Patents

Literature

2343 results about "Papain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Papain, also known as papaya proteinase I, is a cysteine protease (EC 3.4.22.2) enzyme present in papaya (Carica papaya) and mountain papaya (Vasconcellea cundinamarcensis).

Nutritional system for nervous system disorders

A novel composition for treating nervous system disorders. The composition is formed by preparing a mixture comprising an effective amount of vitamin B-6, folic acid, vitamin C, magnesium, vitamin B-3, copper, probiotics, fructo-oligosaccharide (FOS), betaine, pancreatin, papain, pepsin, vitamin B-1, vitamin B-2, vitamin B-12, biotin, pantothenic acid, chromium polynicotinate and a digestive support ingredient selected from the group consisting of dandelion root, juniper, aloe vera, burdock, ginger root, artichoke, and kelp. Other ingredients may include: beta carotene, vitamin E, selenium, zinc, sea vegetation, alfalfa, trace minerals and molybdenum.

Owner:C&D FOREMAN

Ointment wound spray

A spray-on topical wound debrider spray is prepared forming a mist, spray or foam which will not drip significantly after application. The preferred wound debrider is papain. The spray contains a surfactant emulsifier admixture having a composition viscosity of from about 5000 cps to about 50,000 cps and is preferably a fatty alcohol phosphate ester emulsifier composition.

Owner:SMITH & NEPHEW INC

Moringa extract as well as preparation method of moringa extract and moringa feed additive

InactiveCN102669423AImprove bioavailabilityHigh yieldAnimal feeding stuffPectinaseAdditive ingredient

Owner:HAINAN STAND BIO TECH

Process engineering for extracting fishes processing offal fish oil by enzymolysis process

InactiveCN101248821ATake advantage ofHigh extraction rateEdible oils/fatsFood preparationNeutral proteaseHydrolysate

A process technology using enzymolysis method to extract leftover fish oil from fish processing comprises the following steps: preliminary treatment, in which the leftovers from the fish processing are cleaned and minced; protease hydrolysis, in which neutral protease and papain are hydrolyzed simultaneously; oil-water separation, in which hydrolysate is centrifugally filtered to remove residues, and filtrate undergoes oil-water separation via a centrifuge, thereby obtaining the fish oil and hydrolyzed protein; and fish oil refinement, in which refined fish oil can be obtained after the fish oil is degummed, depickled, decolored and deodorized. The leftovers from the fish processing can be hydrolyzed with the proteases to destroy the associative relation of protein and fat, thereby releasing axunge which undergoes oil-water separation by the tubular centrifuge to obtain the fish oil with high quality, and meanwhile, the protein therein can be fully utilized to produce hydrolyzed protein, so as to change wastes into valuables and synthetically and efficiently utilize the resources of the fish and the processing leftovers.

Owner:GUANGDONG OCEAN UNIVERSITY

Plant culture medium and module therof

InactiveCN106106106APromote absorptionAgainst infringementGrowth substratesCulture mediaBiotechnologyBiogenic peptide

The invention relates to a plant culture medium and a module thereof. The medium is characterized by comprising following raw material including 20-40 parts by weight of peat soil, 15-25 parts by weight of compost excrements of livestocks, 15-25 parts by weight of humic acid, 10-25 parts by weight of nitrogen-phosphorus-potassium mixed fertilizers, 3-15 parts by weight of expanded perlites, 3-15 parts by weight of shiitake fungus or fermented straw fine fibers, 3-10 parts by weight of amino acid, 0.1-3 parts by weight of probiotics, 0.1-3 parts by weight of protease, 0.1-3 parts by weight of marine bioactive extracts, 0.1-3 parts by weight of antimicrobial peptides, 0.1-3 parts by weight of rooting agents and 0.1-3 parts by weight of microelements. The marine bioactive extracts adopt sea algae extracts or mussel extracts. The probiotics utilize bacillus subtilis strains. The protease utilizes papain. The module is low in weight, convenient in transport, convenient in application and good in water permeability and air permeability and satisfies all kinds of nutrition needed by plants.

Owner:林志仓

Convenient pickled fish spice

ActiveCN103110079AClear soupThe fish is tender and deliciousFood preparationMonosodium glutamateVegetable oil

The invention discloses a convenient pickled fish spice. The convenient pickled fish spice consists of a pickle bag and a fish-pickling-spice bag, wherein the pickle bag comprises the following components in parts by weight: 100-120 parts of pickled vegetable, 8-12 parts of pickled ginger, 10-15 parts of pickled upturned chili, 5-7 parts of garlic, 20-40 parts of edible vegetable oil, 10-12 parts of edible salt, 4-6 parts of white sugar, 4-7 parts of monosodium glutamate, 2-3 parts of malto dextrin, 4-5 parts of boiled water, 1-3 parts of vine pepper oil, 1-2 parts of green prickleyash and 3-4 parts of spice; the fish-pickling-spice bag comprises the following components in parts by weight: 40-45 parts of starch, 42-46 parts of edible salt, 3-5 parts of ground pepper and 0.8-1.0 part of papain. The invention further discloses a manufacturing method of the pickle bag in the convenient pickled fish spice. The pickled fish spice disclosed by the invention can be used for cooking various fresh fishes; by adopting the pickled fish spice, the pickled fish which is bright in soup, is delicate and delicious in fish and is sour and hot can be cooked out without frying the spice or adding other spices; and meanwhile, the pickled fish spice further can be used for cooking various sour and hot appetizing foods based on Sichuan pickle, such as pickle vermicelli soup, pickle tofu pudding and sour and hot hoof.

Owner:SICHUAN JINGONG CHUANPAI FLAVORING

Hair analysis method

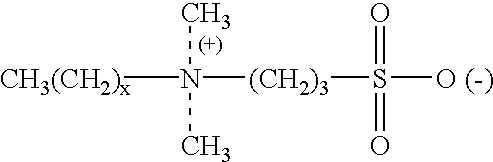

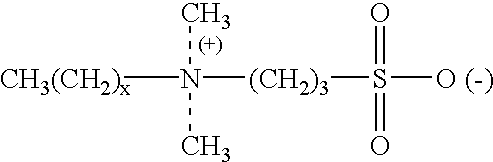

InactiveUS6949344B1Reliable solubilizationAccurate methodPre-tanning chemical treatmentMicrobiological testing/measurementBetaineDigestion

A method the direct analysis of an analyte in keratinized structures, e.g., hair and fingernails, which comprises preparing a mixture containing a low redox potential activator compound such as dithiothreitol or dithioerythritol, an enzyme suitable for the digestion of the keratin structure, a sample of the keratin structure and a biological detergent that aids the digestion of the keratinized structure at a relatively low pH, e.g., between about 6.2 and 8; permitting the enzyme to at least substantially digest the sample of keratin structure, and subjecting the digest solution to analysis, preferably by radioimmunoassay, to determine the identity and amount of analyte in the keratin structure sample. To accelerate the method, cupric sulfate may be added to the mixture after degradation of the keratin sample. The enzyme may be a peptidase, endopeptidase or proteinase, with papain, chymopapain, and proteinase K being preferred for use in the invention. The preferred biological detergents include betaine, sulfo-betaine, alkylglucosides and bile acids.

