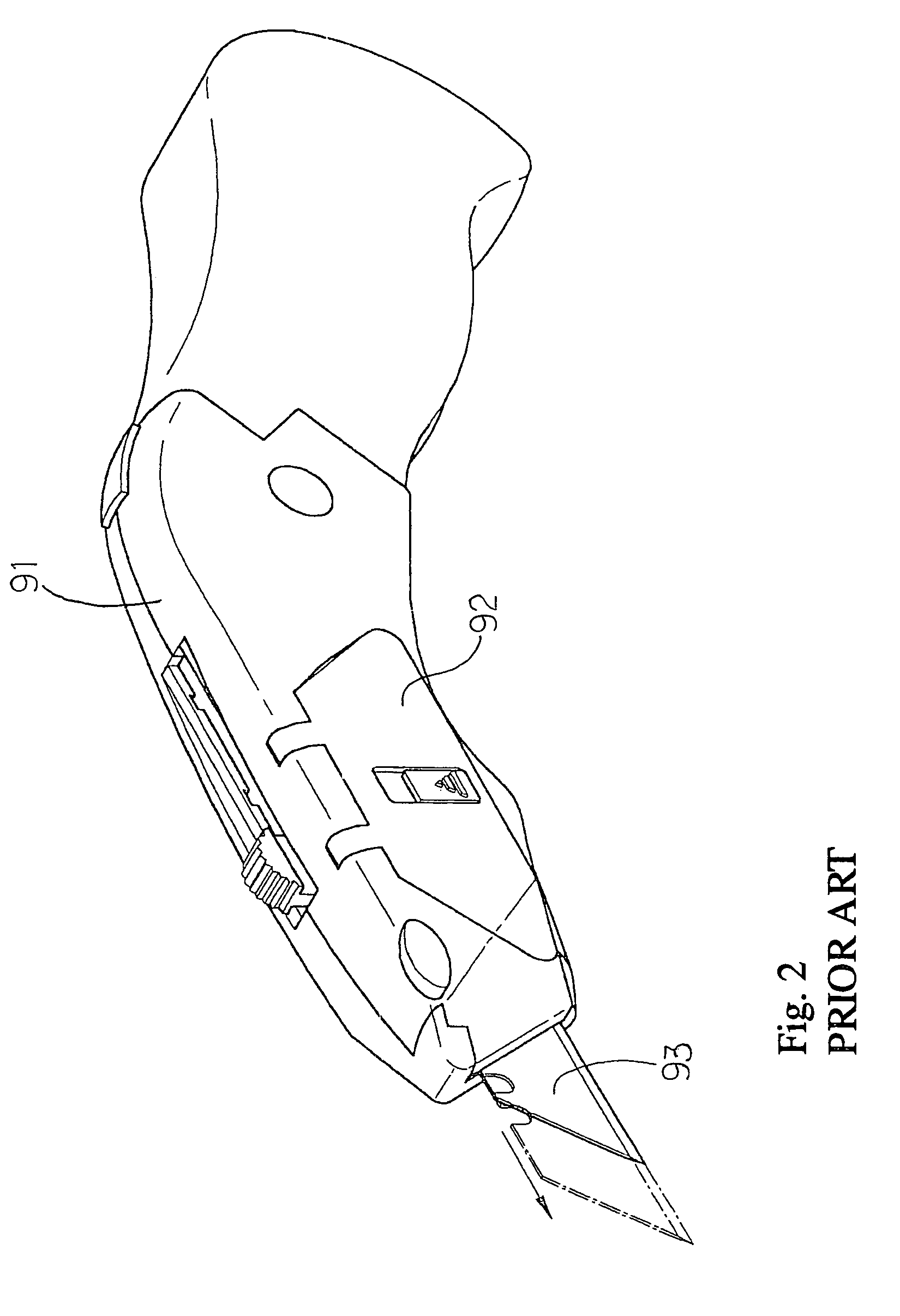

Automatically loadable and blade-stabilizing utility knife

InactiveUS6886257B2Easily and truly and safely loadedPush smoothThrusting weaponsWeapon componentsHand heldEngineering

Owner:CHIH GORDON

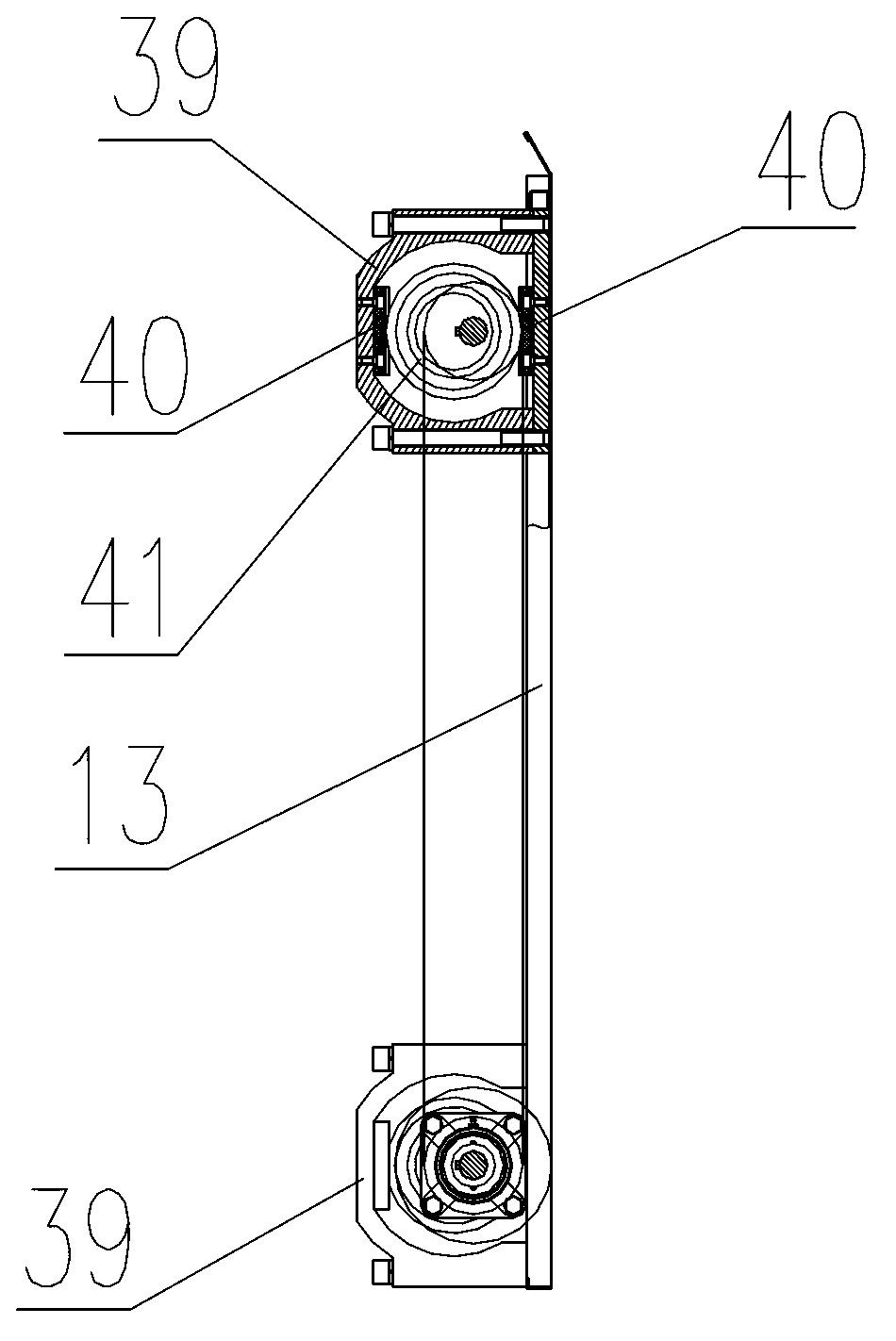

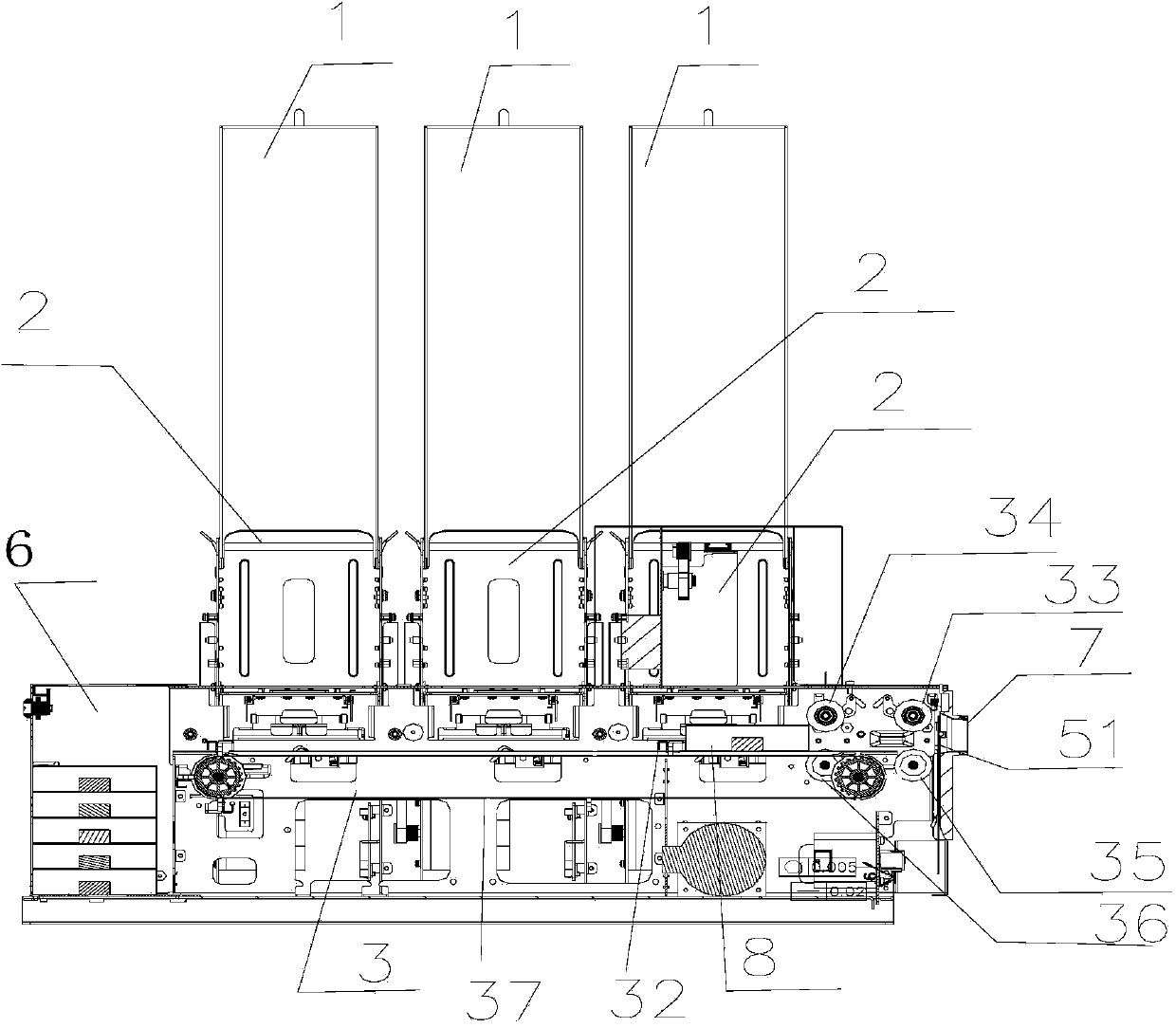

Lifting device and playing card lifting mechanism

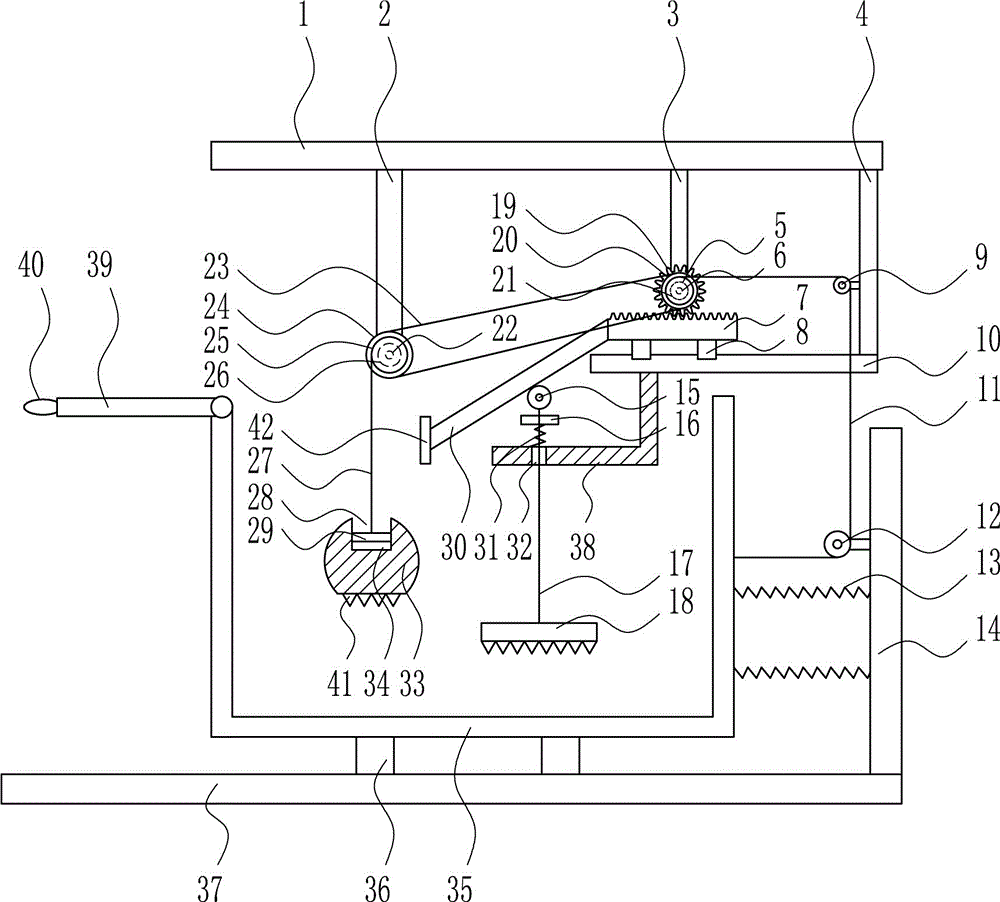

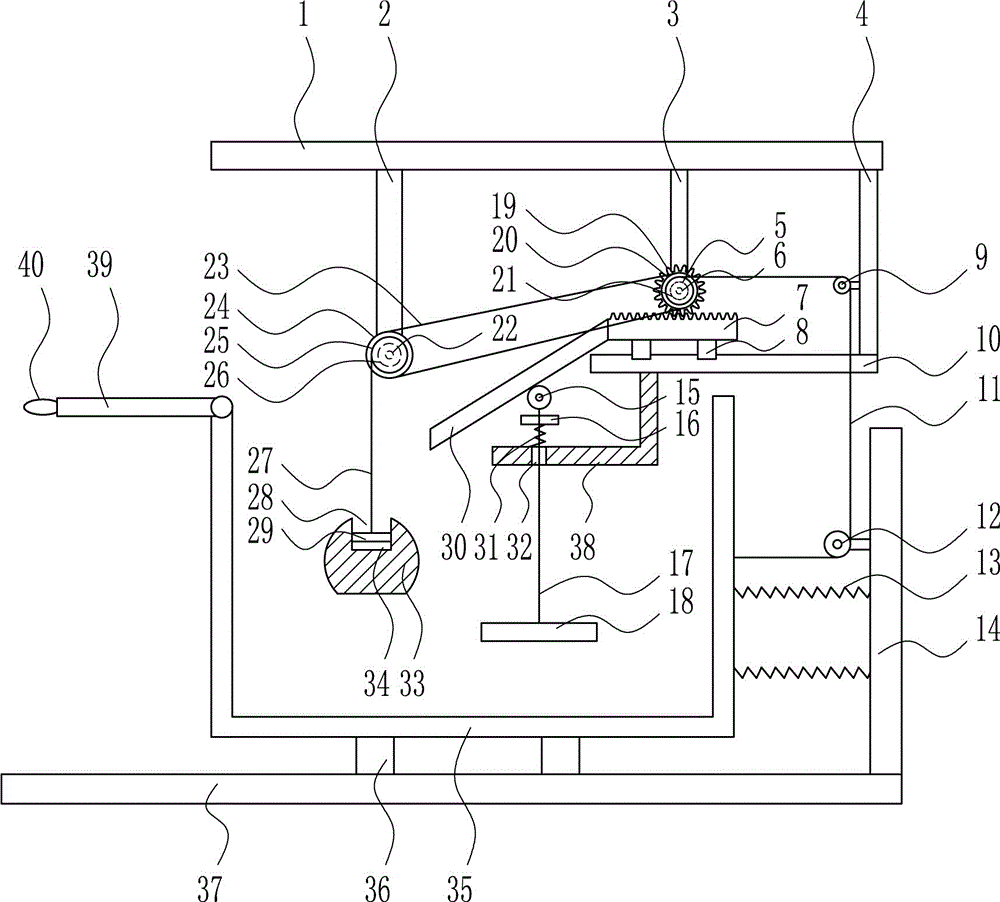

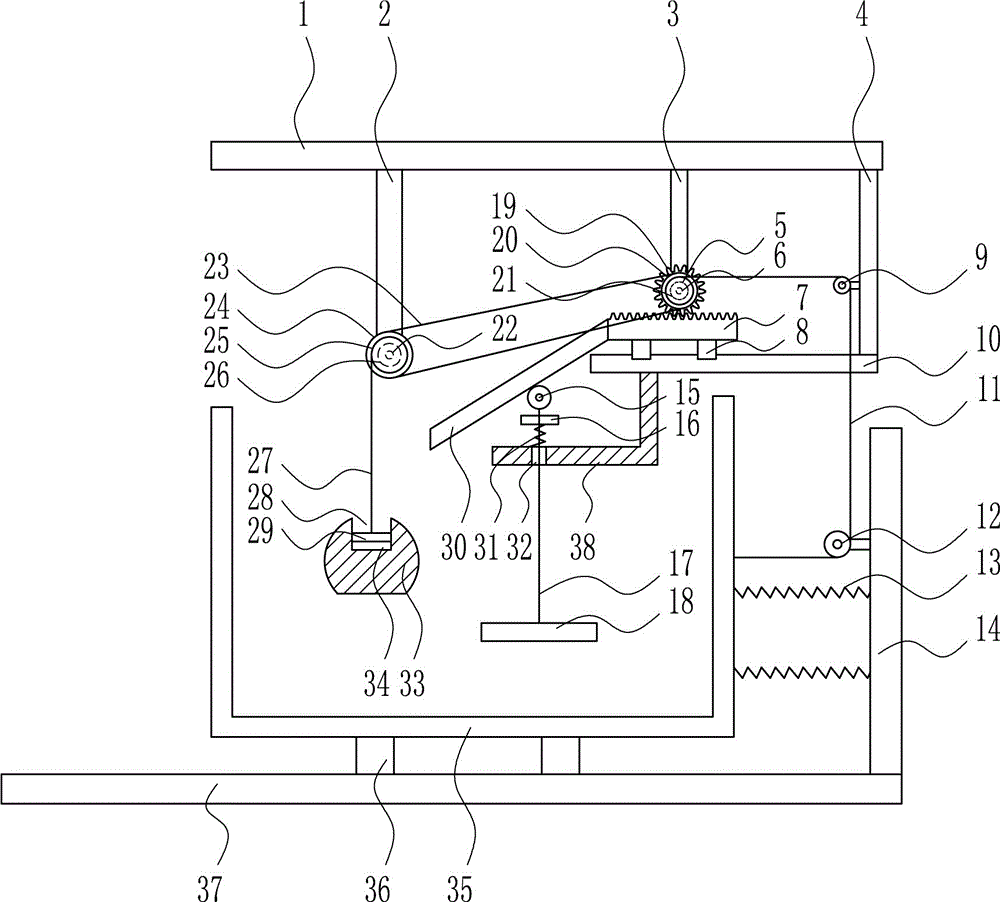

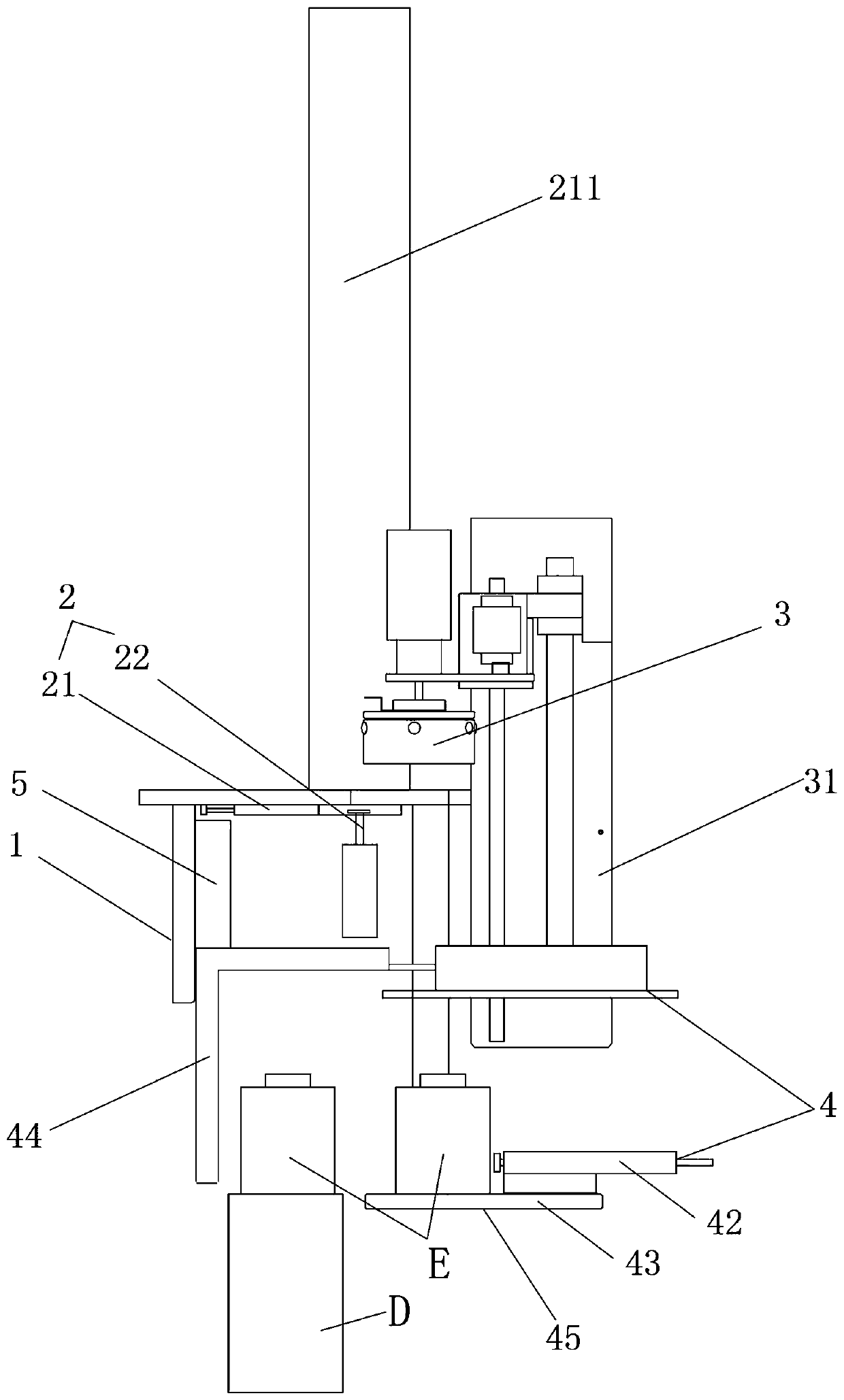

The invention discloses a lifting device of a playing card lifting mechanism of a playing card machine. The lifting device comprises a lifting bracket, wherein a lifting motor, a transmission gear, an inner curve gear and a driven gear are fixedly arranged on the lifting bracket; the lifting motor is connected with the transmission gear; the transmission gear is connected with the inner curve gear; the inner curve gear is connected with the driven gear; the transmission gear drives a lifting sliding block I arranged on the lifting bracket to lift up and down; the lifting sliding block I is fixed with a playing card plate; the driven gear drives a lifting sliding block II arranged on the lifting bracket to lift; and the lifting sliding block II is fixed with a playing card frame. The lifting device on the playing card machine is used on the playing card lifting mechanism and is simple in structure; the whole playing card pushing and feeding device is ingenious in design; when the playing card lifting plate and a playing card carrying frame are flush with each other, a playing card pushing device is driven to push playing cards on the playing card carrying frame to the playing card lifting plate, and finally the playing card lifting plate lifts the playing cards to a tabletop; and a playing card pushing process is stable and reliable.

