Patents

Literature

342results about How to "Guaranteed efficient growth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

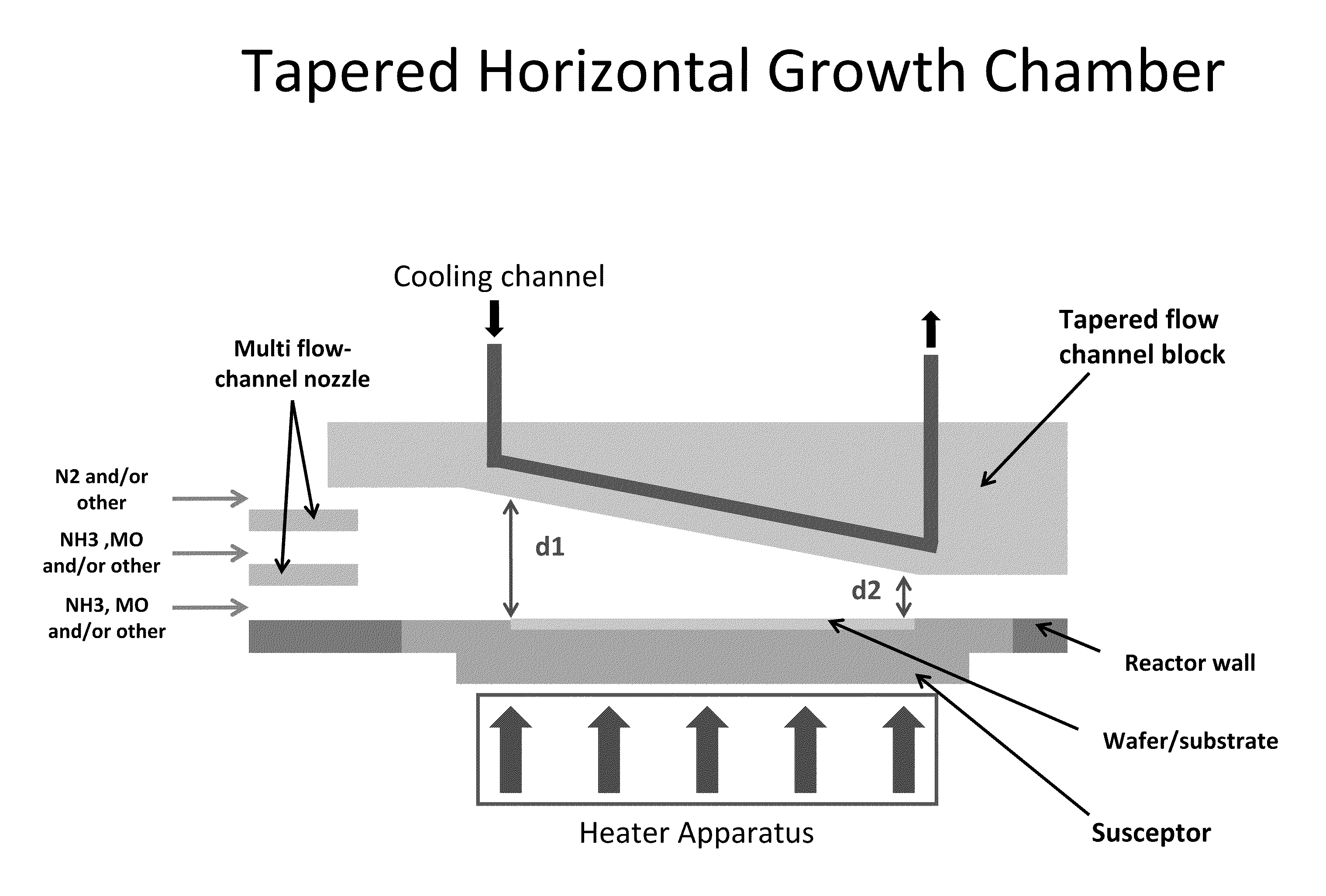

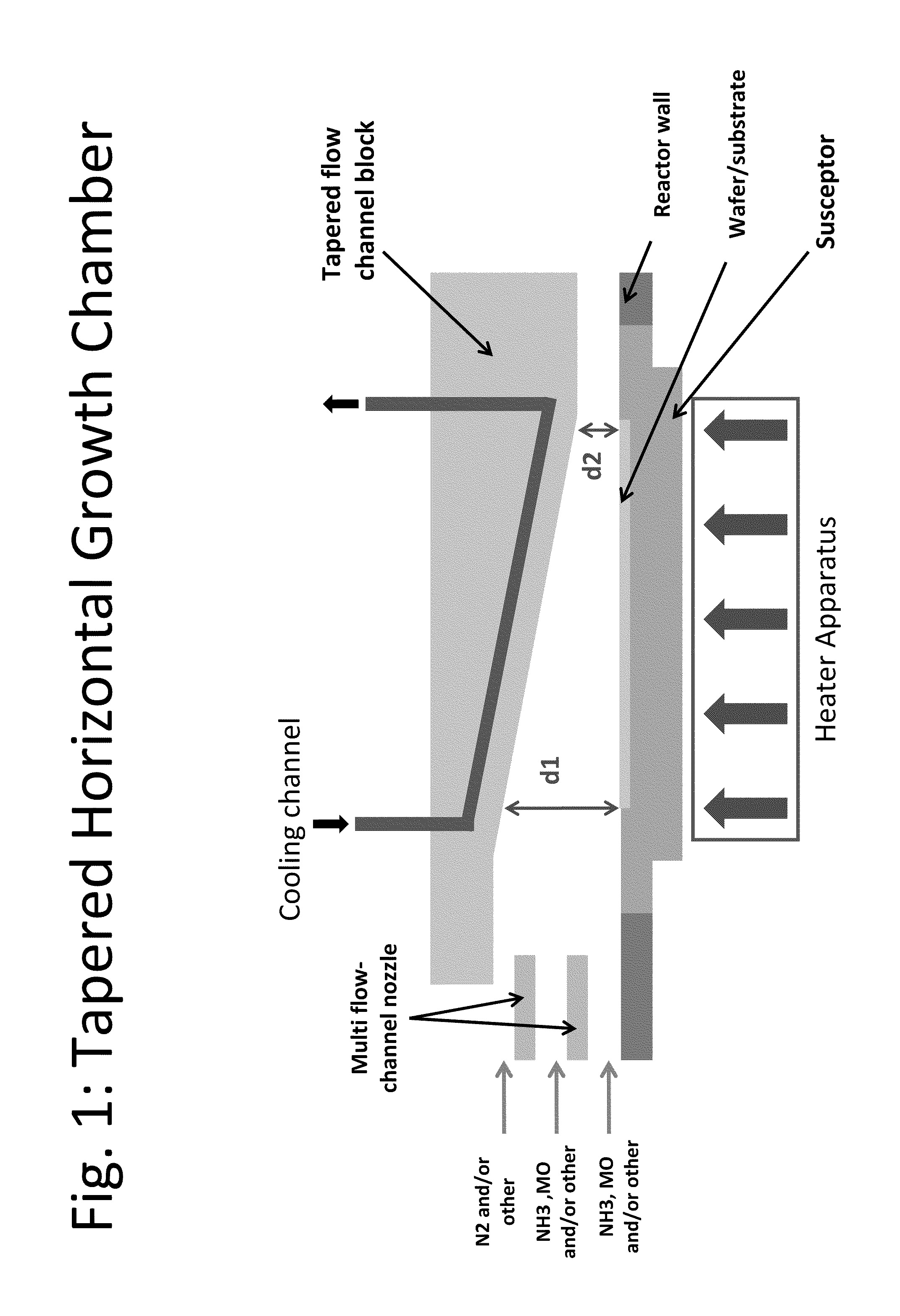

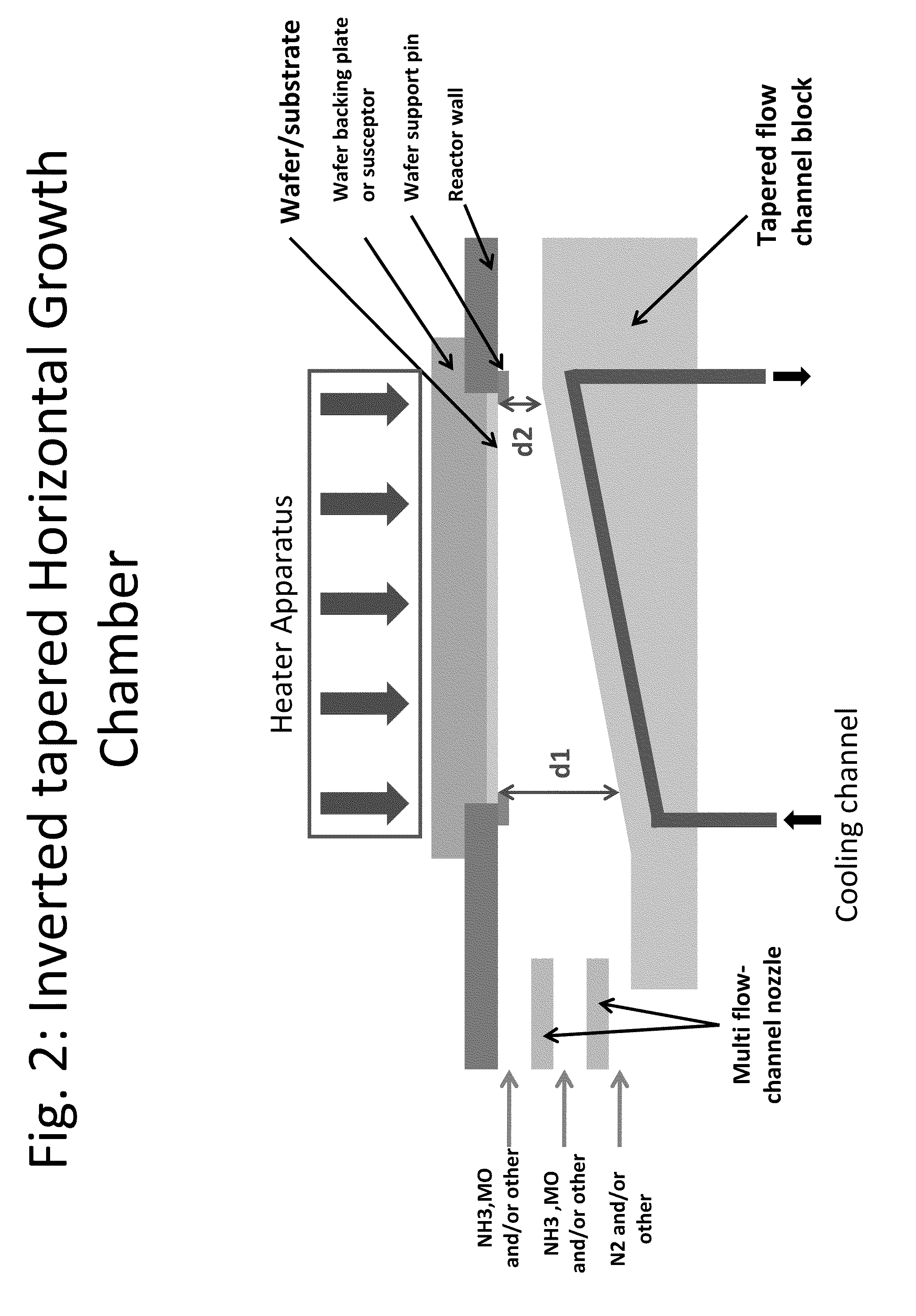

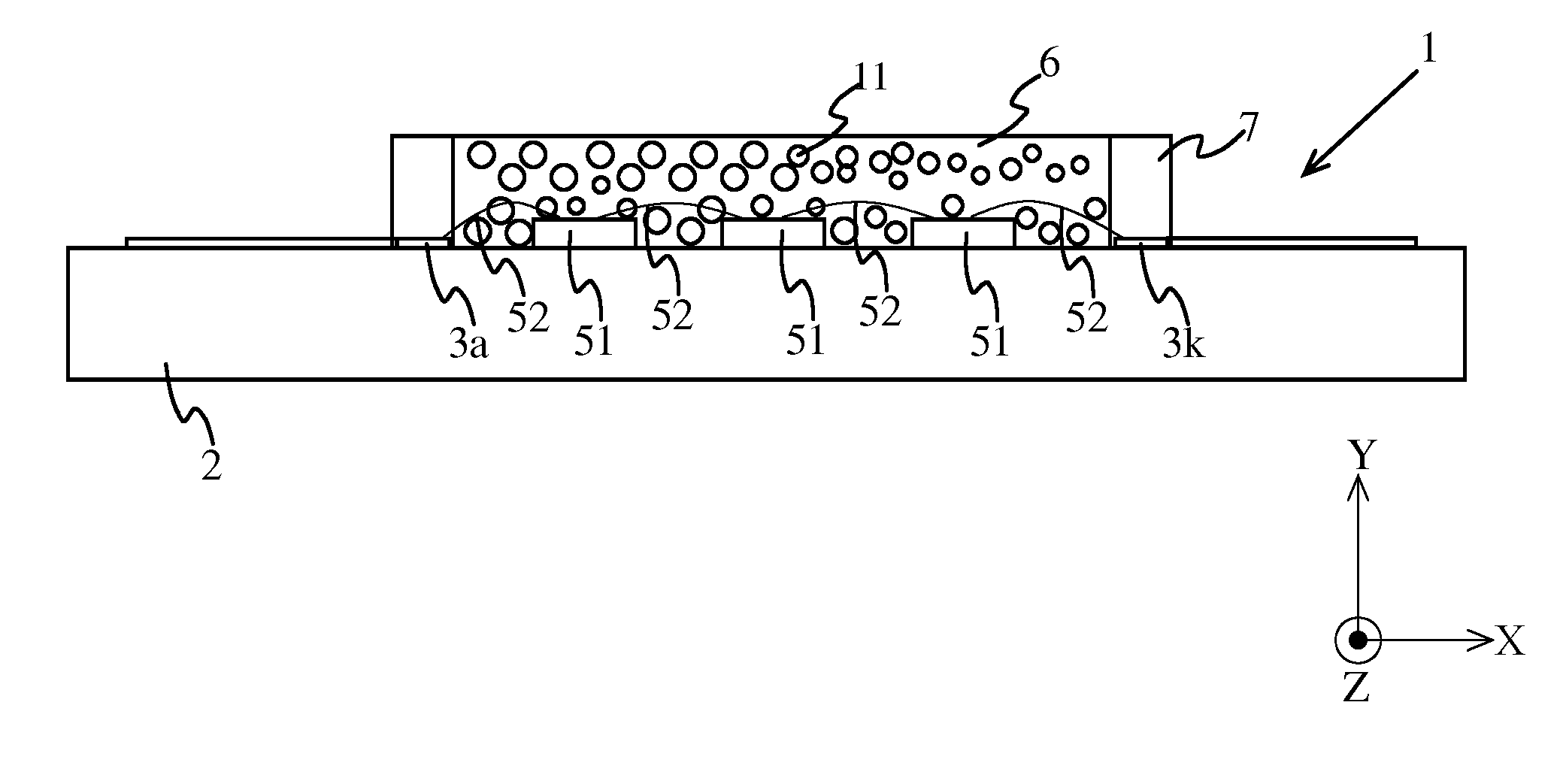

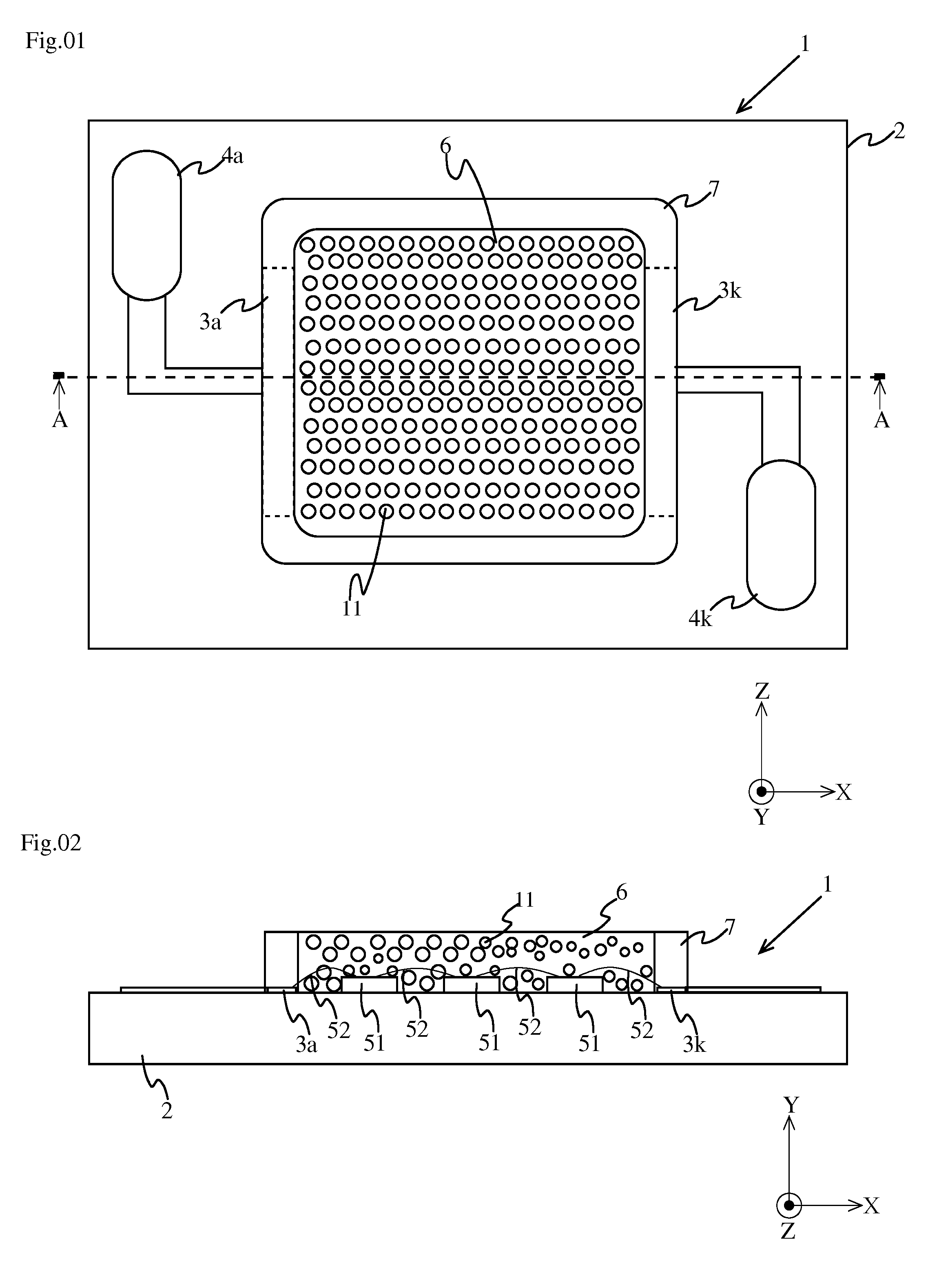

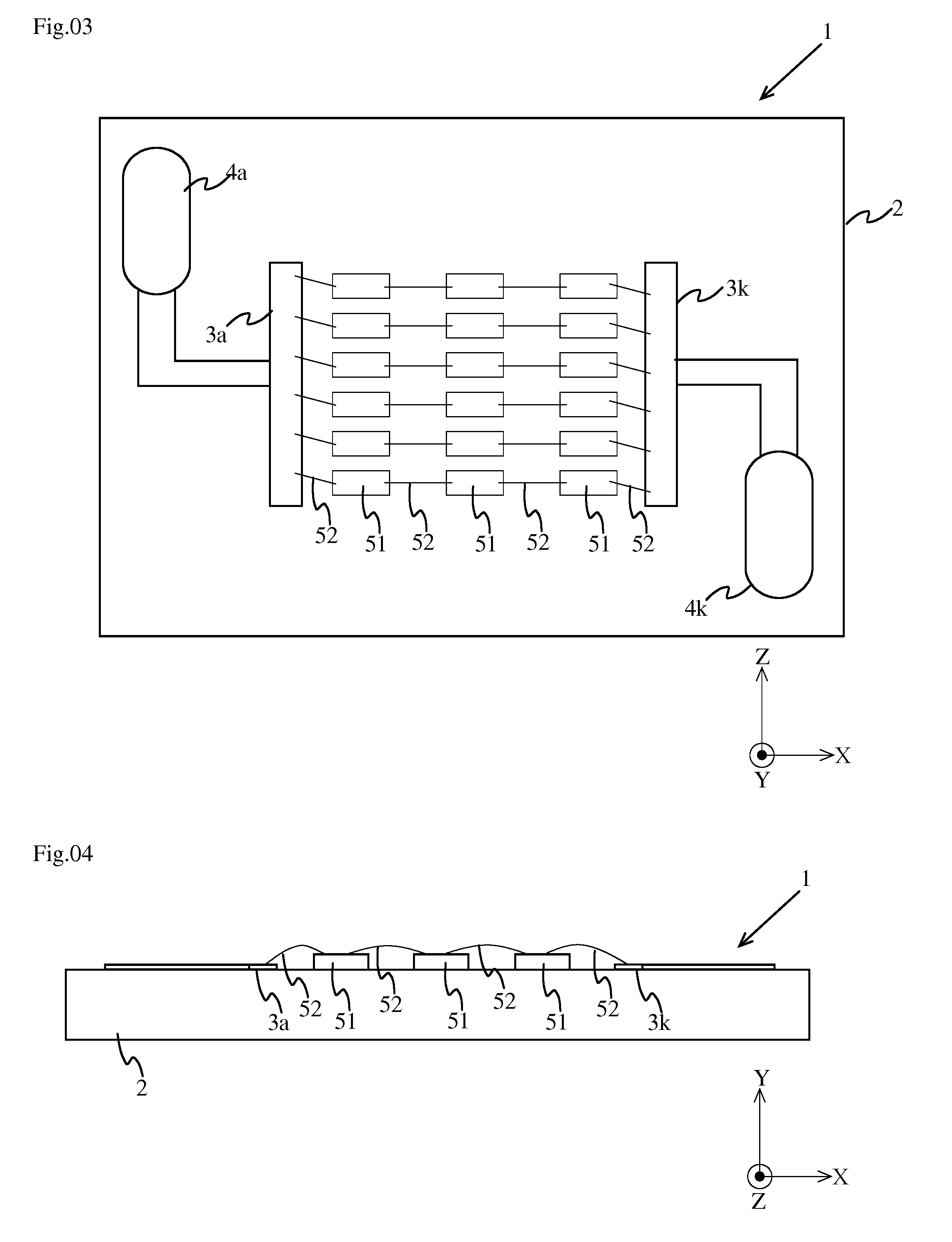

Tapered Horizontal Growth Chamber

InactiveUS20110247556A1Guaranteed efficient growthEfficient reactionPolycrystalline material growthLiquid surface applicatorsSusceptorEngineering

A system and techniques for performing deposition having a tapered horizontal growth chamber which includes a susceptor and a tapered channel flow block. A tapered chamber is formed between the susceptor and the tapered channel flow block. Gaseous species introduced are forced by the tapered channel block to flow toward the susceptor to enhance the efficiency of reactions between the gases species and a wafer on the susceptor.

