Patents

Literature

198 results about "Erythorbic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

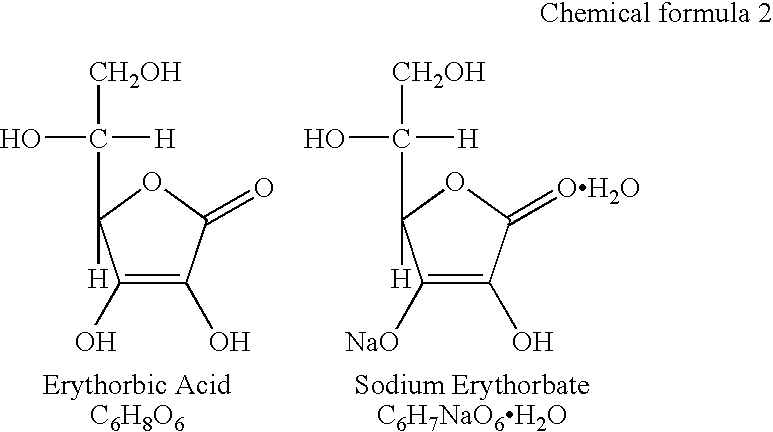

Erythorbic acid (isoascorbic acid, D-araboascorbic acid) is a stereoisomer of ascorbic acid (vitamin C). It is synthesized by a reaction between methyl 2-keto-D-gluconate and sodium methoxide. It can also be synthesized from sucrose or by strains of Penicillium that have been selected for this feature. It is denoted by E number E315, and is widely used as an antioxidant in processed foods.

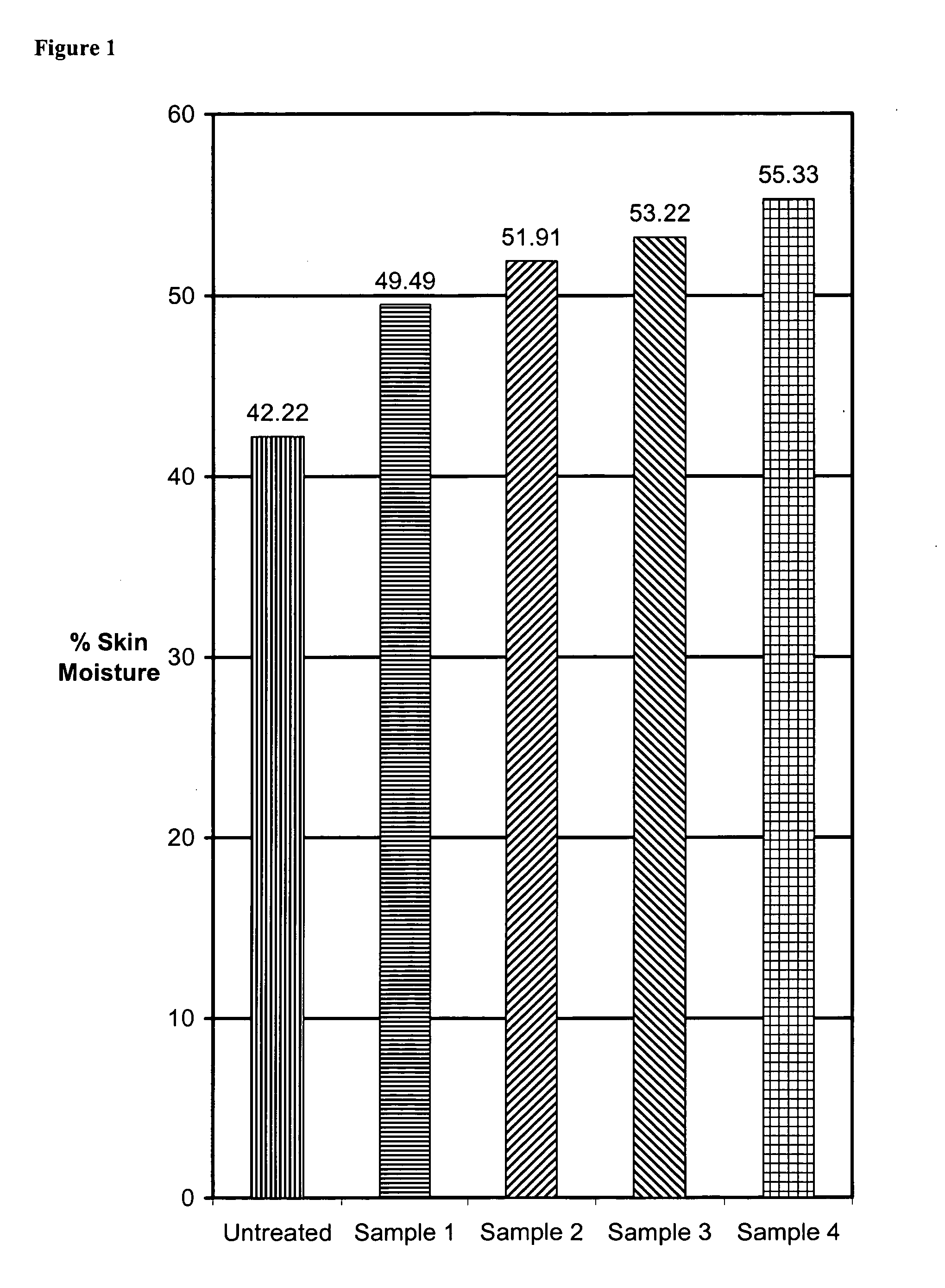

Personal care compositions and concentrates for making the same

InactiveUS20060093634A1Moisturize skin more effectivelyImprove biodegradation prevention efficacyCosmetic preparationsHair cosmeticsPersonal careMedicine

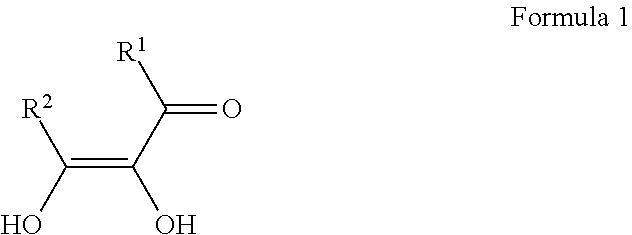

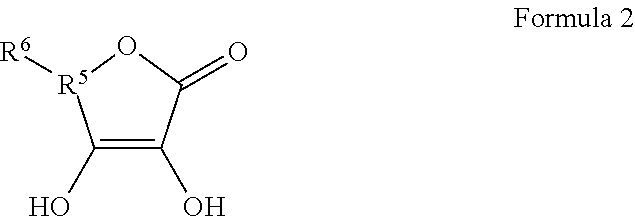

The present invention relates to color stable personal care compositions that provide anti-oxidiation, moisturization, and / or prevent biodegradation in personal care formulations. These compositions contain erythorbic acid or a salt thereof, caffeic acid or a salt thereof, δ-gluconolactone, or a mixture thereof. The present invention further relates to methods of moisturizing skin with erythorbic acid or a salt thereof, or δ-gluconolactone. The present invention also relates to concentrates of active ingredients preloaded with a sufficient amount of an anti-oxidation, moisturizing and / or biodegradation prevention agent so that when it is diluted for use, the final formulation includes an anti-oxidation, moisturizing and / or biodegradation prevention effective amount of the anti-oxidation, moisturizing, and / or biodegradation prevention agent.

Owner:LONZA INC

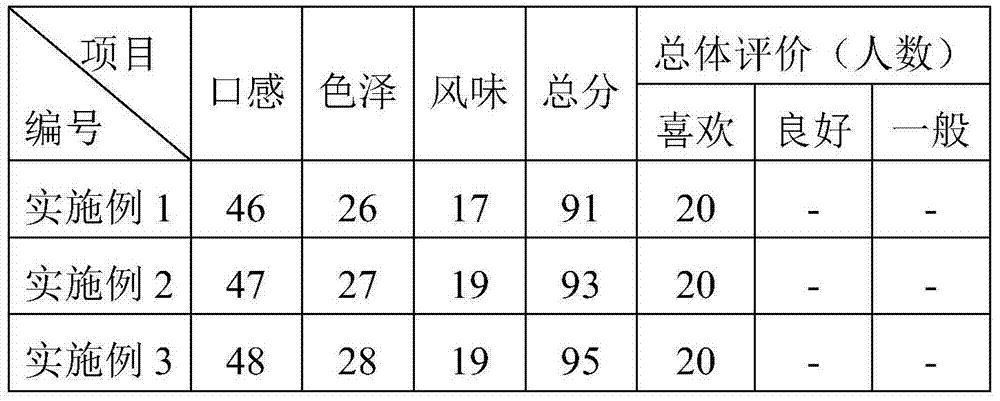

Preparation process for fermented chilli sauce

ActiveCN102919814AGrowth inhibitionReduce accumulationFood preparationCALCIUM LACTOBIONATEToothpaste

The invention discloses preparation process for fermented chilli sauce. The preparation process includes the following steps: placing fresh chilli and ginger into a jar, mixing cultures of lactobacillus planetarium and fermentation lactobacillus, and conducting three times of culture cultivation to obtain fermentation broth; adding the fermentation broth and fermenting; taking the chilli and ginger out of the jar and pulping; stirring and seasoning; packaging the fermented chilli sauce with tins or toothpaste-tube-shaped jars for replacing the jars and vacuum-sealing; and sterilizing through heat to obtain finished products. The chilli sauce is produced through pure-culture fermentation, calcium lactate and calcium chloride are used as a hardener, and color protecting processing is conducted by using 0.1% erythorbic acid combined with 0.1% laurel kojic acid. Simultaneously, the chilli sauce is packaged by using the tins and toothpaste-tube-shaped cans and has the advantages of being short in fermenting time, low in nitrite content, stable in product quality and good in product appearance quality.

Owner:HUNAN HUAKANG FOOD

Methods for preserving fresh produce

Methods of preserving fresh produce with a produce preservative which extends the shelf life of fresh produce, particularly cut fresh produce, and preserves the texture, flavor, appearance, crispness, and color of the fresh produce, particularly the exposed surface of the fresh produce, are provided. The method comprises: providing a solution of produce preservative comprising: water; a preservative cation which is selected from the group consisting of a strontium ion, lithium ion, barium ion, aluminum ion, copper ion, ammonium ion, iron ion, manganese ion, potassium ion, or mixtures thereof; and ascorbate ions, or erythorbate ions; wherein the ascorbate ions or erythorbate ions and the preservative cation are present in an ion ratio of preferably from 0.2:1 to 8:1, more preferably 0.75:1 to 8:1, even more preferably from 1:1 to 4:1, yet more preferably 1.5:1 to 3:1; most preferably 1.1:1 to 2.5:1; and, applying said produce preservative to the produce. The invention also relates to fresh produce preserved with the produce preservatives.

Owner:MANTROSE HAEUSER

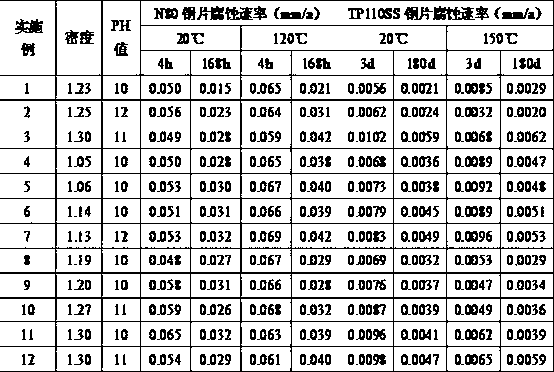

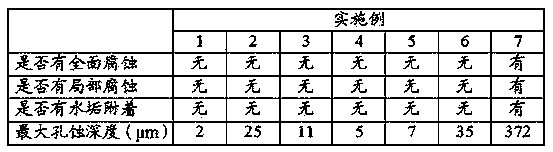

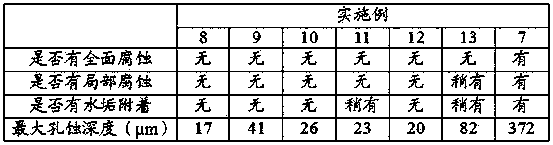

Annular protecting liquid for oil and gas well

ActiveCN102719233AExtended service lifeImprove thermal stabilityBorehole/well accessoriesActive agentCarbonate

The invention relates to an annular protecting liquid for oil and gas wells and belongs to the chemical technology field. In the liquid, a solution of organic acid salts is used as a density modifier, an imidazoline quaternary ammonium salt is used as a corrosion inhibitor, a quaternary ammonium salt cationic surfactant is used as a bacteriostatic agent and an isoascorbic acid alkali metal salt or an optical isomer thereof is used as a deoxidant. And an iron-centric coordination compound with two-valence ion or basic zinc carbonate can be added as a Desulphurizing Reagent, according to the sulfur-containing situation of a casing annulus. With a corrosion rate to N80 steel discs of 0.070mm / a and a corrosion rate to TP110SS steel discs of 0.0105mm / a, the annular protecting liquid, which is capable of prolonging the service life of an annular tubular column of a shaft by over 50% and decreasing the safety accidents resulted from corrosion perforation by over 30%, satisfies the requirements of annular protecting liquid for wells with different depths, has the characteristics of low stratum damage rate and no pollution and is applicable to the annular protection of oil and gas wells with high content of sulfur or other oil and gas wells.

