Patents

Literature

17267results about "Tunnel lining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

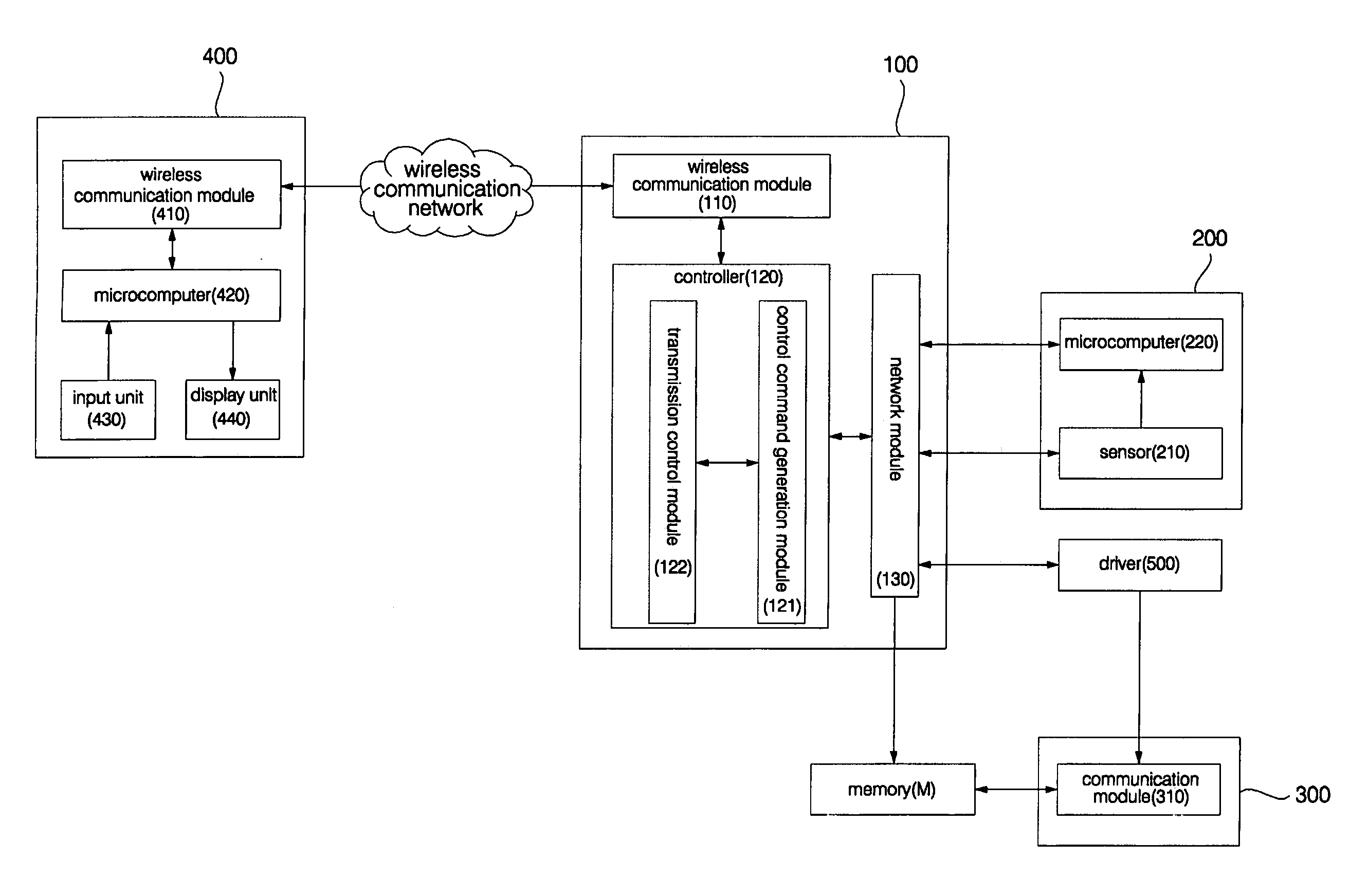

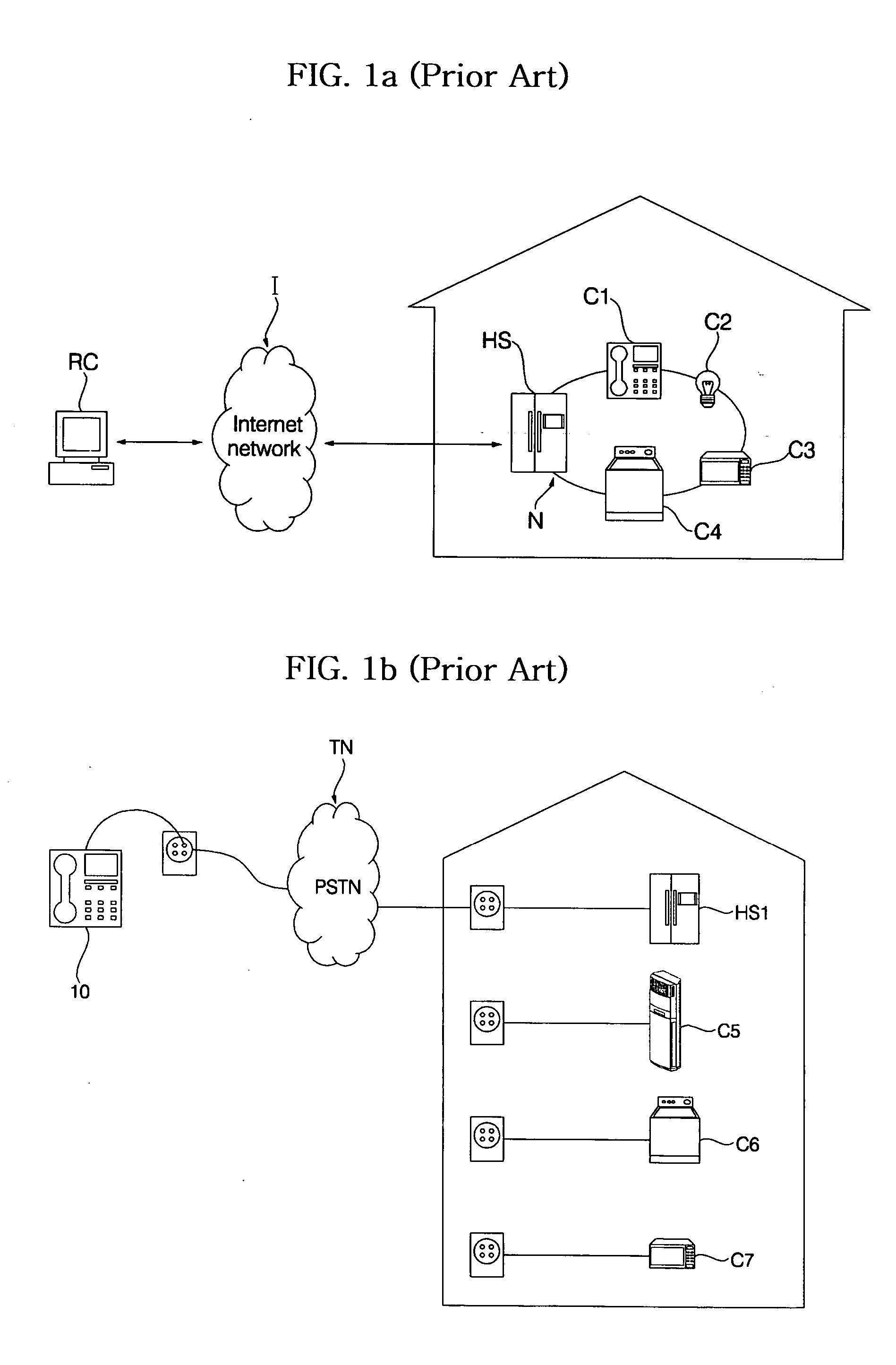

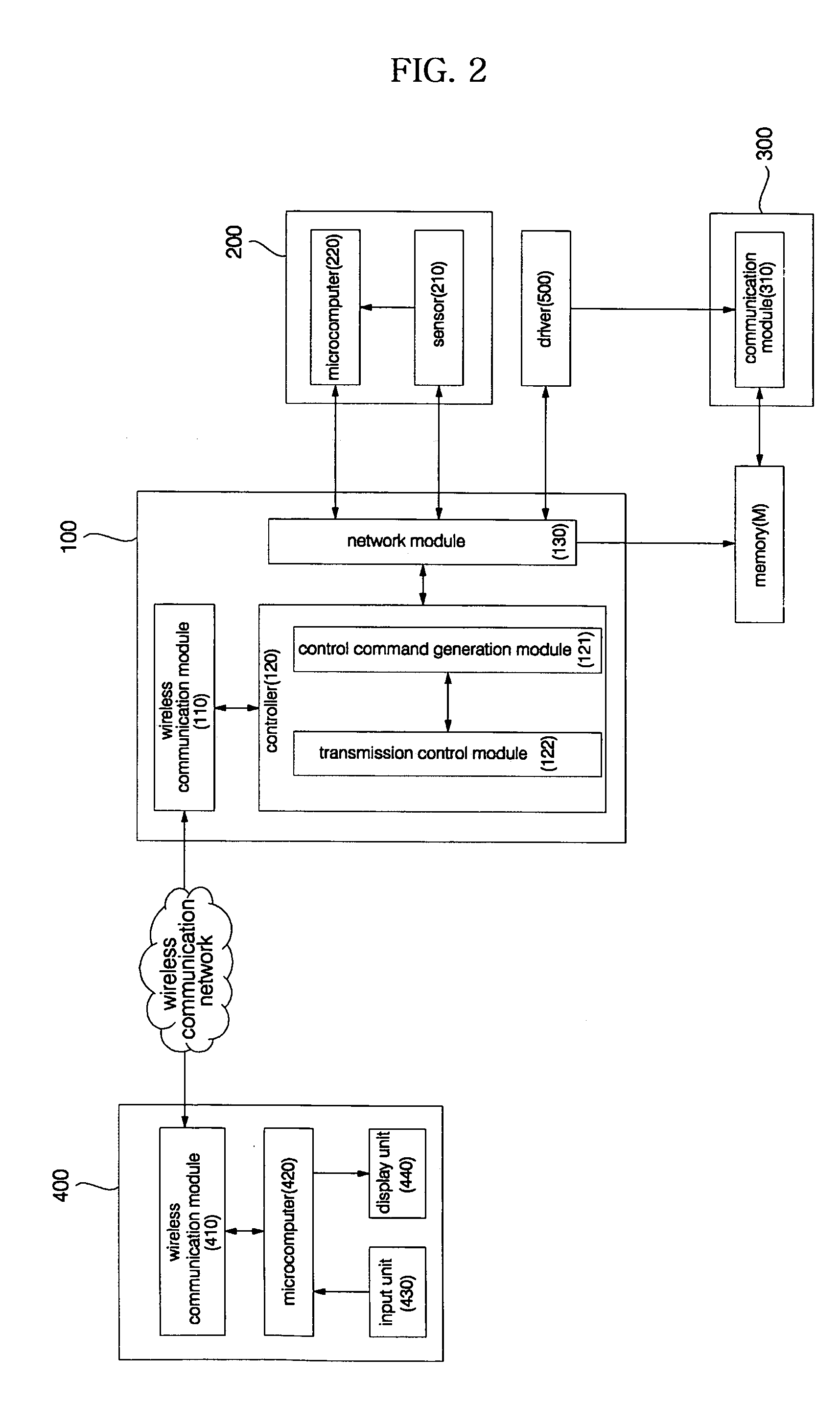

Wireless terminal-interoperable home network system and method controlling the same

ActiveUS20050184865A1Improve control efficiencyImprove ease of useProtective foundationSubstation remote connection/disconnectionImage InspectionTelecommunications

Disclosed herein are a wireless terminal-interoperable home network system and a method for controlling the same. A home server is linked with a security device and camera installed in a building to, when the security device senses entrance / exit of an outsider into / from the building, acquire an internal image of the building from the camera and send the acquired image to a wireless terminal of a user to enable the user to monitor the internal situation of the building in real time. The user can access the home server over a wireless communication network from a remote place outside of the building without separate access to the Internet to receive the internal image of the building and check the internal situation of the building on the basis of the received internal image, resulting in an increase in convenience of use.

