Patents

Literature

156results about How to "Keep hydrophilic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Micromesohole silicon dioxide heterocompound and its preparation method and use

InactiveCN1459474AHas antibacterial functionWide range of usesBiocideInorganic pigment treatmentSilica particleActive component

An antibacterial composition for paint, ceramics, rubber, plastics, etc. is composed of microporous or mesoporous SiO2 particles as carrier and silver phosphate and / or TiO2 as active components which are compounded on the surface of the said SiO2 particle. Its advantages are high antibacterial effect, high hydrophilicity and low cost.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Waterborne polyurethane emulsion and preparation method thereof

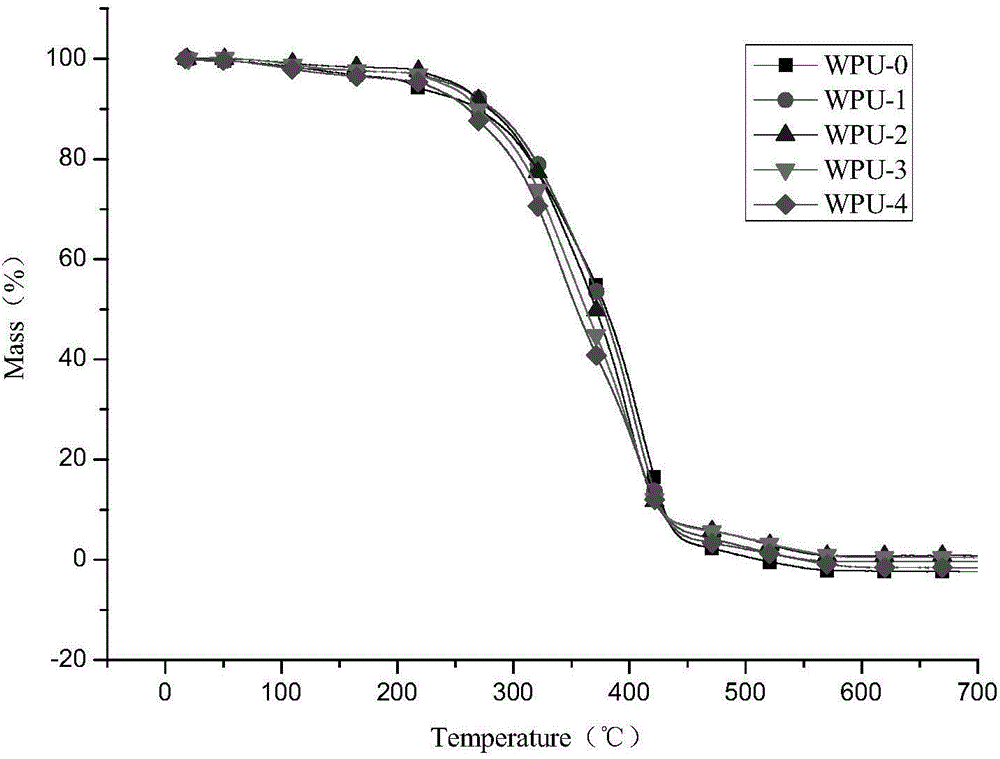

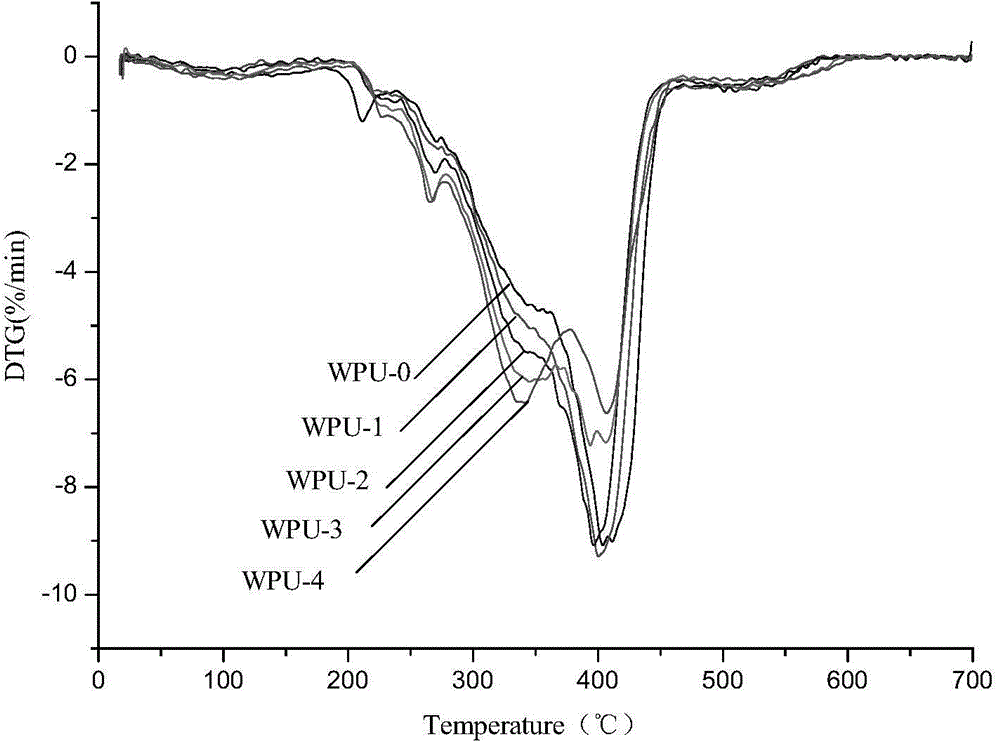

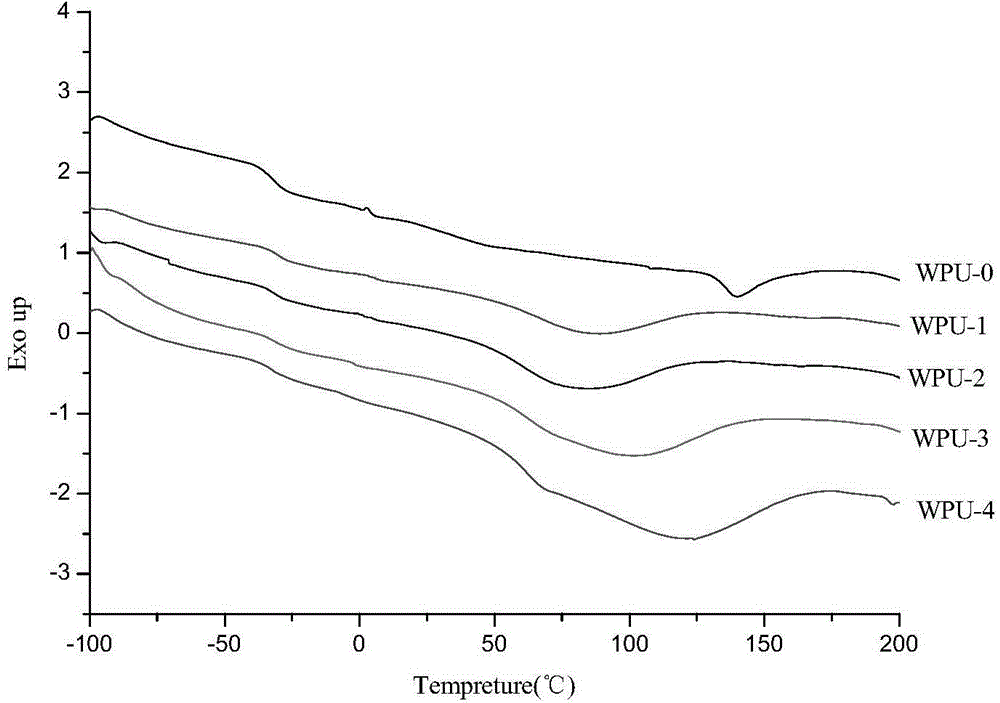

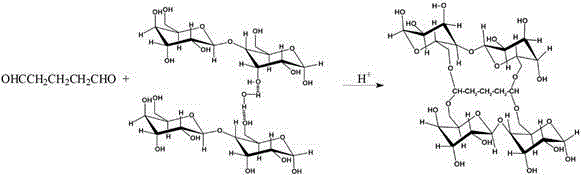

InactiveCN104974327AImprove performanceKeep hydrophilicPolyurea/polyurethane coatingsLeather surface finishingPolymer scienceEmulsion

The invention discloses a waterborne polyurethane emulsion and a preparation method thereof. The preparation method comprises the following steps: firstly carrying out vacuum dehydration on polymer polyol, a hydrophilic chain extender, isosorbide and N-methyl pyrrolidone at 90 DEG C for 1-2 hours, reducing the temperature to 80-90 DEG C, adding diisocyanate and reacting for 2.5-3 hours until NCO% reaches the theoretical value; then reducing the temperature, adding a neutralizer to an NCO-terminated polyurethane prepolymer and reacting at 60 DEG C for 0.5 hour until the neutralization degree is 95-100%; finally dispersing the polyurethane prepolymer containing isosorbide into deionized water under the high-speed shearing action of an agitator and dropwise adding a mixture of diamine and water after dispersing for a period of time, thus obtaining the waterborne polyurethane emulsion. Isosorbide is successfully introduced into the waterborne polyurethane emulsion, thus obviously improving the glossiness of waterborne polyurethane films.

Owner:JINCHUANGJING NEW MATERIAL TECH SHANGHAI

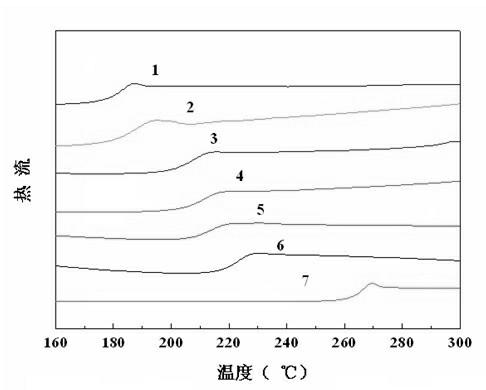

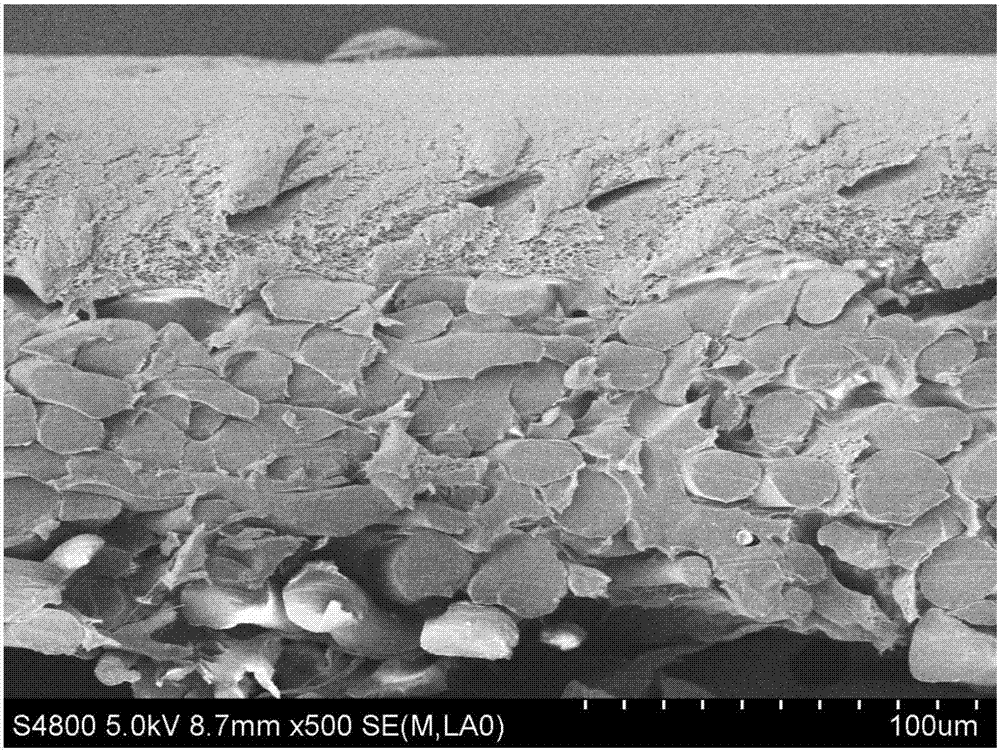

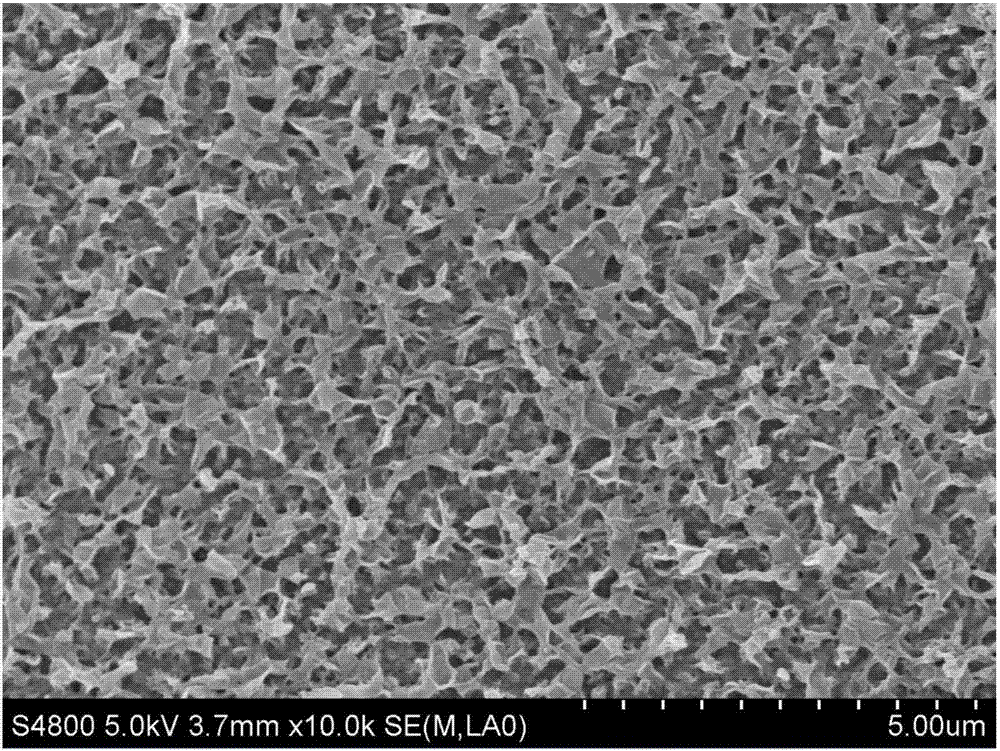

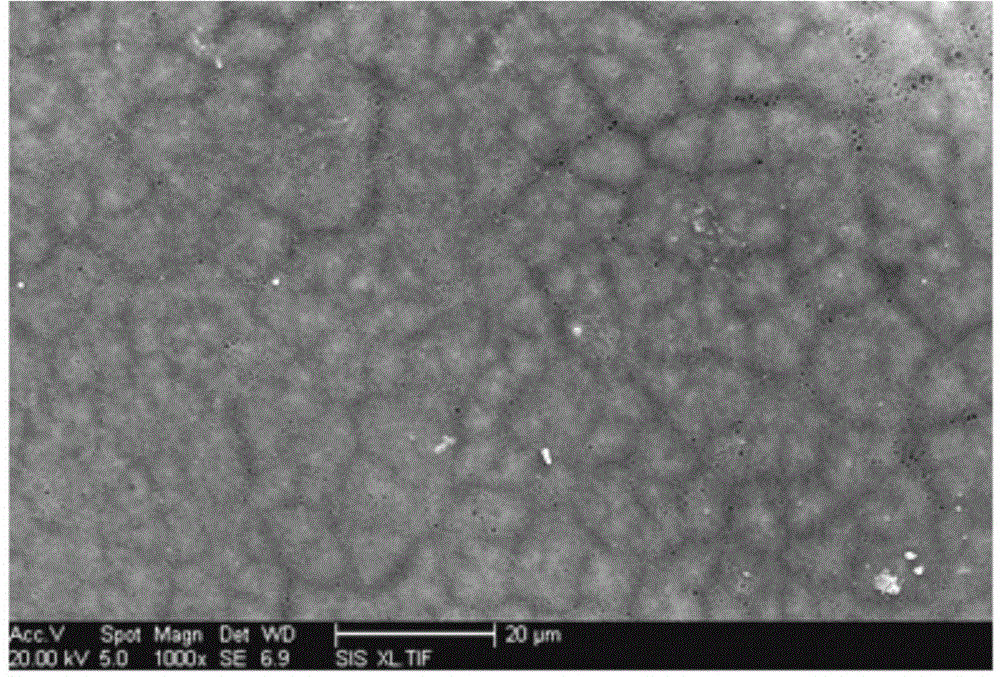

Preparation method of hydrophilic PTFE (polytetrafluoroethylene) composite microporous membrane

