Board double-end cutting and edge aligning device

A wood board and double-end technology, which is applied in the field of wood board double-end cutting and trimming device, can solve the problems of increased labor, insufficient processing precision, and inflexibility, etc., and achieves the effects of convenient operation, improved versatility, and guaranteed flushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

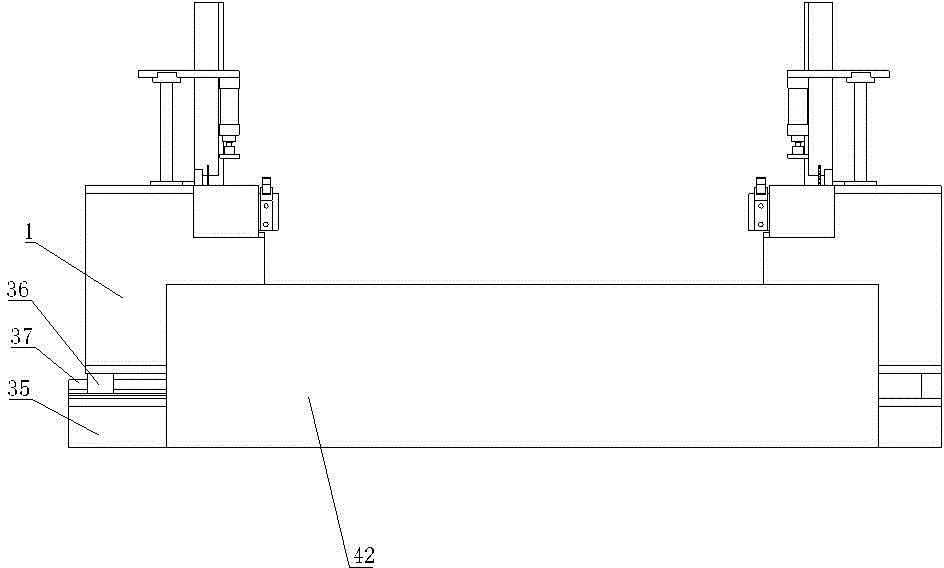

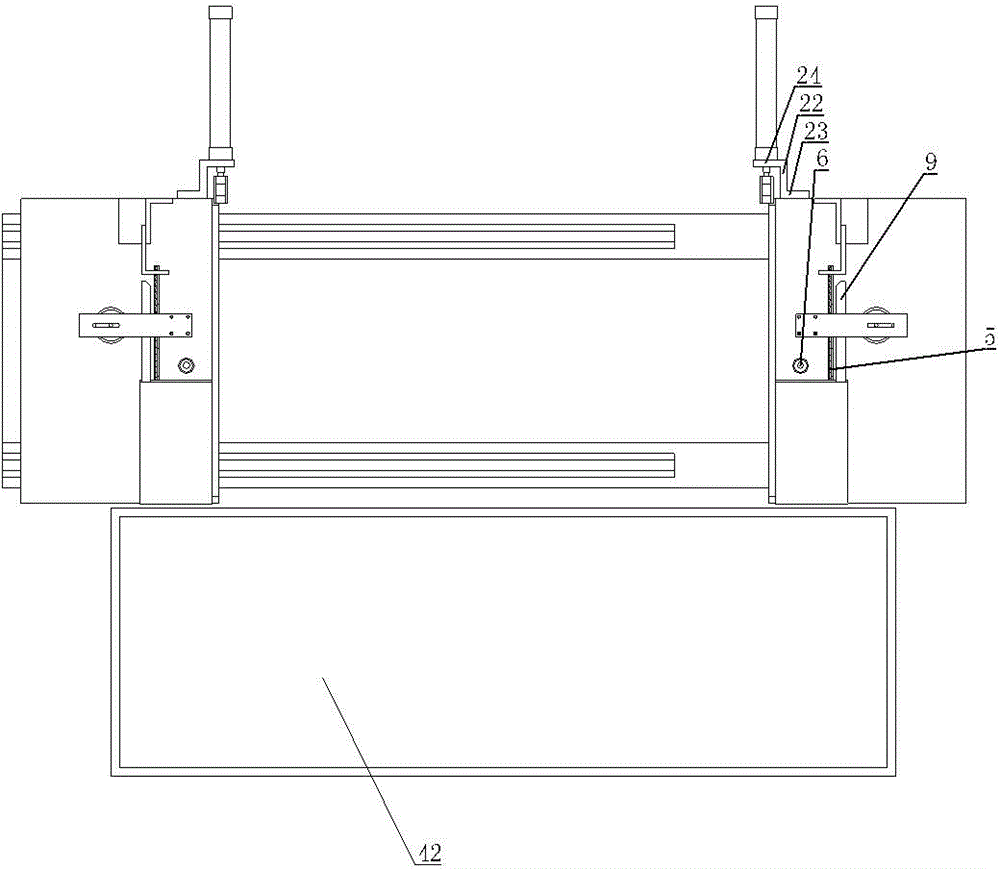

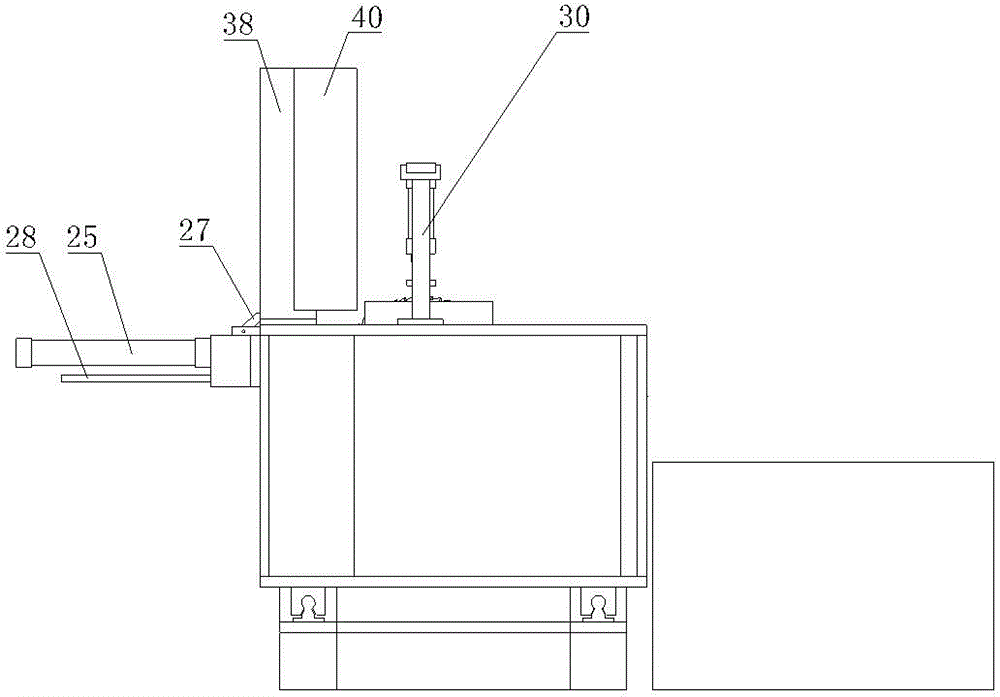

[0027] like Figure 1 to Figure 13 , including two bases 1 arranged on the base 35, a slide block 36 is provided at the bottom of one base 1, and a slide rail 37 matched with the slide block 36 is provided on the base 35, so that the base 1 can move along the slide rail 36 on the base Move on the seat 35, the base 1 includes an installation box 2, the installation box 2 is provided with a base plate 3, the base plate 3 is provided with a blanking mechanism parallel to the cutting direction, the installation box 2 is provided with a saw blade 5 driven by a motor 4, The cylinder (not shown in the figure) used to lift the saw blade 5, the positioning cylinder 7 connected with the positioning block 6, and the bottom plate 3 are respectively provided with a saw groove 8 and a positioning hole for the saw blade 5 and the positioning block 6 to pass through. 9. The outer side of the saw groove 8 is parallel to the saw groove 8, and a limiting plate 9 is arranged, and a pressing mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com