Patents

Literature

1411results about "Light resistant fibres" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

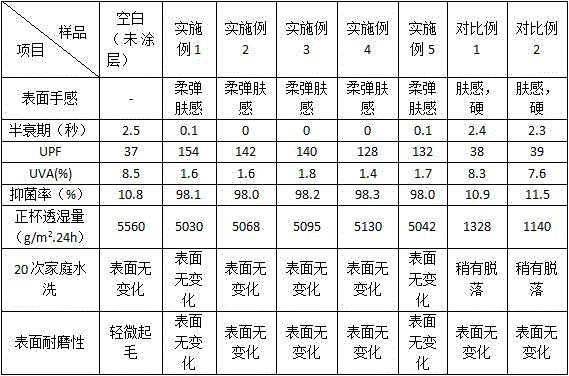

Preparation method of composite functional fabric with antimicrobial, anti-ultraviolet, deodorization and self-cleaning functions

ActiveCN104294583ASimple methodGood antibacterial, anti-ultraviolet and deodorizing propertiesLight resistant fibresWrinkle resistant fibresStaphylococcusHydrogen

The invention discloses a preparation method of a composite functional fabric with antimicrobial, anti-ultraviolet, deodorization and self-cleaning functions. The preparation method comprises the steps of preparing an activated modified treatment liquid, preparing a nano-titania dispersion liquid, processing fabrics by virtue of the activated modified treatment liquid, processing the fabrics by virtue of the nano-titania dispersion liquid, and the like. After the composite functional fabric is processed, the UPF value is more than 100, the deodorization rate is more than 95%, the photocatalysis self-cleaning fading rate of the composite functional fabric to chili oil is 96.7%, and the antibacterial rate (to staphylococcus) is 98.6%; after the composite functional fabric is washed for ten times in families, the UPF value is more than 50, the deodorization rate of the composite functional fabric to substances (including ammonia gas, formaldehyde, acetaldehyde, sulfureted hydrogen, nicotine and trimethylamine) is more than 90%, the photocatalysis self-cleaning fading rate of the composite functional fabric to chili oil is 93.9%, and the antibacterial rate (to staphylococcus) is 95.8%.

Owner:江苏巧雅纺织科技有限公司

Fabrics having a topically applied silver-based finish exhibiting a reduced propensity for discoloration

InactiveUS20040106341A1Highly beneficial durabilityImprove performanceBiochemical fibre treatmentSynthetic resin layered productsTopical surfaceIon exchange

Improvements in the wash durability and discoloration levels for fabrics having topically applied silver-ion treatments (such as ion-exchange compounds, like zirconium phosphates, glasses and / or zeolites) are provided. Such solid compounds are generally susceptible to discoloration and, due to the solid nature thereof, are typically easy to remove from topical surface applications. The inventive treatment requires the presence of a specific polyurethane binder, either as a silver-ion overcoat or as a component of a dye bath mixture admixed with the silver-ion antimicrobial compound. In addition, specific metal halide additives (preferably substantially free from sodium ions) are utilized to combat the discolorations typical of such silver-ion formulations. As a result, wash durability, discoloration levels, or both, can be improved to the extent that after a substantial number of standard launderings and dryings, the inventive treatment does not wear away in any appreciable amount and the color of the treatment remains substantially the same as when first applied. The particular treatment method as well as the treated fabrics are also encompassed within this invention.

Owner:MILLIKEN & CO

Methods and compositions for improving light-fade resistance and soil repellency of textiles and leathers

ActiveUS20050022313A1Easy to useImpart propertyDispersed particle filtrationPhysical treatmentAdditive ingredientChemical compound

One method includes applying to a post-manufactured textile material a liquid composition resulting from a combination of ingredients. The ingredients include one or more anti-fading compounds, one or more anti-soiling compounds, one or more silicon-based compounds, and one or more carrying media. One composition is a liquid composition resulting from a combination of ingredients, with the ingredients including a benzotriazole, a fluorocarbon, an organosiloxane, and odorless mineral spirits.

