Patents

Literature

355results about "Gaskets" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

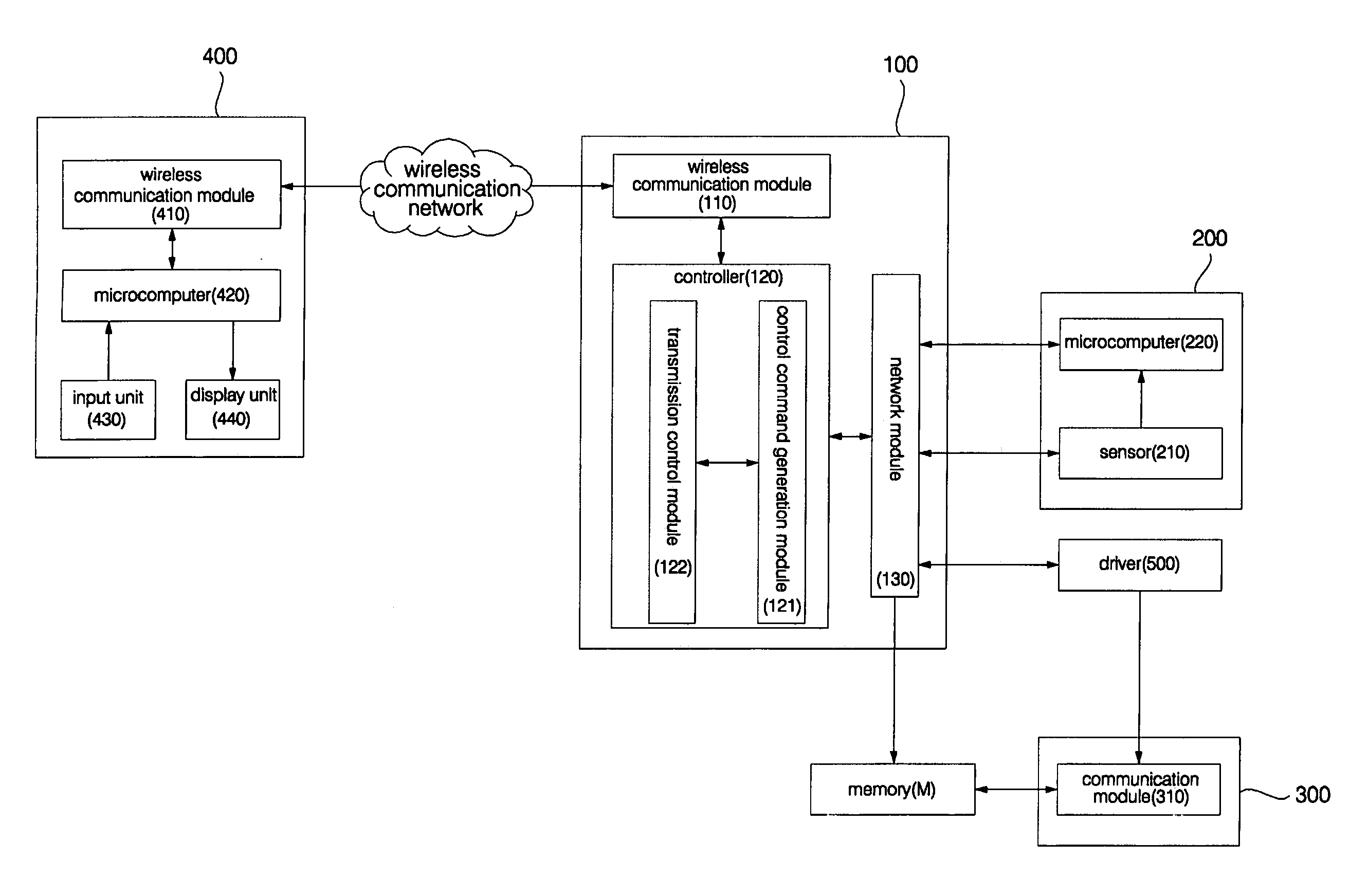

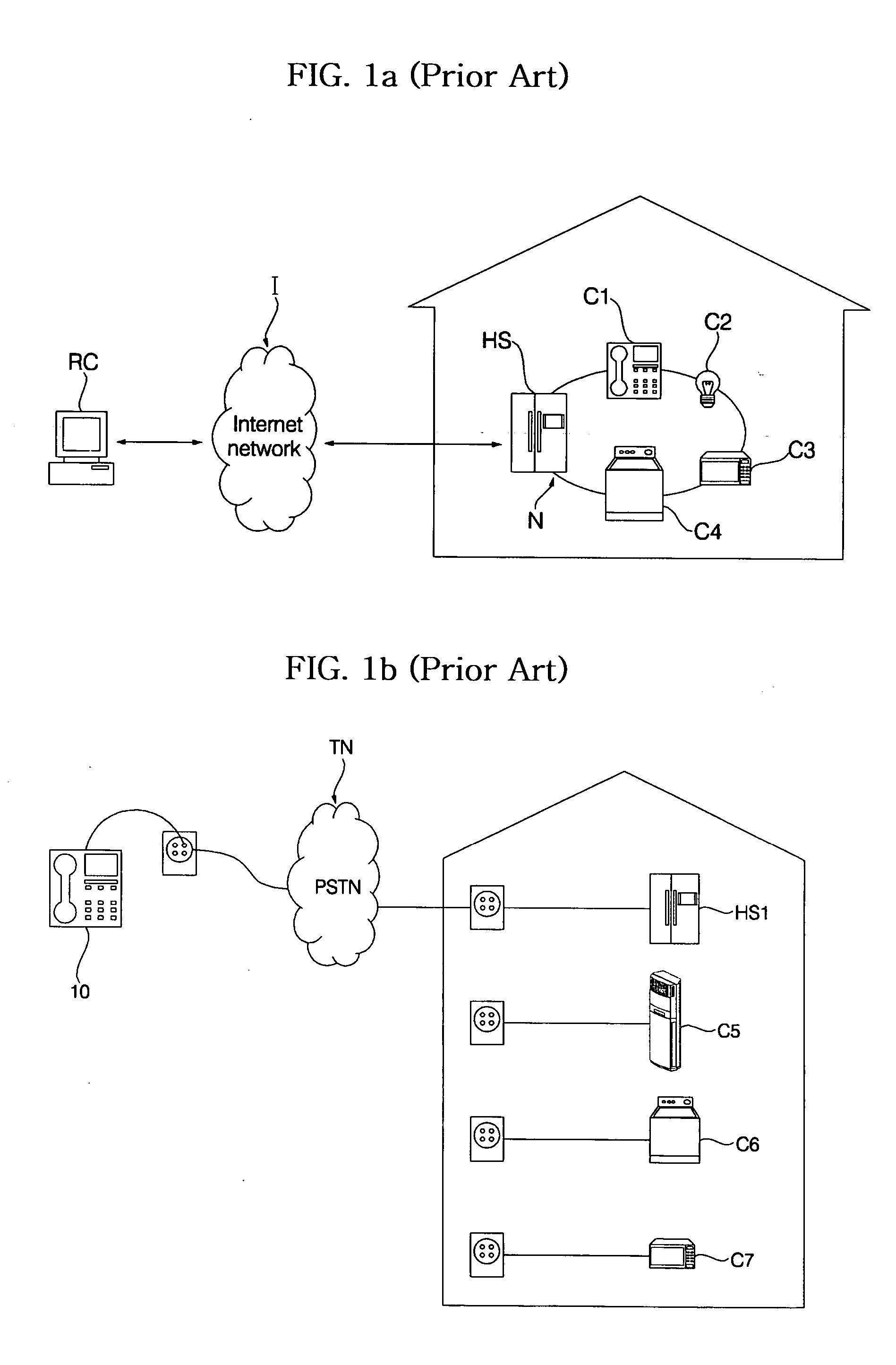

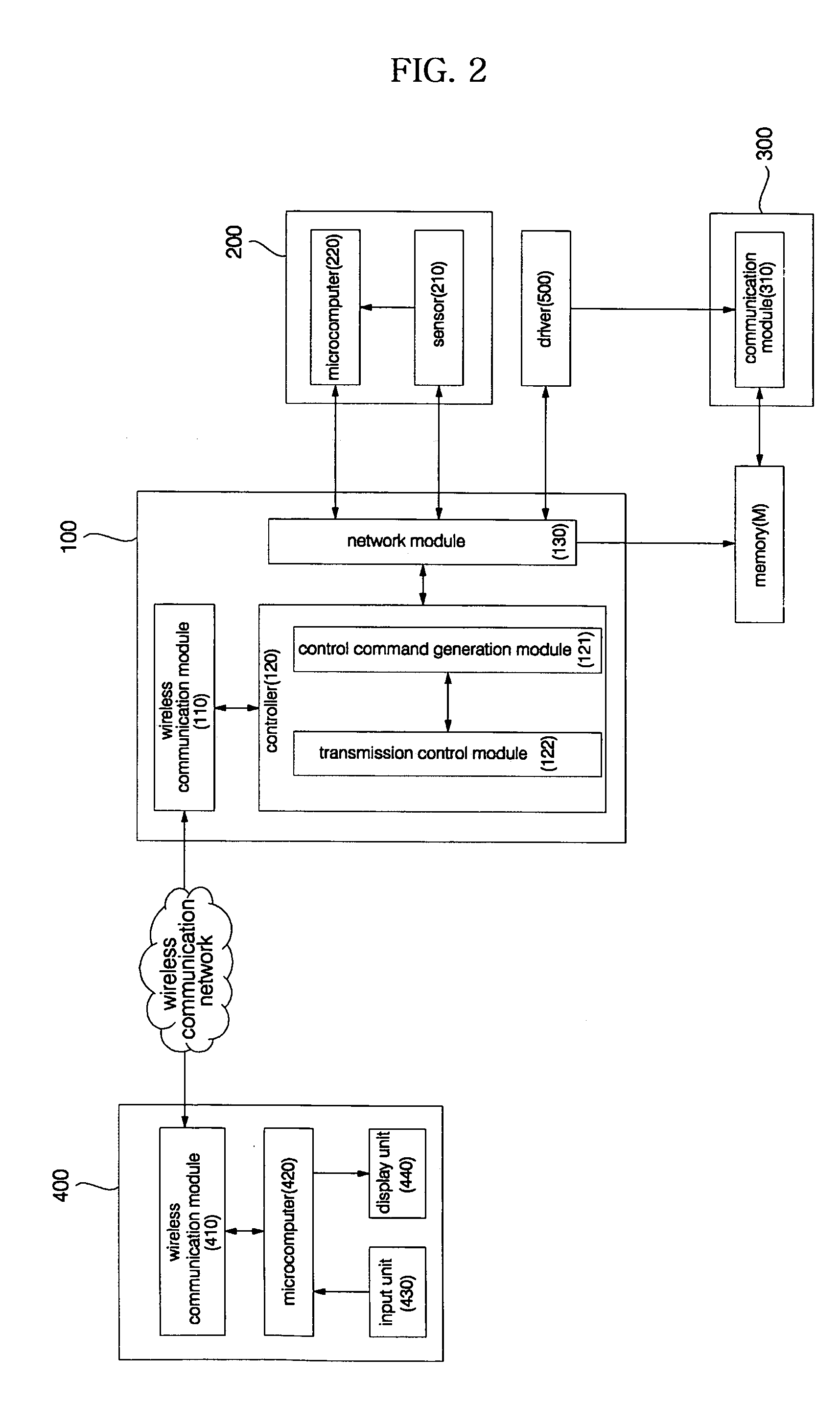

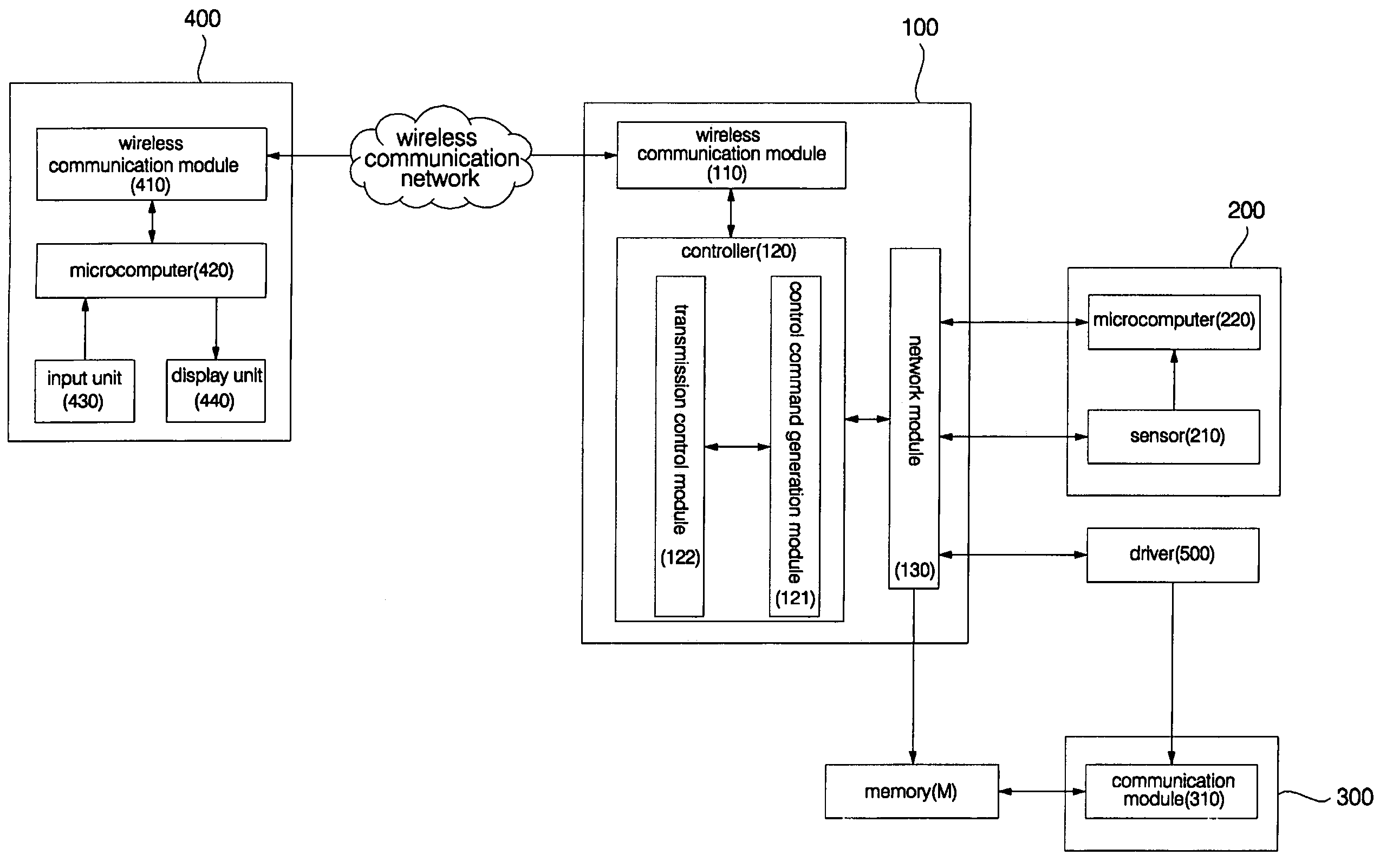

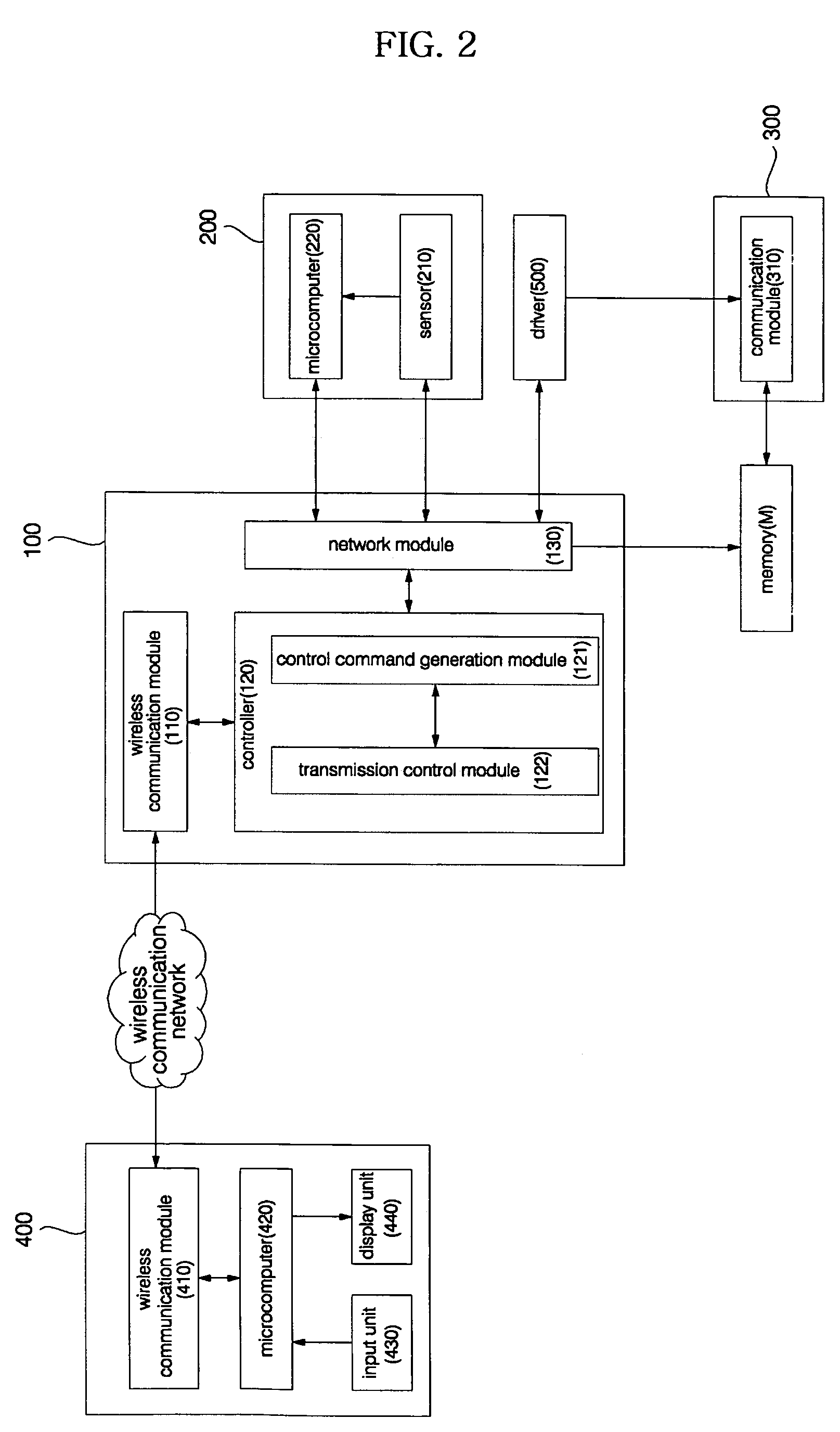

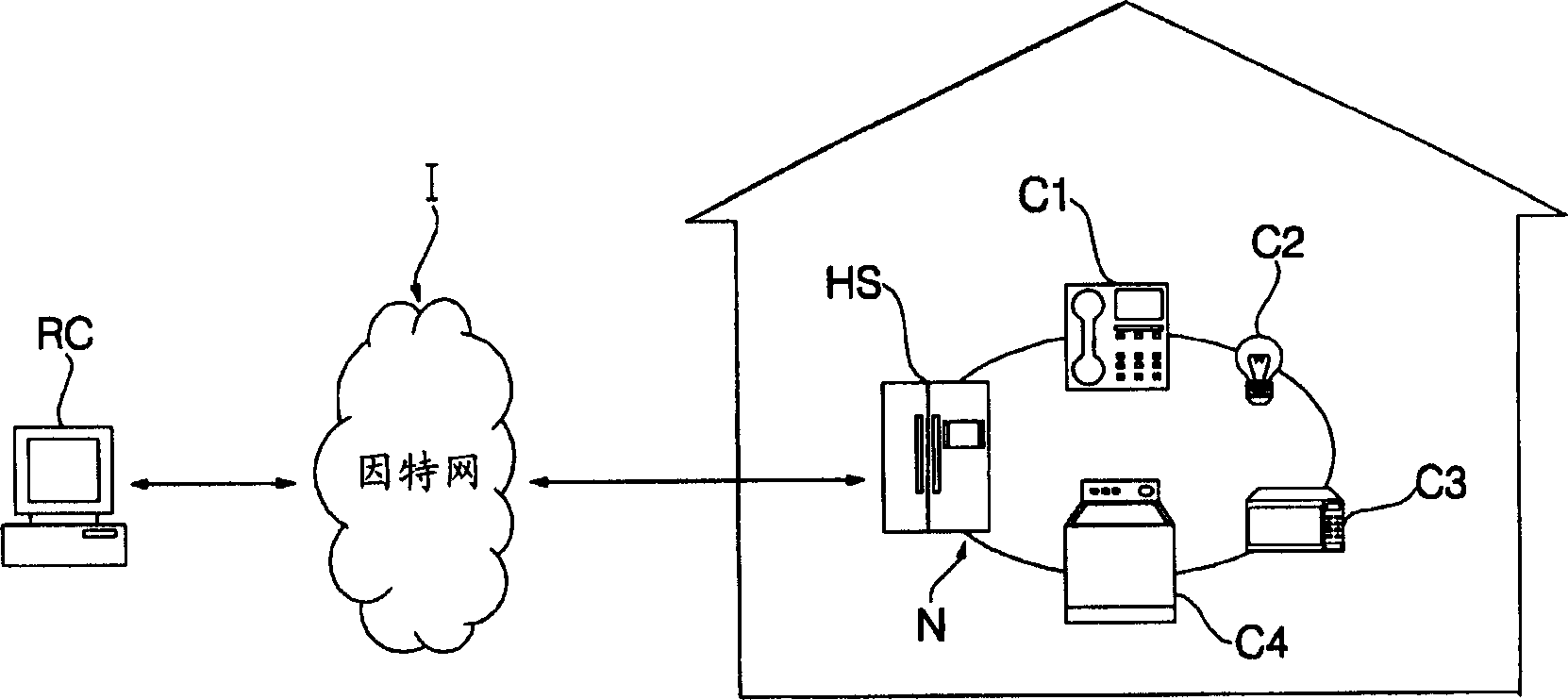

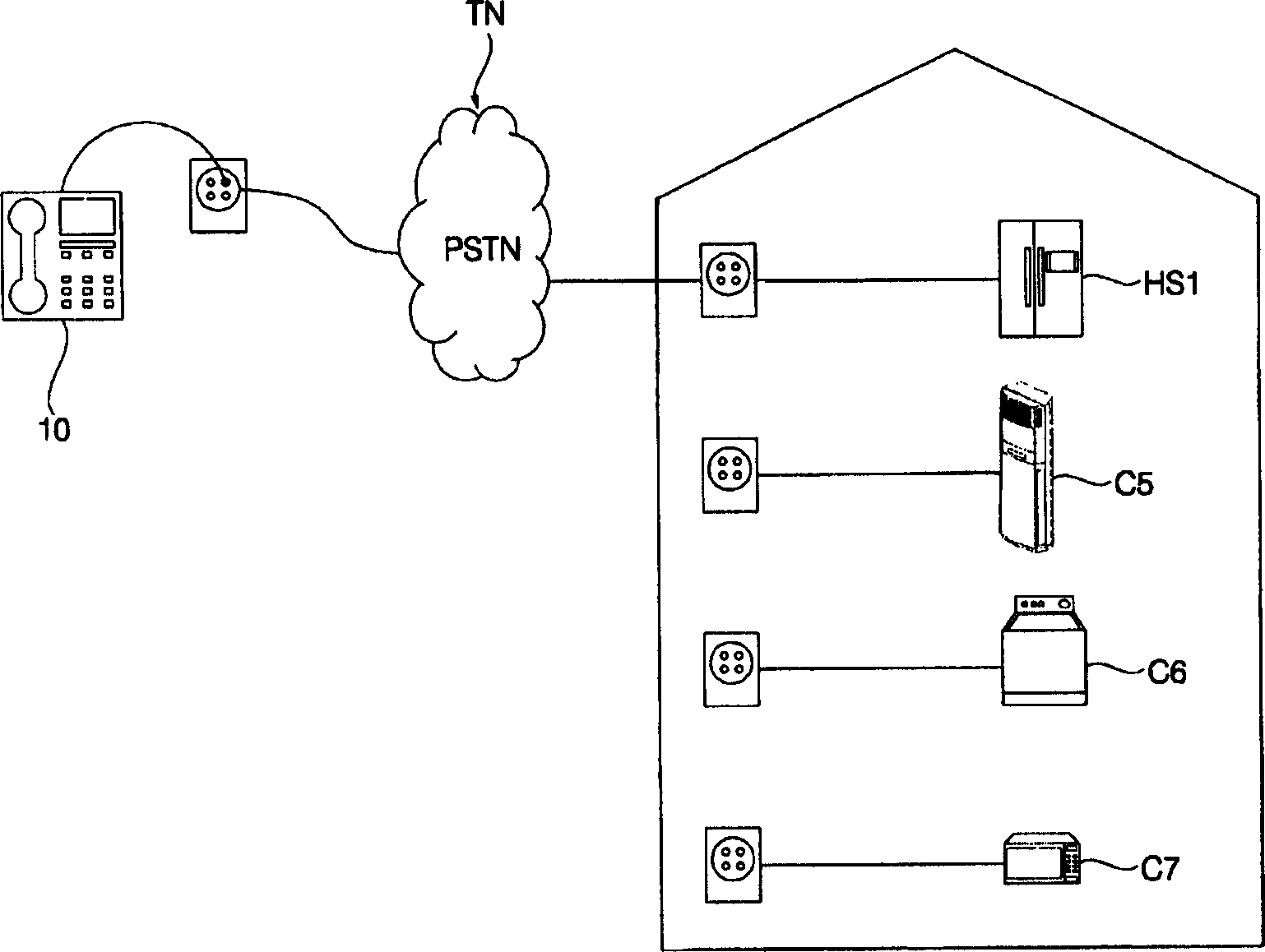

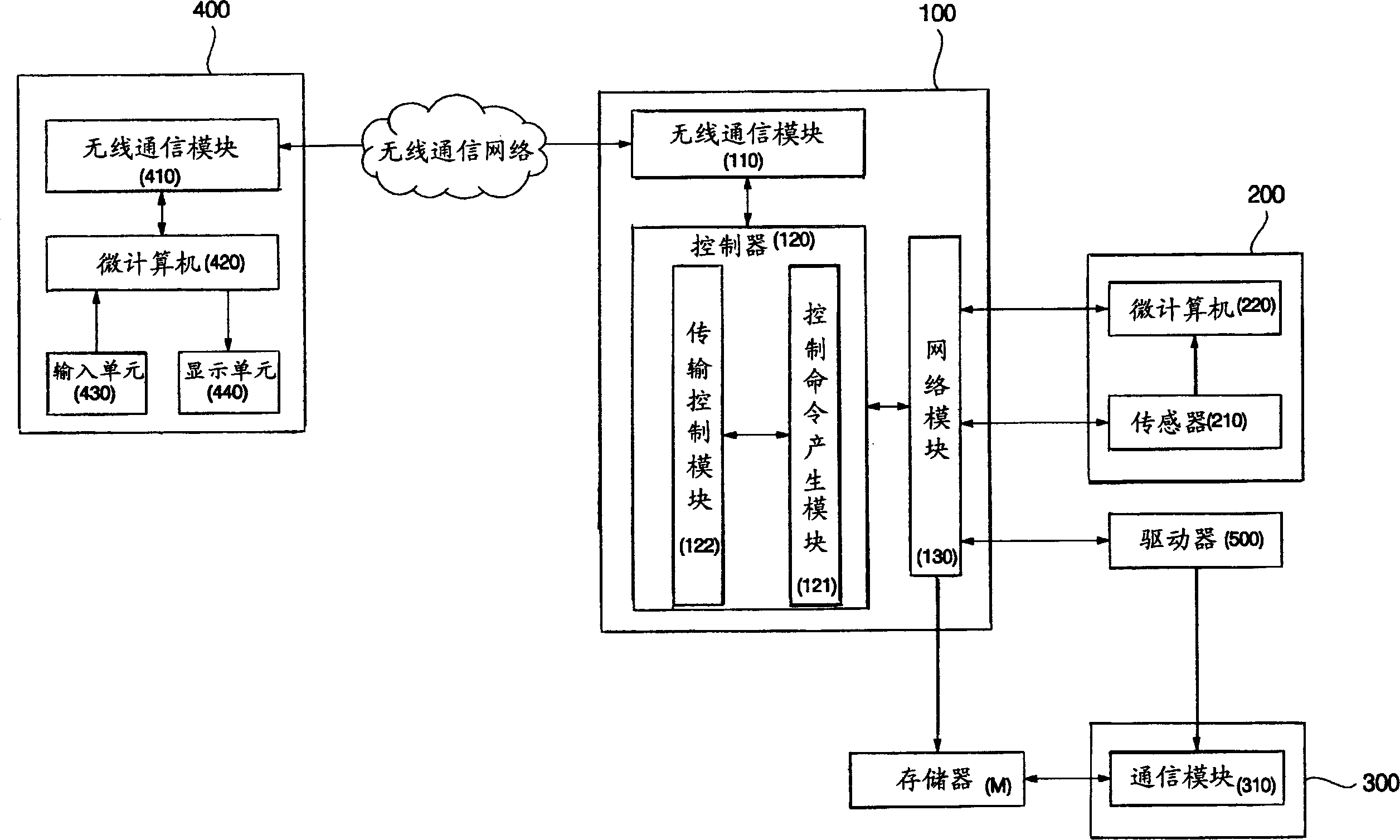

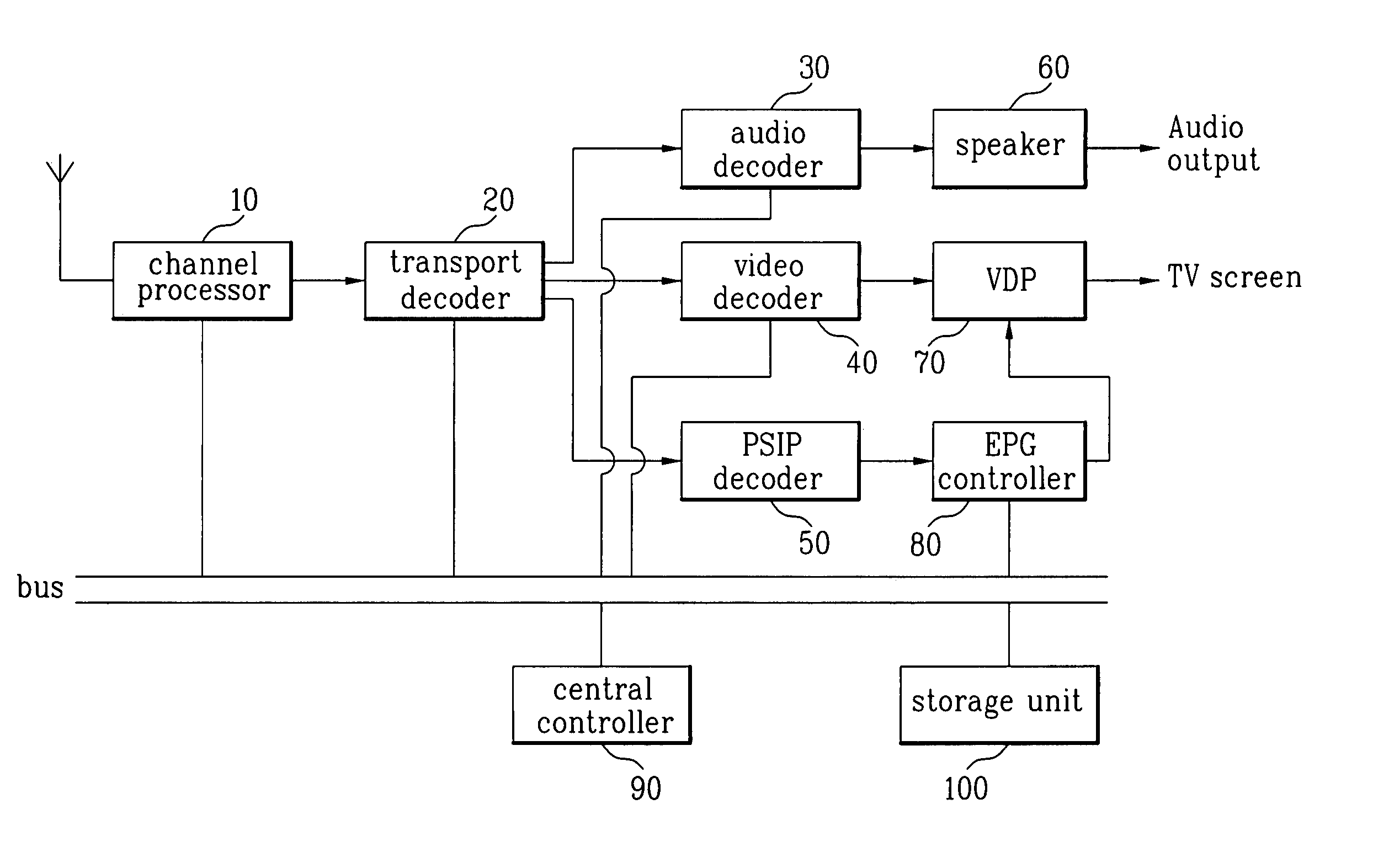

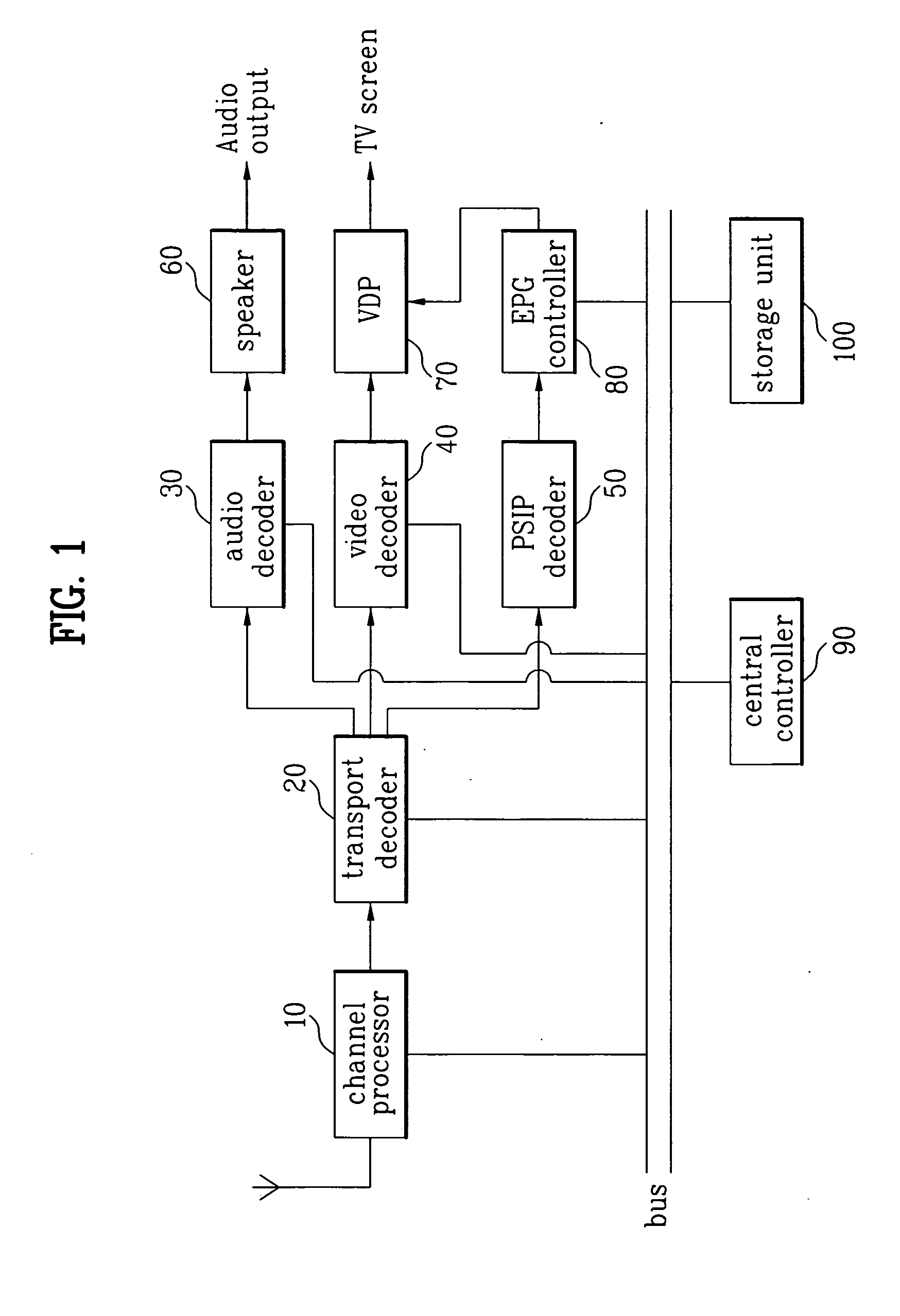

Wireless terminal-interoperable home network system and method controlling the same

