Patents

Literature

183results about How to "Long corrosion life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

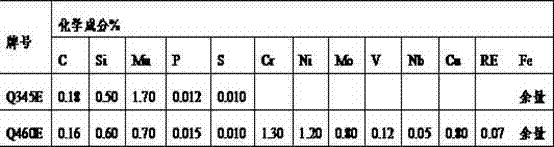

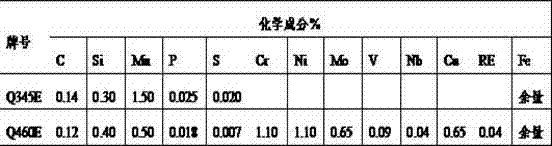

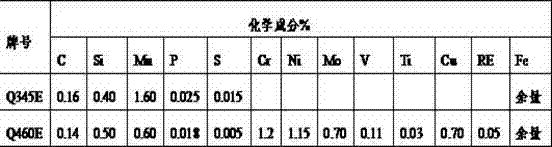

Material used in offshore wind power equipment, and workpiece manufacturing process

ActiveCN102851609AHigh yield strengthHigh tensile strengthFurnace typesHeat treatment furnacesRare earthImpurity

The invention discloses a material used in offshore wind power equipment, and a workpiece manufacturing process. The material comprises the chemical components of carbon, silicon, manganese, phosphorous, sulfur, chromium, nickel, molybdenum, vanadium, copper and rare earth, and balance of iron and inevitable impurities. According to the invention, through steps of high-quality molten iron selecting, KR molten iron pre-treating, top and bottom composite converter blowing, argon blowing treating, LF furnace refining, VD vacuum degassing treating, round billet continuous casting, heap cooling, sawing and blanking, billet heating, free forging, punching, fine coining, heat treating, mechanical processing, flaw detecting, inspecting, packaging, storing, and the like, a material used in key components of offshore wind power equipment of more than 5 megawatts can be produced. The material is advantageous than Q345E-performance steel, high yield strength, good low-temperature impact toughness, and better marine-atmosphere-corrosion resistance. The invention adopts a serried of optimizing technical measures upon smelting and manufacturing processes of the steel, such that user requirements are satisfied.

Owner:JIANGYIN HENGRUN HEAVY IND

Hot dip galvanizing method for steel pieces

ActiveCN101092682ALong corrosion lifeImprove uniformityHot-dipping/immersion processesRare-earth elementAlloy

This invention discloses a method for hot-dip galvanizing on steel work piece. The method comprises: checking black work piece, suspending, degreasing, rinsing, washing with acid, rinsing, treating with a galvanizing aid, drying with hot air, hot-dip galvanizing and cooling. During the hot-dip galvanizing process, Al, Ni, Si and rare earth element are added into the galvanizing solution. The galvanizing solution comprises: Al 7-9 wt. %, Ni 3-6 wt. %, Si 0.5-0.8 wt. %, rare earth element 0.5-1.0 wt. %, and Zn as balance. The addition of Si can reduce Fe content in the galvanizing solution, and the formation of Zn-Fe alloy residue. The Zn consumption is lowered by nearly 1%, and the surface quality of galvanized steel is improved.

Owner:南京大吉铁塔制造有限公司

Concrete structure heavy-duty nano composite coating and protection method

The invention relates to a heavy anti-corrosion nano composite coating and a protection method for a concrete structure. The protection method belongs to a method for protecting the reinforced concrete structure. The heavy anti-corrosion nano composite coating for the concrete structure has a three-layer structure and comprises nano modified epoxy sealing coatings, a nano modified epoxy micaceous iron oxide intermediate paint and a nano modified fluorine-containing polyurethane finish or a fluorine-containing polysiloxane finish from inside to outside in turn. By adoption of the nano composite coating protection technology to perform anti-corrosion coating on the concrete structure, the anti-corrosion service life can reach more than 20 years, and the adhesion of the coating can be doubled compared with a common anti-corrosion coating; the coating has better impact resistance, sediment incrustation resistance, weathering resistance and flexibility; and the construction method is simple, and easy to popularize and apply, and has low cost.

Owner:JIANGSU CUMT DAZHENG SURFACE ENG TECH

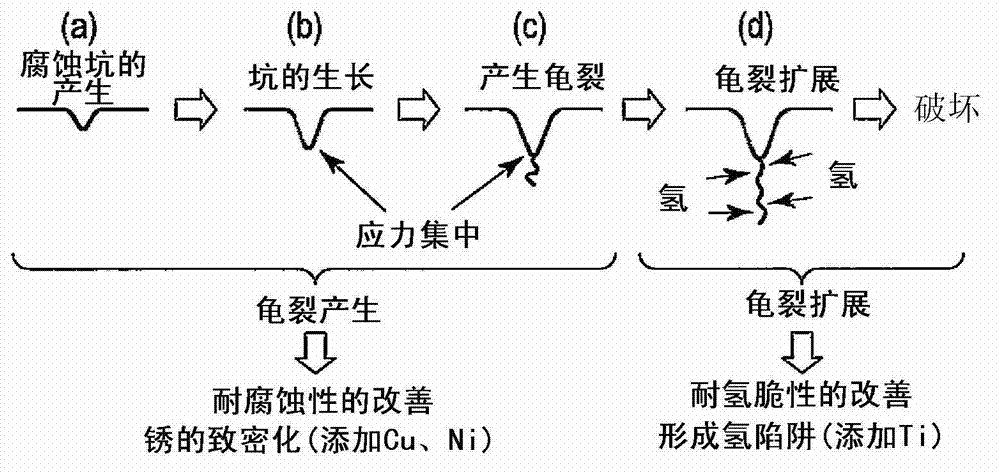

Corrosion-resistant twisted steel and production method thereof

The invention discloses corrosion-resistant twisted steel and a production method thereof. The twisted steel comprises the following components (weight percentage): basic components, a selective component and remain iron and impurities, wherein the basic components comprise carbon (C) 0.18-0.25%, silicon 0.40-0.80%, manganese (Mn) 0.30-1.00%, phosphorus (P) 0.02-0.04%, sulfur (S)<=0.01%, chromium(Cr) 0.45-1.00% and copper (Cu) 0.05-0.20%, and the selective component is the combination of any one or more than two components of vanadium (V) 0.01-0.05%, niobium (Nb) 0.01-0.04%, nickel (Ni) 0.01-0.20%, titanium (Ti) 0.01-0.05% and boron (B) 5-30ppm. The production process comprises electric furnace or converter smelting, refining out of the furnace, square blank continuous casting, hot rolling, cold bed air cooling, multiple length shearing and an end-flattening procedure which are performed sequentially, the corrosion service life of the corrosion-resistant twisted steel is more than 1.5 times that of a conventional steel product, and production cost, mechanical property, welding performance, processing performance and the like are identical with the conventional product.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

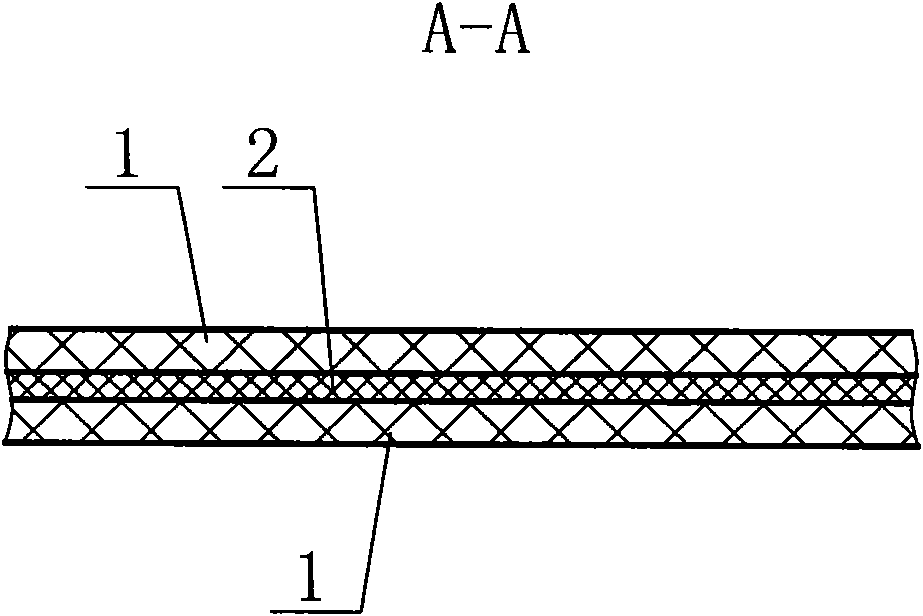

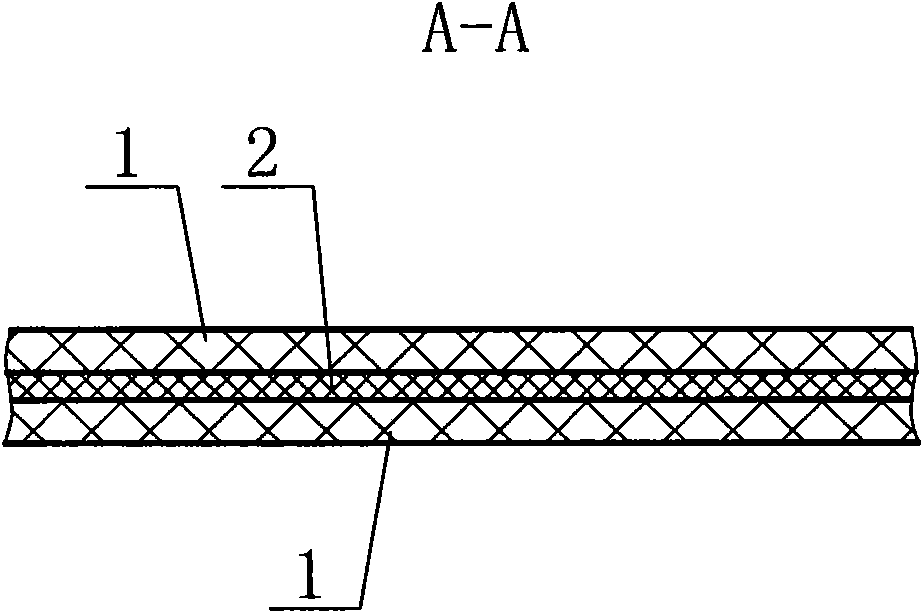

High-temperature resistant fiber layer composite filter material and method for preparing same

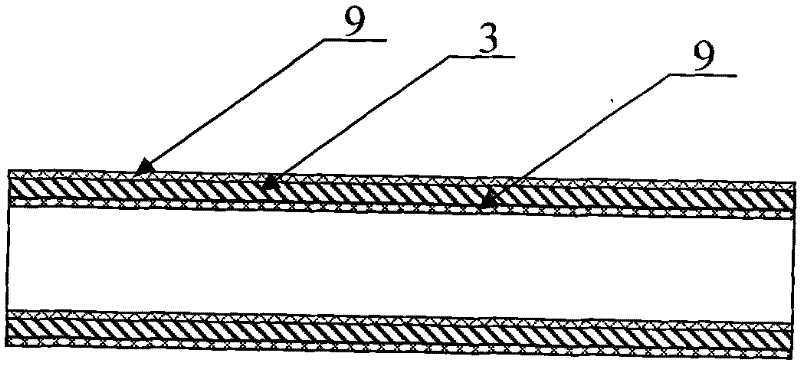

ActiveCN101862567AImprove thermal stabilityGood chemical stabilityCellulosic plastic layered productsFiltration separationPlanar networkMixed materials

The invention discloses a high-temperature resistant fiber layer composite filter material and a method for preparing the same. The cross section of the material adopts a triple-layer structure, the upper layer and the lower layer are both a mixed fiber layer, and the middle layer is the PTFE base fabric layer. The preparation comprises the following steps of: preparing PPS fibers and PTFE fibers for later use; mixing two kinds of raw materials in a cotton-mixing box to obtain a preliminary mixed material; loosening the preliminary mixed material in a loosening machine; performing refined mixing of the loosened material in the cotton-mixing box; carding the refined mixing material into planar network fibers by a carding machine; spreading the planar network fibers by a lapping machine to make the mixed fiber layers; adding the PTFE base fabric layer between the two mixed fiber layers; preparing the composite fiber material by a needling machine; and putting the composite fiber material in shaping equipment for shaping, putting the composite fiber material in coating equipment for coating, and then performing surface singeing treatment to obtain the filter material. The filter material of the invention possesses high thermal stability, chemical stability, corrosion resistance and electrical property, and compared with the conventional materials, the oxidation resistance and the corrosion resistance of the filter material are greatly improved.

