Patents

Literature

405 results about "Fucoidan" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

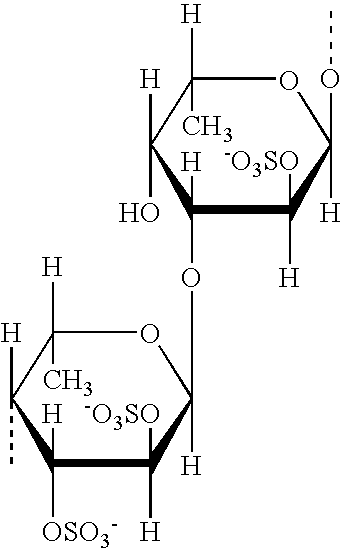

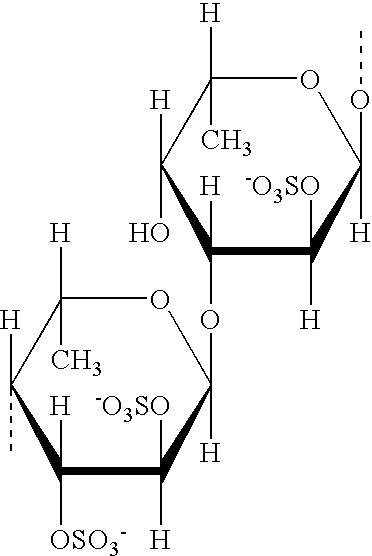

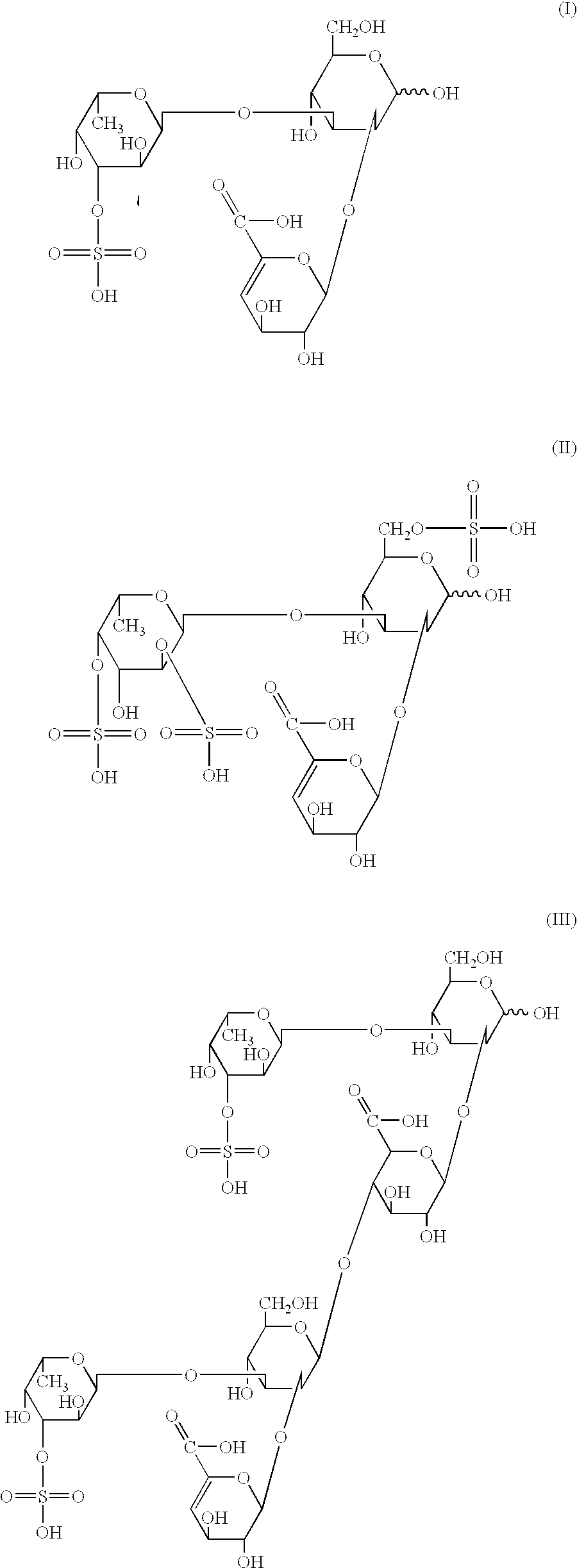

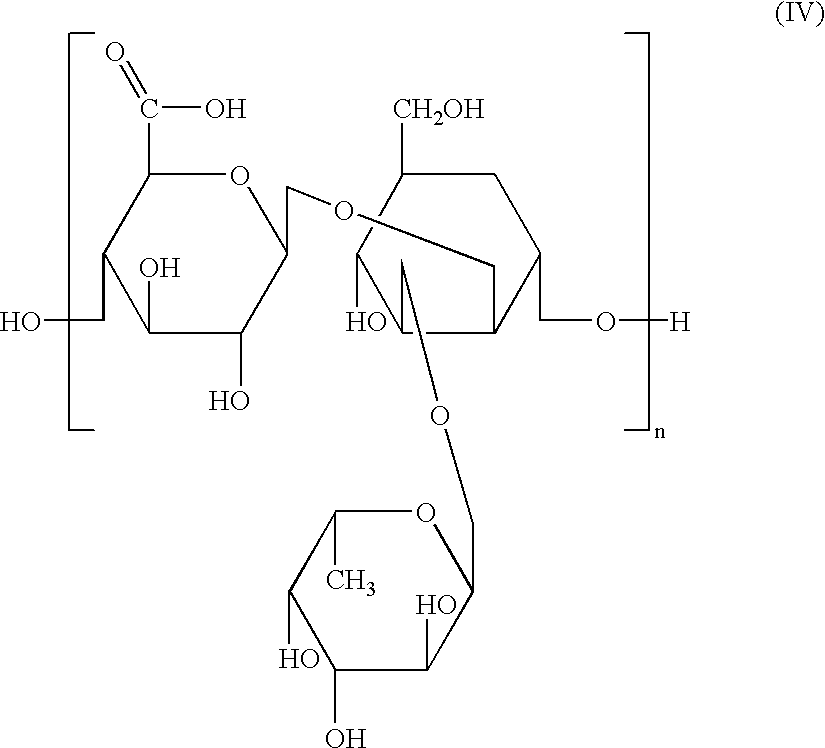

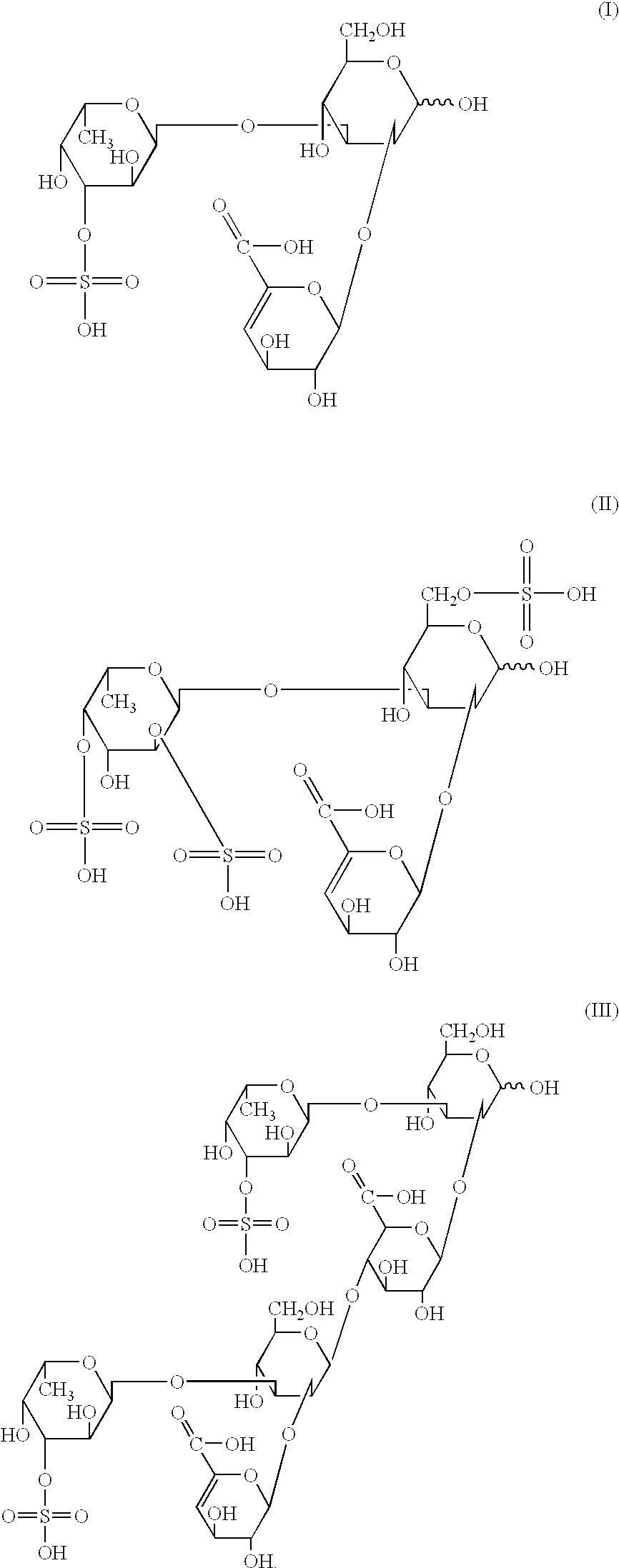

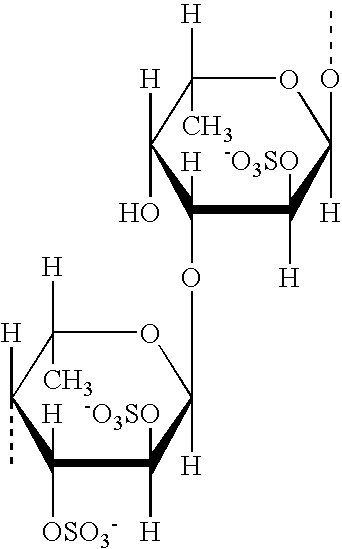

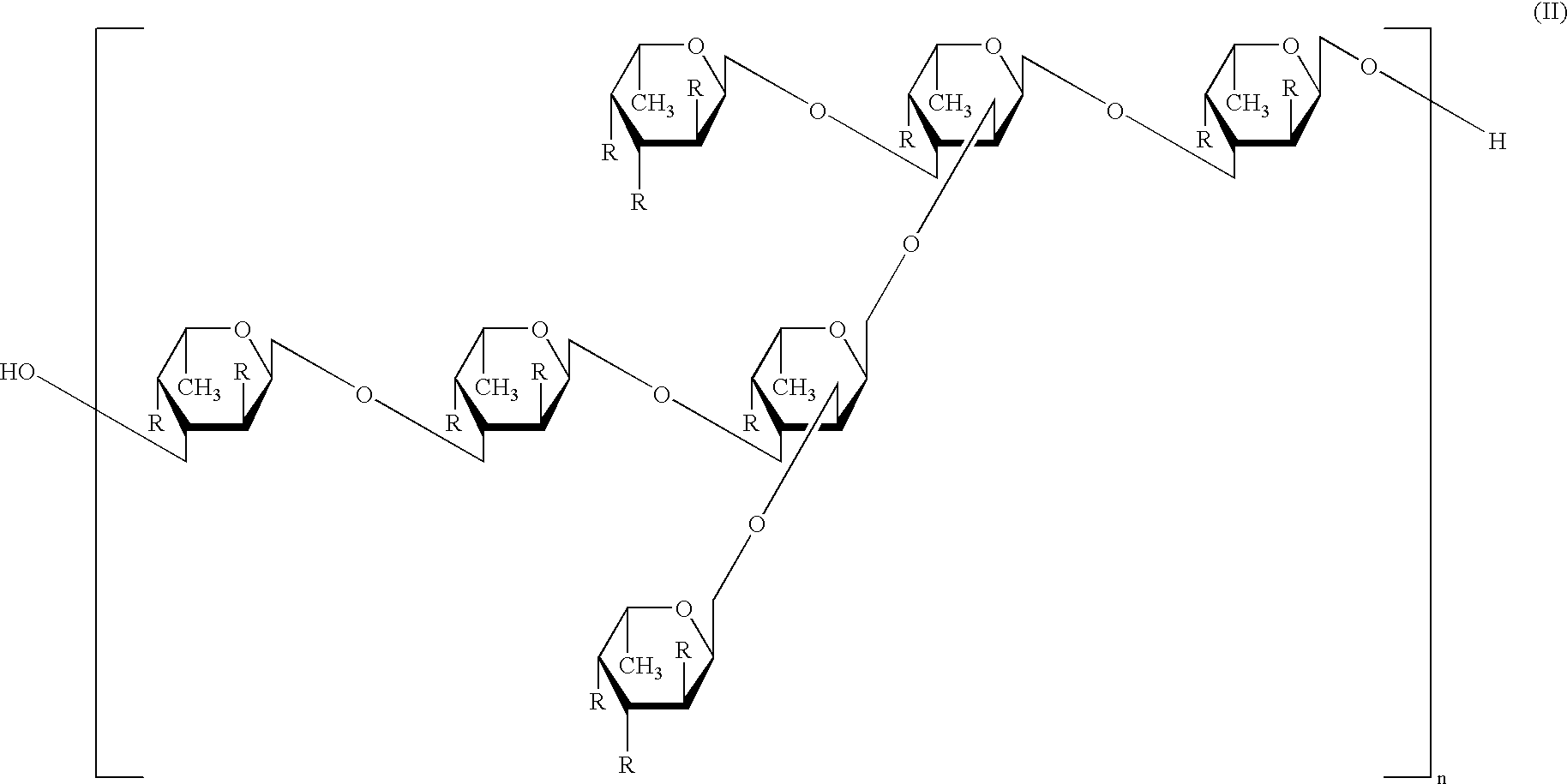

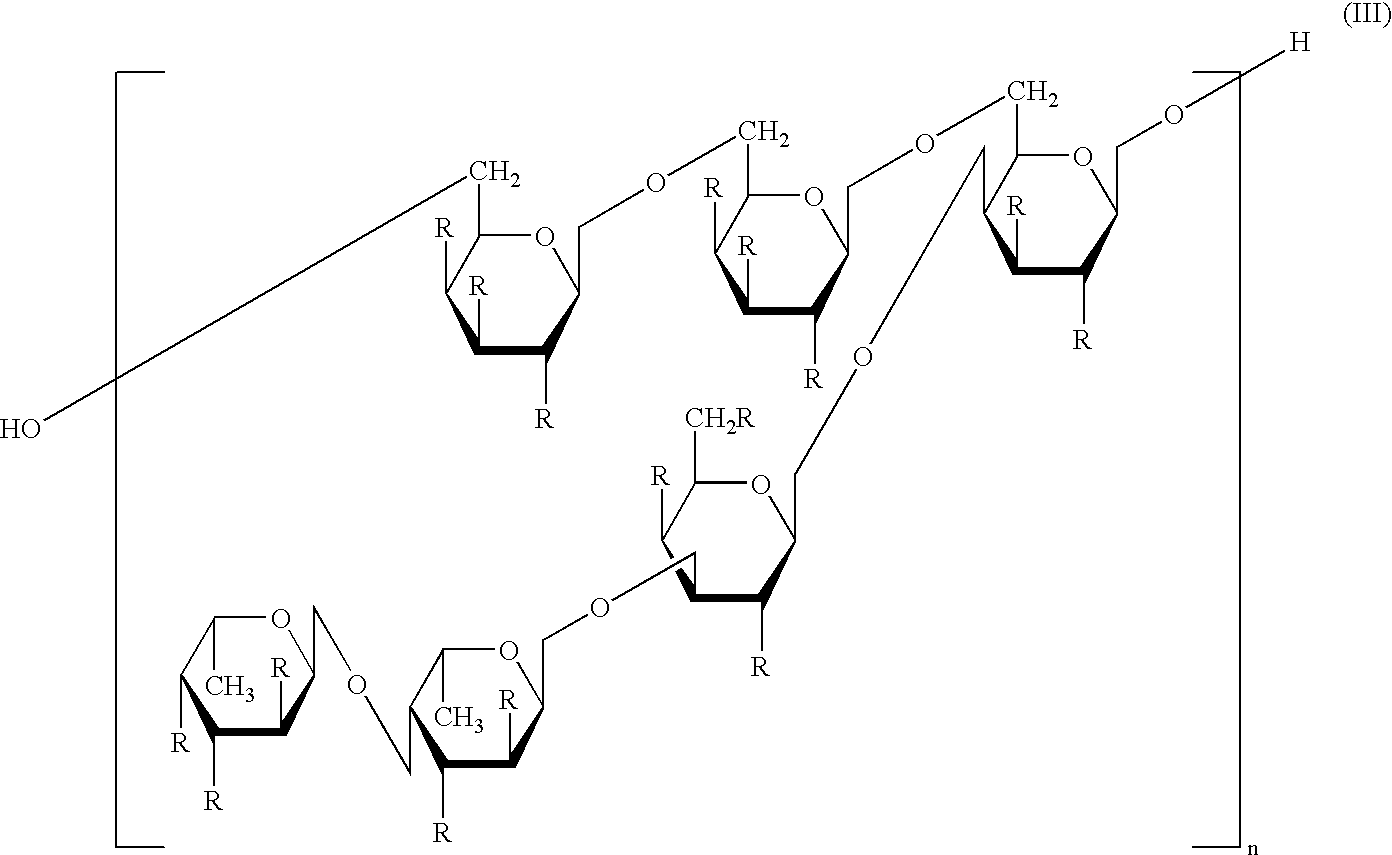

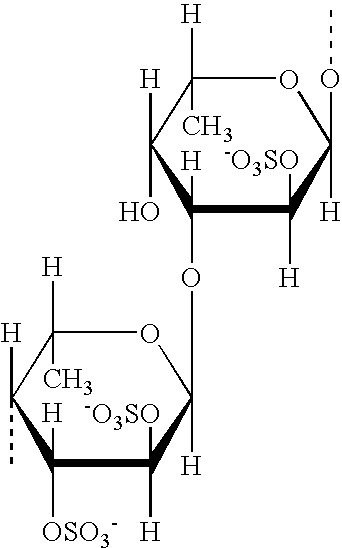

Fucoidan is a sulfated polysaccharide (MW: average 20,000) found mainly in various species of brown algae and brown seaweed such as mozuku, kombu, bladderwrack, wakame, and hijiki (variant forms of fucoidan have also been found in animal species, including the sea cucumber).

Infant formula composition

An infant formula composition including fucoidan, a protein, and a lipid. The fucoidan may be partially hydrolyzed, and also may be sulfonated. The protein may be derived from quinoa. Also disclosed are infant formula kits to be assembled in the field. The kits may include a substantially dehydrated infant formula composition and a diluting agent. The kit may alternatively include a ready-to-consume infant formula composition and substantially dehydrated additives which may be added to the formula before consumption.

Owner:SAKURA PROPERTIES LLC

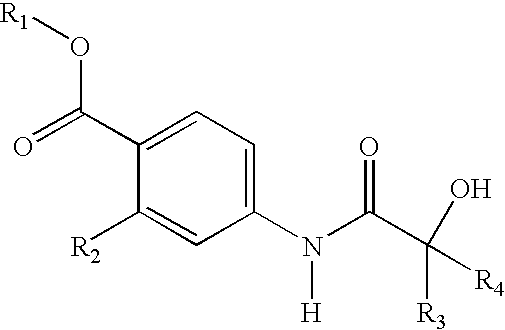

Compositions and methods for treating estrogen-dependent diseases and conditions

A pharmaceutical composition for the treatment of an estrogen-dependent disease or condition comprises: (1) at least one polysaccharide selected from the group consisting of an alginate and a fucoidan in a quantity effective to treat an estrogen-dependent disease or condition; and (2) a pharmaceutically acceptable carrier. The composition can include both an alginate and a fucoidan. The composition can include other ingredients such as at least one compound selected from the group consisting of diindolylmethane and indole-3-carbinol in a quantity sufficient to inhibit the activity of estrogen. Methods for use of the composition for the treatment of an estrogen-dependent disease or condition, especially endometriosis, are described.

Owner:CONCOURSE HEALTH SCI

Sports drink concentrate

A sports drink concentrate, comprising a composition of partially hydrolyzed fucoidan, a carbohydrate, an electrolyte, and water. The composition may be in a concentrated form and diluted before consumption.