ActiveCN104353370AImprove hydrophilicityImprove adsorption stabilitySemi-permeable membranesPolymer scienceOrganic chemistry

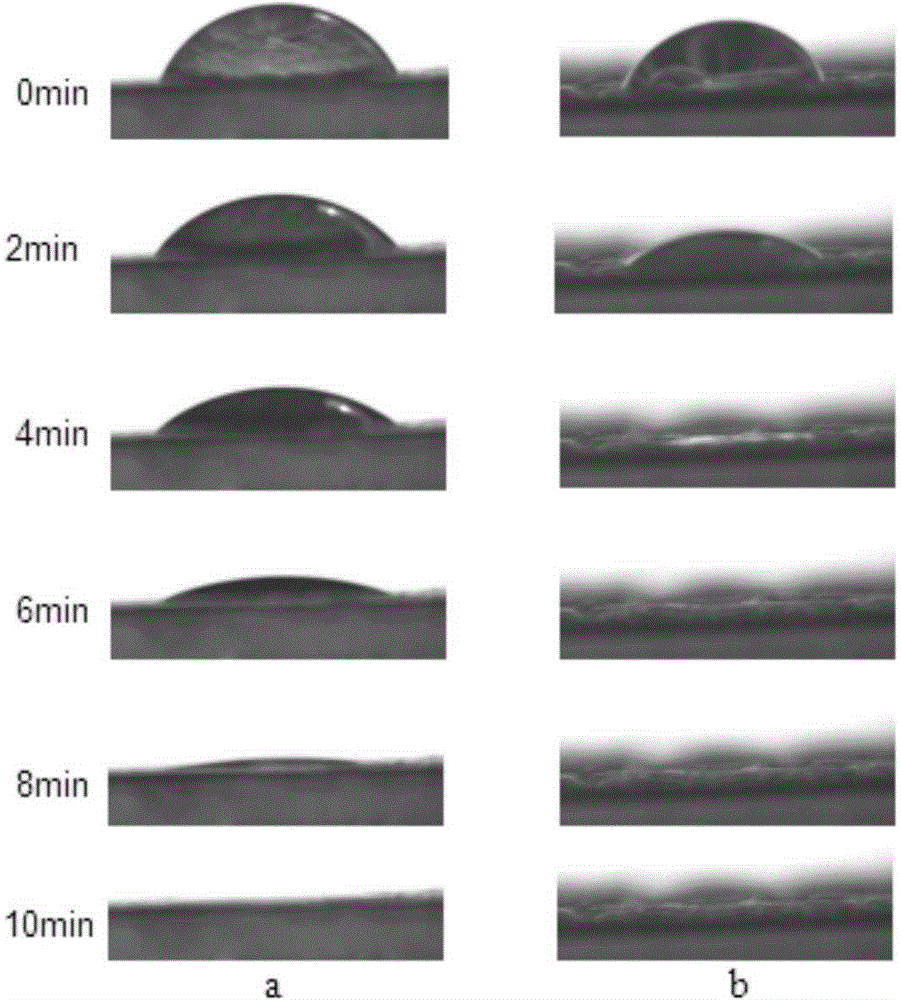

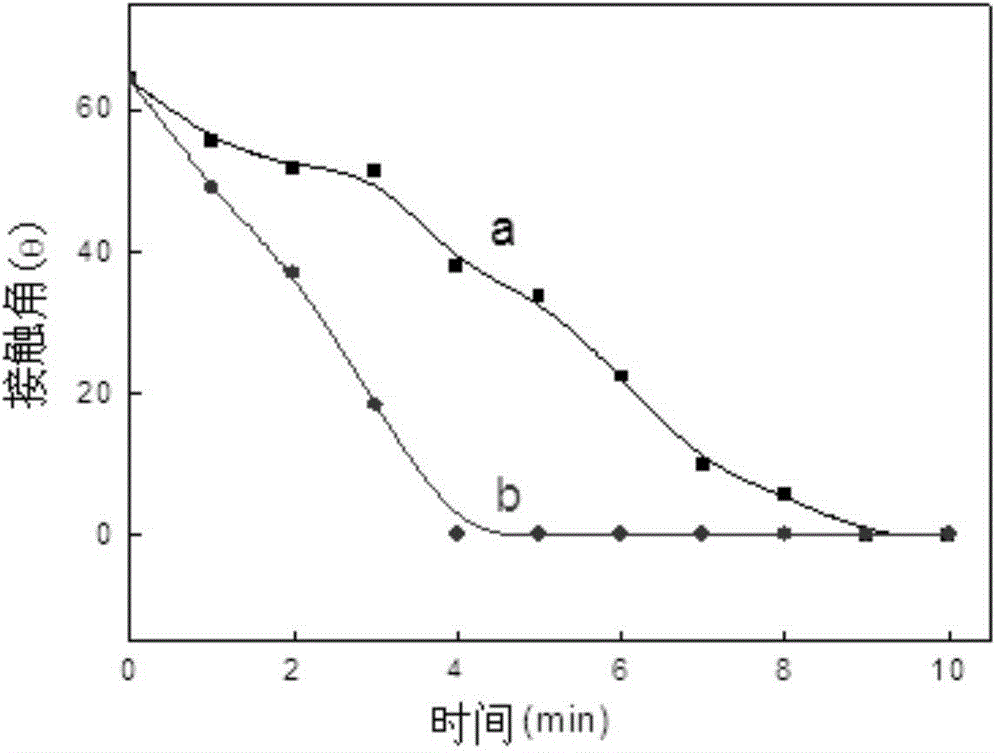

The invention relates to a preparation method of a hydrophilic PTFE (polytetrafluoroethylene) composite microporous membrane. The preparation method comprises the following steps: 1, adding inorganic nano particles in the formula of a PTFE raw material, uniformly mixing and stretching to obtain a PTFE composite microporous membrane; 2, adding a polyhydroxy compound and a couping agent to water to prepare a modified water solution, soaking the PTFE composite microporous membrane obtained in the step 1 until the membrane is transparent, then dipping into the modified water solution, taking out and drying; and 3, dipping the dried PTFE composite microporous membrane in a pentanedial solution, and after taking out, washing and drying to obtain the hydrophilic PTFE composite microporous membrane. The preparation method has the advantages that after the PTFE composite microporous membrane is treated by the modifying method, the hydrophilic property of the membrane is remarkably improved; persistence of the hydrophilic property is obviously improved while the hydrophilic property is ensured; the preparation process is easy and feasible, is low in cost and is suitable for industrial production.

Owner:中材科技膜材料(山东)有限公司

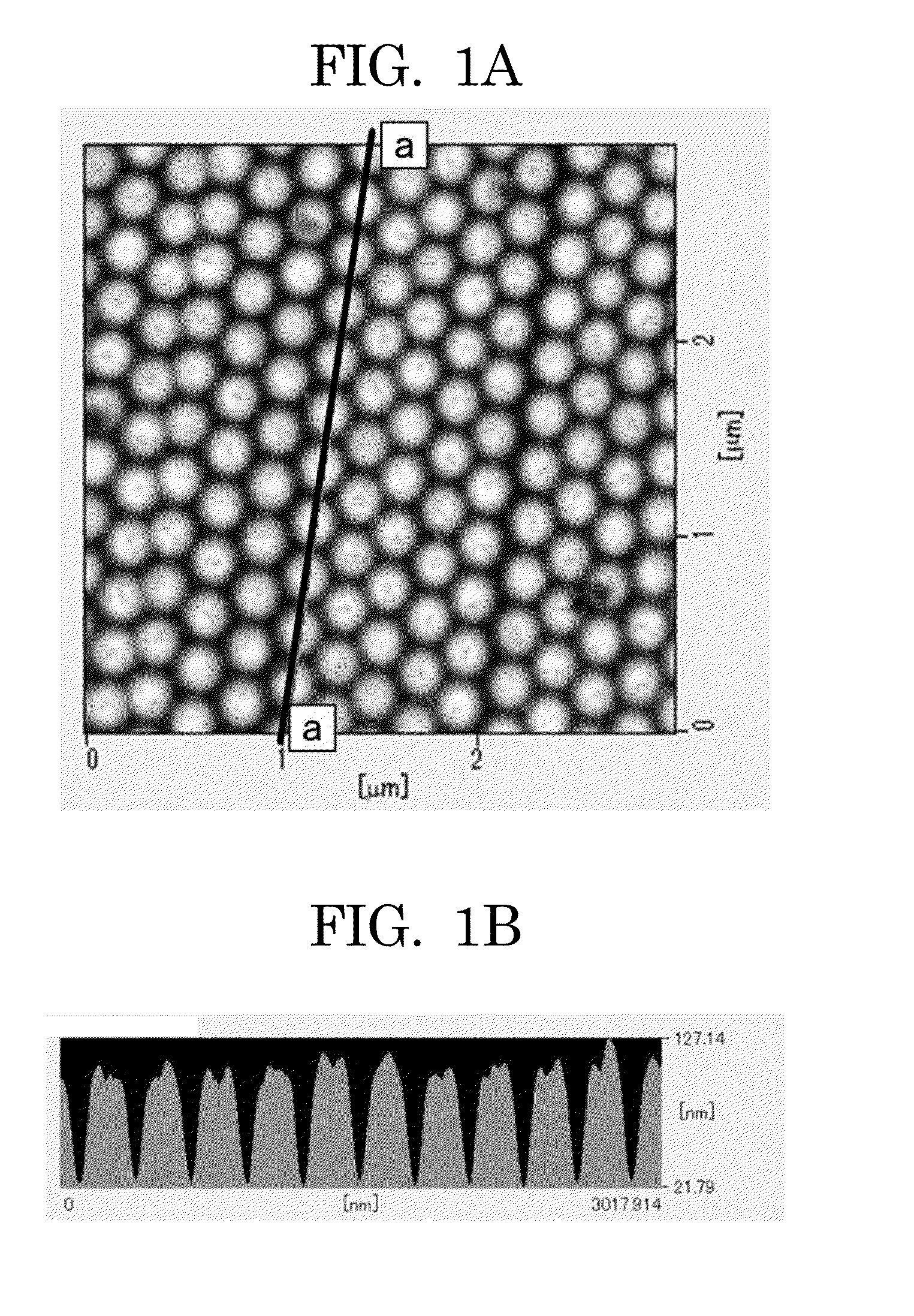

Hydrophilic polyethene microporous membrane and preparation method thereof

The invention provides a hydrophilic polyethene microporous membrane and a preparation method thereof, belonging to a polyethene microporous membrane containing blending compatilizer with a polar group, calcium carbonate and thinner and a preparation method thereof. In the preparation method of the microporous membrane, polyethene, blending compatilizer, calcium carbonate and thinner are taken as raw materials; and hydrophilic polyethene microporous membrane is finally prepared by blending processing, membrane pressing by a flat bed presser, quenching by water bath in constant temperature, extracting by extracting agent, acid cleaning, washing and drying. The invention is characterized in that the blended compatilizer with a polar group is selected to react with the calcium carbonate particles, calcium carbonate particles are evenly filled into polyurethane base body through blending processing; and porous structures are formed by the thermal induced phase separation method and the method for removing fillings by acid cleaning. As for the hydrophilic polyethene microporous membrane prepared by the method, the range of the internal average aperture is 0.1-10mu m, the aperture rate is greater than 50% and the contact angle is less than 80 degrees.

Owner:PETROCHINA CO LTD

Multifunctional softener and preparation method for same

ActiveCN103321053AImprove biological activityPromote degradationFibre treatmentWater soluble chitosanAqueous solubility

The invention provides a multifunctional softener and a preparation method for the same. The multifunctional softener is composed of amino silicon oil, a compound emulsifier, water-soluble chitosan and water, wherein amino silicon oil is added in the compound emulsifier, and the mass ratio of the amino silicon oil to the compound emulsifier is 1:(0.2-0.8); then the water-soluble chitosan is added, and the added amount is 1-8% of the mass of the mixed solution of the amino silicon oil and the compound emulsifier; finally, water is added, and the mass of water is 10-50% of the total mass of the mixed solution aforementioned. The preparation method comprises the following steps of: preparation for the water-soluble chitosan, preparation for the compound emulsifier, and preparation for the multifunctional fabric softener. The multifunctional integrated softener obtained after compounding has all the excellent characteristics of modified chitosan on the basis of a soft function. Compared with the existing softener with an anti-bacterial function, the preparation process flow is simple, a complex configuration process is not required, and industrialized production is easy to realize.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

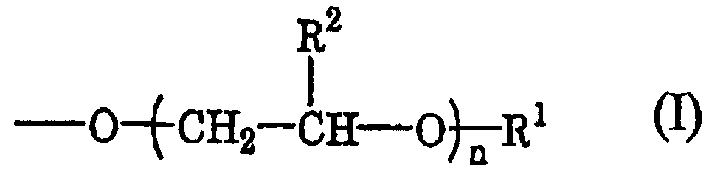

Preparation method of organic silicon-modified polyurethane copolymer fabric softener

InactiveCN106432670AKeep hydrophilicImprove wearing comfortLight resistant fibresLiquid repellent fibresPolyolPrepolymer

The invention discloses a preparation method of an organic silicon-modified polyurethane copolymer fabric softener. The method comprises the following steps: (a) carrying out a stirring reaction on polyether polyol, a hydroxyl-terminated polysiloxane linear body and diisocyanate for 2-3h at the temperature of 75-85 DEG C under the action of a tin catalyst, so as to obtain an isocyanate-terminated organic silicone-modified polyurethane prepolymer; (b) adding a small molecular amine chain extender into the organic silicone-modified polyurethane prepolymer, and carrying out a stirring reaction for 1-2h at the temperature of 50-60 DEG C, so as to obtain an organic silicon-modified polyurethane copolymer; (c) evenly mixing the organic silicon-modified polyurethane copolymer obtained in the step (b) with an emulsifying agent at the temperature of 50-70 DEG C, and slowly adding deionized water into the mixture for emulsifying, so as to obtain the organic silicon-modified polyurethane copolymer fabric softener. The softener prepared by the method is good in stability, endows fabric with excellent softnesss, smoothness and hydrophilic property, has excellent yellowing resistance, and can maintain the brightness of the light-colored fabrics and the whiteness of the white fabrics.