Owner:SCHEIDLER KARL J

Regenerable antimicrobial polymers and fibers with oxygen bleaches

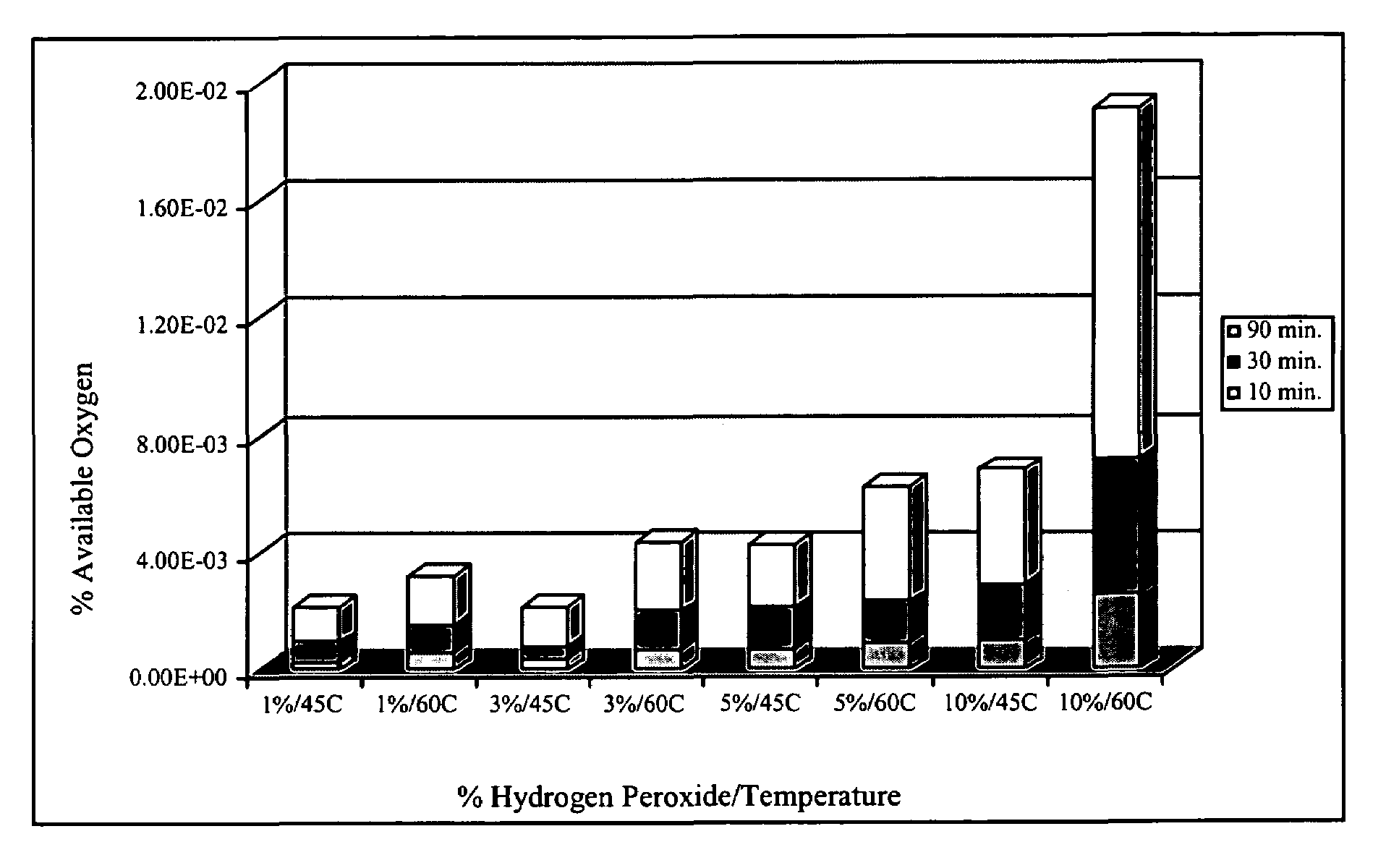

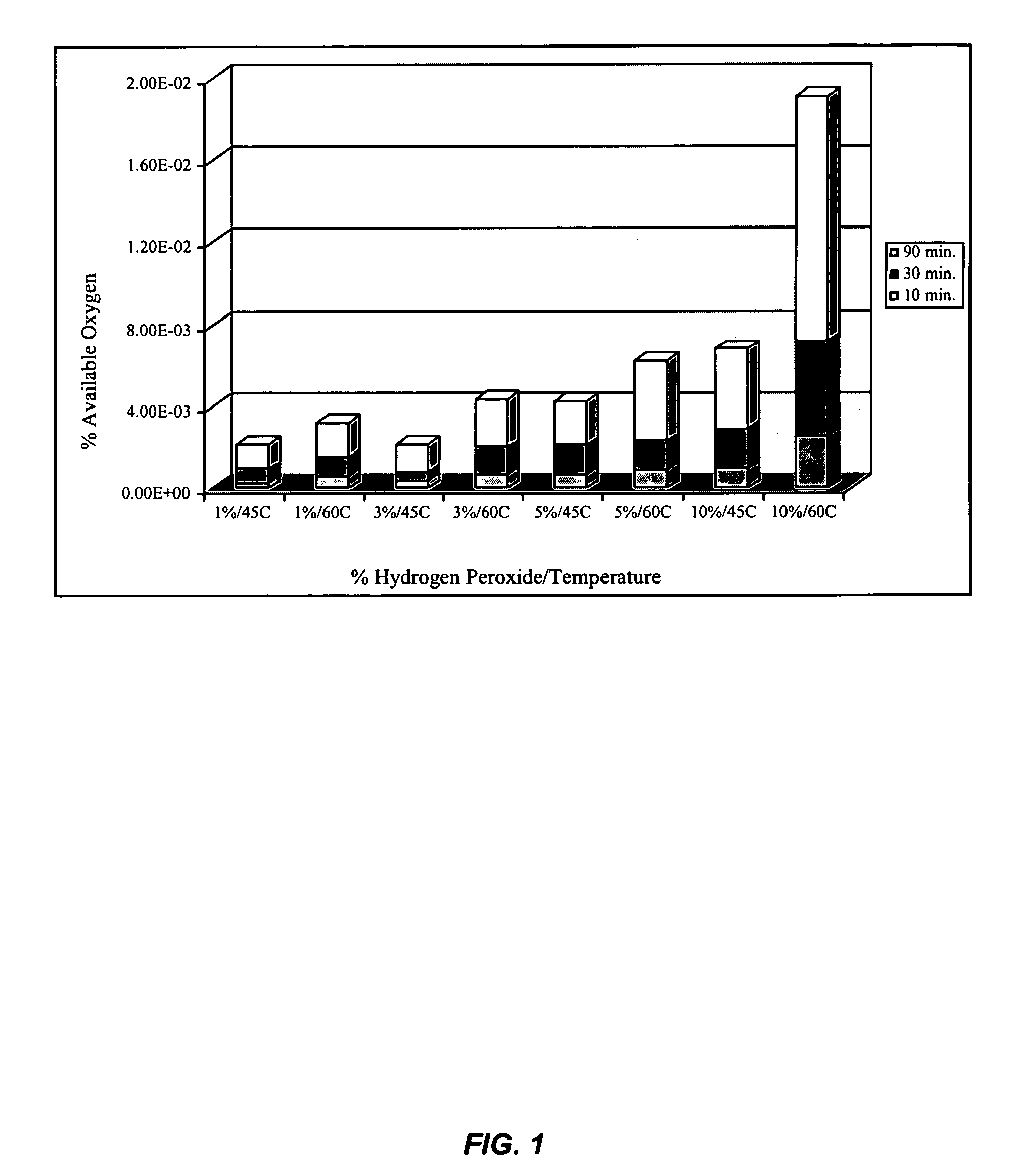

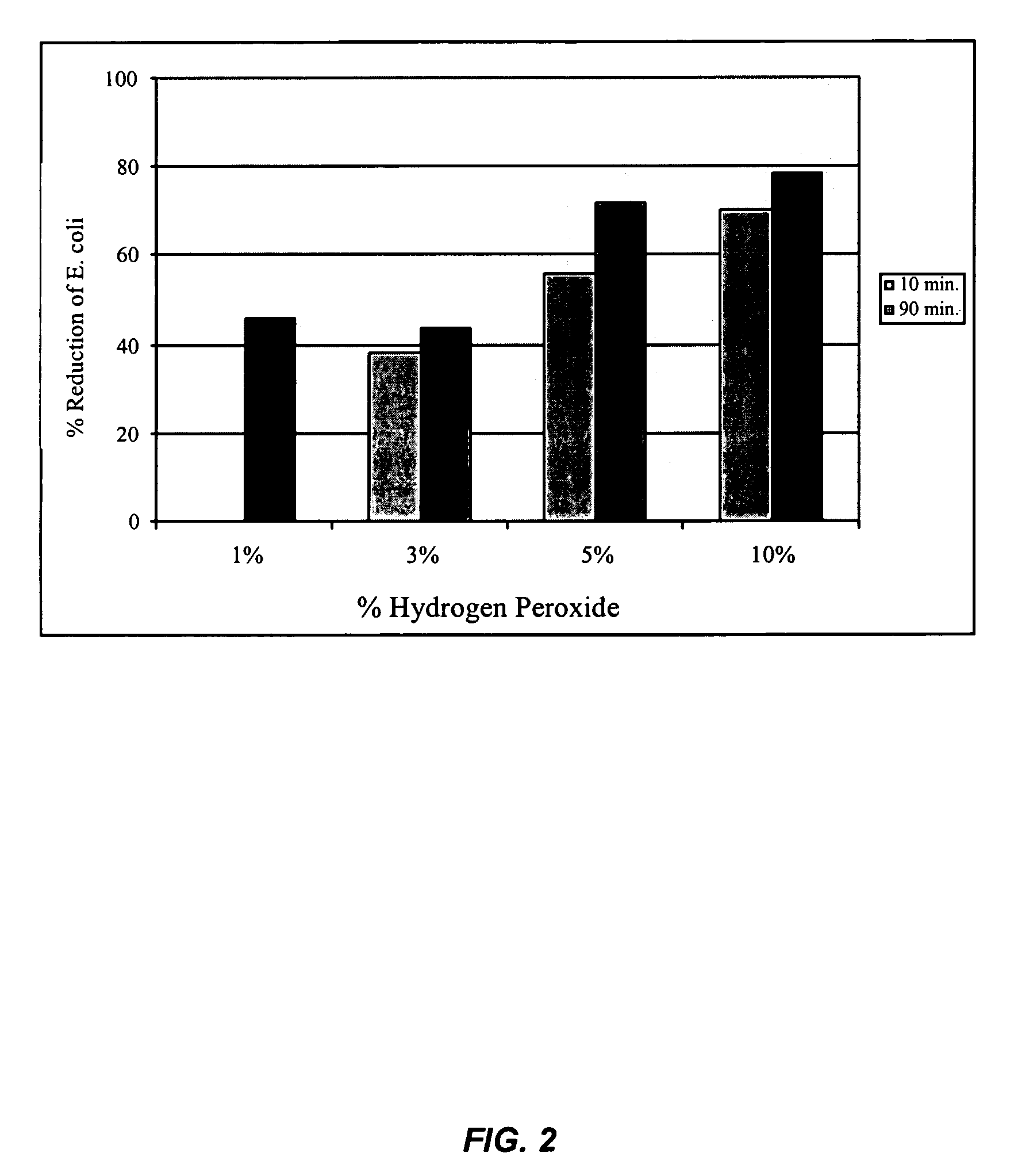

InactiveUS6962608B1Easy to prepareBroad of biocidal activityLight resistant fibresDetergent compounding agentsFiberColour fastness

The present invention provides durable and regenerable antimicrobial fibers and methods for preparing the same. These fibers have excellent colorfastness and washfastness, and are environmentally friendly. The antimicrobial fibers of this invention are suitable for a variety of purposes, including medical uses, sportswear, and uniforms.

Owner:CALIFORNIA UNIV OF SAN FRANCISCO

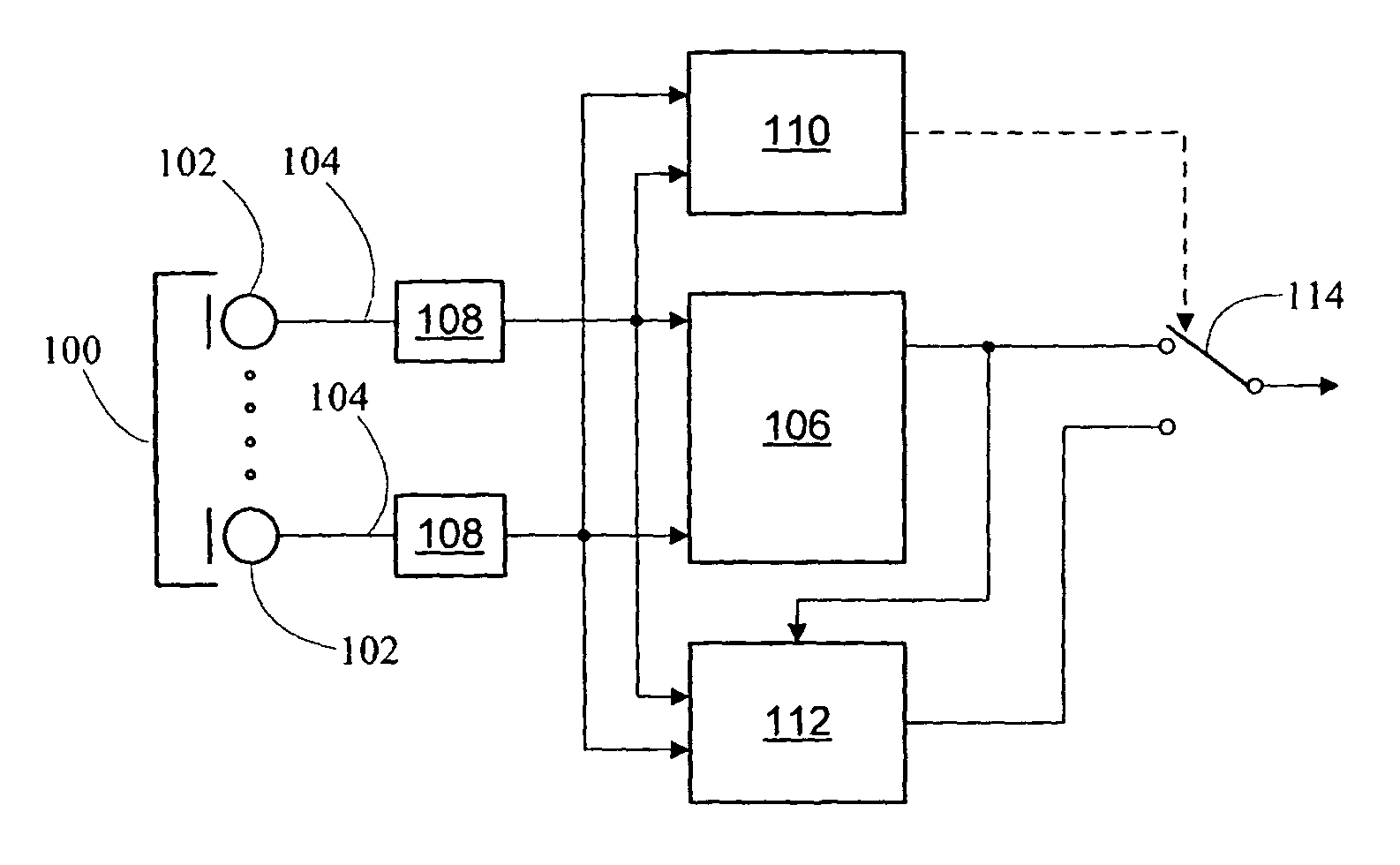

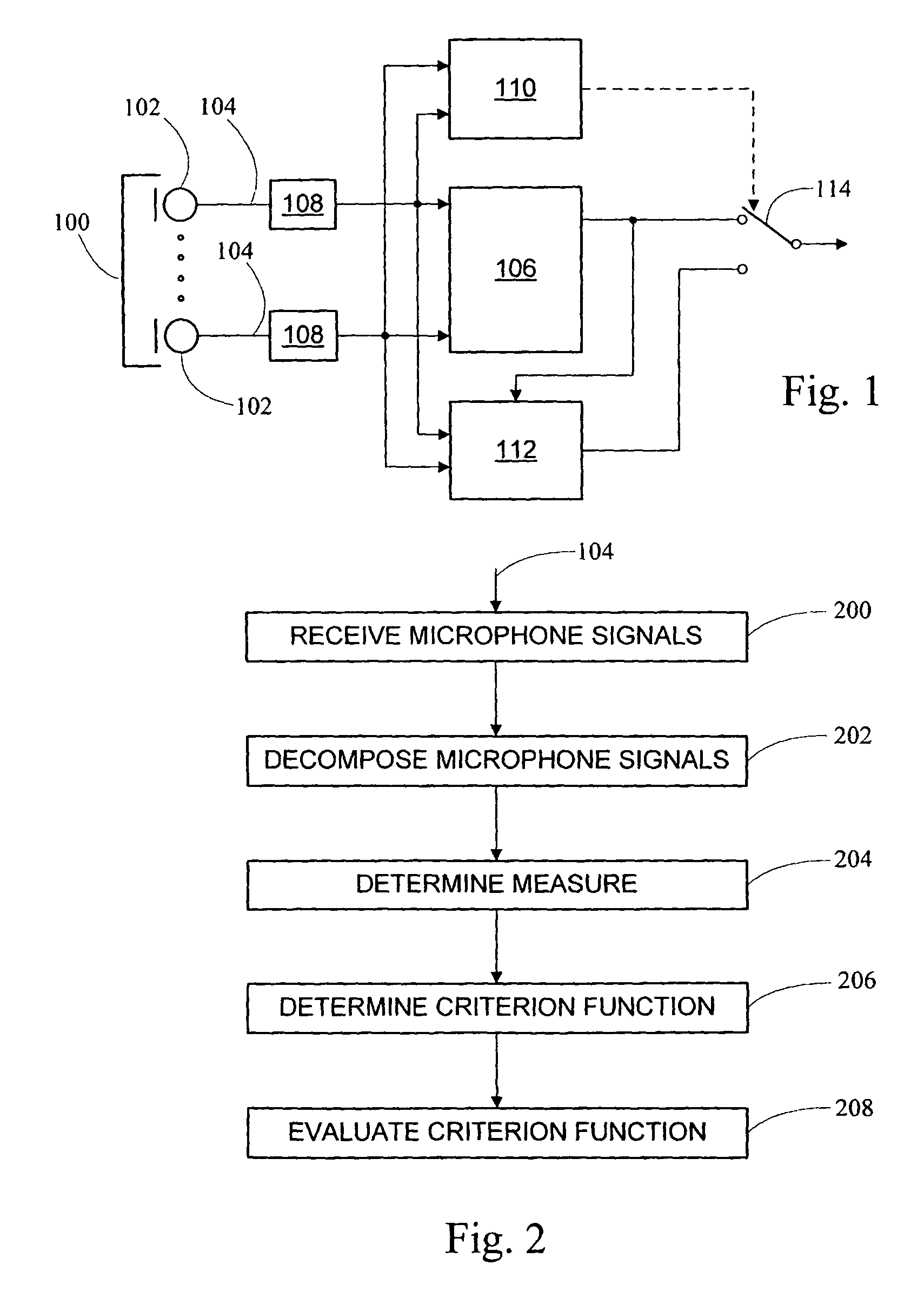

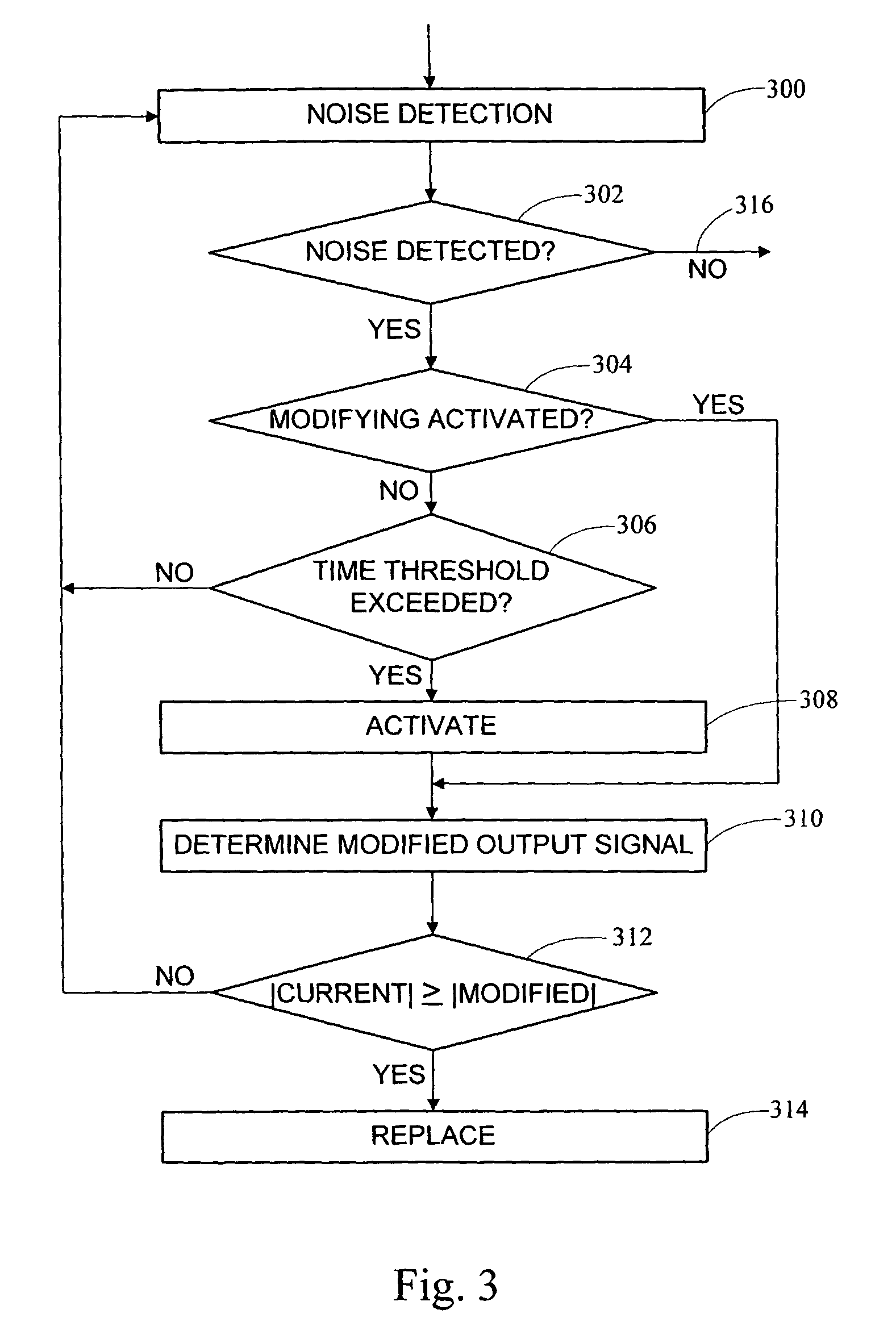

System for detecting and reducing noise via a microphone array

ActiveUS7881480B2Reduce noiseTwo-way loud-speaking telephone systemsEar treatmentAcoustic noise reductionSignal-to-noise ratio (imaging)

A system for detecting noise in a signal received by a microphone array and a method for detecting noise in a signal received by a microphone array is disclosed. The system also provides for the reduction of noise in a signal received by a microphone array and a method for reducing noise in a signal received by a microphone array. The signal to noise ratio in handsfree systems may be improved, particularly in handsfree systems present in a vehicular environment.