Owner:KYOCERA SLD LASER INC

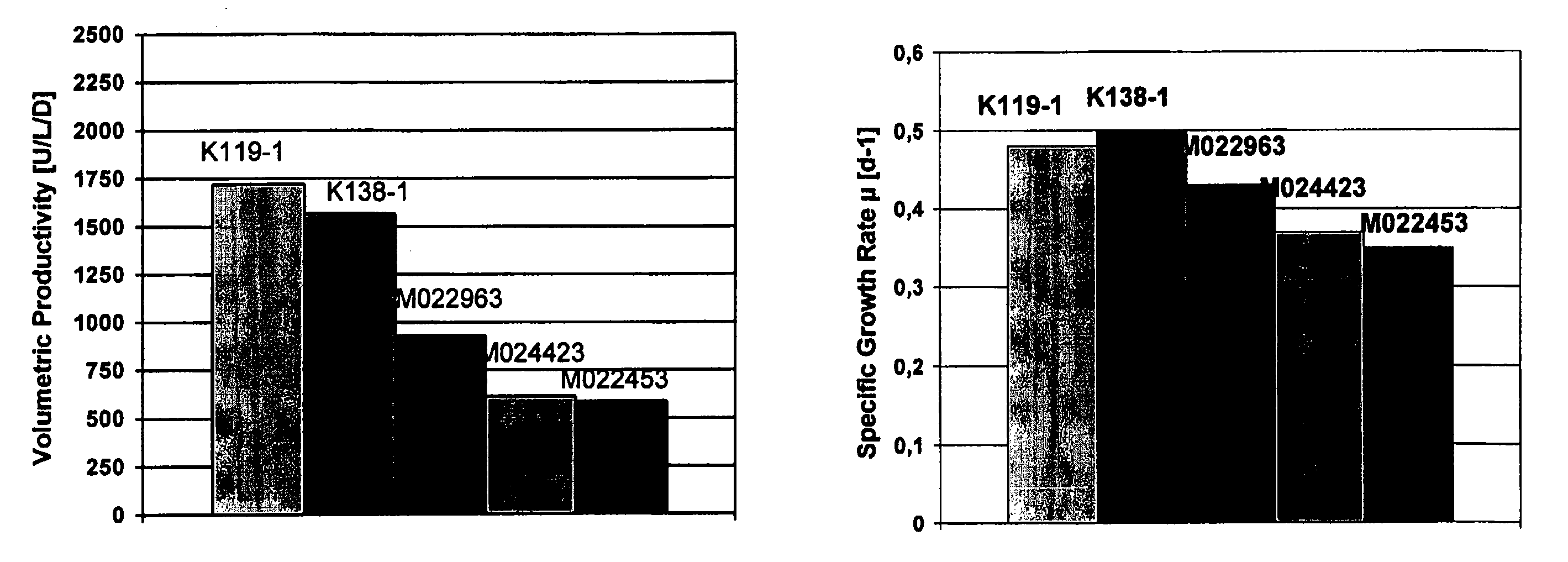

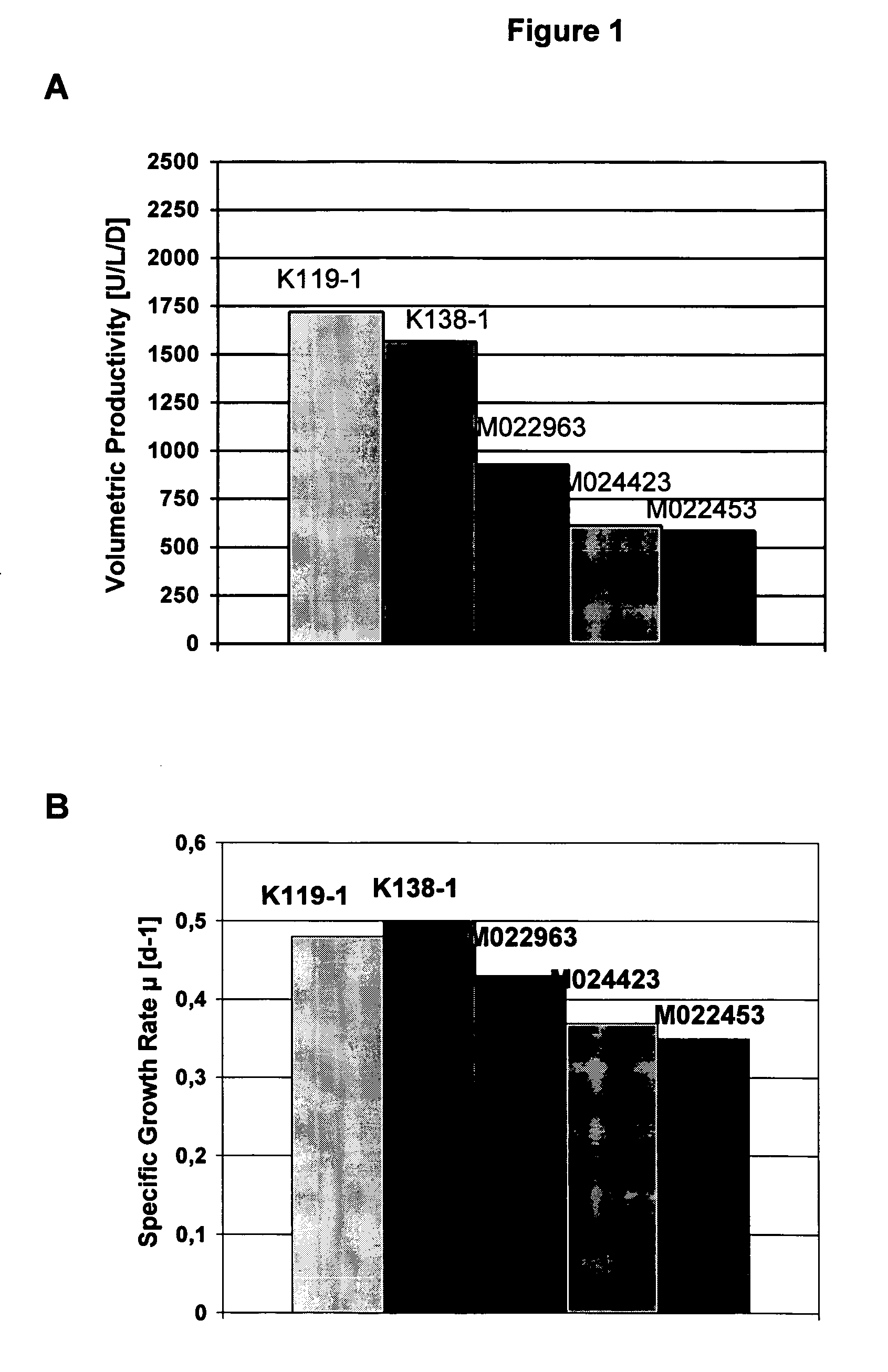

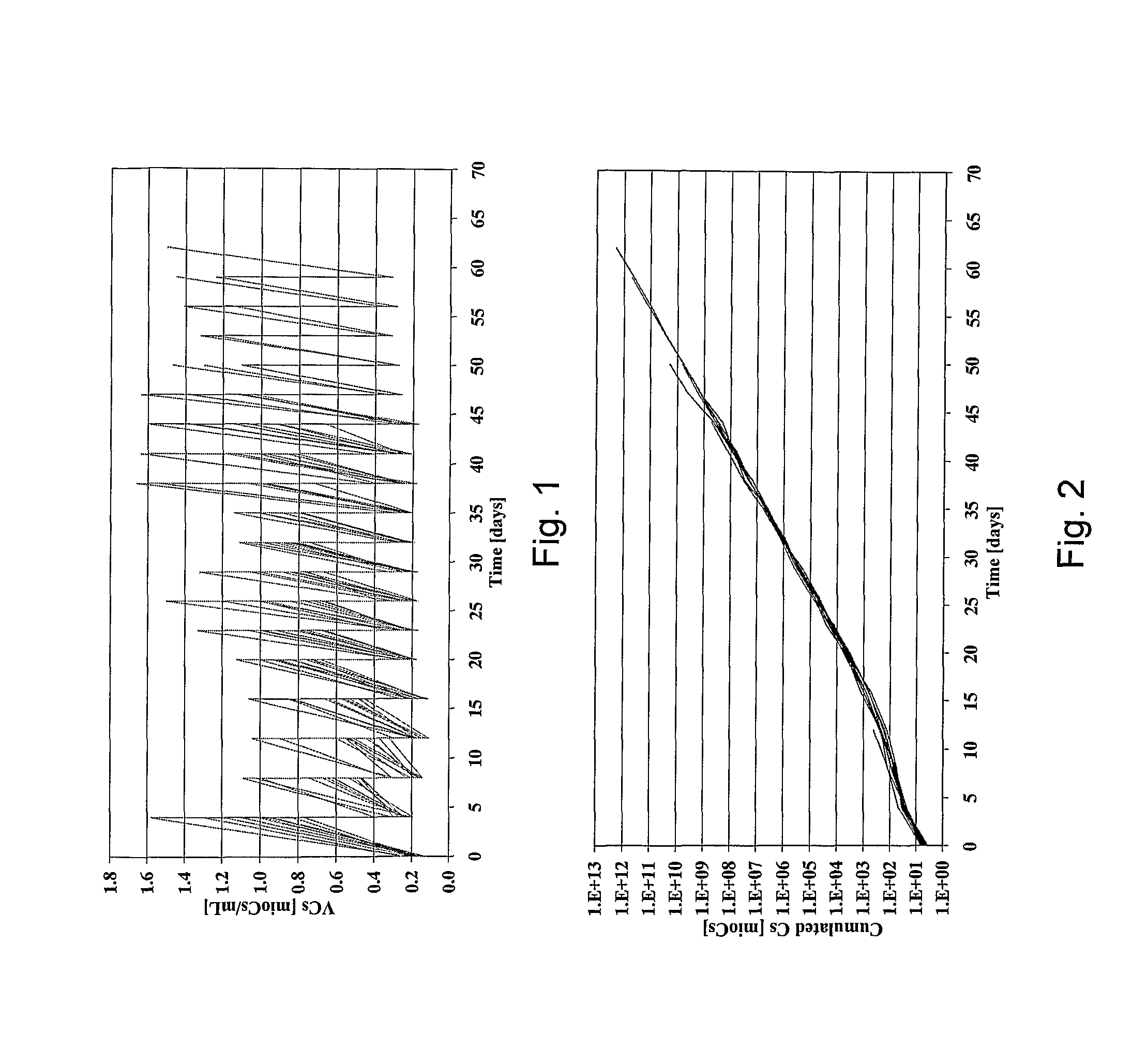

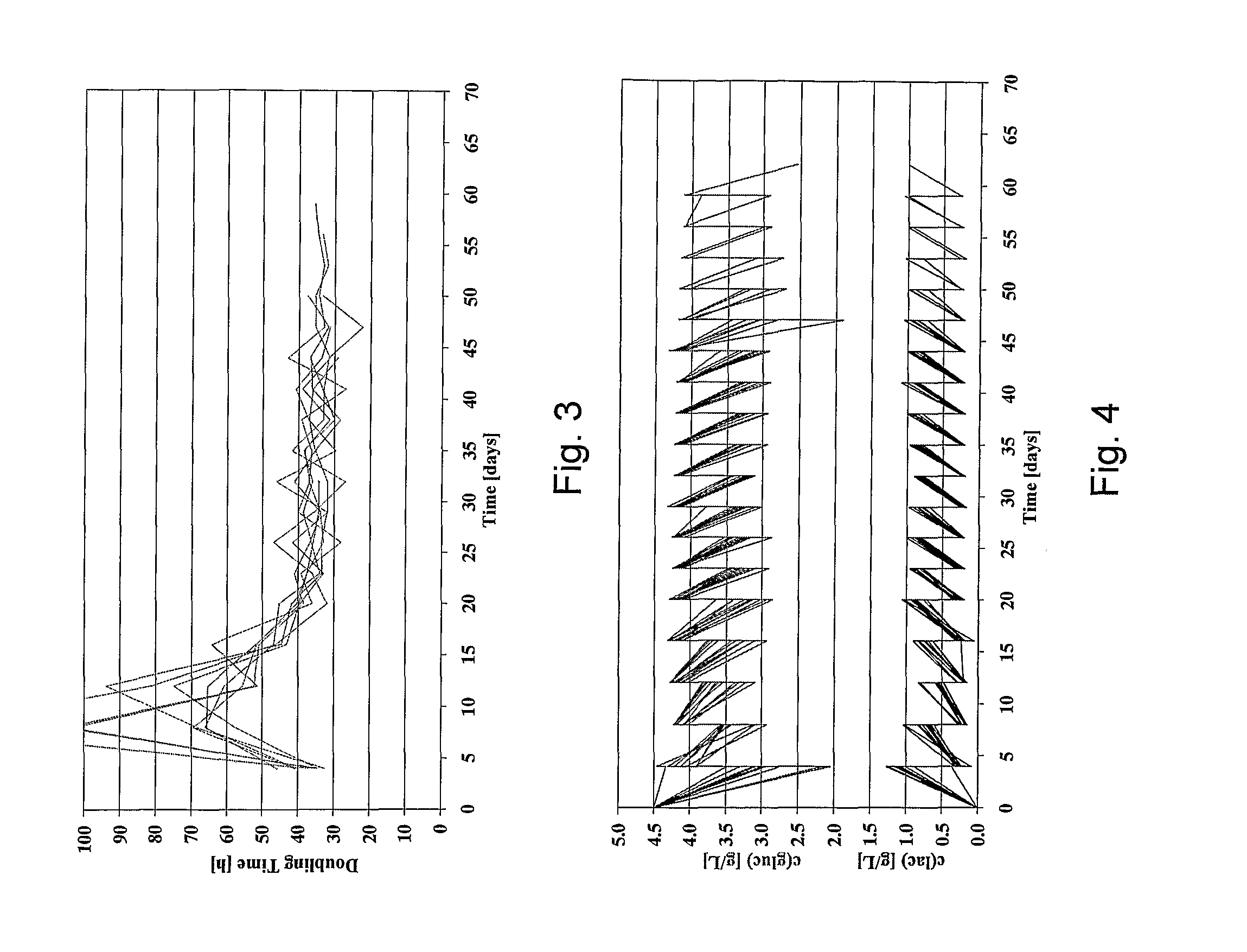

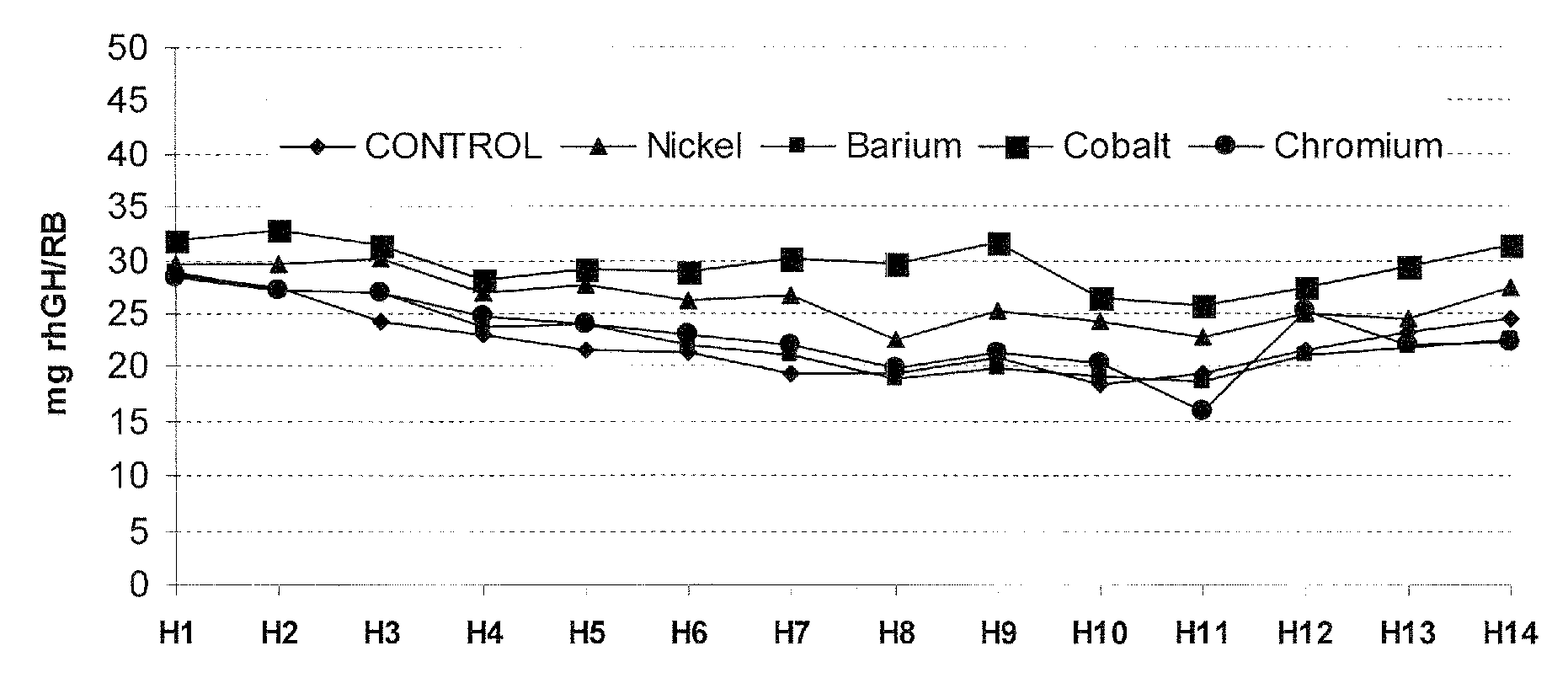

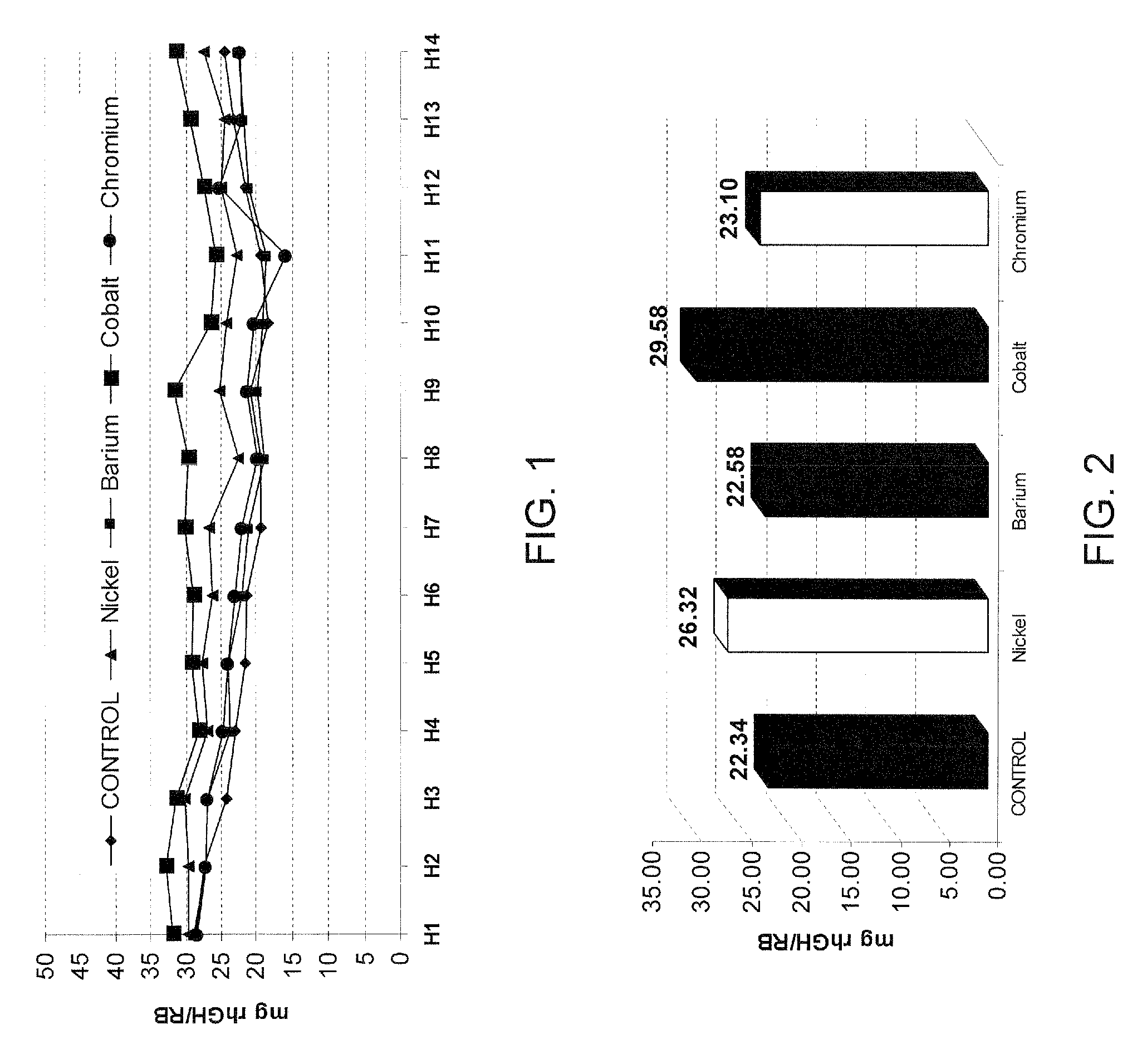

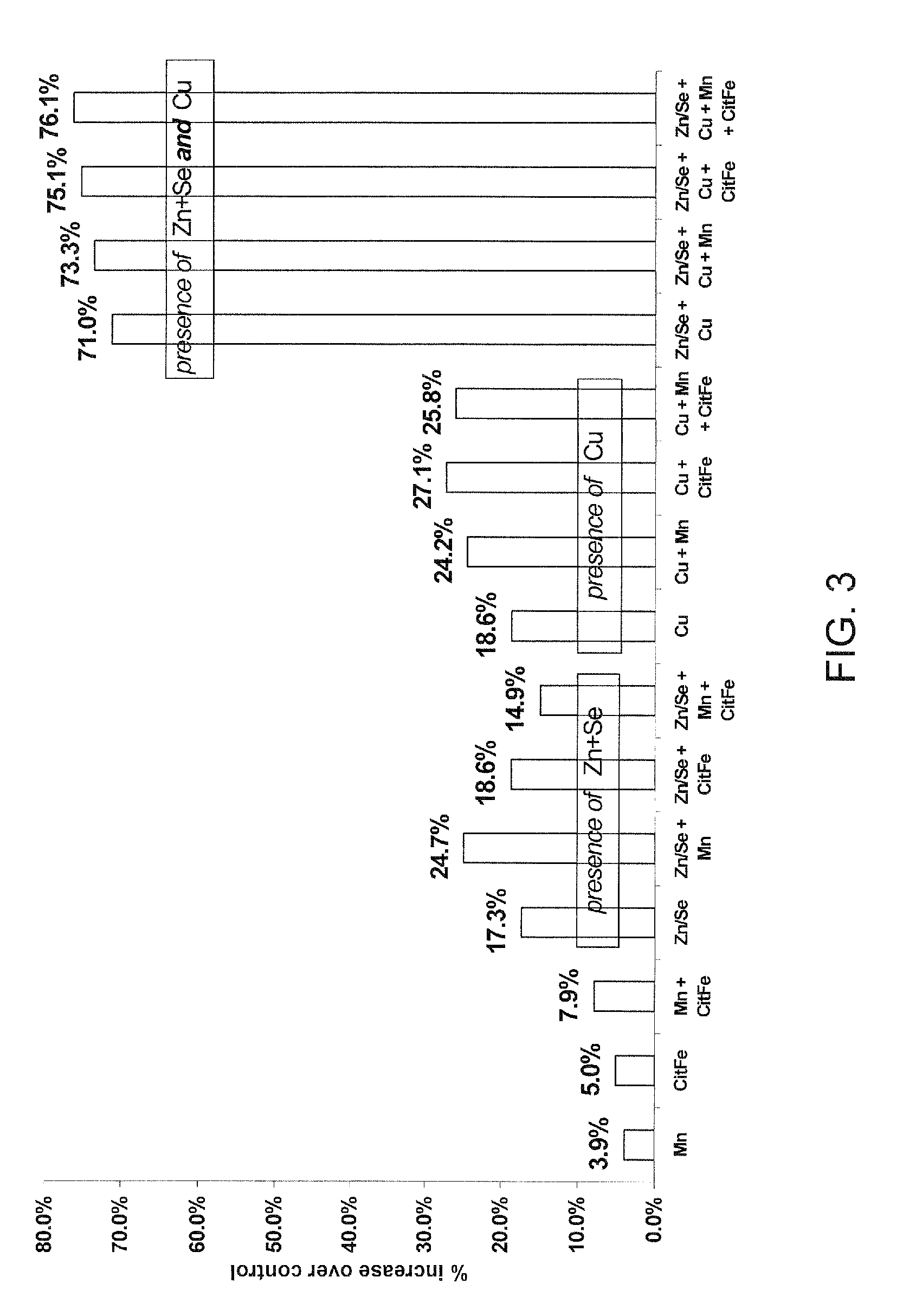

Animal protein-free media for cultivation of cells

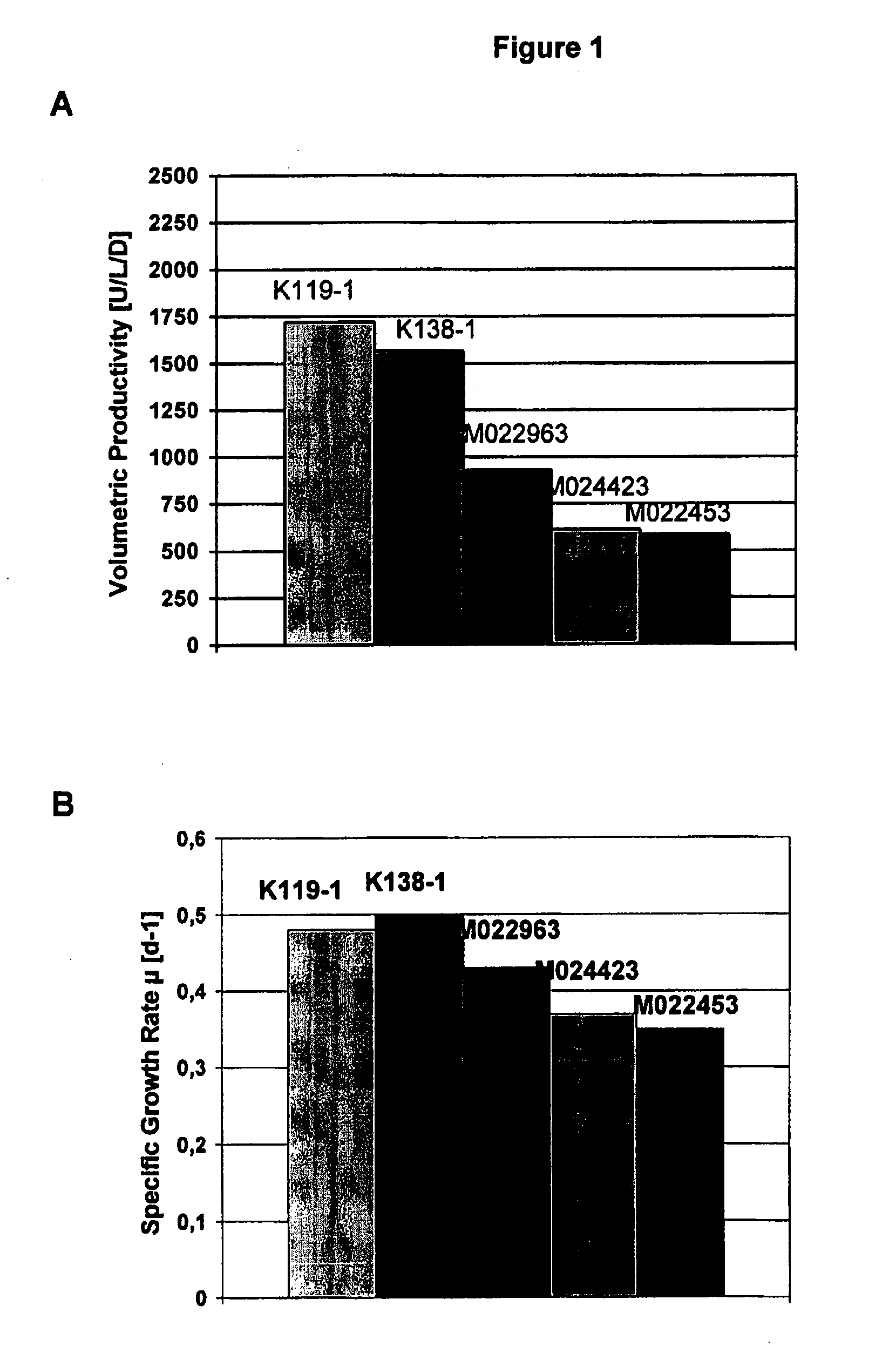

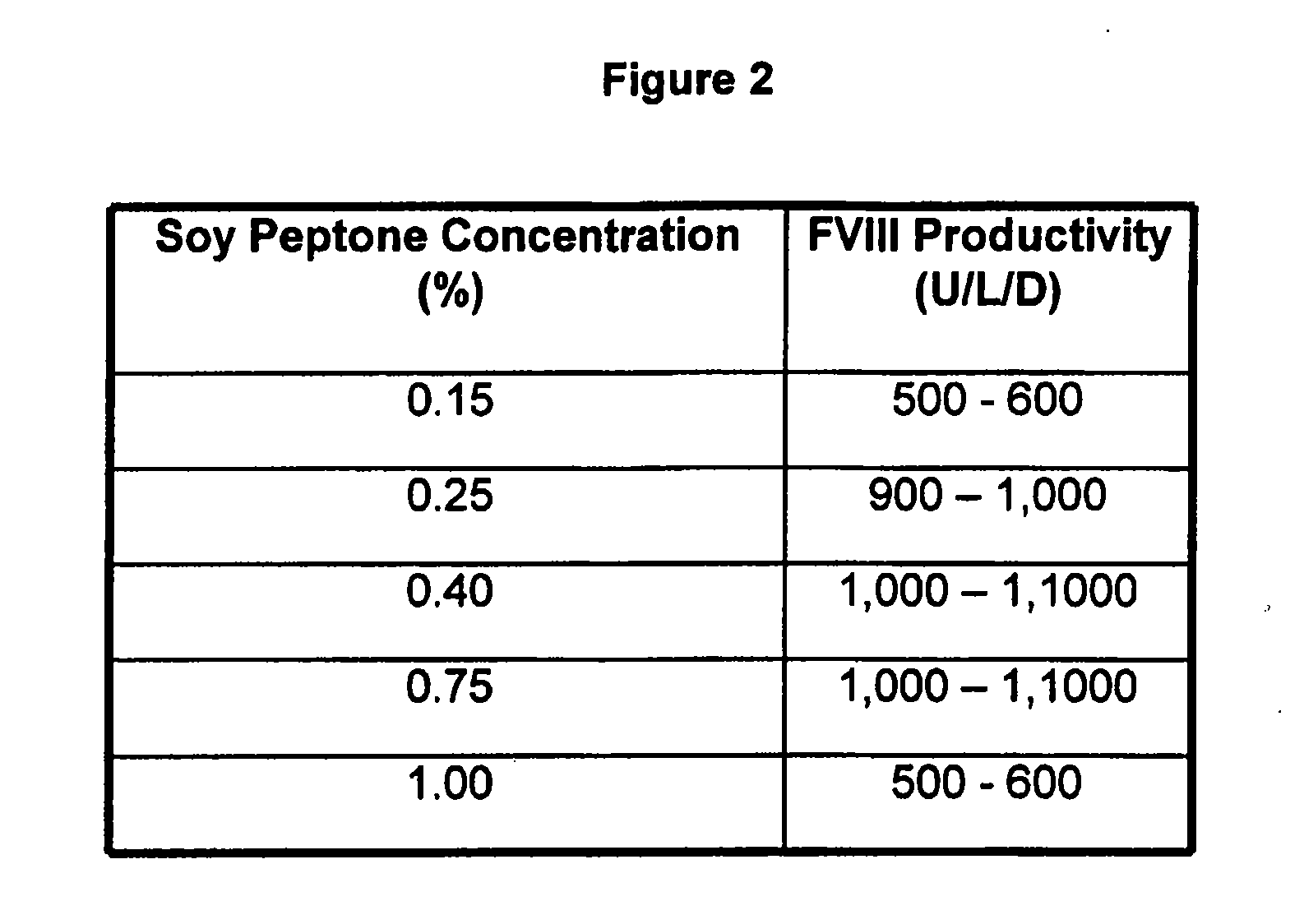

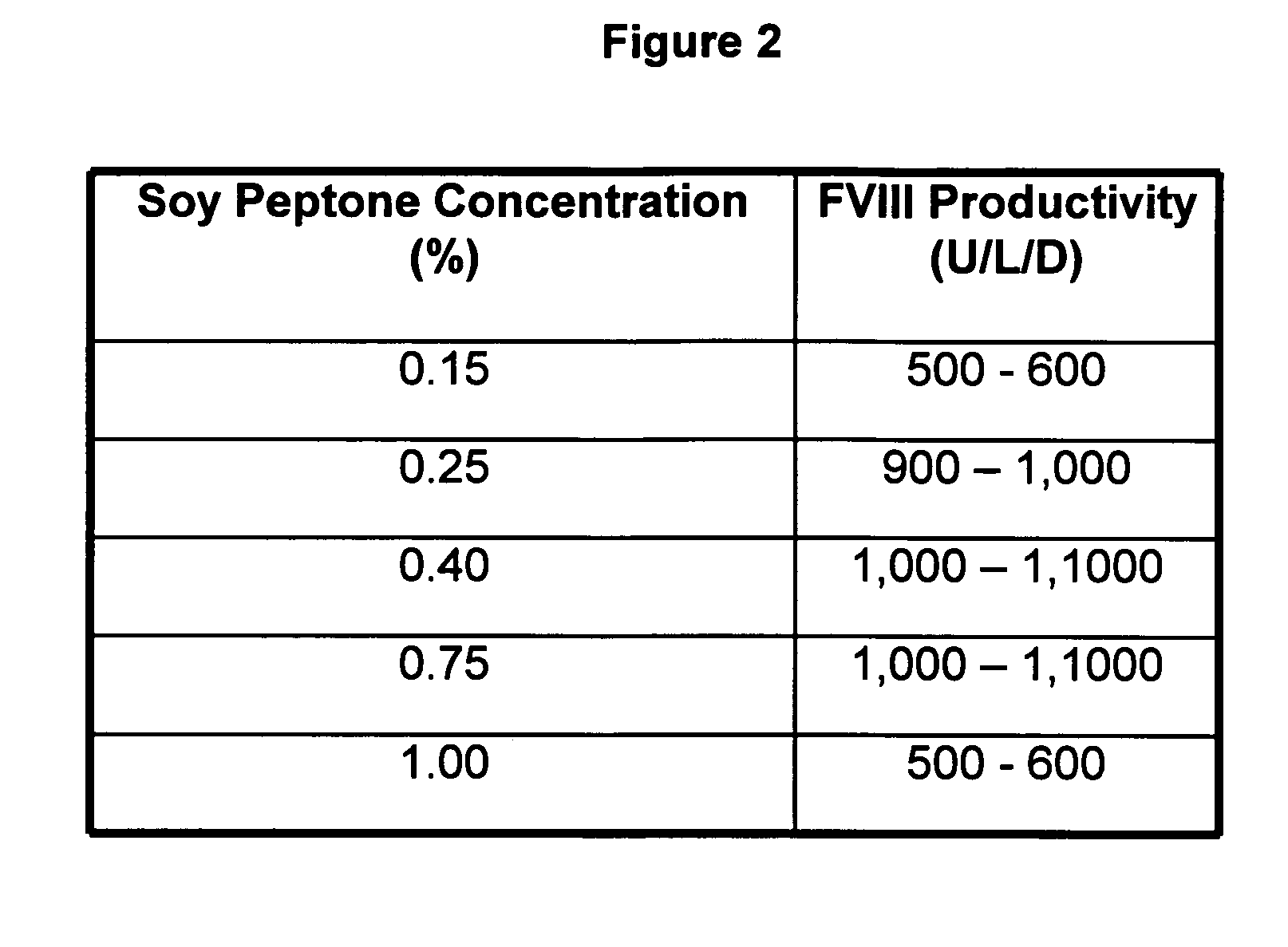

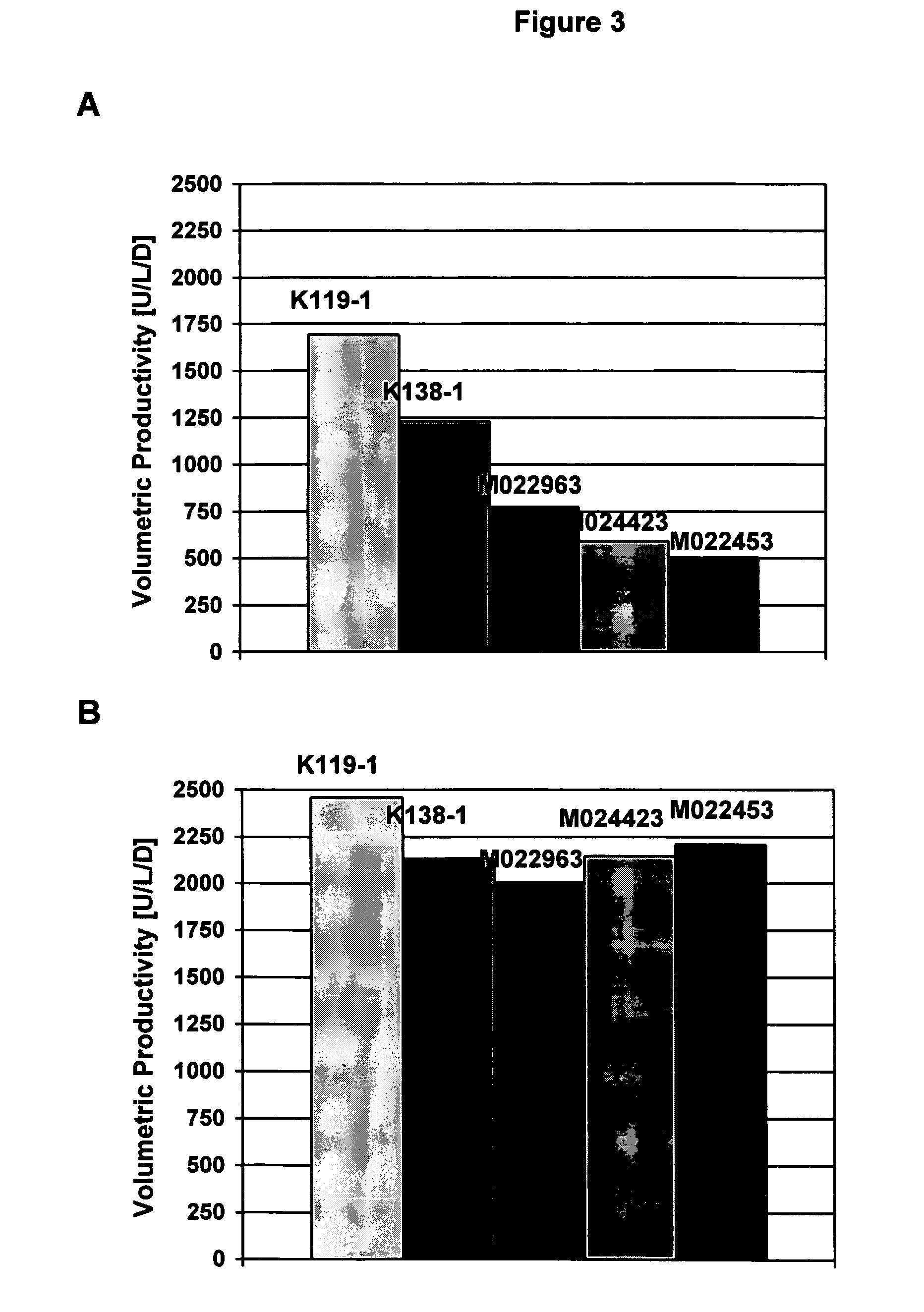

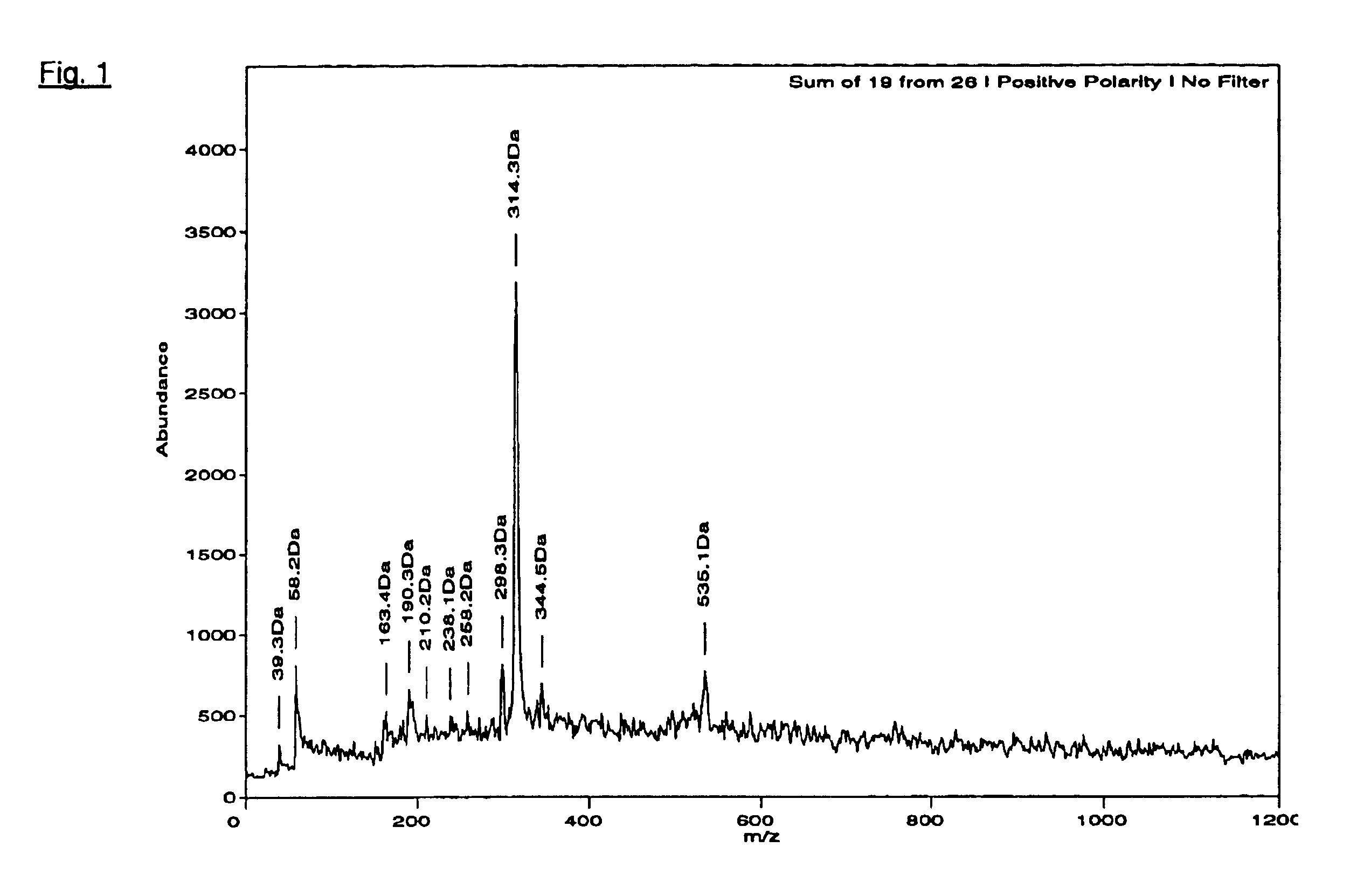

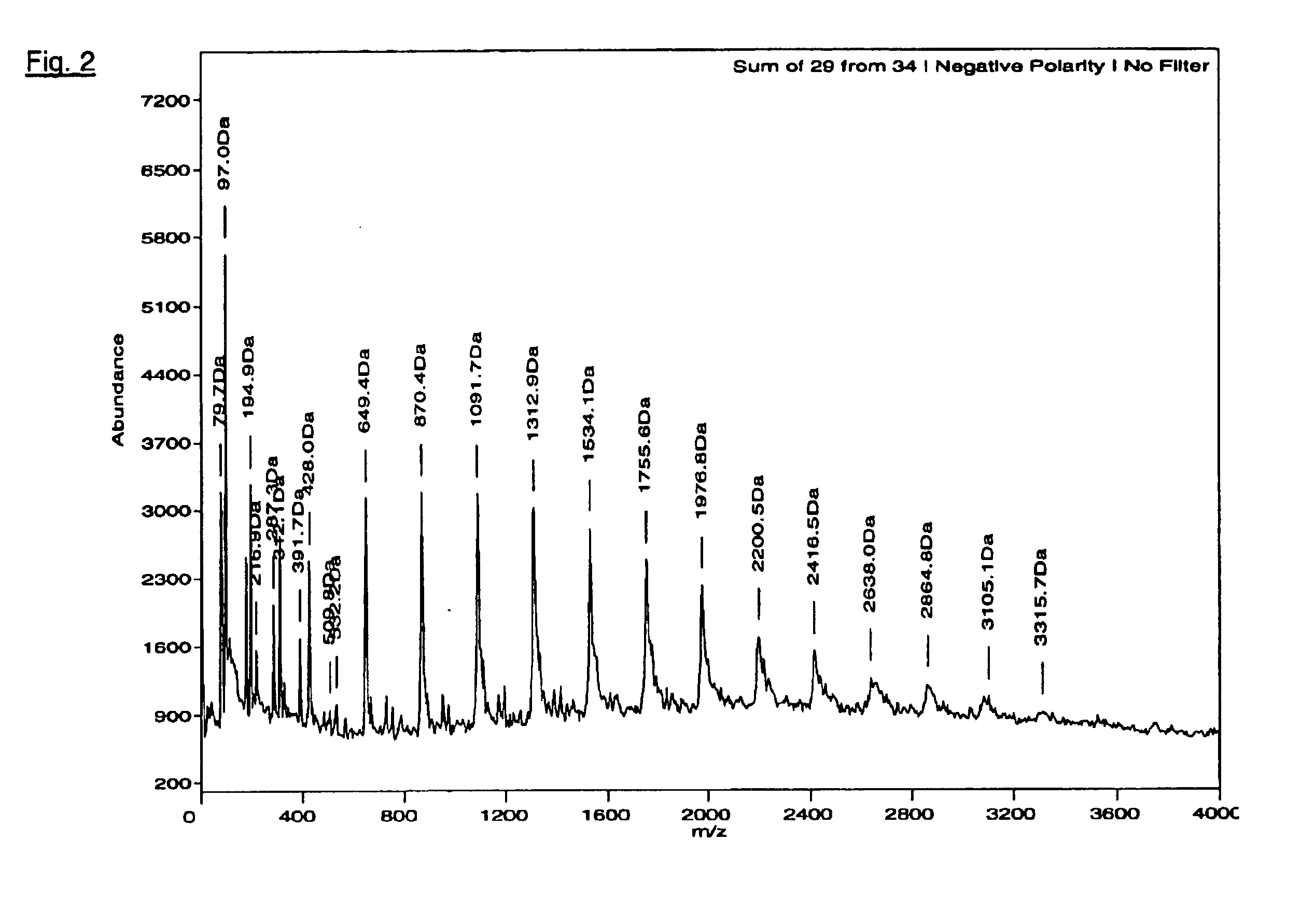

InactiveUS20080009040A1Efficient expressionGuaranteed efficient growthMicroorganismsCulture processHydrolysateCell culture media

The present invention relates to animal protein-free cell culture media comprising polyamines and a plant- and / or yeast-derived hydrolysate. The invention also relates to animal protein-free culturing processes, wherein cells can be cultivated, propagated and passaged without adding supplementary animal proteins in the culture medium. These processes are useful in cultivating cells, such as recombinant cells or cells infected with a virus, and for producing biological products by cell culture processes.