Owner:LG ELECTRONICS INC

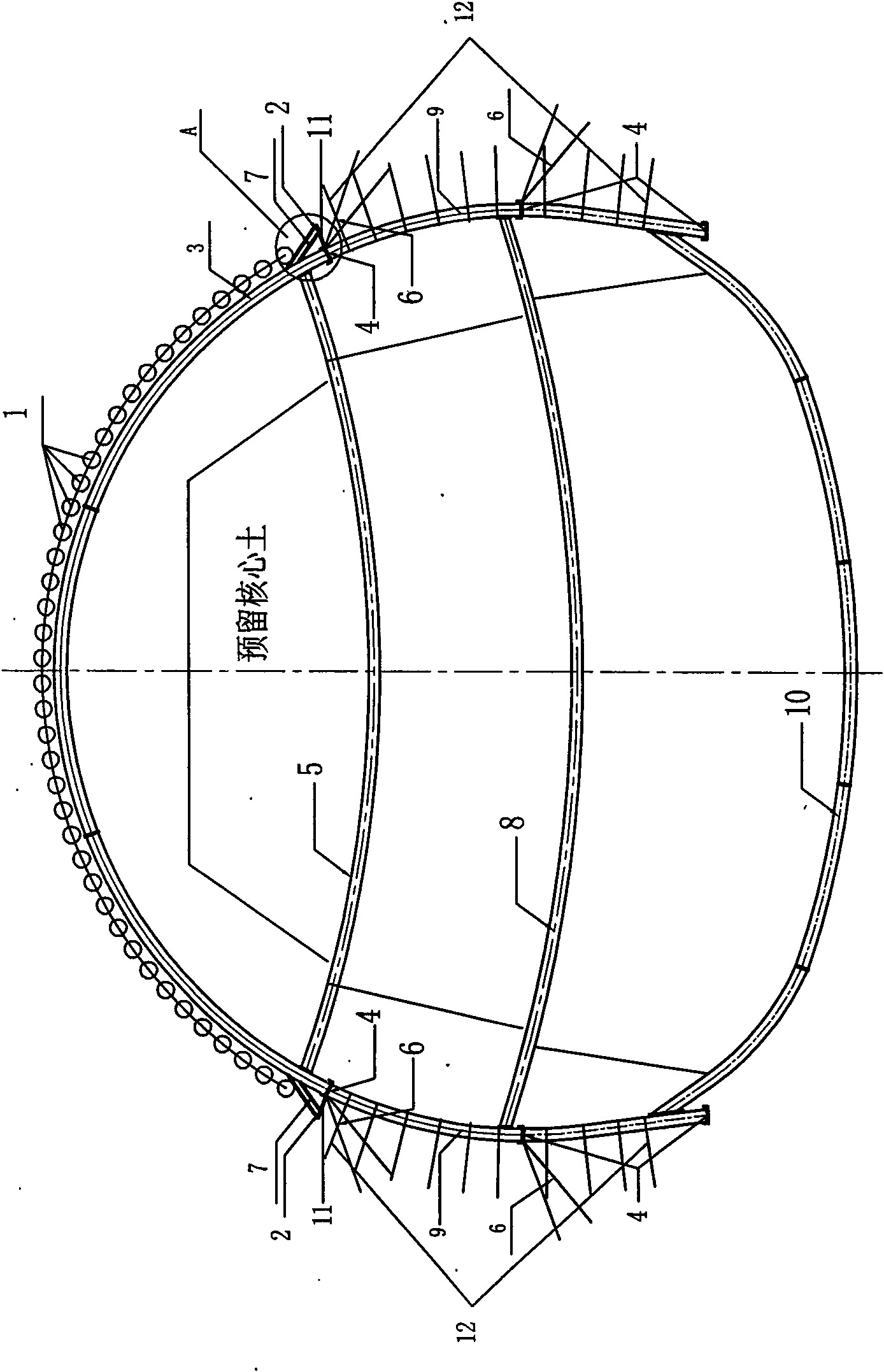

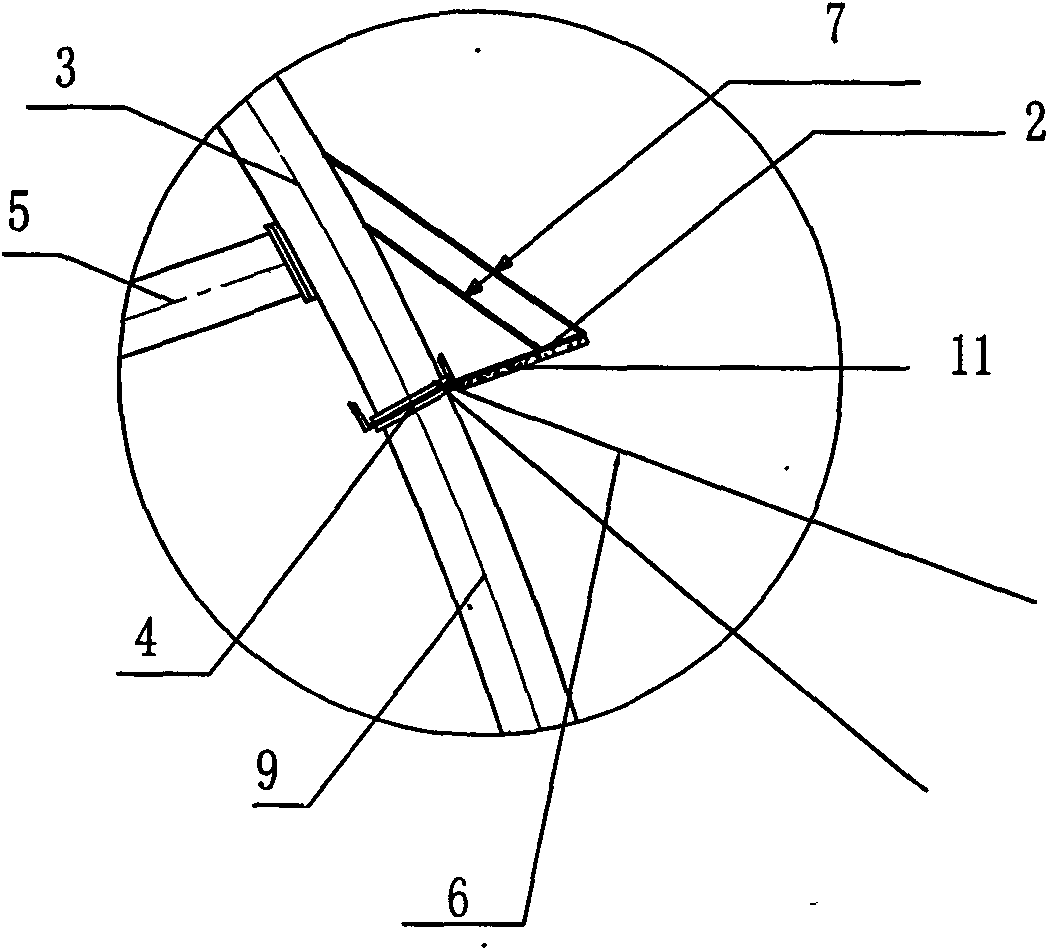

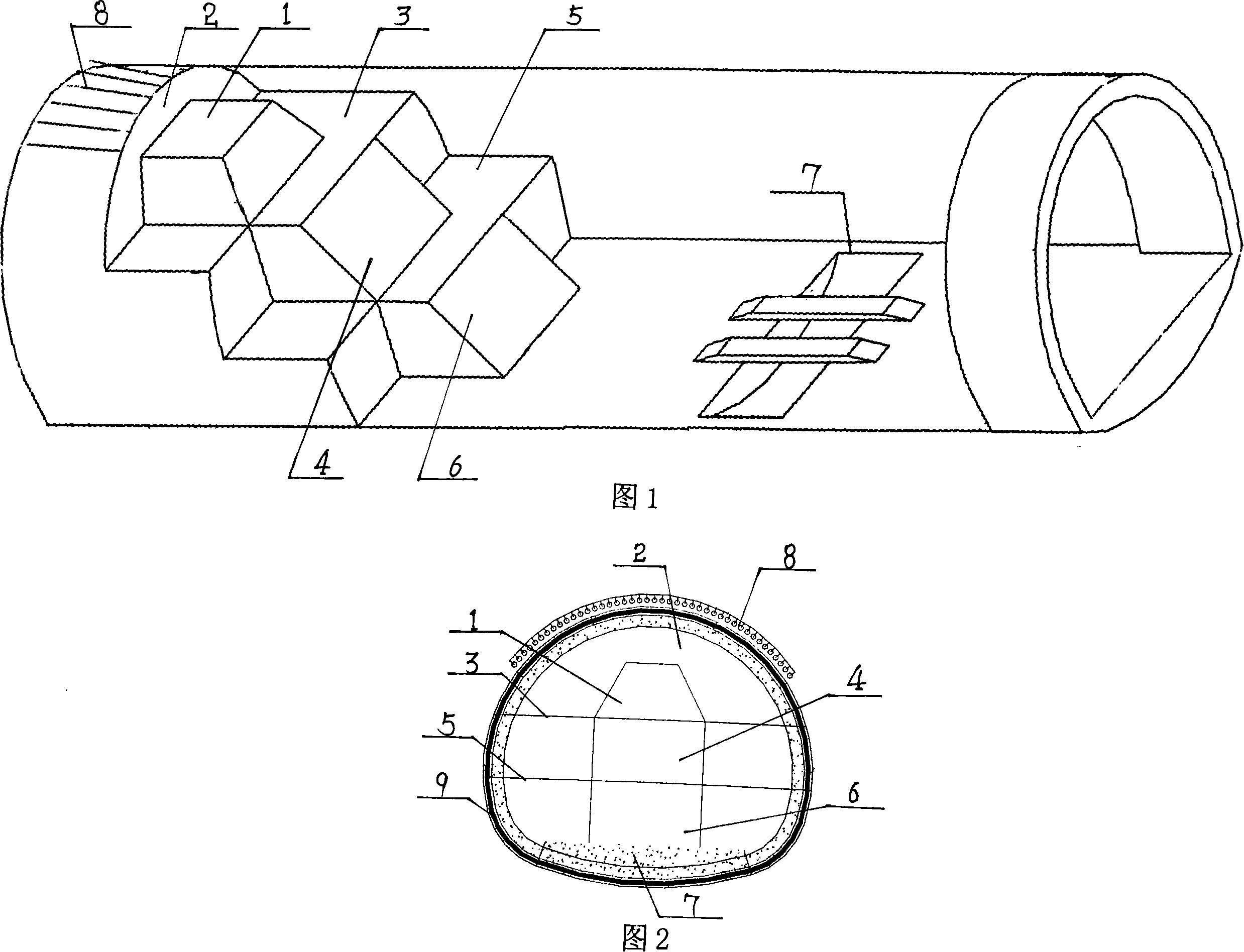

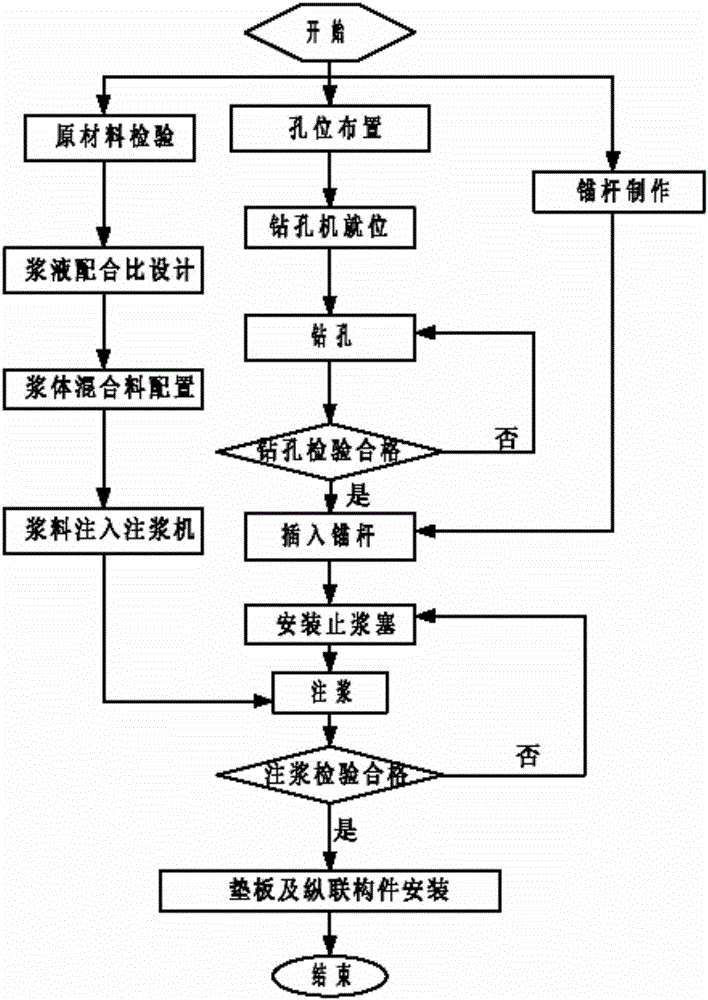

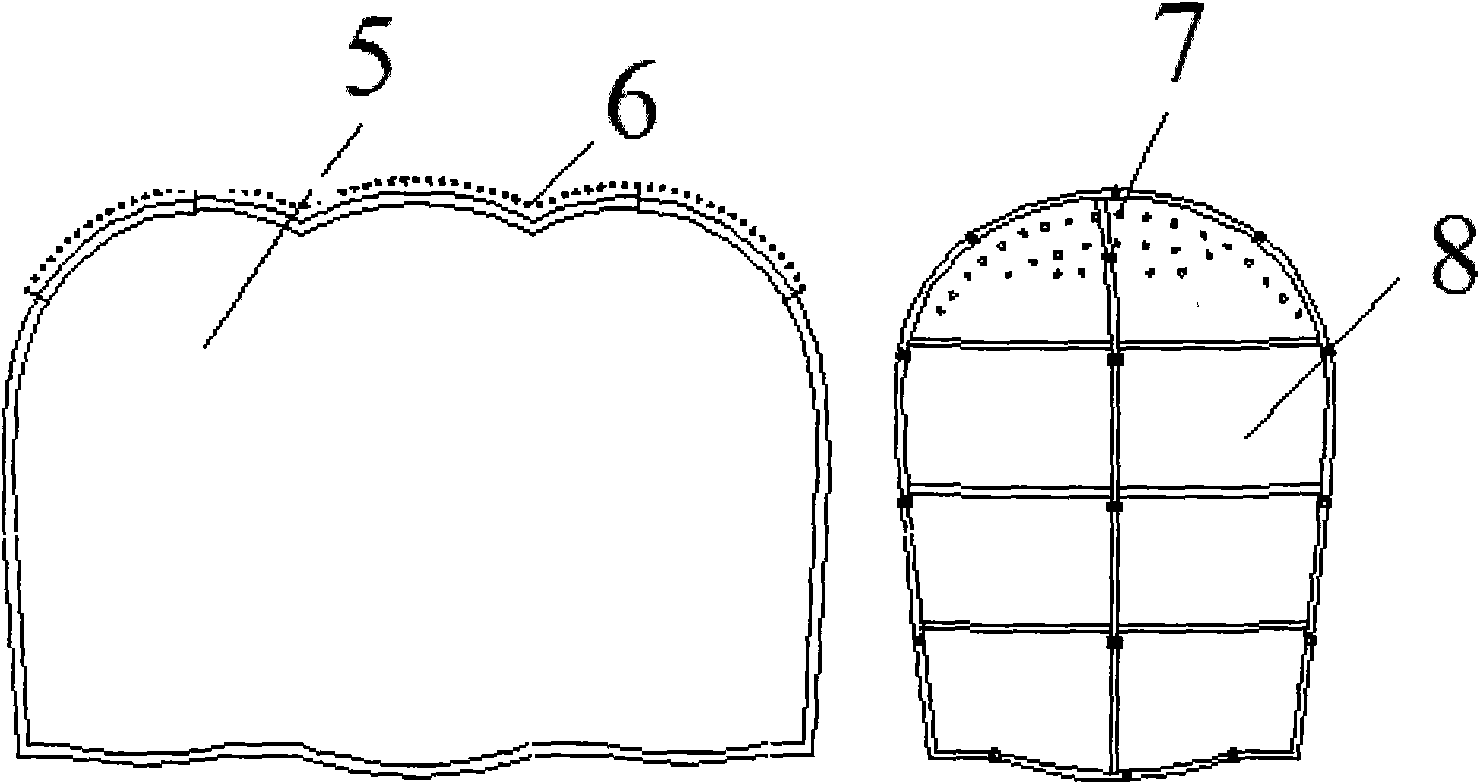

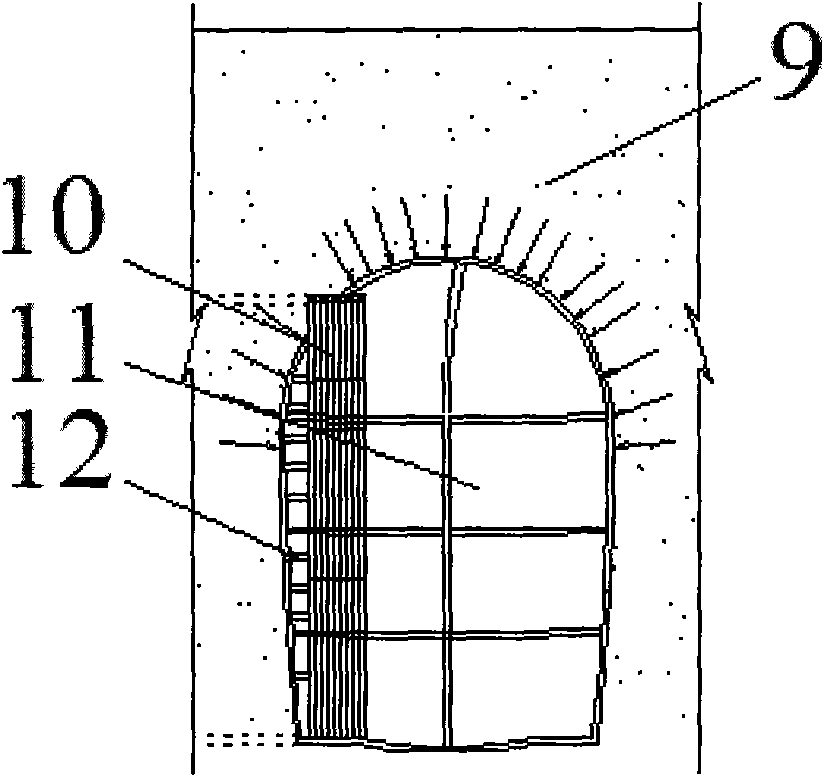

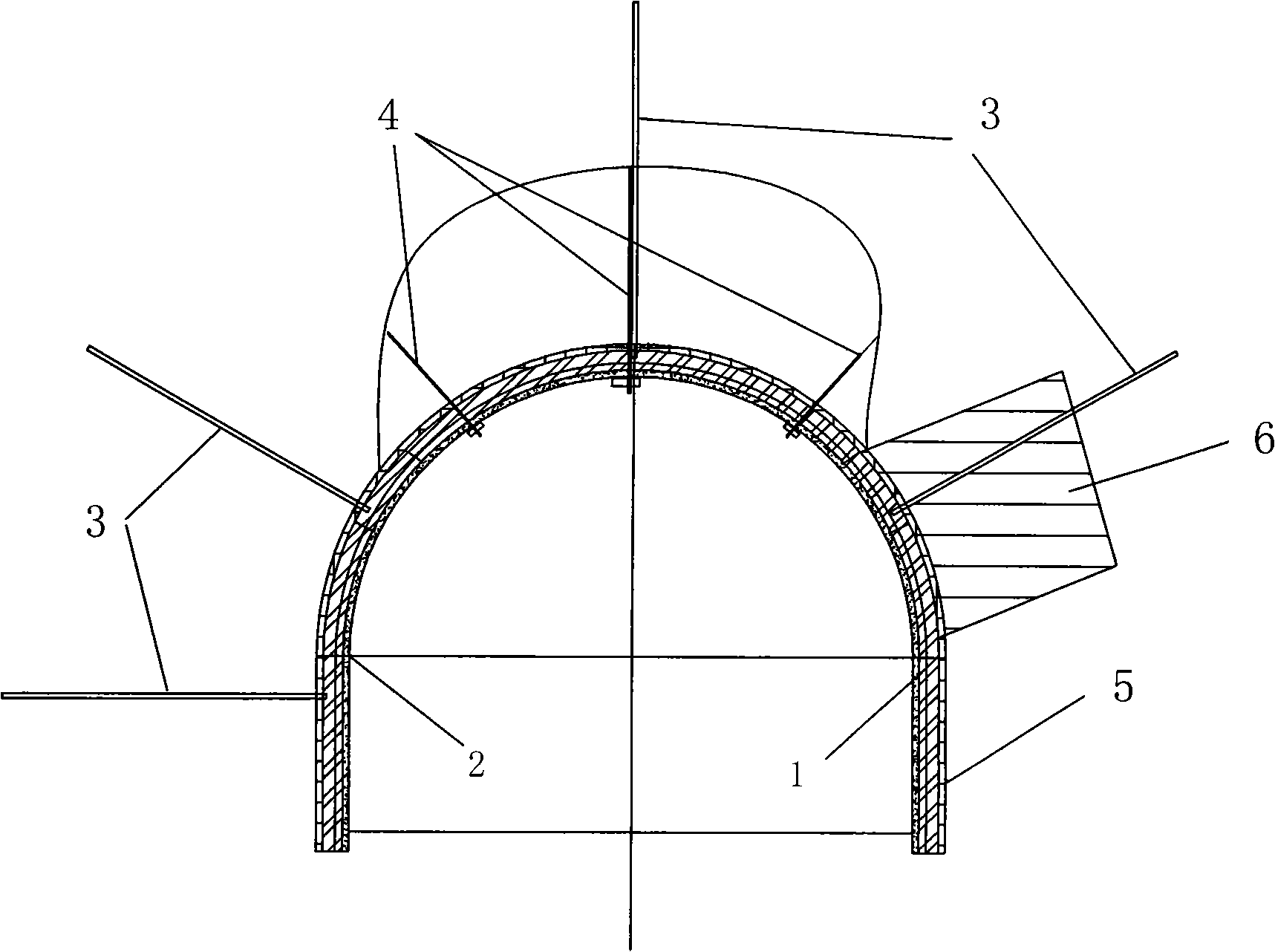

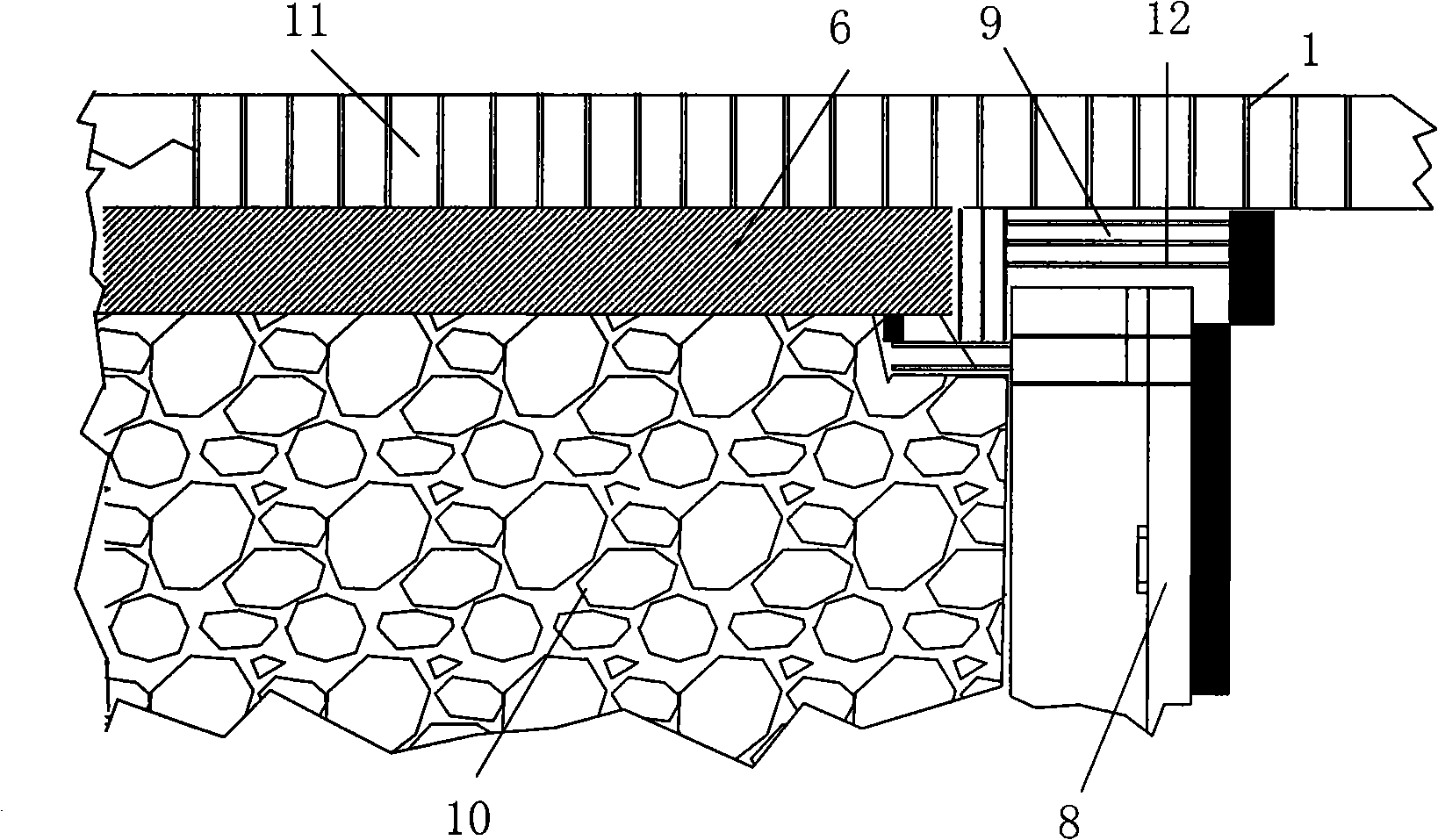

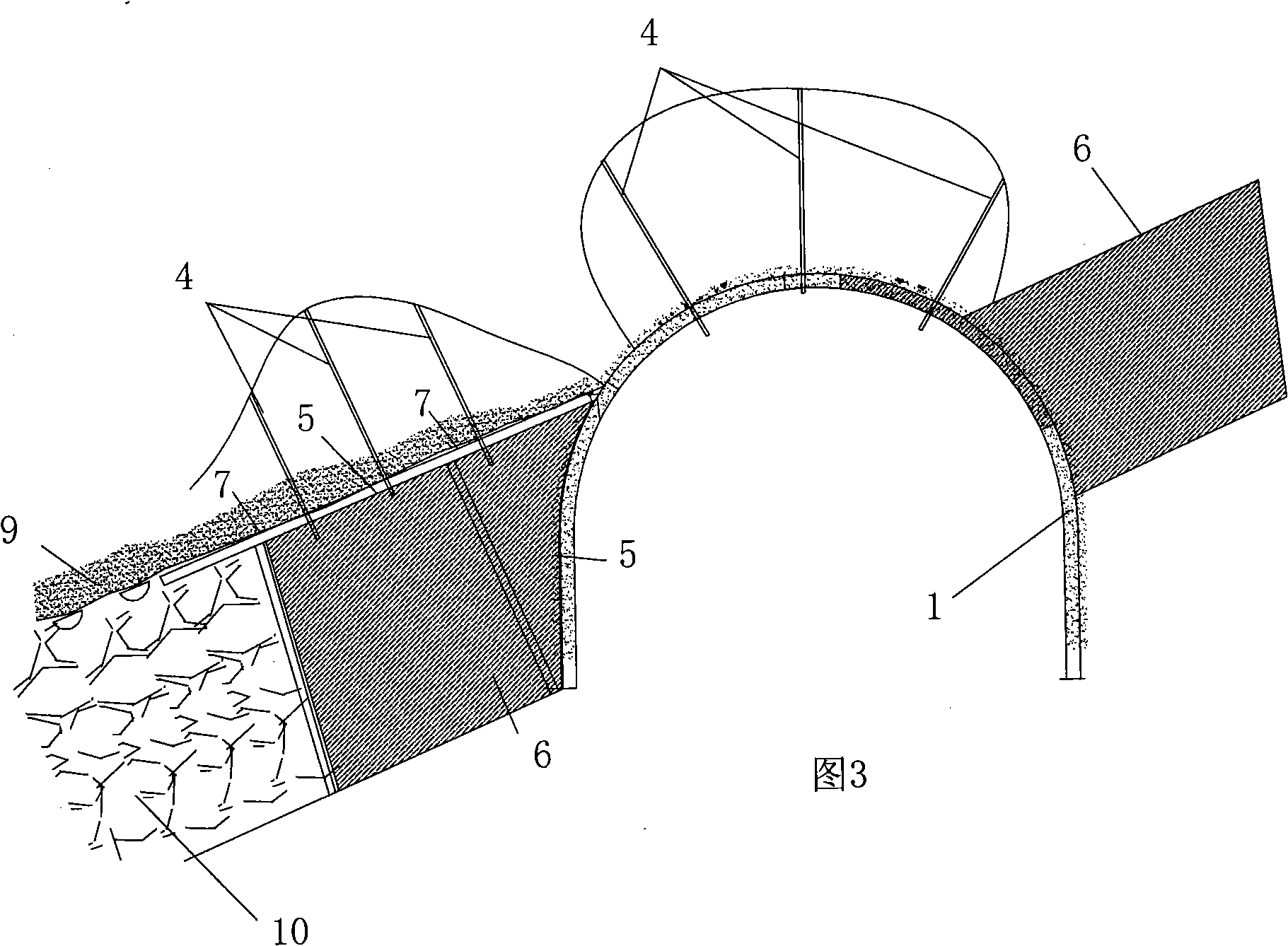

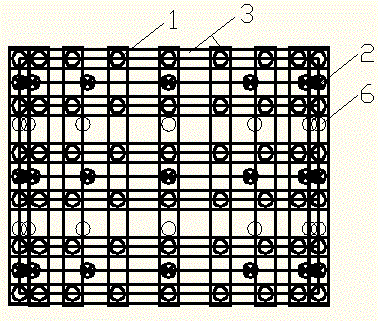

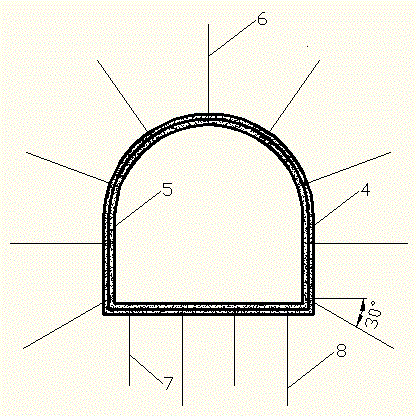

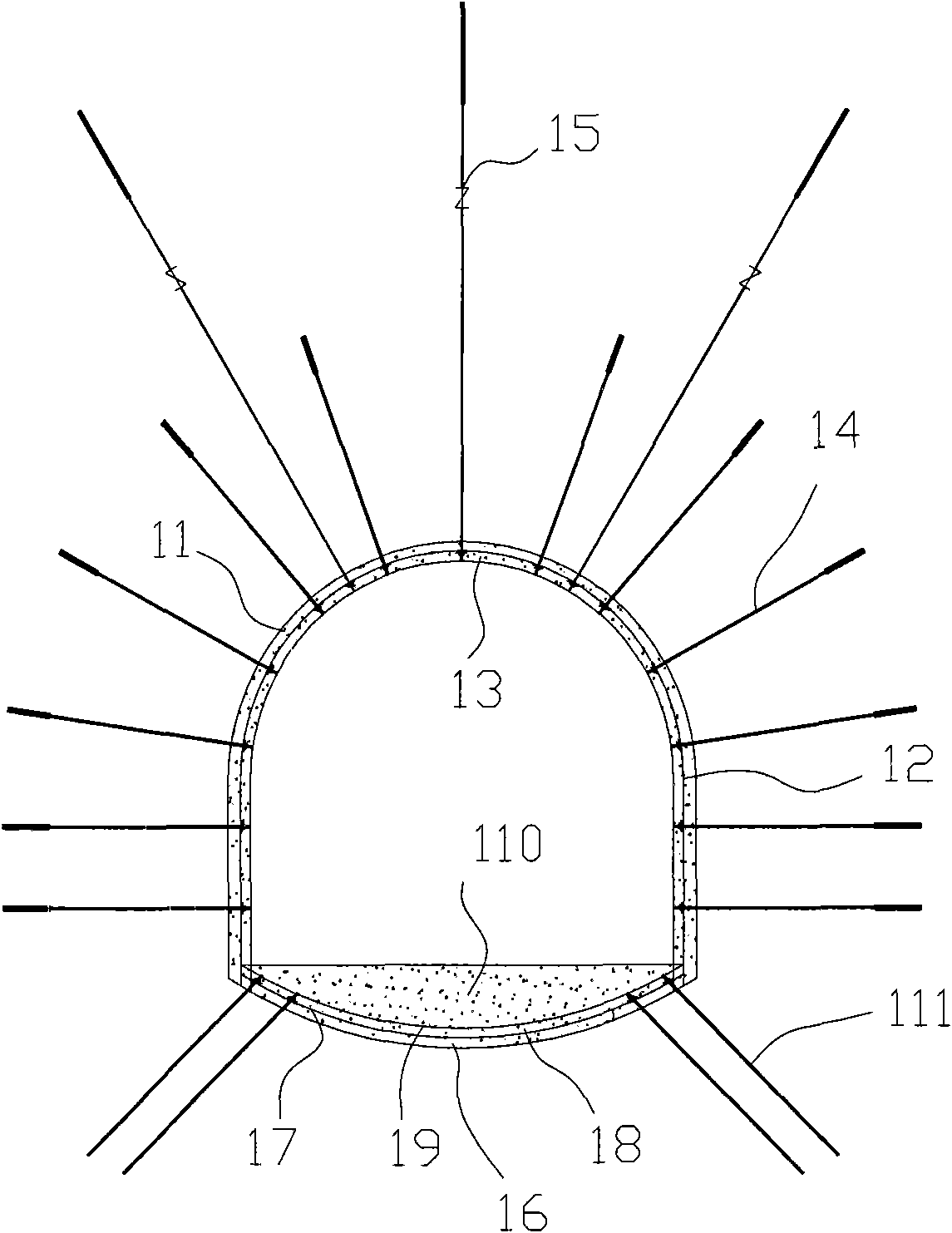

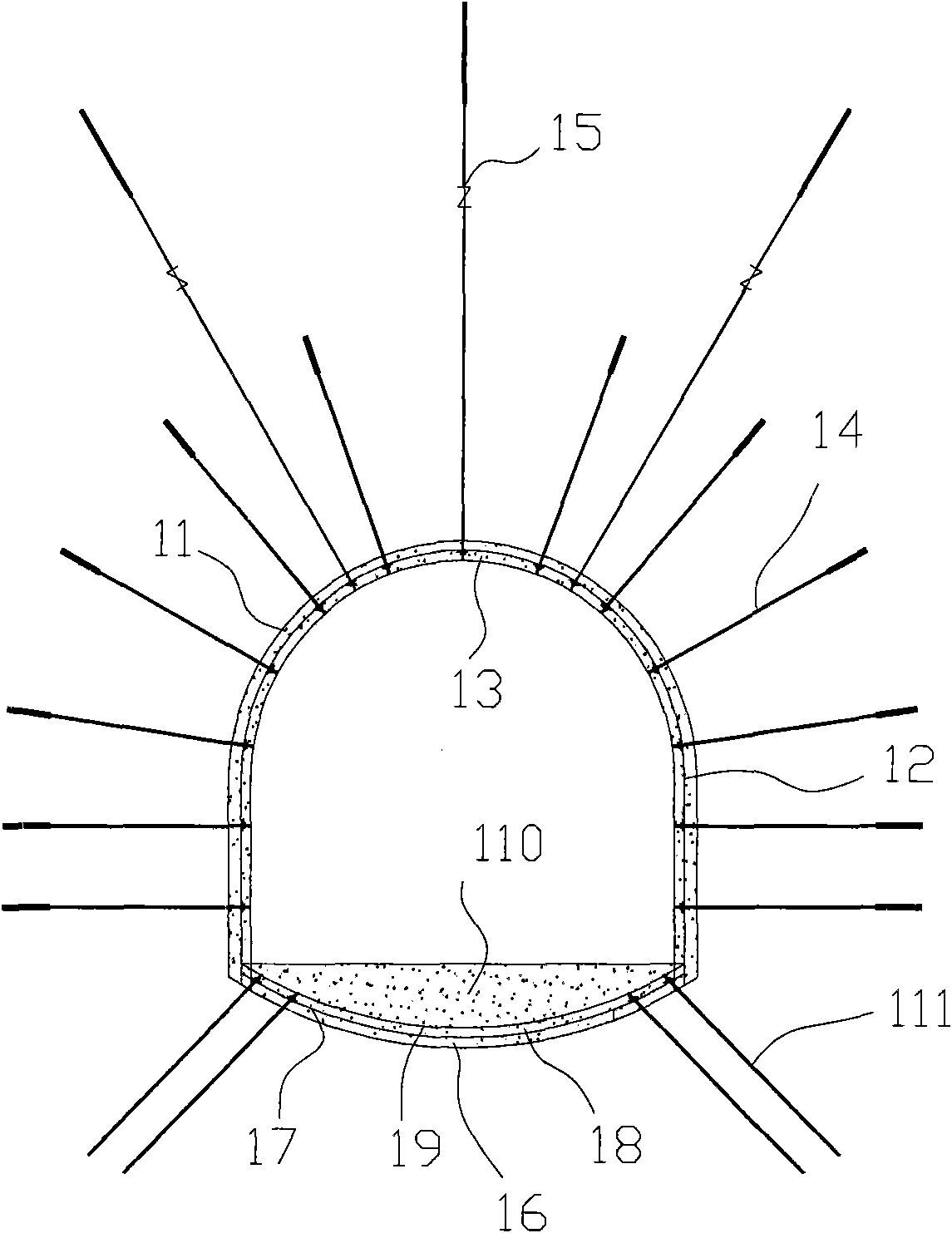

Construction method of V-level surrounding rock tunnel

InactiveCN101614125AAvoid defects such as cavity collapseRealize safe constructionUnderground chambersTunnel liningRock tunnelTunnel wall

The invention relates to a construction method of a V-level surrounding rock tunnel, comprising the following steps: (1) making a drill guiding I-beam steel lagging jack, i.e. mounting an I-beam steel lagging jack, a groove steel trimming beam, a lock pin anchor rod, a guiding steel pipe, a longitudinal connection steel rib and face injecting concrete in sequence; and (2) construction and support in the tunnel, i.e. drilling pipe shelter steel pipe holes, mounting pipe shelter steel pipes, filling slurry inwards. The earthwork construction of a pilot tunnel comprises earthwork construction, primary support, injecting concrete on a pilot tunnel wall, suspending steel bar nets, casting concrete basis, mounting I-beam steel lagging jack, groove steel trimming beam, steel pads, I-shaped steel inclined strut and lock pin anchor rods, welding longitudinal connection steel bar, injecting concrete on the face and removing core soils; mounting a first-level step temporary inverted arch comprises: constructing lower-level earthwork, performing primary support in the pivot tunnel, mounting the second-level step temporary inverted arch, constructing the following level of earthwork, performing primary support, casting and filling inverted arch, and casting lining concrete at a time inside the pivot tunnel. The invention has the advantage of rapid penetration speed and safe construction.