Owner:SAKURA PROPERTIES LLC

Food or beverage additive containing fucoidan and food and beverage containing fucoidan

Food or beverage where fucoidan which is derived from a fucoidan-containing substance is contained therein, added thereto and / or diluted therein. Food or beverage where fucoidan which is derived from a fucoidan-containing substance and where algins are reduced or eliminated, is contained therein. Apoptosis-inducing food or beverage where an effective amount of fucoidan having an apoptosis-inducing ability is contained therein.

Owner:TAKARA HOLDINGS

Fucoidan compositions and methods for dietary and nutritional supplements

ActiveUS20060210609A1Promote growthHigh energyCosmetic preparationsBiocideDietary supplementAdditive ingredient

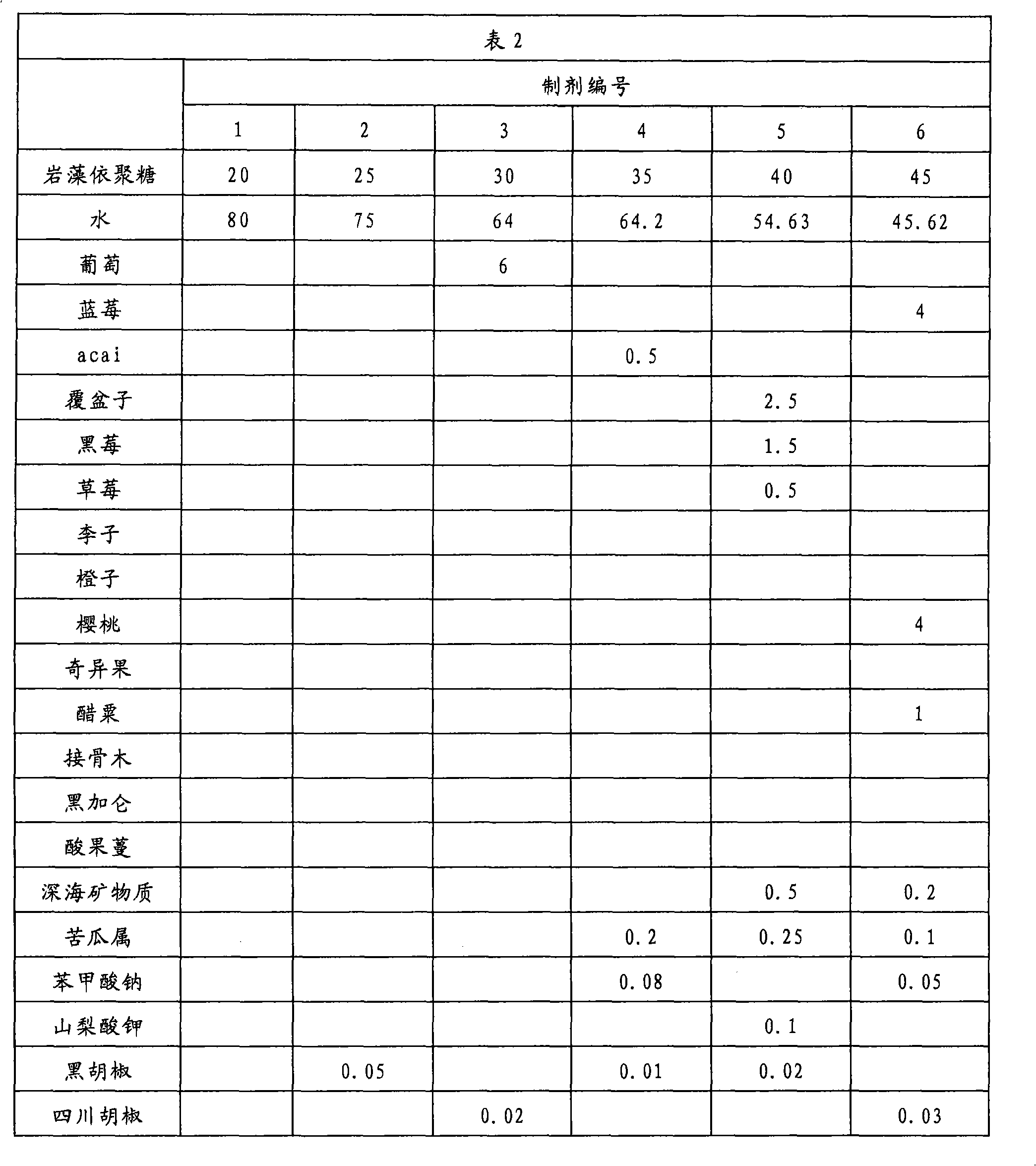

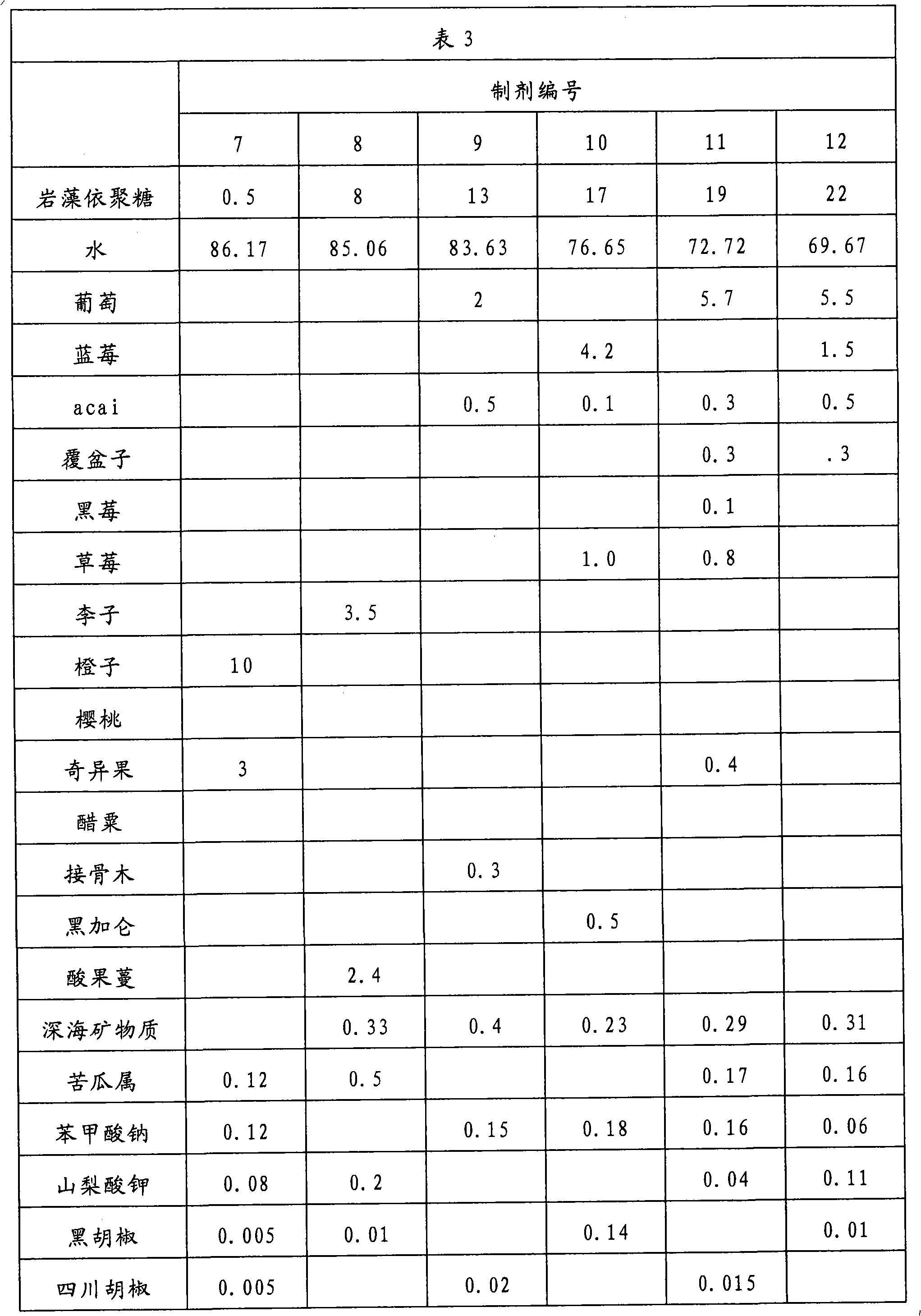

Compositions and methods relating to partially hydrolyzed fucoidan for use in dietary supplements are described. Fucoidan from brown seaweeds is partially hydrolyzed and then mixed with other ingredients for use as a dietary supplement in beverage, capsule, or tablet form. The fucoidan is partially hydrolyzed with acid and heat. The partially hydrolyzed fucoidan can also be sulfonated. Other ingredients that can be included in the dietary supplement include high-ORAC-value antioxidants, minerals, pepper extract, flavoring agents, coloring agents, and preservatives. The compositions can be in the form of beverages, tablets, capsules, powders, and the like.

Owner:SAKURA PROPERTIES LLC

Fucoidan compositions and methods

InactiveUS20080089941A1Effective treatmentPromote healingOrganic active ingredientsCosmetic preparationsAdditive ingredientDietary supplement

Compositions and methods relating to partially hydrolyzed fucoidan for use in dietary supplements and skin-care products are described. Fucoidan from brown seaweeds is partially hydrolyzed and / or sulfonated and then mixed with other ingredients for use as a dietary supplement in beverage, capsule, or tablet form or for use as a skin-care product. Other ingredients that can be included in the dietary supplements include vitamins, minerals, amino acids, carotenoids, flavonoids, antioxidants, aminosugars, glycosaminoglycans, and botanicals. Skin care products according to the present invention comprise partially hydrolyzed fucoidan and a base.

