Patents

Literature

50results about How to "Intensity does not affect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

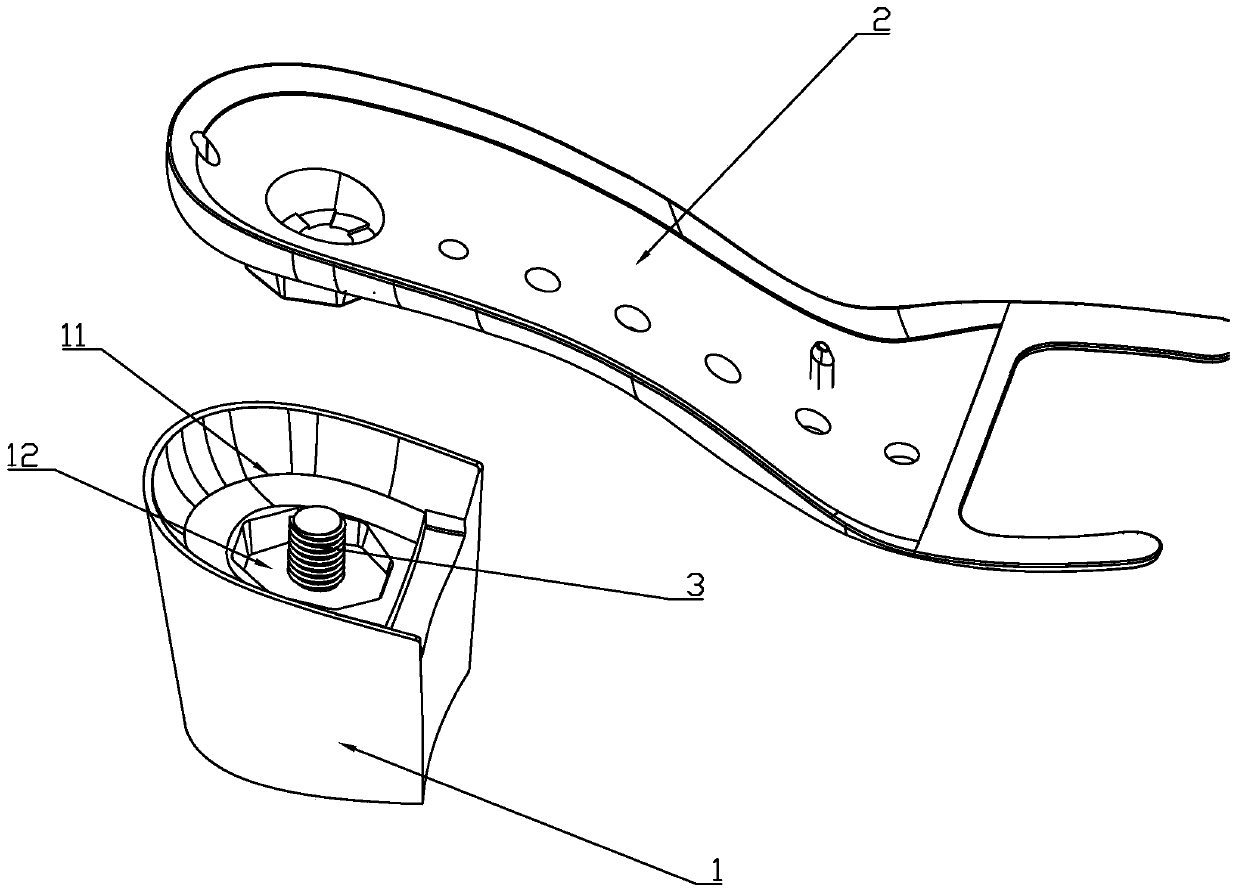

Manufacturing method of vehicle frame longitudinal beam and vehicle frame longitudinal beam manufactured by same

ActiveCN102248360AHigh strengthDecreased strength and toughnessUnderstructuresIncreasing energy efficiencyMaterials preparationVehicle frame

The invention discloses a manufacturing method of a vehicle frame longitudinal beam, and the method comprises a material preparation step, a longitudinal beam forming step, a perforation step, an induction heat treatment reinforcement step and subsequent steps. In the induction heat treatment reinforcement step, the strength of the longitudinal beam is increased by means of scan-type continuous heating and scan-type continuous water spray cooling. The vehicle frame longitudinal beam manufactured by the method is a dual-phase steel material which contains (by volume) 20-30% of non-molten ferrite and 70-80% of low-carbon martensite, and the tensile strength of the vehicle frame longitudinal beam is 1100 to 1300 MPa and the yield strength of the vehicle frame longitudinal beam is 1000 to 1200 MPa. By utilizing the design disclosed by the invention, the strength of the longitudinal beam is greatly increased and the production process is simplified; and besides, the production cost is reduced and the application range is enlarged.

Owner:DONGFENG MOTOR CORP HUBEI

Light-weight porous floor tile and manufacturing method thereof

InactiveCN106630939AHigh strengthIntensity does not affectSingle unit pavingsCeramic materials productionSlagSlurry

The invention relates to a light-weight porous floor tile and a manufacturing method thereof. The light-weight porous floor tile is formed by mixing base materials, additives, filling agents and water, making the materials into slurry, and then performing forming and firing. Aluminum ash, iron ore waste slag and river sand are added into clay for firing the floor tile, so that the reutilization of wastes such as aluminum ash, iron ore waste slag and the like can be realized; in addition, the intensity of the fired floor tile is improved; (aluminum oxide, aluminum and the like contained in aluminum ash and ferric oxide in iron ore waste slag form enhanced body structures similar to hercynite in high-temperature environment during the floor tile firing); the silicon carbide, carbon powder and calcium carbonate powder are added to be used as additives, so that the fired floor tile has some open air pores (or being called as opening air pores) on the surface; the air pores can absorb certain noise; in addition, the surface water downward seepage is also facilitated; meanwhile, the intensity of the floor tile cannot be influenced.

Owner:河南同伟建材有限公司

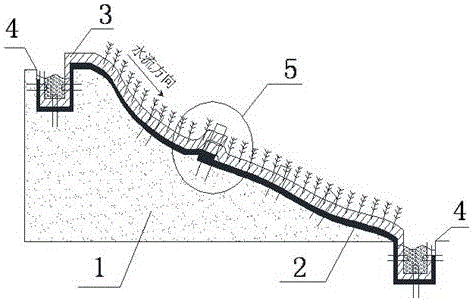

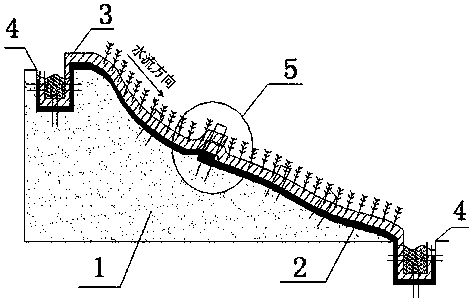

Anti-washout ecological greening protective face of refuse landfill side slope and construction method for anti-washout ecological greening protective face

ActiveCN105862886AHigh strengthIntensity does not affectClimate change adaptationProtective foundationGrowth plantGeomembrane

The invention discloses an anti-washout ecological greening protective face of a refuse landfill side slope. The anti-washout ecological greening protective face comprises a to-be-greened refuse landfill side slope, wherein a geomembrane fixedly covers the refuse landfill side slope; a three-dimensional geomat fixedly covers the geomembrane; and a mixture of greening seeds and a soil body is laid in the three-dimensional geomat. Meanwhile, the invention also discloses a construction method for the ecological greening protective face. The anti-washout ecological greening protective face and the construction method thereof disclosed by the invention solve the problems that a highly-polluted soil body of a refuse landfill is not suitable for plant growth and the planting soil body on the side slope cannot be kept and cannot form a green ecological side slope.

Owner:HOHAI UNIV

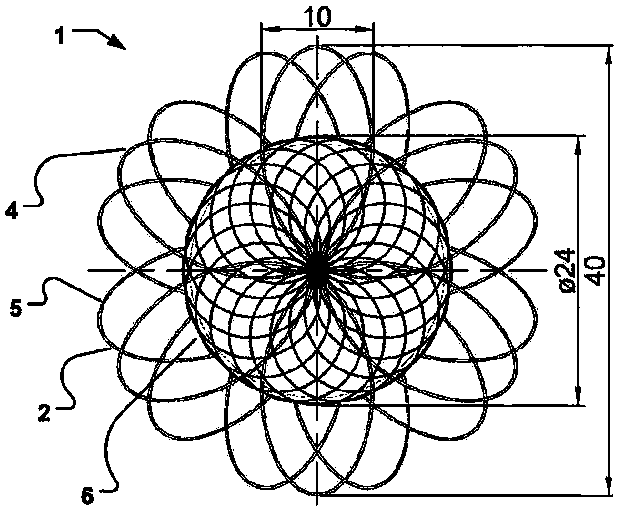

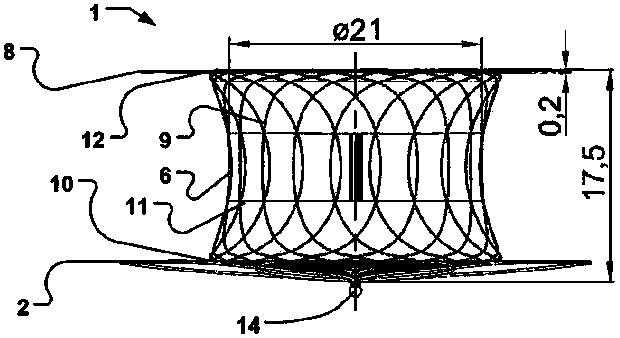

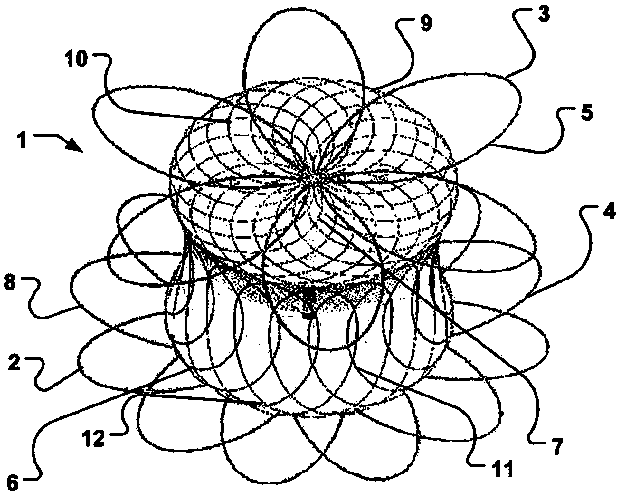

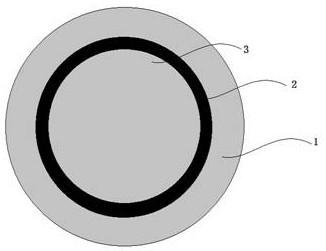

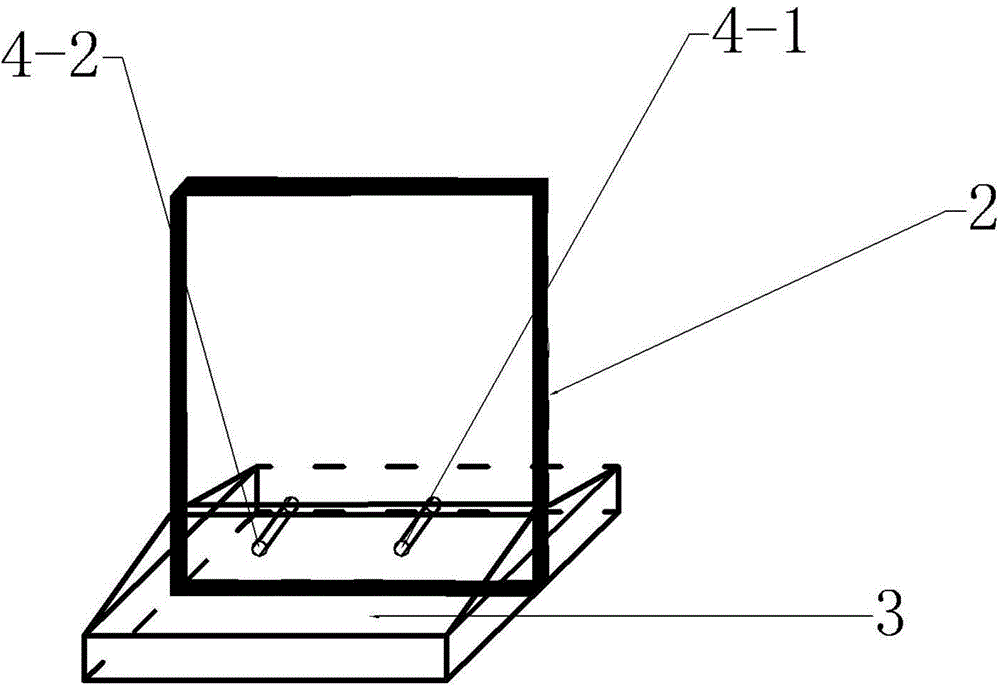

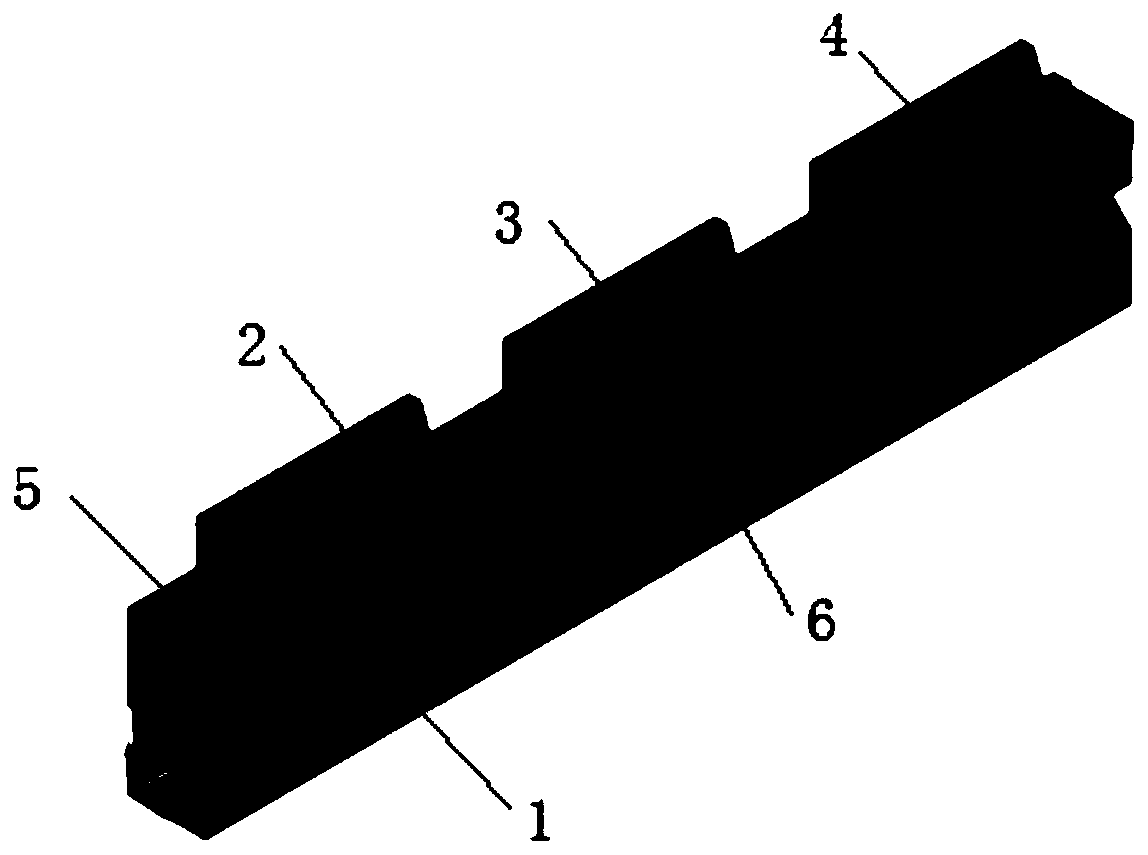

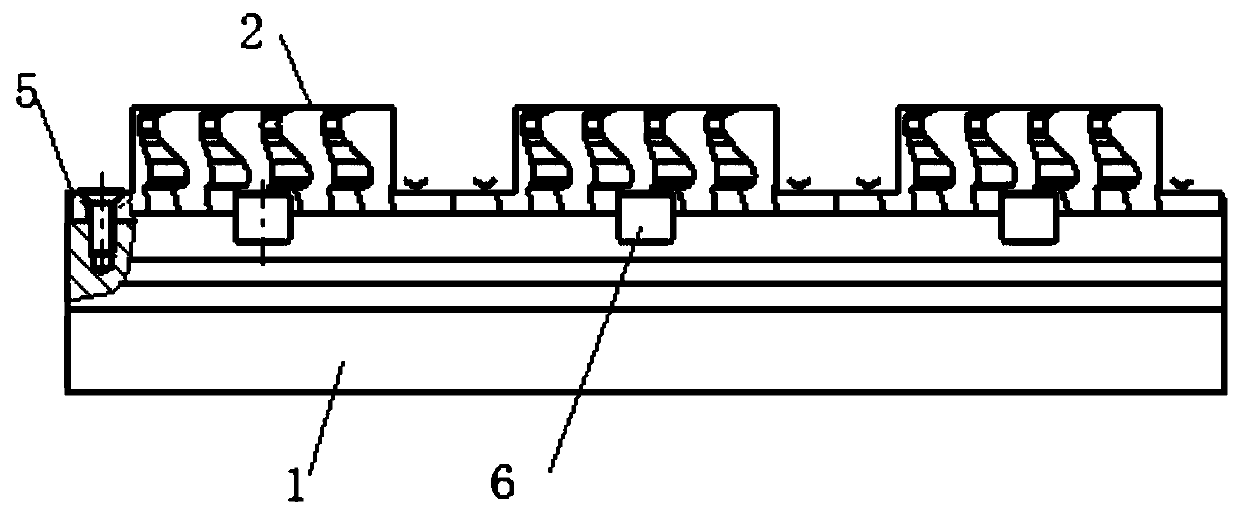

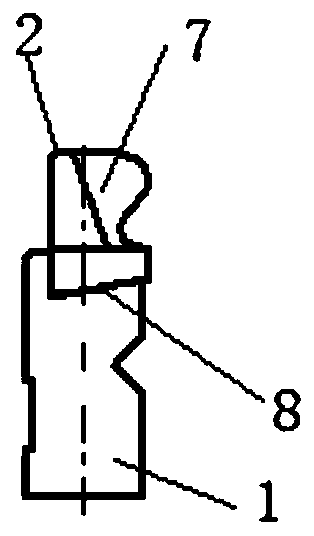

A device for occluding an opening in a body and associated methods

InactiveCN104244843ADoes not tend to increase rupture sizeIncreased rupture sizeOcculdersEngineeringMechanical engineering

The disclosure relates to a device for occluding an opening in a body and associated methods. The device of this disclosure has the advantage that a second element of the device can be made more flexible than a first element and thereby the device is less prone to increase the rupture size of an opening. In one example, a device (1) for occluding an opening in a body is disclosed, which comprises a first element (2), comprising at least one thread or wire (3), and a second element (6), such as a shaft section, said second element (6) being at least in a longitudinal section tubular or oval and comprising a braided material, said braided material comprising at least one thread or wire (9), and wherein a diameter of said second element (6) is of substantially the same size or smaller than said opening for all longitudinal sections, when said device (1) is in a preset, expanded configuration.