Owner:张延青

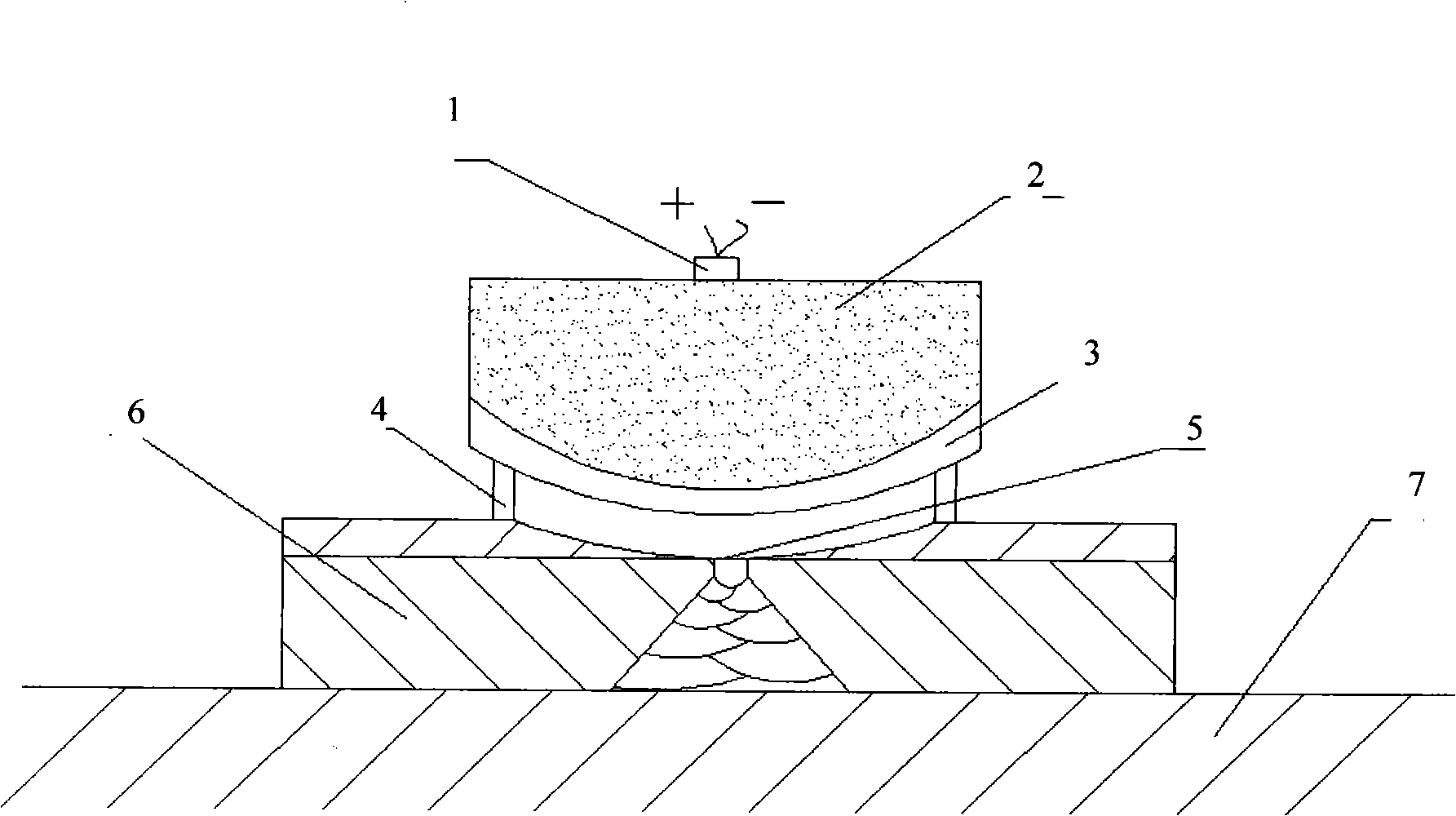

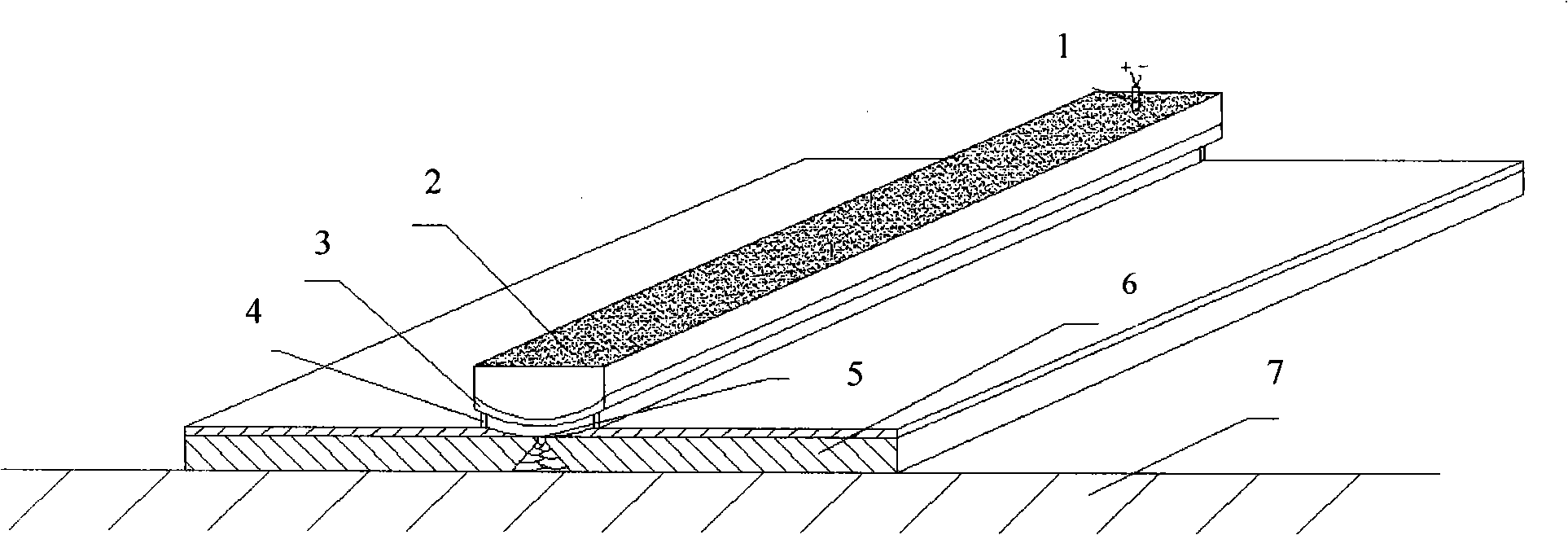

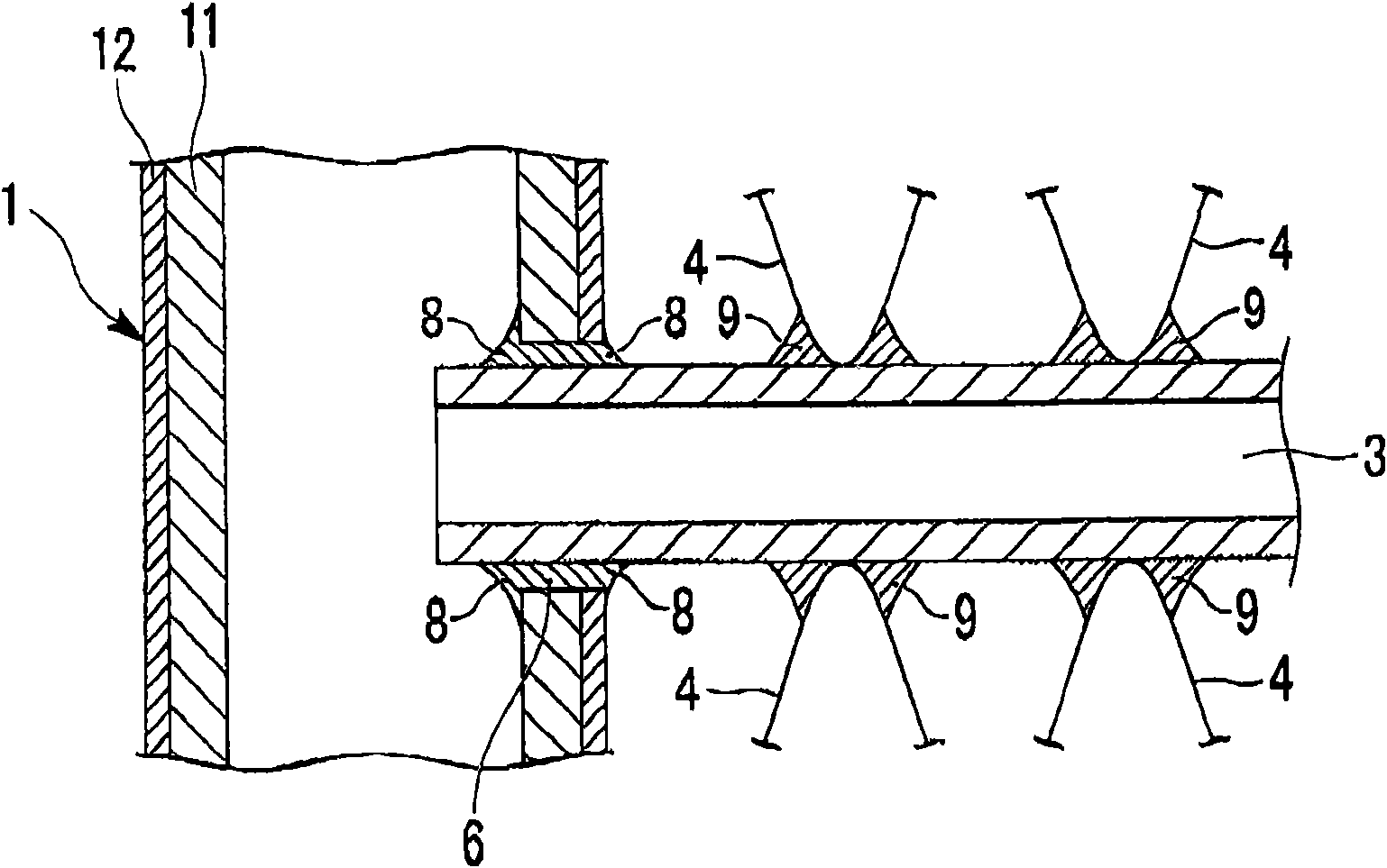

Explosive cladding welding method for titanium-steel composite board soldering joint

InactiveCN101342634AAchieving a complete weldSmooth welding surfaceWelding/soldering/cutting articlesNon-electric welding apparatusDetonatorExplosive cladding

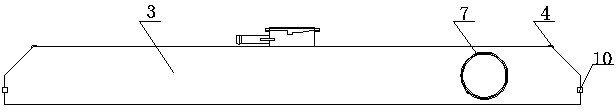

The invention discloses an explosion cladding and welding method of titanium-steel compound plate welding seams. The titanium plate used for cladding is firstly pressed into an arc-shaped titanium plate 3. The base plates of two pre-butt-jointed titanium-steel compound plates are processed into smooth arcs corresponding to the arc-shaped titanium plate 3. A groove is formed on the compound plates. The smooth arcs of the base plates, the groove of the compound plates and the arc-shaped titanium plate are grinded by abrasive paper or buffing wheel to remove the oxides on the surface of the metals and expose metallic luster. Then, the titanium-steel compound plate is arranged on a sand foundation 7, and the arc-shaped titanium plate is arranged over the smooth arcs of the base plate supported by a supporter 4. The height of the supporter is adjustable, ensuring that an arc-shaped welding seam 5 is formed between the smooth arc and the arc-shaped titanium plate. The explosive 2 is arranged on the upper surface of the arc-shaped titanium plate. Explosive charge quantity is determined by the area of explosion cladding unit. The explosive is ignited by 8# industrial electric detonator, ensuring that the arc-shaped titanium plate and the base plate are clad into an integrated body, and a complete welding titanium-steel compound plate with full penetration is gained. The welding seam has a smooth surface, is good-looking and corrosion resistance, and has a long service life.