Owner:SAKURA PROPERTIES LLC

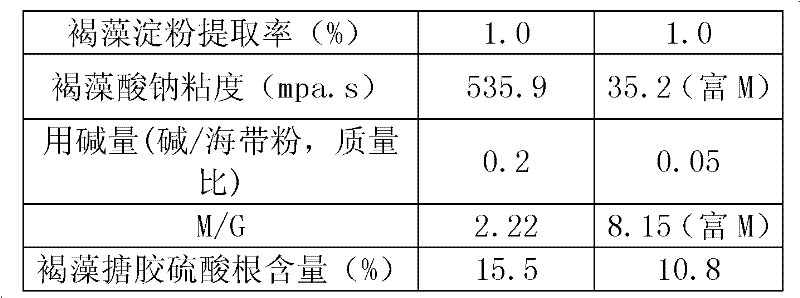

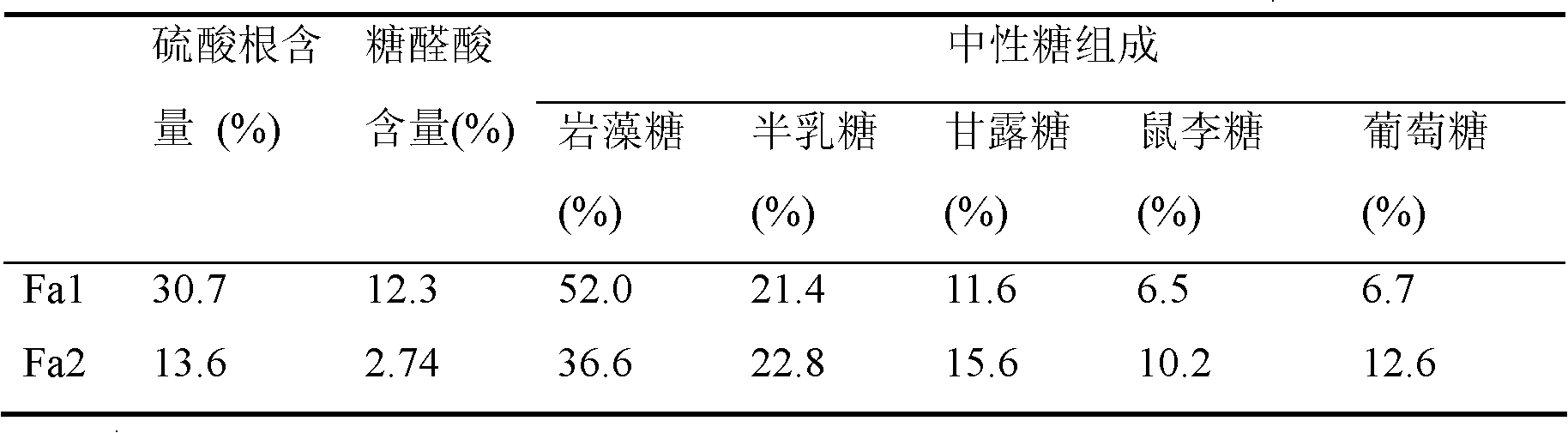

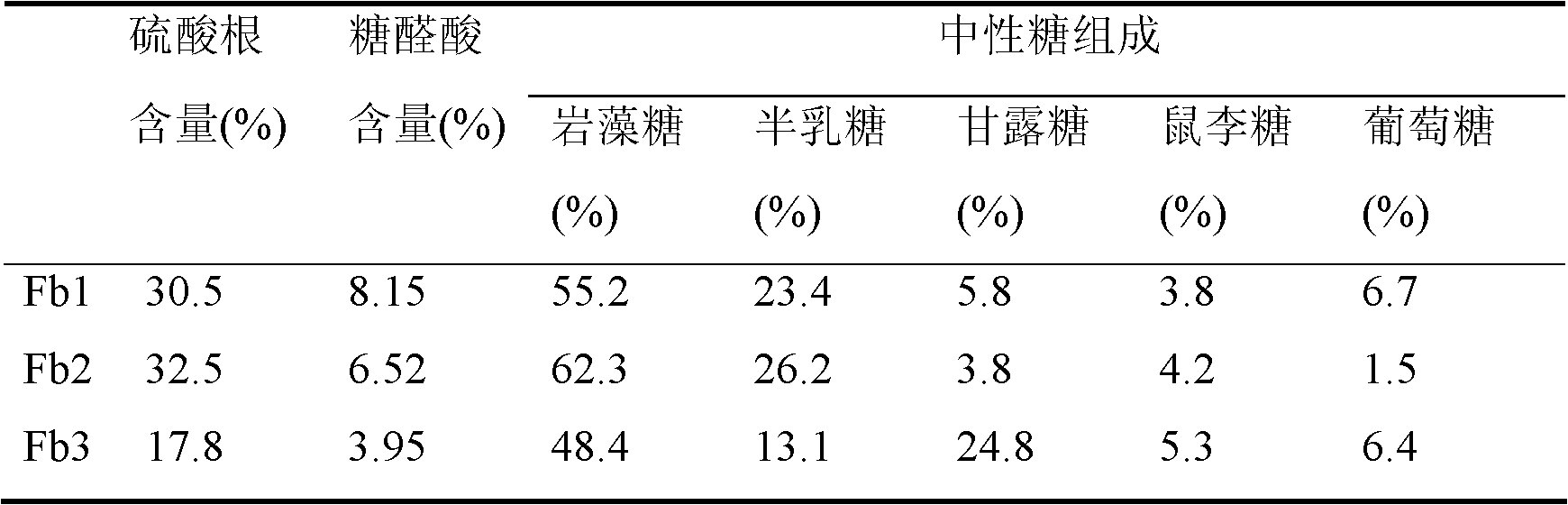

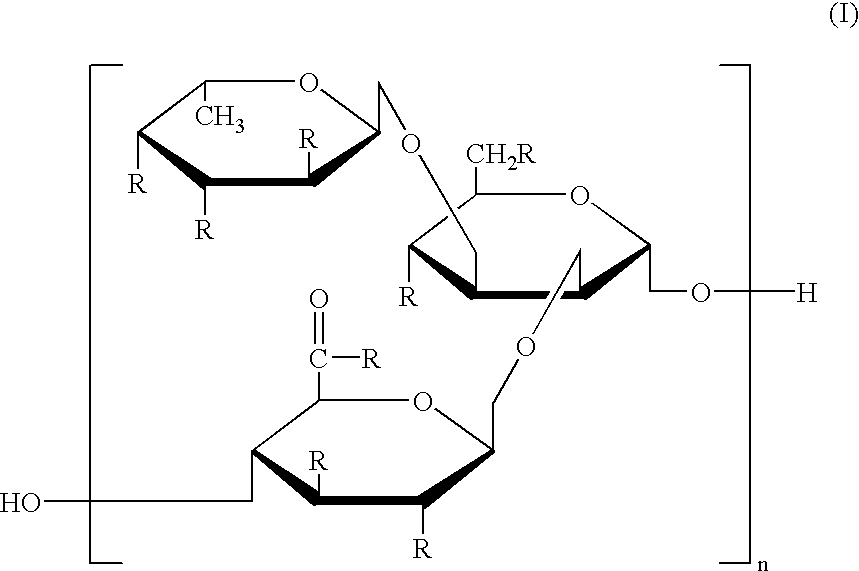

Method for extracting active polysaccharides from brown algae

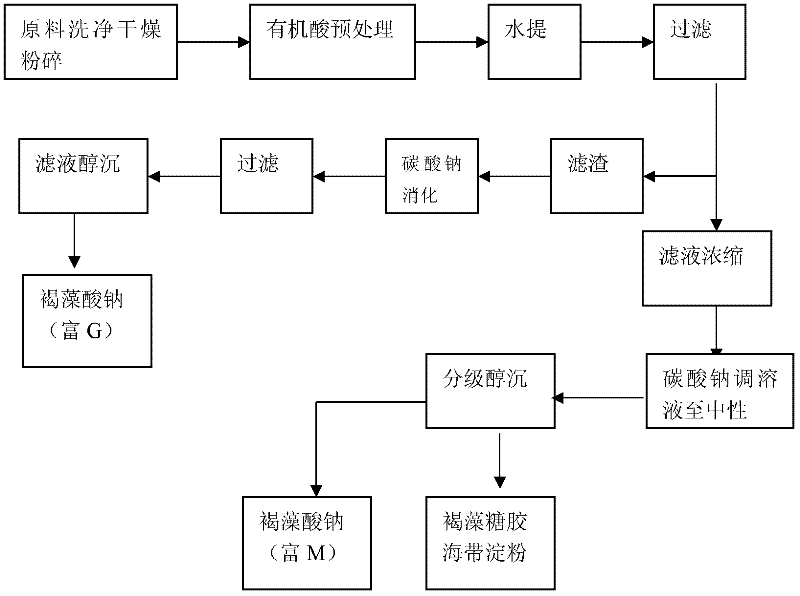

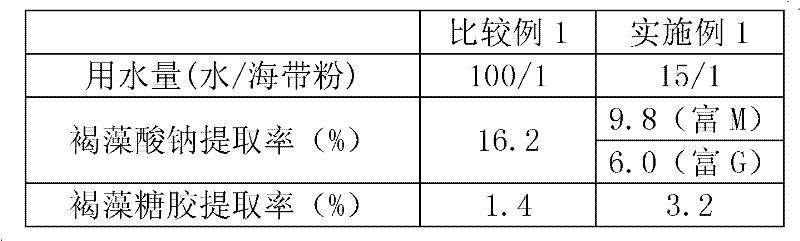

The invention relates to a method for extracting active polysaccharides from brown algae. The method comprises the following specific steps of: putting a cleaned, dried and smashed alga raw material into an extraction container, and adding an organic acid solution or organic-inorganic mixed acid solution; heating a stirred and wetted material to 50-150 DEG C to realize partial degradation of highpolymer polysaccharide substances of brown algae; fully washing with an organic solvent till the acid solution in the material is discharged completely; adding 5-8 times of volume of water for extracting, concentrating an extracting solution, regulating the PH value to neutral, and gradually depositing in alcohol to obtain align, fucoidin and laminaran which are rich in mannuronic acid fragments (rich in M) respectively; and pretreating brown alga raw material residues with water-extracted organic acid according to an alkali digestion process to obtain align which is rich in guluronic acid fragments (rich in G). By adopting the method, the defects of high water consumption, severe pollution and the like existing in the conventional align production process are overcome; and the method has the advantages of saving in energy, reduction in emission, high product yield, small extraction solvent dosage, and the like.

