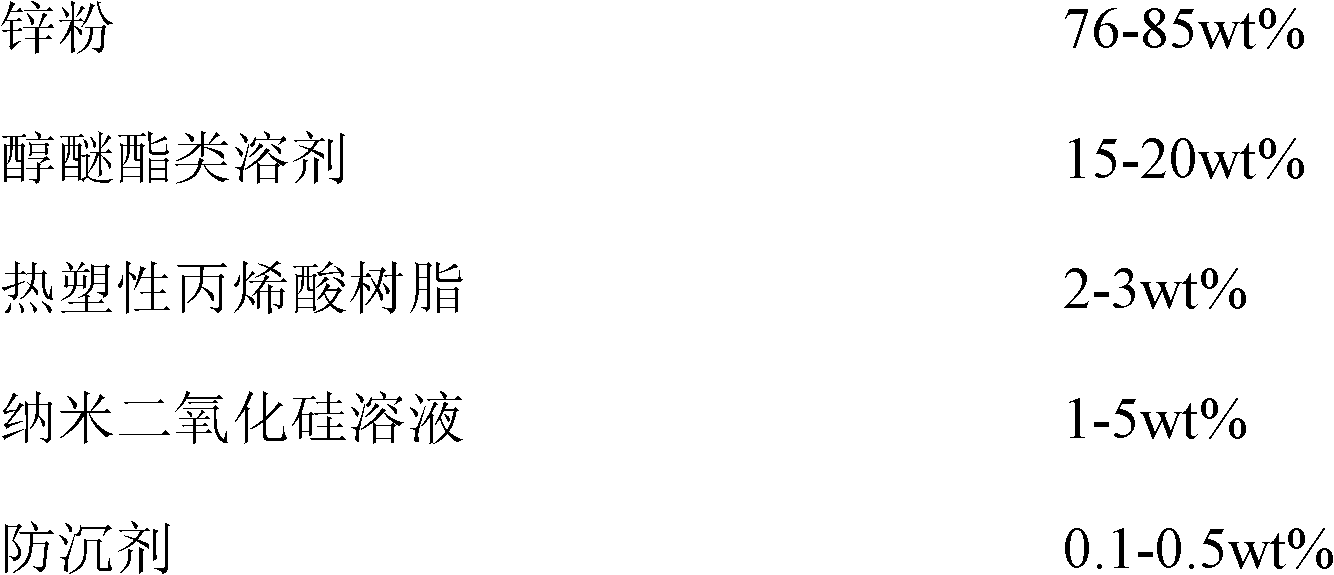

Primer-topcoat cold-spray zinc coating and preparation method for same

A technology of cold spray zinc and coating, applied in anti-corrosion coatings, rosin coatings, polycarbonate coatings, etc., can solve the problems of gaps in arrangement, complicated operation steps, poor sealing performance of new coatings, etc., and achieve beautiful coating surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] A cold-sprayed zinc coating with bottom and surface is composed of the following components: thermoplastic solid acrylic resin B-66 (acid value 0.2mgKOH) 25kg; zinc powder 770kg; polyamide wax ULTRA 2kg; nano-silica solution VK- S01Y 25kg; solvent PMA 178kg.

[0070] The preparation method of described cold spray zinc paint:

[0071] 1. First add 100kg of solvent PMA into the reaction kettle;

[0072]2. Start the disperser to 400 rpm, add 25kg of thermoplastic solid acrylic resin B-66, dissolve until transparent;

[0073] 3. Add 770kg of zinc powder slowly, and increase the speed of the disperser to 1200 rpm until the paint fineness is less than 40 microns;

[0074] 4. When the temperature of the paint naturally rises to 50-60 degrees, the speed of the disperser is reduced to 800 rpm, and 2kg of polyamide wax ULTRA is added, and stirred for 30 minutes;

[0075] 5. Add the remaining 78kg solvent PMA and stir for 15 minutes;

[0076] 6. Reduce the speed of the dispers...

Embodiment 2

[0081] A kind of cold-sprayed zinc coating with bottom and surface is composed of the following components: 10 kg of thermoplastic solid polycarbonate resin (acid value 0.8 mgKOH); 900 kg of zinc powder (purity ≥ 99.5%, particle size 20-30 μm); 1 kg of olefin wax; 10 kg of nano silicon dioxide solution (10-30 nm in particle size, 10 wt %); 79 kg of solvent butyl ether acetate.

[0082] The preparation method of described cold spray zinc paint:

[0083] 1. First add 39kg of ethylene glycol butyl ether acetate into the reaction kettle;

[0084] 2. Start the disperser to 200 rpm, add thermoplastic solid polycarbonate resin, dissolve until transparent;

[0085] 3. Slowly add zinc powder, and increase the speed of the disperser to 1300 rpm until the paint fineness is less than 50 microns;

[0086] 4. When the temperature of the paint naturally rises to 45-60 degrees, the speed of the disperser is reduced to 850 rpm, and polyolefin wax is added, and stirred for 30 minutes;

[008...

Embodiment 3

[0090] A cold-sprayed zinc coating with bottom surface combined with the following components: 100kg of thermoplastic polymerized modified rosin resin (acid value 0.3mgKOH); 750kg of zinc powder (particle size 2-20μm, purity ≥ 99.9%); modified 10kg of hydrogenated castor oil; 100kg of nano silicon dioxide solution (20-50nm in particle size, 30wt% concentration); 40kg of solvent ethylene glycol ether acetate.

[0091] The preparation method of described cold spray zinc paint:

[0092] 1. First add 67kg of ethylene glycol ether acetate into the reaction kettle;

[0093] 2. Start the disperser to 500 rpm, add thermoplastic polymerized modified rosin resin, dissolve until transparent;

[0094] 3. Slowly add zinc powder, and increase the speed of the disperser to 1000 rpm until the paint fineness is less than 40 microns;

[0095] 4. When the temperature of the paint naturally rises to 55-70 degrees, the speed of the disperser is reduced to 550 rpm, and the modified hydrogenated c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com