Patents

Literature

85 results about "Stress process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stress Management Process:- Stress is a biological or psychological reaction from a tension. The stress can be positive or negative depending on the importance of the tension. If the tension is too high, the stress can generate negative effects on the physical and mental health of the individual.

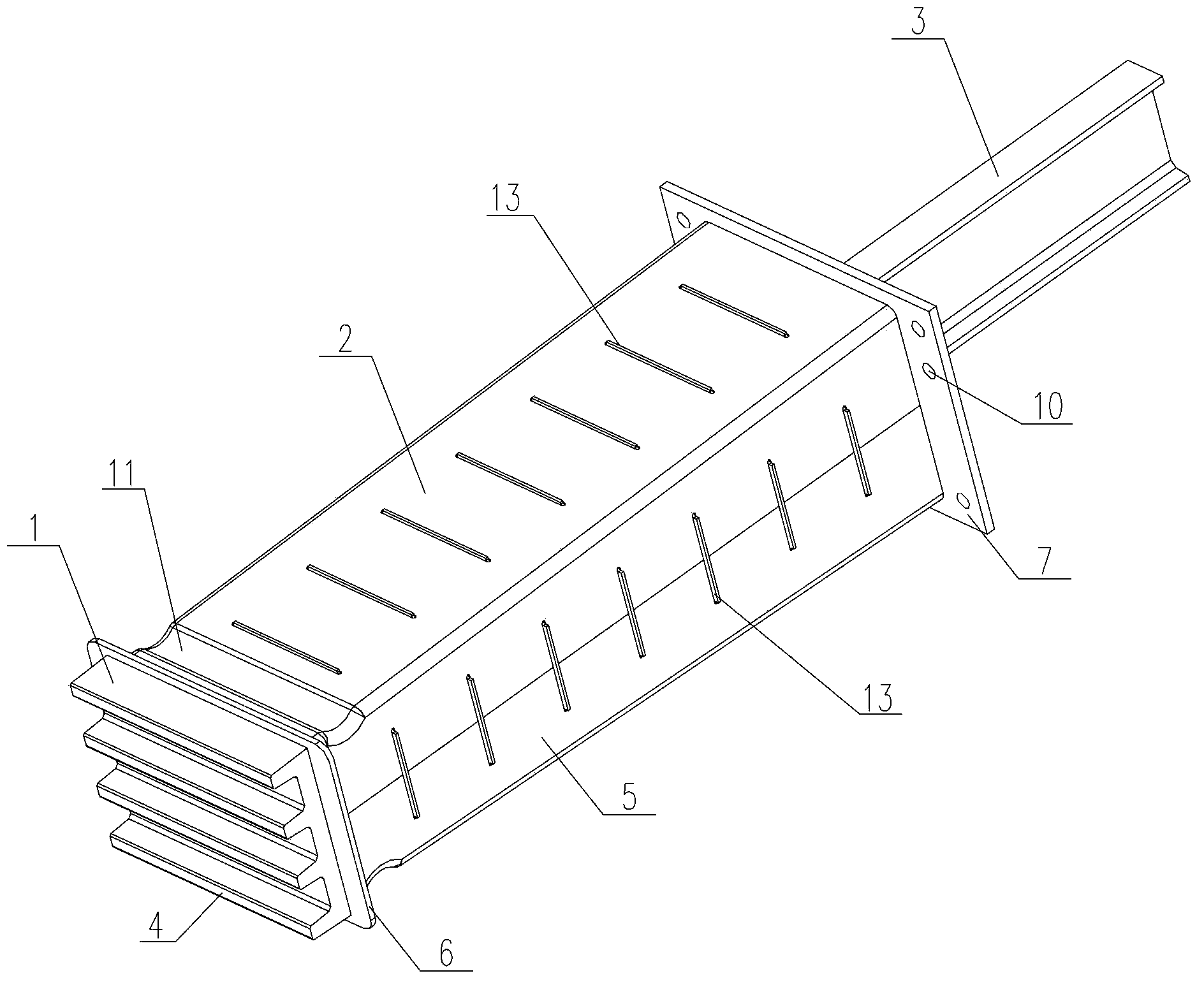

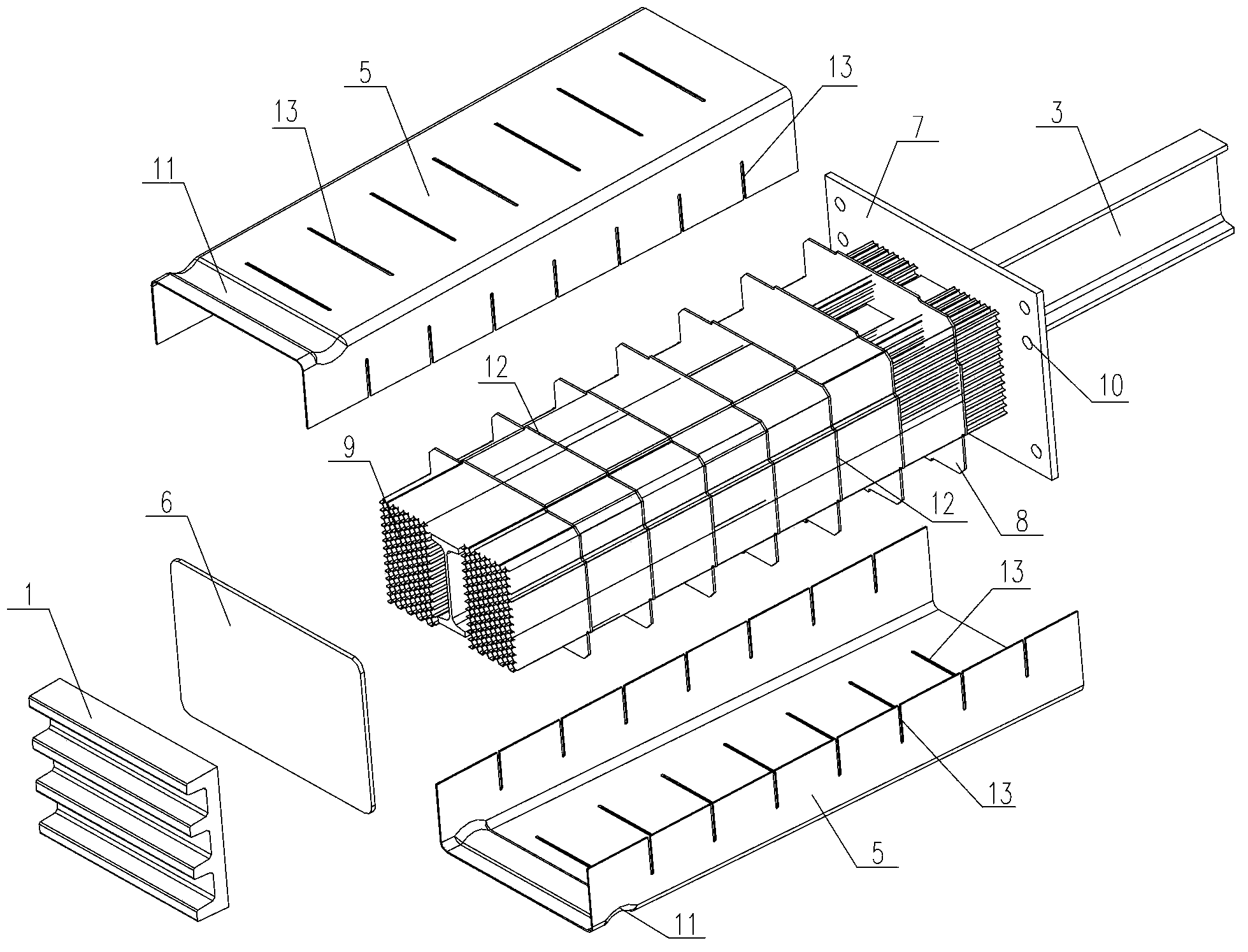

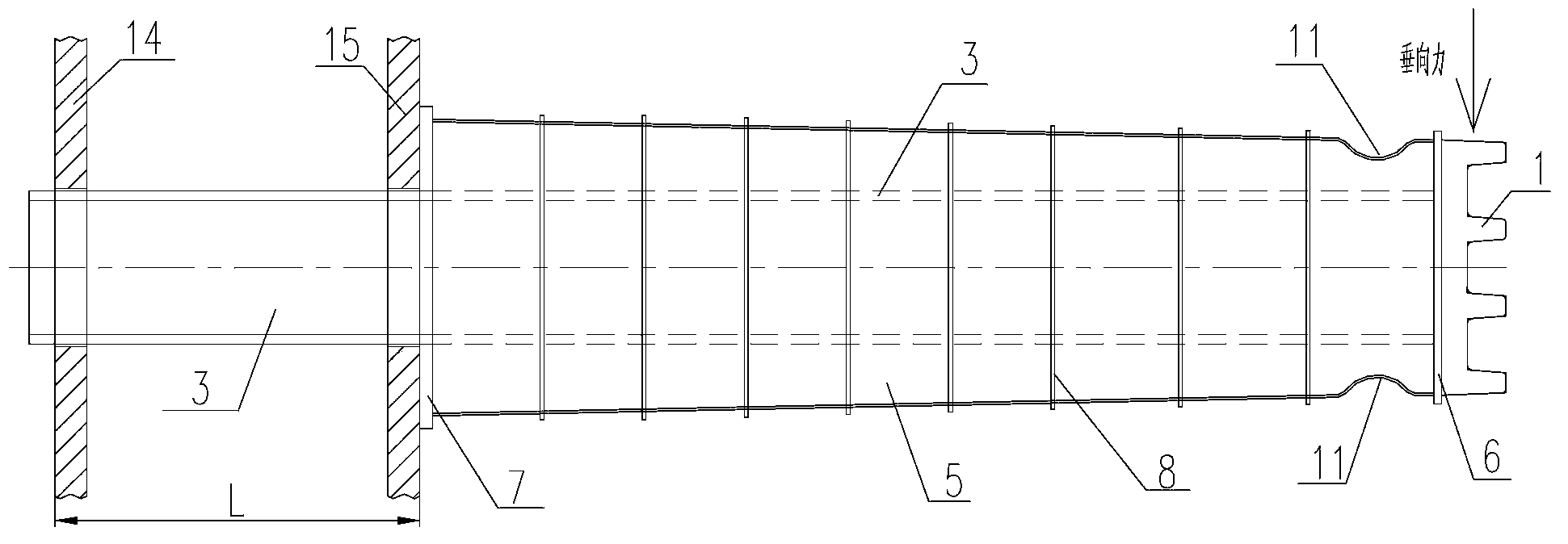

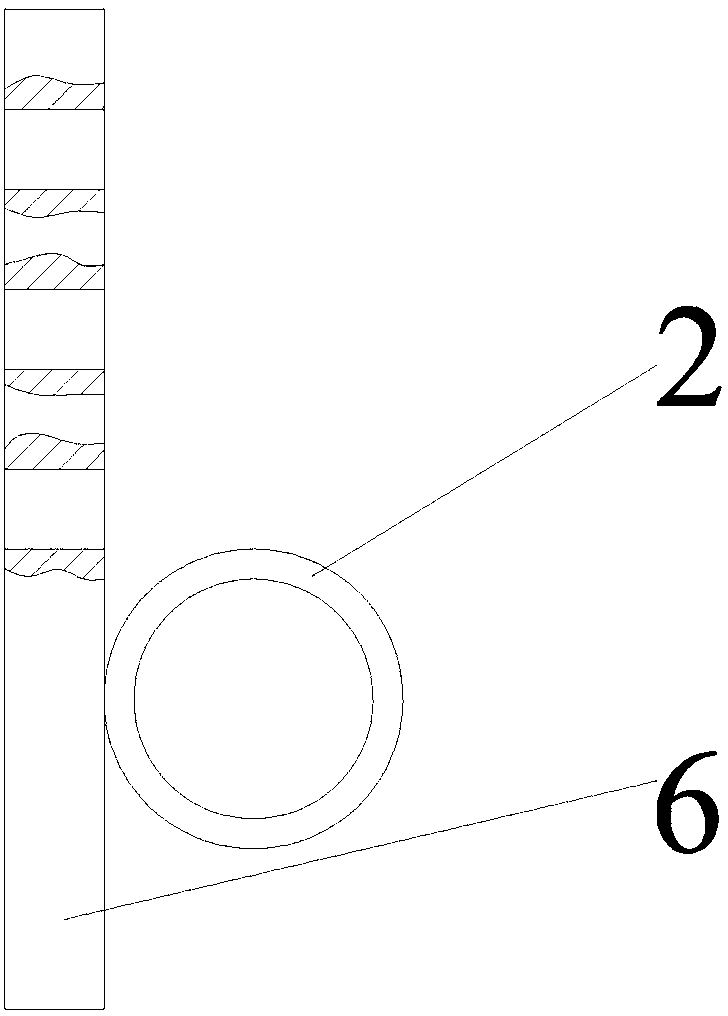

Anti-creeping energy absorption device for railway vehicle

InactiveCN103786741APrevent vertical instabilityNo creeping phenomenon will occurRailway wheel guards/bumpersStress processEnergy absorption

The invention relates to an anti-creeping energy absorption device for a railway vehicle. The anti-creeping energy absorption device consists of an anti-creeping device, an energy absorption body and a guiding rod, wherein multiple anti-creeping teeth are transversely arranged on the front end face of the anti-creeping device, and the energy absorption body consists of an outer cover plate, a front installing plate, a rear installing plate, multiple rib plates and an energy absorption material. The front installing plate and the rear installing plate are respectively welded at two ends of the outer cover plate to form a box-shaped structure, the rib plates are parallelly arranged in the inner cavity of the box-shaped structure, and the energy absorption material is filled in the box-shaped structure. The front-end portion of the guiding rod and the anti-creeping device are fixed on the front installing plate, the guiding rod penetrates the inner cavity of the box-shaped structure and the rear installing plate and extends for a certain length, and the rear-end portion of the guiding rod is in sliding connection with a supporting plate. The anti-creeping energy absorption device can be prevented from being vertically unstable in the stress process, the energy absorption body performs energy absorption in a composite mode that the outer cover plate and the energy absorption material simultaneously deform plastically, the energy absorption effect is remarkable, and further vehicle body completion and person safety are ensured to the most extent.

Owner:CRRC QINGDAO SIFANG CO LTD

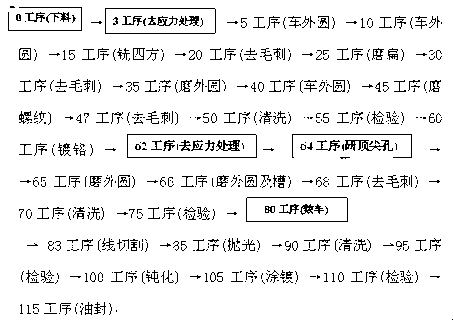

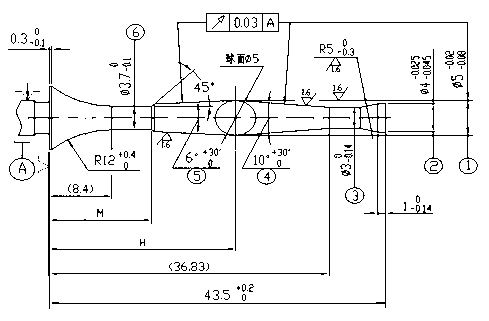

Method for machining high-accuracy special profile of elongated rod

A method for machining a high-accuracy special profile of an elongated rod comprises the processes of blanking, rough machining, de-stressing, semi-finish machining, heat treatment, datum correction and finish machining. During blanking, the quality of the raw material state is improved to determine an optimum hardness value; by collection of similar part machining data and analysis of conventional technological processes, main factors and processes affecting the needle plug quality are determined, the technological processes are adjusted, and the de-stressing process is added after rough machining and before semi-finish machining, accordingly, effects of residual stress of machining in the subsequent heat treatment process are eliminate; before finish machining, the correction process is added for correcting a machining datum, so that the machining accuracy is guaranteed; and a high-accuracy curved surface is subjected to one-step clamping machining through a high-accuracy numerically-controlled lathe and is cut through an imported cutter, reasonable machining parameters are searched, rough and finish machining allowances are reasonably distributed, and elongated rod special-profile parts are machined to the accuracy meeting technological requirements.

Owner:GUIZHOU HONGLIN MACHINERY

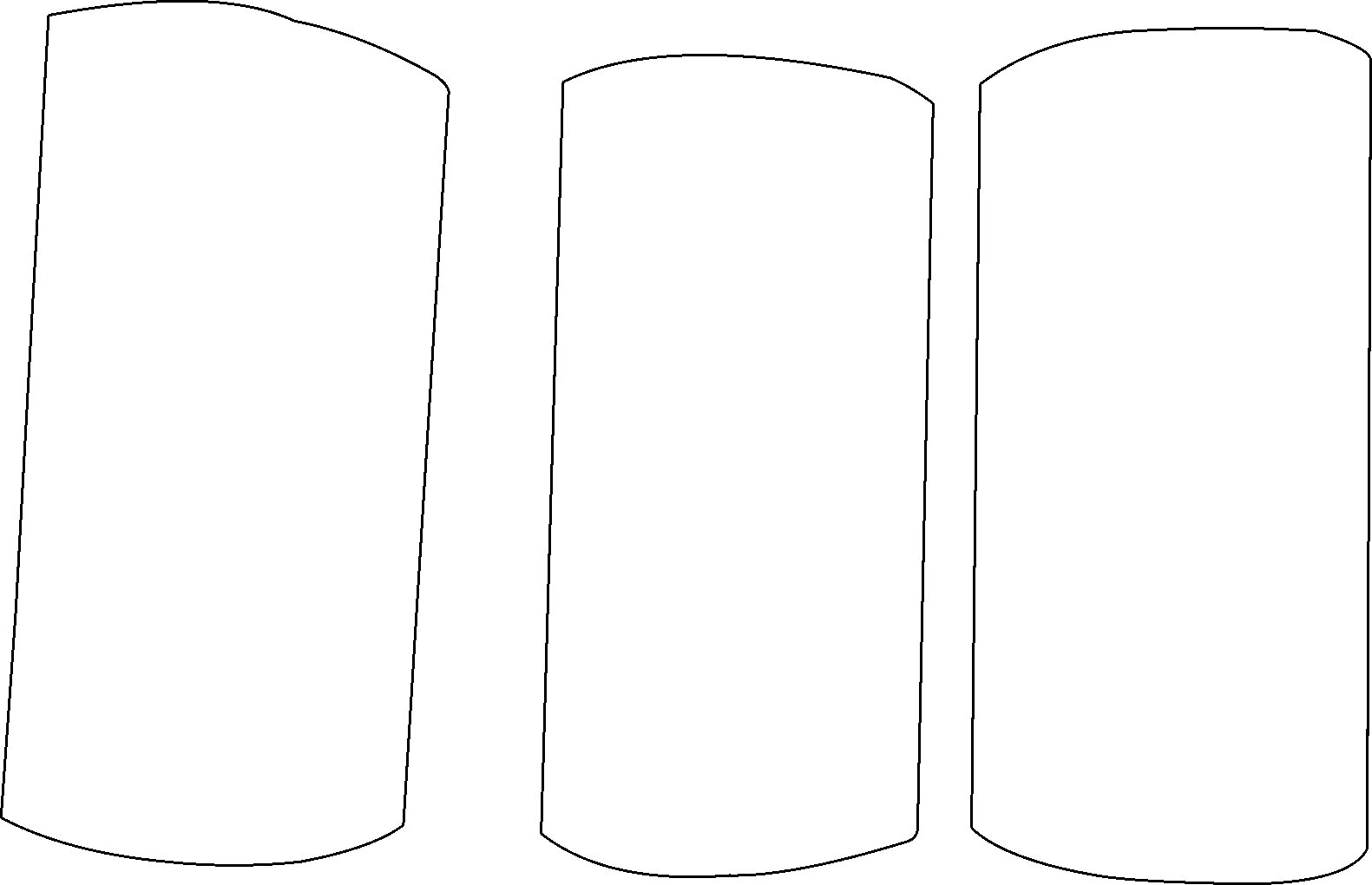

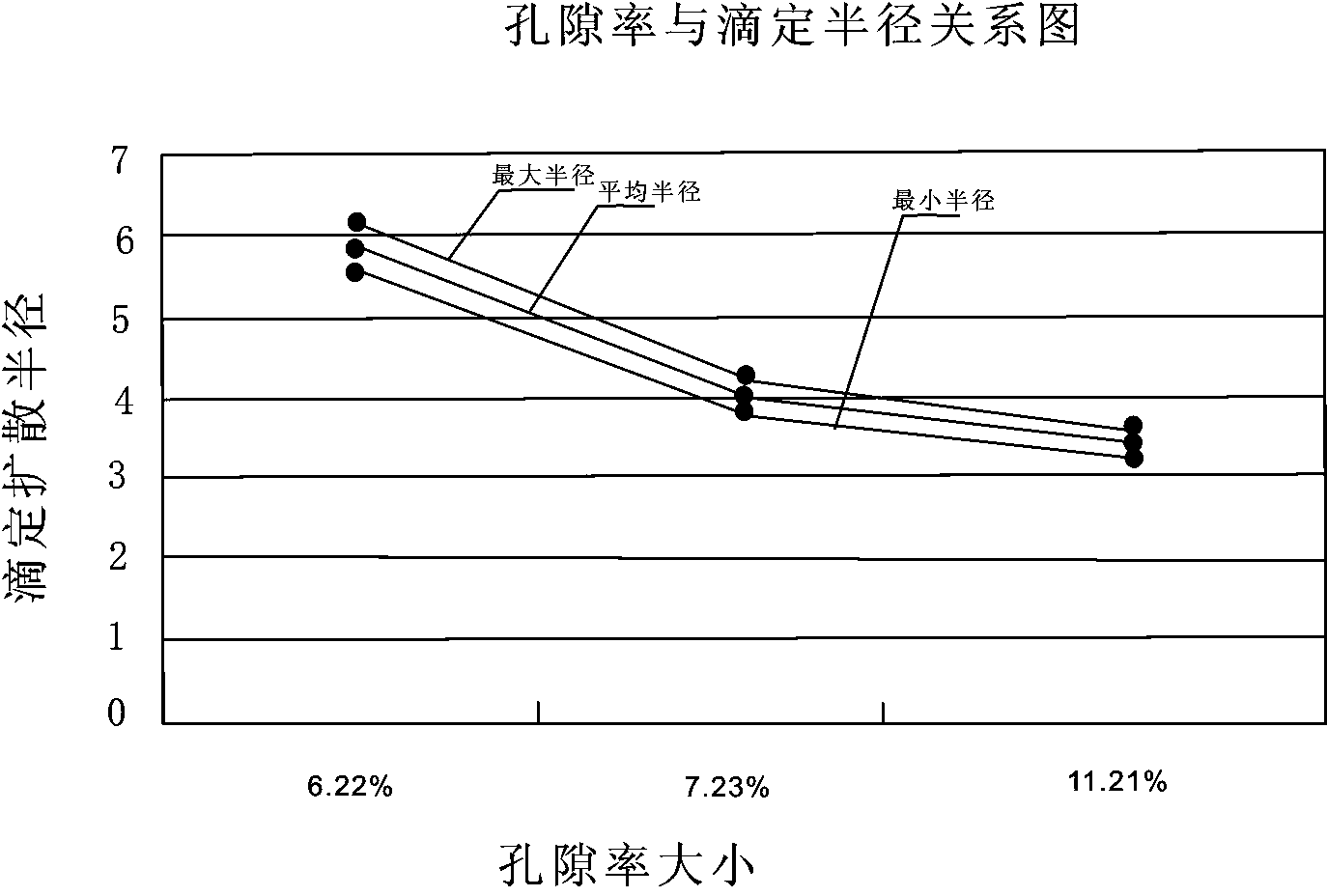

Real-time measuring method for rock sample damage in circulation loading process

ActiveCN103512816AReal-time damage detectionRealize non-destructive testingPermeability/surface area analysisMaterial strength using repeated/pulsating forcesDiffusionPorosity

The invention discloses a real-time measuring method for rock sample damage in a circulation loading process. The real-time measuring method comprises the following steps: 1) drawing a relational graph of rock porosity and titration diffusion radius of rock through experiment, and representing internal damage of the rock from the graph; 2) drawing a relational graph of the titration diffusion radius and an axial pressure value of the rock sample in the loading process; 3) obtaining the change of the porosity of the rock sample in the loading process from the relational graph of the titration diffusion radius and the axial pressure value of the rock sample in the loading process, obtained in the step 2), and the relational graph of the rock porosity and the titration diffusion radius of rock, obtained in the step 1), so as to obtain the damage degree in different positions of the rock sample, and realize real-time measurement on the damage of the rock sample in the circulation loading process. Due to the adoption of the real-time measuring method for rock sample damage in the circulation loading process, the change of the porosity of the rock in the stress process is reflected through the appearance phenomenon of the rock surface through a nondestructive testing technique, so that the damage degree of the rock in the stress process is represented.