Owner:张劲松

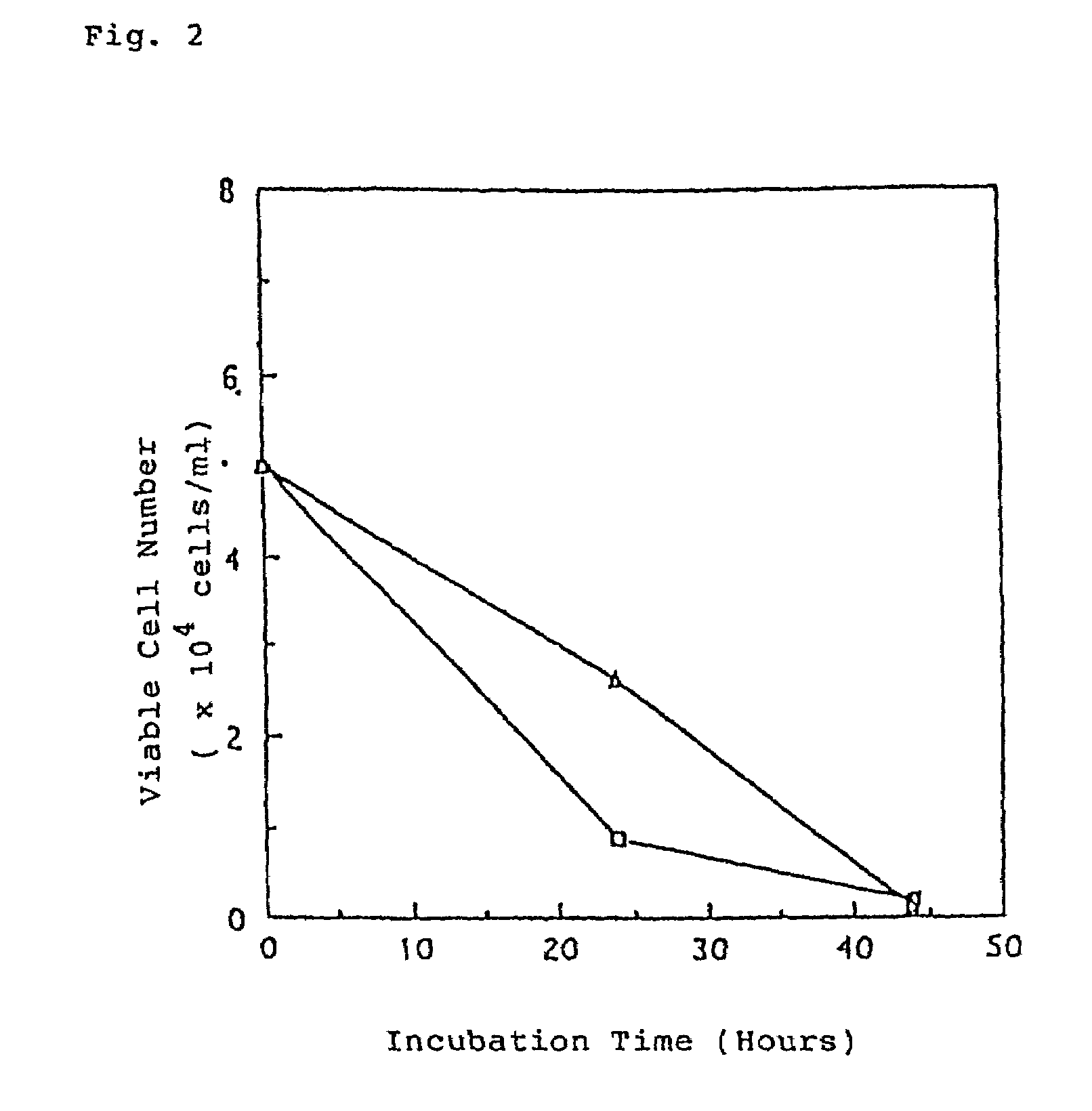

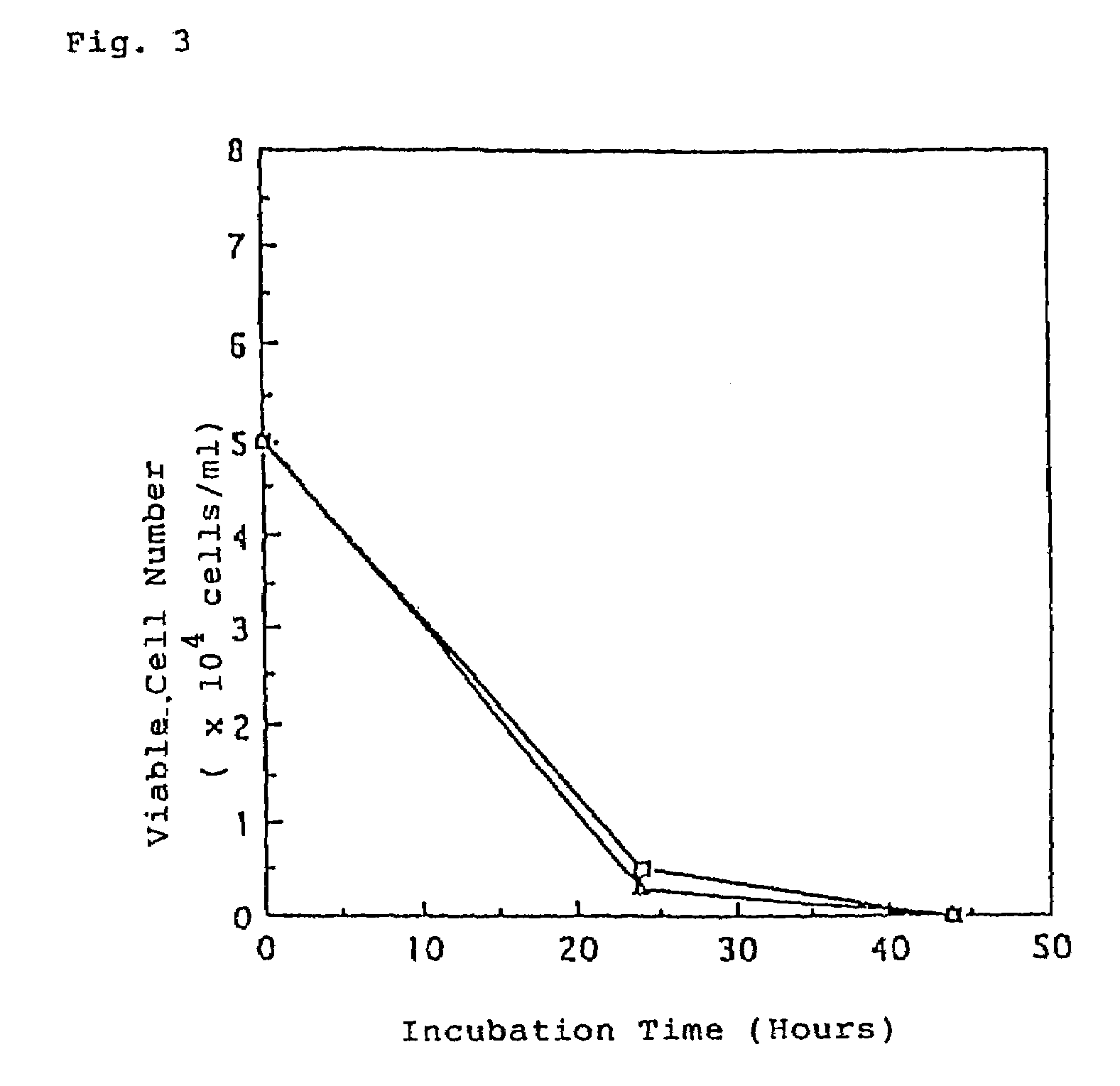

Method for preparing low molecular weight brown seaweed fucoidan sulfate

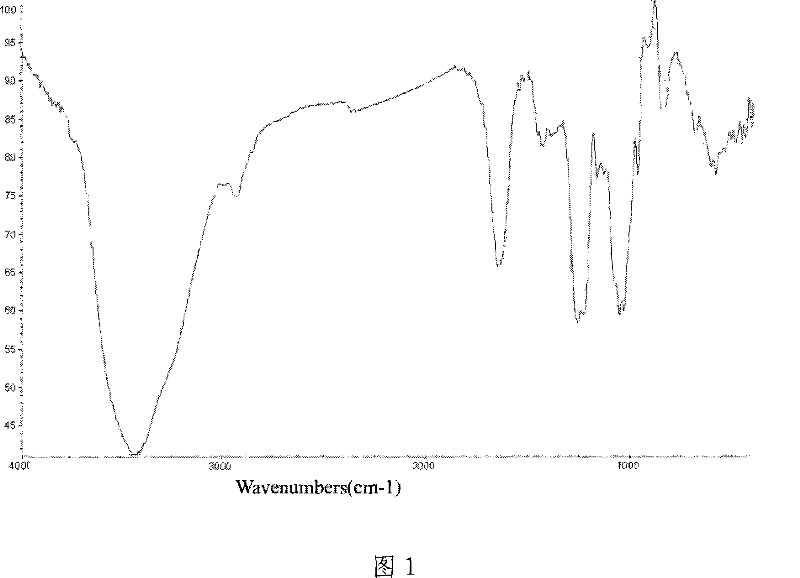

InactiveCN101962415AAutomatically consumed completelyEffective separation and purificationAntiviralsAntineoplastic agentsSulfated polysaccharidesSeparation technology

The invention relates to a method for preparing low molecular weight brown seaweed fucoidan sulfate. The method comprises a step of oxidatively degrading brown seaweed sulfated polysaccharides by hydroxyl radical and a step of ultrafiltration membrane separation and purification, wherein raw sugar of the brown seaweed sulfated polysaccharide is used as a raw material, the hydroxyl radical generated by the reaction of copper ions and hydrogen peroxide is adopted to oxidatively degrade the raw sugar of the brown seaweed sulfated polysaccharide, and the membrane separation technology is combined in the method for preparing the low molecular weight fucoidan sulfate from the brown seaweeds. In the preparation process, the oxidizing speed is uniform, the reacting condition is mild, and the controllability and repeatability are good; the copper ions are removed by a chelating column after the oxidation reaction is finished, so the operation process is simple. Furthermore, the pH value is adjusted by adding little acid and alkali, so the salt content in the product is low, and can be completely removed by a 300Da ultrafiltration membrane in the ultrafiltration membrane separation and purification process. The ultrafiltration membrane can effectively separate and purify the brown seaweed fucoidan with different molecular weights along with high separating speed and large treatment amount. The method is suitable for industrial production.

Owner:OCEAN UNIV OF CHINA

Cosmetics

InactiveUS20030039670A1Good effectRestoring hairCosmetic preparationsBiocideFucoidanAdditive ingredient

To find a substance which has a skin cosmeticizing effect such as prevention of skin aging, amelioration of sensitive skin, or antipruritic action, and can serve as an effective ingredient for a hair-care product, thereby providing cosmetics comprising the effective ingredient. Concretely, there are provided cosmetics characterized in that the cosmetics comprise as an effective ingredient a compound selected from a fucoidan, a degradation product thereof, a sulfated monosaccharide or a salt thereof.

