Patents

Literature

738results about How to "Does not damage the structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

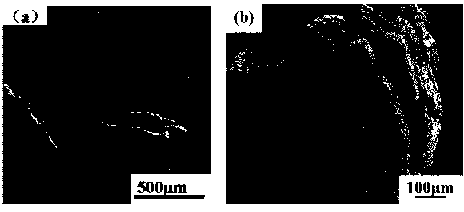

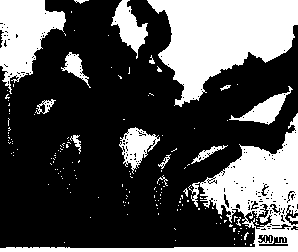

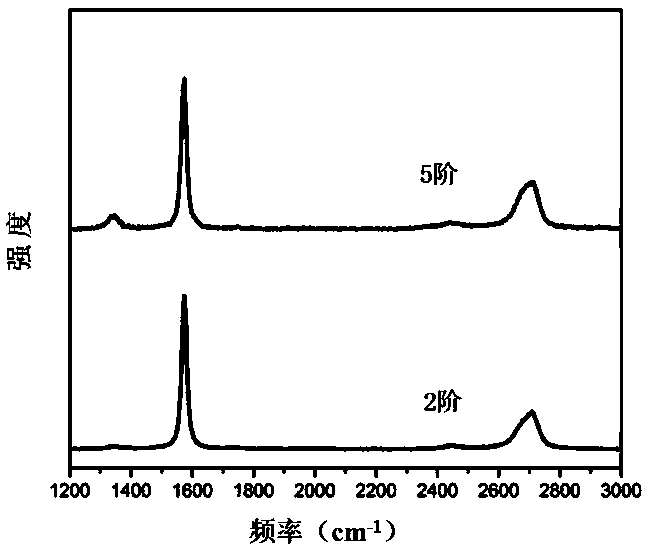

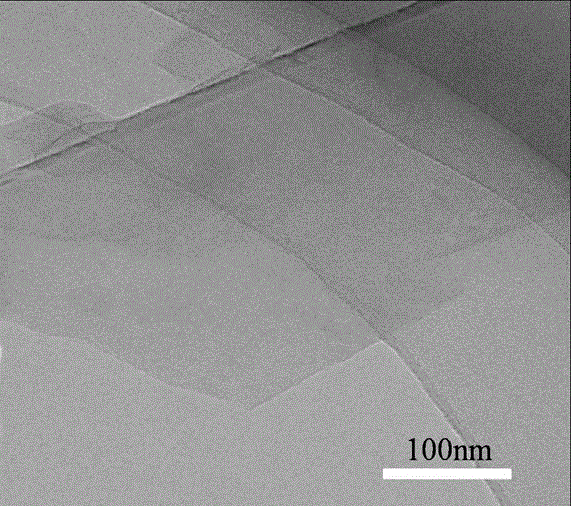

Method for preparing large-size high-quality graphene with controllable number of layers

The invention discloses a method for preparing large-size high-quality graphene with controllable number of layers, wherein graphite powder or flake graphite is mainly adopted as a raw material. The method specifically comprises the steps of intercalating the graphite raw material by virtue of an intercalating agent to initially weaken the intercalation interaction force and obtain different orders of graphite intercalation compounds (GICs); soaking the GICs in an appropriate expander, and then under the case that an auxiliary agent is added or not, enabling the intercalation materials to be quickly reacted with the expander to release a gases to obtain highly expanded wormlike graphene aggregate and further to cause the distances among graphene lamellar layers to be increased; and after certain processing, peeling, and then repeatedly centrifuging and dispersing to obtain a graphene dispersion with different numbers of layers. According to the method disclosed by the invention, the intercalation-expansion-peeling process is involved, raw materials are cheap, the reaction process is simple and easily controlled, and the number of layers of graphene is precisely controlled; the obtained graphene lamellar layers have the advantages of few defects, large size, high conductivity, high yield and the like, the large-scale industrial production is easily implemented, and the problems of high cost, low productivity, poor quality, small size, uncontrollable number of layers and the like in an existing graphene preparation technology are solved.

Owner:安徽百特新材料科技有限公司

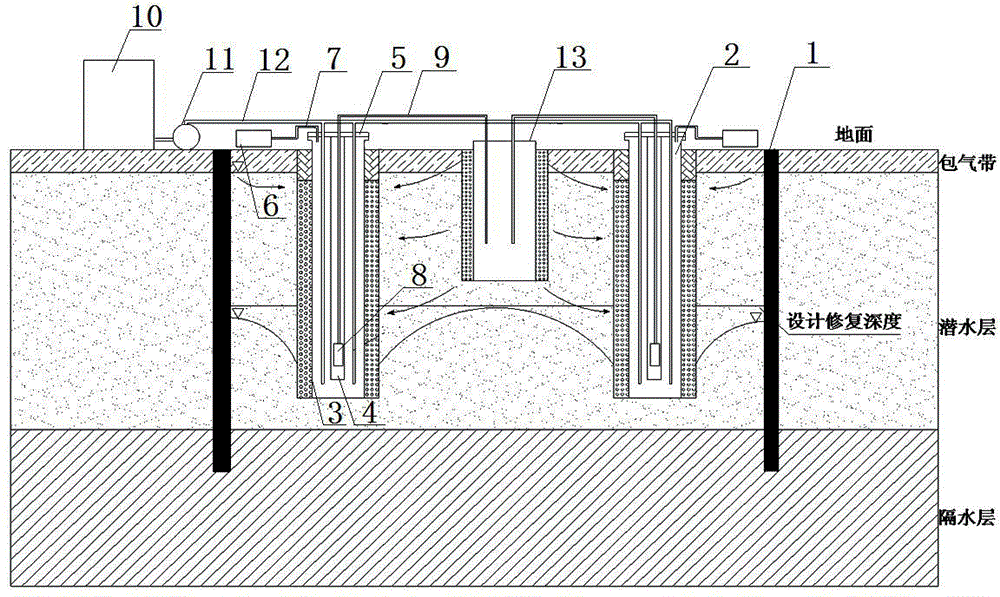

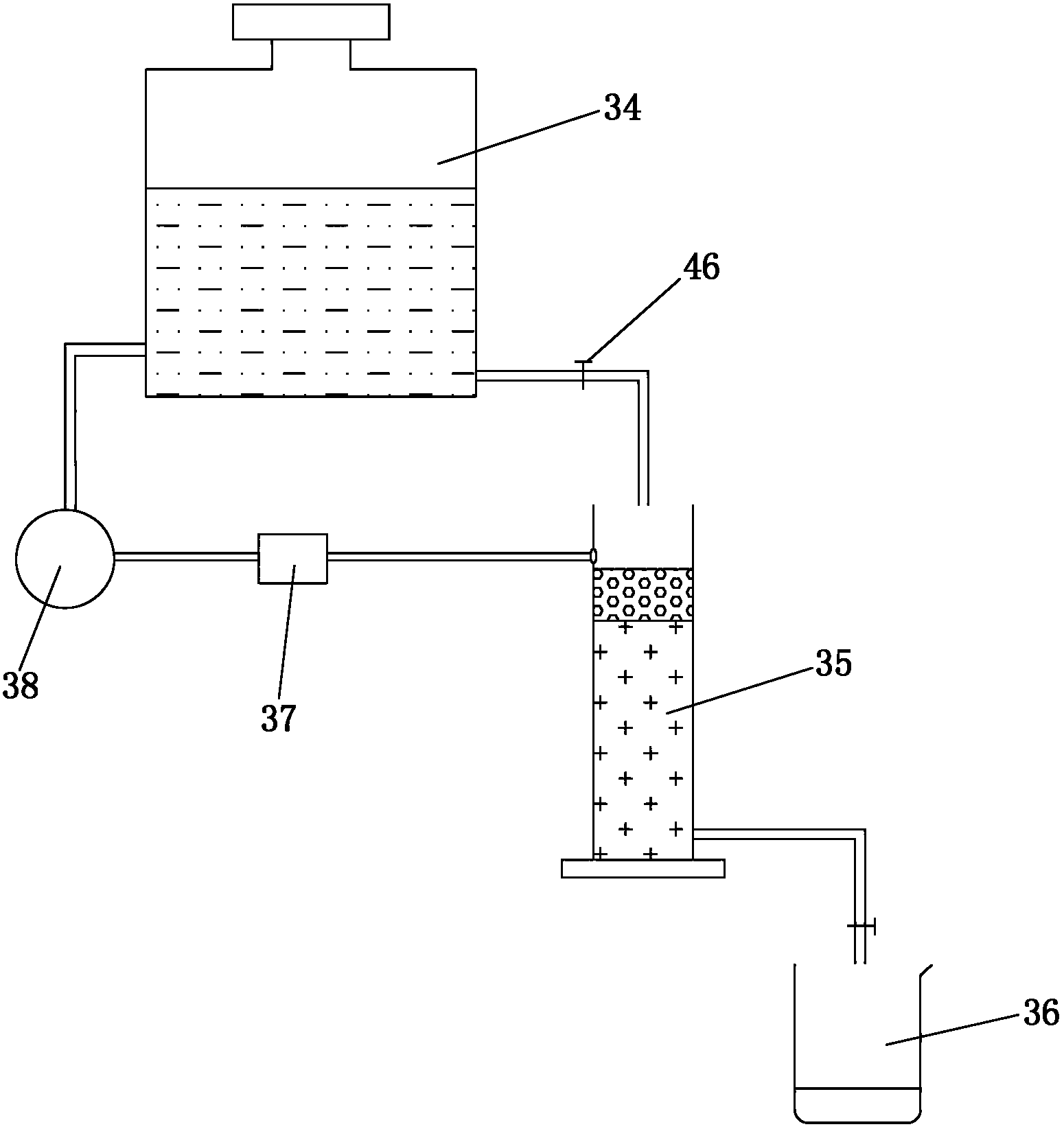

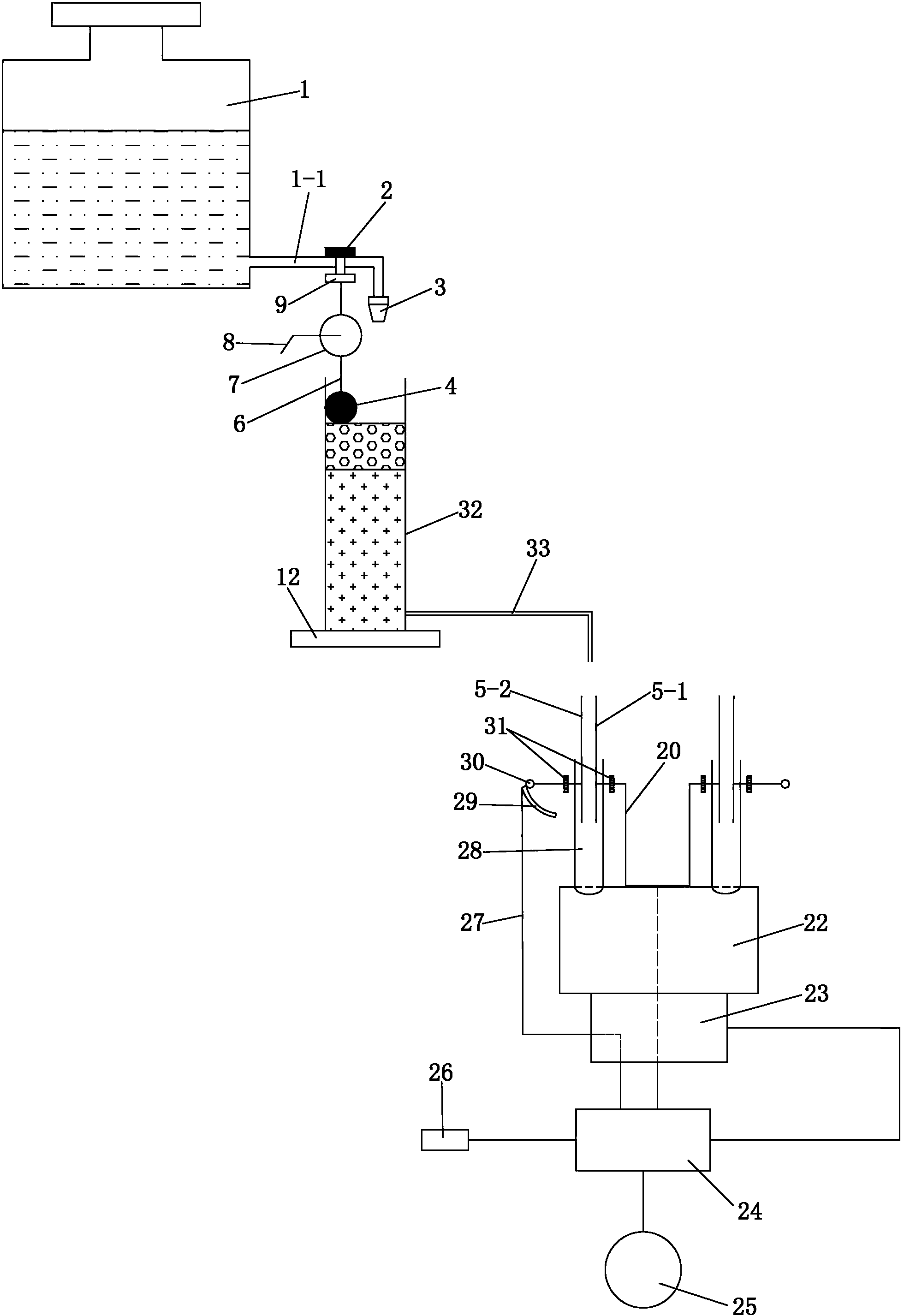

Vacuum tube well precipitation and disposal method for rapidly restoring in-situ water and soil in polluted place

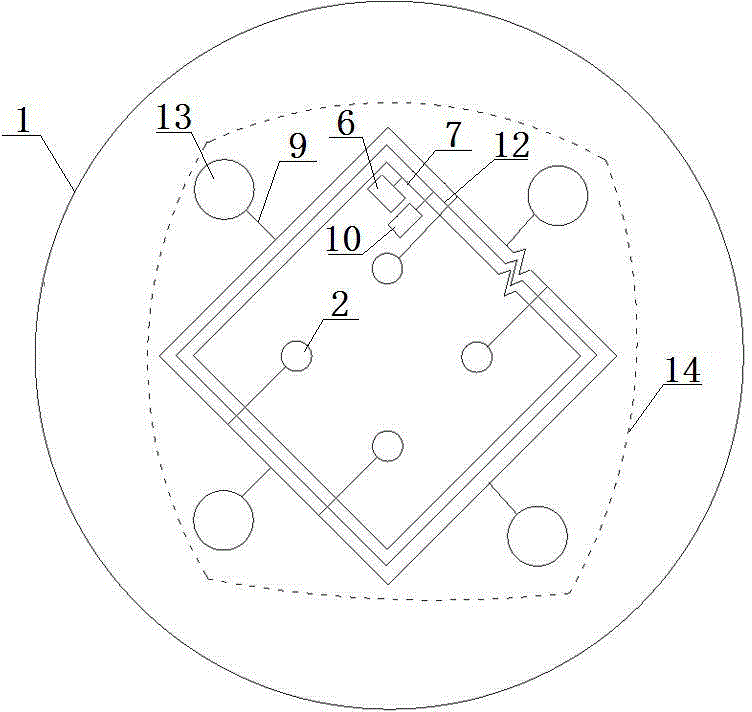

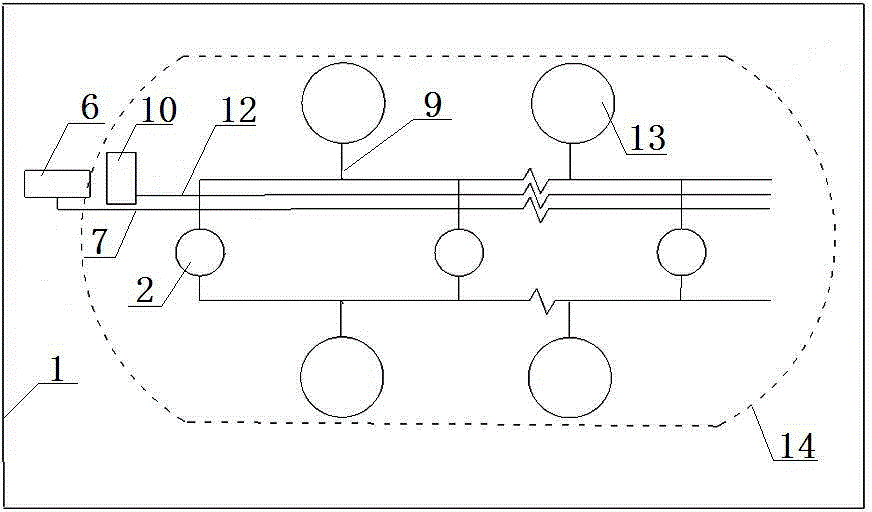

ActiveCN104358267ALarge amount of waterImprove water collection efficiencySoil preservationEnvironmental engineeringVacuum pump

The invention discloses a vacuum tube well precipitation and disposal method for rapidly restoring in-situ water and soil in a polluted place. The method comprises the following steps: arranging a precipitation tube well in a polluted region, and arranging a vacuum pump air extracting system, a submerged pump water pumping system and a chemical filling pipe in the precipitation tube well; arranging a disposal well in the polluted region, and connecting the disposal well with the submerged pump water pumping system; starting the vacuum pump air extracting system so as to guide polluted water in soil to flow into the precipitation tube well; continuously adding a restoring chemical into the chemical filling pipe, and reacting with the polluted water entering the precipitation tube well; after reacting for certain time, starting the submerged pump water pumping system, delivering pumped water into the disposal well, infiltrating the water in the disposal well into the soil again, repeatedly operating in the way, and finishing restoring after detecting that water and oil specimens meet standards. The method has the advantages of low cost, high water collecting efficiency, large affecting radius and capability of promoting underground water hydraulic circulation, and realizes water and soil integrated restoration in the polluted place.

Owner:SHANGHAI GEOTECHN INVESTIGATIONS & DESIGN INST

Nano crystallite composite filter material and supplement of manufacture method thereof

The invention extends the connotation range required to be protected on the basis of a previously issued patent ZL200710025045.4, i.e., a nanometer microcrystalline composite filter material and a preparation method thereof, belonging to the field of a water disposal technique material. According to weight percentage, the nanometer microcrystalline composite filter material comprises 3-95 percent of attapulgite clay, 5-80 percent of sepiolite clay, 2-25 percent of kaolinite clay, 2-97 percent of tubular halloysite, 5-75 percent of diatomite, 5-75 percent of natural zeolite (clinoptilolite, mordenite and the like), 0-25 percent of pillared montmorillonite, 0-50 percent of expanded vermiculite, 0-5 percent of expanded perlite and 0-50 percent of active carbon or bamboo carbon powders. All raw materials which are powder shapes are mixed according to proportion and stirred to granulate by adding an inorganic adhesive, then sintered and activated at the temperature of 900-500 DEG C (inert gas is required for sintering and activating the filter material added with active carbon). The nanometer microcrystalline composite filter material has smooth shape, rough surface and uniform particle size, with the diameter of 1-10mm, and is used for biological filter tanks and high-class adsorption filter materials in deep purification systems of drinking water and reclaimed water sewage disposal systems.