Owner:LUOYANG SHUANGRUI METAL COMPOSITE MATERIAL

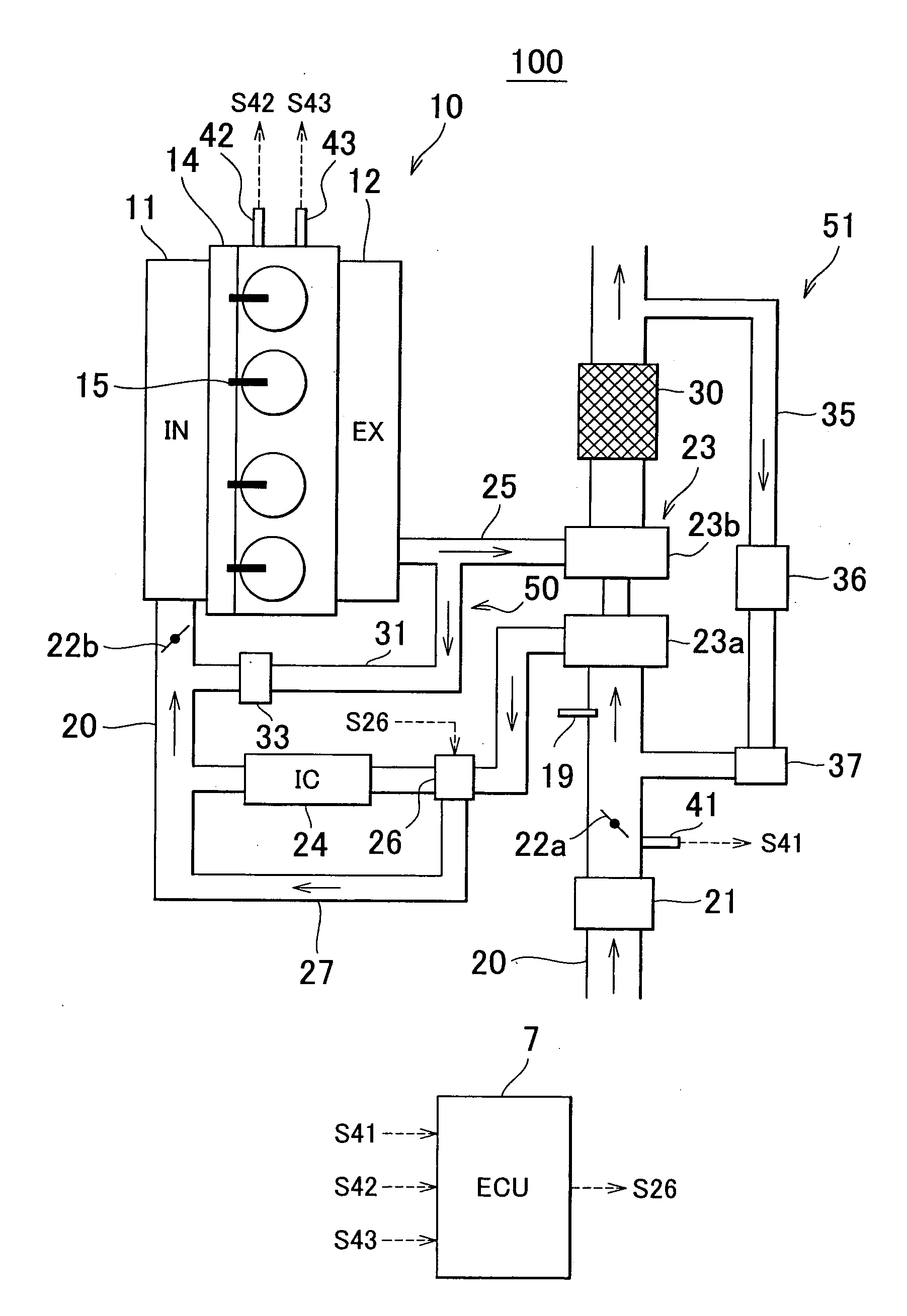

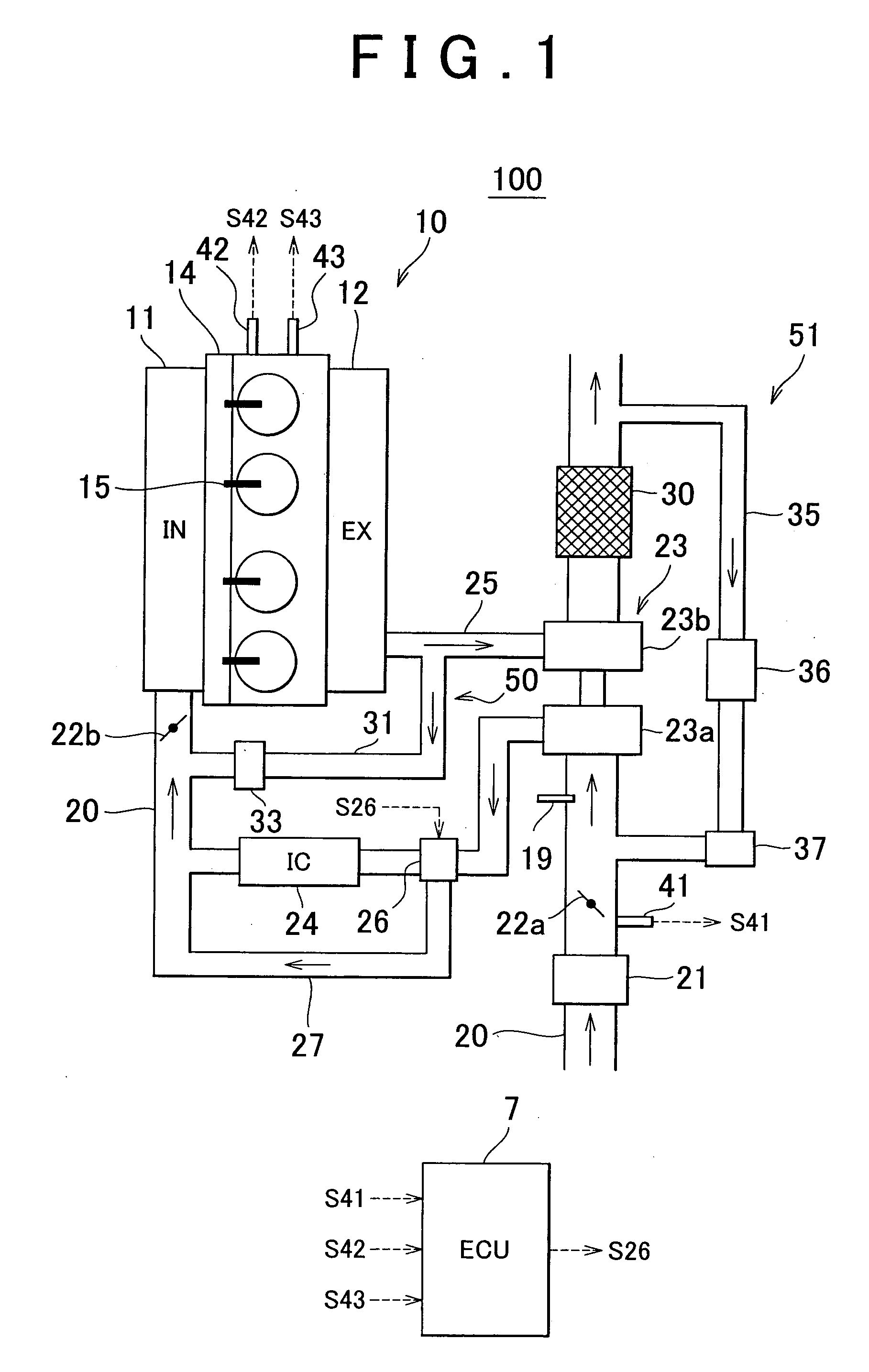

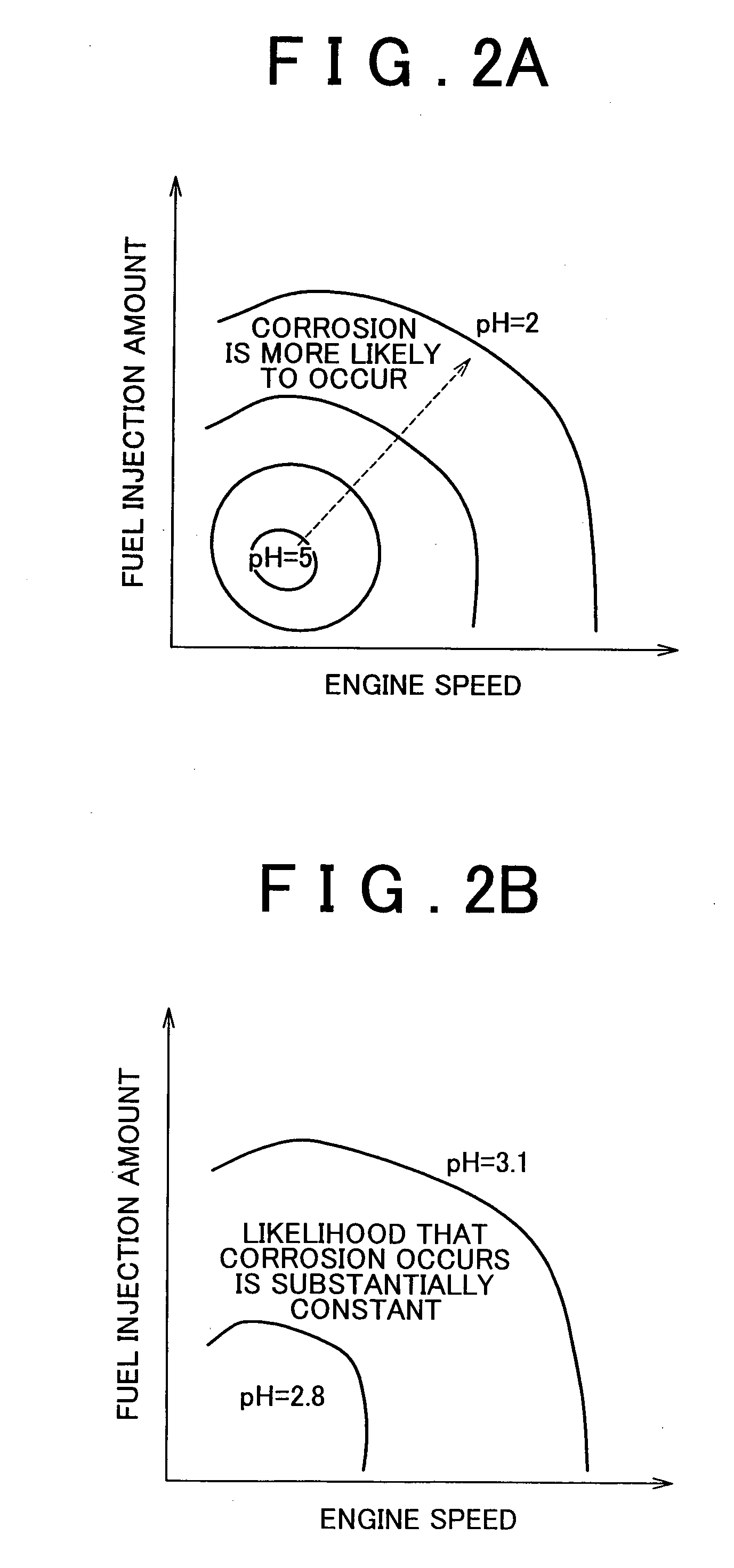

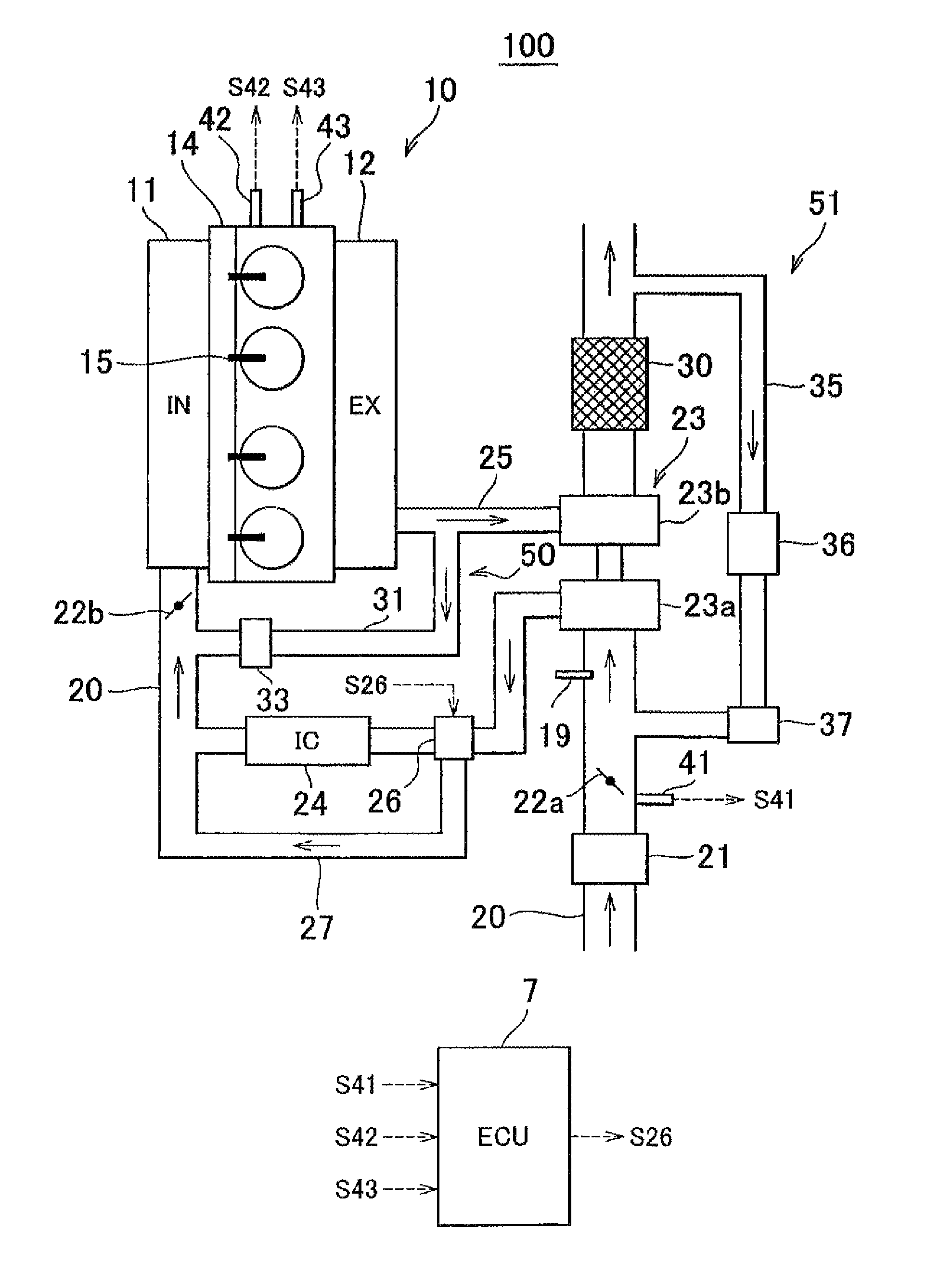

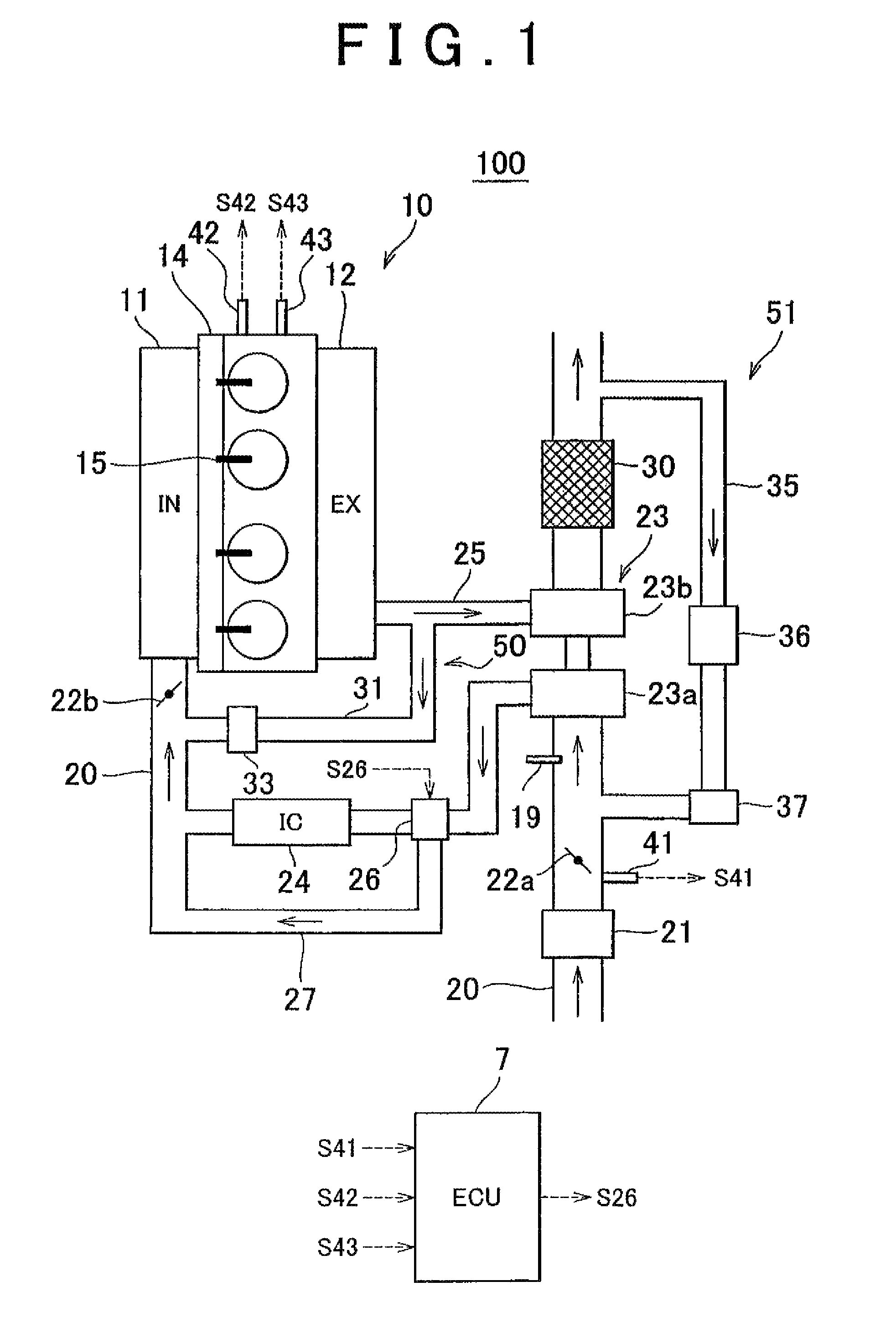

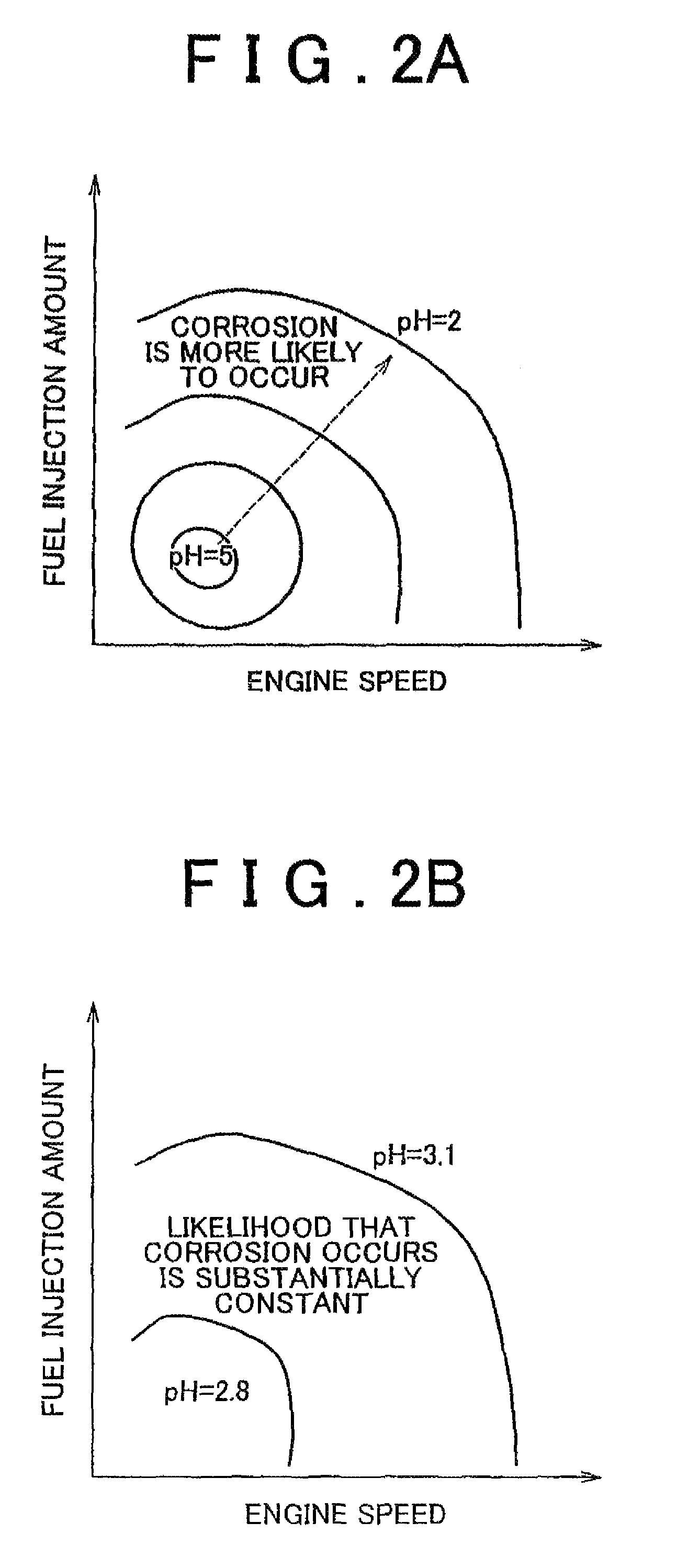

Control apparatus for internal combustion engine and method for controlling the same

InactiveUS20090308071A1Ensure reliabilityAvoid it happening againElectrical controlInternal combustion piston enginesExternal combustion engineExhaust fumes

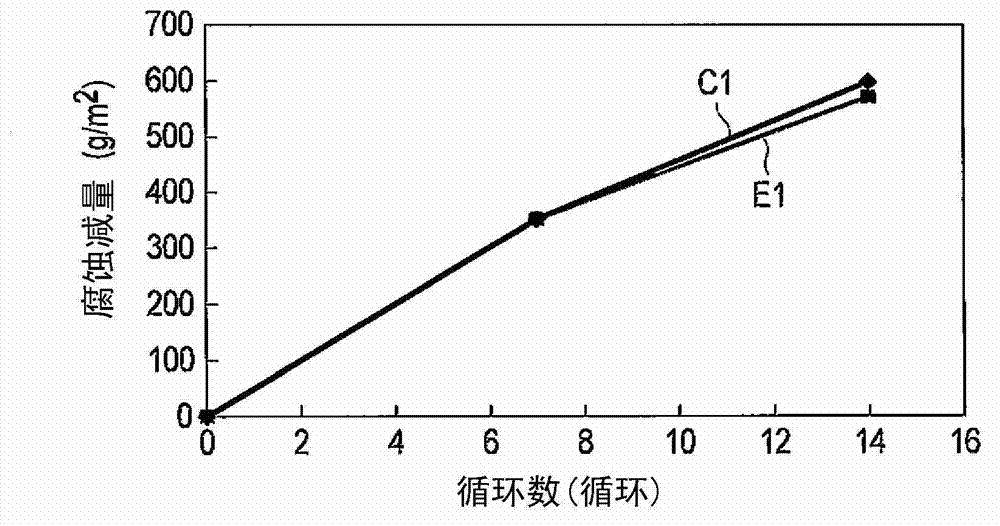

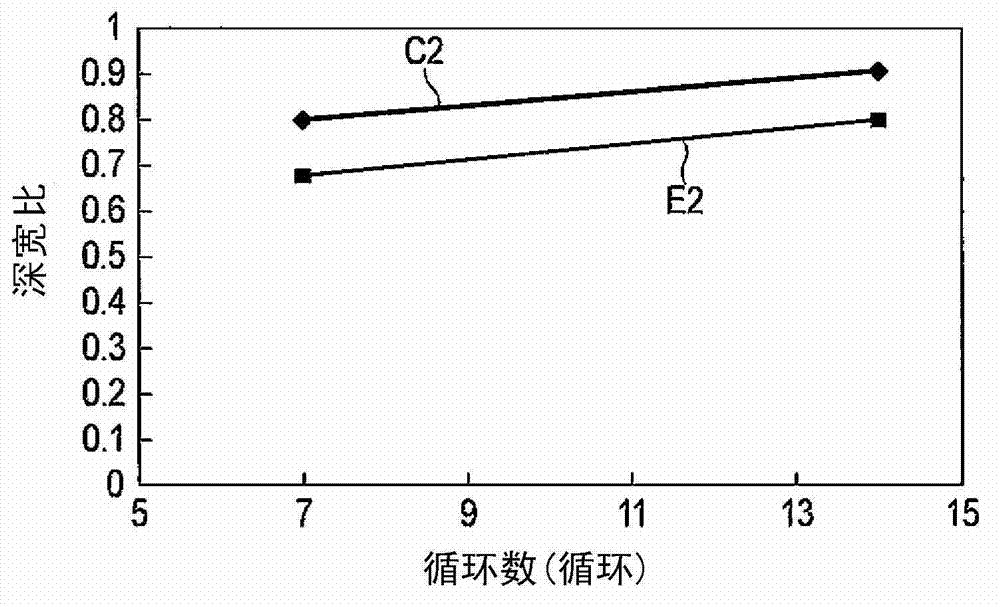

A control apparatus for an internal combustion engine includes an exhaust gas recirculation unit; an intercooler that is provided in the intake passage, at a position downstream of a position to which the exhaust gas is recirculated back; a bypass passage through which an intake air flow bypasses the intercooler. When it is determined that the pH of the condensed water obtained from the exhaust gas is at the level at which the intercooler corrodes in the state where the exhaust gas is recirculated back by the exhaust gas recirculation unit, the control apparatus executes a control for cutting off an intake air flow toward the intercooler to direct the intake air flow only to the bypass passage. Thus, it is possible to ensure reliability of the intercooler.

