Comprehensive wiring box cover

A technology of integrated wiring and box cover, applied in the direction of fiber mechanical structure, etc., can solve the problems of inability to guarantee the strength, the panel is not easy to correct, adjust, and affect the normal transmission of signals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

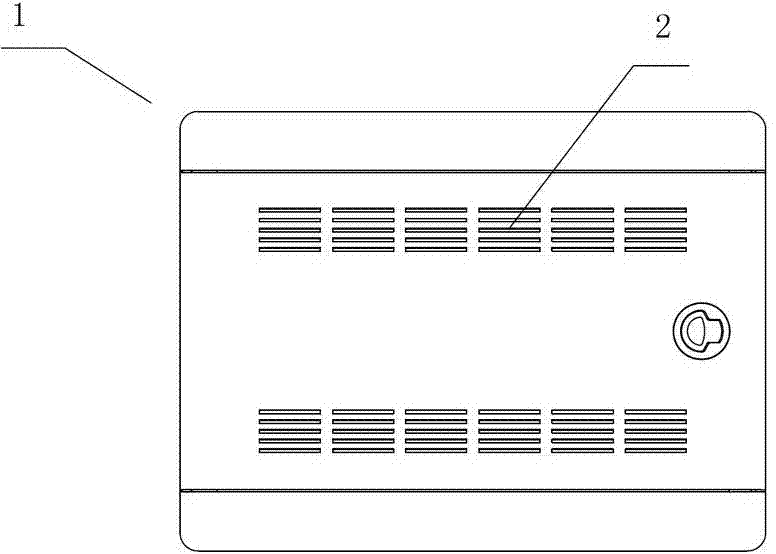

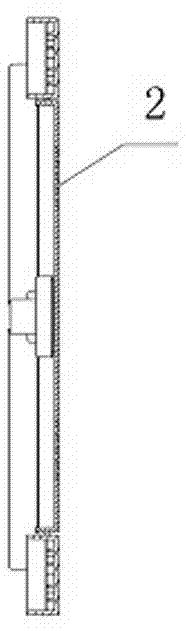

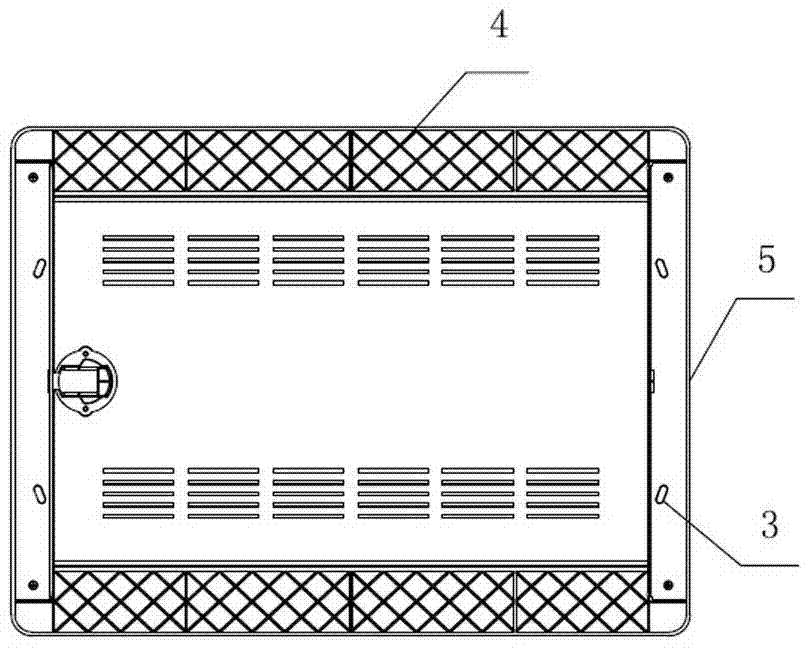

[0026] see Figure 1 to Figure 4 , the cover of the integrated wiring box includes a panel main body 1 that is placed outside the wiring box, the surface of the panel main body 1 is provided with cooling holes 2, the inner surface of the panel main body 1 is provided with adjustment holes 3, and the panel main body 1 passes through the adjustment holes 3 Rotate relative to the wiring box.

[0027] The wiring box needs to be buried in the wall. The panel body 1 is covered outside the wiring box. The adjustment hole 3 can be used for adjustment and correction of the panel body. For details, please refer to image 3 As shown, the adjustment holes 3 are provided on the left and right sides of the inner surface of the panel body 1 , and the adjustment holes 3 are located on a circle centered on the center of the panel body 1 . There are four adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com