Owner:CHINA RAILWAY NO 9 GRP

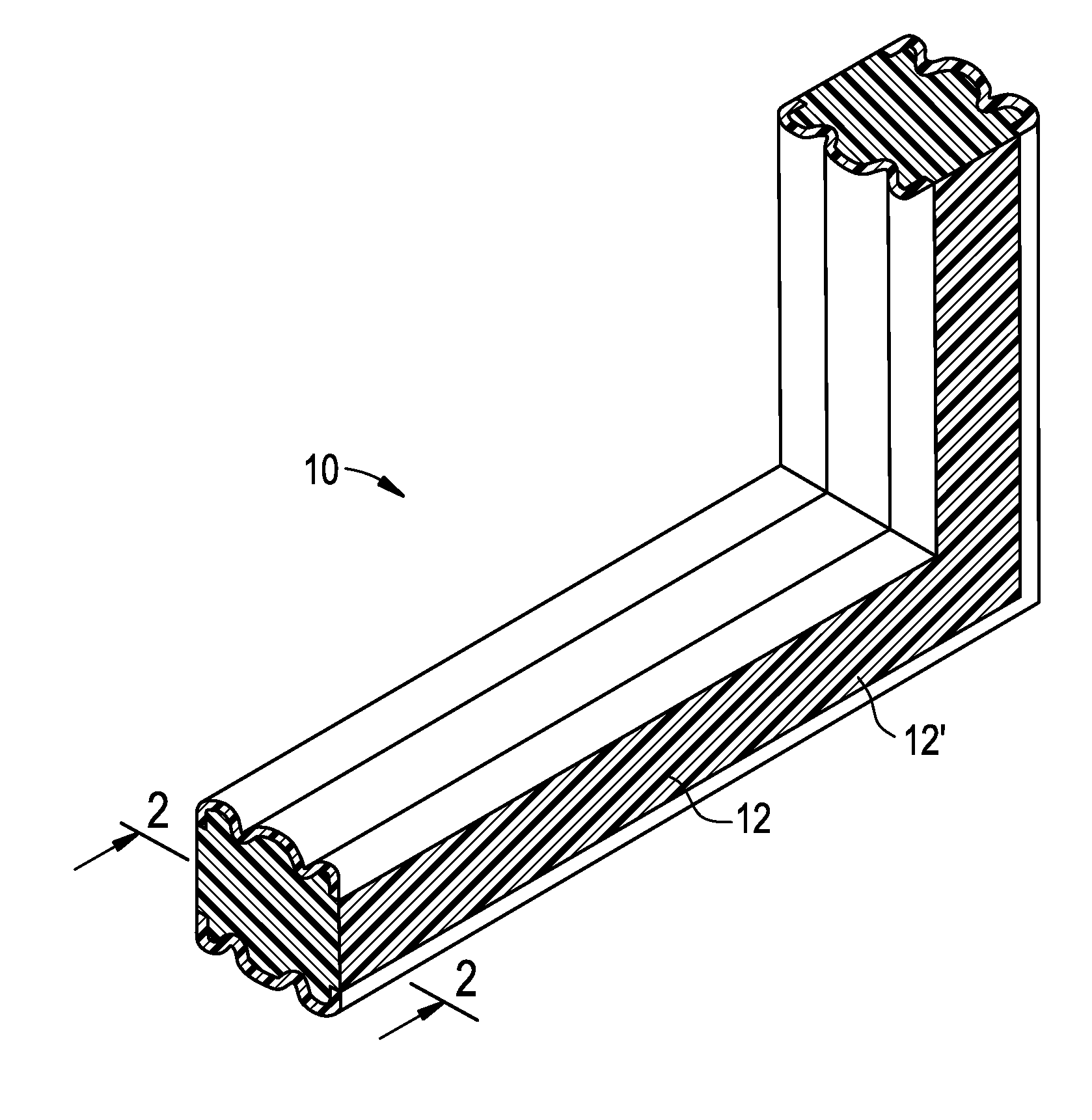

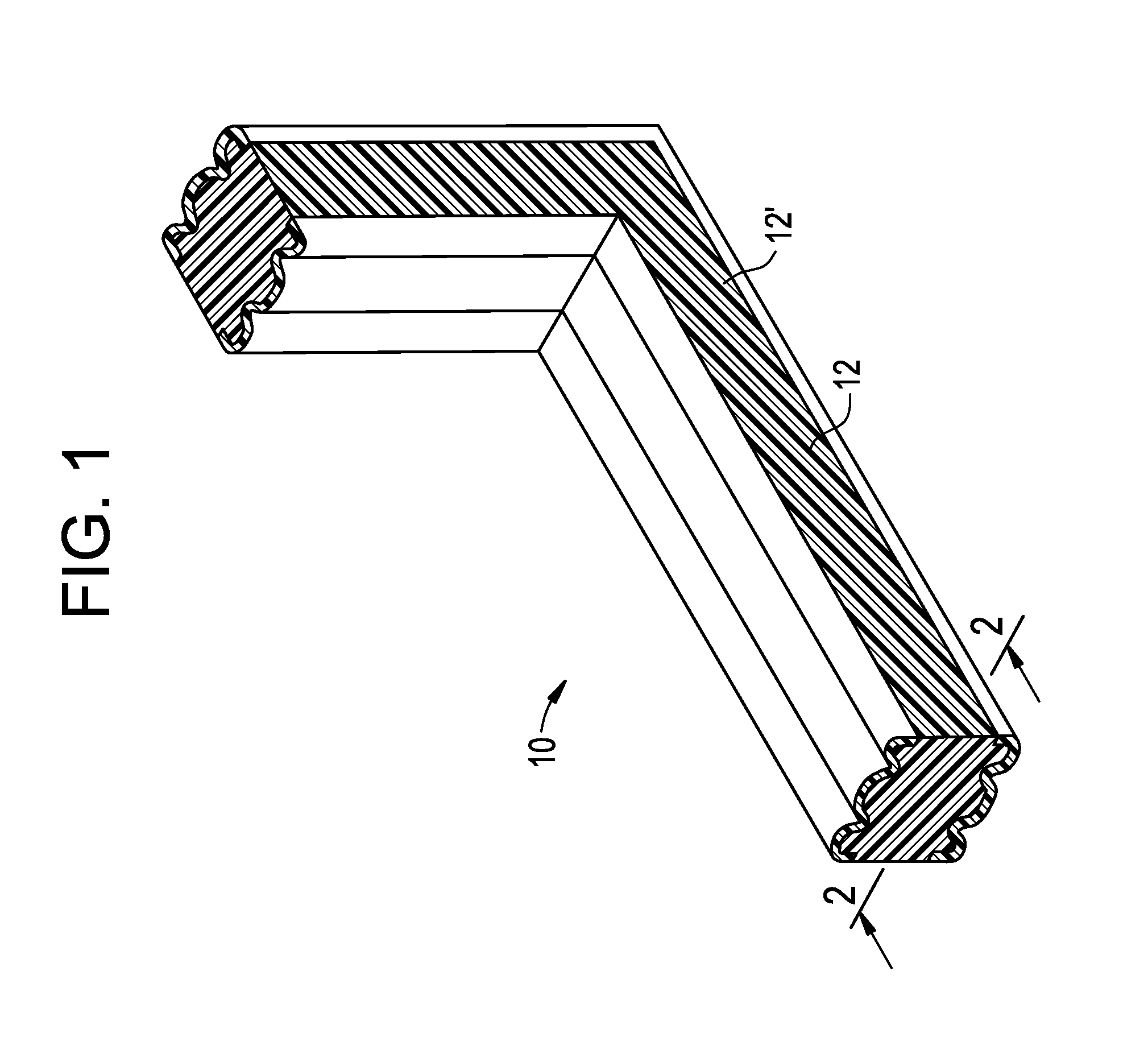

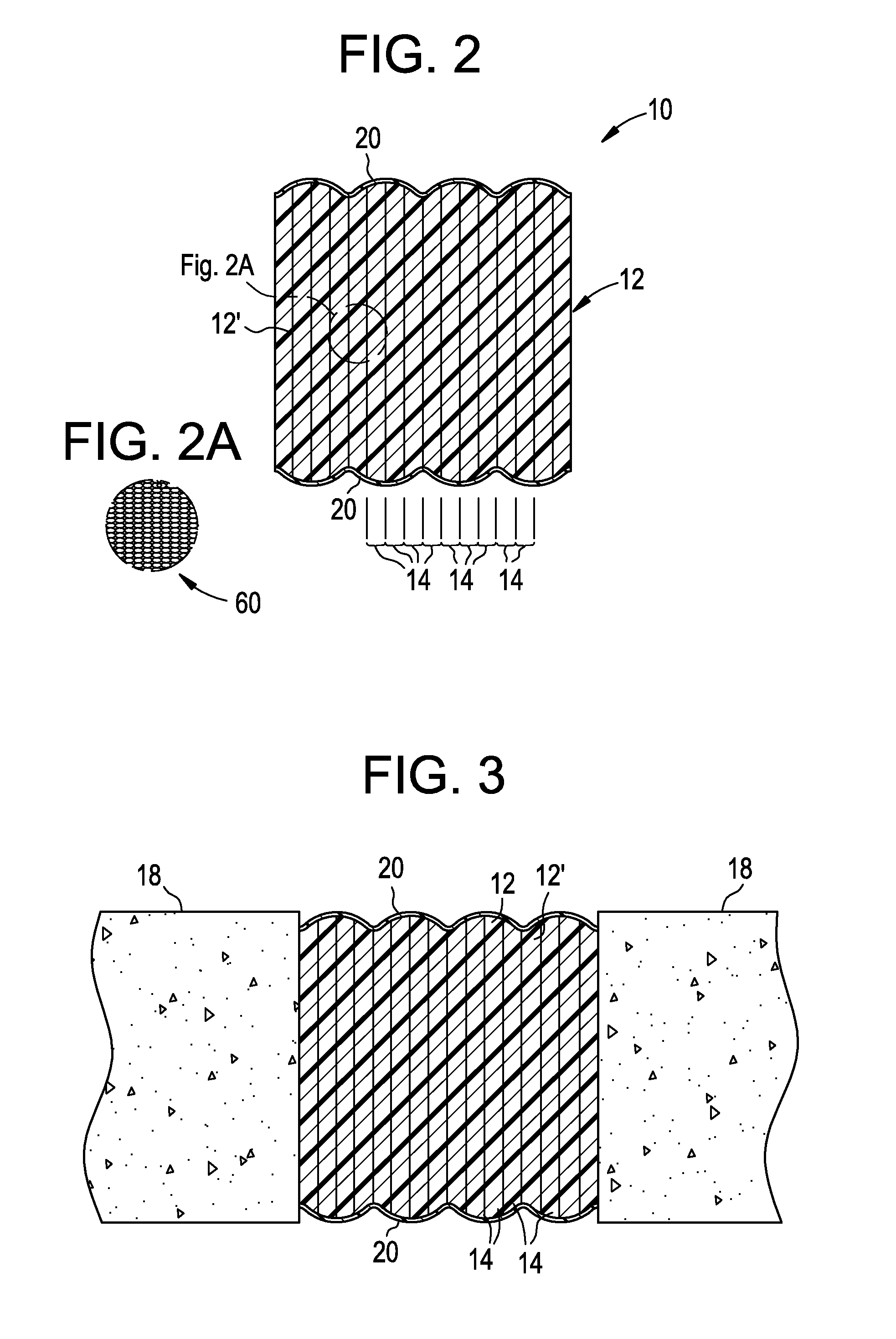

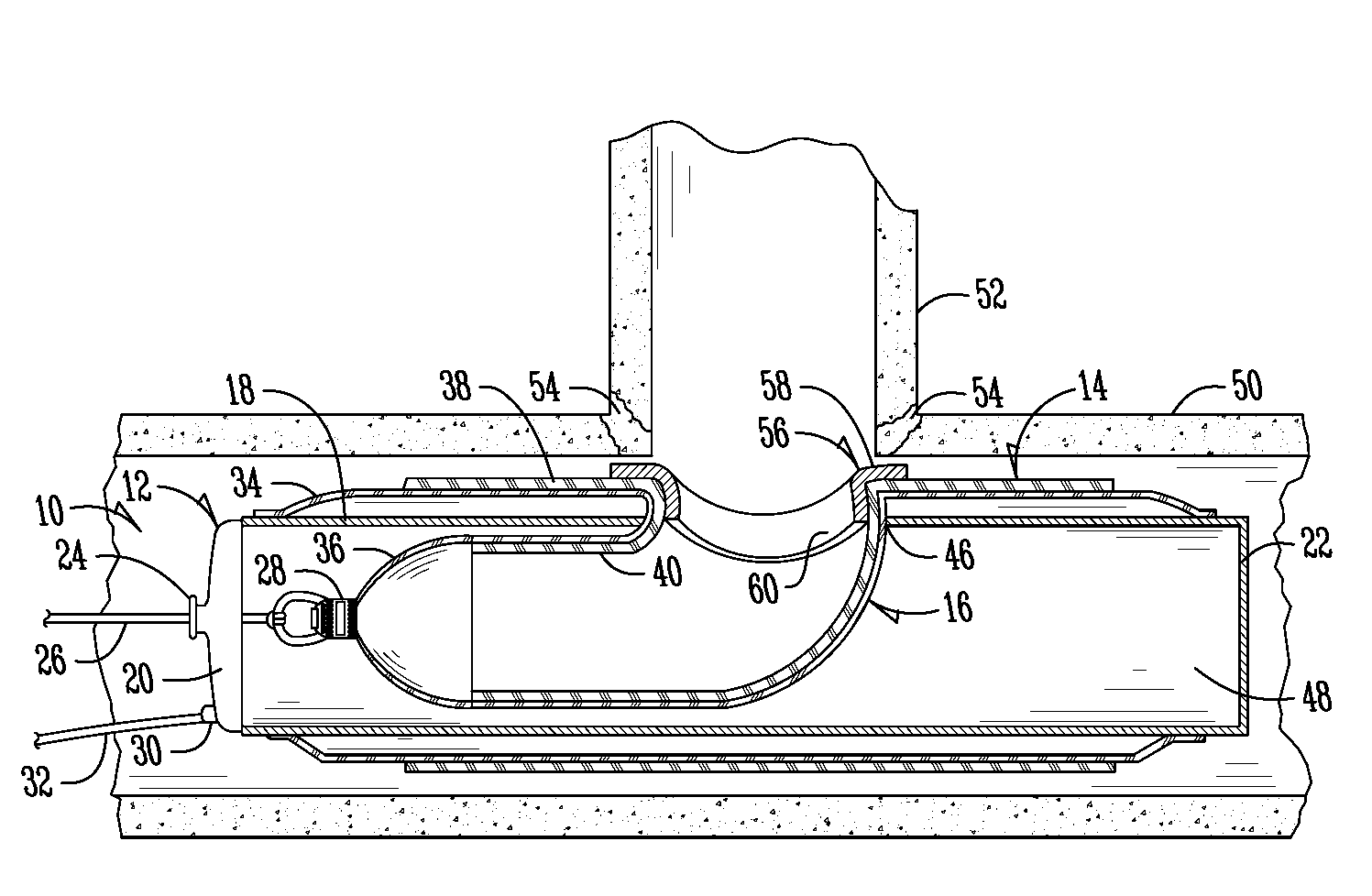

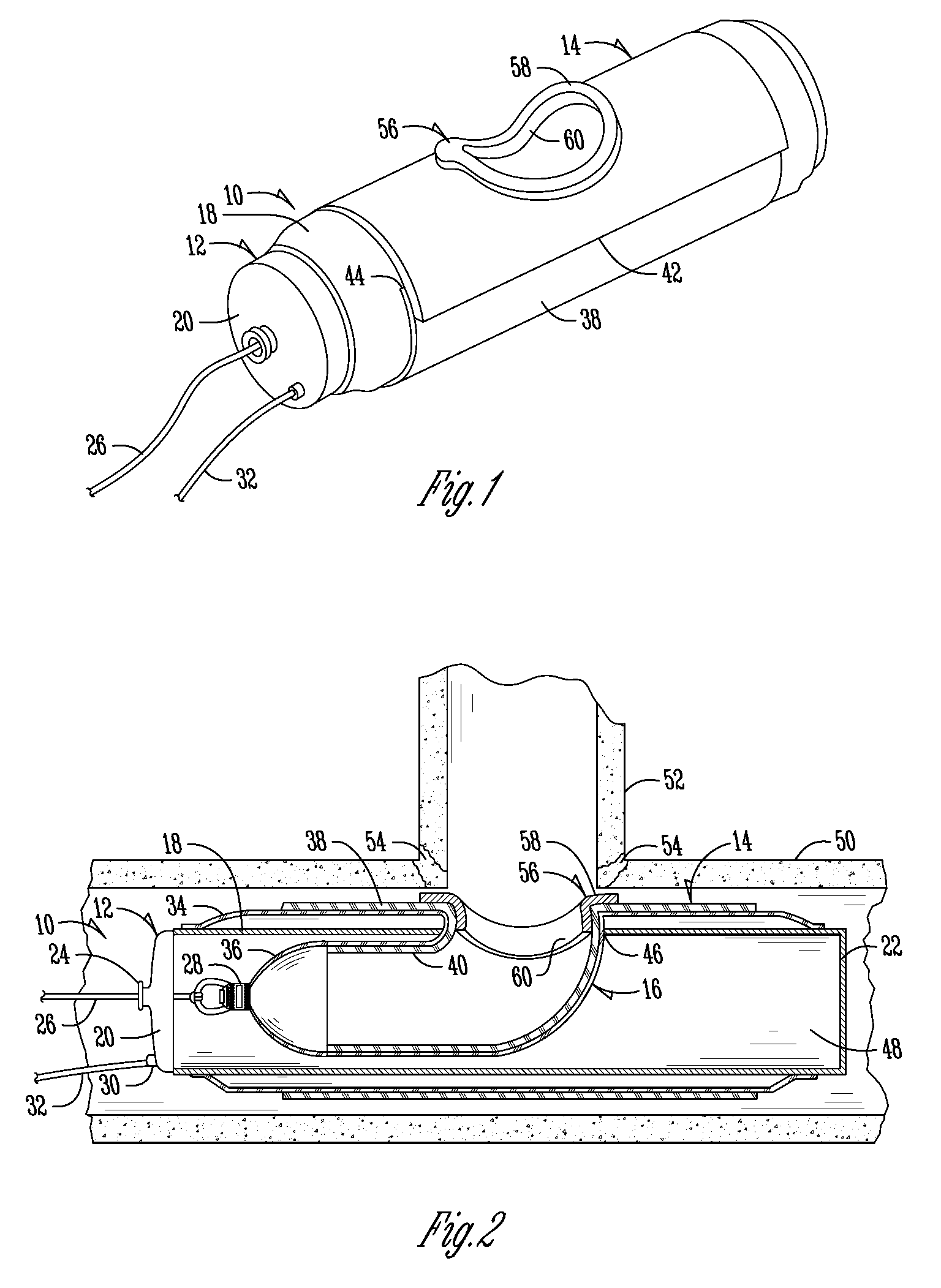

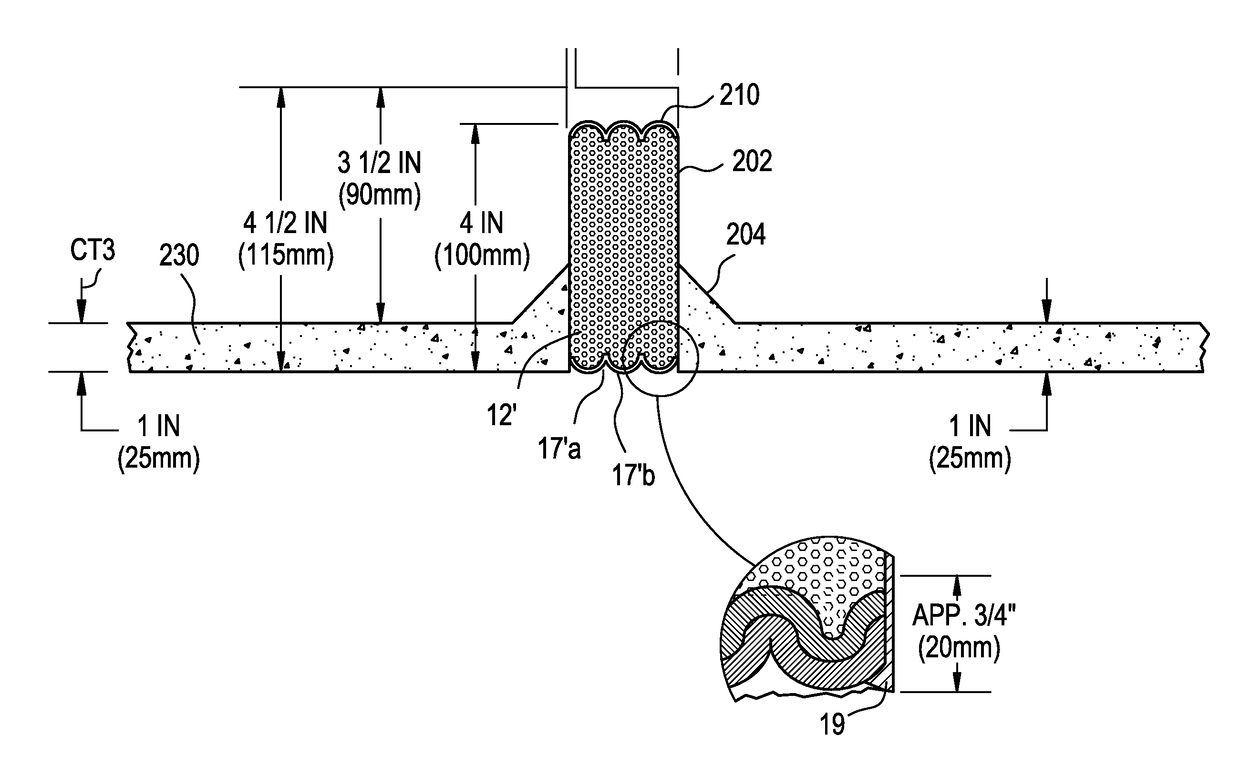

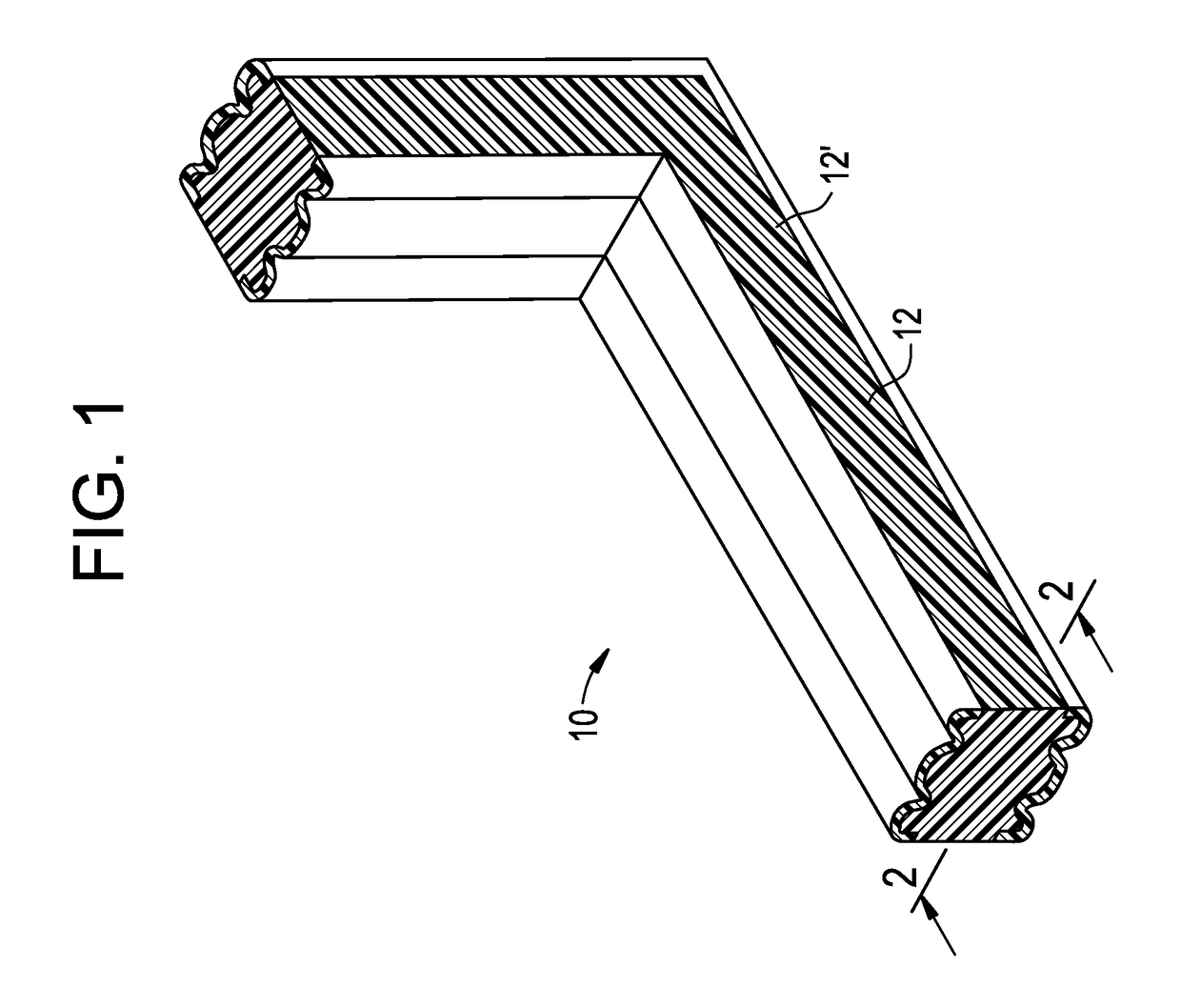

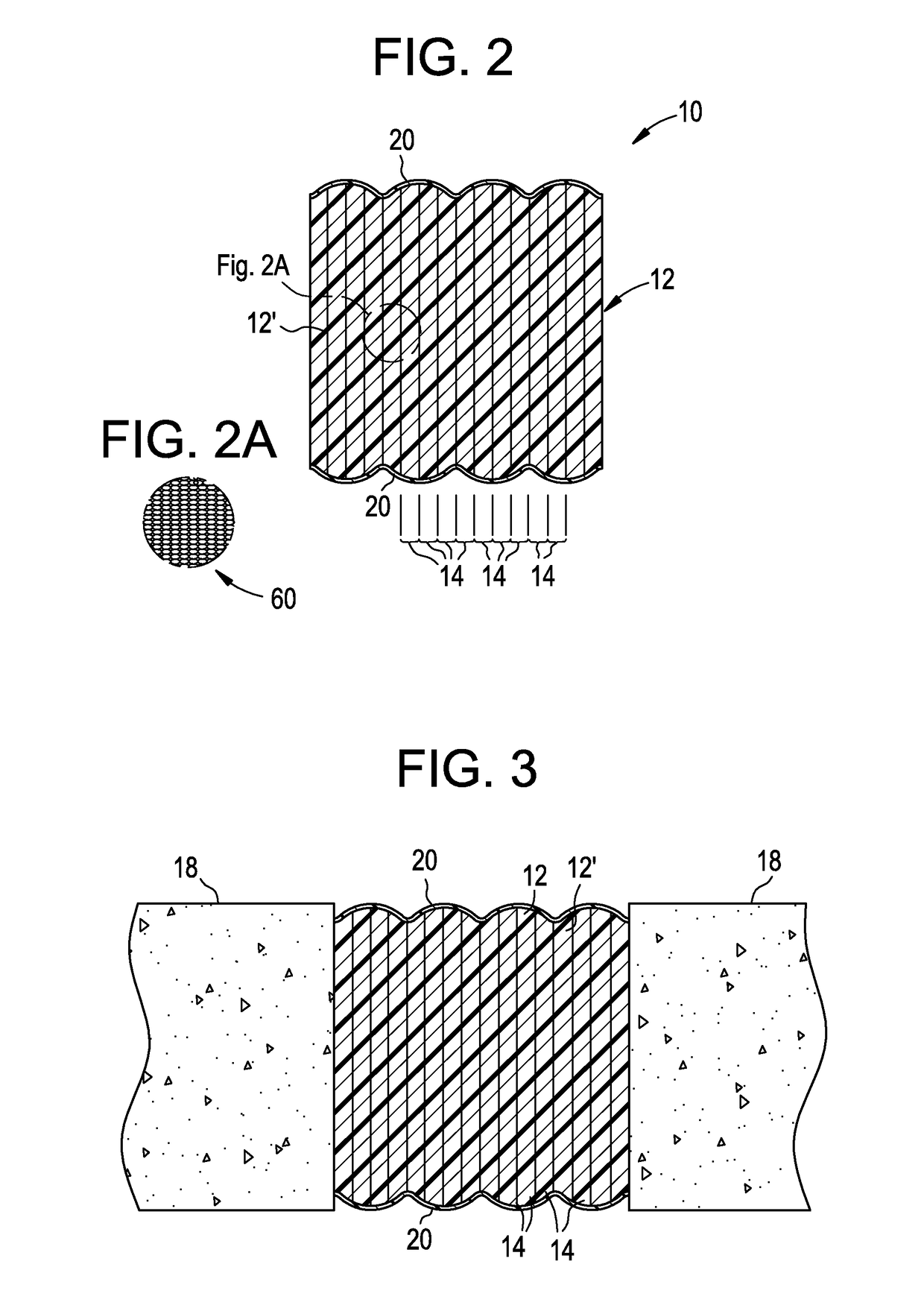

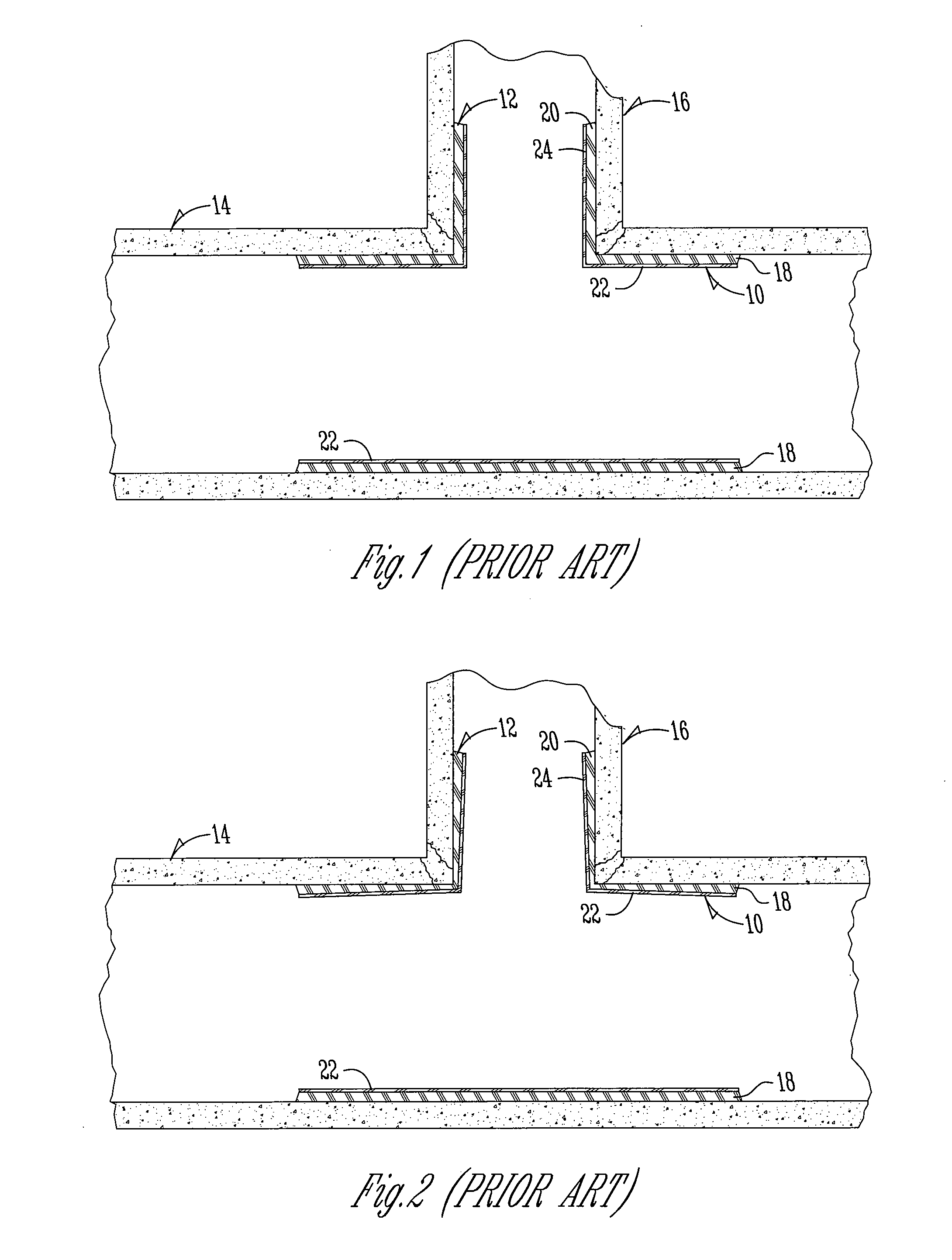

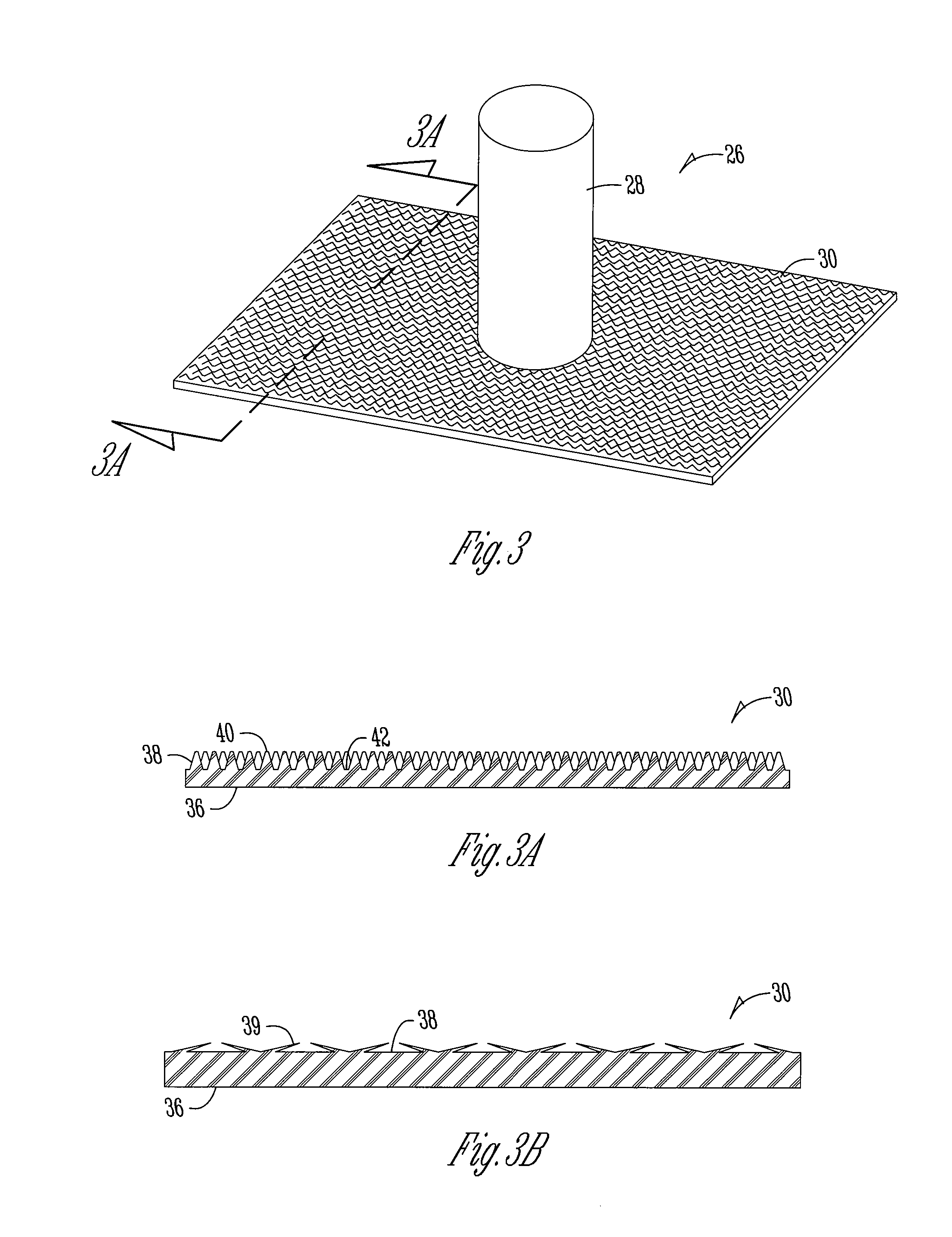

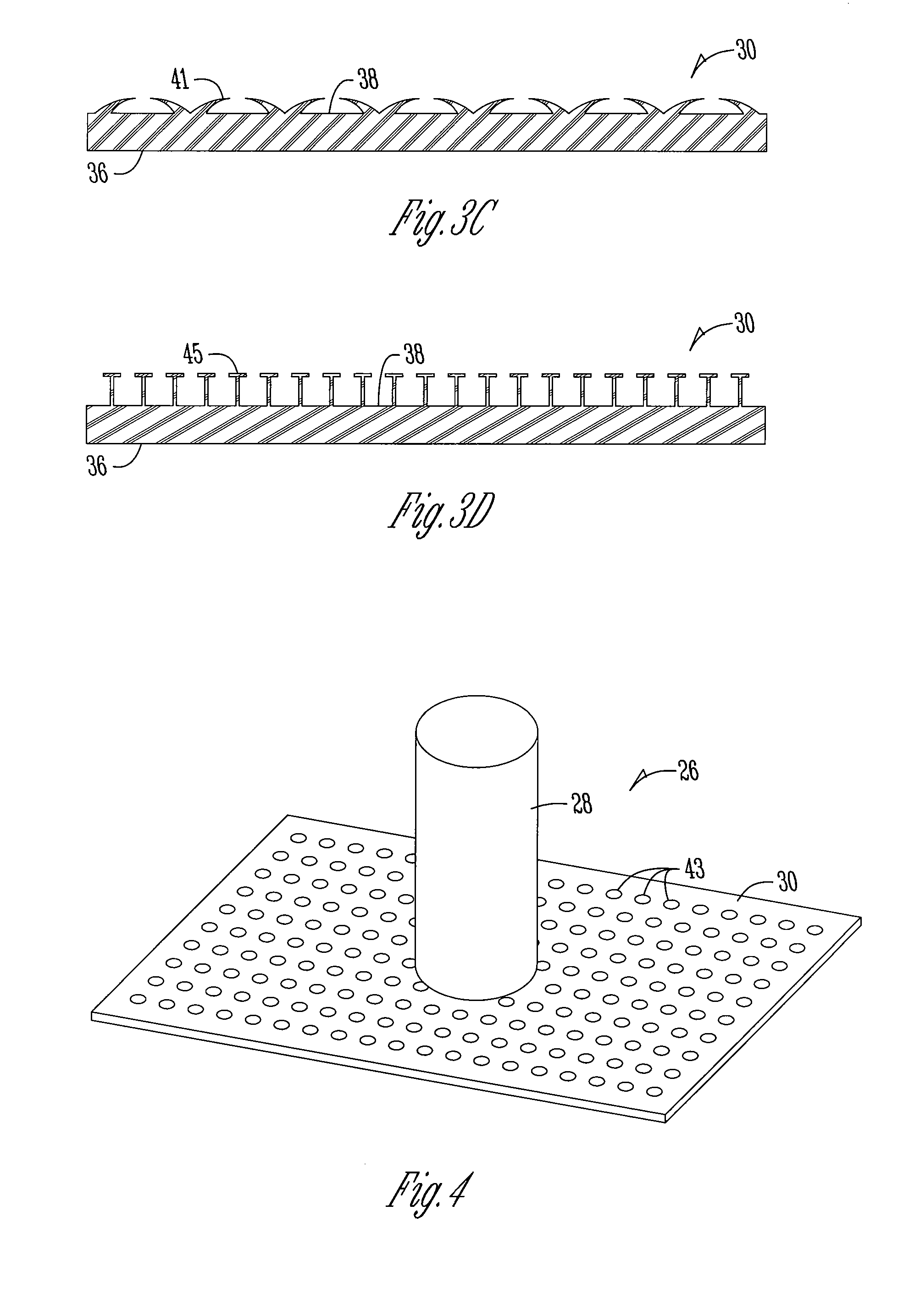

Factory fabricated precompressed water and/or fire resistant tunnel expansion joint systems, and transitions

InactiveUS20140360118A1On-site operationMinimize opportunityFurnace componentsUnderwater structuresWater resistantExpansion joint

A fire and / or water resistant expansion joint system for installation between substrates of a tunnel. The system includes a coating applied at a predetermined thickness to the substrates and a fire and water resistant expansion joint. The expansion joint includes a core and a fire retardant infused into the core. The core is configured to define a profile to facilitate the compression of the expansion joint system when installed between the substrates. The coating and the fire and water resistant expansion joint are each capable of withstanding exposure to a temperature of at least about 540° C. or greater for about five minutes.