Owner:CHINA PETROLEUM & CHEM CORP +1

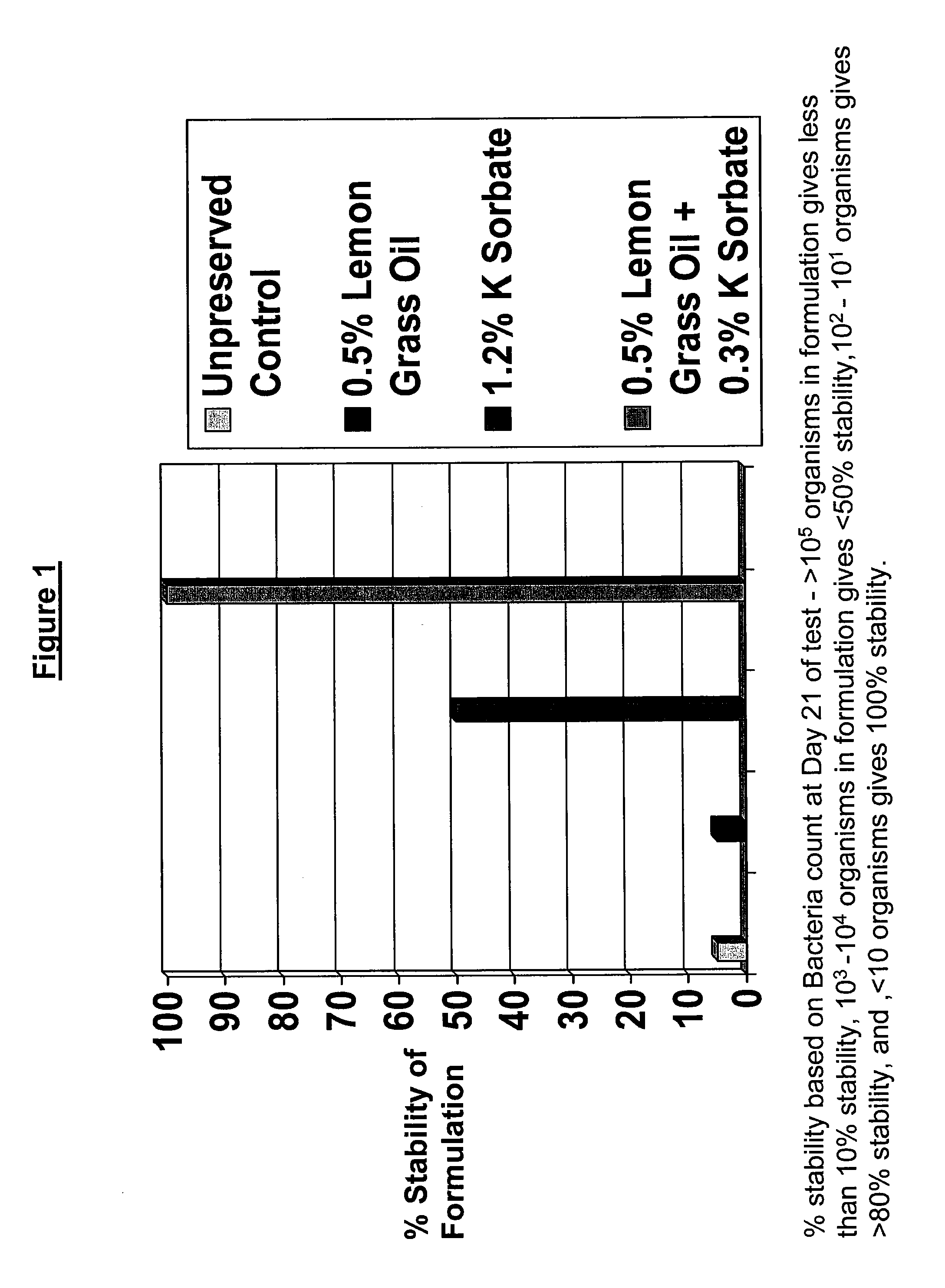

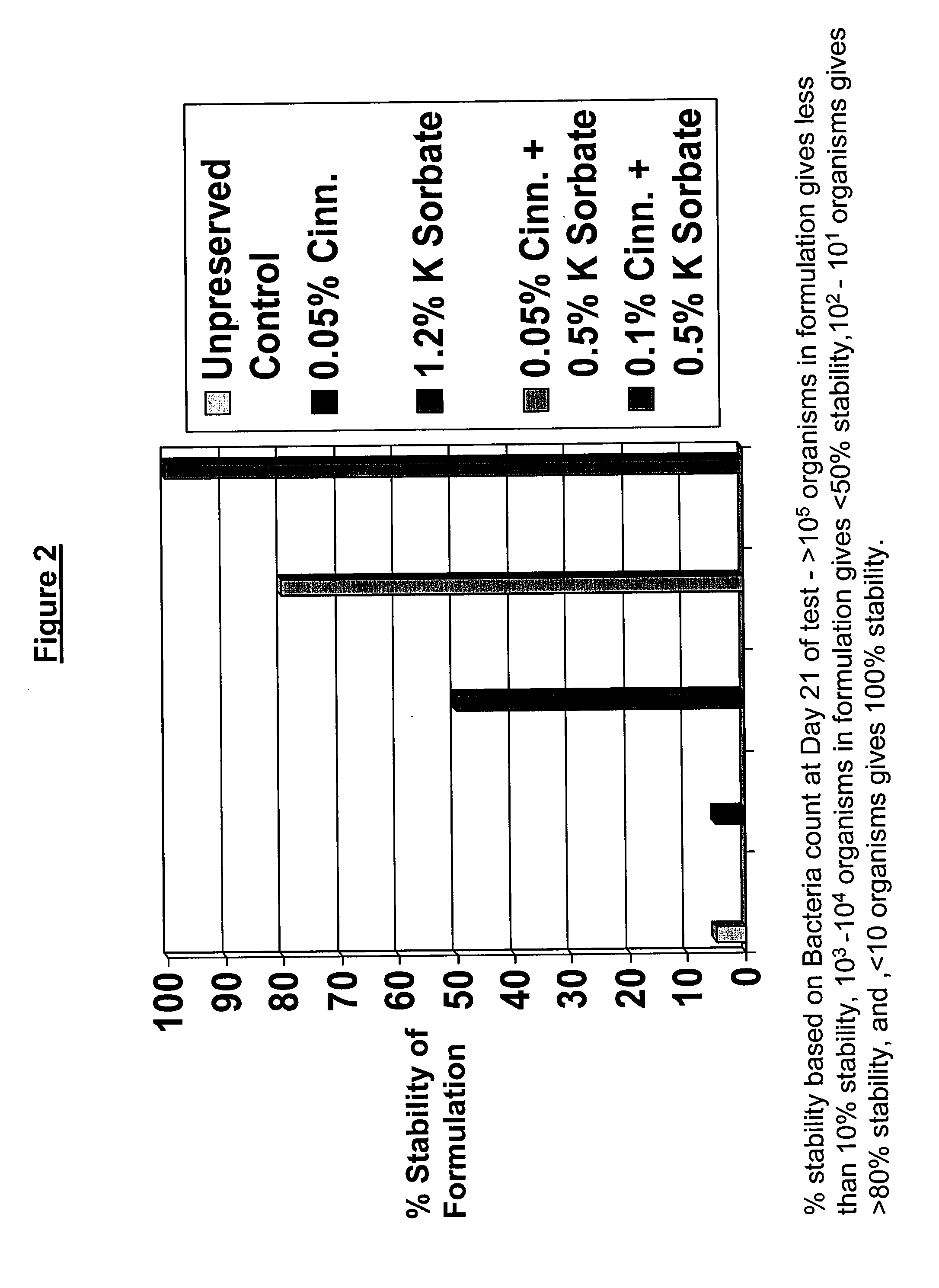

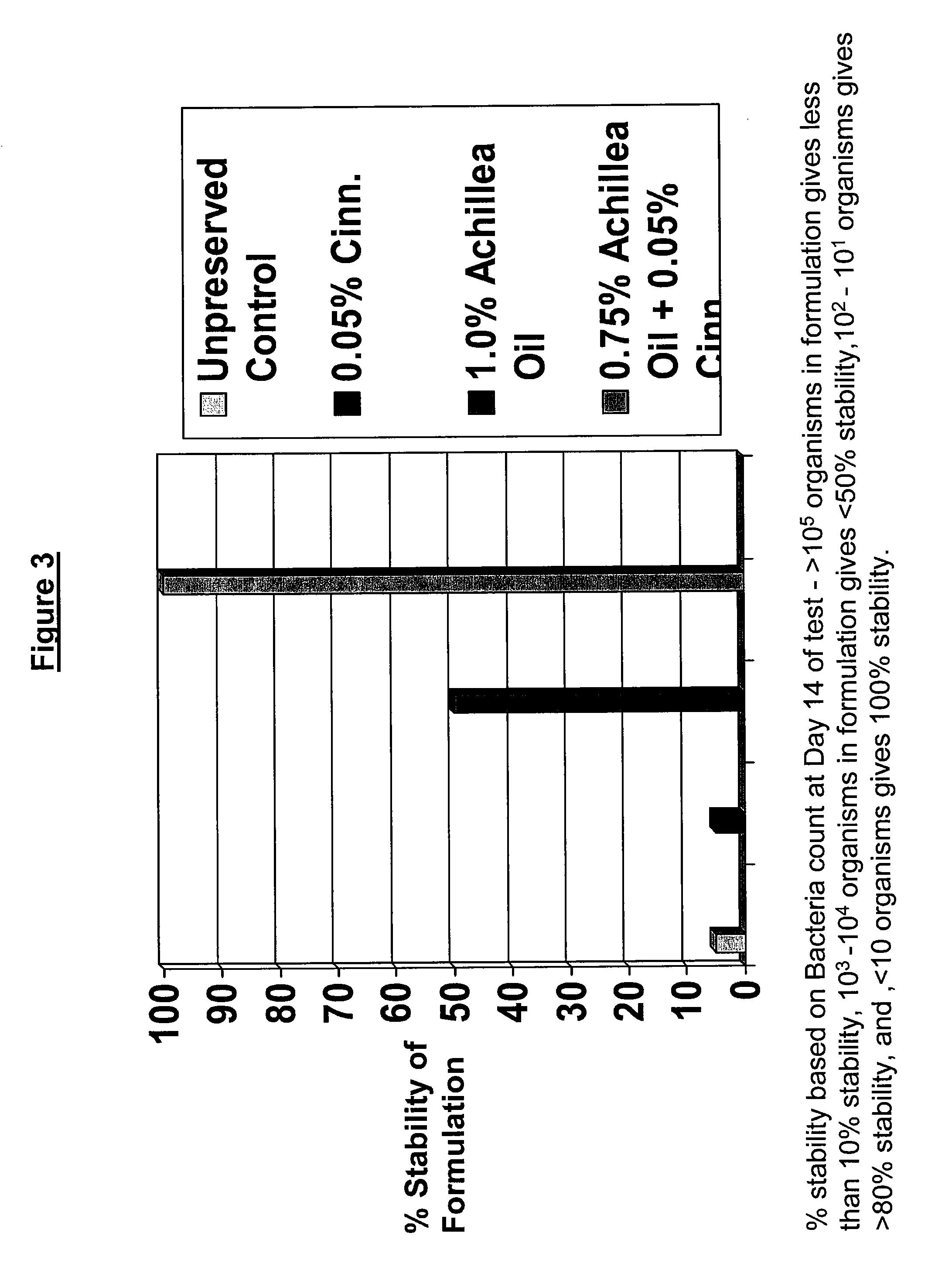

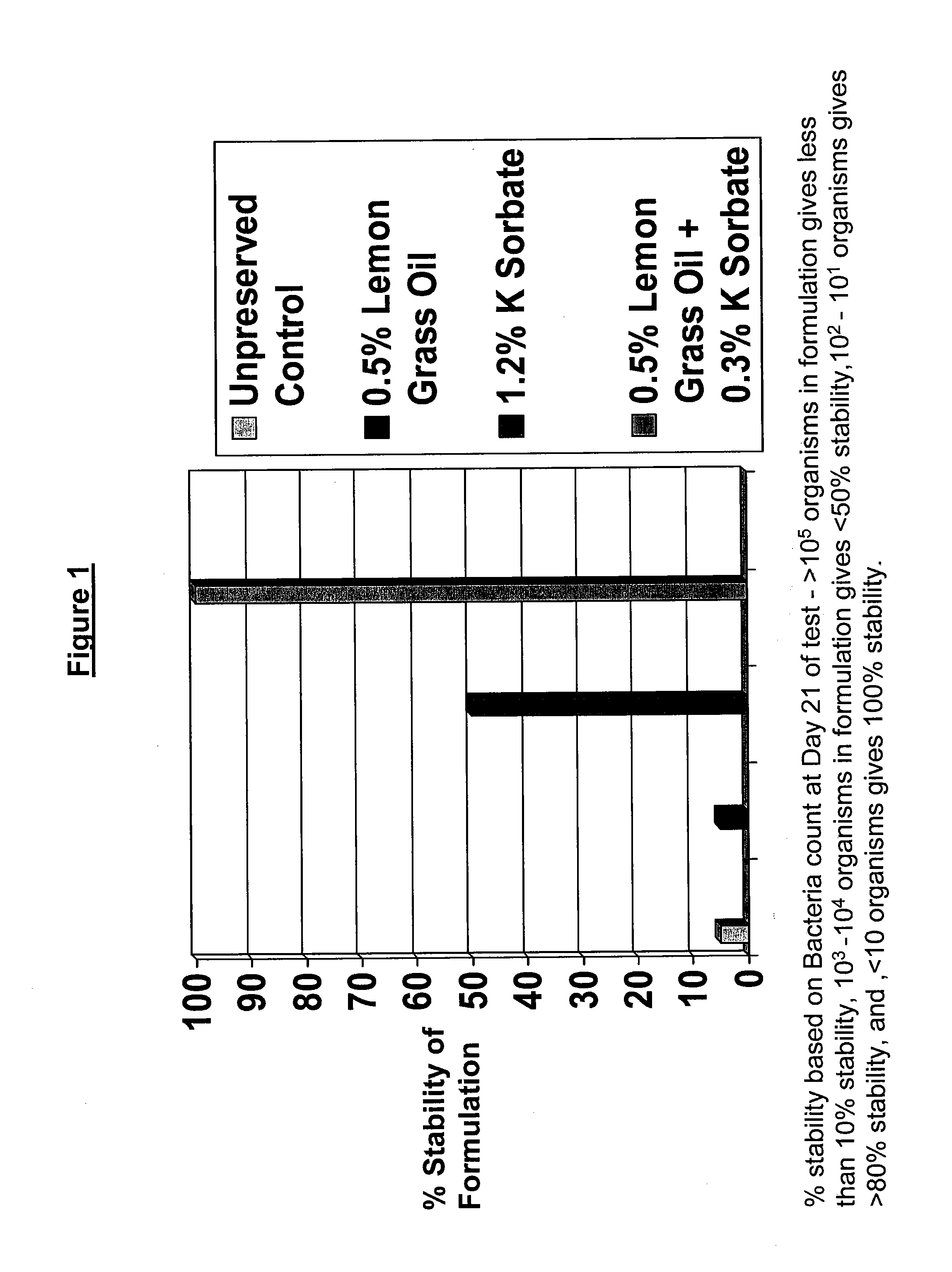

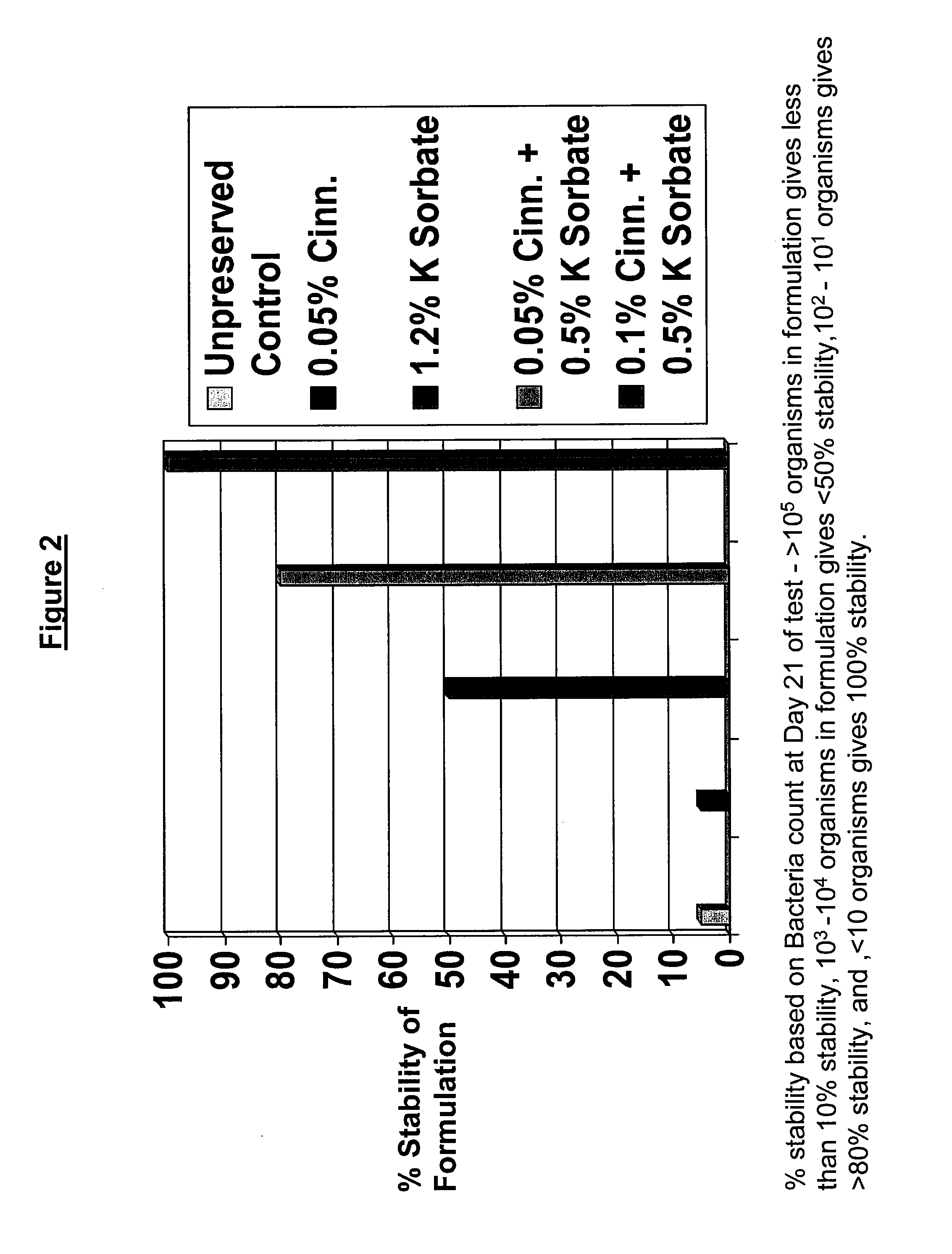

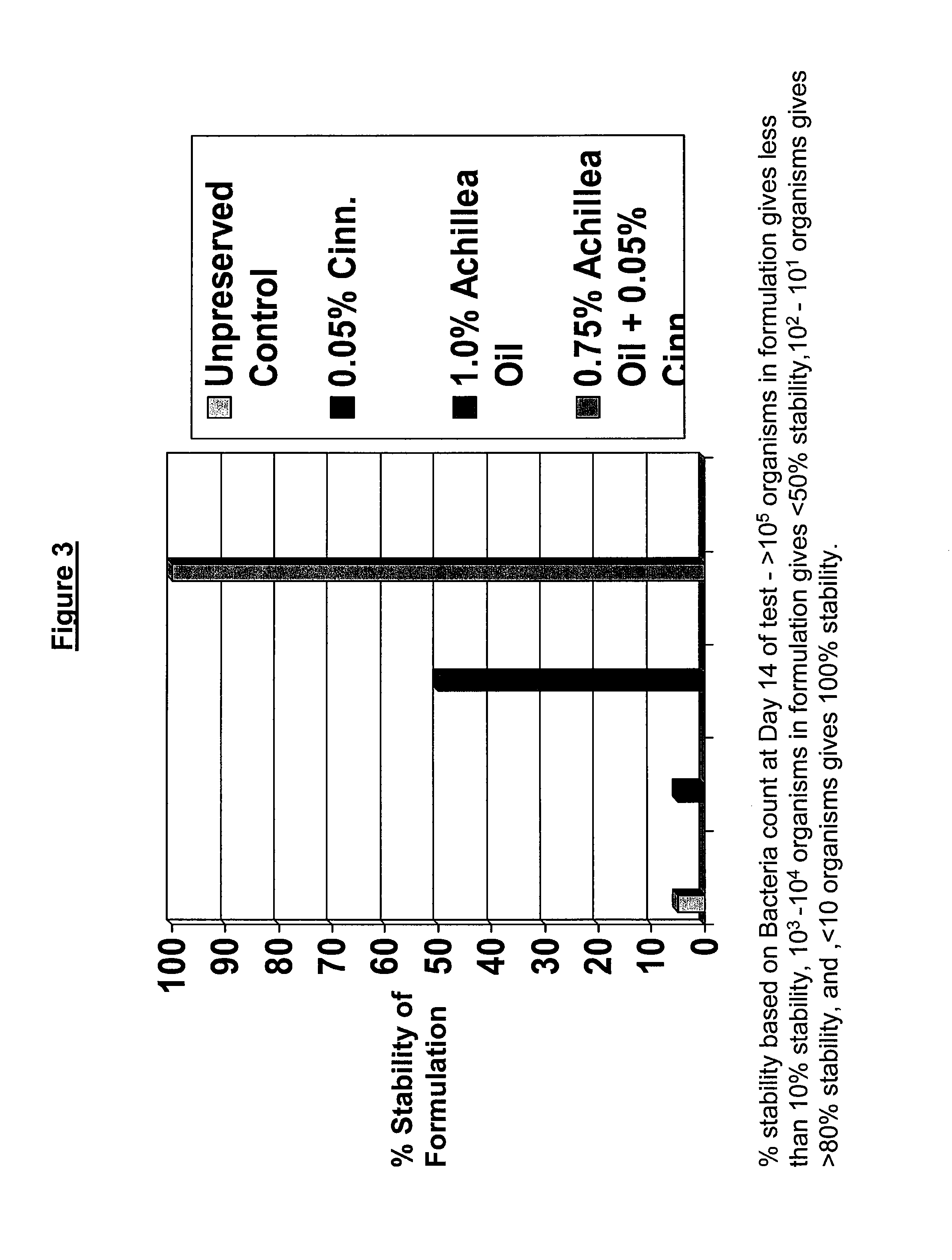

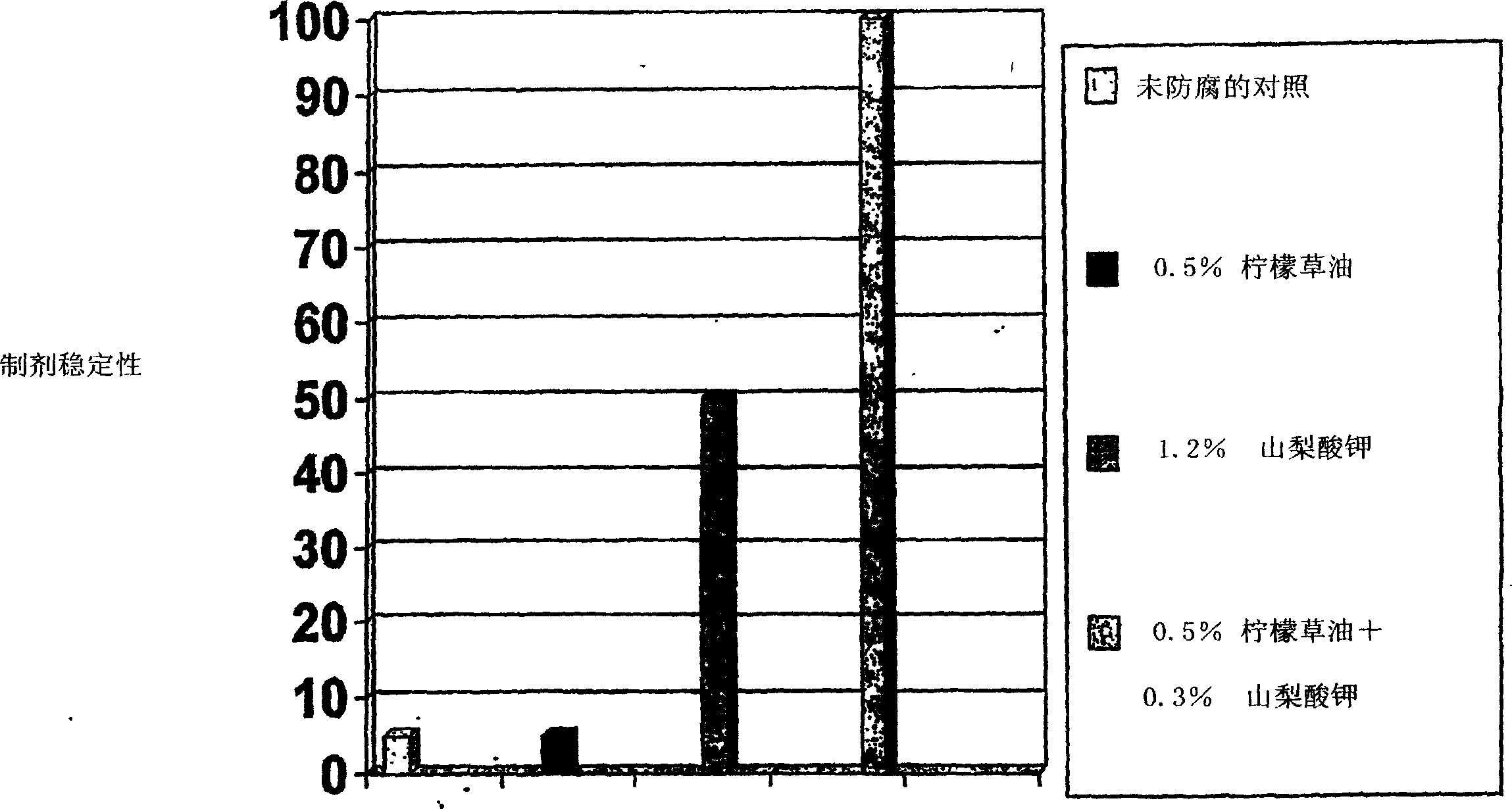

Antimicrobial compositions

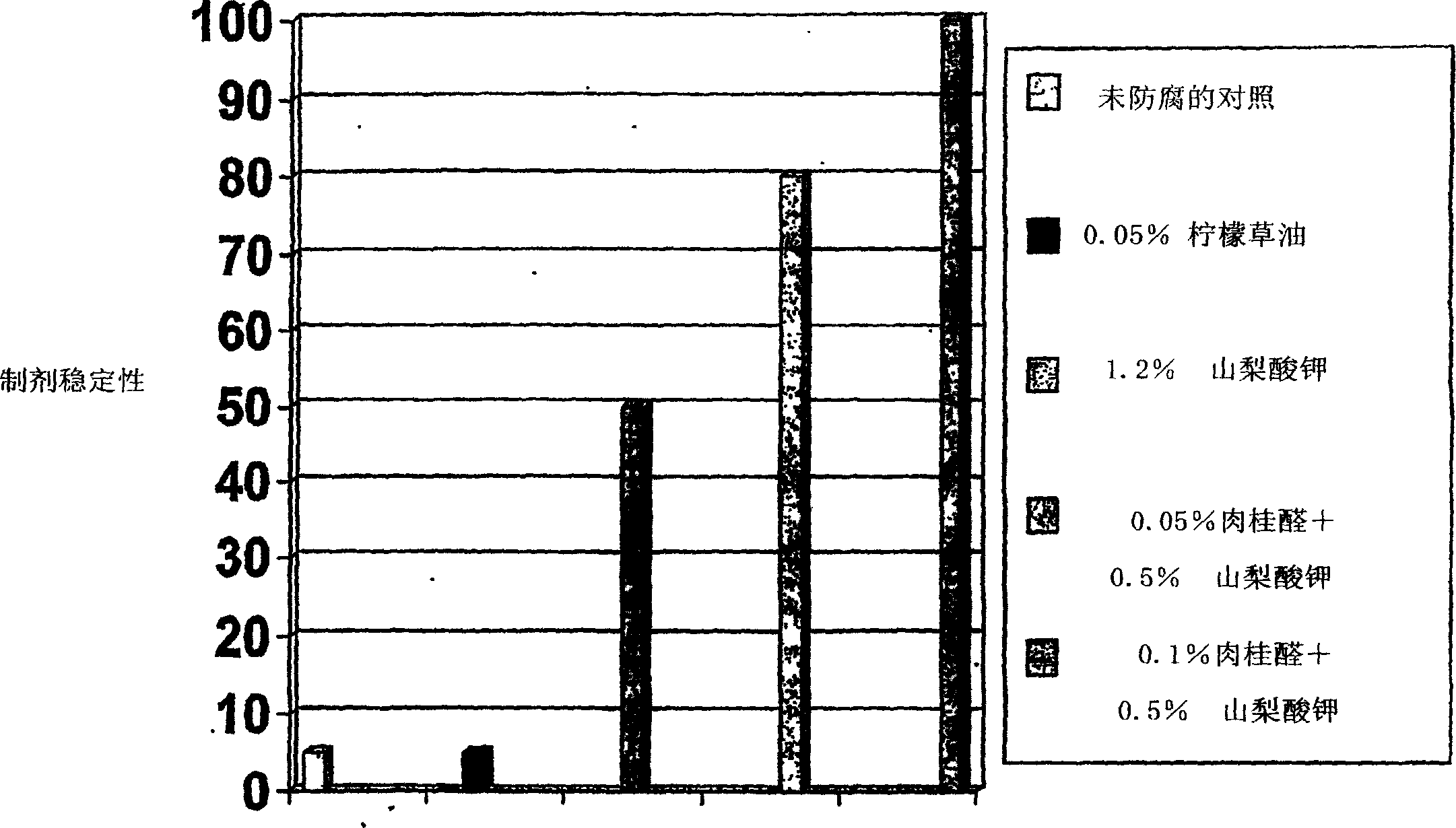

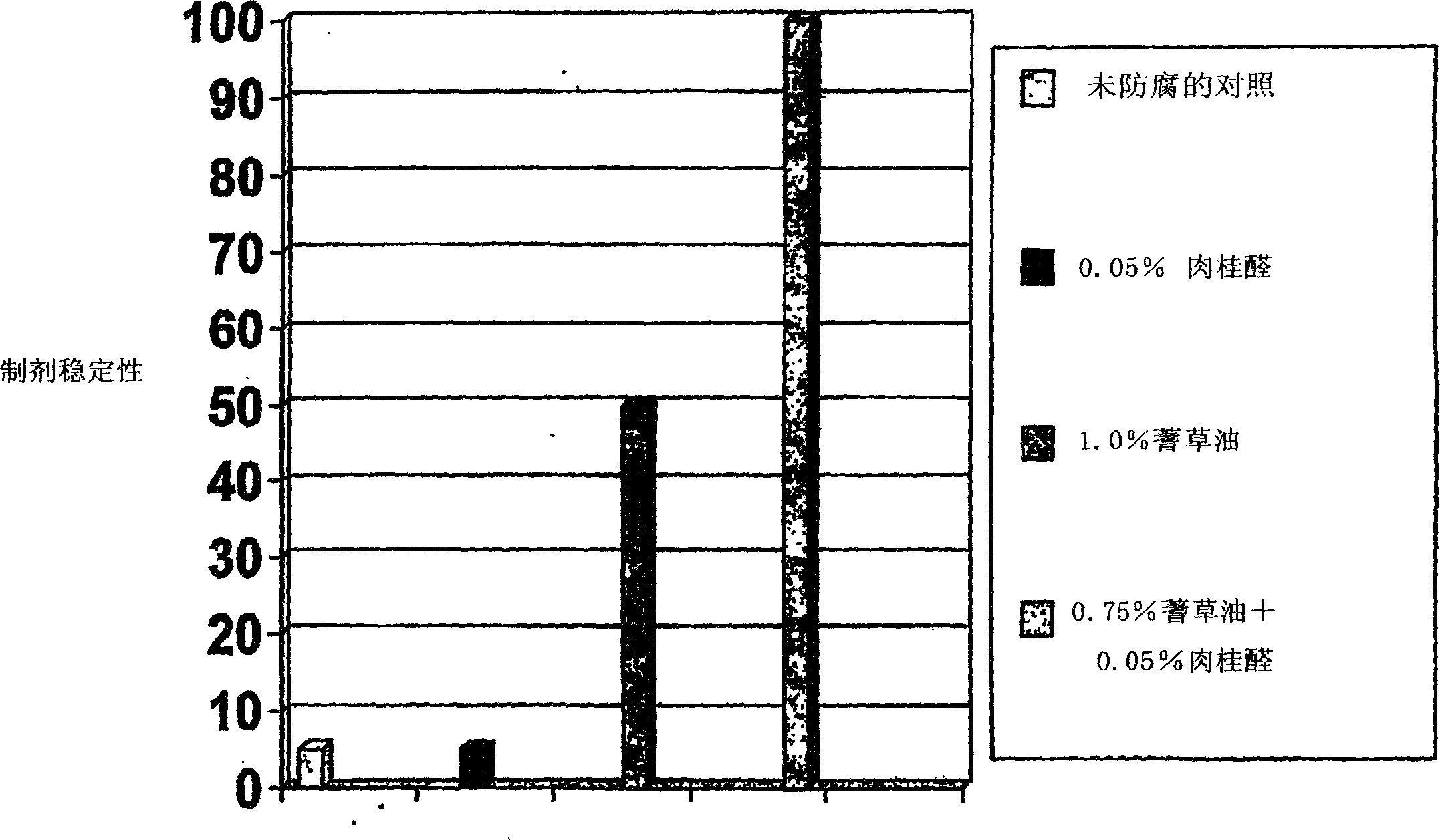

The present invention provides an antimicrobial composition comprising an antimicrobial effective amount (such as a preservative, bactericidal, and / or fungicidal effective amount) of a mixture comprising at least two of:(a) lemon grass oil;(b) cinnamaldehyde, cinnamon oil, Cinnamomum cassia, cinnamon extract, cassia leaf oil, 3,4-dihydroxycinnamic acid or salt thereof, or a mixture thereof;(c) sorbic acid, or a salt thereof;(d) erythorbic acid, or a salt thereof;(e) benzoic acid, or a salt thereof;(f) arabinogalactan, galactoarabinan, or a mixture thereof;(g) a hexahydro-iso-alpha-acid, tetrahydro-iso-alpha-acid, or a mixture thereof;(h) Achillea fragrantissima (Santolina fragrantissima Forssk., lavender cotton) oil; and(i) δ-gluconolactone.The present invention also provides a product (preferably a