Owner:ZIBO LURUI FINE CHEM CO LTD

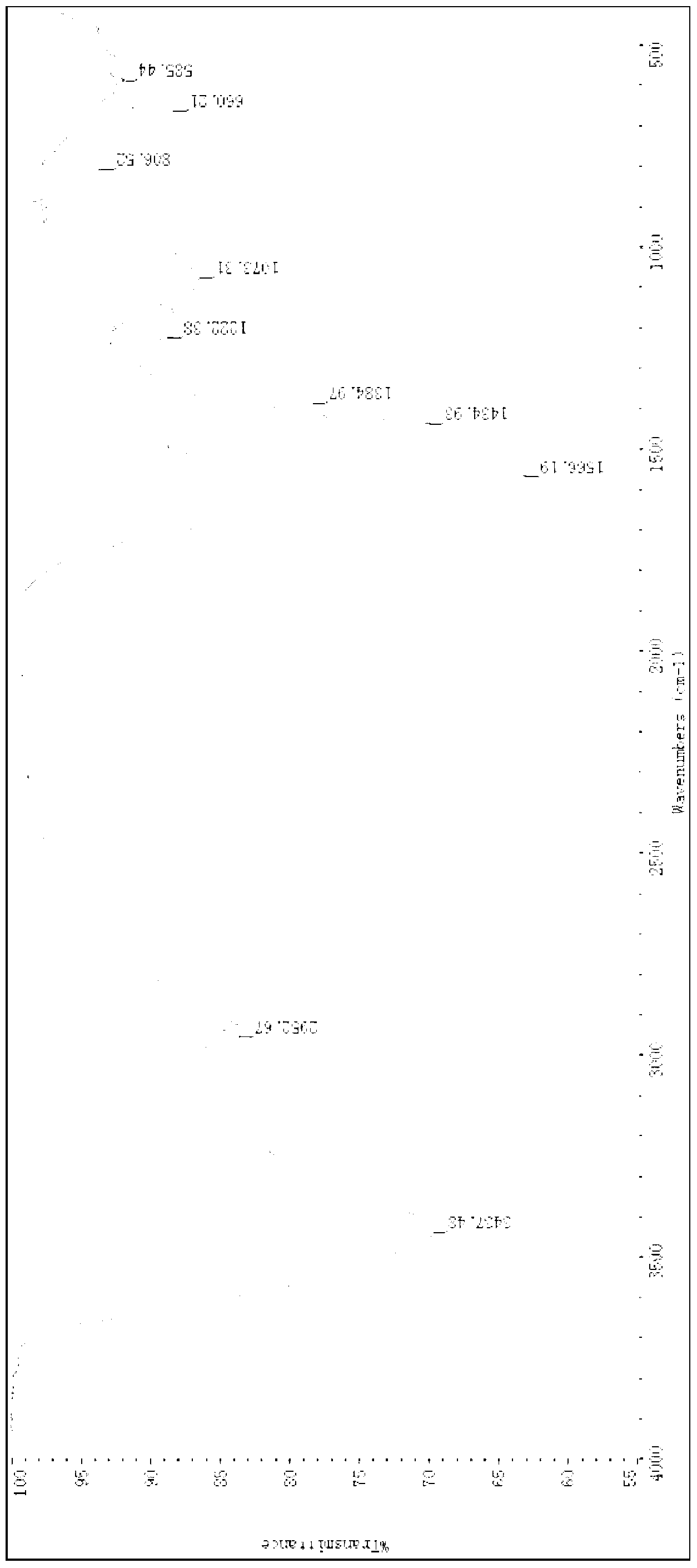

Hydrophilic laminate and method for manufacturing the same, antifouling laminate, product and method for manufacturing the same, and antifouling method

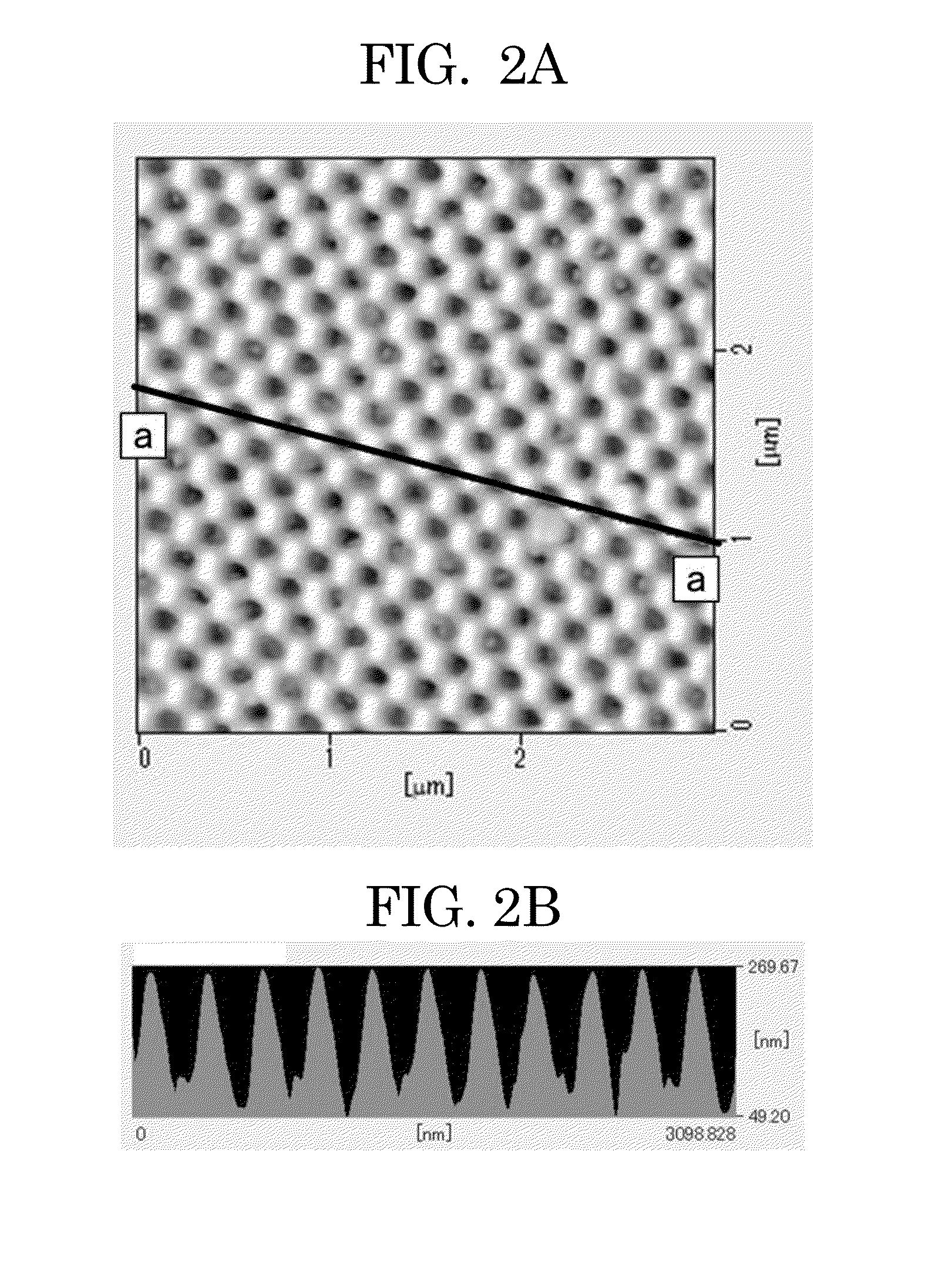

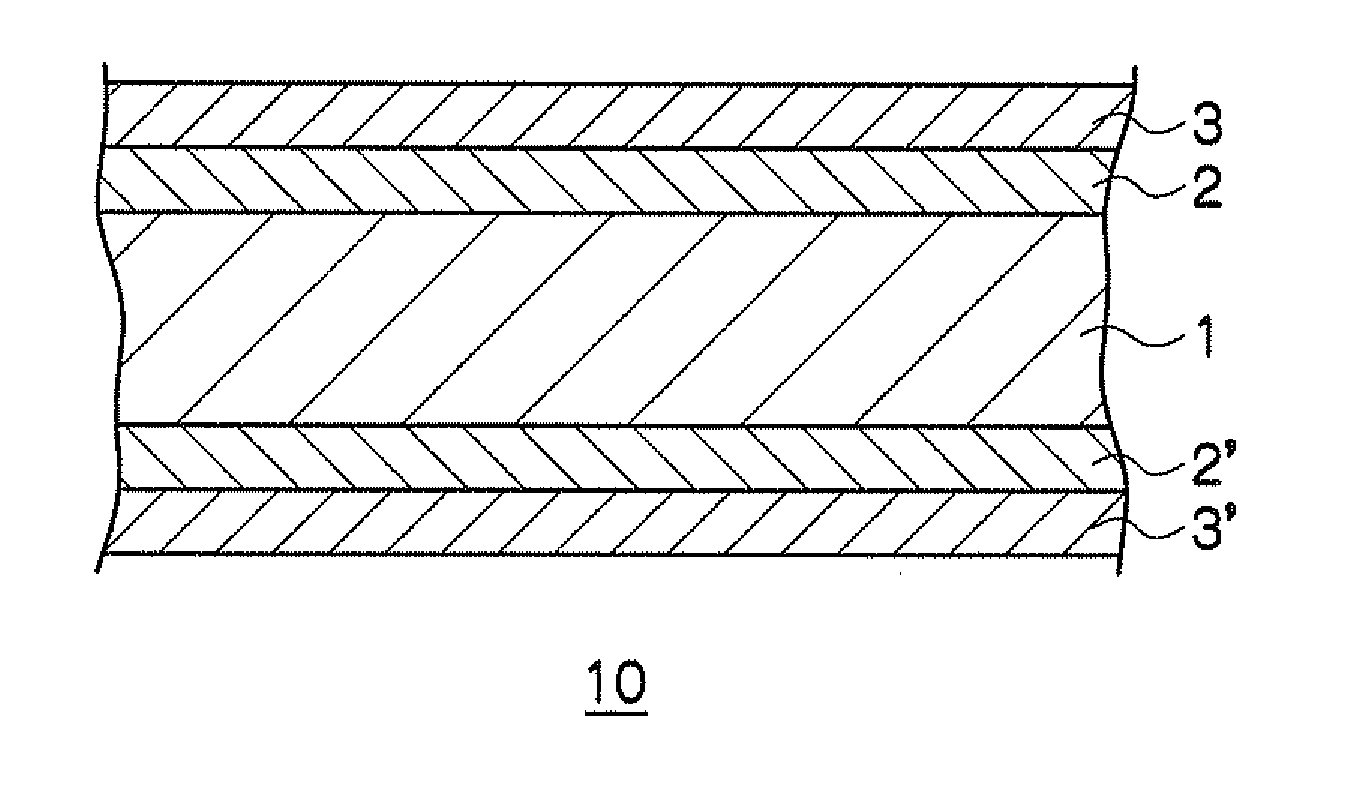

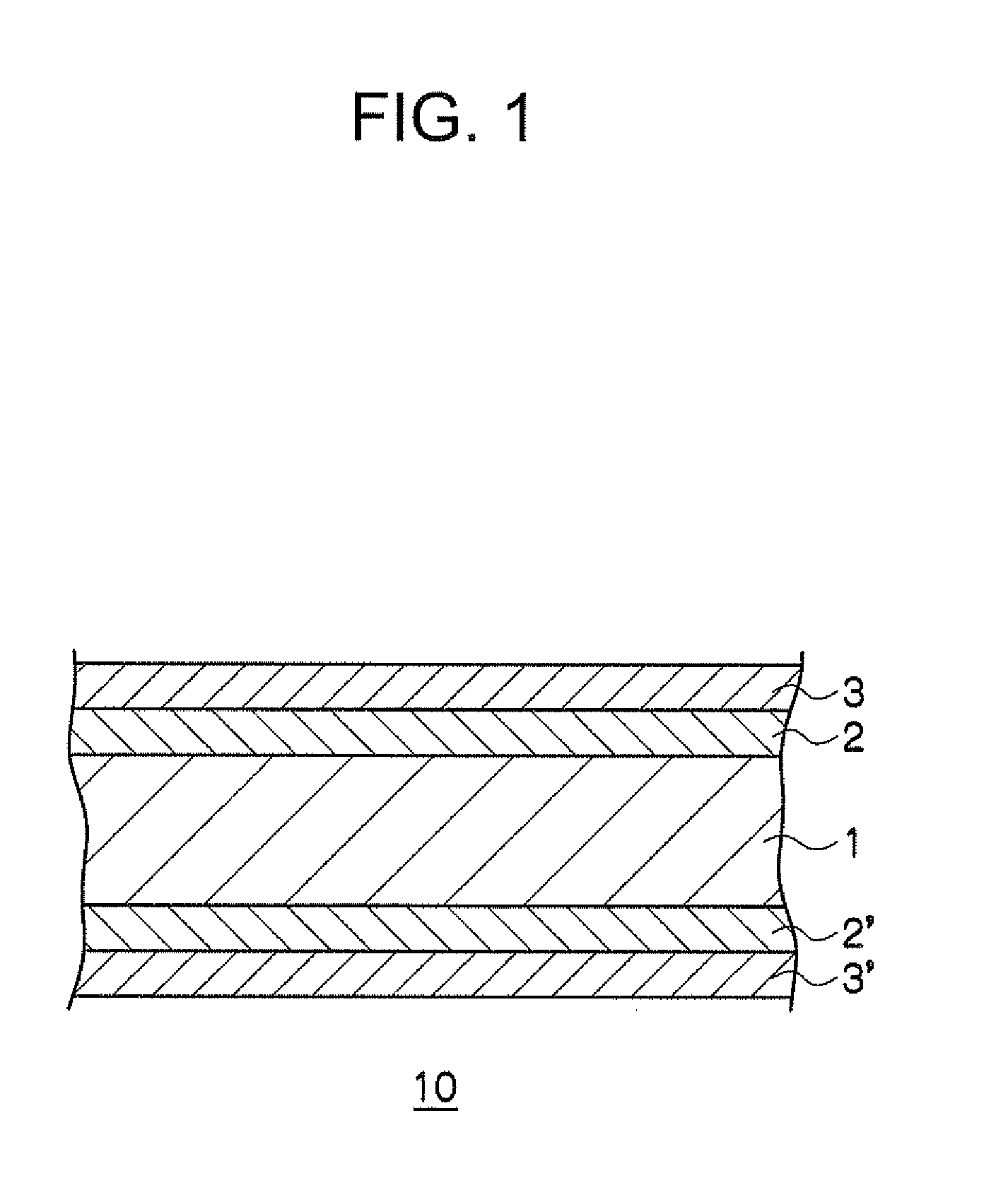

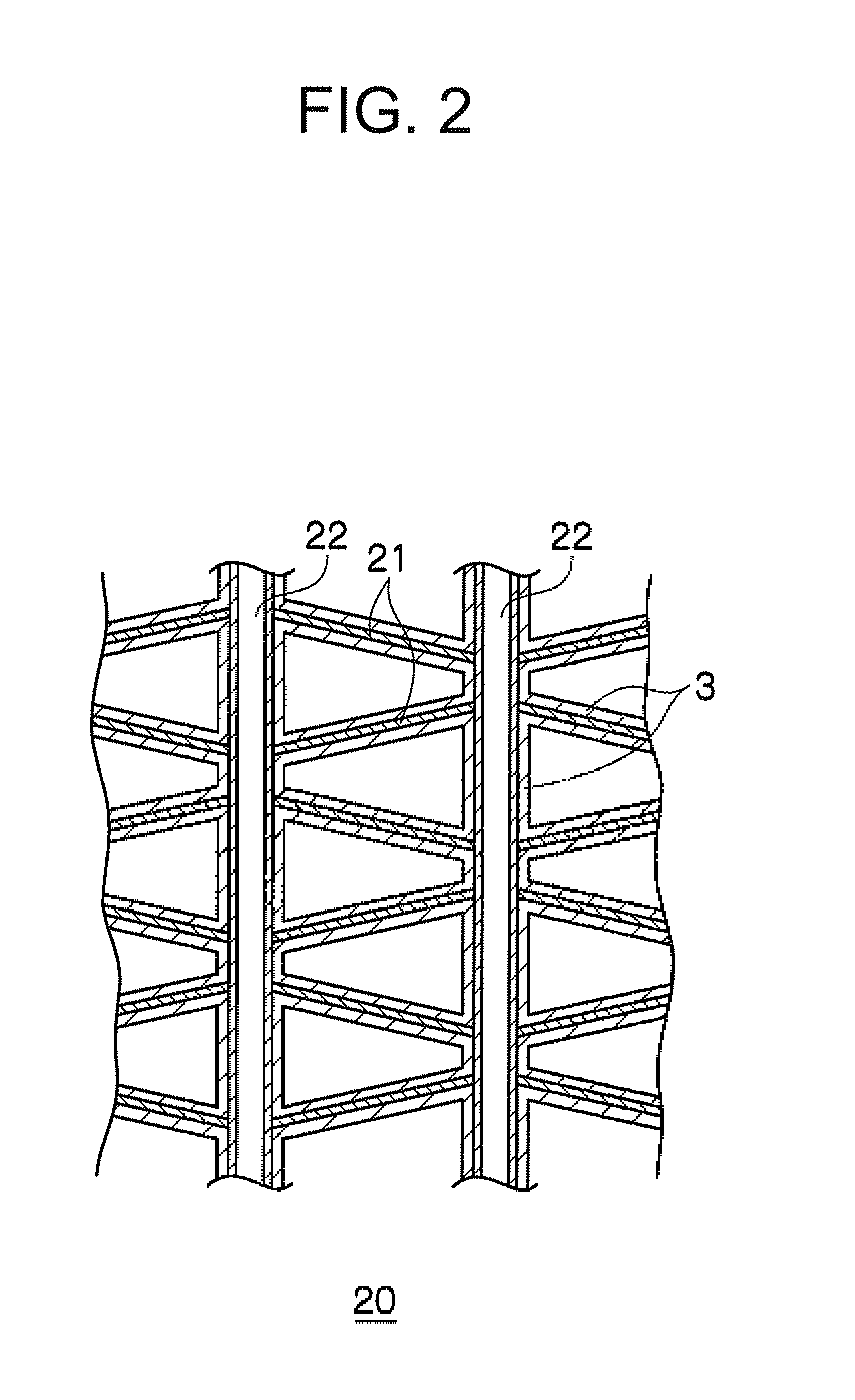

ActiveUS20140205801A1HydrophilicityKeep hydrophilicFouling preventionLayered productsWater contactChemistry

A hydrophilic laminate, including: a substrate made of a resin; and a hydrophilic resin layer on the substrate made of a resin, wherein the hydrophilic resin layer comprises micro convex portions or micro concave portions in a surface thereof, and wherein a pure water contact angle of the surface of the hydrophilic resin layer is less than 40°.