Owner:CERENCE OPERATING CO

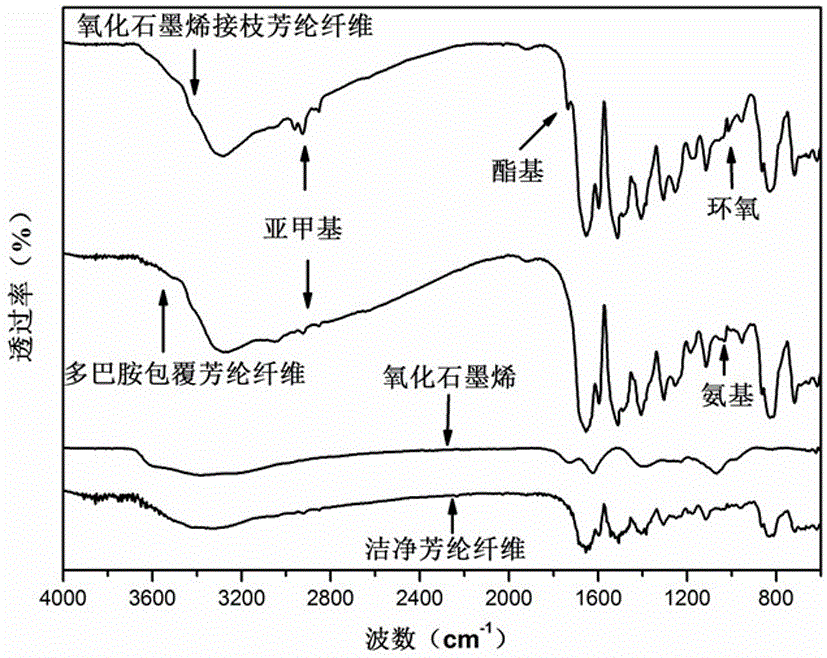

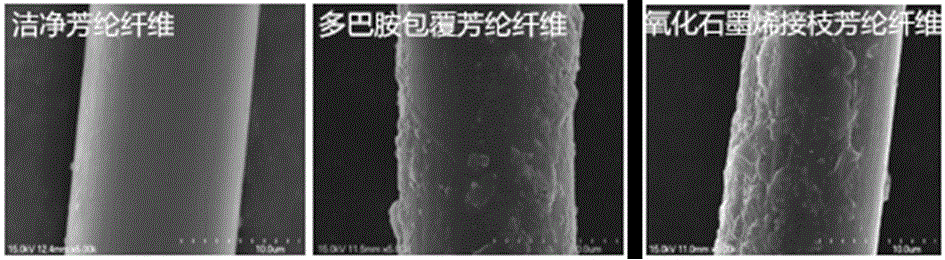

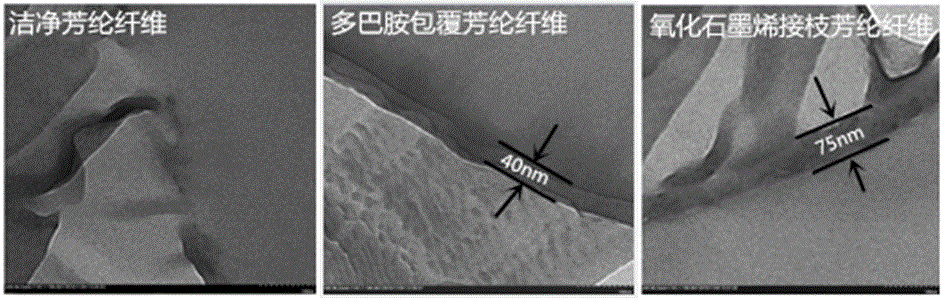

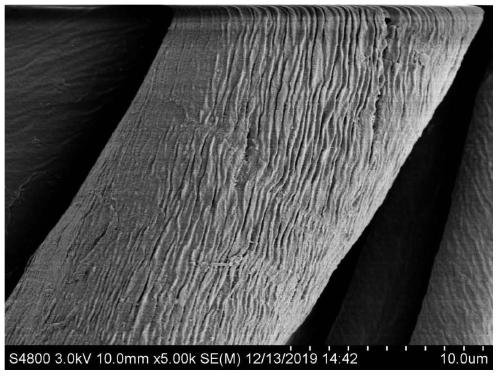

Surface modified aramid fiber and preparation method thereof

ActiveCN105603717AFacilitate graftingOutstanding UV resistancePhysical treatmentLight resistant fibresGraphenePre treatment

The invention discloses a surface modified aramid fiber and a preparation method thereof. Clean aramid fiber which is cleaned is dipped into a dopamine solution under a weak basicity condition to obtain a dopamine wrapped aramid fiber; through an esterification reaction and pi-pi interaction between oxidized graphene and the dopamine wrapped aramid fiber, a high-grafting-ratio oxidized graphene layer is formed on the surface of the aramid fiber, so that the surface modified aramid fiber is obtained. The surface modified aramid fiber has excellent ultraviolet resistance and is provided with a lot of active groups, in this way, the surface activity of the aramid fiber is obviously improved, and conditions are provided for further modification and application of the fiber. Meanwhile, in the process of modifying the aramid fiber, it is not needed to pretreat the aramid fiber, the preparation process is environmentally friendly, the operation technology is simple and controllable, and the surface modified aramid fiber is suitable for large-scale industrialized production.

Owner:SUZHOU UNIV

Sun protective fabric

InactiveUS6025284AReduce ultraviolet radiation transmissionLow production costGarment special featuresSynthetic fibresWrinkle skinPolyester

Wrinkled fabrics comprising ultraviolet absorbers are disclosed which provide improvements in ultraviolet transmission, wearer comfort, and cost over those of the prior art. The preferred fabric is polyester and the preferred UV absorbers are chlorobenzotriazoles. The polyester is wrinkled permanently so as to provide an extra barrier to ultraviolet radiation from solely utilizing UV absorbers alone. This wrinkled product is also more comfortable to a wearer, particularly in warm weather or hotter climates. Other non-apparel uses are also contemplated including tents, awnings, and crowd covers. A method of making such a fabric is also disclosed comprising stuffing a jet dyeing machine with a more than normal load amount of fabric and eventually heat setting such resultant wrinkles into the finished product.

Owner:MILLIKEN & CO +1

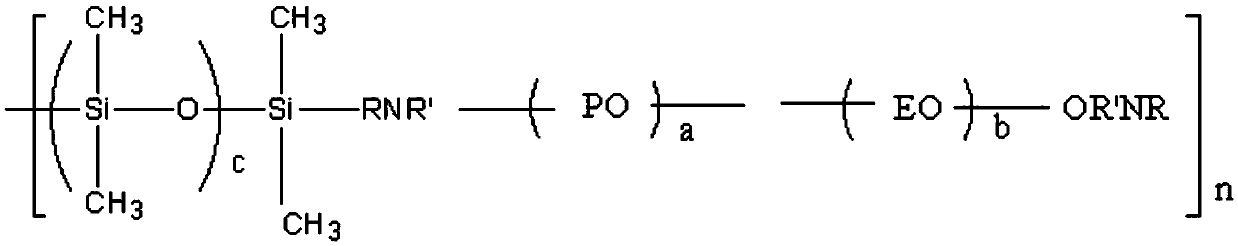

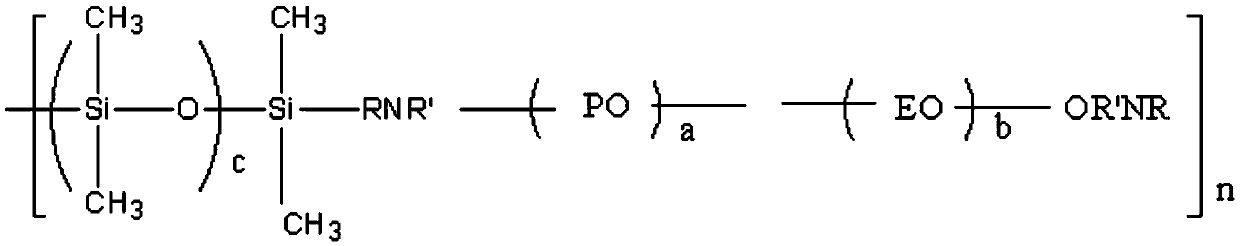

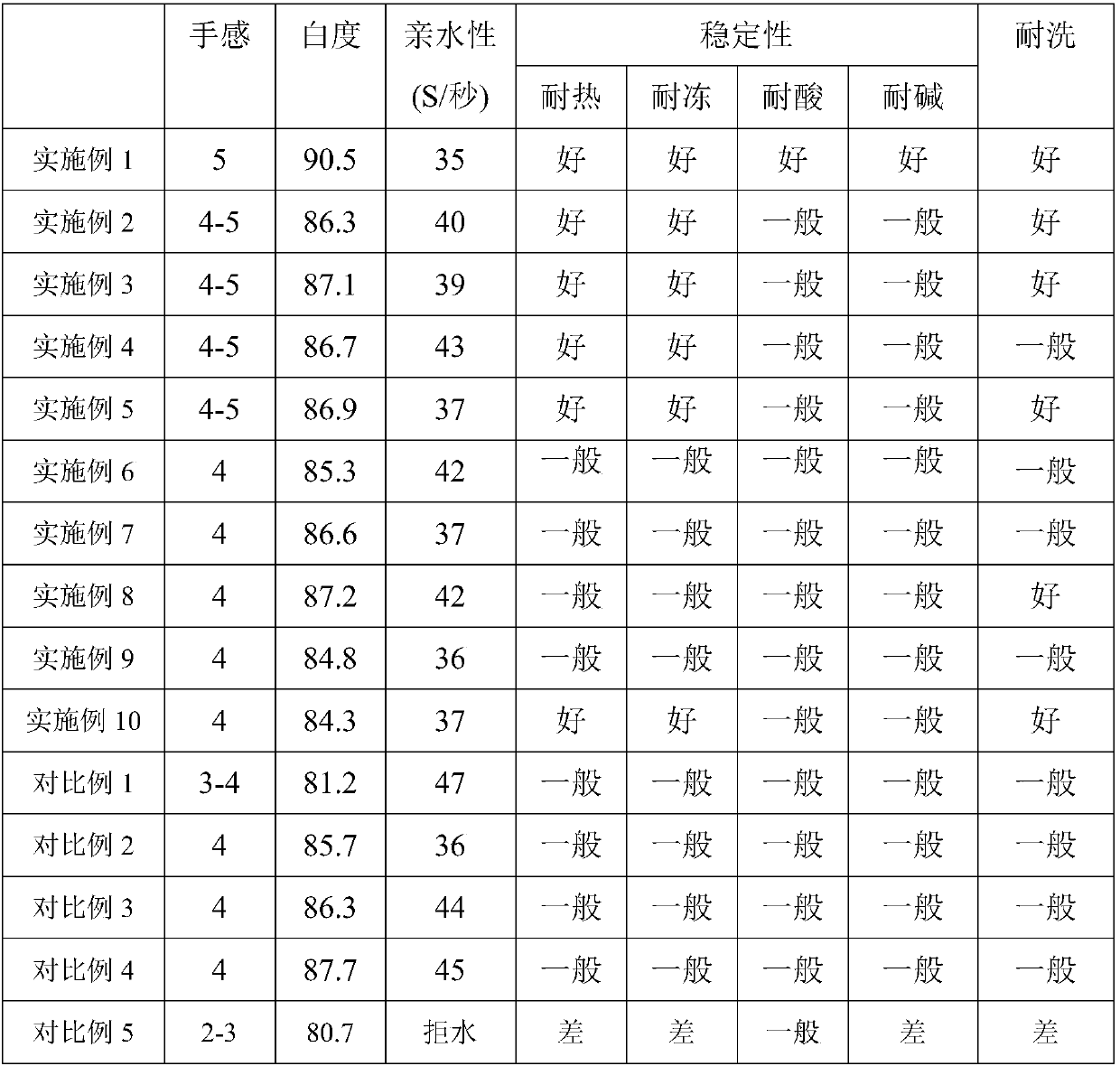

Ternary polymerization block polyether amino silicon oil softening agent and preparing method thereof

InactiveCN105504298AHydrophilicImprove hydrophilicityLight resistant fibresLiquid repellent fibresPolyesterAlkane

The invention relates to the technical field of softening agents, in particular to a ternary polymerization block polyether amino silicon oil softening agent. The structural formula is shown in the description, wherein R=-CH2CH2CH2, -CH3 or -CH2CH3, R'=C1-22 alkane, PO=OC3H6, EO=OC2H4, a and b are any integer from 5 to 24, c is any integer from 10 to 60, and n is any integer from 10 to 60. Yellowing, instability and hydrophobicity of ordinary amino silicon oil are overcome, fabric has excellent hand feeling, hydrophilia, washability and stability, and the softening agent is suitable for various kinds of pure cotton fabric, cotton-polyester blended fabric, wool and other kinds of fabric.