Owner:TOYOTA JIDOSHA KK

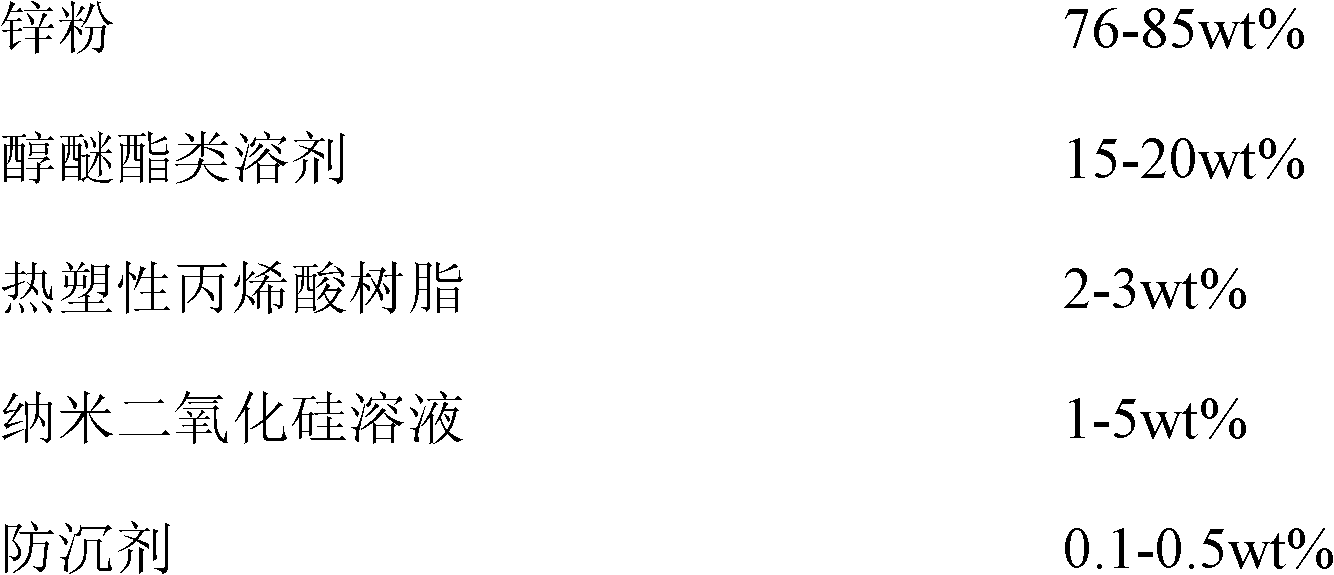

Primer-topcoat cold-spray zinc coating and preparation method for same

InactiveCN102618132ALong corrosion lifeGood compatibility with the bottom surfaceRosin coatingsAnti-corrosive paintsCoated surfaceWeather resistance

The invention relates to primer-topcoat cold-spray zinc coating, which comprises zinc powder, organic solvent, organic resin and filler, wherein the organic resin refers to thermoplastic resin, and the filler is silicon dioxide solution. The primer-topcoat cold-spray zinc coating is longer in anticorrosion service life, good in primer compatibility and compact in coating layer surface, and has good primer performances such as adhesion, anticorrosion and the like and fine weather resistance of topcoat.

Owner:TIANCHANG JULONG TRAVEL PAINT

Novel spraying technology for corrosion prevention and abrasion prevention of boiler

InactiveCN104878344ASimple process operationImprove work efficiencyMolten spray coatingCorrosion resistantThermal spraying

The invention belongs to the technical field of corrosion prevention and abrasion prevention of boilers, and provides a novel spraying technology for corrosion prevention and abrasion prevention of a boiler, so as to solve the problem in the prior art that the surface of the internal water wall of a boiler is easy to corrode. The novel spraying technology comprises the following steps: adopting supersonic arc spraying, and using an iron-based self-adhesion alloy wire for carrying out bottom spraying with the thickness of not smaller than 0.05 mm; then, using an LX88A ultrahard abrasion-resistant alloy wire or a 45CT Ni-Cr-Ti alloy wire as an anti-abrasion spraying material for carrying out spraying with the coating thickness of 0.5-0.6 mm; using an LG-3 type high-temperature abrasion-resistant anti-corrosion special hole-sealing agent to perform hole-sealing on the surface of the thermal spraying coating of the metal, so as to enable the whole coating to be more compact and further achieve the effect of sealing capillary pores. According to the invention, the working efficiency is high, materials are saved, no pollution is realized, and the energy consumption is low; the operation of the technology is convenient, the problem that the possibility of corrosion of the boiler is high during the actual running of the boiler can be effectively solved, and the boiler maintenance cost is reduced; a coating formed by the technology is corrosion-resistant and has excellent abrasion resistance, stability, corrosion resistance and stress cracking resistance, and the corrosion prevention time of the coating can be prolonged to be one year or above, so that the fact that service life of the boiler is prolonged by one year or above is ensured.

Owner:SHANXI HUAHUI HENGYUAN ANTICORROSION ENG

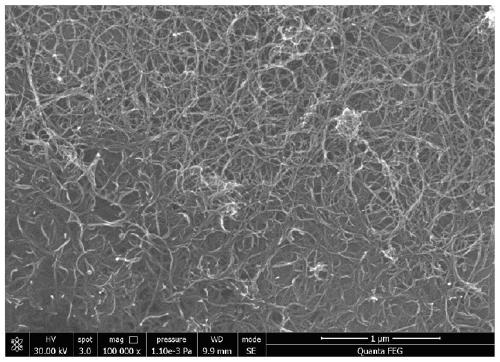

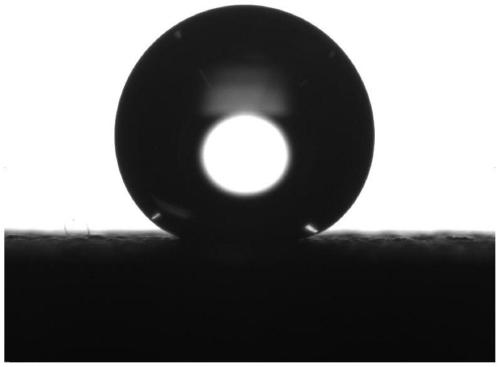

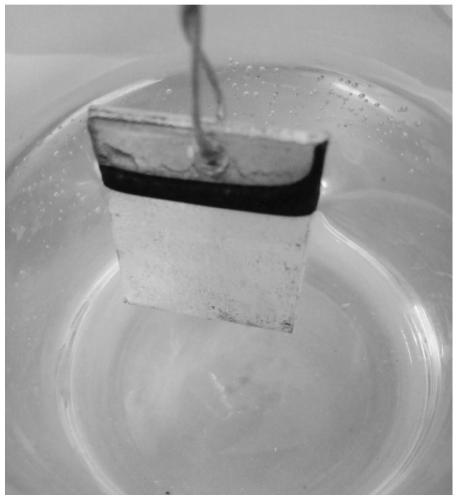

Anti-corrosion carbon nanotube/silane composite super-hydrophobic coating and preparation method

ActiveCN109852972AIncreased mechanical stability and wear resistanceSave resourcesPretreated surfacesMetallic material coating processesSurface energyCorrosion resistant

The invention provides an anti-corrosion carbon nanotube / silane composite super-hydrophobic coating and a preparation method thereof. According to the anti-corrosion carbon nanotube / silane composite super-hydrophobic coating, environment-friendly pollution-free organosilane is adopted as a film forming agent; a multi-wall carbon nanotube loaded with a corrosion inhibitor is adopted as a carrier; afunctional surface with the super-hydrophobic property is prepared through a one-step dip-coating technology; a special wetting surface is organically combined with an environment-friendly silane passivation technology; and then, the anti-corrosion life of galvanized steel is greatly prolonged and the maintenance cost is reduced. The preparation method mainly comprises the following steps: immersing a degreased and hydroxylated galvanized steel substrate in a silane solution for 1-10 minutes' treatment, wherein the silane solution contains the carbon nanotube loaded with the corrosion inhibitor, inorganic nanoparticles and a low-surface-energy modifier; and then, taking out the galvanized steel substrate slowly, removing an excess liquid by adopting compressed air, carrying out cleaning by adopting absolute ethanol, and carrying out curing and firm forming for 10-40 minutes at 80-150 DEG C. The anti-corrosion carbon nanotube / silane composite super-hydrophobic coating provided by the invention is simple in preparation process and low in cost, has no limitation to the shapes and sizes of workpieces, is suitable for large-scale preparation, and is expected to develop into a novel environment-friendly surface treatment technology.

Owner:TIANJIN GONGDA GALVANIZING EQUIP CO LTD

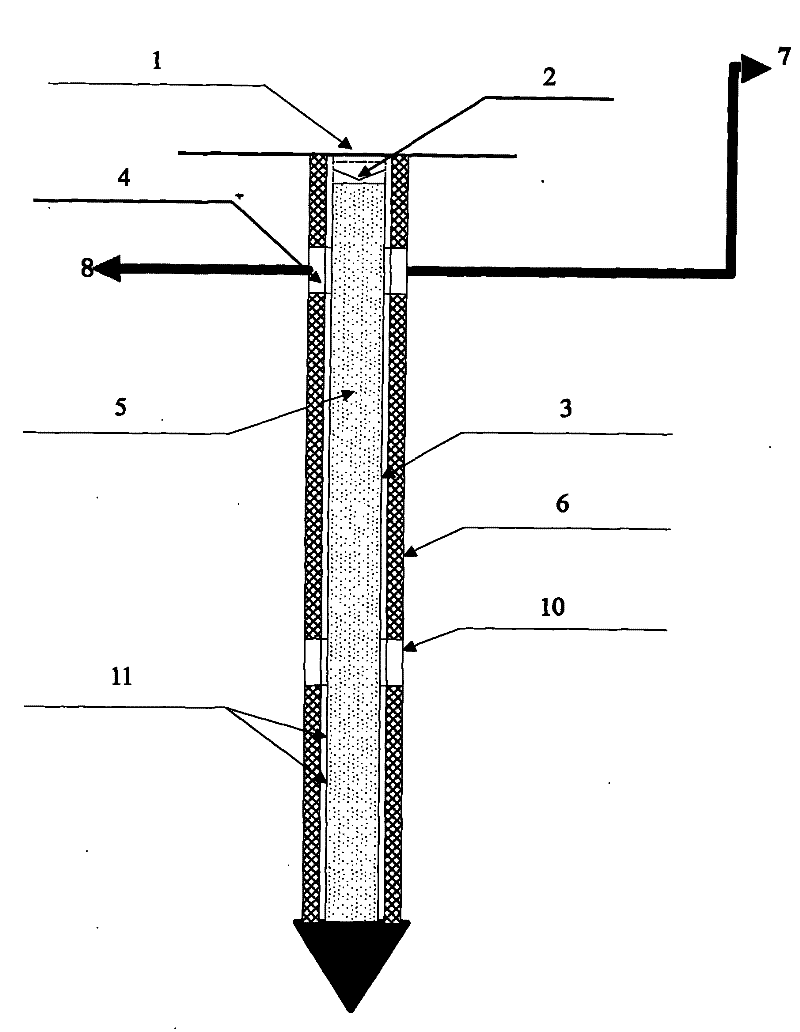

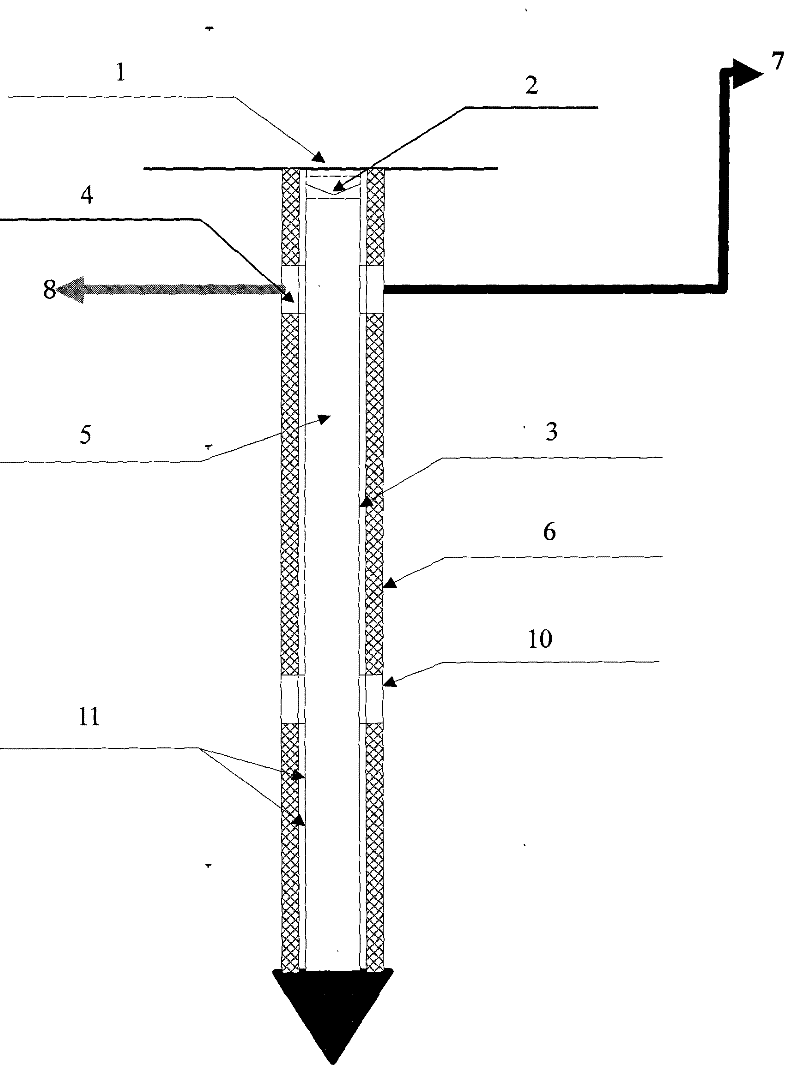

Grounding electrode of anti-corrosion and adjustable grounding resistor

InactiveCN101752684ALong corrosion lifeWith anti-corrosion functionConnection contact member materialTransformerGrounding resistance

The invention relates to a grounding electrode in a lightning protection grounding system of a power station, a transformer grounding network, a high-voltage power transmission line iron tower, an electrified railway grounding system, a wireless communication transmitting tower, a transformer neutral point, a high-rise building, a large computer and a microelectronic equipment system equipment center. The grounding electrode comprises a grounding electrode main body which is a thick-walled and seamless steel tube; the thickness of the wall of the steel tube is more than 8-10mm, the inner wall and the outer wall thereof are provided with an anti-corrosion conducting film, the lower end thereof is provided with a sealing head, the top end thereof is provided with an openable packing port, and the wall thereof is provided with a releasing hole; and the steel tube is externally provided with an external packing with good electric conduction, corrosion prevention and water permeability, and an interface connected with the grounding network and an equipment grounding lead. The grounding electrode has convenient and fast installation and construction, good resistance-reducing effect and convenient maintenance with the service life thereof of being not lower than that of the grounding equipment, and is a grounding electrode which not only meets the anti-corrosion function of the grounding electrode in the grounding network, but also reduces the grounding resistance performance of the grounding electrode.