Owner:浙江承驰科技有限公司

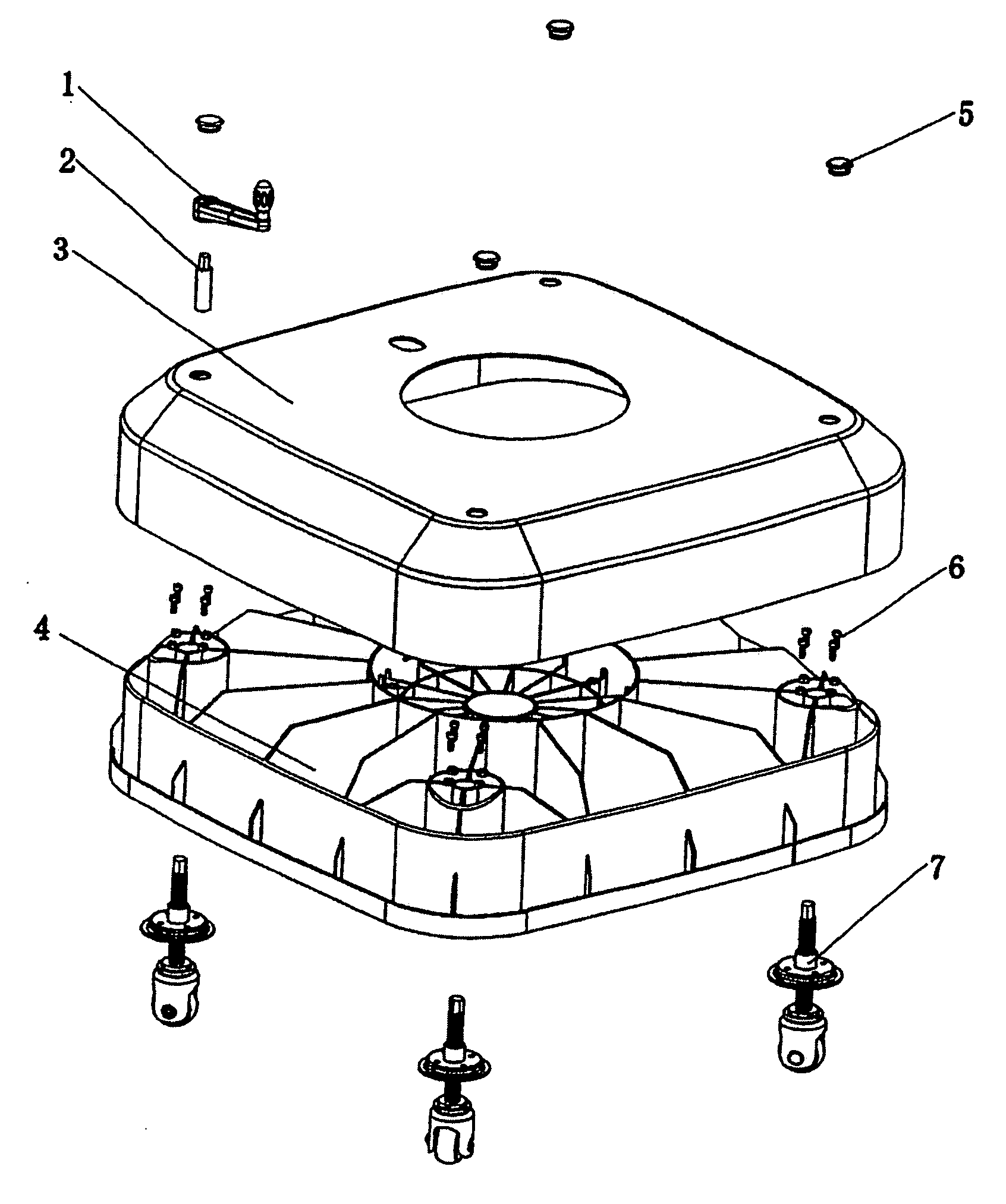

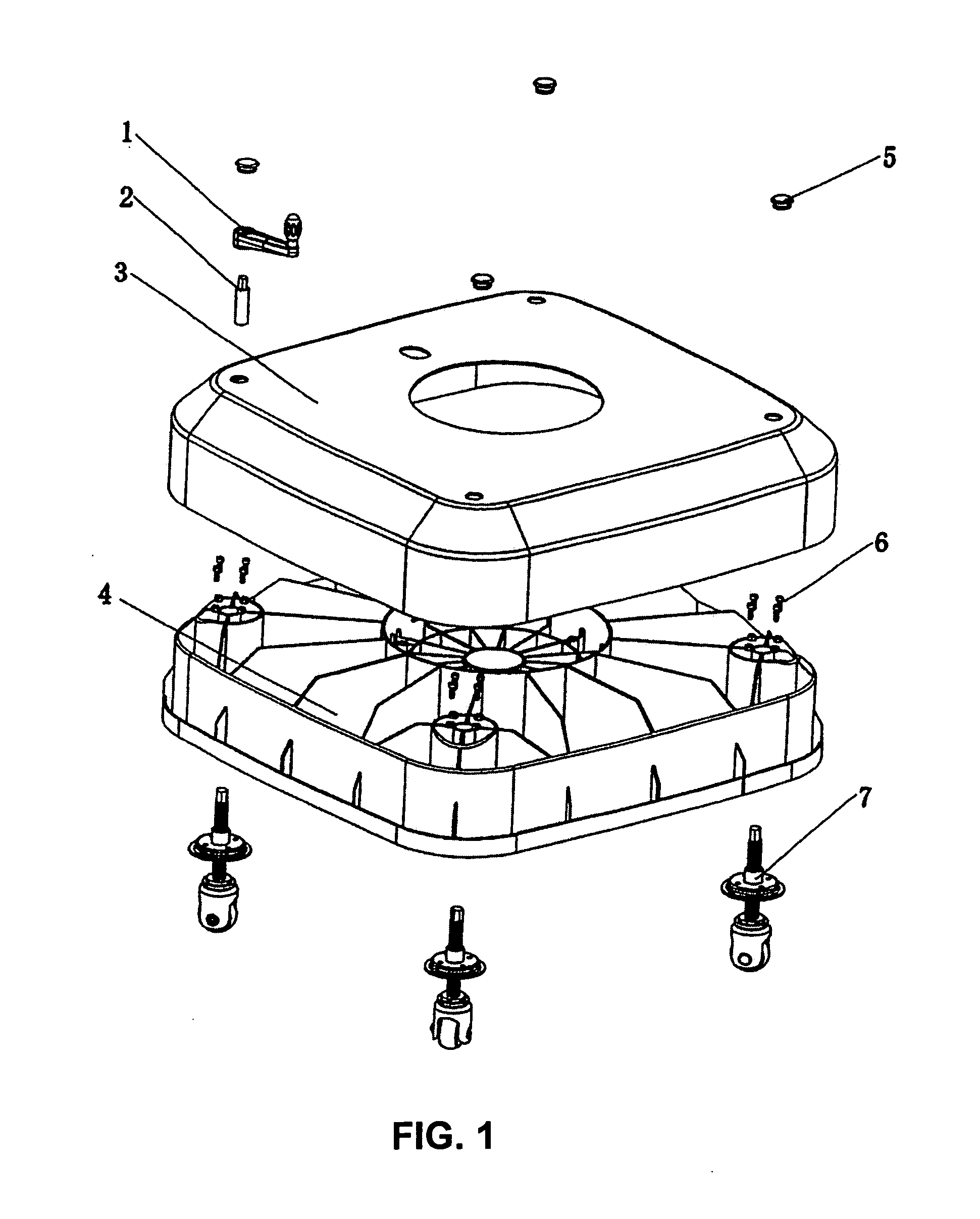

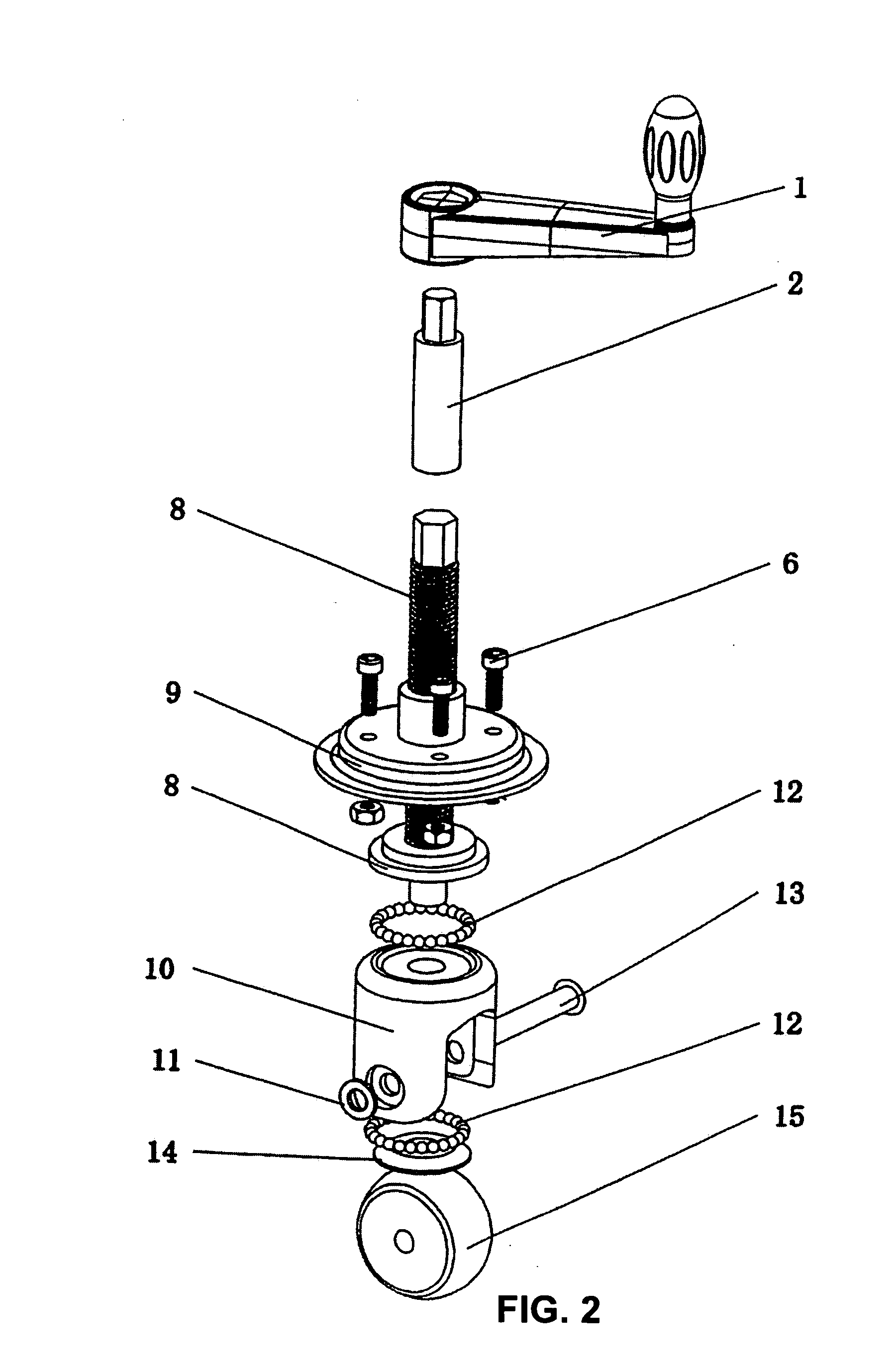

Base of sunshade umbrella

The present utility model is a large-sized sunshade umbrella which is used at fixed site outdoor. The interior of the base is divided into several independent portions, a protection case which is mated with the base is brought to cover the base, and the devices of caster wheel which can be stretched-out and drawn-back are provided in the holes at the corners of the base. Sand or water as the counterweight in the base can be added or reduced freely. When the base needs to fix, the caster wheels are drawn-back into the base through manual regulation to make the base rest on the ground to increase the attaching force; when the umbrella needs to move, the four caster wheels are stretched-out from the base to contact with the ground, so that a man or woman can push the umbrella smoothly to the site where he or she intends to place it.

Owner:CHEN NENGSEN

Multi-component display and merchandise systems

ActiveUS8627965B2Enhance pushing leverageWider productRacksShow shelvesEngineeringMechanical engineering

Owner:RTC IND

Multi-Component Display and Merchandise Systems

Owner:RTC IND

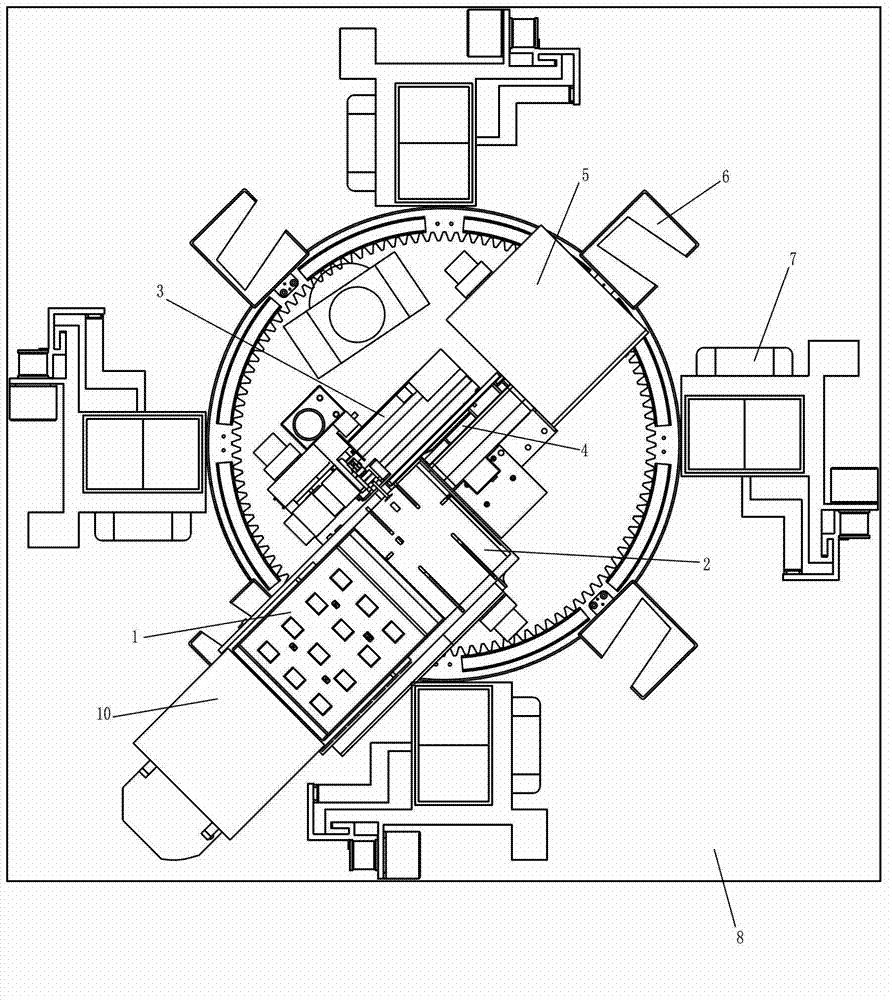

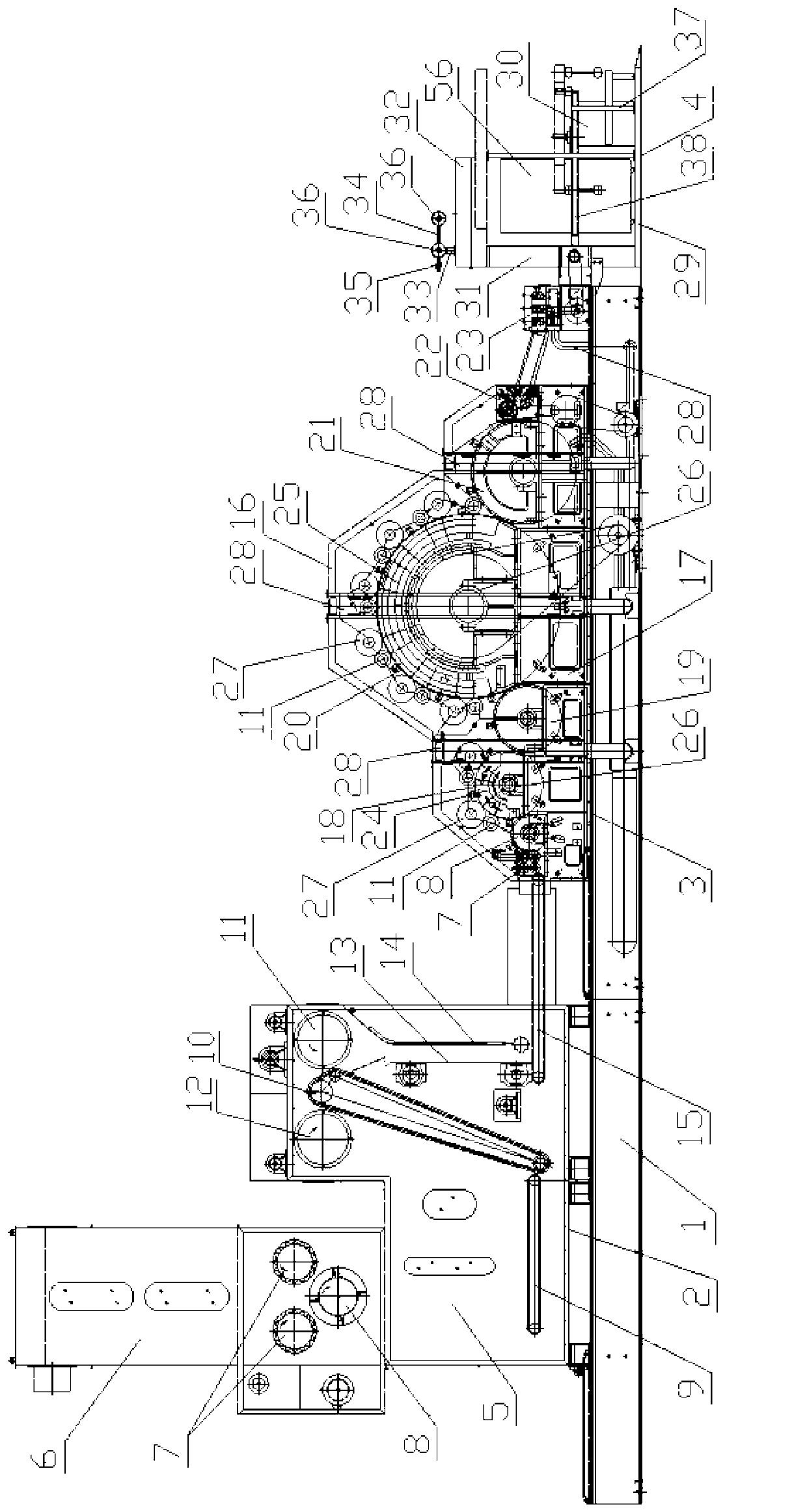

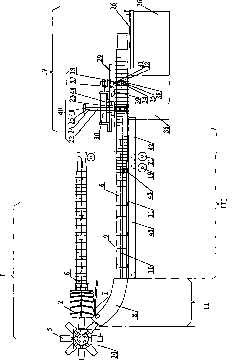

High-speed carding machine

InactiveCN102995167AGuaranteed stabilityGuaranteed speedCarding machinesEngineeringUltimate tensile strength

A high-speed carding machine comprises a base and a vibration wool feeding machine, a high-speed carding device and an automatic three-position barrel changing device which are connected with one another sequentially. The vibration wool feeding machine in the high-speed carding machine utilizes a translational vibration plate and a baffle to push textile raw materials uniformly, and moreover, the falling and outputting speeds of the textile raw materials are increased. A shaft seat of the high-speed carding machine is arranged on a breast cylinder wallboard and a large cylinder wallboard, so that the phenomenon that the positions of a breast cylinder and a large cylinder are changed relatively to the positions of a working roller and a wool stripping roller due to the high-speed rotation is avoided, the production quality is ensured, a suction pipe is arranged to suck the textile raw materials and reduce air flow which is generated by high-speed rotation, and the operation stability and high speed of the carding machine are ensured. The automatic three-position barrel changing device can control rotating wheels to change collection barrels, so that the high-speed carding machine is simple in structure and the labor intensity of the working personnel is reduced; and a U-shaped guardrail can ensure that the operation tracks of the collection barrels are stable when the collection barrels are changed, so that the whole barrel changing operation is carried out stably, and the collection barrels are prevented from tipping over during the barrel changing process.