Owner:闭塞科技控股有限公司

Manufacturing method of vehicle frame longitudinal beam and vehicle frame longitudinal beam manufactured by same

ActiveCN102248360BHigh strengthDecreased strength and toughnessUnderstructuresIncreasing energy efficiencyMaterials preparationVehicle frame

The invention discloses a manufacturing method of a vehicle frame longitudinal beam, and the method comprises a material preparation step, a longitudinal beam forming step, a perforation step, an induction heat treatment reinforcement step and subsequent steps. In the induction heat treatment reinforcement step, the strength of the longitudinal beam is increased by means of scan-type continuous heating and scan-type continuous water spray cooling. The vehicle frame longitudinal beam manufactured by the method is a dual-phase steel material which contains (by volume) 20-30% of non-molten ferrite and 70-80% of low-carbon martensite, and the tensile strength of the vehicle frame longitudinal beam is 1100 to 1300 Mpa and the yield strength of the vehicle frame longitudinal beam is 1000 to 1200 Mpa. By utilizing the design disclosed by the invention, the strength of the longitudinal beam is greatly increased and the production process is simplified; and besides, the production cost is reduced and the application range is enlarged.

Owner:DONGFENG MOTOR CORP HUBEI

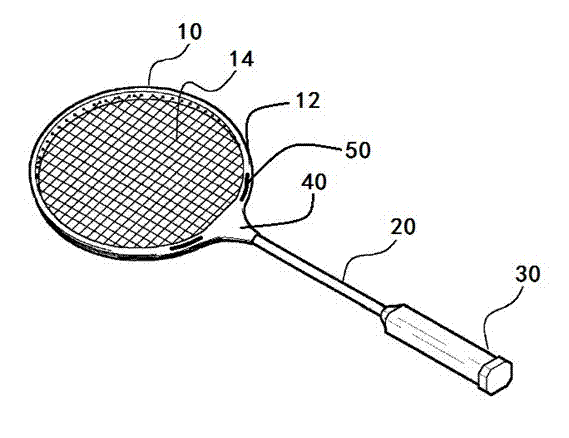

Badminton racket

ActiveCN103083877AHigh strengthIntensity does not affectLuminescent compositionsStringed racketsEngineeringGravity center

The invention relates to a badminton racket. The badminton racket comprises a racket head and a racket rod, wherein the racket head comprises a racket frame and racket lines penetrating in the racket frame, the bottom of the racket frame is connected with the top of the racket rod through a connection part, the bottom of the racket rod is connected with a racket handle, and a plurality of air guiding grooves are formed at two sides of a position, close to the connection part, of the bottom of the racket frame along the longitudinal axis central line. The plurality of air guiding grooves do not affect the strength of the racket, are capable of effectively lowering the gravity center position of the badminton racket, and lowers the difficulty of swinging of the racket. Viridescent fluorescent powder is arranged on the racket lines of the badminton racket, is capable of indicating the position of the racket lines at night, and assists in accurate batting to improve the accuracy of batting. The badminton racket is made of special aluminum alloy, is good in batting feeling, good in vibration absorption, shuttlecock control and safety, and is suitable for being used by amateurs.

Owner:梁栌伊

Ground tile specially used for square and manufacturing method of same

InactiveCN106592367AHigh strengthGuaranteed mechanical strengthSingle unit pavingsSidewalk pavingsButadiene-styrene rubberPlastic materials

A ground tile specially used for square and a manufacturing method of same. A rubber elastomer layer is arranged on the surface of the ground tile. The ground tile is prepared by mixing a basic material, an additive agent, a filler and water to prepare slurry, and shaping the slurry and sintering the ground tile; the rubber elastomer layer is prepared by mixing styrene butadiene rubber, polyacrylonitrile fibers, a vulcanizing agent, carbon black, modified hollow glass micro-bead, silicon dioxide micro-powder, modified potassium tetratitanate whiskers and a reinforcing agent. In the invention, the rubber elastomer layer is pre-formed on the surface of the ground tile, so that the ground tile can prevent bruise when people fall down; by means of the rubber elastomer layer, the comfort degree of the ground tile when people walk thereon is improved. Meanwhile, by means of the pre-formed rubber elastomer layer, a layer of rubber elastomer layer is formed on the ground of a square when the ground tiles are paved. The method, compared with a method of firstly tidying the ground and paving a plastic material or a rubber material on the ground, is greatly improved in pavement efficiency and also reduces construction period.

Owner:河南同伟建材有限公司

Durable antibacterial textile fiber and preparation method thereof

InactiveCN111041606AEvenly dispersedInhibit sheddingMelt spinning methodsConjugated synthetic polymer artificial filamentsTextile fiberPolymer science

The invention belongs to the technical field of chemical fiber preparation, and particularly relates to a durable antibacterial textile fiber and a preparation method thereof. The preparation method of the durable antibacterial textile fiber comprises the following steps of a) mixing a nanoscale antibacterial agent with polyethylene wax, silicon dioxide aerogel, nylon 6 and high-melt-index EVA ina high-speed mixer, then performing melt co-extrusion by using a co-rotating twin-screw extruder, and performing water cooling, dicing and drying to obtain antibacterial master batch; b) adding the nylon 6, the antibacterial master batch and the nylon 6 into three screw extruders respectively for melting, performing compounding by using a multilayer die head to form a filament, wherein an inner layer is the nylon 6, a middle layer is the antibacterial master batch, and an outer layer is the nylon 6; then stretching the filament into a fiber, applying spinning oil, performing cold rolling and winding to obtain the durable antibacterial textile fiber. According to the preparation method, the nanoscale antibacterial agent is dispersed in a high-flow system for processing, so that the dispersity of the antibacterial agent is greatly improved; the master batch is independently formed in the middle layer of the spinning, so that on one hand, the antibacterial agent is prevented from fallingoff during washing, and on the other hand, the quality of the nylon 6 such as strength and color cannot be influenced.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

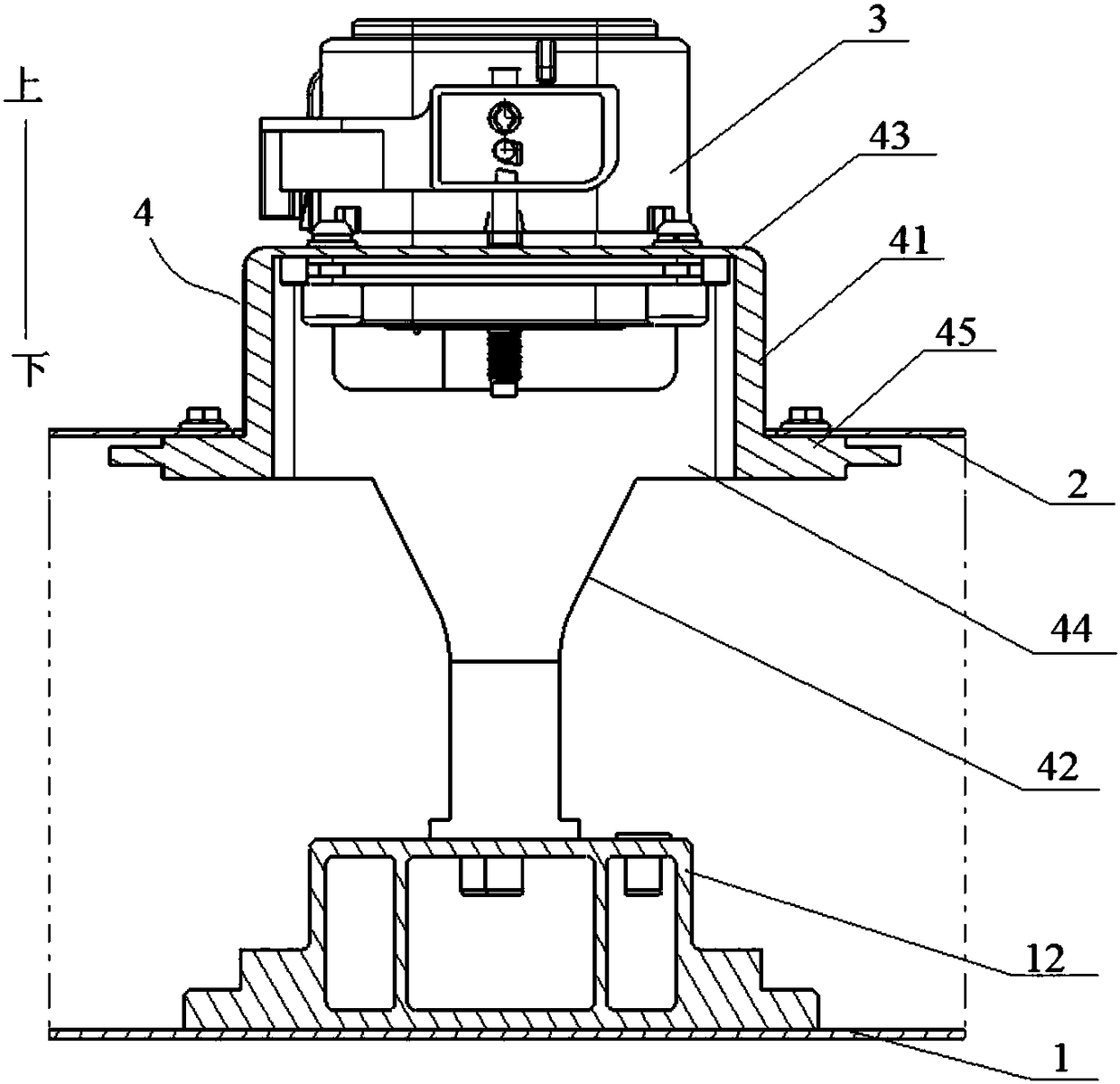

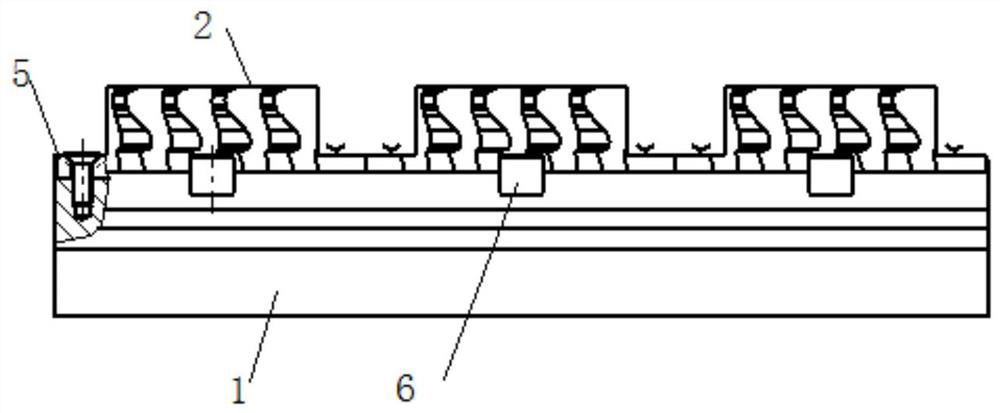

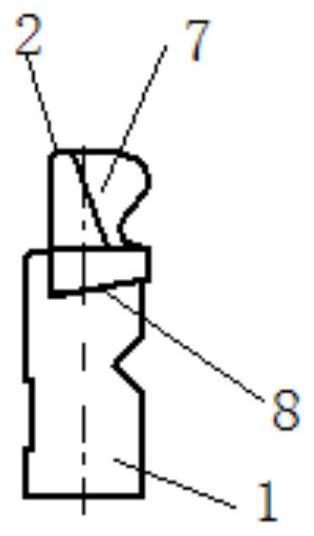

Rivet type lining fluorine axial-flow pump

InactiveCN101566163AIntensity does not affectImprove connection strengthSpecific fluid pumpsPump componentsAxial-flow pumpChemical industry

The invention discloses a rivet type lining fluorine axial-flow pump for conveying liquid with strong corrosivity in the chemical industry field, comprising a metal insert and a lining fluorine layer. A plurality of through holes are evenly distributed on the metal insert. A metal cap is arranged on each through hole at the outer side of the metal insert, whose inner cavity sectional area is larger than the through hole sectional area. The lining fluorine layer is riveted on the inner side of the metal insert by the inner cavity of the metal cap and the through hole. The pump adopts the simple rivet type connection mode. The through hole lining fluorine material and the metal insert are engaged better, not effecting the pump strength. The vacuum siphon generated by the lining fluorine layer in the reinforcing cycling state is removed. The fluorine layer tearing and dropout is avoided. The service life of the pump is greatly enhanced.

Owner:巢国平

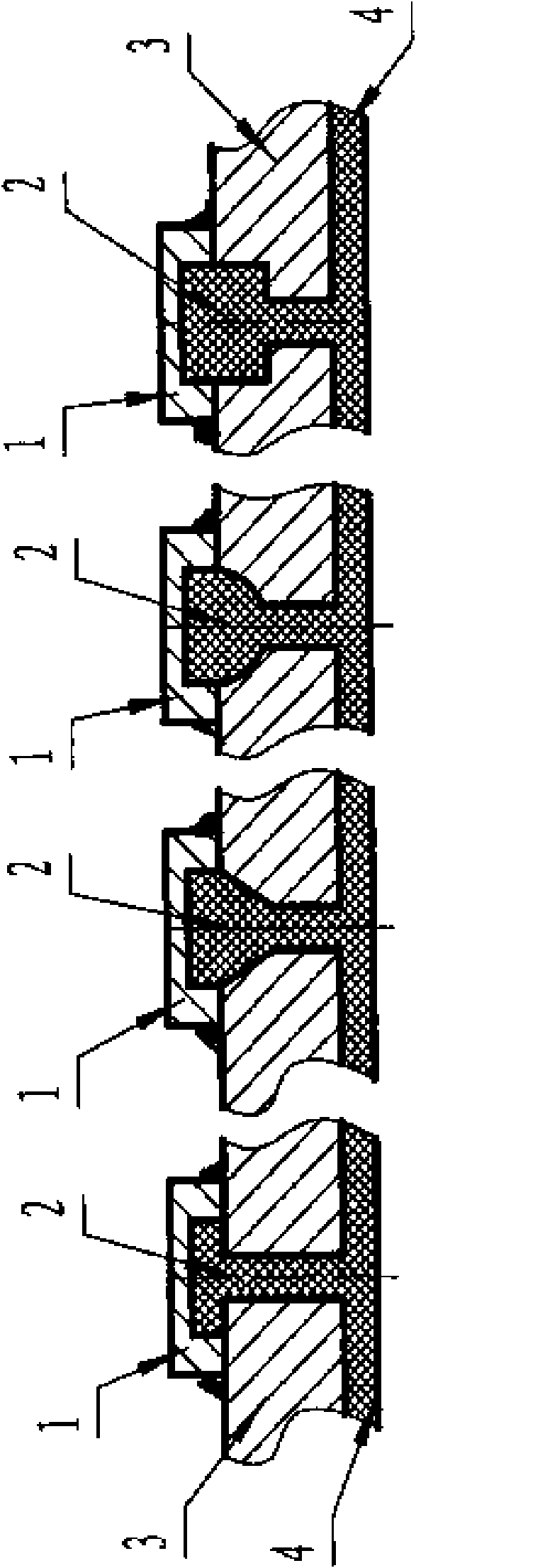

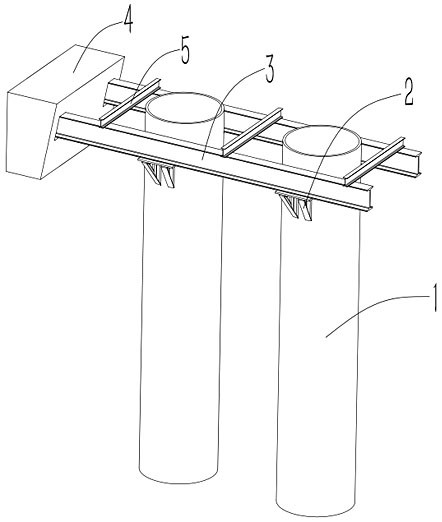

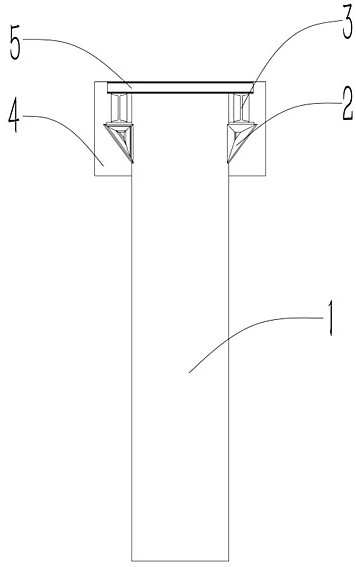

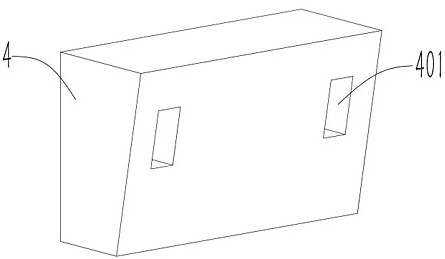

Prefabricated berthing component installation supporting structure and installation method

