Patents

Literature

7267 results about "Liquid waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquid waste can be defined as such Liquids as wastewater, fats, oils or grease (FOG), used oil, liquids, solids, gases, or sludges and hazardous household liquids.

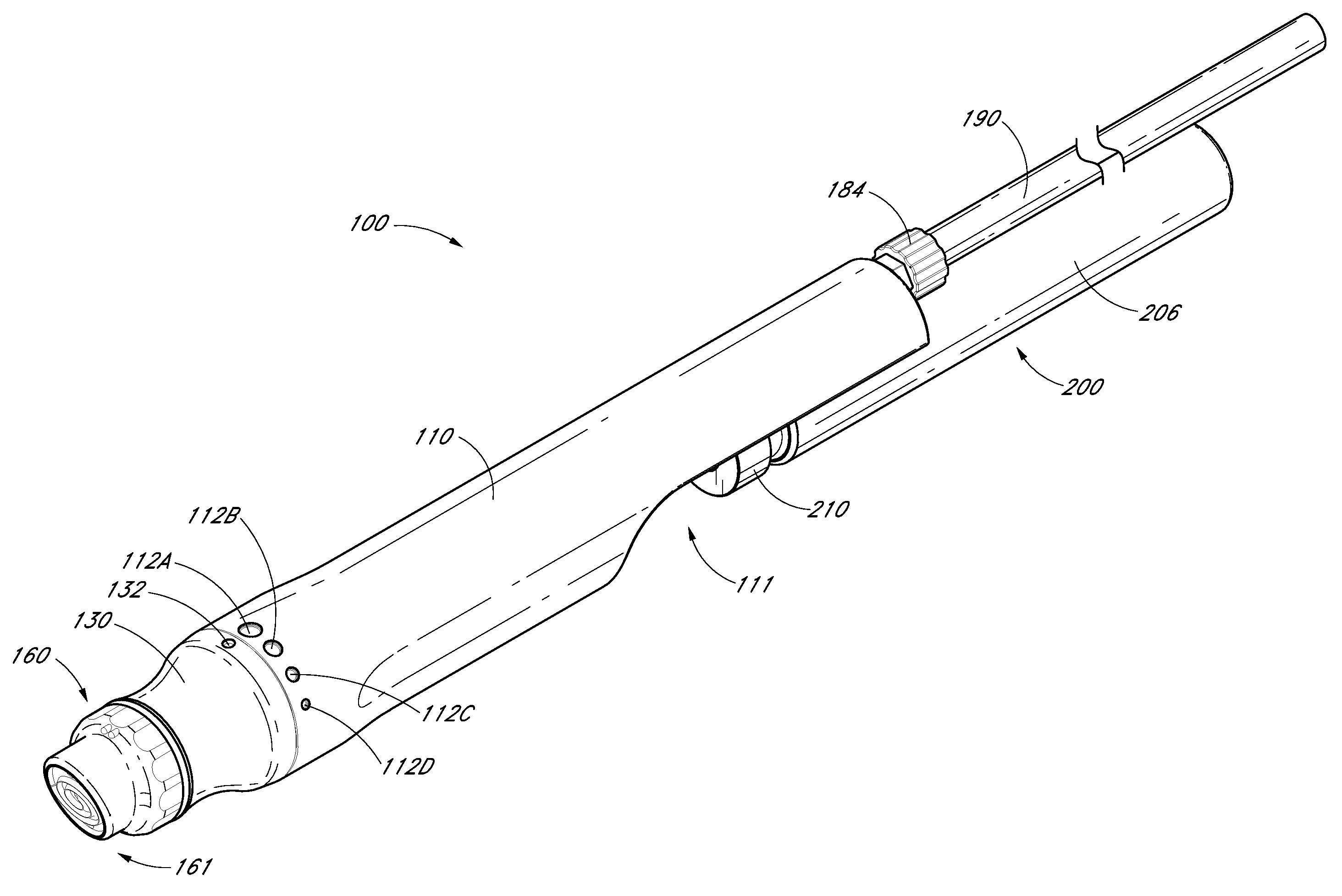

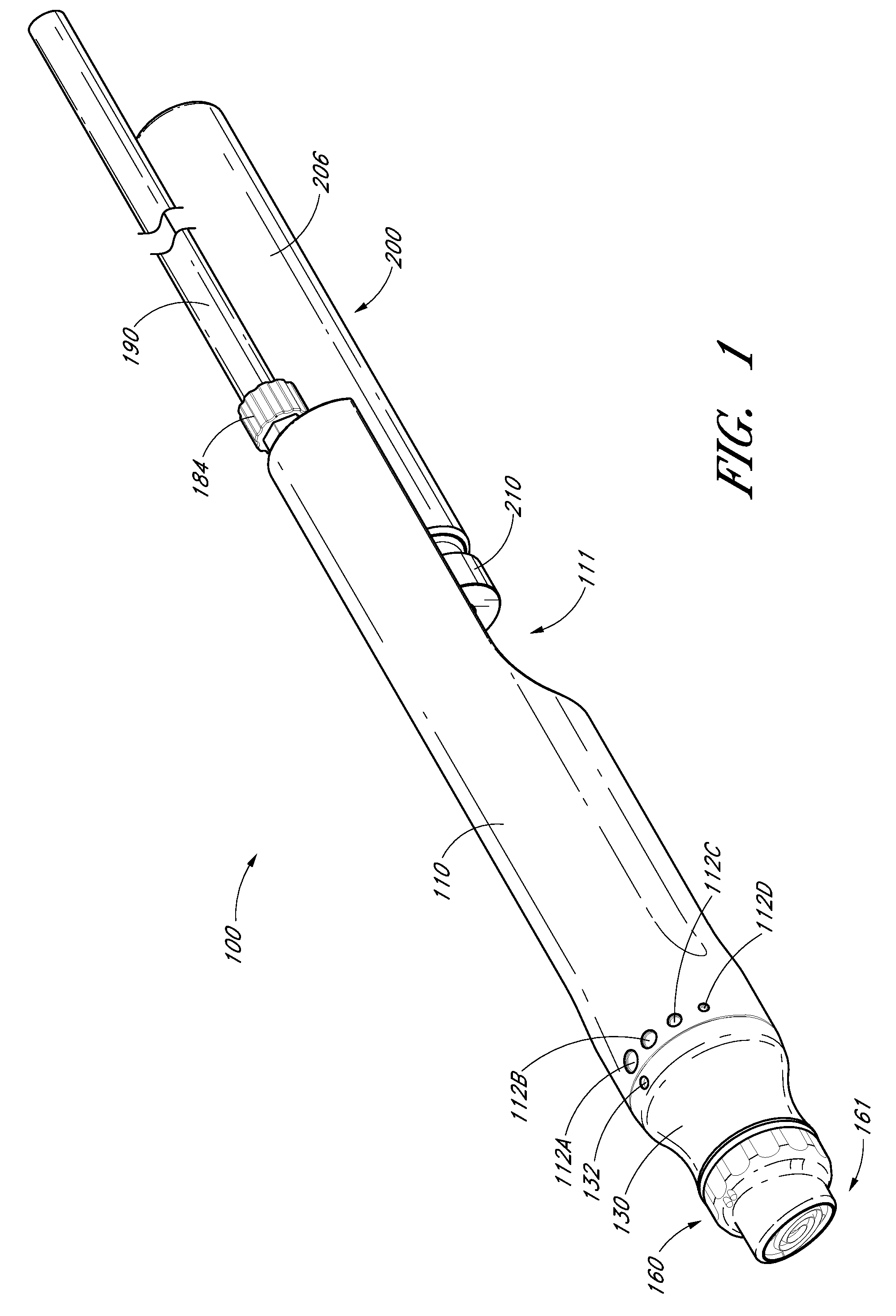

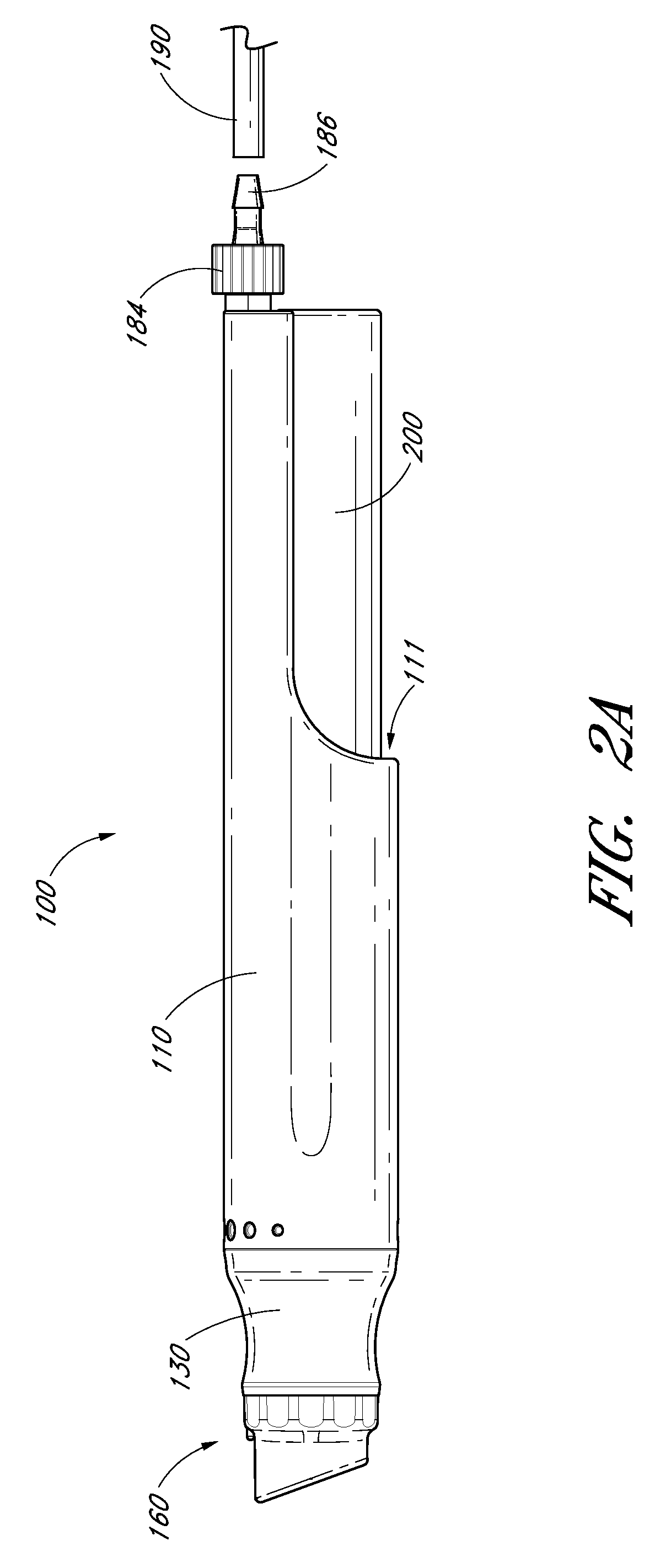

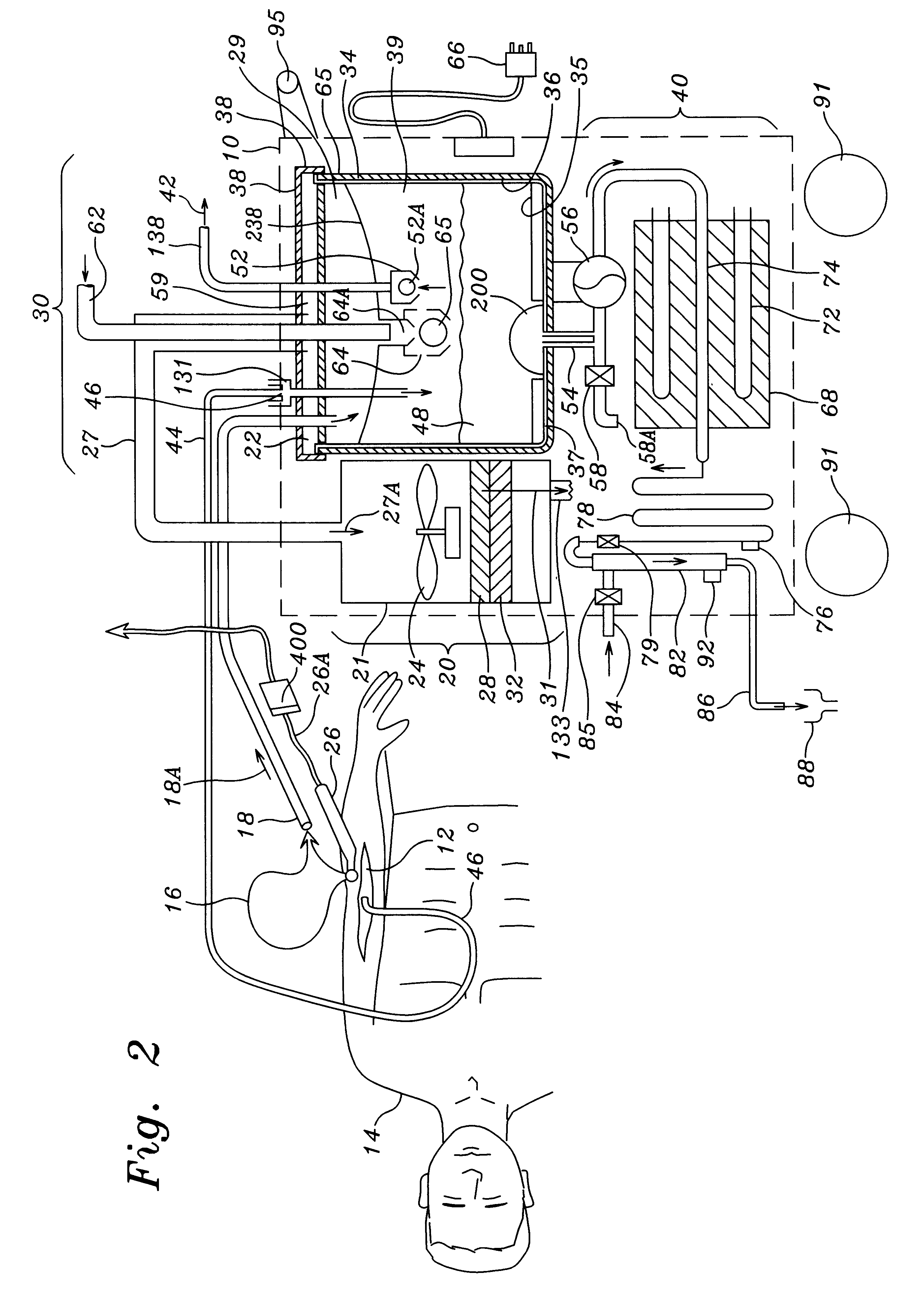

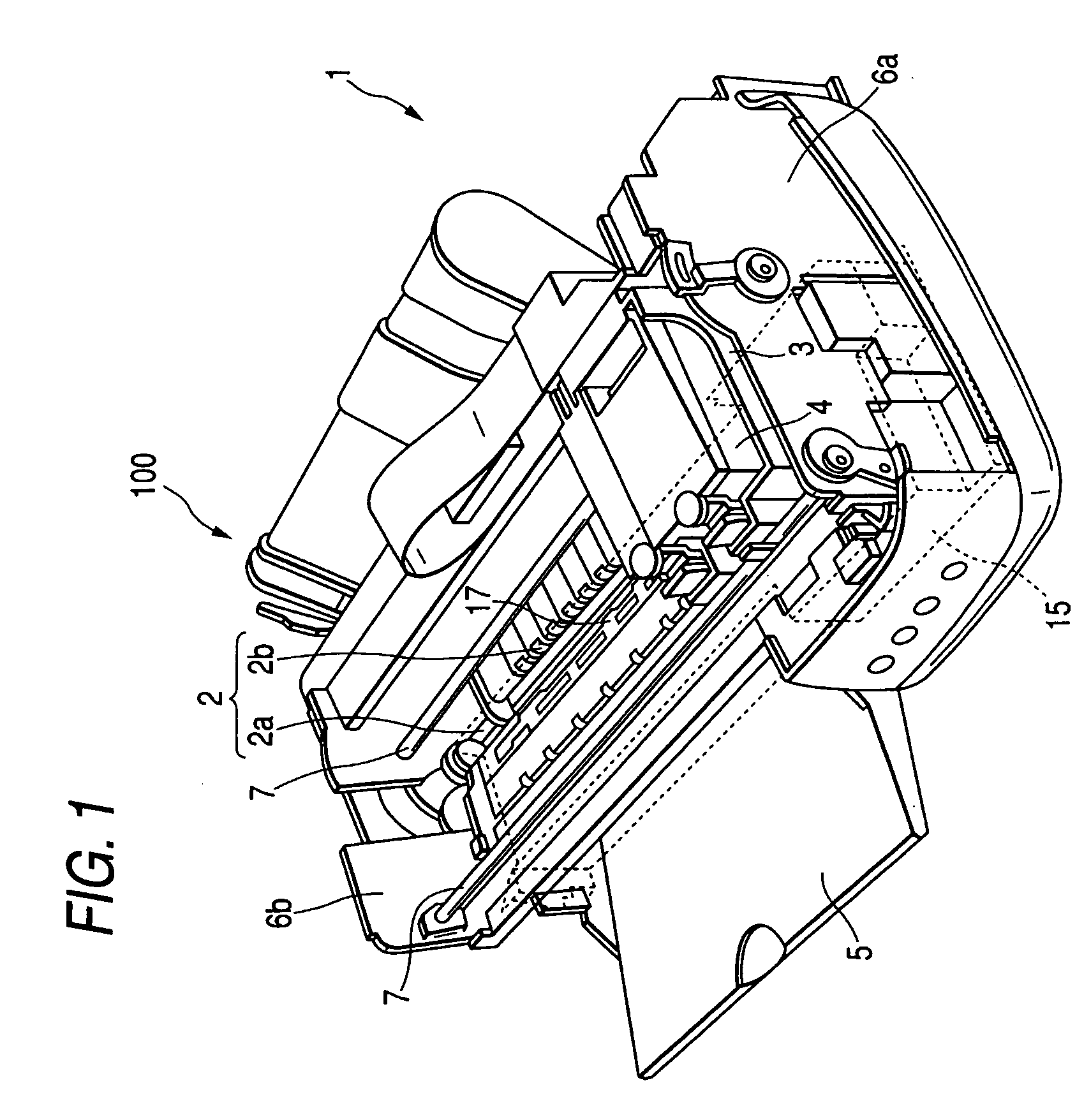

Devices, systems and methods for treating the skin using time-release substances

ActiveUS8814836B2Facilitate treatment procedureConvenient treatmentChiropractic devicesVibration massageLiquid wasteSkin surface

According to some embodiments, a microdermabrasion device for treating skin comprises a handpiece assembly having a distal end and a proximal end. The handpiece assembly includes at least one delivery conduit and at least one waste conduit. The microdermabrasion device additionally comprises a tip configured to be positioned along the distal end of the handpiece assembly, wherein the tip is adapted to contact skin surface. In several embodiments, the tip comprises a lip, a first opening in fluid communication with the fluid delivery conduit and a second opening in fluid communication with the waste conduit. In one embodiment, the device includes one or more abrasive elements positioned along a distal end of the tip, wherein the abrasive elements are configured to selectively remove skin as the tip is moved relative to a skin surface. In some embodiments, the delivery conduit is configured to selectively deliver at least one time-release material to the skin surface being treated.

Owner:HYDRAFACIAL LLC

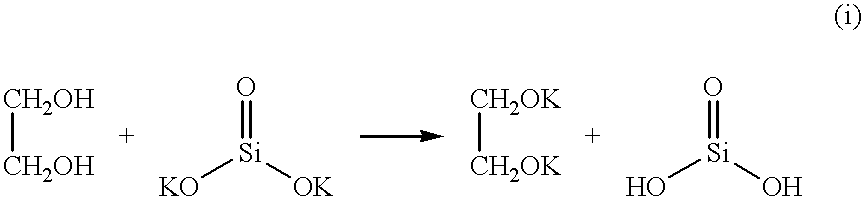

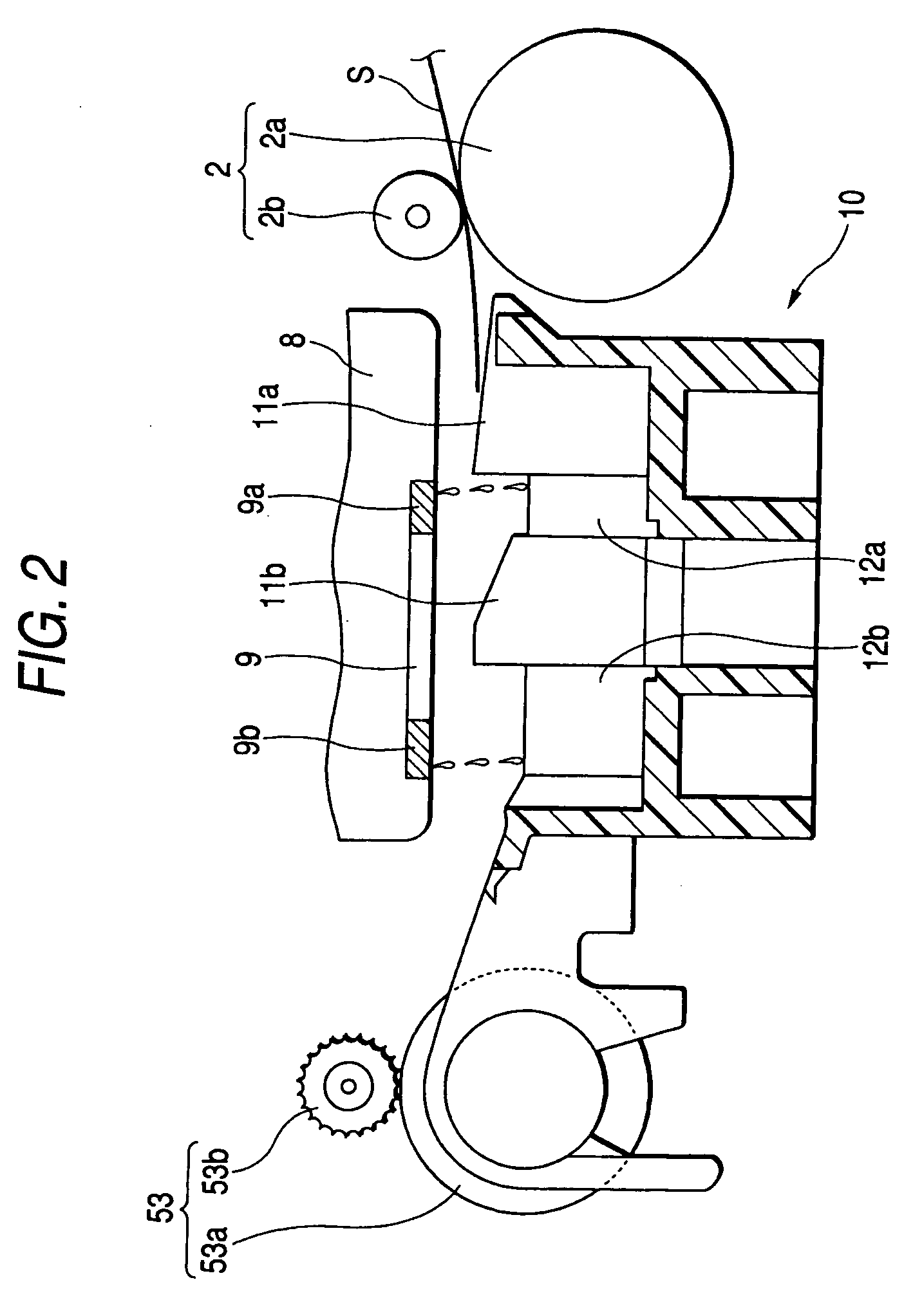

Aqueous compositions, aqueous cutting fluid using the same, method for preparation thereof, and cutting method using the cutting fluid

InactiveUS6221814B1Promote degradationSimple treatmentOther chemical processesWork treatment devicesActivated sludgeLiquid waste

An aqueous cutting fluid which can reduce the impact on working environment and the global environment, and can achieve both preventing precipitates from becoming a hard cake and keeping high dispersibility for abrasive grains is provided. Such an aqueous cutting fluid is obtained by a method comprising dispersing abrasive grains (G) in an aqueous composition comprising a dispersion medium (M) containing a hydrophilic alcohol compound such as ethylene glycol, a lipophilic alcohol compound such as propylene glycol and water, and silica colloid particles dispersed stably in the medium. The dispersion medium (M) is odorless and not flammable. The abrasive grains (G) may settle out after a time, but they do not closely contact with one another, and therefore the resulting precipitates do not become a hard cake, which allows the re-dispersion and reuse of precipitated grains. The instant aqueous cutting fluid is inherently low viscous, and the reduction of viscosity owing to the contamination of water and the increase of viscosity owing to contamination of shavings are both moderate. As a result, the cutting fluid has a long life. And articles which have been cut using the cutting fluid can be washed with water. Further, as the dispersion medium (M) is a biodegradable low molecular weight organic compound, a waste liquid from a process using the cutting fluid can be disposed with an activated sludge.

Owner:SHIN-ETSU HANDOTAI CO LTD +1

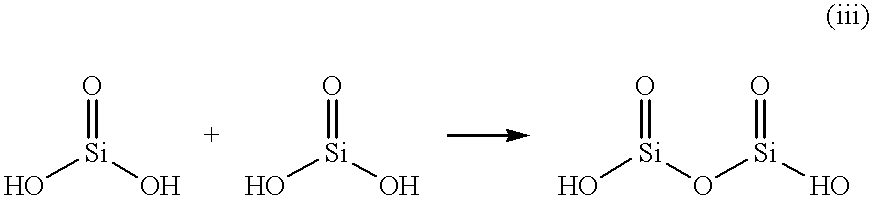

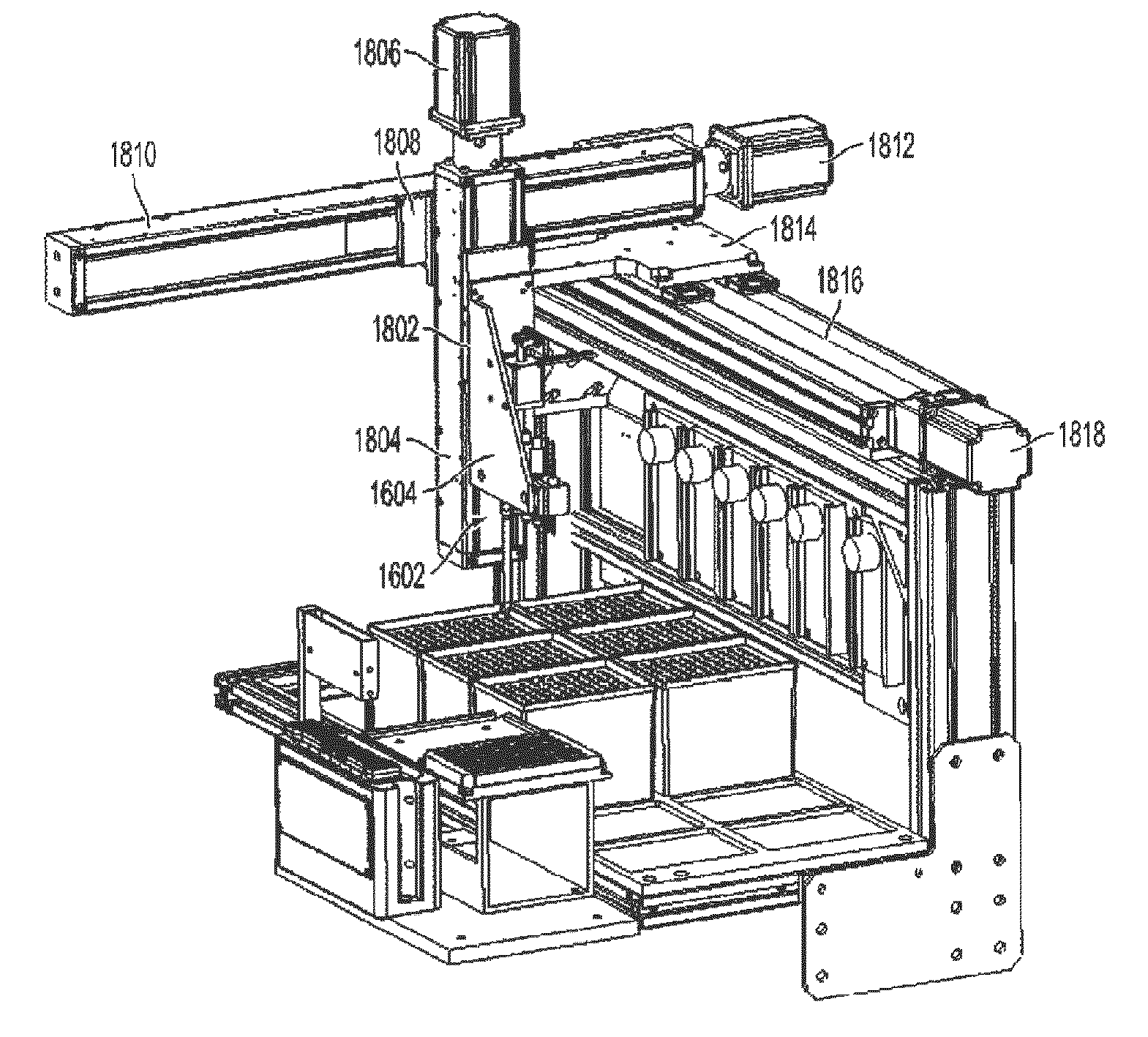

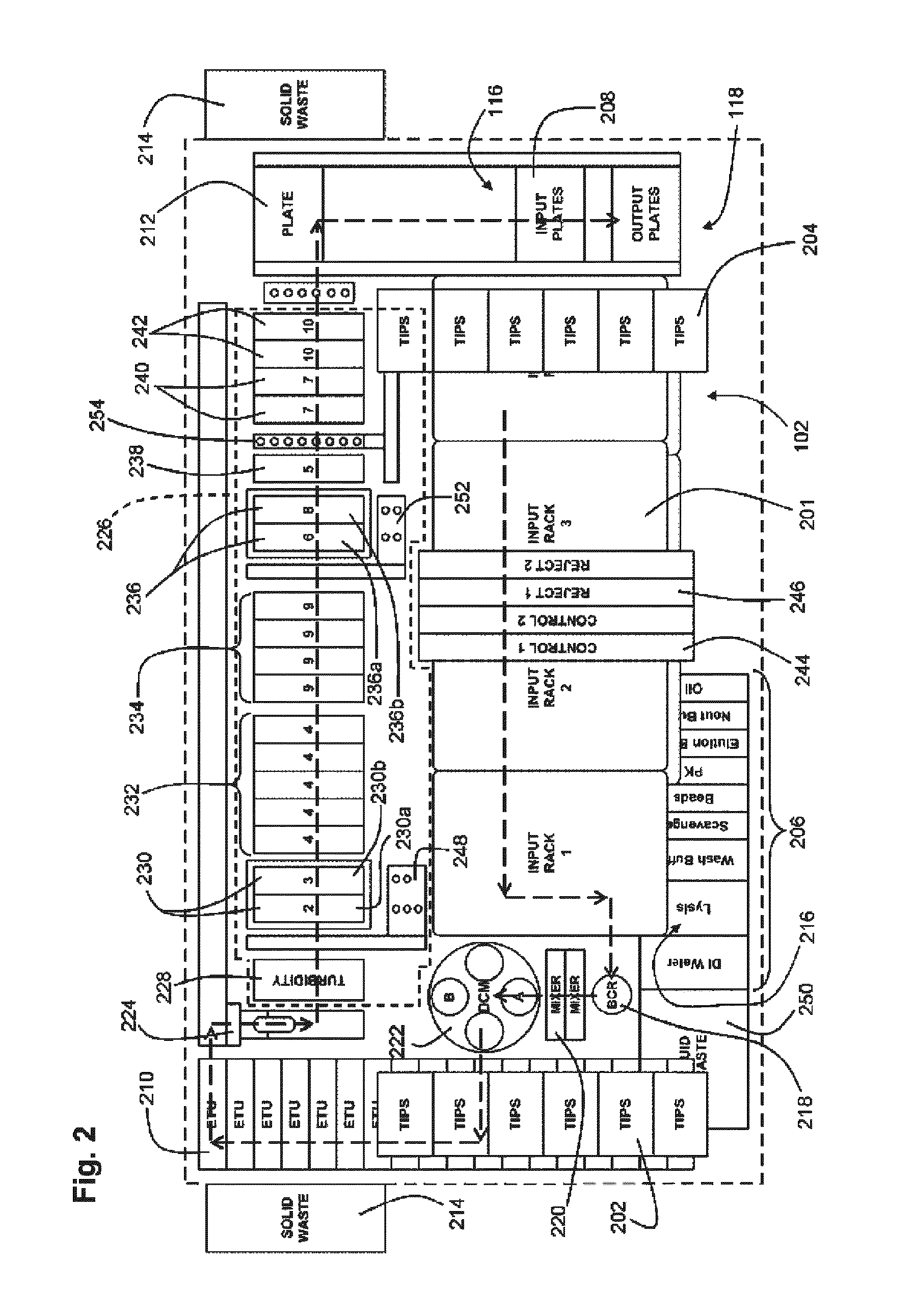

Open platform automated sample processing system

ActiveUS20100126286A1Analysis using chemical indicatorsWithdrawing sample devicesLiquid wasteOpen platform

An automated sample processing system having a sample input adapted to simultaneously receive a number of sample containers, a reagent input adapted to receive one or more new reagent supplies, a consumable input adapted to receive one or more new consumable supplies, a solid waste output adapted to receive used consumable supplies, a liquid waste output adapted to receive one or more used reagent supplies, and a processing center. The processing center includes a decapper adapted to remove a lid from at least one sample container, an aspirator adapted to remove a specimen from the at least one sample container and transfer the specimen to an output vessel, and a capper adapted to replace the lid on the at least one sample container. The system also includes a sample output adapted to receive the output vessel, and a user interface adapted to receive an input from the user to indicate the identity of the at least one sample container, and control at least one operation based on a physical property of the at least one sample container.