Owner:泰州市海通资产管理有限公司

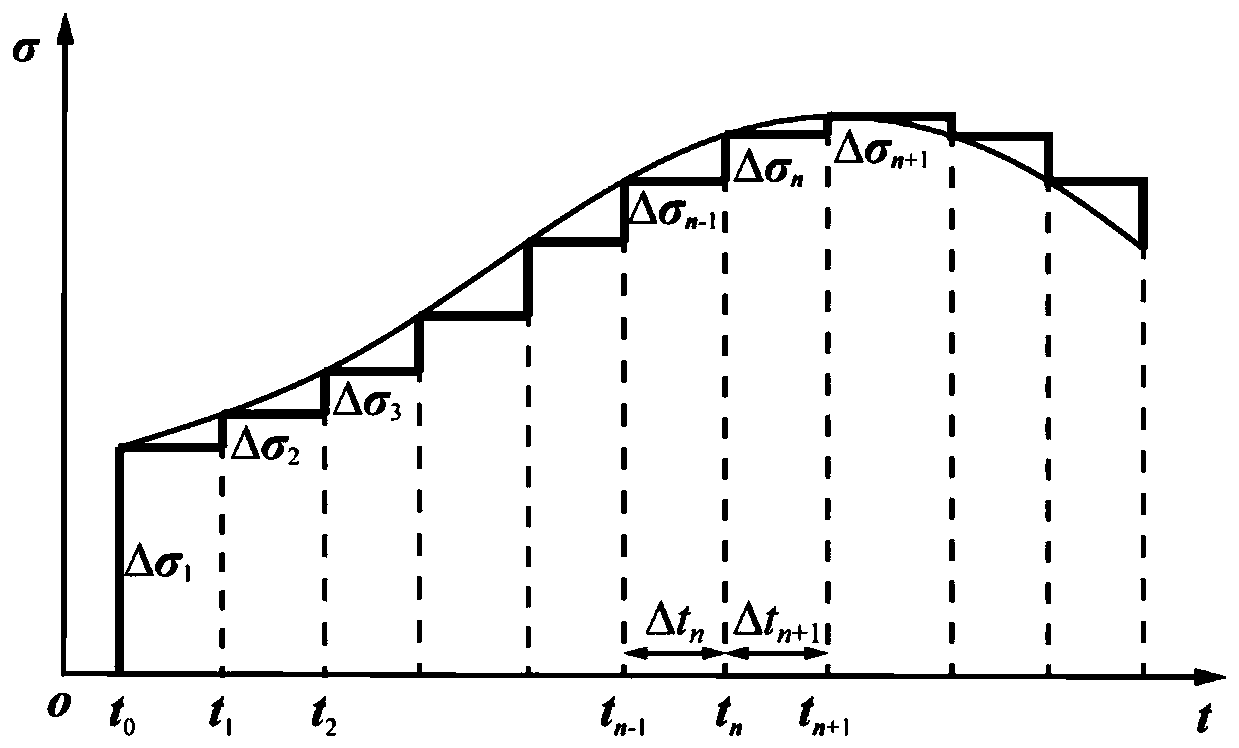

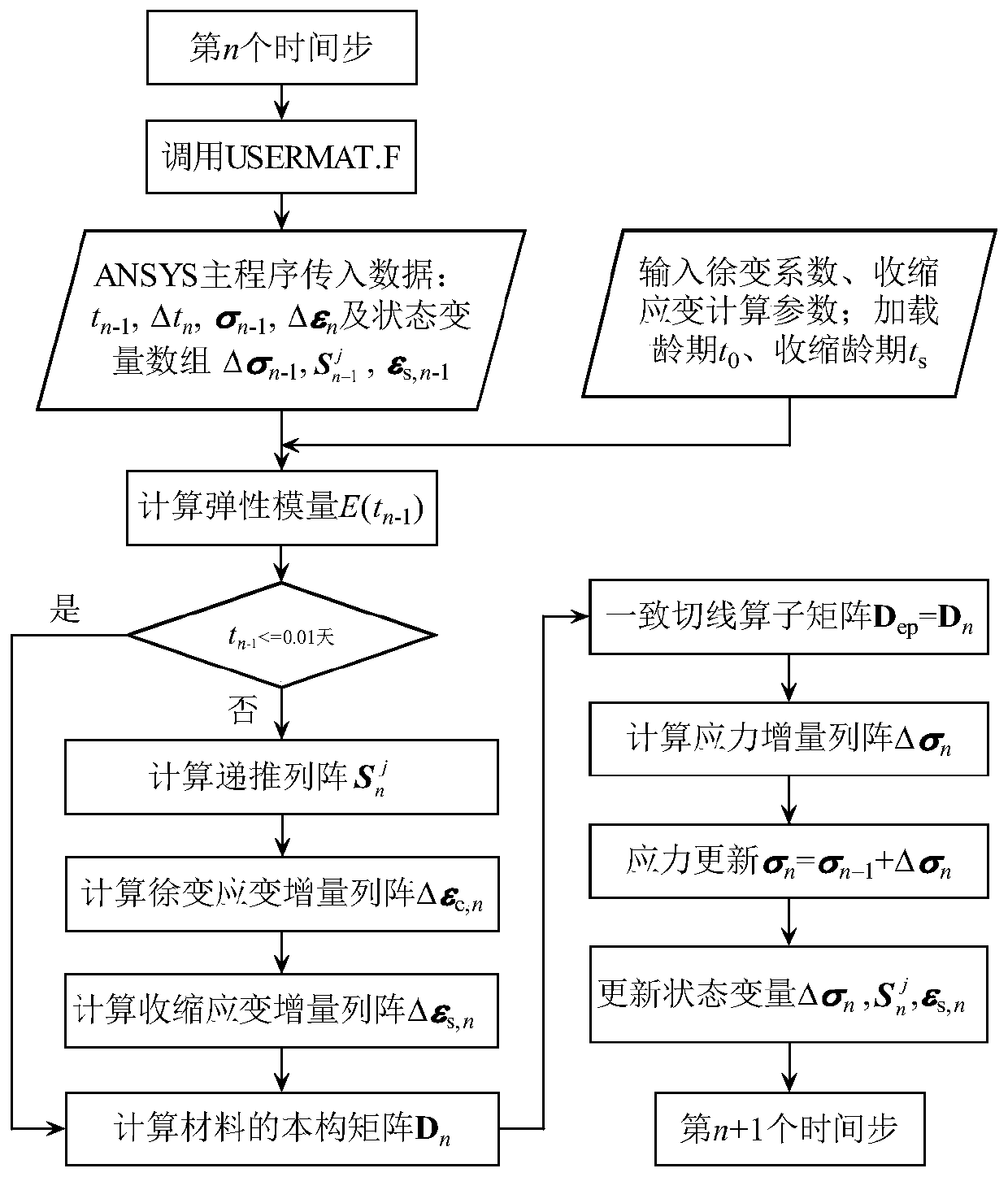

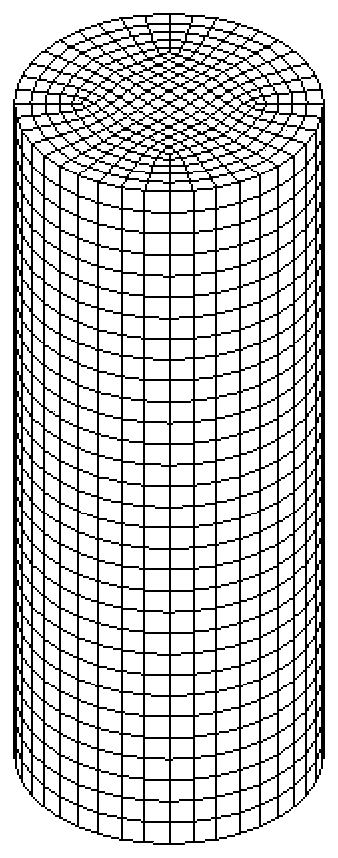

Entity finite element calculation method for time-varying effect of concrete structure

ActiveCN110162827AFine calculation of time-varying effectsOvercoming the disadvantage of difficulty in variable effectDesign optimisation/simulationSpecial data processing applicationsStress processStressed state

The invention relates to an entity finite element calculation method for a time-varying effect of a concrete structure, which comprises the following steps of: 1) discretizing the stress process of concrete according to a stepwise method, and deducing creep strain increment in an nth time period; 2) fitting the creep coefficient expression into an exponential series form by using Matlab software;3) substituting the creep coefficient fitting expression into a creep strain increment calculation formula, and establishing a concrete uniaxial creep strain increment recurrence calculation formula;4) considering the creep Poisson effect, and establishing a concrete time-varying constitutive equation in the constitutive structure of the entity unit material; and 5) developing the time-varying constitutive structure of the concrete in the USERMAT subprogram of the ANSYS software by using the Fortran language. Compared with the prior art, time-varying effect value prediction of the concrete structure in a complex stress process under a spatial stress state can be realized, and the joint with a creep and shrinkage model of a common design specification is good.

Owner:HOHAI UNIV

Damping rubber with low cost and high damping performance and manufacturing method thereof

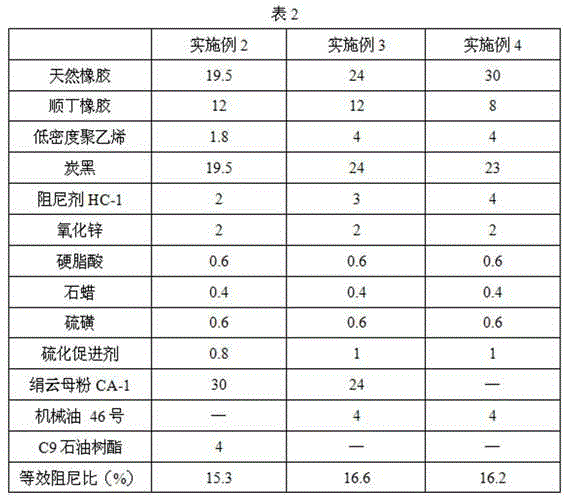

The invention discloses damping rubber with low cost and high damping performance and a manufacturing method thereof. The damping rubber comprises the following components: by weight, 19-30 parts of natural rubber, 8-20 parts of butadiene rubber, 1.8-10 parts of plastics, 19.5-26 parts of carbon black, 2-15 parts of damping agent HC-1 and 1-1.6 parts of vulcanization system. The natural rubber and butadiene rubber are mixed together to improve the relative stability of mechanical property in the repeated stress process of the rubber; the plastics with the temperature much different from the glass-transition temperature of the rubber is added, so that the range of the effective damping temperature of a final product is widened; the damping agent HC-1 is adopted to replace expensive small organic molecules, and the improvement on the damping performance of the rubber is roughly the same under the condition that the adding ratio is basically identical. The cost of the damping rubber formed by adopting the damping agent HC-1 is more than two times that of the damping rubber formed by adopting the small organic molecules.

Owner:CHENGDU POLYTECHNIC

Method for improving yield of epsilon-polylysine by low pH value stress

ActiveCN104498552AIncrease productionEasy to operateMicroorganism based processesFermentationEpsilon-PolylysineStress process

The invention discloses a method for improving the yield of epsilon-polylysine by low pH value stress and belongs to the technical field of fermentation engineering. In a fermentation process, an acid pH stress process is introduced, namely the pH is artificially or spontaneously reduced to 2.5-3.0 and is maintained for 12-48 hours; then the pH is improved to 3.5-4.5 and keeps stable until the fermentation is finished. With the adoption of a pH regulating and controlling method, the specific growth rate of epsilon-polylysine producing bacteria and the specific synthesis speed of the epsilon-polylysine can be remarkably improved; a material supplementing-batch fermentation manner is combined so that the yield of the epsilon-polylysine is improved by more than 50% when being compared with that a common two-phase pH regulating and controlling method. According to the method, a low pH stress method is introduced into an epsilon-polylysine fermentation process so that the fermentation level of the epsilon-polylysine is remarkably improved. Furthermore, the method is simple to operate and has remarkable effect so that the implementation of large-scale industrial production is facilitated.

Owner:JIANGNAN UNIV

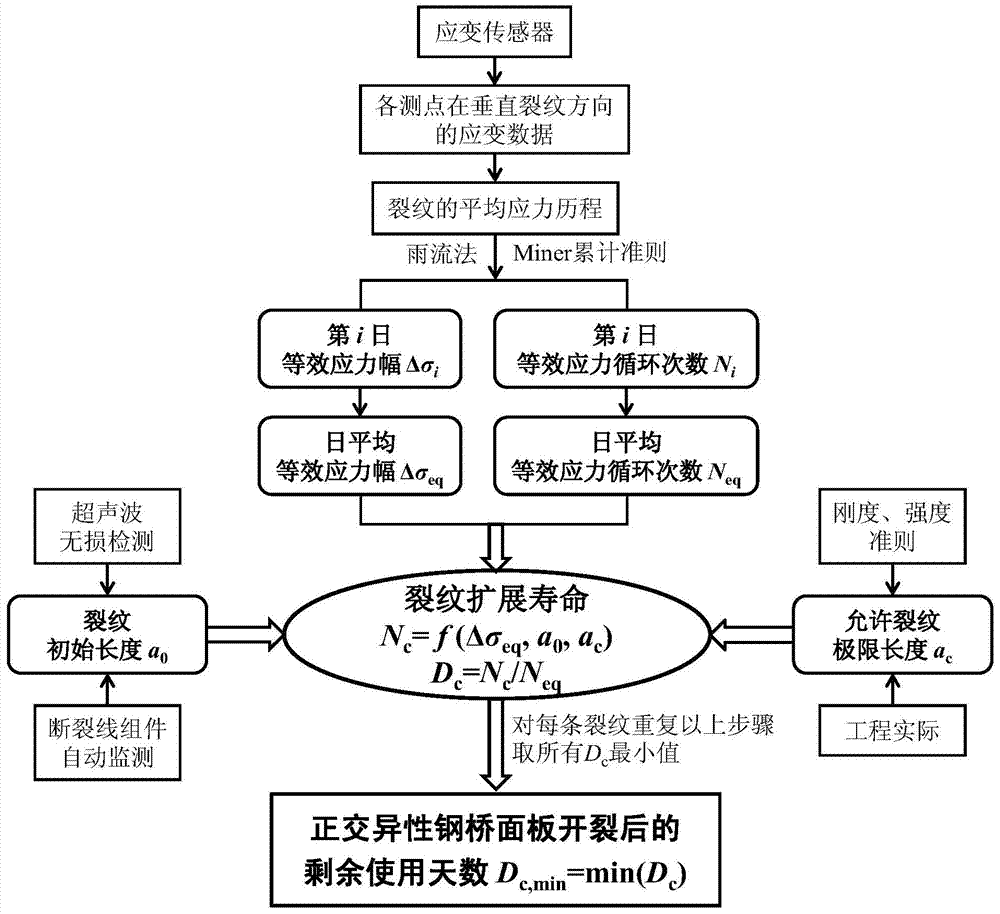

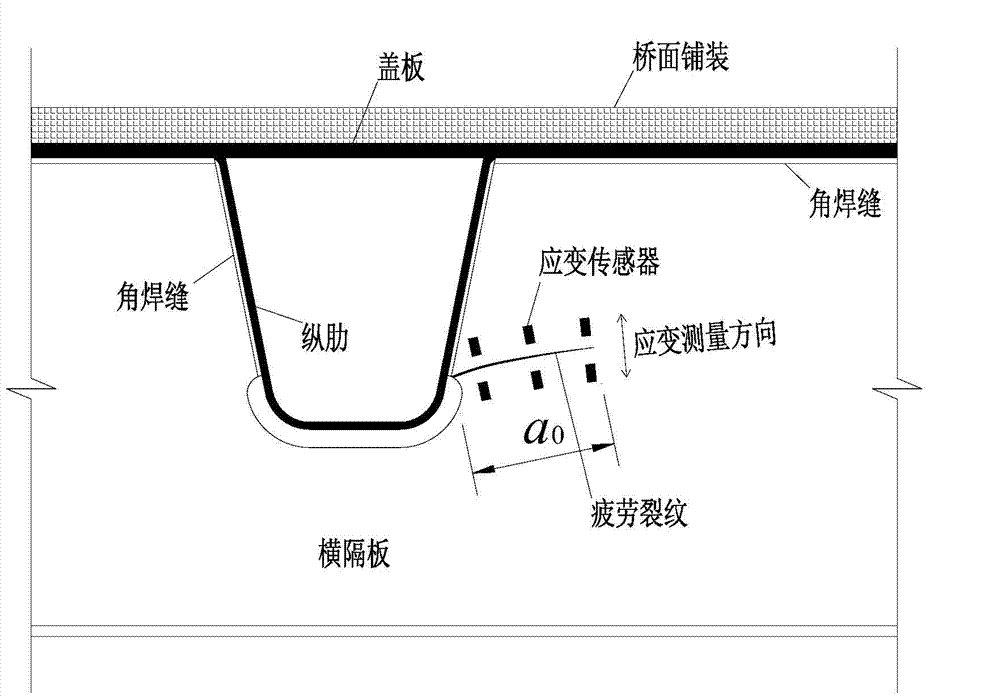

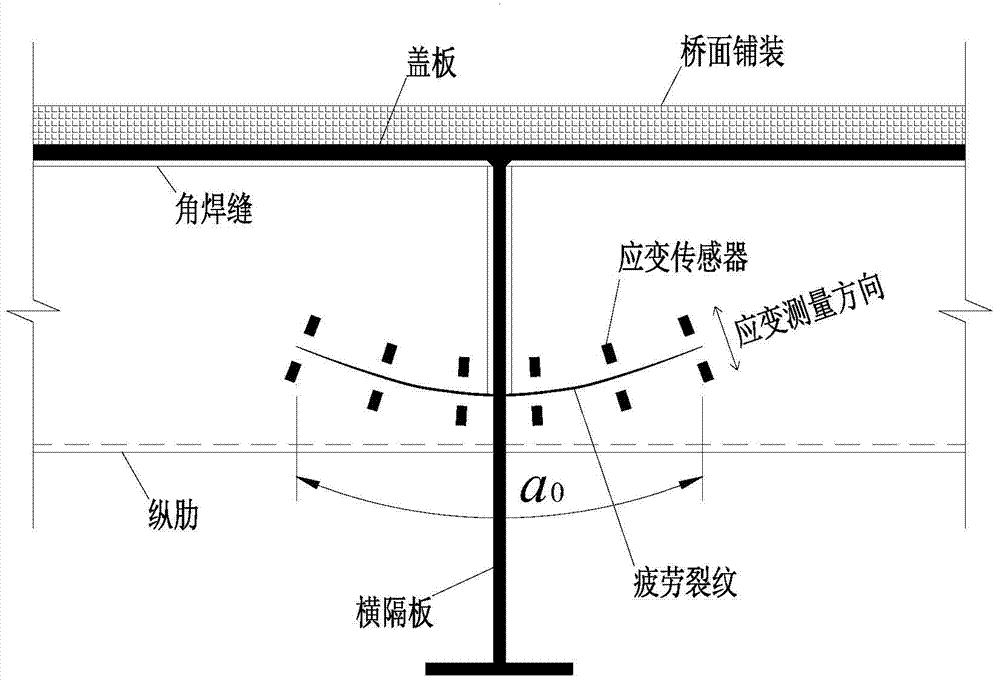

Method for evaluating remaining service life of orthotropic steel deck slab on active service after fatigue cracking

ActiveCN103940626ACan check security operation statusControllable security operation statusStructural/machines measurementNon destructiveTolerance limit

The invention provides a method for evaluating the remaining service life of an orthotropic steel deck slab on active service after fatigue cracking. The method specifically comprises the steps of (1) measuring the actual length a0 of each crack by adopting a non-destructive testing technology, (2) monitoring actual strain data of the two sides of each crack by adopting strain sensors, (3) obtaining stress process data of each crack, (4) calculating the daily mean equivalent stress amplitude delta sigma eq and the daily mean equivalent stress cycle index Neq according to a rain flow method and a Miner accumulation criterion, (5) determining the tolerance limit length ac of each crack by combining actual situations on the basis of rigidity and strength criterions, (6) calculating the propagation life Nc and Dc of each crack on the basis of a Paris formula, and (7) taking the minimum value of the Dc of all the cracks as the remaining fatigue life Dc, min of the steel bridge deck slab. The method for evaluating the remaining service life of the orthotropic steel deck slab on active service after the fatigue cracking is reliable in theory, clear in logic, and simple in detection means and method.