Owner:TAKARA HOLDINGS

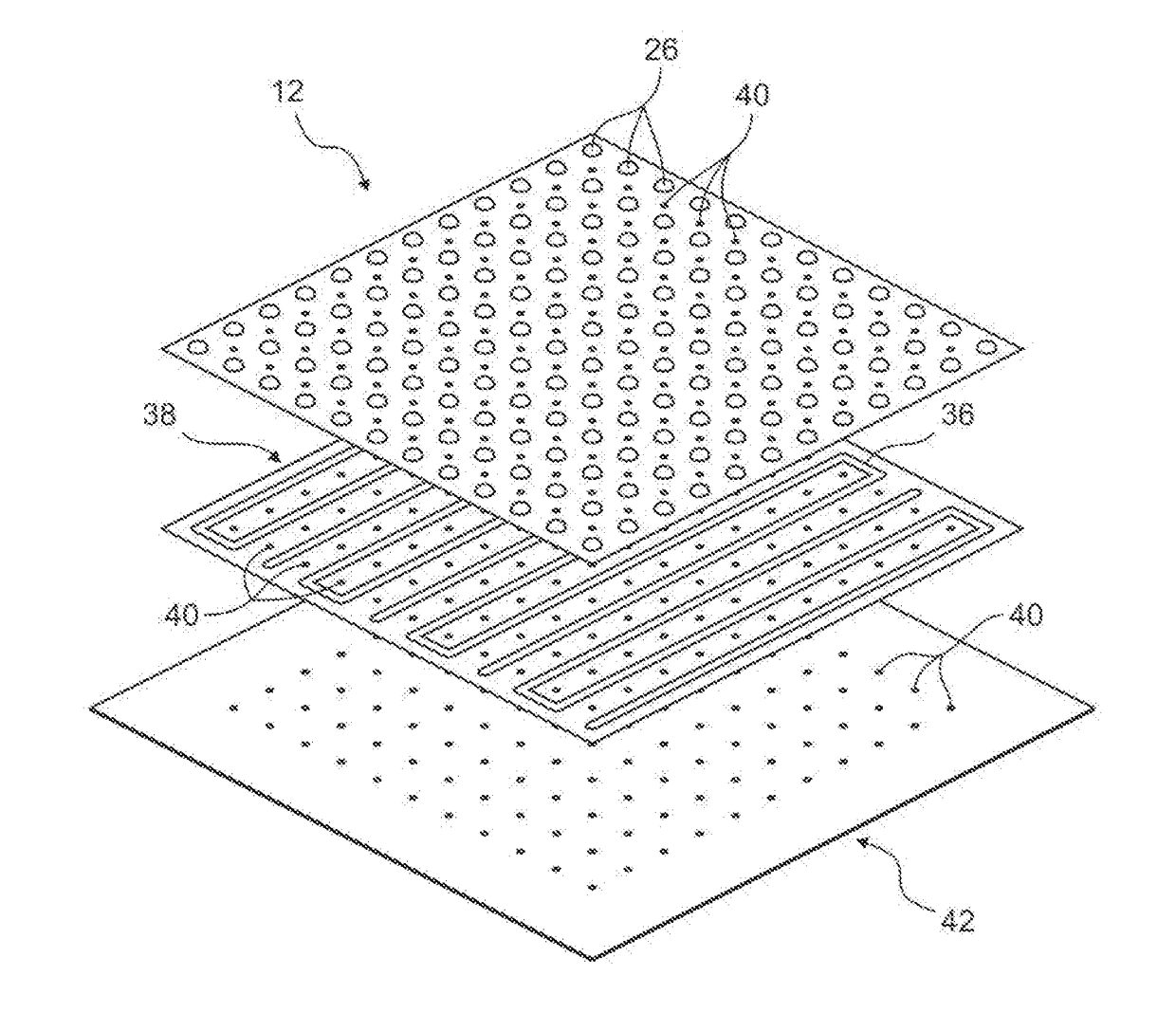

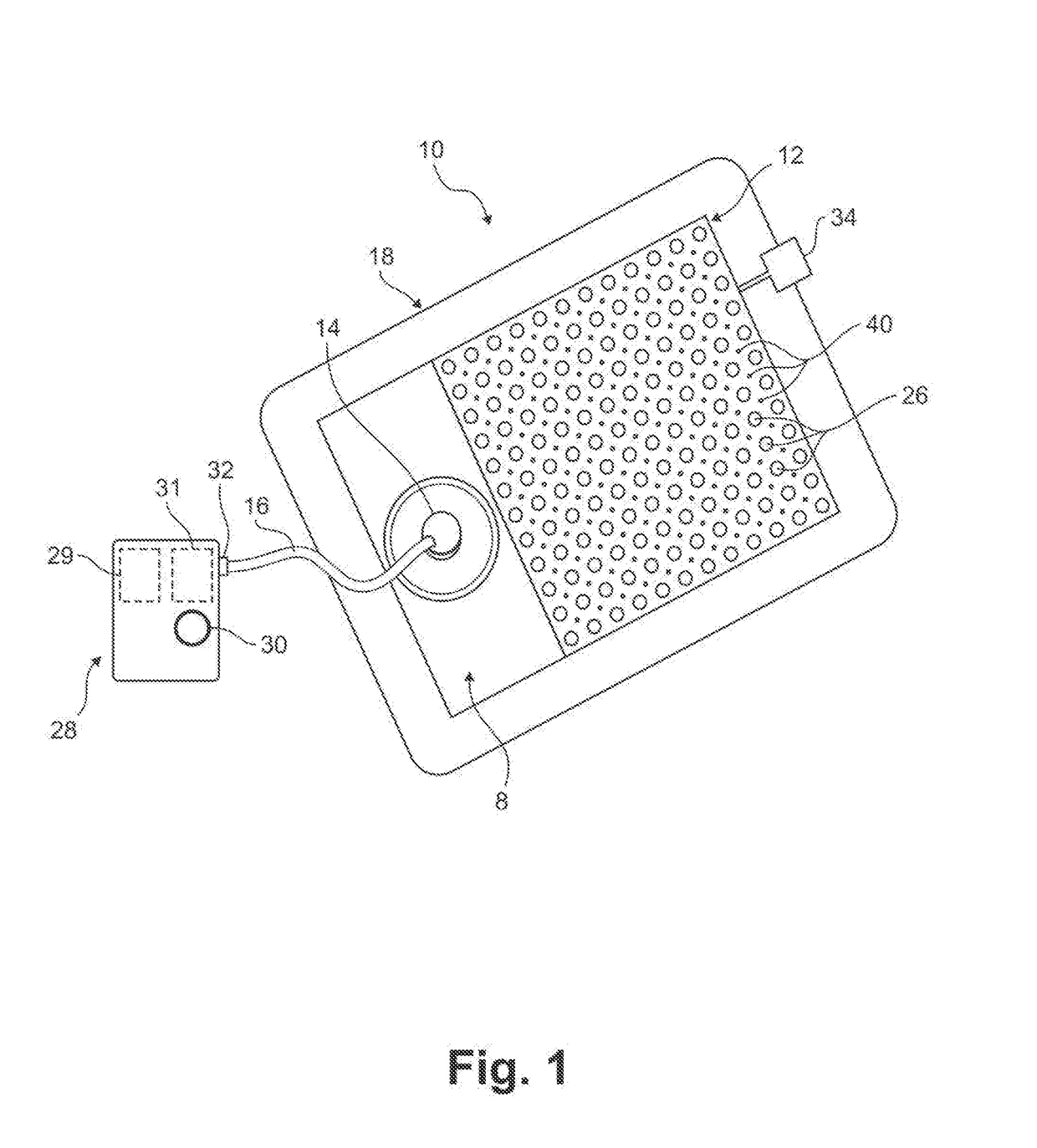

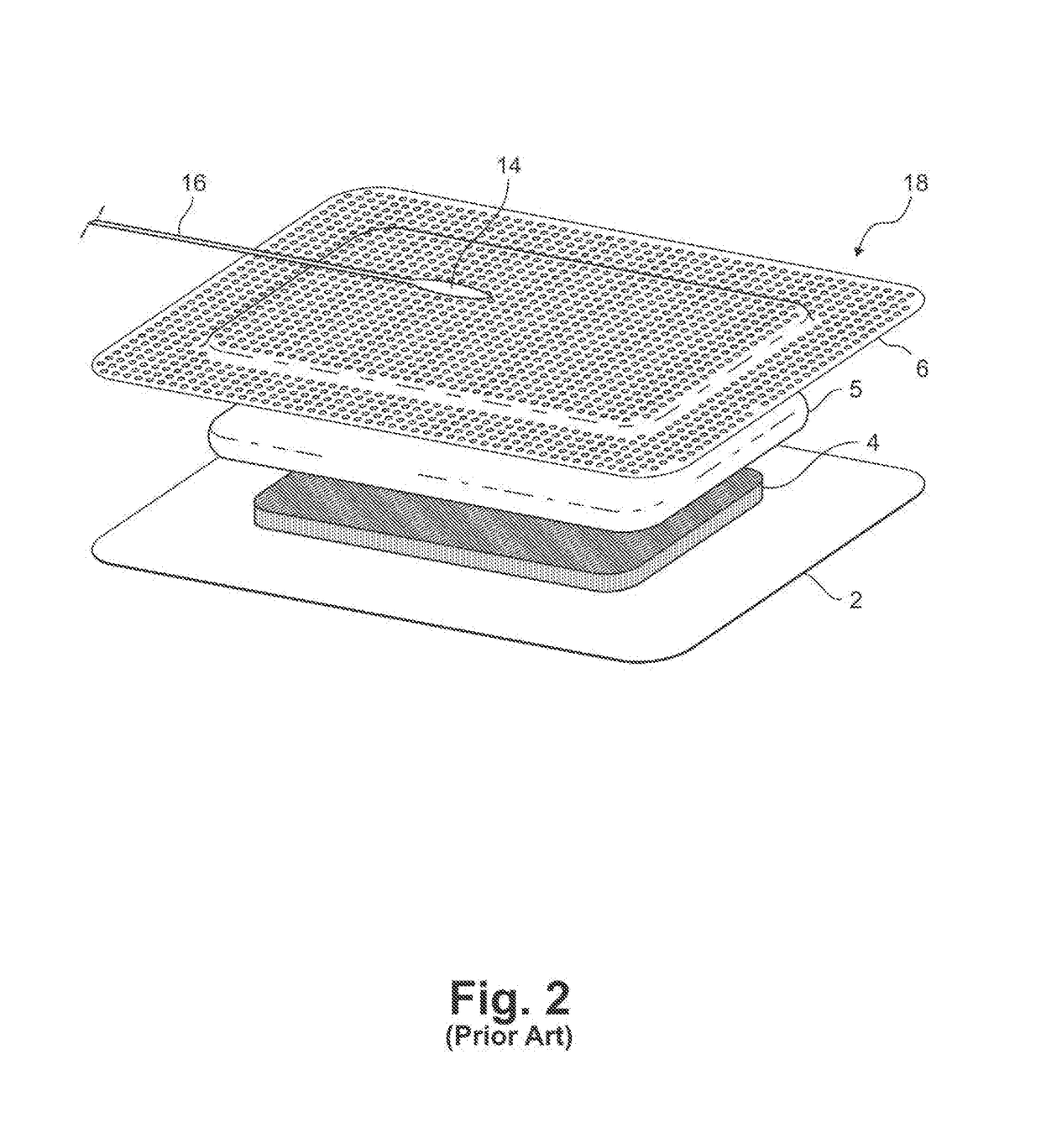

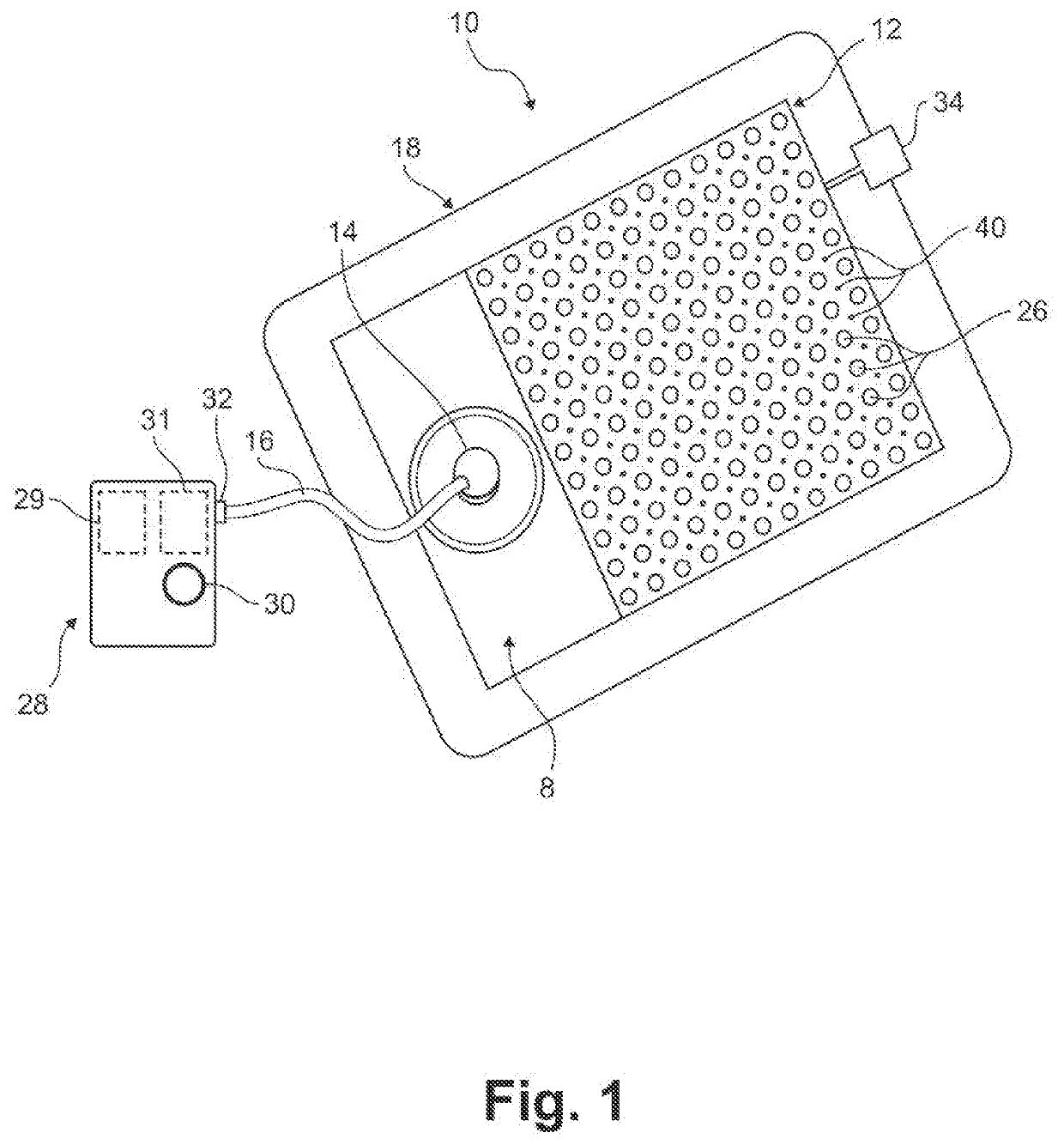

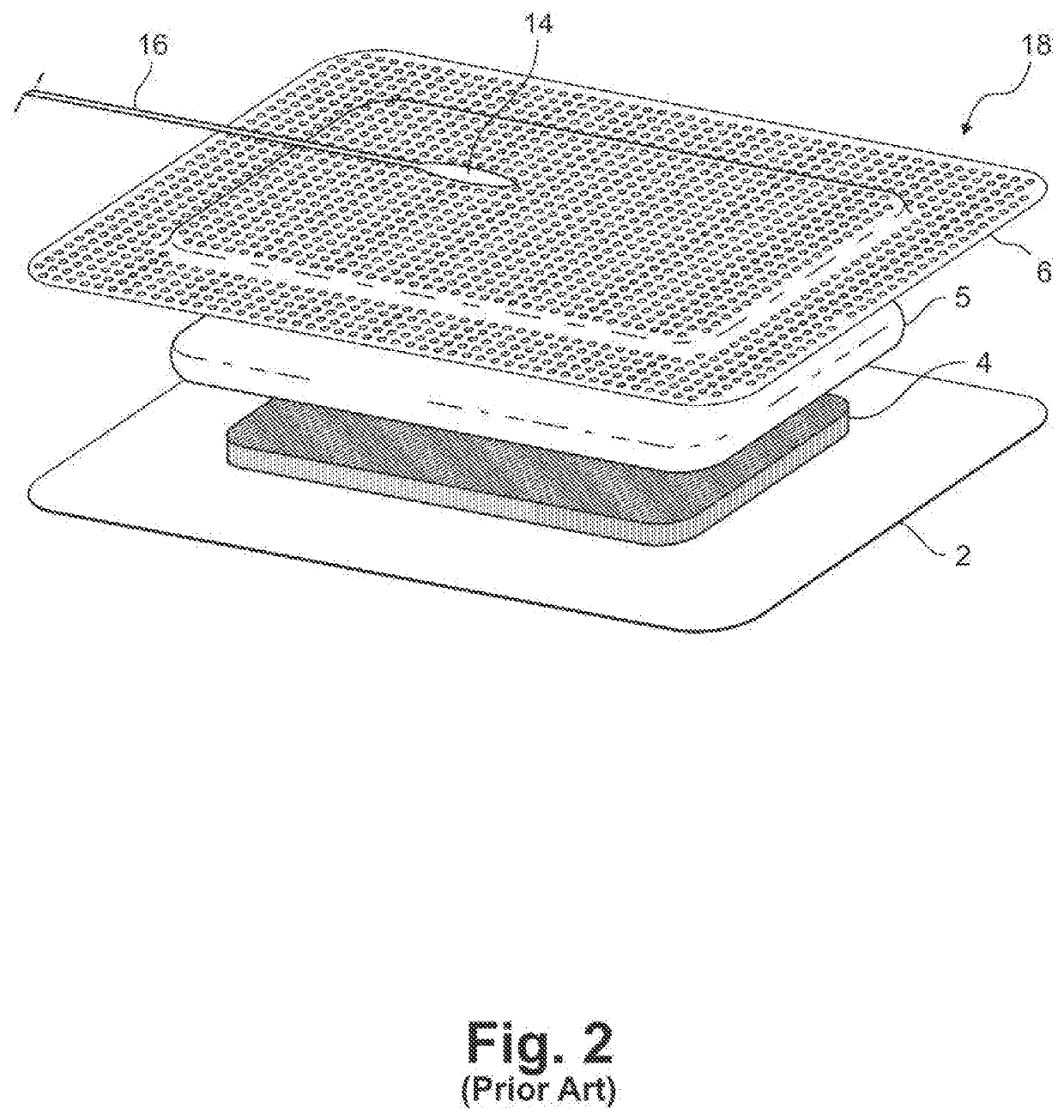

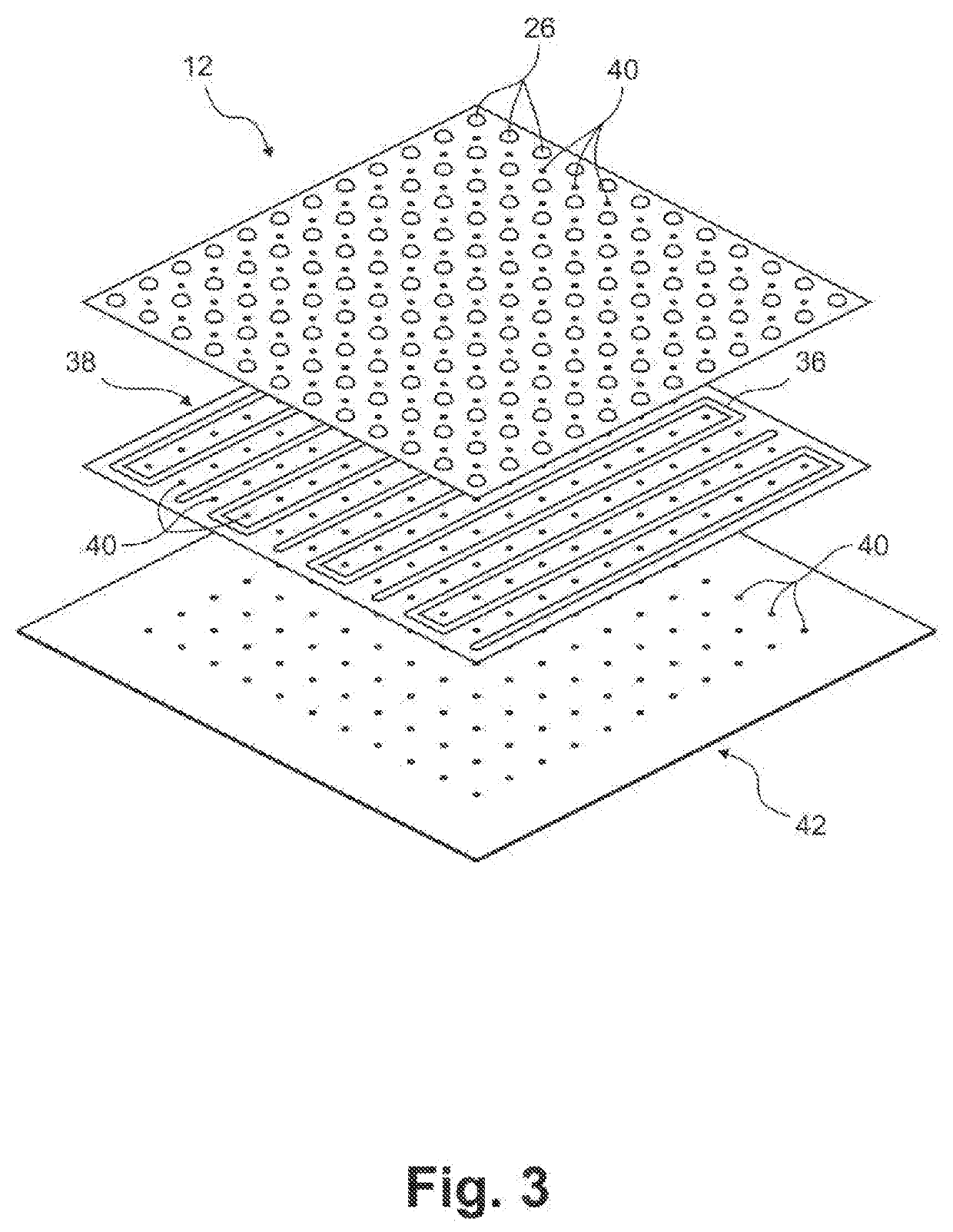

Wearable Micro-LED Healing Bandage

InactiveUS20180056087A1Aid in healing of woundRelieve painMedical devicesAdhesive dressingsFiberWound dressing

A wound dressing and method of use is provided that increases healing of tissues by targeting damaged tissue at a predetermined wavelength. The device includes the use of a negative pressure bandage, a flexible light sheet, and one or more bioactive marine extracts. Light emitted from the flexible light sheet penetrates through the bandage to target damaged tissue, which accelerates the wound healing process and works synergistically with the negative pressure bandage and bioactive marine extracts such as collagen fibers, alginate, chitosan and fucoidan, or any combination thereof to accelerate healing.