Owner:傅成义

Method for repairing soil of cadmium polluted by solanaceae plant

InactiveCN1724184APrevent water erosionReduce water erosionContaminated soil reclamationPollution soilInflorescence

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

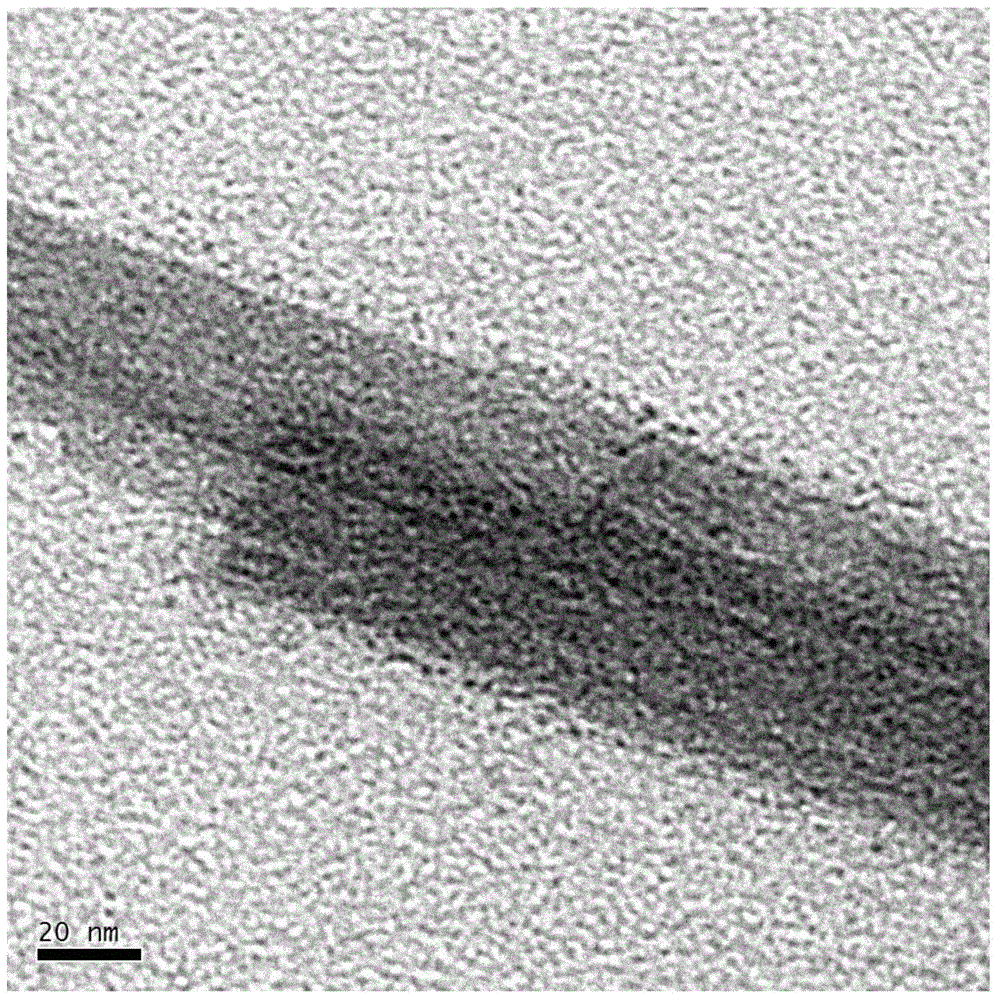

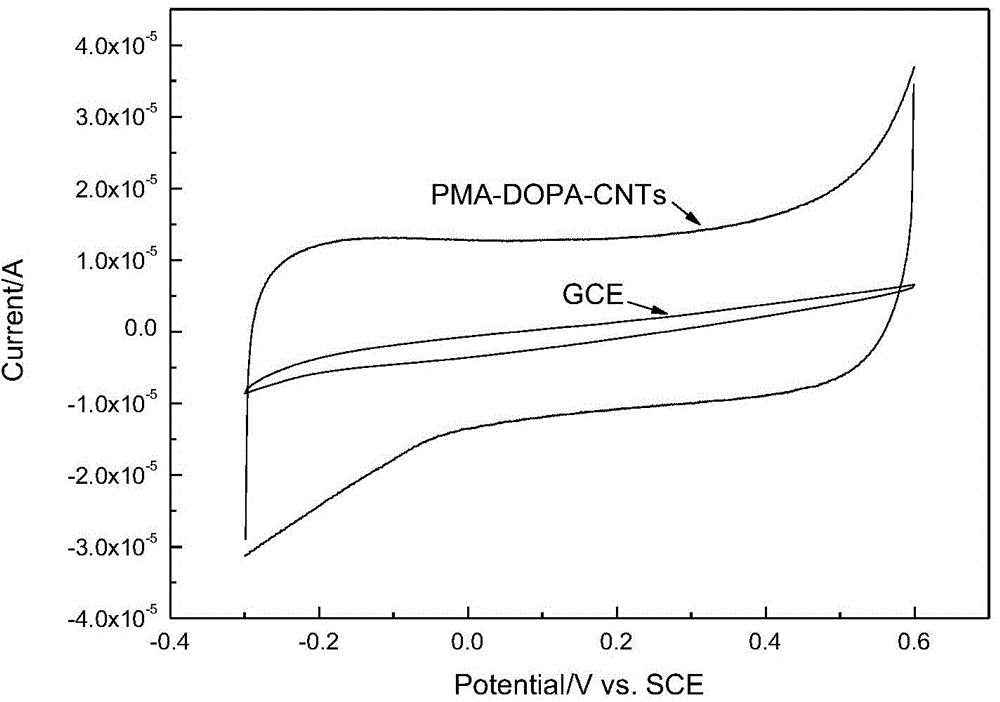

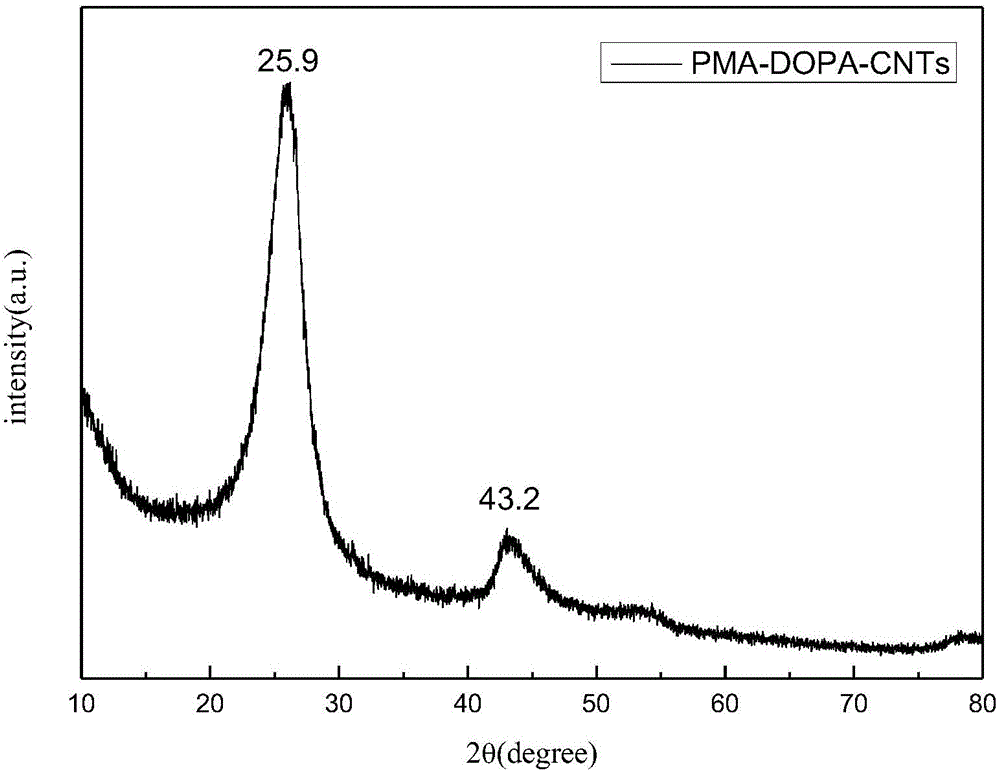

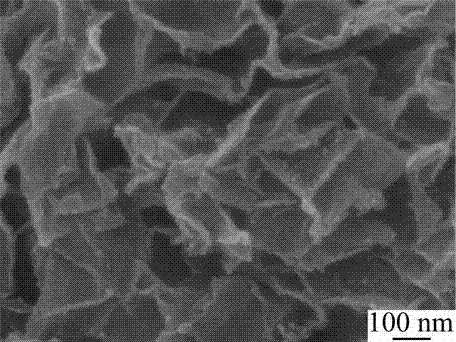

Preparation method for heteropoly acid functional composite material adopting dopamine modified carbon nano tube as carrier

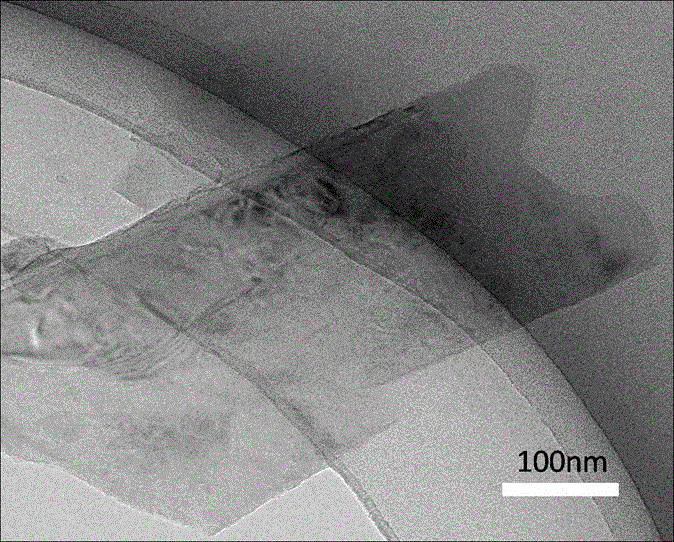

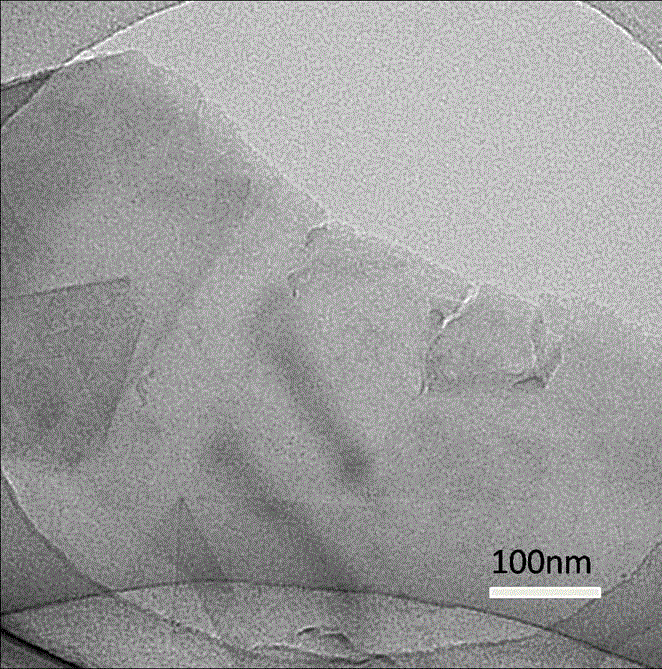

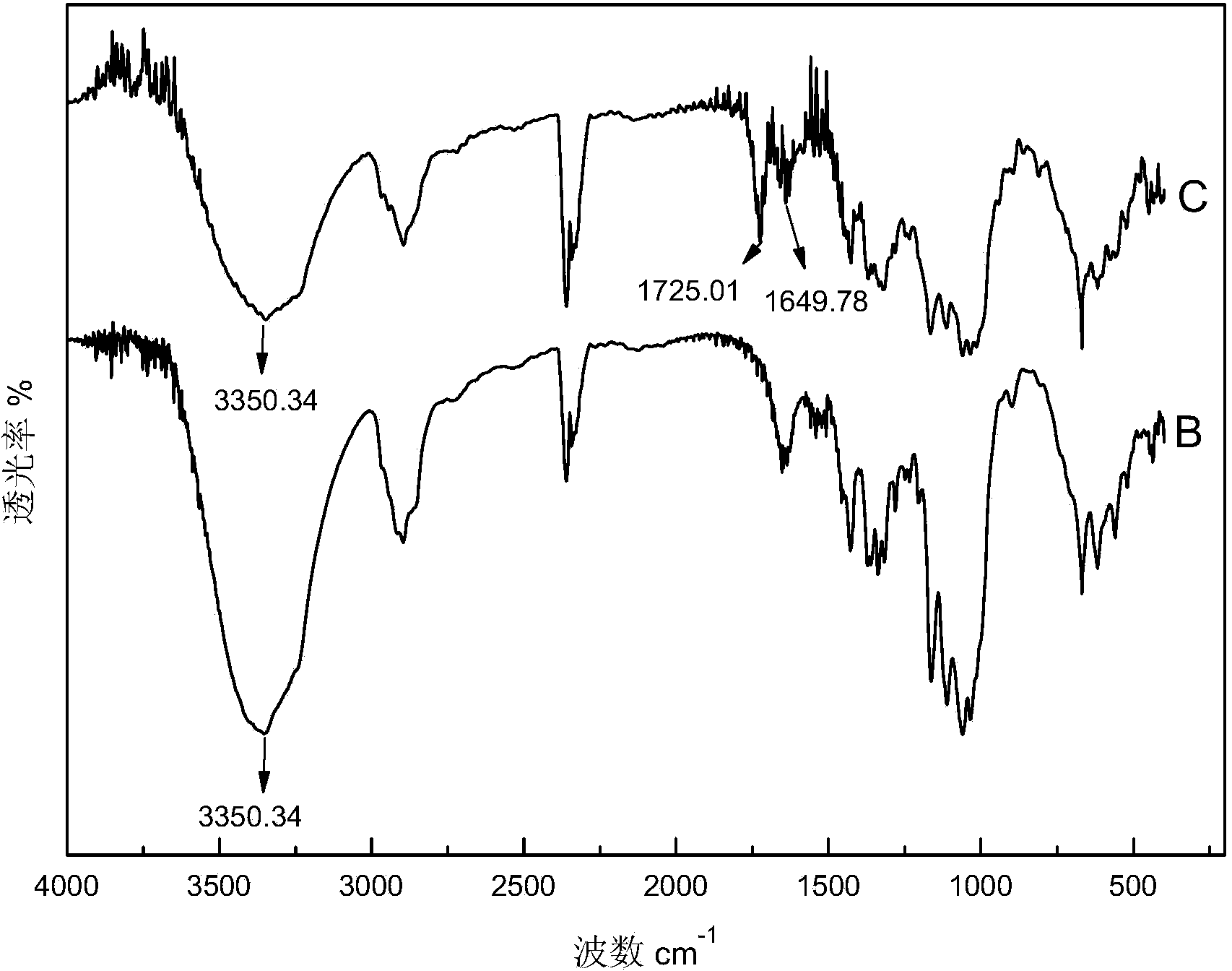

ActiveCN104477881ADoes not damage the structureNon-destructive propertiesMaterial nanotechnologyCarbon nanotubeFunctional composite

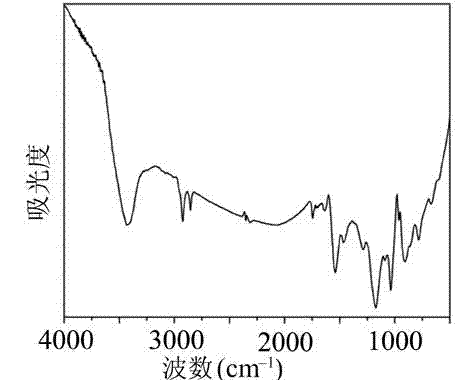

The invention relates to the technical field of nanometer materials, and particularly discloses a preparation method for heteropoly acid functional composite material adopting a dopamine modified carbon nano tube as a carrier. The preparation method comprises the following steps: first, utilizing dopamine to generate oxypolymerization reaction in a Tris-HC1 buffer solution at the room temperature to modify the surface of a carbon nano tube to obtain a poly-dopamine modified carbon nano tube; then adopting an impregnation method to load heteropoly acid on the surface of the poly-dopamine modified carbon nano tube; reacting for certain time so as to obtain the heteropoly acid loading dopamine modified carbon nano tube composite material finally. The preparation method is conducive to realizing uniform and directional loading of heteropoly acid on one hand, improves the utilization ratio and the application range of the carbon nano tube on the other hand, is simple in steps and low in cost, can be reused, and has potential application prospect in the fields of fuel cells, sensors, electric coloration devices and the like.

Owner:HUBEI ENG UNIV

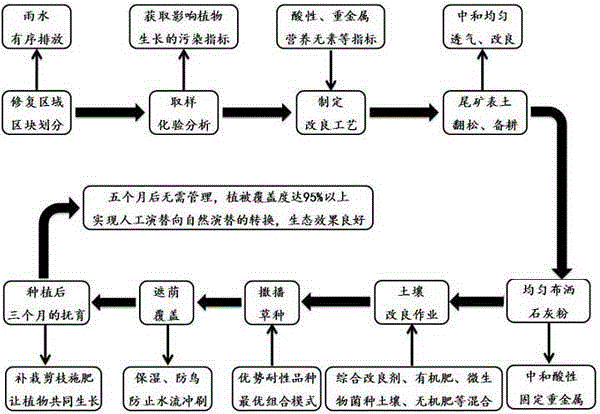

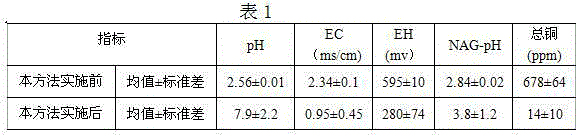

Method for recovering vegetation on strong-acid tailing waste land without soil

ActiveCN104624620AGood water solubilityEffective penetrationContaminated soil reclamationHorticultureRevegetationAcid water

The invention discloses a method for recovering vegetation on a strong-acid tailing waste land without soil. The method is characterized by comprising the following steps: A. performing early-stage preparations, and draining off water; B. changing the pH value of the land; C. culturing the fertility of the tailing waste land; D. screening and culturing plant varieties; and F. managing transplanted seedlings. The method has the advantages that by adopting the method for recovering the vegetation without soil, disturbance to the tailing land is reduced, and the purposes that water can be drained off, the influence of acid water to the vegetation can be alleviated, the heavy metals can be stabilized, and the living environment of plants is improved are achieved. In addition, according to the method, the cost is low, the effect taking is rapid, the effect is good and the operability is high.

Owner:CHINA NERIN ENG

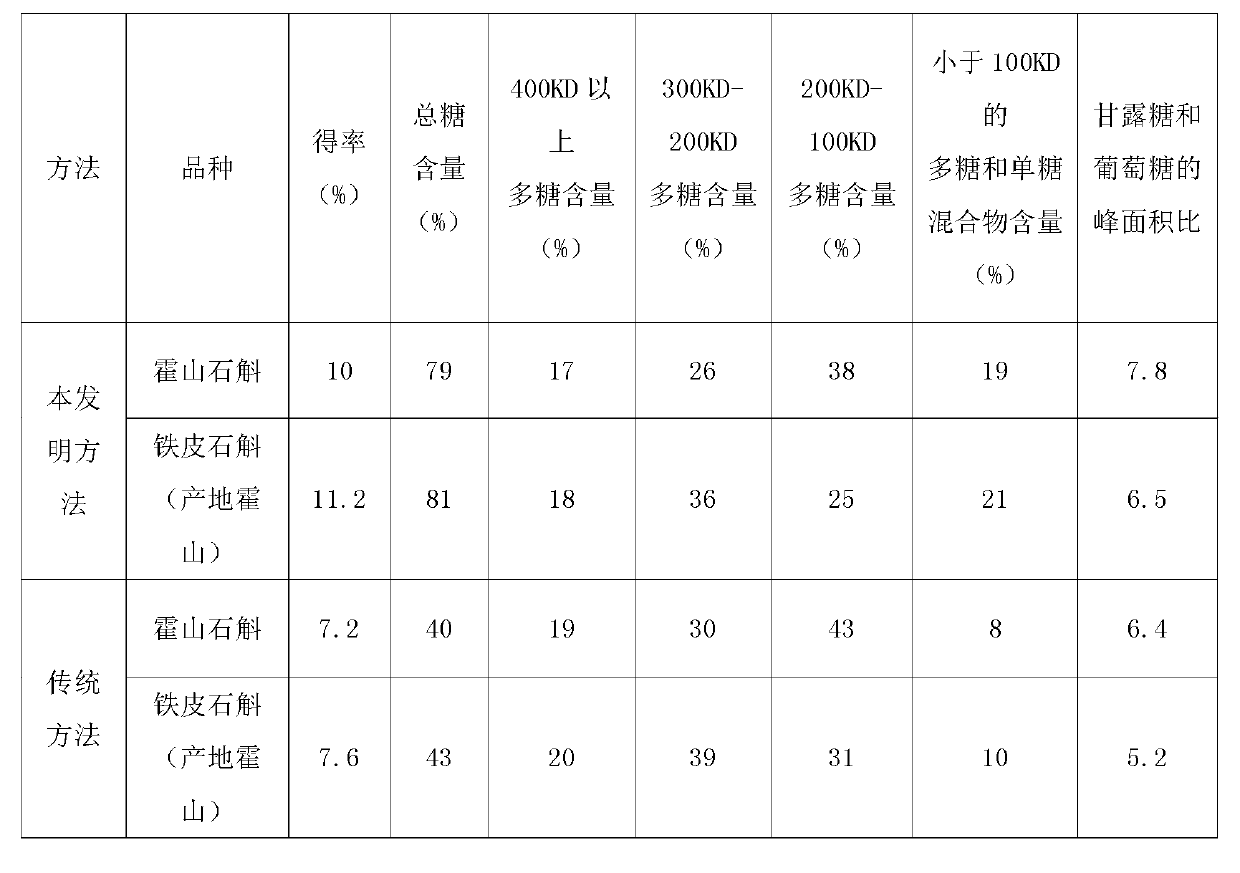

Auxiliary extraction method of biological enzyme for improving dissolution rate of dendrobe bioactive polysaccharide

ActiveCN102964461AImprove dissolution rateLower protein contentAntinoxious agentsImmunological disordersChemistryEnvironmental resistance

The invention discloses an auxiliary extraction method of biological enzyme for improving the dissolution rate of dendrobe bioactive polysaccharide, which is used for auxiliary extracting of the dendrobe polysaccharide by various biological enzymes of which the most proper pH is close to be neutral in a compounding way step by step. The auxiliary extraction method comprises the following steps of: firstly selecting cellulose, xylanase and pectinase to decompose substances of dendrobe cell wall, i.e. cellulose, hemicellulose, pectin substance, decomposing protein and polypeptide in cells by proteasem, so that the polysaccharide can be sufficiently dissolved in water, and carrying out HPSEC (high performance size exclusion chromatography) separation, parallax and refraction detector detection, and a phenol-sulfuric acid method on a final product to detect the content of reducing sugar. According to the auxiliary extraction method, the dissolution rate of dendrobe bioactive polysaccharide can be effectively improved, the protein content can be obviously reduced, the product quality and the yield can be greatly improved, and the use and the discharge of the acid-base solution and the toxic organic reagent and the generation of the microwave radiation can be avoided in the production technology, so that the auxiliary extraction method is more energy-saving and environment-friendly.