Owner:SHANGHAI JIAO TONG UNIV

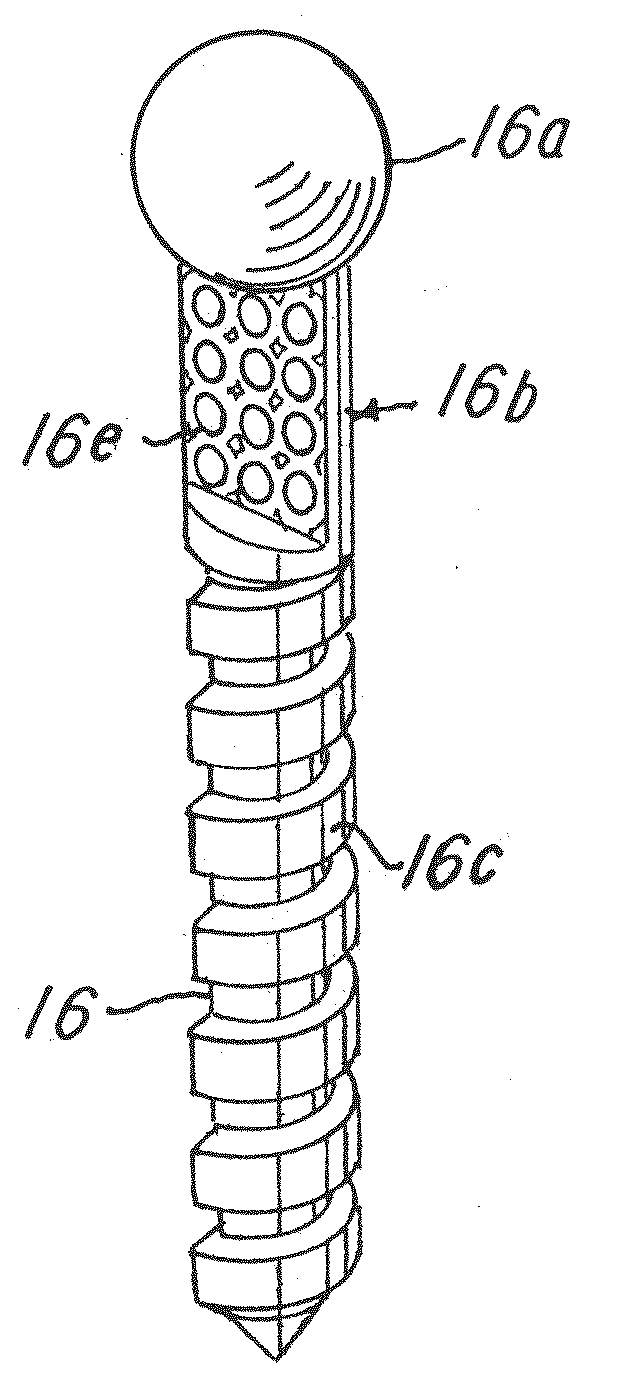

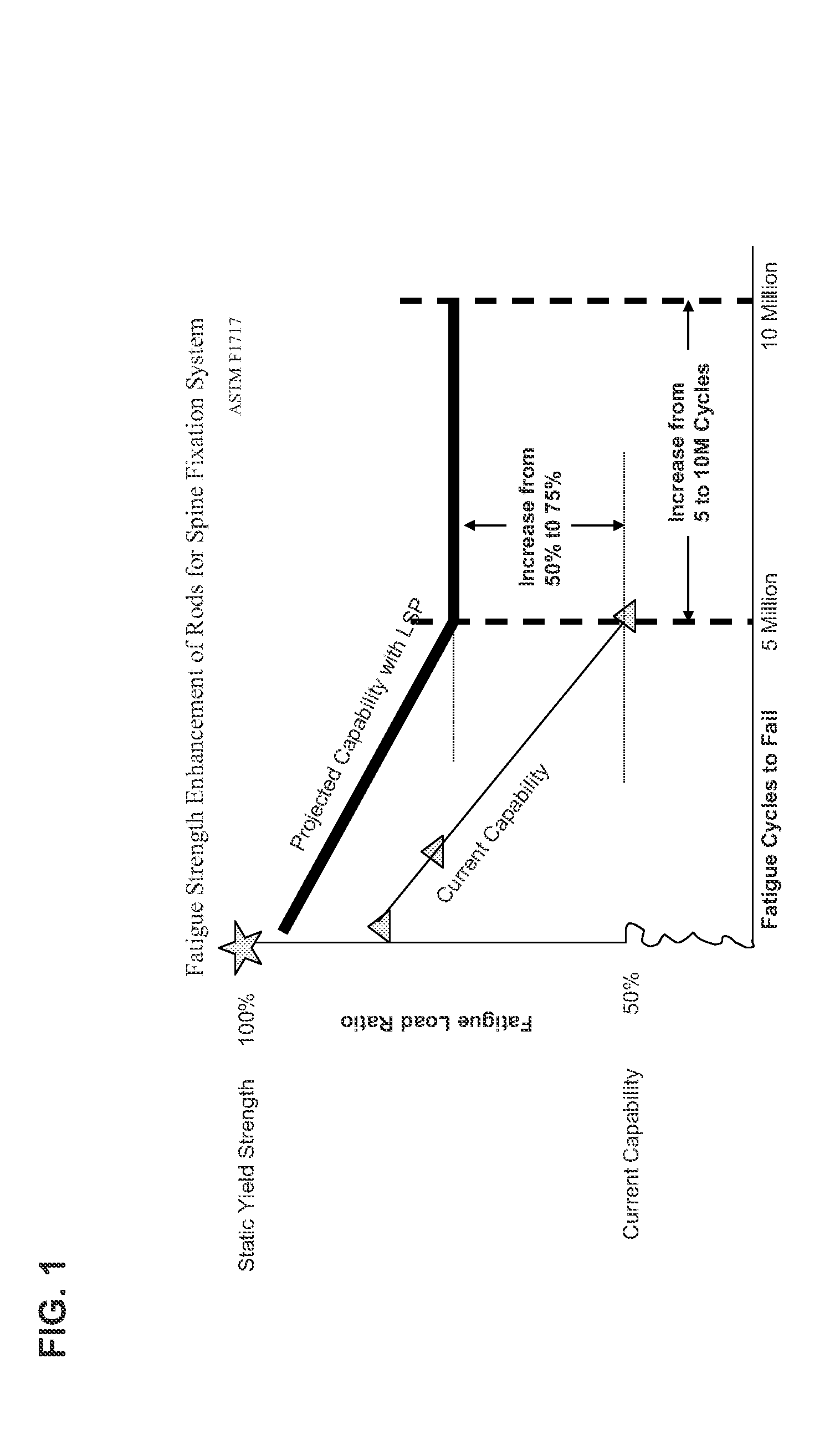

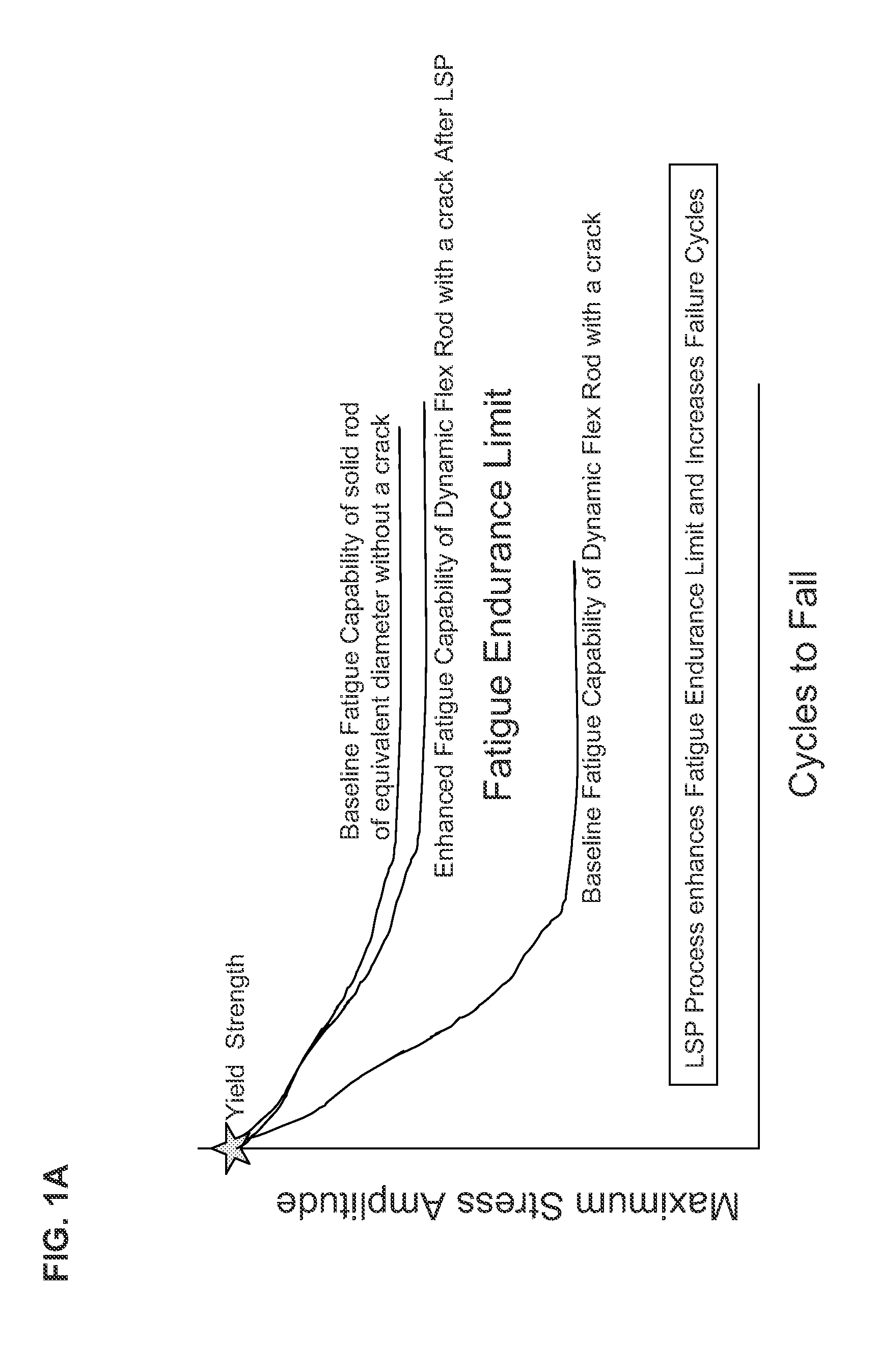

Implant and a system and method for processing, desiging and manufacturing an improved orthopedic implant

InactiveUS20100249926A1Improve fatigue strengthHigh fatigue loadSuture equipmentsInternal osteosythesisHigh densityStress process

A medical or orthopedic implant, system and method for making the implant having areas that are designed to optimize compressive stress processing by, for example, laser shock peening. The implant is designed by identifying stress areas as processing zones. The processing zones are machined, processed or adapted to have a desired shape or configuration to optimize compression. The processed zones or areas are compressive stressed processed to have a higher density at zones or areas compared to areas that are not compressive stress processed. The implant is finished processed and sterilized and ready for use in the patient.

Owner:X SPINE SYST

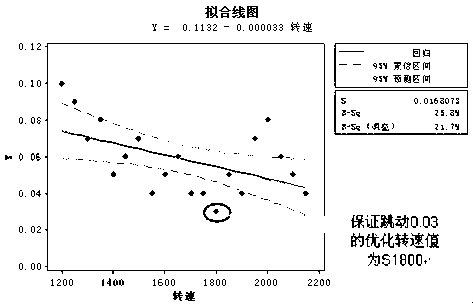

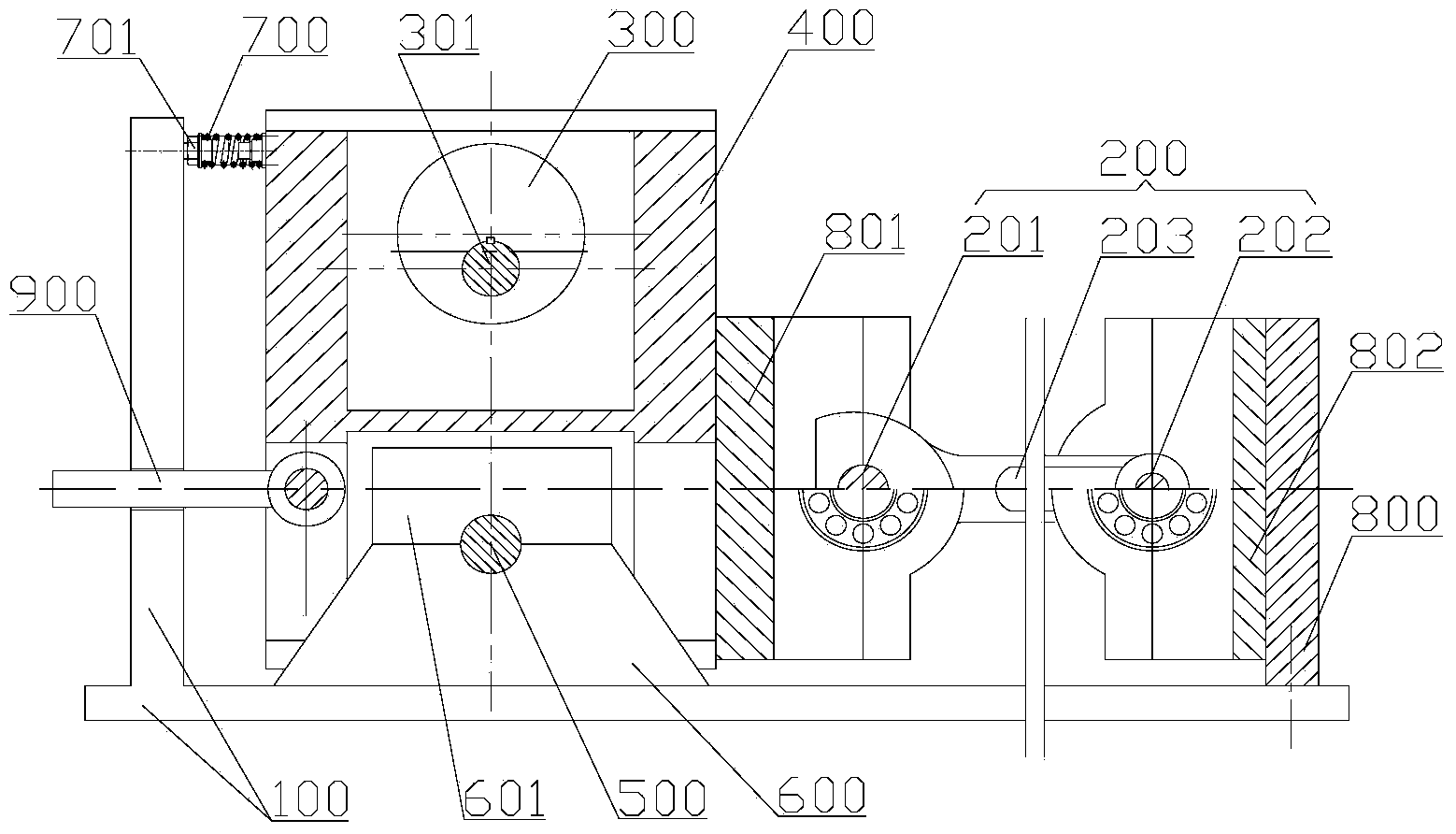

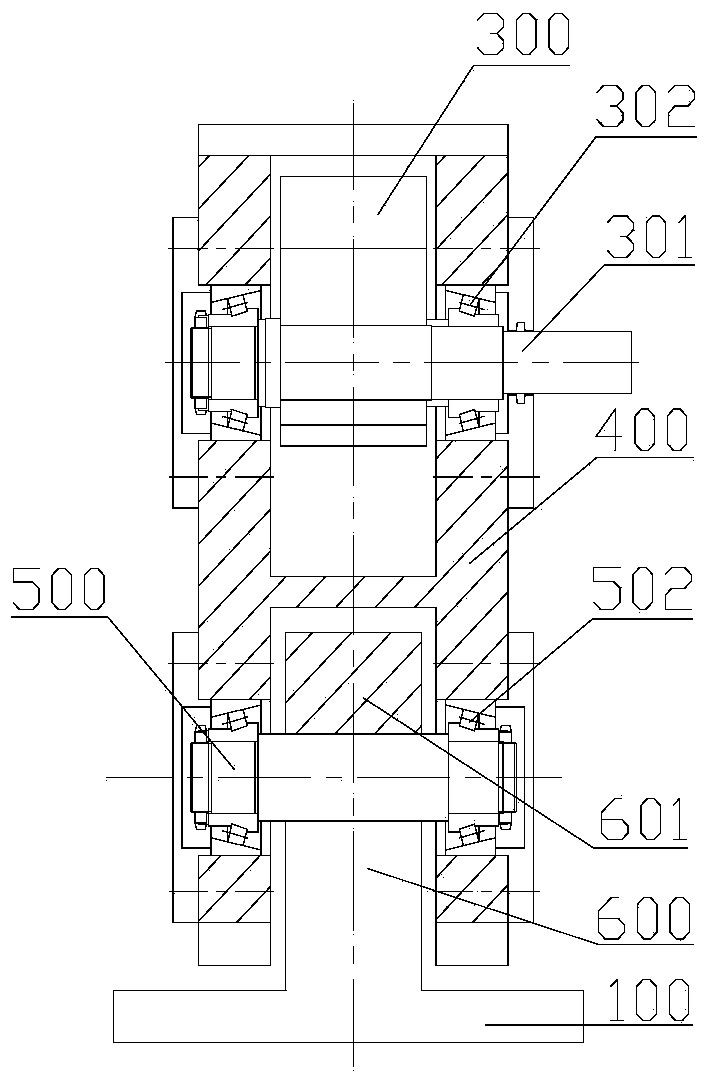

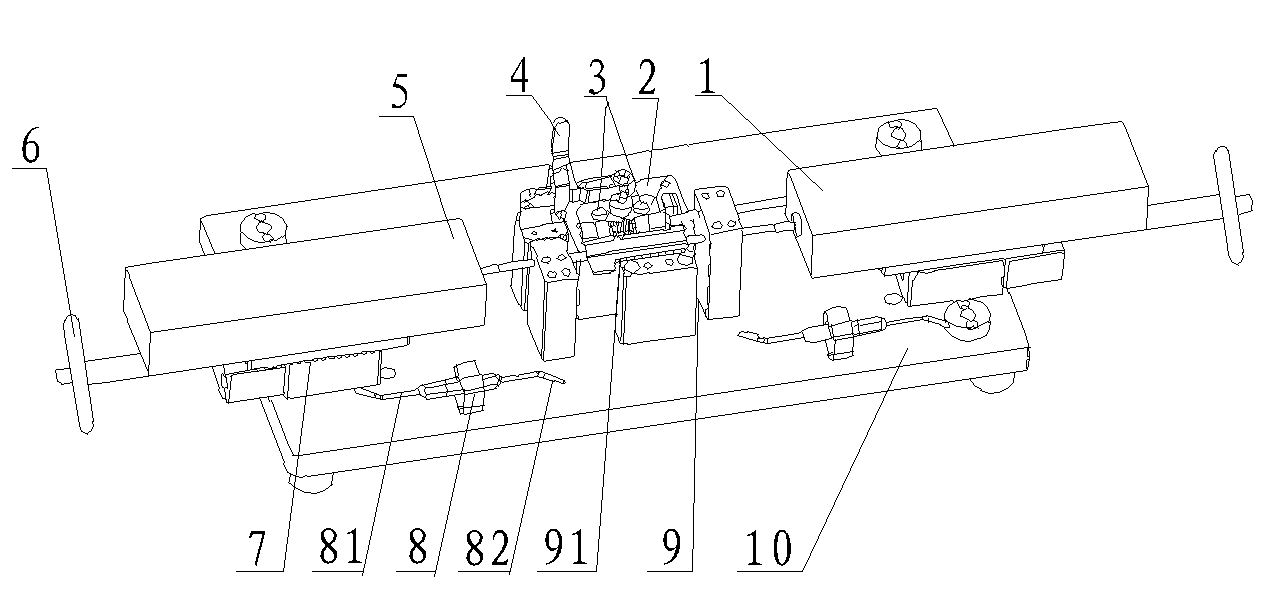

Connecting rod fatigue testing device

ActiveCN104006967AImprove accuracyImprove reliabilityMachine gearing/transmission testingStress processSoftware engineering

The invention discloses a connecting rod fatigue testing device. The connecting rod fatigue testing device comprises a base, a connecting rod and a loading device. One end of the connecting rod is fixed to the base, the other end of the connecting rod is loaded by the loading device, and the loading device repeatedly exerts continuously-changing pressure and tension on the connecting rod. The tension load and the pressure load change continuously from zero to the amplitude value, and the tension and the pressure are converted automatically instead of being exerted or removed forcefully, namely, the stress process of the connecting rod is continuous. Due to the fact that the connecting rod does not bear suddenly-changing loads, the problem of excessive shock is avoided, the phenomenon that a testing result is abnormal cannot occur and the accuracy and the reliability of the testing result are improved.