product other than a foodstuff, pharmaceutical, or cosmetic) comprising a preservative effective amount of cinnamaldehyde or a mixture of cinnamaldehyde and one or more alkanol-dialkyl hydantoins.

Owner:LONZA INC

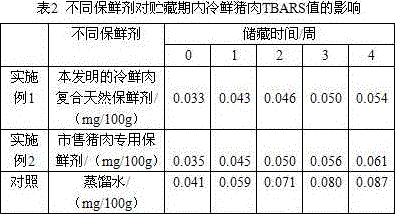

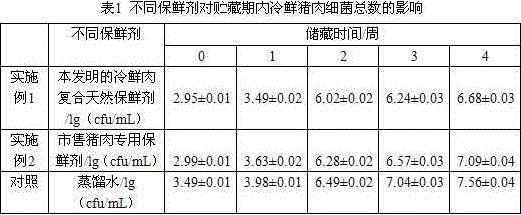

Composite natural fresh-keeping agent for cold fresh meat and application of composite natural fresh-keeping agent

InactiveCN106212635ABroad antibacterial spectrumRich sourcesMeat/fish preservation using chemicalsVitamin CNon toxicity

The invention relates to a composite natural fresh-keeping agent for cold fresh meat and application of composite natural fresh-keeping agent. The composite natural fresh-keeping agent for the cold fresh meat is characterized by comprising tea polyphenol, chitosan, nisin, natamycin, lysozyme, oregano essential oil, vitamin C, vitamin E, erythorbic acid, a spice extract and water in certain proportions by weight, wherein the spice extract is obtained by extracting ginger, garlic, cinnamon, cardamom, clove and rosemary in certain proportions by weight through ethanol extraction. The composite natural fresh-keeping agent for the cold fresh meat is prepared from biological-source raw materials by a simple preparation