Owner:BAXTER INT INC +1

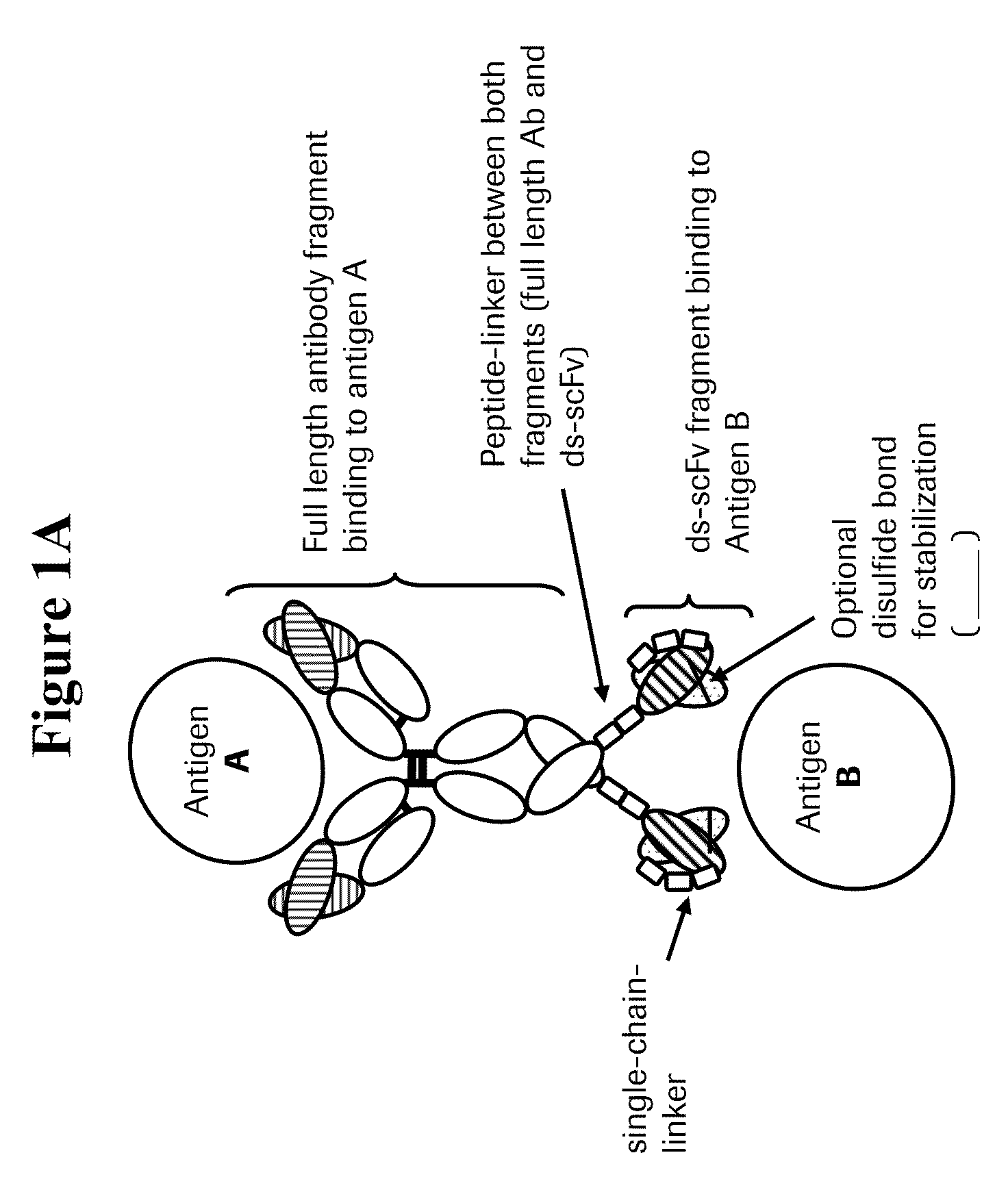

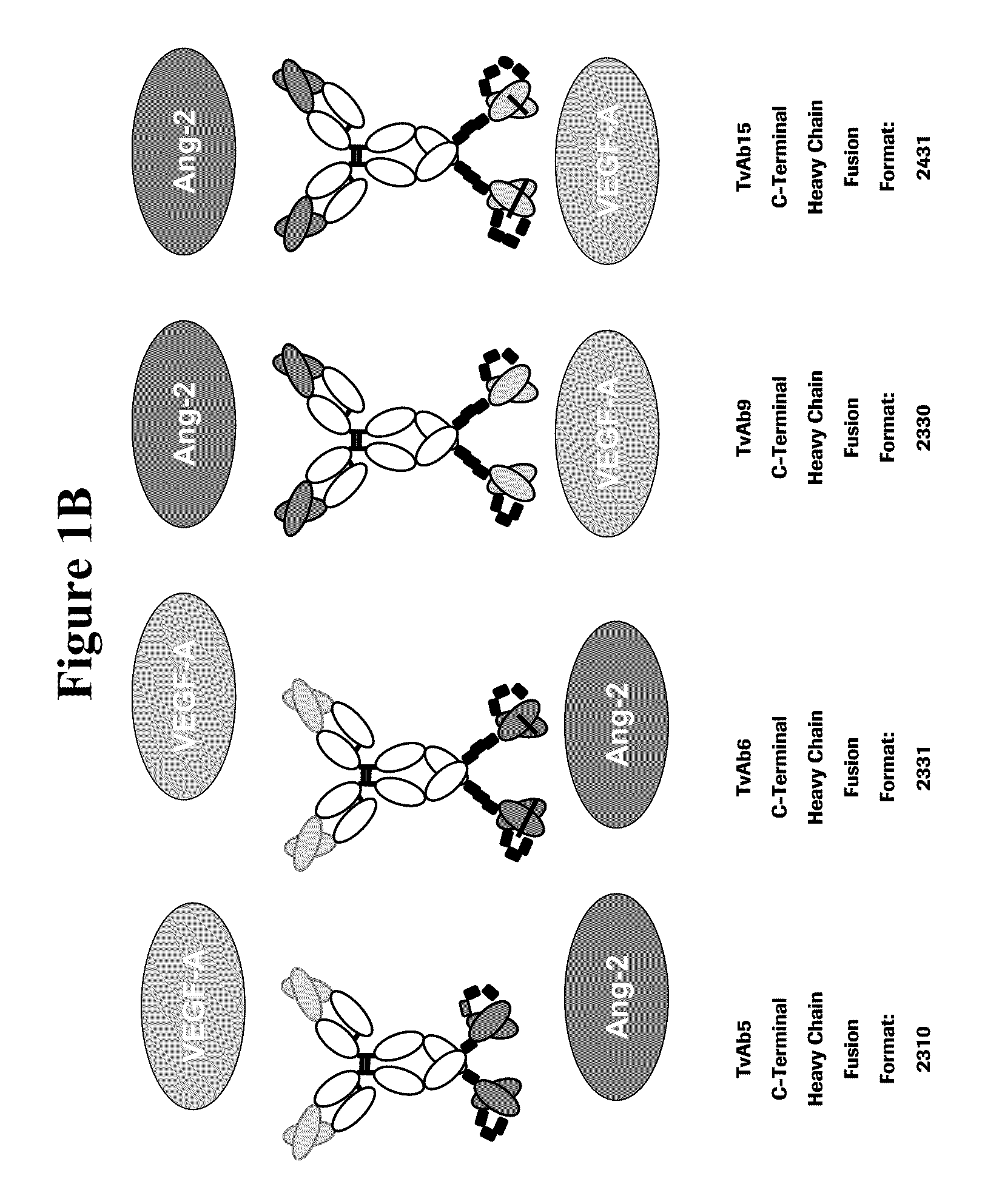

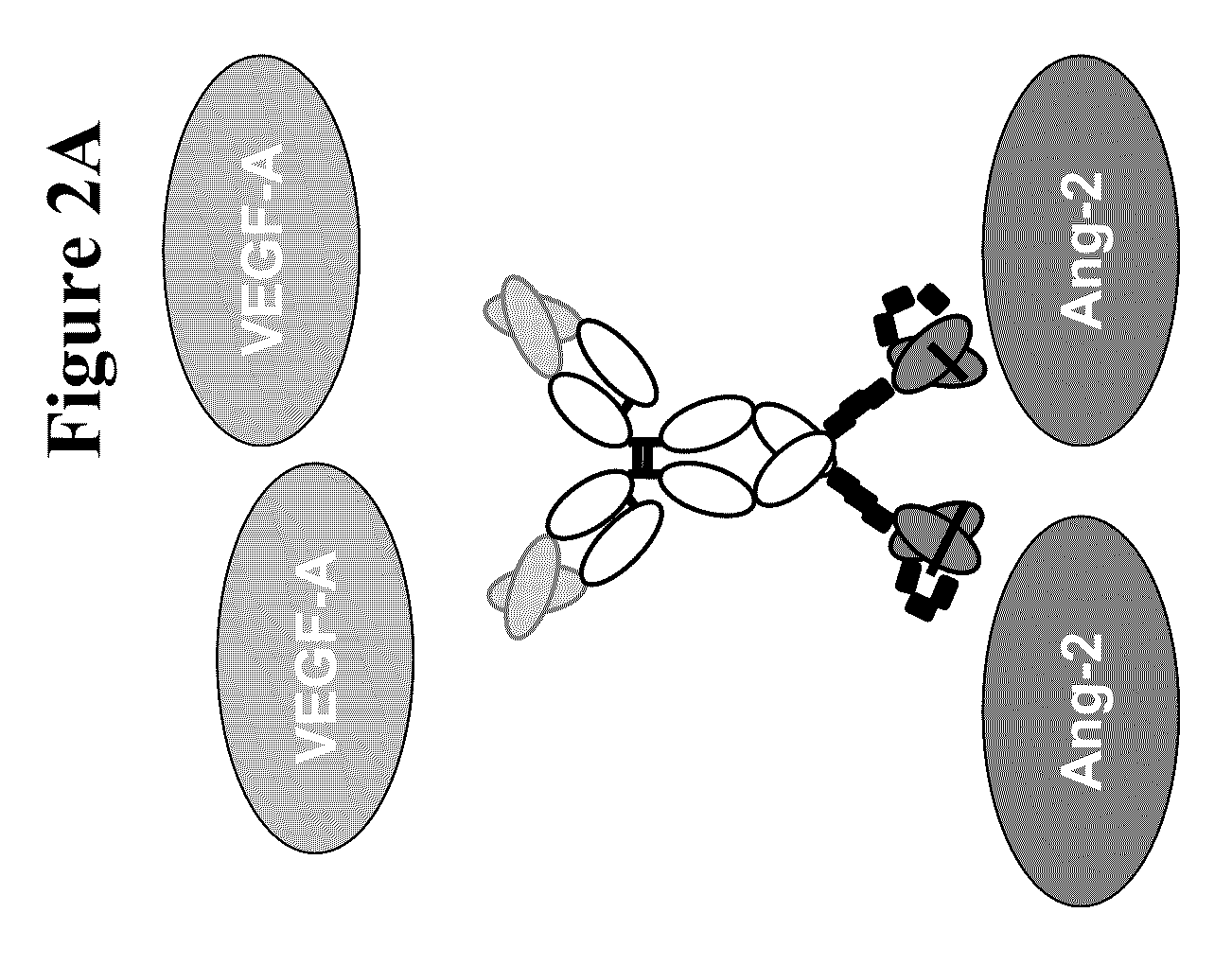

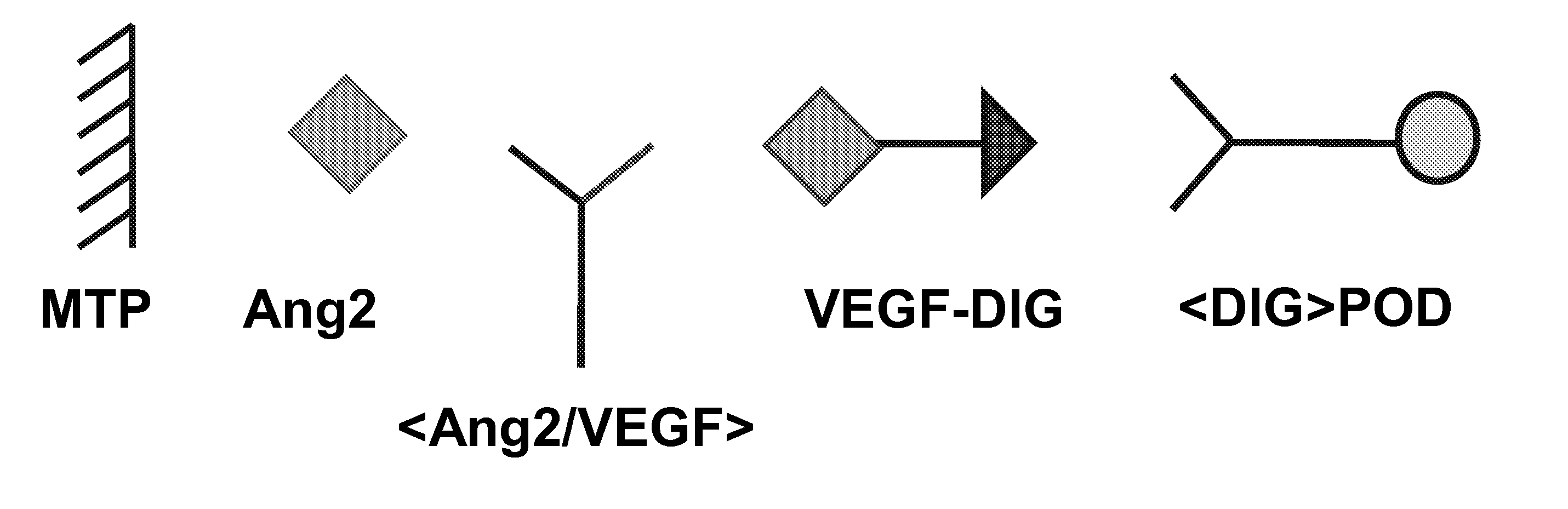

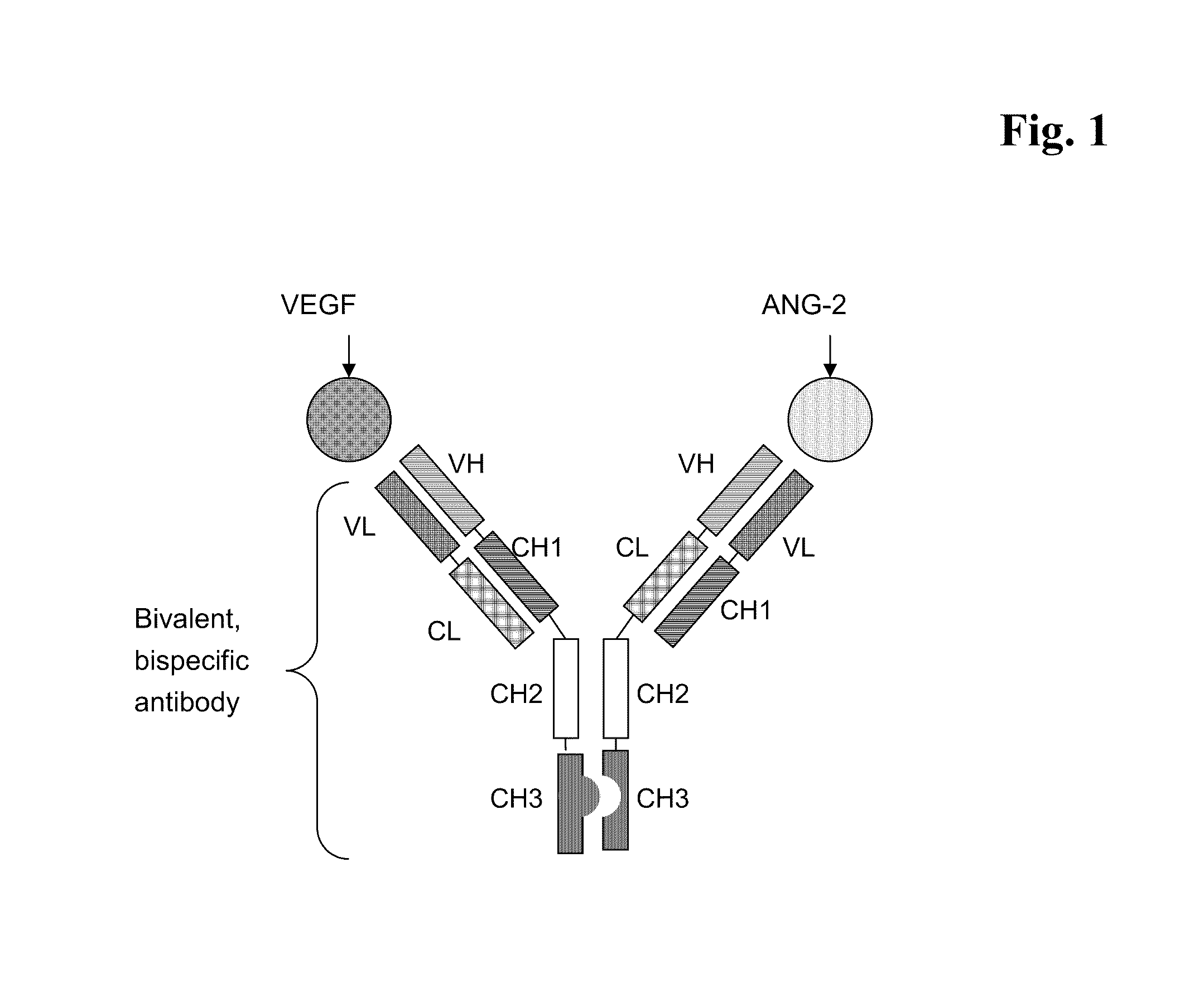

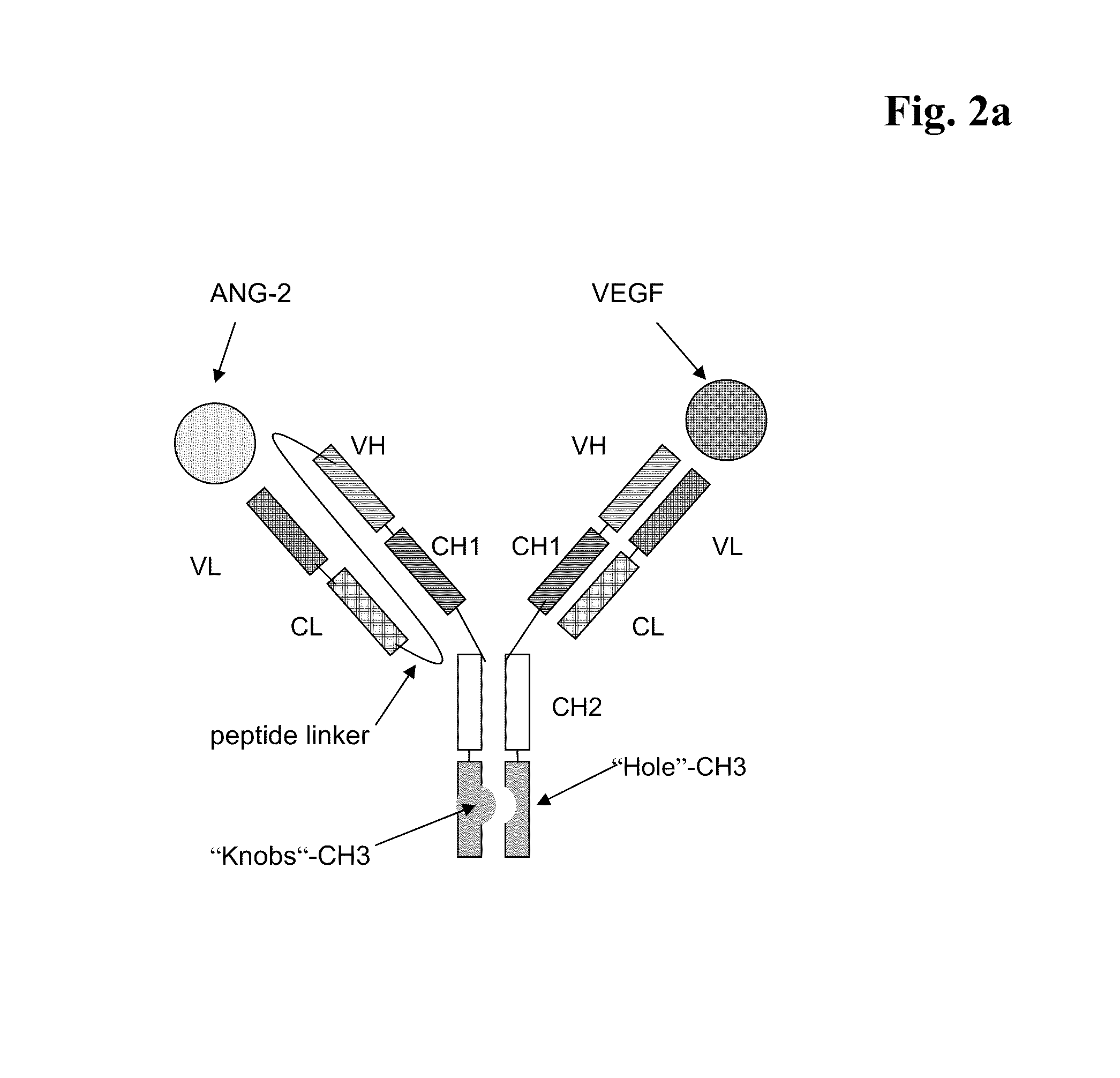

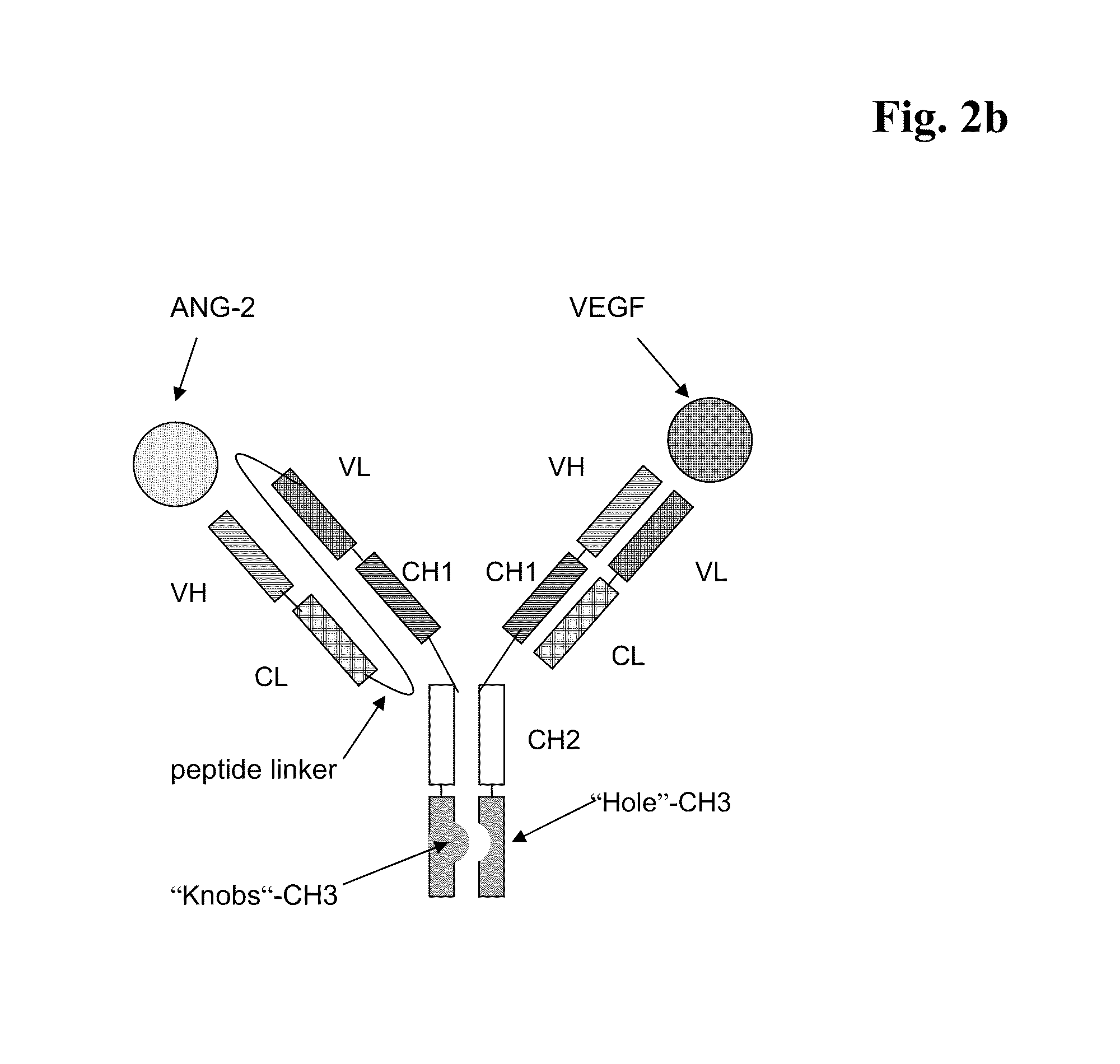

Bispecific anti-VEGF/anti-ANG-2 antibodies

ActiveUS8268314B2Guaranteed efficient growthInhibition is effectiveSenses disorderNervous disorderBispecific antibodyCancer research

Owner:F HOFFMANN LA ROCHE & CO AG

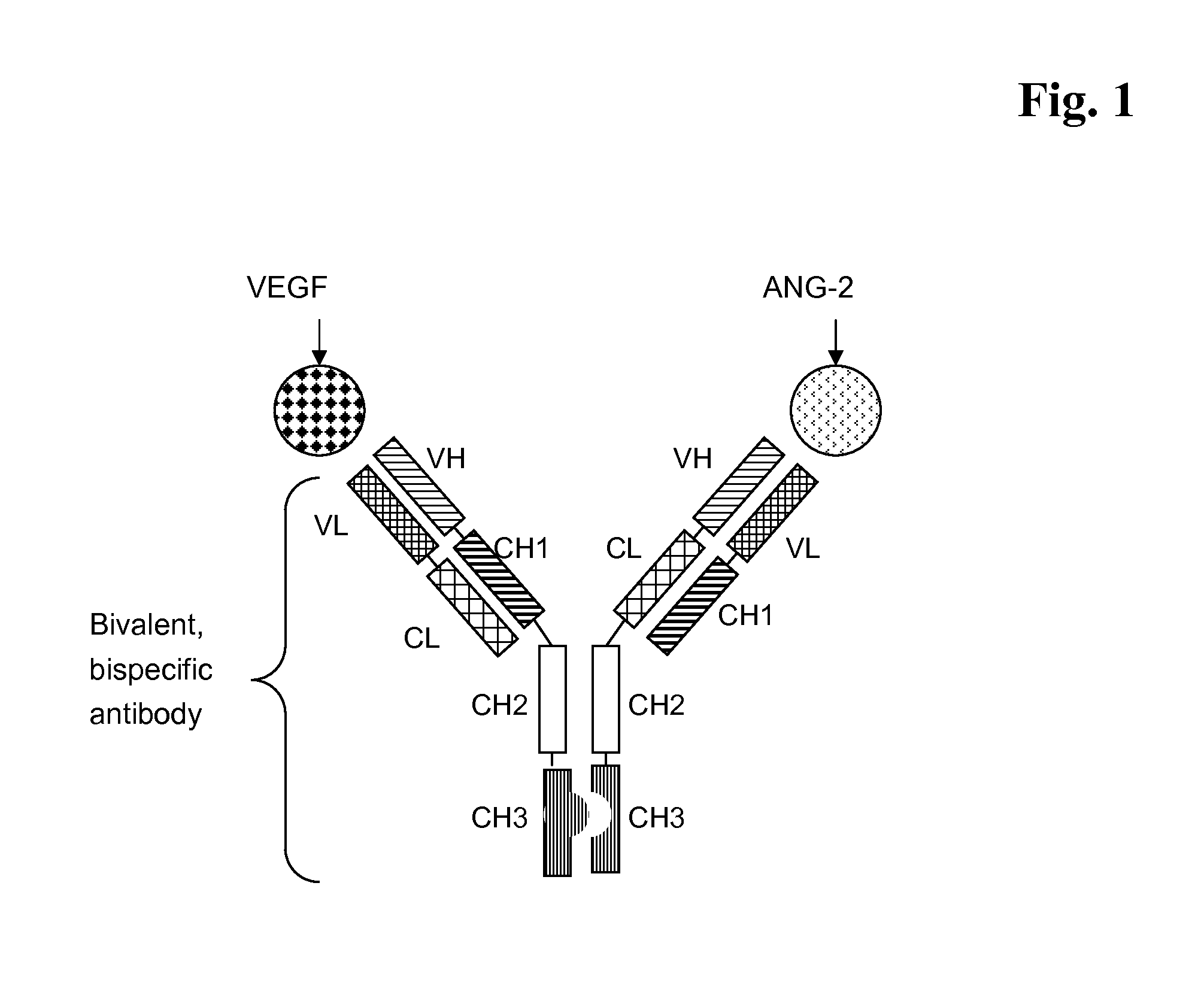

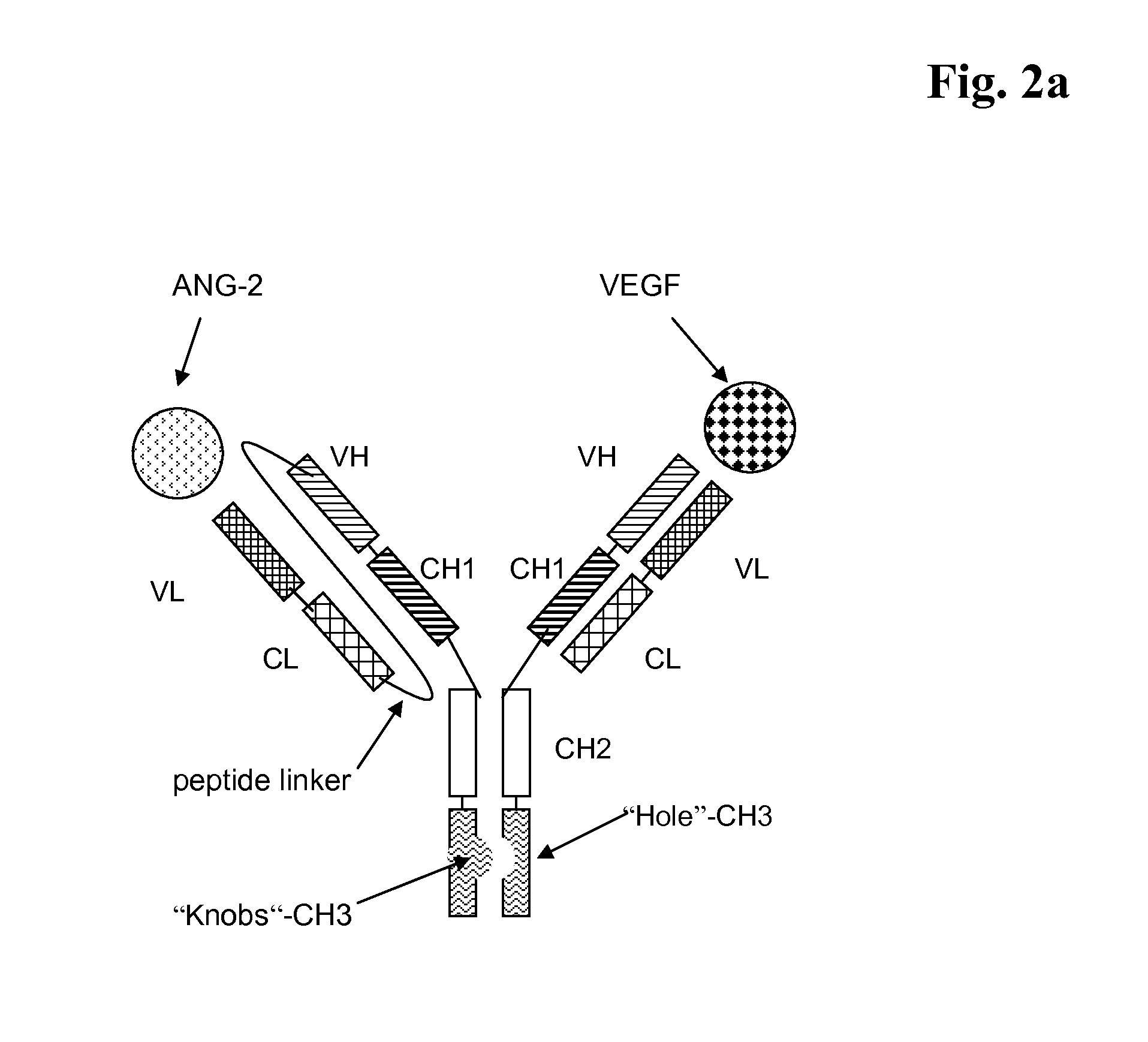

Bispecific, bivalent Anti-vegf/Anti-ang-2 antibodies

ActiveUS20110236388A1Valuable propertyHighly effectiveAnimal cellsHybrid immunoglobulinsEndothelial Growth FactorsAntibody

The present invention relates to bispecific, bivalent antibodies against human vascular endothelial growth factor (VEGF / VEGF-A) and against human angiopoietin-2 (ANG-2), methods for their production, pharmaceutical compositions containing said antibodies, and uses thereof.

Owner:F HOFFMANN LA ROCHE & CO AG

Safe efficient environment protection type feedstuff

InactiveCN101380056AImprove digestibilityReflect environmental protectionFood processingAnimal feeding stuffAnimal scienceSide effect

A safe and high-efficient environment-friendly feed comprises the following raw materials in terms of weight percentage: 6 to 20 percent of corn gluten feed, 3 to 25 percent of soybean meals, 1 to 20 percent of powder, 0 to 15 percent of rice bran, 0 to 40 percent of corn, 3.5 to 10 percent of rapeseed dregs, 1 to 5 percent of cotton seed meals, 1 to 5 percent of bone meals, 2 to 6 percent of fish meals, 1 to 6 percent of meat meals, 3 to 15 percent of wheat and right amount of additives. According to the required amounts of all nutritional components of the livestock in different growing stages, the invention combines energy feed, protein feed and various additives in equilibrium according to certain percentages by adopting a scientific method, thus leading various livestock to obtain the largest feed digesting rate and leading the livestock to absorb the feed to the largest degree; the excrement after the digestion of the livestock have no obvious smell and cause no pollution to the surrounded environmental sanitation and the environment protection after the feed being eaten is shown; moreover, no banned substances are added in the process of the feed processing and the feed is processed from natural products, which have no residue side effects on the livestock.