Owner:WEICHAI POWER CO LTD

Machining method of wind-power center-aligning spherical surface roller bearing retainer

The invention provides a machining method of a wind-power center-aligning spherical surface roller bearing retainer. The method comprises the process steps of: sampling to test whether materials of a retainer is qualified; carrying out heat treatment on a blank cylinder which is centrifugally cast and heating to be at 410-420 DEG C; keeping the heat for 4 hours and cooling to be at 100-150 DEG C along with a furnace; carrying out rough machining on the blank cylinder of the retainer on a numerically controlled lathe according to a pre-set size and keeping 3 millimeters for the size of each part; removing turning stress and annealing after carrying out rough turning machining, wherein the annealing temperature is 220-250 DEG C; keeping the heat for 6 hours; fixing the annealed retainer on the numerically controlled lathe and carrying out finish turning on the size of each part; utilizing an inner diameter size guided in the retainer as a standard and mounting on a mould of a machining center; and carrying out boring machining on a machining center according to a pre-set procedure. A wind-power self-aligning spherical surface roller bearing of the retainer, machined by the method, has good utilization performance and achieves the national advanced level; and the normal operation requirements of a fan can be completely met on the aspects of reliability and stability. Particularly, an inner stress process eliminating process is adopted and the use effect is relatively ideal.

Owner:DALIAN METALLURGICAL BEARING

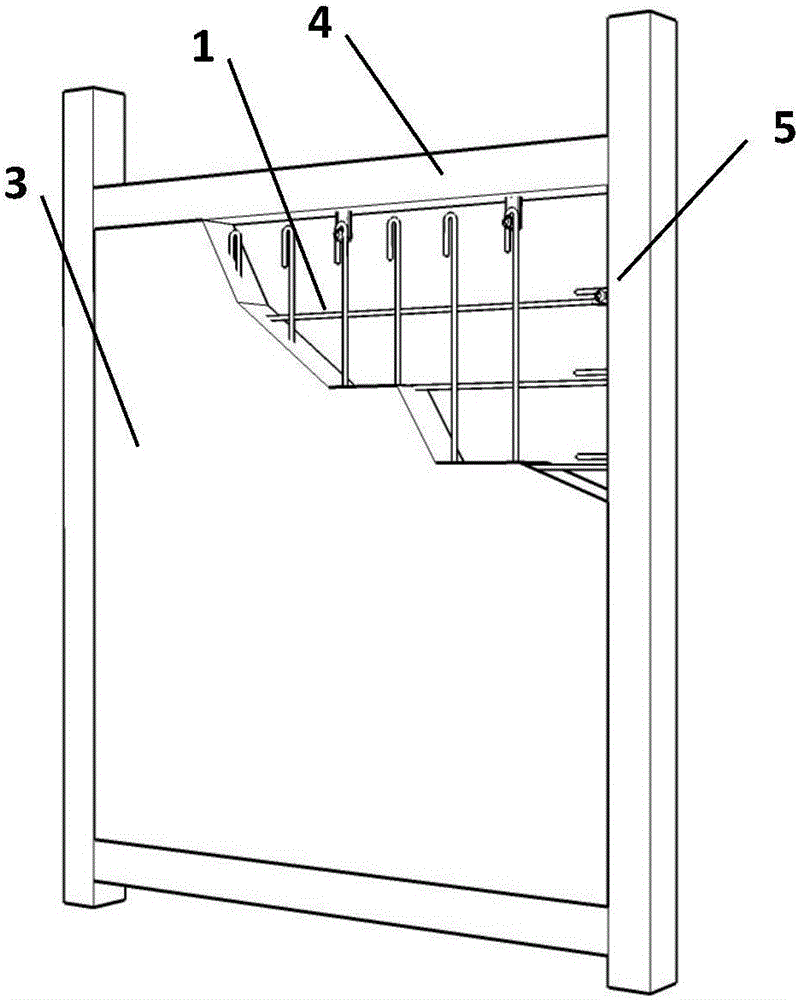

Light steel side frame and main rib type single-row reinforcement recycled-concrete shear wall and construction method

ActiveCN105908868AImprove the level of industrializationIncrease productivityWallsStress processSteel frame

The invention discloses a light steel side frame and main rib type single-row reinforcement recycled-concrete shear wall and a construction method, and belongs to the field of civil engineering. A main rib type single-row reinforcement recycled-concrete shear wall, a light steel beam and a light steel column are prefabricated by a factory and are assembled in field. The main rib type single-row reinforcement recycled-concrete shear wall and a light steel frame are connected through ear plates thereon. The main rib type single-row reinforcement recycled-concrete shear wall and the light steel frame are taken as enclosure and lateral force resisting members, so that sufficient bearing force is provided during construction and usage; in a stress process, light steel and light wall components are mutually coordinated and bear the force commonly; furthermore, a design construction of joint connection is reasonable, and the force transmission is reliable. The light steel side frame and main rib type single-row reinforcement recycled-concrete shear wall combines main rib type single-row reinforcement recycled-concrete shear wall and light steel frame joint connection construction techniques, a prefabricated assembly type house technique and a recycled concrete technique, and is suitable for a multilayer building structure.

Owner:BEIJING UNIV OF TECH

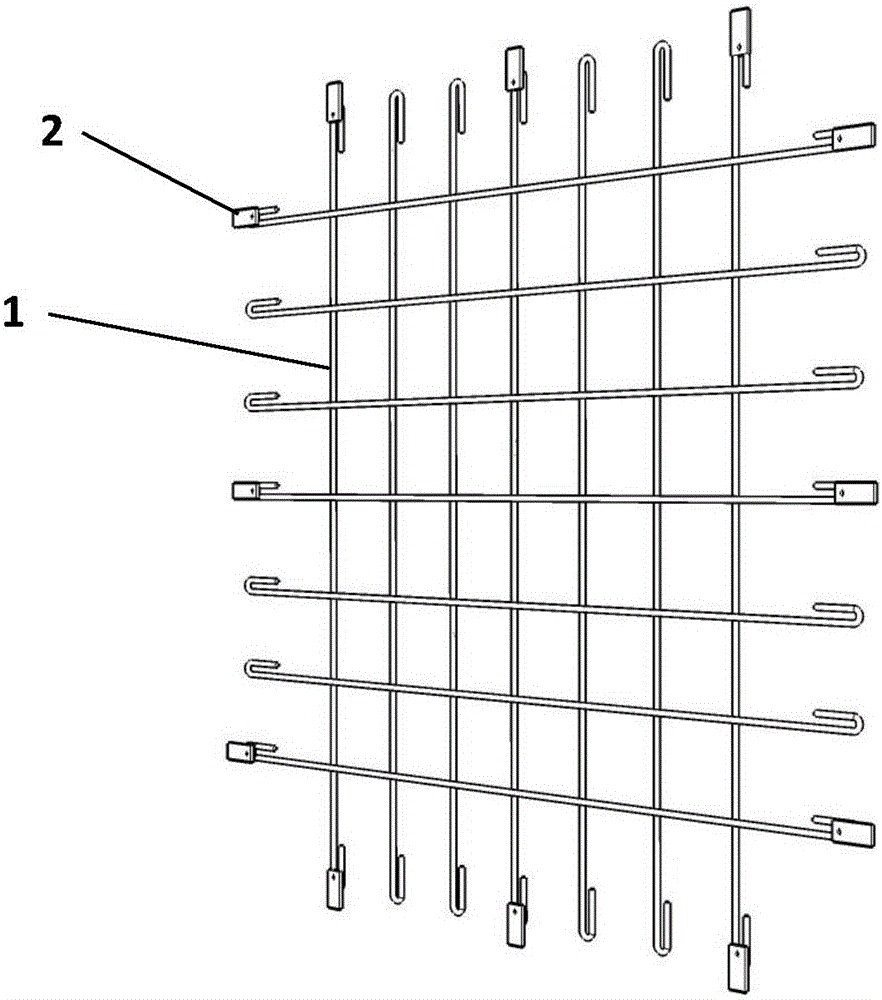

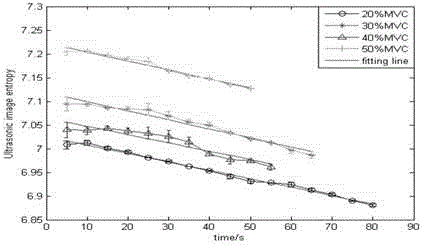

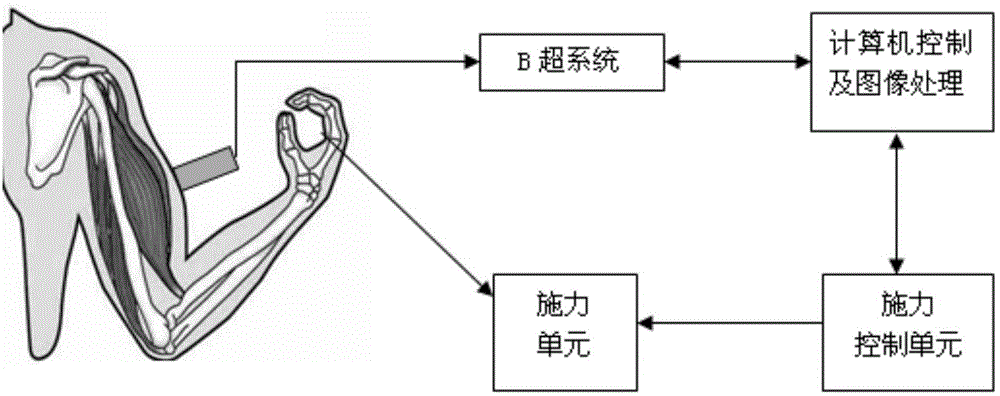

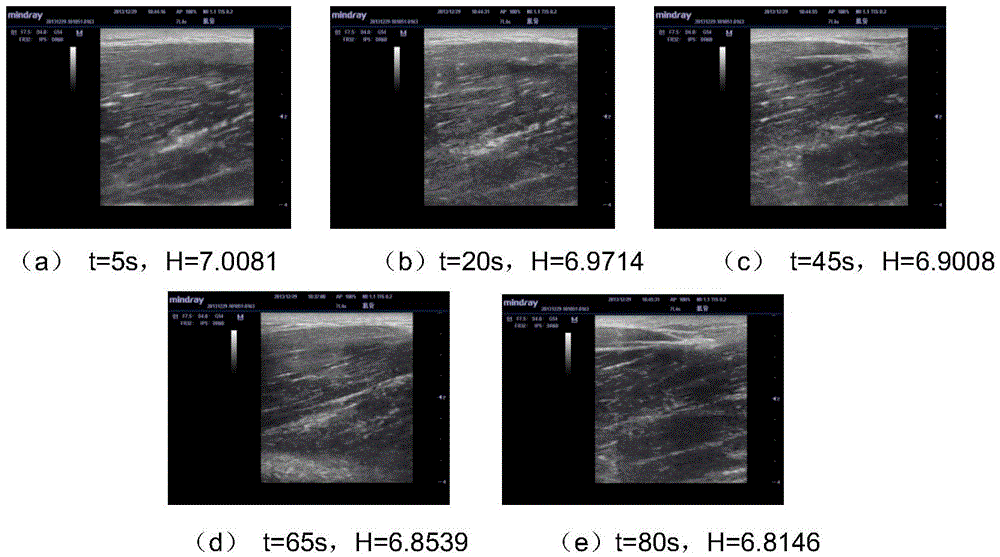

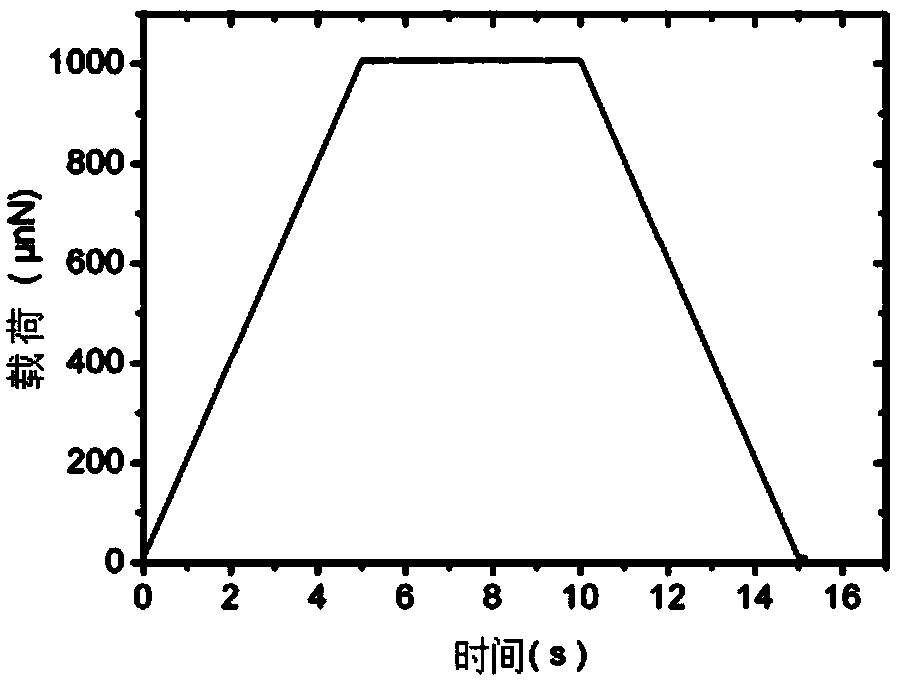

System and method for detecting a muscle fatigue process through ultrasonic image entropy features

ActiveCN104523295AImprove orderReal-time detectionOrgan movement/changes detectionInfrasonic diagnosticsFiberMuscle tissue

The invention provides a system and method for detecting a muscle fatigue process through ultrasonic image entropy features. An ultrasonic transducer is aligned with a target muscle tissue area; constant force is applied to target muscle tissues through a force application unit; the stress process of detected muscle is recorded according to the time sequence; the muscle fiber image entropy textural features are estimated according to B-type ultrasonic images in the muscle fiber direction; according to the principle that muscle fibers are increased in motion along with the fatigue degree, the sectional areas of the muscle fibers are increased in a positively-correlated manner, the muscle overall ordering increase of the overall muscle fibers is formed, and therefore muscle ultrasonic image entropies reflecting the muscle fiber ultrasonic features are decreased in the positive correlation manner, an image entropy threshold value is set to judge the target muscle fatigue degree and process. By means of the system and method, the muscle tissue ultrasonic image entropy features are combined with the muscle tissue fatigue process; a damage-free and intervention-free muscle tissue fatigue process ultrasonic image entropy detection system is designed; and the muscle fatigue process is detected in a real-time, effective and damage-free manner.

Owner:SHAANXI NORMAL UNIV

Soil pressure sensor mounting, loading and testing device, and operating method thereof

InactiveCN103278395AAvoid border effectsReflect compactionMaterial strength using tensile/compressive forcesStress measuresPunching

The invention discloses a soil pressure sensor mounting, loading and testing device, and an operating method thereof. A punching mechanism and an embedding mechanism are not required to excavate a tunnel for embedding a sensor in advance, and are only required to downwards drill a hole for placing the soil pressure sensor along a certain angle; the excavated tunnel is prevented from influencing a boundary effect of a testing point for embedding the soil pressure sensor; the disturbance and the damage to a structural state of in-situ soil can be reduced to the greatest extent; the labor intensity of embedding the soil pressure sensor is reduced; a loading and testing mechanism is controlled by a hydraulic drive which is stable in loading speed and accurate in control; and the transmission condition of stress in a soil body is reflected by a loading load and loading stress measured by the soil pressure sensor embedded in the soil body, so that a compaction and stress process of farmland soil can be reflected more accurately. The soil pressure sensor mounting, loading and testing device is simple in structure, low in cost, convenient to use and accurate in measurement, is widely applicable to testing the compaction condition of the farmland soil, and is suitable for popularization and using.

Owner:NANJING AGRICULTURAL UNIVERSITY

Method for preparing high-performance biphase rare-earth permanent magnet material using hydrogenation heat treatment process

InactiveCN1545107AFine nanostructureRegular nanostructureInductances/transformers/magnets manufactureMagnetic materialsAdhesion processHydrogen

The invention discloses a preparing method of high-performance double-phase, rare-earth, permanent magnetic material by hydrogenation thermal treatment. Firstly, it adopts vacuum welting method to prepare alloy; secondly, adopts fast quenching method or mechanical alloying method to prepare prealloy powder; then, places the prealloy powder in a hydrogen processing device, vacuumize the device and charges in hydrogen for hydrogen absorption and dehydrogenation reactions at 600-1000 deg.C; and finally, adopts adhesion process, cold press process, and thermal press or thermal stress process to prepare an alloyed magnet. It has better synthetic permanent magnetic performance, and its producing device and process are simple, and the consumption of process is low.

Owner:ZHEJIANG UNIV

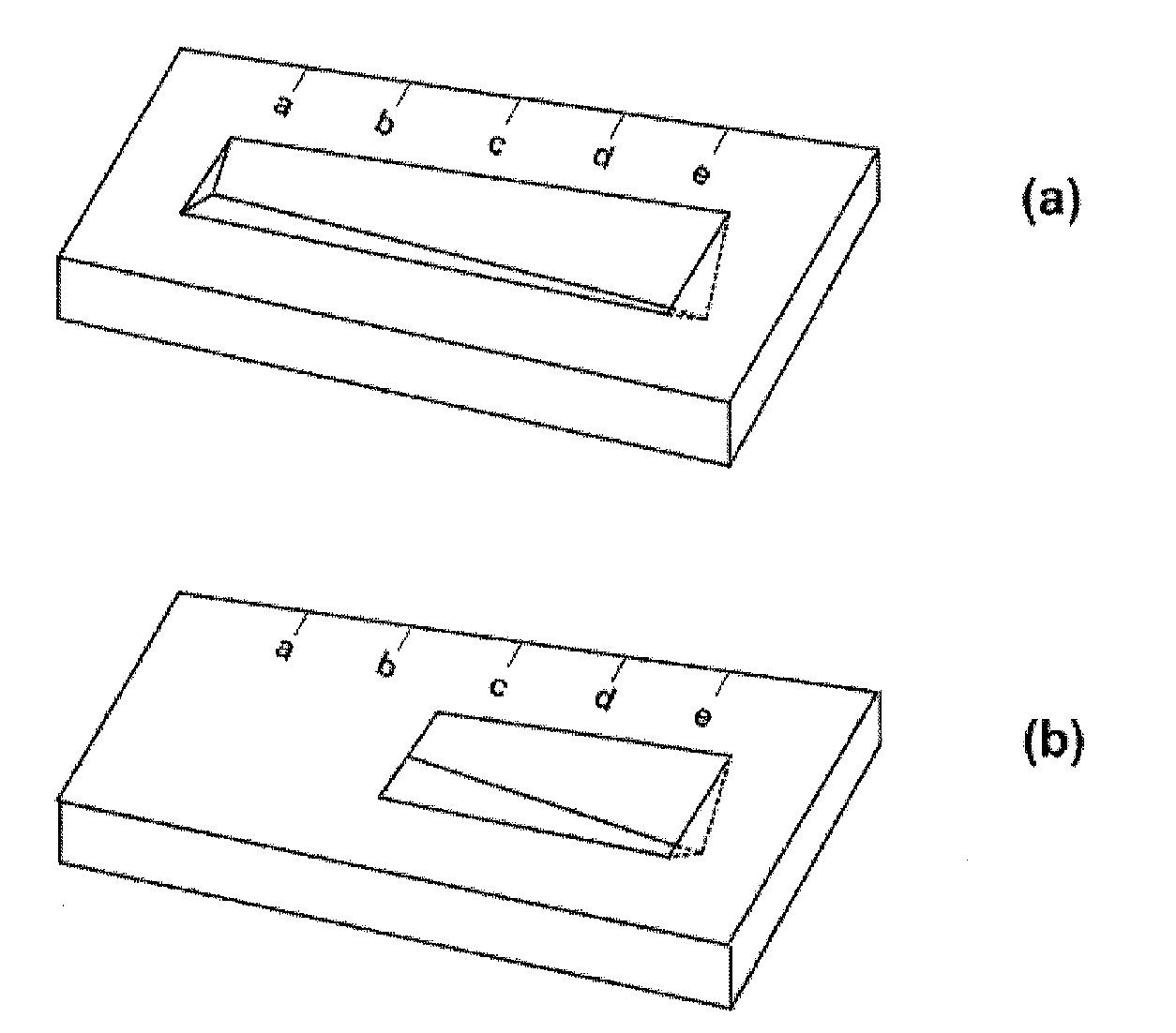

Method for discriminating nonlinearity of pressure sensors under influence of internal stress