method, has the advantages of non-toxicity, safety, broad antibacterial spectrum and the like, is convenient to operate during using and prominent in fresh-keeping effect, and has an important industrial value.

Owner:宋晓燕

Antimicrobial compositions

The present invention provides an antimicrobial composition comprising an antimicrobial effective amount (such as a preservative, bactericidal, and / or fungicidal effective amount) of a mixture comprising at least two of:(a) lemon grass oil;(b) cinnamaldehyde, cinnamon oil, Cinnamomum cassia, cinnamon extract, cassia leaf oil, 3,4-dihydroxycinnamic acid or salt thereof, or a mixture thereof;(c) sorbic acid, or a salt thereof;(d) erythorbic acid, or a salt thereof;(e) benzoic acid, or a salt thereof;(f) arabinogalactan, galactoarabinan, or a mixture thereof;(g) a hexahydro-iso-alpha-acid, tetrahydro-iso-alpha-acid, or a mixture thereof;(h) Achillea fragrantissima (Santolina fragrantissima Forssk., lavender cotton) oil; and(i) δ-gluconolactone.The present invention also provides a product (preferably a product other than a foodstuff, pharmaceutical, or cosmetic) comprising a preservative effective amount of cinnamaldehyde or a mixture of cinnamaldehyde and one or more alkanol-dialkyl hydantoins.