Owner:PSYCHEMEDICS CORPORATION

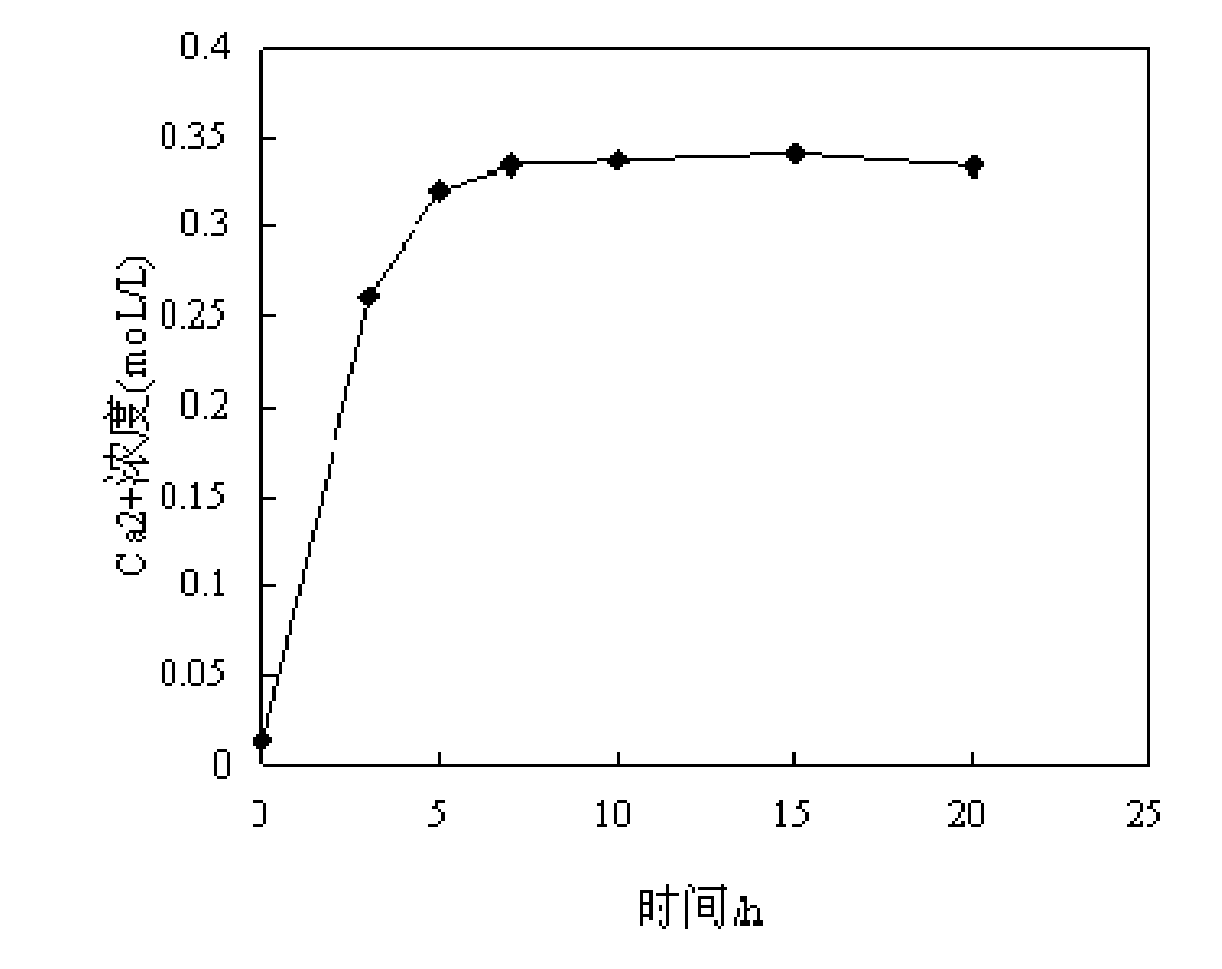

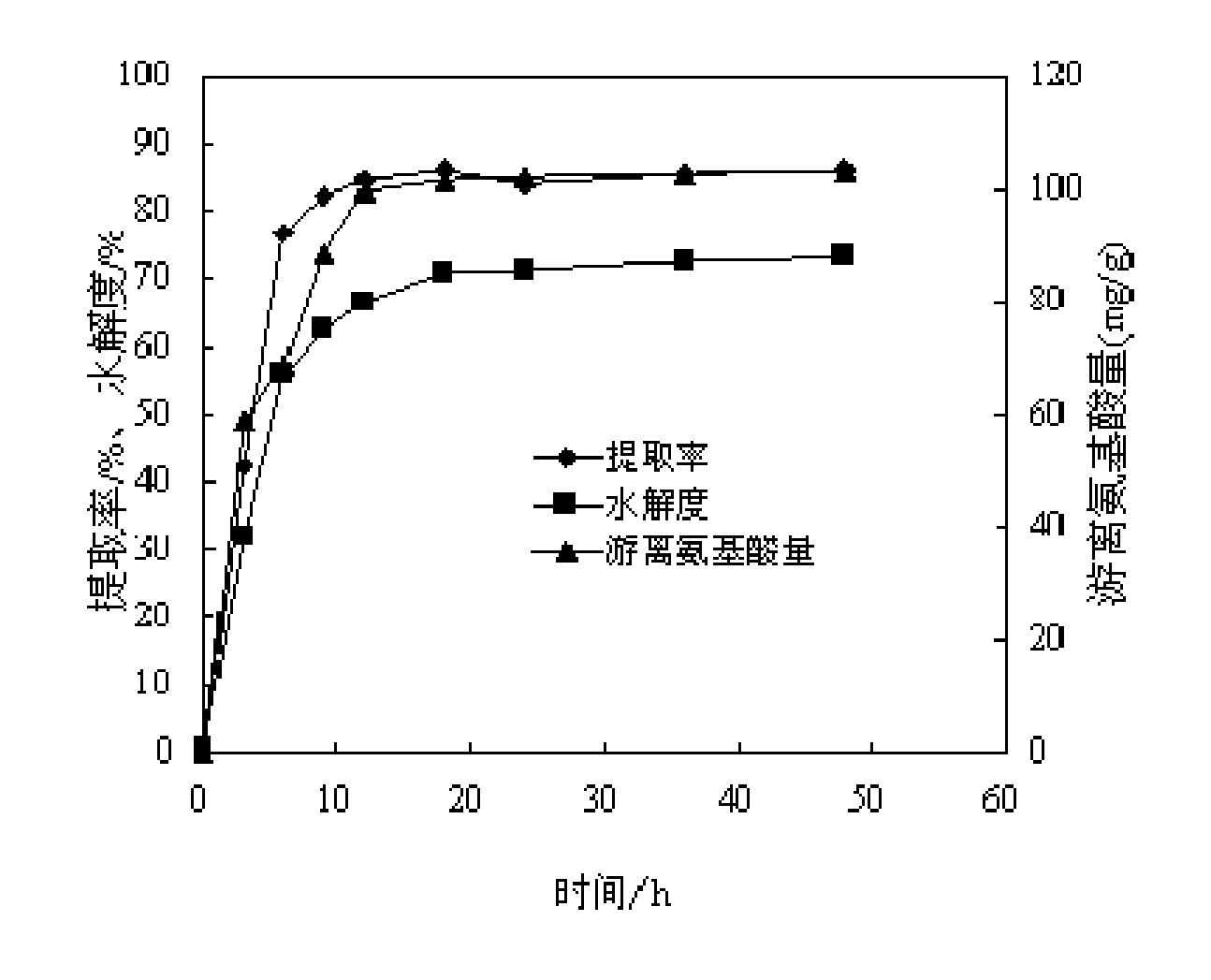

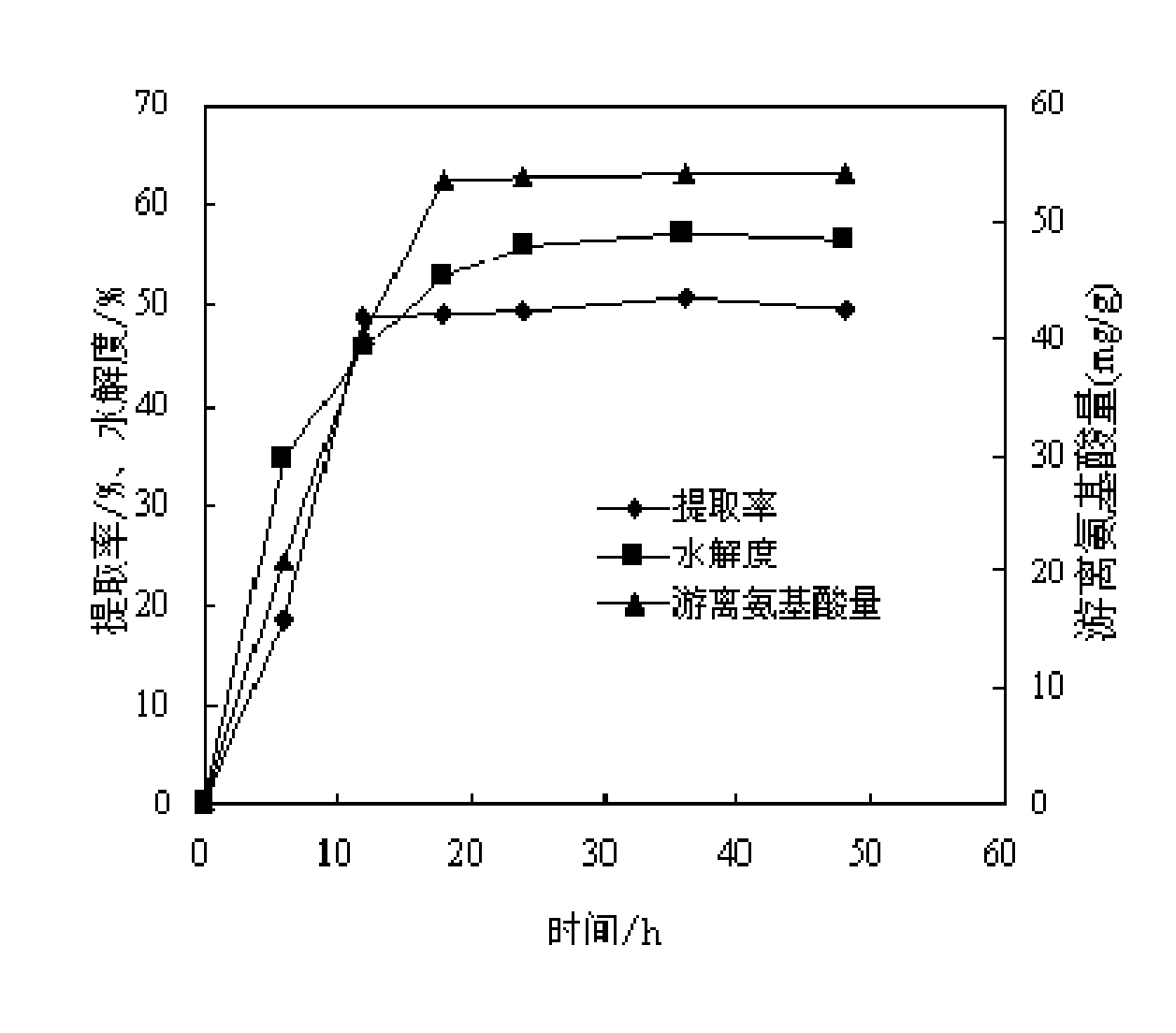

Method for preparing collagen peptide from fish scales

The invention discloses a method for preparing collagen peptide from fish scales, which is characterized by comprising the following steps of: 1, taking the fish scales and immersing hydrochloric acid to remove calcium; washing to be neutral, drying and crushing; 2, adding the calcium-removed, dried and crushed fish scales obtained by the step 1 into an enzyme reactor; adding water and mixed protease to extract the collagen peptide; after the extraction, carrying out enzyme deactivation and centrifuging to obtain an enzymolysis solution, wherein the mixed protease is a mixture of neutral protease, papain and flavored protease; and 3, carrying out film concentration on the enzymolysis solution obtained by the step 2; and freezing and drying a concentrated solution to obtain fish scale collagen peptide powder. According to the fish scale collagen peptide obtained by the invention, the neutral protease, the papain and the flavored protease are used for extracting the fish scale collagen peptide by an enzymic method at one step, so that not only can the enzymolysis time (9 hours)be reduced, but also the extracting rate (72.72%) of the collagen peptide is improved, and solves the special flavor problem of bitter taste of the collagen peptide and the like.

Owner:WENZHOU UNIVERSITY

Method and process for extracting animal micro-molecule polypeptides and amino acids by utilizing complex enzyme

InactiveCN103255190AImprove enzymatic hydrolysis efficiencyReduce manufacturing costFermentationWater bathsNeutral protease

The invention discloses a method and process for extracting animal micro-molecule polypeptides and amino acids by utilizing a complex enzyme. The method comprises the following steps: (1) crushing animal tissues so that the animal tissues can pass through a sieve of 80-200 meshes, and adding water to prepare a suspension with the concentration of 8-30 percent; (2) raising the temperature to be 35-40 DEG C, regulating the pH value to be 8.0-9.0 by using sodium carbonate, adding a complex enzyme I accounting for 0.5-2.0 percent of the animal tissues, performing ultrasonic enzymolysis at 14-16 kHz for 1-2 hours so that the proteins between cells are subjected to full enzymolysis, regulating the pH value to be 6.5-7.5, adding a complex enzyme II accounting for 0.5-3.0 percent of the animal tissues, fully and uniformly stirring, controlling the temperature of the water bath to be 37-45 DEG C, and performing ultrasonic enzymolysis at 15-17 kHz for 1-6 hours; (3) raising the temperature of the enzymolysis solution to be 90-100 DEG C to inactivate the enzyme for 20-30 minutes after the enzymolysis is finished; (4) filtering the solution subjected to enzymolysis through a 0.22mu m microfiltration membrane; and (5) concentrating the filtrate to the relative density of 1:1.0-1:1.2 to prepare the concentrated solution, wherein the complex enzyme II consists of Alcalase, Flavourzyme, Protamex, neutral protease and papain. According to the method, the enzymolysis efficiency can be improved, and the production cost can be reduced.