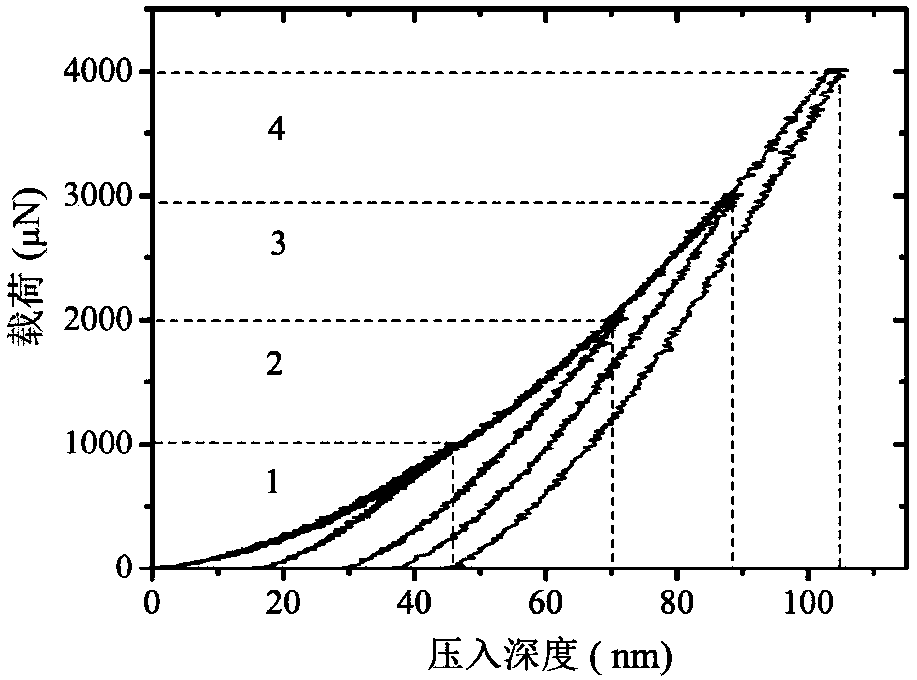

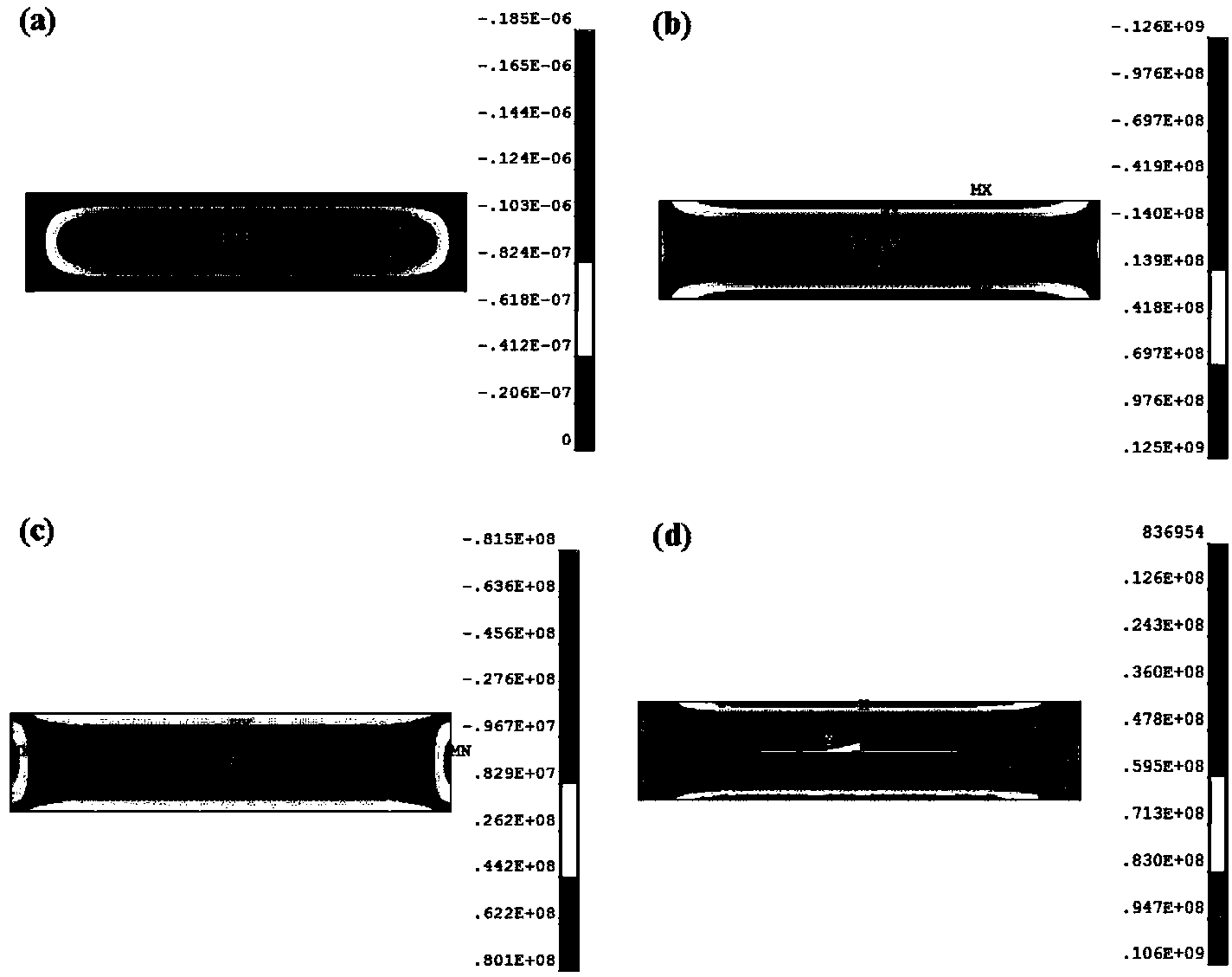

ActiveCN104359611AQuickly Measure Nonlinear ErrorsQuick measure of sensitivityFluid pressure measurementForce/torque/work measurement apparatus calibration/testingStress processYoung's modulus

The invention provides a method for discriminating the nonlinearity of pressure sensors under the influence of internal stress. The method includes measuring Young modulus and initial internal stress values of thin films of structural layers of chips of the pressure sensors; building structural models of the chips of the pressure sensors by the aid of ANSYS software and Solid 186 unit types, and dividing grids of the models after the models are geometrically built and material parameters are defined; applying displacement constraint conditions, fixing peripheral edges of the models, constraining degrees of freedom in an X direction, a Y direction and a Z direction, applying external pressures, and solving stress and deflection distribution to obtain equivalent stress cloud pictures; introducing initial internal stress of the thin films by the aid of an equivalent thermal stress process, simulating input-output characteristics of the pressure sensors under different internal stress conditions and computing the nonlinearity of the pressure sensors. The method has the advantages of simplicity and high accuracy. Besides, nonlinearity errors and sensitivity of the pressure sensors can be quickly balanced, so that optimal designs of the performance of the pressure sensors can be guided.

Owner:WENZHOU UNIVERSITY

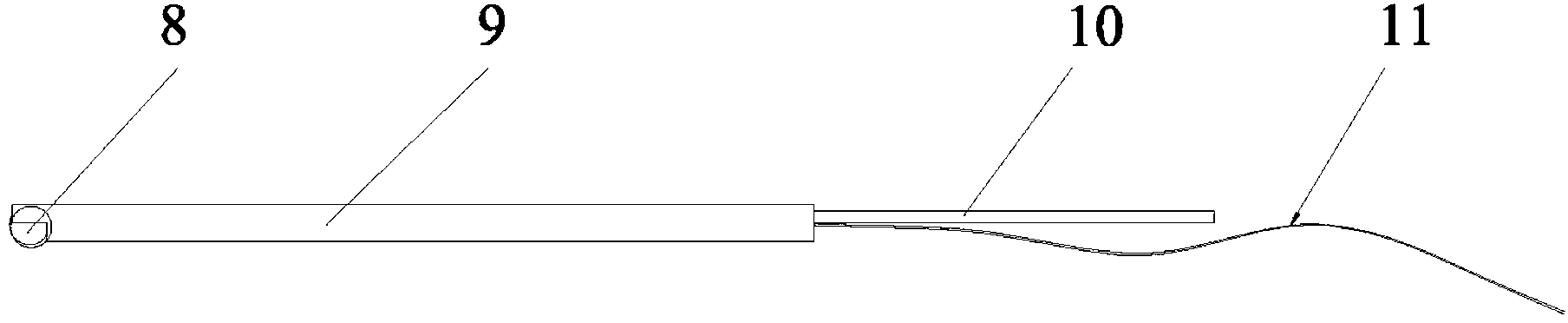

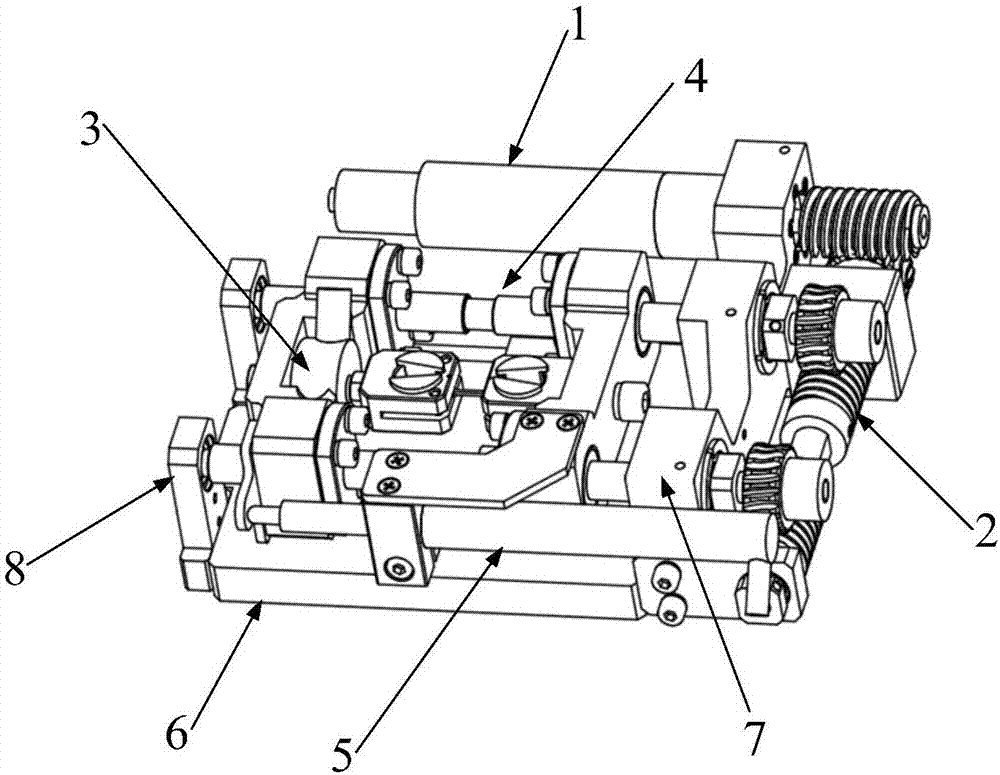

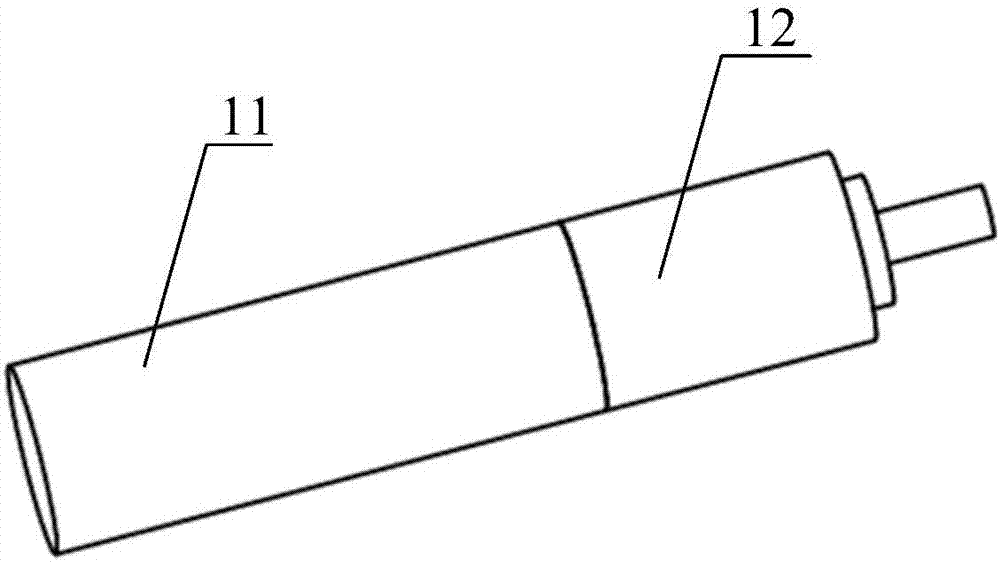

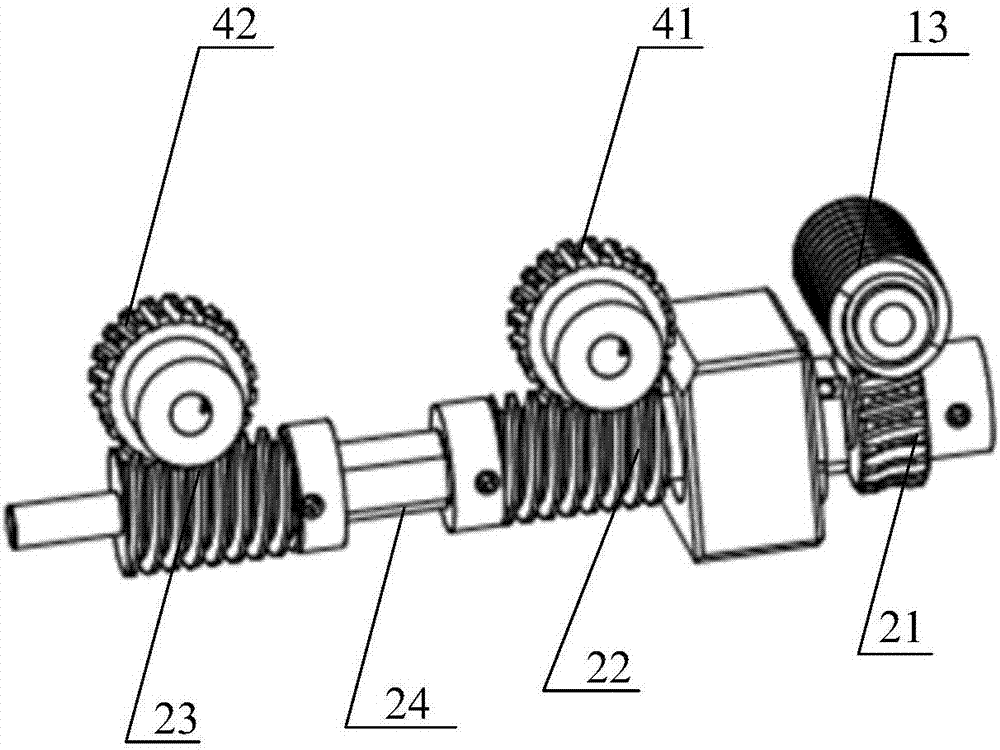

Material mechanics property testing device

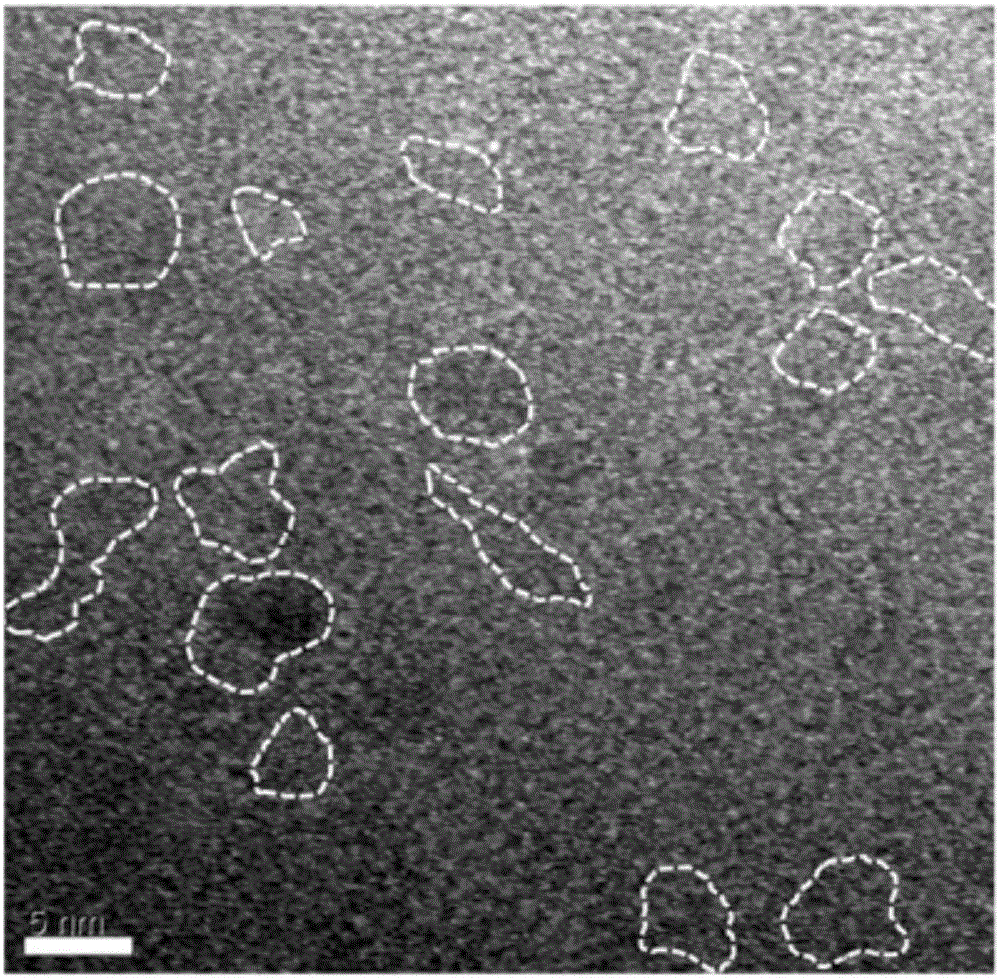

InactiveCN107036890AAchieve mechanical propertiesRealize the synchronization of microscopic topography observationMaterial strength using tensile/compressive forcesProcess dynamicsStress process

The invention discloses a material mechanics property testing device which comprises a microscope for observing the middle position of a sample and an in-situ tensile tester. The in-situ tensile tester comprises a driving unit, wherein the driving unit is connected with a sample tensile unit through a driving unit, the sample tensile unit is connected with a load testing device for testing a tensile force of a sample, a deformation detecting device for measuring sample deformation is connected with the sample tensile unit, and the load testing device and the deformation detecting device are connected with a controller. Due to the fact that a test is performed under the microscope, the whole stress process of the sample can be observed through the microscope, the material mechanics property testing device can conduct whole-process dynamic monitoring on the microcosmic deformation damages of a material under a microimaging system, and thus synchronism of mechanics property testing and microtopography observation can be achieved.

Owner:中机试验装备股份有限公司 +1

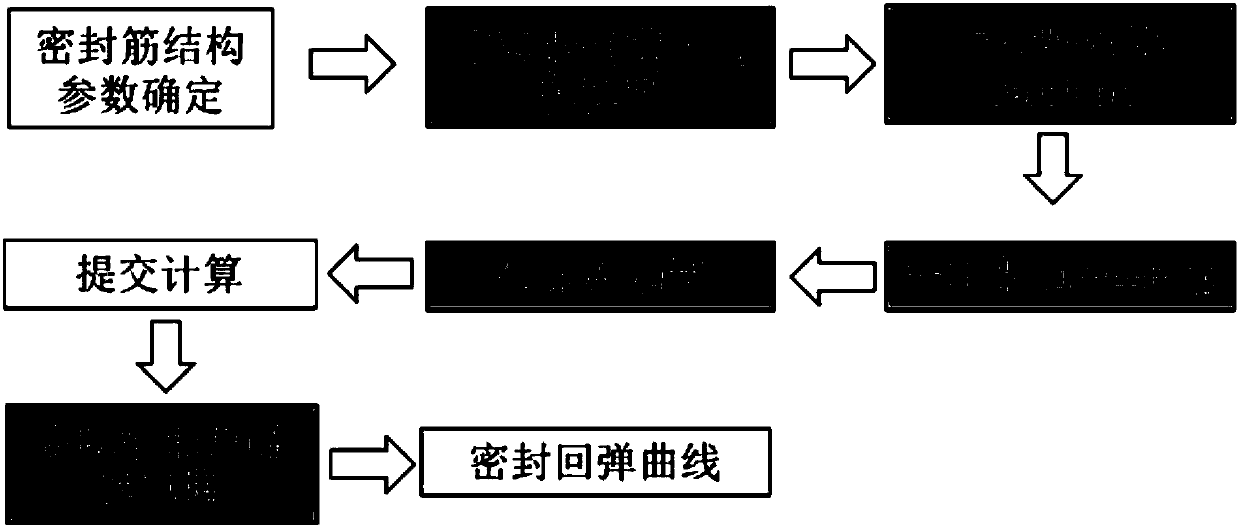

Seal strip rebound curve analysis method

ActiveCN107766687AImprove performanceSimple structureGeometric CADDesign optimisation/simulationElement modelDesign phase

The invention relates to a seal strip rebound curve analysis method. The seal strip rebound curve analysis method includes the specific steps of 1, determining structural parameters of a seal strip; 2, establishing a geometric model according to parameter driving; 3, subjecting the model to initial topologization; 4, dividing grids according to parameter driving; 5, restraining and loading conditions; 6, submitting finite element calculation after a finite element model is established, and reading and storing vertical displacement of rigid plane pressure head and action force of the corresponding placement; 7, generating a seal strip rebound curve. The seal strip rebound curve analysis method has the advantages that a stress process and a corresponding deformation status of the seal stripare simulated and recorded to obtain the rebound curve of the seal strip and complete prediction of the seal strip rebound performance; the seal strip rebound curve analysis method achieves a 'once-through design pair' of the seal strip without analyzing the rebound performance of a seal strip finished product through mechanical equipment and experience traditionally, and optimizes the performanceand the structure of the seal strip in a design phase purposefully, so that the design correct rate and the working efficiency are both increased while the test cost is reduced.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