Owner:安徽同济生生物科技有限公司

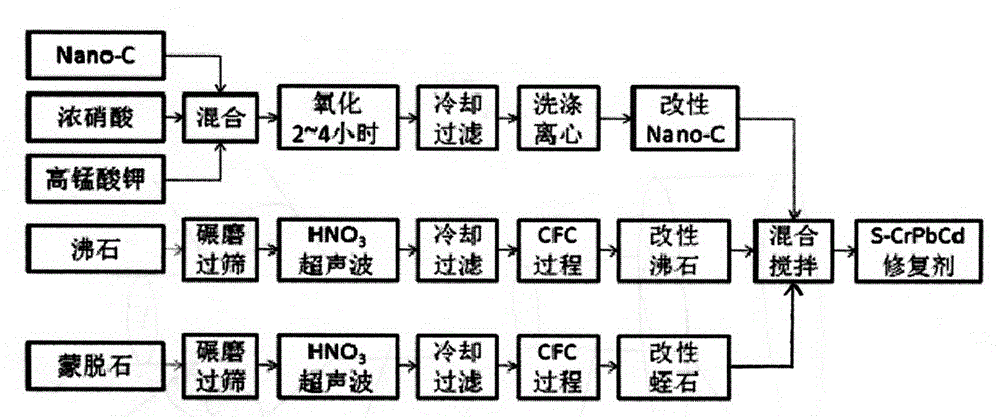

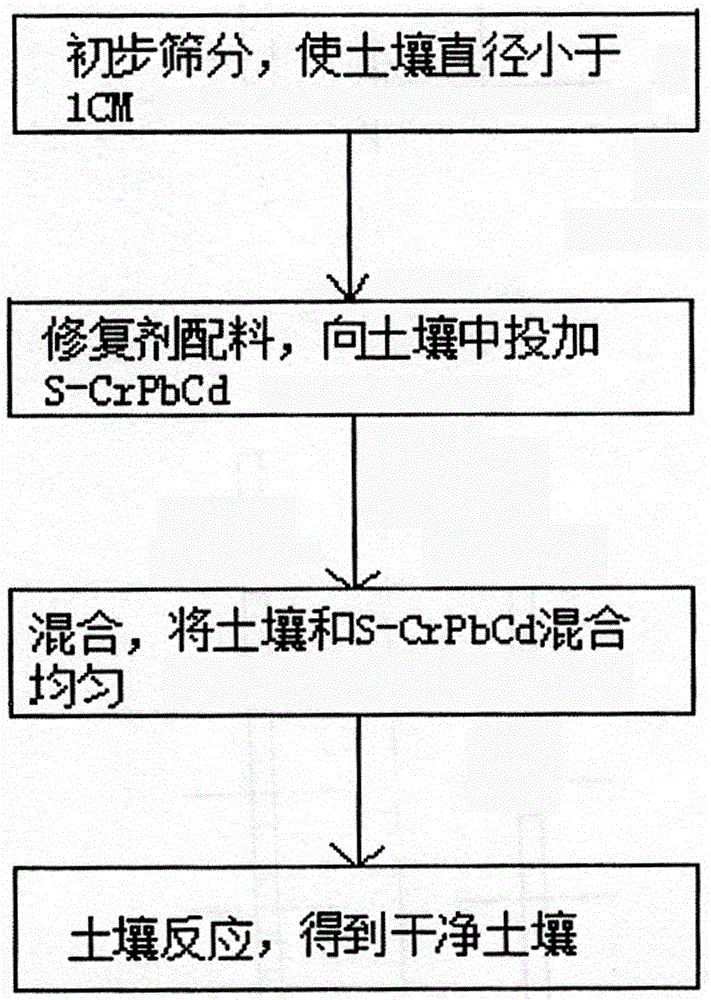

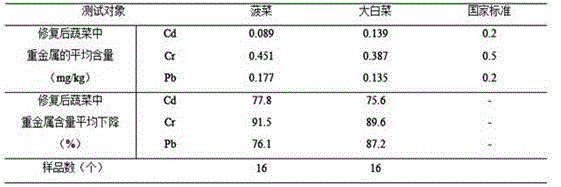

Novel material for repairing heavy metal Cr-Pb-Cd contaminated soil as well as preparation method and using method of novel material

ActiveCN104927870AGood restorativeImprove stabilityContaminated soil reclamationOrganic fertilisersSoil propertiesClay minerals

The invention discloses a novel material S-CrPbCd for repairing heavy metal Cr-Pb-Cd contaminated soil as well as a preparation method and a using method of the novel material S-CrPbCd. The material comprises 5-15 percent of modified carbon nano tube, 10-60 percent of modified clay mineral and 20-60 percent of quicklime. The S-CrPbCd can efficiently adsorb Pb, Cd and Cr in the soil, and does not obviously change the soil property and cultivability. The S-CrPbCd enables the residue amount of Pb, Cd and Cr in sensitive crops to be reduced to 75-90 percent within 1-2 months, and meanwhile, the material has the characteristics of low cost, simple preparation process, no secondary pollution, quick action and easiness in large-area popularization.

Owner:INST OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

Method for improving heavy metal-polluted soil

ActiveCN101722183AGood water solubilityEffectively fixedContaminated soil reclamationOrganic fertilisersSoil conditionerChelation

The invention discloses a method for improving heavy metal-polluted soil, which comprises the steps of: (1) modifying the heavy metal-polluted soil; (2) adding soil conditioner into soil; and (3) covering the soil, evenly mixing, and balancing for 0-6 months. The method restrains the oxidation of matrix by reactions such as absorption, chelation and complexation, and the like, fixes the heavy metal ion, reduces the biological toxicity of the soil, and reduces the diffusion and the leakage of the heavy metal ion to periphery soil or water. The method has low investment cost, can not break the structure of the soil, and is easily preformed.

Owner:SHAOGUAN TAOLIN GREEN TECH

Biological organic fertilizer and preparation method thereof

InactiveCN103483099AEasy to preparePromote growthBio-organic fraction processingOrganic fertiliser preparationBiotechnologyPotassium

The invention discloses a biological organic fertilizer which is composed of the following raw materials in parts by weight: 20-25 parts of chicken manure, 10-15 parts of cattle manure, 10-15 parts of sheep manure, 12-15 parts of peat soil, 6-10 parts of animal bone meal, 4-6 parts of animal wool meal, 4-6 parts of leaves, 6-8 parts of mushroom dregs, 0.01-0.03 part of copper oxide, 0.01-0.03 part of iron oxide, 0.01-0.03 part of magnesium, 2-4 parts of humic acid, 0.01-0.03 part of rhizobia, 0.03-0.06 part of azotobacteria, 0.01-0.03 part of phosphobacteria, 0.01-0.03 part of potassium bacteria, 2-4 parts of straws, 1-3 parts of egg-shell meal, 1-2 parts of rice chaff, 0.5-0.8 part of glucose and 0.05-0.08 part of borax. The invention also discloses a preparation method of the biological organic fertilizer. The biological organic fertilizer has high fertilizing capability, improves loose soil and protects ecological balance.

Owner:合肥科友生物科技有限公司

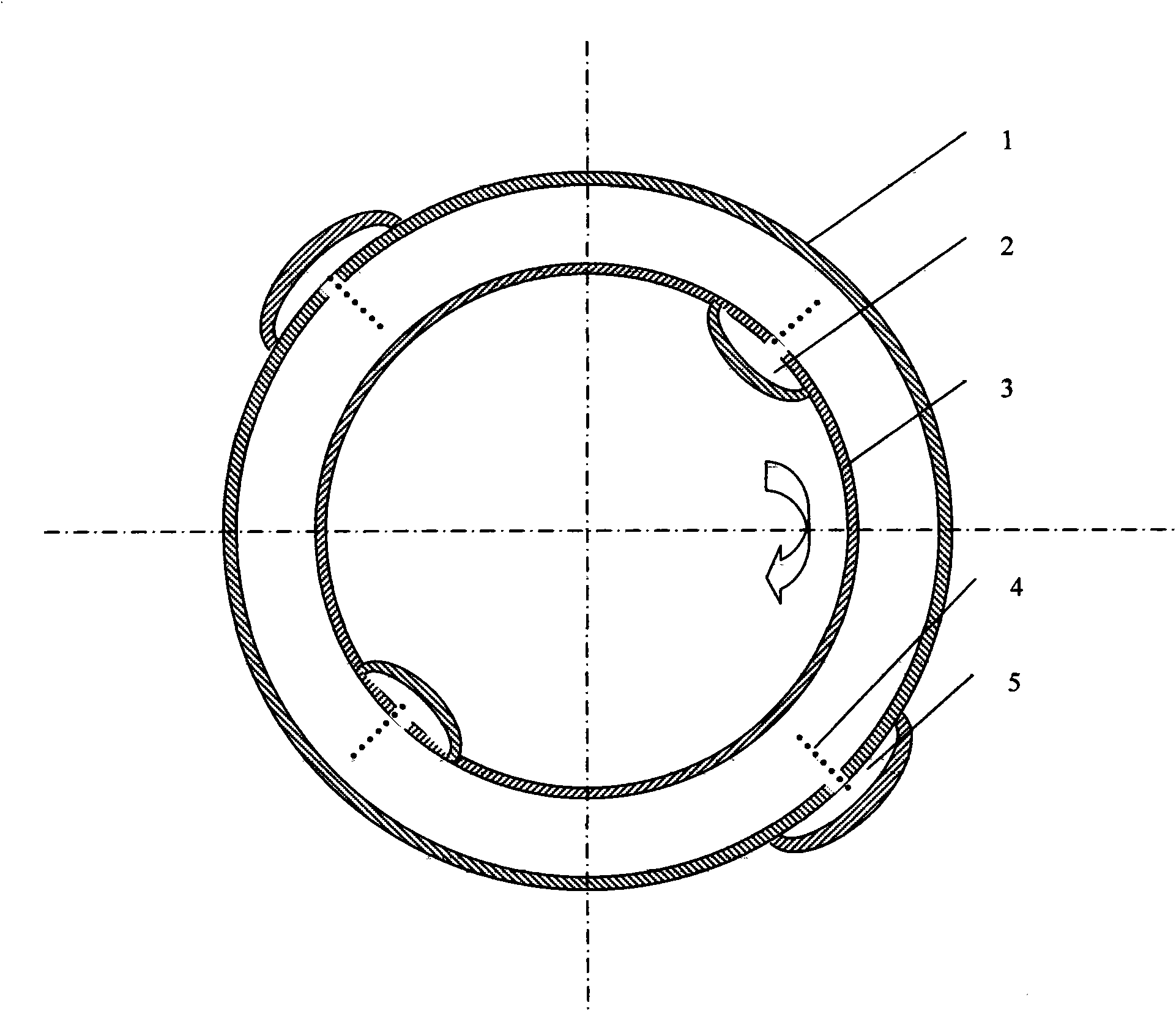

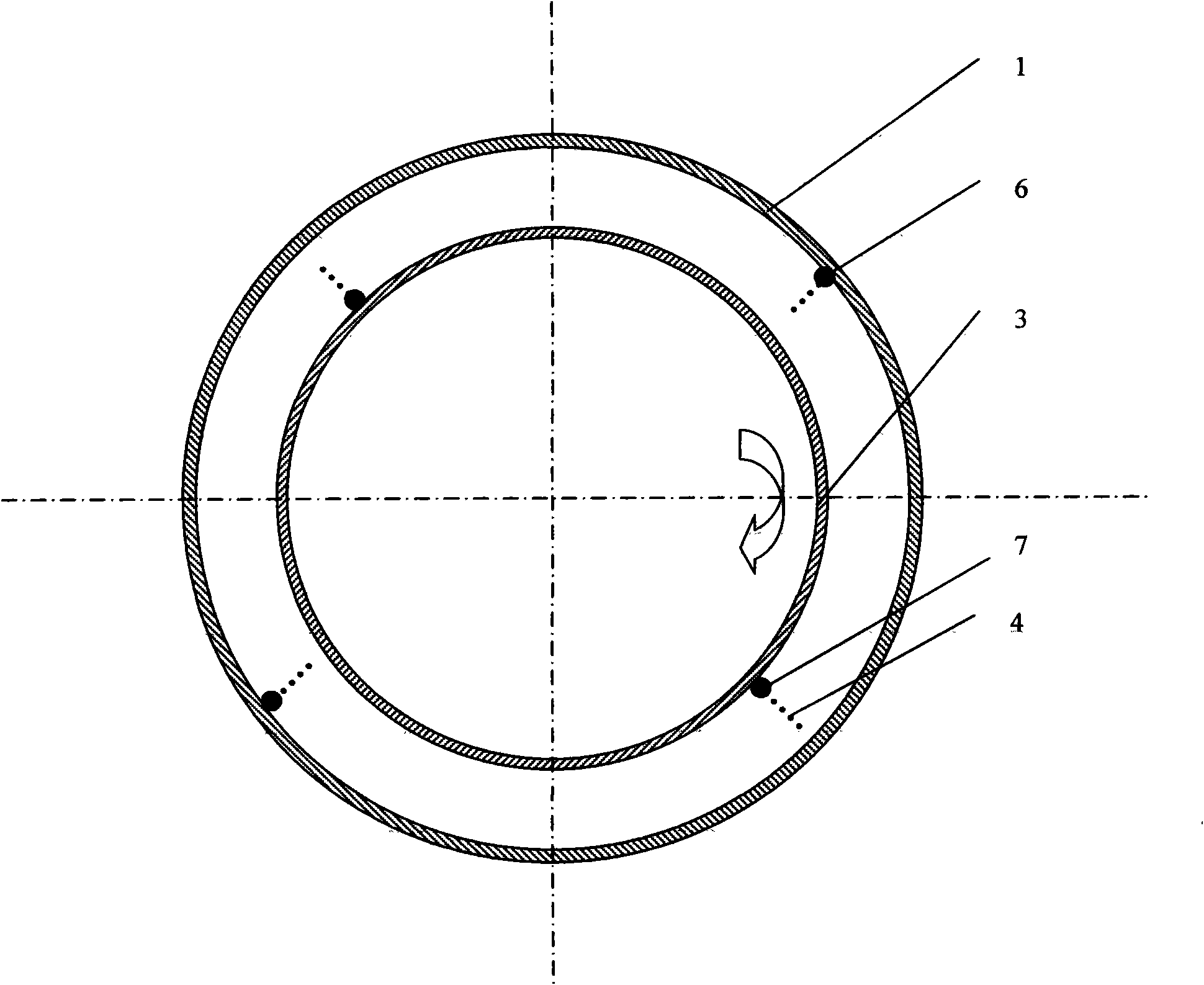

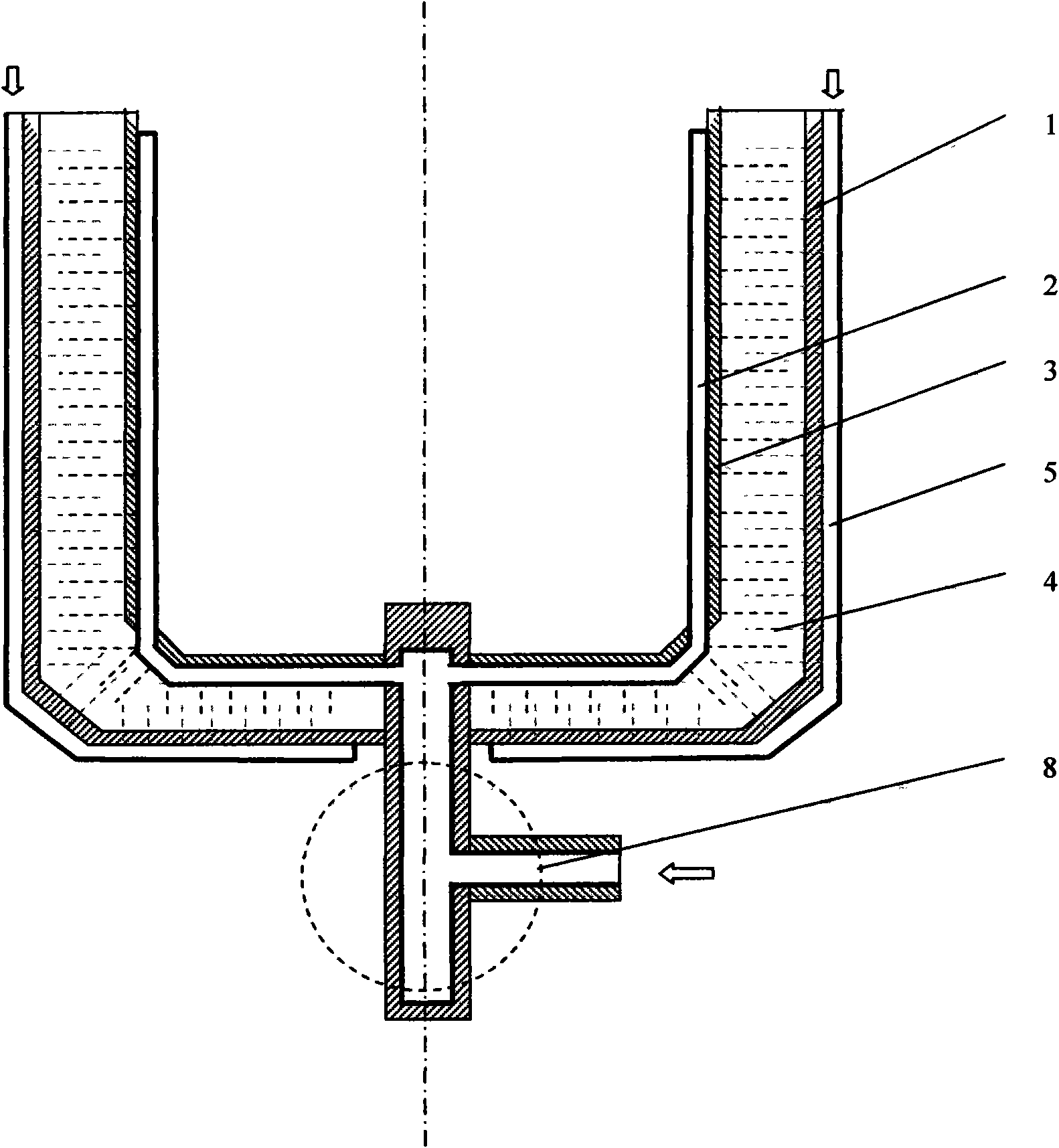

Self-cleaning device for dirt between barrels of washing machine

InactiveCN102134801AWon't wear outAvoid secondary pollutionOther washing machinesTextiles and paperWater flowPulp and paper industry

The invention relates to the technical field of washing machines, in particular to a method and device for simultaneously cleaning the outer wall of an inner barrel and the inner wall of an outer barrel of a washing machine, i.e., a self-cleaning device of a washing machine, which comprises water passages arranged on the inner barrel and the outer barrel of the washing machine; the passages can be integrated with the inner barrel or the outer barrel during manufacturing and can also be independent passages; many intensive holes in the water passages can form water curtains when water in the passages has pressure; a water curtain sprayed from the outer / inner barrel can respectively clean the inner / outer barrel of the washing machine so as to achieve the purpose of thoroughly cleaning dirt between the inner barrel and the outer barrel of the washing machine; cleaning water can be directly pressurized by running water or a booster pump; the water passage on the inner barrel of the washing machine can rotate together with the inner barrel of the washing machine; water in the water passage of the inner barrel is introduced through a rotating shaft of the washing machine; and a dynamic seal water supply device is used when the water is introduced into the rotating shaft, and the dynamic seal water supply device is characterized by supplying water to the hollow part of the shaft when the shaft rotates. A barrel cleaning program can be preset in a computer program when the washing machine is produced, so that the self-cleaning of dirt between the barrels of the washing machine is programmed. The device can be applied to impeller type washing machines and drum type washing machines.

