Method for preparing collagen peptide from fish scales

A technology of collagen peptides and fish scales, which is applied in the field of preparation of collagen peptides from fish scales, can solve problems such as limited application and difficulty in decompression of collagen peptides, and achieve the goal of increasing extraction rate, increasing peptide content and purity, and reducing enzymatic hydrolysis time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Fish scale pretreatment

[0029] The scales are freshwater mixed fish scales, mainly crucian carp scales collected from the vegetable market. They are washed with tap water and then soaked in hydrochloric acid for decalcification. After decalcification, they are washed with tap water to neutrality, and then dried at 60°C (24~48 h ) Then crush it with a crusher.

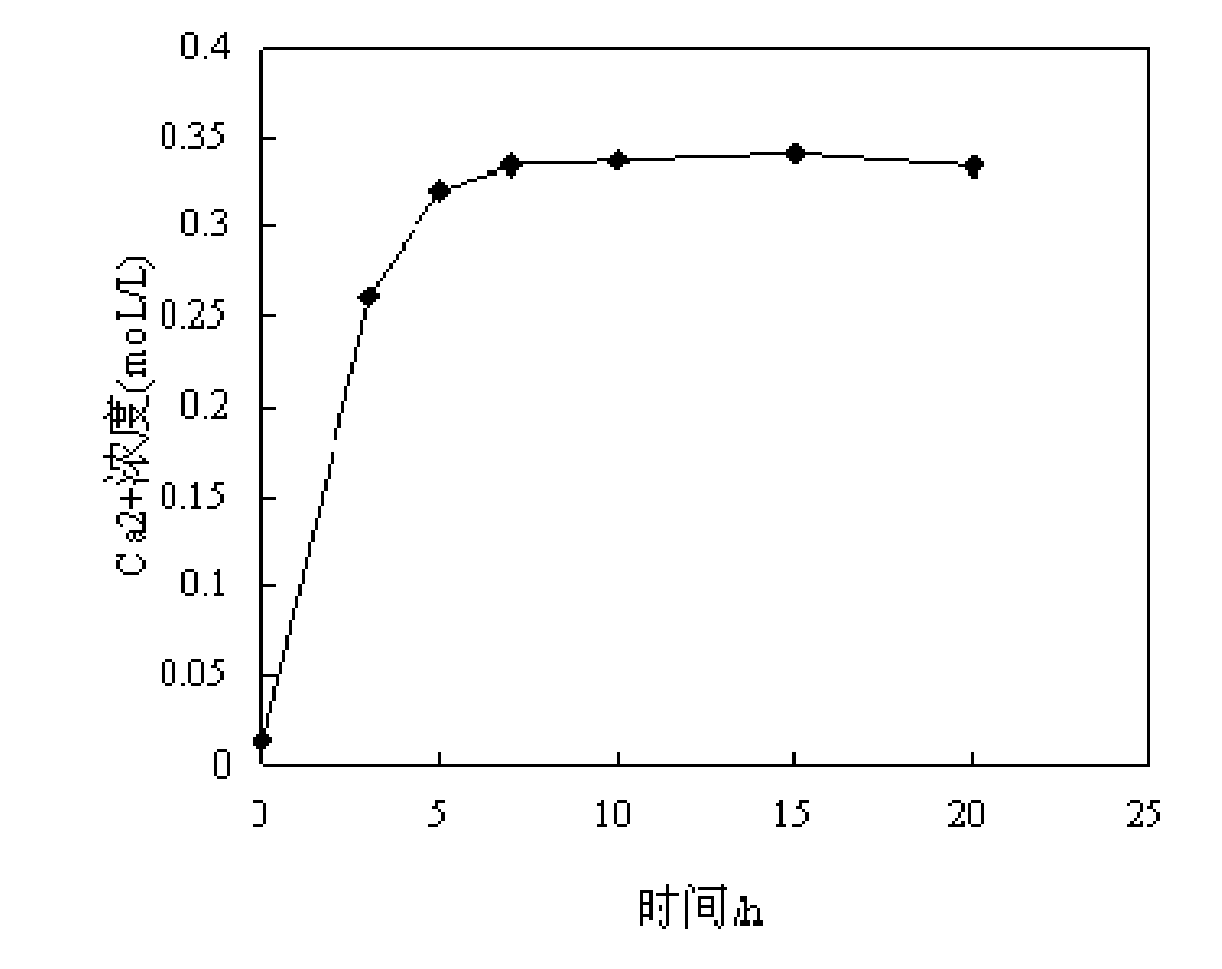

[0030] Analyze the appropriate material-to-liquid ratio, hydrochloric acid concentration and decalcification time (the time when the calcium concentration in the soaking solution becomes stable) for hydrochloric acid decalcification by detecting the calcium concentration of the soaking solution. The calcium concentration is determined by EDTA titration.

