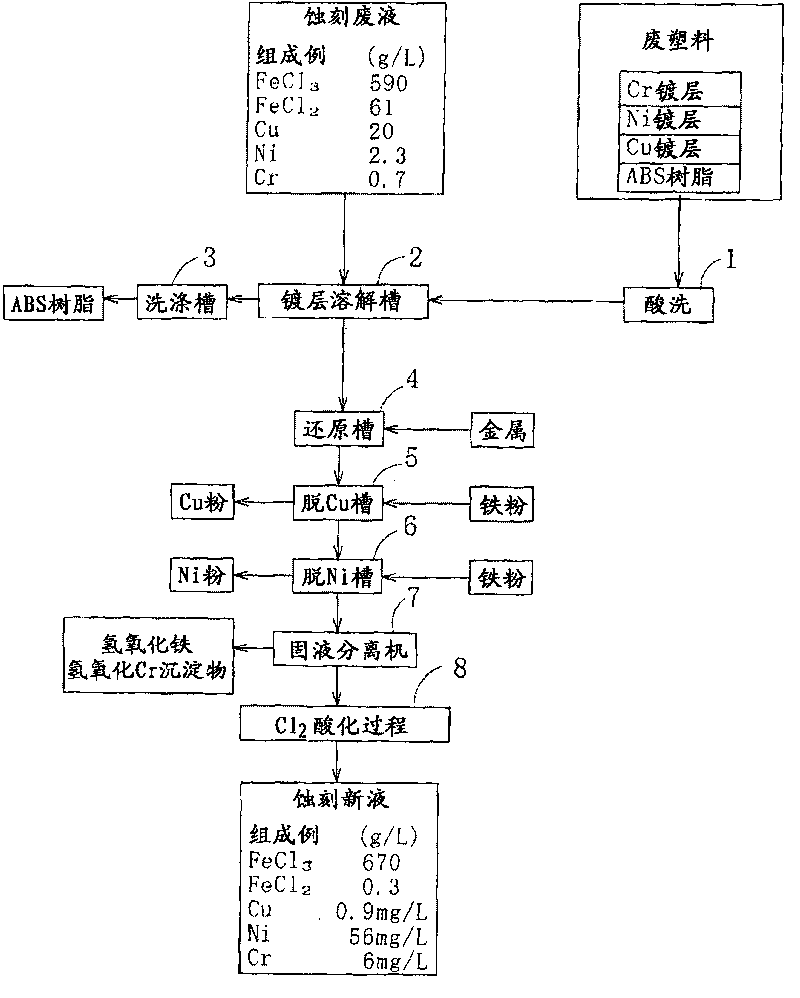

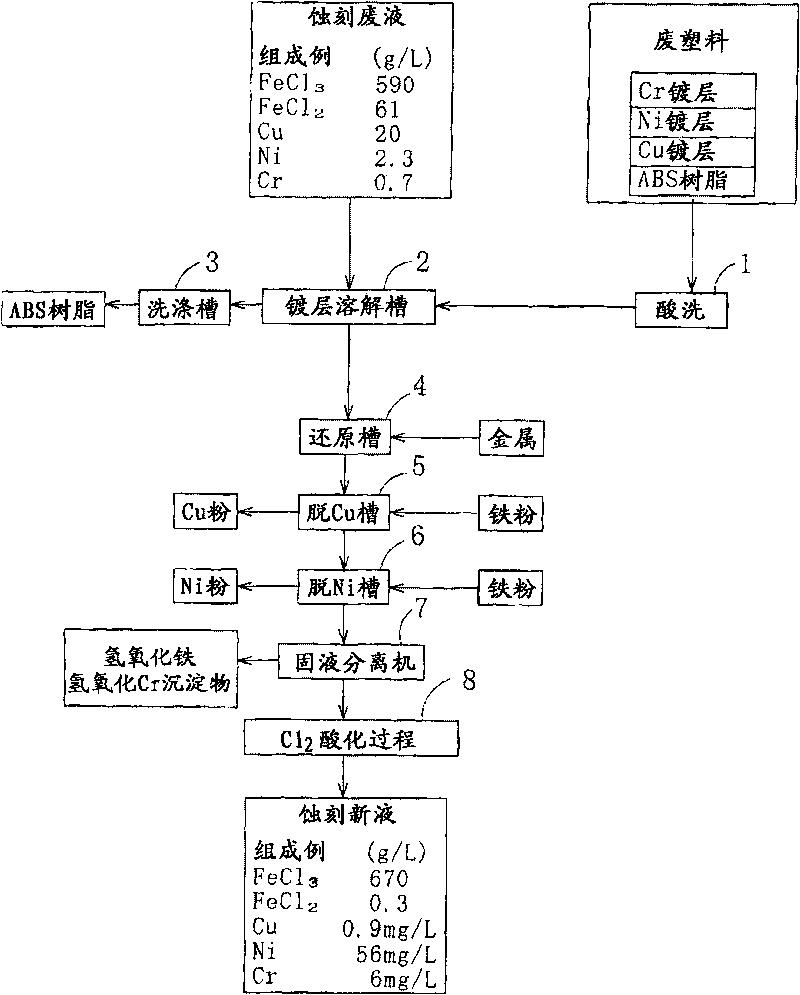

Method for recovering waste plastic and etching waste liquid

A technology for etching waste liquid and waste plastic, applied in chemical instruments and methods, plastic recycling, surface etching compositions, etc., can solve problems such as waste products, large quantities, etc., and achieve the effect of increased removability and improved affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0055] Next, examples performed to confirm the effects of the present invention will be described.

[0056] Here, a product in which copper and nickel metal plating layers were sequentially formed on the surface of a target base material made of ABS resin, which is waste plastic, was recycled. It should be noted that the metal plating layer of copper and nickel is formed on the surface of the target base material by electroless plating and electroplating.

[0057] First, 100 kg of waste plastics on which metal plating was formed (that is, metal plating construction objects) were immersed in a ferric chloride solution to dissolve the metal plating in the ferric chloride solution. This test was performed 8 times in total. In addition, the ferric chloride concentration of the ferric chloride solution used was 37.3 mass % (8 times average), and the immersion time in the ferric chloride solution was 2 cases of 10 hours and 15 hours.

[0058] Next, the target substrate is taken ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com