ActiveUS20050184865A1Improve control efficiencyImprove ease of useProtective foundationSubstation remote connection/disconnectionImage InspectionTelecommunications

Disclosed herein are a wireless terminal-interoperable home network system and a method for controlling the same. A home server is linked with a security device and camera installed in a building to, when the security device senses entrance / exit of an outsider into / from the building, acquire an internal image of the building from the camera and send the acquired image to a wireless terminal of a user to enable the user to monitor the internal situation of the building in real time. The user can access the home server over a wireless communication network from a remote place outside of the building without separate access to the Internet to receive the internal image of the building and check the internal situation of the building on the basis of the received internal image, resulting in an increase in convenience of use.

Owner:LG ELECTRONICS INC

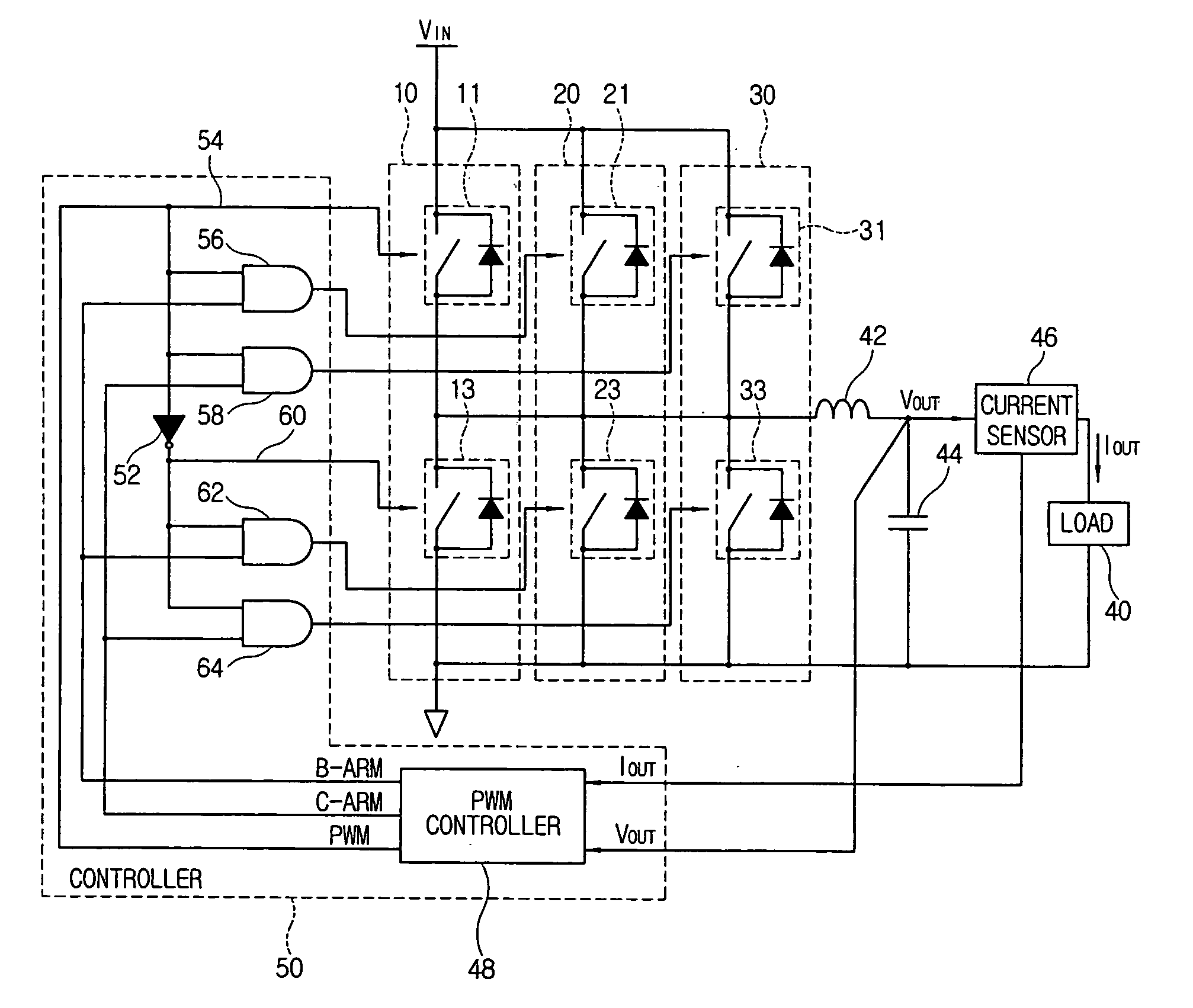

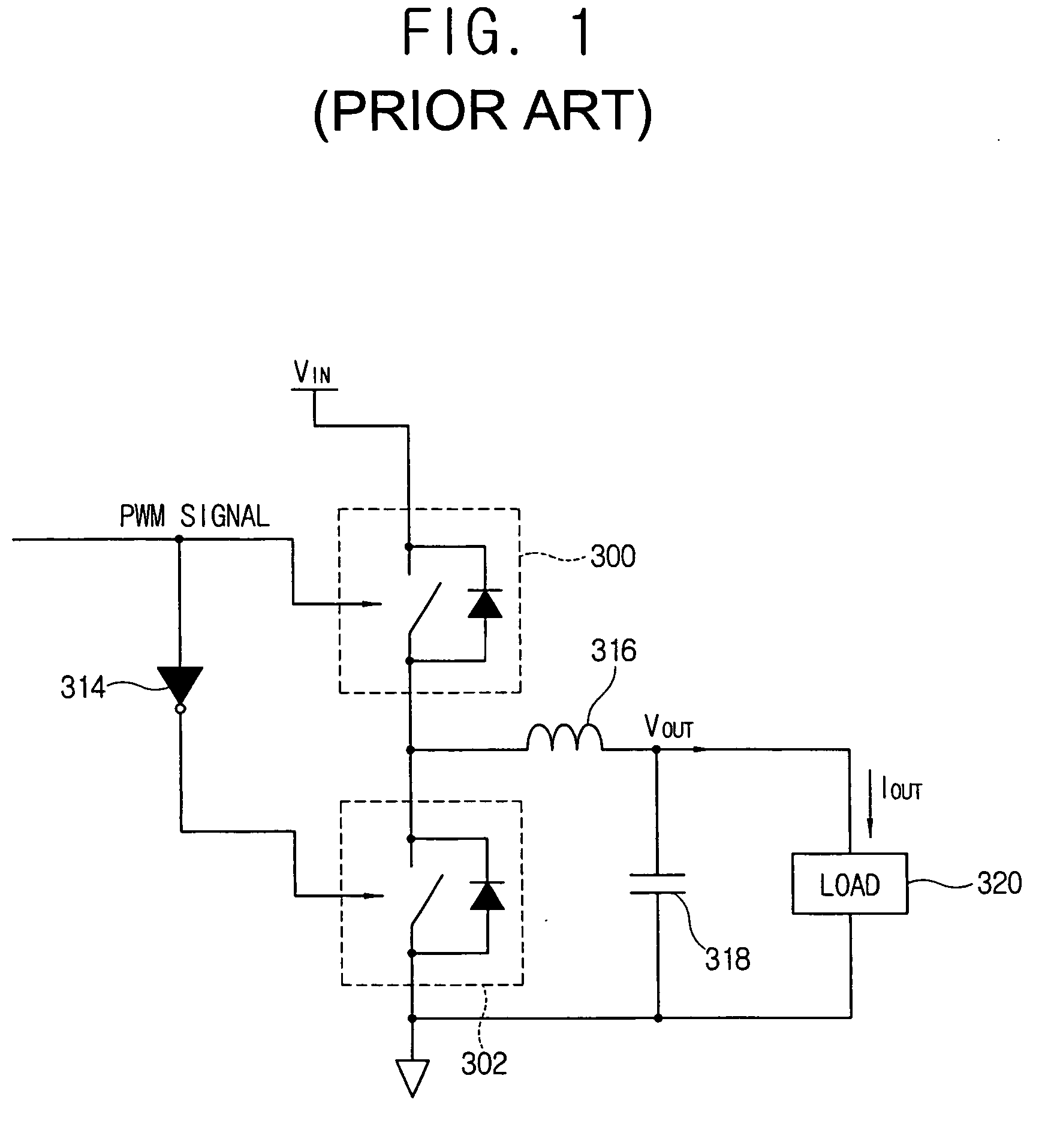

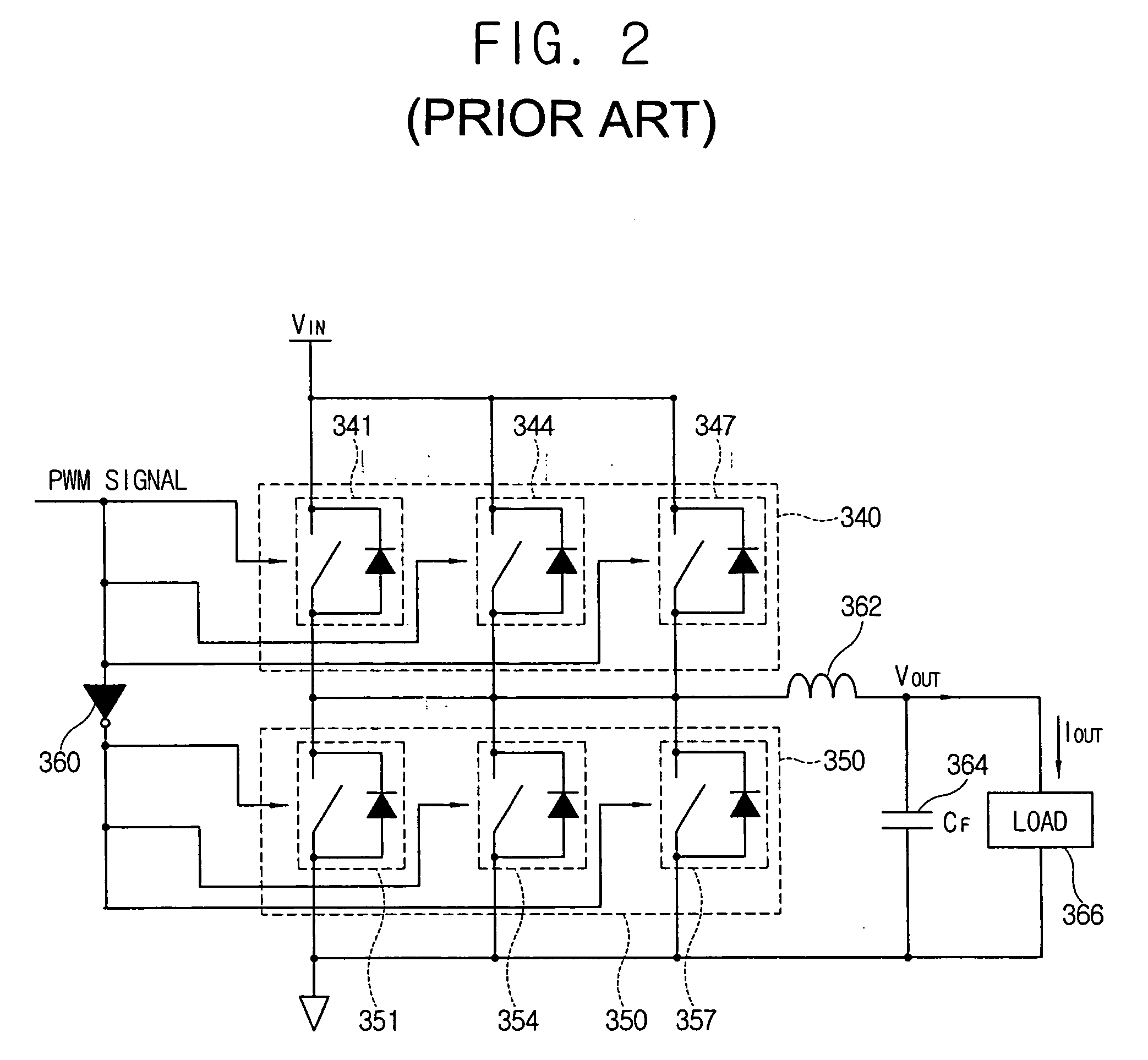

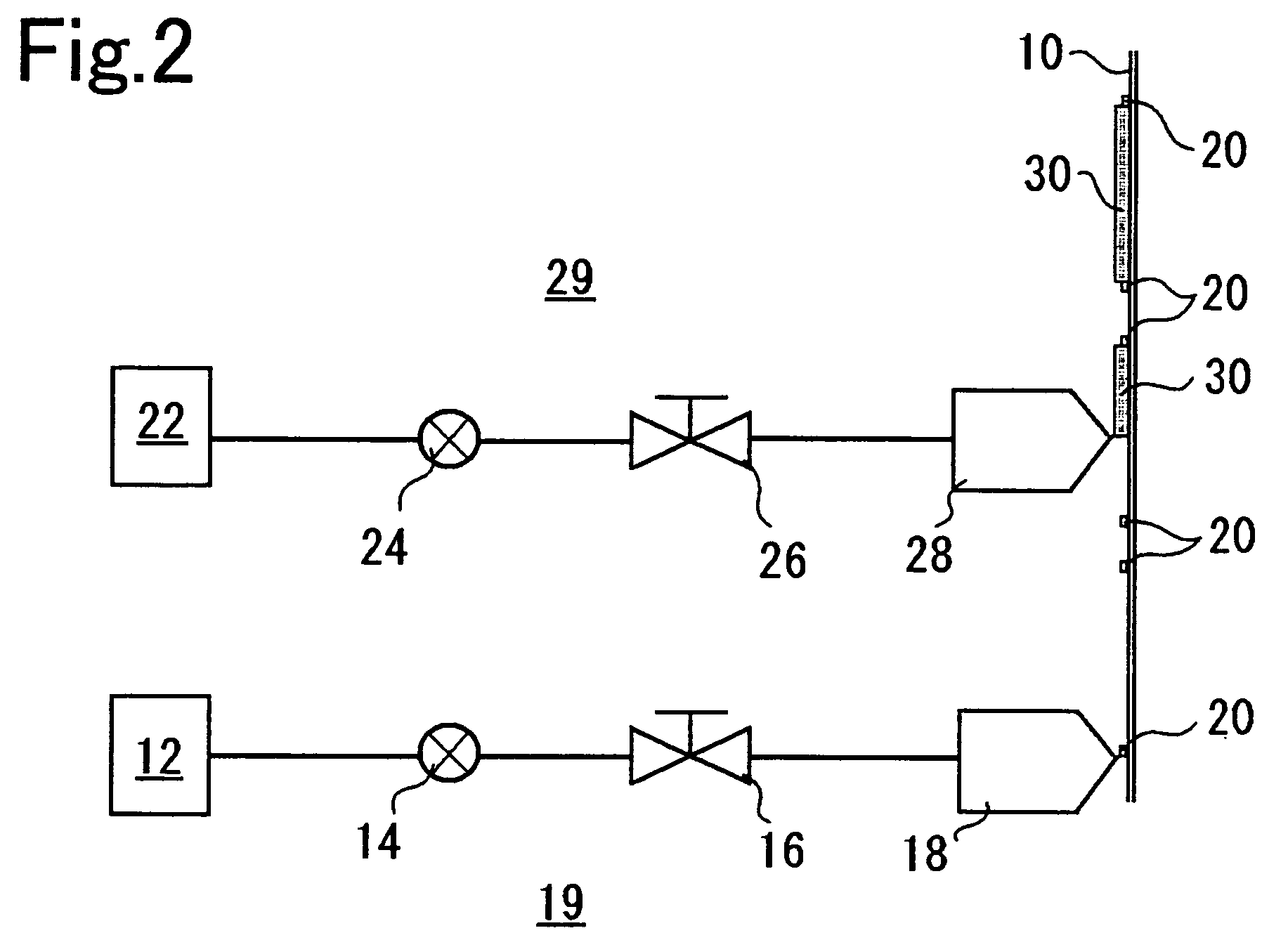

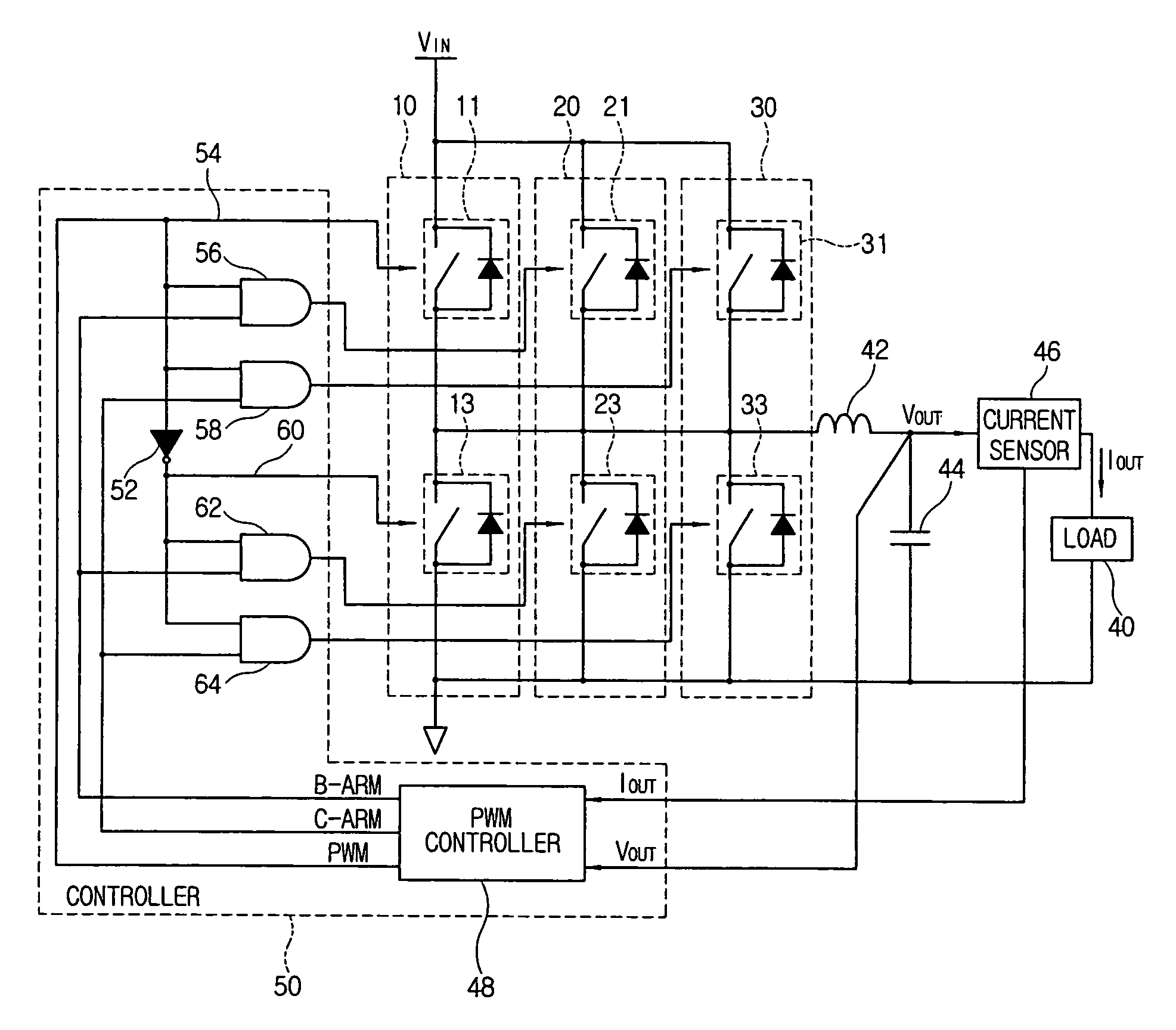

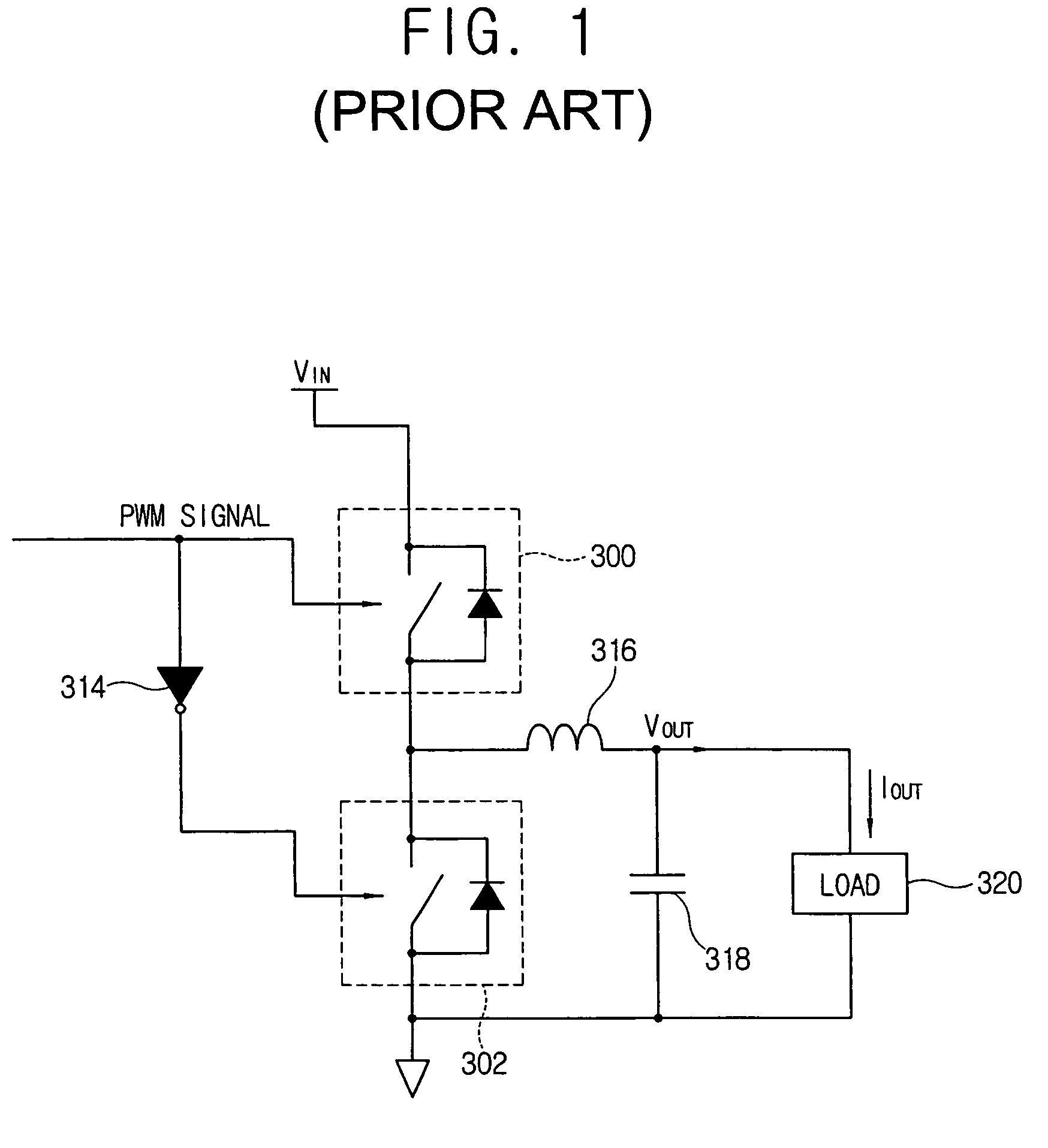

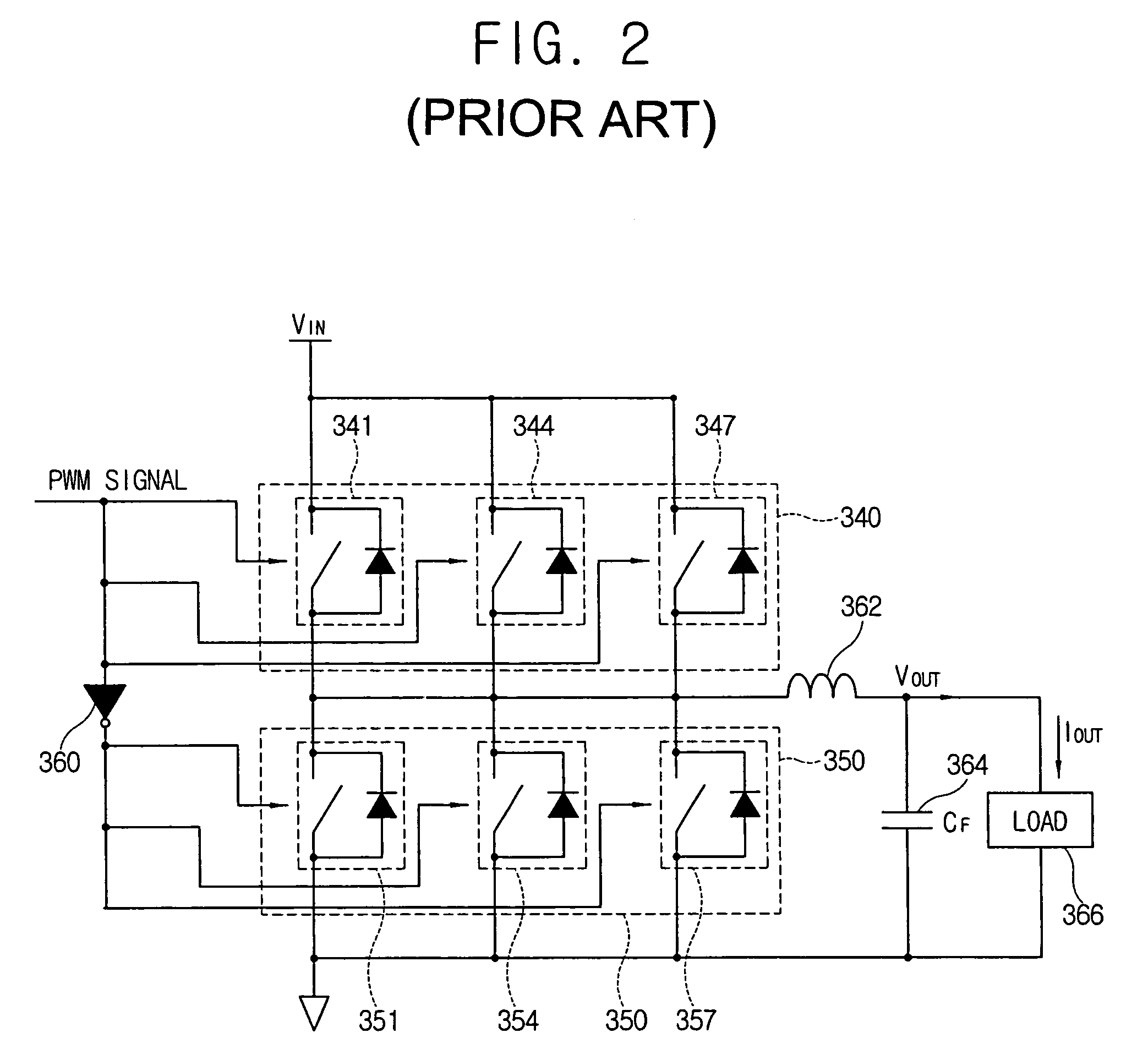

DC-DC converter and control method thereof

InactiveUS20050212497A1MinimizeImprove efficiencyEfficient power electronics conversionElectronic switchingElectricityDc dc converter

A DC-DC converter to convert DC power input from an external source into a predetermined DC power required for an electric load. A switch part in which each of a pair of switches that cuts or supplies the input DC power is connected in parallel with at least one other switch. A current sensor senses a load current flowing through the electric load and a controller controls the switch part to enable a number of the switches according to an intensity of the load current sensed by the current sensor. The enabled switches are driven by a PWM signal to cut or supply the input DC power to the load. By changing the number of enabled switches, unnecessary switching is prevented for lower load currents.