PendingCN114134860AInfluence intensityIntensity does not affectShipping equipmentMarine engineeringPipe

The invention provides a prefabricated berthing component installation supporting structure and an installation method, which comprises a berthing component and a steel pipe pile, and is characterized in that grooves are formed in two sides of one end face of the berthing component, supporting frames are fixedly arranged on two sides of the steel pipe pile, I-shaped steel is arranged on the supporting frames, one end of the I-shaped steel abuts against the interiors of the grooves, and the other end of the I-shaped steel abuts against the steel pipe pile. Balance fixing mechanisms are arranged at the other ends of the I-beams. A plurality of grooves are reserved in one side of the berthing component formed through pouring, so that the berthing component is supported by inserting I-shaped steel into the grooves, the supporting structure is simple, mounting and dismounting are easy and convenient, the problem that the strength of the berthing component is affected by corrosion of a pre-buried supporting rod is solved, the reserved grooves do not affect the strength of the berthing component, and the berthing component is convenient to mount and dismount. Pouring forming is simple and convenient, so that construction difficulty is greatly reduced, and operation efficiency is improved.

Owner:中交二航局第一工程有限公司

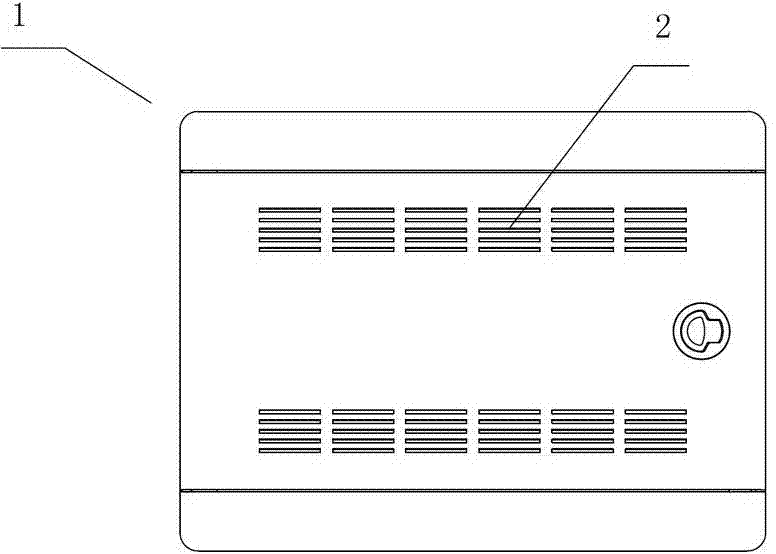

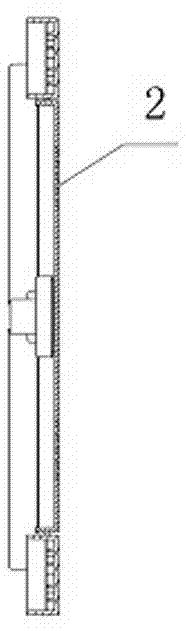

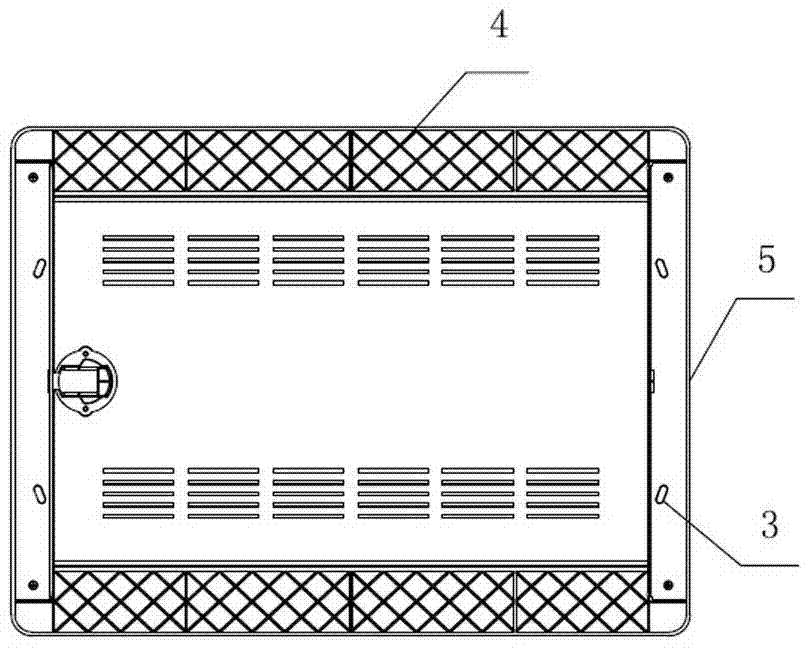

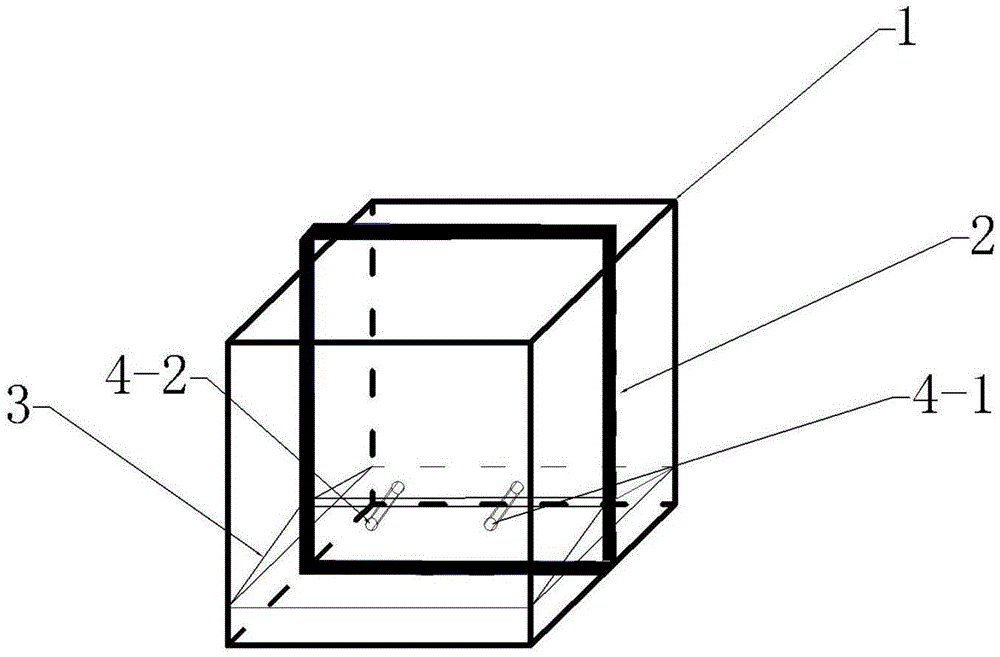

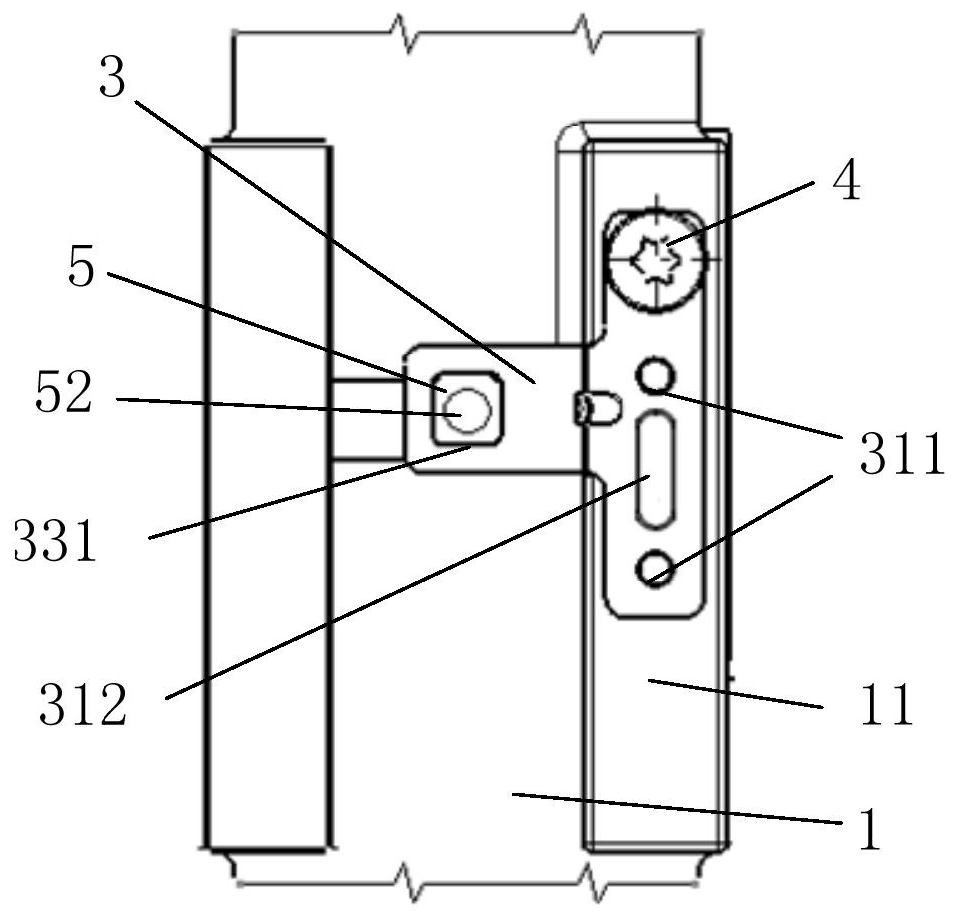

Comprehensive wiring box cover

InactiveCN103941363AHigh strengthIntensity does not affectFibre mechanical structuresUltimate tensile strengthElectrical and Electronics engineering

The invention relates to a comprehensive wiring box cover. The comprehensive wiring box cover comprises a panel body covering a wiring box. Heat dissipating holes are formed in the surface of the panel body. Adjusting holes are formed in the inner surface of the panel body. The panel body and the wiring box rotate relatively through the adjusting holes, the heat dissipating holes are oblique relative to the surface of the panel body, the upper side and the lower side of the inner surface of the panel body are provided with netted reinforcing ribs, and the left side and the right side of the inner surface of the panel body are provided with strip-shaped reinforcing ribs. By means of the structure, the outer surface of the panel body is in an outward-convex arc shape, the strength of the panel body can be enhanced through the arc-shaped design, and the comprehensive wiring box cover is more attractive. The panel body is made of plastics, and the effect on the wireless signal transmission is avoided. The oblique heat dissipating holes are formed in the surface of the wiring box, and water splashing can be prevented. The invisible reinforcing ribs are arranged on the inner surface of the panel body, the strength of the panel body can be improved, and the appearance cannot be affected, and the panel body and the wiring box can be adjusted conveniently through the runway-shaped adjusting holes.