Owner:DEXERIALS CORP

Nano TiO2 coating composition capable of curing quickly at normal temperature and preparation method and coating thereof

InactiveCN102127325ASolve the harsh process conditionsImprove hydrophilicityCoatingsNano sio2Nano tio2

The invention relates to a nano TiO2 coating composition capable of curing quickly at normal temperature, which comprises the following raw materials in part by weight: 0.01 to 20 parts of nano TiO2 sol, 0.01 to 30 parts of nano SiO2 hybrid sol or SiO2 sol, 0.05 to 5 parts of pH regulator, and 0.5 to 90 parts of assistant. The invention also provides the preparation method of the nano TiO2 coating composition and the coating obtained by construction of the composition. When the nano TiO2 coating composition provided by the invention is used, high-temperature heat treatment is not required in a coating process, and the TiO2 coating with high catalytic activity can be obtained at normal temperature or even low temperature.

Owner:深圳市爱思宝科技发展有限公司

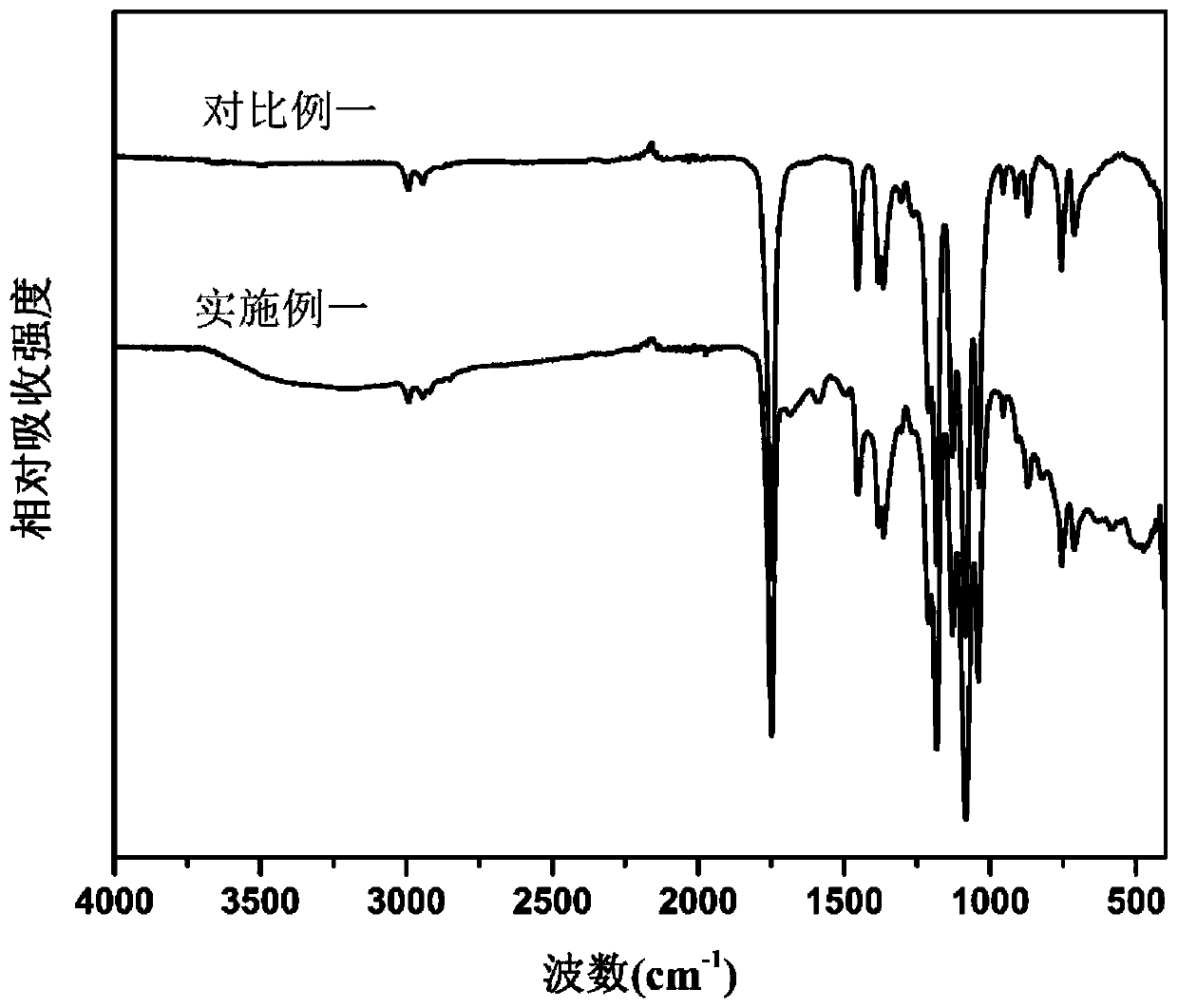

Polyvinylidene fluoride anti-pollution membrane and preparation method thereof

ActiveCN107149882AEasy to makeLow preparation equipment requirementsMembranesSemi-permeable membranesPhase conversionUltraviolet

The invention discloses a polyvinylidene fluoride anti-pollution membrane and a preparation method thereof, and belongs to the field of environmental functional membrane materials. The preparation method comprises: (1) self-polymerizing dopamine on the surface of polyvinylidene fluoride powder, and adhering the generated poly dopamine functional layer onto the surface of the polyvinylidene fluoride powder; (2) preparing a poly dopamine modified polyvinylidene fluoride membrane by using a phase conversion method; and (3) depositing a nano-TiO2 functional layer on the membrane prepared in the step (2) through a liquid phase deposition method to prepare the polyvinylidene fluoride anti-pollution membrane. According to the present invention, by combining the strong adhesion and the polyfunctional group of poly dopamine, the ultraviolet resistance and stable chemical performance of polyvinylidene fluoride, and the advantages of hydrophilicity, high photocatalytic activity and the like of nano-TiO2, the polyvinylidene fluoride anti-pollution membrane is developed; and the prepared polyvinylidene fluoride anti-pollution membrane has excellent pollution resistance, and can be used in various membrane separation fields.

Owner:天津鼎芯膜科技有限公司

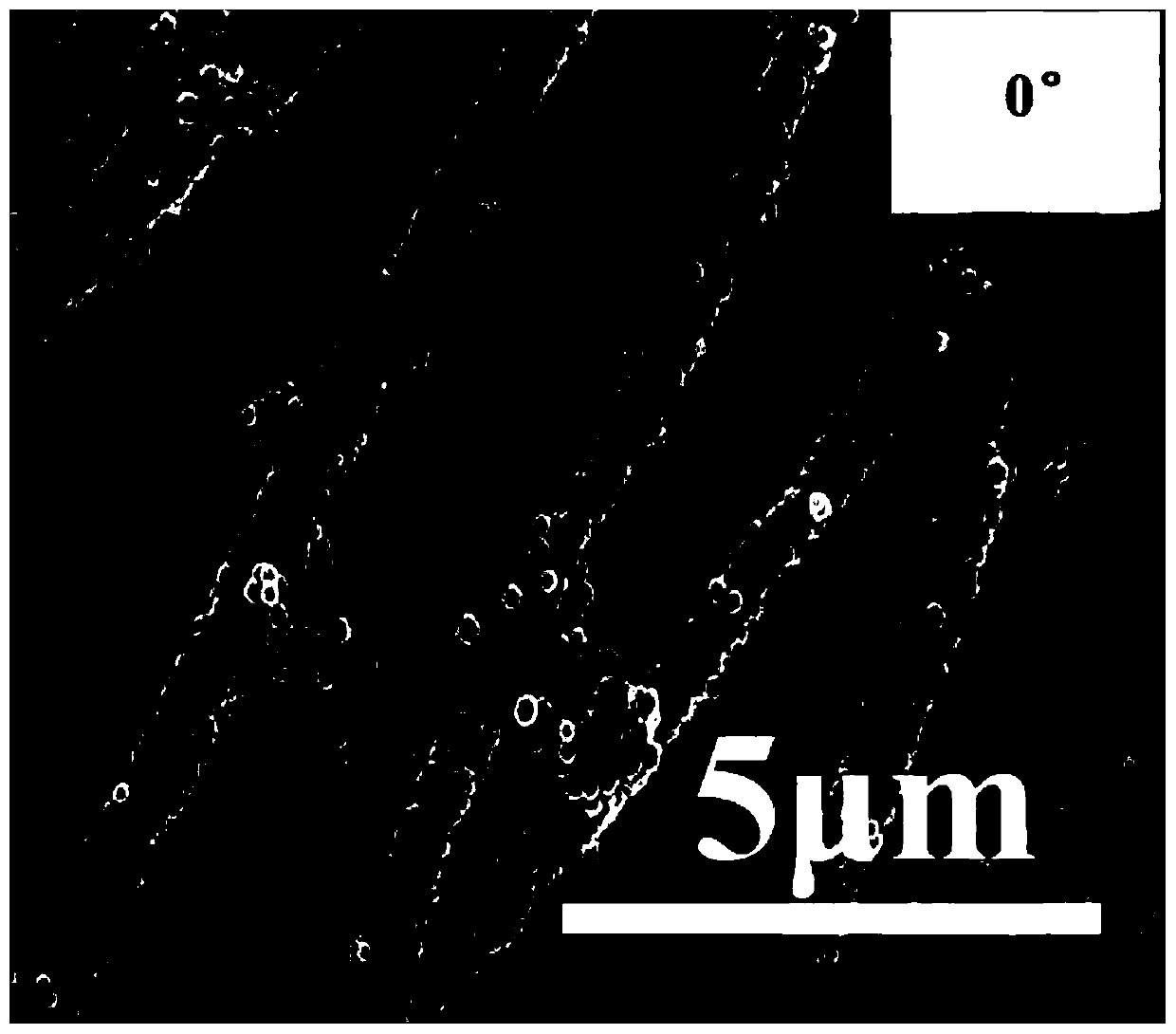

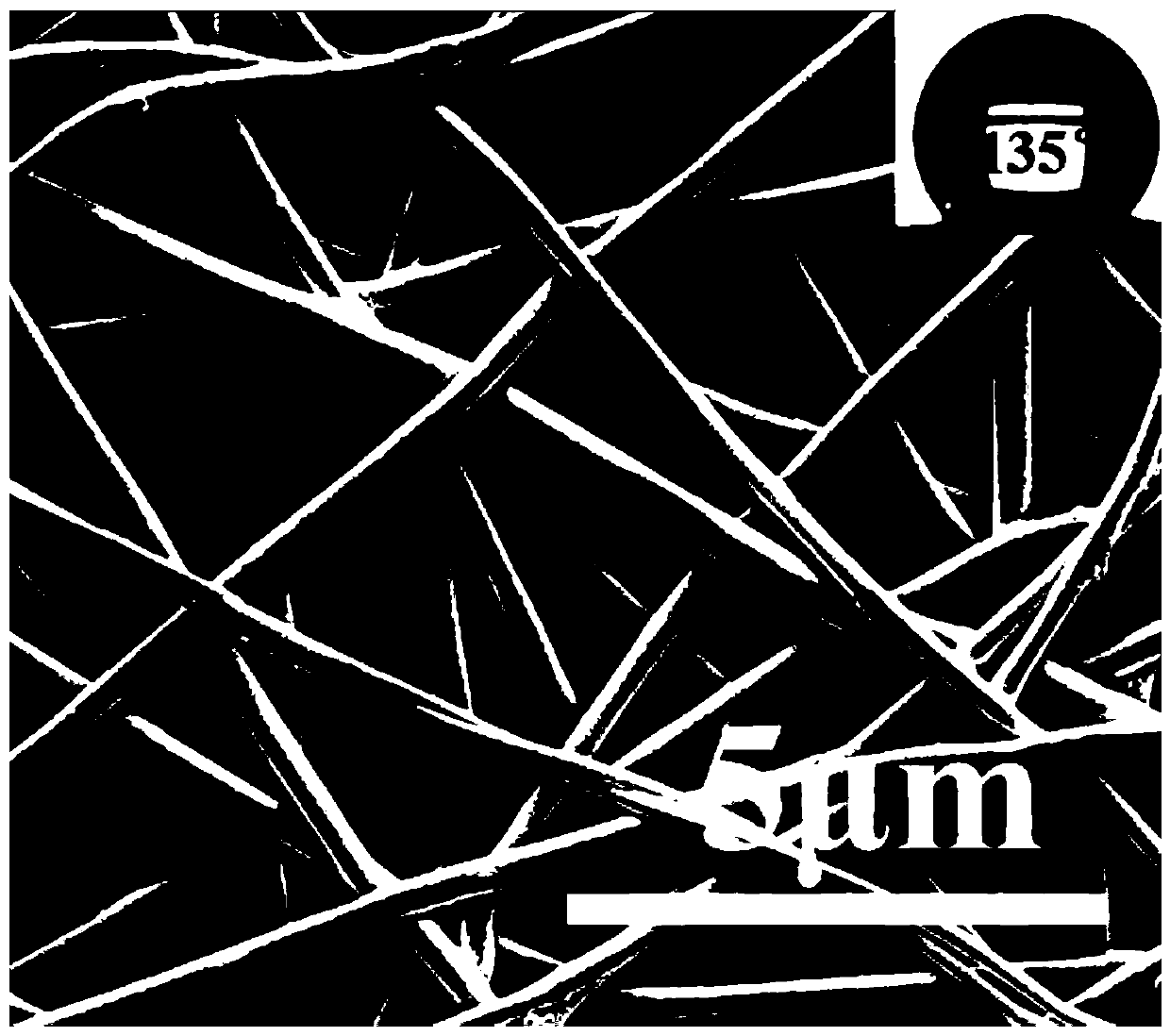

Super-hydrophilic self-cleaning oil-water separation membrane as well as preparation method and application thereof

ActiveCN109847598AReduce energy consumptionNo pollution in the processSemi-permeable membranesLiquid separationHydrophilic coatingCarboxylic acid

The invention belongs to the field of high polymer materials, and relates to a super-hydrophilic self-cleaning oil-water separation membrane as well as a preparation method and application thereof. The invention provides a super-hydrophilic self-cleaning oil-water separation membrane. The oil-water separation membrane is a modified membrane formed by coating the surface of a base membrane with a super-hydrophilic coating. The super-hydrophilic coating is a super-hydrophilic coating formed by a reaction of plant polyphenol and a titanium dioxide precursor and containing carboxylic acid titaniumcoordination bonds. The base membrane is a polymer membrane or a non-polymer membrane, which can be used for oil-water separation. The oil-water separation membrane obtained by the invention is super-hydrophilic and can be used for rapidly and effectively separating various oil-water layered mixtures and oil-in-water emulsion with stable surface activity. Meanwhile, under UV illumination, due tothe photocatalytic degradation characteristic of titanium dioxide, the membrane has excellent self-cleaning and anti-fouling performance, namely, the membrane has good cyclic separation performance.

Owner:SICHUAN UNIV

Method for preparing hydrophilic polypropylene microporous film

The invention relates to a method for preparing hydrophilic polypropylene microporous film. The method includes subjecting low-melting-index polypropylene and diluents in a weight ratio of (20:80) to (80:20), a blending compatilizer containing polar groups and accounting for 0.5% to 20% of the total weight of the polypropylene and the diluents, and a material which is composed of nucleating agents and accounting for 0.05% to 10% of the total weight of the polypropylene and the diluents to solution blending or melt blending at a temperature ranging from 180 DEG C to 210 DEG C to obtain mixed materials; forming film by using a film scraping method or a hot-press method at a temperature of 170 DEG C to 190 DEG C; quenching the film in thermostatic waterbath at a temperature between 0 DEG C and 50 DEG C; extracting the film in an extracting agent to remove the diluents; dipping the film in a hydrochloric acid aqueous solution, and washing the film through distilled water and drying the film to obtain the hydrophilic polypropylene microporous film. According to the hydrophilic polypropylene microporous film prepared by the method, the average bore diameter range is between 0.1 micron and 10.0 microns, poriness is larger than or equal to 40%, and the water contact angle is smaller than or equal to 95 degrees.