Owner:上海氟聚化学产品股份有限公司

Composition of a water-repellent agent

InactiveUS7396395B1Improve waterproof performanceHigh color fastnessGroup 4/14 element organic compoundsOther chemical processesEmulsionTear resistance

A composition of a water-repellent agent has a solvent and a solute. The solvent is water. The solute is dissolved in water and has isocyanate-acryl, non-ionic fluoro-acryl, 4,4-dipheylmethane diisocyanate, zinc acetate and polyethylene wax. Isocyanate-acryl has a concentration in a range of 10˜40 gram in per liter of the water-repellent agent (i.e. 10˜40%). Non-ionic fluoroacryl has a concentration in a range of 80˜150% t. 4,4-dipheylmethane diisocyanate has a concentration in a range of 5˜12%. Zinc acetate has a concentration in a range of 1˜20%. Polyethylene wax emulsion has a concentration in a range of 1˜40%. Therefore, a fabric treated with the present invention has good waterproof ability, widely enhanced color fastness in light and improved tear-resistance strength at the same time.

Owner:EVEREST TEXTILE CO LTD

Compositions for improving the light-fade resistance and soil repellancy of textiles and leathers

ActiveUS7157018B2Easy to useConveniently preparedDispersed particle filtrationLight resistant fibresBenzotriazoleOdorless mineral spirits

Owner:SCHEIDLER KARL J

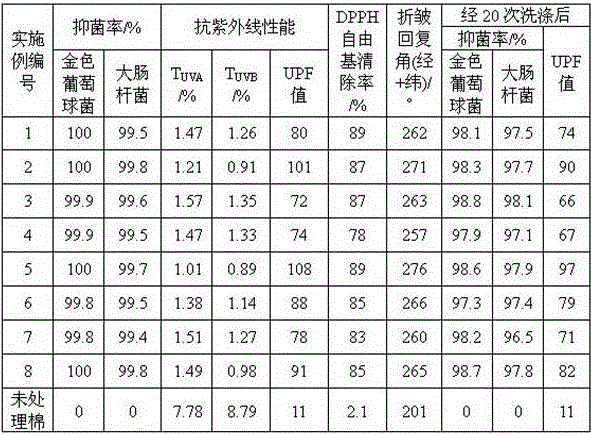

Treatment method for antibacterial and anti-ultraviolet cotton fabrics

ActiveCN106758216AImprove antibacterial propertiesImproves UV resistanceBiochemical fibre treatmentLight resistant fibresGrape seedUltraviolet

The invention discloses a treatment method for antibacterial and anti-ultraviolet cotton fabrics. The treatment method comprises the following steps: step 1, soaking the cotton fabrics with a nonionic surfactant; step 2, modifying the cotton fabrics with chitosan quaternary ammonium salt; step 3, dipping the cotton fabrics with antibacterial finishing liquid prepared by mixing 5-15 parts of a natural antibacterial agent composed of extracts of grape seeds, persimmon leaves, ginkgo leaves and licorice roots, 0.3-1 part of polyoxyethylene-40 hydrogenated castor oil and 1000 parts of water; step 4, soaking the cotton fabrics in a mixed aqueous solution containing 0.001-0.005mol / L of silver nitrate or silver sulfate or silver acetate and 1-3 g / L of soluble starch or hydroxyethyl cellulose to prepare the nano-silver attached antibacterial cotton fabrics. The prepared cotton fabrics not only have good antibacterial performance and anti-ultraviolet performance, but also have performance of resisting oxidation and scavenging free radicals, and have improved anti-wrinkle performance and good washing durability.

Owner:EASTERN LIAONING UNIV

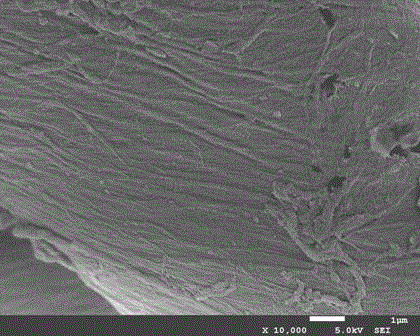

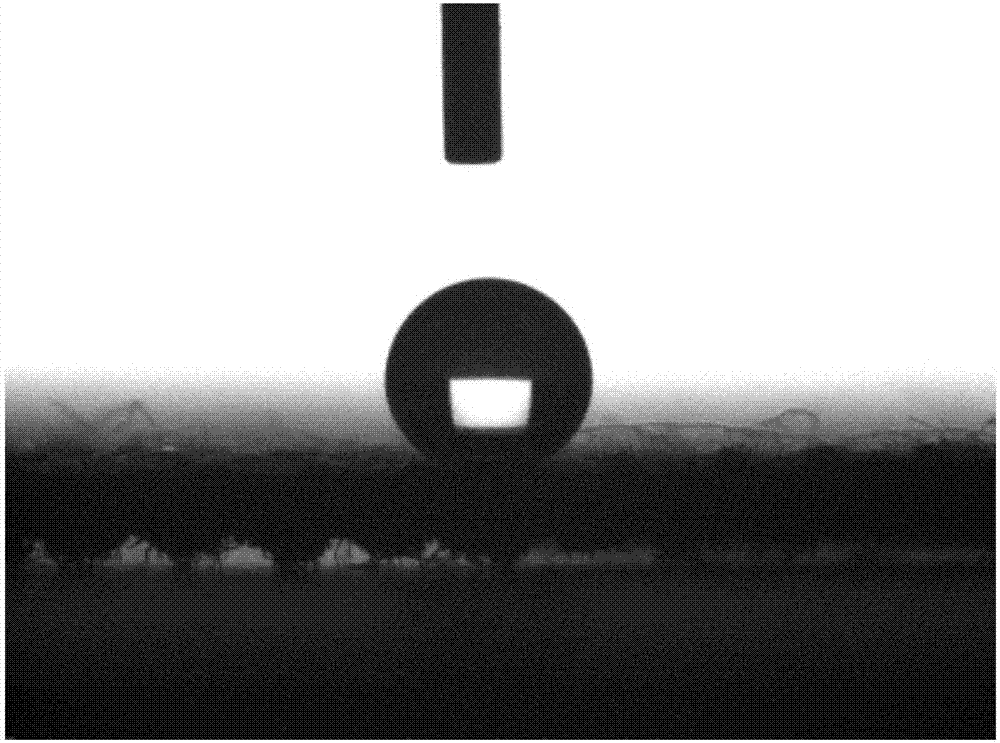

Preparation method of double-self-cleaning fabric with lasting and good photocatalytic self-cleaning and surface super-hydrophobic effects

ActiveCN105671934ASimple processLow costPhysical treatmentBiochemical fibre treatmentHydrophobic effectTitanium dioxide

The invention discloses a preparation method of double-self-cleaning fabric. The method comprises steps as follows: 1, modified nano titanium dioxide is added to water; 2, the fabric is irradiated for treatment; 3, the fabric treated in the step 2 is soaked in a modified nano titanium dioxide water solution prepared in the step 1 and then taken out to be dried, and the self-cleaning fabric is obtained. The preparation method adopts a simple process, the cost is low, and industrial production is easily realized. The fabric prepared with the method has double self-cleaning effects including a photocatalytic self-cleaning effect and super-hydrophobic self-cleaning effect and has lasting photocatalytic activity.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY +1