Owner:SIMON ELECTRIC CHINA

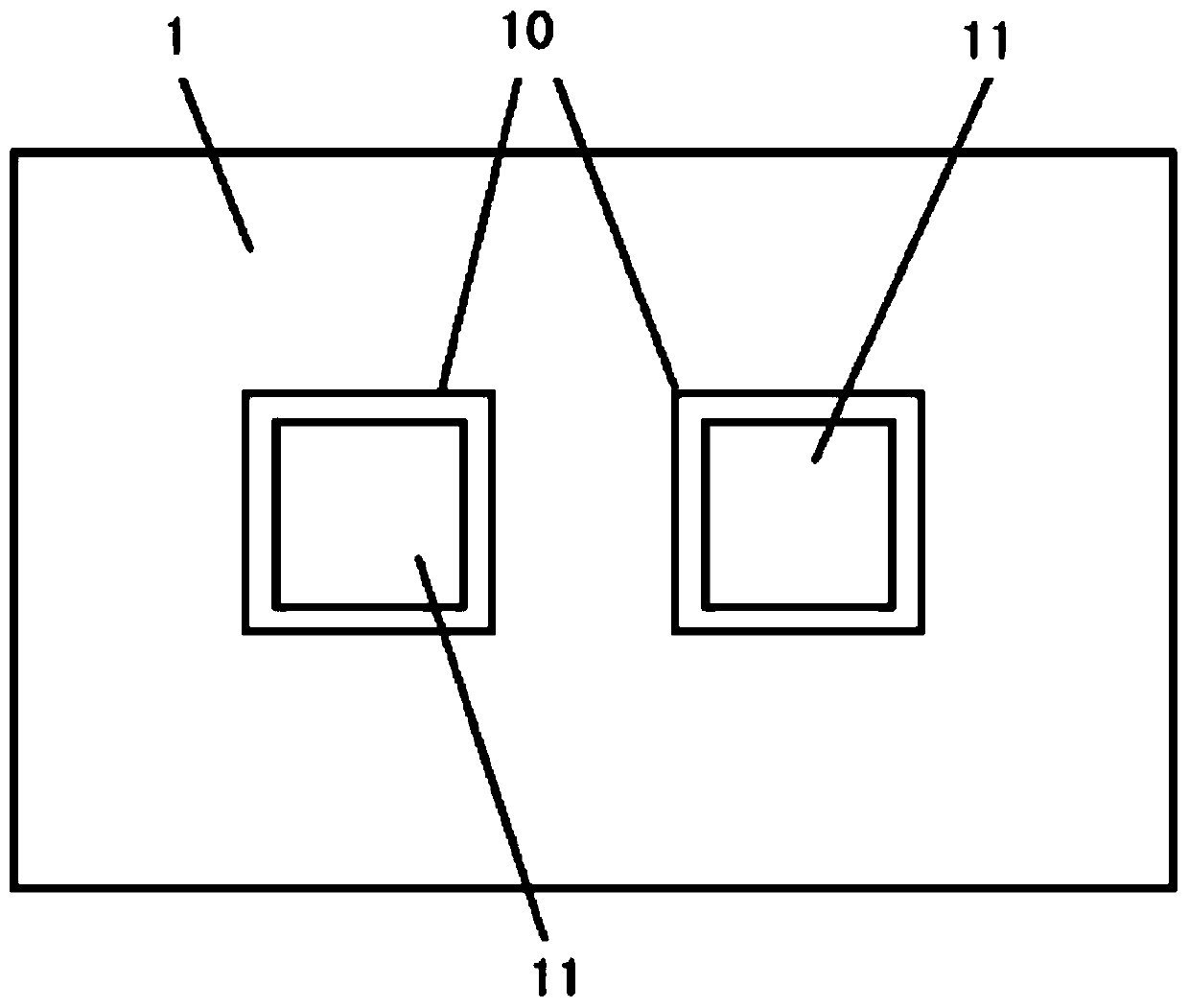

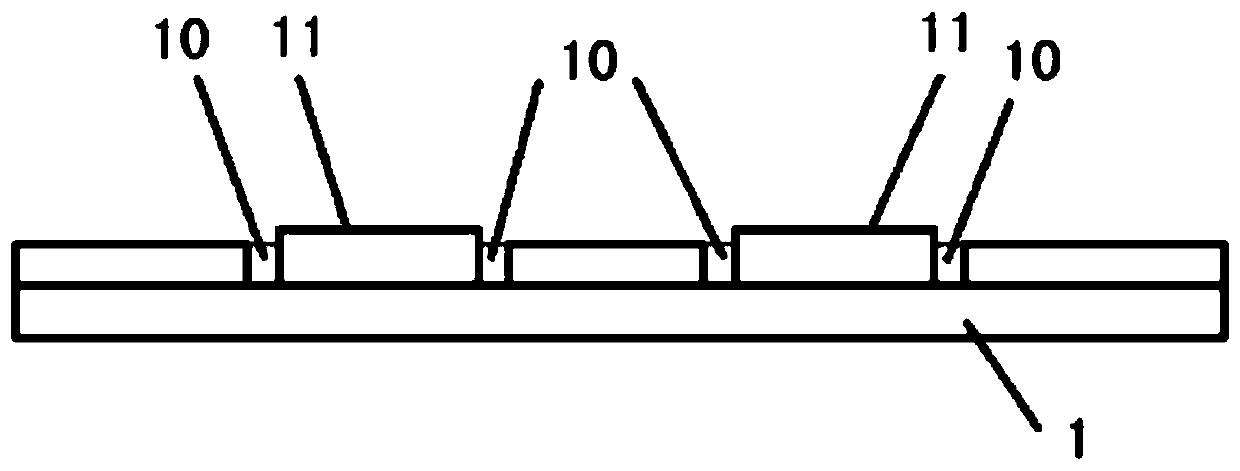

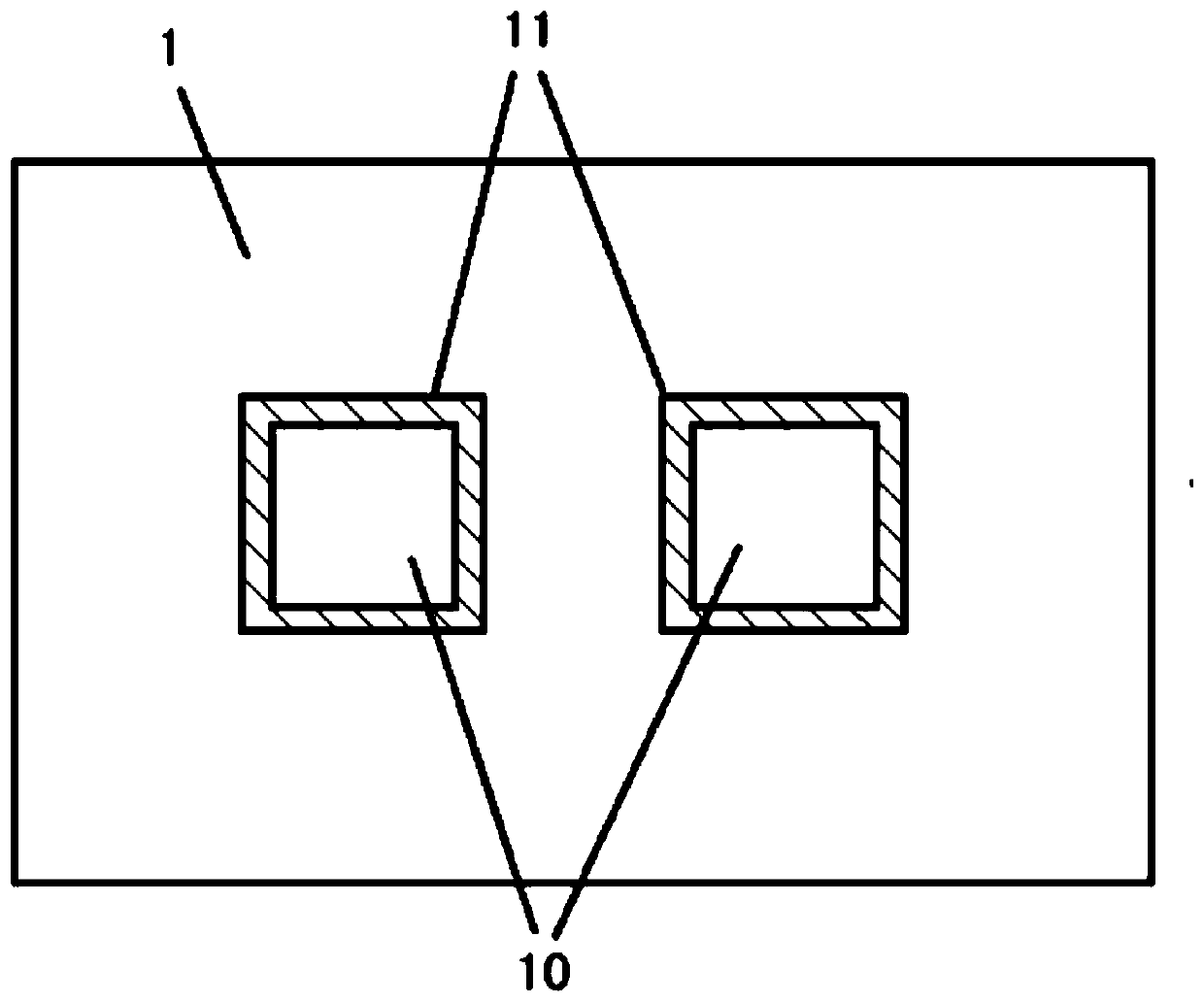

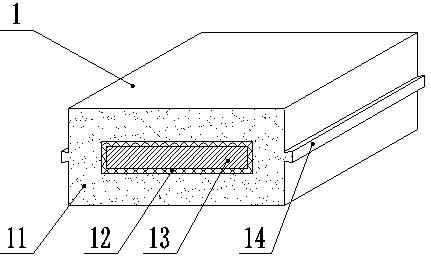

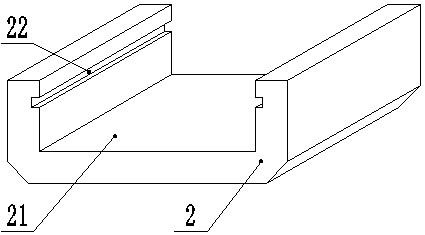

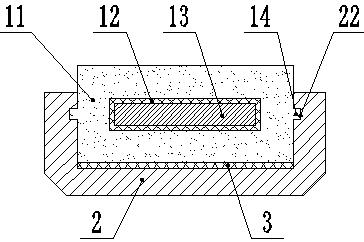

Concrete die aiming at single-face salt freezing experimental development

InactiveCN104897448AIntensity does not affectIncreased durabilityPreparing sample for investigationEngineeringOrganic glass

The invention provides a concrete die aiming at single-face salt freezing experimental development, comprising a standard die with specification of 150*150*150mm<3>, a middle clapboard, a bottom support and a connecting rod, wherein the middle clapboard, the bottom support and the connecting rod are all made from organic glass material. The concrete die can quickly, economically and quickly perform making and dismounting of a test piece, and can perform filling of two mixing ratios, and die stripping is relatively convenient and quick, thus providing relatively convenient and economical test conditions for research on the durability of concrete.

Owner:HARBIN ENG UNIV

Method for improving strength of welding pad

ActiveCN109714894AHigh strengthIntensity does not affectFinal product manufacturePrinted circuit secondary treatmentSolder maskWeld strength

The invention discloses a method for improving strength of a welding pad. The method comprises the steps of: acquiring a direction of an external force applied to the welding pad through analysis in advance; determining an expanding direction of the welding pad according to the direction of the external force, expanding the welding pad along the expanding direction, and shrinking a window of a solder mask in the corresponding direction; and covering the edge of the welding pad in the expanding direction with the solder mask. The method has the beneficial effects that: the size of the welding pad and the window of the solder mask are adjusted through analyzing the direction of the external force applied to the welding pad, so that the welding pad is expanded in the expanding direction, thewindow of the solder mask is shrunk along the direction of the external force, thus the solder mask covers the edge of the welding pad in the direction that the external force is applied, the strengthof the welding pad is further improved, the method can neither shrink the electrical spacing of welding pads on a PCB nor affect the welding strength, and the reasonable layout space of the PCB is ensured.

Owner:SHANGHAI MITSUBISHI ELEVATOR CO LTD

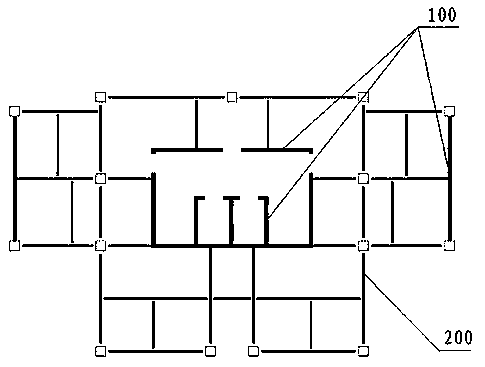

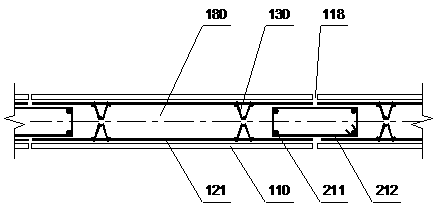

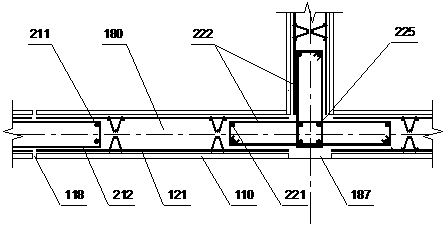

Building of steel frame and concrete shear wall structure and construction method for building of steel frame and concrete shear wall structure

PendingCN111075064AReduce workloadHigh degree of automationWallsBuilding reinforcementsArchitectural engineeringMesh reinforcement

The invention relates to a building of a steel frame and concrete shear wall structure and a construction method for the building of the steel frame and concrete shear wall structure. The building comprises a steel frame structure and shear wall bodies arranged in the steel frame structure. Each shear wall body is mainly composed of steel bar truss fixing formworks located on the two sides of thewall body and a concrete layer poured between the steel bar truss fixing formworks on the two sides. Each steel bar truss fixing formwork comprises a face plate, a steel mesh and steel bar trusses, wherein the steel mesh and the steel bar trusses are located on the inner side of the face plate and are solidified in the corresponding concrete layer. Corresponding steel bar connecting stands are arranged in various wall body joints respectively. In the construction method, construction of the shear wall bodies comprises the steps of formwork installing, formwork fixing, concrete pouring, wall body maintaining and the like. The building of the steel frame and concrete shear wall structure and the construction method for the building of the steel frame and concrete shear wall structure are beneficial to reduction of the work amount and labor intensity of shear wall construction, the degree of influences of human factors on building quality can be reduced, construction cost can be reduced,arrangement of pipelines on the building can be facilitated, and the adverse effect brought by arrangement of the pipelines on the wall bodies can be relieved or avoided.