Owner:WEIHAI KANGBOER BIOLOGICAL PHARMA +1

Process for producing a bio-organic calcium composition and nutrient agent containing the same

InactiveUS6342252B1Extended storage timePromote absorptionMammal material medical ingredientsFood preparationSlurryNeutral fat

A process of producting bio-organic calcium composition from animal bones comprises steps of preliminarily removing lipids from the bones by steaming / boiling; milling the bones to form a bone slurry; adding neutral lipase to conduct secondary lipid removing; adding protease to the bone slurry to produce a primary enzymatic decomposed liquid; adding papain to the primary enzymatic decomposed liquid for producing secondary enzymatic decomposed liquid; and acidifying / activating of the secondary enzymatic decomposed liquid to produce a final product. The product produced by this process contains bio-organic calcium composition readily absorbable by human body.

Owner:TIANJIN TIANSHI GROUP

Processing method for beche-de-mer in East China Sea

ActiveCN101558779AOvercome effectivenessOvercoming the Difficulties of IndustrializationFish washing/descalingFood preparationHydrolysisAcaudina leucoprocta

Owner:宁波超星海洋生物制品有限公司

Micromolecule walnut peptide and preparation method thereof

InactiveCN105002247AHigh egg contentLow costPeptide preparation methodsFermentationAlkaline proteaseProtein structure

The invention relates to a micromolecule walnut peptide and a preparation method thereof. The preparation method sequentially comprises the following steps of protein extraction, twice enzymolysis, filtering, purification, concentration and drying. In the twice enzymolysis process, alkaline protease with the mass being 1-3% that of the walnut protein is added into a walnut protein extracting solution for once enzymolysis; enzyme deactivation is performed on a once enzymolysis solution after the once enzymolysis is finished; one or more kinds of proteinase including the flavored proteinase, the neutral proteinase and the papain with the mass being 1-3% that of the walnut protein are added after the once enzymolysis solution obtained after enzyme deactivation is performed is cooled for secondary enzymolysis. According to the preparation method, the twice enzymolysis method is adopted, due to the specificity of the structure of the walnut protein structure, sufficient enzymolysis cannot be performed on the walnut protein through enzymolysis of one proteinase, and the twice enzymolysis method is adopted for ensuring that the enzymolysis is brought into play on the most suitable condition of each proteinase, and therefore the obtained walnut peptide content is high.