Owner:RIBEIRO ADOLFO +2

Method for preparing L-fucoidan in sea tangle

InactiveCN1670028AHigh purityHigh yieldSugar derivativesSugar derivatives preparationFucoidanAlcohol

The invention relates to a simple method for preparing L-fucoidan by a kind of sea-tangle from Qingdao as materials which comprises: extracting and purifying the said sea-tangle by the water extract and ethanol precipitation to get purified fucoidan sulfate, then hydrolyzing sulphuric acid, filtering and the filtrate desalting through a column, deoxidizing and decolouring, filtering and the filter liquor rotating and concentrating in vacuum, alcohol depositing, the filter liquor rotating and concentrating to get syrup in vacuum, alcohol depositing, the filter liquor rotating and concentrating to get syrup in vacuum, adding the right amount mixture of alcohol and acetone, and adding several L-fucoidan particles to standard seed and crystal. The production purity is 98.1 %, and the productivity is 16.2-17.0 % in the invention.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Dehydrated sports drink powder

A dehydrated sports drink powder, comprising a solution of partially hydrolyzed fucoidan, a carbohydrate, and an electrolyte. According to another embodiment is a sports drink which includes a solution of the dehydrated sports drink powder and water.

Owner:SAKURA PROPERTIES LLC

Method for extracting brown algae polysaccharide sulfated

The invention relates to ocean chemical engineering technique field, concretely is a method for extracting fucoidan from a kelp soak solution, which includes steps: adding 1-10 ml flocculant to kelp soak solution per 150 ml, stirring for 2-10 min, flocculating for 10 min to 8 h, swelling for 1-24 h under condition that pH is 2-6 after centrifuging and depositing, stirring for 1-4 h to dissolve, filtrating and adjusting the filtrate to neutrality, decompressing and concentrating, adding ethanol to the concentrated solution, filtrating to obtain deposition, washing and drying the deposition to obtain the fucoidan. The invention relates to employs chitosan and its derivative as flocculant to flocculate and deposit ''sugar glue'' from kelp soak solution, and then extracts fucoidan from the ''sugar glue''. The advantages of the invention are: resources are utilized comprehensively, operation is simply, quantity of used acid and base is reduced, and quantity of the obtained fucoidan reaches 5-16% of quantity of the deposition.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Application of fucoidan in the preparation of medicine and health-care products for preventing and treating neurodegenerative diseases

InactiveCN101040867AOrganic active ingredientsCosmetic preparationsMarine invertebratesNeuro-degenerative disease

The invention discloses a fucose sulfate or a compound whose active component is fucose sulfate, in the drug preparation on the treatment of nerve retrograde disease and cognition damage. And the invention discloses the relative application. The inventive fucose sulfate is mainly from marine invertebrate animal as sea-tangle, sea cucumber or the like, with wide resource, easy production, batch production, and wide application.

Owner:SHANDONG UNIV

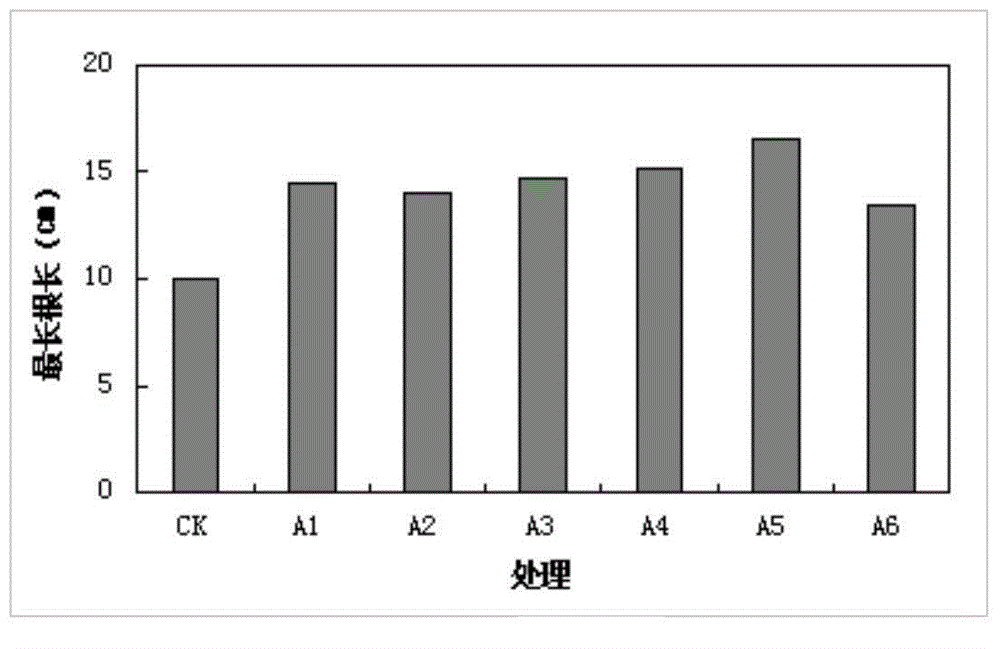

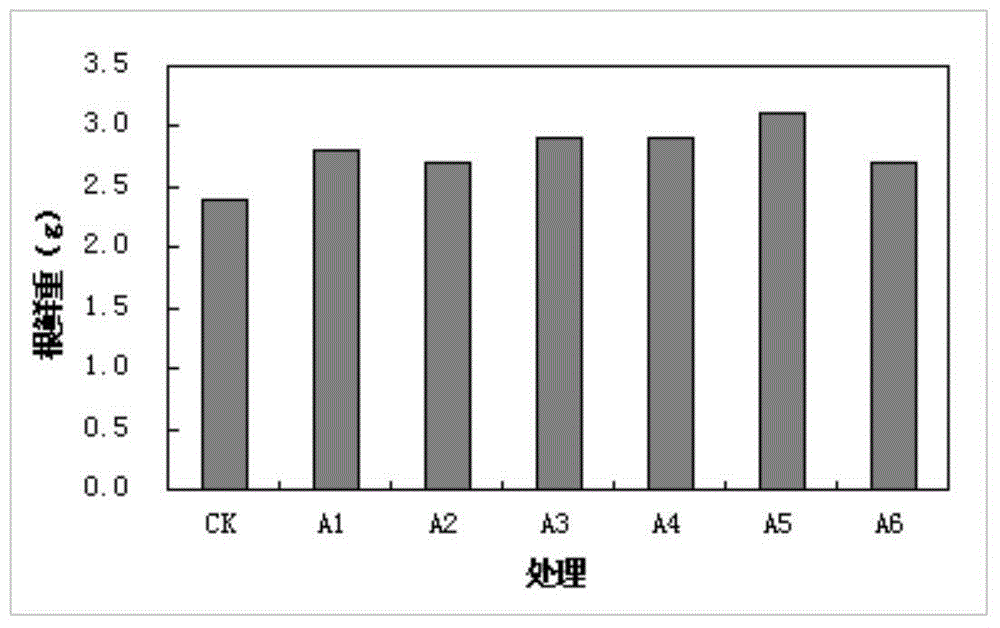

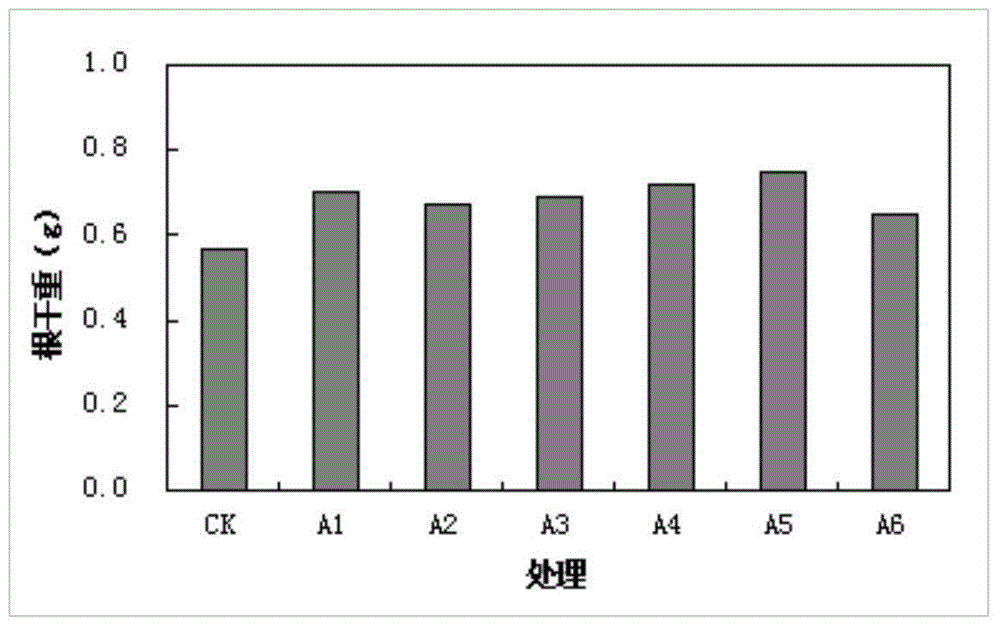

Seaweed water-soluble fertilizer and preparation method thereof

The invention relates to seaweed water-soluble fertilizer and a preparation method thereof and solves the problems that existing methods cannot comprehensively utilize fresh kelp blanching waste water and are complex in extraction processing and high in processing cost. The seaweed water-soluble fertilizer comprises one or more of fucoidan, mannitol, major elements, medium elements, trace elements, humic acid and amino acid. The preparation method is applicable to kelp blanching waste water processing and seaweed water-soluble fertilizer preparing. The seaweed water-soluble fertilizer includes organic seaweed water-soluble fertilizer, seaweed water-soluble fertilizer containing humic acid, seaweed water-soluble fertilizer containing amino acid, seaweed water-soluble fertilizer containing major elements, seaweed water-soluble fertilizer containing medium elements and seaweed water-soluble fertilizer containing trace elements.

Owner:荣成恒欣源水产有限公司

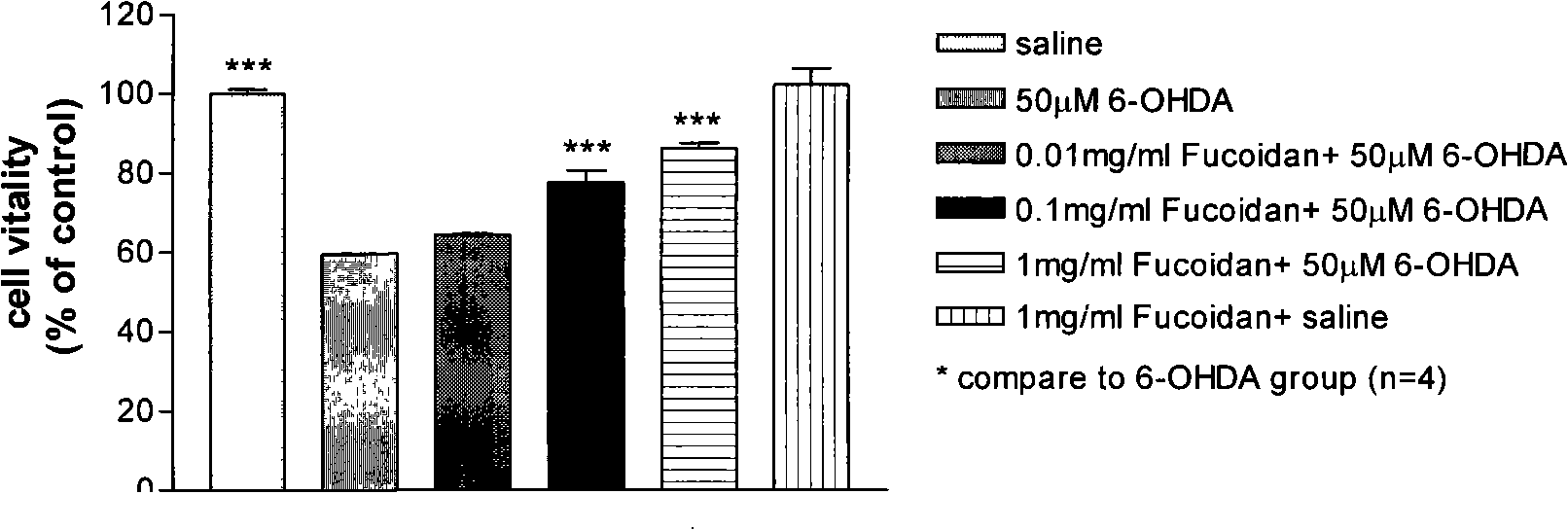

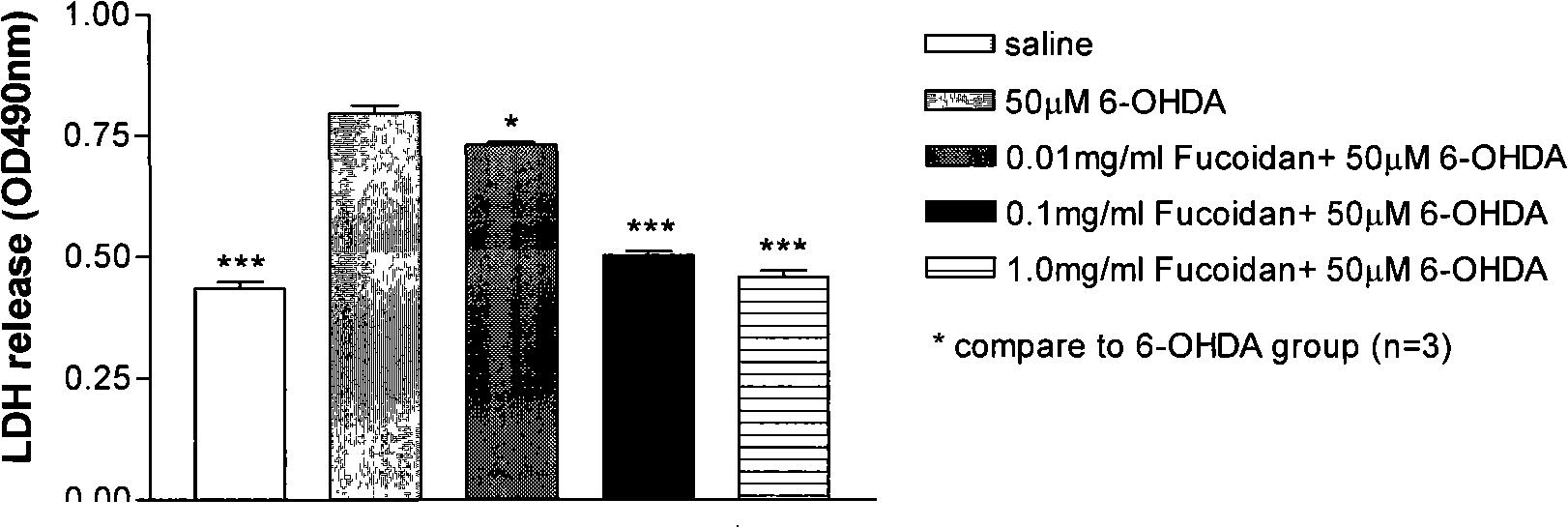

Use of brown alga polysaccharide sulfate in preventing and treating Parkinson's disease

ActiveCN101301310AImprove securityEnsure long-term medication needsOrganic active ingredientsNervous disorderCholinergic cellsSulfated polysaccharides

The invention discloses a novel application of fucoidan sulfate in prevention and cure of a parkinson disease. According to the experiments of an isolated PD cell model and an in vivo animal model, fucoidan sulfate has a certain neuroprotection effect on DA cholinergic neurons of the PD cell model and animal model and can prevent and cure the PD disease. The fucoidan sulfate of the invention can be natural polysaccharide extracts obtained form brown alga such as kelp, focus, bladder wrack, sea-tangle or chorda filum and also can be materials such as low molecular weight SSPSA or oligosaccharide which are obtained through the degradation of fucoidan sulfate.