Owner:ZHONGQINGDA TECH HLDG CO LTD

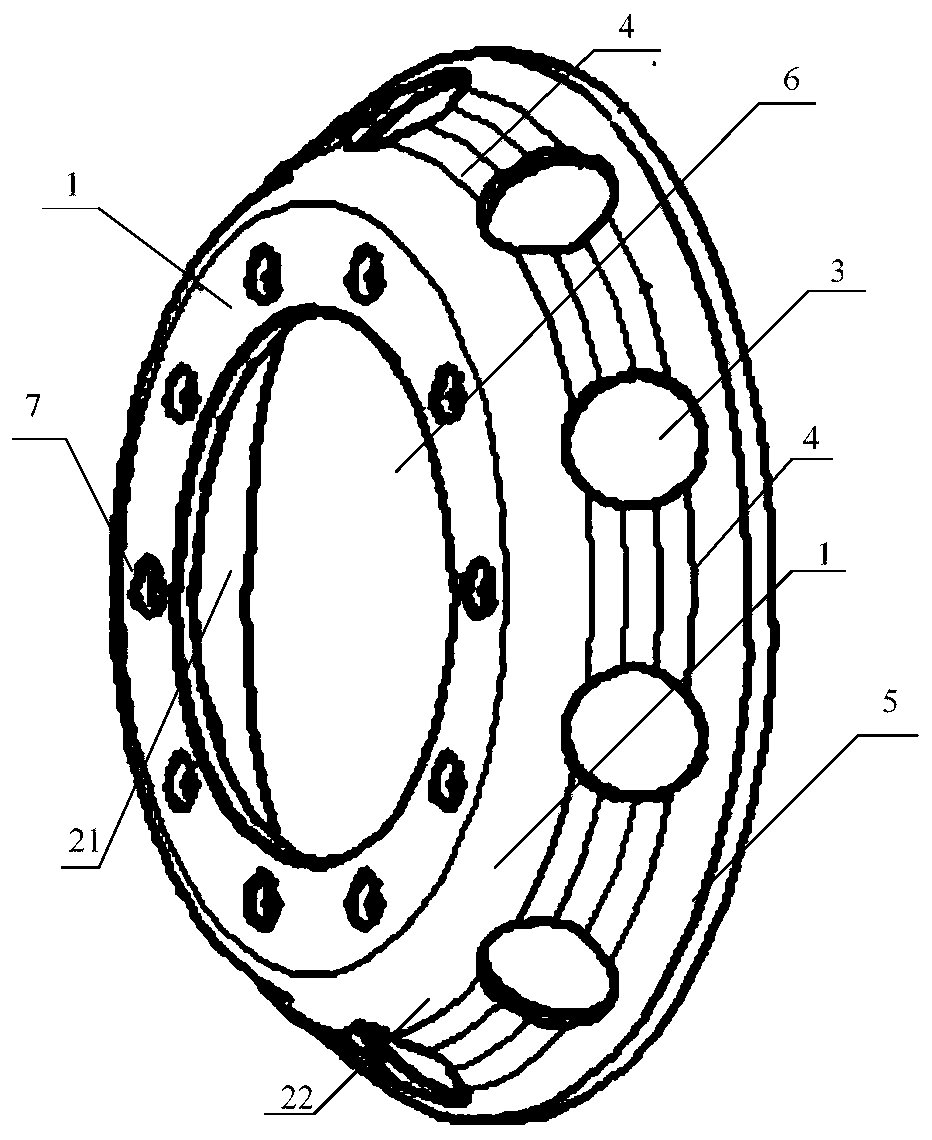

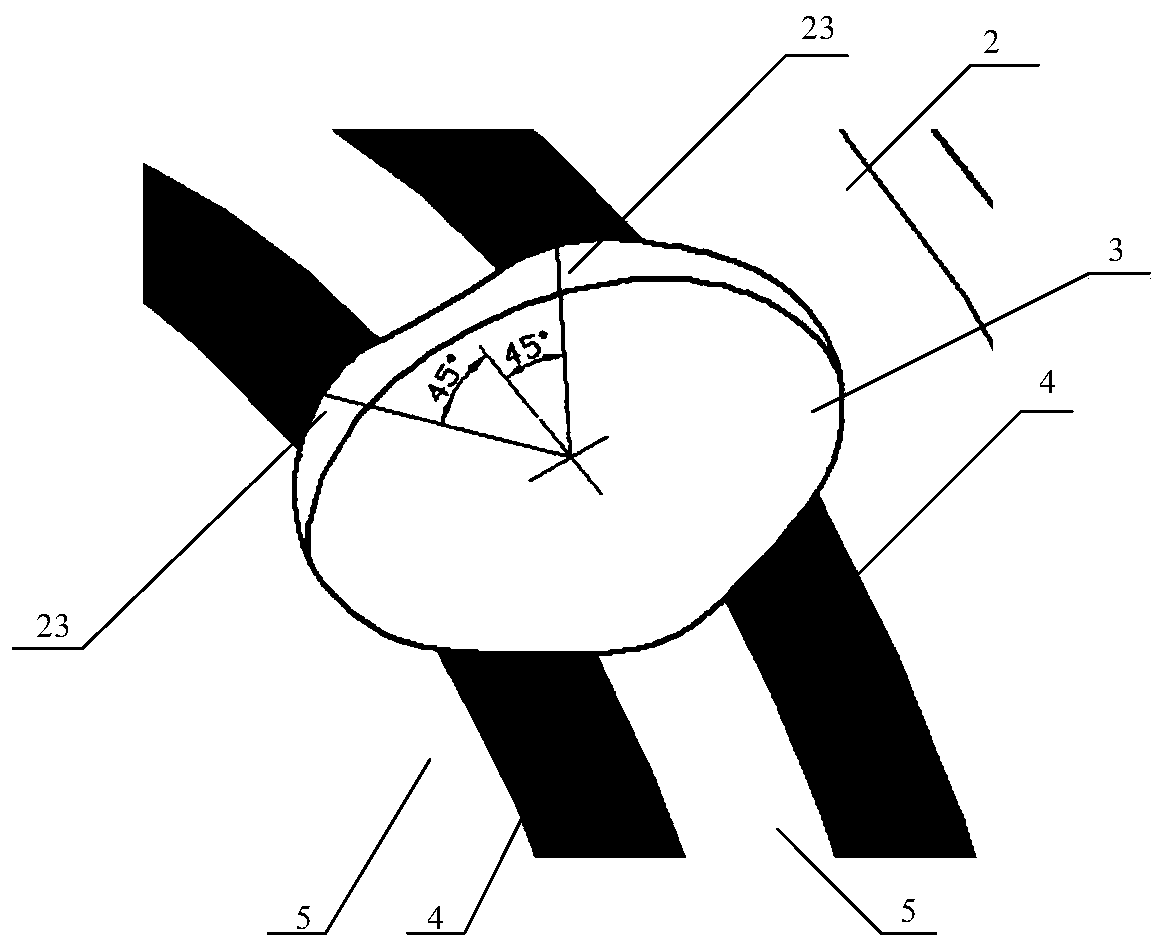

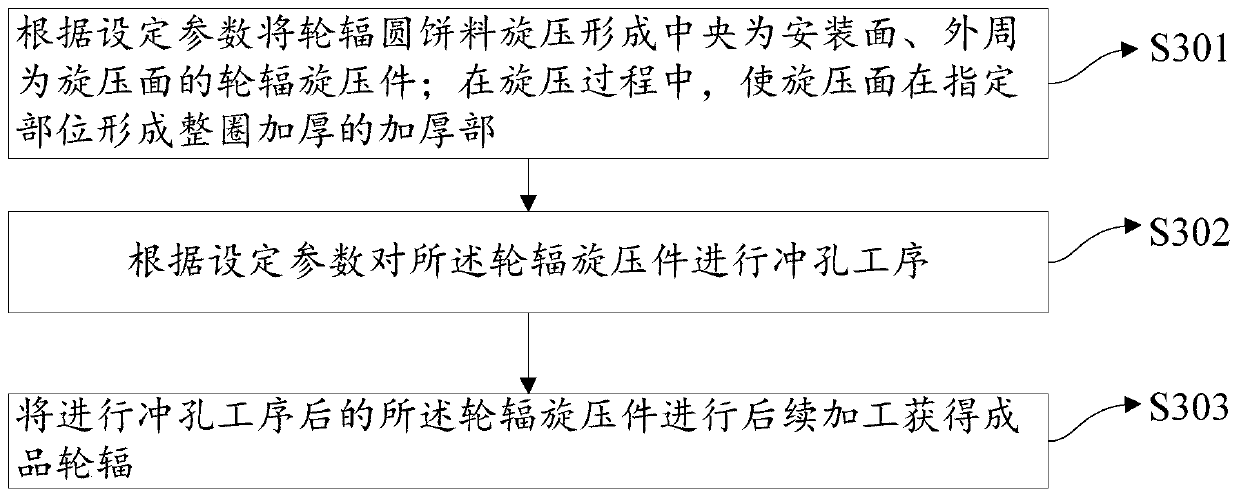

Wheel spoke and production method thereof

The invention provides a wheel spoke, which comprises a mounting surface positioned at the center and a spinning surface positioned at the periphery and forming a set angle with the mounting surface;a plurality of radiating holes are arranged on the spinning surface in the circumferential direction; the intersection point position of two straight lines which form a 45-degree angle with the circumferential tangent line of the spinning surface at the central point of the radiating hole and the edge of the radiating hole is provided with a whole circle thickening parts according to a set width.According to the wheel spoke, the whole circle thickening parts are arranged according to the set width at the intersection point position of the two straight lines which form the 45-degree angle withthe circumferential tangent line of the spinning surface at the central point of the radiating hole and the edge of the radiating hole, so that the strength of the wheel spoke can be directly and effectively enhanced; since the thickening part is only arranged at the weak strength position, in some optional schemes, a whole circle thinning part is arranged at the strength surplus part, so that the whole quality of the wheel spoke can be controlled and the whole performance of the wheel spoke can be improved. The invention also provides a production of the wheel spoke.

Owner:东风汽车底盘系统有限公司

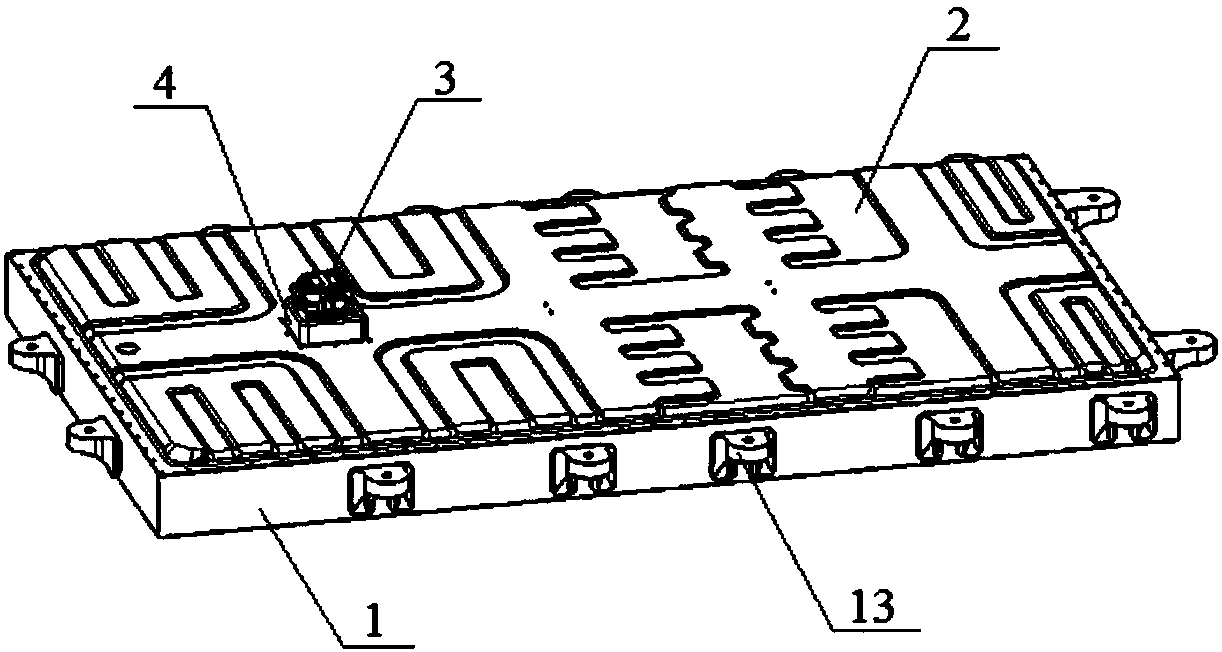

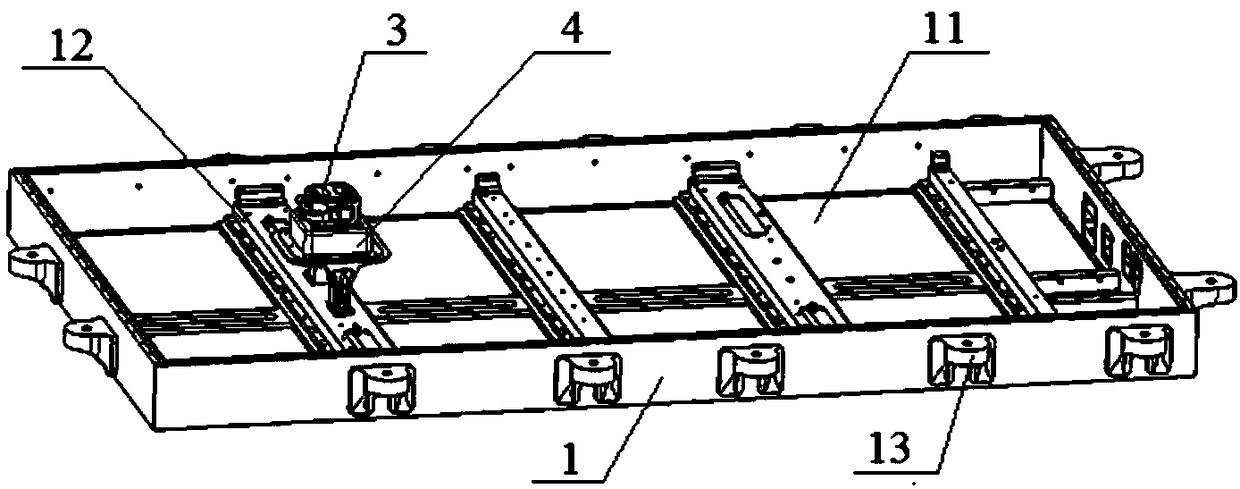

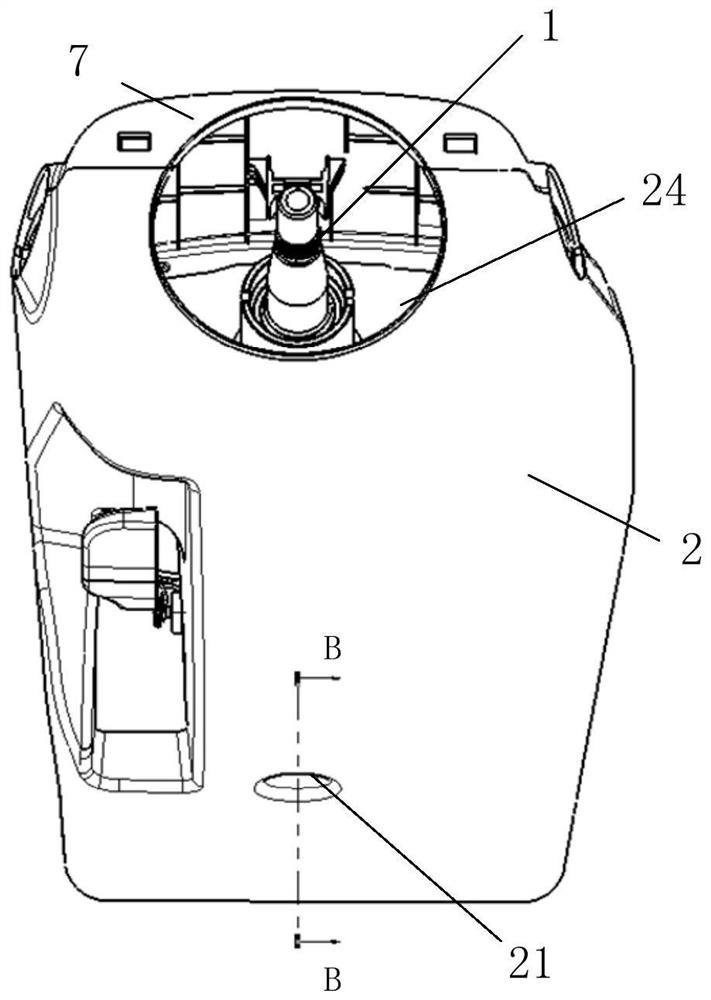

Electric vehicle and battery pack casing thereof

PendingCN109494322AEasy to plug and unplugIntensity does not affectElectric propulsion mountingCell component detailsEngineeringElectric vehicle

The invention provides an electric vehicle and a battery pack casing thereof. An MSD (manual service disconnector) is mounted on a lower casing of the battery pack casing through an adapting support;the structural strength of an upper casing is unaffected, and the requirements on mounting strength and space arrangement can be met. The battery pack casing includes the lower casing and the upper casing covering each other; the lower casing has a receiving cavity to receive a battery pack; the battery pack is connected with the MSD; the battery pack casing also includes the adapting support formounting the MSD; the adapting support is connected with the lower casing, and the MSD is supported above the upper casing. The MSD is adapted to the lower casing through the adapting support; the strength of the upper casing is unaffected. The MSD can also be supported above the upper casing within an operation range of an interior maintenance port; the MSD is actuated via the interior maintenances port; the requirement on space arrangement is satisfied at the premise of satisfying the requirement of the MSD upon mounting strength.

Owner:NEUSOFT REACH AUTOMOTIVE TECH SHANGHAI CO LTD

Anti-erosion ecological greening protection surface for landfill slope and its construction method

ActiveCN105862886BHigh strengthIntensity does not affectClimate change adaptationProtective foundationGrowth plantGeomembrane

The invention discloses an anti-washout ecological greening protective face of a refuse landfill side slope. The anti-washout ecological greening protective face comprises a to-be-greened refuse landfill side slope, wherein a geomembrane fixedly covers the refuse landfill side slope; a three-dimensional geomat fixedly covers the geomembrane; and a mixture of greening seeds and a soil body is laid in the three-dimensional geomat. Meanwhile, the invention also discloses a construction method for the ecological greening protective face. The anti-washout ecological greening protective face and the construction method thereof disclosed by the invention solve the problems that a highly-polluted soil body of a refuse landfill is not suitable for plant growth and the planting soil body on the side slope cannot be kept and cannot form a green ecological side slope.

Owner:HOHAI UNIV

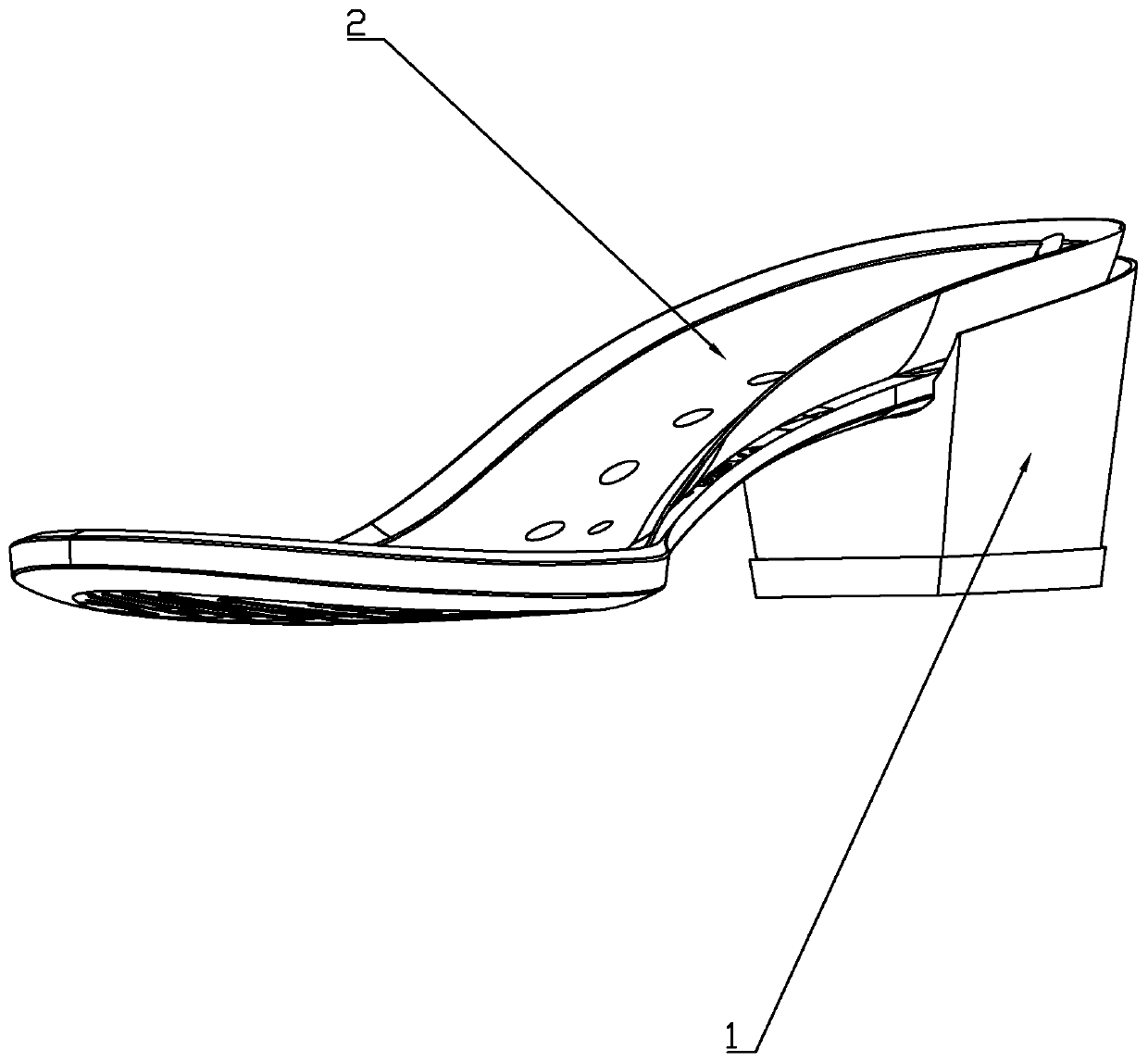

High-heeled shoe heel

PendingCN110893034APrecise positioningGuaranteed accuracyHeelsTop-piecesEngineeringStructural engineering

The invention discloses a high-heeled shoe heel which comprises a heel body and is characterized in that a connecting column used for being matched with a waist support for installation is arranged onthe heel body, the connecting column and the heel body are fixed into a whole, and the high-heeled shoe heel is high in installation strength and stable in installation.