Owner:BECTON DICKINSON & CO

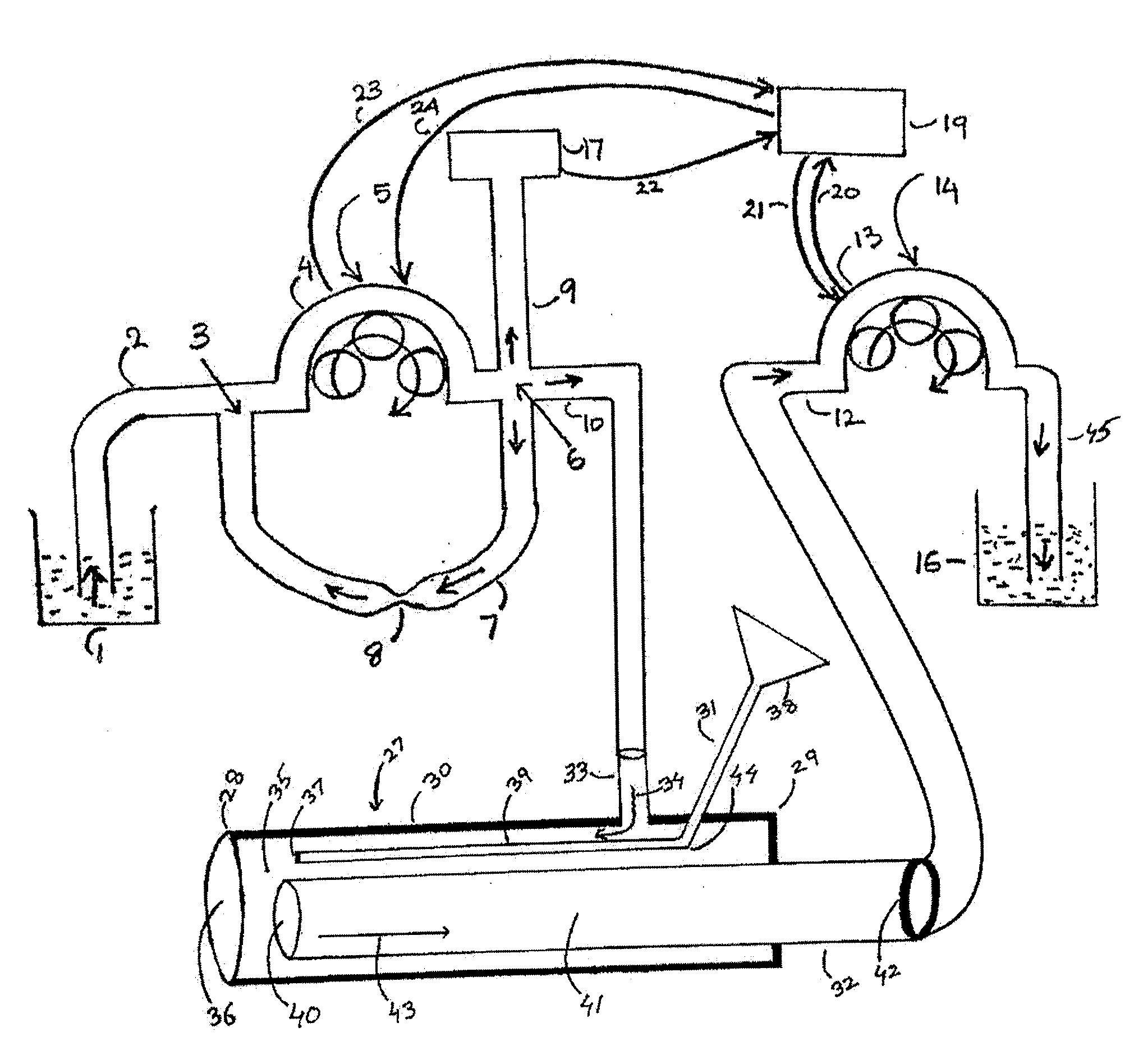

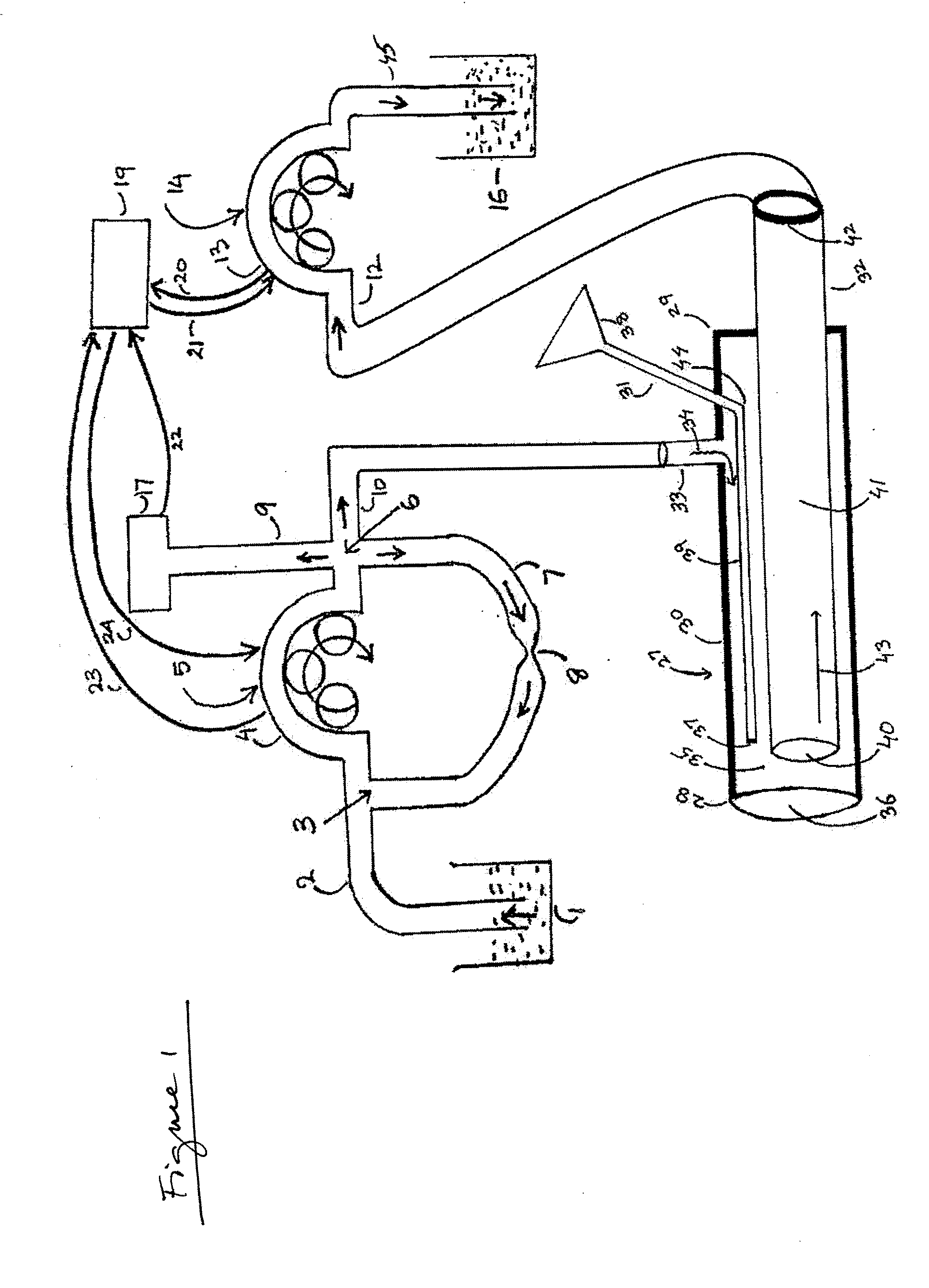

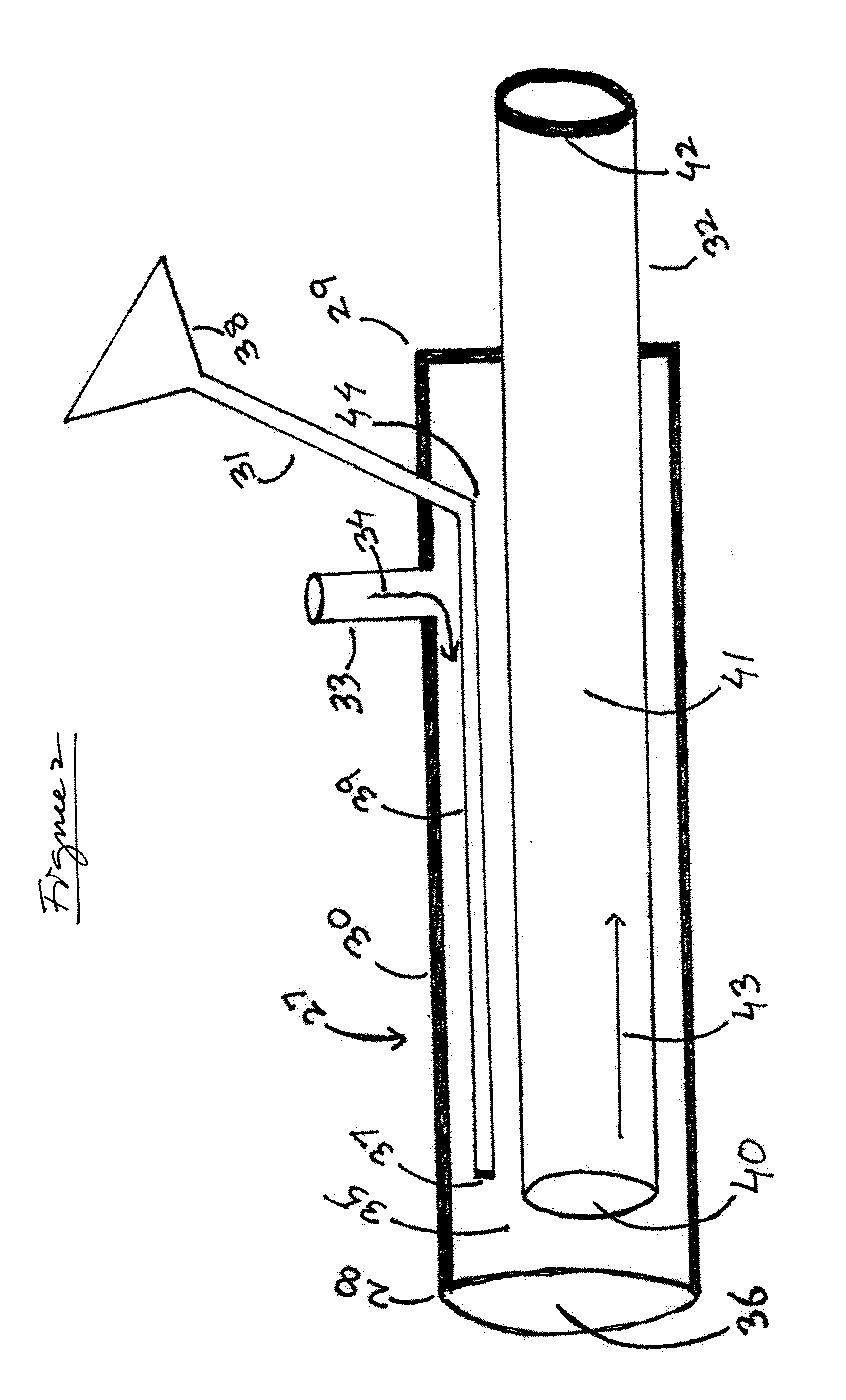

System for evacuating detached tissue in continuous flow irrigation endoscopic procedures

A continuous flow irrigation endoscope and a continuous flow irrigation fluid management system, both designed to be compatible to each other and to function as a single system. The endoscope and the fluid management system are synergistic to each other such that both enhance the efficiency of each other. The invented system allows a body tissue cavity to be distended by continuous flow irrigation so that detached tissue pieces and waste fluid present inside a body tissue cavity are continuously automatically evacuated from the tissue cavity without causing the cavity to collapse at any stage and without the need of withdrawing the endoscope of a part of the endoscope from the tissue cavity. No type of feedback mechanism, such as mechanical or electrical, or valve or valve like systems, are incorporated in the endoscope to influence or facilitate the removal of detached tissue pieces or waste fluid in any manner.