Owner:青岛诚利佳机械有限公司

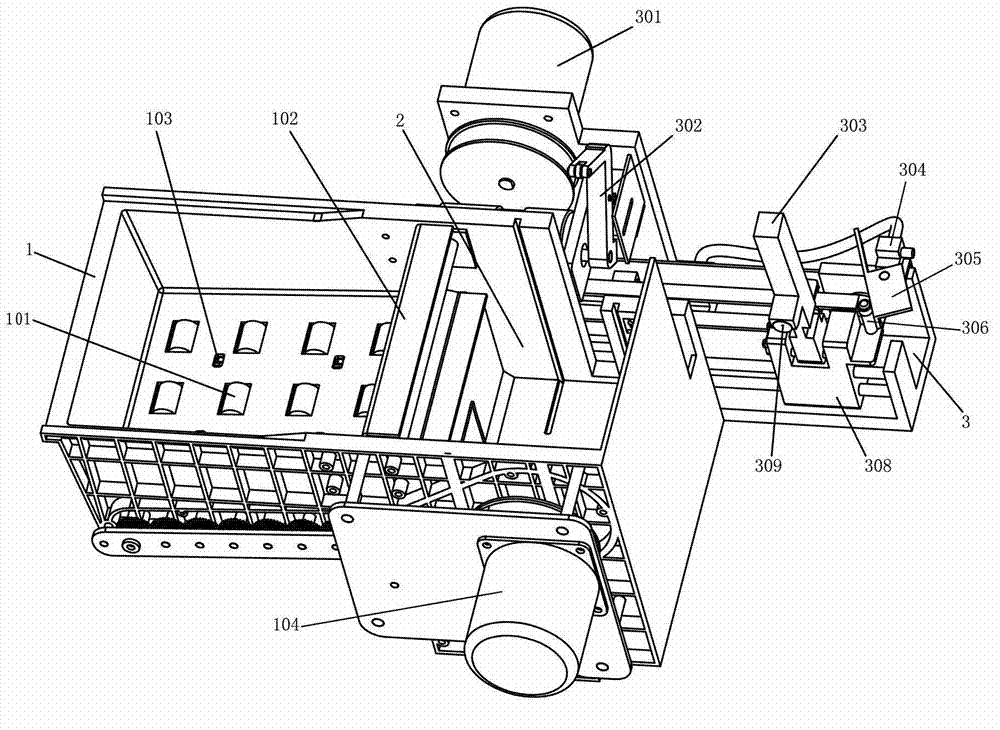

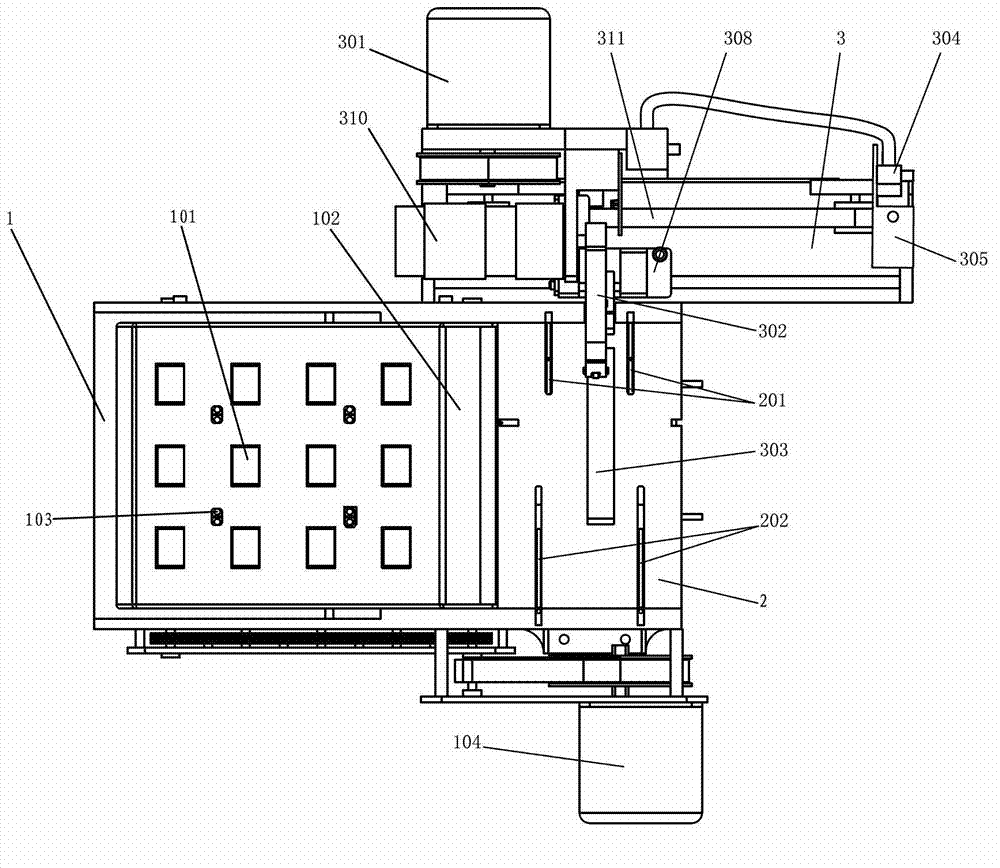

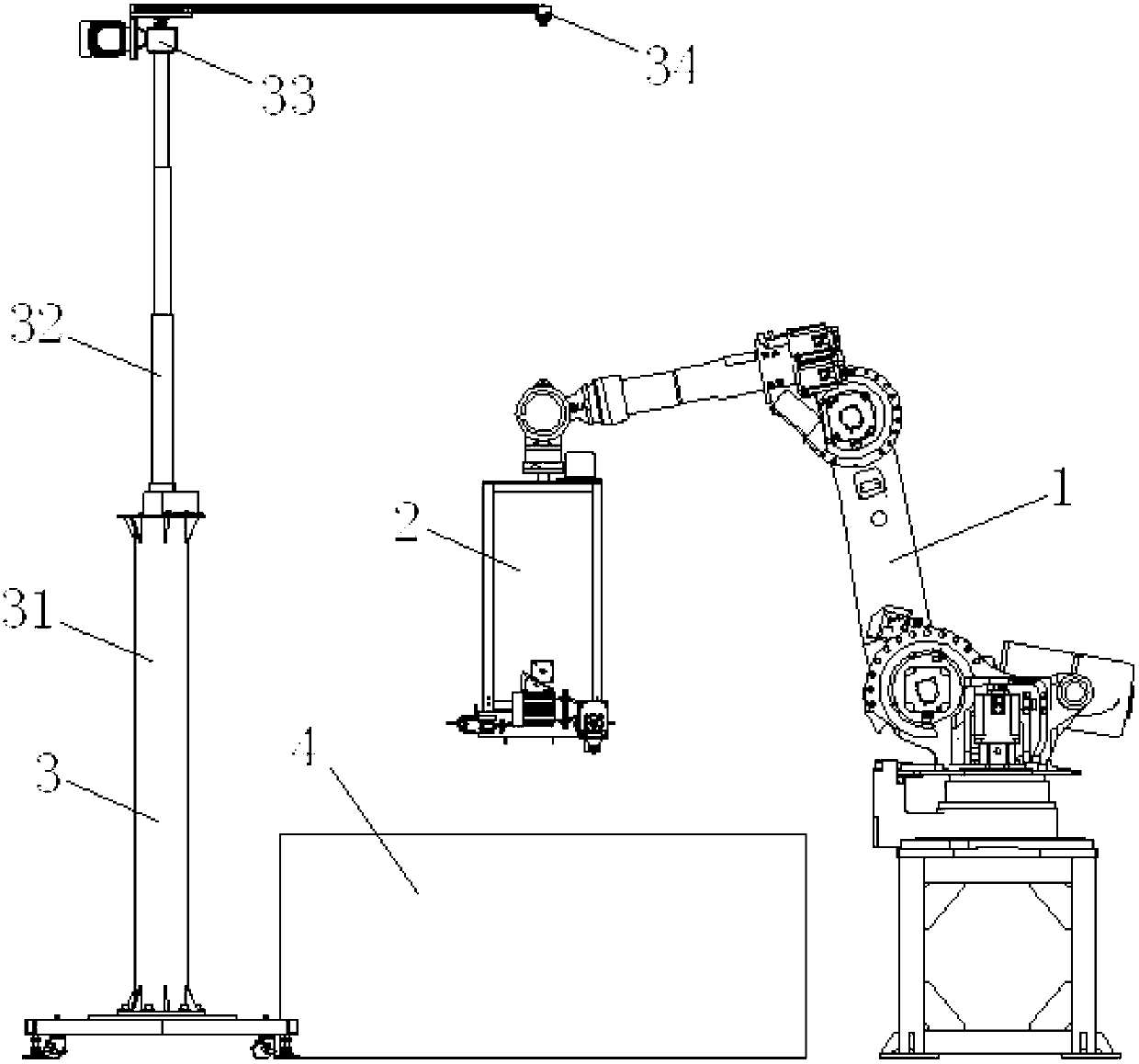

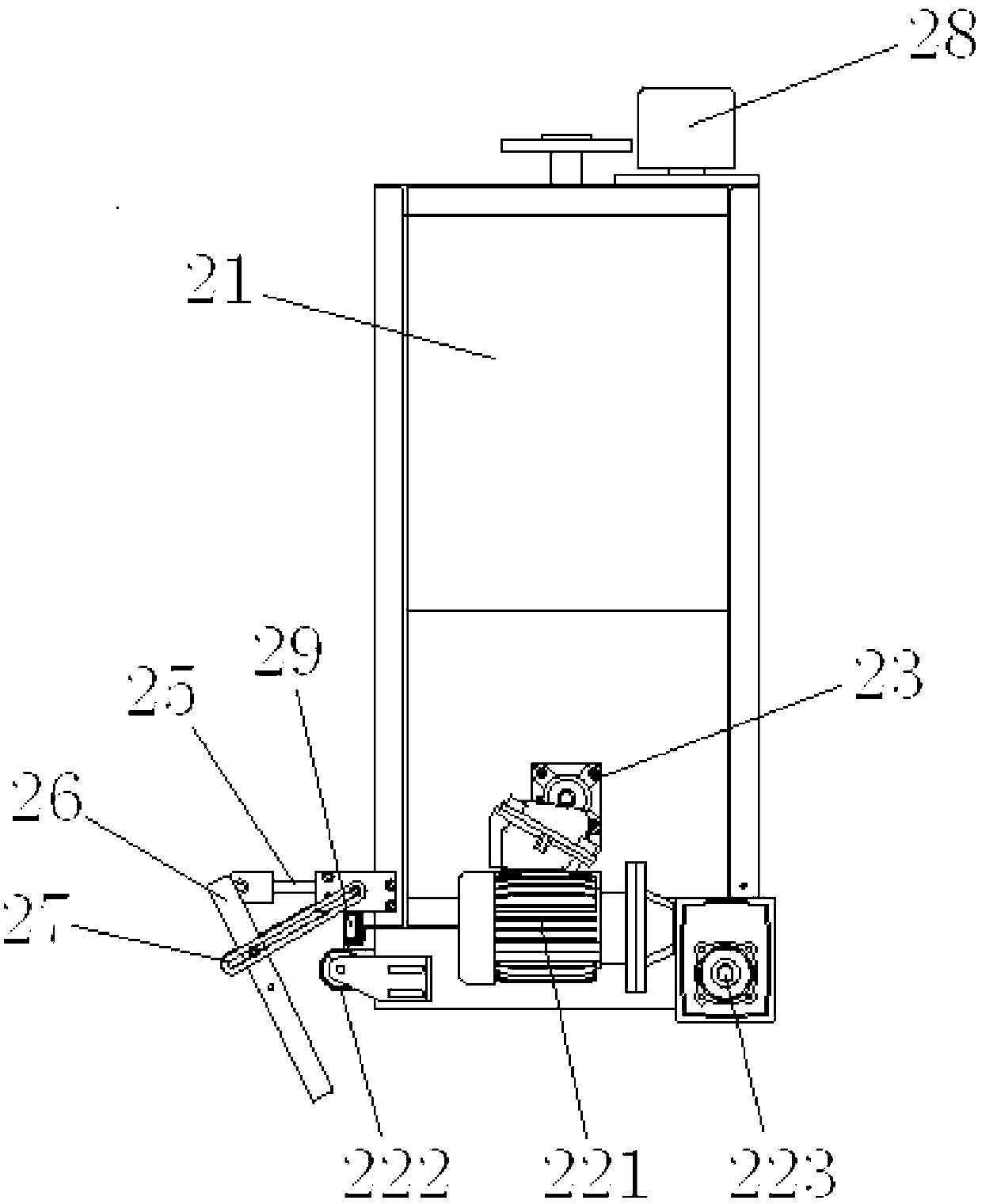

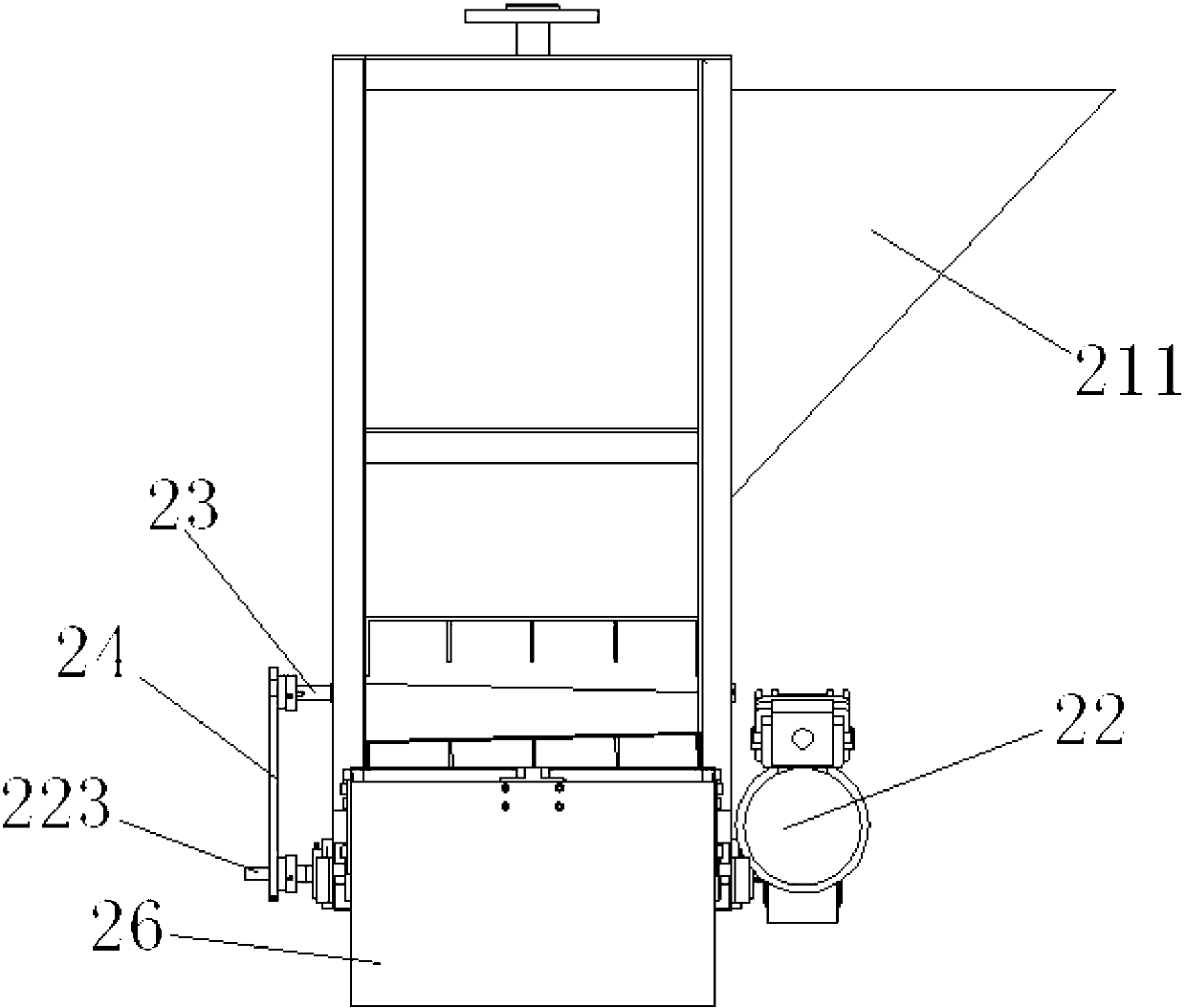

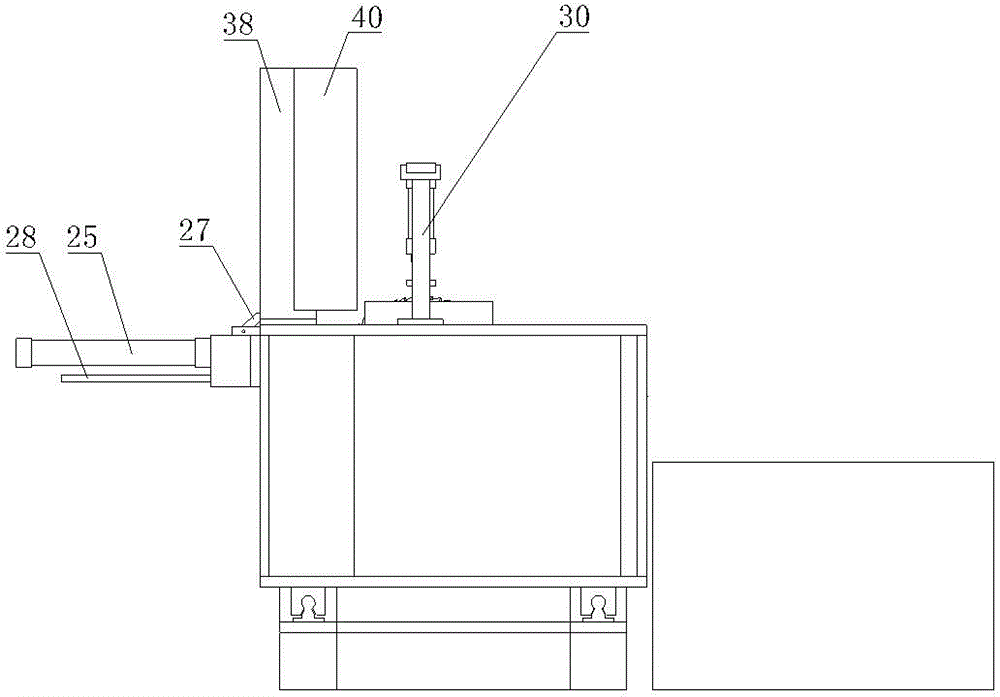

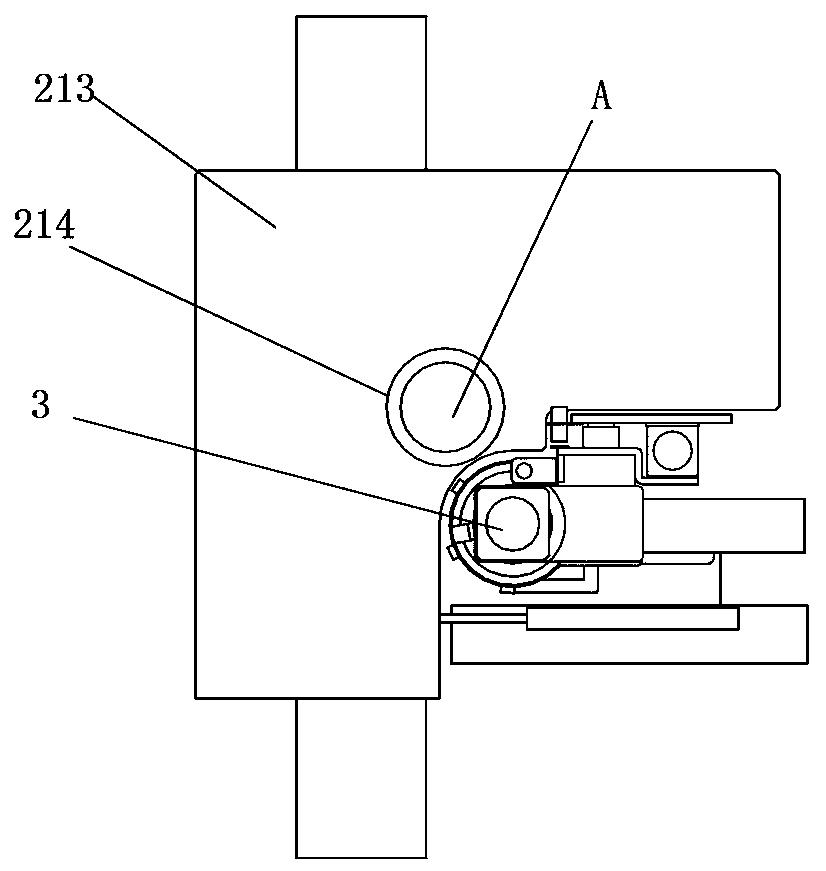

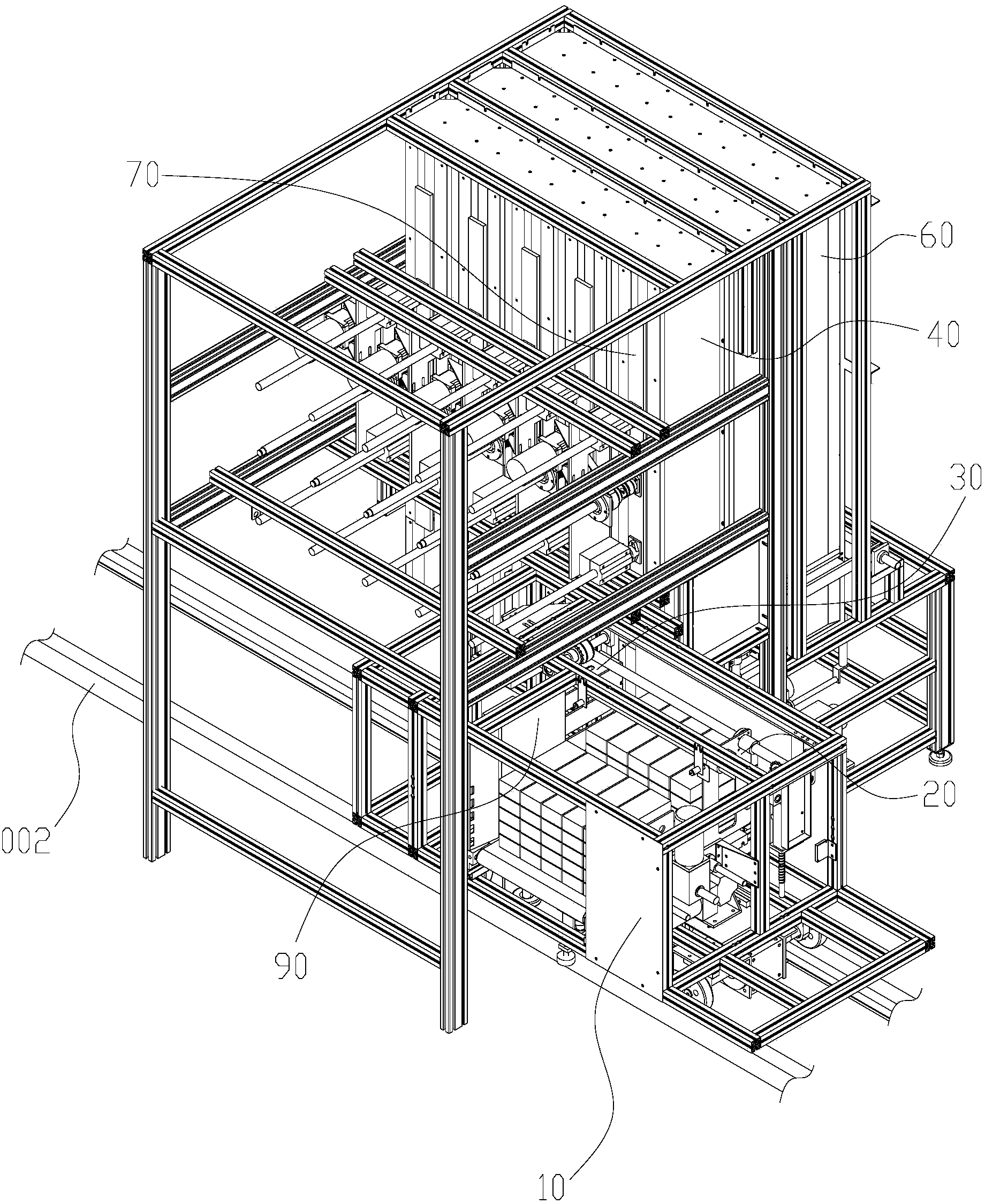

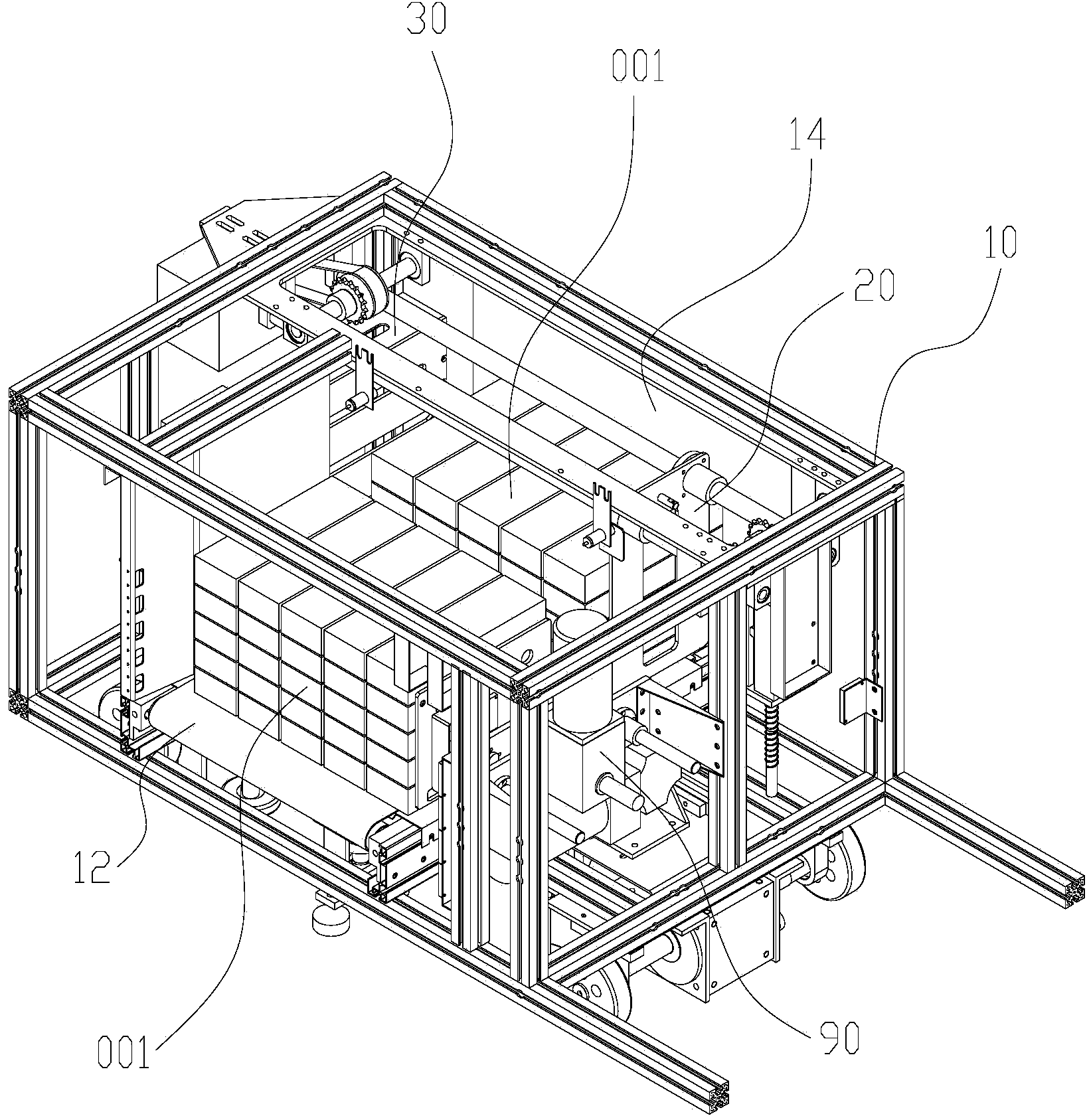

Full-automatic retort installing system and retort installing method thereof

ActiveCN103101773AAchieve mechanical propertiesRealize informatizationLoading/unloadingInformatizationEngineering

The invention discloses a full-automatic retort installing system and a retort installing method of the full-automatic retort installing system. The full-automatic retort installing system comprises a multi-joint robot, a retort installing executing mechanism, a retort installing vision measurement and control mechanism, a center control mechanism and a feeding mechanism. The retort installing executing mechanism is fixed at the tail end of the multi-joint robot and is located above a retort barrel. The retort installing vision measurement and control mechanism monitors and controls temperature and height of a charge level in the retort barrel in real time. The center control mechanism receives information collected by the retort installing vision measurement and control mechanism and sends control information to the multi-joint robot and the retort installing vision measurement and control mechanism. The feeding mechanism feeds the retort installing executing mechanism. The full-automatic retort installing system can fully simulate manual retort installing, is more high-efficient and accurate, and achieves full mechanization and informatization of wine making retort installing technology.

Owner:百特(福建)智能装备科技有限公司

Tampon Applicator

A tampon applicator which includes an ejector tube, an outer tube dimensioned to fit closely and telescopically over said ejector tube and having a distal discharge end, and a restraining means between said tubes for preventing the disassembly of said ejector tube from said outer tube in the proximal direction is disclosed. The restraining means includes a circumferentially-extending raised means and a set of at least three adjacent circumferentially-extending raised rings.