Owner:高政

Transmission line fastening piece alloy coating and preparation process thereof

InactiveCN101935815ALong corrosion lifeLong-term anti-corrosion lifeHot-dipping/immersion processesTransmission towerRare earth

The invention relates to a transmission line fastening piece alloy coating and a preparation process thereof. The alloy coating is characterized by comprising the following components in percentage by weight: 0.045 to 3 percent of aluminum, 0.03 to 3 percent of magnesium, 0.03 to 3 percent of rare earth, 0.01 to 2 percent of copper and the balance of zinc. The preparation process comprises the following steps of: 1) washing a coating piece with an acid and water, namely performing acid washing on the coating piece for 5 to 30 minutes before a hot dip process by adopting 10 to 20 percent hydrochloric acid; and washing the coating piece with the water after the acid washing; 2) fluxing treatment, namely performing fluxing on the coating piece obtained from the step 1) in a fluxing agent for 20 to 120 seconds at the temperature of between 50 and 120 DGE C; and 3) performing the hot dip process. The alloy coating can effectively prolong the anti-corrosion lifetime of a hot dip coating of a fastening piece in a transmission tower in power industry, make the fastening piece of a stressed part of the transmission tower have prolonged anti-corrosion lifetime under complex corrosive environment conditions, ensure that the thickness of a coating is not increased, and simultaneously improve the anti-corrosion lifetime for over 3 times compared with hot-dip plated pure zinc in industry.

Owner:CHINA ELECTRIC POWER RES INST +1

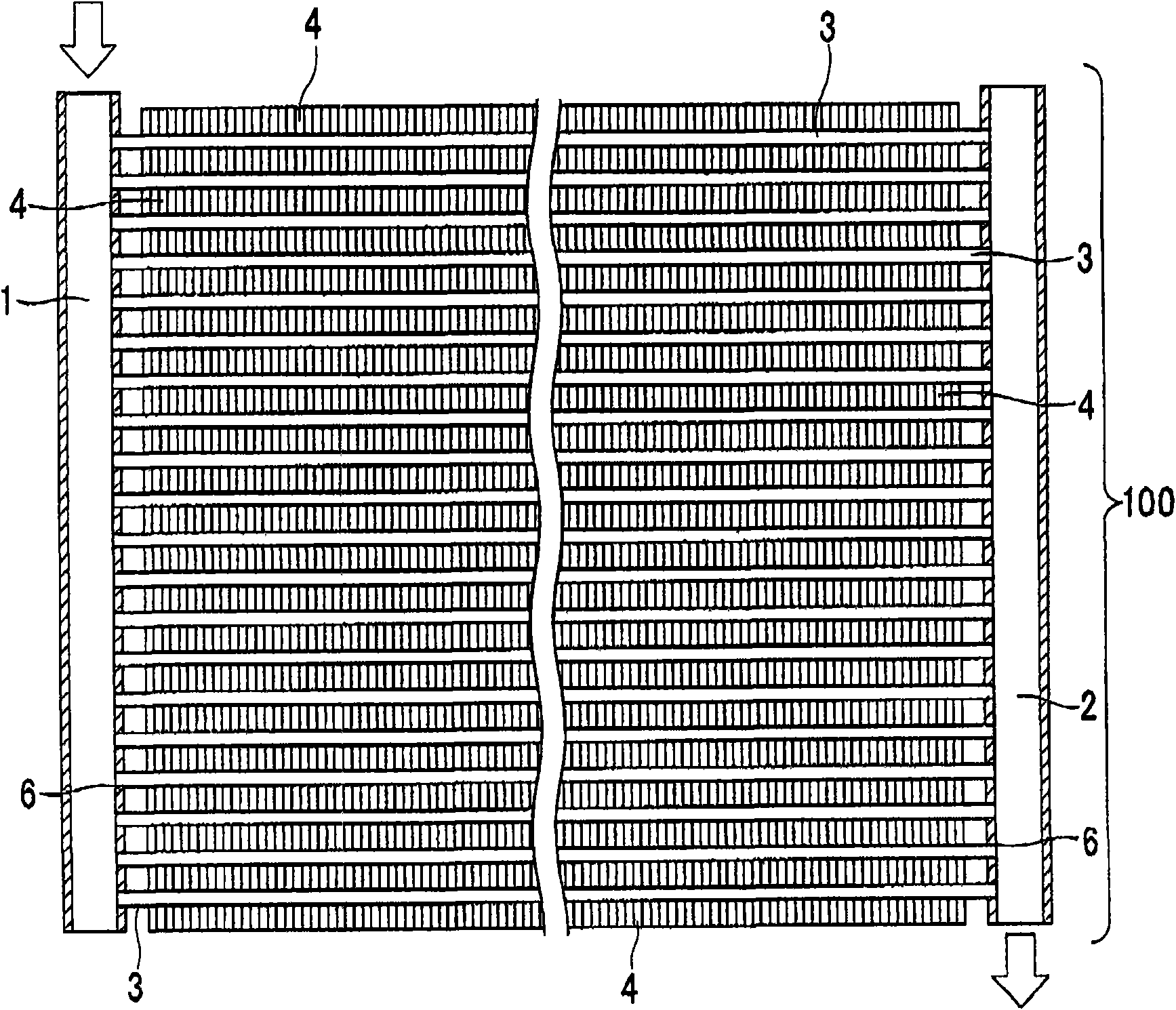

Heat exchanger made of aluminum alloy and method of producing same

ActiveCN101676667AReduce the amount of ZnInhibition of preferential corrosionSoldering apparatusStationary conduit assembliesPlate heat exchangerHeat sink

A heat exchanger comprising a tube, a fin, and a header pipe, wherein the tube contains, in mass %, 0.15 to 0.45% of Mn, 0.20 to 0.50% of Si, and the balance of A1 and unavoidable impurities, and is coated with a coating of brazing composition containing 1.0 to 5.0g / m 2 of Si powder, 4.0 to 10.0 g / m 2 of KZnF 3 , and 0.5 to 3.0 g / m 2 of binder; the fin contains, in mass %, 1.20 to 1.80% of Zn, 0.70 to 1.20% of Si, 0.30 to 0.80% of Fe, 0.90 to 1.50% of Mn, one or two or more selected from 0.05 to 0.20% of Zr, 0.01 to 0.10% of V, and 0,01 to 0.10% of Cr, and the balance of Al and unavoidable impurities; and the header pipe comprises a core material, outer sacrificial corrosion protection material, and an inner brazing material.

Owner:MARELLI CORP +1

Primer and topcoat syncretic zinc cold spray coating and preparation method thereof

InactiveCN102766378ALong corrosion lifeGood compatibility with the bottom surfaceRosin coatingsAnti-corrosive paintsCoated surfaceOrganic solvent

The invention relates to a primer and topcoat syncretic zinc cold spray coating, which comprises zinc powder, an organic solvent, organic resin and a filling, wherein the organic resin is thermoplastic resin; and the filling is selected from a silicon dioxide solution. According to the primer and topcoat syncretic zinc cold spray coating, the anticorrosion service life is prolonged, the overcoatability of primer and topcoat is high, the surface of a coating layer of the coating is compact, and the primer and topcoat syncretic zinc cold spray coating has the performance of the high adhesive force, corrosion prevention and the like of the primer, and has high weather fastness of the topcoat.

Owner:TIANCHANG YINHU PAINT

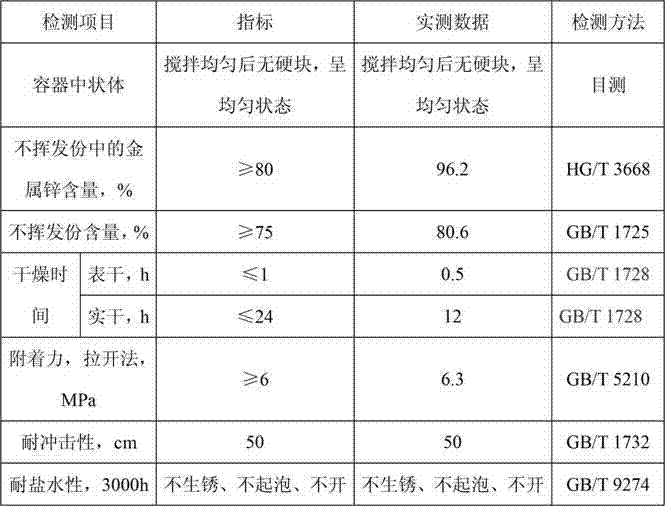

Two-component epoxy organic anticorrosive paint and preparing method and using method thereof

InactiveCN106221563AStrong corrosion resistanceStrong adhesionAnti-corrosive paintsEpoxy resin coatingsSolventChemistry

The invention discloses two-component epoxy organic anticorrosive paint. The paint comprises a component A and a component B; the component A is prepared from, by weight, 33-43 parts of epoxy organic silicon resin, 27-35 parts of epoxy resin, 4-7 parts of glass flake, 13-17 parts of pigment, 4-7 parts of filler, 1.3-2.2 parts of auxiliary and 2-4 parts of diluents; the component B is prepared from, by weight, 35-50 parts of polyamide curing agent, 13-17 parts of pigment, 4-7 parts of filler, 0.7-1.2 parts of anti-settling agent and 40-60 parts of solvent. The two-component epoxy organic anticorrosive paint the advantages that it is indicated through the comprehensive detection results of the paint that all physicochemical indexes reach the industrial standard, and a coating is tough, large in adhesive force, high in mechanical strength and long in anticorrosion life. The paint has good corrosion resistance, and it is proved through detection that salt mist resisting time reaches 4000 h, the paint does not bubble or rust. As the coating contains the glass flake with high pigment volume concentration, the glass flake is arrayed in the coating in an alternately overlapping mode to form a labyrinth effect, and the coating is excellent in shielding performance and impermeability and is resistant to permeation and corrosion of a corrosive medium.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

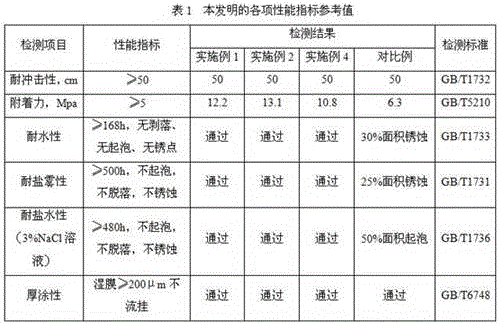

High-strength spring steel, method for producing high-strength spring, and high-strength spring

ActiveCN103201404ALow costNot susceptible to price changesFurnace typesWound springsHardnessHigh intensity

This high-strength spring steel is characterized by: containing, by mass%, 0.38-0.44% of C, 2.00-2.30% of Si, 0.79-1.25% of Mn, 0.10-0.43% of Cr, 0.15-0.35% of Ni, 0.15-0.35% of Cu, 0.05-0.13% of Ti, no greater than 0.02% of P, no greater than 0.02% of S, 0.003-0.10% of Al, 0.002-0.012% of N, no greater than 0.0002% of O, the remainder comprising iron and unavoidable impurities; the AC3 transformation point, which is an index for decarbonizing performance determined from the belowmentioned formula (1), being in the range of 859-885 DEG C inclusive; the maximum quenching diameter (DI), which is an index for quenching performance determined from the belowmentioned formula (2), being in the range of 70-238 mm inclusive; and the tempered hardness (HRC), which is an index for spring performance determined from the belowmentioned formula (3), being in the range of 50-55 inclusive. Ac3=910-203vC -15.2Ni+44.7Si+104V+31.5Mo+13.1W ...(1); DI=DOfSifMnfPfSfCufNifCr ...(2); and HRC=38.99 + 17.48 C + 2.55 Si - 2.28 Ni + 2.37 Cr + 8.04 Ti ...(3); where D0=8.65vC, fSi=1 + 0.64 %Si, fMn=1 + 4.10 %Mn, fP=1 + 2.83 %P, fS=1 - 0.62 %S, fCu=1 + 0.27 %Cu, fNi=1 + 0.52 %Ni, and fCr=1 + 2.33 %Cr.

Owner:NHK SPRING CO LTD

Control apparatus for internal combustion engine and method for controlling the same

InactiveUS8051659B2Avoid it happening againLong corrosion lifeElectrical controlInternal combustion piston enginesExhaust gas recirculationAutomotive engineering

A control apparatus for an internal combustion engine includes an exhaust gas recirculation unit; an intercooler that is provided in the intake passage, at a position downstream of a position to which the exhaust gas is recirculated back; a bypass passage through which an intake air flow bypasses the intercooler. When it is determined that the pH of the condensed water obtained from the exhaust gas is at the level at which the intercooler corrodes in the state where the exhaust gas is recirculated back by the exhaust gas recirculation unit, the control apparatus executes a control for cutting off an intake air flow toward the intercooler to direct the intake air flow only to the bypass passage. Thus, it is possible to ensure reliability of the intercooler.

Owner:TOYOTA JIDOSHA KK

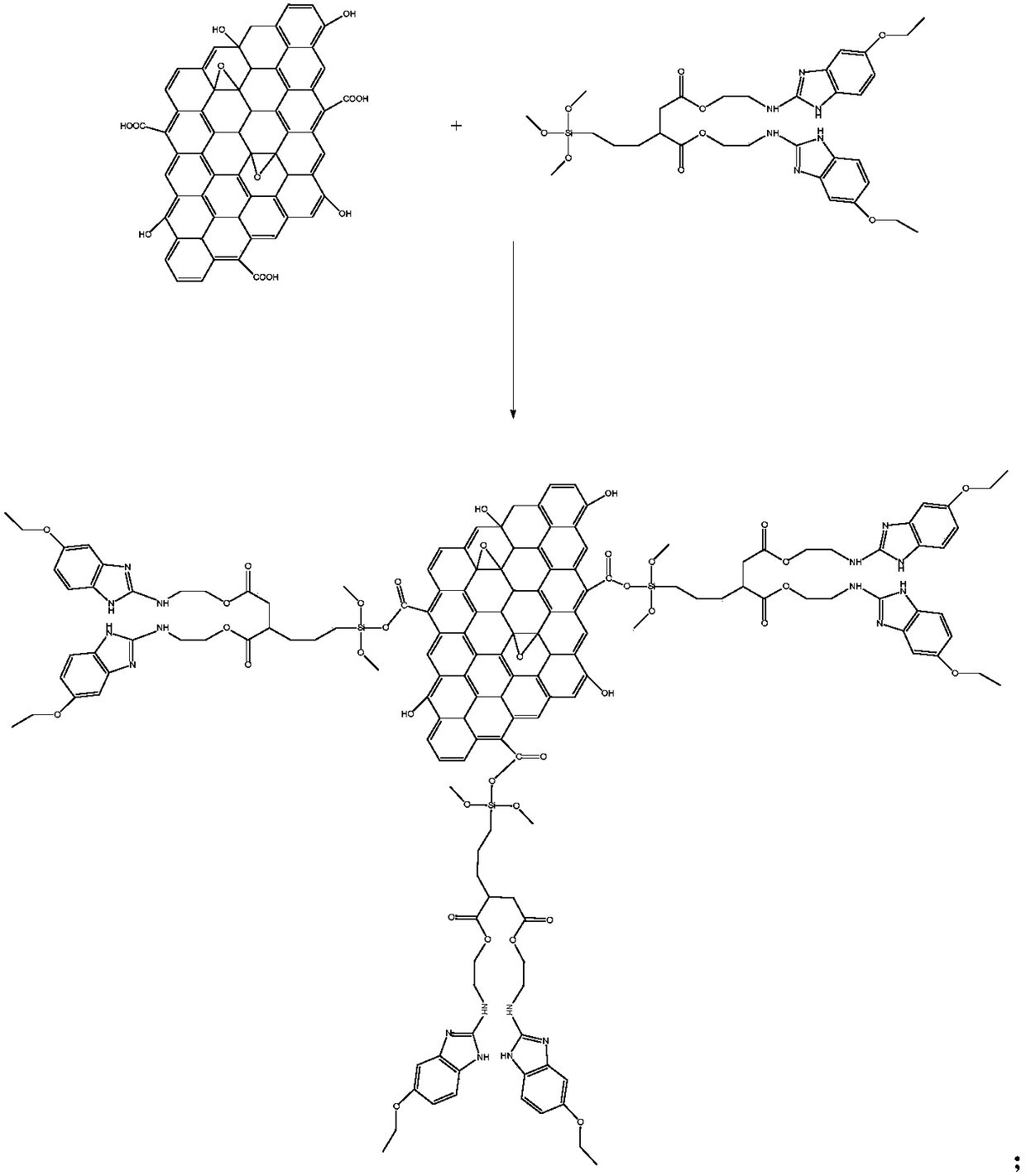

Aqueous anticorrosive coating based on carbon nano composite material and preparation method thereof

ActiveCN110003774AImprove hydrophilic abilityEvenly dispersedAnti-corrosive paintsPolyurea/polyurethane coatingsModified carbonCarbon nanocomposite

The invention provides an aqueous anticorrosive coating based on a carbon nano composite material and a preparation method thereof. The aqueous anticorrosive coating based on the carbon nano compositematerial is prepared from the following raw materials: 20 to 60 parts of aqueous resin emulsion, 10 to 30 parts of modified graphene and 5 to 25 parts of modified carbon nanotubes. A preparation method of the modified graphene or modified carbon nanotubes comprises: mixing graphene or carbon nanotubes with a mixed solution of sulfuric acid and nitric acid, dispersing the mixture, diluting the mixture with water, and filtering the mixture to obtain a solid matter; mixing the solid matter with water to obtain a mixture, adding a surfactant, and dispersing and filtering the latter mixture to obtain an insoluble matter; mixing the insoluble matter with water, and dispersing the mixture. The preparation method comprises: mixing the aqueous resin emulsion, the modified graphene and the modifiedcarbon nanotubes, and then grinding the mixture. The aqueous anticorrosive coating based on thecarbon nano composite material, provided by the invention, can form a dense composite structure, and greatly improves the adhesion and mechanical strength of a coating layer, thereby improving the corrosion resistance of the coating.