Owner:KUMAR BV

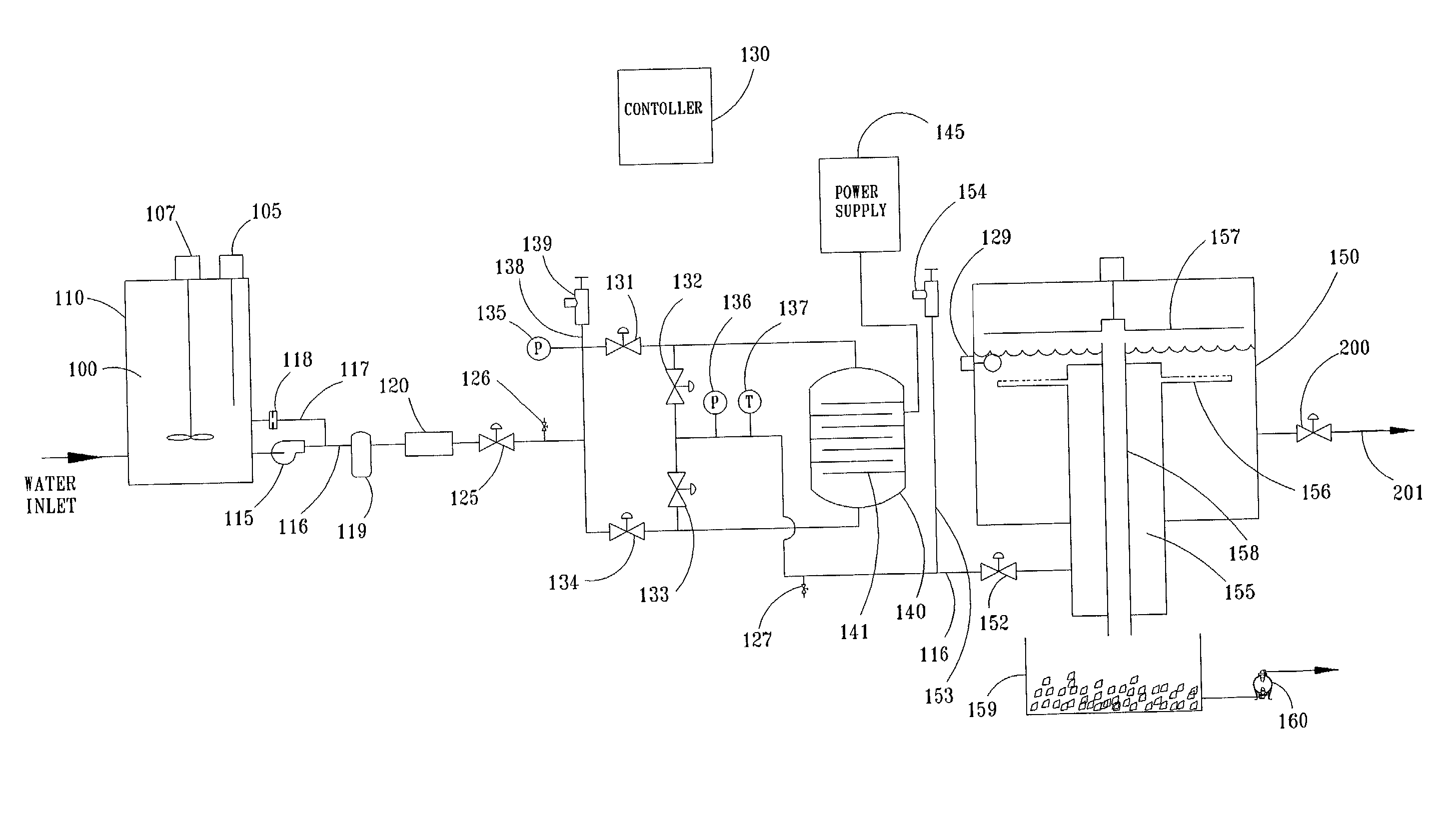

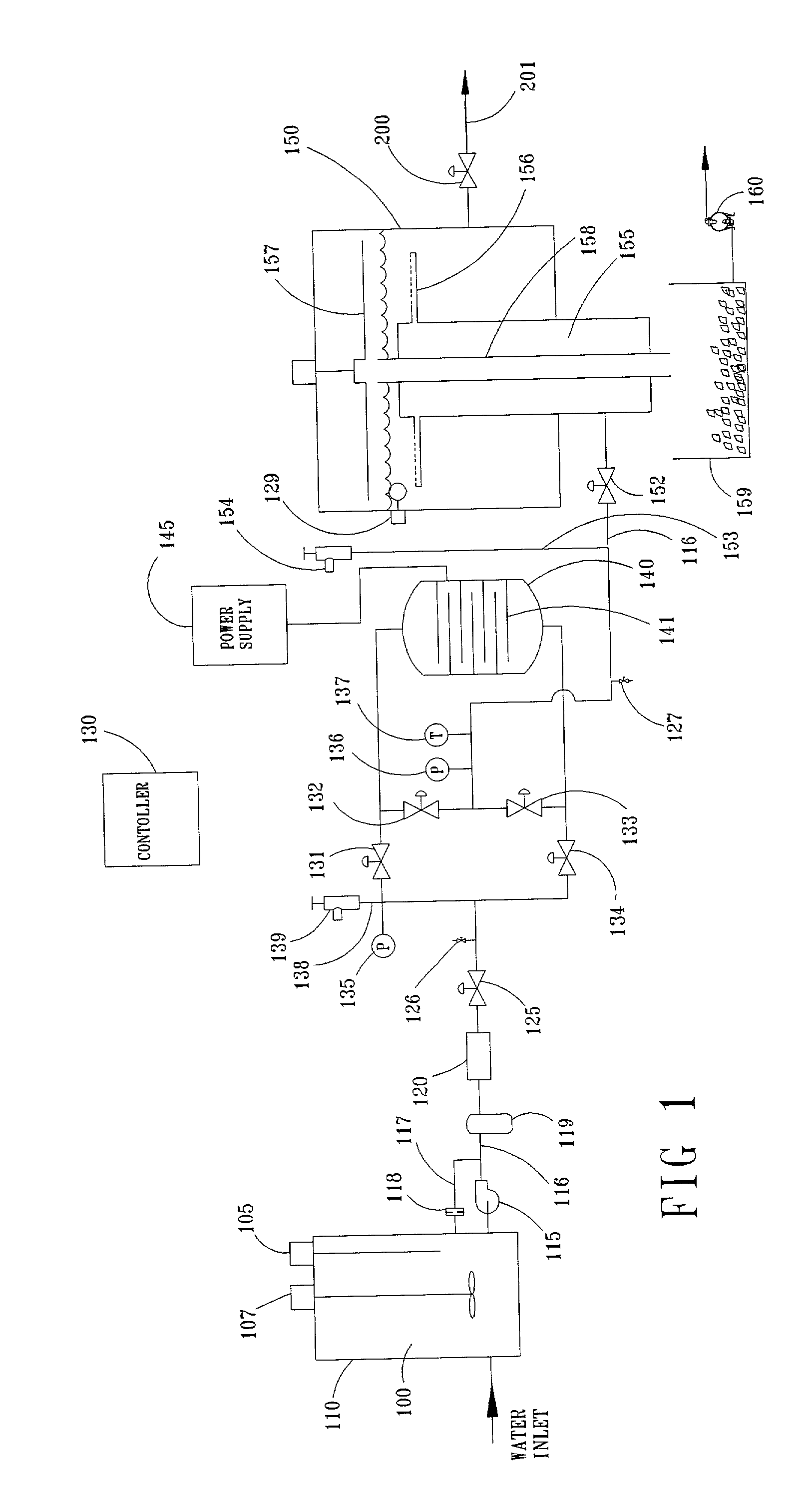

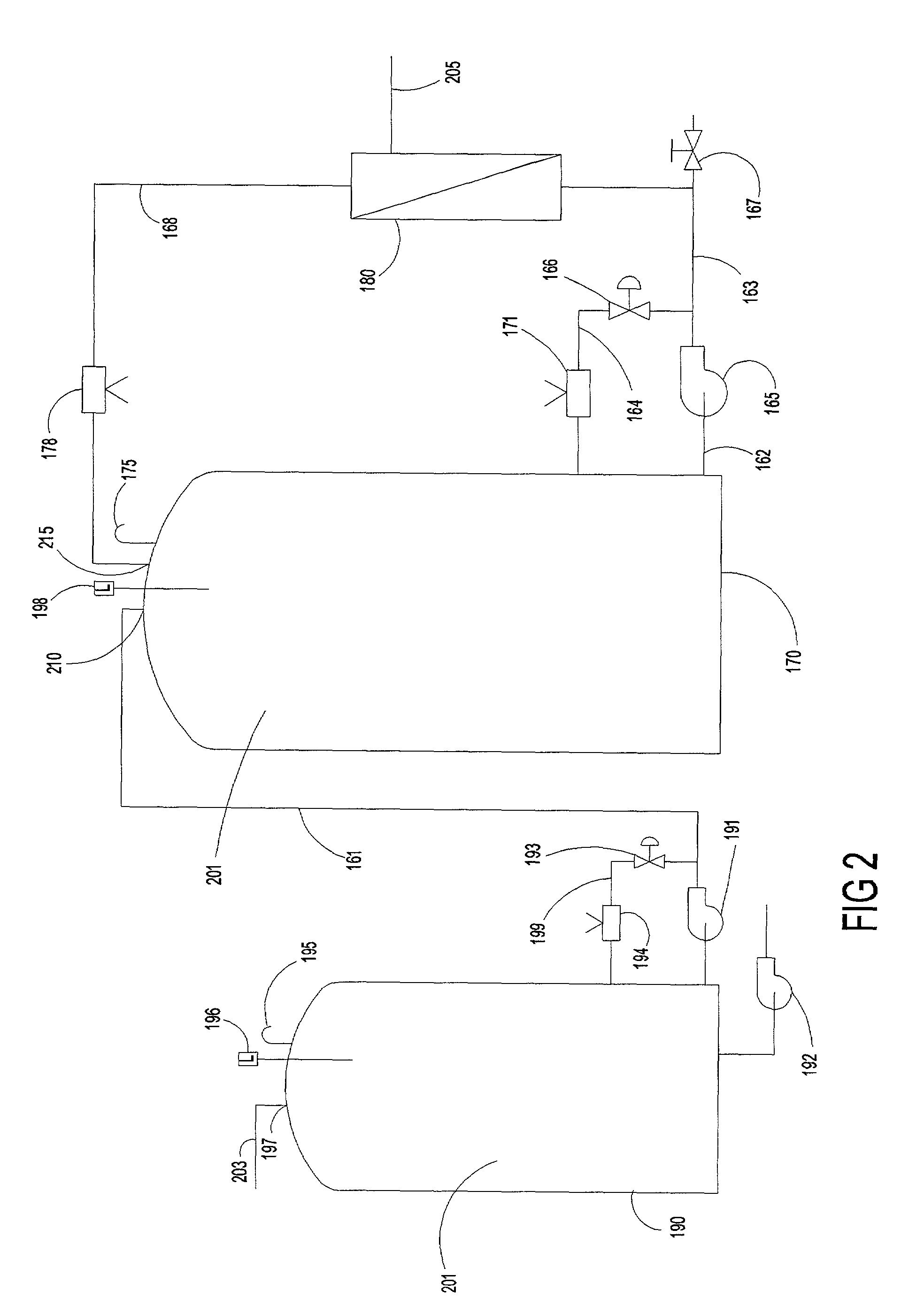

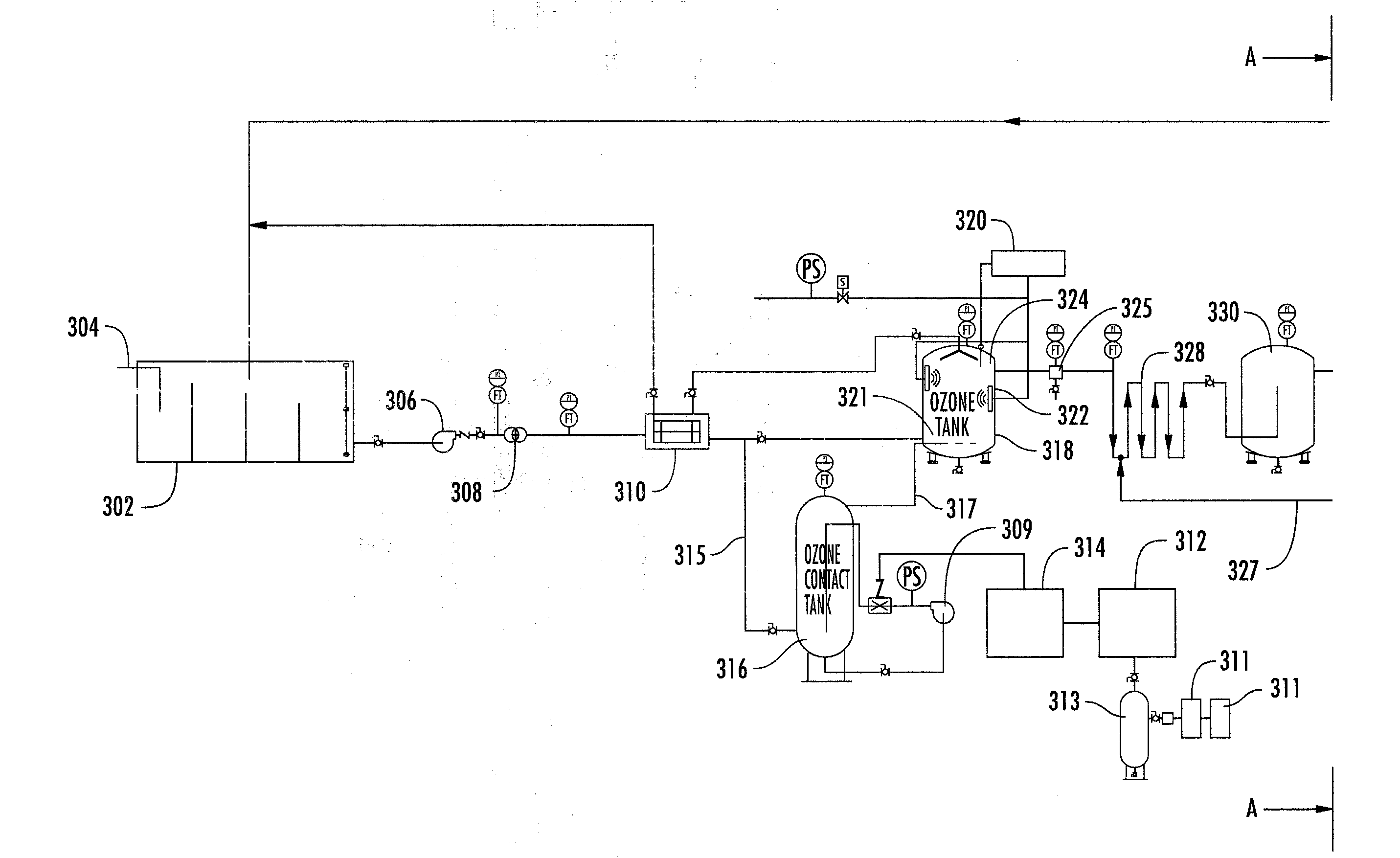

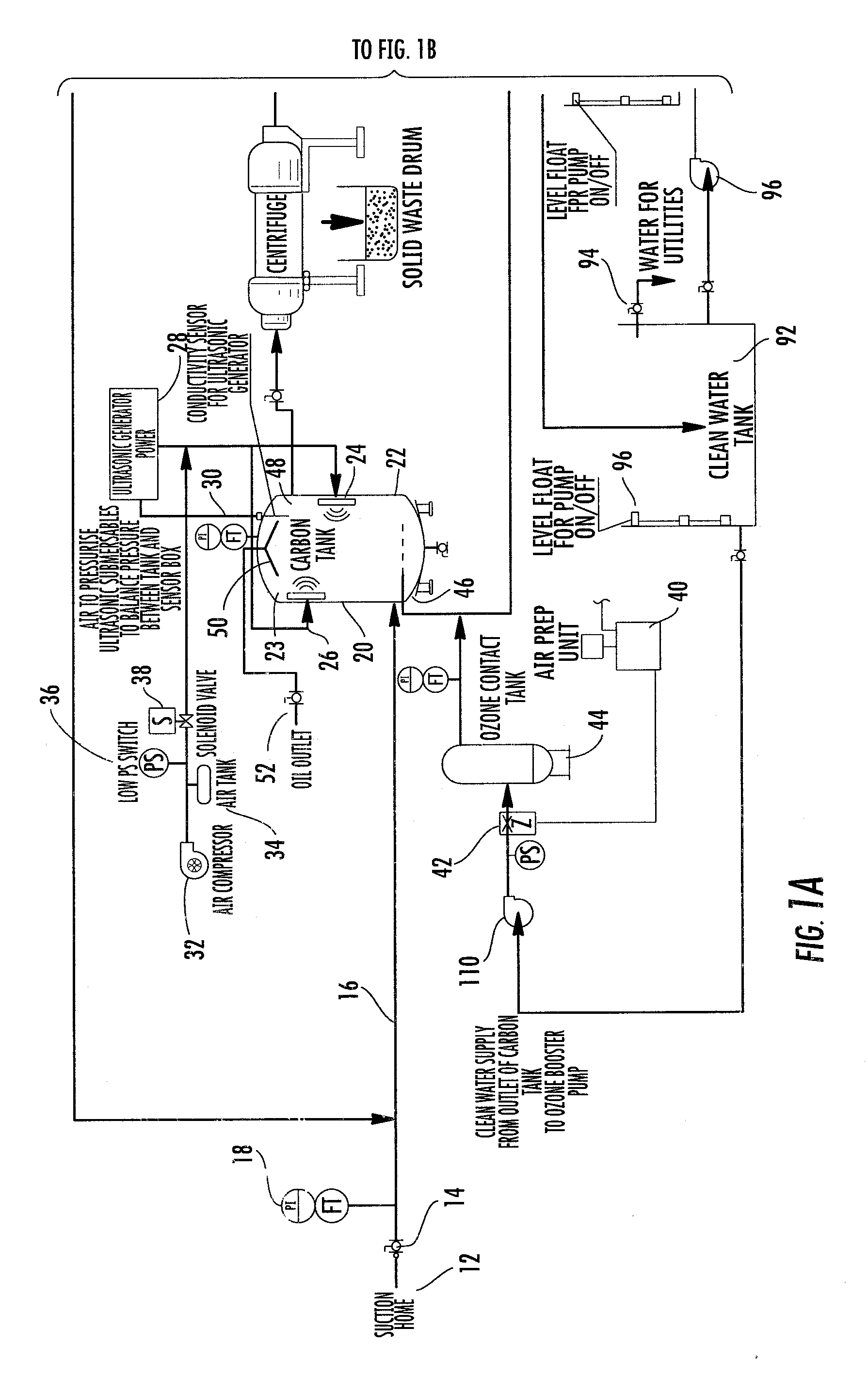

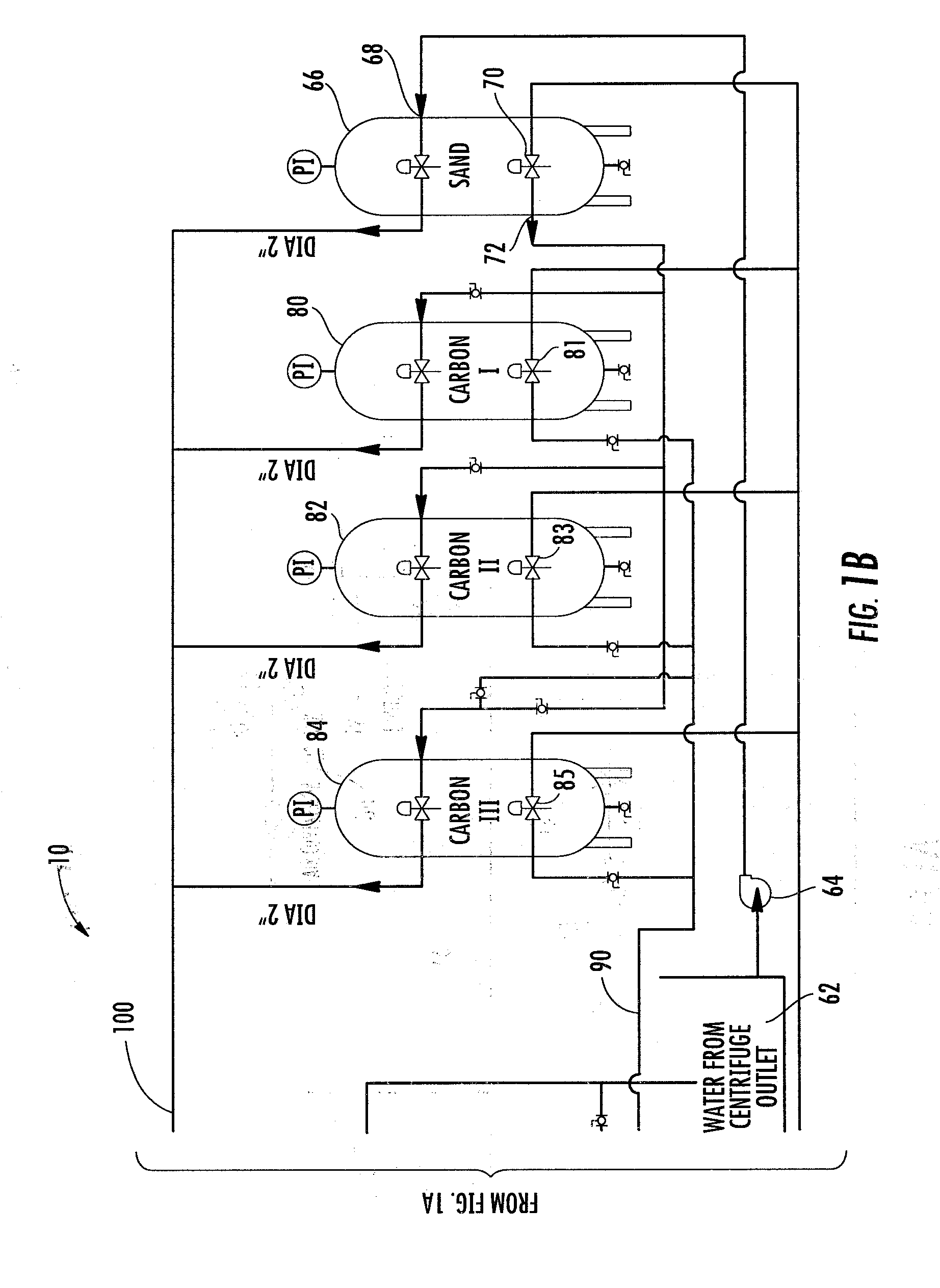

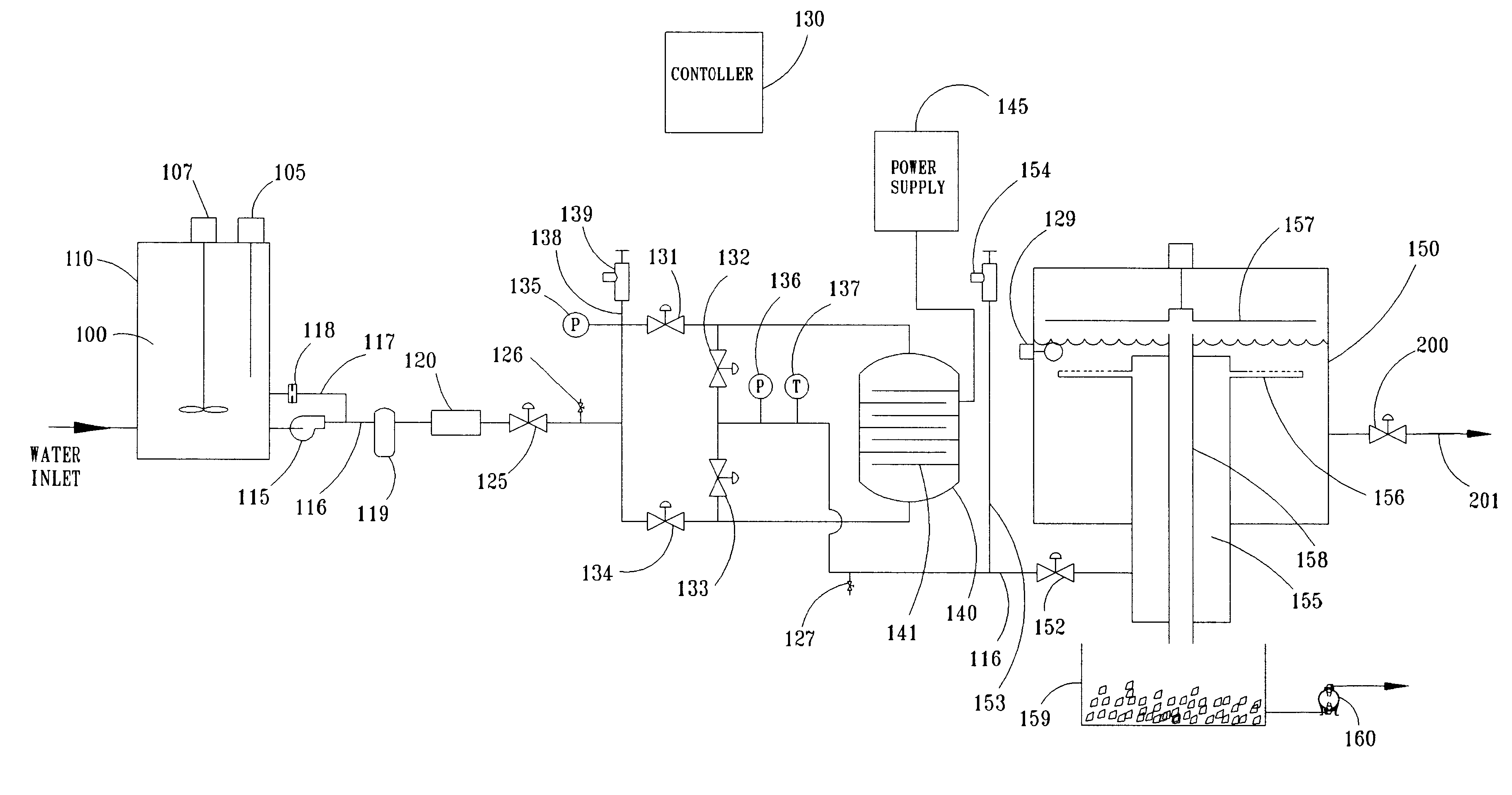

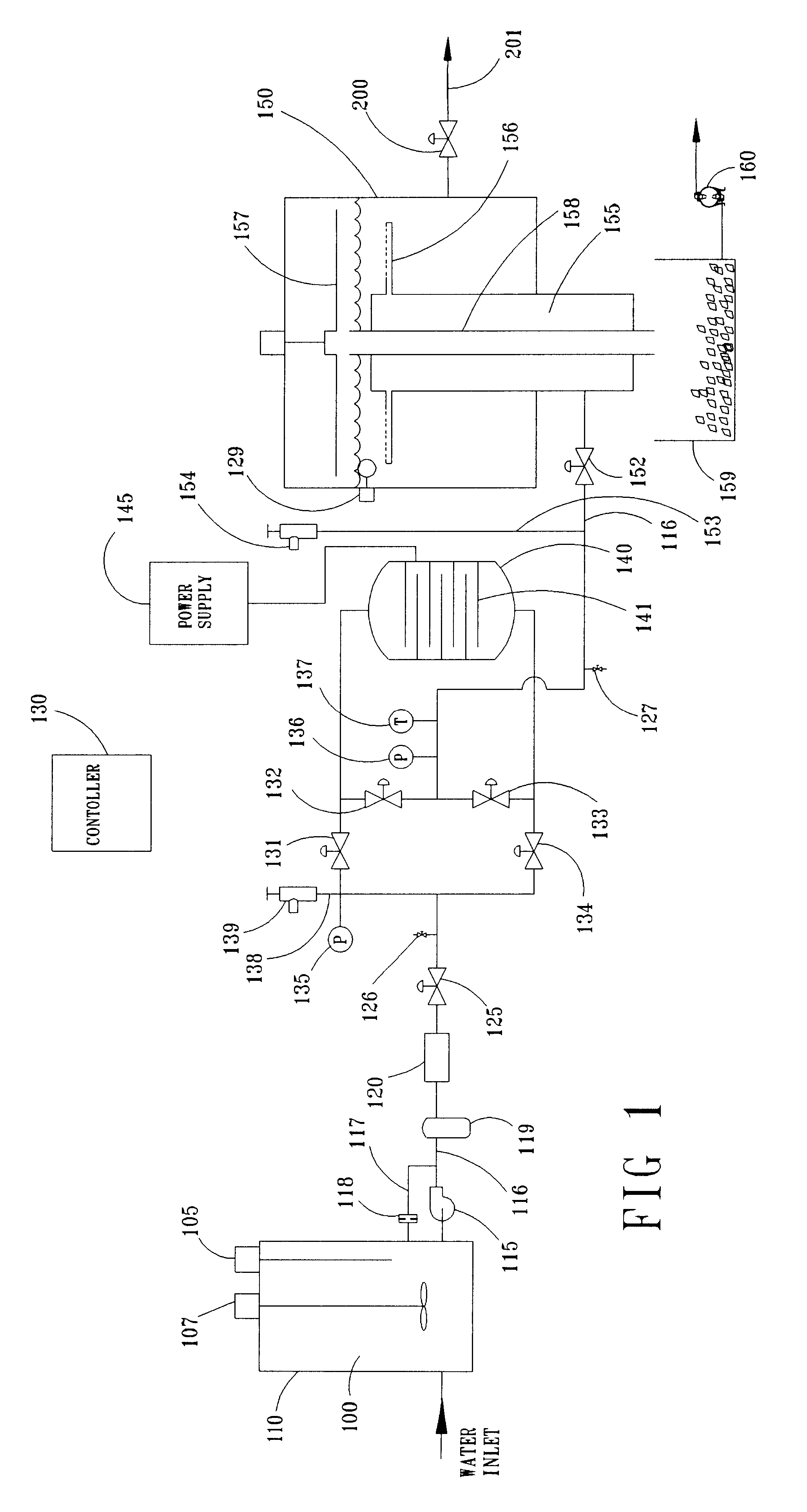

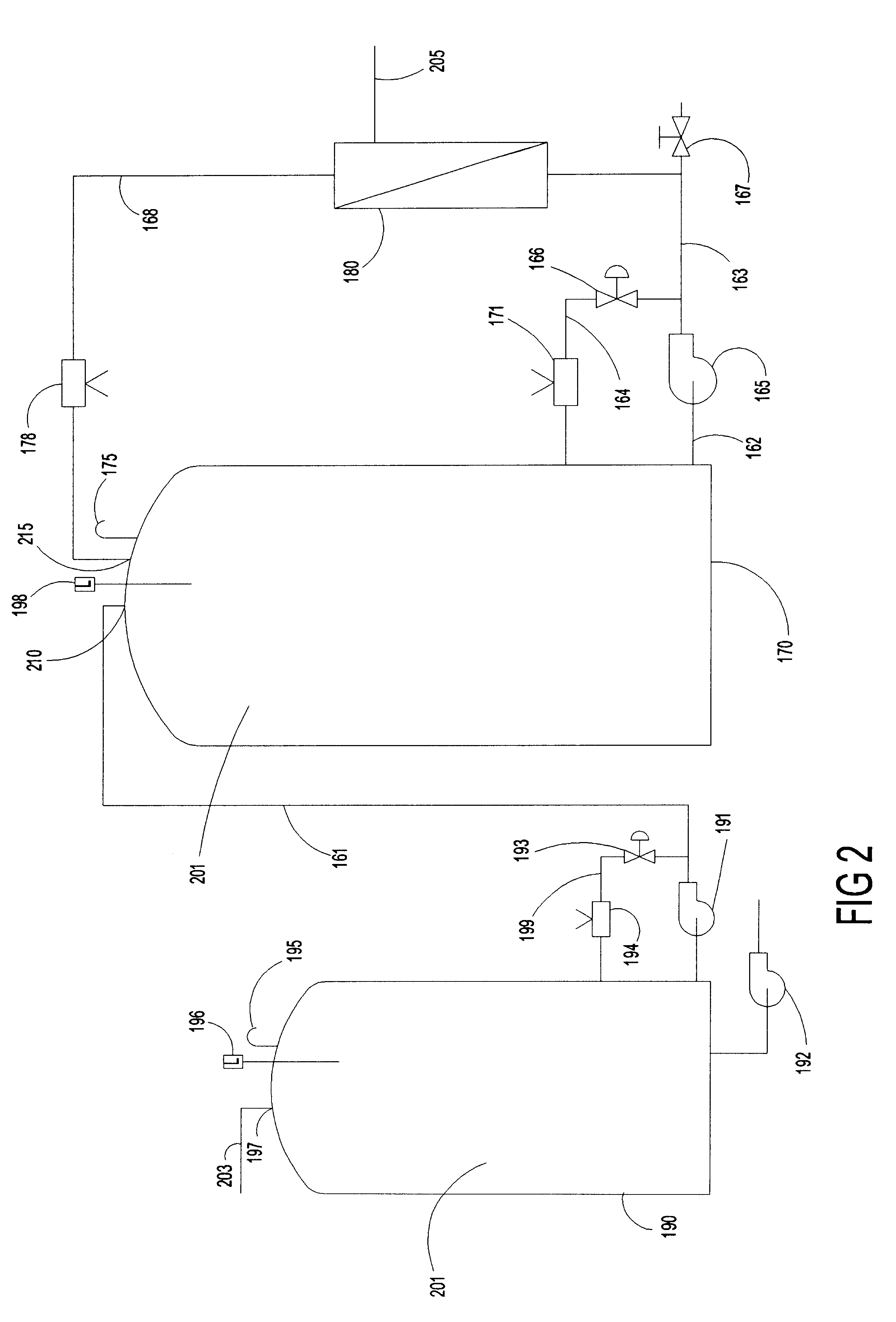

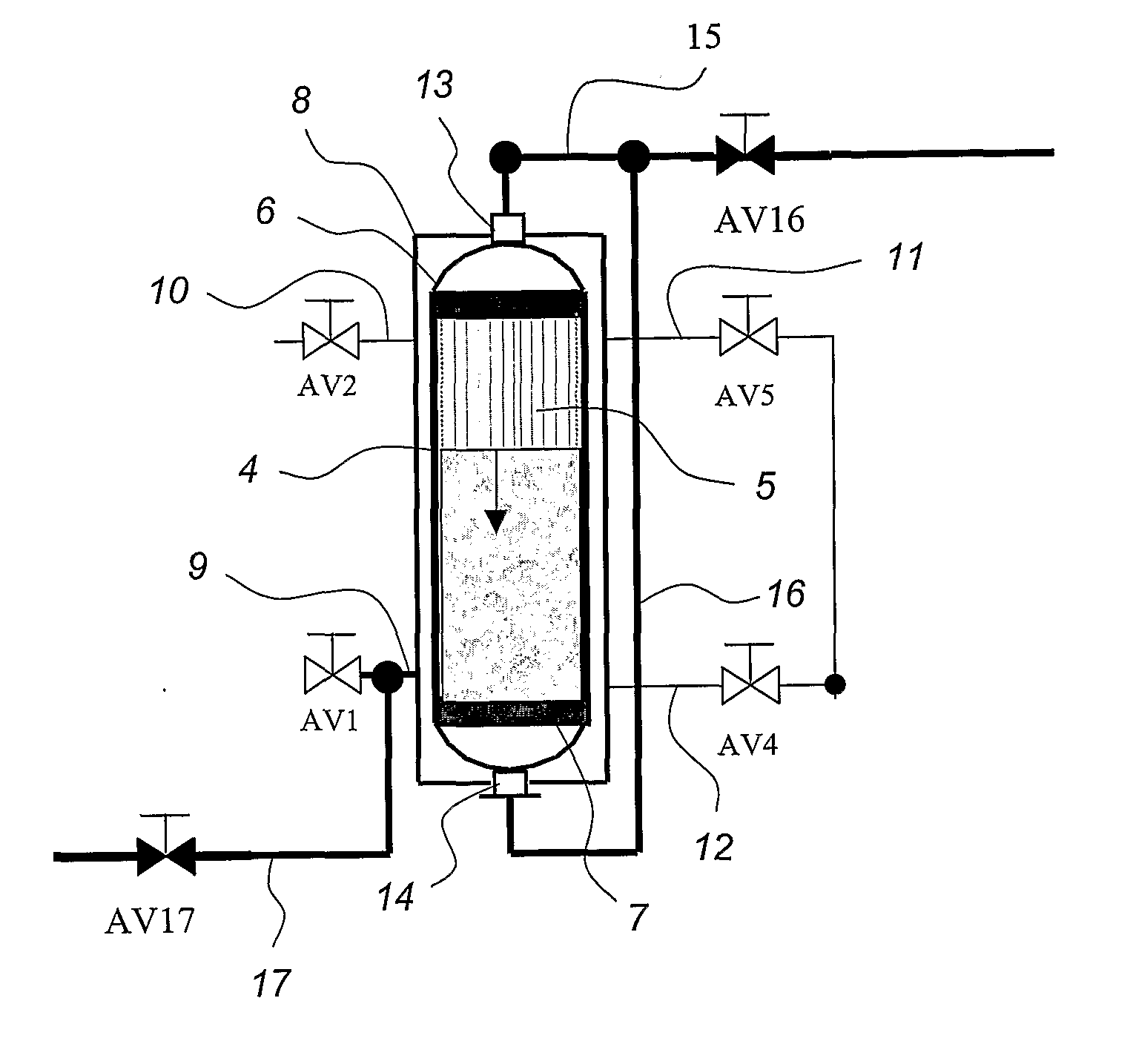

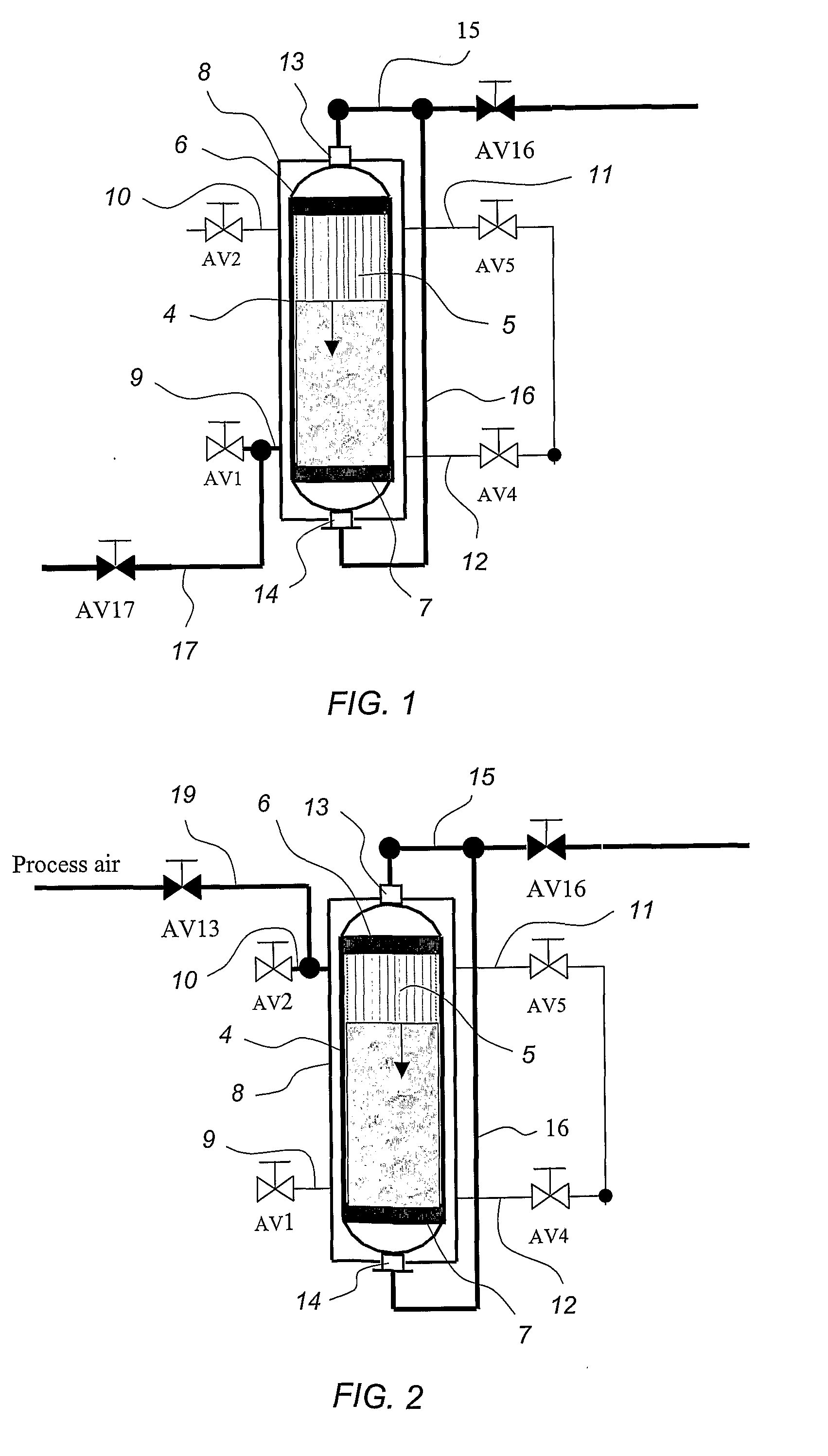

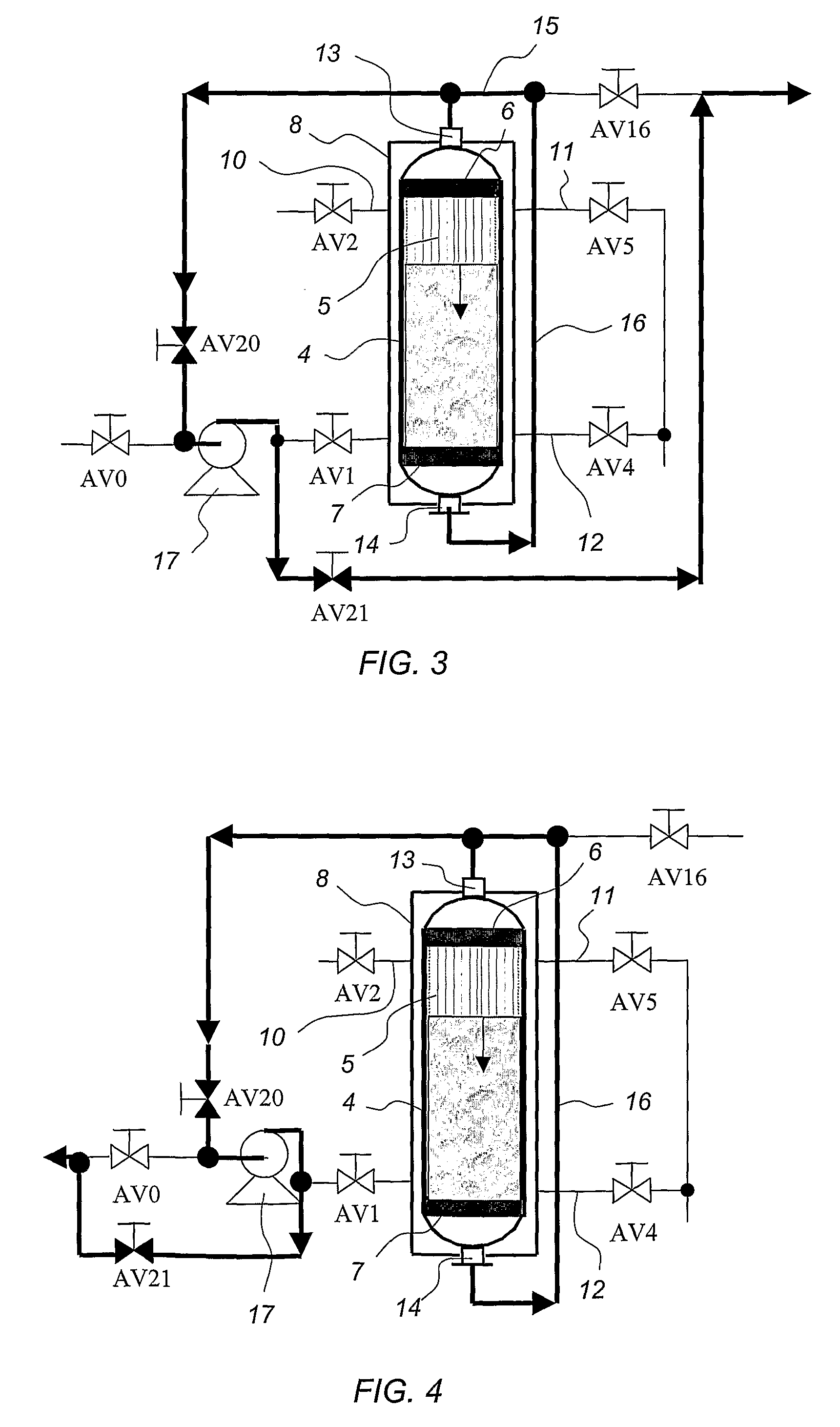

Enhanced water treatment for reclamation of waste fluids and increased efficiency treatment of potable waters

ActiveUS20090050572A1Low costCurrent expensiveWaste water treatment from quariesTreatment involving filtrationLiquid wastePotable water

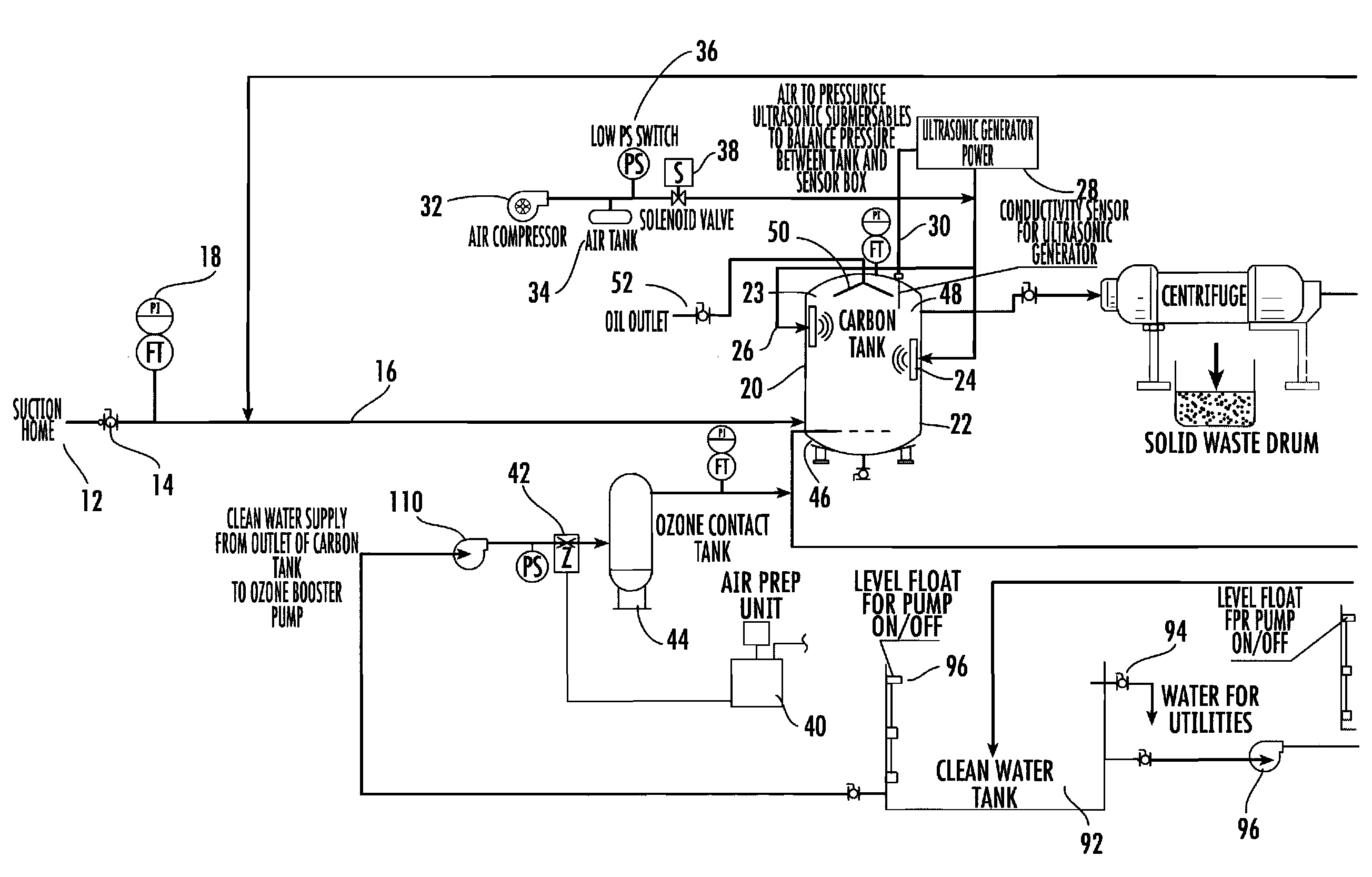

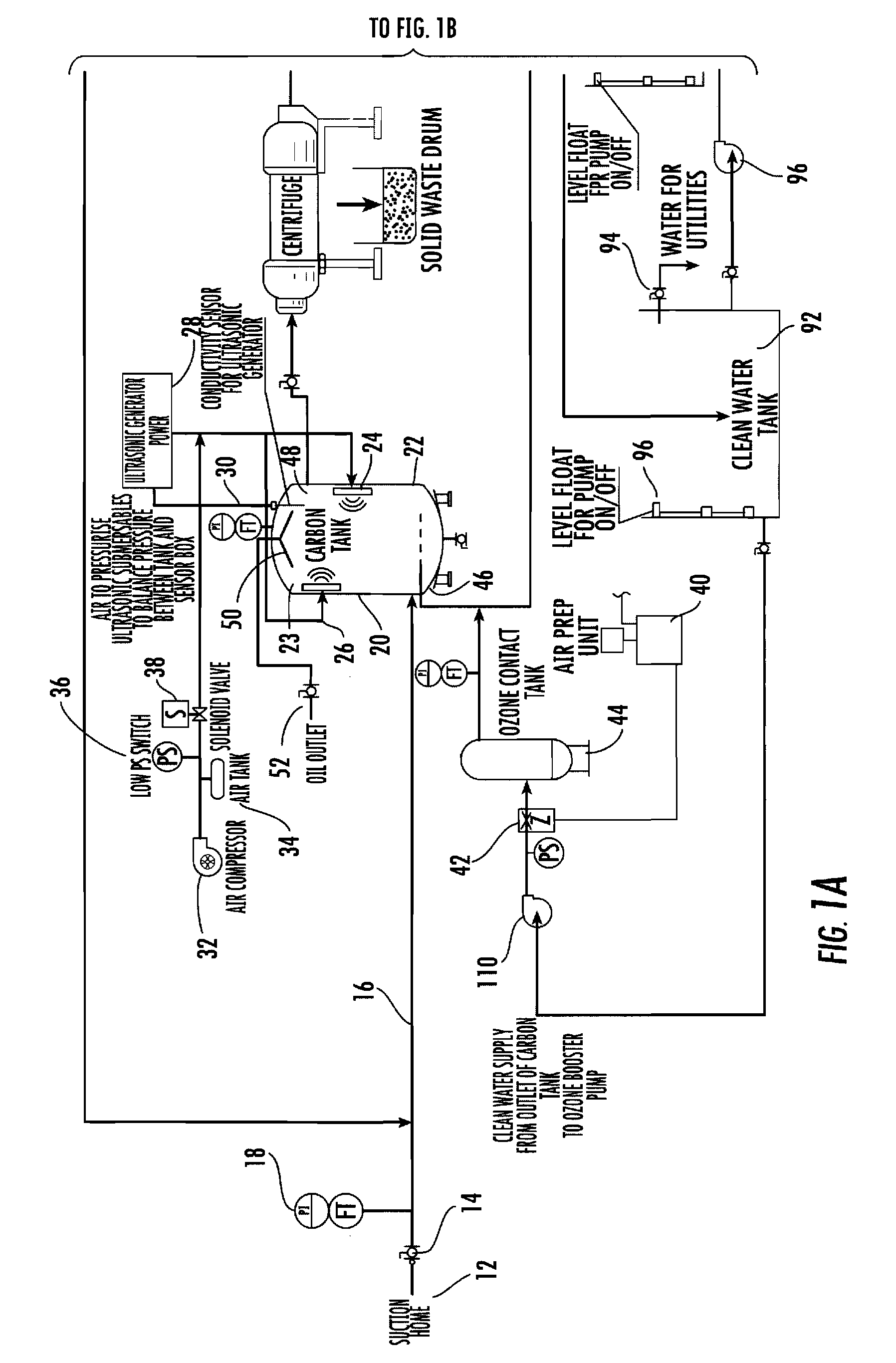

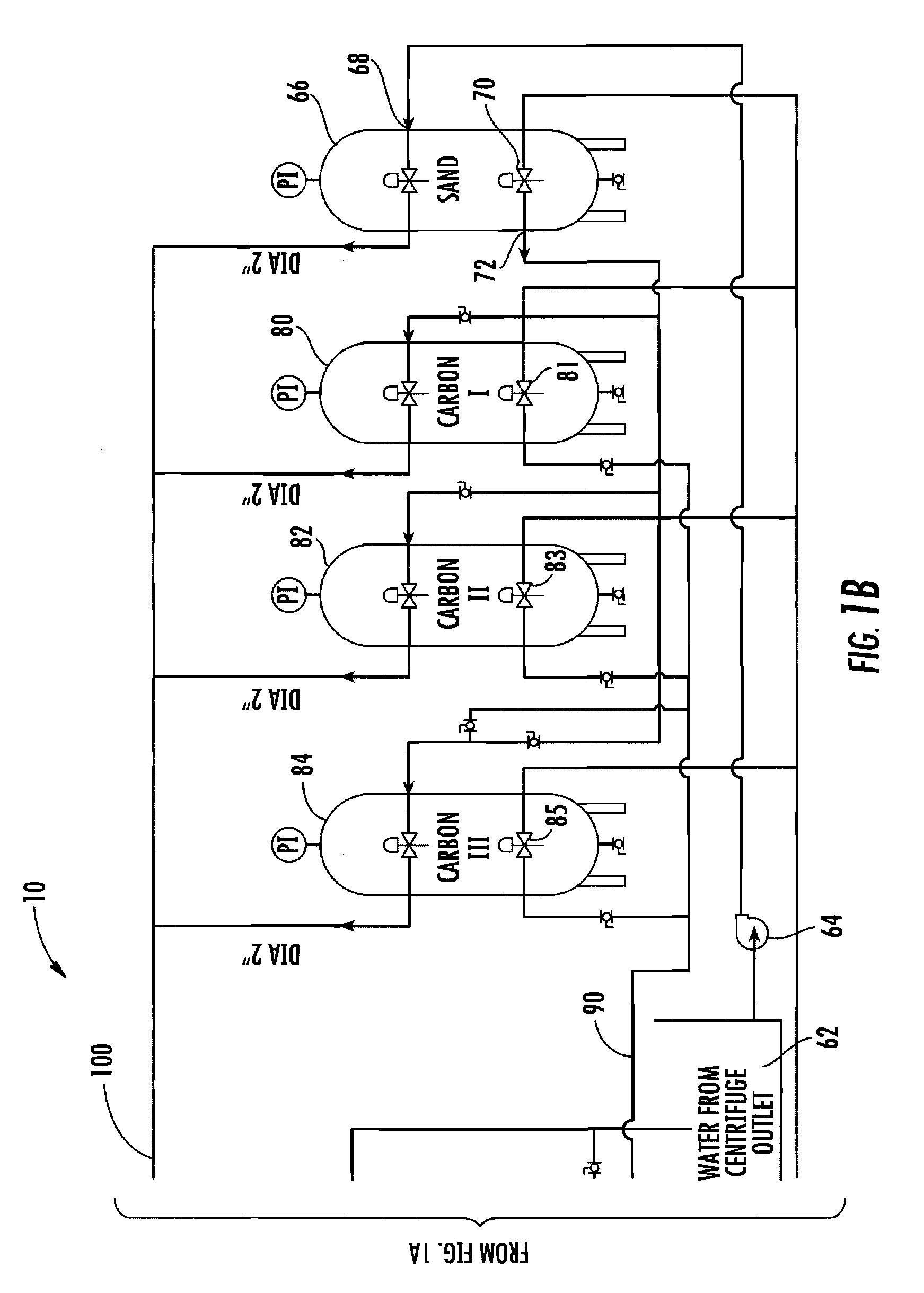

Disclosed is a process for reclamation of waste fluids. A conditioning container is employed for receipt of waste material on a continuous flow for treatment within the container by immersible transducers producing ultrasonic acoustic waves in combination with a high level of injected ozone. The treated material exhibits superior separation properties for delivery into a centrifuge for enhanced solid waste removal. The invention discloses a cost efficient and environmentally friendly process and apparatus for cleaning and recycling of flowback, or frac water, which has been used to stimulate gas production from shale formations. The apparatus is mobile and containerized and suitable for installation at the well site.