Owner:SAMSUNG ELECTRONICS CO LTD

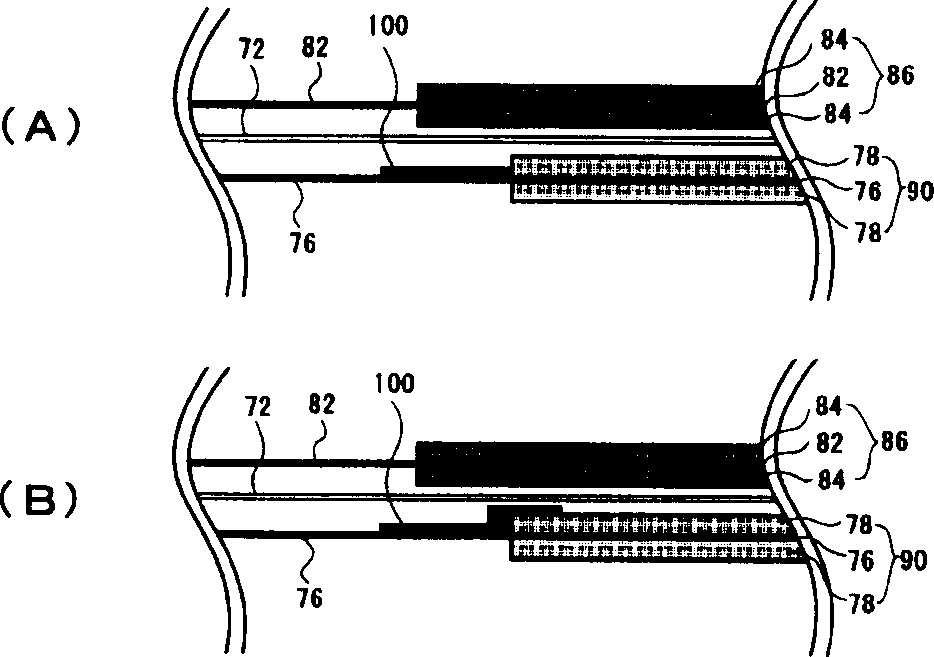

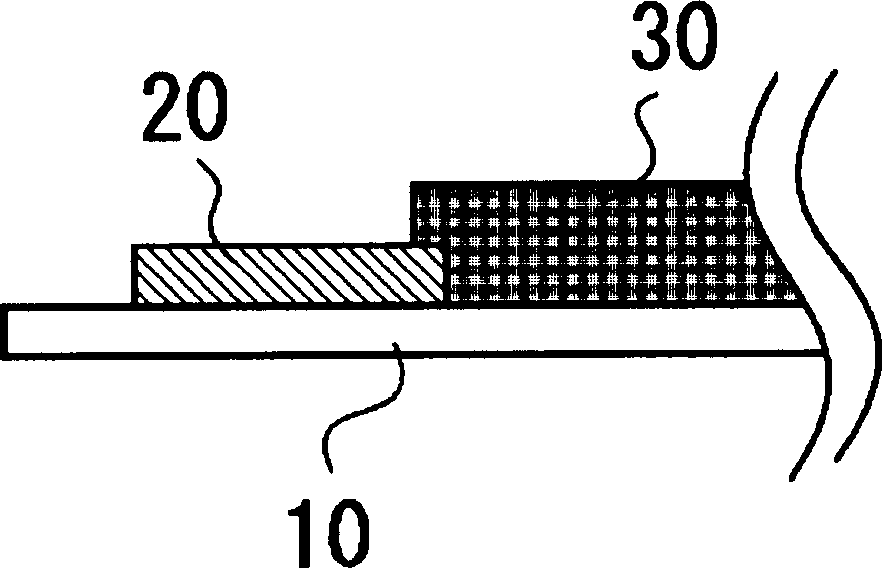

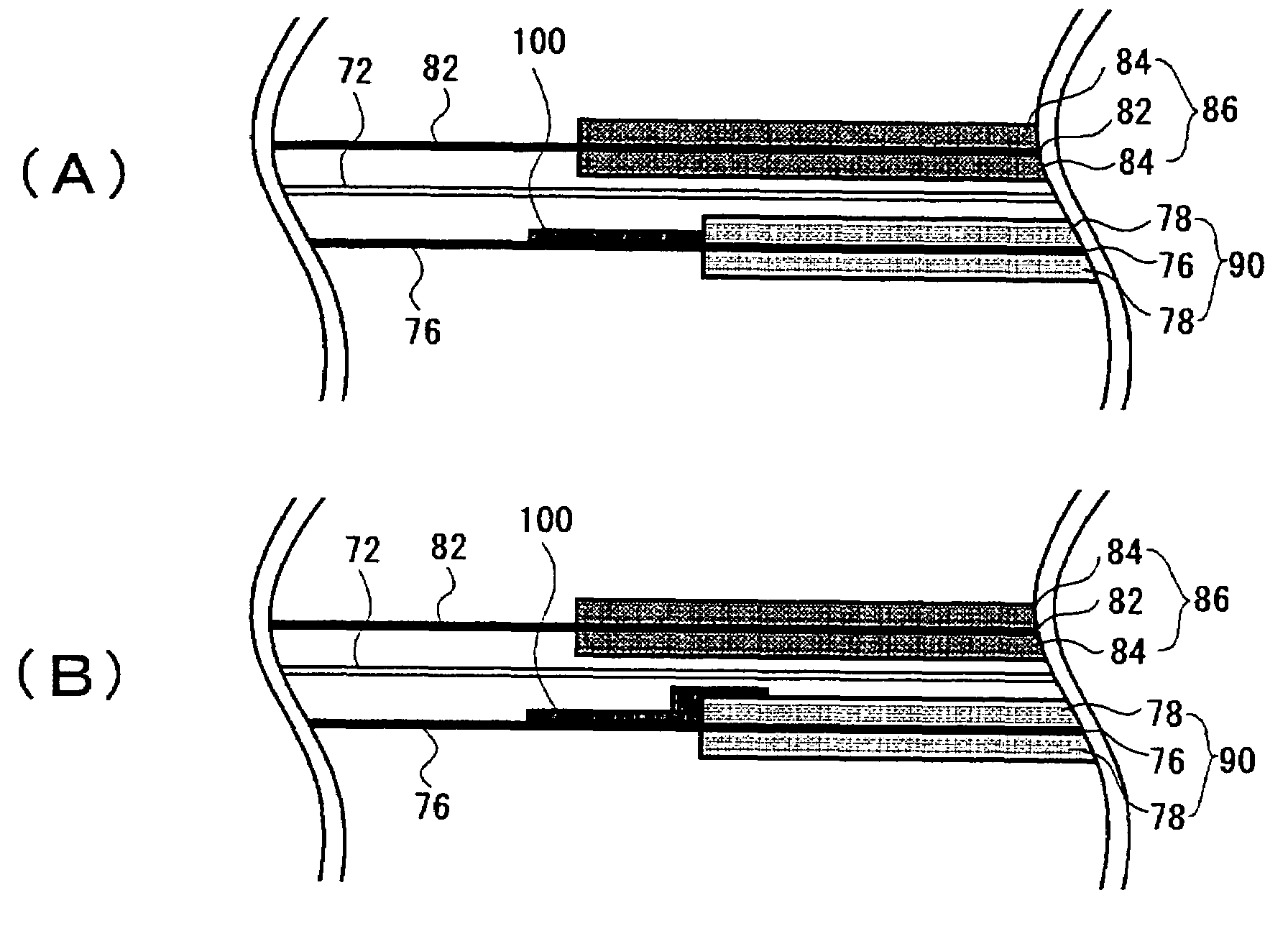

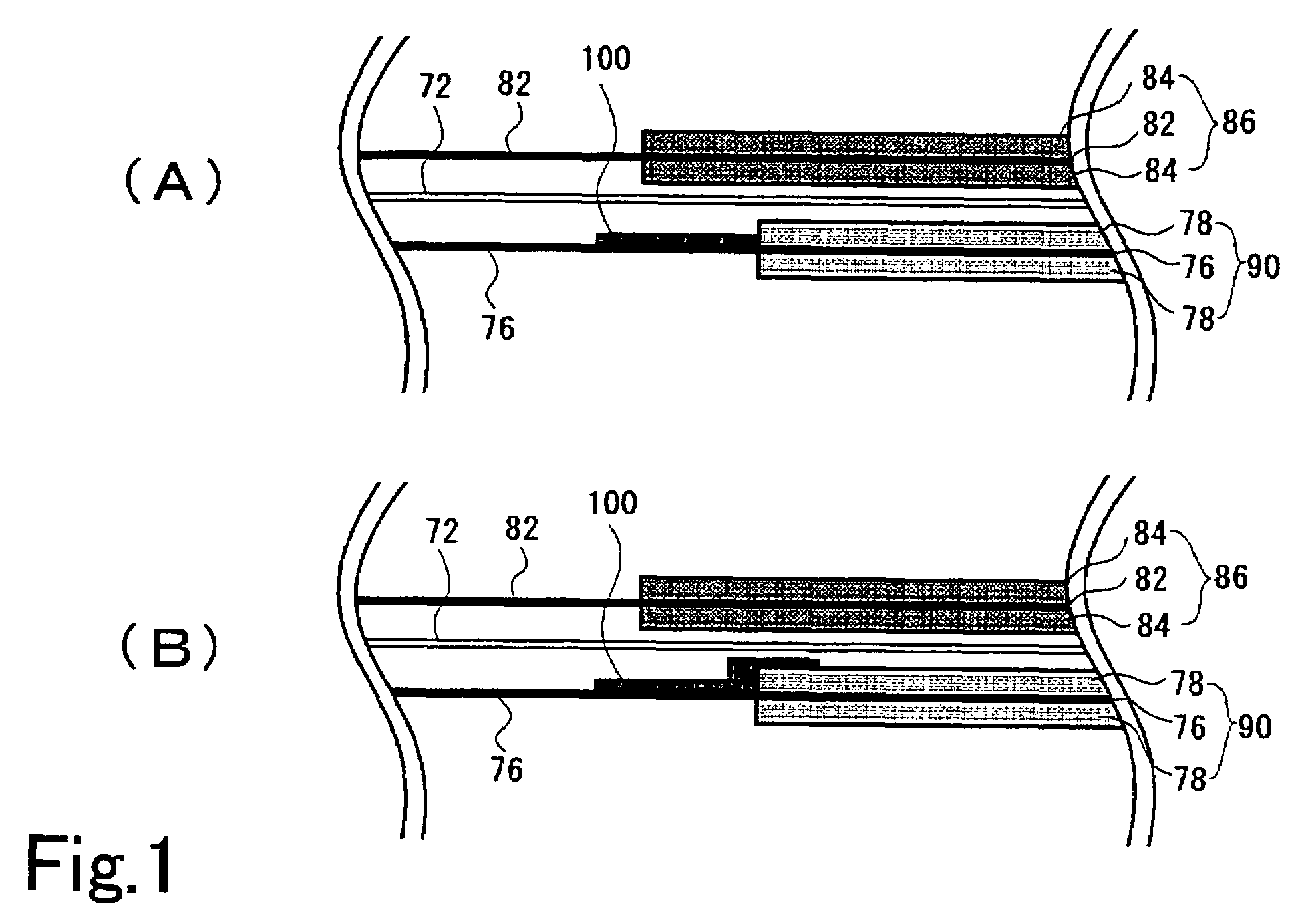

Manufacturing method for non-aqueous electrolyte secondary battery and used electrode thereof

InactiveCN1525591AFully automatedAvoid various problems caused by pasteElectrode rolling/calenderingFinal product manufactureHot melt coatingMaterials science

In this nonaqueous electrolyte secondary battery having a positive electrode 90 formed by applying a positive electrode mix 78 containing a positive electrode active material storing and releasing lithium ions onto a metallic core foil 76, the negative electrode 86 formed by applying a negative electrode mix 84 containing a negative electrode active material storing and releasing lithium ions onto a metallic core foil 82, and a spiral electrode body laminated and rolled through a separator 72, an insulating layer 100 is formed in the portion facing the portion coated with the negative electrode mix 84 in the negative electrode 86 through the separator 72, which is the portion uncoated with the positive electrode mix where the positive electrode mix 78 of the positive electrode 90 is not applied onto the metallic core foil 76, by a dry coating method, a thermal fusing method, or a hot melt coating method.

Owner:SANYO ELECTRIC CO LTD

Wireless terminal-interoperable home network system and method controlling the same

ActiveUS7301456B2Improve control efficiencyImprove convenienceProtective foundationSubstation remote connection/disconnectionImage InspectionTelecommunications

Disclosed herein are a wireless terminal-interoperable home network system and a method for controlling the same. A home server is linked with a security device and camera installed in a building to, when the security device senses entrance / exit of an outsider into / from the building, acquire an internal image of the building from the camera and send the acquired image to a wireless terminal of a user to enable the user to monitor the internal situation of the building in real time. The user can access the home server over a wireless communication network from a remote place outside of the building without separate access to the Internet to receive the internal image of the building and check the internal situation of the building on the basis of the received internal image, resulting in an increase in convenience of use.