Preparation method of graphene composite nonwoven cloth

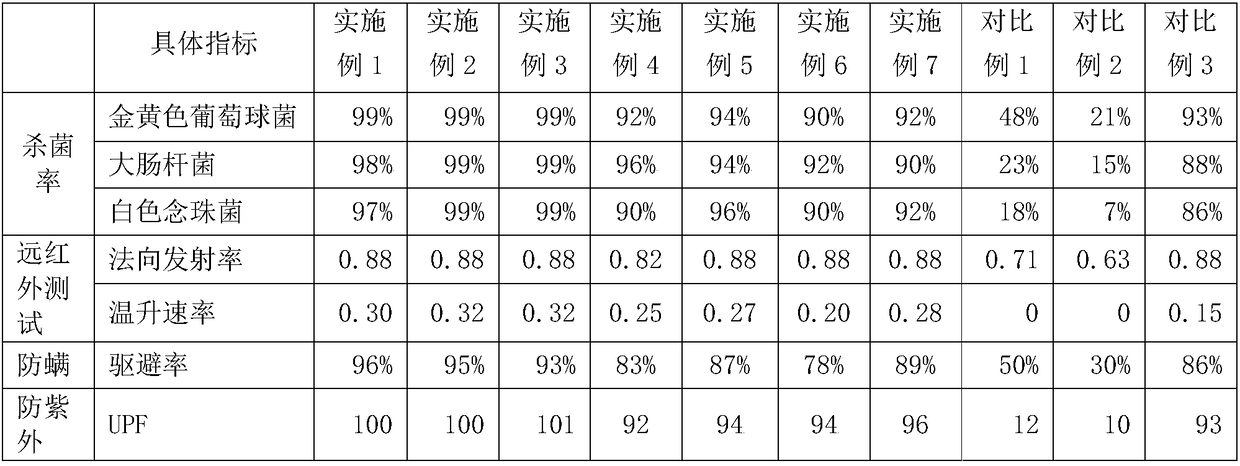

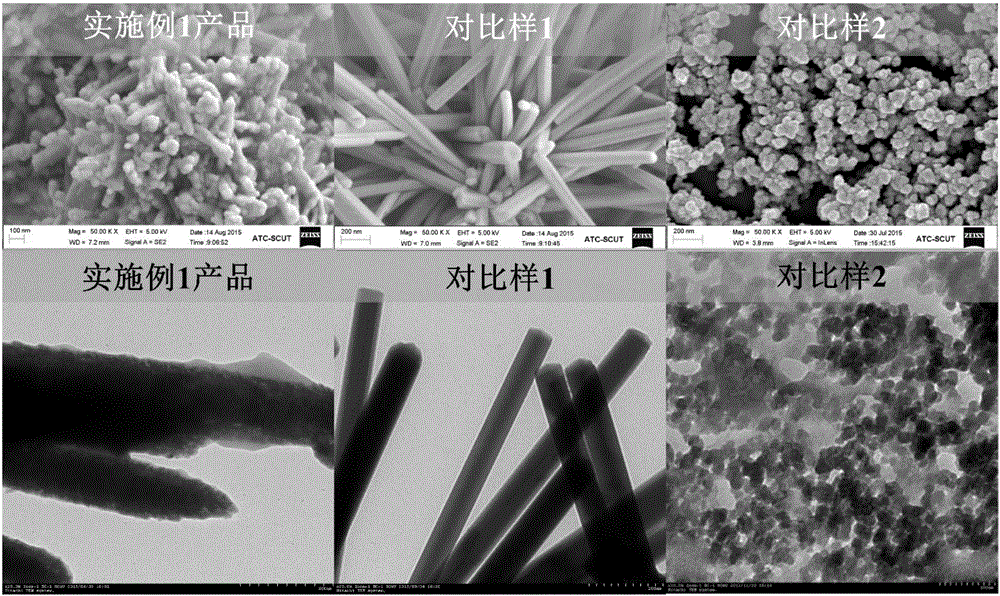

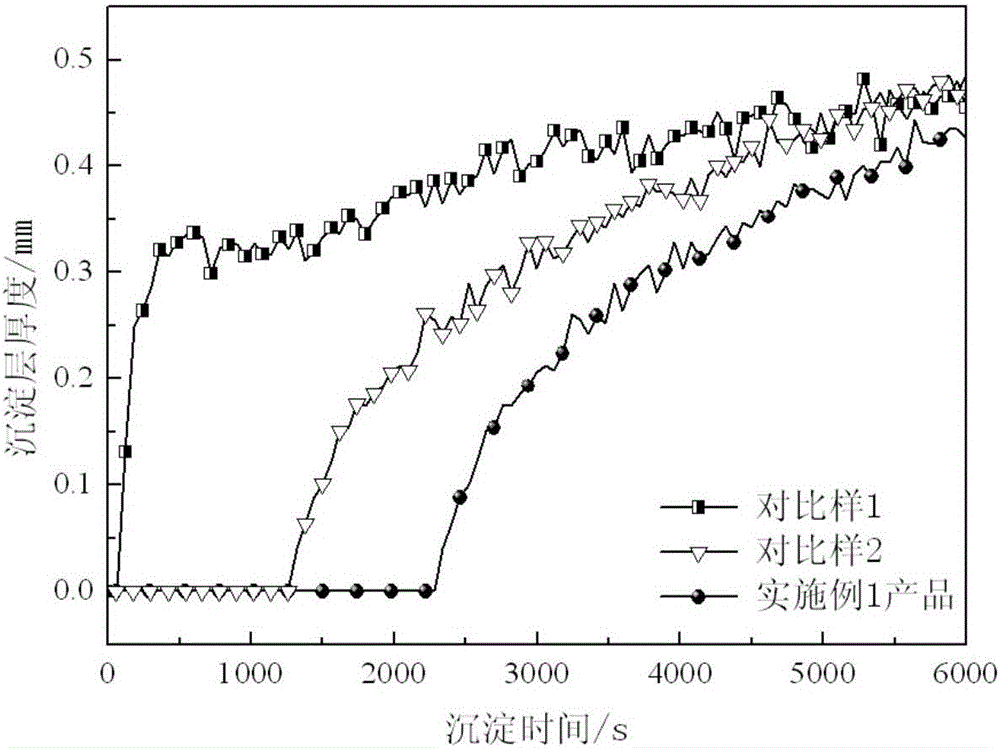

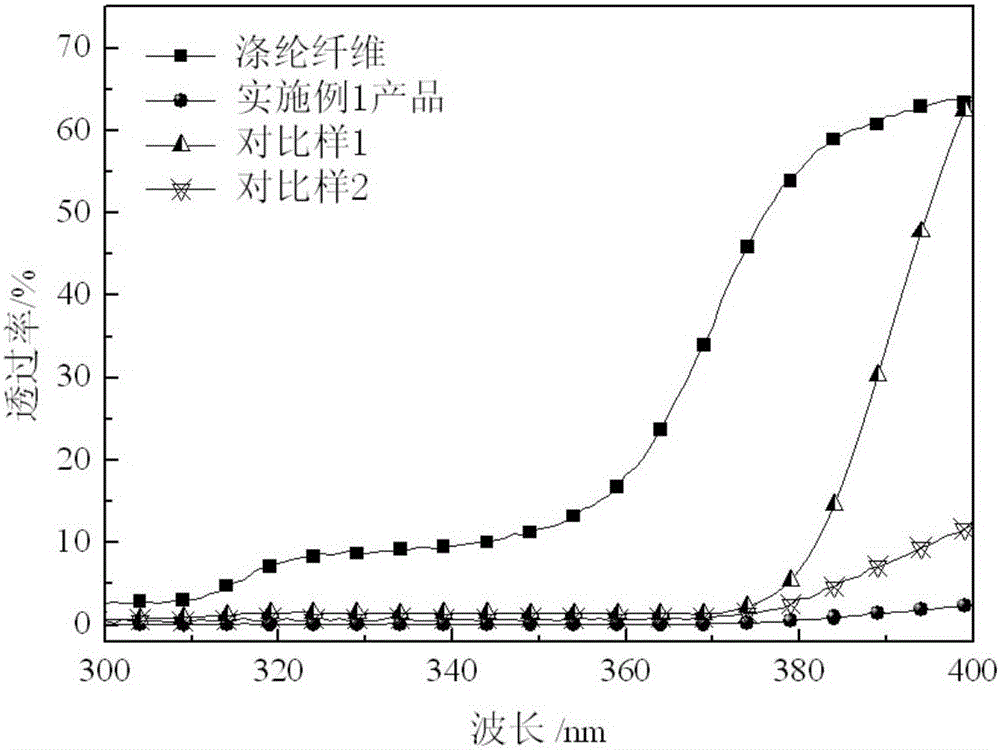

ActiveCN108301201ALong-lasting anti-miteWith far infrared effectBiochemical fibre treatmentLight resistant fibresGrapheneNonwoven fabric

The invention relates to a preparation method of graphene composite nonwoven cloth. The preparation method comprises the following steps: A1, preparing nonwoven cloth from common fiber; A2, mixing a graphene raw material with active carbon, water, an antioxidant, stearate and glue, and uniformly stirring the materials to form spraying liquid; A3, uniformly spraying the spraying liquid formed in Step A2 onto the nonwoven cloth prepared in Step A1, and drying and rolling the nonwoven cloth to prepare the graphene composite nonwoven cloth. The preparation method has the following beneficial effects: 1, the graphene-containing spraying liquid is sprayed onto the common nonwoven cloth, so that the long-acting anti-mite, antibacterial and antiultraviolet graphene composite nonwoven cloth havinga far infrared effect can be obtained; 2, the preparation method disclosed by the invention is simple and efficient, and can be widely applied to industrial production to prepare facial mask cloth, antibacterial costumes, antibacterial underwear, antibacterial socks, gauze masks, bedroom supplies and the like.

Owner:NANTONG QIANGSHENG GRAPHENE TECH CO LTD

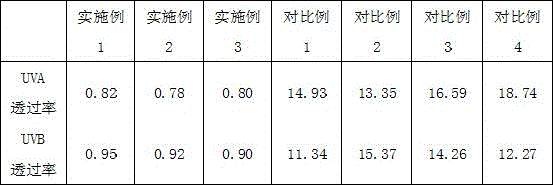

Anti-ultraviolet radiation lignin-based zinc oxide composite particles and preparation method and application thereof

The invention belongs to the technical field of nanocomposites, and discloses anti-ultraviolet radiation lignin-based zinc oxide composite particles for fabric and a preparation method and application in the fabric of the particles. The preparation method comprises the following steps that 1, pH of a lignin sulfonate aqueous solution is adjusted to be alkaline, heating is conducted, an active agent is added for reacting, a carboxylated reagent is added, an isothermal reaction is conducted, and carboxylated lignin sulfonate is obtained; 2, carboxylated lignin sulfonate prepared in the first step is prepared into an aqueous solution, the pH is adjusted to be alkaline, a zinc salt is added for reacting, reacting is conducted by heating, the pH is adjusted to be 9 to 11, reacting is conducted continuously, a cross-linking agent is added for reacting, cooling, ageing, separating and drying are conducted, and the lignin-based zinc oxide composite particles are obtained. According to the composite particles, agglomeration among nano zinc oxide particles is overcome, the particles are dispersed uniformly, adhesion to fabric fibers is improved, effective protection of UVA and UVB full-wave bands is provided, and the problem that the ultraviolet-protection capacity is limited is solved.

Owner:SOUTH CHINA UNIV OF TECH

Ultraviolet-proof polyester-cotton fabric and preparation method thereof

InactiveCN105625032AStrong antibacterial and anti-ultraviolet effectGood hygroscopicityBiochemical fibre treatmentLight resistant fibresWater basedPolyethylene glycol

The invention relates to ultraviolet-proof polyester-cotton fabric and a preparation method thereof. The ultraviolet-proof polyester-cotton fabric is prepared by blending the following raw materials in parts by weight: 60-80 parts of polyester fiber, 40-60 parts of long-staple fiber, 5-15 parts of polyamide fiber, 5-15 parts of linen fiber, 5-15 parts of ramie fiber and 5-15 parts of apocynum fiber, and then treating by using an antibacterial ultraviolet-proof finishing solution, wherein the antibacterial ultraviolet-proof finishing solution contains 5-10 parts of chitosan, 5-10 parts of tea polyphenol, 0.5-3 parts of 2-hydroxy-4-methoxy diphenylketone, 0.5-3 parts of phenyl-o-hydroxybenzoate, 0.5-2 parts of sodium tripolyphosphate, 5-8 parts of myristyl trimethyl ammonium chloride, 5-10 parts of polyethylene glycol, 5-15 parts of nano-titanium dioxide, 3-8 parts of diethanolamide cocoate and 5-10 parts of water-based polyurethane. The ultraviolet-proof polyester-cotton fabric has a super-strong antimicrobial and ultraviolet-proof efficacy, is anti-pilling, breathable, good in moisture absorption, soft, comfortable and durable, and is very suitable for production of various kinds of overclothes, shirts, working clothes, curtains and the like.

Owner:卢洁

Microwave preparation method of smooth type quaternization block organosilicon polymer

The invention provides a microwave preparation method of a smooth type quaternization block organosilicon polymer. The microwave preparation method comprises the following steps of (1) adding allyl epoxy polyether and silicone oil into a reactor, uniformly mixing, radiating by microwaves at the power of 50 to 600W, leading nitrogen, heating to 80 to 100 DEG C, adding a platinum catalyst, and warming for 30 to 60min, so as to obtain terminated epoxy silicone oil; (2) adding the obtained terminated epoxy silicone oil in step (1), polyether amine and an organic solvent into the reactor, uniformlymixing, radiating by microwaves at the power of 50 to 600W, leading nitrogen, heating to 70 to 85 DEG C, and warming for 1 to 5h, so as to obtain a block organosilicon intermediate A; (3) adding an chain extender into the step (2), reacting for 15 to 90min at the temperature of 70 to 85 DEG C, enabling the block organosilicon intermediate A to continue to extend chain, and using glacial acetic acid to adjust the pH (potential of hydrogen) value of the system to neutral property, so as to obtain the smooth type quaternization block organosilicon polymer.

Owner:HT FINE CHEM CO LTD

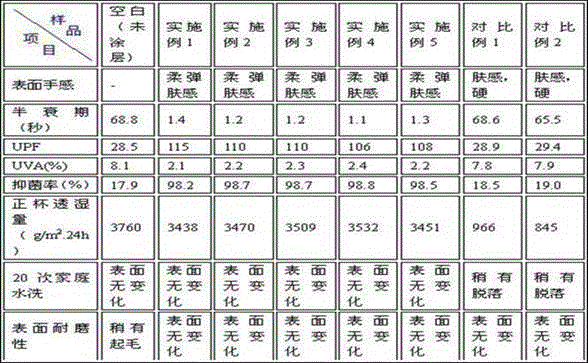

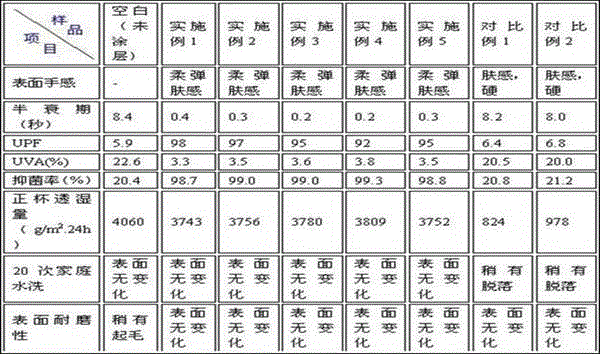

Antistatic, anti-ultraviolet, antibacterial, breathable, skin-touch waterborne polyurethane coating adhesive for textile and preparation method thereof

ActiveCN106436324AGuaranteed antistatic effectGuaranteed UV resistanceBiochemical fibre treatmentLight resistant fibresPolyesterPolymer science

The invention provides an antistatic, anti-ultraviolet, antibacterial, breathable, skin-touch waterborne polyurethane coating adhesive and a preparation method thereof. The coating adhesive is prepared from, by weight, 20-30 parts of deionized water, 0.5-3.0 parts of diisopropyl octadecanalkoxyl acetyl aluminum chelate, 5.0-15 parts of modified hemp lignocellulose powder, 3.0-5.0 parts of polyurethane elastic powder, 50-70 parts of polyurethane adhesive, 0.1-0.3 part of defoaming agent, 1.0-5.0 parts of associative polyurethane thickener, 2.0-5.0 parts of anti-static agent, 5.0-10 parts of organic silicon smooth handfeel agent, 2.0-5.0 parts of organic silicon anti-sticking agent and 1.0-3.0 parts of ultraviolet absorbent in a compounding mode. The coating adhesive is suitable for pure cotton, polyester, chinlon and various blended fabrics and good in wear resistance and washability.