Owner:朱雨轩 +1

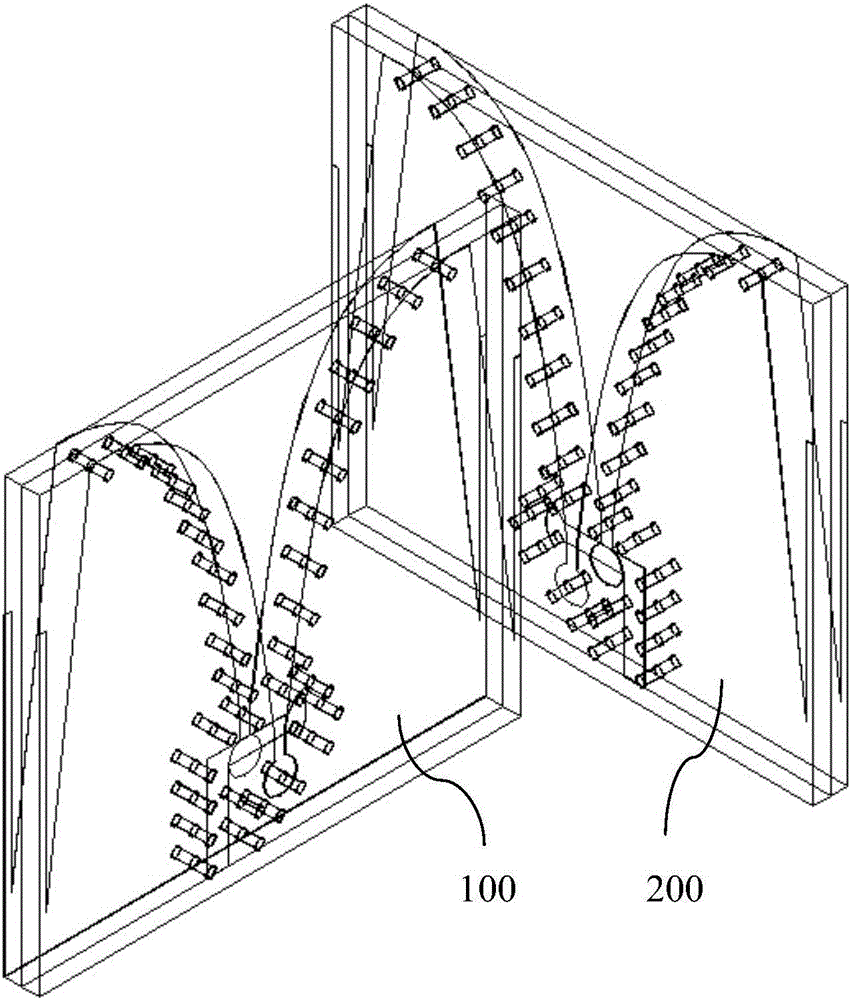

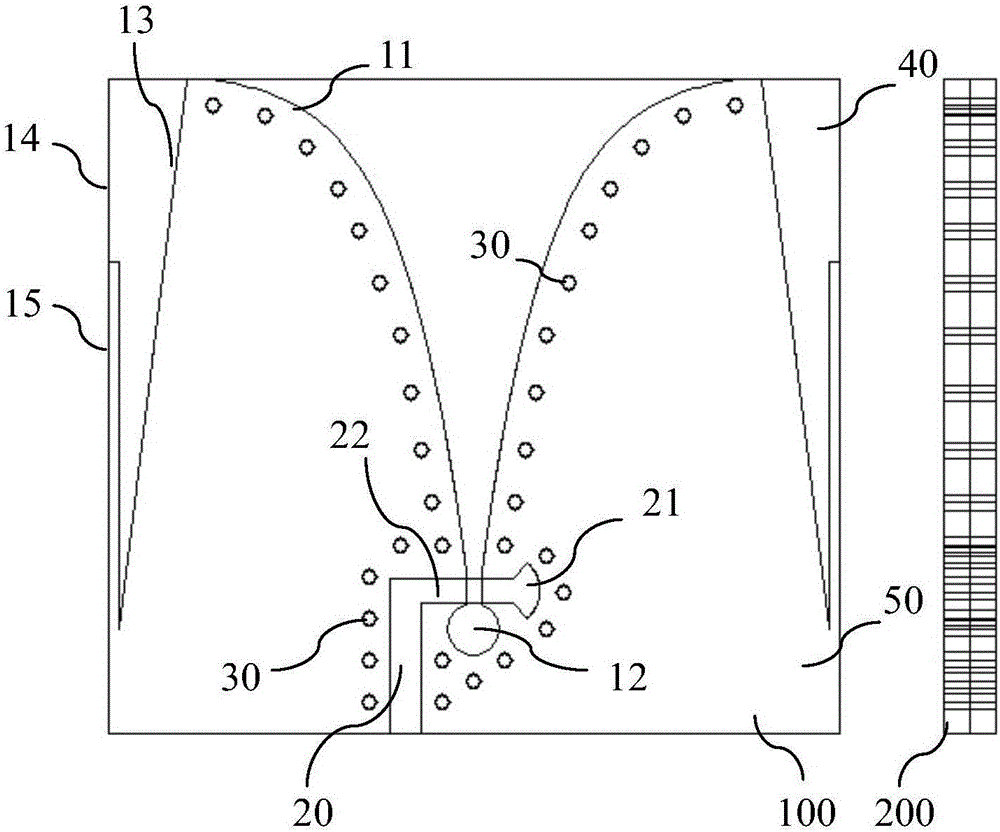

Broadband dual-linear polarization cone chopping groove antenna

ActiveCN106450702AFirmly connectedBroadened beamwidthRadiating elements structural formsAntennas earthing switches associationDual linear polarizationResonance

The invention relates to a broadband dual-linear polarization cone chopping groove antenna; a cone chopping groove radiating paste with a parasitic element and an inclined side is established; a series of metallic via holes are arranged at outline edges of the index line of the cone chopping groove antenna and a feed microstrip line; moreover, two linear polarized cone chopping groove antenna units are aligned according to T-shaped structure with disconnected middle part, so as to form a dual-line polarized antenna. The broadband dual-linear polarization cone chopping groove antenna has the property of wide wave beam of the broadband, and can eliminate the standing wave distorted point caused by resonance in scanning the wide angle of the broadband.

Owner:SHANGHAI RADIO EQUIP RES INST

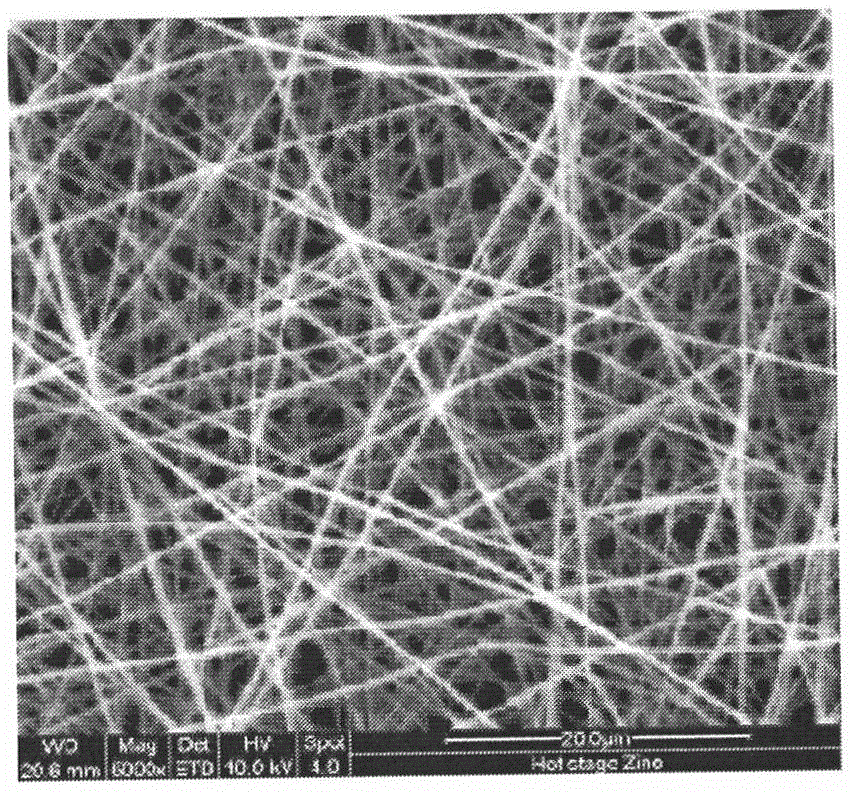

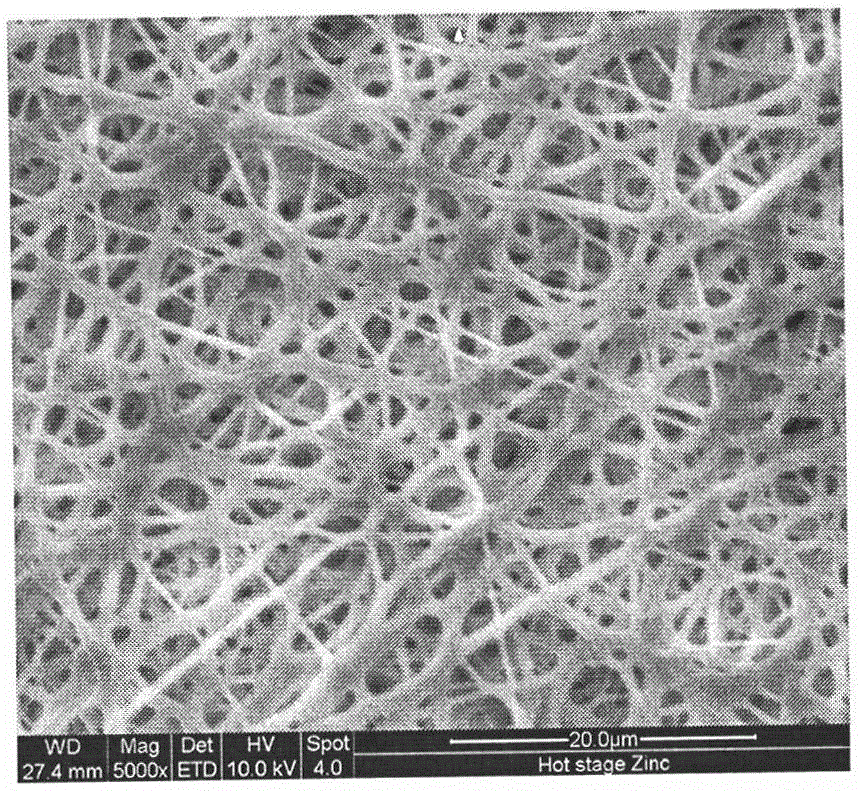

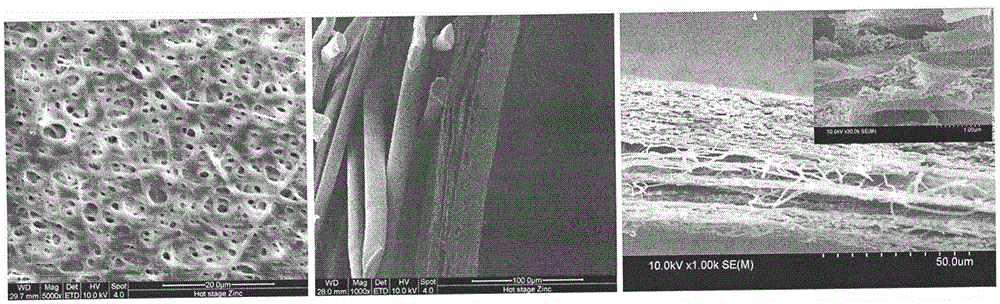

Preparation method of asymmetric porous membrane based on electrostatic spinning technology

InactiveCN105536579ASimple processEasily Control ApertureSemi-permeable membranesMembranesWound dressingNonwoven fabric

The invention provides a preparation method of an asymmetric porous membrane based on electrostatic spinning technology. The preparation method comprises the following steps of: (1) dissolving one or more polymers in a corresponding solvent to obtain a spinning solution of certain concentration; (2) carrying out electrostatic spinning with the spinning solution and receiving with common non-woven fabric to prepare a double-layer fiber membrane; (3) preparing a crosslinking solution with a certain ratio from one or more solvents, and placing in a specific container; and (4) covering the specific container with the double-layer fiber membrane, sealing the whole device with the membrane material while ensuring that the electrospun nano fiber layer faces the crosslinking solution, and carrying out fumigation crosslinking at 10-250 DEG C for 0-5h to obtain the asymmetric porous membrane. According to the preparation method, the nano fiber layer undergoes gradient crosslinking to obtain the porous membrane with asymmetric functional layers; and the average pore diameter of the porous membrane is easily adjustable in the range of 20-3000nm. The preparation method is simple in preparation process and low in equipment requirement; and the prepared porous membrane has high flux and good retention performance, and can be applied to the fields of membrane separation, tissue engineering, cell culture, wound dressings, cell diaphragms and the like.

Owner:TIANJIN POLYTECHNIC UNIV

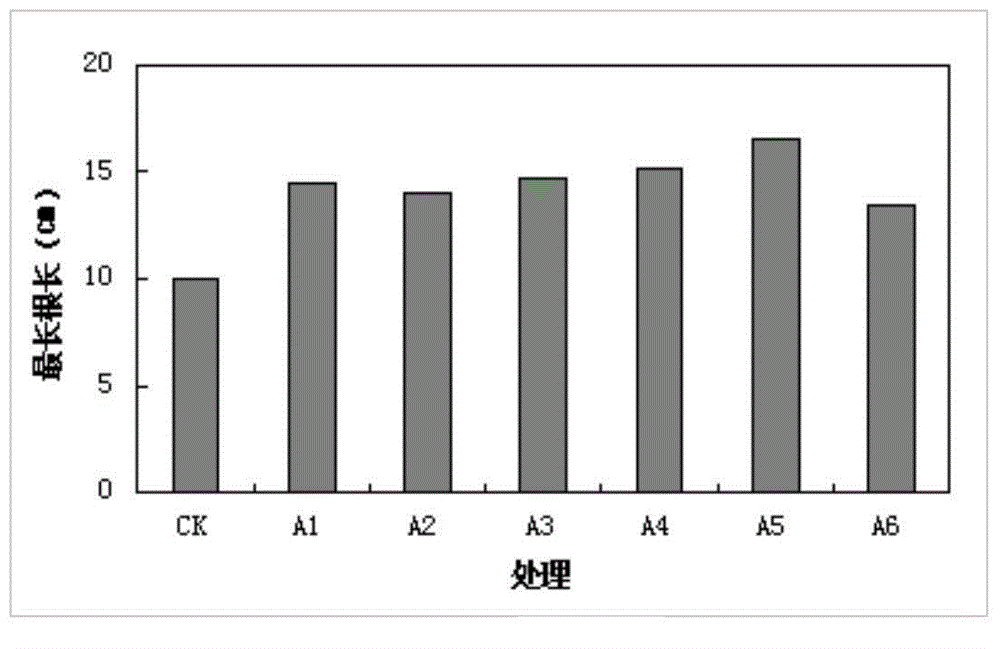

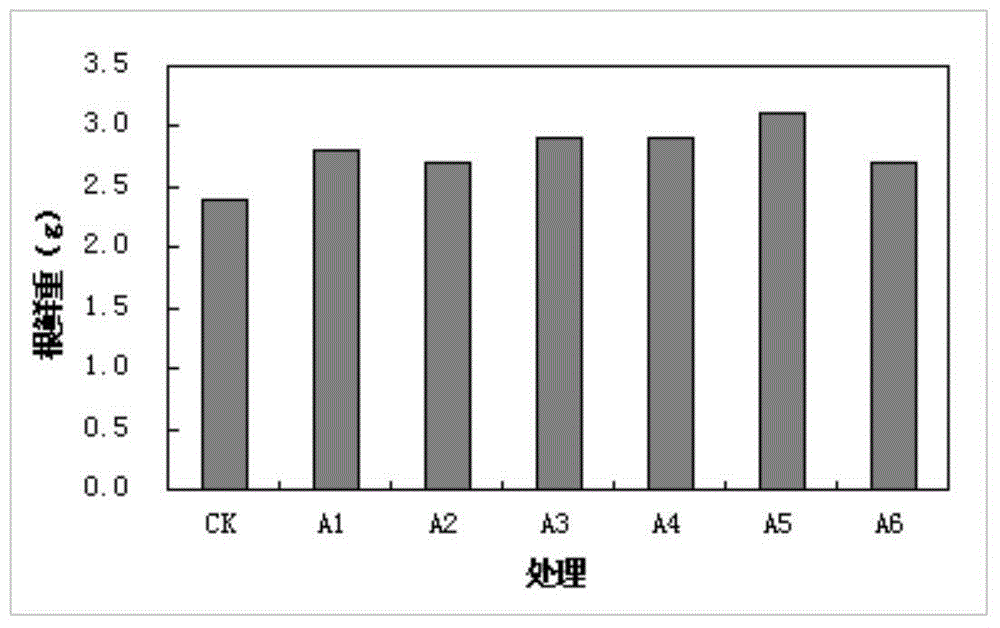

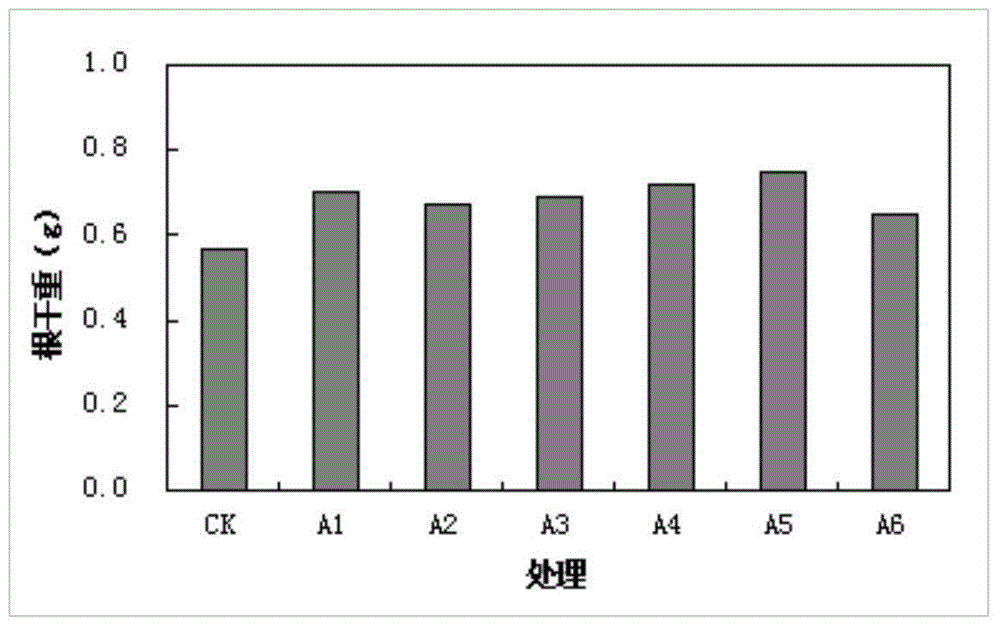

Seaweed water-soluble fertilizer and preparation method thereof

The invention relates to seaweed water-soluble fertilizer and a preparation method thereof and solves the problems that existing methods cannot comprehensively utilize fresh kelp blanching waste water and are complex in extraction processing and high in processing cost. The seaweed water-soluble fertilizer comprises one or more of fucoidan, mannitol, major elements, medium elements, trace elements, humic acid and amino acid. The preparation method is applicable to kelp blanching waste water processing and seaweed water-soluble fertilizer preparing. The seaweed water-soluble fertilizer includes organic seaweed water-soluble fertilizer, seaweed water-soluble fertilizer containing humic acid, seaweed water-soluble fertilizer containing amino acid, seaweed water-soluble fertilizer containing major elements, seaweed water-soluble fertilizer containing medium elements and seaweed water-soluble fertilizer containing trace elements.