Owner:ARXADA LLC

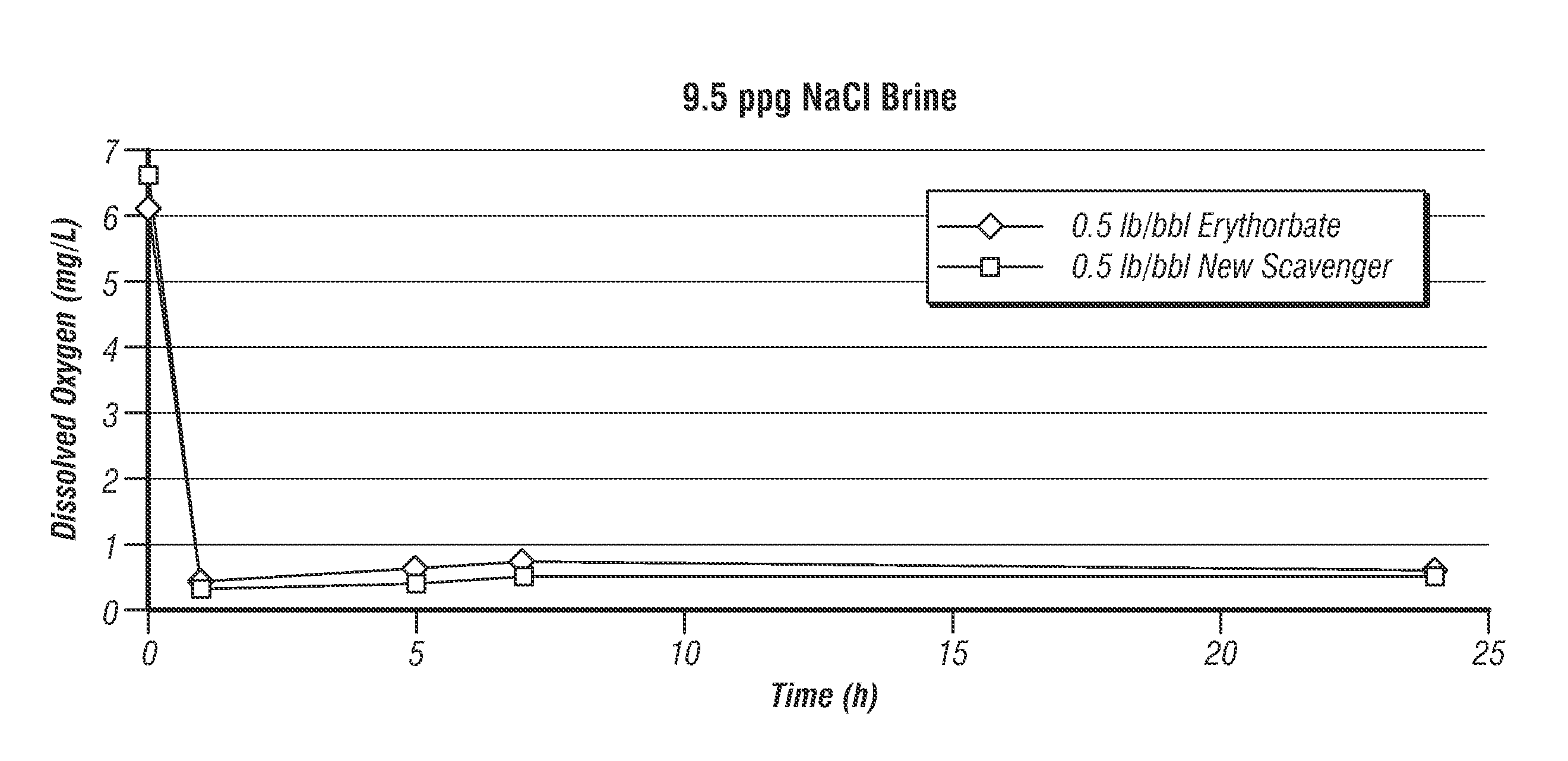

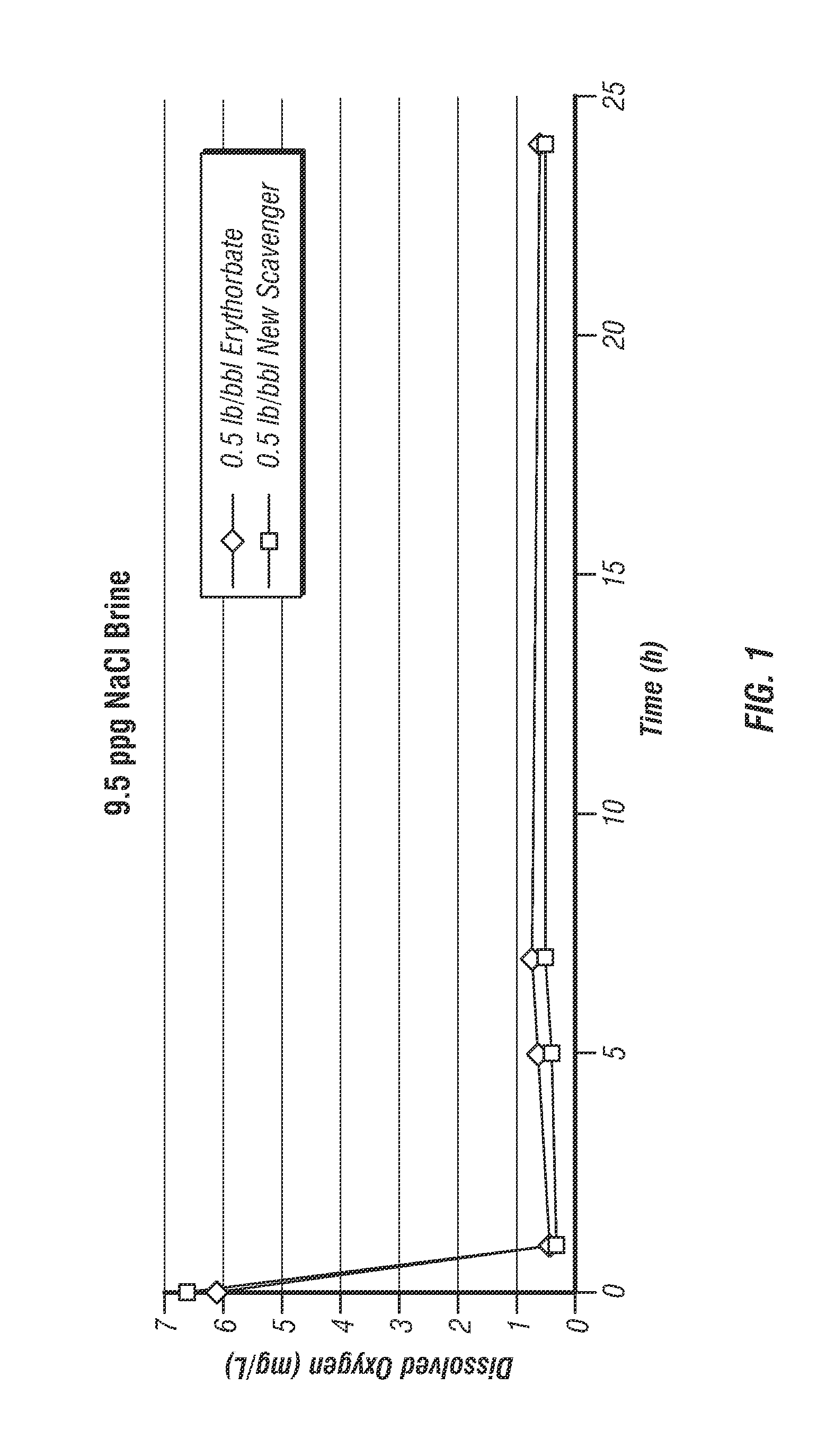

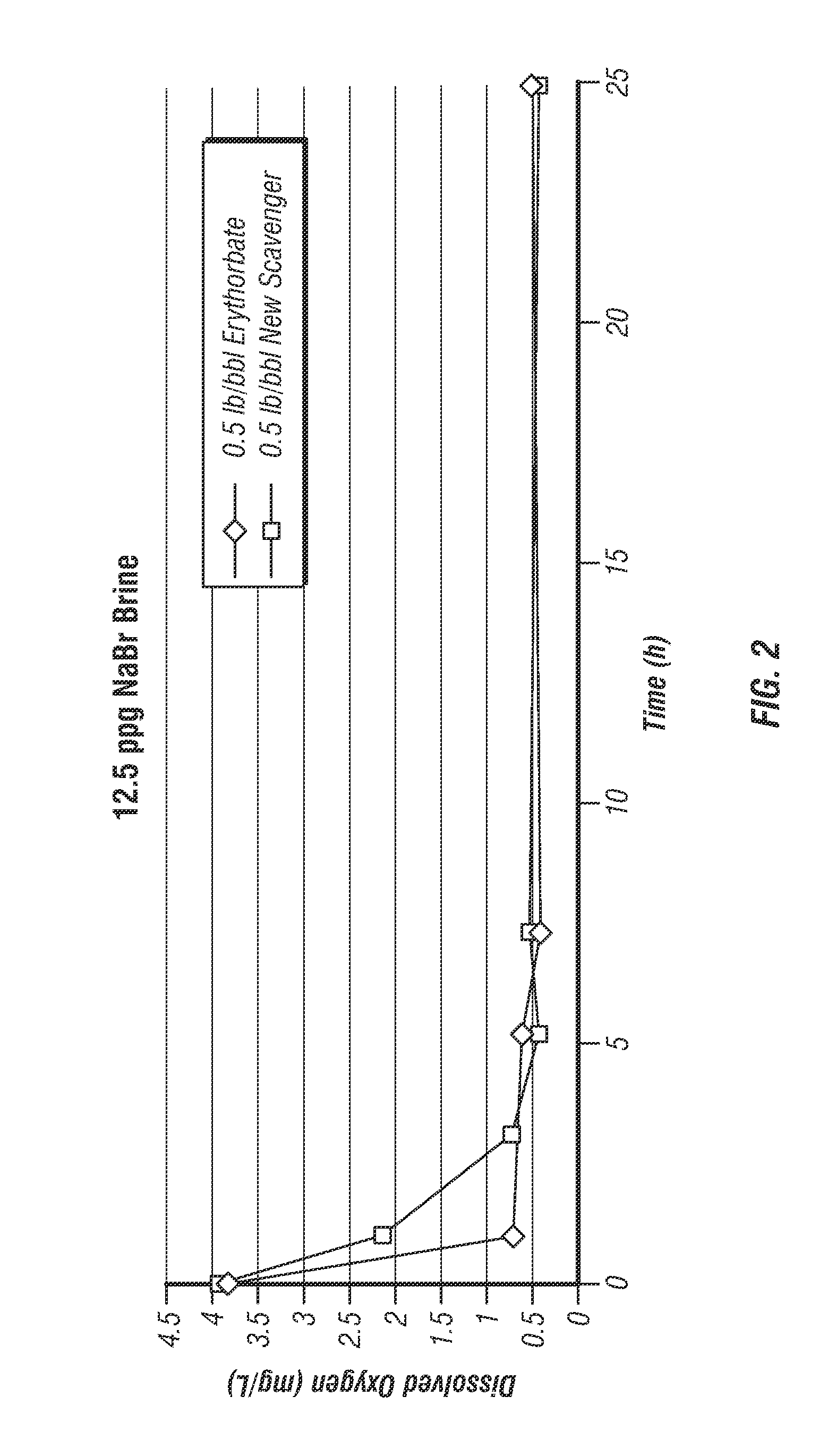

Agents for enhanced degradation of controlled electrolytic material

A method for degrading a downhole article includes exposing the downhole article comprising a controlled electrolytic material to a composition that comprises a reducing agent. The method also includes contacting the downhole article with the reducing agent to degrade the downhole article. Additionally, a composition for degrading a downhole article includes water, chelant, metal ions, and a reducing agent that includes ascorbic acid, erythorbic acid, a derivative thereof, a salt thereof, or a combination thereof.

Owner:BAKER HUGHES INC

Highly crystalline silver powder and process for production of the same

InactiveCN101218051AExcellent heat shrinkage resistanceSmooth surface roughnessTransportation and packagingMetal-working apparatusFiltrationMicroparticle

The invention aims at providing a process for the production of highly crystalline silver powder which comprises silver particles falling within the fine particle region and has an excellent particle size distribution and highly crystalline silver powder obtained by the process. The aim is attained by a process for the production of highly crystalline silver powder which is characterized by preparing the first aqueous solution containing gelatin, silver nitrate and nitric acid and having a temperature of 45 to 55 C and the second aqueous solution containing erythorbic acid and / or ascorbic acid and a water-soluble organic acid, adding the second aqueous solution mildly to the first aqueous solution, stirring the mixed solution after the completion of the addition to form silver particles through particle growth, allowing the resulting system to stand to settle the silver particles, removing the supernatant, and then subjecting the remainder to filtration and washing to recover the silver particles.

Owner:MITSUI MINING & SMELTING CO LTD

Methods for preserving fresh produce

InactiveUS20050084602A1Extended shelf lifePreserve textureMilk preservationDough treatmentAluminum IonFood flavor

Methods of preserving fresh produce with a produce preservative which extends the shelf life of fresh produce, particularly cut fresh produce, and preserves the texture, flavor, appearance, crispness, and color of the fresh produce, particularly the exposed surface of the fresh produce, are provided. The method comprises: providing a solution of produce preservative comprising: water; a preservative cation which is selected from the group consisting of a strontium ion, lithium ion, barium ion, aluminum ion, copper ion, ammonium ion, iron ion, manganese ion, potassium ion, or mixtures thereof; and ascorbate ions, or erythorbate ions; wherein the ascorbate ions or erythorbate ions and the preservative cation are present in an ion ratio of preferably from 0.2:1 to 8:1, more preferably 0.75:1 to 8:1, even more preferably from 1:1 to 4:1, yet more preferably 1.5:1 to 3:1; most preferably 1.1:1 to 2.5:1; and, applying said produce preservative to the produce. The invention also relates to fresh produce preserved with the produce preservatives.

Owner:MANTROSE HAEUSER

Non-phosphorus type environment-friendly slow-release scaling inhibitor

InactiveCN105776589ASimple production processHigh anti-scaling efficiencySpecific water treatment objectivesScale removal and water softeningAraboascorbic AcidFatty alcohol

The invention discloses a non-phosphorus type environment-friendly slow-release scaling inhibitor which is prepared from the following components: tannin, polyacrylic acid, ammonium salt, D-erythorbic acid, silicate, a non-phosphorus polymeric corrosion inhibitor, a maleic acid-crylic acid copolymer, fatty alcohol-polyoxyethylene ether, zinc salt, a dispersing agent and deionized water. The non-phosphorus efficient slow-release scaling inhibitor with safe and environment-friendly components is provided, due to the reasonable design, all the substances in the formula can be prepared into the environment-friendly corrosion inhibitor with a good corrosion inhibition effect and high storage stability.

Owner:SUZHOU NENGHUA ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

Beef seasoning and production method of seasoned beef

The invention provides a beef seasoning that makes the prepared conditioned beef taste fresh and tender, and has a unique flavor, including sodium pyrophosphate, sodium hexametaphosphate, sodium tripolyphosphate, 5'-taste nucleotide disodium, and yeast extract , D-erythorbic acid, oyster sauce, beef extract, dark soy sauce and soybean protein; the present invention also provides a production method of conditioning beef, the method comprises thawing Niu Lin and cutting into strips, beef seasoning and cutting The Niu Lin mixed with the Niu Lin was vacuum-tumbled and marinated; the marinated Niu Lin was sterilized; the sterilized Niu Lin was quick-frozen and frozen to obtain the finished beef product. The beneficial effects of the present invention are: the above-mentioned beef seasoning is mixed with thawed Niu Lin for tumbling, so that the obtained conditioned beef can retain the original fresh and tender taste of the beef while having a unique flavor, and make the meat fresh and tender. Attractive color and long shelf life.