Owner:罗喜华

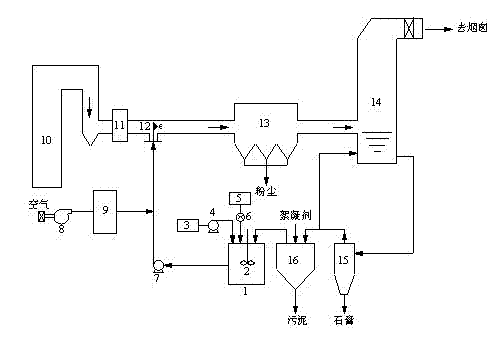

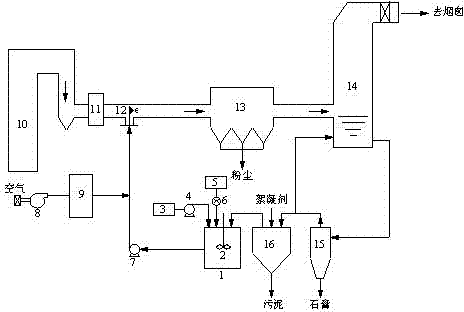

Method for cooperatively promoting agglomeration growth of PM (particulate matter) 2.5 and treating desulfuration wastewater in evaporation manner and device of method

InactiveCN102380278ALow running costConvenient sourceCombination devicesWater/sewage treatmentAir preheaterFlue gas

The invention discloses a method for cooperatively promoting agglomeration growth of PM (particulate matter) 2.5 and treating desulfuration wastewater in an evaporation manner and a device of the method. The method particularly includes steps that agglomeration liquor prepared by desulfuration wastewater, high polymer adhesive and wetting agent is sprayed into an inlet flue of an electric precipitator and is evaporated by the aid of heat of flue gas, in an evaporation process, the wetting agent promotes dust to enter drops of the agglomeration liquor, the high polymer adhesive is connected with PM2.5 via a polymer chain with polar groups, the grain diameter of the PM2.5 is prompted to be enlarged, so that the PM2.5 can be gathered by the follow-up electric precipitator, the desulfuration wastewater is evaporated completely, suspended matters and dissolvable pollutants in the wastewater are converted into solid to be dissolved out, and the suspended matters and the dissolvable pollutants in the wastewater, together with dust in the flue gas, are gathered by the electric precipitator. The device consists of a boiler, an air preheater, the electric precipitator, a desulfurizing tower, a hydraulic cyclone, a desulfuration wastewater clarification tank and an agglomeration liquor preparation tank, and a double-fluid atomizing nozzle is arranged in the flue between the air preheater and the electric precipitator.

Owner:SOUTHEAST UNIV

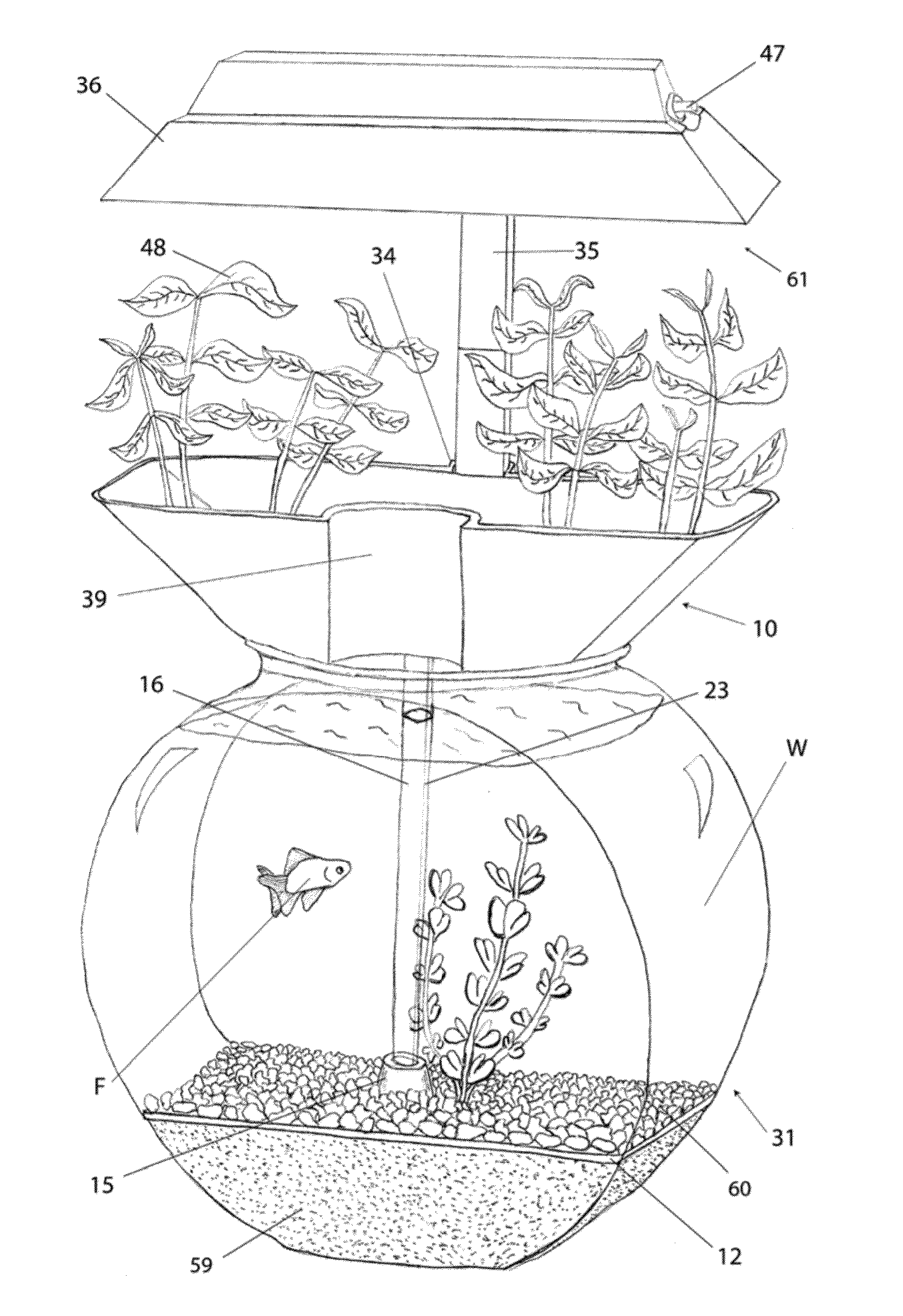

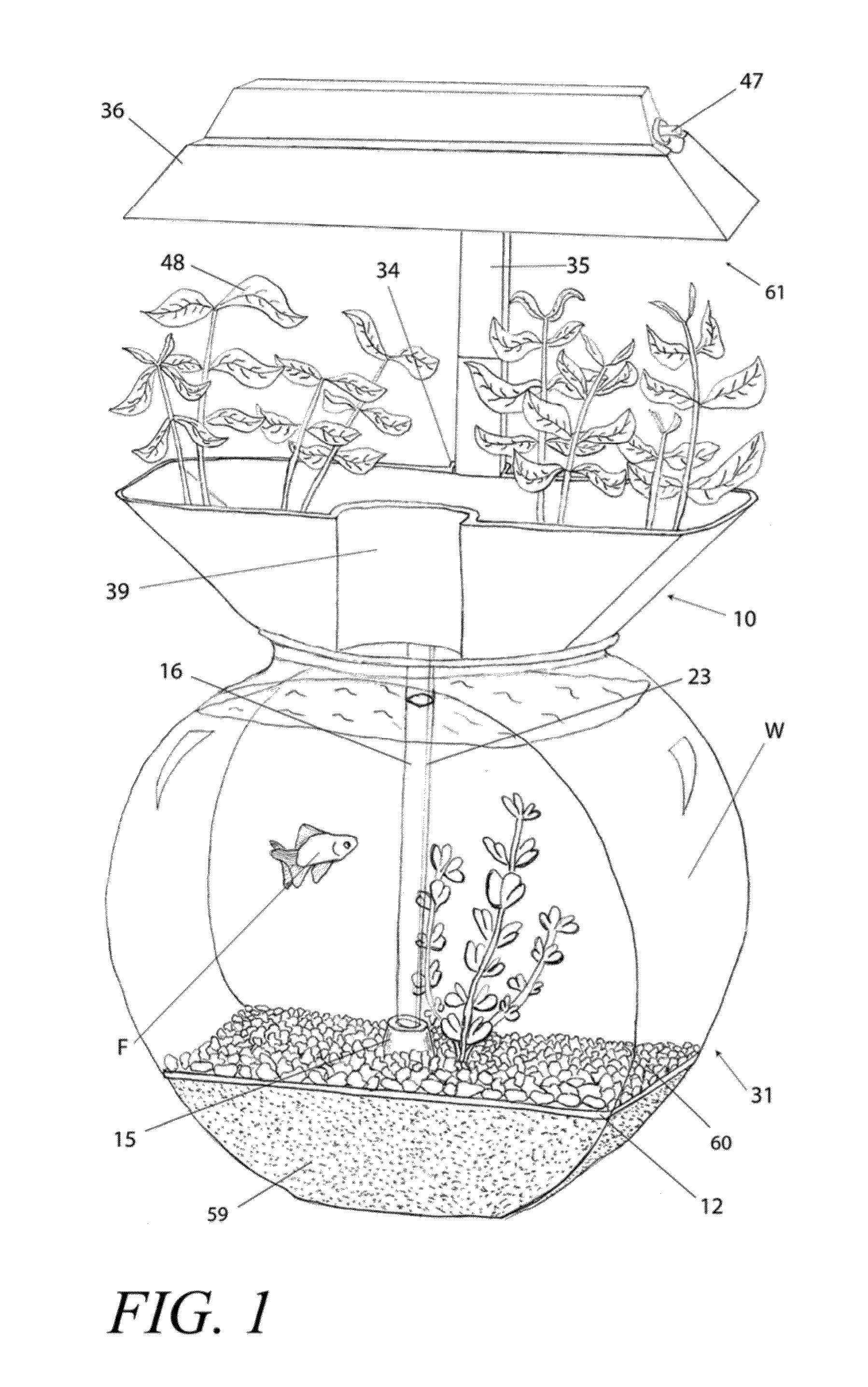

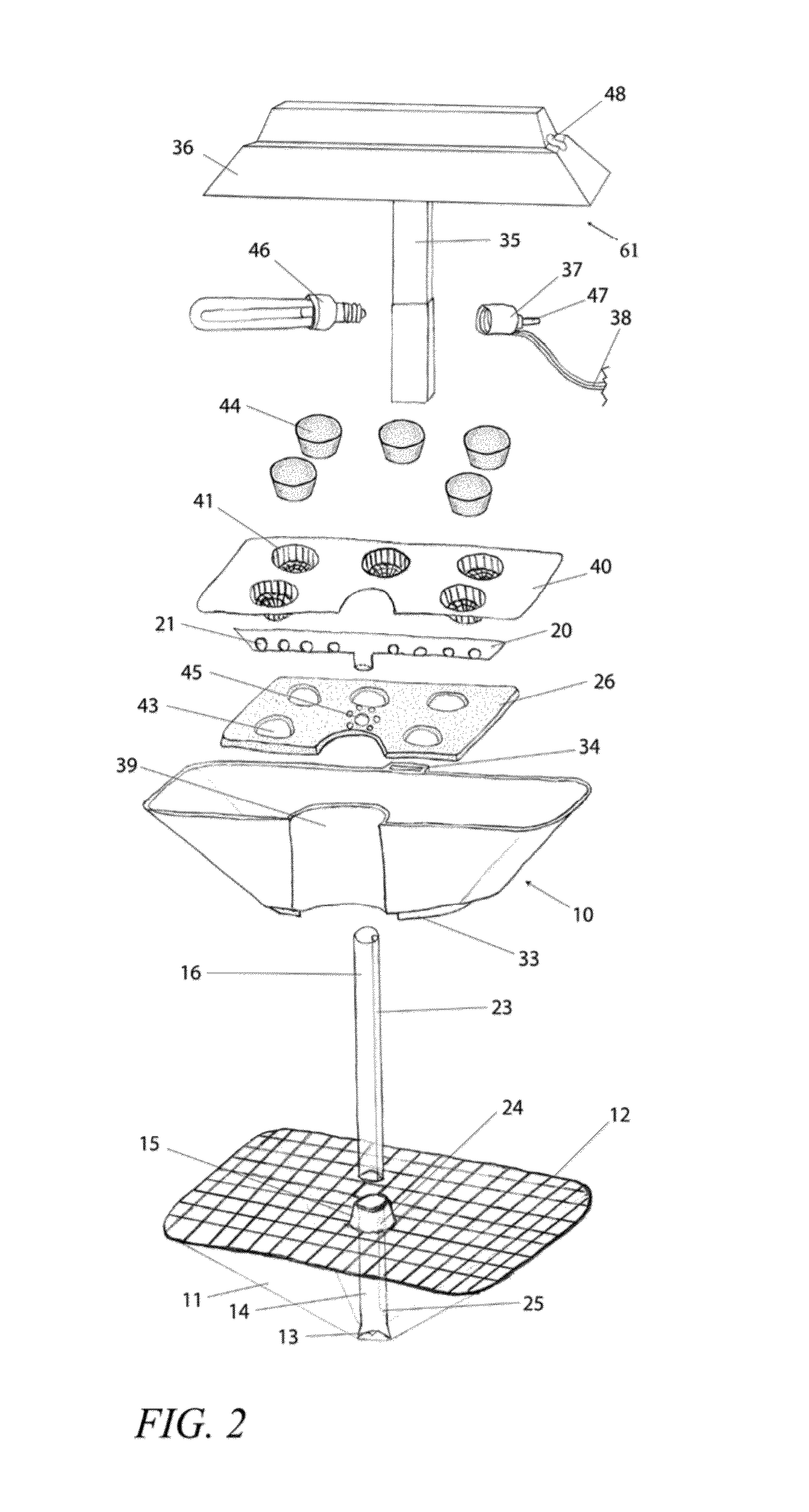

Filtration system for use in aquariums

InactiveUS20140223818A1Effective growth of plantGuaranteed efficient growthPisciculture and aquariaAgriculture gas emission reductionLiquid wasteActivated carbon

An inexpensive aquaponic conversion kit for aquariums that uses a combination of mechanical, biological, and chemical filtration components along with terrestrial plants to filter aquarium water. The system includes a funnel shaped undergravel filter that concentrates solid waste towards an airlift pump that transports solid and liquid waste into a planter containing terrestrial plants. These waste nutrients are trapped in the planter in layers of activated carbon and filamentous material that adsorb and trap waste particles where the roots of plants turn the waste into biological material and aid in cleaning the tank. A grow light and hood are able to be attached to a bracket at the back of the planter to grow healthy plants.

Owner:COGHLAN RYAN

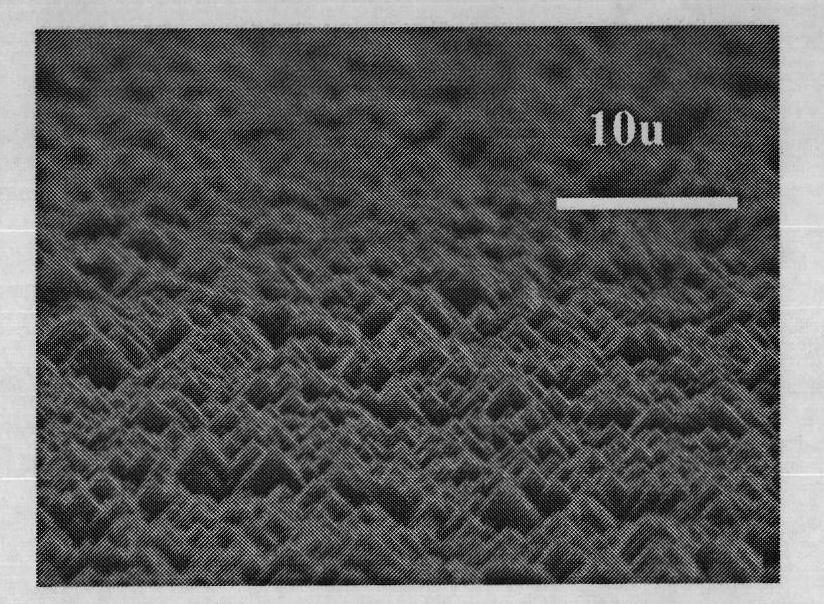

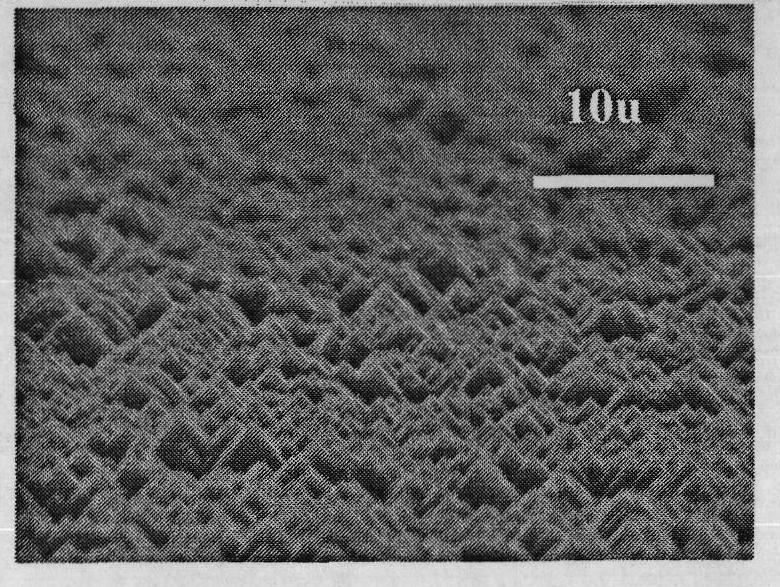

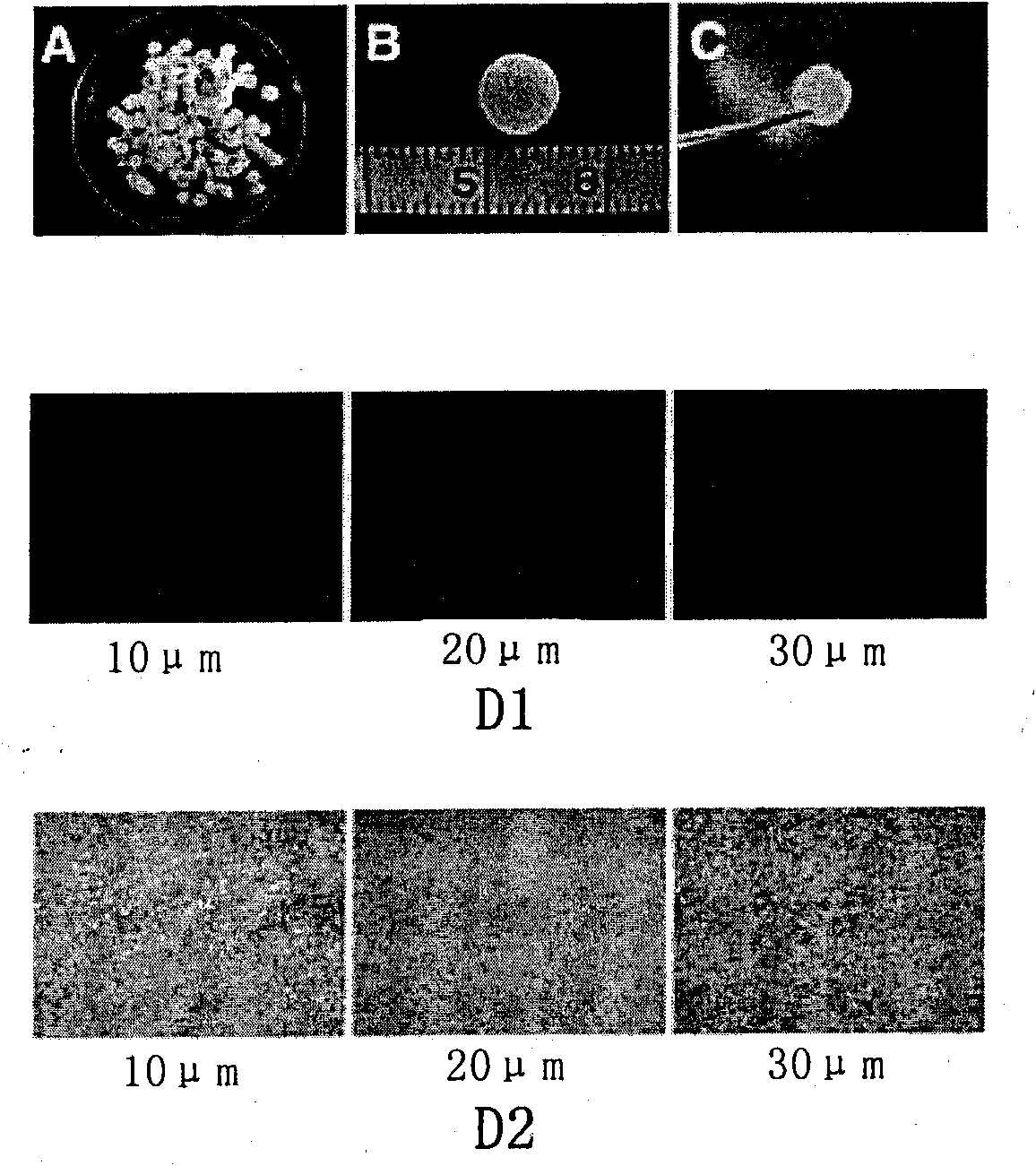

Velvet manufacturing solution of monocrystalline silicon additive

InactiveCN101818378AUniform sizeGuaranteed efficient growthAfter-treatment detailsOrganic acidSurface-active agents

The invention discloses a velvet manufacturing solution of a monocrystalline silicon additive, which comprises an alkaline etching solution, a surface active agent and organic acid or salt, wherein the mass of the surface active agent is 0.05% to 0.5% of the mass or volume of the alkaline etching solution, and the mass of the organic acid or salt is 0.1% to 10.0% of the mass or volume of the alkaline etching solution. The velvet manufacturing solution enables the pyramid size of a velvet surface of monocrystalline silicon to be uniform without blaze or obvious impression. Under a proper temperature condition, the velvet surface is quickly and effectively formed and is matched with traditional production equipment.

Owner:HANWHA SOLARONE QIDONG

Animal protein-free media for cultivation of cells

InactiveUS20060094104A1Efficient expressionGuaranteed efficient growthMicroorganismsCulture processBiotechnologyHydrolysate

The present invention relates to animal protein-free cell culture media comprising polyamines and a plant and / or yeast-derived hydrolysate. The invention also relates to animal protein-free culturing processes, wherein cells can be cultivated, propagated and passaged without adding supplementary animal proteins in the culture medium. These processes are useful in cultivating cells, such as recombinant cells or cells infected with a virus, and for producing biological products by cell culture processes.

Owner:BAXTER INT INC +1

Preparation and use of nanosize pigment compositions

InactiveUS6902613B2Guaranteed efficient growthEfficient preparationNanostructure manufactureQuinacridonesParticle growthNanometre

A mixture of an organic nanosize pigment comprising of from 50 to 99% by weight of the nanosize pigment and 1 to 50% by weight based of a low molecular weight naphthalene sulfonic acid formaldehyde polymer and its use as a particle growth and crystal phase director for the preparation of a direct pigmentary organic pigment or in pigment finishing.