Owner:ONTEX HIGIENEARTIKEL DEUT GMBH

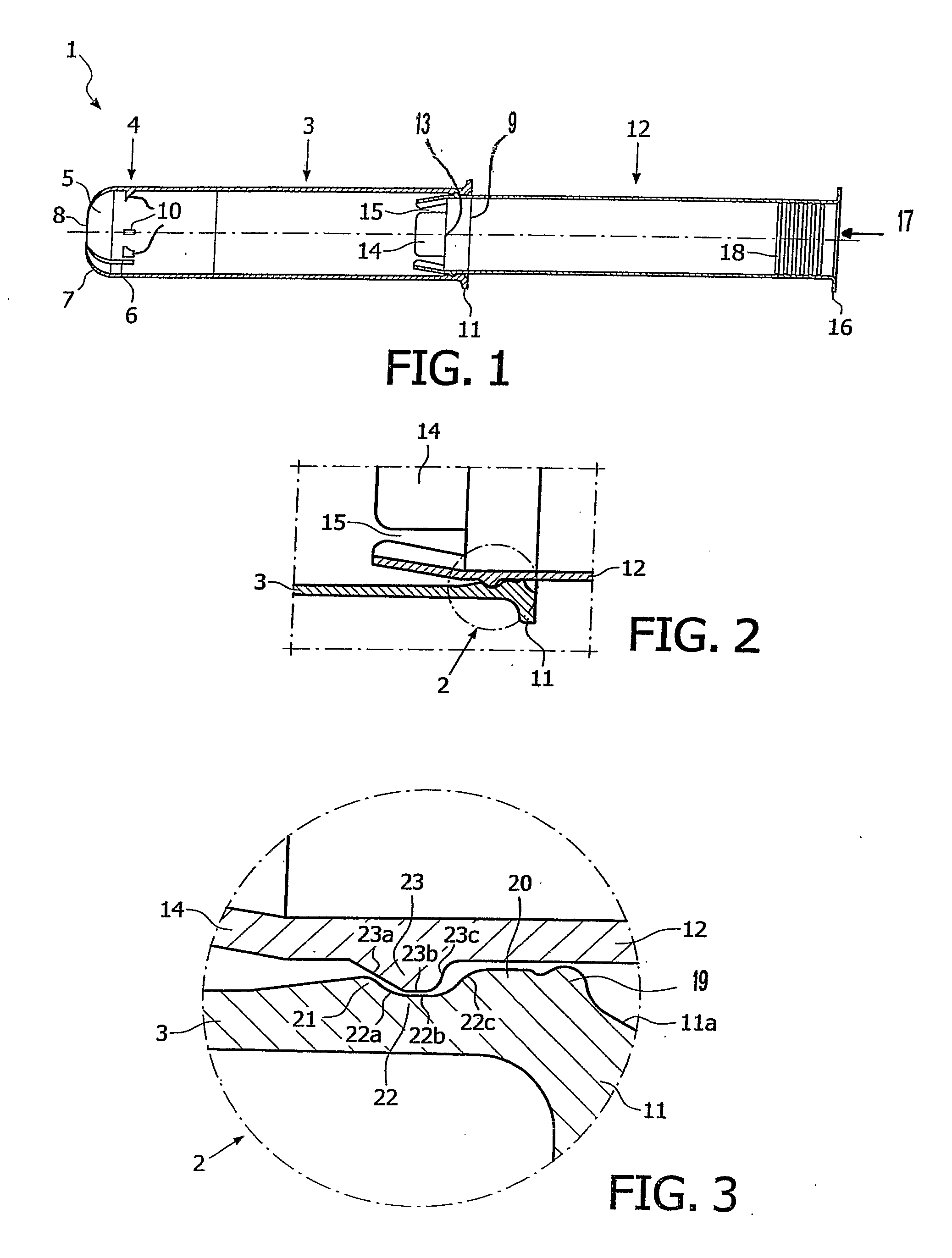

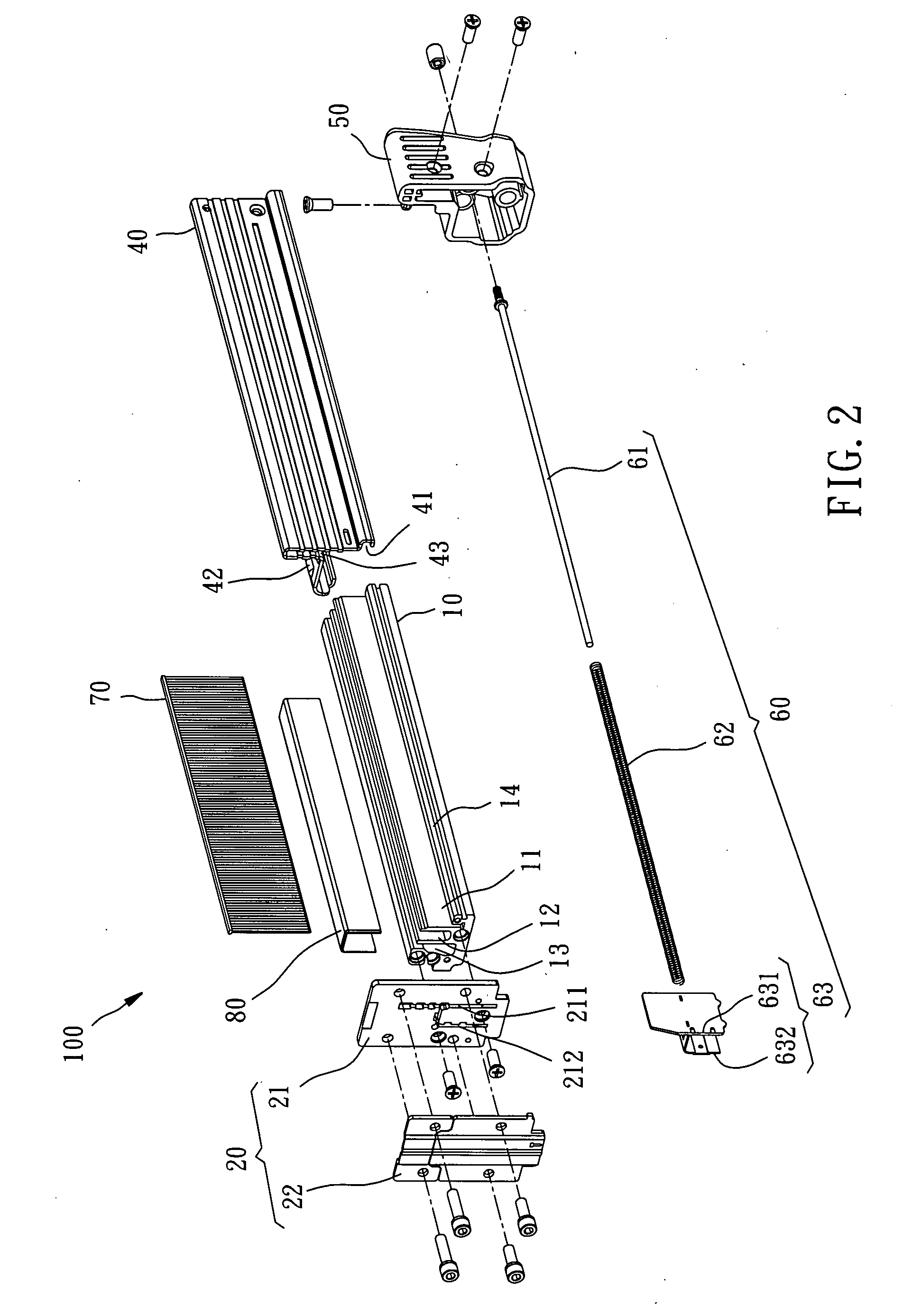

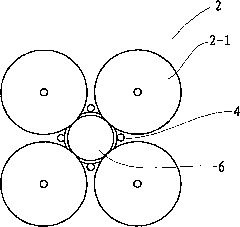

Dual-use nail magazine for U-shaped nail and T-shape nail

InactiveUS20080296340A1Preventing a nail jamPush smoothStapling toolsNailing toolsEngineeringShape Nail

A dual-use nail magazine for alternatively accommodating a T-shaped nail strip or an inverted U-shaped nail strip includes a track bar defining a first channel for receiving the T-shaped nail strip when it is used alone, a second channel, and a third channel cooperated with the first channel for receiving the inverted U-shaped nail strip. A nail pushing mechanism has a rod member suspended in the second channel, a nail push plate movably sleeved onto the rod member and having a first nail-pushing portion inserted into the first channel, and a second nail-pushing portion inserted into the third channel, and a compression spring sleeved onto the rod member for supporting and moving the nail pusher along the first channel and the third channel so as to push the T-shaped nail strip in the first channel or the inverted U-shaped nail strip in the first and third channels.

Owner:MOBILETRON ELECTRONICS

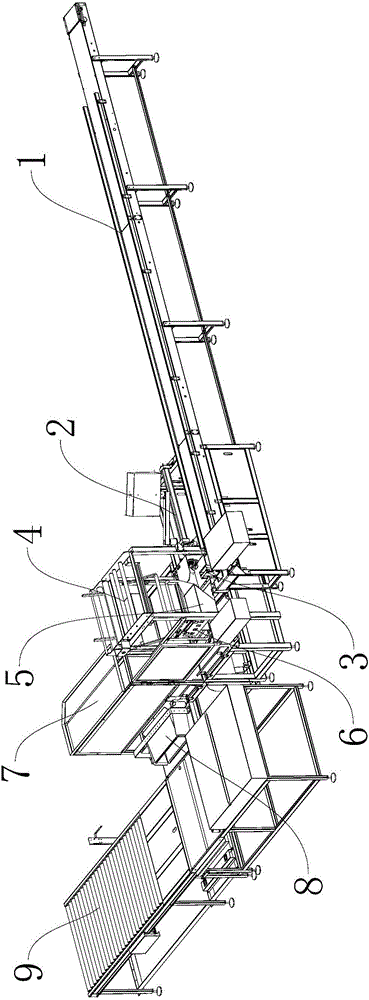

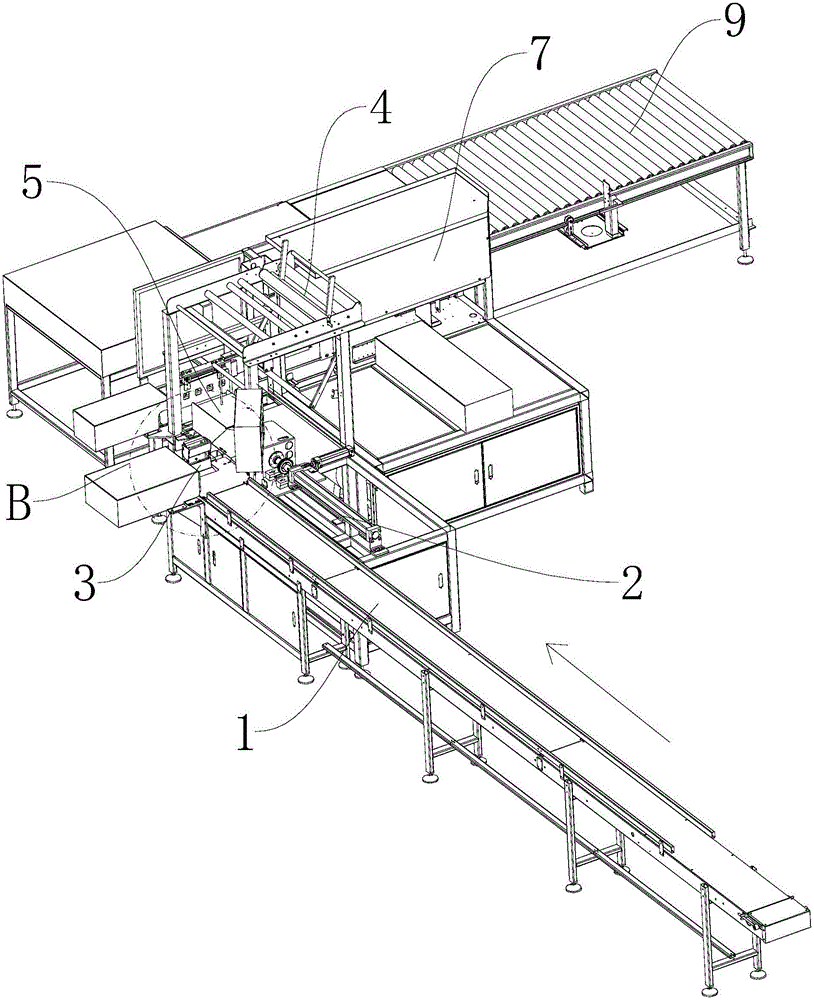

Full-automatic intelligent cheese packaging machine

ActiveCN105151355ALink connection is tight and reliableImprove efficiencyPackaging automatic controlIndividual articlesProgrammable logic controllerHigh-density polyethylene

The invention relates to a full-automatic intelligent cheese packaging machine. The machine comprises a programmable logic controller (PLC) control panel, a cheese input roller device, a cheese charging barrel automatic overturning mechanism, a bobbin positioning information testing device, a high-density polyethylene (HDPE) film conveying and compositing roller structure, an HDPE film inlet assembly, a cheese hot shearing system, a cheese semi-packaged finished product pushing system, a finished cheese product woven bag packaging device and a bagged cheese output roller device. The full-automatic intelligent cheese packaging machine fully takes procedures of all links of cheese packaging into consideration, and mechanical and automatic improvement is carried out according to all the links; link connection among a cheese weighing machine, a cheese packaging machine and a cheese stacking machine is close and reliable; a running mechanism can work for a long time, the whole production line only needs one operator, and packaging efficiency is greatly improved. Meanwhile, the weight of cheese of each batch is precisely controlled, deviation is reduced, and economic benefits in all aspects can be remarkably improved.

Owner:江苏晨阳机械有限公司

Occluder delivery system for cardiac surgery department

The invention relates to an occluder conveyance system comprising a puncture sheath with a puncture sheath tube and a propel member displaced therein, an occluder tubular carrier having a unilateral valve in the end and a conveyance steel cable used for cardiac surgery department. The puncture sheath tube and the occluder tubular carrier form a detachable connection by a set of connection member. The occluder conveyance system introduces the occluder from the body surface directly to the affected part by the puncture sheath under the guidance of an ultrasonic equipment. It is free of radiation, contrast and other interference tool, having no request on patient age and no impact on peripheral vessel, in addition, it has short operation time and low therapycost.

Owner:BEIJING BALANCE MEDICAL

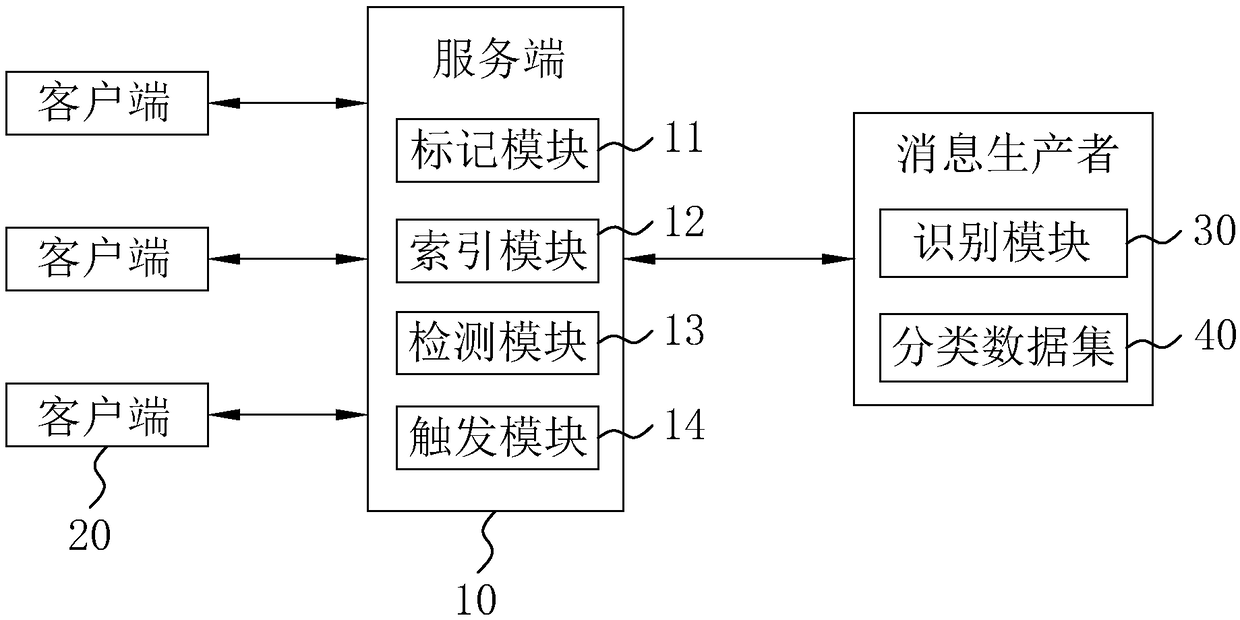

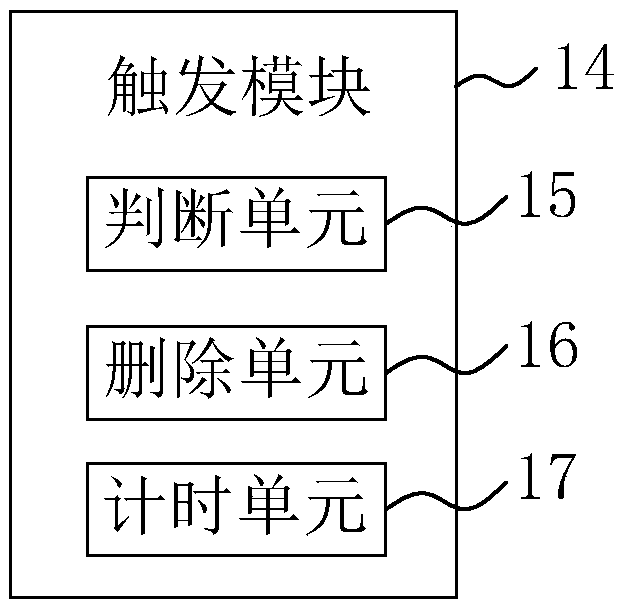

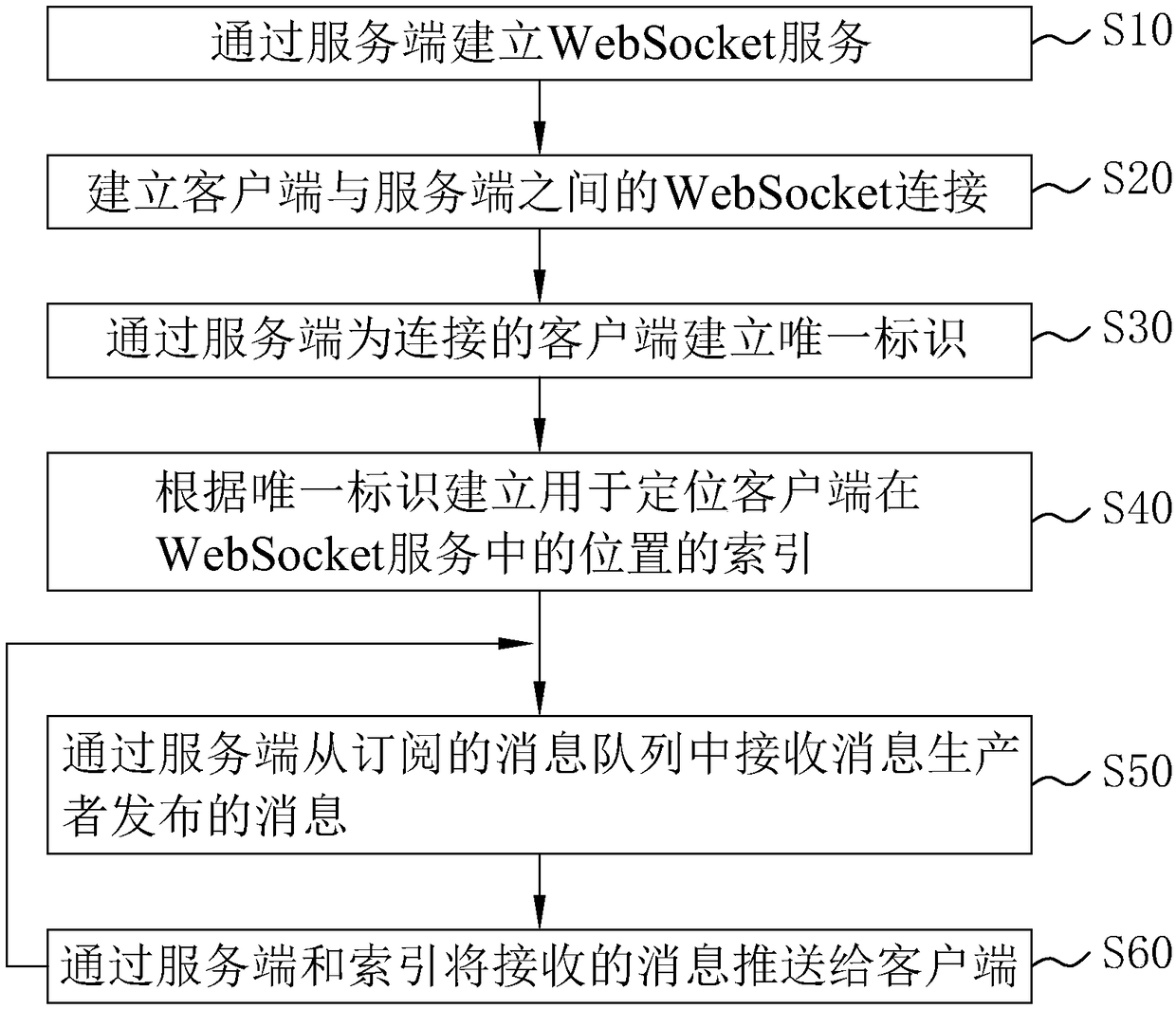

Bidirectional real-time communication system and method based on WebSocket and message queue

InactiveCN109361770APush smoothPrecise pushTransmissionClient-sideProtocol for Carrying Authentication for Network Access

The invention discloses a bidirectional real-time communication system and method based on a WebSocket and a message queue and relates to the technical field of communication. The problem that an existing real-time communication scheme based on the WebSocket protocol is liable to result in the condition that rear end service and a database need to bear a great deal of concurrent pressure is solved. According to the technical scheme key point, the system comprises a server and clients. The server comprises a marking module which is used for establishing unique identifications for the clients connected with the server, and an index module which is used for establishing indexes according to the unique identifications established by the marking module, wherein the indexes are used for positioning positions of the clients in WebSocket service. The server receives messages issued by a receiving message producer from a subscribed message queue in a message queue consumer mode and pushes the received messages to the clients according to the indexes. The server receives the messages passively and then pushes the messages to the corresponding clients, so the performance problem resulting from polling is solved.