Owner:WENZHOU MENGLANI SHOES

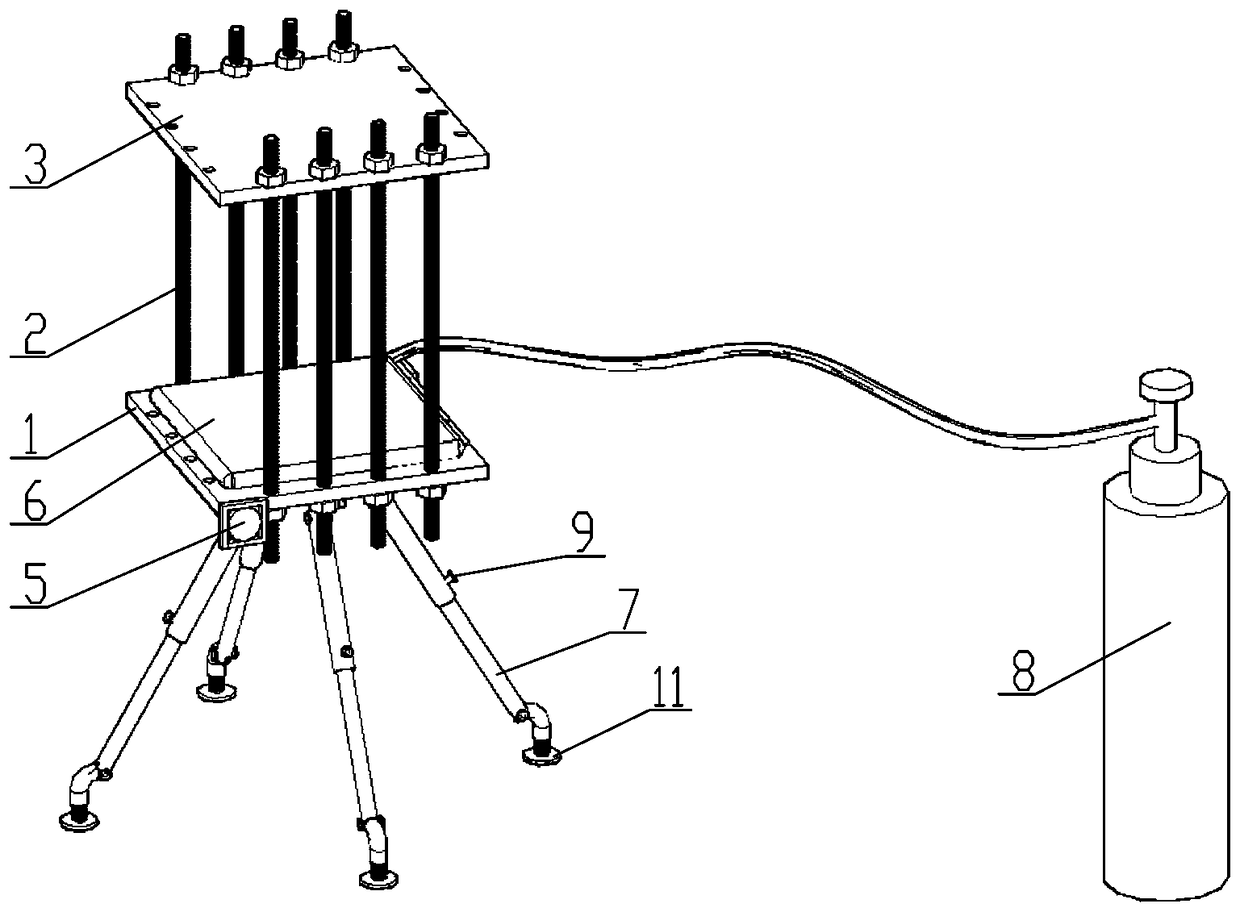

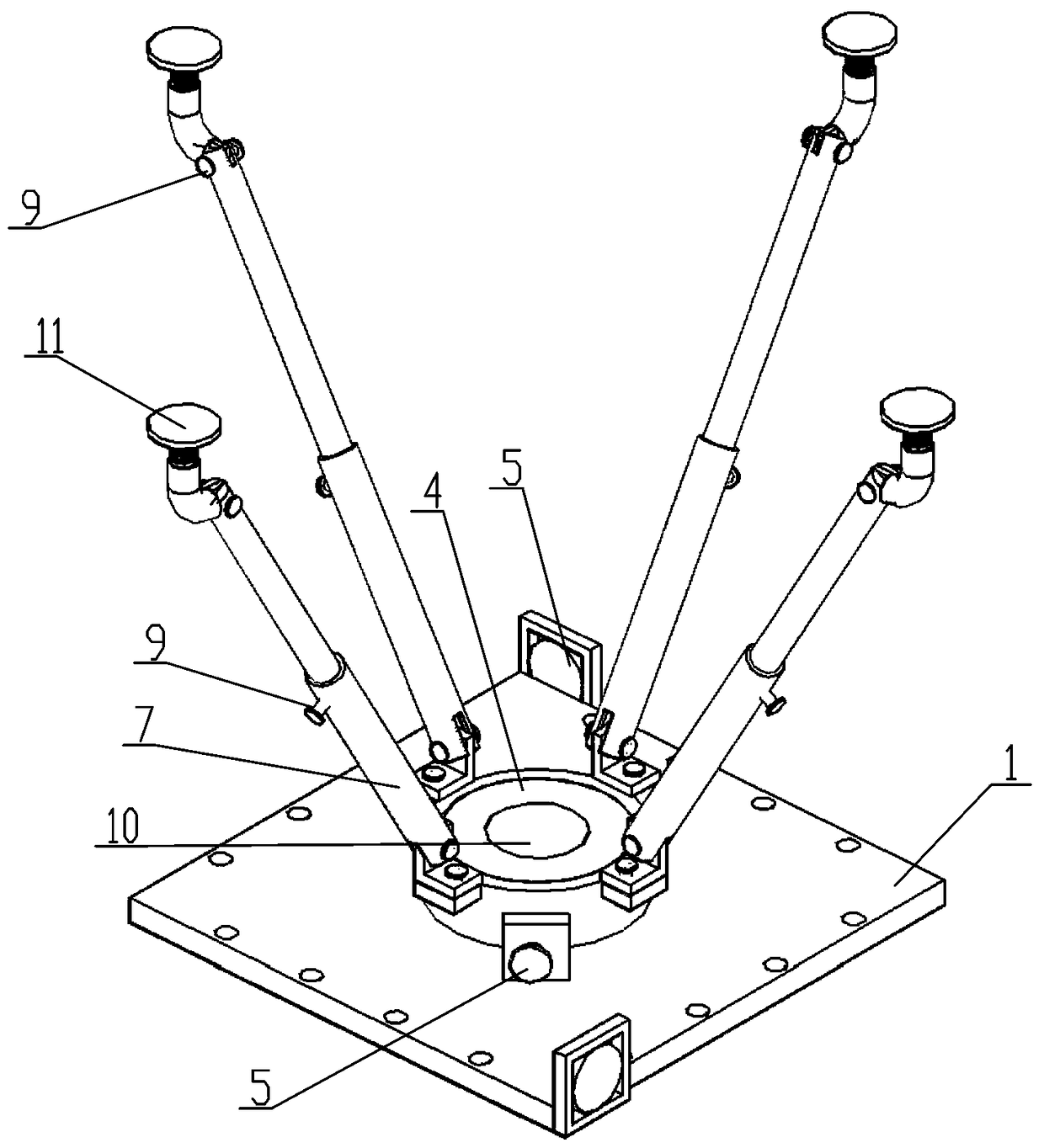

Simulation space multi-angle normal stress reaction frame and use method

ActiveCN108918286AHigh strengthIntensity does not affectMaterial strength using tensile/compressive forcesMeasuring instrumentNitrogen

The invention discloses a simulation space multi-angle normal stress reaction frame and a use method. The simulation space multi-angle normal stress reaction frame comprises a bearing plate, a universal rotating wheel is arranged at the bottom center location of the bearing plate, angle measuring instruments are arranged two adjacent sidewalls of the bearing plate, compression steel plate is arranged at the top of the bearing plate through the support of the threaded rod, a compression air cushion is arranged at the top of the bearing plate, and a steel footpad with the multi-level telescopicstructure is arranged at the bottom of the universal rotating wheel; the compression air cushion is connected with a nitrogen gas cylinder through the air pipe so as to provide the high-pressure nitrogen. The device exerts the pressure on the rock through the threaded rod, the space multi-angle force condition of the rock can be simulated by adjusting the universal rotating wheel and the stretching length of the steel footpad.

Owner:重庆艾信包装制品有限公司

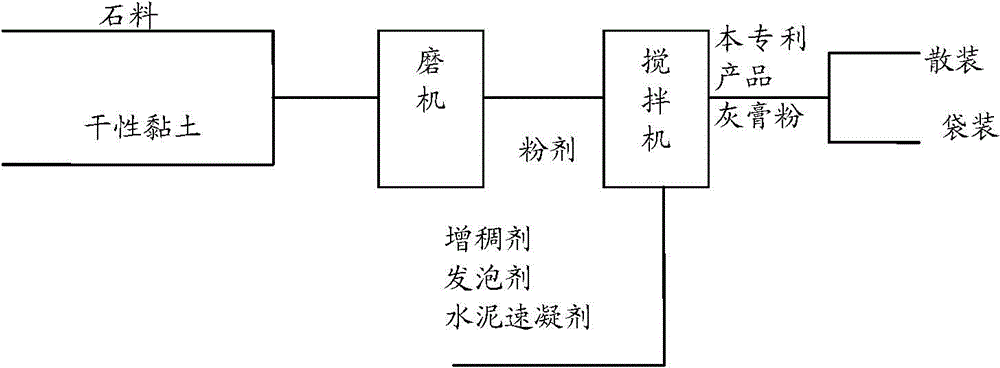

Production method of environment-friendly plaster powder

The invention relates to a production method of an environment-friendly plaster powder. The method is as below: mixing and grinding 2-98 wt.% of stone and 2-99 wt.% of dry clay to 150-3000 mesh, or respectively grinding and then mixing, adding a thickening agent, a foaming agent and a cement fast solvent, and stirring evenly to obtain the plaster powder. The plaster powder has the advantages of good viscosity, high hardness, convenience for construction, low cost, no decomposition in water and certain sedimentation and stability.

Owner:袁烈春

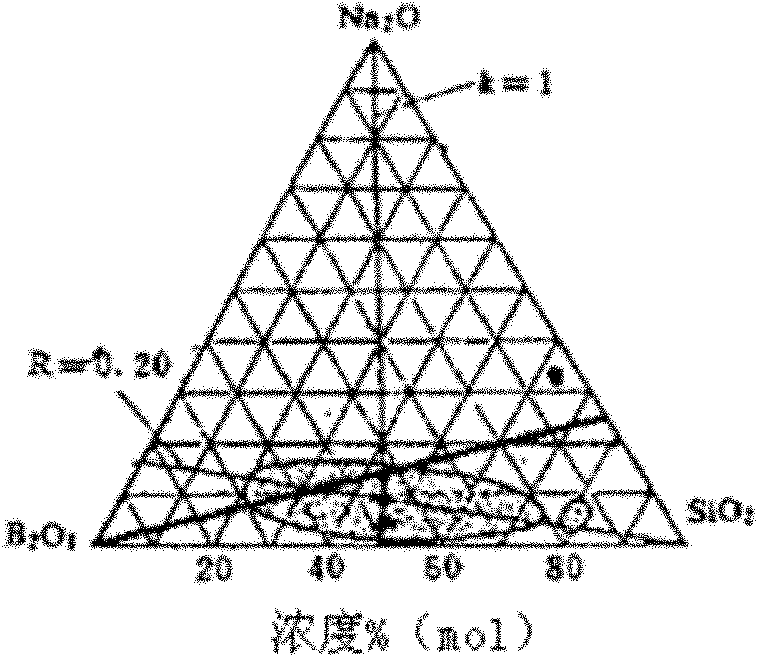

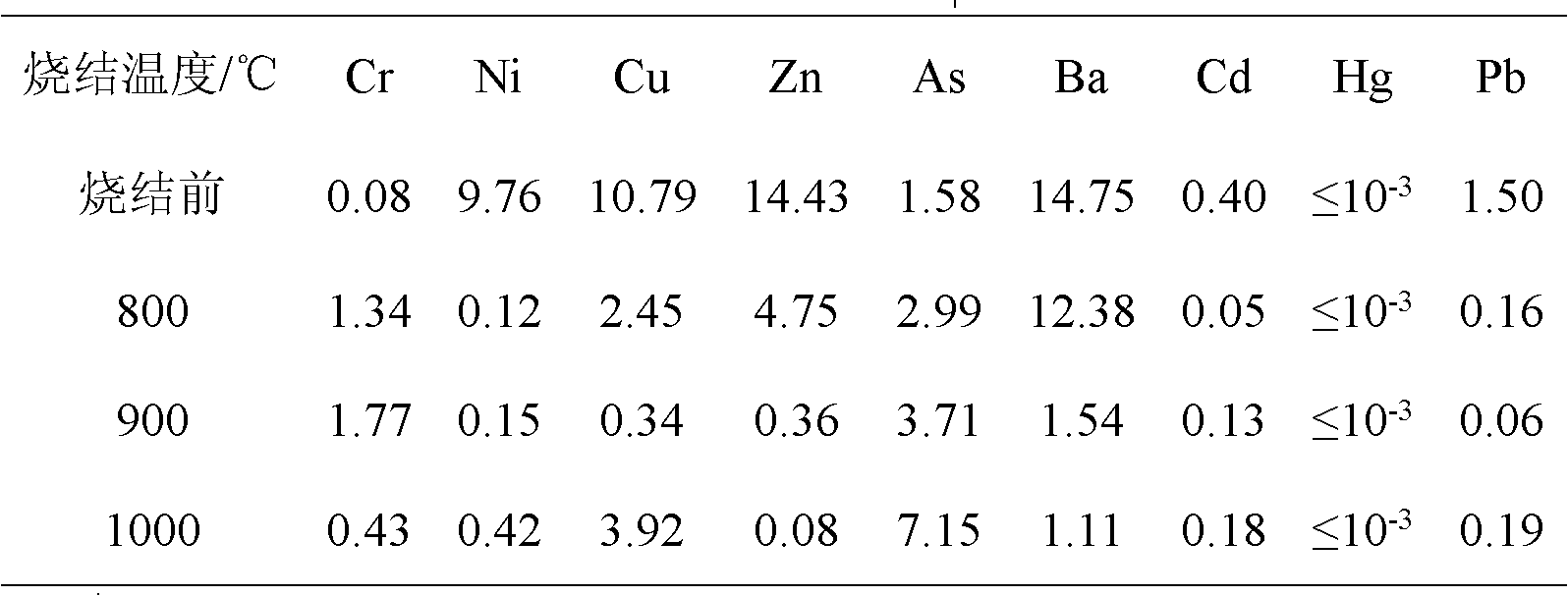

Preparation method for sludge baked brick resisting leaching of heavy metal

InactiveCN102153330BHigh strengthIntensity does not affectSludge treatmentCeramic materials productionMetal leachingBrick

The invention relates to a preparation method for a sludge baked brick resisting leaching of heavy metal. The preparation method includes the steps as follows: (1) adding boric acid in water glass and stirring to obtain sodium borosilicate ternary sol original solution; and then adding water for mixture to obtain sodium borosilicate ternary sol diluted solution; (2) adding the diluted solution in sludge, wherein the added diluted solution accounts for 8%-15% sludge in quantity, stirring, and standing for 12-24 hours; and (3) baking according to conventional flow, so that the sludge baked brick can be obtained. The preparation method is simple, convenient and feasible, and suitable for industrial production; and in the treated sludge baked brick, the leaching of chromium is lowered by 40% minimally and the leaching of arsenic is lowered by 60% minimally.

Owner:宁波荣山新型材料有限公司

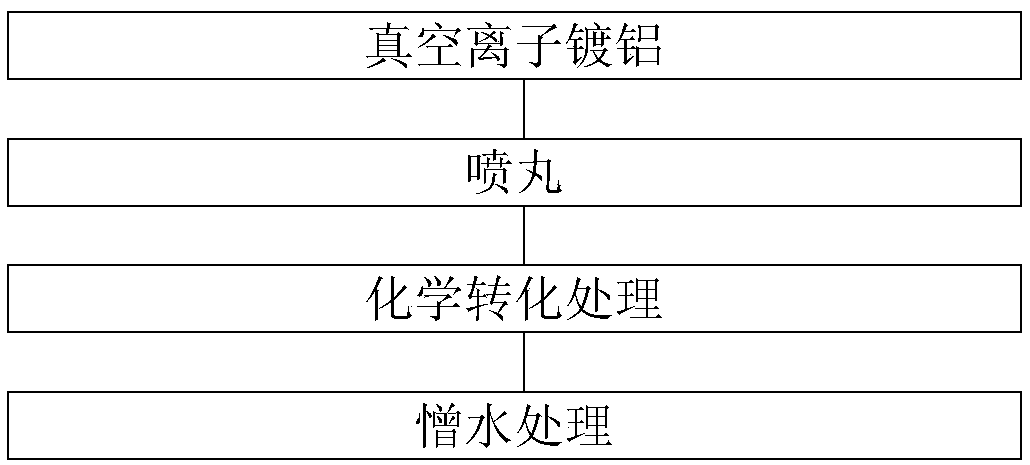

Preparation method of corrosion prevention plating coating

InactiveCN109182973AImprove corrosion resistanceIntensity does not affectVacuum evaporation coatingSputtering coatingHydrogenNonferrous metal

The invention provides a preparation method of a corrosion prevention plating coating. The corrosion prevention plating coating which can protect a high-strength material against hydrogen brittlenessand solve the problem of contact corrosion between the high-strength material and nonferrous metals and has different appearance colors can be prepared through the vacuum ion plating technology, the shot blasting technology, the chemical conversion technology and the hydrophobic treatment technology. The preparation method is used for solving the problems of hydrogen brittleness of the high-strength material in aerospace parts and other weaponry parts and contact corrosion between the high-strength material and the nonferrous metals. Through the preparation method, the surfaces of the parts are protected through ion plating aluminum, shot blasting, chemical conversion and hydrophobic treatment to meet the protection requirements. The corrosion prevention plating coating which can protect the high-strength material against hydrogen brittleness and solve the problem of contact corrosion between the high-strength material and nonferrous metals different appearance colors and has differentappearance colors are prepared so as to solve the problems of hydrogen brittleness of the high-strength material in the aerospace parts and other weaponry parts and contact corrosion between the high-strength material and the nonferrous metals.