Owner:LG ELECTRONICS INC

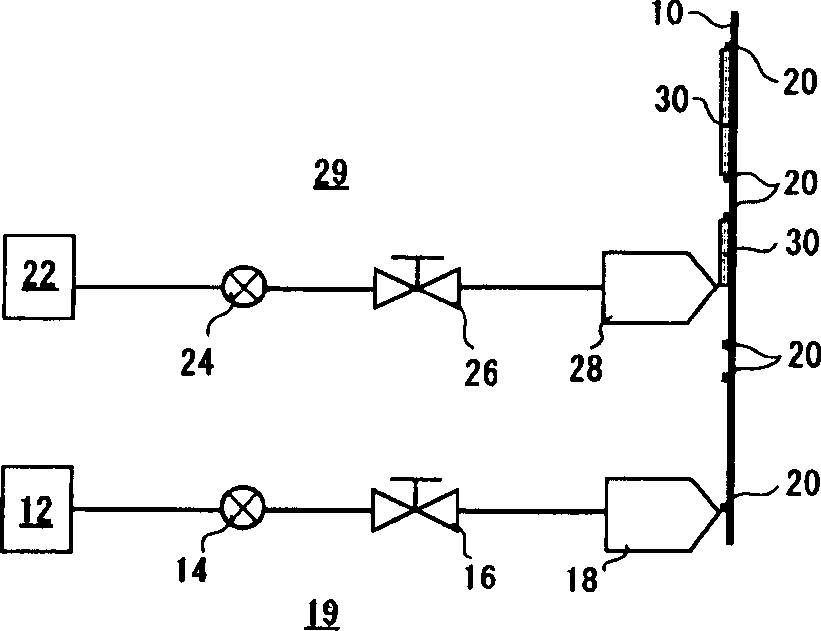

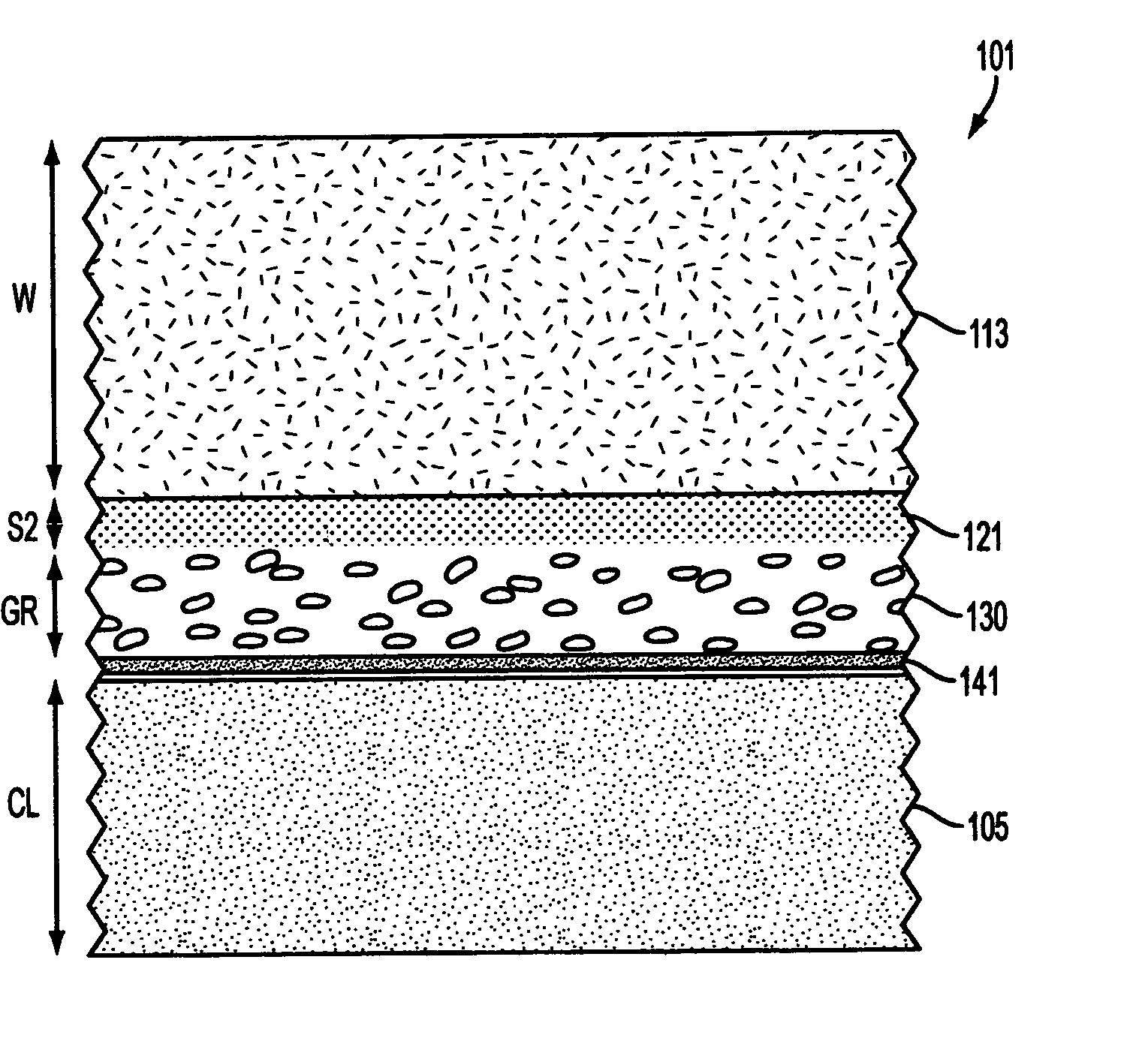

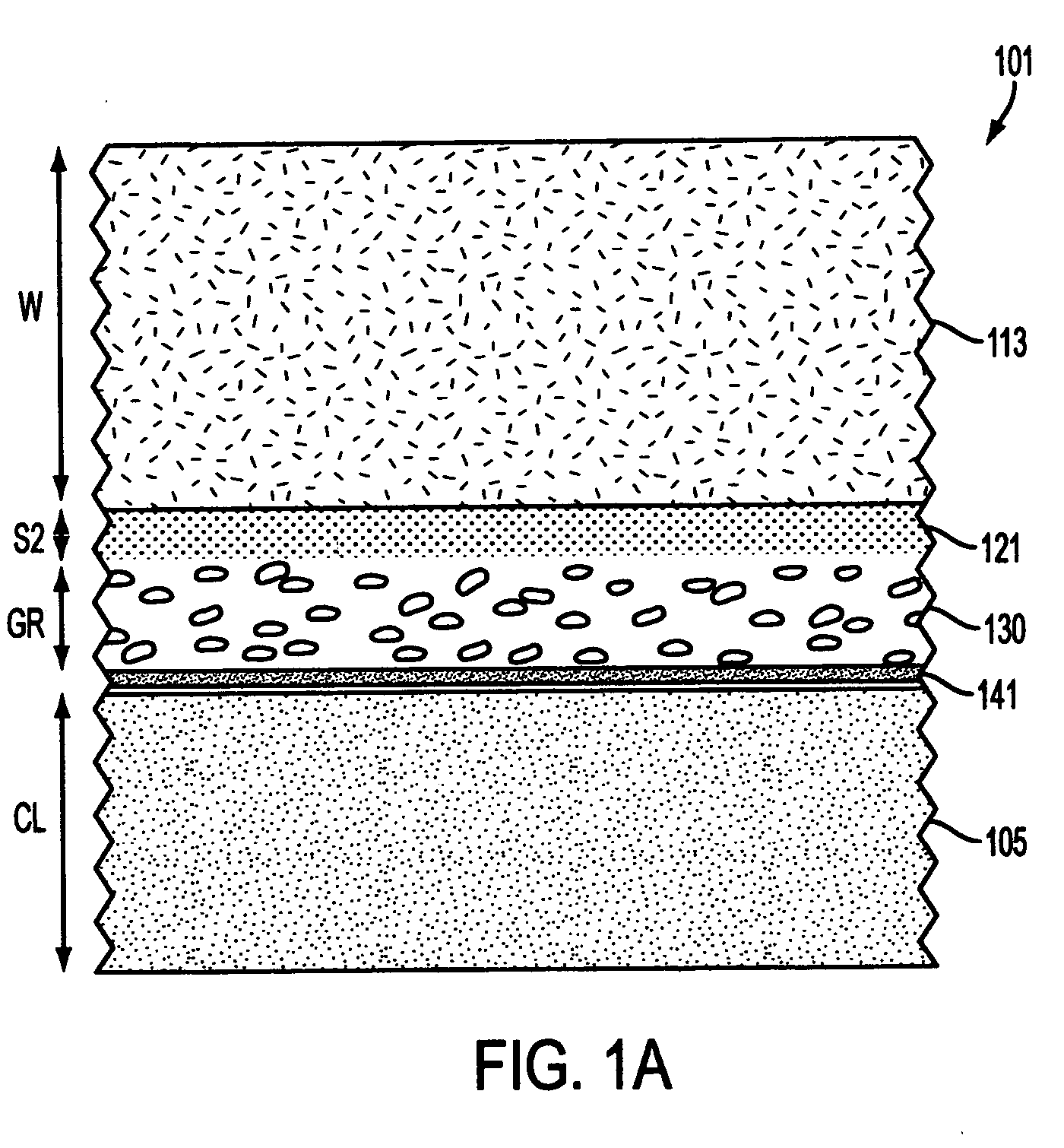

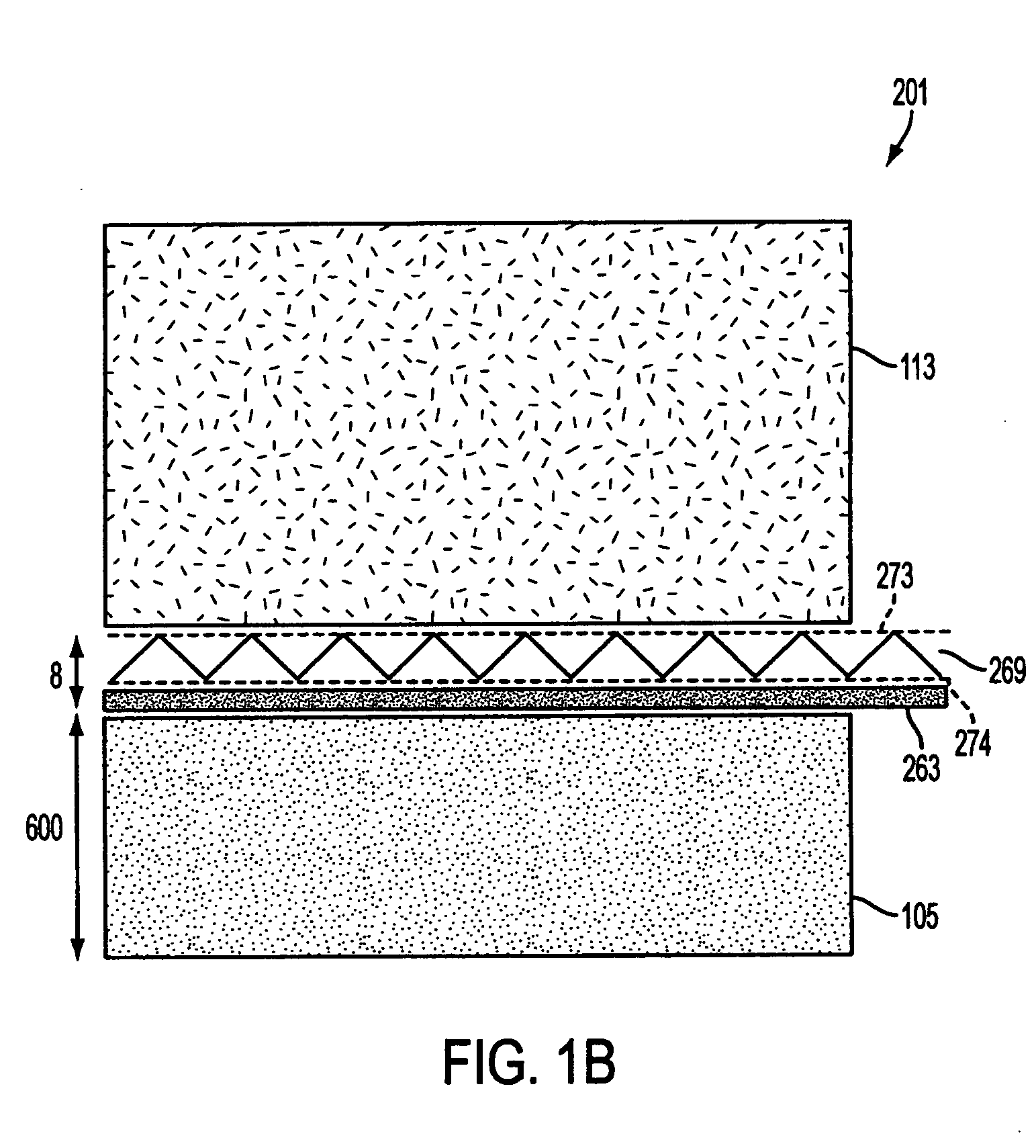

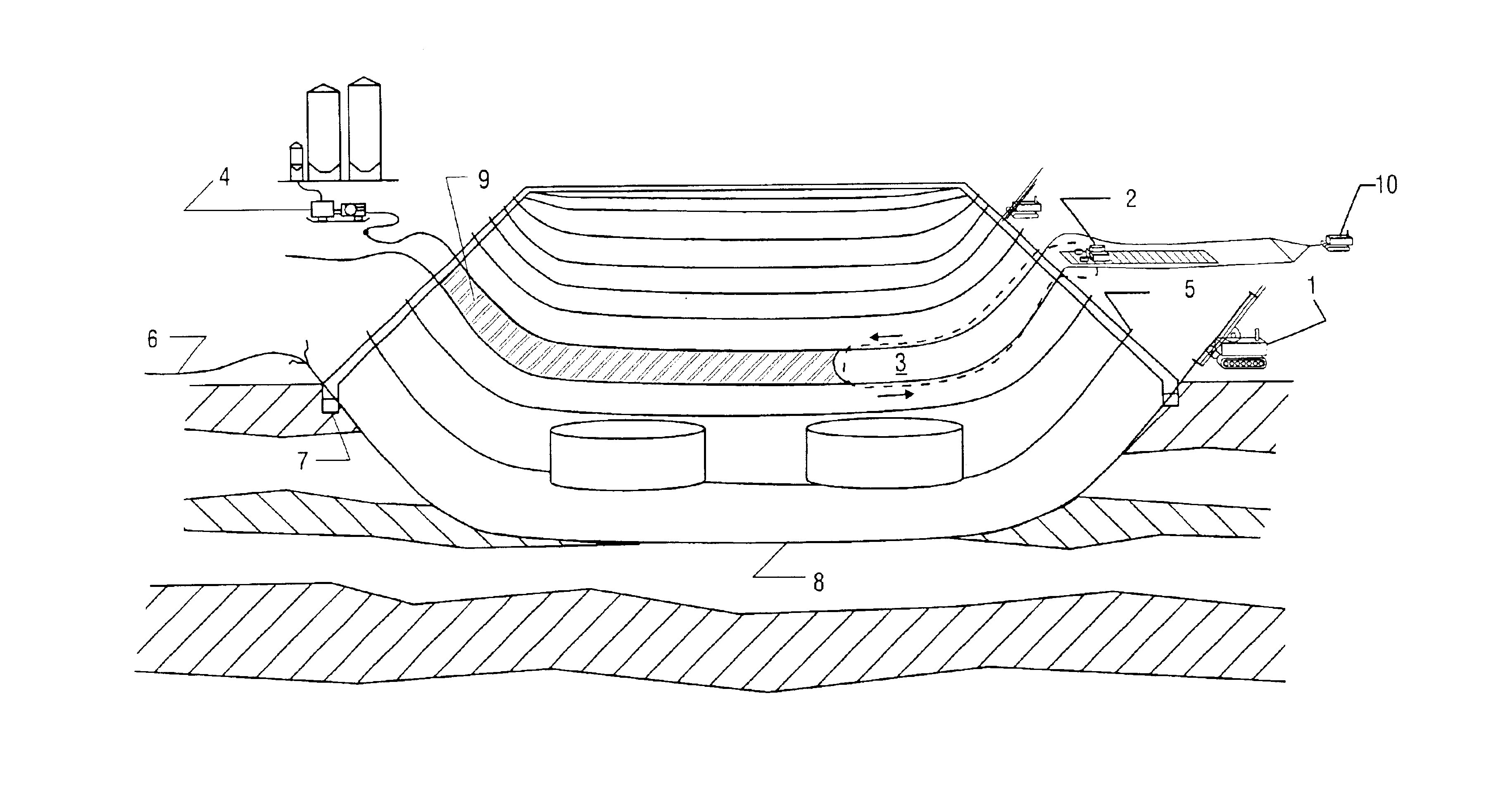

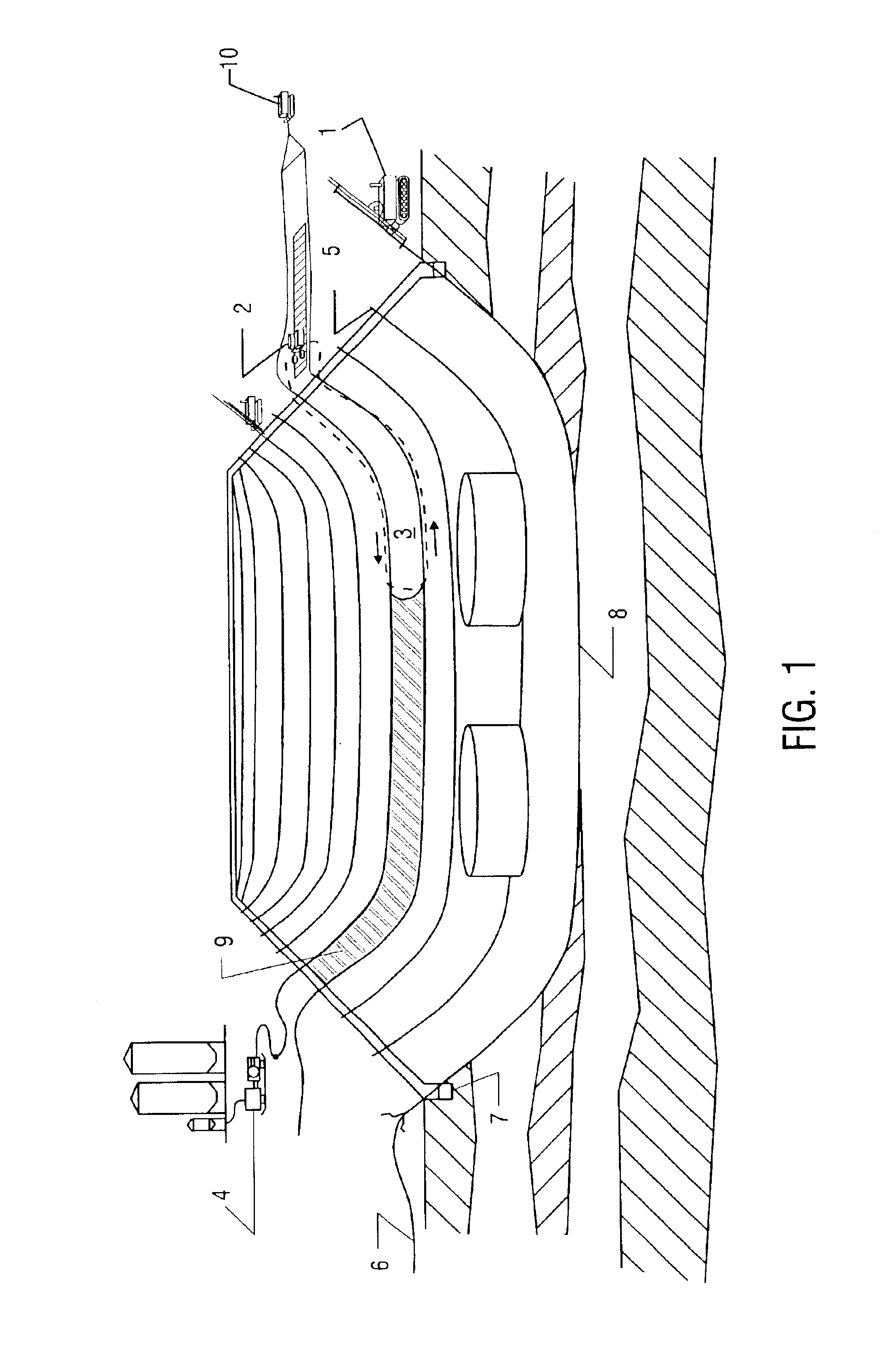

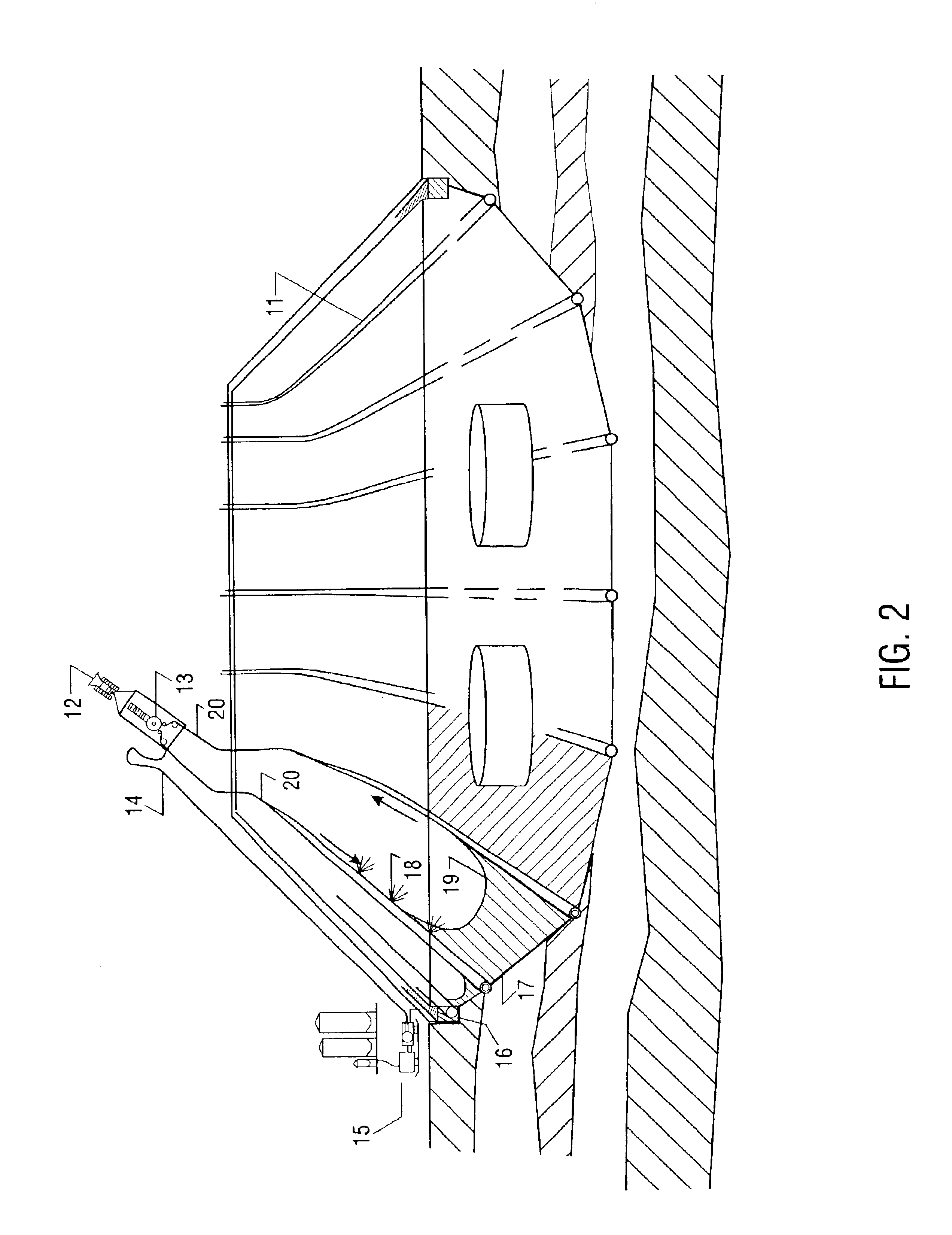

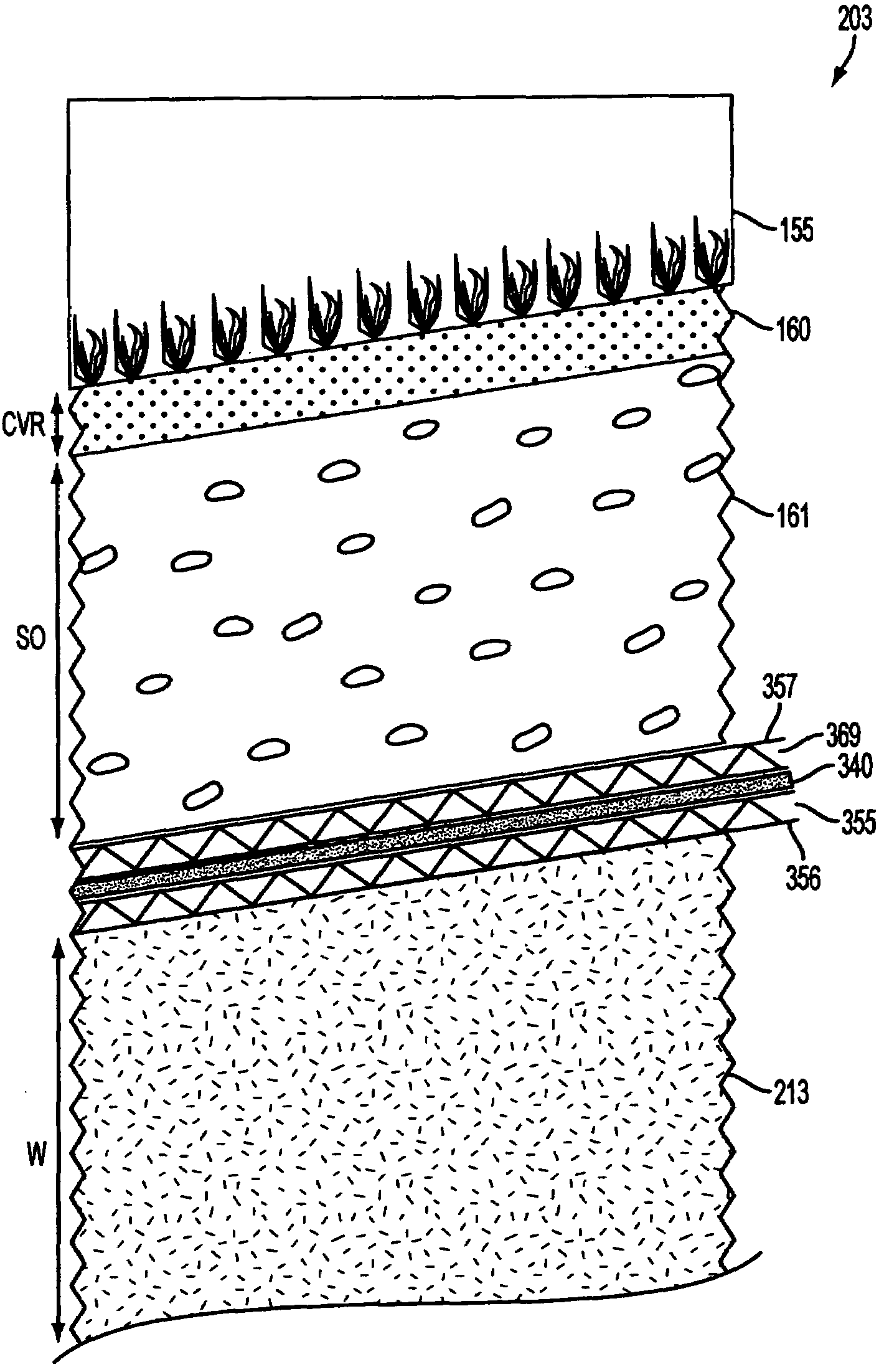

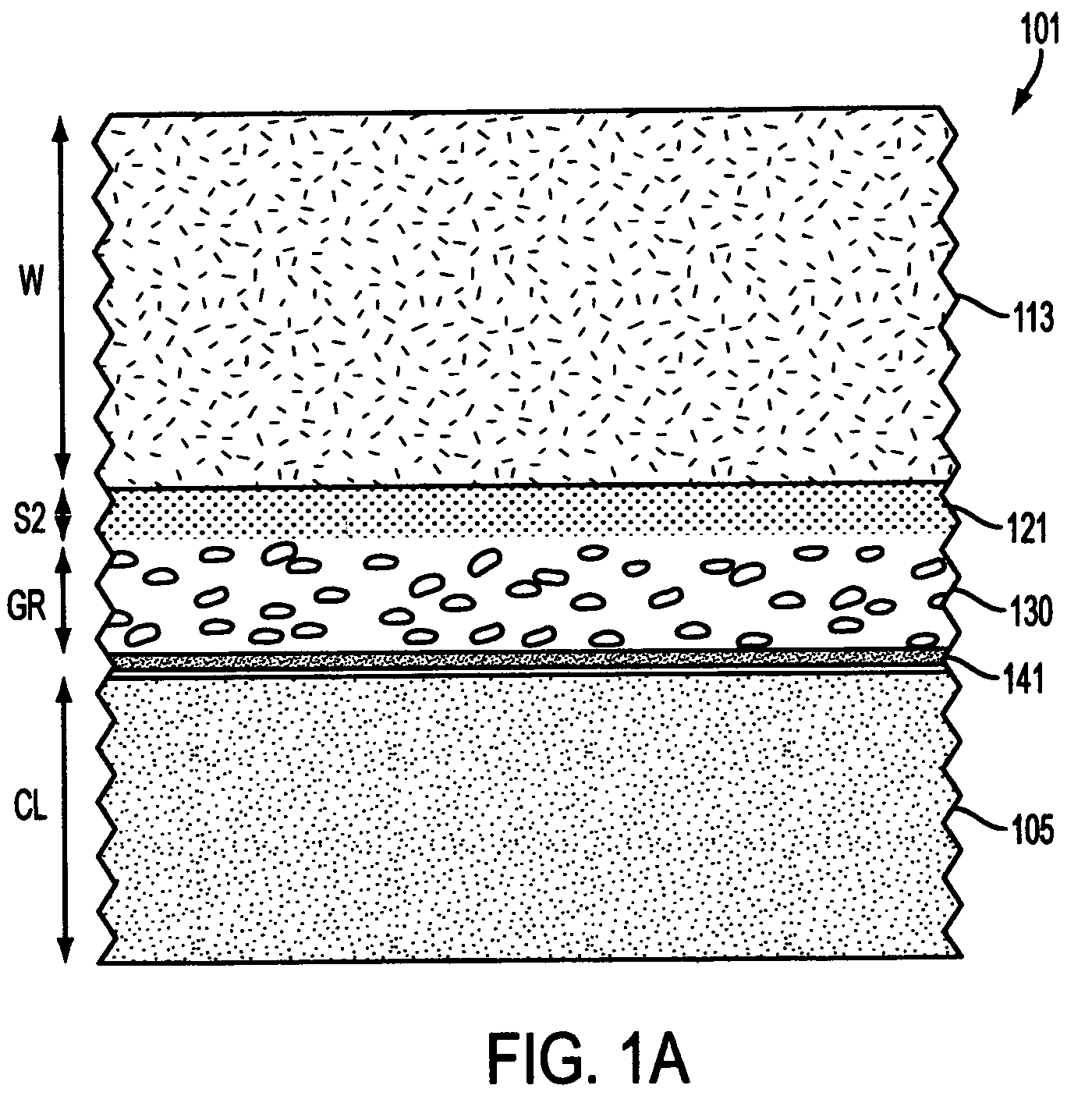

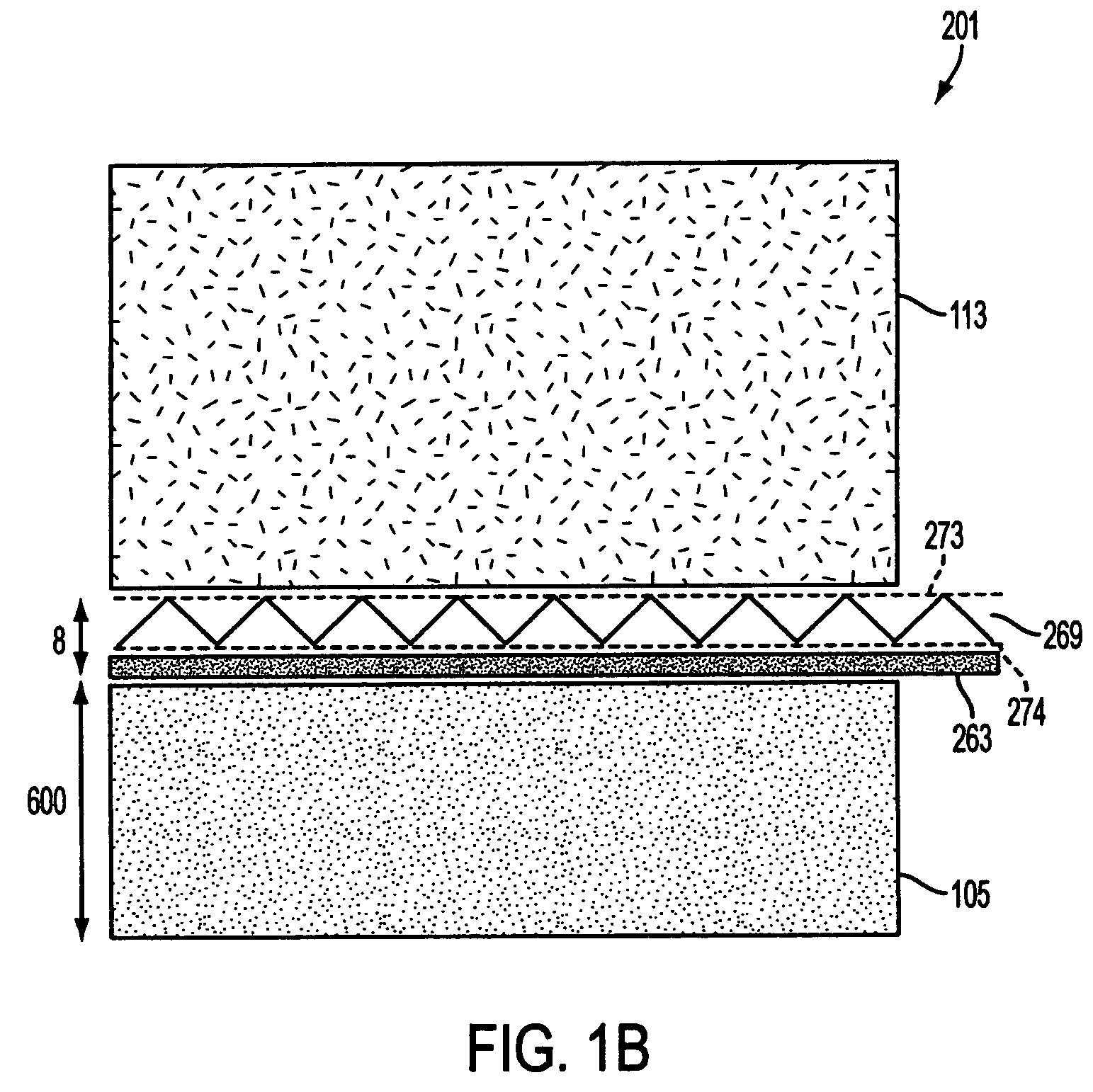

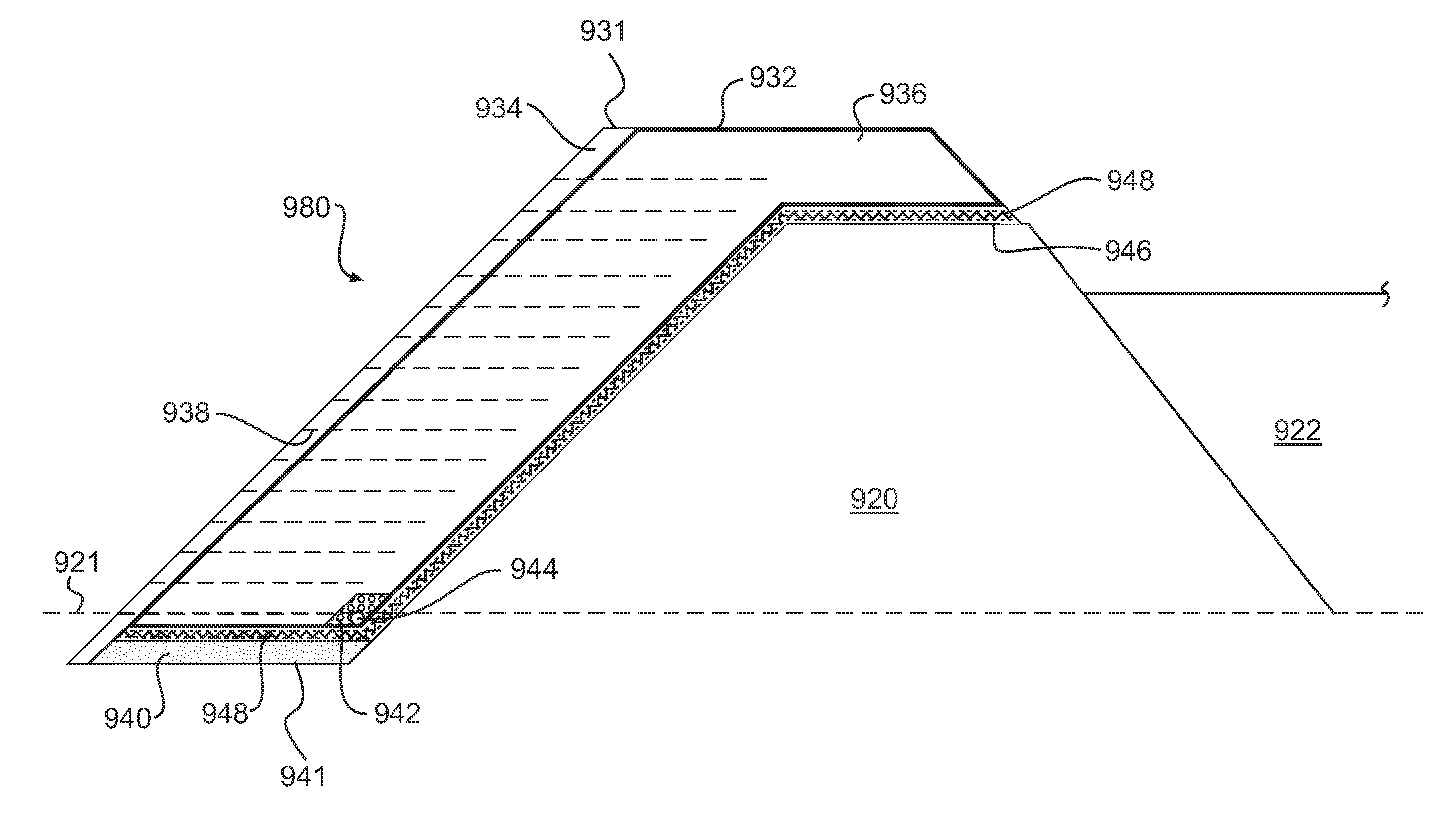

Void-maintaining synthetic drainable base courses in landfills and other large structures, and methods for controlling the flow and evacuation of fluids from landifills

Numerous embodiments of one or more layers of void-maintaining synthetic drainable base courses (“VMSDBC's”) are provided as incorporated into landfills and other waste containment facilities. Key advantages of landfills and methods according to the invention include a substantial decrease in the necessity for conventional gravel and sand layers, and an increase in the effective volume of a landfill or similar facility. Moreover, the invention decreases the cost attendant to locating, transporting, and forming conventional rock, sand and gravel materials into discreet layers.

Owner:ADVANCED GEOTECH SYST

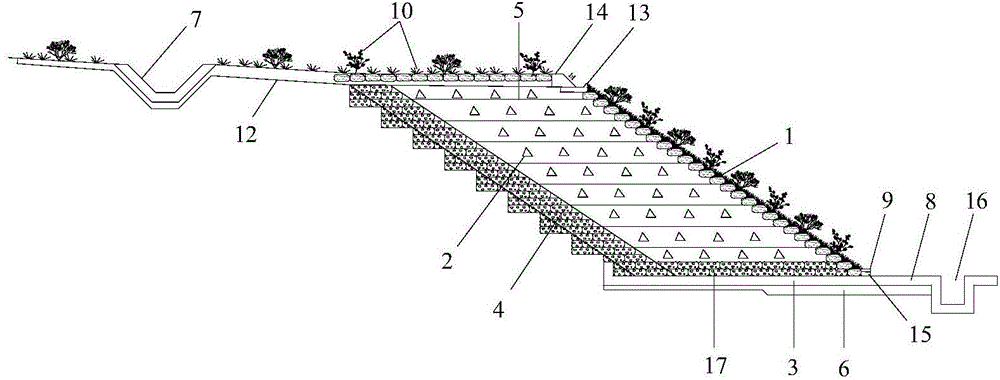

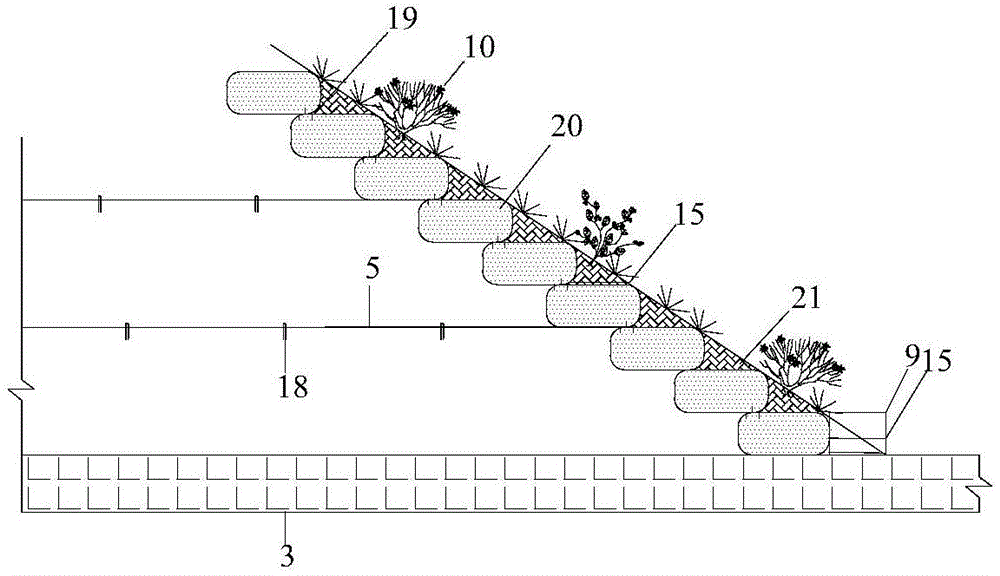

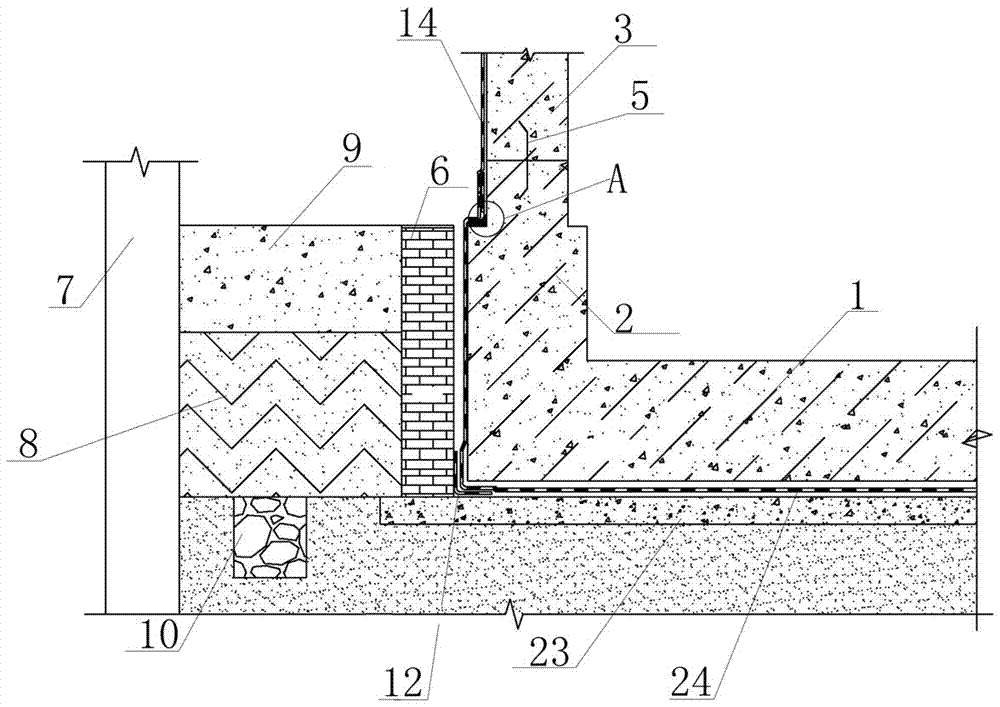

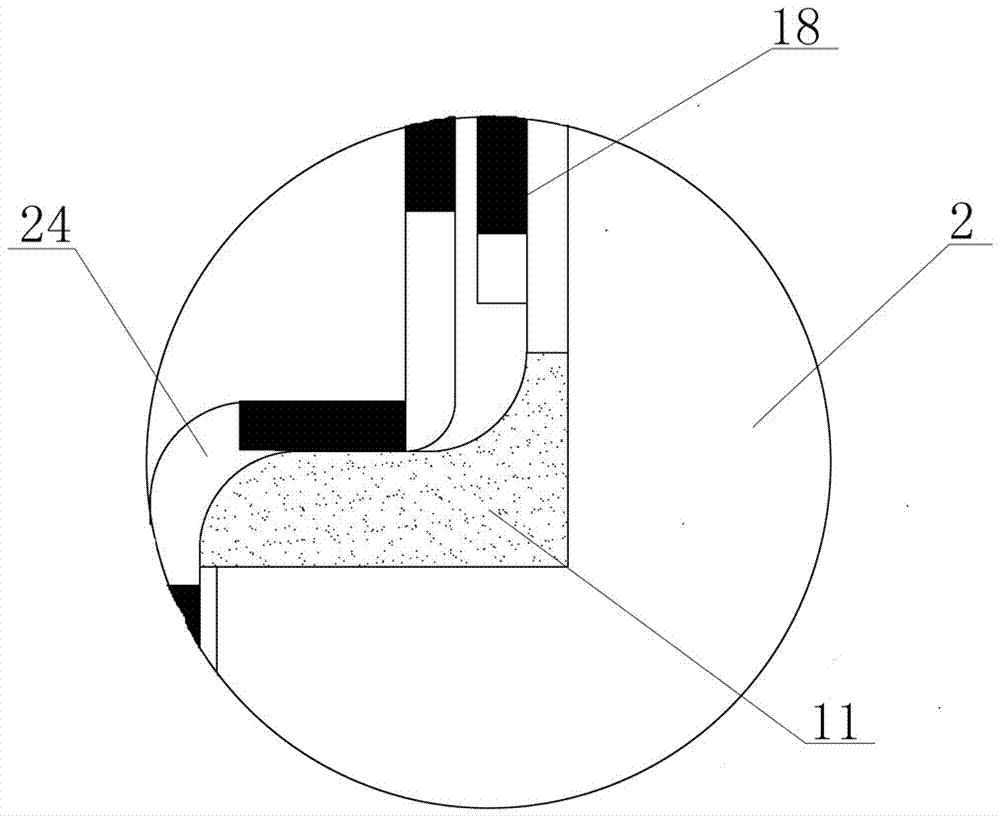

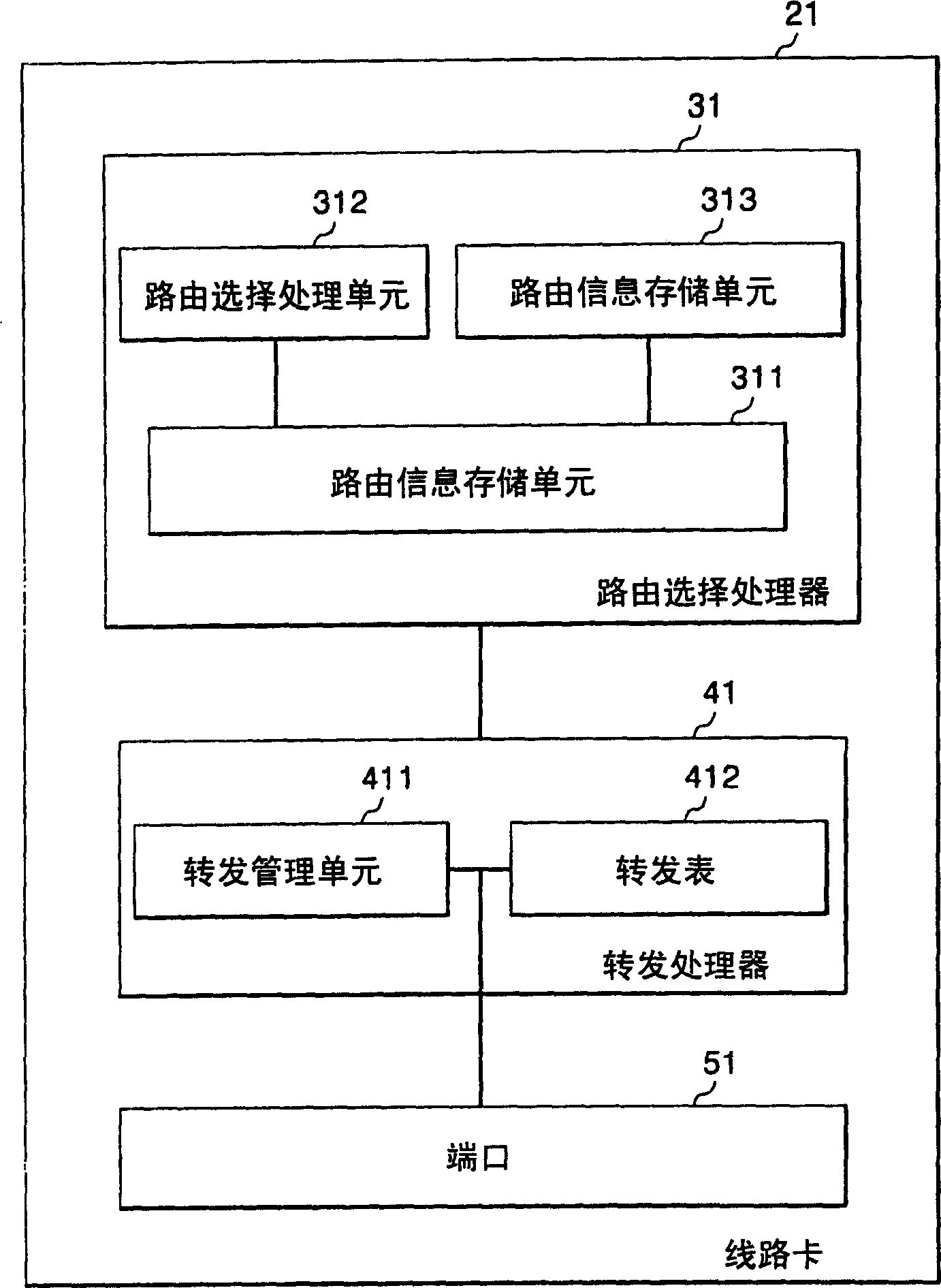

Flexible expansion reduced ecological slope protection construction

InactiveCN104532857ASolve technical problemsSave engineering investmentExcavationsGasketsCut and fillEngineering

Flexible expansion reduced ecological slope protection construction effectively solves the technical problem of expansion soil or expansion rock in road cut slope protection, ensures that the road slope protective structure has the good short-term and long-term protective effect, and is beneficial to reducing the project investment of slope protection. The flexible expansion reduced ecological slope protection construction comprises an ecological slope protection face, a filling or refilling soil layer, foundations, a drainage system and a waterproof system. The filling or refilling soil layer is formed to be a flexible reinforced body by layered filling and layered compacting non-expansion soil or weak-middle-expansion soil and a geogrid paved in the expansion soil in layers. The ecological slope protection face is formed by ecology bags which are paved on the top surface and outside face of the filling or refilling soil layer. Slope covering soil is paved outside the ecological slope protection face. Green plants are planted on the slope covering soil.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Non-aqueous electrolyte secondary battery and manufacturing methods of an electrode used therein

InactiveUS7258948B2Reduce production efficiencyLowering possible occurrenceElectrode rolling/calenderingFinal product manufactureHot melt coatingEngineering

To provide a non-aqueous electrolyte secondary battery adapted to prevent an internal short circuit between an positive electrode and a negative electrode caused by the penetration of electrically conductive micro particles through a separator, which occurs when winding up electrodes, and manufacturing methods of an electrode used therein, whereby the non-aqueous electrolyte secondary battery having a coiled electrode assembly is formed through the multilayer winding of an positive electrode 90 having a metallic collector 76 coated with an positive electrode mixture 78 composed of an positive electrode active material that occludes and liberates lithium ions, a negative electrode 86 having a metallic collector 82 coated with a negative electrode mixture 84, composed of a negative electrode active material that occludes and liberates lithium ions, and a separator 72 interposed between the positive electrode and the negative electrode, wherein the positive electrode 90 has an insulating layer 100 formed by means of the dried coating method, the heat seal tape method, or the hot melt coating method on a portion of the metallic collector 76 which is uncoated with the positive electrode mixture 78 and opposed to the negative electrode 86 coated with the negative electrode mixture 84, through the separator 72.