Owner:荣成恒欣源水产有限公司

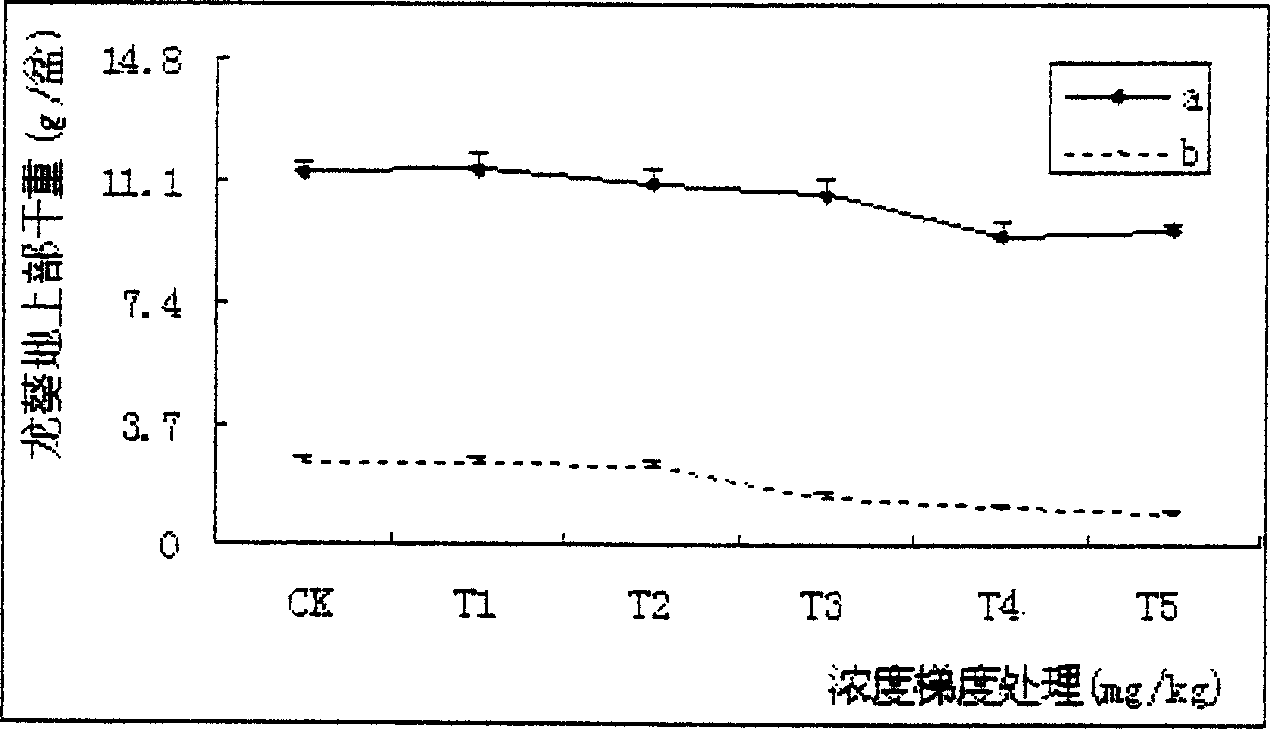

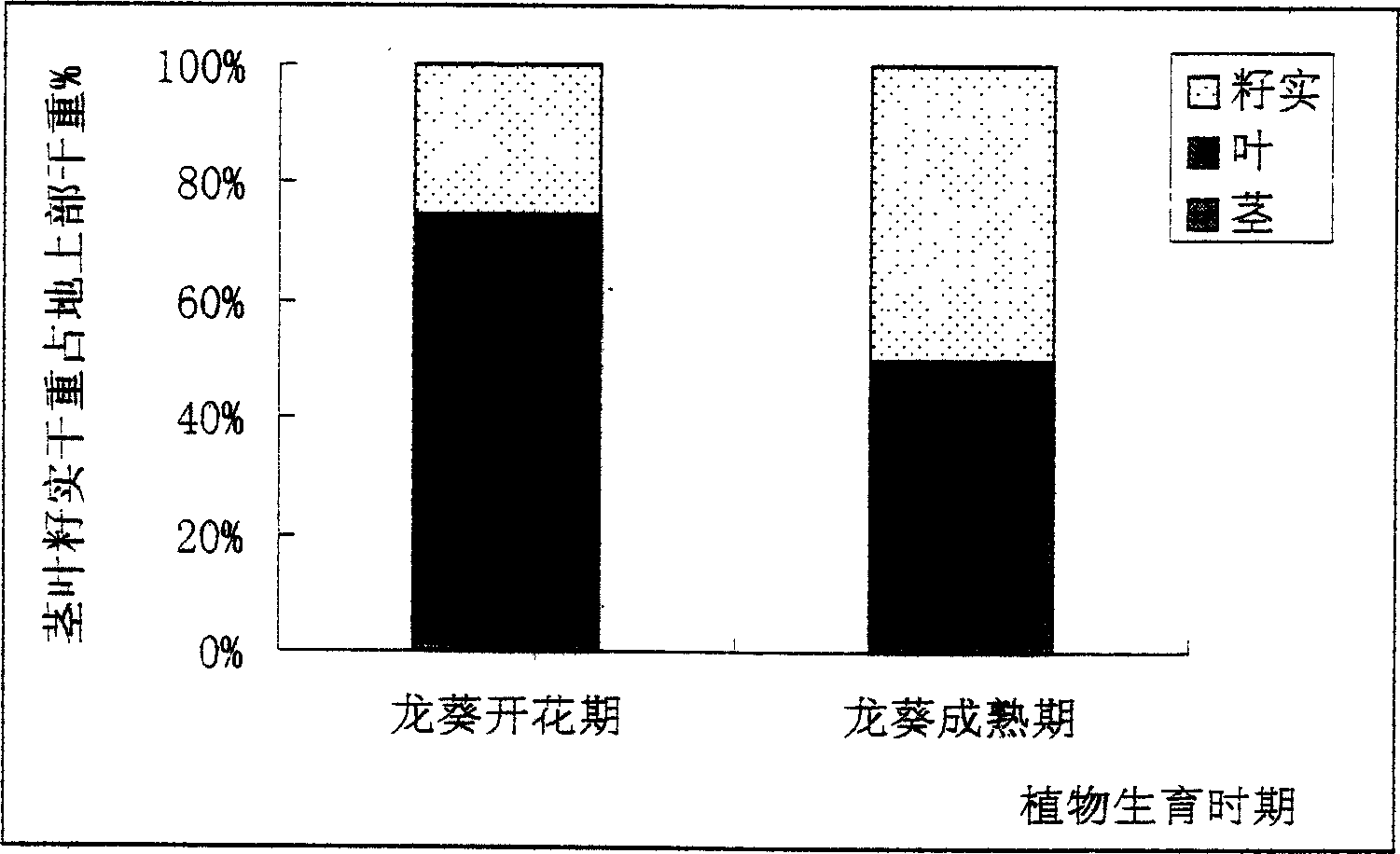

Method for restoring cadmium polluted soil by using amaranth

InactiveCN101096033APromote growthSolve pollutionContaminated soil reclamationFertilising methodsPollution soilCadmium Cation

The invention discloses a method of repairing pollution soil by amaranth. As amaranth is planted in soil polluted by cadmium amaranth root adsorbs cadmium from pollution soil in large amount and amaranth is transferred to stem and leaf of cadmium so on. When the plant grows to flower period or mature period the upper part plant is transferred away from pollution soil so as to realize the purpose that cadmium is removed from pollution soil.

Owner:SUN YAT SEN UNIV

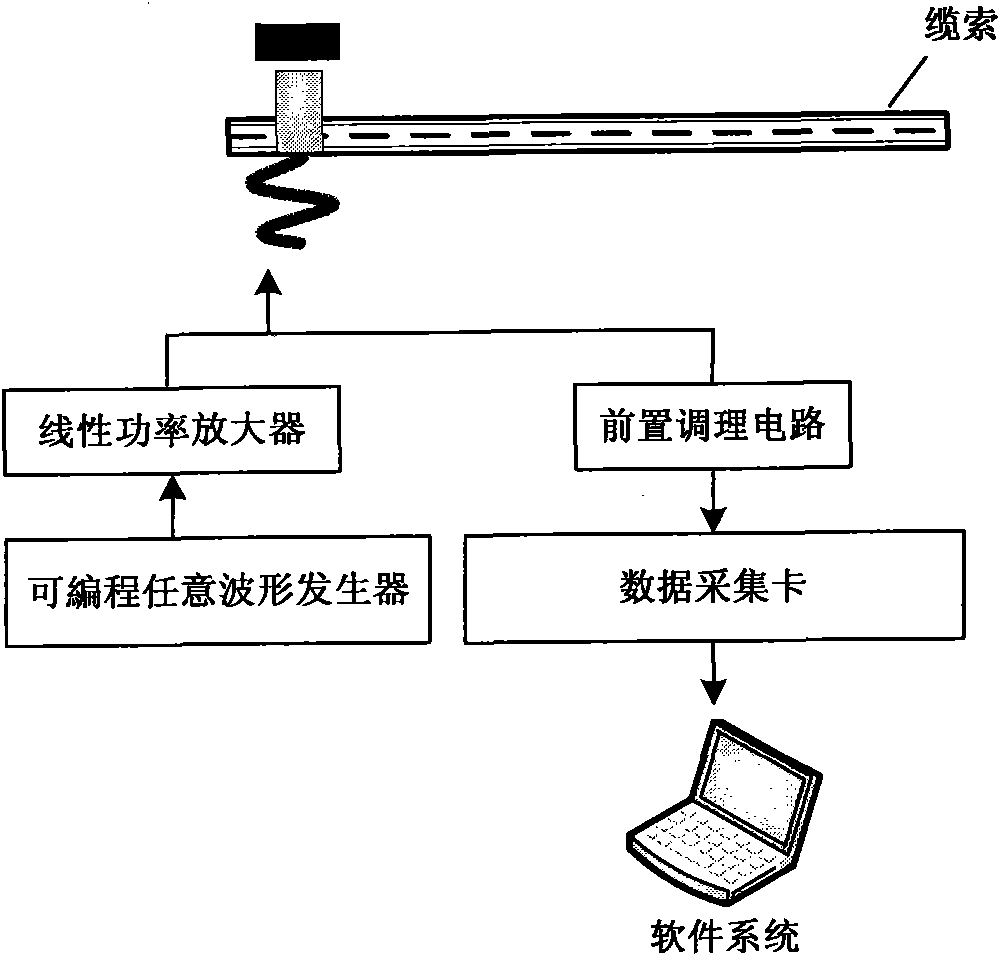

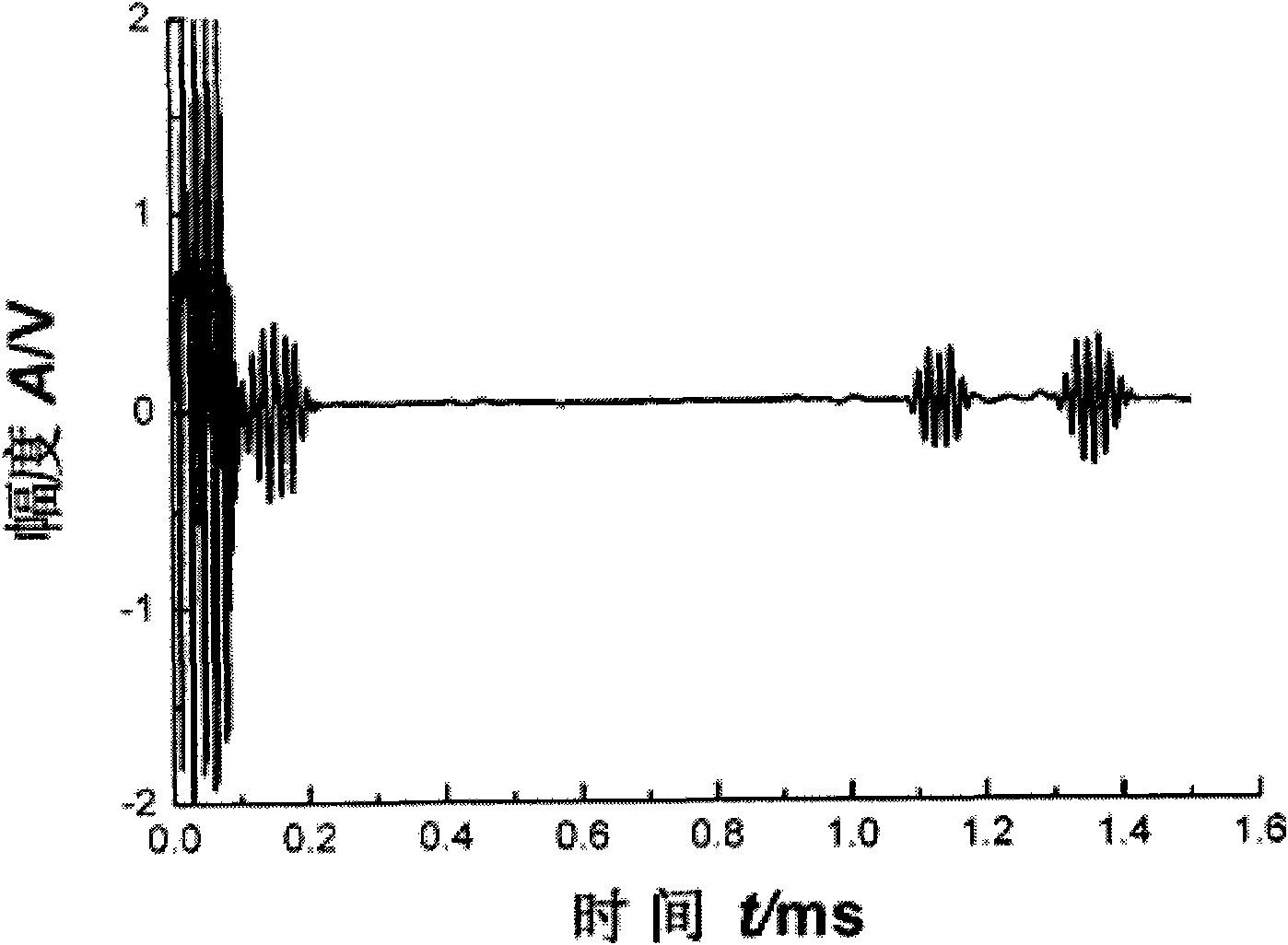

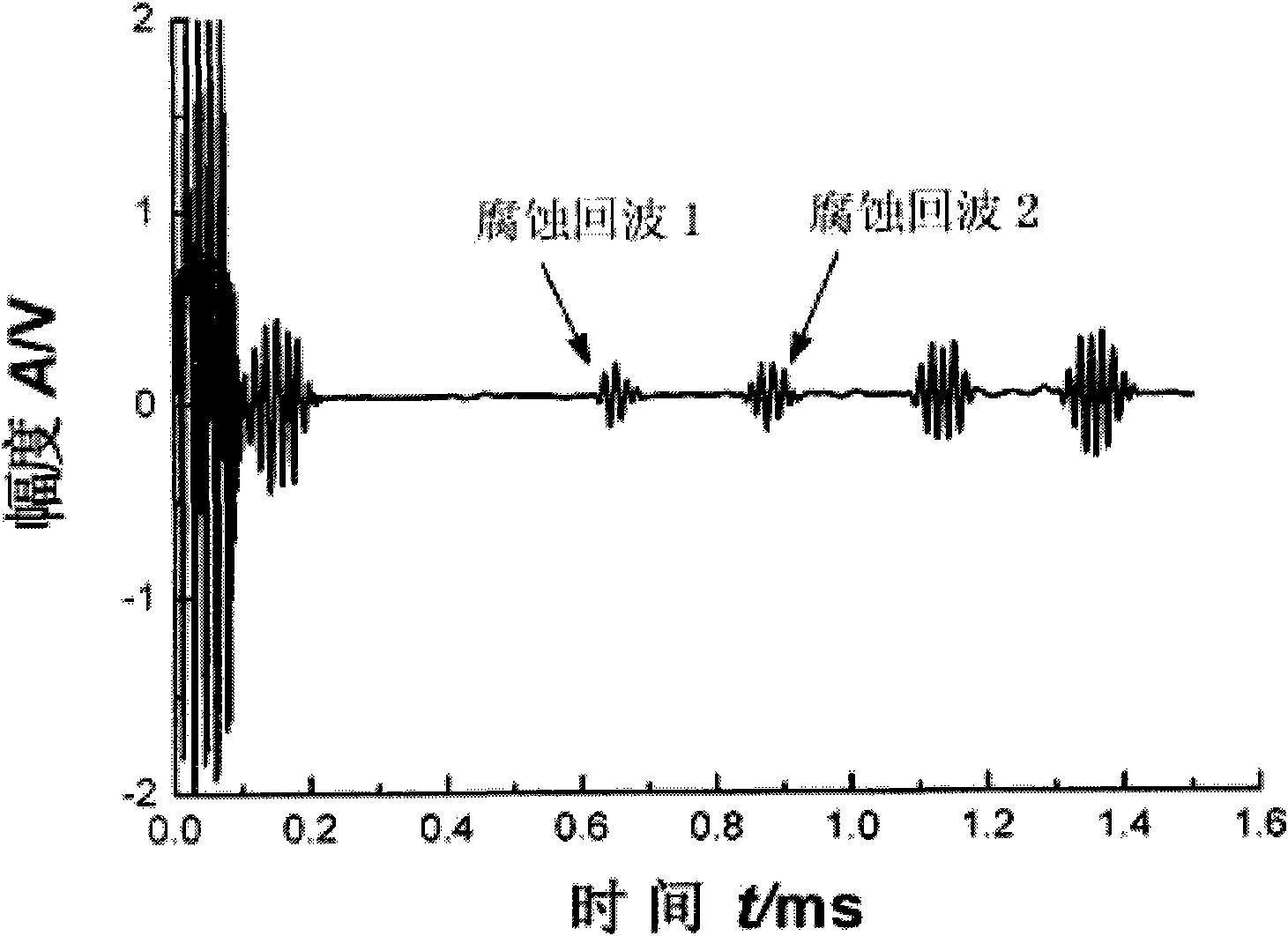

Method for judging and positioning bridge cable corrosion

ActiveCN101943681AReduce calculation errorsAvoid Linear DistortionAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial analysis using acoustic emission techniquesFinite element techniqueNeural network analysis

The invention discloses a method for judging and positioning bridge cable corrosion. The method comprises the following steps of: arranging a sensor on a cable to be detected, acquiring an actual measured signal by using the sensor and reading the signal into a laptop by using a data acquisition card; establishing a fine numerical model for the cable corrosion judgment by adopting the finite element technology according to geometric dimension, material characteristics and excitation signal conditions of the cable, initializing the numerical model, analyzing and calculating to obtain a simulation response signal, and providing a standard comparison signal for the actual measured signal; using the actual measured signal as a judgment signal of the cable corrosion, and comparing the judgment signal and the standard comparison signal and analyzing the judgment signal by adopting a neural network analysis method, if the damage does not exceed a threshold value, judging that the cable is not corroded, otherwise alarming and positioning the corroded part; generating a recording report and recording a local database. The method for judging and positioning the bridge cable corrosion has the advantages of high resolution, high judging precision and no influence on normal use of the cable.

Owner:ZHEJIANG UNIV

Method for extracting and purifying Codonopsis pilosula polysaccharide

InactiveCN102731668ADoes not damage the structureDoes not impair activityBiotechnologyCodonopsis pilosula

The invention discloses a method for extracting and purifying Codonopsis pilosula polysaccharide. The preparation method comprises steps of: adding water into Codonopsis pilosula raw material pretreated with degreasing and ethanol solution for bath reflux extraction; concentrating an extracting solution; carrying out alcohol precipitation to obtain a Codonopsis pilosula polysaccharide crude extract; and decolorizing and purifying with macroporous adsorption resin to obtain the Codonopsis pilosula polysaccharide extract. The method of the invention can remove most pigment and other impurities in the Codonopsis pilosula polysaccharide and improve the purity of the Codonopsis pilosula polysaccharide, on the premise of no damage on the structure and activity of the Codonopsis pilosula polysaccharide.

Owner:谭智丽 +2

Method for preparing graphene solution based on supercritical carbon dioxide induction solution phase transformation technology

ActiveCN104130538ASimple methodSave raw materialsBulk chemical productionDefective grapheneFunctionalized graphene

The invention belongs to the technical field of graphene preparation, and particularly discloses a method for preparing a graphene solution based on a supercritical carbon dioxide induction solution phase transformation technology. The method comprises the following steps: dispersing 25-50mg of graphite and 100-200mg of polyvinyl pyrrolidone into 5-10ml of water or ethanol; putting a dispersion liquid in a supercritical carbon dioxide reaction device; stirring the dispersion liquid at the temperature of 40-45 DEG C and under the pressure of 6-20MPa for reacting for 0.5-7 hours; after the reaction ends, releasing the pressure to the normal pressure; and removing non-stripped graphite from a reaction liquid to obtain the graphene solution. By adopting the method, the problem of difficulty in preparing high-concentration non-defective graphene at present is solved, and high-yield and high quality preparation and functionalization of the graphene are finished in one step. The method is simple and feasible, raw materials are cheap and readily-available, environmental protection is facilitated, and pollution is prevented. Meanwhile, by adopting the polyvinyl pyrrolidone for modifying the graphene with a non-covalent bond, the surface of the graphene contains polymer groups, and the structure of the graphene is not damaged. The graphene solution has very good development prospects in the fields of graphene composite materials, photoelectric functional materials, biological medicine and the like.

Owner:ZHENGZHOU UNIV

Coal spontaneous combustion preventing inhibition foam material and preparation method thereof

ActiveCN104747228AReduce accumulationSpontaneous combustion reachesDust removalFire preventionFoaming agentCoal spontaneous combustion

The invention discloses a coal spontaneous combustion preventing inhibition foam material and a preparation method thereof. The coal spontaneous combustion preventing inhibition foam material belongs to the technical field of coal mine underground coal spontaneous combustion treatment. The coal spontaneous combustion preventing inhibition foam material is characterized by comprising, by weight percentage, 0.5-10% of foaming agent, 0.2-3% of foaming auxiliaries, 0.02-0.5% of thickener, 0.5-5% of inhibitor, 2.5-15% of enhancer and 66.5-96.28% of water. After being foamed, the coal spontaneous combustion preventing inhibition foam material can take foam as the carrier to effectively convey the target inhibitor and enhancer to areas complicated to handle, and generated inhibiting foam achieves multiple oxygen insulating inhibition effects on coal spontaneous combustion and further achieves the aim of preventing coal spontaneous combustion.