Owner:CHENZHOU TEIKYO CHEM TECH

Anti-corrosive alloy coating for power transmission tower and fastener and preparation process of anti-corrosive alloy coating

ActiveCN103834890ASimple hot-dip plating processShort immersion timeHot-dipping/immersion processesAlloy coatingTower

The invention relates to an anti-corrosive alloy coating for a power transmission tower and a fastener and a preparation process of the anti-corrosive alloy coating. The anti-corrosive alloy coating is prepared by pickling, aided plating, drying, hot dipping, air cooling and other technological processes. The coating comprises the following components: 0.01 to 2.5% of Al, 0.01 to 0.5% of Mg, 0.06 to 2% of Re, 0.02 to 1.5% of Cu, 0.05 to 0.3% of Cr, 0.005 to 0.01% of Nb, 0.005 to 0.01% of Ni, 0.002 to 0.06% of B, and the balance of Zn. The alloy coating is used for prolonging the anticorrosive lifetimes of steel for the power transmission tower and the fastener under a complex salt-spray environment, and prolonging the anticorrosive lifetimes more than 10 times that of an industrial hot galvanizing pure-zinc product on the premise that the thickness of the coating is not increased.

Owner:STATE GRID CORP OF CHINA +2

Novel paint for anti-fouling and anti-corrosion treatment on marine metal component and preparation method of novel paint

InactiveCN105295585AImprove bindingLong corrosion lifeAntifouling/underwater paintsPaints with biocidesIonAluminium

The invention belongs to the technical field of metal corrosion resistance, and particularly relates to novel paint for anti-fouling and anti-corrosion treatment on a marine metal component. The novel paint comprises the following ingredients: 15-20 parts of epoxy resin, 1-5 parts of a corrosion inhibitor, 15-24 parts of fluorocarbon resin, 1-3 parts of a dispersing agent, 15-25 parts of Al-Zn-Ni alloy powder, 0.6-1 part of a bonding agent, 15-20 parts of an organic solvent, 2-9 parts of an anti-foaming agent, 5-10 parts of a nanometer oxide or a modified nanometer oxide, 1-4 parts of a thickening agent and 10-20 parts of deionized water. A preparation method of the novel paint comprises the following steps: (1) adding the organic solvent, the deionized water, epoxy resin and fluorocarbon resin in sequence according to a certain ratio; (2) adding the anti-foaming agent and the dispersing agent in sequence; (3) adding the Al-Zn-Ni alloy powder, the nanometer oxide or the modified nanometer oxide, the corrosion inhibitor, the thickening agent and the bonding agent in sequence; (4) continuously stirring the mixture to obtain a target product, namely the novel paint. The novel paint is high in bonding property, long in corrosion life, ideal in moisture and heat resistance, and remarkable in environmental protection performance.

Owner:SHENYANG POLYTECHNIC UNIV

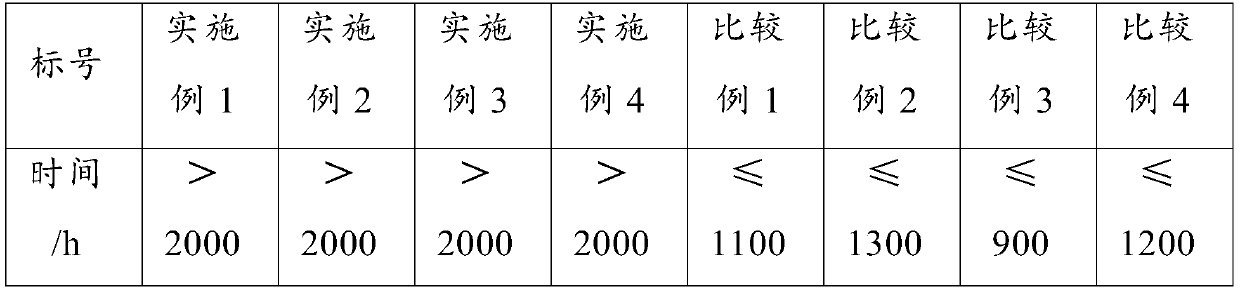

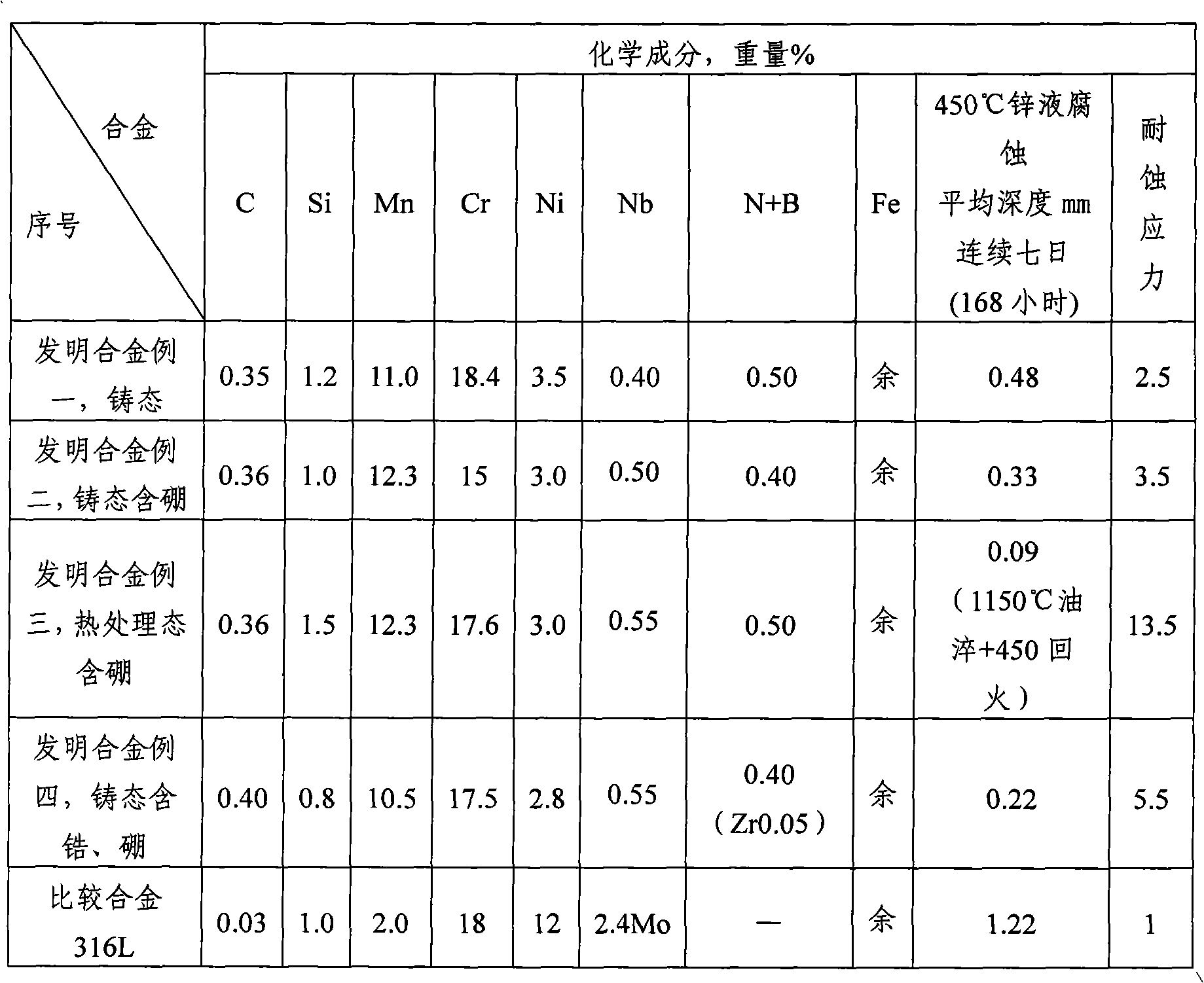

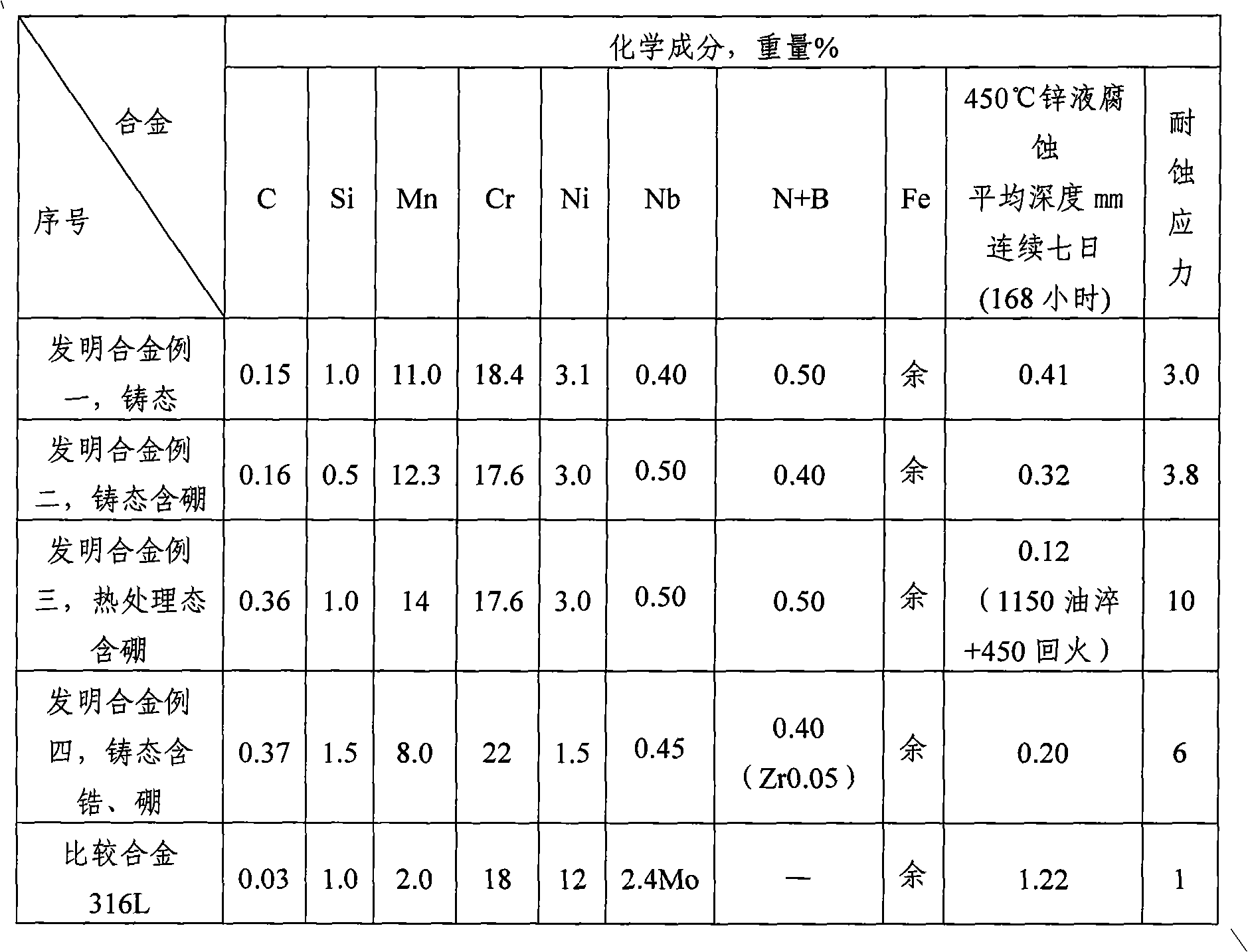

High manganese austenitic iron-based alloy containing boron

The invention relates to a high manganese austenitic iron-based alloy containing boron and a thermal processing method thereof. The alloy comprises the following chemical components of: 0.15-0.40% of C, 0.5-1.5% of Si, 8.0-14.0% of Mn, 15-22% of Cr, 1.5-3.5% of Ni, 0.3-0.55% of Nb, 0.4-0.5% of N+B and the balance being F2 and inevitable impurities. The normal temperature hardness of a cast alloy of the alloy melted by an electric furnace and shaped by centrifugally casting is up to 25-30 HRC; the room temperature extension strength is up to 700-720 MPa; the impact tenacity is up to more than 22 J / cm<2>; the corrosion resisting life is improved by 2.5-3 times more than a 316L stainless steel. Furthermore, the invention provides a thermal processing method for improving the corrosion resistance of the alloy, comprising the following steps of: completely solidly dissolving and separating secondary boride compounds in the issue via the high temperature solidly dissolving treatment and the annealing treatment so that the corrosion resisting life of the alloy is improved to more than 13 times than the 316 L stainless steel. The alloy has excellent liquid metal corrosion resistance and can be used for processing various key members for machining thermal dipping zincing production lines such as sinking rollers, shaft sleeves, bearing bushes, support arms and the like.

Owner:北京北科德瑞冶金工程技术有限公司

Modified waterborne zinc-rich paint

ActiveCN106590088AImprove toughnessImprove film formationAlkali metal silicate coatingsAnti-corrosive paintsDepolymerizationSodium Bentonite

The invention relates to metal corrosion prevention techniques and provides modified waterborne zinc-rich paint. The paint is prepared from flaky zinc powder and a waterborne adhesive base material in a weight ratio of 0.3-1.2:1. The waterborne adhesive base material is prepared from, by weight, 20-40 parts of potassium silicate, 10-20 parts of potassium methyl silicate, 10-20 parts of emulsified asphalt, 0.5-1 part of sodium bentonite, 0.2-0.5 part of tributyl phosphate, 0.2-0.5 part of sodium polyacrylate and 28.6-38.6 parts of water. The modified waterborne zinc-rich paint has advantages that toughness and film forming performance of a polysiloxane structure can be improved, and improvement of comprehensive performances of a zinc coating is benefited; due to excellent corrosion resistance of asphalt, corrosion resistance of a waterborne zinc-rich coating can be improved remarkably; depolymerization and electrochemical corrosion of the polysiloxane structure under water action can be reduced, and anticorrosion service life of the zinc-rich coating can be prolonged.

Owner:TAIZHOU BRANCH ZHEJIANG-CALIFORNIA INT NANOSYSTEMS INST

Inorganic graphene antibacterial alga-resistant zinc-rich anticorrosive coating and preparation method thereof

InactiveCN110527329AAdd release pathImprove conduction efficiencyAntifouling/underwater paintsAlkali metal silicate coatingsEmulsionGraphene

The invention discloses an inorganic graphene antibacterial alga-resistant zinc-rich anticorrosive coating and a preparation method thereof. The inorganic graphene antibacterial alga-resistant zinc-rich anticorrosive coating comprises 30-50 wt% of a stable high-modulus silicate, 0.1-2 wt % of graphene, 40-69 wt% of zinc powder, 0.1-5 wt% of a modified composite antibacterial alga-resistant agent,and 0.1-3 wt% of a coating auxiliary agent, wherein the stable high-modulus silicate is prepared by carrying out a reaction of a silicate, a silane coupling agent and a silicone-acrylic emulsion, themodulus of the silicate is 4.5-7.0, the zinc powder is flake zinc powder and granular zinc powder, the modified composite antibacterial alga-resistant agent is prepared by modifying a composite antibacterial alga-resistant agent with a surface modifier, the surface modifier is an organic silane coupling agent, and the compound antibacterial alga-resistant agent is formed by loading an antibacterial alga-resistant agent on an inorganic porous carrier. By adding anticorrosive fillers such as graphene, the flake zinc powder and the granular zinc powder, and the composite antibacterial alga-resistant agent functional filler, a formed coating layer of the coating is dense, and has relatively few pores, and improvement of a service life of the anticorrosive coating is realized.