Owner:SANYO ELECTRIC CO LTD

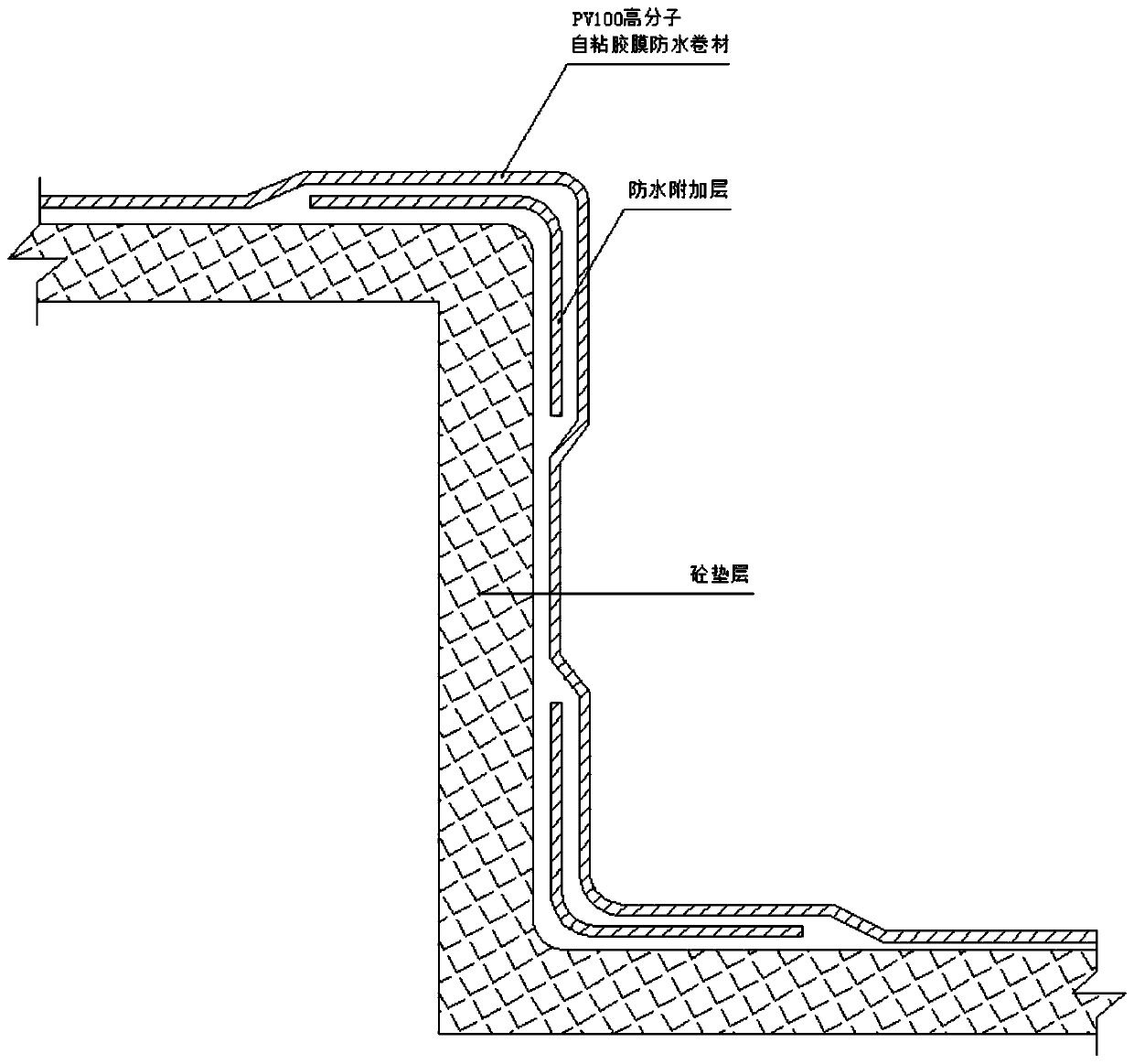

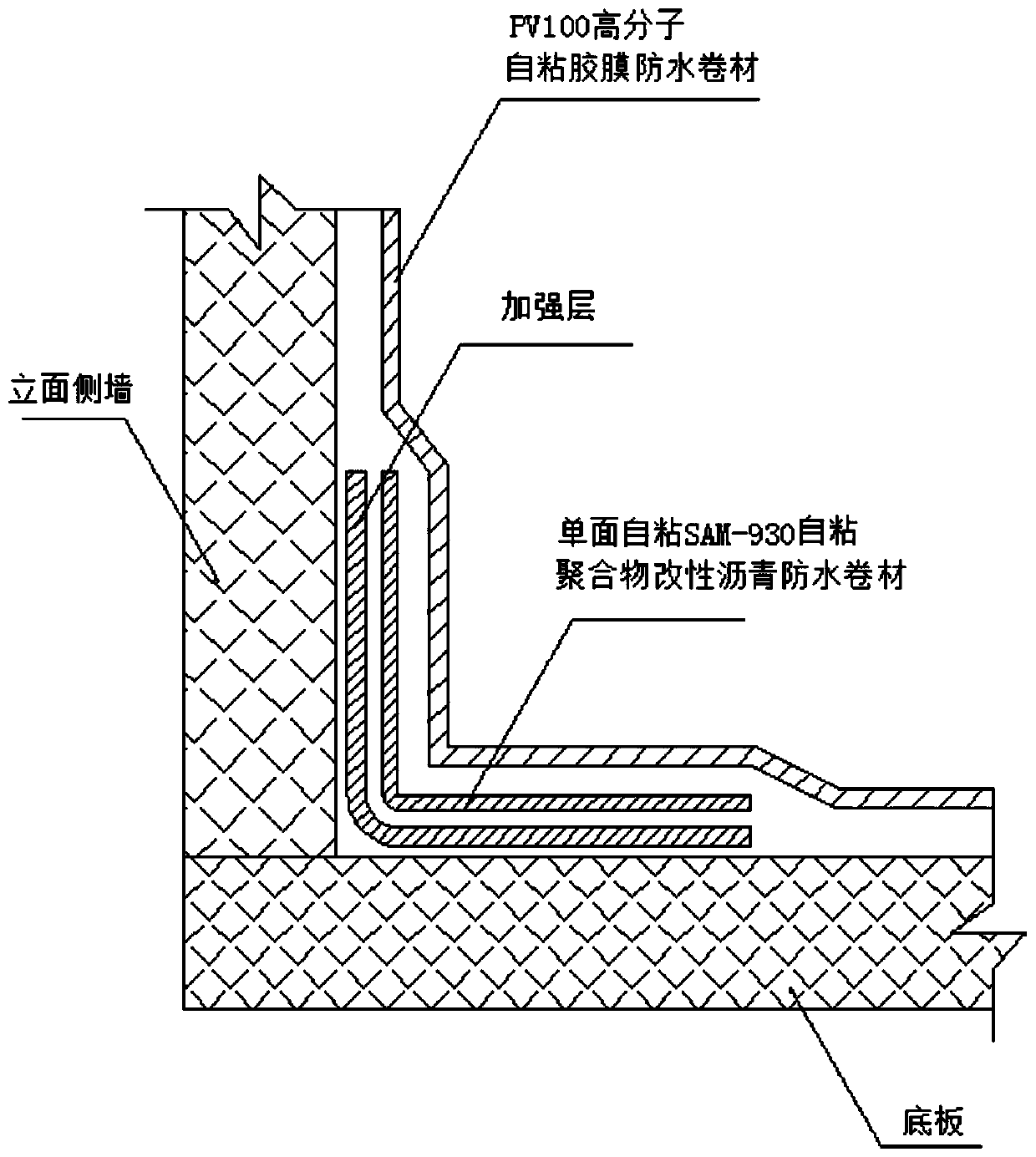

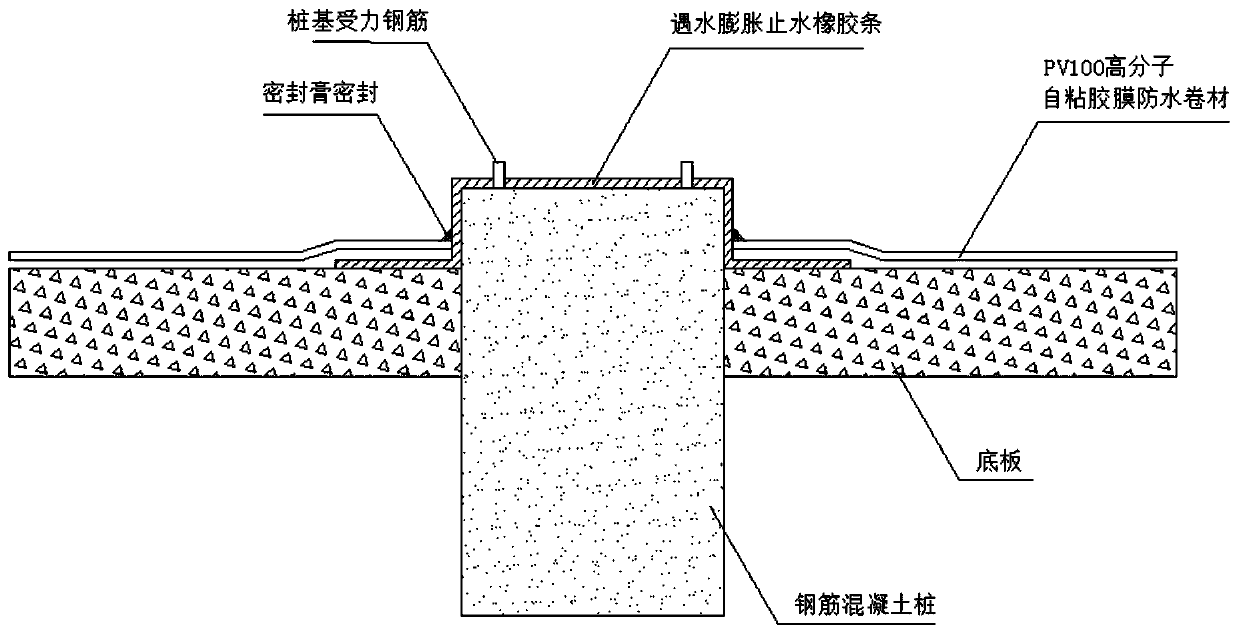

Waterproofing construction method for basement of building engineering

ActiveCN110607809AImprove waterproof performanceStrong toughnessProtective foundationGasketsBasementReinforced concrete

The invention discloses a waterproofing construction method for a basement of building engineering. The method comprises the following steps: S1, dust, sundries, oil stains and visible water on the surface of a base are cleared to make the surface flat and clean; S2, a control line for coil laying is released on the base, so as to accurately control the laying position and lap width of a coil andprevent dislocation, deflection and the like during coil laying; S3, on the basis of foundation treatment and elastic line positioning, construction of 1:2.5 waterproofing mortar is conducted on internal and external corners, the internal and external corners shall be round corners, and R of the arc of the internal and external corners is larger than or equal to 50. Waterproofing performance of inner reinforced concrete is strengthened by the PV100 waterproofing coil, and the PV100 waterproofing coil can form continuous and permanent full adhesion combination with poured concrete, so that water channeling is effectively prevented; the waterproofing coil is tightly adhered to the structure, cannot be affected by uneven settlement of the base, and construction of the next process can be directly performed without construction of a protective layer.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

Grout compositions for construction of subterranean barriers

InactiveUS6860936B2Easy to adjustImprove permeabilitySolid waste disposalProtective foundationEngineeringSensor system

A method is disclosed for constructing, verifying, and maintaining underground vaults that isolate and contain radioactive burial sites. The method employs a buoyant lift technique to isolate a block of soil containing the contaminates from the surrounding soil. An impermeable synthetic liner is embedded in the vault to enhance the integrity of the system. The integrity of the vault is monitored by a system of sensors placed both inside and outside of the sealed vault. The method eliminates the need to excavate or drill in the contaminated areas.

Owner:CARTER JR ERNEST E

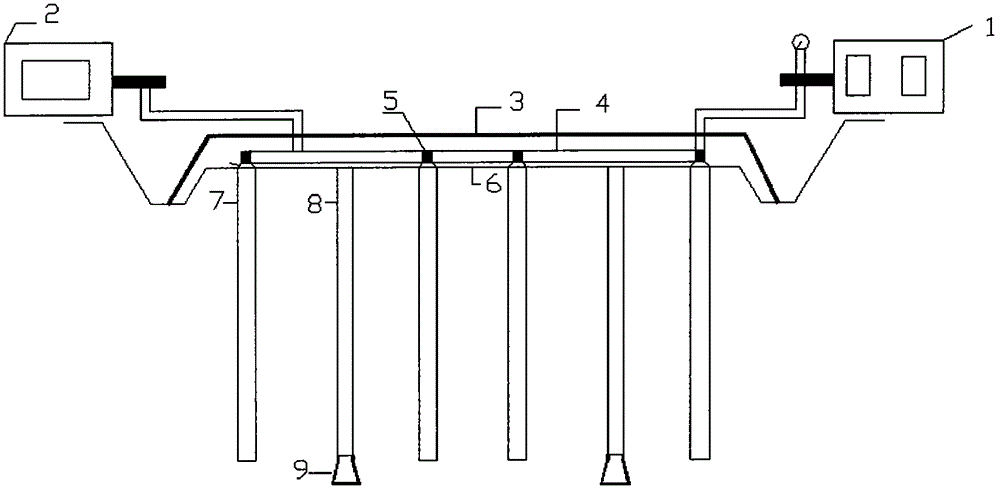

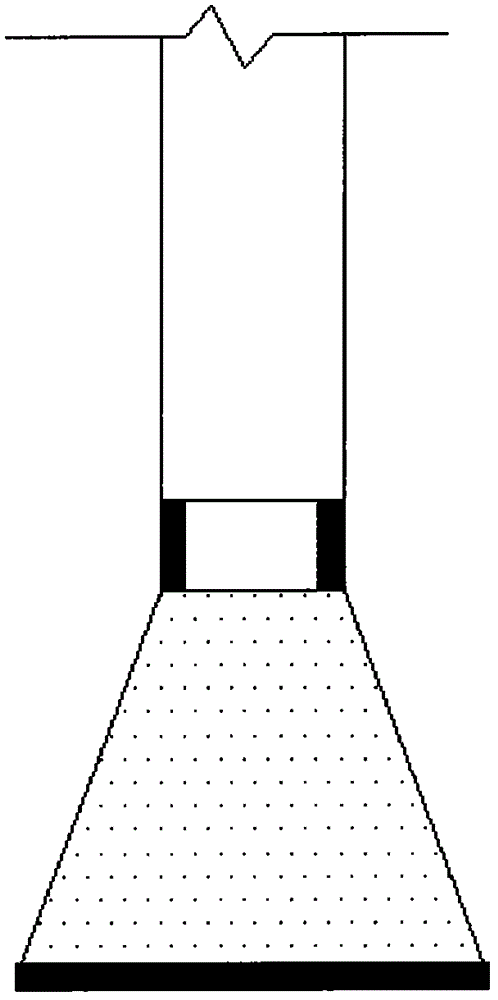

Novel partial deep layer pressurizing type vacuum preloading soft soil foundation processing method

The invention relates to a novel partial deep layer pressurizing type vacuum preloading soft soil foundation processing method. According to the technical scheme, the method comprises a vertical drainage system, a transverse drainage system, vacuum extraction equipment, a pressurizing system, pressurizing equipment and a sealing system; a vertical drainage board adopts a novel anti-clogging drainage board, the vertical drainage board is divided into two parts to be driven, one part is driven into a soil body, and the other part is exposed out of the surface of the soil body. The technology enables a deep soil body to obtain higher air pressure, enables a larger pressure difference to be formed among the deep soil body, an upper soil body and the vertical drainage board, and enables the free water in the deep soil body to fast flow to the upper soil body and the drainage boards. In addition, the flow direction of airflow from a jet head obliquely upwards points to the drainage boards, therefore the seepage of the pore water in the deep soil body to the drainage boards can be accelerated, and the deep soil body can obtain better reinforcement effect.

Owner:WENZHOU UNIVERSITY

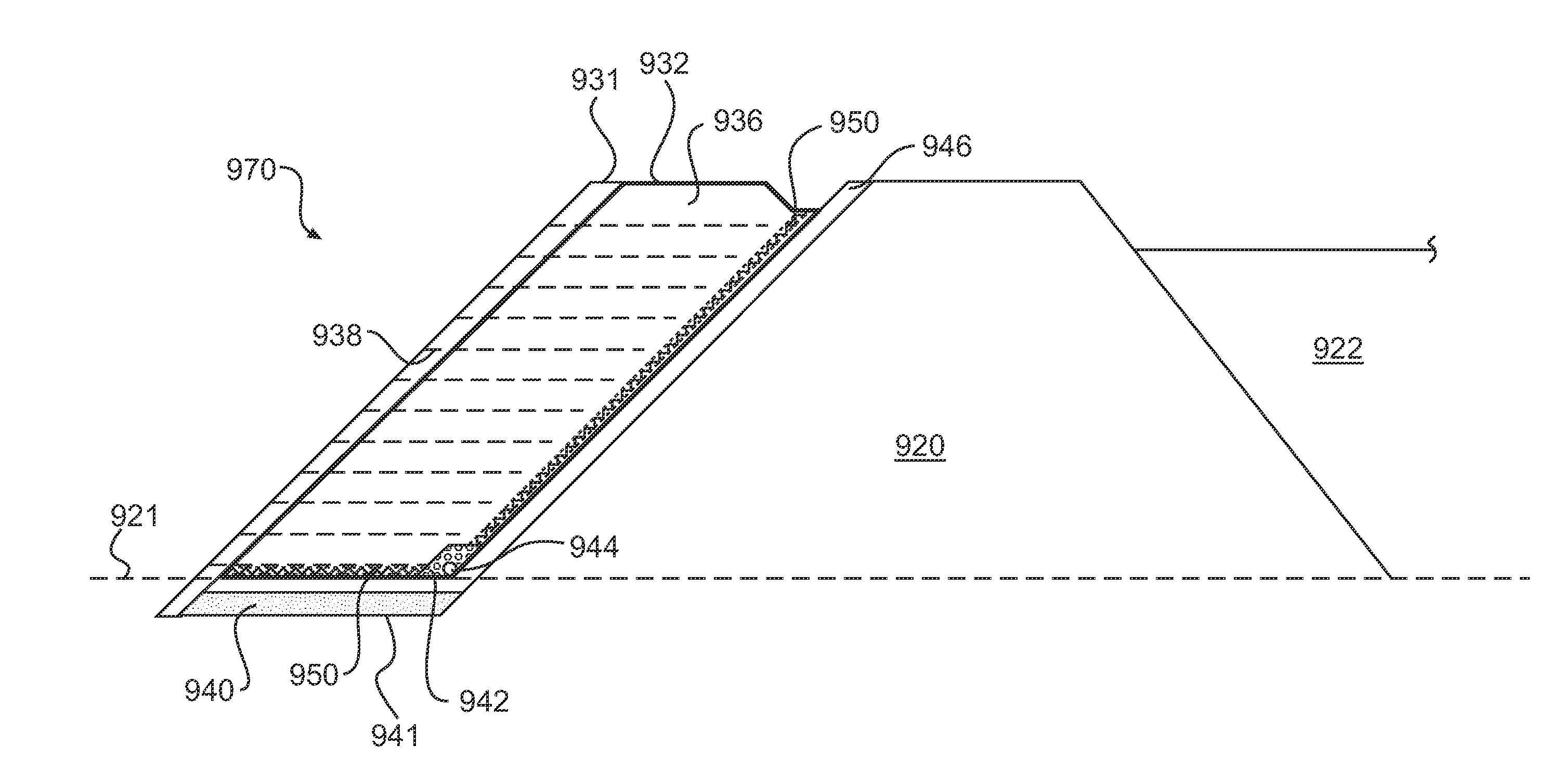

Drainable base course for a landfill and method of forming the same

Numerous embodiments of one or more layers of void-maintaining synthetic drainable base courses (“VMSDBC's”) are provided as incorporated into landfills and other waste containment facilities.

Owner:ADVANCED GEOTECH SYST

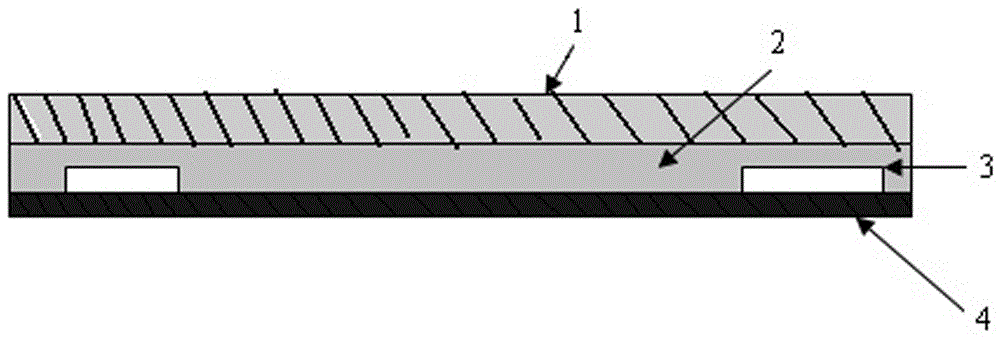

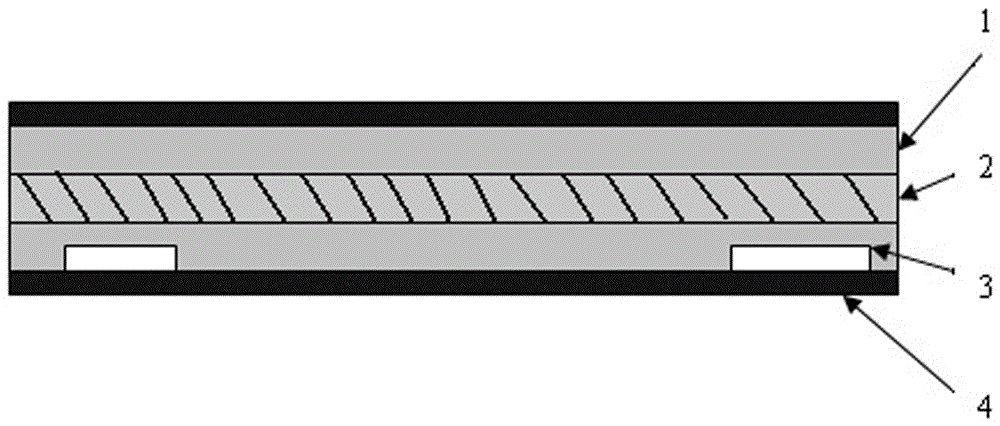

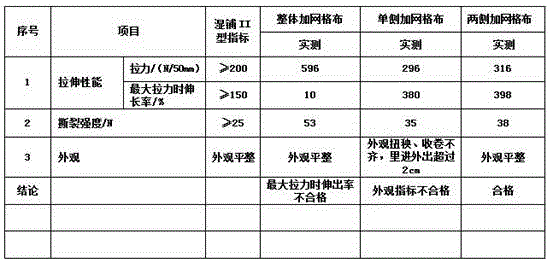

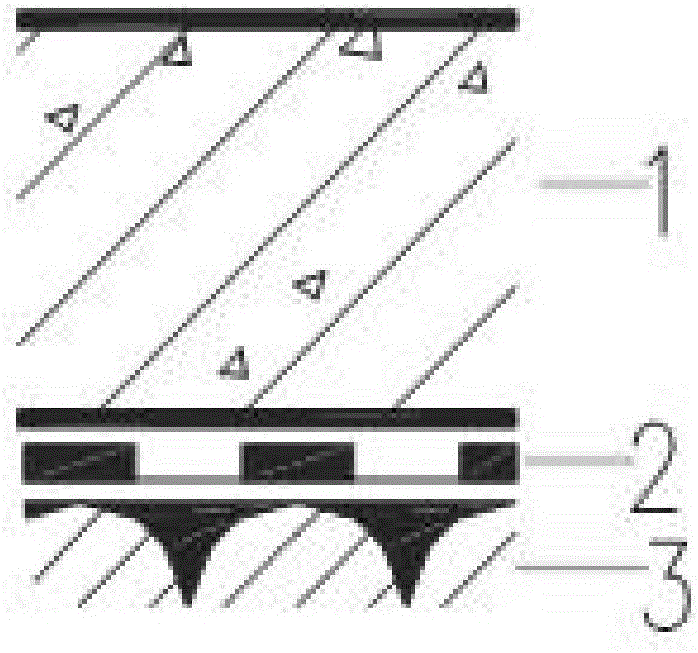

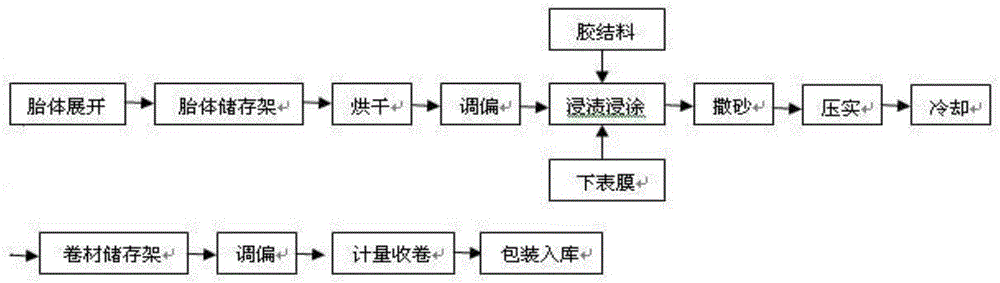

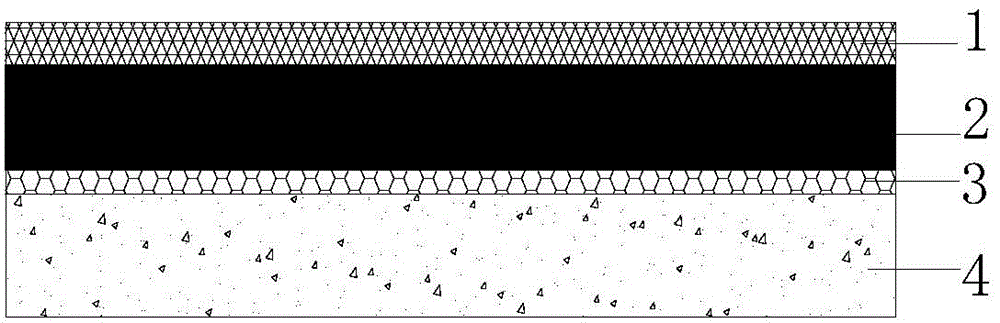

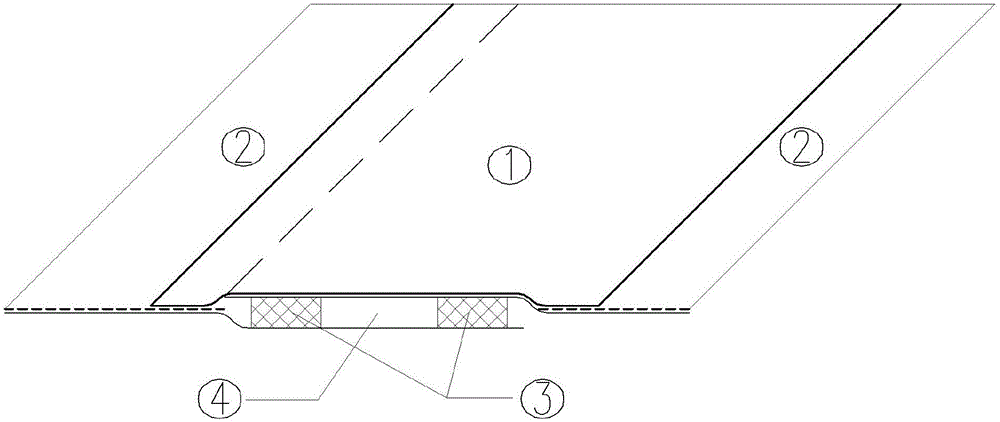

Modified asphalt waterproof coiled material with reinforced overlap edges and production method of modified asphalt waterproof coiled material

InactiveCN107175870AQuality improvementImprove mechanical propertiesRoof covering using flexible materialsSynthetic resin layered productsFiberBituminous waterproofing

The invention relates to a modified asphalt waterproof coiled material with reinforced overlap edges and a production method of the modified asphalt waterproof coiled material. The modified asphalt waterproof coiled material comprises a main body material layer, a modified asphalt layer and an isolating membrane, wherein two strips of fiber cloth are respectively embedded between the parts, which are respectively 0.1-1cm away from the edges of the two sides along the longitudinal direction of the modified asphalt layer, and the isolating membrane, so that the overlap edges are formed. After the method is adopted, the mechanical properties of the overlap edges are obviously improved after the modified asphalt waterproof coiled material is molded, so that the water resistance of the modified asphalt waterproof coiled material is more reliable; the production method provided by the invention solves the problems that in the traditional production process, due to mechanical mismatch of the left side and the right side of the coiled material, the coiled material is neat when being coiled and is twisted when being unfolded, and the like, and improves the quality of the waterproof coiled material.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

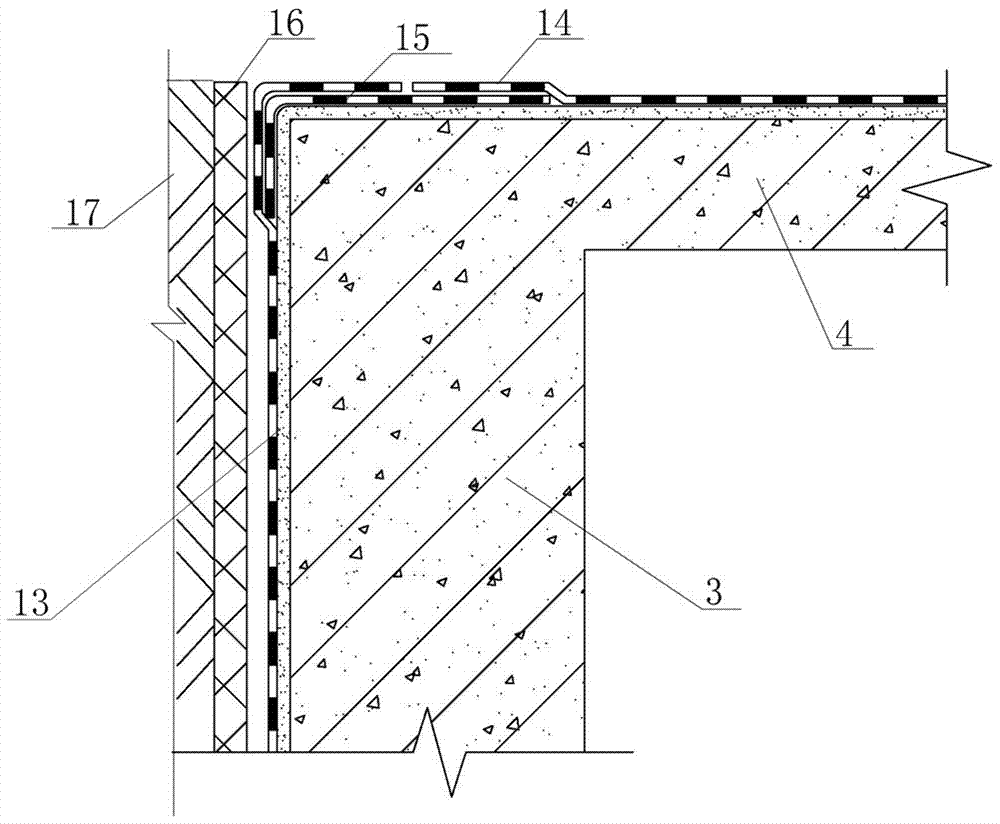

Basement water-proof structure and construction method for basement outer wall water-proof structure thereof

PendingCN107190783AImprove the weak bondEffective waterproof barrierProtective foundationGasketsBasementEconomic benefits

Provided are a basement water-proof structure and a construction method for a basement outer wall water-proof structure thereof. A basement comprises a basic bottom plate, a basement wall body and a basement top plate. Wall bushings are formed in the basement wall body. The basement wall body comprises a guiding wall and a basement outer wall. Construction joints between the guiding wall and the basement outer wall are connected and fixed through water-stop steel plates. A concrete gel layer and a cross film water-proof layer are arranged at the periphery, from inside to outside in sequence, of the basement outer wall and the basement top plate. A second additional cross film water-proof layer is arranged in the portion, located at the inside corner position between the wall bushings and the basement wall body, of the cross film water-proof layer. The tail ends of the cross film water-proof layer and the second additional cross film water-proof layer are fixed to the wall bushings through metal hoops, and are sealed by applying polyurethane. The basement water-proof structure and the construction method for the basement outer wall water-proof structure have the characteristics of being safe and applicable, have good popularization and use value, and can generate good economic benefits after being widely popularized and applied.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

DC-DC converter with load intensity control method

InactiveUS7285941B2Improve efficiencyMinimize unnecessary switchingEfficient power electronics conversionElectronic switchingElectricityDc dc converter

A DC-DC converter to convert DC power input from an external source into a predetermined DC power required for an electric load. A switch part in which each of a pair of switches that cuts or supplies the input DC power is connected in parallel with at least one other switch. A current sensor senses a load current flowing through the electric load and a controller controls the switch part to enable a number of the switches according to an intensity of the load current sensed by the current sensor. The enabled switches are driven by a PWM signal to cut or supply the input DC power to the load. By changing the number of enabled switches, unnecessary switching is prevented for lower load currents.