Owner:CIBA SPECIALTY CHEM CORP

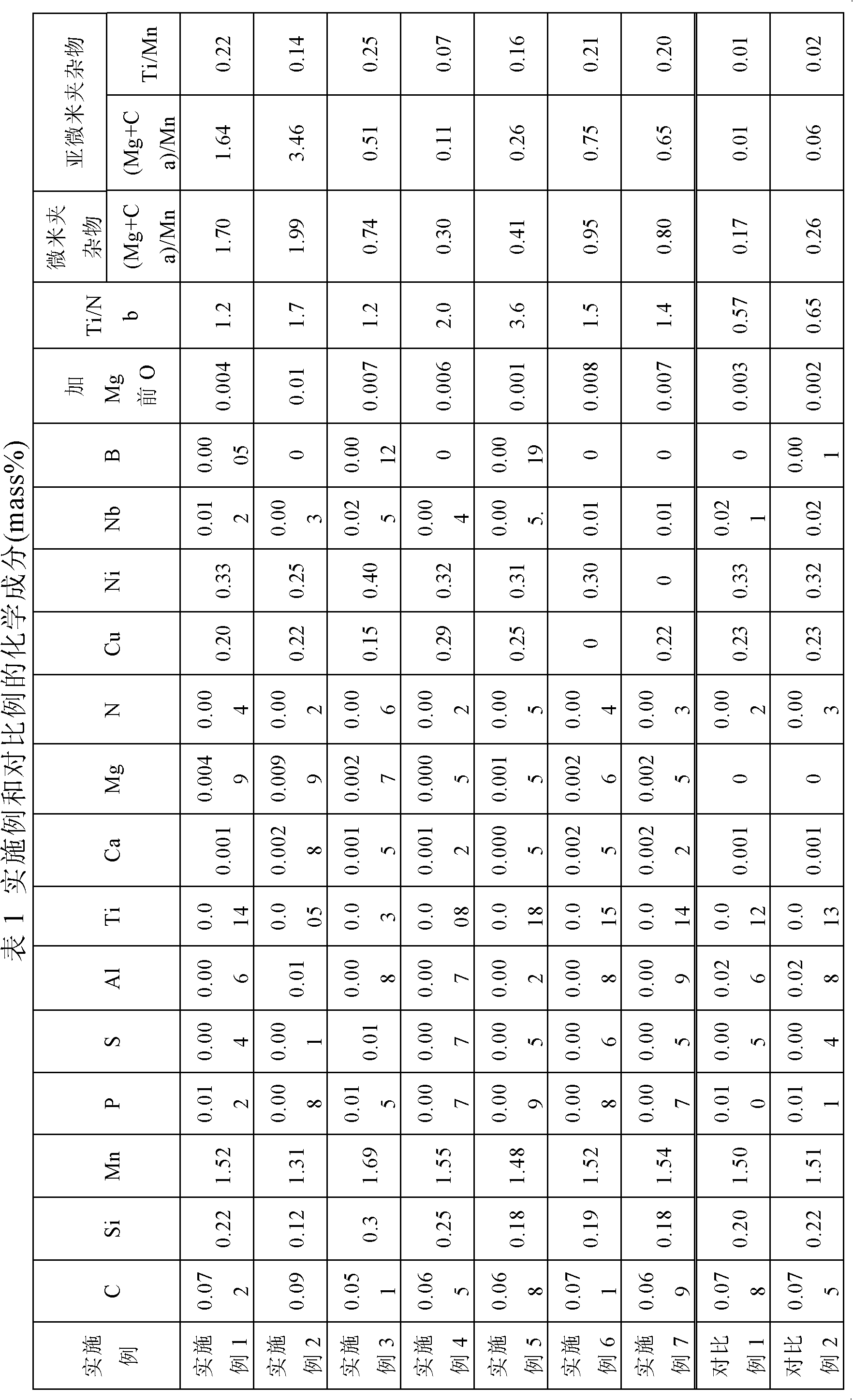

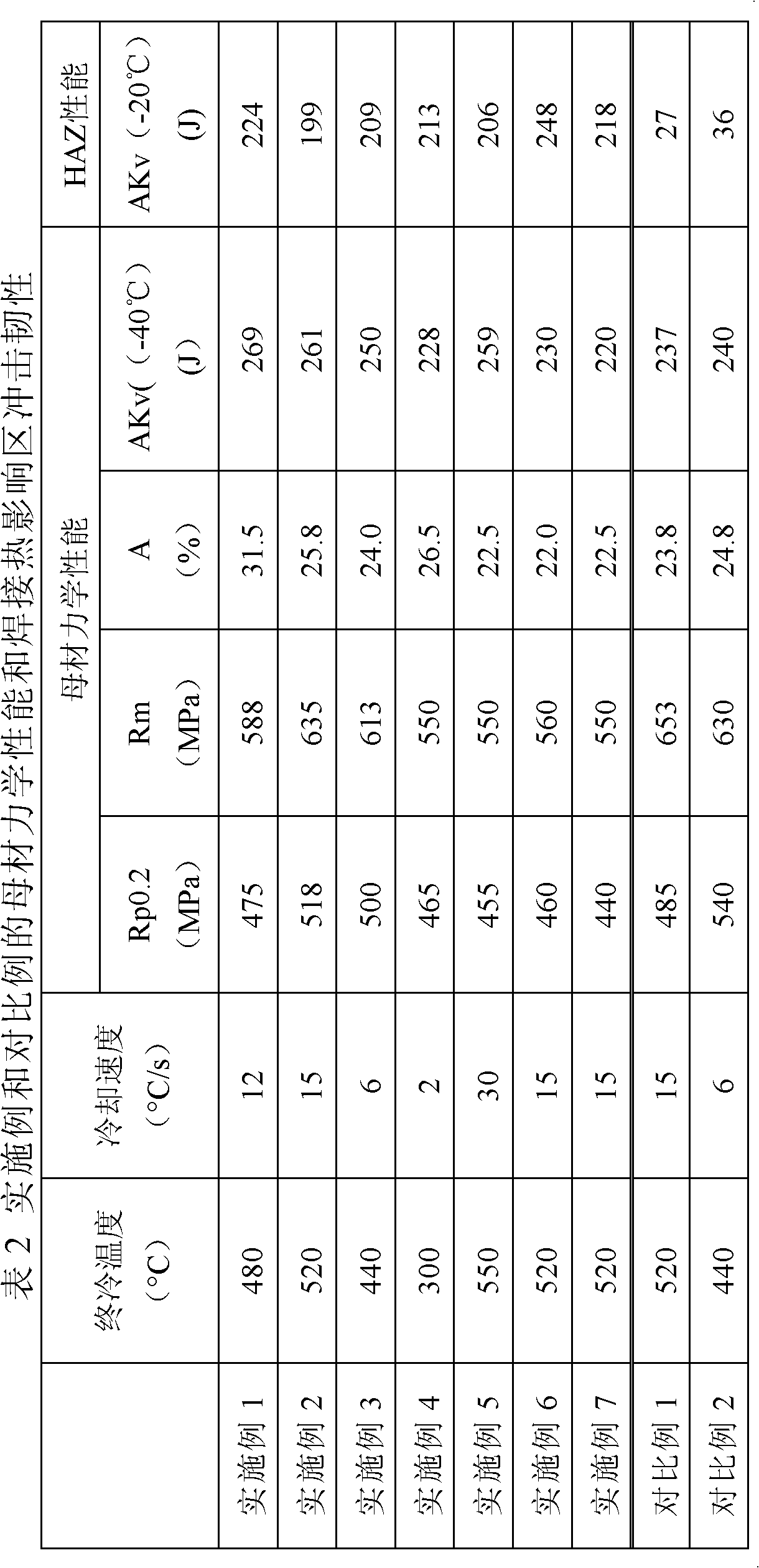

High-heat-input welding thick steel plate and manufacturing method thereof

Disclosed are a high-heat-input welding thick steel plate and a manufacturing method thereof. The manufacturing method includes following steps: a) smelting, refining and continuous casting; b) rolling; and c) cooling. Steel consists of components including, by weight percentage, from 0.05 to 0.09% of C, from 0.10 to 0.30% of Si, from 1.3 to 1.7% of Mn, from 0.005 to 0.03% of Ti, from 0.003 to 0.025% of Nb, from 0.001 to 0.01% of S, smaller than or equal to 0.015% of P, smaller than or equal to 0.006% of N, from 0.0005 to 0.01% of Mg, smaller than or equal to 0.01% of Al, smaller than or equal to 0.003% of Ca, more than one of smaller than or equal to 0.3% of Cu, smaller than or equal to 0.4% of Ni and smaller than or equal to 0.002% of B, and the balance Fe; and Ti / Nb is larger than or equal to 1.2, deoxidant Mn, Si, Al, Ti, Ca and Mg are successively added in a steel liquid deoxidizing process, wherein (Mg+Ca) / Mn is larger than or equal to 0.3 for micrometer impurities with the grain size larger than or equal to 1.0 micrometer in the steel, (Mg+Ca) / Mn is larger than or equal to 0.1 for sub-micron impurities with the grain size ranging from 0.1 micrometer to 1.0 micrometer in the steel, and Ti / Mn is larger than or equal to 0.07. A large quantity of impurities which are distributed in a dispersion manner are formed, growth of austenite grains in a welding heat affected zone can be restrained, growth of intra-granular ferrite is promoted, and the high-heat-input welding performance of the thick plate is greatly improved.

Owner:BAOSHAN IRON & STEEL CO LTD

Photovoltaic greenhouse solar energy distribution method based on crop growth mode and device thereof

InactiveCN103163904AHigh simulationSave time and costPV power plantsControl using feedbackMathematical modelElectrical battery

A photovoltaic greenhouse solar energy distribution method based on a crop growth mode includes: firstly, building an illumination need model based on green house crops, a photovoltaic cell equivalent mathematical model and a luminous environment mathematical model of crop canopies, building a multi-parameter, multivariable and nonlinearity coupling pair time differential equation, achieving utilizing an optimization algorithm to design, regulate and control a photovoltaic greenhouse cell array under conditions of different illumination intensity, different illumination angles and different temperatures by solving the differential equation, and achieving solar energy reasonable distribution of photovoltaic cell maximum electric energy production under a condition which satisfies greenhouse crop growth conditions. The invention provides a device used for achieving the photovoltaic greenhouse solar energy distribution method based on the crop growth mode. The invention provides the photovoltaic greenhouse solar energy distribution method based on the crop growth mode and the device of the photovoltaic greenhouse solar energy distribution method based on the crop growth mode, and the photovoltaic greenhouse solar energy distribution method based on the crop growth mode is capable of effectively achieving greenhouse photovoltaic power generation and effective regulation and control of crop growth and energy.

Owner:浙江海宁经编产业园区开发有限公司

Bispecific, bivalent anti-VEGF/anti-ANG-2 antibodies

ActiveUS8945552B2Guaranteed efficient growthInhibition is effectiveAnimal cellsHybrid immunoglobulinsAntibodyEndothelial Growth Factors

The present invention relates to bispecific, bivalent antibodies against human vascular endothelial growth factor (VEGF / VEGF-A) and against human angiopoietin-2 (ANG-2), methods for their production, pharmaceutical compositions containing said antibodies, and uses thereof.

Owner:F HOFFMANN LA ROCHE INC

Method for preparing probe tip of nano tube

InactiveCN1434461AEasy to controlGuaranteed efficient growthSurface/boundary effectInstrumental componentsPtru catalystHydrophile

The invention is a method for manufacturing nano tube probe tip; the pin applies to various mode of atom microscope. At first, the method decorates hydrophobe single layer film on the surface of various silicon probe pin, then it uses electrical field to eliminate the film or oxides the film into hydrophile film, it calculates the size of the activated area through the action that the pin acts onthe standard sample surface, then it fixed catalyst particles in the hydrophile area on the surface of the pin, finally, puts the pin which carries catalyst nano particles in the nano reactor and forms into nano tube.

Owner:SOUTHEAST UNIV

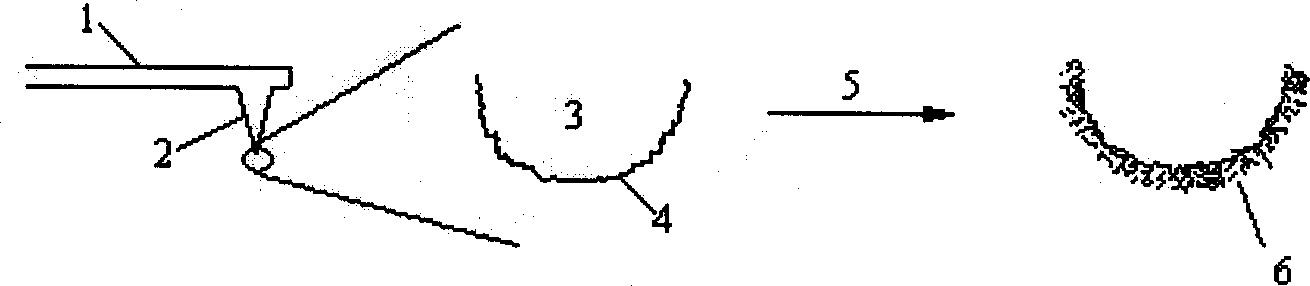

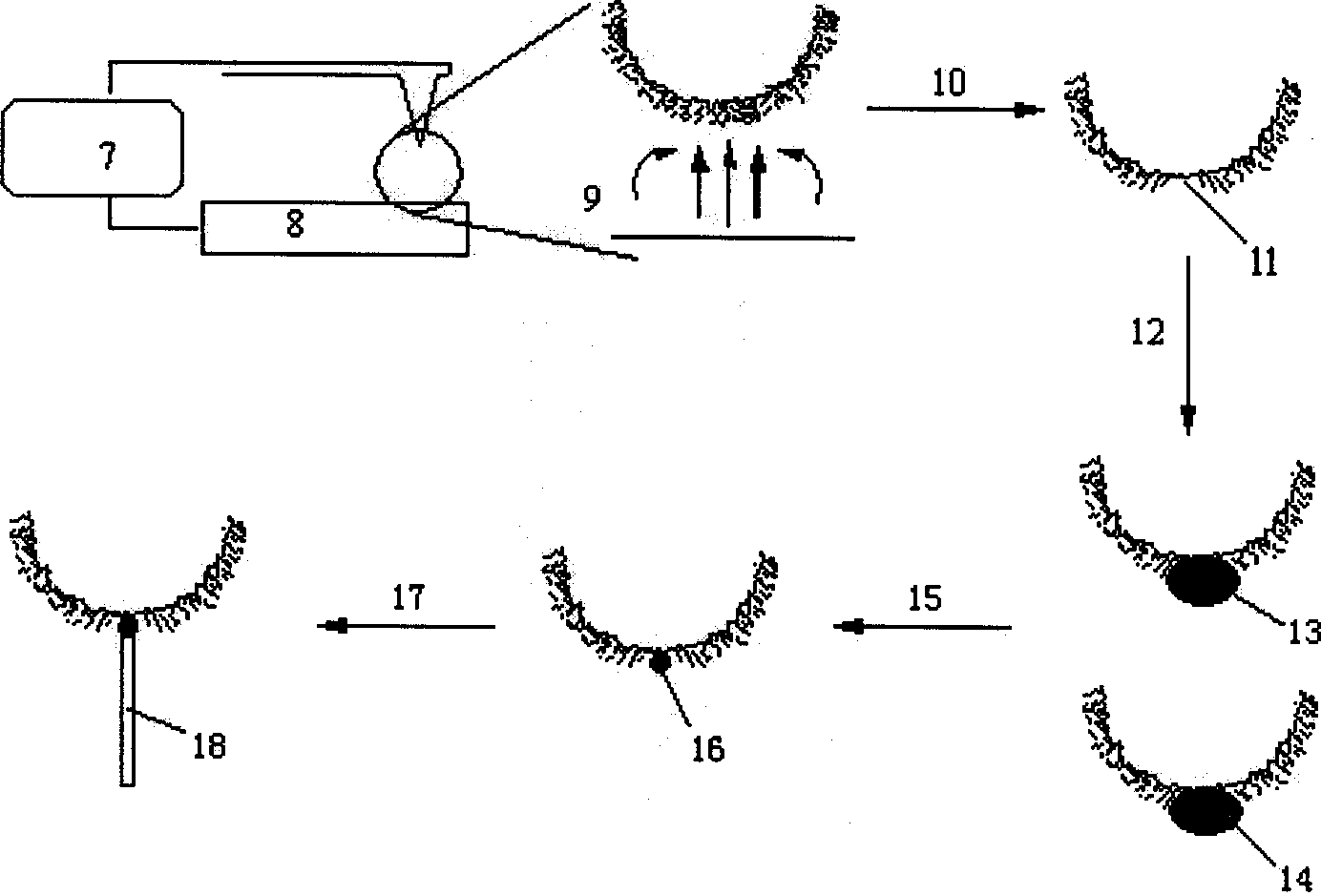

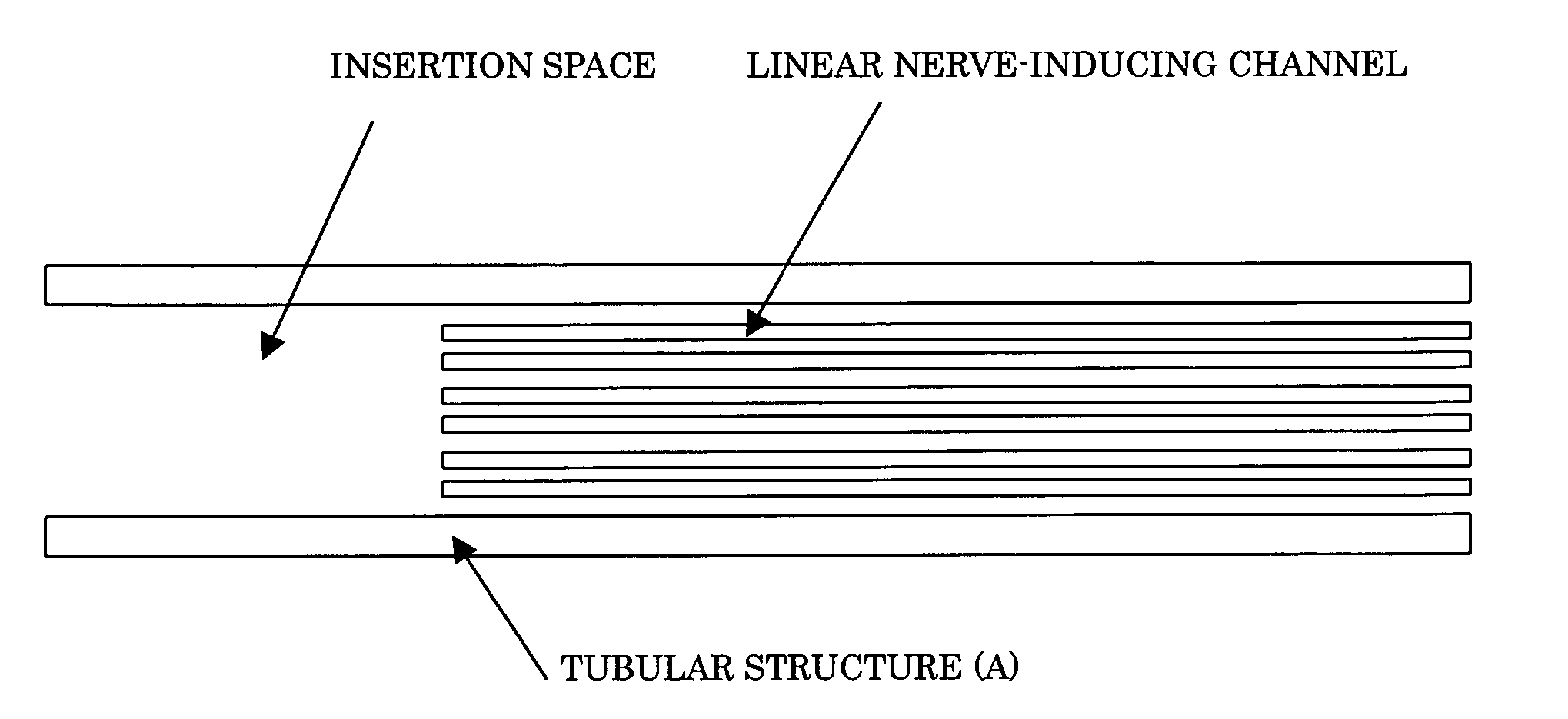

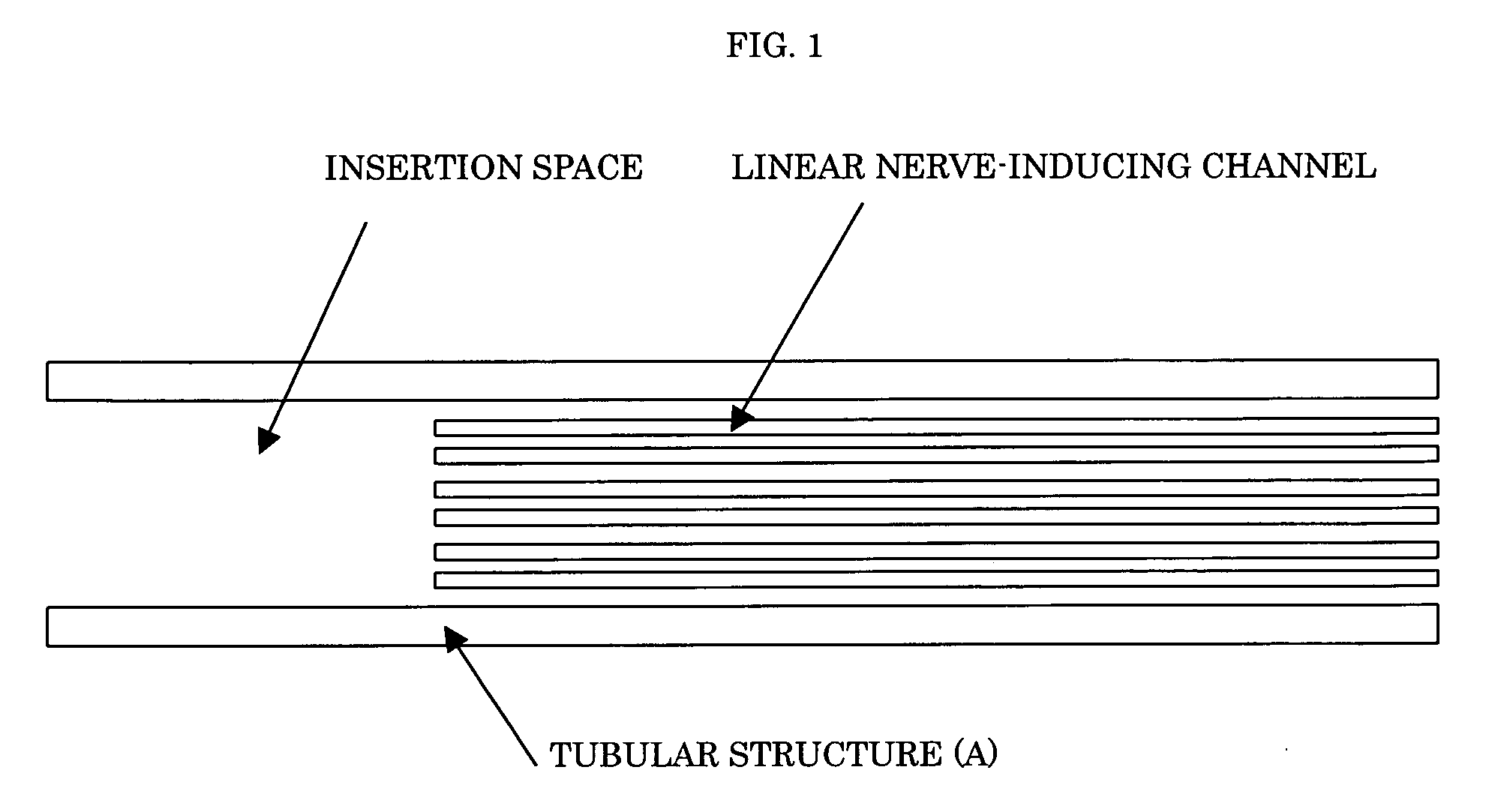

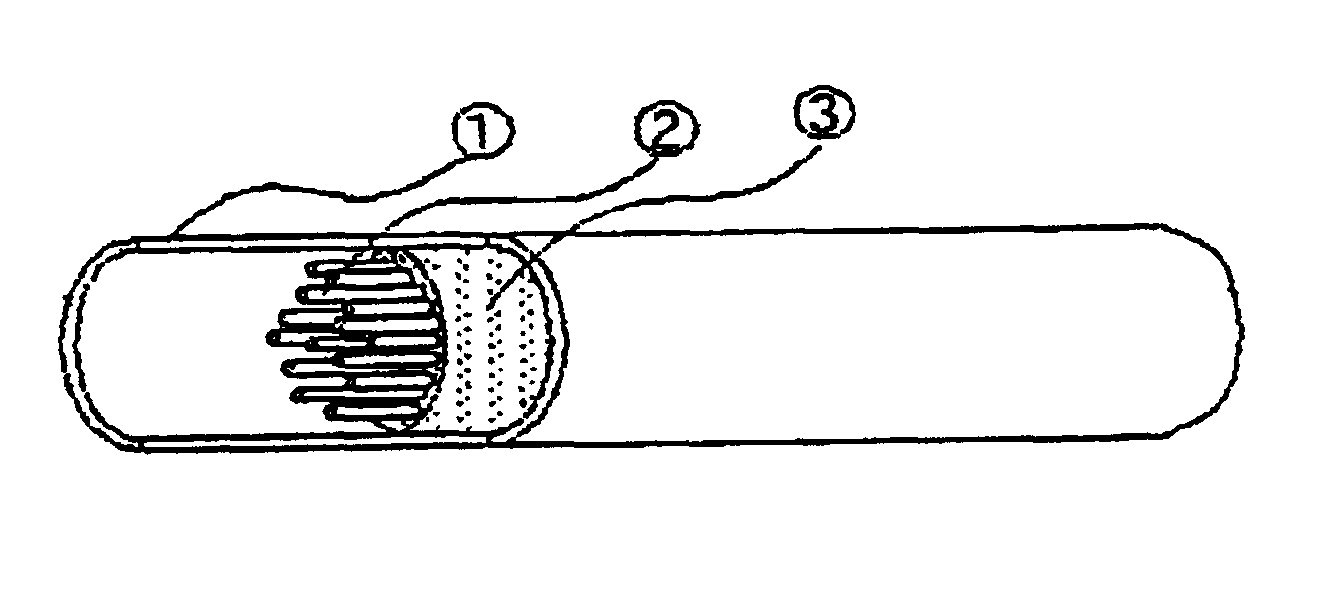

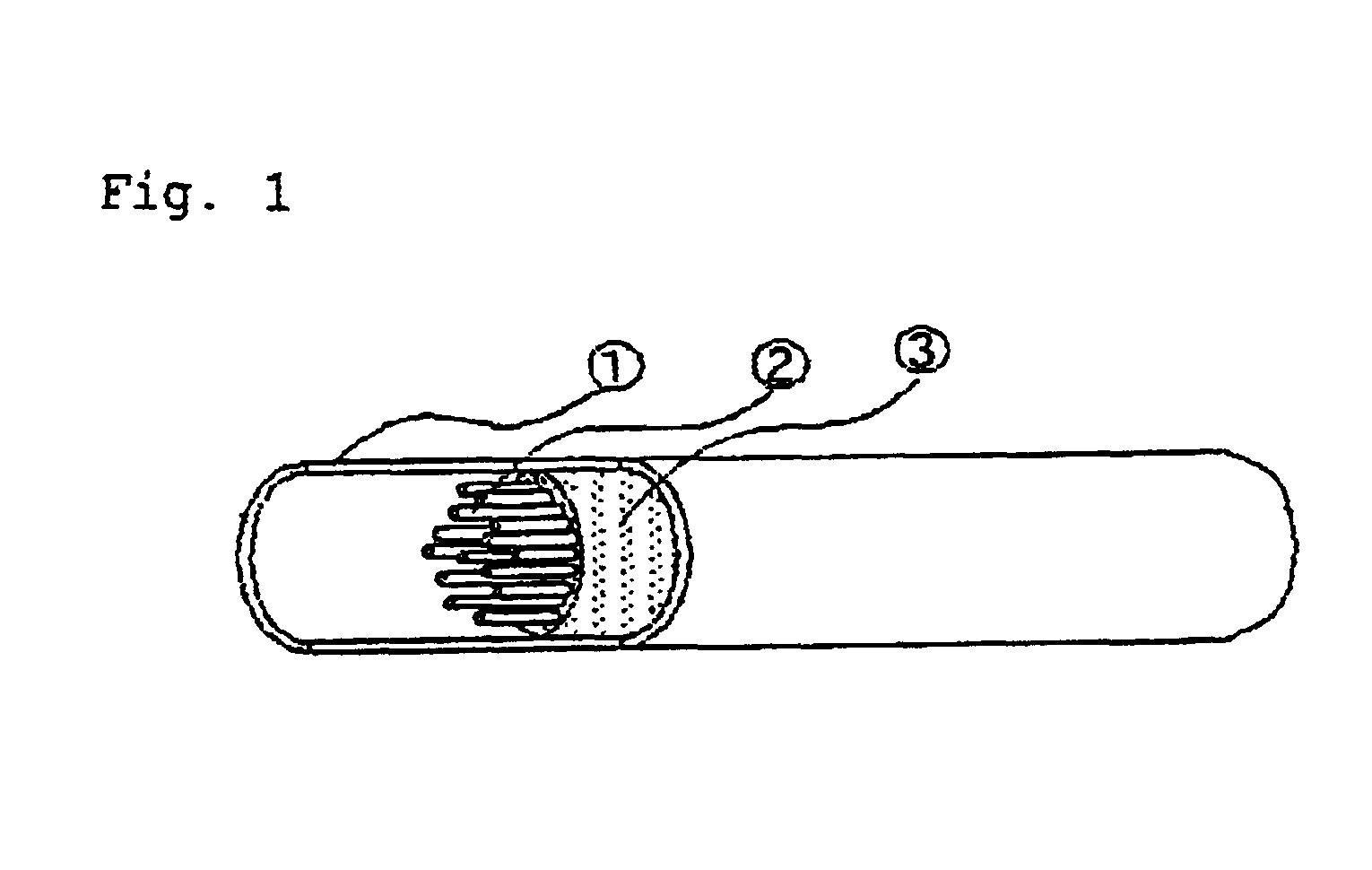

Nerve regeneration-inducing tube comprising

ActiveUS20060100647A1Guaranteed efficient growthPromote efficient proliferationTubular organ implantsTissue regenerationAnatomyAbsorbent material

The present invention provides a nerve regeneration-inducing tube in which nerve is inserted into a tubular structure and can be easily sutured and fixed without resort to any special instruments or operations, thereby allowing nerve cells to efficiently proliferate and grow in the correct direction. The nerve regeneration-inducing tube of the present invention includes: a tubular structure (A) made of a biodegradable material or a bioabsorbable material and provided inside with a matrix (B) having linear nerve-inducing channels and being made of a biodegradable material or a bioabsorbable material; and a definite space part provided at one end of the tubular structure (A).