Owner:XIAN AVIATION BRAKE TECH

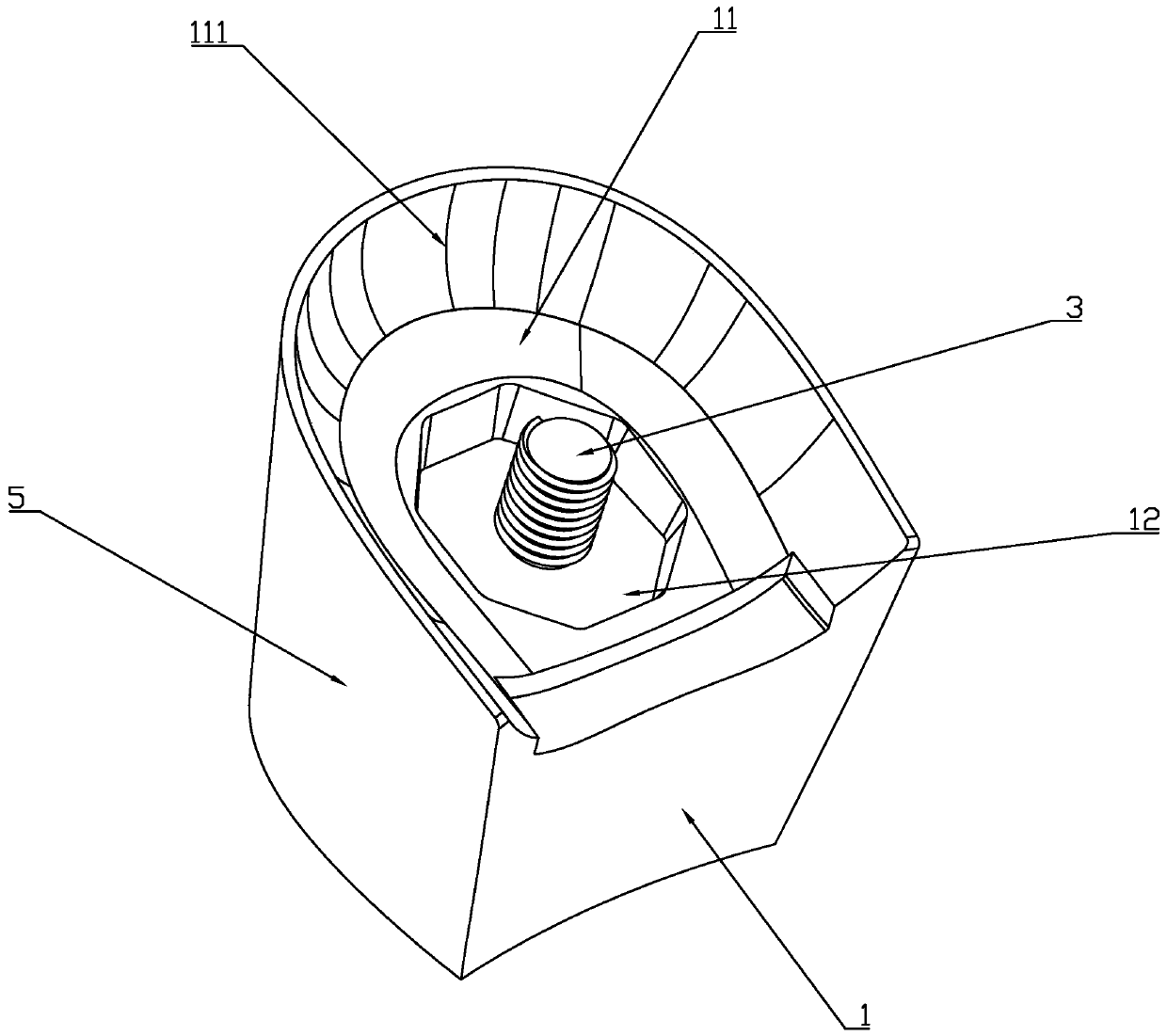

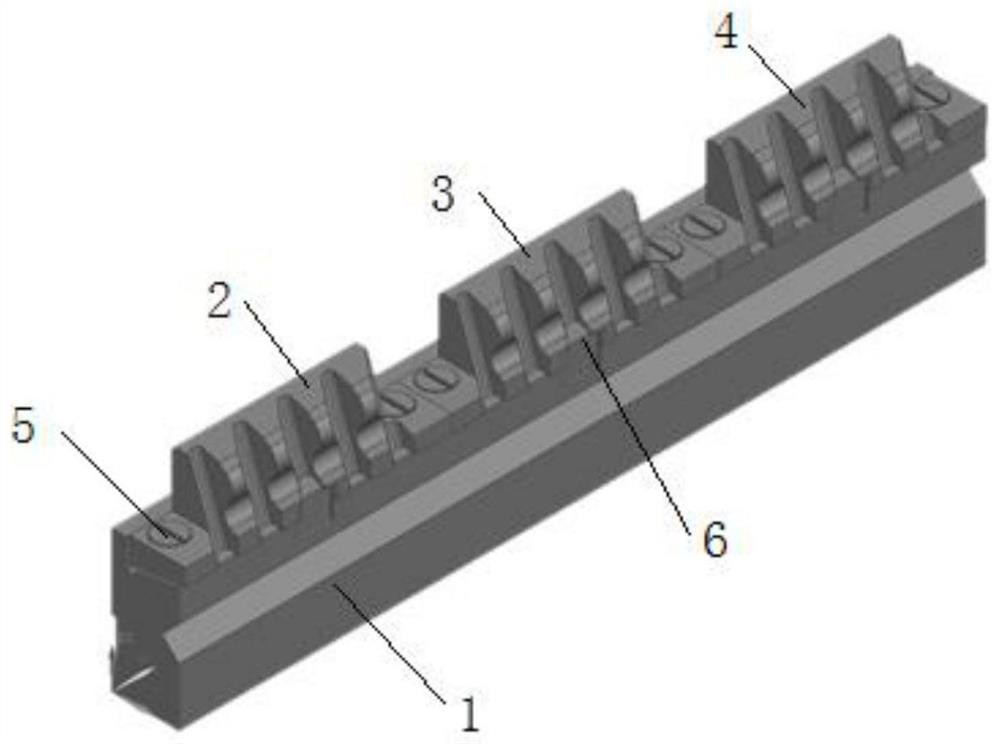

Assembly type broach

ActiveCN110524048AImprove machining accuracyInstalled and disassembledBroaching toolsAlloyMechanical engineering

According to the assembly type broach, a split structure is adopted, the broach body and the blade are machined separately, the machining difficulty of hard alloy is reduced, the machining precision of the broach is improved, and meanwhile the material cost is reduced; secondly, the blade group is mounted on the cutter body through the positioning groove; a positioning key is additionally arrangedbetween the blade group and the cutter body; axial and radial positioning of the blade group and the cutter body is achieved through the positioning groove and the positioning key, mounting and dismounting of the blades and the cutter body are also facilitated, the broach is simple in structure, low in manufacturing cost and convenient to use, and the hard alloy profile finish broach structure has extremely high popularization value in mortise broaching and blade tenon broaching of engine disc parts.

Owner:AECC AVIATION POWER CO LTD

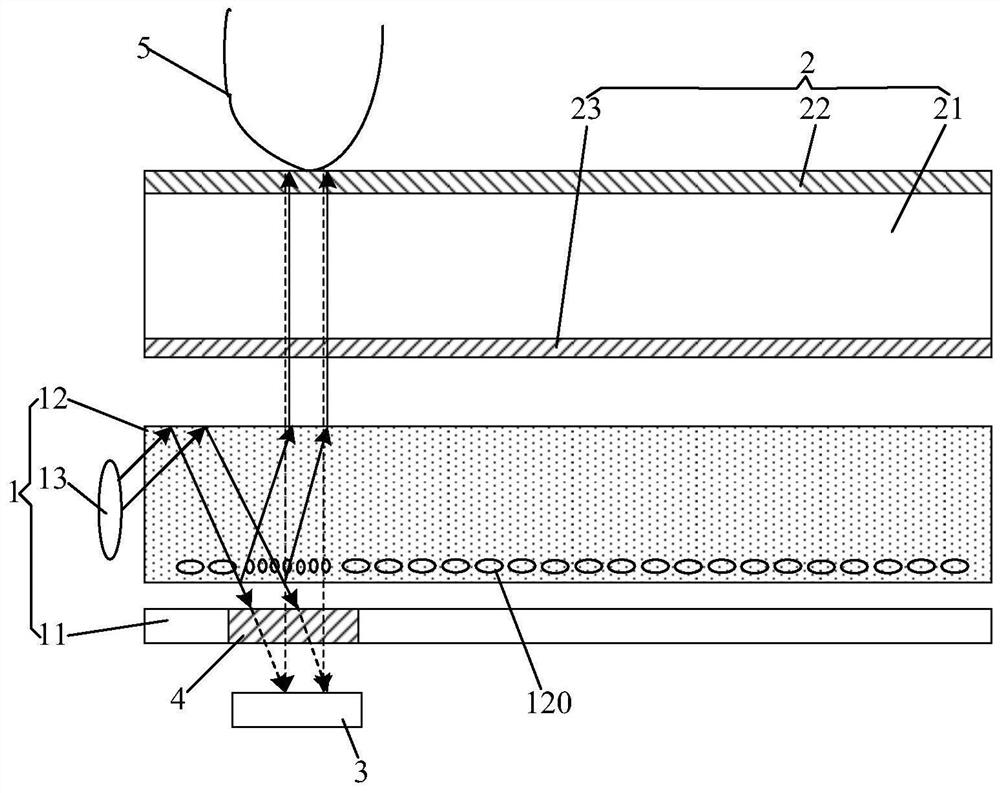

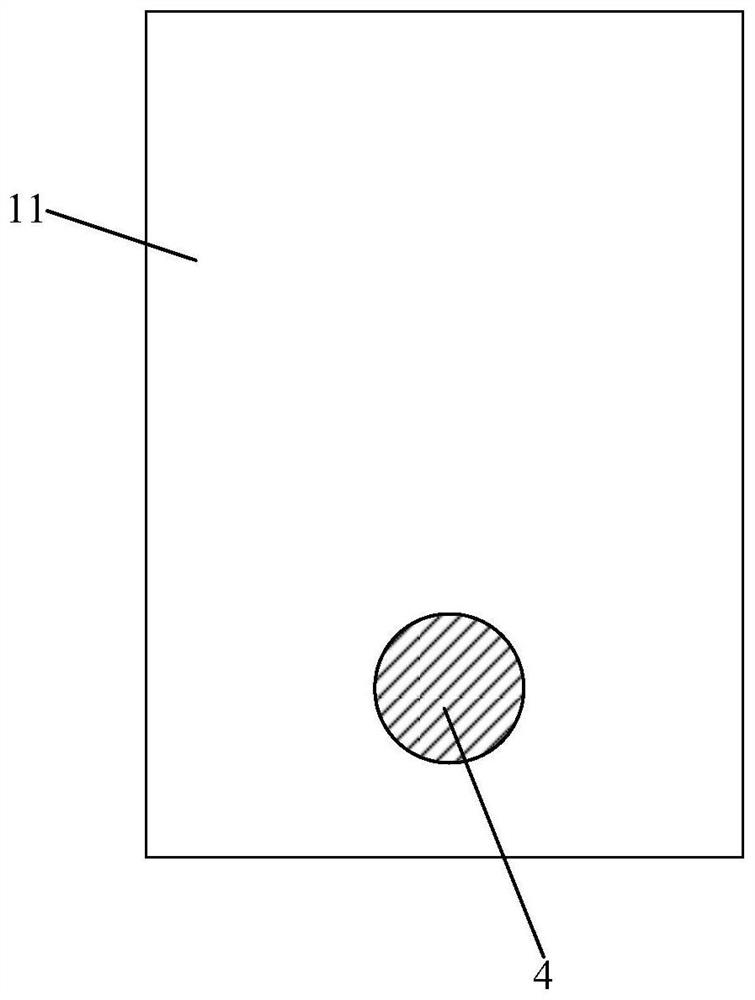

Display panel, driving method thereof, and display device

ActiveCN110441946BReduced impact strengthIntensity does not affectStatic indicating devicesPrint image acquisitionComputer hardwareComputer graphics (images)

The invention provides a display panel, a driving method thereof, and a display device. The display panel includes a backlight module, a display screen and a touch object recognition element, the display screen is arranged on the light emitting side of the backlight module, the touch object recognition element is arranged on the side of the backlight module away from the display Display light is provided, and the touch object identification element is used to identify the touch object that touches the display screen to unlock the display screen. An auxiliary imaging structure is provided in the backlight module, and the auxiliary imaging structure is arranged on the touch object identification element on the backlight module. In the orthographic projection area of the touch object, it is used to receive the light reflected by the touch object and the backlight light, and make the interference light of the two enter the touch object recognition element. When the touch object recognition element in the display panel realizes fingerprint recognition under the screen, even if the thickness of the display screen is large, it will not affect the intensity of the detection light received by the touch object recognition element, so that the touch object recognition element can recognize the touch object. for clear identification.