Owner:苏州创旅天下信息技术有限公司

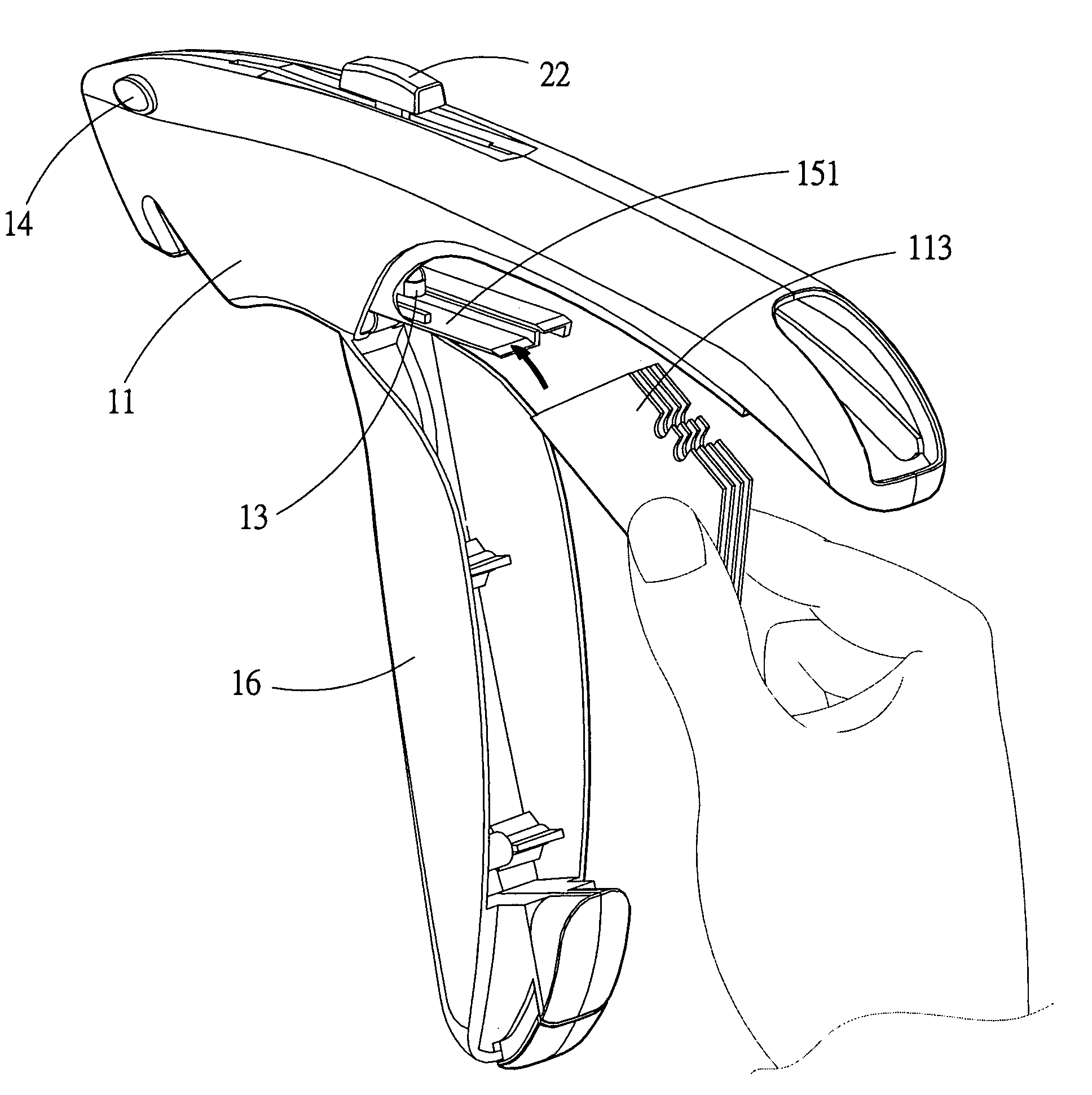

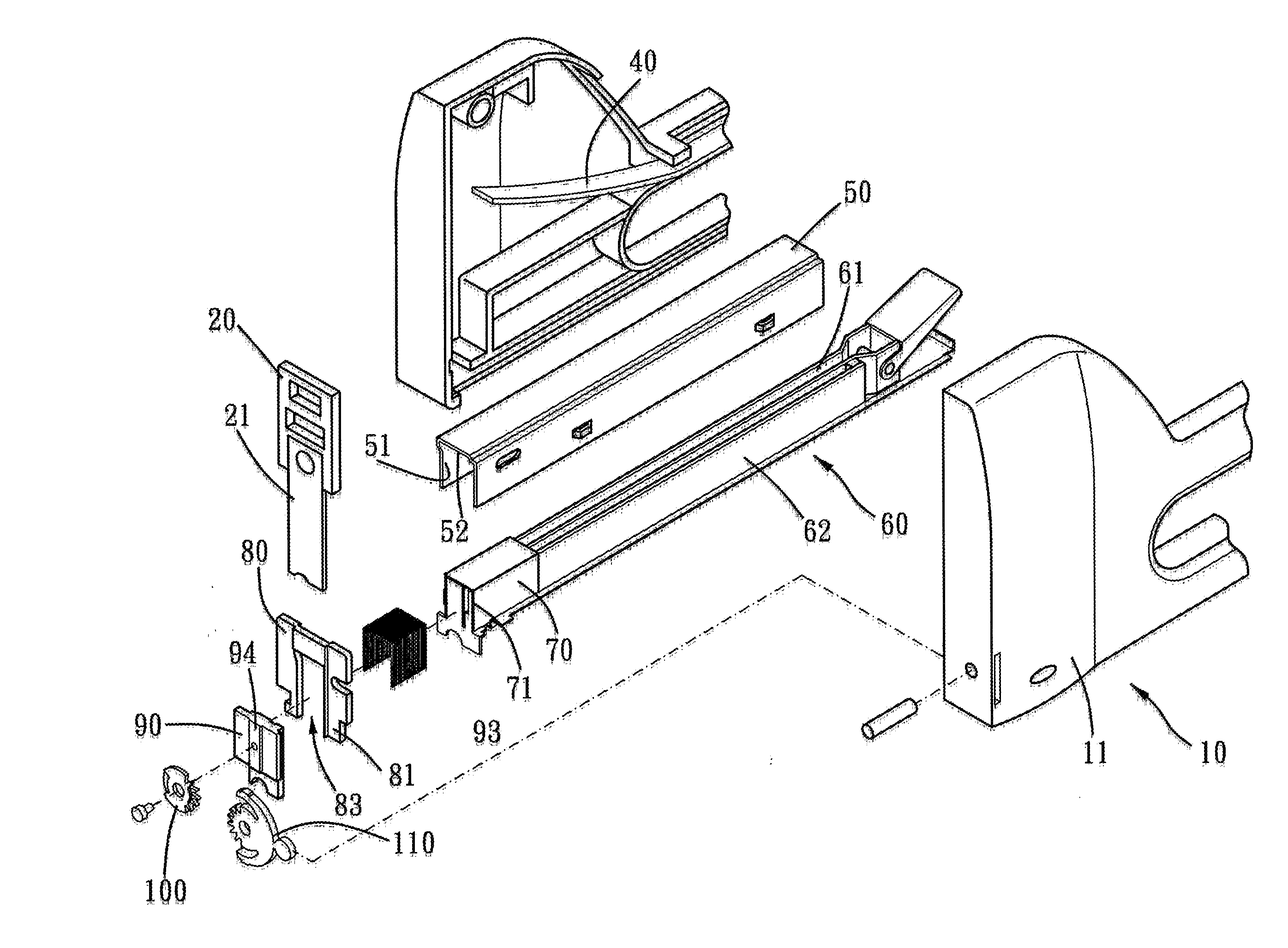

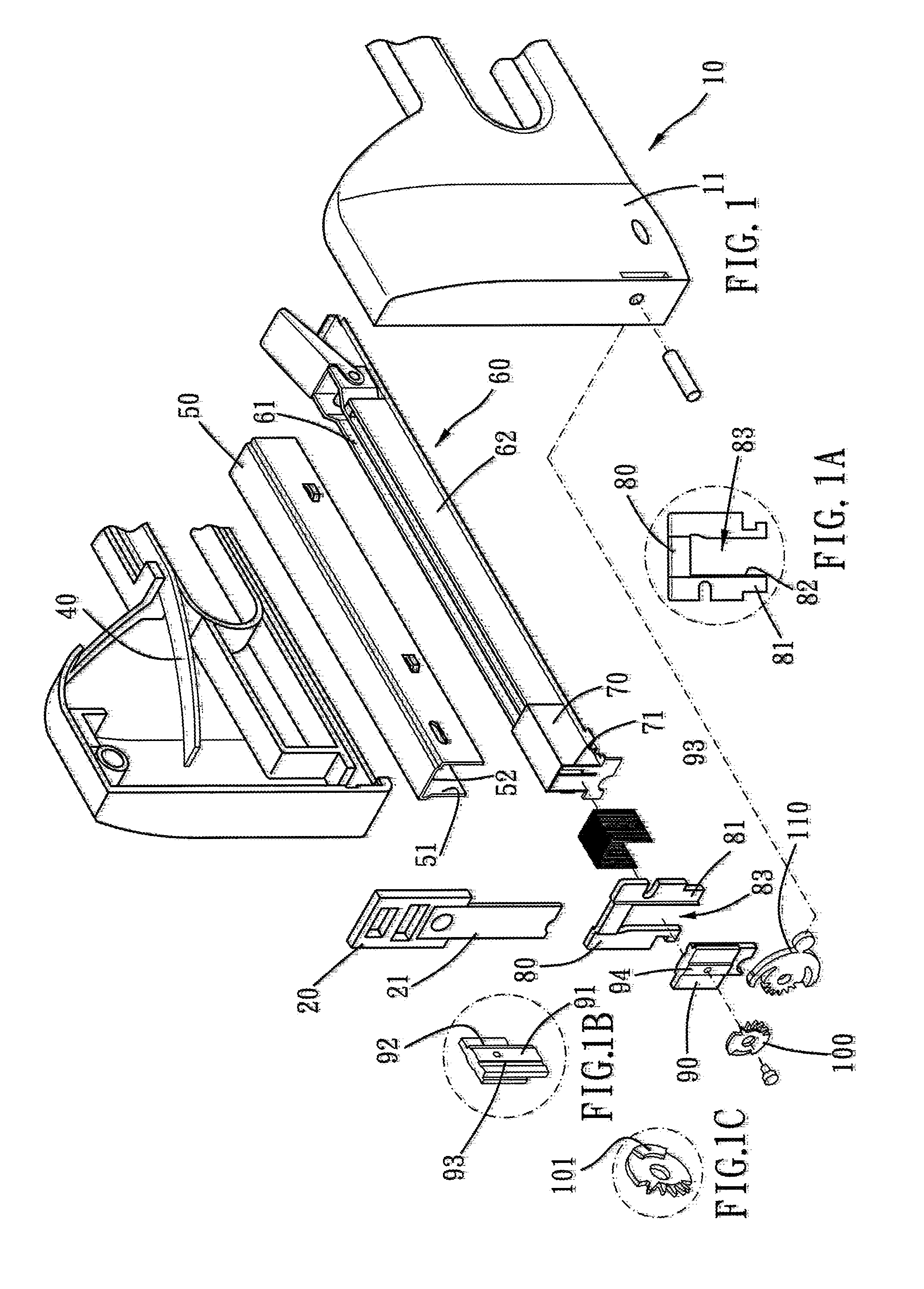

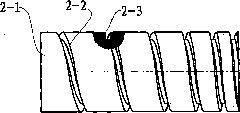

Nailing device adapted for nail units of different sizes

ActiveUS20110180583A1Push smoothly and position steadilyPush smoothStapling toolsNailing toolsEngineeringNail device

A nailing device of the present invention mainly includes a main body, a striker, an actuator, a resilient member, a nail slot, a magazine, a guider, an adjuster and a controlling means. The magazine has a main rail and a sub rail parallel to the main rail, and the main rail is substantially as tall as the sub rail. The adjuster has a protrusive portion having a guiding surface facing the magazine. The guiding surface is vertically formed with two parallel longitudinal grooves and has a bottom end. The longitudinal grooves extend toward the bottom end. The controlling means is for selectively pushing the adjuster to flush the guiding surface with a step surface of the guider.

Owner:APEX MFG

Automatic high-speed conveyer system of EPS (Expandable Polystyrene) cup printing machine

InactiveCN101823361AWidely used valueIncrease productivityRotary pressesProgrammable logic controllerPolystyrene

The invention relates to a cup and bowl printing machine, in particular to an automatic high-speed conveyer system of an EPS (Expandable Polystyrene) cup printing machine, mainly comprising an automatic high-speed cup separating device, an automatic high-speed cup receiving and sending device, an automatic high-speed cup stacking and conveying device, an automatic high-speed cup counting and pushing device and a PLC (Programmable Logic Controller) controller, wherein the automatic high-speed cup separating device separates conveyed cups to be printed, which are sleeved and stacked into a whole strip, into single cups and conveys the cups into a mould of a eight-graduation turntable of a stepper graduator for printing; the printed cups are conveyed to the automatic high-speed cup stacking device through the automatic high-speed cup receiving and sending device; the automatic high-speed cup stacking device sleeves and stacks the cups into a whole cup strip and pushes the cup strip to the automatic high-speed cup counting and pushing device; and after counting, the cups are pushed to a cup receiving groove. The whole process is controlled by the PLC controller to realize the automation of the whole printing process, and the production efficiency is greatly improved.

Owner:GUANGDONG LONGXING PACKAGING IND

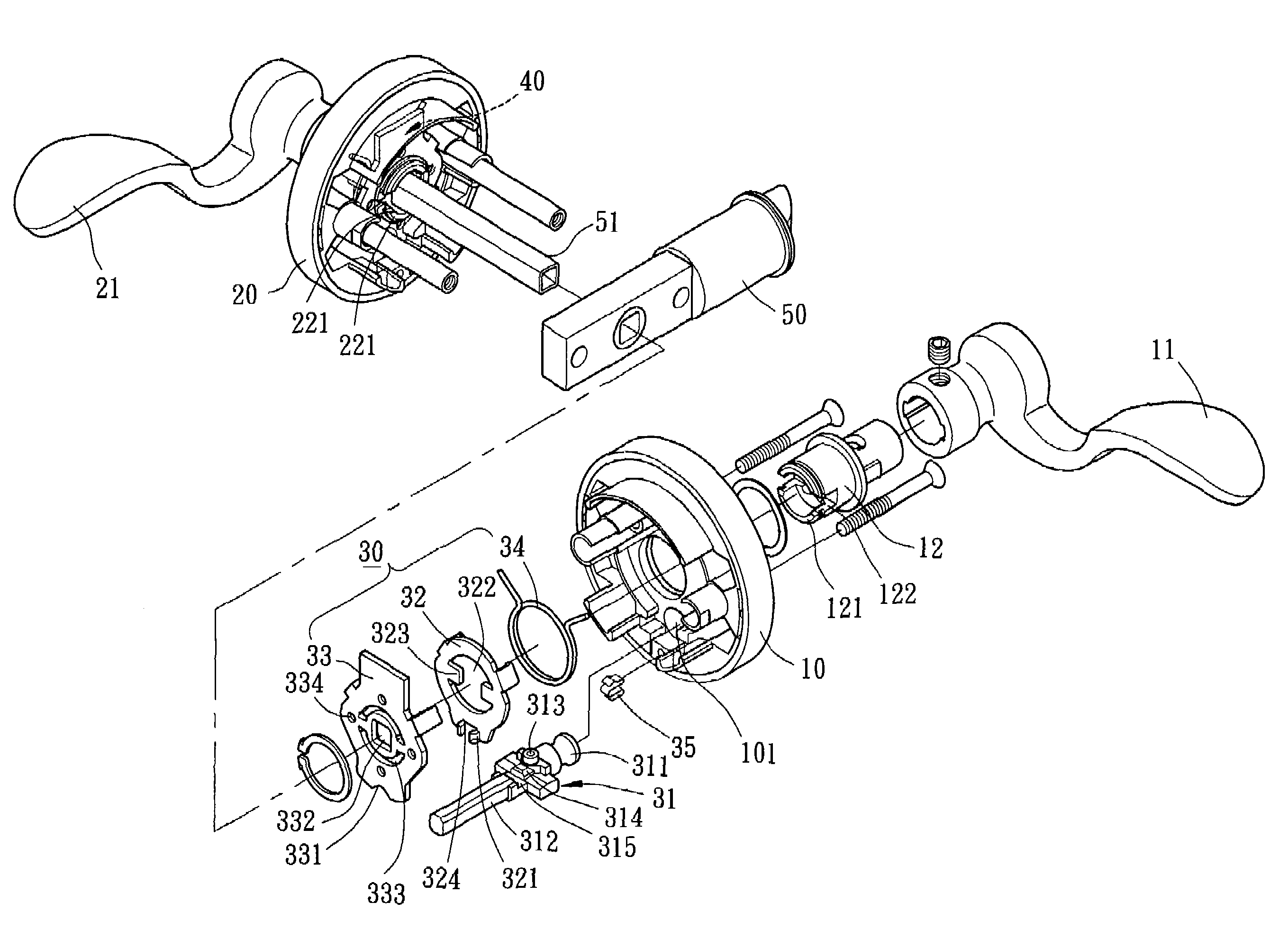

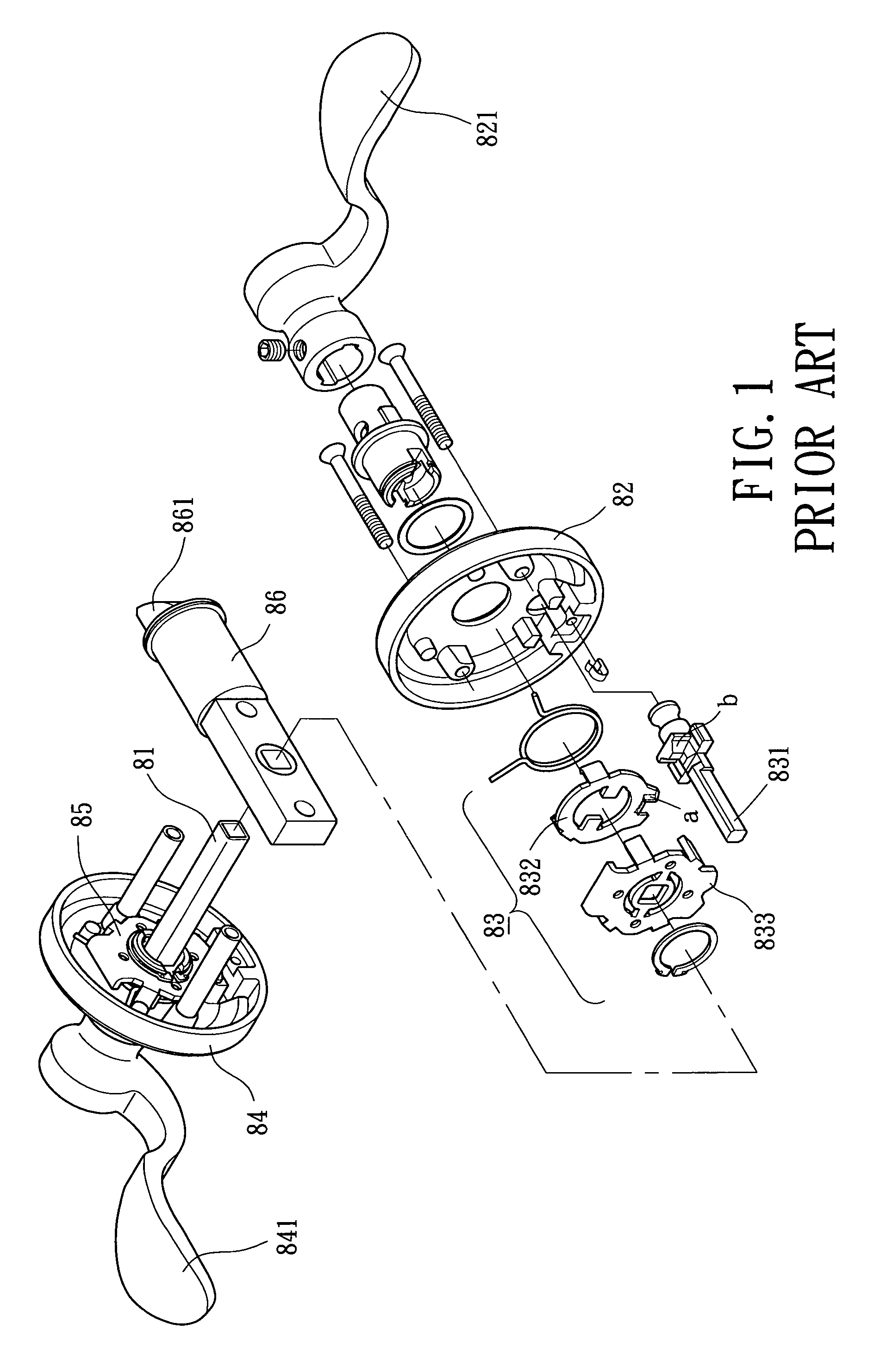

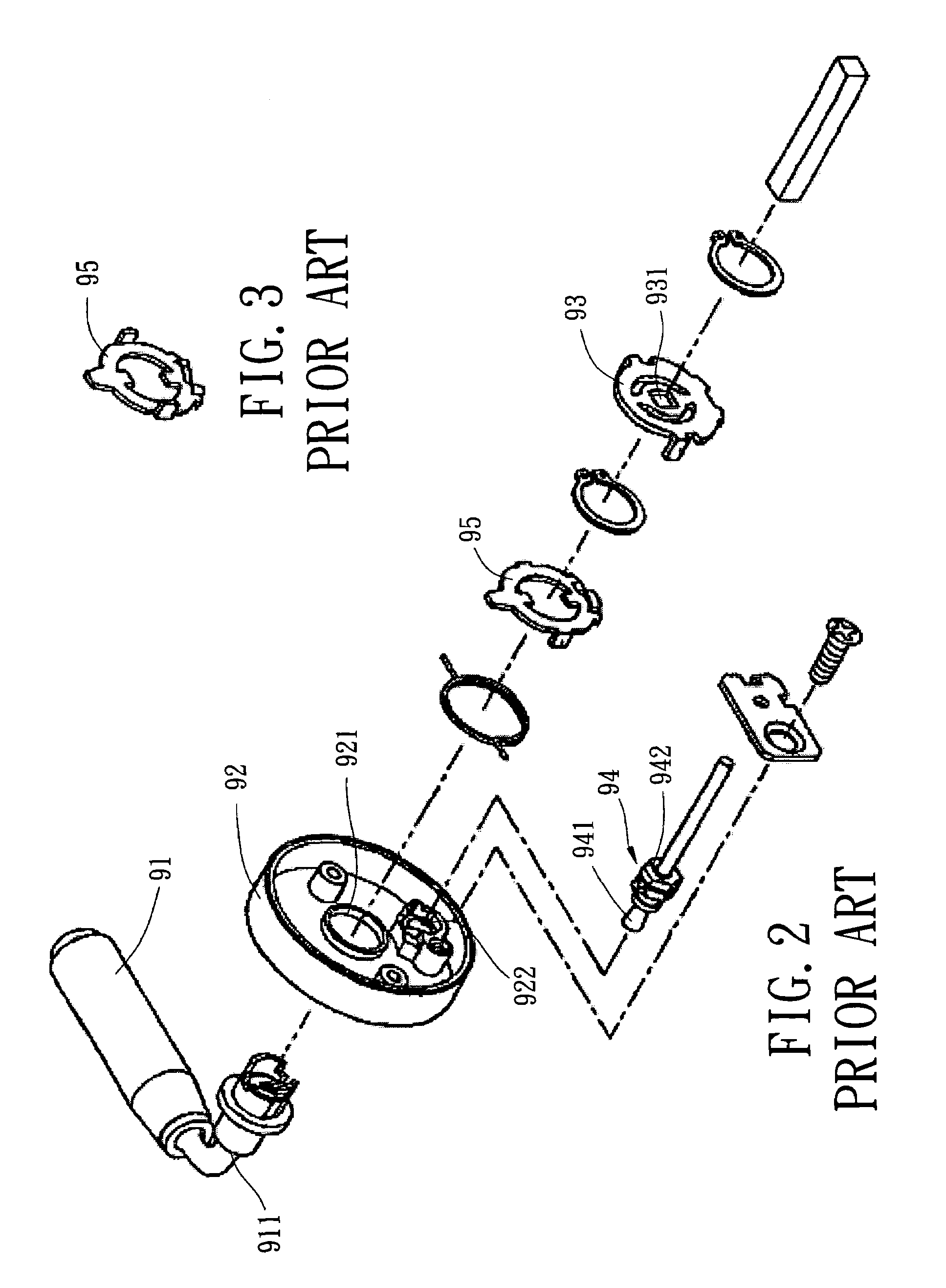

Bathroom lock device having an automatically unlocking structure

ActiveUS7387005B2Guaranteed uptimeSmooth returnKeyhole guardsFastening meansLocking mechanismEngineering

A bathroom lock device includes an inner locking mechanism and a lock set. The inner locking mechanism includes a manual control rod, an unlocking rotary plate and an inner actuating rotary plate. The manual control rod has a rotatable wheel while the unlocking rotary plate has a pair of actuating protrusions. In a locking operation, the manual control rod is pressed to a locking position so as to limit a rotational movement of the inner actuating rotary plate. In an unlocking operation, the manual control rod is returned to an unlocking position by turning a lever so as to permit turning the inner actuating rotary plate. When the lever turns the unlocking rotary plate, the actuating protrusions of the unlocking rotary plate smoothly push the rotatable wheel of the manual control rod so as to return the manual control rod to the unlocking position.