Owner:PETROCHINA CO LTD

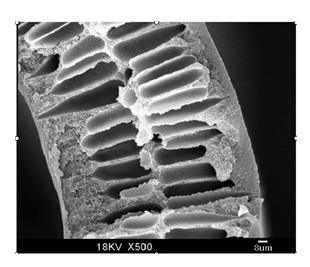

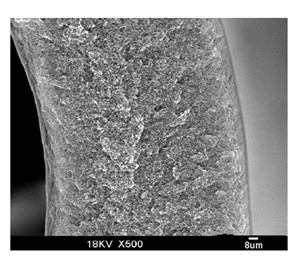

Hydrophilic polyethylene hollow fiber membrane and preparation method thereof

ActiveCN102068918ACreate pollutionNot easy to fall offSemi-permeable membranesSolventCellulose diacetate

The invention discloses a hydrophilic polyethylene hollow fiber membrane and a preparation method thereof. The hollow fiber membrane is prepared by the following method of: (1) previously preparing a hydrophobic primary polyethylene hollow fiber membrane; (2) preparing cellulose diacetate solution, wherein the concentration of the cellulose diacetate solution is 20 to 50 percent; and (3) soaking the primary polyethylene hollow fiber membrane into the cellulose diacetate solution prepared in the step (2), making the cellulose diacetate solution fully soak into pores of membrane yarns, and thenremoving the solvent of the cellulose diacetate solution to obtain the hydrophilic polyethylene hollow fiber membrane. The method is simple, feasible and easy to apply in the industry, can be continued, and can also reduce the cost; and the obtained hydrophilic polyethylene hollow fiber membrane can keep hydrophilic property for long time.

Owner:盐城海普润科技股份有限公司

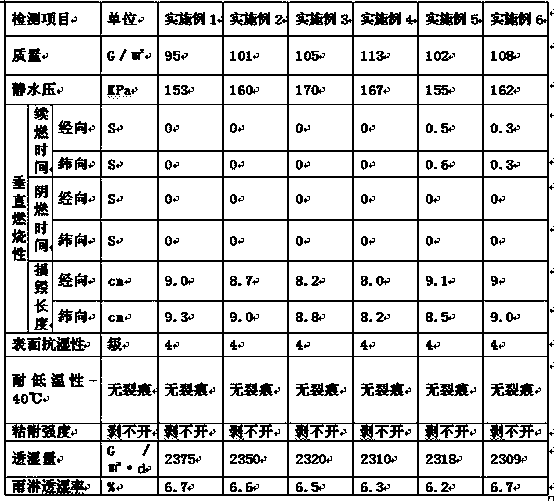

High waterproof moisture-permeable flame-retardant tent fabric processing method

ActiveCN109797567AImprove waterproof performanceGood moisture permeabilityTextiles and paperPolyesterSurface layer

The invention discloses a high waterproof moisture-permeable flame-retardant tent fabric processing method. The method comprises the following steps: 1, selecting water-resistant 65D-100D polyester fabric; 2, preparing a bottom layer micropore polyurethane coating adhesive; 3, preparing an intermediate layer hydrophilic polyurethane flame-retardant coating primer; 4, preparing a surface layer hydrophilic polyurethane coating surface adhesive; 5, processing a coating; 5-1, enabling the bottom layer micropore polyurethane coating adhesive to be coated on the surface of base cloth by using a floating knife dry method coating, wherein a dry increased weight is 10-15 g / m<2>; 5-2, enabling the intermediate layer hydrophilic polyurethane flame-retardant coating primer to be coated on the surfaceof the coating adhesive in the step 5-1 by using the floating knife dry method coating, wherein the dry increased weight is 15-25 g / m<2>; and 5-3, enabling the surface layer hydrophilic polyurethane coating surface adhesive to be coated on the surface of the coating adhesive in the step 5-2 by using the floating knife dry method coating, wherein the dry increased weight is 7-10 g / m<2>. Obtained high waterproof moisture-permeable well-flame-retardant tent fabric has excellent waterproof performance in heavy rain, has the characteristics of light weight and thin thickness, good adhesion strength, low-temperature resistance and the like, and is suitable for a tent used for mountain climbing or in dangerous environments.

Owner:DANDONG UNIK TEXTILE

Hydrophilic polyethersulfone with cardo alloy ultrafiltration membrane and preparation method thereof

ActiveCN102512997AImprove connectivityHigh porosityUltrafiltrationWater/sewage treatment bu osmosis/dialysisFiberHollow fibre

The invention discloses a novel hydrophilic polyethersulfone with cardo alloy ultrafiltration membrane and a preparation method thereof. According to the invention, hydrophilic polyethersulfone with cardo (PES-C) and hydrophilic polyvinylpyrrolidone (PVP) with a high molecular weight are blended, and a flat or hollow fiber ultrafiltration membrane is prepared by using an immersion-precipitation process or a dry / wet phase inversion process; and then the PES-C / PVP alloy ultrafiltration membrane with permanent hydrophilicity is prepared through hydrophilic long-lasting aftertreatment. The preparation method provided in the invention is simple, convenient, highly efficient and economy and is favorable for realization of industrial application. The prepared ultrafiltration membrane has good high temperature resistance, chemical solvent resistance, acidic and alkaline corrosion resistance and osmotic separation performance and excellent anti-pollution ability and can be used in the fields of purification of water quality, treatment of industrial waste water, recycling of domestic sewage, purification and separation of biological medicine products, etc.

Owner:TIANBANG NAT ENG RES CENT OF MEMBRANE TECH

Method for preparing polyvinylidene-fluoride bilayer hollow fiber membrane

InactiveCN103432915AHigh porosityImprove pore making abilitySemi-permeable membranesPolymer scienceHydrophilic polymers

The invention relates to the technical field of membrane separation and particularly relates to a method for preparing a polyvinylidene-fluoride bilayer hollow fiber membrane. According to the method, aiming at the problem that the flux of the general commercial polyvinylidene fluoride separation membranes is relatively low, a scheme of spinning a bilayer polyvinylidene fluoride membrane, adding additives into an outer layer membrane and adding hydrophilic polymers of different concentrations into an inner layer so as to improve the hydrophilicity of the bilayer polyvinylidene fluoride membrane is designed, and membrane distillation membranes with higher flux are prepared.

Owner:长沙奕景环保科技有限公司

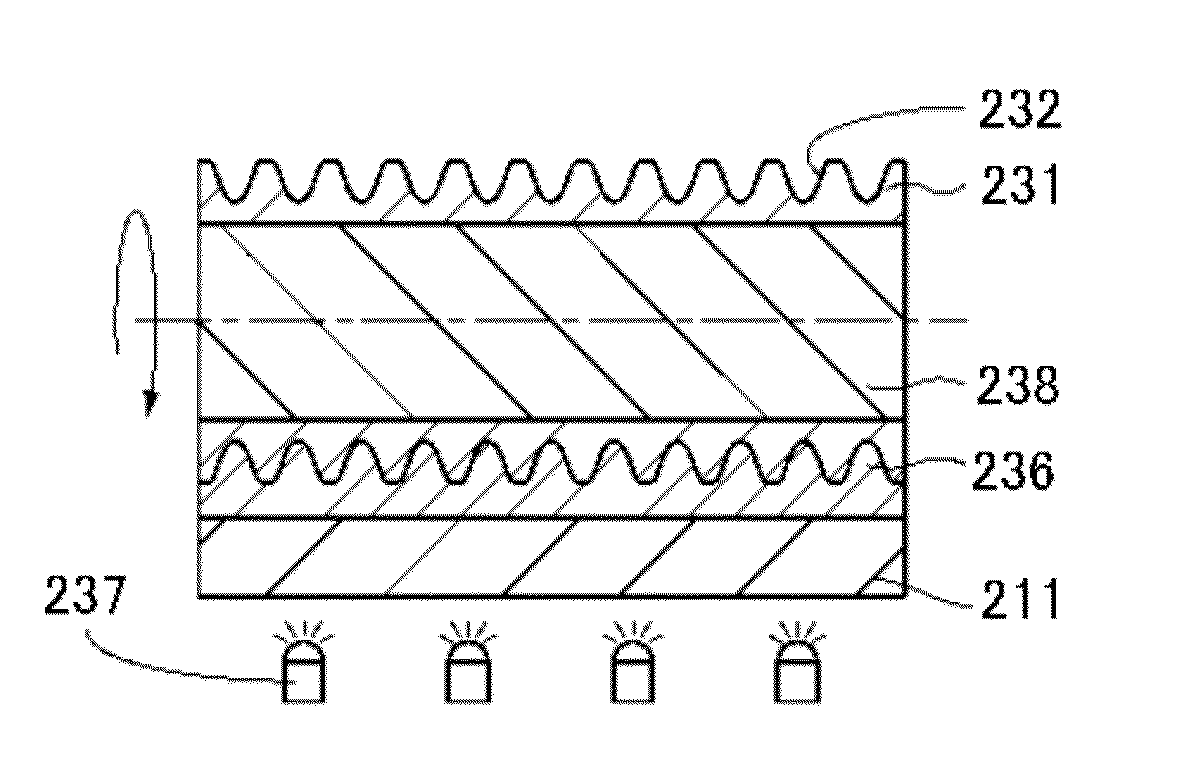

Aluminum or aluminum alloy material having surface treatment coating film, and method for treating a surface thereof

ActiveUS20130034743A1Improve applicationImprove heat exchanger efficiencyPretreated surfacesPaints with biocidesHydrophilic polymersSide chain

Provided is an aluminum or aluminum alloy material having a surface treatment coating film on a surface of a substrate formed by an aluminum or aluminum alloy. The aluminum or aluminum alloy material has: a substrate formed by an aluminum or aluminum alloy; and a first protective layer and a second protective layer in the order on a surface of the substrate, wherein the first protective layer is a conversion coating film including vanadium and at least one or more types of metals selected from titanium, zirconium, and hafnium, the second protective layer is an organic coating film having a composition that includes (1) a chitosan derivative and a solubilizing agent, (2) a modified polyvinyl alcohol formed by graft polymerization of a hydrophilic polymer to a side chain of polyvinyl alcohol, and (3) a water-soluble crosslinking agent.

Owner:NIHON PARKERIZING +1

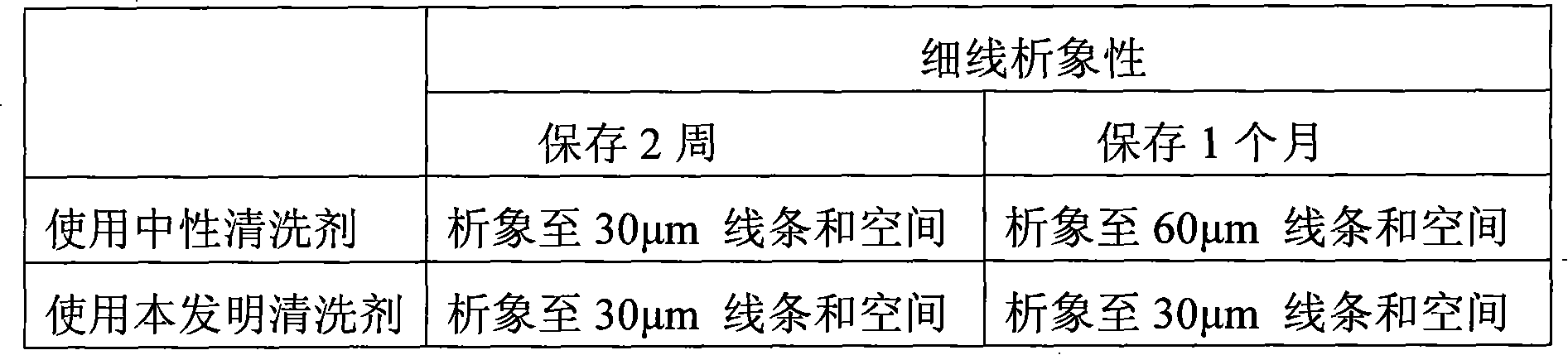

Silk screen cleaning agent for silk screen printing

InactiveCN101629131APrevent precipitationPrevent dark reactionPhotomechanical apparatusOrganic non-surface-active detergent compositionsScreen printingOrganic solvent

The invention relates to a silk screen cleaning agent for silk screen printing, which consists of 100 portions of aqueous solution and 0.01 to 10 portions of phosphoric acid containing ionic compound in portion by weight, wherein the aqueous solution is prepared by mixing 12 to 50 percent of water-soluble organic solvent and 50 to 88 percent of deionized water in percentage by weight. Compared with the prior art, the silk screen cleaning agent can prevent iron ions from being separated out from the surface of a stainless steel silk screen, prevent dark reactions of diazonium series photosensitive materials, persistently obtain the most suitable picture features, and keep the hydrophilic property on the surface of stainless steel silk screen, so the adherence of the photosensitive material consisting of the silk screen cleaning agent and water-soluble resin is improved, and subtle patterns of the plate-making process step and the printing process step are prevented from being broken off.

Owner:MURAKAMI MURAKAMI PRECISION STENCIL (KUNSHAN) CO LTDSTENCIL (KUNSHAN)

Inorganic hydrophilic coating solution, hydrophilic coating film obtained therefrom, and member using same

ActiveUS20140127514A1Excellent level of hardnessExcellent level of transparencySynthetic resin layered productsPhotovoltaicsHydrophilic coatingAlcohol

An inorganic hydrophilic coating solution including (a) an aqueous solution containing an amorphous silicate compound obtained by hydrolyzing and condensing a tetrafunctional silicon compound having a purity of 99.0 mass % or greater in an aqueous medium in the presence of a basic compound at a temperature within a range from normal temperature to 170° C., (b) water, and optionally, (c) not more than 30 mass % of an alcohol, a ketone, or a surfactant, where the concentration of the solid fraction derived from the aqueous solution containing the amorphous silicate compound is 0.01 to 2.0 mass % and the pH is 5 to 8; an inorganic hydrophilic coating film formed from a dried and cured product of the inorganic hydrophilic coating solution; a member having a substrate and the inorganic hydrophilic coating film formed on the surface of the substrate; and a cover panel for a solar cell module including the member.