Owner:BOE TECH GRP CO LTD +1

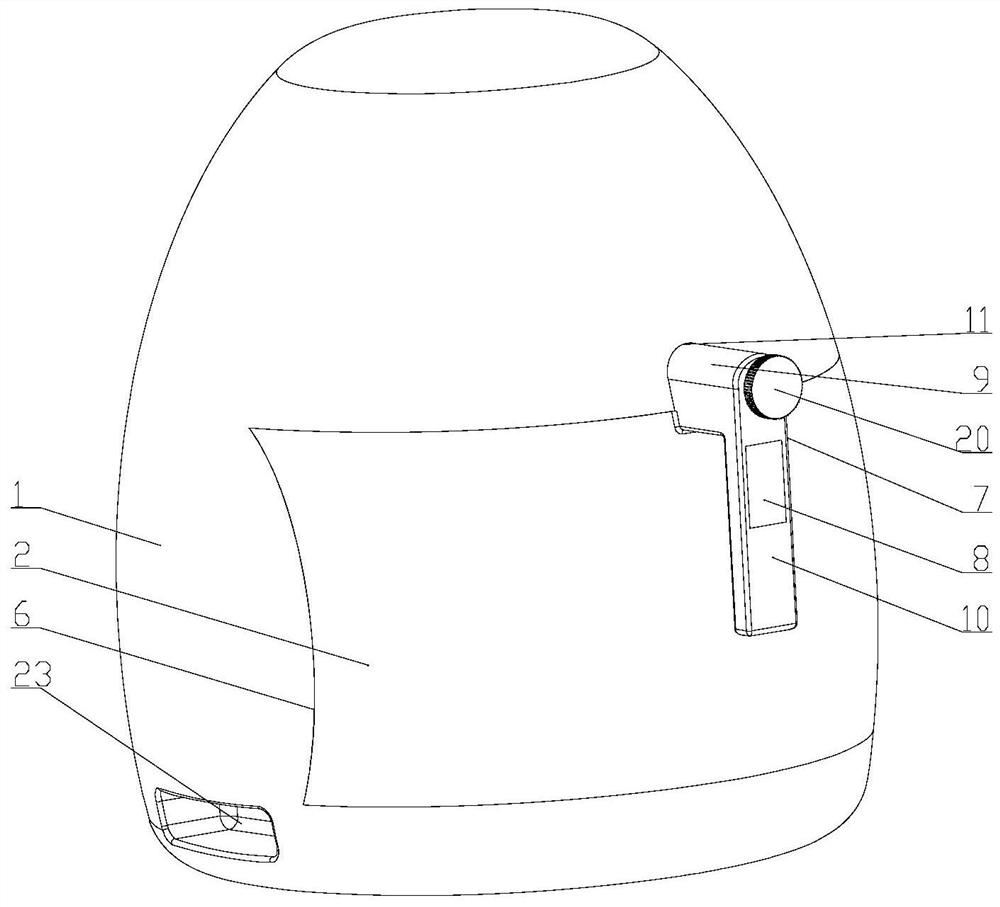

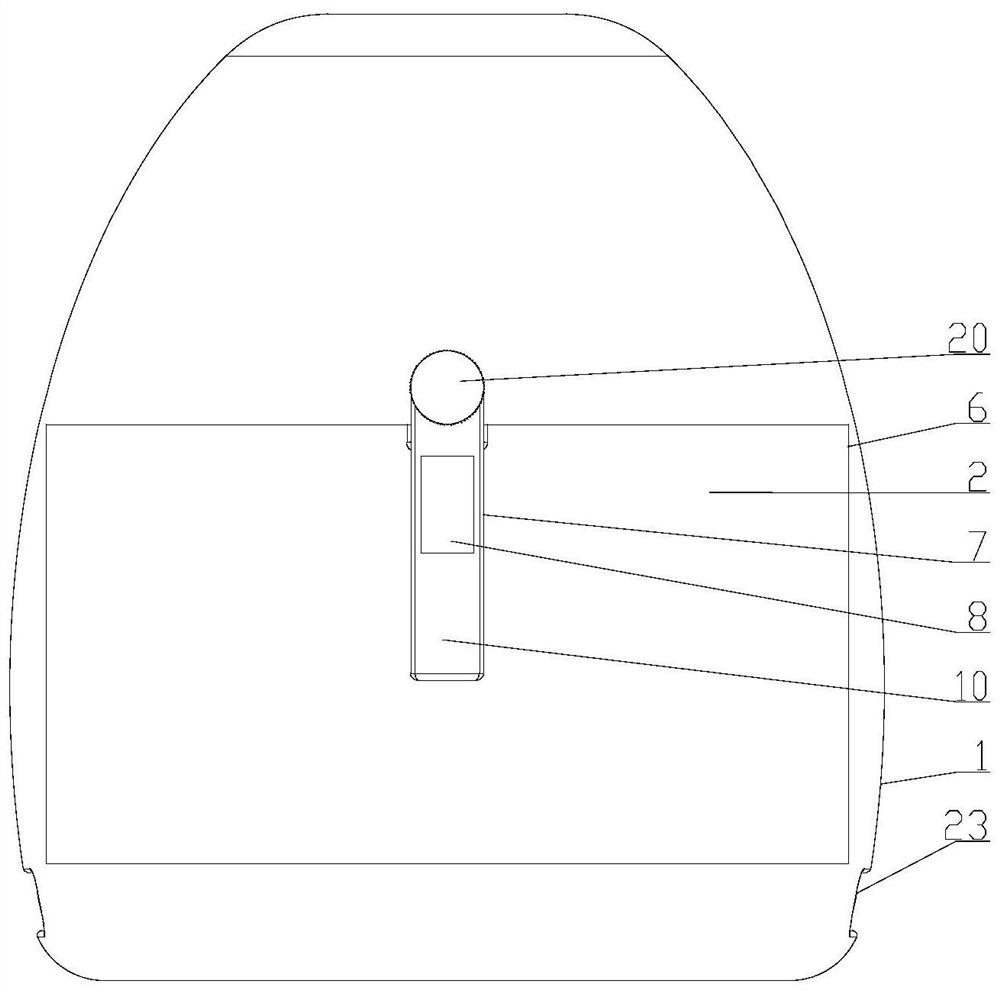

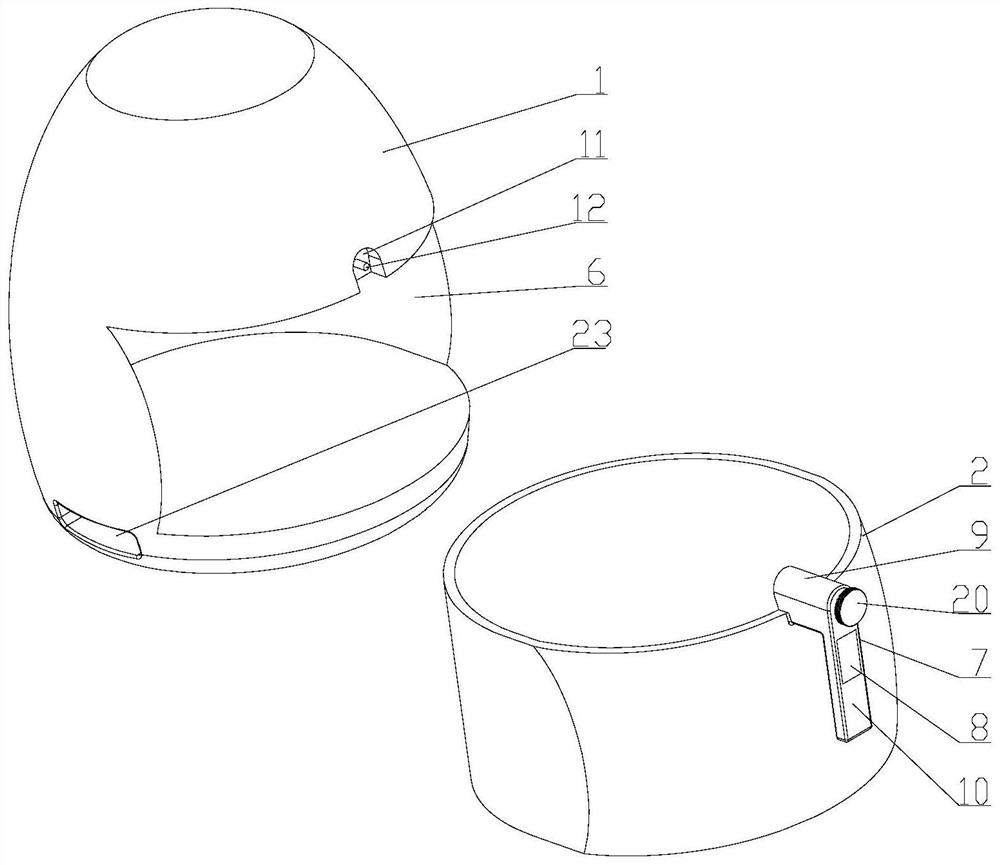

Air fryer

ActiveCN112401681ARealize the operation functionIntensity does not affectRoasters/grillsEngineeringFan blade

The invention discloses an air fryer which comprises a fryer shell and a fryer body; a control panel, a heating body, a motor and fan blades are arranged in the upper portion of the fryer shell, wherein the heating body and the motor are both electrically connected with the control panel, the fan blades are located under the motor and are in driving connection with the motor; a containing cavity is formed in the lower portion of the fryer shell; an opening allowing the fryer body to be inserted therein is formed in the front side of the containing cavity; a handle is arranged on the front sideof thefryer body; an operation screen is embedded in the handle; and after thefryer body is inserted into the containing cavity from the opening, the operation screen is electrically connected with the control panel. The operation screen is embedded in the handle of the fryer body, and after the fryer body is inserted into the containing cavity from the opening, the operation screen is electrically connected with the control panel, so that the operation function of the operation screen can be achieved, and the technical defects that the fryer shell is difficult to manufacture and low in strength due to the fact that the operation screen is installed on the front side of the fryer shell can be overcome; and meanwhile, the operation screen is installed on the handle, so that the user can carry out operation more easily, and a certain decorative effect can be achieved.

Owner:GUANG DONG SHUNDE CHENGHE ELECTRIC APPLIANCE CO LTD

A Composite Bulletproof Plate for Armor

ActiveCN109870075BPlay the role of energy absorptionPenetration slowed downArmour platesEnergy absorptionAdhesive

A composite bulletproof plate for armor, including a protective plate and several groups of unit bodies, each group of unit bodies includes a base and a basic micro-element structure; the base is set as a U-shaped structure, and the two sides of the concave structure of the U-shaped structure There are positioning grooves on the inner wall of each unit, and the basic micro-element structure is put into the concave structure of the base to form a unit body, and the basic micro-element structure protrudes from the base to lay out; the U-shaped bottom of the adjacent unit body base is isolated by a buffer rod , and the gap between the protective plate and the unit body and the buffer rod is filled with adhesive; in the length direction, adjacent unit bodies are arranged repeatedly at intervals, and the unit bodies at the left and right ends pass through the buffer rod and the left and right inner walls of the energy-absorbing cavity touch. The composite bulletproof plate used on the armor mainly plays the role of energy absorption when it is impacted. First, the aramid fiber guard plate is used for blocking and buffering, and then the ceramic matrix structure works to absorb energy and consume most of the energy. , to achieve a good energy absorption effect.

Owner:HENAN POLYTECHNIC UNIV

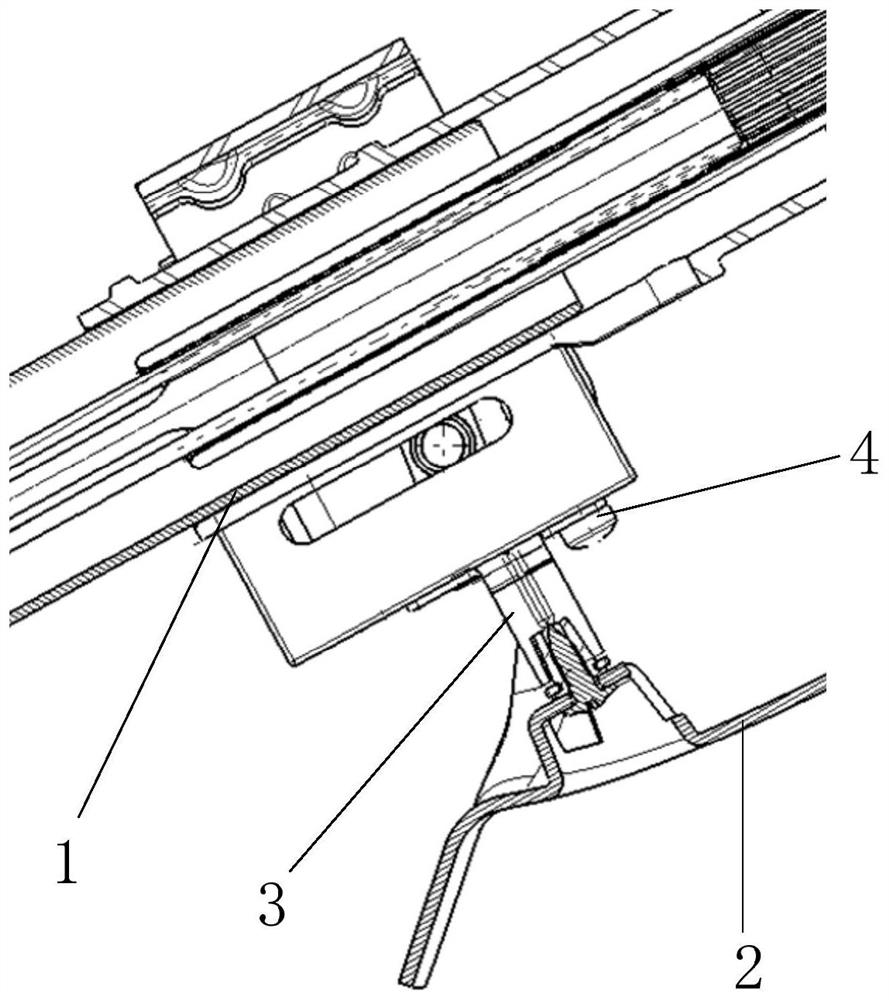

Steering column guard bracket installation structure and vehicle

The application discloses a steering column shield bracket installation structure and a vehicle, which belong to the technical field of vehicles. In the steering column guard bracket mounting structure, the steering column guard bracket connects the steering column and the steering column lower guard. When a serious collision occurs to the vehicle, the driver's knee will smash the lower shield of the steering column and hit the steering column shield bracket. The bracket middle plate of the steering column shield bracket is provided with a breakable groove, so that The bracket can be broken at the position of the breakable groove, absorbing the energy generated by the collision, and protecting the driver's knee. This steering column guard bracket is made of plastic material, which is easy to break on impact and has less weight.

Owner:CHERY AUTOMOBILE CO LTD

An assembled broach

ActiveCN110524048BImprove machining accuracyInstalled and disassembledBroaching toolsStructural engineeringCemented carbide

An assembled broach disclosed by the invention adopts a split structure, and the cutter body and the blade are processed separately, which reduces the processing difficulty of cemented carbide, improves the processing accuracy of the broach, and reduces the cost of materials; secondly, the blade The group is installed on the cutter body through the positioning groove, and a positioning key is added between the blade combination cutter body, and the axial and radial positioning of the blade group and the cutter body is realized through the positioning groove and the positioning key, which is also convenient for the installation of the blade and the cutter body Disassembly, the present invention is simple in structure, low in manufacturing cost, and convenient to use. The hard alloy profile broach structure has a very high promotional value in the broaching of the tenon and groove of the engine disk parts and the broaching of the blade tenon.

Owner:AECC AVIATION POWER CO LTD

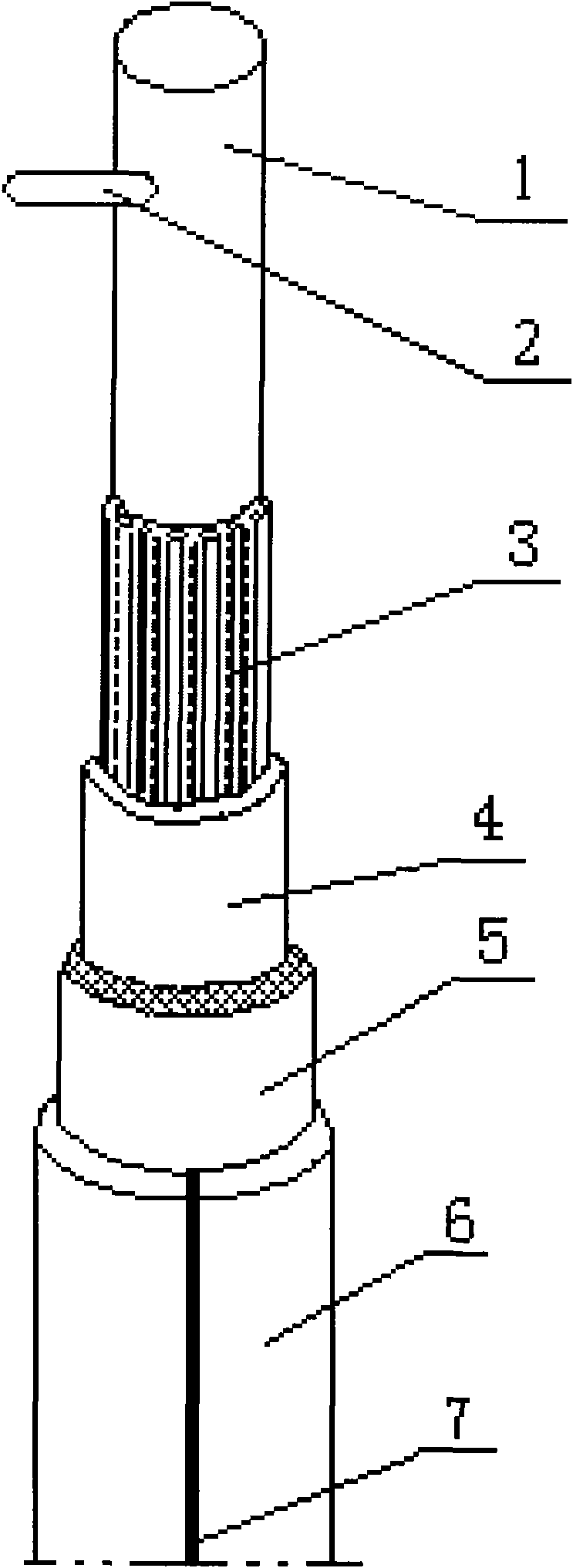

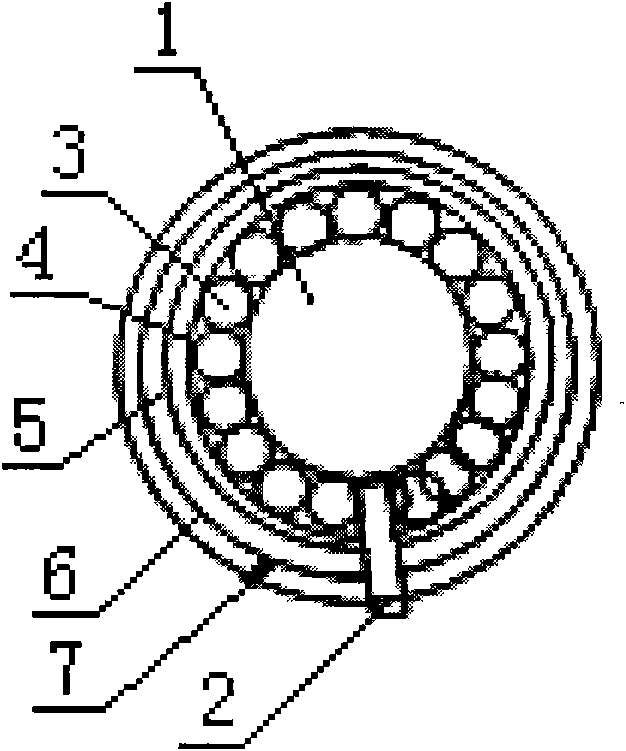

Temperature and pressure monitoring cable with protection tube and manufacturing method thereof

The invention relates to a temperature and pressure monitoring cable with a protection tube. The manufacturing technology of the test and protection tube has the key points that low-carbon alloy steel is selected as long steel materials to improve the twisting strength of a tubular product, the tensile performance and the weldability of the tubular product; underwater low-temperature welding outer protection tubes are adopted in the welding process and are formed and welded into a whole at one time in a manner of being directly embedded into an internal cable, the cable prefabrication is not required so as to prevent the internal cable from being distorted, extruded and collided, therefore the site construction workload is reduced, and the test construction success rate is improved; and the treatment to the positions of all pressure measurement ports is finished under the non-cutting-off condition so as not to affect the strength of the cable and the test and protection tube. The manufacturing technology of the high-strength test and protection tube has novel concept, is reasonable to design and is easy to implement; and by the utilization of the technology, the high-temperature, high-pressure and corrosion resistant high-strength cable protection cable can be manufactured, the site construction workload can be reduced, and the test operation success rate can be improved.

Owner:PETROCHINA CO LTD

Top-grade sunproof wool fabric for automotive interior

InactiveCN106223002AEfficient modificationGood light stabilityLight resistant fibresDry-cleaning apparatus for textilesMicroorganismBacillus amyloliquefaciens

The invention discloses a making method of top-grade sunproof wool fabric for an automotive interior. According to the making method, natural environment-friendly materials such as microorganisms (bacillus aceticus, lactobacillus acidophilus and bacillus amyloliquefaciens) and biological enzymes are sufficiently applied, the optimal parameters of the production technology are verified through a large quantity of experiments, and the top-grade sunproof wool fabric for the automotive interior is obtained. Wool fibers are modified through saccharifying enzymes during wool treatment, the following microorganism fermenting technology is used in cooperation, the wool fibers are subjected to great excellent modification, wool can be sunproof, good in light stability and easy to dye, and the certain anti-pilling effect is achieved; in addition, the strength of the wool fibers is not influenced, and the top-grade sunproof wool fabric is particularly suitable for autumn and winter.

Owner:罗敏凯

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com