Friction pendulum support equipped with annular steel plates

A technology of friction pendulum bearings and ring-shaped steel plates, which is applied to bridge parts, building components, bridges, etc., can solve the problems of easy to be thrown out of the upper structure, poor self-balancing ability, sudden change, etc., to achieve fast and flexible assembly, reduce damage, The effect of large damping and isolation displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

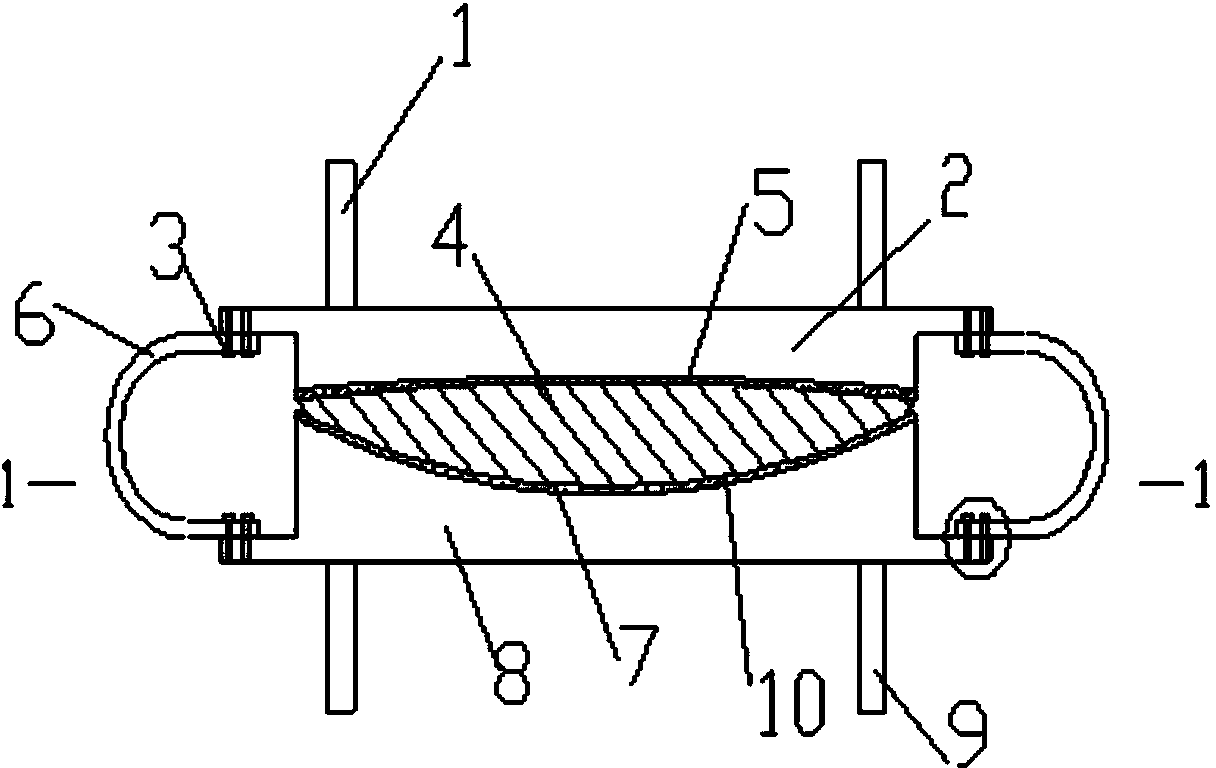

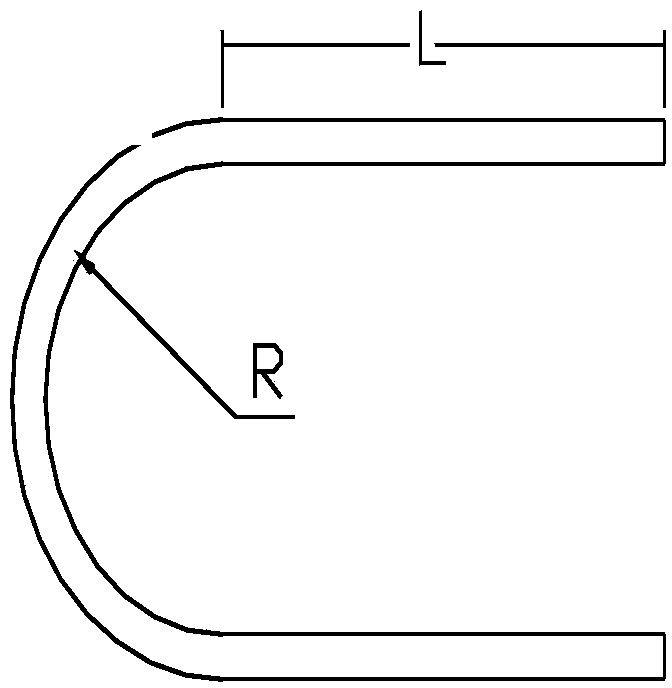

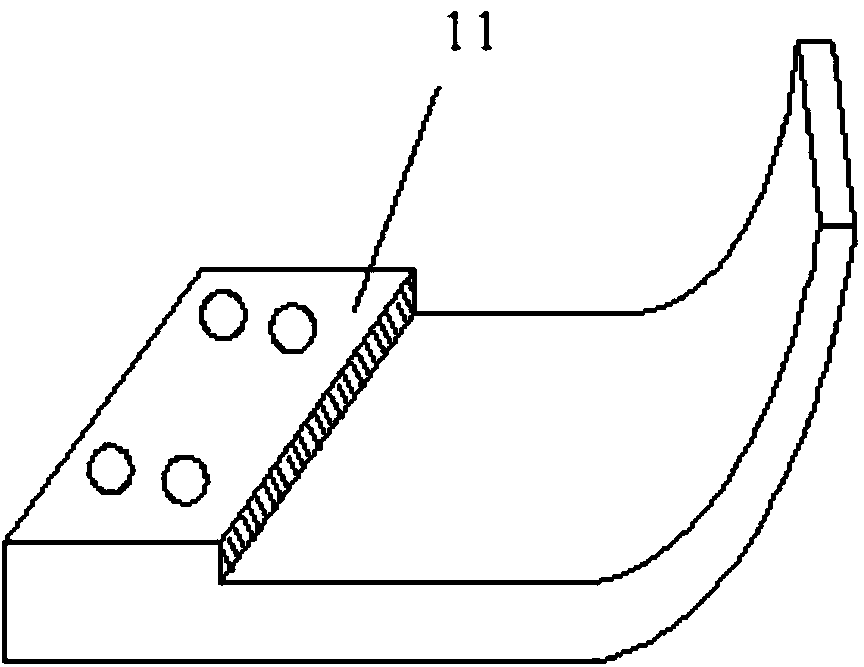

[0025] Such as Figure 1-5 Shown: a friction pendulum support equipped with a ring-shaped steel plate, including an upper anchor rod 1, an upper support plate 2, a high-strength bolt 3, a spherical crown 4, an upper wear-resistant plate 5, an annular steel plate 6, and a lower wear-resistant plate 7 , the lower bearing plate 8, the lower anchor rod 9 and the sliding surface 10;

[0026] The upper support plate 2 is in cylindrical contact with the upper wear plate 5, the lower support plate 8 is in cylindrical contact with the lower wear plate 7, and the spherical cap 4 is in contact with the upper support plate 2, The contact between the lower support plates 8 is spherical contact, the connection between the upper part of the spherical cap 4 and the upper wear-resistant plate 5 is a hinge joint that can rotate relative to each other, and the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com