Owner:NIPRO CORP +1

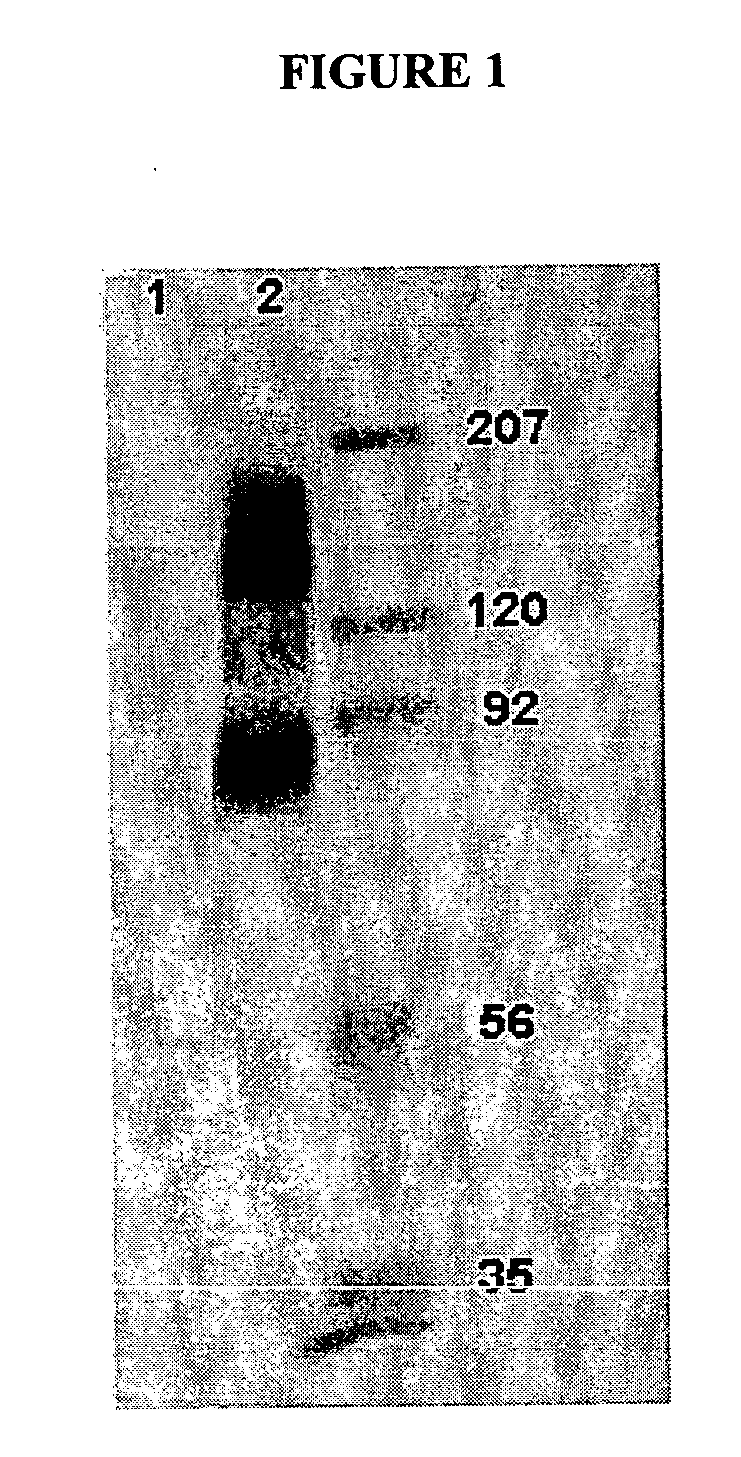

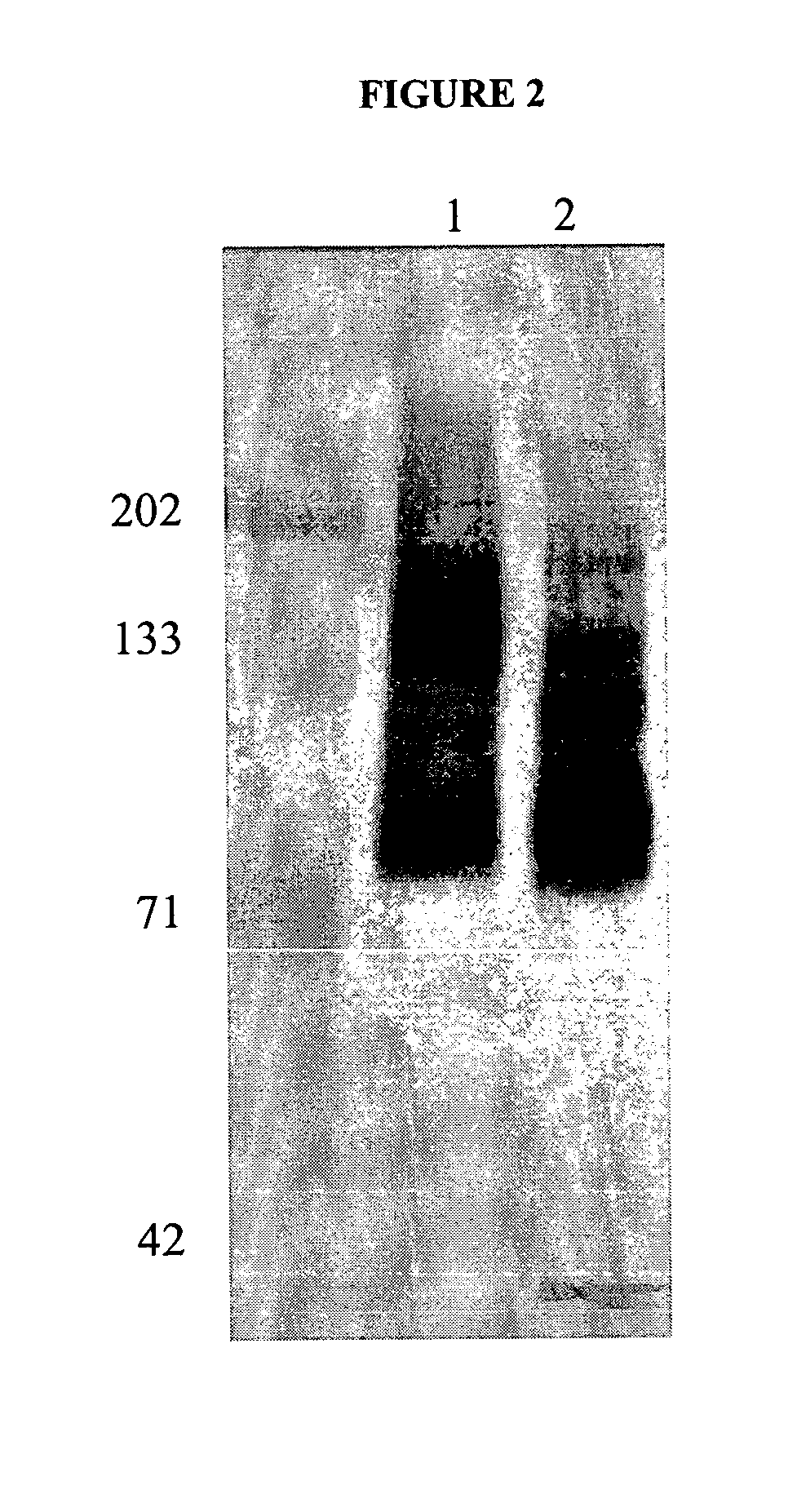

Cytotoxicity mediation of cells evidencing surface expression of CD44

InactiveUS20050008646A1Guaranteed efficient growthLose weightImmunoglobulins against cell receptors/antigens/surface-determinantsAntibody ingredientsCD44Tumor cells

This invention relates to the diagnosis and treatment of cancerous diseases, particularly to the mediation of cytotoxicity of tumor cells; and most particularly to the use of cancerous disease modifying antibodies (CDMAB), optionally in combination with one or more chemotherapeutic agents, as a means for initiating the cytotoxic response. The invention further relates to binding assays which utilize the CDMABs of the instant invention.

Owner:F HOFFMANN LA ROCHE & CO AG

Use of a serum-free cell culture medium for the production of il-18bp in mammalian cells

ActiveUS20070196895A1Effective cell growth of cellEffective maintenanceAntibacterial agentsAntipyreticSerum freeCell culture media

Owner:ARES TRADING SA

Instrument for regenerating living organism tissue or organ

InactiveUS6953482B2Efficient growth processEasy to insertSurgeryJoint implantsBiological bodyAnatomy

This invention relates to an instrument for regenerating a living organism tissue or organ, characterized in that a support (A) formed from a biodegradable material or a bioabsorbable material includes a sponge-like fine matrix (B) formed from a biodegradable material or a bioabsorbable material and a linear guide channel (C) for a living organism tissue or organ.

Owner:UEDA MINORU

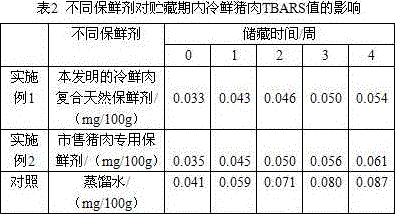

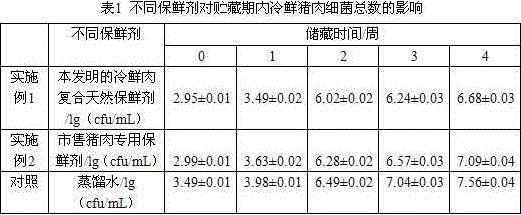

Composite natural fresh-keeping agent for cold fresh meat and application of composite natural fresh-keeping agent

InactiveCN106212635ABroad antibacterial spectrumRich sourcesMeat/fish preservation using chemicalsVitamin CNon toxicity

The invention relates to a composite natural fresh-keeping agent for cold fresh meat and application of composite natural fresh-keeping agent. The composite natural fresh-keeping agent for the cold fresh meat is characterized by comprising tea polyphenol, chitosan, nisin, natamycin, lysozyme, oregano essential oil, vitamin C, vitamin E, erythorbic acid, a spice extract and water in certain proportions by weight, wherein the spice extract is obtained by extracting ginger, garlic, cinnamon, cardamom, clove and rosemary in certain proportions by weight through ethanol extraction. The composite natural fresh-keeping agent for the cold fresh meat is prepared from biological-source raw materials by a simple preparation method, has the advantages of non-toxicity, safety, broad antibacterial spectrum and the like, is convenient to operate during using and prominent in fresh-keeping effect, and has an important industrial value.

Owner:宋晓燕

Light emitting device

ActiveUS20150357532A1Sufficient crystal growthBrighter lightSolid-state devicesSaving energy measuresPhosphorFar-red

This light emitting device is provided with: a light emitting element which emits excitation light; and a far-red phosphor which is excited by the light of the light emitting element and emits light that has a peak wavelength within the range of 700-800 nm. The far-red phosphor has a median diameter within the range of 1-20 μm.

Owner:SHARP KK

Yunnan olive fruit wine

InactiveCN1389562AEliminate bitternessSoothes throatAlcoholic beverage preparationYeastTemperature control

There is a kind of dian-olive juice wine. The inventino uses mild fruit dia-olive which exists specially in yunnan as main material, it is produced through processes of extracting, sterilizing, filtering, distributing, fermenting, low temperature aging etc. The invention also can confect the purified dian-olive juice into dew-wine. Aiming at the technology difficulty that the content of tannin in dian-olive juice and that the Ph value is 1-2, the invention uses technique measure such as acidproof yeast cluster and ferment temperature control etc. It assorts with growth of dian-olive natural yeast cluster effectively, resists growth of harmful yeast and mixed germ, these play a crucial significance to color, taste feeling, physical and chemical sanitation index of the product.

Owner:张志美

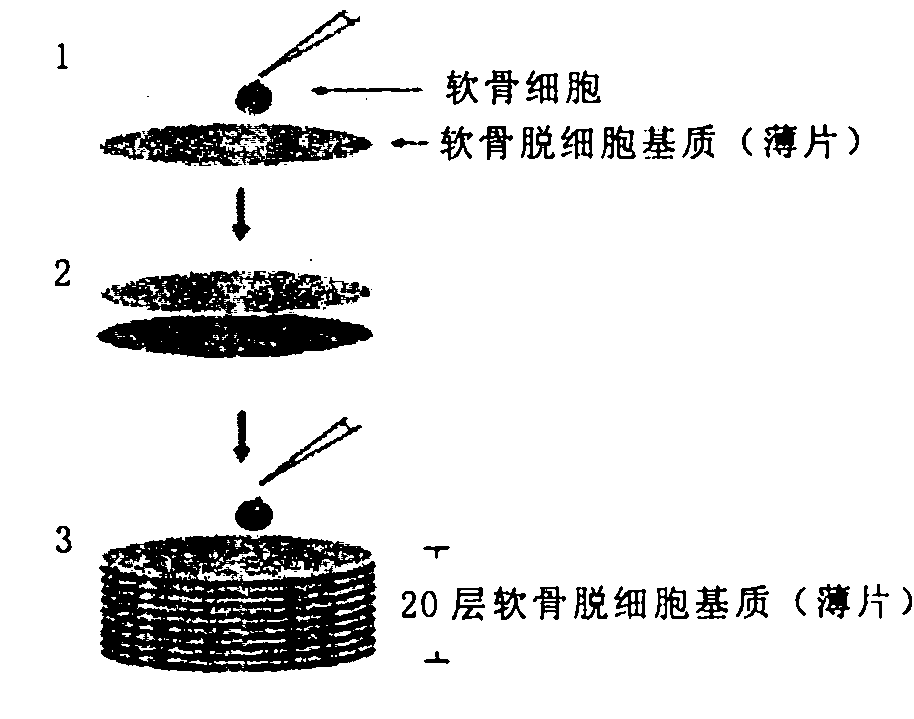

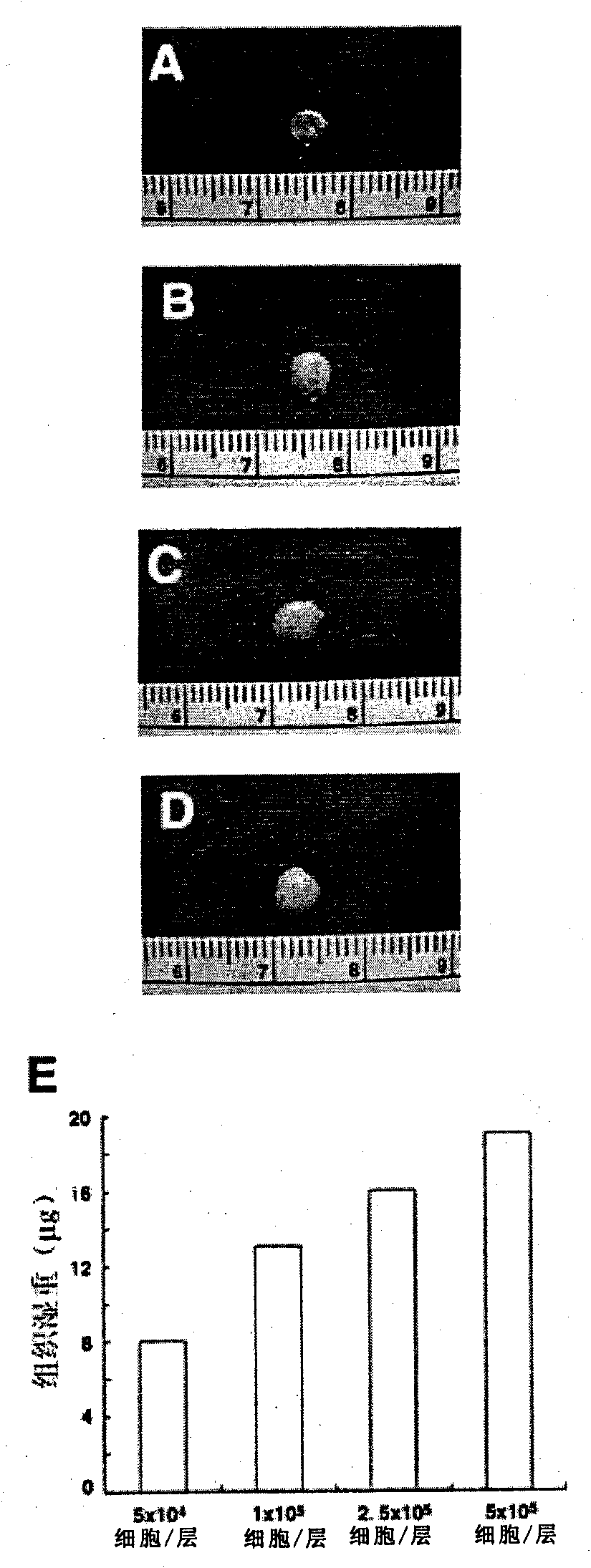

Cartilage cell removal matrix and preparation method and application thereof

The invention discloses a cartilage cell removal matrix and a preparation method and application thereof. The thickness of the cartilage cell removal matrix is 1 to 30 microns, and the cartilage cell removal matrix is prepared by the following method of: (1) cutting an animal cartilage into slices with thickness of 1 to 30 microns, and (2) performing cell removal treatment on the slices obtained in the step (1). The invention also discloses a preparation method for a tissue engineered cartilage implant, which comprises the following steps of: (a) inoculating seed cells to one surface of the cartilage cell removal matrix; (b) covering the cartilage cell removal matrix of the other sheet on the surface of the matrix inoculated with the seed cells; and (c) repeating the steps (a) and (b) till the layer number of the cartilage cell removal matrix provided by the invention is 10 to 30 so as to obtain the tissue engineered cartilage implant, wherein the seed cells are selected from cartilage cells, bone marrow matrix stem cells hBMSCs or mixture thereof.

Owner:SHANGHAI TISSUE ENG LIFE SCI

Serum-free cell culture medium for mammalian cells

ActiveUS7709229B2Guaranteed efficient growthEffective maintenancePeptide/protein ingredientsImmunoglobulinsSerum free mediaSerum free

Owner:KONINK PHILIPS ELECTRONICS NV +1

Unsaturated fatty acid feed addictive capable of improving quality of skin and hair of cats and dogs

InactiveCN1631207AGuaranteed efficient growthImproves fur qualityAnimal feeding stuffAccessory food factorsNervous systemColneleic acid

The invention relates to an unsaturated fatty acid feed addictive capable of improving quality of skin and hair of cats and dogs, wherein the feed addictive comprises unsaturated fatty acids or their ester derivatives whose weight ratio is, linoleic acid 82.2-88.3, arachidonic acid 0.8-2.7, linolenic acid 8.5-14.8, EPA and DHA 0.5-2.2. The additive can reinforce the growth of fur-bearing animals especially the growth of nervous systems of cats and dogs.