Owner:TAIWAN FU HSING INDAL

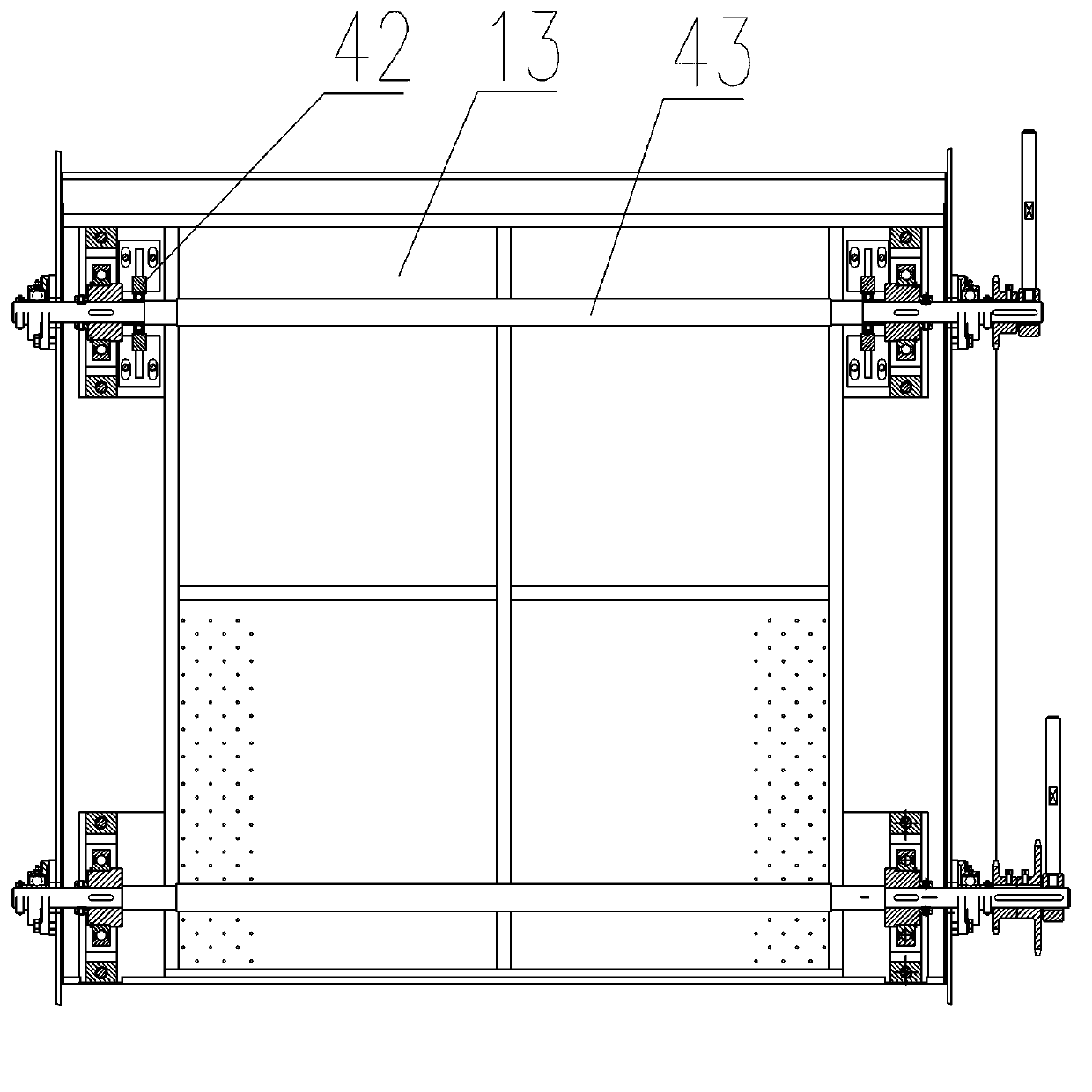

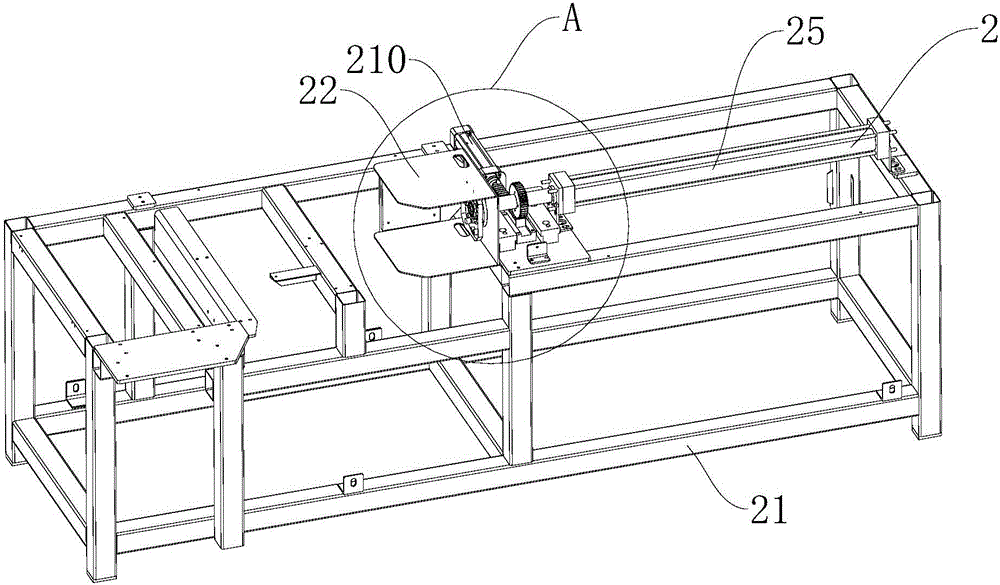

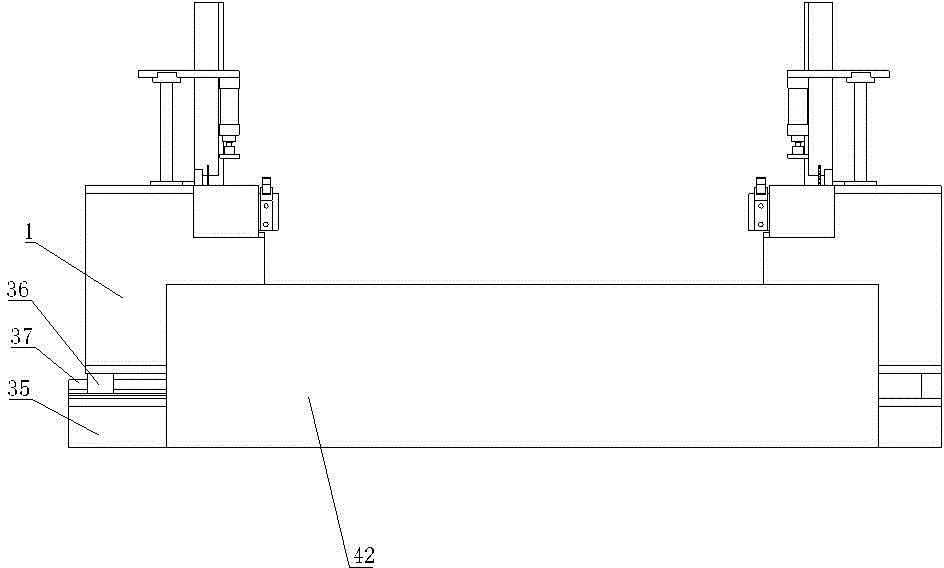

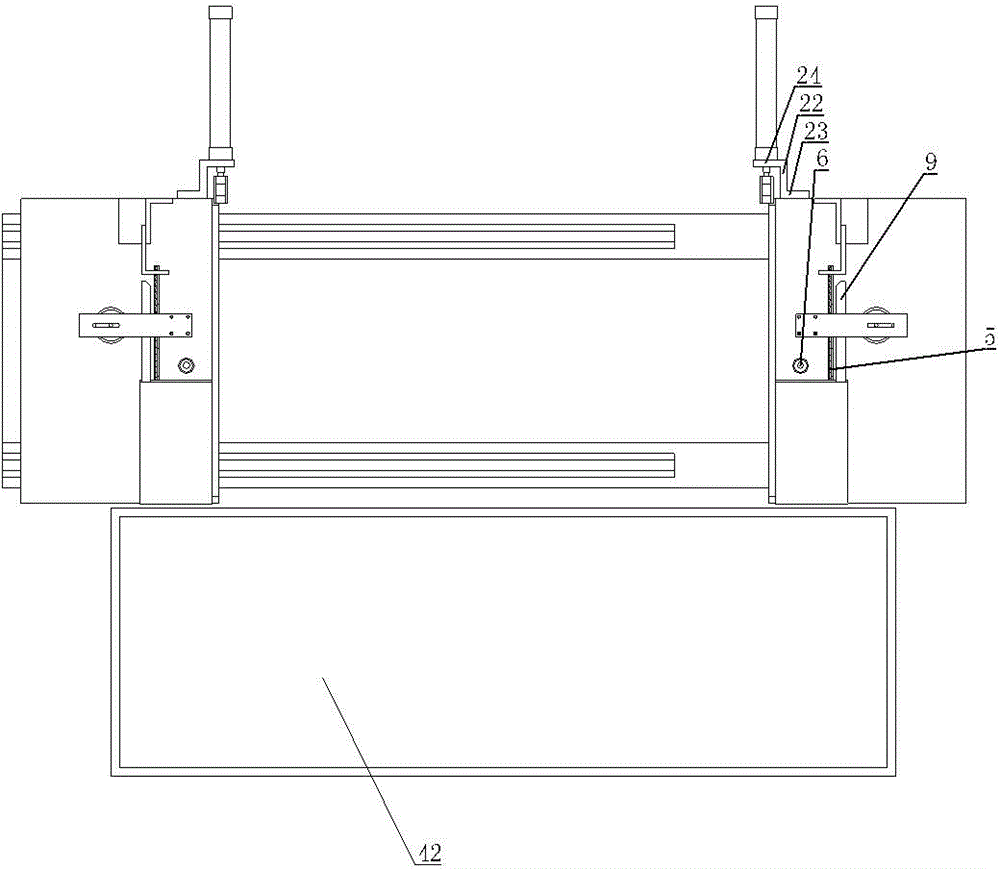

Board double-end cutting and edge aligning device

InactiveCN105690485APlay a limiting rolePush smoothFeeding devicesCircular sawsEngineeringSlide plate

The invention provides a board double-end cutting and edge aligning device. The board double-end cutting and edge aligning device is simple in structure, manual pushing is replaced, a board can be conveniently fixed and positioned, the two ends of a board are subject to cutting and edge aligning at the same time, and cut edge alignment is ensured. The board double-end cutting and edge aligning device comprises two bases arranged on a base seat, sliding blocks are arranged at the bottom of one base, sliding rails matched with the sliding blocks are arranged on the base seat, and each base comprises a mounting box; a bottom plate is arranged on each mounting box, and a discharging mechanism parallel to the cutting direction is arranged on each bottom plate; a saw blade driven by a motor, an air cylinder for lifting the saw blade and a positioning air cylinder connected with a positioning block are arranged in each mounting box; a saw groove allowing each saw blade to pass through and a positioning hole allowing each positioning block to pass through are formed in each bottom plate; a limiting plate is arranged at the position, parallel to each saw groove, of the outer side of each saw groove, and a compressing mechanism is further arranged at the position, corresponding to the outer side of each limiting plate, of each bottom plate, and a pushing mechanism is further arranged at the rear end of each bottom plate; a rear sliding plate is arranged at the position, corresponding to the rear side of each saw groove, of each base, and the rear end of each rear sliding plate inclines downwards; and a receiving box is arranged on the rear side of each base.

Owner:WUXI FORMEN TECHN

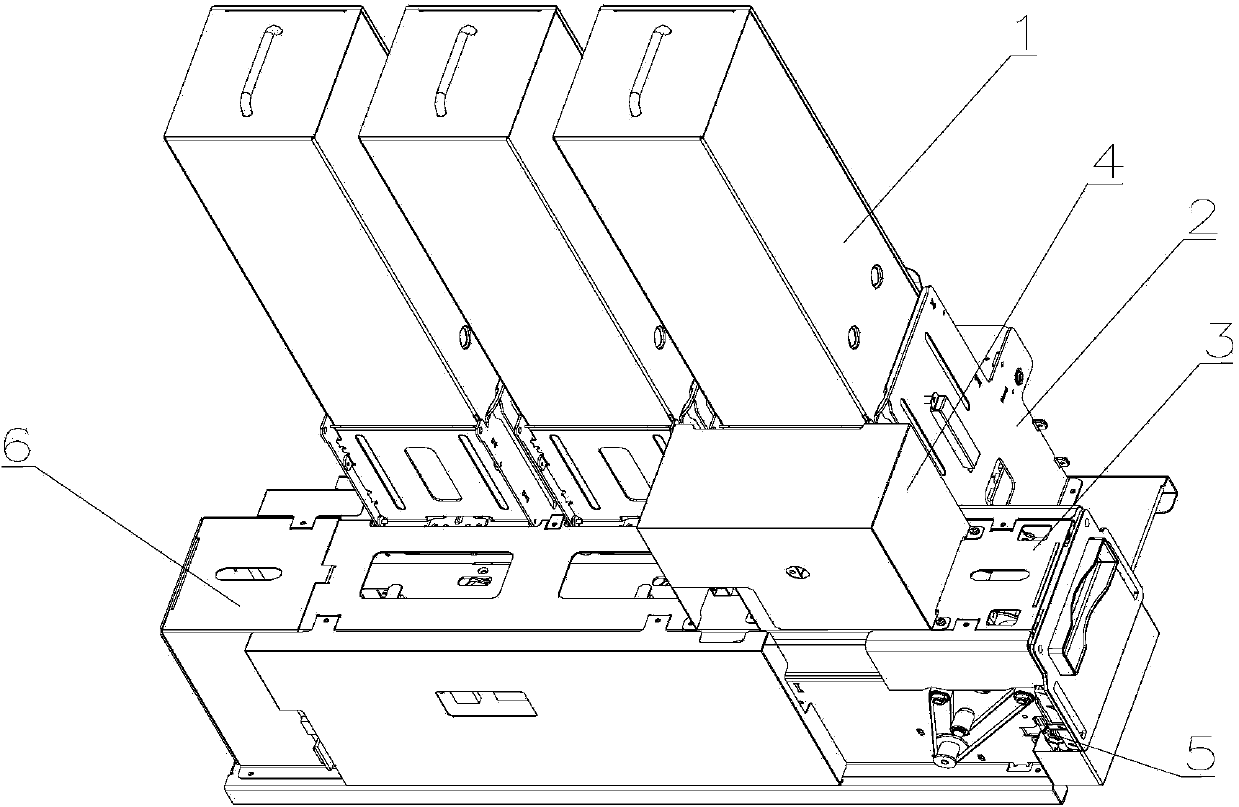

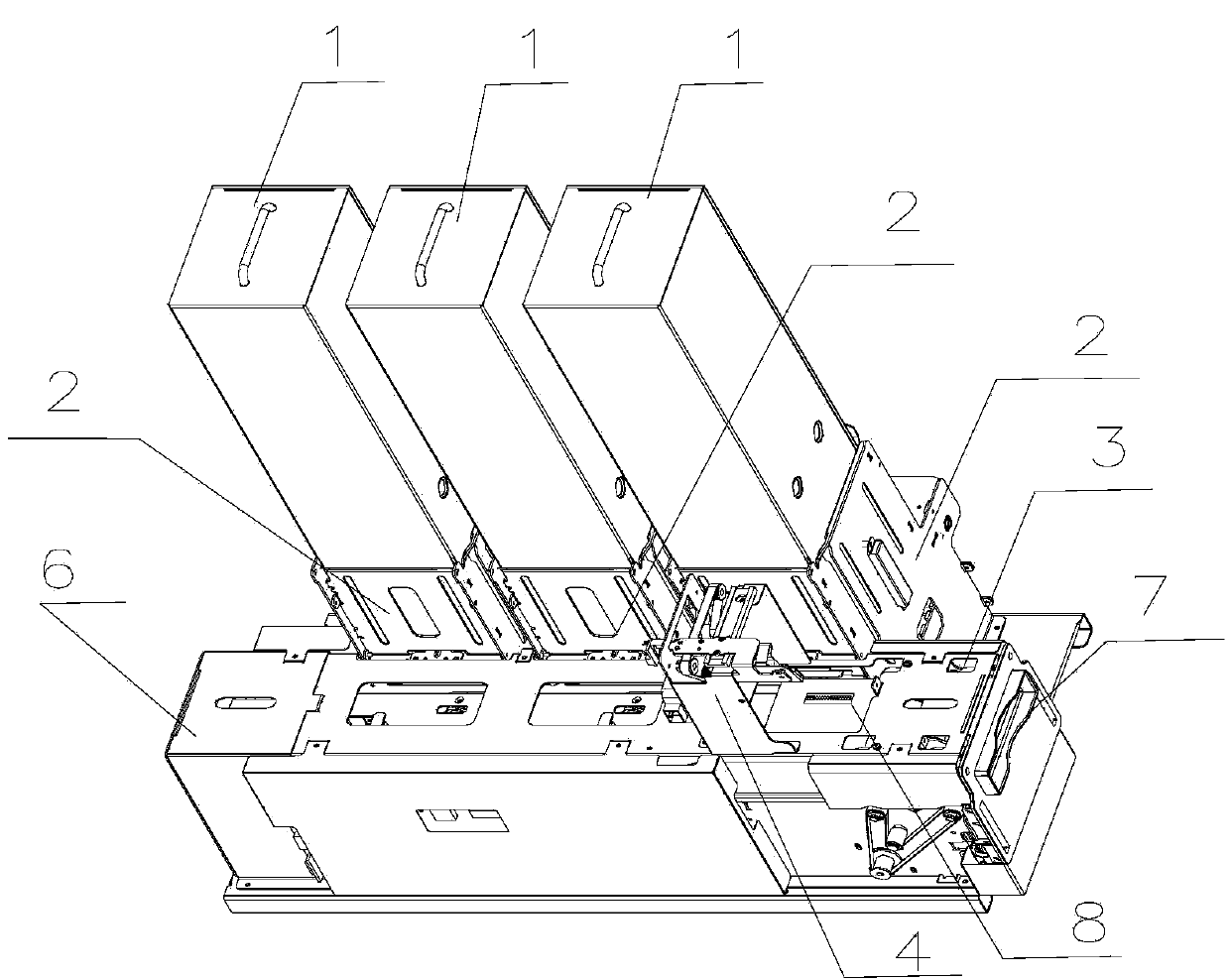

Method for issuing high-capacity internetbank verification modules

ActiveCN104200241ACompact structureSave spaceComplete banking machinesConveying record carriersLarge capacityAutomation

The invention discloses a method for issuing high-capacity internetbank verification modules. The method includes steps of (1) transmitting any one of KEY boxes stored in storage boxes to a transmission channel in a transmission mechanism by a pushing mechanism, transmitting the KEY box to a gate mechanism from the transmission channel by the transmission mechanism, opening a gate of the gate mechanism to let the KEY box extend out of the gate, and issuing the KEY box to a user; (2) if the user fails to take away the KEY box within a preset time (detecting whether the KEY box is taken away or not by a thru-beam sensor), transmitting the KEY box back to a recovery box through the transmission passage by the transmission mechanism. The method for issuing the high-capacity internetbank verification modules automatically has the advantages of automation and intelligentization and is applicable to issuing high-capacity KEY boxes.

Owner:HUNAN GREATWALL INFORMATION FINANCIAL EQUIP

Aeration tine device

InactiveUS6945332B2Guaranteed uptimeImprove controllabilitySoil-working equipmentsDragsHard metalEngineering

A highly durable aeration tine device attached to a soil aerator has a tubular tine member extending cylindrically and a hard metal tip made of a hard metal material and typically made in a frustum shape of a cone, which is in an area contact with the tubular tine member between the surfaces of the tubular tine member and the hard metal tip. Each surface of the tubular tine member and the hard metal tip is extending in a plane perpendicular to the axial direction and can be fabricated easily, and the drive force provided from the soil aerator can be transmitted without loss.

Owner:KASHIWATOOL CORP

High-reliability glass crushing device

The invention relates to a crushing device and particularly relates to a high-reliability glass crushing device. The technical problem to be solved by the invention is to provide a high-reliability glass crushing device which is uniform in crushing. In order to solve the technical problem, the invention provides the high-reliability glass crushing device comprising a top plate, a first supporting rod, a second supporting rod, a third supporting rod, a rotating motor, a first rotating shaft, a rack, a first sliding block, a first fixed pulley, a first sliding rail and the like; the right side of the top of a second sliding rail is provided with a fourth supporting rod located at the right of a second sliding block; the top of the second sliding block is provided with a crushing tank; a first elastic element is arranged between the right side of the crushing tank and the left side of the fourth supporting rod; and a second fixed pulley is arranged above the left side of the fourth supporting rod. By using the high-reliability glass crushing device, the effects that glass can be uniformly crushed, the crushing treatment efficiency is high, and the device is simple in operation are achieved.