Owner:EMSEAL JOINT SYST

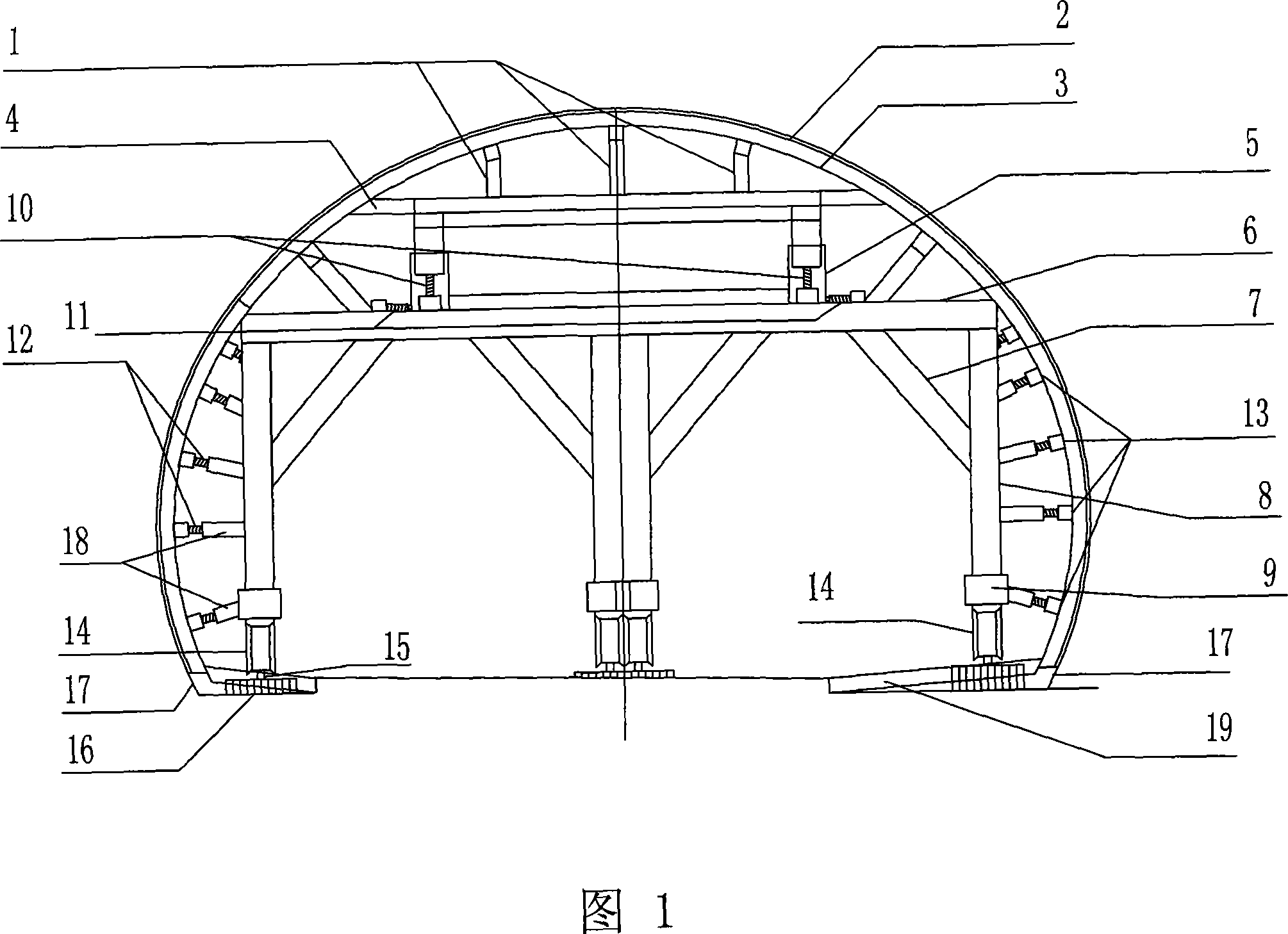

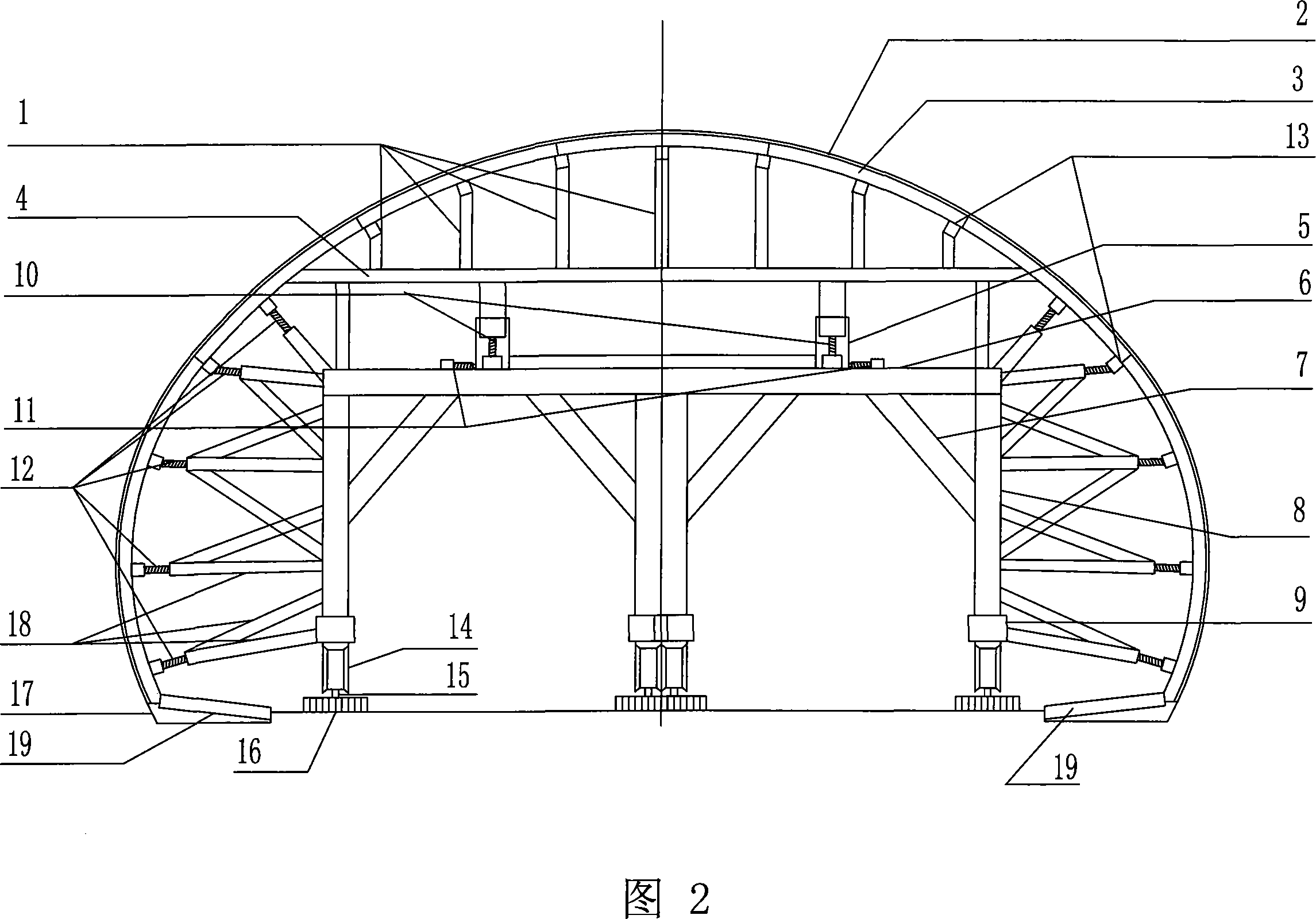

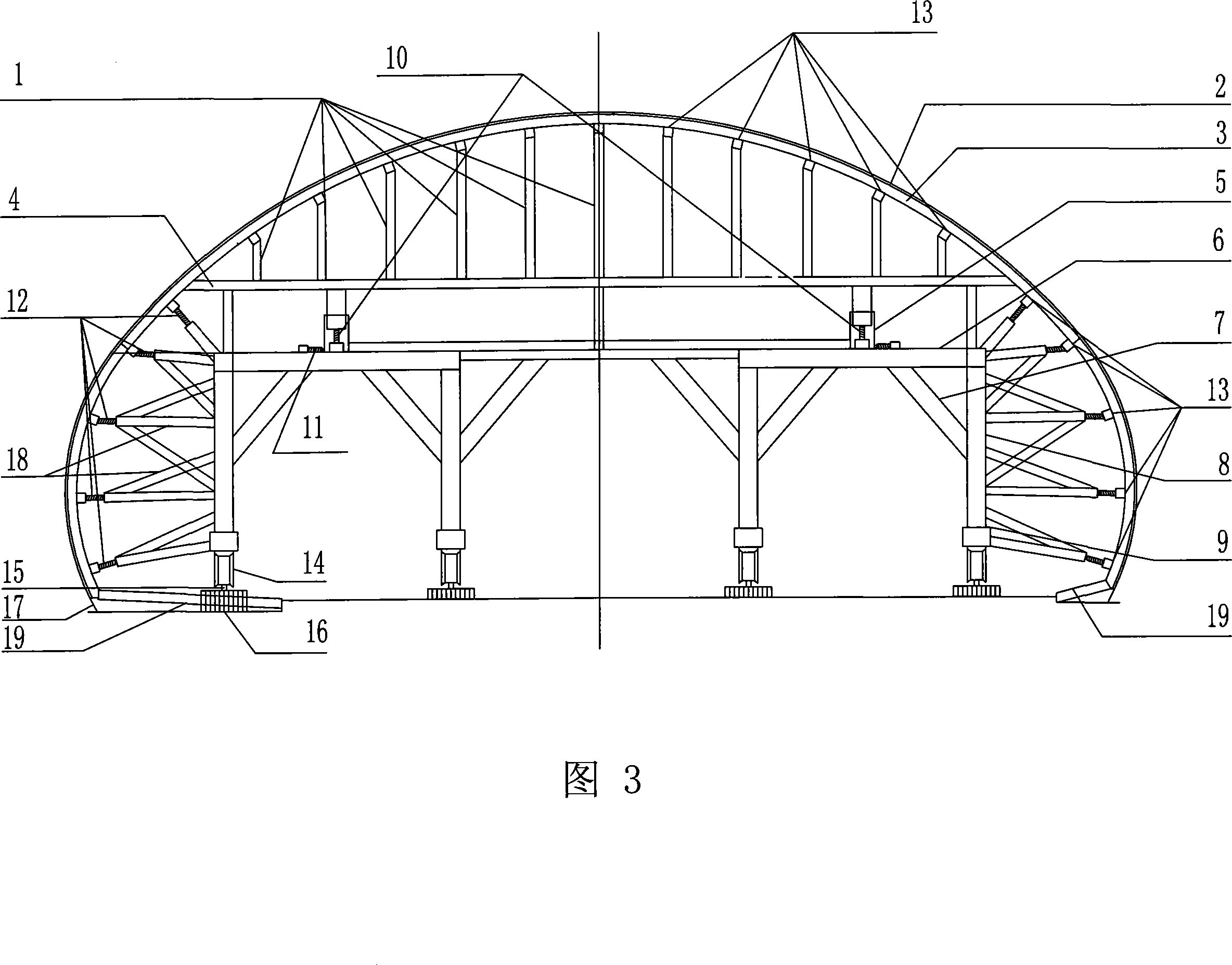

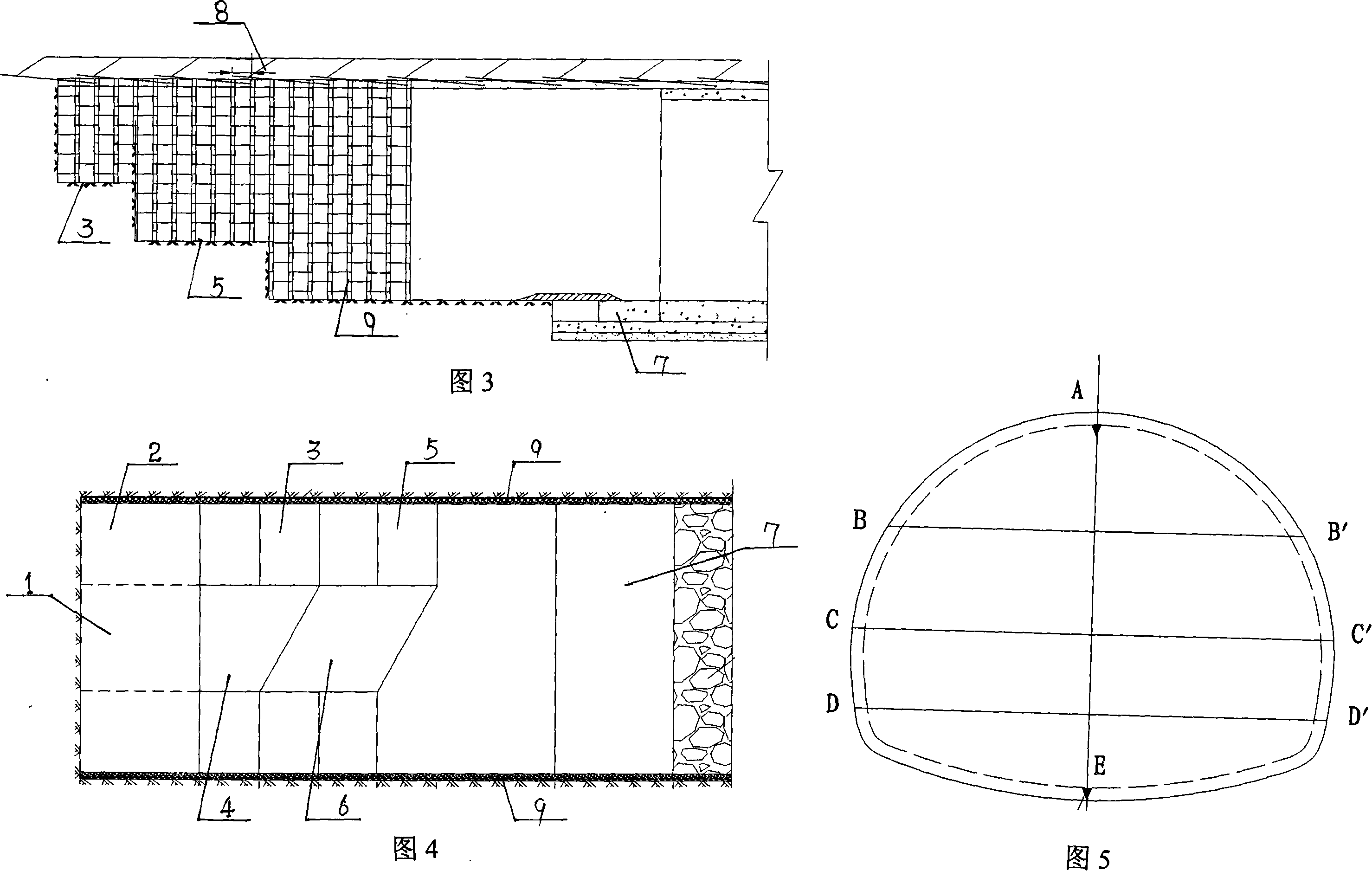

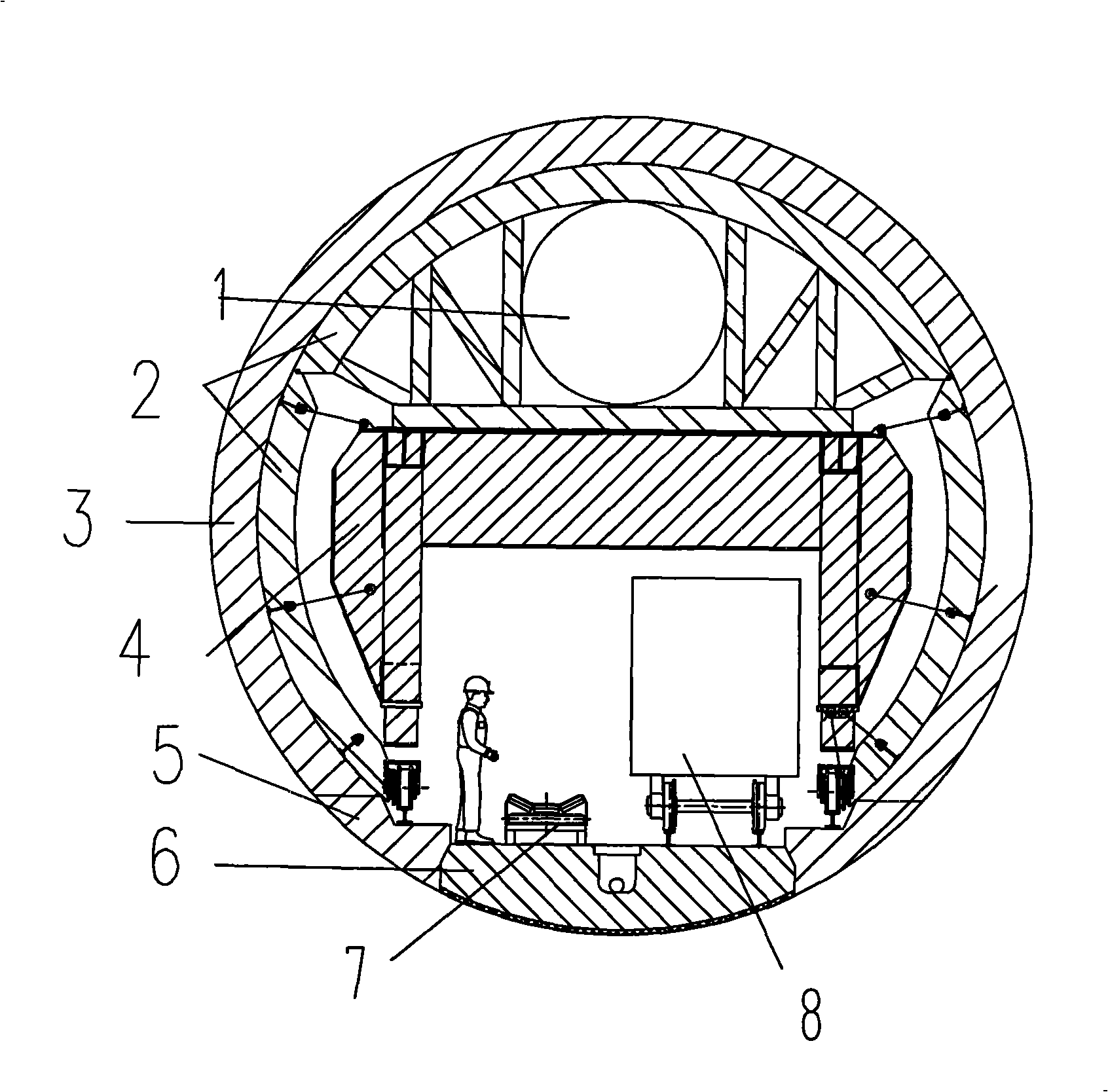

Construction method for large section and multiple sections tunnel lining

ActiveCN101230785AImprove construction progressQuick disassemblyUnderground chambersTunnel liningAssembly lineConstruction management

The invention discloses a large cross-section and multiple cross-section tunnel lining construction method. Combined type lining trolleys are chosen to carry through the trolley assembly lining to the cross-section, and adding a gantry mounting on the basis of a normal trolley single gantry mounting can form an assembled and detachable lining trolley. Steel molding plates, road wheels, main gantry mountings, etc. are listed in unchanged components in the process of the assembly trolleys with different cross-sections, and lateral adjusting driving screws, upper platform chord members, upper platform upright posts, lining steel arches, etc. are listed in adjustable components. In the process of the construction from one cross-section to another cross-section, the unchanged components do not change, and only the changeable components are carried through the refitting and assembly. The construction method has the characteristics of fast construction progress, low cost, easy control of site construction management, etc., can save a great deal of manpower, physical resources and financial resources and obtain good technical economic effect, and has the remarkable economic, social and environmental benefits; the invention is especially adapted to the large cross-section and multiple cross-section type lining construction of tunnels and underground constructions.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

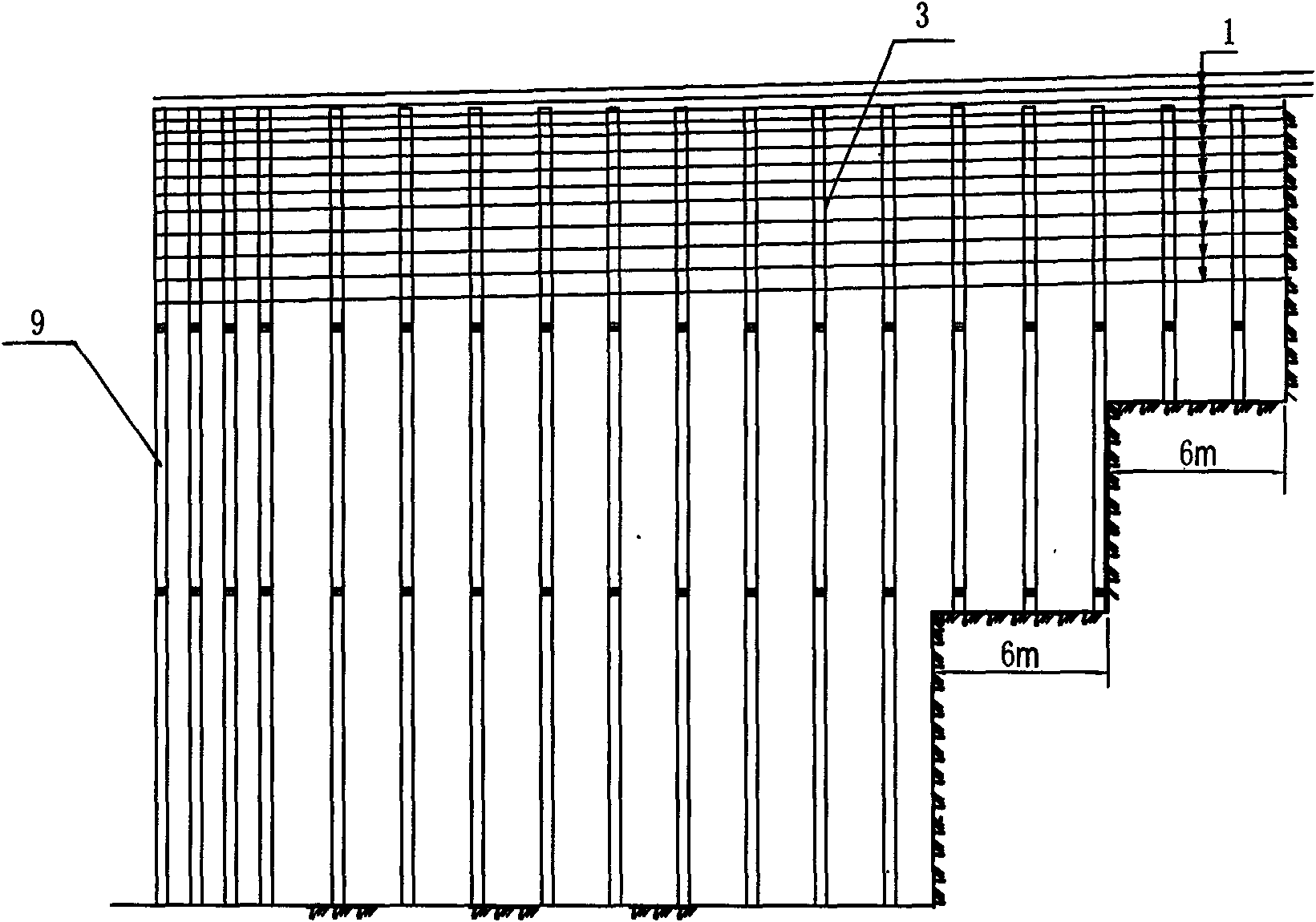

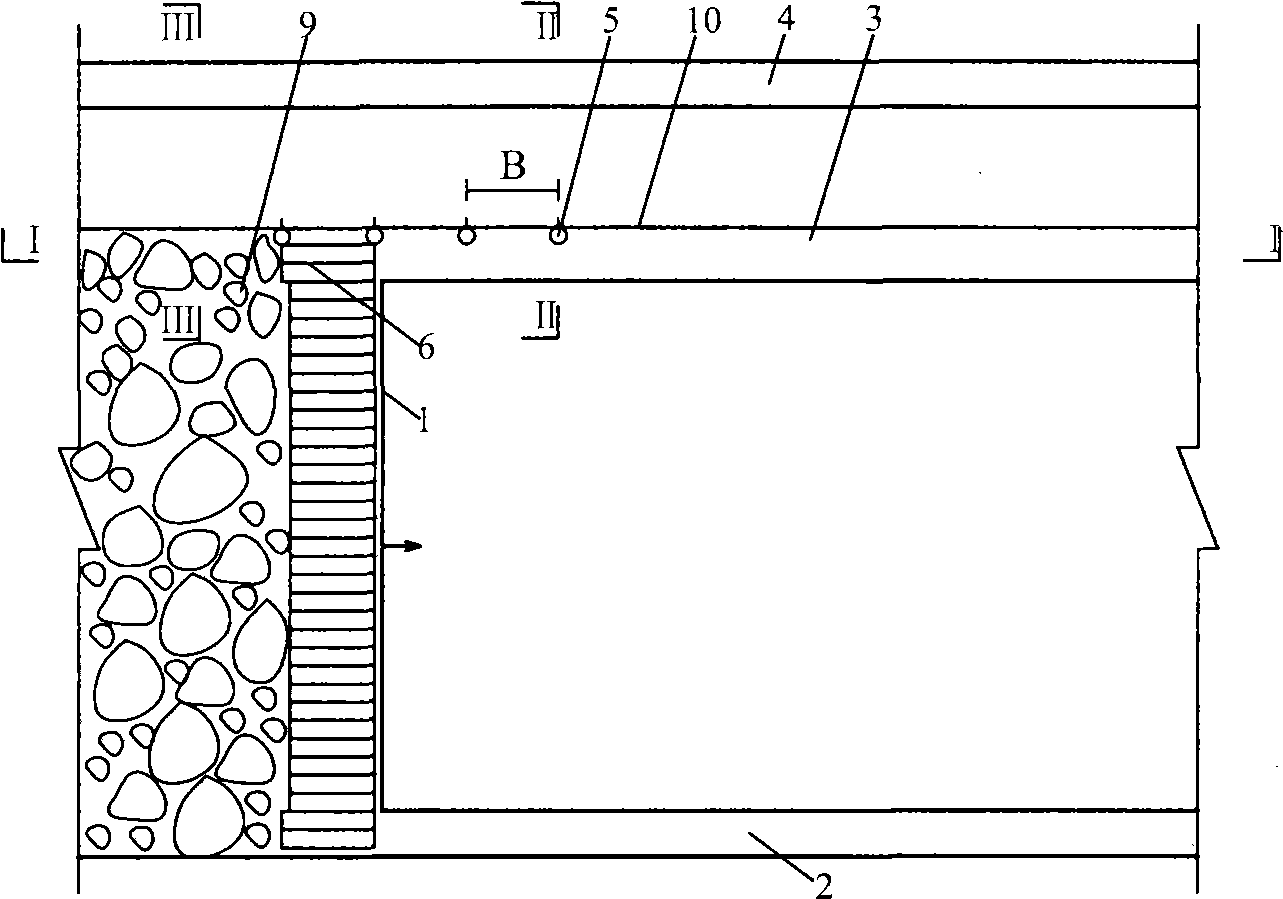

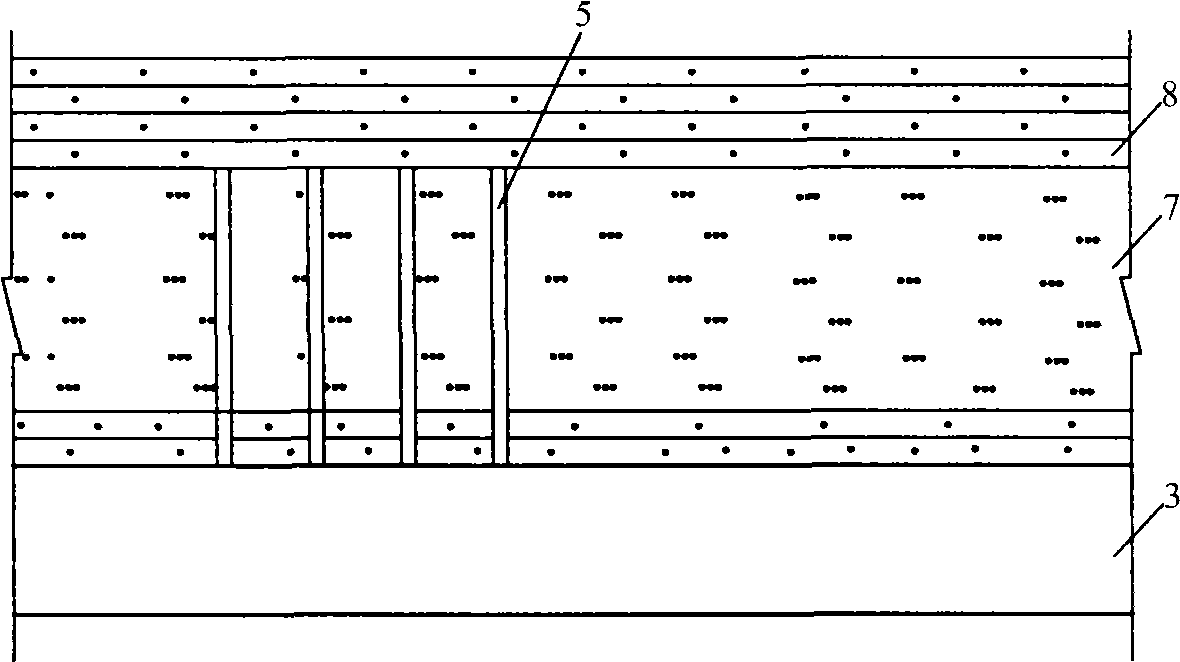

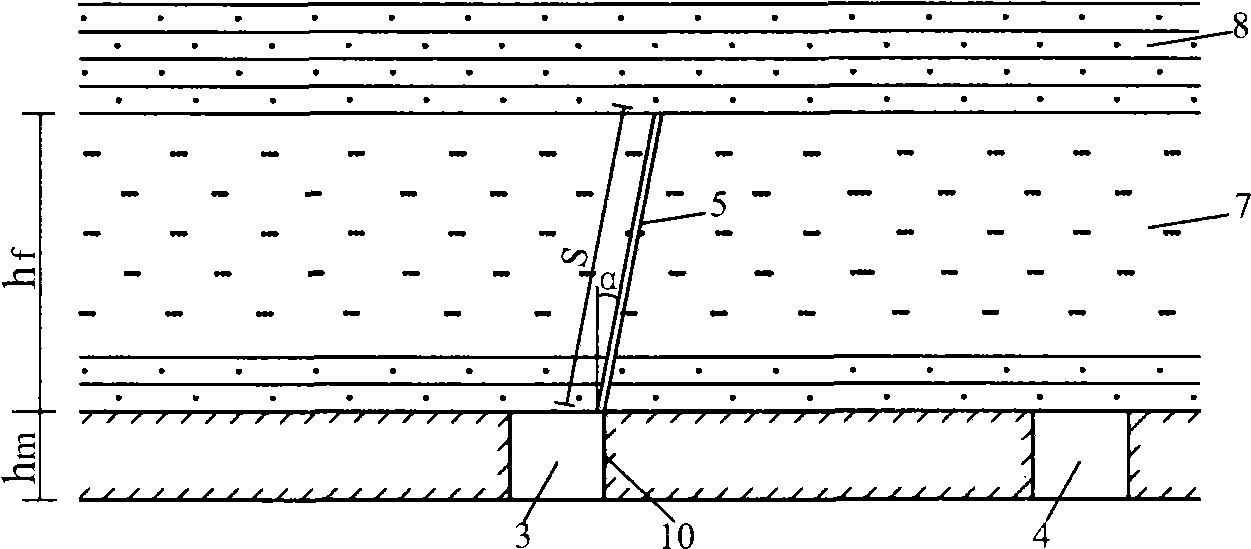

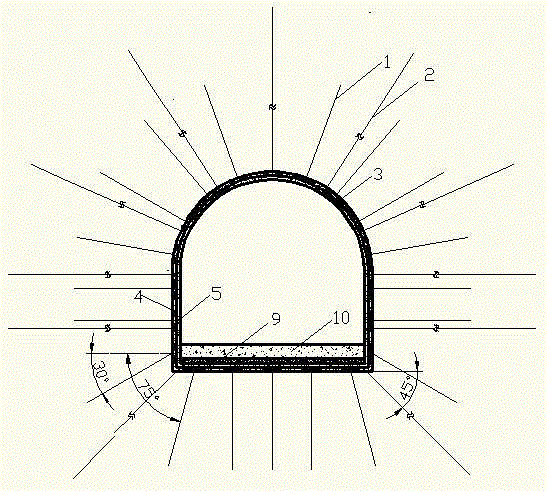

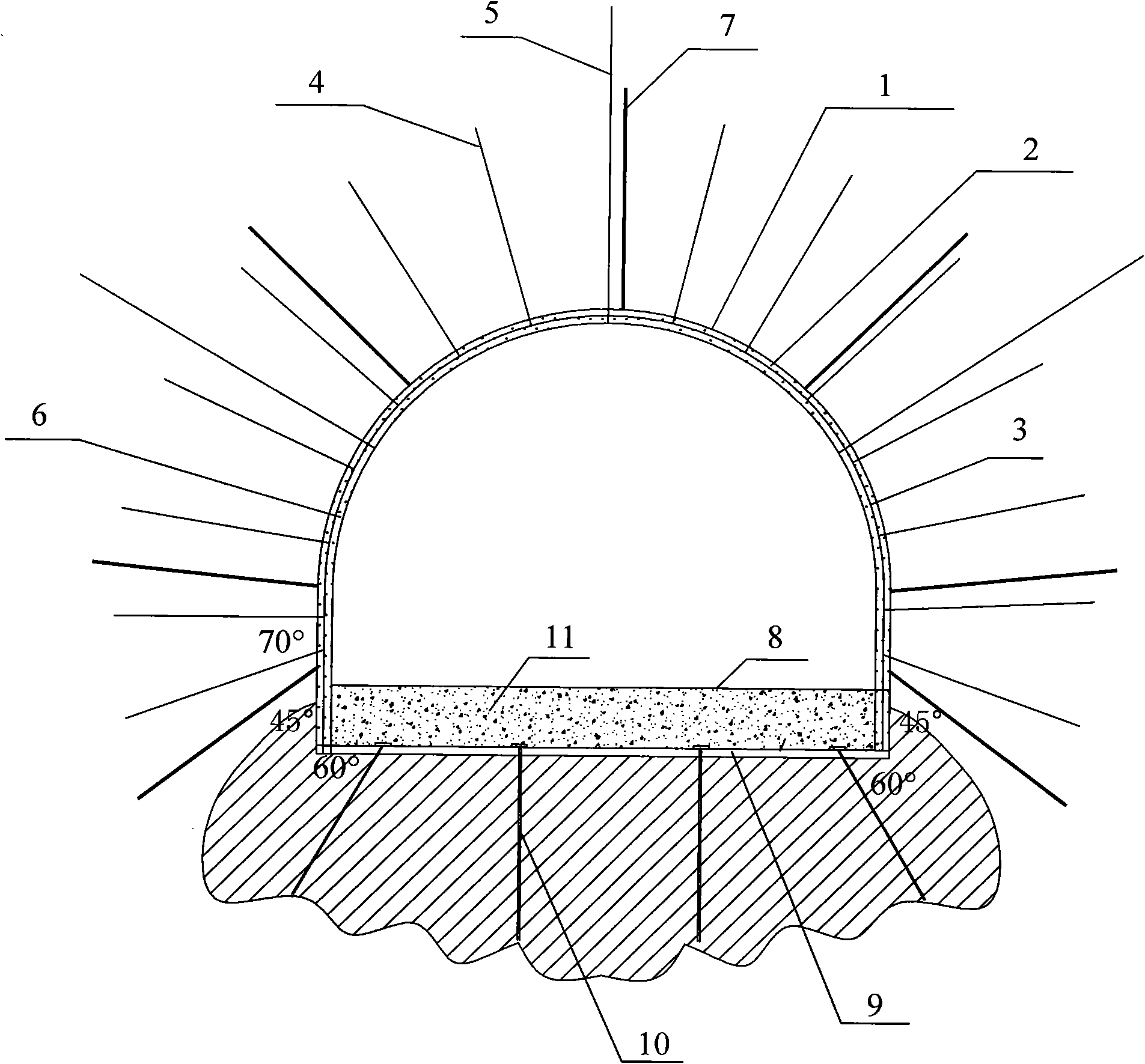

Tunnel dredging method suitable for railway large section IV, V class rock tunnel

ActiveCN101105131ASimple and fast operationLarge construction spaceUnderground chambersTunnel liningRailway tunnelRock tunnel

The invention relates to the technical field of railway tunnel construction, specifically a digging method of IV and V-class surrounding rock railway tunnel with large cross section, aiming to solve the problems of the existing railway tunnel digging method including narrow operation space, low work efficiency, inflexible construction method, instable construction progress, high deformation potential of surrounding rock, and inconvenient operation. The method comprises performing leading support, digging arc-shaped pilot tunnel and preserving core soil; staggeredly digging left / right side walls of middle sidestep and preserving core soil; staggeredly digging left / right side walls of lower sidestep and preserving core soil; sequentially digging upper, middle and lower sidesteps and preserving core soil; and digging inverted arch and carrying out preliminary support. The invention has large construction space and high work efficiency, and can perform multi-job parallel operation. When the geologic conditions are changed, the invention can be flexibly and timely converted to other construction method. Preservation of core soil and left / right staggeredly digging are helpful to the stability of the digging working face. When the surrounding rock has large deformation, the invention can adjust closure time as soon as possible under the prerequisite of assuring safety and meeting requirements of clearance cross section.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

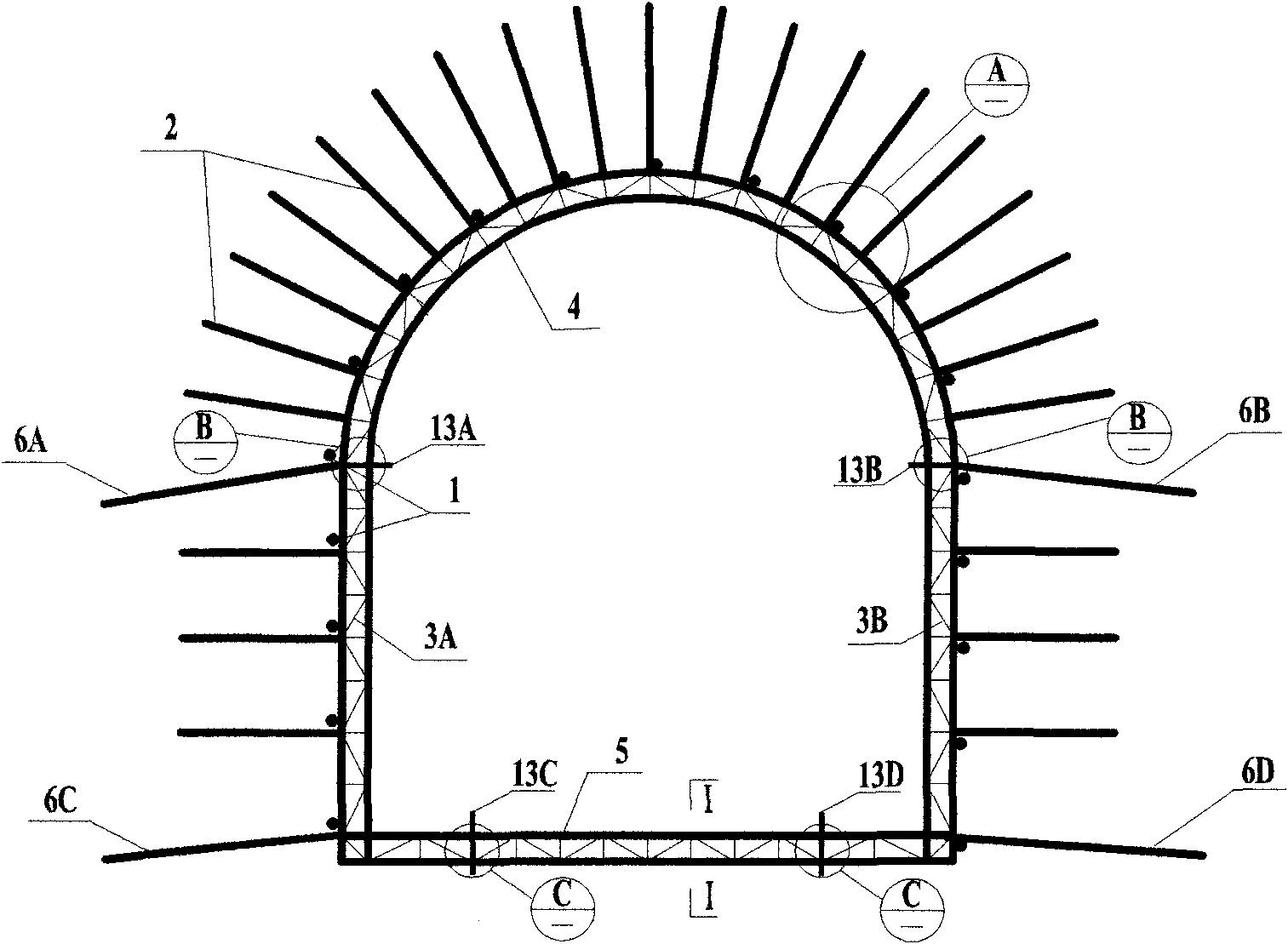

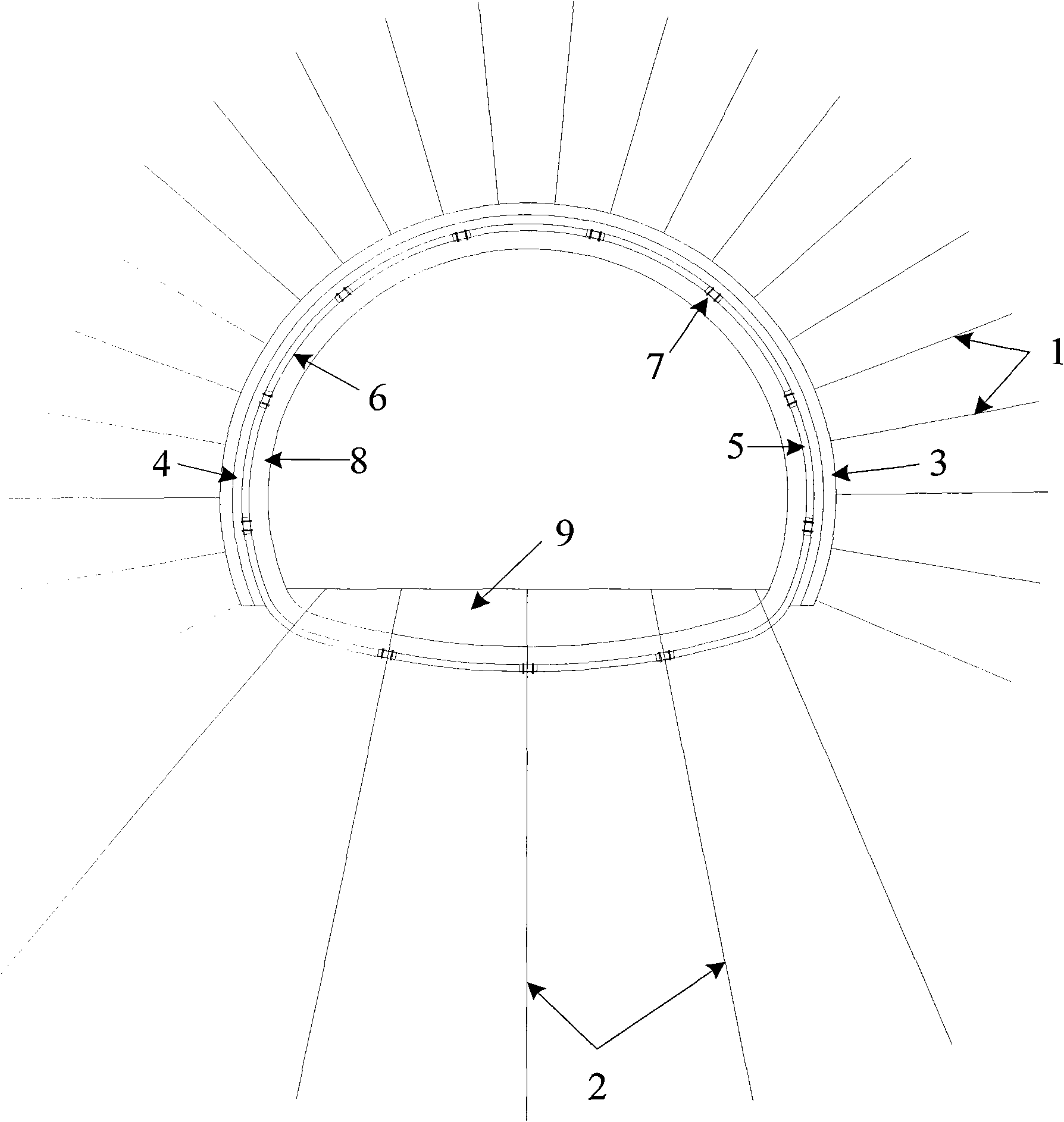

Quick supporting method for large-deformation roadway easy to fall, break and loosen and apparatus thereof

InactiveCN101852083AImprove stress statusStop looseningUnderground chambersMine roof supportsFiberSupporting system

The invention discloses a quick supporting method for large-deformation roadway easy to fall, break and loosen and an apparatus thereof. The method comprises the following steps of: (1) clearing away the loose stones on the wall of the surrounding rock of the roadway; (2) hanging a reinforcing steel bar mesh along the digging outline of the roadway and initially spraying one thin concrete layer; (3) arranging an anchor rod in the drill hole of the roadway wall; (4) arranging a side-wall steel grating arch to support the surrounding rock of the side wall; (5) arranging a top-supporting steel grating arch, touching the top and supporting the upper surrounding rock; (6) clearing away the floating slag at the bottom of the roadway, arranging a steel grating arch of the inverted arch, supporting and sealing the system into a ring; (7) carrying out the cement injection construction on the anchor rod; (8) welding the exposed part of the cement injected anchor rod on the steel grating arch to form a whole structure; and (9) multi-spraying concrete or steel fiber concrete along the roadway wall. The apparatus comprises an anchor rod, a side-wall steel grating arch, a steel grating arch of top arch, a steel grating arch of inverted arch, and a concrete spray layer of reinforcing steel bar. The invention has the advantage of remarkable support effect, simple method and convenient operation and solves the problem that the bracket and the surrounding rock are not adhered tightly.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