Owner:FUJIAN YAMING FOOD

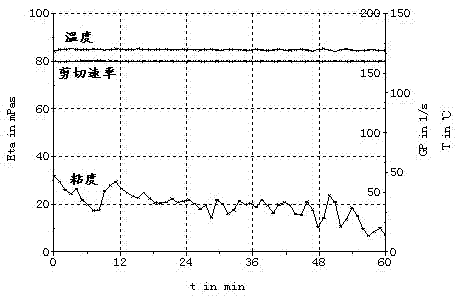

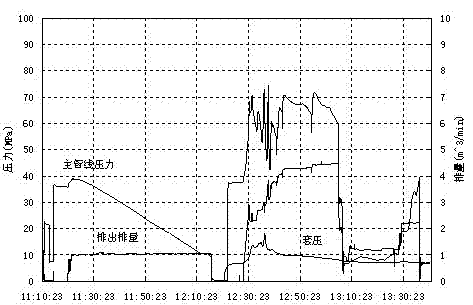

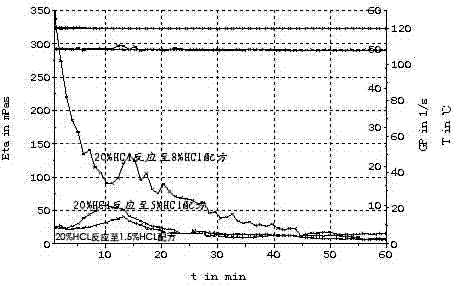

Diverting acid for carrying out acidification and transformation on high-temperature oil and gas well with long well segment

InactiveCN102585797AUniform transformationHigh viscoelasticityDrilling compositionBetaineTemperature resistance

The invention relates to diverting acid for carrying out acidification and transformation on a high-temperature oil and gas well with a long well segment, which comprises the following components: 4.5 to 5.0 percent by mass of diverter octadecanoyl amido ethyl dimethylamine betaine, 1.0 to 2.0 percent by mass of corrosion inhibitor Mannich base, 1.0 to 2.0 percent by mass of ferric ion stabilizererythorbic acid or sodium erythorbate, 20 percent by mass of hydrochloric acid and the balance water. According to the invention, the characteristic that the diverting acid has different molecule aggregation morphologies and aggregation numbers under different pH values is utilized; the high temperature resistance diverting acid with viscoelasticity is prepared by adding the corrosion inhibitor Mannich base and the ferric ion stabilizer erythorbic acid or sodium erythorbate; and after the diverting acid is injected into a formation, the viscosity of the acid is rapidly improved along with theconsumption of the acid and the injection pressure at the bottom of the well also rises along with the consumption of the acid, so that the acid is forced to permeate and divert toward the formation,a reservoir is uniformly acidified and the acidification effect is obviously improved.

Owner:SOUTHWEST PETROLEUM UNIV

Antimicrobial compositions

InactiveCN1688329ACosmetic preparationsOrganic detergent compounding agentsBenzoic acidGlucono delta-lactone

The present invention provides an antimicrobial composition comprising an antimicrobial effective amount (such as a preservative, bactericidal, and / or fungicidal effective amount) of a mixture comprising at least two of: (a) lemon grass oil; (b) cinnamaldehyde, cinnamon oil, cinnamomum cassia, cinnamon extract, cassia leaf oil, 3,4-dihydroxycinnamic acid or salt thereof, or a mixture thereof; (c) sorbic acid, or a salt thereof; (d) erythorbic acid, or a salt thereof; (e) benzoic acid, or a salt thereof; (f) arabinogalactan, galactoarabinan, or a mixture thereof; (g) a hexahydro-iso-alpha-acid, tetrahydro-iso-alpha-acid, or a mixture thereof; (h) Achillea fragrantissima oils, Santolina fragrantissima oils, Forssk oils, Lavender cotton oils; and (i) Glucono Delta Lactone. The present invention also provides a product (preferably a product other than a foodstuff, pharmaceutical, or cosmetic) comprising a preservative effective amount of cinnamaldehyde or a mixture of cinnamaldehyde and one or more alkanol-dialkyl hydantoins.

Owner:LONZA LTD

Boiler pre-filming corrosion and scale inhibitor

ActiveCN103508566AImprove heat transfer performanceExtended service lifeScale removal and water softeningWater/sewage treatment by neutralisationSulfite saltPotassium hydroxide

The invention discloses a boiler pre-filming corrosion and scale inhibitor. The boiler pre-filming corrosion and scale inhibitor comprises a pretreatment filming agent, a deoxidizing agent, a scale inhibitor, a pH regulator and a solvent, wherein the pretreatment filming agent is composed of one or more of zinc sulfate, zinc chloride and sodium silicate; the deoxidizing agent is composed of one or more of azodicarbonamide, sodium sulfite and erythorbic acid; the scale inhibitor is composed of one or more of polyepoxy sodium succinate, ethylenediamine tetraacetic acid disodium and sodium polyacrylate; the pH regulator is sodium hydroxide, potassium hydroxide or a mixture of the both; the solvent is water. By virtue of the method, the boiler pre-filming corrosion and scale inhibitor can effectively prevent corroding and scaling from the heat transfer surface of the boiler, enables the boiler to achieve excellent heat transfer performance and prolongs the service life of the boiler, synchronously overcomes the pollution problem of the environment due to the conventional water treatment agent, is beneficial to sustainable development of the environment, and is prepared from non-toxic raw materials, so that the boiler scale dispersing agent is of high safety.

Owner:HEBEI CHAOLYU ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

Reverse Kleiner method for manufacturing nitrogen dioxide, nitric oxide, nitric acid, metallic ascorbates and alkyl ascorbates of vitamin C

In this invention new chemical reactions, new chemical processes are established, and these chemical reactions and chemical processes can be used with the system designed to produce nitrogen dioxide, nitric oxide, nitric acid as well as metallic ascorbates or alkyl ascorbates, either as main or as secondary products. Ascorbic acid solution is reacted at room temperature or at elevated temperature with either sodium nitrite or potassium nitrite or calcium nitrite or alkyl nitrite such as isobutyl nitrite or barium nitrite or silver nitrite solution. All the second reactants except alkyl nitrites such as isoamyl nitrite or isopropyl nitrite or isobutyl nitrite, as well as the first reactant, ascorbic acid, are in aqueous solutions. The reaction vessel contains the ascorbic acid solution; into this solution, under, certain pressure, is delivered the choosen aqueous nitrite solution. Gas mixture of nitrogen dioxide and nitric oxide is produced by addition of the choosen nitrite solution. The generated and collected gas mixture is then mixed with oxygen, thus the nitric oxide in the gas mixture converts—by reacting with oxygen—into nitrogen dioxide, then this homogeneous gas is dissolved in water, thus giving us nitric acid. In this chemical reaction system two sets of chemical reactions take place; one on the surface of the solution(s) that produces the main part of the gas mixture, and this is the major part of the chemical reaction system. In the liquid phase of the reaction processes form the metallic ascorbates as well as the alkyl ascorbates. All the same can be done with isoascorbic acid; the chemical reactions will go somewhat slower.

Owner:KLEINER BELA

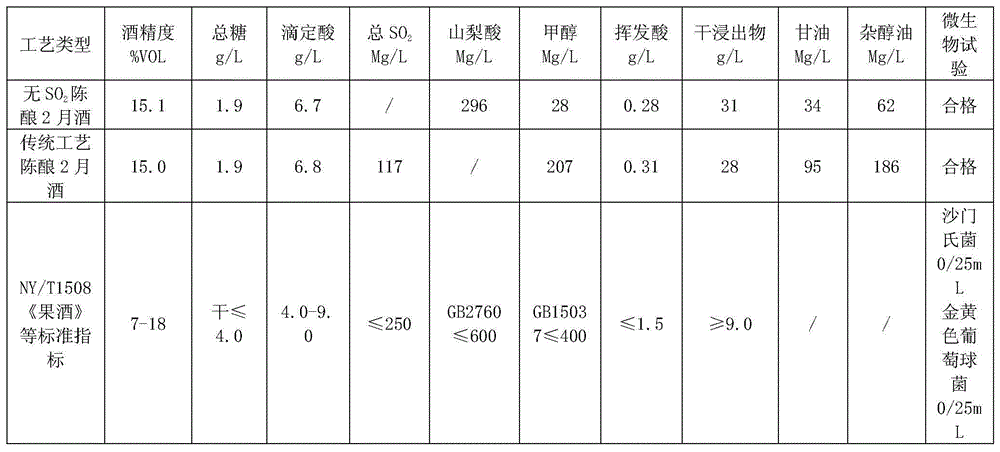

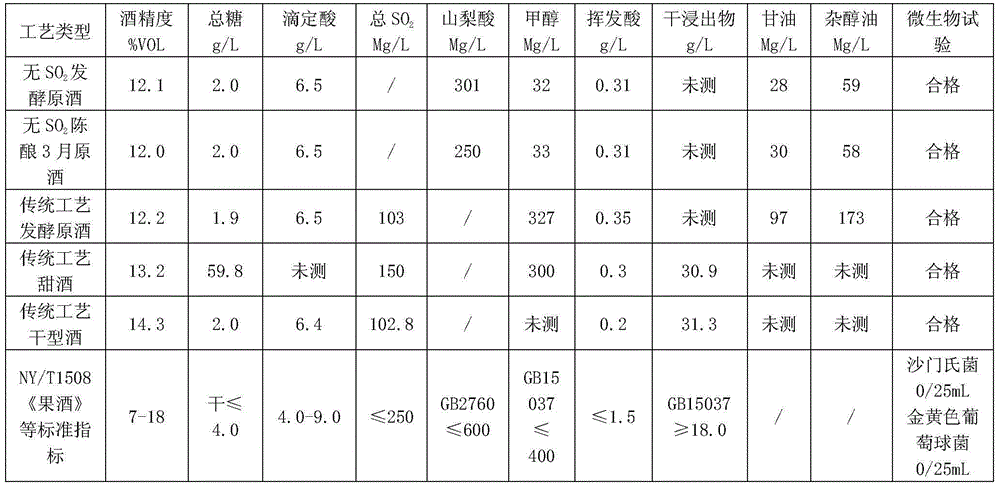

Sulfur-dioxide-free full juice fermented kiwifruit wine and production process thereof

ActiveCN104130904AGuaranteed normal fermentationInhibit G+ bacteriaAlcoholic beverage preparationVitamin CFruit juice

The invention provides a sulfur-dioxide-free full juice fermented kiwifruit wine and a production process thereof, belonging to fermented fruit wines and production technologies thereof. The production process comprises the steps of crushing and juicing, adjusting the acidity of the juice, removing turbidity, resisting bacteria and adjusting the sugar content, preparing mother liquor of the wine, blending and fermenting the juice, ageing the wine base and transiting and storing. The kiwifruit wine has the beneficial effects that an innovative process of replacing SO2 with a composite of six non-toxic materials such as antibacterial and oxidation-resistant D-erythorbic acid, nisin, sorbic acid, chitosan, vitamin C and ethanol materials (refined alcohols and the like) is adopted; compared with traditional processes, in the production process, the operation of adding toxic gaseous and liquid SO2 step by step is safer and more convenient; the production process is an innovation of popularizing the traditional processes of wines for more than a hundred years to make wine with other fruit raw materials; the kiwifruit wine produced by the technology does not contain SO2 and has the advantages that the content of methanol is reduced by about 90%, the content of fusel oil is reduced by about 65% and the harmful ingredients such as bioamine, sulfate, methanol, fusel oil and the like are controlled compared with the fruit wines produced by the traditional processes.

Owner:万源市大面山酒业有限公司

Sulfur-dioxide-free full juice fermented orange wine and production process thereof

ActiveCN104130905AGuaranteed normal fermentationInhibit bacteriaAlcoholic beverage preparationMicroorganism based processesFruit juiceAdditive ingredient

The invention provides a sulfur-dioxide-free full juice fermented orange wine and a production process thereof, belonging to fermented fruit wines and production technologies thereof. The production process comprises the steps of making the juice turbid and making the pulp resist oxidation, adjusting the acidity of the juice and neutralizing bitter precursor substances, making the juice resist bacteria and adjusting the sugar content, preparing mother liquor of the wine, blending and fermenting the juice, ageing the wine base, fining and blending the aged wine base and adjusting the taste of the aged wine base, wherein the juice comprises essential oil, calcium oil and bitter substances. The orange wine has the beneficial effects that an innovative process of replacing SO2 with a composite of non-toxic materials such as antibacterial and oxidation-resistant D-erythorbic acid, nisin, sorbic acid, chitosan and the like is adopted; compared with traditional processes, in the production process, the operation of adding toxic gaseous and liquid SO2 step by step is safer and more convenient; the production process is an innovation of popularizing the traditional processes of wines for more than a hundred years to make wine with other fruit raw materials; the navel orange wine produced by the technology does not contain SO2 and has the advantages that the content of methanol is reduced by about 90%, the content of fusel oil is reduced by about 65% and the harmful ingredients such as bioamine, sulfate, methanol, fusel oil and the like are controlled compared with the fruit wines produced by the traditional processes.

Owner:达州市好汉子酒业有限公司

Rapid demulsifier for fracturing acidification and preparation method thereof

InactiveCN102250608AReduce manufacturing costShort demulsification timeDrilling compositionDemulsifierEther

The invention relates to a rapid demulsifier for fracturing acidification and a preparation method thereof. The rapid demulsifier consists of the following components in percentages by weight: 2-10% of polyoxypropylene polyoxyethylene octadecyl ether, 5-15% of alkylphenyl polyoxyethylene ether, 0.1-1% of stabilizer, 5-30% of cosolvent and the balance of water, wherein the stabilizer is isoascorbic acid or citric acid and the cosolvent is methanol, ethanol, ethylene glycol or isopropyl alcohol. By the synergy of the multiple compounded components, the demulsifier provided by the invention can shorten the demulsification time, improve the demulsification efficiency and save the production cost and has broad market prospects; and the preparation method of the demulsifier is reliable in principle and simple to operate.