Owner:王志文

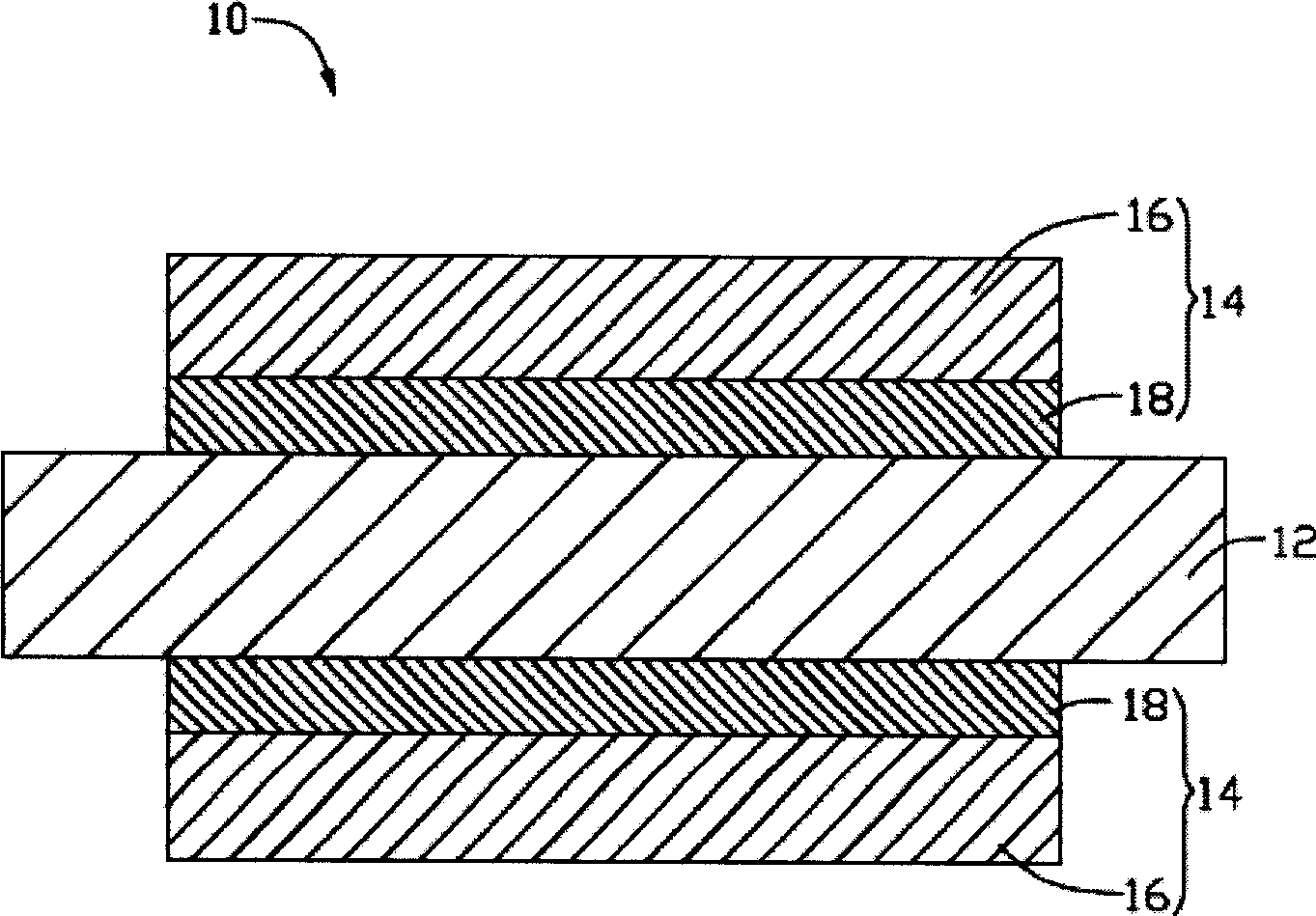

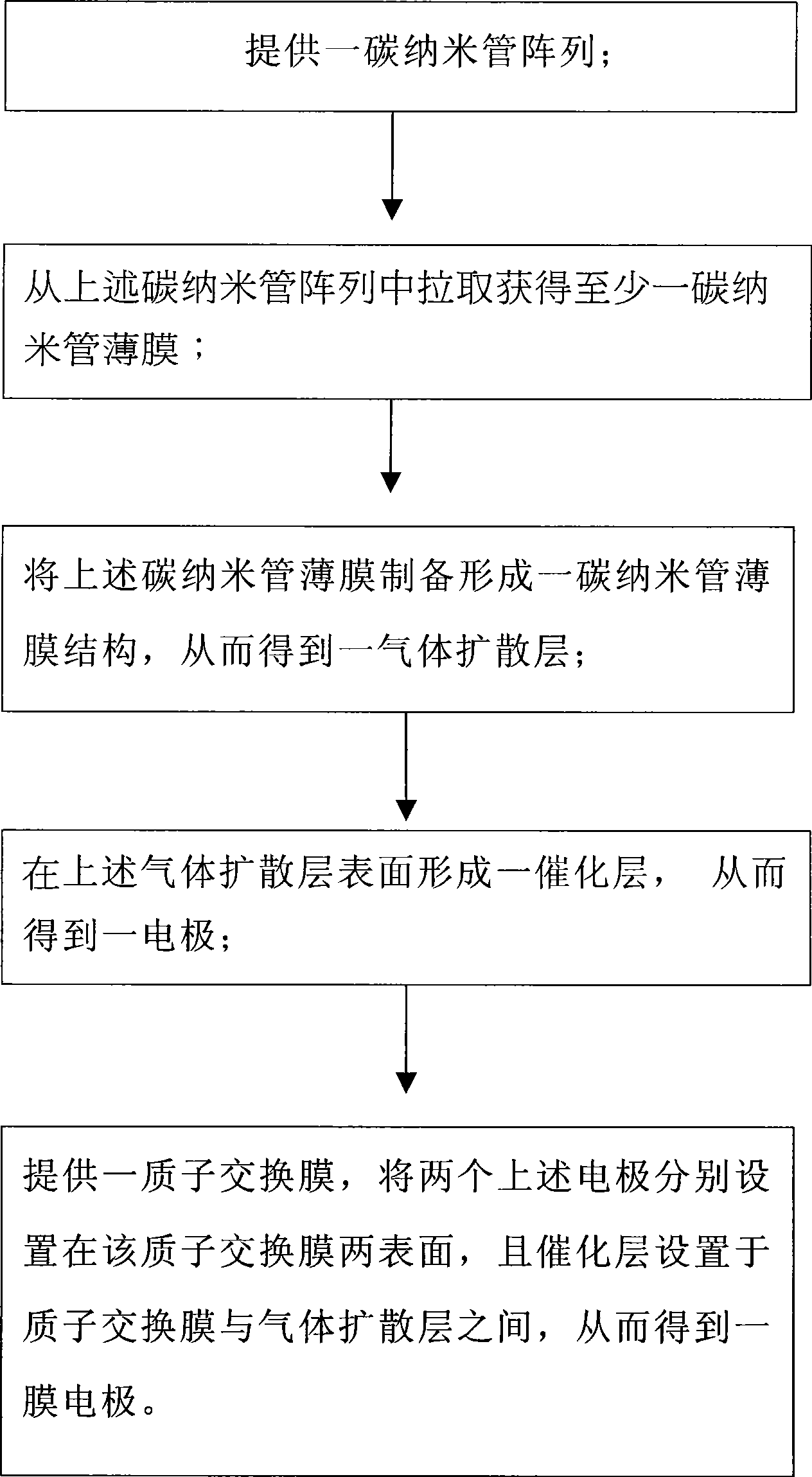

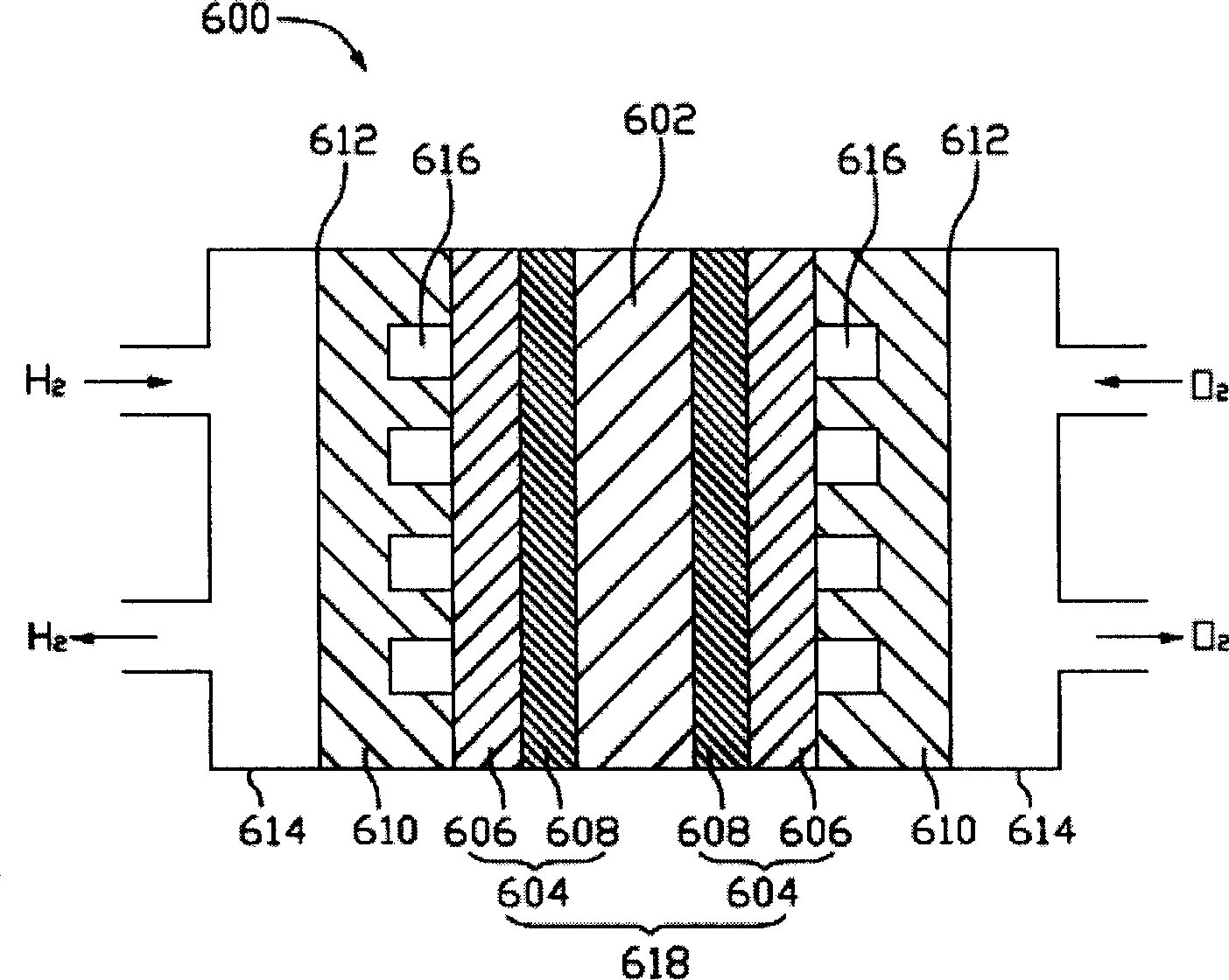

Fuel battery membrane electrode and preparation method thereof

ActiveCN101465434AHigh reactivityHigh mechanical strengthMaterial nanotechnologyFinal product manufactureProtonCarbon nanotube

Owner:TSINGHUA UNIV +1

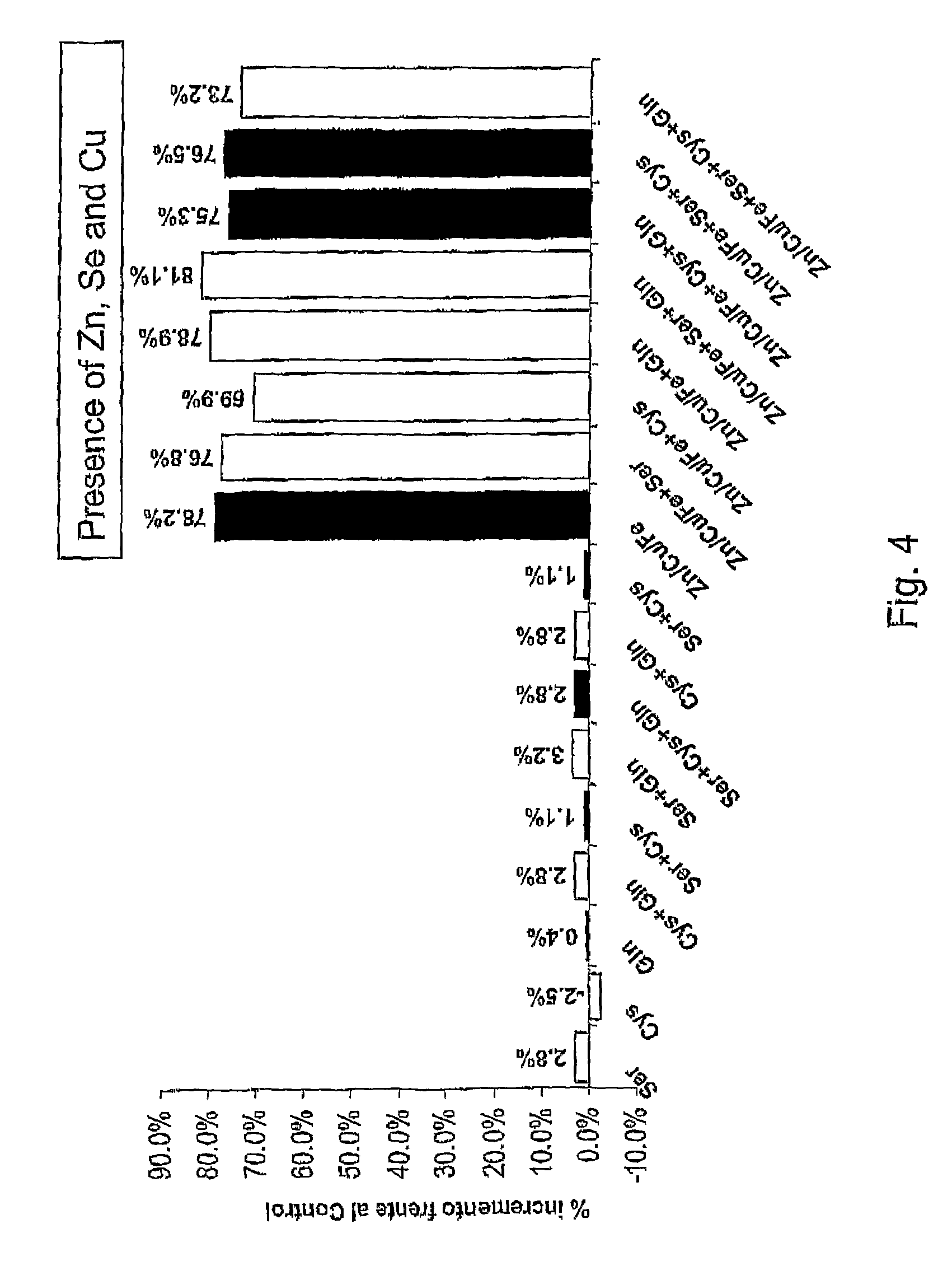

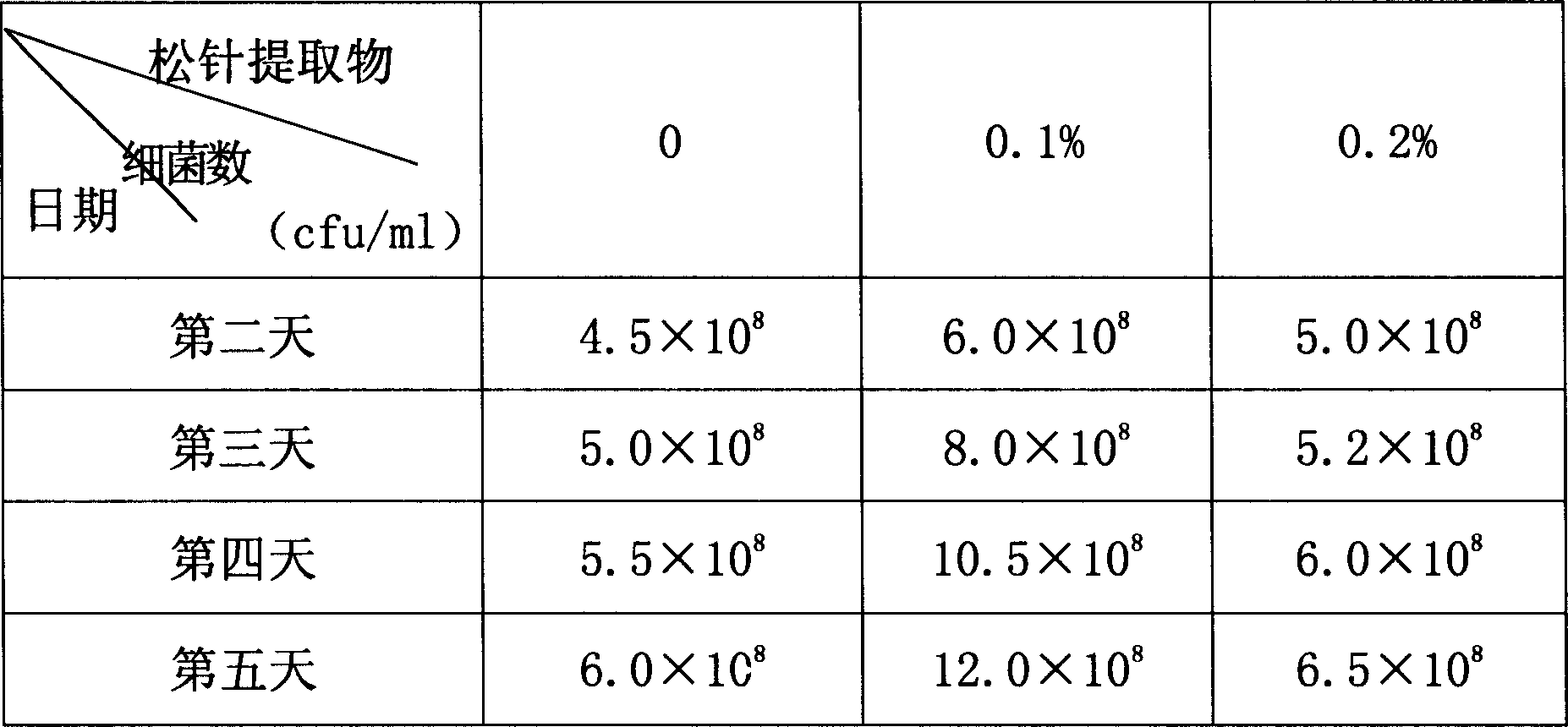

Feed additive for improving animal disease-resistant ability

A feed additive for increasing the resistance of animal to diseases is prepared from the fragments of the plants in pinaceae through pulverizing and extracting in hot water. Its contains polyphenol compound and polyose for regulating the balance between floras in animal's intestinal tract.

Owner:浙江德清利欣生物科技有限公司

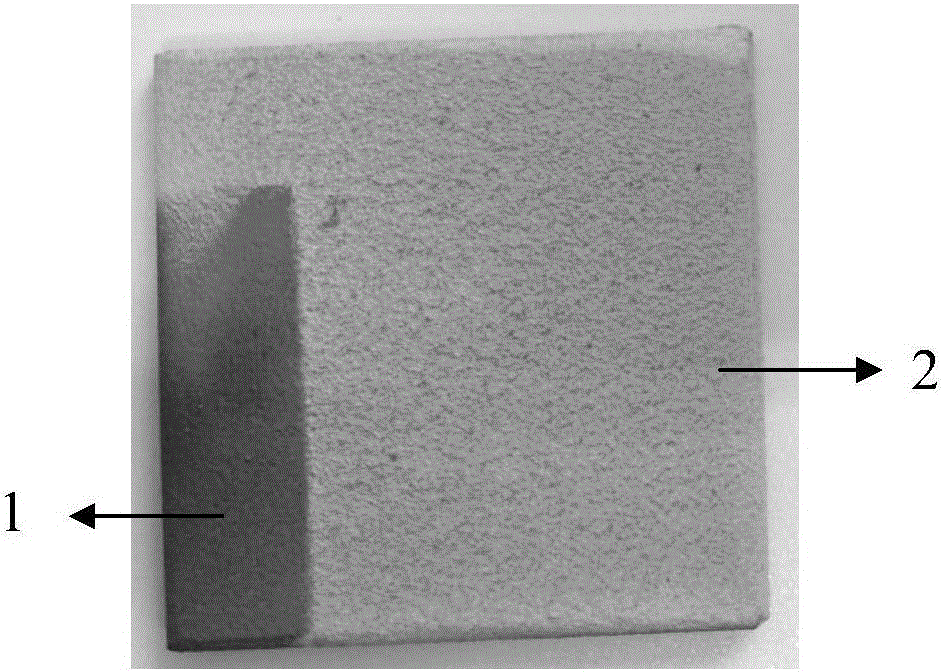

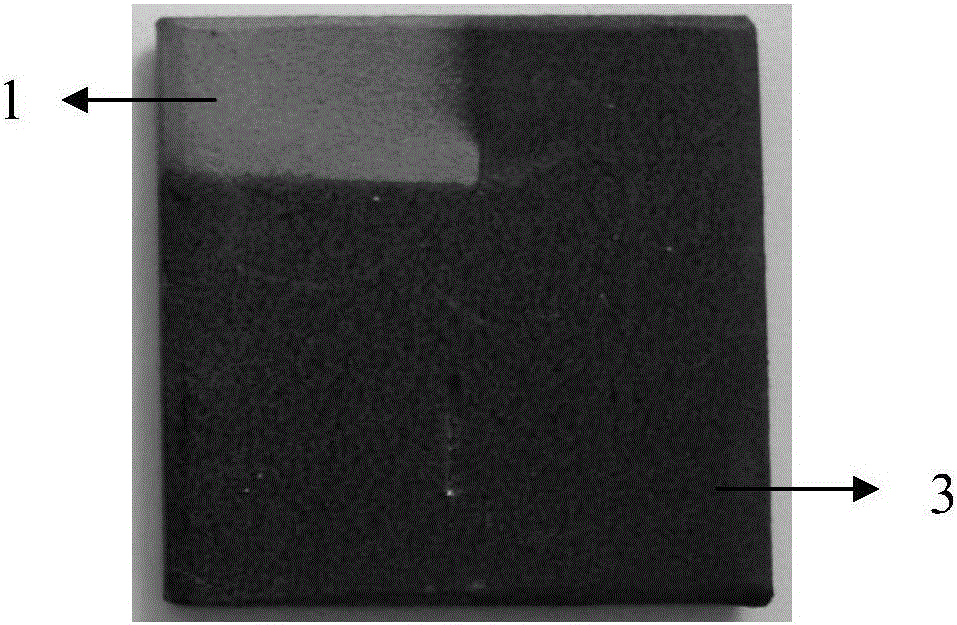

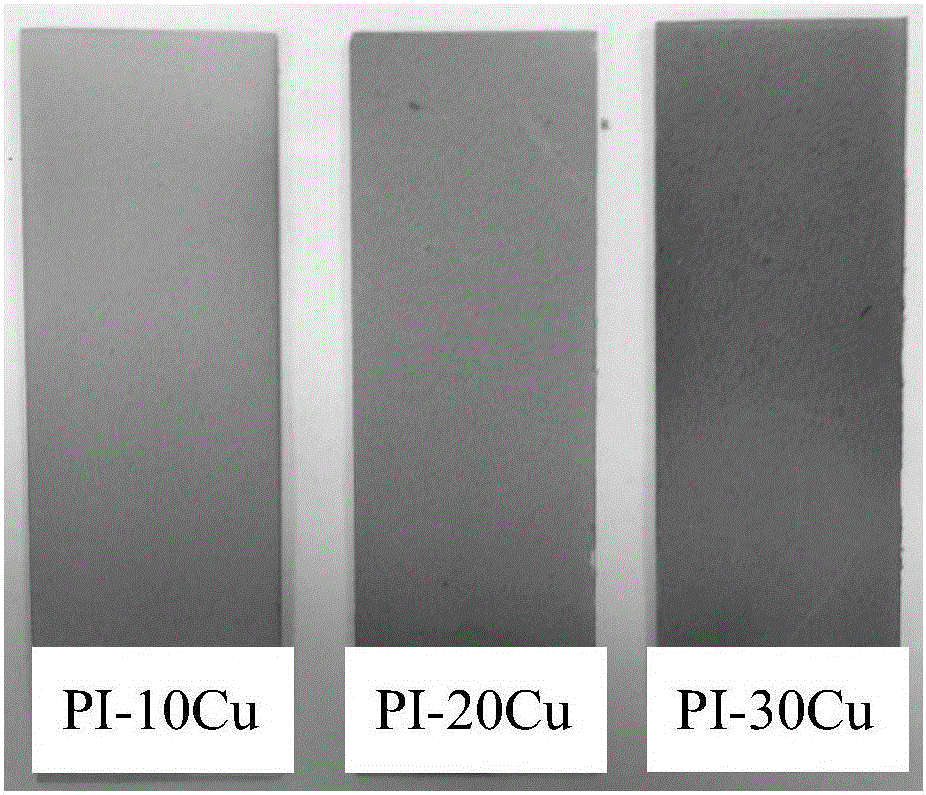

Polyimide composite coating and preparation method thereof and application thereof

ActiveCN105838239ASimple processImprove efficiencyLiquid surface applicatorsAntifouling/underwater paintsThermal sprayingThermoplastic polyimide

The invention discloses a preparation method of polyimide composite coating. The method includes the following steps: step 1: preparing the polyimide spraying raw material, wherein the polyimide spraying raw material is thermosetting polyimide composite precursor slurry, thermoplastic polyimide composite precursor slurry or thermoplastic polyimide composite powder; step 2: performing surface oil-removing of the matrix and coarsening processing; and step 3: sending the spraying raw material prepared by step 1 to a thermal spraying flame flow, and spraying on the treated matrix surface to form the polyimide composite coating. The invention discloses the preparation method of polyimide composite coating, and the method has simple technology, high efficiency and low cost, and is suitable for site operation. The spraying is not limited by the size and shape of the workpiece. The prepared polyimide composite coating is combined well with the matrix, has effective antifouling and anticorrosion performances, and can be used for a plurality of antifouling and anticorrosion occasions such as external surface of industrial component used for ocean.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

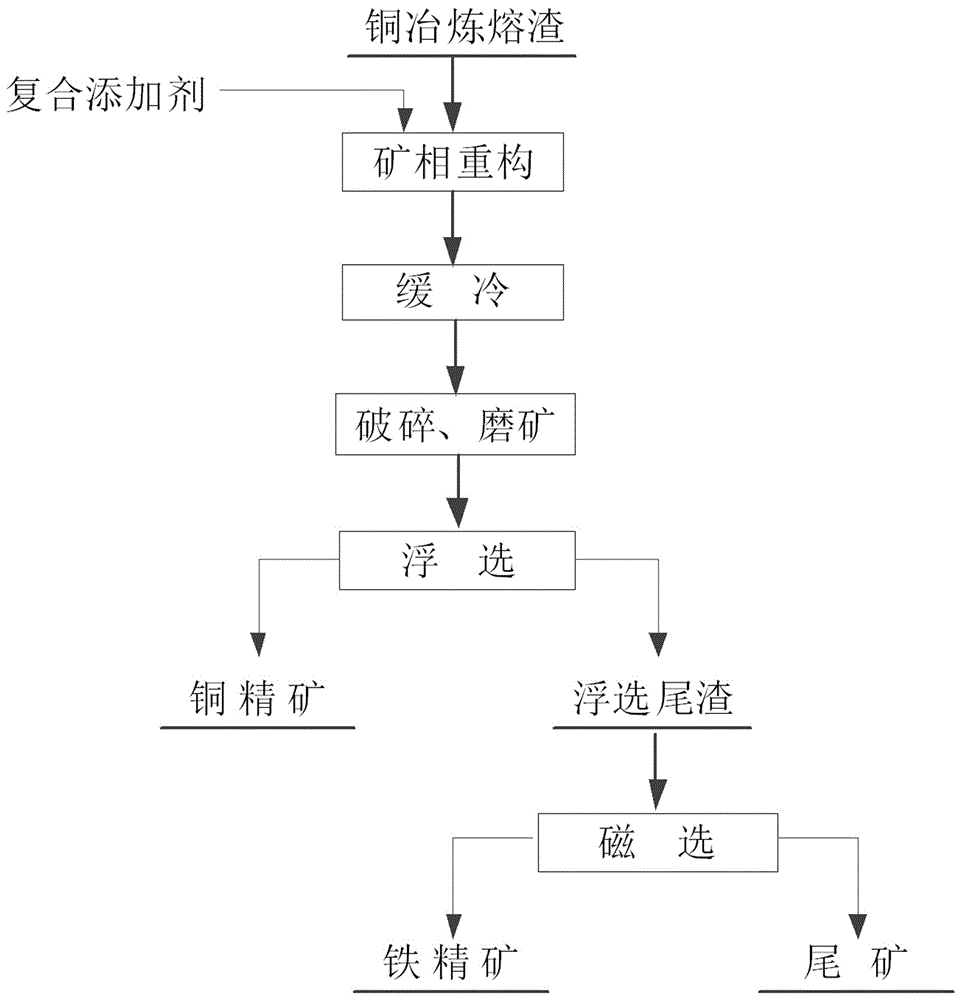

Process for comprehensively recycling copper and iron through ore phase restructuring of copper smelting molten slag

ActiveCN106676281AReduce slag viscosityImprove mobilitySolid separationBrown iron oxideSmelting process

The invention relates to a process for comprehensively recycling copper and iron through ore phase restructuring of copper smelting molten slag. The process comprises the following steps of 1, molten slag ore phase restructuring, wherein when the copper smelting slag is in the molten state, a composite additive accounting for 8-20% of the mass of the copper slag is added, then gradual cooling treatment is conducted, and the composite additive is composed of 40-50% of quick lime, 10-15% of manganous oxide, 10-15% of pyrite, 5-15% of chalcopyrite and 10-20% of an iron oxide; 2, flotation, wherein after modified slag obtained in step 1 is subjected to crushing and ore grinding, floatation treatment is conducted; and 3, magnetic separation, wherein tailings obtained through flotation conducted in step 2 are subjected to wet type magnetic separation, so that iron ore concentrate and magnetic separation tailings are obtained. According to the process for comprehensively recycling the copper and the iron, starting from the high-temperature molten slag generate in the copper smelting process, smelting slag ore phase restructuring is conducted by fully utilizing heat of the molten slag; the iron and the copper are each made to form ore easy to separate, and grains of the ore are pushed to grow; and efficient iron recycling is achieved while the copper is recycled successfully.

Owner:CENT SOUTH UNIV +1

Method for preparing rare earth barium copper oxide superconducting block material

InactiveCN101717256AGuaranteed efficient growthHigh success rate of preparationRare earthHigh temperature superconducting

A method for preparing rare earth barium copper oxide superconducting block material comprises the steps of executing calcining and grinding processes in turn after mixing the RE123 and RE211 in the mole ratio of 100: (20-35); pressing the ground powder into precursor bottom piece and precursor top piece respectively; putting the precursor top piece on top of the precursor bottom piece; putting seed crystal on the precursor top piece, then putting the precursor bottom piece on a zirconium oxide bead substrate; rising temperature for heating in a sealing container, and then cooling to prepare the rare earth barium copper oxide superconducting block material. The method can prepare the high temperature superconducting block material with high performance, large single domain structure and good growth orientation under the conditions that no impurity exists and crystal lattices match completely, thereby solving the key problems of the growth and application of the superconducting block material.

Owner:SHANGHAI JIAO TONG UNIV

Serum-Free Cell Culture Medium for Mammalian Cells

ActiveUS20100227819A1Guaranteed efficient growthEffective maintenancePeptide/protein ingredientsImmunoglobulinsSerum free mediaSerum ige

The invention relates to a process for the manufacturing of a protein in mammalian cells cultured in a serum-free medium.

Owner:ARES TRADING SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com