Owner:BEIJING TIANTAI BIOTECH

Globefish skin active collagen and method for preparing peptide thereof

ActiveCN101182357ABroaden the field of useIncrease profitConnective tissue peptidesFermentationUltrafiltrationPepsin

The preparation methods of globefish skin active collagen and the peptide of the active collagen are that the globefish skin is cut into small pieces to be frozen, dried, crushed and put into sodium chloride solution to be stirred for 12 hours and then for centrifugation to discard supernatant and remove non-collagen proteins, deposition is put in to acetum, pepsin is added under 0 DEG C to 10 DEG C for enzymolysis and centrifugation, the supernatant is put through an ultrafiltration membrane, and the above part is frozen and dried to obtain the collagen. After the active collagen is prepared, the rest deposition is centrifugated until the pH value is between 2.0 to 7.0, papain is added into the deposition for the enzymolysis, the supernatant is centrifugated and respectively put through the ultrafiltration membrane after enzyme-denaturing to obtain the globefish skin collagen peptide of different molecular weight ranges, and the globefish skin collagen peptide are frozen and dried to obtain the light yellow or white powdery globefish skin collagen active peptide which has good antioxidation character and takes effects of eliminating free radical and reducing the senescence degree.

Owner:DALIAN POLYTECHNIC UNIVERSITY +1

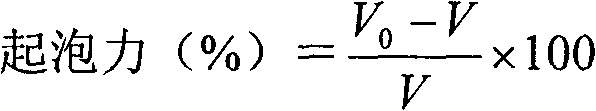

Egg white powder with high foamability and preparation method thereof

The invention provides egg white powder with high foamability and a preparation method thereof and relates to reconstruction of whey protein structure and functional properties, belonging to the technical field of biological processing of foodstuffs. According to the invention, on the basis of preliminary work, enzymatic hydrolysis of lipase in advance and cooperative enzymatic hydrolysis of composite protease are utilized for treatment of egg white; total usage amount of lipase and composite protease is less than usage amount of individually used lipase or protease, and however, foamability and foam stability of egg white powder obtained by combined utilization of lipase and composite protease are higher than those of egg white powder obtained by individual utilization of lipase or composite protease; the egg white powder obtained in the invention can meet demands for high-grade products on the market, and the advantages of a simple process and high cost performance are achieved in the invention. According to the invention, the ratio of active usage amount of Aspergillus oryzae protease, papain and trypsin is determined to be 1:1:1; the usage amount and other technological parameters cooperatively allow egg white powder with high foamability to be obtained; egg white powder with high foamability provided in the invention enables the additional output value of eggs to be increased, lays a technical foundation for development and industrial production of special-purpose egg white powder products and increases economic benefits for enterprises.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

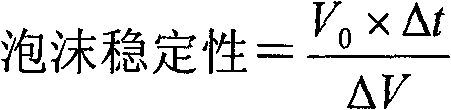

Preparation method of instant fresh water fish peptide powder

The invention relates to a preparation method of instant fresh water fish peptide powder. By using fresh water fish as raw materials, the preparation method comprises the following steps: removing fish skin and fish belly fat by a skin remover and a cube cutter, and then removing fishy smell and partial fat of the fish by using the technology of soaking with a mixture of CaCl2 and C2H4O2; then adding papain and Bacillus subtilis neutral proteinase for hydrolysis, carrying out inactivation and degreasing by the superhigh pressure technology, and separating slag from liquid by utilizing a centrifuge; and then adding activated carbon to the hydrolysate for bitterness and fishy smell removing treatments, filtering by utilizing a plate and frame filter press, concentrating the obtained filtrate in vacuum, and carrying out spray drying to obtain the instant fresh water fish peptide powder. The product prepared by the method has the characteristics of water solubility, creamy white color, palatefullness, no fishy smell and the like, and no organic reagent is used in the entire production process flow. The product is rich in small peptide, oligopeptide and various amino acids, can be used for manufacturing nutriment food for infants, advanced nutriment and health products for adults and the like, and also can be used as the ingredient for preparing advanced nutriment peptide coffee, flavorings and the like.

Owner:JIANGNAN UNIV

Method for extracting polyoses from bagasse

The invention provides a method for extracting polysaccharides from bagasse, the method is: after degreasing the bagasse, using one or more of cellulase, papain and pectinase at pH 4-6, Hydrolyze at 40-80°C for 0.5-1.5 hours, then treat with ultrasonic waves with a frequency of 59KHz for 0.5-1.5 hours, filter, and finally use ethanol to precipitate polysaccharides in the filtrate. The method of the invention adjusts the type and amount of enzymes and the technological conditions of enzyme treatment and ultrasonic extraction on the basis of the process of extracting fungal polysaccharides, and finds a low energy consumption and high-efficiency method for extracting bagasse polysaccharides.

Owner:SOUTHERN MEDICAL UNIVERSITY

Giant salamander active peptide and application

ActiveCN106047968AImprove immunityPromote proliferationPeptide preparation methodsFermentationFiltration membraneHydrolysate

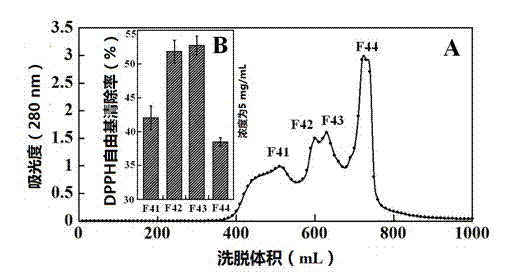

The invention discloses a giant salamander active peptide and an application. The giant salamander active peptide is prepared by the following steps: conducting enzymatic hydrolysis on giant salamander meat which serves as a raw material by virtue of a complex enzyme of marine alkaline protease and papain; separating an enzymatic hydrolysate by virtue of a trypsin immobilized ultra-filtration membrane separator; and then conducting separation and purification by virtue of Sephadex LH-20 molecular sieve chromatography and high performance liquid chromatography, so that the giant salamander active peptide is obtained. The giant salamander active peptide is capable of effectively scavenging free radicals and boosting body immunity, and meanwhile, the active peptide can also promote proliferation of skin fibroblasts; therefore, the giant salamander active peptide has a broad application prospect in the fields of food, medicines and cosmetics.