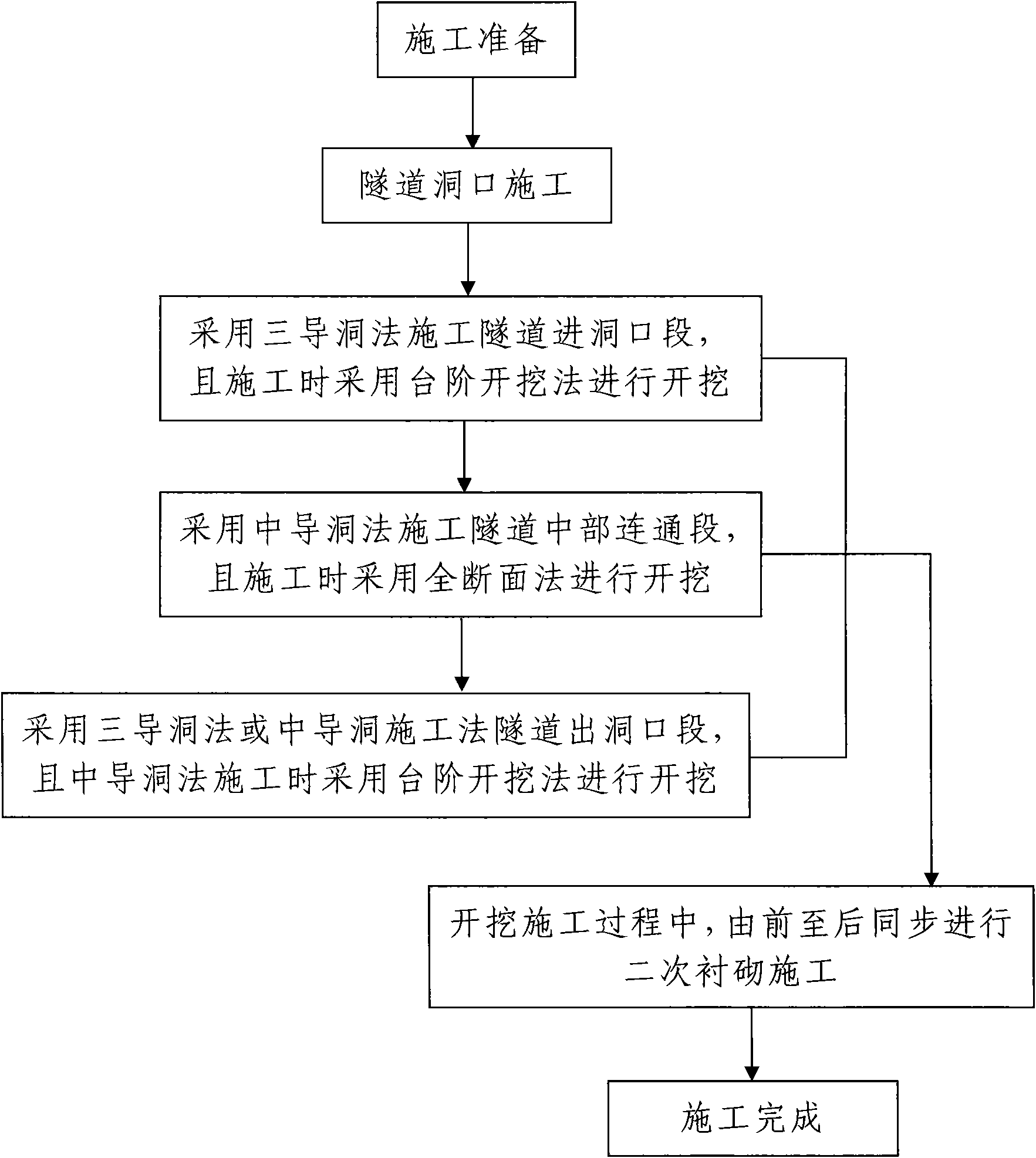

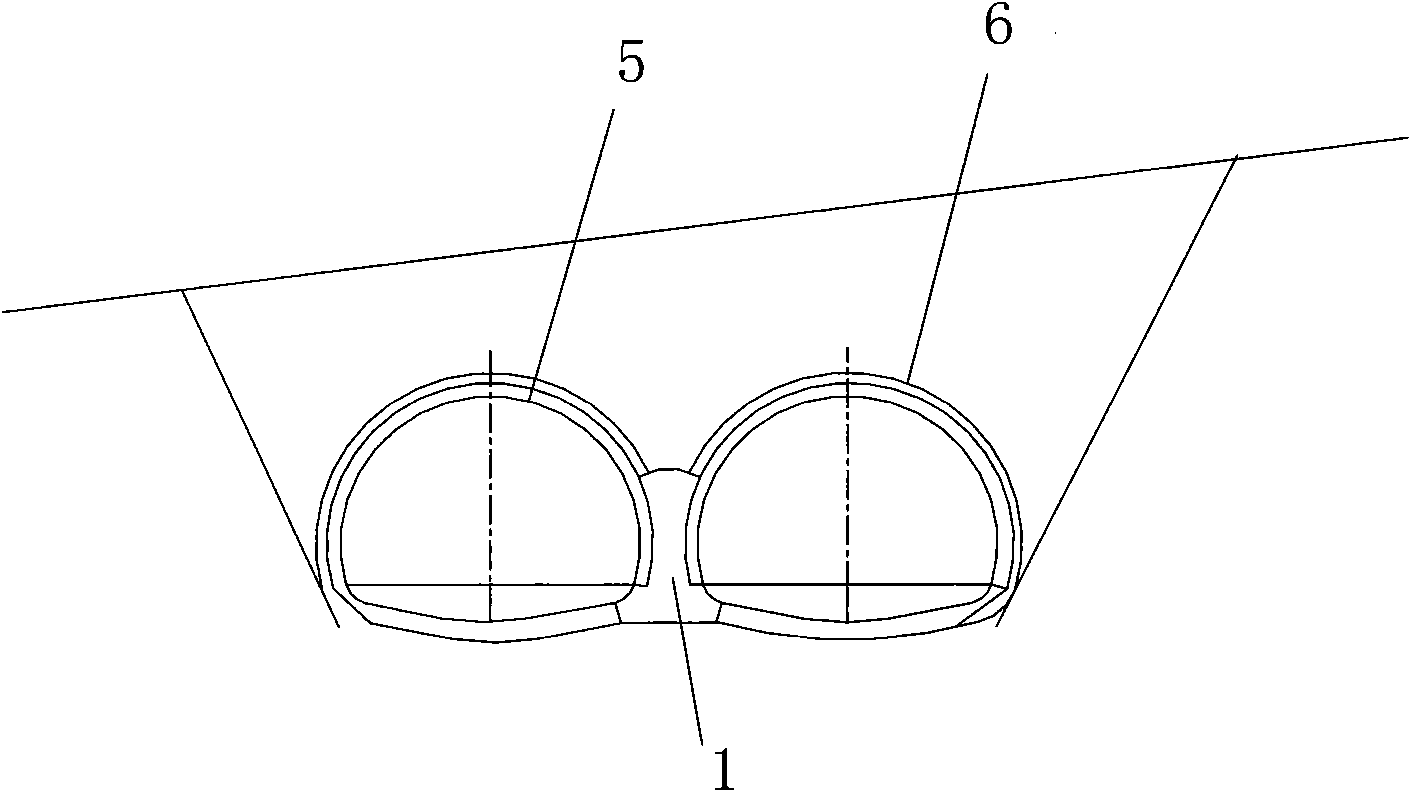

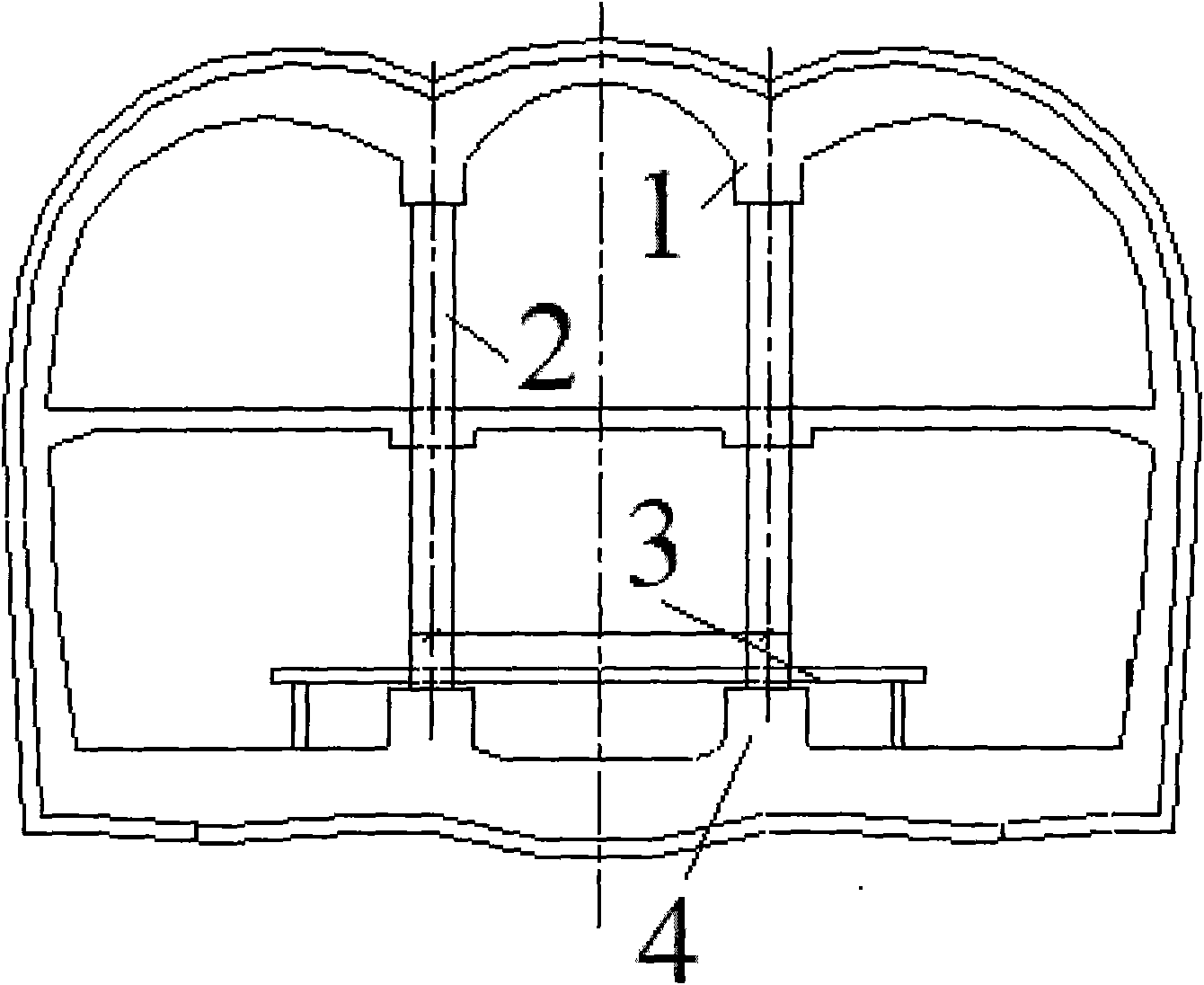

Carst region double-arch road tunnel construction method

ActiveCN101864960AReasonable designSimplify construction stepsUnderground chambersTunnel liningTunnel constructionChannel inlet

The invention discloses a carst region double-arch road tunnel construction method, which comprises the following steps; 1. carrying out construction preparation; 2. carrying out construction at channel openings; 3. adopting a three-pilot-tunnel method for constructing the channel inlet opening section, and adopting a step digging method for digging during the three-pilot-tunnel method construction; 4. adopting a middle-pilot-tunnel method for constructing the middle communication section of the channel, and adopting a full cross section method for digging during the middle-pilot-tunnel method construction; 5. adopting the three-pilot-tunnel method or the middle-pilot-tunnel method for constructing the channel outlet opening section, adopting the step digging method for digging when the middle-pilot-tunnel method is adopted for digging construction of the channel outlet opening section, and synchronously carrying out secondary lining construction from the front part to the back part in the digging construction process of the channel inlet opening section, the middle communication section of the channel and the channel outlet opening section. The invention has the advantages of reasonable design, simple and convenient construction, safe and reliable construction process, flexible construction mode, short construction period and greatly simplified construction steps, and effectively overcomes various defects during the traditional carst region double-arch road tunnel construction.

Owner:CHINA RAILWAY 20 BUREAU GRP +3

Subea pipeline blockage remediation method

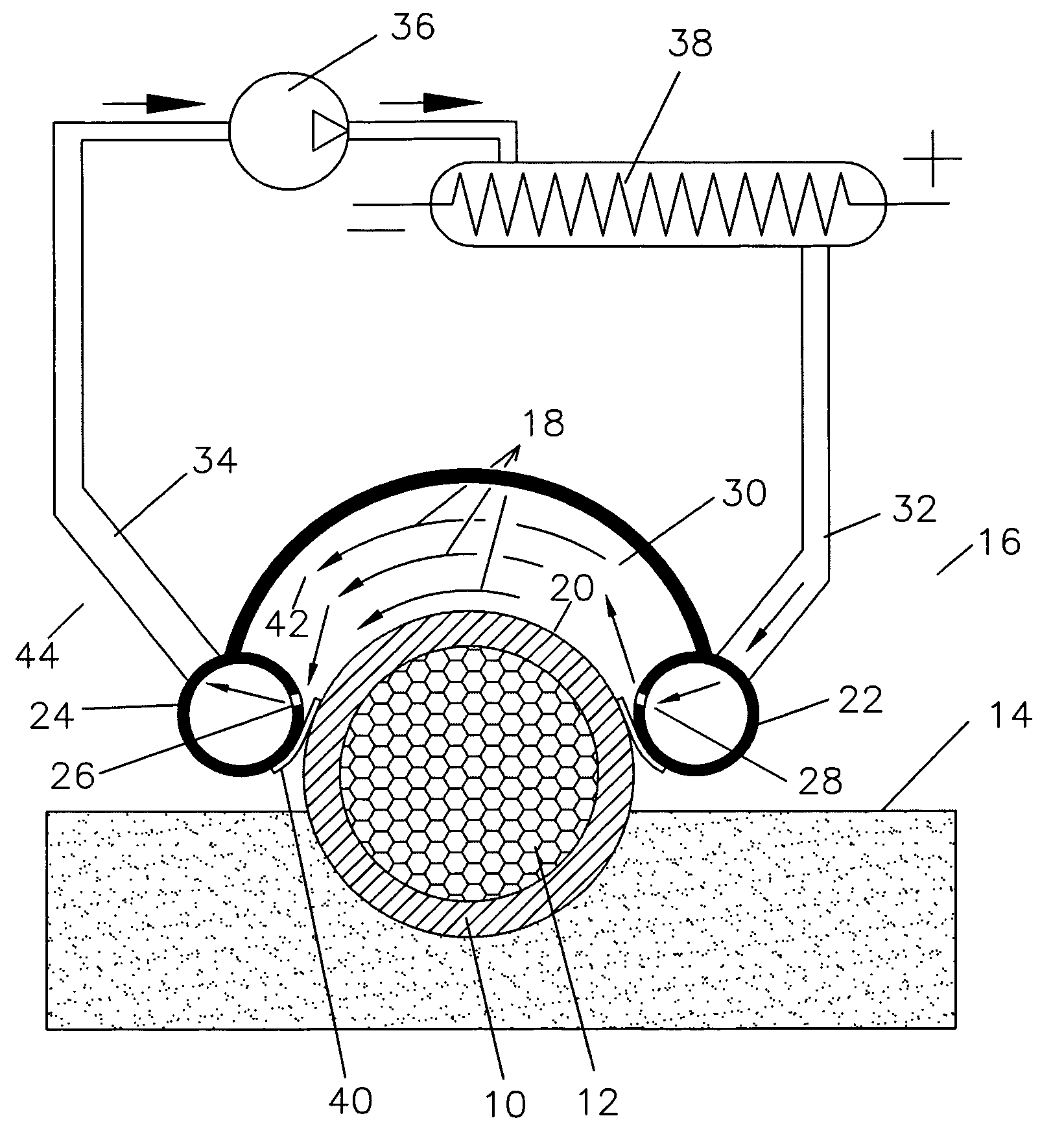

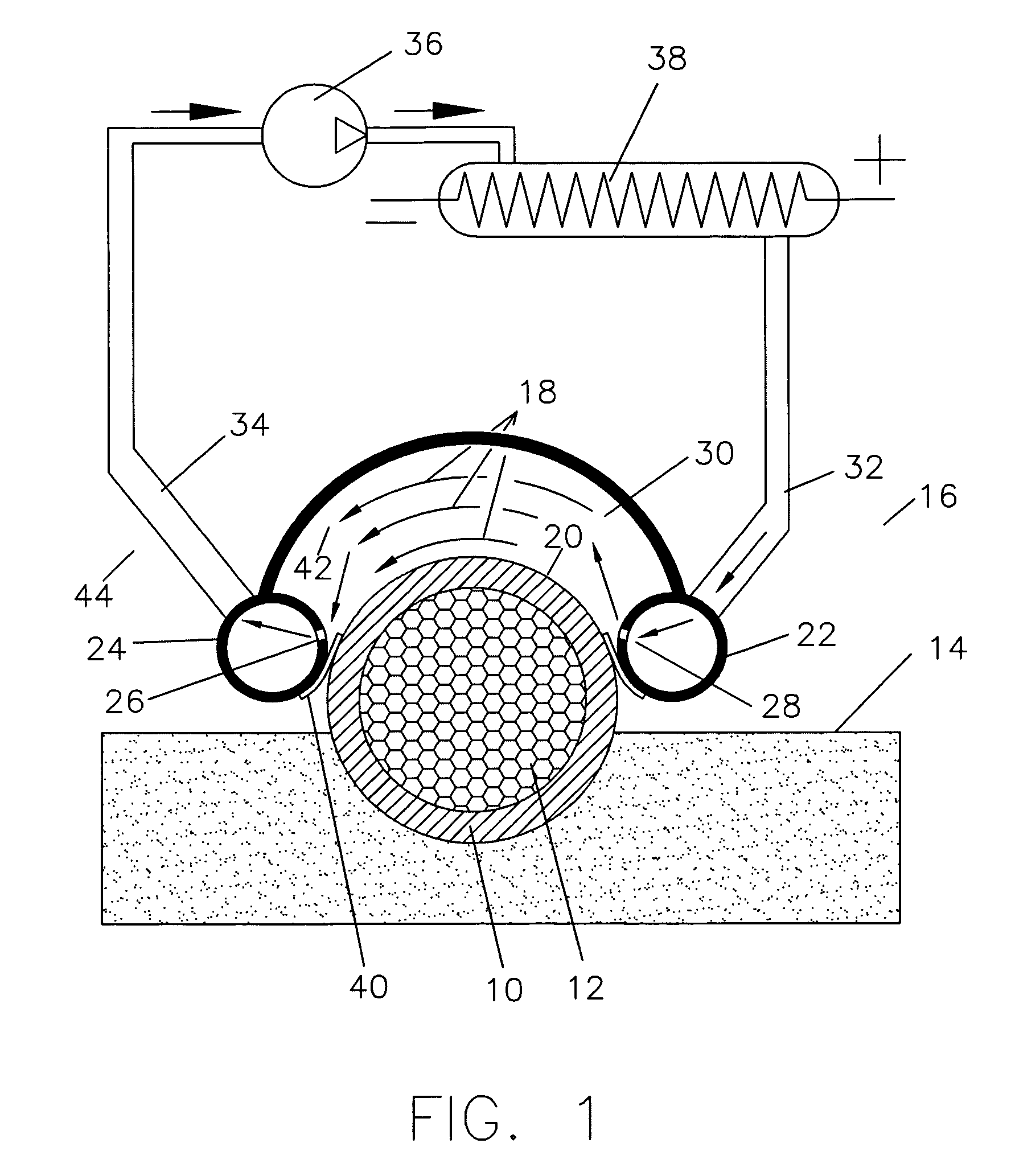

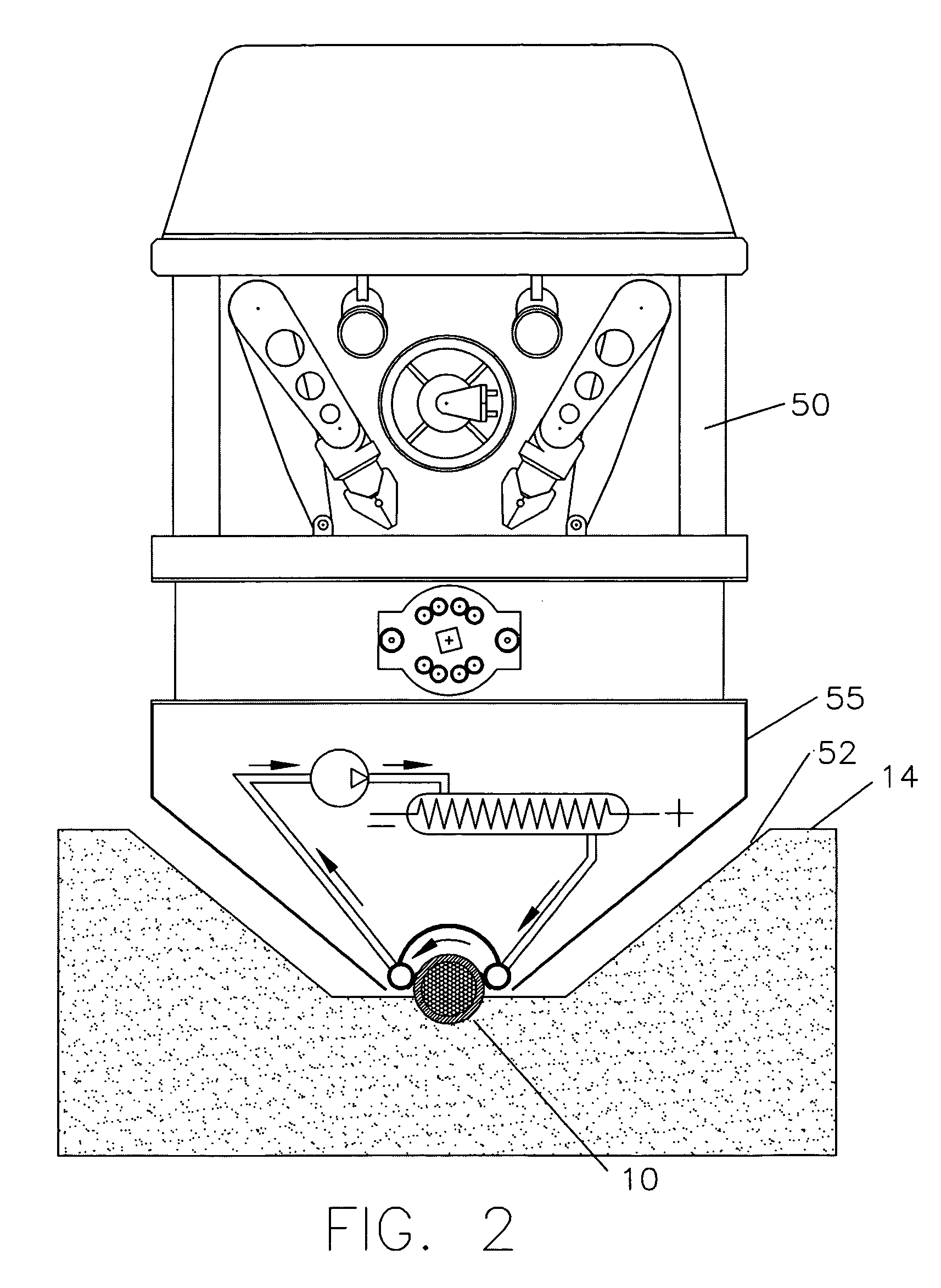

InactiveUS6939082B1Raise the outlet temperatureMinimize disturbanceUnderground chambersPipe heating/coolingOcean bottomMarine engineering

The method of taking a remotely operated vehicle to the ocean floor to land on and move along a subsea pipeline above or below the seafloor and repeatedly circulate seawater which has been heated electrically, mechanically, or chemically across the outer surface of the pipeline to melt hydrates or paraffins which have formed on the inside of the pipeline.

Owner:BAUGH BENTON F

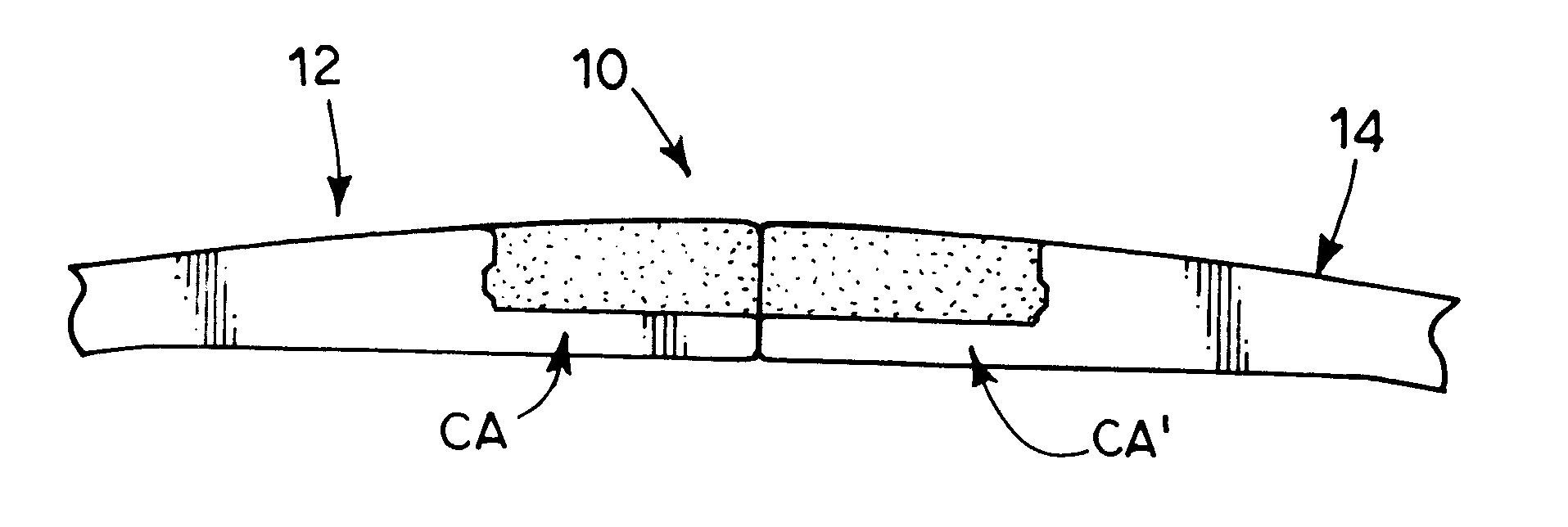

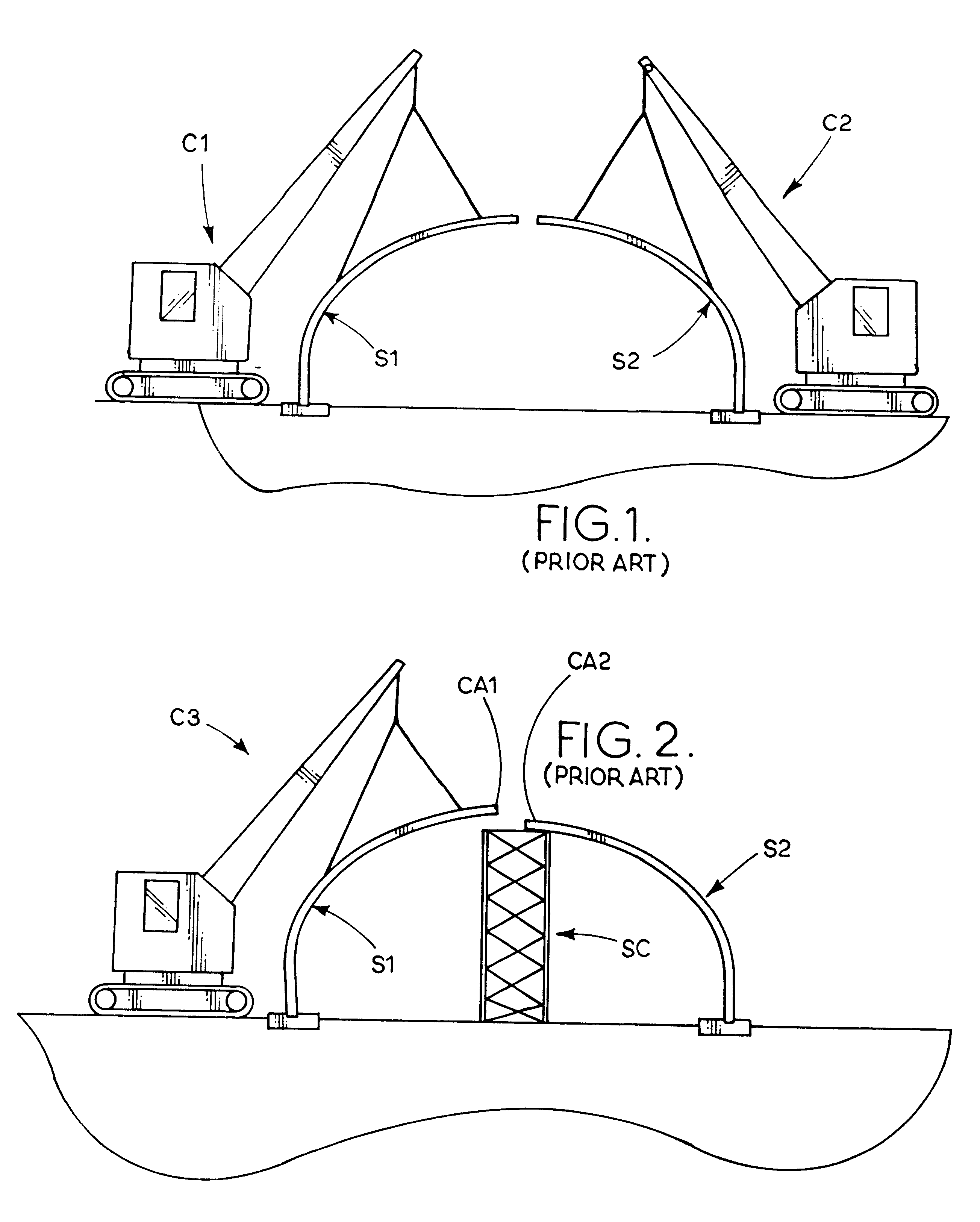

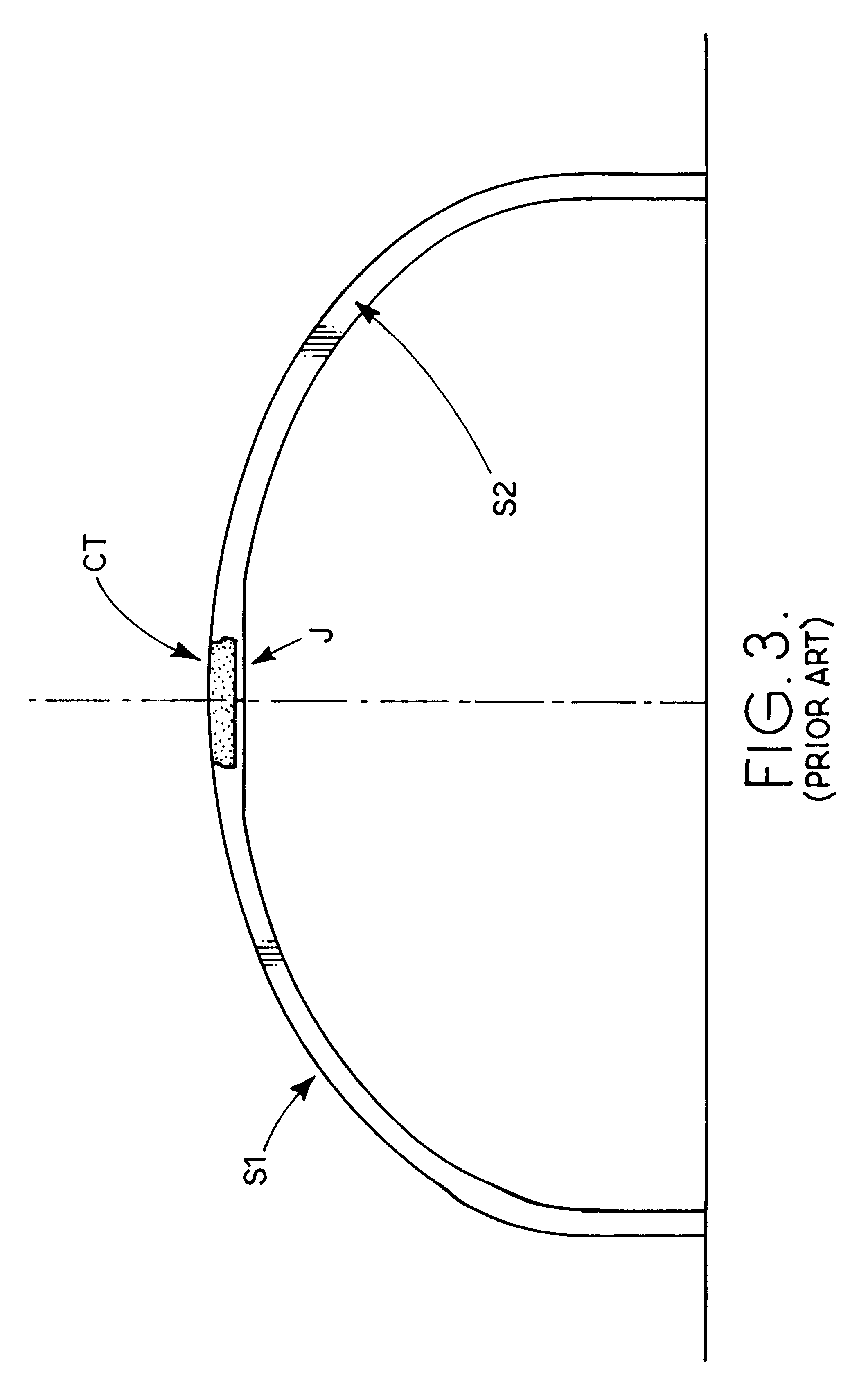

Joint for pre-cast concrete twin-leaf arch sections

InactiveUS6243994B1Efficiently and accurately formForming accuratelyUnderground chambersBuilding material handlingControl theoryPrecast concrete

A joint for pre-cast concrete twin-leaf arch sections is self-aligning when the two arch sections are initially brought into abutting contact with each other. The joint provides a rigid connection between the twin units and is achieved on site by means of re-inforced cast-in-place concrete. Reinforcement splices for the connection are lap splices, and the joint allows pouring the cast-in-place concrete without the need of formwork. For load distributing purposes, a continuous connection of individual arch rings in the longitudinal direction at the arch crown is possible. An initial abutting contact between the twin units is provided by the joint of the present invention. The contact provided by the joint of the present invention is self-aligning, locking, allows the controlled transmission of the abutting force and allows for a temporary connection. The joint includes mechanical elements for aligning and locking the two arch sections together. The mechanical elements include, in the preferred embodiment, a projection on one arch section and a depression on the other arch section. Cast-in-place concrete is placed in boxed-out, or step, sections located adjacent to the mechanical elements and completes the joint.