Owner:SHENZHEN ACAD OF AEROSPACE TECH

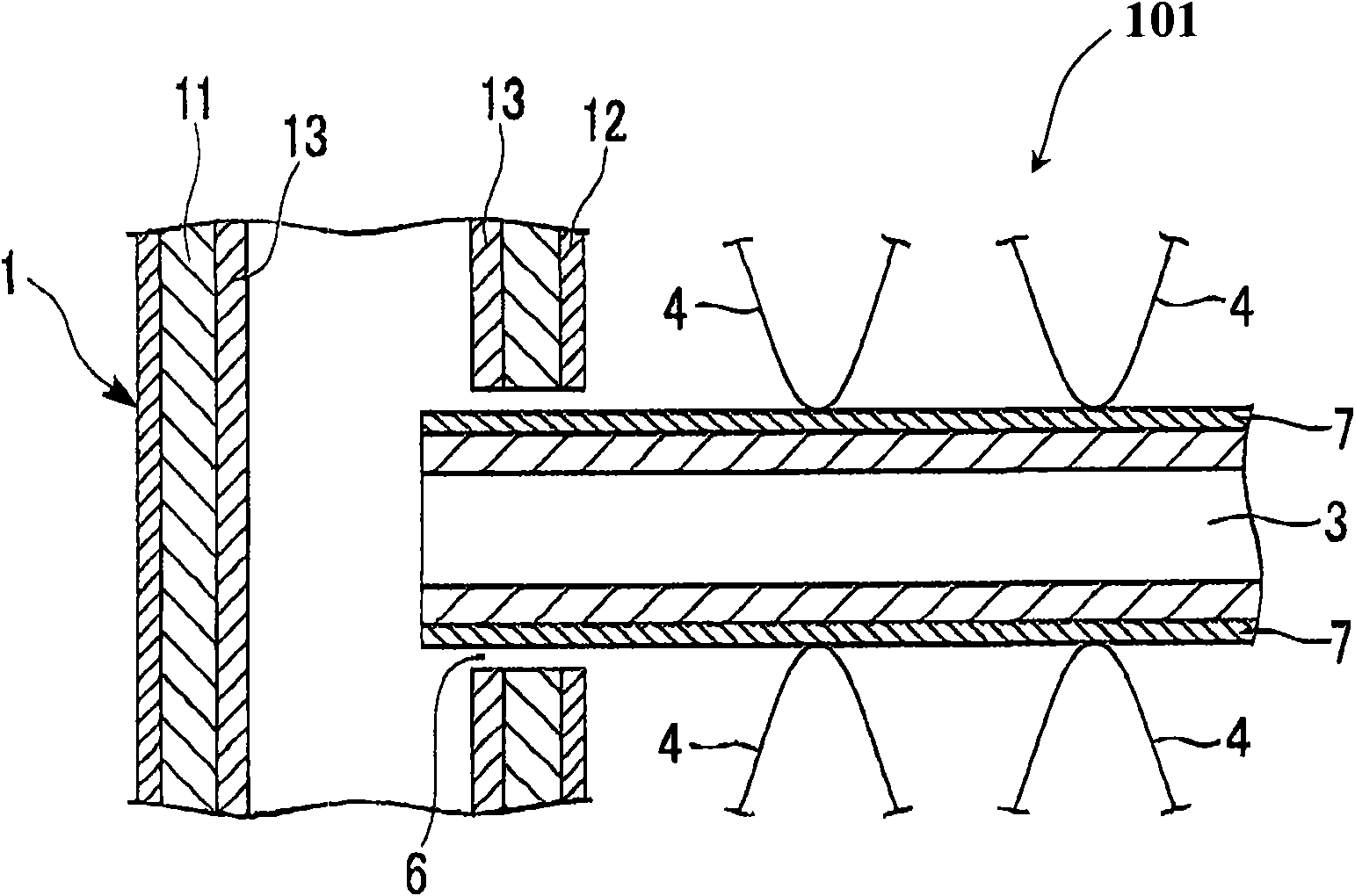

Collecting chamber, production method of collecting chamber, automobile radiator, and production method of automobile radiator

ActiveCN104236372ASimple structureSimple manufacturing processStationary conduit assembliesHeat exchanger casingsWeld seamHeat spreader

The invention discloses a collecting chamber, a production method of the collecting chamber, an automobile radiator, and a production method of the automobile radiator, which belong to the technical field of automobile radiators. The invention aims to reduce welding seams and improve one-time welded rate of a product. The invention adopts the technical scheme that the collecting chamber comprises a collecting chamber main body and block boards, wherein the collecting chamber main body is a square pipe; a plurality of collecting holes are formed in the bottom surface of the collecting chamber body; a transverse cut-through welding seam is formed in the top surface of the collecting chamber body; the block boards are sealed and fixed on two ends of the collecting chamber body; a water inlet and outlet hole is formed in the side face of the collecting chamber main body. The production method of the collecting chamber comprises the following steps of blanking, stamping to form at the first time, stamping bulges to form the collecting holes, stamping the water inlet and outlet hole, stamping to form at the second time, and fixing the block boards. The automobile radiator is provided with the collecting chamber. The production method of the automobile radiator comprises the following steps of assembling the automobile radiator into a whole, and putting into a brazing furnace for welding at one step.

Owner:山东厚丰汽车散热器有限公司

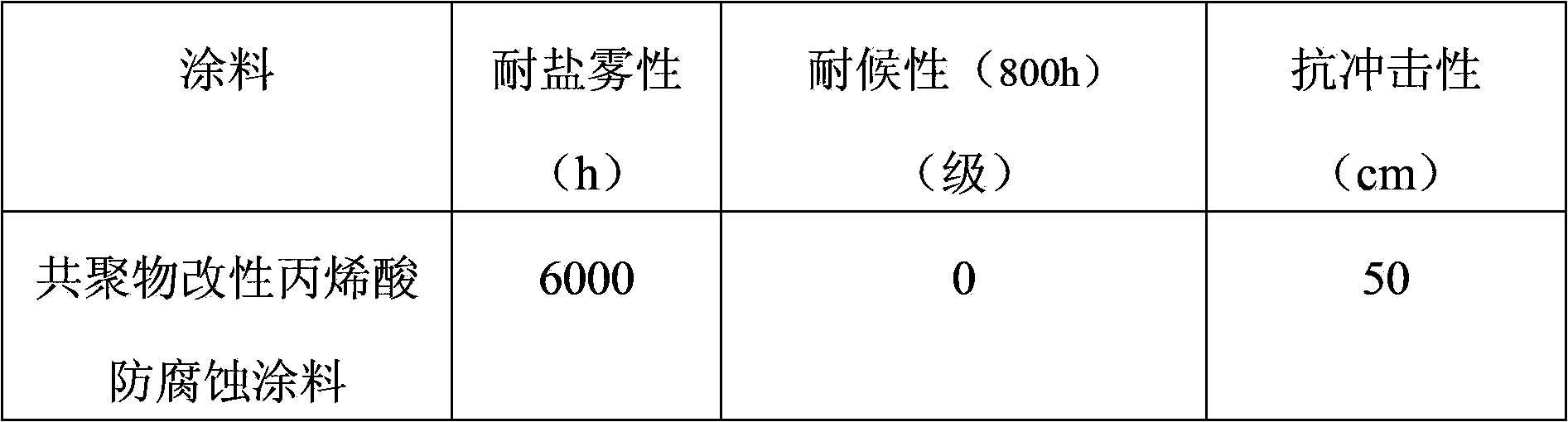

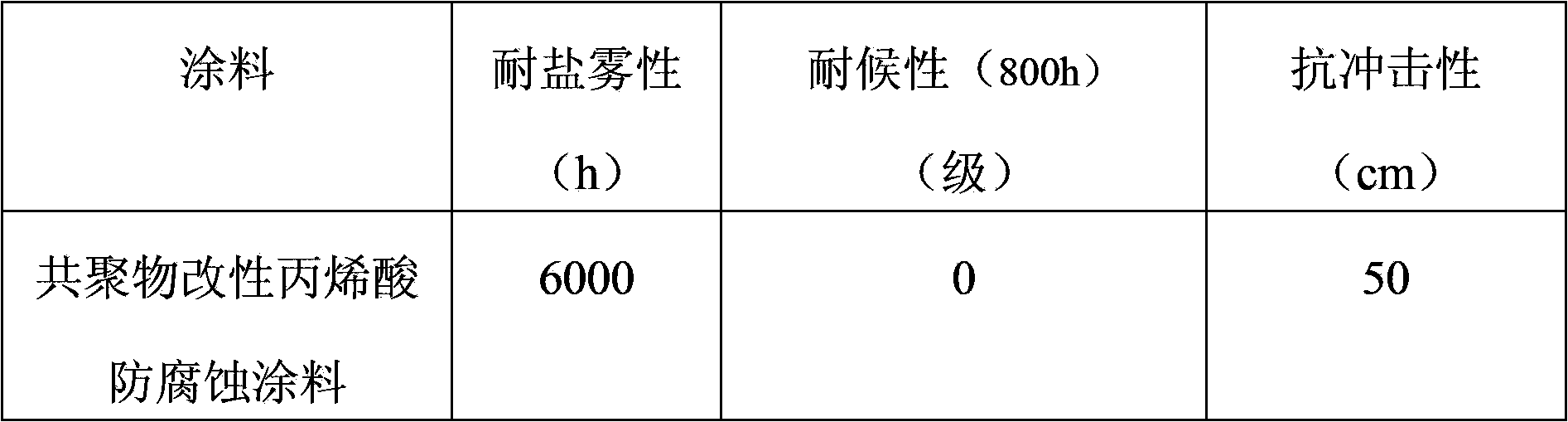

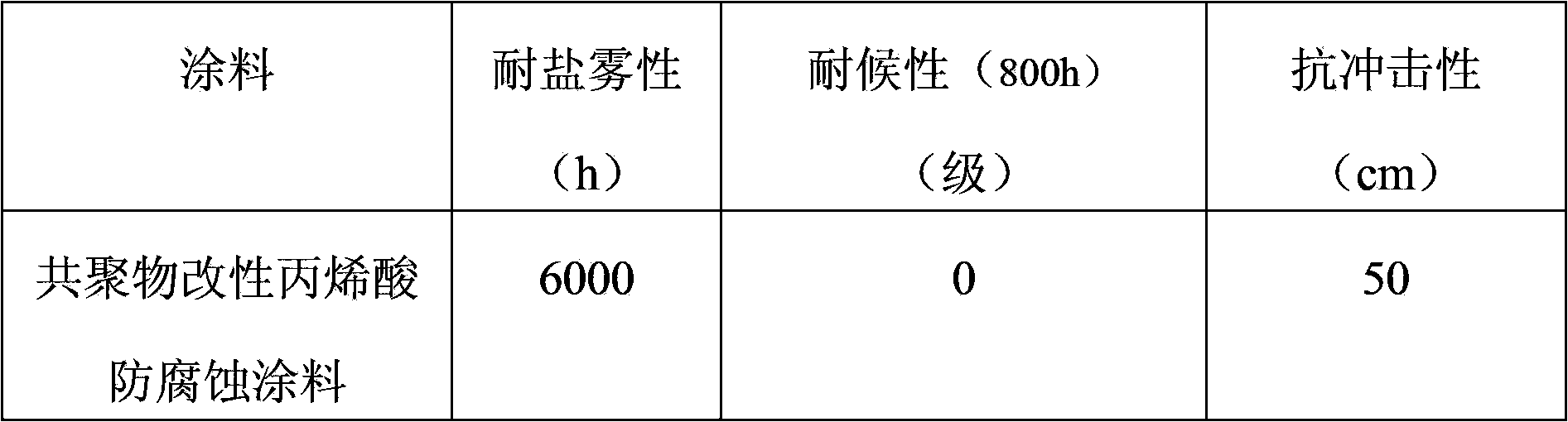

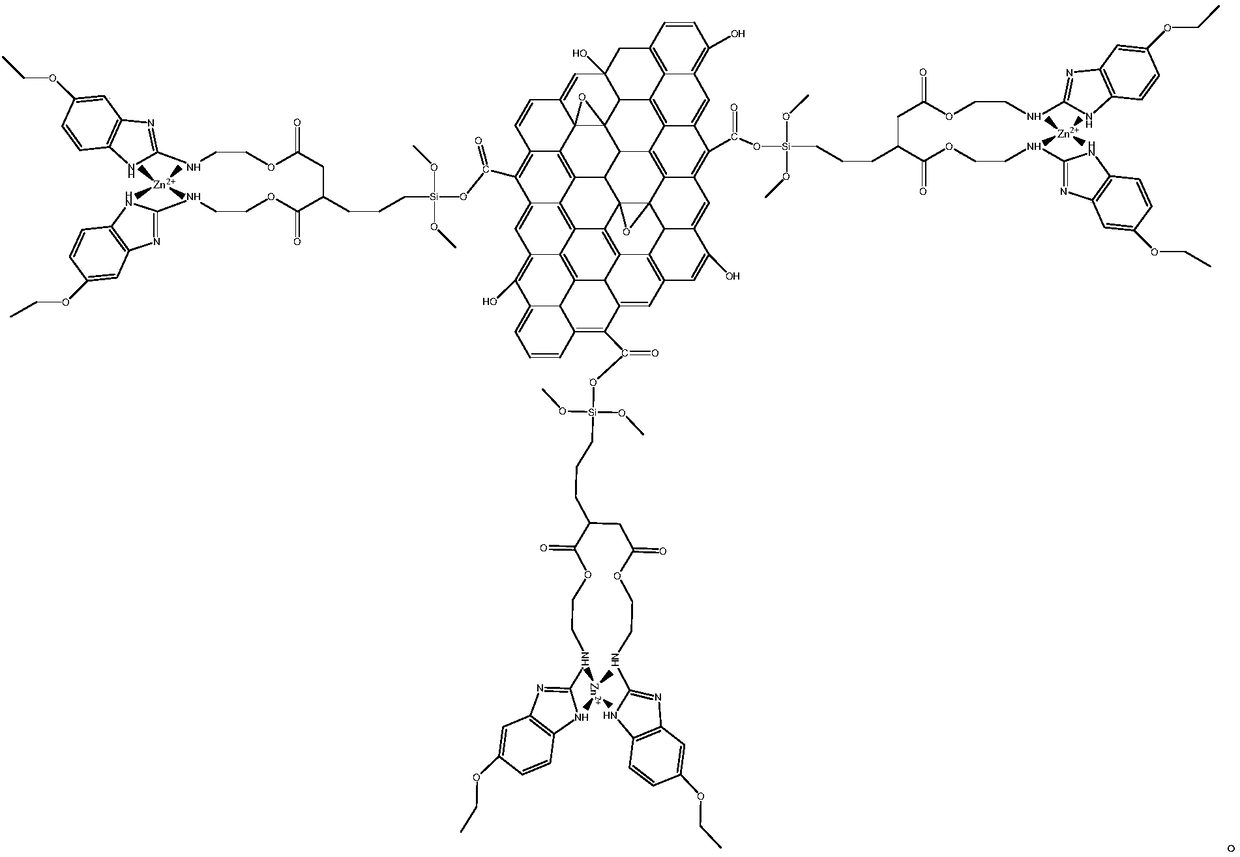

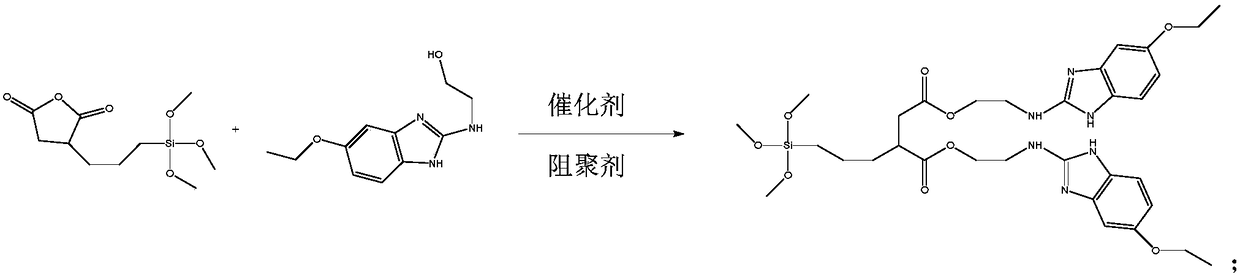

Copolymer modified acrylic acid anticorrosive coating and manufacture method thereof

InactiveCN103450756AImprove adhesionImprove impact resistanceAnti-corrosive paintsCellulose acetate-butyratePolymer chemistry

The invention relates to a copolymer modified acrylic acid anticorrosive coating and a manufacture method thereof. The copolymer modified acrylic acid anticorrosive coating comprises thermoplastic acrylic resin, an ethylene chloride-vinyl acetate copolymer, xylene, n-butanol, n-butyl acetate, cellulose acetate butyrate, petroleum resin, rutile-type titanium dioxide, powdered steatile, mica powder, a dispersant, an adhesion improver, a scratch-resistant agent, an antifoaming agent without organosilicone, a flatting agent, an anti-settling agent and an ultraviolet light absorbent. The manufacture method comprises steps of mixing, high-speed dispersion and grinding; and during usage, a film is formed along with volatilization of the solvents. The coating has the advantages of good weatherability, long salt spray resistance, resistance to erosion of a plurality of chemical media, can be prepared into a plurality of colors and is convenient for construction; and the copolymer modified acrylic acid anticorrosive coating can be applied to anticorrosion of steel objects including ocean platform, ship deck, bridge, building, pipeline and storage tank.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +1

Chemical holding multilayer cladding compound protection method for fastener of transmission tower

ActiveCN104074281AImprove fastnessImprove anti-looseningNon-macromolecular adhesive additivesFilm/foil adhesivesAdhesive cementTransmission tower

The invention relates to fastening and anticorrosion technologies, in particular to a chemical holding multilayer cladding compound protection method applicable to a transmission tower with alternating loads in corrosion environment. Curing factice, non-curing factice, anti-corrosive tapes and adhesives are sequentially arranged on the surface of a protected structure. The curing factice is used for fastening and sealing the fastener, and the surface of a projected object to be coated needs to be subjected to treatment such as oil removal, rust removal and water removal. The non-curing factice is used for leveling a special-shaped structure; meanwhile, the curing factice is coated for building anaerobic environment; the chemical holding effect of the curing factice can be conveniently achieved; the alternating loads can be born; and the loosening is prevented. The adhesives are used for fast film forming; the adhesives and the anti-corrosive tapes are used for isolating the contact with corrosive media such as moisture and air in environment; the anticorrosion performance is good; and meanwhile, an effect of attractive appearance is achieved.