Owner:青岛穗禾集成房屋有限公司

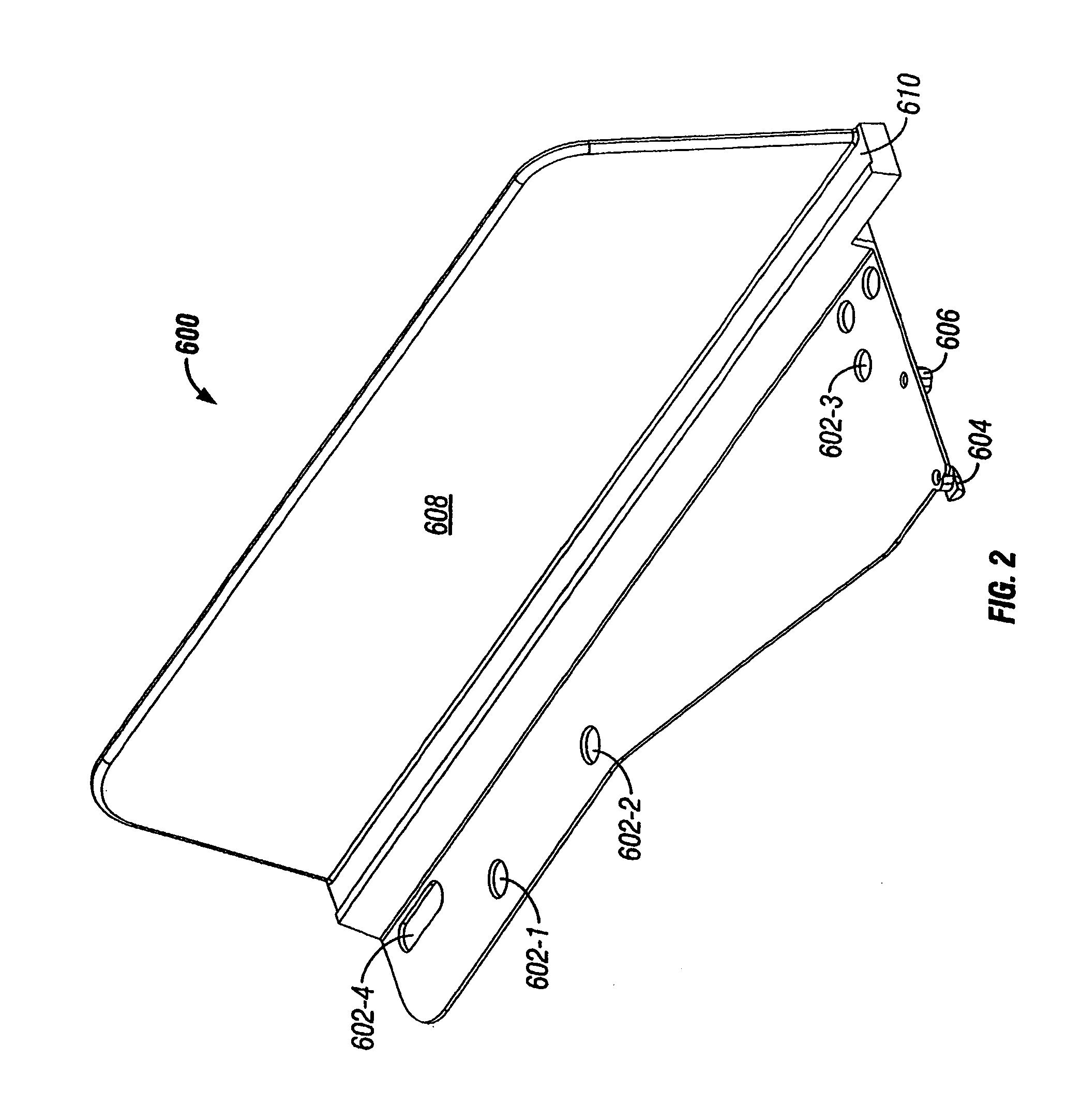

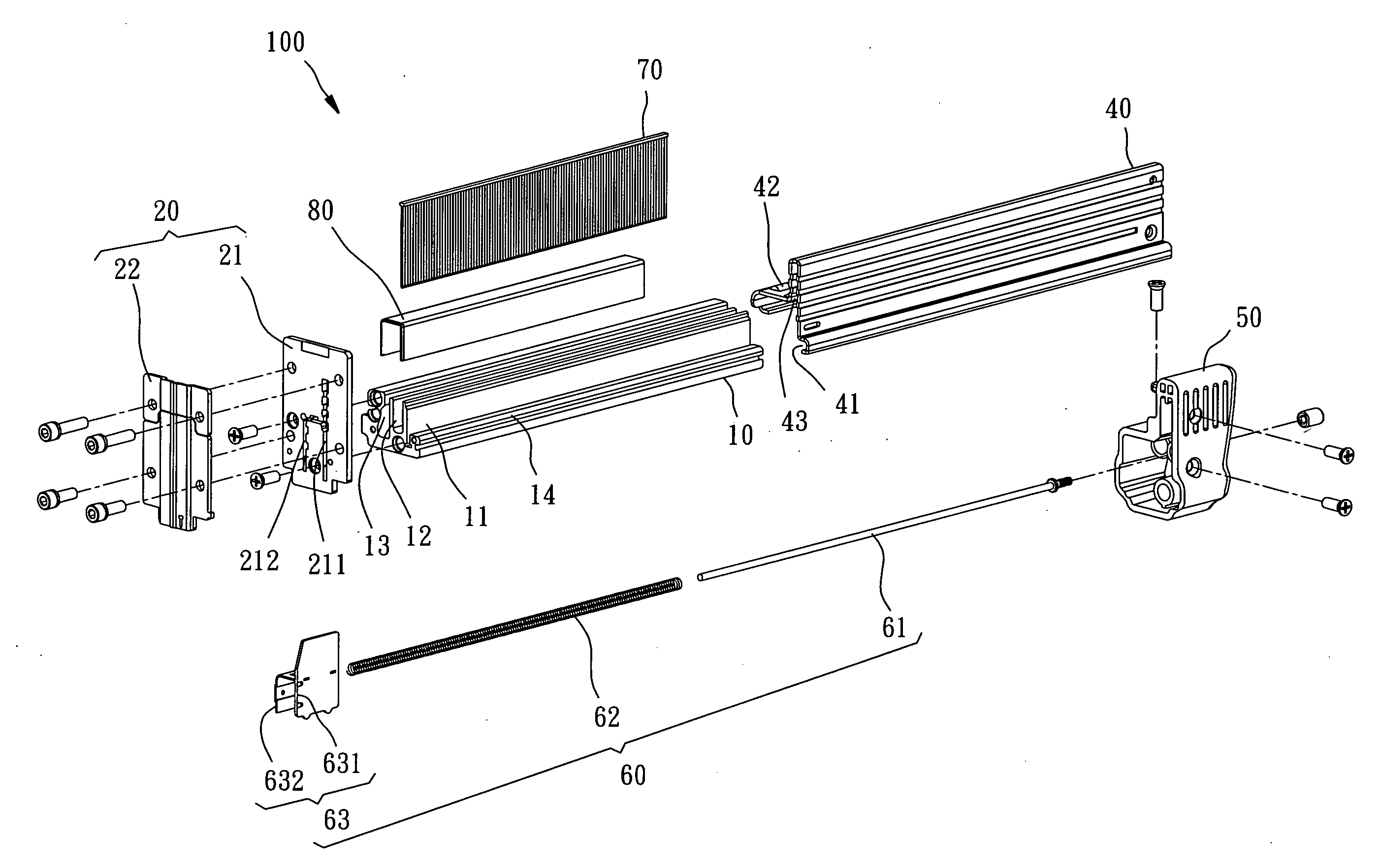

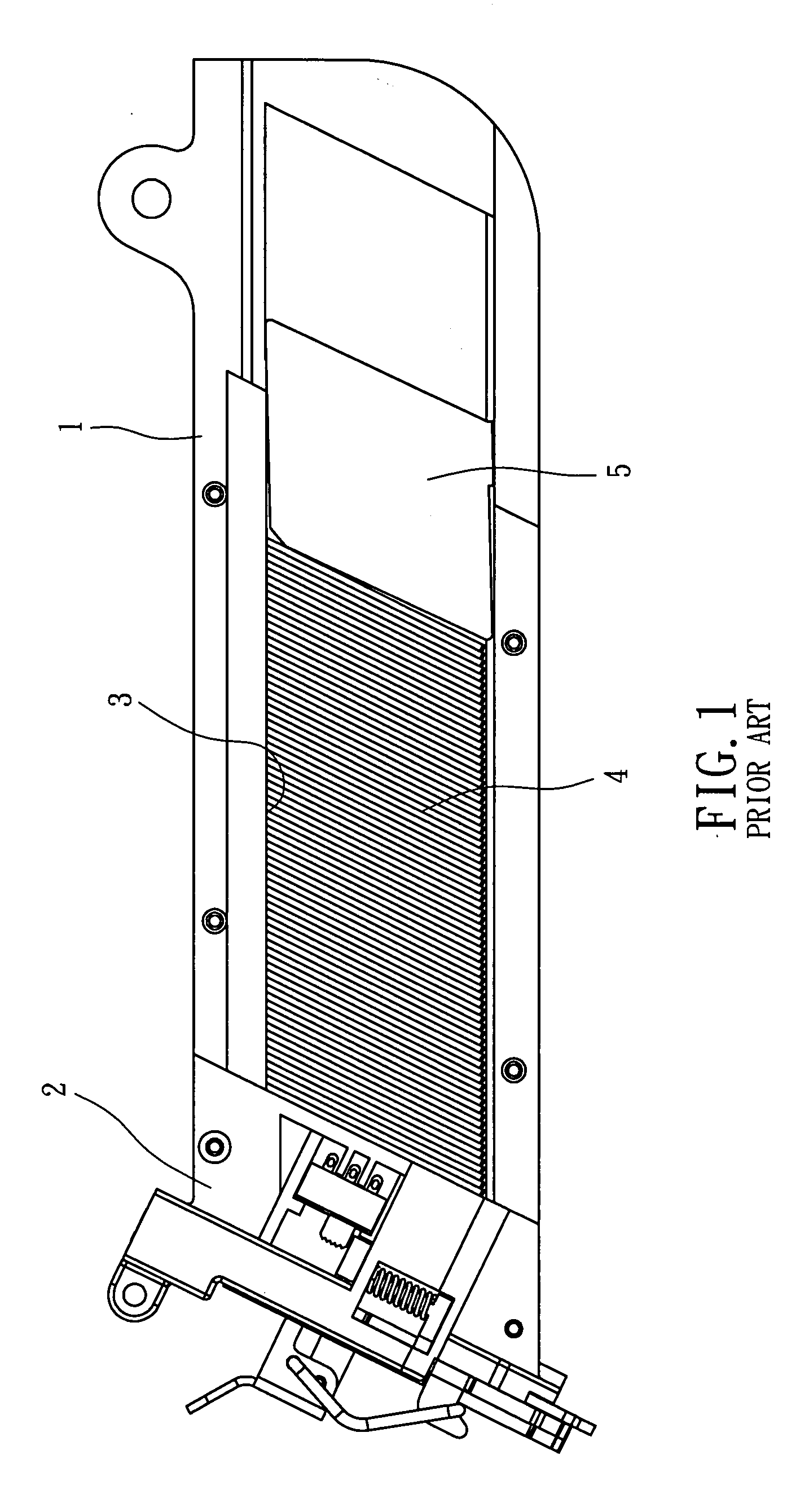

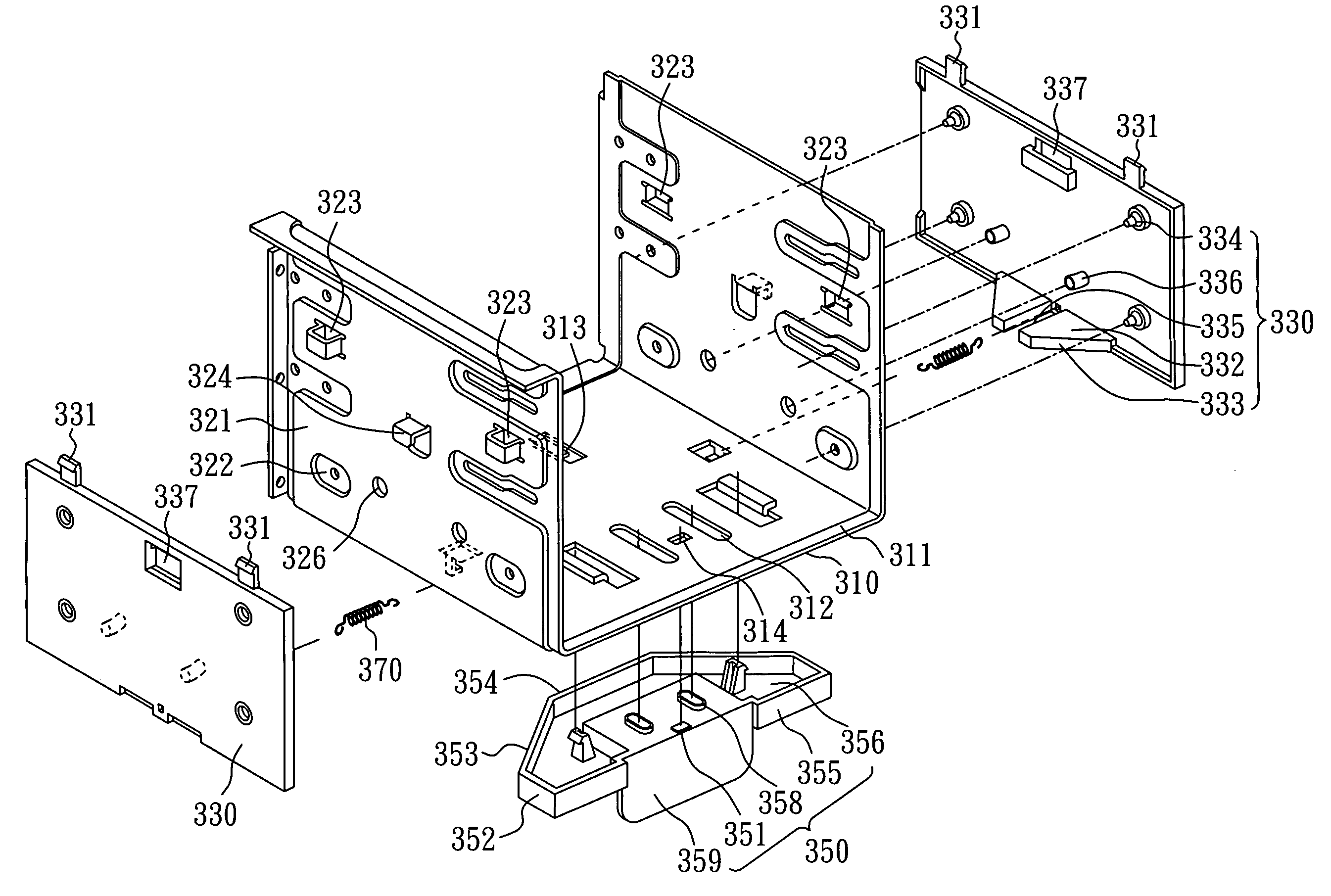

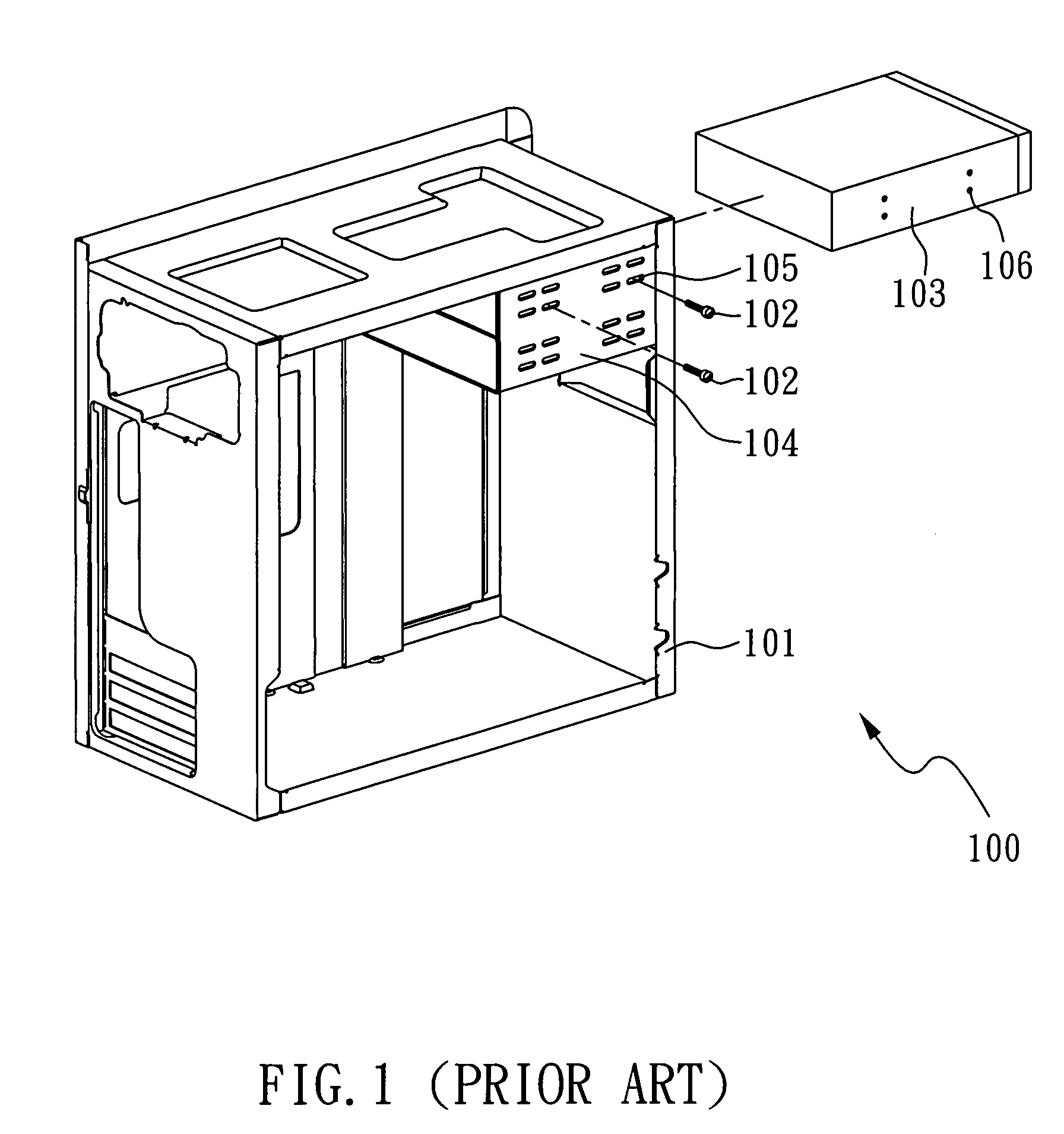

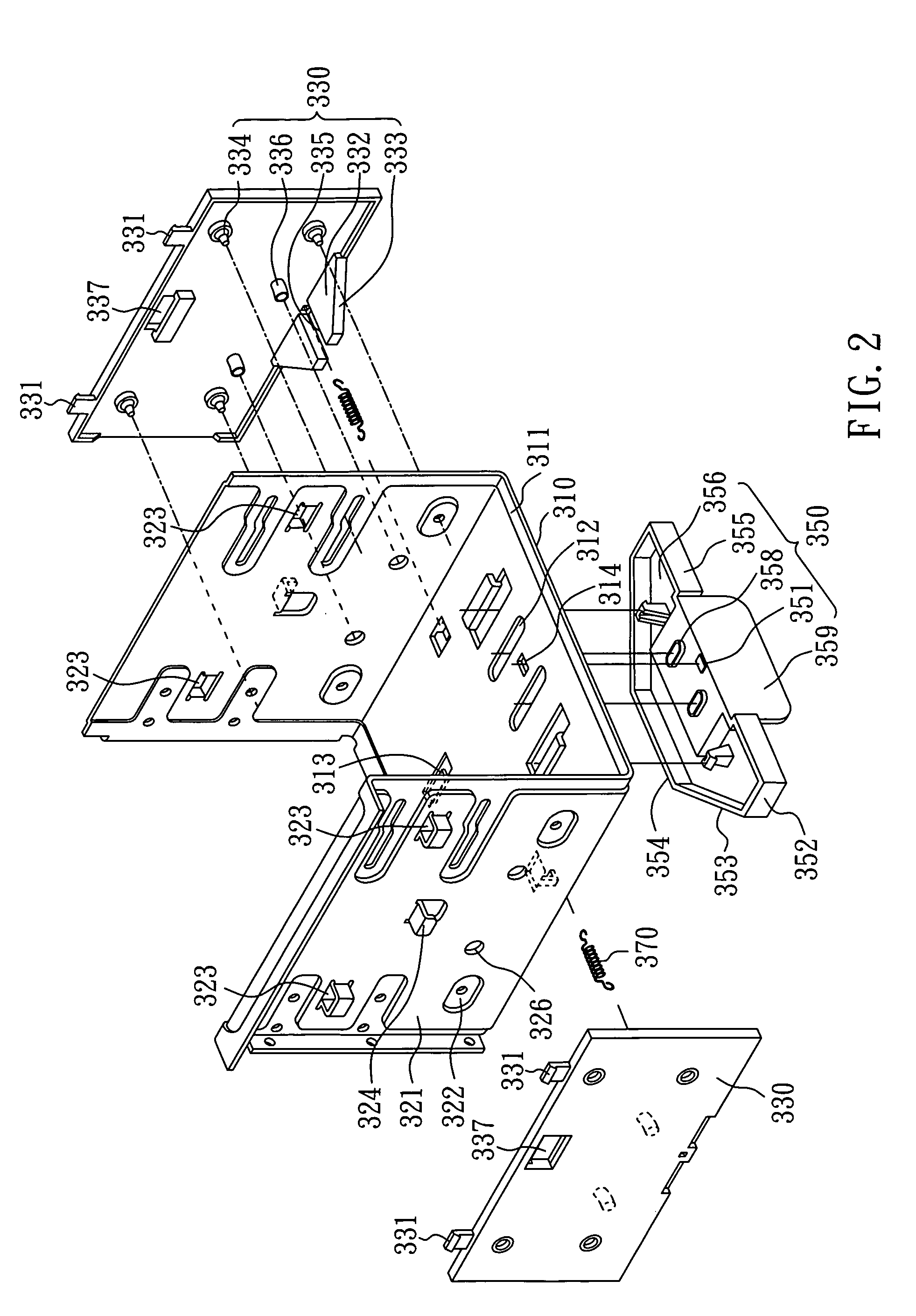

Apparatus for fastening data storage device

ActiveUS7471510B2Shorten the timeSimple stepsApparatus modification to store record carriersDigital data processing detailsEngineering

Owner:ASUSTEK COMPUTER INC

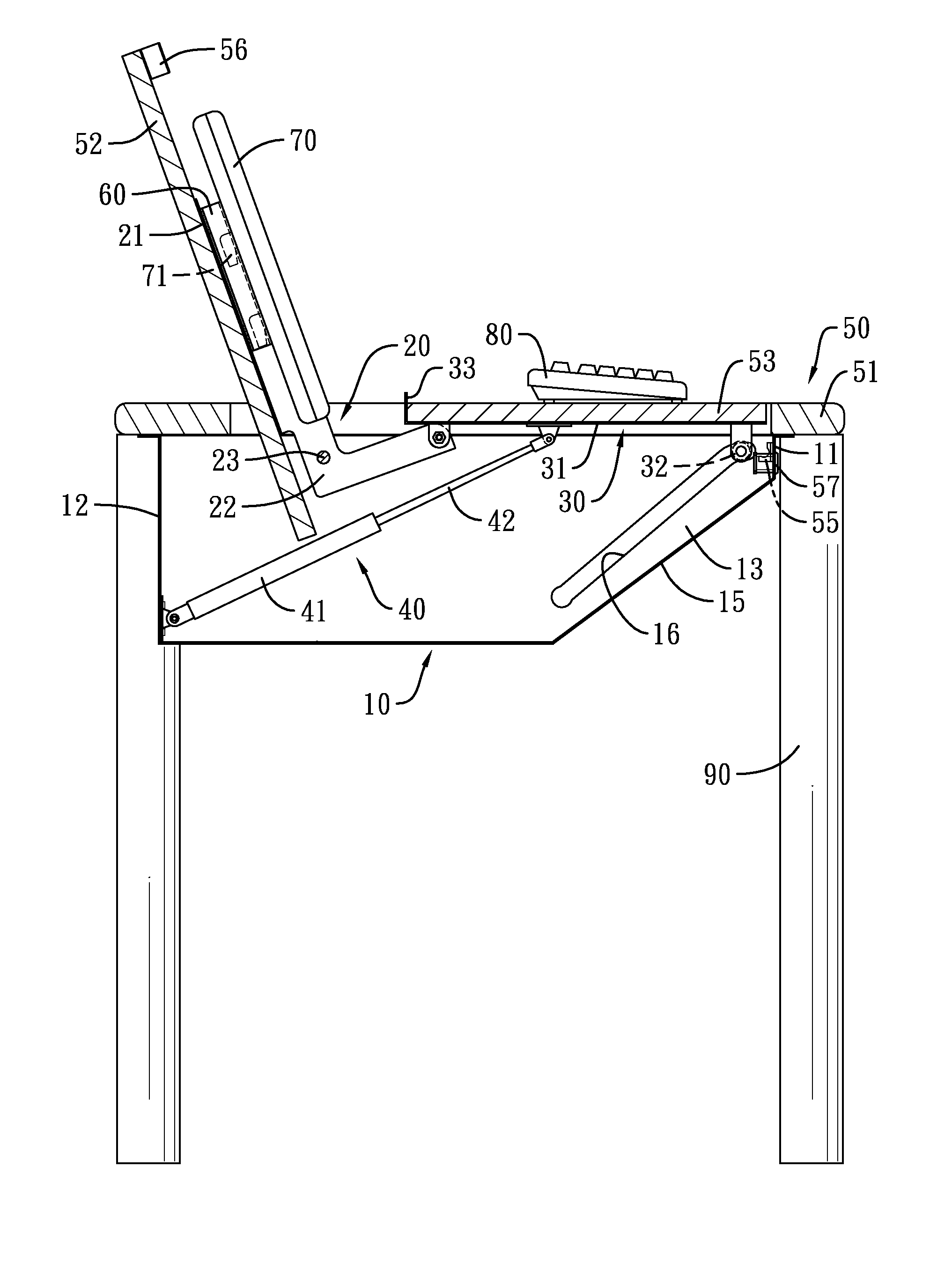

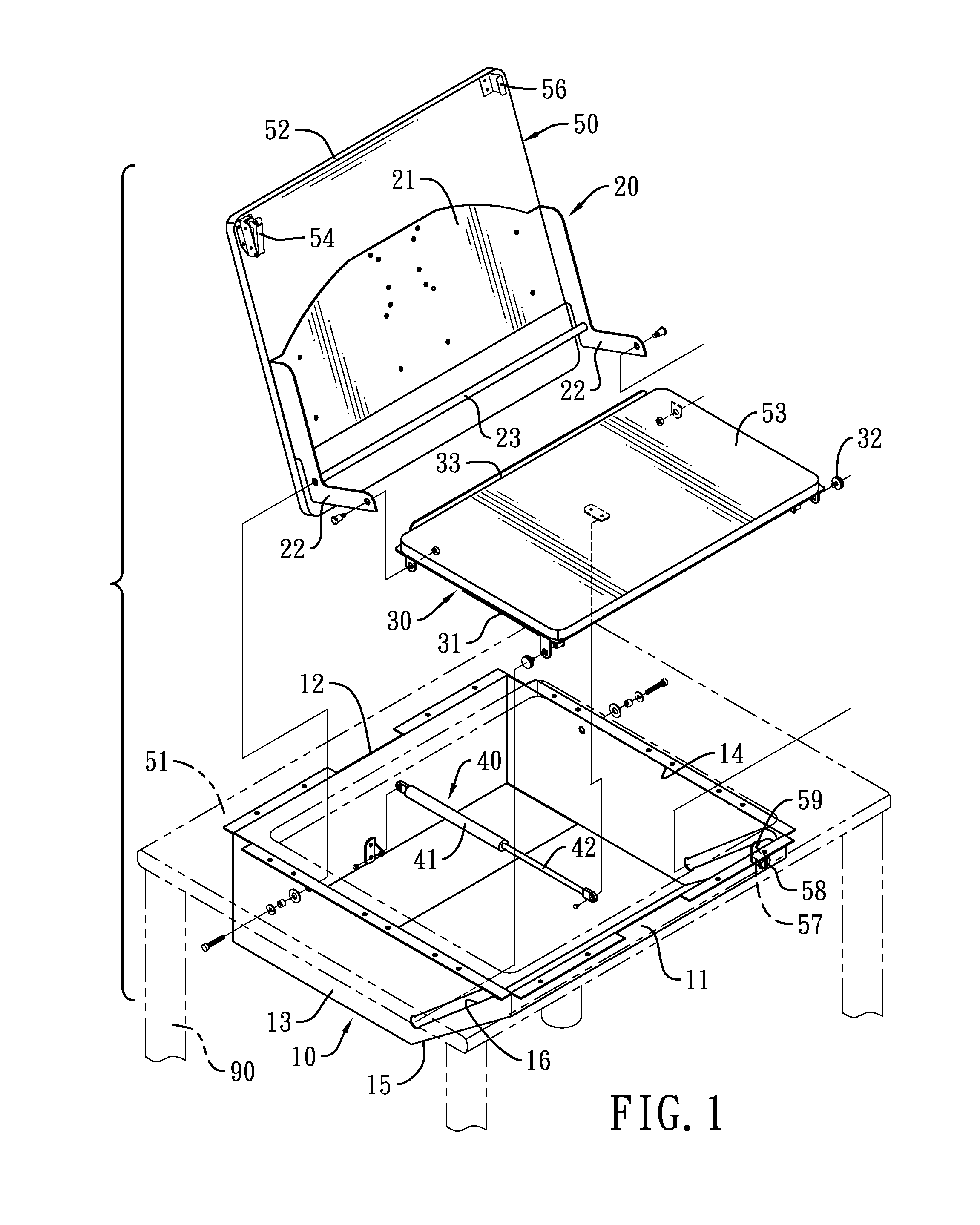

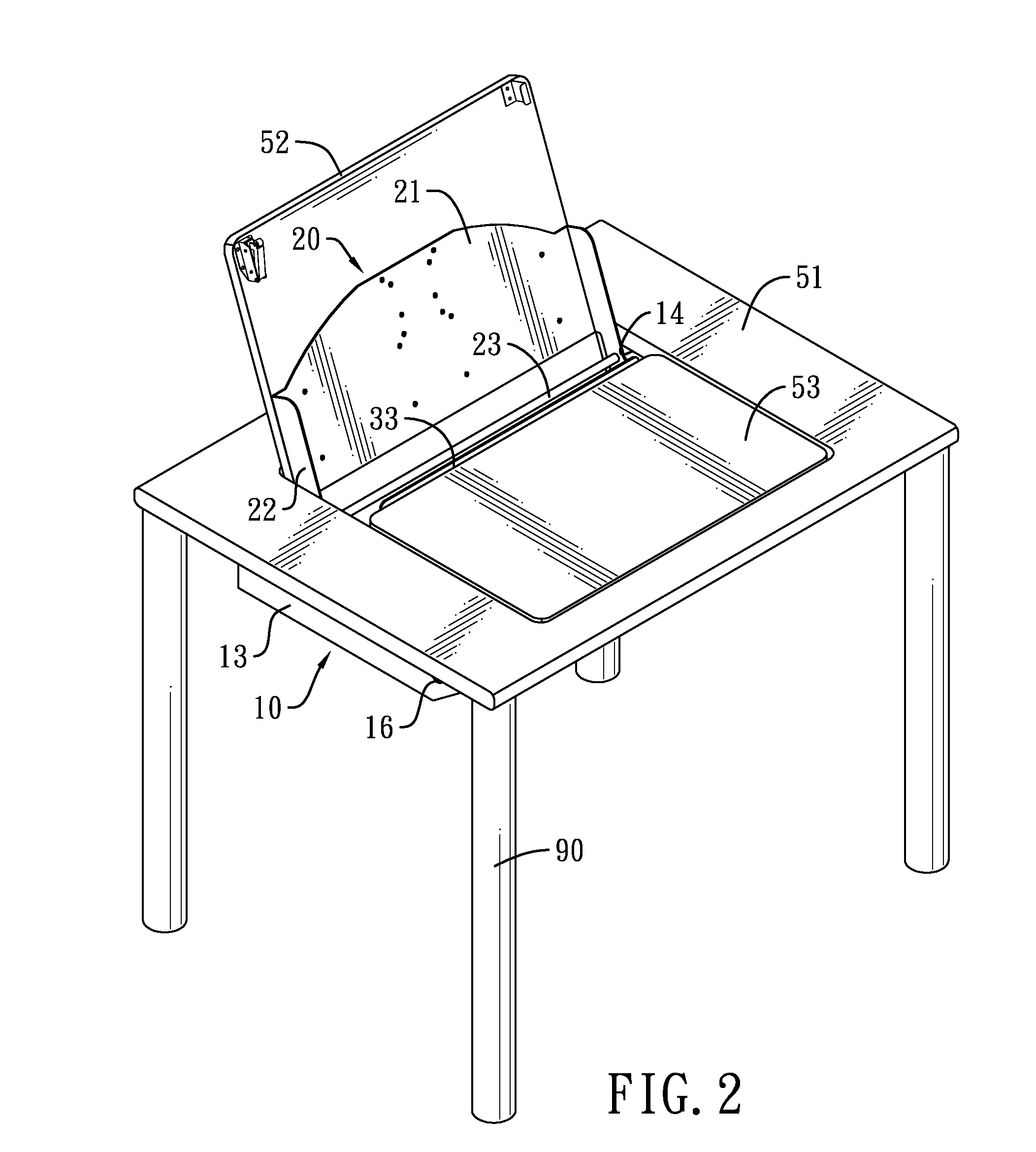

Desk board raising apparatus

InactiveUS20130068141A1Easy to operateReduce maintenance costsOffice tablesShow shelvesEngineeringDesk