Owner:ANHUI UNIV OF SCI & TECH

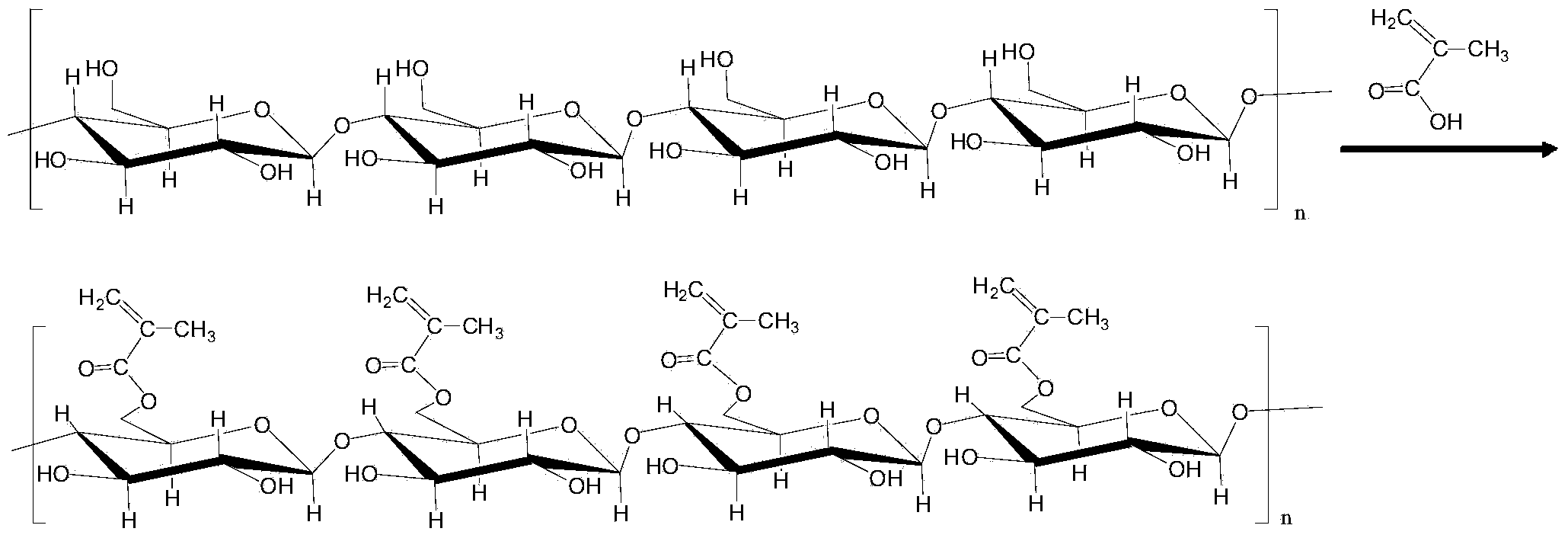

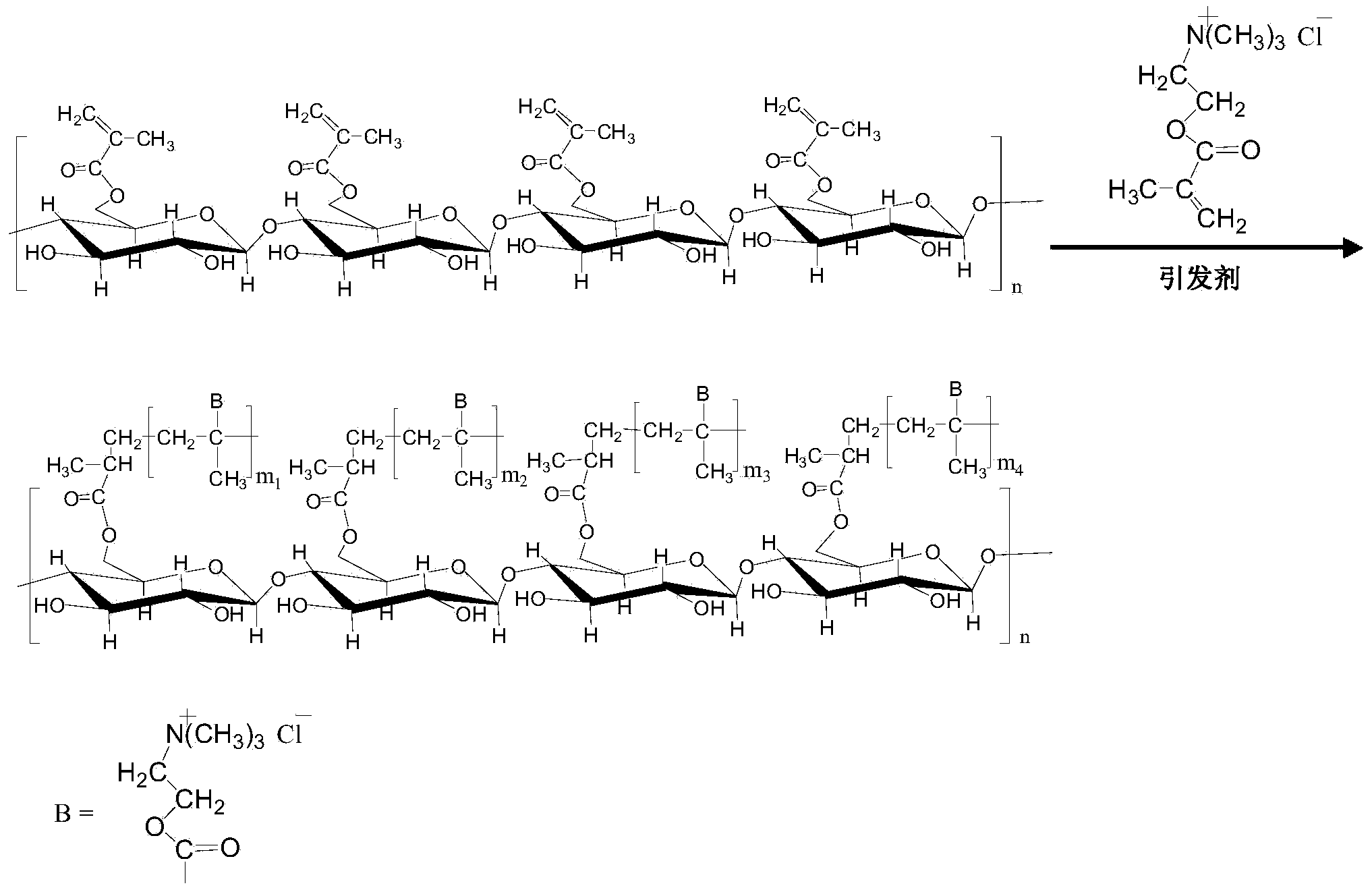

Antimicrobial bacterial cellulose and preparation method thereof

ActiveCN103724568AGood chemical stabilityImprove antibacterial propertiesProsthesisWound healingChemical stability

The invention provides antimicrobial bacterial cellulose and a preparation method thereof. According to the antimicrobial bacterial cellulose provided by the invention, a large number of hydroxyl functional groups existing on the bacterial cellulose are utilized, a quaternary ammonium salt antimicrobial group is introduced by surface modification, the structure of the bacterial cellulose is not damaged, the shape of hydrated gel is maintained, the effect of promoting healing of a wound is realized, and the antimicrobial bacterial cellulose prepared by the preparation method provided by the invention simultaneously has the advantages of good chemical stability and lasting antimicrobial effect.

Owner:SHENZHEN INST OF ADVANCED TECH

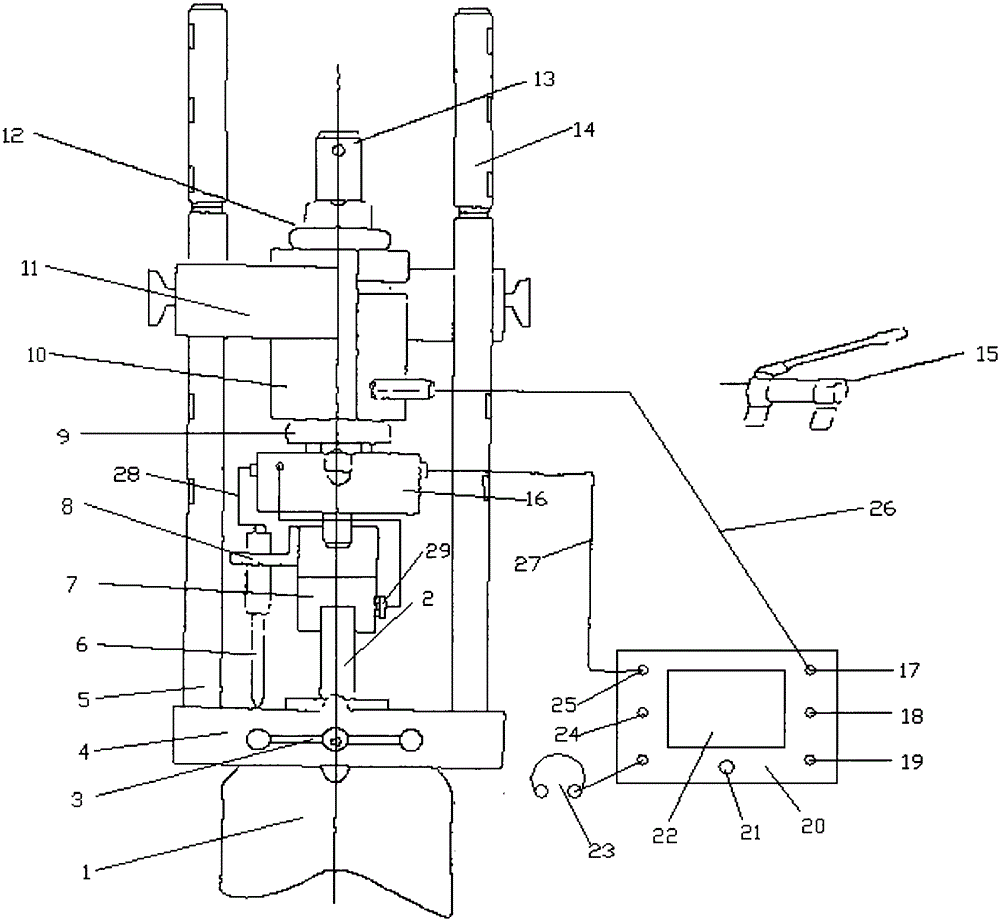

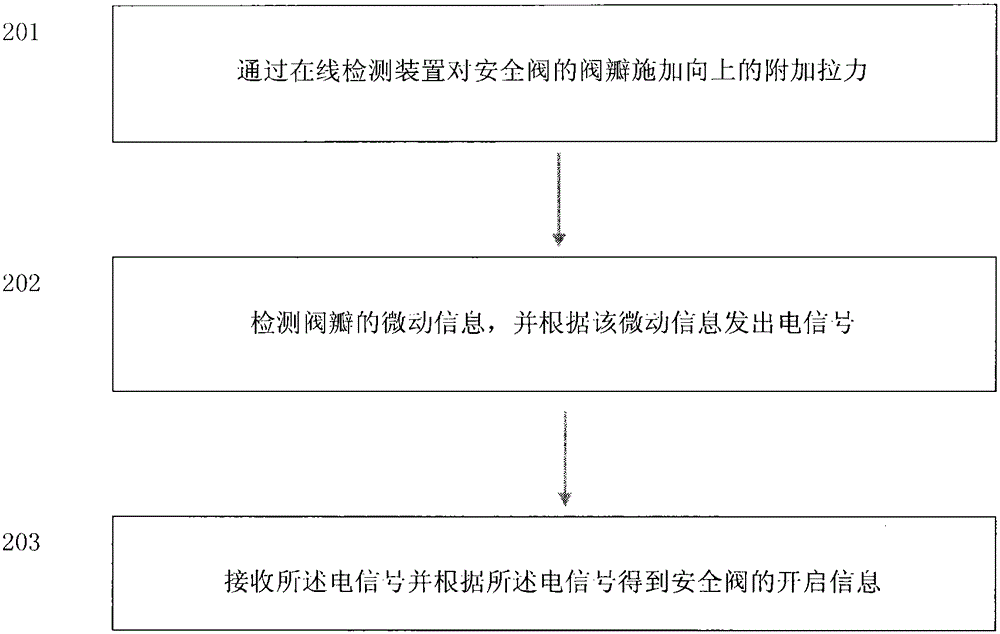

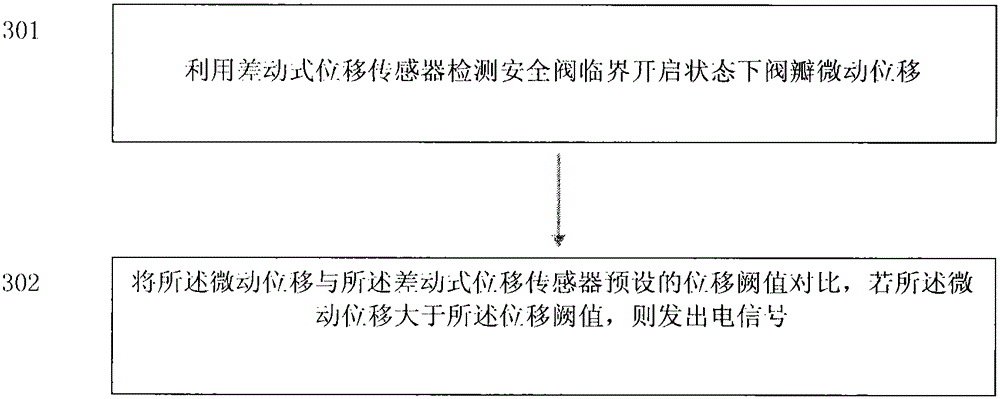

Online testing device for safety valve and online testing method thereof

InactiveCN105067233ADoes not damage the structureImprove securityMachine part testingEngineeringHuman–computer interaction

The invention belongs to the field of online testing for a safety valve and a relief valve, and particularly relates to a safety valve online testing device in a continuous production process, an on determining method for the safety valve, and an online testing method. The safety valve online testing device comprises three parts, namely a hydraulic device, a mechanical clamping device and a host computer. The data processing unit of the host computer is connected with a force sensor, a differential type displacement sensor and a sound pickup through sensor information wires. Tested on-and-off change information of the safety valve is simultaneously transmitted to the host computer. Then analysis, data processing and data storage are performed on the measured data. The online testing device has advantages of reasonable mechanical structure, easy operation, accurate on-and-off determination, good man-machine interaction environment and high suitability for an online testing field of the safety valve.

Owner:李治涛

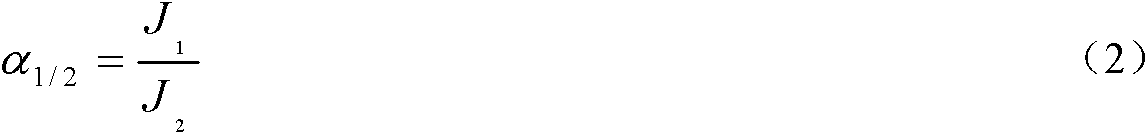

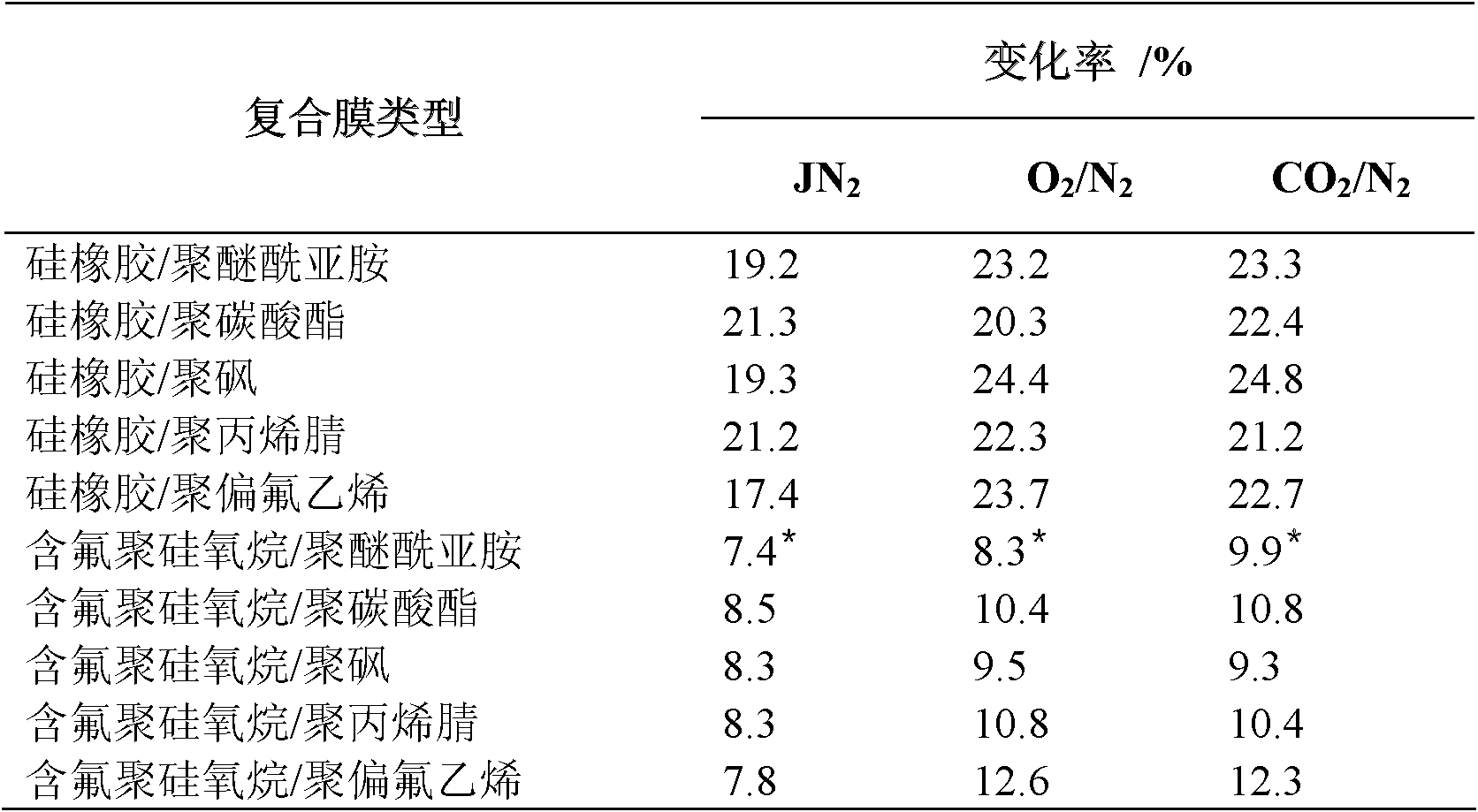

Fluorine-containing polysiloxane rubber state composite gas separation membrane, preparation method and application thereof

ActiveCN102327747AMild preparation conditionsResistant to swellingSemi-permeable membranesDispersed particle separationCross-linkProduct gas

The invention discloses a fluorine-containing polysiloxane rubber state composite gas separation membrane, a preparation method and an application thereof. A porous polymer material is used as a support membrane, and a fluorine-containing polysiloxane material is coated on the surface of the support membrane. The preparation method of the fluorine-containing polysiloxane rubber state composite gas separation membrane comprises the following steps of: dissolving fluorine-containing polysiloxane into a solvent to prepare coating liquid; adding a cross-linking agent and a catalyst into the obtained solution; uniformly stirring, standing and de-foaming; coating the coating liquid on the porous support membrane; and heating, curing and cross-linking until the porous support membrane is dried to obtain the fluorine-containing polysiloxane rubber state composite gas separation membrane. The composite gas separation membrane provided by the invention can be applied to separations of oxygen gas from nitrogen gas, carbon dioxide from nitrogen gas, and organic vapors, and has the characteristics of swelling resistance, resistance to pressure, weather fastness, and the like.