Owner:LIAONING FIXED STAR FINE CHEM

Multifunctional surface treatment for textiles

InactiveUS20040117915A1Without altering appearanceSimple processPhysical treatmentLight resistant fibresOxide matrixChemical Linkage

Owner:THE HONG KONG POLYTECHNIC UNIV

Preparation method of organic silicon-modified polyurethane copolymer fabric softener

InactiveCN106432670AKeep hydrophilicImprove wearing comfortLight resistant fibresLiquid repellent fibresPolyolPrepolymer

The invention discloses a preparation method of an organic silicon-modified polyurethane copolymer fabric softener. The method comprises the following steps: (a) carrying out a stirring reaction on polyether polyol, a hydroxyl-terminated polysiloxane linear body and diisocyanate for 2-3h at the temperature of 75-85 DEG C under the action of a tin catalyst, so as to obtain an isocyanate-terminated organic silicone-modified polyurethane prepolymer; (b) adding a small molecular amine chain extender into the organic silicone-modified polyurethane prepolymer, and carrying out a stirring reaction for 1-2h at the temperature of 50-60 DEG C, so as to obtain an organic silicon-modified polyurethane copolymer; (c) evenly mixing the organic silicon-modified polyurethane copolymer obtained in the step (b) with an emulsifying agent at the temperature of 50-70 DEG C, and slowly adding deionized water into the mixture for emulsifying, so as to obtain the organic silicon-modified polyurethane copolymer fabric softener. The softener prepared by the method is good in stability, endows fabric with excellent softnesss, smoothness and hydrophilic property, has excellent yellowing resistance, and can maintain the brightness of the light-colored fabrics and the whiteness of the white fabrics.

Owner:ZIBO LURUI FINE CHEM CO LTD

Preparation method of graphene composite electrically conductive fiber textile

InactiveCN108085966AReduce dosageSimple production processLight resistant fibresVegetal fibresTextile fiberSilanes

The invention relates to a preparation method of a graphene composite electrically conductive fiber textile, wherein the preparation method includes the steps: carrying out surface modification of textile fibers; soaking the textile fibers in a silane coupling agent KH560 solution with a concentration of 1%-30% for 2-3 hours, placing in a 50-65 DEG C oven, drying, and thus preparing surfactant-modified textile fibers; reducing graphene oxide; impregnating the modified textile fibers into an aqueous solution containing graphene oxide or derivatives thereof and having the pH of 2-6; preparing agraphene dispersion system; by a chemical reduction method, preparing graphene from a graphene oxide aqueous solution prepared by a Hummer's method, under the action of a dispersant, preparing uniformand stable graphene dispersion system, and preparing graphene composite fibers; and soaking the textile fibers in the graphene dispersion system for 2-3 hours, and placing in a 50-65 DEG C oven, anddrying, to obtain the graphene composite electrically conductive fibers. The preparation method has the advantages of simple production process, easy operation, high output and less amount of graphene.

Owner:HENAN XINYE TEXTILE

Energy-absorbing textile material

ActiveUS20120286177A1Improve energy absorptionPromote absorptionChemical protectionHeat protectionArc flashEnergy absorption

A textile material exhibiting enhanced energy absorption (e.g., enhanced near-infrared energy absorption) and, optionally, flame resistance. The textile material comprises a textile substrate and a finish disposed on at least one surface of the textile substrate. The finish comprises a binder and an energy-absorbing agent. A method for protecting an individual from infrared radiation that can be generated during an arc flash comprises the step of positioning a textile material between an individual and an apparatus capable of producing an arc flash.

Owner:MILLIKEN & CO

Fabric having ultraviolet radiation protection

ActiveUS8690964B2Improve protectionComfortable to wearOrganic detergent compounding agentsPhysical treatmentZincPolymer

A method for treating a fabric for protection from ultraviolet radiation is disclosed which comprises the steps of dispensing a suspension of zinc oxide particles treated with an acid polymer into a washing machine during a time in which a fabric is being washed in the washing machine and mixing the treated zinc oxide particles and the fabric for the treated zinc oxide particles to bind to the fabric. Other methods for treating a fabric for protection from ultraviolet radiation are also disclosed.

Owner:THE SWEET LIVING GROUP

Complexes of ultraviolet absorbers and quaternary ammonium compounds which are substantially free from unwanted salts

InactiveUS6046330AUneven solubilityPoor coatingBiocideOrganic detergent compounding agentsInorganic saltsAmmonium compounds

This invention relates to complexes of ultraviolet absorbers with quaternary ammonium compounds which are substantially free from unwanted salts. Such complexes are formed through ionic bonds formed between the two compounds. The inventive complexes are then removed of substantially all excess inorganic salt so as to obtain an UV absorber compound which exhibits improved light- and washfastness properties, which easily coats subject surfaces, which provides excellent non-fogging and non-cracking characteristics, and which also possesses anti-static, anti-microbial, and anti-abrasion properties. This invention also concerns methods of making and utilizing such inventive ultraviolet absorbing complexes.

Owner:MILLIKEN & CO

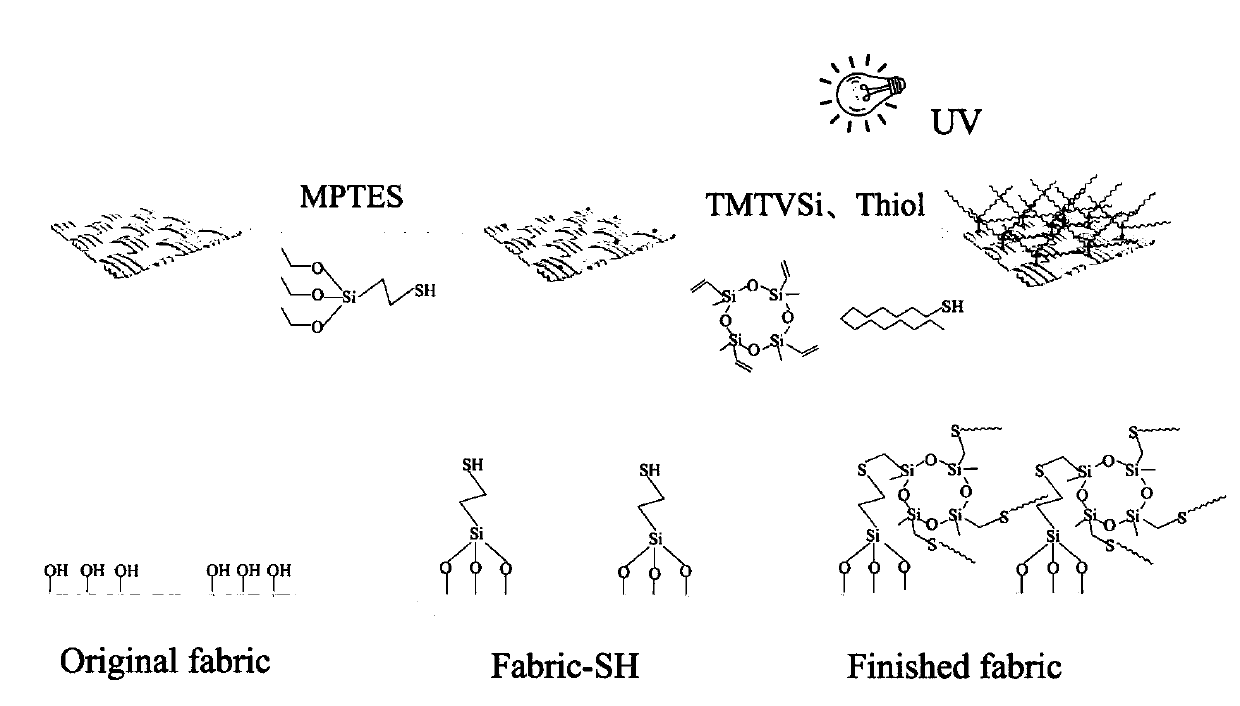

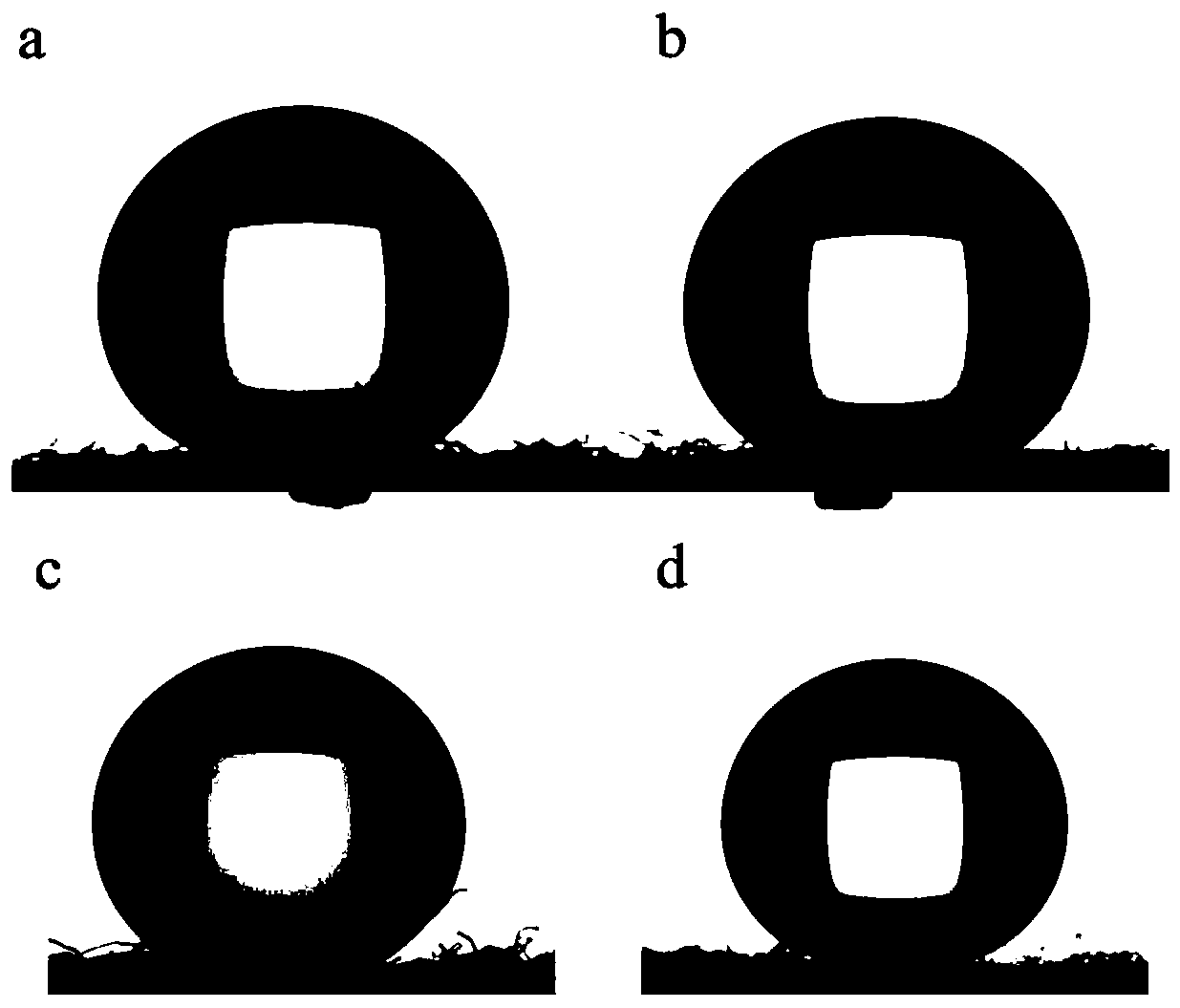

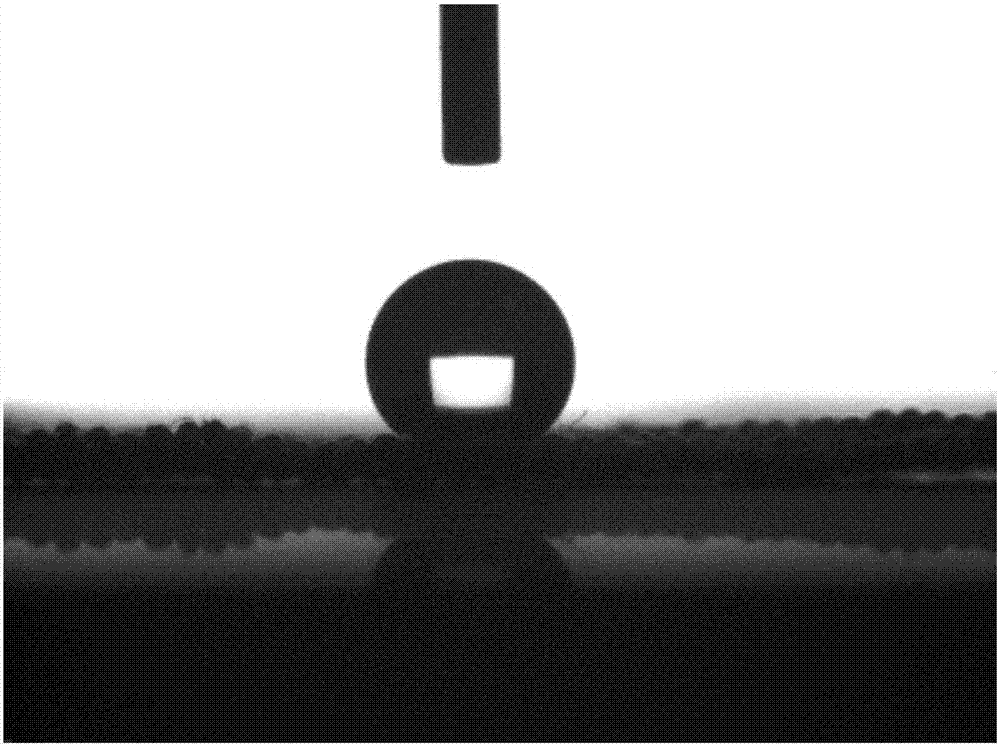

Method for preparing superhydrophobic cotton textile by thiol-ene click chemistry modification

ActiveCN111188183AImprove hydrophobicityLower surface energyPhysical treatmentLight resistant fibresFiberPolymer science

The invention discloses a method for preparing a superhydrophobic cotton textile by thiol-ene click chemistry modification. The method comprises the following steps of Step 1, pretreating cotton fabrics so that thiol groups are introduced to the fiber surfaces; Step 2, grafting thiol silane onto the surfaces of the pretreated cotton fabrics; and Step 3, soaking the cotton fabrics grafted with thethiol silane into a mixed solution prepared from ethyl acetate, 2,4,6,8-Tetravinyl-2,4,6,8-tetramethylcyclotetrasiloxane, octadecanethiol and benzoin dimethyl ether to take a reaction through UV irradiation, and after the reaction is completed, performing cleaning and drying to obtain the superhydrophobic cotton textile. The invention also discloses the superhydrophobic cotton textile prepared bythe method. The superhydrophobic cotton textile prepared by the method provided by the invention has the advantages that hydrophobic substances are grafted onto the surfaces of the fabrics in a chemical bond form; and the performance of resisting acid, alkali, water washing, friction, UV irradiation and the like of the superhydrophobic textiles can be improved.