Owner:CAPITAL UNIVERSITY OF MEDICAL SCIENCES +1

Food or beverage containing fucoidan and method of production thereof

Owner:TAKARA HOLDINGS

Pharmaceutical compositions and methods relating to fucans

InactiveUS20070238697A1Good treatment effectEliminate side effectsOrganic active ingredientsBiocideFucoidanMedicine

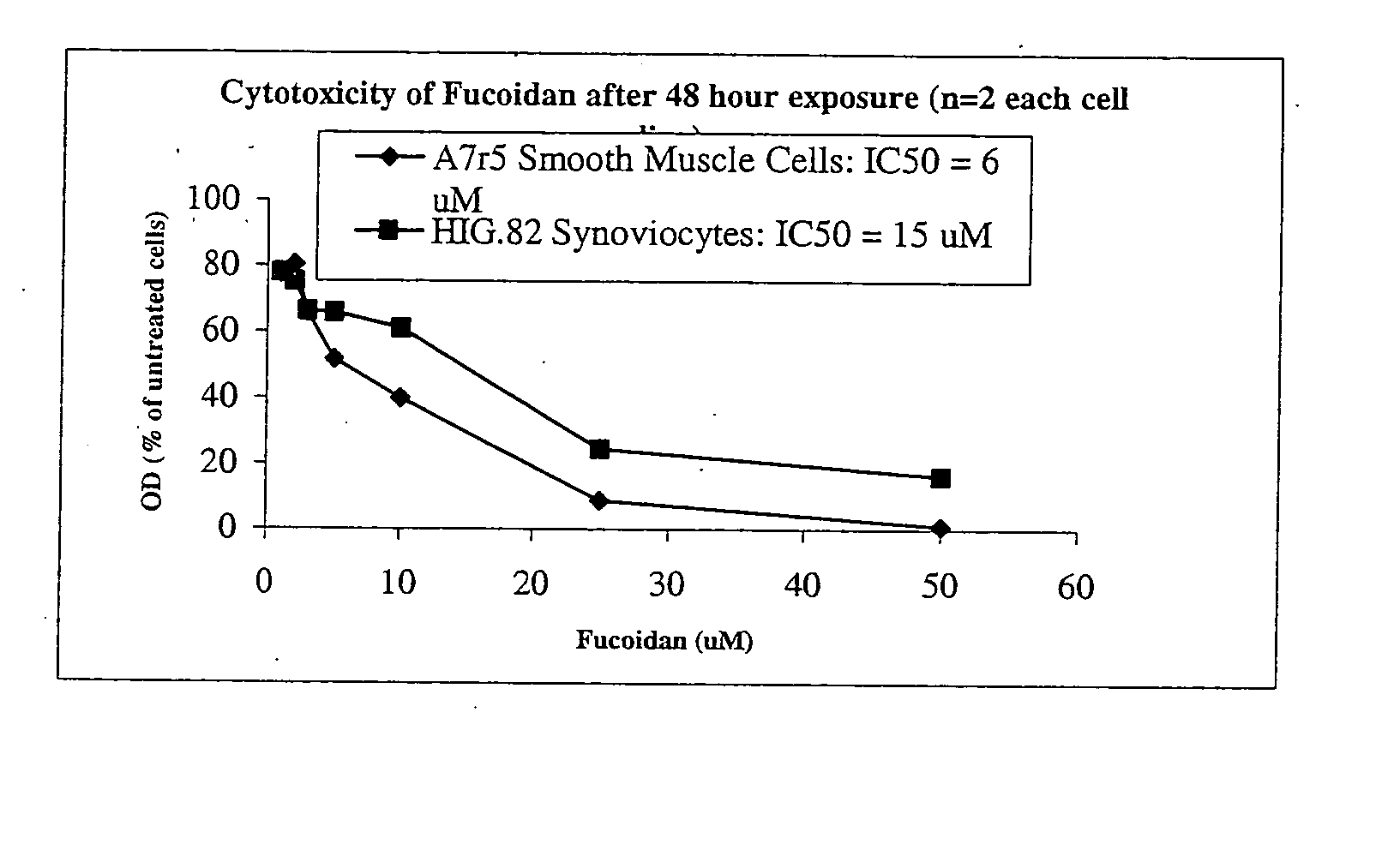

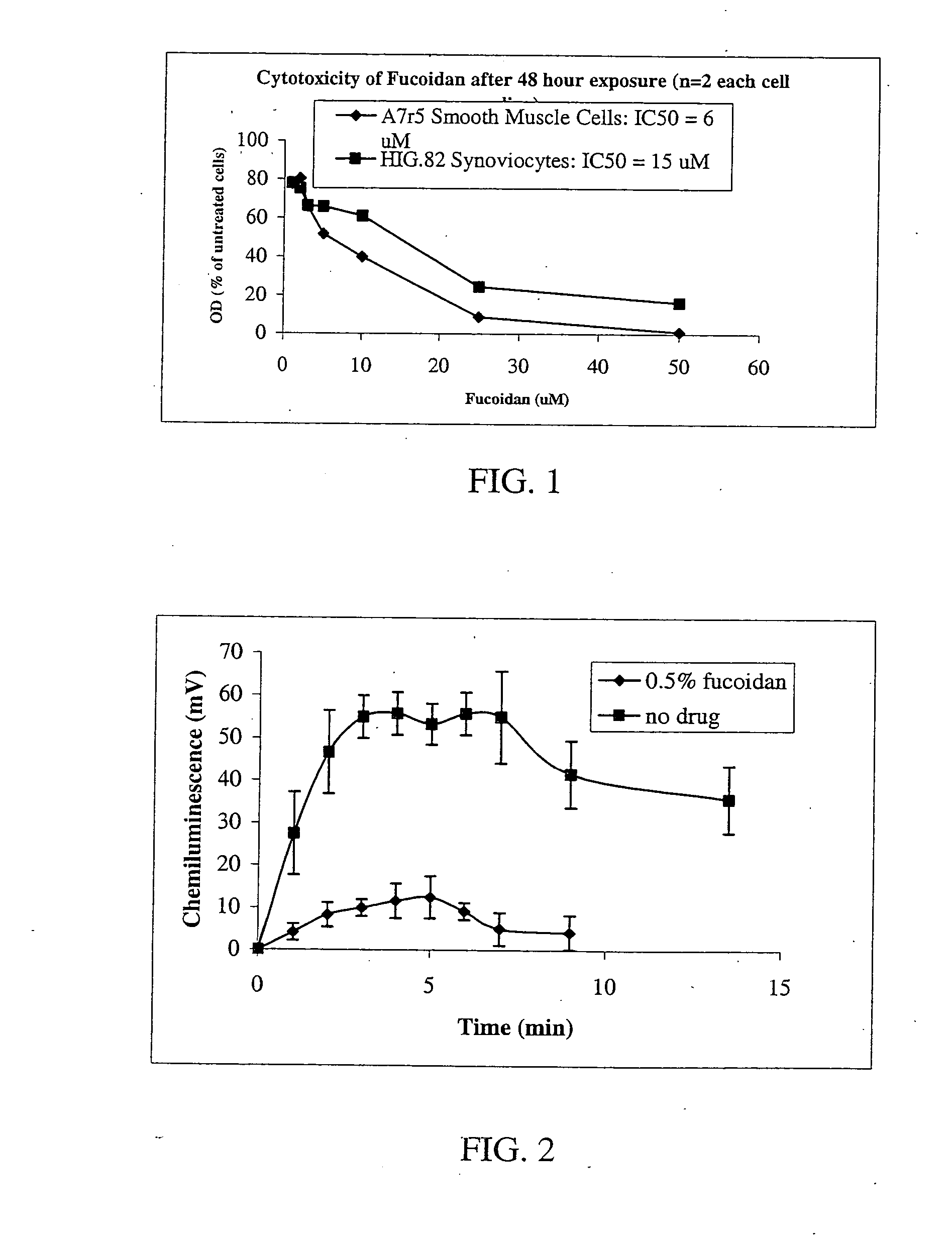

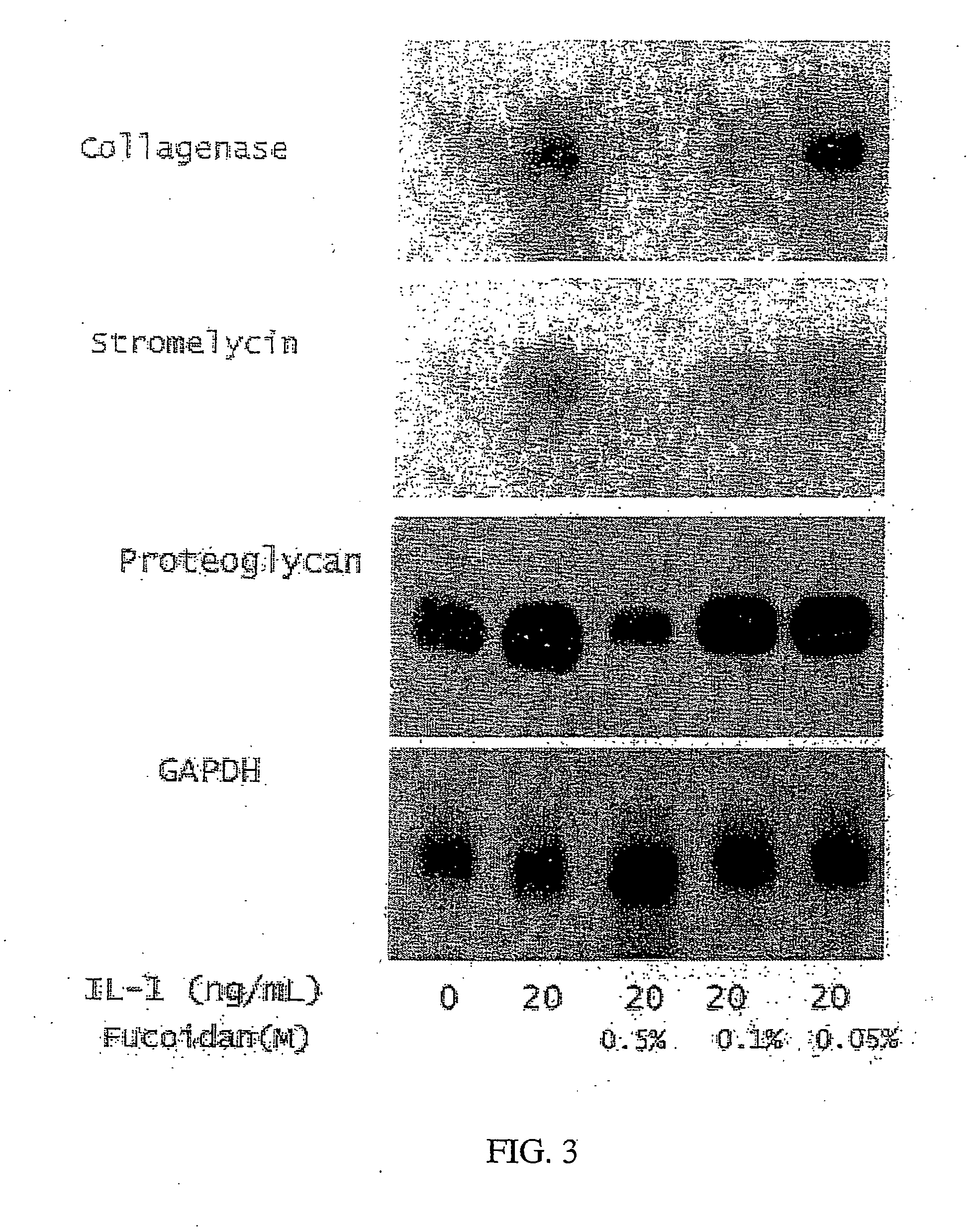

Compositions, methods and the like comprising fucans such as fucoidan to treat surgical adhesions, arthritis, and psoriasis.

Owner:THE UNIV OF BRITISH COLUMBIA

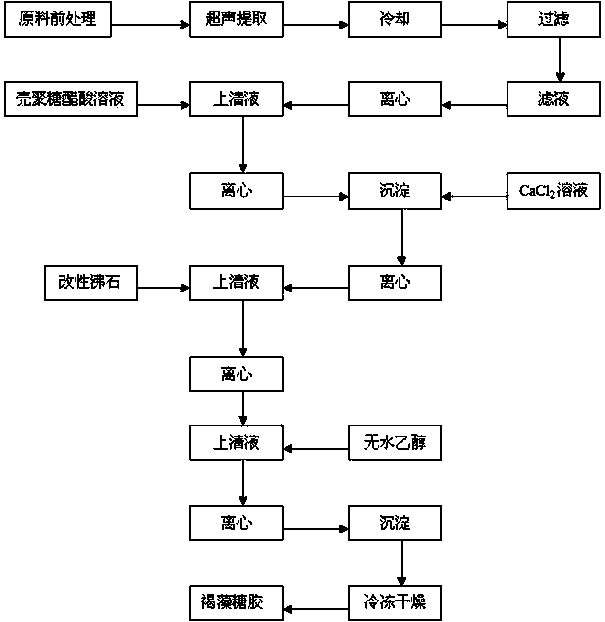

Method for extracting fucoidan and removing heavy metals from kelps

The invention discloses a method for extracting fucoidan and removing heavy metals from kelps. The method comprises the following steps of: pre-treating raw materials; extracting the fucoidan; settling to obtain a crude product of the fucoidan; reversely extracting the fucoidan; removing the heavy metals; and secondarily settling to obtain the fucoidan. According to the invention, normal temperature ultrasonic extraction is adopted, so that the extracting efficiency is high, and the economic value of the kelps is increased; the cost and the energy consumption can be reduced, and the environment can not be polluted; and the obtained product is high in purity, low in impurity content, safe in eating and suitable for industrial production.