Owner:ZHANGJIAJIE JINCHI ANDRIAS DAVIDIANUS BIOLOGICAL SCI

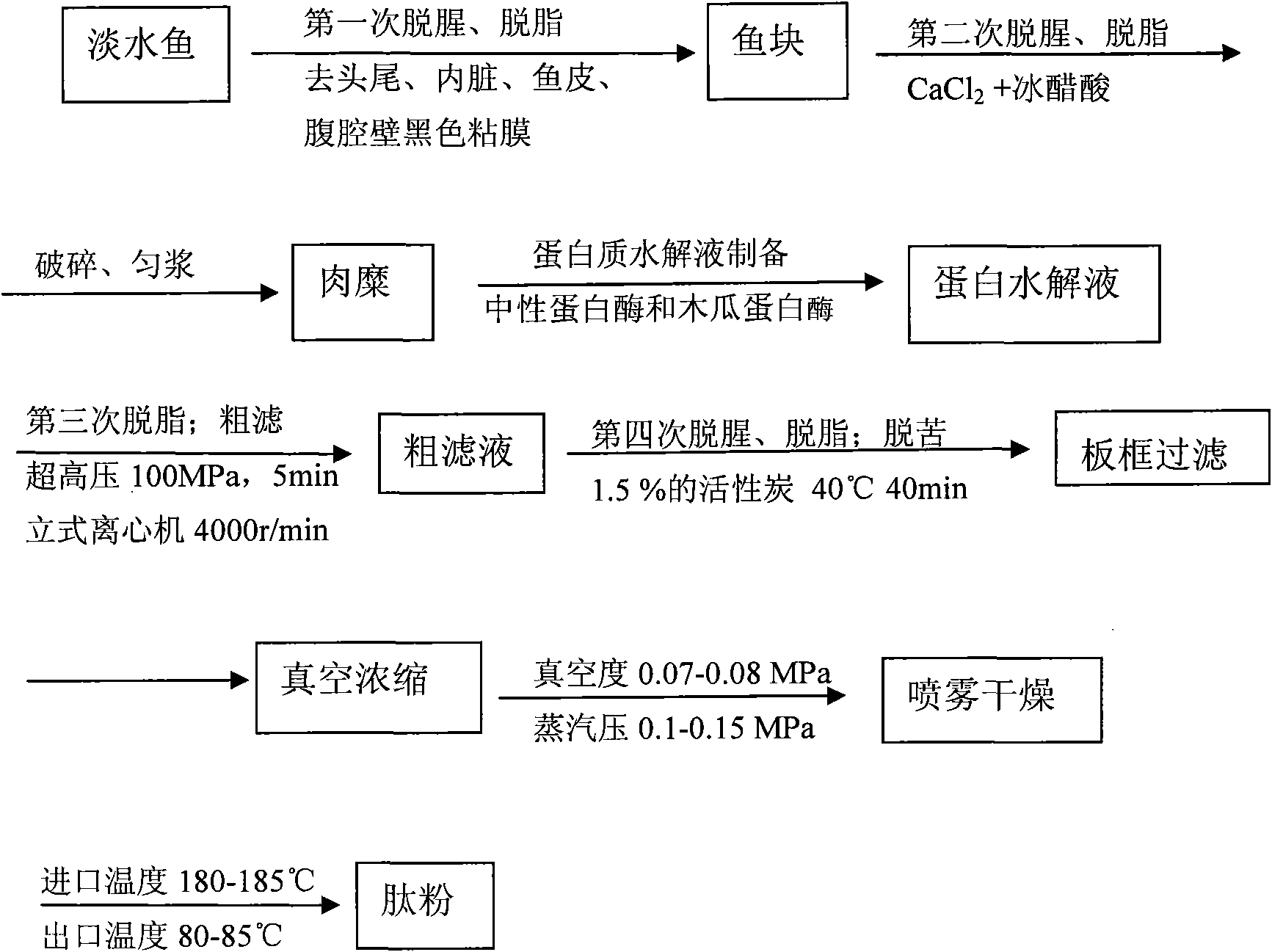

Minced tuna protein antioxidative peptide and its preparation method and use

ActiveCN103073621AHigh activityImproves antioxidant activityPeptide/protein ingredientsAntinoxious agentsBiotechnologyFood additive

The invention discloses a minced tuna protein antioxidative peptide and its preparation method and use. The minced tuna protein antioxidative peptide has an amino acid sequence of Tyr-Glu-Asn-Gly-Gly. The preparation method comprises the following steps of adding a phosphate buffer solution into defatted minced tuna as a raw material, adjusting a pH value of the mixture to 5.0 to 7.0 to obtain a mixed solution, preheating the mixed solution with stirring, adding papain into the preheated mixed solution to obtain an enzymolysis product, carrying out enzyme deactivation of the enzymolysis product, and orderly carrying out desalination, ultrafiltration and chromatography to obtain the minced tuna protein antioxidative peptide. The preparation method has the advantages of scientific and reasonable processes and easy monitoring of enzymolysis. The minced tuna protein antioxidative peptide obtained by the preparation method has the advantages of safety, no toxic and side effect, strong antioxidant activity and easy digestive absorption, and can be used as a drug, a health-care food and a food additive.

Owner:安徽盛美诺生物技术有限公司

Method for preparing antihypertensive peptide by utilizing combined enzyme enzymolysis silkworm chrysalis protein

The invention relates to the technical field of biological engineering, in particular to a method for preparing antihypertensive peptide by utilizing combined enzyme enzymolysis silkworm chrysalis protein. The method comprises the following steps: dissolving degreased dry silkworm chrysalis powder or silkworm chrysalis protein powder in water in the mass ratio of 1: 7 to 8, adjusting the pH value of the dissolved solution to be 7.5 to 8.5, and then adding combined protease to carry out enzymolysis reaction, wherein the content of alkaline protease is 0.3 to 0.5 percent of the degreased dry silkworm chrysalis powder or the silkworm chrysalis protein powder, the content of papain is 0.05 to 0.1 percent, the content of neutral protease is 0.05 to 0.1 percent, the enzymolysis reaction temperature is 55 to 65 DEG C, and the enzymolysis reaction time is 180 to 240 minutes. The prepared antihypertensive peptide has higher restriction effect on the ACE activity, antihypertensive function on hypertensive patients, does not influence normotensive patients, plays the better health care effect and is safe, has no poison or side effect and is low in cost.

Owner:常州康和生物技术有限公司

Method for producing soybean polypeptide powder

InactiveCN102511648AAdvanced technologyIncrease productivityProtein foodstuffs working-upSolubilityNeutral protease

The invention relates to a method for processing soybean isolated protein by utilizing a biological enzyme technology. The method comprises the following steps of: during preparation, selecting high-quality soy protein isolate, and dissolving; performing thermal denaturation; adjusting the pH value to 8.0 to 9.0; adding composite hydrolase of alkali protease, neutral protease, papain and trypsin, and reacting for 2 to 3 hours; adjusting the pH value to 4.0 to 6.0; inactivating enzyme; when cooling to a temperature below 50 DEG C, adding filter aid enzyme; collecting filtrate to dissolve filter residues; adding composite hydrolase of acidic protease, neutral protease, papain and trypsin, and reacting for 1 to 2 hours; inactivating the enzyme; when cooling to temperature of below 50 DEG C, adding the filter aid enzyme; filtering by a paperboard; performing ultrafiltration; drying by microwaves under vacuum; and crushing and sieving. The soybean polypeptide powder prepared by the method can improve the solubility of albumen powder to a maximum limit and keep the color and luster of appearance, mouthfeel, flavors and the bioactivity of active ingredients, offers a good mouthfeel, is easy to absorb and can be widely applied to industry of dairy products, drinks and health-care products.