Owner:SAMSUNG ELECTRONICS CO LTD

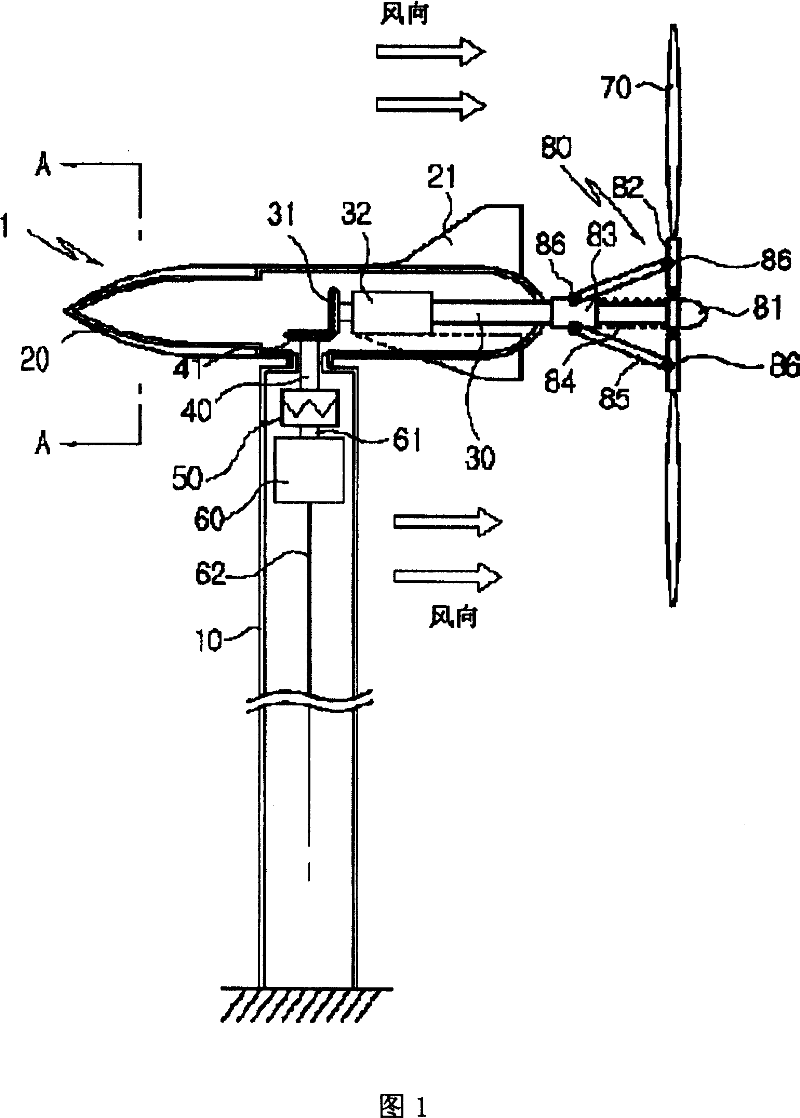

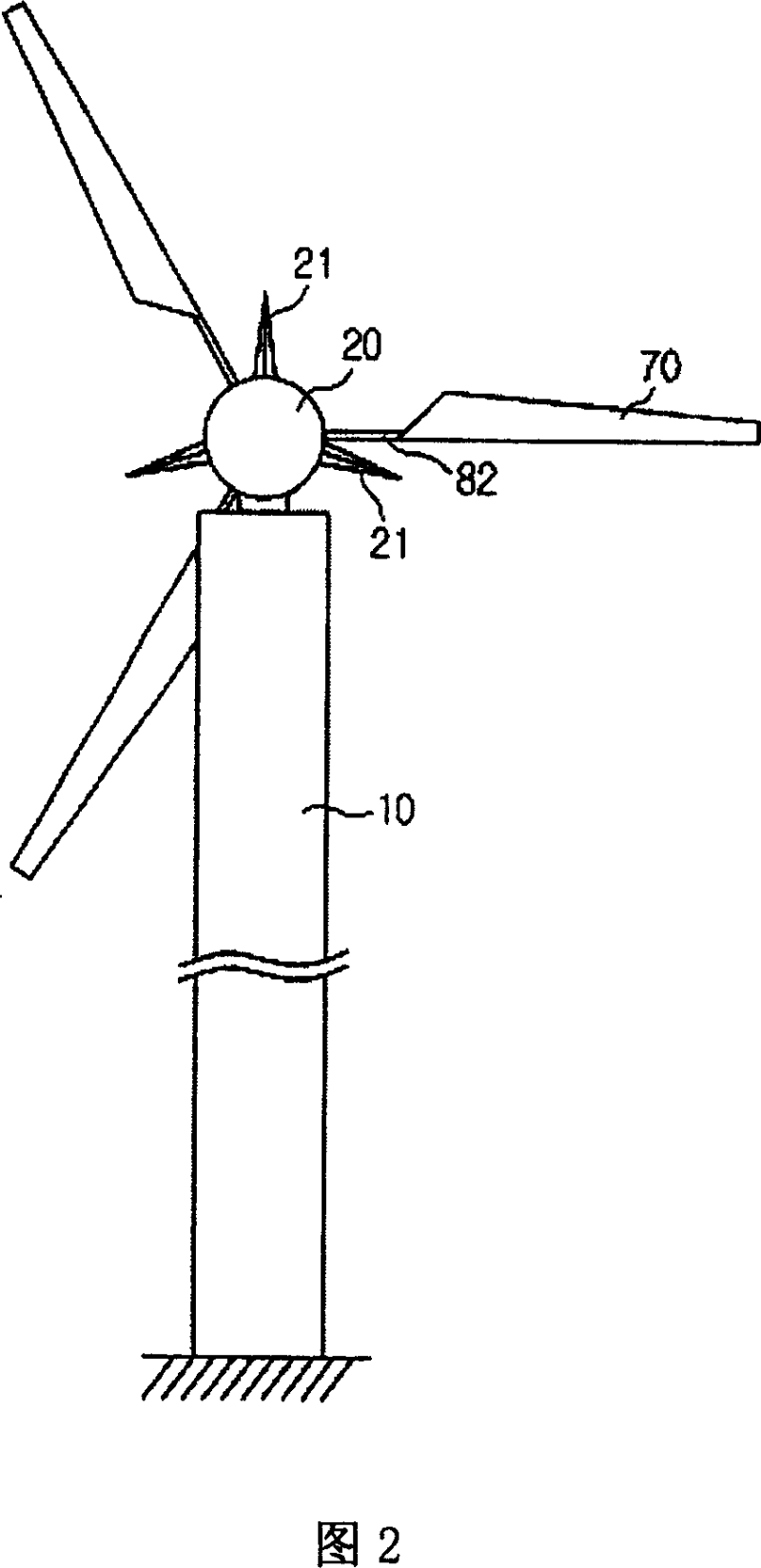

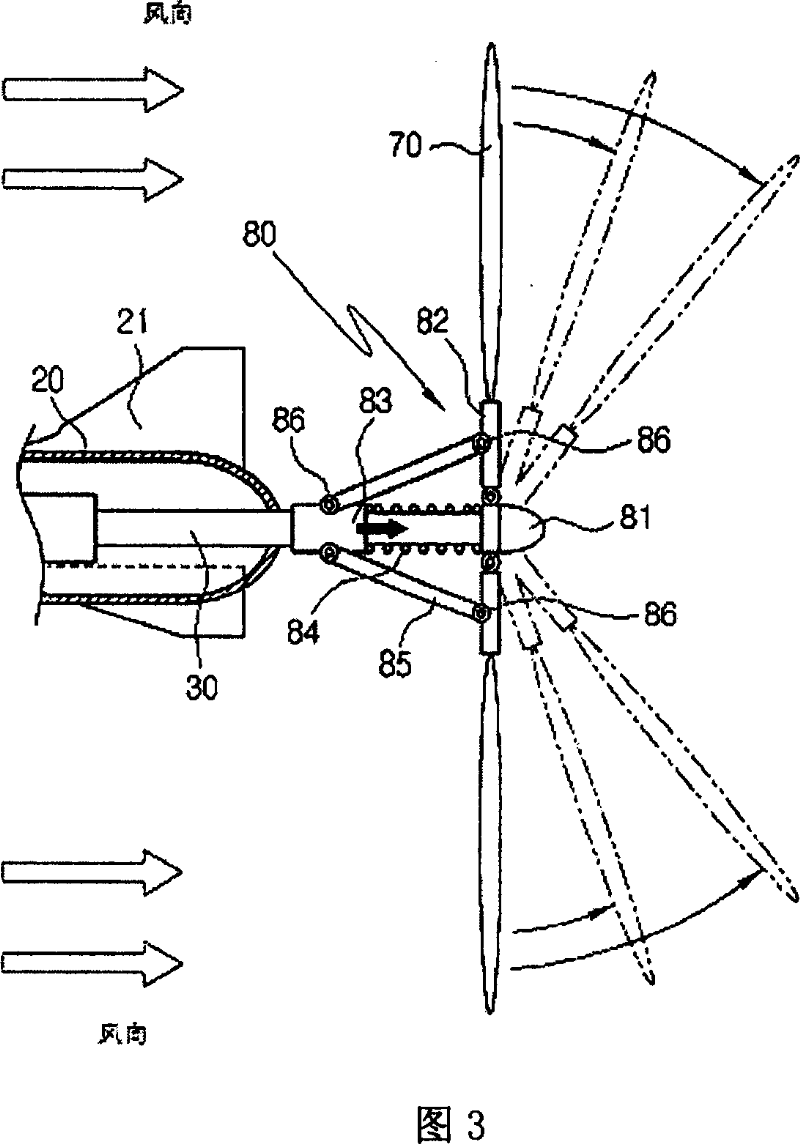

Wind driven power generating system

InactiveCN100338359CAvoid overloadAvoid entanglementWind motor controlEngine fuctionsWind drivenEngineering

The present invention discloses a wind driven power generator. The wind driven power generating system comprises: a) an aerodynamic unit rotatably mounted at the top of a tower having a certain height; b) a plurality of rudders for aligning the aerodynamic unit with the direction of wind, the rudders being radially formed on the outer surface of the aerodynamic unit; c) a horizontal shaft rotatably and horizontally mounted in the aerodynamic unit, wherein one end of the outwardly from the backend of the aerodynamic unit and the other end of the horizontal shaft remains inside of the aerodynamic unit and is provided with a first bevel gear; d) a blade attached to the rear end of the horizontal shaft, wherein the blade is rotated by the wind and thus rotates the horizontal shaft; e) blade variation means disposed at the rear portion of the aerodynamic unit for slanting the blade backwards and forwards, depending on the wind pressure; f) a power generator installed inside the tower; and g) a vertical shaft for transmitting the rotating power of the horizontal shaft to the power generator, wherein one end of the vertical shaft is provided with a second bevel gear, which is engaged with the first bevel gear, and the other end thereof is connected to a rotor shaft of the power generator.

Owner:金 东 龙 +1

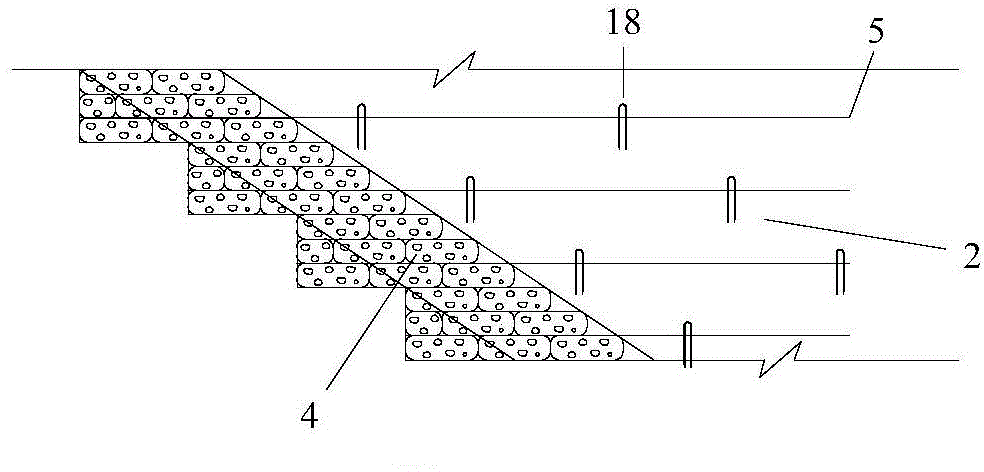

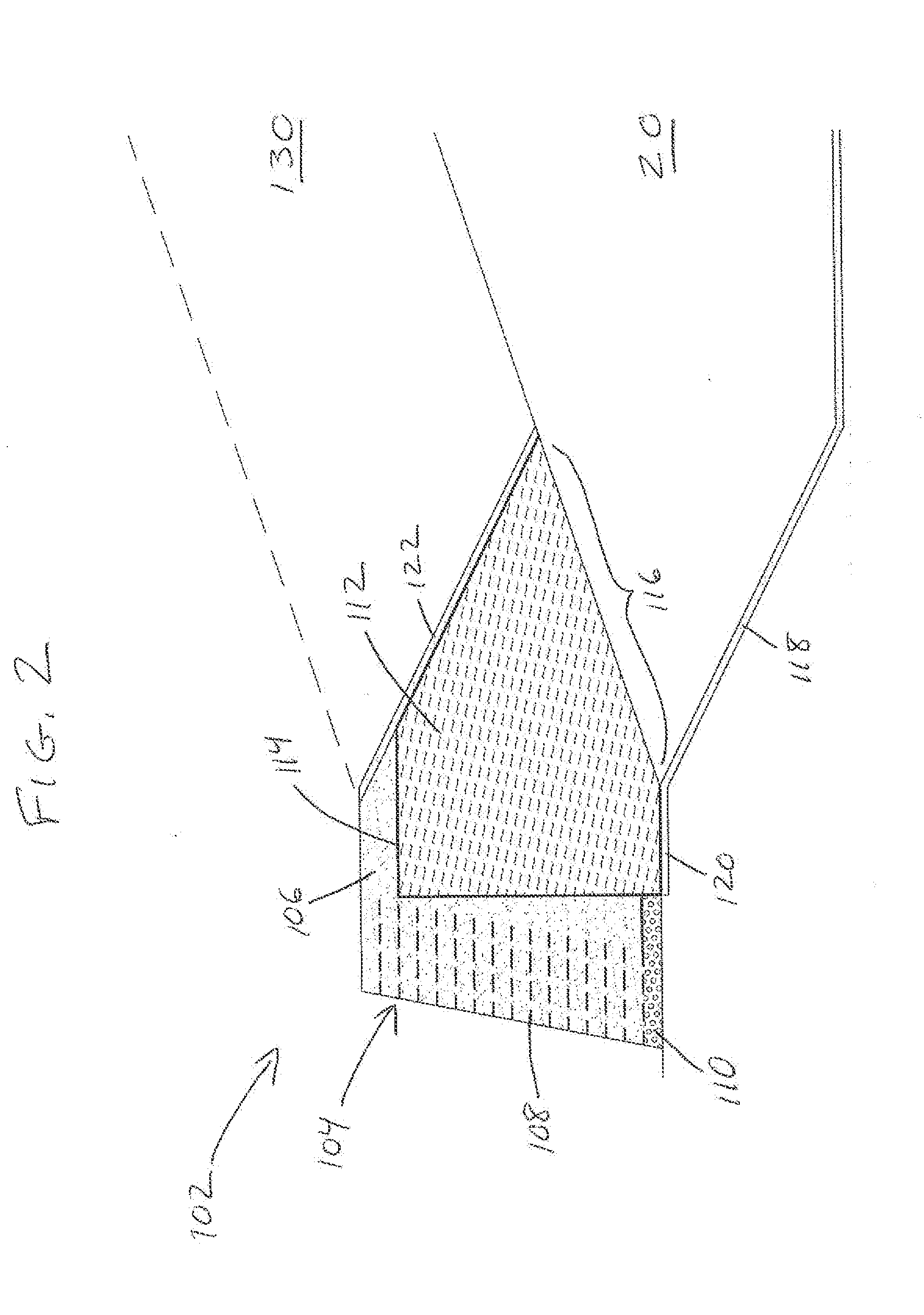

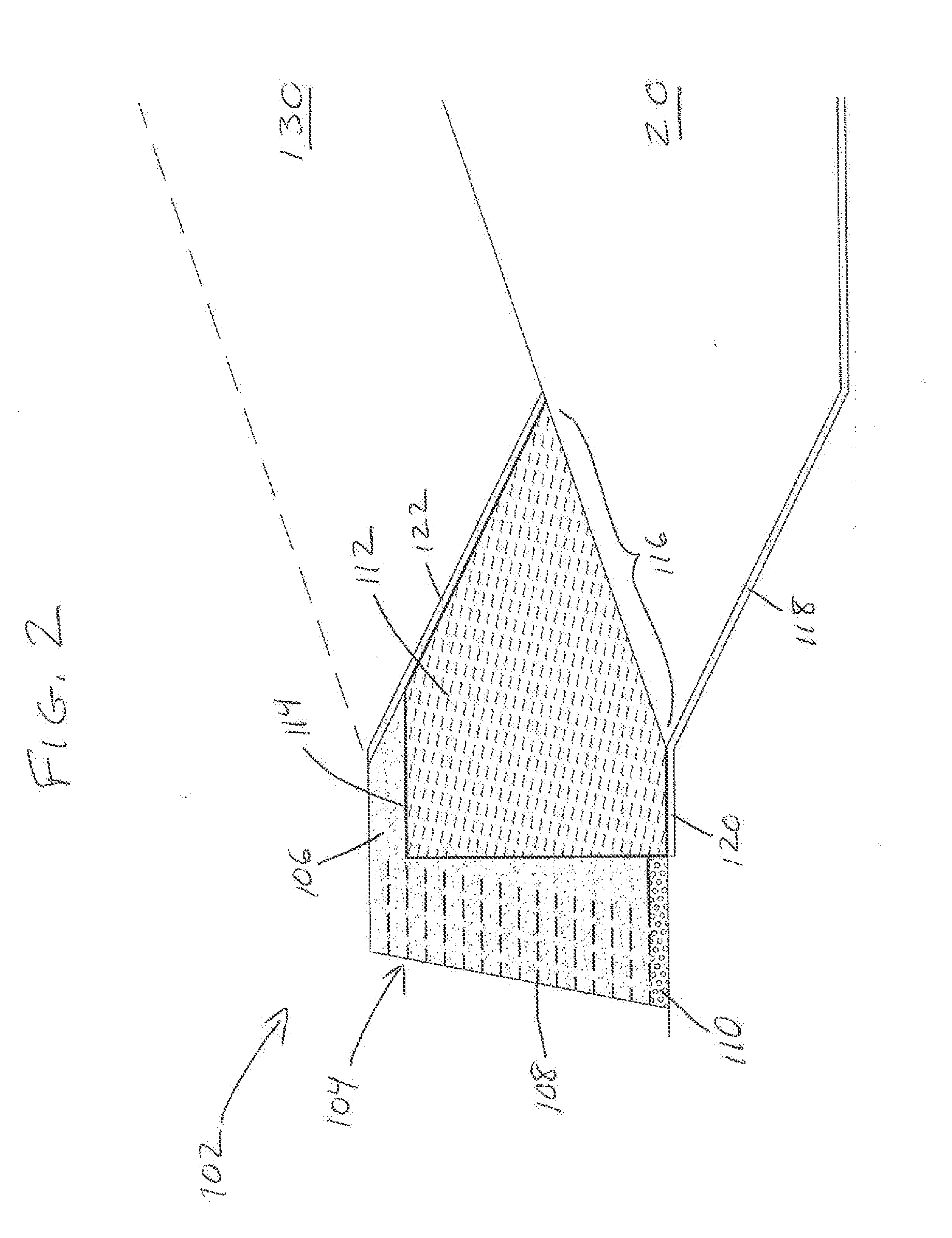

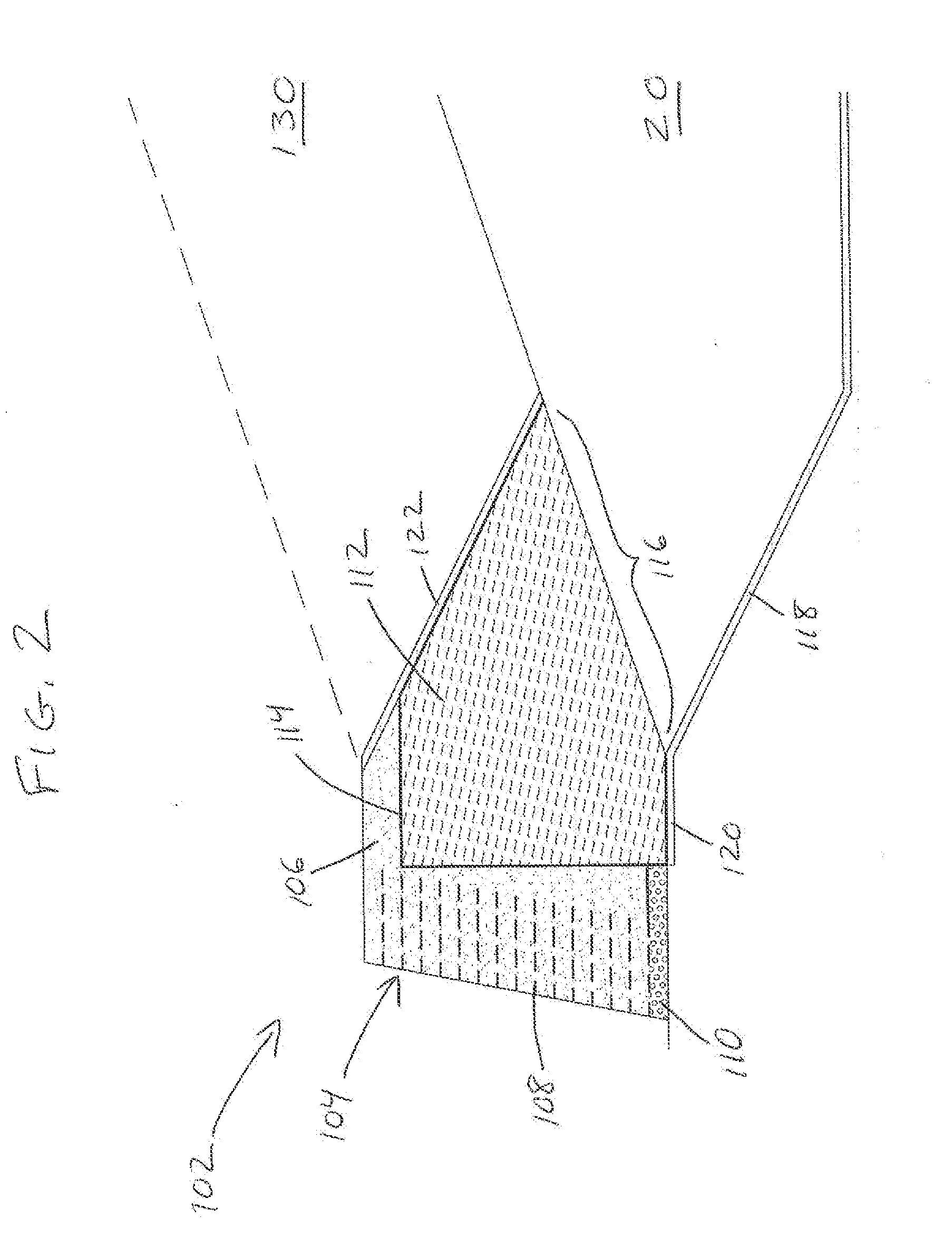

Berm and method of construction thereof

A system for reinforcing and facing a wall comprises a plurality of facing baskets and corresponding substantially horizontal reinforcing members, arranged in a plurality of layers. An impermeable membrane is positioned to uninterruptedly span two or more layers. At each of one or more layers, different portions of the impermeable membrane are positioned (a) between the substantially horizontal portion of the facing basket and the bottom surface of the corresponding reinforcing member, (b) around the outer end of the corresponding reinforcing member, (c) along the top surface of the substantially horizontal portion of the facing basket, and (d) angled upward toward an adjacent layer.

Owner:AWT IP

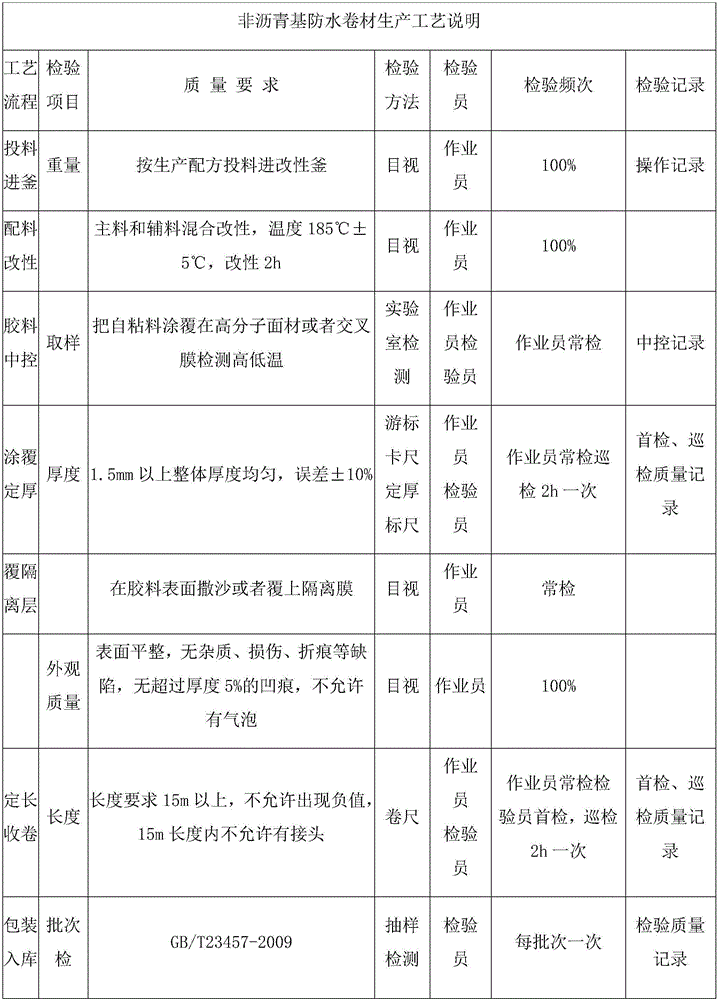

Waterproof coiled material pre-paving and inverted sticking process

InactiveCN105908787AResist radiationGuaranteed bonding performanceProtective foundationGasketsBasementEngineering

The invention provides a waterproof coiled material pre-paving and inverted sticking process. A waterproof coiled material is paved under a basement bottom plate and on a cushion layer and comprises an HDPE bottom film, a self-adhesive glue film and a reaction sand anti-sticking layer. The reaction sand anti-sticking layer is arranged on the self-adhesive glue film. The HDPE bottom film is arranged under the self-adhesive glue film. The waterproof pre-paving construction technology comprises the following processes of a, basic layer examination and acceptance, b, working surface transfer, c, basic layer cleaning, d, joint enhancement treatment, e, snapline positioning; f, coiled material paving, g, coiled material lapping treatment, h, coiled material head unwinding and fixing, i, self-checking and acceptance and j, working surface transfer. According to the waterproof coiled material pre-paving and inverted sticking process, compared with a traditional waterproof method, the construction time and the maintenance time of a leveling layer and a protective layer are omitted, the structure level is optimized, so that the construction period is greatly shortened, and the construction cost is greatly reduced; and the effects of environmental protection and safety are achieved, solvent and fuel are not needed in the construction process, environmental pollution and firefighting hidden dangers are avoided, and energy sources are saved.