Owner:BRISBEN WATER SOLUTIONS

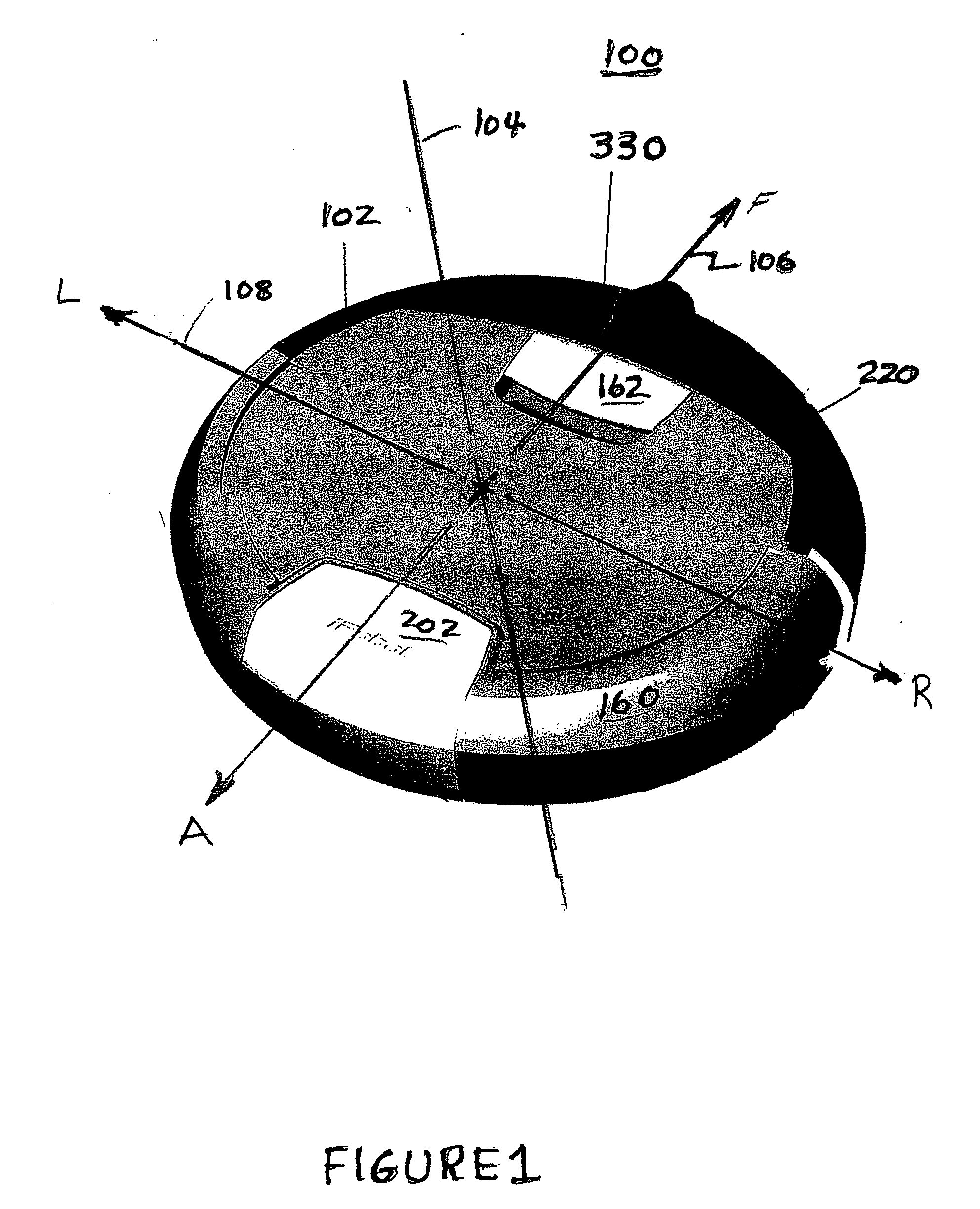

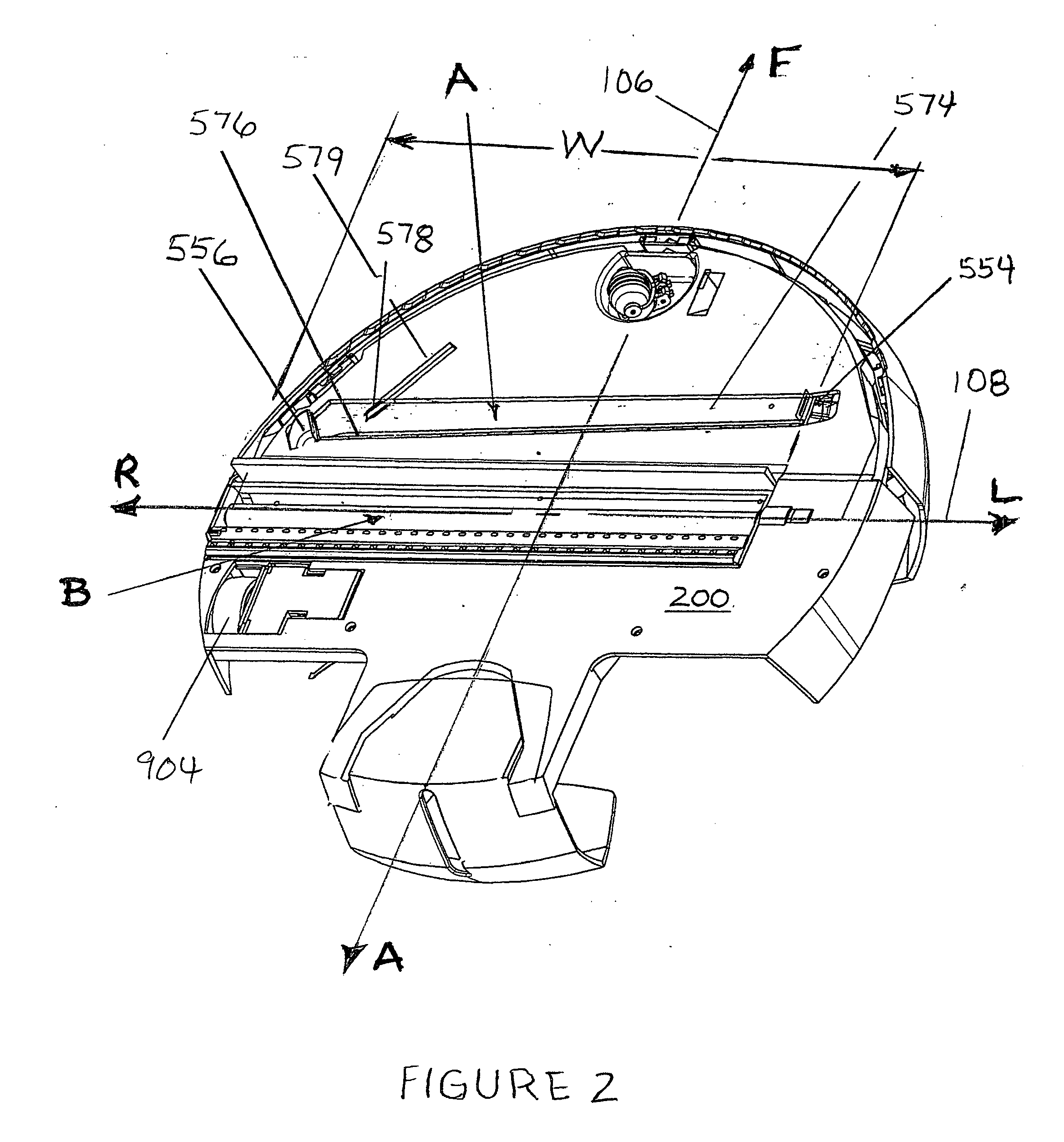

Autonomous surface cleaning robot for wet cleaning

InactiveUS20060184293A1Low costAffordable for home useCarpet cleanersFloor cleanersLiquid wasteSurface cleaning

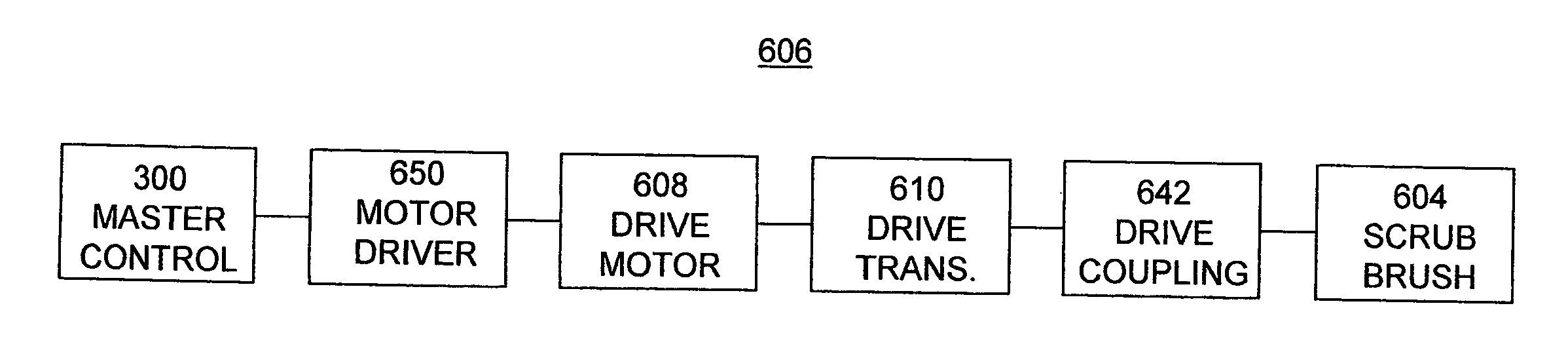

An autonomous floor cleaning robot includes a transport drive and control system arranged for autonomous movement of the robot over a floor for performing cleaning operations. The robot chassis carries cleaning elements arranged to spray a liquid cleaning fluid onto the cleaning surface across a cleaning width. The cleaning fluid mixes with contaminated on the floor, which become emulsified or otherwise mixed with the cleaning fluid. The robot further include cleaning elements configured to suction up waste materials and particularly the liquid waste material generated by the mixing of the cleaning fluid and contaminates.

Owner:IROBOT CORP

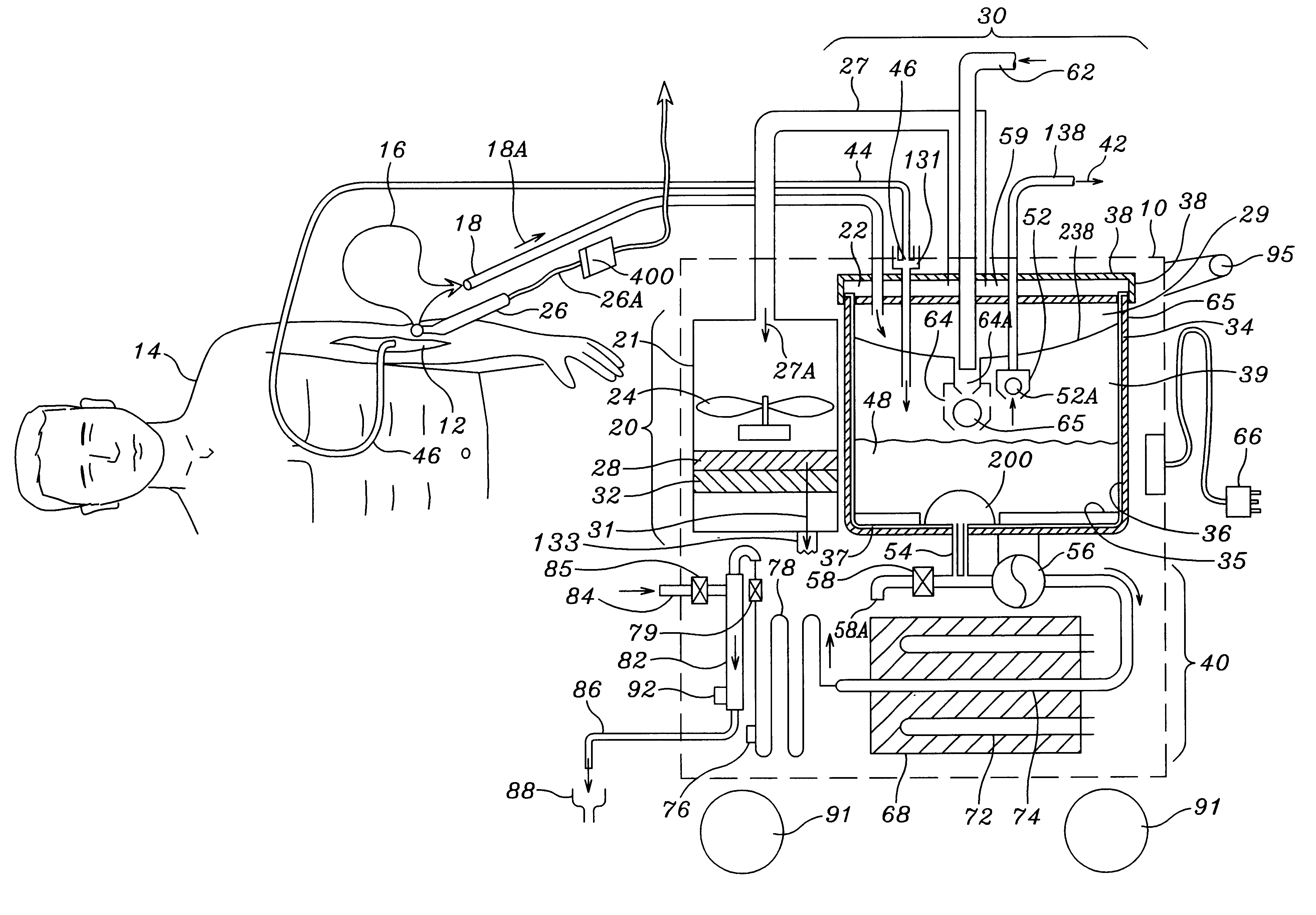

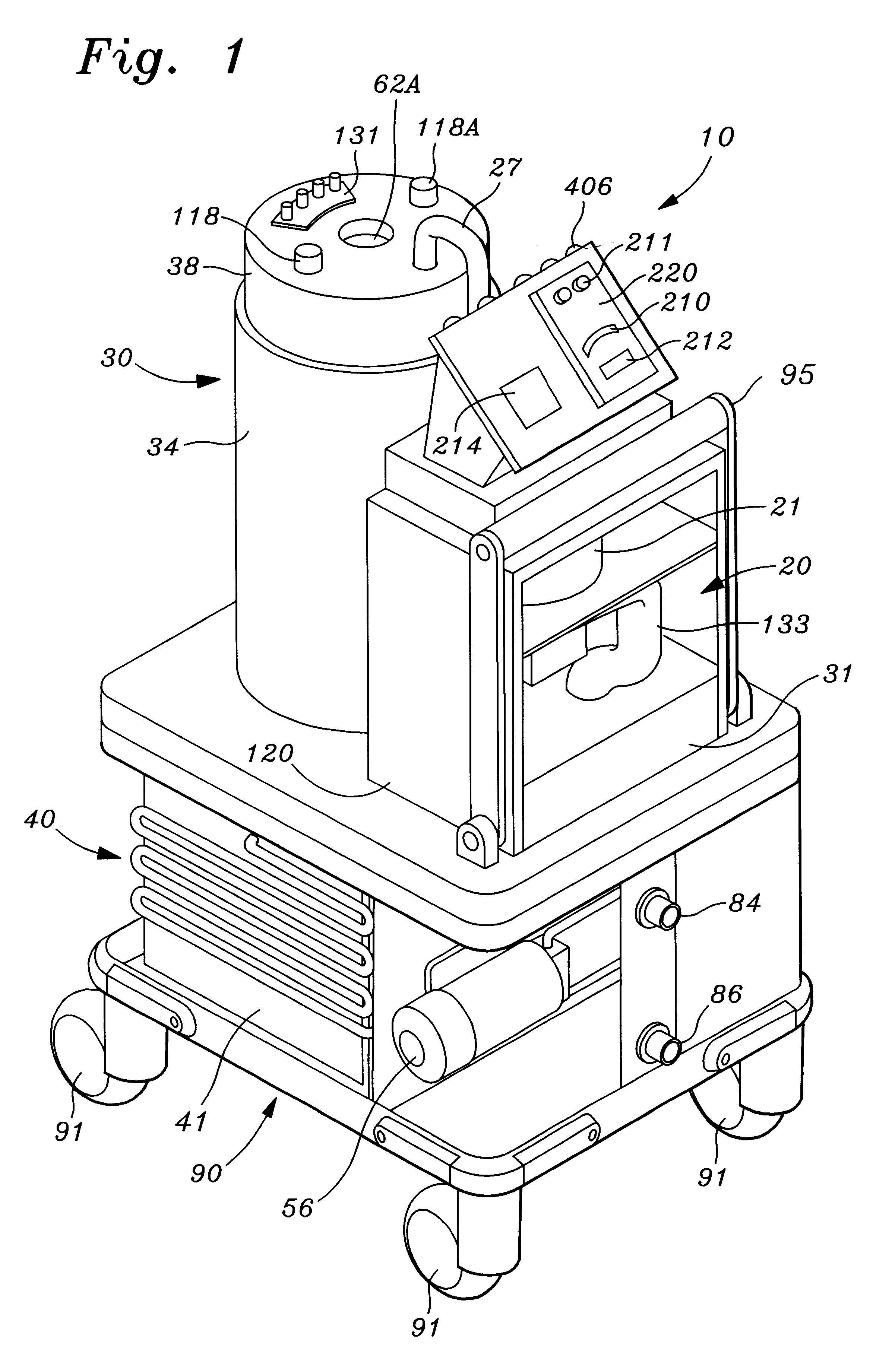

Surgical waste liquid and smoke disposal system

InactiveUS6180000B1Quickly and easily and efficiently maintain integrity of surgical siteLow efficiencyLiquid separation auxillary apparatusCombination devicesLiquid wasteCollection system

A waste liquid and smoke disposal system which combines the functions of a smoke extraction system and a waste (typically, liquid) collection system, typically in, but not limited to, a surgical environment. The smoke extraction system and the liquid waste collection system are connected to supply the waste materials collected thereby to a waste treatment (e.g. decontamination and / or sterilization) and disposal system. In a preferred embodiment, the waste treatment system includes a plurality of heat exchanger units for efficient controlling of the temperature of the waste material during the waste treatment process. These three systems are all combined into a integrated system wherein the treated waste can be safely returned to the ambient. In one embodiment, the system is provided as a cart-mounted apparatus to provide mobility.

Owner:STRYKER CORP

Process for electrocoagulating waste fluids

An electrocoagulation process for removing organic and metal contaminants from a pressurized waste fluid is disclosed in which a clarified waste fluid is produced when the pressure is released.

Owner:GAVREL TOM G +1

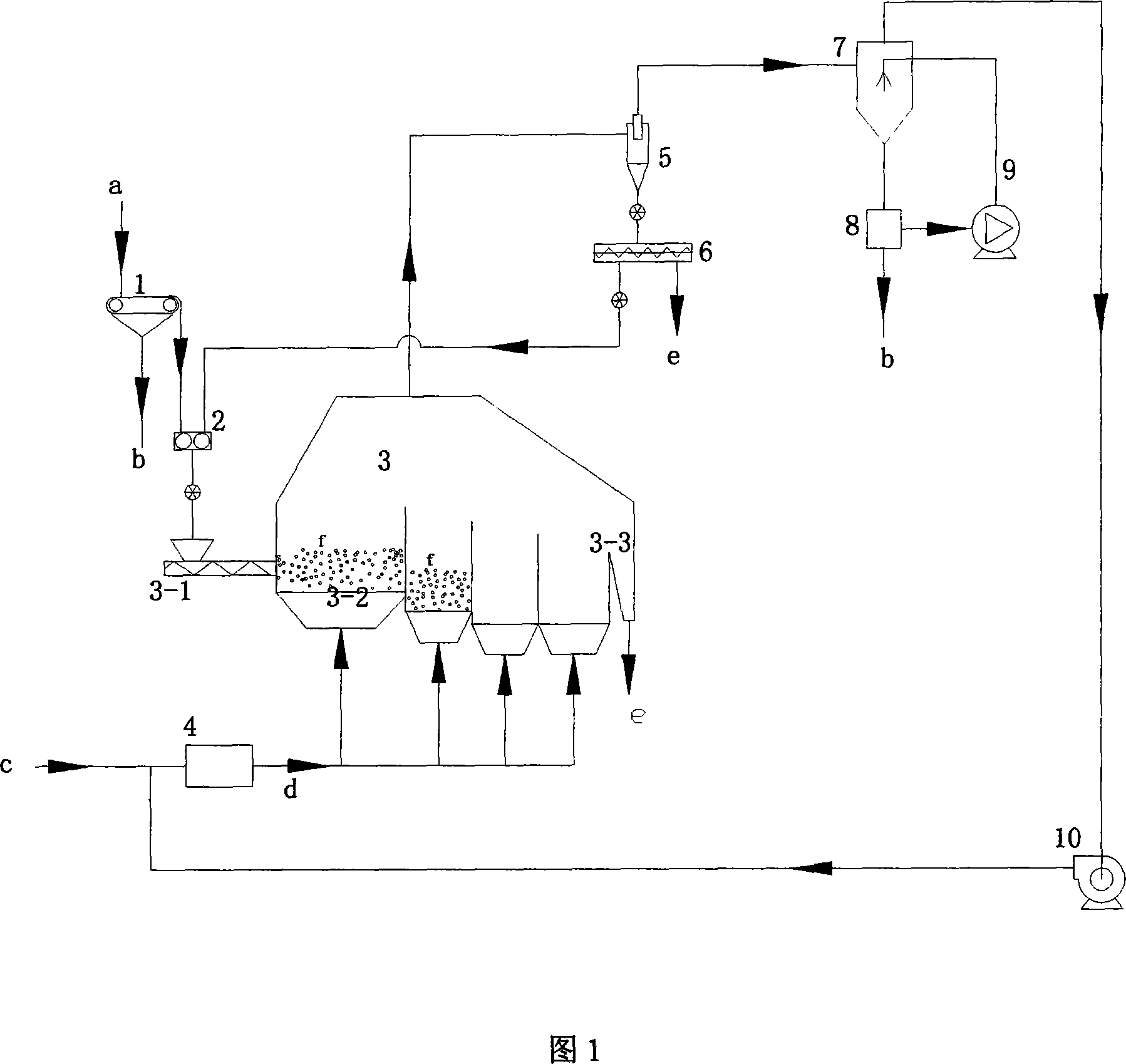

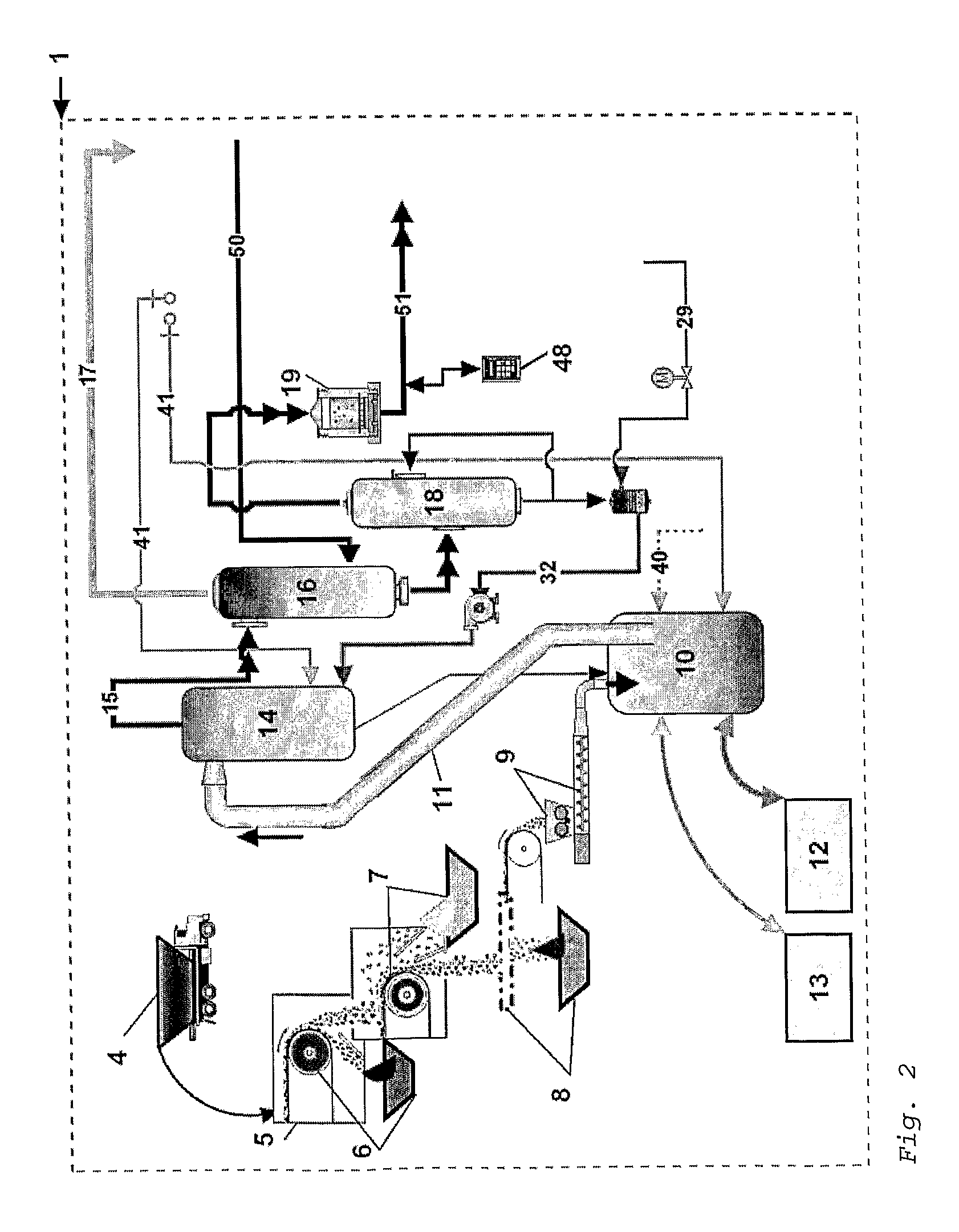

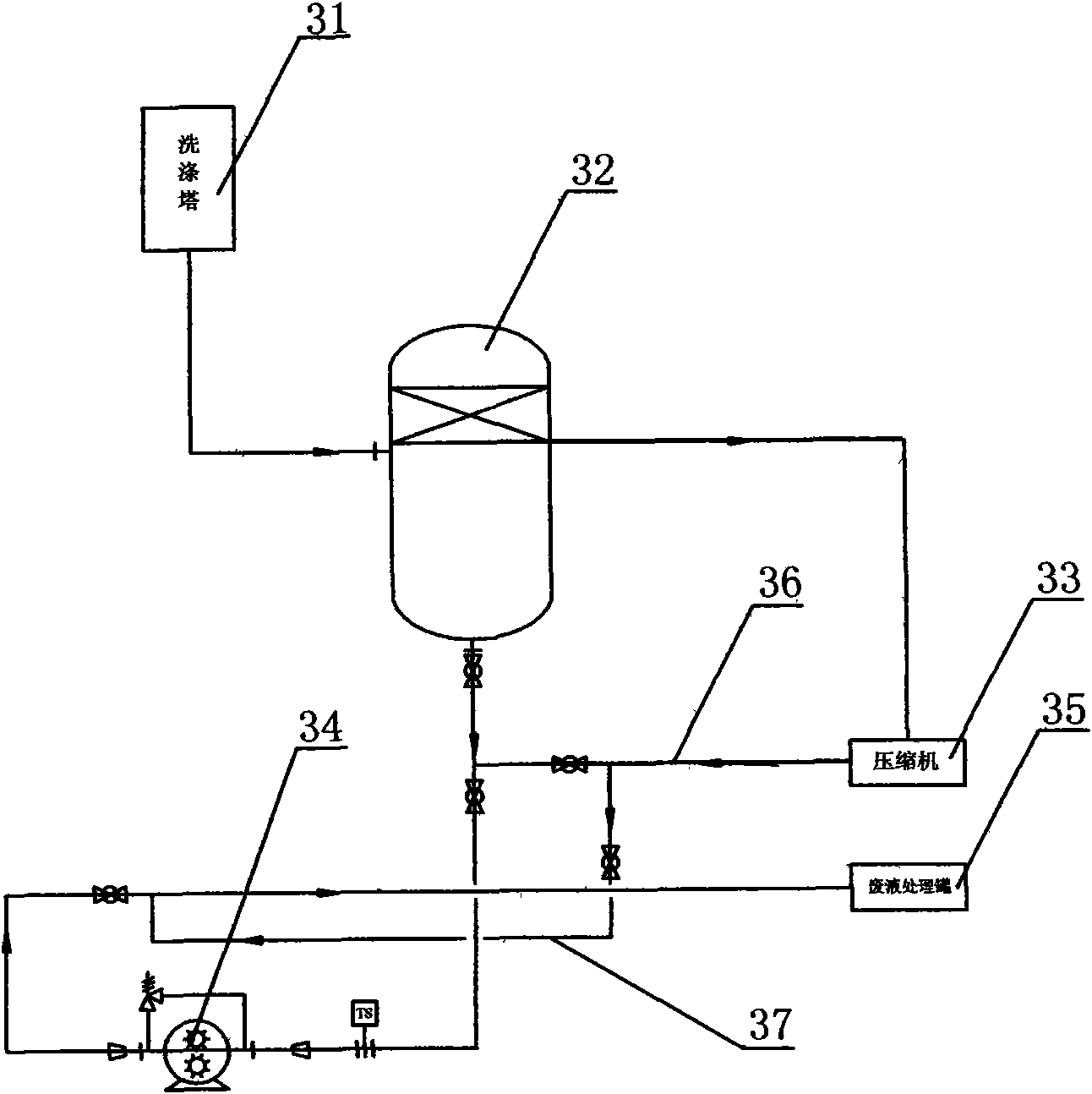

Enclosed multi-chamber fluidized bed drying method for sludge

InactiveCN101186422AUniform humidityReduce breakageSludge treatment by de-watering/drying/thickeningLiquid wasteFluidized bed drying

A closed multi-room fluidized bed sludge drying method is provided, which is a sludge drying method having the advantages of simple equipment structure, convenient operation, strong sludge adaptability, high thermal efficiency, safety, continuity, stability, etc. After the mechanically dewatered sludge is mixed with the back-mixed sludge, the mixture is dried room by room in an inert particles multi-room fluidized bed dryer (3). The first room and the second room of the inert particles multi-room fluidized bed dryer (3) adopt inert particles (f) as heat storage medium. Gas from a cyclone separator (5) goes through a spray tower (7) and returns into an air heating unit (4) through a circulating fan (10). Part of dried sludge (e) at the lower part of the cyclone separator (5) enters the inert particles multi-room fluidized bed dryer (3) through the back-mixing in a mixer (2). Waste liquid from the bottom of the spray tower (7) enters a waste liquid circulating pool (8), with part of waste liquid circulating into the spray tower (7) and part into a sewage treatment system.