Owner:DALIAN UNIV OF TECH

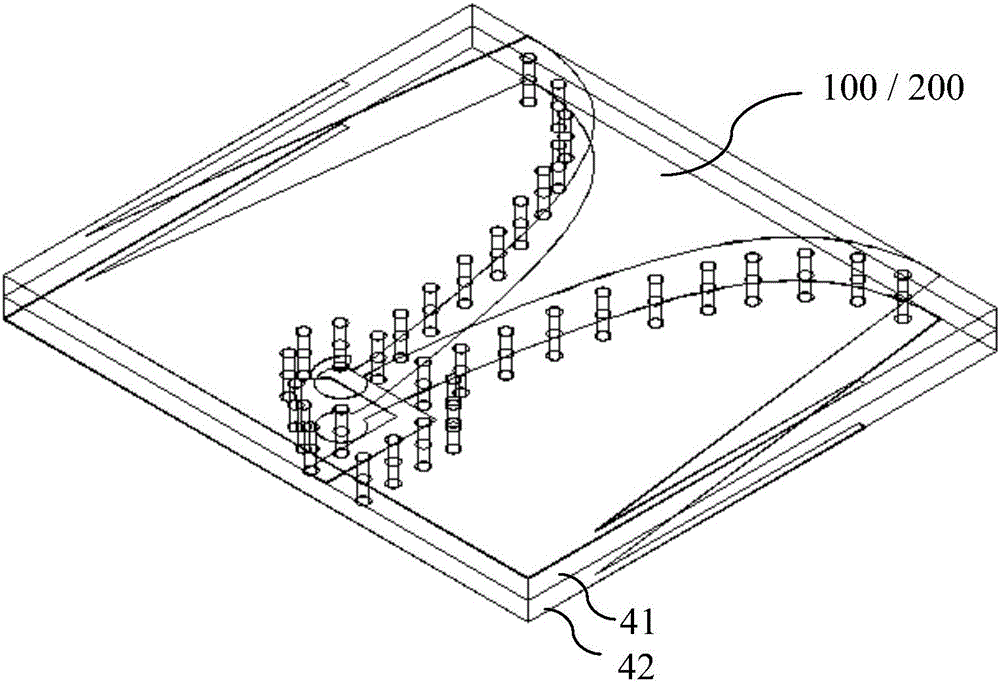

Production method for seamless nickel sheet with microprism array

InactiveCN103009016AAvoid pollutionImprove stitching accuracyElectroforming processesElectroformingNickel plate

The invention relates to a production method for a seamless nickel sheet with a microprism array. The production method includes the steps of manufacturing unit nickel sheets of required amount; performing finish machining to and removing burrs of the unit nickel sheets, and cutting two sides of a front surface of each unit nickel sheets to form a cut surface with certain angle; arranging the machined nickel plates as required, and welding the unit sheets from reverse surfaces to be sequentially connected to form a required large nickel sheet matrix; bending the welded large nickel sheet matrix, selecting a plastic cylinder with smooth inner wall, and fixing the bent large nickel sheet matrix on the smooth inner wall of the plastic cylinder; and placing the plastic cylinder with the large nickel sheet matrix adhered into an electroforming groove for electroforming, and forming the required seamless nickel sheet on the front surface of the large nickel sheet matrix. Cutting precision and splicing precision of the unit nickel sheets are controlled strictly, the surface of a die for producing the large nickel sheet matrix of the nickel sheet is seamless by the aid of the cylinder, and accordingly production of the seamless nickel sheet is truly achieved.

Owner:CHANGZHOU HUA R SHENG REFLECTIVE MATERIAL

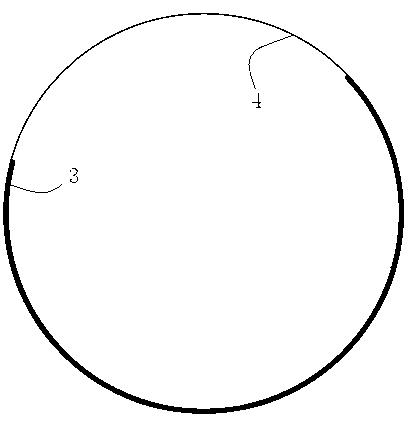

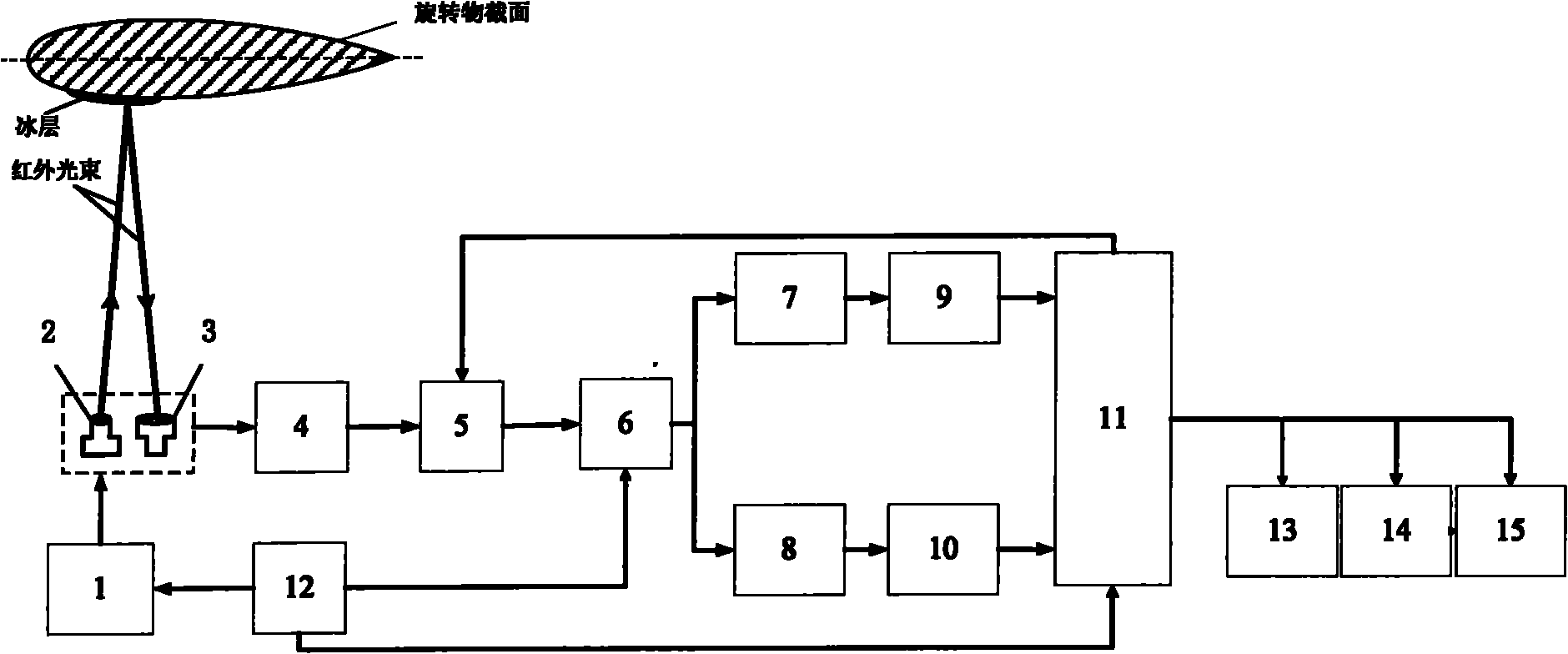

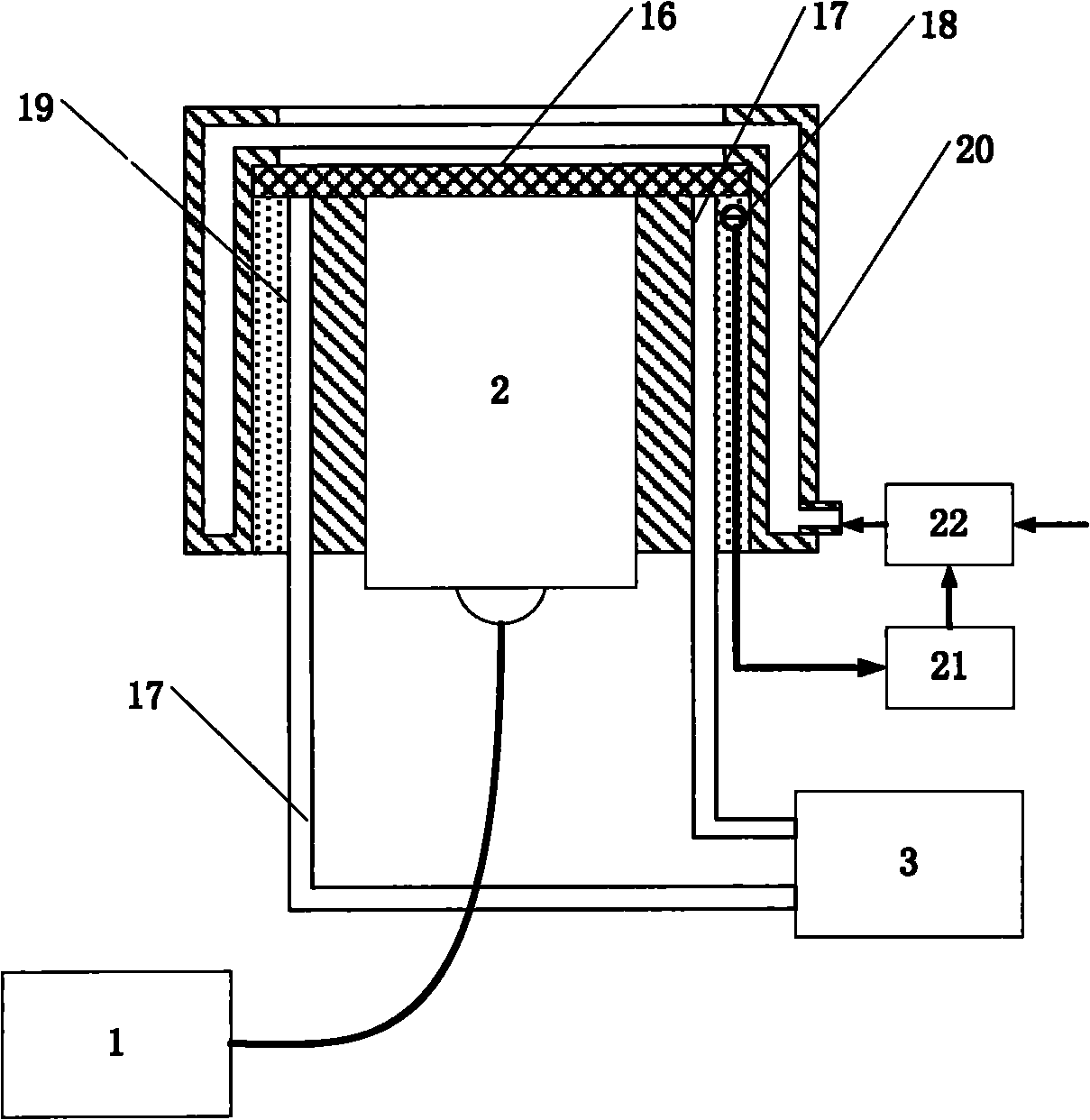

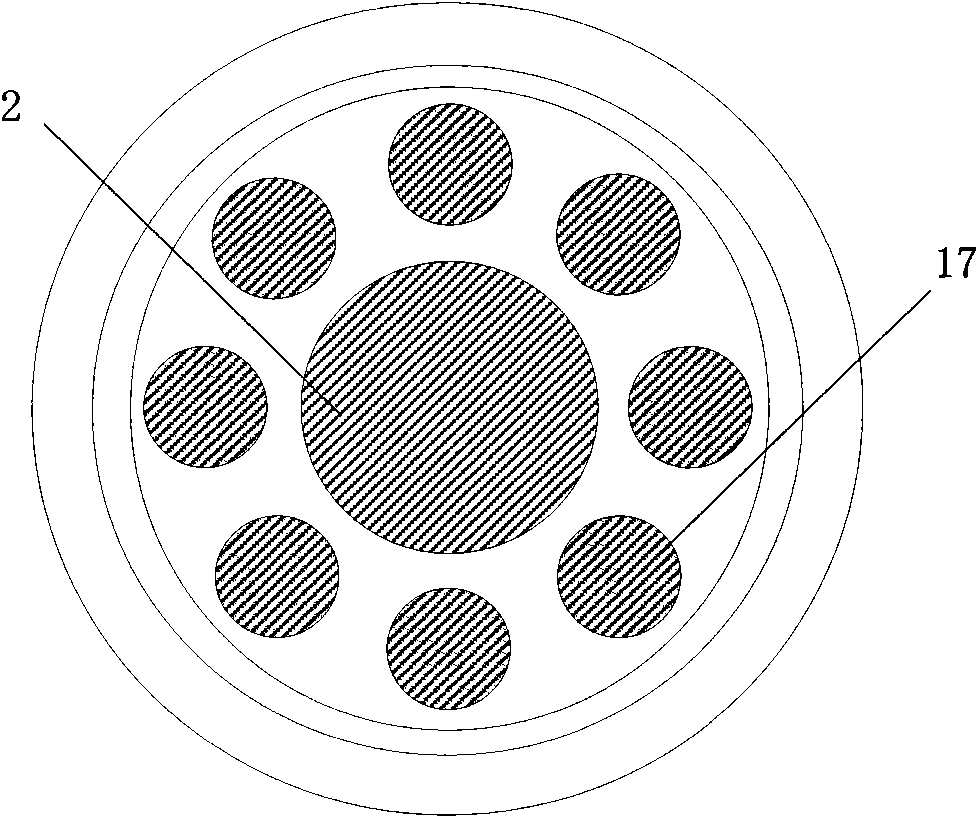

Rotating body surface non-contact icing detector

InactiveCN101792021AEasy to installAvoid passingDe-icing equipmentsAlarmsTransit timeSignal-to-noise ratio (imaging)

The invention relates to a rotating body surface non-contact icing detector. A signal generator drives a laser probe to generate laser pulses emitted to the surface of a rotating body; a photoelectric detector receives returned optical signals and converts the optical signals into electrical signals; the electrical signals are divided into two paths after signal amplification and improvement on signal to noise ratio; one path reaches a signal processor through a high threshold comparator and a high threshold stretcher, and is used for judging distribution range of chordwise icing on the surface of the rotating body; the other path reaches the signal processor through a low threshold comparator and a low threshold stretcher, and is used for judging transit time that the surface of the rotating body passes the upper side of the probe of photoelectric detector; and the signal processor generates icing alarm signals according to judgment results of both paths of signals and outputs the icing alarm signals to an alarm circuit. The icing detector directly detects the icing state and the icing range on the surface of a detected object in a non-contact way, avoids transmitting movable component measuring signals, and is suitable for detecting the icing state on the surface of helicopter rotor wings and surfaces of other rotating bodies in real time.