Owner:STATE GRID CORP OF CHINA +1

Long-lasting anticorrosive finishing paint for metal substrate and preparation method thereof

ActiveCN109337568AHigh mechanical strengthWeather resistantAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedSolvent

The invention belongs to the technical field of anticorrosive coating, and particularly relates to long-lasting anticorrosive finishing paint for a metal substrate and a preparation method thereof. The long-lasting anticorrosive finishing paint comprises a component A and a component B, wherein the component A comprises the following raw materials in parts by weight: 35-45 parts of an epoxy-organosilicone resin modified acrylate-polyurethane emulsion, 10-15 parts of functionalized modified graphene, 12-18 parts of fillers, 5-10 parts of a pigment, 8-12 parts of a cosolvent, 0.3-0.8 part of a defoaming agent, 0.5-1 part of a leveling agent, 0.5-1 part of a thickening agent, 0.5-1 part of a water-based drier, 0.8-1 part of a wetting agent and 20-30 parts of deionized water; the component B comprises the following raw materials in parts by weight: 55-65 parts of an isocyanate curing agent and 35-45 parts of a cosolvent. The long-lasting anticorrosive finishing paint for the metal substrate has the advantages of long-lasting excellent anticorrosive performance, strong substrate adhesion, high mechanical strength, excellent friction resistance, excellent salt spray resistance, strong construction adaptability and the like.

Owner:广东恒立信息科技有限公司

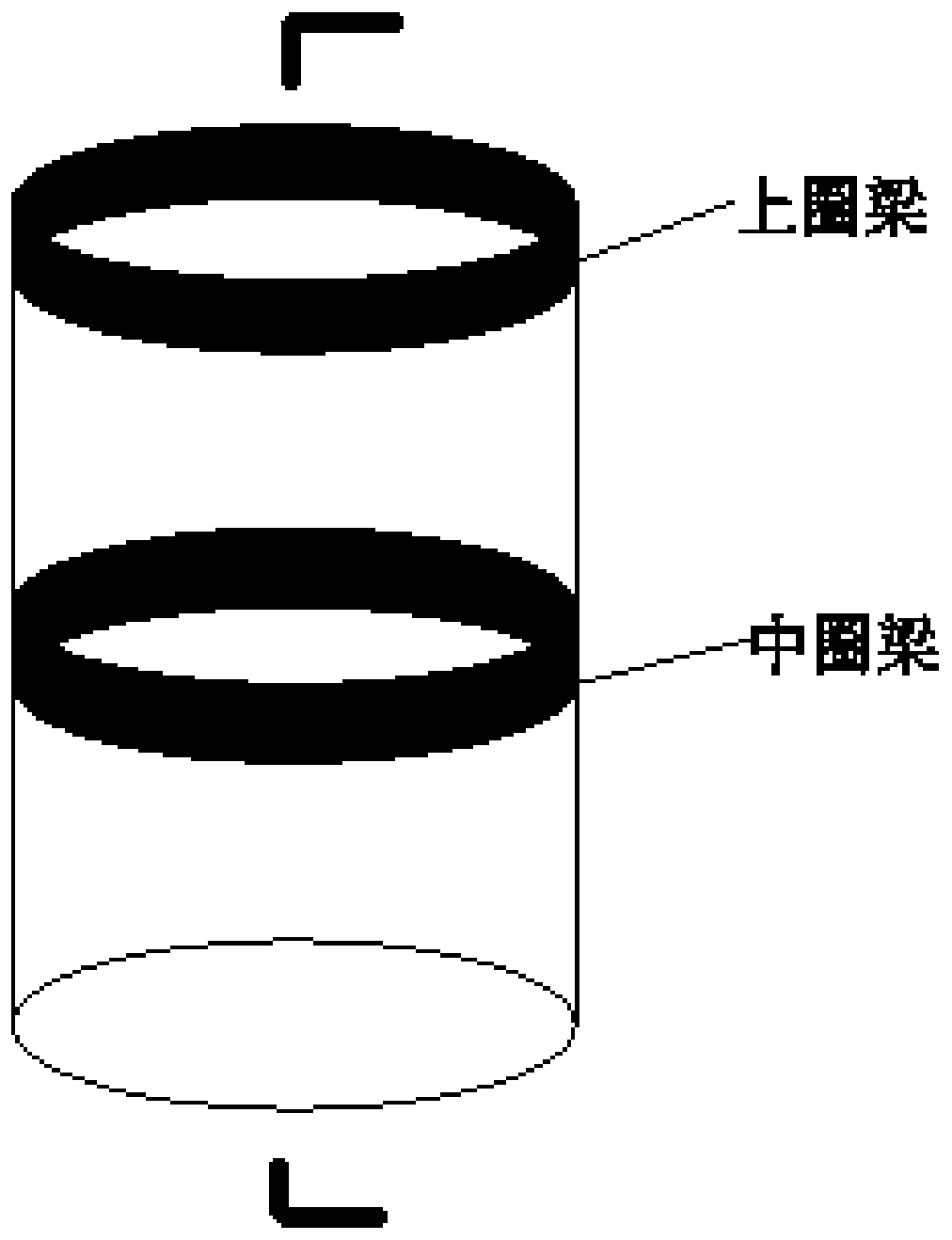

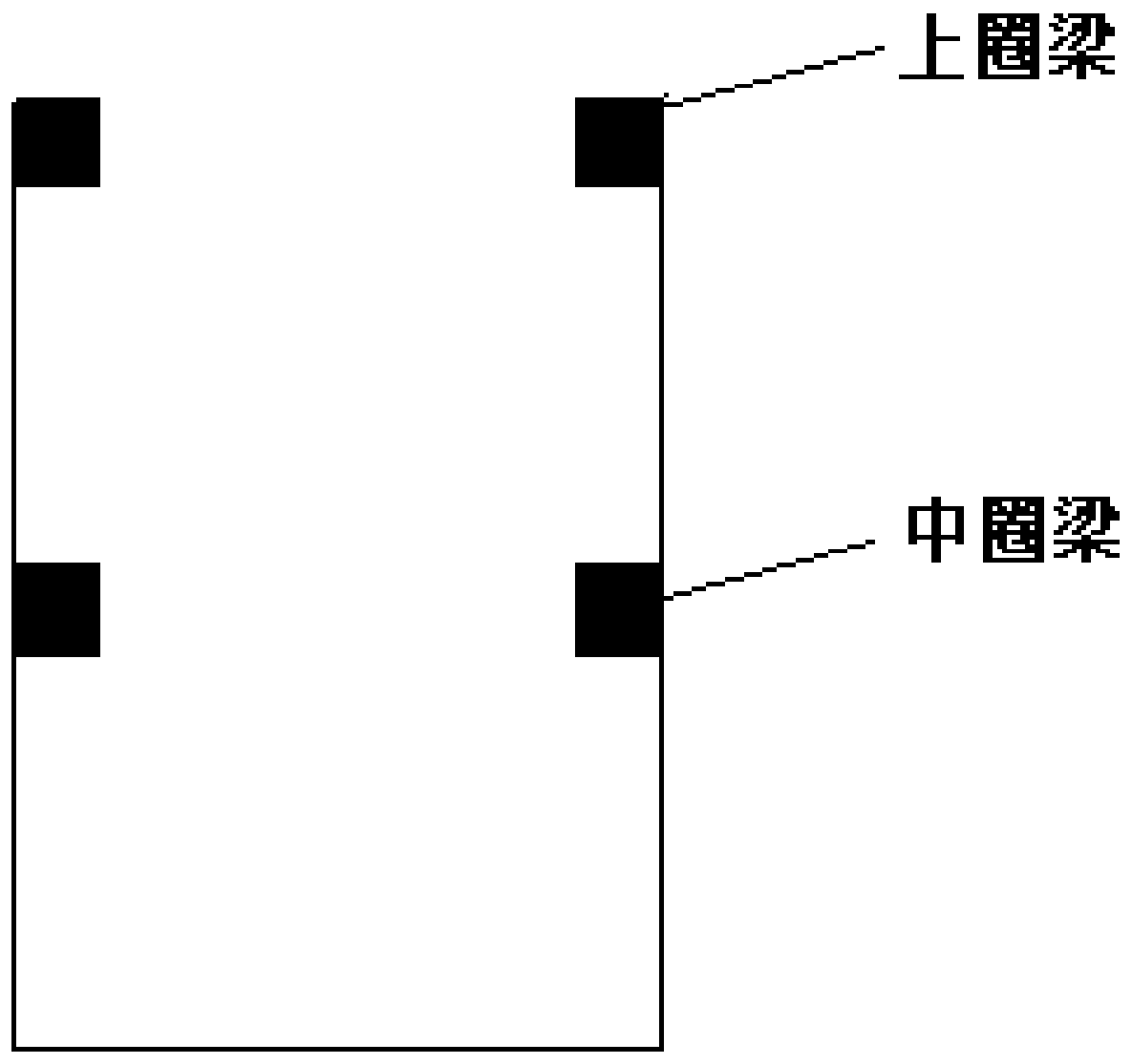

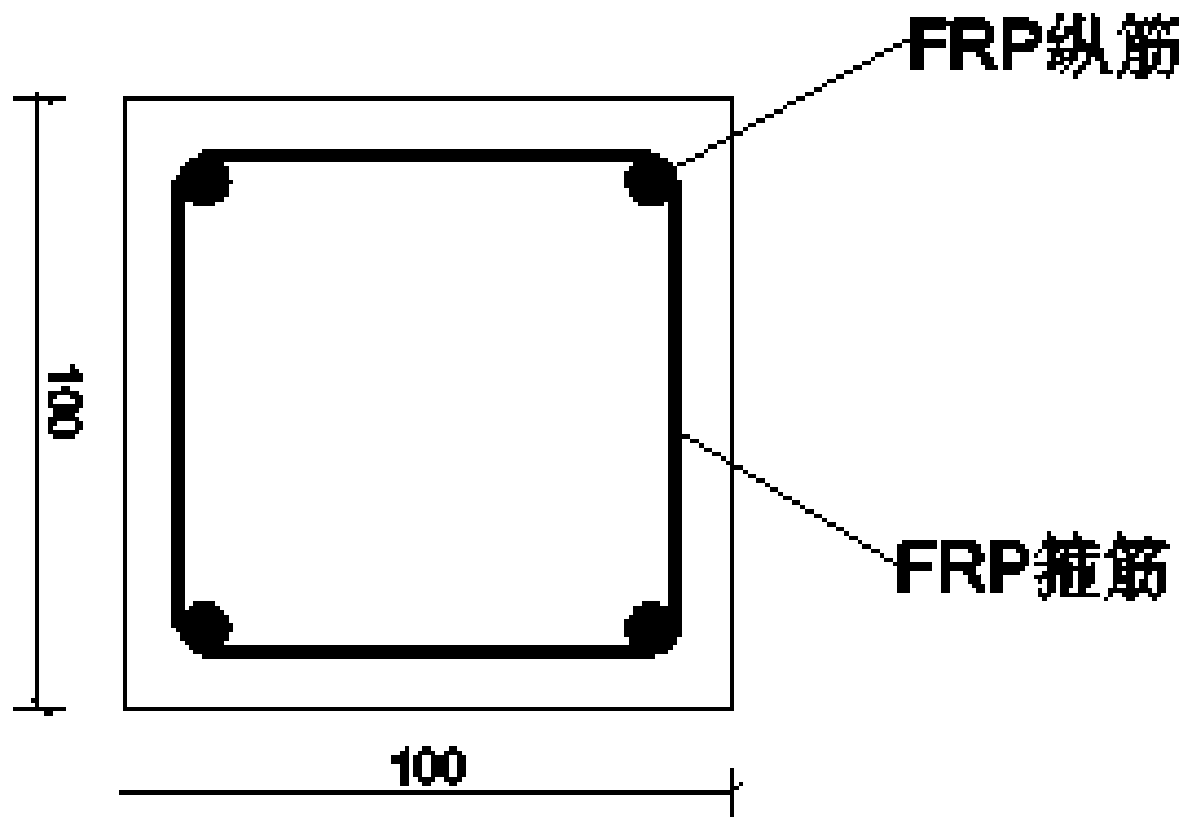

Method for reinforcing electric power tunnel by means of fiber grid enhanced polymer mortar and material

ActiveCN110952996AImprove crack resistanceIncrease ultimate bearing capacityUnderground chambersTunnel liningCelluloseGlass fiber

The invention discloses a method for reinforcing an electric power tunnel by means of fiber grid enhanced polymer mortar and a material, and belongs to the technical field of fiber grid enhanced cement-based composite material reinforcing. Raw material components comprise cement, polymers, polyvinyl alcohol fibers, alkali-resistant glass fibers, sand, water, a water reducer, starch ether, cellulose ether and the like. The method comprises the steps that pre-repairing such as filling and blocking is conducted on masonry or concrete tunnel wall cracks with the polymer mortar, and the mortar is embedded into the cracks; the surfaces of rusted steel bars are painted with a steel bar corrosion remover, and the tunnel wall is painted with one or two layers of an interface agent; and structural reinforcing is conducted on the tunnel and the well wall through multiple layers of the fiber grid enhanced polymer mortar. In order to improve the anti-seismic overall property, 1-3 fiber rib enhancedconcrete ring beams are arranged; and pretreatment is conducted firstly, and then reinforcing is conducted.

Owner:BEIJING UNIV OF TECH

Epoxy glass flake anticorrosive paint

InactiveCN101875808AImprove permeabilityImprove wear resistanceAnti-corrosive paintsPolyamide coatingsEpoxyPlasticizer

The invention discloses an epoxy glass flake anticorrosive paint. The paint comprises a component A and a component B, wherein the component A comprises the following components in parts by weight: 25 to 38 parts of epoxy resin, 5 to 15 parts of polystyrene resin, 5 to 15 parts of butyral resin, 25 to 35 parts of glass flakes, 10 to 20 parts of solvent and 1.5 to 5 parts of plasticizer; and the component B comprises the following components in parts by weight: 50 to 70 parts of polyamide and 20 to 30 parts of solvent. The anticorrosive coating prepared by the anticorrosive paint has wide application range, excellent medium permeability resistance and abrasion resistance, tough coating, strong adhesion, high mechanical strength and long anticorrosive life. The coating with the dried film thickness over 100 microns can be obtained by utilizing the anticorrosive paint of the invention to carry out once coating, and the anticorrosive paint of the invention can be coated at normal temperature and solidified naturally at normal temperature, has simple and convenient construction, and does not require adding lining in construction, and has high mechanical strength.

Owner:刘昆虎

Nano-modified epoxy zinc-rich coating

InactiveCN108117816AReduce entryImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsEpoxyPotassium trimethylsilanolate

The invention provides a nano-modified epoxy zinc-rich coating. The nano-modified epoxy zinc-rich coating is prepared from a first component and a second component, wherein the first component is prepared from 15 to 25 parts of epoxy resin, 30 to 70 parts of zinc powder, 5 to 10 parts of nano-zinc oxide, 5 to 10 parts of nano-silica, 5 to 10 parts of nanometer titania, 5 to 10 parts of nano alumina, 5 to 15 parts of emulsified asphalt, 5 to 10 parts of potassium trimethylsilanolate, 1 to 2 parts of defoaming agent and 2 to 3 parts of wetting agent; the second component is prepared from 30 to 70 parts of curing agent and 10 to 50 parts of solvent, wherein the use ratio of the first component to the second component is (1 to 5) to 1. Under the combined action of the zinc powder and nanometeroxide in the coating, the immersion of a corrosive medium in the coating is reduced; in addition, by adding the emulsified asphalt, the wetting agent and other components, the coating uniformity, adhesion and impact resistance of the coating are improved.

Owner:宁波远欣石化有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com