Owner:SHENZHEN LANDUN WATERPROOF ENG

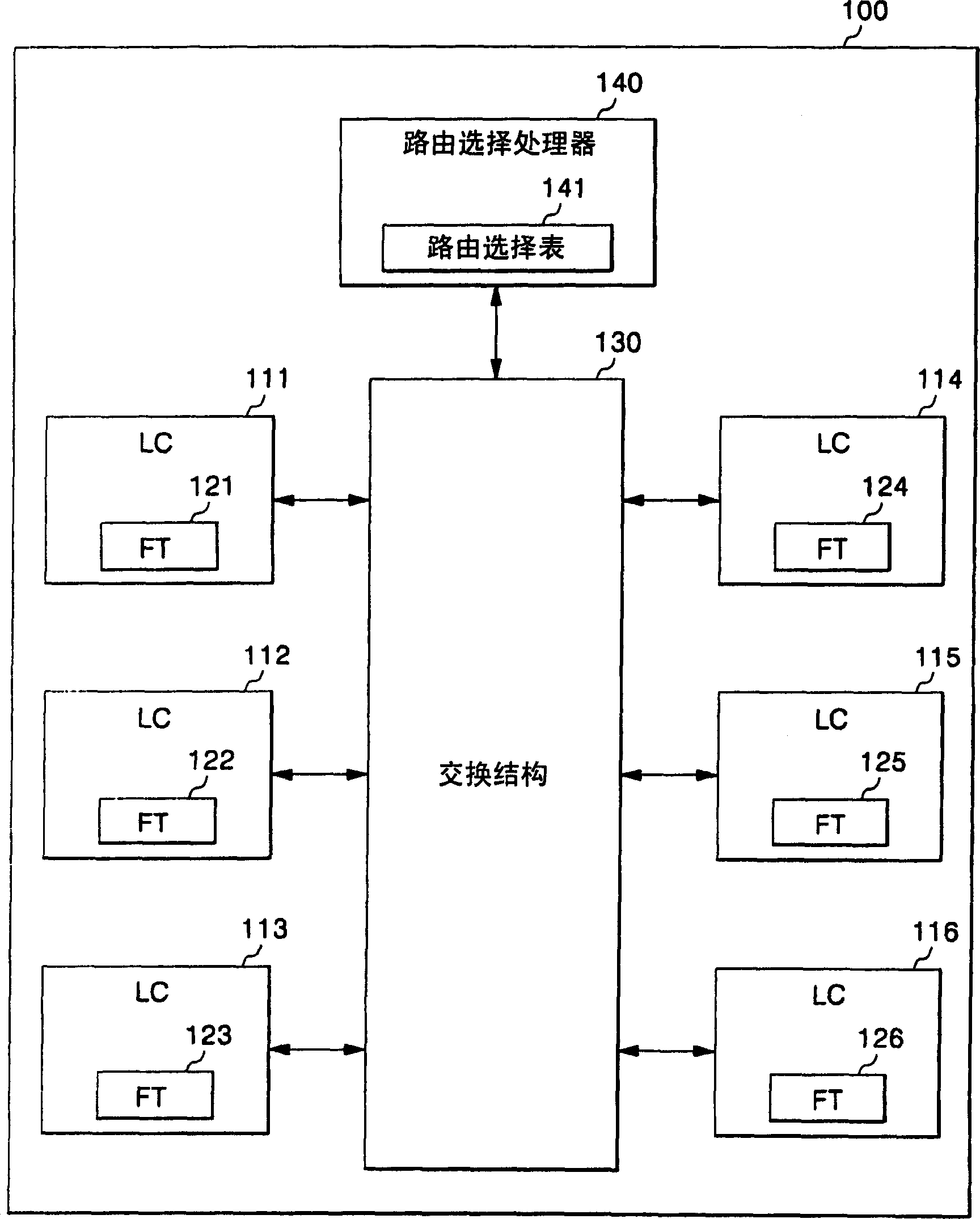

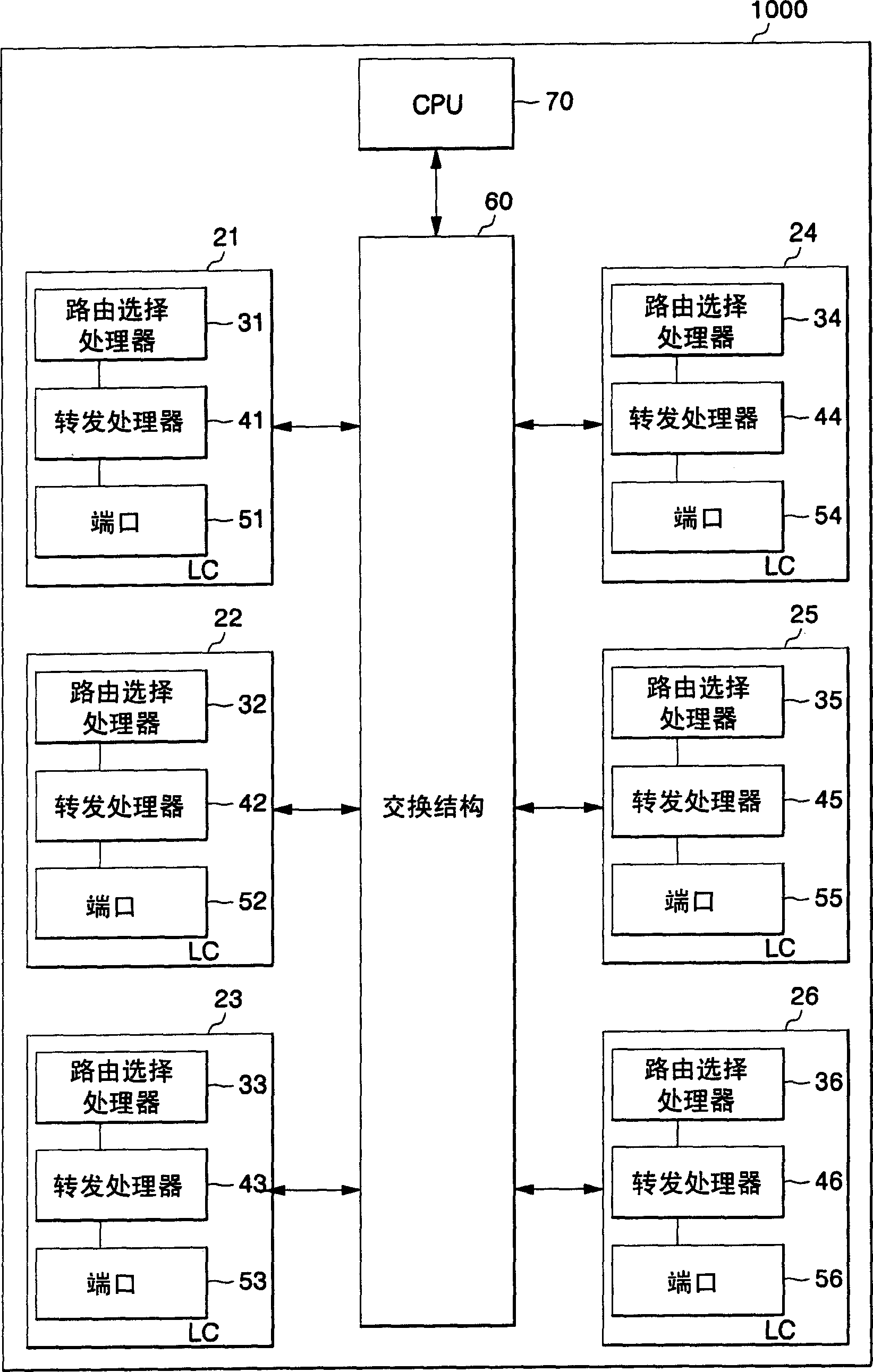

Distributed router

InactiveCN1652528AImprove management efficiencyUnderwater structuresNetworks interconnectionProtocol processingNetwork connection

A distributed router includes: a number of ports adapted to be connected to peers via a network, to receive messages containing packets and entry information from the peers, and to output the packets for transmission to destinations; a switching fabric adapted to switch the packets received through the respective ports to output the packets to corresponding output ports; and at least one line card adapted to extract the entry information of the peers from the messages received via the input ports, to process the entry information according to a preset routing protocol to determine a best route, and to output the packets received from the peers through the corresponding output ports according to the best route.

Owner:SAMSUNG ELECTRONICS CO LTD

Anti-washout ecological greening protective face of refuse landfill side slope and construction method for anti-washout ecological greening protective face

ActiveCN105862886AHigh strengthIntensity does not affectClimate change adaptationProtective foundationGrowth plantGeomembrane

The invention discloses an anti-washout ecological greening protective face of a refuse landfill side slope. The anti-washout ecological greening protective face comprises a to-be-greened refuse landfill side slope, wherein a geomembrane fixedly covers the refuse landfill side slope; a three-dimensional geomat fixedly covers the geomembrane; and a mixture of greening seeds and a soil body is laid in the three-dimensional geomat. Meanwhile, the invention also discloses a construction method for the ecological greening protective face. The anti-washout ecological greening protective face and the construction method thereof disclosed by the invention solve the problems that a highly-polluted soil body of a refuse landfill is not suitable for plant growth and the planting soil body on the side slope cannot be kept and cannot form a green ecological side slope.

Owner:HOHAI UNIV

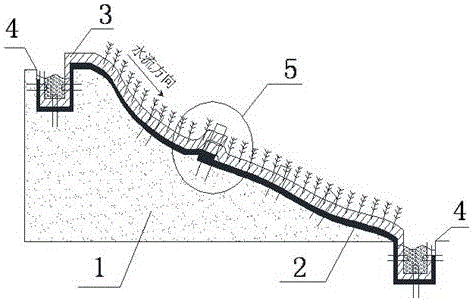

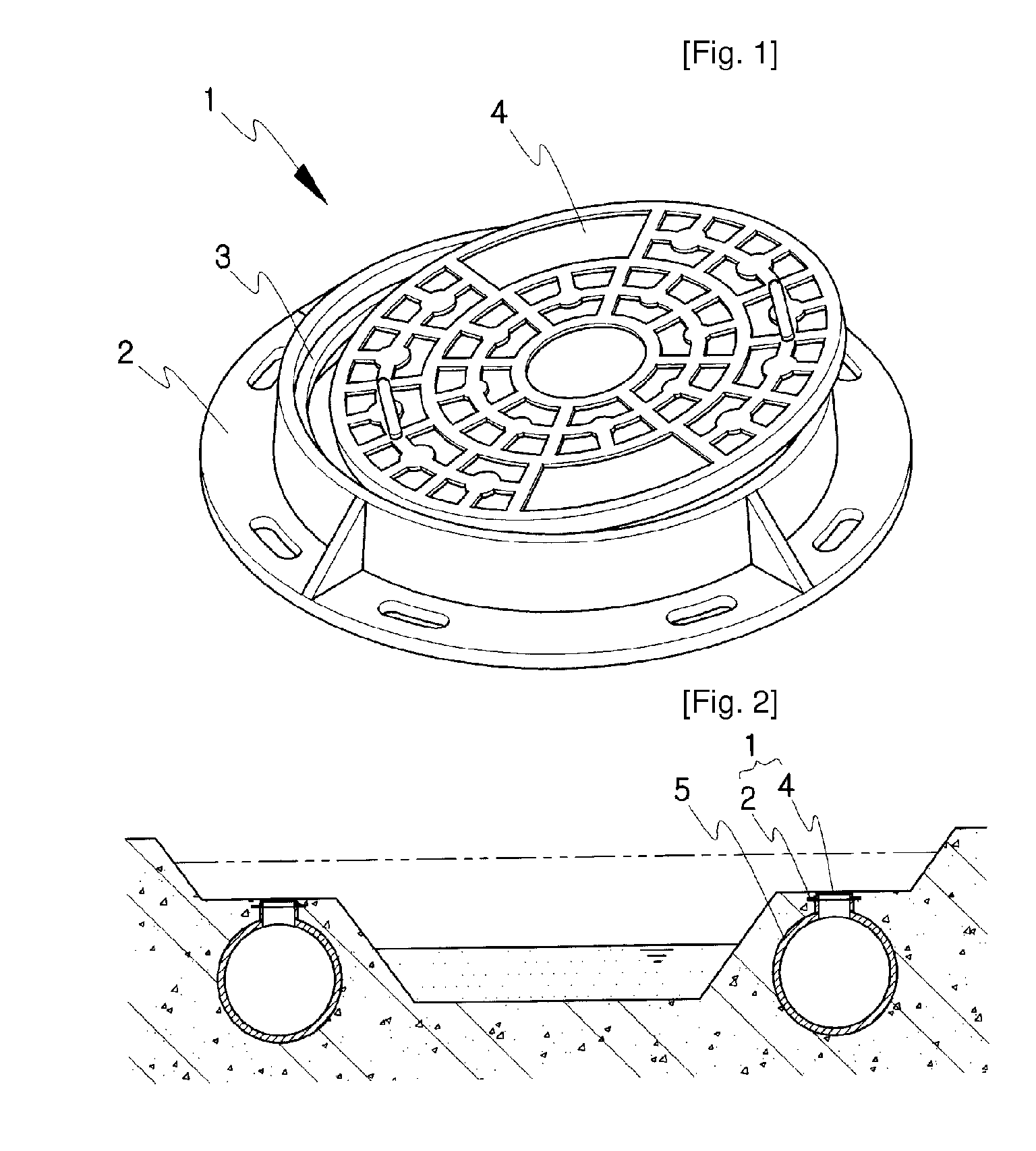

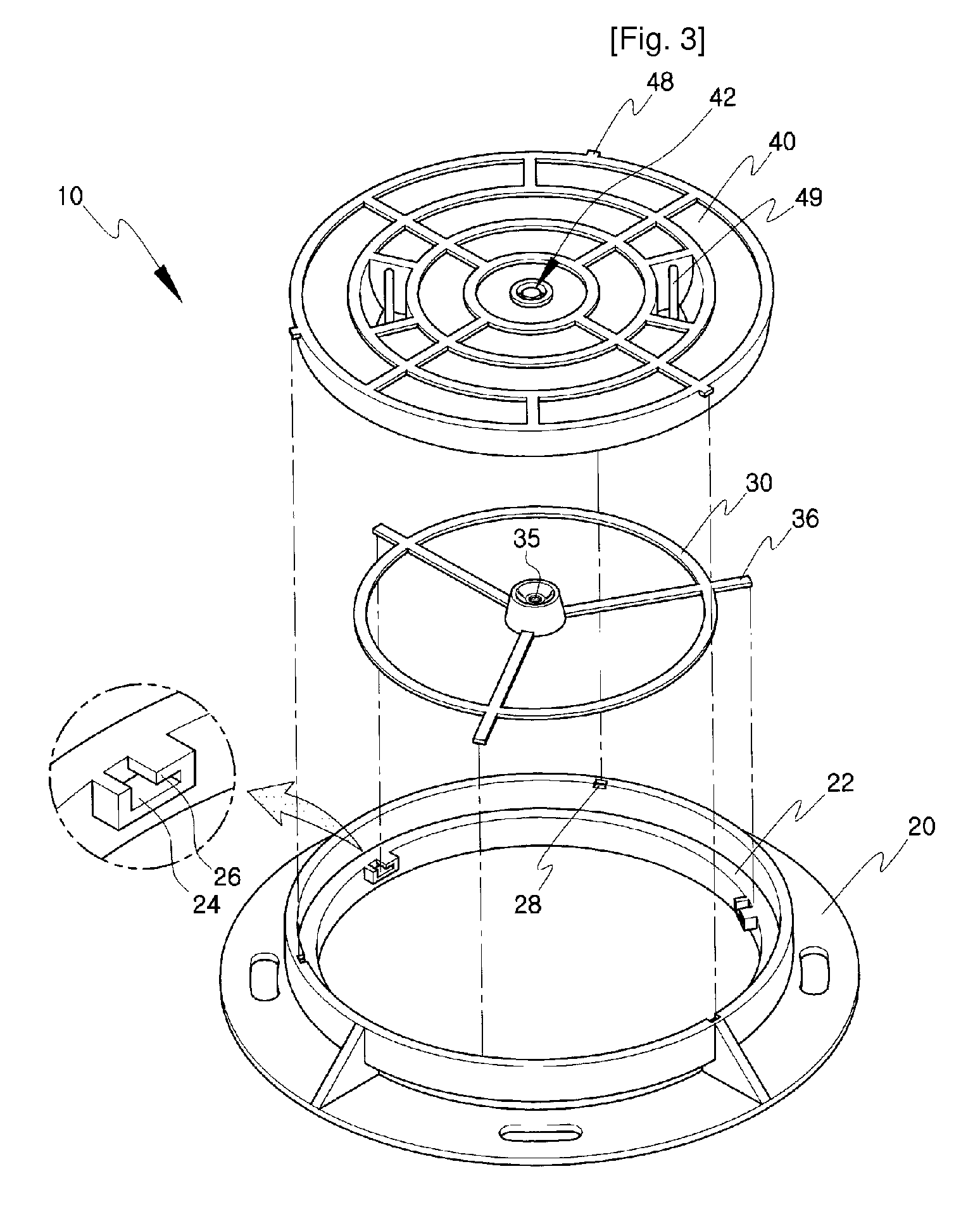

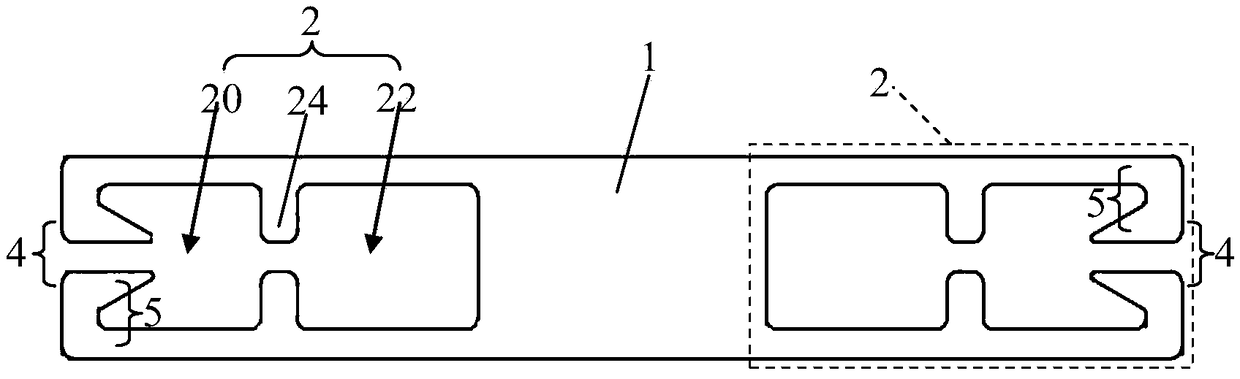

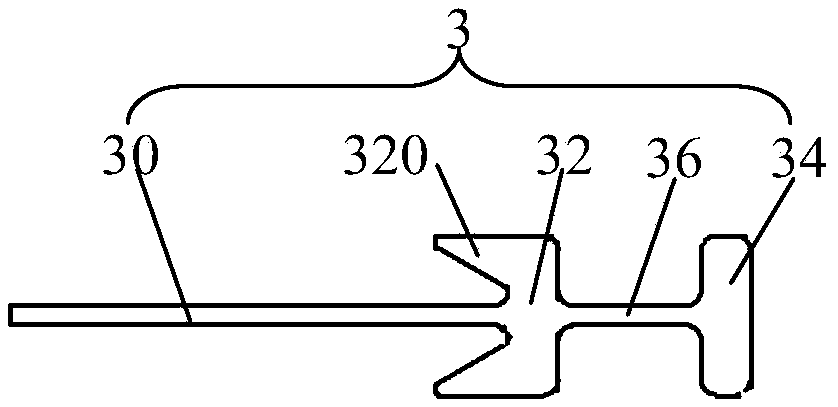

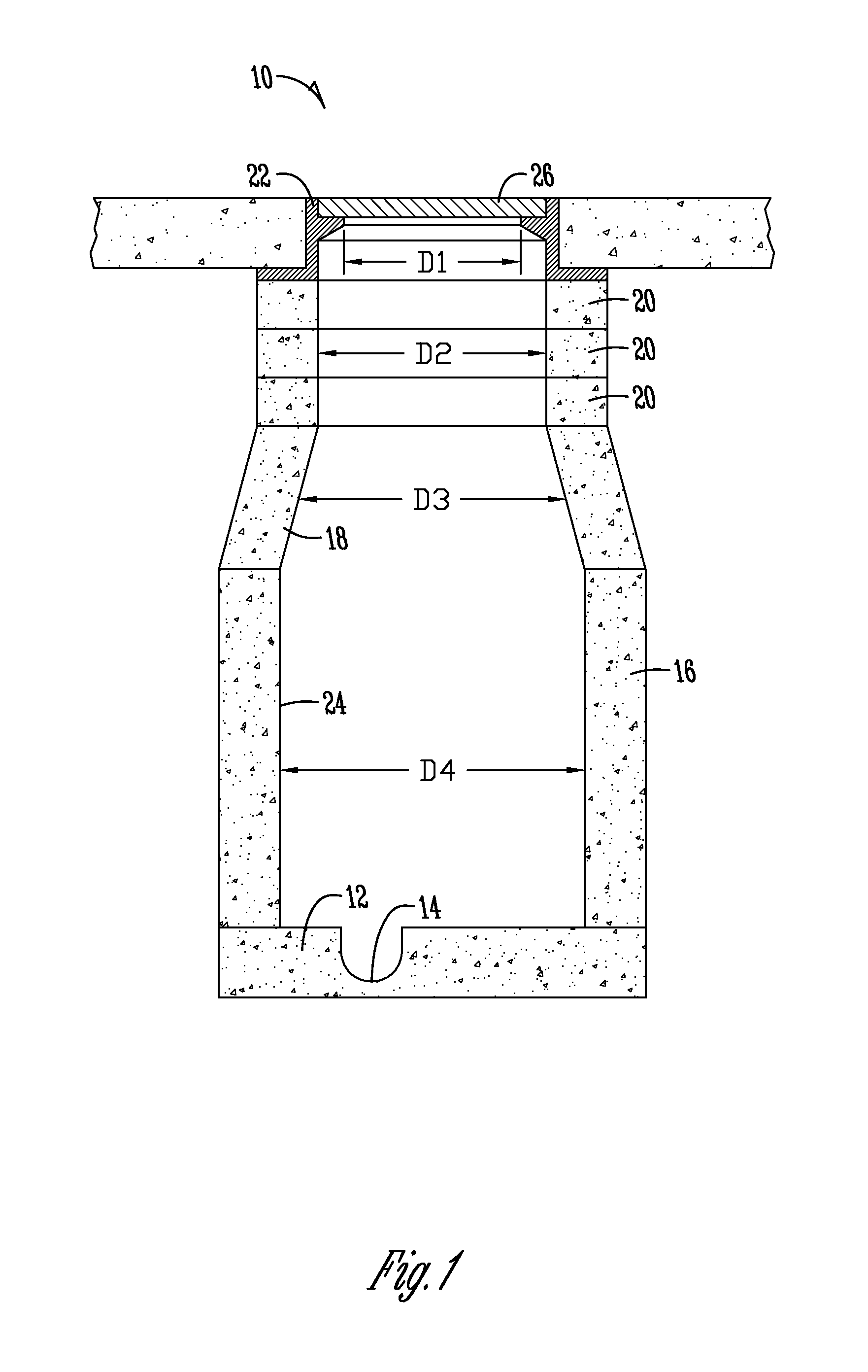

Manhole with locking device

InactiveUS7744305B2Avoid separationOpens and closes easilyArtificial islandsBuilding locksEngineeringWater tightness

The present invention relates to a manhole (10) with a locking device, and more particular to a manhole with a locking device, which comprises a manhole frame (20) having a plurality of insertion slots (24) inwardly protruded from an inner circumferential surface thereof, each insertion slot (24) having a latching protrusion (26) formed in such a manner that a top surface of the insertion slots (24) is partially opened; a bearing member (30) having a female screw portion formed on the center thereof and a plurality of fastening pieces (36) radially formed outwardly from the outer circumferential edge thereof, so that the bearing member (30) is detachably fastened to the manhole frame (20); and a manhole cover (40) having a through-hole (41) centrally formed therein so that an upper portion of the vertical screw rod (42) is rotatably inserted into the through-hole (41), the vertical screw rod (42) having a male screw portion (45) formed on the lower portion thereof so as to be threadably fastened to the female screw portion (35) of the bearing member, a head portion (43) formed on the upper portion thereof so as to abut against an upside surface of the manhole cover (40), and a support portion (44) formed on the upper portion thereof so as to abut against an underside of the manhole cover (40), so that the manhole cover (40) is closed by rotating the head portion (40) of the vertical screw rod (42). Thus, in a case of the manhole (10) mounted on a vehicle road, the manhole cover (40) is prevented from being separated from the manhole frame (20) without permission by a vehicle running at a high speed as well as from frictional noise generated between the manhole cover (40) and the manhole frame (20). Further, in a case of the manhole (10) mounted on the waterside of a river, the manhole (10) maintains its watertightness and is readily opened and closed by an operator.

Owner:SAEGYE CAST IRON

Composite anti-seepage structure for red mud tailing ponds

ActiveCN104805872AReduce peeling damagePrevent subsidenceProtective foundationGasketsRed mudUltraviolet lights

The invention discloses a composite anti-seepage structure for red mud tailing ponds, which comprises an anti-seepage layer, a flexible protective layer and a rigid protective layer, wherein the anti-seepage layer is arranged on a side slope, the flexible protective layer is arranged on the anti-seepage layer, the rigid protective layer is arranged under the anti-seepage layer, an isolating layer is also arranged between the rigid protective layer and the anti-seepage layer, wheat straws or rice straws and clay are mixed to form the isolating layer, and the materials of the anti-seepage layer include polycarbonate, polytetrafluoroethylene, polybutylene terephthalate, fly ash, hammer-milled glass fibers, graft copolymerization acrylic acid derivative, antioxidant, ultraviolet light absorber and anti-aging agent. The physical and chemical properties of the adopted anti-seepage materials are stable, the low-temperature properties and the ageing resistance are excellent, the right-angled tear resistance is high, the reliability of joints is high, the strength of the whole anti-seepage layer structure is high, and the composite anti-seepage structure has extremely high tensile strength and elongation in order to adapt to local anti-piercing strength on sand and stones in a large-area tailing stack, thus ensuring that wastewater from red mud cannot seep into the ground during the usage of the stack.

Owner:乐陵市建兴装饰工程有限公司

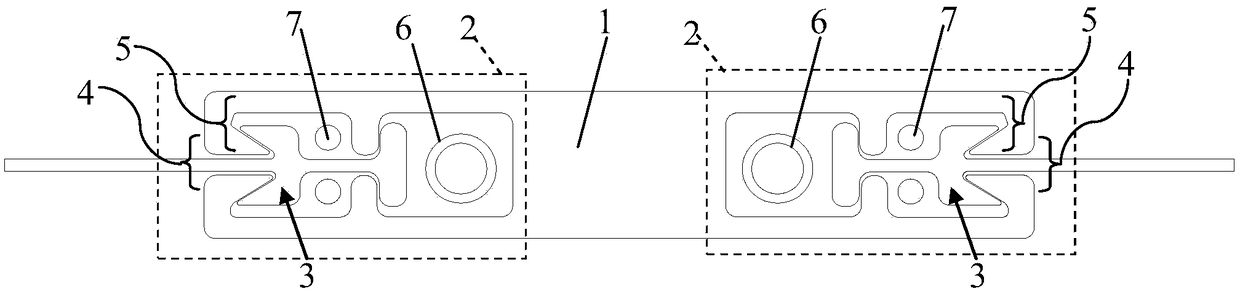

Underground impermeable-membrane plug connector and construction method thereof

PendingCN109056838AImprove anti-seepage effectConstruction is more convenient and efficientProtective foundationGasketsMechanical engineeringMembrane configuration

Owner:SHANGHAI YUANFANG GROUNDWORK ENG

Wireless terminal-interoperable home network system and method controlling the same

InactiveCN1661977AImprove control efficiencyImprove convenienceProtective foundationSubstation remote connection/disconnectionTelecommunicationsOperating energy

Disclosed herein are a wireless terminal-interoperable home network system and a method for controlling the same. A home server is linked with a security device and camera installed in a building to, when the security device senses entrance / exit of an outsider into / from the building, acquire an internal image of the building from the camera and send the acquired image to a wireless terminal of a user to enable the user to monitor the internal situation of the building in real time. The user can access the home server over a wireless communication network from a remote place outside of the building without separate access to the Internet to receive the internal image of the building and check the internal situation of the building on the basis of the received internal image, resulting in an increase in convenience of use.

Owner:LG ELECTRONICS INC

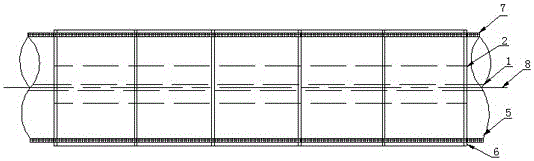

High-molecular self-adhesive film waterproof roll welding and lapping structure and construction method

ActiveCN105672367ASolve the problem that cannot be constructedMake up for the defects that are not easy to applyProtective foundationGasketsAdhesive beltWeld seam

The invention discloses a high-molecular self-adhesive film waterproof roll welding and lapping structure and construction method. The structure comprises two pairs of rolls, two welding seams in the lapping edges, a reserved cavity positioned between the two welding seams in the lapping edges, and a sealing adhesive tape covering and bonded to the upper part of the lapping part, wherein the rolls at the lapping part adopt the structures without adhesive layers. The construction method comprises the following steps: taking the two pairs of high-molecular self-adhesive film waterproof rolls in place; removing the self-adhesive layers at the lapping part of the rolls through special equipment, and exposing a base layer plate; lapping the two welding seams in the lapping edges, where the adhesive layers are removed, of the two pairs of rolls through a welding machine; detecting the welding and sealing quality through the cavity reserved between the two welding seams; covering the lapping edges through sealing tapes to enable the lapping edges and the rolls on the two sides to both achieve the property of the self-adhesive film rolls. According to the structure and construction method, through the treatment of the adhesive layers, the rolls can be welded and lapped, the lapping edges can be subjected to airtight detection, the lapping is firm and reliable, and the adaptability is strong.

Owner:BEIJING GENERAL MUNICIPAL ENG DESIGN & RES INST

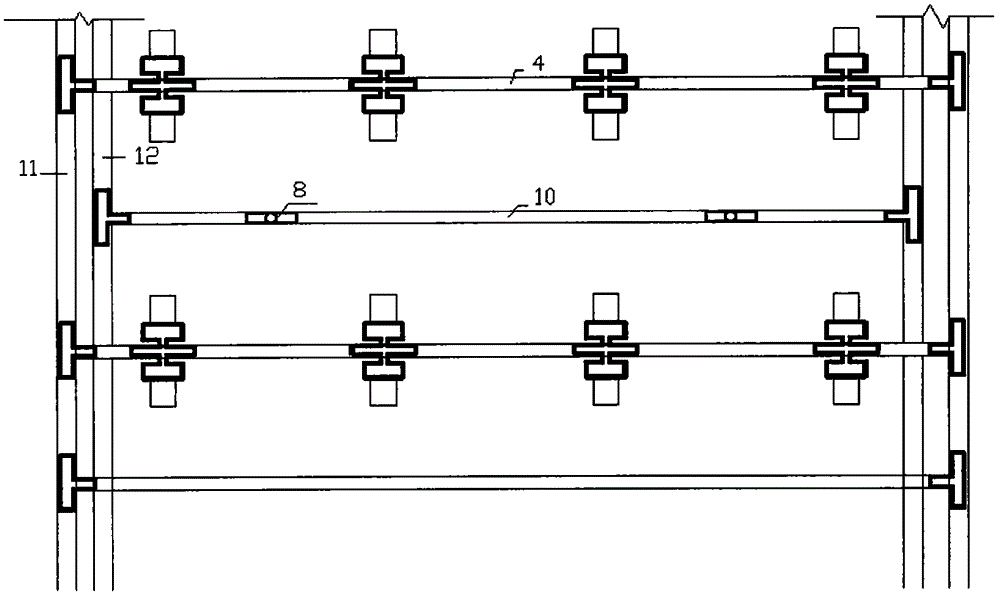

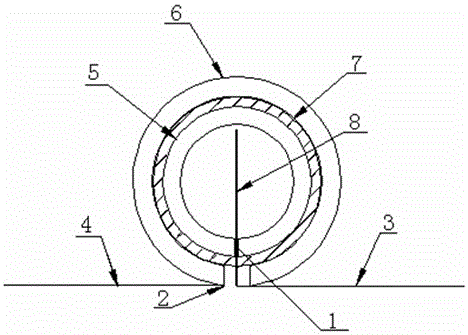

Building foundation impermeable membrane connecting device and building foundation impermeable membrane connecting method

ActiveCN106368172AGuarantee the construction qualityImprove anti-seepage performanceProtective foundationGasketsHydraulic engineeringFunctional requirement

The invention relates to a building foundation impermeable membrane connecting device and a building foundation impermeable membrane connecting method, which are suitable for engineering construction of hydraulic engineering dams, reservoir dams, channels, ponds and the like so as to meet impermeable functional requirements, the tensile strength between new membranes as well as between a new membrane and an old membrane in an impermeable system can be effectively guaranteed, and the impermeable requirements are satisfied. The connecting device comprises inner pipes and outer pipes, wherein insertion openings are axially formed in pipe bodies of the inner pipes, bayonets are axially formed in pipe bodies of the outer pipes, and the outer pipes are clamped on the upper surfaces of impermeable membrane coiling layers which are wrapped outside the inner pipes, so that impermeable membranes I and impermeable membranes II which are used by two building foundations are connected together segment by segment, and the outer pipes as well as the inner pipes are abutted one by one. According to the building foundation impermeable membrane connecting device and the building foundation impermeable membrane connecting method, the leakage problem of the connecting positions of the impermeable membranes is solved, the impermeable purpose is achieved, and the engineering quality is effectively increased.