Owner:SHIN ETSU CHEM IND CO LTD

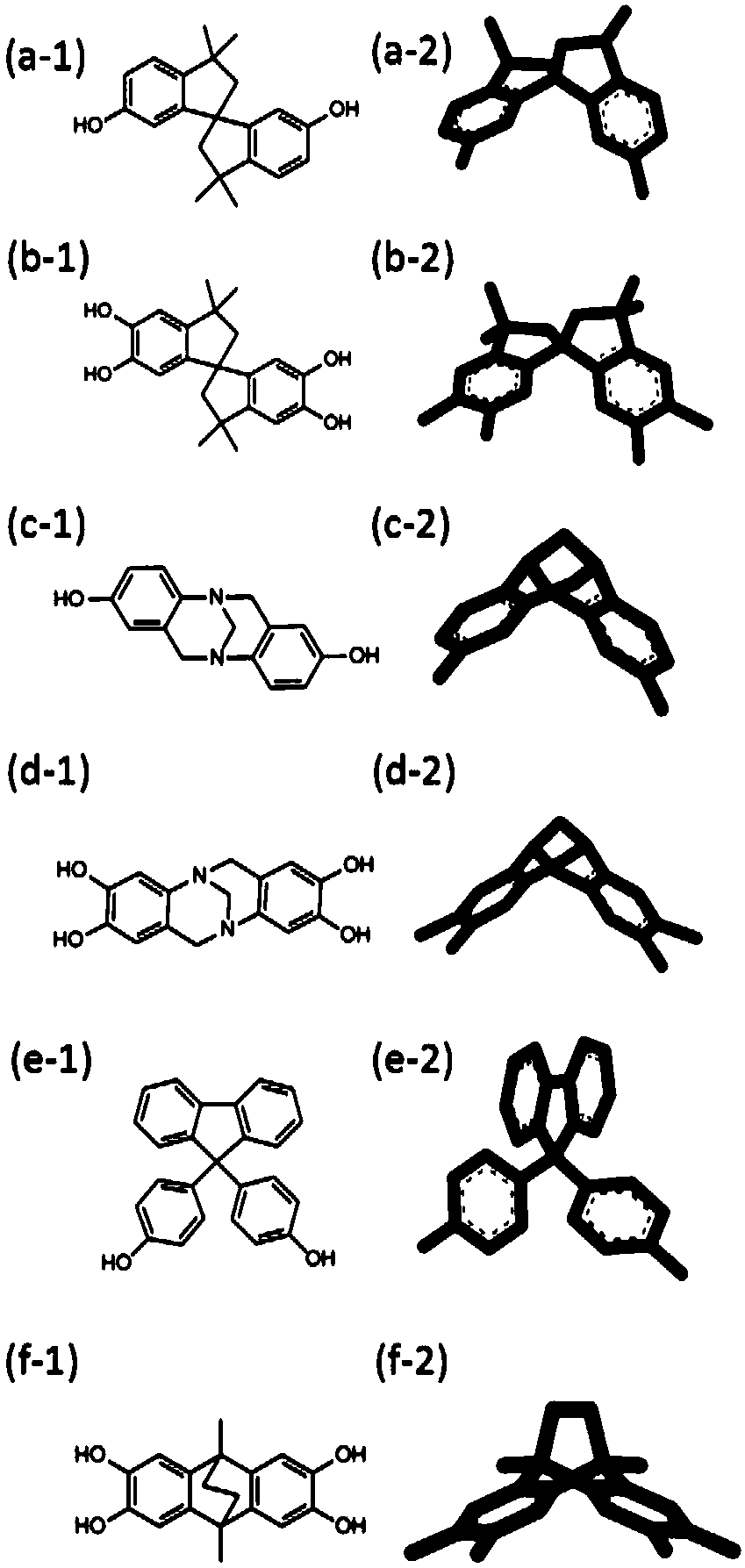

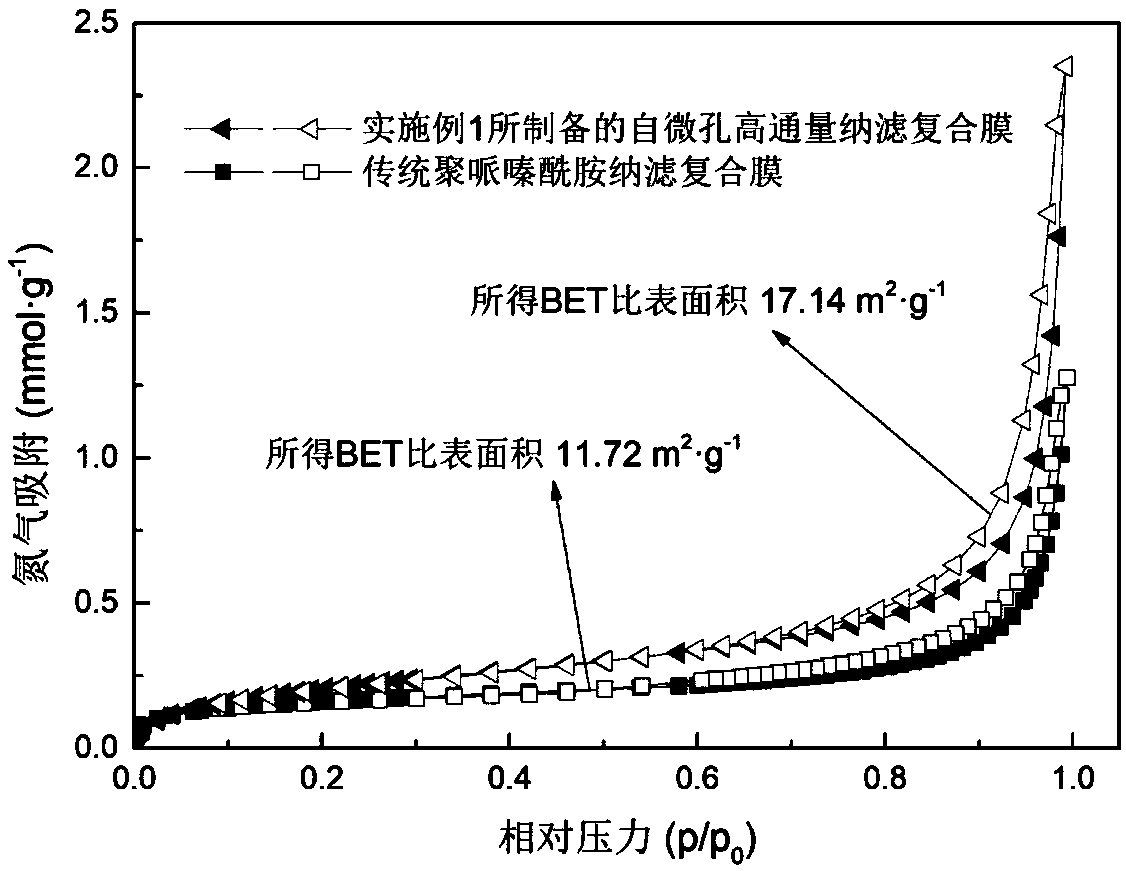

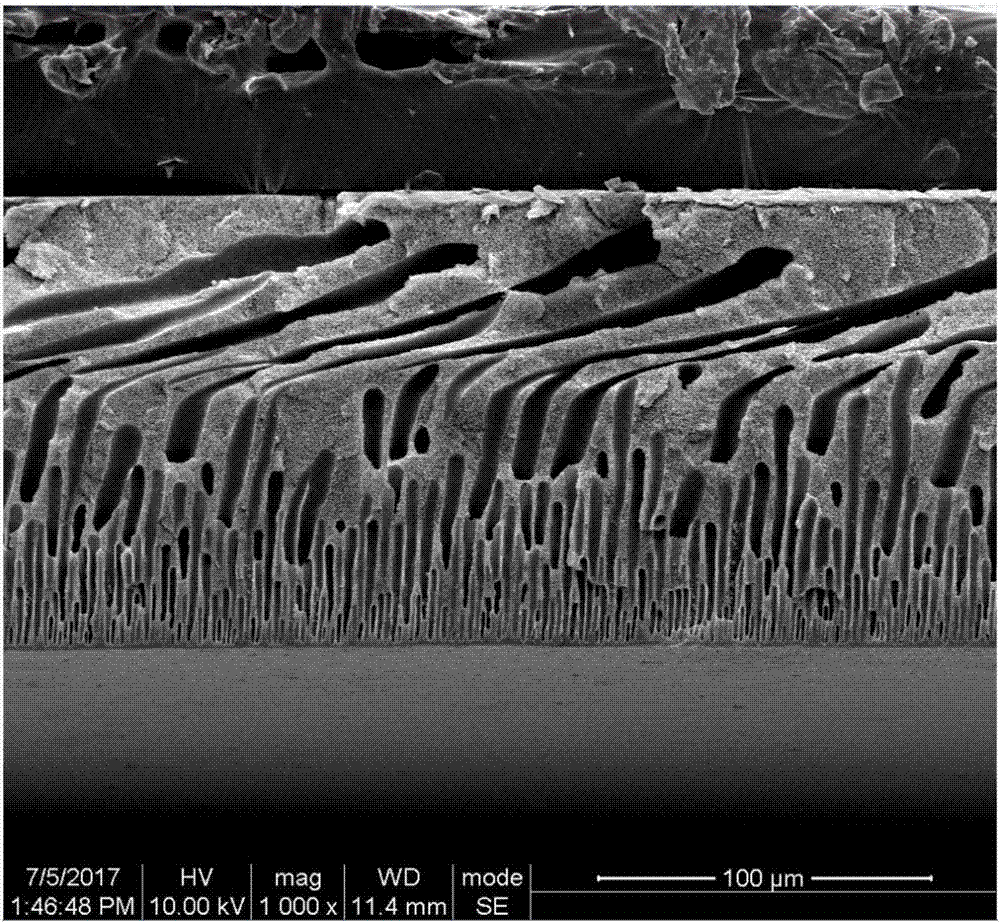

Self-microporous high-flux nano-filtration composite membrane and preparation method thereof

The invention discloses a self-microporous high-flux nano-filtration composite membrane and a preparation method thereof. The preparation method comprises: (1) dissolving a polyfunctional organophenolhaving a rigid twist structure in an alkali aqueous solution to obtain a solution 1, dissolving a polyfunctional organic amine in water to obtain a solution 2, and mixing the solution 1 and the solution 2 to obtain a mixed solution; (2) immersing an ultra-filtration support layer in the mixed solution, soaking, taking out, carrying out blow drying, soaking the upper surface of the membrane by using a polyfunctional organic acyl chloride solution, placing, and pouring off; and (4) carrying out heat treatment to obtain the product. According to the present invention, the polyfunctional organophenol having the rigid twist structure is introduced into the interfacial polymerization reaction, and the stacking of the molecular chain segments during the film forming is hindered by the special molecular structure, such that the separation layer of the prepared microporous high-flux nano-filtration composite membrane has a large number of micro-pores; with the method, the defects caused by theaddition of nanometer materials in the prior art are overcome; the product has advantages of good hydrophilicity, high water flux and high retention; and the method has advantages of simple operationand low cost.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Polyarylene sulfide sulfone compound separating film and preparation method thereof

The invention discloses a polyarylene sulfide sulfone compound separating film and a preparation method thereof. The polyarylene sulfide sulfone compound separating film comprises a polyarylene sulfide sulfone base film and a selective separating functional layer, wherein the selective separating functional layer is prepared from any one of fatty polyamide, aromatic polyamide, methyl-silicone andcellulose acetate through a coating method or an interfacial polycondencation method. According to the invention, the selective separating functional layer is added to the polyarylene sulfide sulfonebase film and the defects on the surface of the polyarylene sulfide sulfone base film are covered by the compact selective separating functional layer, so that the surface of the polyarylene sulfide sulfone compound separating film has a uniformly distributed pore structure, the porosity is increased and the pore size distribution is uniform; the interception capacity thereof is obviously promotedafter the selective separating functional layer is added; when the selective separating functional layer with hydrophilic group is adopted, hydrophilic modification for the polyarylene sulfide sulfone is not required.

Owner:四川中科兴业高新材料有限公司

Hydrophilic modifying method and heat exchanger treated with it

InactiveCN1377738AKeep hydrophilicLiquid surface applicatorsCoatingsPolymer sciencePolyvinyl alcohol

Owner:NIPPON PAINT SURF CHEM +1

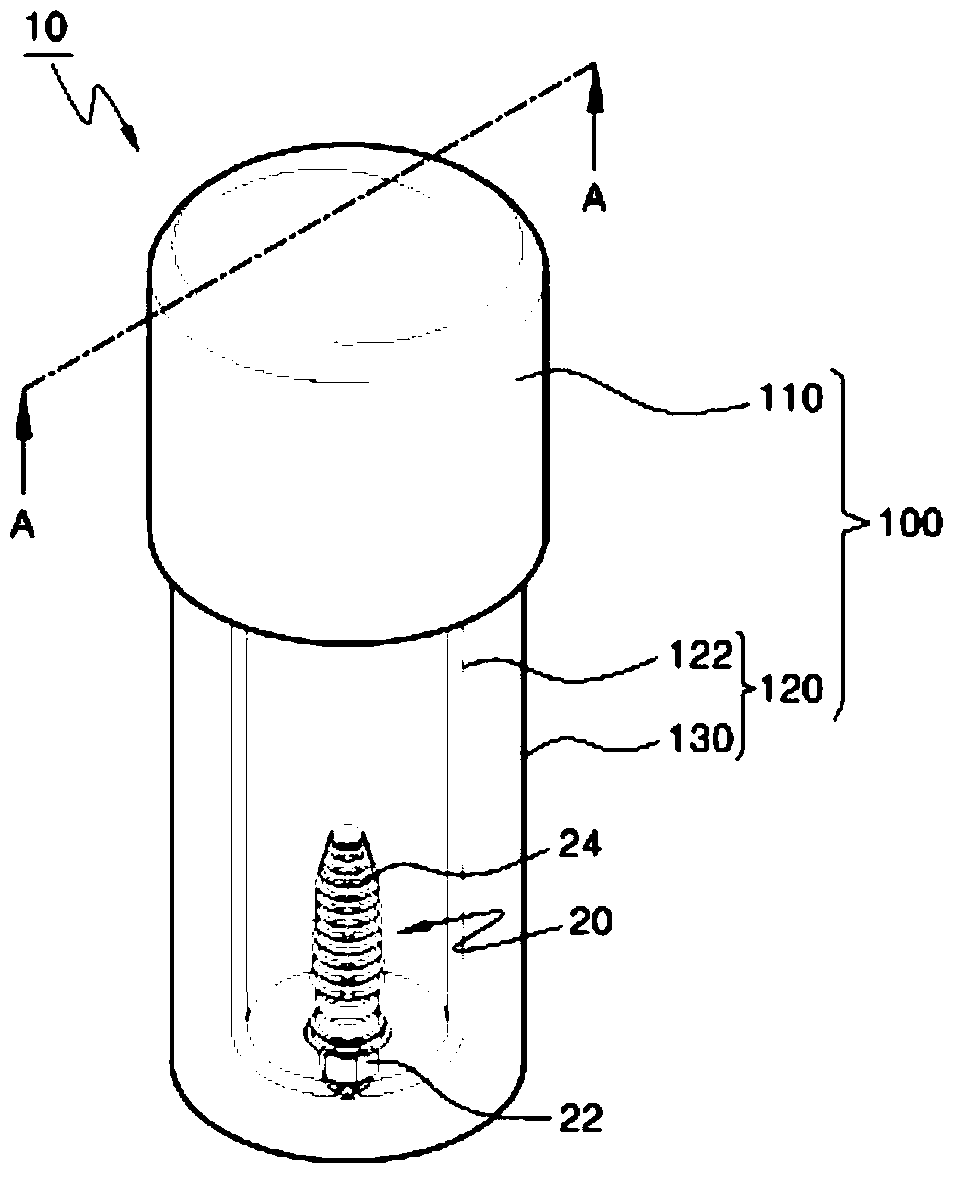

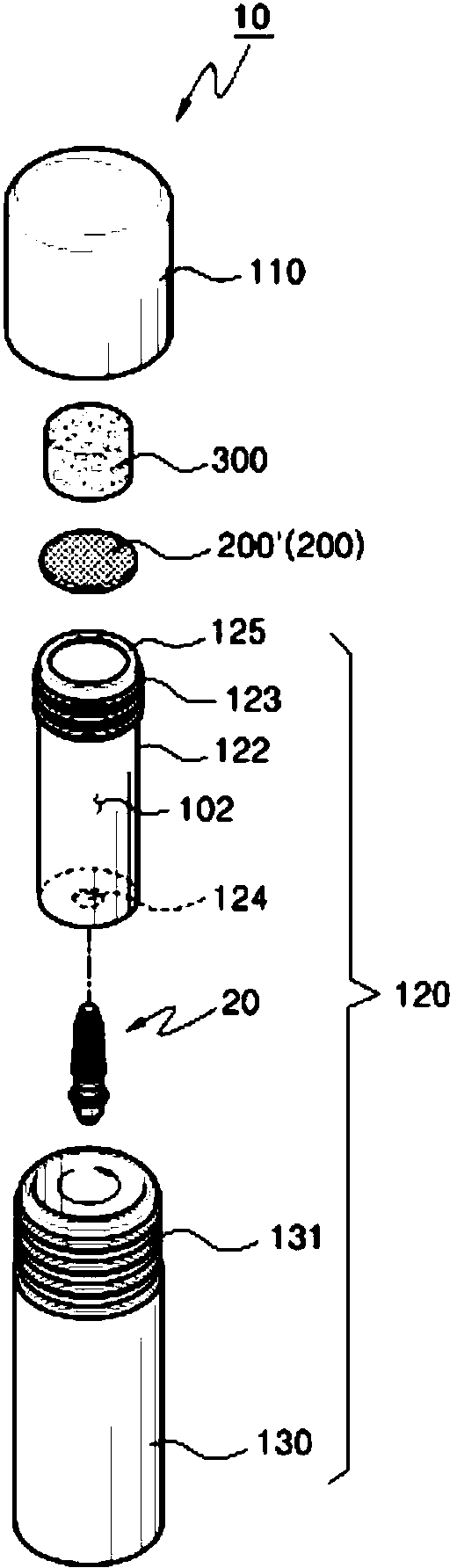

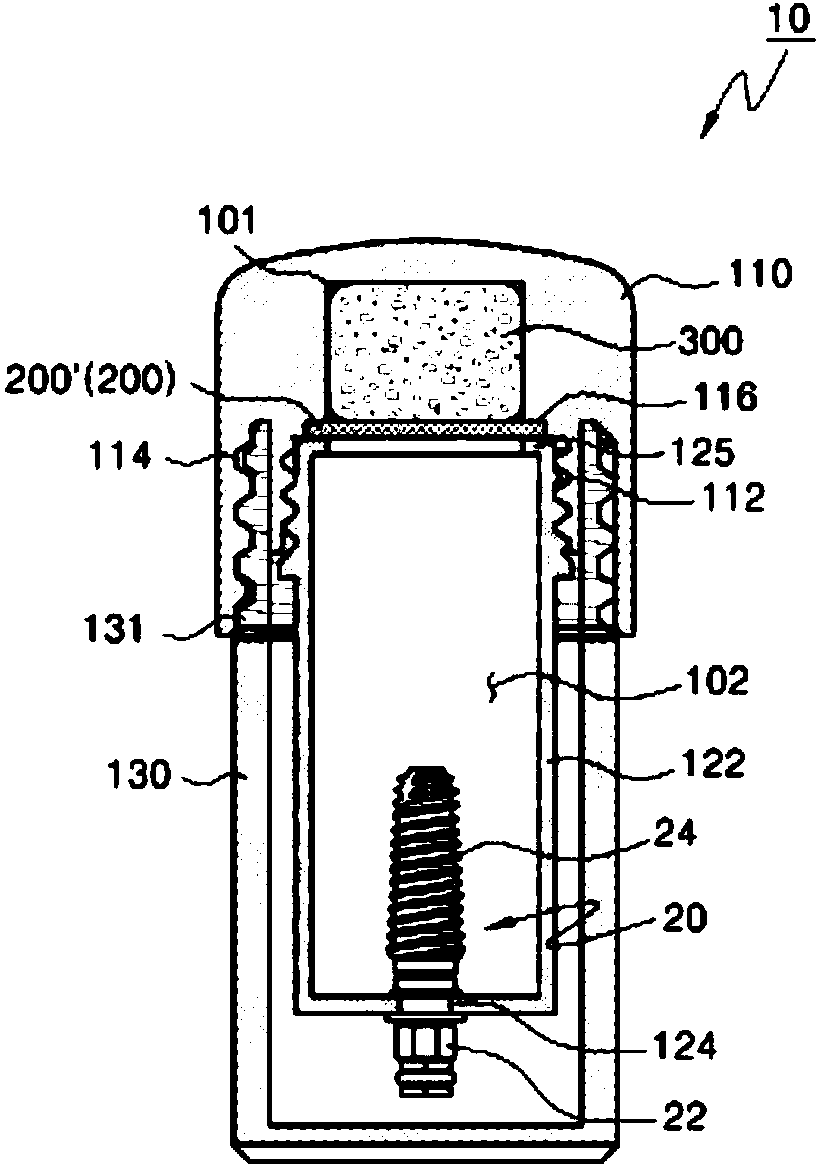

Ampoule for storing implant capable of maintaining humidity

Disclosed is an ampoule for storing an implant capable of maintaining humidity, comprising: a container capable of airtight sealing at least momentarily or temporarily; a partition member which divides an accommodation space inside the container into two spaces, first and second spaces, and allows vaporized water molecules to be transported between the divided spaces; and a water molecule supply source which is accommodated in the first space of the two spaces divided by the partition member and supplies the vaporized water molecules. Therefore, the invention enables the construction of an environment which allows the hydrophilicity of the implant to be maintained for a long time, wherein the hydrophilicity is imparted to and protected from the surface of the implant or a coating layer formed on the surface of the implant.