Owner:SOUTHEAST UNIV

Enhanced water treatment for reclamation of waste fluids and increased efficiency treatment of potable waters

ActiveUS20090230059A1Low costCurrent expensiveSolid sorbent liquid separationSedimentation separationLiquid wastePotable water

Disclosed is a process for reclamation of waste fluids. A conditioning container is employed for receipt of waste material on a continuous flow for treatment within the container by immersible transducers producing ultrasonic acoustic waves in combination with a high level of injected ozone. The treated material exhibits superior separation properties for delivery into a centrifuge for enhanced solid waste removal. The invention discloses a cost efficient and environmentally friendly process and apparatus for cleaning and recycling of flowback, or frac water, which has been used to stimulate gas production from shale formations. The apparatus is mobile and containerized and suitable for installation at the well site.

Owner:BRISBEN WATER SOLUTIONS

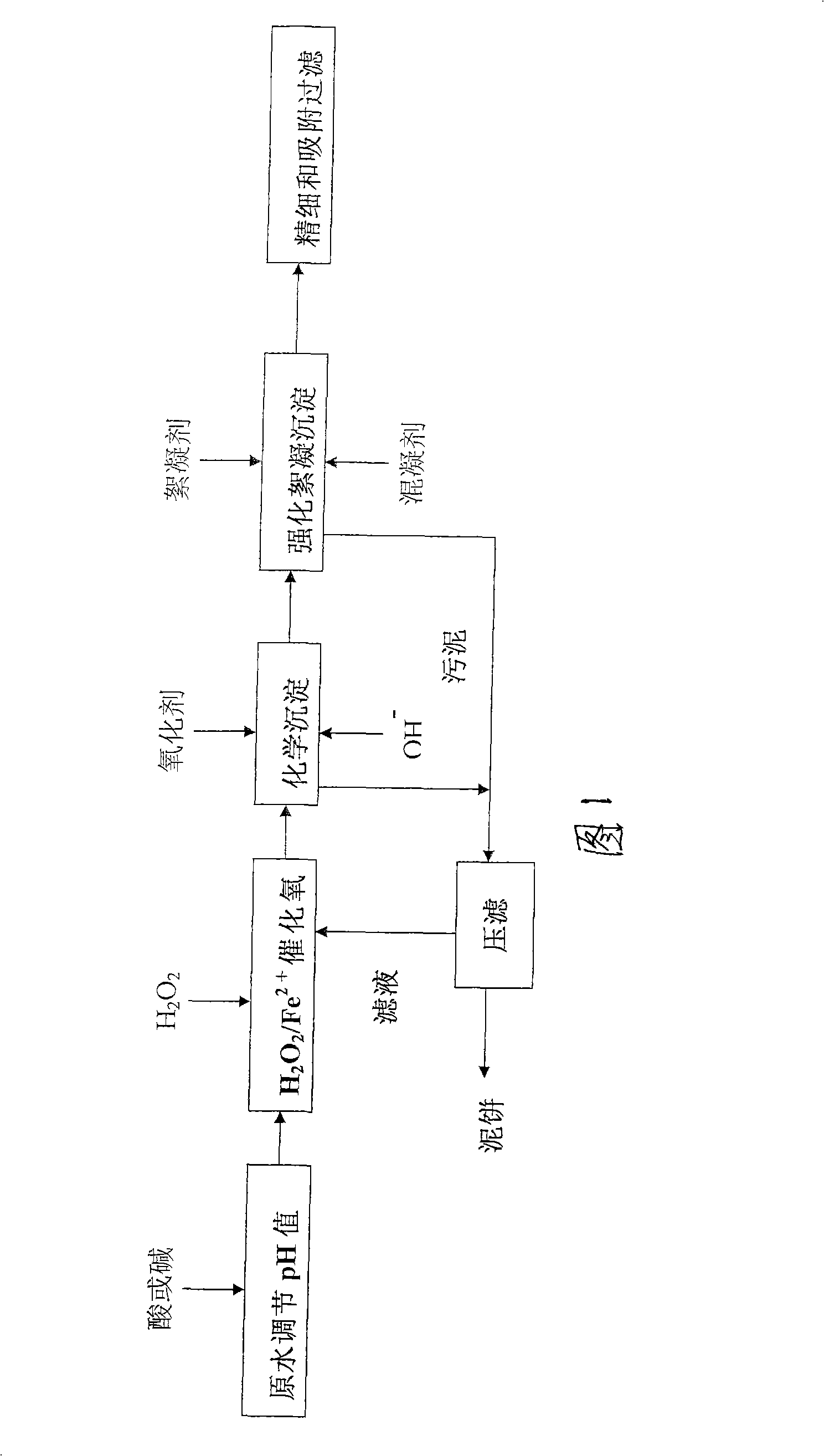

Method for processing oil-gas field fracturing waste liquor

ActiveCN101302065AMultistage water/sewage treatmentWater/sewage treatment by neutralisationLiquid wasteBrick

The invention provides a method for treating fracturing waste fluid in an oil-gas field, belonging to the oil-gas field waste fluid treatment technology, which overcomes the problems existed in other methods. The process steps of the method are as follows: the water quality achieves a recirculation standard or accords with the II grade discharge standard of the integrated sewage discharge standard GB8978-1996, through technical treatments of raw water (pH) adjustment, H2O2 / Fe<2+> catalytic oxidation, chemical precipitation, enhanced flocculation and sedimentation, fine filter and adsorption filtration, and system settling sludge, then the settled sludge is subject to filter pressing and dehydrating, press filtrate returns to the front end for after-treatment, and mud cake is desiccated and manufactured into bricks for application or is treated through using the incinerating treatment technology. The method is an effective method for treating the fracturing waste fluid in the oil-gas field.

Owner:PUYANG TIANDIREN ENVIRONMENTAL PROTECTION TECH CO LTD

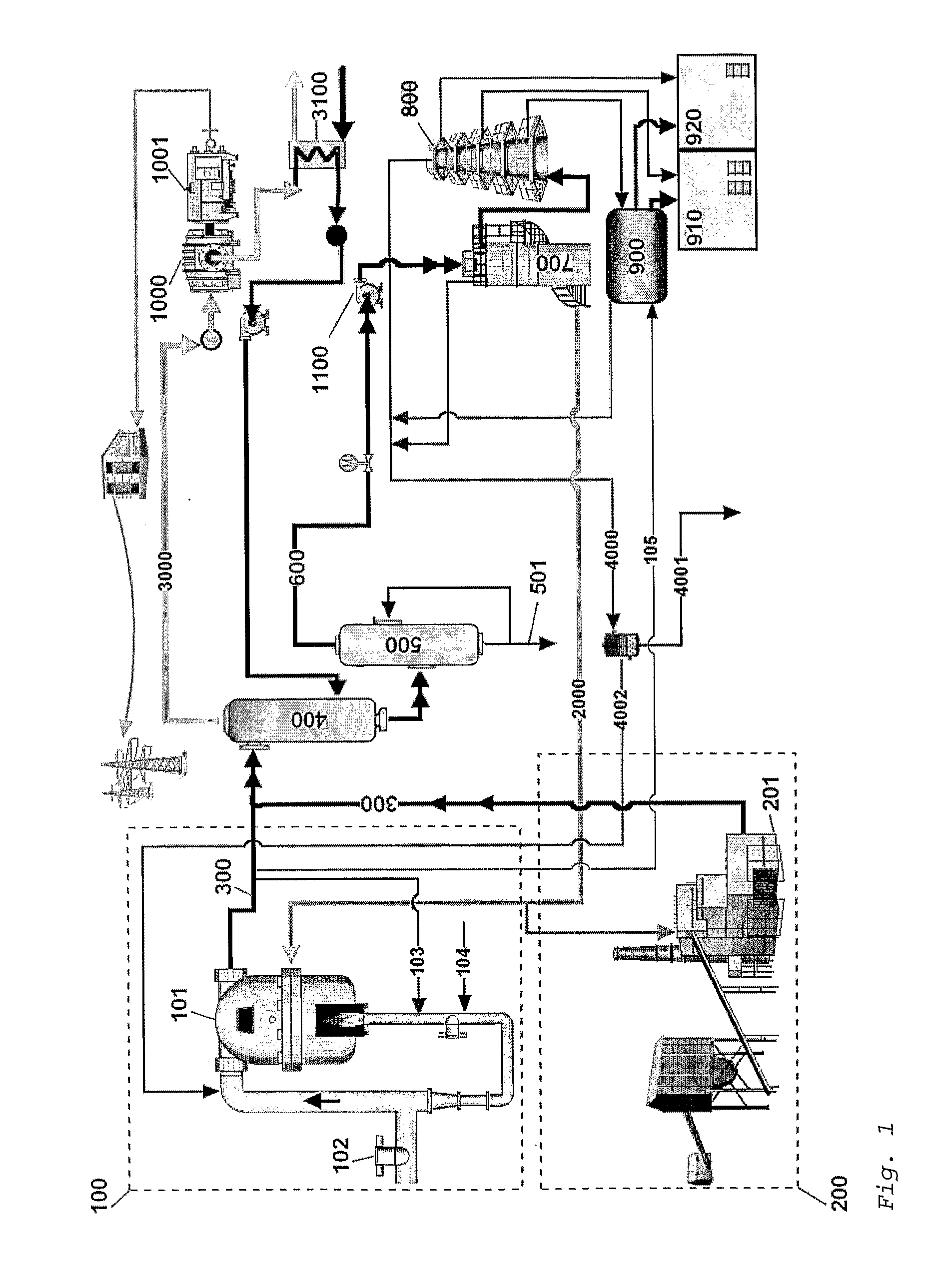

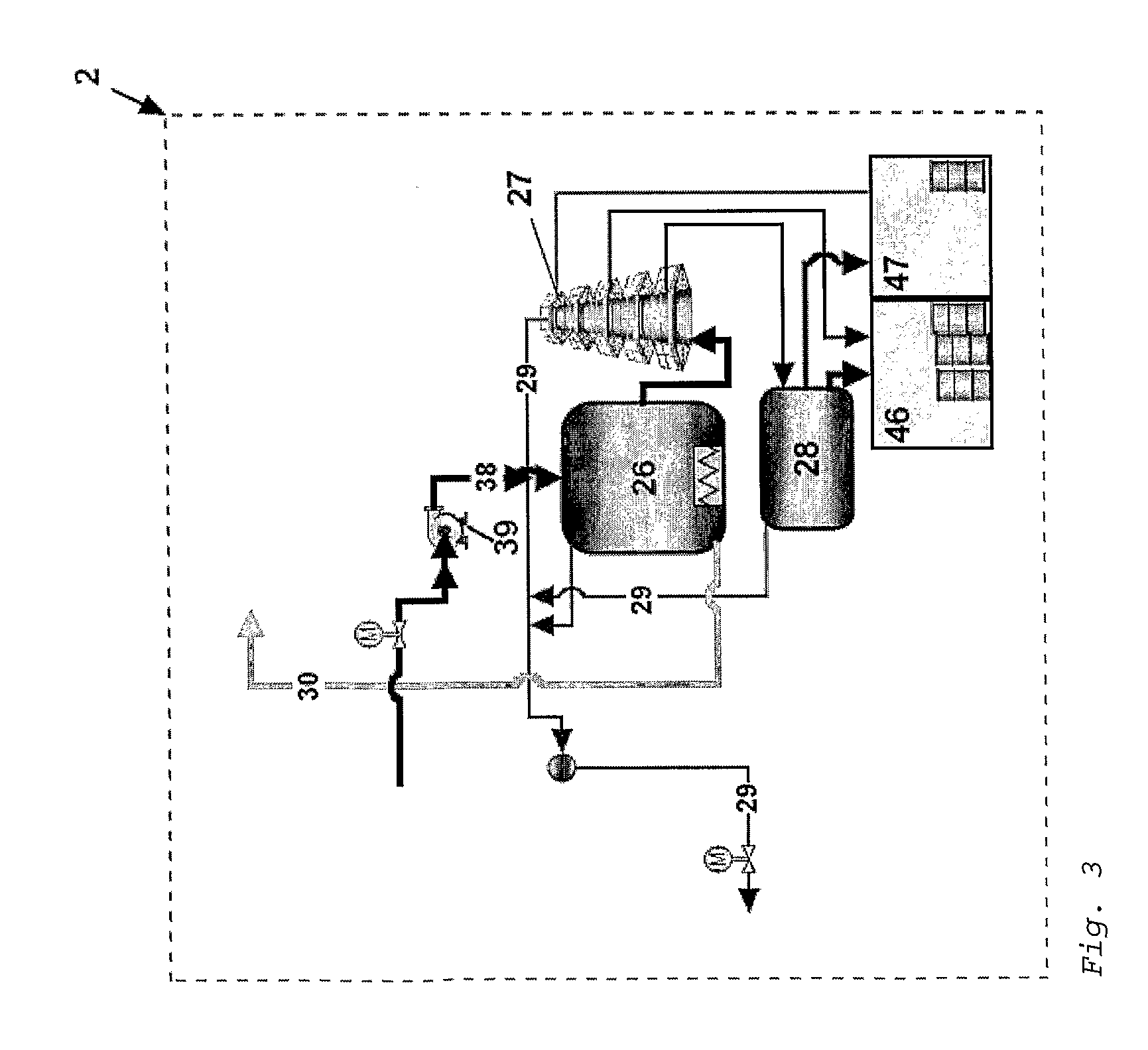

Waste to liquid hydrocarbon refinery system

InactiveUS20110158858A1Eliminate concernsReduce dependenceDirect heating destructive distillationCombustible gas catalytic treatmentLiquid wasteCogeneration

A Waste to Liquid Hydrocarbon Refinery System that transforms any municipal solid wastes and hazardous industrial wastes, Biomass or any carbon containing feedstock into synthetic hydrocarbon, particularly, but not exclusively, diesel and gasoline and / or electricity and co-generated heat, comprising three major subsystems: i) the Pyro-Electric Thermal Converter (PETC) (10) and Plasma Arc (PA) waste and biomass gasification subsystem (1); ii) the hydrocarbon synthesis subsystem (2); and iii) the electricity generation and heat co-generation subsystem (3).

Owner:ALVES RAMALHO GOMES MARIO LUIS

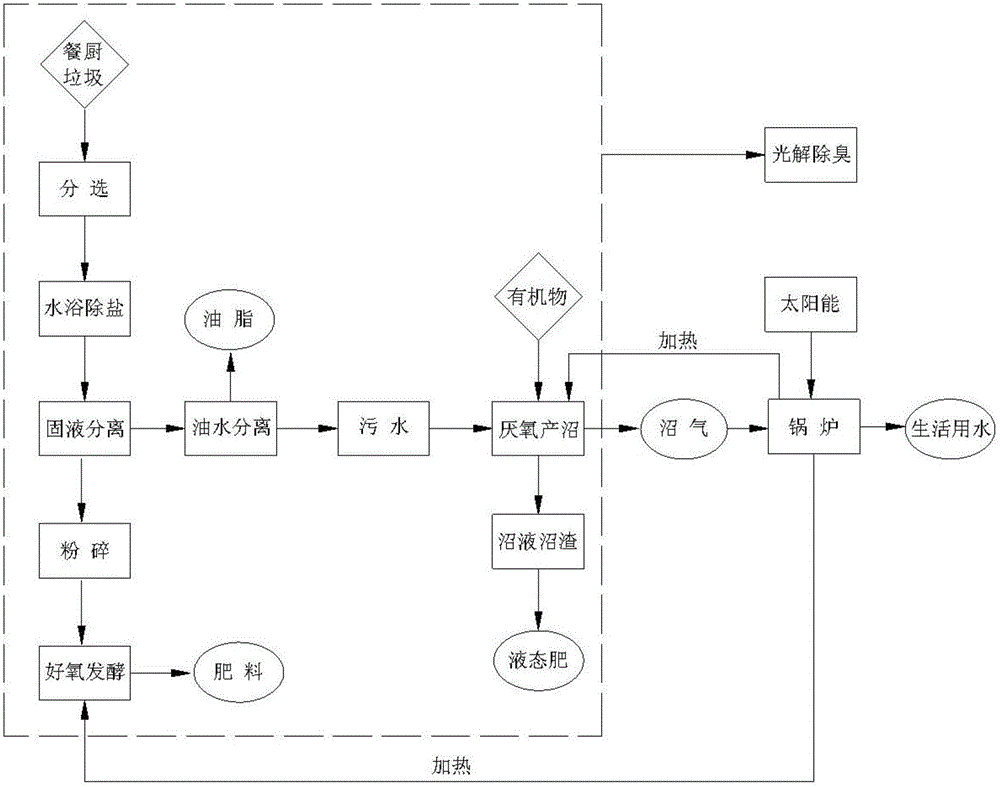

Resource-based and harmless treatment method for kitchen waste

InactiveCN104030738AEfficient removalGrowth inhibitionBio-organic fraction processingClimate change adaptationWater bathsLiquid waste

Relating to the technical field of resource recovery and recycling, the invention discloses a resource-based and harmless treatment method for kitchen waste. The method is directed at the problems of high salt content in fertilizer products, easy cause of soil salinization, and large equipment investment for anaerobic fermentation of total waste in existing kitchen waste treatment methods. The method comprises the steps of: (a) kitchen waste sorting; (b) water bath desalting: adding water, and conducting heating and stirring to dilute salt; (c) solid-liquid separation: dehydrating the waste; (d) solid material aerobic fermentation: crushing the dehydrated solid material into small particles, and conducting aerobic fermentation and drying treatment to obtain an organic fertilizer; and (e) waste liquid anaerobic fermentation: conducting oil-water separation on the waste liquid, recovering grease, subjecting sewage to anaerobic fermentation, making the produced biogas residue and biogas slurry into a liquid fertilizer, and taking the produced biogas as the fuel of a biogas boiler. The method provided by the invention is particularly suitable for resource-based and harmless treatment of kitchen waste.

Owner:习建华 +1

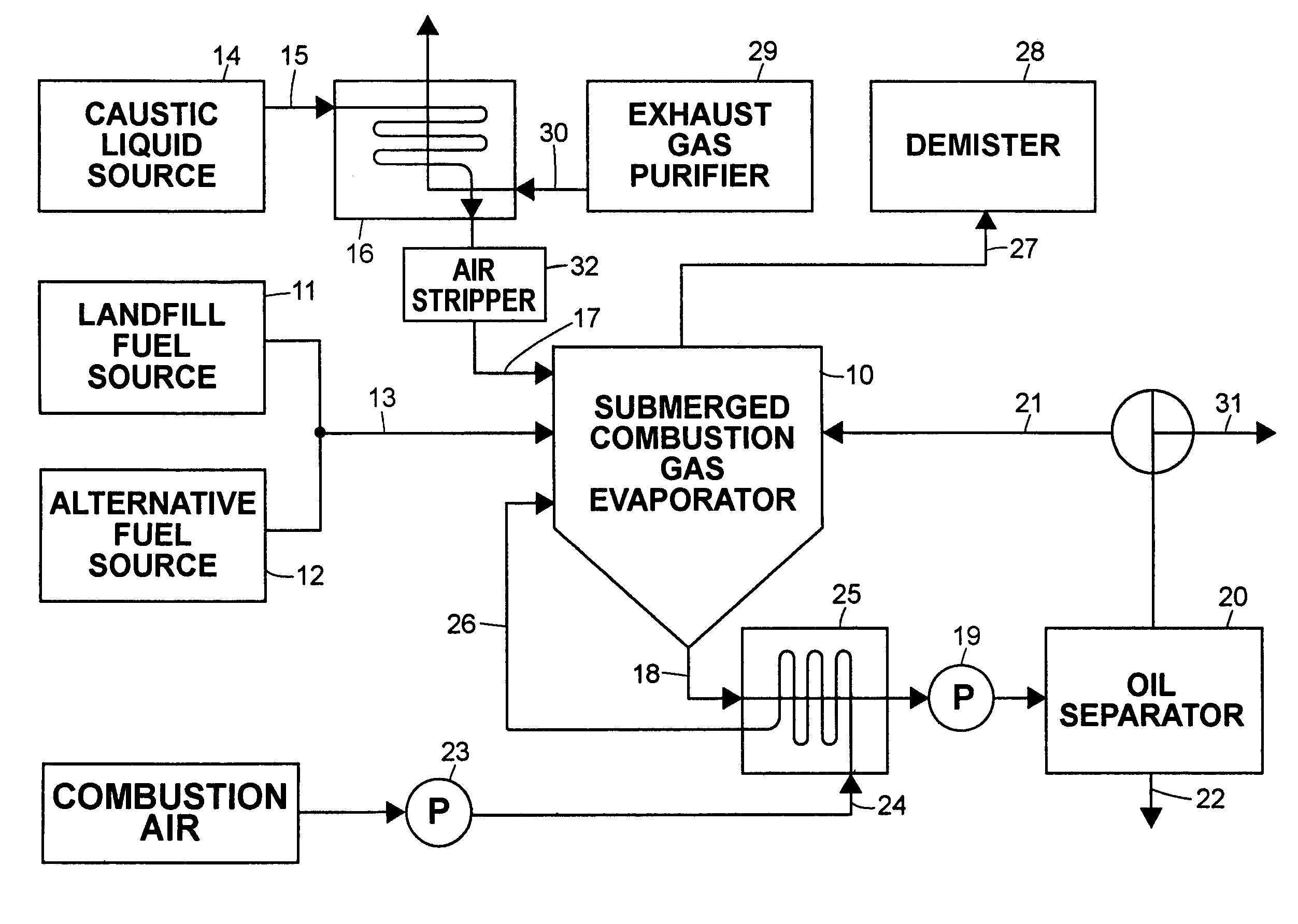

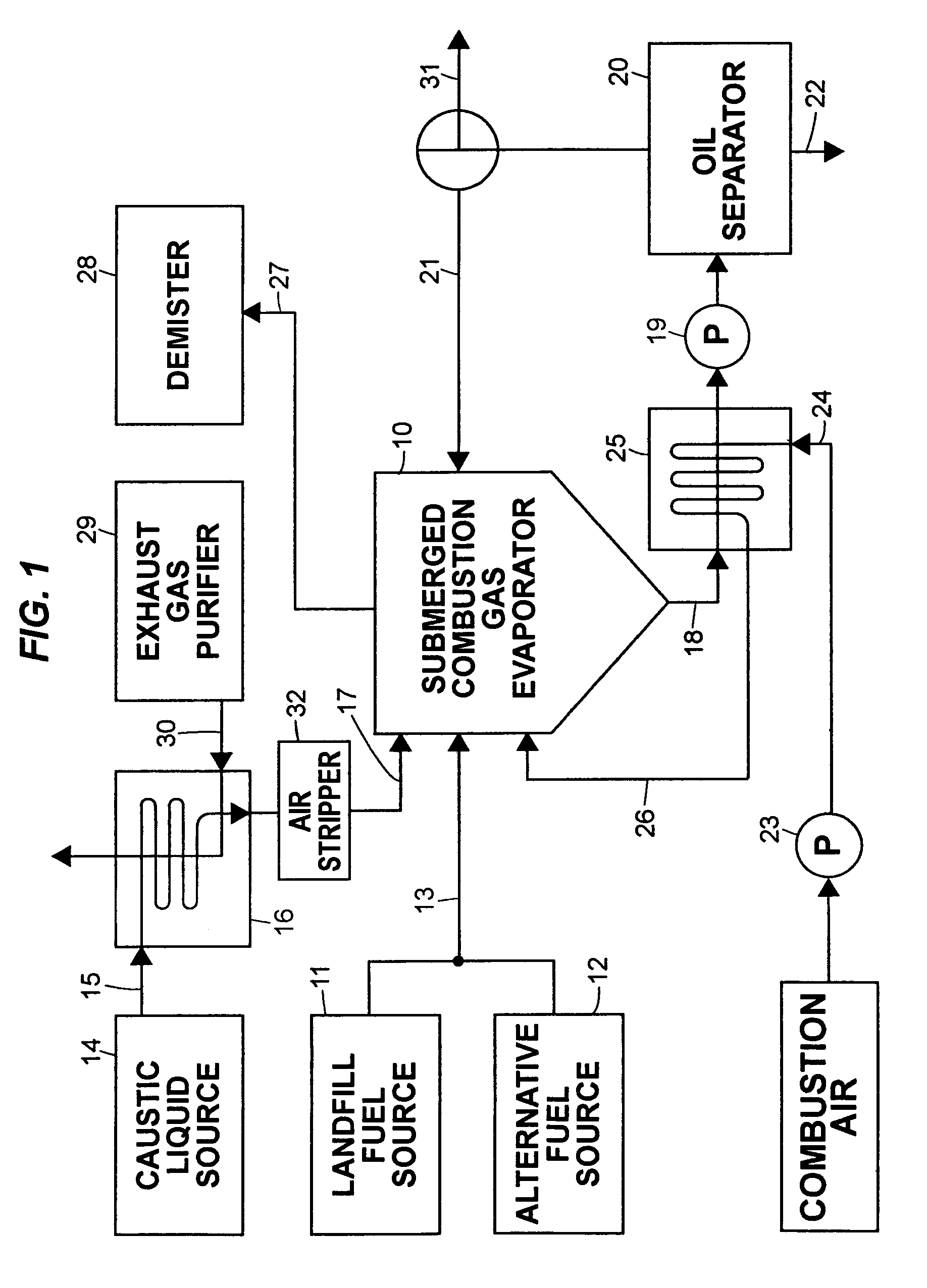

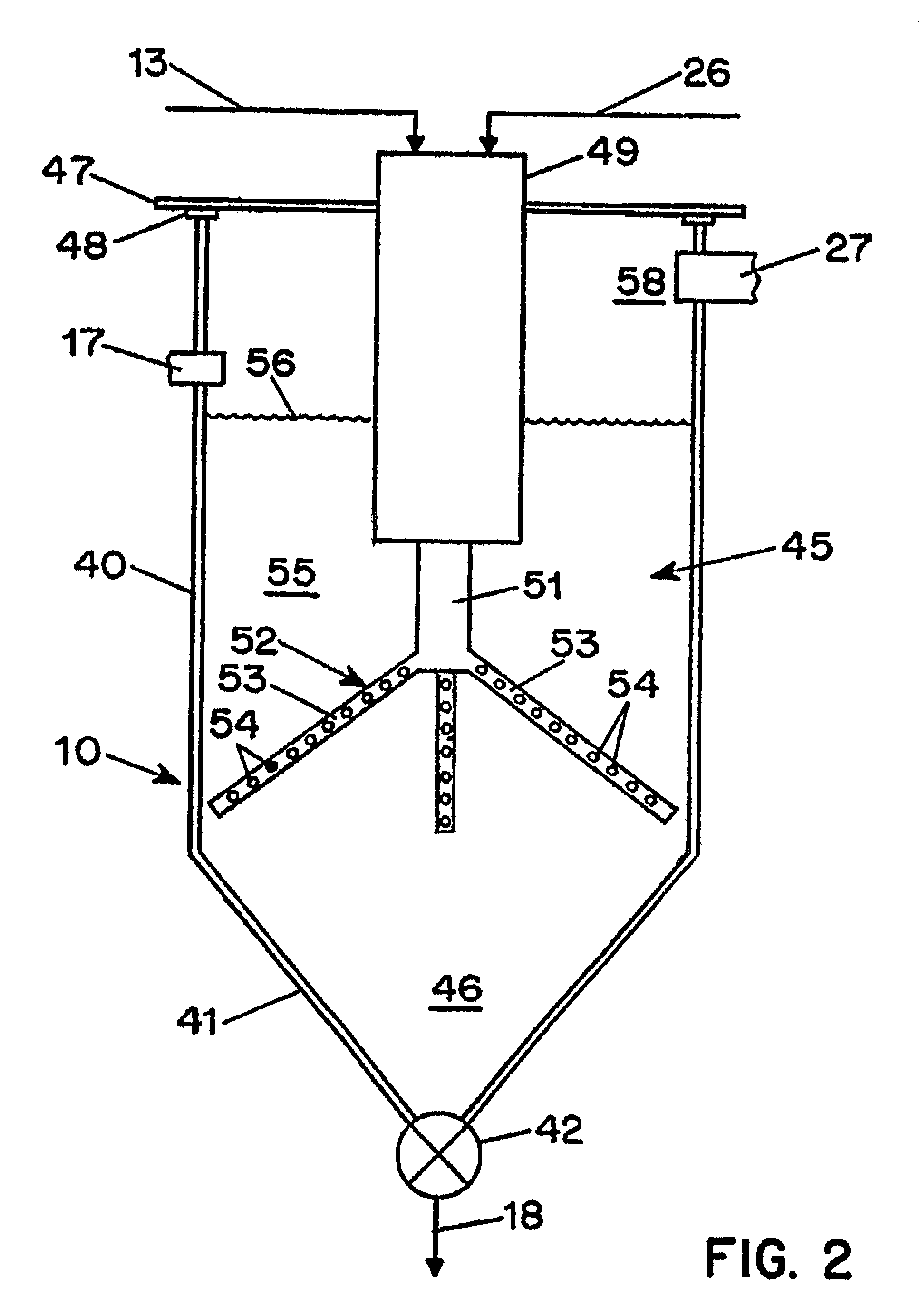

Treatment of spent caustic refinery effluents

InactiveUS7214290B2Avoid spreadingDrying using combination processesLiquid degasificationLiquid wasteCombustion

In the methods for treatment of caustic effluents described in the specification, a spent caustic refinery effluent is supplied to a submerged combustion gas evaporator in which hot combustion gas containing carbon dioxide is injected into the caustic liquid to concentrate the liquid and convert a hydroxide constituent to a carbonate. Where the caustic effluent is from a petroleum refinery, oil in the waste liquid is separated from the aqueous constituent before, during or after concentration.

Owner:GEI LIQUID SOLUTIONS +1

Process for electrocoagulating waste fluids

InactiveUS6719894B2CellsWater/sewage treatment by centrifugal separationLiquid wasteElectrocoagulation

An electrocoagulation process for removing organic and metal contaminants from a pressurized waste fluid is disclosed in which a clarified waste fluid is produced when the pressure is released.