Owner:中石化石油工程技术服务有限公司 +1

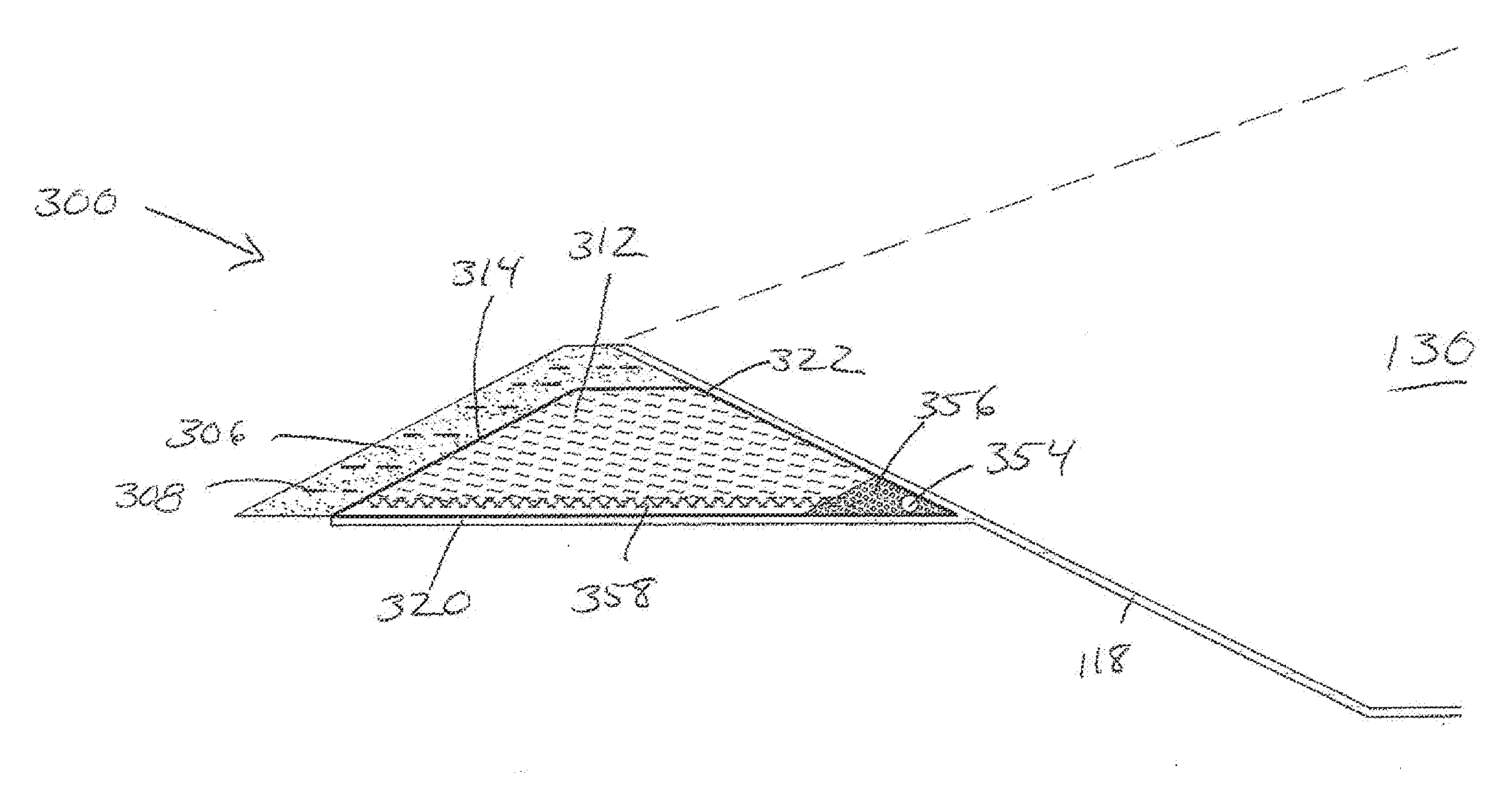

System and method for strengthening a sloped structure such as a berm, basin, levee, embankment, or the like

Embodiments of the invention comprise a system for strengthening a sloped structure such as a berm, basin, levee, or embankment. The comprises first and second opposing sides, the second side being adjacent the sloped structure; a bottom side adjoining bottom edges of the first and second sides, thereby forming a cavity within the first, second, and bottom sides; fill material disposed within the cavity; an impermeable membrane encapsulating at least a portion of the fill material; and a plurality of reinforcing members disposed within the fill material.

Owner:AWT IP

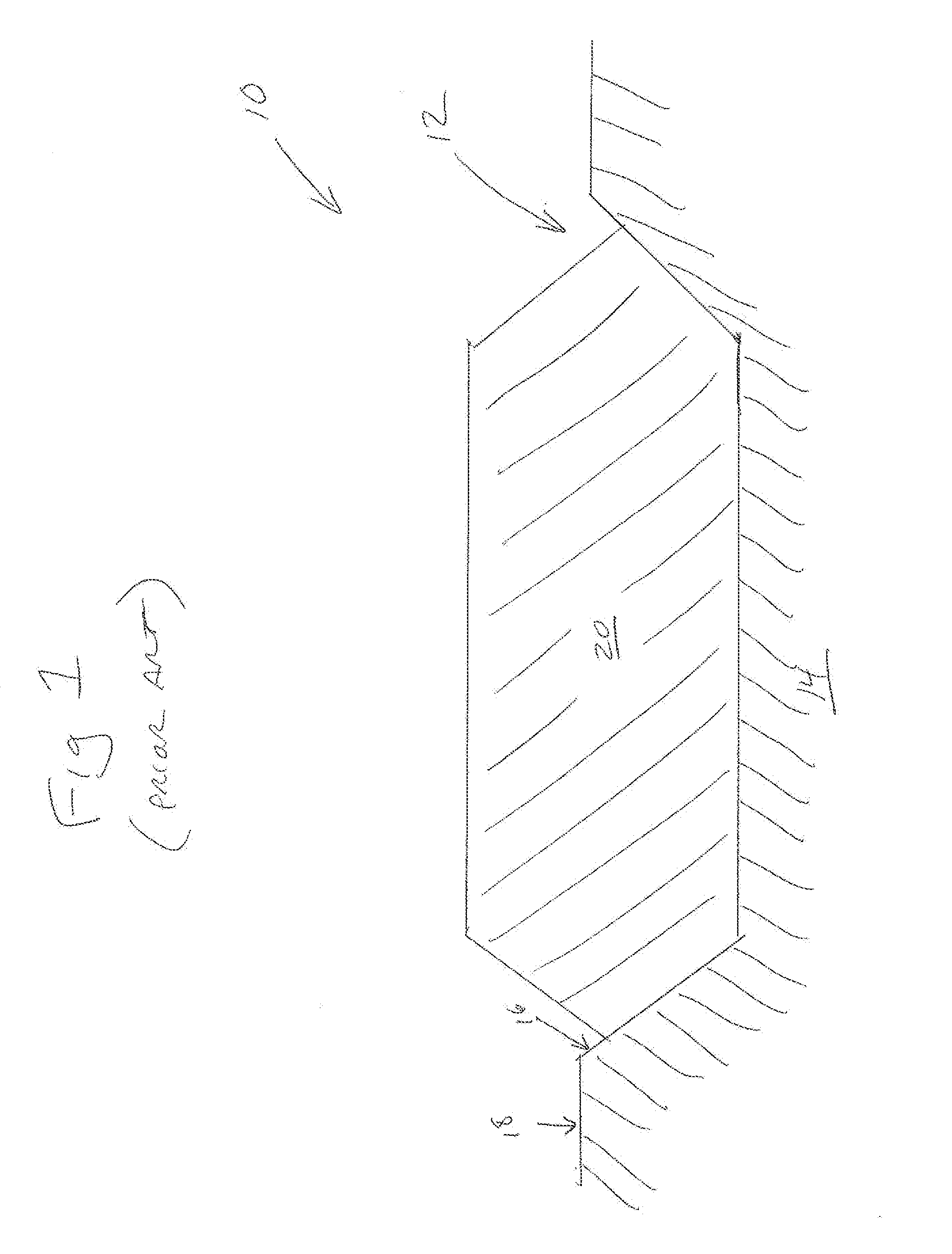

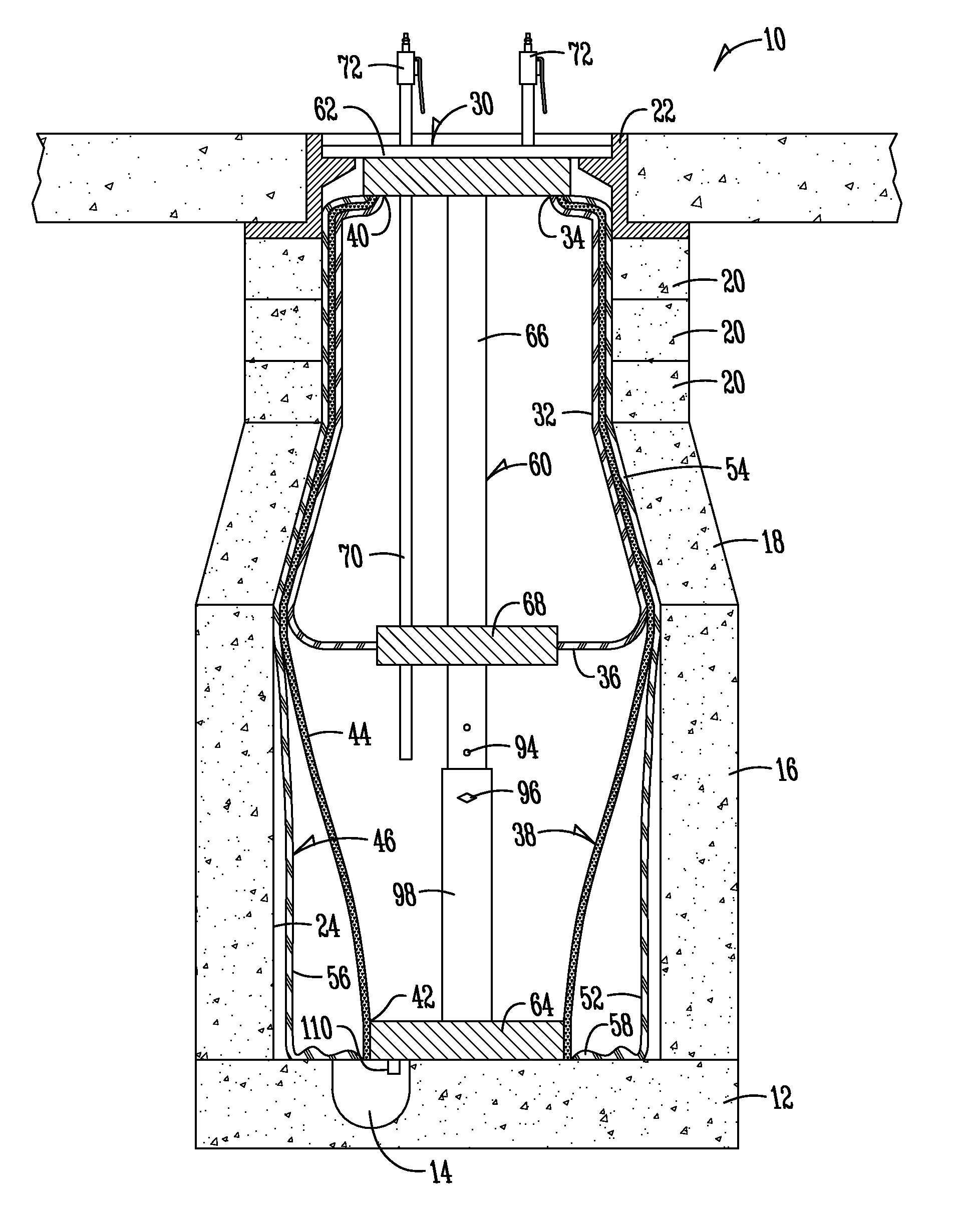

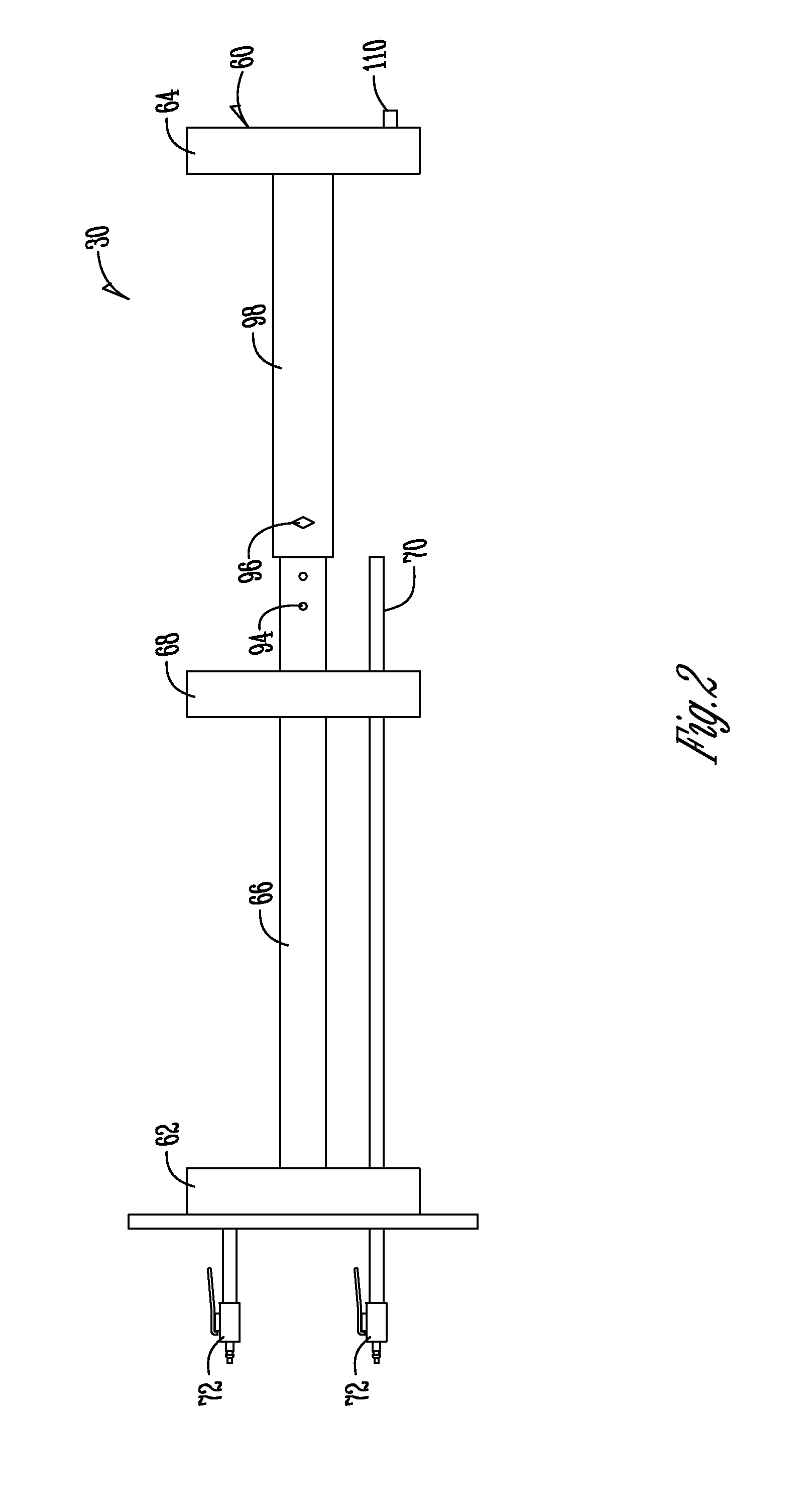

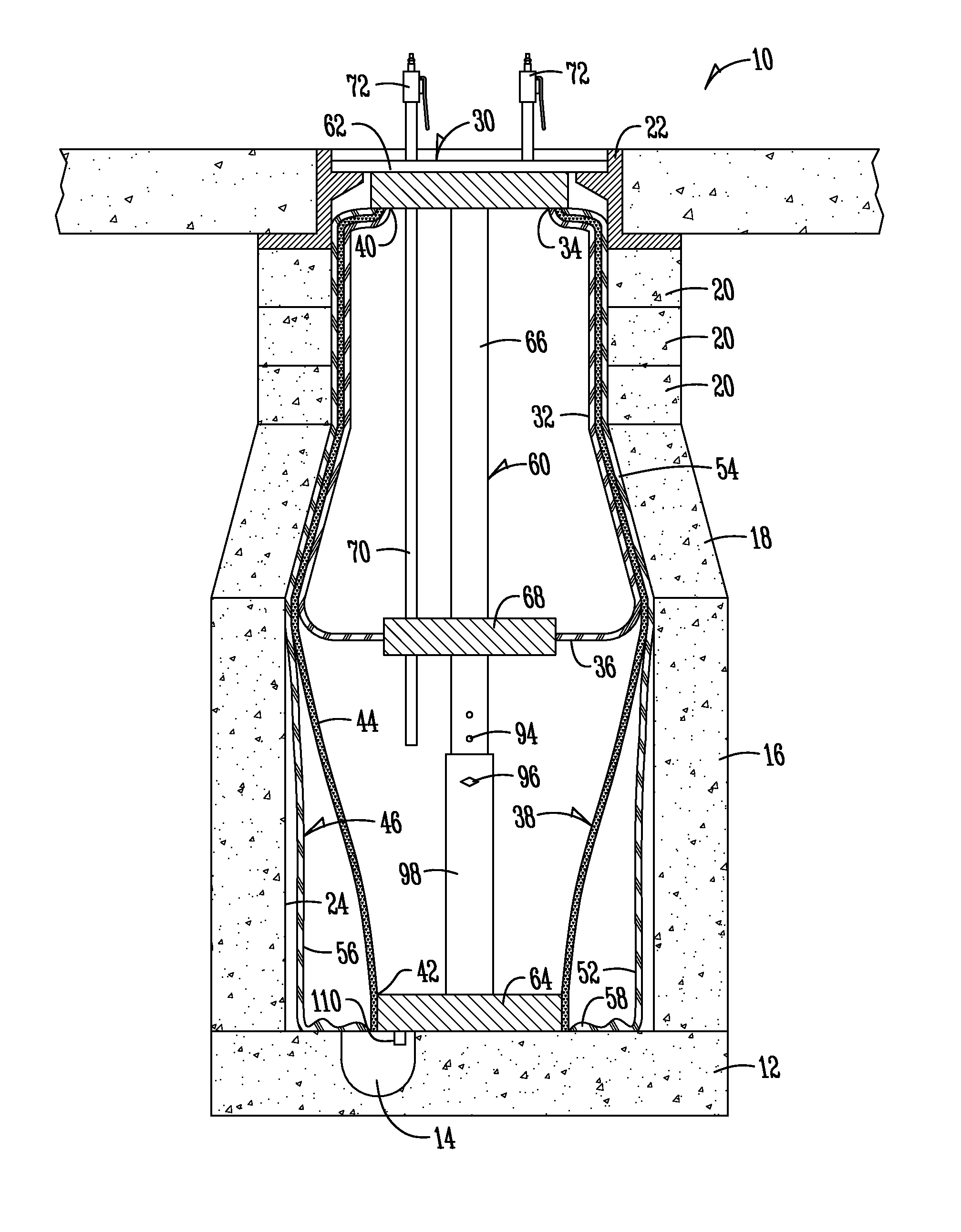

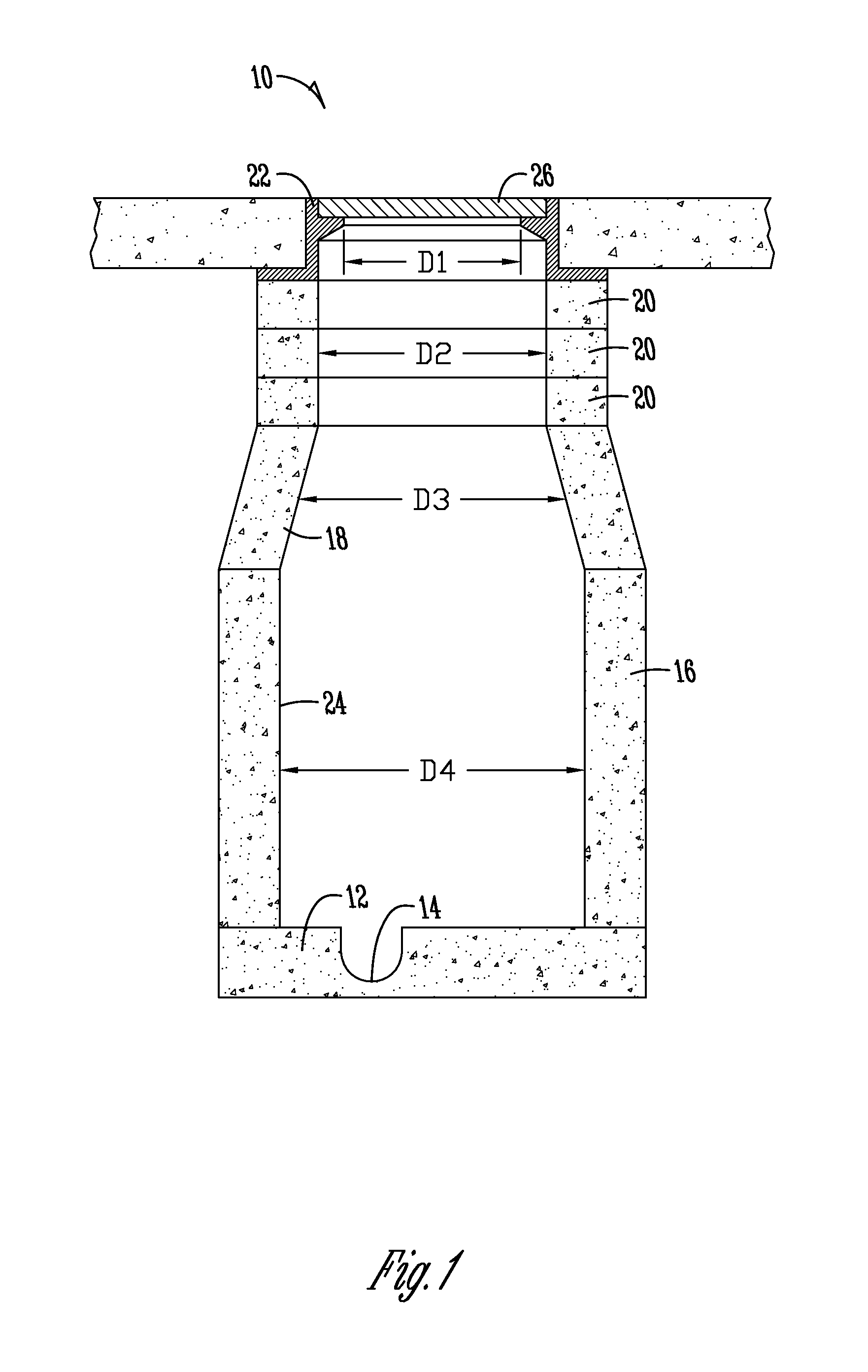

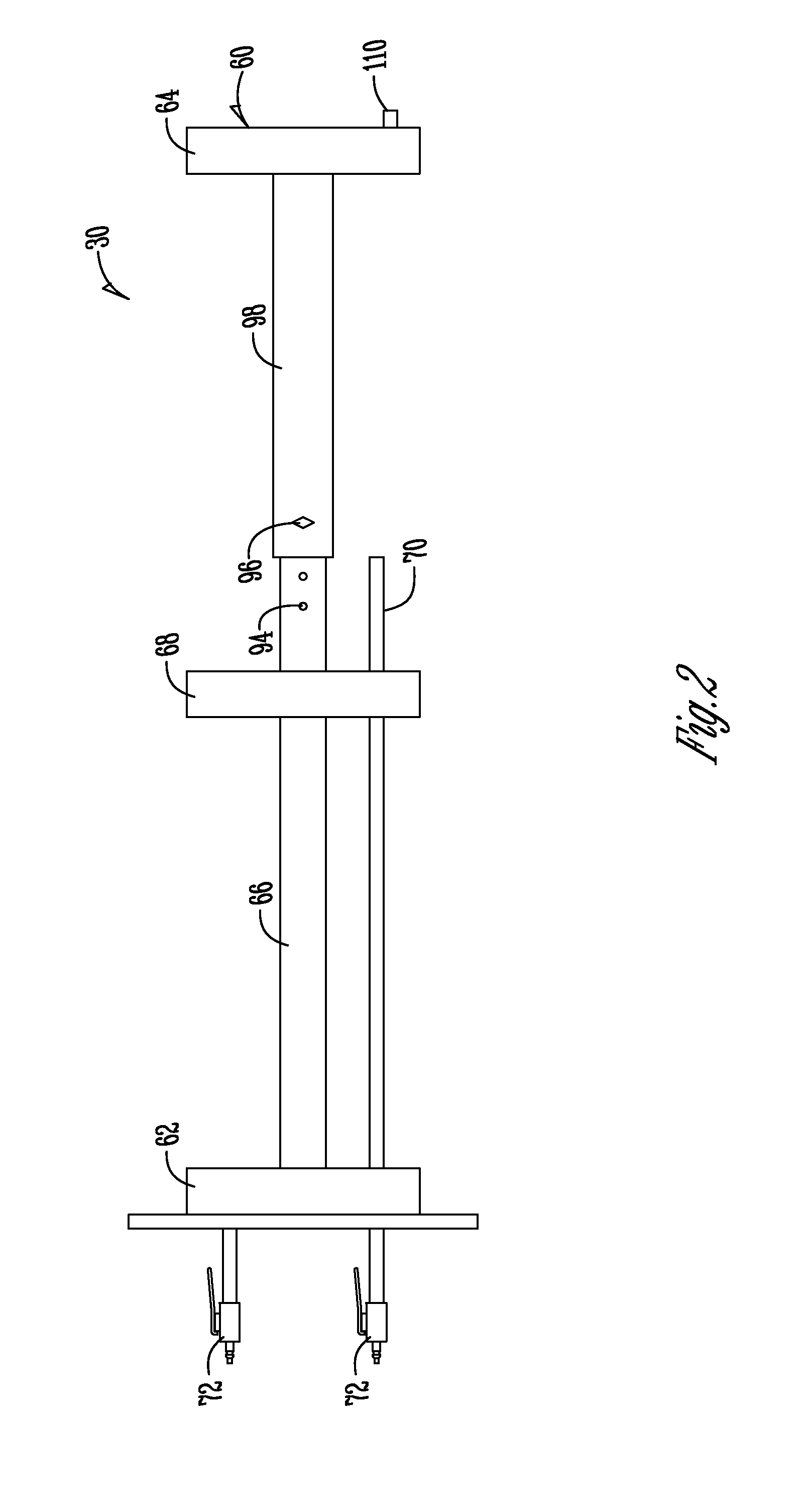

Method and means of lining a manhole

An apparatus and method is provided for lining the wall of a manhole. The apparatus may include a liner assembly, which includes an expansion device, an auxiliary bladder, a primary bladder, and a liner. The auxiliary bladder is first inflated near the top of the manhole. Next the primary bladder may be expanded to press the liner against the wall of the manhole. The liner, being impregnated with a resinous material, is pressed against the wall until the resinous material cures and hardens. The expansion device, auxiliary bladder, and primary bladder are then removed from the manhole. The result is a repaired manhole wall.

Owner:LMK TECH LLC

Berm and method of construction thereof

Embodiments of the invention comprise berm to increase capacity of an existing landfill. The landfill comprises a waste-receiving recess having a surface and an outer perimeter, an edge surface peripherally adjacent at least a portion of the outer perimeter, and an existing accumulation of waste within the recess. The berm comprises a reinforced portion having opposing inner and outer surfaces and comprising fill material and a plurality of reinforcing members disposed therein, backfill material having an inner surface adjacent the inner surface of the reinforced portion, and an impermeable membrane encapsulating at least a portion of the backfill material, at least a portion of the fill material, and at least a portion of one or more of the reinforcing members.

Owner:AWT IP

Method and means of lining a manhole

An apparatus and method is provided for lining the wall of a manhole. The apparatus may include a liner assembly, which includes an expansion device, an auxiliary bladder, a primary bladder, and a liner. The auxiliary bladder is first inflated near the top of the manhole. Next the primary bladder may be expanded to press the liner against the wall of the manhole. The liner, being impregnated with a resinous material, is pressed against the wall until the resinous material cures and hardens. The expansion device, auxiliary bladder, and primary bladder are then removed from the manhole. The result is a repaired manhole wall.

Owner:LMK TECH LLC

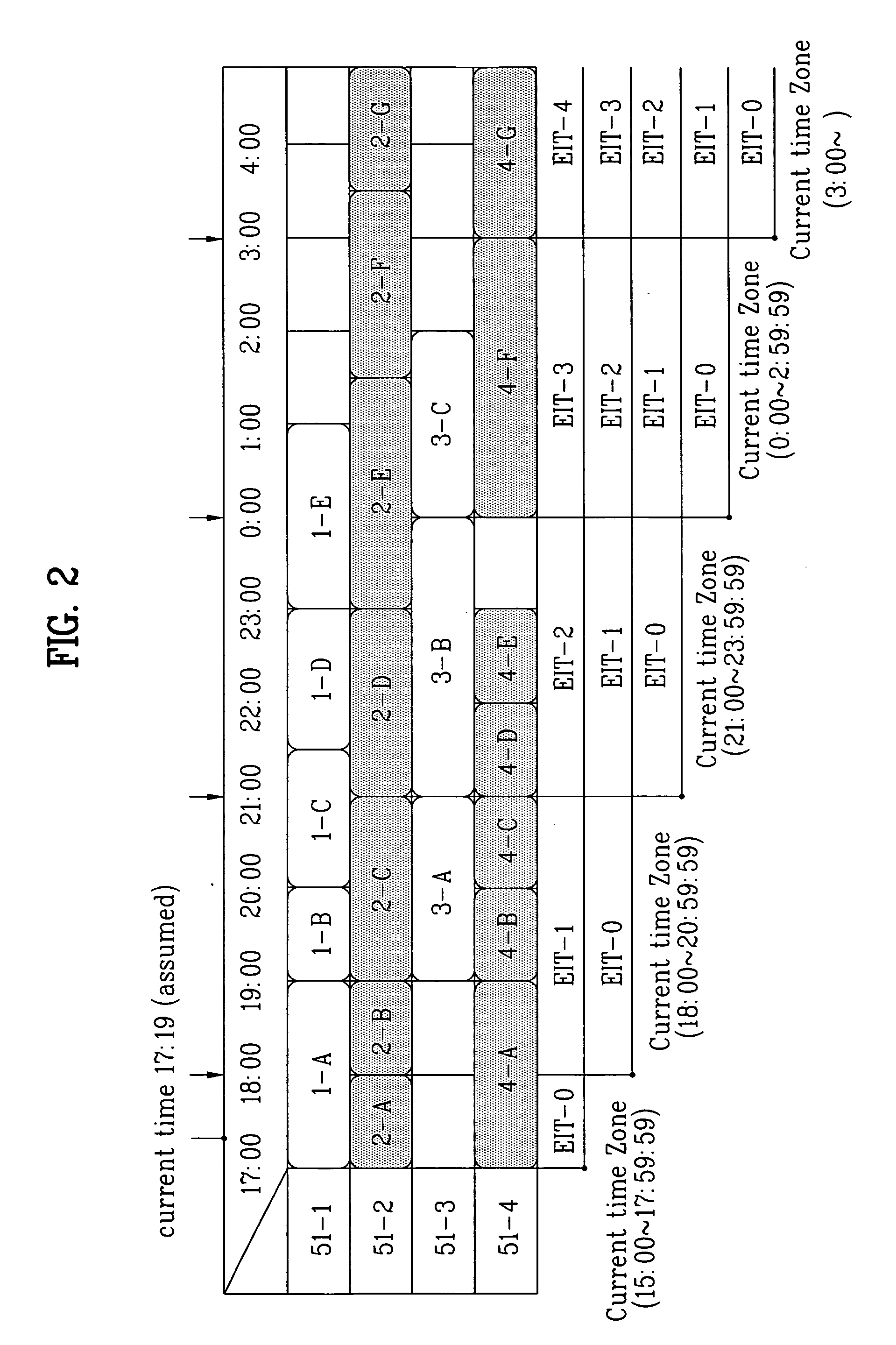

Digital video recording apparatus and method

A digital video recording apparatus and method is disclosed. Under the condition in which the user sets information of a preferred program in the digital video recording apparatus, a broadcast stream received by the digital video recording apparatus is analyzed. Based on the results of the analysis, the preferred program can be automatically recorded. In accordance with the digital video recording apparatus and method, there is convenience in that it is unnecessary for the user to directly check there is a preferred program, to be recorded, in the broadcast stream, or to manually enable recording of the preferred program.

Owner:LG ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com