Owner:SOUTHWEST PETROLEUM UNIV

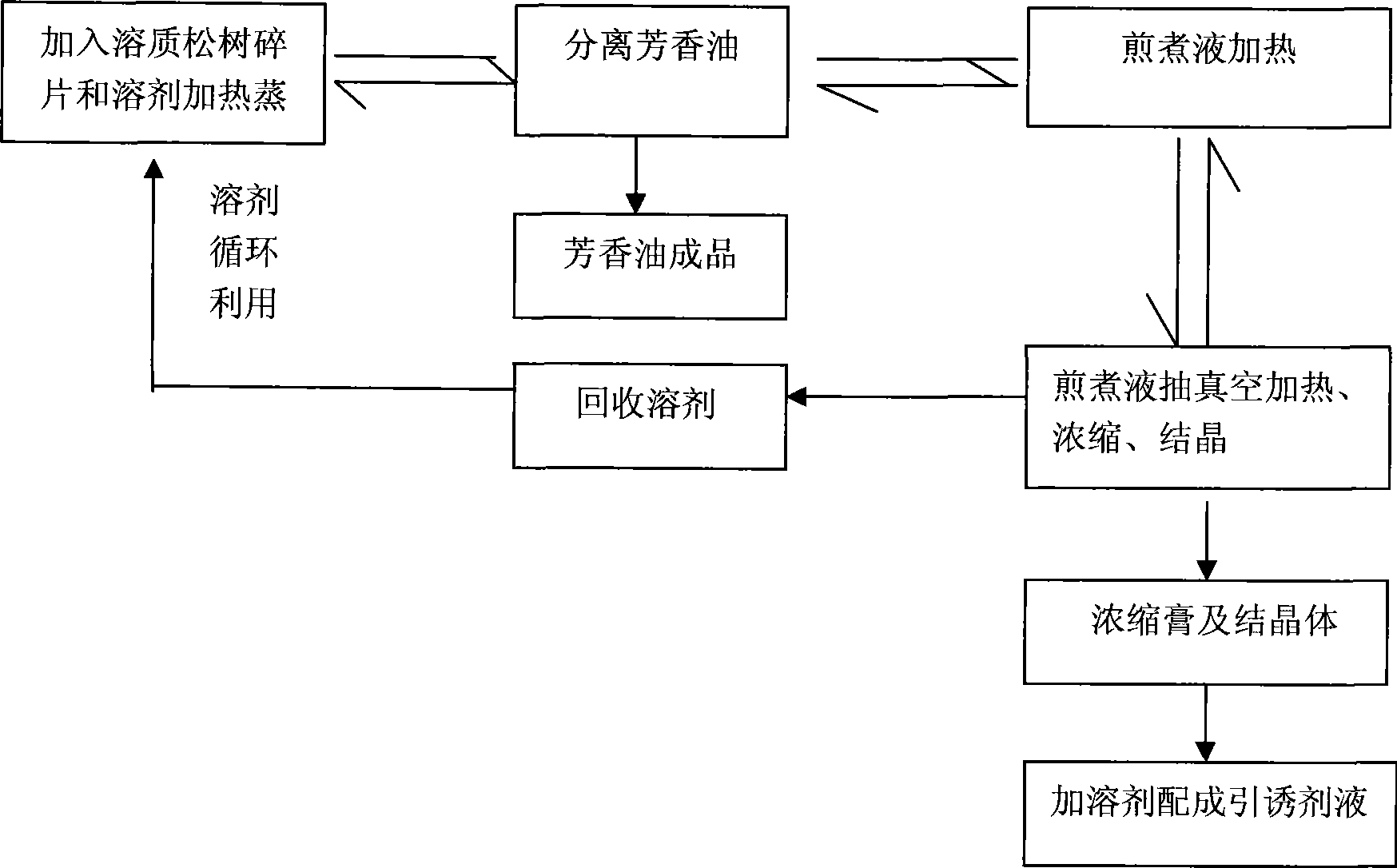

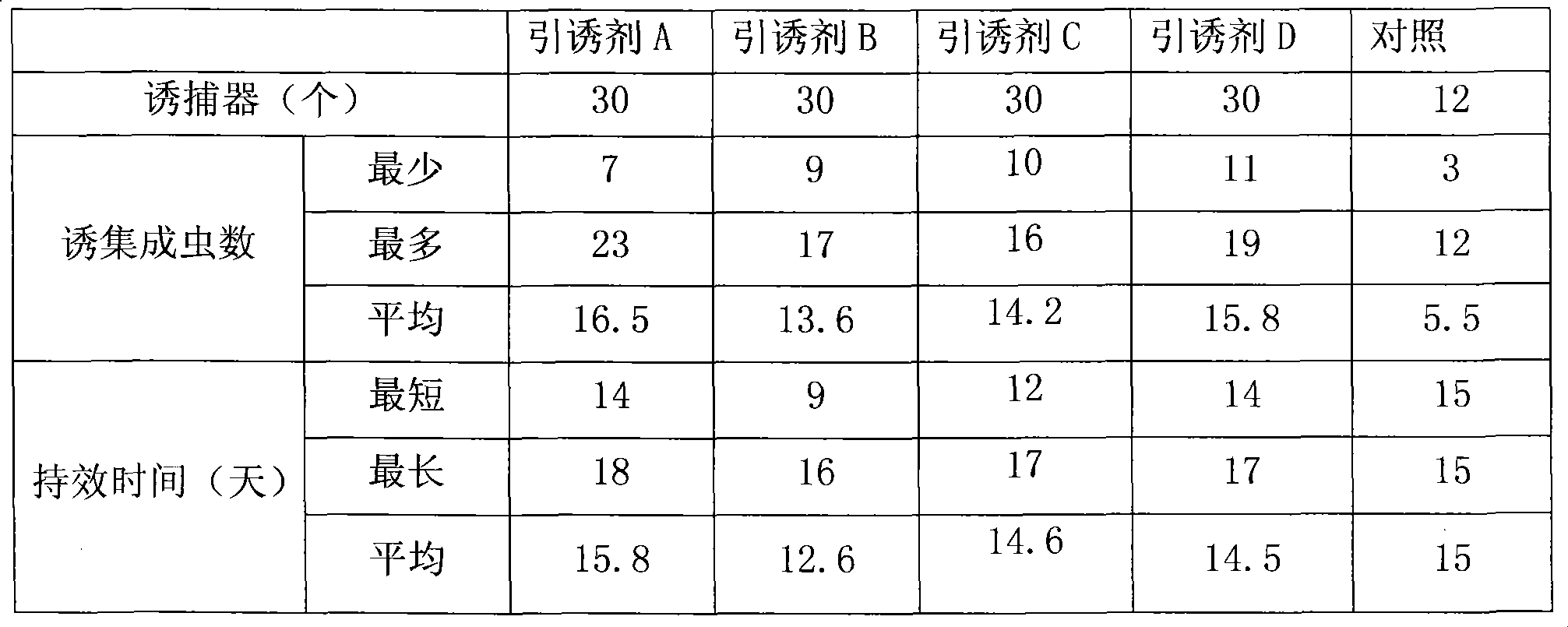

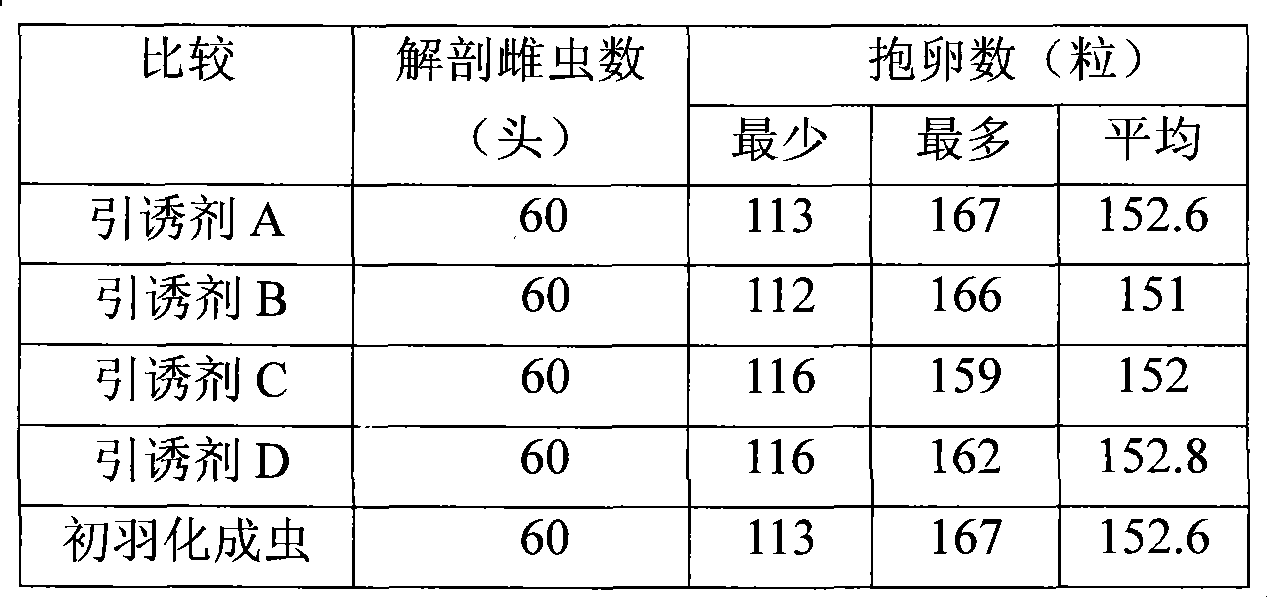

Pine moth rod type destructive insect attractant

The invention discloses a pine stem-borer attractant, which is prepared by a pine extract and a solvent. The main compositions of the pine stem-borer attractant by weight percent are 42 to 56 percent of alpha-pinene, 11 to 23 percent of beta-pinene, 5 to 10 percent of cinene, 3 to 5 percent of longifolene, 1 to 3 percent of caryophyllene and 15 to 30 percent of the solvent. The manufacturing method comprises the following steps: pine splinters are added with adequate solvent, cooked for 2 hours at a temperature of between 78 and 85 DEG C, and concentrated for 1 hour into cream and crystals; the cream and the crystals are then added with anhydrous alcohol and stirred until the solution is fully dissolved, and a saturated liquid is prepared; and a supernatant is taken and added and uniformly mixed with 0.1 percent of 6.D-arabo-ascorbic acid, namely an attractant liquid is obtained. The using method is to entrap pests by utilization of a special trap. The attractant has good inducing function on pests such as pine sawyer, ahropalus rusticus and so on; the continuous effective time of each bottle of liquid medicines is more than 15 days; and the attractant not only has high attractive activity but also does not pollute the environment, has low cost and simple manufacturing technique, saves the cost and is safe, direct, environment-friendly and high-efficiency.

Owner:TAISHAN RES INST OF FORESTRY

Tippy tea scent liquor and production technology thereof

InactiveCN105039087ACater to maintenance-focused, health-conscious requirementsAdapt to entertainment needsAlcoholic beverage preparationBiotechnologySugar

The invention discloses tippy tea scent liquor and a production technology thereof. Each kilogram of the tippy tea scent liquor is prepared from 350-370 parts of 64.8% vol fermented primary pulp tea liquor, 30-50 parts of white granulated sugar, 0.4-0.8 part of tea powder, 0.1-0.3 part of D-erythorbic acid and 0.3-0.4 part of tea essence. The 64.8% vol fermented primary pulp tea liquor is prepared from, by weight, 54-68 % of sorghum, 5-10 % of wheat, 15-18 % of corn, 4-8 % of glutinous rice, 8-10 % of rice and 0.4-1.0 % of tea. The tea liquor meets the requirement that mass customers pay attention to health care and health. The tea liquor enables the customers to spiritually have a liquor feeling and materially feel a tea flavor. The tea liquor has the effects of body building and disease prevention and treatment. The tea liquor is particularly suitable for meeting the social engagement requirement of people after 80's and 90's and young people of a new generation.

Owner:信阳市鸡公山酒业有限公司

Sashimi preservative

InactiveCN106359537AReduce usageKeep the tasteMeat/fish preservation using chemicalsSodium lactateVitamin C

The invention discloses a sashimi preservative, which is prepared from chitosan, sodium lactate, erythorbic acid sodium, citric acid, vitamin C, lecithin, sucrose ester, tea polyphenol and amino acid. The preservative provided by the invention is prepared from antioxidant and anticorrosive ingredients of safe, non-toxic and high-efficient natural food aiming at different microscopic flora, is simple in preparation method, less in raw material usage amount, and safe and reliable to use, and can be eaten together with food. The preservative provided by the invention not only can enable sashimi to maintain original taste and delicate flavor, but also has antioxidant and anticorrosive functions, so that the freshness of the sashimi can be greatly prolonged.