[0031] The experimental results under different experimental conditions are as follows:

[0032] Table 1 Experimental results of fish scale decalcification under different experimental conditions

[0033] Experiment number1234 The ratio of scale and hy...

Embodiment 2

[0035] Example 2: Extracting fish scale collagen peptides by mixing enzymes

[0036] Take the decalcified, dried and pulverized fish scales prepared in Experiment 2 of Example 1 into the enzyme reactor, and then add water and mixed protease for mixed enzyme extraction of fish scale collagen peptides. After the mixed enzyme extraction is completed, the enzymes are inactivated and centrifuged at 4000 rpm for 10 minutes Afterwards, the enzymolysis solution is obtained, in which the mixed protease is a mixture of neutral protease, papain and flavor protease. The specific steps of inactivating the enzyme are: heating the enzymatic hydrolysate to above 90°C for 10 minutes.

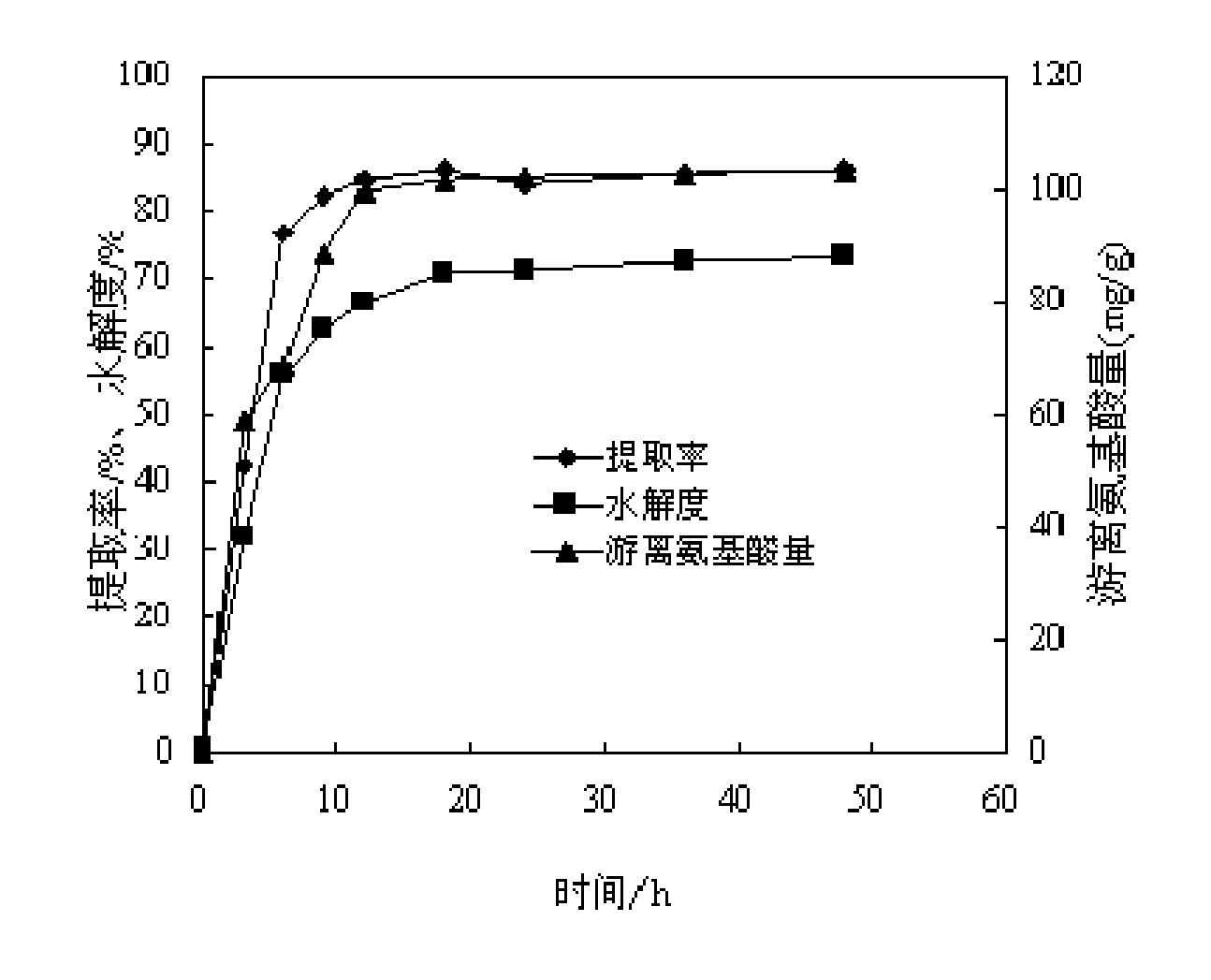

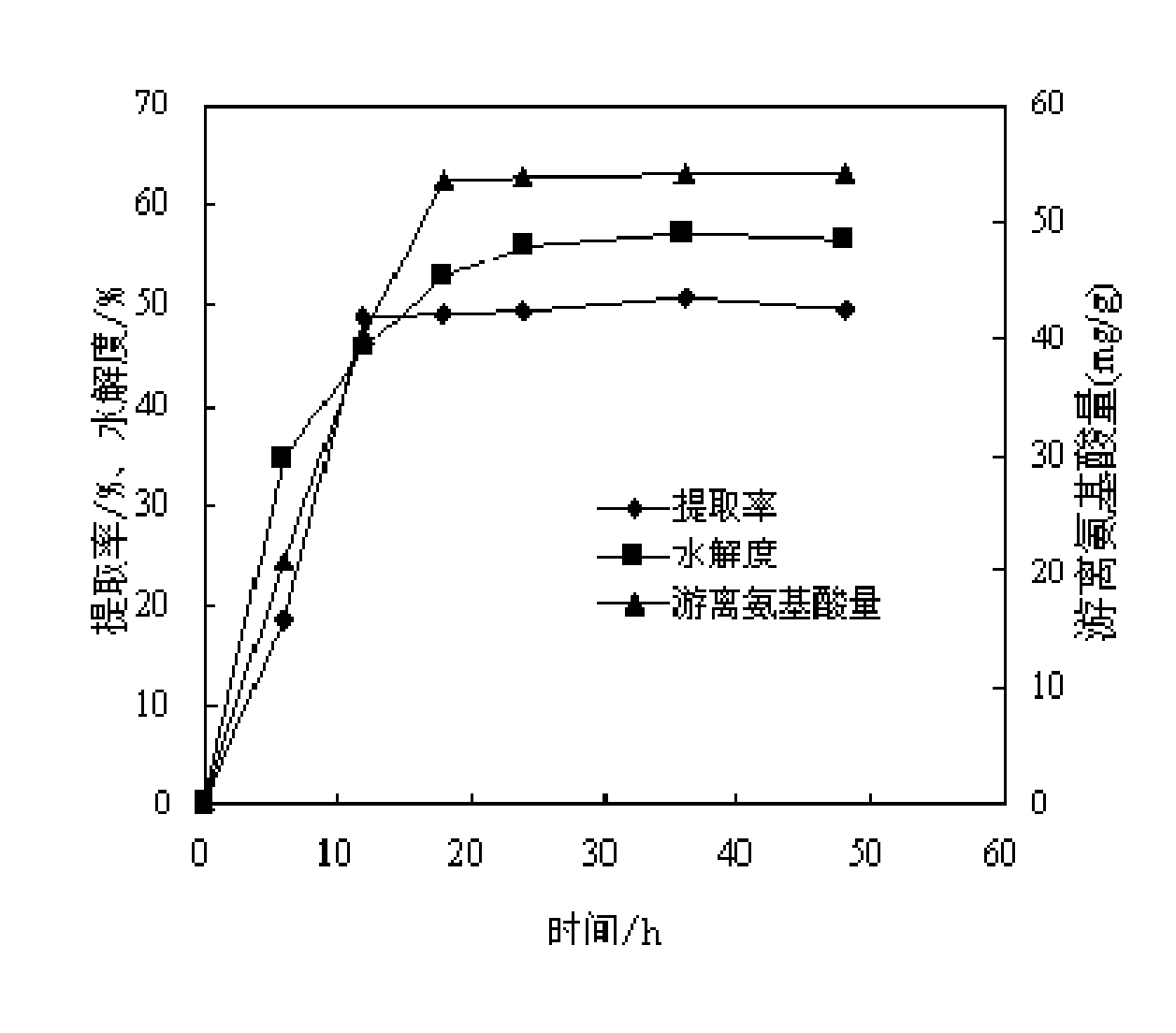

[0037] The extraction rate of fish scale collagen peptides, the degree of hydrolysis and the amount of free amino acids in the enzymatic hydrolysis solution were used as the detection and analysis indicators. During the extraction process, when the extraction rate of fish scale collagen peptides in the solution tend...

Embodiment 3

[0057] Example 3: Membrane concentration of fish scale collagen peptides

[0058] The enzymatic hydrolysate prepared in Experiment 3 of Example 2 was centrifuged at 4000 rpm for 10 minutes to obtain the supernatant, and then the filtrate was concentrated in the combined membrane equipment. The primary membrane is a roll membrane with a molecular weight of 2000Da, which is carried out at room temperature and 1.0-1.5Mpa. The secondary membrane is a roll membrane with a molecular weight of 400Da, which is carried out at room temperature and 2.5~3.0Mpa. The secondary membrane is concentrated and freeze-dried to obtain fish scale collagen peptide powder.

[0059] Table 3 shows the yield of collagen peptides concentrated by the secondary membrane, and Table 4 shows the peptide content, molecular weight distribution and bitterness of the collagen peptide powder.

[0060] The yield of membrane-concentrated collagen peptides (%)=total hydroxyproline after concentration / total hydroxyproline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com