Owner:GAVREL TOM G +1

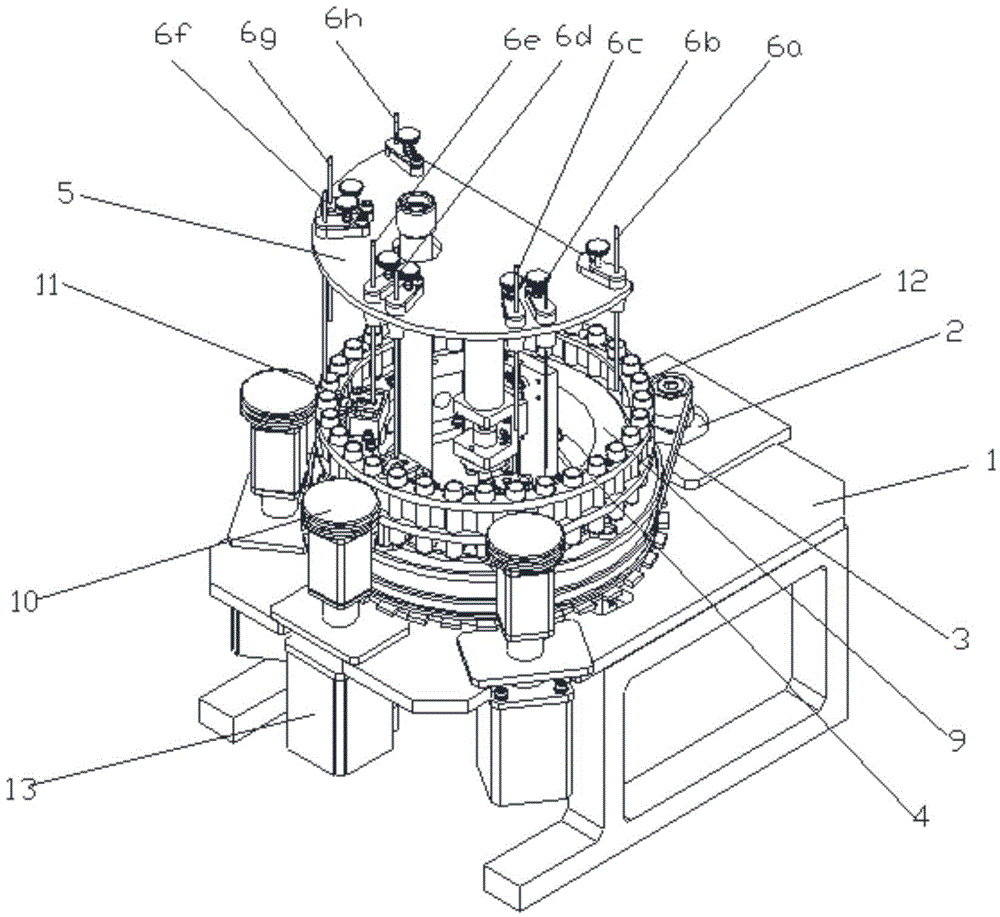

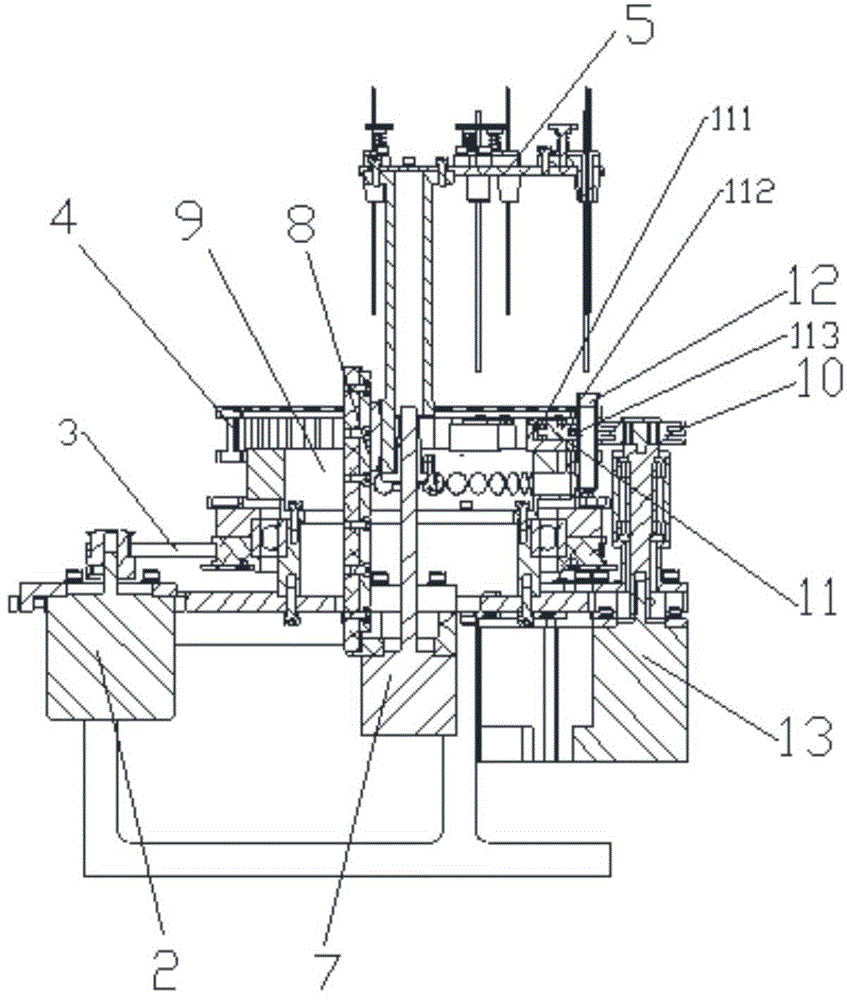

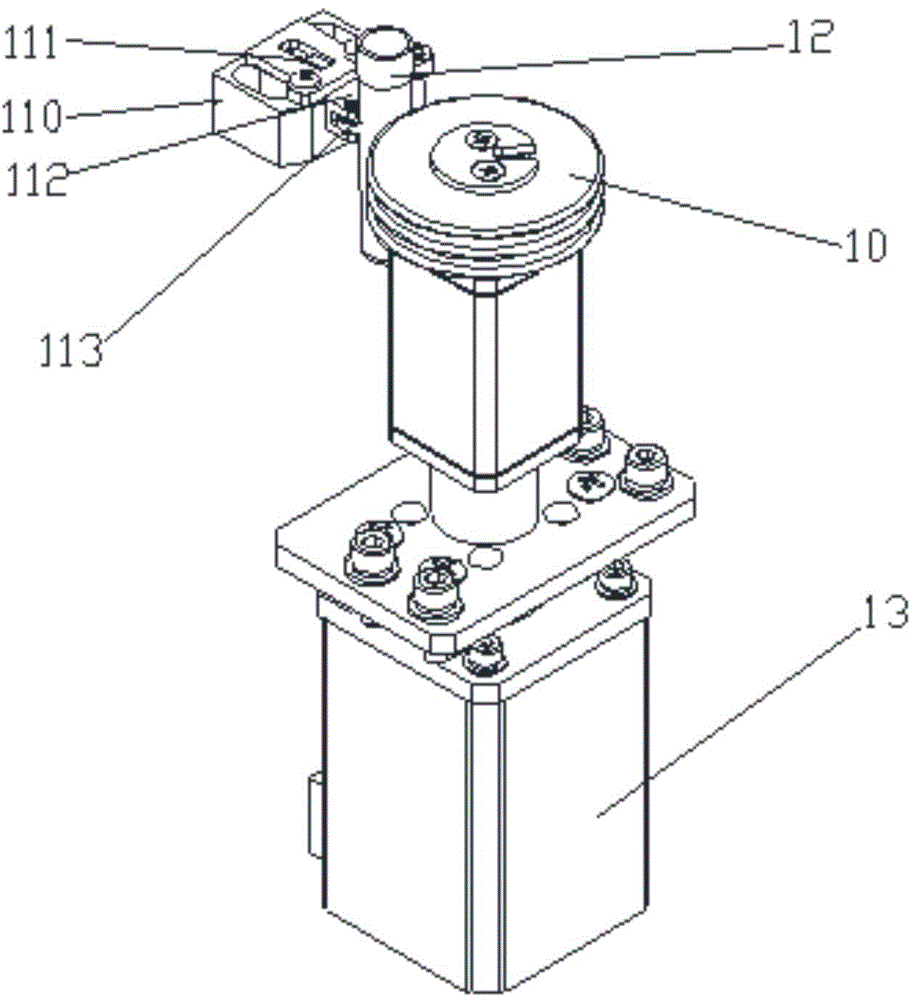

Full-automatic chemiluminescence immune analyzer magnetic bead washing device

ActiveCN103599898ARealize pipeline cleaningReduce lossesCleaning using liquidsLiquid wasteIndependent function

A full-automatic chemiluminescence immune analyzer magnetic bead washing device comprises a reaction cup rotation disc, a lifting needle support, a magnetic bead absorbing device and mixing devices. The lifting needle support is driven by a lead screw motor to move vertically along a linear sliding track. An eight-washing-needle assembly is arranged on the lifting needle support, four needles are liquid injecting needles and used for injecting washing liquid into a reaction cup, and other four needles are liquid sucking needles and used for sucking waste liquid in the reaction cup. The eight washing needles conduct washing liquid injection movement and waste liquid sucking movement on the reaction cup sequentially, and once diluting and three-time washing are conducted on magnetic beads in the reaction cup. An annular magnetic bead absorbing device is arranged below the inner side of the reaction cup rotation disc, and the plurality of mixing devices are arranged above two sides of the reaction cup rotation disc respectively. By means of the device, assembly line type washing of the magnetic beads is achieved, washing is thorough, magnetic bead loss is smaller, structure is optimized, control is simple, relatively independent functions are achieved, and the device is suitable for a whole automatic system.

Owner:BEIJING LEADMAN BIOCHEM

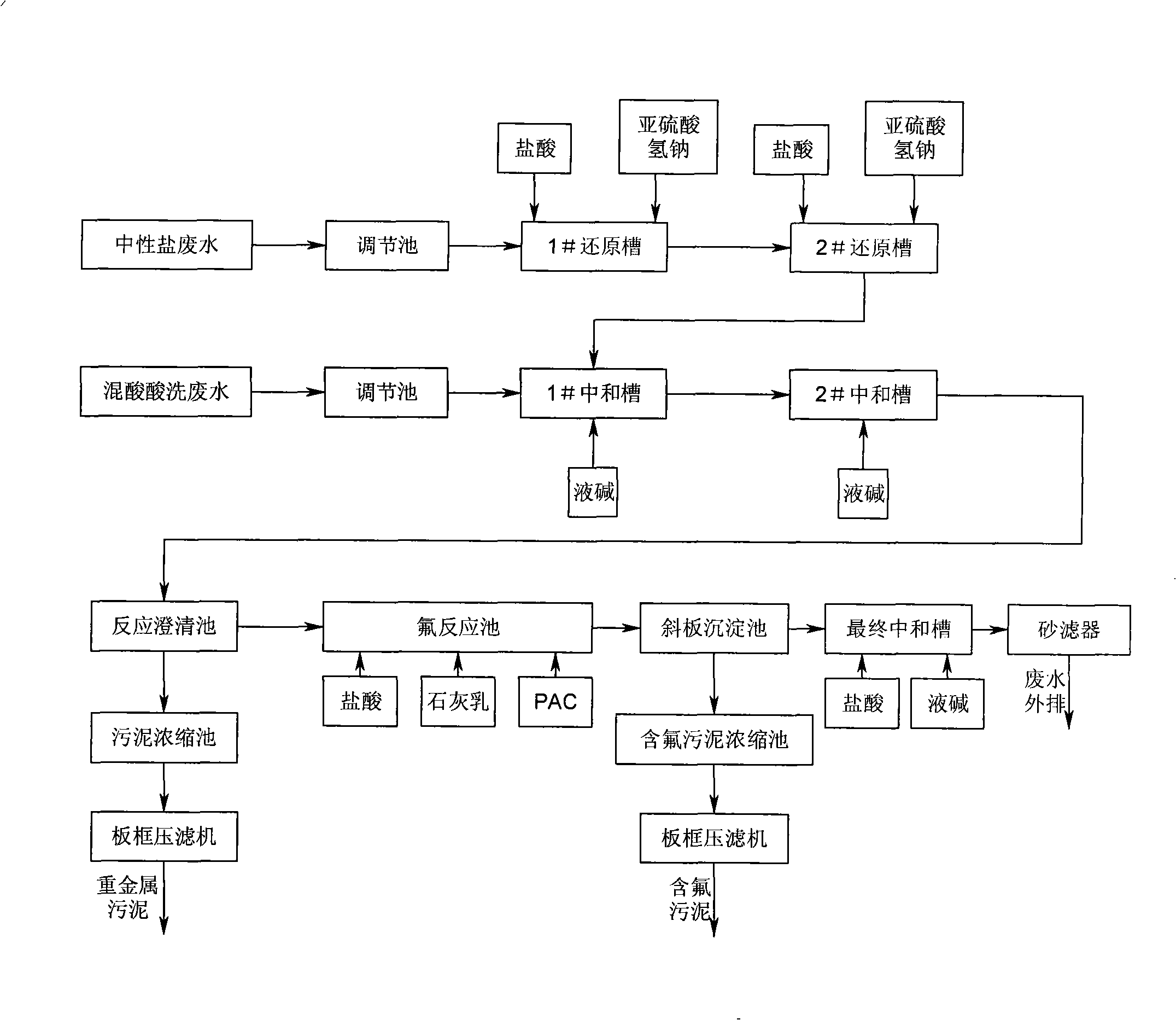

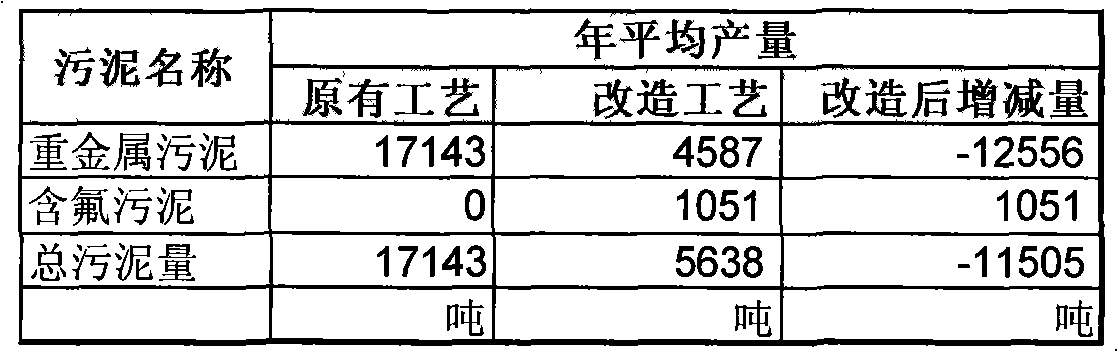

Processing method for stainless steel acid cleaning waste water and liquid

InactiveCN101269889AMeet emission compliance requirementsMeet compliance requirementsSludge treatment by de-watering/drying/thickeningIron oxides/hydroxidesLiquid wasteSludge

The invention relates to a processing method of stainless steel pickling waste liquid, which is characterized in that the processing method includes the steps that: neutral salt wastewater flows into a neutral reduction cell, and mixed acid pickling waste waters flow into a neutralizing tank; reducing agent is added into the neutral reduction cell, and then the reduced wastewater liquid is put into the neutralizing tank and is mixed with the adjusted mixed acid pickling waste waters, and liquid alkali is added into the neutralizing tank; the separated clear waste liquid removes fluorin ions in a settlement tank; neutralizing liquid is added into a final neutralizing tank to cause the pH value of treatment liquid to adjust to be neutralized wastewater liquid which passes through a sand filter to be discharged. The processing method has the advantages that metal ions and fluorin ions are performed the subsection treatment, and neutralizing agent is changed into the liquid alkali from lime cream, the requirement of reaching the standard of the waste liquid emission is not only achieved, but also the mud quantity produced by a mass of lime cream is greatly reduced, heavy metal mud of a retention pond only contains heavy metal compound, the salts of calcium fluoride and calcium sulphate, etc. are separated from the inclined plate settlement tank during the fluoridation stage, thereby the treatment cost is effectively lowered.

Owner:NINGBO BAOXIN STAINLESS STEEL

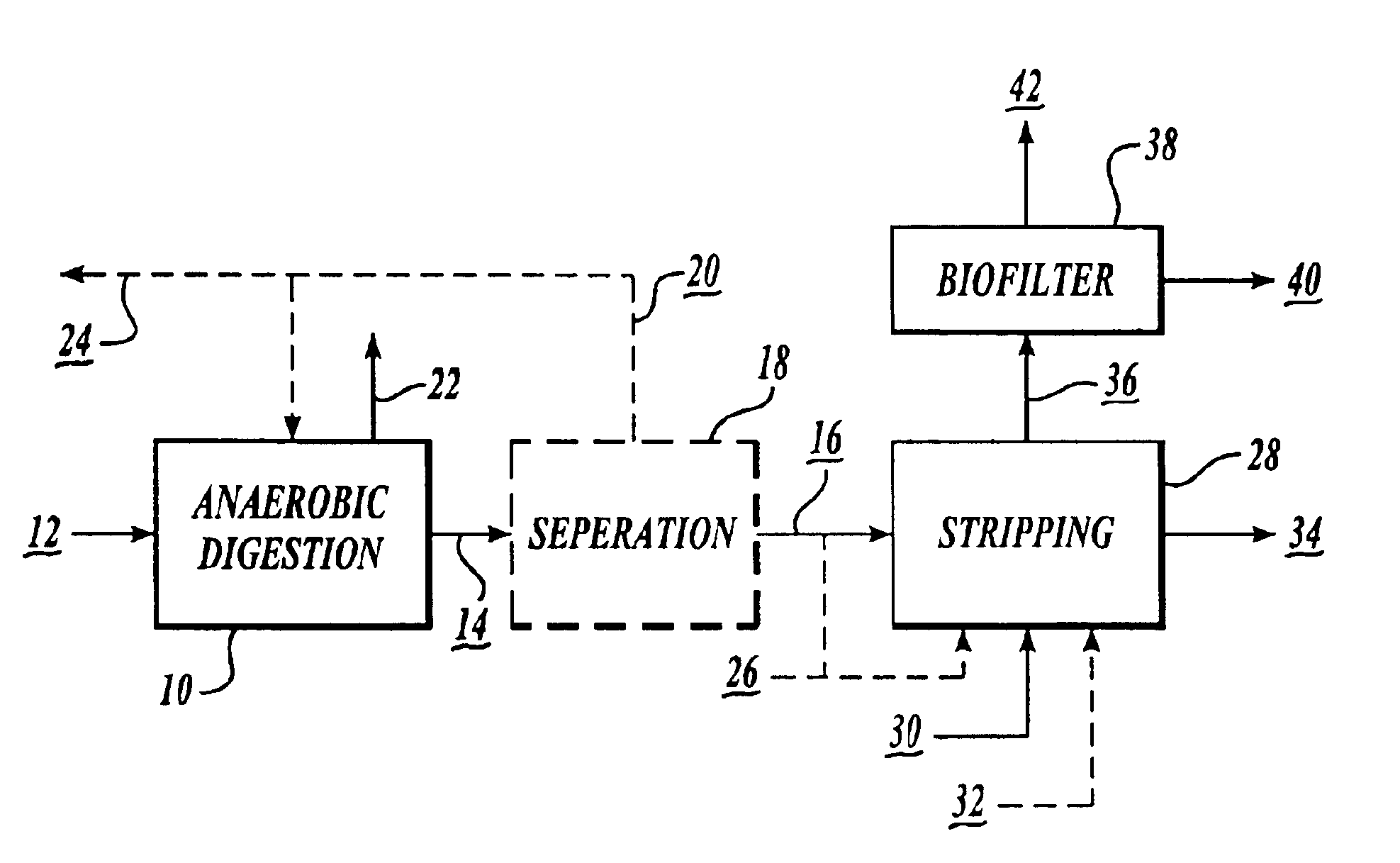

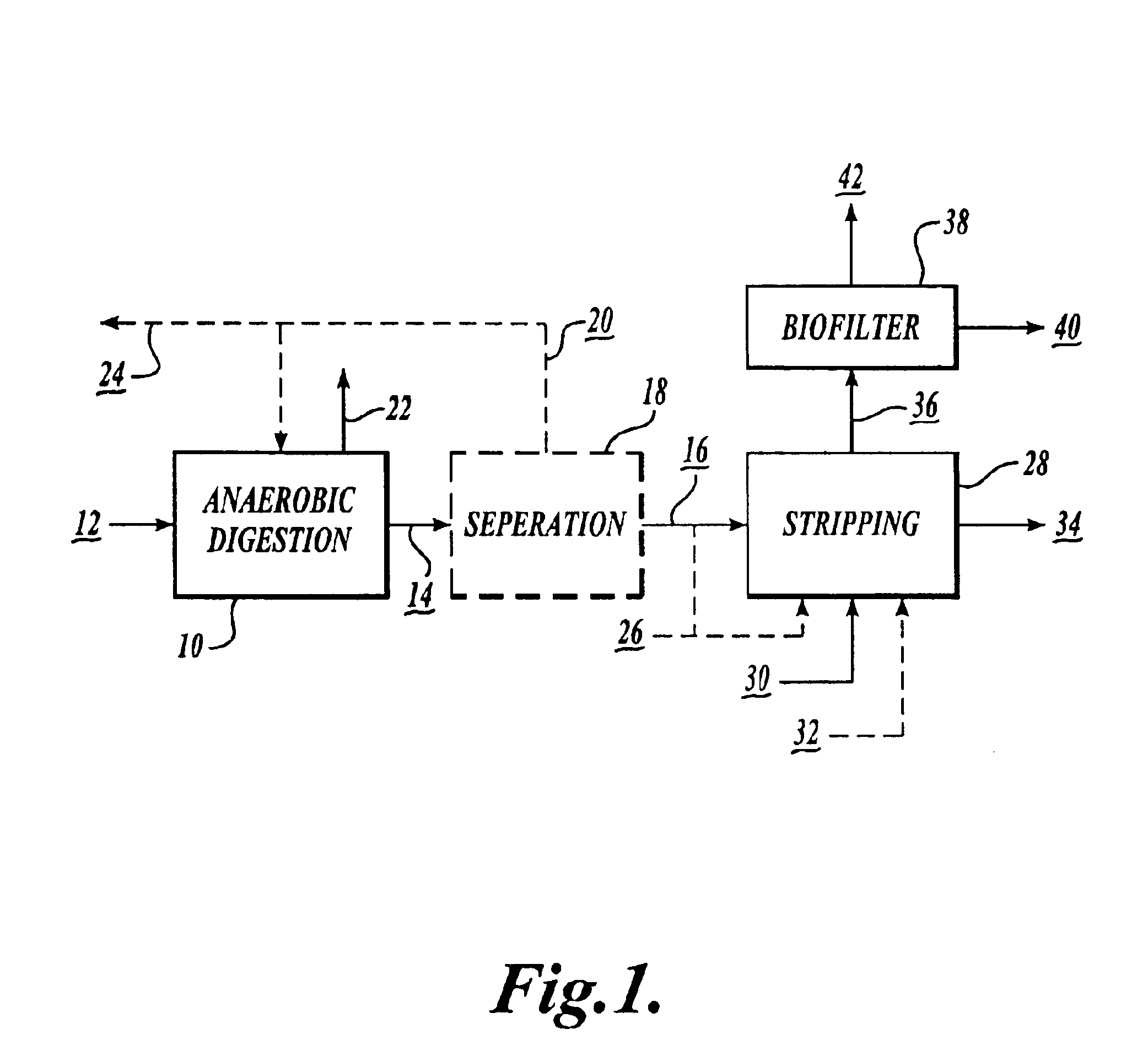

Nitrogen recovery system and method

InactiveUS6866779B1Less greenhouse gasGood health benefitsBio-organic fraction processingCyanogen compoundsLiquid wasteNitrate

A process for the recovery of nitrogen from anaerobically digested liquid waste and for the collection of the nitrogen as nitrate compounds that can be used to produce fertilizer and compost, includes stripping ammonia from anaerobically digested liquid waste, and converting the ammonia into nitrates via nitrification.

Owner:ENVIRONMENTAL ENERGY & ENG

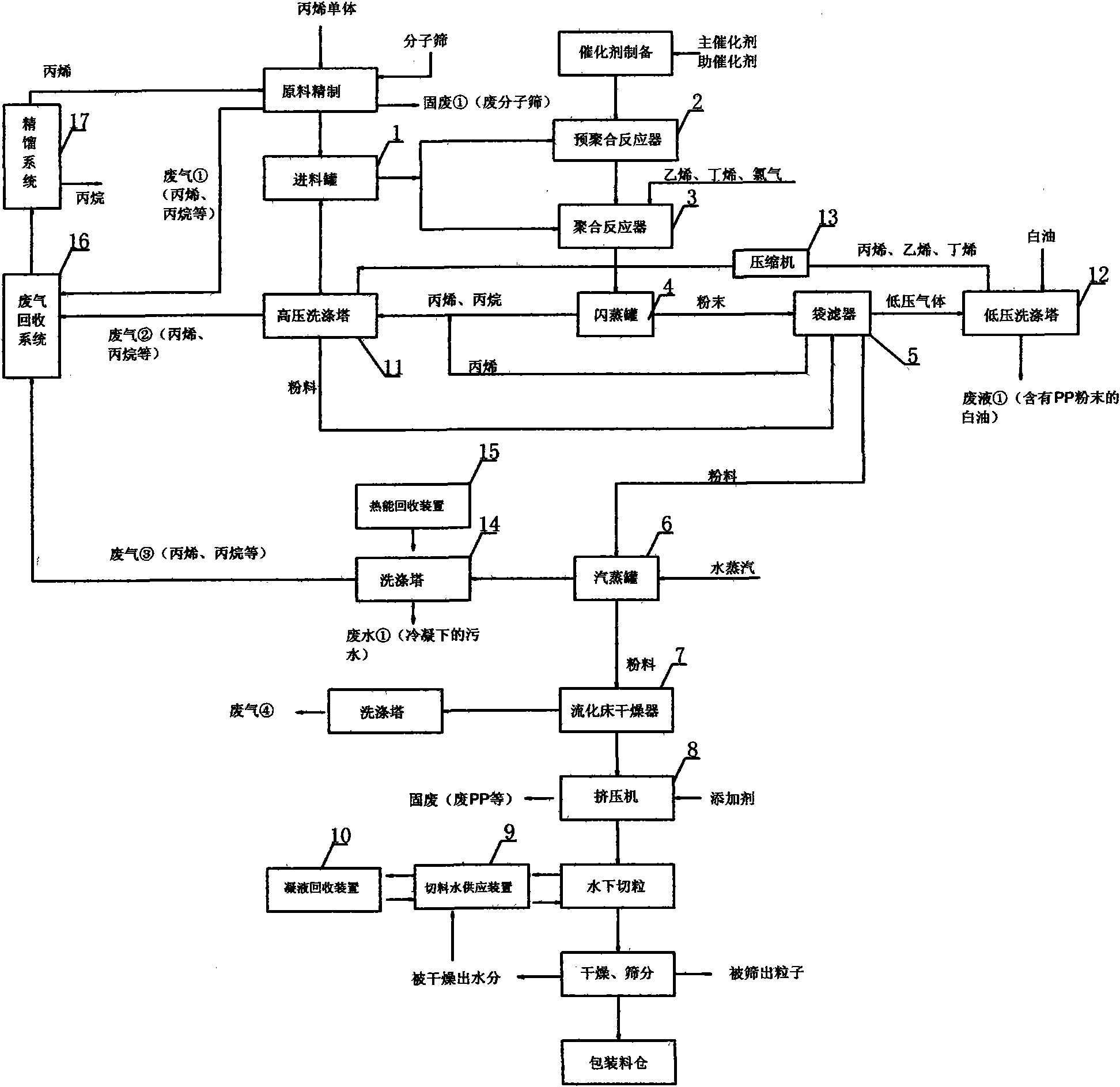

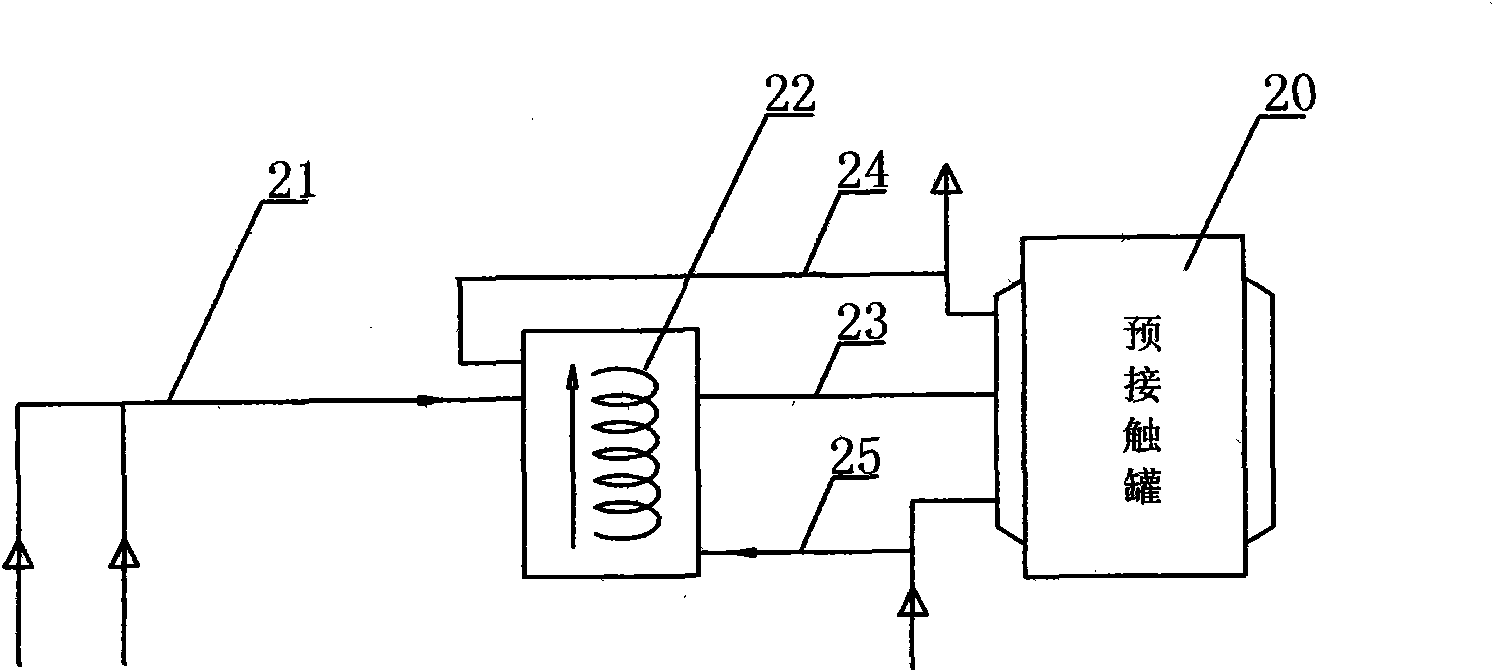

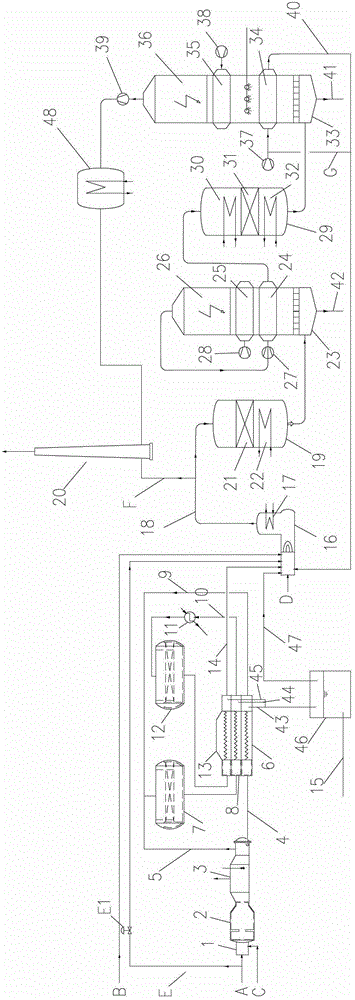

Production method of polypropylene and device thereof

The invention discloses a production method of polypropylene with an English name of Polypropylene (short for PP) and a device thereof, belonging to the technical field of polymer synthesis. The production method comprises the steps of: prepolymerization, polymerization-flash vaporization, degasification-steaming, drying-extruding, granulating-product package and the like. By optimizing the technique steps and parameters of prepolymerization, polymerization, flash vaporization, degasification, steaming, drying, extruding, granulating and the like, the invention improves the utilization ratio of raw materials, simultaneously adds a waste gas and waste liquor recovery system creatively, adds a heat recovery system of a washing tower, uses recovered heat for heating grease, and improves heat utilization ratio; the setting of powder and condensate recovery device improves production efficiency and reduces production cost; a standby water tank is added for granulating and water supply, thus preventing machine stopping caused by fault of the water tank and improving production efficiency; and the improvement of gas-exiting pipelines and exhaust pipelines eliminates potential safety hazard, saves cost and has good environment protection.