Owner:CONTECH ENGINEERED SOLUTIONS

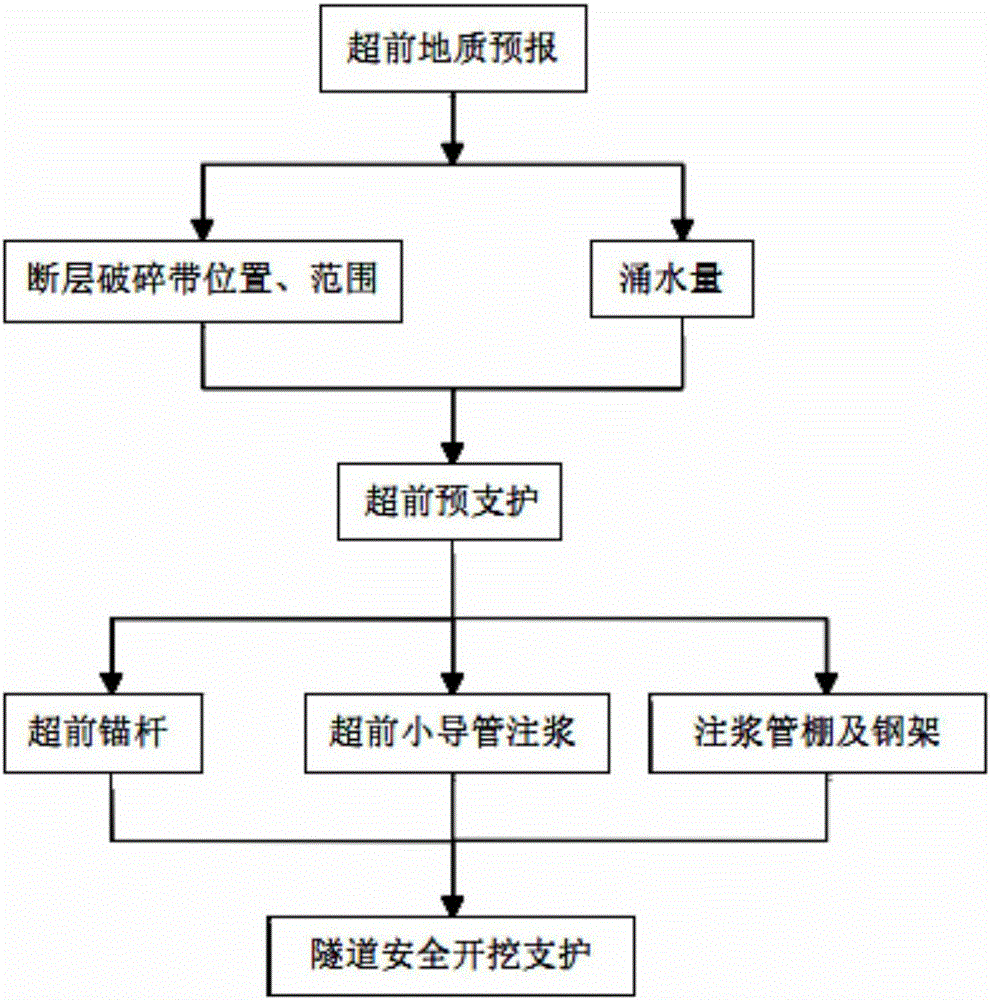

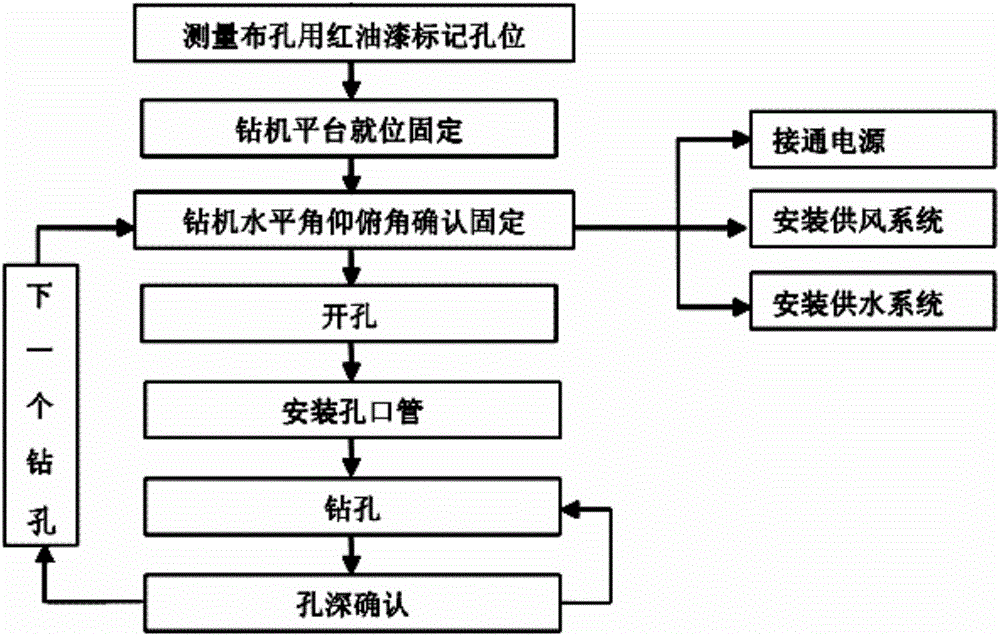

Construction method for fault fracture zone surrounding rock tunnel

InactiveCN106837352AEnsure safetyImprove applicabilityUnderground chambersTunnel liningGeomorphologyShortest distance

The invention discloses a tunnel construction method in a fault fracture zone, which comprises the following steps: a. adopting the method of combining geophysical prospecting and drilling and combining long-distance and short-distance to ascertain the geological situation in front, and carry out advanced geological prediction; b. adopting advanced Anchor construction, pre-grouting construction of the surrounding walls of small conduits in advance, and advance support construction of grouting pipe shed and steel frame, and advance pre-support; c. Tunnel excavation and support. It provides a theoretical basis for detecting the specific location, range and water inflow of the fault fracture zone; ensures the safety of tunnel construction; on the basis of analyzing the specific location and scope of the fault fracture zone and adopting a reasonable advanced pre-support method, comprehensive and specific According to the geological conditions, choose a reasonable tunnel excavation method. It has strong applicability for the construction of expressway tunnels crossing fault fracture zones; at the same time, it has reference and reference significance for the construction of railway, municipal and water conservancy tunnels (holes) with similar geological conditions.

Owner:CENT SOUTH UNIV +2

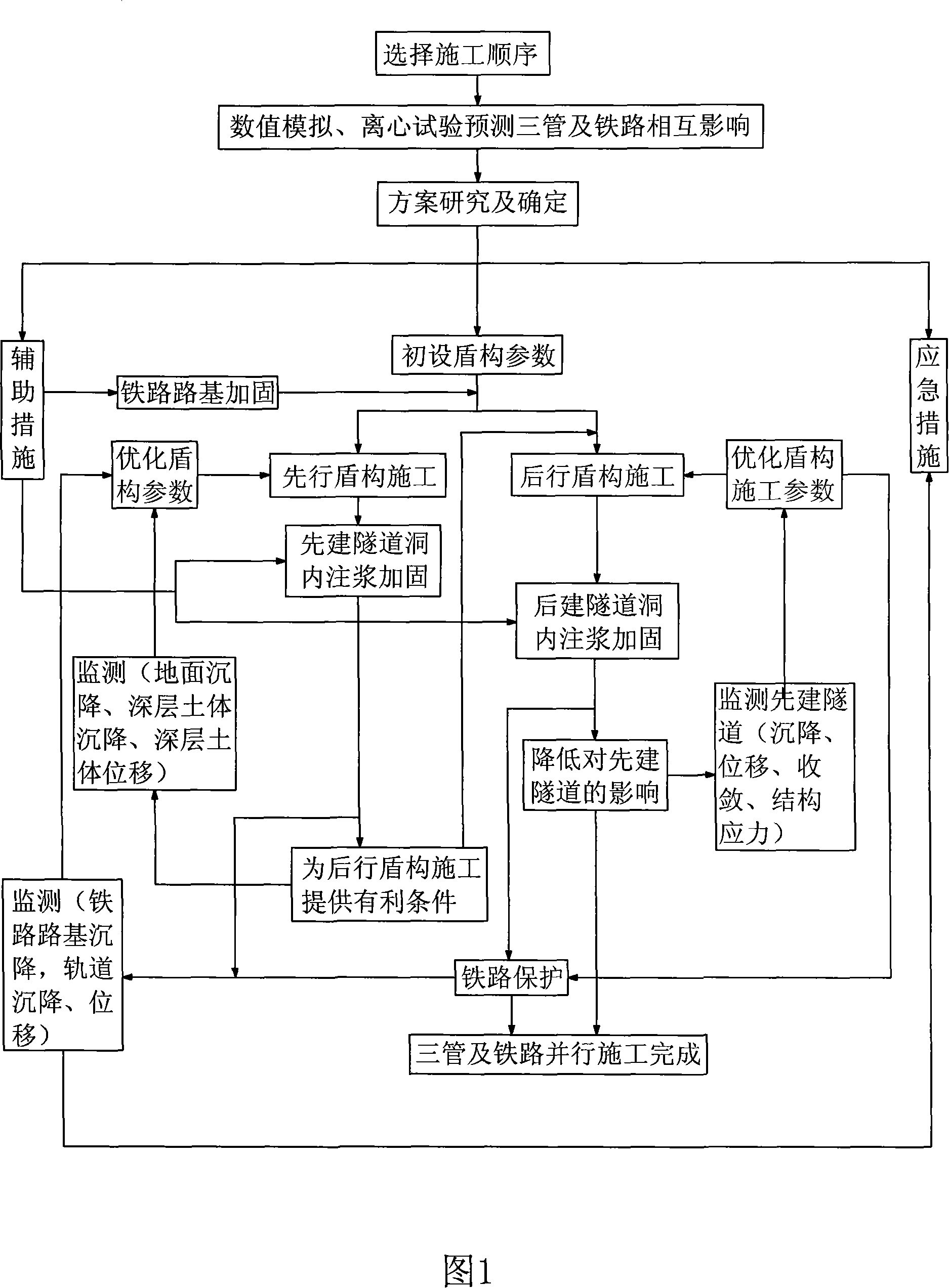

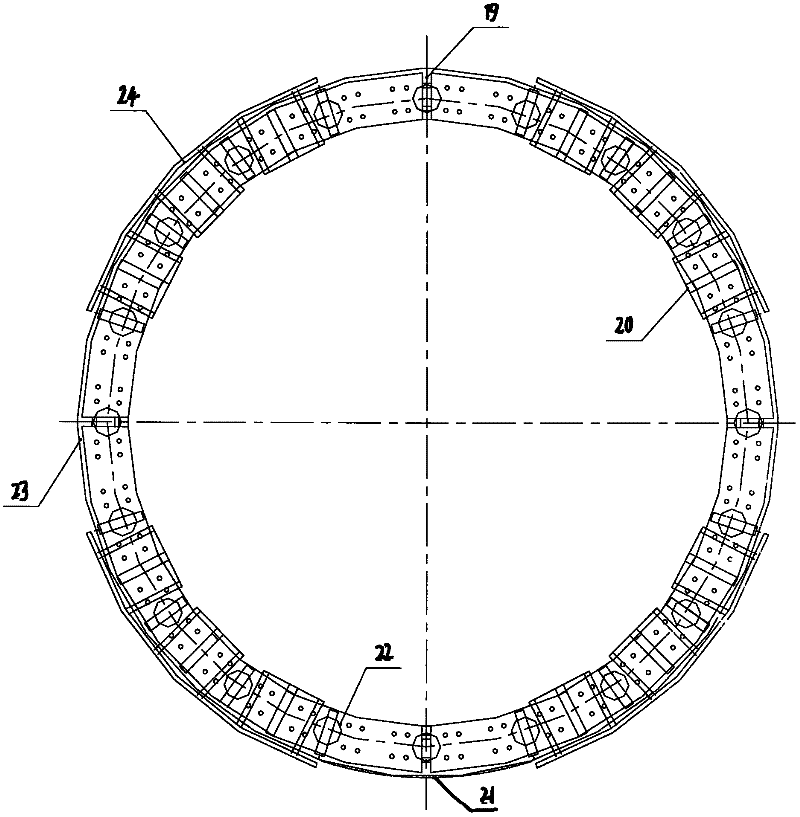

Shield construction method for three-line parallel under-passing trunk railway tunnel

ActiveCN101126318AEffective control of deformationEffective control of displacementUnderground chambersTunnel liningRailway tunnelEconomic benefits

The invention discloses a shield construction method of digging three parallel tunnels under a trunk railway, which belongs to the field of tunnel construction technology. The construction method of the invention comprises the procedure that: the model analysis on each construction sequence and method is made by a three-dimensional finite element and the shield construction sequence is selected; to select the reinforcement project of the railway bed is selected according to the influence degree of the dynamic stress, the load-carrying structural model is adopted to calculate and decide the shield area reinforcing bars enhancement project under the dynamic load of the railway train; the construction parameters are selected according to the test results and the performance of the shield machine, the front earth pressure is reasonably set , the synchronizing mortar injection is enhanced, the forward digging speed and the axis deviation are strictly controlled, the secondary mortar injection is made, the foam or mud is filled by utilizing a pre-embedded injection hole; the strict monitoring measures to monitor the shield construction process is adopted so that the construction unit can adjust the construction parameters in time and guarantee the construction safety. The invention not only guarantees the construction quality and the construction safety of the project but also creates good economic benefit.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD

Device and method for repairing pipe

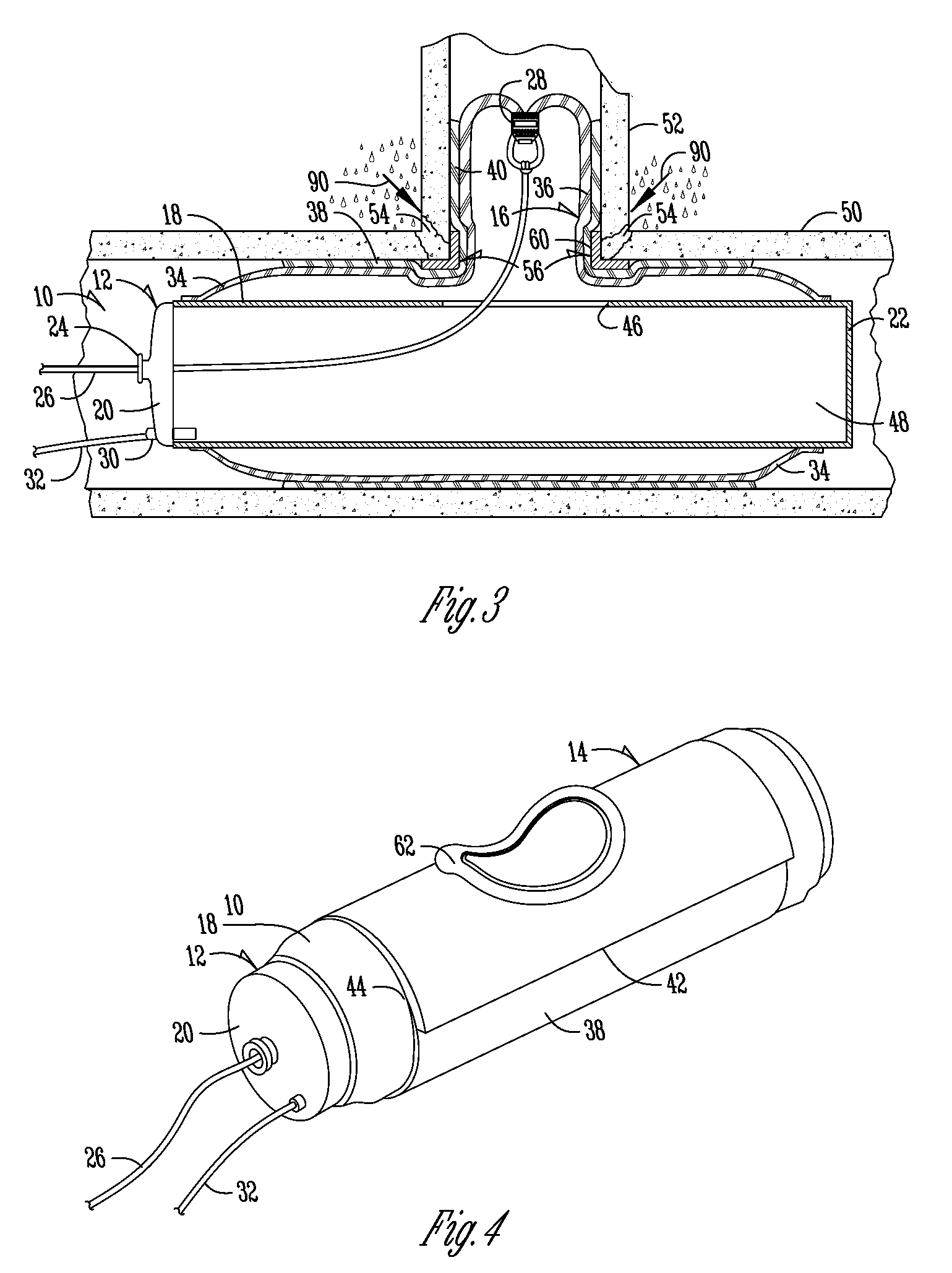

ActiveUS20090056823A1Suitable for useEffectively seal against entry of ground waterUnderground chambersPipe elementsEngineeringGasket

A liner tube is provided for repairing either a single pipe line or a main pipe line having a lateral pipe line connected thereto. The liner tube assembly includes a liner tube impregnated with a liquid material capable of curing and hardening. The liner tube includes a gasket or band positioned about the juncture of the pipe lines. The gasket or bands form a tight seal between the liner tube and the pipe line.

Owner:LMK TECH LLC

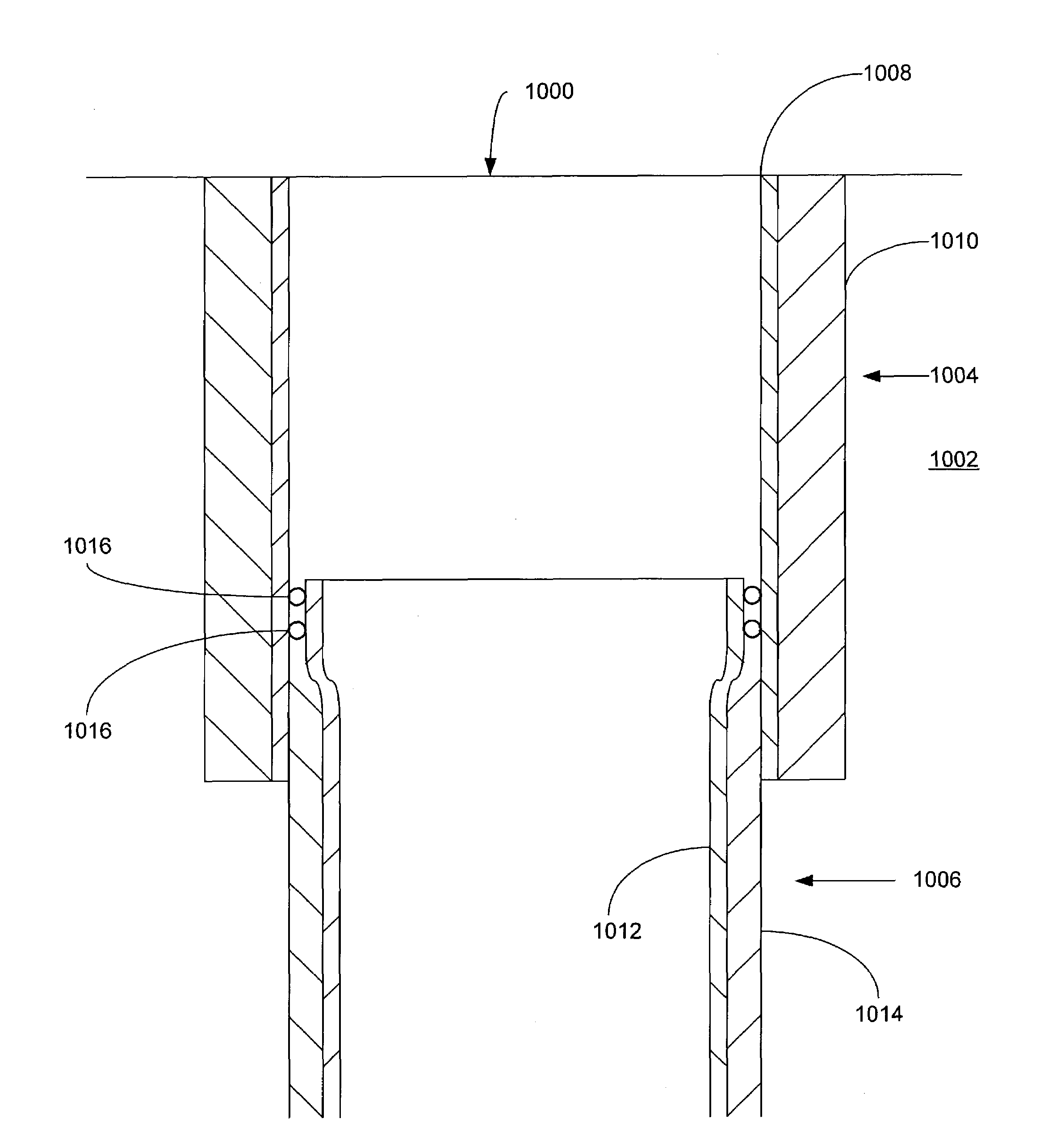

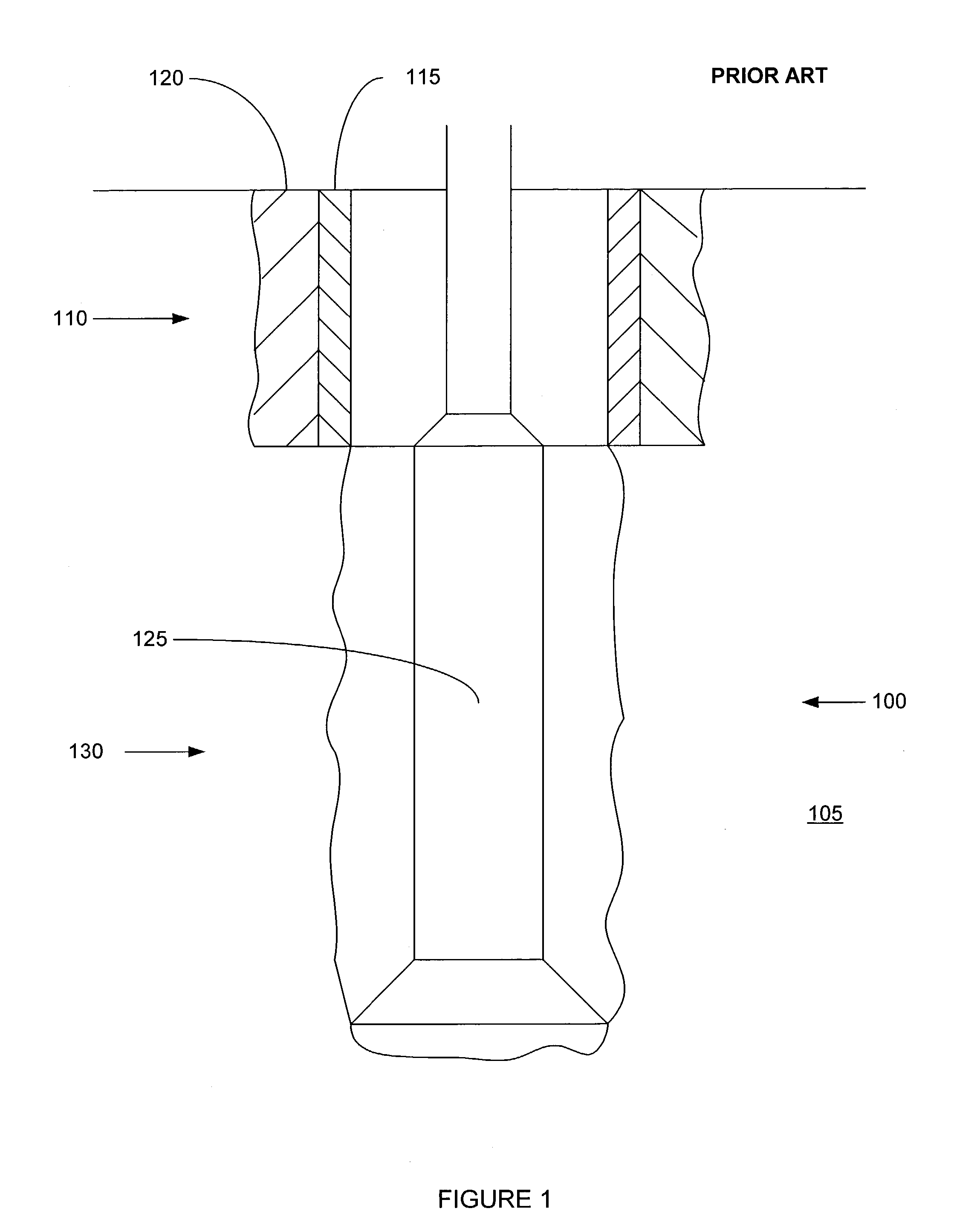

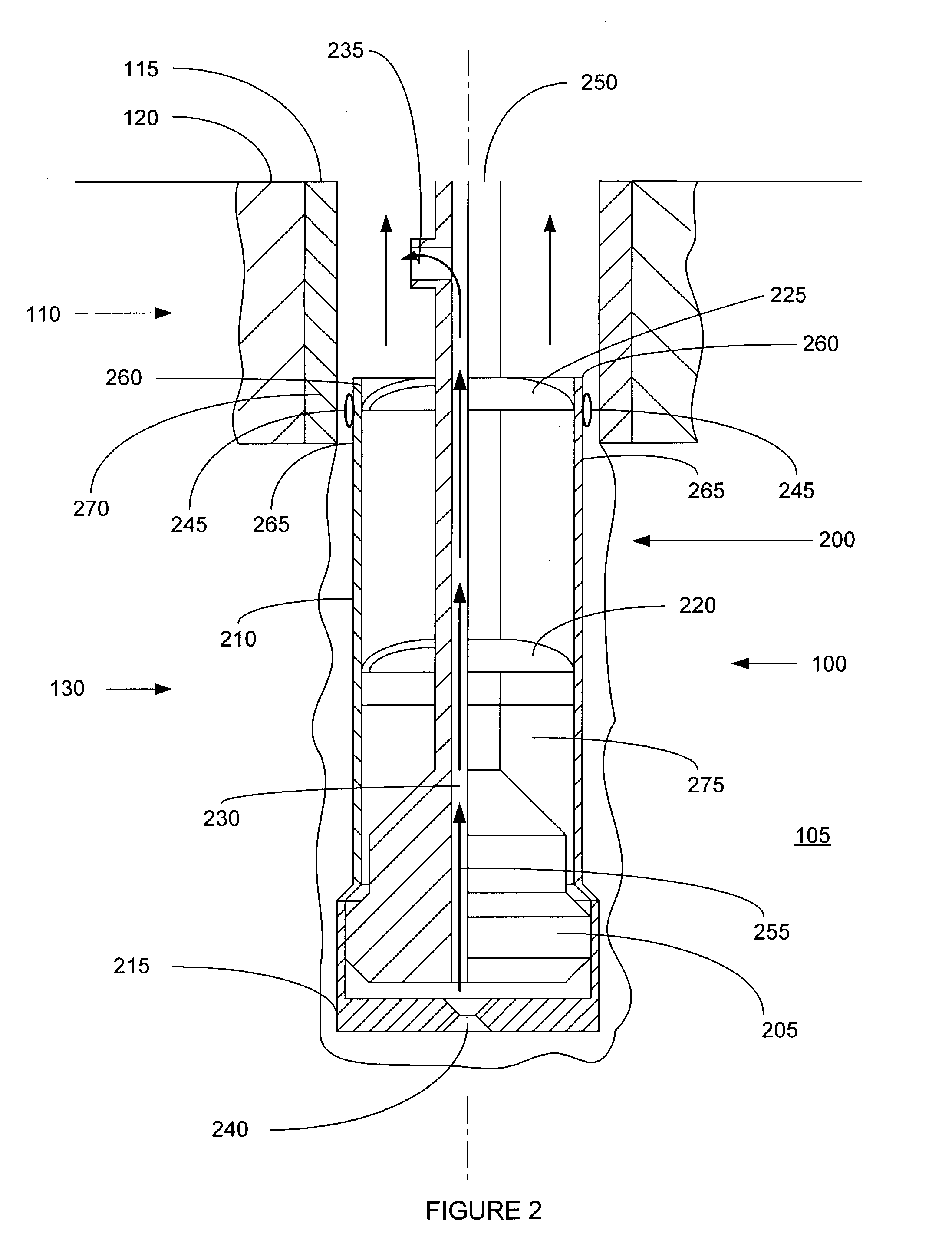

Tubular liner for wellbore casing

A method for expanding tubulars including providing an expandable tubing and a larger diameter tubing, wherein the larger diameter tubing has an expandable, tapering end portion; coupling an end portion of the expandable tubing to the expandable tapering end portion of the larger diameter tubing; running the connected tubing into a bore; and expanding the expandable tubing. Prior to the expanding of the expandable tubing, a wall thickness of the end portion of the expandable tubing coupled to the expandable tapering end portion of the larger diameter tubing is less than a wall thickness of another end portion of the expandable tubing.