Owner:NANTONG TEXTILE & SILK IND TECH RES INST +1

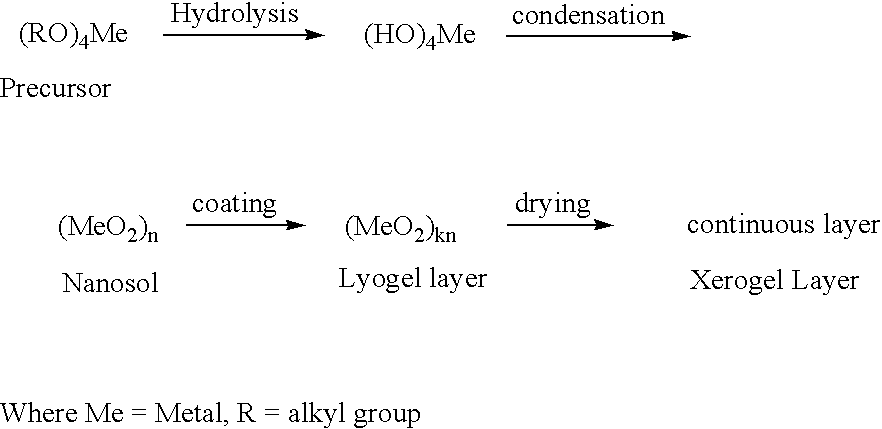

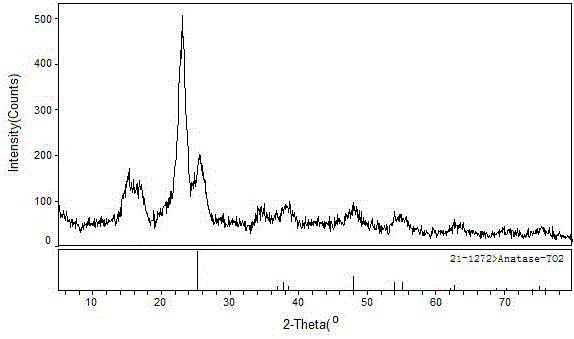

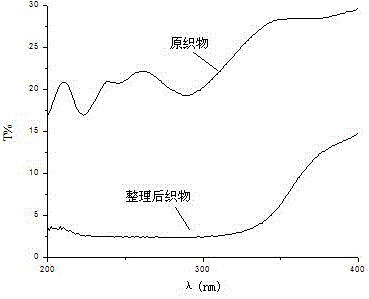

Arranging method for loading nanometer titanium dioxide on textiles

ActiveCN105696308AGood dispersionImprove bindingLight resistant fibresVegetal fibresWater bathsUltraviolet

The invention discloses an arranging method for loading anatase type nanometer titanium dioxide on textiles. The arranged textiles have a photocatalytic self-cleaning function and an ultraviolet resisting function. The method specifically includes the following process steps and conditions of firstly, conducting textile pretreatment, wherein the textiles are boiled to remove impurities and auxiliaries and then sufficiently dried for standby application; secondly, preparing working liquid, wherein titanate type precursors and alcohol solvent are rapidly stirred and evenly mixed to prepare the working liquid; thirdly, soaking the dry textiles obtained in the first step in the working liquid obtained in the second step, or spraying the working liquid obtained in the second step on the single faces or double faces of the dry textiles obtained in the first step; fourthly, putting the textiles in the third step in a water bath to be subjected to water heating or steaming, and taking out the textiles to be washed and dried. The arranging method is simple in process, little in medicine consumption, and capable of saving time and energy, the arranged textiles have photocatalytic performance and excellent ultraviolet resistance under ultraviolet and visible light, and loaded nanometer titanium dioxide and textiles have good combining firmness.

Owner:SICHUAN UNIV

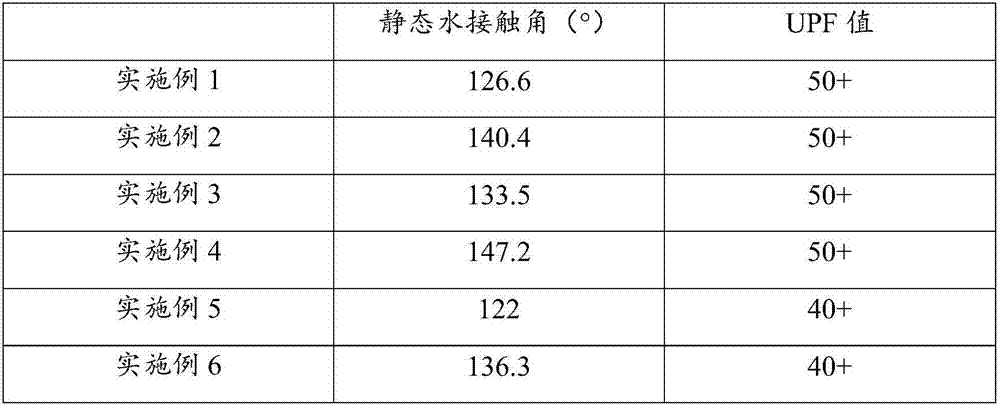

Hydrophobic anti-ultraviolet fabric and preparation method thereof

ActiveCN107503120AThe method is simple and flexibleSuitable for mass productionLight resistant fibresLiquid repellent fibresHigh volume manufacturingUltraviolet

The invention discloses a hydrophobic anti-ultraviolet fabric and a preparation method thereof. A base material of the fabric has a hydrophilic surface, and the fabric is loaded with graphene oxide and aminopropyl isobutyl silsesquioxane. In the preparation method disclosed by the invention, the graphene oxide and the aminopropyl isobutyl silsesquioxane are jointly used for preparing a functional fabric for the first time, thereby endowing the hydrophilic base material of the fabric with hydrophobic and anti-ultraviolet properties, and improving the application value of the fabric; and preparation method disclosed by the invention only adopts a two-step finishing process to obtain a fluorine-free hydrophobic fabric with excellent performance. The preparation method is easy and flexible, green and environmentally friendly, and suitable for mass production.

Owner:江苏华佳控股集团有限公司 +1

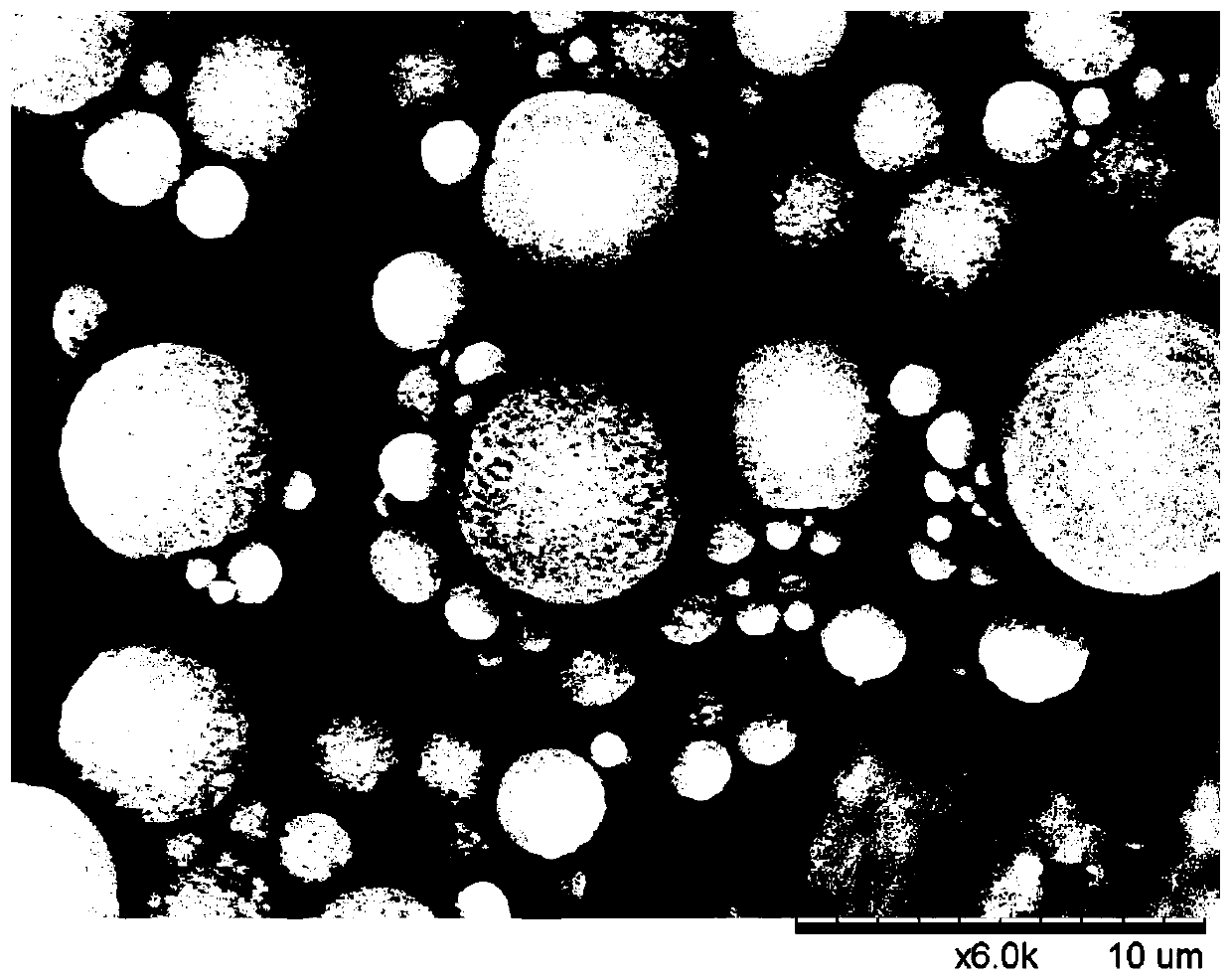

Microcapsule with integrated ultraviolet shielding function and preparation method thereof

ActiveCN110983791AGood anti-ultraviolet effectStrong UV Absorbing PropertiesLight resistant fibresVegetal fibresUv absorbanceUltraviolet

The invention relates to a microcapsule with an integrated ultraviolet shielding function and a preparation method thereof. The microcapsule is composed of an anti-ultraviolet capsule wall, an anti-ultraviolet emulsifier and an anti-ultraviolet capsule core. Compared with a microcapsule with an ultraviolet absorption material added in a capsule core only in the prior art, the capsule wall, the capsule core and the selected and used emulsifier in the prepared microcapsule have the anti-ultraviolet functions, so that the microcapsule has the more excellent anti-ultraviolet performance.

Owner:上海驰纺材料科技有限公司

Novel textile downproof technology

InactiveCN105821670AIncrease productivityGood fleeceLight resistant fibresLiquid repellent fibresAdhesiveEngineering

Disclosed is a novel textile downproof technology .The novel textile downproof technology comprises the following steps of 1, selecting a fabric, wherein the fabric is a plain weave fabric woven by nylon full-stretching silk, the yarn count is 20 D-40 D, and the density is 290 Tex-400 Tex; 2, performing water-repellency arrangement on the fabric, wherein the grade of getting wet is not smaller then 3; 3, performing calendering on the fabric obtained after water-repellency arrangement through a calender, wherein the pressure is 9-11 MPa, the temperature is 100-110 DEG C, and the speed is 30-40 m / min; 4, preparing a coating adhesive .The downproof effect is achieved through the good combination of a base fabric and the coating adhesive, particularly, the downproof effect at a sewing needle hole is achieved, meanwhile, the selected and prepared coating adhesive can ensure comprehensive indicators of downproofness, cold resistance, moisture penetrability, washing fastness, flexibility and the like of the fabric with the low weight increment, and the wearing comfort of the fabric is better on the premise of achieving functionality .