Owner:ZHEJIANG SHAOXING SANJIN PETROCHEM

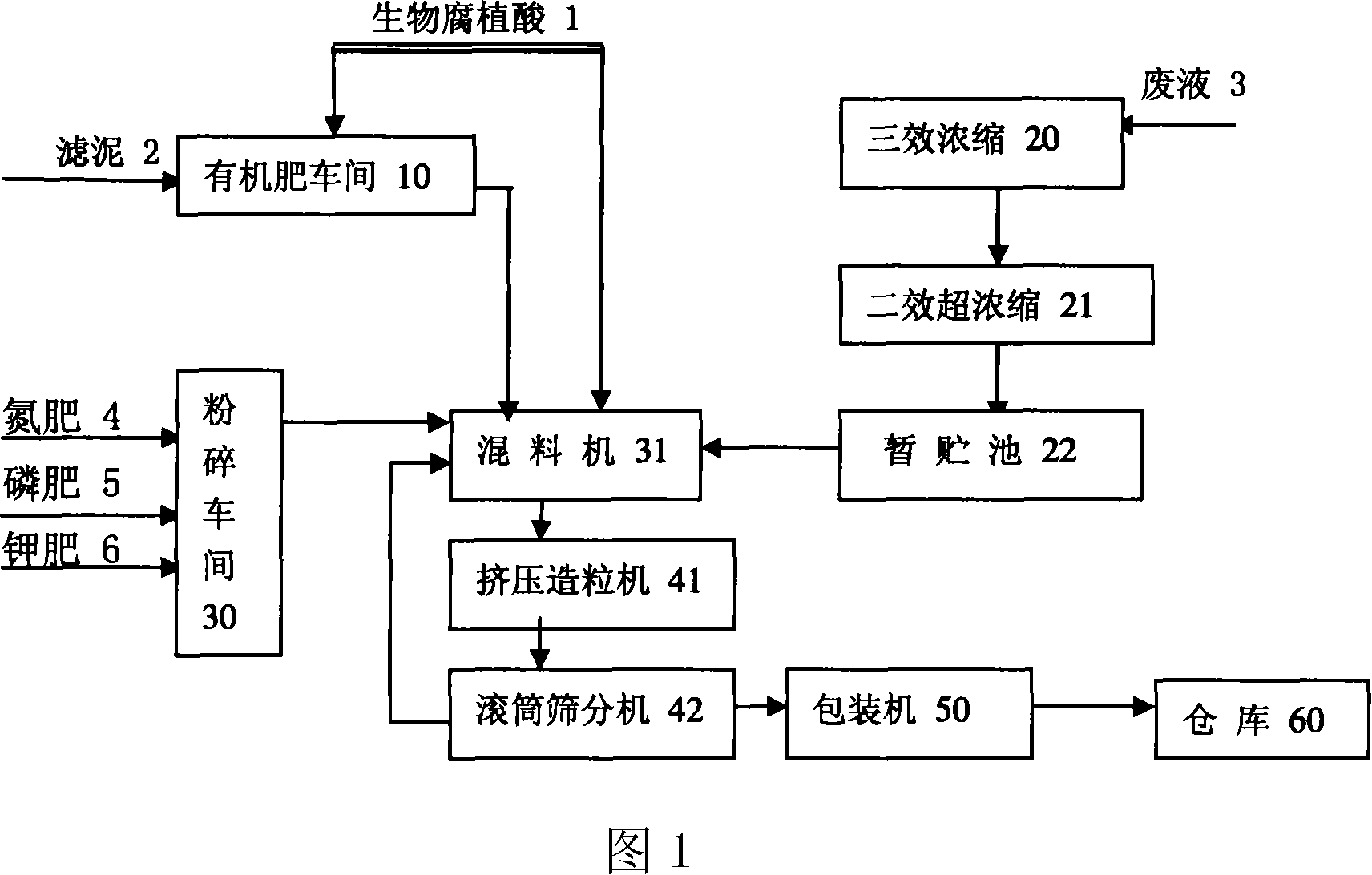

Method of manufacturing organic, inorganic compound fertilizer with molasses zymolysis waste liquor and lime sludge

InactiveCN101108779AImprove efficiencyLow efficiencyBio-organic fraction processingClimate change adaptationLiquid wasteContinuous fermentation

The invention provides a method producing the organic-inorganic compound fertilizer by the molasses fermentation waste liquor and the lime sludge, which relates to a method producing the fertilizer through fermentation and solves the problem of reclaiming and processing the molasses fermentation waste liquor continuously on a large scale. The method of the invention is that the biological humic acid with weight per cent of 0.4 per cent to 0.6 per cent and made by the bagasse is mixed with the lime sludge of 65 per cent to 68 per cent, bagasse powder of 10 per cent to 12 per cent, wheat bran of 1.5 per cent to 2.5 per cent and regulator of 16 per cent to 25 per cent to ferment fully and continuously in a shorter time. The fermented materials with water of 10 per cent to 12 per cent are gained after opening and drying and are crushed into the lime sludge organic fertilizer. The molasses fermentation waste liquor with water of 90 per cent is condensed to the hyperconcentration liquor with water of 26 per cent to 28 per cent by the three-effect forced circulating concentration system and then through the two-effect scraping and steaming hyperconcentration system. The hyperconcentration liquor of 30 per cent to 33 per cent and the biological humic acid of 9 per cent to 10 per cent are stirred and mixed uniformly based on the weight per cent and are added with the fertilizer of 32 per cent to 34 per cent and the lime sludge organic fertilizer of 25 per cent to 27 per cent to stir to produce the organic-inorganic compound fertilizer through dry extrusion and prilling.

Owner:越百年创新肥业(海南)有限公司

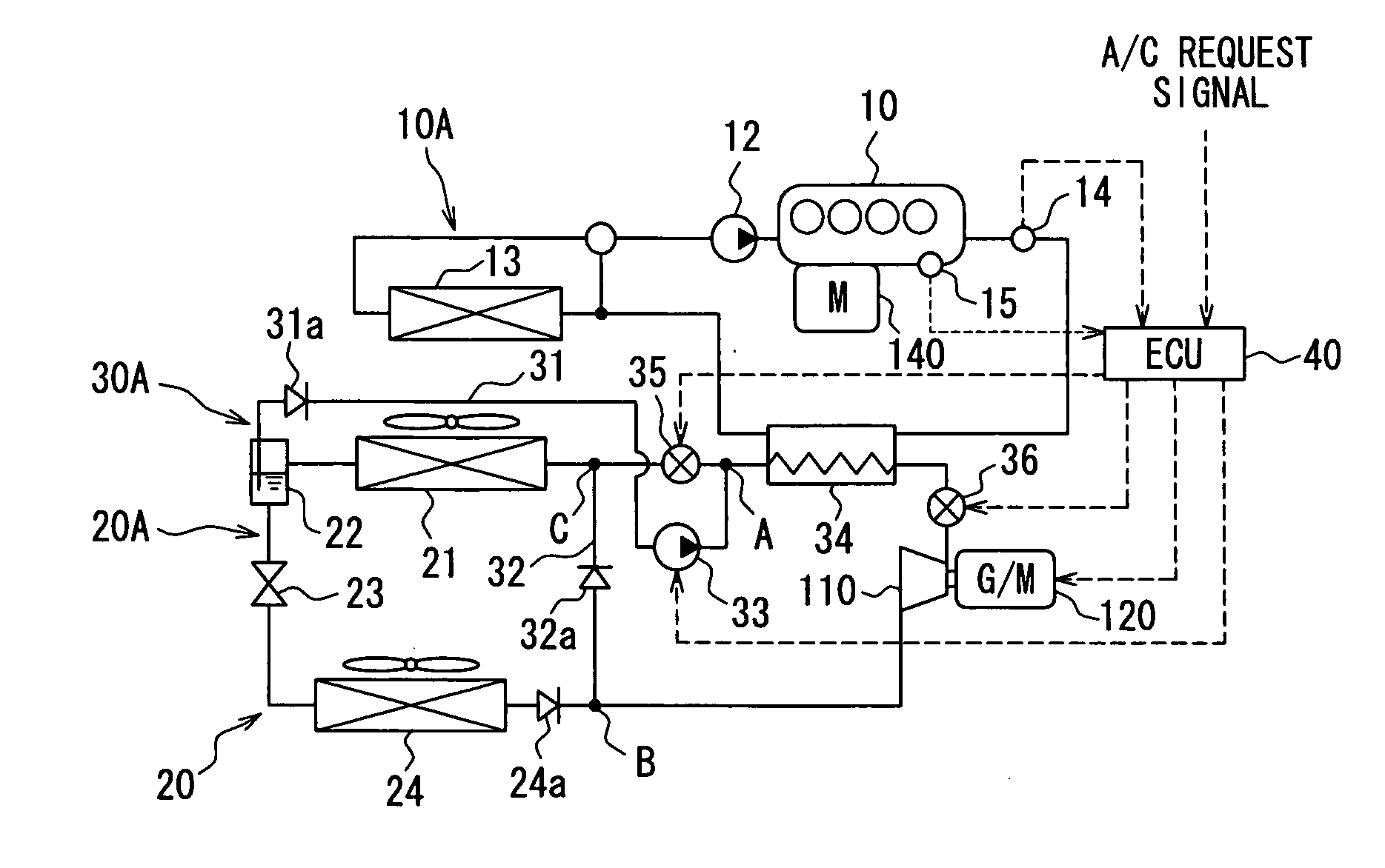

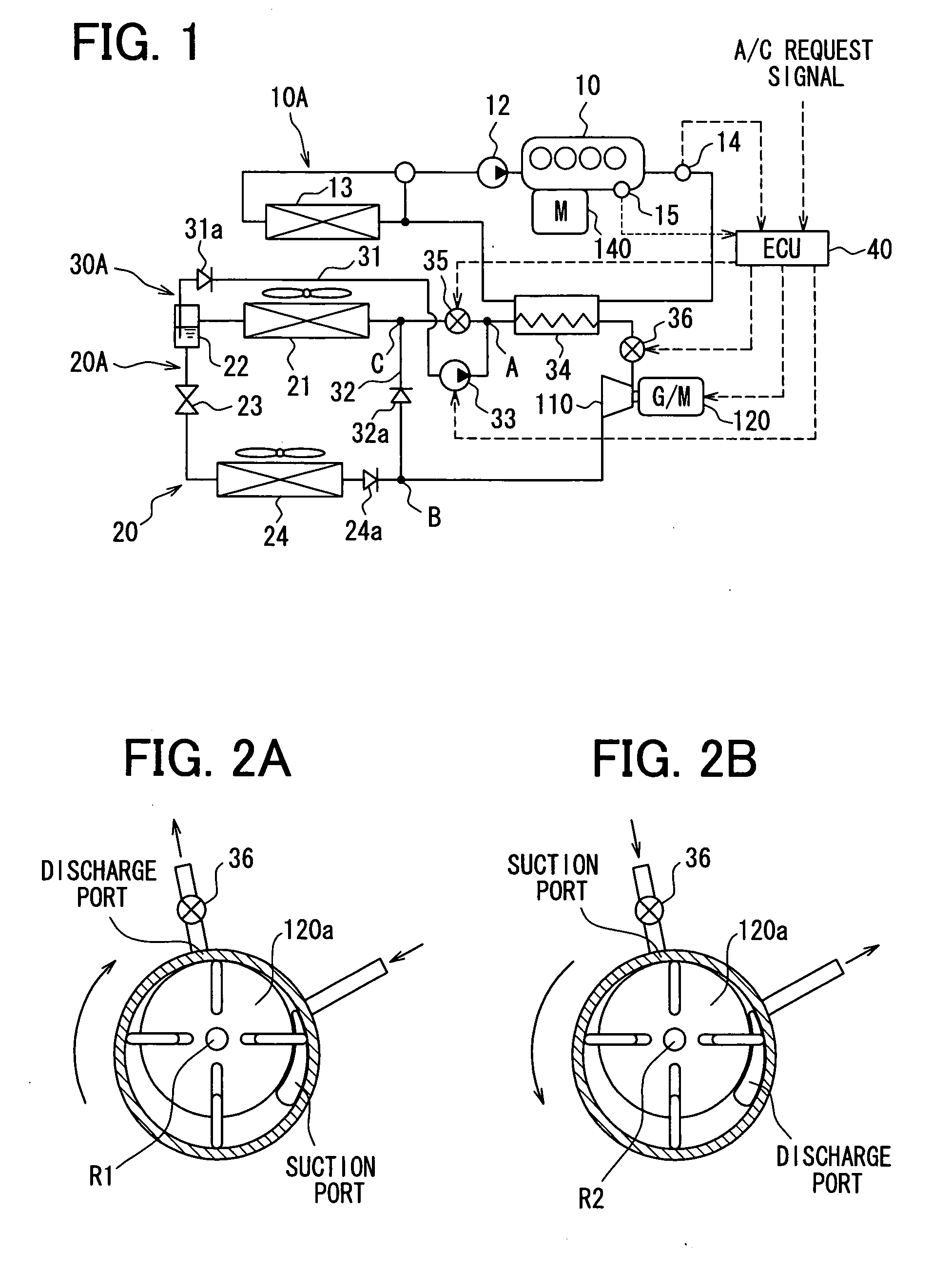

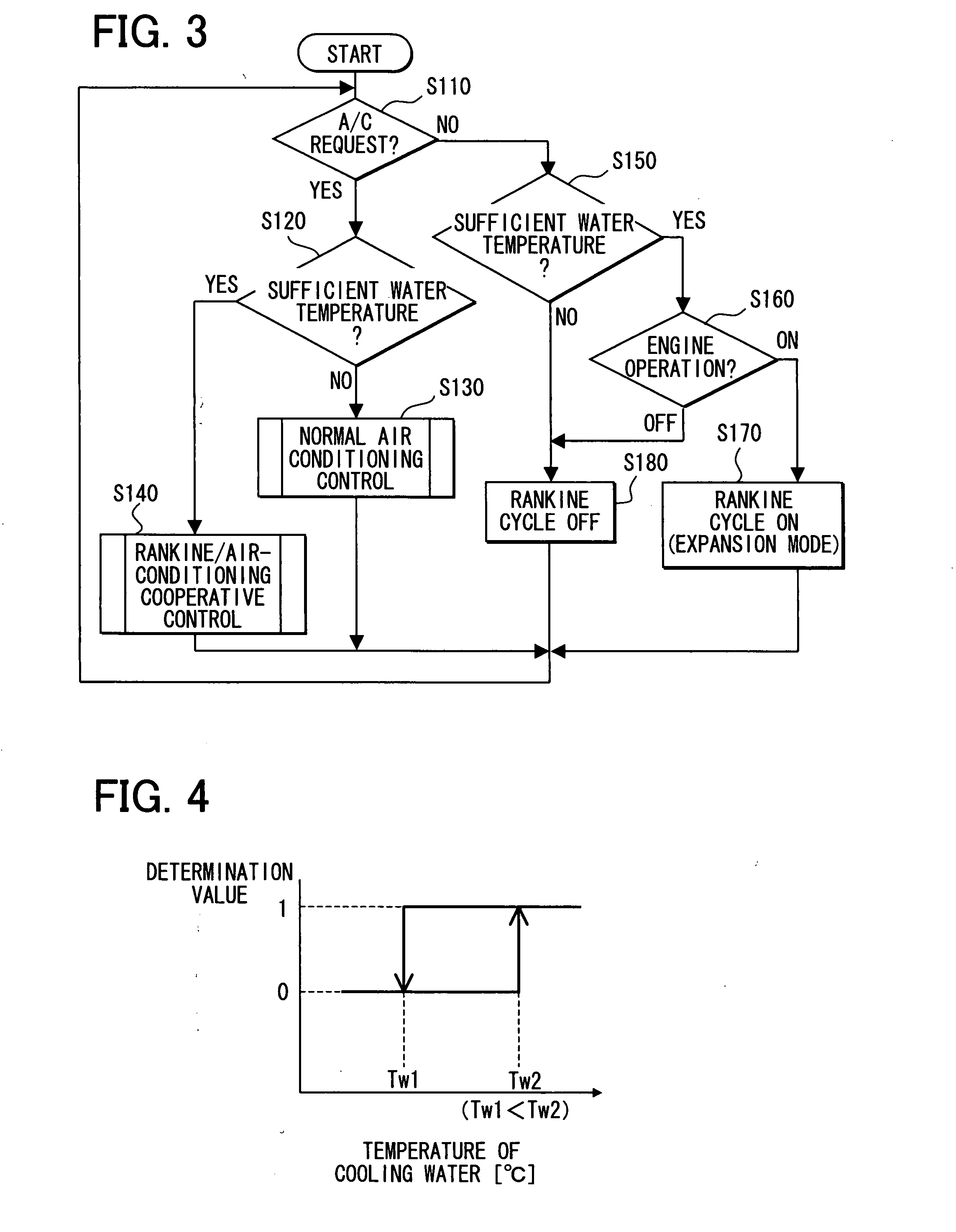

Waste heat utilization device and control method thereof

InactiveUS20070245737A1Waste heat recoveryImprove fuel consumption rateVehicle heating/cooling devicesSteam engine plantsLiquid wasteWorking fluid

A waste heat utilization device includes a Rankine cycle in which an operation fluid circulates, and a control unit which controls an operation of the Rankine cycle. The Rankine cycle has a heater for heating the operation fluid using a waste fluid with a waste heat from a heat engine, an expander that expands the heated operation fluid to recover a mechanical energy, and a condenser for cooling and condensing the expanded operation fluid. The control unit operates the Rankine cycle when a waste fluid temperature is not less than a predetermined temperature and when the waste fluid is in a flowing state in the heat engine.

Owner:DENSO CORP

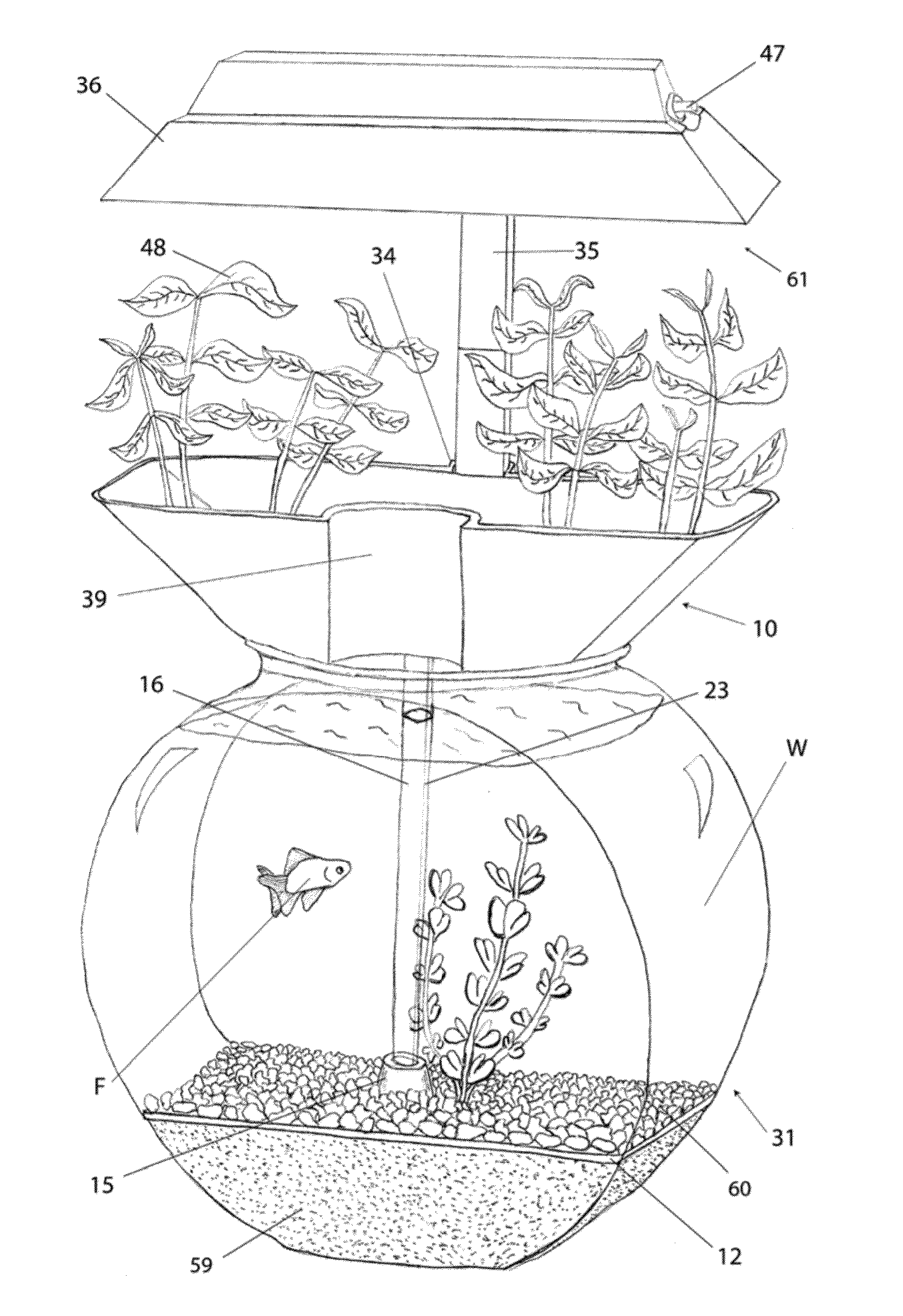

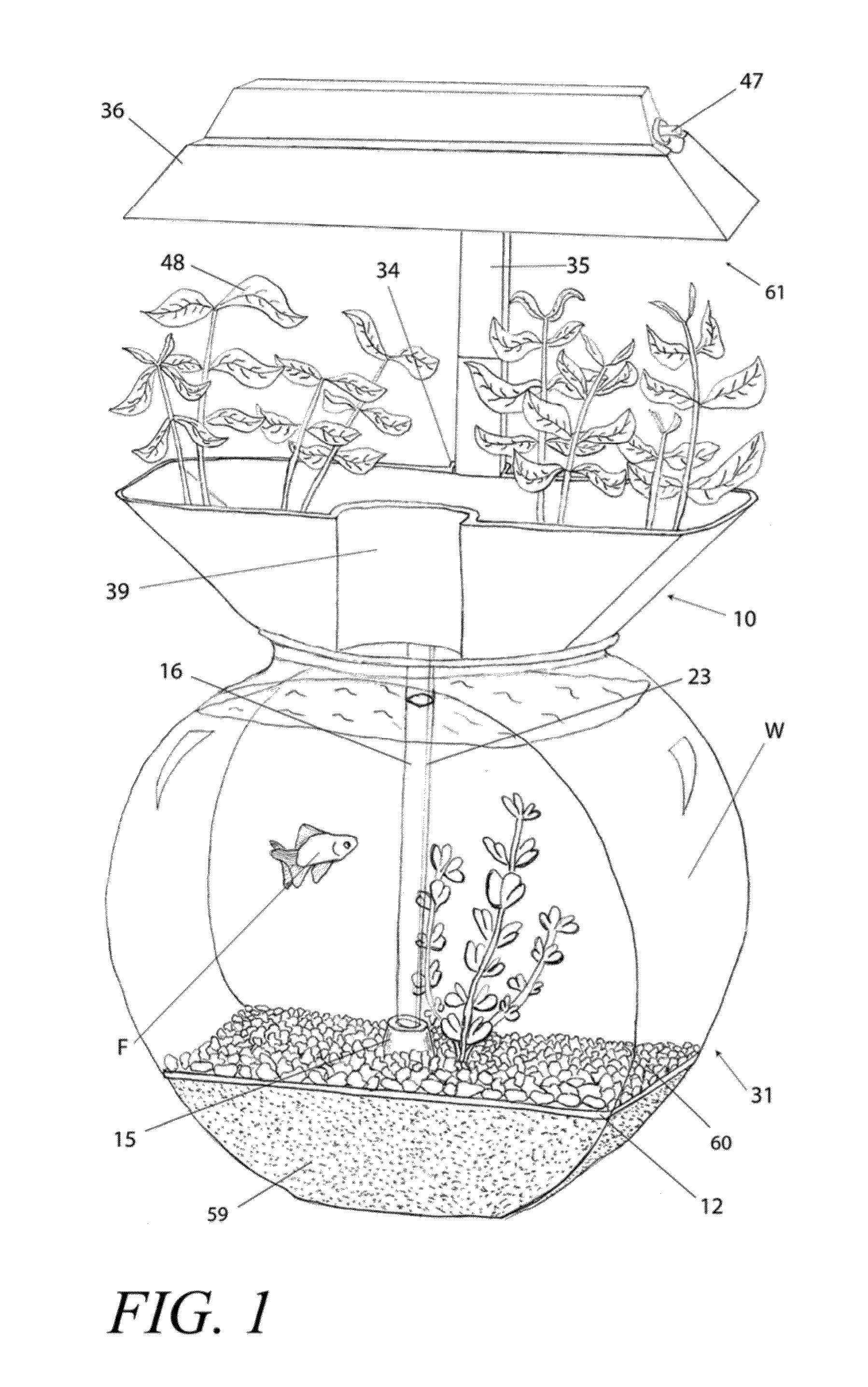

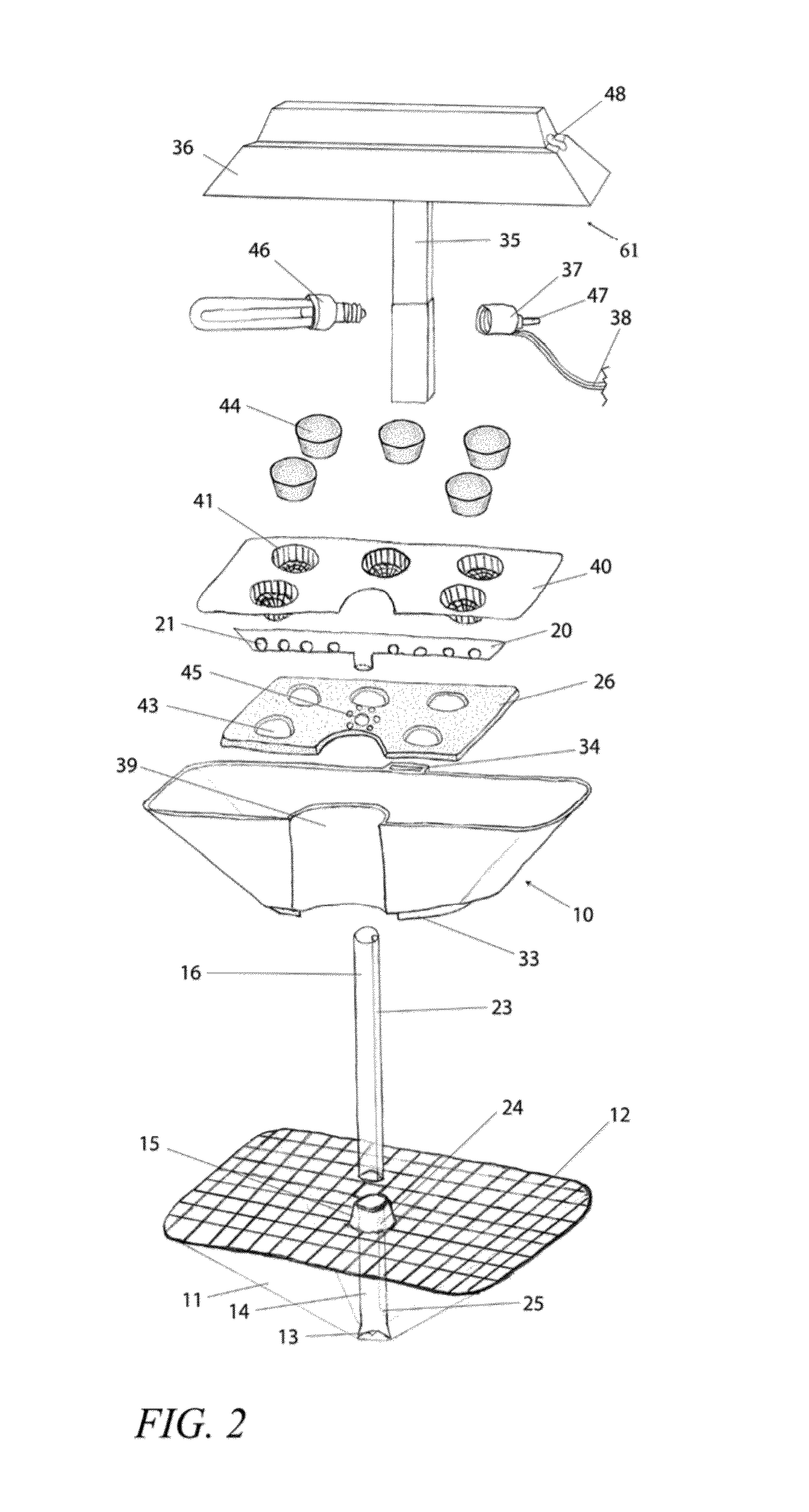

Filtration system for use in aquariums

InactiveUS20140223818A1Effective growth of plantGuaranteed efficient growthPisciculture and aquariaAgriculture gas emission reductionLiquid wasteActivated carbon

An inexpensive aquaponic conversion kit for aquariums that uses a combination of mechanical, biological, and chemical filtration components along with terrestrial plants to filter aquarium water. The system includes a funnel shaped undergravel filter that concentrates solid waste towards an airlift pump that transports solid and liquid waste into a planter containing terrestrial plants. These waste nutrients are trapped in the planter in layers of activated carbon and filamentous material that adsorb and trap waste particles where the roots of plants turn the waste into biological material and aid in cleaning the tank. A grow light and hood are able to be attached to a bracket at the back of the planter to grow healthy plants.

Owner:COGHLAN RYAN

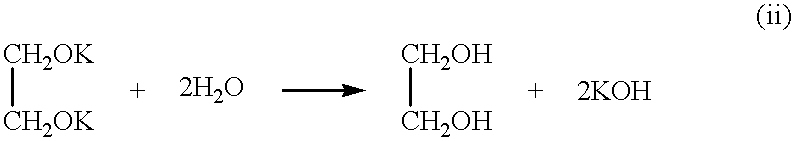

Recovery processing method of silicon slice cut waste mortar

The invention relates to a recovery processing method of silicon slice cut waste mortar, comprising the following steps: (1) separating solid-liquid components in the silicon slice cut waste mortar; (2) further recovering the remained cutting liquid component in a solid; (3) separating silicon powder and silicon carbide through water flow flotation; (4) recovering the silicon powder; (5) recovering the silicon carbide; (6) coarsely filtering, finely filtering, decoloring, vacuum distilling and dehydrating the recovered cutting liquid, and adding component with corresponding amount for secondary filter. The method can get various recovered products, such as silicon carbide micro powder, cutting liquid and silicon powder, has high recovery rate and recovery profit and can save the cost of the mortar by at least 40 percent; meanwhile, the invention effectively solves the problem of possible secondary pollution caused by single recovery; the cutting function of recovered and treated silicon carbide micro powder is recovered again, thereby changing waste into wealth, realizing the resource reutilization in true sense, and promoting the development of recycling economy; and the method basically realizes the zero emission of waste liquid by reutilizing the treated waste water after combining a sewage treatment process, thereby being beneficial to environment protection.