Owner:(CO LTD) AOJITAI IMPLANT CO LTD

Hydrophilic modification method of PVDF multihole film

InactiveCN104524997AImprove hydrophilicityGood compatibilitySemi-permeable membranesPolyvinylidene fluorideMethyl methacrylate

The invention discloses a hydrophilic modification method of a PVDF multihole film, relates to a film modification method, belongs to the field of multihole film modifying, and aims at solving the technical problems that the PVDF multihole film is high in hydrophobicity, the driving force needed in the separating process is large, the water flux is low, and the PVDF multihole film is contaminated easily in the using process. The hydrophilic modification method comprises the following steps that a solution with the mass concentration of 2-acrylamide-2-methyl propanesulfonic acid ranging from 20 percent to 40 percent is prepared, methyl methacrylate and azodiisobutyronitrile are added to the solution, and a reaction system is obtained; the reaction system is heated, reduced pressure distillation is carried out, the reaction system is poured into precipitator, precipitate is obtained and dried, and copolymer is obtained; the copolymer, polyvinylidene fluoride and polyvinylpyrrolidone are added to dimethylformamide to be stirred and cooled to the indoor temperature, the mixture is subjected to standing, and casting film liquid is obtained; the casting film liquid is poured to a glass plate on a film laying machine for film laying, the casting film liquid is dried, and then the PVDF multihole film is obtained. The modified PVDF multihole film is high in hydrophilia.

Owner:HARBIN UNIV OF SCI & TECH

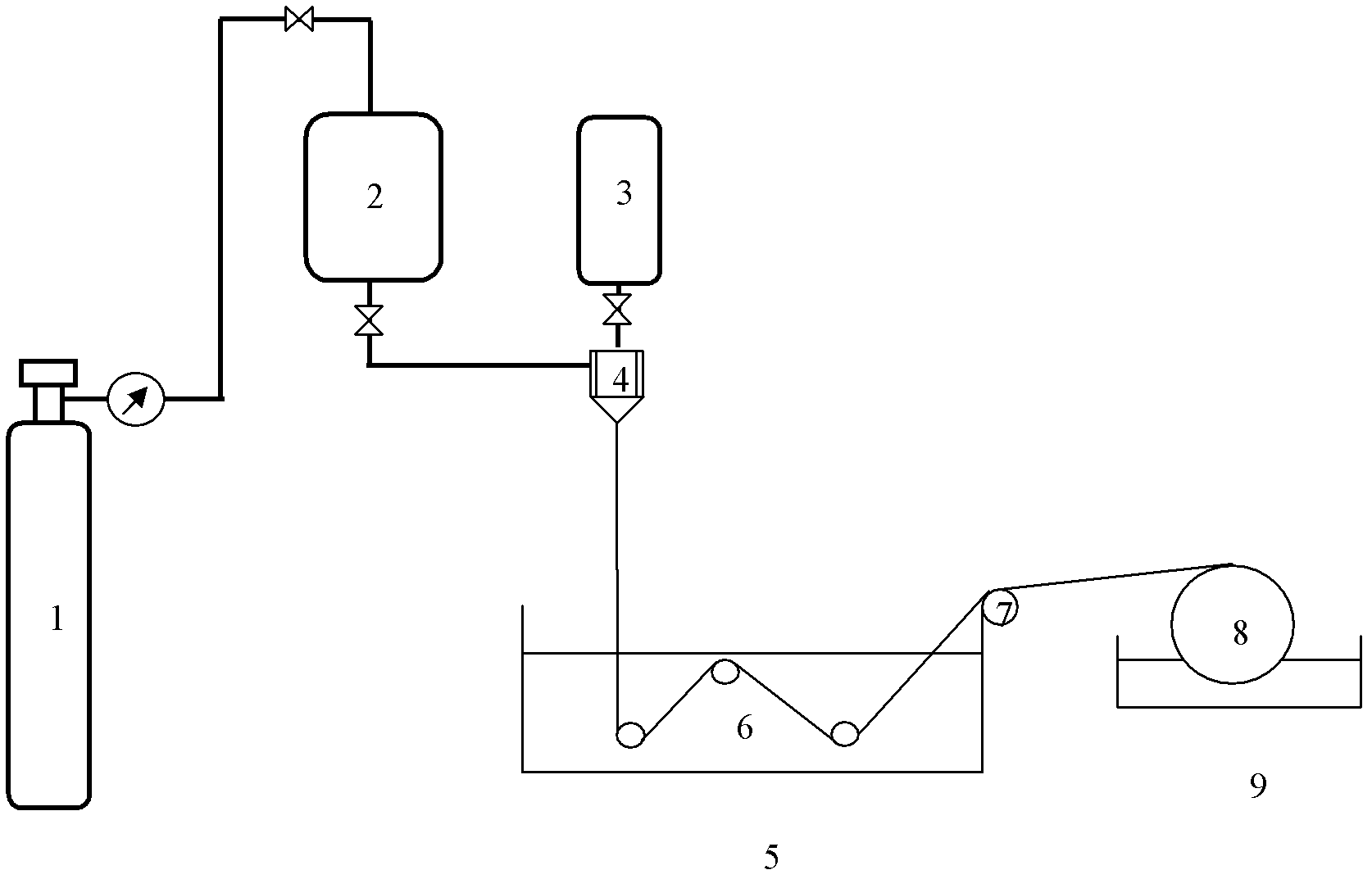

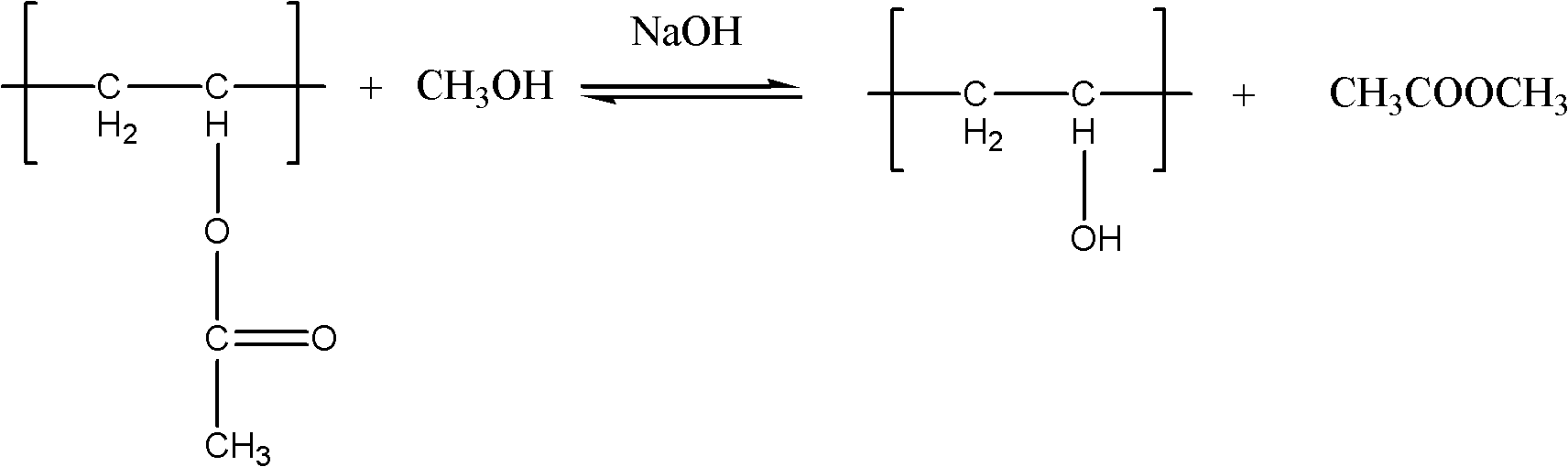

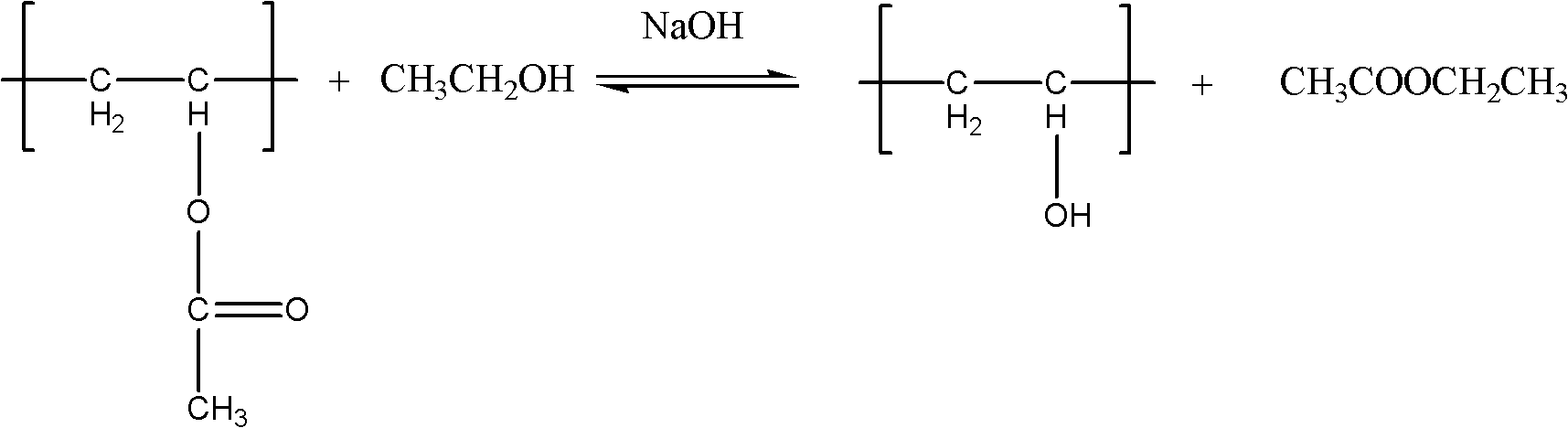

Polyvinylidene difluoride hollow fiber micro-filtration membrane with permanent hydrophilicity, and preparation method thereof

ActiveCN102489184AImprove hydrophilicityKeep hydrophilicSemi-permeable membranesFiberFiltration membrane

The invention relates to a polyvinylidene difluoride hollow fiber micro-filtration membrane and a preparation method thereof. The preparation method comprises steps of spinning liquid preparing, core liquid and coagulation bath preparing, dry-wet spinning, alcoholysis, cleaning, and the like. Compared to existing technologies, the polyvinylidene difluoride hollow fiber micro-filtration membrane provided by the invention has permanent hydrophilicity. With the micro-filtration membrane, a long-term stable pure water flux is maintained, and the pure water flux is high.

Owner:BEIJING ORIGIN WATER FILM TECH

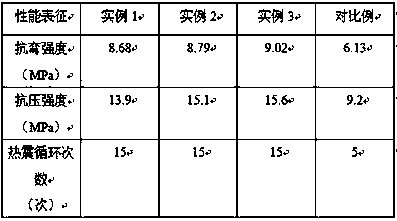

Method for preparing composite foam ceramic

InactiveCN109734476AInhibit aging phenomenonImprove antioxidant capacityCeramicwareSlurryMechanical property

The invention relates to a preparation method of a composite foam ceramic, and belongs to the technical field of materials. According to the invention, zirconium oxide and aluminum oxide are used as raw materials to prepare the composite foam ceramic, and the aluminum oxide is added to generate obvious crack bifurcation and bending to lengthen a crack path, so that the phase change effect of the zirconium oxide is strengthened; and meanwhile, by thermal mismatch of the aluminum oxide and the zirconium oxide, the aluminum oxide is compressed in a matrix, a semi-coherent interface and carbonitriding structure is not easily formed at a crystal boundary, and quite high mechanical strength of the material is maintained. A composite foam ceramic is prepared by taking the polyurethane foam as a foam matrix, the polyurethane foam has an open network structure, it can be ensured that ceramic slurry freely permeates and mutually adheres, the polyurethane foam modified by a surfactant has certainhydrophilicity, the mechanical property of a final product is improved, by the sufficient resilience of the final product, it can be ensured that the shape can be quickly restored after excess slurryis extruded, and the polyurethane foam can be completely gasified without residues during high-temperature sintering.

Owner:常州兆威不锈钢有限公司

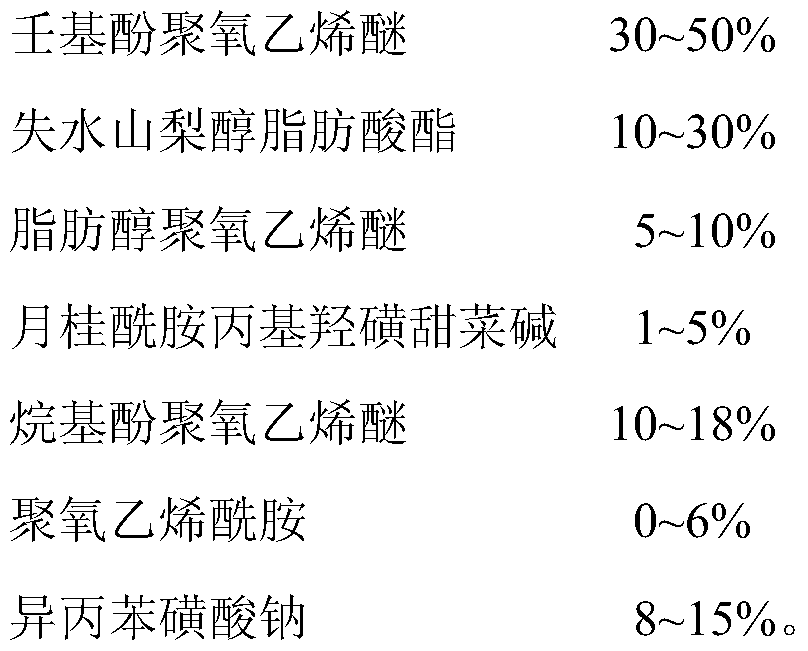

Water-soluble lubricant composition for hydrophilic coating aluminum foil and its preparation and usage method

InactiveCN1884458ASmall coefficient of frictionReduce lossBase-materialsSolubilityPolyethylene oxide

The invention discloses water-solubility lubricating composition and preparing method, comprises 70-90% poly ethylene glycol ether, 5-15% water-soluble resin, 0.5-1.5% levelling agent, 0.5-1.5% anti-freeze agent, 1-7% polyethylene oxide wax and 1.5-10% deionized water. The method comprises the following steps: carrying out polymerization reaction for diisocyanate and carbowax, terminating active end-group with terminating agent, diluting, cooling, getting polyethylene glycol ether, putting the materials into dispersion machine, stirring, and getting the product. The compound is coated on the surface of aluminum foil with roller coating cloth method, the net roll depth is 40-100 mu, the line is 75-165 line / inch, curing temperature is 100-250Deg.C, and curing time is 10-30s.