Owner:福建华尔康生物科技有限公司

Fucoidan compositions and methods

Compositions and methods relating to partially hydrolyzed fiicoidan for use in dietary supplements and skin-care products are described. Fucoidan from brown seaweeds is partially hydrolyzed and / or sulfonated and then mixed with other ingredients for use as a dietary supplement in beverage, capsule, or tablet form or for use as a skin-care product. Other ingredients that can be included in the dietary supplements include vitamins, minerals, amino acids, carotenoids, flavonoids, antioxidants, aminosugars, glycosaminogrycans, and botanicals. Skin care products according to the present invention comprise partially hydrolyzed fiicoidan and a base.

Owner:SAKURA PROPERTIES LLC

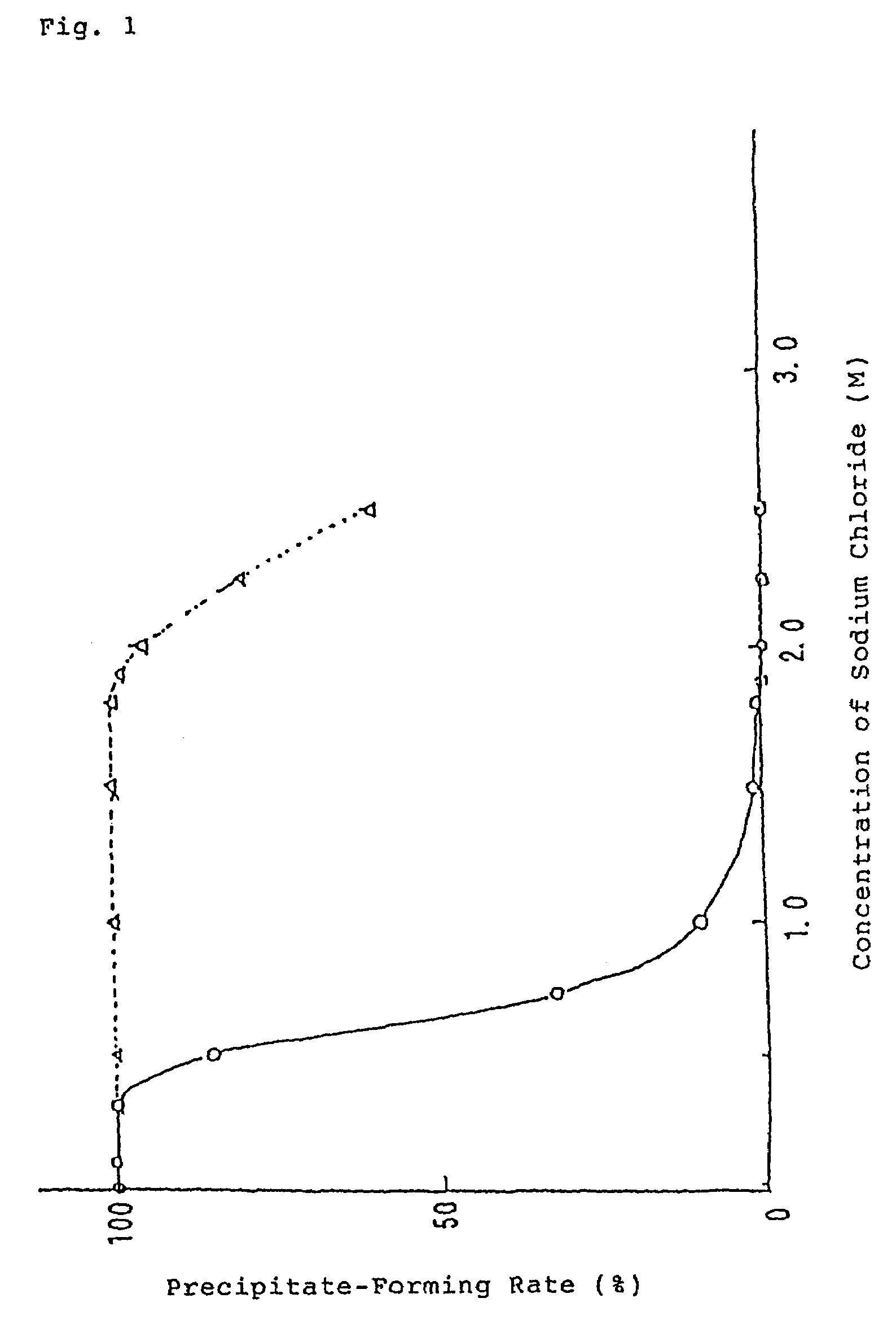

Preparation method of fucoidan sulfuric ester with high purity and high-sulfate radical content

The invention discloses a preparation method of fucoidan sulfuric esterwith high purity and high-sulfate radical content, comprising the following steps: (1) adding water in dry kelp for soaking and rinsing to remove sediment and then grinding; (2) adding the kelp in 95 percent ethanol for stirring, extracting and separating to obtain kelp residue A; (3) adding water in the kelp residue A, adjusting the pH value to 6-8, and stirring, extracting and separating the mixture to obtain kelp residue B and supernatant; (4) adding super calcium chloride in the supernatant, standing and filtering to obtain filtrate; (5) condensing the filtrate to concentrated solution; and (6) directly spraying and drying the condensed solution, or depositing the fucoidan with 40-70 percent ethanol and drying and crushing the dried fucoidan, and finally obtaining the fucoidan sulfuric ester with high purity and high-sulfate radical content, wherein the content of fucose is 40-70 percent and the content of sulfate radical is 30-50 percent. Compared with the prior art, the invention is free from using acid base for treatment and adjusting the pH value, has simple method, less consumption of organic solvent, few steps and low cost, and is suitable for industrial production.

Owner:SHANDONG UNIV AT WEIHAI

Methods for fucoidan purification from sea weed extracts

Methods for purifying fucoidan in extracts from brown seaweed are disclosed. In particular, methods of purifying fucoidan in the extract to remove heavy metal ions, bacterial and endotoxin contaminants, and other impurities are disclosed. The methods include the use of a chelating agent, selective precipitation, and filtration.

Owner:TAKEDA PHARMA CO LTD

Antiviral composition comprising a sulfated polysaccharide

InactiveUS20110059919A1Lower Level RequirementsReduced likelihoodOrganic active ingredientsBiocideDiseaseSulfated polysaccharides

The present invention provides for the use of iota- and / or kappa-carrageenan for the manufacture of an antiviral pharmaceutical composition for the prophylaxis or treatment of a pathological condition or disease caused by or associated with an infection by a respiratory virus selected from the group consisting of orthomyxovirus, paramyxovirus, adenovirus and coronavirus. The present invention further provides for the use of fucoidan, in particular of high molecular weight fucoidan, for the manufacture of an antiviral pharmaceutical composition for the prophylaxis or treatment of a pathological condition or disease caused by or associated with an infection by a respiratory virus selected from the group consisting of orthomyxovirus and paramyxovirus.

Owner:MARINOMED BIOTECHNOLOGIE GMBH

Hair growth formula

A hair treatment composition for topical application to the skin and / or hair, comprising partially hydrolyzed fucoidan and a pharmaceutical carrier. The composition may contain further additives. The carrier may be hydrophyllic or anhydrous. The composition may also include natural components such as honey and / or mangosteen. The composition may also include flavonoids, analgesics, radiation protecting agents, and / or anti-oxidants.

Owner:SAKURA PROPERTIES LLC

Wearable Micro-LED Healing Bandage

InactiveUS20200009400A1Relieve painIncrease speedMedical devicesAdhesive dressingsWound healingWound dressing

A wound dressing and method of use is provided that increases healing of tissues by targeting damaged tissue at a predetermined wavelength. The device includes the use of a negative pressure bandage, a flexible light sheet, and one or more bioactive marine extracts. Light emitted from the flexible light sheet penetrates through the bandage to target damaged tissue, which accelerates the wound healing process and works synergistically with the negative pressure bandage and bioactive marine extracts such as collagen fibers, alginate, chitosan and fucoidan, or any combination thereof to accelerate healing.

Owner:MARINE BIOLOGY & ENVIRONMENTAL TECH LLC

High-pressure water vapor degradation method for marine sulfated polysaccharides

The invention relates to a high-pressure water vapor degradation method for marine sulfated polysaccharides. The method is characterized in that the marine sulfated polysaccharides are prepared into water solution, then the water solution is treated by high-pressure water vapor at the temperature of 101-150 DEG C for 0.01-24hours, and the obtained treatment solution is dried for obtaining degraded products of the polysaccharides. The marine sulfated polysaccharides comprise seaweed fucoidan, carrageenan and agaropectin which are sourced from marine plants, as well as sea cucumber chondroitin sulfate, sea cucumber fucoidan and abalone sulfated polysaccharides, which are sourced from marine animals. The method has the advantages that no inorganic salt is introduced, and the final products can be obtained by drying after degradation without desalinization; the molecular weight of the polysaccharides can be reduced continuously and uniformly, and the degraded products with different molecular weight can be obtained by controlling the treatment conditions and the treatment time; the method is stable, and the reproducibility is good; and the requirement on equipment is low, and the operation is simple.

Owner:OCEAN UNIV OF CHINA

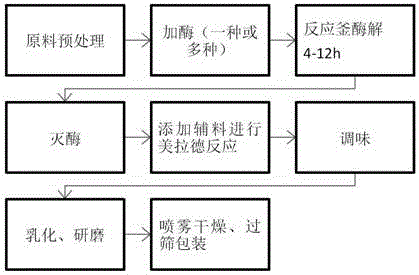

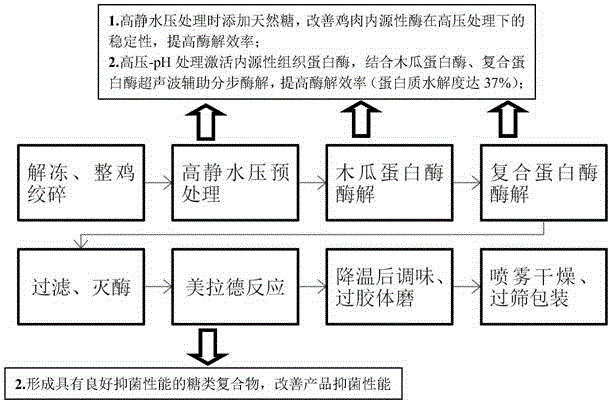

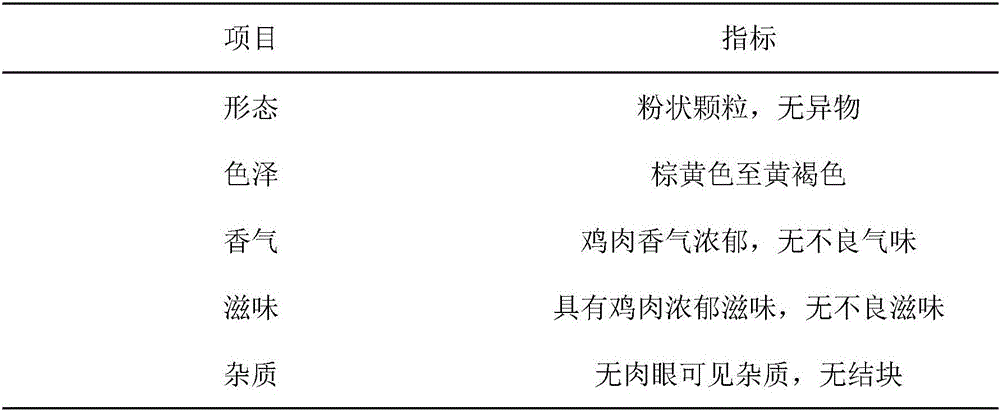

Production method of halal chicken-flavor seasoning powder

InactiveCN106262663AImprove enzymatic hydrolysis efficiencyIncrease the degree of hydrolysisFood scienceMaillard reactionUltra high pressure

The invention relates to a production method of halal chicken-flavor seasoning powder. The method comprises the following steps: (1) crushing a whole chicken by using a meat grinder, evenly mixing the crushed chicken with water, fucoidan and mannose, wherein 2-10ml of the water, 3-5mg of the fucoidan and 5-10mg of the mannose are added into per gram of raw material, carrying out high hydrostatic pressure treatment on the obtained mixture, and then adjusting the pH value to be within a range of 6.5-7.0 to obtain chicken homogenate; (2) firstly, carrying out first-step ultrasonic-assisted enzymolysis on the chicken homogenate under the action of papain; after that, carrying out second-step ultrasonic-assisted enzymolysis under the action of compound protease; after enzymolysis is finished, filtering to remove impurities, and carrying out ultra-high pressure sterilization and enzyme deactivation to obtain enzymatically hydrolyzed chicken; (3) adjusting the pH value of the enzymatically hydrolyzed chicken to be within a range of 7.0-8.0, adding an auxiliary material X, and carrying out a Maillard reaction at the temperature of 88-105 DEG C; (4) after the Maillard reaction is finished, cooling, adding ingredients for seasoning, and grinding to obtain seasoning liquid with emulsification fineness reaching up to 2-40mu m; (5) carrying out spray drying on the seasoning liquid, then sieving, and packaging to obtain the halal chicken-flavor seasoning powder. The product produced by the method is pure and lasting in flavor, and has good bacteriostatic and antiseptic properties.

Owner:浙江金华味海食品股份有限公司

Total-nutrient kelp oligosaccharide biological synergistic fertilizer and preparation method thereof

InactiveCN102584432AWith energy saving and emission reductionCombination of medicine and fertilizerFertilizer mixturesDiseaseLyase

The invention relates to a total-nutrient kelp oligosaccharide biological synergistic fertilizer and a preparation method thereof. The preparation method comprises the steps of: firstly soaking kelps in water and filtering soaking water; crushing the soaked kelps, adding kelp powder into the filtered soaking water and adding alginic acid lyase for enzymolysis; and after the enzymolysis is completed, conducting low-temperature concentration to enzymatic hydrolyzate to complete the preparation of liquid fertilizer. Since the temperature in the whole production process is controlled to be below 50 DEG C and any chemical is not used, the total-nutrient kelp oligosaccharide biological synergistic fertilizer has the characteristics of environmental friendliness, ecological and environmental protection, energy saving and emission reduction, natural plant growth promoting factors in the kelps are fully reserved, compositions such as iodine, alginic acid oligosaccharide, mannitol and fucoidan capable of resisting diseases and adversity, preserving water and moisture and resisting ionizing radiation, ultraviolet radiation and nuclear radiation are added and the efficacy that medicine and the fertilizer are combined together is obtained.

Owner:青岛丰泰海洋生物科技有限公司 +1

Method for extracting fucoidan for brown seaweed

The invention relates to a fucoidan extract method, in particular to a method for extracting fucoidan for brown seaweed, comprising the following steps: 1. desalting: adopting fresh brown seaweed or unfreezed frozen brown seaweed to soak in pure water to remove salt; 2. enzymolysis: adding enzyme in the desalted brown seaweed to perform enzymolysis at 40-60 DEG C for 1-3h; 3. abstraction: adding calcium chloride in enzymatic hydrolyzate obtained by enzymolysis, and heating the solution to 90-100 DEG C for 1-4h to obtain the fucoidan extract. The invention is characterized of simple operation, high application security, high extraction efficiency, high extraction purity and the like and the extraction process is applicable to factory mass production.

Owner:大连海宝生物技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com