Owner:天津诺奥酶生产力促进有限公司

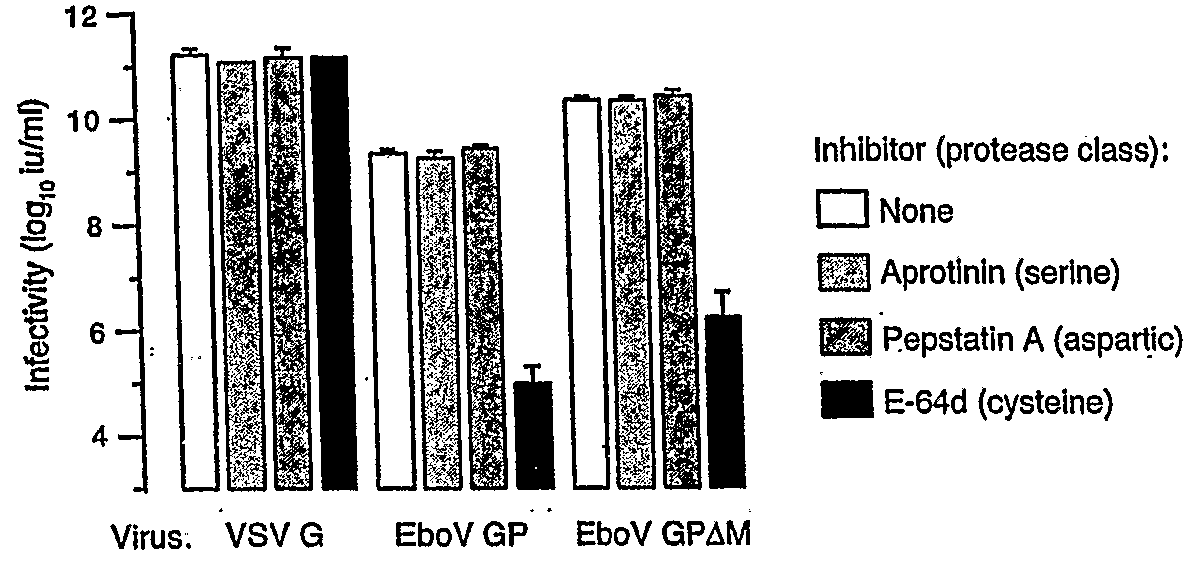

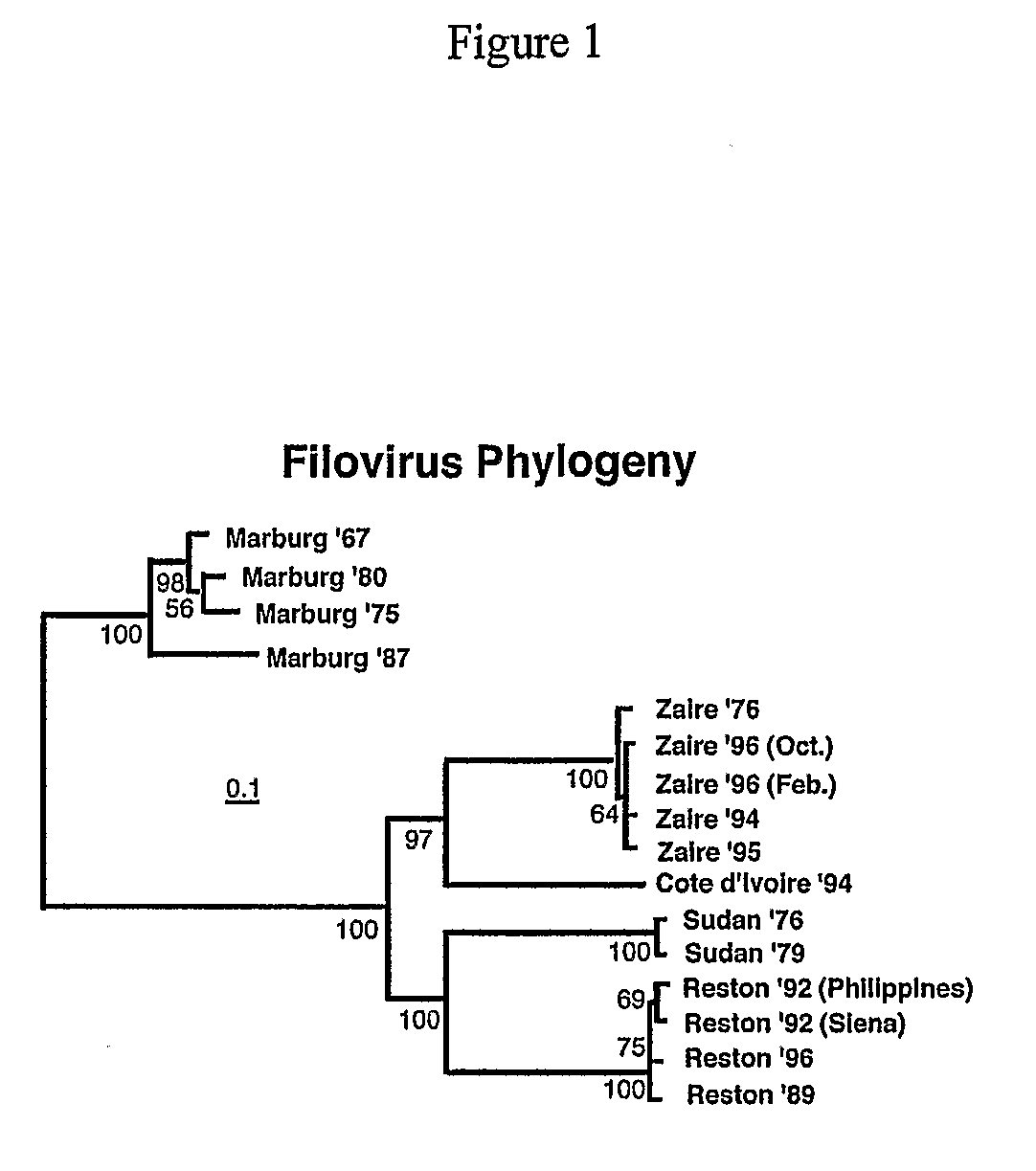

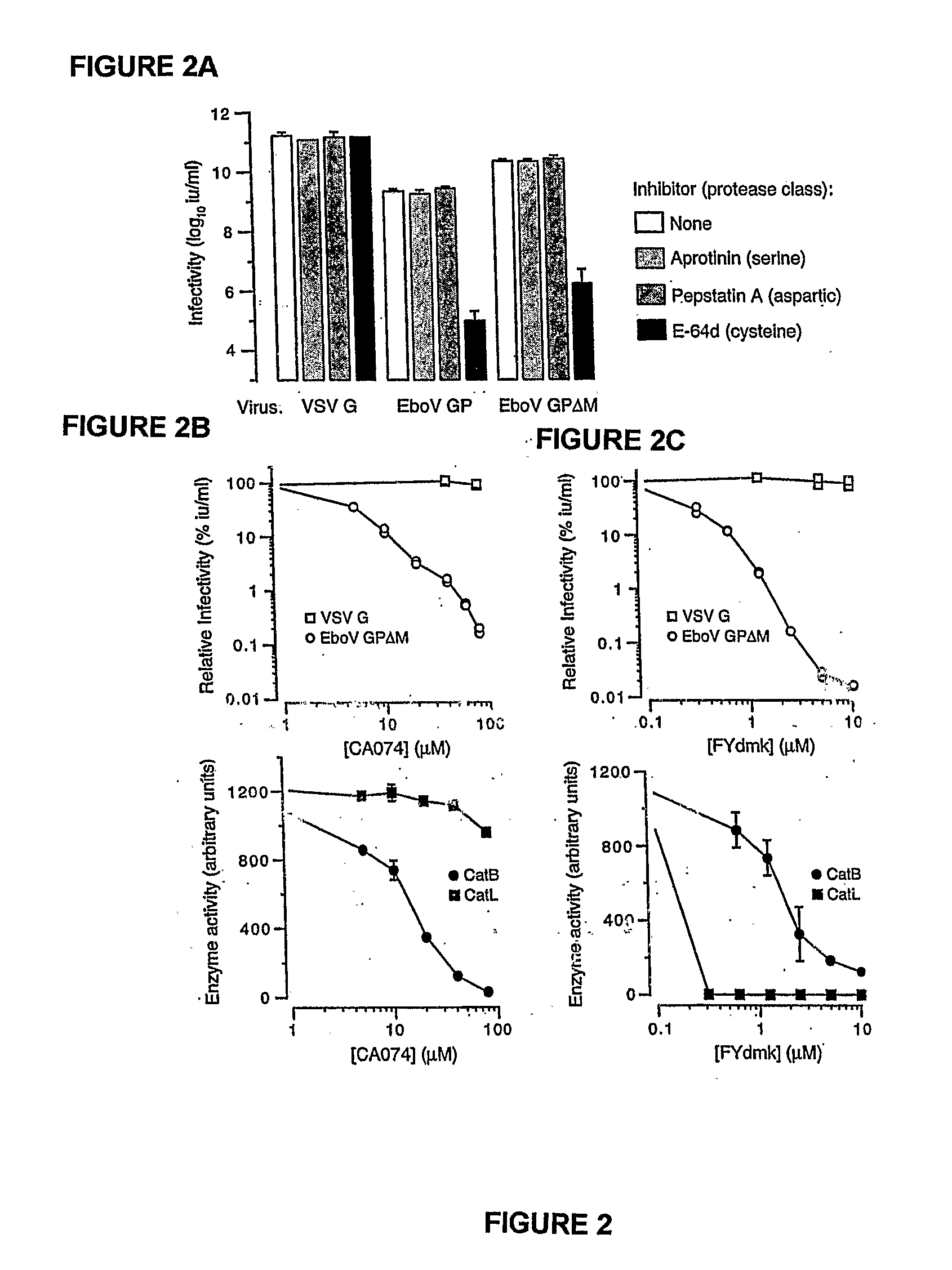

Inhibitors of Enveloped Virus Infectivity

ActiveUS20090053263A1Organic active ingredientsPeptide/protein ingredientsPapain-Like Cysteine ProteaseCathepsin

The present invention relates to treatment of infection by enveloped viruses through the use of papain-like cysteine protease inhibitors and kits thereof. Specifically, methods for treatment of filoviruses as well as other enveloped viruses such as Nipah, in particular using cathepsin inhibitors are described.

Owner:THE BRIGHAM & WOMEN S HOSPITAL INC

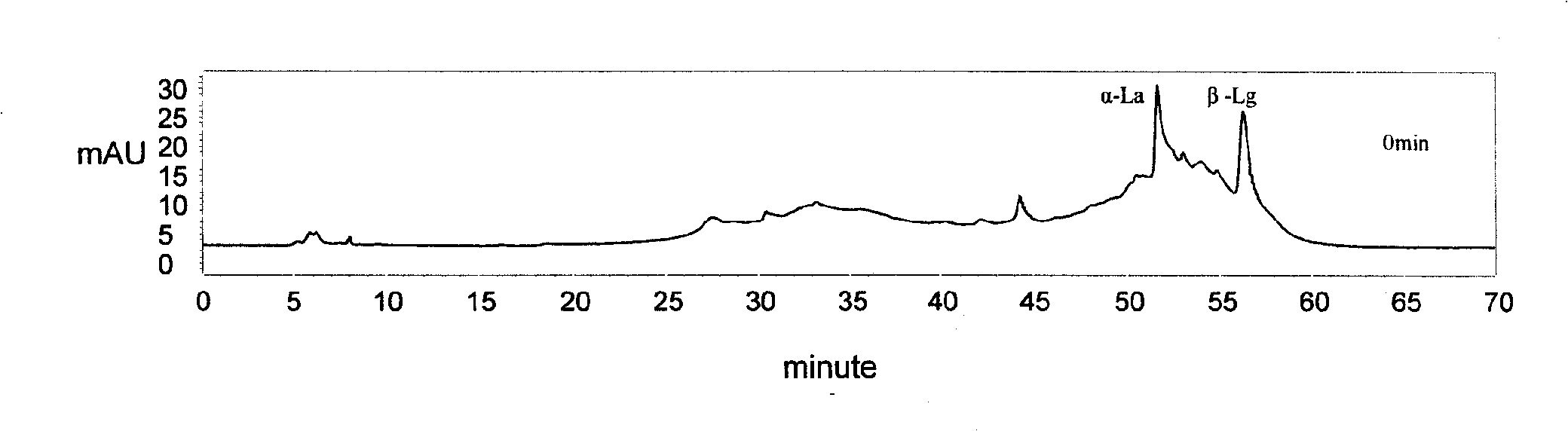

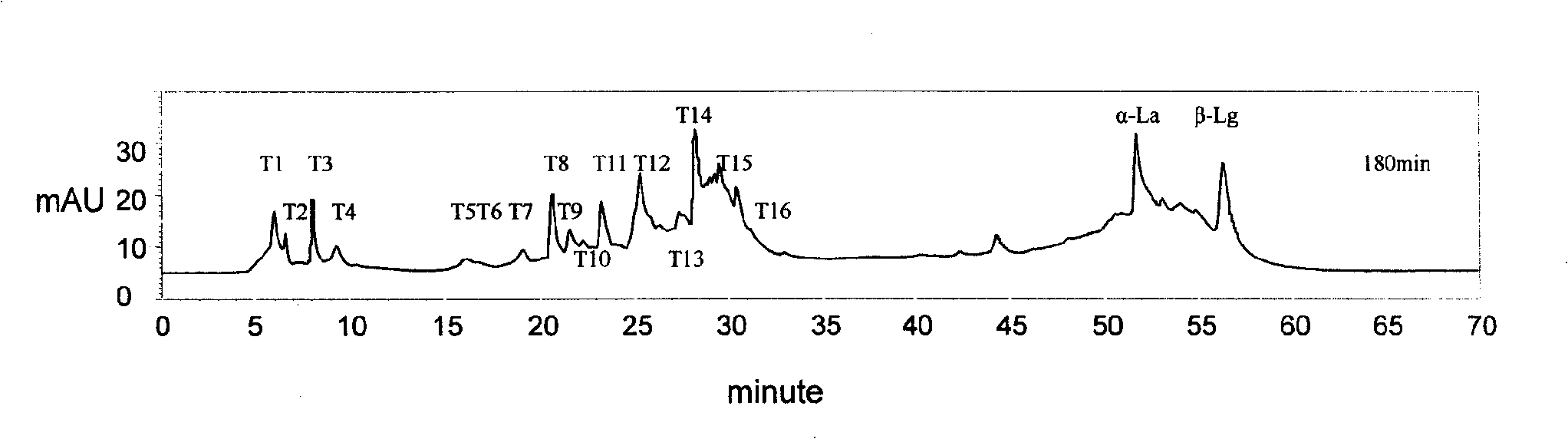

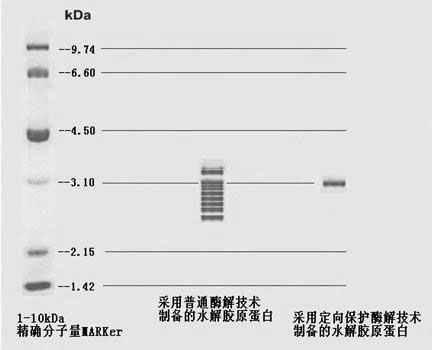

Subsensitive lactalbumin hydrolysate and preparation method thereof

The invention discloses a muting sensitive lactalbumin hydrolysate and a preparation method thereof. The method mainly comprises the following steps: dissolving condensed whey protein in the water, then carrying out denaturation under high temperature, carrying out hydrolysis by using the protamex composed of alkali protease, papain and flavourzyme, treating the lactalbumin hydrating solution with desalinization and drying to obtain the lactalbumin hydrolysate of the invention. The lactalbumin hydrolysate of the invention has high suppression ratio of Beta-lactoglobulin and Alpha- lactalbumin, can reduce or eliminate cow milk allergic reaction; furthermore, the lactalbumin hydrolysate can also produce other active materials, thus also having the functions of promoting immunity, being easy to digest and absorb and reducing blood pressure; and the lactalbumin hydrolysate has high security and no side effect, bitter taste or other bad flavors.