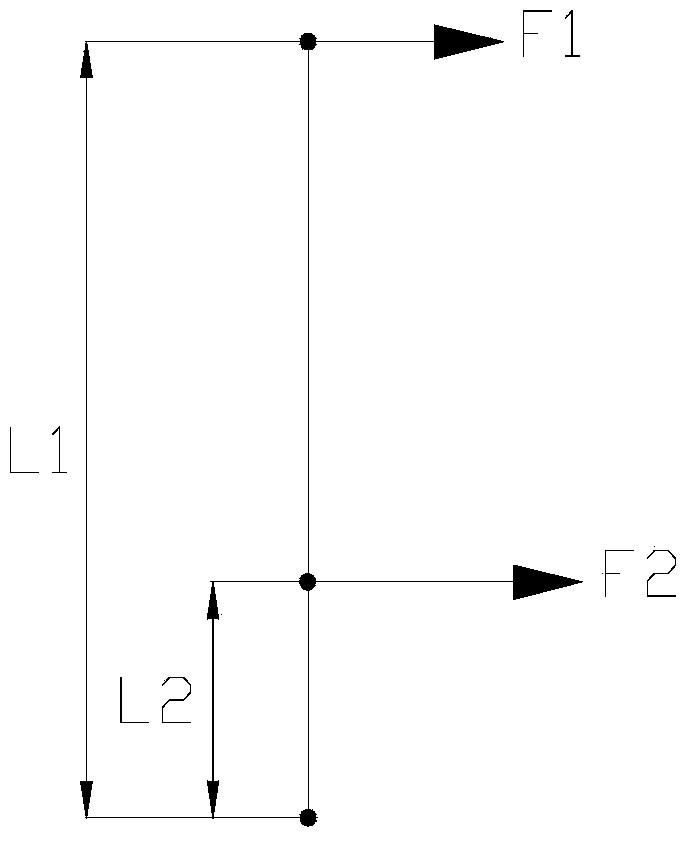

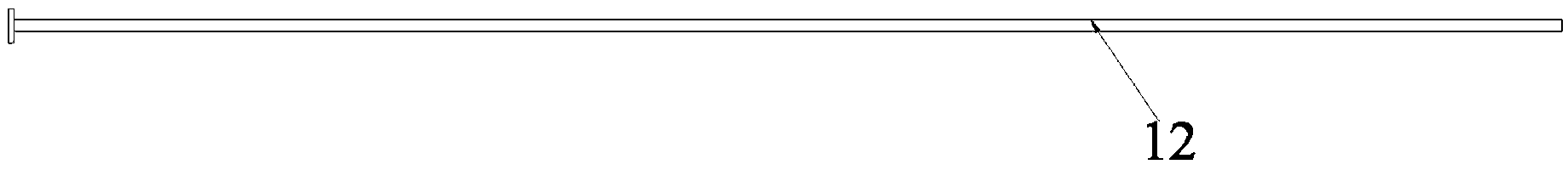

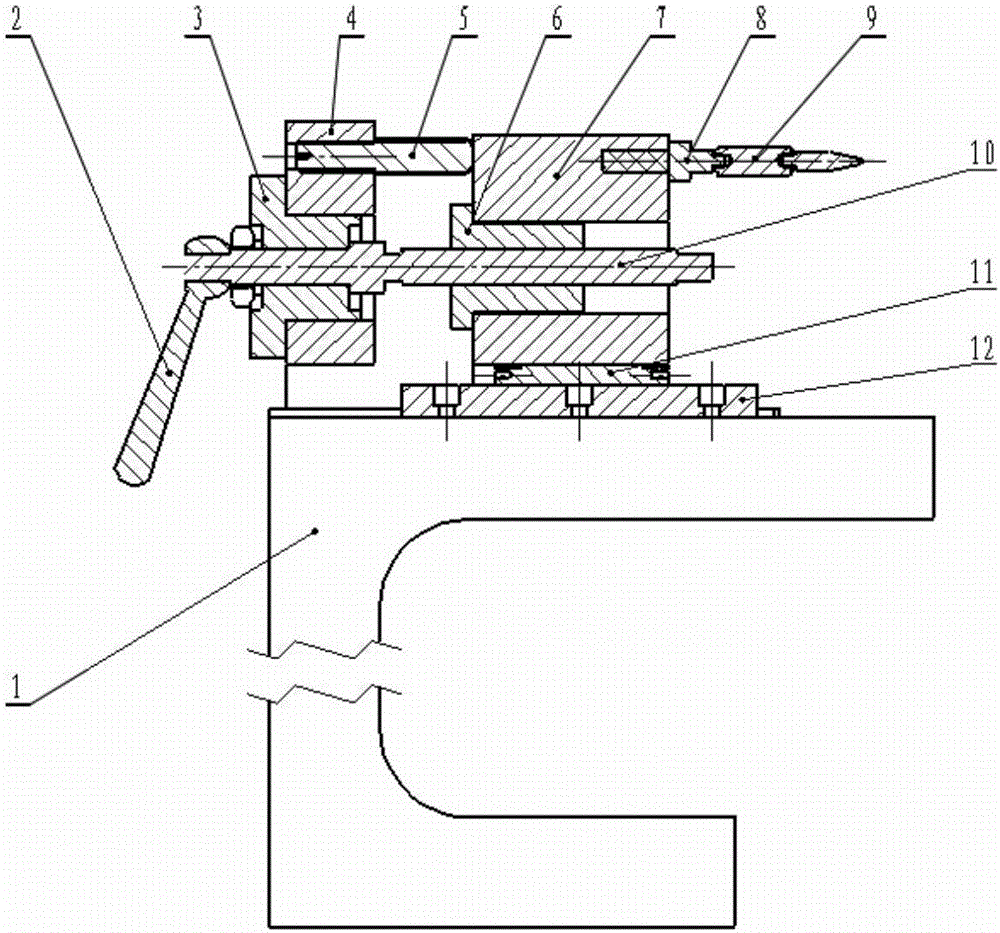

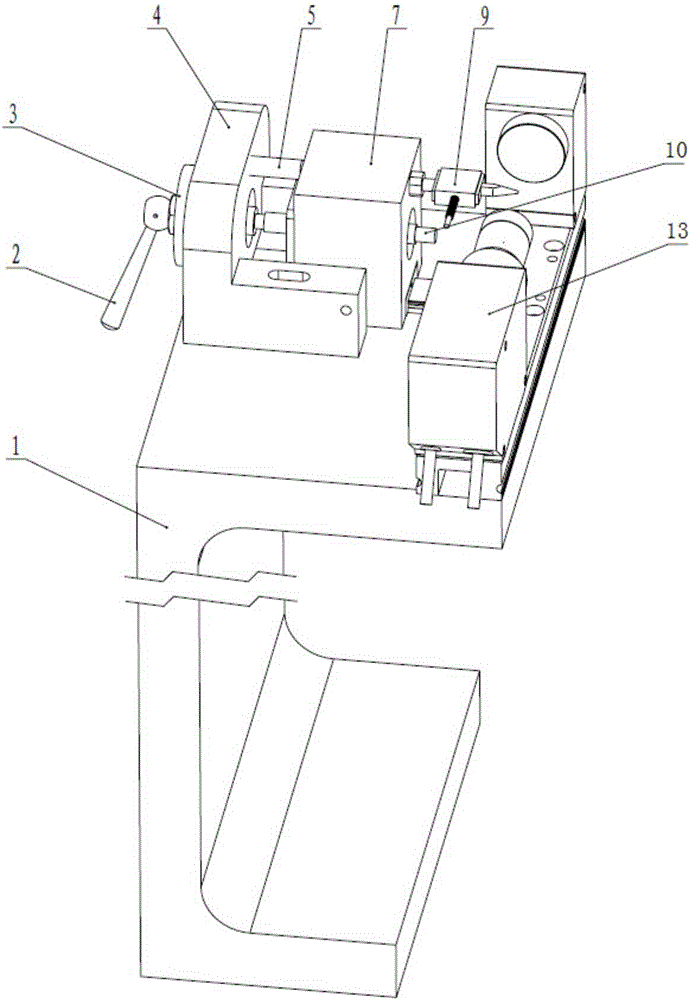

Online measurement system for measuring part deflection

InactiveCN106289967AAvoid the influence of human factorsImprove efficiencyMaterial strength using tensile/compressive forcesStress processStress change

The invention relates to the field of deflection measurement, and discloses an online measurement system for measuring part deflection. The online measurement system comprises a bottom frame, a fixed installation base, a slide installation base, a lead screw, a guide rail, a pressure testing device and a displacement detecting device. The guide rail is fixedly arranged on the upper surface of the bottom frame. The slide installation base is arranged on the guide rail in a sliding mode. The lead screw penetrates through the fixed installation base and the slide installation base and is connected with the slide installation base in a threaded mode. The end, located on the fixed installation base, of the lead screw is connected with a drive device. The end, located on the slide installation base, of the lead screw is used for exerting force on a to-be-detected part. The pressure testing deice is adjusted to lean on the to-be-detected part to sense the stress change through the position change of the slide installation base. The displacement detecting device is used for detecting the displacement change of the to-be-detected part in the stress process. Artificial factor influences during detection can be avoided, and the efficiency and reliability of part deflection measurement are improved.

Owner:北京市电加工研究所有限公司 +1

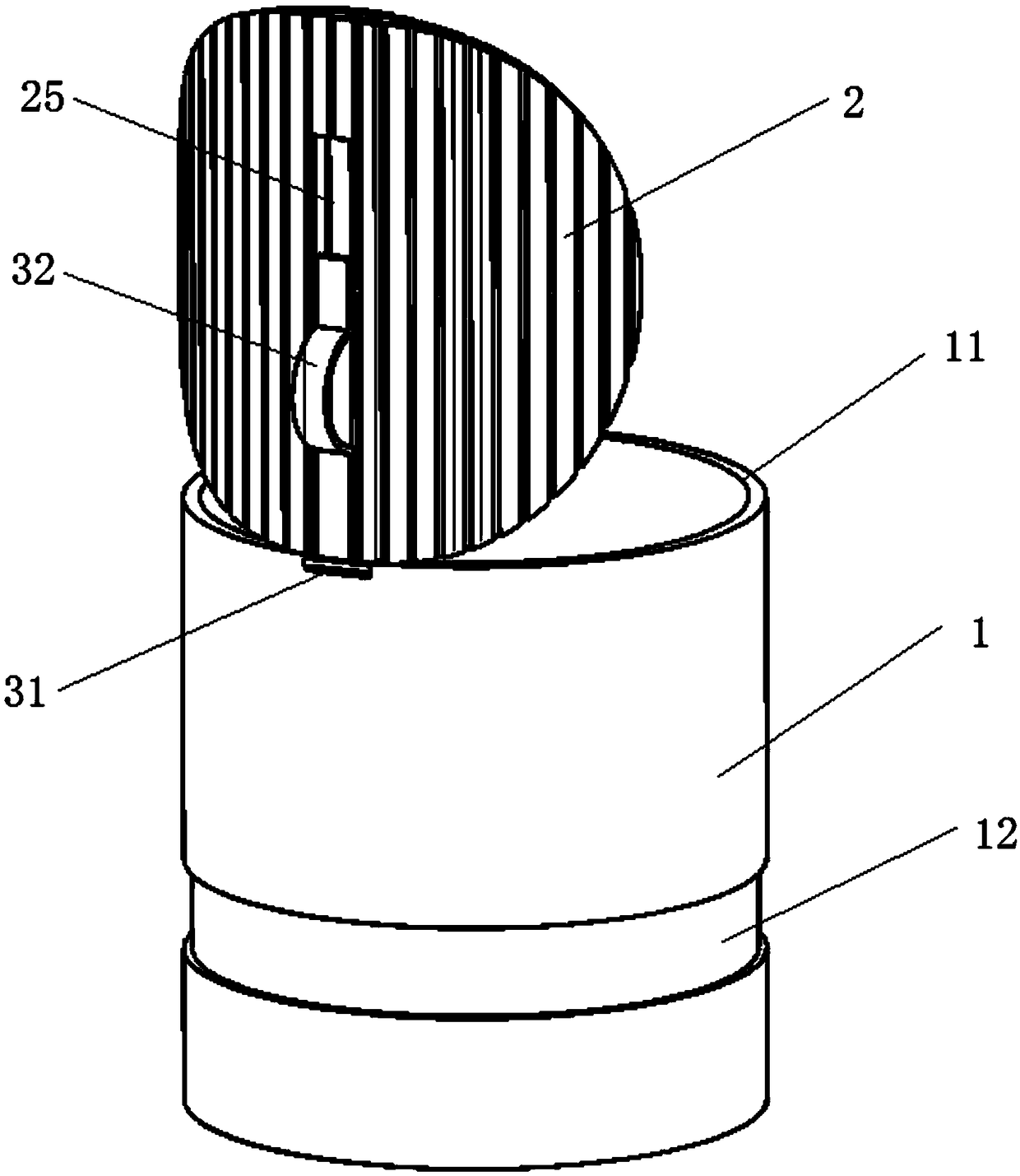

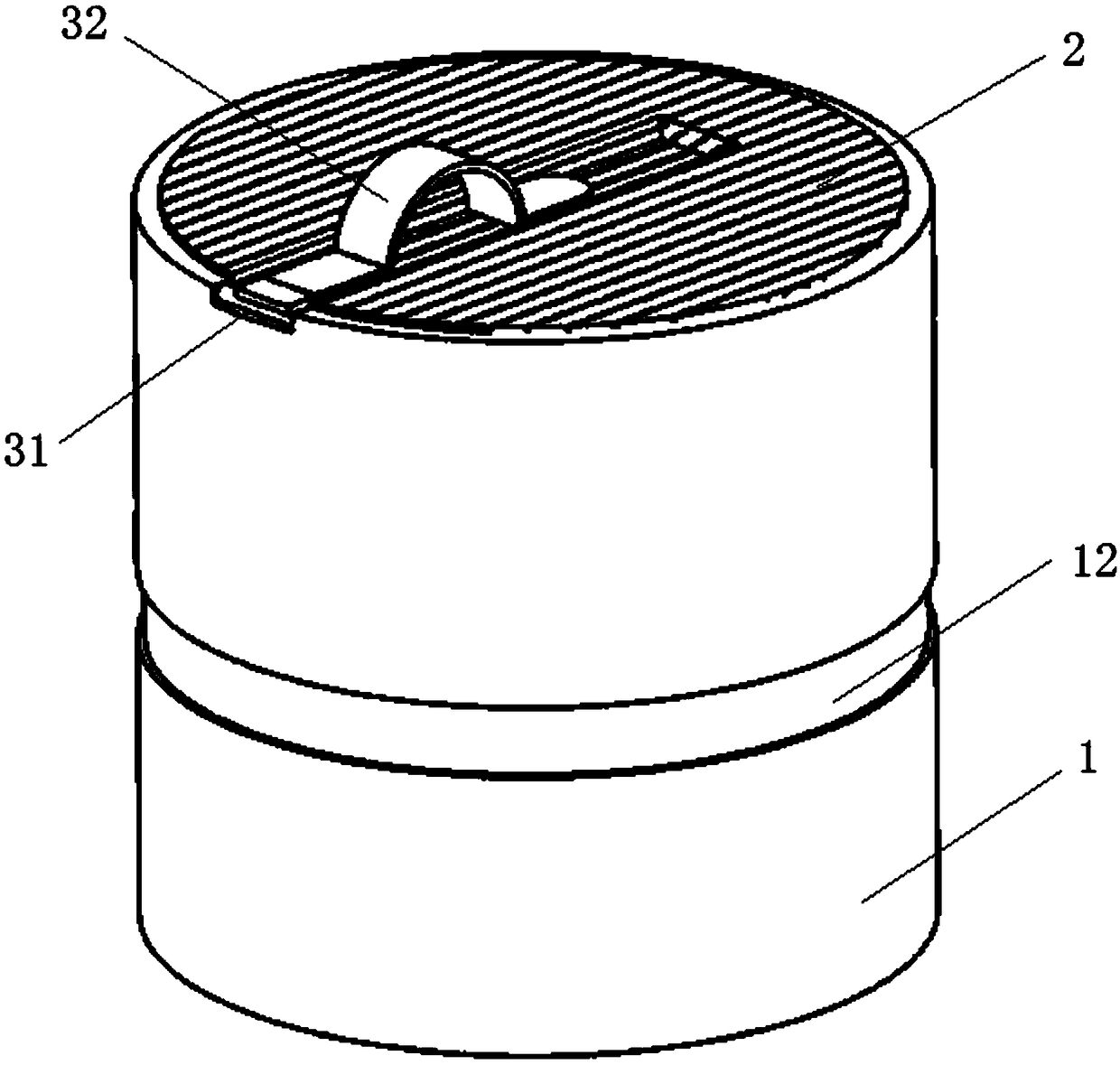

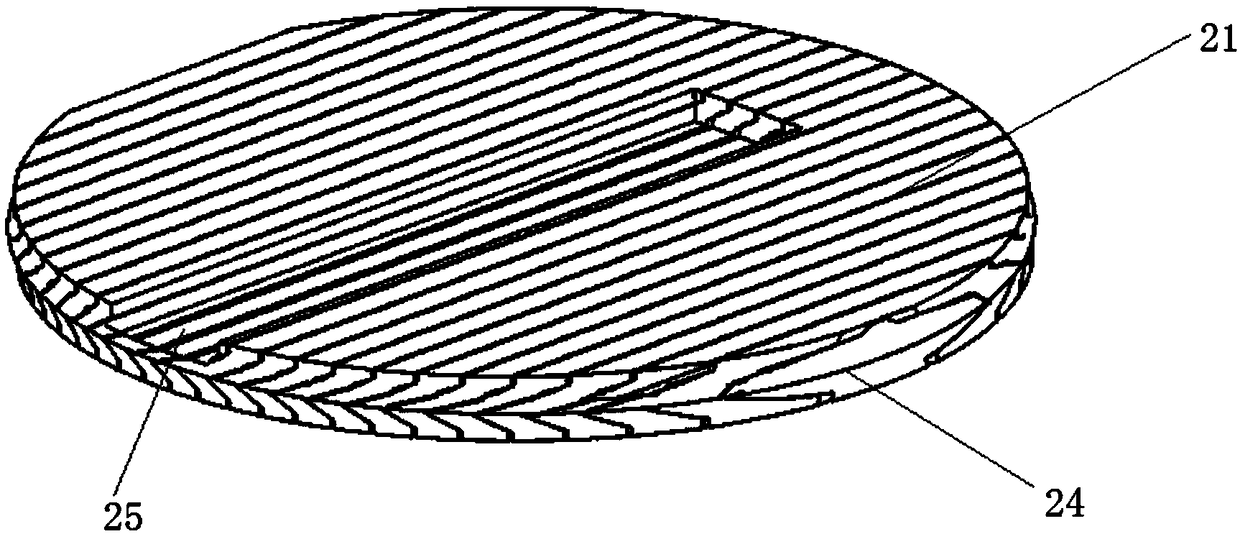

Chain armor type flap valve

PendingCN108953624AImprove deformation abilityImprove cooperation success rateLift valveCore removalStress processSelf locking

The invention relates to a chain armor type flap valve which comprises a valve base and a chain armor type valve clack. The valve clack comprises elastic sealing rings, elastic connecting strips, sealing parts and multiple lock strips sequentially arranged in parallel. The elastic connecting strips connect all the lock strips in series, and the elastic sealing rings hoop all the lock strips together to form a whole structure. Each lock strip is provided with a clamping groove fit with the corresponding elastic sealing ring. The elastic sealing rings are installed in the clamping grooves. The sealing parts are arranged between every two adjacent lock strips. One end of the valve clack is movably connected to the outer side wall of the upper end of the valve base. The top of the valve base is provided with a valve opening sealing face matched with the valve clack. When the valve clack makes contact with the valve base in a sealing manner, the two adjacent lock strips make contact in a sealing manner. According to the flap valve, the deformation ability of the valve clack is high, the sealing and fitting position can be adjusted automatically, the success rate of matching is high, andthe sealing performance is reliable. The flap valve is particularly applicable to sealing of the lower end of a pressure keeping cylinder in the pressure keeping and core pulling process, in the opening process, the valve clack can be attached to the outer wall of the pressure keeping cylinder closely, space is saved, and the flap valve has a reverse self-locking characteristic in the pressure keeping and stressing process.

Owner:SICHUAN UNIV +1

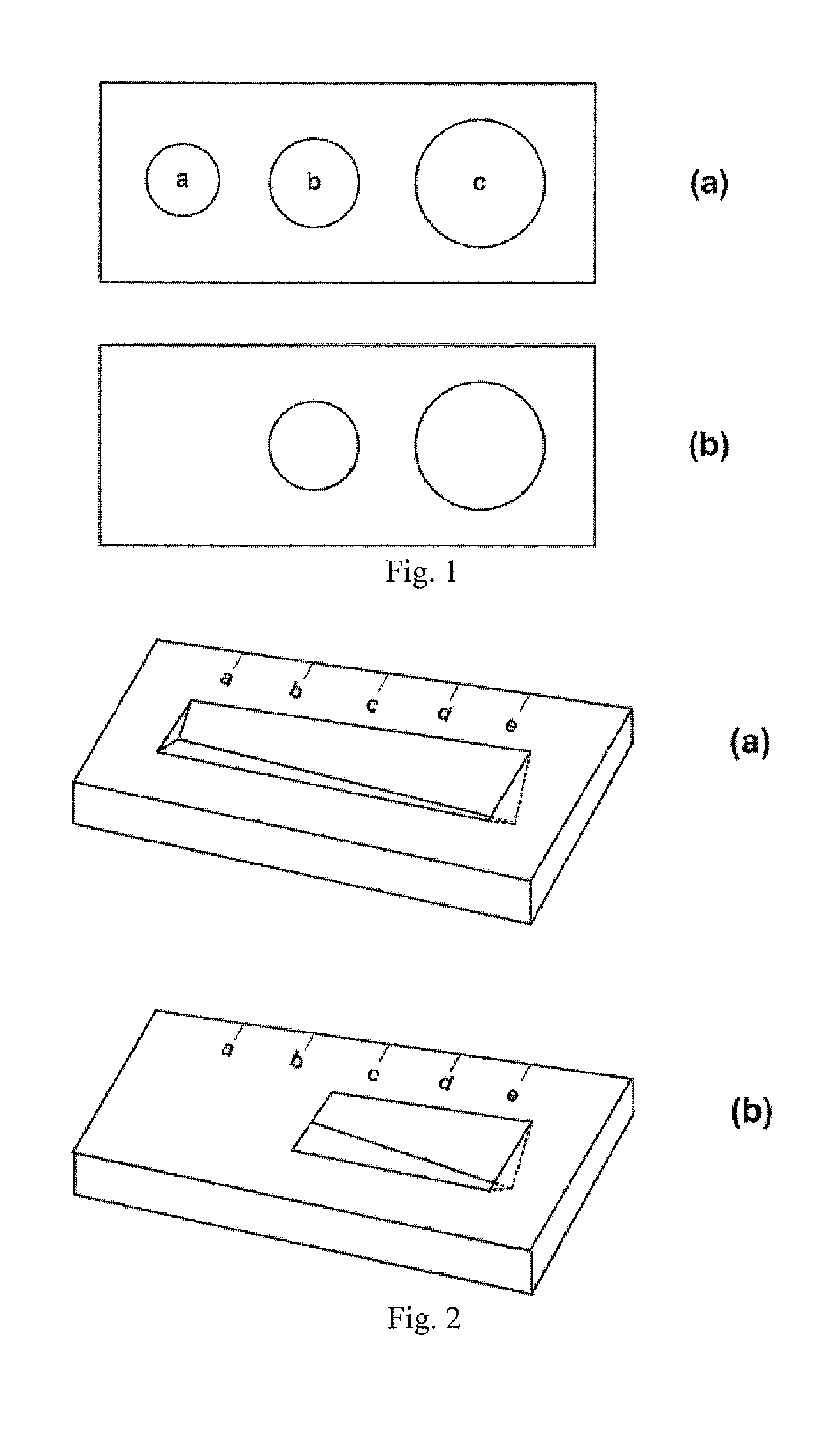

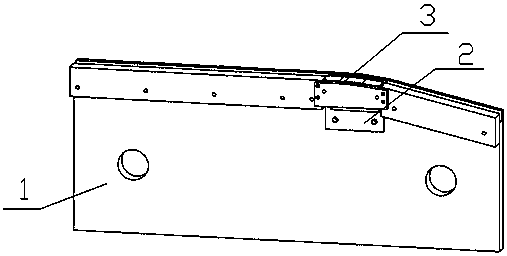

Temperature indication or multilevel Anti-counterfeit indication label based on shape memory polymer and temperature indication or multilevel Anti-counterfeit indication method thereof

ActiveUS20150360499A1Increase productivityEasy to makeStampsOther printing matterStress processEngineering

The present invention relates to temperature detection and indication technology and anti-counterfeit indication technology, and particularly to a temperature indication or multilevel anti-counterfeit indication label and a temperature indication or multilevel anti-counterfeit indication method based on a shape memory polymer. The temperature indication or multilevel anti-counterfeit indication label based on the shape memory polymer includes a matrix of a thermally driven shape memory polymer material, and one or more predeformations are formed on the matrix; the predeformation is formed in one or more stress processes at the same temperature; when multiple predeformations are formed, the sizes of the multiple predeformations are different; and when one predeformation is formed, the geometrical dimension of the predeformation continuously changes along the extension direction of the predeformation.