Owner:JIANGSU ALCHA ALUMINUM CO LTD

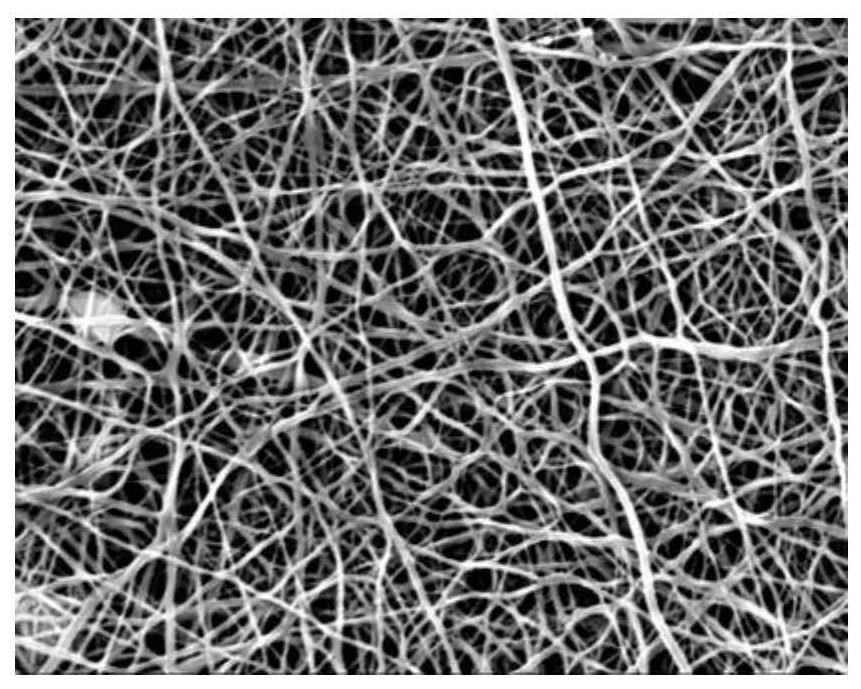

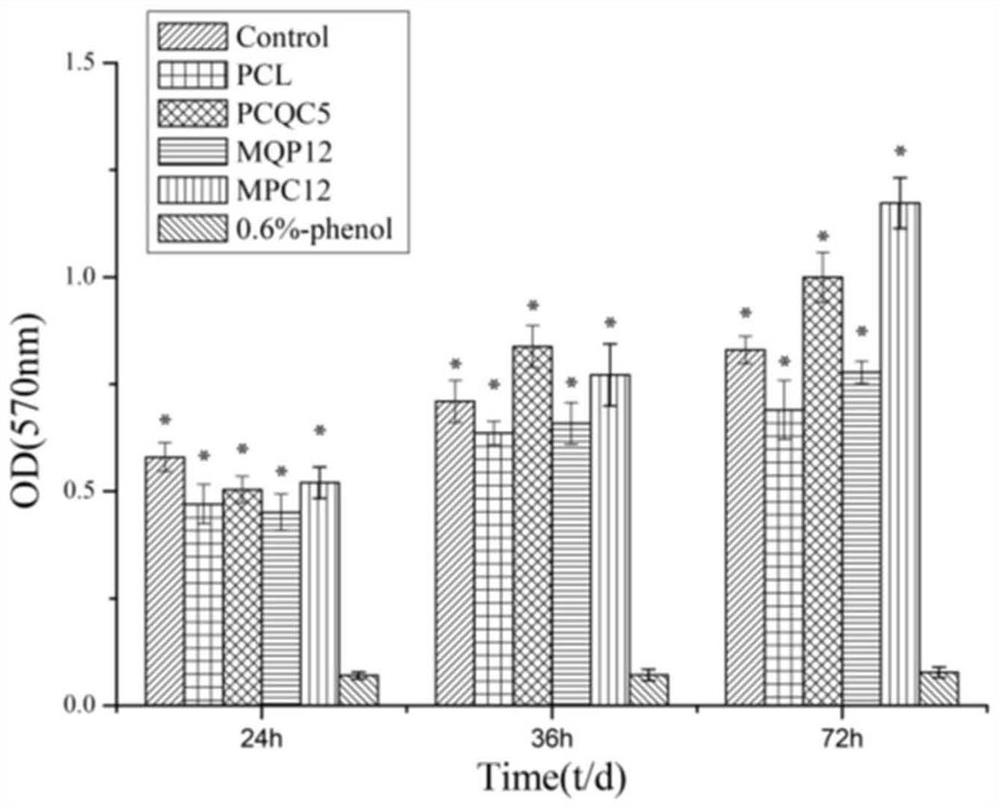

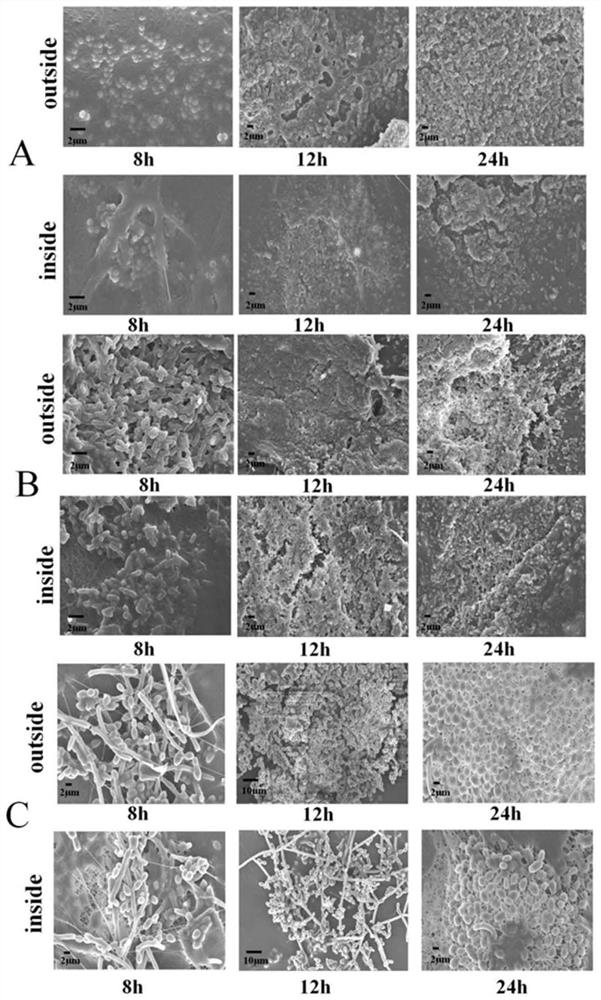

Medical composite nanofiber dressing as well as preparation method and application thereof

ActiveCN111939307AExcellent physical and chemical propertiesGood biological propertiesConjugated cellulose/protein artificial filamentsAbsorbent padsPolymer scienceTissue repair

The invention relates to a medical composite nanofiber dressing and a preparation method thereof. The dressing is divided into an inner layer and an outer layer, the inner layer contains polyvinyl alcohol, collagen and quaternized chitosan, the outer layer contains polycaprolactone and dodecyl substituted quaternized silicone, the polyvinyl alcohol, collagen and quaternized chitosan are mixed, aninner layer PCQC5 is prepared through an electrostatic spinning method, the polycaprolactone and dodecyl-substituted quaternized silicone QP12 are used as raw materials, and an outer layer is preparedthrough an electrostatic spinning method on the basis of the inner layer PCQC5. The dressing can be used for tissue repair or scar repair, and has wide application in the field of antibacterial materials or medical instruments.

Owner:BINZHOU MEDICAL COLLEGE

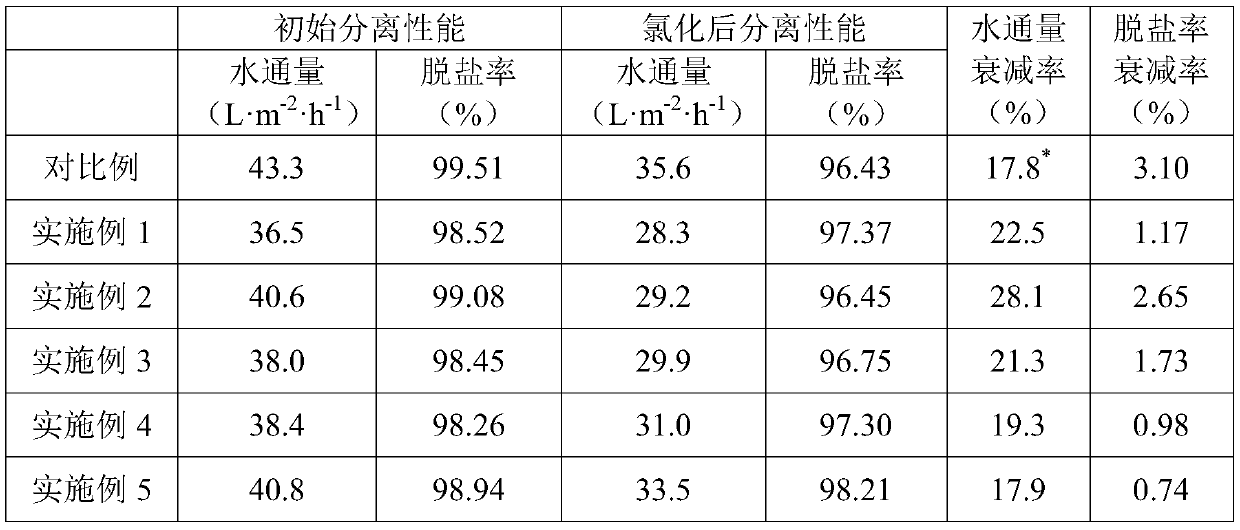

Polyamide composite reverse osmosis membrane with chlorine resistance and preparation method thereof

ActiveCN111282458ADoes not damage the structureImprove chlorine resistanceSemi-permeable membranesMembranesPolymer scienceReverse osmosis

The invention belongs to the technical field of organic membrane materials, and particularly relates to a polyamide composite reverse osmosis membrane with chlorine resistance and a preparation methodof the polyamide composite reverse osmosis membrane. The polyamide composite reverse osmosis membrane comprises a porous ultrafiltration membrane support layer, an aromatic polyamide separation layerand a sulfur-containing sacrificial functional component. The porous ultrafiltration membrane supporting layer is covered with the aromatic polyamide separation layer, the aromatic polyamide separation layer is covered with the sulfur-containing sacrificial functional component, and the sulfur-containing sacrificial functional component is connected with the aromatic polyamide separation layer through a covalent bond to form the polyamide composite reverse osmosis membrane with chlorine resistance. The sulfur-containing sacrificial functional component comprises a polyamine mediation unit anda sulfur-containing sacrificial unit, and the polyamine mediation unit and the sulfur-containing sacrificial unit are covalently bonded and pre-assembled and then introduced to the surface of the aromatic polyamide separation layer through a chemical bonding method. The sulfur-containing sacrificial functional component can effectively prevent active chlorine from diffusing to the aromatic polyamide separation layer, so that the chlorine resistance of the polyamide composite reverse osmosis membrane is greatly improved.

Owner:自然资源部天津海水淡化与综合利用研究所

Preparation method of porous folded graphene with high specific surface area

ActiveCN108033440AFacilitate ultrasonic atomization treatmentReduce reunionGrapheneCvd grapheneSolvent

The invention provides a preparation method of porous folded graphene with high specific surface area. A oxidized graphene solution and a water-soluble nitrogenous compound are mixed; after reaction is performed for certain time at certain temperature, pore forming agents are added and are uniformly mixed to obtain mixed liquid; the mixed liquid is subjected to ultrasonic atomization; heating is performed at certain temperature, so that the solvent in the mixed liquid is volatilized; oxidized graphene / pore forming agent powder particles are obtained; the obtained oxidized graphene / pore forming agent powder particles are collected and are subjected to heat treatment under the inert gas protection; a folded graphene product with high specific surface area is obtained, wherein the heat treatment temperature is 600 to 1100 DEG C; the pore forming agents are NaOH, KOH, K2CO3 and the like; the specific surface area of the obtained product is 1000 to 2000m<2> / g. The appearance of the foldedgraphene is maintained; meanwhile, high specific surface area can be obtained.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

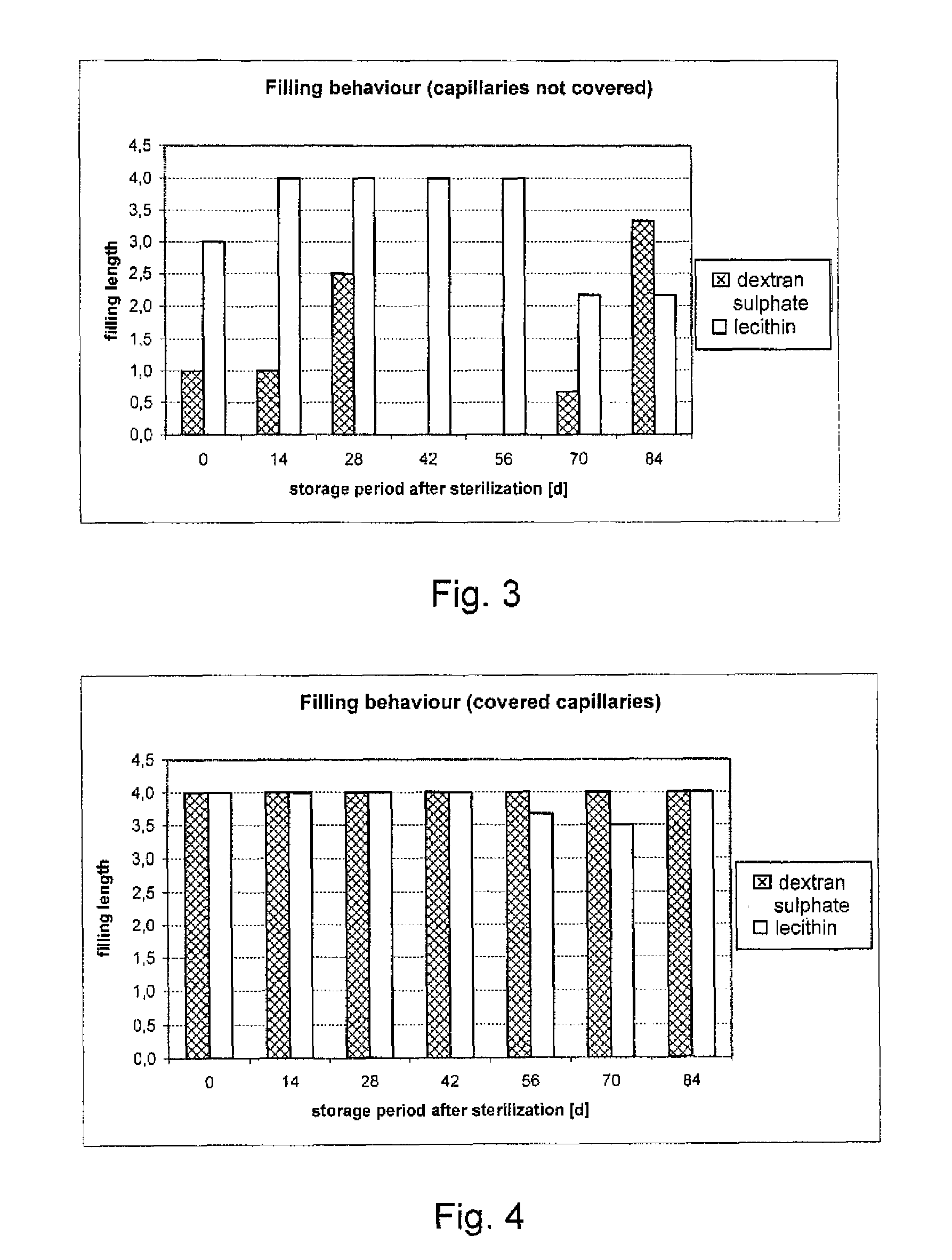

Package for an object having a hydrophilic surface coating

ActiveUS20090198119A1Reduce adsorptionIncreasing costSurgical needlesLaboratory glasswaresChemistrySurface coating

A package for an object having a hydrophilic surface includes at least one of a loose cover for the hydrophilic surface and an adsorbing surface, the affinity of which for apolar gases is equal to or greater than that of the hydrophilic surface.

Owner:ROCHE DIABETES CARE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com