Owner:CHINA AGRI UNIV

Preparation of functional feed protein dried porcine saluble

InactiveCN101209082ASolve the current situation of shortageImprove hydrolysis effectAnimal feeding stuffAlkaline proteaseNeutral protease

The invention discloses a method for preparing functionality feed protein intestinal membrane albumen powder, which solves the problems that simultaneous hydrolyzing of multienzyme can affect the hydrolyzing degree and the acquiring rate of the protein peptide, more particularly, the lower acquiring rate of small peptide in the existing intestinal membrane albumen powder preparing technique. The technical scheme includes (1) treating before materials; (2) adding protease to hydrolyze; (3) adding a carrier; (4) preparing through sponging drying; wherein, in the step of hydrolyze the protease, hydrolyzing is carried through on any two of neutral protease, pawpaw protease and alkali protease by adopting a multienzyme grading hydrolyzing method. The functionality feed protein intestinal membrane albumen powder prepared by the method has the obvious advantages in the aspects of the acquiring rate of the protein peptide and the acquiring rate of the small peptide. The invention mixed to feed with other feeds can remarkably improve the performance trait of immature animals.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Extraction method of hericium erinaceus polysaccharide

The invention provides a hericium erinaceus polysaccharide extraction method with high product yield and good purity. The method comprises that: hericium erinaceus dried powder is added with water, is extracted by 8 to 20 KHz ultrasonic under the temperature of 50 to 80 DEG C for 0.5 to 2.0 hours, and is filtered; the filtrate is hydrated orderly by sufficient cellulose, pectinase and papain, finally is added with hydrogen peroxide to be stirred in heat preservation under the temperature of 30 to 50 DEG C for 0.5 to 1 hour, and is hyperfiltrated by a hyperltration membrane; the components with the molecular weight of more than 10000 dalton are collected, frozen and dried to obtain the hericium erinaceus polysaccharide. The hericium erinaceus polysaccharide extraction method has the advantages that 1. the prepared product has high purity; wherein, the content of Beta-dextran is as high as more than 40 percent and the biological activity is high, and the hericium erinaceus polysaccharide yield can reach 12.2 percent; 2. the hydrogen peroxide is adopted to decolorize, the conditions are mild, the polysaccharide structure is difficult to damage and the by-product is water, the method is green and environment-friendly, and coincides with the production requirements of the health care food.

Owner:ZHEJIANG ESSENCE FUNGI DEV

Technique for extracting Grifola frondosa water-soluble polysaccharide

InactiveCN101736053AReduce dosageHigh ultrasonic extraction rateFermentationActivated carbonFreeze-drying

The invention relates to a technique for extracting Grifola frondosa water-soluble polysaccharide. The technique is implemented by soaking raw material sporocarp of Grifola frondosa in water for 2-3h, ultrasonic extracting 2-4 times, regulating pH, depriving protein by papain enzymolysis process, adding activated carbon for decoloring, filtering decoloring solution by membranes for retaining and concentrating, precipitating with ethanol, and freeze drying to obtain the finished product. By adopting the technique to produce polysaccharide, cost is low, energy consumption is low, purity is high, and activity of Grifola frondosa polysaccharide is retained.

Owner:NANJING ZELANG MEDICAL TECH

Method for extracting hydrolyzed collagen from bovine cartilage

ActiveCN101948900AAchieve hydrolysisGuaranteed HalalPeptide preparation methodsFermentationBovine CartilageCollagen VI

The invention provides a method for extracting hydrolyzed collagen from bovine cartilage. The method sequentially comprises the following steps of: processing fresh bovine cartilage which is obtained from a Muslim slaughter house and serves as a raw material with solution of sodium hydroxide; adding papain and alkali protease into the obtained product by stages and simultaneously adding a composite enzymolysis protecting agent into the obtained product; raising temperature for inactivating enzyme after two enzymolysis processes; decoloring by oxidation; filtering and performing ultra-filtering; collecting retained solution; and performing spray-drying on the solution to obtain the hydrolyzed collagen. In the method, the bovine cartilage of the Muslim slaughter house is used as a basic rawmaterial, and other animal derived enzyme preparations are not added during the entire process, so that the Muslim property and no pollution of the product can be ensured.

Owner:SHANGHAI AL AMIN BIOTECH

Preparation method of pearl hydrolysate

ActiveCN102018727ALow yieldEasy to operateCosmetic preparationsToilet preparationsNeutral proteaseHydrolysate

The invention relates to a preparation method of a pearl hydrolysate. The method comprises the following steps of: (1) adding pearl powder in an aqueous solution of hydrochloric acid, stirring until the pearl powder and the aqueous solution of hydrochloric acid fully react, adjusting the pH value of the mixed solution with ammonia to be neutral and centrifugating to obtain a sediment (A); (2) dissolving the sediment (A) with purified water, adjusting the pH value of the solution with ammonia to be 7.5-8.5 and centrifugating to obtain a sediment (B); (3) dissolving the sediment (B) with purified water, adding enzyme for enzymolysis, centrifugating an enzyme solution to obtain a supernatant and a sediment (C), wherein the enzyme is the mixture of snail protease and pawpaw protease, and the addition of the enzyme is 0.3-1.05 percent by weight of the sediment (B); (4) dissolving the sediment (C) with purified water, adding enzyme for secondary enzymolysis, centrifugating and collecting a supernatant, wherein the enzyme is the mixture of the trypsinase, the pawpaw protease and neutral protease, and the addition of the enzyme is 0.2-0.45 percent by weight of the sediment (B); and (5) mixing the two supernatants, boiling and filtering with a nanofiltration membrane with the aperture of 1-3nm to obtain the pearl hydrolysate.

Owner:GUILIN NATURAL INGREDIENTS CORP

Yeast cell wall and preparation method thereof, forage additive and preparation method thereof, and forage

ActiveCN103243028ASolve pollutionImprove reproductive performanceMicroorganism lysisAnimal feeding stuffBiotechnologyManno-oligosaccharide

The invention relates to a yeast cell wall, comprising 20%-70% by mass of beta-yeast glucan and 20%-70% by mass of mannan oligosaccharide. The invention also relates to a forage additive, comprising the yeast cell wall, sodium modified montmorillonite and selenium yeast, and by mass, a ratio of the yeast cell wall to the sodium modified montmorillonite is 1 : 9-9 : 1; and a ratio of a total of the yeast cell wall and the sodium modified montmorillonite to the selenium yeast is 10 : 1-20 : 1. The invention also relates to a preparation method for the yeast cell wall. The preparation method comprises the steps of breaking the cell wall of live yeast through self-dissolution, degrading the yeast with a compound enzyme, separating, purifying, drying and deactivating the enzyme to obtain the yeast cell wall, wherein the compound enzyme comprises papain, nuclease and bacteria protease, and by mass, the addition amount of the papain, nuclease and bacteria protease is 0.1-0.3%, 0.05-0.2% and 0.01-0.03% that of the dry material of the yeast. The invention also relates to forage, an addition level of the additive in the forage is 1.5-2.5 g / kg.

Owner:ANGELYEAST CO LTD

Method for preparing seaweed plant vegetative growth regulating agent by using biological enzymolysis method

The invention relates to a method for preparing a seaweed plant vegetative growth regulating agent by using a biological enzymolysis method. The method comprises the following steps of: pre-treating fresh seaweeds or dry seaweeds and crushing the seaweeds into seaweed slurry; respectively carrying out first-grade, second-grade and third-grade enzymolysis by utilizing cellulase, papain and pectinase, wherein the enzymolysis temperature in each grade is 50-55 DEG C and the enzymolysis lasts for 4-6 hours; and after the enzymolysis is finished, filtering and concentrating enzymatic hydrolysate until that the density of the enzymatic hydrolysate is 1.2-1.3 grams per cubic centimeter, so as to obtain the seaweed plant vegetative growth regulating agent. The product disclosed by the invention is used as a plant growth regulating agent; and the method disclosed by the invention has no pollution, improves the activity and the stability of cytex and obviously improves the output of applied crops.

Owner:山东嘉丰海洋生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com