A desk board raising apparatus has a seat, an active module, a passive module, and a cylinder. The active module is pivotally mounted in the seat and has a base, two linking arms, and a pivot. The linking arms are L-shaped. The pivot is deposited between the linking arms and pivotally mounted in the seat. The passive module is mounted in the seat and has a passive board pivotally connected with the linking arms. The cylinder is mounted in the seat and is adapted to push the passive board. Thus, the base lifted up or down can drive the passive board to move up or down. Therefore, the desk board raising apparatus uses a simple structure to synchronize the movements of the passive board and the base, and therefore has the advantages of convenient operation, low manufacturing cost, low maintenance cost, and consuming no power.

Owner:HSIAO CHENG PO

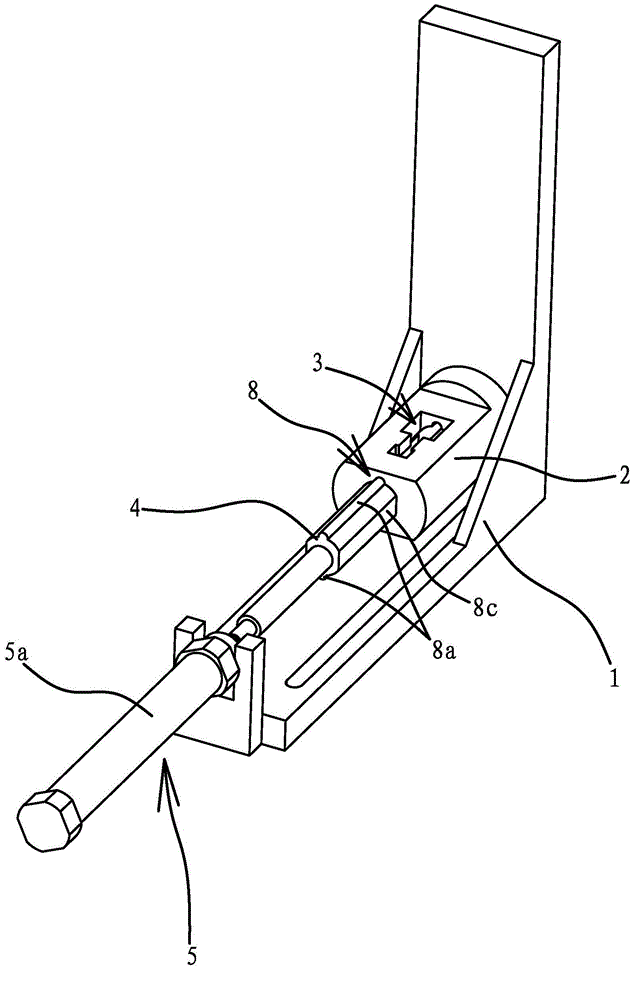

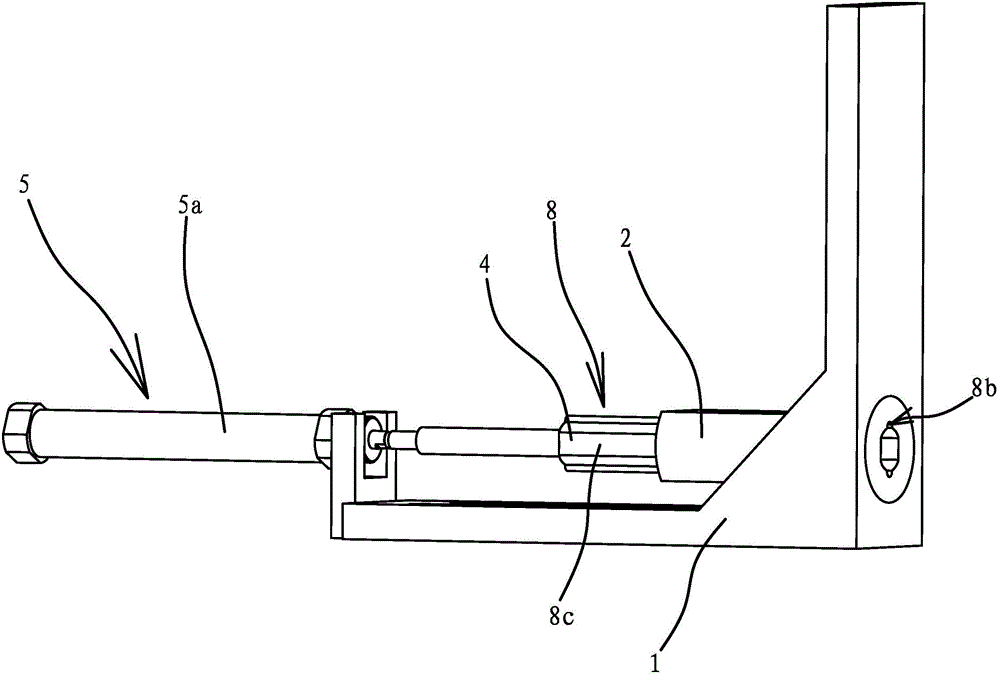

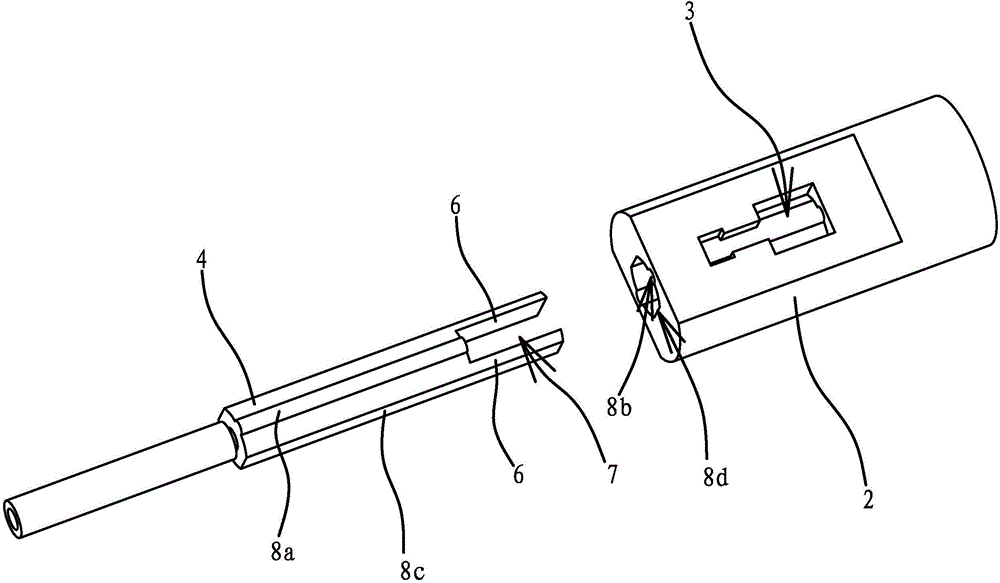

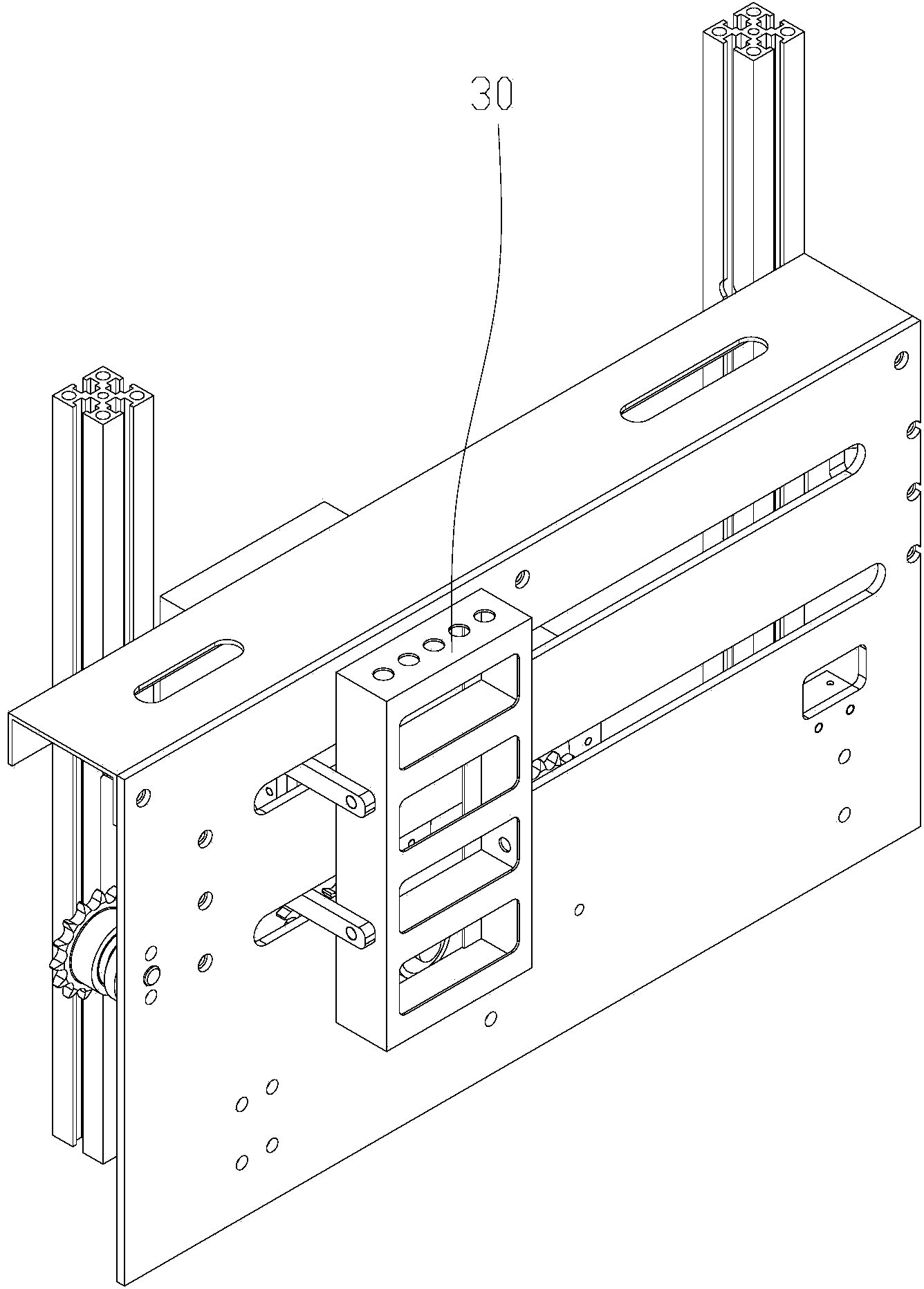

Pushing mechanism of feeding device

ActiveCN103978400AWork reliablyGood positioning effectMetal working apparatusGastric tube feedingFeeding tube

The invention provides a pushing mechanism of a feeding device, belongs to the technical field of machine components, and solves the problem of incapability of pushing smoothly of the existing feeding device. The pushing mechanism of the feeding device comprises a support and a feeding tube arranged on the support, wherein one side of the feeding tube is provided with a feed port I which is communicated with a cavity of the feeding tube; a pushing rod is arranged in the feeding tube; the support is further provided with a driving mechanism I capable of driving the pushing rod to do reciprocating movements; a pushing part which is protruded out of the end face of the pushing rod and is in a shape of a column is arranged on the inner end face of the pushing rod. The pushing mechanism of the feeding device has the advantages of reliable operation and smooth feeding of workpieces.

Owner:JINING XINRUIDA INFORMATION TECH CO LTD

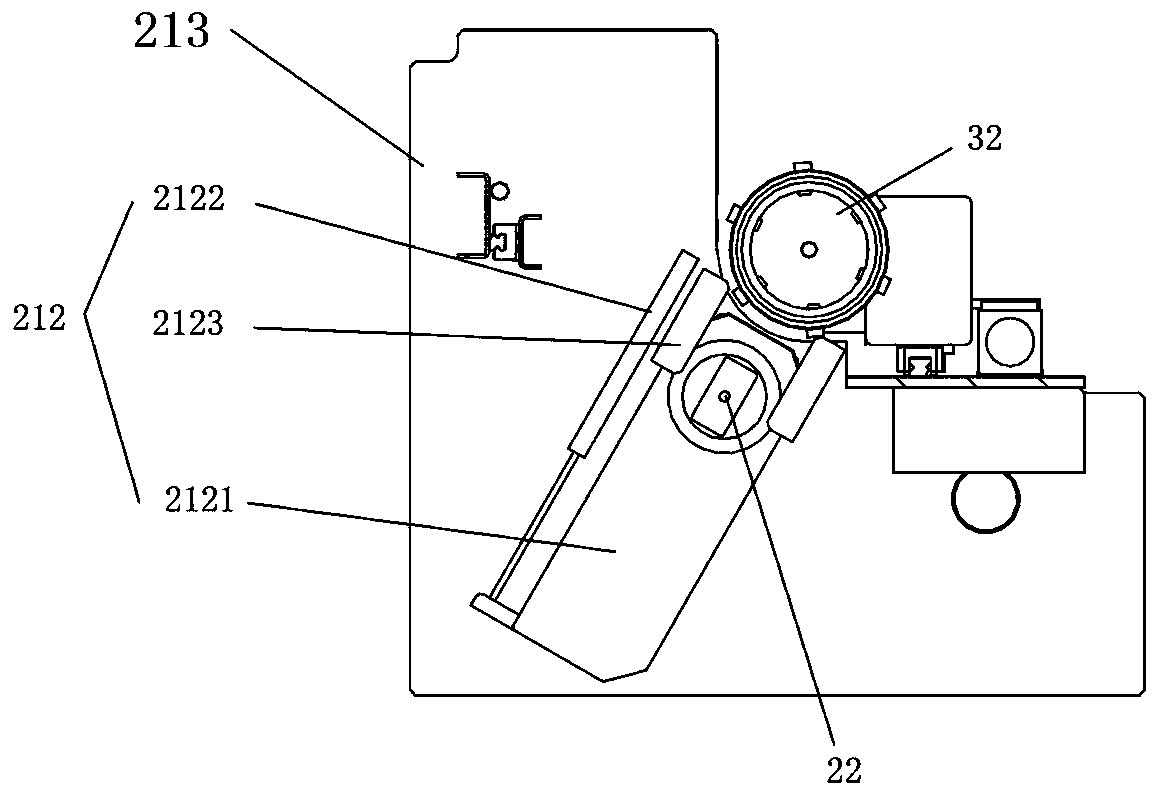

Automatic sample bottle cap screwing machine

PendingCN107814338AHigh degree of automation and intelligenceSimple and compact structureClosing machinesCapsEngineeringAutomation

The invention discloses an automatic sample bottle cap screwing machine which comprises a rack, wherein a cap conveying device and a cap screwing device which are matched with each other are arrangedon the rack; the cap screwing device comprises a lifting assembly and a rotary puncher chip assembly arranged on the lifting assembly; the cap conveying device comprises a cap conveying assembly and acap jacking assembly; the cap conveying assembly is used for transferring multiple bottle caps to a position below the rotary puncher chip assembly one by one; the cap jacking assembly is arranged onthe cap conveying assembly in a rising and falling manner, is used for jacking up the bottle caps transferred in place, and then returns after conveying the bottle caps into the rotary puncher pin assembly; a bottle body fixing station is arranged below the rotary puncher pin assembly; and after receiving the bottle caps, the rotary puncher pin assembly rotates and falls towards the bottle bodiesunder the driving of the lifting assembly to drive the bottle caps to carry out cap screwing work. The automatic sample bottle cap screwing machine disclosed by the invention has the advantages of simple and compact structure, high automation and intelligence degree and high stability.

Owner:HUNAN SUNDY SCI & TECH DEV

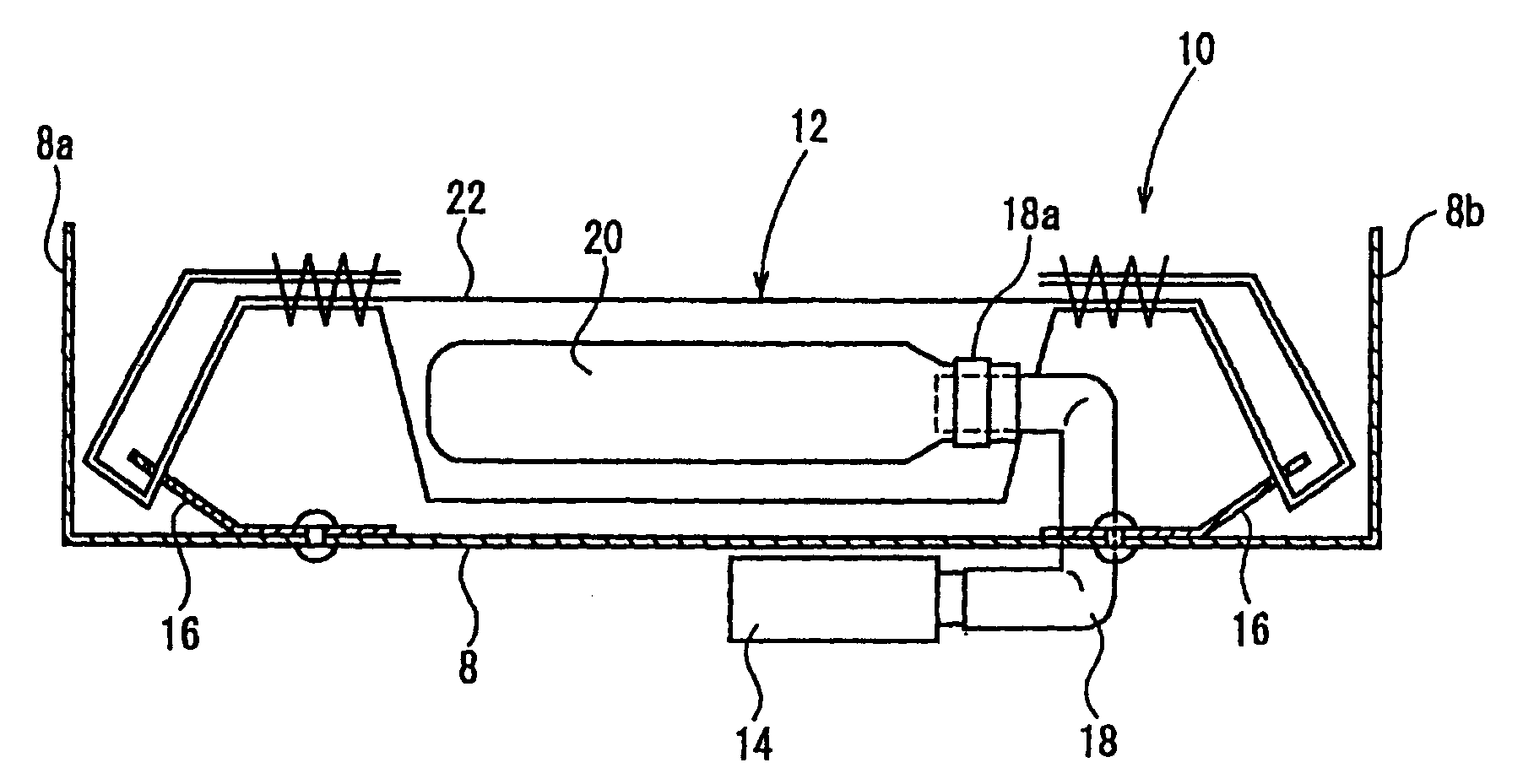

Occupant protection system

InactiveUS7497462B2Easily be mounted to seatEasy to installVehicle seatsPedestrian/occupant safety arrangementAirbagProtection system

An occupant protection system, which can easily be mounted to a seat, includes a seat pan placed between the front parts of the side frames of a seat, an airbag arranged above the seat pan, and a gas generator for inflating the airbag. The airbag extends along the width direction of the seat pan, opposite ends of the airbag being connected to the seat pan through anchors. The gas generator is arranged on the upper surface of the seat pan and is fixed to the seat pan with a bracket. The gas generator is connected to the airbag via a pipe.

Owner:JOYSON SAFETY SYST JAPAN KK

Supplementing method for cartons of cigarettes and vertical sorting system adopting same

The invention discloses a supplementing method for cartons of cigarettes and a vertical sorting system adopting the supplementing method. The supplementing method includes the steps that the twenty five cartons of cigarettes are stacked in order on a cigarette supplementing trolley in five layers and five columns, and the cigarette supplementing trolley moves to the cigarette supplementing station; a transverse cigarette pushing mechanism pushes a cigarette stack to move forwards and makes the cartons of cigarettes in the first column be aligned to a longitudinal cigarette pushing mechanism; the longitudinal cigarette pushing mechanism pushes the cartons of cigarettes in the first column into a vertical buffering cigarette bin and places the cartons of cigarettes in the first column on a jacking mechanism; the longitudinal cigarette pushing mechanism returns, the transverse cigarette pushing mechanism pushes the cigarette stack to continue moving forwards and makes the cartons of cigarettes in second column be aligned to the longitudinal cigarette pushing mechanism, and the jacking mechanism jacks the cartons of cigarettes in the first column upwards and crosses a one-way valve; the jacking mechanism descends and returns, and the one-way valve stops the cartons of cigarettes in the first column to prevent the cartons of cigarettes in the first column from falling off; a longitudinal cigarette pushing plate pushes the twenty five cartons of cigarettes in the buffering cigarette bin into a vertical sorting bin. The cartons of cigarettes are stacked into vertical columns, so that the occupied area is small. The cartons of cigarettes can be pushed into the vertical sorting bin from the buffering cigarette bin, and sorting continuity and sorting efficiency are improved.

Owner:TIANHAI OUKANG TECH INFORMATION XIAMEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com