Owner:NANJING SKY LONG PHARMA

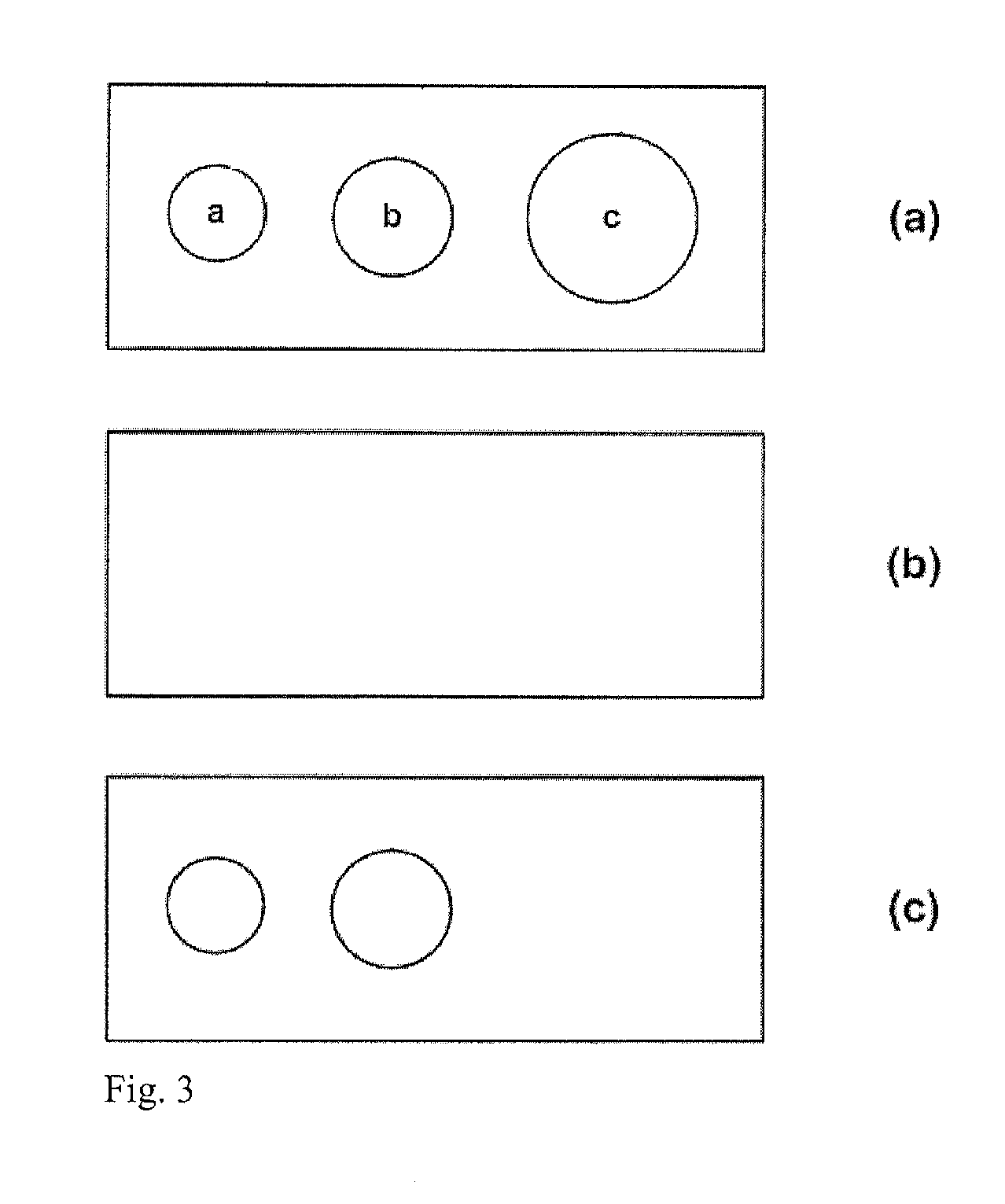

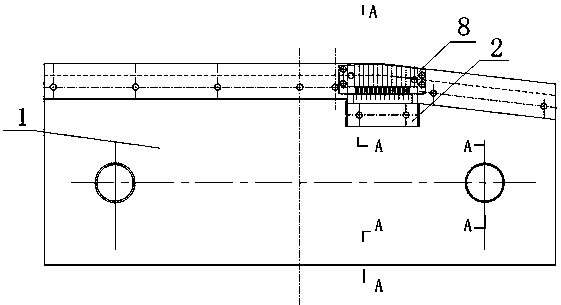

Profile-adjustable stretch-bending forming mold for stand column-like components of railway vehicles

InactiveCN107695145AHigh forming precisionImprove work efficiencyShaping toolsVehicle componentsStress processUltimate tensile strength

The invention relates to a profile-adjustable stretch-bending forming mold for stand column-like components of railway vehicles and belongs to the technical field of stretch-bending forming of metal profiles. A mold body is fixed to a stretch-bending machine, and the adjustable profile is fixedly connected to the mold body through a supporting block and side baffles; the side baffles and a bottomboard form a mounting framework; the side baffles are used for achieving left-right positioning of base bodies and limiting left-right deflection or turning of the base bodies in the stress process; and the base bodies are compactly arranged, the ends are limited by two end baffles which are limited in stop blocks of the mold body, and accordingly reliable positioning of the base bodies in the front-back direction is achieved. The profile-adjustable stretch-bending forming mold for the stand column-like components of the railway vehicles has the advantages that the stand column forming precision is improved, mold modification is not needed, and the adjusting and shaping procedures which are necessary during formation with a traditional stretch-bending mold due to poor quality precision ofstretch-bent parts are omitted, so that the production cycle is greatly shortened, the labor intensity is relieved, the production cost is reduced, and the working efficiency is improved; and meanwhile, the profile-adjustable stretch-bending forming mold is suitable for different stand column formed parts, is quite high in universality and has a quite great practical significance.

Owner:JILIN UNIV

Surface treatment method for corrosion-resistant sintered NdFeB magnet

ActiveCN110136949AAvoid magnetic degradationImprove corrosion resistancePermanent magnet manufactureBatch processingSurface layer

The invention relates to a surface treatment method for a corrosion-resistant sintered NdFeB magnet. The method is applicable to sintered NdFeB magnets of various compositions. The method comprises NdFeB magnet pre-stage surface pretreatment, a magnet surface grain refinement process, atmosphere protection measures during the refining process and a subsequent ultralow-temperature de-stressing process. The method realizes the effective control of the surface grains of the magnet by the high and low frequency composite impact on the magnet by a hard alloy sphere, and improves the corrosion resistance of the magnet on the basis of ensuring the original magnetic performance. Compared with other methods of improving corrosion resistance measures, the method avoids the influence of other elements added on the magnetic properties of the magnet and reduces costs. The method is simple in process, low in equipment requirements, and beneficial to the batch processing of the magnet surface layer,and has a very wide application value.

Owner:江西永磁磁浮科技有限责任公司

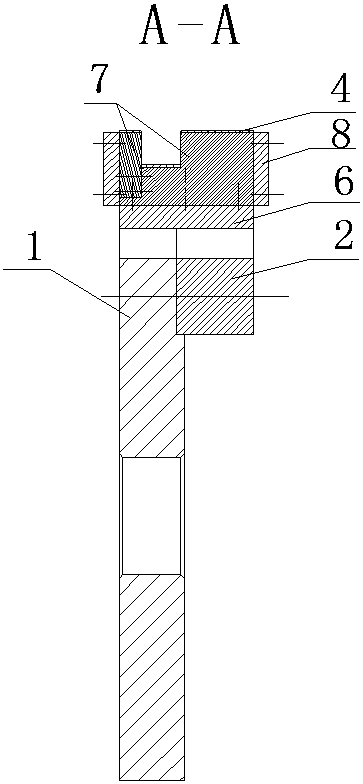

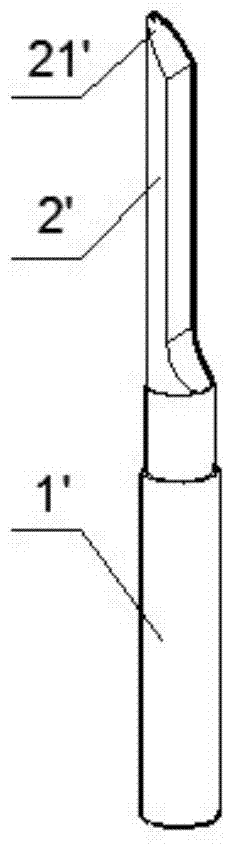

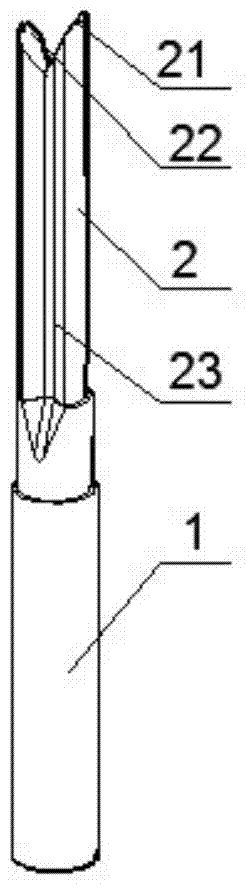

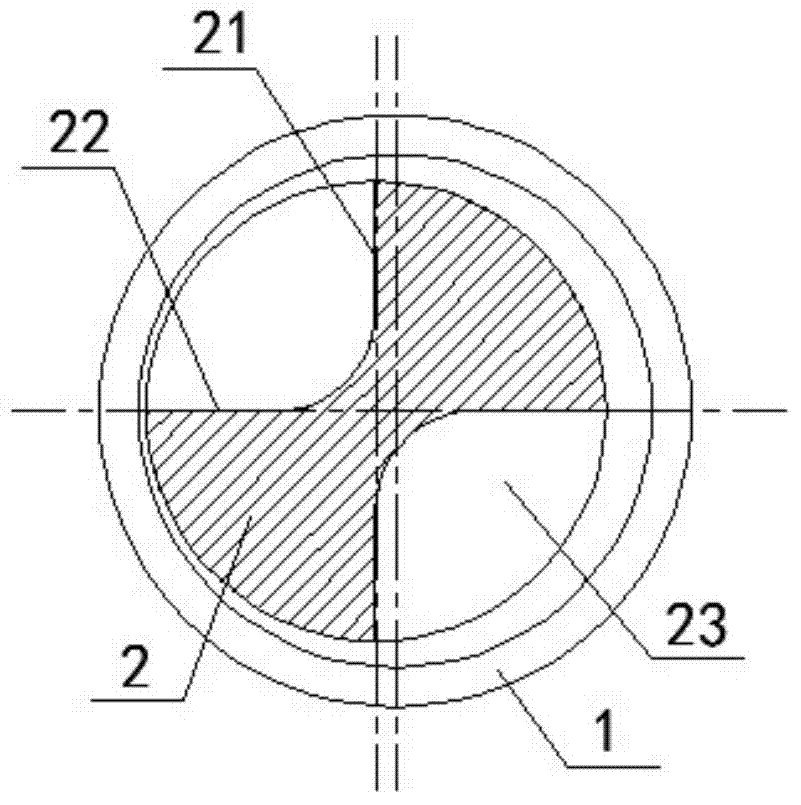

Dual-edge eccentric copper-foil punching tool with improved structure

InactiveCN103586508ASolve adhesionNo glitchTransportation and packagingMetal working apparatusPunchingCrack free

The invention discloses a dual-edge eccentric copper-foil punching tool with an improved structure. The dual-edge eccentric copper-foil punching tool comprises a tool handle and edges. The dual-edge eccentric copper-foil punching tool is characterized in that the edges are of a dual-edge structure comprising a main cutting edge and an auxiliary cutting edge; a chip discharge groove is formed between bodies of the main cutting edge and the auxiliary cutting edge; the top end of the main cutting edge is 0.5-2.0mm longer than that of the auxiliary cutting edge. When the punching tool is used for punching a pin hole of copper foil, the main cutting edge pre-cuts the copper coil, and then the auxiliary cutting edge cuts the copper foil finely, so that cutting force of the edges to the copper foil is divided into two stress processes, and adhesion caused by overlarge cutting force to the copper foil during punching is avoided. The dual-edge eccentric copper-foil punching tool has the advantages of simple structure, convenience in operation, high practicability and the like; the edge of the pin hole is smooth, burr-free and crack-free, and accordingly, great convenience is brought to follow-up processing.

Owner:DALIAN PACIFIC ELECTRONICS

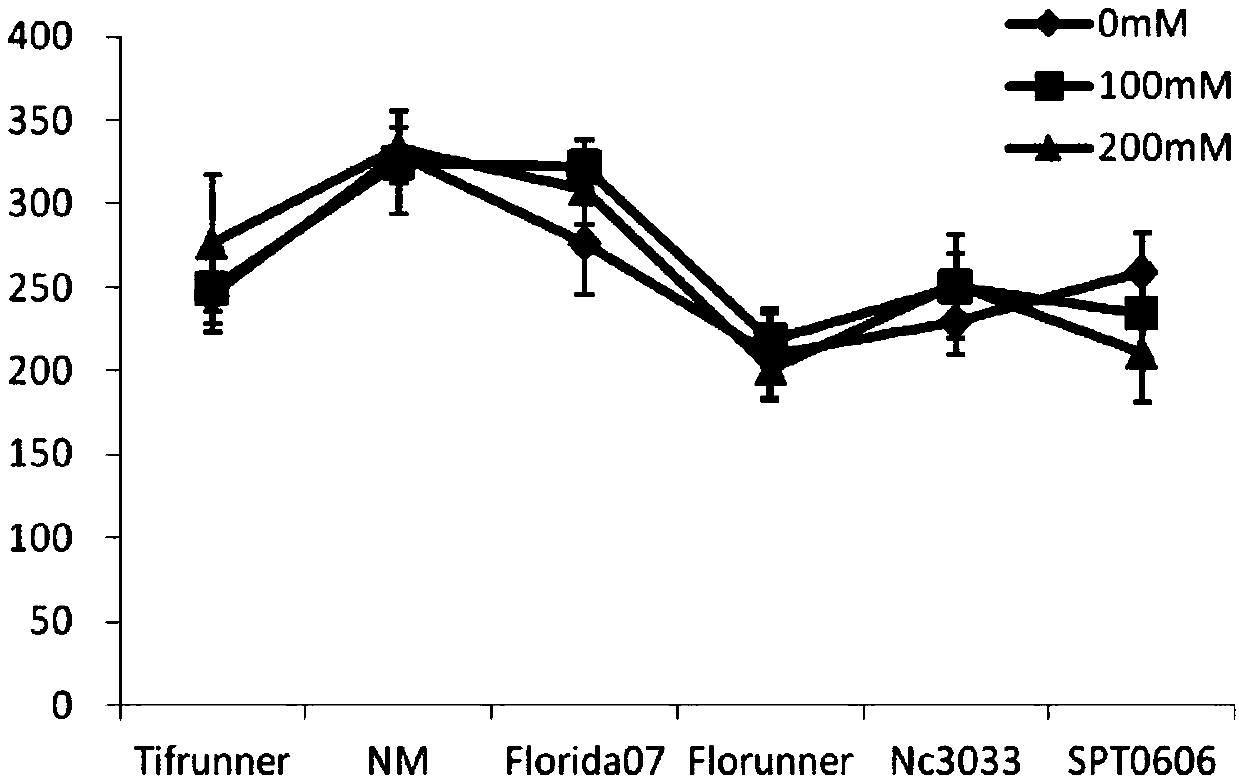

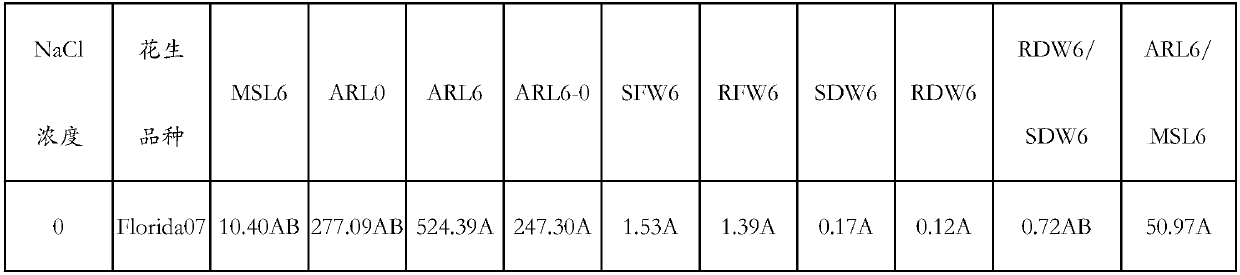

Method for identifying salt tolerance of peanuts in seedling stage

InactiveCN108040848AIntegrity guaranteedAvoid damageCultivating equipmentsSoilless cultivationMaterials preparationAgricultural science

The invention relates to a method for identifying salt tolerance of peanuts in a seedling stage, and belongs to the technical field of agricultural field variety evaluation. The method comprises the steps of material preparation-salt stress treatment. According to the method, a novel method for identifying salt tolerance of the peanuts in the seedling stage is established, germination bags are used and Hoagland's nutrient solution is adopted for culturing so that dynamic changes of peanut root growth in a salt stress process can be observed to provide a basis for detection dynamic indicators of salt stress of the peanuts in the seedling stage, and meanwhile, integrity of a root system can be maintained to avoid damage to the root system when materials are drawn.

Owner:SHANDONG PEANUT RES INST

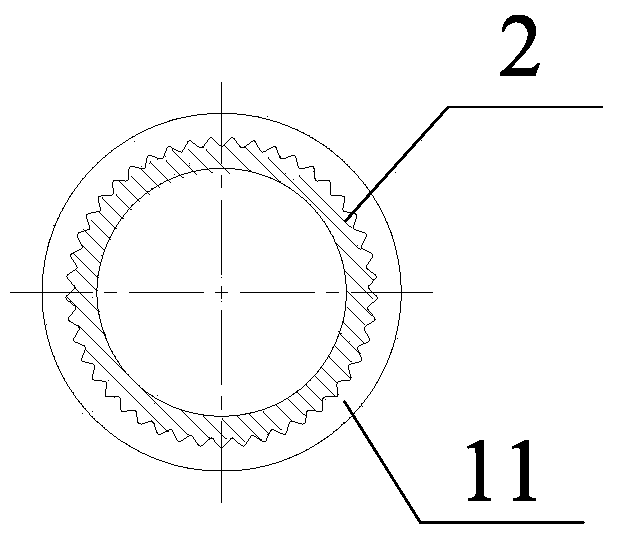

Middle connection structure of tubular busbar

InactiveCN103618272AAchieve connectionIncrease contact areaPartially enclosed bus-bar installationsBusbarStress process

The invention provides a middle connection structure of a tubular busbar, and aims to achieve connection of two tubular busbars. The tubular busbars are connected by a middle connector; two ends of the middle connector are respectively sheathed by the two tubular busbars; the middle connector is a tubular structure corresponding to the tubular busbars; when the middle connector and the tubular busbars are connected, the middle connector is sheathed inside the tubular busbars to form a connection structure, or one end of each tubular busbar is extended into the middle connector to form a connection structure; a pipe sleeve structure formed between the middle connector and the tubular busbars is a circumferential contact surface; the contact surfaces between the middle connector and the two tubular busbars are provided with locking screws along the length direction of the middle connector; the locking screws enable the contact surface area to increase between the middle connector and the tubular busbars; the tight fit is realized; relative rotation between the middle connector and the tubular busbars is avoided in a stress process; and the stability of connection is improved.