Owner:ENVENTURE GLOBAL TECH LLC

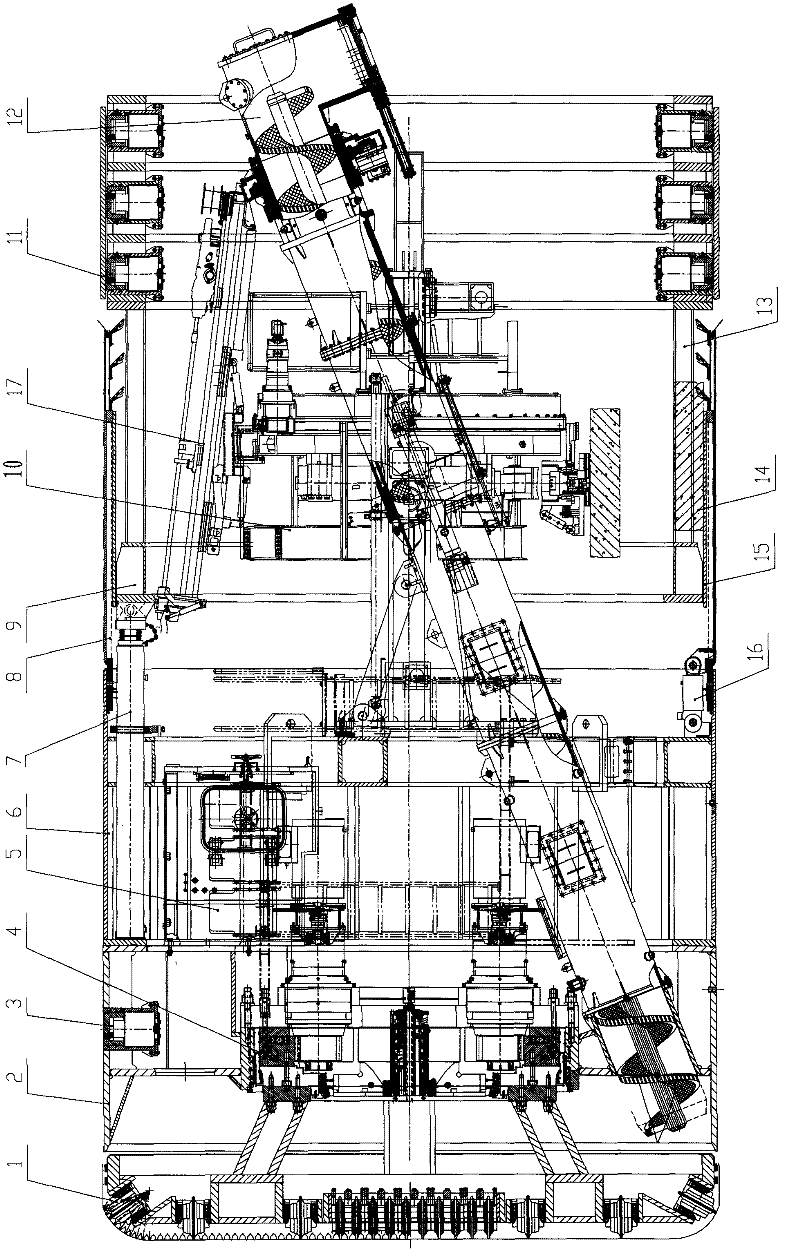

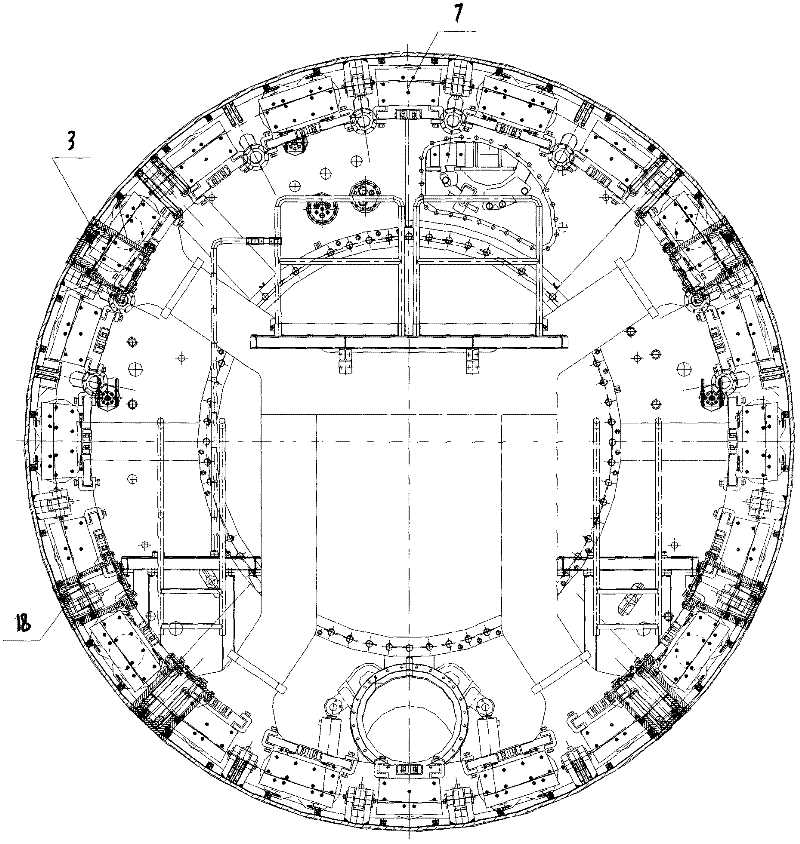

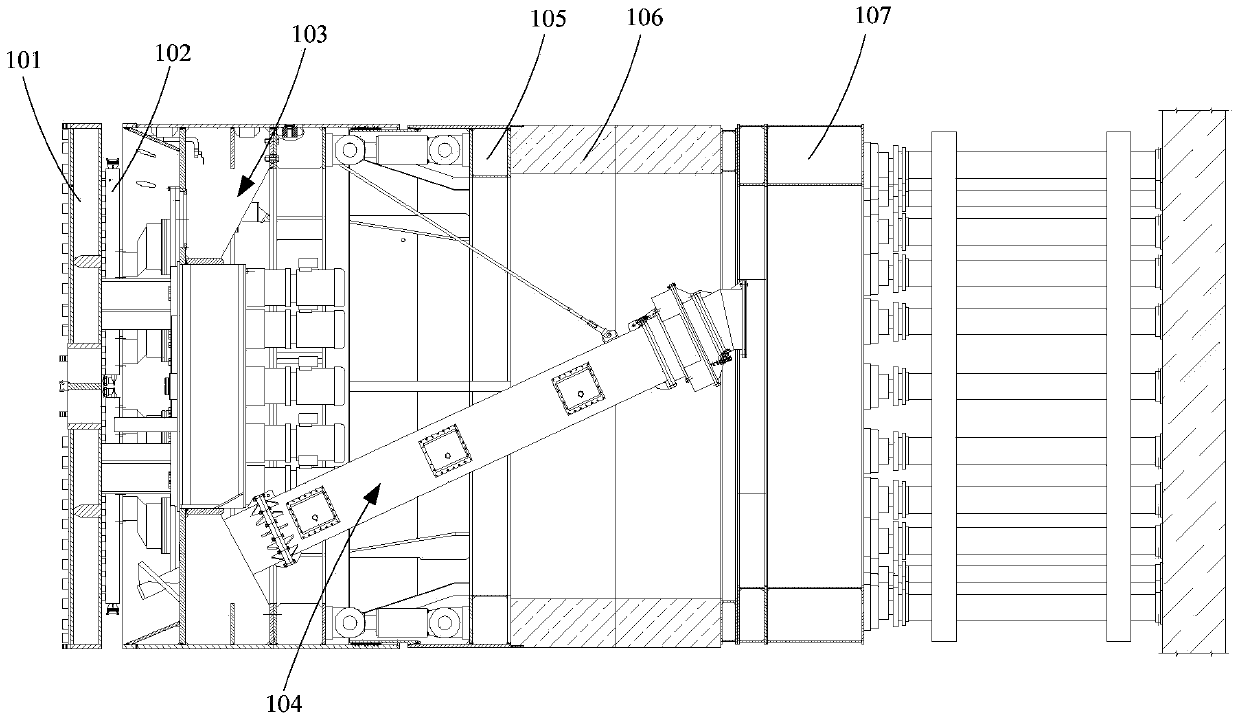

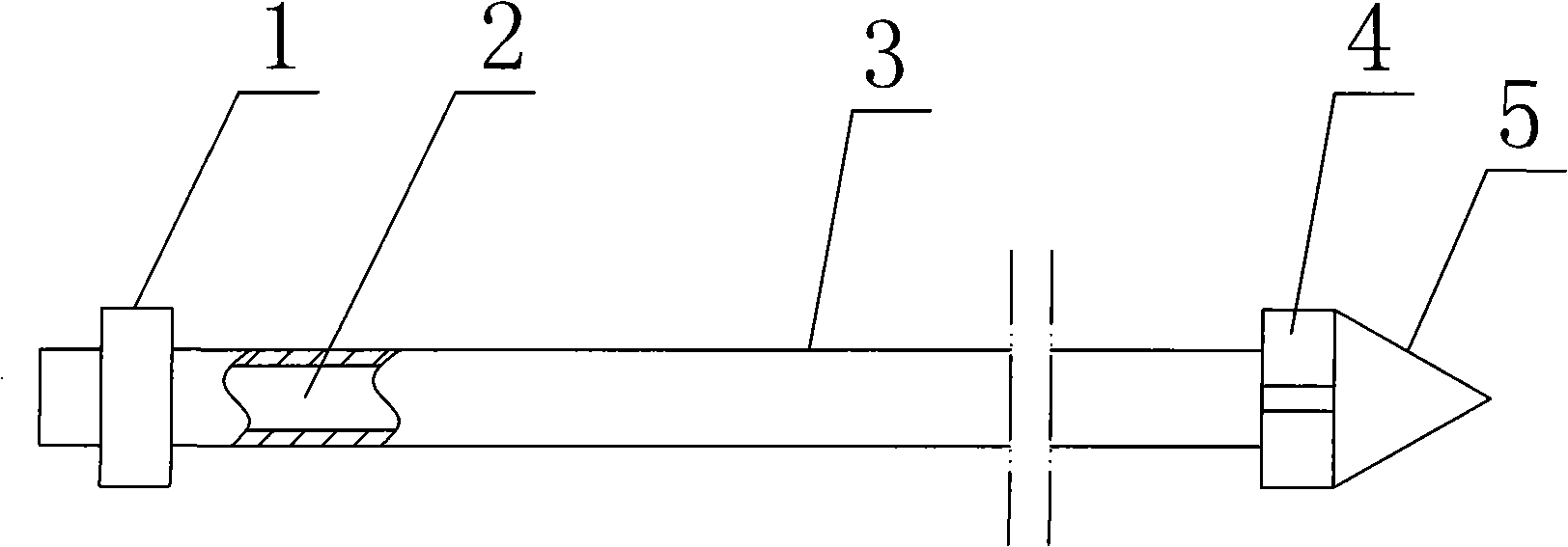

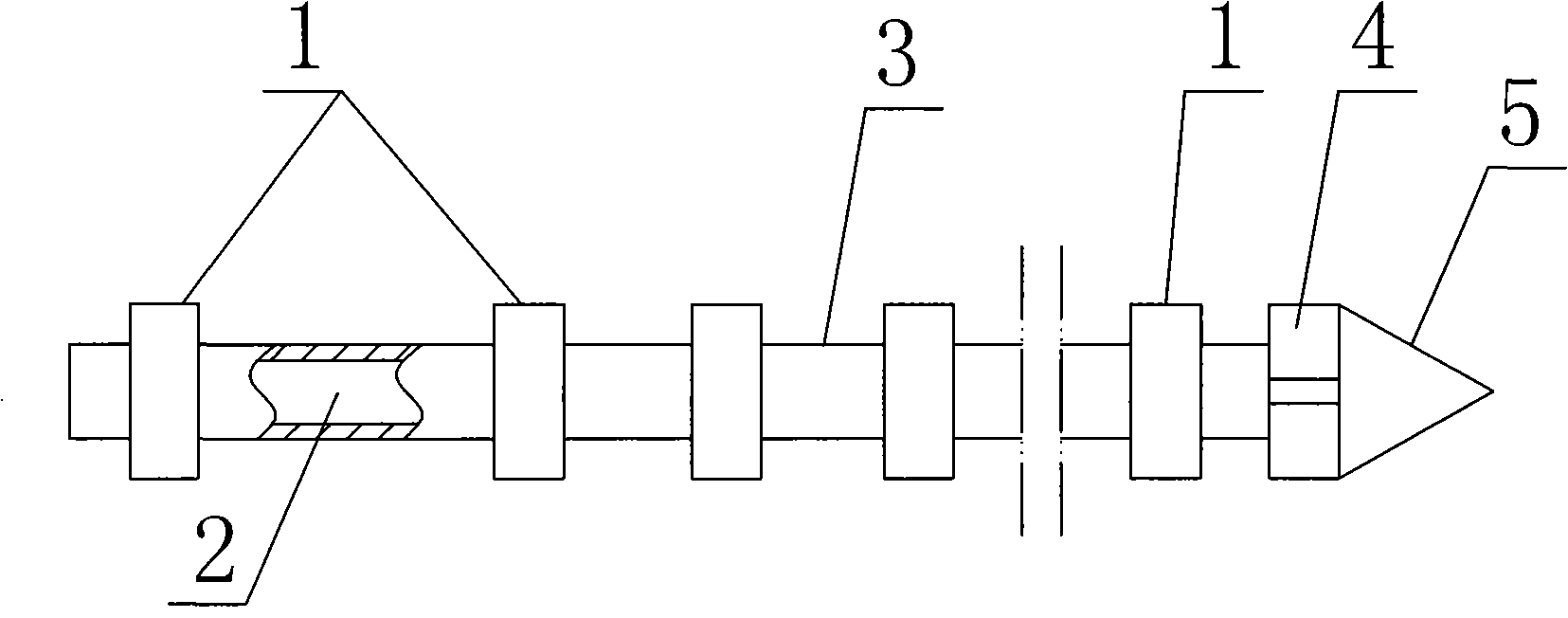

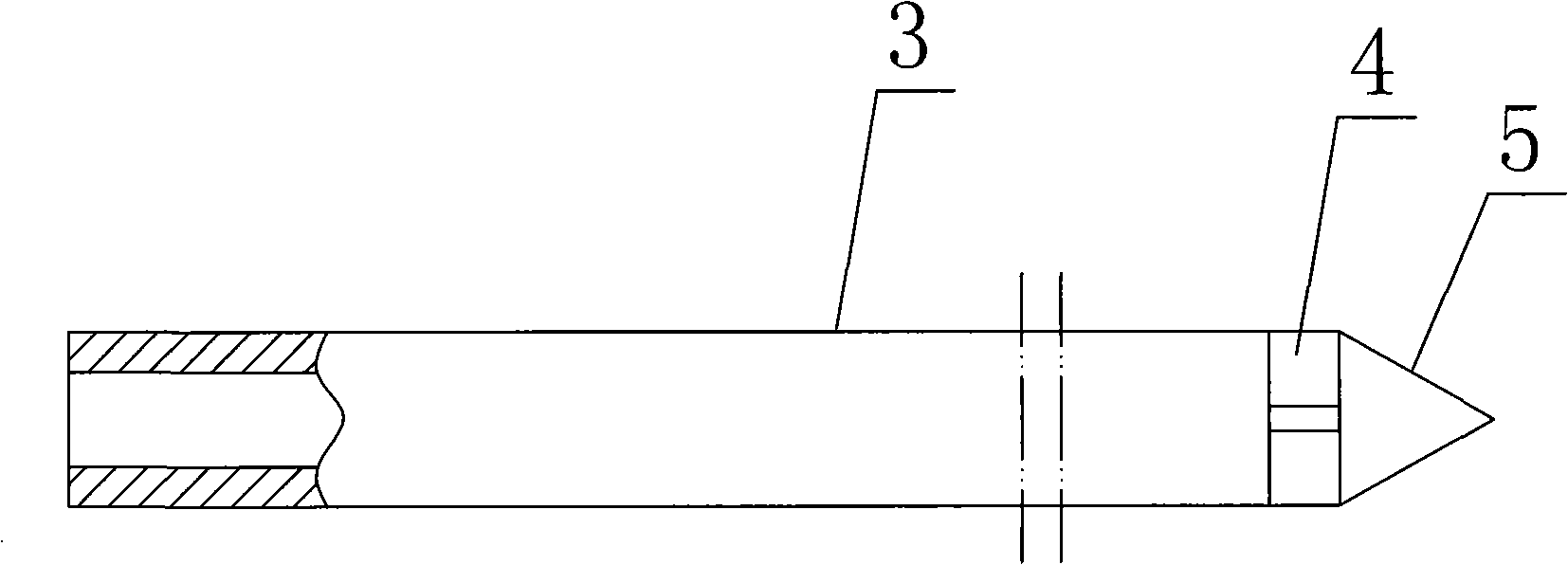

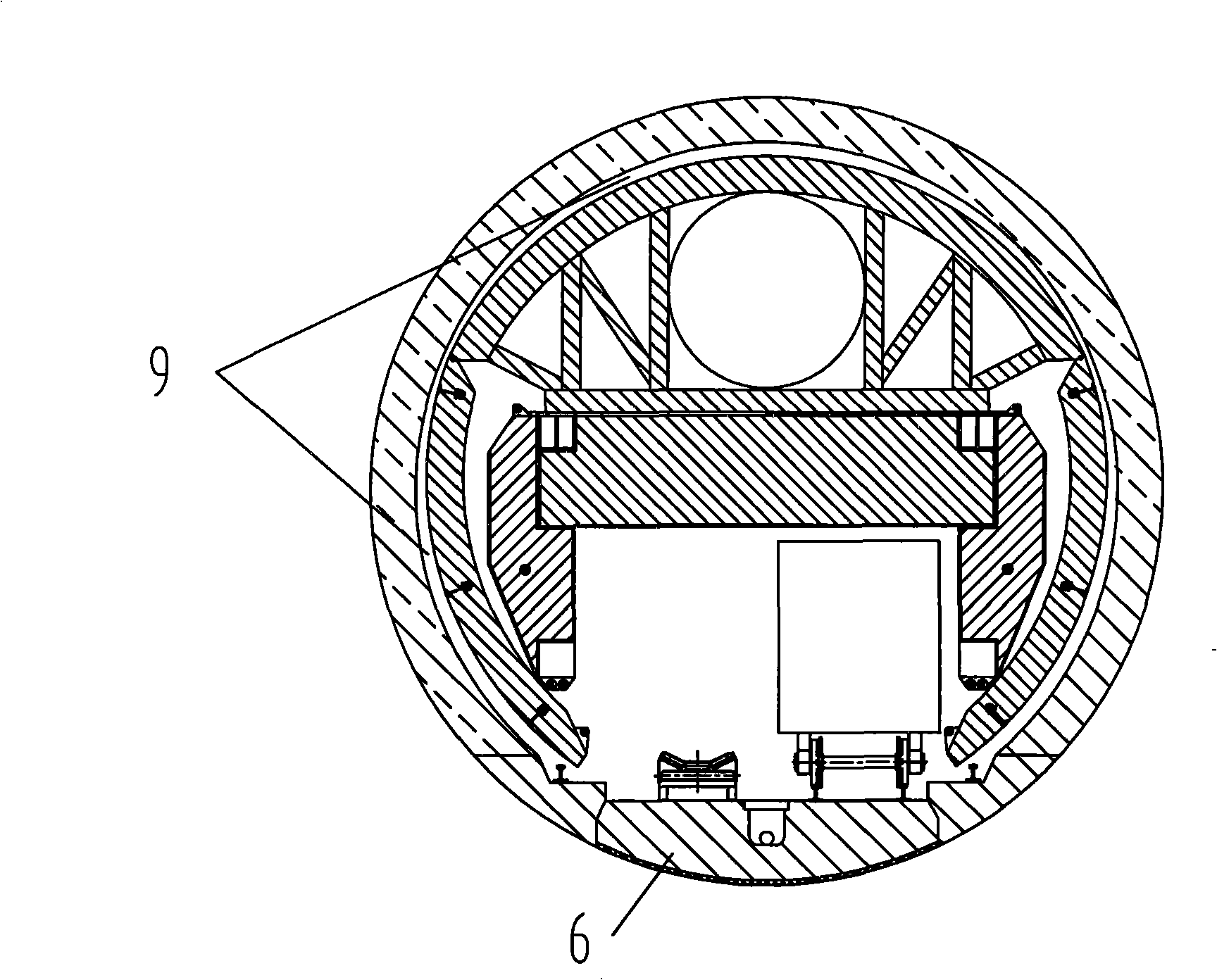

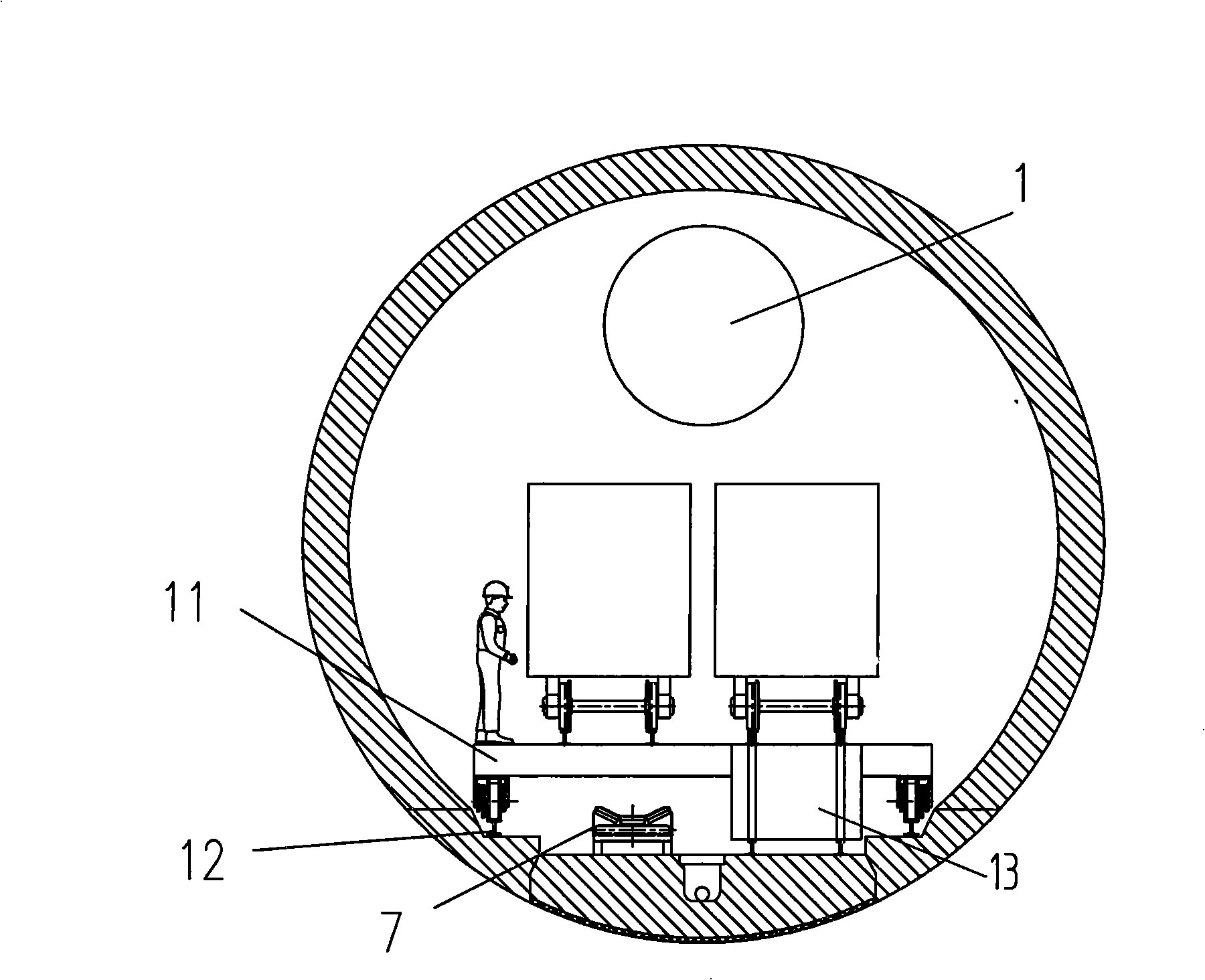

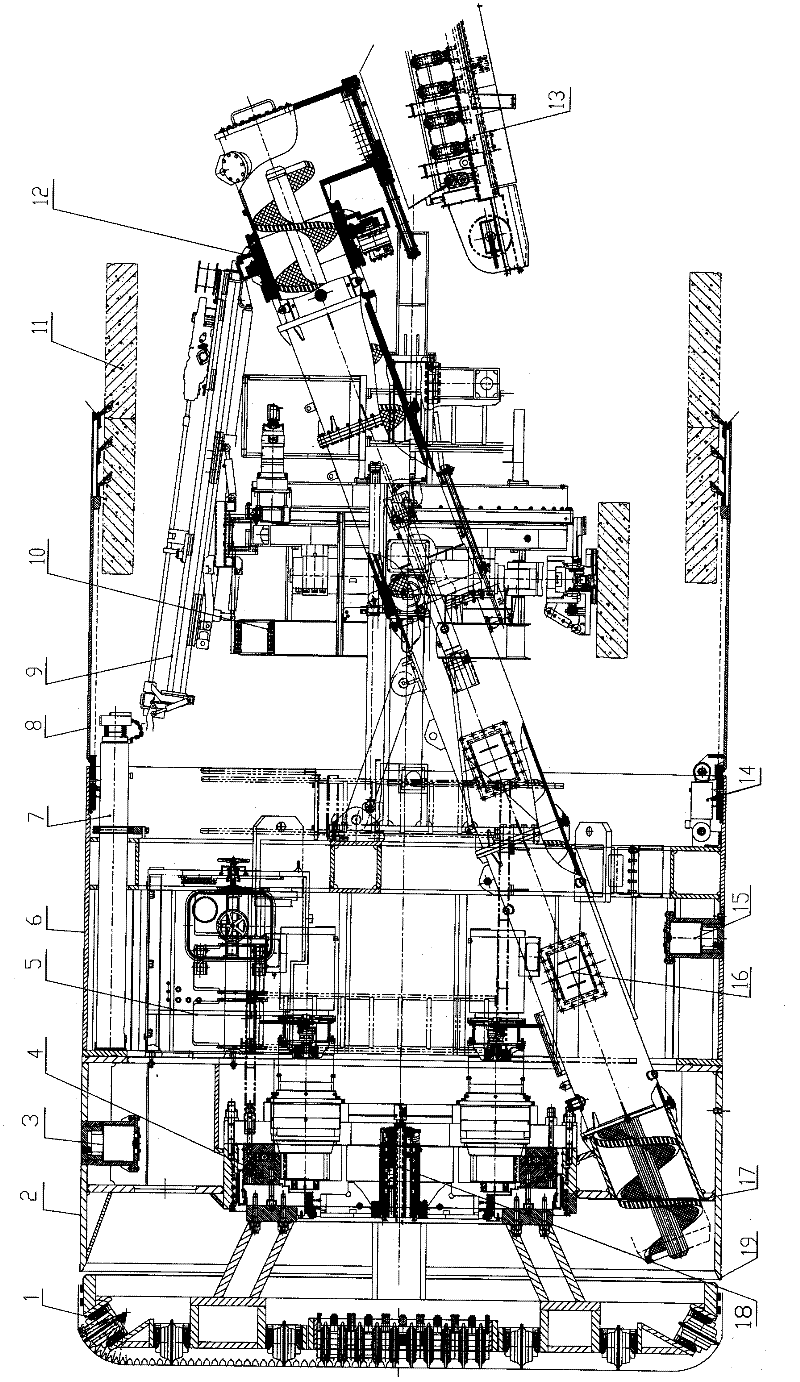

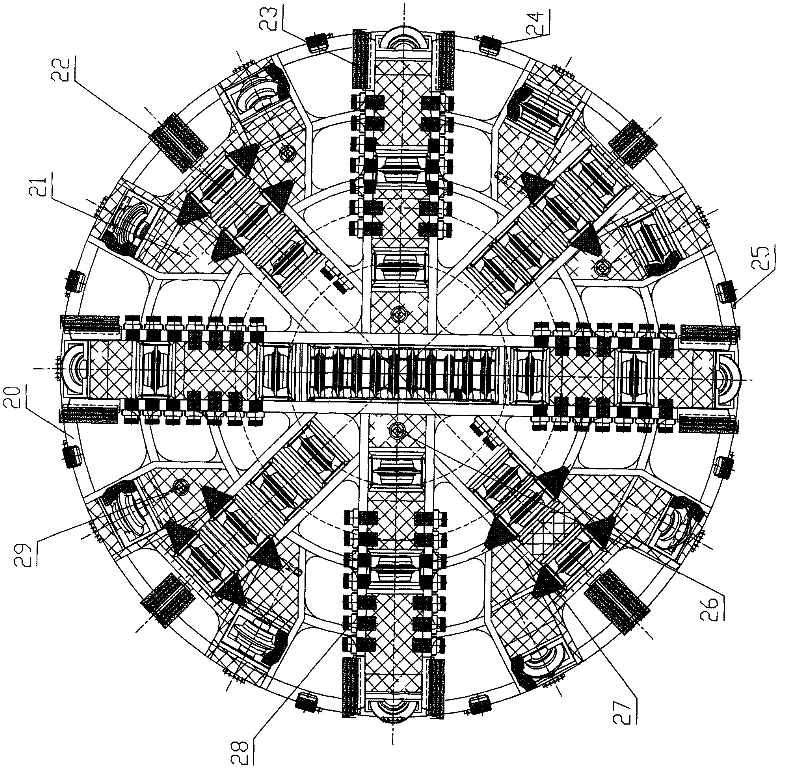

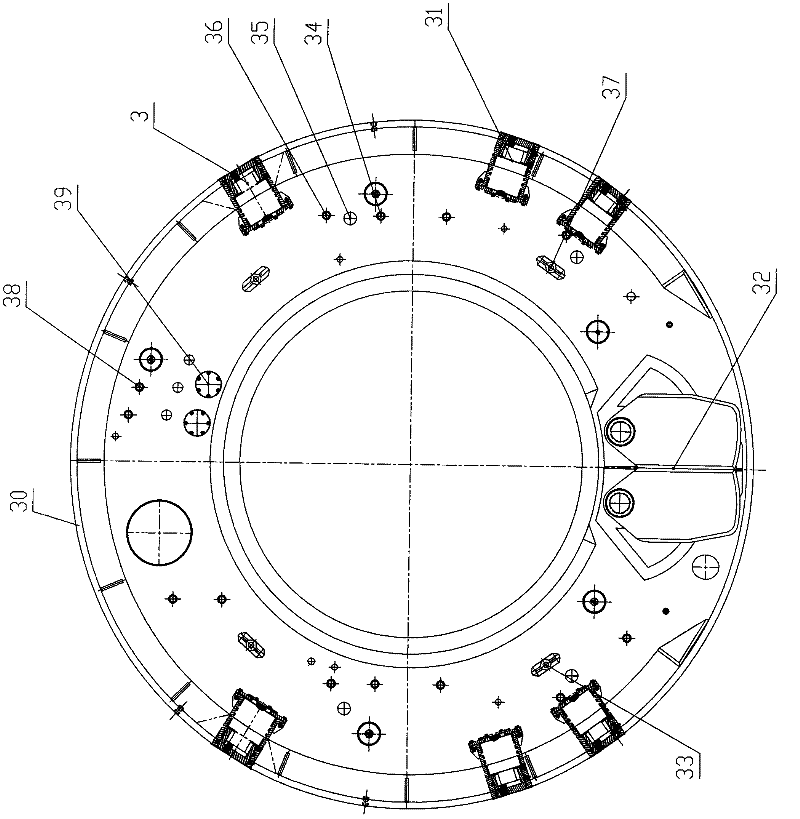

Novel dual-mode TBM (tunnel boring machine) and control method thereof

ActiveCN102410027AOvercome usabilityWith excavation face balancing functionUnderground chambersTunnel liningDual modeEngineering

The invention discloses a novel dual-mode TBM (tunnel boring machine) and a control method thereof used for the field of tunnel shield and TBM construction. Two tunneling modes can be realized by the equipment. An EPB (Earth Pressure Balance) tunnel shield mode of soft rock tunneling is utilized when an excavated surface cannot be autostable; and a TBM mode of hard rock tunneling is utilized when the excavated surface is good in autostability; and the two modes are converted easily. According to the novel dual-mode TBM and the control method thereof disclosed by the invention, the problems that the traditional earth pressure balance tunnel shield is of limited use in encountering a complex rock soil stratum, the TBM does not adapt to a soft soil stratum and the like are solved; the two tunneling modes of hard rock and soft soil are realized, the advantages of two tunnel support technologies of segment erection and hole wall support are combined; the novel mixing type TBM which is integrated with a hard rock tunneler technology and a soft soil tunnel shield technology not only has a hard rock quick tunneling function but also has an excavated surface balancing function, so that the tunnel shield technology and the TBM technology are mutually integrated, the geological adaptation range of the equipment is broadened, the single tunneling equipment has wider geological adaptability, can effectively reduce the construction risk and is simple to operate and low in cost.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Method for tunneling construction of main structure of underground station

ActiveCN101864959AEffectively control land subsidenceAvoid unfavorable stress statesUnderground chambersTunnel liningSoil massEngineering

The invention discloses a method for tunneling construction of a main structure of an underground station. In the method, the air shaft and air duct are excavated at first for the station and are then used as construction channels for excavation of the main structure of the station. The method for tunneling construction of the main structure of the station comprises the following steps: forming a reinforcing ring at the air duct port with a composite initial support; excavating the soil mass of a middle hole according to a certain sequence; constructing the internal structure of the middle hole; excavating the soil mass of a side hole; and constructing the internal structure of the side hole. The scheme can realize the smooth force transfer in the excavation of the soil mass, the initial support and the construction of permanent structures, avoid excessive adverse force-bearing states during the construction of the permanent structures, facilitate the construction, enhance the construction safety and construction efficiency, improve working conditions and ensure the quality of the project.

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD

Precompressed water and/or fire resistant tunnel expansion joint systems, and transitions

A fire and / or water resistant expansion joint system for installation between substrates of a tunnel. The system includes a coating applied at a predetermined thickness to the substrates and a fire and water resistant expansion joint. The expansion joint includes a core and a fire retardant infused into the core. The core is configured to define a profile to facilitate the compression of the expansion joint system when installed between the substrates. The coating and the fire and water resistant expansion joint are each capable of withstanding exposure to a temperature of at least about 540° C. or greater for about five minutes.

Owner:EMSEAL JOINT SYST

The roof caving and tunnel protecting method

InactiveCN101509395AHighlight substantiveReduce widthUnderground chambersMaterial fill-upMining engineeringFissure

The invention relates to a method for controlling caving and lane-guarding. The method is characterized in that in a working surface roadway, drilling, blasting or cracking are carried out on a roof of a coal seam of complete hard strata with large thickness of a hanging arch in a goaf; bursting or cutting off are carried out on a complete hard roof strata with large thickness to facilitate the hanging arch in the goaf to collapse at the back of a force piece; collapsed waste rock fills the goaf, supports superincumbent stratum in a fissure zone and releases high bearing stress passed into the coal body adjacent to the goaf from weight of the large-thickness complete hard strata of the hanging arch in the goaf and the superincumbent stratum in the fissure zone thereof, so that the bearing stress in the coal body adjacent to the goaf is reduced and laneways in the space are protected. The method of the invention fundamentally improves stability of surrounding rock of laneways adjacent to the goaf and increases coal mining rate of ends of thick coal seam caving coal working surface.

Owner:TAIYUAN UNIV OF TECH

Goaf surrounding rock around gob-side supporting method under three soft geological condition

ActiveCN101280684ASolve support problemsPromote safe productionUnderground chambersTunnel liningEngineeringTechnical support

Disclosed is a method for retaining roadway and supporting the surrounding rock in goafs under geological condition, which is characterized by first reinforcing and retaining roadway for the first time, then constructing the exceeded roadway and finally constructing and retaining roadway for the second time. The method of the invention forms an effective supporting for the secondary retaining roadway along the goafs, thus overcoming the difficulty in supporting roadway in a condition of multi mining activities. The roadway is primarily guaranteed perfect during the mining period and the amount of shrinkage is in the allowed control range, thereby providing technical support and guarantee for smoothly realizing the Y-type ventilation of the working face with high content of methane and promoting the safety production in mine wells.

Owner:HUAINAN MINING IND GRP +2

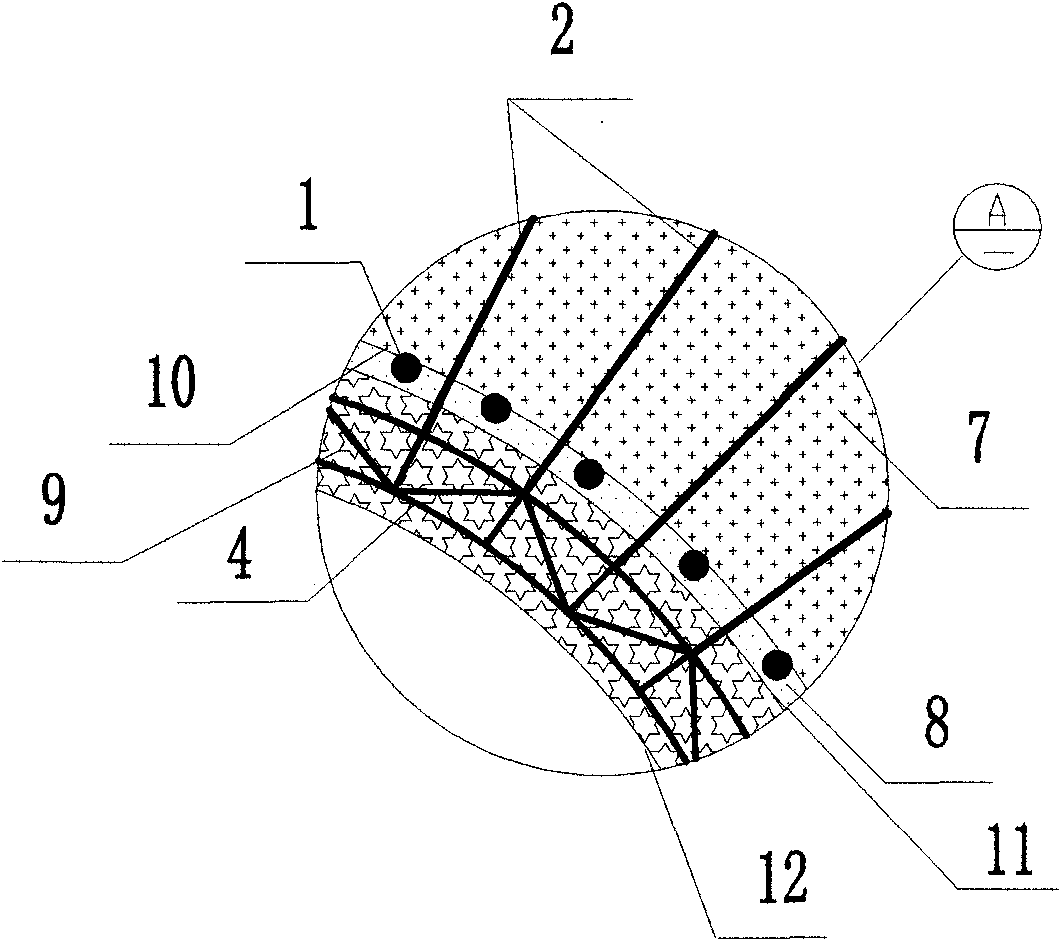

Total-section closed type deep-shallow coupling yielding, bolting-grouting and supporting method for incompact and fractured soft-rock roadway

InactiveCN105178981AImprove support strengthWatch protection effect is goodUnderground chambersTunnel liningCouplingStructure of the Earth

The invention relates to a total-section closed type deep-shallow coupling yielding, bolting-grouting and supporting method for an incompact and fractured soft-rock roadway. On the basis of a multilayered cooperative supporting principle, a spraying net combined isolating arch, an anchor rod extruding reinforcing arch, a total-section closed type grouting reinforcing ring and a deep slurry diffusion reinforcing arch are respectively formed on surrounding rock of the roadway from shallow to deep finally, and are combined to form a multilayered effective combined arch by a suspension effect of a high-strength grouting anchor cable, advantages of yielding supporting, bolting-grouting supporting and deep-shallow coupling supporting are combined organically, bearing range, integrity and bearing capability of a supporting structure are improved obviously, a control effect on deformation characteristics of large deformation, high speed, long duration, wide destroying range, peripheral pressing, obvious floor heaves and the like of the surrounding rock of the incompact and fractured soft-rock roadway is excellent, and various deformations of the surrounding rock of the incompact and fractured soft-rock roadway are controlled effectively. The total-section closed type deep-shallow coupling yielding, bolting-grouting and supporting method is particularly suitable for a large-section incompact and fractured soft-rock roadway of a deep well, is simple in work procedures and low in cost, and has high field promotion and application value; and parallel operation can be realized.