Owner:莫丽婷

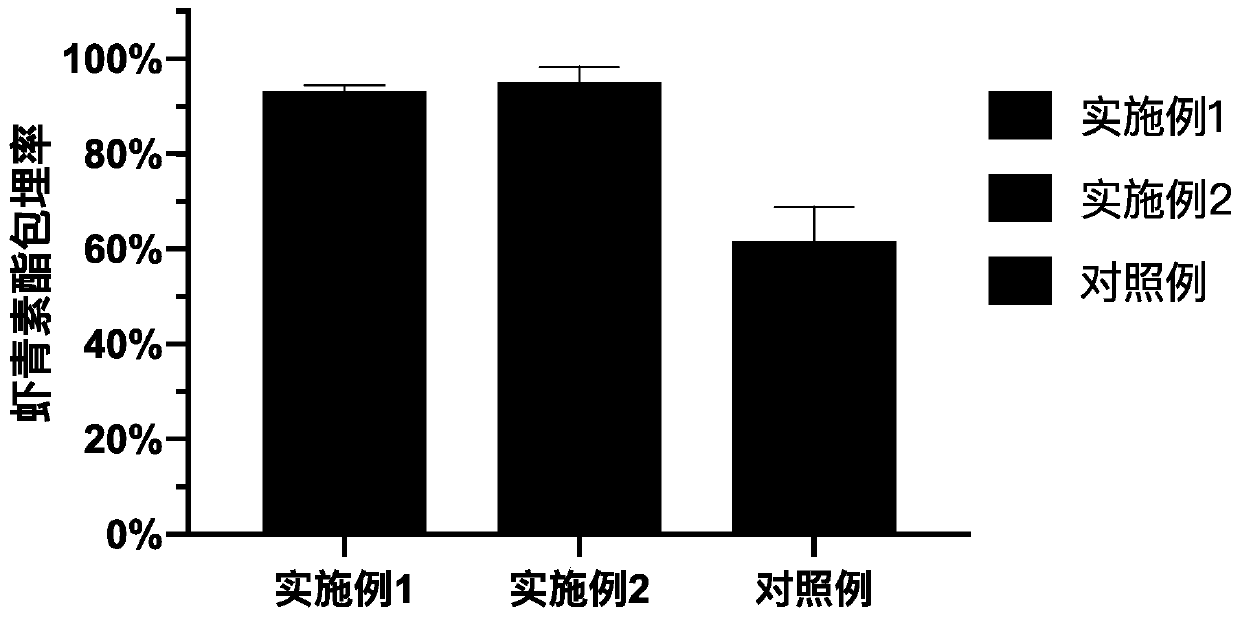

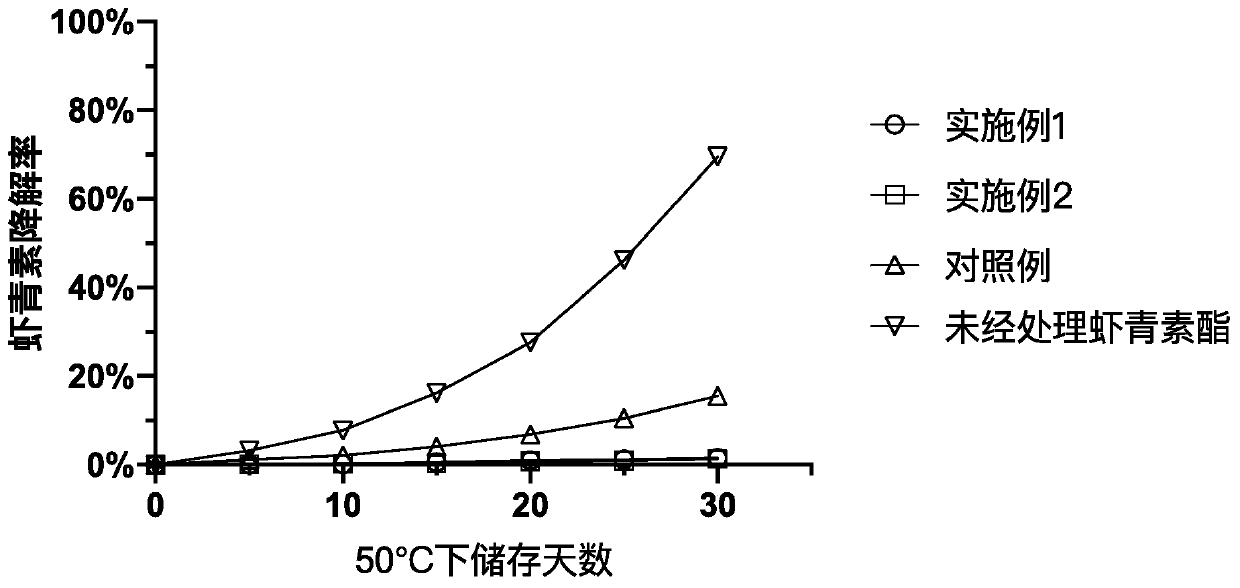

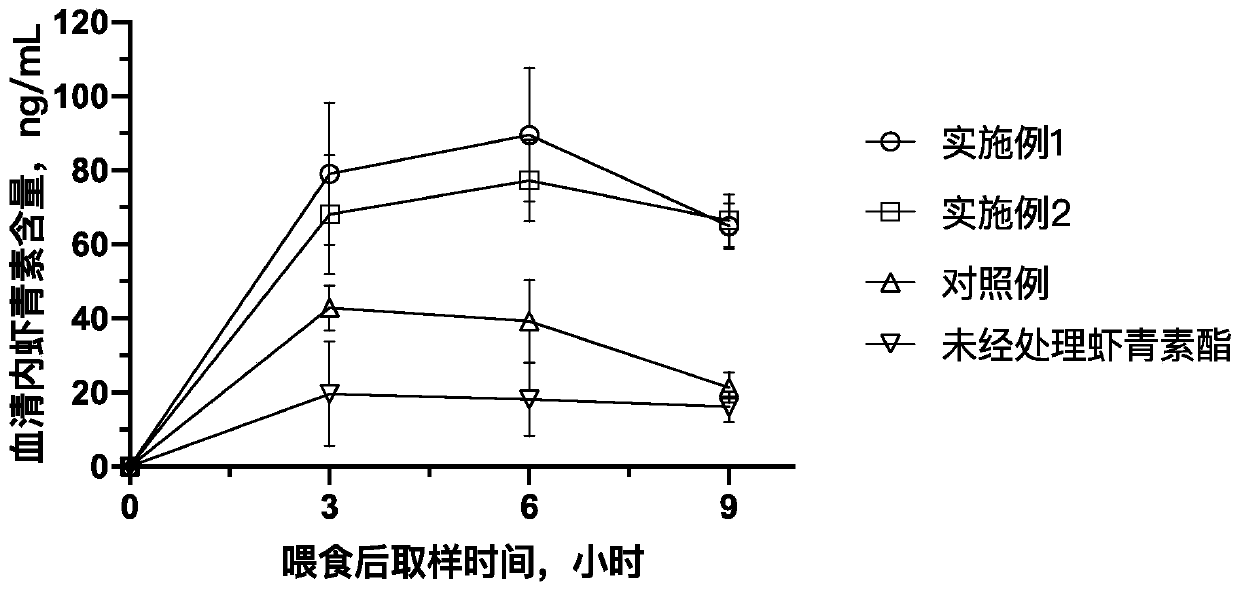

Microcapsule containing natural astaxanthin ester and preparation method thereof

InactiveCN109820837AAdjust the rupture conditionGood water dispersibilityOrganic active ingredientsCosmetic preparationsSucroseAdditive ingredient

The invention discloses a microcapsule containing natural astaxanthin ester and a preparation method thereof. The microcapsule comprises a capsule wall material and an oil phase which is wrapped by the capsule wall material and contains natural astaxanthin ester. The capsule wall material includes a main ingredient and an auxiliary ingredient, the main ingredient is one or more of glue, polysaccharide, glycan, protein and peptide, and the auxiliary ingredient is one or more of sucrose ester, polyalcohol aliphatic ester, ascorbic acid and salts thereof, erythorbic acid and salts thereof, ethylenediamine tetraacetic acid and natural polyphenol. The oil phase includes natural astaxanthin ester, fat, oil, phospholipid, polyalcohols and a stabilizer. The preparation method is high in embeddingrate, can remarkably improve the storage stability of natural astaxanthin ester, has the good flowability, and can remarkably improve the living body absorption rate of natural astaxanthin ester. Themicrocapsule can be applied to products of food, beverages, cosmetics, skincare products, medicines and the like.

Owner:睿藻生物科技(苏州)有限公司

Process for preparation of soybean protein

InactiveUS6051265AImprove the immunityDiscoloration of soybean proteinsMilk preparationProtein composition from vegetable seedsDry weightAntioxidant

A process for preparing a separated soybean protein, by the steps of preparing an aqueous slurry of defatted soybeans, removing water-insoluble components from the slurry and collecting a protein component from the obtained soybean milk, wherein in preparing an aqueous slurry of defatted soybeans, an antioxidant and a chelating agent are added, or at least one member selected from the group consisting of ascorbic acid, erythorbic acid and their salts is added in an amount of at least 0.1 part by weight per 100 parts by dry weight of the defatted soybeans. The process gives a soybean protein which shows improved resistance to discoloration when heat-treated at a high temperature.

Owner:FUJI OIL CO LTD

Natural food preservative

InactiveCN105105281AImprove anti-corrosion performancePlay freshFood preservationAdditive ingredientPolyphenol

The invention belongs to the technical field of food processing and particularly relates to a natural food preservative which comprises nisin, natamycin, kojic acid, seaweed extract, tea polyphenols and water. The ingredients are respectively, by mass parts, 2-7 parts of nisin, 8-11 parts of natamycin, 7-12 parts of kojic acid, 12-16 parts of seaweed extract, 4-10 parts of tea polyphenols and 80-100 parts of water. The used ingredients such as nisin, natamycin, kojic acid, seaweed extract, tea polyphenols, water, essential oil, D-erythorbic acid and allicin can be widely applied to foods and have effects of preservation; the main ingredients are natural ingredients such as nisin, natamycin, kojic acid and comprise extracts of natural plants, so that it can be guaranteed that even if the eating amount is high, no large damage is caused to health of consumers, and the natural ingredients are better in preservative effect.

Owner:SICHUAN HUIQUAN CANNED FOOD

Composite color protecting agent and production process for canned solid pack apple

InactiveCN104054813AConsistent colorInhibits enzymatic browningFruit and vegetables preservationPhytic acidChloride

The invention discloses a composite color protecting agent and a production process for canned solid pack apple in order to solve the problem of easy color change in an apple processing process. The composite color protecting agent comprises the following components by weight percent: 1%-3% of citric acid, 0.2%-0.5% of D-erythorbic acid, 0.1%-0.3% of calcium chloride, 0.01%-0.02% of phytic acid and the balance of water. According to the production process, the composite color protecting agent is added in reduced pressure pre-vacuum treatment, the advantages of various single color protecting agents are integrated, and the enzymatic browning is inhibited to the maximum extent, so that the canned solid pack apple is light yellow in appearance, uniform in color and free of browning.

Owner:SICHUAN HUIQUAN CANNED FOOD

Japanese pepper processed pleurotus eryngii and preparation method thereof

The invention discloses Japanese pepper processed pleurotus eryngii and a preparation method thereof. The method comprises the following steps: uniformly mixing salted pleurotus eryngii and a sodium hydrosulfite water solution; rinsing and immersing; discharging water and screening and washing by flow water to obtain a material A; under a water boiling condition, blanching the material A by using a citric acid water solution; under the water boiling condition, uniformly mixing the blanched material A with a boiling solution; boiling for 10-20 minutes; leaching to remove the boiling solution to obtain a material B; mixing the material B, Japanese peppers, potassium sorbate and D-erythorbic acid; filling and packaging in vacuum; and carrying out normal-pressure sterilization or normal-pressure interval sterilization to obtain the product. The preparation method of the Japanese pepper processed pleurotus eryngii is simple, is easy to operate and is suitable for large-scale industrial production; the flavor of the prepared Japanese pepper processed pleurotus eryngii is richer and mellower than that of traditional Japanese pepper processed pleurotus eryngii; the Japanese pepper processed pleurotus eryngii is tough in mouth feel and chewable, is nutritional and delicious and has good color and luster; the nutritional ingredients are easy to absorb and the product does contain nitrite and has a long guarantee period.

Owner:上海大山合菇粮生物科技有限公司

Multi-taste cheese piece for pets and processing method of multi-taste cheese piece

The invention relates to a multi-taste cheese piece for pets and a processing method of the multi-taste cheese piece. The multi-taste cheese piece is characterized by being prepared from the following raw materials in parts by weight: 80-120 parts of livestock and fish meat, 15-24 parts of cheese powder, 15-25 parts of an emulsifier, 3-8 parts of sodium lactate, 30-45 parts of starch, 0.2-1 part of composite phosphate, 0.1-1 part of an antioxidant and 0.05-1 part of a preservative. The processing method comprises the following steps: weighing raw materials, chopping the livestock and fish meat into muddy flesh, sequentially adding erythorbic acid, potassium sorbate and composite phosphate into the muddy flesh, further adding glycerinum, starch and cheese powder, finally mixing to obtain a uniformly mixed muddy material, forming the muddy material, baking, and cutting into pieces. The palatability experiment shows that compared with hot-sale products with good palatability in market, the multi-taste cheese piece can be selected by more than 90% of study subjects.

Owner:YANTAI CHINA PET FOODS GRP

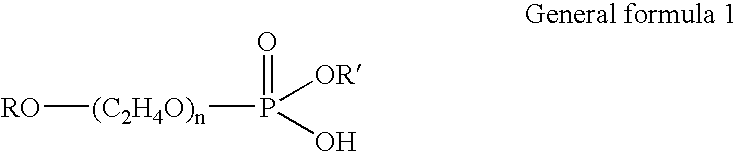

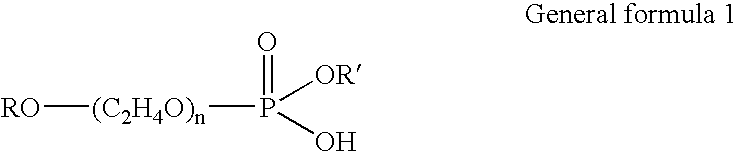

Water based ink composition for rollerball pen

Disclosed is a water based ink composition for a rollerball pen that includes at a least colorant, a water-soluble organic solvent, water, a shear thinning viscosity property-providing agent, a lubricant, and a bubble suppressant. The ink composition includes a phosphate-ester based surfactant having a structure of general formula 1 as the lubricant, and an erythorbic acid or a derivative thereof as the bubble suppressant(n represents an integer of 1 or more, R represents an alkyl group having carbon numbers of 12 to 15, and R′ represents H or R—(C2H4O)n—).

Owner:PILOT PEN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com