Owner:JIANGSU DONGBANG TECH

Hygroscopic breathable anti-static polyester filament yarn with cool feeling, and preparation method thereof

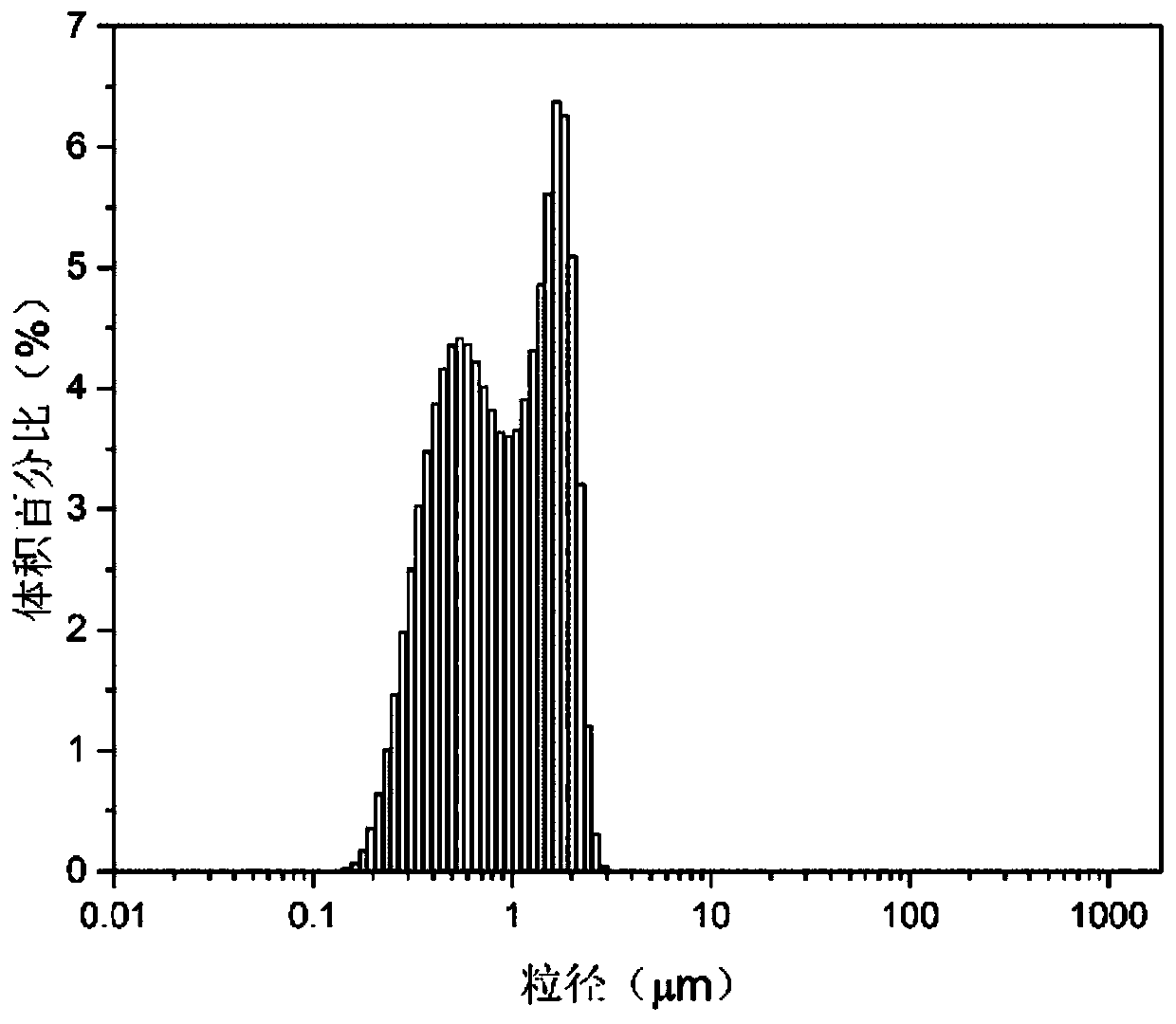

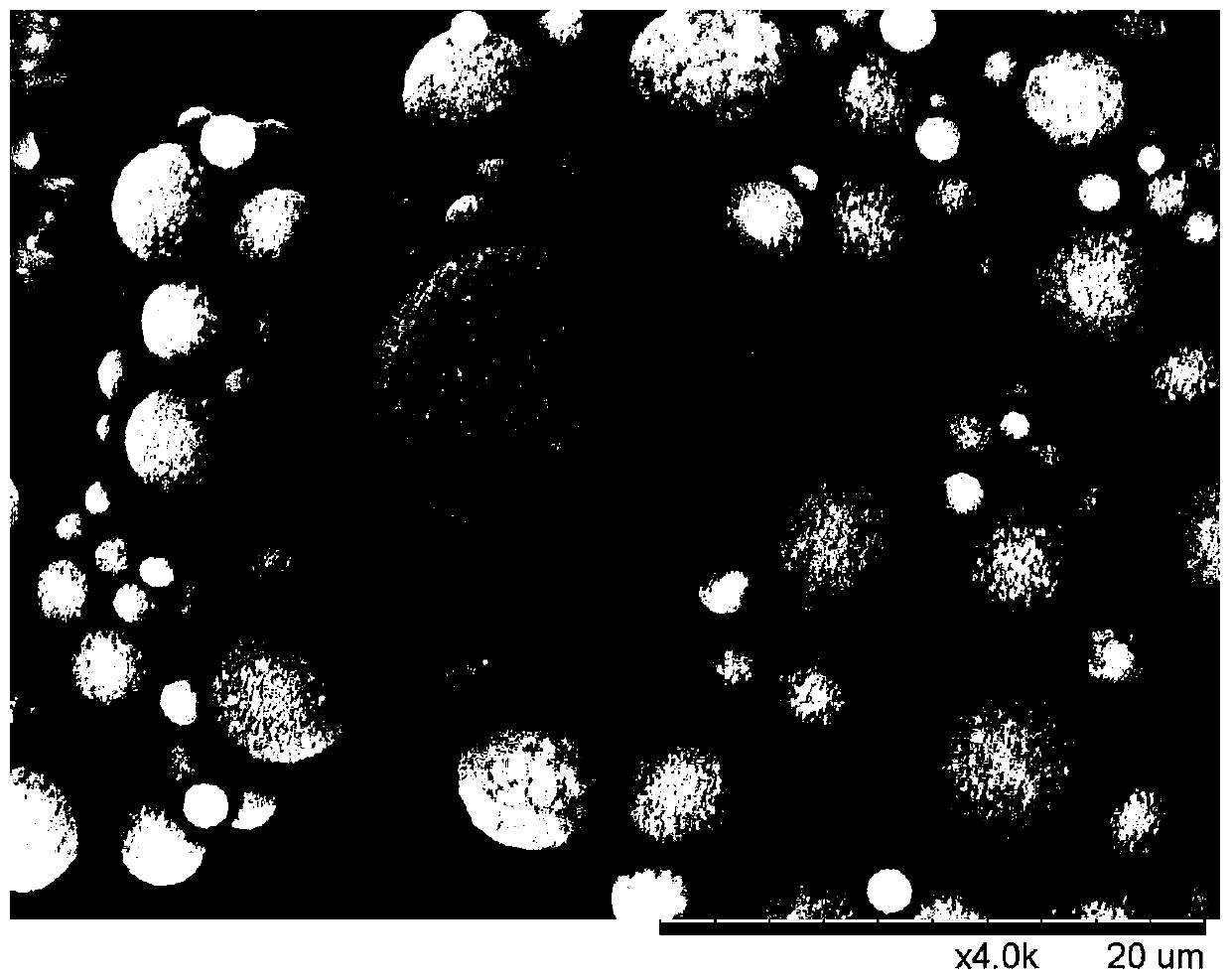

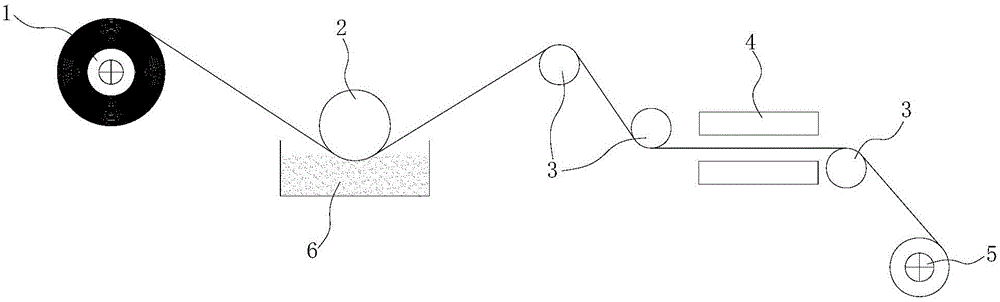

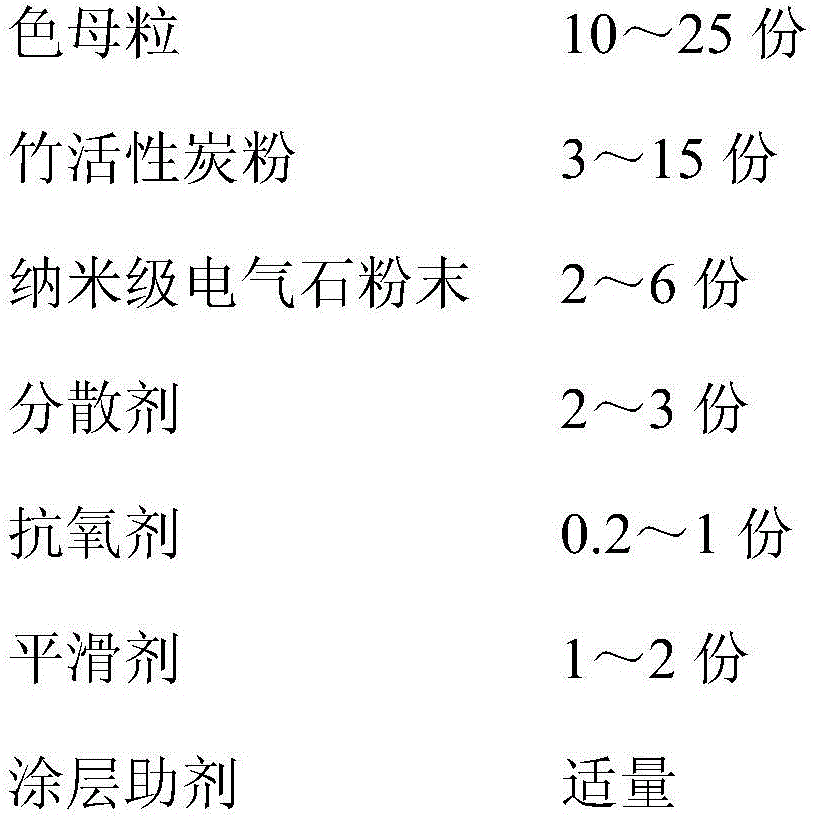

ActiveCN106400158AProtectiveHigh tensile strengthElectroconductive/antistatic filament manufactureLight resistant fibresActivated carbonUltraviolet

The invention belongs to the technical field of polyester fiber, and discloses hygroscopic breathable anti-static polyester filament yarn with cool feeling. The hygroscopic breathable anti-static polyester filament yarn with cool feeling is prepared from, by mass, 100 parts of polyester chip, 10 to 25 parts of a color master batch, 3 to 15 parts of bamboo activated carbon powder, 2 to 6 parts of nanoscale tourmaline powder, 2 to 3 parts of a dispersing agent, 0.2 to 1 part of an antioxidant, 1 to 2 parts of a smoothing agent, and an appropriate amount of a coating additive. The invention also provides a preparation method of the hygroscopic breathable anti-static polyester filament yarn with cool feeling. The preparation method comprises following steps: raw material preparation; POY preparation; POY examination; preparation of DTY via elasticizing; DTY examination; coating of an anti-static layer with cooling feeling; and examination and packaging. The preparation method is capable of providing polyester filament yarn with moisture absorption performance, mildew resistance, air purifying functions, antibacterial activity, disinsection effect, cooling feeling, skin refreshing capacity, and anti-static functions, and UV resistance and protection effect, and is capable of increasing tensile strength and elongation at break of polyester filament yarn, and prolonging service life of polyester filament yarn.

Owner:嘉兴桃原化纤股份有限公司

Fabric having ultraviolet radiation protection

ActiveUS20140342970A1Improve protectionComfortable to wearInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsZincPolymer

A method for treating a fabric for protection from ultraviolet radiation is disclosed which comprises the steps of dispensing a suspension of zinc oxide particles treated with an acid polymer into a washing machine during a time in which a fabric is being washed in the washing machine and mixing the treated zinc oxide particles and the fabric for the treated zinc oxide particles to bind to the fabric. Other methods for treating a fabric for protection from ultraviolet radiation are also disclosed.

Owner:THE SWEET LIVING GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com