Owner:CHINA UNIV OF MINING & TECH

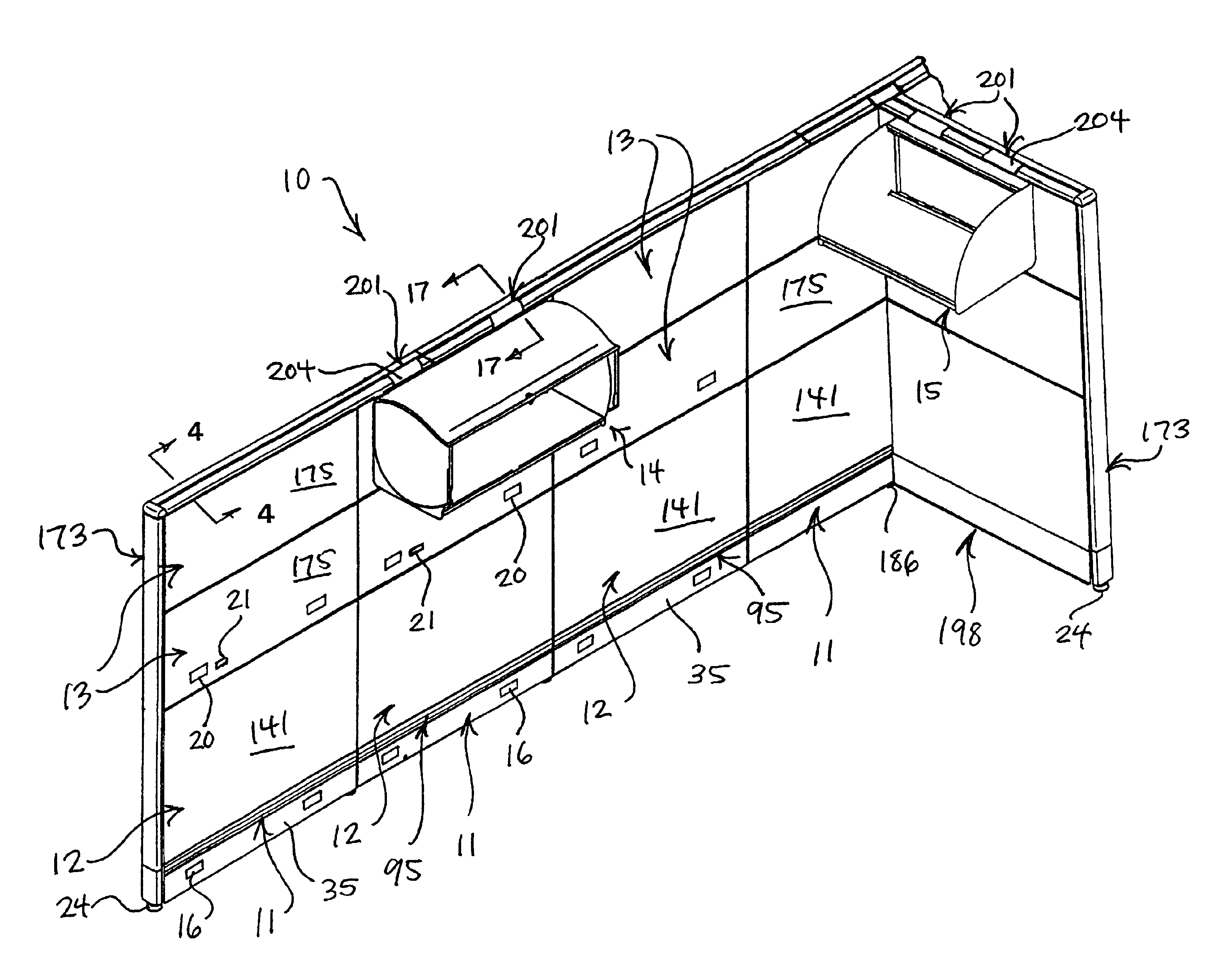

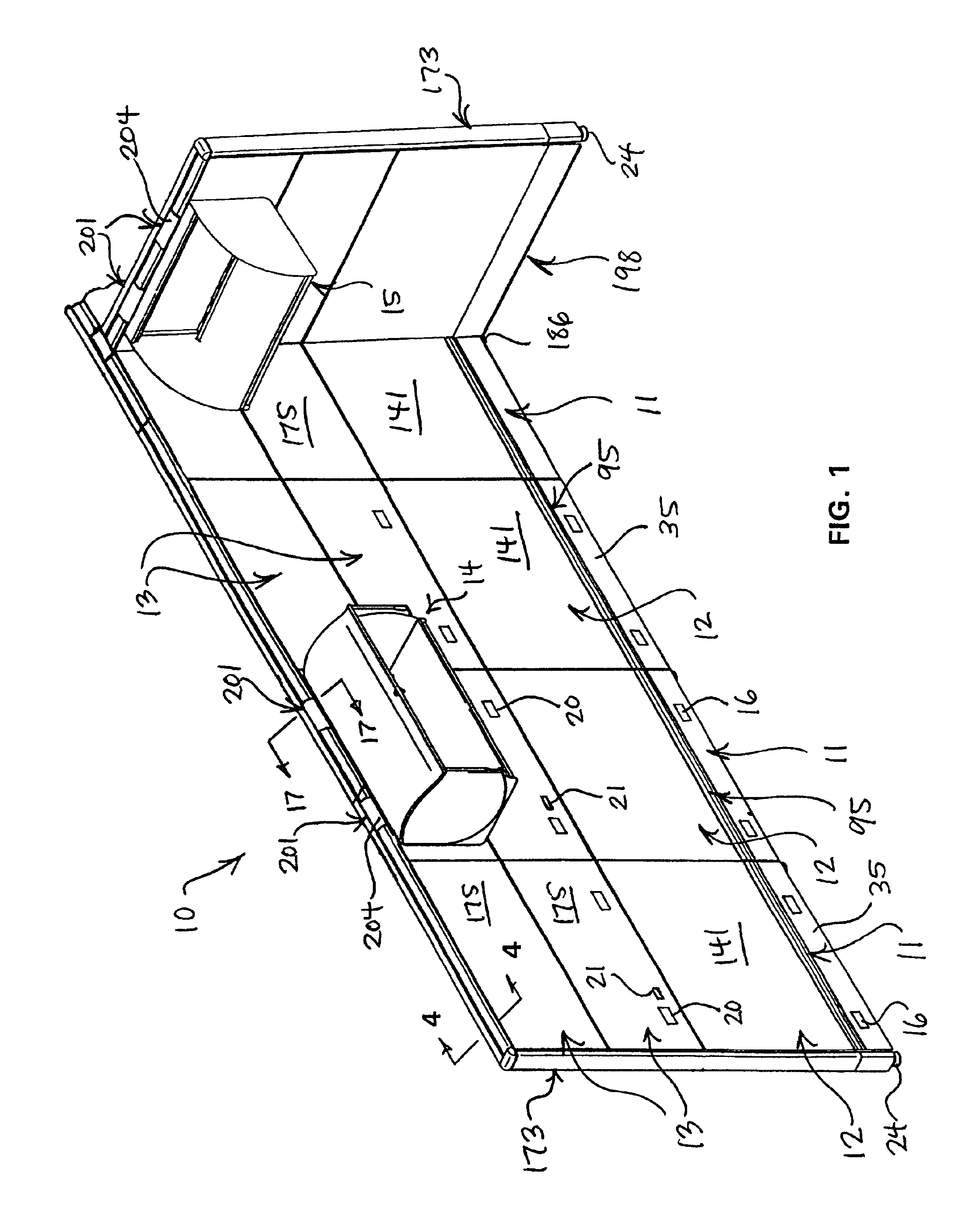

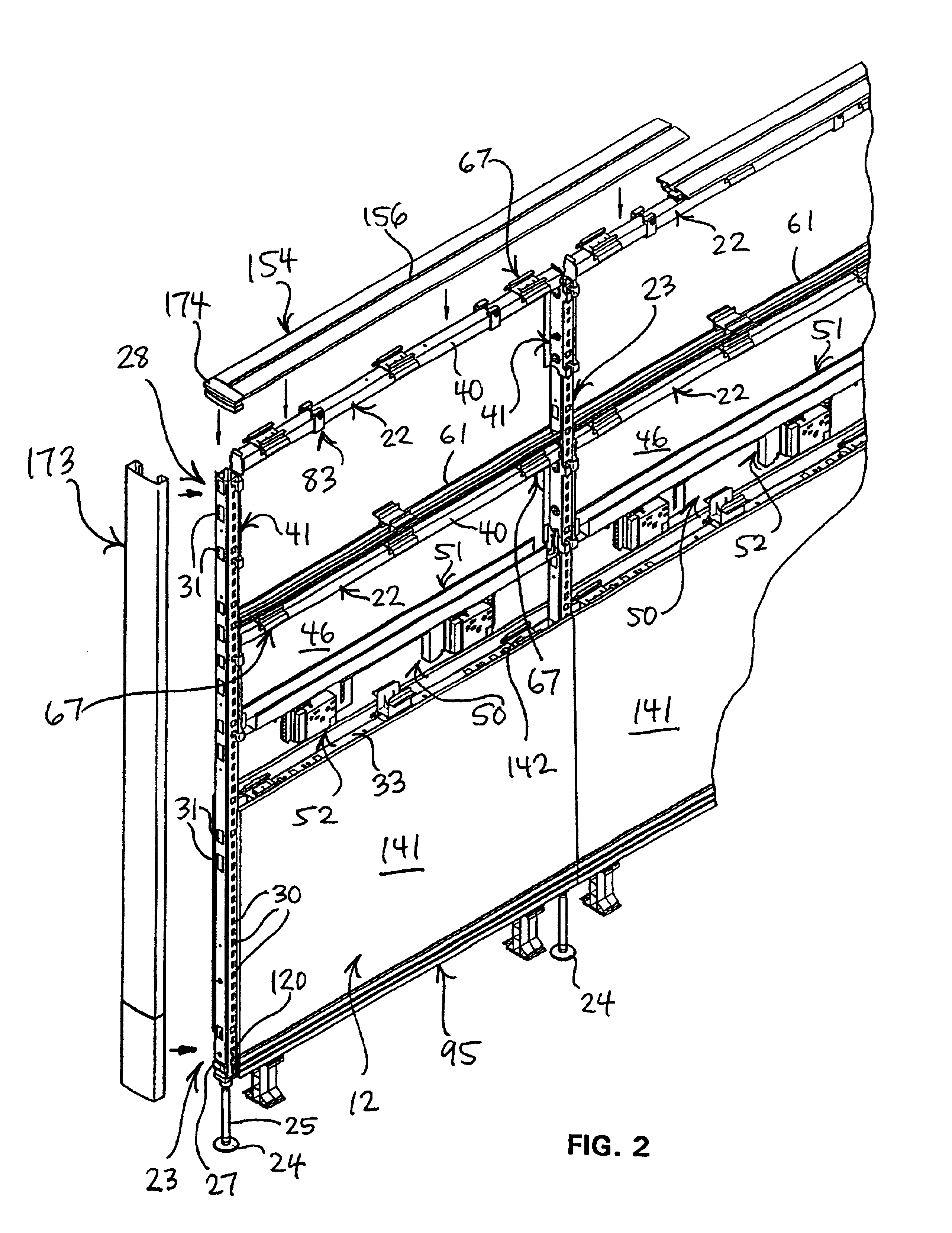

Wall panel arrangement with accessory-supporting top cap

InactiveUS6920727B2Good flexibilityLarge load bearing capabilityUnderground chambersWallsWorkstationElectric power

A space-dividing wall panel arrangement having a plurality of upright wall panels serially connected one with the other by an upright support post. The wall panel arrangement additionally includes an open-frame structure which allows routing of cabling therethrough to provide power and communication capabilities to a workstation defined by the wall panels, and a removable and rigid top cap which is capable of supporting various furniture-type accessories at selected locations along the longitudinal extent of the panel arrangement, and which also permits mounting of return wall panels to permit greater flexibility in configuring a workstation.

Owner:HAWORTH SPA

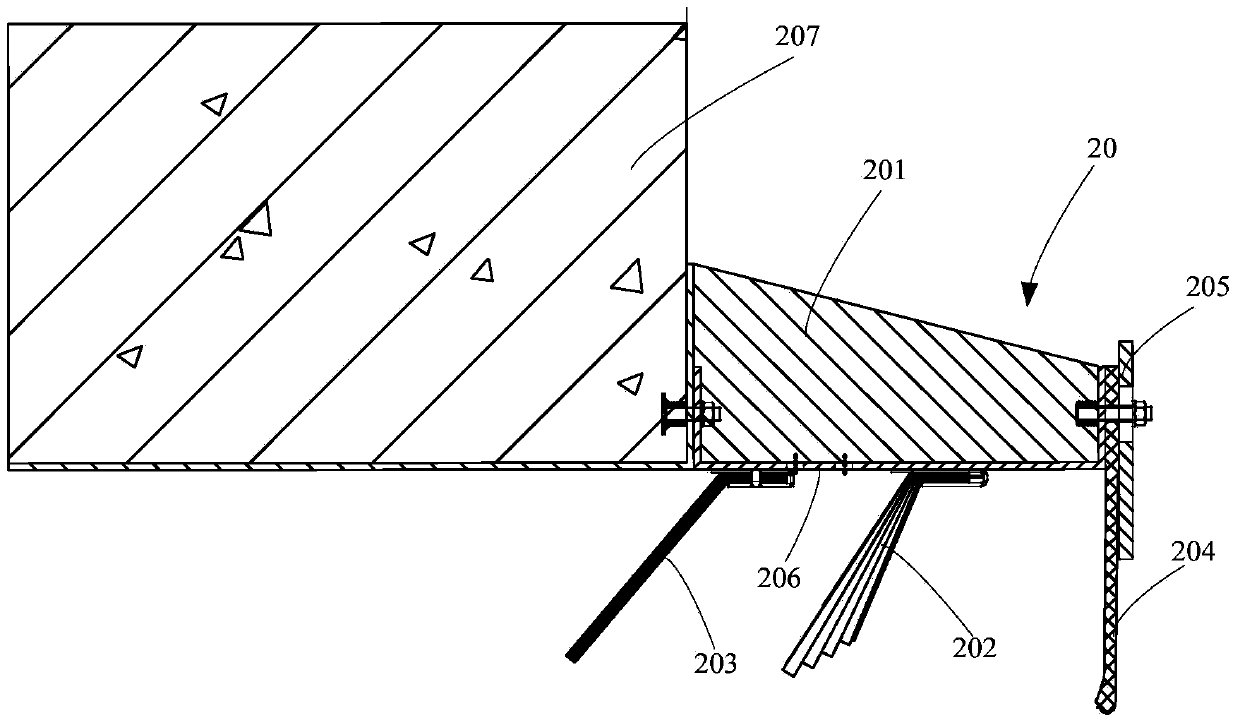

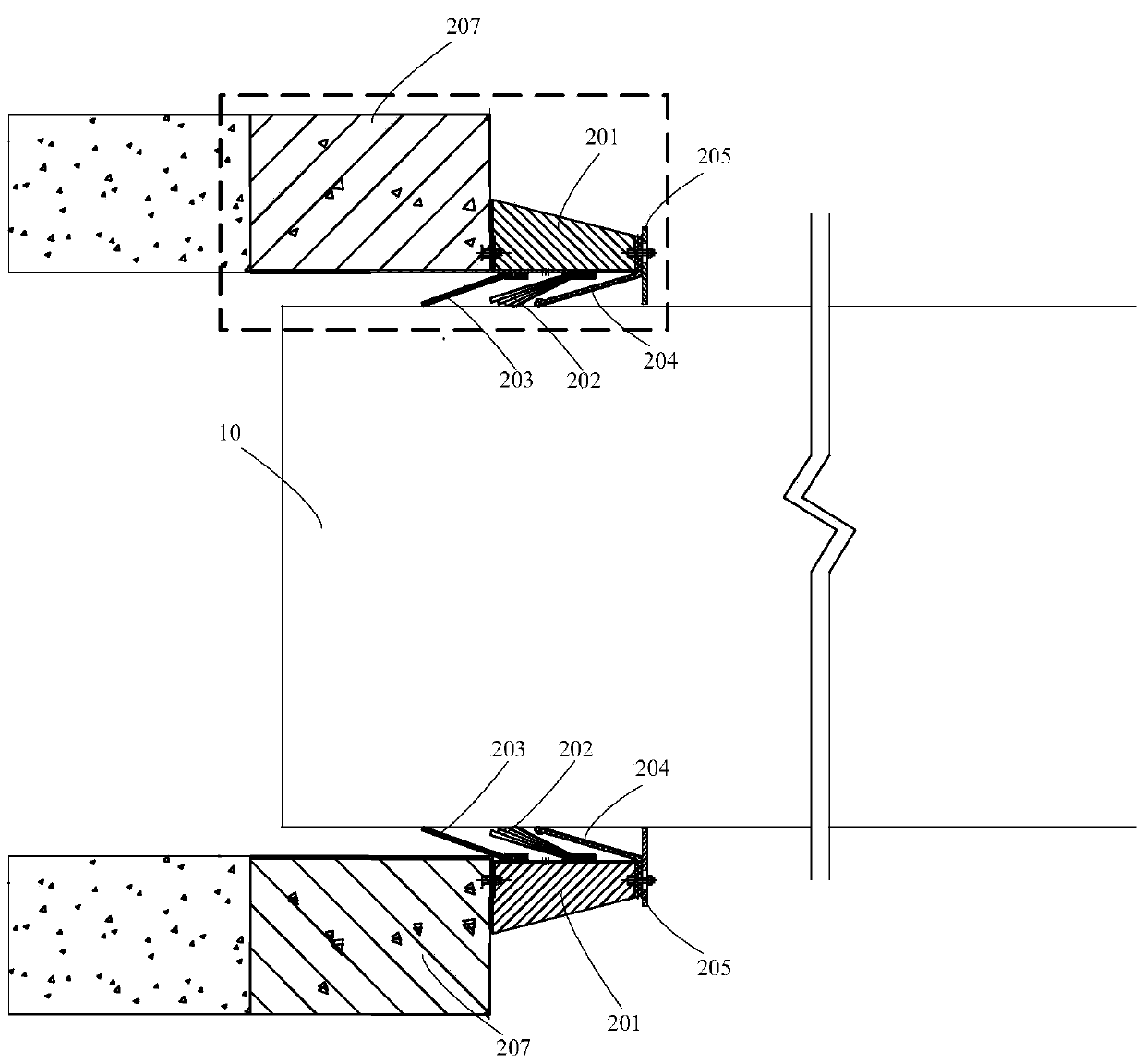

Ultra-large full-face rectangular pipe jacking tunneling construction method

ActiveCN104265321AExcavation construction realizationSolve large sectionsUnderground chambersTunnel liningSlurryBuilding construction

The invention relates to an ultra-large full-face rectangular pipe jacking tunneling construction method, which comprises the following steps that: a tunnel line axial line is determined, and a launching shaft and a receiving shaft are set; a pipe jacking machine is arranged on a guide rail arranged in the launching shaft to be debugged; the pipe jacking machine performs tunneling along the tunnel line axial line, and pipe joints are spliced in the launching shaft; when the pipe jacking machine reaches the receiving shaft, the pipe joints are separated from the pipe jacking machine, and the tunnel breakthrough is realized; curing slurry is injected to pipe joint peripheries through slurry injecting holes formed in the pipe joints, and soil bodies around the tunnel are reinforced; and shaft joints are cast in connecting positions of structure lined walls and the pipe joints in the positions of the receiving shaft and the launching shaft. The ultra-large full-face rectangular pipe jacking tunneling construction method has the advantages that the hole entering and exiting and non-excavation tunneling construction of the pipe jacking machine is realized; the ultra-large full-face rectangular tunneling construction is realized; and the problems in a long-face long-distance and curve tunneling process in the conventional ultra-large full-face rectangular pipe jacking tunneling construction are solved.

Owner:SHANGHAI TUNNEL ENG CO LTD +1

Device and method for repairing pipe

ActiveUS20090194184A1Improves over and solvesSacrificing wall thicknessUnderground chambersPipe elementsEngineeringAbsorbent material

The present invention relates to a new liner for repairing a damaged portion of a pipe. A lining tube formed from a non-resin absorbent material has an exterior surface adapted to receive a curable resin and contact an interior wall of the pipe. The present invention also includes a main / lateral liner assembly for repairing the junction between main and lateral pipes using a non-resin absorbent liner for at least a portion of the lining.

Owner:LMK TECH LLC

Construction method for double-circular shield near-distance passing through building or structure

InactiveCN1932244AUnderstand situationUnderstand the lawUnderground chambersTunnel liningArchitectural engineeringEarth surface

The present invention relates to a double circular shield construction method passing through building or structure, belonging to the field of building engineering technology. Said construction method includes the following steps: 1, earlier stage preparation for passing through building or structure; 2, adopting protection measure for building or structure; 3, construction monitoring; 4, making double circular shield be passed through building and structure; and 5, adopting secondary grounting measure.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD.

Drifting sand layer and gravel stratum water-moving double-liquid high pressure slip-casting water-blocking construction method

InactiveCN101255698AHigh strengthImprove water stabilitySolid waste managementUnderground chambersWater blockCement slurry

The present invention discloses a running sand layer and sandy gravel layer dynamic-water double-liquid high-pressure slurry-injecting water-shutoff construction method which comprises the following construction steps: drilling a hole, flushing the hole, executing double-liquid high-pressure slurry-injecting operation and sealing the hole. The running sand layer and sandy gravel layer slurry-injecting liquid adopts an ordinary portland cement (P.O.42.5) and 40''Be sodium silicate as material for preparing the slurry, according to the weight proportion of water: cement, namely the cement slurry is prepared with the water cement ratio for 0.5-1.2:1. Then the slurry-injecting liquid is prepared with the volume ratio of cement slurry: sodium silicate for 1:0.08-0.15. The sodium silicate is taken as additive for regulating the initial setting time of the slurry-injecting liquid. The cement slurry can also be doped with fly-ash with cement consumption (weight proportion) for 10%-15%. The invention executes water-insulating construction aiming at the characteristics of large pressure of the underground dynamic water and high flowing velocity in the running sand layer and sandy gravel layer, and can obtain the maximal application sphere and optimum water-shutoff effect.

Owner:HUNAN CONSTR ENG GRP COR

High ground stress soft rock stress-relief construction method

InactiveCN101644160AMature technologyGood effectUnderground chambersTunnel liningShotcretePolystyrene

The invention discloses a high ground stress soft rock stress-relief construction method which comprises the following steps: A. anchor shotcreting constructing, tagging the anchor shotcreting constructing with heading, and eliminating dangerous rock; B. cystosepiment hanging, carrying out hanging construction on polystyrene cystosepiment; C. inverted arch excavating and U shape steel spanning, lining tunnel to a ring, and carrying out re-spraying with shotcrete on clearance of steel racks; D. inverted arch backfilling, carrying out construction of a waterproof barrier layer after completing spanning of the U shape steel so as to conserve concrete; E. waterproof barrier layer constructing, carrying out waterproof barrier layer constructing when the convergence rate of tunnel is stabilized;F. secondary lining constructing, carrying out secondary lining constructing when the waterproof barrier layer constructing is completed; and G. prestress anchor line constructing, determining a holesite of an anchor line and the drilling direction through field lofting, and clearing the location of the hole site. The construction method has obvious effect for controlling large deformation of the soft rock with the high ground stress, is simple and convenient, and has the advantages of simple operation, obvious effect and relatively low cost.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

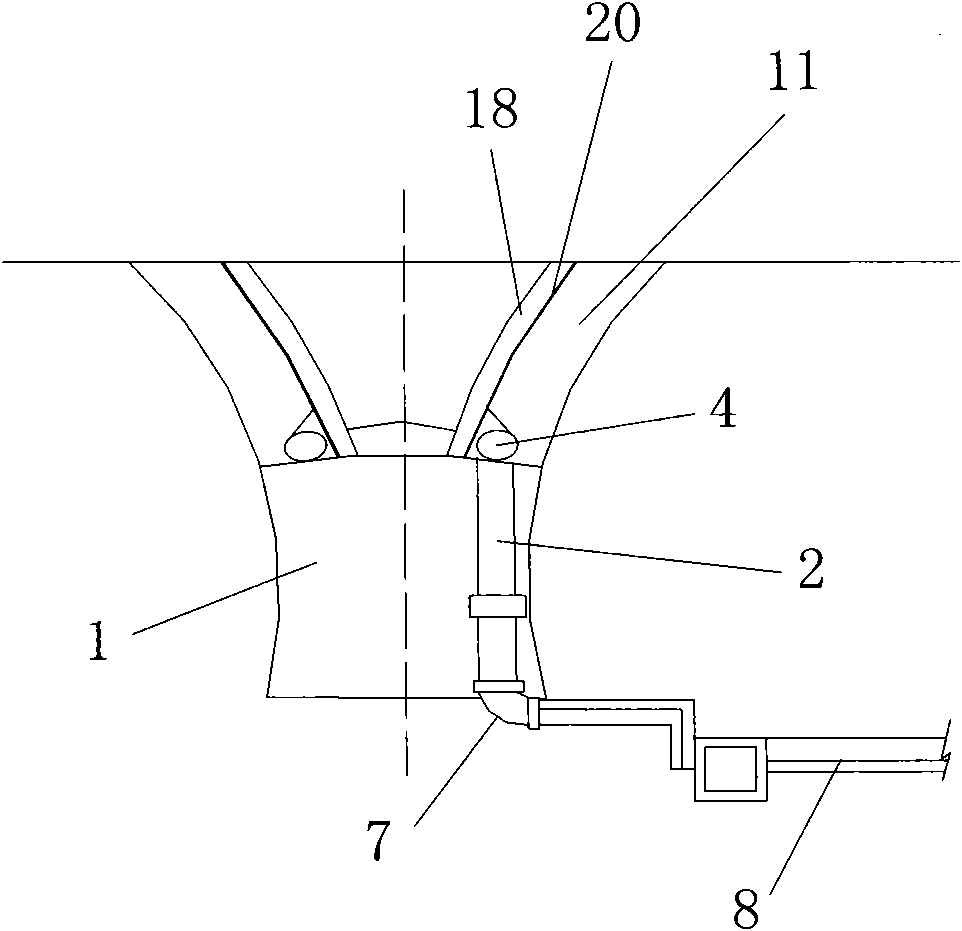

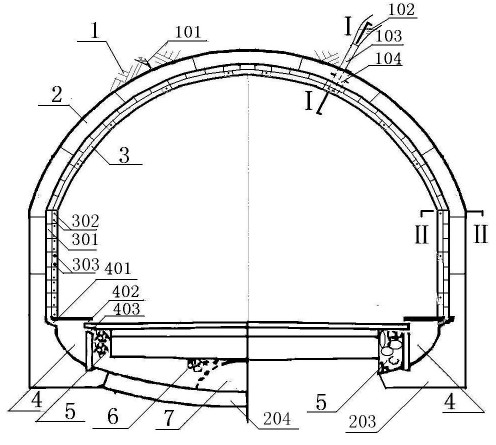

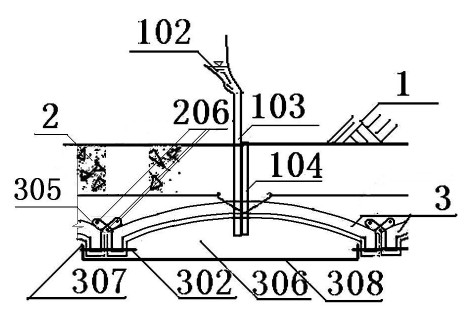

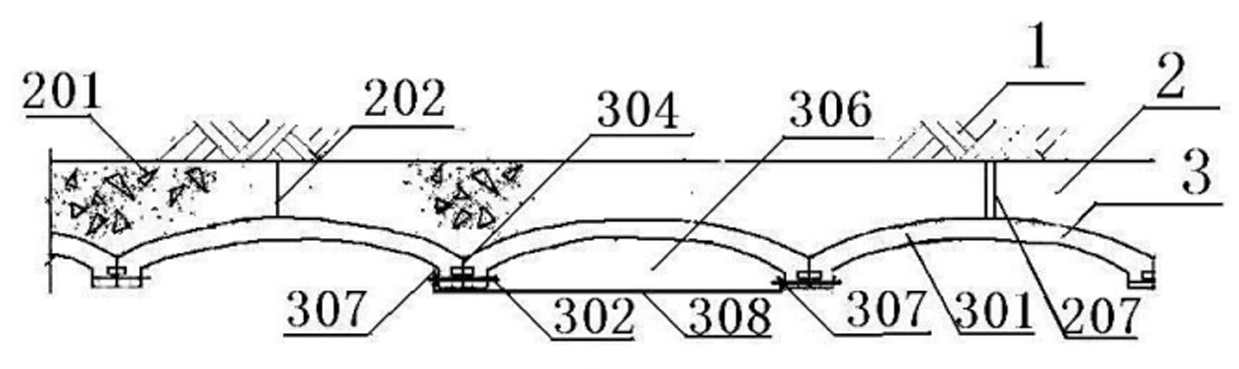

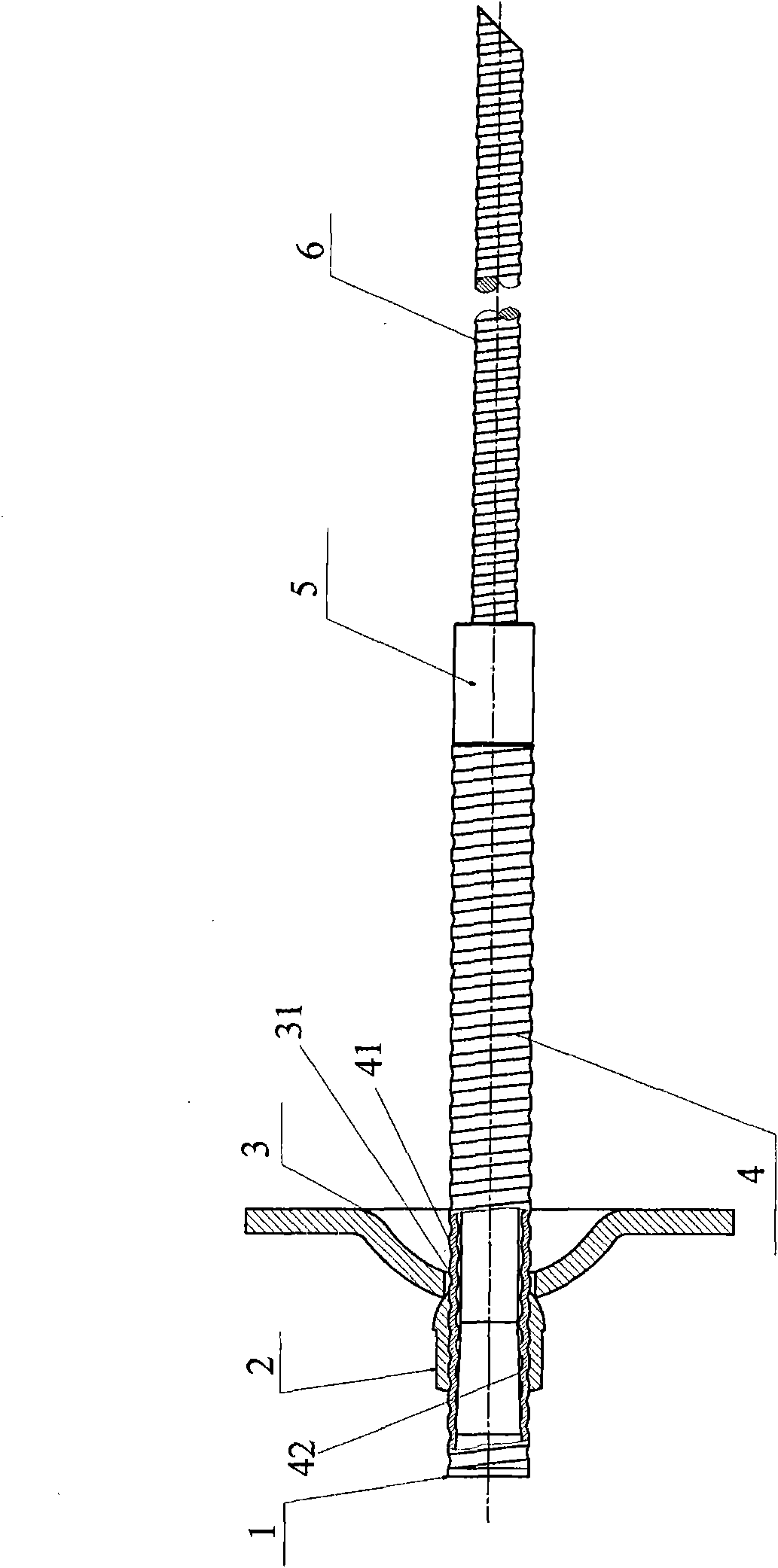

Tunnel lining self waterproof drainage system

InactiveCN102434175AGuaranteed reliabilityImprove waterproof qualityUnderground chambersDrainagePondingTube drainage

The invention relates to a tunnel lining self waterproof drainage system, which comprises a surrounding rock bearing arch, a cast-in-place cement main waterproof layer, a pre-cast cement arch sheet layer and longitudinal drainage channels. Arch sheet layer construction gaps and cast-in-place cement main waterproof layer construction gaps are interlaced. The tunnel lining self waterproof drainage system is characterized in that movable drainage grooves are fixedly arranged below the pre-cast cement arch sheet layer of centralized bursting water seepage points of loose surrounding rocks, and form arch sheet drainage spaces with an inwards concave surface of the pre-cast cement arch sheet layer, the parallel drainage spaces distributed along the section of a tunnel form a movable drainage channel, the longitudinal drainage channels are communicated and are arranged on two sides of the movable drainage channel and the pavement of the tunnel, pre-embedded water guiding pipes are arranged at the centralized bursting water seepage points, a water outlet end of each pre-embedded water guiding pipe is arranged on the inwards concave surface of the pre-cast cement arch sheet layer, and pre-embedded grouting pipes are arranged outside the pre-embedded water guiding pipes. The invention completely solves stubborn problems of the tunnel on cracking, seeping, frost heaving, ponding or freezing and the like on the premise of not arranging an interlayer waterproof layer and a hidden seepage water blind pipe drainage system, and the tunnel lining self waterproof drainage system disclosed by the invention has a simple structure and is convenient to construct.

Owner:中国市政工程西北设计研究院有限公司

Method for preventing and treating large deformation and collapse of softrock tunnel

ActiveCN101906977AImprove pullout resistanceGuaranteed stabilityUnderground chambersTunnel liningLarge deformationRock bolt

The invention relates to a method for preventing and treating large deformation and collapse of a softrock tunnel, which comprises the following steps: tunneling molding or enlarging a tunnel; primarily spraying the first layer of concrete, and hanging a side net and a top net at the first layer of concrete; arranging a constant-resistance large deformation rock bolt; multiply spraying the second layer of concrete; arranging a constant-resistance large deformation anchor cable on the top plate; digging and laying the first layer of base plate concrete; hanging a layer of backing screen on the first layer of base plate concrete, and arranging a base angle anchor rod at the base angle; laying the second layer of base plate concrete onto the grade level; setting a long-term ground pressure monitoring point, if the tunnel deforms to a certain preset valve, carrying out secondary support at the key position of the tunnel and carrying out pressurization and slip casting on surrounding rock. The invention can well ensure the stability of softrock tunnel under the condition of large deformation, in addition, the invention has the advantages of simple and practicable implement and lower cost.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Deep well tunnel cable anchor rigid-flexible coupling support and surrounding rock overall reinforced support method

InactiveCN101967984AImprove carrying capacityPrevent shear deformationUnderground chambersTunnel liningPre stressCoupling

Owner:ANHUI UNIV OF SCI & TECH

Construction method for tunnel continuous mucking, lining and excavation synchronization

ActiveCN101403305AImprove construction efficiencyShorten the construction periodUnderground chambersTunnel liningFalseworkTransport facility

The invention provides a construction method for the continuous mucking, lining and excavation synchrony of tunnels (caves), which comprises the following steps: the front end of a belt conveyer is positioned in an excavation work area, the belt conveyer from the excavation work area to the lining area of a steel moulding plate trolley is positioned on an inverted arch precast block (6) or hung at the top of the tunnel; the belt conveyer in front of the steel moulding plate trolley causes a conveyer (7) to be positioned at one internal side of a moulding plate trolley gantry (4) when passing through the moulding plate trolley on the basis of being positioned on the inverted arch precast block or a cast-in-situ inverted arch; a falsework (14) is arranged in front of the moulding plate trolley (2) and positioned on a track (12) which is connected in front of the self-circulation of the steel moulding plate trolley; and the belt conveyer is positioned on the inverted arch precast block or hung at the top of the tunnel from a lining operating area to a tunnel entrance after passing through the steel moulding plate trolley. The construction method can realize the continuous mucking of the belt conveyer and the synchronous lining of the moulding plate trolley along with the excavation of the tunnel in tunnel construction and cause transport equipment such as cars or the track to transport facilities and other materials needed by tunnel construction.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

Hard rock composite TBM (Tunnel Boring Machine) suitable for composite stratum and tunneling mode thereof

ActiveCN102364049AOvercome the shortcomings of limited use and the inability of TBM to be used in soft soil formationsWith excavation face balancing functionUnderground chambersTunnel liningGeomorphologyTunnel boring machine

The invention discloses hard rock shield construction equipment which is suitable for a single stratum of soft soil, soft rock, hard rock and the like and is simultaneously suitable for a soft and hard alternate stratum and a transition stratum, particularly silt, clay, powder, sand, gravel, decayed rock stratum. In the invention, two tunneling modes can be realized: an earth pressure balance tunneling mode and an open tunneling mode. When an excavated surface has poor stability or soft soil, a sand stratum and a sand gravel stratum with high water content are excavated, the earth pressure balance tunneling mode is used for construction; and when surrounding rock of the excavated surface can be self-stabilized, the open mode is used for construction when the rock stratum has high stability, particularly, a composite cutter head is used for tunneling. The equipment has extremely strong geological adaptability, is particularly suitable for construction of a soft and hard complex stratum of a municipal metro, and also has low construction interference and is convenient to control; and the overall manufacturing cost is greatly reduced compared with a hard rock tunneling machine.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com