A special paint pretreatment agent for metal and preparation method thereof

A pre-treatment agent and paint technology, applied in coatings, anti-corrosion coatings, etc., can solve problems such as environmental pollution, and achieve the effects of good weather resistance, time saving, and good anti-rust function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

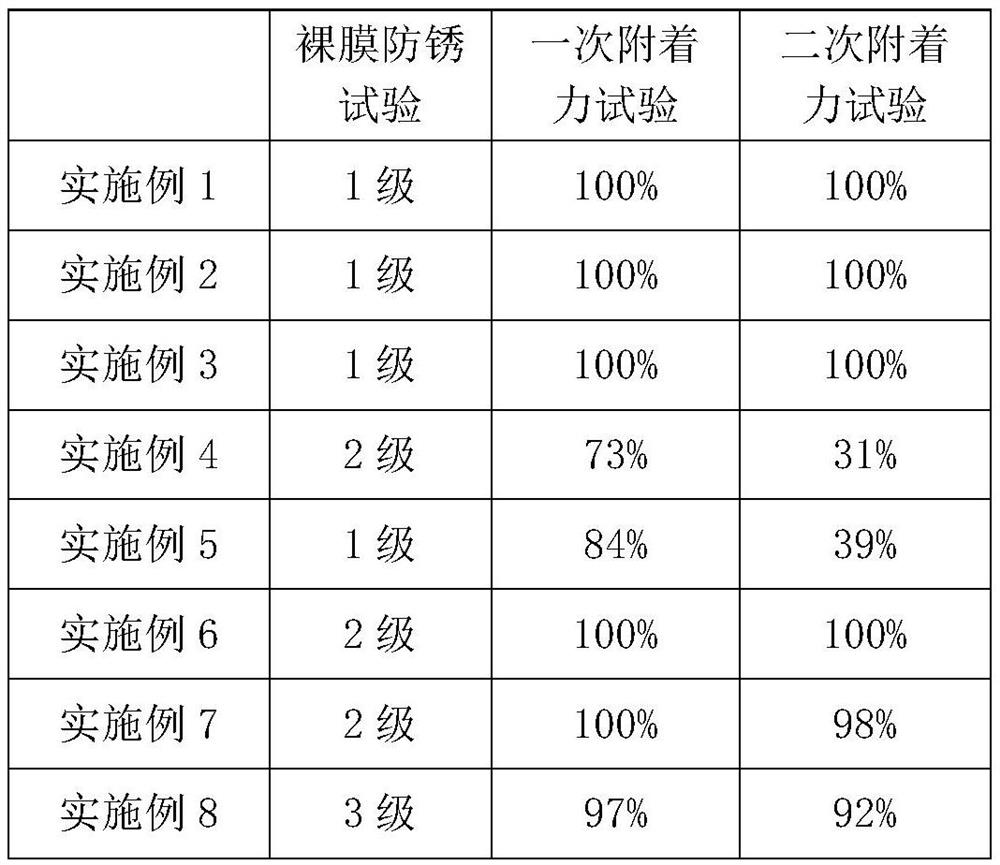

Examples

Embodiment 1

[0061] Embodiment 1 of the present invention specifically provides a kind of pretreatment agent for metal special paint, and described pretreatment agent comprises, by weight, 40 parts of acid-resistant resin, 30 parts of solvent, 8 parts of monocitric acid, 4 parts of citric acid , 0.4 parts of film-forming agent, 0.8 parts of defoamer;

[0062] The acid-resistant resin is a water-based acrylic resin; the water-based acrylic resin is a hyperbranched modified water-based acrylic resin; the solid content of the hyperbranched modified water-based acrylic resin is 45%;

[0063] Described solvent comprises alcohol solvent; Described alcohol solvent is ethanol and Virahol; The weight ratio of described ethanol and Virahol is 3:1; Described solvent also comprises aprotic solvent; The weight of described aprotic solvent is 20% by solvent weight; the aprotic solvent is an aprotic polar solvent; the aprotic polar solvent is N,N-dimethylformamide;

[0064] Described film forming agent ...

Embodiment 2

[0068] Embodiment 2 of the present invention specifically provides a kind of pretreatment agent for metal special paint, and described pretreatment agent comprises, by weight, 55 parts of acid-resistant resin, 40 parts of solvent, 14 parts of monocitric acid, 7 parts of citric acid , 0.8 parts of film-forming agent, 1.2 parts of defoamer;

[0069] The acid-resistant resin is a water-based acrylic resin; the water-based acrylic resin is a hyperbranched modified water-based acrylic resin; the solid content of the hyperbranched modified water-based acrylic resin is 60%;

[0070] Described solvent comprises alcohol solvent; Described alcohol solvent is ethanol and Virahol; The weight ratio of described ethanol and Virahol is 5: 1; Described solvent also comprises aprotic solvent; The weight of described aprotic solvent is 35% of the solvent weight; the aprotic solvent is an aprotic polar solvent; the aprotic polar solvent is N,N-dimethylformamide;

[0071] Described film forming ...

Embodiment 3

[0075] Embodiment 3 of the present invention specifically provides a kind of pretreatment agent for metal special paint, and described pretreatment agent comprises, by weight, 46 parts of acid-resistant resin, 35 parts of solvent, 11 parts of monocitric acid, 6 parts of citric acid , 46 parts of film-forming agent, 1 part of defoamer;

[0076] The acid-resistant resin is a water-based acrylic resin; the water-based acrylic resin is a hyperbranched modified water-based acrylic resin; the solid content of the hyperbranched modified water-based acrylic resin is 50%;

[0077] Described solvent comprises alcohol solvent; Described alcohol solvent is ethanol and Virahol; The weight ratio of described ethanol and Virahol is 4:1; Described solvent also comprises aprotic solvent; The weight of described aprotic solvent is The solvent weight is 28%; the aprotic solvent is an aprotic polar solvent; the aprotic polar solvent is N,N-dimethylformamide;

[0078] Described film forming agent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com