Owner:HENAN XINDAXIN SCI & TECH

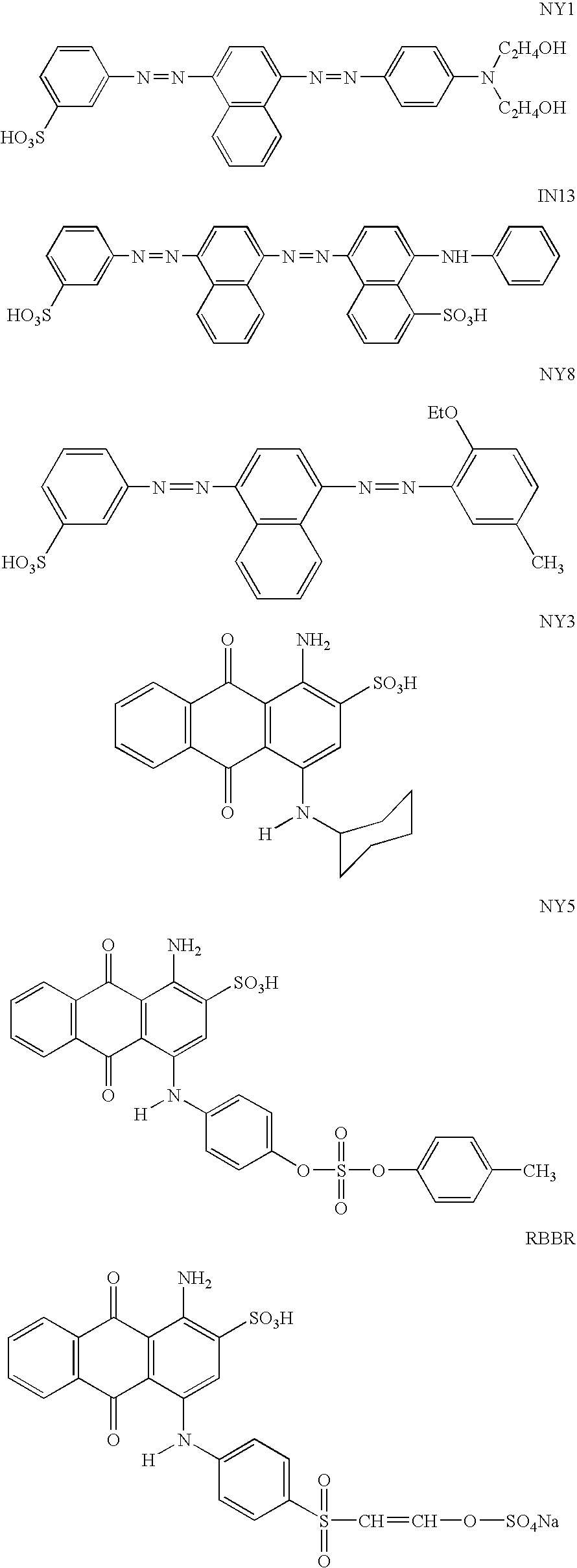

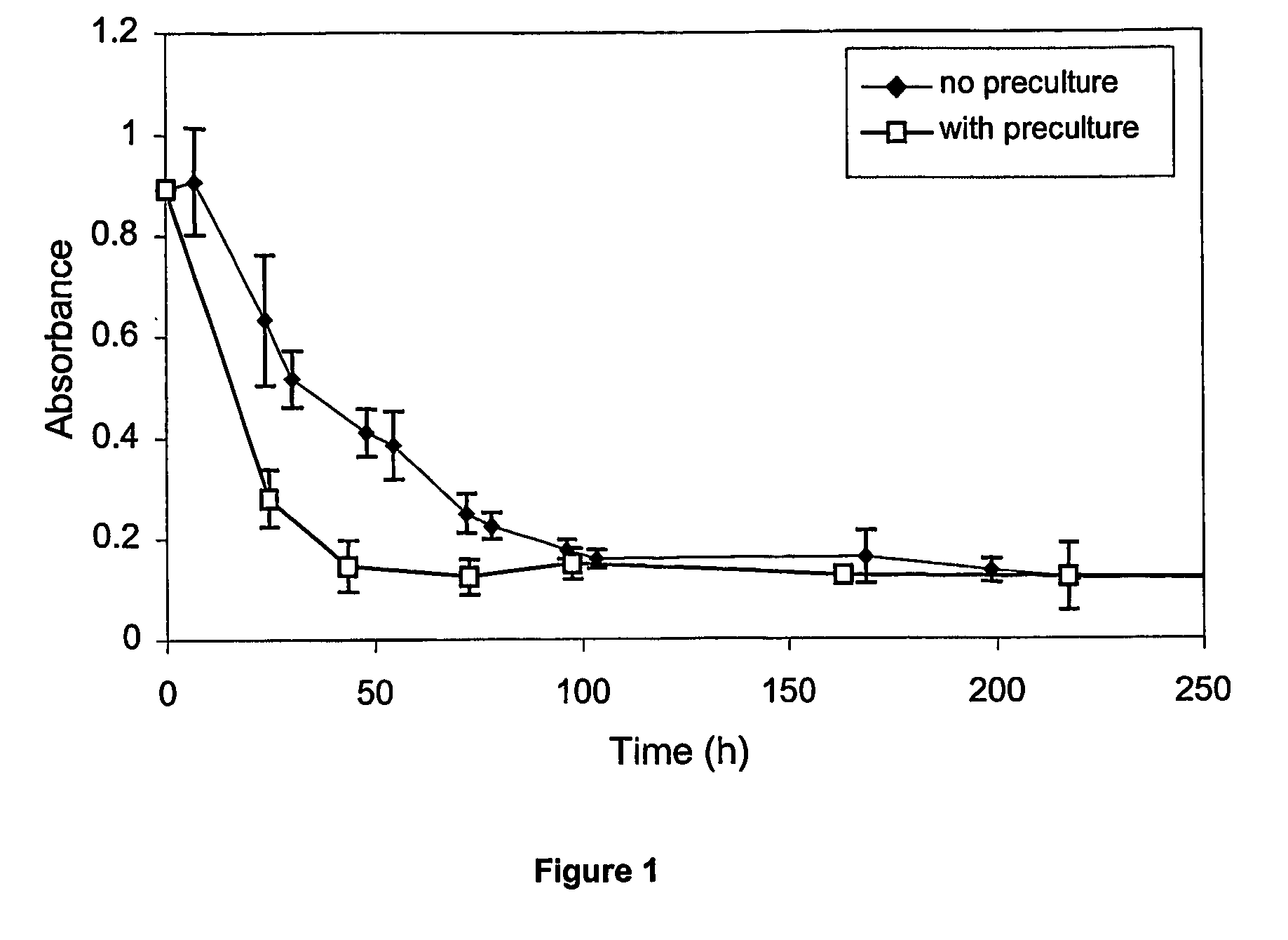

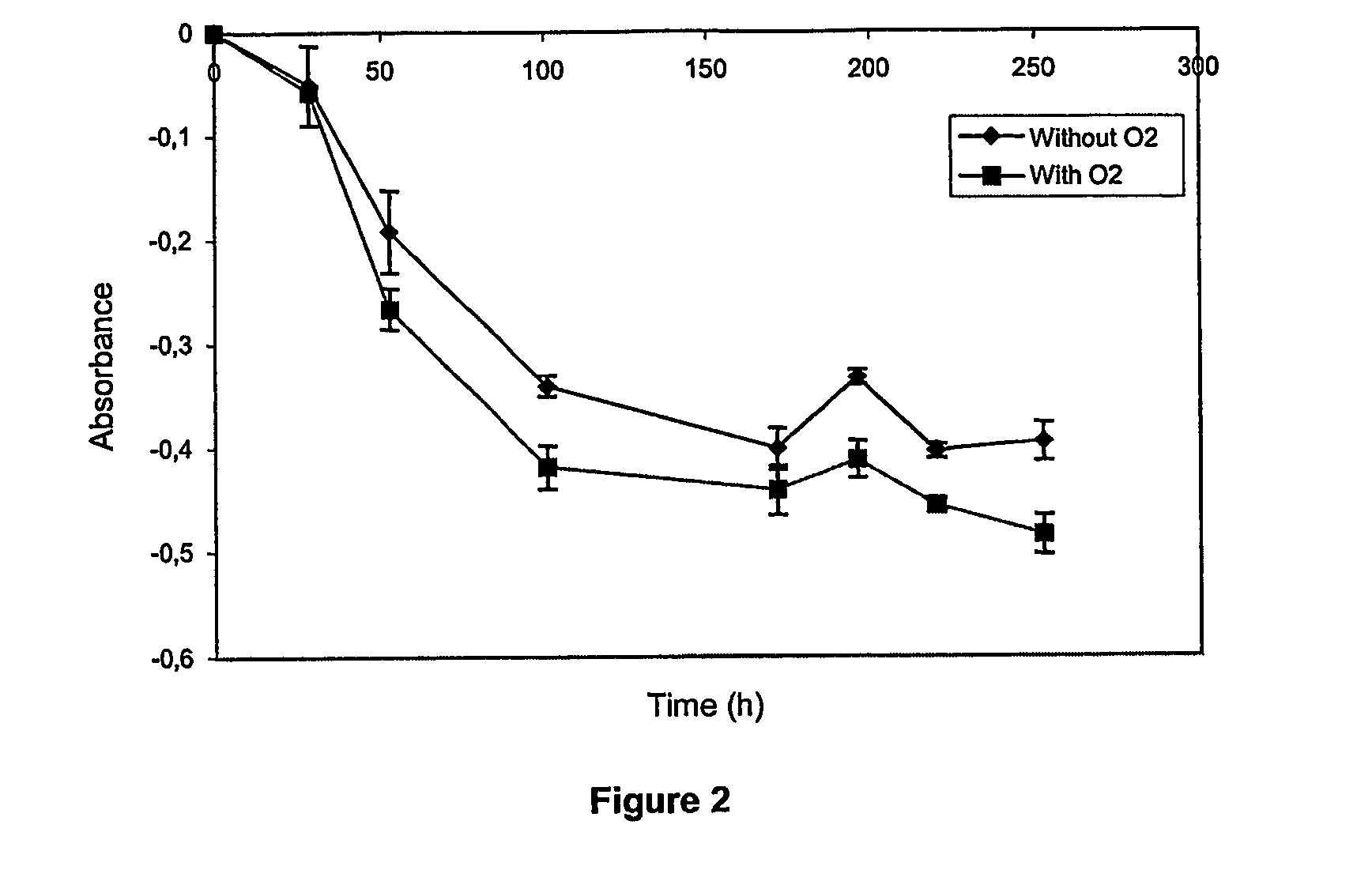

Sustainable process for the treatment and detoxification of liquid waste

InactiveUS20050067347A1Efficient decolorizationEfficiently detoxifyWater contaminantsWaste water treatment from animal processingLiquid wasteFungal microorganisms

A method for treatment of liquid waste is disclosed that includes the steps of (a) submitting the liquid waste to a pretreatment and (b) submitting the pretreated liquid waste to the action of fungi or active agents thereof. In particular, the described process is useful for the effective decoloration and detoxification of dye-containing liquid wastes using white rot fungi or active agents thereof.

Owner:UNIVERSITE CATHOLIQUE DE LOUVAIN

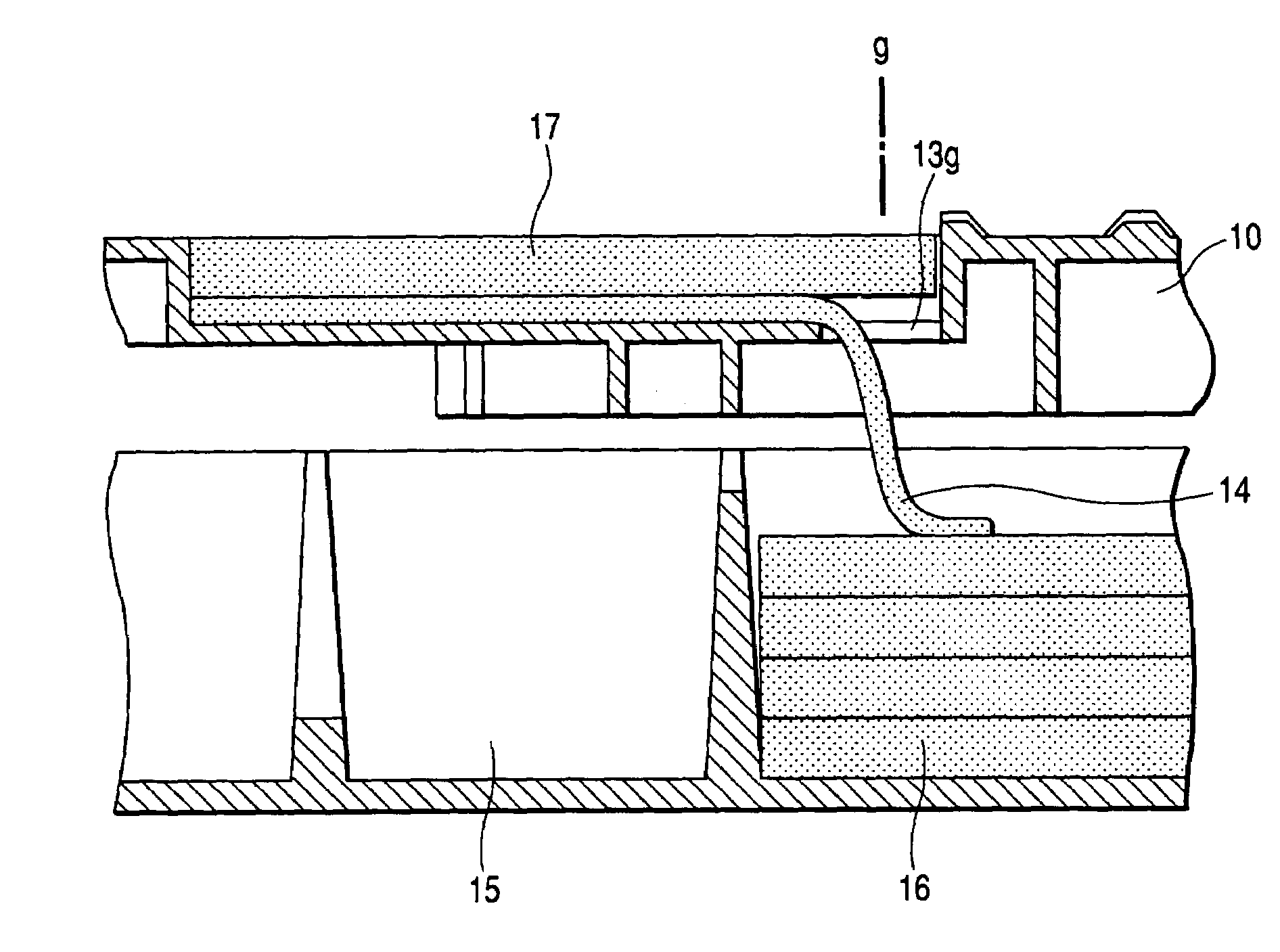

Waste liquid treating device and liquid ejecting apparatus incorporating the same

Owner:SEIKO EPSON CORP

Reduction of Backwash liquid Waste

A method of filtering solids from a liquid suspension comprising providing a pressure differential across the walls of permeable, hollow membranes (5) immersed in the liquid suspension contained in a vessel (8), the liquid suspension being applied to the outer surface of the porous hollow membrane (5) to induce and sustain filtration through the membrane walls. Some of the liquid suspension passes through the walls of the membranes (5) to be drawn off as permeate from the hollow membrane lumens, and at least some of the solids are retained on or in the hollow membranes or otherwise as suspended solids within the liquid surrounding the membranes (5). The method includes the steps of suspending the flow of the liquid suspension to the vessel (8); reducing the volume of liquid suspension within the vessel (8); suspending the filtration process; cleaning the membranes (5) by dislodging at least some of the solids retained on or in the membranes (5); and removing the liquid containing dislodged solids from the vessel (8).

Owner:EVOQUA WATER TECH LLC

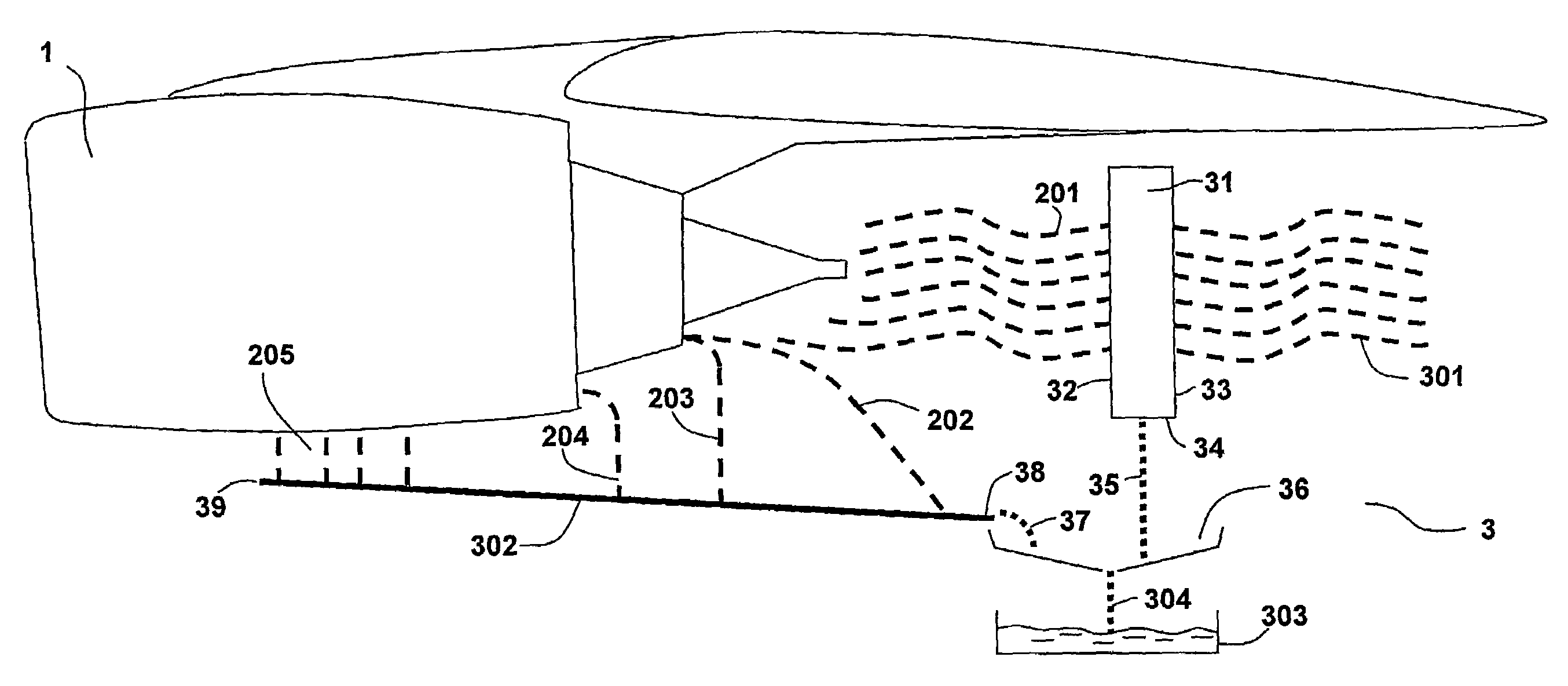

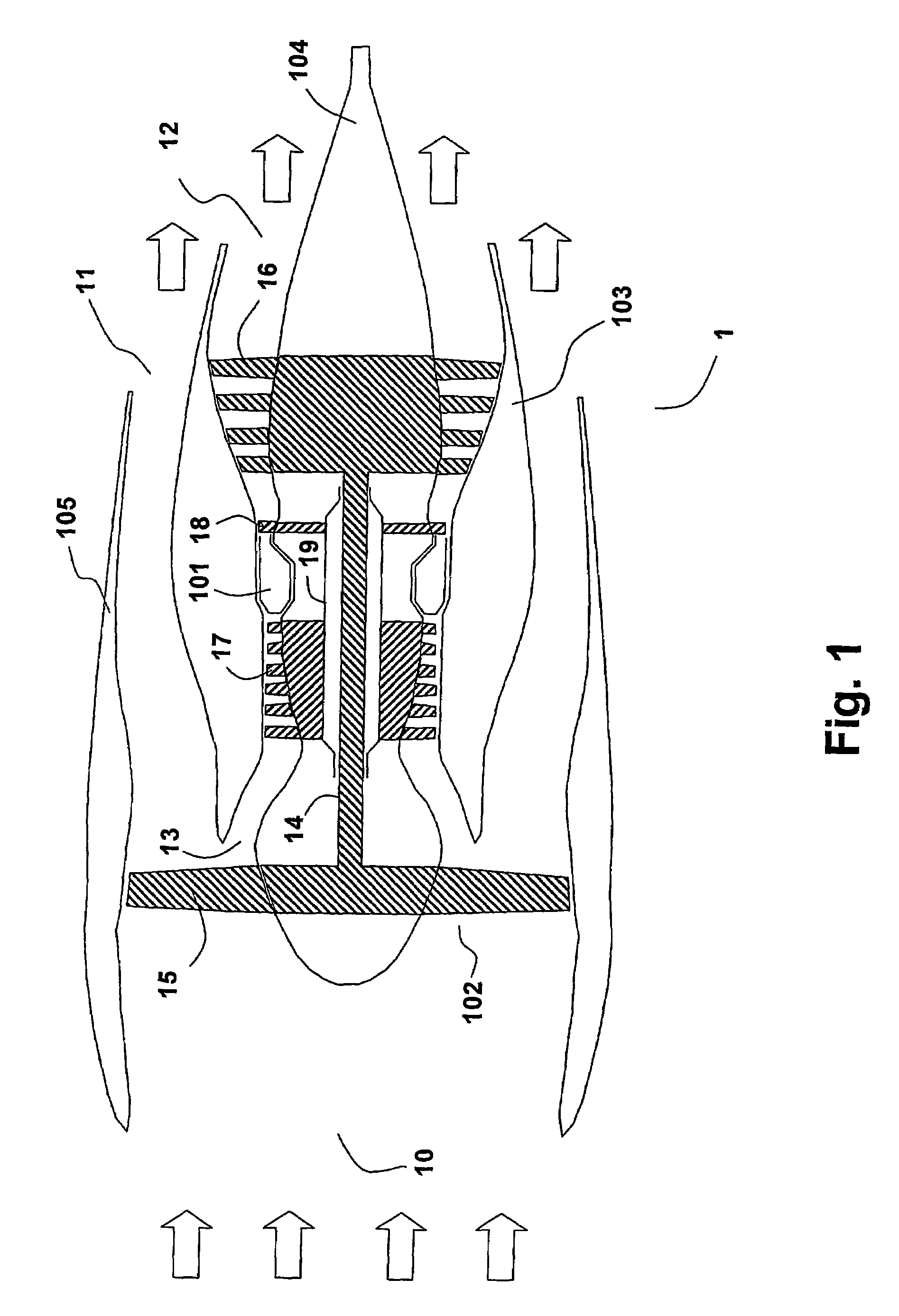

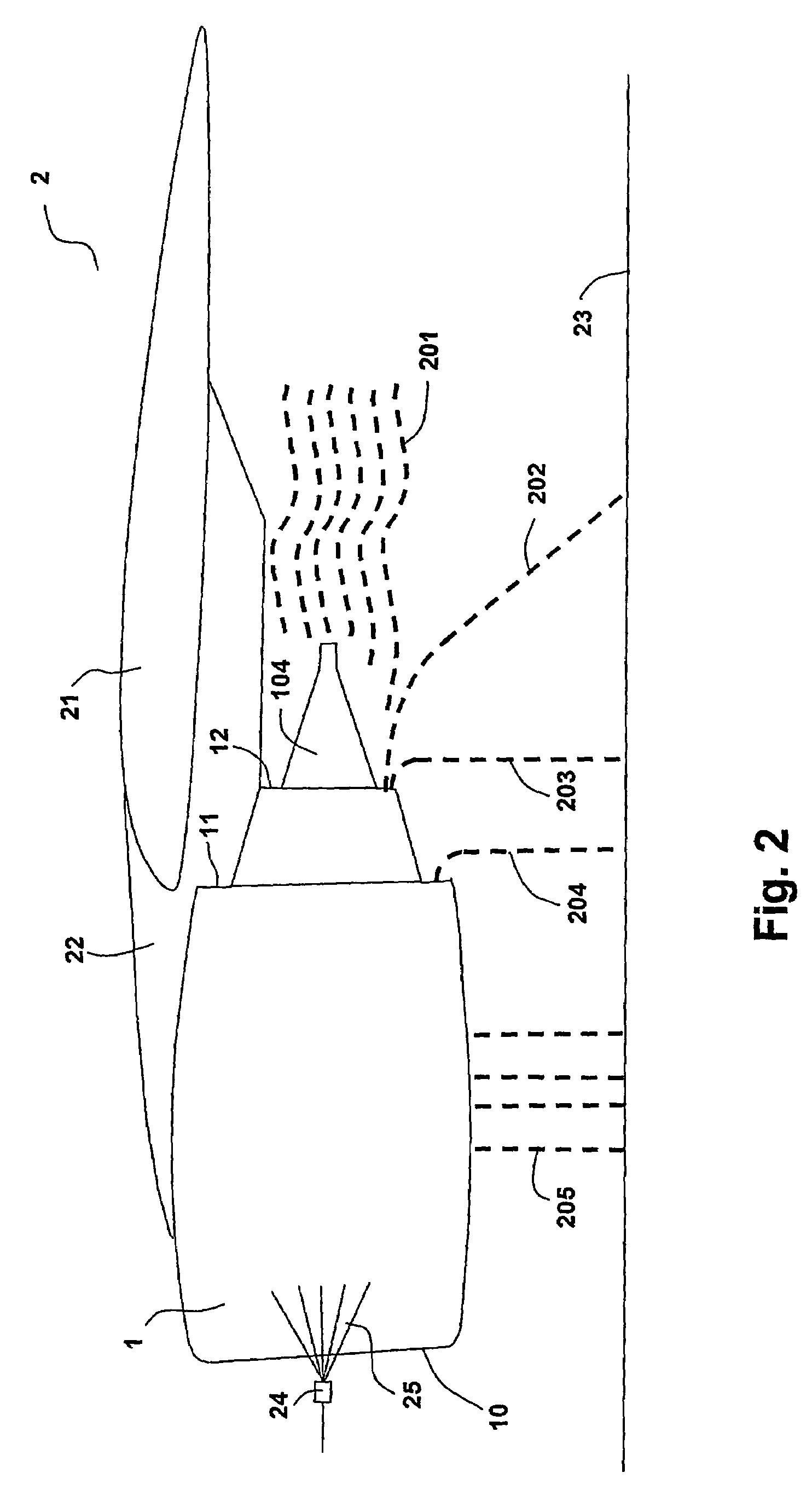

System and devices for collecting and treating waste water from engine washing

ActiveUS7297260B2Increase flexibilityLow costLiquid degasificationVehicle cleaning apparatusLiquid wasteWastewater

Owner:ECOSERVICES

Method for recovering alkali and hemicellulose from chemical fibre waste liquid

InactiveCN1450001AEfficient separationEfficient purificationArtificial filament recoveryTextile/flexible product manufactureLiquid wasteFiltration

The method for recovering alkali and hemicellulose from waste liquor produced by producing optical fibre includes the folloiwng steps: making the pressed liquor containing alkali and hemicellulose undergo the processes of prefiltration and fine filtration, and feeding it into membrane separation equipment to obtain the penetrated liquor containing alkali and concentrate containing hemicellulose, and the alkaline liquor concentration in the obtained penetrated liquor can be up to 80-250 g / l, and the final alkali content in the concentrate is 5-30 g / l, and the hemicellulose content is 100-200 g / l. Said technological process is simple, can effectively separate and purify hemicellulose and alkali liquor.

Owner:凯能高科技工程(上海)有限公司

System and method for treating waste acid gas

ActiveCN102910593ANo emissionsLower requirementEnergy inputSulfur preparation/purificationLiquid wasteSulfur

Owner:美景(北京)环保科技有限公司

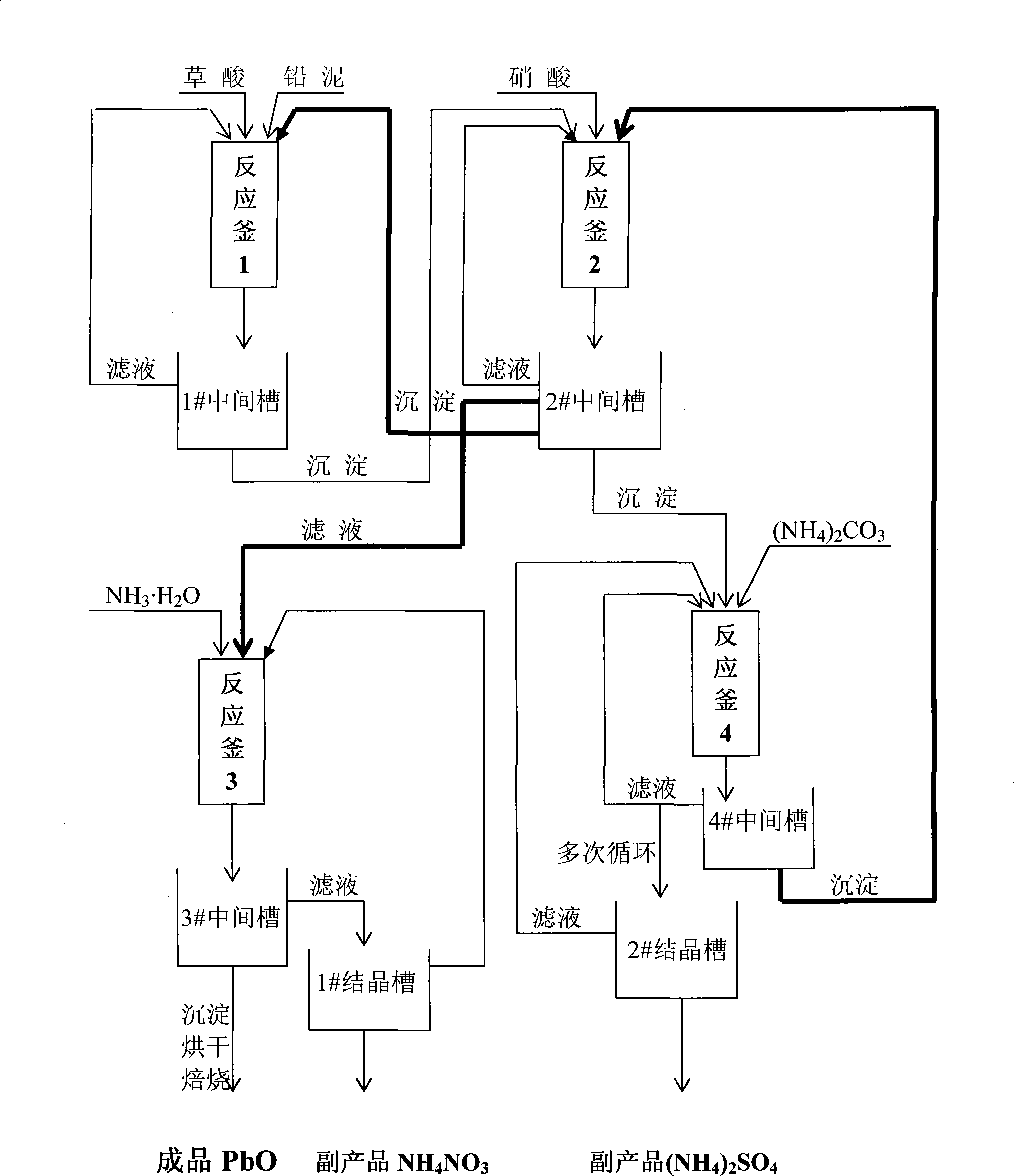

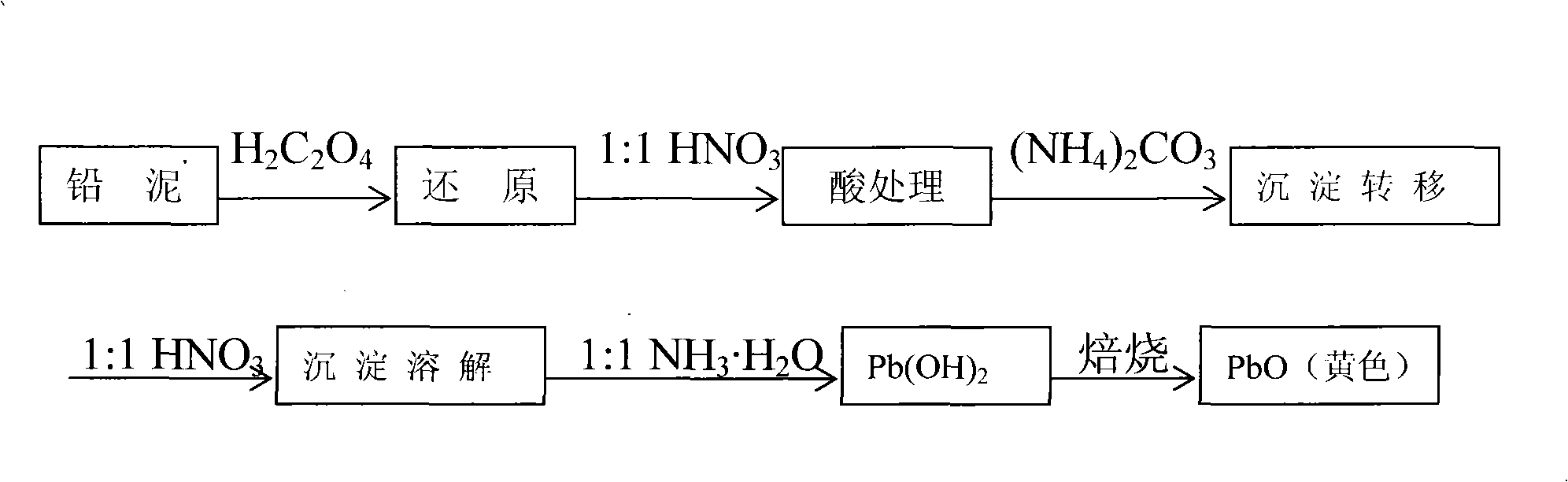

Method for recovering lead oxide by waste lead-acid storage battery

InactiveCN101514395AReduce energy consumptionReduce pollutionProcess efficiency improvementLiquid wasteFiltration

A method for recovering lead oxide by a waste lead-acid storage battery is disclosed. The waste lead-acid storage battery is crushed together with lead slime subsequent to acid cleaning, a grid plate and a filler comprising the lead slime are obtained by screening, the grid plate is fused-cast to an alloy ingot, the filler and the lead slime are ball-milled, and fine stuff is added with saturated oxalic acid solution for reaction at 25-65 DEG C and then for filtering and depositing; the deposition is then treated by excessive 30% nitric acid at the temperature of 40-45 DEG C for subsequent filtration and deposition, and the deposition is reacted with 4wt% sal volatile at the temperature of 25-65 DEG C for subsequent filtration and deposition; the deposition is added into recovered HNO3 to be dissolved at the temperature 40-45 DEG C until no bubble is generated, the filtered filtrate is added with 25% ammonia for reaction, filtration, washing and deposition to be neutral, and the lead oxide is obtained by drying and roasting. Recoverable nitramine and ammonium sulfate are recycled in all the filtrates in the technologies; thereby discharging no waste liquid. The utilization rate of raw material is 90.1-92.1%, the yield is 95.0-96.7%, and the content of PbO is 98.0-98.9%.

Owner:DALIAN WUHUATIANBAO TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com