Owner:上海振大电器成套集团有限公司

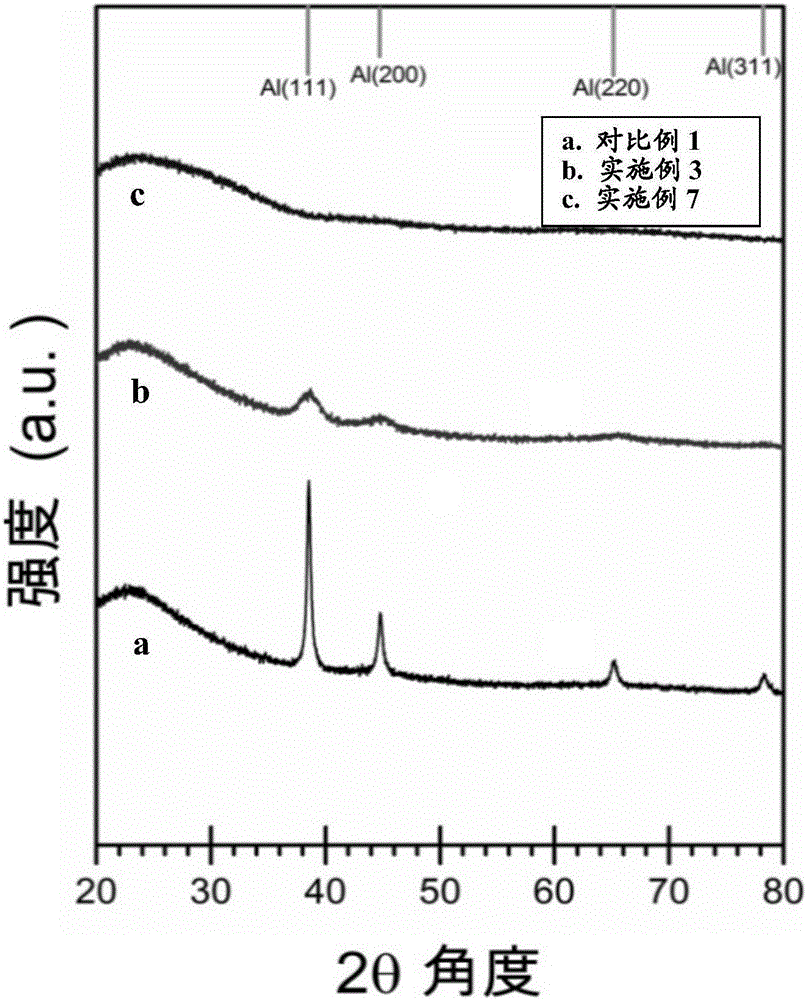

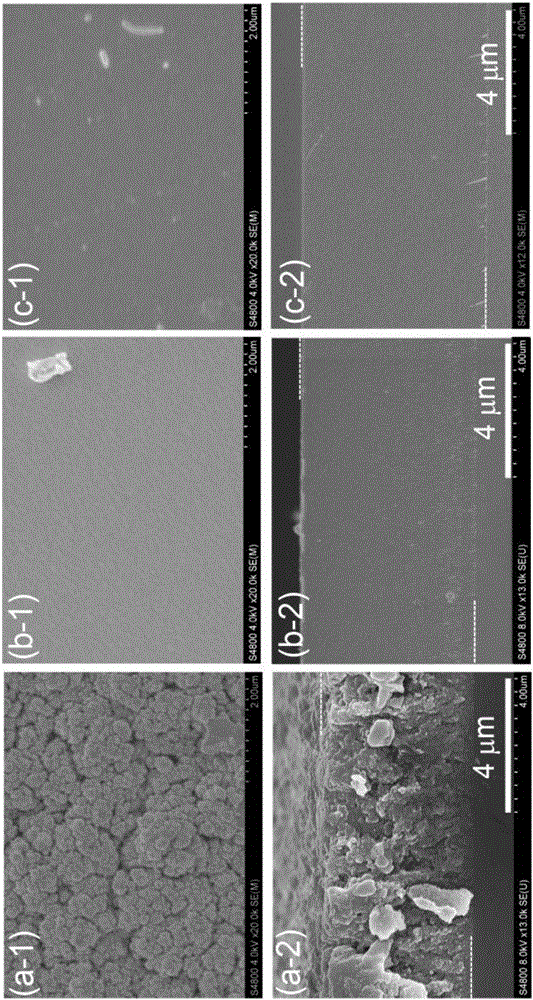

Corrosion resistant coating layer with self-repair capacity and preparation method thereof

ActiveCN106048529ALong corrosion lifeIncrease deposition rateVacuum evaporation coatingSputtering coatingStress processOxygen

The invention discloses a corrosion resistant coating layer with self-repair capacity. The coating layer is compounded by two phases of crystalline state Al and amorphous state Al2O3, and is represented as Al1-xOx, wherein x is 0.25-0.62, x is the atomic ratio, and the density of the coating layer is 3.0-3.4 g / cm3. The invention further discloses a preparation method of the corrosion resistant coating layer with self-repair capacity; and the preparation method comprises the steps of: (1) cleaning of a basal body; and (2) deposition of the coating layer: the cleaned basal body is put in a vacuum chamber; when the vacuum degree of a cavity is 1*10-5-5*10-5 Pa, argon and oxygen are introduced; the flow ratio of argon to oxygen is 2: 1; the sputtering air pressure is controlled as 0.25-0.4 Pa; the sputtering power density of a target is adjusted as 7.0-9.5 W / cm2; then, oxygen is gradually introduced; and when the voltage of the target reaches the lowest value, a sample baffle plate is opened for depositing the surface of the basal body to obtain the corrosion resistant coating layer with self-repair capacity. The prepared coating layer uses an Al corrosion product as a repair element for repairing through holes generated in later stress process of the coating layer to improve the corrosion resistance of the coating layer.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for preparing biphase rare-earth permanent magnet material using hydrogenation heat treatment process

InactiveCN1242427CFine nanostructureRegular nanostructureInductances/transformers/magnets manufactureMagnetic materialsAdhesion processHydrogen

Owner:ZHEJIANG UNIV

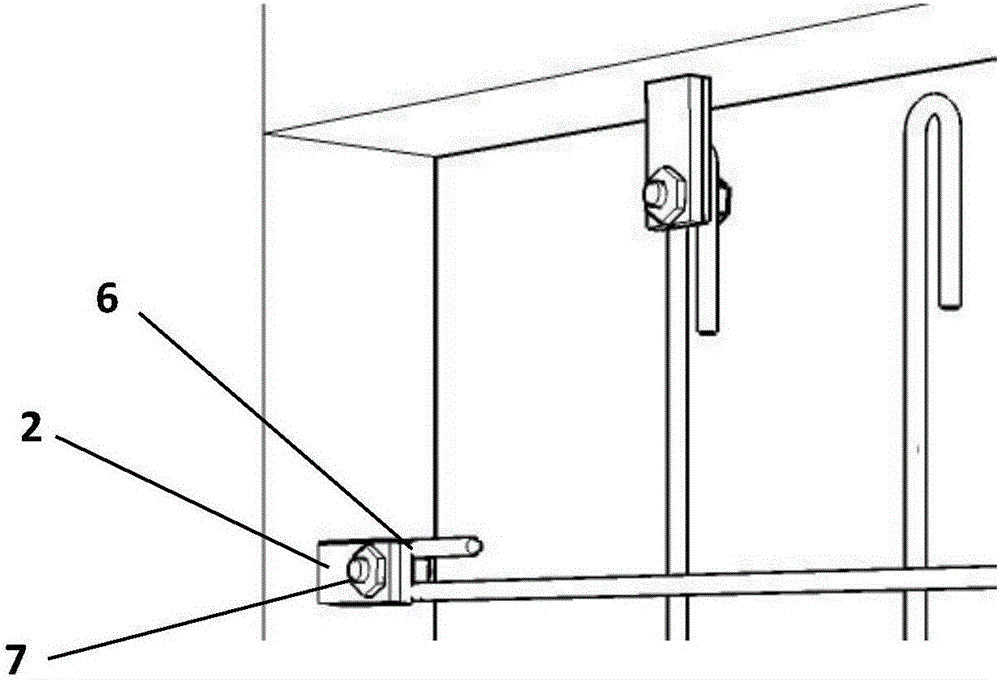

Stressed component measurement device

ActiveCN104034586AGood precisionImprove work efficiencyMaterial strength using tensile/compressive forcesMechanical solid deformation measurementsMeasurement deviceStress process

The invention discloses a stressed component measurement device. The changes of a stressed component in a stress process are simulated by connecting a force measuring mechanism to a screw rod, and the deformation of a measured component in the stress process is monitored in real time by adopting a check pass-stop pin, so that the measured component can meet the using requirements in the overall stress process; the manner of measuring deformation by manual detection and manual measurement is replaced; the inspection cycle of measured components, particularly components produced in batches, is shortened; the work efficiency is improved.

Owner:ANHUI XINYUE PRECISION MACHINERY

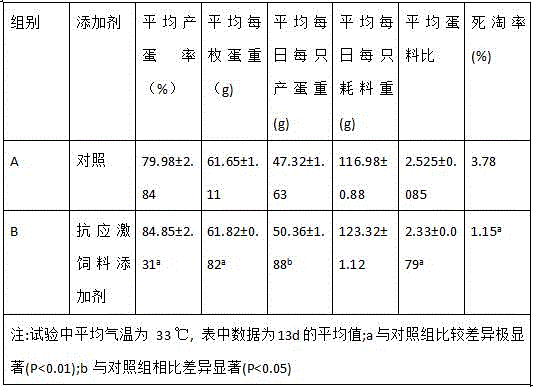

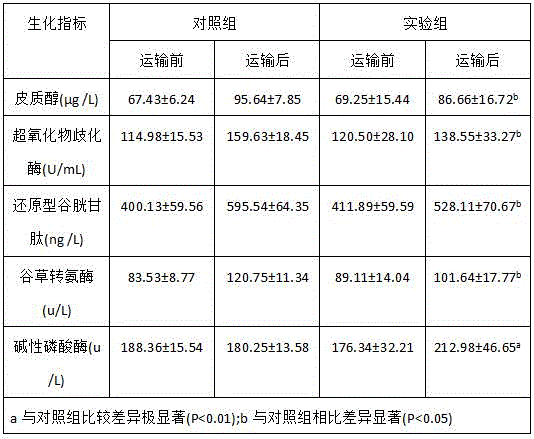

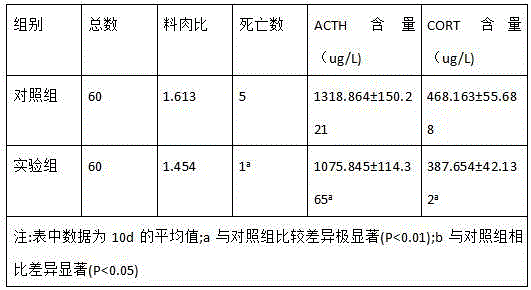

Anti-stress feed additive and application method thereof

InactiveCN106721067AImprove anti-stress effectImprove stress resistanceAccessory food factorsAnti stressFLUNIXIN MEGLUMINE

The invention relates to an anti-stress feed additive which is composed of 1.9-2.1% of radix astragali polysaccharide extract, 24-26% of xylooligosaccharide, 39-41% of vitamin C, 0.9-1.1% of vitamin B1, 1.2-1.3% of vitamin B2, 0.7-0.8% of flunixin meglumine and 29-31% of glucose. The preparation method comprises the following steps: uniformly mixing the components, and drying to obtain the feed additive. The application method comprises the following steps: (1) the anti-stress feed additive is added into a livestock / poultry feed according to the proportion of 0.1-0.2%, and is uniformly mixed; (2) heat stress is continuously applied for 15 days, and the feed is used after 5 days; (3) in the immunity stress process, it is suggested to start using the feed five days before immunization, and the feed is continuously used for 20 days; and (3) the feed is added in the whole transport stress process, and is continuously used. The anti-stress feed additive can enhance multiple anti-stress capacities of livestock and poultry, and improves the anti-stress effect of animal organisms.

Owner:NINGXIA UNIVERSITY

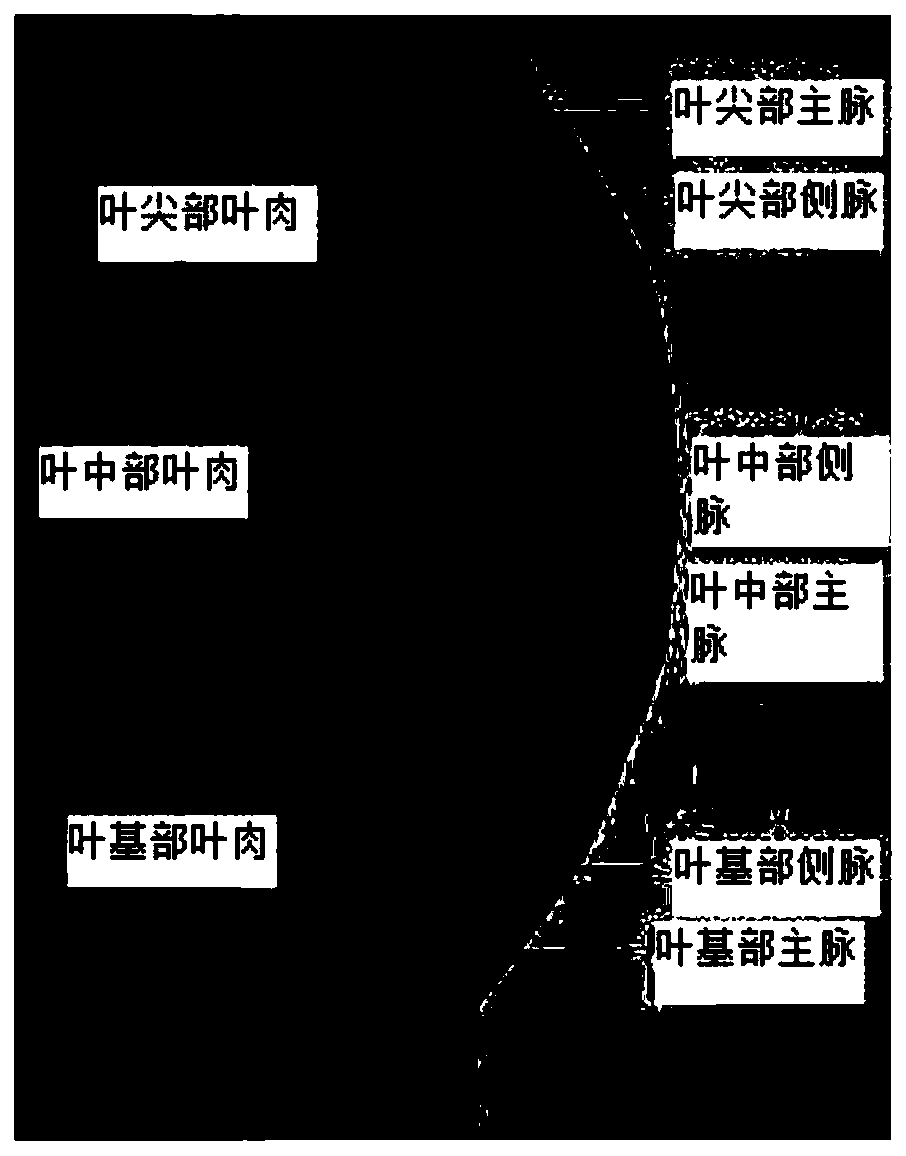

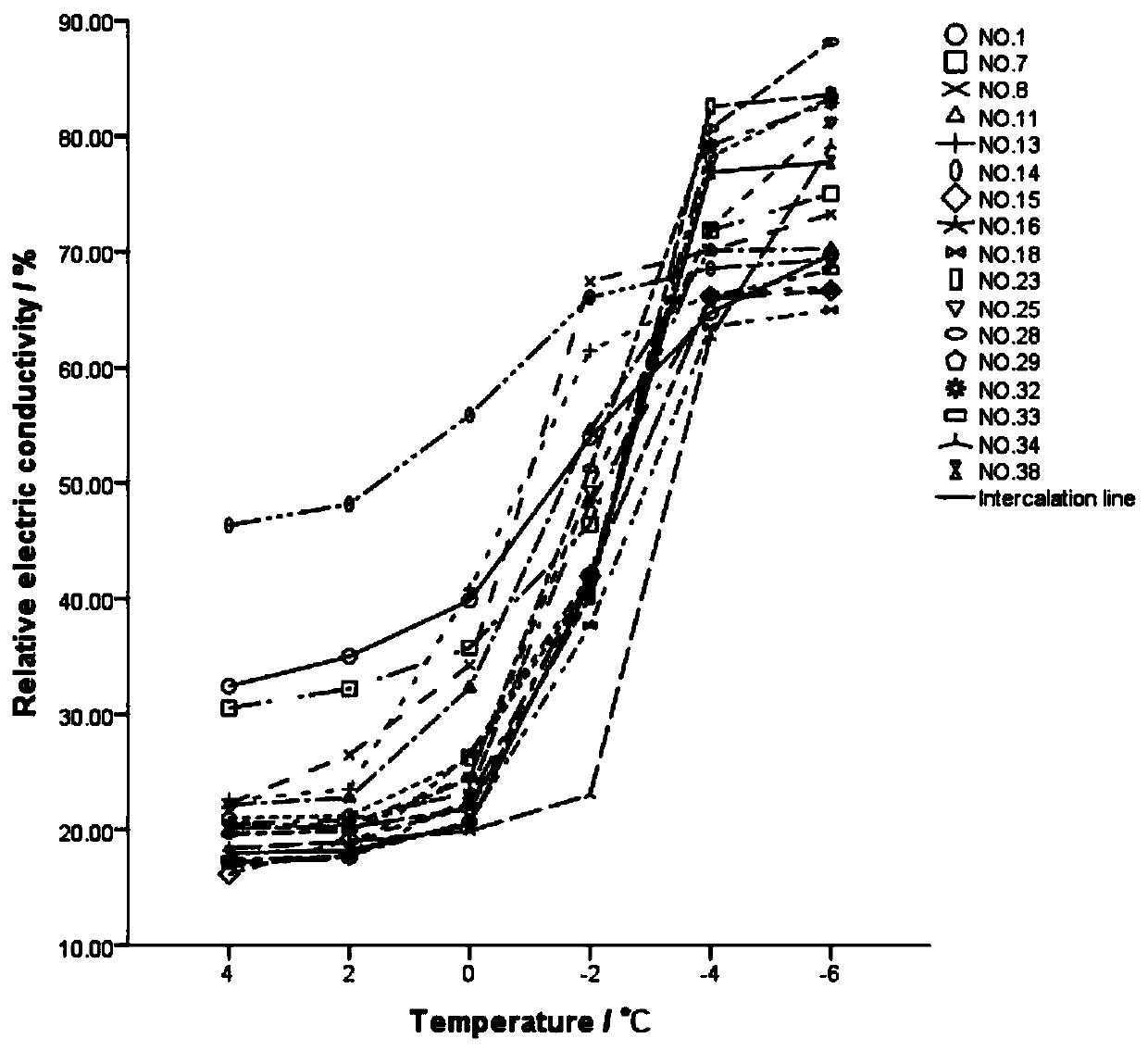

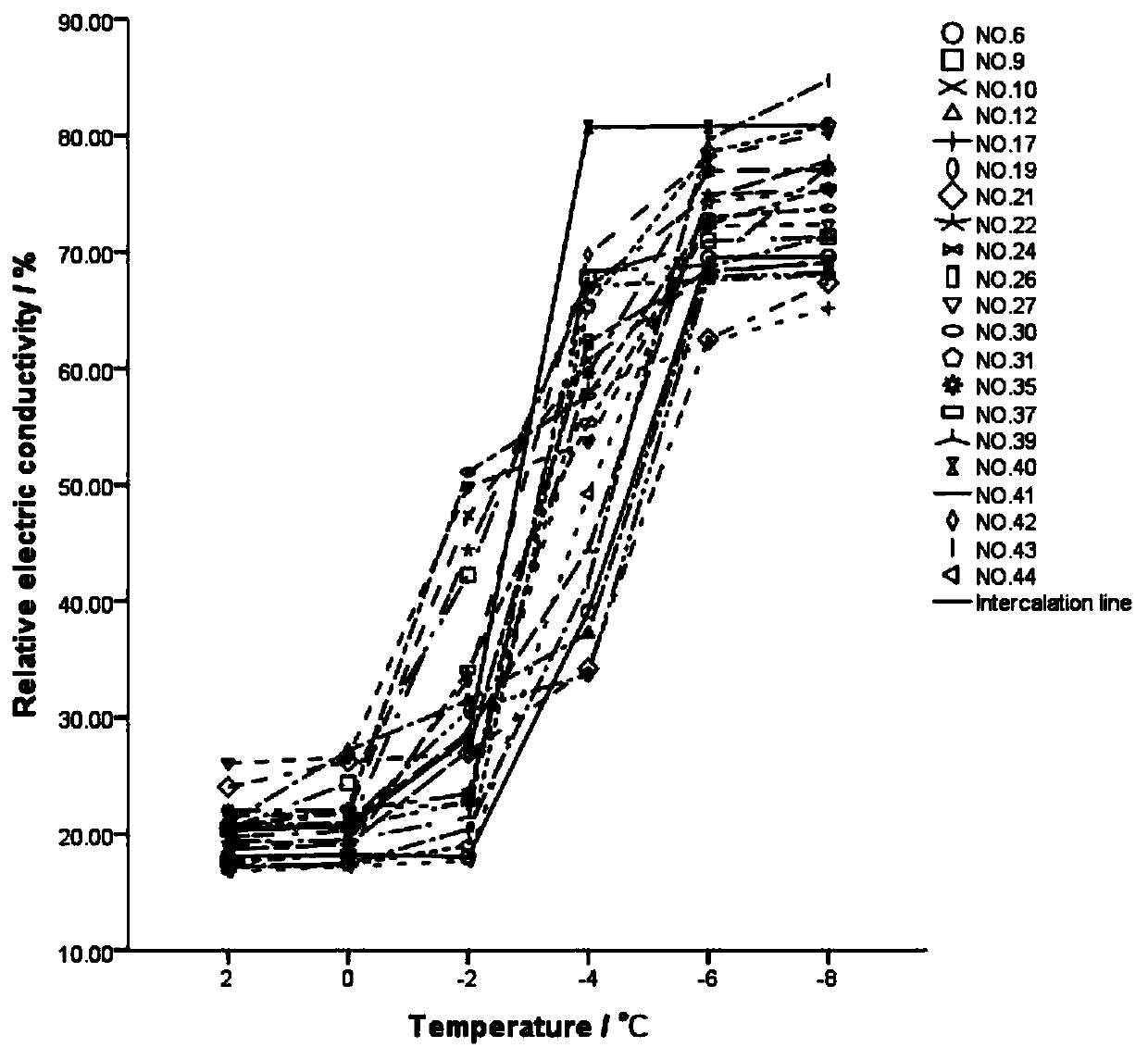

High-efficiency living body identification method for cold-resistant performance of plant

ActiveCN110308247ARapid determinationImprove accuracyTesting plants/treesMaterial resistanceCapacitanceNon destructive

The invention provides a high-efficiency living body identification method for the cold-resistant performance of a plant. The method comprises the following steps: (1), measuring the capacitance of asuitable part of a mature leaf of a plant by using a capacitance tester; (2), comparing capacitances of the same parts of different types of mature leaves of plants and indicating the low cold-resistant performance of the type by the lower capacitance. According to the invention, the capacitance tester measures the capacitances of suitable parts of the mature leaves of the plants at field to identify and compare the cold-resistant performance relationship of different types of plants. Because the method does not require the low temperature stress process of the plant sample, the method can beperformed at a normal temperature. The method has characteristics of simpleness, great convenience, high accuracy, and non-destructive detection and is novel method for measuring the cold-resistant performance of a plant in field efficiently and rapidly.

Owner:HAINAN UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com