Owner:HUAZHONG UNIV OF SCI & TECH

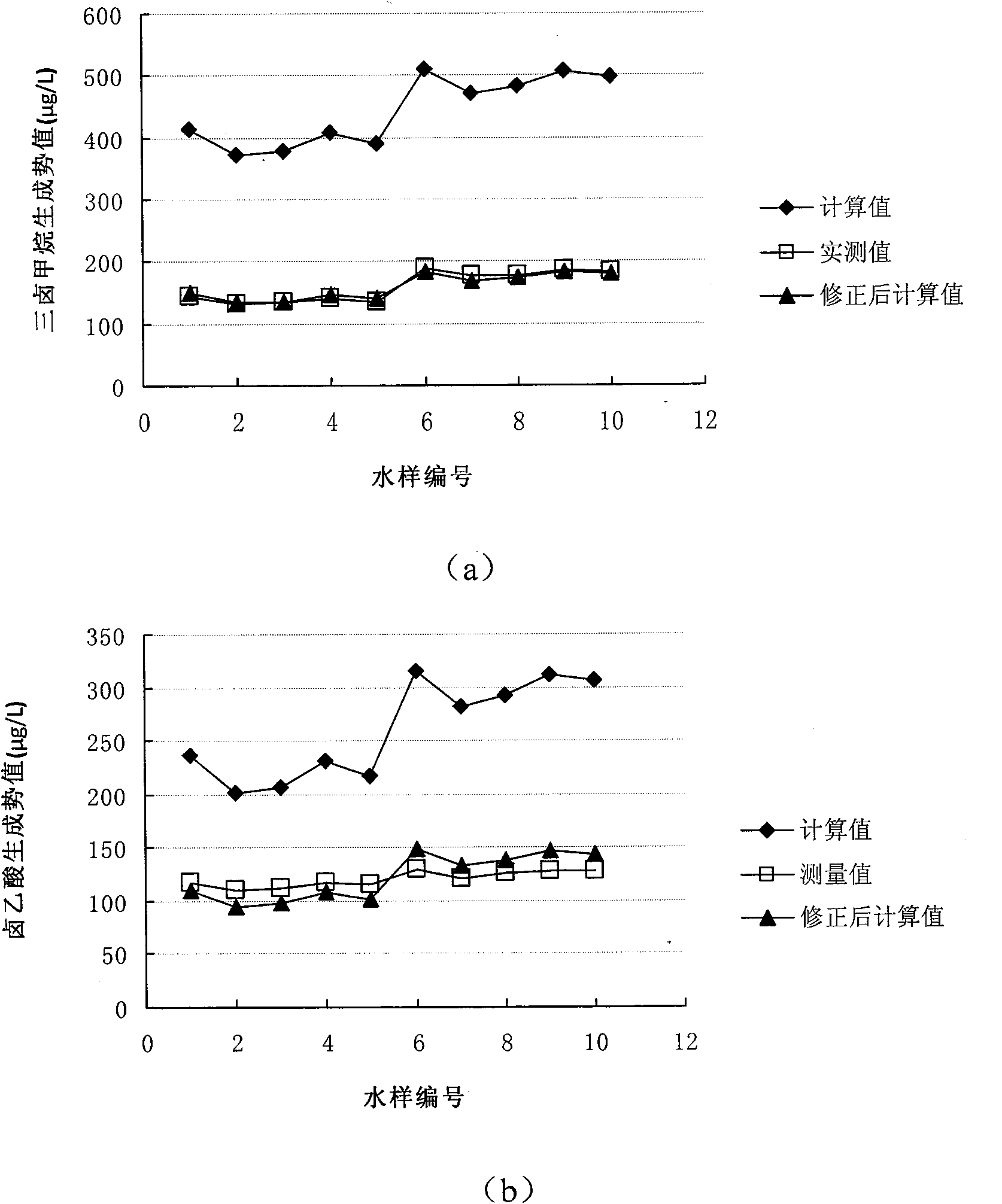

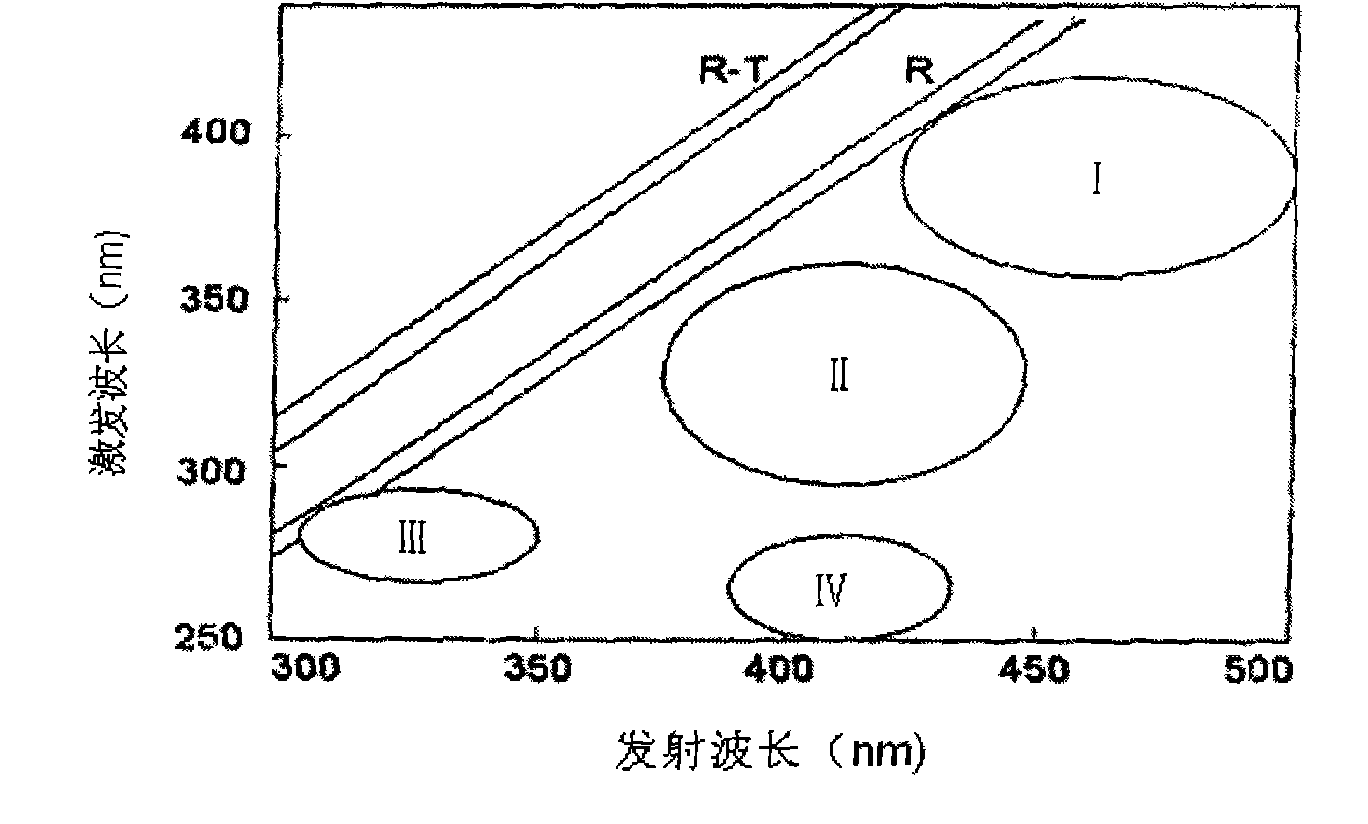

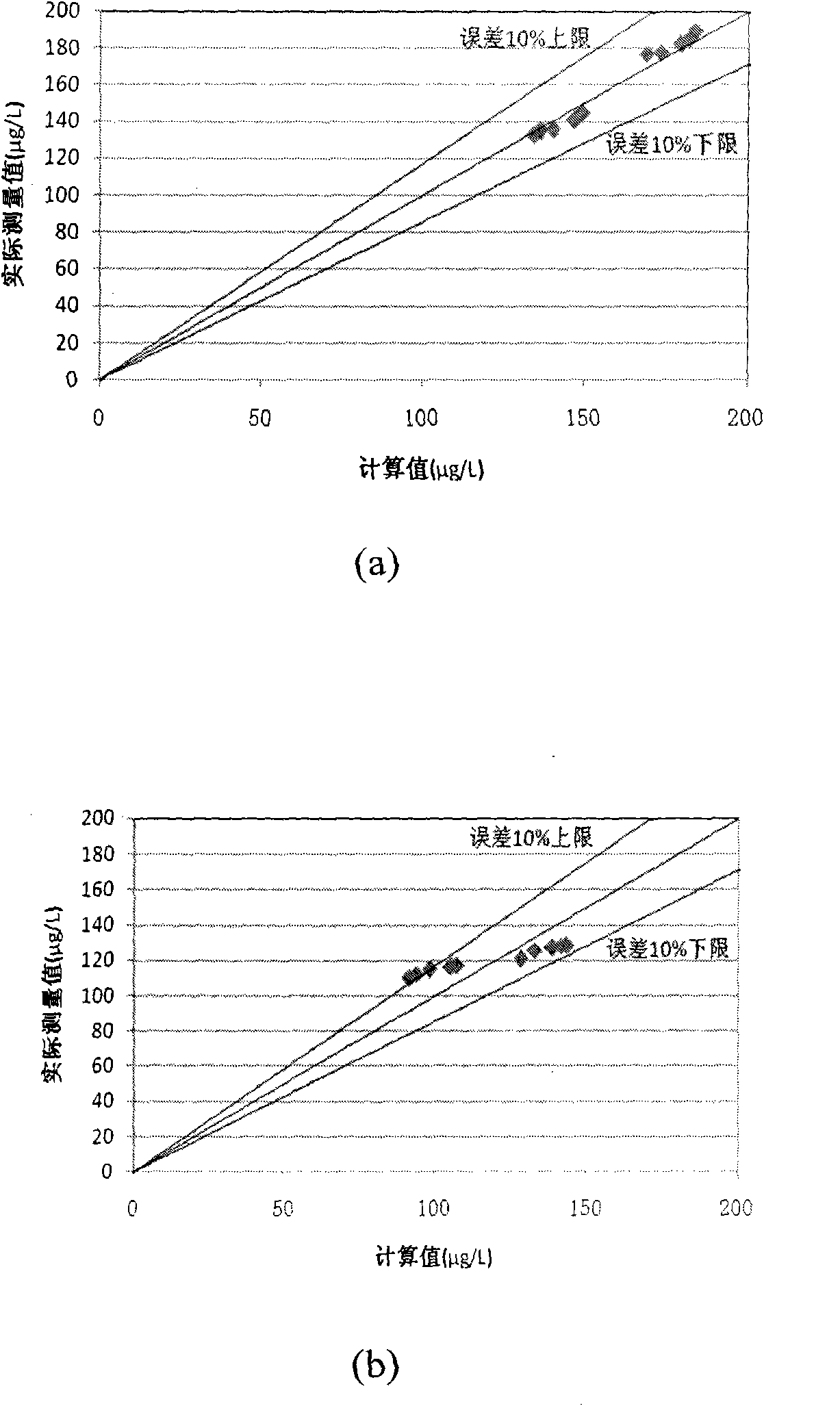

Three-dimensional fluorescence spectrum method for measuring chlorine disinfection by-product precursor in water

InactiveCN101819148AEasy to operateRapid determinationFluorescence/phosphorescenceTechnical supportWater sample

The invention belongs to the environmental monitoring and analysis technical field, which can be used for measuring a chlorine disinfection by-product precursor in water, and provides technical support for pollution control. Aiming at the problems of the measuring method of the existing chlorine disinfection by-product precursor, such as complicated steps and indefinite results, the feasibility for characterizing the chlorine disinfection by-product precursor by three-dimensional feature fluorescence parameters is researched, the correlation between the feature fluorescence characteristic parameters of the chlorine disinfection by-product precursor and the generation potential thereof is confirmed, and the simple and fast method for measuring the chlorine disinfection by-product precursor in water is developed. The measuring method comprises the following steps: establishing a linearity correction equation between the feature fluorescence intensity of the chlorine disinfection by-product precursor and the generation potential thereof; scanning a water sample to be tested with a three-dimensional fluorescence spectrum; and calculating the generation potential of the chlorine disinfection by-products and performing result correction. By adopting the method, the chlorine disinfection by-product precursor in water can be classified and analyzed without complex sample processing and testing; the average relative error is about 10%; and a sample structure is not damaged, and on-line inspection is easily realized.

Owner:BEIJING UNIV OF TECH

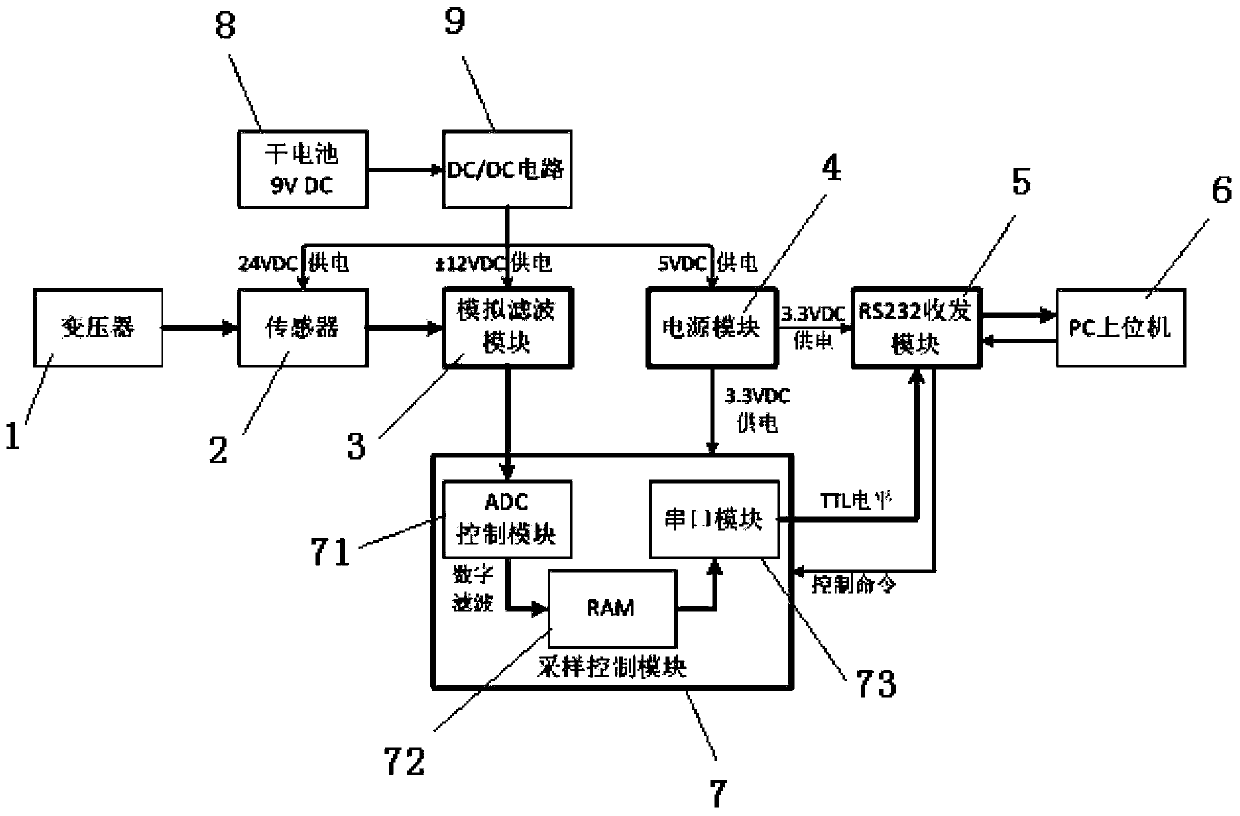

Transformer diagnosis system and diagnosis method

InactiveCN103472350ADoes not affect normal operationDoes not damage the structureSubsonic/sonic/ultrasonic wave measurementElectrical testingTransformerEngineering

The invention discloses a transformer diagnosis system which comprises a transformer, a sensor, an analog filter module, a power supply module, an RS232 transceiving module, a PC upper computer, a sampling control module, a battery and a DC-DC circuit. According to the invention, acoustic features generated during transformer failure detection in a frequency range of 20Hz-10kHz are compared to diagnose the operation state of a transformer; and the magnetically mounted vibration or acoustic sensor clings to the surface of the transformer to perform signal monitoring, is high in signal to noise ratio and convenient to mount, is less influenced by external interference, does not influence normal operation of the transformer and does not cause damage to the transformer structure. The invention also discloses a transformer diagnosis method using the transformer diagnosis system.

Owner:威胜百楚电力科技有限公司

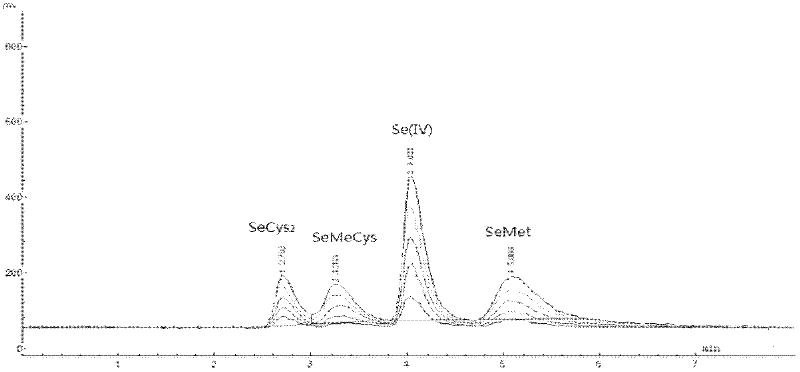

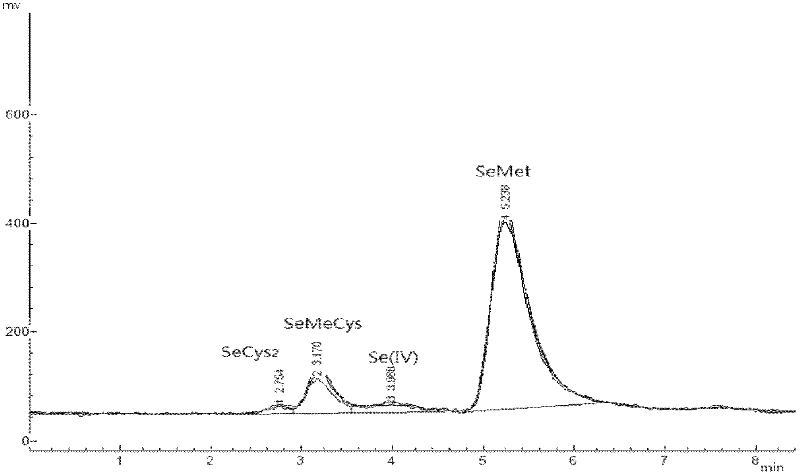

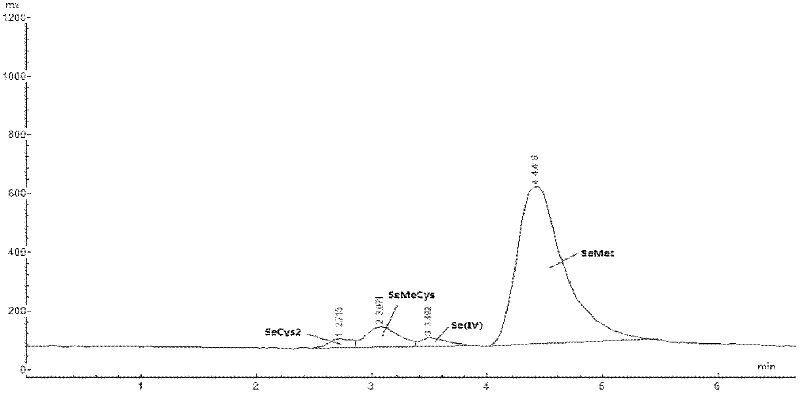

Method for determination of form of selenium in selenium-rich plant material

InactiveCN102520104AStable formImprove extraction efficiencyComponent separationAnalysis by material excitationSpectroscopyAtomic fluorescence spectrometry

The invention discloses a method for determination of the form of selenium in a selenium-rich plant material. The method provided by the invention is characterized by comprising the following steps of 1, a selenium-rich plant material pretreatment process comprising carrying out extraction of a crushed selenium-rich plant material sample by an extraction buffer Tris-HCl, after the extraction, adding cellulase into the extract, carrying out wall breaking of cells of the selenium-rich plant material sample, orderly adding effective amounts of protease K and protease XIV into the extract, and carrying out hydrolysis extraction to obtain a solution of a sample needing to be detected, and 2, carrying out determination processes respectively on a solution of selenium having a standard form and the solution of the sample needing to be detected by the combination of the hydride generation-atomic fluorescence spectroscopy technology and the high performance liquid chromatography. The method provided by the invention is simple, can be realized easily, adopts nontoxic reagents and does not produce pollution.

Owner:SUZHOU SETEK

Halogen-free flame retardant olefin foam body and preparation method thereof

The invention discloses a halogen-free flame retardant olefin foam body which comprises the following preparation materials (in terms of weight): (1) 50-120 parts of ethylene-vinyl acetate (EVA) copolymer, (2) 10-80 parts of polyolefin elastomers (POE), (3) 10-35 parts of foaming agent, (4) 1-10 parts of blowing promoter, (5) 1-6 parts of coupling agent, (6) 1-6 parts of antioxidant, (7) composite flame retardant which is the mixture of 6-15 parts of red phosphorus or phosphate flame retardant, 30-80 parts of magnesium hydroxide and 5-20 parts of zinc borate, or the mixture of 20-66 parts of ammonium polyphosphate, 10-36 parts of melamine pyrophosphate or polyphosphate and 7-24 parts of pentaerythritol; and the materials are mixed, mill-mixed , extruded, radiated and foamed, so that the foaming body is prepared. The halogen-free flame retardant olefin foaming body disclosed by the invention is a halogen-free high flame retardant olefin foaming body, which has the advantages that the foaming expansion magnification is high, broken holes are hardly formed in the foaming process, the foaming body structure is not damaged, and the mechanical performance is high.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL

Preparation method of conducting polymer/grapheme composite nanometer material

InactiveCN102789842AHigh purityImprove conductivityNanotechnologyCable/conductor manufactureConductive polymerSolvent

The invention provides a preparation method of conducting polymer / grapheme composite nanometer material. The preparation method comprises the following steps that: (1) graphene is dipped in an oxidizing agent solution, and then is centrifugally separated and dried to obtain graphene which contains an oxidizing agent; (2) the graphene which contains the oxidizing agent and a conducting polymer monomer are respectively positioned in different positions in a closed container for reaction; and (3) the reaction product is centrifuged, washed and dried to obtain the conducting polymer / grapheme composite nanometer material. According to the preparation method disclosed by the invention, a solvent is not used, the condition is simple, the purity is high, and the structure of the graphene is not destroyed; film thickness is controllable, and the film thickness can be controlled by changing the proportion of the monomer and the graphene and the time of polymerization; the quality of the film is good, and the film thickness is uniform; the graphene and the conducting polymer have high compatibility due to the conjugate structure of the graphene and the conducting polymer; and the prepared composite material has high conductivity, excellent electrochemistry activity and good cycling stability, and can be applied in the fields of energy sources such as a super capacitor, a lithium battery and the like, and the fields of a sensor and the like.

Owner:QINGDAO UNIV OF SCI & TECH

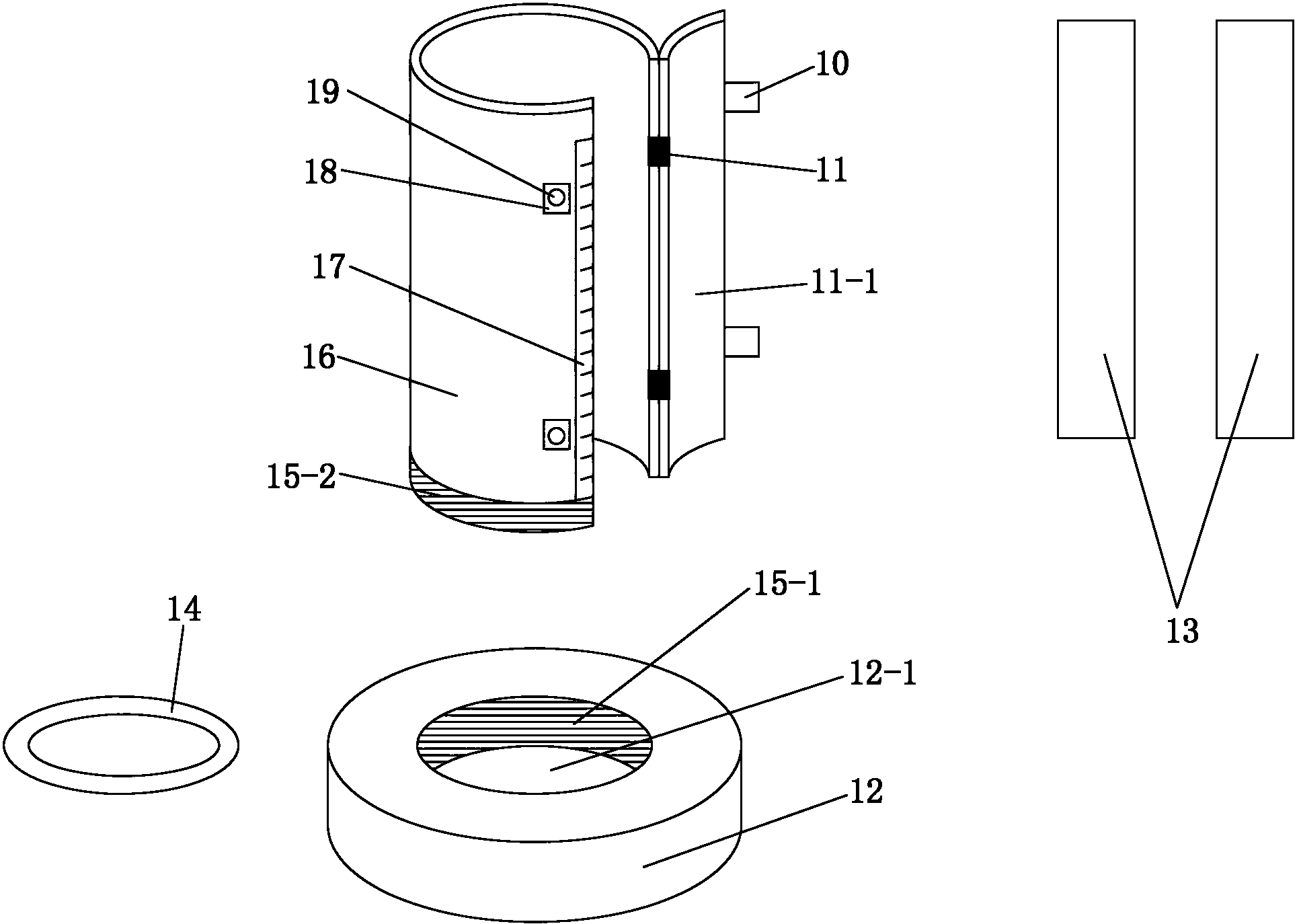

Fully-automatic earth pillar leaching experiment device

The invention discloses a fully-automatic earth pillar leaching experiment device. The fully-automatic earth pillar leaching experiment device comprises an automatic constant head height solution outflowing device, a detachable earth pillar body and an automatic continuous sampling device; the automatic constant head height solution outflowing device consists of a target pollutant solution containing bottle and an automatic constant head height mechanism, and the automatic constant head height mechanism consists of a magnet, a valve, a rotating wheel, a bracing wire and a buoyancy ball; and the automatic continuous sampling device consists of a sampling plate, a motor, a relay, a power supply and a timer, the motor is connected with the power supply by the relay, the timer is connected with the relay, a plurality of grooves are evenly formed in the circumference of the upper surface of the sampling plate, a first liquid level probe and a second liquid level probe are arranged in a test tube, the first liquid level probe is connected with the relay by a conductive wire, and the second liquid level probe is electrically connected with the relay by a hard conductive wire, a touch type chute and a conductive metal ball. The fully-automatic earth pillar leaching experiment device has a simple structure, is reasonable in design, convenient to use and strong in automation, saves labor force, and is applicable to popularization.

Owner:CHANGAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com